Patents

Literature

169results about How to "Reasonable particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

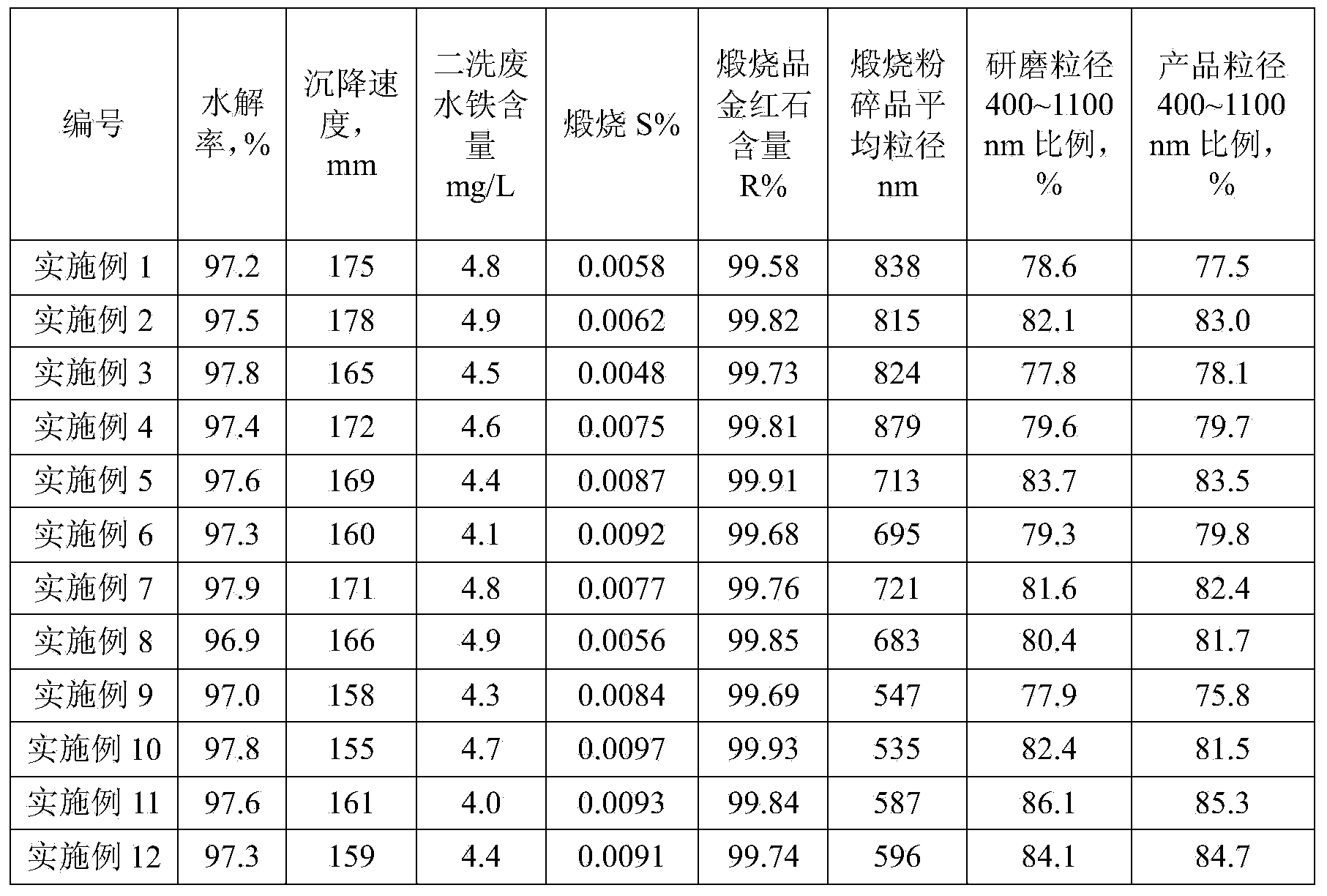

Production method of titanium dioxide particles

ActiveCN103880070AStrong scattering abilityReasonable particle size distributionTitanium dioxideCoatingsInfraredPhysical chemistry

The invention relates to a production method of titanium dioxide particles applied to paint. According to the production method and on the basis of the existing sulfate process titanium dioxide production line, technical indexes and operation methods of processing steps such as titanium liquid index, preparation of seed crystal, normal-pressure hydrolysis, salt treatment, calcining and aftertreatment are regulated and improved and detection and control are also regulated correspondingly, thus obtaining total rutile type titanium dioxide particles more than 60% of which have the particle size being 400 to 1100 nanometers. The titanium dioxide particles produced by the production method disclosed by the invention has an excellent capability of reflecting a near-infrared ray wave part of the sunlight, and products such as the paint and plastic products prepared from the titanium dioxide particles have good cooling and consumption reduction effects.

Owner:JIANGSU TOP FINE NEW RAW MATERIAL CO LTD +1

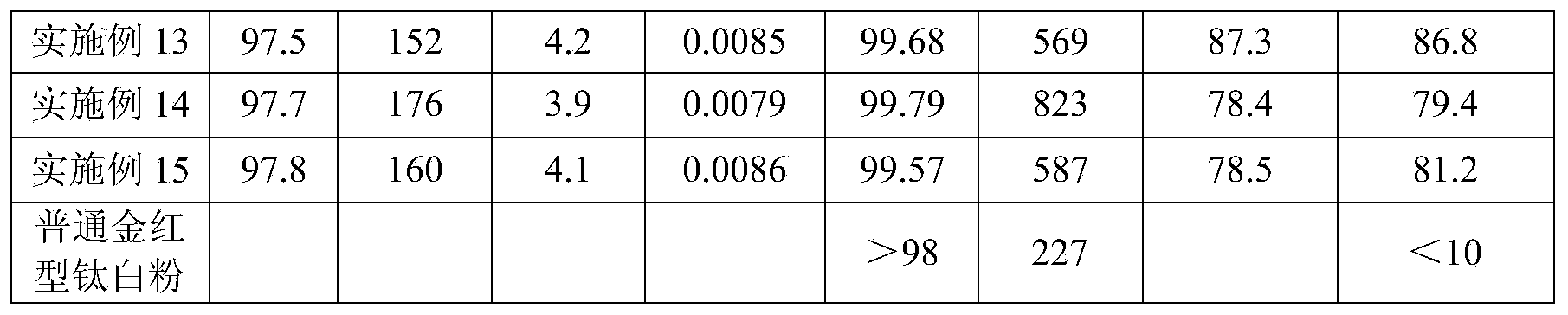

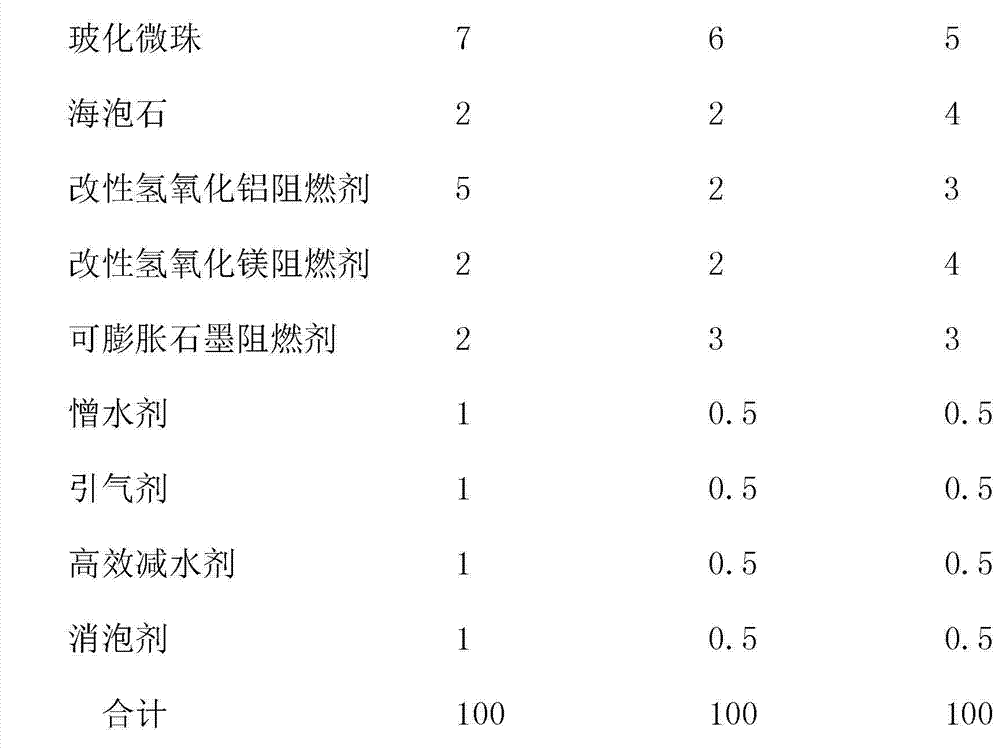

Thin fire-resistant/flame-retardant paint for tunnel and preparation method thereof

The invention relates to thin fire-resistant / flame-retardant paint for a tunnel and a preparation method thereof. The paint is prepared from the following raw materials in percentage by weight: 40-50% of silicate cement, 5-10% of high-alumina cement, 1-5% of fly ash, 1-5% of redispersible rubber powder, 1-5% of aluminum silicate fiber, 5-10% of expanded perlite, 5-10% of vermiculite, 5-10% of hollow glass microsphere, 5-10% of vitrified microsphere, 1-5% of sepiolite, 1-5% of modified aluminum hydroxide flame retardant, 1-5% of modified magnesium hydroxide flame retardant, 1-5% of expandable graphite flame retardant, 0.5-1% of air entraining agent, 0.5-1% of water reducing agent, 0.5-1% of water repelling agent and 0.5-1% of defoaming agent. The paint provided by the invention has excellent bonding strength, high fire resistance, low heat conductivity and remarkable sound absorption and noise reduction effect, further has favorable moisture resistance, water resistance and durability, and effectively reduces the coating thickness, saves the resources and lowers the construction difficulty on the premise of meeting Chinese standards and related specifications.

Owner:BAOJI TIEJUN CHEM ENG ANTI CORROSION INSTALLATION

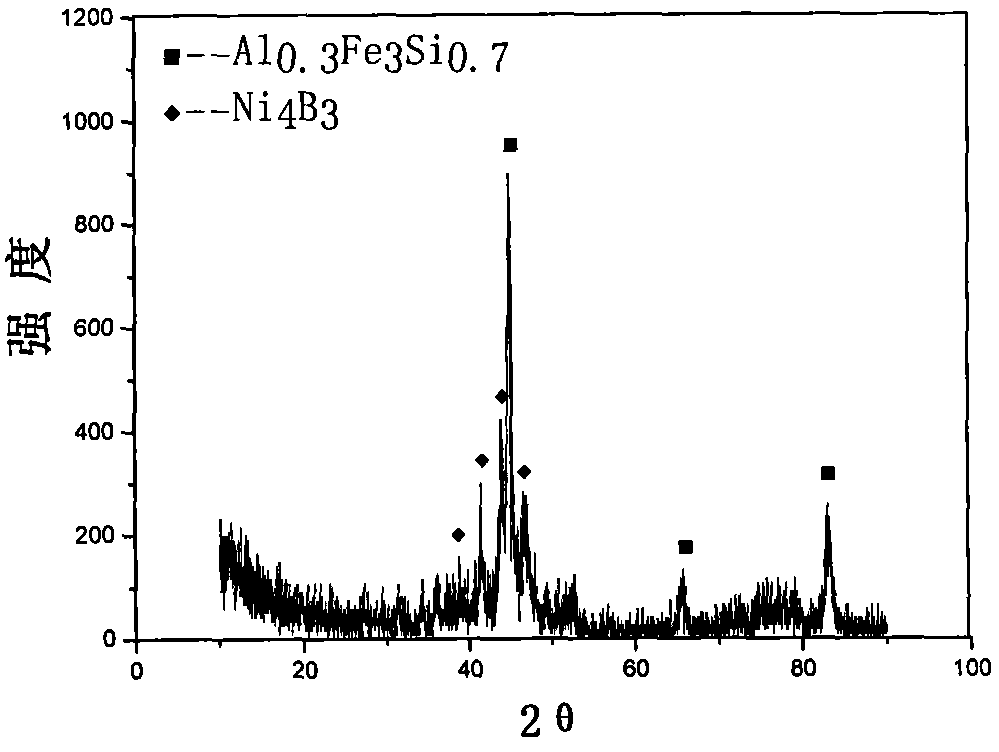

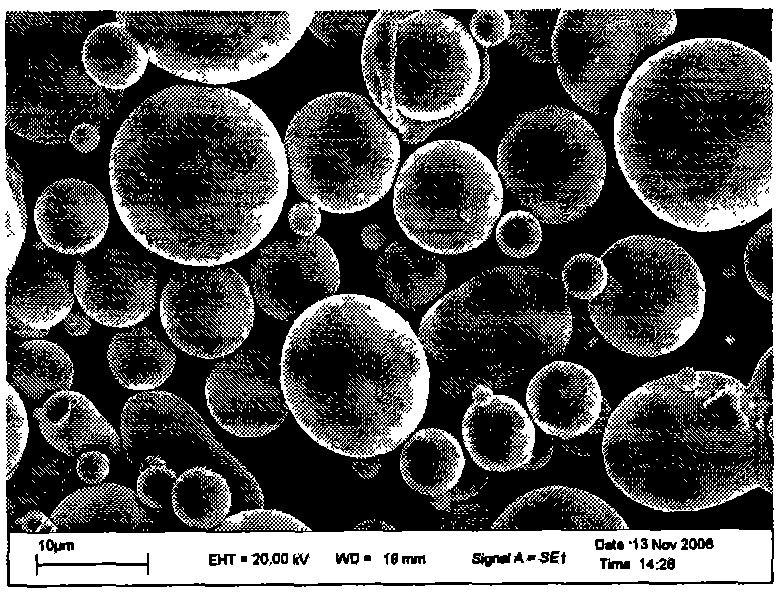

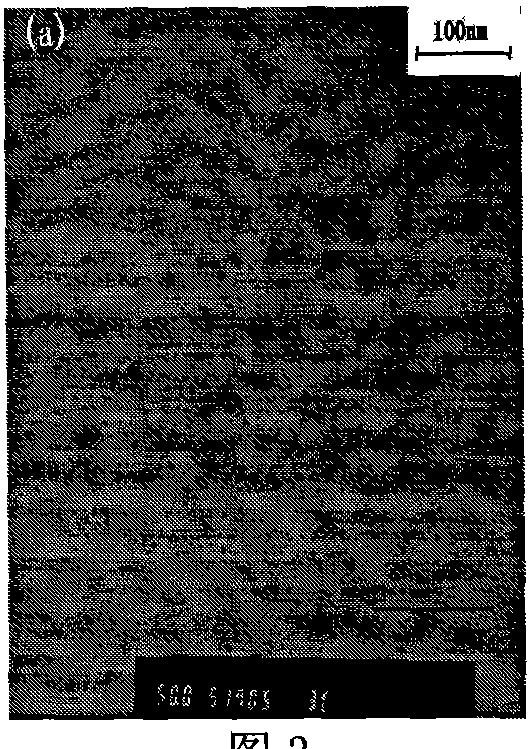

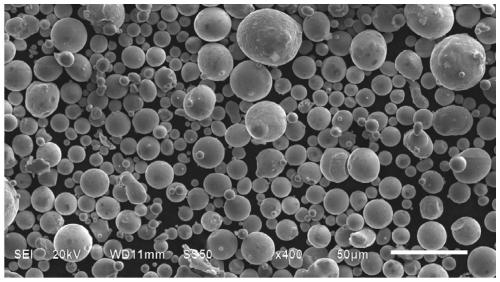

Fe-based amorphous nano-coating powder and its argon atomization production

A Fe-based amorphous nano-crystal spraying powder and its argon atomizing production are disclosed. The spraying powder consists of Cr 8-15wt%, Ni 8-16wt%, Si 2.8-5.7wt%, B 2.8-5wt%, W 2-8wt%, Mo 2-8wt%, Co 0.5-1wt%, Al 1-4wt% and Fe residues. The process is carried out by proportioning for ingredients, vacuum smelting, atomizing and screening powders. It has excellent fluidity and stability.

