Patents

Literature

451results about How to "Modulus improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced polymers

InactiveUS6331265B1Less tangleImprove mechanical propertiesMaterial nanotechnologyWood working apparatusPolymer scienceNanotube

Provided is a method for the production of a reinforced polymer, which method comprises:(a) introducing carbon nanotubes into a polymer to provide a mixture of the polymer and the nanotubes;(b) stretching the mixture at or above the melting temperature (Tm) of the polymer to orient the carbon nanotubes; and(c) stretching the mixture in the solid state to further orient the carbon nanotubes.

Owner:FINA RES SA

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

Advanced polymer wood composite

InactiveUS6015611AHigh modulusHigh compressive strengthSynthetic resin layered productsPlastic recyclingWater basedThermoplastic

A composition in the form of pellets comprising a thermoplastic and wood fiber composite material suitable for forming structural members as a replacement for wood in the manufacture of doors and windows. The composite has less than about 10 wt % water based on pellet weight and a Young's modulus of at least about 500,000. Structural members are typically formed from the composite in an extrusion or an injection molding process.

Owner:ANDERSEN CORPORATION

Block composites in soft compounds

ActiveUS8686087B2Modulus improvementImprove performanceFilm/foil adhesivesMixingMaterials sciencePolymer science

Owner:DOW GLOBAL TECH LLC

Block composites in soft compounds

ActiveUS20110082249A1Improve low temperature impact performanceModulus improvementFilm/foil adhesivesMixingMaterials science

