Patents

Literature

137results about How to "Improve interlayer bonding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser-CMT welding aluminum alloy additive manufacturing method and forming system

PendingCN107283061AImprove stabilityImprove interlayer bonding performanceWelding/soldering/cutting articlesLaser beam welding apparatusSlag (welding)Molten bath

The invention discloses a laser-CMT welding aluminum alloy additive manufacturing method and a forming system. A laser and an electric arc are adopted as a composite heat source, the cold metal short circuiting transfer manner is adopted, and additive manufacturing forming for an aluminum alloy component is achieved. According to the provided laser-CMT welding additive manufacturing method, the problems that in the process of aluminum alloy component manufacturing through laser additive, the required laser power is high, and forming is difficult are solved, the problems that in the traditional process of aluminum alloy manufacturing through electric arc additive, the heat input amount is large, deformation is serious, and a molten bath is prone to overflowing or webbing are solved, and the problem that in the process of aluminum alloy manufacturing through CMT welding additive, incomplete fusion or slag inclusion or the like is likely to happen is solved; and the additive manufacturing method based on the laser-electric arc composite heat source principle is provided for additive manufacturing forming for the aluminum alloy component.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN +1

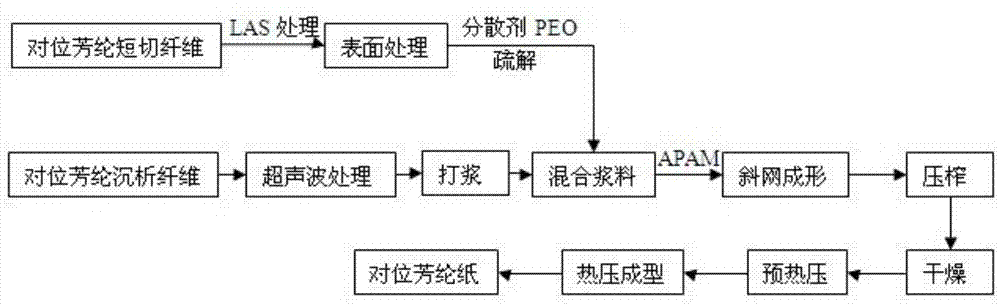

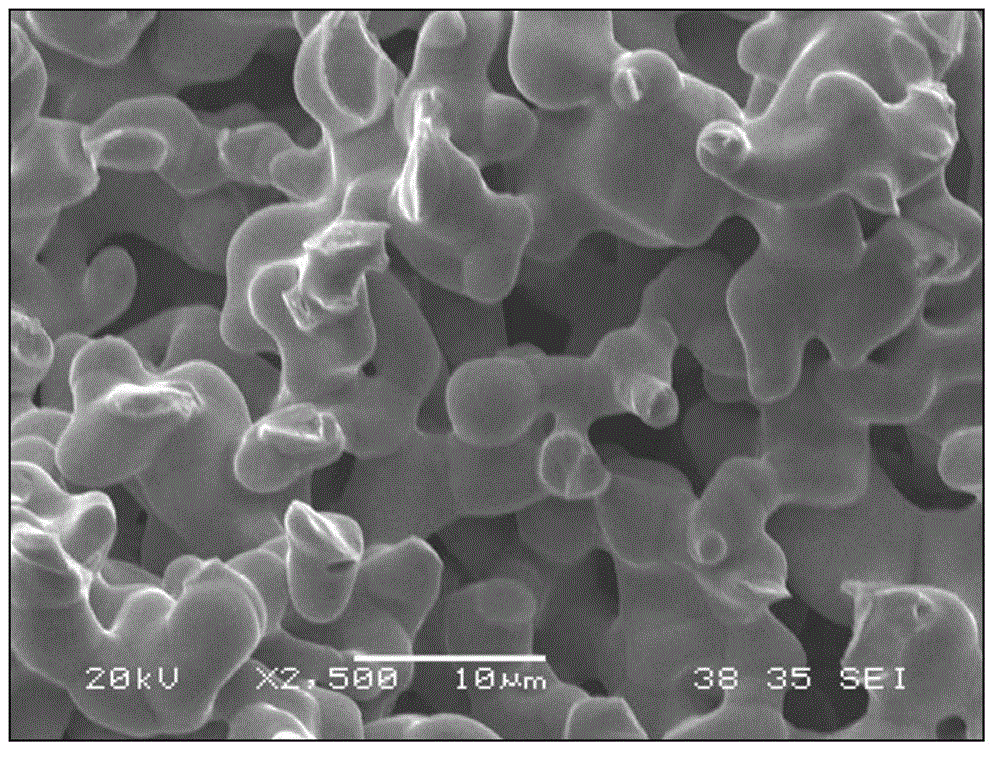

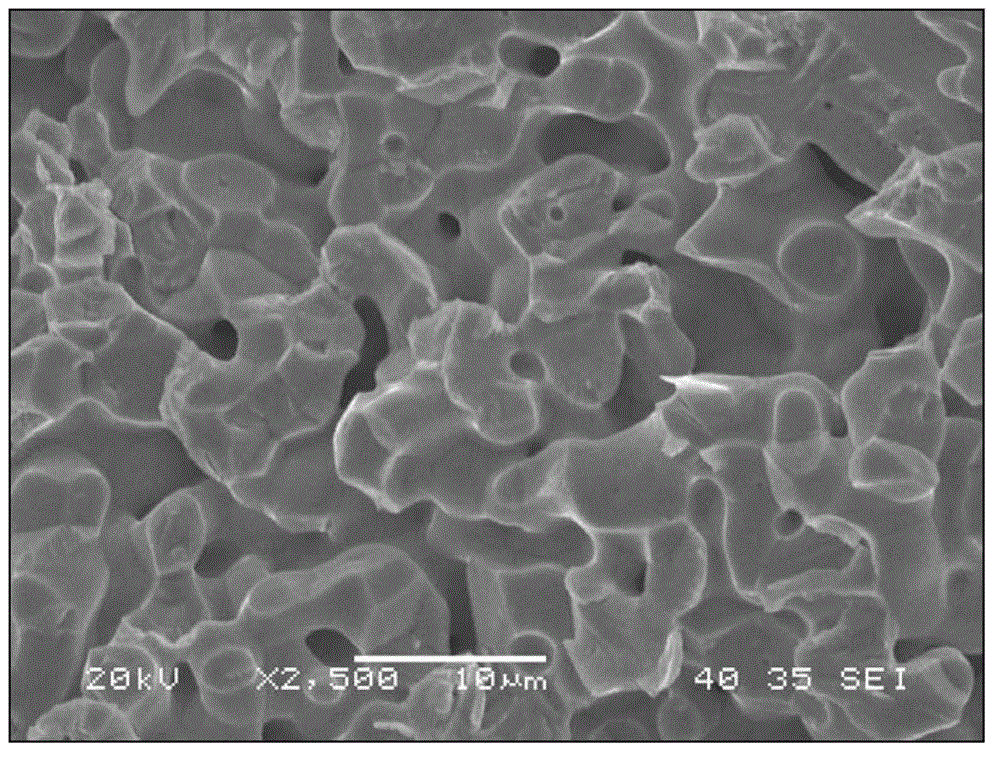

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

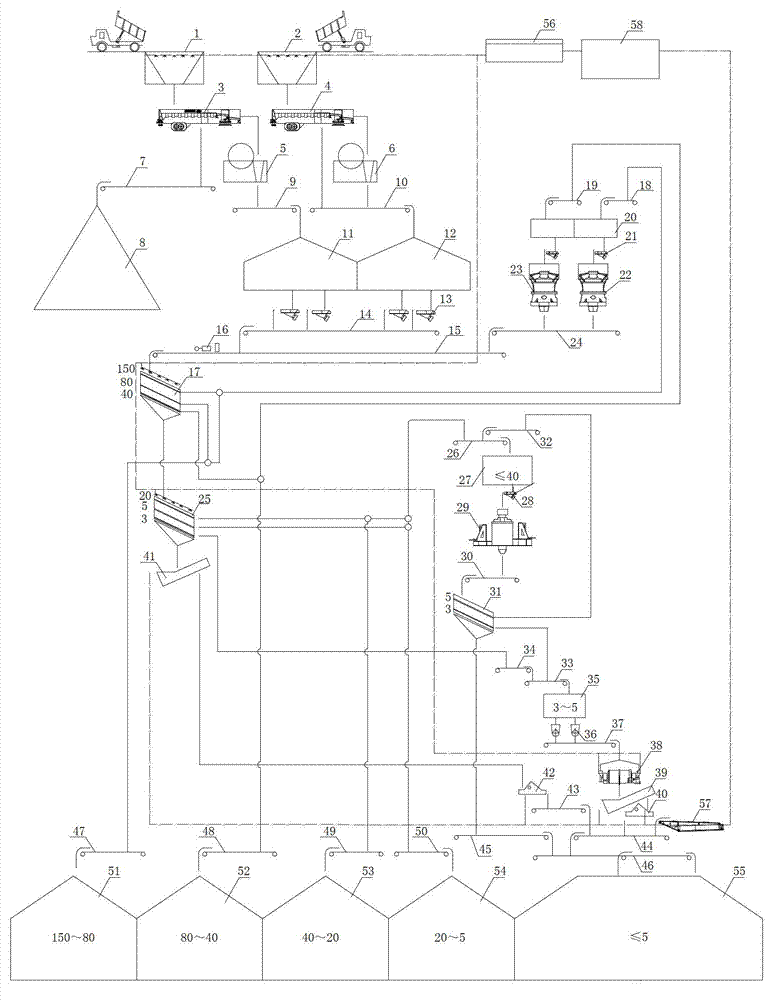

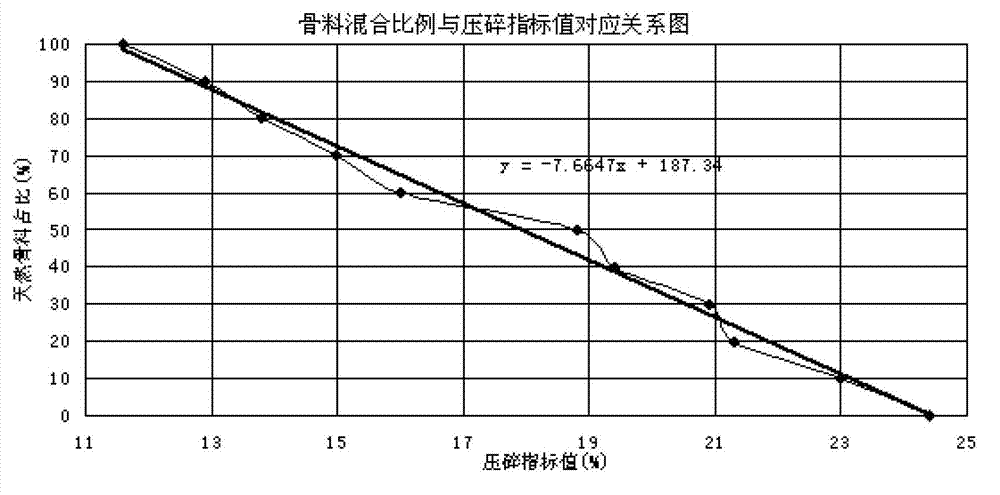

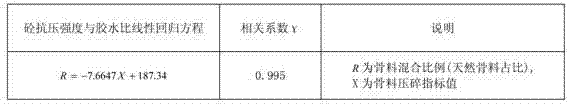

Processing system of concrete combined aggregate and construction method

InactiveCN102814862AFacilitate adjustment of gradingIncrease productivityMixing operation control apparatusControl apparatusEngineeringMachining system

The invention provides a concrete combined aggregate processing system, which comprises a first receiver bin. A first bar type feeder is disposed below the first receiver bin, the undersize part of the first bar type feeder is connected to a rejected material storage yard through a first adhesive tape machine, and the oversize part of the first bar type feeder is connected to a first jaw crusher. The discharge port of the first jaw crusher is connected to an artificial break stone storage yard through a second adhesive tape machine. A second bar type feeder is disposed below a second receiver bin. The oversize part of the second bar type feeder is connected to a second jaw crusher, and the undersize part of the second bar type feeder as well as the discharge port of the second jaw crusher is connected to a natural gravel storage yard through a third adhesive tape machine. The system provided in the invention can adopt two material sources at the same time to conduct production and processing, and the processed combined aggregate can satisfy the quality requirements of concrete aggregates, so that the work efficiency of the aggregate processing system can be enhanced. Moreover, the system is in favor of the sufficient use of project excavation ballast materials so as to reduce resource investment and project investment, and is also beneficial to environmental protection.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Optical conversion luminous film and preparation method thereof

ActiveCN101571235AGood luminous consistencyPrevent glareLuminescent paintsSynthetic resin layered productsChemistryColor rendering index

The invention relates to an optical conversion luminous film and a preparation method thereof. The optical conversion luminous film is formed by a diffusion film and a mixed paint layer on the diffusion film; the optical conversion luminous film has the thickness of 30-200mum, wherein, the thickness of the diffusion film is 20-70mum; the mixed paint layer is made of 10.000-30.000% of yellow luminous fluorescent material, 0.001-2.000% of red luminous fluorescent material, 60.000-89.000% of polymer resin, 1.000-5.000% of bi-amino silane, 0.000-20.000% of diluting agent and 0.000-5.000% of accessory ingredient. By combining the yellow luminous fluorescent material and the red luminous fluorescent material, the invention can realize the aim of regulating chromaticity coordinate, color temperature and color rendering index, thus preparing the optical conversion luminous film which is made of the fluorescent materials and has the advantages of high color rendering index of the photodiffusion effect, good property of uniform light, anti-dazzle, high light conversion efficiency, low cost, excellent aging characteristic and simple production technique.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

Infiltration preparation method of Cu-MoCu-Cu three-layer composite plate

ActiveCN102941702AImprove bindingShort processTransportation and packagingSemiconductor/solid-state device detailsCopperComposite plate

The invention provides an infiltration preparation method of a Cu-MoCu-Cu three-layer composite plate, which comprises the following steps: 1. pressing molybdenum powder into a plate blank, and sintering into a porous molybdenum framework; 2. laying the porous molybdenum framework between copper plates to carry out infiltration, thereby obtaining a Cu-MoCu-Cu three-layer composite material; 3. smoothing the surface; 4. carrying out multi-channel hot rolling; 5. carrying out annealing treatment; 6. carrying out multichannel cold rolling; and 7. carrying out surface treatment and finished product shearing to obtain the Cu-MoCu-Cu three-layer composite plate. The steps of infiltration and compounding are carried out synchronously to prepare the Cu-MoCu-Cu three-layer composite plate, thereby greatly shortening the technical process and enhancing the production efficiency; the layers are combined in an infiltration mode, thereby obviously enhancing the interlayer binding force and effectively avoiding the problem of interlayer oxidization; and the Cu-MoCu-Cu three-layer composite plate prepared by the method provided by the invention has the advantages of favorable interlayer combination and favorable thermal conductivity, and can solve the problem of heat dissipation in the large-scale integrated circuit.

