Patents

Literature

2199 results about "Kiln burner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

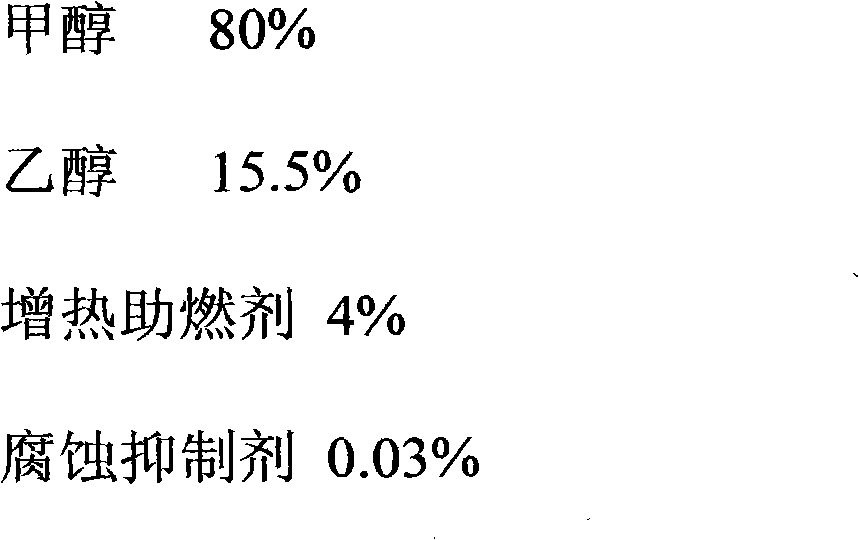

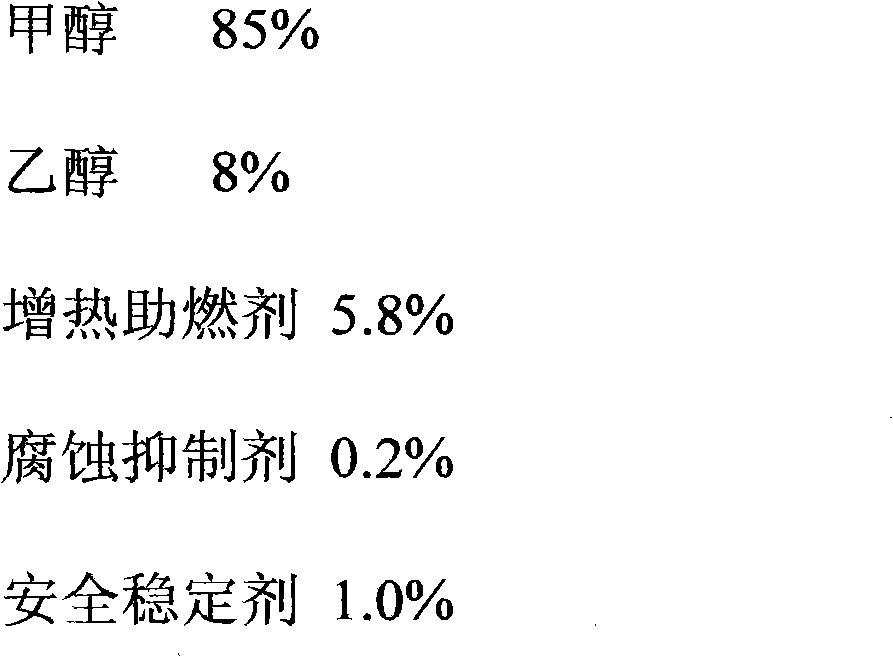

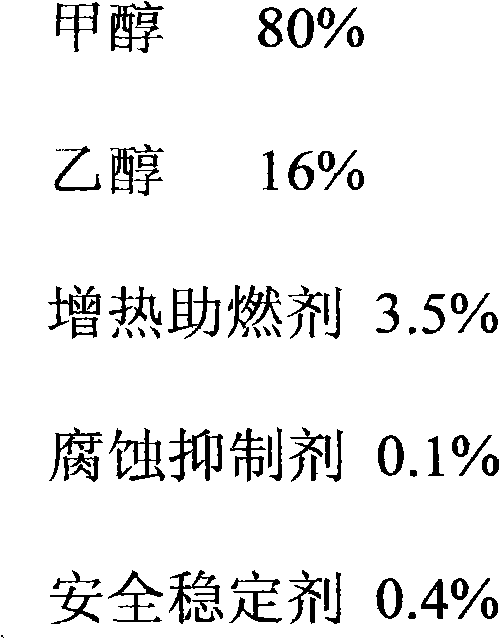

Novel high-heat anticorrosive biomass alcohol-based fuel

The invention relates to a novel high-heat anticorrosive biomass alcohol-based fuel, and relates to the field of environment protection. The alcohol-based fuel is prepared with main combustion agents of methanol and ethanol and auxiliary materials of alcohol-based fuel additives. The fuel is prepared from 60-90% of methanol, 10-30% of ethanol, 2-8% of a combustion-enhancing heat-gain agent, 0.01-0.2% of a corrosion inhibitor, and 0.1-1% of a safe stabilizer. The fuel provided by the invention has the advantages of high heat value, easy ignition, stable combustion, corrosion resistance, no air resistance, explosion-proof safety, clean property and no odor, low emission, low cost, energy saving, and environment friendliness. The heat value can be increased to 6500-7000 kcal / kg, and a central flame temperature can reach 1200-1300 DEG C. The fuel provided by the invention can be used in fields such as stoves, boilers, industrial furnaces, and the like.

Owner:QIQIHAR NORTH KUN SYNTHETIC POLYMER MATERIALS

Thermal-shock-resistant corundum-spinel refractory castable and preparation method thereof

The invention discloses thermal-shock-resistant corundum-spinel refractory castable which comprises the following raw materials in percentage by weight: 65-80% of corundum particles and fine powder, 3-10% of aluminum oxide fine powder, 2-8% of materials containing Zr, 10-15% of magnesium-aluminum spinel fine powder, 3-8% of bonding agent, 0.05-0.1% of organic fiber (additional) and 0.2-0.6% of water reducing agent (additional). The preparation method of the corundum-spinel refractory castable comprises the following process steps of burdening, mixing, molding, maintaining, drying, storage and transportation, using and the like. Compared with the prior art, the thermal-shock-resistant corundum-spinel refractory castable provided by the invention has high thermal-shock-resistant property, and favorable high-temperature resistance and anti-erosion capability, and is suitable for steel ladles, intermediate ladles, RH (relative humidity) immersion tubes, cement high-temperature kilns and the like.

Owner:LUOYANG LIER REFRACTORY MATERIAL +2

Composite fire resistant pouring material

The invention relates to an organic-inorganic composite combined advanced monolithic refractory which has the formula of 40 to 56 percent of 5-1mm corundum or bauxite, 12 to 30 percent of 1-0.0088mm corundum or bauxite, 16 to 25 percent of corundum or bauxite with d90 less than 0.088mm, 0 to 5 percent of alpha alumina micropowder, 1 to 8 percent of hydratable alumina, 1 to 6 percent of siliceous dust, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid, 1 to 6 percent of external water and 0 to 3 percent of external heat-resistant steel fiber. Casting materials of the invention have excellent performances of condensation, hardening, demoulding, drying and heating and are suitable for high-temperature furnace projects with changeful field conditions.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

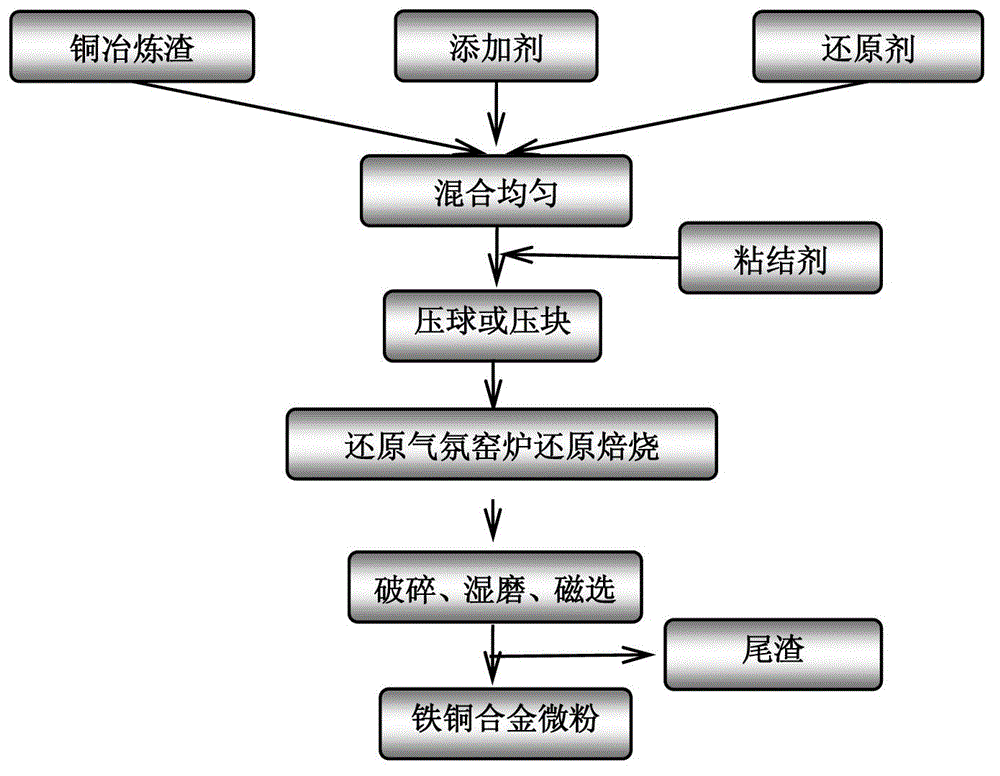

Method for rapidly reducing copper slags to produce iron-copper alloys in kiln in reducing atmosphere

ActiveCN102719676AIncrease added valueAchieve restorationProcess efficiency improvementSilicic acidReducing atmosphere

