High-wear-resistance non-stick coating special for cooker and preparation method thereof

A technology of non-stick coatings and cookware, applied in the direction of coating, etc., can solve the problems of inability to obtain very good wear resistance, affect the performance and service life of cookware, and lose the use value of non-stick pans, so as to make up for durability defects and maintain Performance advantages, the effect of excellent wear resistance

Active Publication Date: 2018-12-11

HANGZHOU JIHUA POLYMER MATERIAL CO LTD +1

View PDF8 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the non-stick cookware industry, the poor wear resistance of non-stick coatings seriously affects the performance and service life of cookware

Pure polytetrafluoroethylene (PTFE) has low strength, flexible and stretchable mechanical properties, so that when the coating encounters the impact of cooking with a spatula or cleaning and wiping with hard fiber cloth, it is very easy to produce irreversible and detectable wear, so that it does not stick. The pot loses its use value in a short period of time and is scrapped ahead of schedule

In order to improve the service life of the PTFE coating, organic resins are often used to modify it. For example, the patent CN101717601A discloses a non-stick coating made of polytetrafluoroethylene as a film-forming substance. It is mainly composed of polytetrafluoroethylene, solvent gasoline, Composed of alkyd resin, surfactant, and wear-resistant filler, but it can't get very good wear-resistant effect

The PTFE coating still has the disadvantages of poor wear resistance and easy scratches

Patent CN 102643582A discloses a non-stick coating containing main film-forming fluororesin, acrylic emulsion and water, with or without additives. Although its surface has no pinholes and no yellowing defects, it also has insufficient wear resistance The problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