Owner:UNIV OF SCI & TECH BEIJING

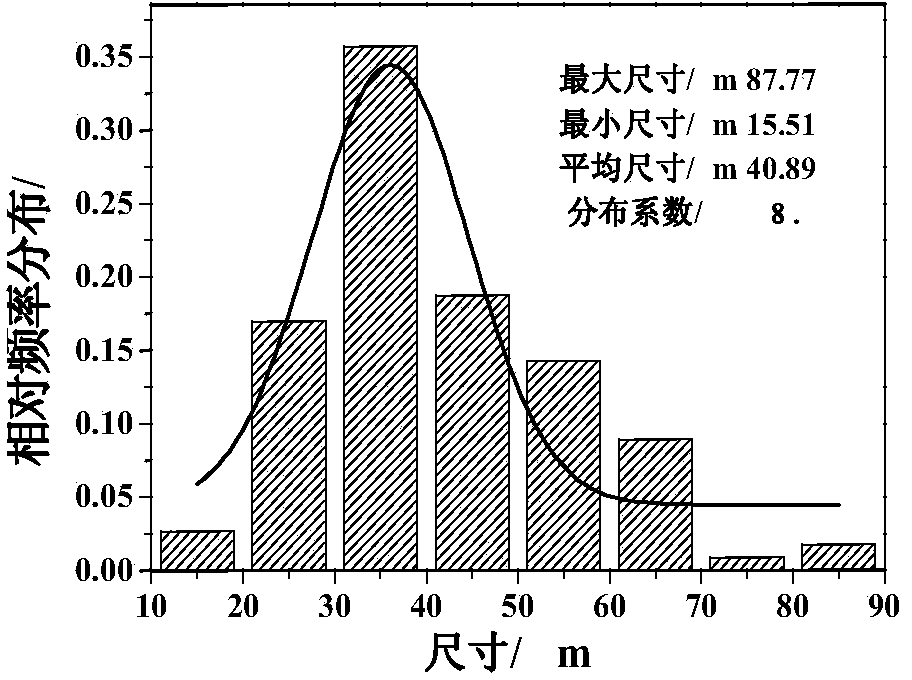

Highly dispersed sliver powder and conductive silver paste for film batteries

ActiveCN103192074AIncrease or decrease exposure timeIncrease or decrease dosageConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention discloses highly dispersed sliver powder and conductive silver paste for film batteries. The highly dispersed sliver powder comprises polymer microspheres and nano-sliver coatings on the surfaces of the polymer microspheres. The polymer microspheres are made from methacrylic resin, photoinitiator 2, 4, 6-trimethylbenzoyl-diphenylphosphine oxide, and polyvinyl alcohol by ultraviolet irradiation. The conductive silver paste for film batteries is formed by well mixing the highly dispersed sliver powder with glass binder and organic solvent. The highly dispersed sliver powder has the advantages that the polymer microspheres are predictable and controllable in morphology and reasonable in size distribution by increasing or decreasing the time of UV (ultraviolet irradiation), the nano-silver powder synthetized in situ can be evenly and compactly coated on the surfaces of the polymer microspheres, the consumption of noble metal, the sliver powder, can be decreased, production cost is lowered, dispersibility and stability of the nano-sliver powder are also increased greatly, and conductivity of the sliver paste is further increased.

Owner:SUZHOU YUXI NEW MATERIAL TECH

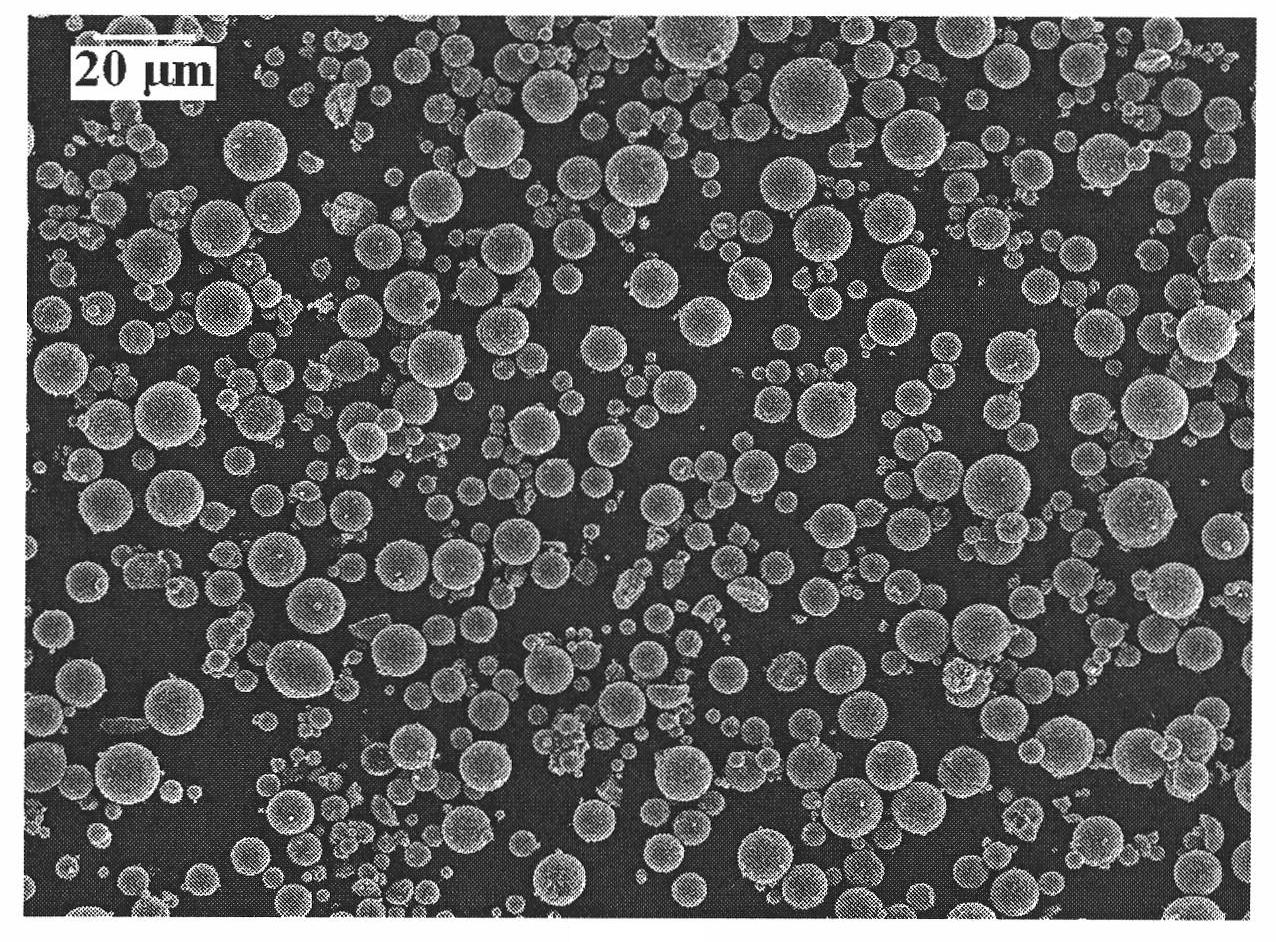

Method of preparing alumina ceramic prilling powder for sealed ring

The invention relates to a preparation method for alumina ceramic granulated powder used by a sealing ring, which is characterized in that the preparation process comprises: (1) weighting and mixing alpha alumina, silicon powder, light calcium carbonate, kaolin, burning talc magnesia and yttria, carrying out dry milling, crashing and uniformly mixing; (2) placing the uniformly mixed powder in a ball mill, diluting, adding a dispersant, a binder and a release agent and milling into slurry; (3) screening the milled slurry, removing iron, putting in a spray drying tower to carry out spray granulation; and (4) screening the spray granulated powder by a 40-mesh screen and a 200-mesh screen, taking the powder between the two screens as the finished product. The granulated powder prepared by the method of the invention has the advantages of solid granule, reasonably distributed granularity, large loose packed density, moderate strength, good fluidity and easy mold release. Moreover, the alumina sealing ring can be provided with microcrystalline structure only through the common dry pressing and sintering technology. The ceramic article has high tightness, and the surface of which has no pores found when being amplified by 20 times after abrasive polishing.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS

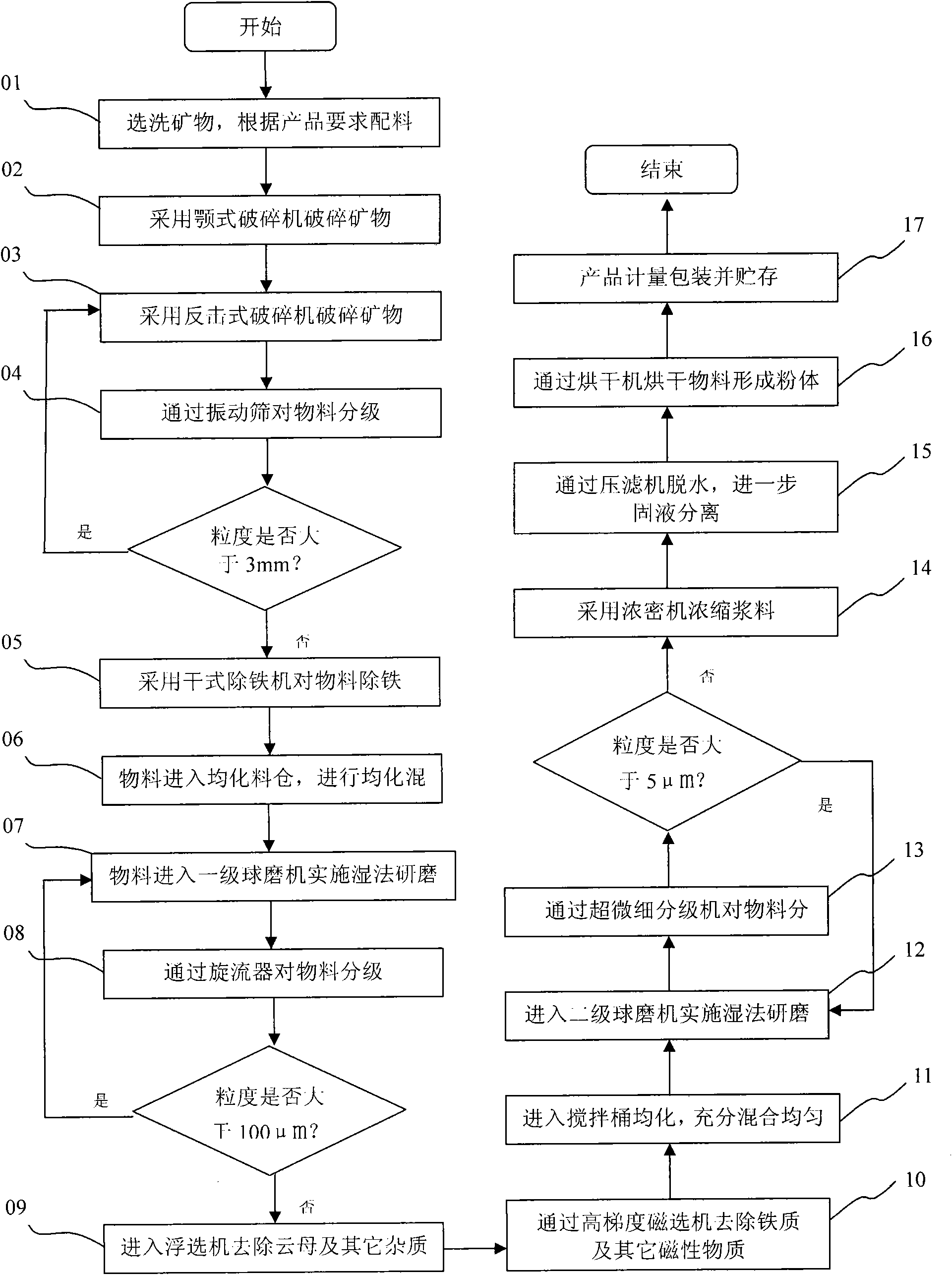

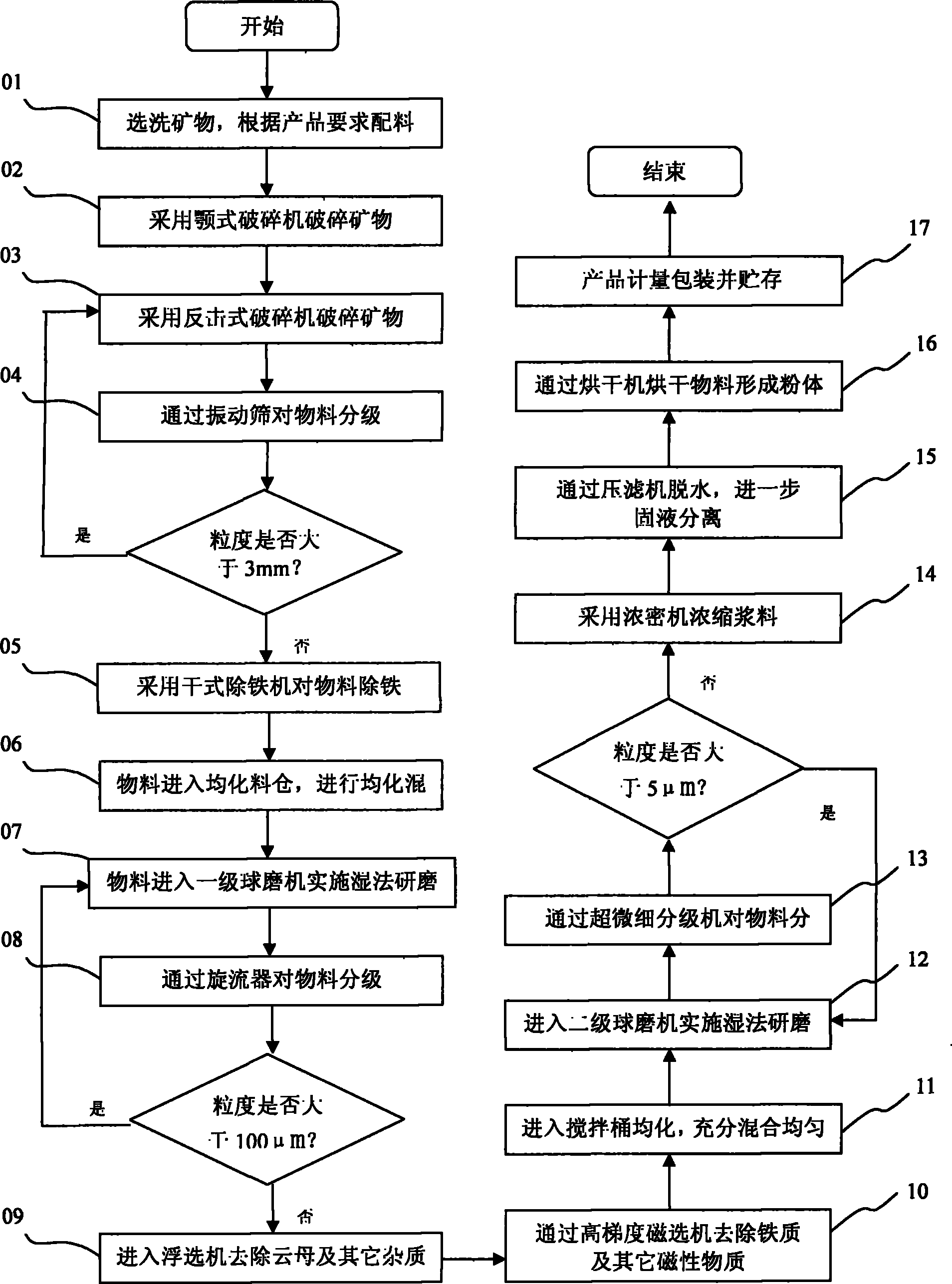

Method for preparing nepheline syenite powder

InactiveCN101912811AMeeting Structural Ceramic RequirementsUniform changeFlotationWet separationClosed loopEngineering

The invention relates to a method for preparing nepheline syenite powder. The method comprises the following steps of: elutriating and washing raw materials; smashing ores; performing graded screening; performing ball milling and fine crushing; removing impurities and filtering; and dewatering and drying, wherein the impurity-removing and filtering step comprises a flotation procedure for removing mica in the nepheline syenite. A two-stage closed-loop wet grinding process, a flotation process and a magnetic separation and impurity removing process are adopted by the method, so that impuritiessuch as the mica and the like can be removed basically and a contradiction between purification and super small product particle size is solved. Material smashing and grinding are performed by using a closed-loop system, so that power consumption is lowered to the maximum extent and the reasonable distribution of the product particle size is ensured simultaneously. A new high-purity nepheline syenite material which hardly contains any mica impurity and is prepared by the method has TiO2 content of lower than 0.01 percent and Fe2O3 content of lower than 0.10 percent and meets the requirements of functional ceramics and structural ceramics.