A method for rapidly reducing copper slags to produce iron-copper alloys in a kiln in a reducing atmosphere is characterized by including the steps: proportionally mixing the copper slags, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20%-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, uniformly mixing, producing the uniformly mixed mixture to pellets with the diameters ranging from 15mm to 30mm and small cylindrical briquettes with all the heights ranging from 15mm to 30mm by a pellet press or a briquetting machine, and drying the pellets or small cylindrical briquettes; flatly laying the dried pellets or small cylindrical briquettes at the bottom of the kiln, wherein the material layer thickness ranges from 20mm to 45mm, the material layer reducing temperature ranges from 1250 DEG C to 1450 DEG C, and the reducing time is 10-40min; and subjecting the reduced pellets or the briquettes to cooling, crushing, wet grinding and wet separation so that iron-copper alloy powder with the iron recovery rate of 85%-99% is obtained. According to the method, iron in a great quantity of silicate iron in the copper slags, which cannot be separated out by the traditional technology, is extracted and turns into the iron-copper alloy micro powder with high added value so that iron and copper in the copper slags are extracted and used simultaneously, and physical and chemical heat energy in strong reducing waste gas can be completely recovered during rapid depth reduction.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

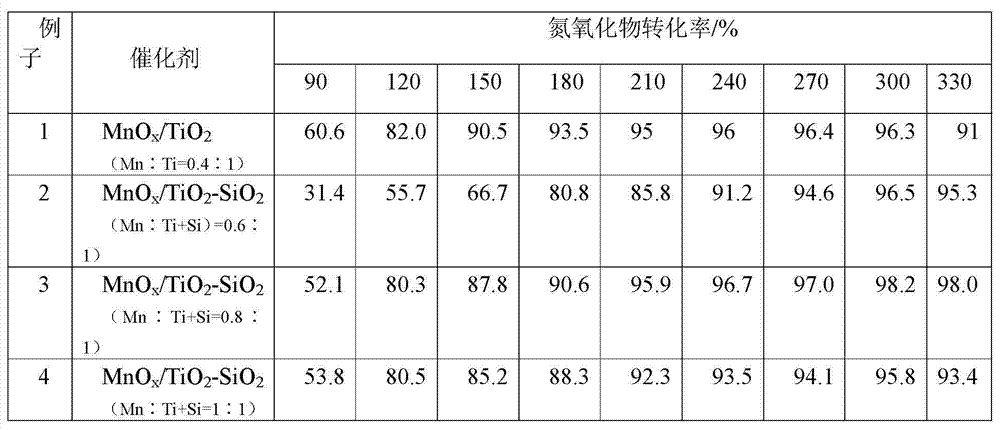

Manganese-based low-temperature denitration catalyst taking TiO2-SiO2 as carrier and preparation method thereof

ActiveCN103240081ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseBULK ACTIVE INGREDIENT

The invention relates to a manganese-based low-temperature denitration catalyst taking TiO2-SiO2 as a carrier and a preparation method thereof, belonging to the field of environmental catalysis and environmental protection. According to the manganese-based low-temperature denitration catalyst, a MnOx / TiO2-SiO2 catalyst is prepared by adopting a sol-gel method, wherein the mass percentage of SiO2 in the composite carrier is 40-60%, and the mass ratio of Mn to Ti+Si is (0.5-1.0): 1. The manganese-based low-temperature denitration catalyst is characterized in that due to the addition of SiO2, the specific surface area of the carrier is greatly increased, and the dispersion and stability of active substances on the surface of the carrier are benefited; and the TiO2-SiO2 is taken as the composite carrier, so that the alkali metal poisoning resistance of the catalyst can be improved. An active ingredient is low in cost, is non-toxic and can have good denitration catalysis activity at a lower temperature, so that the catalyst is applicable to the denitration catalysis of NOx of a low-temperature environment of a cement kiln after dust removal.

Owner:BEIJING UNIV OF TECH

Calcium-based catalytic desulfurization agent for cement kiln

ActiveCN105779074AGuarantee high temperature sulfur fixationReduce pollutionSolid fuelsFuel additivesIron oxideMagnesium

The invention discloses a calcium-based catalytic desulfurization agent for a cement kiln.The calcium-based catalytic desulfurization agent comprises calcium hydroxide, calcium oxide, iron oxide, magnesium oxide, barium carbonate and a rare element compound, and the desulfurization agent is added into the kiln together with cement raw materials so as to lower the concentration of SO2 generated by flue gas emission of the cement kiln.According to the calcium-based catalytic desulfurization agent, a tiny amount of the calcium-based catalytic desulfurization agent is blended into the raw materials, potential of pulverized coal combustion of the new dry process cement kiln can given fully play, high temperature sulfur fixation of the cement kiln is guaranteed, meanwhile, SO2 emitted into air due to the high sulfur content of the raw materials can be effectively lowered, air pollution is reduced, and in addition, no adverse impact is generated to performance of cement clinker; meanwhile, the calcium-based catalytic desulfurization agent is easy to produce and operate, and great practical significance is achieved for solving the problems of cement industry energy crisis and environmental pollution.

