Patents

Literature

450results about "Artificial filaments from cellulose solutions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

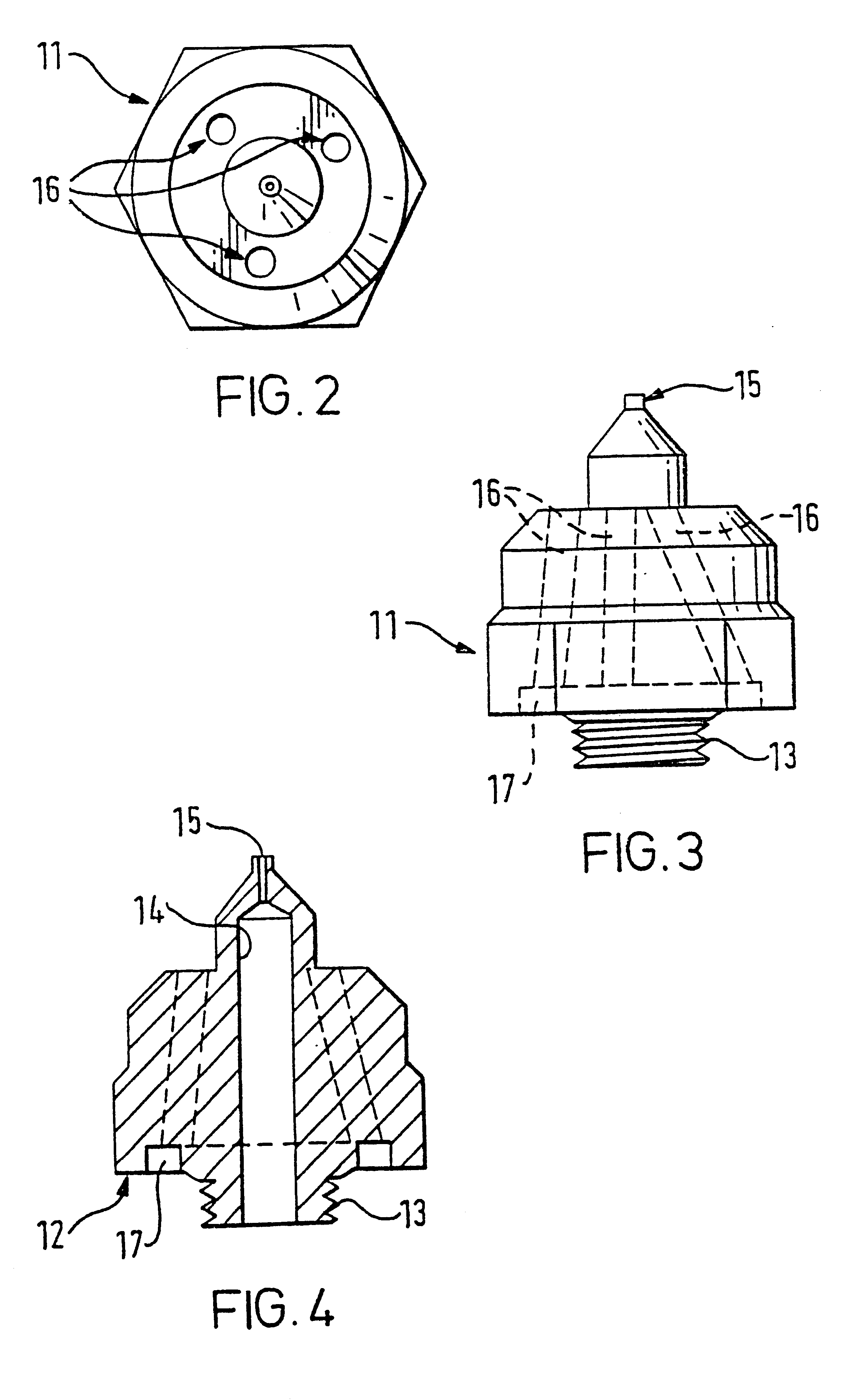

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

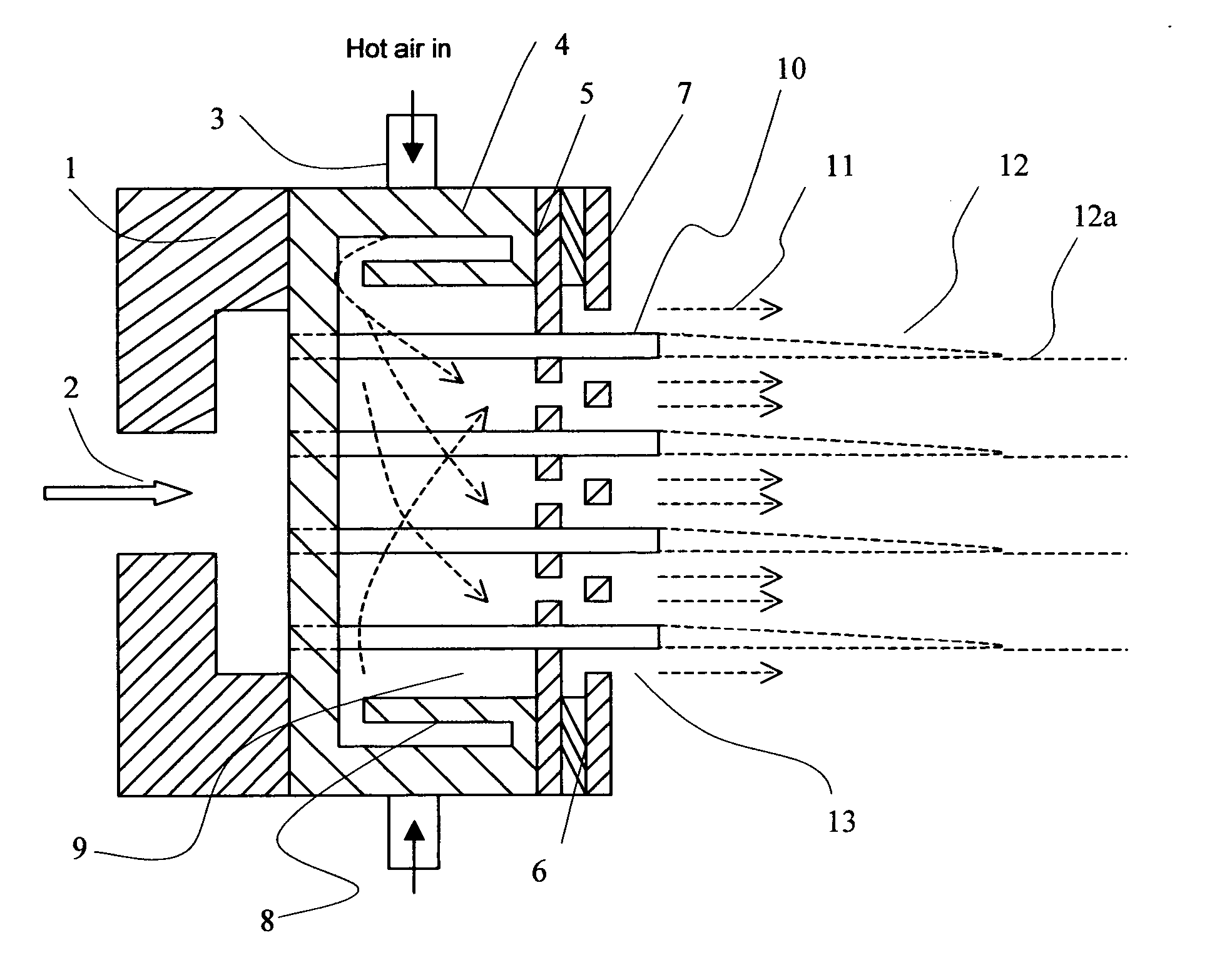

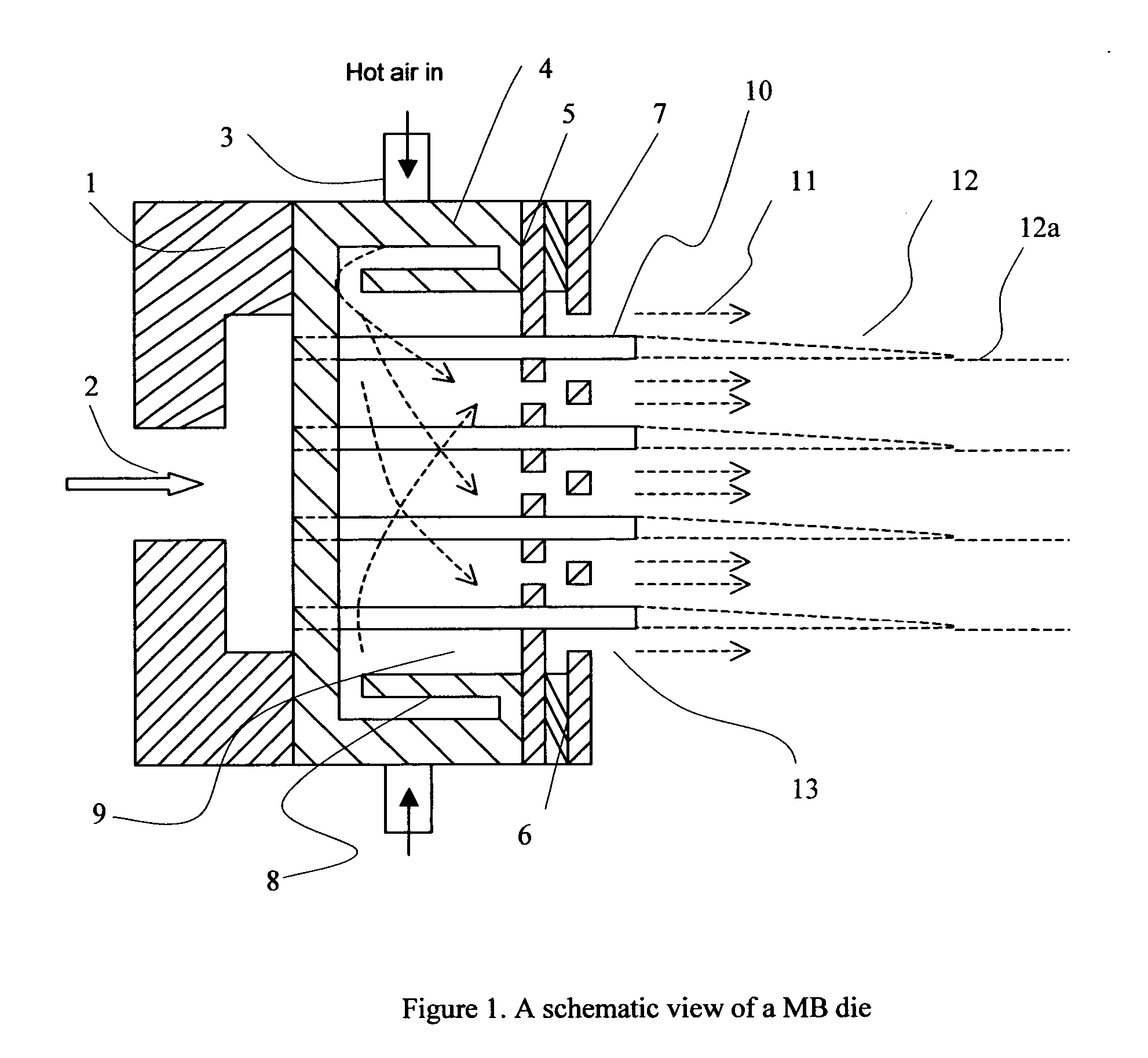

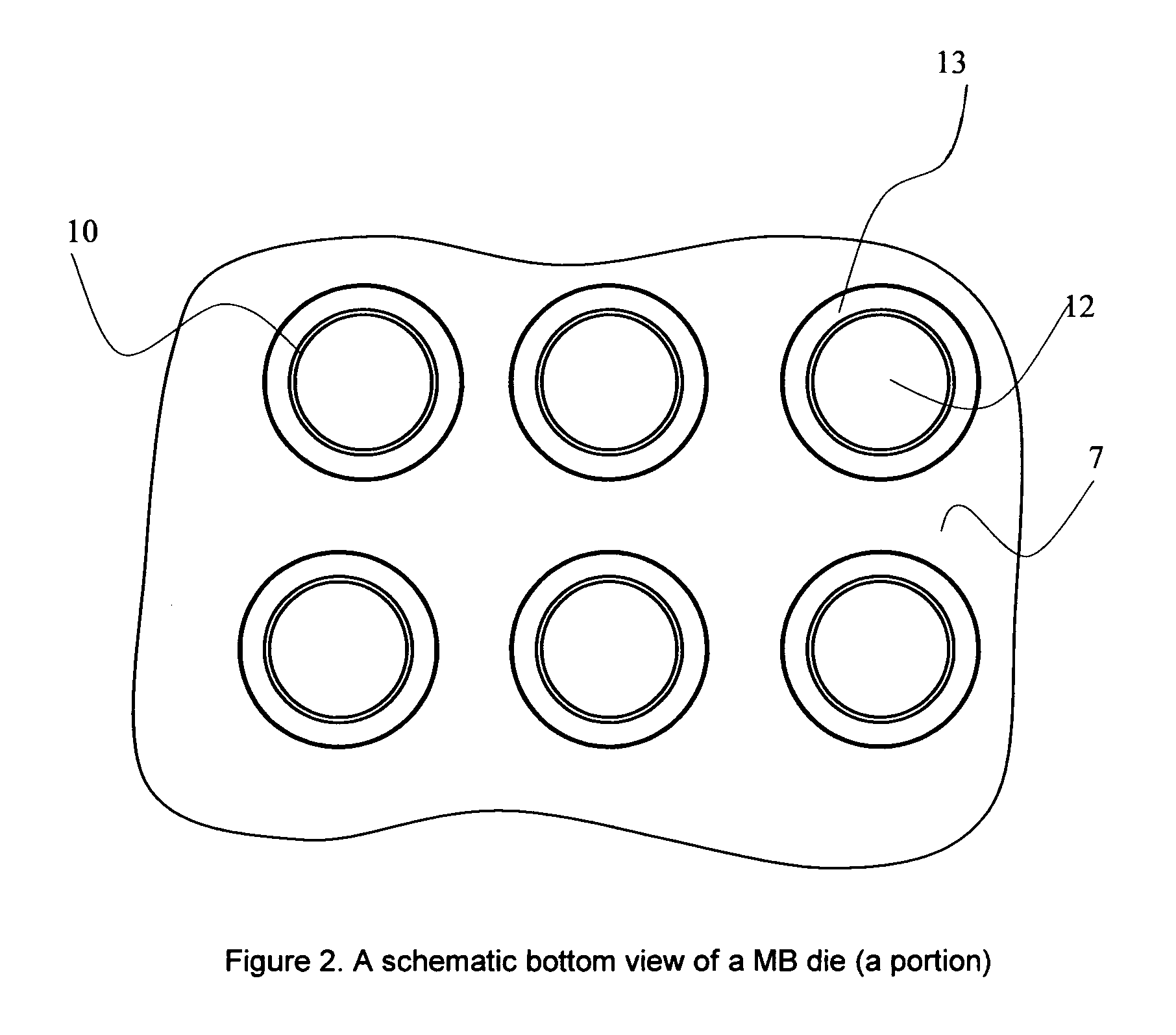

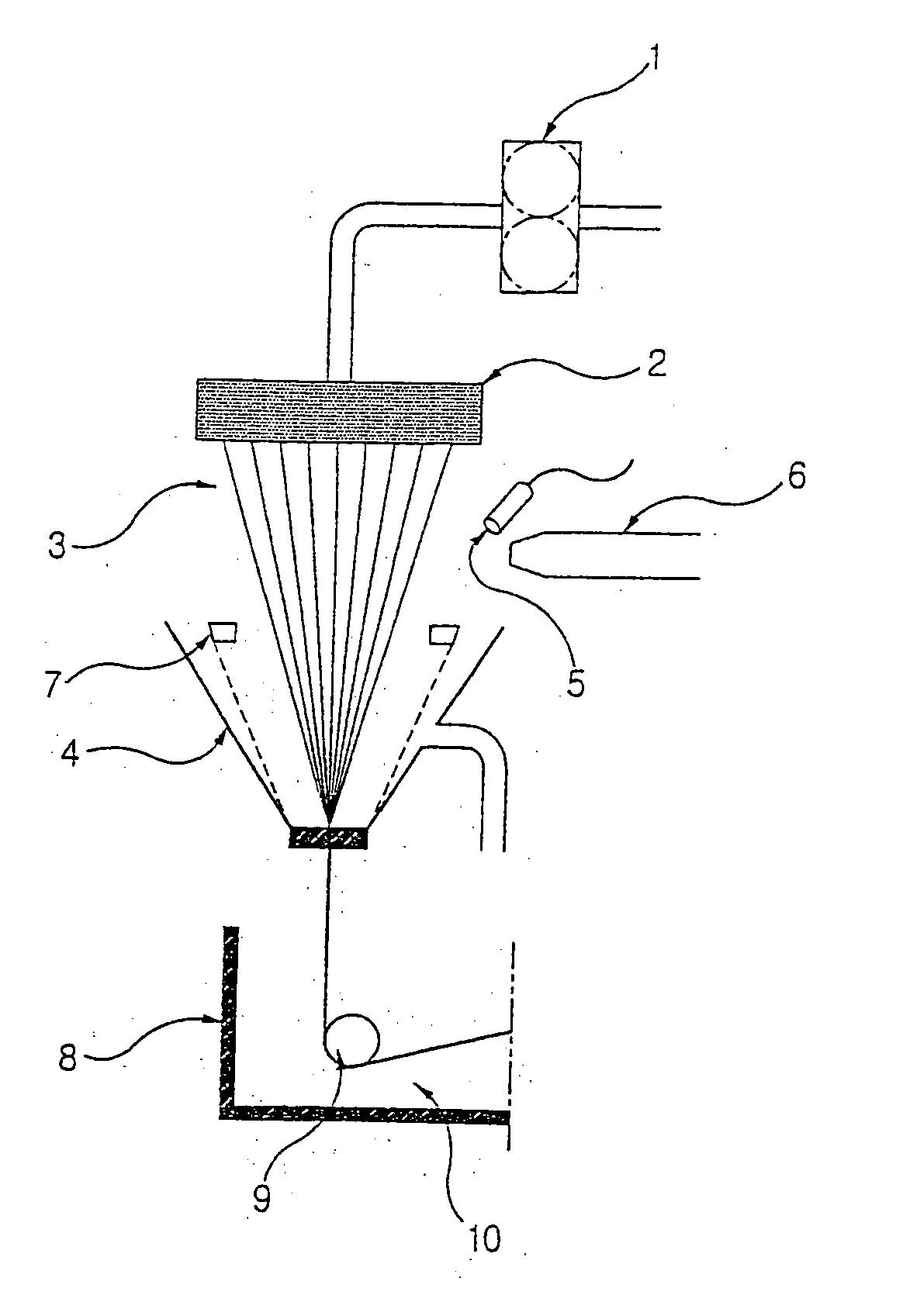

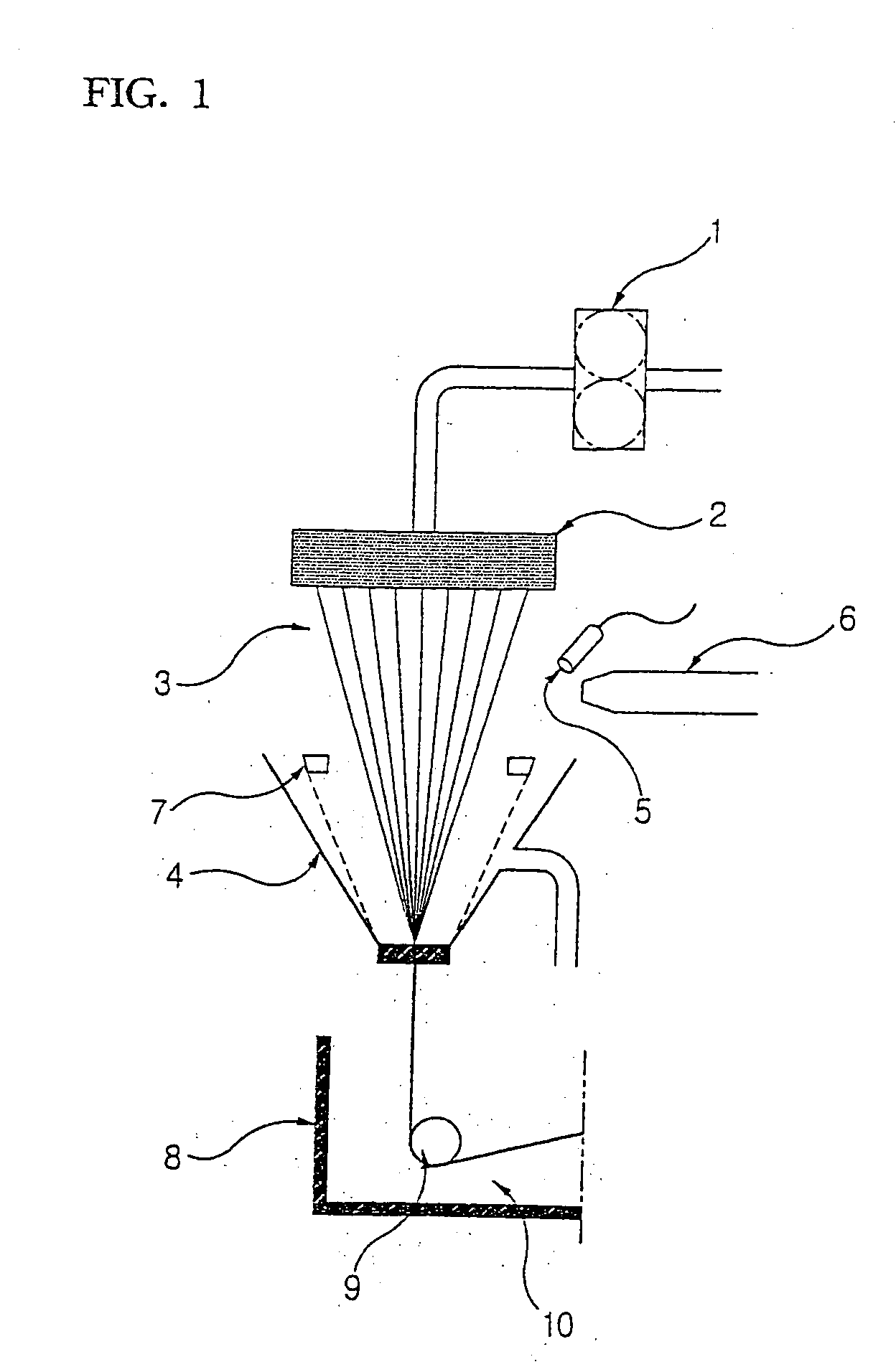