Owner:DOW GLOBAL TECH LLC

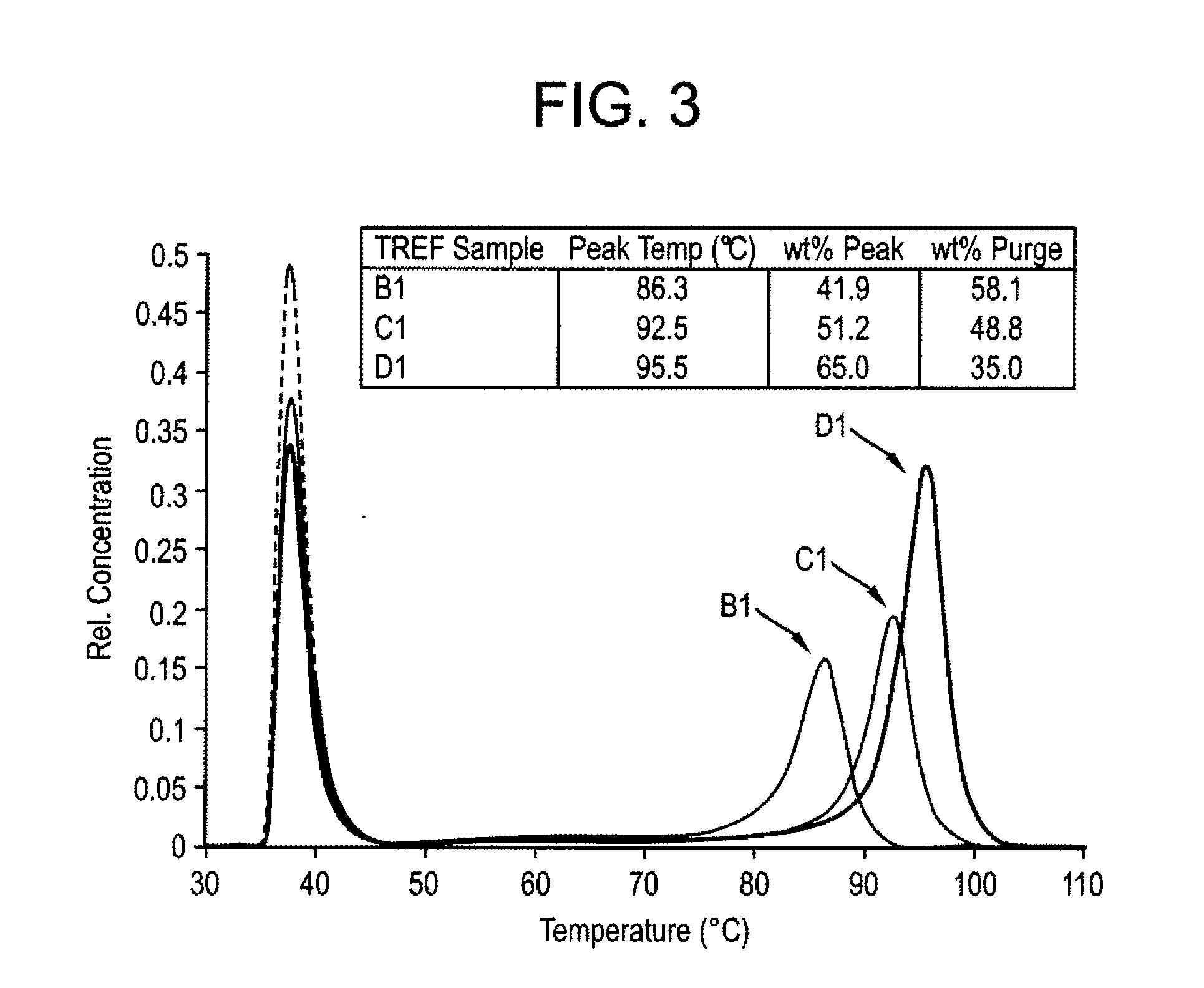

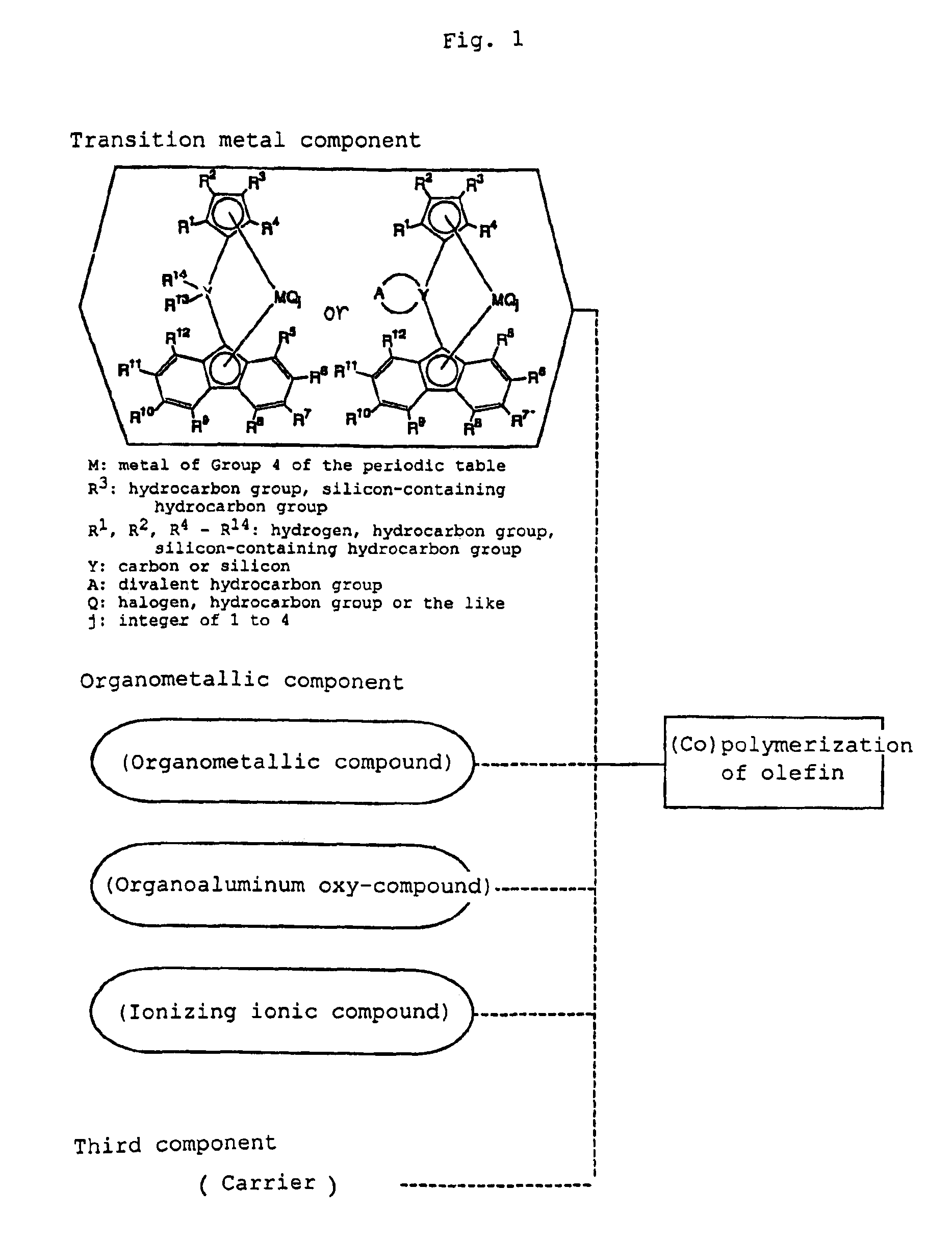

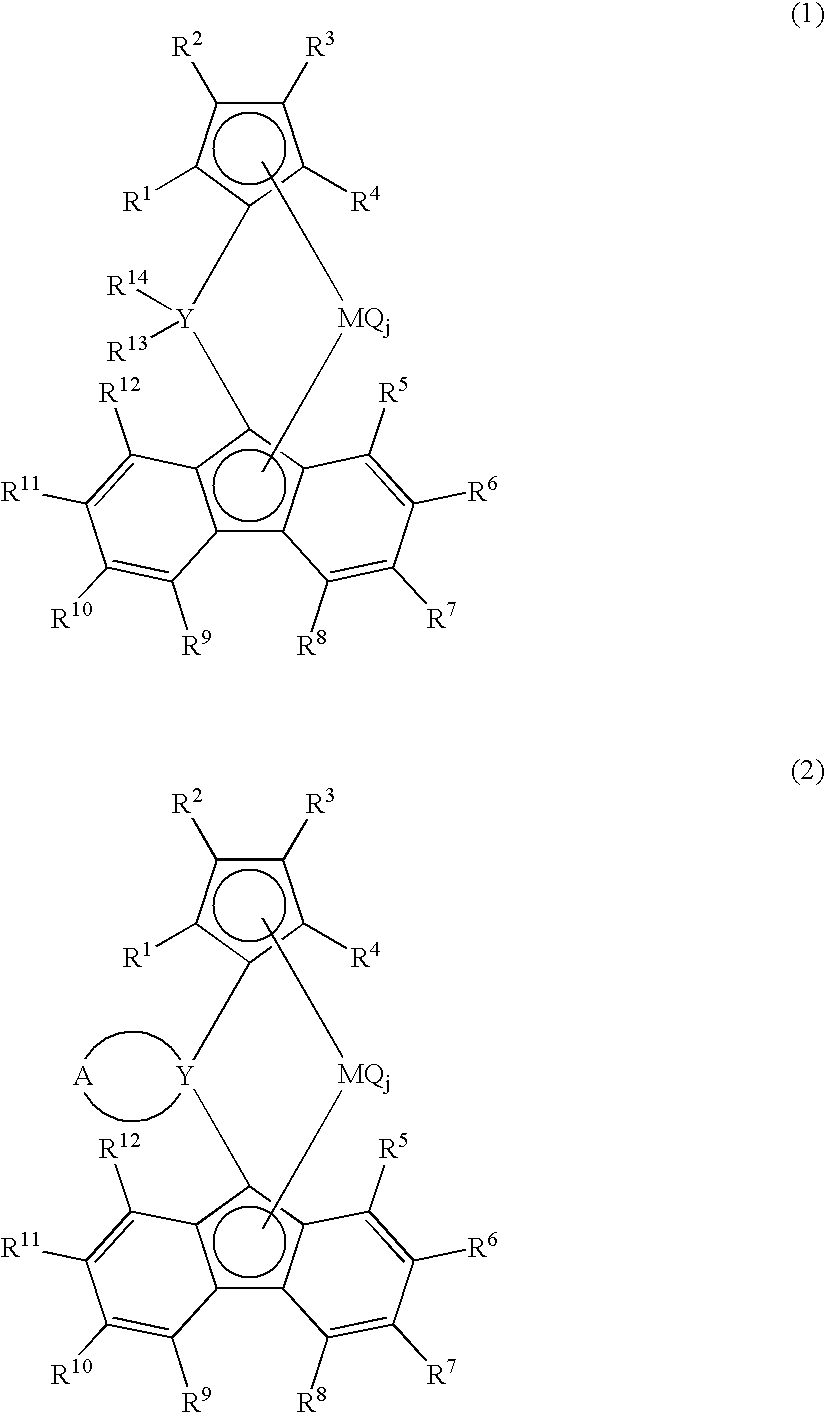

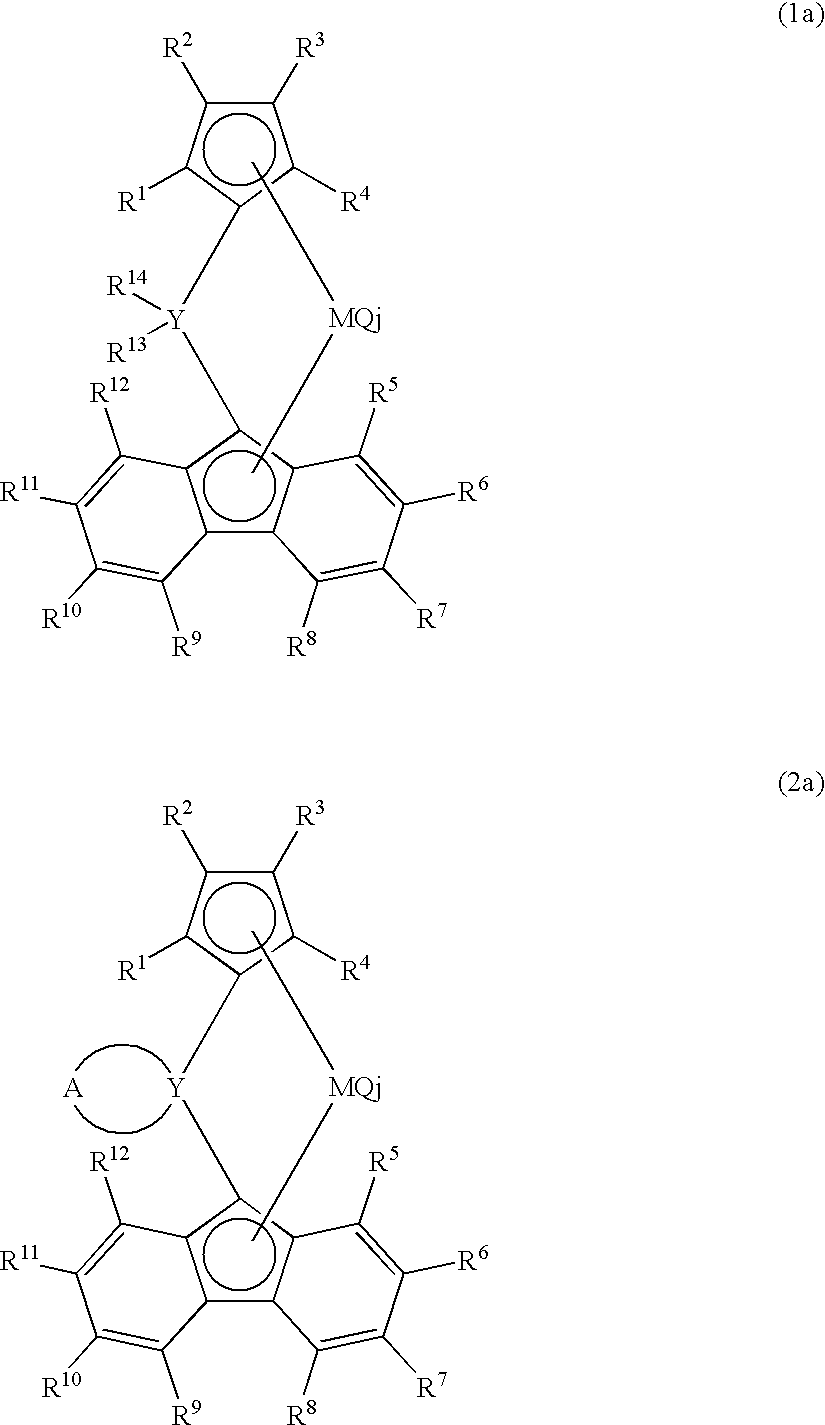

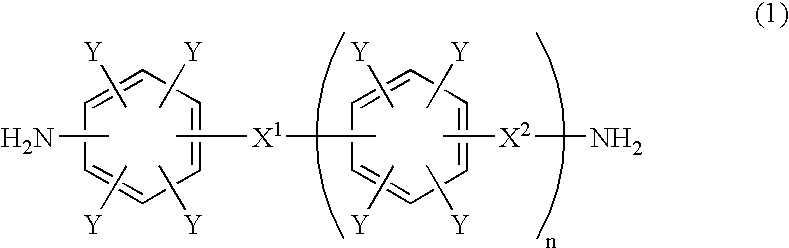

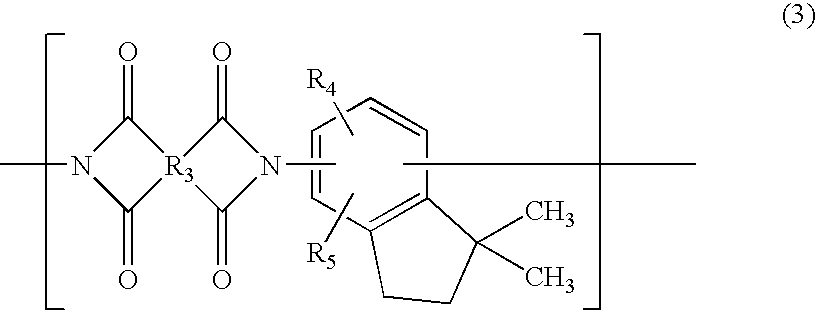

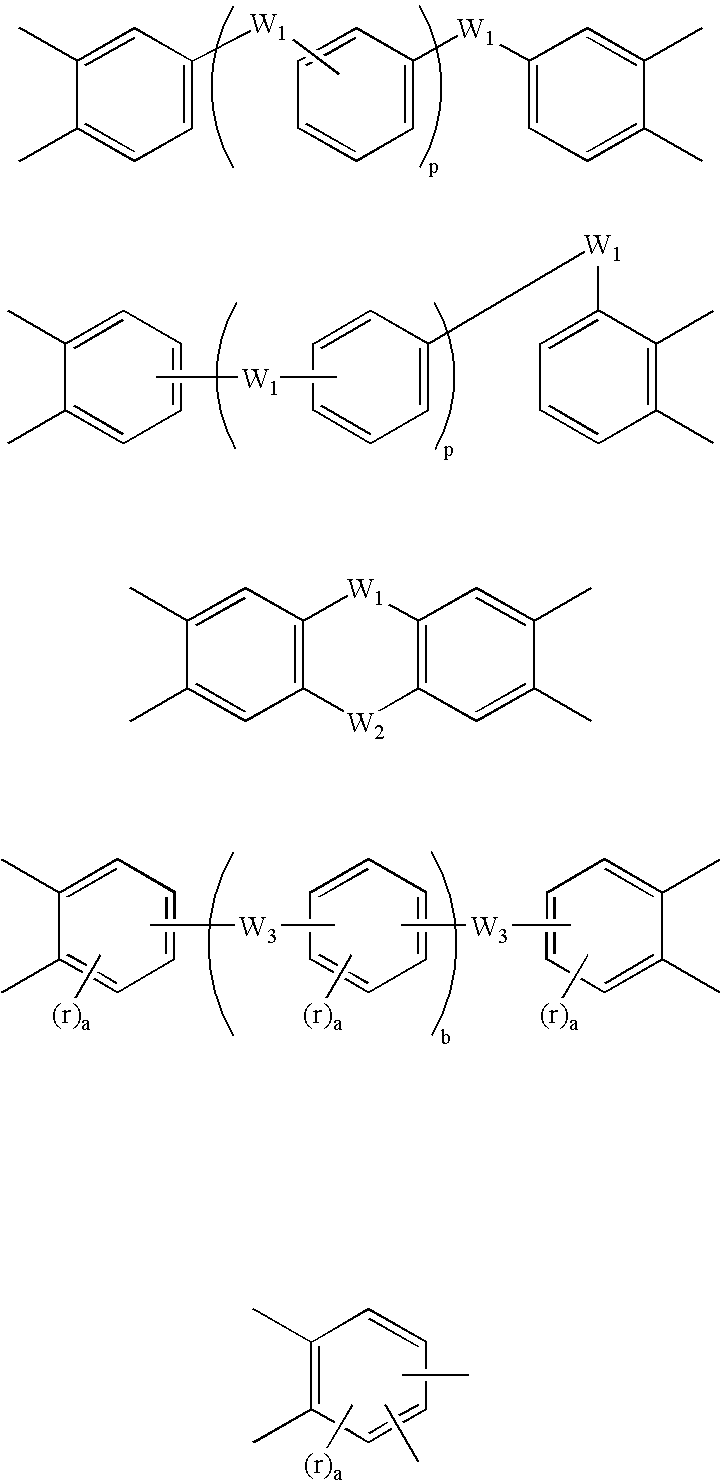

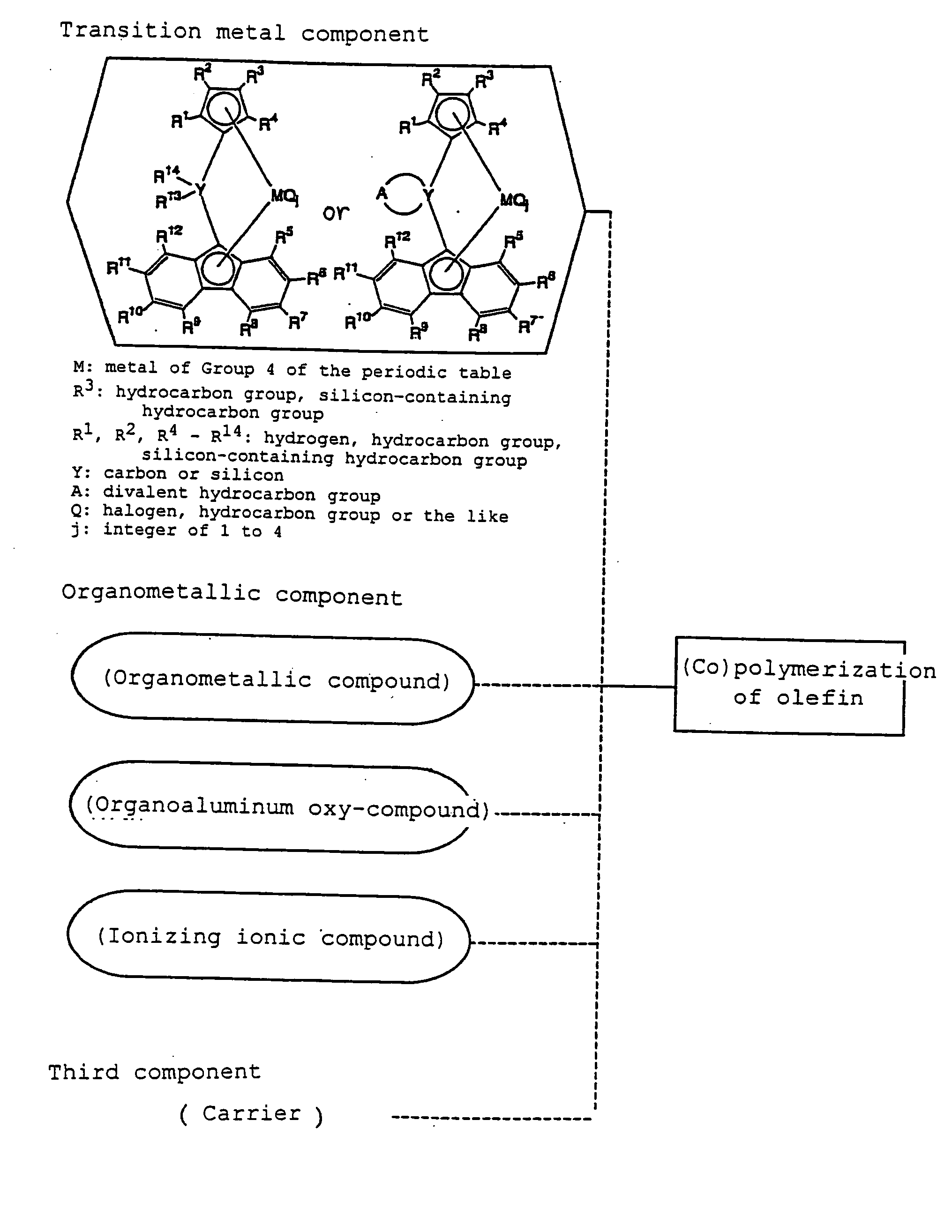

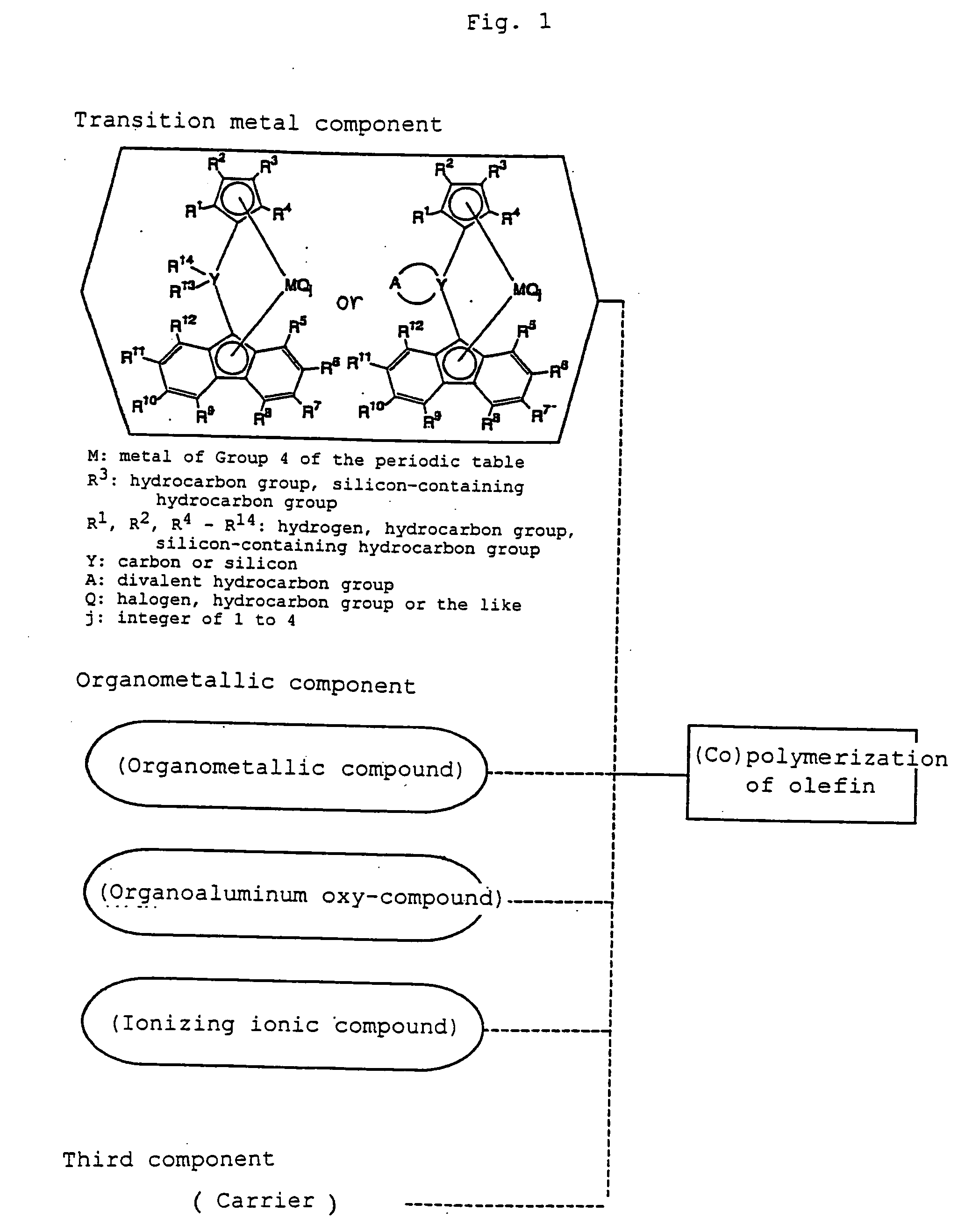

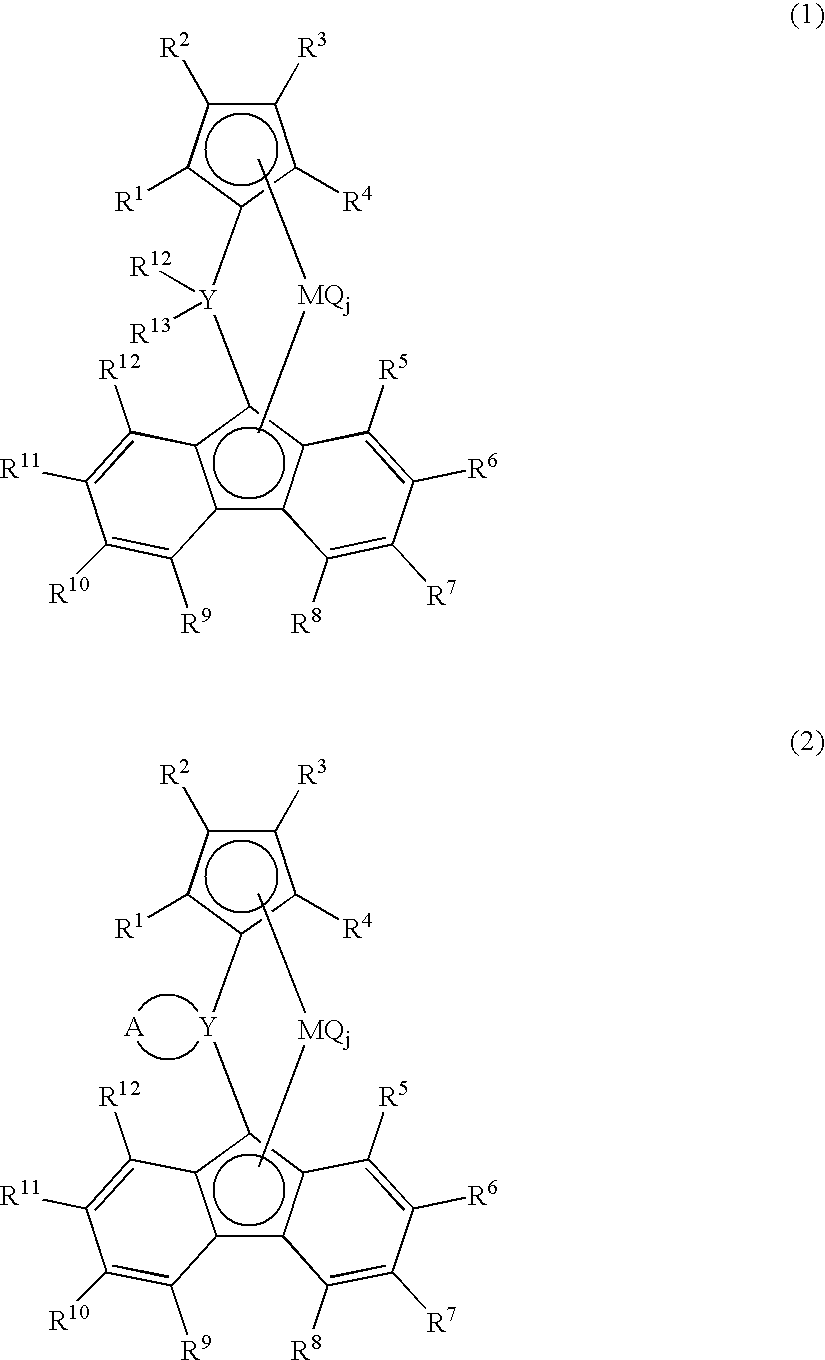

Metallocene compound, process for producing metallocene compound, olefin polymerization catalyst, process for producing polyolefin, and polyolefin

InactiveUS6939928B1High activityModulus improvementSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