Owner:广东万引科技股份有限公司

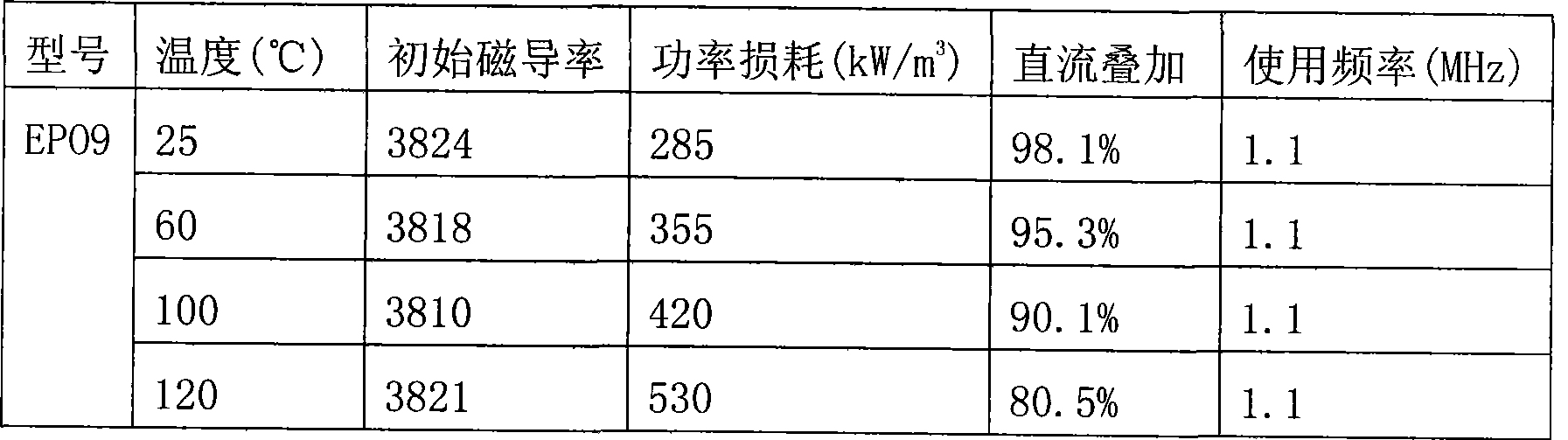

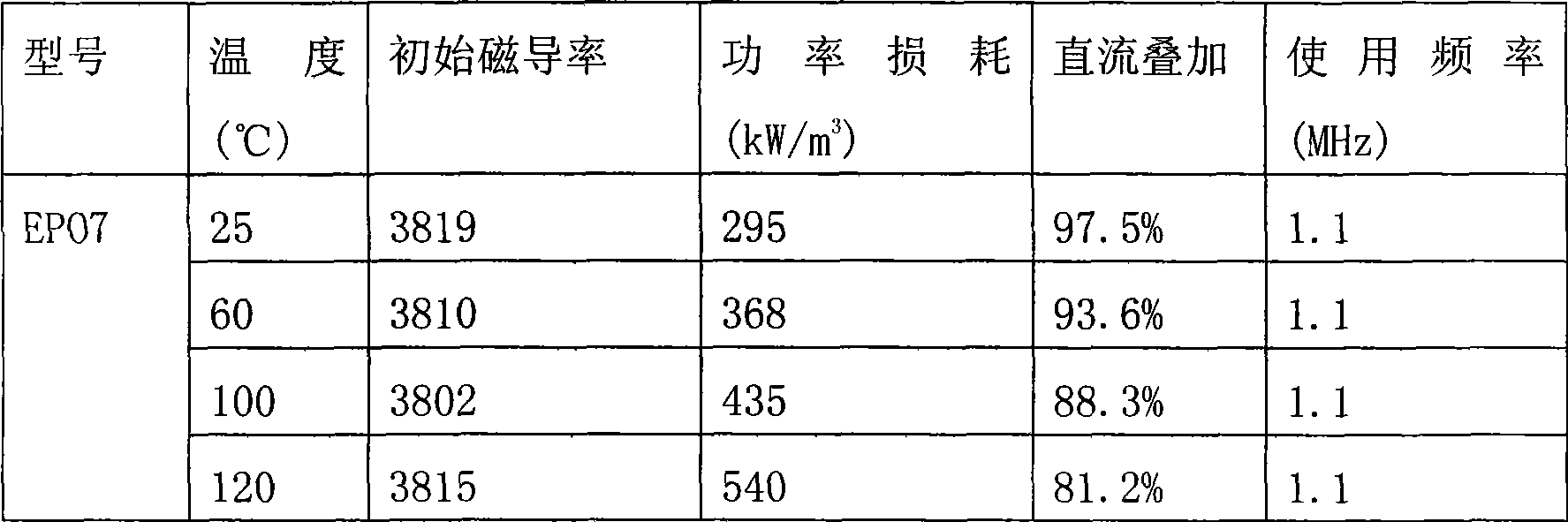

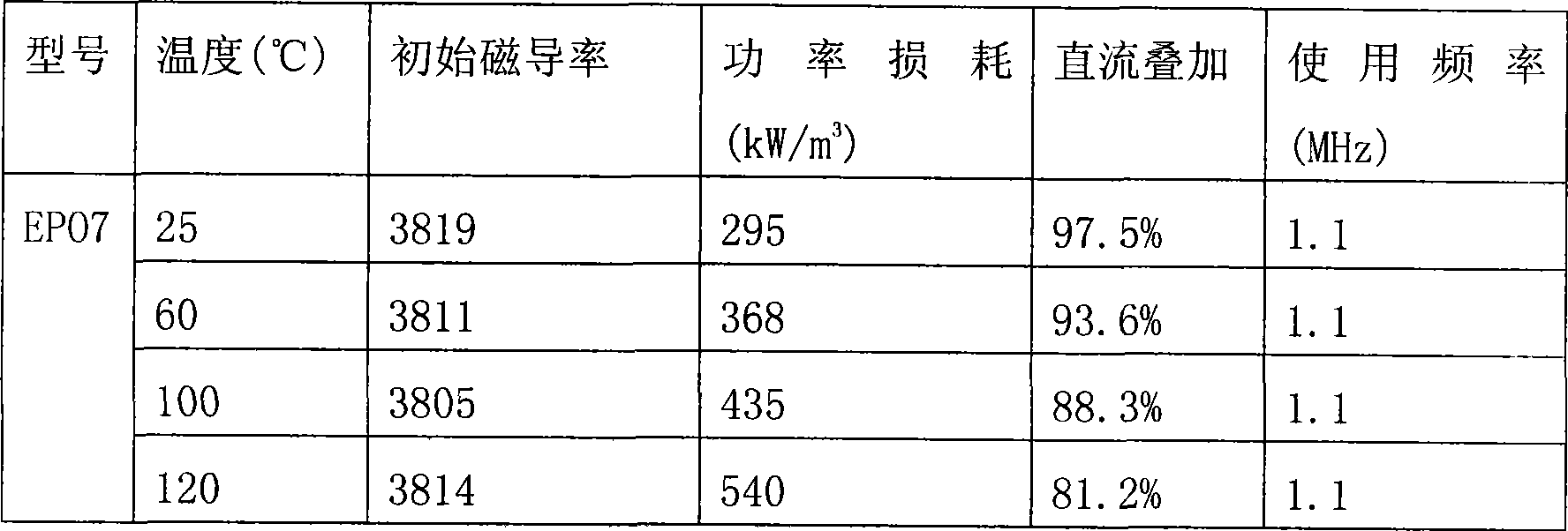

Ferrite magnetic core for network communication and method for producing the same

The invention relates to a manganese-zinc ferrite magnetic core for network communication and a method for preparing the same. The magnetic core comprises the following compositions in terms of mol ratio: 51 to 58 mol percent of Fe2O3, 23 to 38 mol percent of MnO, 6 to 14 mol percent of ZnO, 0.01 to 5 mol percent of NiO, and 0.01 to 3 mol percent of CuO. The method for preparing the magnetic core comprises the following steps sequentially: first time of material blending and ball milling, presintering, second time of material blending and ball milling, spraying granulation to obtain granule materials, pressing the materials into biscuits, and biscuit sintering. The sintering is performed in push board kiln in an N2 protective atmosphere, experiences different sintering temperature stages, and finally keeps the temperature for 3 to 8 hours in the N2 atmosphere until the temperature is cooled to room temperature. The magnetic core has the performances of high MU i, high superposition, broad band and low loss. The magnetic core is widely used in the fields of network communication and electronic power, in particular in an ADSL technical separator.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +2

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

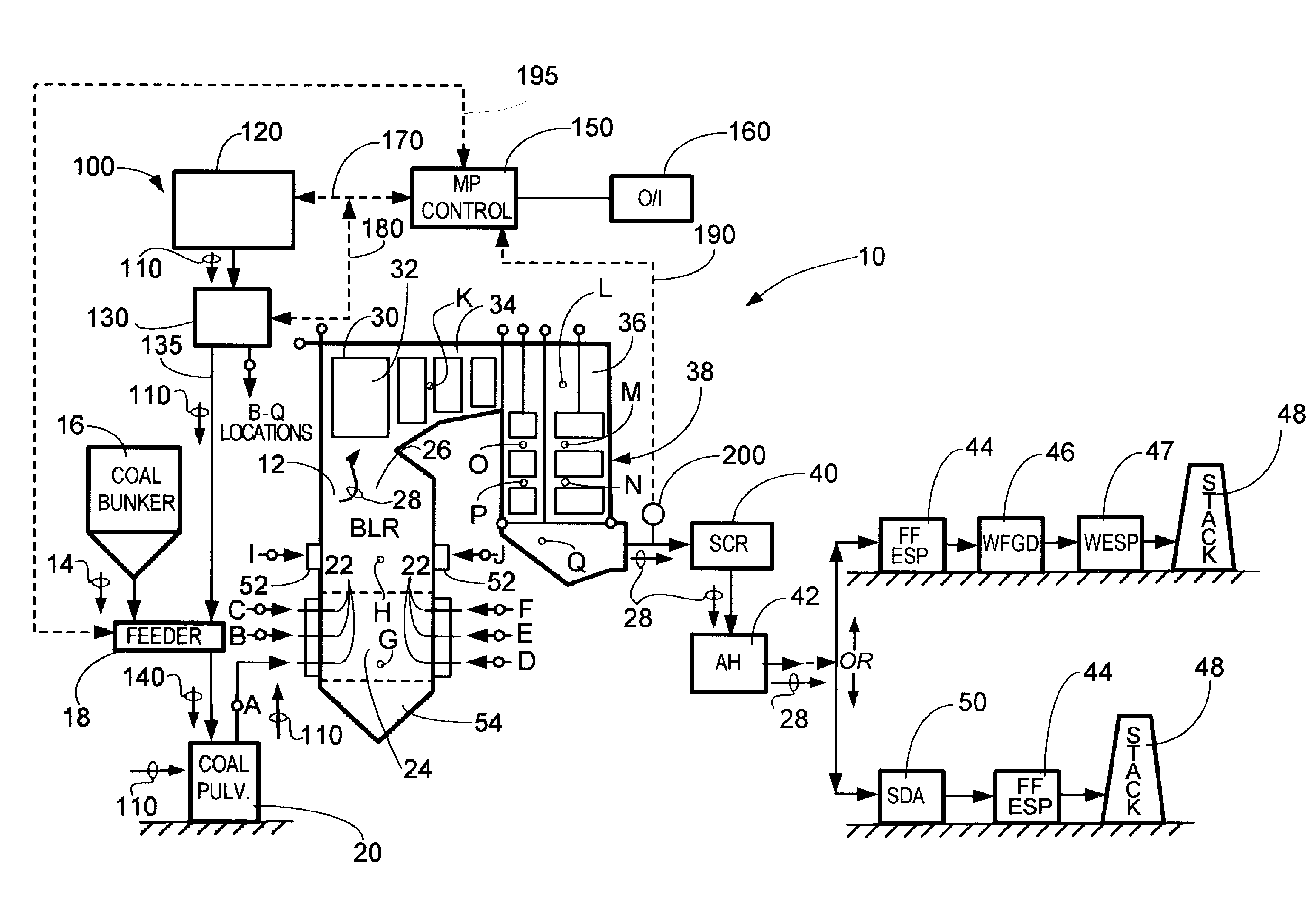

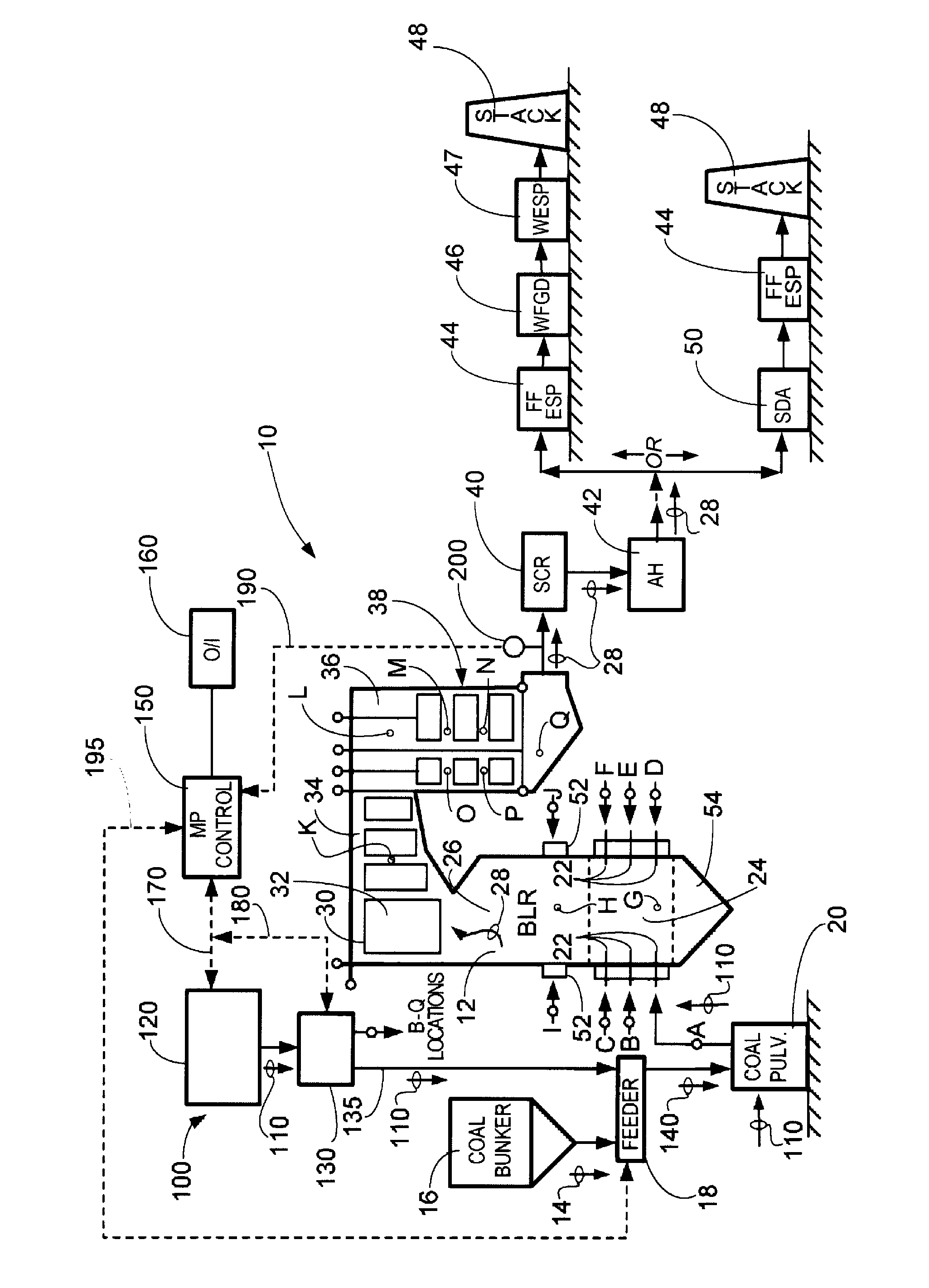

System and method for protection of SCR catalyst and control of multiple emissions