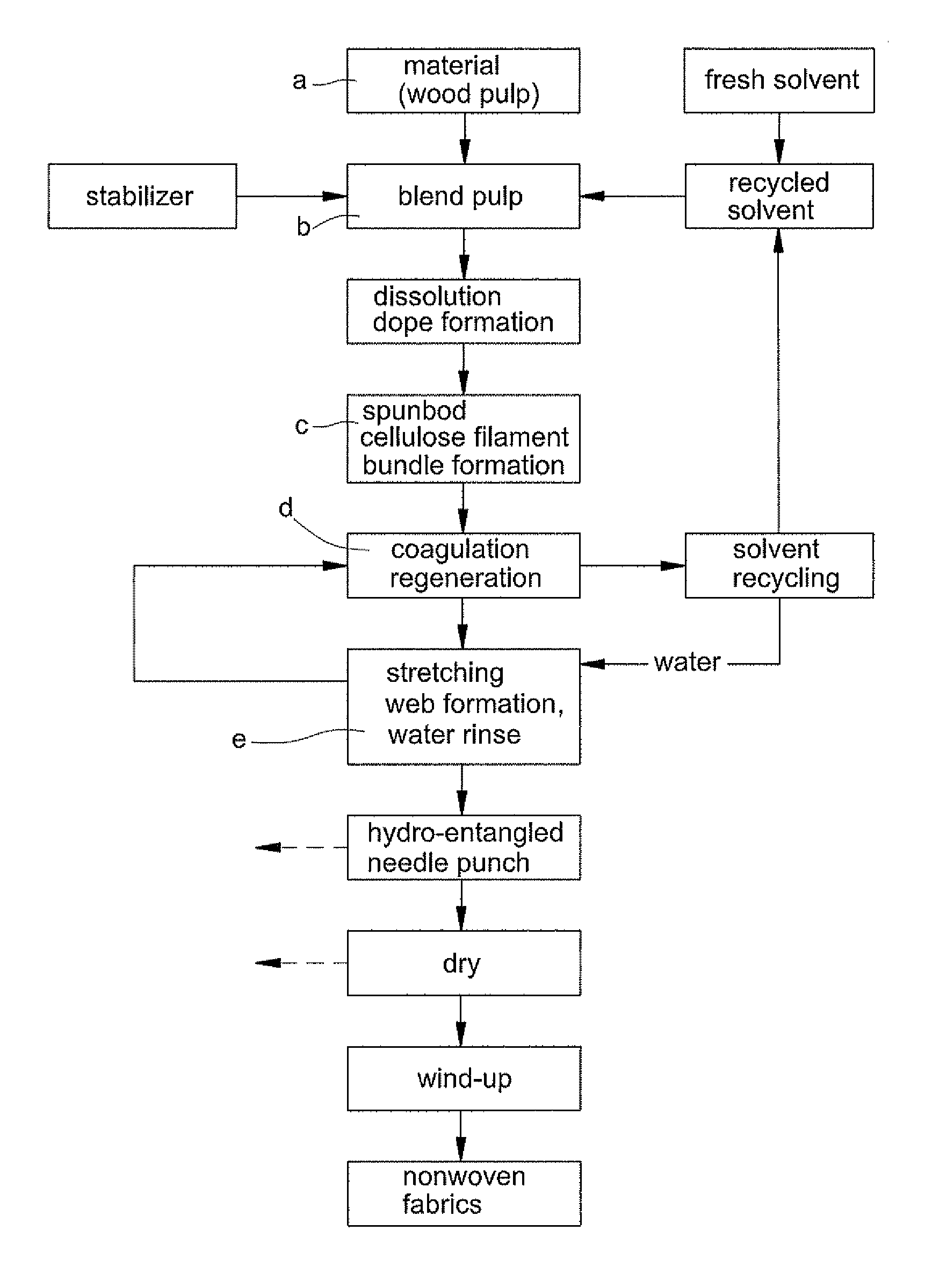

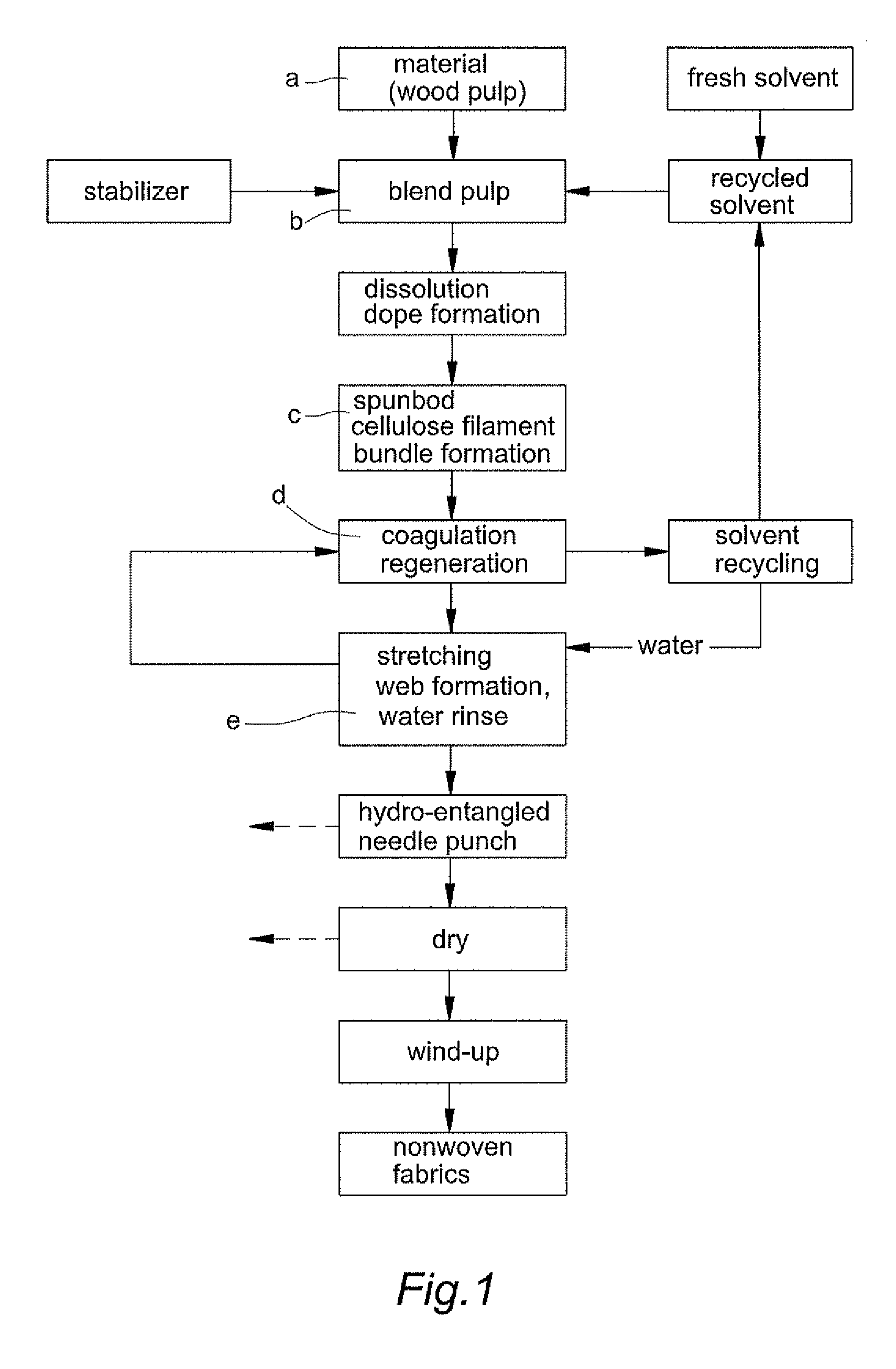

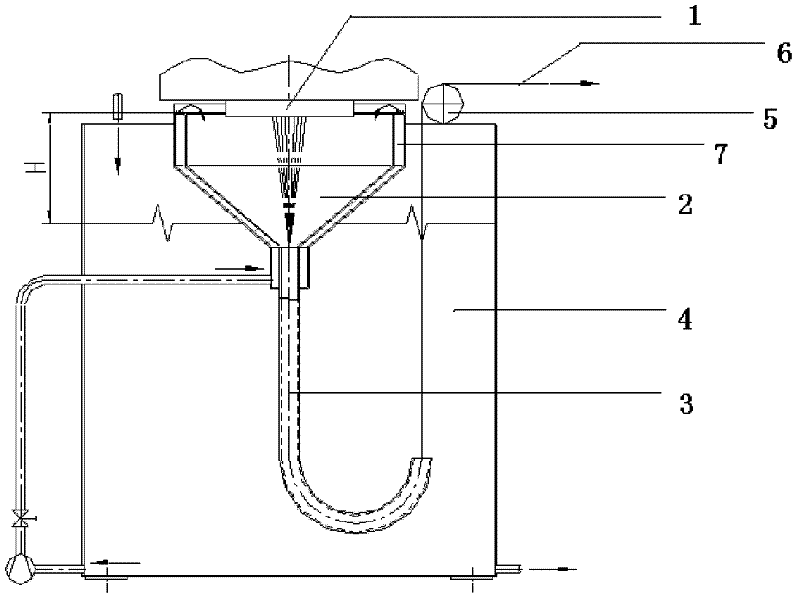

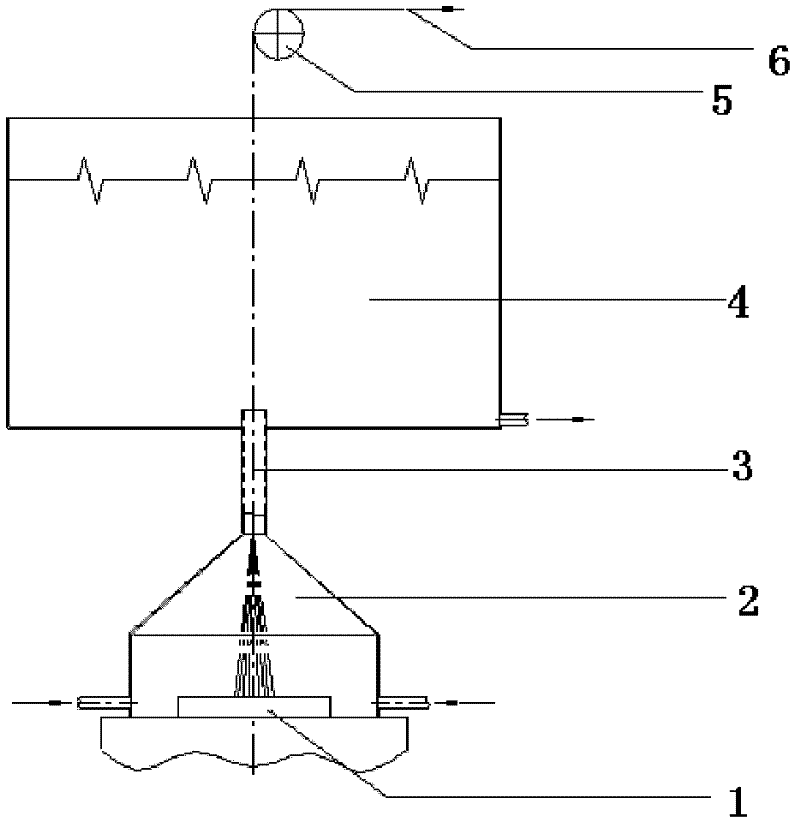

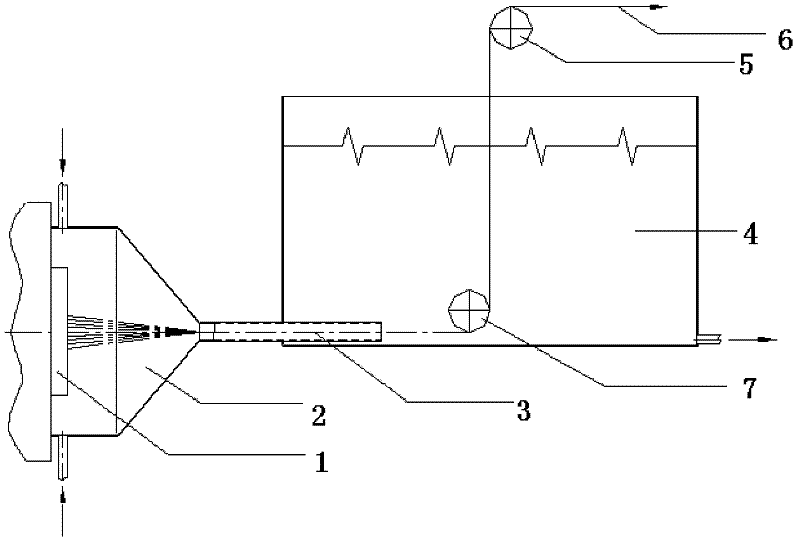

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

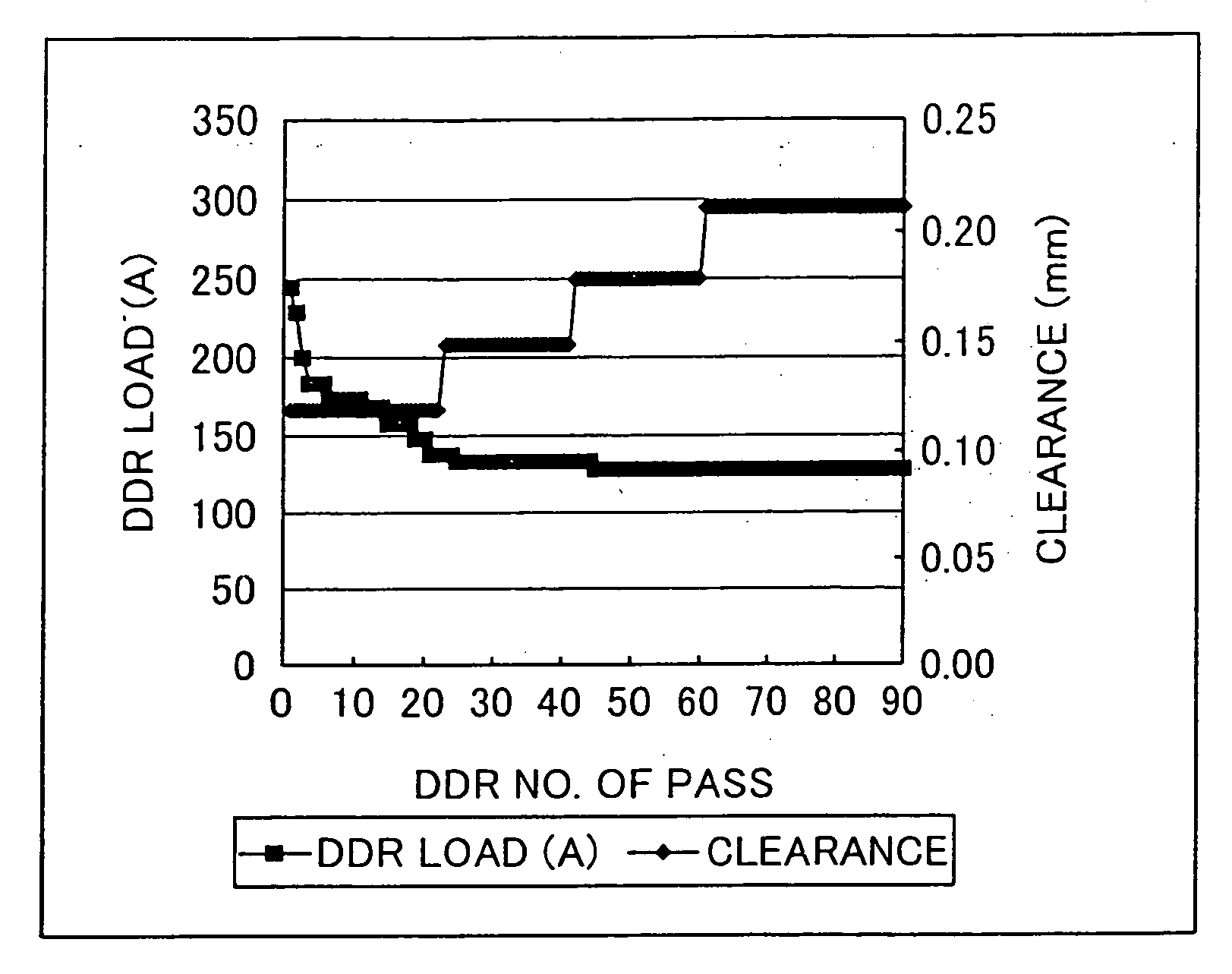

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS7381294B2Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