The metallocene compound according to the invention and the olefin polymerization catalyst containing the compound are intended to produce a catalyst capable of preparing an isotactic polymer with a high polymerization activity. The metallocene compound contains a substituted cyclopentadienyl group and a (substituted) fluorenyl group and has a structure wherein these groups are bridged by a hydrocarbon group or the like. The process for preparing a metallocene compound according to the invention is intended to selectively prepare a specific metallocene compound so as not to produce an isomer, and in this process an intermediate product is synthesized by a specific method. The process for preparing a polyolefin according to the invention is intended to prepare a polyolefin having excellent impact resistance and transparency, and this process comprises homopolymerizing an α-olefin of 3 to 8 carbon atoms or copolymerizing an olefin of 3 to 8 carbon atoms and another α-olefin in the presence of an olefin polymerization catalyst containing the above-mentioned metallocene compound.

Owner:MITSUI CHEM INC

Block composites and impact modified compositions

Owner:DOW GLOBAL TECH LLC

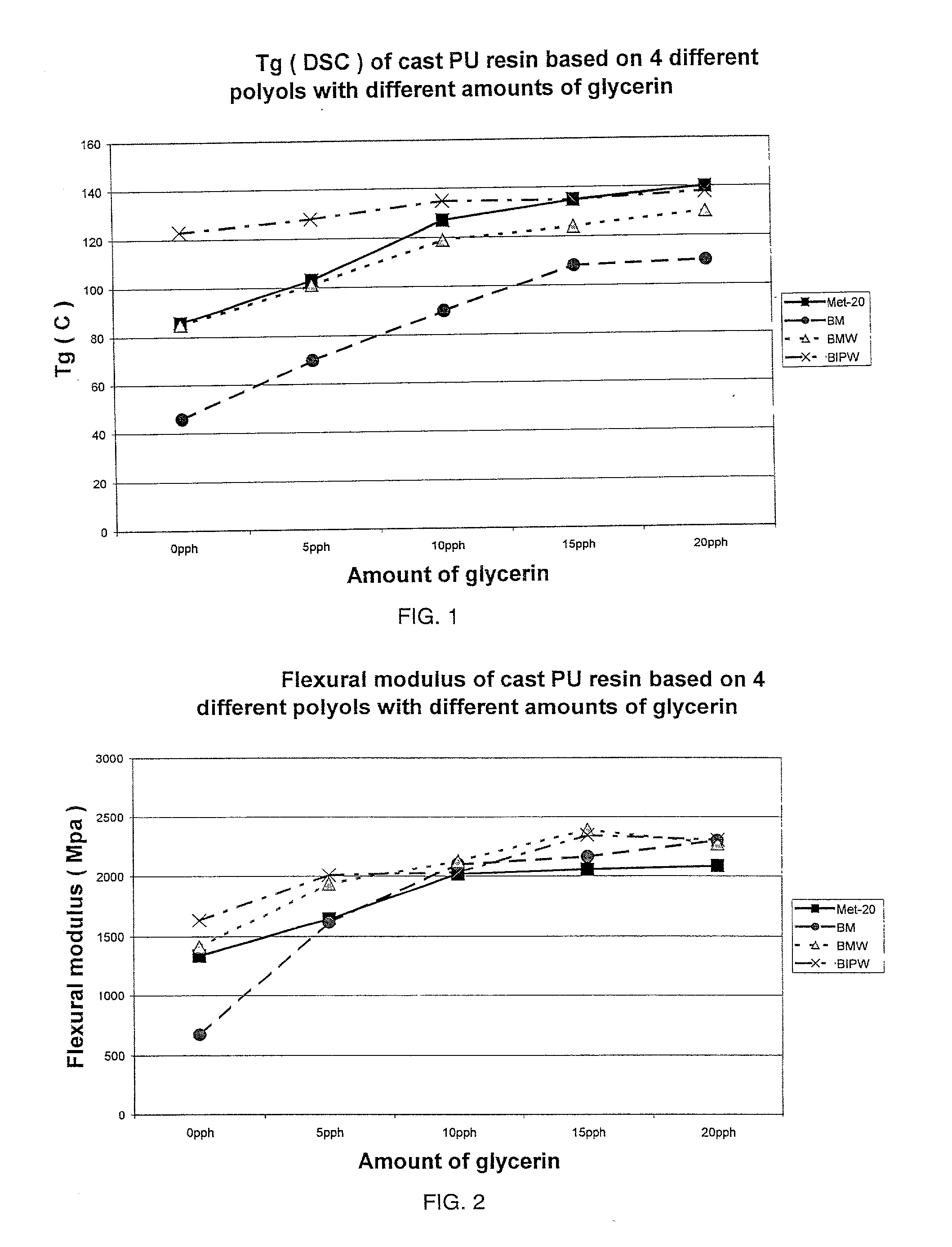

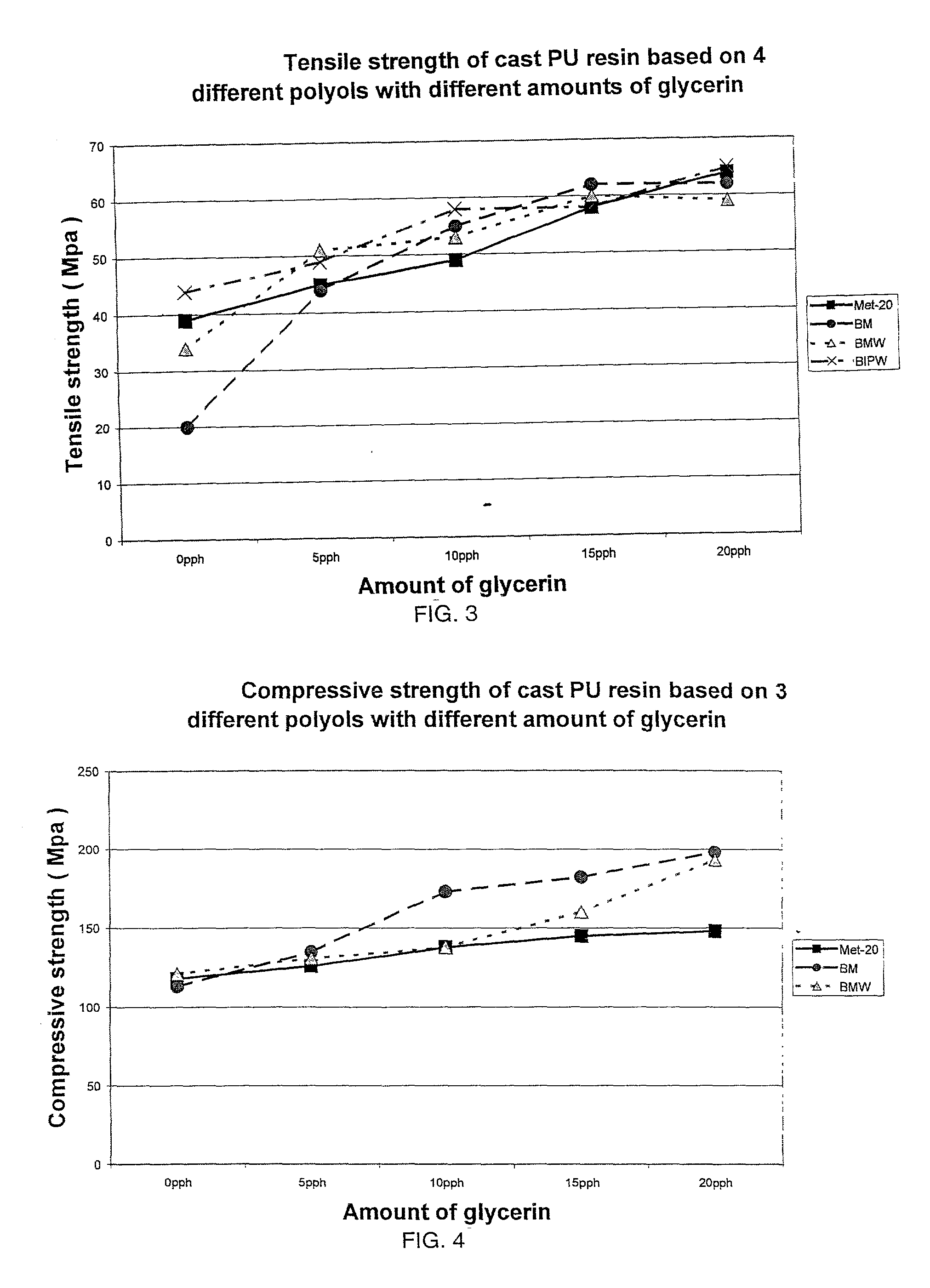

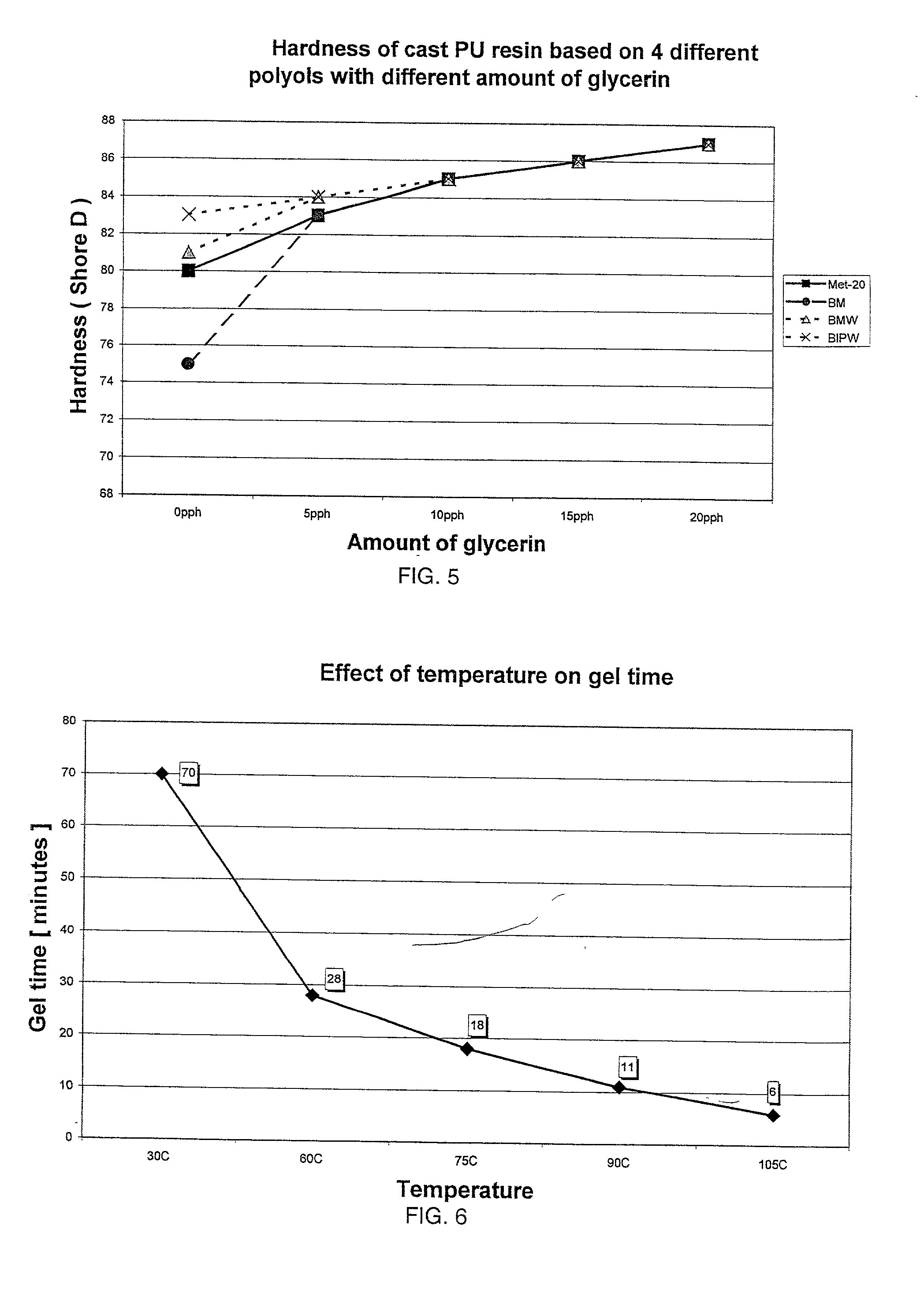

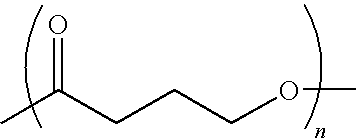

Polymer concrete and method for preparation thereof

InactiveUS20030090016A1High compressive strengthGood splitting tensile strength and flexural strengthSolid waste managementBuilding constructionsIsocyanatePolymer chemistry

