Ferrite magnetic core for network communication and method for producing the same

A manganese-zinc ferrite and magnetic core technology, which is applied in the field of ferrite magnetic core and its preparation, can solve the problem of low superposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

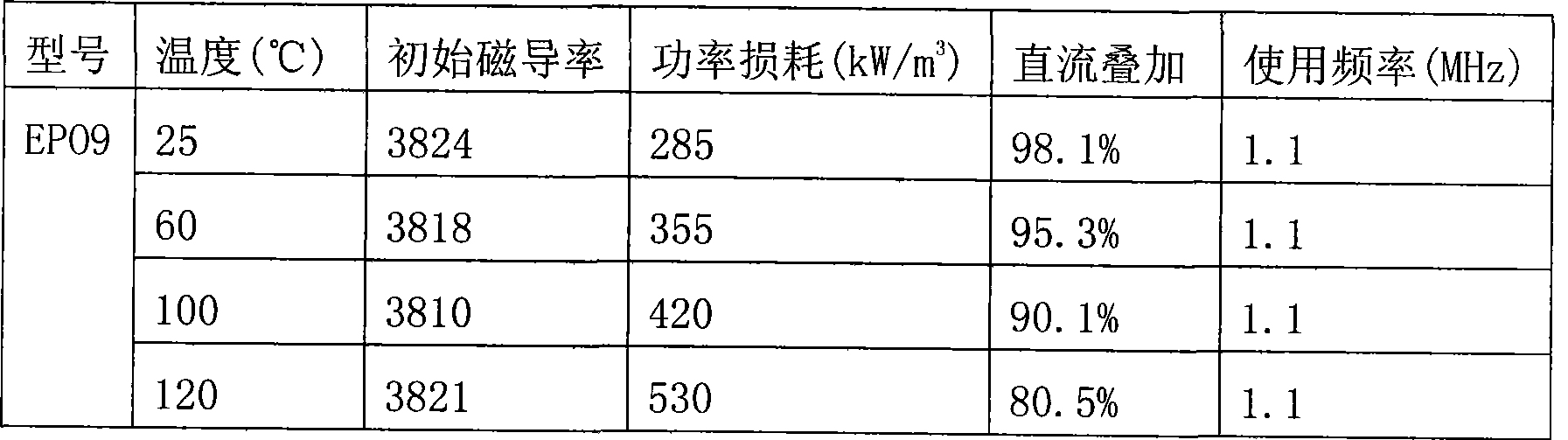

[0013] Accurately weigh Fe 2 o 3 (purity≥99.3%): 53.5mol%; MnO (containing manganese≥71%): 33.2mol%; ZnO (purity≥99.7%): 8.9mol%, NiO (purity≥98.5%): 1.5mol%, CuO ( Purity ≥ 99%): 2.9mol%, use a ball mill to mix the raw materials evenly, the average particle size of the red slurry is required to reach 0.9-1.5μm, pre-calcine after spray drying, and keep the temperature at 950±50°C for 2-3 hours . During secondary ball milling, auxiliary components, Co 2 o 3 0.065wt%, WO 3 0.02wt%, SnO 2 0.08wt%, Bi 2 o 3 0.03wt%, CaO 0.05wt%, Nb 2 o 5 0.03wt%, V 2 o 5 0.02wt%, and an appropriate amount of pure water and dispersant for ball milling to obtain a black slurry with an average particle size of 1.0-1.6μm, adding 0.8-1.8wt% of PVA and 0.1-0.2wt% of defoamer during spray granulation to obtain Granular material with a particle size distribution of 75 μm to 250 μm. Compress T25×15×10(mm), EP09 magnetic cores with a rotary press, and the green density is 3.0±0.25g / cm 3 ...