Owner:THE BABCOCK & WILCOX CO

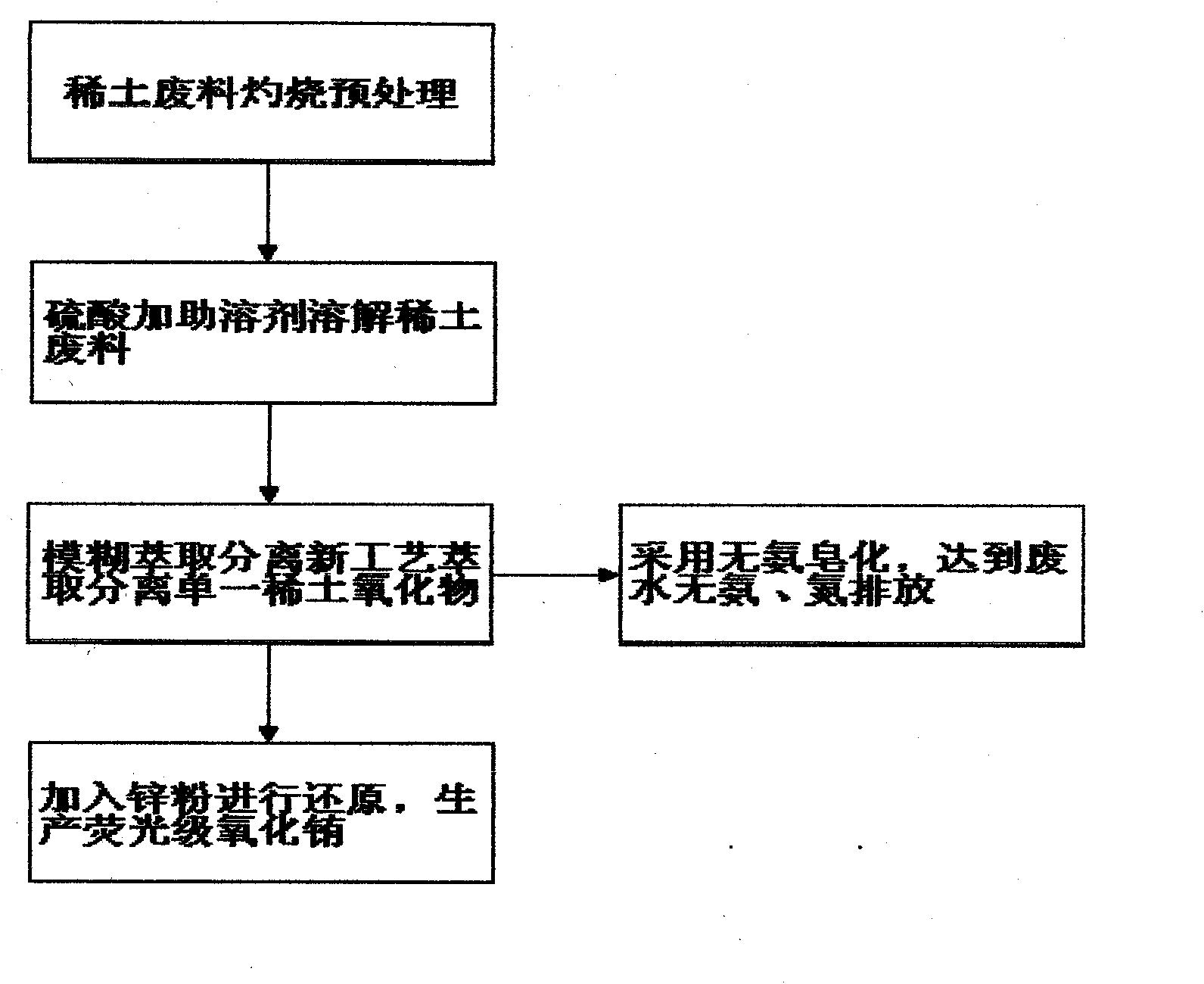

Method for recovering rare earth oxide from fluorescent powder and polishing powder waste

InactiveCN102115822AExpand the scope of recyclingAcid dissolution yield increasedProcess efficiency improvementRare earthSolvent

The invention relates to a method for recovering rare earth oxide from fluorescent powder and polishing powder waste, which comprises the following five steps of: (1) firing the waste by using a self-designed firing kiln; (2) dissolving the rare earth waste in H2SO4, glacial acetic acid and cosolvent mixed solution, returning filter residue, and continuously dissolving; and adding filtrate into a multistage extraction tank for rare earth extraction separation; (3) performing extraction separation by a fuzzy extraction separation and purification technology to obtain single rare earth oxide; (4) adding zinc powder into SmEuGd rare earth chloride solution obtained by separation and performing reduction and extraction and purification to produce fluorescent grade europium oxide; and (5) performing ammonia-free saponification to discharge wastewater without ammonia nitrogen. The wastewater is recovered and used for preparing ammonia-free saponification liquid. By the method, the rare earth fluorescent powder and polishing powder waste is recovered in a low-cost and pollution-free mode.

Owner:吴泉锦

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

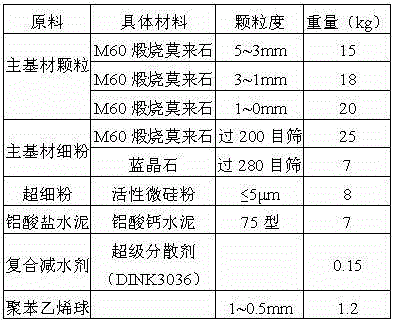

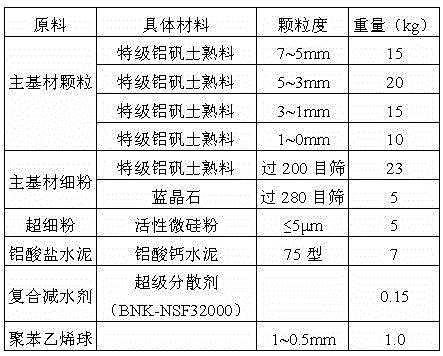

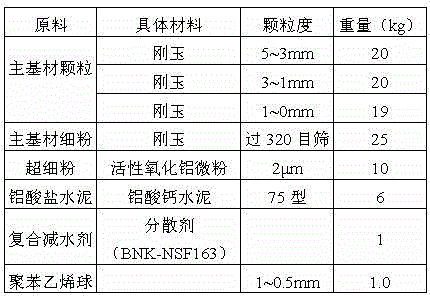

High temperature resistant lightweight heat insulation castables

Disclosed is high temperature resistant lightweight heat insulation castables. Substrate raw materials and the weight percentage are as follows: 53-60% of main substrate particles with the average particle size less than or equal to 7 millimeters, 25-32% of main substrate fine powder which can pass through a target screen mesh not less than 200, 5-10% of ultrafine powder with the average particle size less than or equal to 10 microns, and 6-7% of aluminate cement. The sum of the weight of the substrate raw materials is an entirety, compound water-reducing agents need to be added besides the substrate raw materials, and the weight of the compound water-reducing agents is 0.1-1% of that of the entirety. Besides the substrate raw materials, polystyrene spheres need to be added, the average particle size of the polystyrene spheres is 1-0.5 millimeter, and the weight of the polystyrene spheres is 1-3% of that of the entirety. The high temperature resistant lightweight heat insulation castables can be used as working lining of a thermal furnace which does not contact with molten liquid, the use temperature is from 1250-1650 DEG C according to different main substrates, and the volume density of the high temperature resistant lightweight heat insulation castables can be 1.2-1.7g / cm<3> by adding burning articles with different quantities.

Owner:宜兴天霸非金属材料有限公司

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Alumina-magnesia refractory brick containing light porous aggregate and its making process

The present invention relates to one kind of alumina-magnesia refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-MgO refractory material 30-70 wt%, compact Al2O3-MgO refractory material 0-35 wt%, fine magnesia powder 5-30 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine corundum powder 0-25 wt% and fine spinel powder 0-25 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-magnesia refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

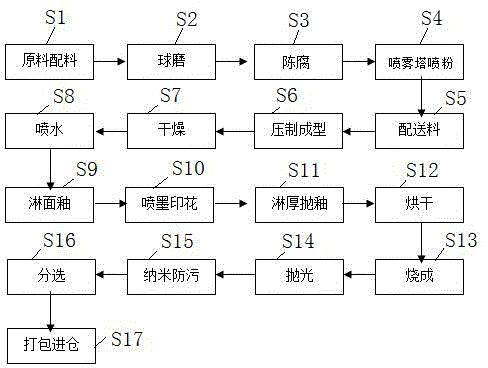

Raw-glaze novel microcrystalline tactile sensation-imitation thick glaze-polished brick and production method thereof

The invention discloses a novel microcrystalline tactile sensation-imitation raw glaze-polished brick and a production method thereof. The method comprises the following steps: over-glazing the surface of a green body, carrying out inkjet printing, carrying out raw material sprinkling and thick glaze polishing, and sintering in a kiln to obtain a finished product. Formula innovation is carried out to enhance the strength of the green body in order to solve green body deformation and fast firing problems. The raw thick sprinkling thick glaze polishing is carried out, then the obtained material is added to a double layer drying kiln, and the waste heat of the kiln is used to dry the brick body, so the water of the green body before the green body enters the kiln is reduced, energy is saved, and the brick break problem is solved. The method realizes industrial maximum glaze polishing production of marble glaze-polished bricks, and solves the problem of unable realization of stereo perception of a microcrystalline brick, and good color, abundant patterns and easy control of a glaze-polished brick existing in present ceramic bricks.

