Patents

Literature

1863results about "Flame-proof filament manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

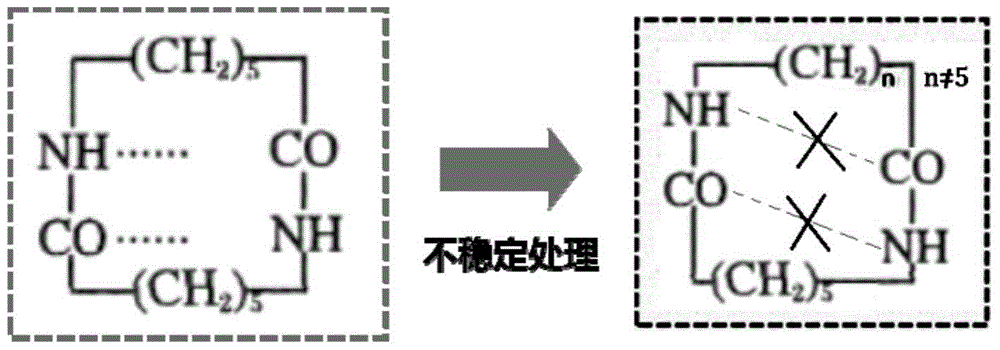

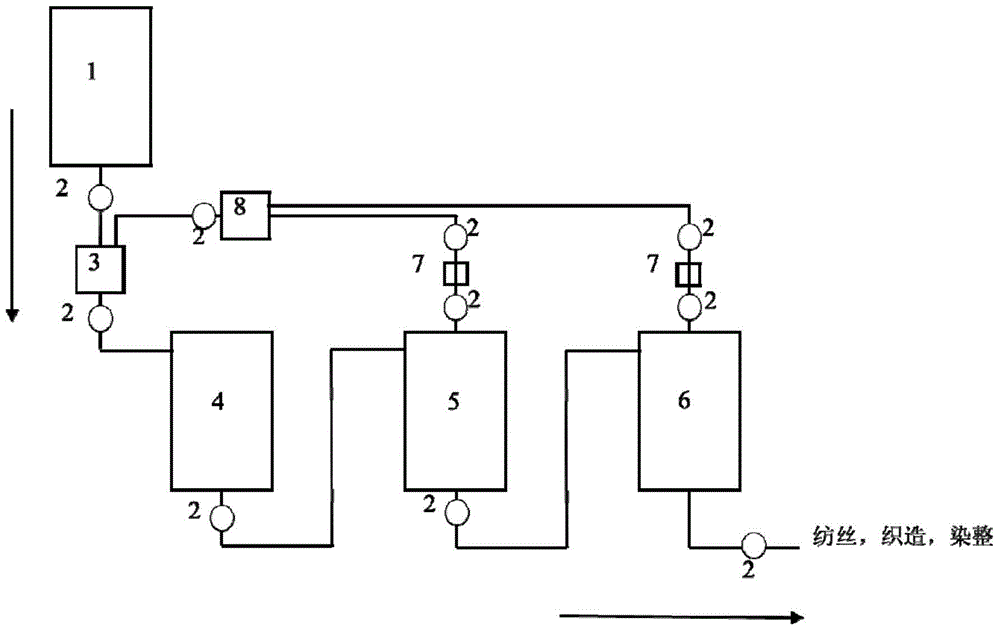

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

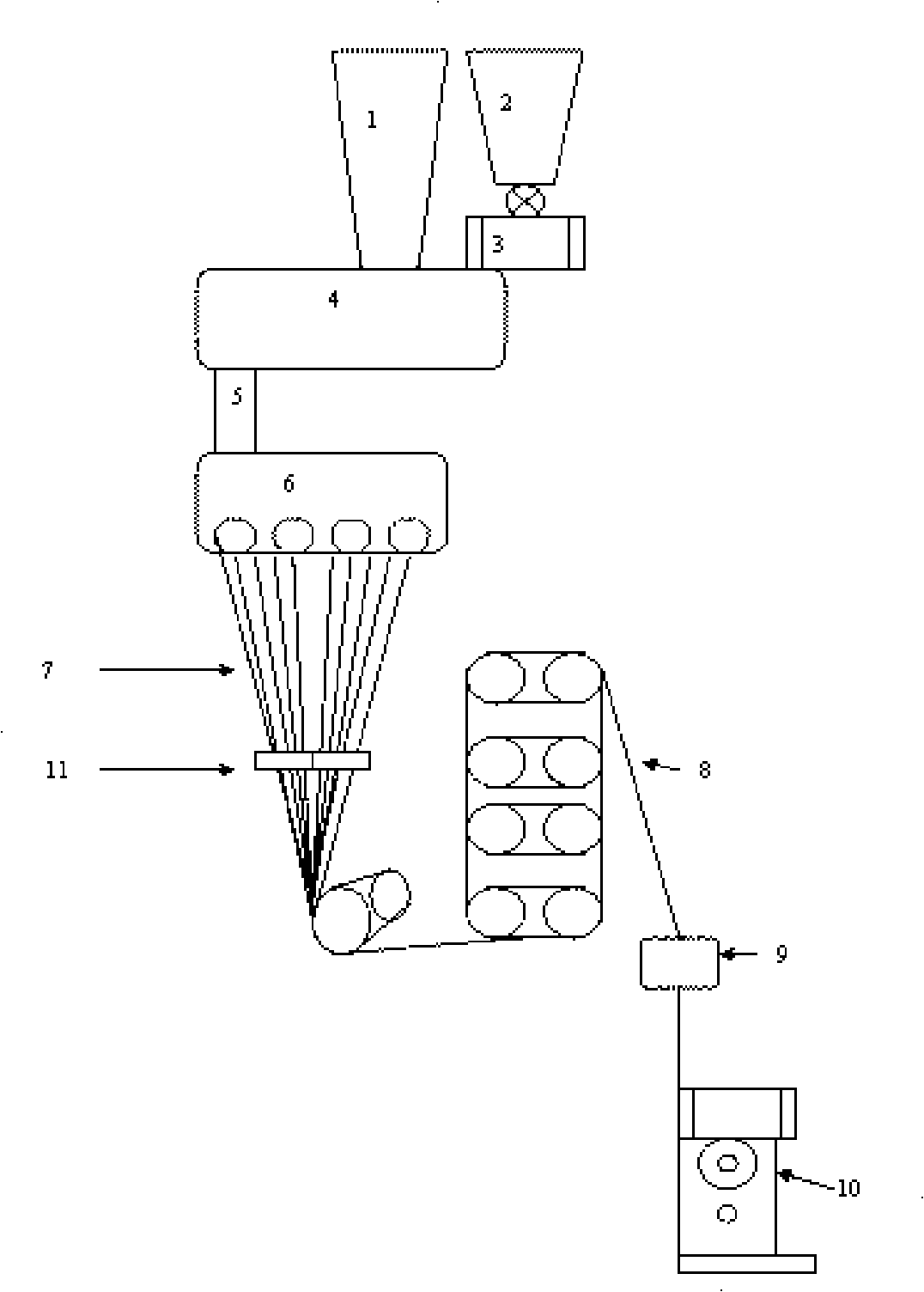

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

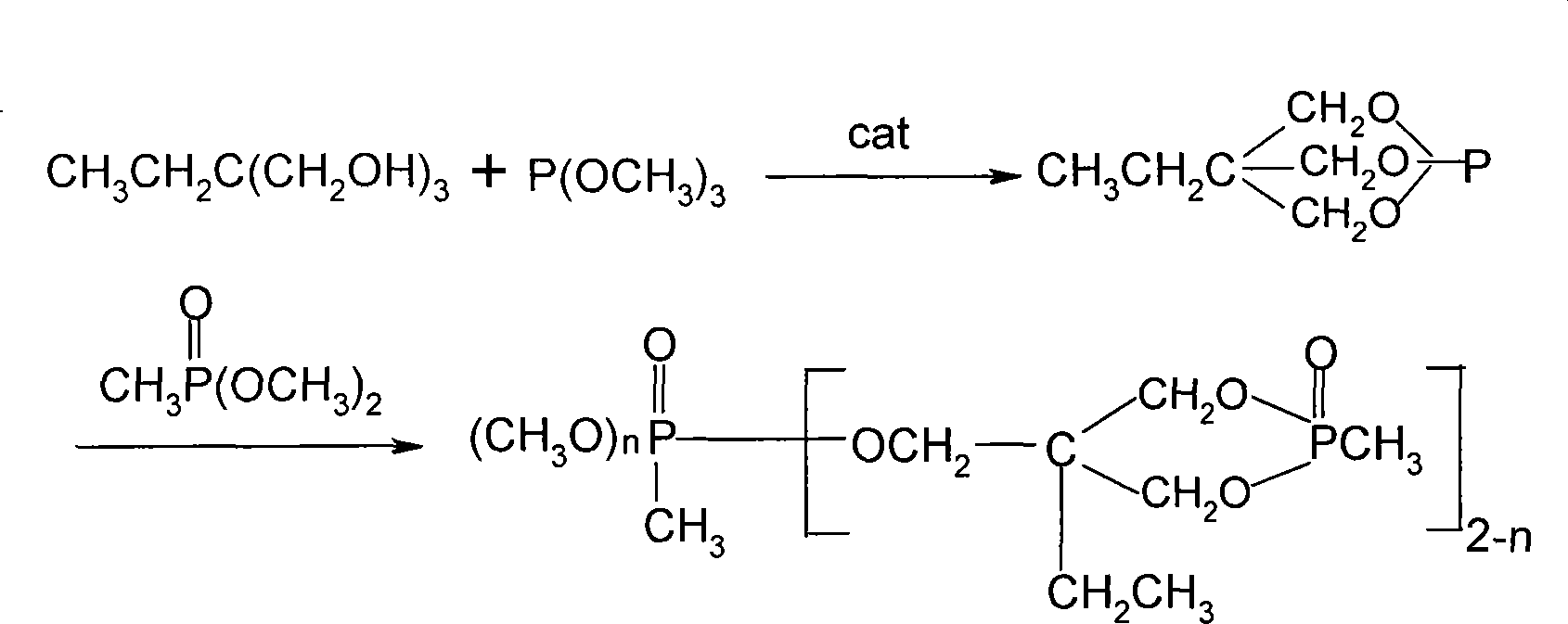

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

Negative ion flame-retardant anti-bacterial fiber and preparation method thereof

InactiveCN101586267ASimple manufacturing methodWith mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolyester

The invention provides negative ion flame-retardant anti-bacterial fiber belonging to the field of textile industry technique and a and preparation method thereof, the weight percentages and components thereof are as follows: polyester fibre 92-99%, compound combustion inhibitor 0.6-6.4%, antimicrobial powder 0.1-1.6% and negative ion generating agent 0.1-1.6%. The method provided by the invention can prepare negative ion flame-retardant anti-bacterial fiber which can simultaneously reach national architectural material flame-retardant performance B1 grade standard and conform to national antimicrobial material specification, with 6140 / cm of negative ion generating number density.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

Carpet Fiber Polymeric Blend

ActiveUS20080157425A1Improve fire resistanceImprove spinnabilityFlame-proof filament manufactureCeramic shaping apparatusYarnPolymer chemistry

The invention provides carpet fibers prepared from a blend of polymeric components, said fiber exhibiting improved properties, such as improved spinnability and improved fire resistance. The carpet fibers particularly comprise a majority of polytrimethylene terephthalate (PTT) and a minority of polyethylene terephthalate (PET). The invention further provides yarns and carpets prepared from the inventive fibers, said yarns and carpets likewise exhibiting improved properties. The invention also provides methods of improving various physical properties (such as fire resistance, spinnability, and elongation) of a polymeric composition.

Owner:ALADDIN MFG CORP

Method for preparing flame-proof viscose fiber

InactiveCN101215726ASimple and convenient filteringFilter is not easy to clogFlame-proof filament manufactureMonocomponent cellulose artificial filamentPolymer scienceEmulsion

The invention discloses a process for preparing flame retarding cellulose viscose, which adopts pyrophosphate exchange reaction flame retardant particle whose mean particle diameter is <= 1.0um, non-ionic surface active agent, dispersing agent and solvent water to mix and obtain flame retardant emulsion, each percentage by weight is pyrophosphate exchange reaction flame retardant 20-45 wt%, non-ionic surface active agent 5-10 wt% and dispersing agent 0.5-1.0 wt%, and residue is solvent water. The process for preparation comprises adding pyrophosphate exchange reaction flame retardant of flame retardant emulsion which is corresponded to alpha cellulose 15-30 % into spinning original liquid which is filtered to mix, shaping spinning by adopting spinning bath which is low acid, low salt, low temperature and high zinc. The spinning original liquid of the invention has simple and convenient preparation, fiber does not contain halogen elements, which avoids environmental pollution, when in burning, the invention is not melted, while charring only happens to keep the original shape of fiber, the invention prevents dripping which is melted in high temperature from scalding human body, and flame retardant is distributed evenly in adhesive, which can not smolder after leaving fire and easy to be self-extinguished.

Owner:CHTC HELON

Process for preparing flame-retarding phosphorus copolymerized terylene chips

InactiveCN1359962AImprove stabilityUniform and long-lasting flame retardant effectFlame-proof filament manufacturePolyesterPhosphoric acid

A flame-retarding copolymerized terylene chip is prepared on the basis of ordinary preparing process of terylene chip and is characterized by that after the esterifying step in the process to prepare polyester is finished, the flame-retarding agent, which is prepared from 2-carboxyethyl phenylphosphoric acid through dissolving it in ethylene glycol (EG), is added. Its advantages are high and durable flame-retarding effect, no toxicity and high spinnability.

Owner:济南齐鲁化纤集团有限责任公司

Blended yarn weaved fabric based on novel flame retardant viscose, preparation method and application thereof

InactiveCN101538764AIdeal twistImprove flame retardant performanceWeft knittingFlame-proof filament manufactureYarnChemical treatment

The invention relates to a novel flame retardant fabric, a preparation method and an application thereof, particular to a blended yarn weaved fabric based on novel flame retardant viscose, a preparation method and an application thereof. The flame retardant viscose is prepared by blended spinning with nanometer SiO2 and cellulose solution; wherein the blended ratio of the flame retardant viscose and natural fiber is 20:80 to 80:20. The invention also provides the preparation method of the flame retardant blended yarn weaved fabric. As the nanometer SiO2 particles are adopted as inorganic flame retardant, the novel flame retardant blended yarn weaved fabric is good in fire resistance; limited oxygen index is more than 28%, meltdown or dripping can not appear when combusting, only a small quantity of flue gas which is safe and innoxious is produced, and the fabric is washing resistant and chemical treatment resistant. The invention has air and moisture permeability and soft feel. The blended yarn weaved fabric is mainly composed of the flame retardant viscose and cotton fiber, and can be applied to preparation of bedding such as bed sheet, quilt cover, pajamas, etc.