A soy-based polyol is mixed with an isocyanate and aggregate to produce a soy-based polyurethane having superior mechanical properties. The aggregate composition may be varied to obtain different mechanical properties, as can the amount of resin. The resin may be crosslinked using a low molecular weight polyol, such as glycerine, to also improve structural performance. A catalyst may be added to accelerate curing time without reducing structural performance.

Owner:PETROVIC ZORAN +3

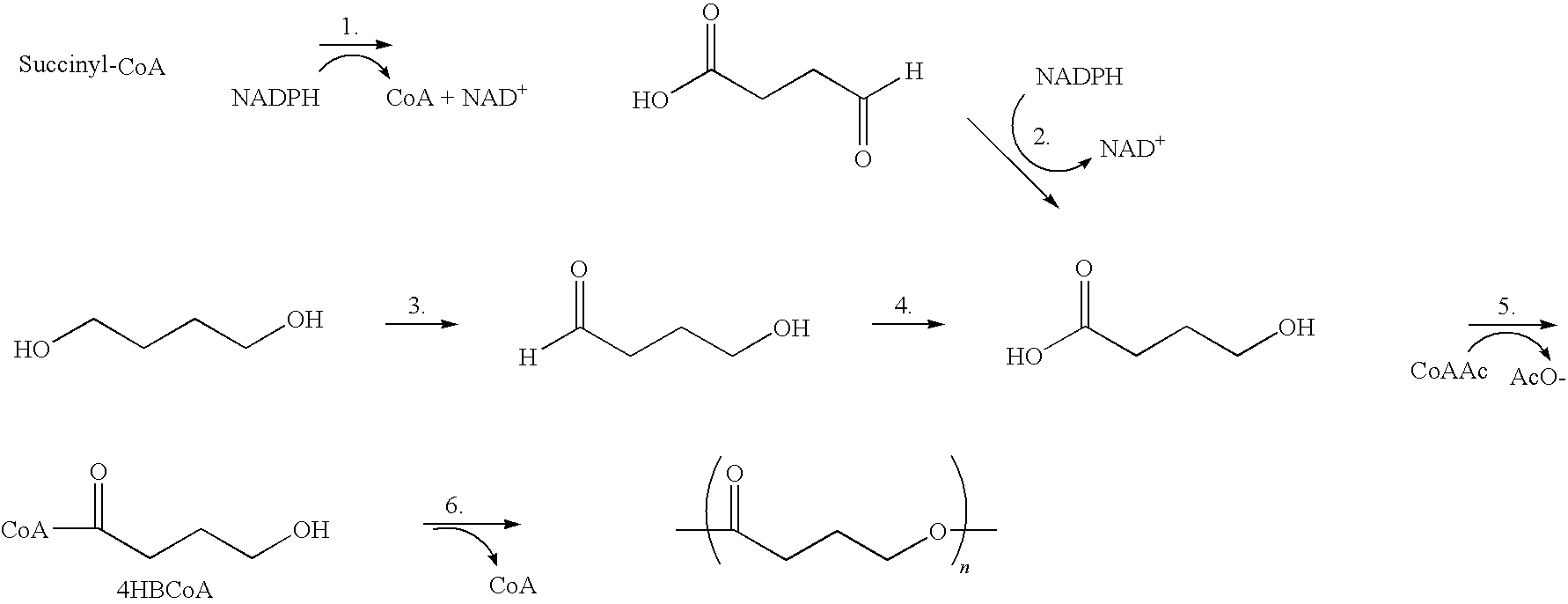

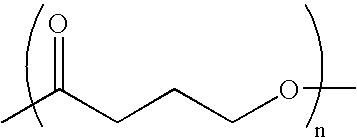

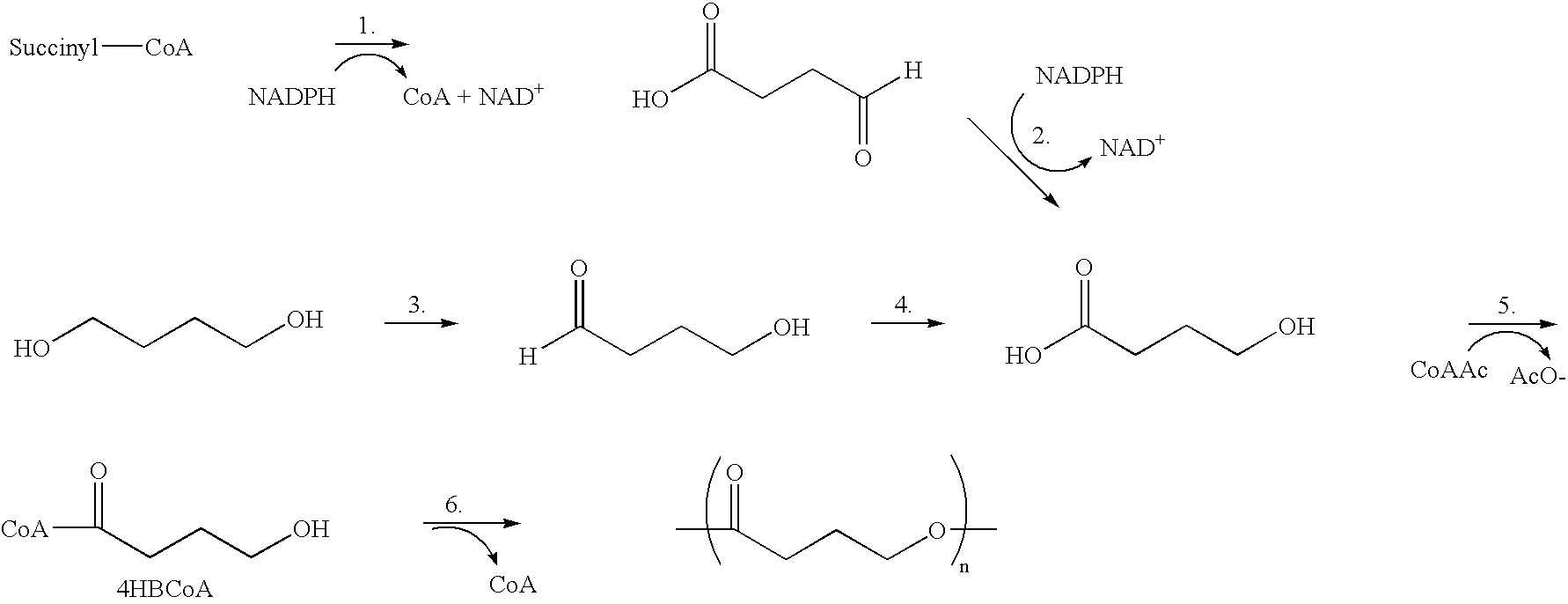

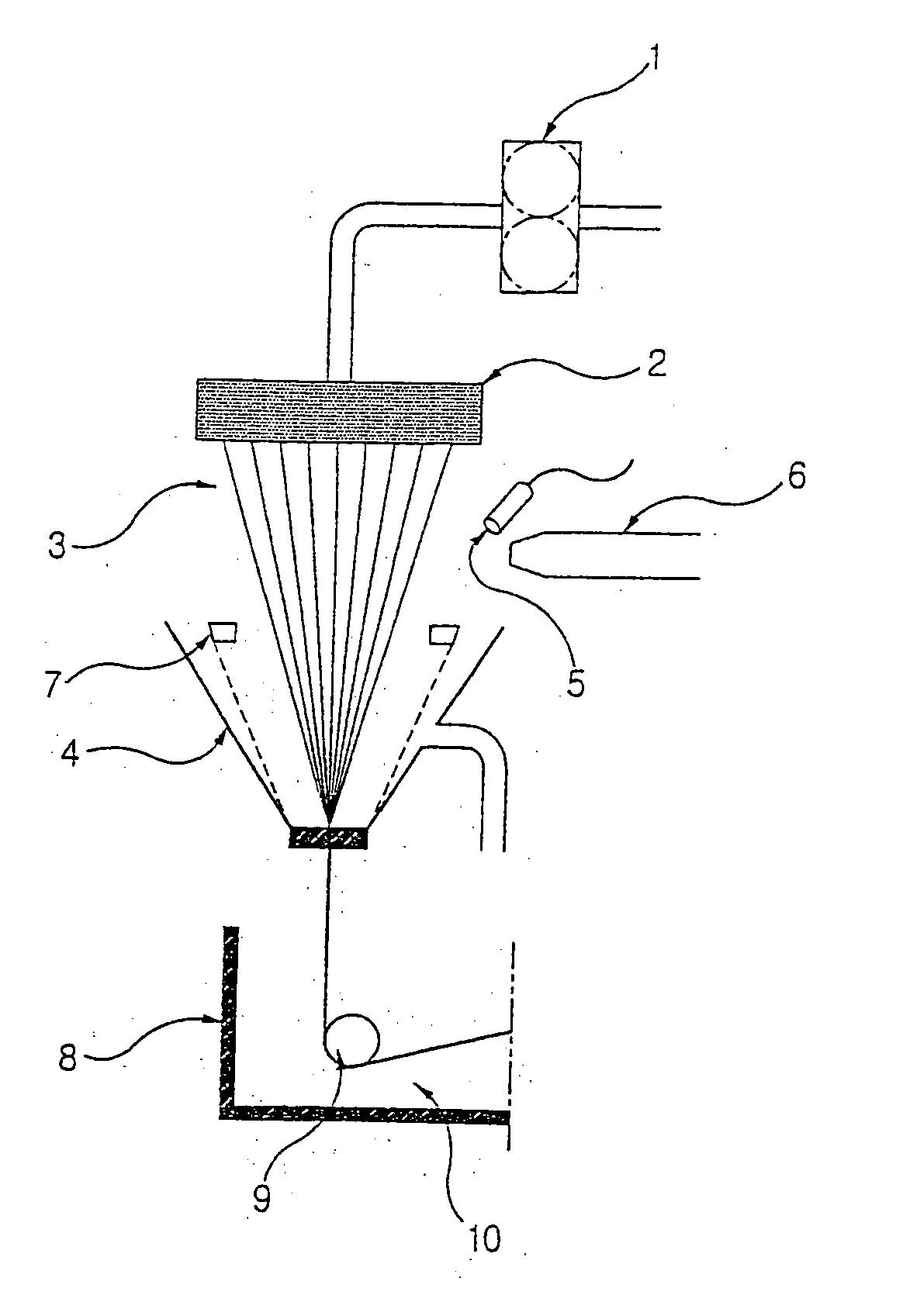

Method of making a polyhydroxyalkanoate filament

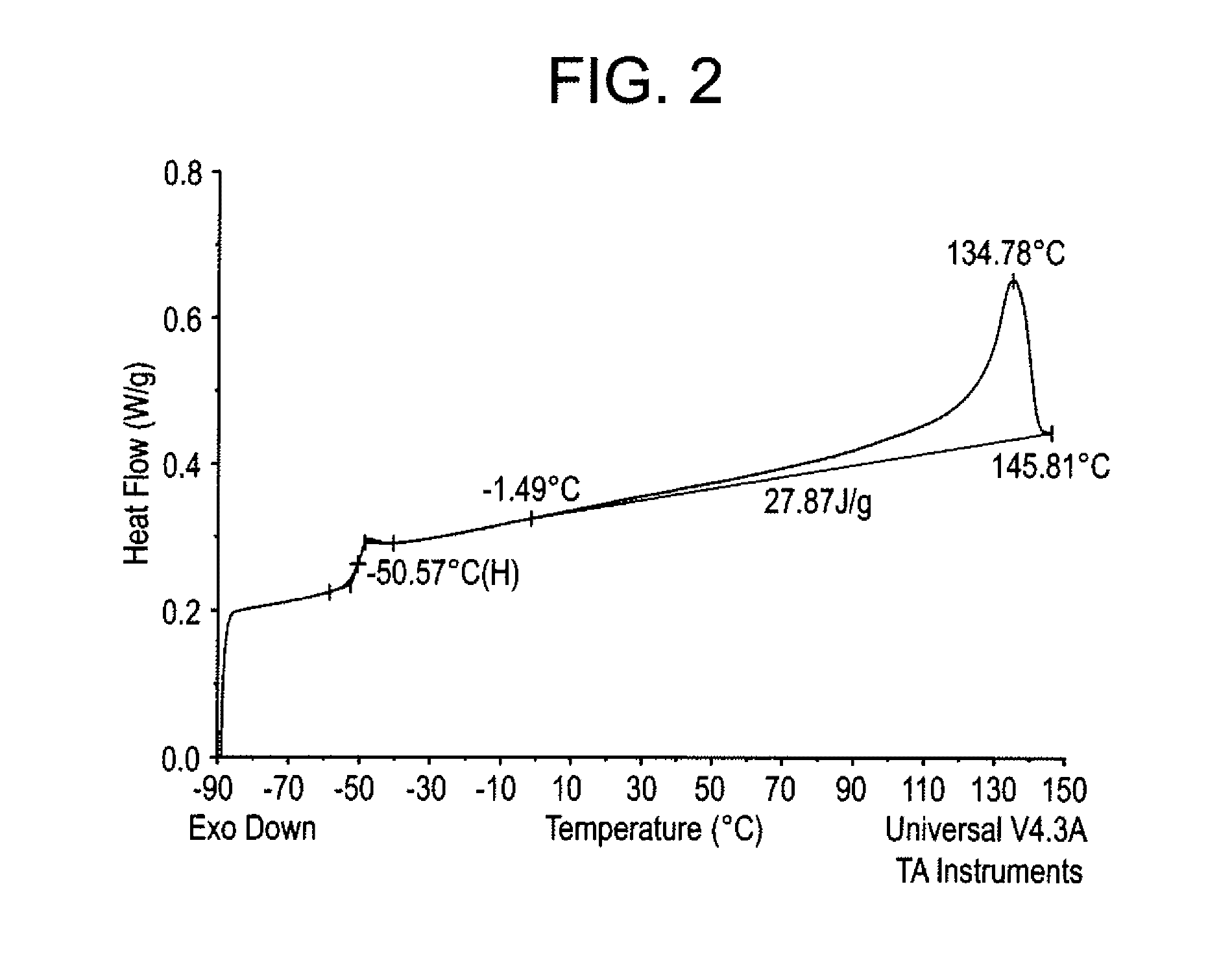

ActiveUS7641825B2Improve handlingImprove methodSuture equipmentsMovable spraying apparatusPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with improved handling properties have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available and have a decreased tendency to curl, in the preferred embodiment, due to the inclusion of relaxation and annealing steps following methods are characterized by the following physical properties: (i) elongation to break from about 17% to about 85% (ii) Young's modulus of less than 350,000 psi, (iii) knot to straight ratio (knot strength / tensile strength) of 55-80% or (iv) load at break from 1100 to 4200 grams.

Owner:TEPHA INC

Non-curling polyhydroxyalkanoate sutures

ActiveUS20060058470A1Improve handlingSimple materialSuture equipmentsMovable spraying apparatusPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with improved handling properties have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available and have a decreased tendency to curl, in the preferred embodiment, due to the inclusion of relaxation and annealing steps following extrusion and orientation of the fiber. Filaments prepared according to these methods are characterized by the following physical properties: (i) elongation to break from about 17% to about 85% (ii) Young's modulus of less than 350,000 psi, (iii) knot to straight ratio (knot strength / tensile strength) of 55-80% or (iv) load at break from 1100 to 4200 grams.

Owner:TEPHA INC

Polyimide metal laminate

InactiveUS20050048297A1High modulus of elasticityEasy to useSynthetic resin layered productsPrinted circuit aspectsPartial hydrolysisPolyamic acid

The polyimide metal laminate has at least one resin layer produced from a silica-dispersed polyimide composition obtained by reacting (A) alkoxysilane and / or its partial hydrolysis polycondensate with (B) an amino-containing compound having a functional group capable of forming a bond with silica, in the presence of water in a polyimide solution and / or a polyamic acid solution.

Owner:MITSUI CHEM INC

Advanced polymer wood composite

InactiveUS20020106498A1High modulusHigh modulus of elasticityFibreboardWood working apparatusThermoplasticPolymer science

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprise, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of an elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

Metallocene compound, process for preparing metallocene compund, olefin polymerization catalyst, process for preparing polyolefin, and polyolefin

InactiveUS20050228155A1High activityModulus improvementSilicon organic compoundsMetallocenesPolymer sciencePolyolefin

The metallocene compound according to the invention and the olefin polymerization catalyst containing the compound are intended to produce a catalyst capable of preparing an isotactic polymer with a high polymerization activity. The metallocene compound contains a substituted cyclopentadienyl group and a (substituted) fluorenyl group and has a structure wherein these groups are bridged by a hydrocarbon group or the like. The process for preparing a metallocene compound according to the invention is intended to selectively prepare a specific metallocene compound so as not to produce an isomer, and in this process an intermediate product is synthesized by a specific method. The process for preparing a polyolefin according to the invention is intended to prepare a polyolefin having excellent impact resistance and transparency, and this process comprises homopolymerizing an α-olefin of 3 to 8 carbon-atoms or copolymerizing an olefin of 3 to 8 carbon atoms and another α-olefin in the presence of an olefin polymerization catalyst containing the above-mentioned metallocene compound.

Owner:MITSUI CHEM INC

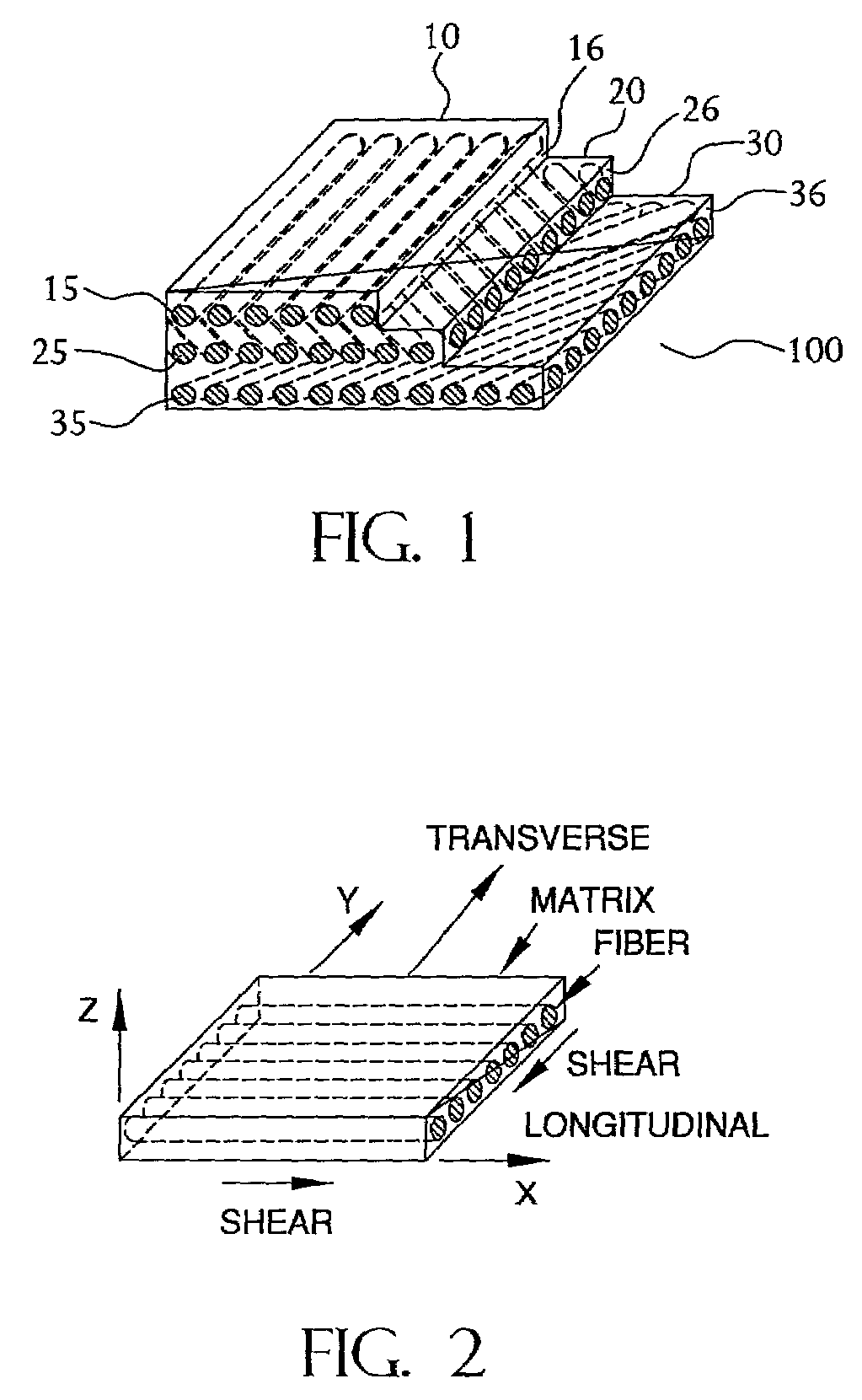

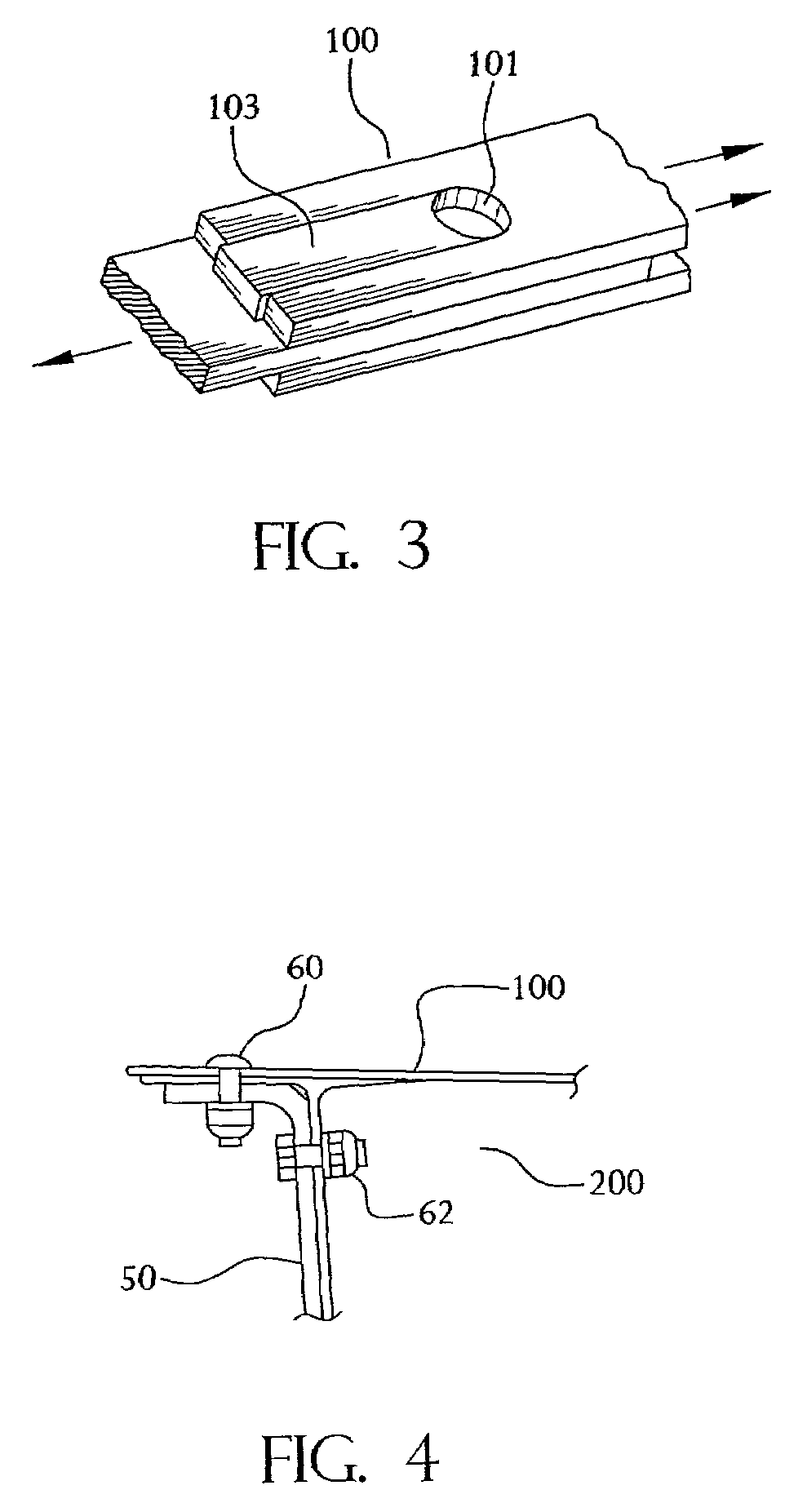

Energy absorbent laminate

InactiveUS7087296B2Tensile modulusImprove toughnessAutomatic/semiautomatic turning machinesSynthetic resin layered productsFiberFlexural modulus

Owner:SAINT GOBAIN TECHN FABRICS CANADA +1

Polyurethane elastomers having improved physical properties and a process for the production thereof

InactiveUS7045650B2Excellent characteristicsMaintain good propertiesUrea derivatives preparationIsocyanic acid derivatives preparationPolyurethane elastomerPolyol

A polyol composition having a number average molecular weight of from about 1,000 to about 3,000 Daltons is made up of (1) at least 60% by weight of a low monol polyoxypropylene polyol having a number average molecular weight of from about 2,000 to 12,000 Da and a degree of unsaturation less than or equal to 0.02 meq / g and (2) no more than 40% by weight of a polyol having a number average molecular weight of from about 400 to about 1,000 Da and a polydispersity index greater than 1.1. This polyol composition is reacted with a diisocyanate, a polyisocyanate, an isocyanate-terminated prepolymer or an isocyanate-terminated quasi-prepolymer to produce polyurethane elastomers having good physical and mechanical properties. Any of the known processes for producing polyurethane elastomers, including one-shot processes, may be used to produce elastomers in accordance with the present invention.