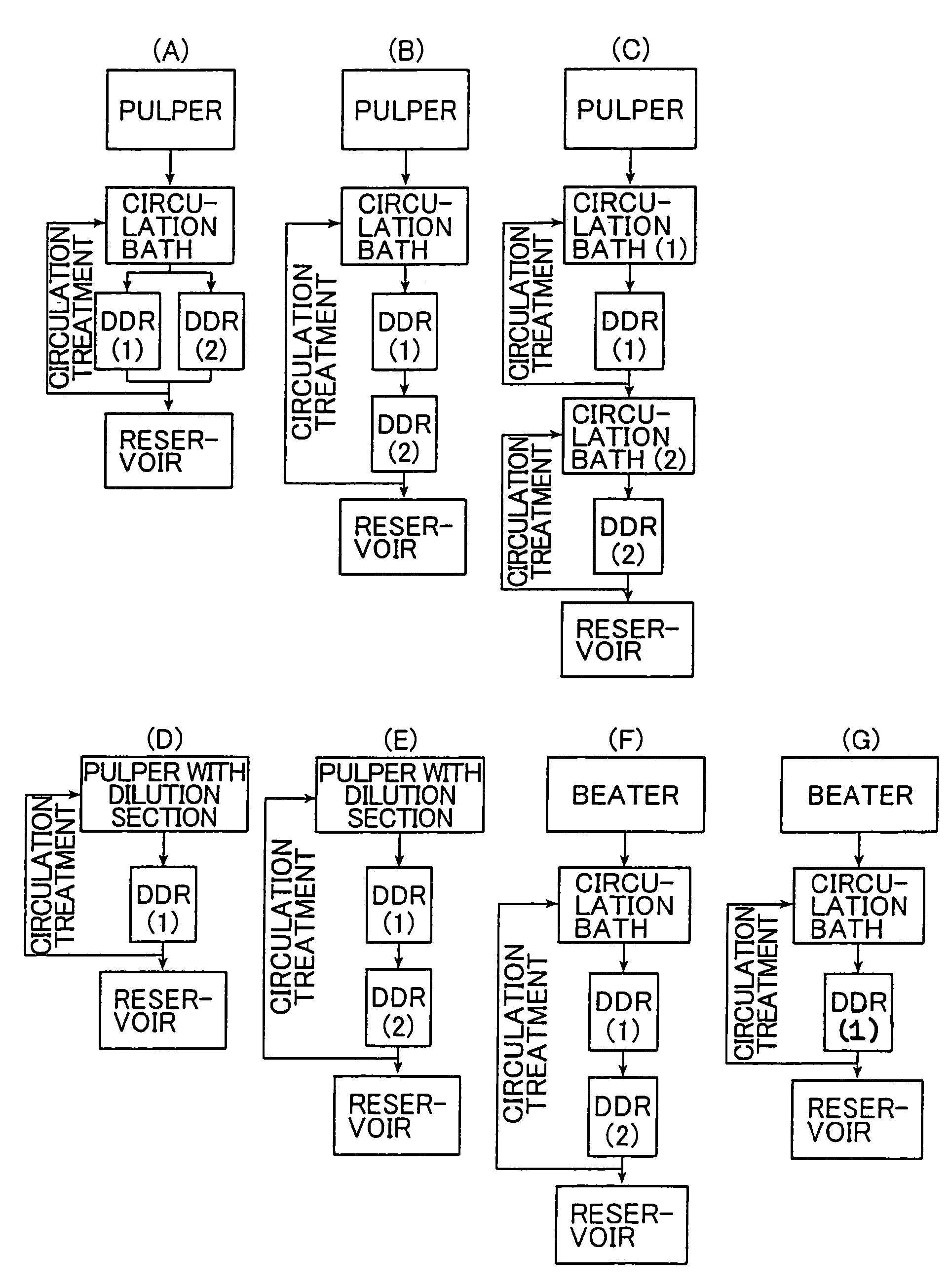

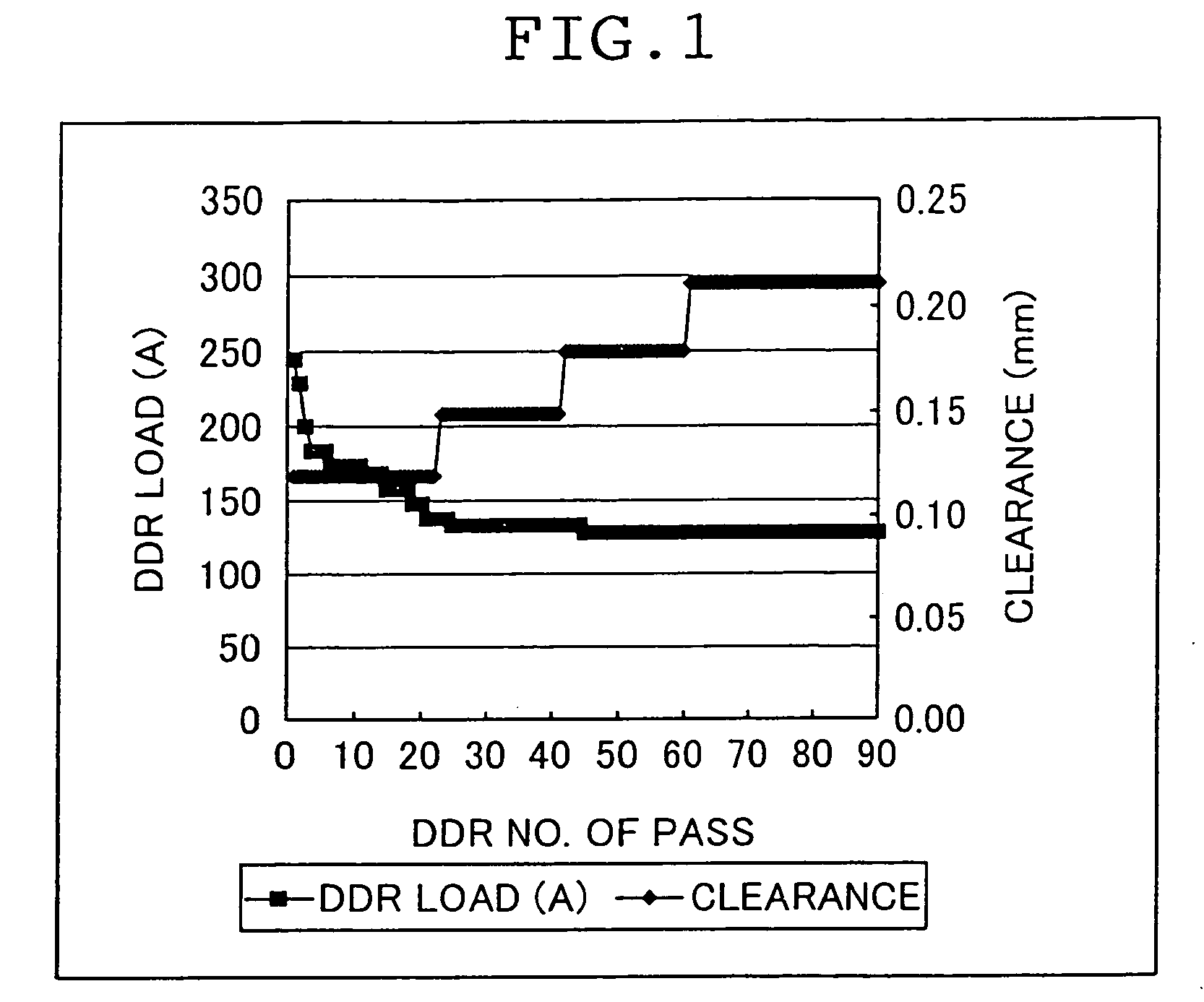

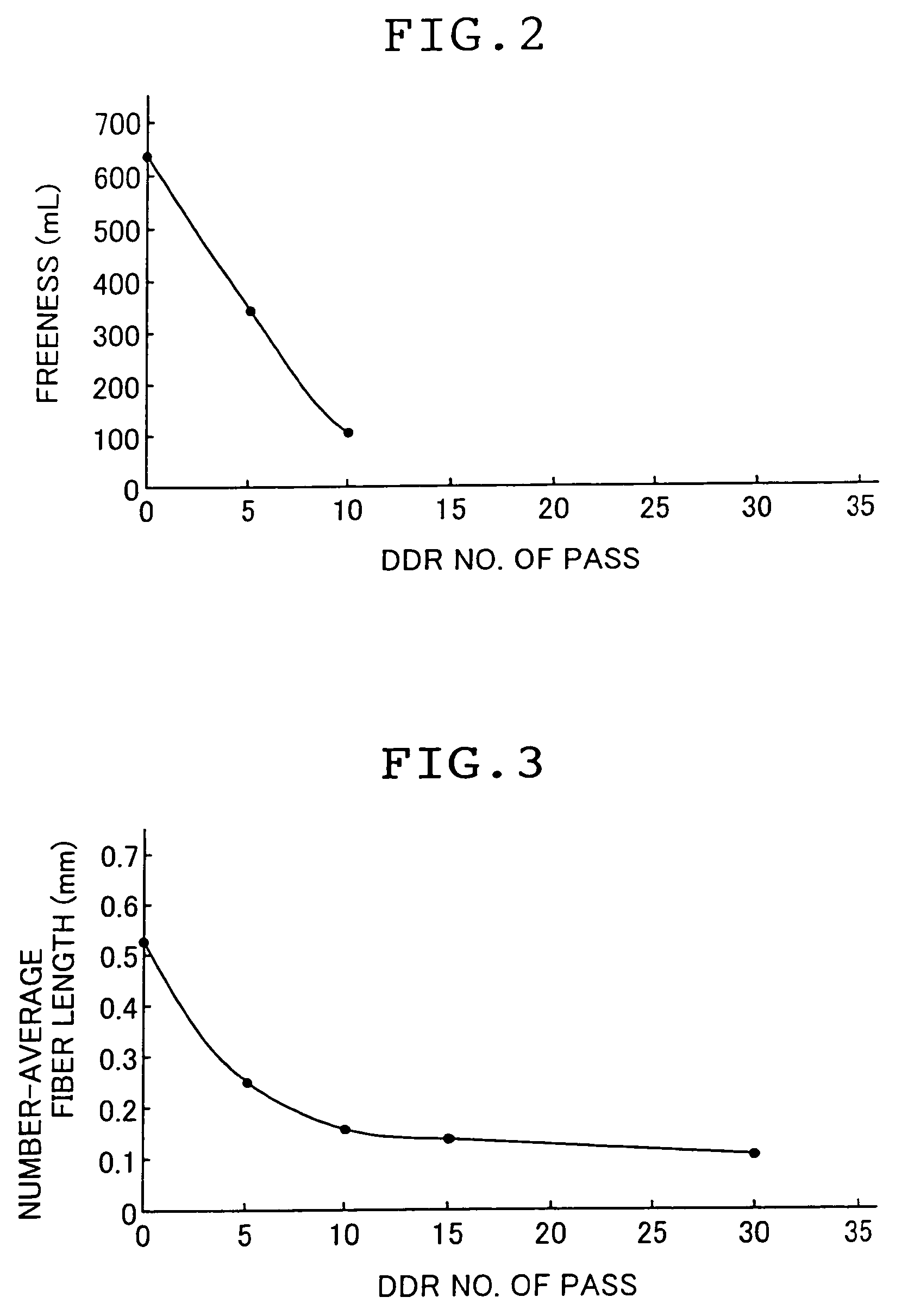

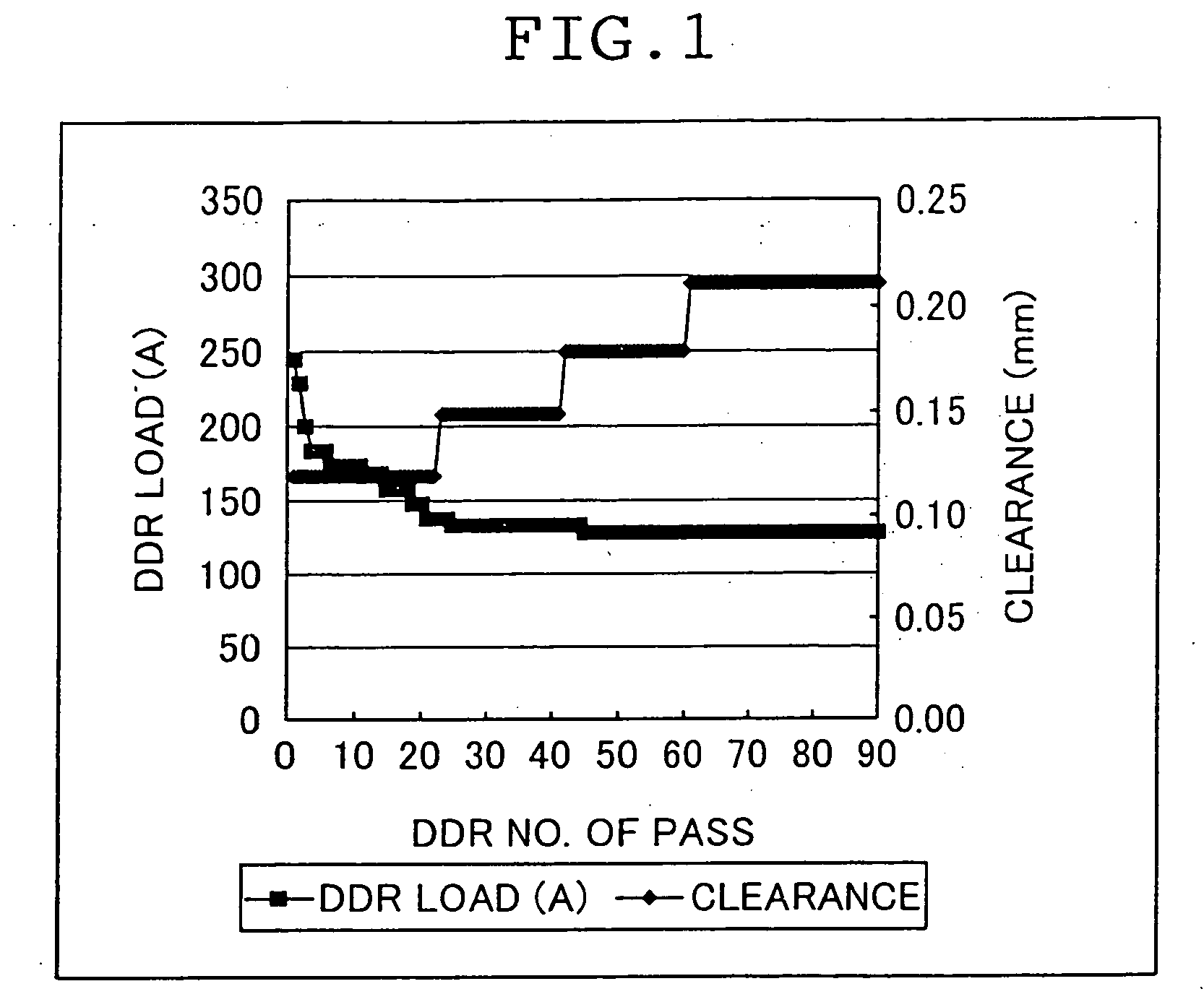

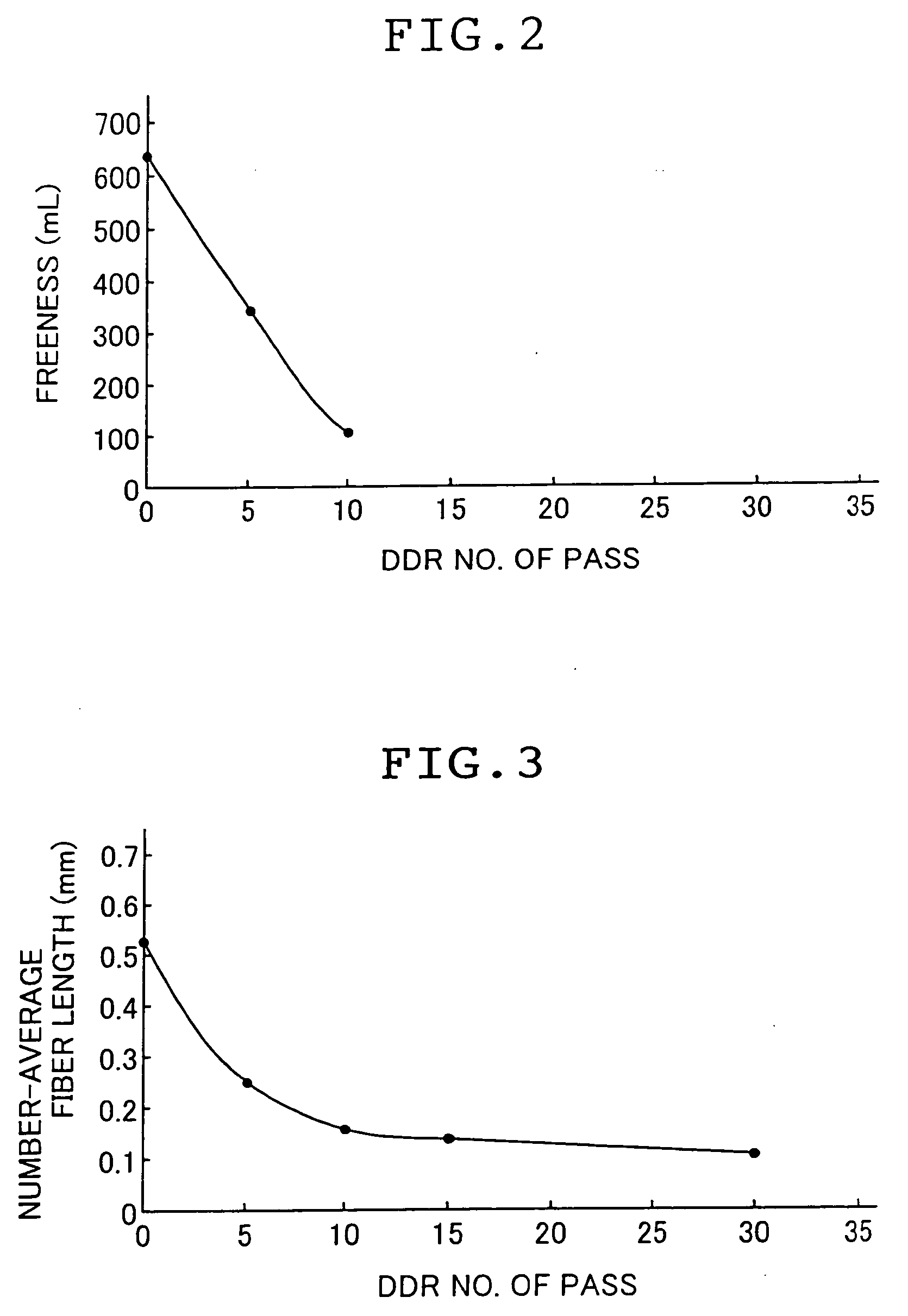

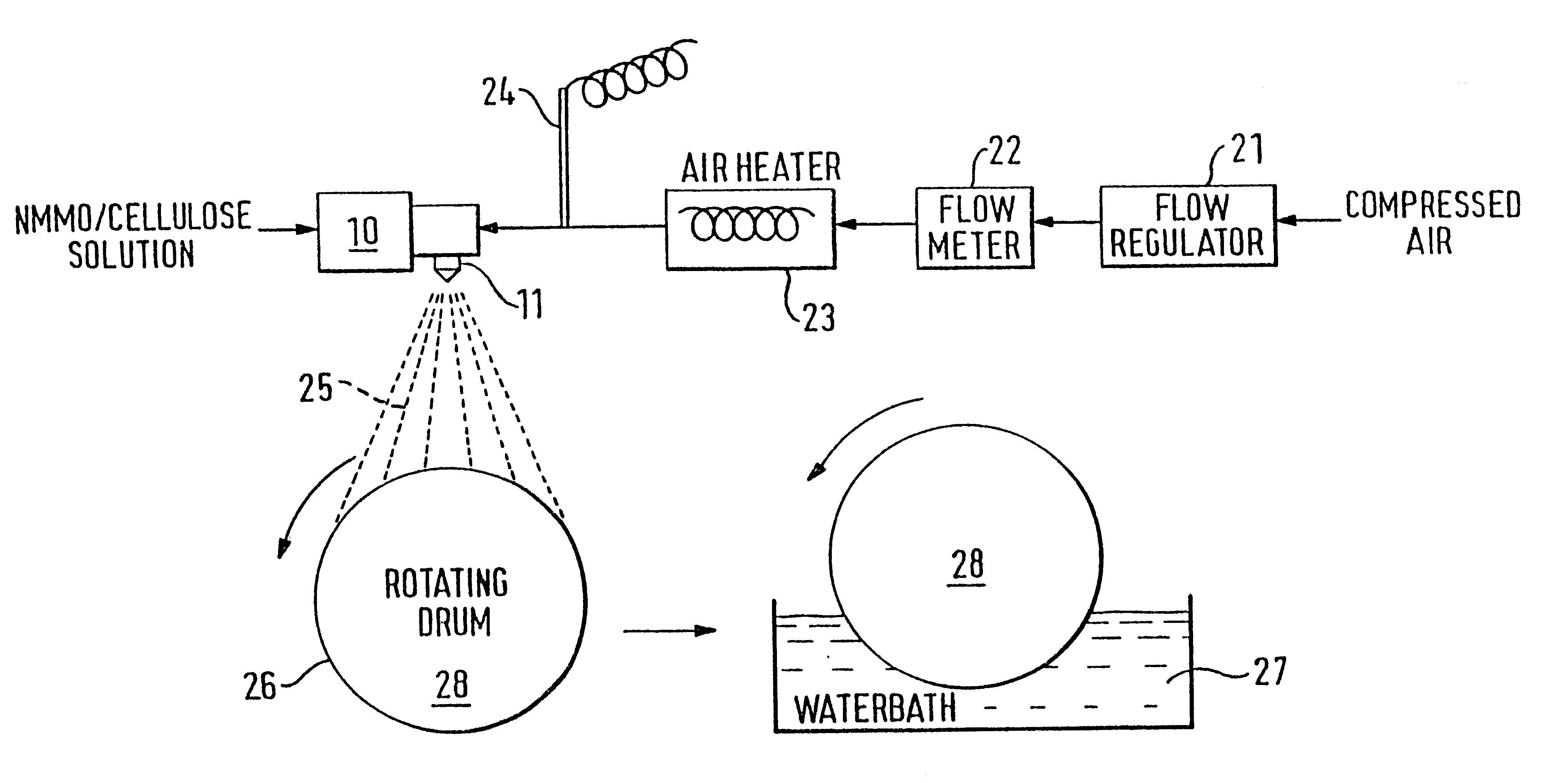

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

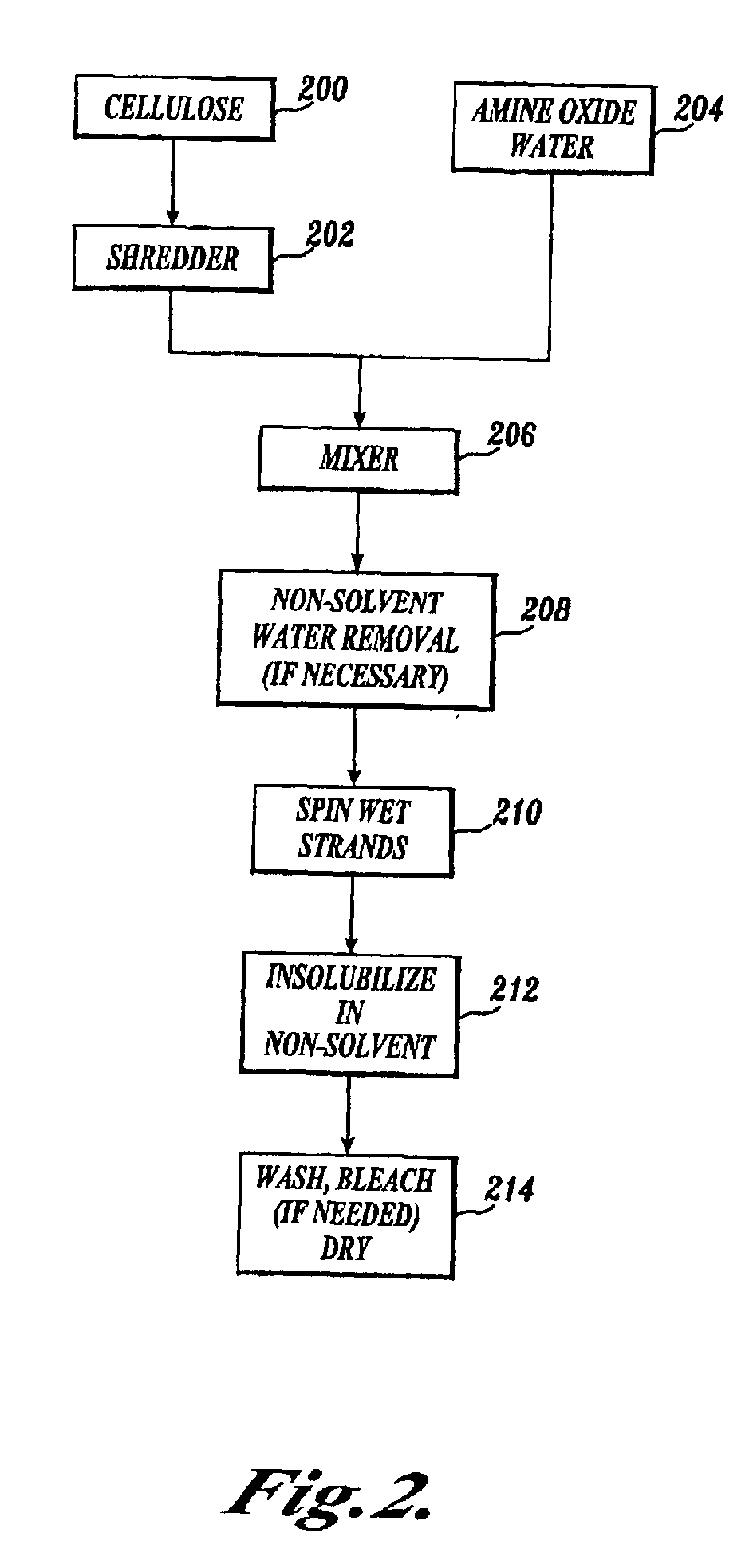

Process for making lyocell fiber from sawdust pulp

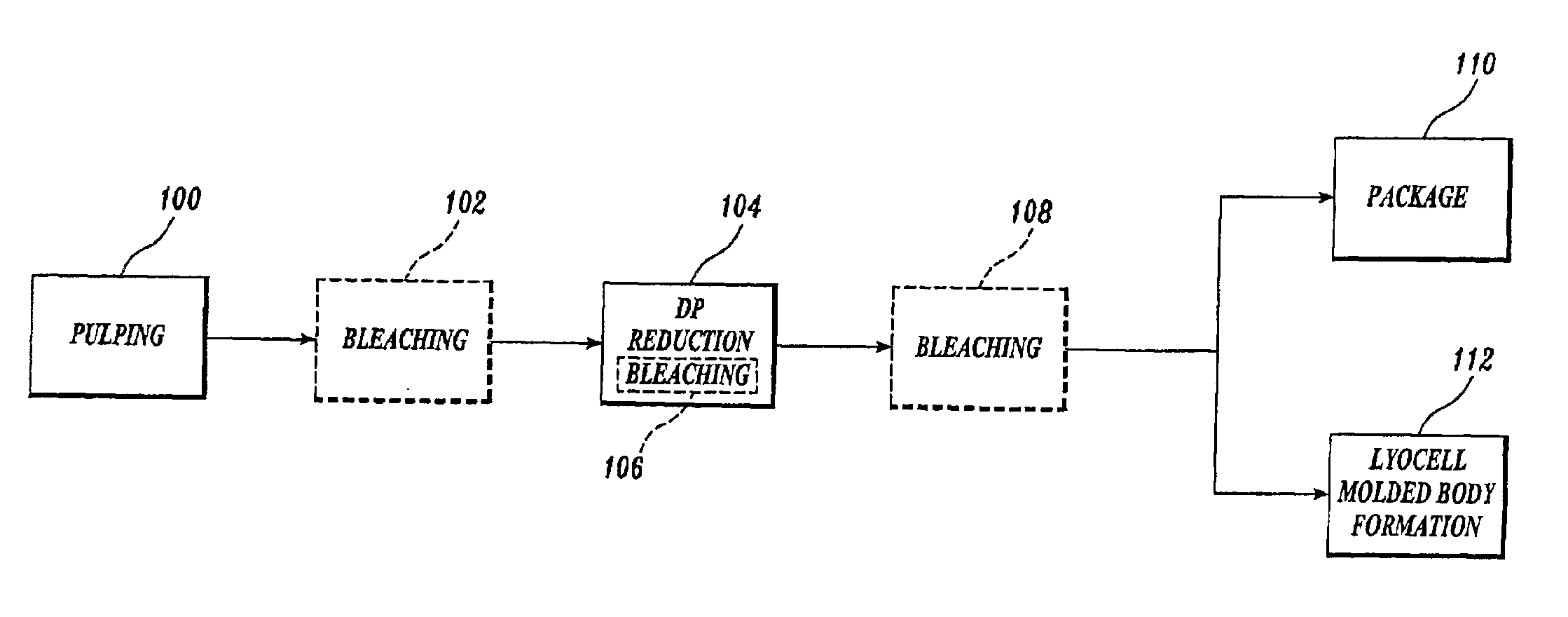

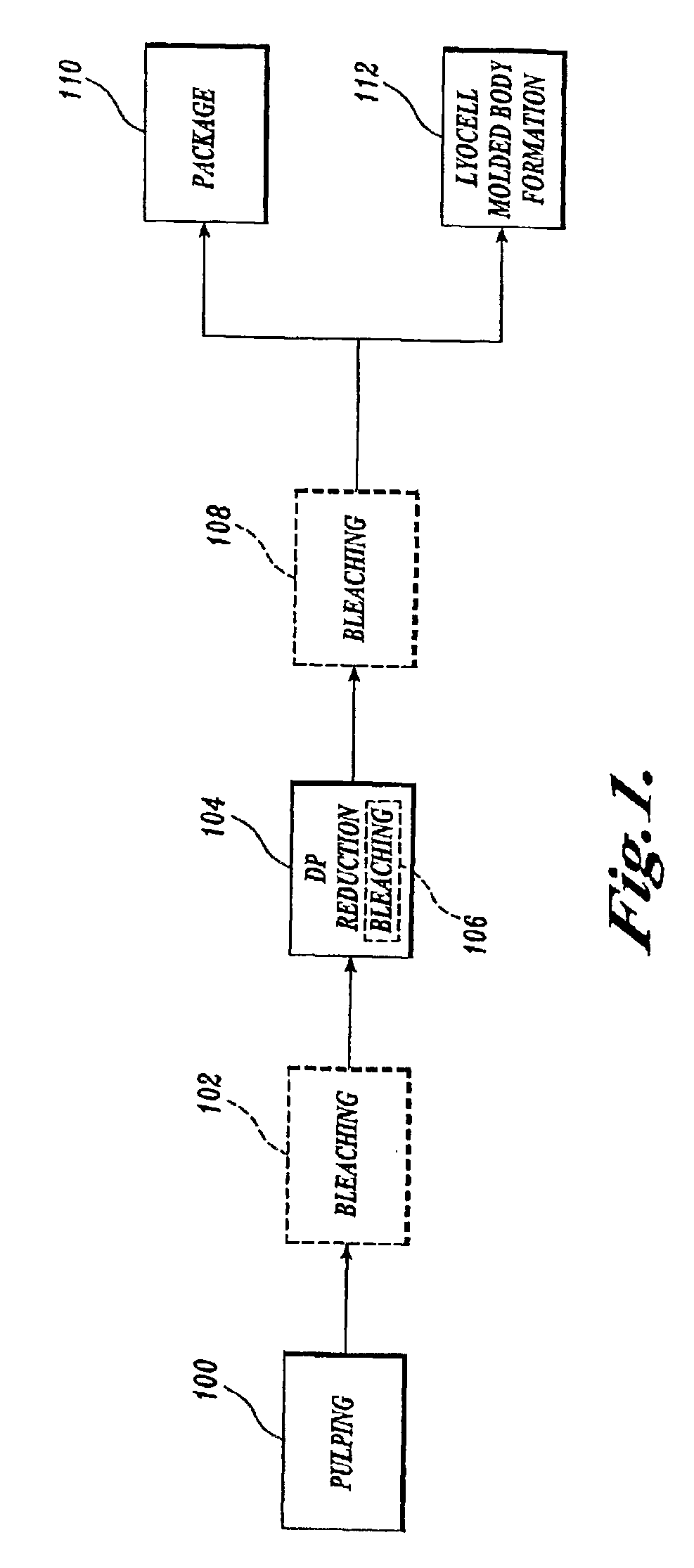

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