Owner:上海神九纺织科技有限公司

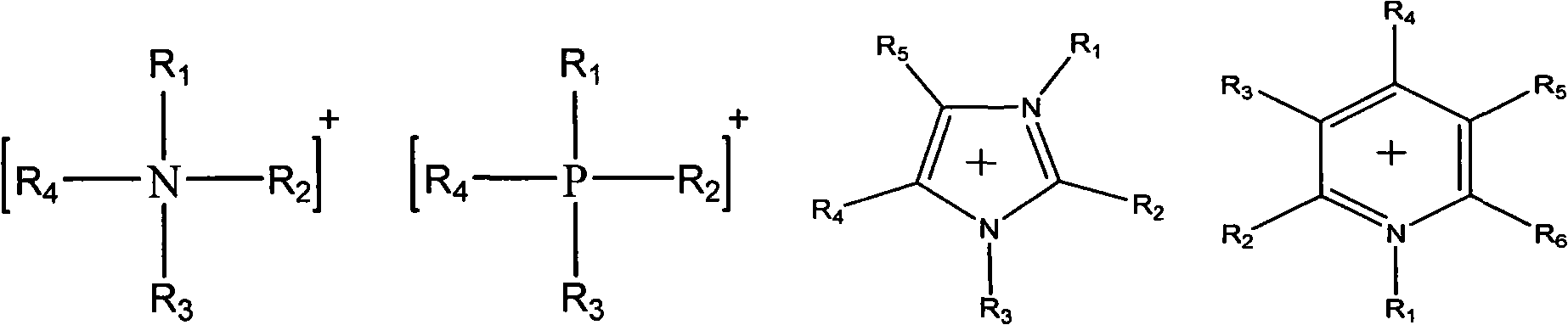

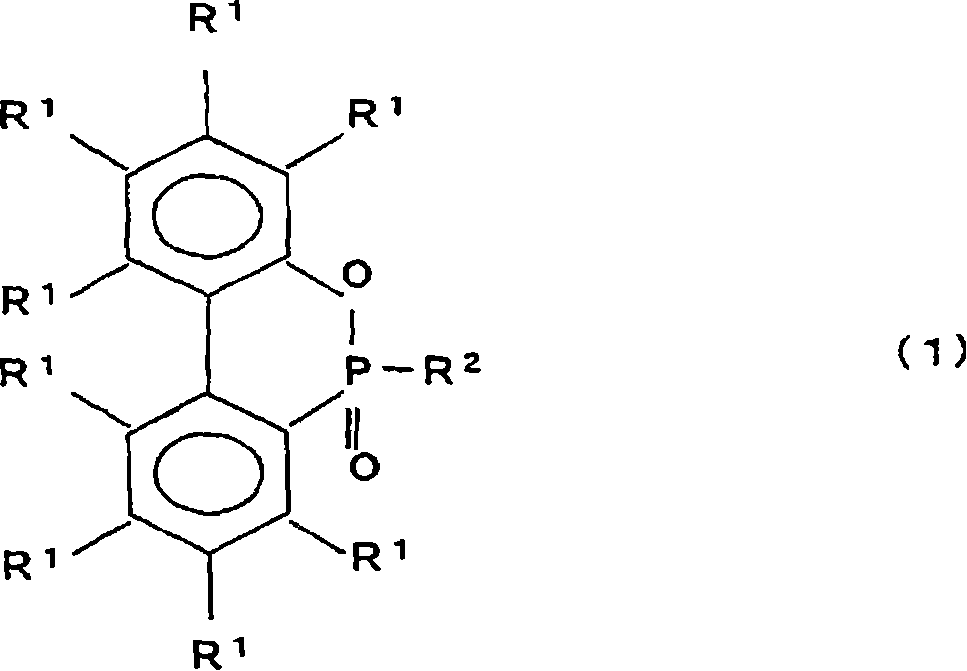

Flame resistant synthetic resin composition

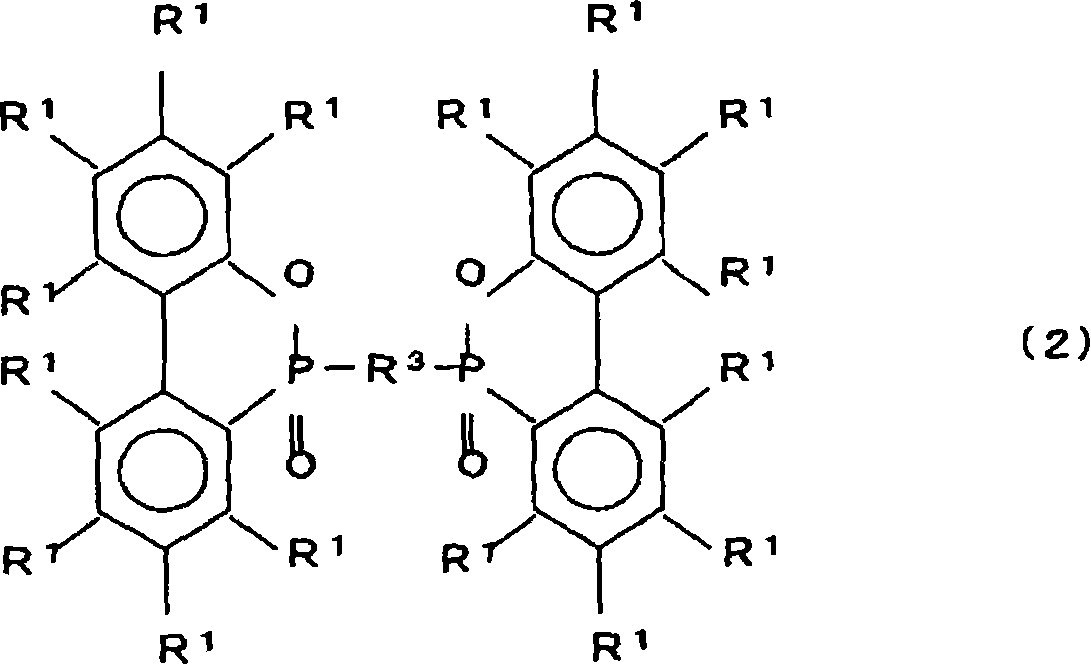

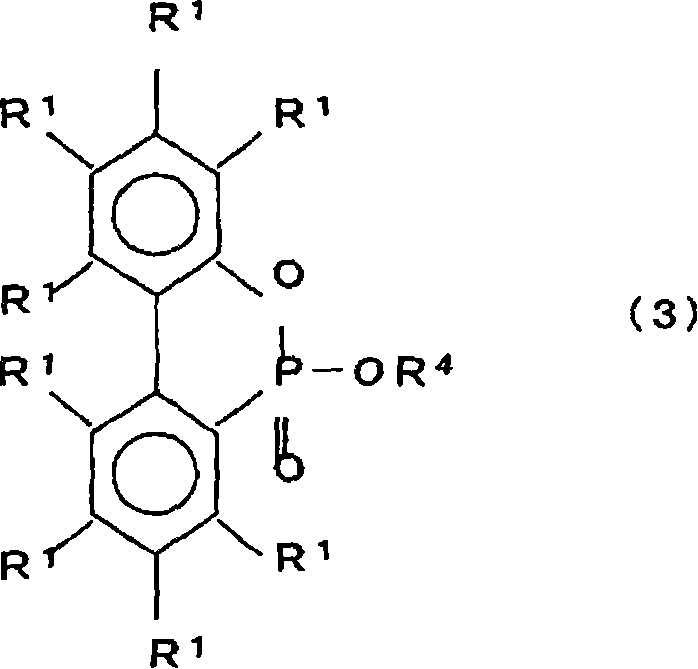

InactiveUS20060247343A1High densityReduce deteriorationFlame-proof filament manufactureGroup 5/15 element organic compoundsPolymer scienceOrganic phosphorus

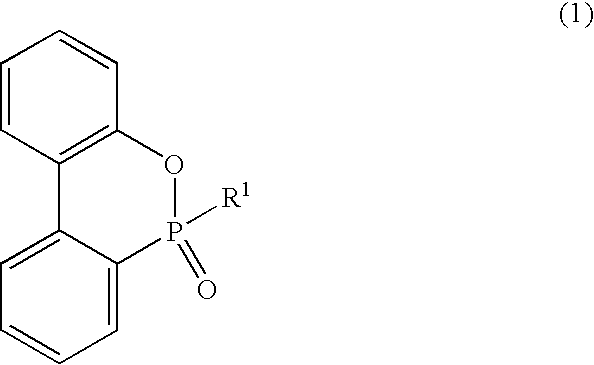

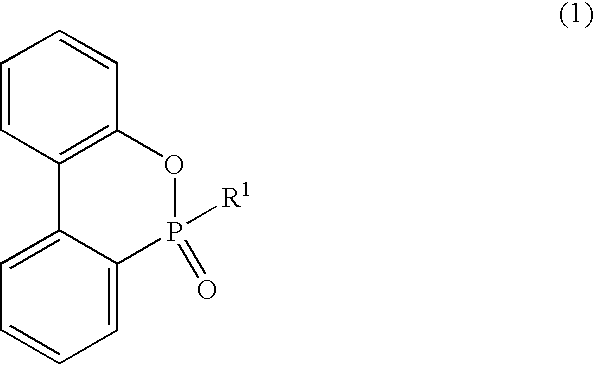

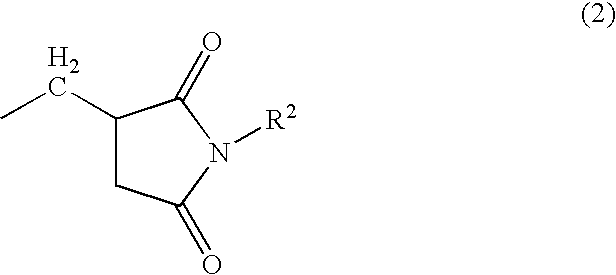

A flame-retardant synthetic resin composition characterized by comprising 1-40 parts by weight of at least one type of organic phosphorus compound represented by the following general formula (1): (wherein R1 represents alkyl, aralkyl, etc.) with respect to 100 parts by weight of a synthetic resin.

Owner:SANKO CO LTD +1

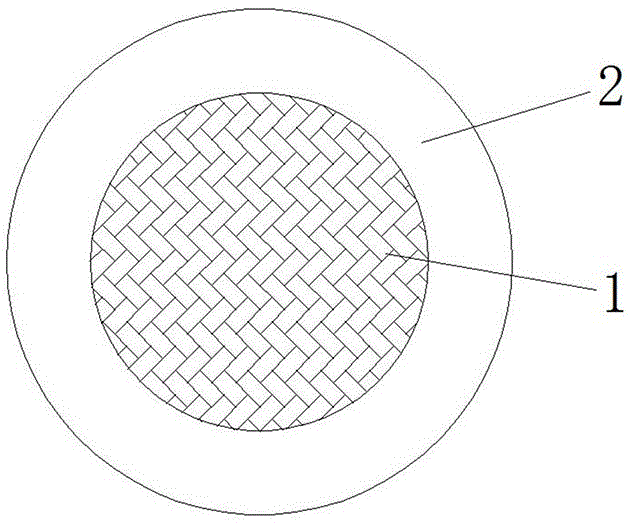

Multi-purpose sheath-core composite monofilament as well as production method and application thereof

InactiveCN106048777AElectroconductive/antistatic filament manufactureFlame-proof filament manufactureMosquito netPolypropylene

The invention relates to a multi-purpose sheath-core composite monofilament for weaving reticulated as well as a production method and application thereof, and belongs to the technical field of production of composite fibers. The multi-purpose sheath-core composite monofilament comprises a sheath layer and a core layer, wherein the sheath layer covers the core layer; the core layer is prepared from PP, TPU or TPEE; the sheath layer is prepared from PE, POE, TPU or TPEE; the melting point of the sheath layer is 120 to 170 DEG C; the melting point of the core layer is 150 to 210 DEG C; the content of the sheath layer is 30 to 70 percent; the content of the core layer is 70 to 30 percent. The multi-purpose sheath-core composite monofilament comprising two components can be applied to weaving of gauze, window screens, curtains, abat vents, light equalization cloth, anti-mosquito nets, anti-haze gauze, filter screen cloth, shoe screen cloth, and base materials of power transmission belts.

