Patents

Literature

856 results about "Polytrimethylene terephthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

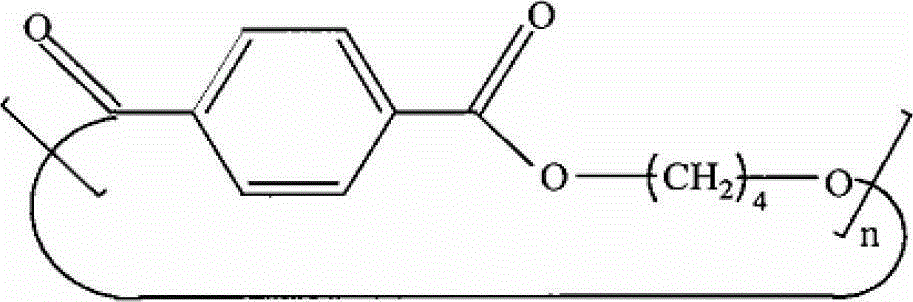

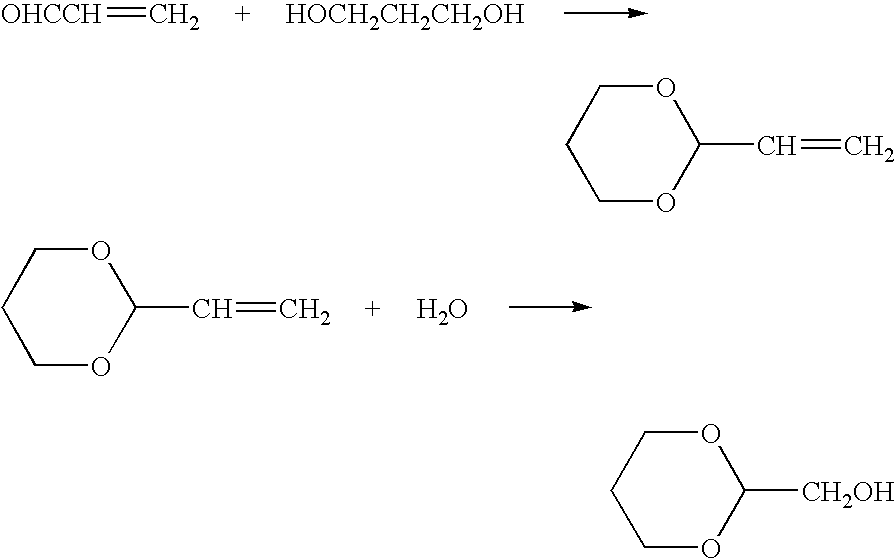

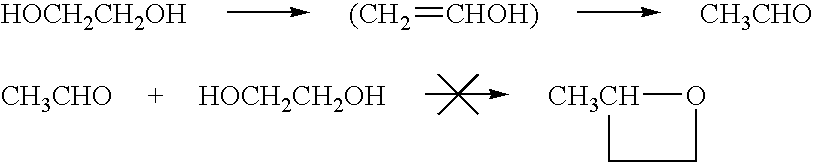

Polytrimethylene terephthalate (PTT), is a polyester synthesized and patented in 1941. It is produced by a method called condensation polymerization or transesterification. The two monomer units used in producing this polymer are: 1,3-propanediol and terephthalic acid or dimethyl terephthalate. Similar to polyethylene terephthalate, the PTT is used to make carpet fibers.

