Patents

Literature

579results about How to "Reduce stretch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

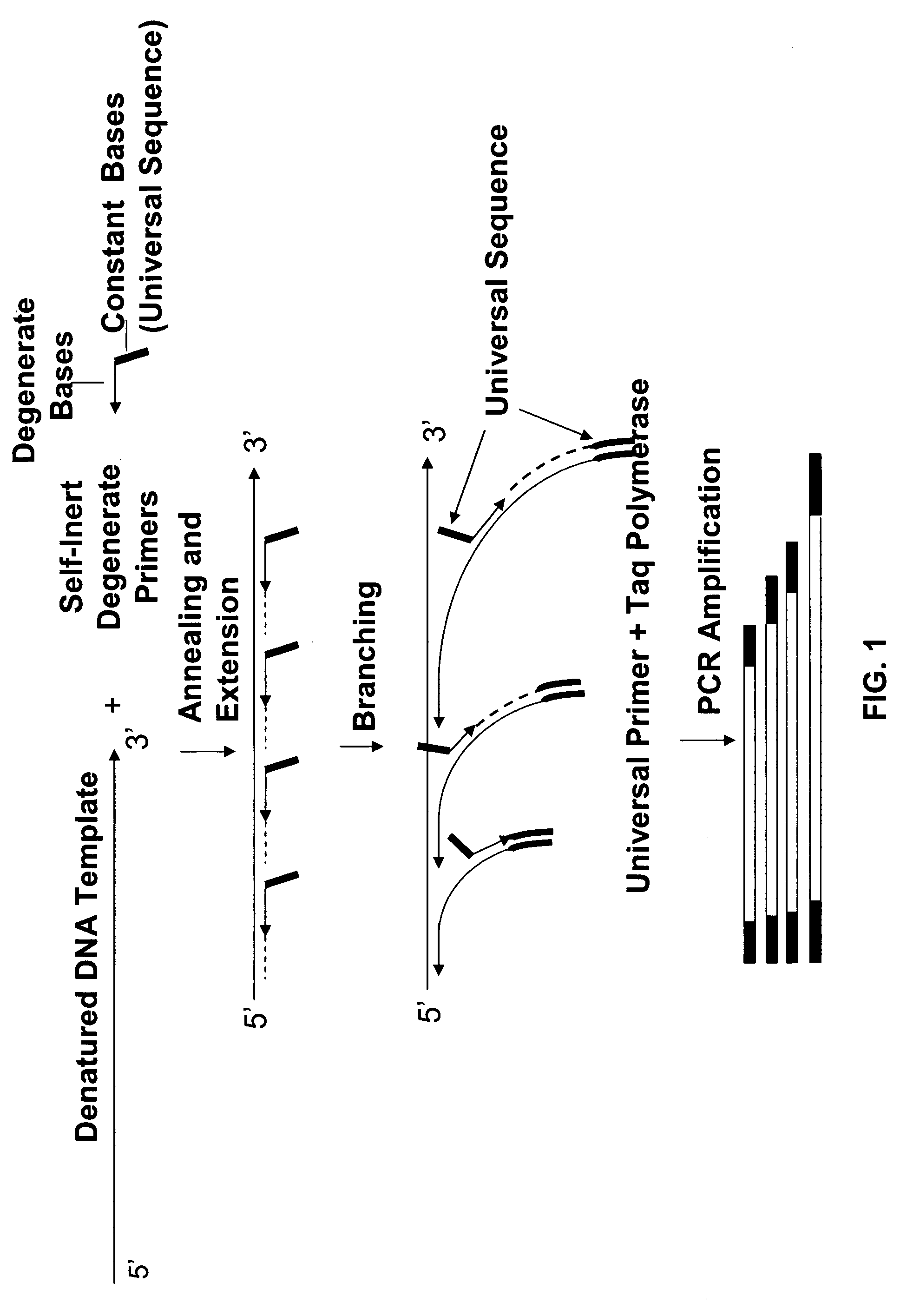

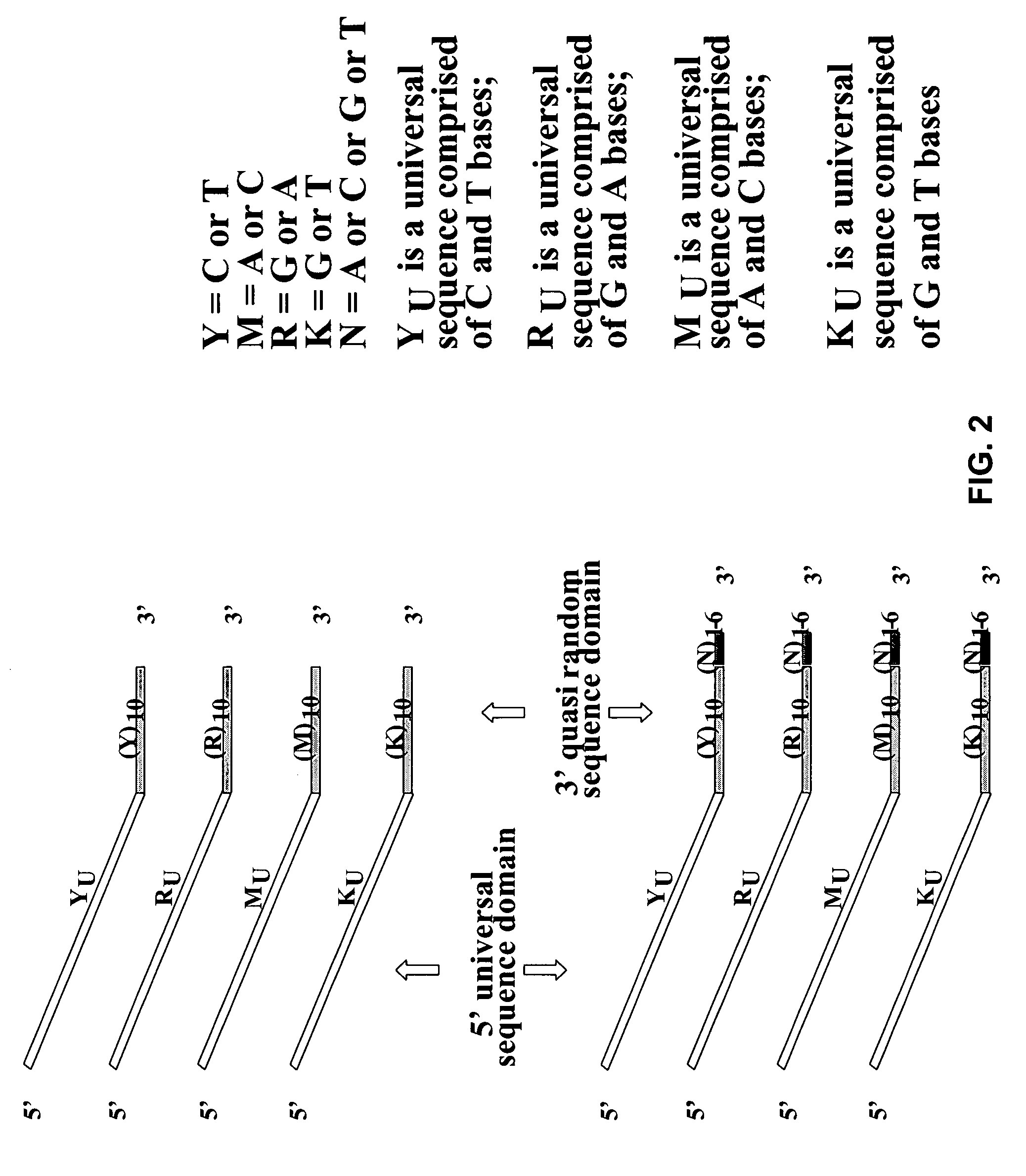

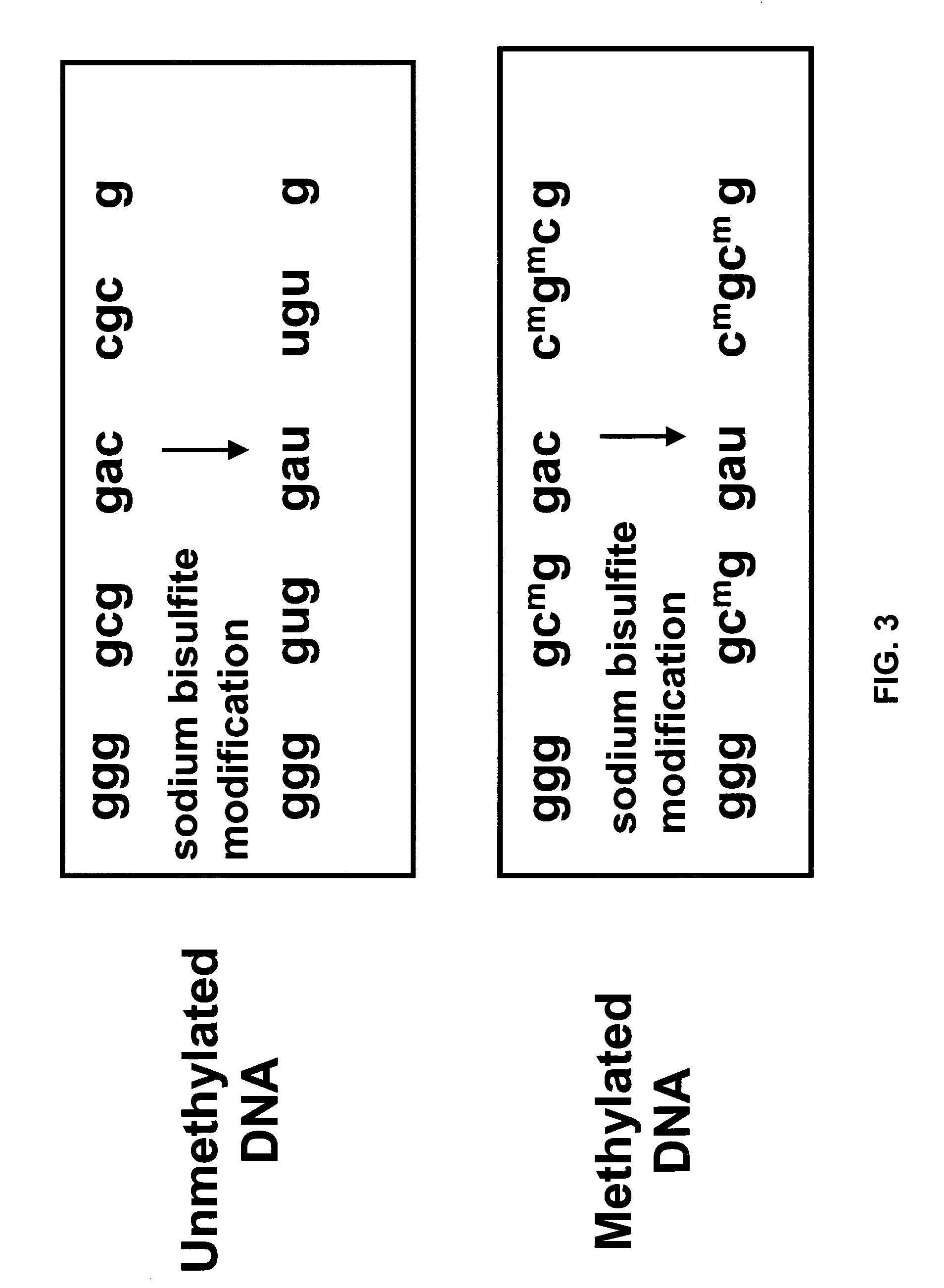

Methods and compositions for generating and amplifying DNA libraries for sensitive detection and analysis of DNA methylation

InactiveUS20050202490A1Reduce stepsReduce stretchMicrobiological testing/measurementFermentationDNA methylationCell free

The present invention regards a variety of methods and compositions for obtaining epigenetic information, such as DNA methylation patterns, through the preparation, amplification and analysis of Methylome libraries. In several aspects of the present invention, there are methods based on methylation-dependent enrichment or depletion of genomic DNA isolated from cellular and cell-free sources. In additional embodiments, there are methods and compositions for single-step high throughput preparations of Methylome libraries.

Owner:TAKARA BIO USA INC

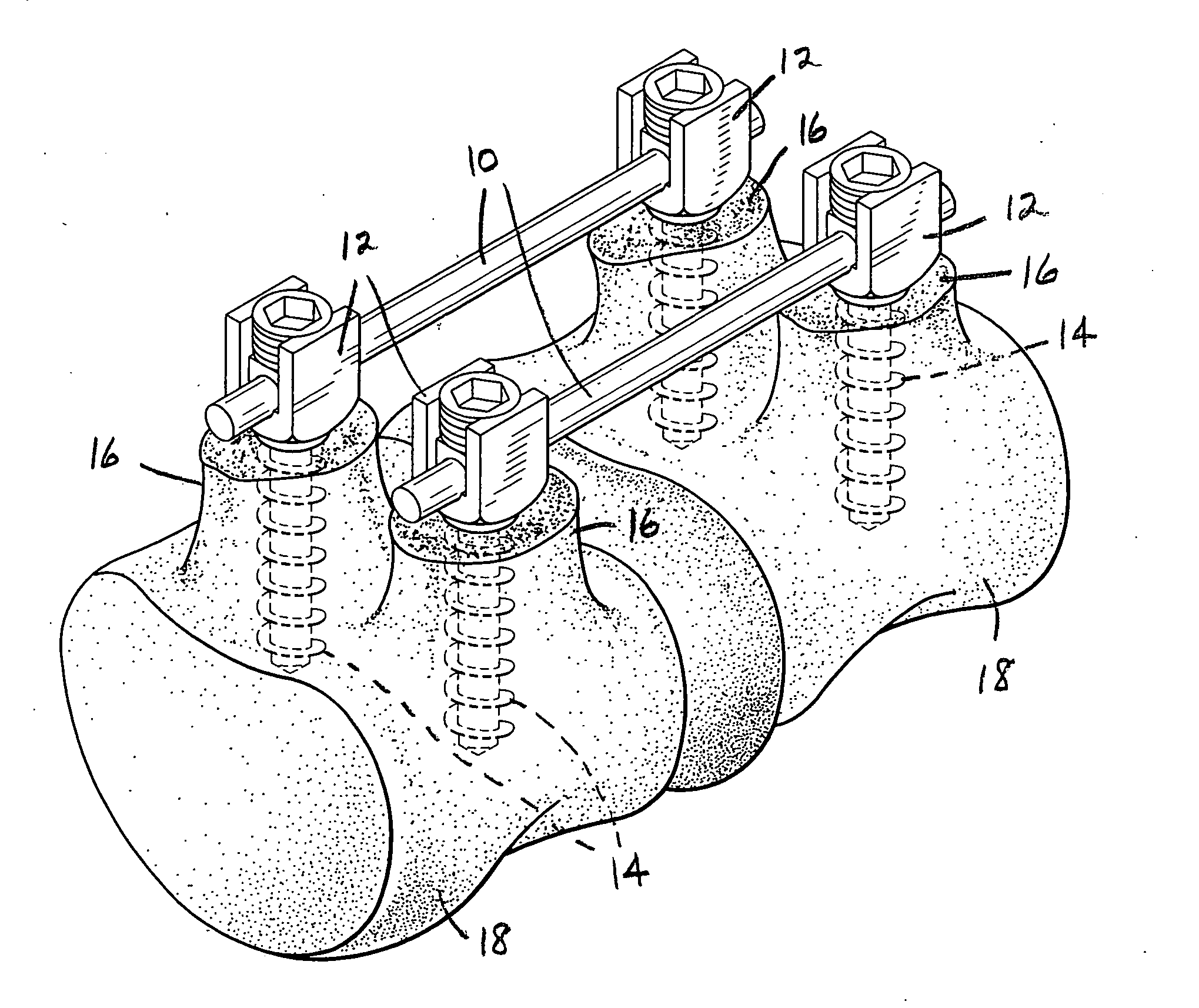

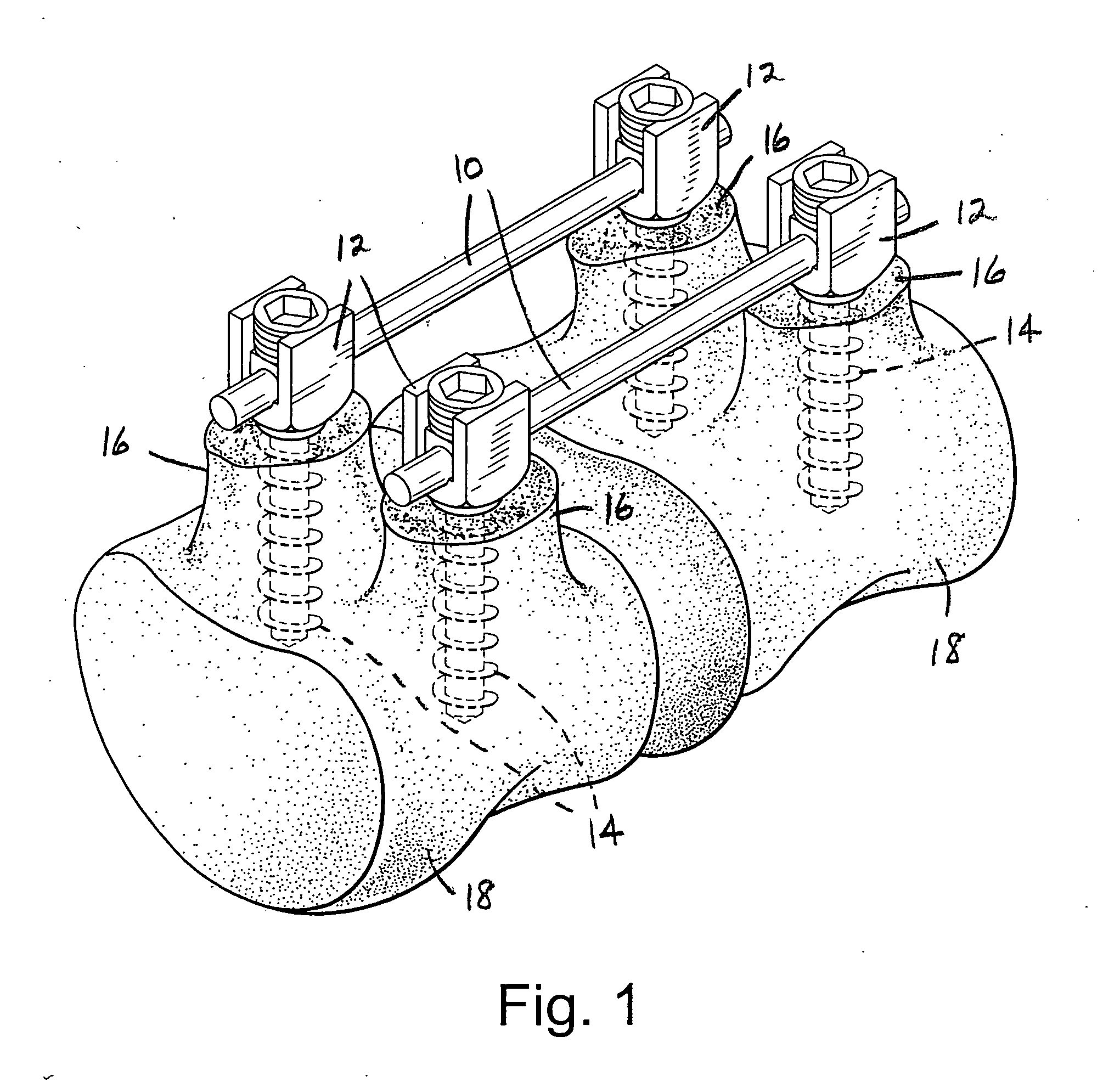

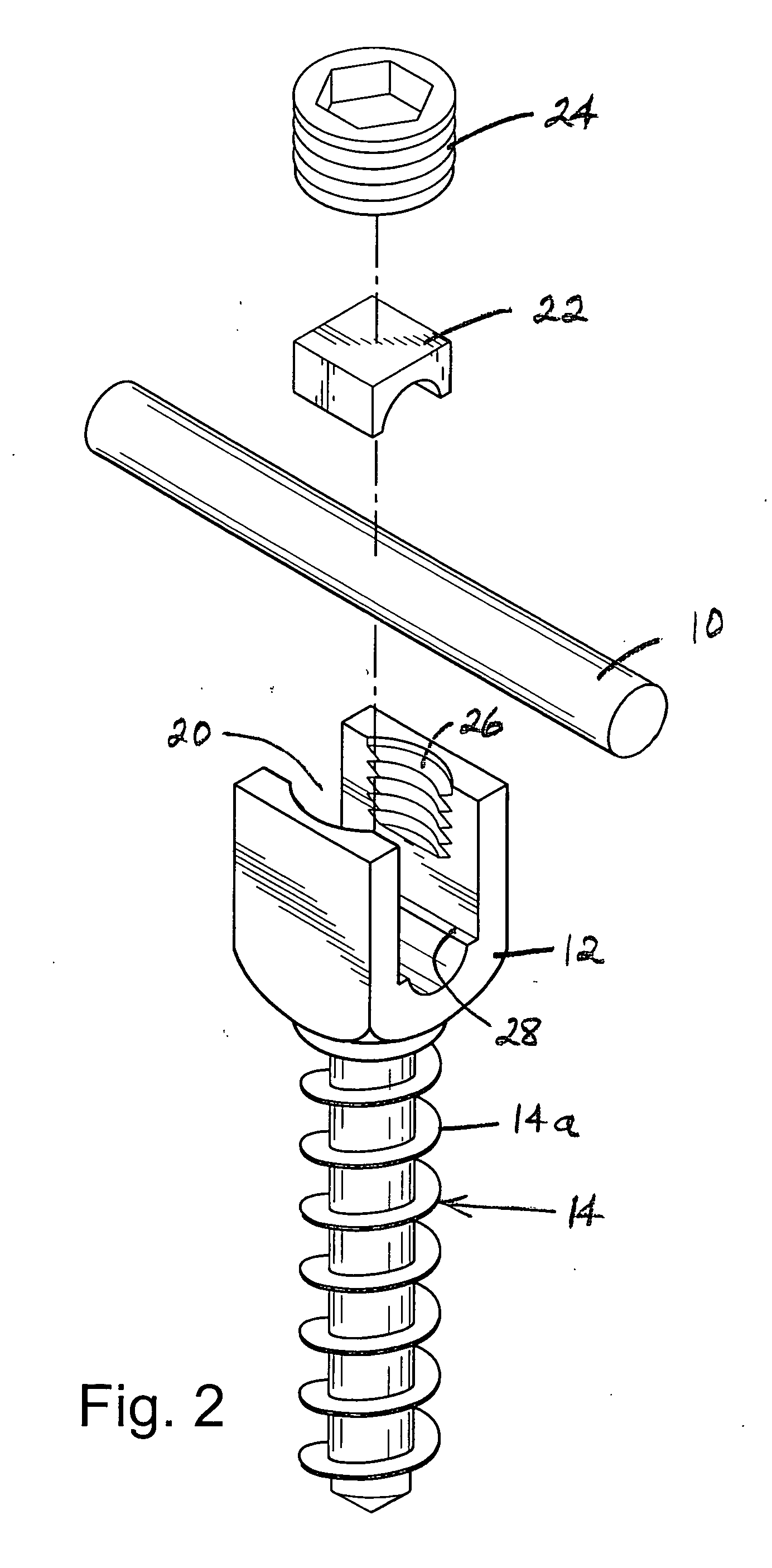

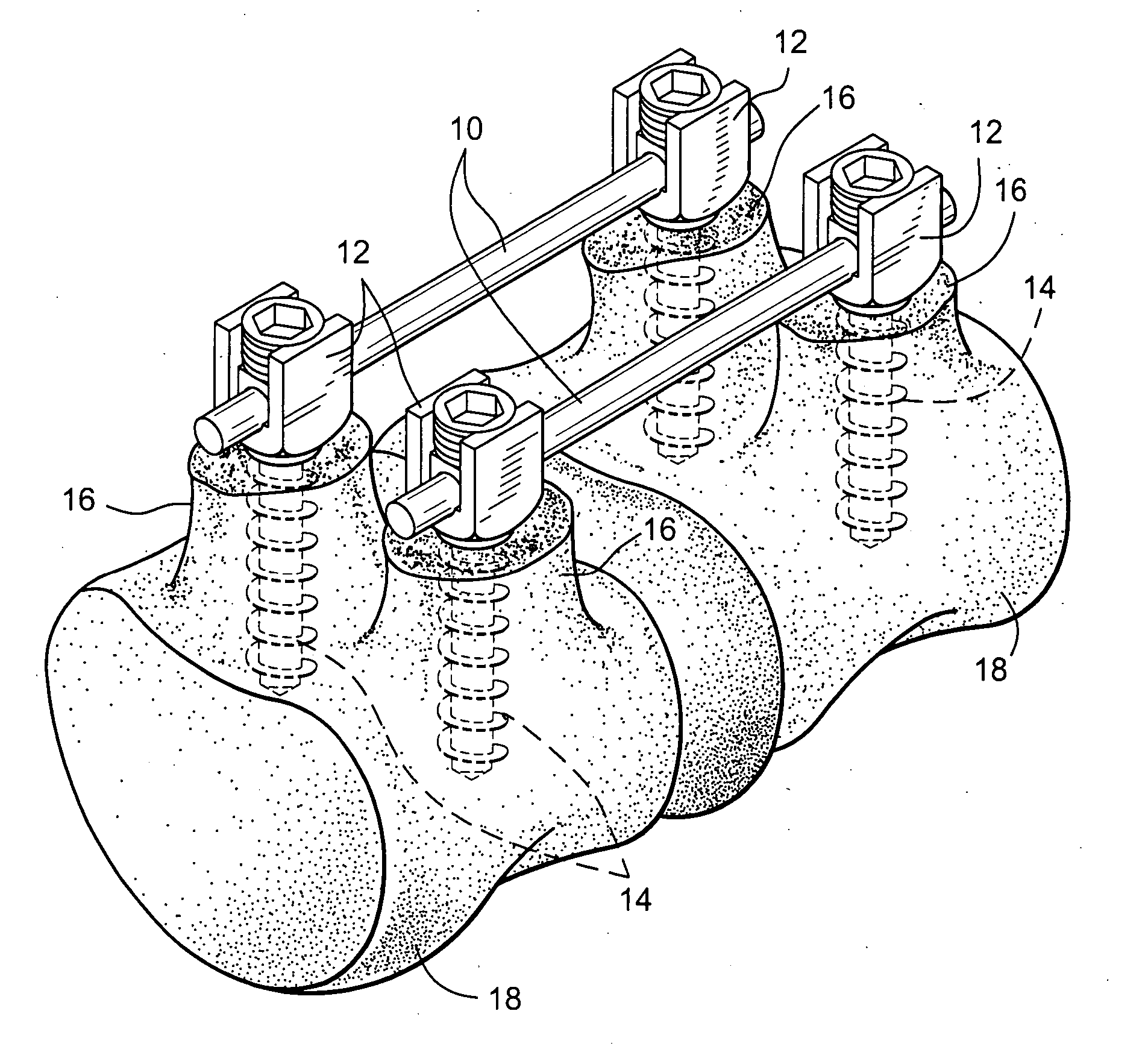

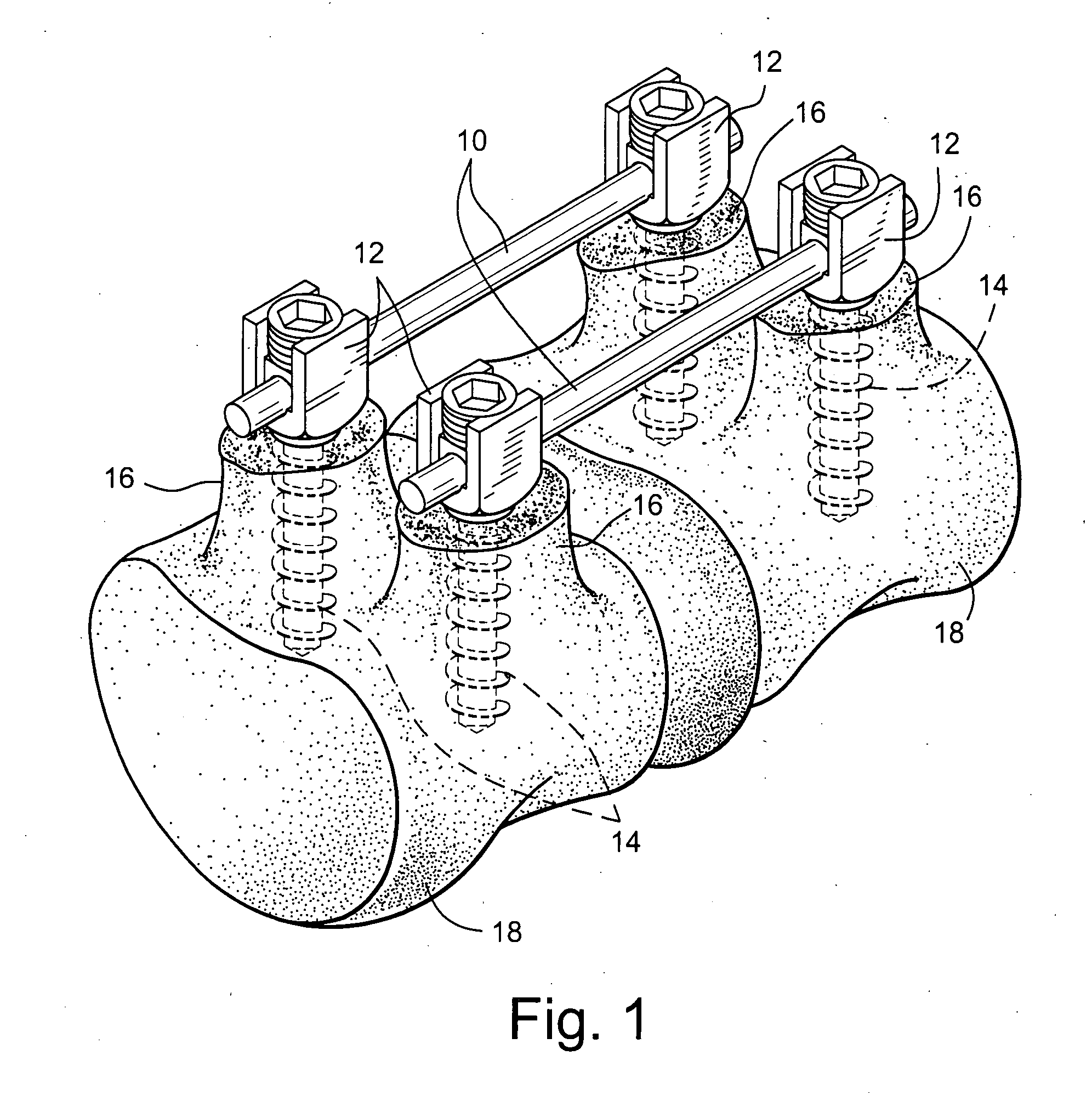

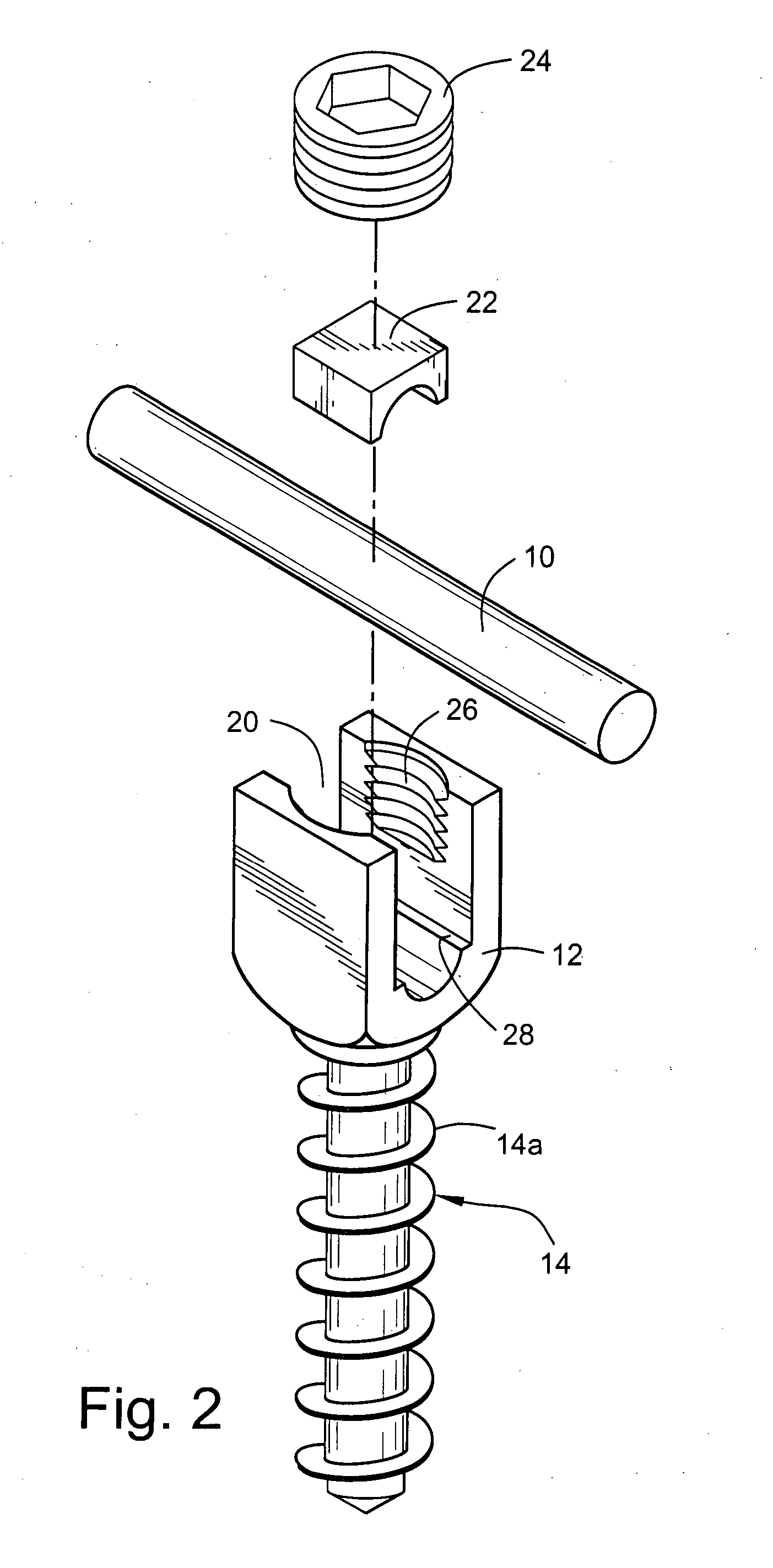

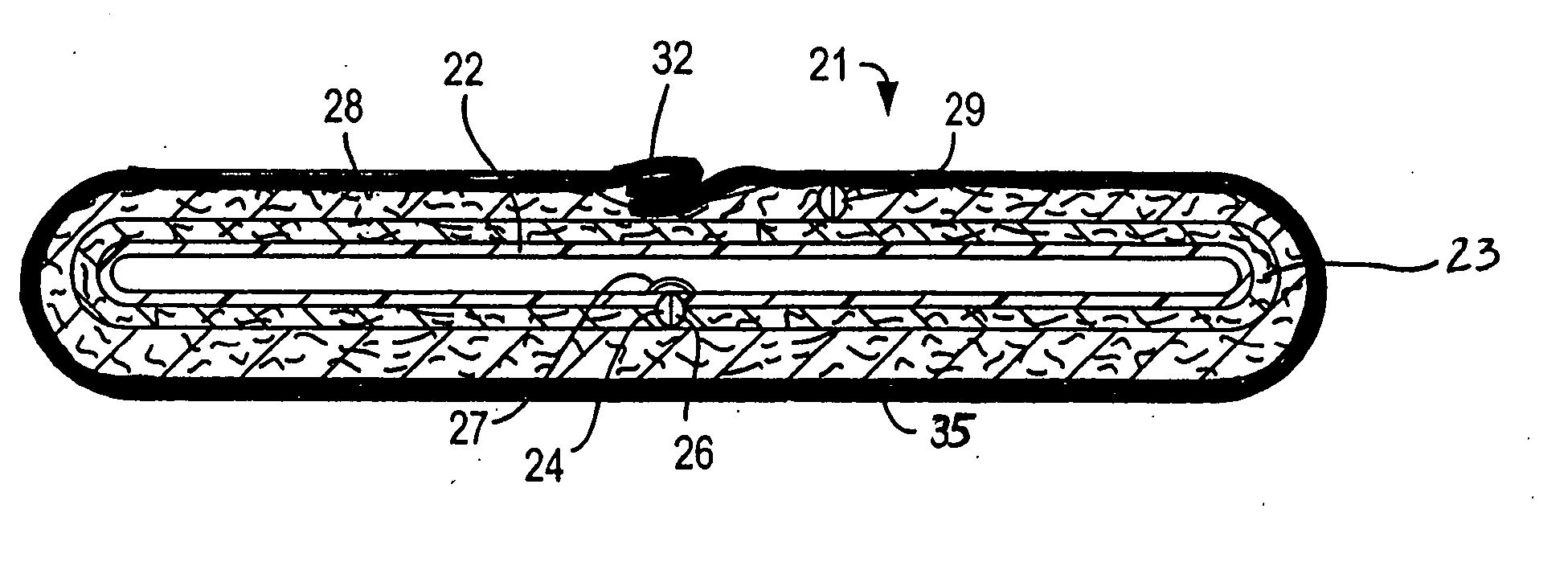

Apparatus and method for flexible spinal fixation

InactiveUS20070233064A1High tensile strengthReduce stretchInternal osteosythesisJoint implantsPlastic materialsUltimate tensile strength

Apparatus for connecting and stabilizing adjacent vertebral segments, comprising a flexible composite connecting rod extending between the segments, and connection devices for connecting the rod to the vertebral segments. The rod comprises a rod member formed of a flexible plastic material having a predetermined compression strength, and a high tensile strength, low stretch, flexible reinforcing element extending longitudinally through the entire length of the rod member and being bonded thereto. The reinforcing element may be in the form of a single cord, rope, braid or monofilament, a plurality of substantially parallel cords, ropes, braids or monofilaments, or a tubular cord, rope or braid extending through the rod member.