Owner:无锡盛烨特邦新材料科技有限公司

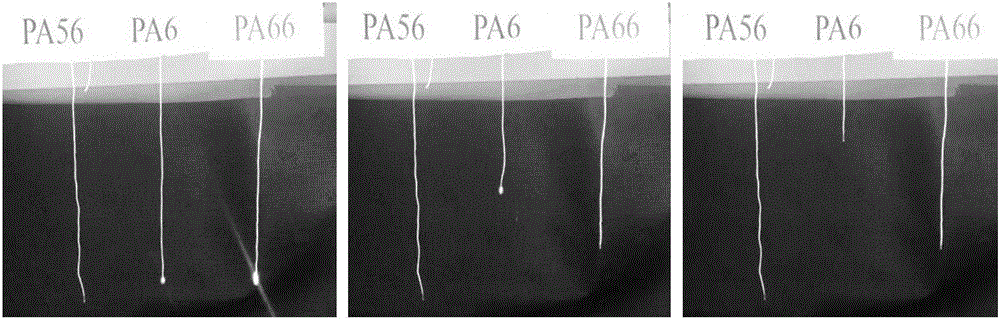

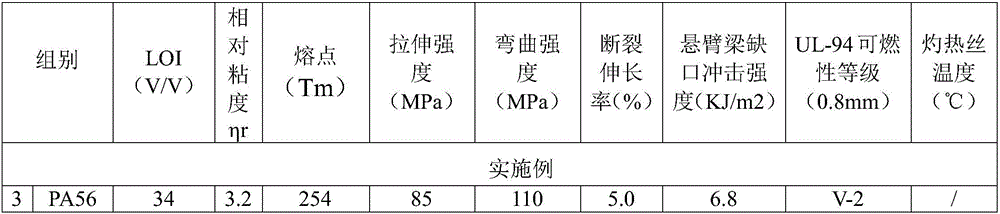

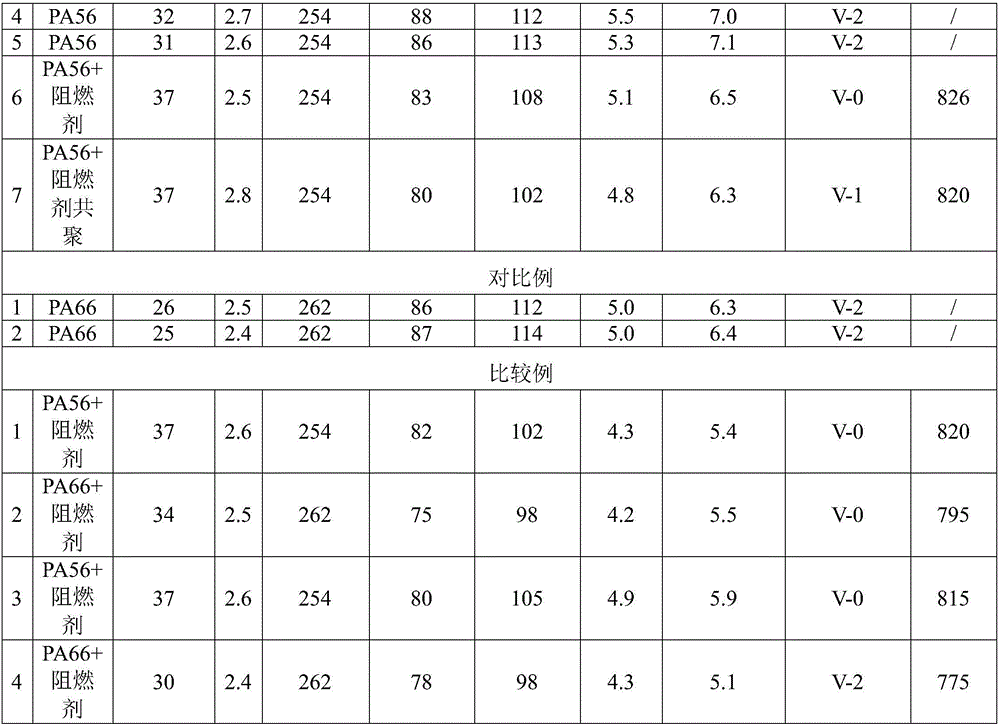

Polyamide 56 material prepared from bio-based 1,5-pentamethylene diamine

ActiveCN106146831ALow toxicityImprove securityFlame-proof filament manufactureMonocomponent polyamides artificial filamentPolymer scienceEngineering plastic

The invention provides a polyamide 56 material prepared from bio-based 1,5-pentamethylene diamine. The polyamide 56 material is renewable and has the high flame-retardant property. The polyamide 56 material comprises polyamide 56 and a composition of nitrogen-containing flame retardants or is a polymer formed by pentamethylene diamine, adipic acid and nitrogen-containing flame retardants serving as a polymeric monomer. The material is good in flame-retardant effect, low in toxicity, high in safety, low in cost and capable of being used as engineering plastics and a spinning material. According to the material, the preparation process is simple and convenient, and wide industrial application prospects are achieved.

Owner:CATHAY R&D CENT CO LTD +2

Method for preparing colorized fire-retardant delustering hollow polyester filament

ActiveCN101597816AWith colorFlame retardantFlame-proof filament manufactureHollow filament manufactureFiberState of art

The invention relates to a method for preparing a polyester filament, in particular to a method for preparing a colorized fire-retardant delustering hollow polyester filament. The method mainly solves the technical problem of the prior art that color master batches and a delustering agent added into a fire-retardant slice can influence the viscosity of a fused mass during the spinning and the friction to a device in the processing process so that colorized, fire-retardant and delustering finished polyester fiber and the like cannot be prepared. The preparation method comprises the following steps: adding a copolymerization fire retardant in the process of preparing a polyester slice to form the fire-retardant slice; performing pre-crystallization on and drying the fire-retardant slice, the color master batches and delustering master batches, and evaporating the water content; mixing the fire-retardant slice with the color master batches and the delustering master batches, passing the mixture into a double screw extruder to perform heating melting, performing filter mixing and measuring allocation on the fused mass, and spinning the fused mass into tows; and performing cooling molding on the tows through lateral blow, and obtaining a finished product after oil tanker oiling, drafting, networking and winding.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

Melt-resistant flame-proof cellulose viscose and method for making same

InactiveCN101037812AImprove flame retardant performanceImprove filtering effectFlame-proof filament manufactureMonocomponent cellulose artificial filamentFiltrationFire retardant

The invention discloses a anti-melting flameretardant fiber and preparation method thereof. The flame-retardant is added in the dissolving procedure to using production method of viscose fiber, and then processed by mixing, filtration, ripening, debubbling, spinning, refinning, drying, and finished product to produce flameretardant fiber. When burning, the said anti-melting flameretardant fiber will not melt but only carbonize to keeping the original shape of fibre, therefore it prevent high temperature melting drip scalding the people. Furthermore the flame-retardant homogeneously disperses in viscose, and does not smolders and is easy to self extinguish after leaving fire source. The said preparation method is simple and easily operated. The flame retardant property is good, and the disperse of flame-retardant is homogeneous.

Owner:CHTC HELON

Method for preparing Nano SiO2 fire retardant viscose fiber, and film

ActiveCN101050559ASimple processEasy to operateFlame-proof filament manufactureArtificial filaments from viscoseFire retardantSodium sulfate

The present invention relates to a preparation method of nano SiO2 fire-retardant viscose fiber and film, specially, it relates to a preparation method of fire-retardant viscose fiber formed from cellulose and SiO2 and organic-inorganic polymer nano composite membrane made of cellulose and SiO2. Said method includes the following steps: adding silicone sol with a certain mass into a viscose solution whose composition contains alpha-cellulose whose mass percentage content is 6-9% and sodium hydroxide whose mass percentage content is 5-6%; fully stirring and mixing them at 10-50 deg.C, deforming so as to obtain viscose-silicone sol solution, then adding said viscose-silicone sol into a coagulation acid bath prepared by using sulfuric acid, sodium sulfate, zinc sulfate and water, coagulating at 10-100 deg.C, spinning so as to obtain nano SiO2 fiber-retardant viscose fiber, utilizing coating process so as to obtain organic-inorganic polymer nano composite membrane of cellulose / SiO2.

Owner:QINGDAO UNIV

Preparation method of halogen-free flame retardant high-intensity polyvinyl alcohol fibers

ActiveCN102002770AImprove stabilityImprove filtering effectFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentPolymer sciencePolyvinyl alcohol

Owner:SICHUAN UNIV +2

Method of preparing melamine formaldehyde resin/polyvinyl alcohol flame-proof fiber

InactiveCN101016658AImprove spinnabilityIncrease productivityFlame-proof filament manufactureWet spinning methodsFiberLimiting oxygen index

The invention discloses a method for producing melamine formaldehyde resin / polyvinyl alcohol flameproof fiber. The invention is characterized in that composing melamine and formaldehyde at the mole ratio as 1:1.2-1:6 and 50-100Deg. C into melamine formaldehyde resin water solution, to be mixed with the polyvinyl alcohol water solution at the solid content ratio as 2:8-8:2 to obtain spinning original liquid, then spinning and shaping the original liquid via general wet method, and treating solidifying bath via acid sodium sulfate saturated water solution, and the primary fiber is drawn, shaped via wet and heat method, washed, coiled, oiled, dried, and heated in dry condition to obtain the final melamine formaldehyde resin / polyvinyl alcohol flameproof fiber. The titer of said flameproof fiber is 10detex, while the strength is 1-3cN / dtex, the crack extended rate is 5-15%, the regain ratio is 5-10%, and the limit oxygen index is 30-45.

Owner:SICHUAN UNIV +1

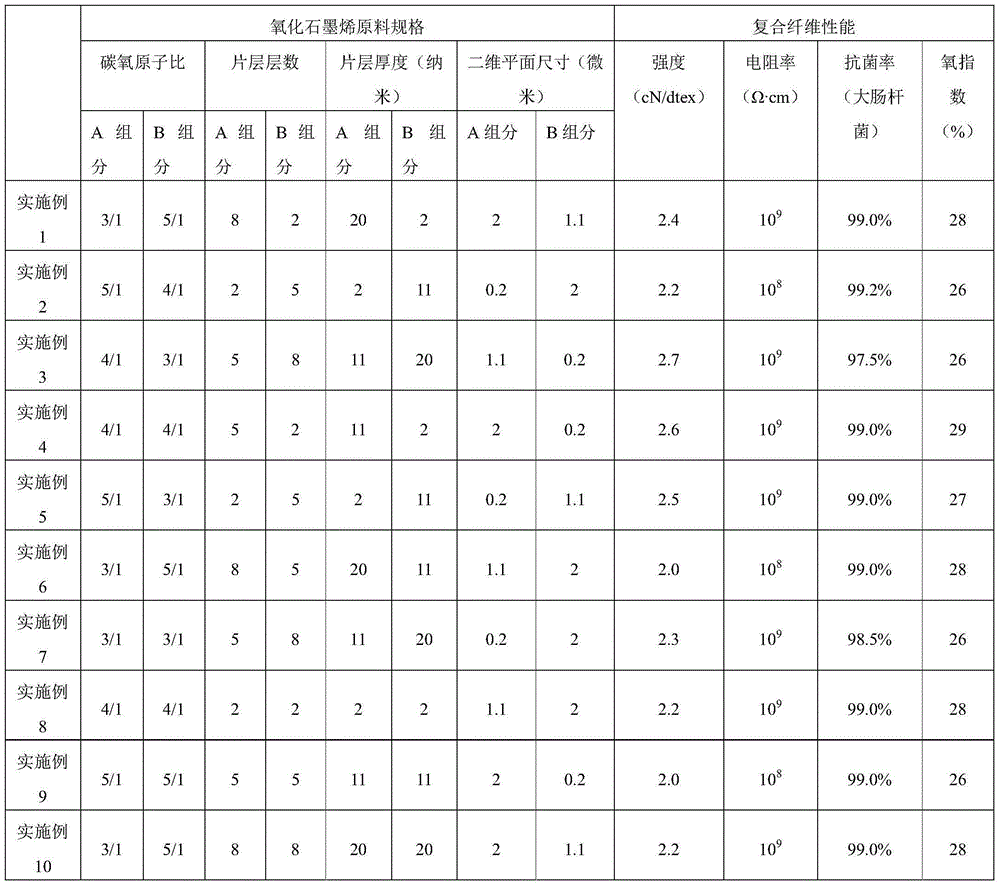

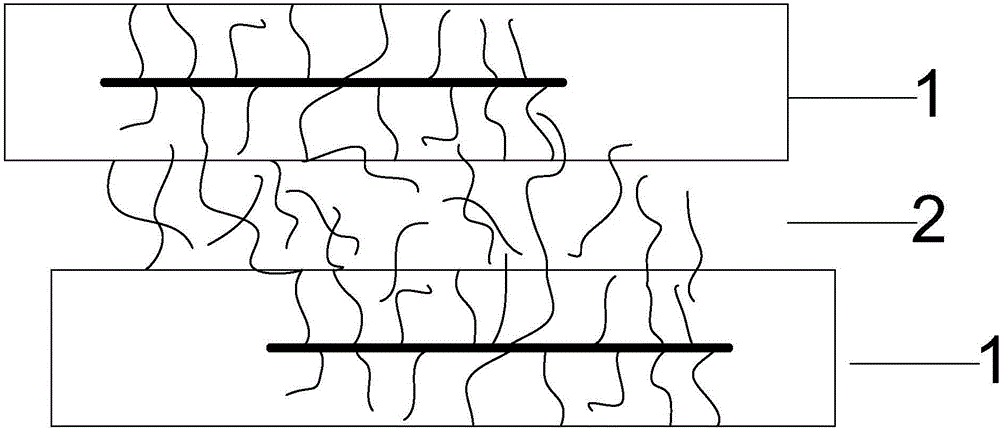

Polymer composite function fibers containing partial graphene, and preparation method thereof