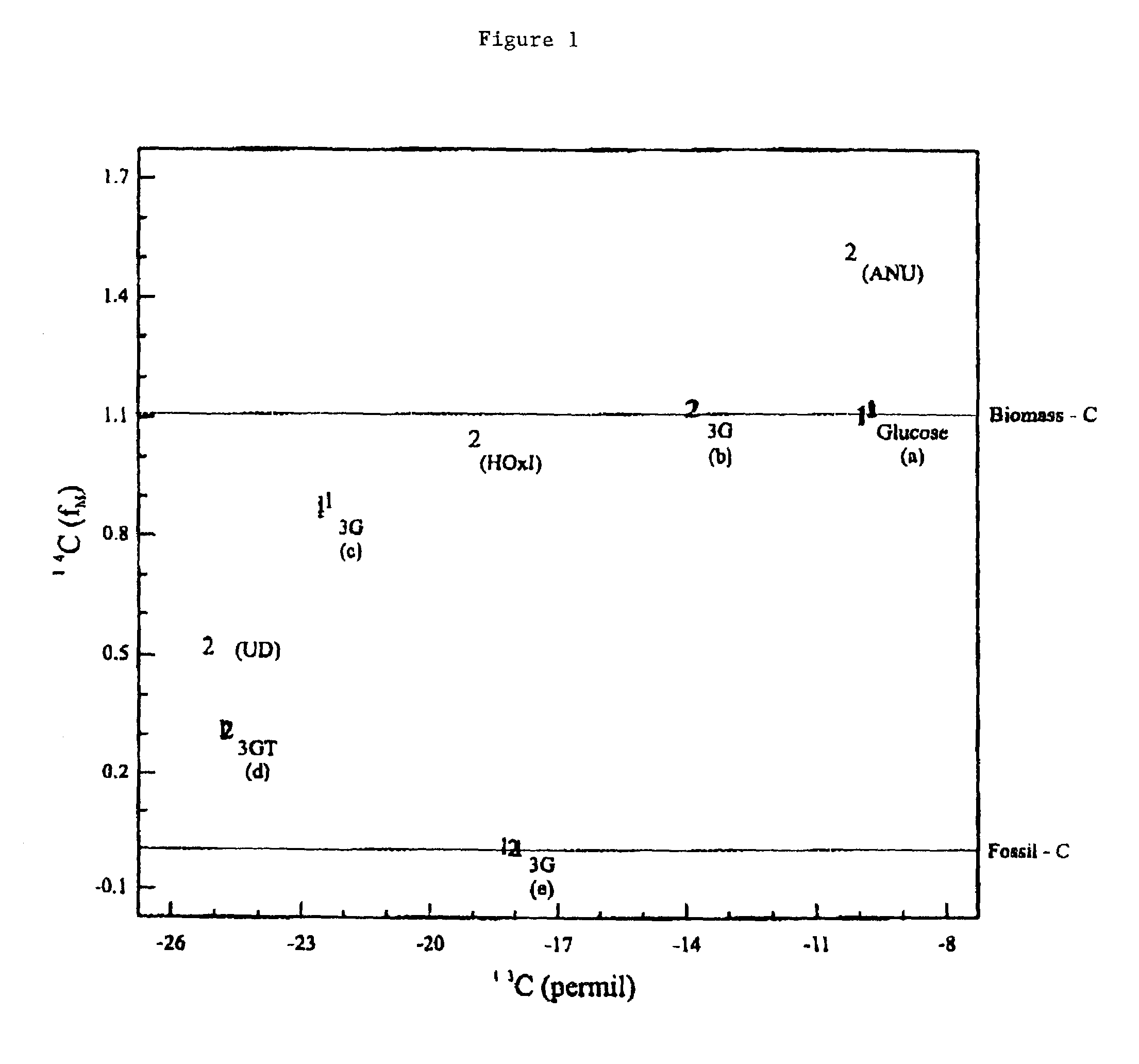

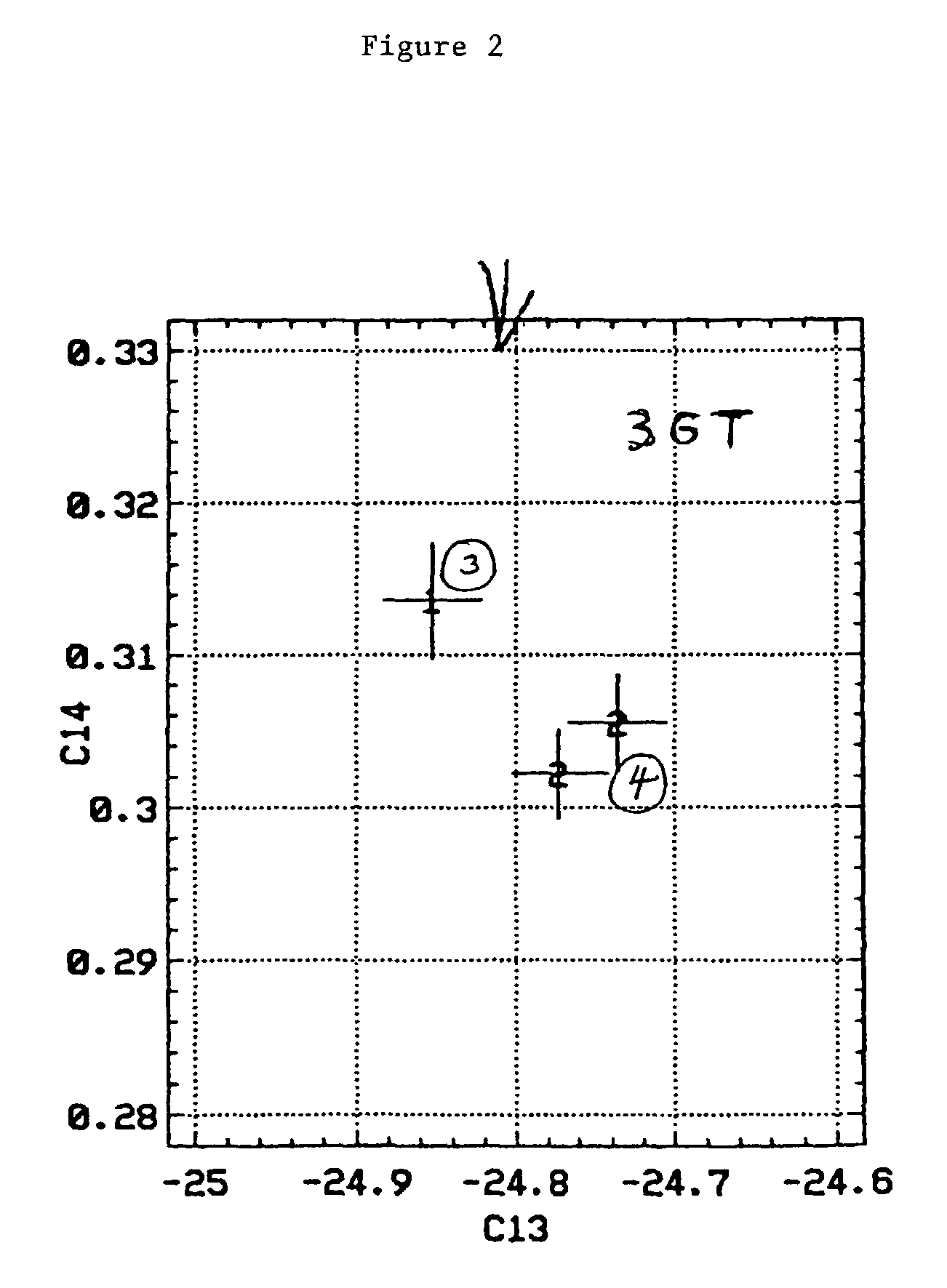

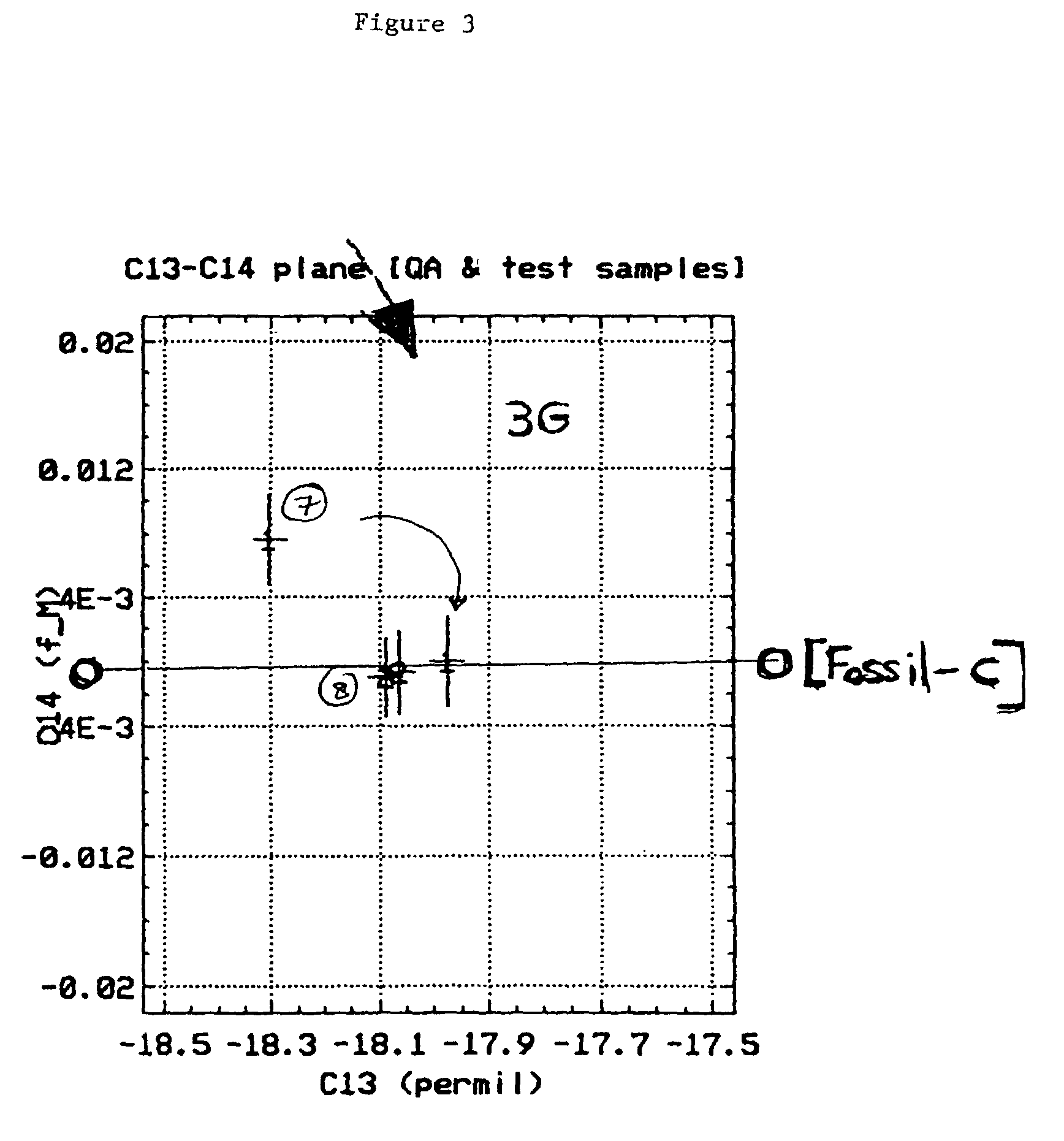

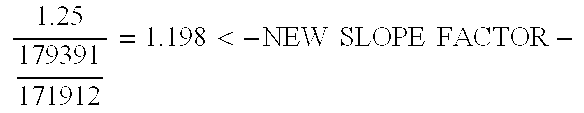

Bioconversion of a fermentable carbon source to 1,3-propanediol by a single microorganism

A new polypropylene terephthalate composition is provided. The polypropylene terephthalate is comprised of 1,3-propanediol and terephthalate. The 1,3-propanediol is produced by the bioconversion of a fermentatble carbon source, preferable glucose. The resulting polypropylene terephthalate is distinguished from petrochemically produced polymer on the basis of dual carbon-isotopic fingerprinting which indicates both the source and the age of the carbon.

Owner:EI DU PONT DE NEMOURS & CO +1

Preparation of poly(trimethylene terephthalate) with low level of di(1,3-propylene glycol)

A process of preparing poly(trimethylene terephthalate) containing less than 2.0 mole % of DPG comprising:(a) providing a molar amount of 1,3-propanediol:C1 to C4 dialkyl ester of terephthalic acid of 1.2:1 to 1.9:1,(b) reacting the 1,3-propanediol with the C1 to C4 dialkyl ester of terephthalic, acid to form bis(3-hydroxypropyl)terephthalate monomer in the presence of 10-100 ppm (as titanium metal) of an organic titanate catalyst, by weight of the poly(trimethylene terephthalate), and(c) polymerizing the bis(3-hydroxypropyl)terephthalate monomer to obtain the poly(trimethylene terephthalate); andpoly(trimethylene terephthalate) produced by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

Preparation method of functional polyester fibers

ActiveCN102719932AHigh crystallinityImprove mechanical propertiesFilament forming substance formingMelt spinning methodsPolytetramethylene terephthalatePolyethylene glycol

The invention provides a preparation method of functional polyester fibers. The preparation method mainly comprises the following two steps of: firstly, mixing functional powders, polybutylene terephthalate cyclic oligomer (CBT) and a dispersing agent, performing reactive extrusion on the mixture by double screws to prepare a polybutylene terephthalate (PBT) functional master batch, wherein the functional powders are one of or several of a carbon nano tube, nano titanium dioxide, tourmaline powders, a nano-silver antibacterial agent, a nano silicon oxide and fluorescent powders; and secondly, blending and spinning the master batch, the PBT, polyethylene glycol terephthalate (PET) or polytrimethylene terephthalate (PTT) to prepare the functional polyester fibers. According to the method, the reactive extrusion process is adopted, the operation is simple and convenient, the process flow is shortened greatly, the obtained PBT functional master batch contains 30wt%-40wt% of the functional powders, and can be well dispersed in a base body, the compatibility of the obtained functional master batch and polyester polymer is good, and the fiber obtained by the method has an obvious functional effect.

Owner:ZHOUSHAN XINXIN CHEM FIBER

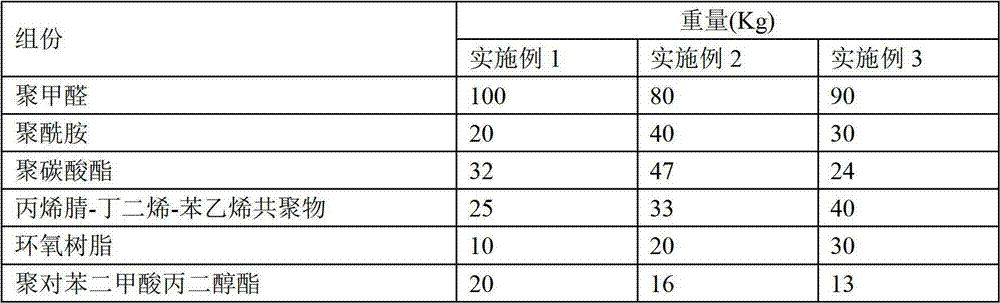

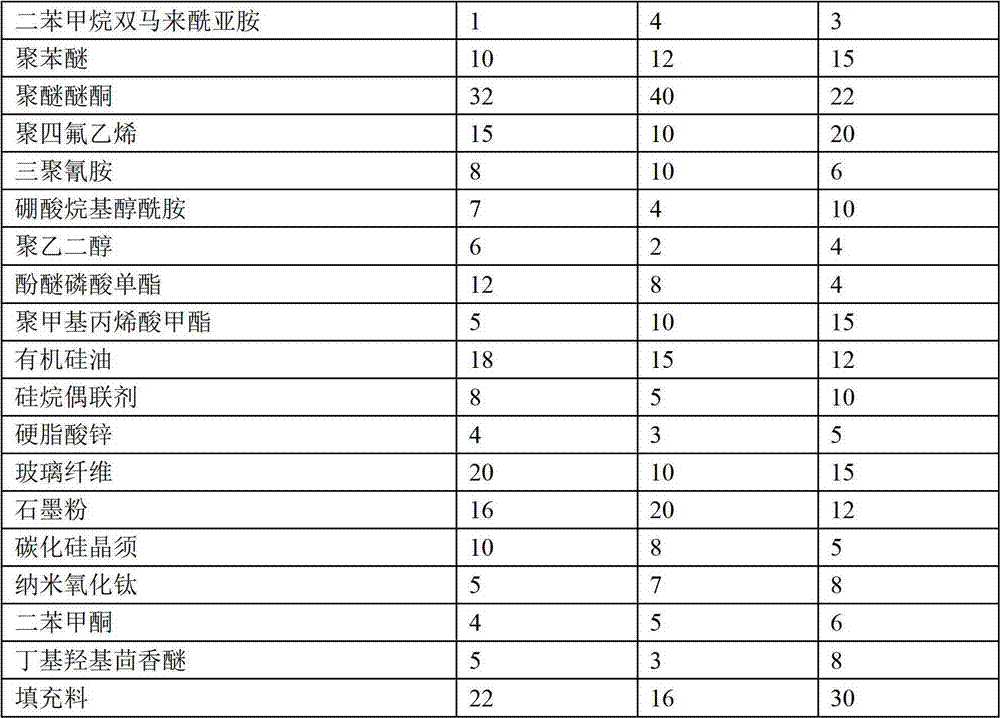

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

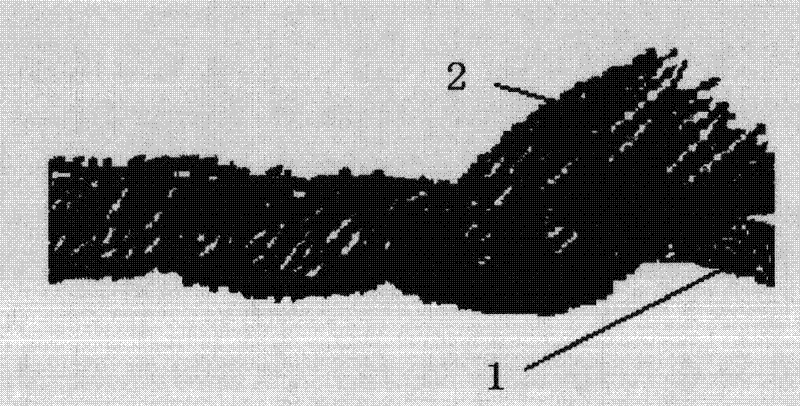

Composite elastic filament core-spun yarn fabric and preparation method thereof

InactiveCN102454004AElasticWon't breakFilament/thread formingWoven fabricsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to a composite elastic filament core-spun yarn fabric and a preparation method thereof. The wefts of the composite elastic filament core-spun yarn fabric are elastic filament core-spun yarns, the warps of the composite elastic filament core-spun yarn fabric are elastic filament core-spun yarns or non-elastic yarns, and the elastic filament core-spun yarn is prepared from a PTT(polytrimethylene terephthalate) / PET (polyethylene terephthalate) parallelly composite elastic filament serving as a core yarn and natural fibers and / or chemical fibers serving as coating fibers, wherein the weight ratio of the core yarn to the coating fiber is (3:7)-(7:3). The weft flotation line of the fabric has 1-4 intersection points, and the fabric is prepared by virtue of a core-spun yarn spinning process, a weaving process and a dyeing and finishing process. The fabric is prepared by coating the PTT / PET parallelly composite elastic filament with cotton fibers and the like with good comfortability, thereby meeting the requirements of elasticity and comfortability. In the subsequent processing and using of the fabric, the elastic structure of the product provided by the invention is not destroyed by mechanical, thermal and chemical conditions. Therefore, the product provided by the invention has the advantage of durable weft-direction elasticity.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Ester-forming monomer

InactiveUS6867322B1High recovery rateEasy to separateOxygen-containing compound preparationOrganic compound preparationDepolymerizationPolymer science