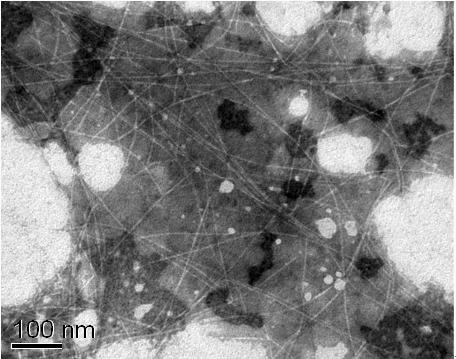

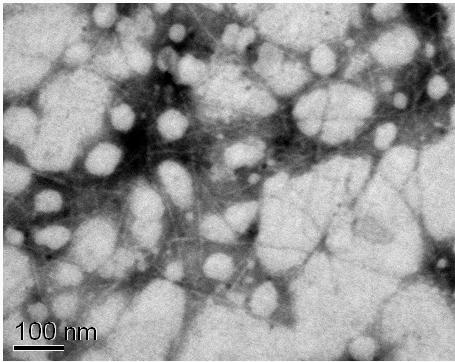

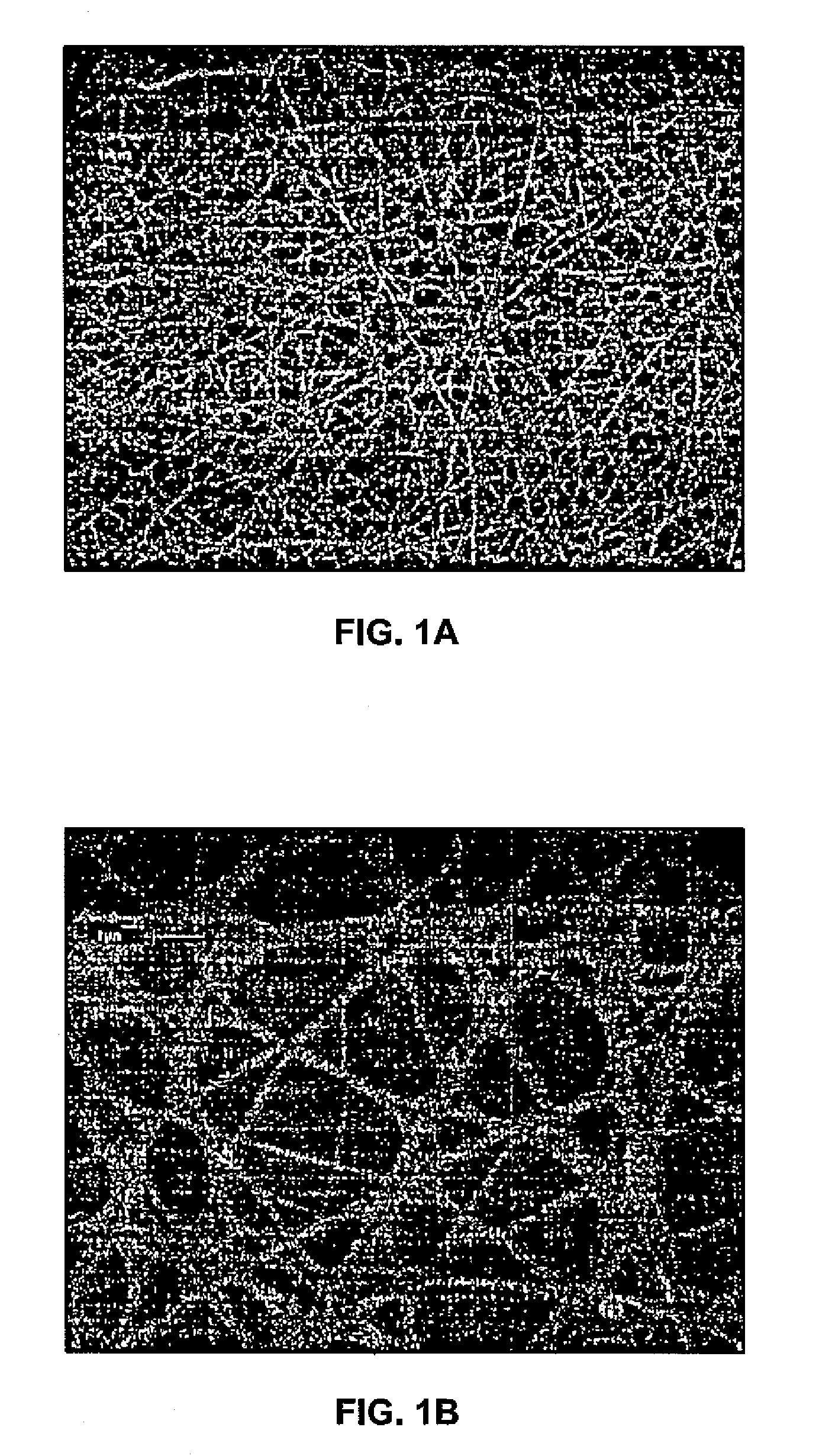

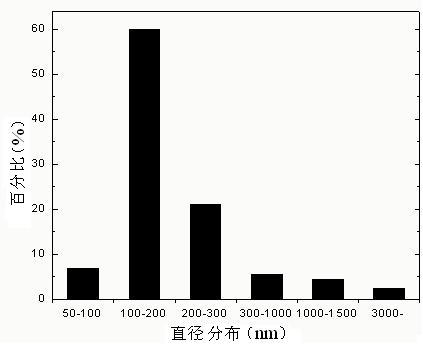

Preparation method of homogenized fine nano-cellulose fiber

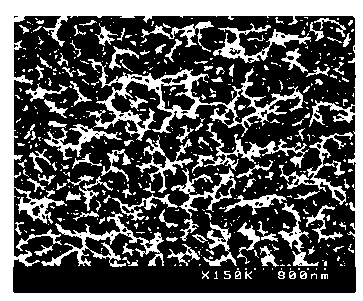

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

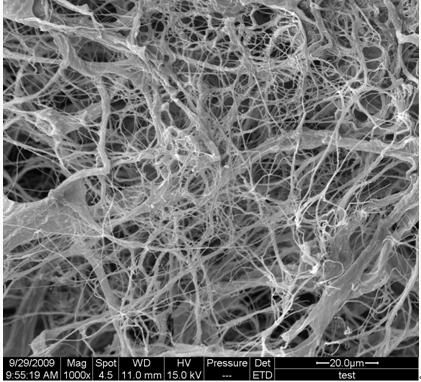

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS20050194477A1Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