Owner:西安宝德九土新材料有限公司

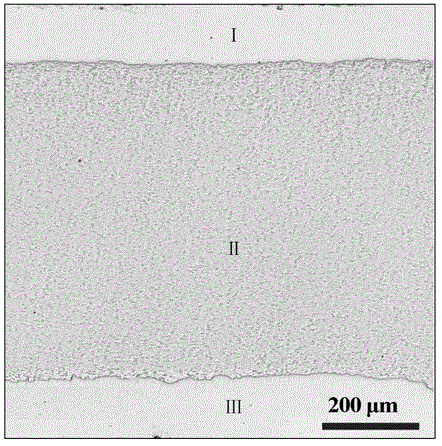

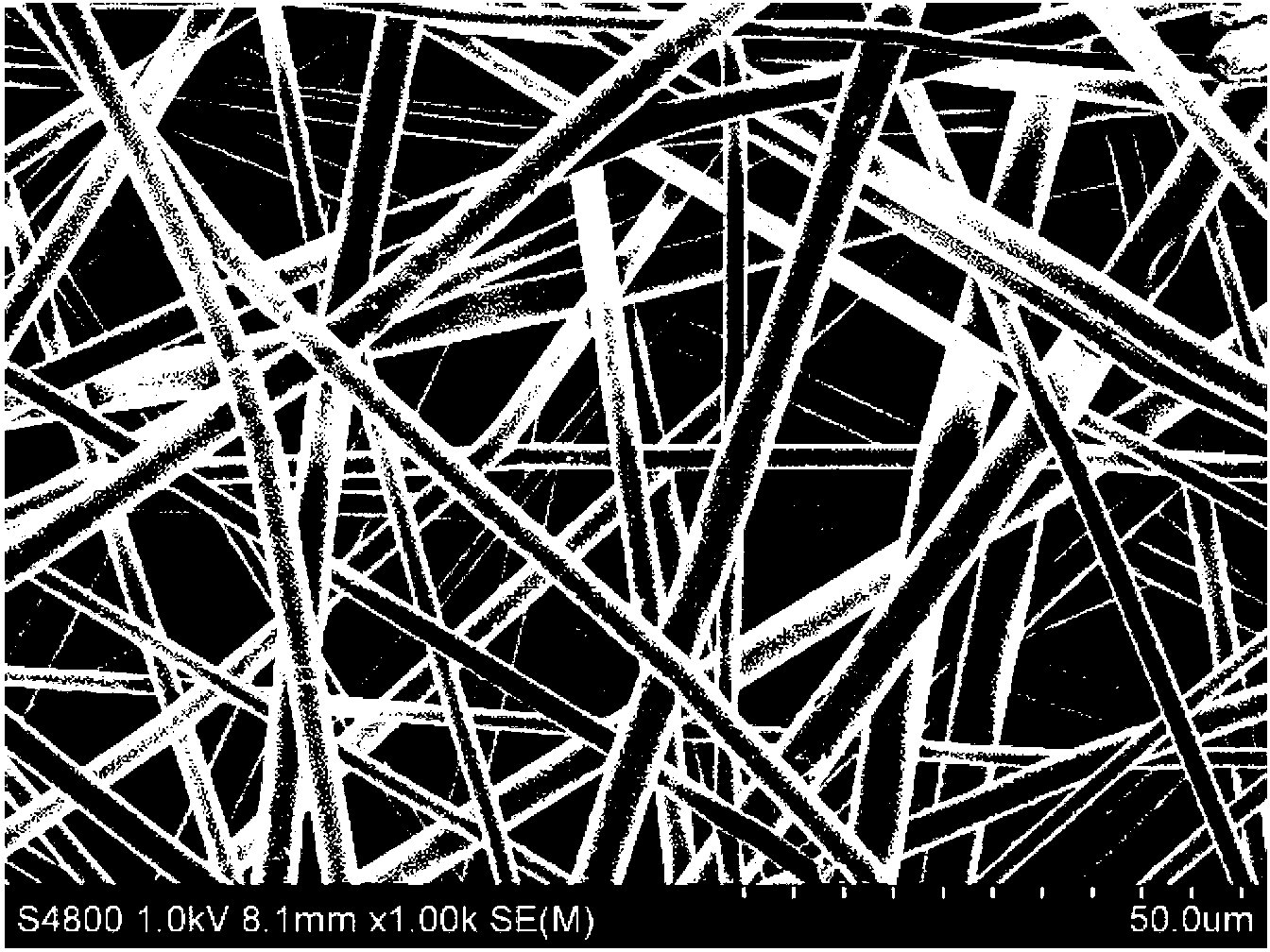

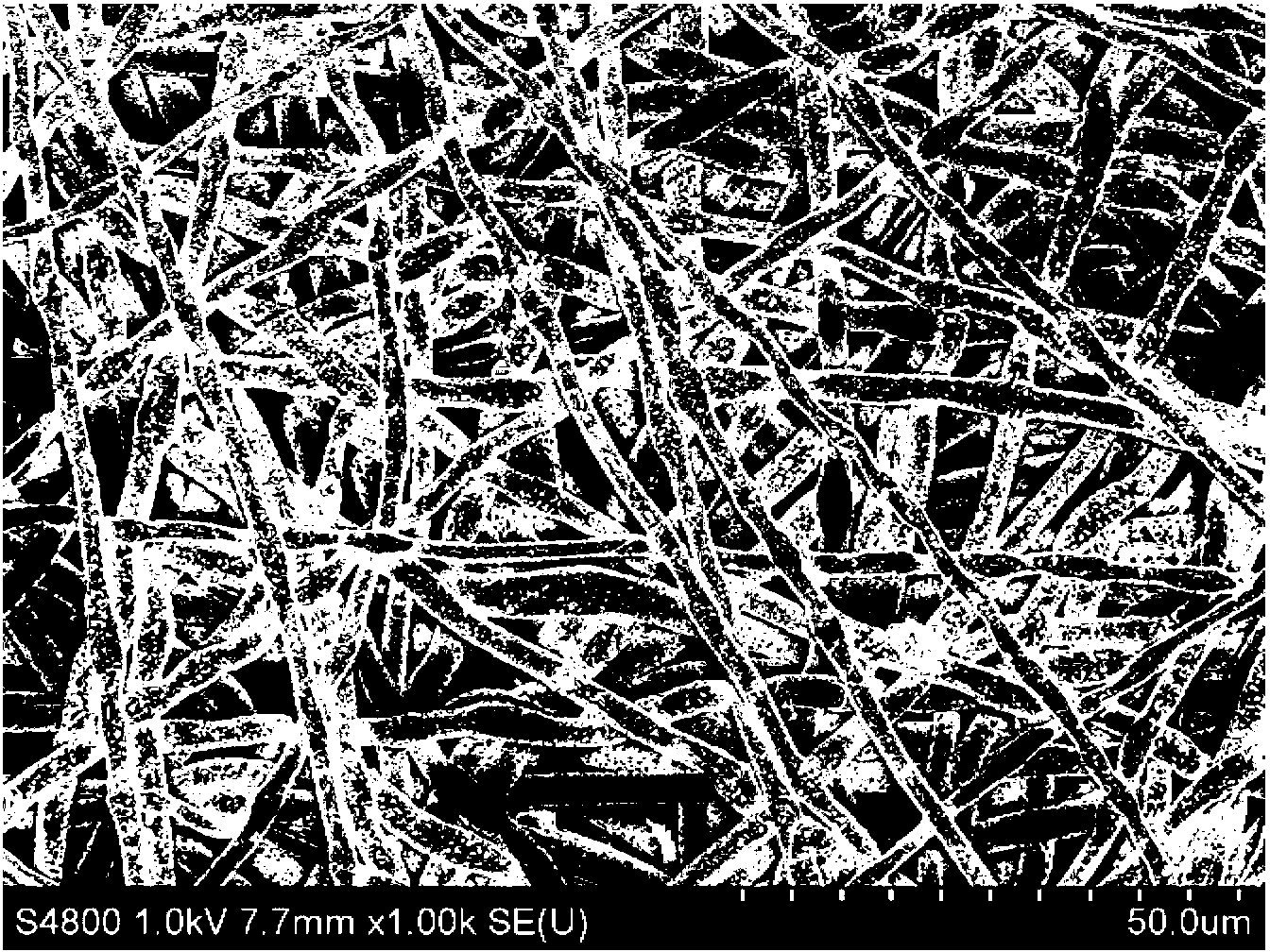

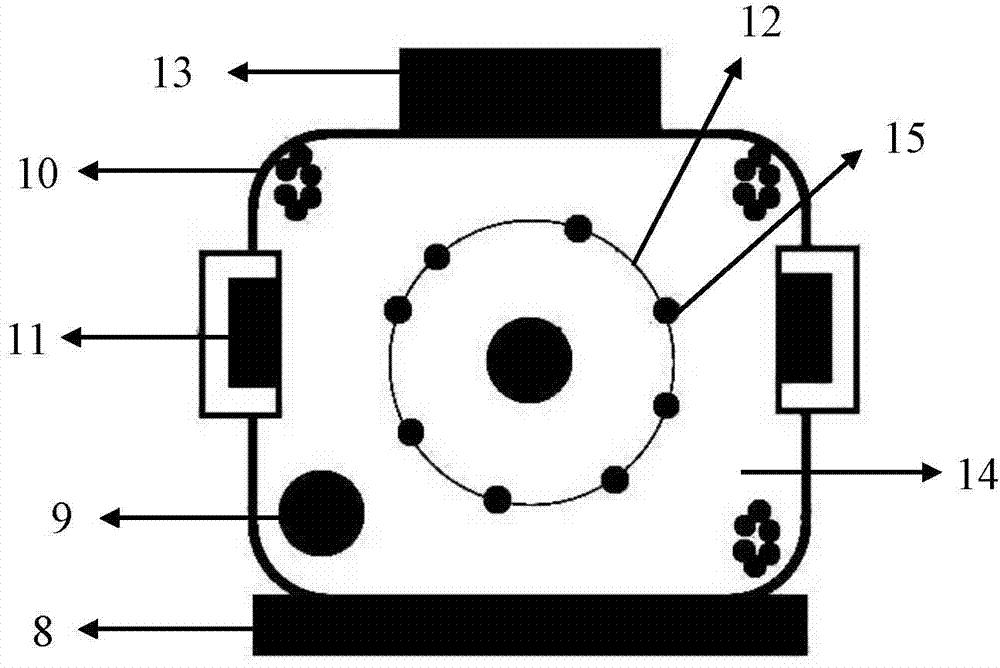

Aliphatic polyester double-layered asymmetric guided tissue regeneration membrane and preparation method thereof

ActiveCN103007364AHigh mechanical strengthGood flexibilitySurgeryPolyesterEthylene Oxide Sterilization

The invention discloses an aliphatic polyester double-layered asymmetric guided tissue regeneration membrane and a preparation method thereof. The aliphatic polyester double-layered asymmetric guided tissue regeneration membrane consists of a compact aliphatic polyester layer and a loose aliphatic polyester layer. The preparation method comprises the following steps: preparing an electrospinning liquid A and an electrospinning liquid B through aliphatic polyester; achieving electrostatic spinning film-forming through the electrospinning liquid A and obtaining the compact layer through hot-pressing; achieving electrostatic spinning film-forming on the electrospinning membrane A through the electrospinning liquid B to obtain the loose layer; achieving vacuum drying, solvent removal and freeze drying of a double-layered asymmetric electrospinning membrane; and finally achieving Co<60> radiation or ethylene epoxide sterilization of the double-layered asymmetric electrospinning membrane to obtain the double-layered asymmetric guided tissue regeneration membrane. The invention has the advantages that the preparation method is simple, the preparation efficiency is high, and the prepared membrane has favorable biocompatibility and mechanical property, appropriate degradation rate and excellent attachment property, can well satisfy the clinical requirements for guided tissue regeneration and repair, and is an ideal guided tissue regeneration membrane material.

Owner:北京市意华健科贸有限责任公司

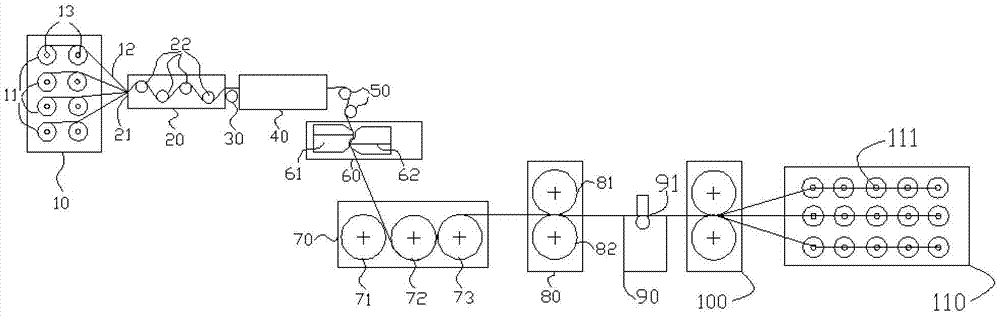

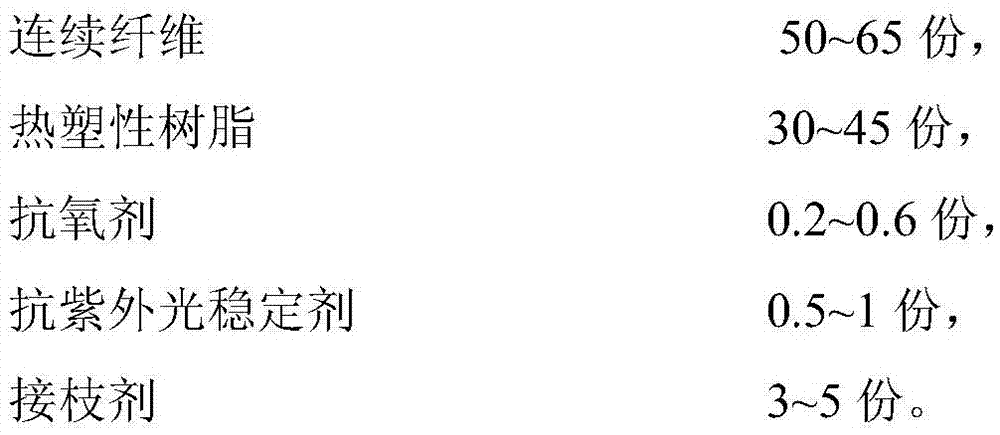

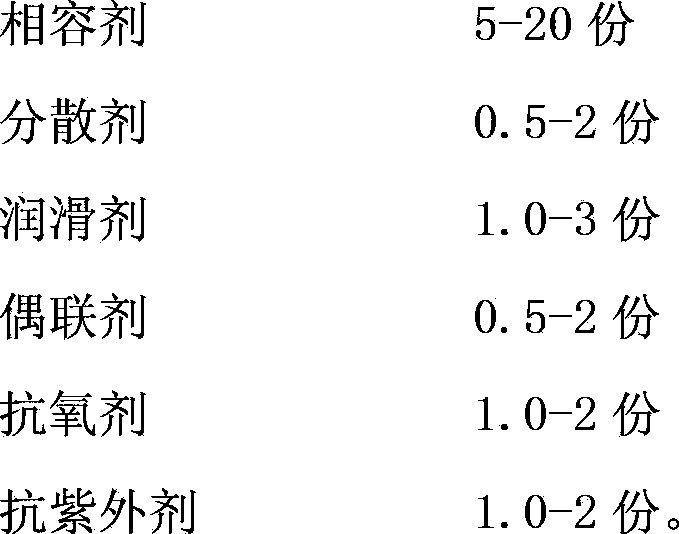

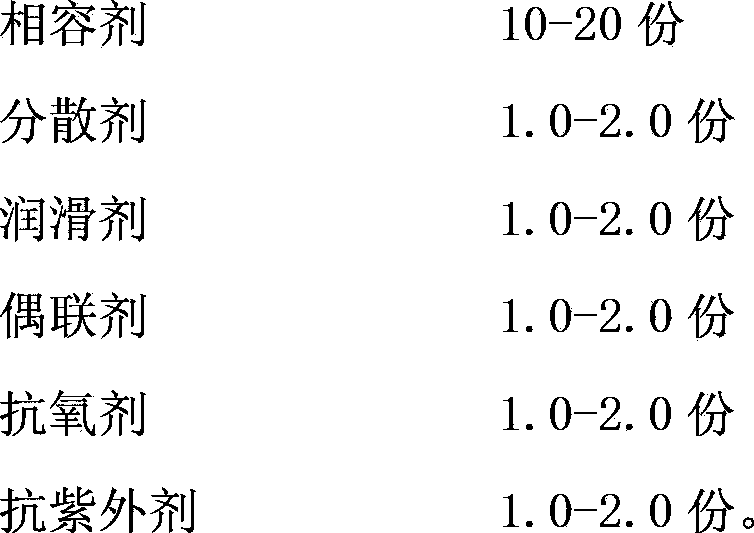

Continuous fiber-reinforced thermoplastic resin prepreg thread and preparation method thereof, and apparatus used in preparation method

The invention discloses a continuous fiber-reinforced thermoplastic resin prepreg thread. The continuous fiber-reinforced thermoplastic resin prepreg thread is prepared from, by weight, 50 to 65 parts of continuous fibers, 30 to 45 parts of thermoplastic resin, 0.2 to 0.6 part of an anti-oxidant, 0.5 to 1 part of an anti-ultraviolet light stabilizing agent and 3 to 5 parts of a grafting agent. The invention also discloses a preparation method for the continuous fiber-reinforced thermoplastic resin prepreg thread and an apparatus used therein. According to the invention, a raw material formula is changed and adjusted; the prepreg thread is prepared from a produced prepreg tape; the produced prepreg thread can be used for braiding of a three-dimensional braided fabric via a three dimensional braiding device; and the eventual purposes of improving interlayer bonding and enhancing the mechanical properties of a product are achieved.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