Owner:COVESTRO LLC

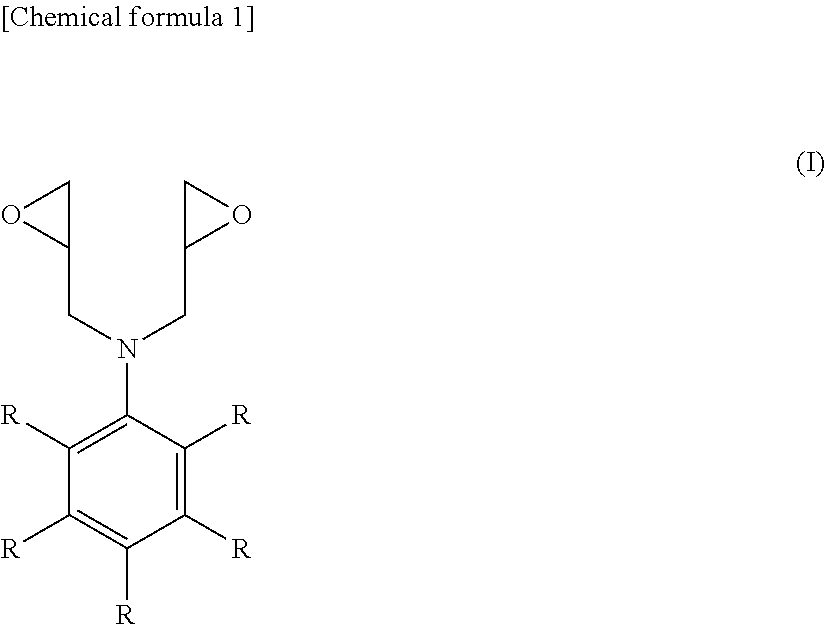

Epoxy resin composition, prepreg and fiber-reinforced composite material

ActiveUS20110184091A1Excellent elastic modulusImprove heat resistanceSynthetic resin layered productsThin material handlingOxazolidoneHeat resistance

An epoxy resin composition comprising an epoxy resin [A], an amine-based curing agent [B] and a block copolymer [C] as components, wherein the epoxy resin [A] contains [Aa] an epoxy resin having at least one structure selected from a condensed polycyclic structure, biphenyl structure and oxazolidone ring structure; [Ab] an epoxy resin selected from a polyfunctional amine type epoxy resin [Ab1] and a liquid bisphenol type epoxy resin [Ab2], and the block copolymer [C] is at least one block copolymer selected from the group consisting of S-B-M, B-M and M-B-M. The present invention provides an epoxy resin composition that can be cured to form a cured product excellent in heat resistance, elastic modulus and toughness.