Owner:HOLT DEV

Apparatus and method for flexible spinal fixation

InactiveUS20080021469A1High tensile strengthReduce stretchInternal osteosythesisJoint implantsPlastic materialsUltimate tensile strength

Apparatus for connecting and stabilizing adjacent vertebral segments, comprising a flexible composite connecting rod extending between the segments, and connection devices for connecting the rod to the vertebral segments. The rod comprises a rod member formed of a flexible plastic material having a predetermined compression strength, and a high tensile strength, low stretch, flexible reinforcing element extending longitudinally through the entire length of the rod member. The reinforcing element may be in the form of a single cord, rope, braid or monofilament, a plurality of substantially parallel cords, ropes, braids or monofilaments, or a tubular cord, rope or braid extending through the rod member in slidable relation or bonded thereto.

Owner:HOLT RICHARD

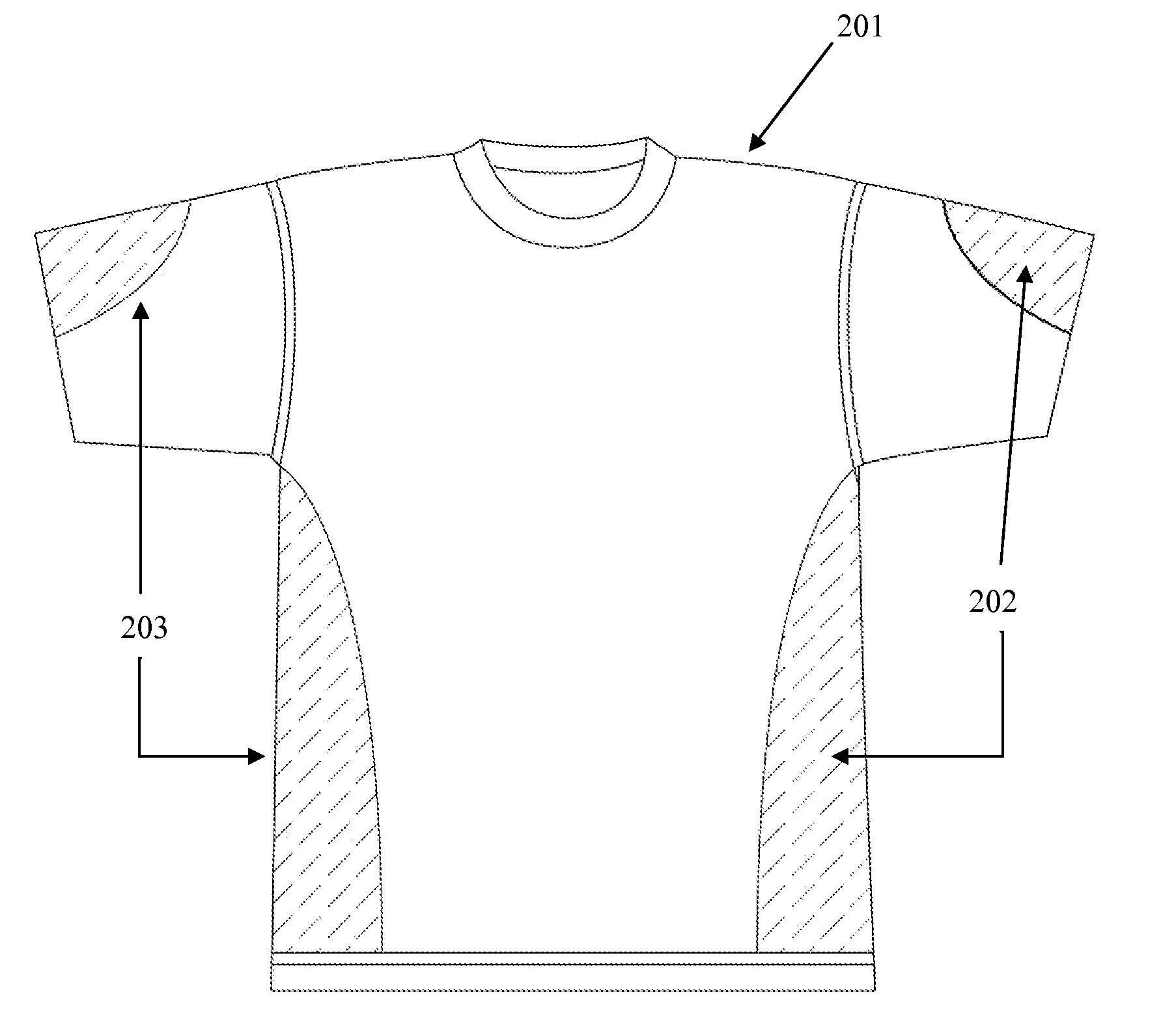

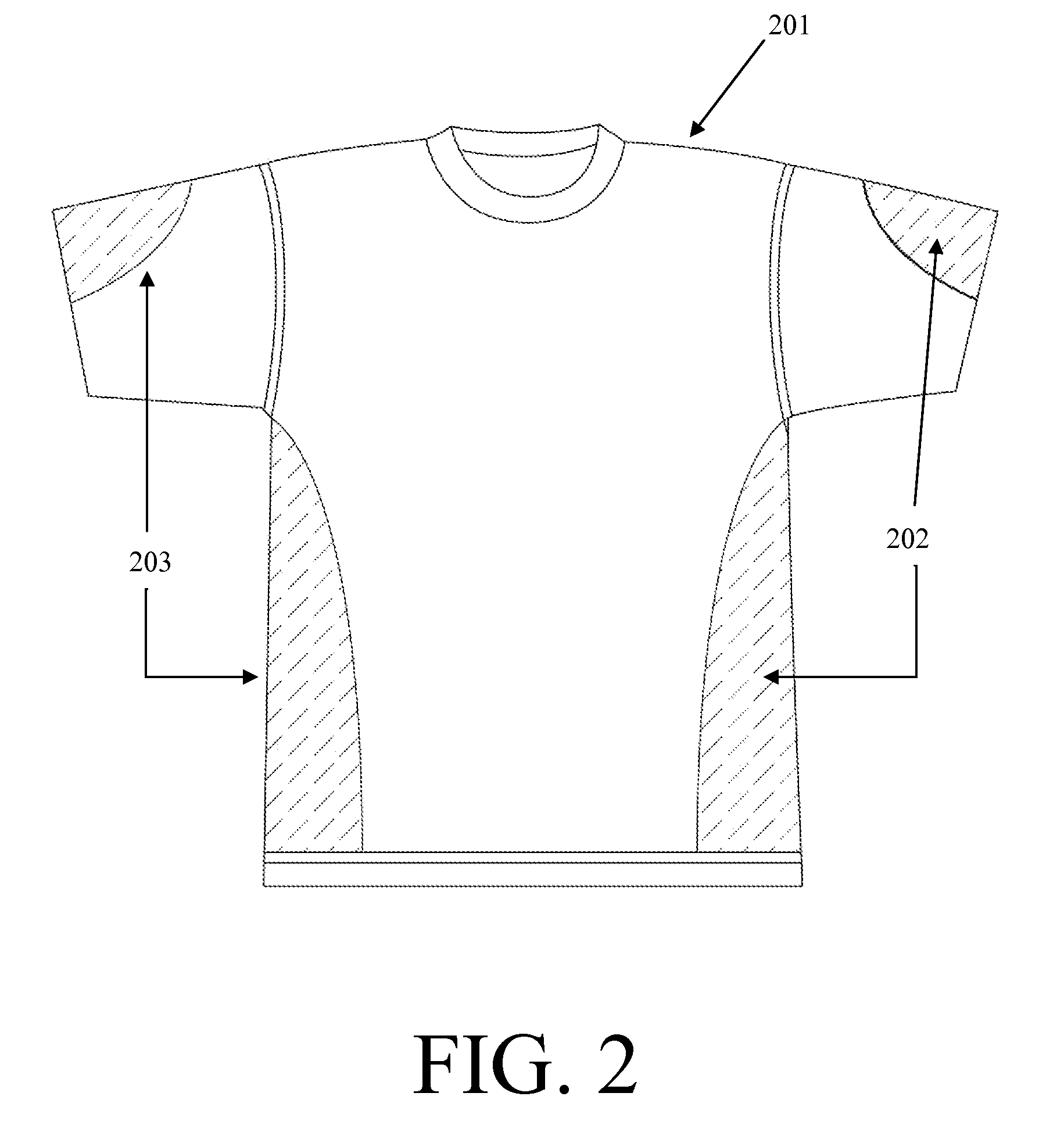

Garment with Elastomeric Coating

InactiveUS20110083246A1Eliminate the problemStretched to limitProtective garmentSpecial outerwear garmentsElastomerEngineering

A garment comprises a fabric and an elastomeric coating on at least a portion of at least one side of the fabric to provide designed, localized stretch and support in a garment, wherein the elastomeric coating is located where reduced stretch of the garment is desired. Garments having structures to facilitate cooling and heating are also described.

Owner:MAS RES & INNOVATION PRIVATE

Fibrous mats having reduced formaldehyde emissions

InactiveUS20070287018A1Reduce stretchTrend downSynthetic resin layered productsLiquid/solution decomposition chemical coatingFiberGlass fiber

A process for making a fibrous product using a binder based on a formaldehyde-containing resin and especially for making fiberglass insulation, and to the fibrous product itself, wherein a formaldehyde scavenger is separately applied to the fibrous mat, such as by treating the fibers with an aqueous mixture consisting essentially of the formaldehyde scavenger, with the result that the fibrous product exhibits a reduced level of formaldehyde emissions.

Owner:GEORGIA PACIFIC CHEM LLC

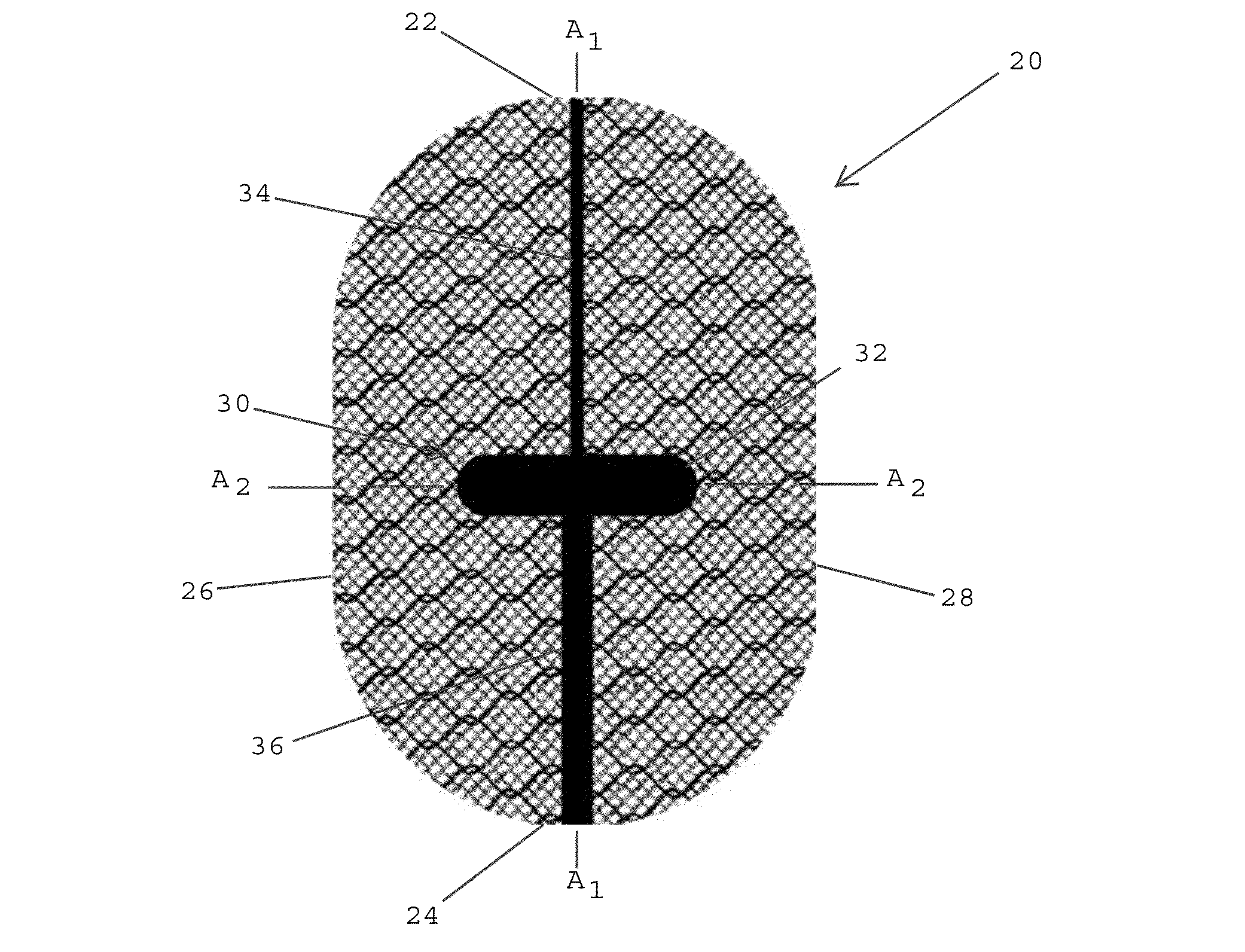

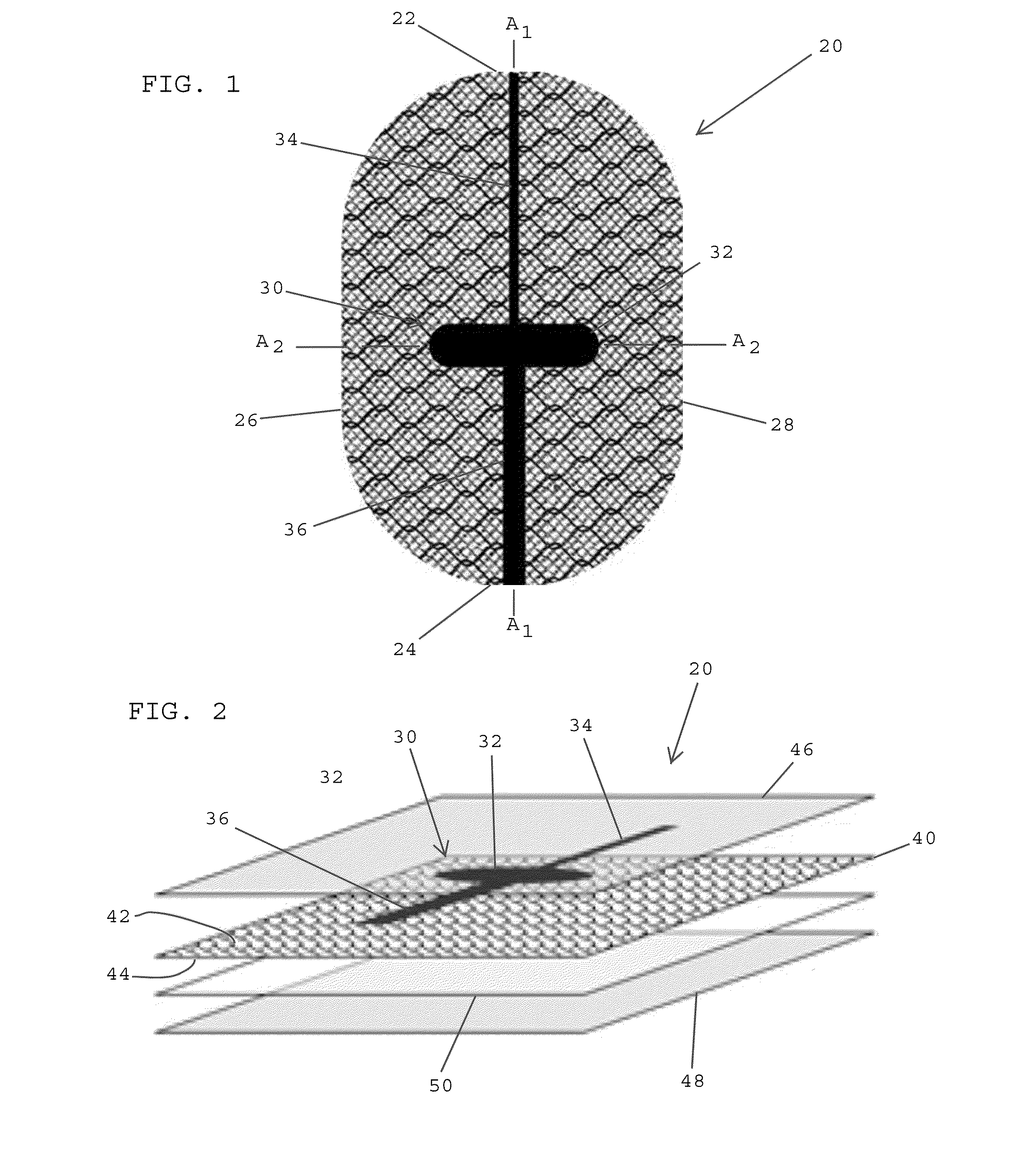

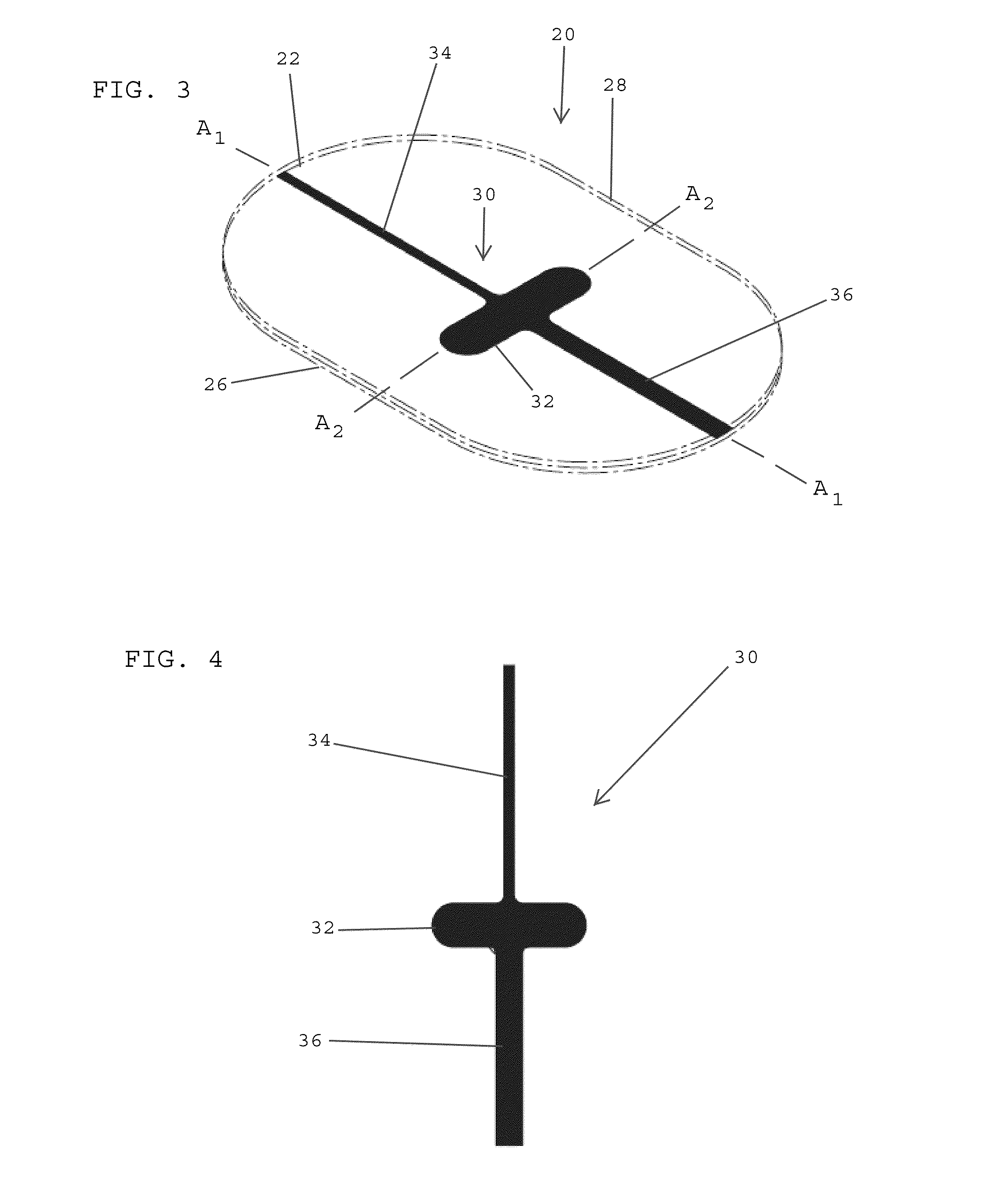

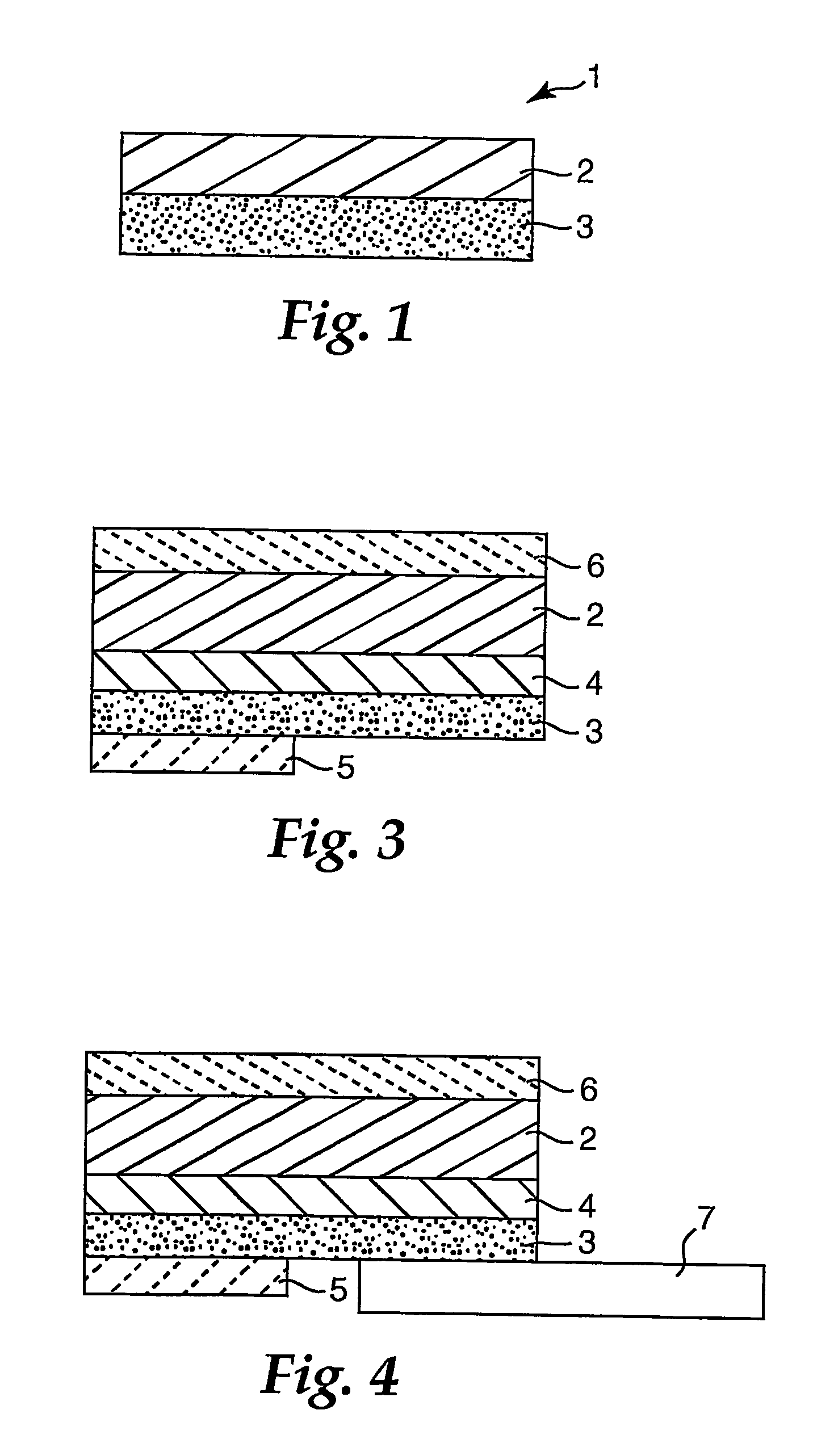

Composite anisotropic tissue reinforcing implants having alignment markers and methods of manufacturing same

ActiveUS20110307077A1Difficult to processDifferent widthLamination ancillary operationsAnti-incontinence devicesBiomedical engineeringMedicine

A composite implant includes an anisotropic surgical mesh having more stretchability along a first axis and less stretchability along a second axis that traverses the first axis, and an alignment marker overlying a first major surface of the anisotropic mesh and extending along the first axis. The implant includes a first absorbable, anti-adhesion film overlying the alignment marker and the first major surface of the anisotropic mesh, and a second absorbable, anti-adhesion film overlying the second major surface of the biocompatible mesh. The alignment marker is disposed between the first and second absorbable films and the first and second absorbable films are laminated to the anisotropic mesh.