Owner:FOSHAN OCEANO CERAMICS

Aluminum-silicon light heat insulation brick and preparation method thereof

ActiveCN102167622ARaw materials are cheap and easy to getSimple production processCeramicwareInsulation layerBrick

The invention relates to an aluminum-silicon light heat insulation brick and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 40-55 percent by weight of light alumina aggregate, 25-40 percent by weight of bauxite chamotte, 5-12 percent by weight of calcium aluminate cement, 8-13 percent by weight of organic polymer, 2-5 percent by weight of silicon powder, 0.05-0.15 percent by weight of water reducing agent and 15-25 percent by weight of water, calendering and molding by casting; curing under the condition of room temperature for 24-48 hours, demolding and drying at the temperature of 100-120 DEG C for 20-36 hours; and preserving heat at the temperature of 1,400-1,550 DEG C for 3-5 hours to obtain the aluminum-silicon light heat insulation brick. The preparation method has the advantages of wide raw materials, simple process and low production cost; the prepared aluminum-silicon light heat insulation brick has the advantages of high compressive strength, low volume density, low heat conductivity, high using temperature, low re-burning linear change rate, high thermal shock stability and the like; the product is applied to various industrial furnace heat insulation layers, has a wide application range and remarkably-reduced energy consumption and temperature outside a furnace, and can be safely and effectively produced.

Owner:WUHAN UNIV OF SCI & TECH

A kind of mullite lightweight brick and preparation method thereof

InactiveCN102276242AImprove insulation effectFulfil requirementsCeramicwareRoom temperatureMaterials science

The invention relates to mullite light bricks and a preparation method thereof. The invention adopts a technical scheme that the preparation method comprises: uniformly mixing 50 to 90 weight percent of coal gangue and 10 to 50 weight percent of alumina, which serve as raw materials, and 8 to 16 weight percent of pore forming agent, 0.5 to 5 weight percent of swelling agent and 0.05 to 0.5 weightpercent of bonding agent; adding water in an amount which is 25 to 40 weight percent based on the raw materials to make a mud material, and aging the mud material for 24 to 36 hours under conditions of a temperature of 20 to 40 DEG C and a humidity of 25 to 80 percent; and performing extruding forming of the aged mud material, and drying for 12 to 36 hours naturally under a room temperature condition; and firing for 12 to 24 hours under a condition of a temperature of 60 to 120 DEG C, performing heat preservation for 2.5 to 12 hours under a condition of a temperature of 1,300 to 1,550 DEG C, and thus, obtaining mullite light bricks. The preparation method disclosed by the invention has the advantages of resource conservation, environment friendliness and continuous production; and the prepared mullite light bricks have the characteristics of high strength and high thermal shock resistant stability, can be directly used as working surface liners for industrial kiln furnaces and can create good economic and social benefit.

Owner:WUHAN UNIV OF SCI & TECH

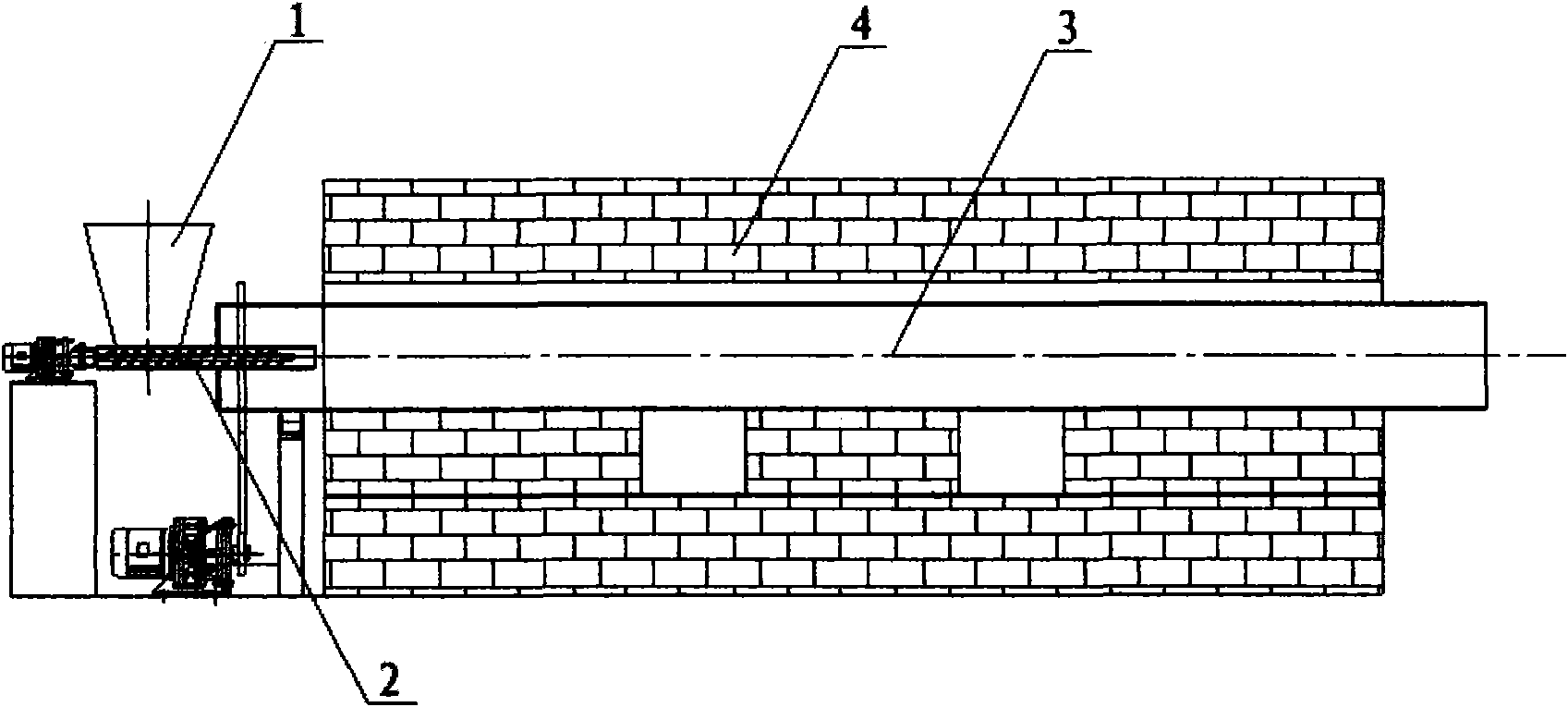

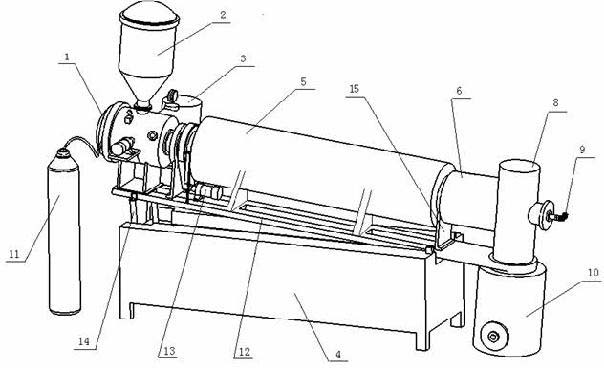

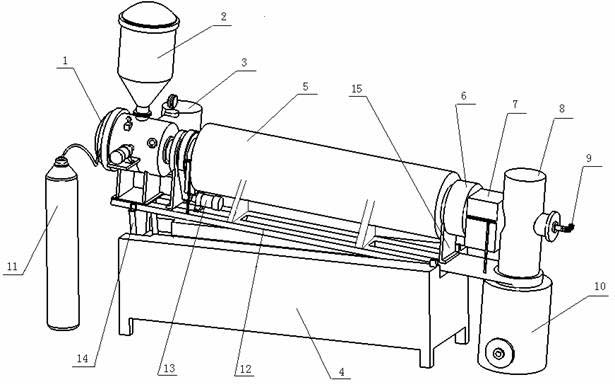

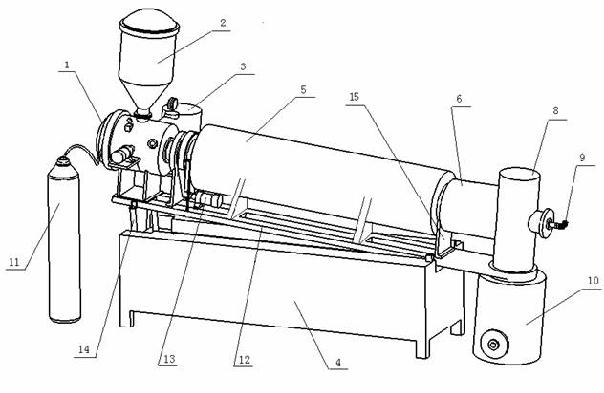

Method for preparing lithium iron phosphate with dynamic sintering method and sintering device thereof

ActiveCN102180454ALow costEvenly heatedCell electrodesPhosphorus compoundsElectricityLithium iron phosphate

The invention discloses a method for preparing lithium iron phosphate with a dynamic sintering method and a sintering device thereof, belonging to the technical field of lithium ion battery anode materials. The processing route of the method comprises the following steps of: preparing materials; ball-milling with a wet method; drying in vacuum at low temperature; sintering; preliminarily crushing; ball-milling; sifting and detecting and packaging. Since a solid phase carbothermic reduction method is combined with dynamic sintering, a sintering process is simplified, raw materials are heated more uniformly, and an obtained lithium iron phosphate product has smaller and more uniform particles and higher electrochemical performance. A special sintering device is also adopted in the method and comprises a feeding device, a double-layer sintering kiln, a discharging valve, a product discharging device and an atmosphere control execution device, wherein a sintering inner hearth cylinder of the sintering kiln is lifted in a reciprocating way and rotated. The invention has the advantages of simple process and equipment, low energy consumption, adequate material mixing, favorable uniformity and high stable performances between batches of the lithium iron phosphate and is widely applied to preparation of the lithium ion battery anode materials.