ActiveCN105002595AIncrease productivityHigh strengthElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolyesterPolymer science

The present invention discloses a polymer composite function fibers containing partial graphene, and a preparation method thereof. The fibers comprise a component A and a component B, wherein the component A and the component B are combined in a partial exposing manner, side-by-side manner or skin-core manner, and 20-100% of the outer area of each fiber is the component B. The method comprises: crystallizing a polyester containing 0.1-1 wt% of partial reducing graphene and a polyester containing 4-20 wt% of a nanometer composite filler containing partial reducing graphene and TiO2, drying, carrying out melt composite spinning, and carrying out drawing and relaxation heat setting at a temperature of 80-160 DEG C, and reducing the partial graphene in the fibers to achieve the carbon / oxygen atom ratio of 9 / 1-15 / 1 through the reducing treatment. According to the present invention, the prepared fibers can be produced at the high spinning speed, and the production efficiency is high; and the fibers have characteristics of low single fineness, high strength and lower resistivity, meets the antistatic requirement, and further has characteristics of anti-bacterial property and flame retardant property so as to provide good application prospects.

Owner:NINGBO MYBABY BABY & CHILDREN PROD MFG

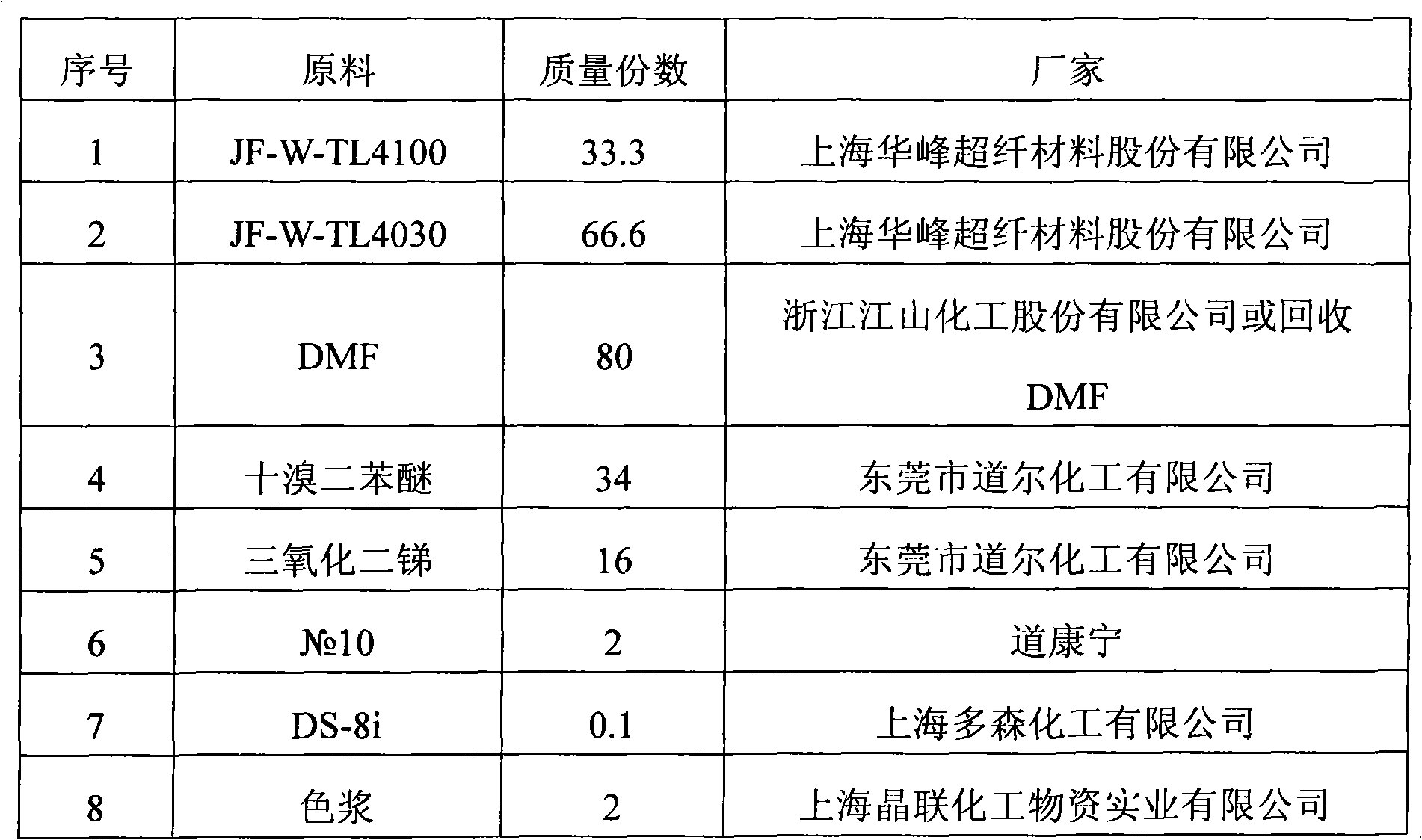

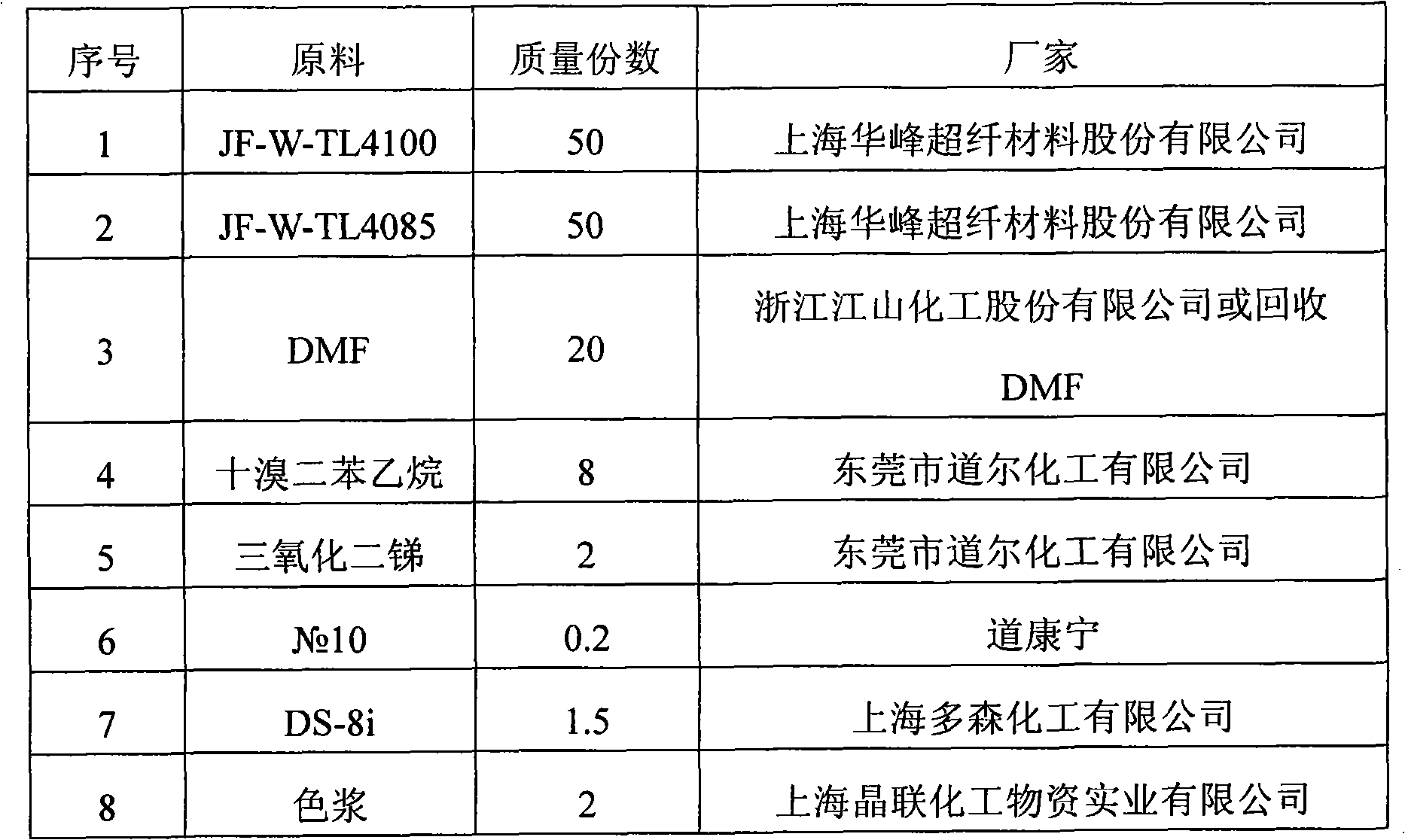

Superfine fiber polyurethane leather and base cloth as well as preparation method and application

InactiveCN101929083AImprove flame retardant performanceImprove performanceFlame-proof filament manufactureFibre treatmentPolymer scienceHigh wear resistance

The invention discloses a preparation method of a superfine fiber polyurethane leather base cloth based on a conventional process, and in the step of spinning, FR-535 flame retardant nylon master batches are added to perform fire retardant treatment on superfine fibers. The invention also discloses the superfine fiber polyurethane leather base cloth prepared by the method, a preparation method of superfine fiber polyurethane leather, the superfine fiber polyurethane leather prepared by the method and an application of the method in preparing leather for automobile trim. The method in the invention can enable the superfine fiber polyurethane leather base cloth and the synthetic leather to have excellent flame retardant property with the horizontal burning time of 3min and damaged length of no more than 81mm. In addition, the superfine fiber synthetic leather has excellent combination property, such as light resistance, favorable fastness, high wear resistance and the like, delicate color, has the physical properties capable of comparing favorably with natural cow leather, and can satisfy the requirement of leather in automobile trim.