Owner:广东奥胜新材料有限公司

Heat insulating and preserving coating for exterior wall of building

ActiveCN103740188AHigh compressive strengthImprove stabilityCoatingsDefoaming AgentsPolymer chemistry

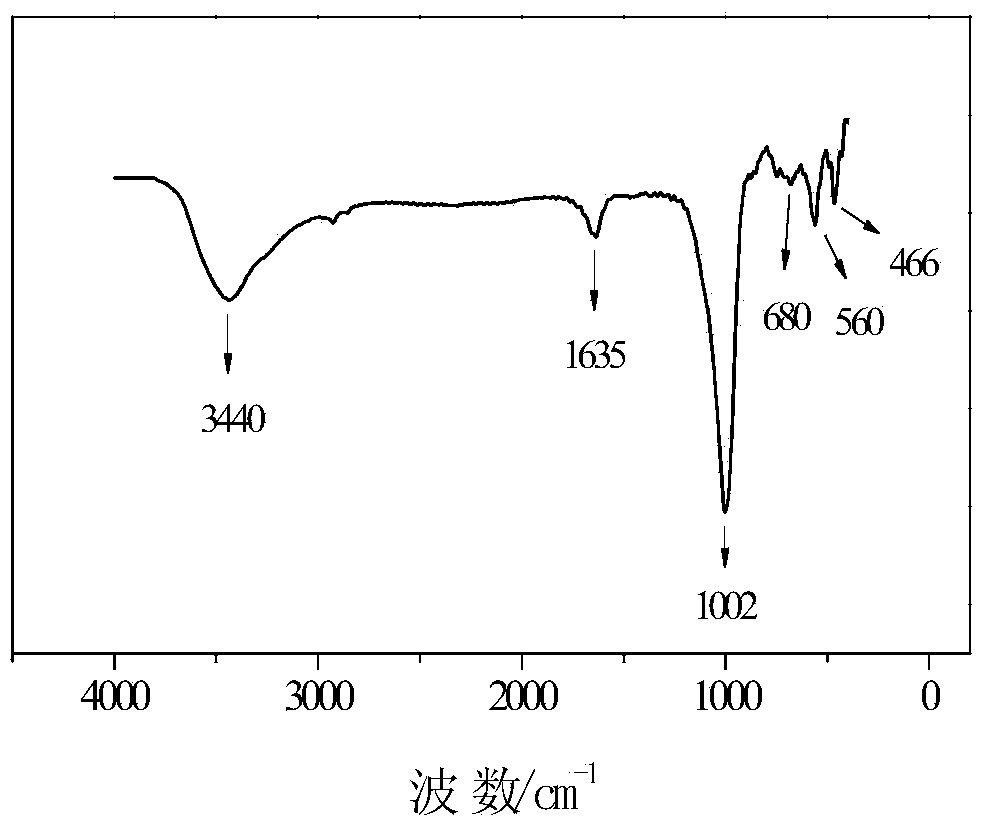

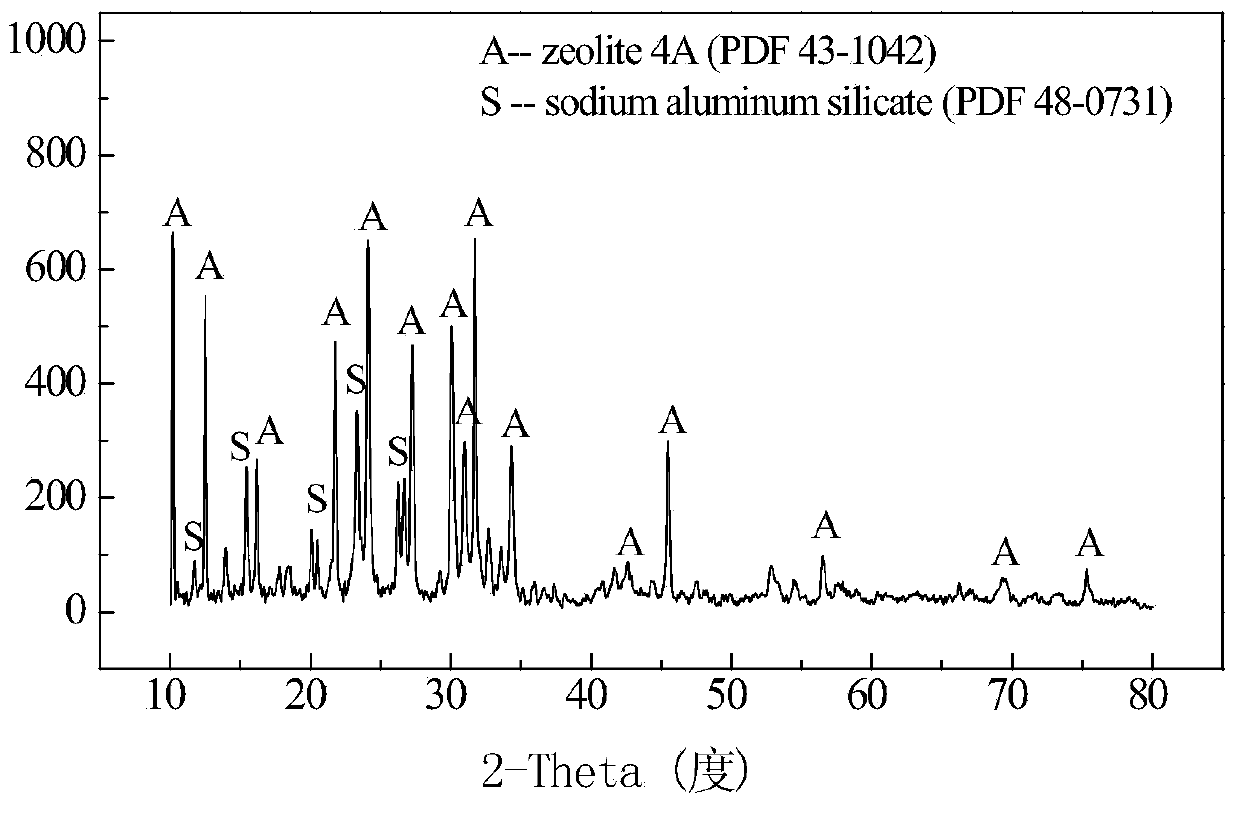

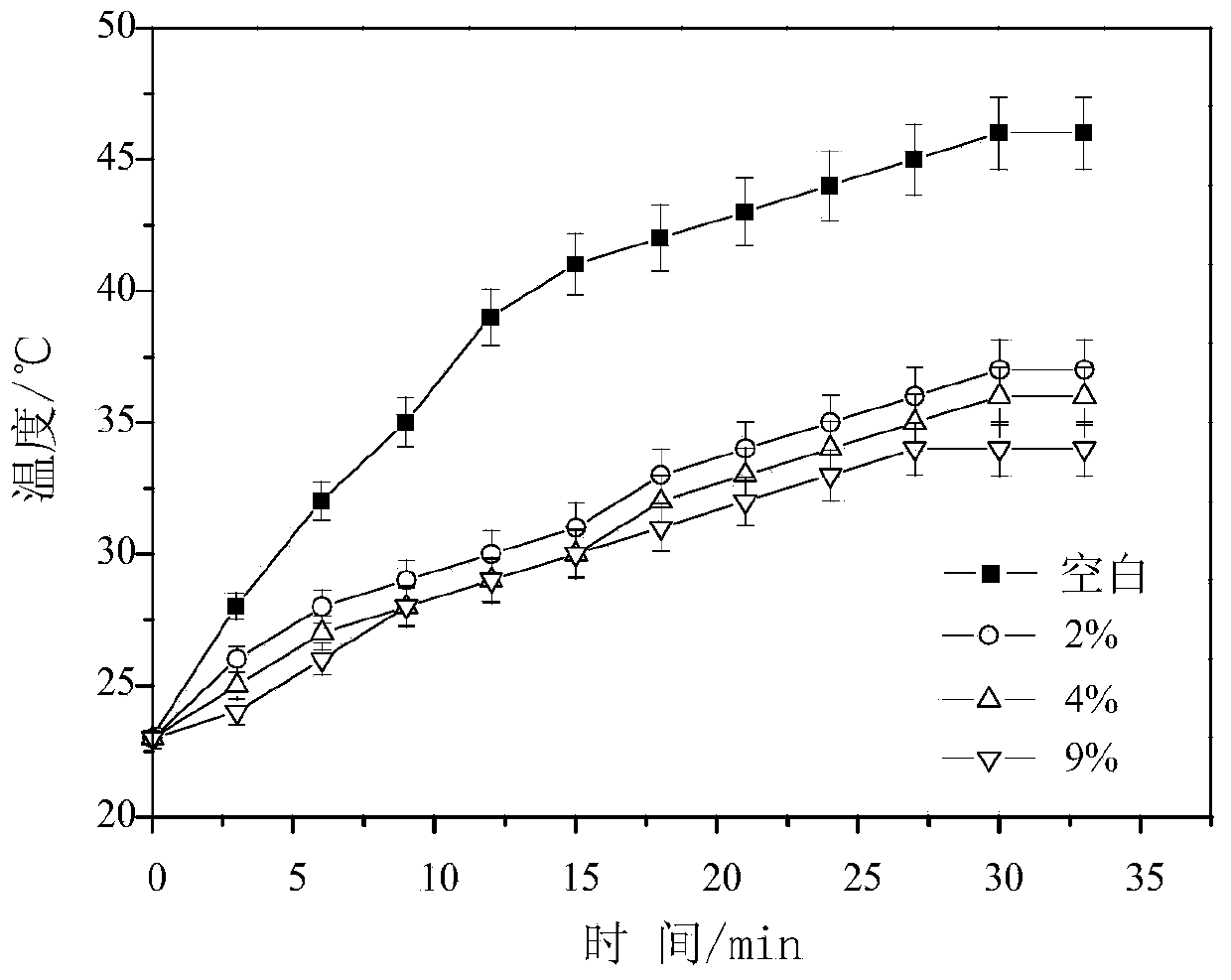

The invention provides a heat insulating and preserving coating for an exterior wall of a building. The heat insulating and preserving coating comprises the components: polymer emulsion, functional filler, titanium dioxide, a thickening agent, a wetting agent, a dispersing agent, a defoaming agent and water, wherein the functional filler is a self-prepared fly ash zeolite molecular sieve; the polymer emulsion is soft styrene-acrylic emulsion. The coating has the advantages that a coating layer formed on a building wall body is outstanding in performance, the heat insulating and preserving effect is superior to that of other similar heat preserving coatings, and the temperature difference can reach more than 10 DEG C compared with a blank phase; in addition, the heat insulating and preserving coating has the advantages of being environmentally-friendly, nontoxic, high in adhesive force, difficult to crack, easy to construct, etc., is applicable to the coating layer for heat preserving of the exterior wall of the building, and shows a remarkable environmental protection and energy saving effect.

Owner:SHANXI UNIV

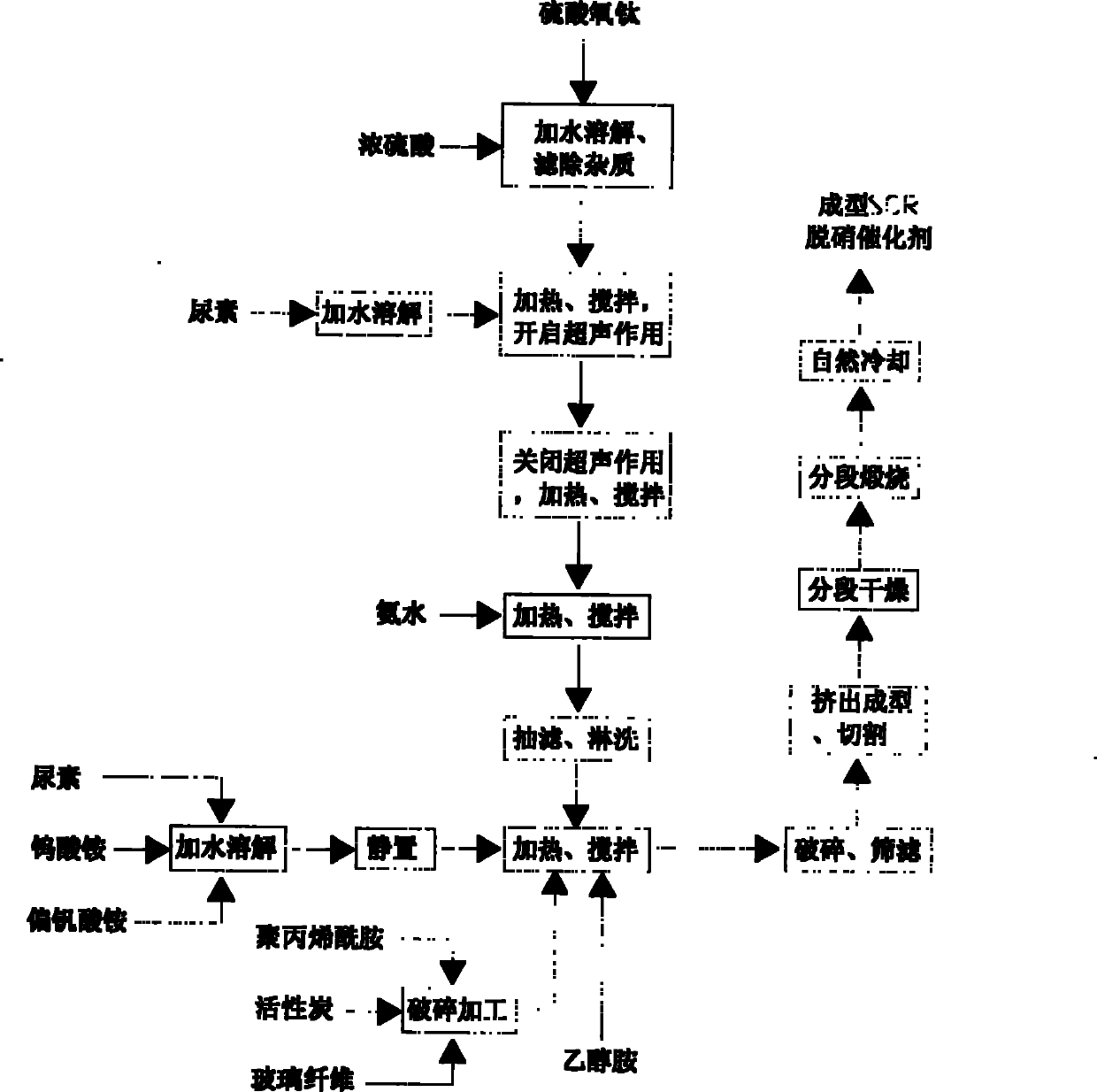

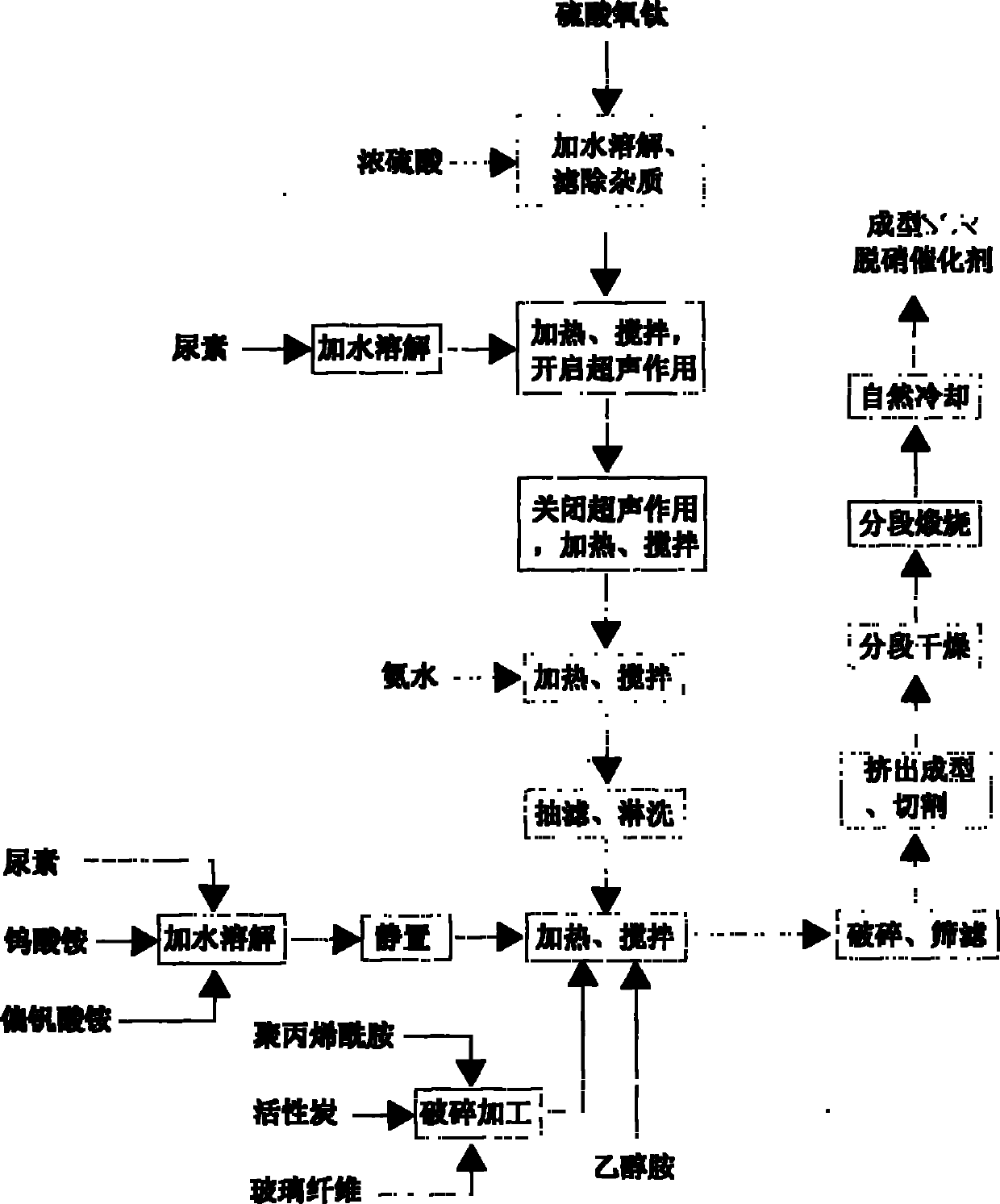

Method for preparing formed selective catalytic reduction denitration catalyst by using ultrasonic mixing sedimentation method