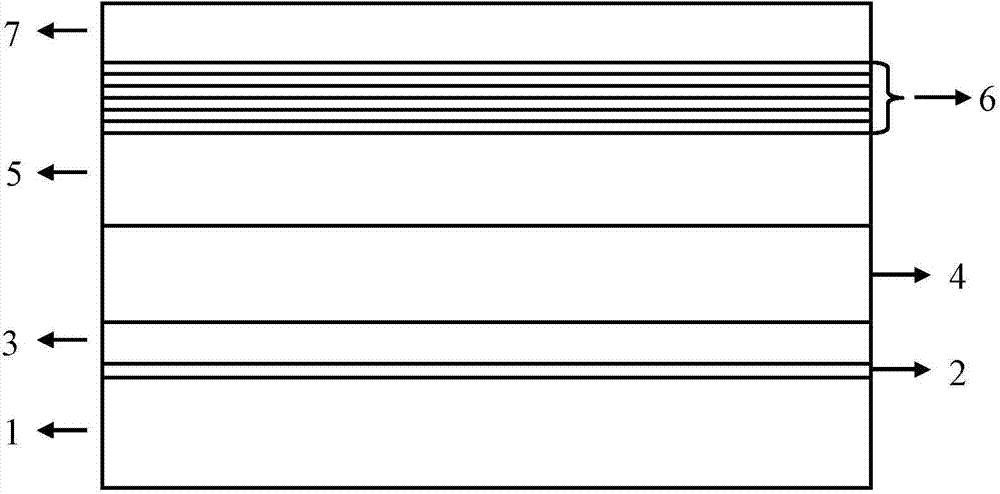

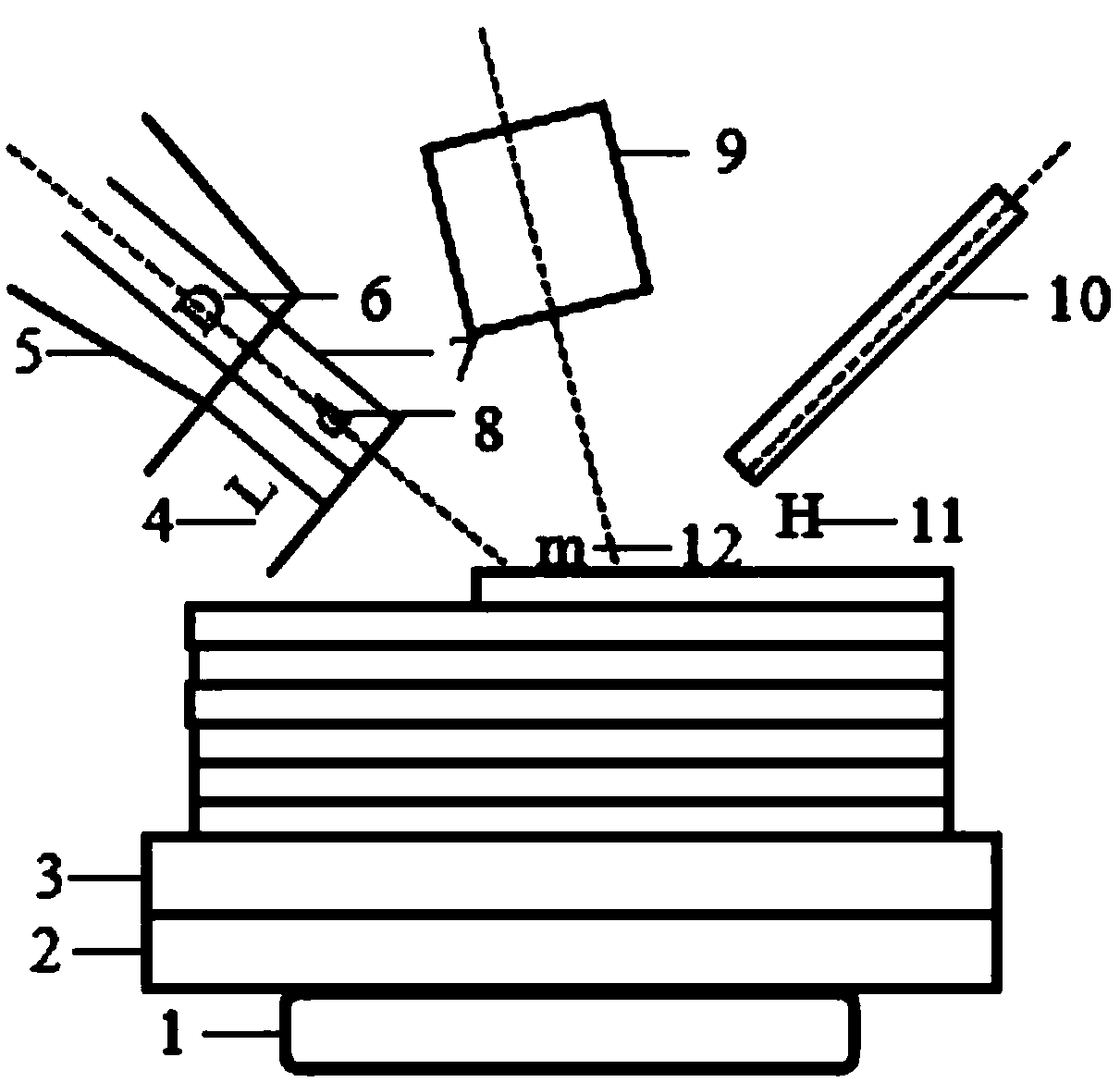

Cr-Cr nanometer composite metal ceramic coating as well as preparation method and device thereof

ActiveCN104711515AReduce coating stressGood cushioning effectVacuum evaporation coatingSputtering coatingCorrosion resistantCermet

The invention provides a Cr-Cr nanometer composite metal ceramic coating as well as a preparation method and device thereof. The coating is provided with a Cr diffusion layer, a Cr bonding layer, a Cr transition layer, a CrNx supporting layer, a Cr / CrN corrosion-resistant layer and a Cr decoration layer, wherein the CrNx supporting layer satisfies 0<=x<1; the Cr / CrN corrosion-resistant layer is an alternating layer of Cr layers and CrN layers and provided with at least one layer of Cr layer and one CrN layer. The coating provided by the invention has gradual changes of structure and composition, good interlayer bonding and excellent corrosion resistance and comprehensive properties.

Owner:AEROSPACE PRECISION PROD INC LTD

Reinforcement for asphaltic paving, method of paving, and process for making a grid with the coating for asphaltic paving

ActiveUS8038364B2Improve interlayer bonding performancePaving reinforcementsIn situ pavingsPolymer chemistryCoating

A composite material comprises: an open grid comprising at least two sets of strands. Each set of strands has openings between adjacent strands. The sets are oriented at a substantial angle to one another. A tack film is laminated to the open grid. The tack film has first and second major surfaces, such that a material of the tack film at its first and second major surfaces is a material including about 50% or more of resinous non-asphaltic component and about 50% or less of asphaltic component.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Heat-Curable Silicone Rubber Composition For Rubber Laminate

ActiveUS20100055449A1High efficiencyGood propertySynthetic resin layered productsSpecial tyresBonds hydrogenSide chain

A heat-curable silicone rubber composition for a rubber laminate composed of a silicone-rubber layer and a rubber layer of a material other than silicone, the composition comprising: an alkenyl-containing diorganopolysiloxane (A) which comprises: 50 to 99 mass % of a diorganopolysiloxane (A1) that contains alkenyl groups, is capped at molecular terminals with alkenyl-containing organosilyl groups, and is free of alkenyl groups in side molecular chains; 1 to 50 mass % of an alkenyl-containing diorganopolysiloxane (A2) having two or more alkenyl groups in a side molecular chain; a fine silica powder (B); an organohydrogenpolysiloxane (C) having in one molecule at least two silicon-bonded hydrogen atoms; and an organic peroxide (D).

Owner:DOW TORAY CO LTD

Preparing method of TiAl alloy turbine blade

ActiveCN107931609ASmall internal thermal stressAvoid deformationTurbinesAdditive manufacturing apparatusVacuum pumpingTurbine blade

The invention discloses a preparing method of a TiAl alloy turbine blade. The method comprises the steps that a three-dimensional model of the turbine blade is built, slicing treatment is carried out,and layer cutting data are obtained; secondly, secondly, a forming cavity of an electronic beam area selection rapid forming device is subject to vacuum pumping, and a forming substrate is preheated;thirdly, TiAl alloy powder is laid on the preheated forming substrate, and preheating is carried out; fourthly, the preheated TiAl alloy powder is subject to area selection melting scanning, and a single-layer solid piece layer is formed; fifthly, the third step and the fourth step are repeated, and an electronic beam area selection melting forming part is formed; sixthly, after cooling, the TiAlalloy turbine blade is obtained. The TiAl alloy turbine blade is prepared through the electronic beam area selecting rapid forming method, preheating of the forming substrate and the TiAl alloy powder is achieved, forming temperature of the TiAl alloy turbine blade is controlled, internal heat stress of the TiAl alloy turbine blade is reduced, deforming and breaking of the TiAl alloy turbine blade are avoided, and matching of strength and plasticity of the TiAl alloy turbine blade is enhanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

