Processing system of concrete combined aggregate and construction method

A processing system and concrete technology, applied in the direction of mixing operation control, chemical instruments and methods, mixing operation control devices, etc., can solve the problems of unfavorable aggregate processing system gradation adjustment, unfavorable interlayer bonding of concrete structures, increased engineering operation and Manage costs and other issues to achieve the effects of inter-layer integration, improving construction quality, and saving engineering construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

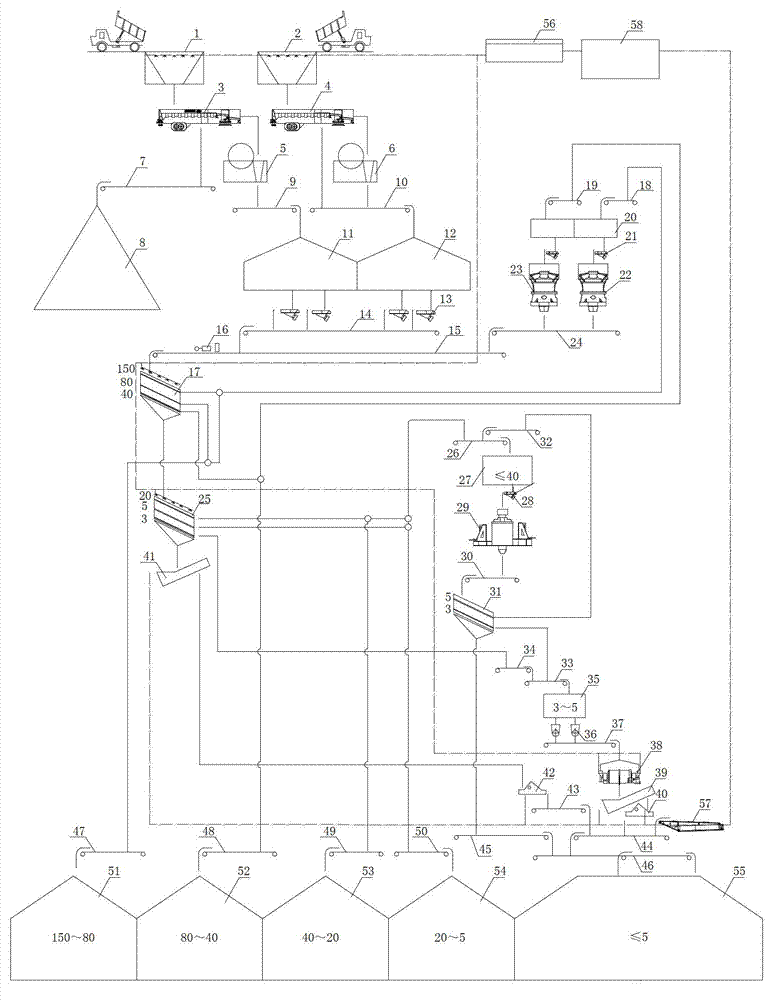

[0040] see figure 1 , a concrete composite aggregate processing system, which includes a first material receiving bin 1, a first rod type feeder 3 is arranged under the first material receiving bin, and the screen of the first rod type feeder passes through the second A belt conveyor 7 is connected to the waste yard 8, the screen of the first bar feeder is connected to the first jaw crusher 5, and the discharge port of the first jaw crusher 5 passes through the second belt conveyor 9 It is connected with the artificial gravel stockyard 11; the second receiving bin 2 is provided with a second bar feeder 4, and the screen of the second bar feeder is connected with the second jaw crusher 6, Under the sieve of the second rod type feeder and the discharge port of the second jaw crusher are connected with the natural gravel stockpile 12 by the 3rd belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com