Polymer composite function fibers containing partial graphene, and preparation method thereof

A composite function, graphene technology, applied in the manufacture of fire-resistant and flame-retardant filaments, conductive/antistatic filaments, conjugated synthetic polymer artificial filaments, etc., can solve the problem of weakening high specific area, high conductivity and low overweight Problems such as permeation threshold, unfavorable industrial application, and low preparation efficiency have achieved the effect of meeting antistatic requirements, good application prospects, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

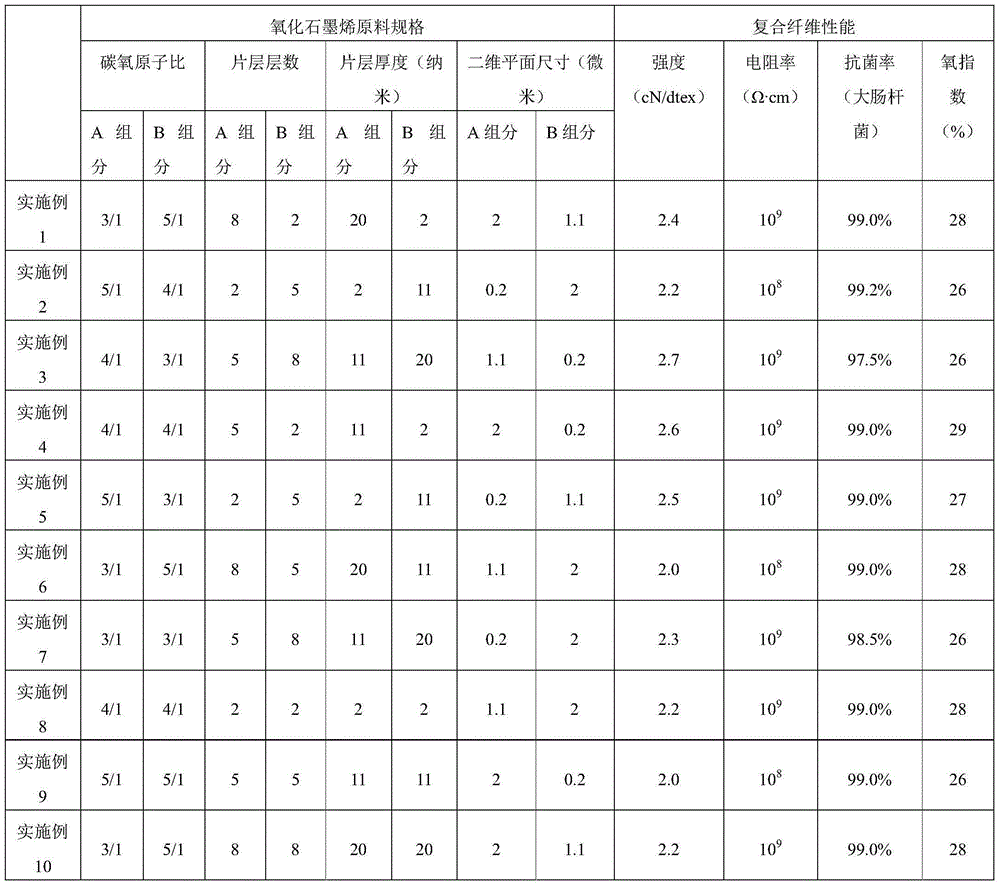

Examples

Embodiment 1

[0056] Take 2.8 kg of graphene oxide powder of the specifications shown in Table 1 and add it to 100 kg of ethylene glycol, stir mechanically for 30 minutes at room temperature, and then disperse with ultrasonic waves for 30 minutes to form a uniform and stable dispersed mixed slurry A; mix the mixed slurry A and purified terephthalic acid are added into the reaction kettle according to the molar ratio of ethylene glycol / purified terephthalic acid of 1.2 / 1, and antimony or titanium catalysts are added to carry out esterification at 215-235°C, and then at 260 Polyethylene terephthalate (PET) containing partially reduced graphene with a mass percentage of 1% is obtained by polymerizing at ~280°C as the A-component polyester. After testing, the intrinsic viscosity of the polyester is is 0.67dL / g, and the carbon / oxygen atomic ratio of partially reduced graphene is 3.5 / 1;

[0057] Get 5.7 kilograms of graphene oxide powder of specification shown in table 1 and mean diameter be the ...

Embodiment 2

[0060] Take 0.24 kg of graphene oxide powder of the specifications shown in Table 1 and add 100 kg of 1,3-propylene glycol, mechanically stir for 10 minutes at room temperature, and then disperse by ultrasonic waves for 60 minutes to form a uniform, stable and dispersed mixed slurry A; The mixed slurry A and purified terephthalic acid are added to the reaction kettle according to the molar ratio of 1,3-propanediol / purified terephthalic acid is 1.2 / 1, and a titanium series catalyst is added to carry out esterification at 205-225 °C, and then in Polytrimethylene terephthalate (PTT) containing partially reduced graphene with a mass percentage of 0.1% is obtained by polymerizing at 230-260°C as component A polyester. After testing, the intrinsic viscosity of the polyester is 0.92dL / g, the carbon / oxygen atomic ratio of partially reduced graphene is 5.3 / 1;

[0061] Get 5.8 kilograms of graphene oxide powder of specification shown in table 1 and mean diameter be the nano-titanium dio...

Embodiment 3

[0064] Take 1.2 kg of graphene oxide powder of the specifications shown in Table 1 and add it to 100 kg of 1,4-butanediol, stir it mechanically for 20 minutes at room temperature, and then disperse it by ultrasonic waves for 45 minutes to form a uniform, stable and dispersed mixed slurry A ;Put the mixed slurry A and purified terephthalic acid into the reaction kettle according to the molar ratio of 1,4-butanediol / purified terephthalic acid to 1.2 / 1, and add a titanium catalyst to carry out esterification at 215-235°C and then polymerized at 220-250°C to prepare polybutylene terephthalate (PBT) containing partially reduced graphene with a mass percentage of 0.55% as A-component polyester. After testing, the The intrinsic viscosity of polyester is 0.90dL / g, and the carbon / oxygen atomic ratio of partially reduced graphene is 4.2 / 1;

[0065] Get 7.8 kilograms of graphene oxide powders of specification shown in table 1 and mean diameter be the nano-titanium dioxide (TiO2) of 18 na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com