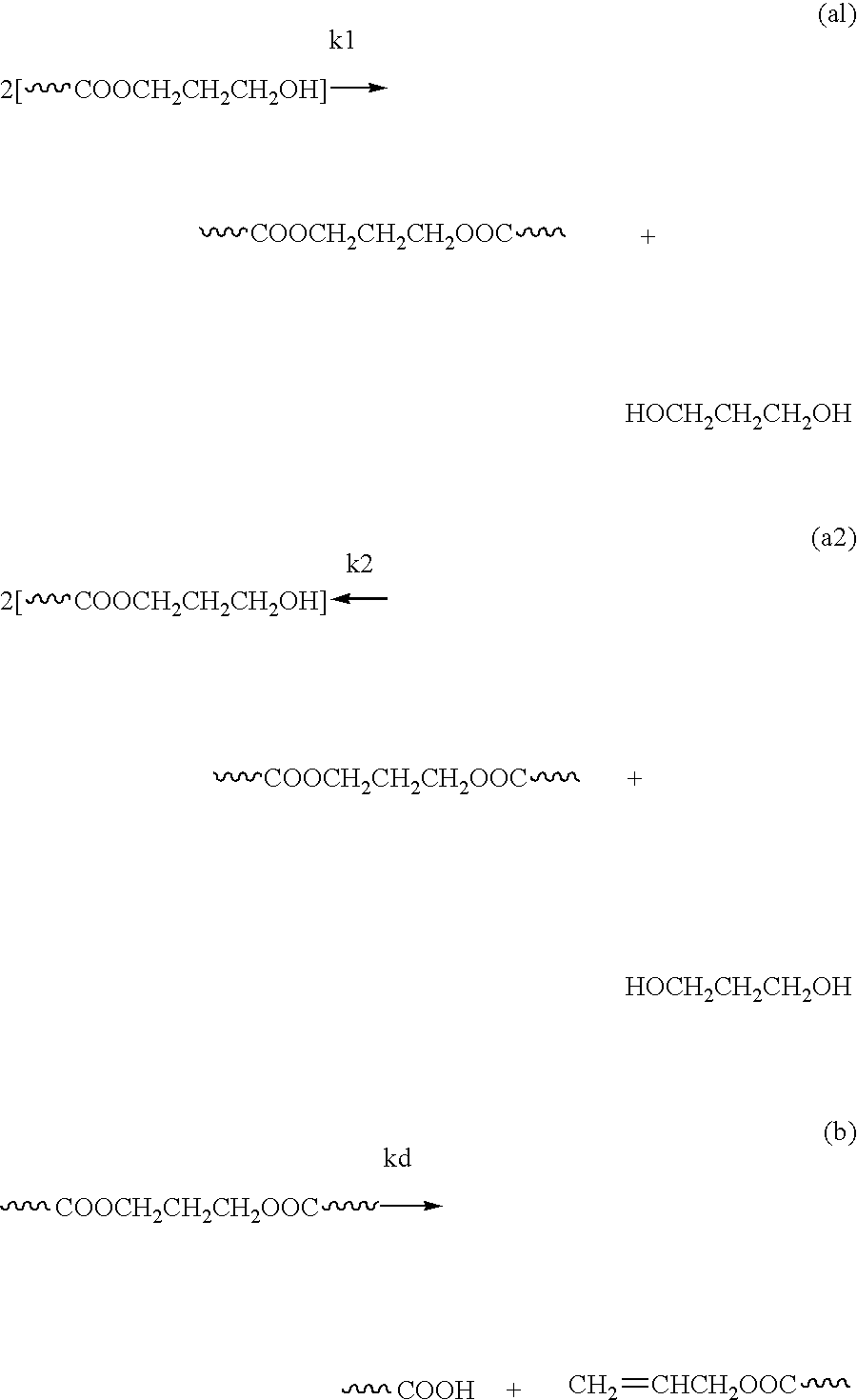

An ester-forming monomer obtained by depolymerization of polytrimethylene terephthalate and having an acrolein content of no greater than 0.5 wt %. Polymers obtained using the monomer and fibers, films and molded articles comprising the polymers. The ester-forming monomer is obtained by reacting polytrimethylene terephthalate with at least one compound selected from among monoalcohols, 1,3-propanediol and water in the presence of a basic substance. When the recovered ester-forming monomer is used as the starting material for production of a polymer, it is possible to produce a molding polymer for fibers, films and the like with quality equivalent to or higher than that obtained using virgin monomer.

Owner:ASAHI KASEI KK

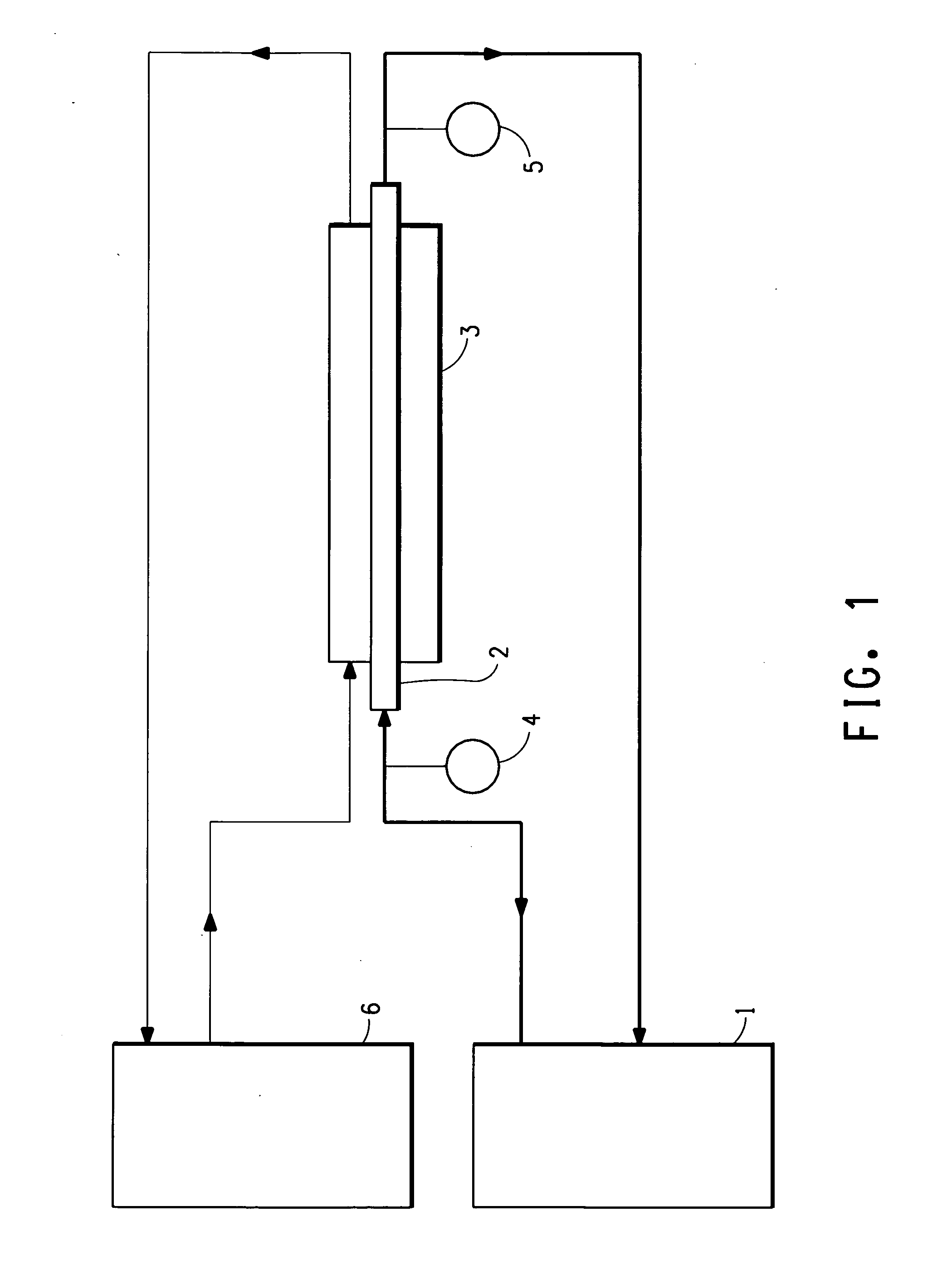

Continuous process for producing poly(trimethylene terephthalate)

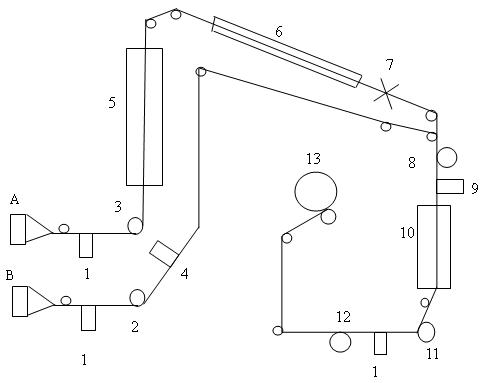

InactiveUS20070191580A1Quality improvementReduce the amount requiredPiezoelectric/electrostrictive microphonesMicrobiological testing/measurementPolytrimethylene terephthalatePropanediol

This invention relates to a continuous process for production of poly(trimethylene terephthalate), wherein gaseous 1,3-propanediol by product resulting from the process is condensed in a condenser, and a portion of the condensed by-product is recycled back into the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

Phosphor series polyester flame-proof fiber and producing method

ActiveCN101104963AImprove spinnabilityImprove flame retardant performanceFlame-proof filament manufactureMelt spinning methodsPolytetramethylene terephthalatePolyethylene terephthalate glycol

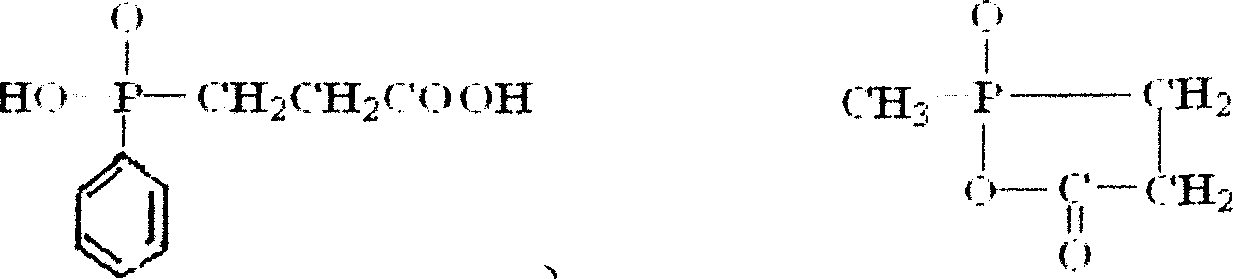

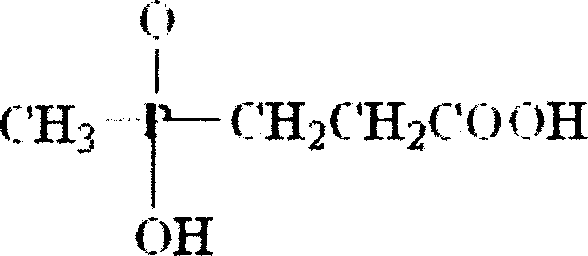

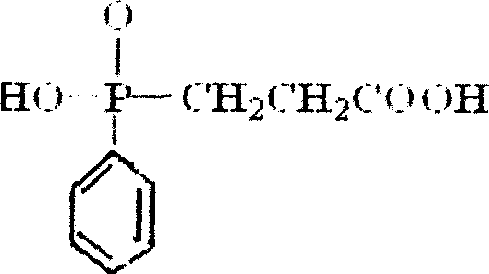

The invention discloses a P-based polyester fire-retardant fiber which comprises a fiber body containing polyethylene terephthalate, polytrimethylene terephthalate, polybutylene terephthalate or cation-modified polyethylene terephthalate. The fiber body further contains a P-based fire retardant selected from 2-carboxyethylphenyl phosphoric acid, 2-carboxyethyl methylphosphonate or 2-carboxyethyl methylphosphoric acid. The production process of the fiber comprises mixing polyesters for forming the fiber body with the P-based fire retardant, performing melt-spinning to obtain fire-retardant fiber precursor, subjecting to winding, stretching and netting processes to make fire-retardant polyester long filament (that is P-based polyester fire-retardant fiber). The inventive fire-retardant fiber has the similar physical property to the common polyester fiber and is superior in good spinning property and excellent fire-retarding effect.

