Graphene oxide and tannic acid compound enhanced polylactic acid 3D printing material and preparation method thereof

An enetannic acid, 3D printing technology, applied in the field of 3D printing, can solve the problems of high price of polylactic acid, poor functionality, poor heat resistance, etc., and achieve the effects of low equipment requirements, improved mechanical properties, and smooth and dense structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

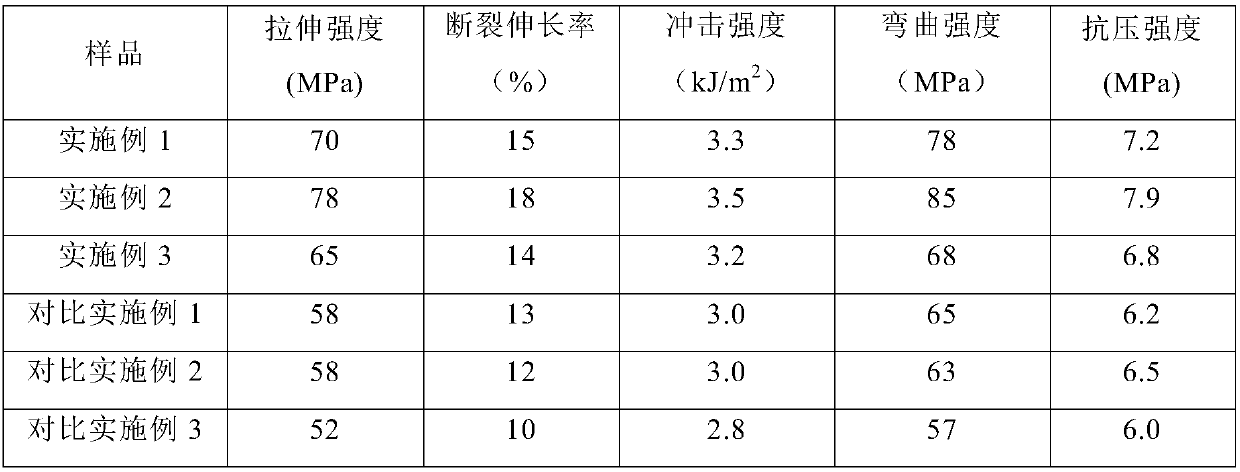

Examples

Embodiment 1

[0019] Preparation of graphene oxide tannic acid composite reinforced polylactic acid 3D printing material

[0020] (1) Add graphene oxide and tannic acid into water according to the mass-volume ratio of 1:1:500, ultrasonicate with 100w ultrasonic power for 30min, place it in the reactor, and react at 180°C for 12h to obtain a hydrogel. After the hydrogel is crushed, it is washed with water, filtered, and dried at 80° C. for 0.5 h to obtain a graphene oxide tannic acid complex; the unit of mass-volume ratio is g:g:mL;

[0021] (2) Mix the graphene oxide tannic acid compound prepared in step (1) with polylactic acid at a mass ratio of 1:49, extrude and granulate through an extruder, and dry at 80°C for 3 hours to obtain graphite oxide Ethylene tannic acid complex polylactic acid particles;

[0022] (3) Drawing the graphene oxide tannic acid composite polylactic acid particles obtained in step (2) through a wire drawing machine to obtain a graphene oxide tannic acid composite r...

Embodiment 2

[0024] Preparation of graphene oxide tannic acid composite reinforced polylactic acid 3D printing material

[0025] (1) Add graphene oxide and tannic acid into water according to the mass volume ratio of 1:0.5:500, ultrasonicate with 150w ultrasonic power for 20min, place it in the reactor, and react at 175°C for 12h to obtain a hydrogel. The hydrogel was crushed, washed with water, filtered and dried at 60° C. for 1 h to obtain a graphene oxide tannic acid complex; the unit of mass-volume ratio was g:g:mL;

[0026] (2) Mix the graphene oxide tannic acid compound prepared in step (1) with polylactic acid at a mass ratio of 1:19, extrude and granulate through an extruder, and dry at 60°C for 2.5 hours to obtain oxidized Graphene tannic acid composite polylactic acid particles;

[0027] (3) Drawing the graphene oxide tannic acid composite polylactic acid particles obtained in step (2) through a wire drawing machine to obtain a graphene oxide tannic acid composite reinforced pol...

Embodiment 3

[0029] Preparation of graphene oxide tannic acid composite reinforced polylactic acid 3D printing material

[0030] (1) Add graphene oxide and tannic acid into water according to the mass volume ratio of 1:1.5:500, ultrasonicate with 125w ultrasonic power for 25min, place in the reactor, and react at 185°C for 11h to obtain a hydrogel. After the hydrogel is crushed, it is washed with water, filtered, and dried at 70°C for 1 hour to obtain a graphene oxide tannic acid complex; the unit of the mass-volume ratio is g:g:mL;

[0031] (2) Mix the graphene oxide tannic acid compound prepared in step (1) with polylactic acid at a mass ratio of 1:9, extrude and granulate through an extruder, and dry at 70°C for 2 hours to obtain graphite oxide Ethylene tannic acid complex polylactic acid particles;

[0032] (3) Drawing the graphene oxide tannic acid composite polylactic acid particles obtained in step (2) through a wire drawing machine to obtain a graphene oxide tannic acid composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com