Owner:SHANGHAI UNIV

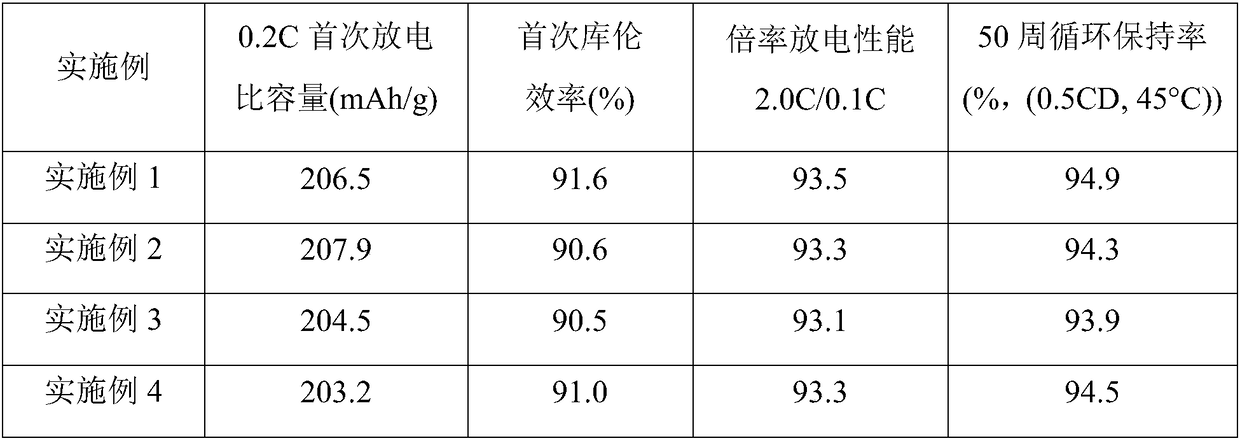

Method for preparing graphene modified high-nickel series positive electrode material through spray drying process and positive electrode material prepared by same

InactiveCN108539152AImprove electronic conductivityImproved magnification performanceCell electrodesSecondary cellsEmulsionLithium hydroxide

The invention discloses a method for preparing a graphene modified high-nickel series positive electrode material through a spray drying process and the positive electrode material prepared by the same. The method includes following steps: 1), well mixing high-nickel precursor with lithium carbonate or lithium hydroxide according to a certain molar ratio, calcining in an oxygen atmosphere roller way kiln, and smashing to obtain a high-nickel primary smashed material; 2), adding a dispersant, a binder and graphene into a solvent, and stirring and dispersing well to form graphene electroconductive paste with certain solid content, wherein the graphene electroconductive paste is a uniform emulsion in dispersion state; 3), stirring and mixing an oxygen-containing compound source with the high-nickel primary smashed material, adding the graphene electroconductive paste, stirring to obtain graphene mixed paste; 4), utilizing a spray dryer for drying, calcining in the oxygen roller way kiln,smashing, and screening to obtain a final graphene modified high-nickel product. The graphene modified high-nickel positive electrode material produced by adopting the method has the advantages of lowresidual alkali and excellent rate performance and circulating performance and is suitable for industrial production.

Owner:宁夏汉尧石墨烯储能材料科技有限公司

Shell casting method through contraction and then gasification of high-performance coating foam and mold sample of evanescent mode

InactiveCN102672103AStrong enoughSufficient dimensional accuracyFoundry mouldsFoundry coresSurface finishInvestment casting

The invention discloses a shell casting method through contraction and then gasification of high-performance coating foam and a mold sample of an evanescent mode. The method comprises the following steps of: manufacturing the mold sample; preparing an inner-layer coating and an outer-layer coating; spreading the coatings; drying the coatings; performing reduction and contraction; performing gasification and evanescence; and packing and casting, wherein the inner-layer coating is prepared by mixing and stirring an additive special for a Guilin No. 5 evanescent mode coating, refractory aggregate powder with 180-220 meshes and water; and the outer-layer coating is prepared by mixing and stirring an additive special for a Guilin No. 5 evanescent mode coating, refractory aggregate powder with thickness being 70-100 meshes and180-220 meshes in half and water; According to the method, the mold sample has sufficient strength, dimensional accuracy and surface smoothness; carbon defects such as recarburization, slag inclusion, air holes, cockles and carbon black caused by the foam mold sample can be eliminated; the method is applicable in casting the evanescent mode with any steel; the situation that 5-10 layers of coatings are coated, and 5-10 layers of dry sand are spread when in investment casting does not needed; roasting at the temperature of 1000 DEG C in a kiln is unnecessary; and the process is simple, has low cost, and has energy conservation and emission reduction.

Owner:刘翔 +1

Alumina-silica refractory brick containing light porous aggegate and its making process

The present invention relates to one kind of alumina-silica refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-SiO2 refractory material 30-70 wt%, compact Al2O3-SiO2 refractory material 0-35 wt%, fine corundum powder 5-25 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine mullite powder 5-15 wt% and fine clay powder 0-10 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% and one or two kinds of silicasol as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-silica refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