Owner:TORAY IND INC

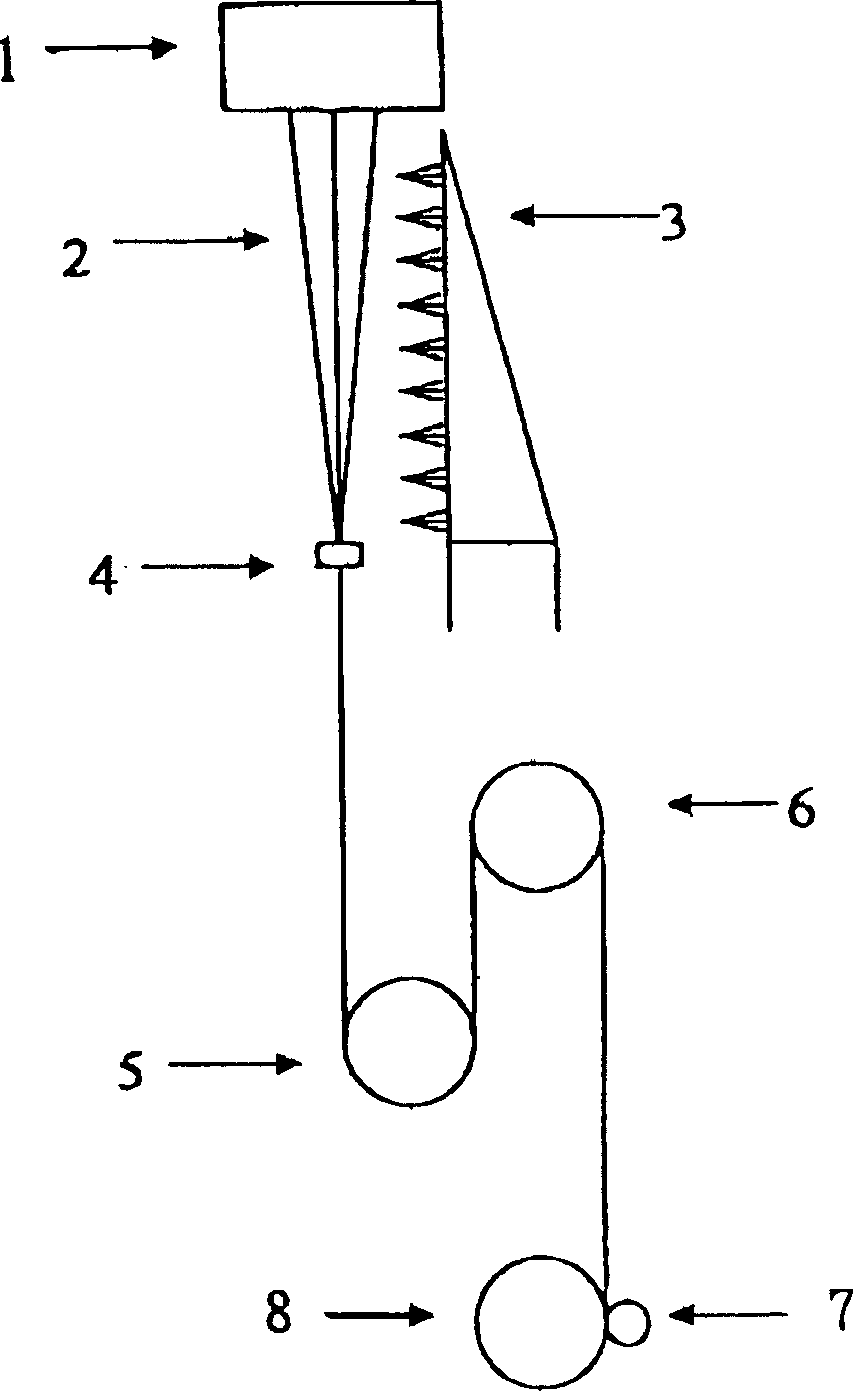

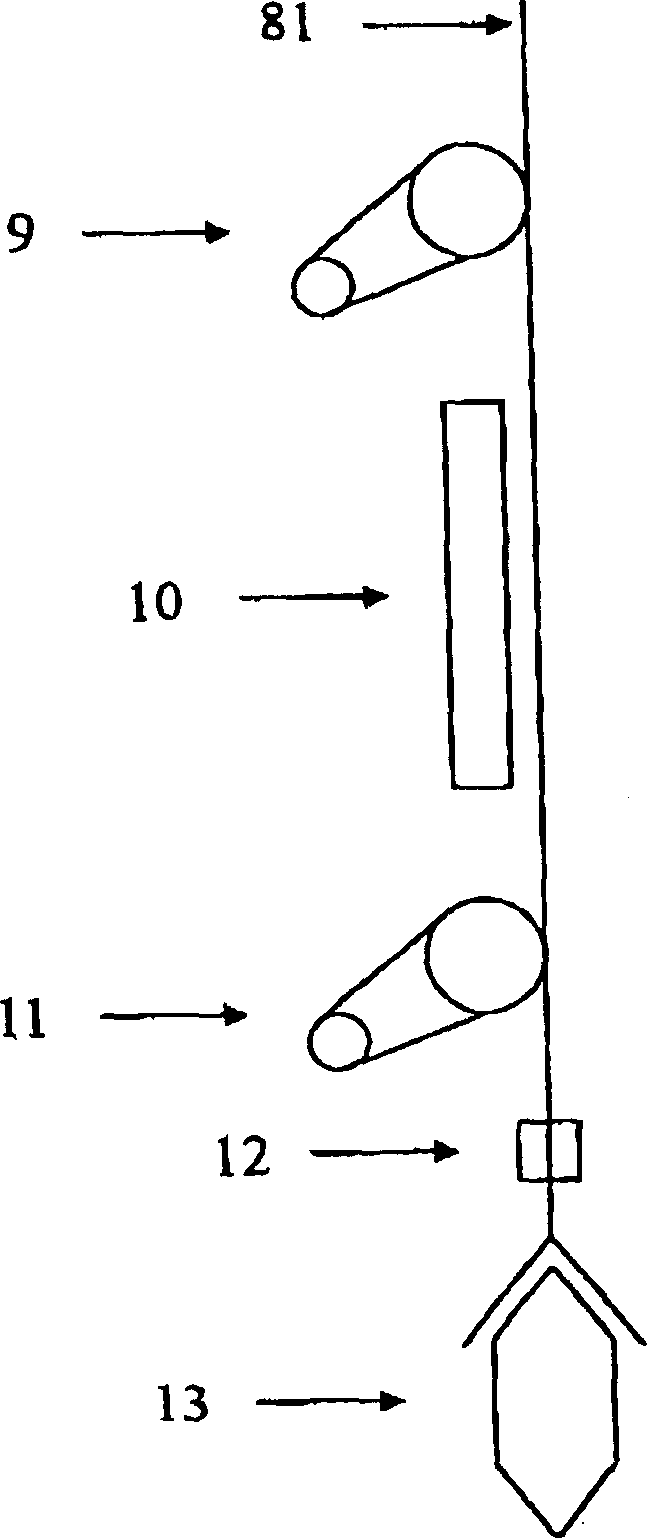

Process of making poly (trimethylene dicarboxylate) fibers

InactiveUS6923925B2Raise the draw ratioGood orientationLayered productsDrafting machinesPolymer scienceSpinning

A process for preparing poly(trimethylene dicarboxylate) multifilament yarns and monofilaments. One process for preparing poly(trimethylene dicarboxylate) multifilament yarns includes (a) providing a polymer blend including poly(trimethylene dicarboxylate) and about 0.1 to about 10 weight % styrene polymer, by weight of the polymer in the polymer blend, (b) spinning the polymer blend to form poly(trimethylene dicarboxylate) multiconstituent filaments containing dispersed styrene polymer, and (c) processing the multiconstituent filaments into poly(trimethylene dicarboxylate) multifilament yarn including poly(trimethylene dicarboxylate) multiconstituent filaments containing styrene polymer dispersed throughout the filaments. Another process includes spinning at a speed of at least 3,000 m / m and processing a blend including poly(trimethylene dicarboxylate) to form partially oriented poly(trimethylene dicarboxylate) multifilament yarn. A poly(trimethylene terephthalate) yarn including poly(trimethylene terephthalate) multiconstituent filament containing styrene polymer dispersed throughout the multiconstituent filament. The invention is also directed to uses of the filament yarns and monofilament.

Owner:DUPONT IND BIOSCIENCES USA LLC

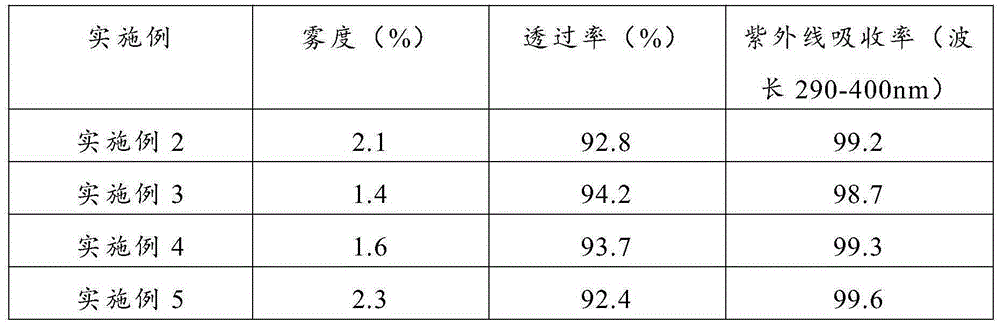

Heat-insulation anti-ultraviolet automobile membrane and preparation method thereof

The invention provides a heat-insulation anti-ultraviolet automobile membrane and a preparation method thereof. According to the technical scheme, polyethylene terephthalate, polytrimethylene terephthalate, polyimide, molybdenum disulfide, a plasticizer, carboxymethyl cellulose, nanometer silicon dioxide, ethylene-alpha-alkene copolymer, an antioxidant and an anti-ultraviolet anti-ageing nanometer composite material are taken as raw materials. Compared with the prior art, the nanometer-cerium-dioxide-coated nanometer zinc oxide composite material possesses the characteristics of being resistant to ultraviolet irradiation, resistant to heat, non-toxic, strong in stability and the like, and is capable of shielding ultraviolet and reflecting ultraviolet outside of the membrane. Therefore, the heat-insulation anti-ultraviolet automobile membrane is simple in preparation technology, and possesses the characteristics of being good in heat-insulation effect, resistant to high temperature, resistant to ultraviolet and resistant to ageing. The invention also provides a preparation method for an anti-ultraviolet anti-ageing nanometer composite material, and the anti-ultraviolet anti-ageing nanometer composite material possesses god anti-ultraviolet and anti-ageing performances.

Owner:广州市宝裕新型材料有限公司

Method for manufacturing seamless knitted dress employing PTT fiber

InactiveCN101177831AGood elasticity and durabilitySoft touchWeft knittingWarp knittingTextile technologyExtensibility

The invention relates to a production method of seamless knitted garments adopting polytrimethylene terephthalate fibre, including the steps of (1) selecting raw materials according to product purposes, requirement of style and performance and characteristics of the raw materials; (2) establishing textile technology and weaving garment blank by a knitting machine; (3) according to colored woven garment and grey garment sorting and making a finishing process flow; (4) confirming key finishing process parameter. The finished PTT seamless knitted garments by adopting the invention have soft texture, good extensibility, good rebound elasticity, and are comfortable and beautiful; the elasticity in particular lasts long; compared with the existing products made of nylon and spandex, the product has incomparable advantage in chlorine fastness, sun fastness and high-temperature processing resistance, etc., which leads possible extended application of the seamless knitted garments to high grade swimwear, sportswear, high temperature printing, etc.

Owner:DONGHUA UNIV +1

Bi-component sheath-core composite high-stretch fiber and preparation method thereof

ActiveCN101845686AEasy accessImprove dyeing effectConjugated synthetic polymer artificial filamentsStretch-spinning methodsPolytetramethylene terephthalatePolytrimethylene terephthalate

The invention provides a bi-component sheath-core composite high-stretch fiber. The bi-component is a polyester component and a polyamide component respectively, wherein the polyamide component forms an outer sheath part; the polyester component forms an inner core part; the outer sheath part is coated around the inner core part; and the polyester component may be one or more of a cationic normal-pressure dyeable polyester, a polytrimethylene terephthalate and a polybutylene terephthalate. As the bi-component sheath-core composite high-stretch fiber provided by the invention utilizes a polyester of which a molecular chain has flexible branched chains, such as the cationic normal-pressure dyeable polyester, the polytrimethylene terephthalate, the polybutylene terephthalate and the like, the prepared composite fiber is looser, and dyes can enter the fiber more easily to achieve higher dying performance under a conventional dying condition. The invention also provides a preparation method for the bi-component sheath-core composite high-stretch fiber.