Method of manufacture of nonwoven fabric

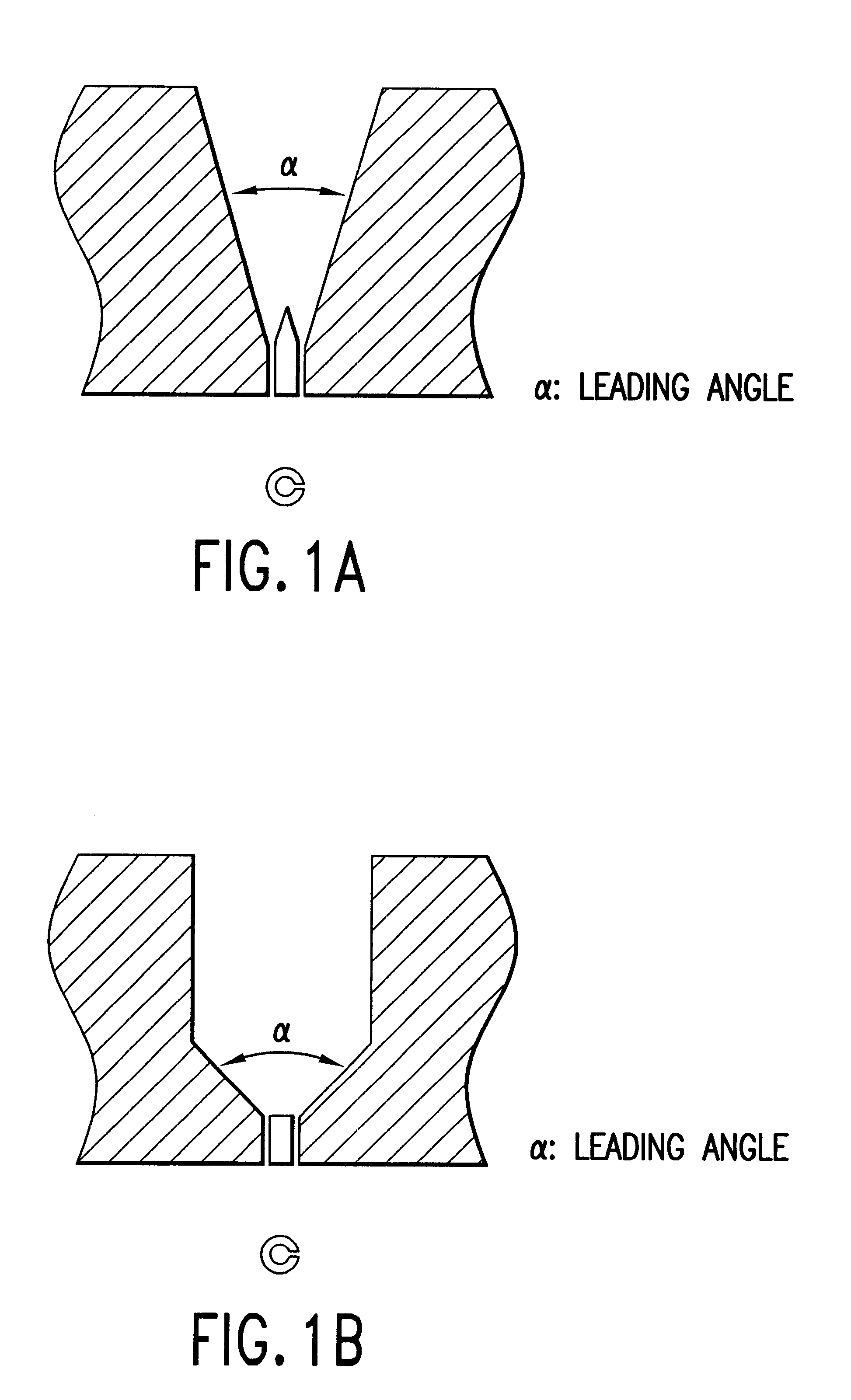

InactiveUS6358461B1Artificial filaments from cellulose solutionsCeramic shaping apparatusCelluloseEngineering

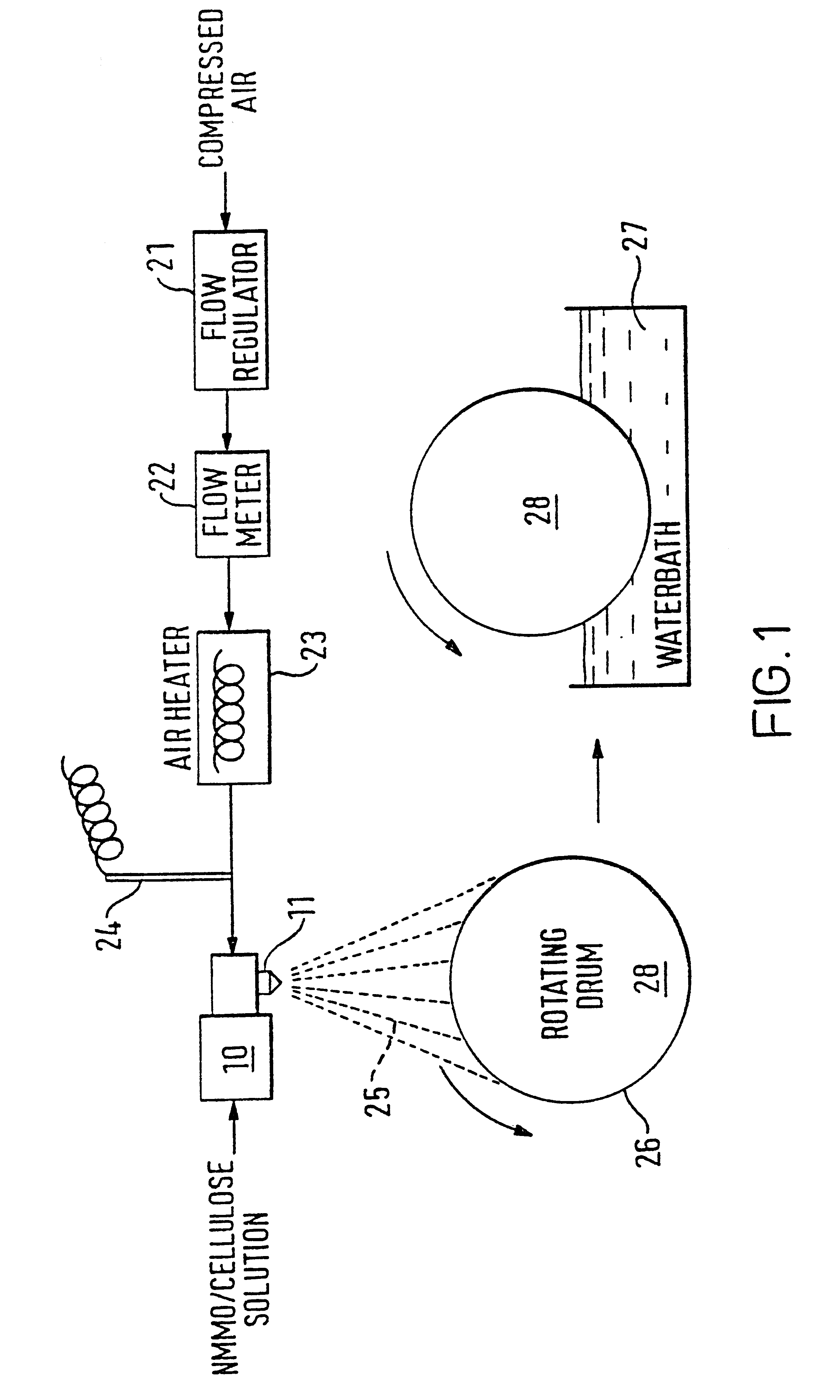

A method of manufacture of a nonwoven cellulose fabric is disclosed. The fabric is made from fibers formed by extrusion of a solution of cellulose through a spinning jet. The extruded fiber is attenuated with a high velocity gas flow, and the attenuated fiber is collected on a surface (such as the curved surface of a rotating drum) on which the fiber web is subsequently coagulated. Apparatus for carrying out the method is also disclosed. The method and apparatus permit the manufacture of a nonwoven lyocell fabric web in which fibers are bonded together without the use of a binder.

Owner:LENZING AG

Bamboo charcoal cellulose fiber and manufacturing method thereof

ActiveCN101104960AImprove solubilityHarm reductionArtificial filaments from cellulose solutionsIonNanometre

The invention discloses a bamboo charcoal cellulose fiber and the manufacturing method thereof. The manufacturing method comprises dissolving cellulose in an ionic solution to obtain a spinning stock solution, adding bamboo charcoal to obtain a modified spinning stock solution, and spinning in a coagulating bath together with the ionic aqueous solution. The content of bamboo charcoal nanoparticles is 4-30 percent by weight of the final fiber product. The manufacturing method has the advantages of simple operation, high yield, less environmental pollution, and less hazard to operator. The produced bamboo charcoal cellulose fiber has strong absorbability and good antibacterial and bacteriostatic effects.

Owner:潍坊欣龙生物材料有限公司

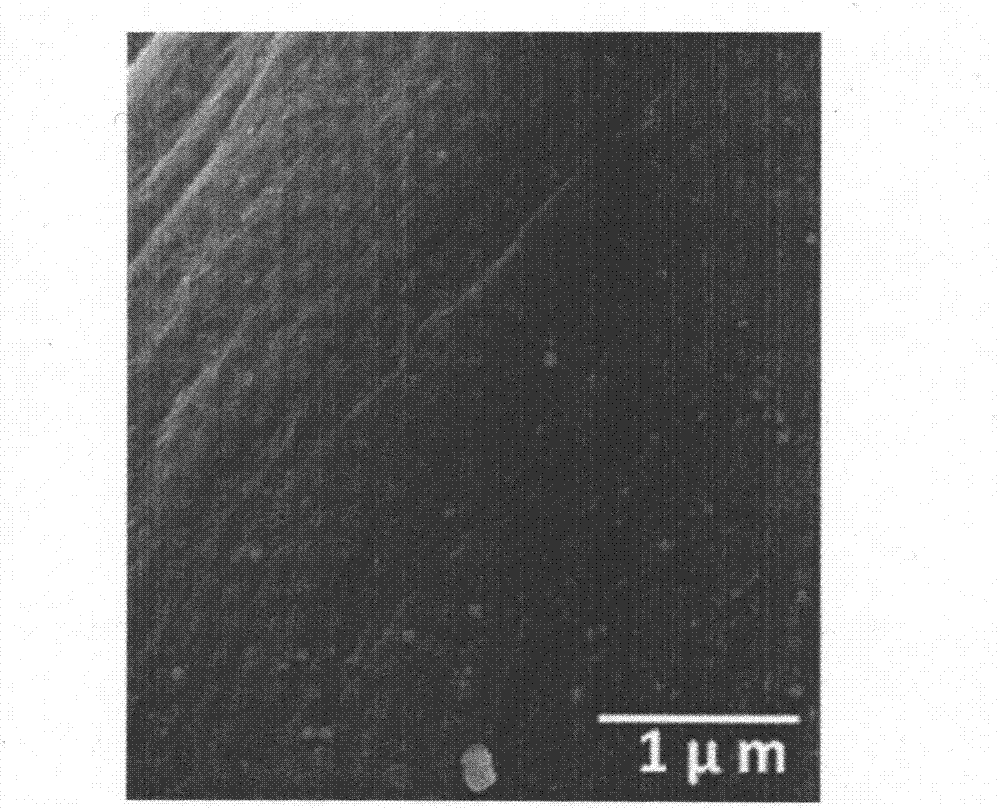

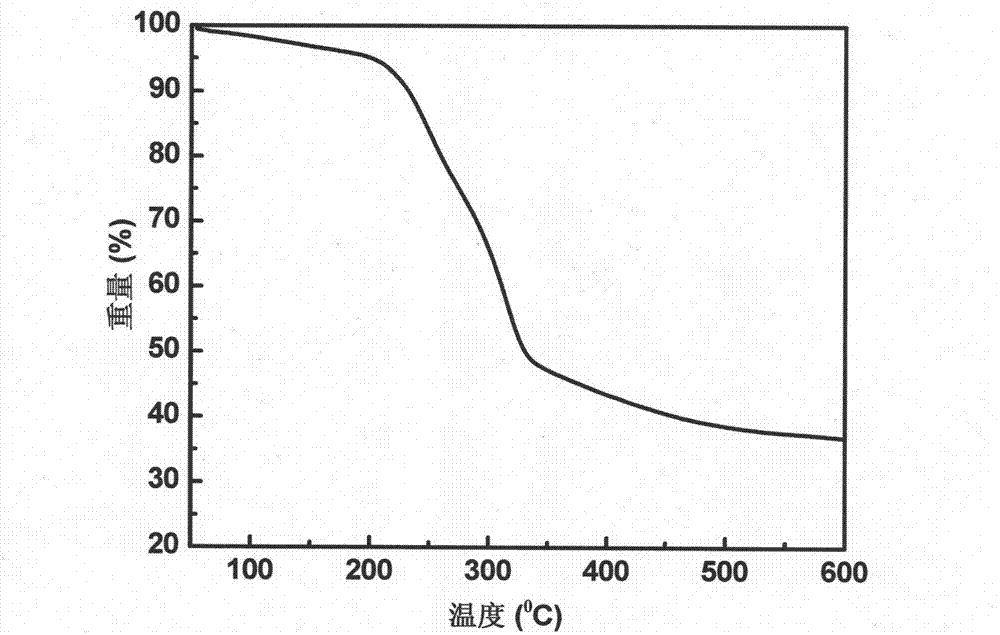

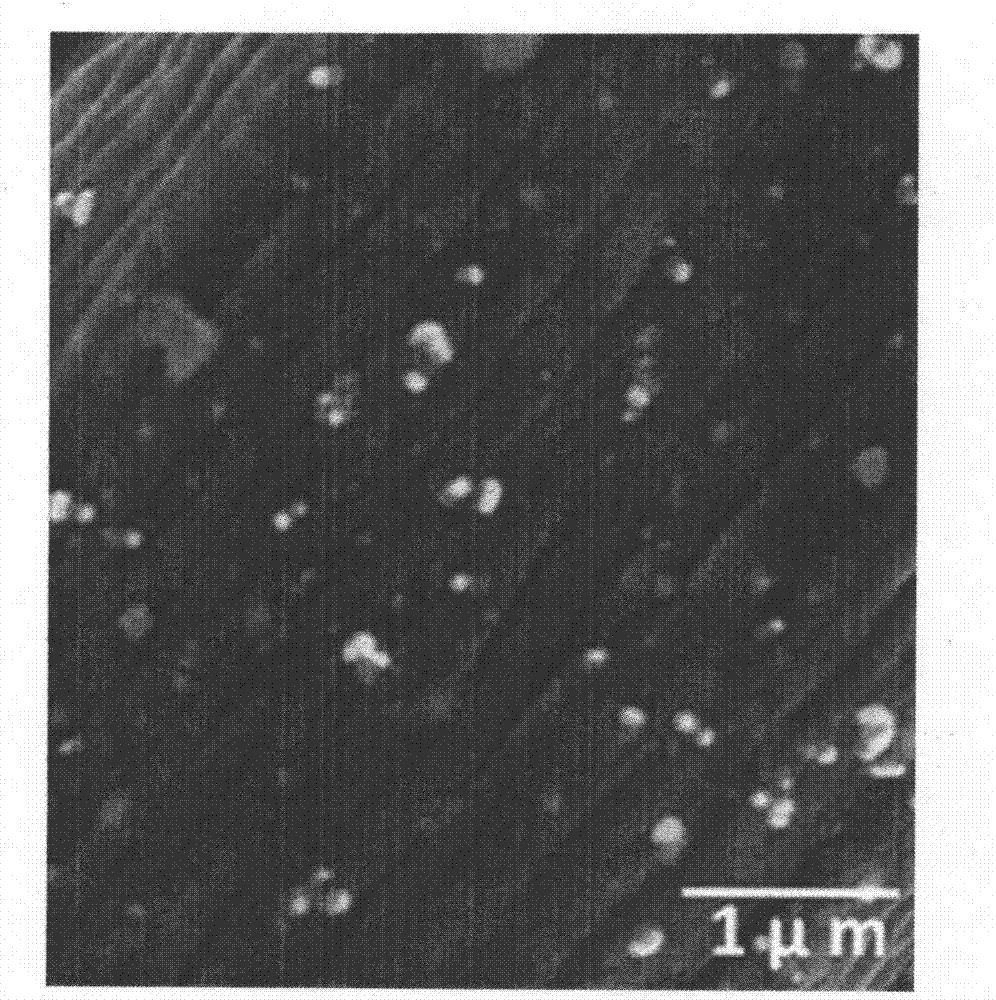

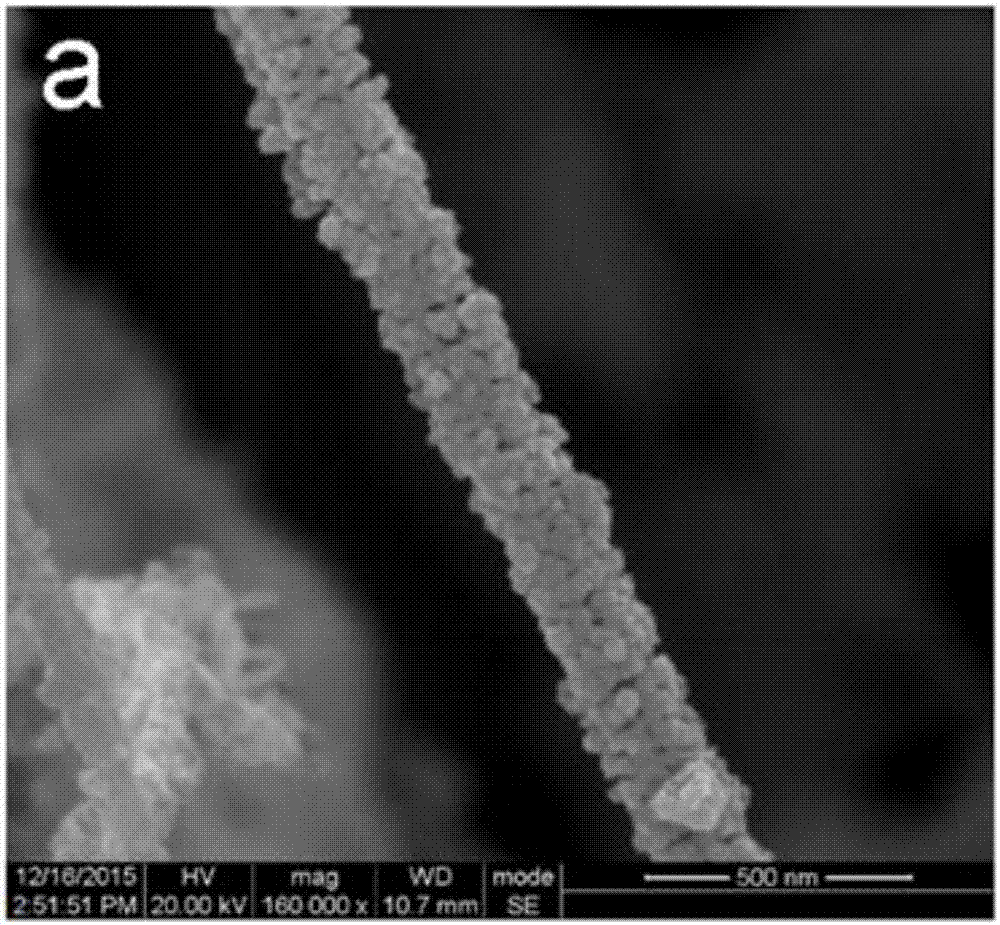

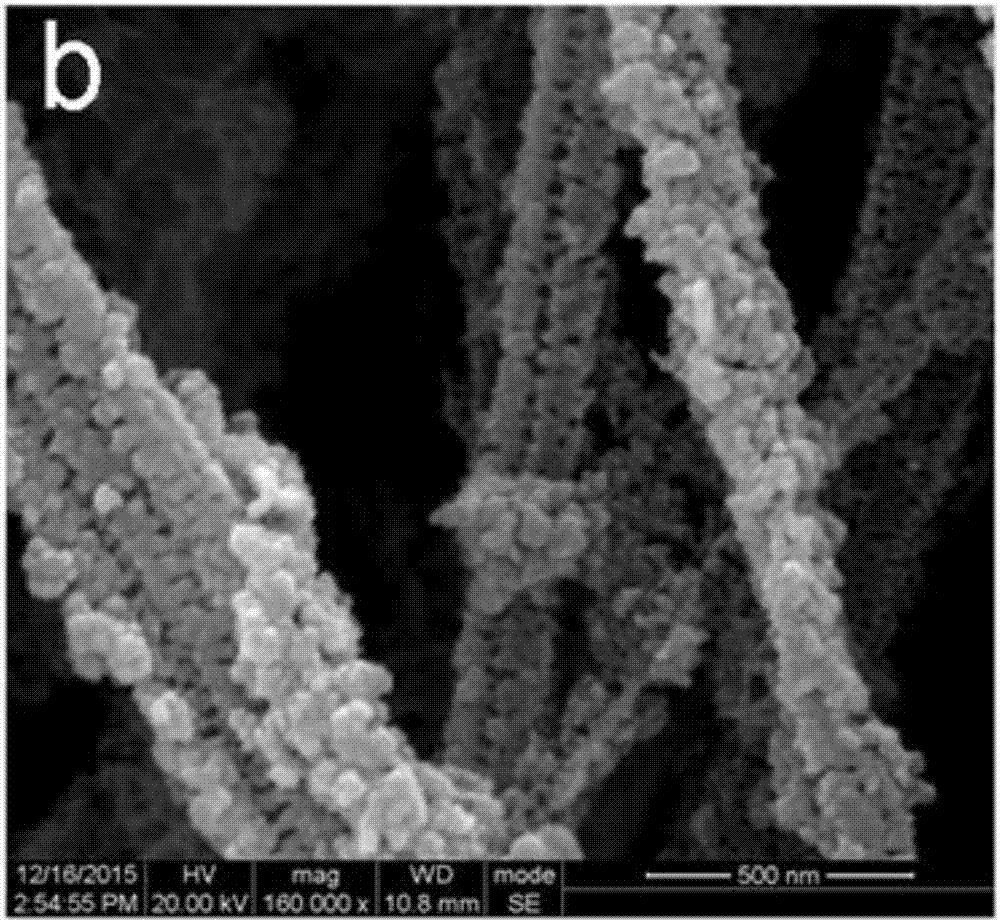

Cellulose fiber-supported nano silver antibacterial material and preparation method thereof

InactiveCN102776594ARich sourcesLow priceArtificial filaments from cellulose solutionsCellulose/protein filament chemical after-treatmentControlled releaseWound dressing

The invention discloses a cellulose fiber-supported nano silver antibacterial material and a preparation method thereof. The preparation method comprises the steps of: conducting chemical pretreatment on cellulose fibers, then conducting TEMPO (2, 2, 6, 6-tetramethylpiperidine-1-oxyl) selective oxidization on the cellulose fibers, and finally on the premise that not any reducing agent is added, enabling the oxidized cellulose fibers to react with silver nitrate in silver nitrate water solution through a short-time microwave heating method to prepare the cellulose fiber-supported nano silver antibacterial material with small-diameter and even-structure nano silver particles. By adopting the preparation method, on the premise that not any reducing agent is added, in-situ reduction and growth of nano silver on carboxylated cellulose fiber supporters are realized. The prepared cellulose fiber-supported nano silver antibacterial material has the advantages of small nano grain size and even size, and can be widely applied to the fields of antibacterial operation clothes, wound dressing, drug controlled release, textile coating and the like.