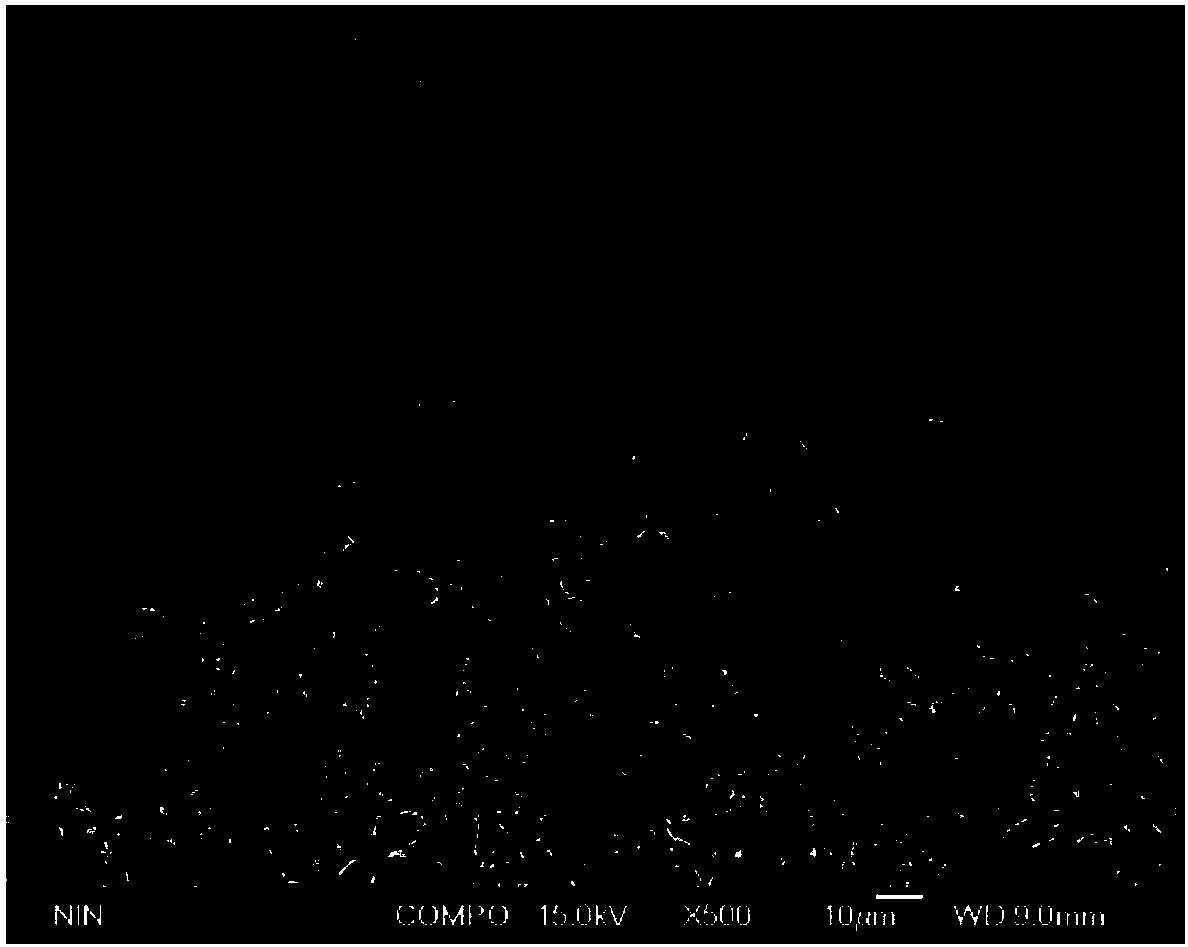

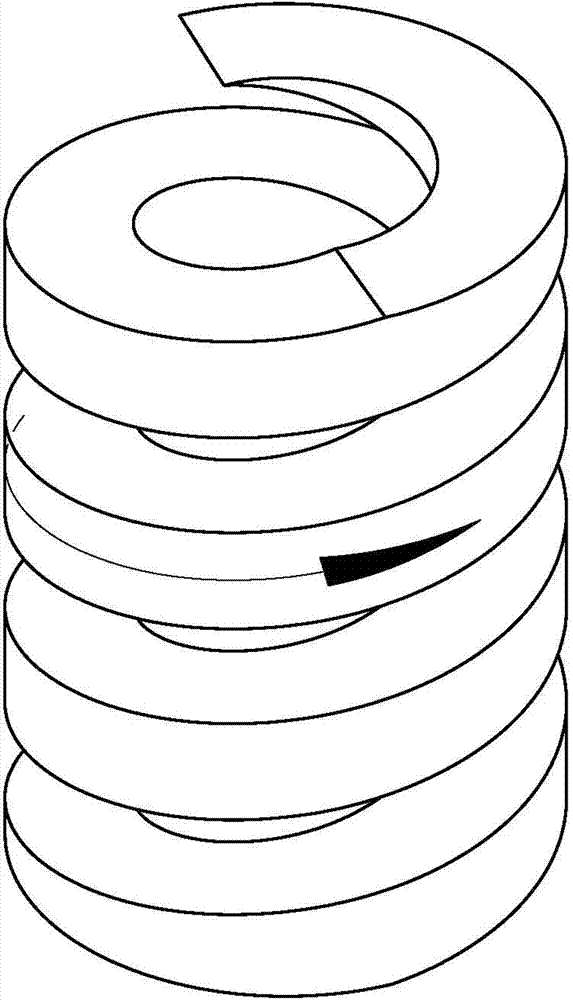

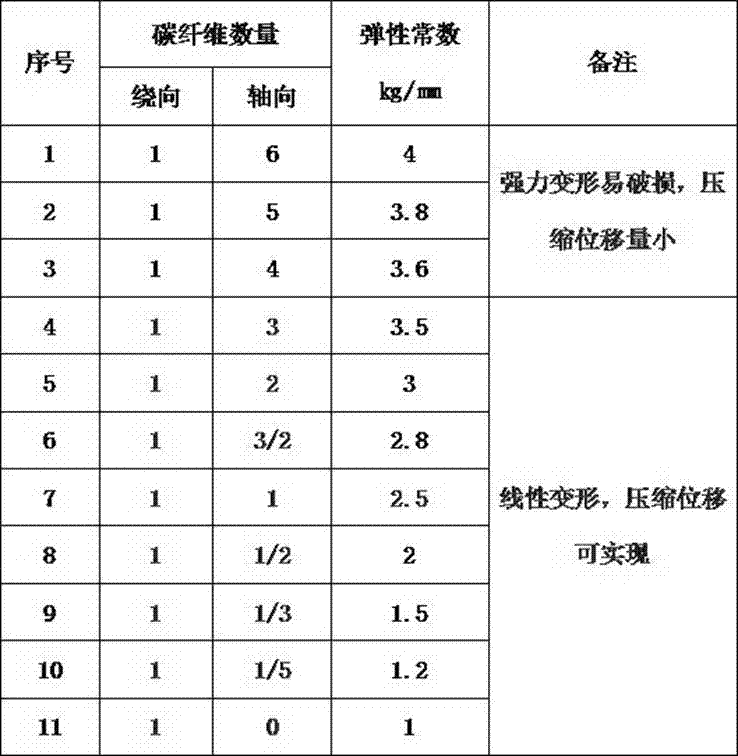

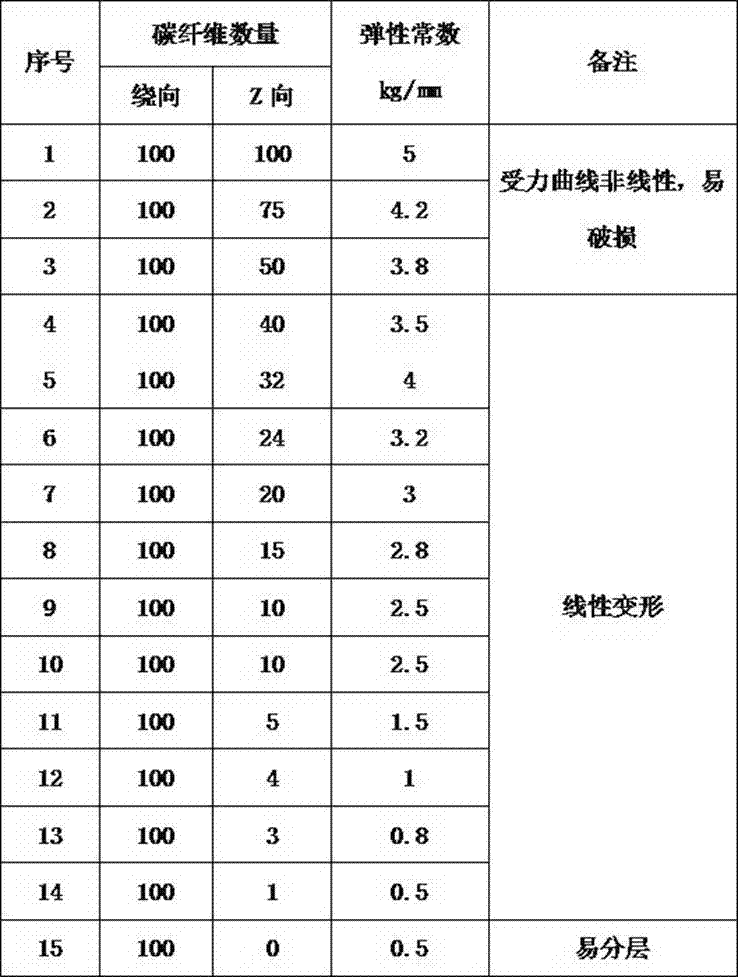

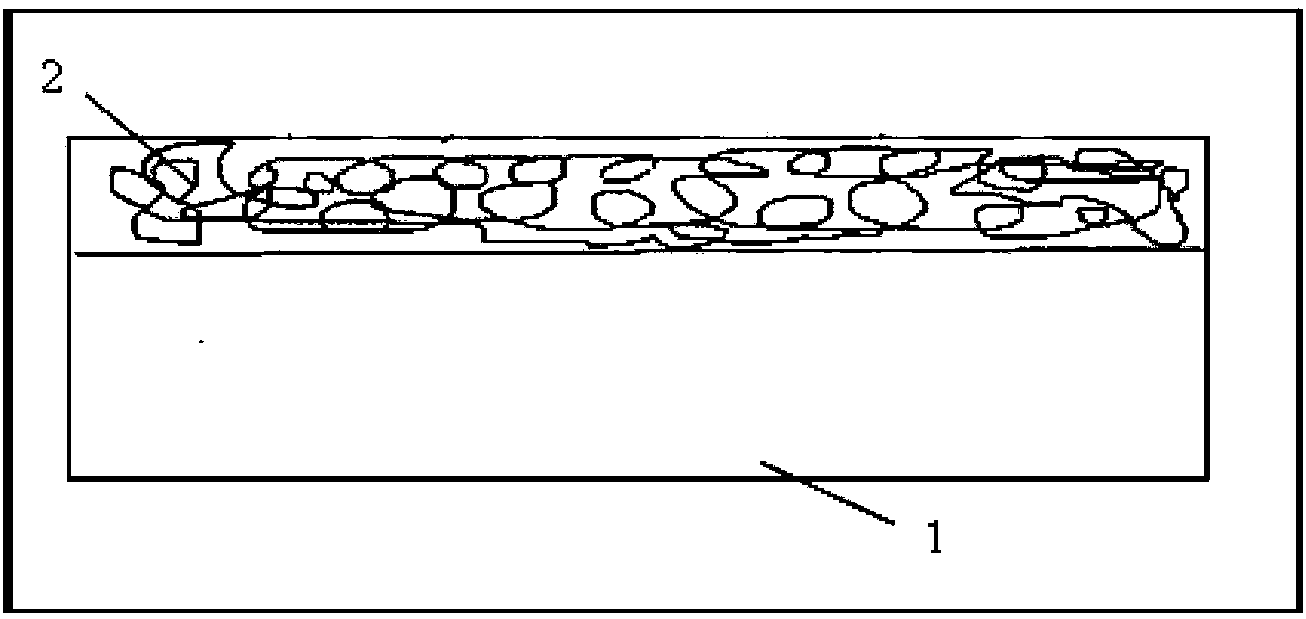

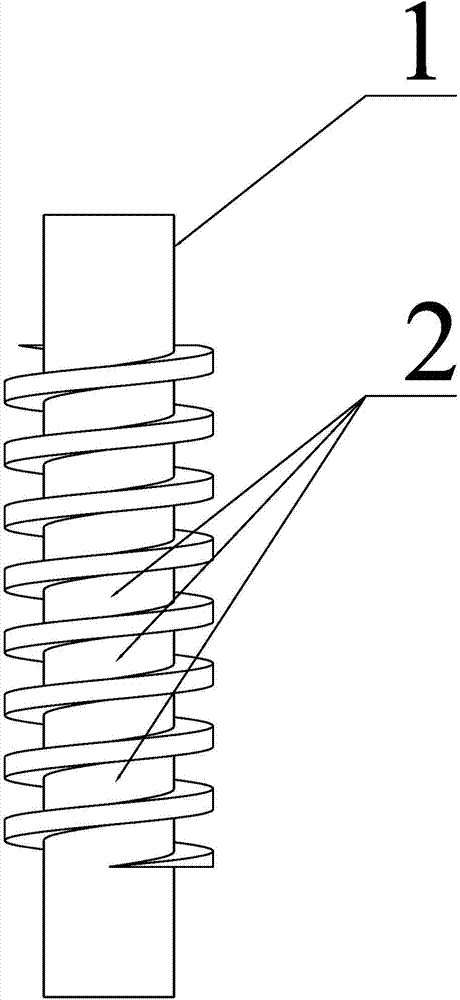

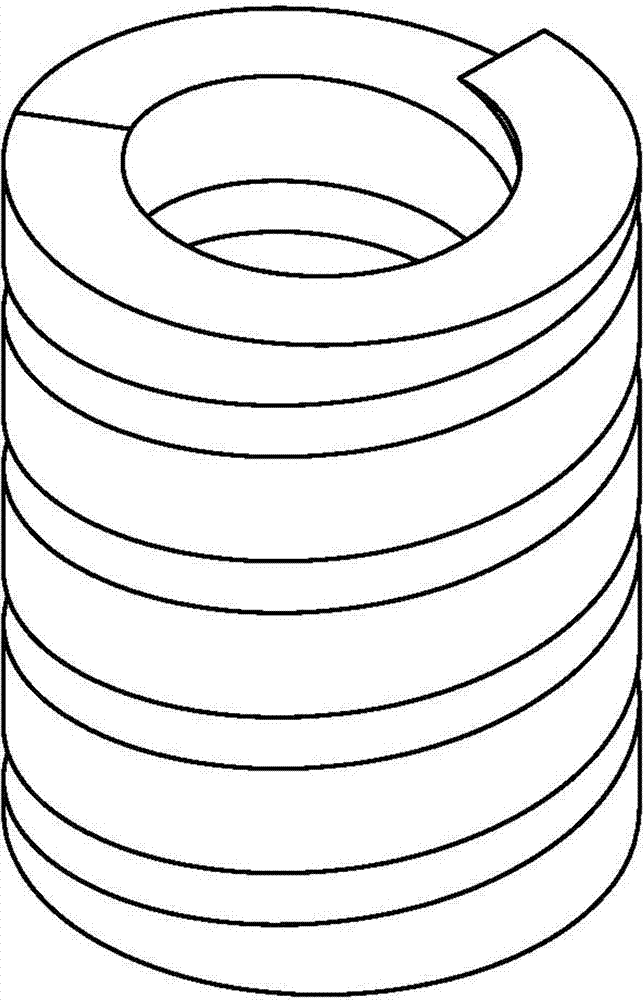

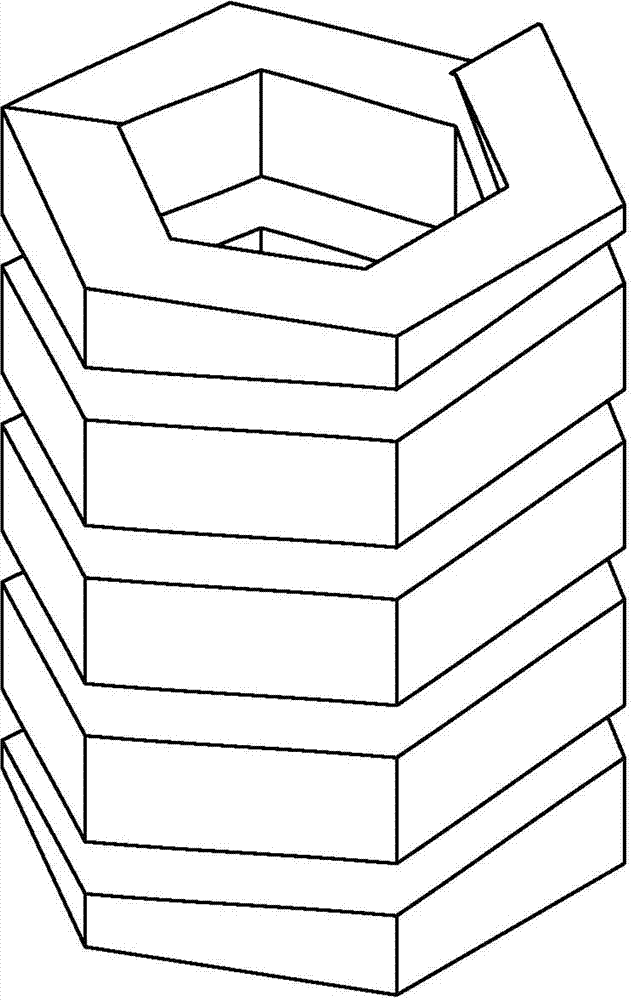

Carbon based composited material helical spring and production method thereof

ActiveCN107285796AImprove mechanical propertiesImprove interlayer bonding performanceSprings/dampers functional characteristicsSprings/dampers manufactureFiberHelical line

The invention discloses a carbon based composited material helical spring production method. Z-direction carbon fibers are introduced into the helical spring from an axial direction, which is perpendicular to the helical spring. The production method is characterized by comprising the following steps: (1) blank preparation: winding a carbon fiber beam or carbon fiber cloth around a core mould along the helical line direction of a spring, wherein the moving direction of continuous long fibers of the carbon fiber beam or carbon fiber cloth is the same as the helical line direction of the spring; then winding a carbon fiber net tire around the core mould, carrying out needling along the radial direction of the core mould, and repeating the abovementioned process to prepare a carbon fiber spring preform; (2) density increasing; and (3) mechanical processing. The ratio of the number of continuous carbon fiber along the helical line direction of the spring to the number of the Z-direction carbon fibers is 1:0.01-0.4. The elastic constant of the helical spring is 0.5 to 10 kg / mm. During the blank making process, Z-direction fibers are introduced into the helical spring from an axial direction perpendicular to the helical spring, the interlayer bonding is good, and thus the mechanical properties of the prepared carbon based composited material helical spring are good.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Skid and scrub resistant rotationally molded product and preparation method thereof

ActiveCN103772798AImproves surface slip resistanceExtended service lifeCoatingsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a skid and scrub resistant rotationally molded product and a preparation method thereof, and belongs to the technical field of rotationally molded materials. The skid and scrub resistant rotationally molded product comprises a low-density polyethylene base and a skid and scrub resistant layer added on the base, and the skid and scrub resistant layer is composed of linear low-density polyethylene, an inorganic wear-resisting agent, a high molecular reinforcing agent and an auxiliary agent. The rotationally molded product is prepared through three steps: processing of the inorganic superfine wear-resisting agent, preparation of a rotational molding composition for the skid and scrub resistant layer, and preparation of the rotationally molded product. The skid and scrub resistant rotationally molded product has smooth inner surface and outer surface, is good in layer combination, and has no warping, no deformation, no foams and no recesses, the scrub-wear volume loss of the product is reduced by 50% or more, and the preparation method of the skid and scrub resistant rotationally molded product is simple, safe and obvious in effect.

Owner:CHINA PETROLEUM & CHEM CORP

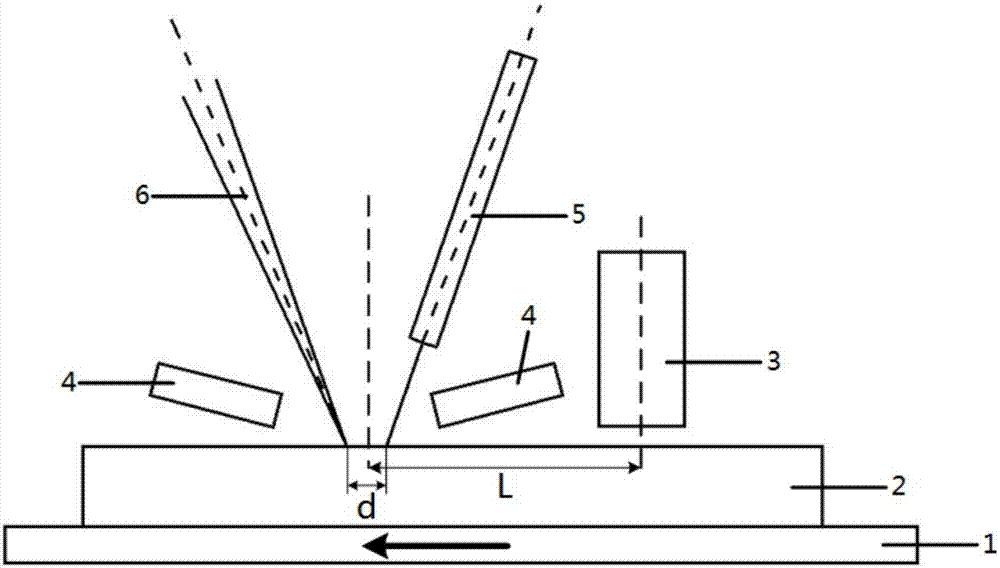

Aluminum alloy laser-TIG composite additive manufacturing method

ActiveCN108393587AImproved reflectivity, high reflectivity, difficult to shapePower optimizationWelding/soldering/cutting articlesLaser beam welding apparatusManufacturing technologyAdditive layer manufacturing

The invention belongs to the technical field of metal additive manufacturing, and provides an aluminum alloy laser-TIG composite additive manufacturing method. According to the composite additive manufacturing method, a laser and an electric arc are used as composite heat sources, and a TIG mode is adopted, so that additive manufacturing forming of the aluminum alloy thin-wall type (single-channelmulti-layer) structure is realized. The method comprises the following steps of S1, determining the relative position relation among the laser, the electric arc and a wire, and carrying out base plate preheating treatment; S2, forming aluminum alloy laser-TIG composite additive single-channel single-layer structure; and S3-S5, forming aluminum alloy laser-TIG composite additive thin-wall type (single-channel multi-layer) structure. According to the composite additive manufacturing method, the defects that formation is not easy when the laser is used as a single heat source due to the fact that the reflectivity of the aluminum alloy is high, and deformation is serious and the forming quality is poor when the electric arc is used as a single heat source due to the fact that the heat input quantity is high are overcome; and the method is suitable for additive manufacturing of aluminum alloy thin-wall type (single-channel multi-layer) structure and can effectively inhibit air hole defects.