Owner:厦门象屿兴泓特种材料有限公司

New elastic fiber and preparation method thereof

InactiveCN101357980ADyeing processConjugated synthetic polymer artificial filamentsPolytrimethylene terephthalateCopolyester

The invention provides a high elasticity fiber, which is a bicomponent composite fibre. One component of the bicomponent composite fiber is synthetic high contractility copolyester HSPET, which is prepared with terephthalic acid, m-phthalic acid, glycol and neopentyl glycol through esterification and polycondensation reaction; and the other component of the bicomponent composite fiber is polytrimethylene terephthalate. After the bilateral composite fiber is heated, a helical tridimensional curled structure is got so that the fiber has excellent elastic elongation and elastic recovery. The bicomponent composite fiber is a novel functional fibrous material applicable for weaving elastic textiles.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

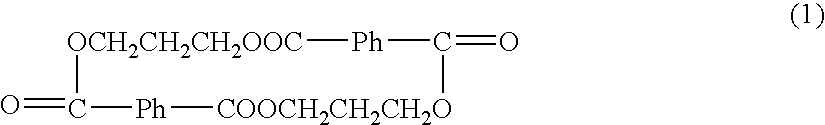

Polytrimethylene terephthalate

InactiveUS20060020103A1Reduce contentNot easy to produceMonocomponent polyesters artificial filamentArtifical filament manufactureHydrogen atomAlkaline earth metal

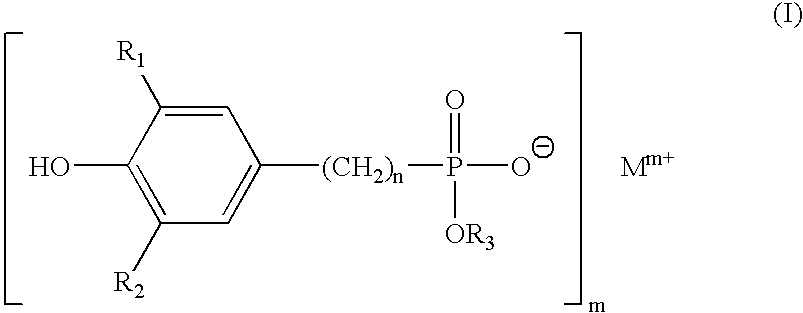

Polytrimethylene terephthalate which has a low content of a cyclic dimer and hardly produces the cyclic dimer when it is melt molded and a fiber made from the polytrimethylene terephthalate. Polytrimethylene terephthalate (A) is essentially composed of a trimethylene terephthalate unit, has an intrinsic viscosity of 0.5 to 1.6 dl / g and contains 0.01 to 0.5 wt % of a compound represented by the following formula (I) or (II): (R1, R2 and R3 are the same or different hydrocarbon groups having 1 to 10 carbon atoms, n is an integer of 1 to 5, M is an alkali metal atom or alkali earth metal atom, and m is 1 when M is an alkali metal atom and 2 when M is an alkali earth metal atom), (R4 and R5 are the same or different and each a hydrogen atom or hydrocarbon group having 1 to 10 carbon atoms).

Owner:SOLOTEX CORP

Preparation method of novel wool-like differential fibers

The invention discloses a preparation method of novel wool-like differential fibers, which is characterized by comprising the following steps of: 1) adopting polytrimethylene terephthalate (PTT) as a raw material to prepare a pre-oriented yarn (a); 2) adopting modified high-shrinkage polyester as a raw material to prepare fully-drawn high boiling water shrinkage fibers (b); and 3) on a DTY machine, passing the pre-oriented yarn (a) through a roller, a hot box and a cooling plate, performing drawing false twisting on the pre-oriented yarn on a false twister, converging the pre-oriented yarn with the high boiling water shrinkage fibers (b) in front of two rollers, and performing network compounding on the pre-oriented yarn and the high boiling water shrinkage fibers, and then passing the pre-oriented yarn and the high boiling water shrinkage fibers through two hot boxes to obtain a composite yarn product. The preparation method develops the novel wool-like differential fibers, the PTT fibers floating on the surface layer are much closer to wool fibers in performance and are superior to common wool-like products in the performance of elastic recovery, handfeel, antistatic property, dyeing and the like, and simultaneously, the treatment of forming different sections of the two raw materials ensures that the products have significant improvements on luster and fibrillation resistance.

Owner:嘉兴逸鹏化纤有限公司

Polyytrimethylene terephthalate fiber cross-blended yarn and its production process

This invention relates to the polyterephthalic acid propane diols ester fibre mixing spinning and its production technology. This invention includes output and method. And this product is spinned by the following steps: spinning with the PPT polyster short fibre and cotton, spinning with the PPT polyster short fibre and mucilage glue, modal, Lyocell, tencel knitted fabric fiber; spinning with the PPT polyster short fibre and wool, pashm, knitted fabric fibre. This technology uses the conventional device of the national cotton factory, wherein the clear cotton is the best as the comb pin; and the relative humidity of the clear cotton should be high; the clear cotton of the comb cotton should be kept well; and in the drafting and roving working procedure, it needs a higher humidity and not high temperature; the ration of the roving should be controlled in a fit mount; the twist modulus is to be 280-340ú¼ the combined roots should be 6 as its best. The product in this invention has a better handle and simulating characteristic.

Owner:SHANGHAI NO 17 COTTON TEXTILE MILL

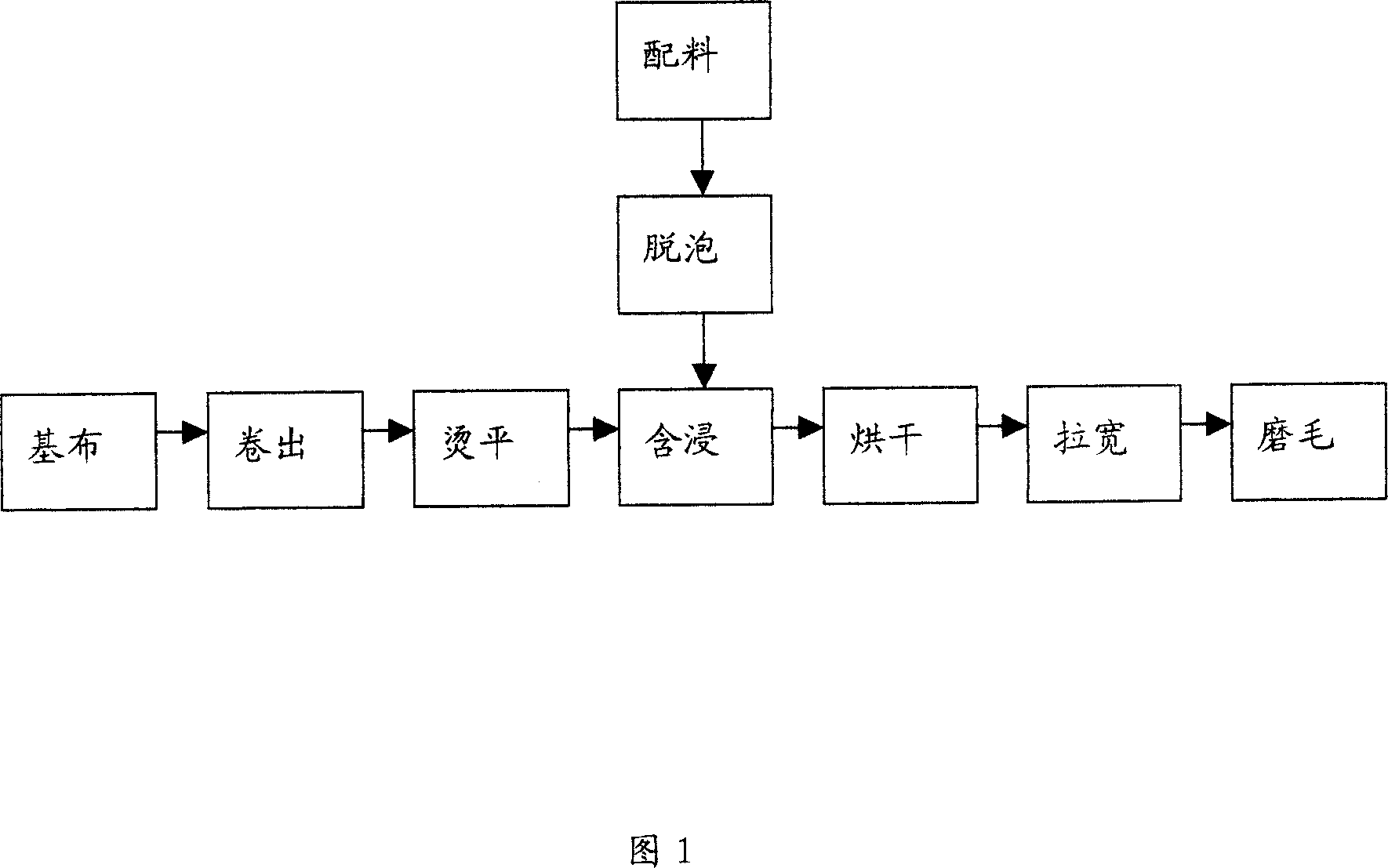

Method for making aqueous polyurethane elastic suede leather

InactiveCN1952253AReduce manufacturing costReduce pollutionTextiles and paperPolyurethane dispersionWater based

The invention relates to a production method for water-based polyurethane elastic chammy suede leather. The procedure is that a. polyurethane is coated to the elastic island substrate of chammy suede; b. it is dried and formed by hot setting machine; c. chammy suede leather is made by roughing. Wherein, the substrate in a step is PTT / PET island chammy suede with PTT island component. Said coating process for polyurethane is that the substrate is set in dipping tank with aqueous polyurethane dispersion and dipped. By the dipping operation for substrate by polyurethane, it decreases freezing, water washing procedures compared with original technology that the leather is dried directly in hot setting machine after dipped. The production cost is lessened and pollution is decreased largely because a mass of organic media is spared. Compared with chammy suede fabric made by island fiber with nylon or nylon6, chosen substrate made by island fiber with PTT is provided with good elastic expansion.

Owner:慈文传媒股份有限公司

Manufacturing method of antibacterial deodorizing polyester fiber

ActiveCN102965760AWashableLong-lasting antibacterial and deodorant functionFilament/thread formingConjugated synthetic polymer artificial filamentsPolyethylene terephthalate glycolAntibacterial agent

The invention relates to a manufacturing method of an antibacterial deodorizing polyester fiber, which comprises the following steps of: compounding zinc oxide whiskers with sterilizing and antibacterial functions, palygorskite fibers and various antibacterial agents with different antibacterial effects into a broad-spectrum antibacterial agent; preparing the broad-spectrum antibacterial agent and ethanediol into antibacterial ethanediol in the presence of a tiny amount of sodium hexametaphosphate; when polymerization esterification rate reaches 85%-90%, adding the antibacterial ethanediol to a polycondensation kettle, and polymerizing to prepare a copolyester antibacterial polyester, or blending and fusing the broad-spectrum antibacterial agent and the conventional polyester to prepare a blended antibacterial polyester; and fusing, compounding and spinning the antibacterial polyester as a shell layer and PET (Polyethylene Terephthalate) and PTT (polytrimethylene Terephthalate) serving as a core layer together to obtain the shell-core antibacterial deodorizing polyester fiber.