InactiveCN101791549ASmall particle sizeGood dispersionDispersed particle separationCatalyst activation/preparationTungstateAmmonium metavanadate

The invention discloses a method for preparing a formed selective catalytic reduction (SCR) denitration catalyst by using an ultrasonic mixing sedimentation method, comprising the following steps of: preparing metatitanic acid as a dipping carrier by using the processes of uniform sedimentation and direct sedimentation sequentially and being assisted by an ultrasonic strengthened reaction process by taking industry titanyl sulfate as a raw material; then mixing with an ammonium metavanadate-ammonium tungstate-oxalate solution, a flocculating agent comprising polyacrylamide and glass fibre, a structure promoter, and the like, and stirring to finish the processes of active component dipping and loading and plastic pasty master batch preparation synchronously. The prepared master batch is processed by a vacuum-extruder after finely crushed to obtain a formed catalyst green body, and finally the preparation process of the formed SCR denitration catalyst is finished through drying and sintering operations. Compared with the traditional preparation process of the SCR denitration catalyst, the method has simple and clear process and high production efficiency, and the raw materials for preparing the carrier of the catalyst have wide sources and low cost, thereby lowering the production cost to a certain extent.

Owner:SOUTHEAST UNIV

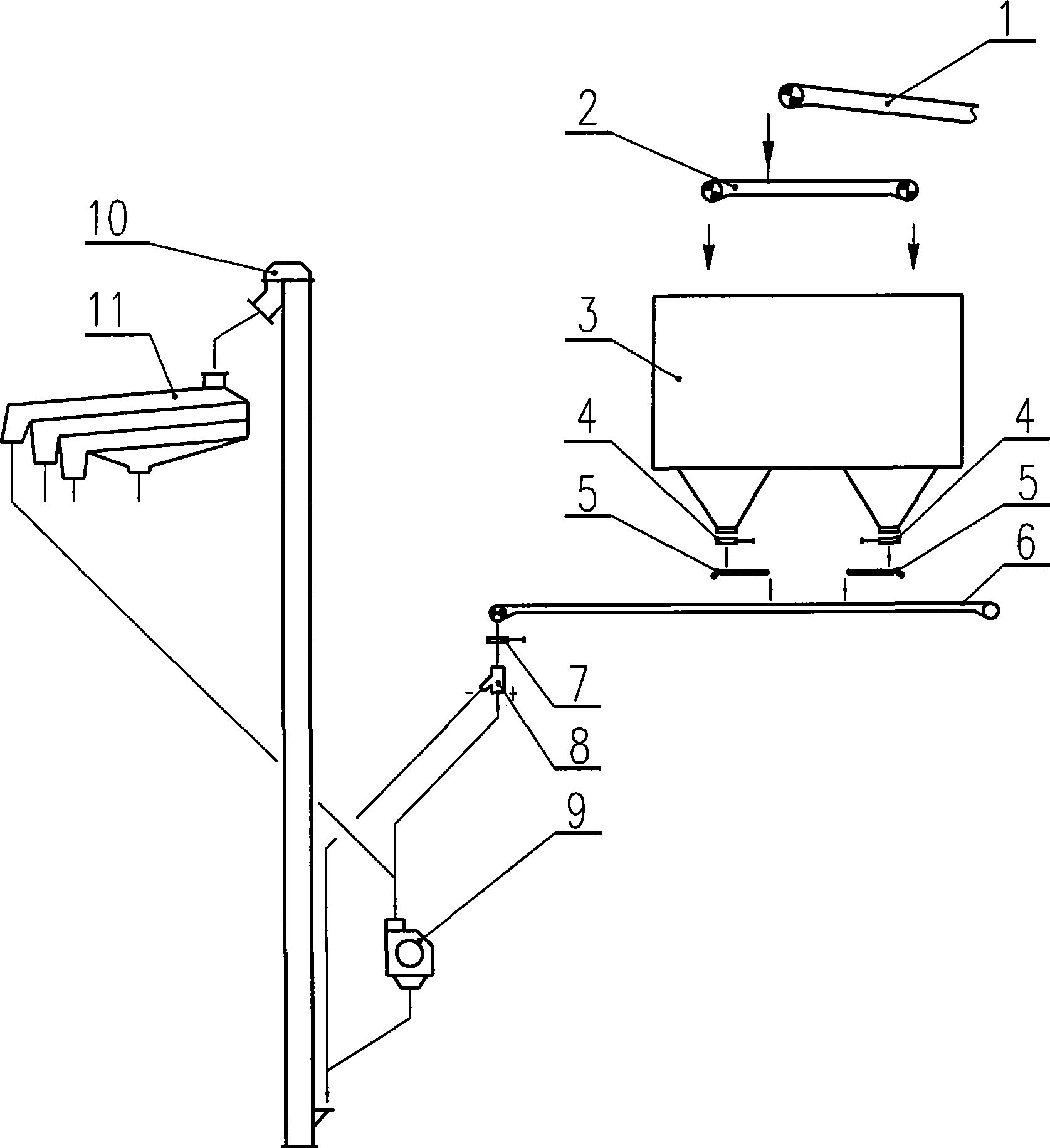

Carbon raw material crushing screening method and system

InactiveCN101450333AAvoid overloadThe particle size distribution of ingredients is reasonableGrain treatmentsAluminum electrodeParticle-size distribution

The invention discloses a method and a system for crushing and sieving carbon raw materials, and in particular relates to a method and a system for crushing and sieving raw materials suitable for producing aluminum anodes, aluminum cathodes and aluminum electrodes. The method for crushing and sieving the carbon raw materials comprises: sending the raw materials to a belt conveyer; analyzing the raw materials by an online sampling analyzer which is arranged at the tail end of the belt conveyer; controlling a triple valve to discharge the raw materials according to the size fraction of the raw materials; and sending the raw materials to a bucket elevator which sends the raw materials to a sieving device for sieving. The method and the system have the advantages that the technological process of sieving first and crushing later or crushing first and sieving later can be selected according to the particle size distribution result of the materials by the novel technology for crushing and sieving the carbon raw materials; and oversize is returned back to a crusher for continuous crushing, and undersieves with different size fractions enter different proportioning bins respectively, so that overloading of the sieving device and a crushing device and overcrushing of the raw materials are avoided.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

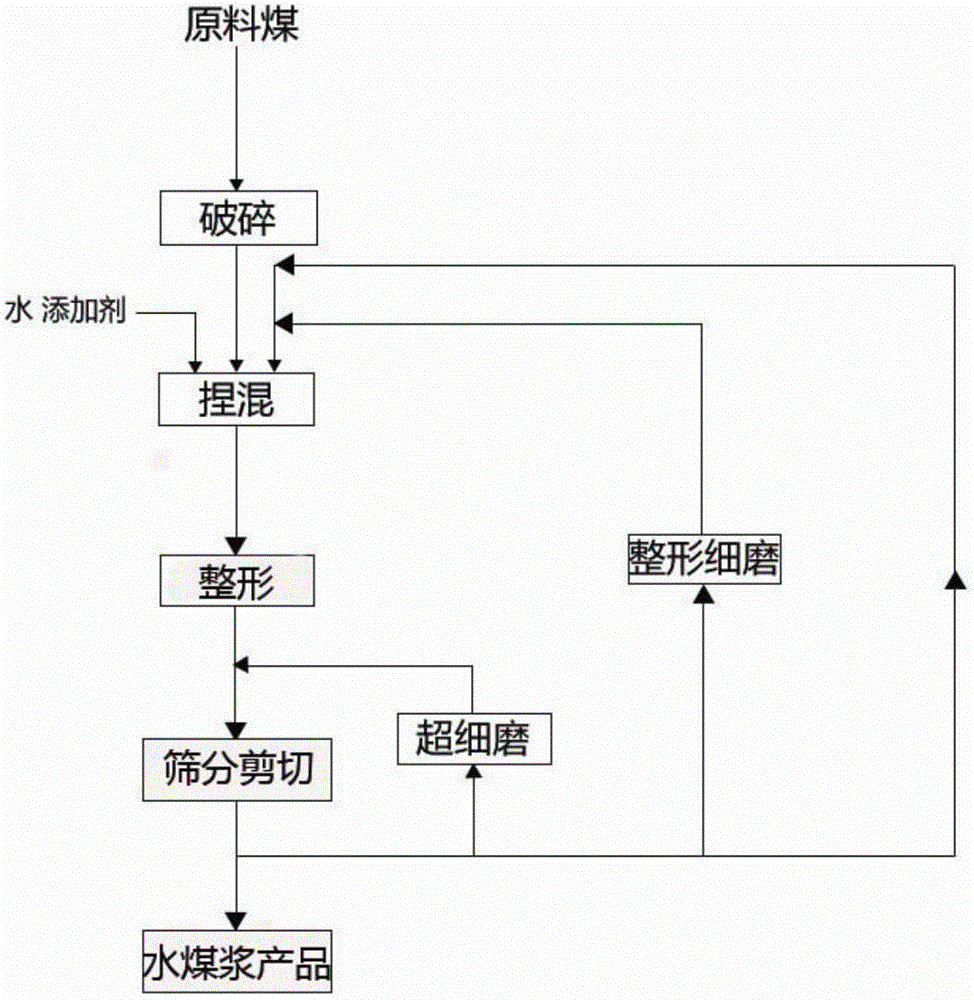

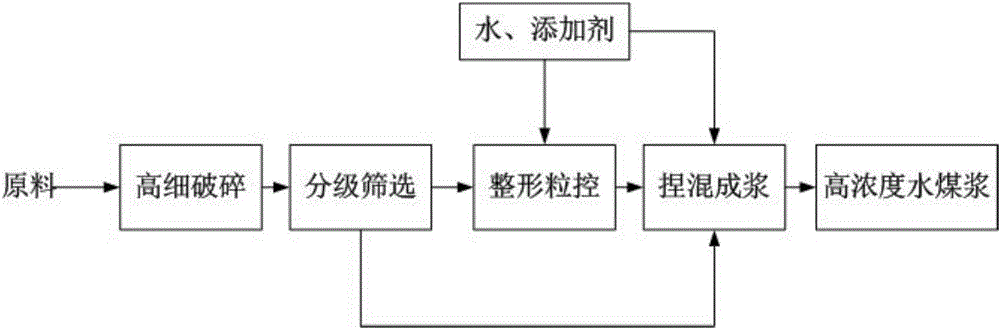

Novel coal water slurry preparation method and coal water slurry prepared by using same

ActiveCN105885973ASave spaceIncrease concentrationLiquid carbonaceous fuelsCoal waterSuperfine grinding

The invention provides a novel coal water slurry preparation method and coal water slurry prepared by using the same. The novel coal water slurry preparation method comprises steps of kneading, mixing, shaping, screening, shearing, superfine grinding and shaping fine grinding, so that the grain size distribution of the prepared coal water slurry is reasonable, gaps of coal powder can be effectively filled, the slurry concentration is increased, the concentration can be up to 65.5wt%, the coal powder granularity of the coal water slurry is uniform, the average particle size is 50-150mu m, and the prepared coal water slurry can be used as fuel coal water slurry and gasified coal water slurry; moreover, by adopting the novel coal water slurry preparation method, the energy consumption of slurry preparation is effectively reduced, and due to a continuous production process, continuous, stable and low-consumption production requirements on preparation of the fuel coal water slurry and the gasified coal water slurry can be met.

Owner:CCTEG CLEAN ENERGY CO LTD

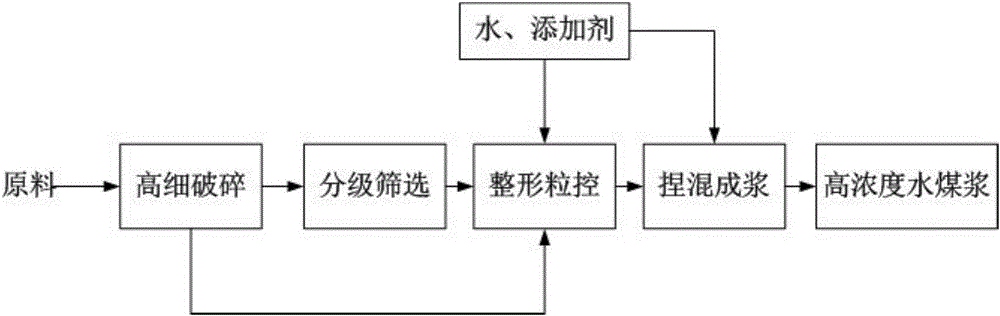

High-concentration coal water slurry and method for efficient classified grain control preparation of high-concentration coal water slurry

ActiveCN106244268AIncrease concentrationReasonable particle size distributionLiquid carbonaceous fuelsHigh concentrationCoal water

The invention provides high-concentration coal water slurry and a method for efficient classified grain control preparation of the high-concentration coal water slurry. Components of the high-concentration coal water slurry comprise coarse-grained coal powder, fine-grained coal slurry or fine-grained coal powder, an additive or water, and the concentration of the coal water slurry is 50 to 75 weight percent, wherein the mass ratio of the dry basis content of the coarse-grained coal powder, the dry basis content of the fine-grained coal slurry or the fine-grained coal powder and the additive is (0-90):(10-100):(0.1-1.0). The high-concentration coal water slurry is reasonable in grain size distribution and high in coal slurry concentration, flowability, stability and atomization performance. By the preparation method, the accumulation efficiency of the coal slurry can be improved, grain size distribution of the coal slurry can be optimized, and compared with a conventional single-rod / ball mill water coal slurry preparation process, the method has the advantage that the concentration can be increased by 4-6 percent or above; the flow is simple, extremely high in operability and extremely low in energy consumption, and long-term safe and continuous production requirements can be met; the prepared coal slurry can meet requirements on gasifying water coal slurry and combustion coal water slurry.