Owner:DALIAN UNIV OF TECH

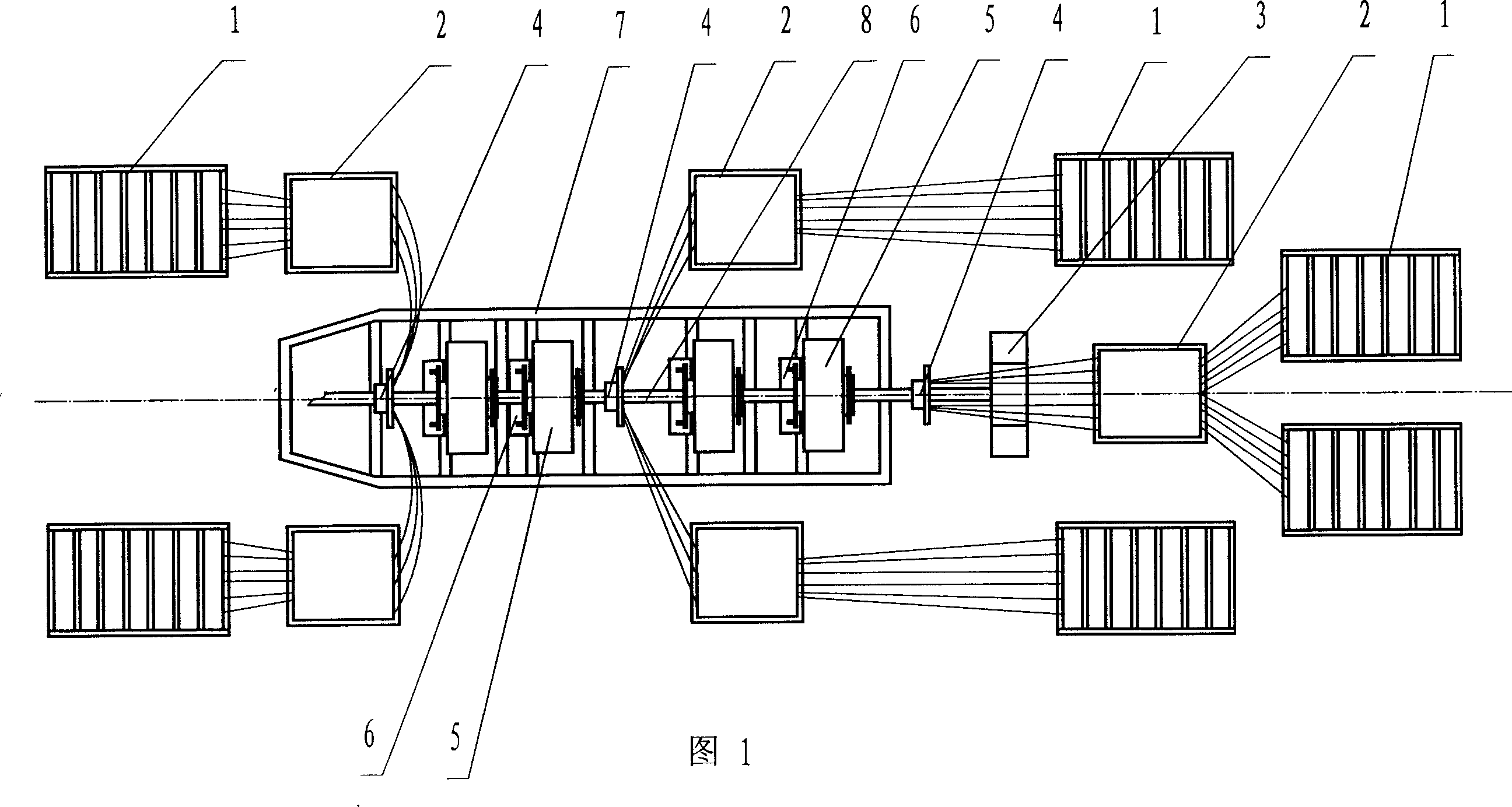

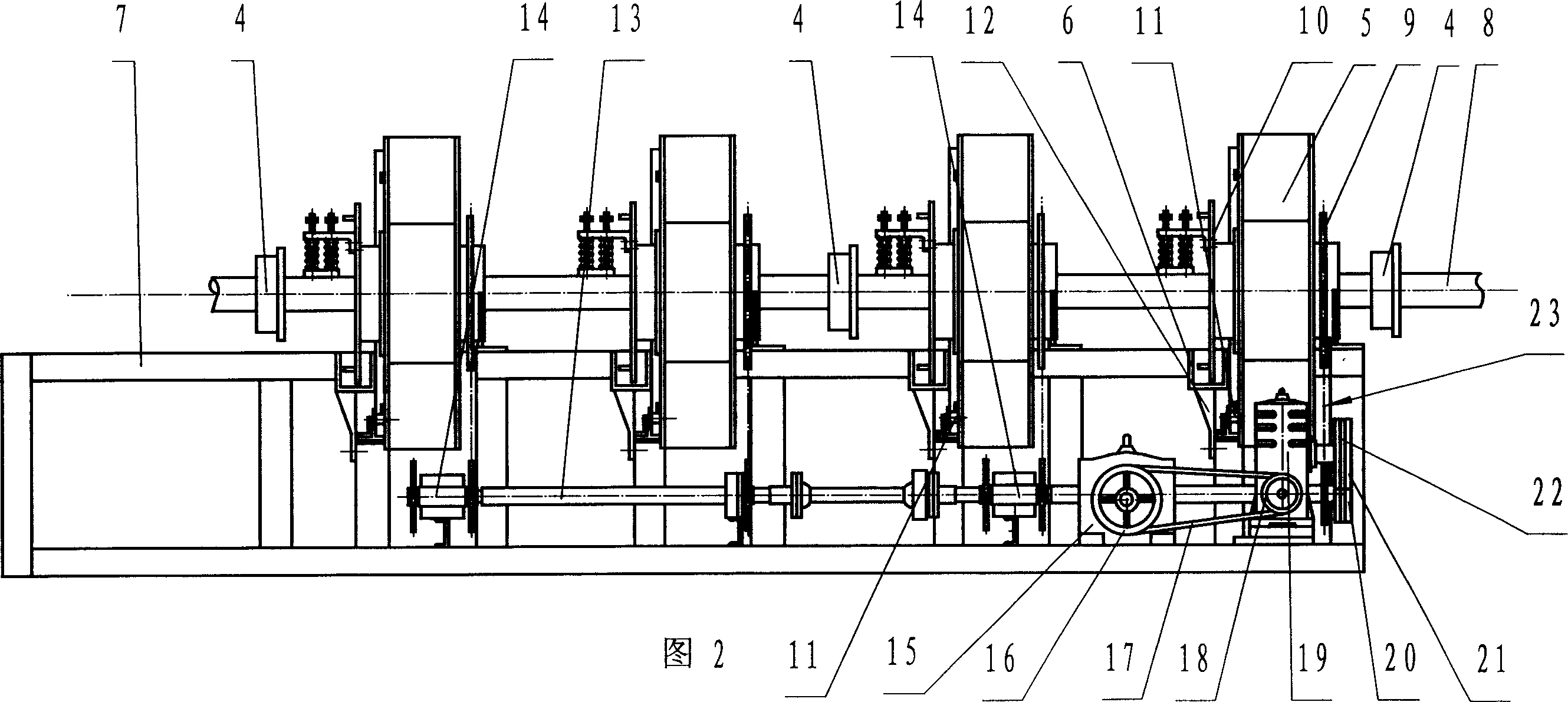

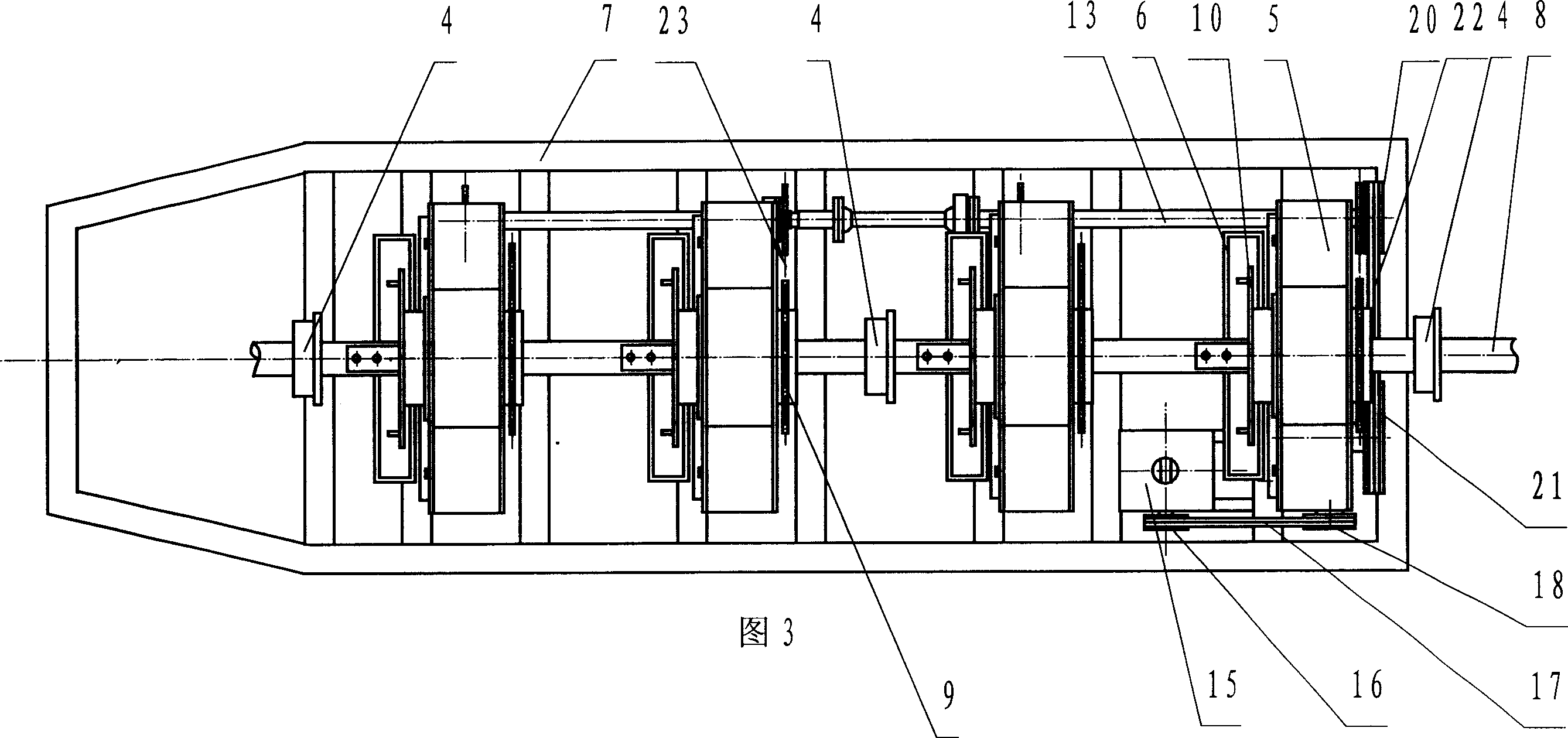

Vertical and ring direction gum dipping wet process glass fiber reinforced plastic tubing continuous pipe twining machine

InactiveCN1603093AEliminate insufficient impregnationImprove interlayer bonding performanceGlass fiberYarn

The invention relates to a vertical hoop stress cement dipping wet method glass-reinforced plastic pipe continuous compaction machine. It includes core axle, base, power drive, vertical yarn rack, vertical yarn dip bath, and distributor. The power drive is set on the seat. There are many sets of vertical yarn rack, vertical yarn dip bath, and distributor. Its features are that many sets of hoop stress cement dipping yarn racks and hoop stress yarn dip baths are set on the seat; the hoop stress cement dipping yarn rack is connected to the power drive, and drove to rotate by it; the hoop stress cement dipping yarn rack has an internal cylinder, and circle yarn rack is set on it; the hoop stress cement dipping yarn rack also set a yarn guiding device, and it has a yarn guiding rack; and the guiding yarn rack is set many yarn guiding wheels and cradles. Its advantages are that both the vertical and hoop stress are cement dipping, this can fundamentally prevent the cement from dipping deficiently; and each of the hoop stress spiral wrapping layer is reverse superposition alternately; the vertical hoop stress yarn layer are alternately overlapped, so that the density and the mechanical strength of the glass-reinforced plastic pipe are greatly improved.

Owner:张国志

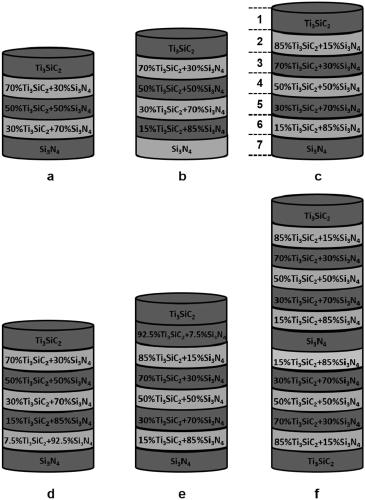

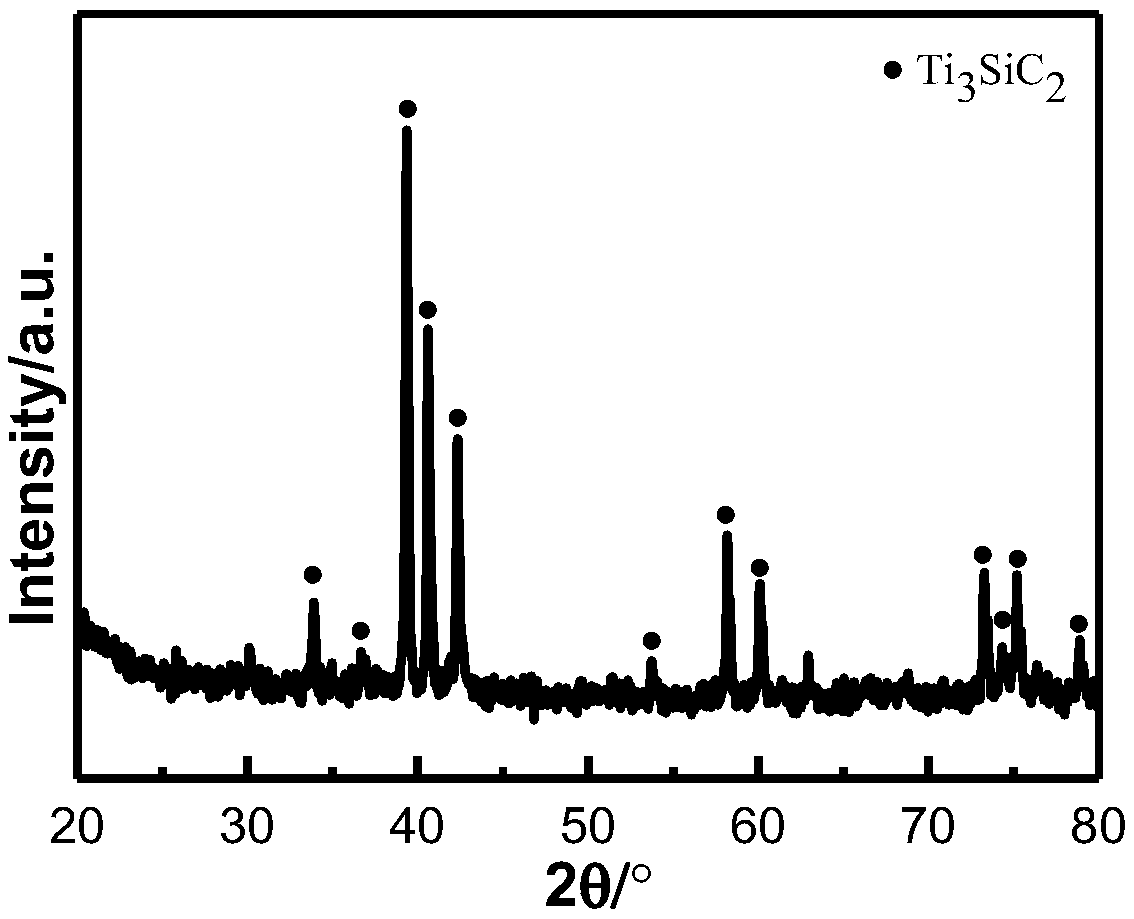

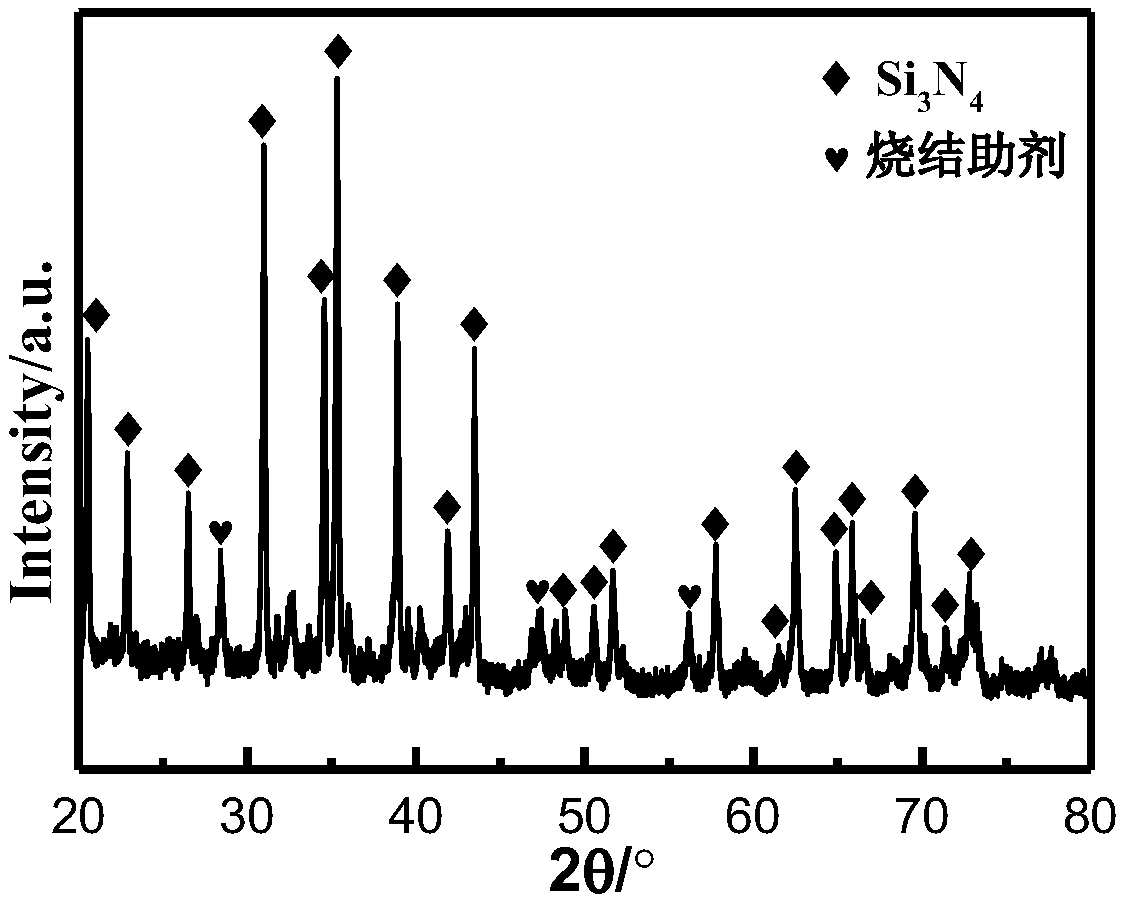

MAX phase/nitride ceramic laminated gradient composite material as well as rapid preparation method and application thereof

ActiveCN109400164AHigh temperature strengthImprove thermal shock resistanceCeramic layered productsHigh densityNitrogen

The invention discloses a MAX phase / nitride ceramic laminated gradient composite material as well as a rapid preparation method and application thereof, belonging to the technical field of preparationof ceramic matrix composite materials. The method adopts an SPS sintering technology to prepare the MAX phase / nitride ceramic laminated gradient composite material; the method introduces an electricfield on the basis of a temperature field and a pressure field, thus playing a role in plasma activation of raw materials, and further quickly preparing the dense multiphase ceramic material under theconditions of lower sintering temperature and shorter heat preservation time; furthermore, the activation of plasma also contributes to the diffusion of atoms, so that the interlayer bonding of a MAXphase and nitride is promoted, and the high-performance connection between the MAX phase and the nitride is realized; the method has the advantages of being high in heating rate, low in sintering temperature and short in heat preservation time. The method can be used for quickly preparing the MAX phase / nitrogen ceramic laminated gradient composite material with high density, low impurity contentand good interface bonding property.