Owner:RONGSHENG PETROCHEM

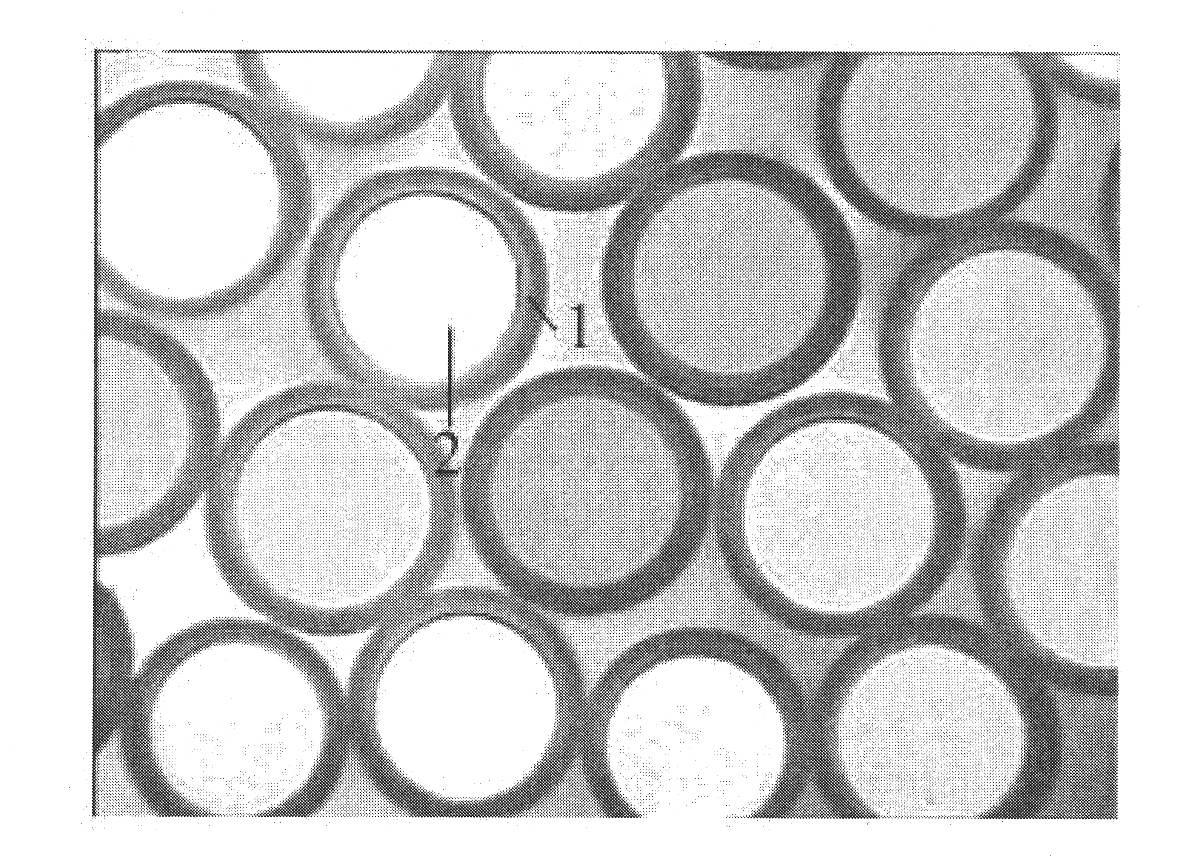

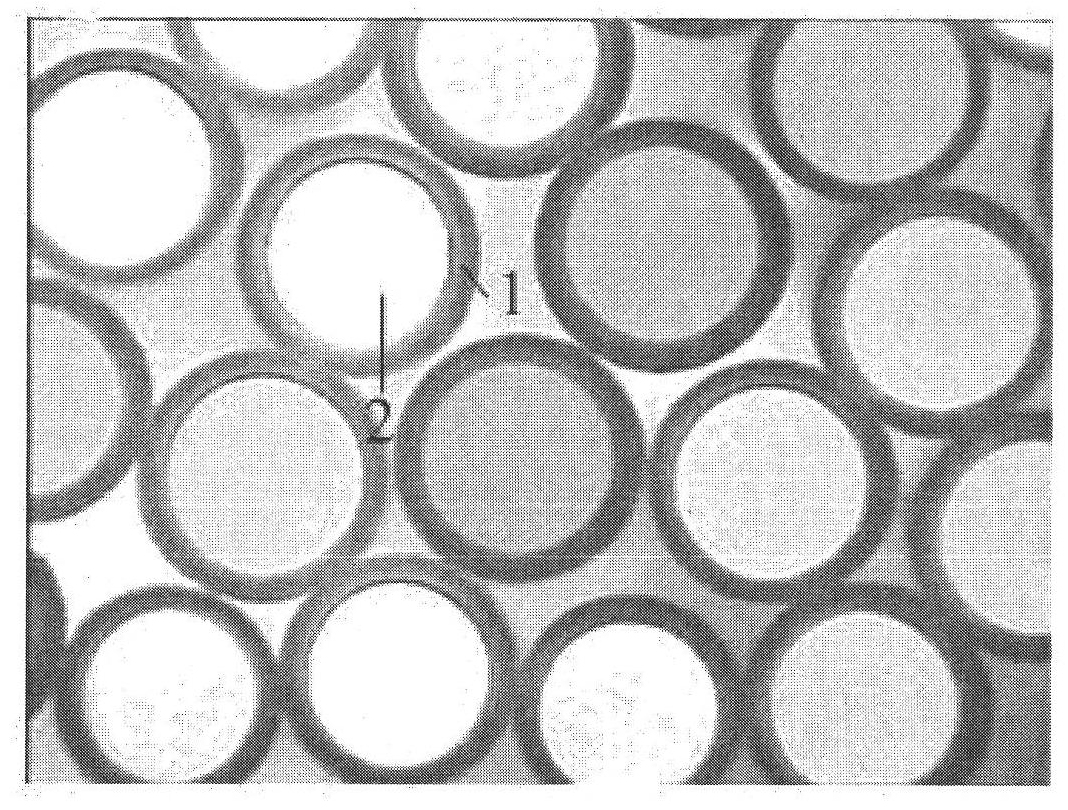

Bicomponent fiber and yarn comprising same

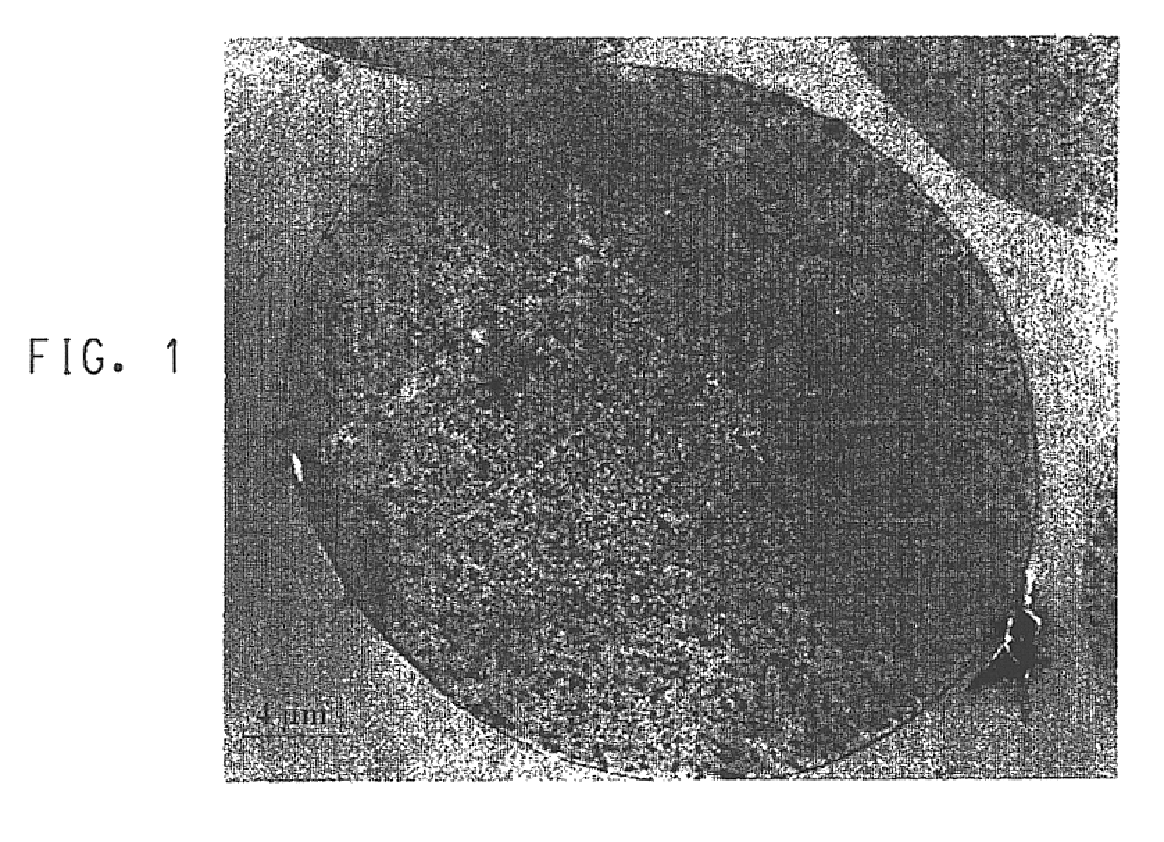

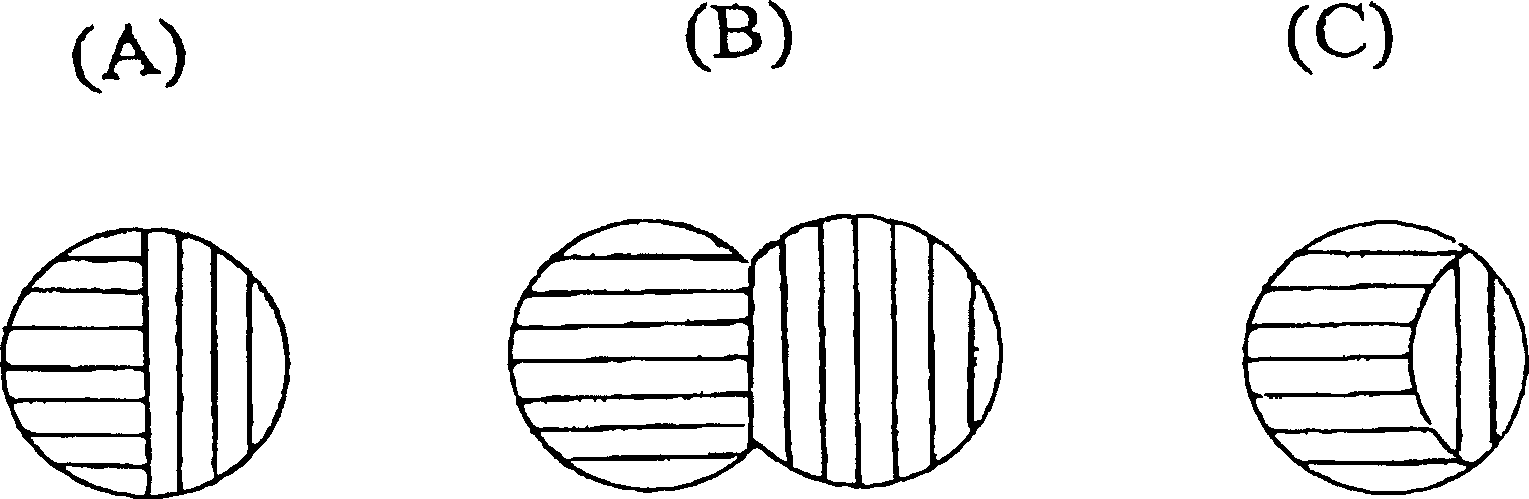

The invention provides a bicomponent staple fiber comprising poly(ethylene terephthalate) and poly(trimethylene terephthalate) wherein the bicomponent fiber has a substantially oval cross-section shape having an aspect ratio A:B of about 2:1 to about 5:1 wherein A is a fiber cross-section major axis length and B is a fiber cross-section minor axis length, a polymer interface substantially perpendicular to the major axis, a cross-section configuration selected from the group consisting of side-by-side and eccentric sheath-core, a tenacity at 10% elongation of about 1.1 cN / dtex to about 3.5 cN / dtex, a free-fiber length retention of about 40% to about 85%, and a tow crimp development value of about 30 to 55%, and a spun yarn comprising the bicomponent staple fiber.