Owner:CCTEG CLEAN ENERGY CO LTD

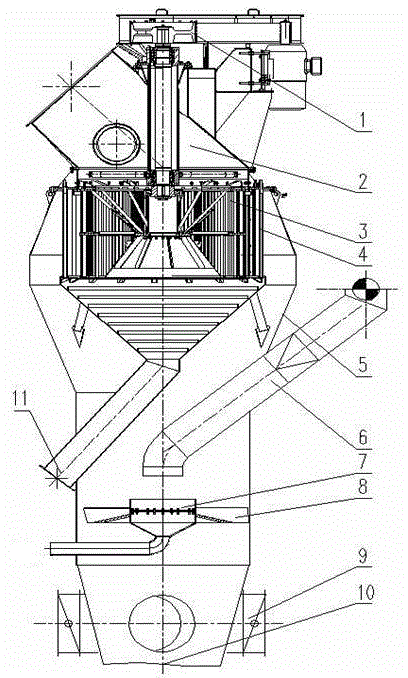

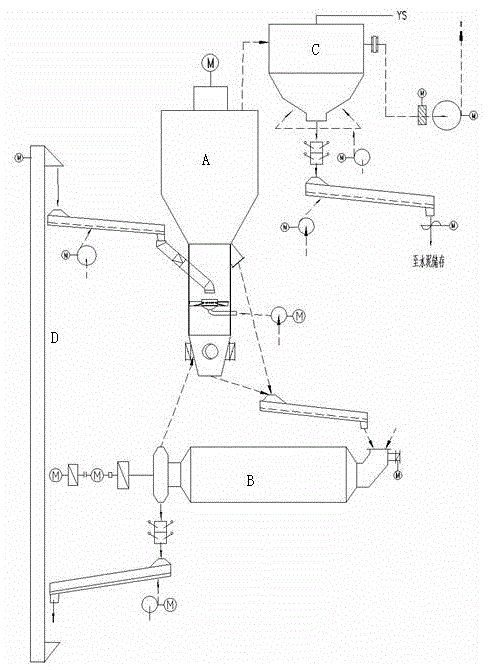

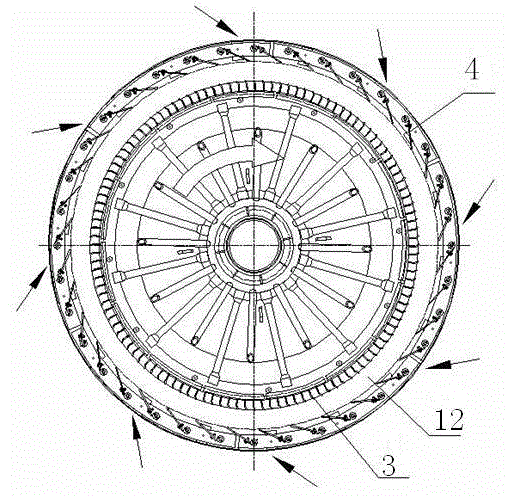

Rotor type powder concentrator

ActiveCN104984911AIncrease productionReduce power consumptionGas current separationMetallurgyDevice form

The invention discloses a rotor type powder concentrator. Bottom feeding is adopted in the powder concentrator, and materials entering the powder concentrator through a feeding device form an air mixture through a powder gas mixing system, wherein the powder gas mixing system comprises a powder dispersing device and a blowing device, and the blowing device is located on the periphery of the powder dispersing device and surrounds the powder dispersing device; an outlet of the feeding device is suspended above the powder dispersing device, wherein the blowing device is provided with a plurality of flow guide paddles, and the flow guide paddles are distributed on the periphery of the powder dispersing device and have the slant angles so that sprayed airflow can rotate in the powder concentrator; and the spirally-rising air material mixture is formed. By means of the rotor type powder concentrator, the yield is increased, the power consumption is reduced, and the product size distribution is more reasonable.

Owner:弥勒羚羊能源有限公司

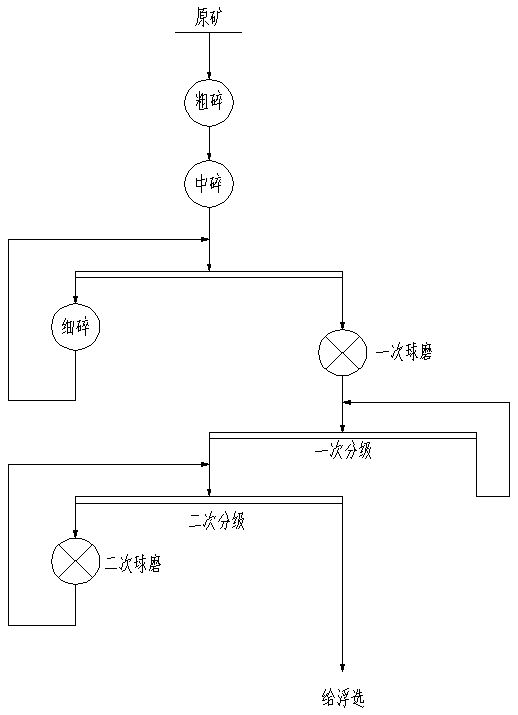

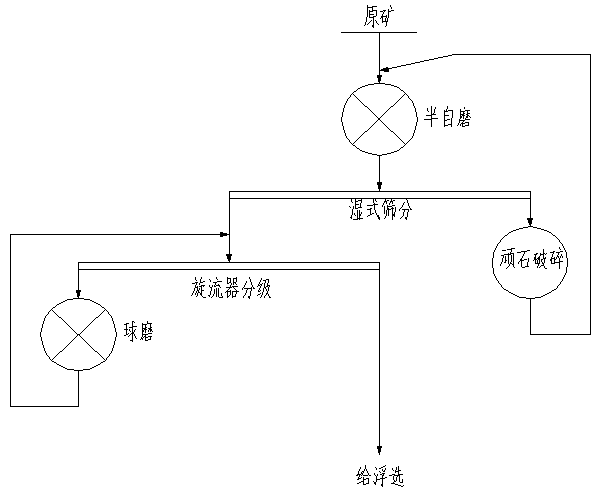

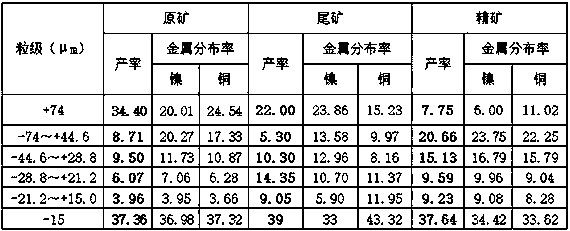

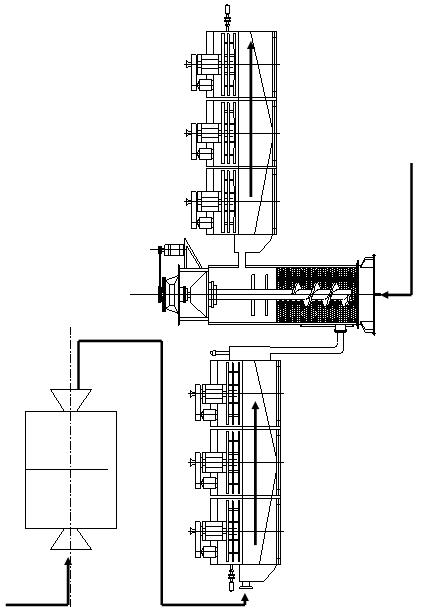

Crushing and grinding process for treating nickel copper sulfide ore

ActiveCN109569837AStable particle sizeReasonable particle size distributionGrain treatmentsMetallic NickelWorking environment

The invention discloses a crushing and grinding process for treating nickel copper sulfide ore, and belongs to the technical field of metal mineral processing. The crushing and grinding process comprises the specific process steps of semi-autogenous grinding, wet-type screening, insensate stone crushing, cyclone classification and ball-milling classification. According to the crushing and grindingprocess for treating the nickel copper sulfide ore, semi-autogenous grinding equipment is used for crushing, an original crushing way of ore is changed, the production process is simplified, comparedwith a conventional crushing and grinding process of nickel copper sulfide ore, the particle size of grinding products is stable, particle grade distribution is more reasonable, excessive crushing ofmetal minerals is reduced, pollution of iron to useful minerals is reduced, more powerful conditions for flotation are created, and the content of the particle grade being -74 to +10 [mu]m suitable for enrichment and recovery of the flotation process is increased by 14%, while the content of the particle grade being -10 [mu]m not suitable for flotation process treatment is decreased by about 5%;the number of equipment is less, and the production cost is low; and back-and-forth transport of the ore in a production link is reduced, dust pollution to the working environment of staff is avoided,and the risk of occupational disease of personnel is reduced.

Owner:JINCHUAN GROUP LIMITED

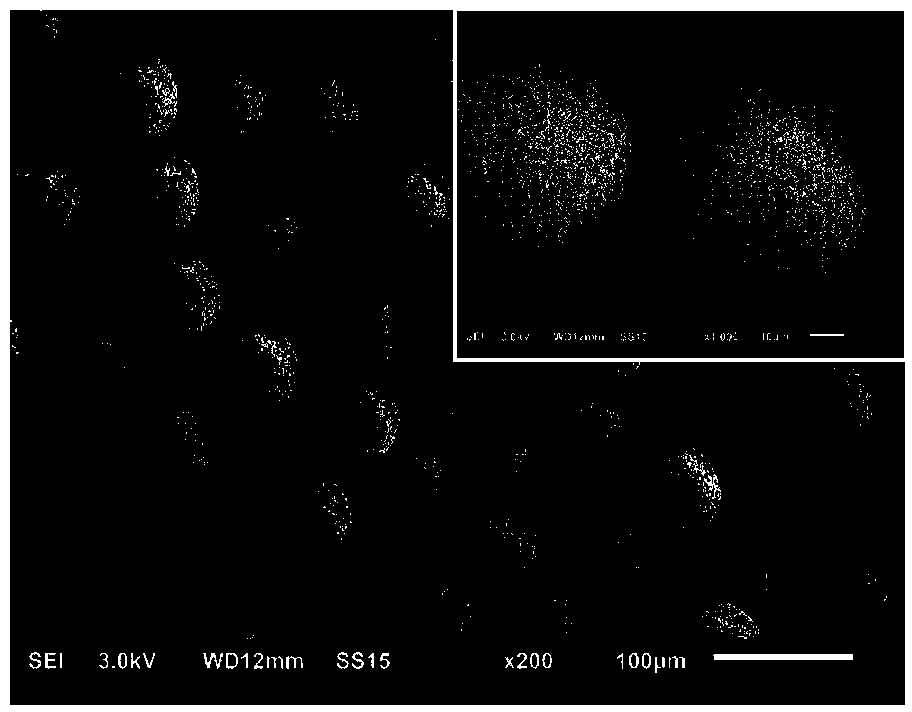

Preparation method of nano-silver wrapping polymer microsphere composite conductive silver paste

InactiveCN103219090AIncrease or decrease exposure timeIncrease or decrease dosageCable/conductor manufactureSilver pasteMicrosphere

The invention discloses a preparation method of nano-silver wrapping polymer microsphere composite conductive silver paste. The preparation method of the nano-silver wrapping polymer microsphere composite conductive silver paste comprises the following steps: preparing a polymer microsphere by adoption of a photopolymerization method at first; preparing nano silver by adoption of a situ synthesis method and enabling the nano silver to wrap the polymer microsphere at the same time; and preparing the nano-silver warping polymer microsphere composite conductive silver paste at last. The preparation method of the nano-silver wrapping polymer microsphere composite conductive silver paste has the advantages that by means of increase or reduction of radiating time of ultraviolet (UV) light, the morphology of the polymer microsphere is predictable and controllable and particle size distribution is reasonable. Due to the fact that nano-silver powder after the situ synthesis can evenly and compactly wrap the surface of the polymer microsphere, not only can the usage amount of precious metal silver powder and production cost be reduced, but also dispersibility and stability of the nano-silver powder can be improved, and conductive performance of the silver paste can be further improved.

Owner:深圳磐汩新能源有限公司

Copper alloy coated composite powder and its preparation method

InactiveCN1868637AImprove performanceReasonable particle size distributionIron powderChemical composition

Owner:成都平和同心金属粉末有限公司

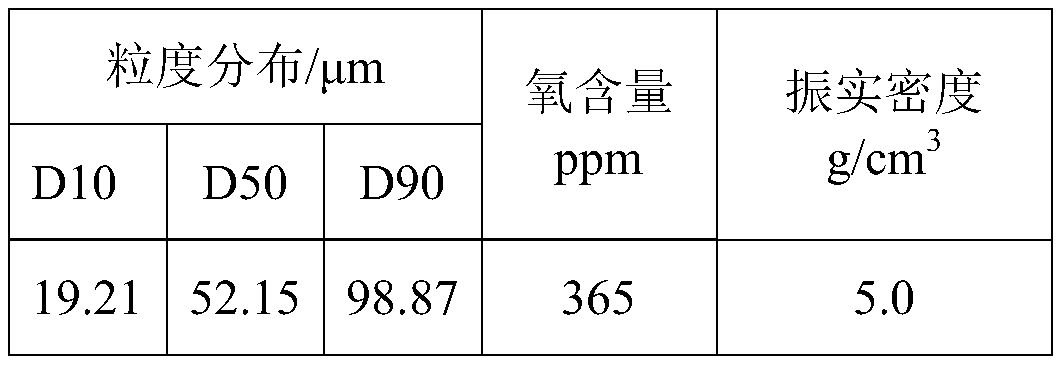

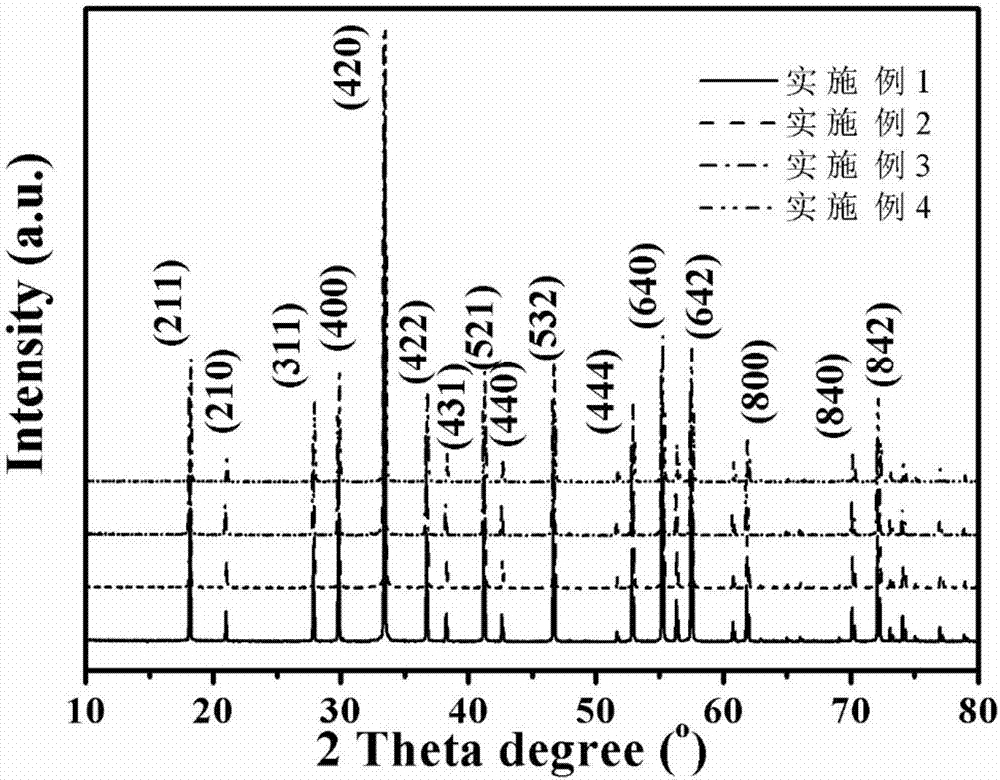

Preparation method of FeSi alloy powder with high direct current superposition characteristics

ActiveCN110039060AHigh tap densityImprove DC Superposition CharacteristicsTransportation and packagingMetal-working apparatusManganeseAlloy

The invention discloses a preparation method of FeSi alloy powder with high direct current superposition characteristics, and belongs to the technical field of alloy powder preparation. The FeSi alloypowder is mainly made of pure iron and metal silicon, and a small amount of manganese and chromium are added. The preparation method comprises the following steps of weighing the ingredients according to a specific proportion, carrying out non-vacuum melting to obtain the alloy melt of required components, and then atomizing to prepare alloy raw powder with an inert gas, obtaining fine powder after the raw powder is collected, screened and graded. According to the preparation method of FeSi alloy powder with high direct-current superposition characteristics, the alloy powder with uniform components and high purity can be obtained, and the powder spherical degree is high; the uniform and compact insulating layer can be easily formed after insulation coating, so that the contact of the alloy matrix is effectively blocked, and the pressed magnetic powder core has good direct-current superposition characteristics.