Owner:XI AN JIAOTONG UNIV

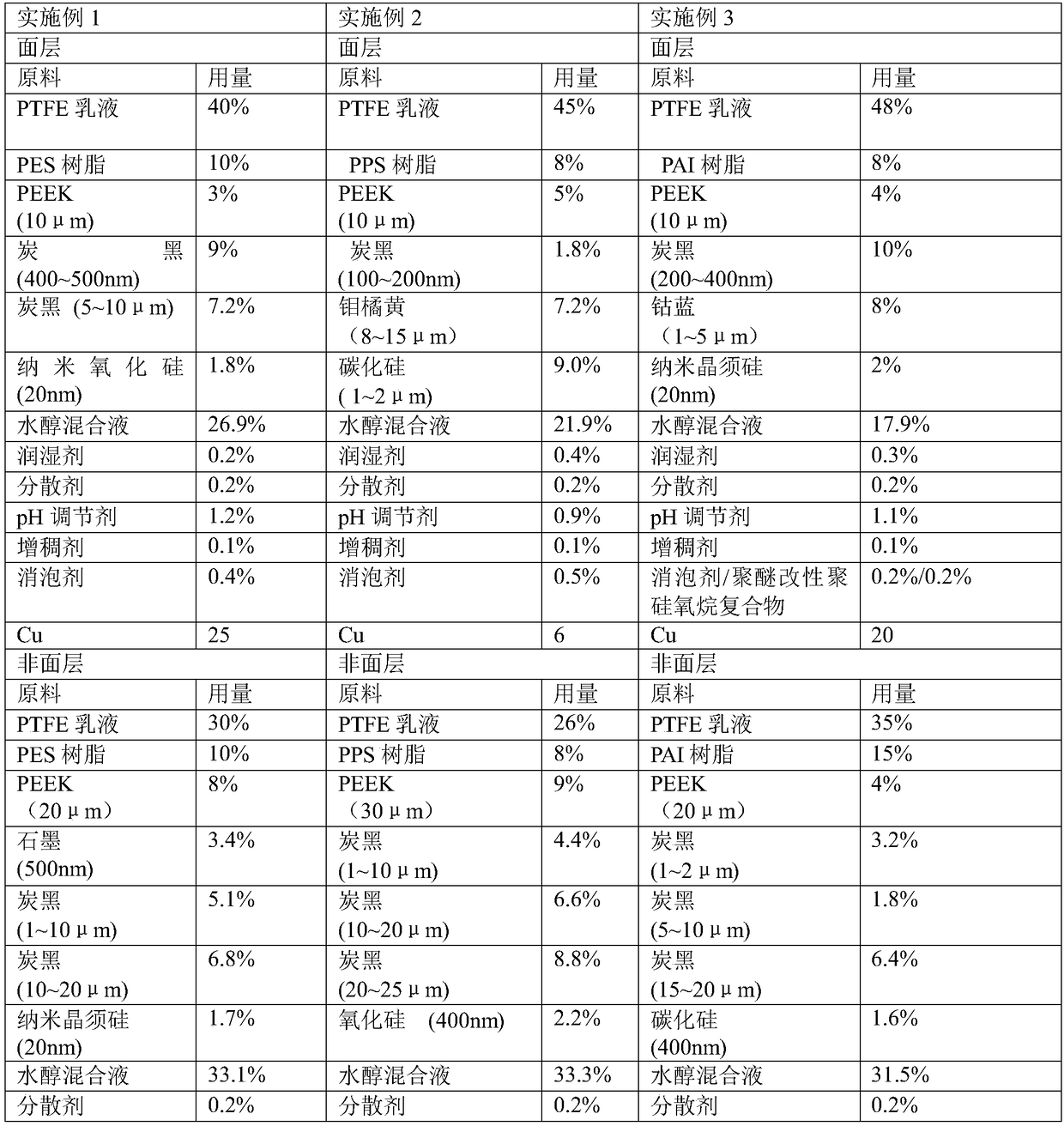

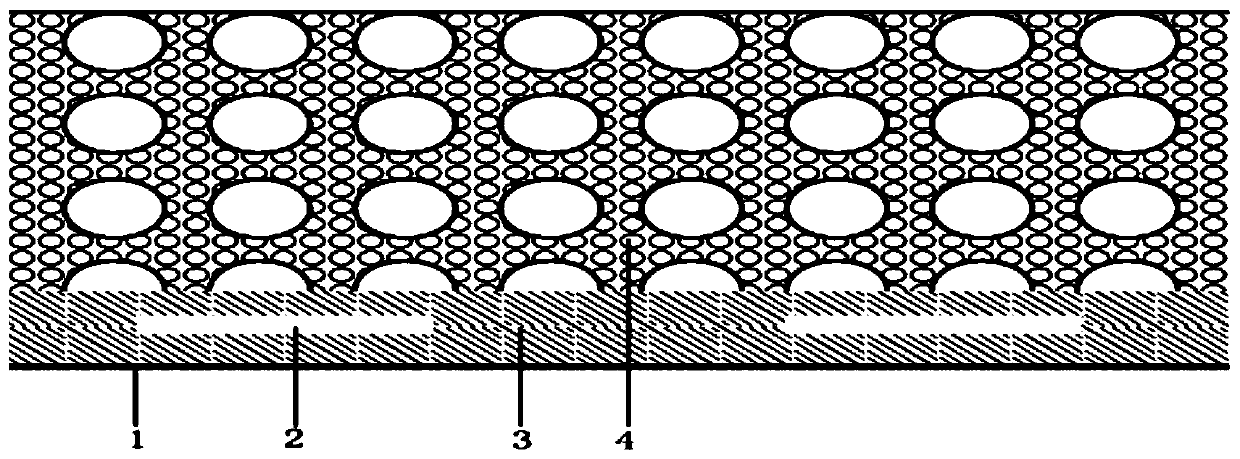

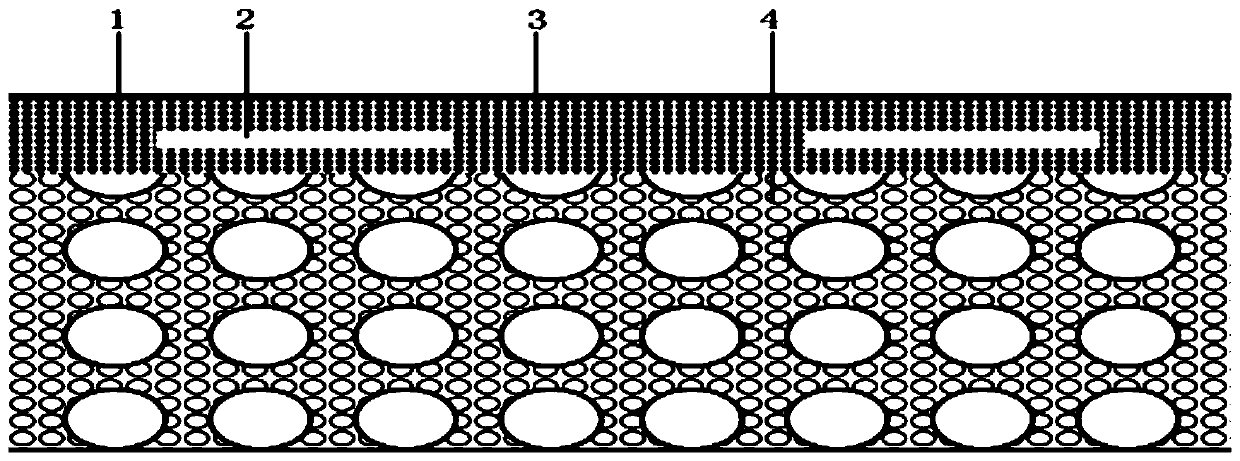

High-wear-resistance non-stick coating special for cooker and preparation method thereof

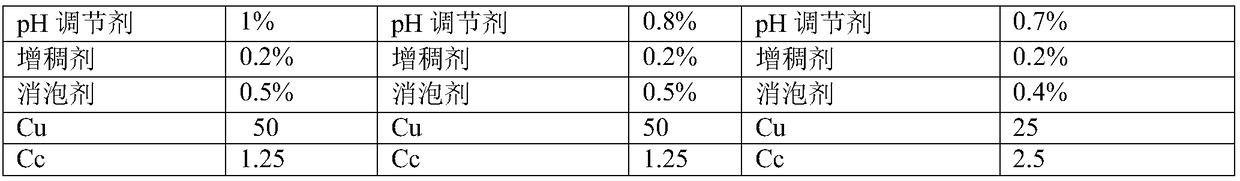

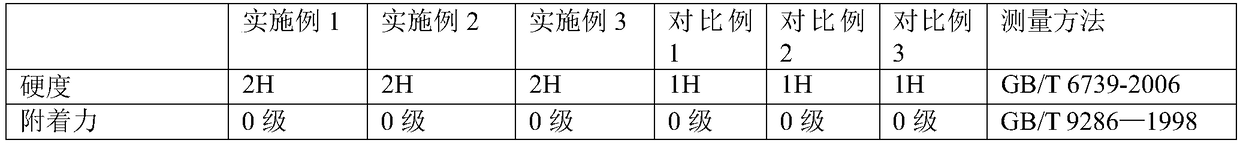

The invention relates to the field of coatings, and discloses a high-wear-resistance non-stick coating special for a cooker. The coating comprises a primary layer coating body and a non-primary layercoating body; each of the primary layer coating body and the non-primary layer coating body is prepared from a polytetrafluoroethylene emulsion, bonding resin, wear-resistant resin, a pigment, a filler and an auxiliary agent; in the primary layer coating body, the non-uniform coefficient Cu of the particle size of the pigment and the filler is greater than 5; in the non-primary layer coating body,the particle size of the pigment and the filler adopts discontinuous grading, the non-uniform coefficient Cu is larger than 5, and the curvature coefficient Cc is equal to 1-3, wherein Cu accounts for d60 / d10, and Cc accounts for d30<2> / d60*d10; the particle size of the pigment and the filler in the primary layer coating body is smaller than the particle size of the pigment and the filler in thenon-primary layer coating body; and the filler is insoluble in the coating and can be uniformly dispersed. The wear-resistant non-stick coating has the advantages of being outstanding in non-viscosity, good in wear resistance, capable of effectively resisting scraping of a truner and long in service life.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD +1

Viscoelastic damping material and embedded co-curing damping composite material manufacturing technology

ActiveCN104004305AImprove interlayer bonding performanceViscoelastic dampingManufacturing technology

The invention discloses a viscoelastic damping material. The viscoelastic damping material comprises, by mass, 100 parts of fluororubber, 30 parts of carbon black, 14 parts of triallyl isocyanurate, 3.8 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane and 1.5 parts of N,N'-m-phenylene dimaleimide. The invention also discloses an embedded co-curing damping composite material manufacturing technology utilizing the viscoelastic damping material. The embedded co-curing damping composite material manufacturing technology comprises damping material virgin rubber manufacture, viscoelastic damping film manufacture, and paved layer and member manufacture. The embedded co-curing damping composite material obtained by the manufacturing technology can resist a high temperature and keep high damping at a normal temperature.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

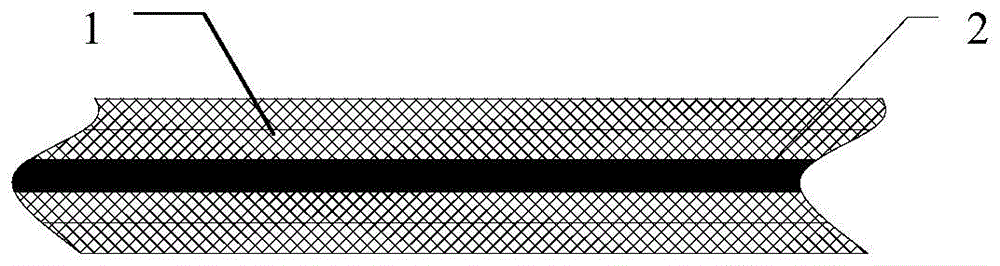

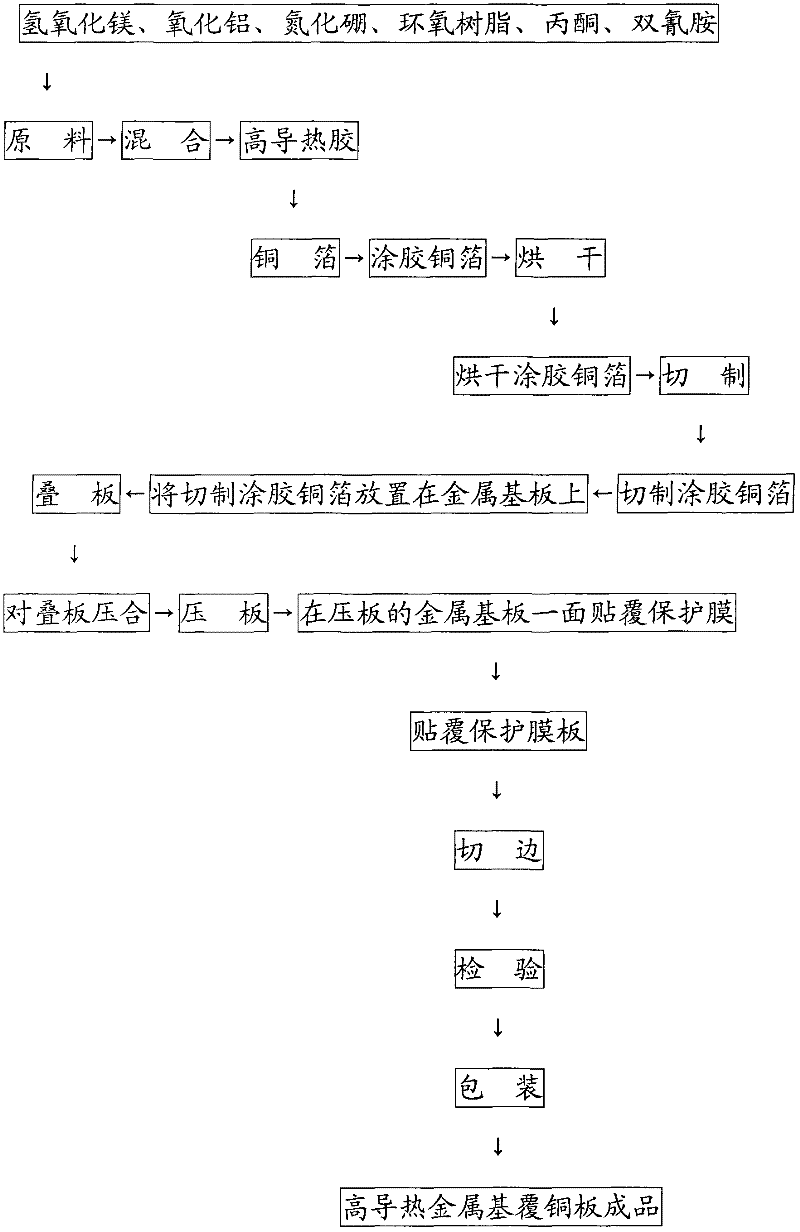

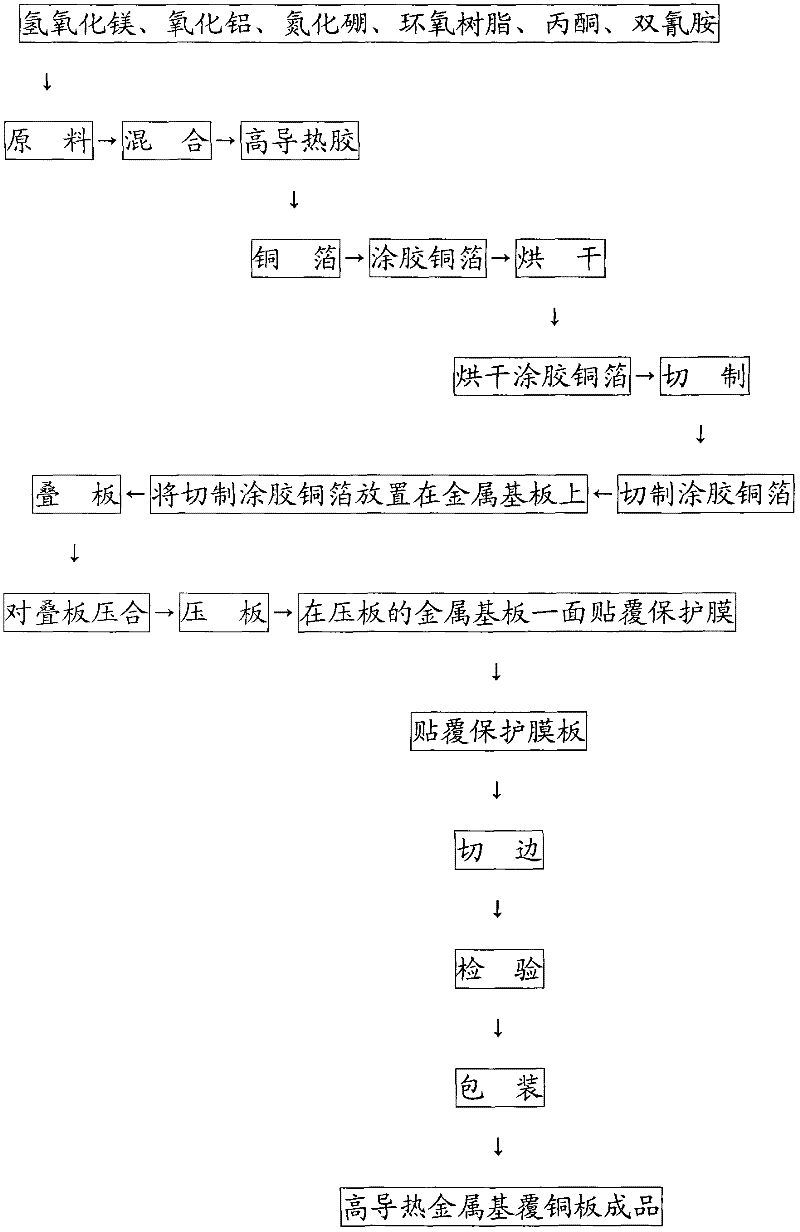

Method for manufacturing high thermal conductivity metal-base copper-clad plate

InactiveCN102514348ALow costSimple processLaminationLamination apparatusEpoxyEnvironmental resistance

The invention relates to a method for manufacturing a high thermal conductivity metal-base copper-clad plate, belonging to the technical field of a circuit board. The method takes high thermal conductivity glue as key technology, and comprises the steps of: spreading the high thermal conductivity glue prepared by magnesium hydroxide, aluminum oxide, boron nitride, epoxy resin, acetone and dicyandiamide on the back of a copper foil, putting the copper foil spread with the high thermal conductivity glue on a metal base plate after drying and cutting, laminating the copper foil on the metal base plate, sticking a protective film on the copper foil, then trimming, examining and packaging, and finally, obtaining the finished product of the high thermal conductivity metal-base copper-clad plate. The high thermal conductivity metal-base copper-clad plate is used for the circuit board of a light-emitting diode (LED) lamp, an igniter, a power supply, a backlight lamp or the like with high power and heat dissipation performance. After the method is adopted, the product quality is good, the cost is low, the technical process is simple, the interlayer binding force is good, and the method is environment-friendly and beneficial to being popularized and applied.