Owner:TORAY IND INC

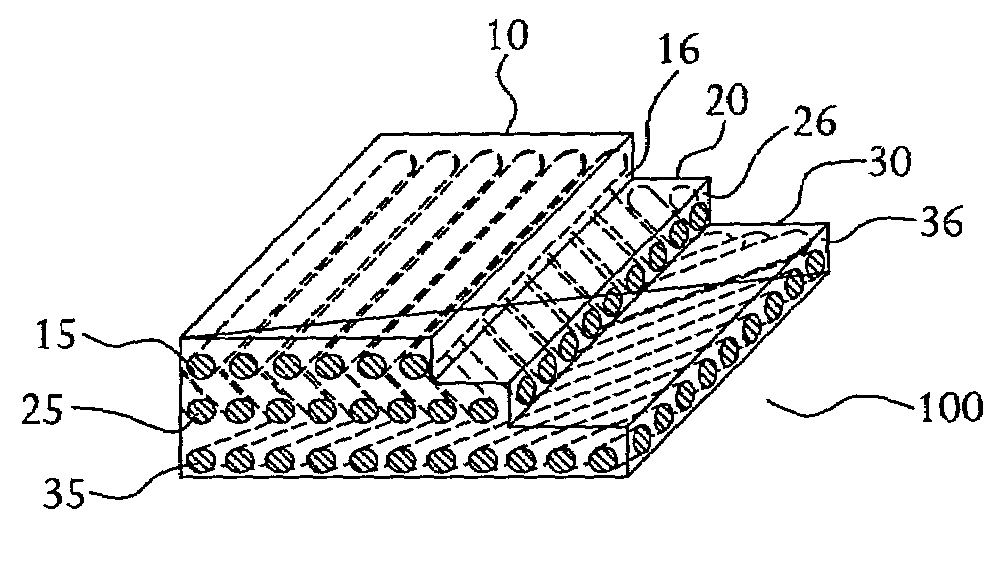

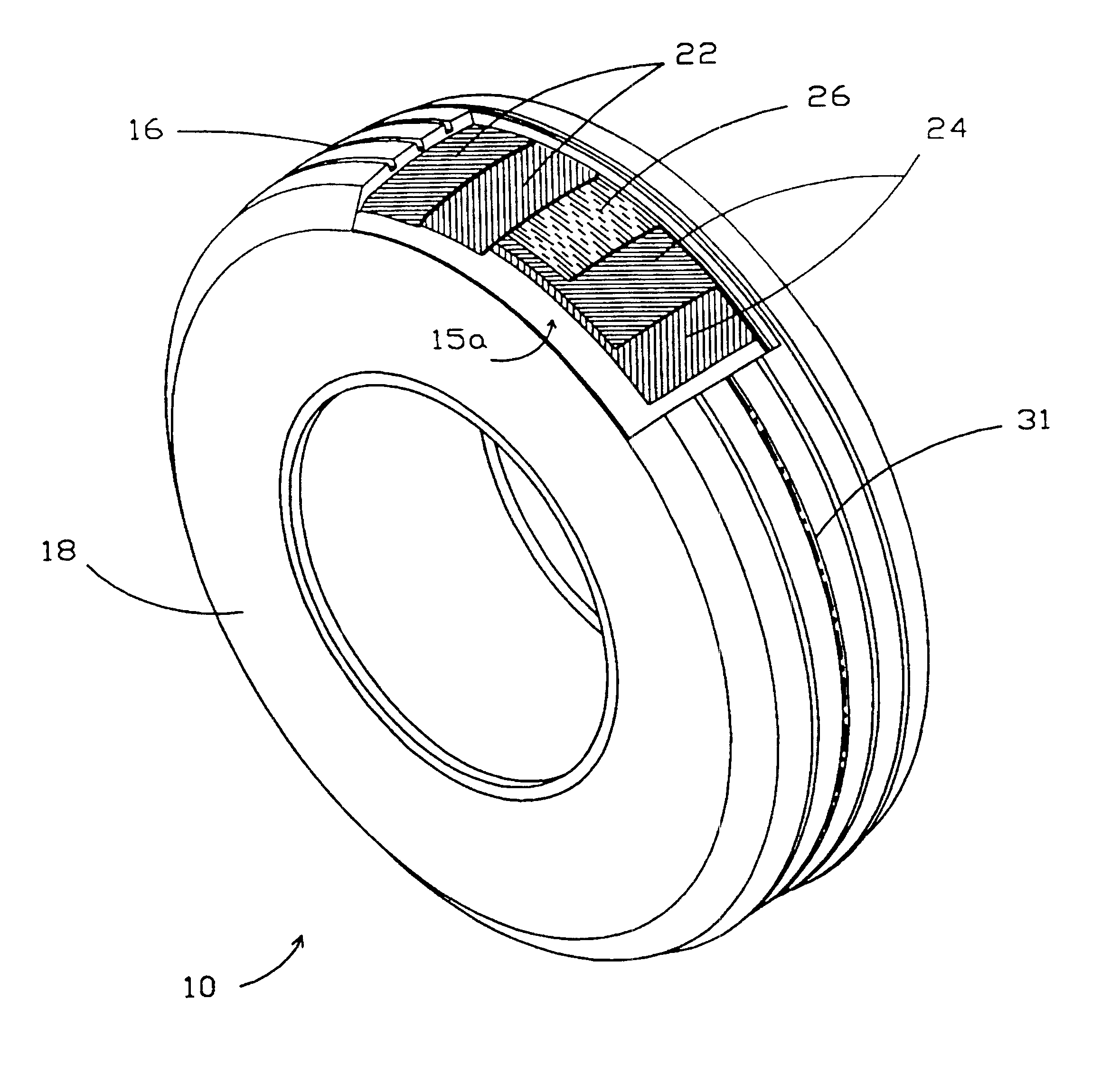

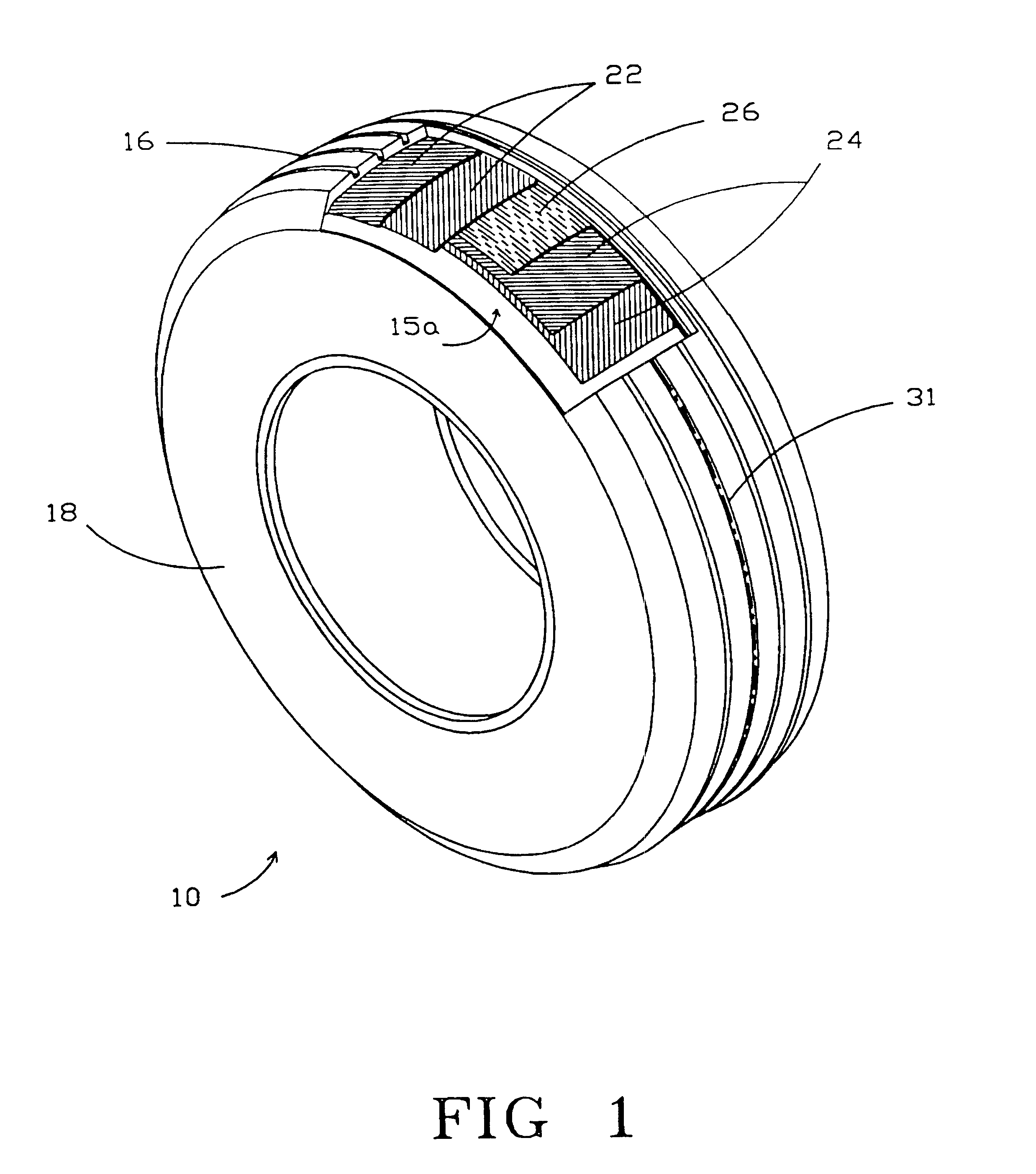

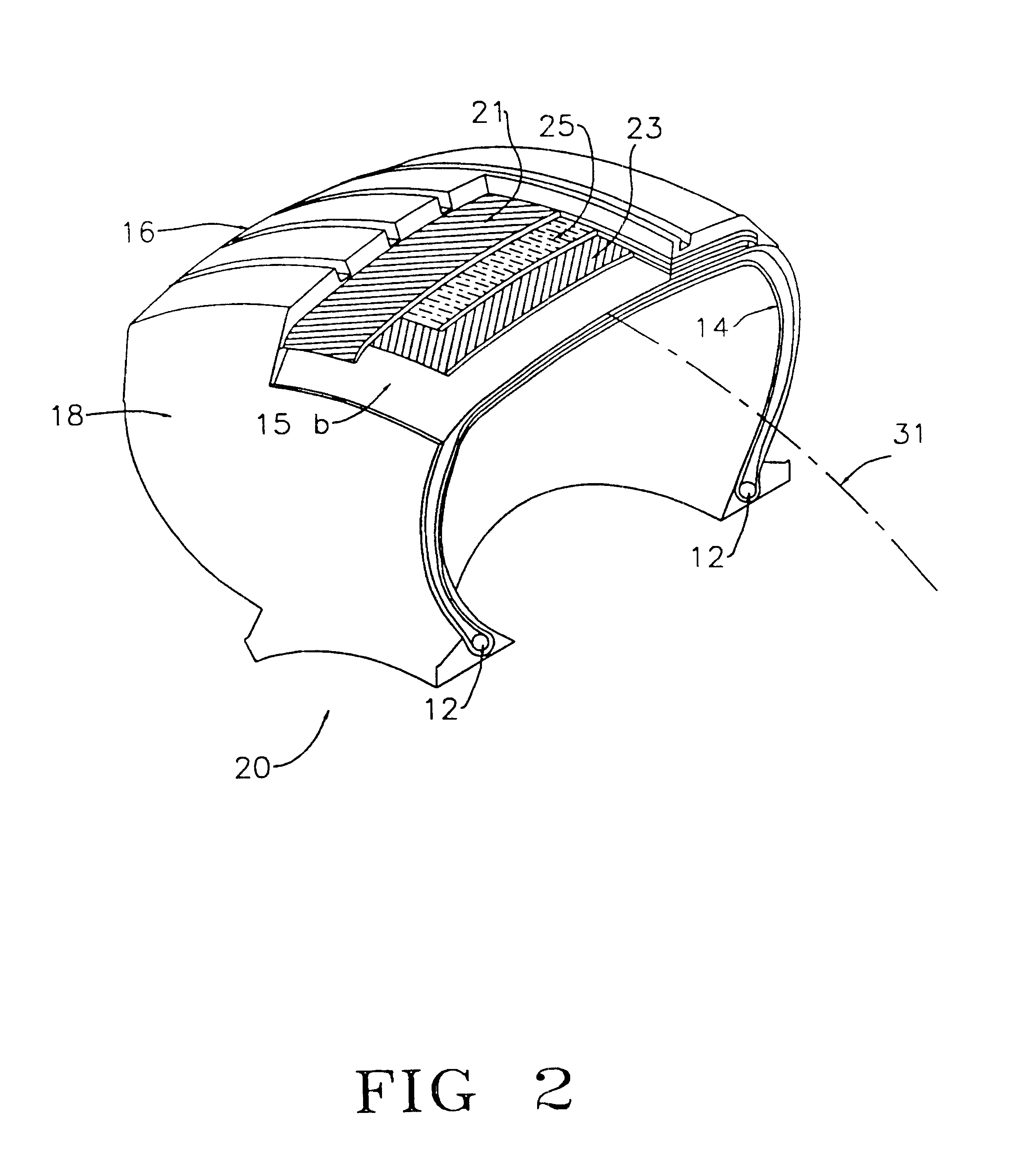

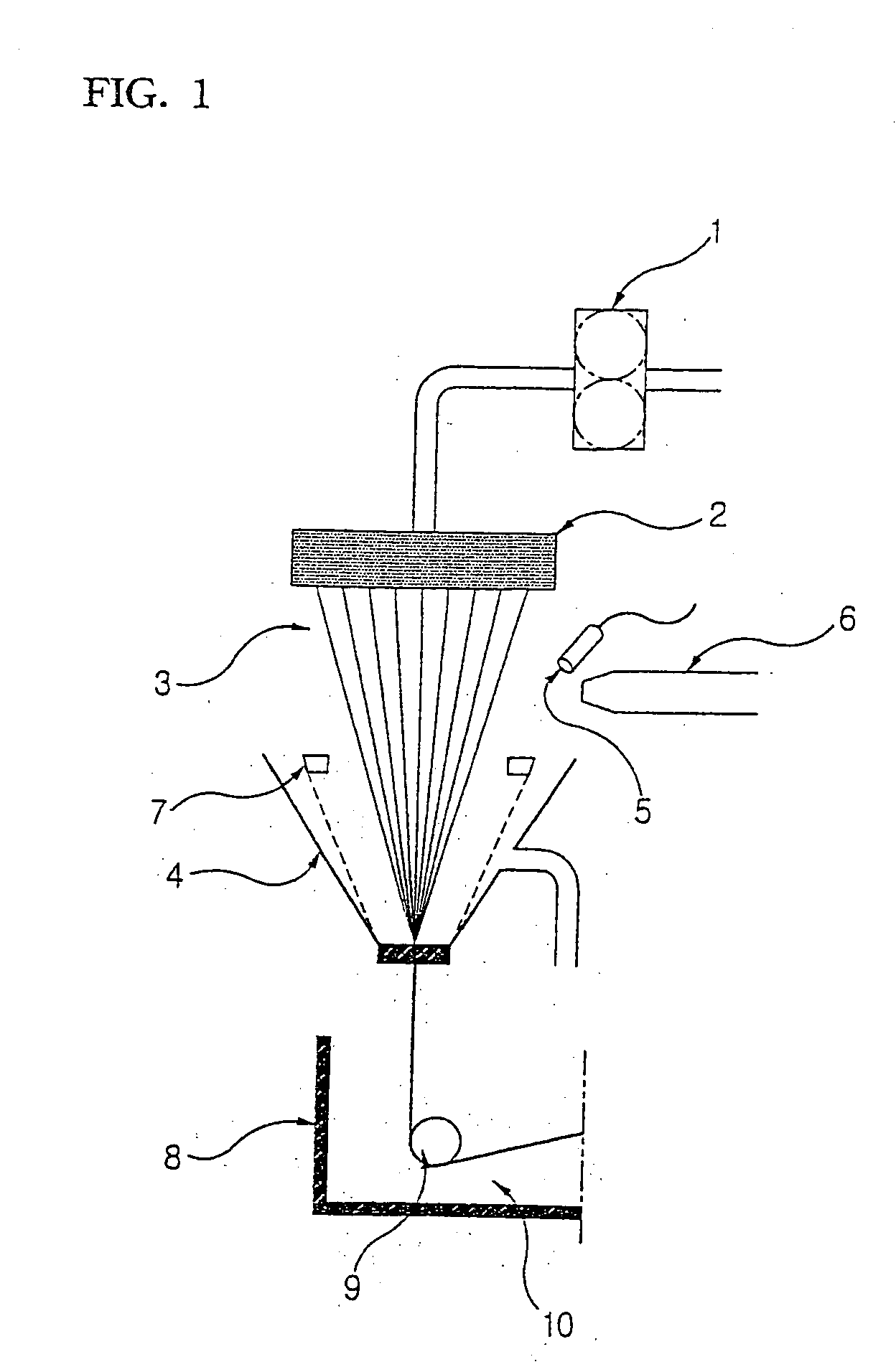

Reinforcement package for tires

InactiveUS6668889B1Good dimensional stabilityModulus improvementPneumatic tyre reinforcementsWheelsEngineeringMechanical engineering

A pneumatic tire (10) having a reinforcement package including a mid-ply belt having reinforcement at a 0° angle with respect tothe equatorial plane (EP) of the tire shows improved handling and durability. The mid-ply belt comprises reinforcing cords or filaments (28) that are discontinuous. The dicontinuous cords or filaments (28) make possible the production of a uniform tire in most tire designs, and the reinforcement of the mid-ply belt provides a tire with improved durability and handling properties. A tire with superior properties was produced using reinforcing cords or filaments (27) and (28) which are made from polyethylene napthalate.

Owner:THE GOODYEAR TIRE & RUBBER CO

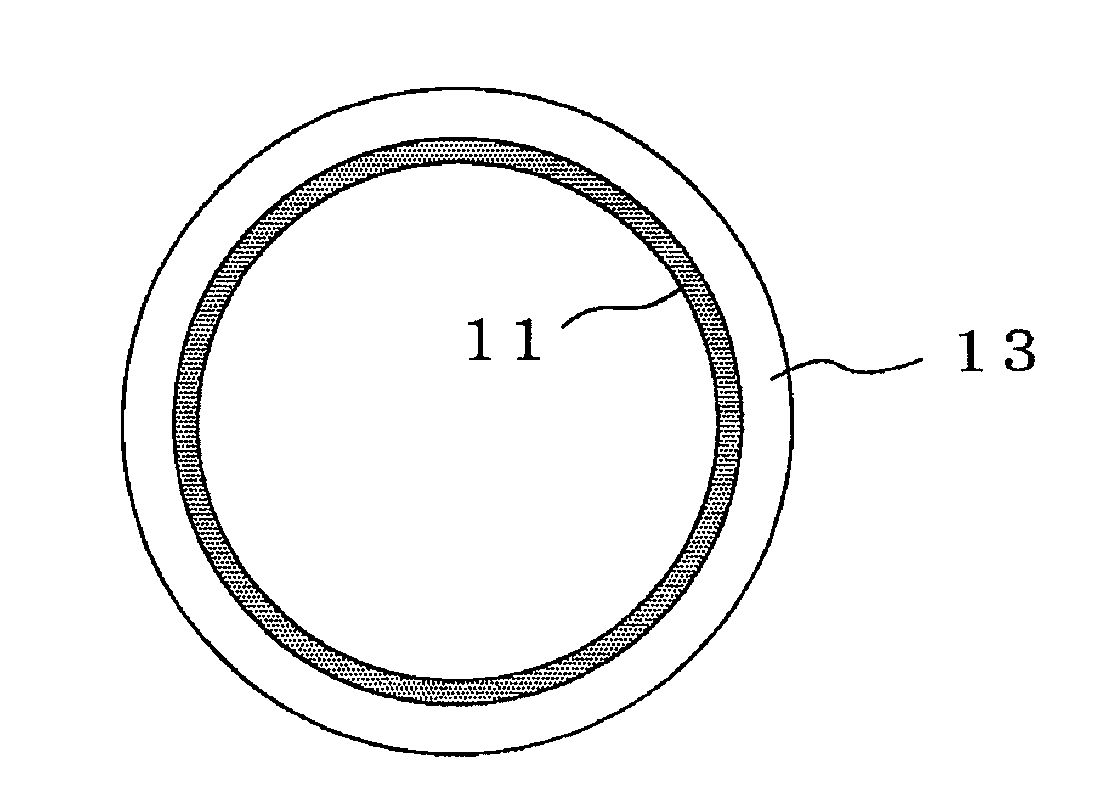

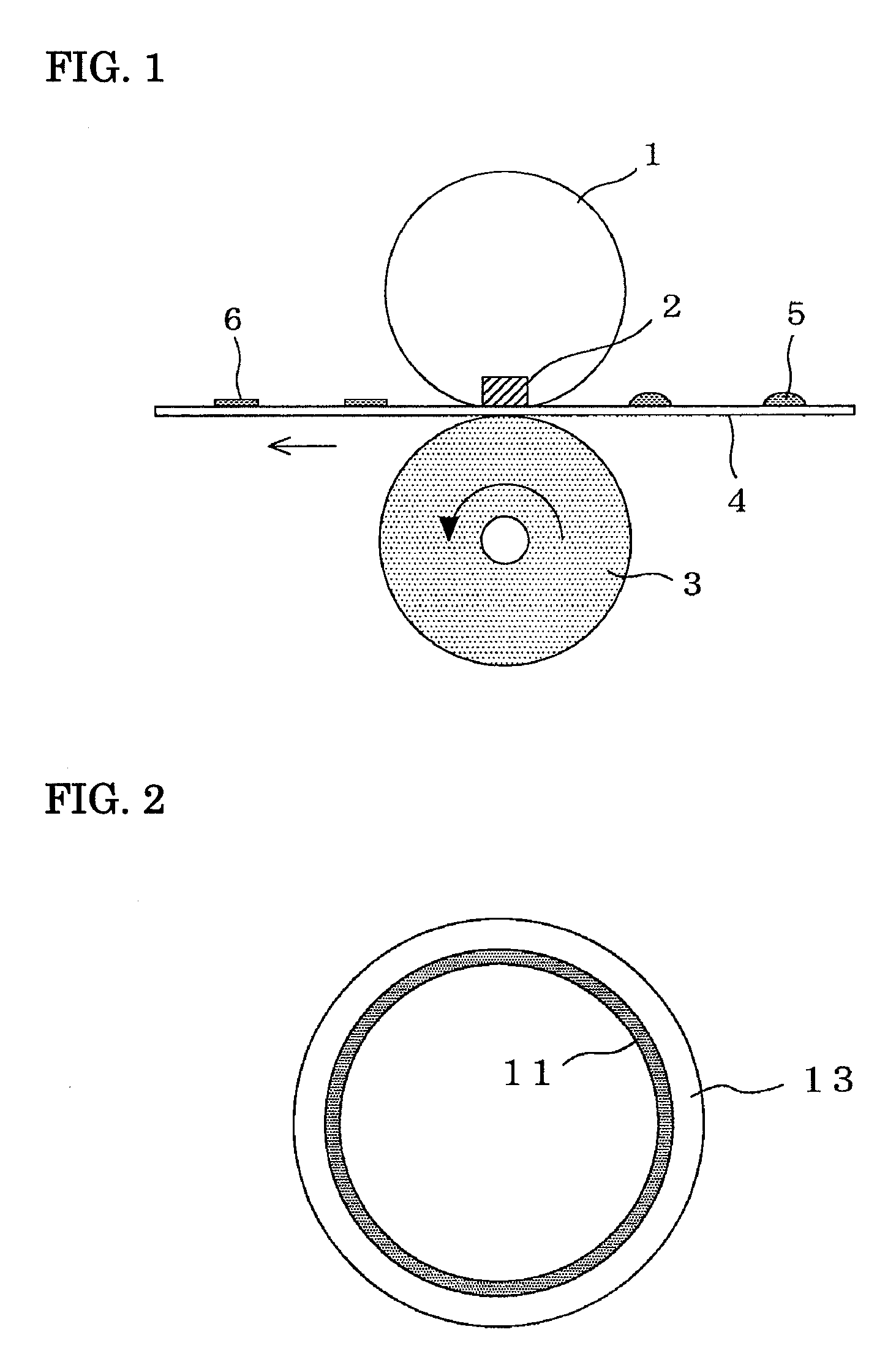

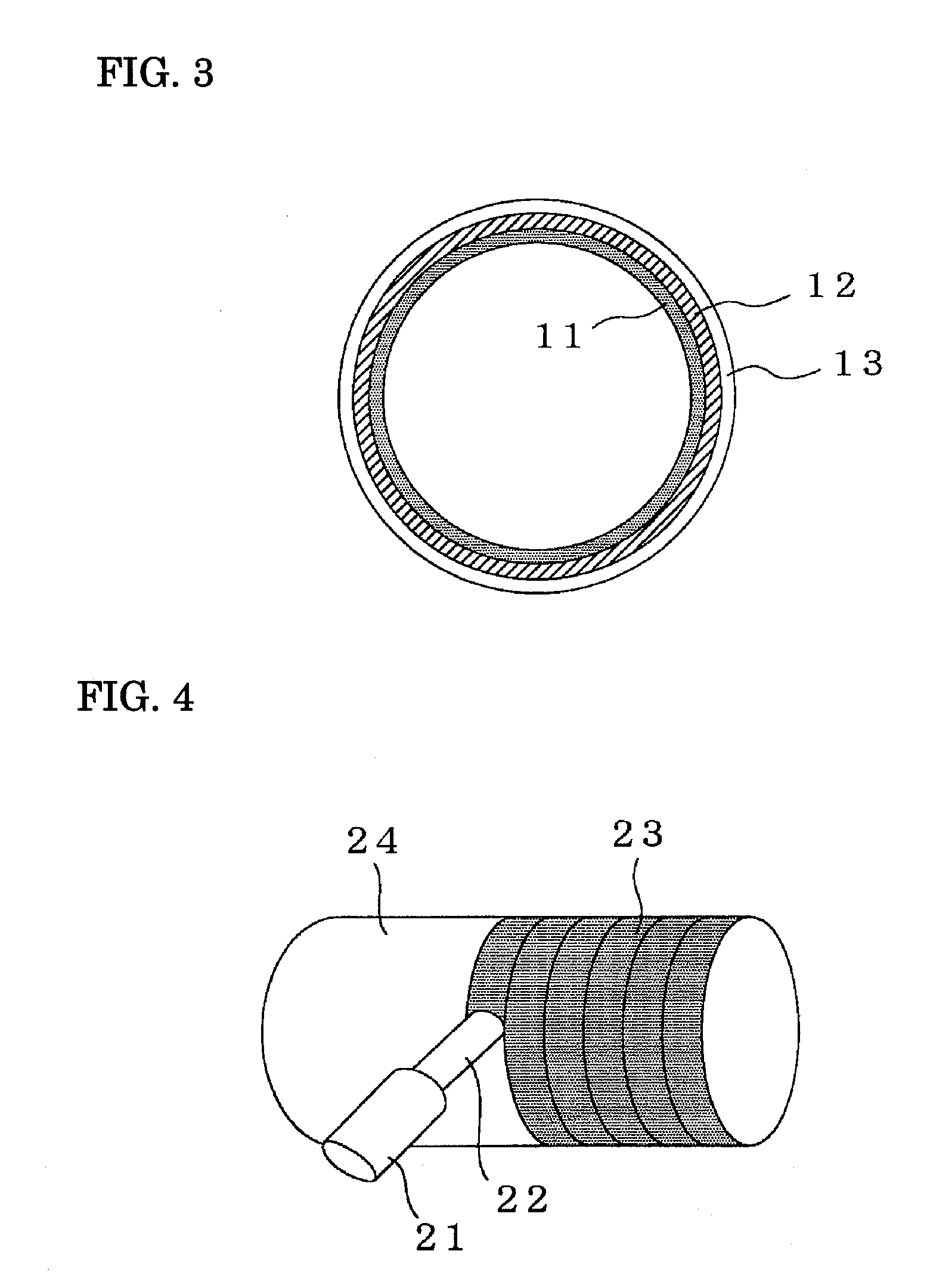

Polyimide tube, method for production thereof, method for production of polyimide varnish, and fixing belt

ActiveUS20100055365A1Improve thermal conductivityModulus improvementSynthetic resin layered productsCeramic shaping apparatusBoron nitrideVarnish

A polyimide tube composed of a polyimide resin composition in which 5 to 23.5 volume percent of boron nitride and 1 to 15 volume percent of an acicular substance are dispersed as a filler in a polyimide resin on the basis of the total volume of the composition, a method of producing the tube, a method of producing a polyimide varnish used for producing the tube, and a fixing belt including the tube as a base member are provided.