Embodiment 2

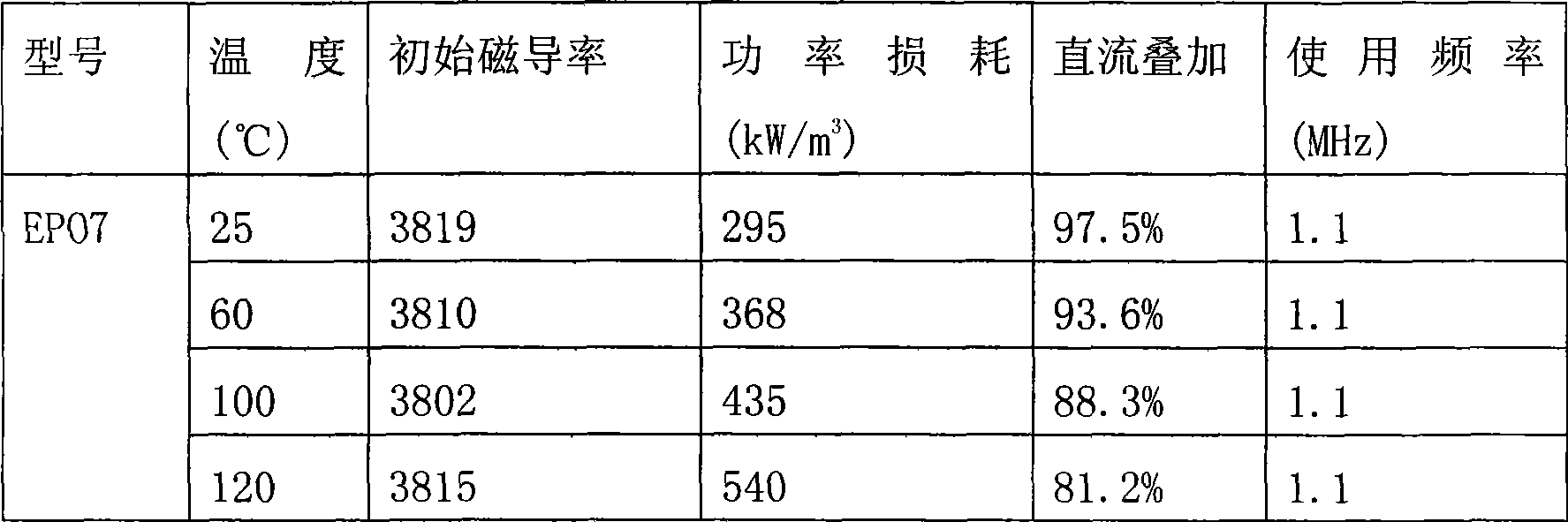

[0018] Accurately weigh Fe 2 o 3 (purity≥99.3%): 51.2mol%; MnO (containing manganese≥71%): 37.8mol%; ZnO (purity≥99.7%): 9.35%; NiO (purity≥98.5%): 0.01~5mol%, CuO (Purity ≥ 99%): 0.01~3mol% Use a ball mill to mix the raw materials evenly. The average particle size of the red slurry is required to reach 0.9~1.5μm. Hours, control the formation of spinel phase to 20% to 35%. During secondary ball milling, auxiliary components, Co 2 o 3 0.085wt%, WO 3 0.03wt%, SnO 2 0.1wt%, Bi 2 o 3 0.02wt%, CaO 0.03wt%, Nb 2 o 5 0.03wt%, V 2 o 5 0.025wt%, and an appropriate amount of pure water and dispersant for ball milling to obtain a black slurry with an average particle size of 1.0-1.6μm, adding 0.8-1.8wt% of PVA and 0.1-0.2wt% of defoamer during spray granulation, and making Granular materials with a particle size distribution of 75 μm to 250 μm are obtained. Press and form T25×15×10(mm), EP07 magnetic cores with a rotary press, with a green density of 3.0±0.25g / cm3; sinte...

Embodiment 3

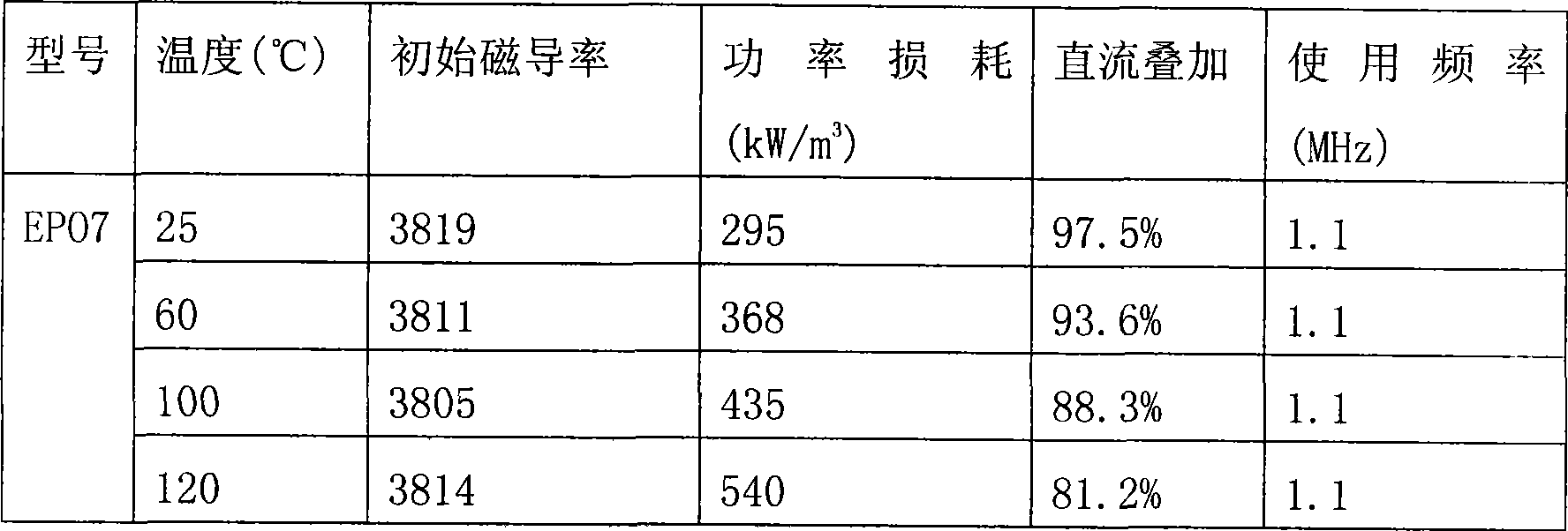

[0023] Accurately weigh Fe 2 o 3 (purity≥99.3%): 57.2mol%; MnO (containing manganese≥71%): 25.8mol%; ZnO (purity≥99.7%): 9.35%; NiO (purity≥98.5%): 0.01~5mol%, CuO (Purity ≥ 99%): 0.01~3mol% Use a ball mill to mix the raw materials evenly. The average particle size of the red slurry is required to reach 0.9~1.5μm. Hours, control the formation of spinel phase to 20% to 35%. During secondary ball milling, auxiliary components, Co 2 o 3 0.085wt%, WO 3 0.03wt%, SnO 2 0.1wt%, Bi 2 o 3 0.02wt%, CaO 0.03wt%, Nb 2 o 5 0.03wt%, V 2 o 5 0.025wt%, and an appropriate amount of pure water and dispersant for ball milling to obtain a black slurry with an average particle size of 1.0-1.6μm, adding 0.8-1.8wt% of PVA and 0.1-0.2wt% of defoamer during spray granulation, and making Granular materials with a particle size distribution of 75 μm to 250 μm are obtained. Press and form T25×15×10(mm), EP07 magnetic cores with a rotary press, with a green density of 3.0±0.25g / cm3; sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com