Owner:ETHICON INC

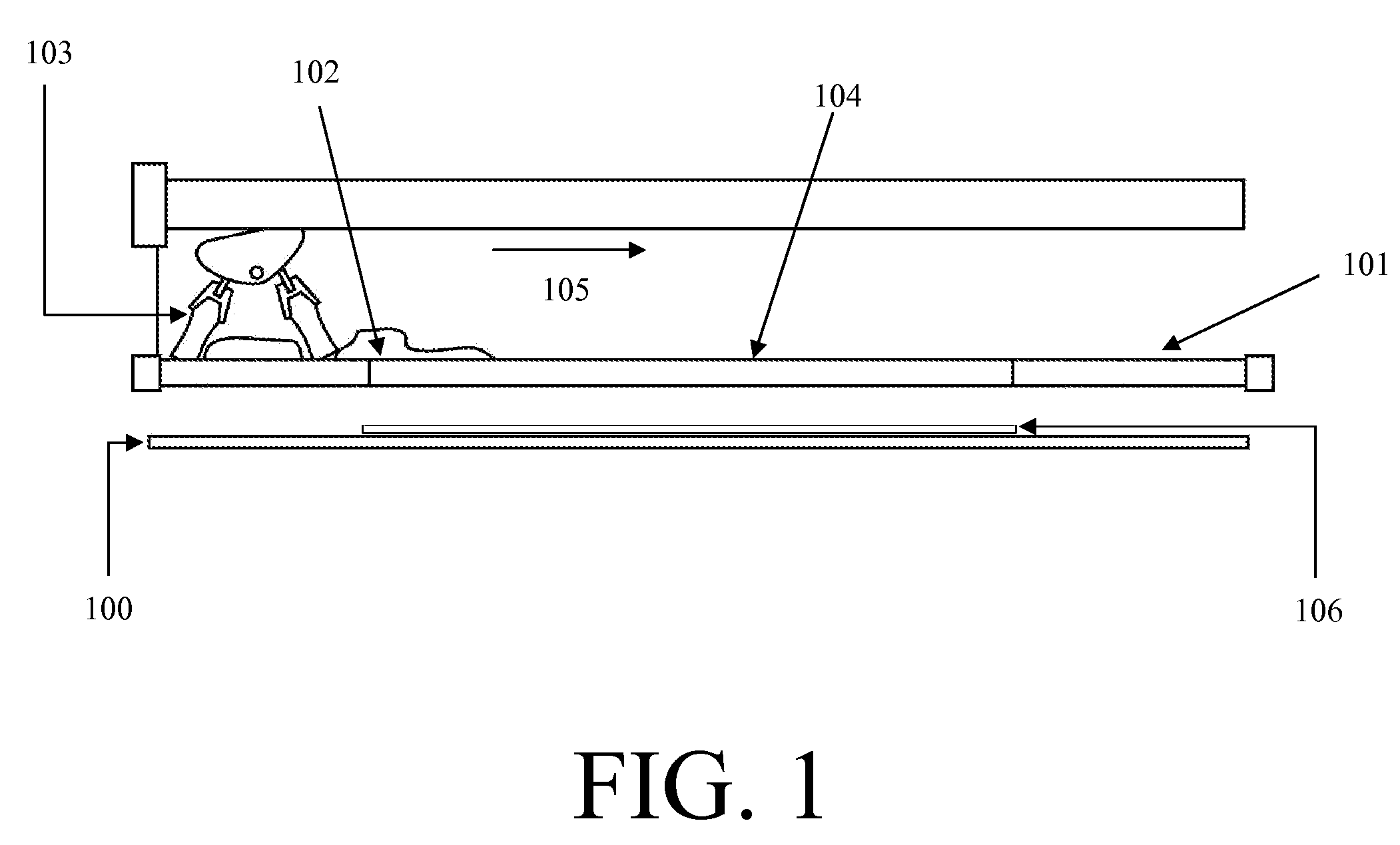

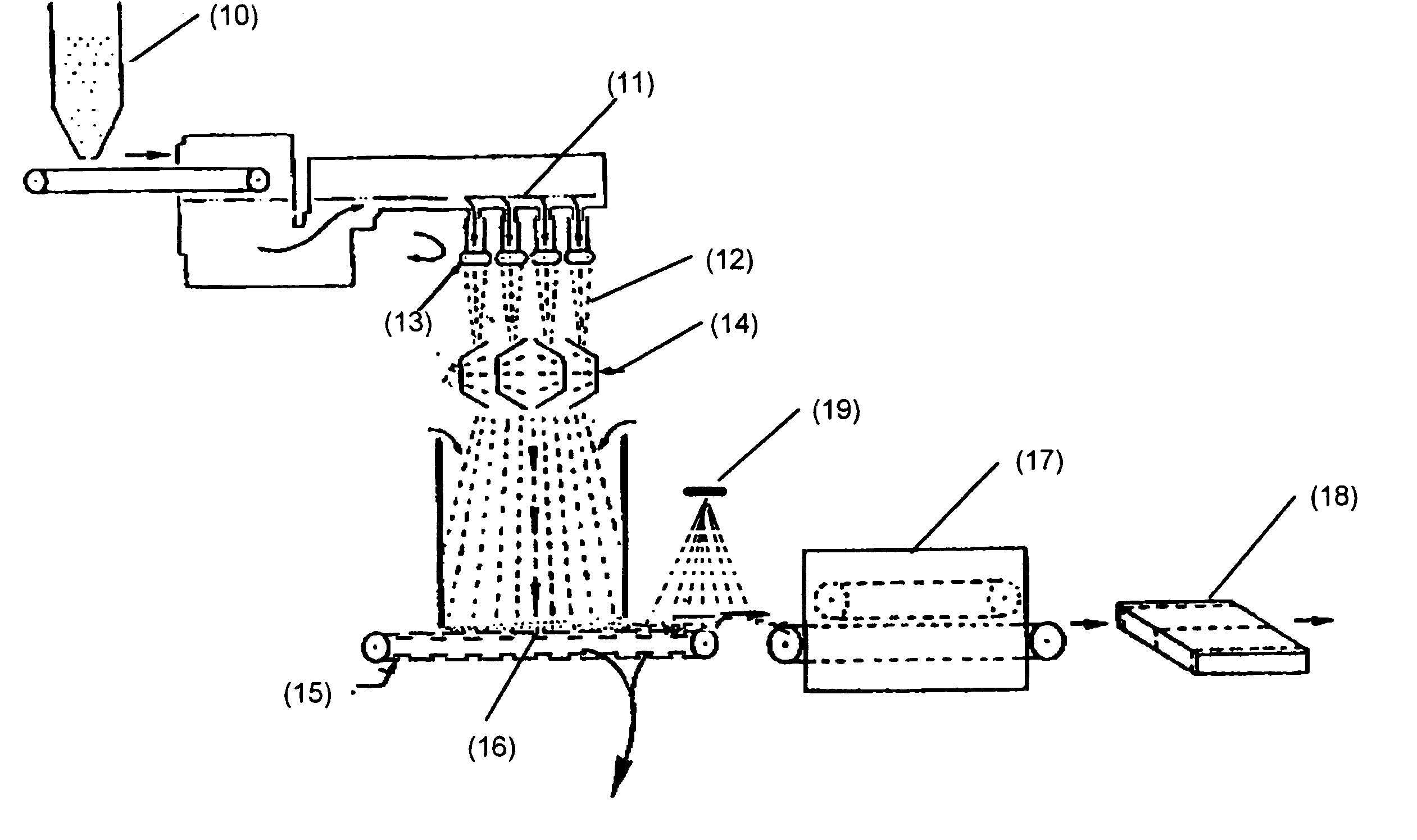

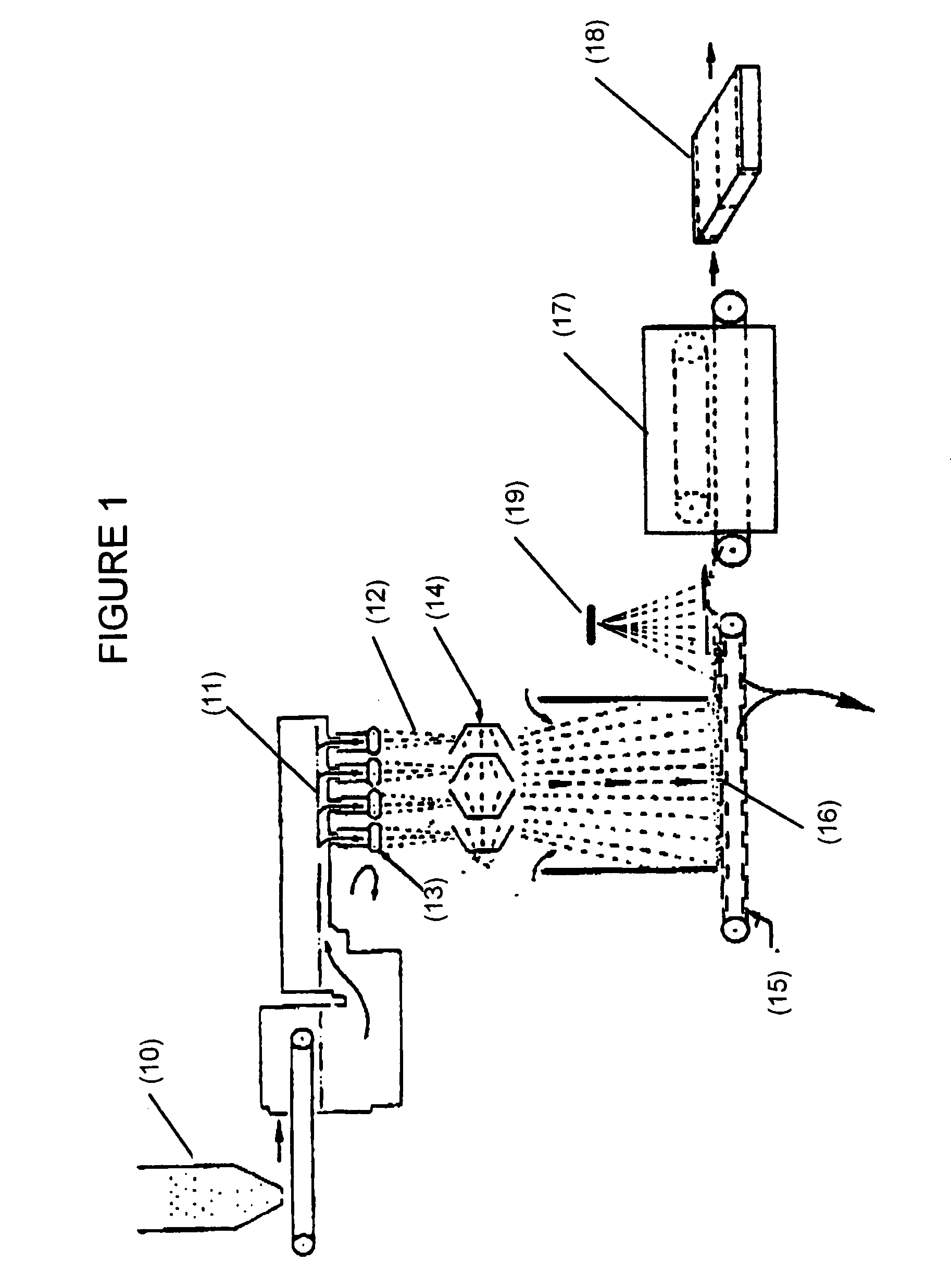

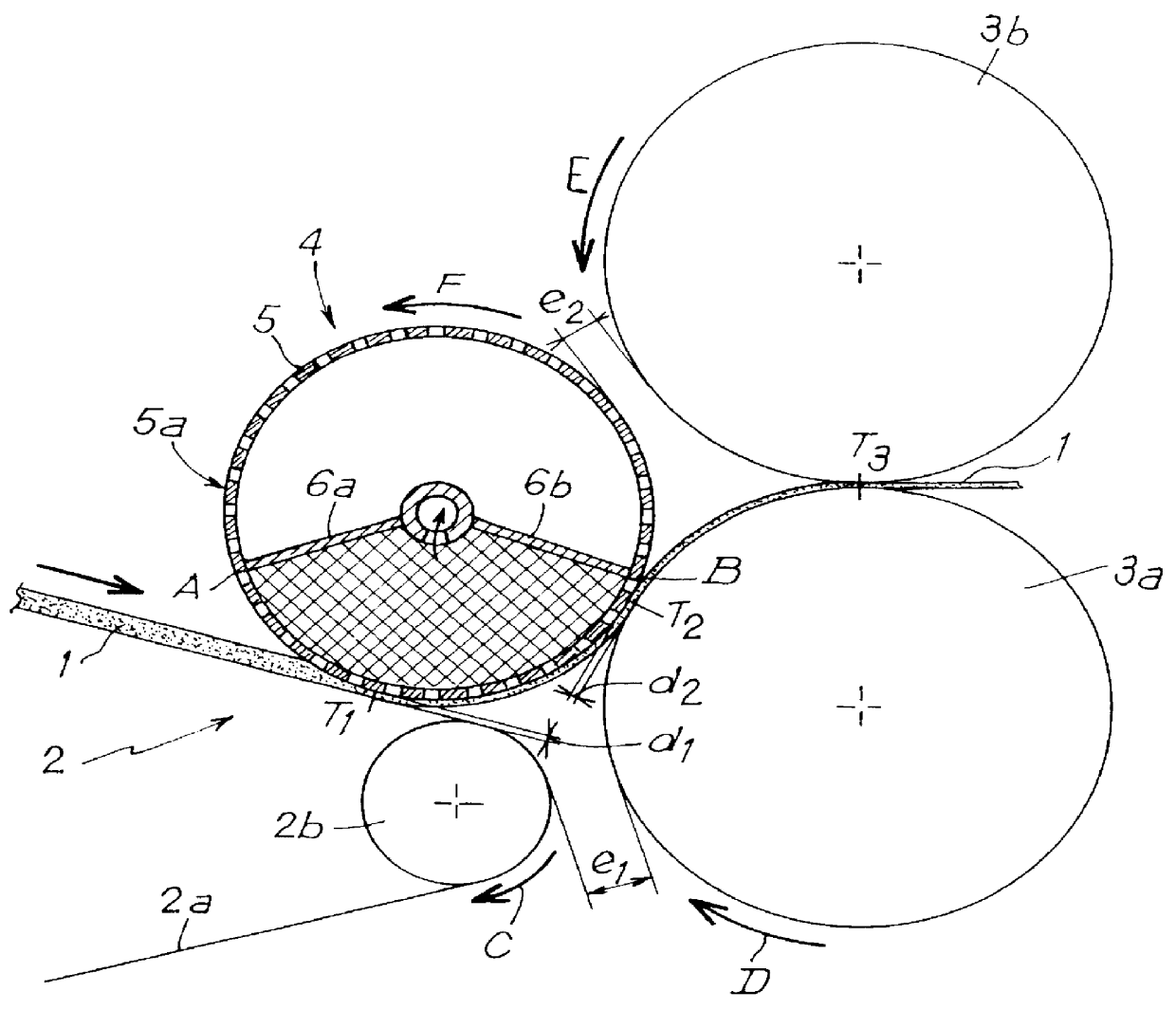

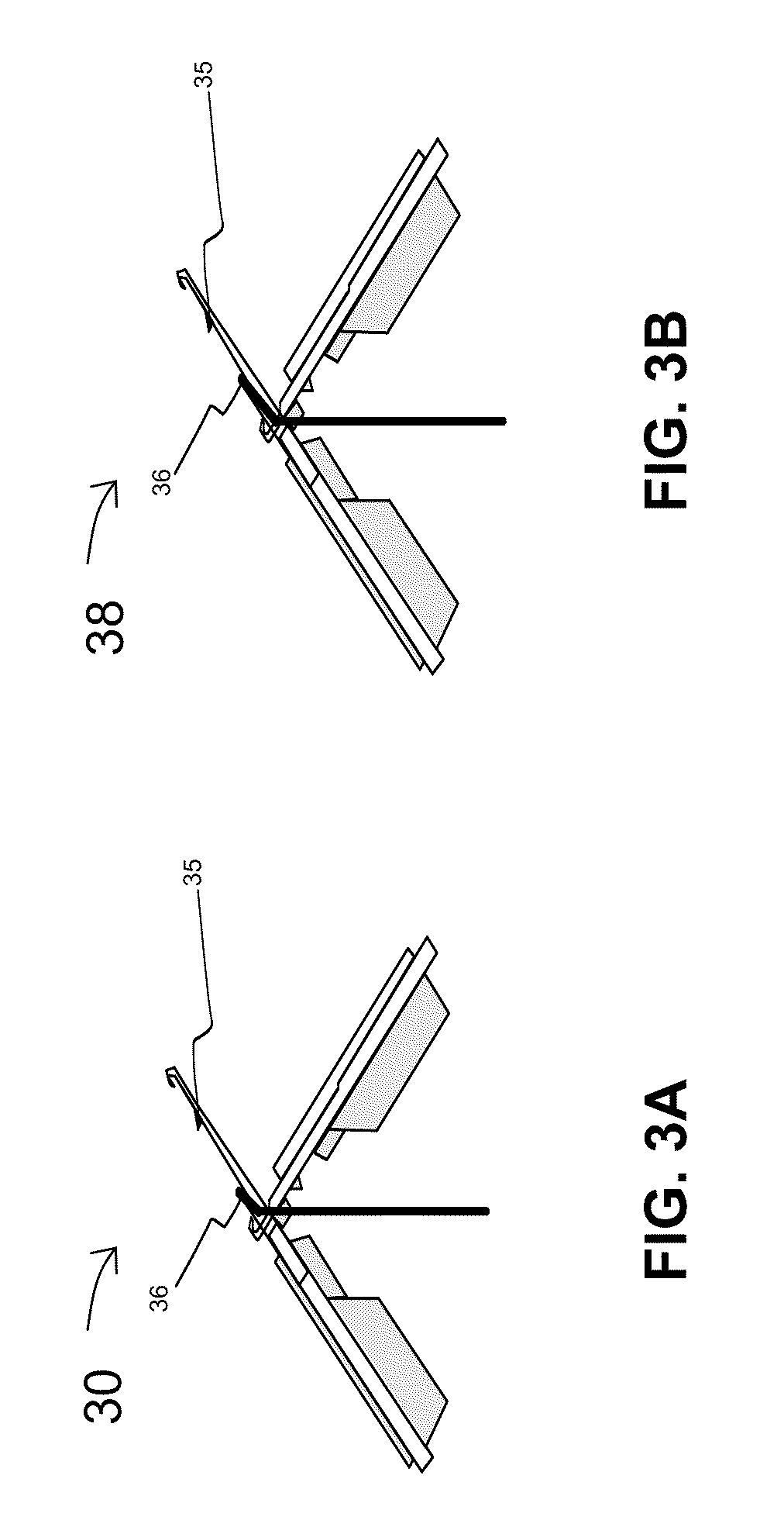

Suction cylinder which transfers fiber web from a conveyer belt to two calendering cylinders

A fiber web transferring device comprising a conveyor belt, a suction cylinder, a lower calendering cylinder and an upper calendering cylinder. The suction cylinder having a stationary suction sector and rotates in a direction which corresponds to a linear moving direction of the conveyor belt. The suction cylinder transfers a non-consolidated fiber web from the conveyor belt to the lower calendering cylinder and is substantially tangential to the lower calendering cylinder so as to cooperate therewith to define a pre-calendering zone for the fiber web. The suction cylinder is positioned such that the suction cylinder sucks the fiber web from the conveyor belt and holds the fiber web against the outer surface of the suction cylinder to the pre-calendering zone. The fiber web then adheres to the outer surface of the lower calendering cylinder past the pre-calendering zone until the fiber web reaches the upper calendering cylinder.

Owner:THIBEAU

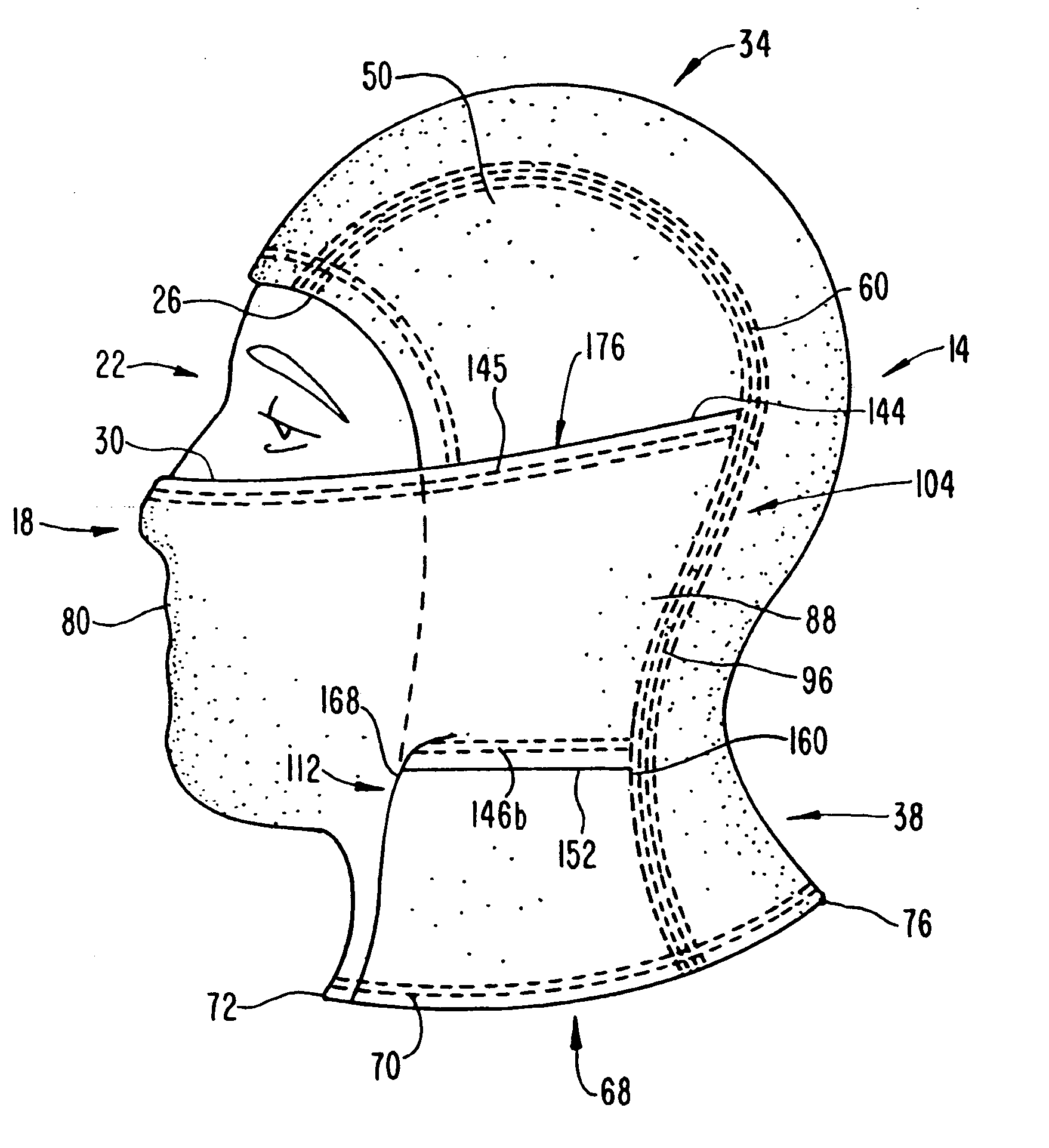

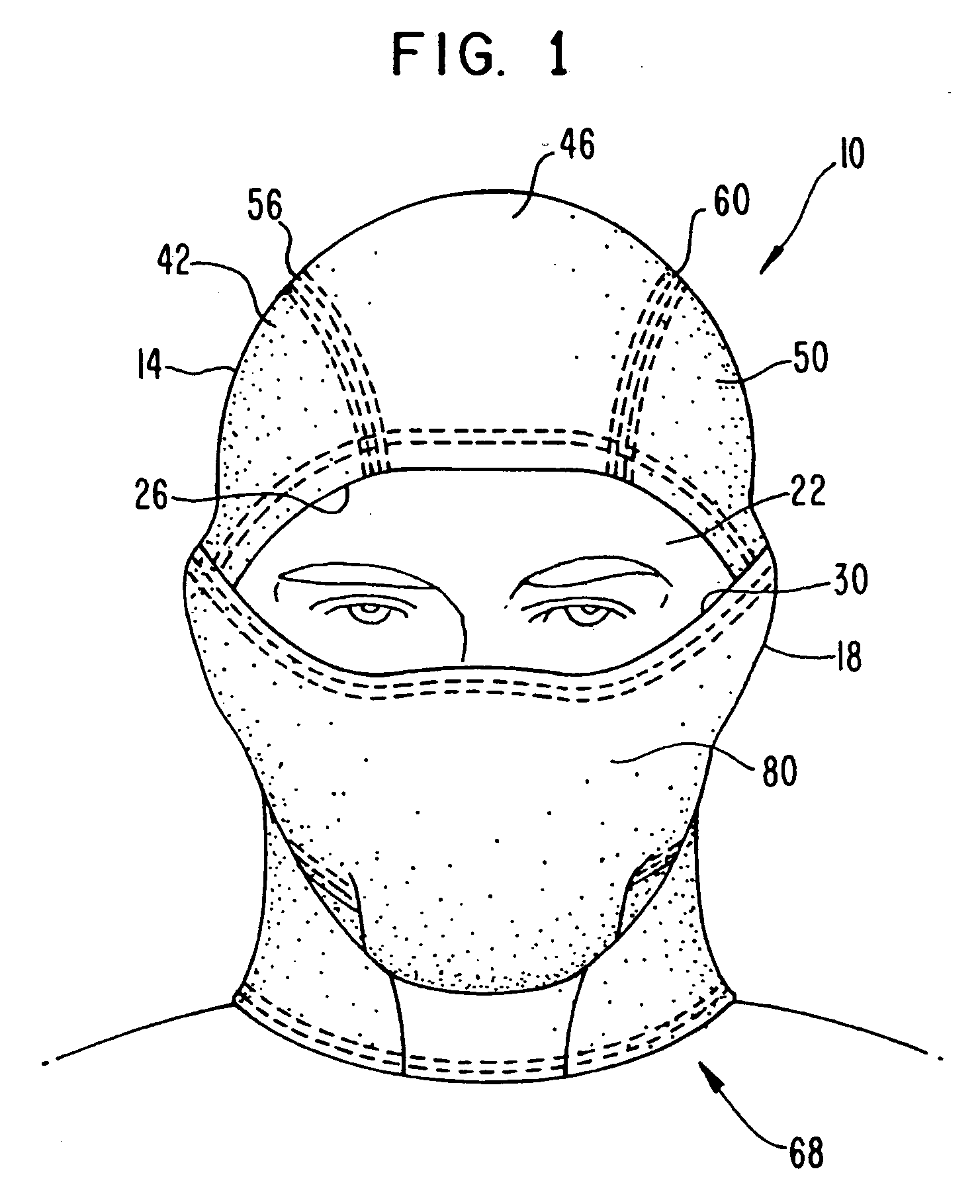

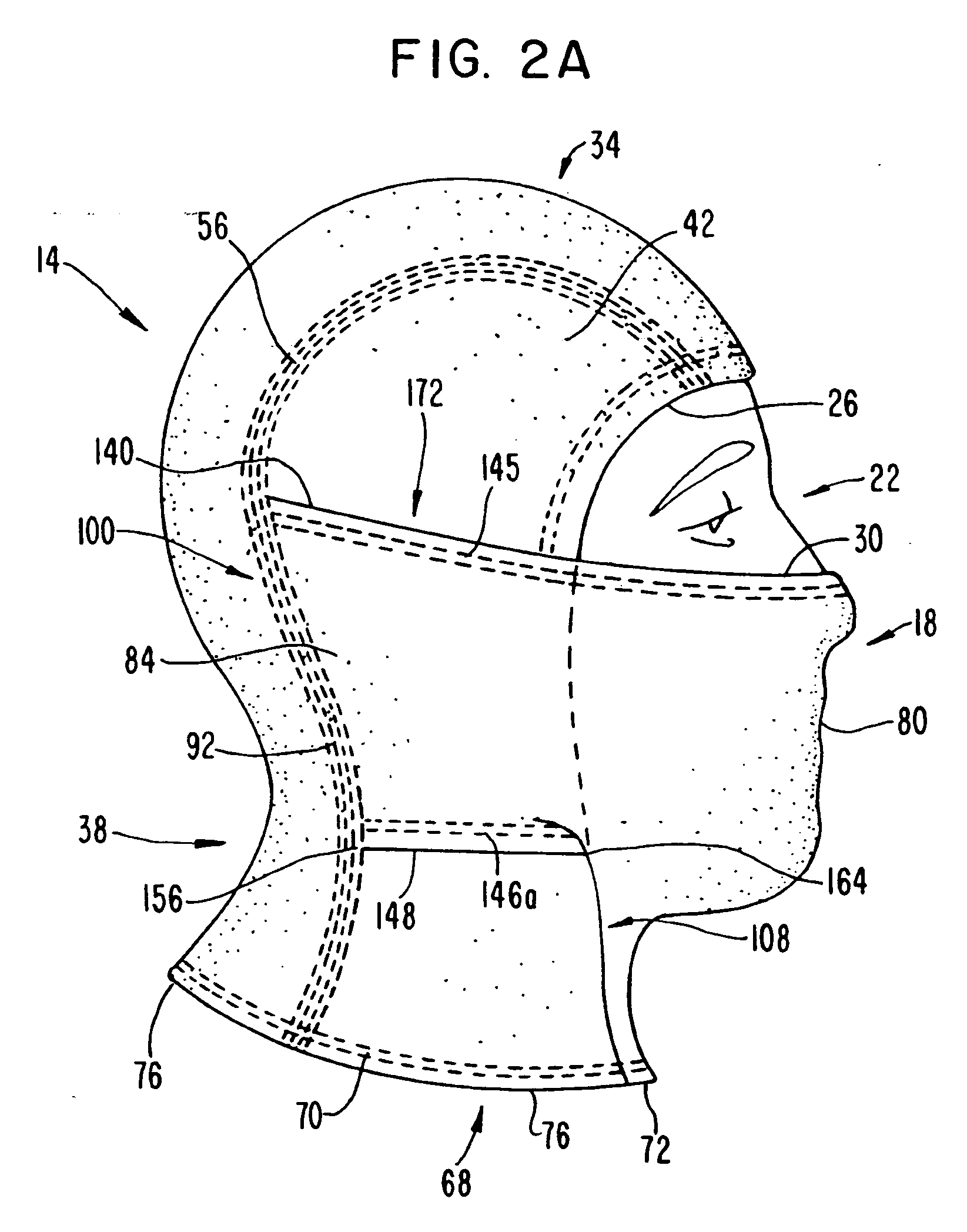

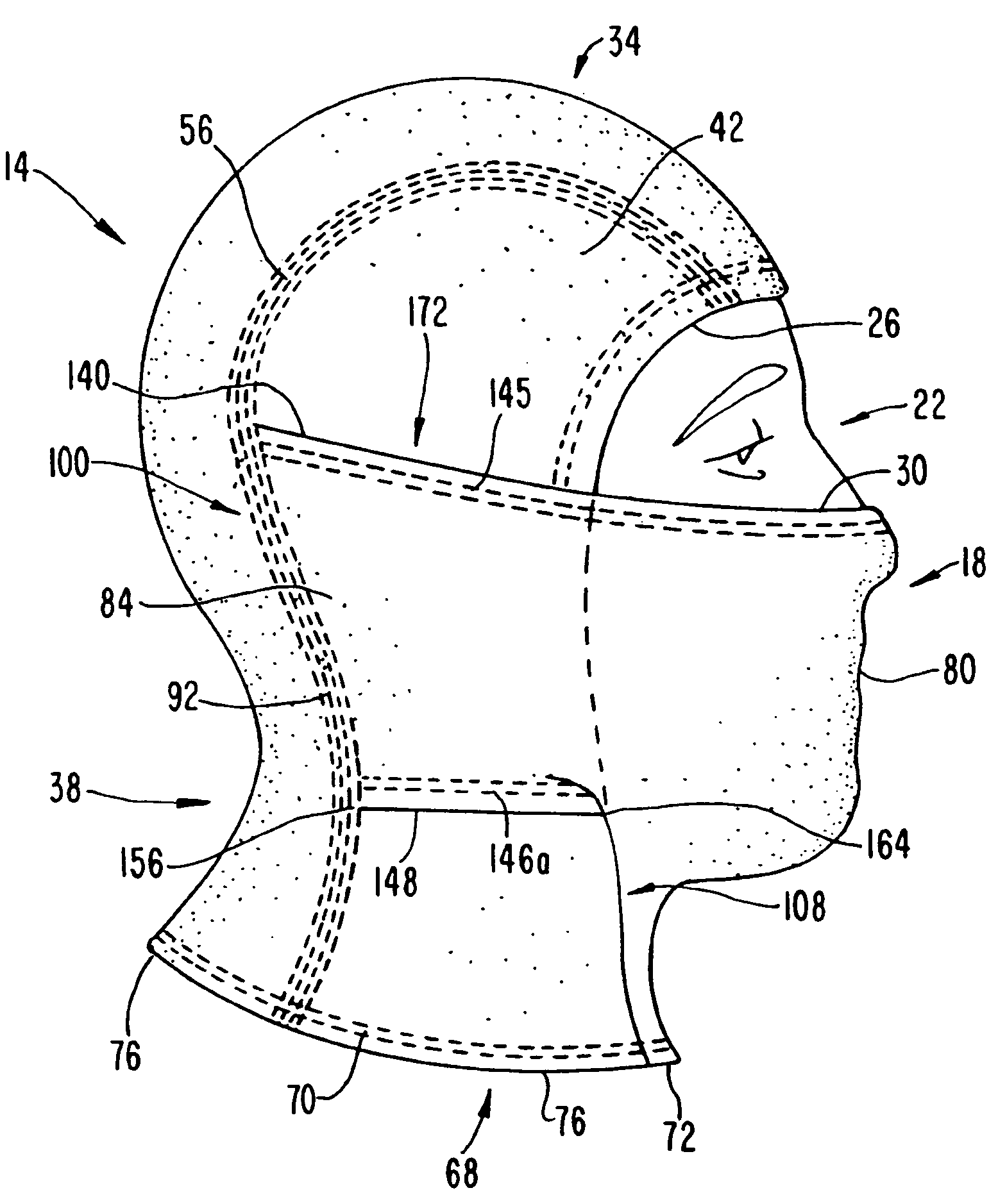

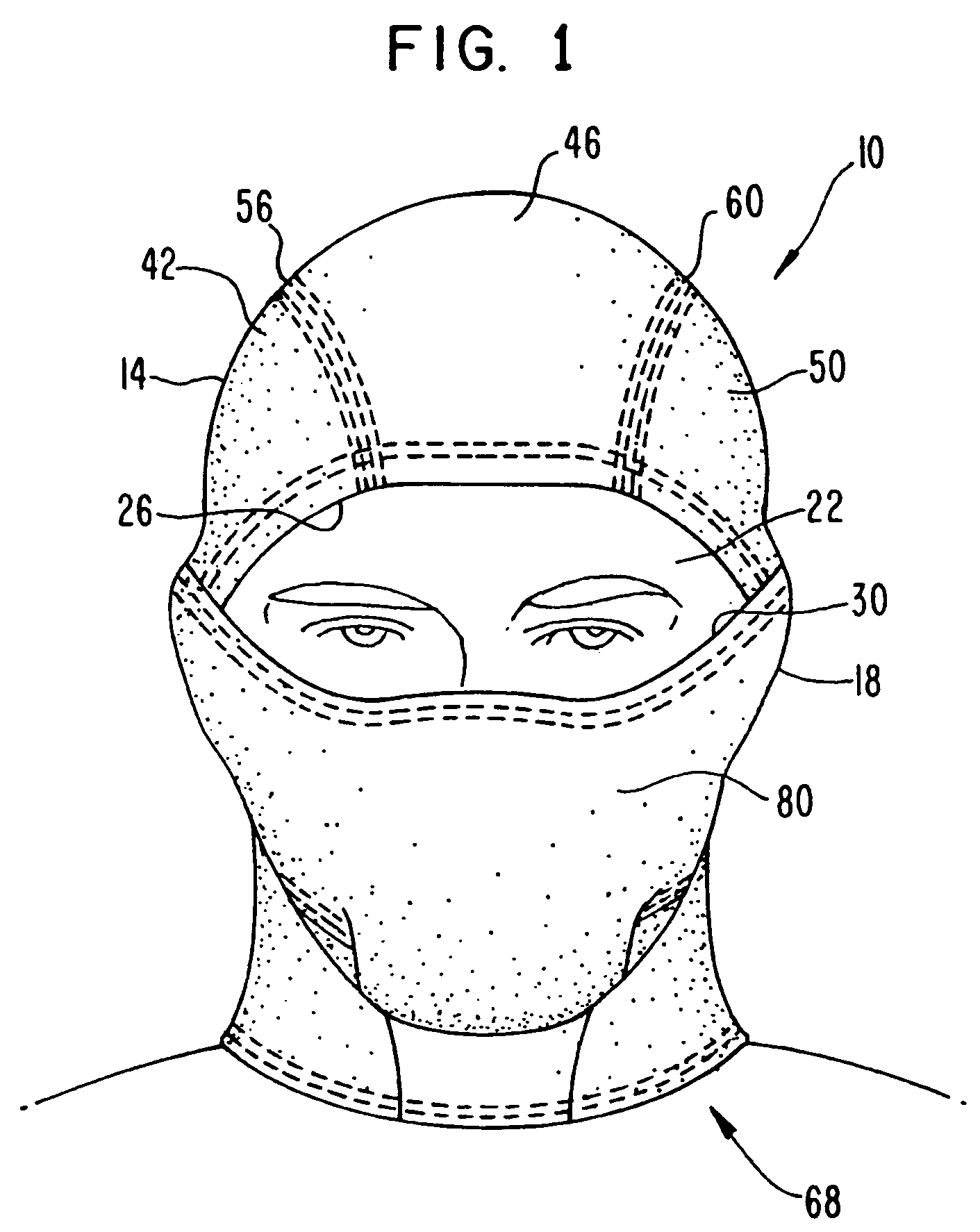

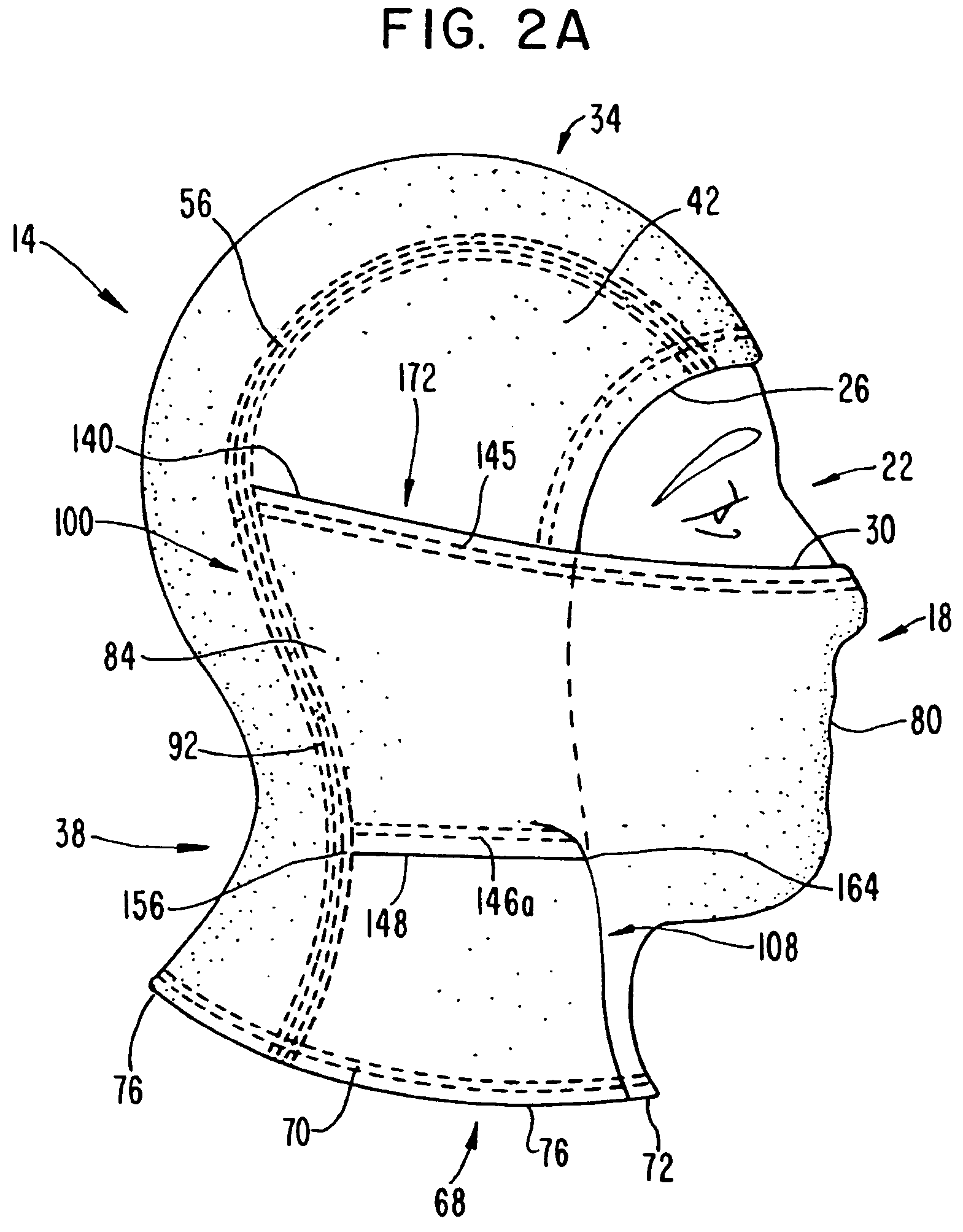

Hood with hinged mask piece

ActiveUS20060130213A1Temperature regulationReduce stretchHatsHeadwear capsForeheadElectrical and Electronics engineering

A hood is provided that includes a lid and a mask which are pivotally connected and separately moveable. The mask and lid form an opening that increases or decreases in size when the mask pivots. The lid is moveable between an up and down position. In the up-position, an edge of the lid is disposed on a user's forehead and in the down-position the edge is disposed on a posterior of the user's. The mask is connected to the lid by a hinge portion which allows the mask to provide varying levels of coverage to a user's face.