Owner:DONGHUA UNIV

Method for preparing cellulose spinning fluid

ActiveCN101240461AIncrease in sizeLow viscosityArtificial filaments from cellulose solutionsHigh concentrationOrganic solvent

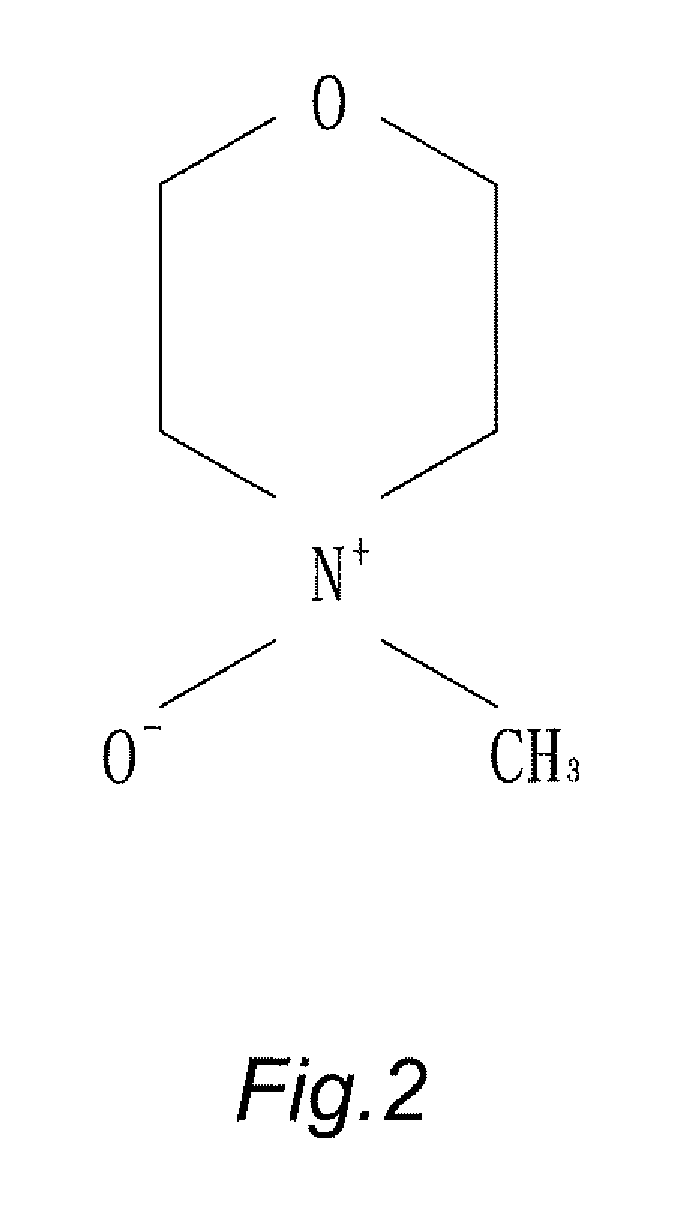

The invention relates to a preparation method of cellulose spinning solution, including a mixed solvent with low boiling point, volatile, polar organic solvent as a promoter and the N-methylmorpholine-N oxides (NMMO) of 8-18% moisture content; the cellulose pulp is mixed with the mixed solvent forming a uniform mixed materials; the low boiling point volatile organic solvent is removed from the mixed materials and the low content is lower than 5%, the cellulose of mixed materials is dissolved in the NMMO forming the cellulose spinning solution under heating. The invention is used the promoter delaying swelling and preventing premature dissolution of cellulose to reduce the solvent viscosity, the cellulose is dissolved uniformly, completely, the advantage which the pulp is impregnated directly in the high concentration solvent, and overcomes the abuse of uneven mixed, the used promoter is easy to extract and to recycle.

Owner:CHINESE TEXTILE ACAD

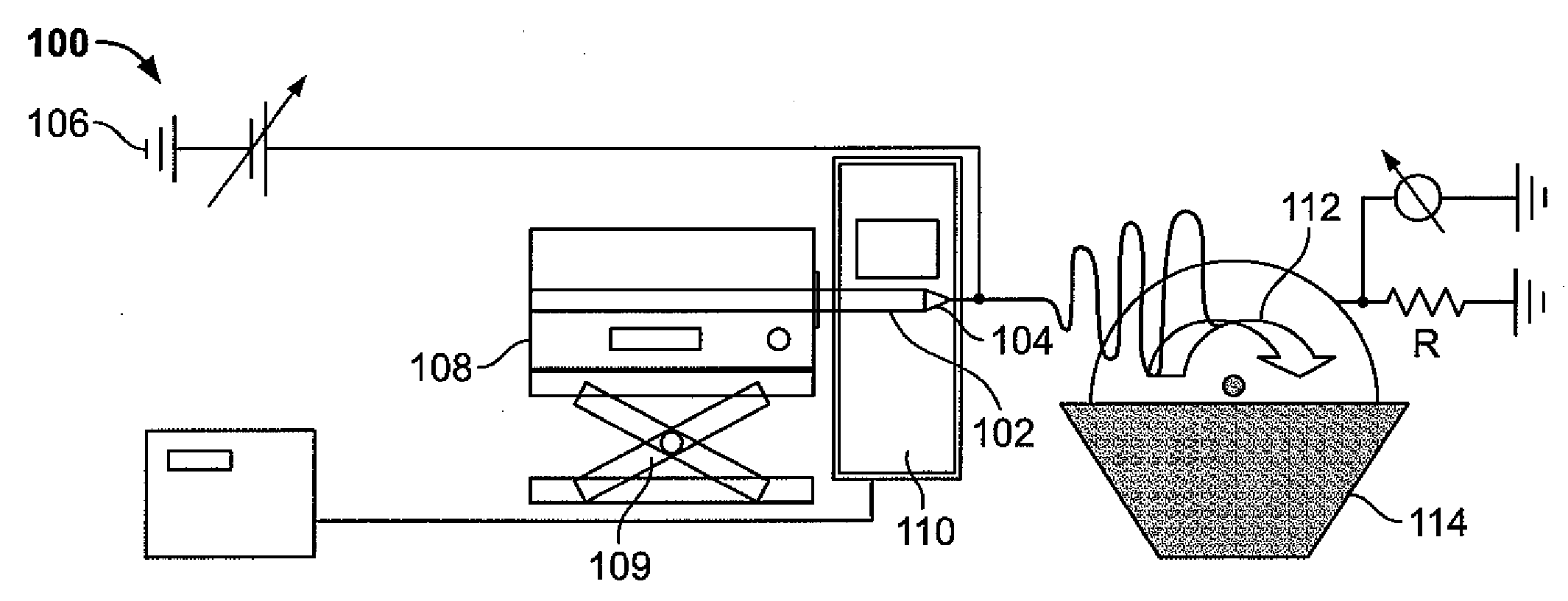

Apparatus and Method for Producing Electrospun Fibers

InactiveUS20080296808A1Artificial filaments from cellulose solutionsElectric discharge heatingFiberBiomedical engineering

An apparatus for making electrspun fibers comprises a collector that may be submerged in a coagulation bath. The collector may be automatically movable between a first position and a second position, wherein at least a portion of the collected fibers are submerged in a coagulation bath in the first position and spaced apart from the coagulation bath in the second position. The collector may be a rotating collector. A process for making electrospun fibers comprises electrospinning a dispersion and collecting a plurality of electrospun fibers, followed by submerging the collected fibers in a coagulation bath.

Owner:CORNELL RES FOUNDATION INC

Process for producing bacteria cellulose fibre with high degree of polymerization

InactiveCN101492837AEasy to prepareSuitable for industrial productionArtificial filaments from cellulose solutionsWet spinning methodsYarnBiocompatibility Testing

The invention relates to a method for preparing a high polymerization degree bacterial cellulose fiber. The method comprises the following steps: (1) dissolving the bacterial cellulose in solvent to prepare bacterial cellulose solution with mass fraction of 1-30 percent, filtering and standing the solution for deaeration, thus obtaining spinning solution; (2) forming the spinning solution in the step (1) by solidifying after the solution is sprayed through a spinneret orifice, and preparing a finished product after several conventional processes, such as stretching, washing, shaping and drying. The preparation method is simple and is applicable to industrial production; compared with other cellulose fibers, the bacterial cellulose fiber has high rupture strength and module reaching the level of high-tensile industrial yarn, and has the advantages of good biocompatibility, odegradability, hydrophilicity and binding property with rubber.

Owner:JIANGSU SHENGFENG DENGTAI BIOTECH

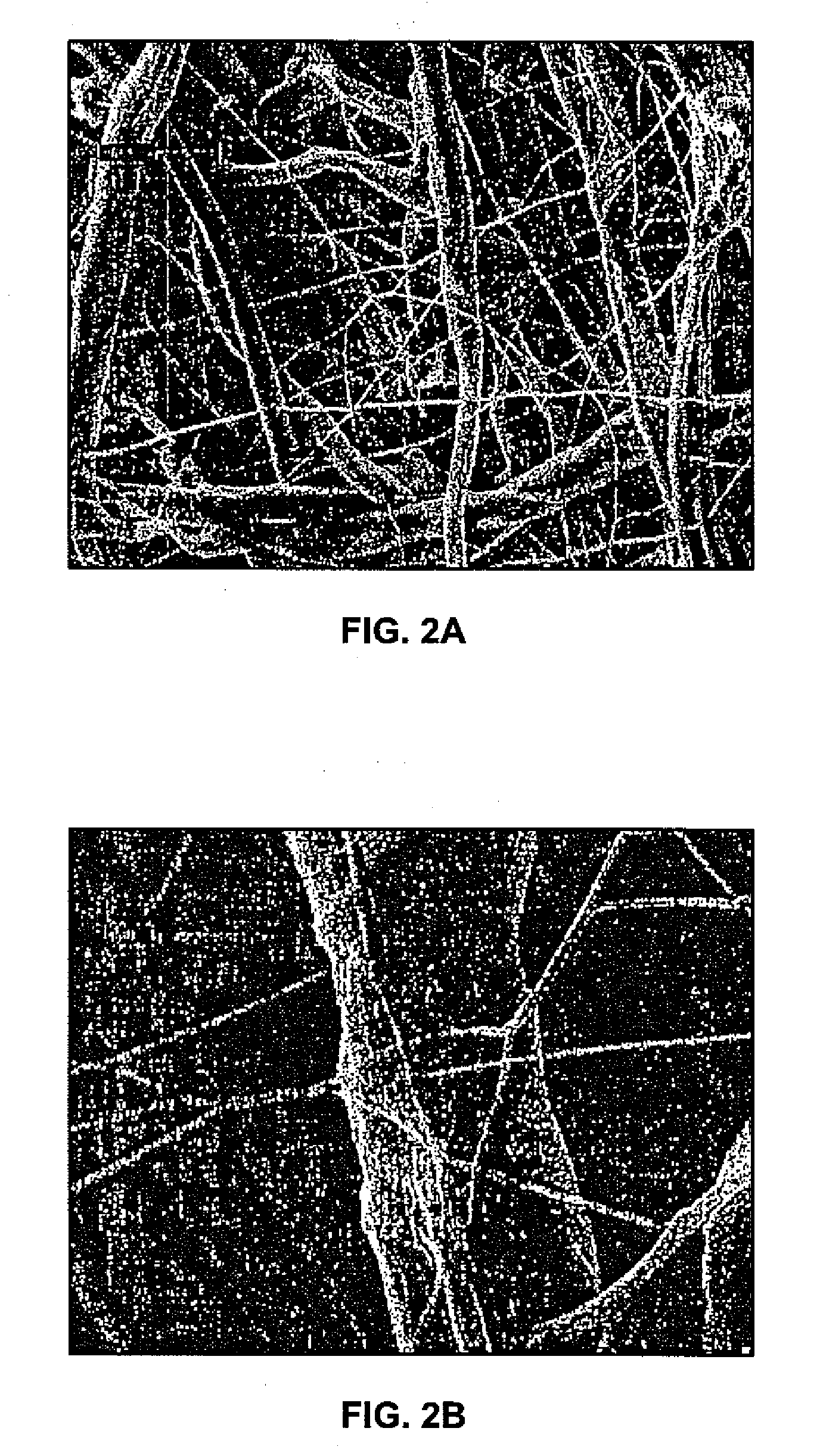

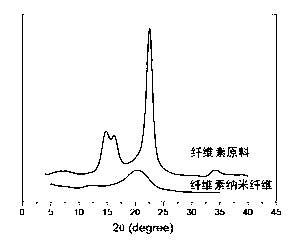

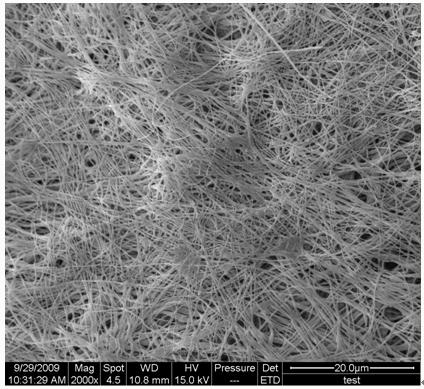

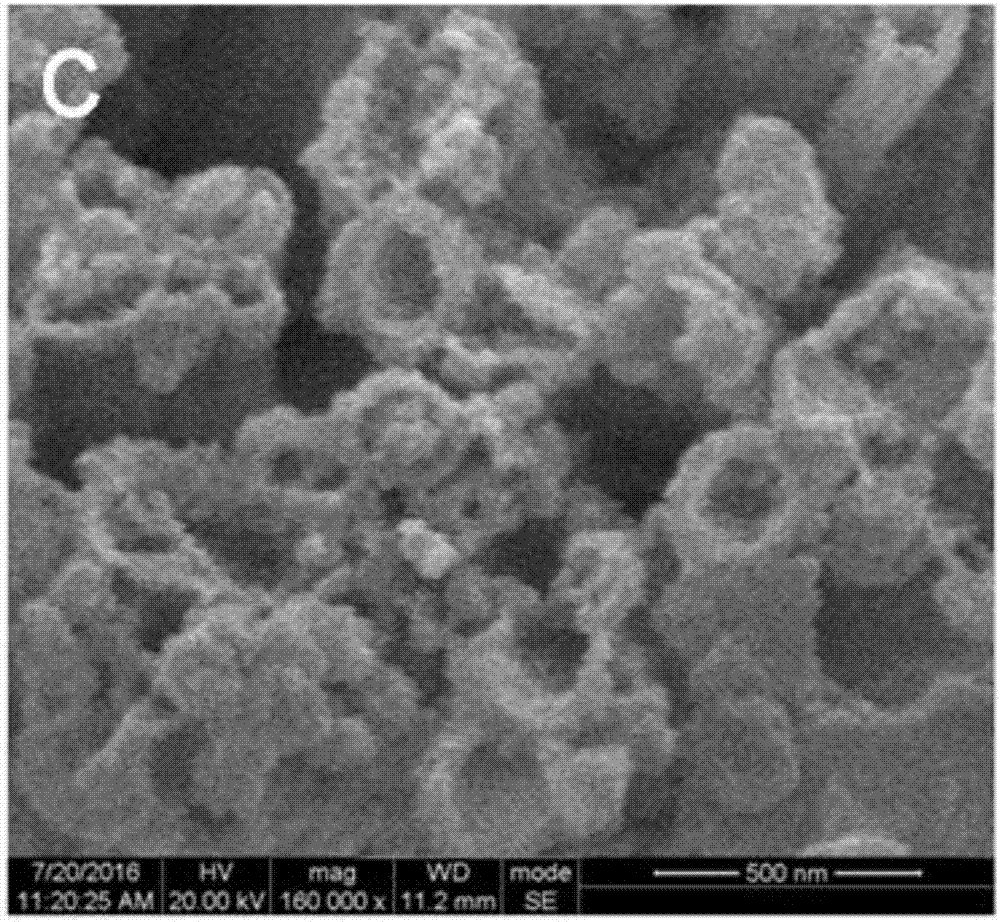

Preparation method of cellulose nanofiber

The invention discloses a preparation method of cellulose nanofiber. The method comprises the following steps of: dissolving cellulose to obtain a cellulose solution; slowly adding a nonsolvent into the cellulose solution under stirring, thus enabling the cellulose to gradually regenerate from the solution; removing substances except for the cellulose and water, and re-dispersing the solution to obtain cellulose nanofiber dispersion liquid; and removing dispersion media, thus obtaining the cellulose nanofiber. The cellulose nanofiber has a cellulose II type crystal structure, and the diameter of the nanofiber is less than 50 nanometers. The cellulose nanofiber prepared by the method is long and is high in strength.