Owner:马鞍山新康达磁业股份有限公司

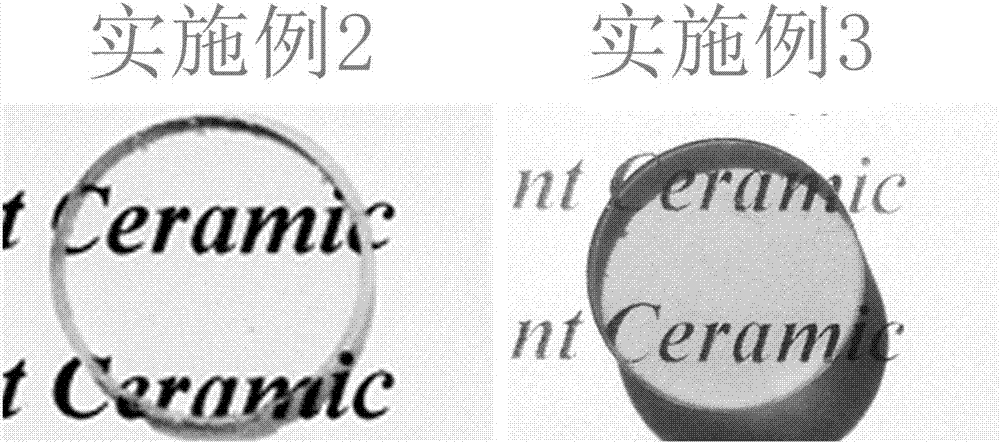

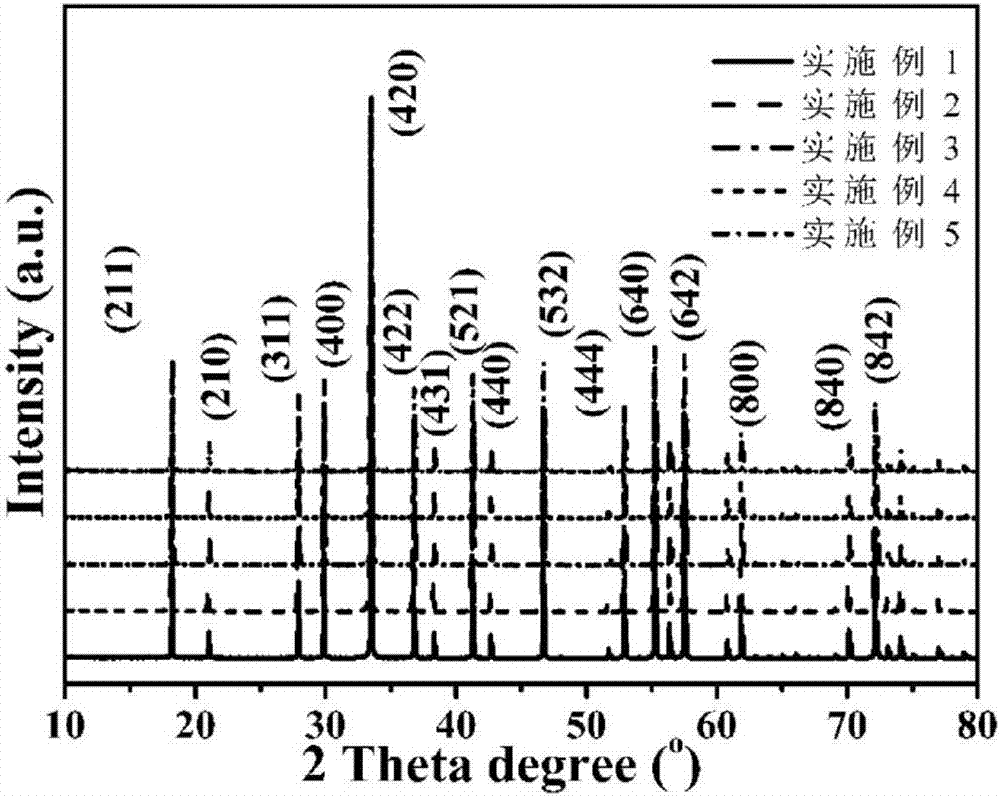

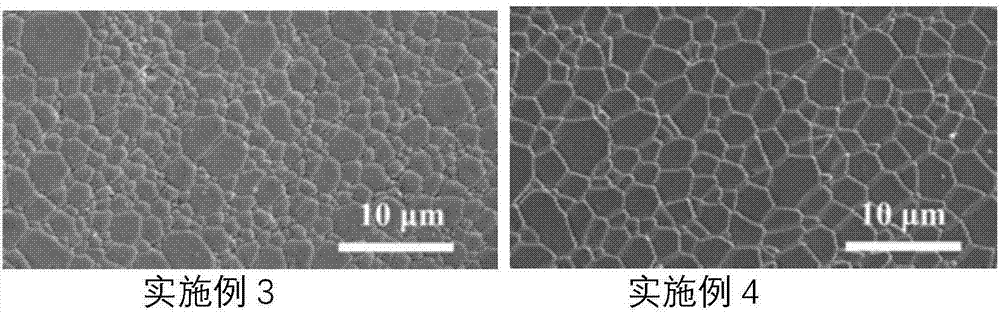

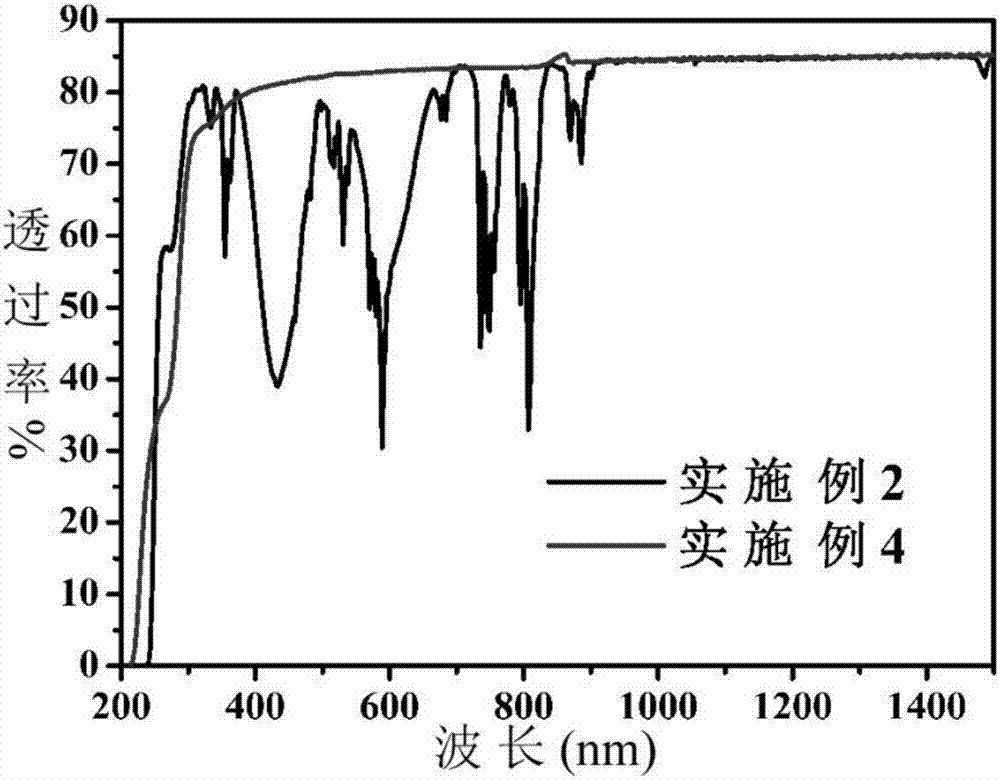

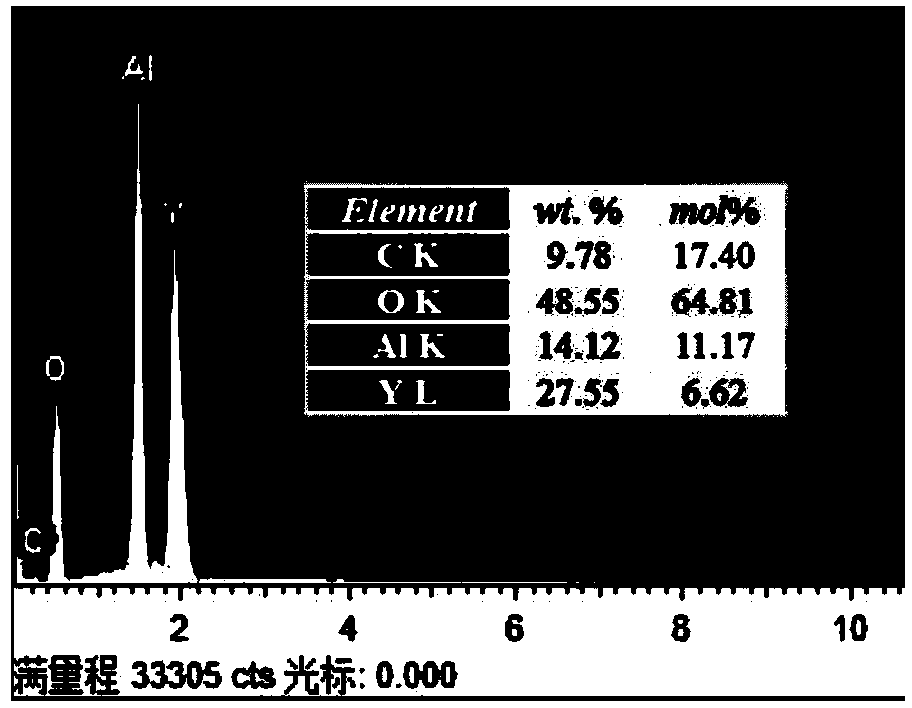

Method for preparing YAG-based transparent ceramics under Mg aid system

The invention provides a method for vacuum sintering preparation of yttrium aluminium garnet (Y3Al5O12, YAG)-based transparent ceramics under a non-annealing mechanism based on a few Mg single sintering aid system. A small quantity of Mg is taken as a single sintering aid, and a single-step vacuum sintering method is adopted to prepare the YAG transparent ceramics with favorable optical quality and fine grains without later-stage annealing treatment.

Owner:XUZHOU NORMAL UNIVERSITY

Method for producing electric-melting zirconia used for turquoise pigment and glaze

ActiveCN101703958ANarrow particle size distributionThe particle size distribution range is reasonableGrain treatmentsZirconium oxidesCalorescenceAtmospheric pressure

The invention relates to a method for producing electric-melting zirconia used for turquoise pigment and glaze, which is characterized in that: in a process of fine crushing, a feed particle size D50 is controlled between 20 and 25mu m, the working air pressure of a nozzle of a jet mill is 0.8MPa, a cyclonecluster is adjusted to 45Hz, a grader is adjusted to 18Hz, and the size distribution after the crushing meets the conditions that: D10 is not less than 3mu m, D50 is kept between 14 and 15mu m, and the difference between D90 and D10 is not more than 30mu m. The method has the advantages that: the narrow size distribution range of zirconia powder is realized, and reasonable grain size distribution is realized; and the electric-melting zirconia is favorable for color development of the turquoise pigment and glaze compared with the traditional electric-melting zirconia, comprehensively improves the blue degree of corresponding pigment and glaze, reduces a brightness value, makes the pigment develop more bright and vivid color in the glaze, and improves the beautifulness of corresponding ceramic products. The electric-melting zirconia after reasonable particle size control and adjustment can improve the high temperature resistance of the turquoise pigment and glaze more obviously than the electric-melting zirconia which is not controlled, and still can keep bright tone at the temperature higher than 1,200DEG C so as to promote the application to high temperature pigments.

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD

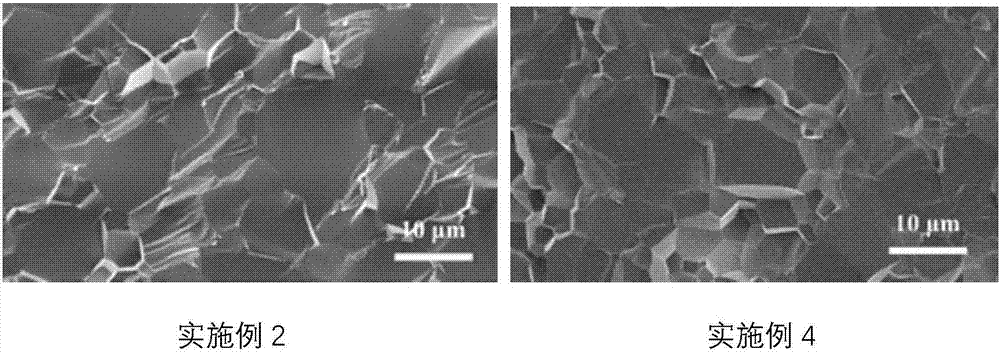

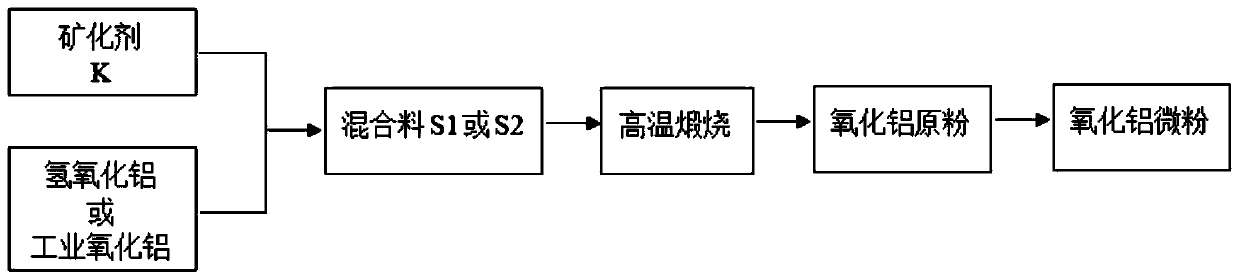

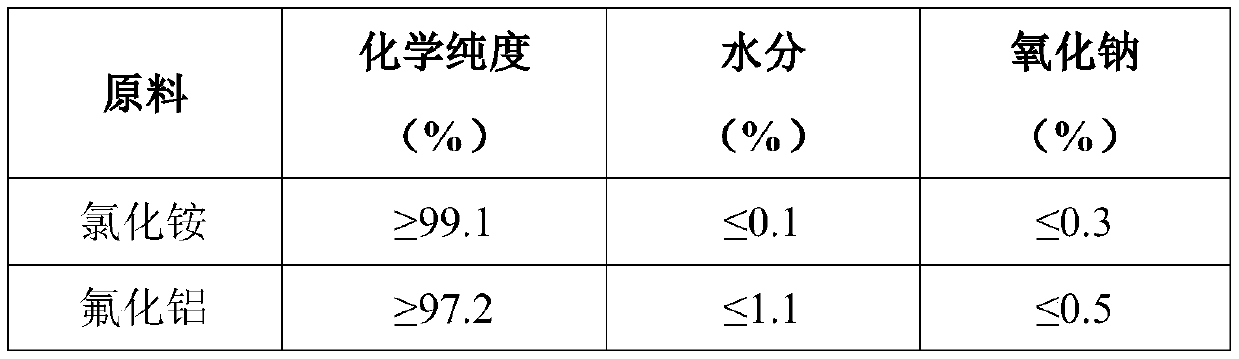

Preparation method of low-sodium and high-activity special alpha-Al2O3 micro powder

InactiveCN110342556AWide variety of sourcesHigh chemical purityAluminium compoundsAluminium hydroxideHigh activity

The invention discloses a preparation method of low-sodium and high-activity special alpha-Al2O3 micro powder. The preparation method comprises the steps that aluminum hydroxide or industrial aluminaserves as main raw materials, and ammonium chloride and aluminum fluoride serve as a mineralizer; the aluminum hydroxide or the industrial alumina and the mineralizer are mixed, a mixture is subjectedto high-temperature calcination to prepare low-sodium and high-specific-surface-area alpha-Al2O3 raw powder, the alpha-Al2O3 raw powder is placed into a ball mill for grinding, and the alpha-Al2O3 micro powder is prepared. According to the preparation method, the raw materials are wide in source, sodium removal is conducted through the ammonium chloride and aluminum fluoride composite mineralizer, the whole technology is completed through one step, neither a drying technology after acid pickling and nor silicon sand screening with silicon sodium removal is not needed, the overall cost is low,boric oxide and silicon dioxide do not remain in a final product, the alpha-Al2O3 micro powder is high in chemical purity, low in sodium oxide content, high in specific surface area and high in activity, the alpha-aluminum oxide conversion rate is greater than or equal to 96.0%, and grain size distribution is reasonable.