Owner:UNDER ARMOUR

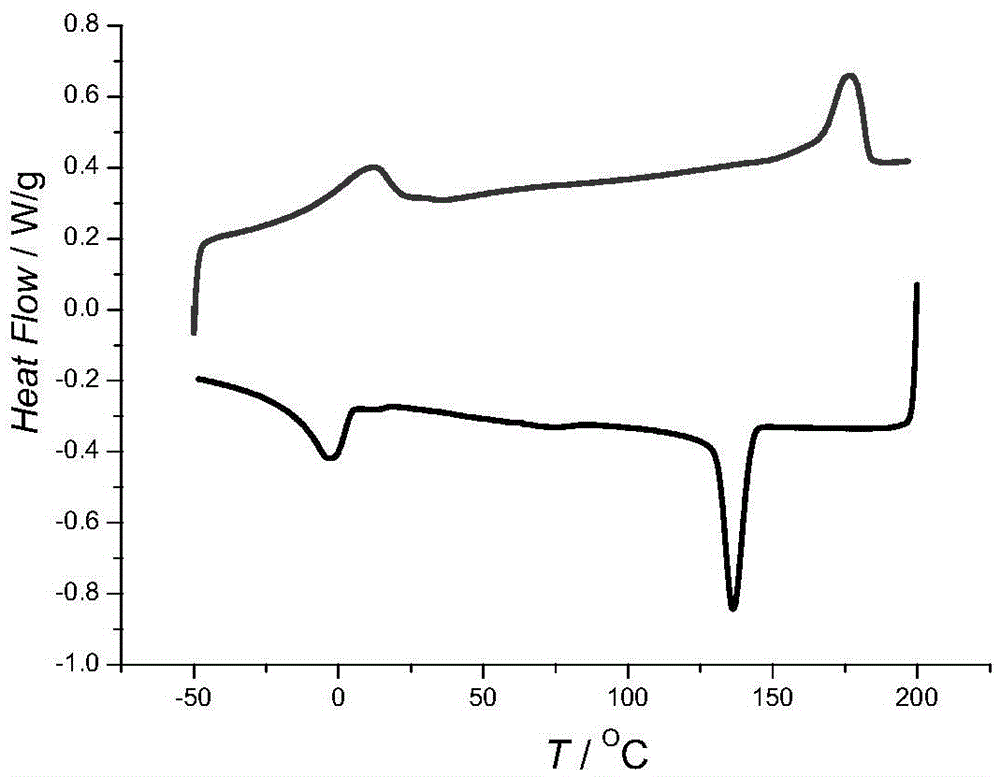

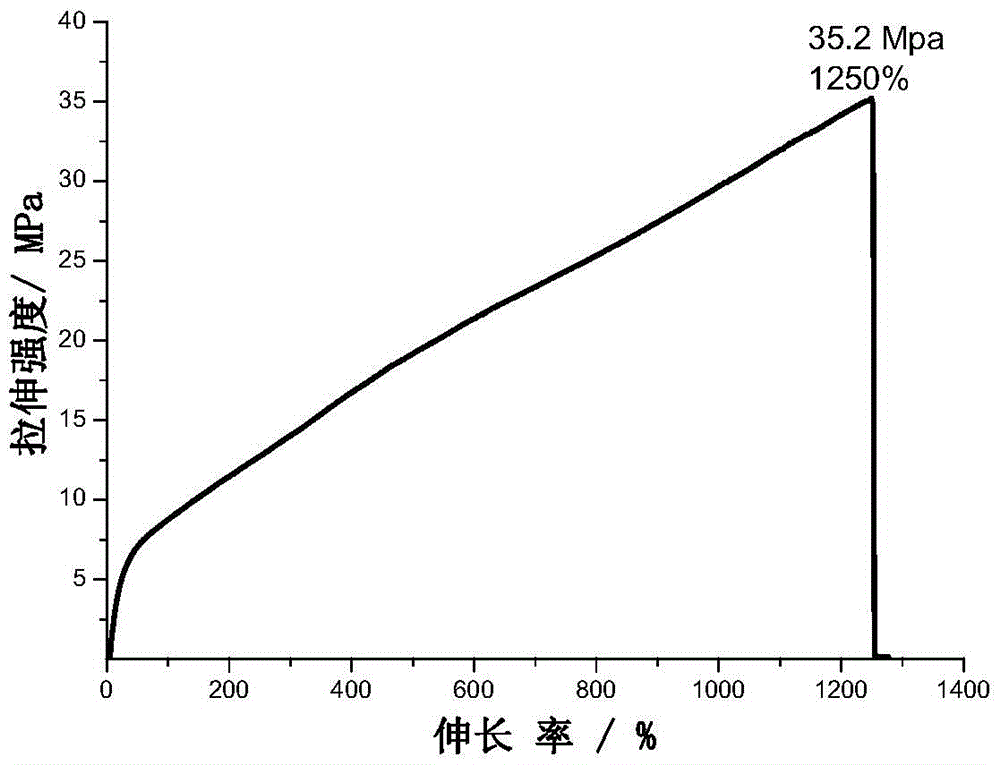

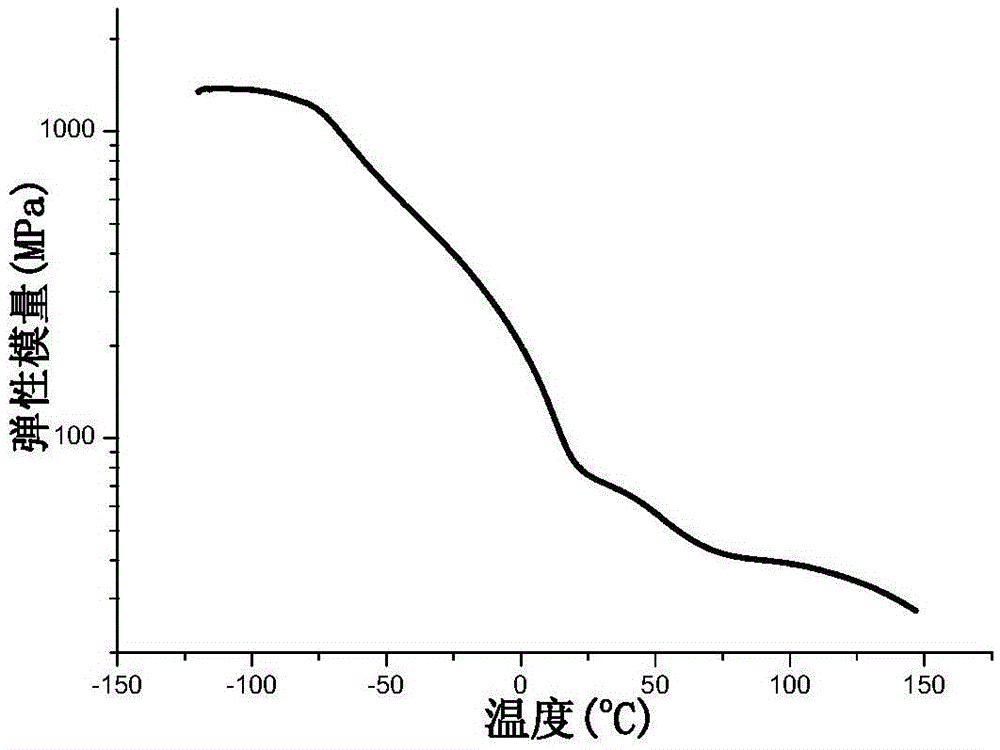

Polyamide 1012 serial thermoplastic elastomer material and preparation method thereof

Provided are a long-carbon-chain polyamide 1012 serial thermoplastic elastomer material and a preparation method thereof. The thermoplastic elastomer material is a block copolymer, wherein long-carbon-chain polyamide 1012 blocks serve as hard segments of the block copolymer, and polyether blocks and / or polyester diol blocks serve as soft segments of the block copolymer. The preparation method of the long-carbon-chain polyamide 1012 serial thermoplastic elastomer is a body melt phase polycondensation method under the control of certain temperature and pressure. The preparation cost of the long-carbon-chain polyamide 1012 serial elastomer is lower, and the performance-cost ratio is better; meanwhile, the long-carbon-chain polyamide 1012 serial elastomer has the multiple advantages of long-carbon-chain polyamide and polyether and / or polyester materials, has the advantages of being good in thermal stability, good in solvent resistance, low in water absorbing capacity, good in elasticity, good in wear-resisting property and the like and can be applied in the fields such as soles of high-end sports shoes, medical catheter materials, micro-drive mechanical parts, vibration-absorptive materials for sports equipment and damping and sound insulating materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