Owner:HUAFON MICROFIBER SHANGHAI

Modified polypropylene fiber and preparation method thereof

InactiveCN104499089AReduce stretchDecreased spinnabilityFlame-proof filament manufactureFilament/thread formingHindered amine light stabilizersMelt blowing

The invention relates to a modified polypropylene fiber and a preparation method thereof. The invention is characterized in that the fiber has a skin-core structure, wherein the core layer is composed of pure polypropylene; and the skin layer is composed of 0.5-60 parts of functional material, 0-5 parts of compatilizer and the balance of polypropylene, totaling 100 parts. The viscosity-average molecular weight of the polypropylene is 0.18-0.3 million, and the degree of isotacticity is greater than 95%. The functional material is a functional polypropylene fiber master batch prepared by blending and granulating inorganic or organic functional micropowder, a compatilizer and polypropylene, wherein the functional micropowder is composed of one or more of nano silicon dioxide, nano titanium dioxide, nano silicon dioxide, an anti-mite agent and an N-substituted alkoxy hindered amine flame retardant. The polypropylene fiber can be subjected to skin-core conjugate spinning according to the skin-core formula, and can be further processed into a polypropylene fiber spunbonded nonwoven fabric or melt-blown nonwoven fabric by spunbonding or melt-blowing. The method has the advantages of simple production technique and small modification for equipment, and is easy for practical popularization and application.

Owner:BINZHOU COC CARPET

Flame-retardant polyester-based fiber for artificial hair

InactiveCN1846019AUsually heat resistanceUsual strengthFlame-proof filament manufactureWigsPolyesterFiber

The present invention provides a common polyester fiber which maintains fiber physical properties such as heat resistance and elongation, and is excellent in flame retardancy, fixation, drip resistance, transparency, and devitrification resistance, and the fiber beauty is controlled Polyester fiber and its artificial hair. It consists of 100 parts by weight of polyester (A) composed of one or more of polyalkylene terephthalate polyesters and copolyesters mainly composed of polyalkylene terephthalate polyesters, and organic cyclic phosphorus compounds and / or a composition obtained by melt-kneading 2 to 20 parts by weight of a phosphate ester amide compound (B), and a composition in which organic microparticles (C) and / or inorganic microparticles (D) are mixed in the composition, by By melt spinning, a flame-retardant polyester-based artificial hair fiber having solved the above-mentioned problems was obtained.

Owner:KANEKA CORP

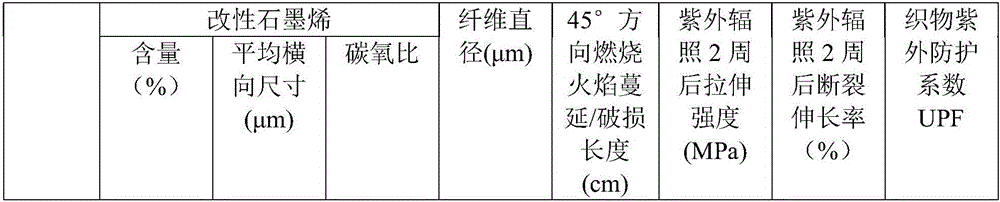

Graphene/nylon 6 fiber with flame-retarding and ultraviolet-proof properties and preparation method of graphene/nylon 6 fiber

ActiveCN106835333AAvoid cloggingImprove bindingFlame-proof filament manufactureMonocomponent polyamides artificial filamentGraphene nanocompositesNylon 6

The invention discloses a graphene / nylon 6 fiber with flame-retarding and ultraviolet-proof properties and a preparation method of the graphene / nylon 6 fiber and belongs to the technical field of functional high molecular materials. The graphene / nylon 6 fiber with the flame-retarding and ultraviolet-proof properties is prepared through high-speed melting spinning of a graphene / nylon 6 nano composite material; the graphene / nylon 6 nano composite material is prepared by compounding modified graphene, caprolactam and various auxiliary agents. The graphene / nylon 6 nano composite material obtained by the invention can continuously pass through a melting spinning hole at a high speed and continuous high-speed spinning is realized; the diameter of the fiber is 5mum to 50mum; compared with a pure nylon 6 fiber, the prepared graphene modified nylon 6 fiber has excellent flame-retarding, melt-dripping-resisting and ultraviolet-proof performances and the like.

Owner:HANGZHOU GAOXI TECH CO LTD

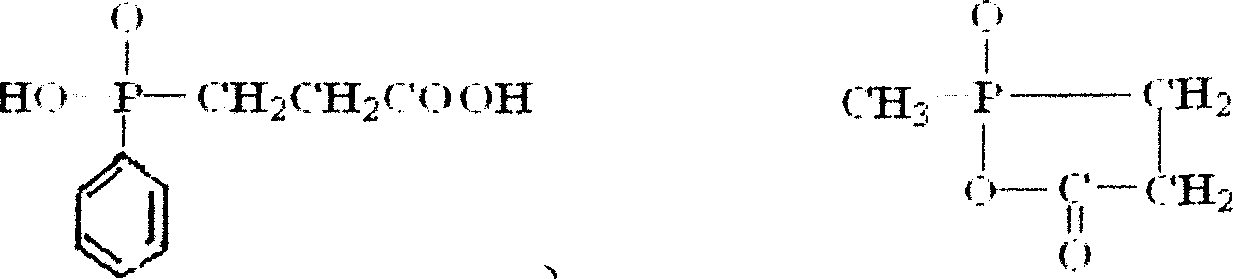

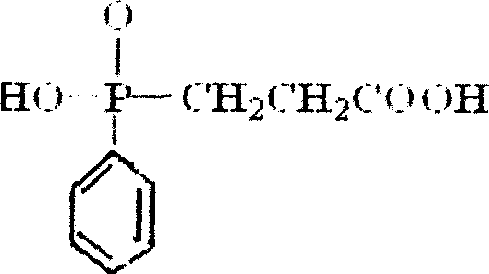

Phosphor series polyester flame-proof fiber and producing method

ActiveCN101104963AImprove spinnabilityImprove flame retardant performanceFlame-proof filament manufactureMelt spinning methodsPolytetramethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a P-based polyester fire-retardant fiber which comprises a fiber body containing polyethylene terephthalate, polytrimethylene terephthalate, polybutylene terephthalate or cation-modified polyethylene terephthalate. The fiber body further contains a P-based fire retardant selected from 2-carboxyethylphenyl phosphoric acid, 2-carboxyethyl methylphosphonate or 2-carboxyethyl methylphosphoric acid. The production process of the fiber comprises mixing polyesters for forming the fiber body with the P-based fire retardant, performing melt-spinning to obtain fire-retardant fiber precursor, subjecting to winding, stretching and netting processes to make fire-retardant polyester long filament (that is P-based polyester fire-retardant fiber). The inventive fire-retardant fiber has the similar physical property to the common polyester fiber and is superior in good spinning property and excellent fire-retarding effect.

Owner:TORAY IND INC

Technological process of producing fire retardant antiflux fiber

ActiveCN1847476AHigh strengthGuaranteed alkali resistanceFlame-proof filament manufactureMonocomponent cellulose artificial filamentCellulose pulpFire retardant

The present invention discloses technological process of producing fire retardant antiflux fiber. The fire retardant antiflux fiber is produced with cellulose pulp as material, and the production process includes the steps of: dipping, squeezing, crushing, ageing, sulfidizing, maturating, spinning, refining and stoving. The refining step includes washing, cross-liking and dewatering and oiling; and in the sulfidizing step, the silicon fire retardant is compounded into solution added into the alkali cellulose through stirring for dissolving and mixing to produce viscose of fire retardant fiber. The fire retardant antiflux fiber of the present invention has high fire retardant antiflux effect, high fiber strength and excellent filtering performance.