Owner:苏州盛曼特新材料有限公司

Cement grinding aid and preparation method thereof

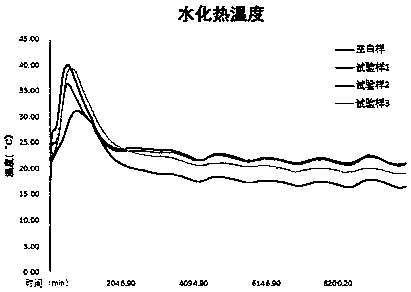

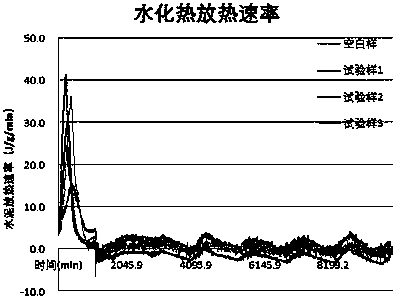

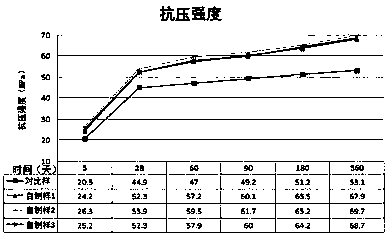

The invention discloses a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from the following components by mass content: 5 to 10% of polyethylene glycol, 5 to10% of sorbitol, 1 to 3% of polyglycerol fatty acid ester, 5 to 10% of diethanolisopropanolamine, 5 to 10% triisopropanolamine, 1 to 5% of sodium hydroxide, 2 to 8% of sodium polyacrylate, 1 to 5% ofmicrocrystalline cellulose and the balance of water. The cement grinding aid disclosed by the invention has the beneficial effects that no matter which can affect concrete performance and building service life and has harm to human health is doped into the cement grinding aid, so that the cement grinding aid has safety and environmental friendliness; all the raw materials have a synergistic effect, so that cement fineness reduction is facilitated, reasonable particle size distribution of the cement grinding aid is guaranteed, an early hydration heat release rate of cement where mineral admixture is doped is reduced, and cement strength is improved; under the condition of guaranteeing cement strength and use, production cost can be reduced, and economical benefit and social benefit of cement production enterprises are improved.

Owner:DONGHAI CONSTR GRP

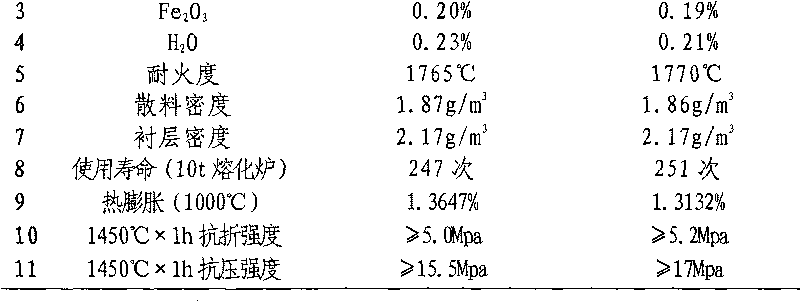

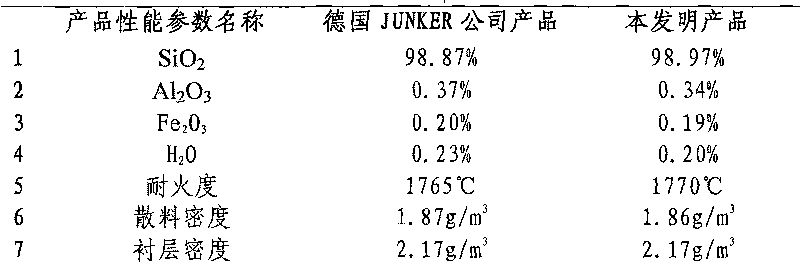

Novel acid furnace lining refractory material

The invention discloses a novel acid furnace lining refractory material. The novel acid furnace lining refractory material comprises the following raw materials in percentage by weight: 19 to 23 percent of 3 to 5mm high-purity microcrystal quartz sand, 28 to 32 percent of 1 to 2mm high-purity microcrystal quartz sand, 20 to 24 percent of 0 to 1mm semi-sintered microcrystal quartz sand, 24 to 28 percent of 325-mesh semi-sintered microcrystal quartz sand, 0.8 to 1.1 percent of B2O3 and 0.04 to 0.06 percent of special sintering flux. In the novel acid furnace lining refractory material, pre-sintered semi-sintered microcrystal quartz sand powder with stable volume and low thermal expansion is used as the raw material, and the special sintering flux is added so as to form a solid solution structure at a high temperature, so the volume expansion generated in the use process of a furnace lining is remarkably reduced, the furnace lining is prevented from forming cracks easily and the service life of the furnace lining is greatly prolonged.

Owner:长沙环宇耐火材料有限公司

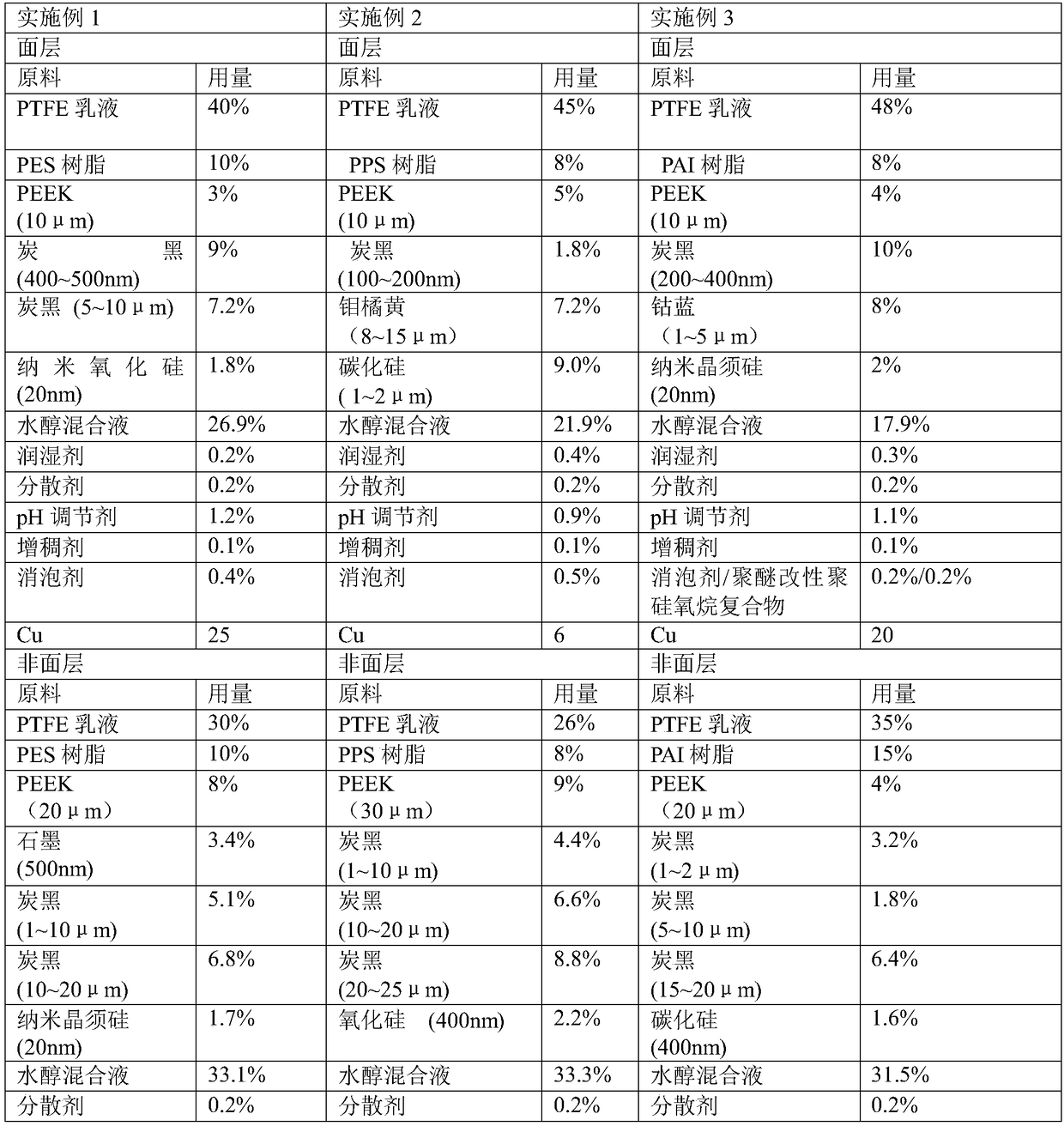

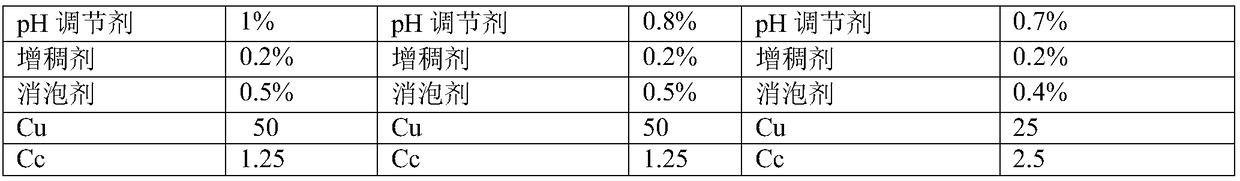

High-wear-resistance non-stick coating special for cooker and preparation method thereof

The invention relates to the field of coatings, and discloses a high-wear-resistance non-stick coating special for a cooker. The coating comprises a primary layer coating body and a non-primary layercoating body; each of the primary layer coating body and the non-primary layer coating body is prepared from a polytetrafluoroethylene emulsion, bonding resin, wear-resistant resin, a pigment, a filler and an auxiliary agent; in the primary layer coating body, the non-uniform coefficient Cu of the particle size of the pigment and the filler is greater than 5; in the non-primary layer coating body,the particle size of the pigment and the filler adopts discontinuous grading, the non-uniform coefficient Cu is larger than 5, and the curvature coefficient Cc is equal to 1-3, wherein Cu accounts for d60 / d10, and Cc accounts for d30<2> / d60*d10; the particle size of the pigment and the filler in the primary layer coating body is smaller than the particle size of the pigment and the filler in thenon-primary layer coating body; and the filler is insoluble in the coating and can be uniformly dispersed. The wear-resistant non-stick coating has the advantages of being outstanding in non-viscosity, good in wear resistance, capable of effectively resisting scraping of a truner and long in service life.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD +1

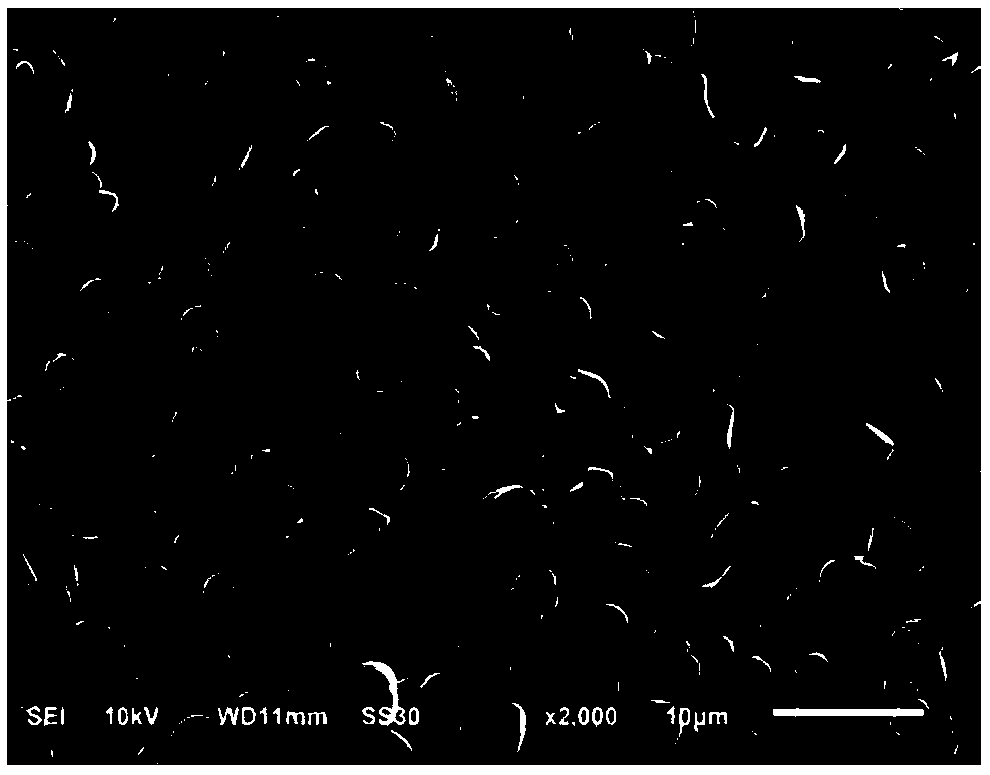

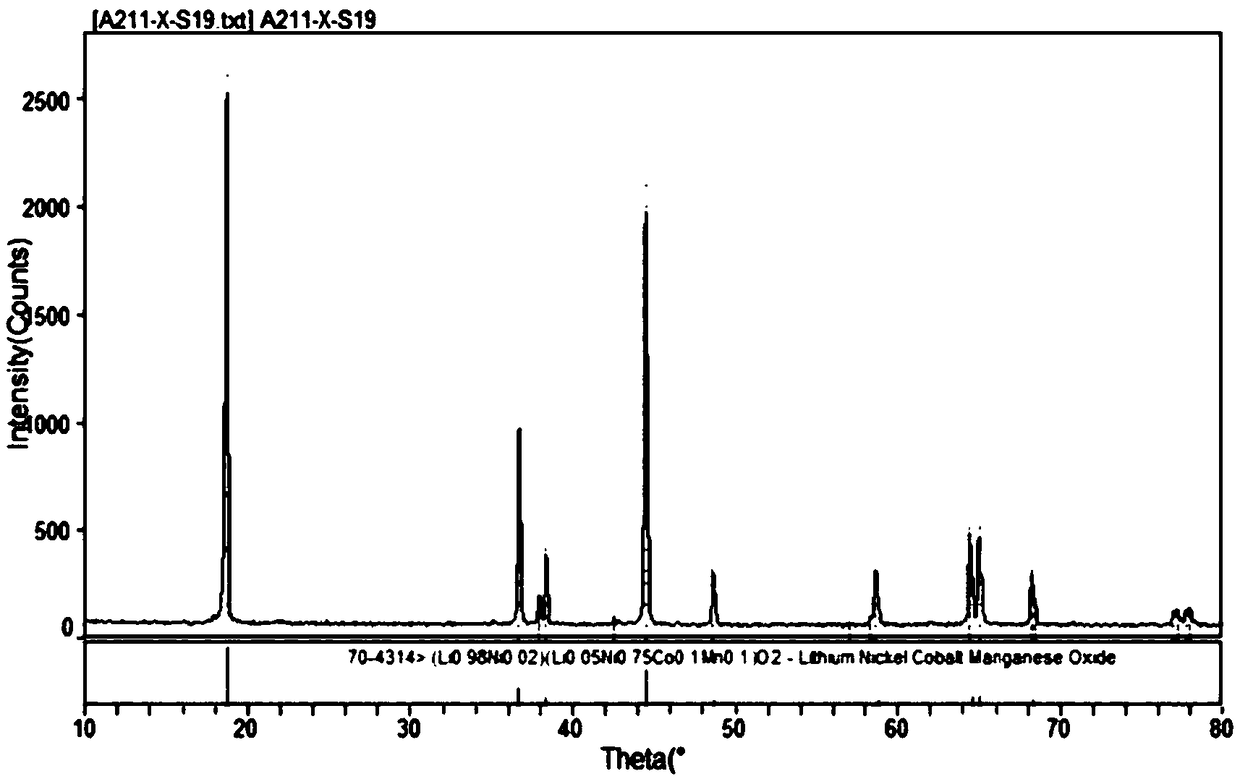

A high-pressure monocrystalline nickel-cobalt-manganese ternary material and a preparation method thereof

ActiveCN109037614AImprove cycle performanceLower pass rateElectrode thermal treatmentSecondary cellsLithiumManganese

The invention discloses a preparation method of a high-pressure monocrystalline nickel-cobalt-manganese ternary material, comprising the steps of preparing a precursor by a co-precipitation method; mixing a lithium source, a coating agent and the precursor and performing primary sintering to obtain an intermediate; mixing the intermediate and the lithium source in proportion, and performing secondary sintering and shaping to obtain the product The invention effectively improves the average particle size of the ternary material, reduces the specific surface area of the ternary material, furtherimproves the compaction density, improves the first charge-discharge capacity and improves the cycle performance of the ternary material battery through the process of solid-state coating and sintering of two times.

Owner:FOSHAN DYNANONIC

Preparation method of yttrium aluminum garnet (YAG)-based transparent ceramics in system taking Ca as auxiliary agent

The invention provides a method for preparing yttrium aluminum garnet (Y3Al5O12, YAG)-based transparent ceramics by means of vacuum sintering based on a system taking a small amount of Ca as a single-sintering auxiliary agent. According to the method, the small amount of Ca is used as the single-sintering auxiliary agent, and a single-step vacuum sintering method is adopted, so that the YAG-based transparent ceramics having good optical quality and fine crystalline grain size can be prepared under the condition of not adding post annealing treatment.