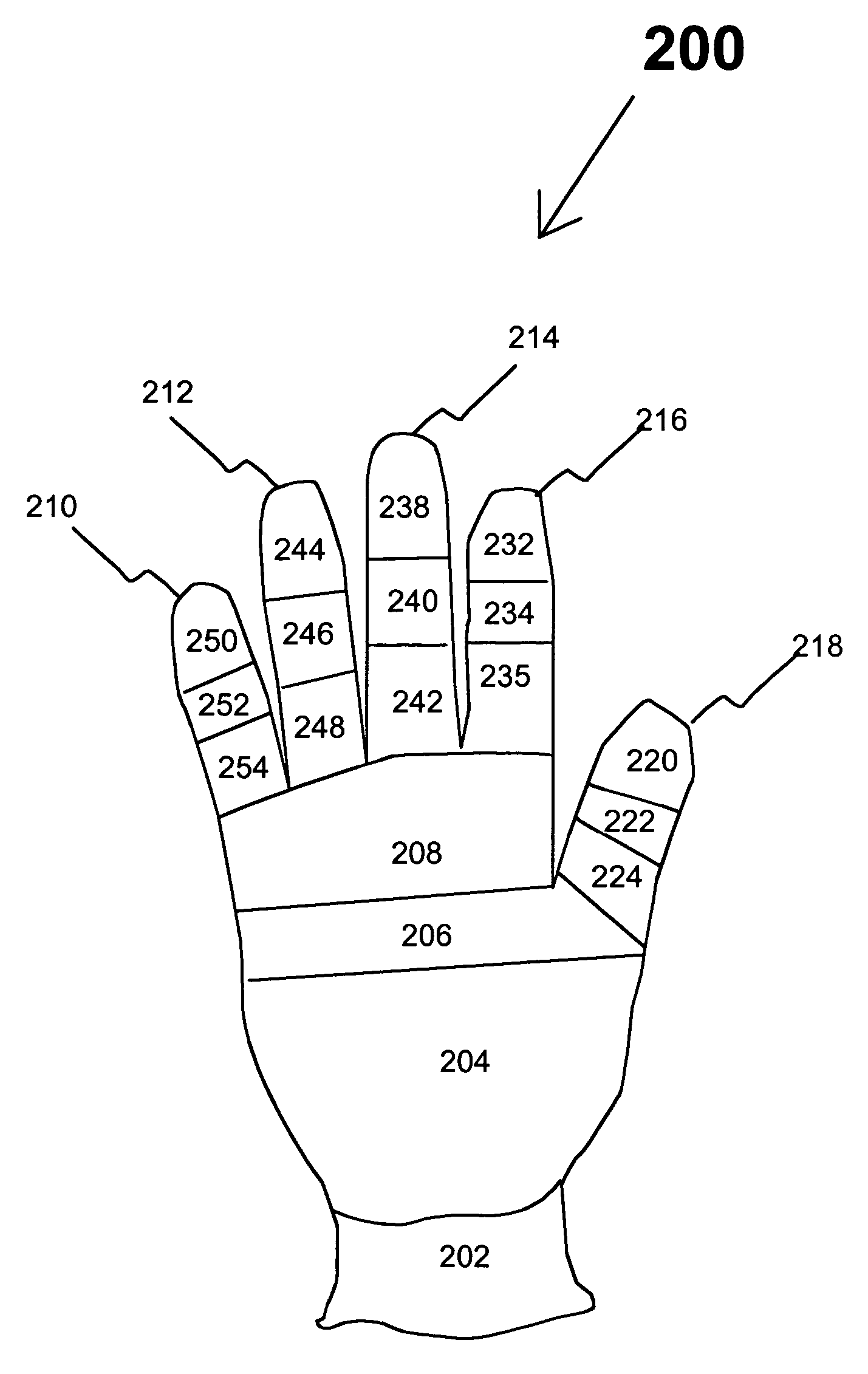

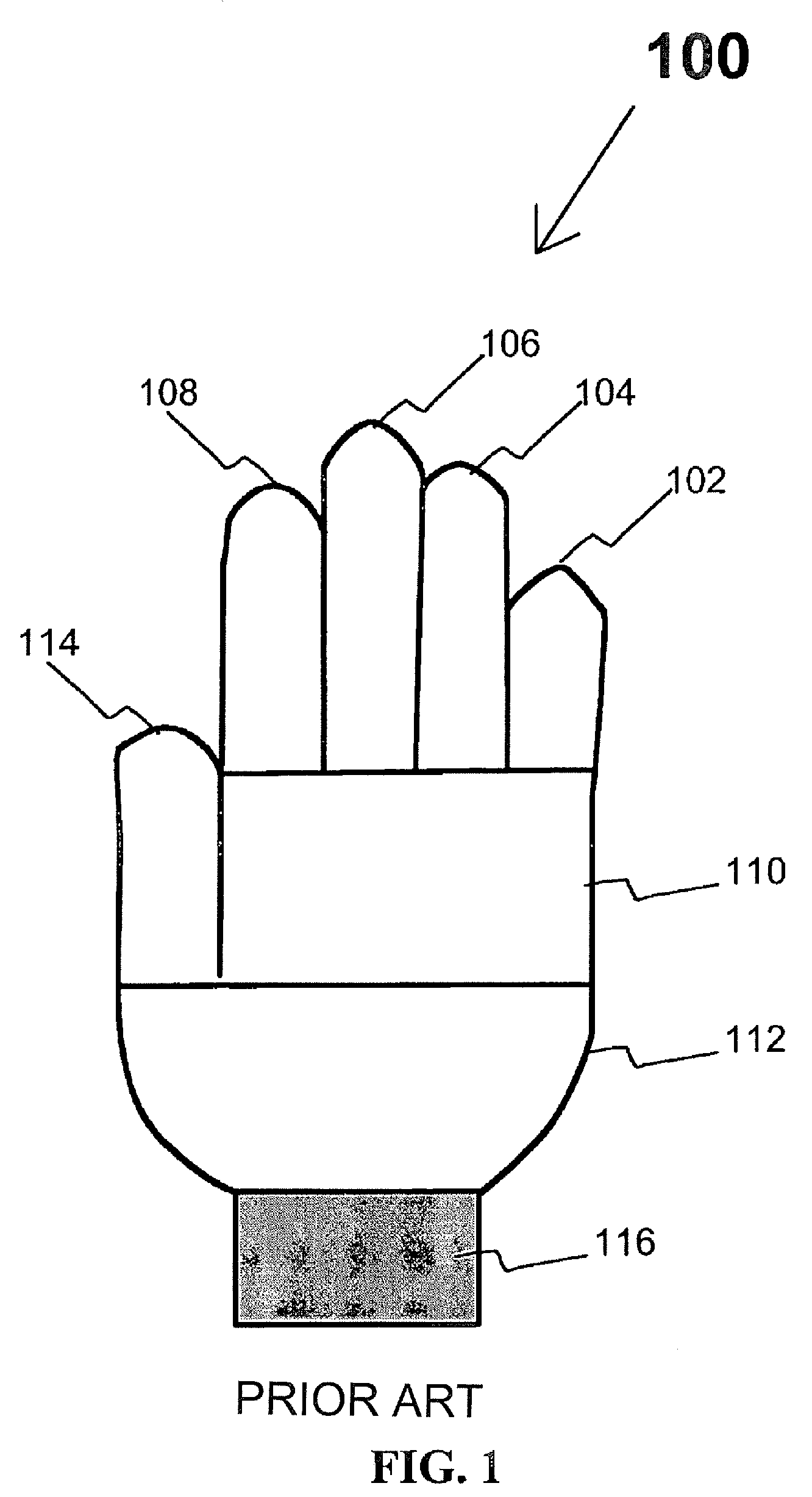

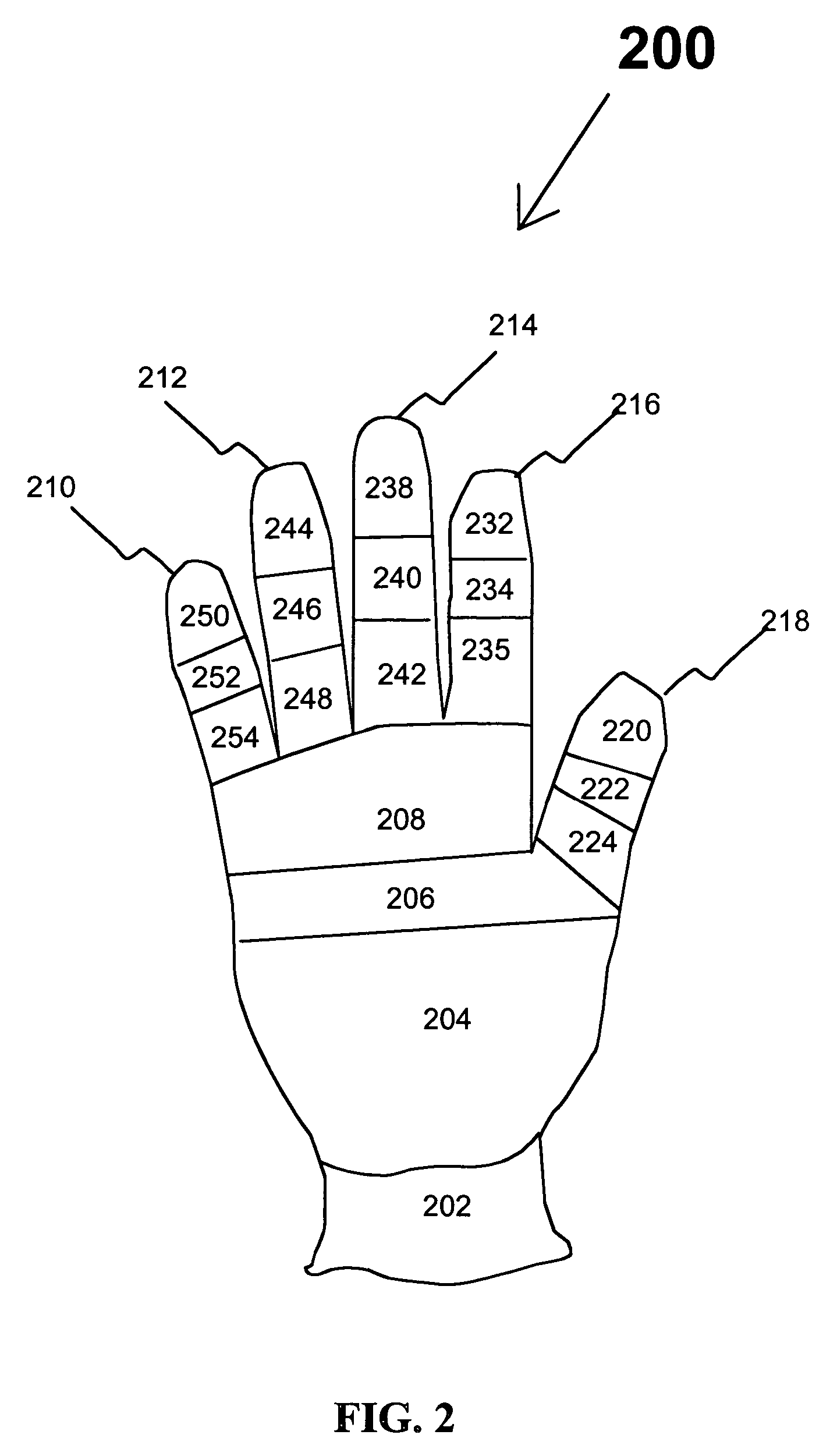

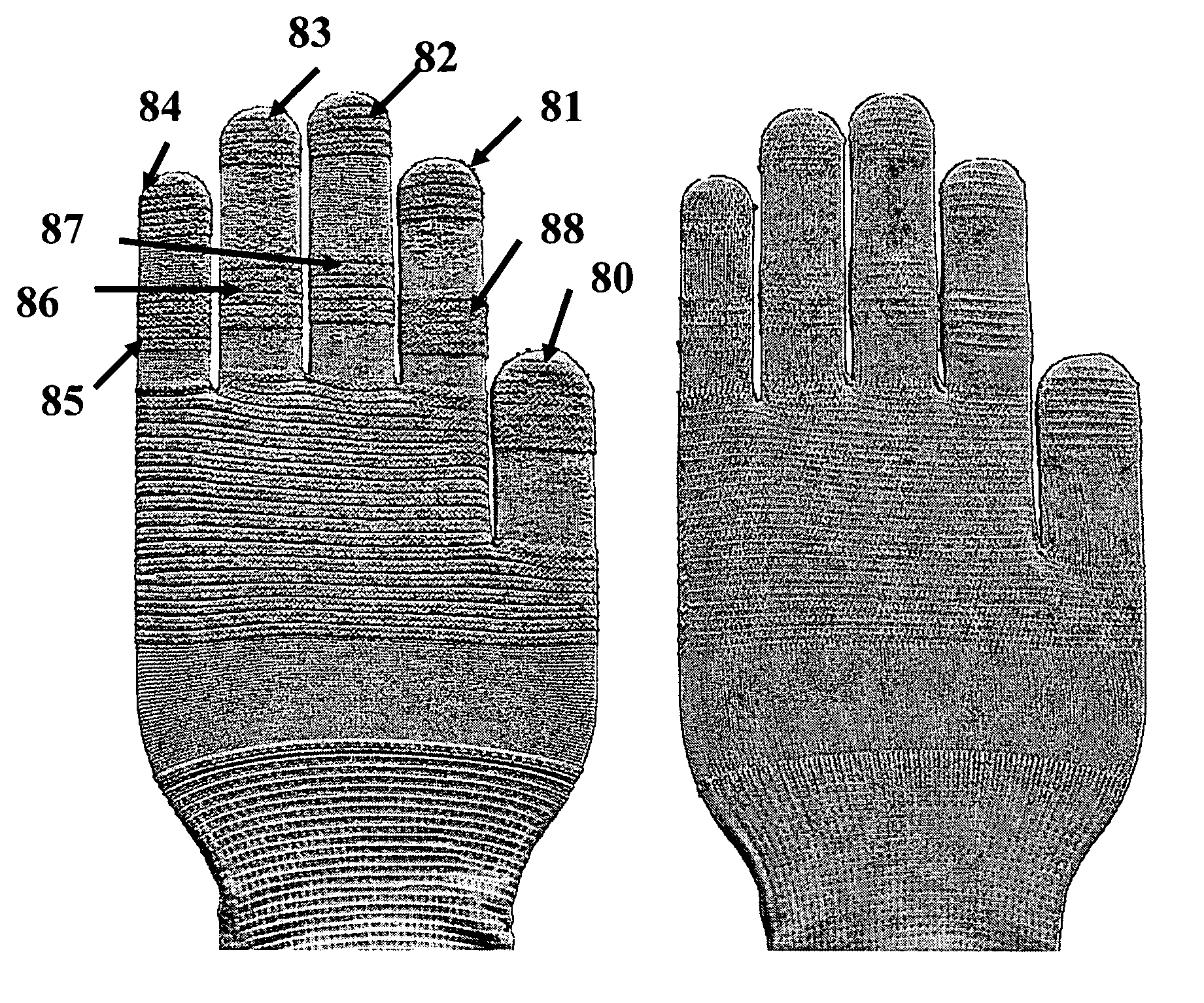

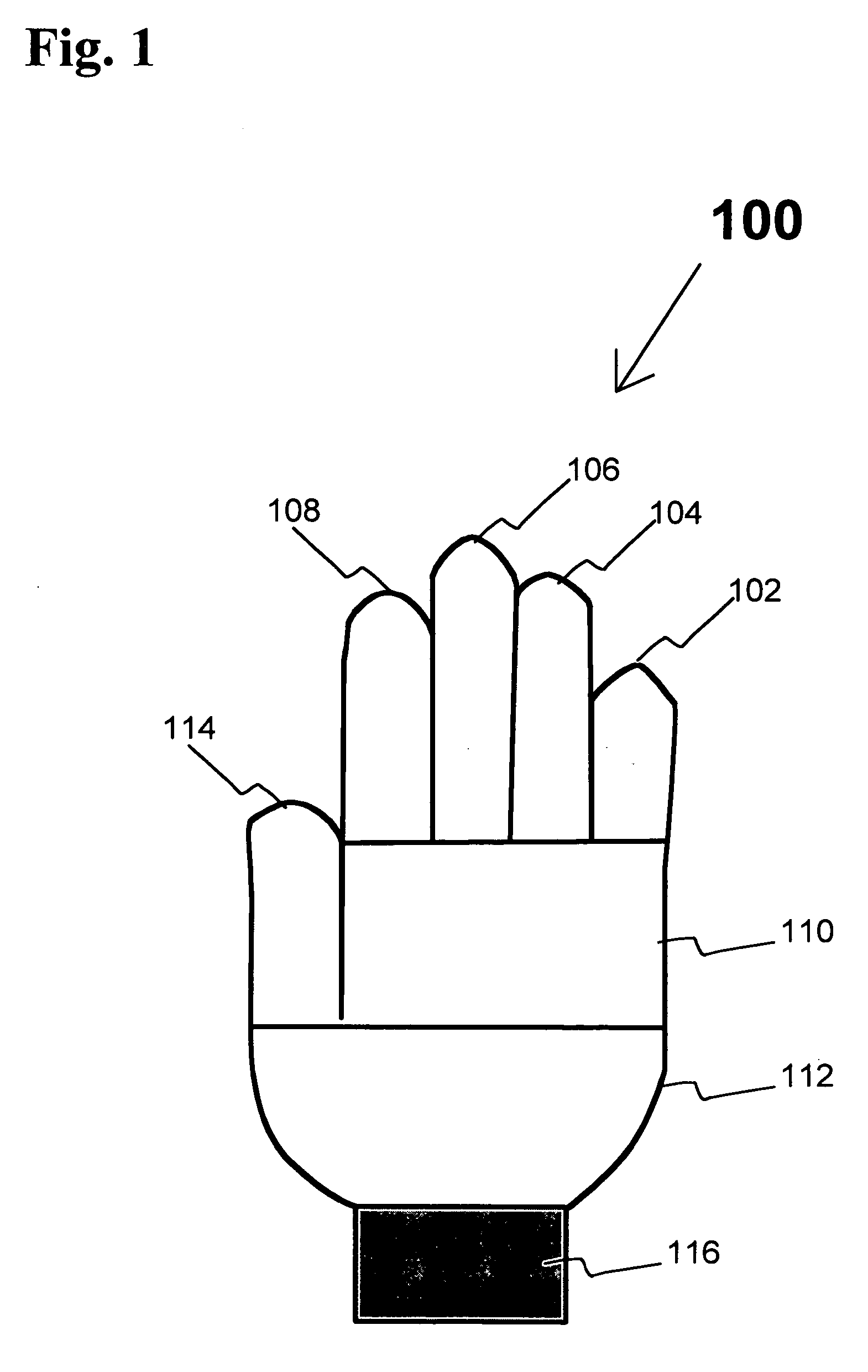

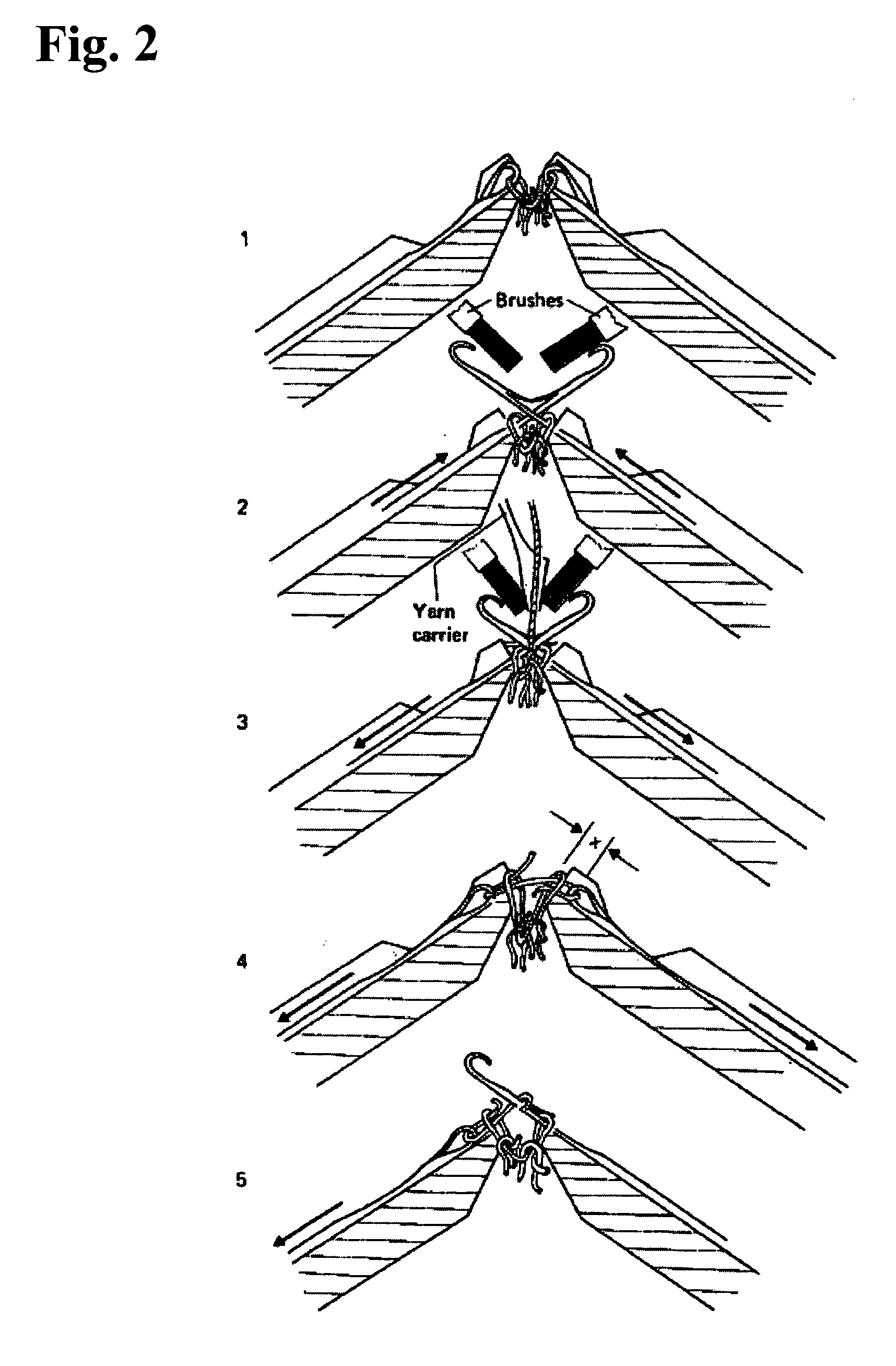

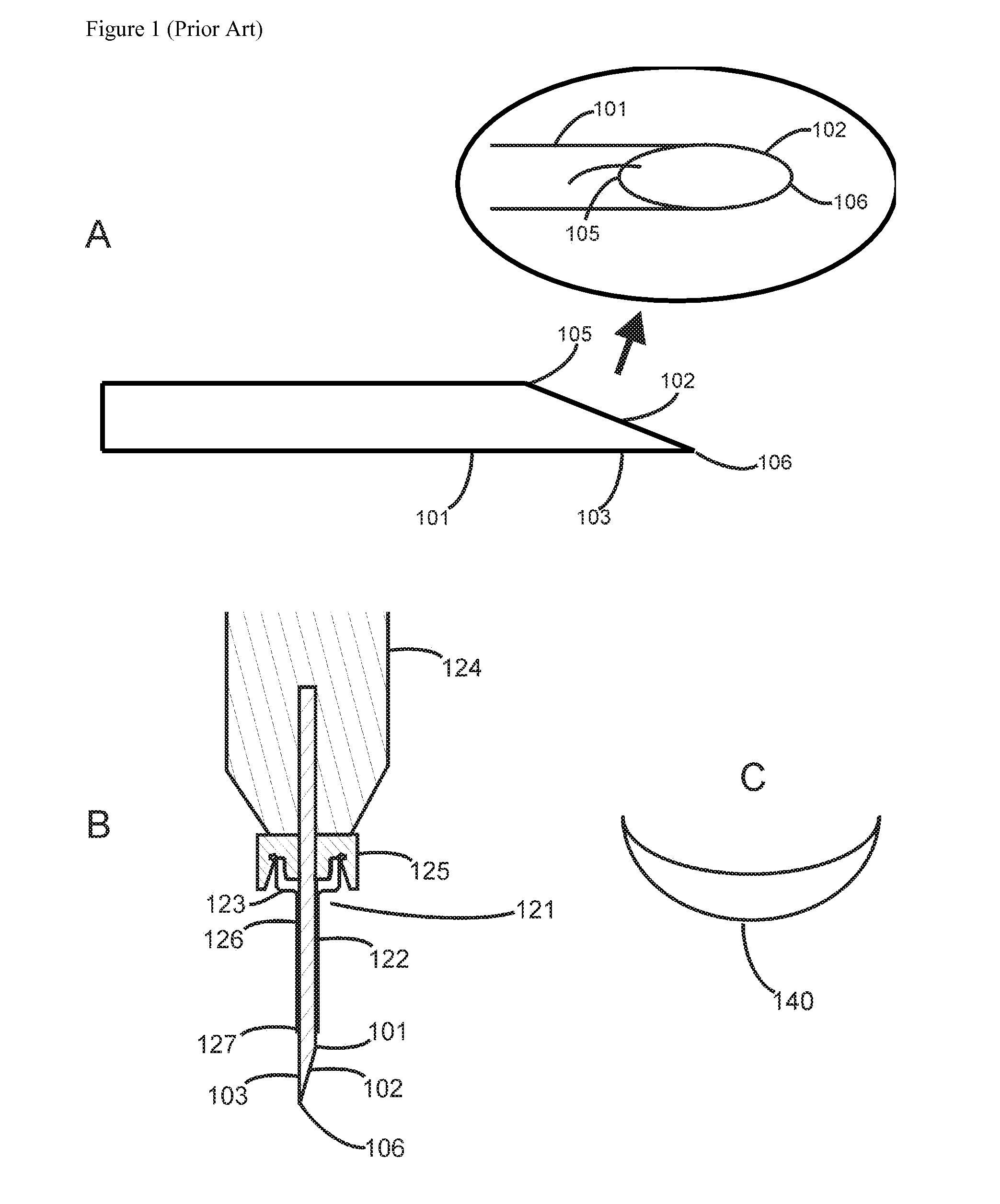

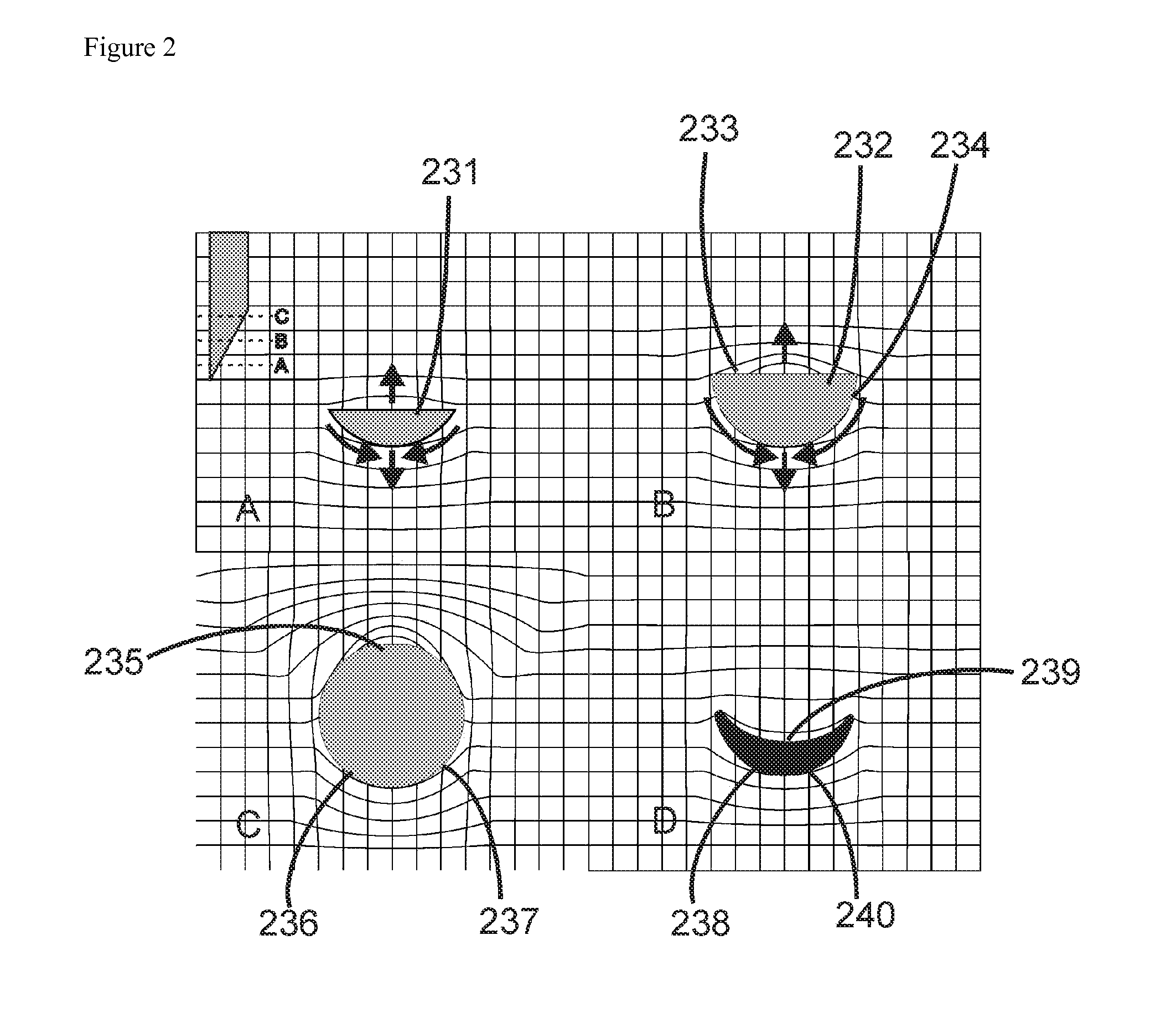

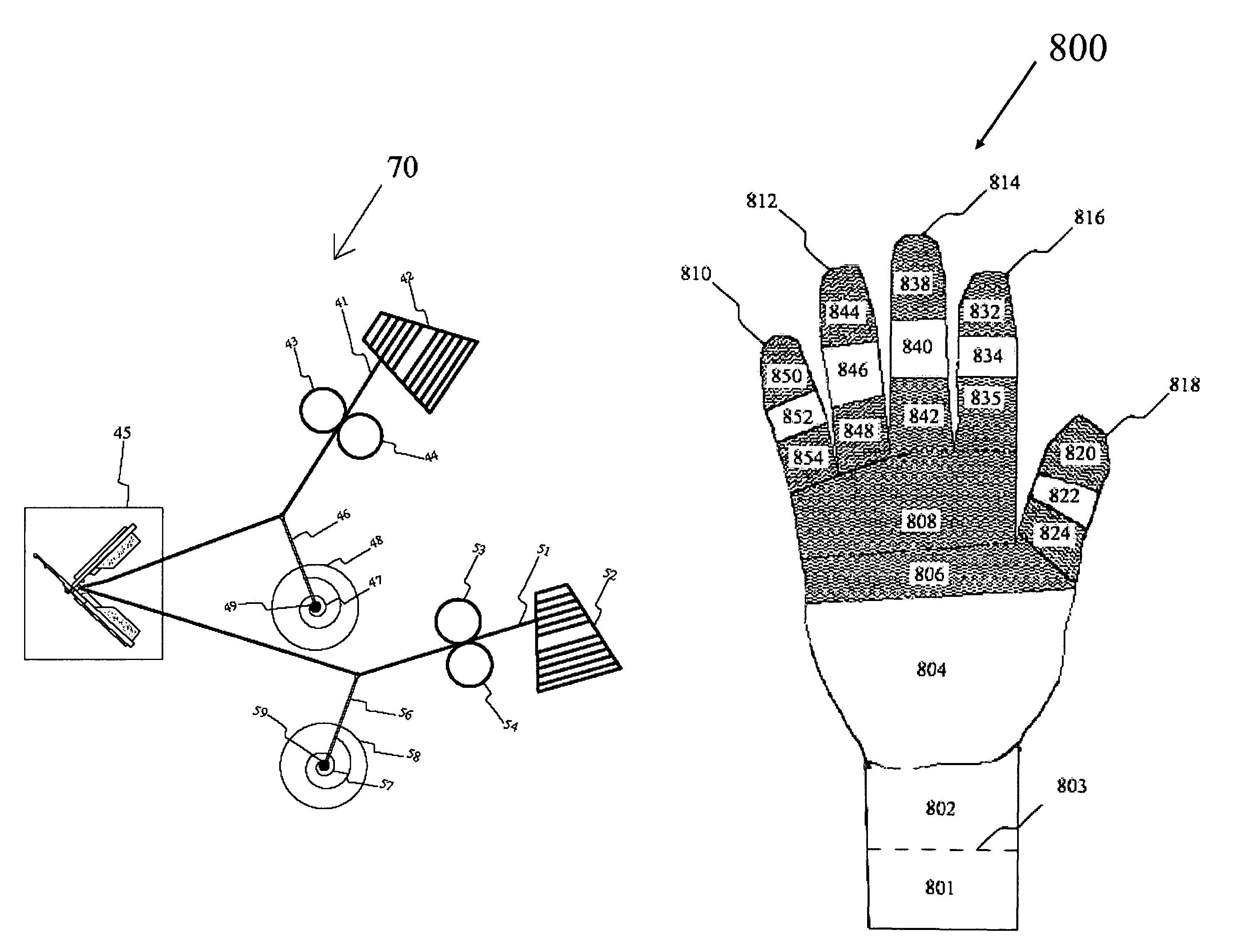

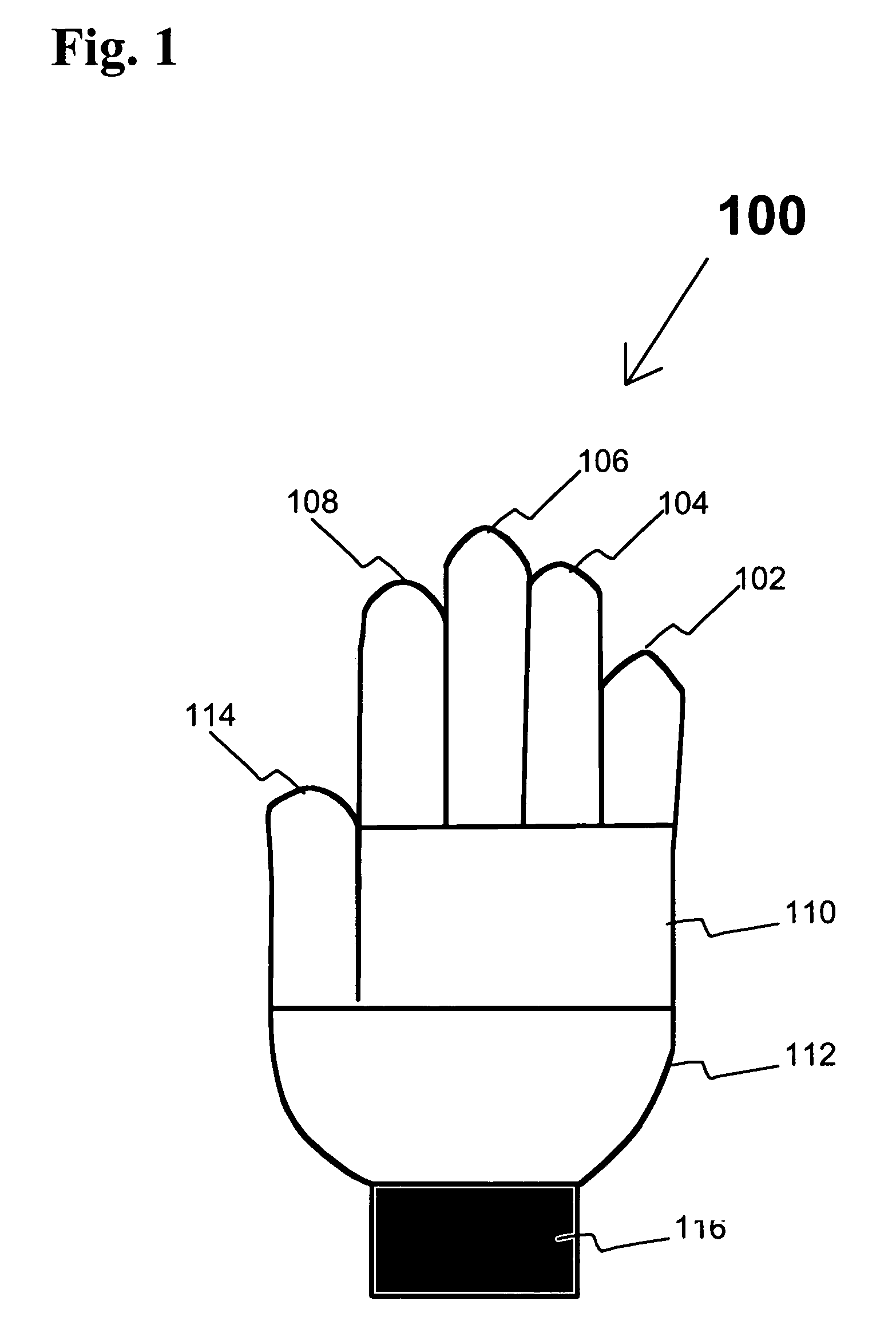

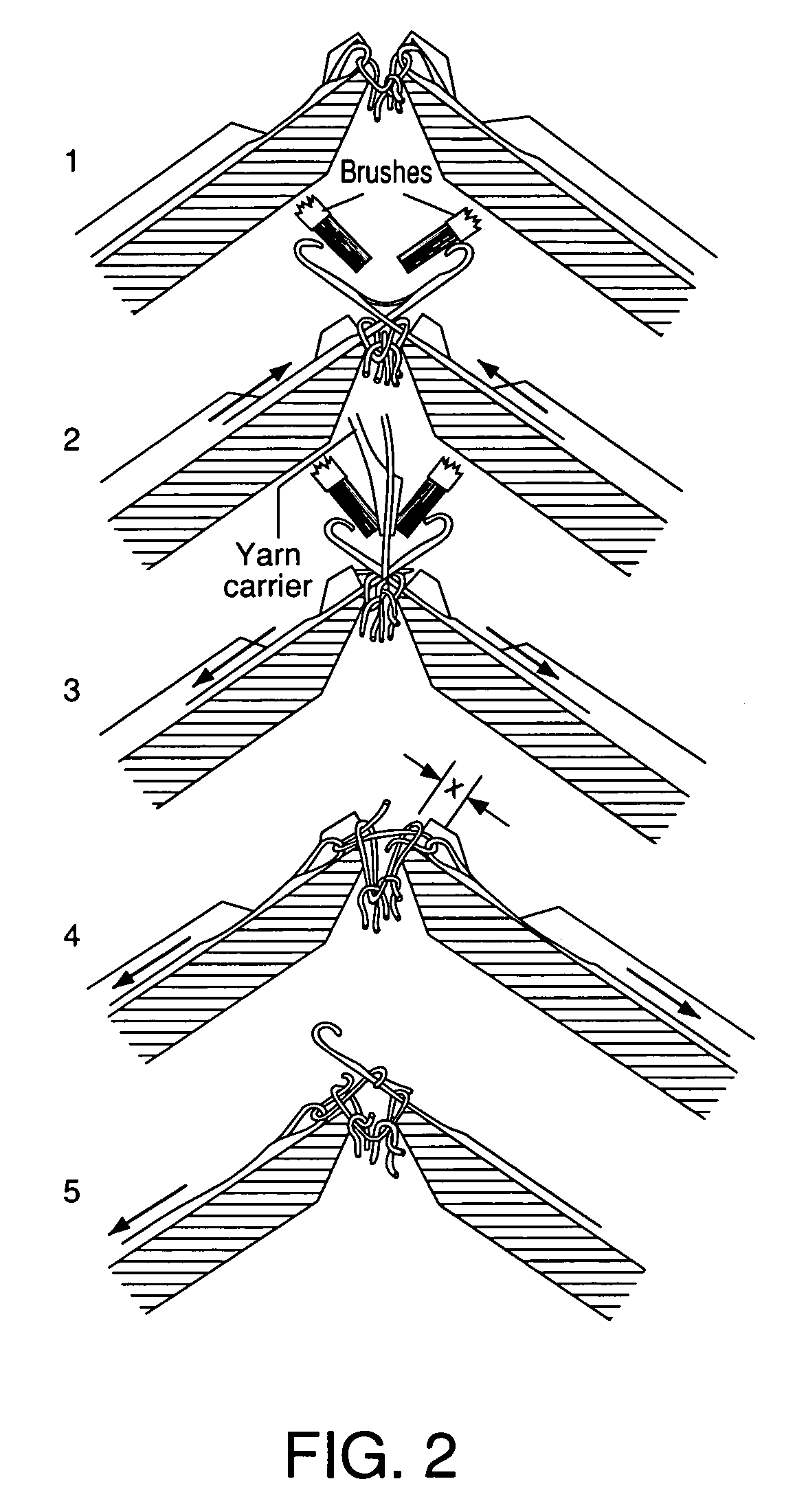

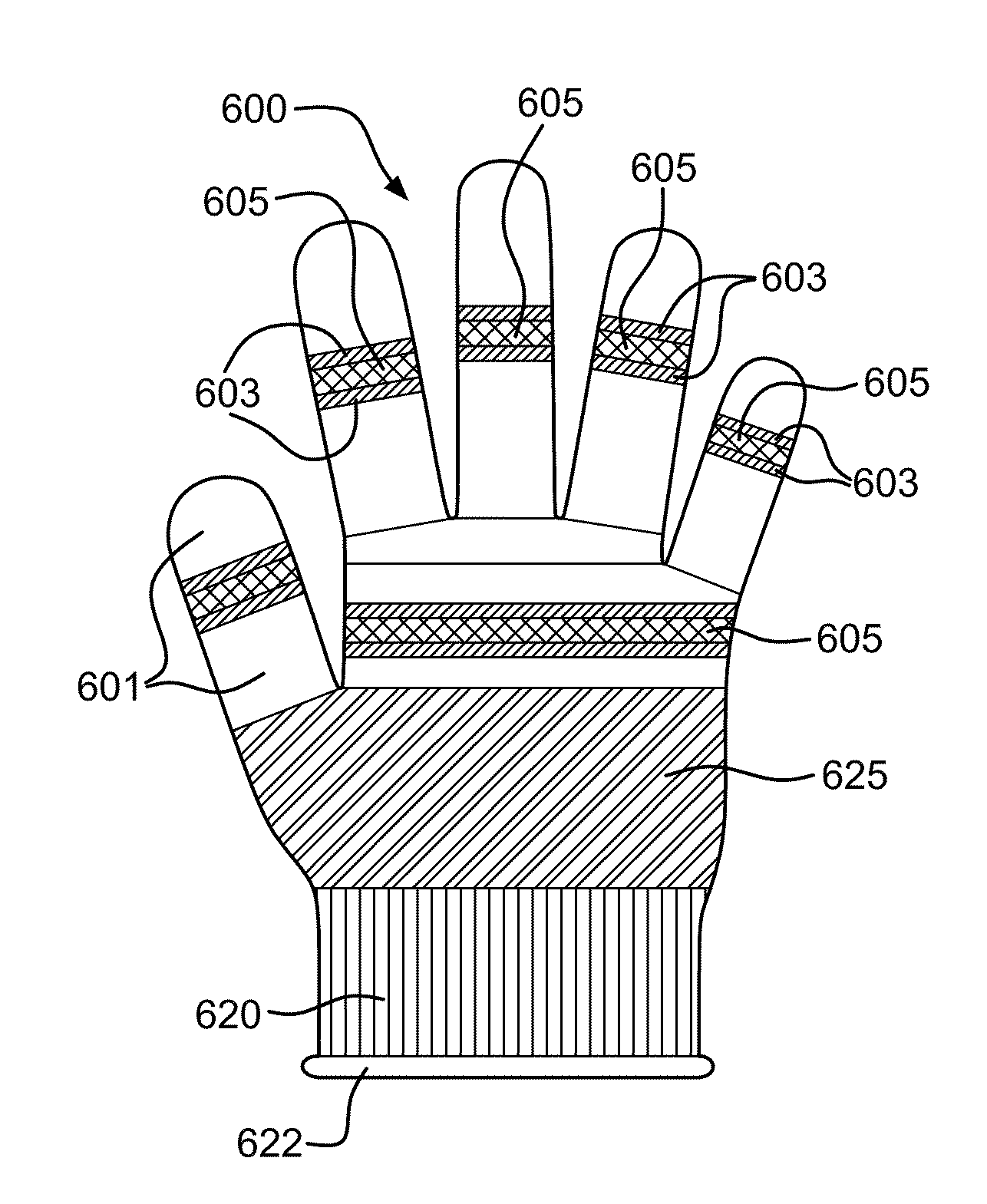

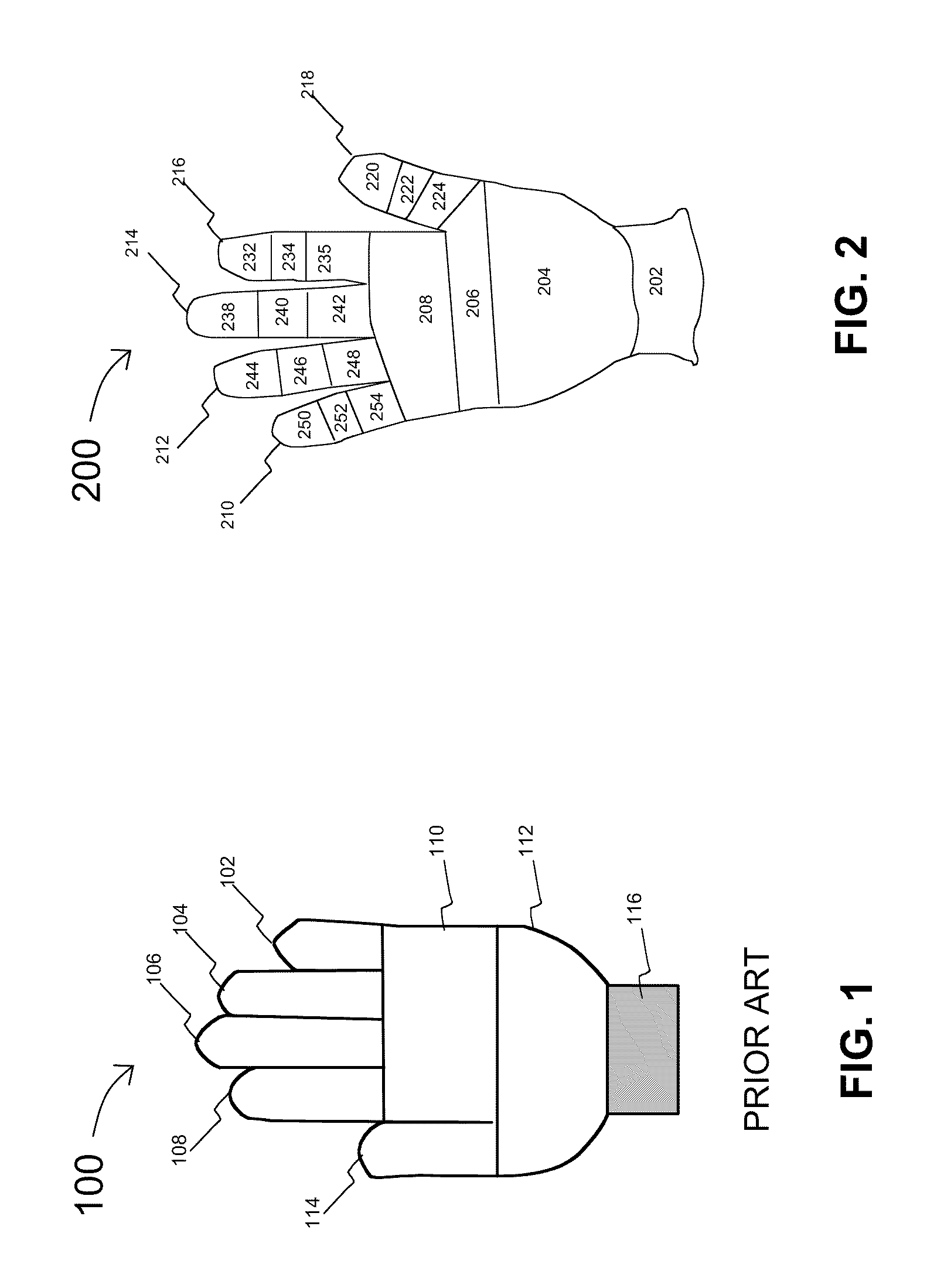

Knitted glove with controlled stitch stretch capability

ActiveUS7213419B2Improve tensile propertiesComfortable glove feelOrnamental textile articlesGlovesYarnDepth of penetration

A knitted glove made by creating each of the sections of the glove using a separate knitting course on a flat knitting machine providing variable stitch dimensions. Each of these sections provides its own designed stretch characteristics so that the glove fits tightly, yet provides flexibility and ease of movement. The variable stitch dimension is achieved by 1) varying the depth of penetration of a knitting needle into a fabric being knitted by a computer program, 2) adjusting the tension of yarn between a pinch roller and a knitting head by a mechanism controlled by a computer, and 3) casting off or picking up additional stitches in a course. The glove includes a plurality of finger components made from at least ten separately knitted sections, two palm components, each of which is made from at least two separately knitted sections, and a wrist component made from at least one knitted section.

Owner:ANSELL HEALTHCARE PRODS

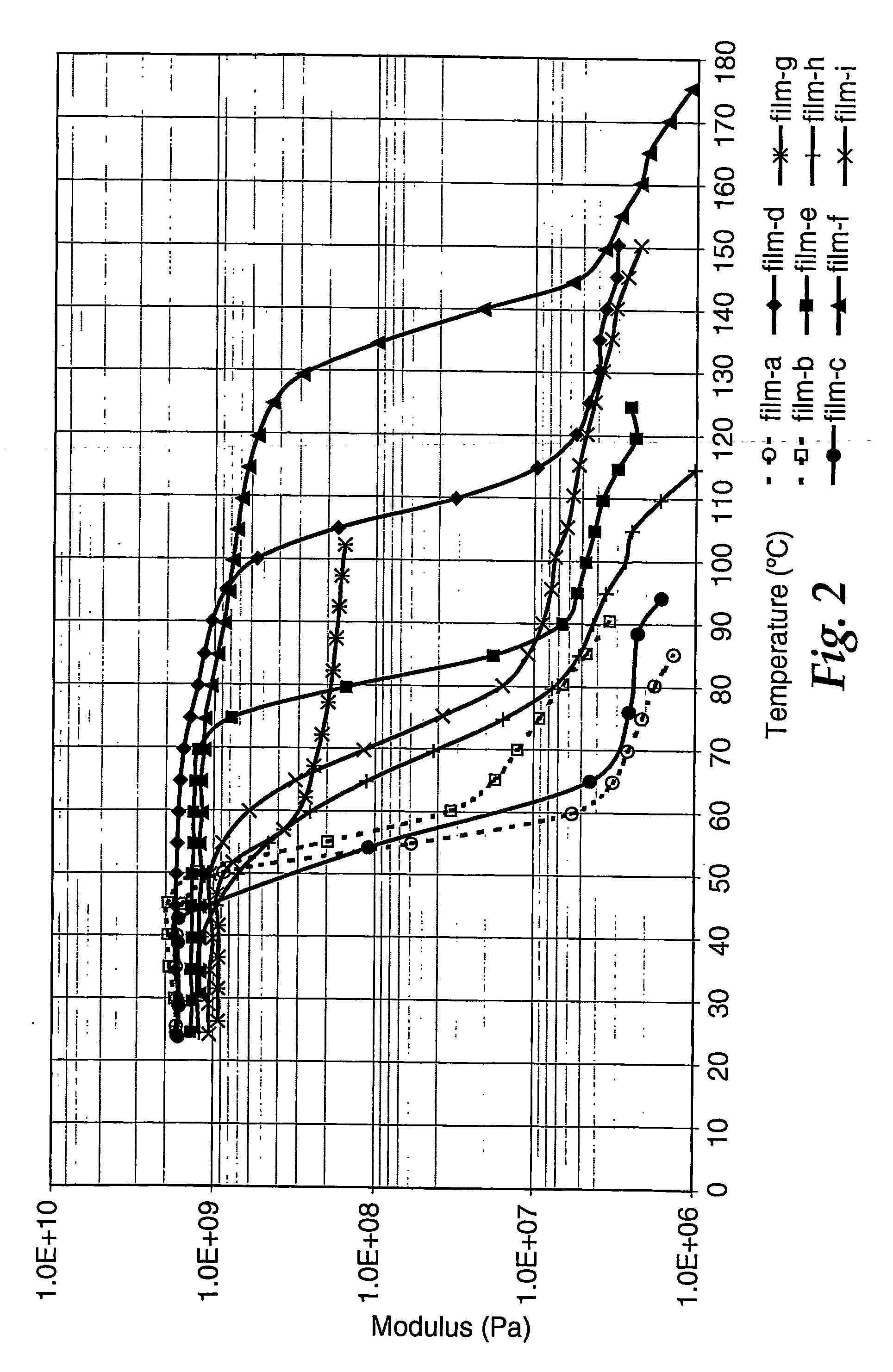

Thermally activatable removable adhesive tapes

InactiveUS20060188706A1Easy to stretchEasy to fixFilm/foil adhesivesAdhesive articlesActivation temperatureChemistry

The present invention provides adhesive tapes that can be firmly bonded to a bonded article at a temperature below an activation temperature and cannot be easily peeled and removed, but can be easily peeled without substantially leaving adhesive residue on the bonded article and without damaging the bonded article at a temperature exceeding the activation temperature.

Owner:3M INNOVATIVE PROPERTIES CO

Regenerated cellulosic fibers and process for producing the same

InactiveUS6183865B1Reduce stretchImprove the immunityMonocomponent cellulose artificial filamentCellulosic plastic layered productsLiquid crystallinePolymer science

It is an object of the present invention to overcome the problem of fibrillation which is a drawback found in solvent-spun regenerated cellulosic fibers and to thereby provide high-quality regenerated cellulosic fibers. The regenerated cellulosic fibers are produced by the use of a spinning dope of cellulose dissolved in a solvent containing N-methylmorpholine N-oxide under the conditions that the average degree of polymerization of cellulose contained in the spinning dope is held to 400 or lower and 5% to 30% by weight of the cellulose is adjusted to a degree of polymerization of 500 or higher. Thus a pseudo-liquid-crystalline phenomenon can be allowed to occur in the stretched filaments during spinning, so that the resulting regenerated cellulosic fibers have improved resistance to fibrillation as well as improved dyeability and feeling.

Owner:TOYOBO CO LTD

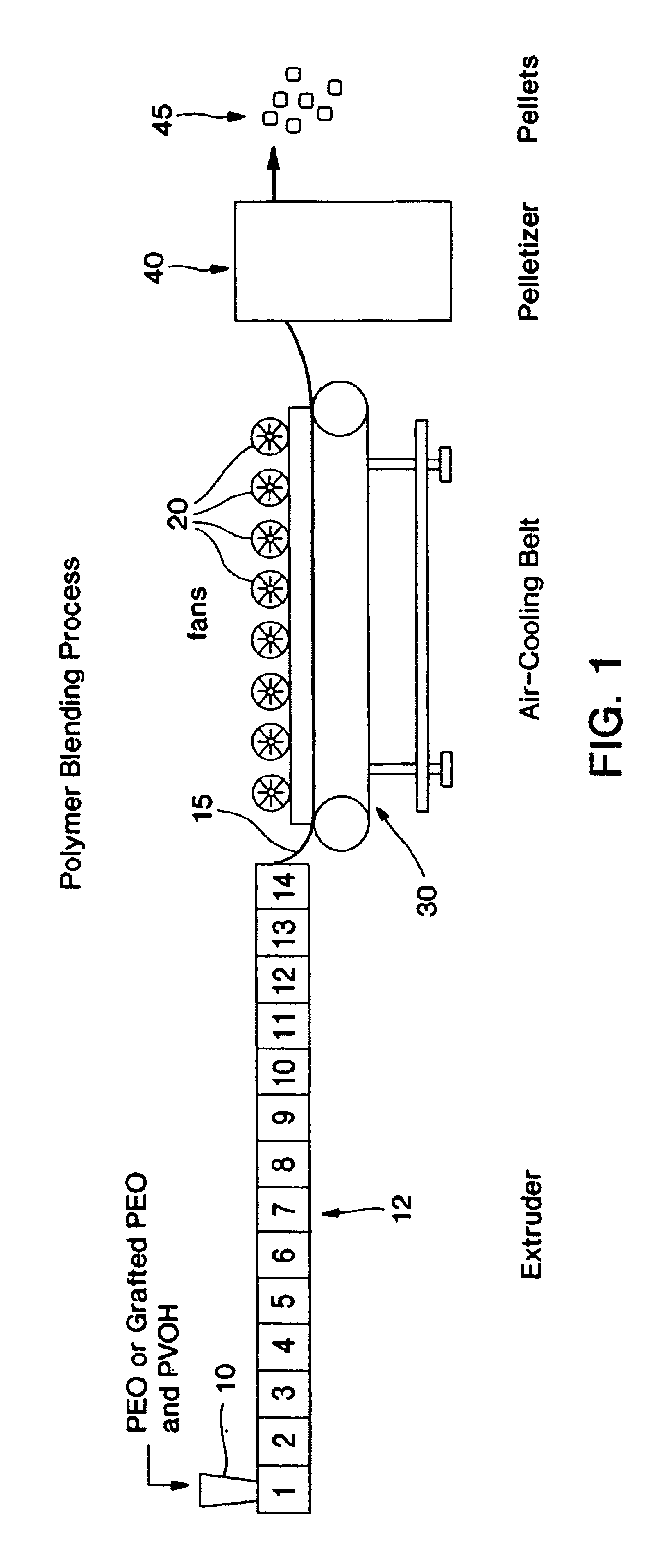

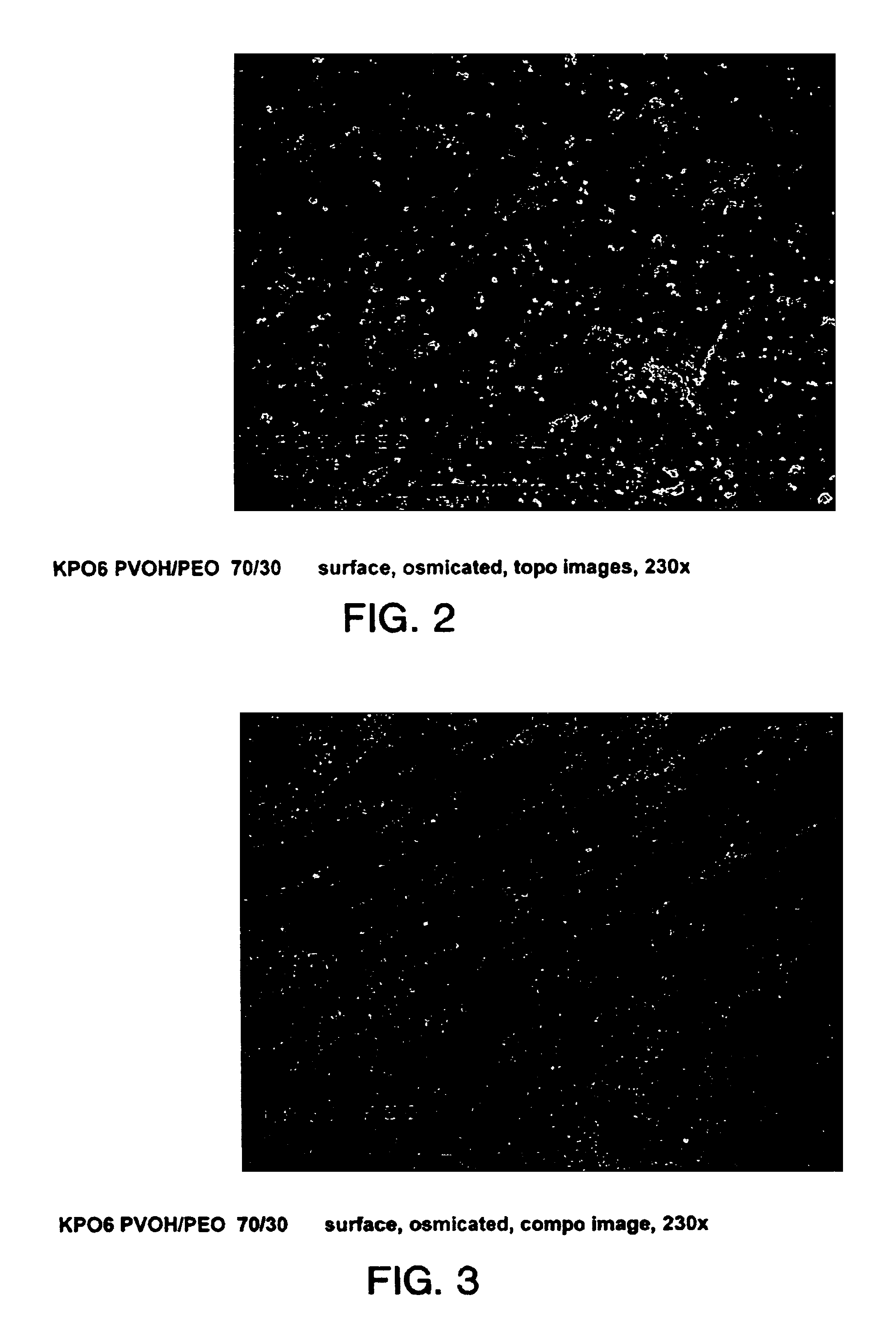

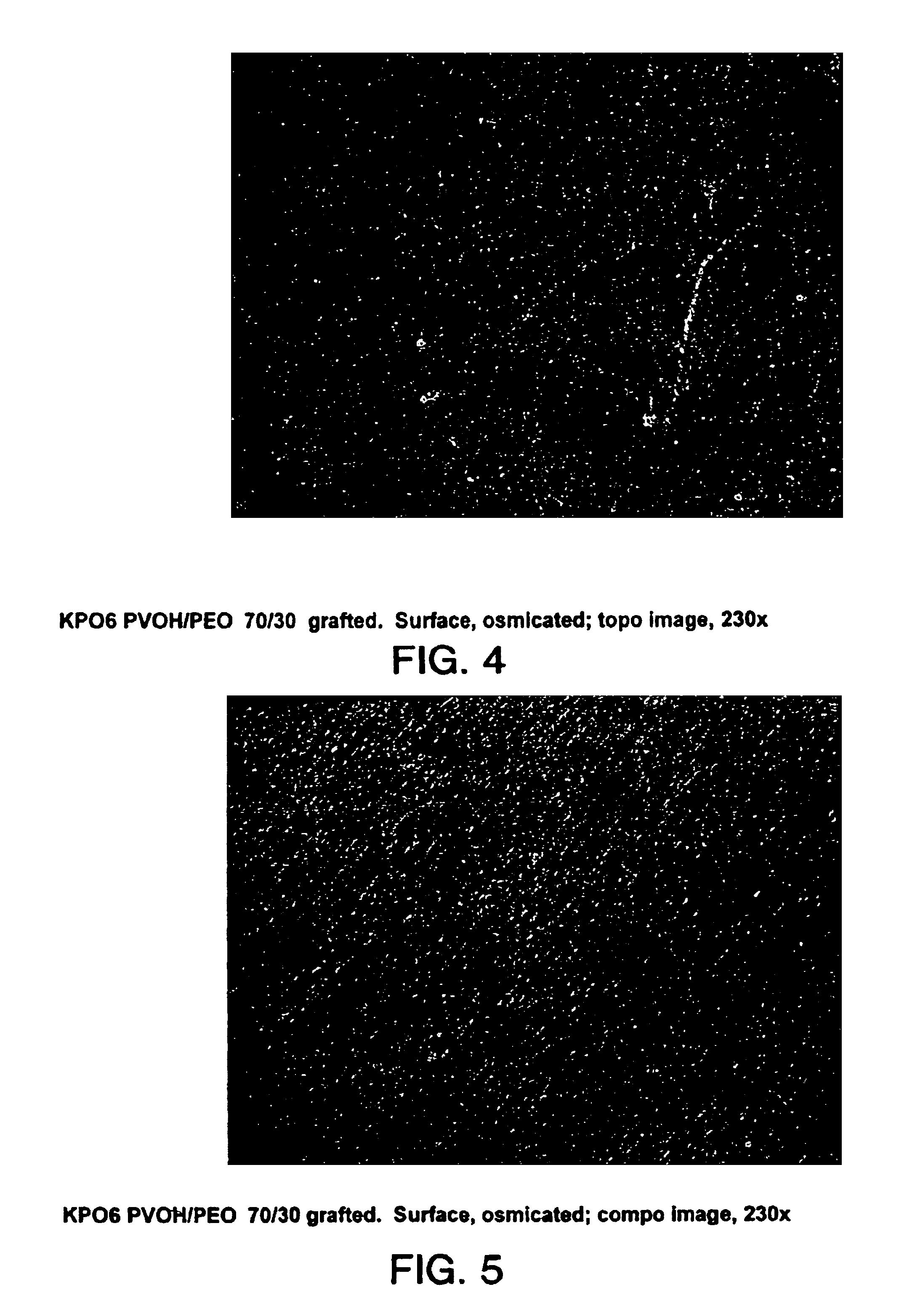

Method of making blends of poly(vinyl alcohol) and poly(ethylene oxide)

The present invention discloses water-soluble compositions comprising a blend of poly(ethylene oxide) and poly(vinyl alcohol) that have improved ductility over water-soluble compositions comprising poly(vinyl alcohol) alone. In one desirable embodiment of the present invention, the poly(ethylene oxide) component of the blend is grafted. Grafted poly(ethylene oxide) resins have improved processability and improved blend compatibility with poly(vinyl alcohol). Films comprising a melt blend of poly(vinyl alcohol) and grafted poly(ethylene oxide) have improved melt processability as well as other improved properties. Films comprising compositions of the present invention have improved ductility over films comprising poly(vinyl alcohol) alone while retaining much of the high strength and water solubility exhibited by such poly(vinyl alcohol) films.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Longitudinally reinforced cured in place liner and reinforced coating

InactiveUS20070113971A1Increased longitudinal reinforcementReduce stretchLayered productsPipe elementsEngineeringUltimate tensile strength

Owner:INA ACQUISITION

Hood with hinged mask piece

Owner:UNDER ARMOUR

Selective multiple yarn reinforcement of a knitted glove with controlled stitch stretch capability

ActiveUS20070022511A1Increasing and decreasing tensionReduce stretchOrnamental textile articlesGlovesYarnEngineering

A knitted glove made by creating each of the at least fifteen sections using a separate knitting course on a flat knitting machine providing variable stitch dimensions with one or two yarns. Each of these sections provides custom stretch characteristics using one or two yarns providing a tight glove that provides flexibility and ease of movement. The variable stitch dimension is achieved by 1) varying the depth of penetration of the knitting needle into fabric being knitted by a computer program, 2) adjusting the tension of yarn between a pinch roll and knitting head by a mechanism controlled by a computer and 3) casting off or picking up additional stitches in a course. The glove includes five finger components made from at least ten separately knitted sections, two palm components each made from at least two separately knitted sections, and a wrist component made from at least one knitted section.