Owner:WUHAN UNIV

Improved preparation of cellulose spinning solution with ion liquid as solvent

InactiveCN101476166AImprove solubilityReduced gel particle contentArtificial filaments from cellulose solutionsSpinning solutions preparationApparent viscosityDistillation

The invention provides a method for preparing an improved fibrino spinning original solution that ion liquid is used as solvent, which includes: two phases of swelling and dissolution, namely, placing dried fibrino dissolving pulp and 1-butyl-3-methyl imidazole villaumite with 1%-20% water ratio into a dissolution device for uniform mixing, firstly, leaving and swelling in 70-100 DEG. C, then stronger stirring for swelling to plasm shape without dissolution; secondly, raising temperature to 80-125 DEG. C slowly in stirring state, stirring and reducing pressure distillation for removing water component, fibrino can be dissolved completely after 2-8h; finally, reducing stirring speed, and reducing temperature of plasm to 90-100 DEG. C and keeping 30-60 min for obtaining straw yellow spinning original solution. The method provided by the invention has advantages that the spinning original solution is more uniform, dissolution is more fully, gelatin particle in the spinning original solution is reduced, the spinning original solution quality is increased; apparent viscosity of the spinning original solution is reduced, accordingly, solid content in the spinning original solution is increased further.

Owner:DONGHUA UNIV

Lyocell multi-filament for tire cord and method of producing the same

InactiveUS20050079348A1Good tenacityModulus improvementArtificial filaments from cellulose solutionsArtificial filament washing/dryingCellulosePolyvinyl alcohol

Owner:HYOSUNG CORP

Dissolution and processing of cellulose using ionic liquids

InactiveCN101007853AArtificial filaments from cellulose solutionsPlastic recyclingCelluloseSolubility

Cellulose is dissolved in an ionic liquid without derivatization, and is regenerated in a range of structural forms without requiring the use of harmful or volatile organic solvents. Cellulose solubility and the solution properties can be controlled by the selection of the ionic liquid constituents, with small cations and halide or pseudohalide anions favoring solution.

Owner:UNIVERSITY OF ALABAMA

Method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment

InactiveCN101851801AUniform fibrillationRegular shapeArtificial filaments from cellulose solutionsBenzeneAlcohol

The invention provides a method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment, which relates to a preparation method of nanometer cellulose fiber. The invention solves the problems of short length, nonuniform fiber diameter distribution and easy interweaving between fiber into cluster nanometer fiber of the nanometer cellulose fiber prepared by the existing method only using mechanical high-pressure homogenization treatment. The method of the invention comprises the following steps that: 1. biomass fiber is extracted by an alcohol benzene solution; 2. the treatment by acidified sodium chlorite is carried out; 3. alkali liquor gradient treatment is carried out; 4. an ultrasonic cell crushing machine is used for treatment; and 5. high-pressure homogenization treatment is carried out, and nanometer cellulose fiber is obtained after being dried. The fiber diameter distribution is uniform, the length is longer than or equal to 150 mum, the slenderness ratio is larger than or equal to 600, and the fiber is mutually interwoven into a reticular winding structure. The method of the invention is applicable to the preparation of nanometer cellulose fiber from wood pulp, papermaking pulp materials, wood materials, bamboo materials and crop straws.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparing method for SiO2/cellulose tough aerogel fibers

ActiveCN105463603AAdjust the size of the specific surface areaAchieve preparationArtificial filaments from cellulose solutionsWet spinning methodsRoom temperatureCellulose fiber

The invention relates to a preparing method for SiO2 / cellulose tough aerogel fibers. The preparing method comprises the steps that silicate or silanol sol is prepared into a spinning solution, a cellulose solution is added, then the mixture is injected into an H2SO4 / Na2SO4 solution for a reaction for wet method spinning, and orthosilicic acid / silicate / cellulose fibers are obtained; the fibers are wound and steeped into an H2SO4 / Na2SO4 solution for aging at the room temperature, the fibers are washed with deionized water to be neutral, solvent replacement is carried out, the fibers are dried, and the SiO2 / cellulose tough aerogel fibers are obtained. The method has the advantages that raw materials are cheap and easy to obtain, the reaction process is simple, and spinnability is good. The prepared continuous SiO2 / cellulose tough aerogel fibers contain abundant holes, have a high specific surface area and are resistant to high temperatures and chemical corrosion; meanwhile, the fibers are adjustable in specific surface area and have certain toughness, the application range of the aerogel fibers can be enlarged, and higher practical value is achieved.

Owner:DONGHUA UNIV

Method for preparing regenerated cellulose fibers from plant fibrous pulp of reeds and stalks

InactiveCN101736426AHigh strengthGood hygroscopicityArtificial filaments from cellulose solutionsWet spinning methodsPolymer sciencePlant fibre

The invention relates to a method for preparing regenerated cellulose fibers from plant fibrous pulp of reeds and stalks. The method is the solvent method, and comprises the following steps of: preparing 8 to 15 mass percent spinning solution of the regenerated cellulose fibers by adopting the direct method or indirect method; and spinning the obtained spinning solution of the regenerated cellulose fiber. The method has the advantages of simple process, little pollution, and good performance of the fiber prepared by the method. The regenerated cellulose fiber of reeds, stalks and the like, prepared by the method, has the advantages of high strength, softness, smoothness, good moisture absorbing property, convenient dyeing and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Solvent for dissolving cellulose and its preparation method and use

InactiveCN1699442ASignificant progressDissolve fastArtificial filaments from cellulose solutionsUreaSodium hydroxide

The invention discloses a solvent for dissolving cellulose which comprises sodium hydroxide, thiocarbamide, urea and water as quaternary system. The solvent has the strongest dissolving capacity at the temperature of -12 to 5 deg. C. The invention also provides the process for rapidly dissolving cellulose by employing the solvent, and the method for preparing cellulose fiber or cellulose film. The solvent system has strong dissolving capacity to cellulose.

Owner:DONGHUA UNIV

Spunbond wetlaid method for producing non-woven fabrics from natural cellulose

ActiveUS8366988B2Reduce manufacturing costDegree of air permeabilityArtificial filaments from cellulose solutionsPattern makingPunchingWater rinsing

Owner:LIN CHIH HSIN

Cellulose fiber, preparation method thereof and equipment

ActiveCN102477591AHigh strengthSmall denierArtificial filaments from cellulose solutionsArtificial thread manufacturing machinesPolymer scienceSpinning

The invention relates to the field of chemical fibers, in particular to a cellulous fiber, a preparation method thereof and equipment. The cellulose fiber mainly comprises cellulous, is prepared by the solidifying liquid co-current drawing and spinning technology, and meets the following conditions that the tension breakage strength of the fiber is higher than or equal to 2.0cN / dtex, the fineness of the fiber is equal to or smaller than 1.67dtex, the content of S elements in the fiber is smaller than or equal to 100ppm, the fibrillation index (F.I.) of the fiber is smaller than or equal to 2. In addition, the cellulose fiber is free of chemical compositions relevant to fibrillation treatment resistance. The invention further relates to the preparation method of the cellulous fiber and the equipment. The cellulose fiber is high in strength, low in fineness and free of fibrillation tendency, the preparation method is simple, and is easy to control and applicable to large-scale industrialized production, and the equipment is simple in structure, skillful in design and stable in condition.

Owner:CHINESE TEXTILE ACAD

Process for producing regenerated cellulosic fibers

InactiveUS6527987B1Maintain good propertiesImprove the immunityArtificial filaments from cellulose solutionsHollow filament manufactureLiquid crystallinePolymer science

It is an object of the present invention to overcome the problem of fibrillation which is a drawback found in solvent-spun regenerated cellulosic fibers and to thereby provide high-quality regenerated cellulosic fibers. The regenerated cellulosic fibers are produced by the use of a spinning dope of cellulose dissolved in a solvent containing N-methylmorpholine N-oxide under the conditions that the average degree of polymerization of cellulose contained in the spinning dope is held to 400 or lower and 5% to 30% by weight of the cellulose is adjusted to a degree of polymerization of 500 or higher. Thus a pseudo-liquid-crystalline phenomenon can be allowed to occur in the stretched filaments during spinning, so that the resulting regenerated cellulosic fibers have improved resistance to fibrillation as well as improved dyeability and feeling.

Owner:TOYOBO CO LTD

Method for producing regenerated cellulose fiber by dual-bath coagulation

InactiveCN101429682ASlow down the curing speedFully curedArtificial filaments from cellulose solutionsFilament manufactureThioureaCellulose fiber

The invention belongs to the material field, and provides a method for preparing a regenerated cellulose fiber by double solidification bath. The method comprises the following steps: precooling cellulose to a temperature of between 8 DEG C below zero and 12 DEG C below zero in a mixed solution which contains the following compositions in weight percentage: 7 to 10 percent of sodium hydroxide, 4.5 to 7 percent of thiourea, 1 to 10 percent of urea, and 73 to 87.5 percent of water to prepare a cellulose solution with concentration of between 2 and 12 percent through filtering and defoaming; spinning the cellulose solution through a spinning machine, and presolidifying and predrafting the cellulose solution in a first solidifying bath; sufficiently solidifying, regenerating, drafting and orientating the cellulose in a second solidifying bath; washing and drying cellulose; and finally, oiling the fiber through a prepared composite oil solution, and winding the fiber to obtain the regenerated cellulose fiber with excellent mechanical performance.

Owner:DONGHUA UNIV

Method for fabricating fiber of regenerative bamboo cellulose

InactiveCN1760412AReduce manufacturing costThe average degree of polymerization decreasedArtificial filaments from cellulose solutionsMorpholinePapermaking

The present invention relates to a production method of solvent spun cellulose fiber in chemical fiber industry. It is characterized by that said production method includes the following steps: using commercial papermaking-grade bamboo pulp as raw material, making it undergo the pretreatment processes of hydrolysis, acidolysis or enzymolysis, then mixing it with N-methyl morpholine oxide aqueous solution according to a certain weight ratio, reducing pressure and dehydrating at 70-15 deg.C to obtain spinning solution; pressurizing said spinning solution, filtering said spinning solution by two prefilters, jetting by spinning nozzle, coagulating and forming in aqueous solution of N-methyl morpholine oxide, rinsing and adopting correspondent conventional process to prepare filament and staple with various specifications.

Owner:DONGHUA UNIV

Method for preparing luminous Lyocell fibre

InactiveCN101298705AHigh recovery rateNo pollutionArtificial filaments from cellulose solutionsLuminescent compositionsNon toxicityAntioxidant

The invention relates to a luminescent Lyocell fiber preparation method. The method includes the following steps: a rare-earth luminescent material and micro antioxidants occupying 1 to 20 percent of a fibrin pulp weight are added into NMMO water solution, and suspension is obtained after ultrasonic dispersing and mechanical stirring; the suspension and fibrin pulp occupying 5 to 15 percent of the NMMO weight are arranged into a reaction kettle, the mixture is swelled for 0.5 to 5 hours under temperature of 90 to 120 DEG C and a vacuum degree of minus 0.1 to minus 0.06 MPa, and then the mixture is stirred mechanically for dissolving to obtain a spinning stock-solution; then the spinning stock-solution is delivered to a spinning machine to obtain the required fiber through a dry-wet spinning process. The prepared fiber takes the fibrin fiber as a basic material and the fibrin is provided with hydrophilic hydroxide radical which can integrate with the rare-earth luminescent material in the fiber, and the fiber cannot be dropped off after washing with long service life. The solvent of the invention has the advantages to of non-toxicity and high-recycling rate and the fibrin fiber can be degraded without contamination to environment.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for the preparation of a material with high water and salt solutions absorbency

InactiveUS6027536ALittle degradationHigh water and salt solution absorbencyNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseFiber

PCT No. PCT / EP97 / 00652 Sec. 371 Date Aug. 6, 1998 Sec. 102(e) Date Aug. 6, 1998 PCT Filed Feb. 12, 1997 PCT Pub. No. WO97 / 30090 PCT Pub. Date Aug. 21, 1997A process for preparing a material having a high water and salt solutions absorbency, the material containing mainly cellulose that is dissolved in a solvent containing phosphoric acid, a solution is obtained that contains 94-100 wt. % of the following constituents: cellulose, phosphoric acid and / or its anhydrides, and water, the solution is then coagulated and washed in a liquid containing less than 50 wt. % of water. This process can be used to obtain cellulose products, such as fibers or pulp, which have a high water and (isotonic) salt solutions absorbency.