Owner:THE LYCRA CO LLC

PET-graphene-AgNW (polyethylene terephthalate-graphene-Ag nanowire) composite transparent conducting film and preparation method thereof

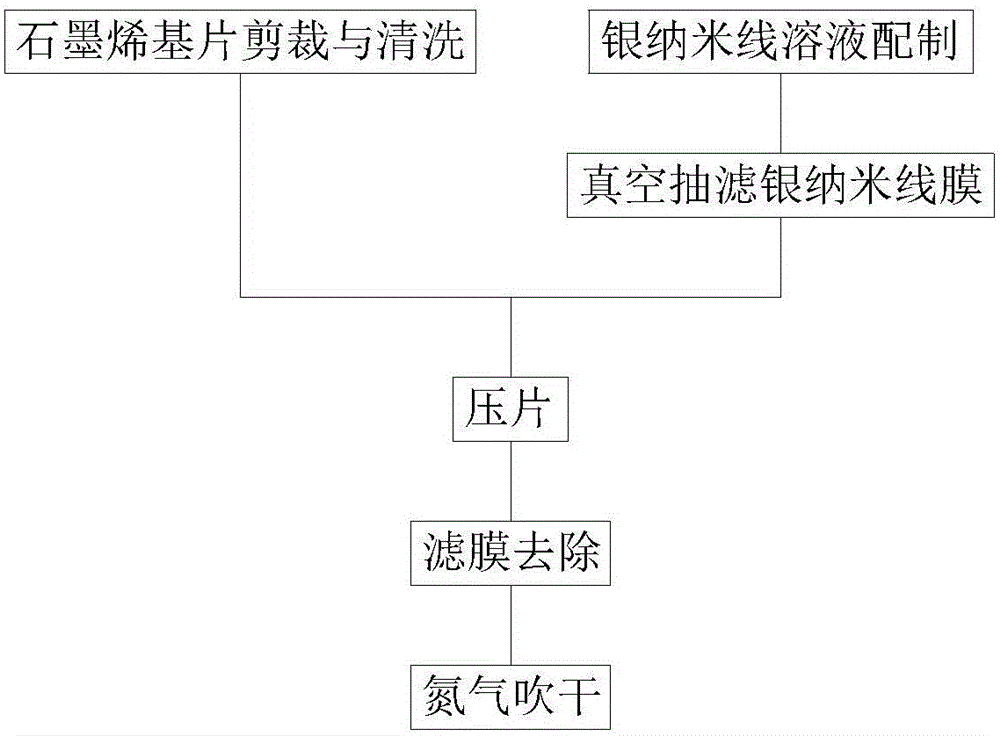

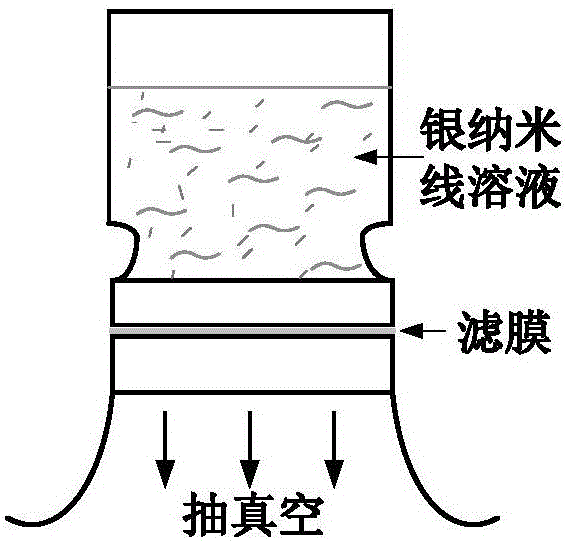

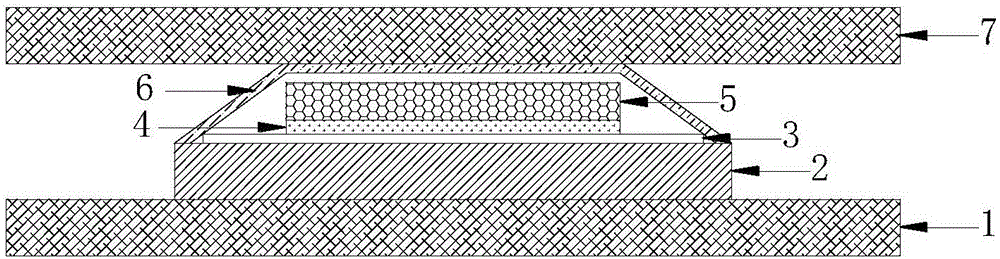

InactiveCN105869719AEvenly dispersedGood mechanical flexibilityConductive layers on insulating-supportsSolid-state devicesPolyethylene terephthalate glycolComposite film

The invention provides a preparation method of a PET-graphene-AgNW (polyethylene terephthalate-graphene-Ag nanowire) composite transparent conducting film. The preparation method comprises steps as follows: cutting and cleaning of a graphene substrate, preparation of an AgNW solution, vacuum filtration of an AgNW film, preforming, removing of a filter film and nitrogen blow-drying. The invention further provides the PET-graphene-AgNW composite transparent conducting film prepared with the method. According to the preparation method, the AgNWs and graphene are subjected to film forming independently and then are composited together, wherein AgNW film forming adopts vacuum filtration, and graphene adopts CVD (chemical vapor deposition) growth, so that the prepared composite film has the advantages of uniformly dispersed AgNWs, controllable thickness, good mechanical flexibility, low square resistance, high optical transmittance and lower surface roughness and can meet the requirement of device applications; according to the composite transparent film, the lower square resistance and the higher optical transmittance can be realized only through composition of a few AgNWs, and the square resistance of the PET-graphene-AgNW composite transparent conducting film is lower than that of a pure silver AgNW film under the same concentration by 20%-40%.

Owner:CHONGQING UNIV

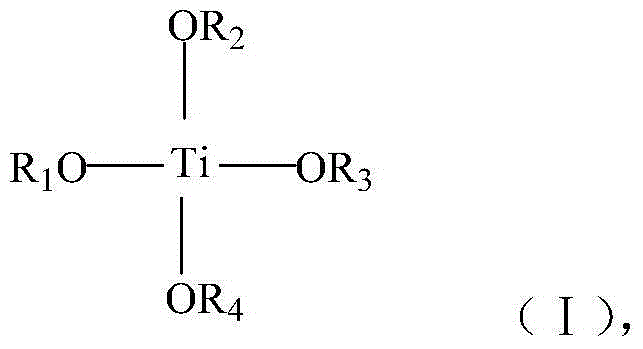

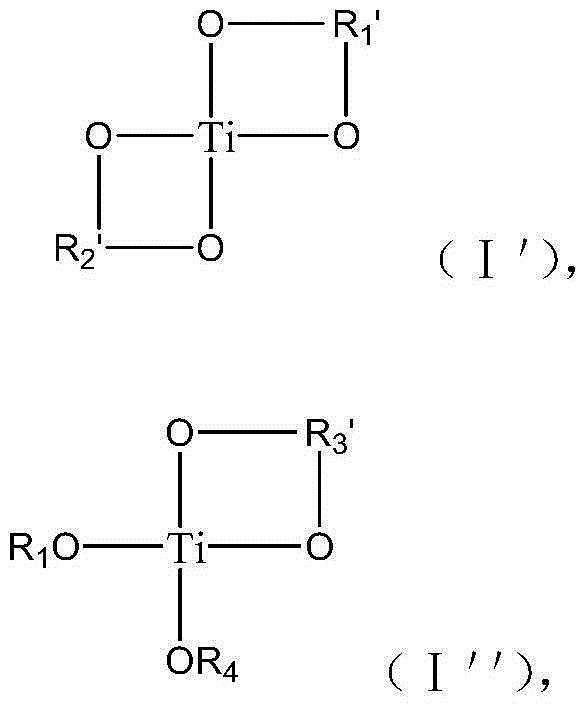

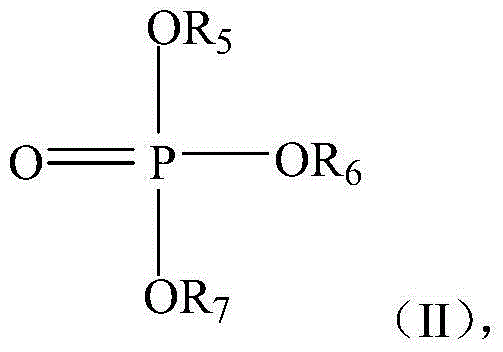

Catalyst used for preparation of polyester, preparation method and application thereof

ActiveCN105273176AResolve liveness issuesPolytetramethylene terephthalatePolyethylene terephthalate glycol

The invention relates to a catalyst used for preparation of polyester, a preparation method and application thereof. The catalyst mainly solves the problem of absence of the catalyst with high catalytic activity in the stages of esterification and polycondensation of polytrimethylene terephthalate in the prior art. A technical scheme of the invention adopts reaction products which comprise the following components: a) a titanium compound, b) a hydroxyl compound, c) organic metal salt, and d) a phosphorus compound; the preparation method for the catalyst comprises the following steps: subjecting the titanium compound and the hydroxyl compound to reaction at 0 to 200 DEG C for 0.1 to 24 hours so as to obtain an intermediate product, adding the metal organic salt and the phosphorus compound into the obtained intermediate product, and carrying out reaction at 0 to 200 DEG C for 0.1 to 24 hours so as to obtain the catalyst used for preparation of polyester; thus, the problem is well solved, and the catalyst can be applied in preparation of polytrimethylene terephthalate, polyethylene terephthalate and polybutylene terephthalate.

Owner:CHINA PETROLEUM & CHEM CORP +1

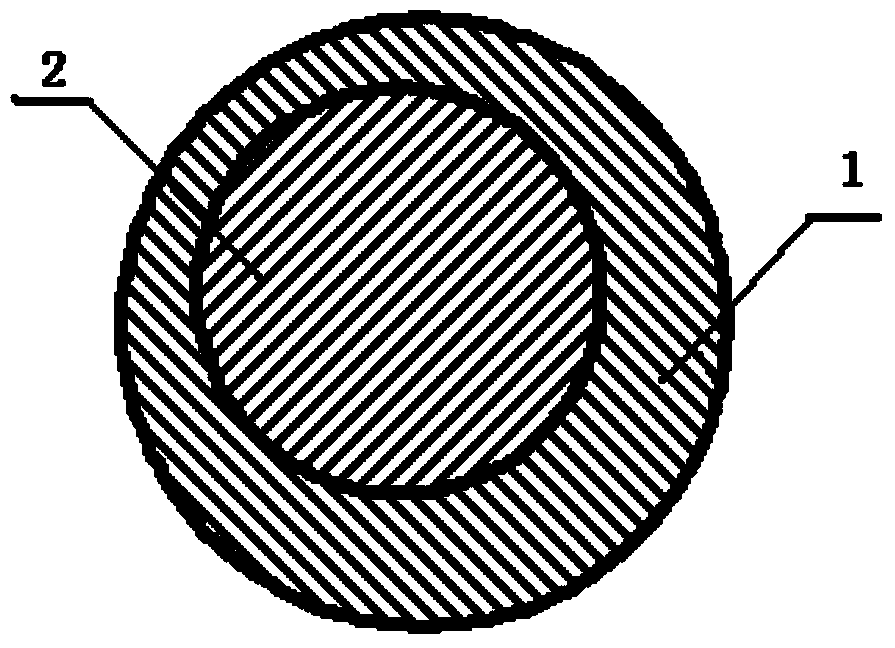

Eccentric sheath-core composite polyester fiber with anti-bacterial function and preparation method thereof

ActiveCN103469354AIncrease elasticityAvoid heat-shrinking post-finishing processesMelt spinning methodsConjugated synthetic polymer artificial filamentsMasterbatchPolytrimethylene terephthalate

The invention relates to an eccentric sheath-core composite polyester fiber with an anti-bacterial function and a preparation method of the eccentric sheath-core composite polyester fiber. The composite polyester fiber comprises a sheath layer and a core layer, and has an eccentric sheath-core structure; the sheath layer consists of polytrimethylene terephthalate (PTT) polyester and nanometer antibacterial agents while the core layer is polyethylene glycol terephthalate (PET) polyester. A preparation method comprises the following steps: (1) preparing antibacterial masterbatch; (2) slicing PTT and performing pre-dispersion on the sliced PTT and antibacterial masterbatch to obtain sheath-layer polyester; slicing the sheath-layer polyester and core-layer PET and melting and conveying the sliced sheath-layer polyester and core-layer PET by respectively using a twin-screw extrusion unit and a single-screw extrusion unit to each spinneret orifice of an eccentric sheath-core spinneret plate; shooting out of the spinneret orifices; finally, cooling and solidifying. The composite polyester fiber has the characteristics of high elasticity, comfort and the like of the conventional composite polyester fiber without post-heat treatment, and also has the anti-bacterial function; in addition, because an antibacterial agent is only loaded on the sheath layer, the influence on the cost is reduced; and therefore, the eccentric sheath-core composite polyester fiber can be widely applied to the fields of blanket fabrics, home textile fabrics and the like.