Owner:ANSELL HEALTHCARE PRODS

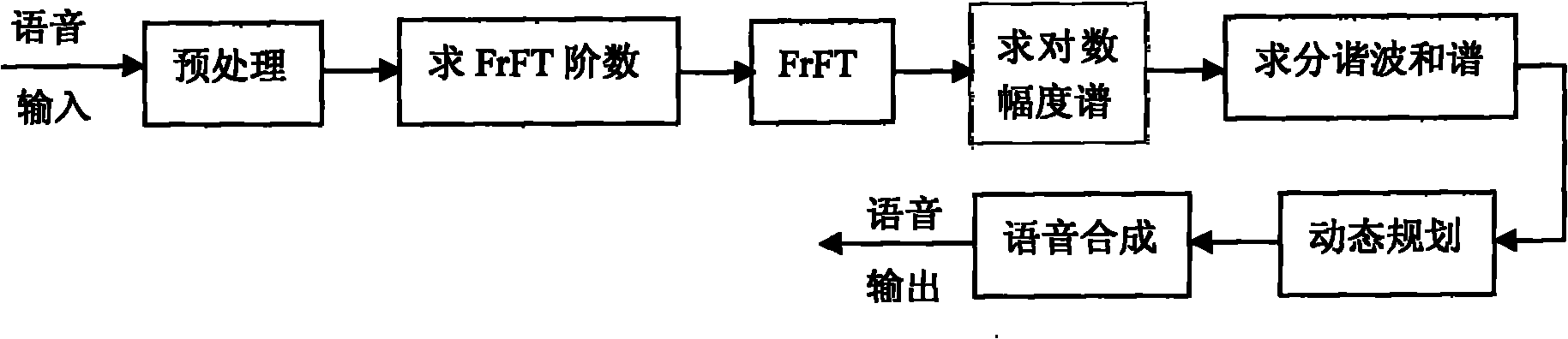

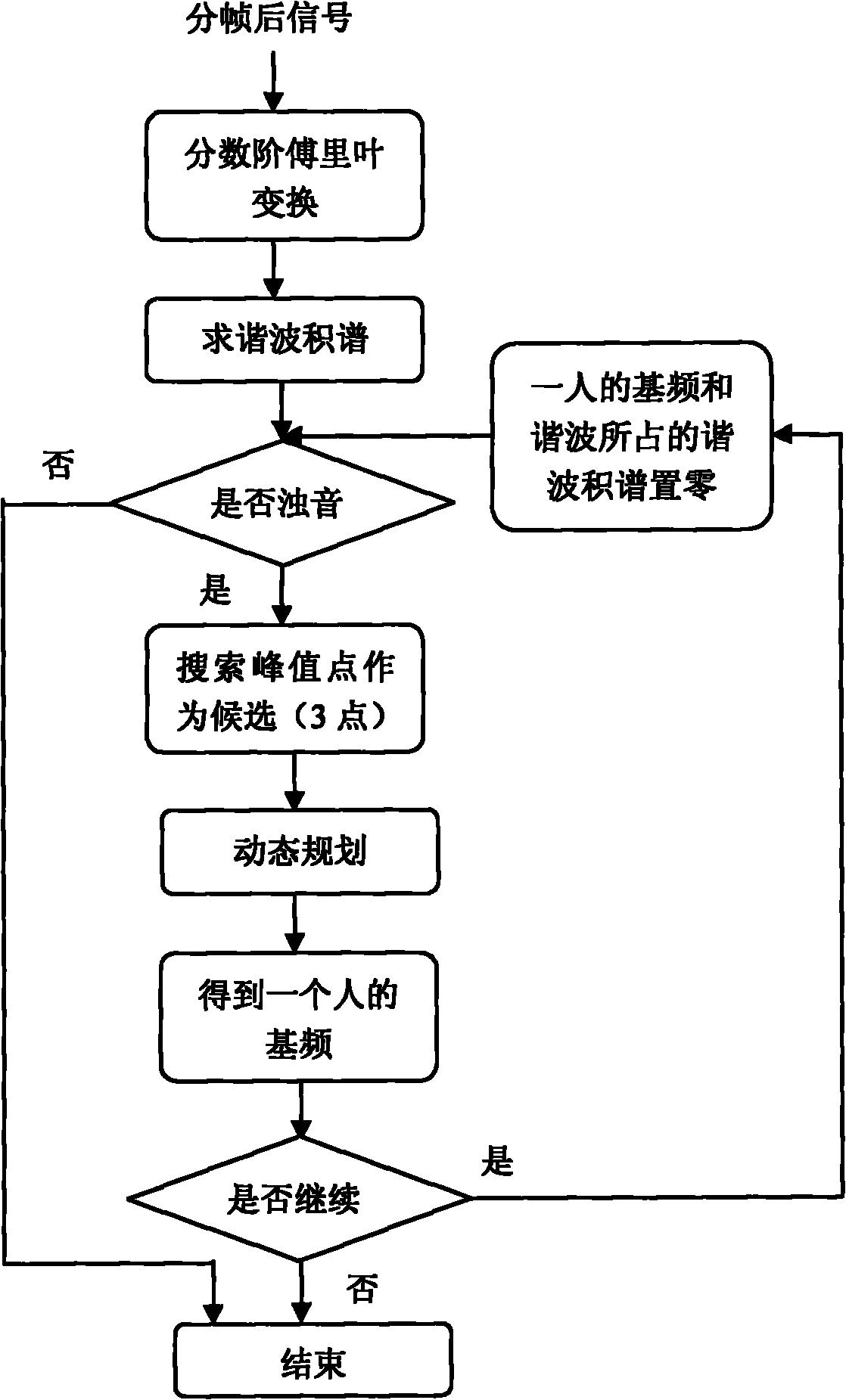

Method for separating monaural overlapping speeches based on fractional Fourier transform (FrFT)

The invention relates to a method for separating monaural overlapping speeches based on fractional Fourier transform (FrFT), which belongs to the technical field of audio signal processing. The method comprises the following steps: firstly, preprocessing overlapping speech signals so as to remove mute-section signals of the overlapping speech signals and find out sonant frames; then, carrying out pitch detection on sonant-frame signals based on FrFT so as to separate the fundamental frequencies of the overlapping speeches; and finally, integrating the fundamental frequencies with a sinusoidal model of speech signals so as to synthesize speeches, thereby obtaining each speech signal subjected to separation. The method provided by the invention has the advantages that the fundamental frequencies of a plurality of overlapping speeches can be separated and extracted effectively, and finally, the effective separation of the overlapping speeches can be realized; and the pitch frequencies are extracted based on FrFT instead of traditional fast Fourier transform (FFT), thereby reducing the extension of a harmonic frequency spectrum and then obtaining more accurate fundamental frequencies of original signals. The method provided by the invention is especially suitable for the separation of monaural overlapping speeches containing speeches of two persons.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Modified polypropylene fiber and preparation method thereof

InactiveCN104499089AReduce stretchDecreased spinnabilityFlame-proof filament manufactureFilament/thread formingHindered amine light stabilizersMelt blowing

The invention relates to a modified polypropylene fiber and a preparation method thereof. The invention is characterized in that the fiber has a skin-core structure, wherein the core layer is composed of pure polypropylene; and the skin layer is composed of 0.5-60 parts of functional material, 0-5 parts of compatilizer and the balance of polypropylene, totaling 100 parts. The viscosity-average molecular weight of the polypropylene is 0.18-0.3 million, and the degree of isotacticity is greater than 95%. The functional material is a functional polypropylene fiber master batch prepared by blending and granulating inorganic or organic functional micropowder, a compatilizer and polypropylene, wherein the functional micropowder is composed of one or more of nano silicon dioxide, nano titanium dioxide, nano silicon dioxide, an anti-mite agent and an N-substituted alkoxy hindered amine flame retardant. The polypropylene fiber can be subjected to skin-core conjugate spinning according to the skin-core formula, and can be further processed into a polypropylene fiber spunbonded nonwoven fabric or melt-blown nonwoven fabric by spunbonding or melt-blowing. The method has the advantages of simple production technique and small modification for equipment, and is easy for practical popularization and application.

Owner:BINZHOU COC CARPET

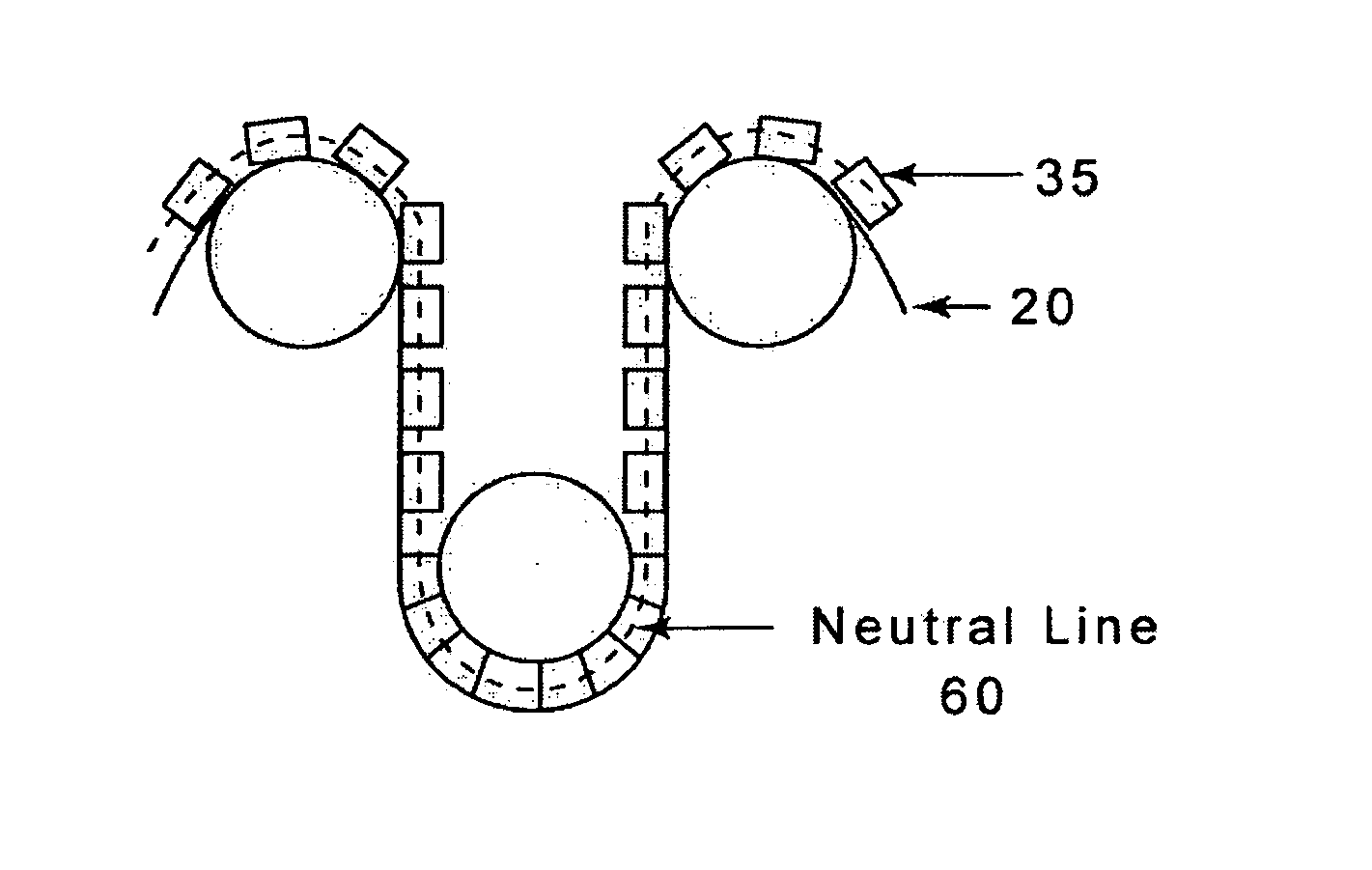

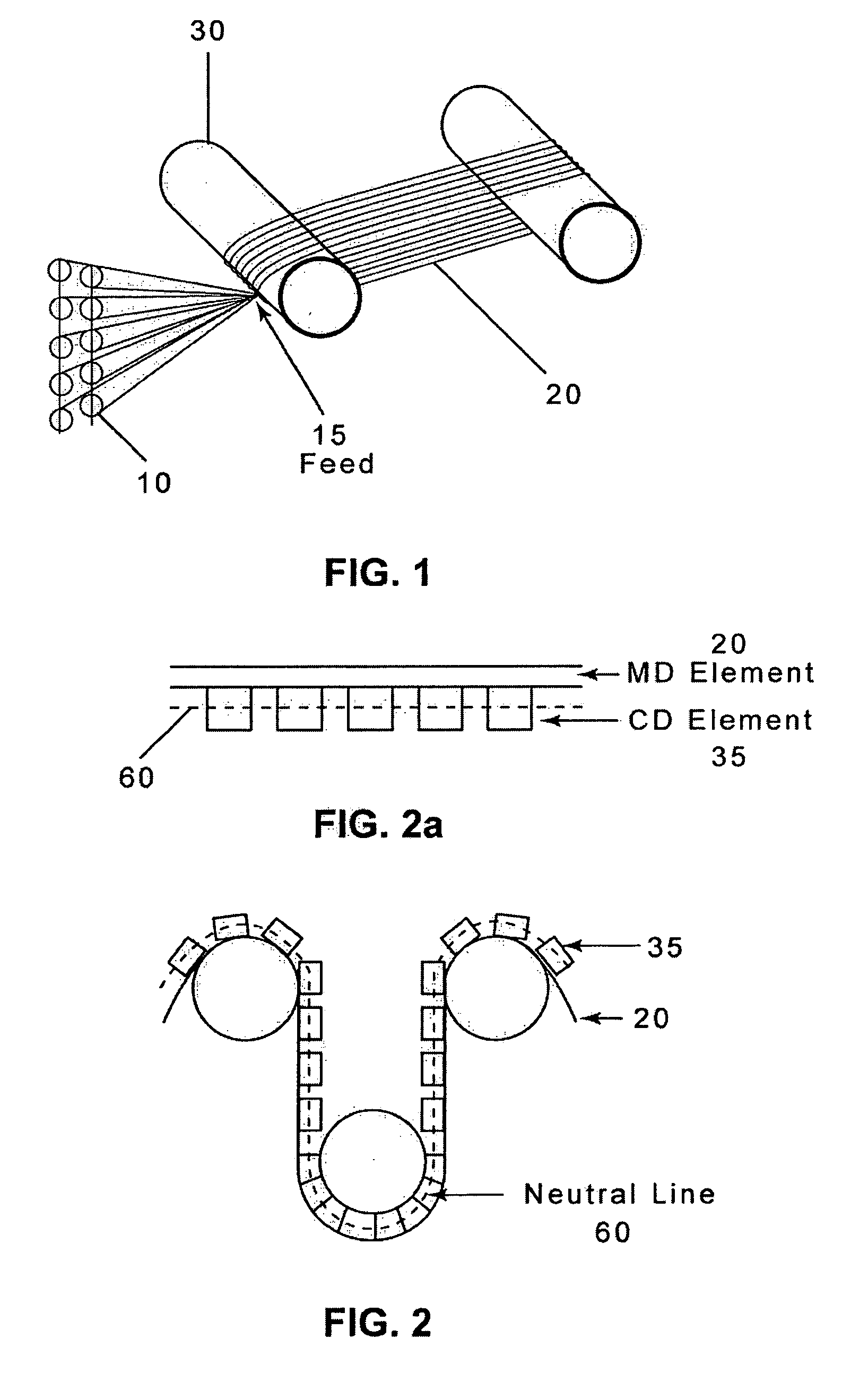

Nonwoven neutral line dryer fabric

InactiveUS6989080B2Reduce stretchNon-fibrous pulp additionNatural cellulose pulp/paperSpiral woundNeutral line

A nonwoven papermaker's fabric, usable in the dryer section of a paper machine, has a spiral wound machine direction (MD) base layer of raw stock which is wound around a pair of parallel rolls or cylinders until the desired length and width is achieved. The spiral wound MD layer is overlaid with a cross-machine direction (CD) layer of similar or dissimilar raw stock and mated by any of a number of means. The spiral wound MD layer can also be mated to another MD layer spiraled in the opposite direction and in one embodiment further mated to a CD layer. The fabric is preferably produced so that its neutral line is oriented toward the paper side of the fabric so that the paper sheet will stretch less than when typical dryer fabrics are used to turn the paper sheet and fabric around the dryer cylinders.

Owner:ALBANY INT CORP

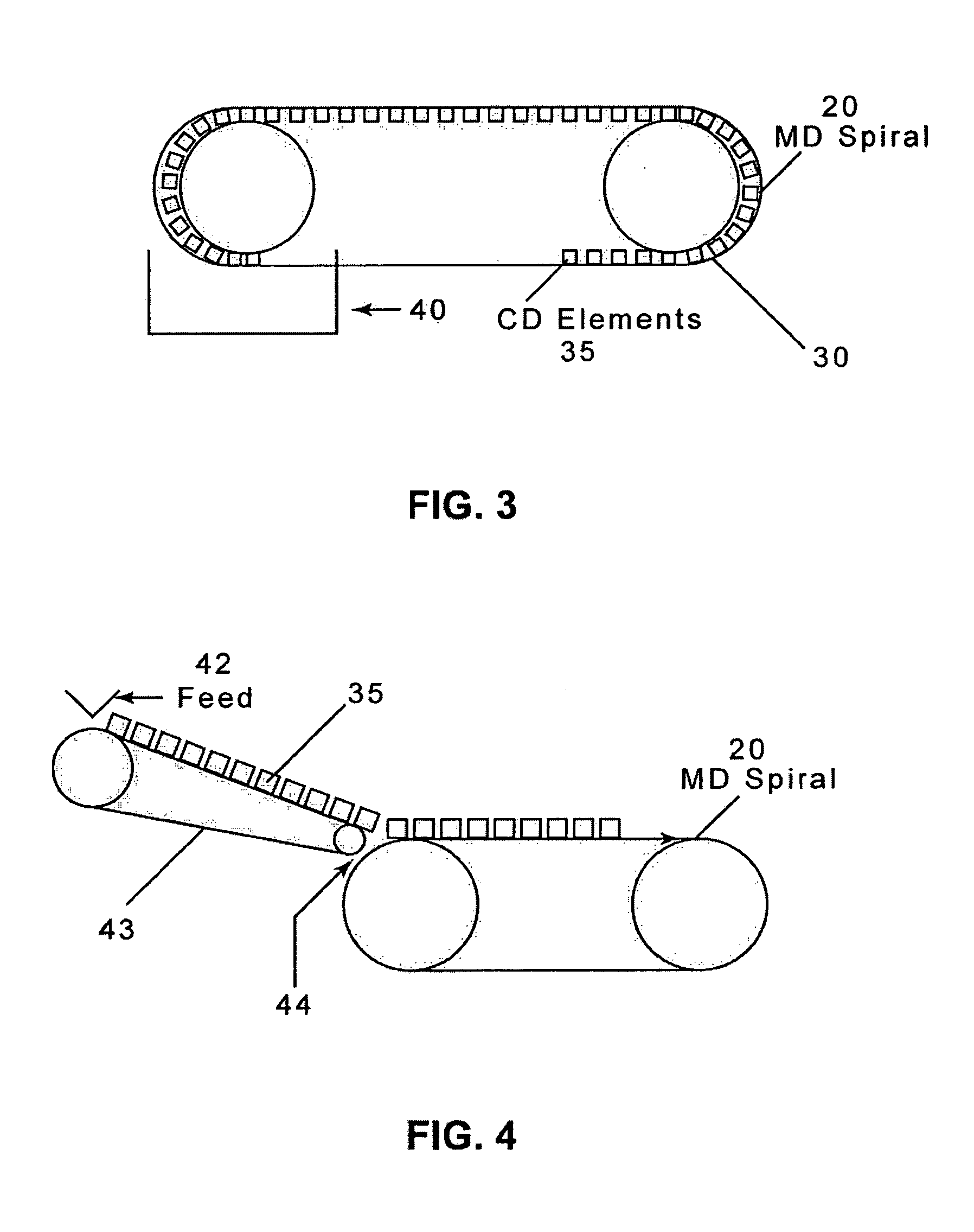

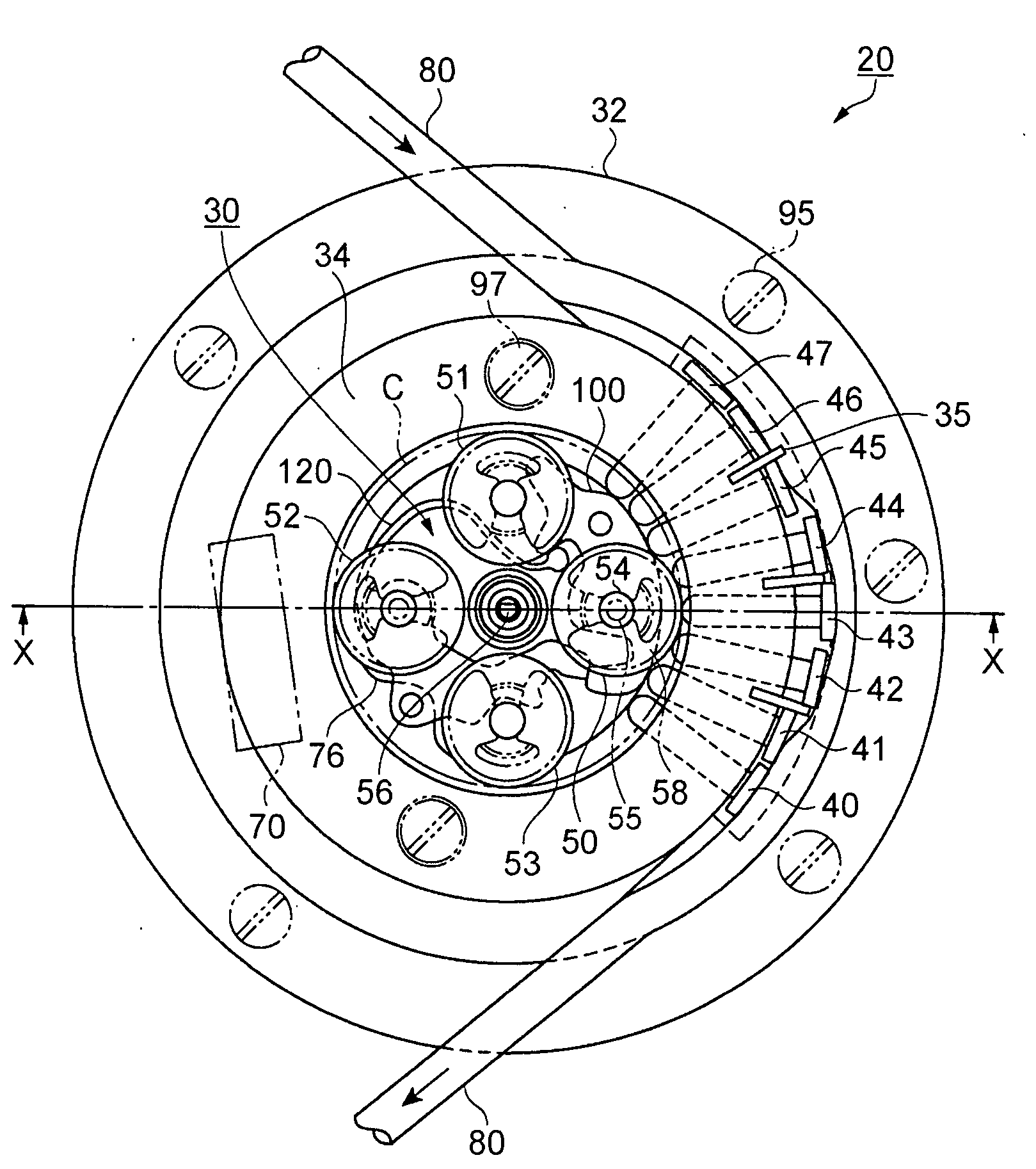

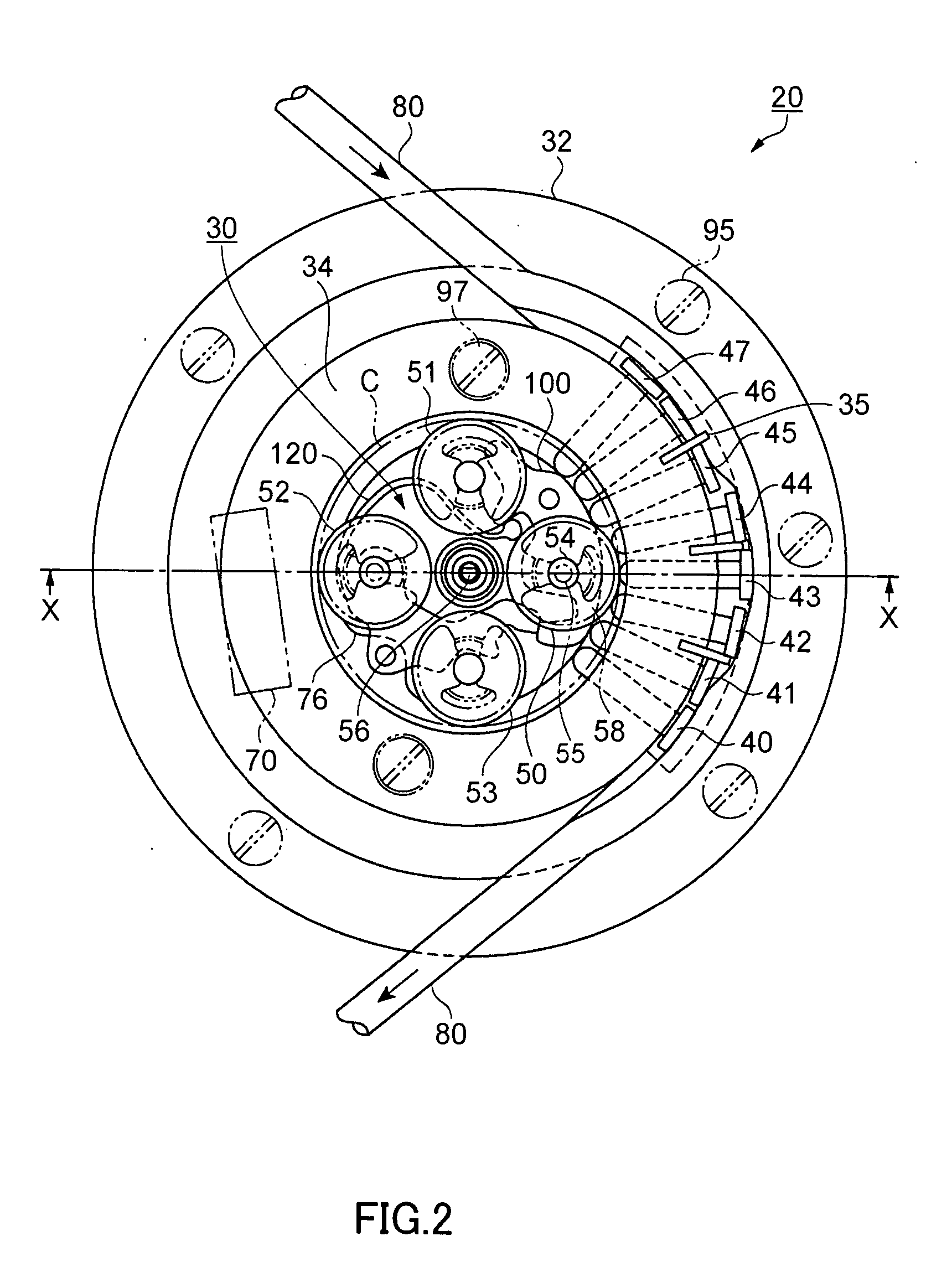

Fluid Transporting Device, and Fluid Transporter

InactiveUS20080138222A1Easy to replaceEasy to handleFlexible member pumpsPositive-displacement liquid enginesFluid transportEngineering

A fluid transporting device comprises a tube frame having a tube guide wall for arranging a tube having an elasticity in an arcuate shape, and a rotary pressure mechanism having a plurality of rollers. The rotary pressure mechanism is arranged, when the tube is arranged in the tube frame, on the side opposite to the guide wall side of the tube, such that its center of rotation is aligned with the center of the arc of the tube guide wall. A plurality of push pins are interposed between the tube and the rotary pressure mechanism and are arranged radially of the center of rotation of the rotary pressure mechanism. A switching mechanism moves at least one of the rollers to a position for the push pins to release the tube and a position for the push pins to press the tube.

Owner:SEIKO EPSON CORP

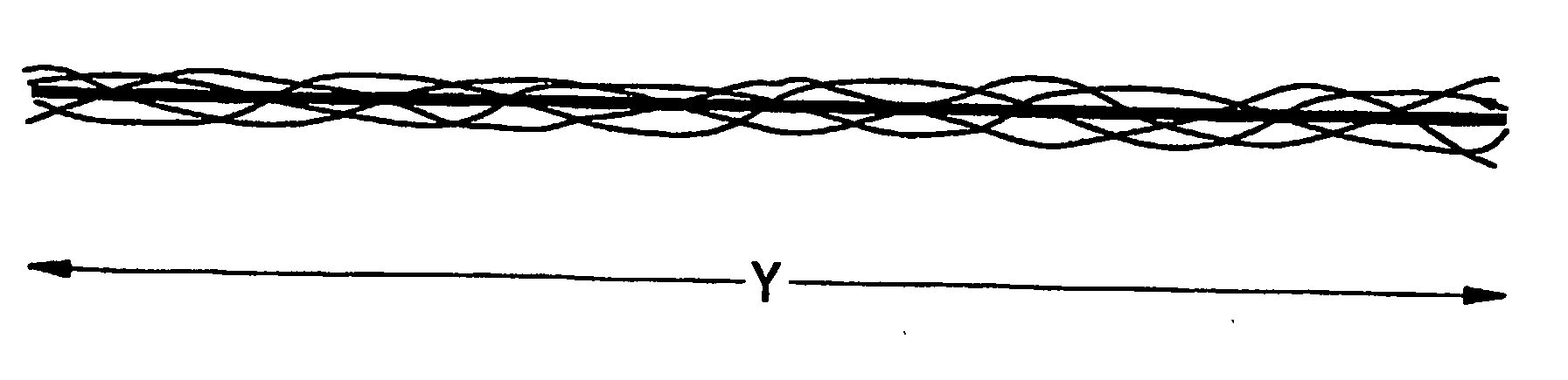

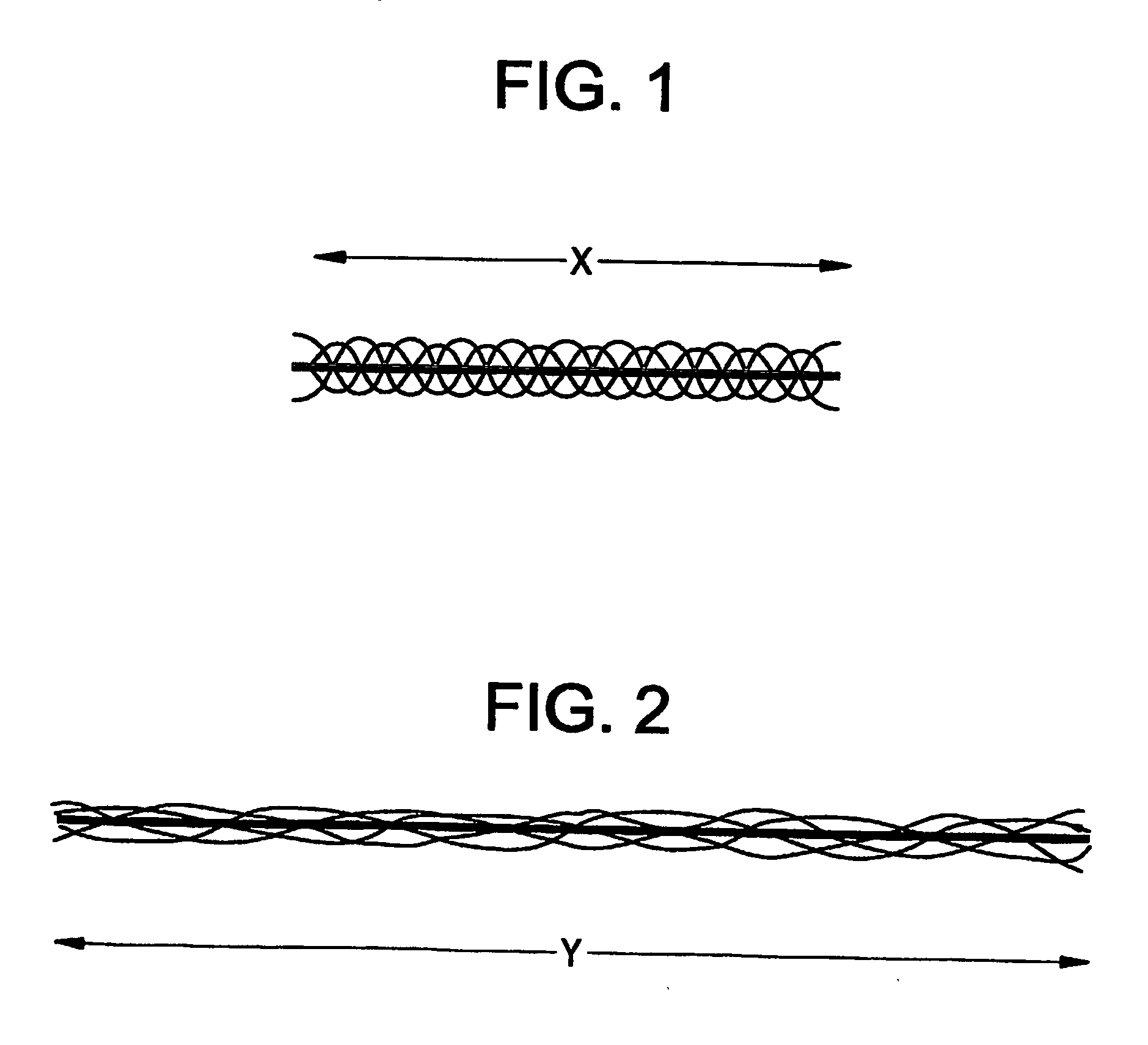

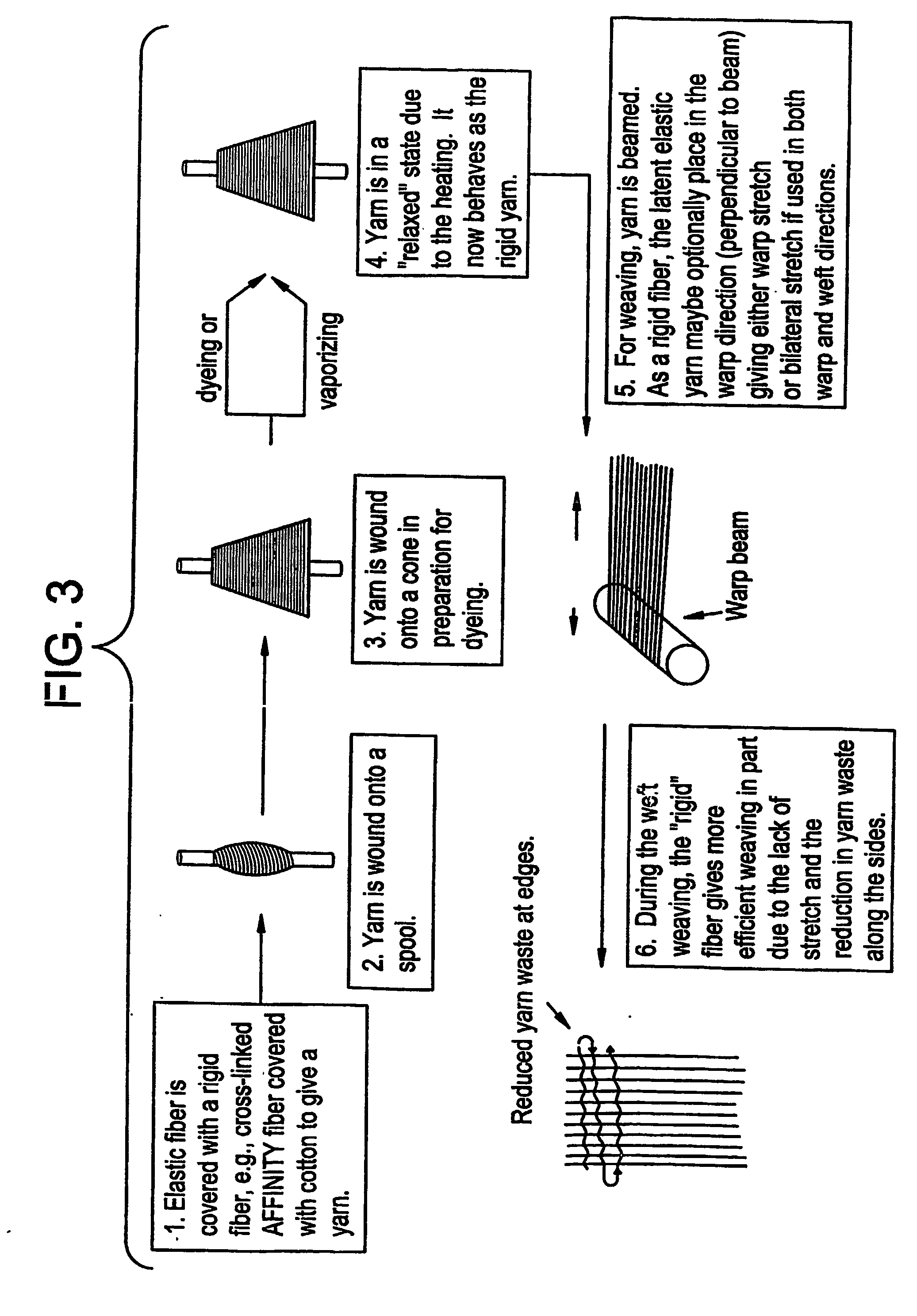

Reversible, heat-set, elastic fibers, and method of making and articles made from same

ActiveUS20050165193A1Reduce stepsReduce the amount requiredShrinkingMonocomponent polyurethanes artificial filamentFiberElastic fiber

A reversible, heat-set covered fiber is described, the covered fiber comprising: A. A core comprising an elastic fiber comprising a substantially crosslinked, temperature-stable, olefin polymer, and B. A cover comprising an inelastic fiber. The fiber is head set by a method comprising: (a) Stretching the covered fiber by applying a stretching force to the covered fiber; (b) Heating the stretched covered fiber of (a) to a temperature in excess of the crystalline melting point of the olefin polymer for a period of time sufficient to at least partially melt the olefin polymer; (c) Cooling the stretched and heated covered fiber of (b) to a temperature below the crystalline melting point of the olefin polymer for a period of time sufficient to solidify the polymer; and (d) Removing the stretching force from the covered fiber.