Owner:潍坊欣龙生物材料有限公司

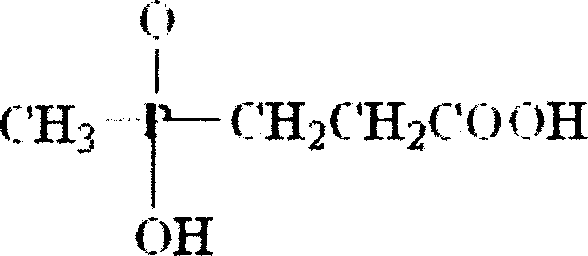

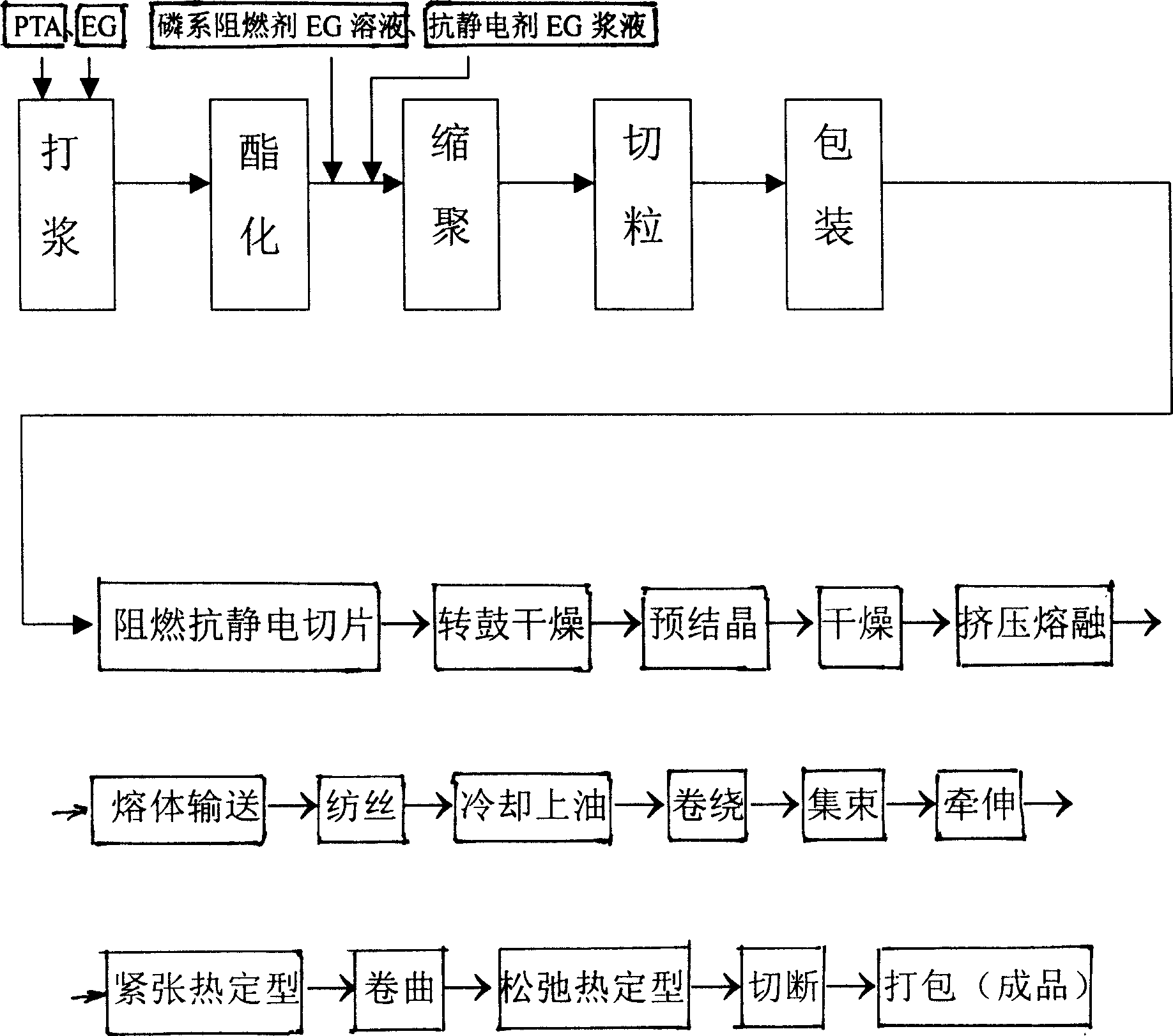

Method for manufacturing fire retardant-antistatic polyester fiber

InactiveCN1763275ATo satisfy the market's needsEvenly distributedFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberAntistatic agent

The invention relates to a making method of flame-proof-and-antistatic polyester fiber, which comprises the following steps: generating BHET terephthalic glycol ester monomer after the esterifying reaction of raw PTA terephthalic acid and EG glycol ester in the heating condition; leading the material into polyaxe; adding the preparing modulated functional additive of inorganic antistat EG glycol ester slurry in the atmospheric polycondensation reaction stage; putting the phosphorus-series flame retardant monomer of EG glycol ester solution into the polyaxe after 5 minutes; starting pressure-relief reaction after 5 minutes; generating the flame-proof-and-antistatic composite functional polyester microtome section by cooling the fondant; textiling the flame-proof-and-antistatic composite functional polyester microtome section into everlasting flame-proof-and-antistatic composite multi-functional polyester staple fiber. The technological program is reasonable and easy to operate.

Owner:天津石油化工公司化纤厂

Flame-resistant and uvioresistant polyester composite material and method for preparing same

ActiveCN101735578AFlame retardant hasHas anti-ultraviolet effectFlame-proof filament manufactureMonocomponent polyesters artificial filamentLow vacuumEsterification reaction

The invention relates to a flame-resistant and uvioresistant polyester composite material and a method for preparing the same. The composite material is prepared by performing an esterification reaction on ethylene glycol, terephthalic acid, uvioresistant agent pulp and a flame retardant and then performing low-vacuum condensation polymerization and high-vacuum condensation polymerization, wherein the added amounts of the uvioresistant agent pulp and the flame retardant are between 0.1 and 20 weight percent and between 0.1 and 20 weight percent respectively; the esterification reaction is performed at the temperature of between 200 and 290 DEG C and under a pressure of between 0.1 and 0.6 MPa for 1 to 4 hours; the low-vacuum condensation polymerization is performed at the temperature of between 200 and 290 DEG C and under the pressure of between 100,000 and 500 Pa for 10 to 90 minutes; the high-vacuum condensation polymerization is performed at the temperature of between 250 and 300 DEG C and under the pressure of between 500 and 50 Pa for 1 to 4 hours; and the uvioresistant agent pulp consists of 5 to 30 weight percent of inorganic nano-oxide and the ethylene glycol. Flame-resistant and uvioresistant polyester fiber fabrics prepared from the material have flame resistance and uvioresistant effect.

Owner:PETROCHINA CO LTD

Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection comprising aramid fiber and modacrylic fiber wherein the modacrylic fiber has less than 1.5 percent antimony and is preferably antimony-free. In one embodiment, the yarn, fabric, and / or garments consist essentially of (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 40 weight percent modacrylic fiber that is antimony-free, (c) 5 to 20 weight percent para-aramid fiber, and (d) 1 to 3 weight percent antistatic fiber, based on the total weight of components (a), (b), (c) and (d). In some embodiments, garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

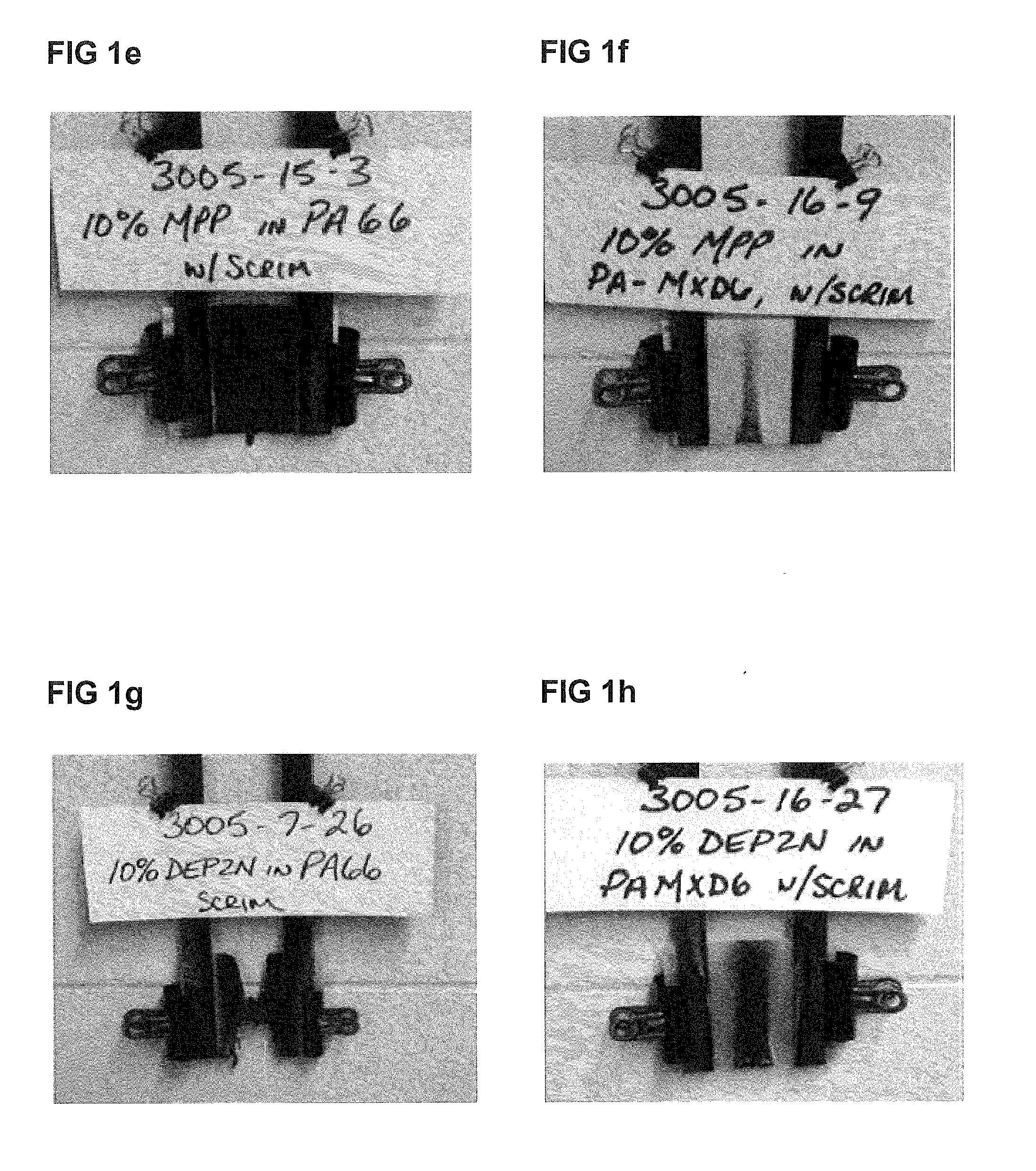

Flame retardant fibers, yarns, and fabrics made therefrom

ActiveUS20130244527A1Eliminate the effects ofImprove flame retardant performanceFlame-proof filament manufactureHeat resistant fibresFiberYarn

Disclosed are technical fibers and yarns made with partially aromatic polyamides and non-halogenated flame retardant additives. Fabrics made from such fibers and yarns demonstrate superior flame retardancy over traditional flame retardant nylon 6,6 fabrics. Further, the disclosed fibers and yarns, when blended with other flame retardant fibers, do not demonstrate the dangerous “scaffolding effect” common with flame retardant nylon 6,6 blended fabrics.