Owner:SHAANXI FELDSPAR ELECTRONICS MATERIALS CO LTD

Rotational molding product and preparation method thereof

InactiveCN106700213AImproves surface slip resistanceExtended service lifeLow-density polyethyleneLinear low-density polyethylene

The invention discloses a rotational molding product and a preparation method thereof and belongs to the technical field of rotational molding materials. The rotational molding product comprises a linear low-density polyethylene substrate; a slipping and abrasion resisting layer is additionally arranged on the substrate; and the slipping and abrasion resisting layer is composed of linear low-density polyethylene, an inorganic abrasion-resisting agent, a macromolecular enhancing agent and an auxiliary agent. The rotational molding product is prepared through three steps of treating an inorganic ultrafine abrasion-resisting agent, preparing a rotational molding composition of the slipping and abrasion resisting layer, and preparing the slipping and abrasion resisting rotational molding product. The slipping and abrasion resisting rotational molding product has smooth inner and outer surfaces; the combination between layers is good; the rotational molding product has no warping, deformation, air bubbles and concave parts; the scraping abrasion loss volume of the product is reduced by 50% or more; the preparation method of the slipping and abrasion resisting rotational molding product is simple and safe and has an obvious effect.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

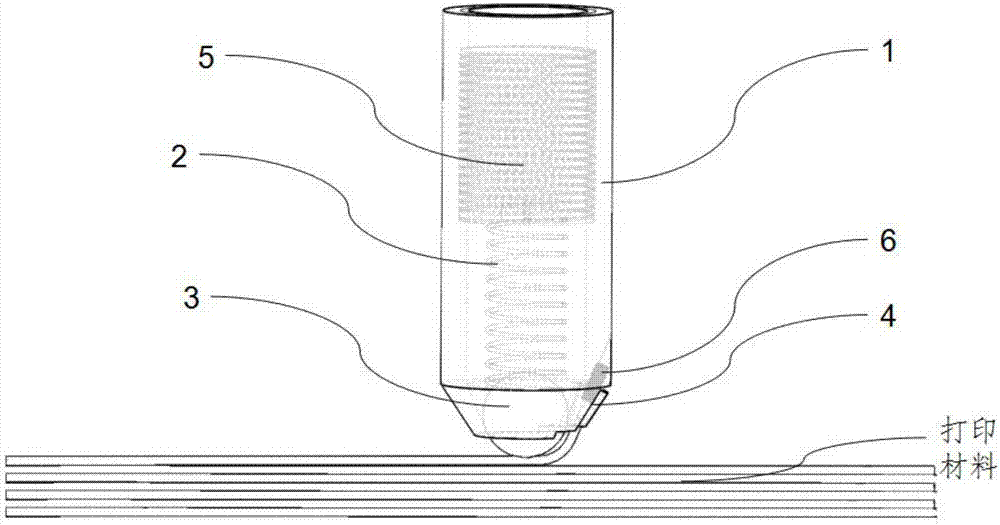

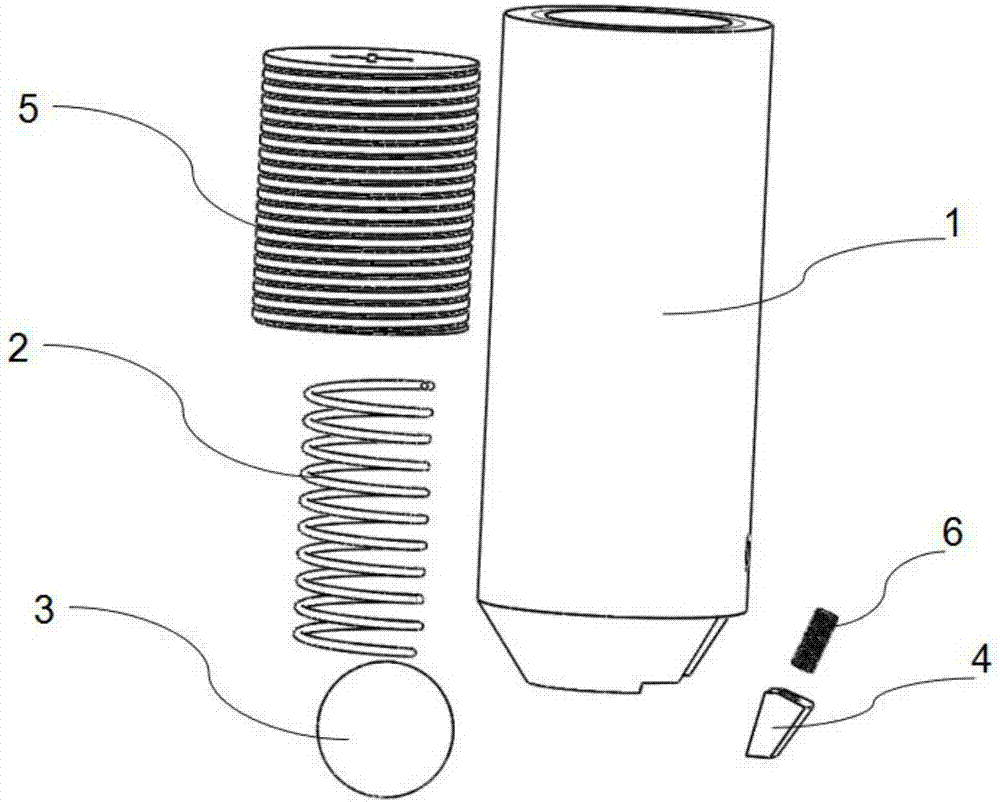

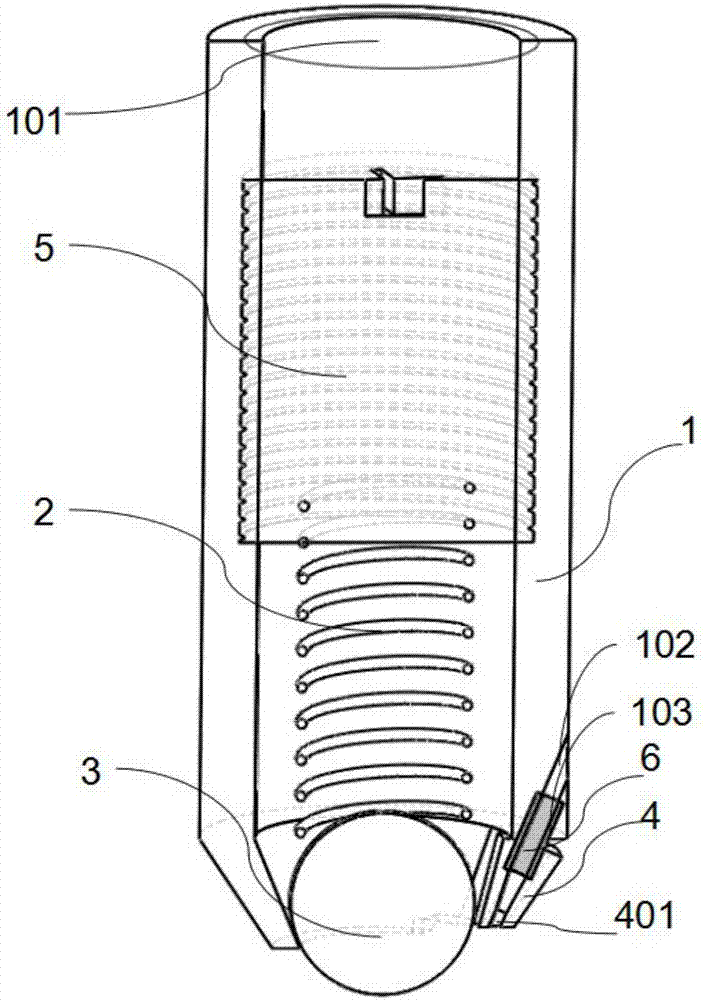

Self-rolling 3D printing integrated sprayer device capable of being used for material extrusion molding

ActiveCN107187044AImprove interlayer bonding performanceHigh densityApplying layer meansForming faceMolten state

The invention discloses a self-rolling 3D printing integrated sprayer device capable of being used for material extrusion molding. The self-rolling 3D printing integrated sprayer device comprises a printing nozzle. The printing nozzle is fixed to the outer portion of the tip end of a sprayer shell through a nozzle fixing bolt. A ball is arranged in the tip end of the sprayer shell. The upper portion of the ball is connected with the lower end of a spring. The upper end of the spring is connected with a positioning bolt. The positioning bolt is installed at the upper end of the interior of the sprayer shell. The positioning bolt is matched with an inner threaded hole in the sprayer shell. The ball is limited at the position of the tip end of the sprayer shell through the spring so that it can be ensured that the ball can rotate flexibly. After a printing material in a molten state is led in, the printing material is extruded out through the printing nozzle and is strengthened under extrusion of the ball. Elastic force of the spring can be changed by adjusting positioning bolts at different heights, and therefore the ball can obtain the effects of extrusion force of different degrees according to different materials and demands. By means of the self-rolling 3D printing integrated sprayer device capable of being used for material extrusion molding, interlayer performance and all boundary performance improving can be better carried out on a forming face.

Owner:深圳协同创新高科技发展有限公司

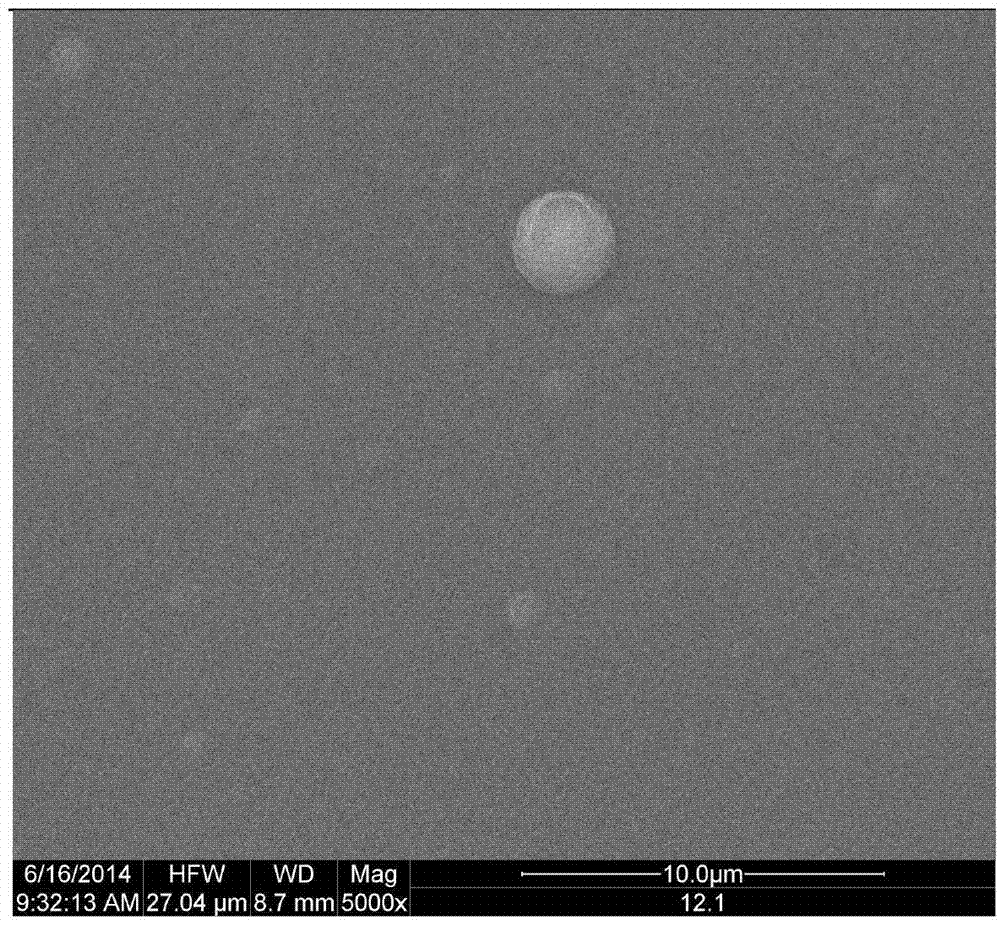

Nano-toughened and carbon fiber reinforced PLA (polylactic acid) 3D printing material and preparation method

The invention discloses a nano-toughened and carbon fiber reinforced PLA (polylactic acid) 3D printing material and a preparation method and relates to the technical field of 3D printing materials. The carbon fiber reinforced PLA 3D printing material prepared with a reactive extrusion method by adding a nano-toughening agent has good 3D printing performance, a print head cannot be blocked, less odor is emitted in a printing process, printing pieces have better inter-layer bonding force and excellent the mechanical properties, and the problems that the PLA 3D printing material prepared with a formula and a preparation method in the prior art produces heavier odor in the printing process, the print head of a printer is blocked easily by the printing material and the mechanical properties of the printing pieces are moderate are solved.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

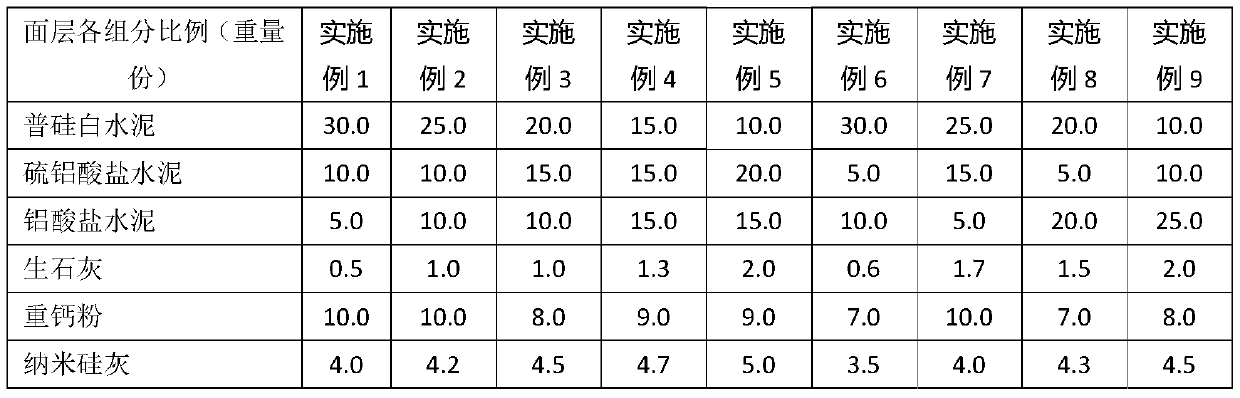

Heat preservation decorative composite board finish material and preparation method thereof

InactiveCN110423075AGood condensation hardening performanceGood adhesionHeat proofingSurface layerSlurry

The invention discloses a heat preservation decorative composite board finish material and a preparation method thereof. A finish material premix of the heat preservation decorative composite board finish material comprises the following components by weight: 10-30 parts of ordinary silicate white cement, 10-50 parts of aluminum-containing cement, 0.1-0.2 part of a retarder and 3-7 parts of an adhesive, wherein the aluminum-containing cement includes at least one of aluminate cement and sulphoaluminate cement. A finish material slurry obtained by mixing of the finish material premix with watercan have good setting and hardening performance and bonding capacity, and then can realize bonding with a heat insulation board or a slurry of the insulation board under a plasticizing state, a unified whole is formed after curing molding, and secondary bonding of a heat insulation board and a decorative surface material with an adhesive is unnecessary, the heat preservation decorative compositeboard obtained by one-time molding can have good interlayer bonding performance and high bonding strength, and the decorative surface layer has high strength, small deformation and good integration.