Owner:AKZO NOBEL NV

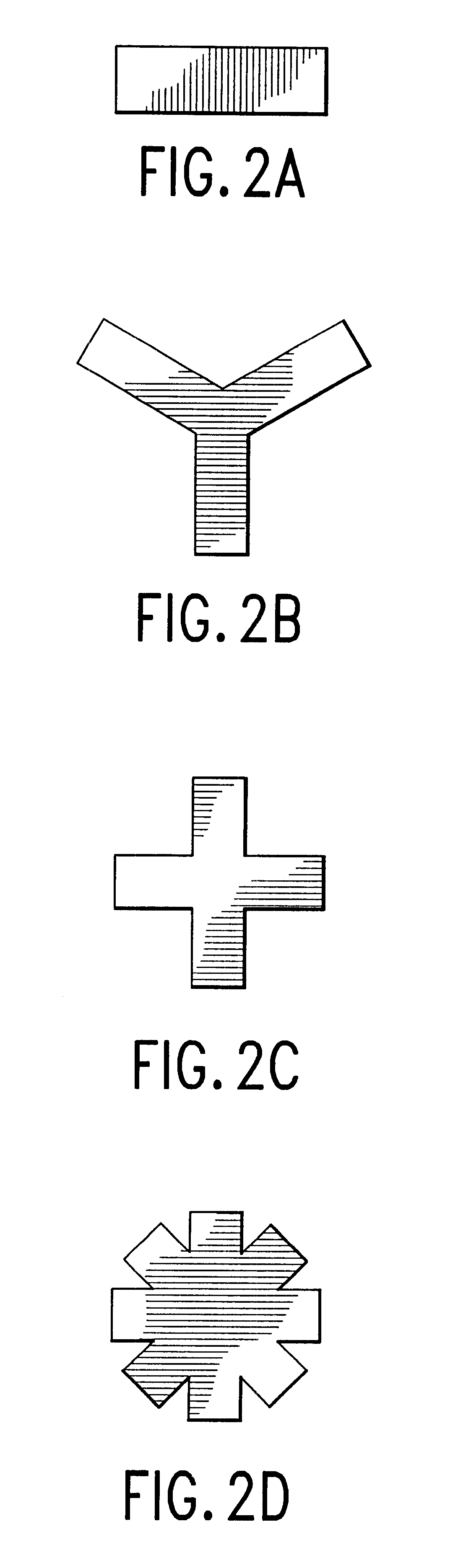

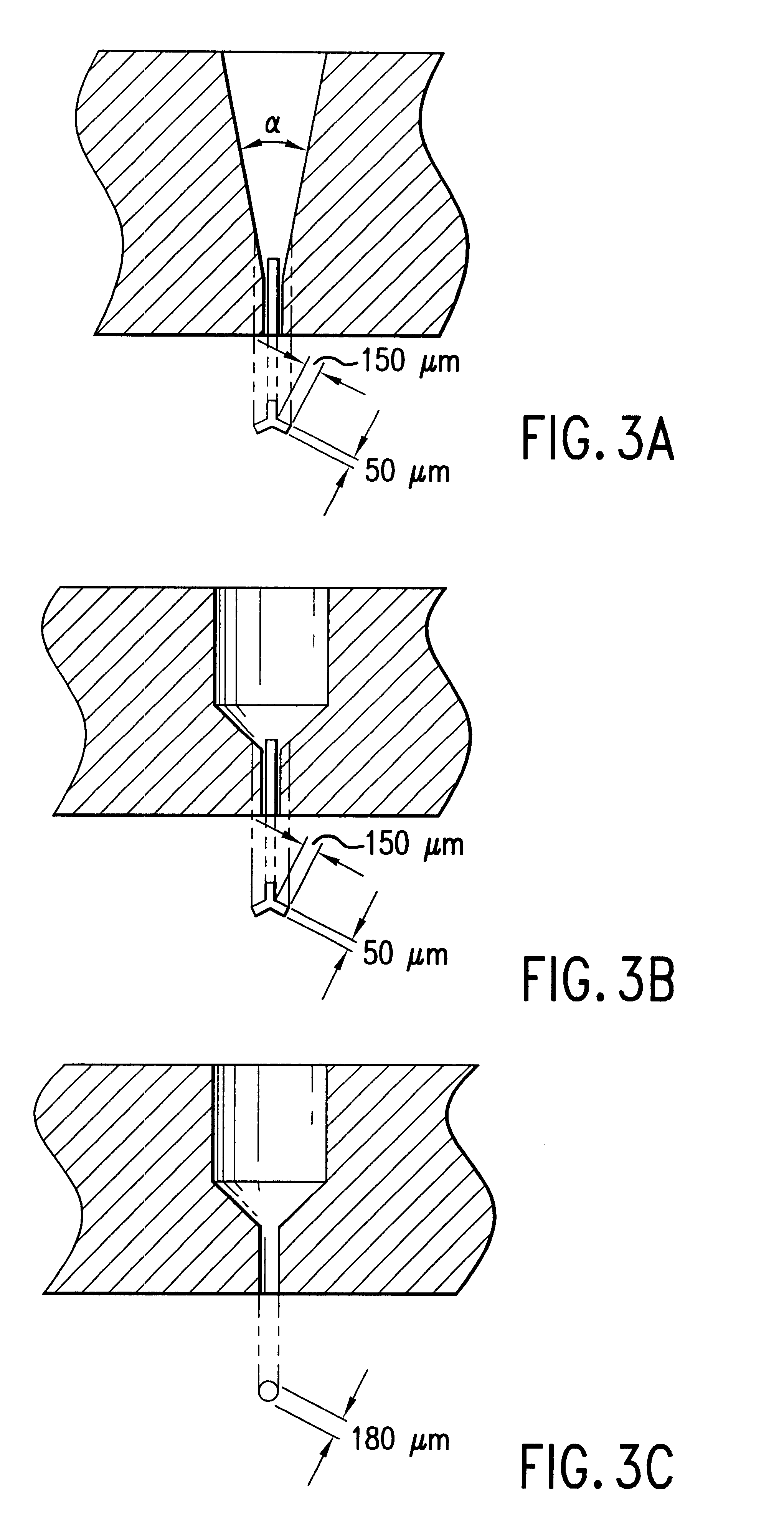

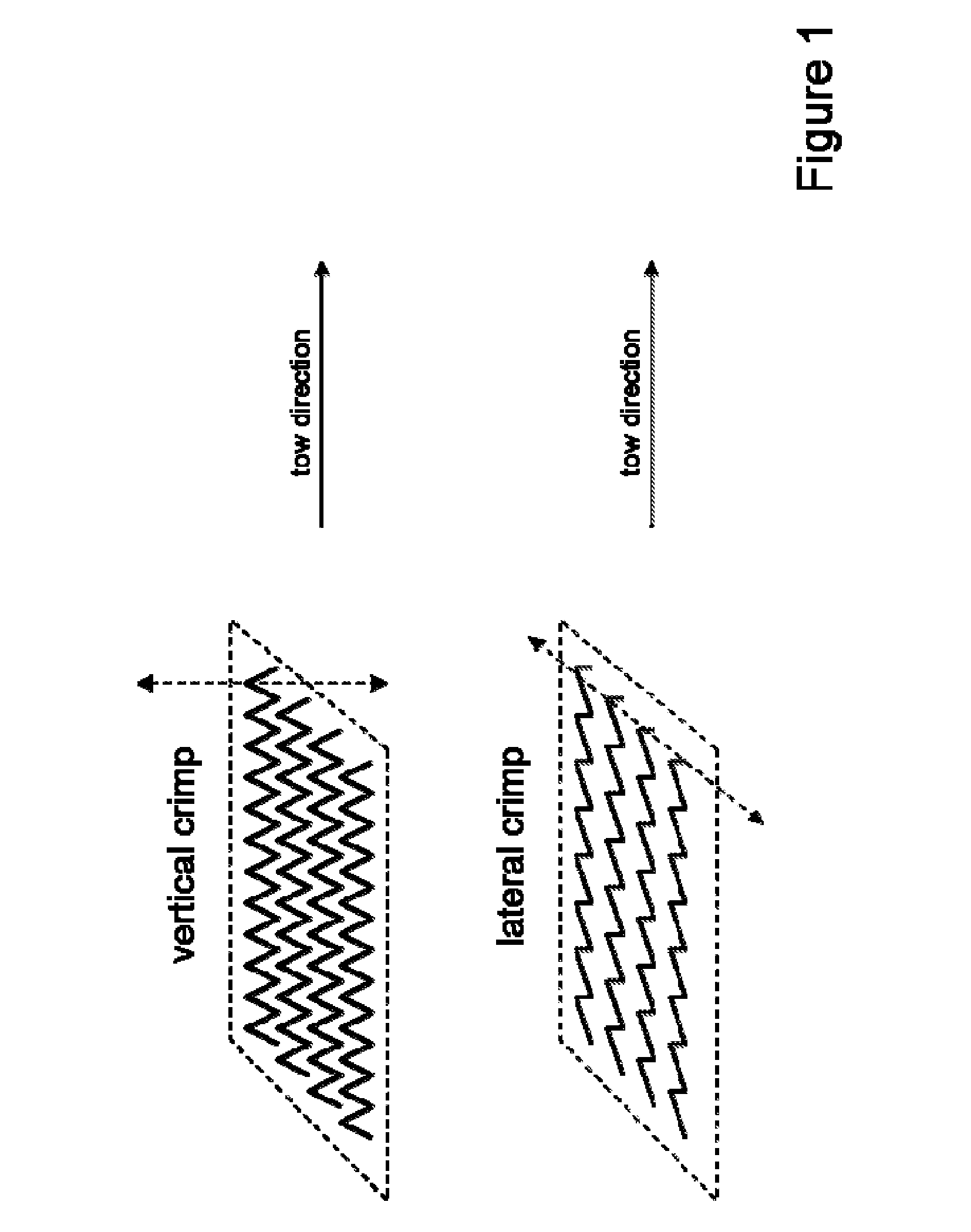

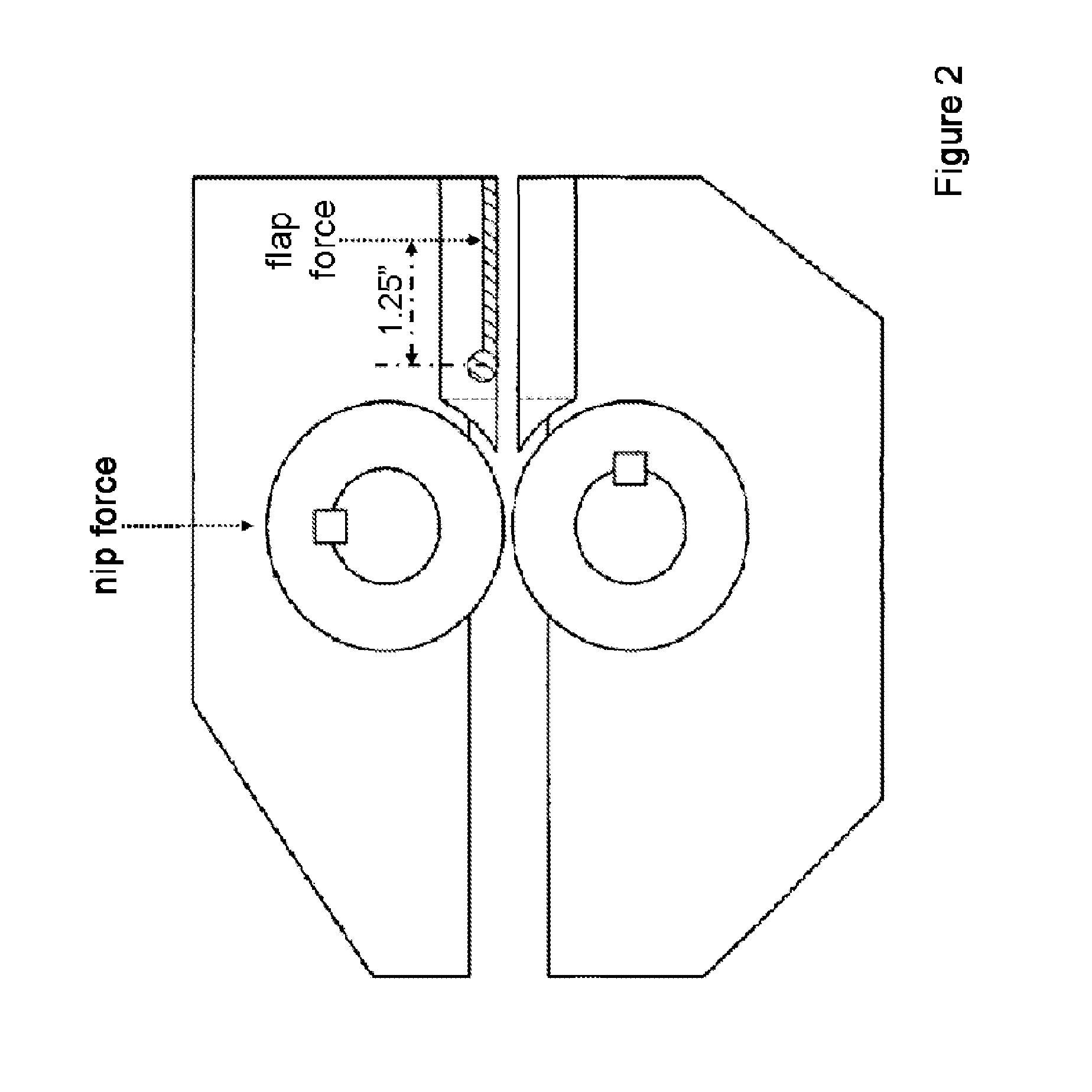

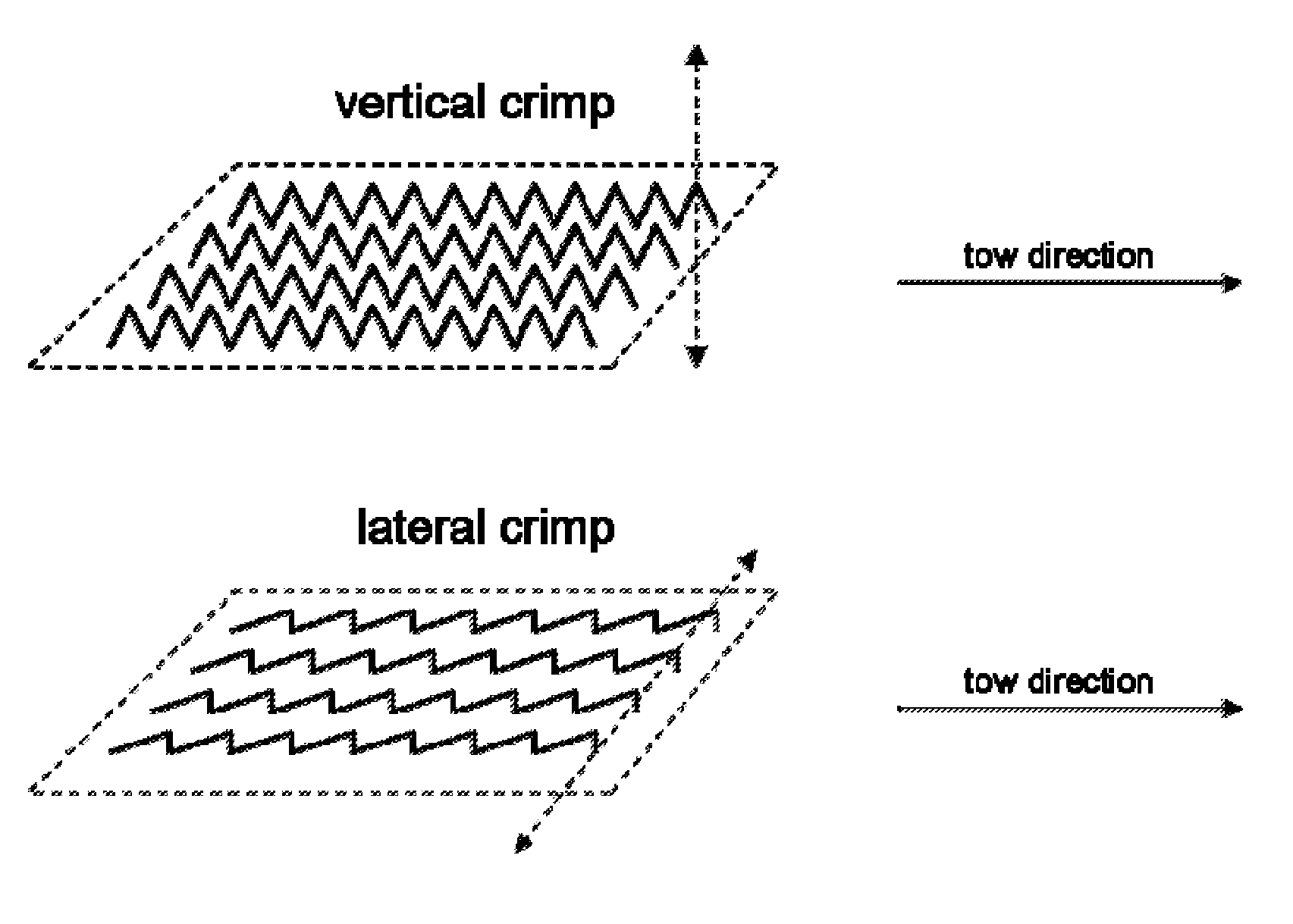

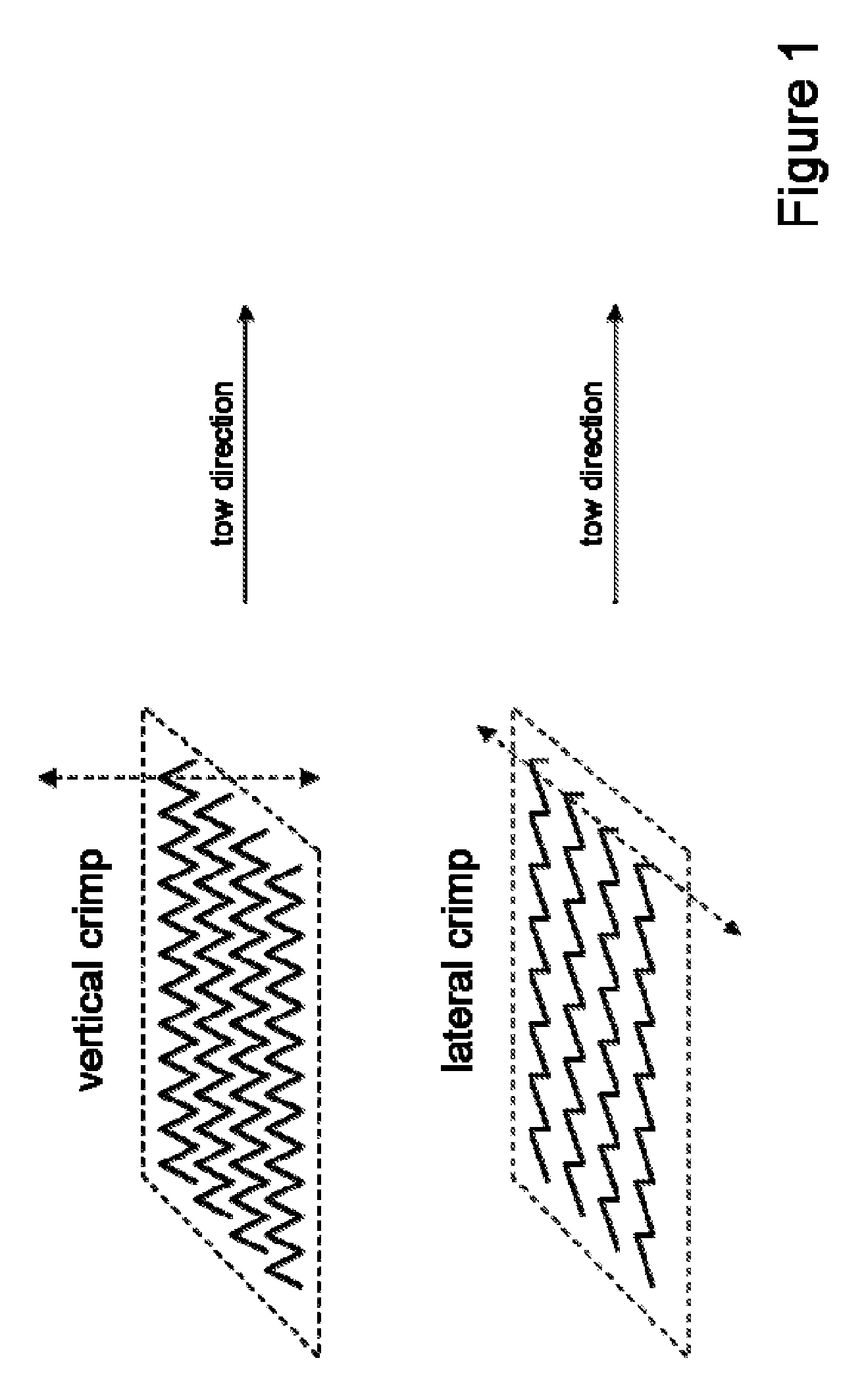

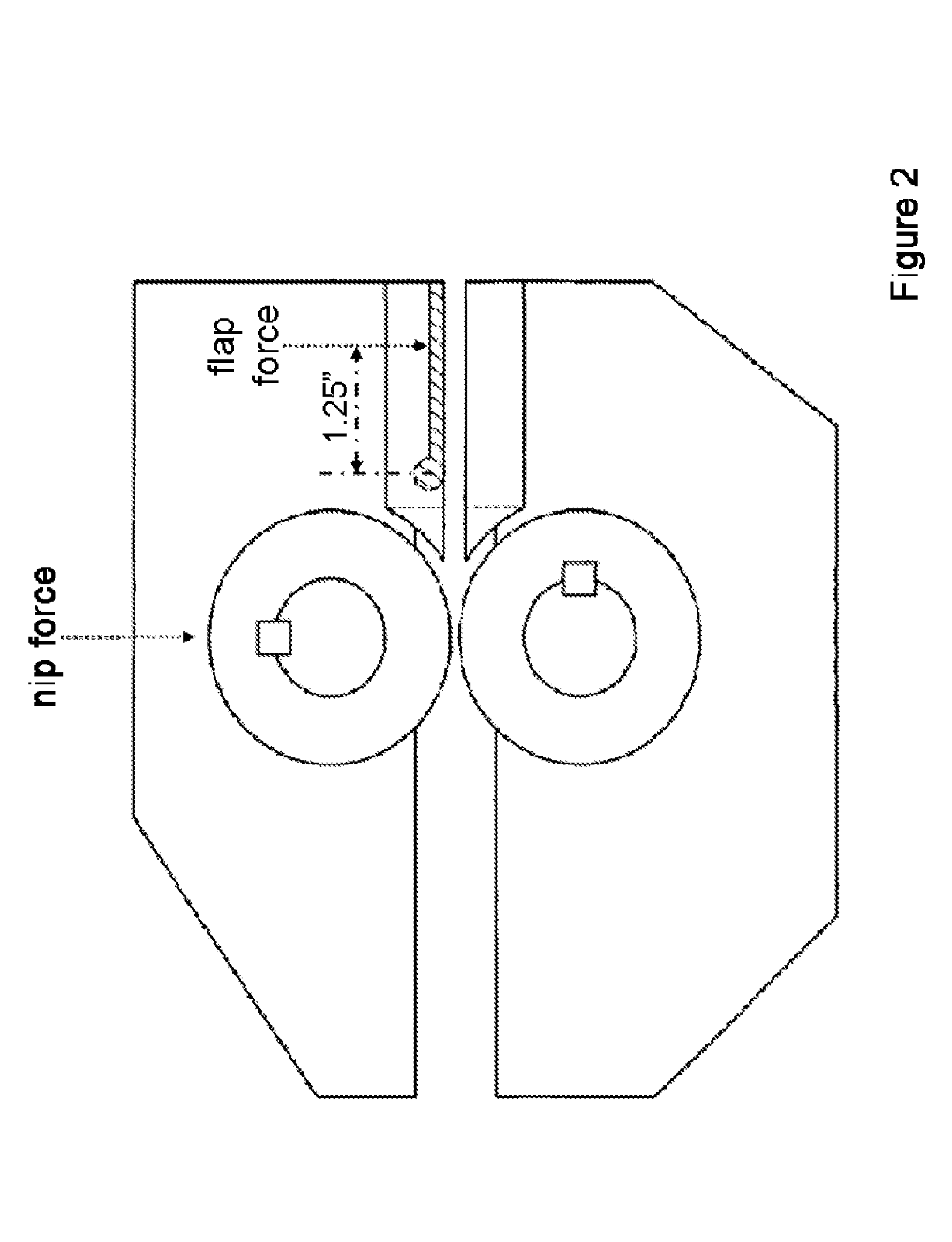

Products of high denier per filament and low total denier tow bands

ActiveUS20150128964A1Readily apparentTobacco treatmentCigar manufactureCellulose acetateMechanical engineering

A method for forming a filter rod may include providing a bale of crimped tow band having about 10 denier per filament or greater and about 20,000 total denier or less, the crimped tow band comprising a plurality of cellulose acetate filaments; and placing the crimped tow band in an apparatus so as to form a filter rod.

Owner:ACETATE INT LLC

Products of high denier per filament and low total denier tow bands

A method for forming a filter rod may include providing a bale of crimped tow band having about 10 denier per filament or greater and about 20,000 total denier or less, the crimped tow band comprising a plurality of cellulose acetate filaments; and placing the crimped tow band in an apparatus so as to form a filter rod.

Owner:ACETATE INT LLC

Method for preparing cellulose fiber

InactiveCN101838861AReduce usageIncrease productivityArtificial filaments from cellulose solutionsMelt spinning methodsYarnHydrogen

The invention discloses a method for preparing cellulose fiber. By using melting spinning technology, the method comprises the following steps of: 1, mixing cellulose and ionic liquid in a mass ratio of 5-8:5-2 to obtain an uniform mixture, wherein the cellulose is wood pulp, cotton pulp or bamboo pulp with degree of polymerization of 400 to 1,000; the ionic liquid consists of cations and anions; the cations are substituent-containing alkyl imidazole ions, wherein the substituent is more than one of hydrogen, C1 to C6 alkyl group, ethyl, propenyl, butenyl, ethoxyl, hydroxypropyl and alkoxy groups; the anions are halogen ions, BF4-, PF4-, SCN-, CN-, OCN-, CNO-, CF3SO3-, CFCOO-, CH3COO-, and (CF3SO2)2N- or (CF3SO2)2Cl-; 2, feeding the mixture into a double-screw extruder for melting spinning and stretching the extruded yarn by 0.5 to 6 times; and 3, washing, performing thermal forming and winding to obtain the cellulose fiber.

Owner:TIANJIN POLYTECHNIC UNIV

Electrostatic spinning preparation method of cellulose nanofibers having hollow porous structures

ActiveCN106987922AWith renewableBiodegradableArtificial filaments from cellulose solutionsFiberCellulose

The invention belongs to the technical field of electrospinning and provides an electrostatic spinning preparation method of cellulose nanofibers having hollow porous structures. The preparation method comprises dissolving a certain amount of cellulose in a DMAc / LiC solvent system, adding a certain amount of a metal salt into the system, carrying out uniform stirring to obtain a cellulose mixed solution, wherein a mass ratio of DMAc to LiC in the DMAc / LiC solvent system is 92: 8, putting the cellulose mixed solution into a syringe, carrying out spinning at an advance rate of 0.03 mL / min, respectively setting positive and negative voltages to 20 KV and -1 KV, wherein a rotating metal roller is used as a collection device and a certain concentration of an alkaline solution is used as a cellulose coagulation bath, and preparing the cellulose nanofibers having hollow porous structures. The preparation method utilizes a single-spinneret electrospinning one-step method to prepare the cellulose nanofibers having hollow porous structures, is free of after-treatment and is simple and efficient. The cellulose nanofibers having hollow porous structures have very high water passability and excellent mechanical properties and flexibility.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com