Owner:INV PERFORMANCE MATERIALS LLC

Blending fire retardant -type terylene industrial filament and its manufacturing technique

ActiveCN101265620AHigh strengthHigh modulusFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyethylene terephthalate glycolPolyethylene terephthalate

Owner:ZHEJIANG UNIFULL IND FIBER

Application of polyamide 5X as flame-retardant material

ActiveCN106147223AImprove flame retardant performanceIncrease the number of washesFlame-proof filament manufactureMonocomponent polyamides artificial filamentPolyamideHigh polymer

The invention provides an application of polyamide 5X as a flame-retardant material. When taken as the flame-retardant material, polyamide 5X has a good flame-retardant effect, is safe to the environment, safe in physiology and compatible with various high-polymer textile materials, cannot damage attractiveness and texture characteristics of textile, and is resistant to repeated washing and cleaning. When taken as the flame-retardant material, polyamide 5X has flame retardance which cannot be reduced with increase of the washing times, and belongs to a permanent flame-retardant type.

Owner:CATHAY R&D CENT CO LTD +1

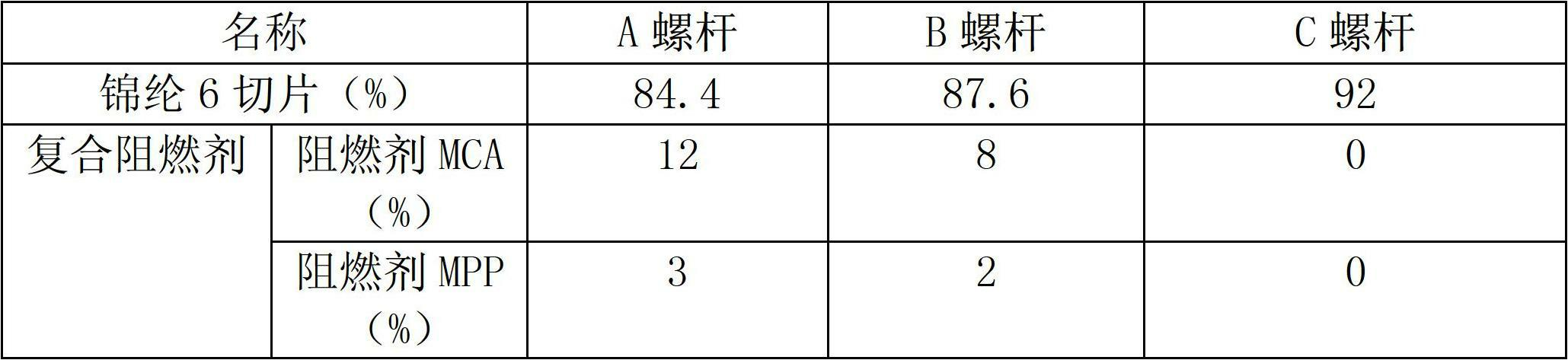

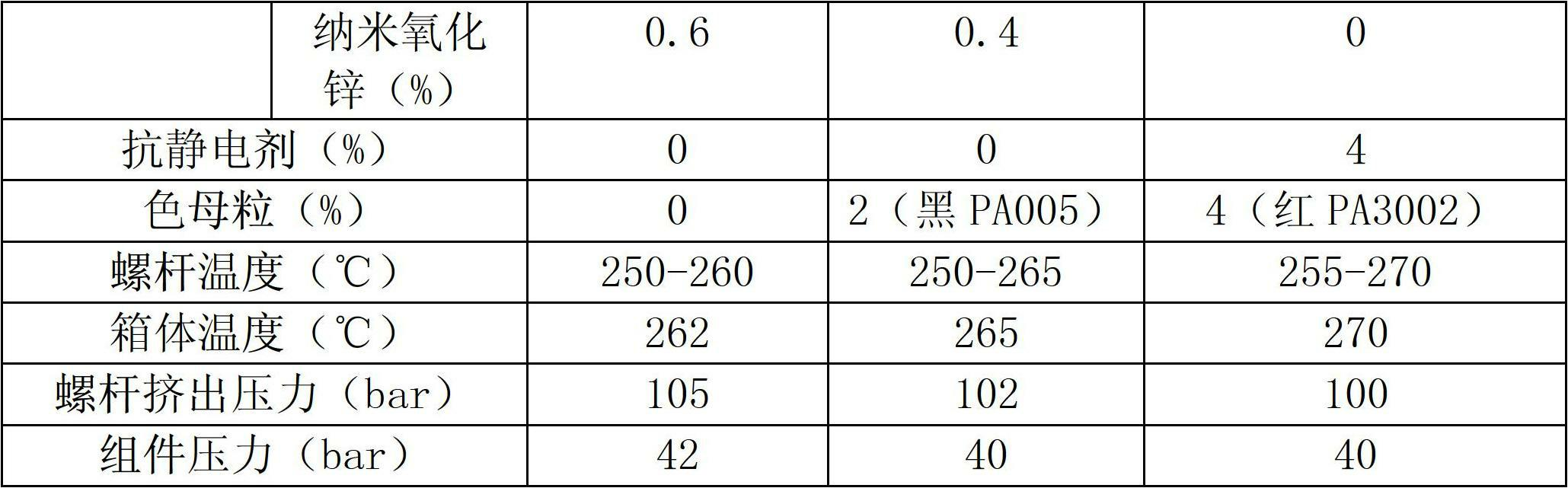

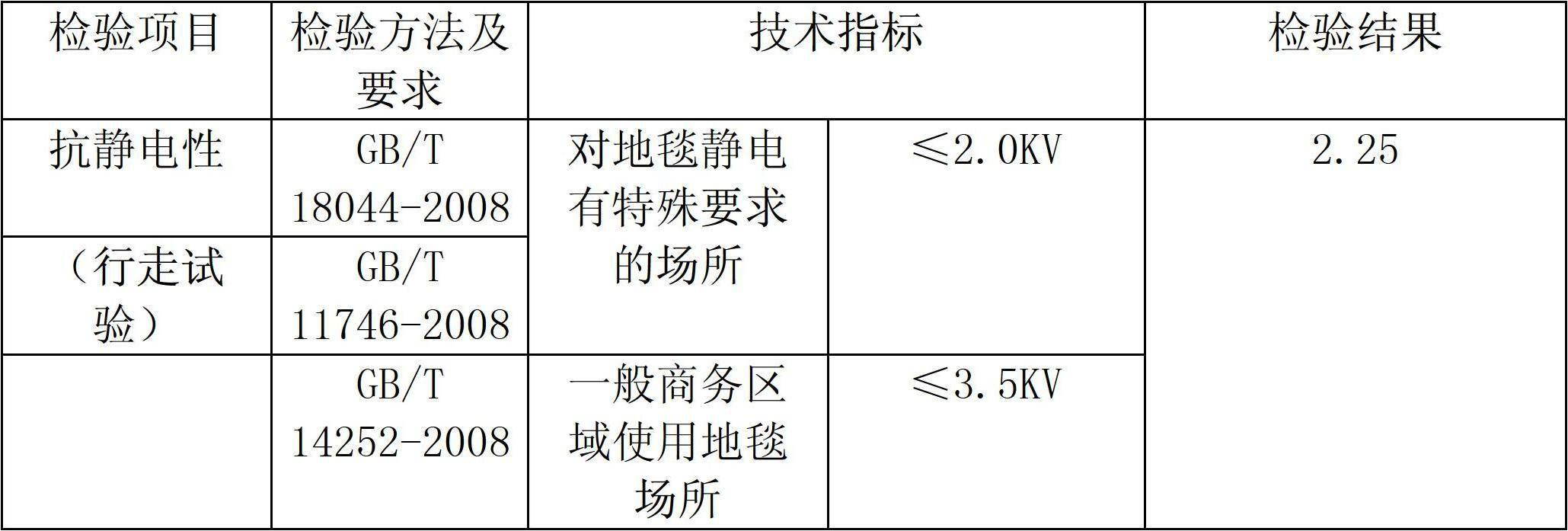

Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

ActiveCN102660819APermanent antistaticGuaranteed wear resistanceFlame-proof filament manufactureYarnComposite functionPolyamide

The invention relates to a permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and a preparation method. The permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn comprises a carpet yarn body, wherein the carpet yarn body consists of two tows of flame-retardant polyamide-6 bulked continuous filaments in different colors or the same color and a tow of antistatic polyamide-6 bulked continuous filaments; single fibers in the three tows of polyamide-6 bulked continuous filaments are random three-dimensional crimped fibers; different types of fibers are randomly mixed and intertwined; and periodical net knots are arranged on the surface of the carpet yarn body. The preparation method is implemented by one step through a tri-screw bulked continuous filament (BCF) spinning machine set. The product substantially maintains the characteristics of abrasion resistance, stain resistance, resilience and the like of polyamide-6, and also has a permanent antistatic function and a flame-retardant function. According to the preparation method, the characteristics of a production process of the tri-screw BCF spinning machine set are utilized, so that the aim of spinning the antistatic flame-retardant polyamide-6 textured carpet yarn by one step is fulfilled, and the production process is simple, practical and efficient.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

Popular searches

Conjugated synthetic polymer artificial filaments Spinning solutions preparation Dyeing process Woven fabrics Filament-forming treatment Pigment addition to spinning solution Artificial filaments from cellulose derivatives Stretch-spinning methods Staple fibre formation Synthetic polymer filament chemical after-treatment

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com