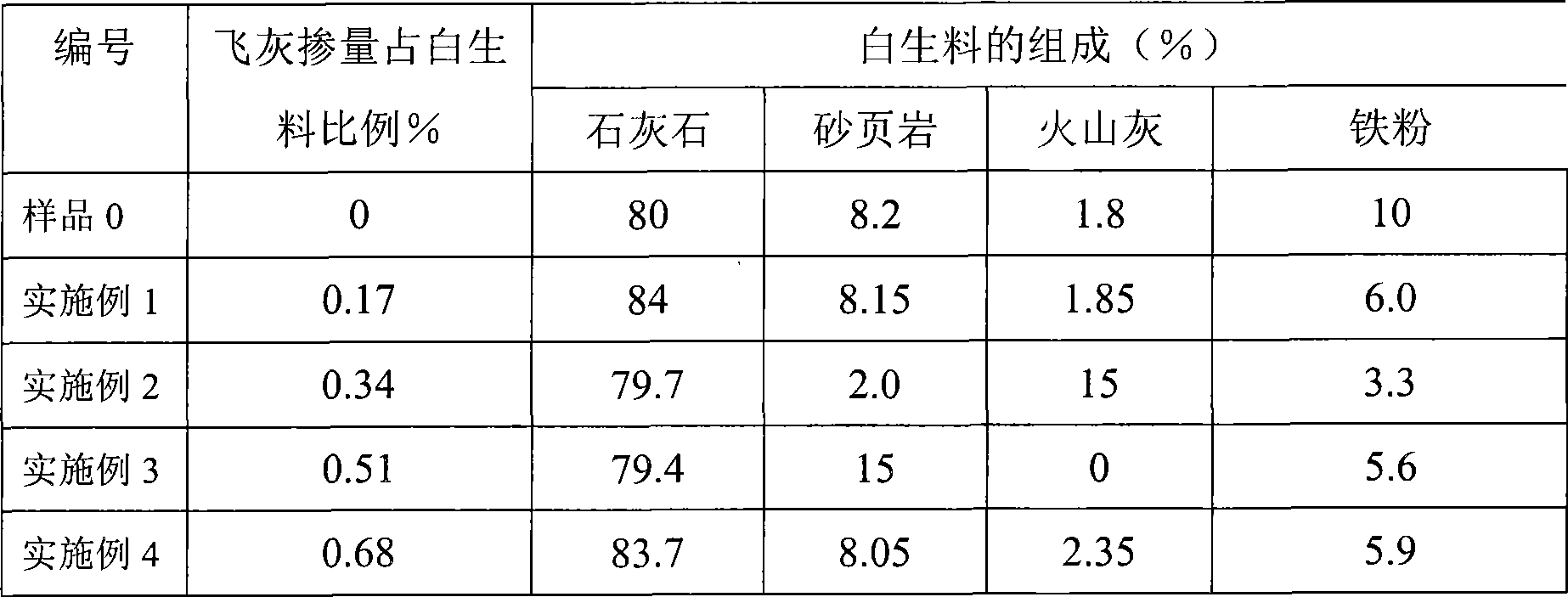

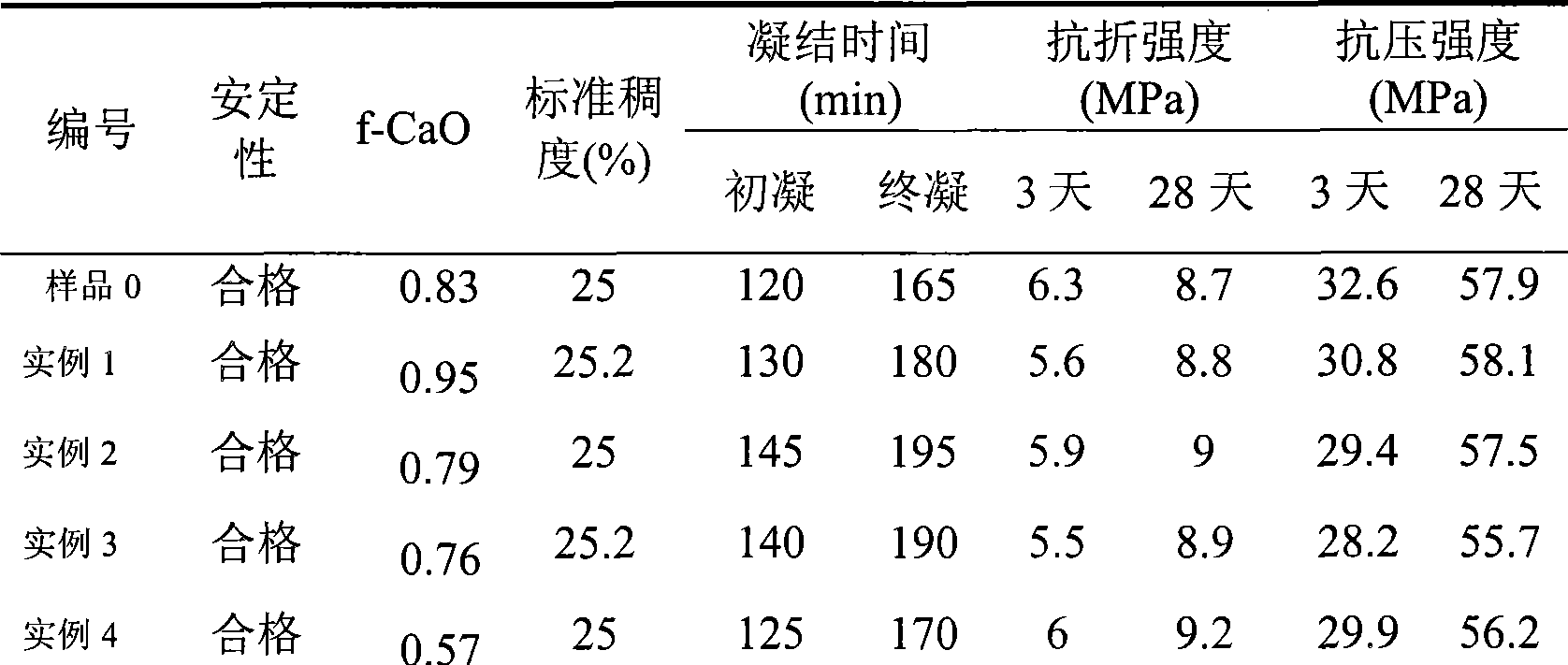

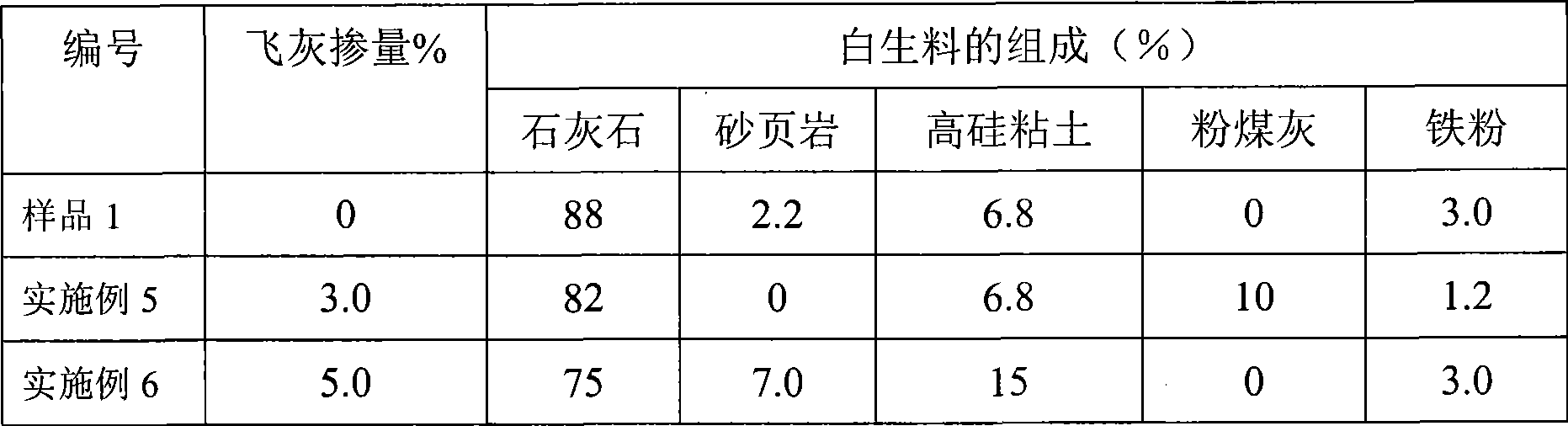

Method for producing portland cement clinker using domestic waste flying ash

The invention relates to a method for producing Portland cement clinker with incineration slag of municipal solid waste. The method solves the problem of crust and blockage caused by chlorine through the reconstruction of the prior kiln which is realized by mounting a by-way air exhaust device. For a kiln system with a kiln row and a furnace row which are independent from each other, the by-way air exhaust device is arranged in an uptake of a kiln end gas chamber in the kiln row close to a five-stage cylinder; while for common industrial kiln, the air exhaust device is arranged between an outlet of decomposing furnace and an inlet of the five-stage cylinder or arranged at an uptake of an outlet of the five-stage cylinder; the fly ash passes through a kiln head, the kiln end gas chamber, or the decomposing furnace and then is sprayed into the kiln. The use frequency of the by-way air exhaust device is between once per four hours and once per three days, the temperature of the air entering the by-way air exhaust device is controlled to be more than 950 DEG C. the method has the advantages of small reconstruction investment, low treatment cost, production of Portland cement clinker having wide application range and meeting JC / T853-1999 standards of Portland Cement Clinker, realization of reclamation, contribution to the development of cyclic economy, and reduction in consumption of natural resources and energy of the cement industry.

Owner:SOUTH CHINA UNIV OF TECH

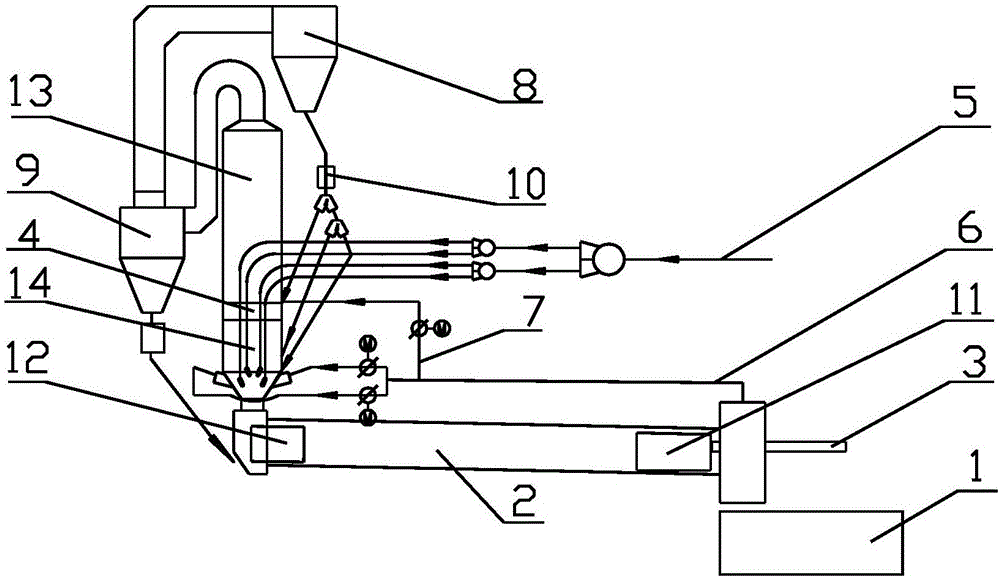

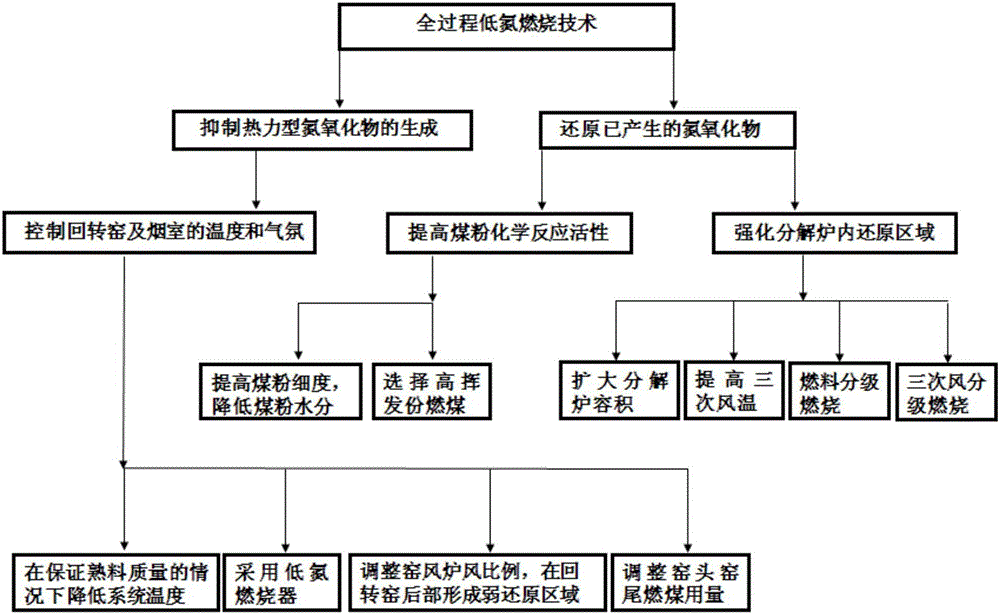

Whole-process low-nitrogen combustion technology applied to cement kiln for reduction of cement kiln NOx discharge quantity

InactiveCN106066126AReduce generationEmission reductionRotary drum furnacesLump/pulverulent fuel preparationNitrogenOxidation zone

The invention discloses a whole-process low-nitrogen combustion technology applied to a cement kiln for reduction of the cement kiln NOx discharge quantity. Preheaters, a decomposing furnace, a rotary kiln, a coal injection pipe, a tertiary air pipe as well as pulverized coal and raw material feeding of a kiln system are taken as a whole for systematic control, a user starts from inhibition of generation of NOx and reduction of generated NOx to scientifically and reasonably adjust and control the quality of the rotary kiln, the quality of decomposing furnaces, the quality of fuel, the mass of the fuel, reasonable distribution of a combustion device and combustion-supporting air and the like, and the temperature field and the atmosphere field of the kiln are systematically controlled. The technology mainly comprises a cooling machine (1), the rotary kiln (2), a kiln head pulverized coal combustion device (3), the decomposing furnace (4), a kiln tail pulverized coal combustion device (5), the tertiary air pipe (6), an air dividing pipe (7) of the tertiary air pipe (6), a fourth-stage suspending preheater (8), a fifth-stage suspending preheater (9) and a discharging pipe (10), wherein the rotary kiln (2) comprises an oxidation zone (11) and a reduction zone (12), and the decomposing furnace (4) comprises an oxidation zone (13) and a reduction zone (14).

Owner:BEIJING TRIUMPH INT ENG

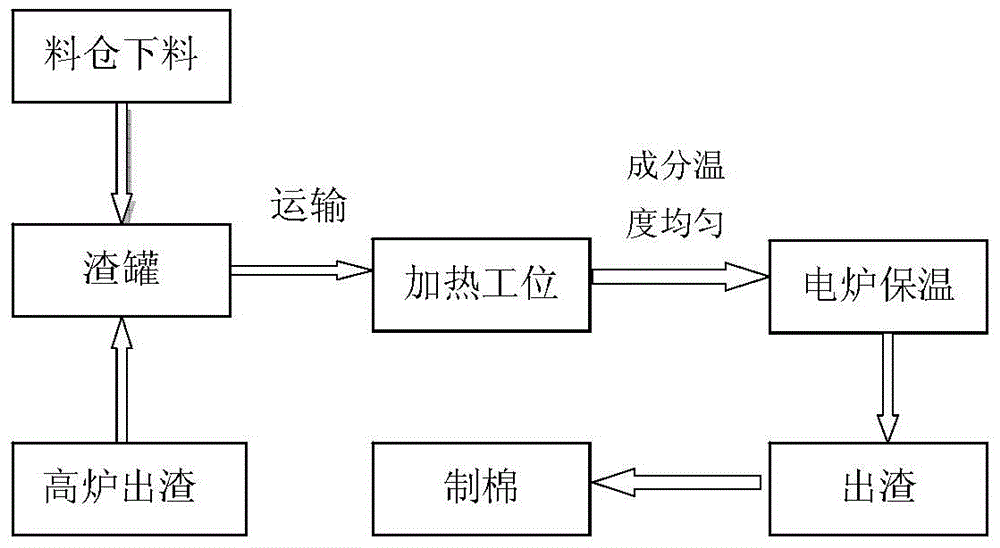

Melting method for production of mineral wool from liquid blast furnace slag

InactiveCN104909540AShorten conditioning cycleRealize economic benefitsGlass making apparatusElectric furnaceElectric furnacesDirect production