Owner:刘佳琪

Carbon based composited material helical spring and production method thereof

ActiveCN107285797AImprove mechanical propertiesImprove interlayer bonding performanceCarbon compoundsShock absorbersHelical lineFiber

The invention discloses a carbon based composited material helical spring production method. Z-direction carbon fibers are introduced into the helical spring from an axial direction, which is perpendicular to the helical spring. The production method is characterized by comprising the following steps: (1) blank preparation: winding a carbon fiber beam or carbon fiber cloth around the helical groove of a core mould along the helical line direction of a spring, wherein the moving direction of continuous long fibers of the carbon fiber beam or carbon fiber cloth is the same as the helical line direction of the spring; then winding a carbon fiber net tire around the helical groove of the core mould, carrying out needling along the radial direction of the core mould, and repeating the abovementioned process to prepare a carbon fiber spring preform with a required size; (2) density increasing; and (3) mechanical processing. The ratio of the number of continuous carbon fiber along the helical line direction of the spring to the number of the Z-direction carbon fibers is 1:0.01-0.4. The elastic constant of the helical spring is 0.1 to 5 kg / mm. During the blank making process, Z-direction fibers are introduced into the helical spring from an axial direction perpendicular to the helical spring, the interlayer bonding is good, and thus the mechanical properties of the prepared carbon based composited material helical spring are good.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

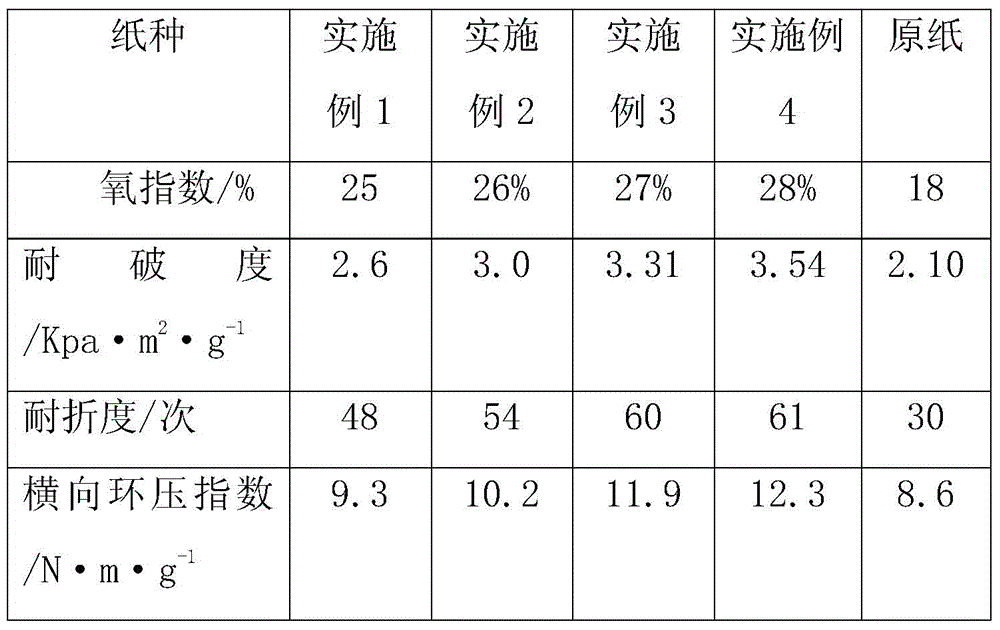

High-strength flame-retarding kraft board paper, preparation method and application thereof

InactiveCN105672048AImprove flame retardant performanceHigh strengthFlexible coversWrappersSurface layerPulp and paper industry

The invention belongs to the technical field of special paper preparation and particularly relates to high-strength flame-retarding kraft board paper, a preparation method and an application thereof. The preparation method includes the steps of: filling a surface layer, a core layer and a bottom layer of the kraft board paper with aluminum hydroxide; spraying the surface layer, the core layer and the bottom layer of the kraft board paper with starch and ammonium polyphosphate; after the surface layer, the core layer and the bottom layer are laminated, spraying the surface of the kraft board paper with the ammonium polyphosphate. In the high-strength kraft board paper, each layer is not only sprayed with the starch but also sprayed with the ammonium polyphosphate and filled with the aluminum hydroxide, so that the kraft board paper has excellent reinforcing and flame-retarding effects, has excellent physical and fire-proof performance and can be used in the various fields such as packaging and the like well.

Owner:SOUTH CHINA UNIV OF TECH

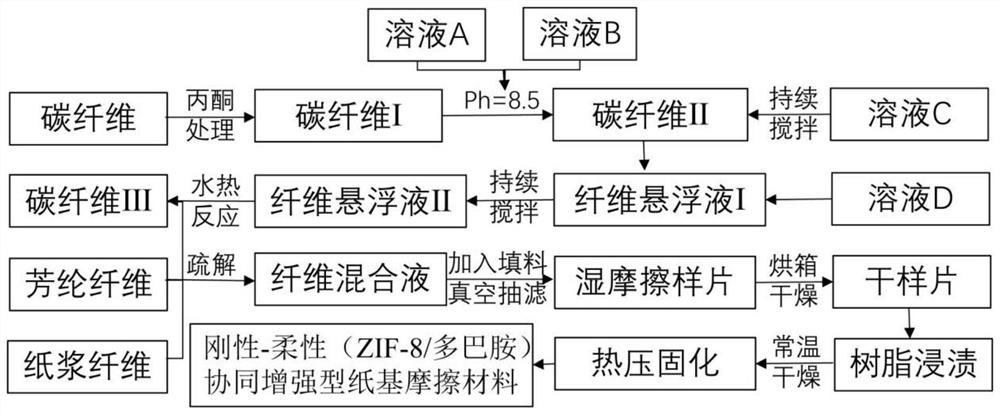

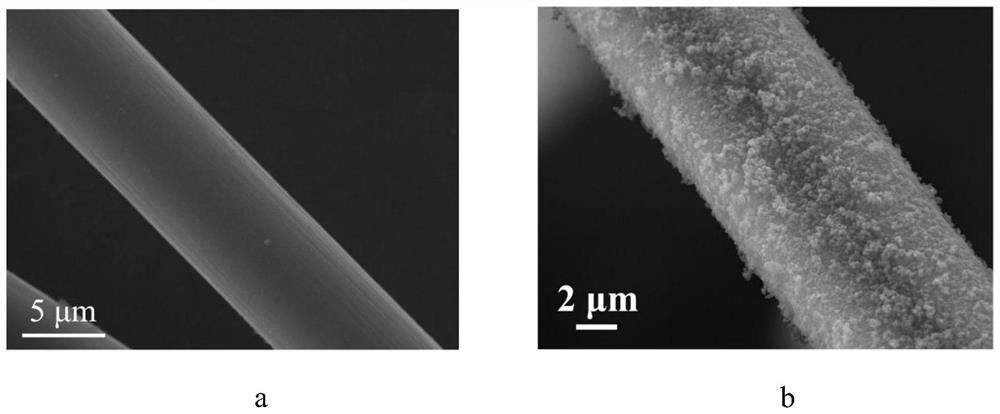

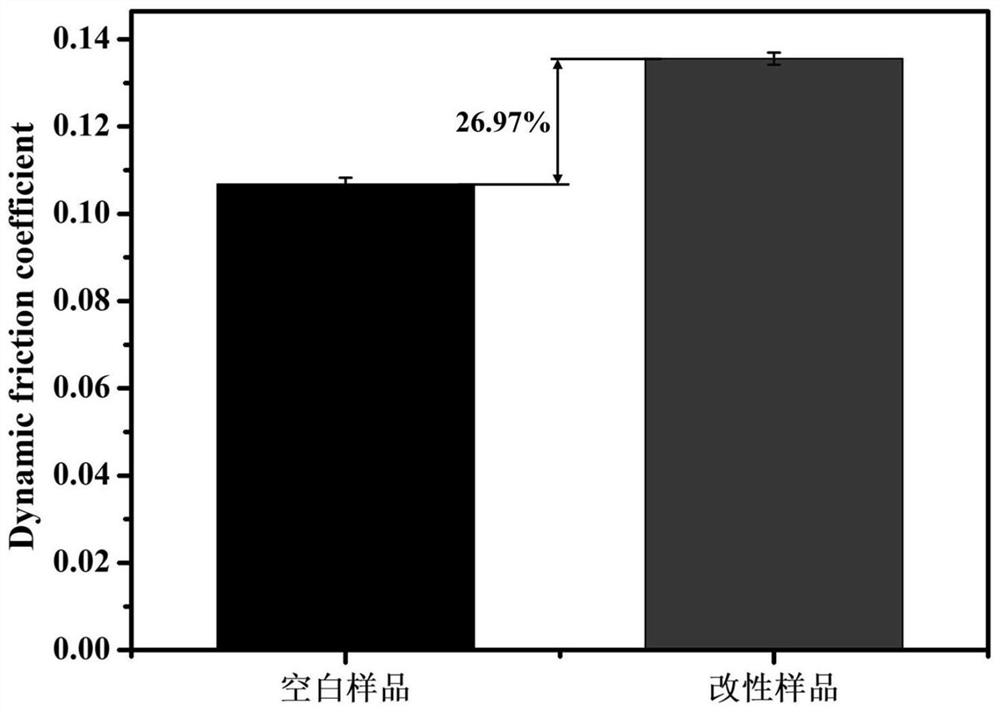

Rigid-flexible ZIF-8/dopamine synergistically enhanced paper-based friction material and preparation method thereof

ActiveCN113445360AImprove performanceEnhanced interface bindingNatural cellulose pulp/paperSpecial paperFiberCarbon fibers

The invention relates to a rigid-flexible ZIF-8 / dopamine synergistically enhanced paper-based friction material and a preparation method thereof. The preparation method comprises the steps that carbon fibers are sequentially placed in tris(hydroxymethyl)aminomethane (Tris buffer solution) and a dopamine solution, and a high-adhesion dopamine flexible film is formed on the surface of the carbon fibers; and then, a compact and uniform nano ZIF-8 crystal rigid layer grows on the surface of the carbon fiber in situ through a green hydrothermal reaction, a rigid-flexible interface enhancement structure is constructed through the modified carbon fiber and a resin matrix, and the ZIF-8 / dopamine synergistic enhancement type paper-based friction material is prepared. The dynamic friction coefficient of the prepared rigidity-flexibility (ZIF-8 / dopamine) synergistically enhanced paper-based friction material is increased from 0.1068 to 0.1356, the increase amplitude is 26.97%, the wear rate is decreased from 3.55*10<-8> cm<3>.J<-1> to 2.45*10<-8> cm<3>.J<-1>, and the decrease amplitude is 30.99%. The synergistic effect of a ZIF-8 / dopamine bi-component enhanced and constructed rigid-flexible interface enhanced structure is fully displayed, and the friction and wear performance of the paper-based friction material can be remarkably improved when the paper-based friction material is applied to the paper-based friction material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparing method and system for damping layer in embedded type co-curing composite material

ActiveCN106000815AIncrease profitImprove production efficiencySpraying apparatusPretreated surfacesBand shapeSpray method

The invention discloses a preparing method and system for a damping layer in an embedded type co-curing composite material. The method comprises the steps that firstly, strip-shaped composite material prepreg and a strip-shaped spraying template are prepared, a set hollow pattern is arranged on the spraying template, and the size of the spraying template is matched with the size of the composite material prepreg; secondly, under the action of conveying rollers, the composite material prepreg and the spraying template are synchronously fed, the spraying template is pressed above the composite material prepreg, a damping glue material is sprayed in a spraying area, the damping layer is obtained, and the width of the spraying area is larger than or equal to the width of a to-be-sprayed area of the composite material prepreg; thirdly, the composite material prepreg and the spraying template are separated, and after separation, the final shape obtained after a damping material on the composite material prepreg is diffused is the preset shape; and fourthly, the damping layer is dried. The damping layer is prepared through a spraying method, and the preparing efficiency of the damping layer can be greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

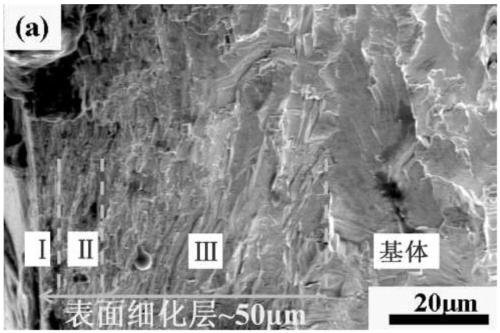

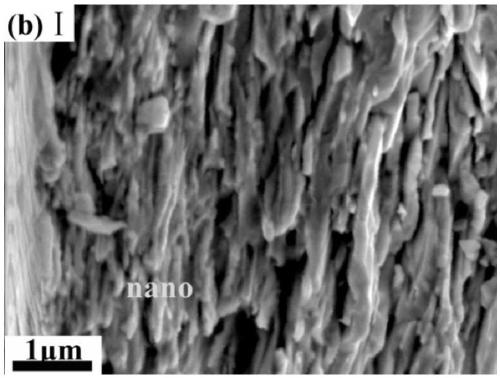

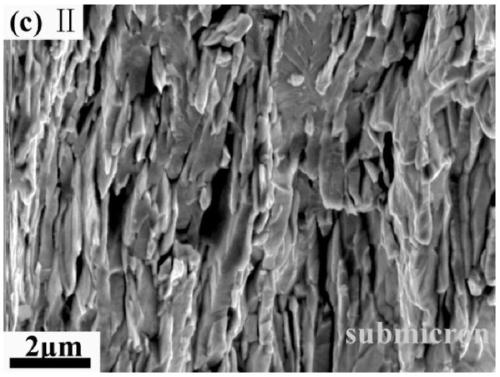

Surface multi-scale structure tungsten material and preparation method of material

The invention relates to a surface multi-scale structure tungsten material and a preparation method of the material, and belongs to the technical field of metal surface treatment. A gradient layer isarranged between the surface structure of the surface multi-scale structure tungsten material and the matrix structure, the grain size of the gradient layer is changed in a gradient mode, and the gradient layer from the surface structure to the matrix structure sequentially comprises a nano-layer, a sub-micron layer and a micro-layer, wherein the grain sizes of the nano-layer, the sub-micron layerand the micron layer are in a nanometer level, a sub-micron level and a micron level respectively. According to the surface multi-scale structure tungsten material, binding between the scale layers is good, no obvious interface exists, and micro-cracking, delamination and other phenomena are avoided. The method is easy and quick to use and suitable for preparing bulk samples.

Owner:PANZHIHUA UNIV

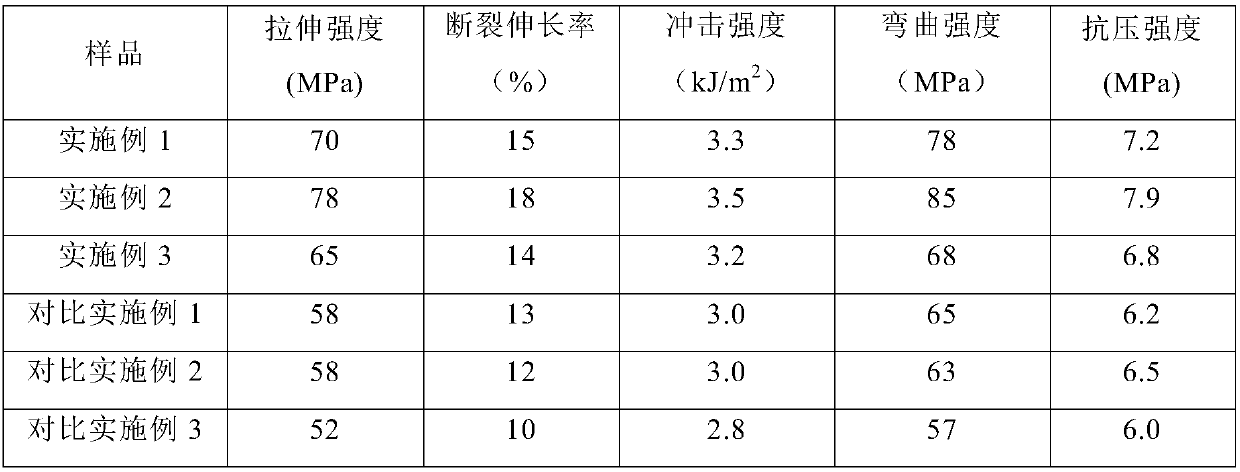

Graphene oxide and tannic acid compound enhanced polylactic acid 3D printing material and preparation method thereof

InactiveCN109593331AHigh tensile strengthHigh impact strengthAdditive manufacturing apparatusPolymer scienceCompressive strength

The invention relates to a graphene oxide and tannic acid compound enhanced polylactic acid 3D printing material and a preparation method thereof and belongs to the technical field of 3D printing. Themethod comprises the steps: adding a graphene oxide and tannic acid compound into polylactic acid, and carrying out pelletizing and wire drawing to finally prepare the graphene oxide and tannic acidcompound enhanced polylactic acid 3D printing material. By controlling the addition amount of the graphene oxide and tannic acid compound in a preparation process, the finally prepared 3D printing material has relatively good tensile strength, impact strength and compressive strength, and a product printed by taking the 3D printing material as a raw material has a smooth and dense appearance and an integrated structure and high printing precision. The preparation method is simple in preparation process, easy to operate, low in equipment requirement, high in production efficiency, environment-friendly, suitable for industrial production and capable of solving the problems of few variety, low production efficiency, complex process and high cost of an existing 3D printing wire.

Owner:广安长明高端产业技术研究院

Hot melt acrylate dot-shaped reflection marked line and preparation method thereof

ActiveCN108384405AWon't fall offImprove adhesionPolyurea/polyurethane coatingsTraffic signalsBenzoyl peroxideAcrylic resin

The invention discloses an acrylate hot melt dot-shaped reflection marked line. The acrylate hot melt dot-shaped reflection marked line comprises free radical polymerization type thermosetting base gel and acrylate type hot melt reflection marked line coating, wherein the free radical polymerization type thermosetting base gel is prepared from activated resin, an activated monomer, an adhesion promoter, N,N-dimethyl-p-toluidine and benzoyl peroxide paste; the acrylate type hot melt reflection marked line coating is prepared from solid acrylic resin, polyterpene phenolic resin, a plasticizer, polyamide wax, a pigment, a reflection material, heavy calcium carbonate, quartz sand and a rheological control agent. By adopting the hot melt acrylate dot-shaped reflection marked line with the structure and the preparation method thereof, the binding power on different road surfaces, especially old road surfaces and cement road surfaces, can be improved.

Owner:保定市科顺达交通设施有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com