Owner:XUZHOU NORMAL UNIVERSITY

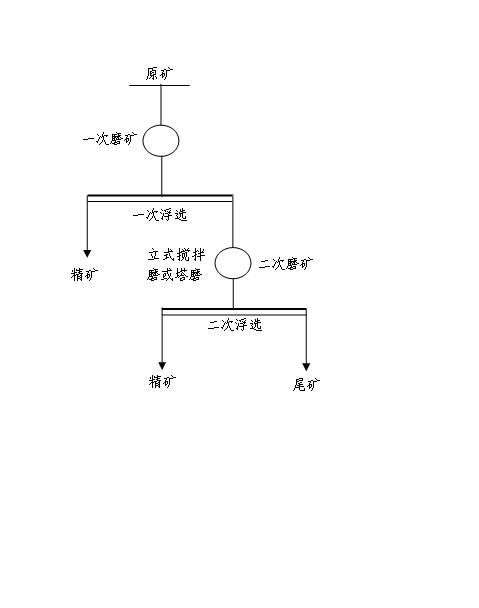

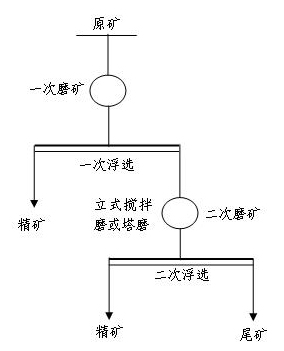

Ore grinding flotation silicon-removing method of bauxite

The invention relates to a process for removing impurities from bauxite, in particular to an ore grinding flotation silicon-removing method of bauxite, which comprises the steps of: carrying out primary floatation on the bauxite after rough grinding, wherein the floated foam is used as a concentrate product; carrying out secondary ore grinding on floating underflow; and carrying out secondary floatation after secondary ore grinding, wherein the floated foam is used as a concentrate product and the underflow is used as tailings to be discharged. The invention has the characteristics of proper granularity of flotation pulp, reasonable fraction distribution, shortened process flow, reduced mineral dressing cost and improved floatation recycling rate due to the adoption of reasonable configuration of ore grinding and floating and equipment selection.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Preparation method of specia electrolytic manganese dioxide for button type alkaline zinc/manganese dioxide cell

InactiveCN103560241AReasonable crystal structureHighly uniform particle size distributionElectrolysis componentsCell electrodesPyriteHeavy metals

The invention belongs to the field of cell material processing and specifically discloses a preparation method of a special electrolytic manganese dioxide for a button type alkaline zinc / manganese dioxide cell. The preparation method comprises the following steps: performing manganese sulfate leaching, neutralizing and removing iron, removing impurities for heavy metals, electrolyzing and performing post-processing. Manganese oxide mineral powder, pyrite powder and industrial sulphuric acid are soaked in the presence of SO2 to prepare crude manganese sulfate liquor; iron is removed by ammonium bicarbonate liquor; heavy metals are removed by utilizing barium sulphide; a manganese dioxide semi-finished product is obtained at a positive electrode through periodic electrolysis; the special electrolytic manganese dioxide is finally obtained by post-processing. According to the preparation method disclosed by the invention, production process is simplified, the production process efficiency is improved, and the performance of obtained products is excellent, and finally, the production cost is lowered.

Owner:GUANGXI GUILIU CHEM CO LTD

Spray granulation preparation method for YAG-based transparent ceramic powder

The invention relates to a spray granulation preparation method for YAG-based transparent ceramic powder. The preparation method particularly comprises the following steps: weighting raw material powder according to the molar ratio of metallic elements needed to compose (Y1-xREx)3Al5O12; adding in a sintering additive, a dispersing agent and a solvent to prepare a sizing agent; mixedly adding in a binder in an upper ball mill of a planetary ball mill; continuously conducting ball milling and mixing to obtain a sizing agent for pray granulation; selecting a centrifugal spray dryer to conducting pray granulation on the sizing agent; sieving granulation powder obtained by collecting to obtain the YAG-based transparent ceramic powder. The prepared YAG-based transparent ceramic powder is high in chemical purity, good in uniformity, good in degree of sphericity, good in liquidity, high in yield and high in productive rate, drying of the sizing agent can be completed in short time, the experimental period is shortened, and the preparation cost is reduced.

Owner:XUZHOU NORMAL UNIVERSITY

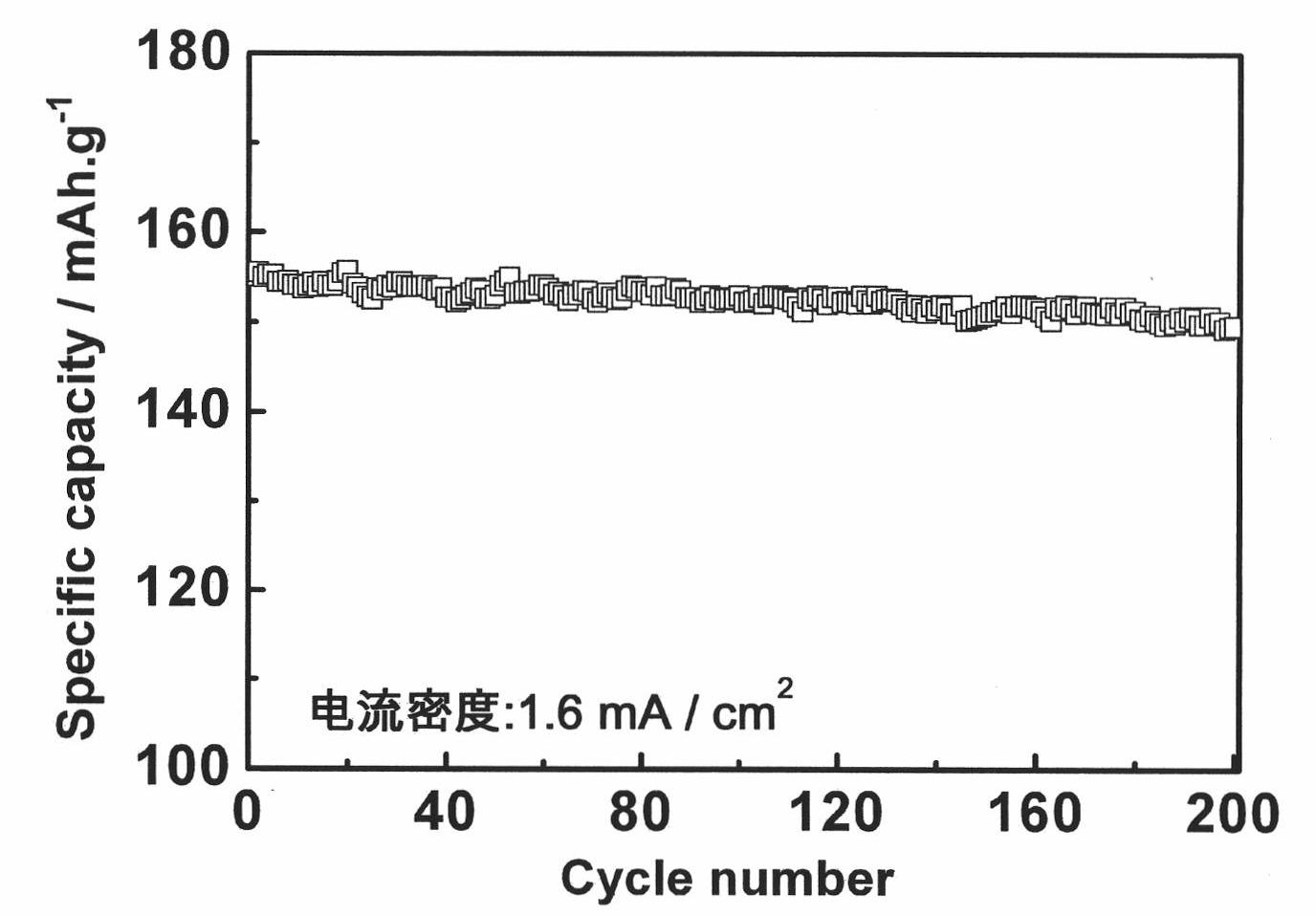

Ion-doped spherical Li4Ti5O12/C lithium ion battery anode material and preparation method thereof

InactiveCN102104142AImprove conductivityStable crystal structureCell electrodesCrystal structurePhysical chemistry

The invention discloses an ion-doped spherical Li4Ti5O12 / C lithium ion battery anode material and a preparation method thereof. The method comprises the following steps of: 1) uniformly dispersing a lithium source compound and a carbon source compound into ion-doped titanium oxide sol and spray-drying to obtain spherical powder; and 2) under the protection of an inert gas, performing heat treatment on the spherical powder to obtain the ion-doped spherical Li4Ti5O12 / C lithium ion battery anode material. The method for preparing the ion-doped spherical Li4Ti5O12 / C lithium ion battery anode material provided by the invention improves the electric conductivity of the material by compounding Li4Ti5O12 with carbon and stabilizes the crystal structure of the material by doping ions so as to further improve the charge-discharging cycle performance of the material. The method has a simple process flow; and the obtained lithium ion battery anode material is spherical, and has suitable particle sizes and reasonable particle diameter distribution, high stacking density and a very good application prospect in the field of lithium ion batteries.

Owner:TSINGHUA UNIV

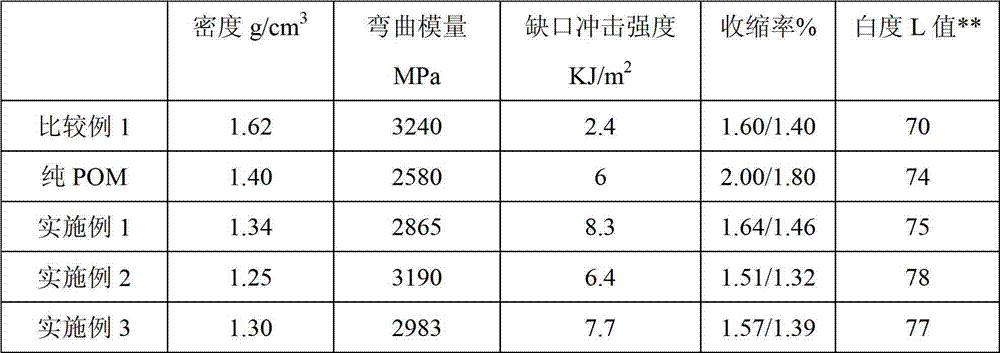

Polyoxymethylene composition and preparation method thereof

ActiveCN103804847AHigh compressive strengthReasonable particle size distributionPolyoxymethyleneAntioxidant

Belonging to the technical field of materials, the invention relates to a polyoxymethylene resin composition and a preparation method thereof. The polyoxymethylene composition comprises the following components by weight: 100 parts of polyoxymethylene, 5-15 parts of hollow glass beads, 0.1-0.2 part of white oil, 0.5-1 part of calcium stearate, 0.3-0.6 part of a main antioxidant, 0.3-0.6 part of an auxiliary antioxidant, 0.5-0.8 part of a formaldehyde absorbent, and 0.1-0.3 part of a nucleating agent. Compared with the prior art, the polyoxymethylene composition prepared by the invention has the characteristics of low density, low shrinkage, good surface quality, high whiteness, good rigidity, and low bead breakage rate.

Owner:HEFEI GENIUS NEW MATERIALS

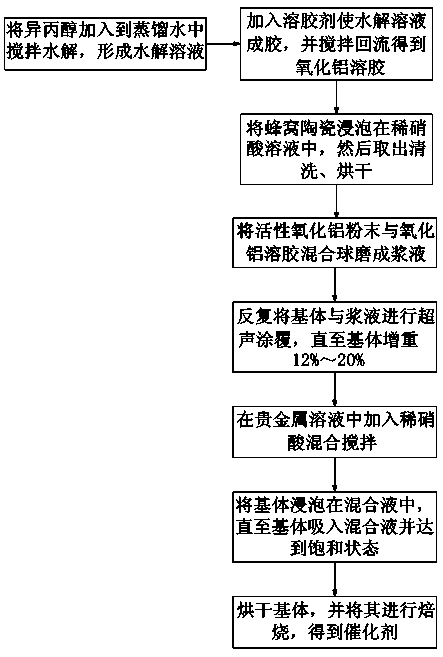

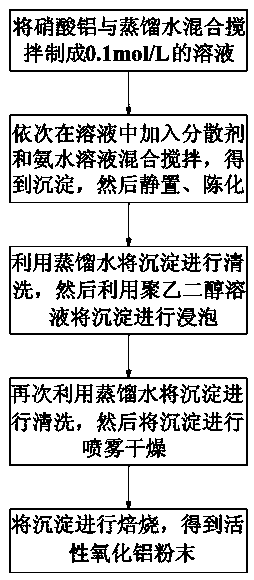

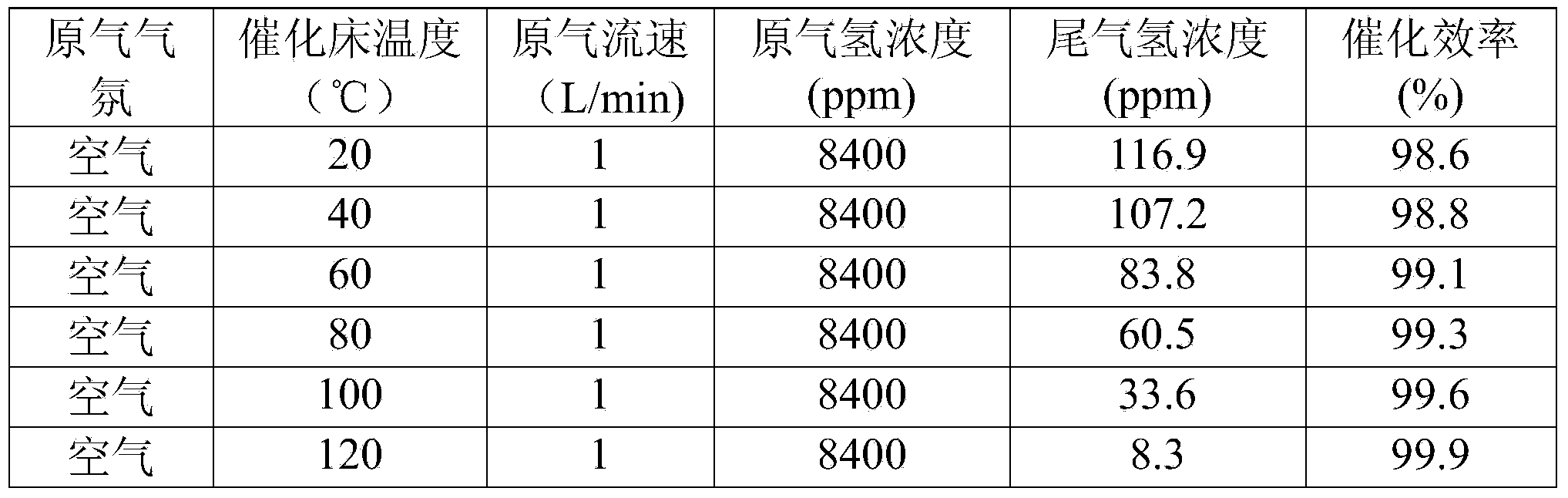

Preparation method of catalyst for removing tritium in tritium-containing air

InactiveCN104383917AReasonable workmanshipEasy to operateCatalyst carriersDispersed particle separationWeight gainingDistilled water

A disclosed preparation method of a catalyst for removing tritium in tritium-containing air comprises: (1) adding aluminium isopropoxide into distilled water and stirring for hydrolysis; (2) adding a peptizing agent to enable the hydrolysis solution to be colloidal, and performing stirring refluxing to obtain an aluminium oxide sol; (3) using honeycomb ceramic as a catalyst matrix and immersing in a diluted nitric acid solution, and then taking out, cleaning and baking; (4) mixing active aluminium oxide powder and the aluminium oxide sol, and performing ball milling to form a slurry; (5) uniformly coating the catalyst matrix with the slurry, and then baking and weighing; (6) repeating the step (5) until the weight gain of the catalyst matrix is 12%-20%; (7) adding diluted nitric acid into a noble metal solution, and mixing with stirring; and (8) immersing the catalyst matrix in the mixed solution to enable the catalyst matrix to absorb the mixed solution to reach a saturation state, and then roasting, so as to obtain the catalyst. The preparation method helps to substantially improve the processing capacity of the catalyst on gases without increasing the gas resistance of the tritium-removal system.

Owner:SICHUAN INST OF MATERIALS & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com