Owner:DOW GLOBAL TECH LLC

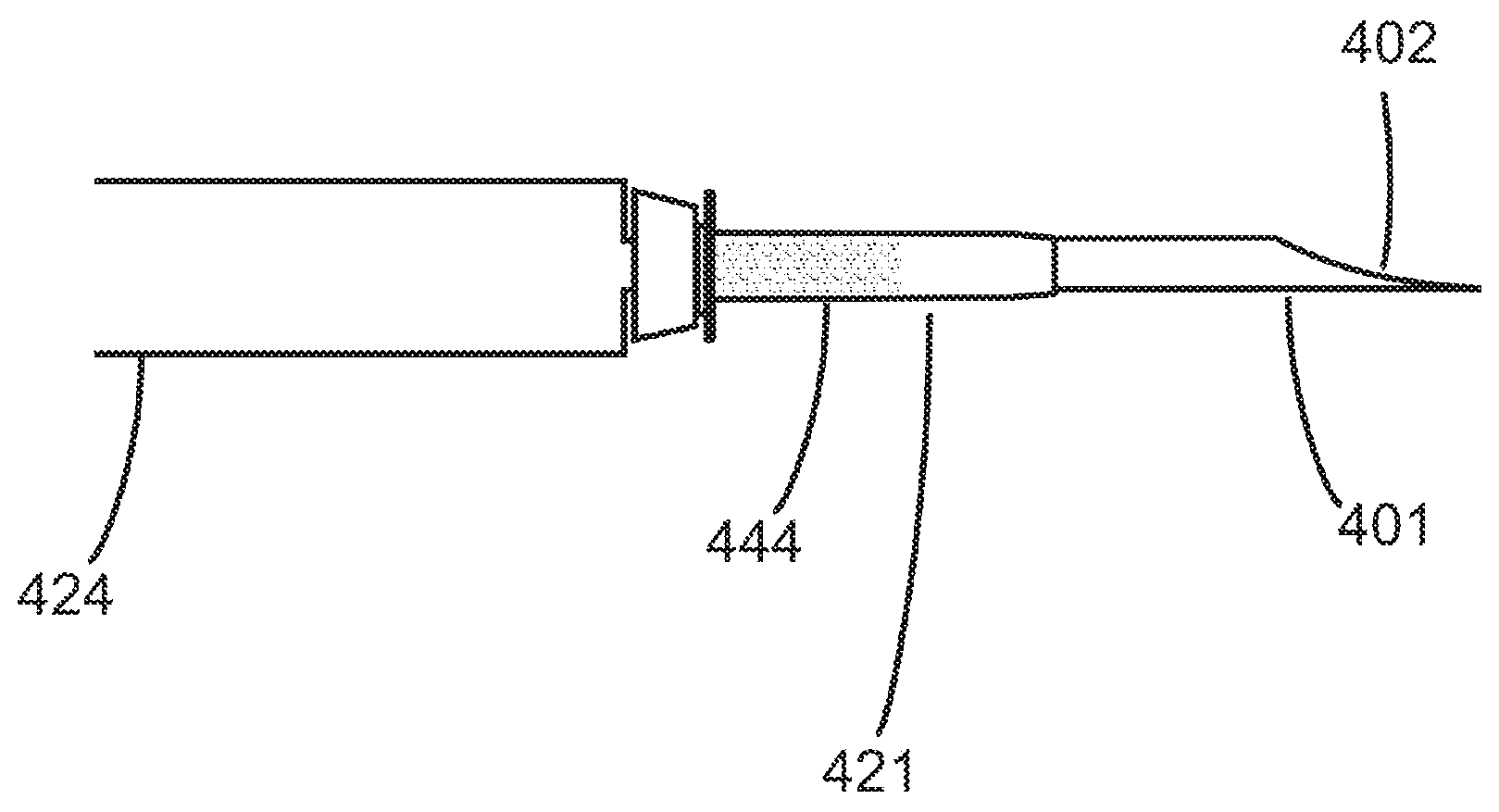

System of instruments for vitrectomy surgery comprising sharp trochar, cannula and canula valve cap and method for its use

ActiveUS20080021399A1Facilitates improved surgical procedureProvide solutionEye surgeryInfusion syringesVitrectomySurgery

A system of instruments is provided for vitrectomy surgery, comprising a sharp trochar, a cannula and a cannula valve cap. The sharp trochar provided also has applicability to other fields of surgery. The sharp trochar has a hollow-ground blade that reduces the force necessary for insertion and upon removal leaves a wound with improved healing characteristics. The trochar is selectably insertable in a cannula, and in a preferred embodiment the cannula and the trochar are adapted with mutually tapered exterior surfaces to as to define a smooth transition in diameter to further facilitate insertion. A sealing valve cap is also provided for the cannula, designed to provide sealing while reducing the force required in for inserting instruments into the cannula. A method for angled insertion of this assembly is also disclosed.

Owner:SPAIDE RICHARD

Knitted glove with controlled stitch stretch capability and enhanced cuff

ActiveUS7555921B2Improve tensile propertiesComfortable glove feelOrnamental textile articlesGlovesYarnDepth of penetration

A knitted glove made by creating each of the at least fifteen sections using a separate knitting course on a flat knitting machine providing varying stitch dimensions with one or two yarns in one or more sections. Custom stretch characteristics can be provided using one or two yarns providing a tight glove that provides flexibility and ease of movement. The varying stitch dimension is achieved by 1) varying the depth of penetration of the knitting needle into fabric being knitted by a computer program, 2) adjusting the tension of yarn between a pinch roll and knitting head by a mechanism controlled by a computer and / or 3) casting off or picking up additional stitches in a course. The glove includes four finger components, a thumb component, two palm components, and a wrist component. A padded cuff section can be added to the wrist component for comfort.

Owner:ANSELL HEALTHCARE PRODS

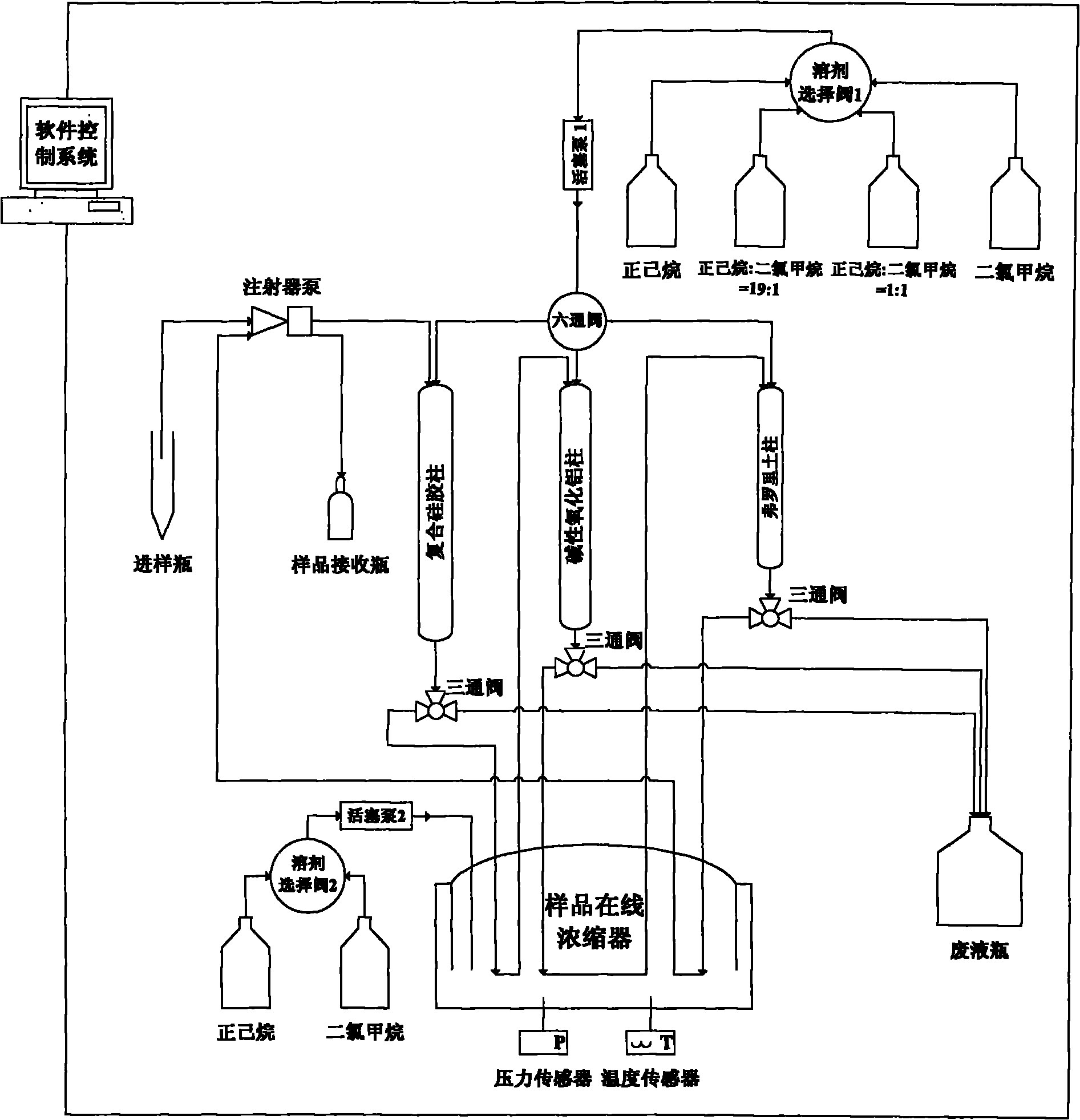

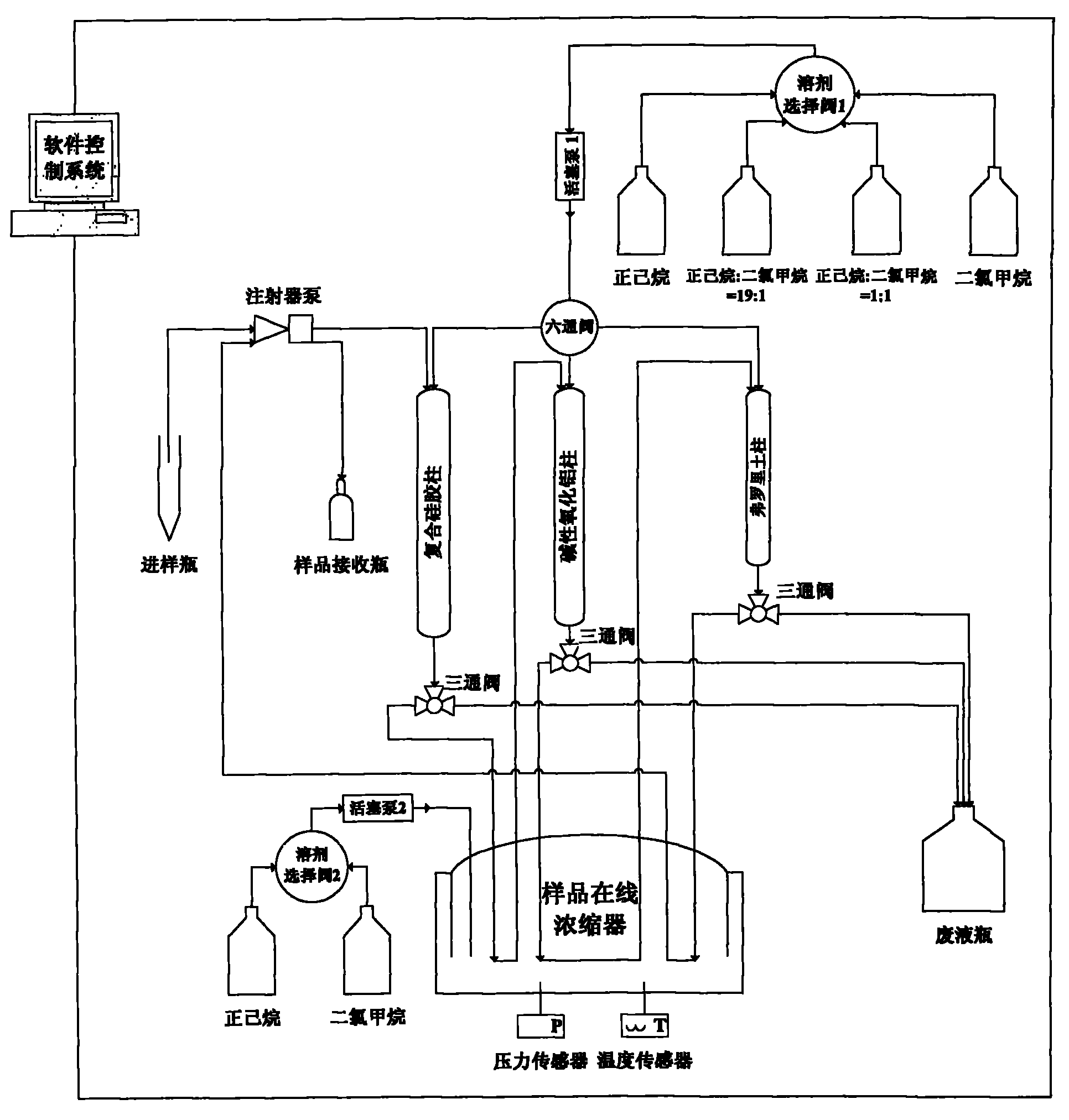

Pretreatment method for purifying extract liquor

InactiveCN102109505AReduce workloadEfficient separationIon-exchange process apparatusComponent separationDiphenyl etherPretreatment method

The invention relates to a pretreatment method for purifying dioxin, polychlorinated biphenyl and polybrominated diphenyl ether in extract liquor. Purifying columns which respectively comprise a compound silicagel column, an alkaline aluminium oxide column and a Florisil column are arranged on an extraction module of a full-automatic solid-phase extractor, wherein fillers in each compound silicagel column comprise the following materials from bottom to top in sequence: silica gel, alkaline silica gel, silica gel, acidic silica gel and anhydrous sodium sulfate, and an eluent is normal hexane; fillers in the alkaline aluminium oxide column comprise the following materials from bottom to top in sequence: alkaline aluminium oxide and anhydrous sodium sulfate, and an eluent is mixed liquor of normal hexane and dichloromethane; fillers in the Florisil column comprise the following materials from bottom to top in sequence: Florisil and anhydrous sodium sulfate, the eluent is divided into two types according to the sequence of the steps, the eluent in the first step is the mixed liquor of normal hexane and dichloromethane, and the eluent in the second step is dichloromethane; and among all purifying columns, the eluents are transferred to an online concentrator for evaporation and concentration, and then are transferred to the next purifying column for purifying and treating.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Knitted glove

ActiveUS7908891B2Improve tensile propertiesComfortable glove feelGlovesCircular knitting machinesYarnEngineering

A knitted glove made by creating each of the sections of the glove using a separate knitting course on a flat knitting machine providing variable stitch dimensions. Each of these sections provides its own designed stretch characteristics so that the glove fits tightly, yet provides flexibility and ease of movement. The variable stitch dimension is achieved by 1) varying the depth of penetration of a knitting needle into a fabric being knitted by a computer program, 2) adjusting the tension of yarn between a pinch roller and a knitting head by a mechanism controlled by a computer, and 3) casting off or picking up additional stitches in a course. The glove includes a plurality of finger components made from at least ten separately knitted sections, two palm components, each of which is made from at least two separately knitted sections, and a wrist component made from at least one knitted section.

Owner:ANSELL HEALTHCARE PRODS

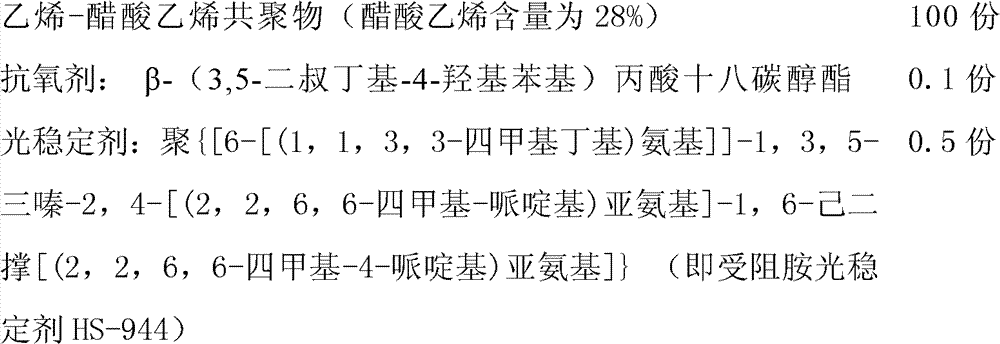

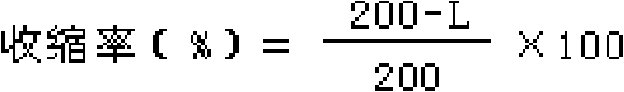

EVA film for packaging solar photovoltaic module and preparation method thereof

ActiveCN103087643ALow heat shrinkageReduce frictionNon-macromolecular adhesive additivesFilm/foil adhesivesUltraviolet lightsSmall footprint

The invention discloses an EVA film for packaging a solar photovoltaic module and a preparation method thereof. The preparation method comprises the following steps of adding an anti-oxidant, a light stabilizer, an ultraviolet light absorber, a coupling agent, a crosslinking agent and a lubricant into an ethylene-vinyl acetate copolymer, uniformly mixing to obtain a mixture, putting the mixture into an extruder, heating and mixing the mixture in the extruder to obtain melt, extruding the melt by a mold, and carrying out molding treatment to obtain the EVA film. The EVA film has the advantages of small internal stress, low shrinking percentage, fast production line speed, high production efficiency, small land occupation area, and low energy and raw material consumption.

Owner:TIANJIN CAIDA NEW MATERIALS TECH CO LTD

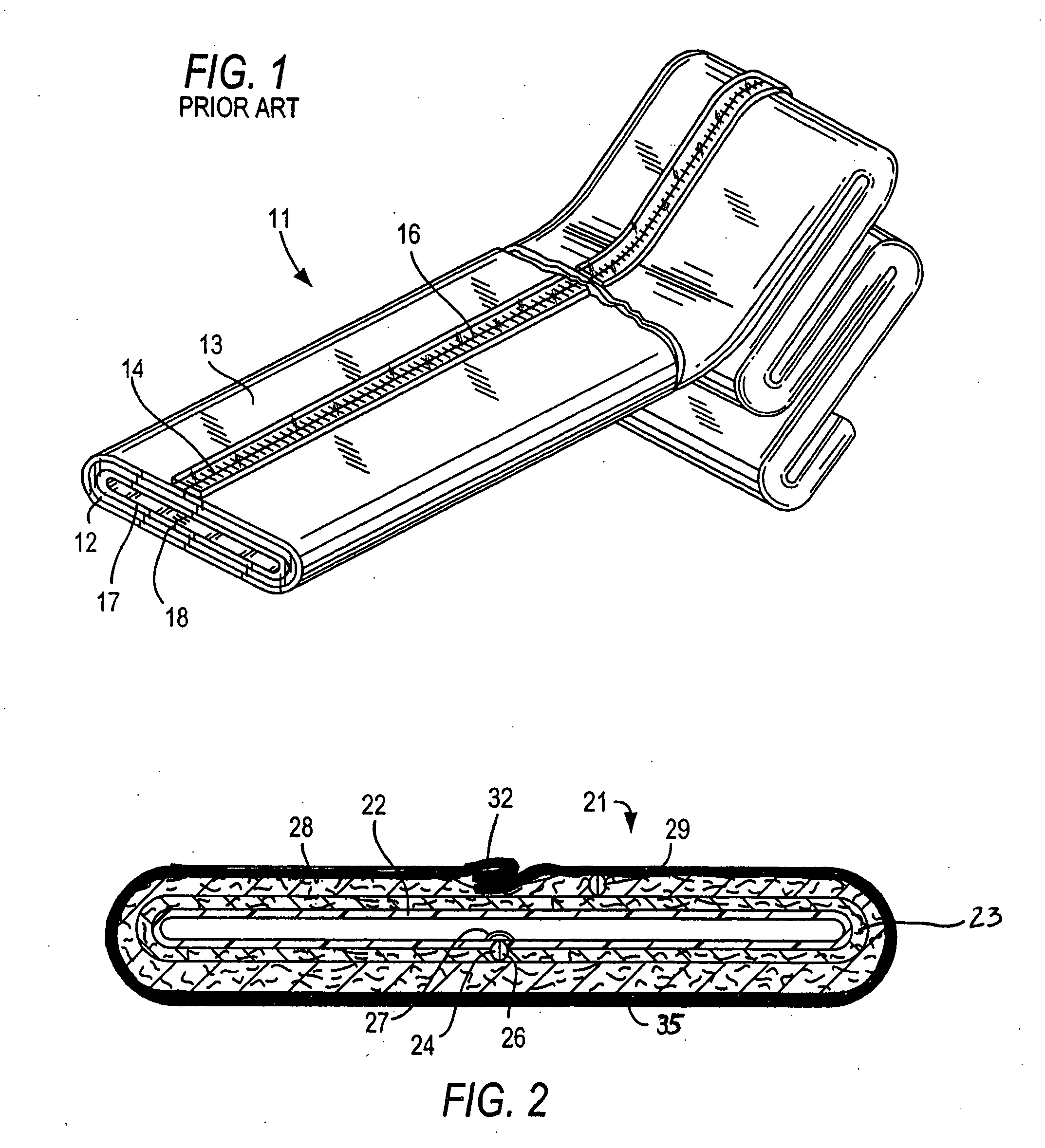

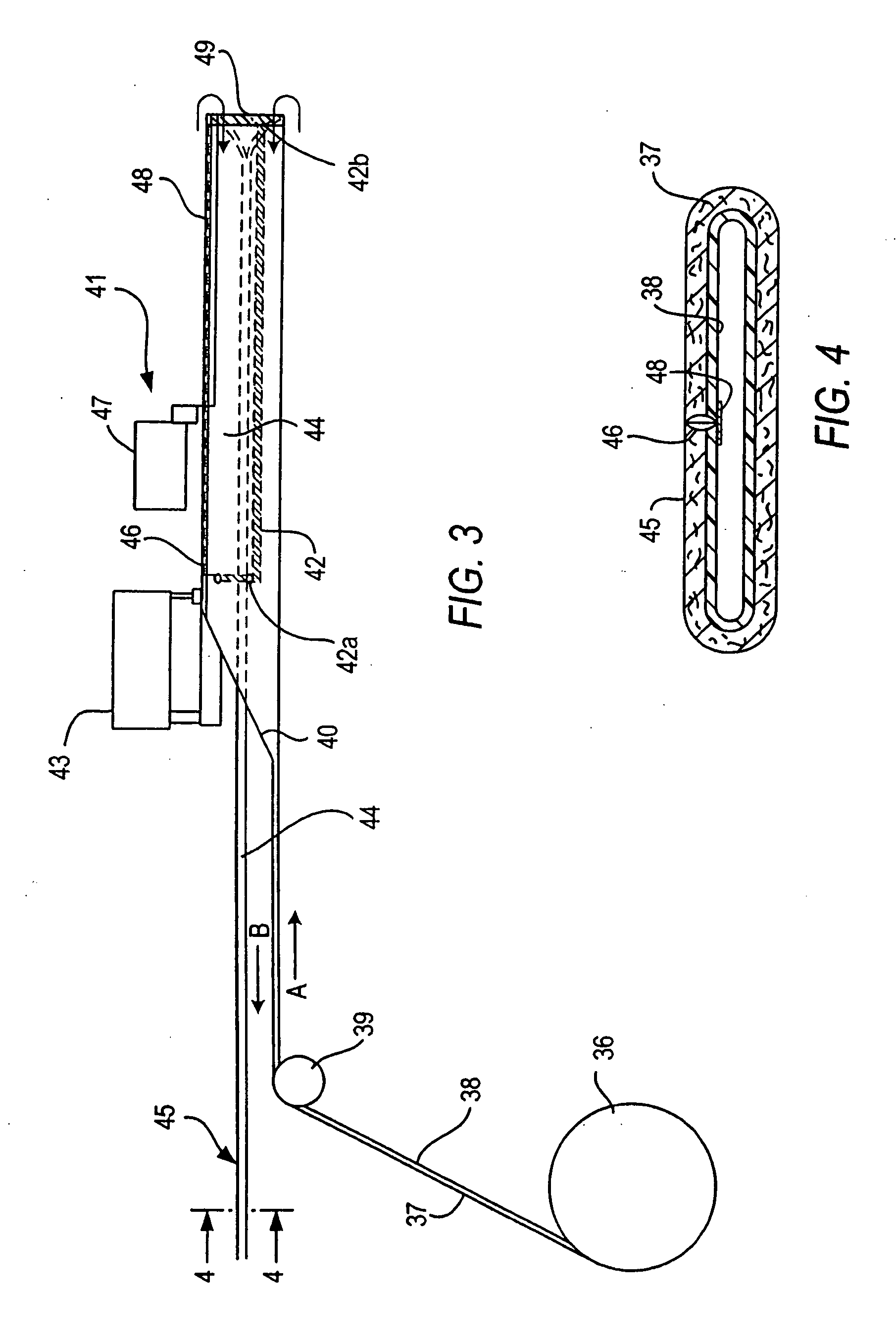

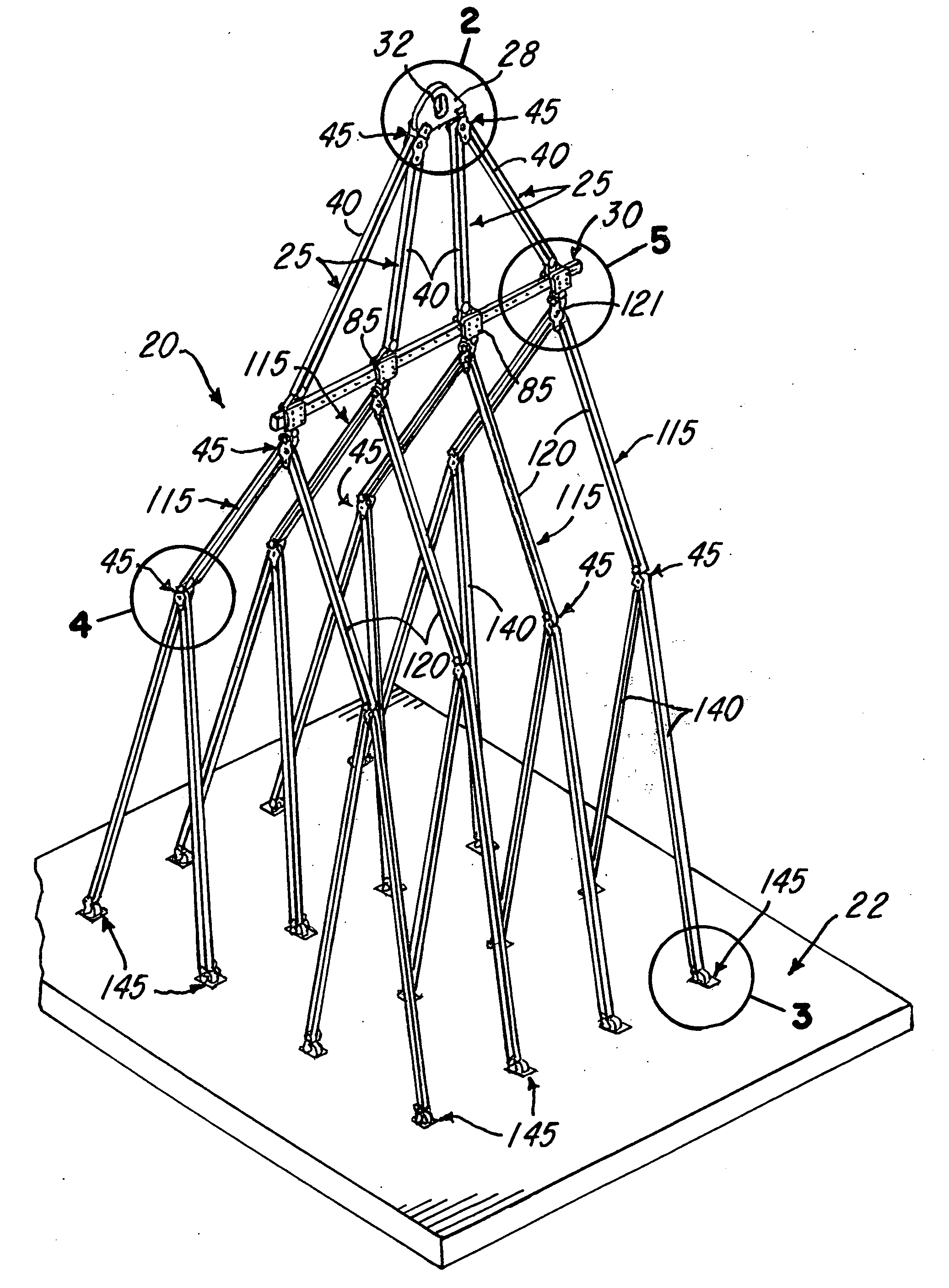

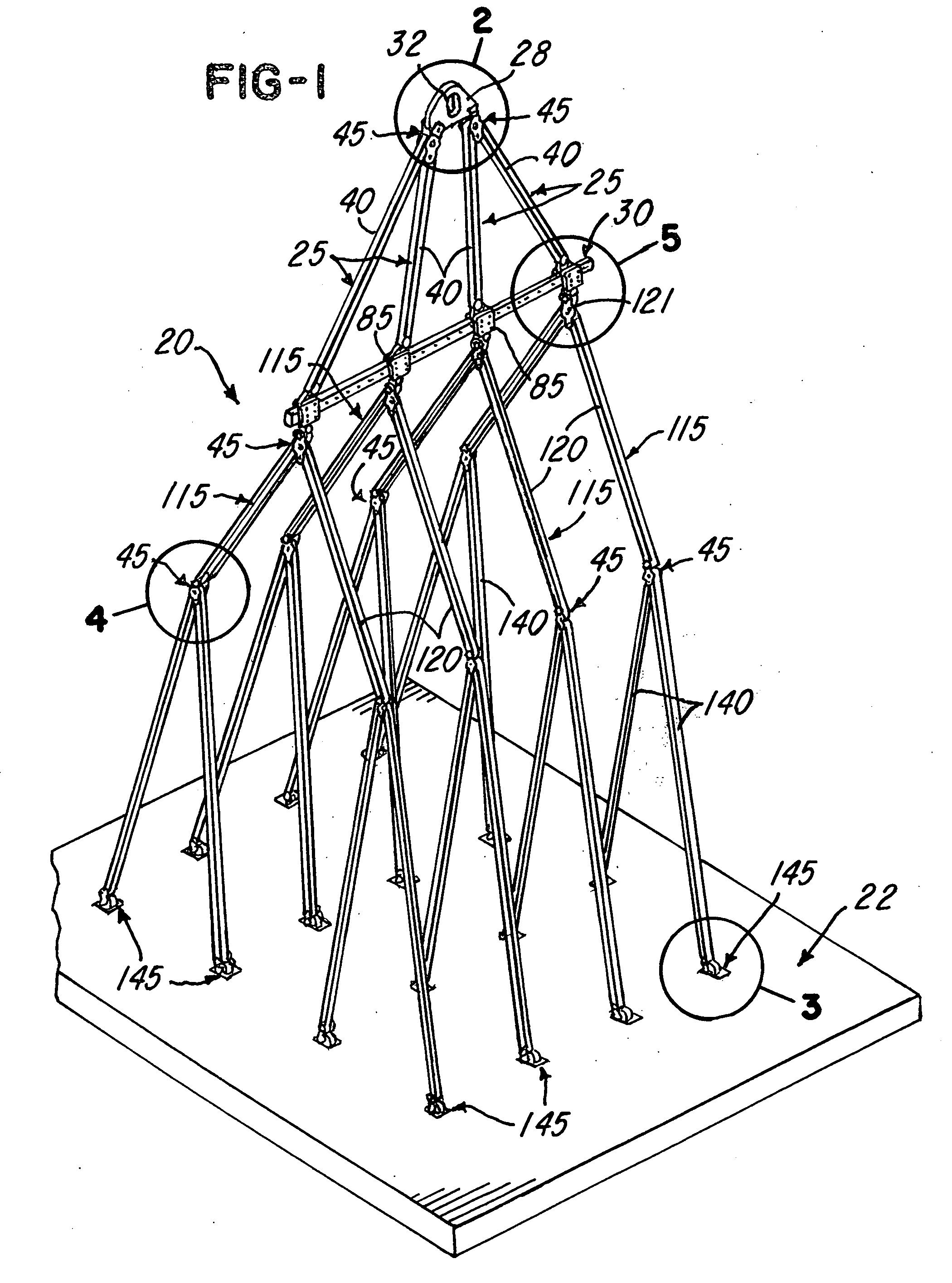

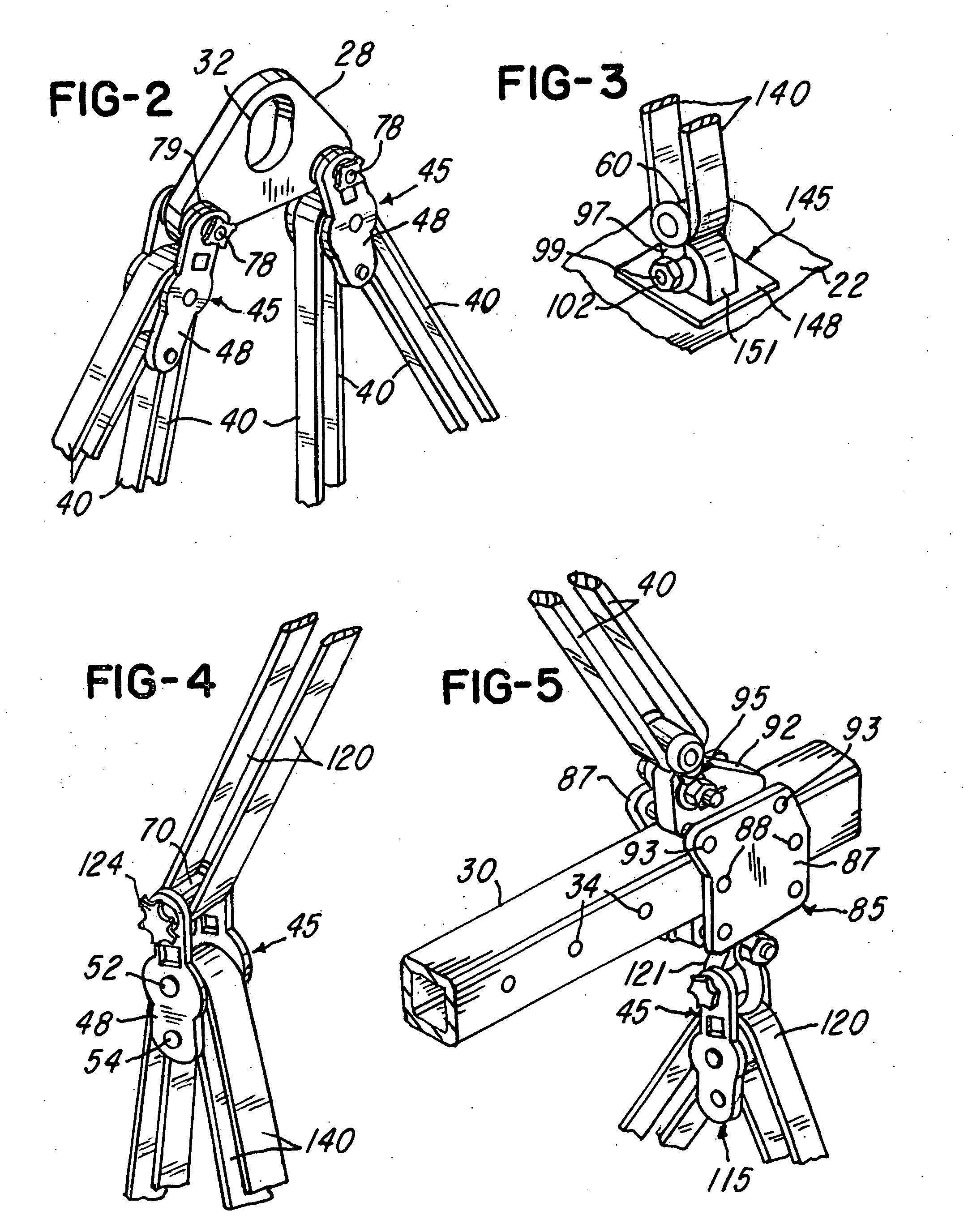

Synthetic fiber sling and roller system for carrying and positioning a load

InactiveUS20110298232A1Increase the number ofEqually distributedLoad-engaging elementsSynthetic fiberEngineering

A sling system comprises a plurality of sling units each including a synthetic fibrous sling and a roller unit which has one or more spool-shaped rollers. The system provides for lifting a load in equilibrium and maintaining the load in that position or be rotated or tilted between horizontal and vertical positions. The system provides for a plurality of attachment points of the sling units to the load, and the sling units and may be set up as a single array or a multiple array depending on the type of load being lifted, transported and positioned. Endless and continuous loop synthetic slings and multiple roller units are used in sling units and provide for uniform and equal distribution of the load throughout the sling system. The spool-shaped rollers may be molded of a rigid plastics material with each roller having end flanges to confine the synthetic sling.