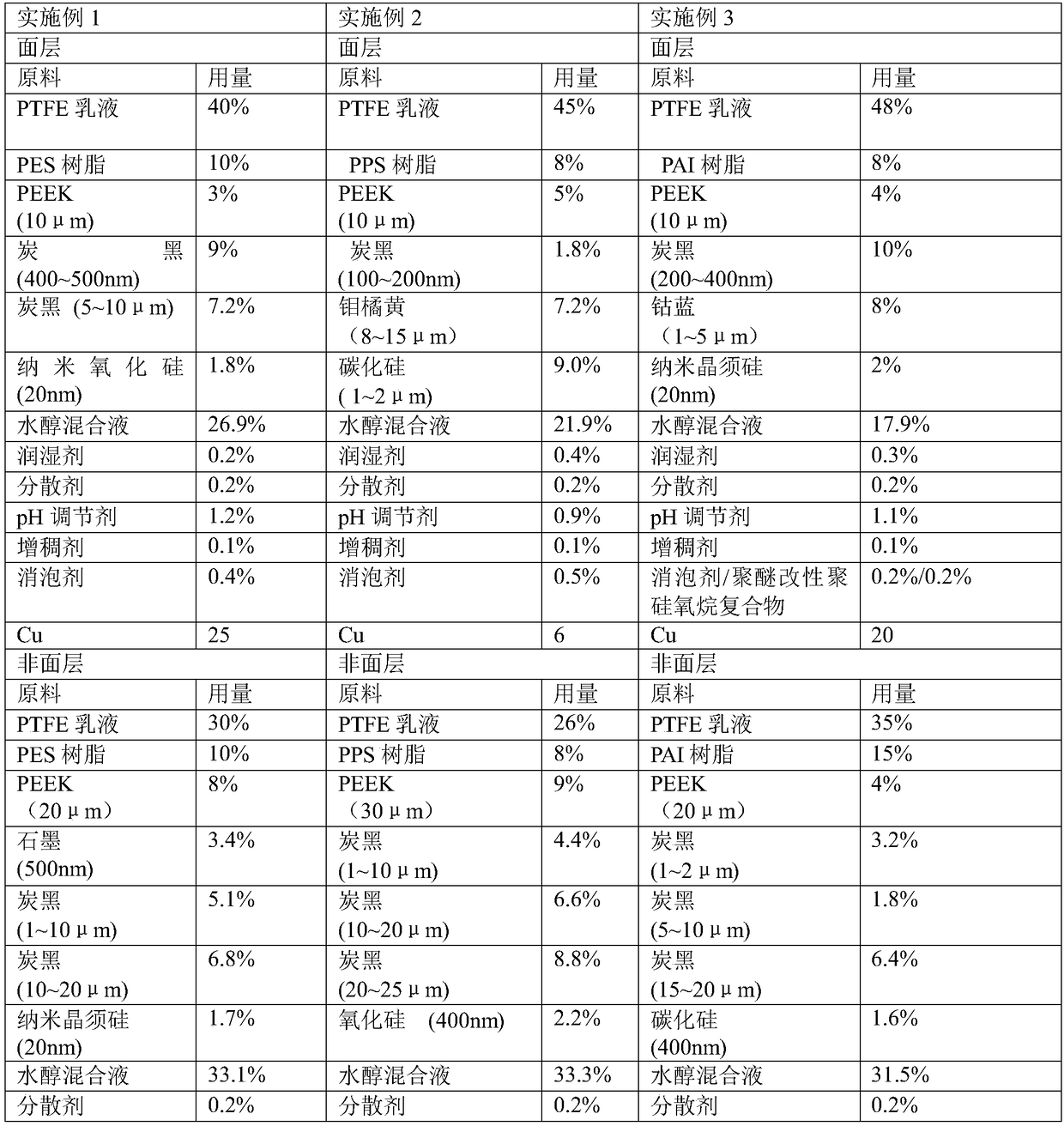

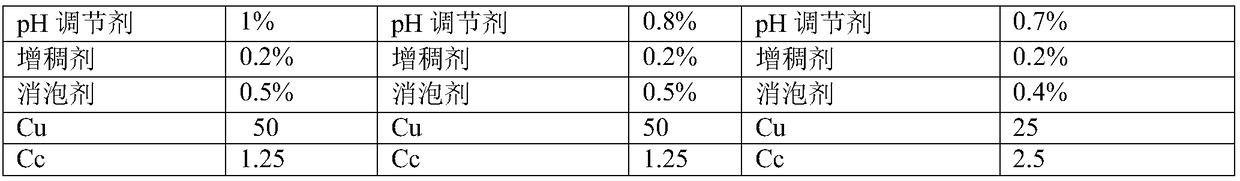

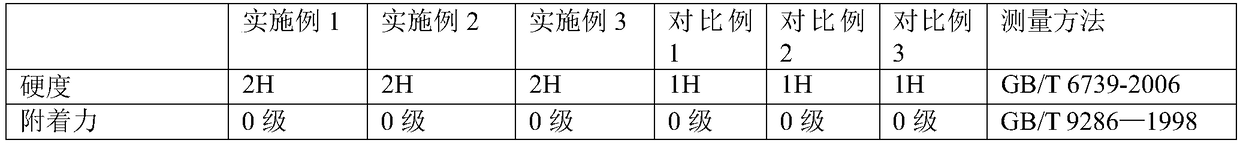

Embodiment 1-3

[0087]

[0088]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| inhomogeneity coefficient | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the field of coatings, and discloses a high-wear-resistance non-stick coating special for a cooker. The coating comprises a primary layer coating body and a non-primary layercoating body; each of the primary layer coating body and the non-primary layer coating body is prepared from a polytetrafluoroethylene emulsion, bonding resin, wear-resistant resin, a pigment, a filler and an auxiliary agent; in the primary layer coating body, the non-uniform coefficient Cu of the particle size of the pigment and the filler is greater than 5; in the non-primary layer coating body,the particle size of the pigment and the filler adopts discontinuous grading, the non-uniform coefficient Cu is larger than 5, and the curvature coefficient Cc is equal to 1-3, wherein Cu accounts for d60 / d10, and Cc accounts for d30<2> / d60*d10; the particle size of the pigment and the filler in the primary layer coating body is smaller than the particle size of the pigment and the filler in thenon-primary layer coating body; and the filler is insoluble in the coating and can be uniformly dispersed. The wear-resistant non-stick coating has the advantages of being outstanding in non-viscosity, good in wear resistance, capable of effectively resisting scraping of a truner and long in service life.

Description

technical field [0001] The invention relates to the field of coatings, in particular to a high wear-resistant and non-stick coating specially used for cookware and a preparation method thereof. Background technique [0002] In the non-stick cookware industry, the poor wear resistance of non-stick coatings seriously affects the performance and service life of cookware. Pure polytetrafluoroethylene (PTFE) has low strength, flexible and stretchable mechanical properties, so that when the coating encounters the impact of cooking with a spatula or cleaning and wiping with hard fiber cloth, it is very easy to produce irreversible and detectable wear, so that it does not stick. The pot loses its use value in a short period of time and is scrapped ahead of schedule. In order to improve the service life of the PTFE coating, organic resins are often used to modify it. For example, the patent CN101717601A discloses a non-stick coating made of polytetrafluoroethylene as a film-forming ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D127/18C09D181/06C09D181/02C09D179/08C09D161/16C09D7/61

CPCC08K2003/2241C08K2003/2272C08K2201/011C09D127/18C09D7/61C08L81/06C08L81/02C08L79/08C08L61/16C08K3/34C08K3/22C08K3/04

Inventor 钱涛罗文秀刘海龙

Owner HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com