Owner:DONGHUA UNIV +1

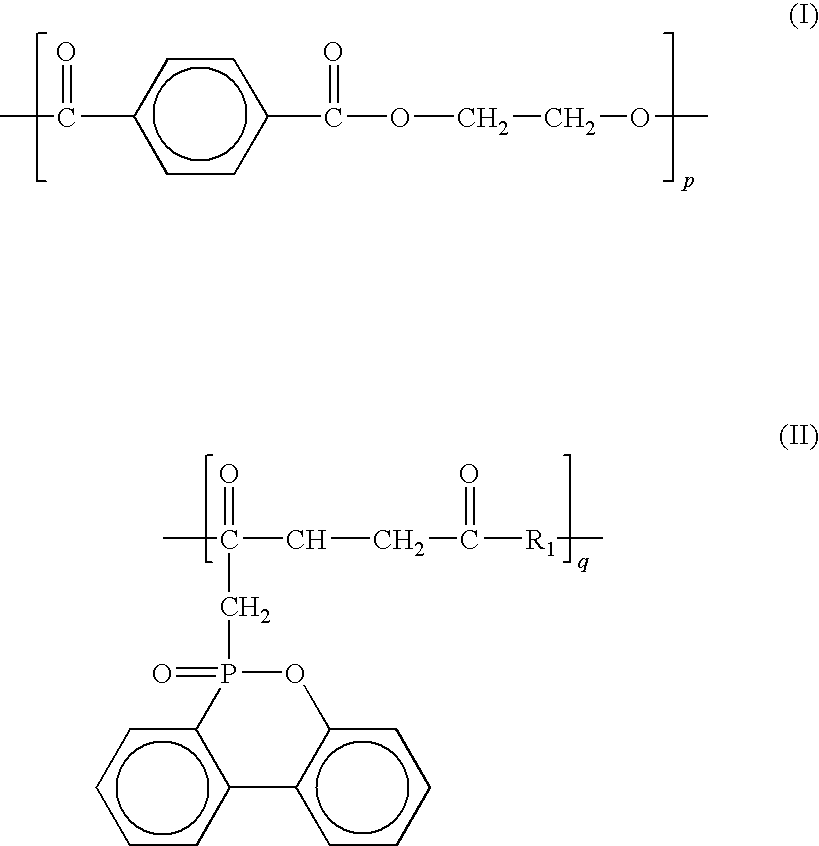

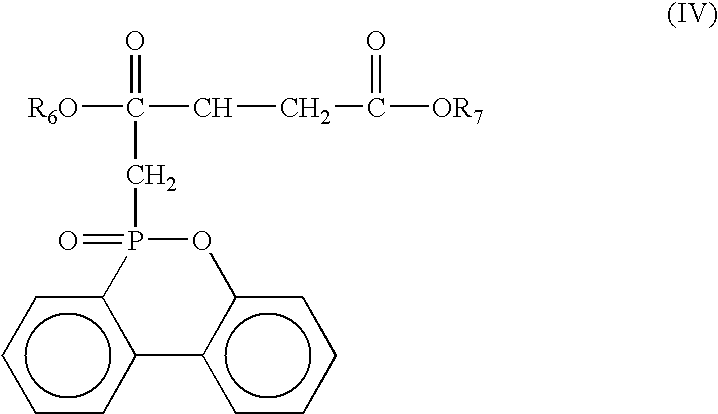

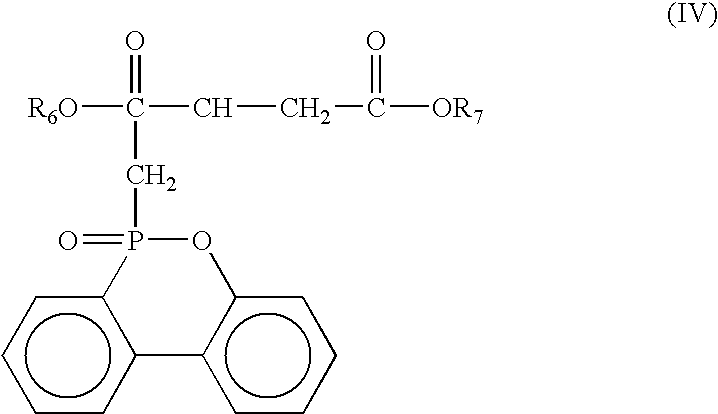

Polymer composition containing flame retardant and process for producing the same

A flame retardant polymer composition and a process for making the composition are provided. The flame retardant polymer composition is a poly(trimethylene terephthalate) co-polymer containing a trimethylene terephthalate monomer and a phosphorous containing flame retardant monomer. The flame retardant polymer composition is produced by a process in which the trimethylene terephthalate monomer or its precursors and the phosphorous containing flame retardant monomer or its precursors are combined to form the poly(trimethylene terephthalate) co-polymer in one or more pre-polymerization and polymerization steps.

Owner:SHELL OIL CO

Polytrimethylene terephthalate (PTT) derived from polyethylene terephthalate (PET) and containing pet residues

ActiveUS20070225473A1Speed up the processUseful performance propertyPlastic recyclingDyeing processPolymer sciencePolyethylene terephthalate

A composition comprising a polytrimethylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and (2) contains at least one residue derived from the polyethylene terephthalate component. Methods for making such copolymers and articles made from such copolymers.

Owner:SHPP GLOBAL TECH BV

Self-crinkling composite fiber and producing method thereof

ActiveCN1772984AConjugated synthetic polymer artificial filamentsPolytetramethylene terephthalatePolymer science

The present invention relates to a composite polyester elastic fibre and its production method said method includes the following steps: using two polymer components, namely polytrimethylene terephthalate (PTT) and polybutylene terephthalate (PBT), adopting side-by-side composite mode to make spinning, making extension heat treatment so as to obtain the invented composite fibre, in which the intrinsic viscosity of PTT is 0.80 dL / g to 1.20 dL / g, and the intrinsic viscosity of PBT is 0.58 dL / g to 0.84 dL / g, the intrinsic viscosity difference value (delta IV) of said two polymers is greater than or equal to 0.15 dL / g. The weight ratio of PTT and PBT is 30:70 to 70:30, and the crimp index of said composite fibre is up to above 40.

Owner:SHINKONG SYNTHETIC FIBERS

Poly fleece textile using polypropylene glycol terephthalate as material and its production method

InactiveCN1730758ABeneficial to stand uprightConsistent grain sizeWeft knittingDyeing processYarnPolytrimethylene terephthalate

The present invention discloses one kind of polyester polar fleece fabric with polypropanediol terephthalate as material and its production process. The polyester polar fleece fabric has facing material of polypropanediol terephthalate yarn or filament and foundation material of other natural or synthetic fiber yarn or filament, and knitted. The polyester polar fleece fabric with polypropanediol terephthalate has soft hand feeling, high loft and elasticity, high dirt resistance, good fuzz resistance and excellent antistatic performance.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Novel melt-blown non-woven cloth and preparation method thereof

InactiveCN104746237AImprove insulation effectImprove adsorption capacityNon-woven fabricsLow-density polyethylenePolytetramethylene terephthalate

The invention discloses a novel melt-blown non-woven cloth and a preparation method thereof. The novel melt-blown non-woven cloth comprises a non-woven cloth manufactured by use of special-shaped fibers; the cross section of the single special-shaped fiber is any one of triangle, pentagon, Y-shape, three-leaf shape, four-leaf shape, five-leaf shape and hollow shape; the special-shaped fibers are produced from any one of polypropylene, high density polyethylene, low density polyethylene, linear low density polyethylene, polyvinyl chloride, polyethylene glycol terephthalate, polytrimethylene terephthalate, polybutylene terephthalate, polyamide-6, polyamide-66, polylactic acid and polyphenylene sulfide. Compared with the traditional non-woven cloth, the novel melt-blown non-woven cloth has better heat retaining property and adsorbability; a waterproofing agent is added so that the non-woven cloth can be waterproof; due to a deodorant added, the non-woven cloth has a deodorization function; a flame retardant is added to enhance the flame retarding effect of the non-woven cloth; as a result, the non-woven cloth is applicable to fields of firefighting and the application fields of the product are expanded.

Owner:TIANJIN POLYTECHNIC UNIV

Brush filaments prepared from a polytrimethylene terephthalate composition and brushes comprising the same

InactiveUS20120159731A1BristleMonocomponent polyesters artificial filamentBristlePolytrimethylene terephthalate

Disclosed herein is a monofilament bristle made of modified polytrimethylene terephthalate composition having s a flexural modulus of 2500 MPa or lower, measured according to ISO178:2001, a tensile modulus of 2600 MPa or lower, and an elongation at break % of about 20% or lower, measured respectively according to ISO527-2:1993, wherein the composition comprises: (a) 65-95 wt. % of at least a polytrimethylene terephthalate, and (b) 5-35 wt. % of at least a copolyether-ester having a Shore Hardness of 55 or higher measured according to ISO868. The invention also discloses brushes comprising the monofilament bristle.

Owner:EI DU PONT DE NEMOURS & CO

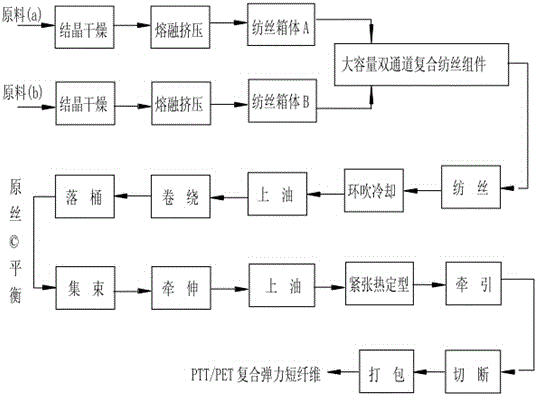

Production method of PTT/PET parallel composite elastic short fibers without mechanical crimping

InactiveCN104593904AIncrease elasticityFluffy goodFilament/thread formingConjugated synthetic polymer artificial filamentsPolytrimethylene terephthalateHeat setting

The invention discloses a production method of PTT / PET parallel composite elastic short fibers without mechanical crimping. The production method comprises the following steps: (1) performing crystallization and drying and melted extrusion on two raw materials, including a modified PET raw material a and a polytrimethylene terephthalate raw material b, with different properties; entering a spinning manifold and a high-volume double-channel composite spinning assembly for compounding to obtain filament bundles in parallel shapes; spinning, annular blowing cooling, oiling, winding and falling into a barrel to prepare a PTT / PET parallel composite elastic short fiber primary filament c; and (2) performing bundling, stretching, oiling, tension heat setting and cutting the primary filament c and feeding into a packaging machine to be packaged. Because the special high-volume double-channel composite spinning assembly and a multi-roller tension heat setting device are adopted, and a crimping device and a loosening heat setting machine in production of conventional polyester short fibers are eliminated, the parallel composite elastic short fibers prepared by using the method are moderate in elasticity and high in stretching resilience and have a good hand feeling.

Owner:福建省海兴凯晟科技有限公司

Polytrimethylene terephthalate composition particles and process for producing same

InactiveUS7332561B2High viscosityHigh molecular weightScale removal and water softeningNatural mineral layered productsPolytrimethylene terephthalateIntrinsic viscosity

Poly(trimethylene terephthalate) composition particles comprising 80% by weight or more of trimethylene terephthalate units based on the entire repeating units, having an intrinsic viscosity from 0.8 to 2 dl / g, and satisfying the following conditions (a) to (c): (a) the composition particles have a particle size of 3 mm or less and a weight of less than 1 mg / particle; (b) the composition particles have a terminal carboxyl group content of 25 meq / kg or less; and (c) the composition particles have a cyclic dimer content of 1.5% by weight or less.

Owner:ASAHI KASEI FIBERS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com