The present invention discloses a melting method for production of mineral wool from liquid blast furnace slag, during use of the liquid blast furnace slag for direct production of the mineral wool, an acidic additive is added into a liquid blast furnace slag tank for conditioning, the liquid blast furnace slag filled tank is heated below an electrode, an inert gas is blown on the bottom of the tank, and stirred, then the liquid blast furnace slag is poured into an electric furnace, the electric furnace is provided with the well-mixed liquid blast furnace slag with the amount of two times of the liquid blast furnace slag tank, and sustainedly heated for heat insulation; finally the furnace is opened for discharge of the slag, the furnace slag is continuously sent into a wool making machine to prepare into the mineral wool. Compared with high energy consumption of traditional cupola furnaces and kilns, by use of the process, sensible heat of the liquid blast furnace slag can be maximumly used, conditioning cycle can be shortened, meanwhile the contradiction between intermittent blast furnace slag discharge and mineral wool continuous production can be solved by the electric furnace, so that blast furnace ironmaking and mineral wool production processes can be better effectively combined to maximize economic benefits.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

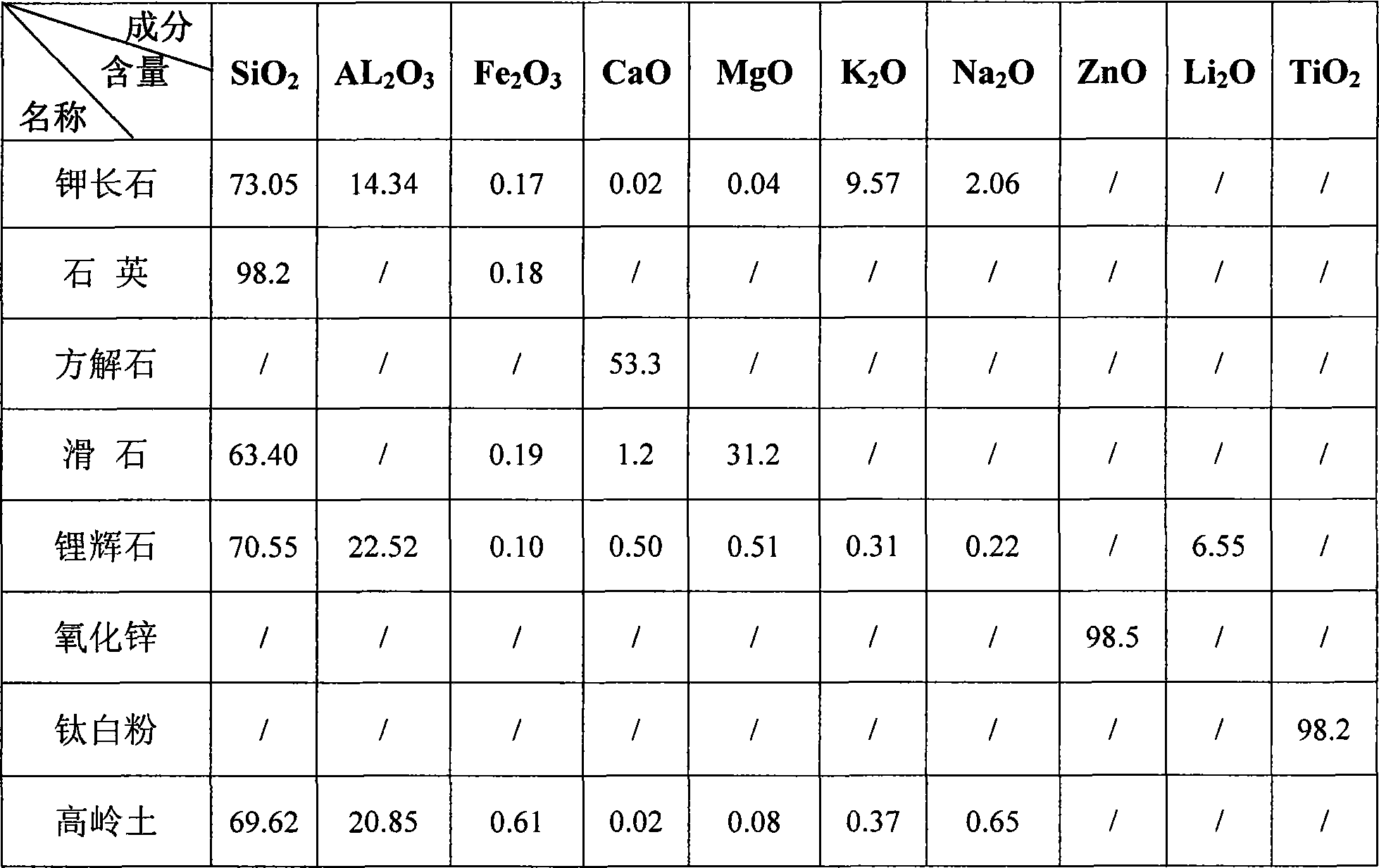

Medium temperature alabastrine galze and its pren process

The present invention is one kind of medium temperature alabastrine glaze including priming glaze and overglaze and its preparation process. The medium temperature alabastrine glaze is prepared with crystallizing agent of TiO2 and ZnO, crystallizing assistant MgO, CaO, Li2O, etc, borax for regulating crystal shape and glaze viscosity. The preparation process includes the following steps: milling the material in a ball mill for 24 hr, 320 mesh sieving, diluting with water to 48-50 Be deg, 120 mesh sieving the glaze sluury, applying priming glaze and applying overglaze, and sintering at 1230- 1280 deg.c in a kiln to form the alabastrine glaze.

Owner:HUNAN HUALIAN YIBAILI CERAMIC IND

High-nickel positive electrode material with composite coating layer and preparation method thereof

PendingCN110931797ASimple processInhibit side effectsMaterial nanotechnologyCell electrodesElectrical batteryLithium compound

The invention discloses a high-nickel positive electrode material with a composite coating layer and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing a high-nickel positive electrode material and a nano-coating material, and carrying out high-temperature sintering, cooling, crushing and sieving in a preheated muffle furnace under an oxygen atmosphere to obtain a nano-material-coated high-nickel positive electrode material; and (2) adding the high-nickel positive electrode material coated with the nano material into deionized water dissolved with a soluble lithium compound, uniformly stirring, slowly adding soluble phosphate, uniformly stirring, carrying out vacuum filtration, drying and re-burning in a kiln, cooling, crushing and sieving to obtain the high-nickel positive electrode material with the composite coating layer. According to the high-nickel positive electrode material with a composite coating layer and the preparationmethod thereof, multi-layer uniform coating of the nano material and phosphate is realized through dry-process and wet-process coating, and the prepared positive electrode material has the advantagesof good cycle performance, good thermal stability and the like, and the preparation process is simple, and the positive electrode material can be used for industrial mass production and has a wide application prospect in lithium ion battery production.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Glass wool for dry vacuum insulated panel core material and production method thereof

The invention discloses a glass wool for a dry vacuum insulated panel core material and a production method thereof. The production method comprises the following steps of mixing the following components in parts by mass to form a mixture: 10.0-40.0 parts of quartz powder, 10.0-12.5 parts of feldspar, 9.0-11.0 parts of sodium borate, 1.5-3.5 parts of calcspar, 2.5-7.0 parts of dolomite, 7.0-15.0 parts of sodium carbonate and 15.0-60.0 parts of plate glass; adding the mixture into a melting tank of a kiln to melt and prepare vitreous humour; putting the vitreous humour into a bushing well and a centrifugal plate, and conveying to a centrifugal machine to spin and prepare the glass wool. The glass wool disclosed by the invention can be directly prepared into the dry vacuum insulated panel core material. Compared with the insulated panel core material produced by a wet process, the glass wool is short in production flow; and wet pulp is prepared without adding water or baking. Therefore, the production efficiency is improved; the energy source is greatly saved; the price of the insulated panel is reduced, and strong popularization and use of the market are facilitated.

Owner:安徽吉曜玻璃微纤有限公司

Wall scraping gypsum powder and its production process

InactiveCN1974470AGood for condensationImprove physical and chemical propertiesAdhesiveSuspending Agents

The present invention provides one kind of wall scraping paint with gypsum as main material and its production process. The wall scraping paint is produced with natural gypsum or chemical gypsum, water retaining agent, adhesive, retarding agent, suspending agent and calcium carbonate powder. The production process includes crushing natural gypsum or chemical gypsum to fineness smaller than 80 mesh, calcining in a kiln at 180 -400 deg.c for 2-4, mixing with water retaining agent, adhesive, retarding agent, suspending agent and calcium carbonate powder, and milling into 250-600 mesh fine powder. The wall scraping paint is scraped to wall and has excellent anticracking capacity, high waterproof property, no pollution and other advantages.

Owner:利文海

Preparation method for high-specific surface anti-alkalosis denitration catalyst applicable to cement kiln

ActiveCN103263913ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention provides a preparation method for a high-specific surface anti-alkalosis denitration catalyst applicable to a cement kiln, which belongs to the field of reduction of NOx in the cement kiln. The preparation method comprises the following steps: uniformly mixing a titanium source solution with SiO2 sol, then adding a manganese salt, a cerium salt and an auxiliary agent and continuing stirring so as to obtain a mixed solution; successively adding a urea solution, ammonia water and hydrogen peroxide into the mixed solution until no precipitate is produced and continuing stirring for 1 to 3 h; and then carrying out centrifugal washing sequentially with distilled water and absolute ethyl alcohol and carrying out drying at a temperature of 75 to 110 DEG C for 6 to 24 h and then calcining at a temperature of 450 to 650 DEG C for 2 to 6 h so as to prepare the 40-mesh to 60-mesh catalyst. Compared with catalysts having same components and prepared by using a sol-gel method and an impregnation method, the catalyst prepared in the invention has the advantages of a high specific surface area, a high denitration rate and alkali resistance. The preparation method for the catalyst is simple, easy to operate and applicable to industrial production.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com