Phosphor series polyester flame-proof fiber and producing method

A technology of flame-retardant fiber and phosphorus-based flame retardant, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester rayon, melt spinning, etc., can solve the problems of unsatisfactory flame-retardant properties and achieve good The effect of spinnability, high strength, flame retardancy and wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

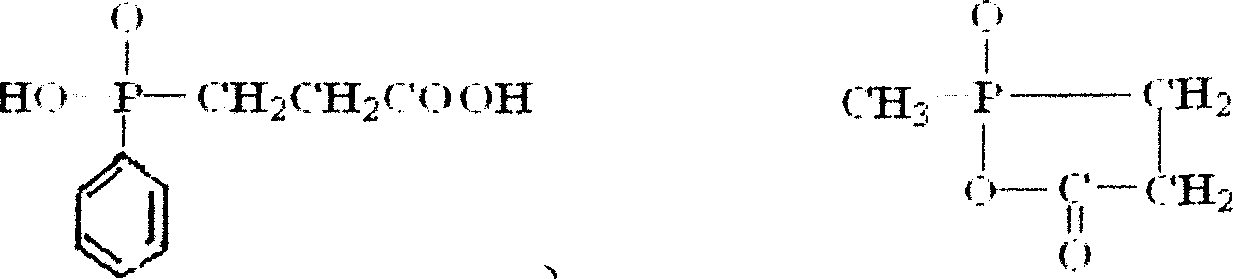

[0044] Take polyethylene terephthalate (or polytrimethylene terephthalate, polybutylene terephthalate, cationic modified polyethylene terephthalate) as the matrix polymer, add barrier Fuel agent 2-carboxyethylphenylphosphoric acid, its structure is as follows:

[0045]

[0046] The amount of P added is 3500ppm, TiO 2 The addition amount is 0.35wt%, and it is made into spun chips for melt spinning to obtain flame-retardant fiber precursors, and further obtained flame-retardant polyester filaments through winding stretching, network, etc., that is, phosphorus-based polyester flame-retardant Fiber: The temperature during spinning is 270°C, the spinning speed is 3000m / min, the DTY ratio of the subsequent process is 1.9 times, and the heater temperature is 160°C.

Embodiment 2

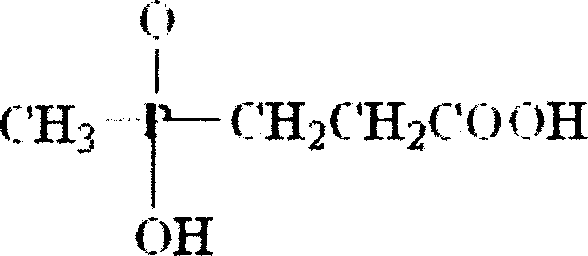

[0047] Embodiment 2: Take polyethylene terephthalate (or polytrimethylene terephthalate, polybutylene terephthalate, cationic modified polyethylene terephthalate) as matrix polymerization Thing, adding flame retardant 2-carboxyethyl methyl phosphate, its structure is as follows:

[0048]

[0049] The amount of P added is 6000ppm, TiO 2 The addition amount is 2.5wt%, and it is made into spun chips for melt spinning to obtain flame-retardant fiber precursors, and further obtains flame-retardant polyester filaments through winding stretching, network, etc., that is, phosphorus-based polyester flame-retardant filaments. Burning fiber; the temperature during spinning is 285°C, the spinning speed is 2750m / min, the DTY ratio of the subsequent process is 1.7 times, and the heater temperature is 135°C.

Embodiment 3

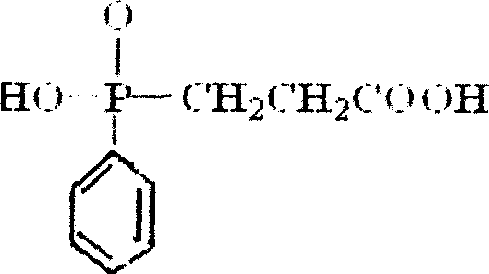

[0050] Embodiment 3: Take polyethylene terephthalate (or polytrimethylene terephthalate, polybutylene terephthalate, cationic modified polyethylene terephthalate) as matrix polymerization Thing, adding flame retardant 2-carboxyethyl methyl phosphoric acid, its structure is as follows:

[0051]

[0052] P addition amount is 7000ppm, TiO 2 The addition amount is 1.5wt%, and it is made into spun chips for melt spinning to obtain flame-retardant fiber precursors, and further obtains flame-retardant polyester filaments through winding stretching, network, etc., that is, phosphorus-based polyester flame-retardant filaments. Burn the fiber; the temperature during spinning is 265°C, the spinning speed is 3200m / min, the DTY ratio of the subsequent process is 2.1 times, and the heater temperature is 195°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com