Owner:REGER ROBERT J

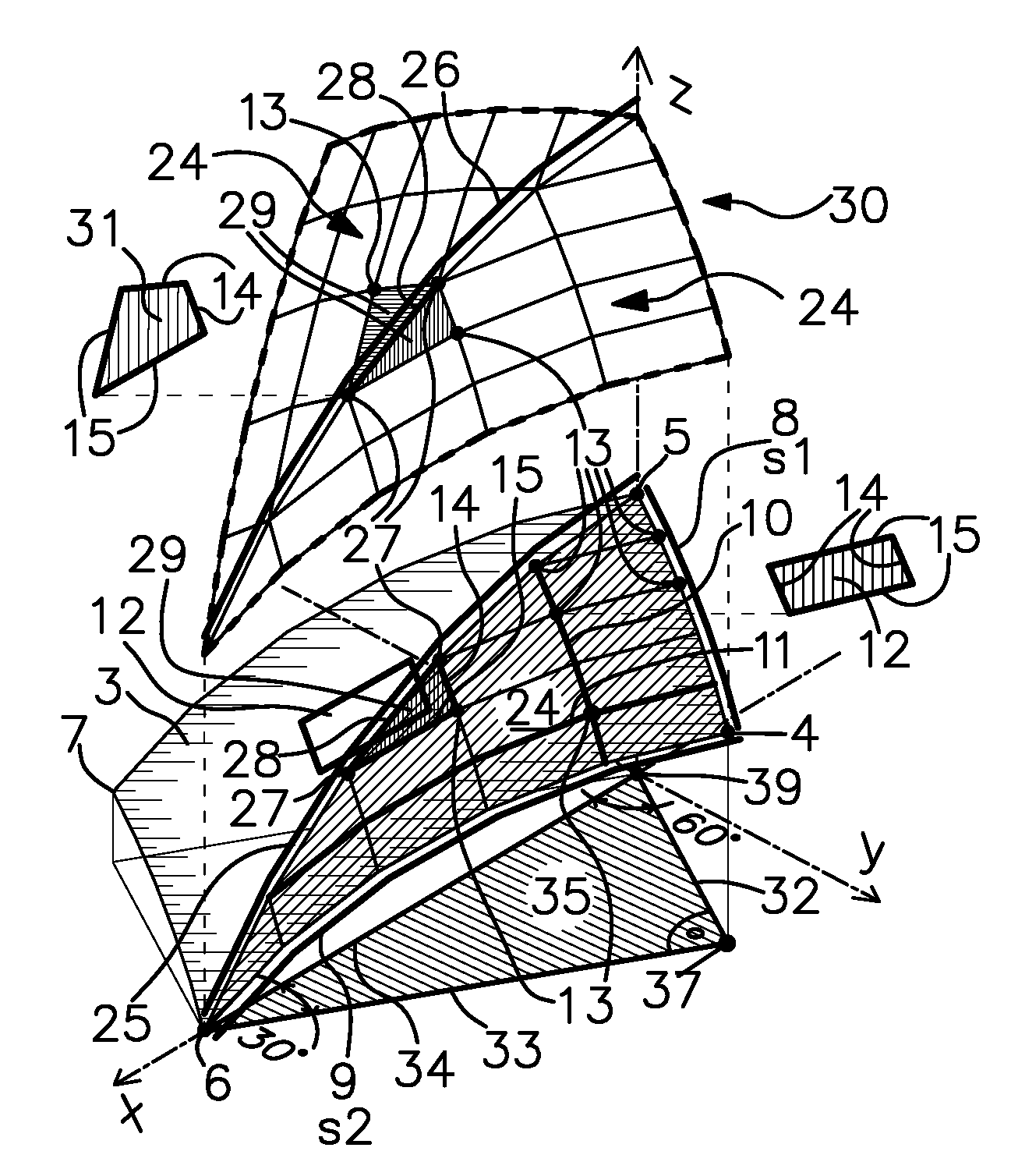

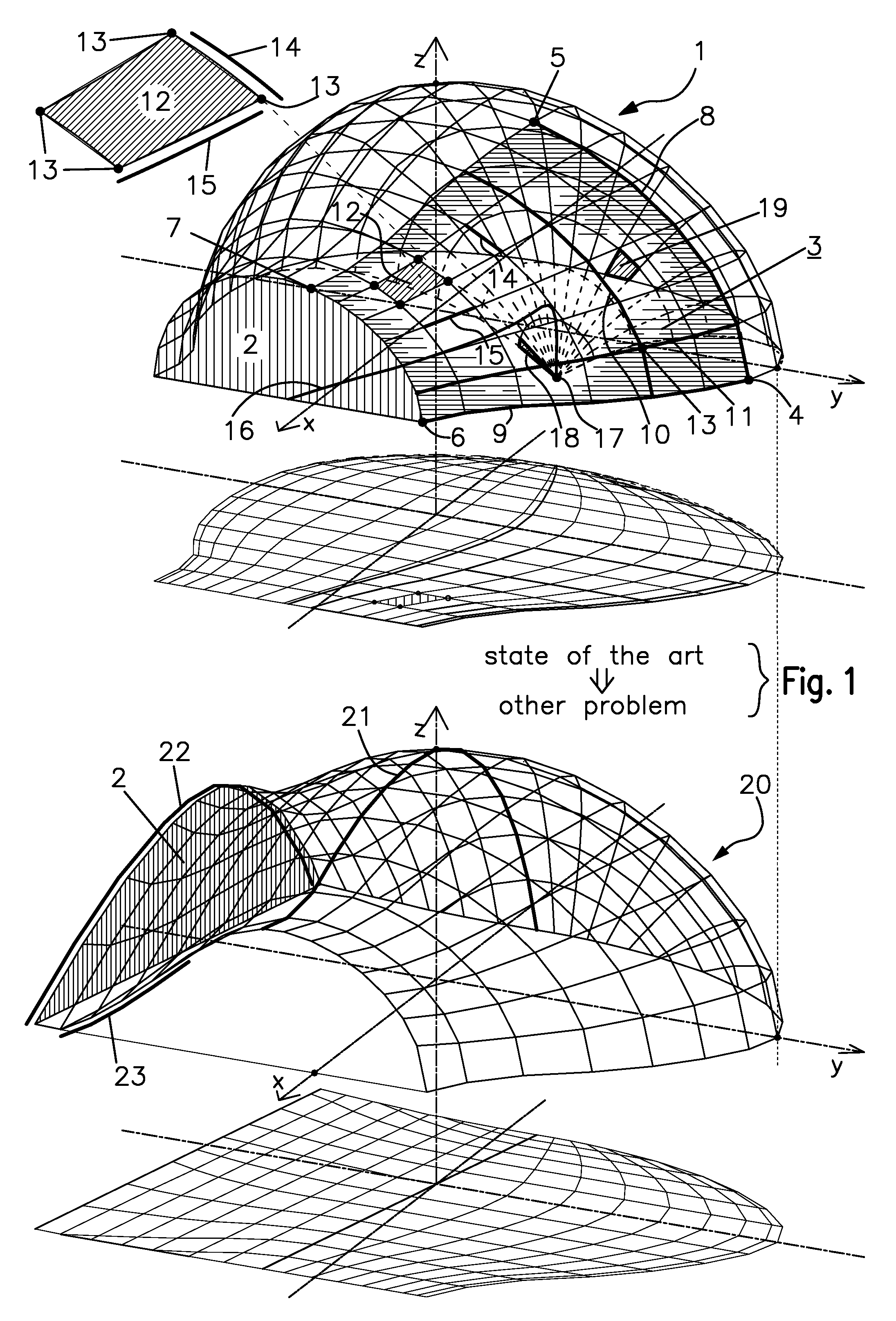

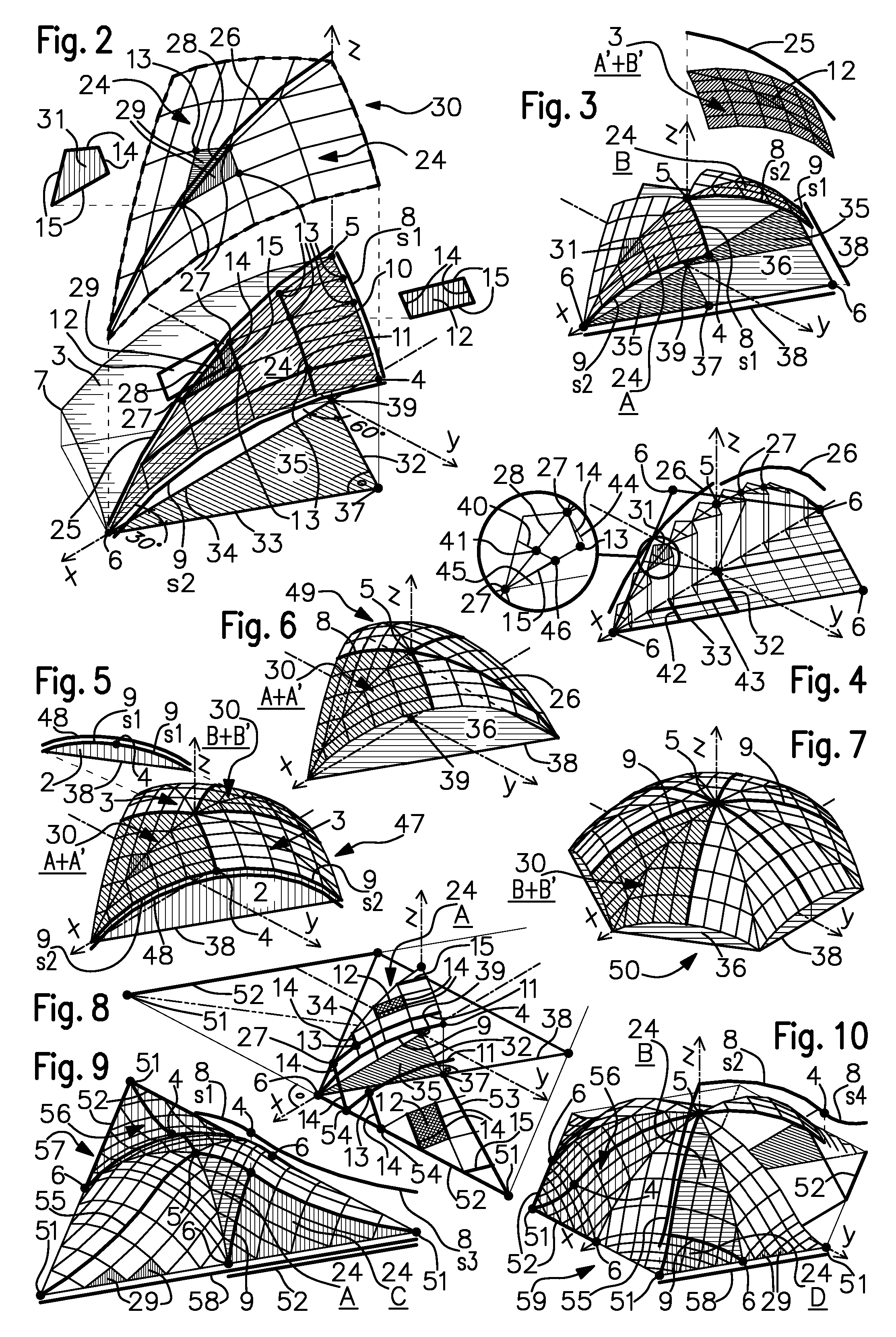

Double-curved shell

Triangulated shells can be free-formed but are uneconomical compared to translational shells that can only be flat. Scale-trans shells are limited in terms of number and arrangement of the openings. The present invention provides a free-formed, custom-tailored shell surface and a regularly shaped, mass-produced shell surface that can be assembled fairly evenly from advantageously quadrangular mesh elements having coplanar node points. The flexibility of a triangle net of shell pieces in a large scale is combined with the evenness of a quad net for meshes in a small scale, whereby triangular meshes at the shared side of adjoining square nets are combined in pairs to give irregular quadrangular meshes having coplanar vertices. The inventive shell is especially suitable for use as an energy-saving building such as a weekend home, emergency shelter, cupola of an observatory, roof of a building or an inner courtyard, as the shell of a large multi-story building or as a sports hall or factory building. It is also suitable as a part of a vault, and as a complex shell consisting of a single continuous surface for exhibition or station buildings. Parts of a Bohemian dome, cushion-roof, Isler shell or blob can be combined within any individual shell.

Owner:TUCZEK FLORIAN

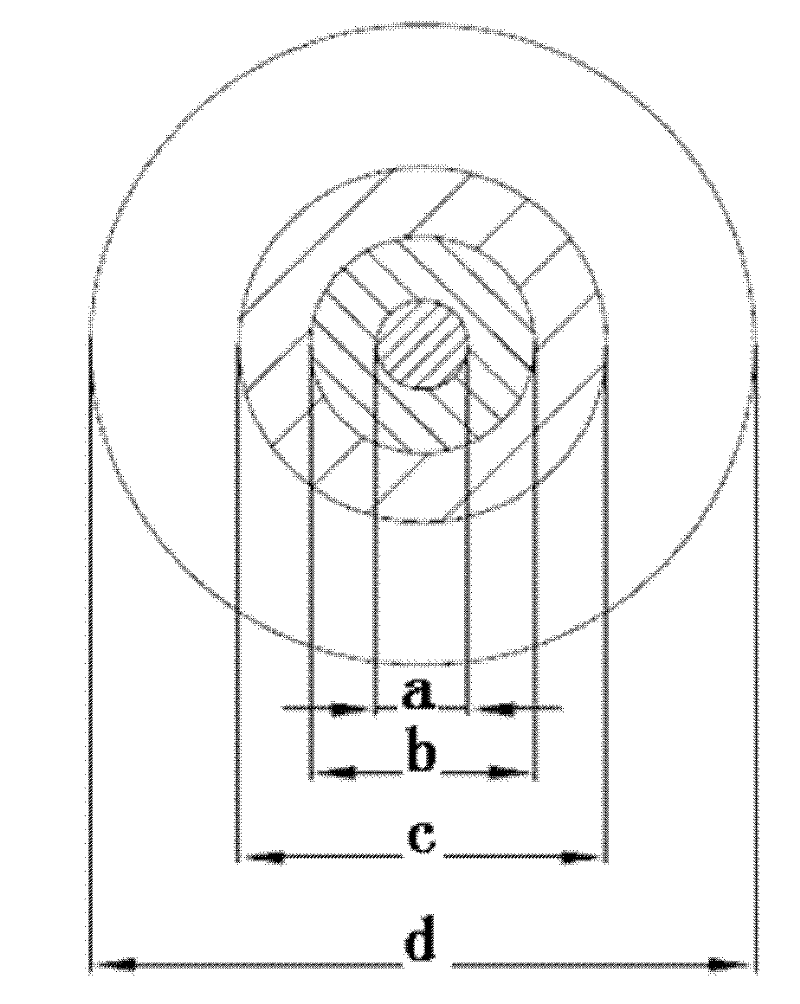

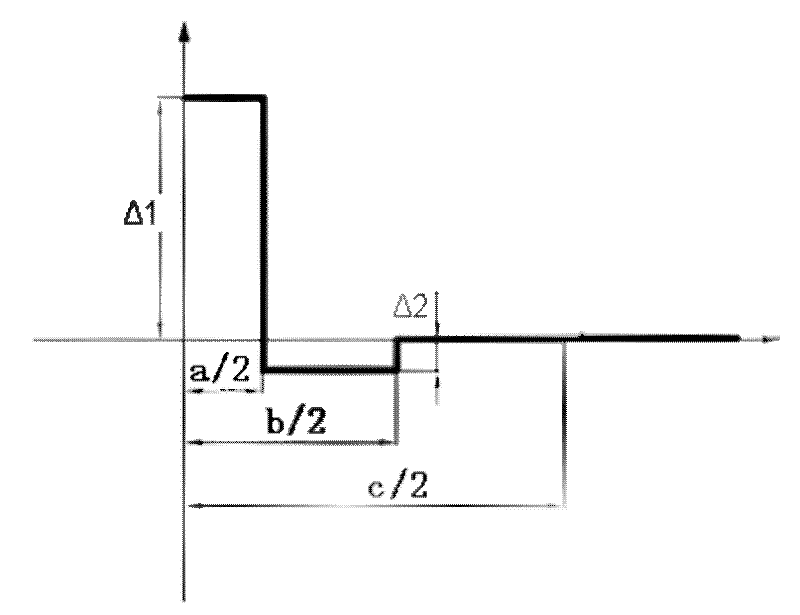

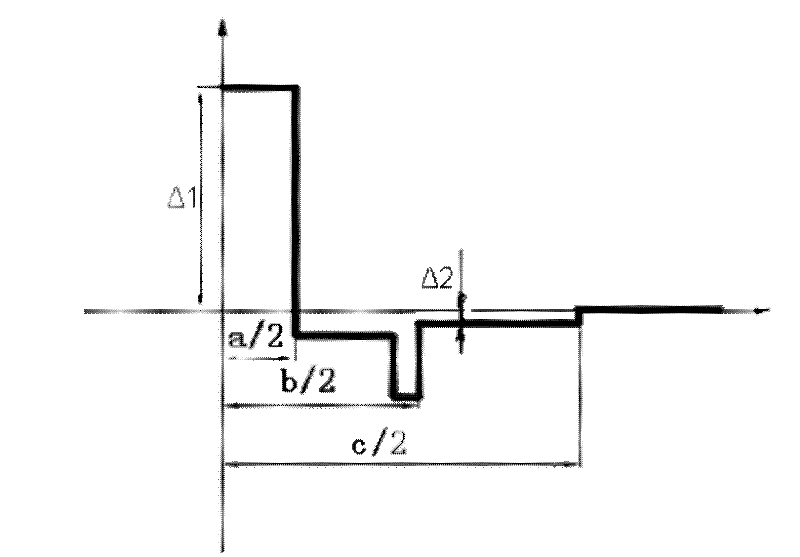

Method for manufacturing large-size low-water-peak prefabricated rod

ActiveCN102249533AOmit polishingReduce stretchGlass making apparatusGlass fibre productsRefractive indexChemical vapor deposition

The invention relates to a method for preparing a large-size low-water-peak prefabricated rod, which comprises the following steps of: 1, depositing a core layer and partial cladding material in a quartz glass lining tube by using an in-tube chemical vapor deposition method to meet the requirement of a waveguide structure and optimize fluorine doped components, wherein the F-doped refractive index contribution of an inner cladding layer prepared by an in-tube method is not more than -0.10 percent and the F-doped refractive index contribution of the core layer is not more than -0.03 percent; 2, melting and shrinking the quartz glass lining tube deposited with the core layer and the partial cladding material at the temperature of between 1,900 and 2,300DEG C into a solid core rod, and manufacturing a core rod of which the b / a is more than or equal to 1.5 and less than or equal to 3.0 and the c / a is more than or equal to 2.3 and less than 4.5; 3, cladding a proper amount of uniform quartz loose body on the outer surface of the core rod directly by using an outside vapor deposition method to obtain a loose body prefabricated rod; and 4, slowly heating the loose body prefabricated rod at high temperature for dehydration, and sintering to obtain the transparent large-size low-water-peak prefabricated rod. The advantage of doping of the in-tube method and the advantage of large size of the outside method are combined, the process is simple, and the method is suitable for producing large-size low-water-peak prefabricated rods at low cost on a large scale.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

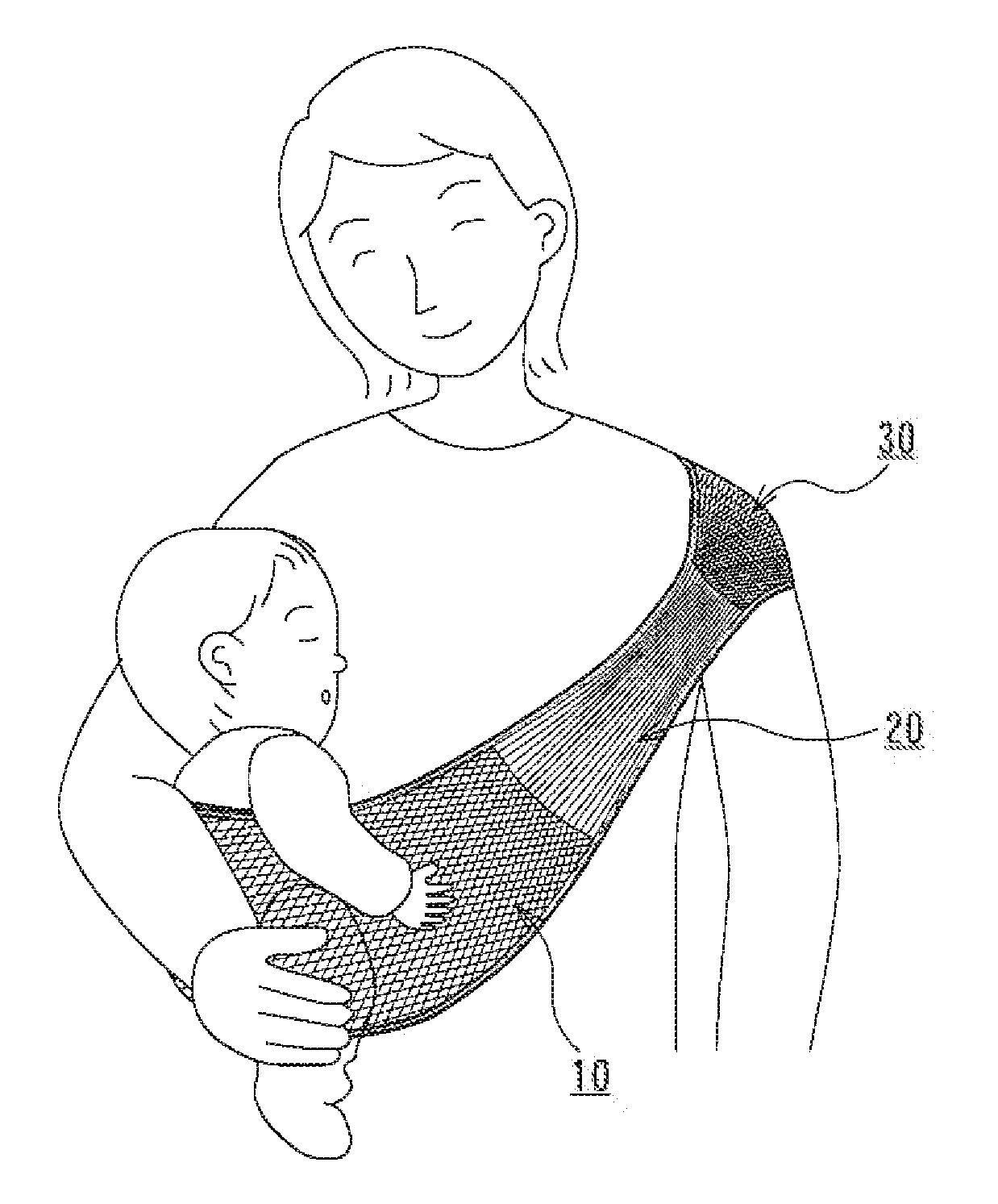

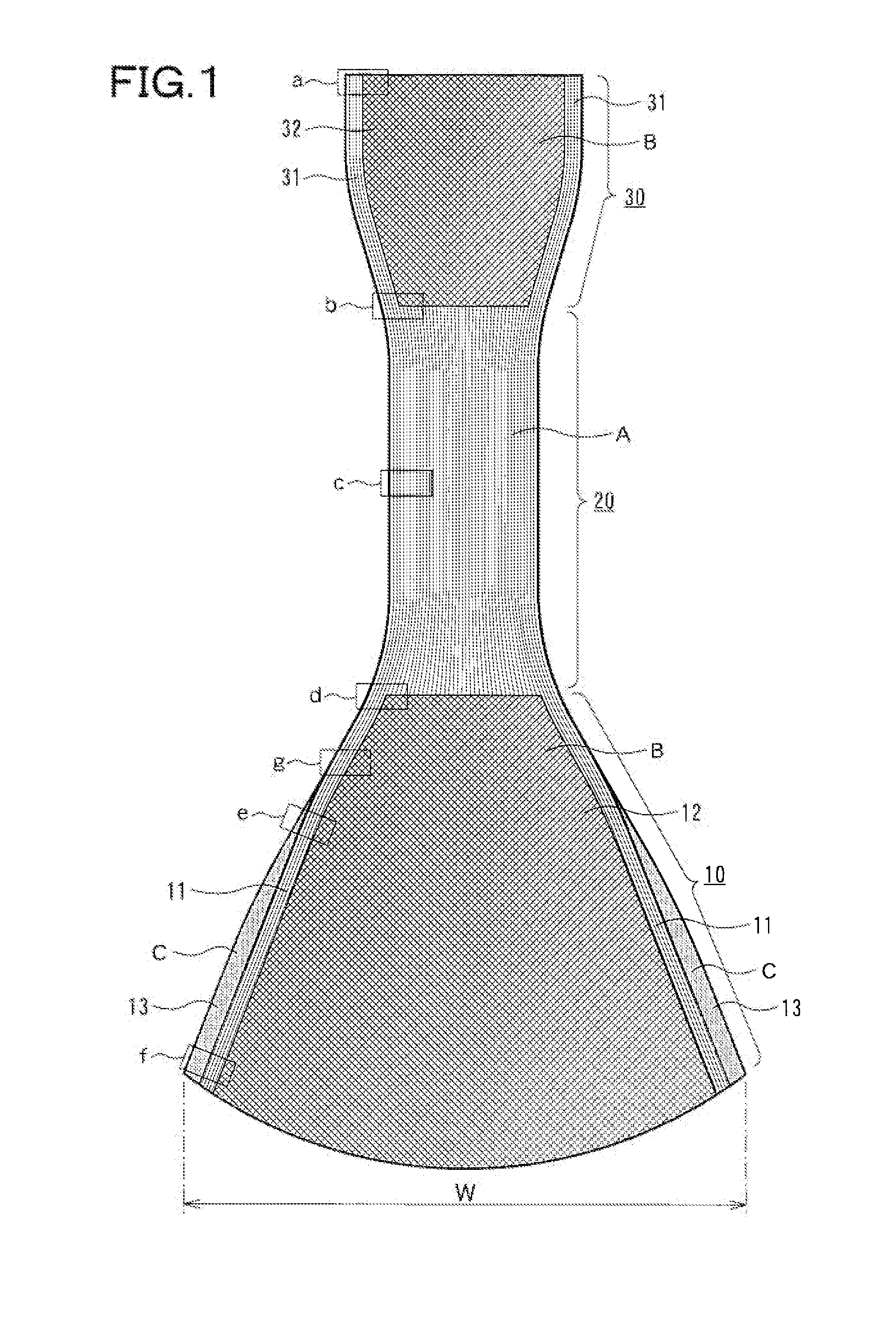

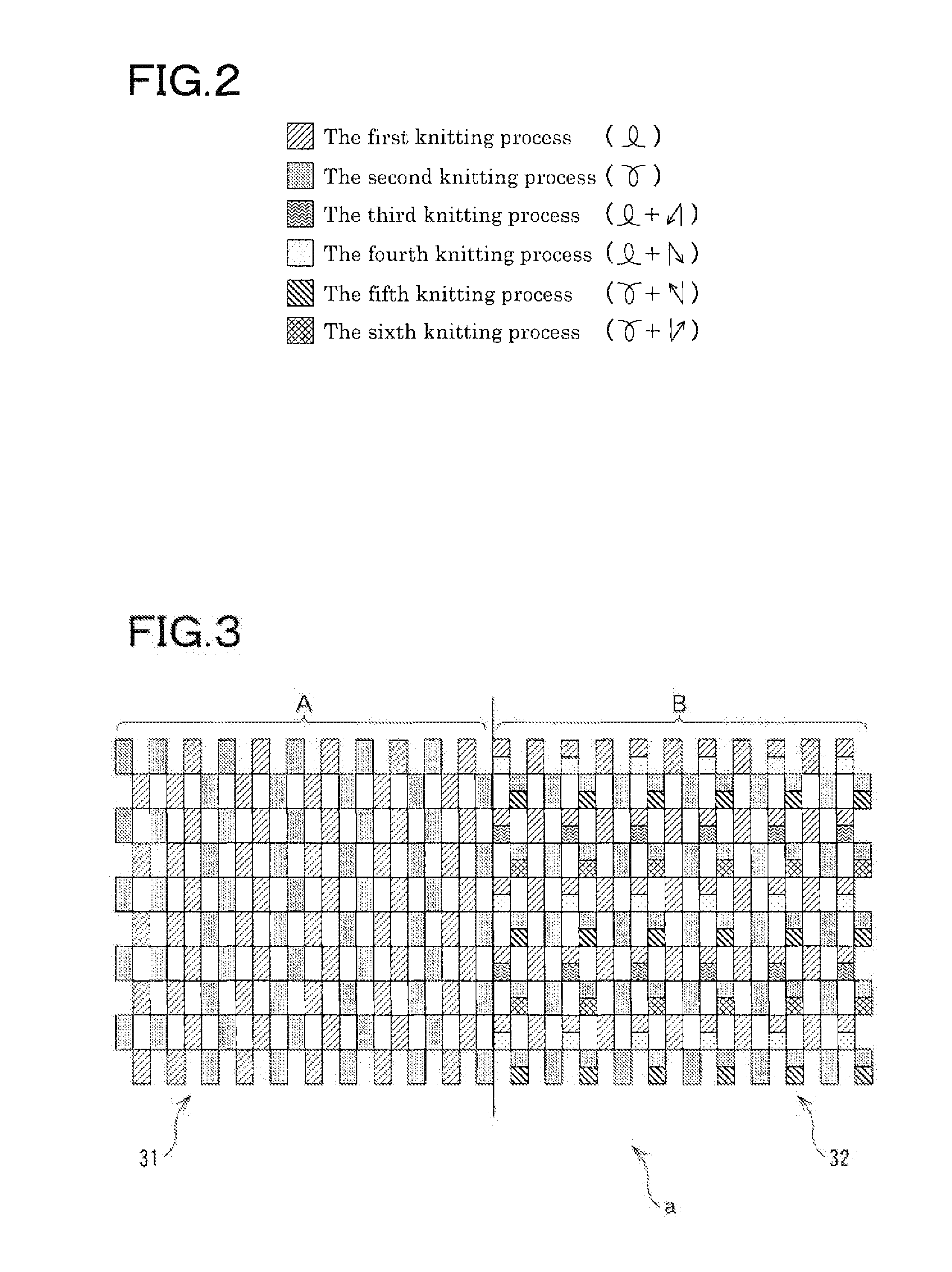

Baby sling

InactiveUS20110226822A1Stable quality controlMinimizing total elasticityStretcherChildren furnitureEngineeringBody weight

A baby sling includes an infant holding part 10 that holds an infant in which the infant holding part 10 has a maximum width W that corresponds to a central part in a longitudinal direction of the baby sling and a gradually decrease in width between both sides in the longitudinal direction of the baby sling, wherein both sides in the longitudinal direction of the baby sling consists of outer parts 11 that are formed of a knitted fabric “A” which has a low elasticity in a width direction which is at right angle to the longitudinal direction of the baby sling and a center side in the longitudinal direction of the baby sling consists of an inner part 12 that is formed of a knitted fabric “B” which has a high elasticity in the width direction which is at right angle to the longitudinal direction of the baby sling. Thereby, the infant's body weight is applied to the inner part 12 that is formed of the high elastic knitted fabric “B” while both sides in the longitudinal direction of the baby sling are guarded with the outer part 11 that is formed of the low elastic knitted fabric “A”. Therefore, the baby sling can stably hold the infant. Accordingly, a safe and secure baby sling can be provided.

Owner:LUCKY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com