Owner:SUMITOMO ELECTRIC IND LTD +1

Thermoplastic Polyurethane From Low Free Monomer Prepolymer

InactiveUS20140342110A1Excellent propertyGreat efficiencyLayered productsThin material handlingPrepolymerChemistry

Thermoplastic polyurethane (TPU) made using low free isocyanate monomer (LF) prepolymer, for example a prepolymer based on p-phenylene diisocyanate (PPDI) with low free isocyanate content, possess unique performance features including exceptional tear strength, low compression set, and an exceptional overall balance of physical properties including high temperature mechanical strength.

Owner:LANXESS SOLUTIONS US INC

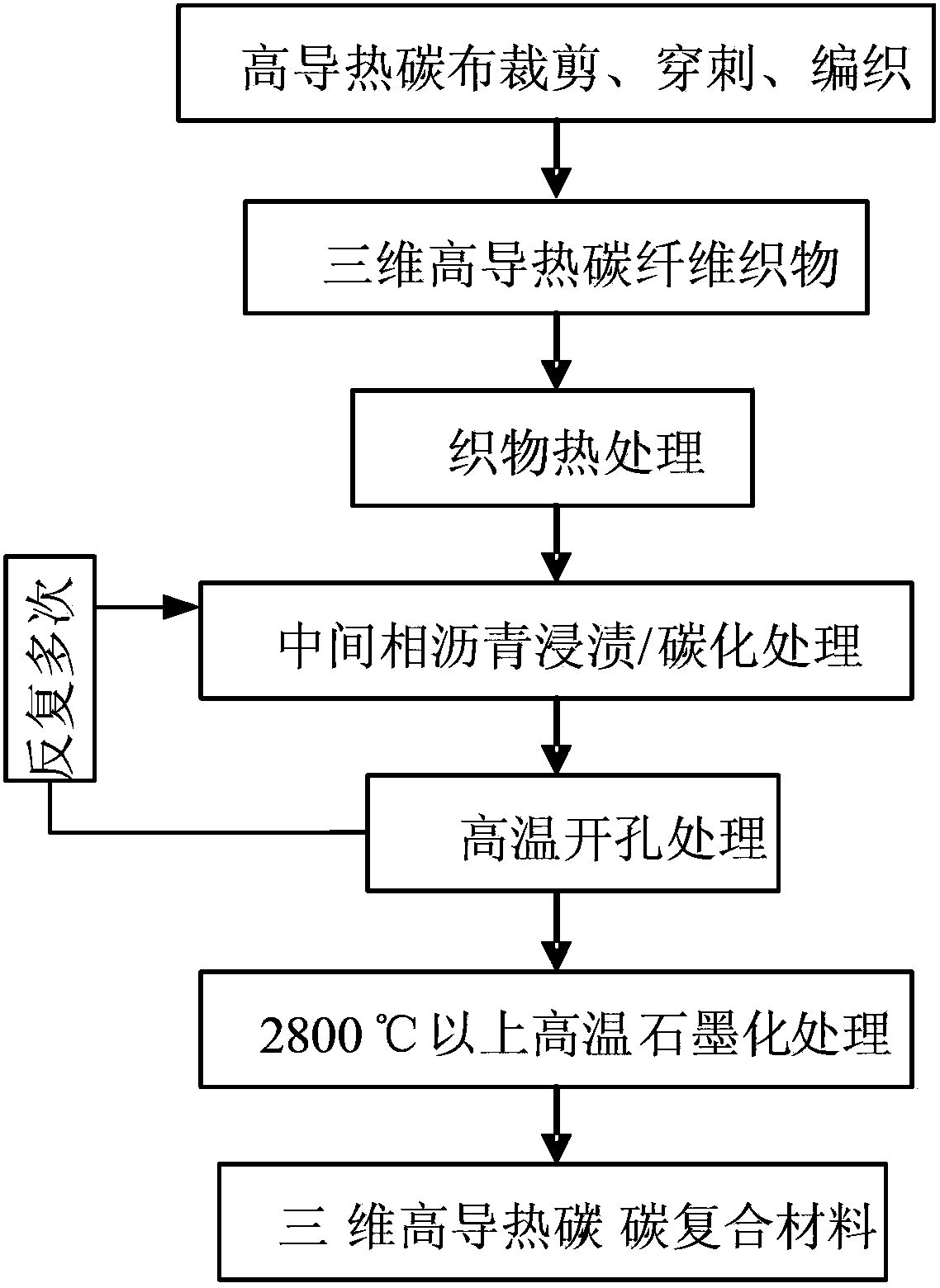

Three-dimensional mesophase pitch-based carbon/carbon composite material with high heat conductivity and preparation technology thereof

The invention relates to a three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity and a preparation technology thereof. The preparation technology comprises the following steps: firstly, by taking a mesophase pitch-based carbon fiber cloth with high heat conductivity as a reinforced body in the XY direction and a high-modulus carbon fiber as a reinforced fiber in the Z direction, preparing three-dimensional carbon fiber fabric with high heat conductivity by adopting a carbon cloth puncturing technology; secondly, by taking mesophase pitch as a precursor of matrix carbon, performing densifying treatment on the three-dimensional carbon fiber fabric with high heat conductivity by adopting a dipping / carbonizing technology; finally, performing graphitization treatment at a high temperature of 2800 DEG C above on the obtained materials, so as to obtain the three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity. Through the adoption of the technology method, the heat conductivity, modulus and dimensional stability of the carbon / carbon composite material are greatly improved, and the highest heat conductivity reaching 3600 w / mK of the material in the XY direction is increased by more than 5 times as compared with the common three-dimensional carbon / carbon composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Lyocell multi-filament for tire cord and method of producing the same

InactiveUS20050079348A1Good tenacityModulus improvementArtificial filaments from cellulose solutionsArtificial filament washing/dryingCellulosePolyvinyl alcohol

Owner:HYOSUNG CORP

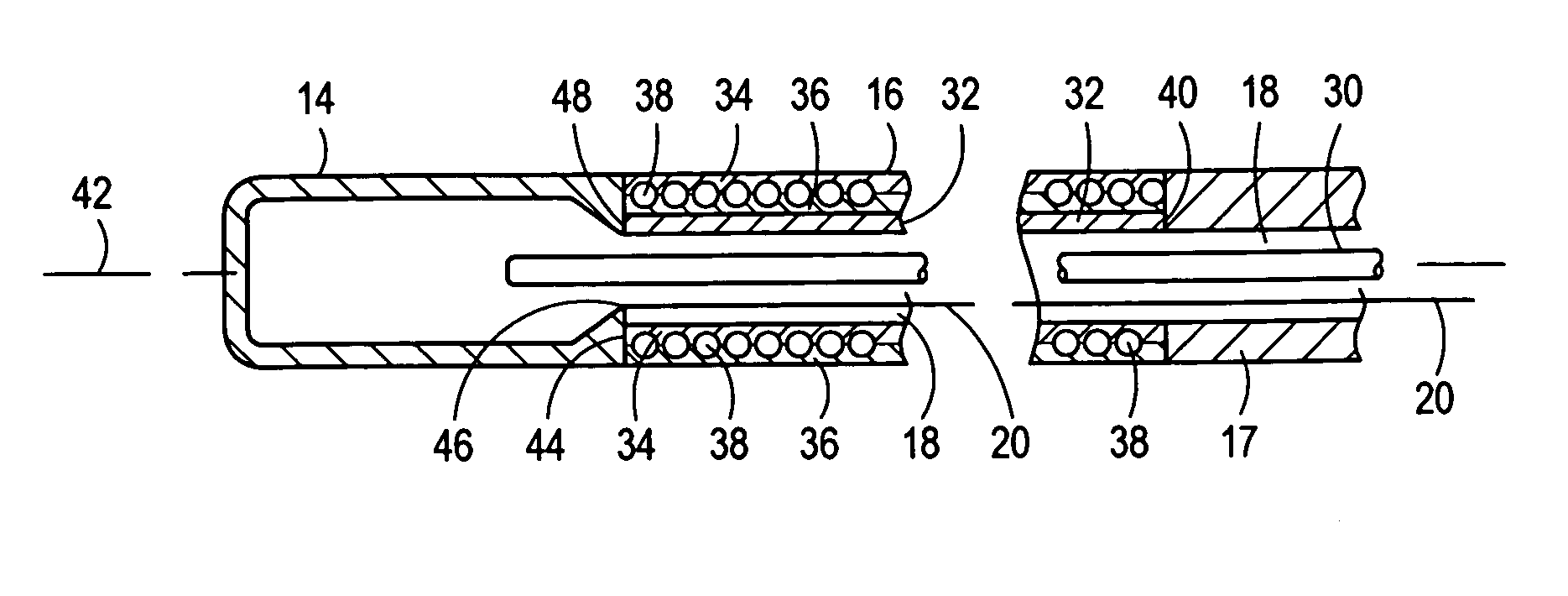

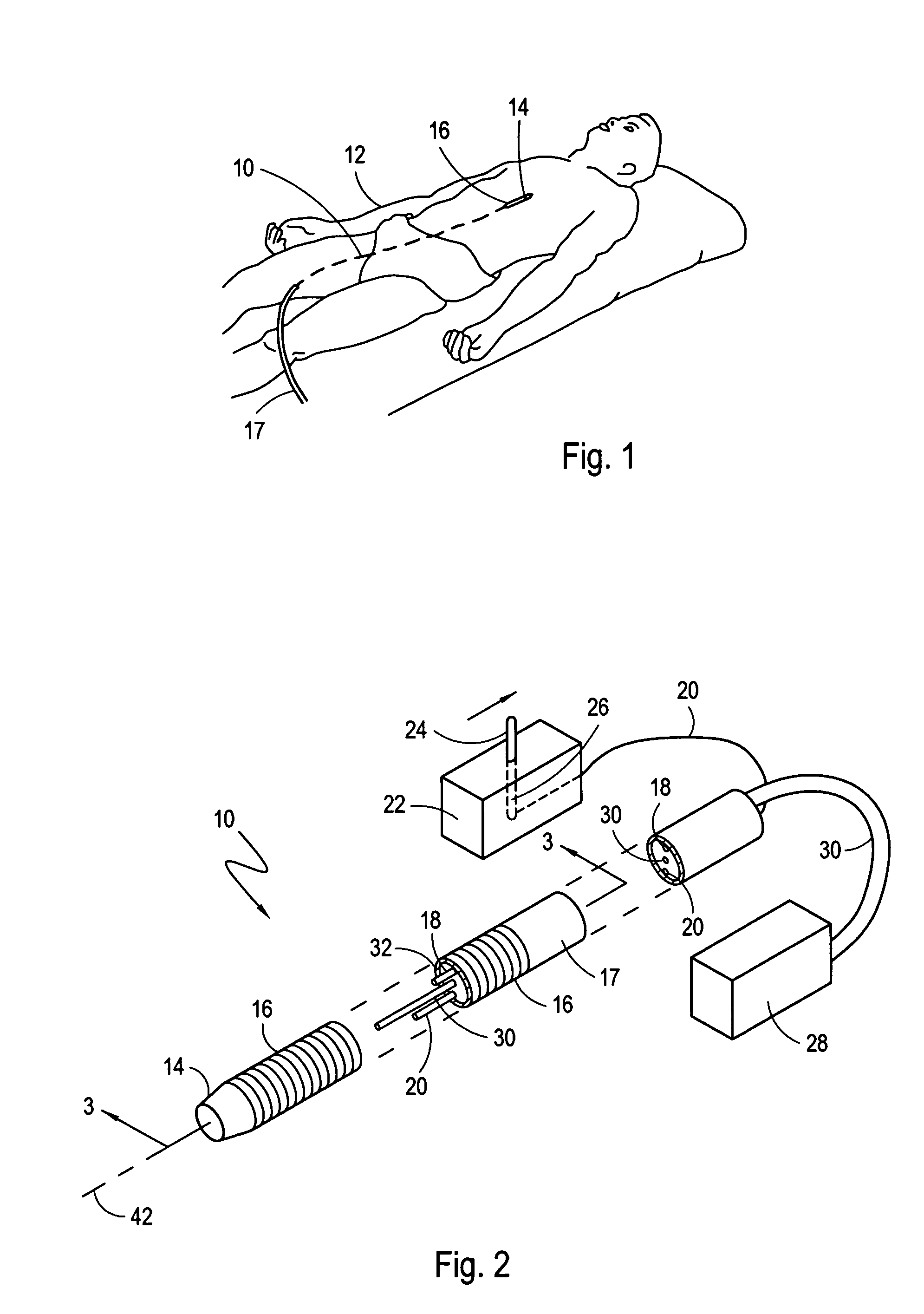

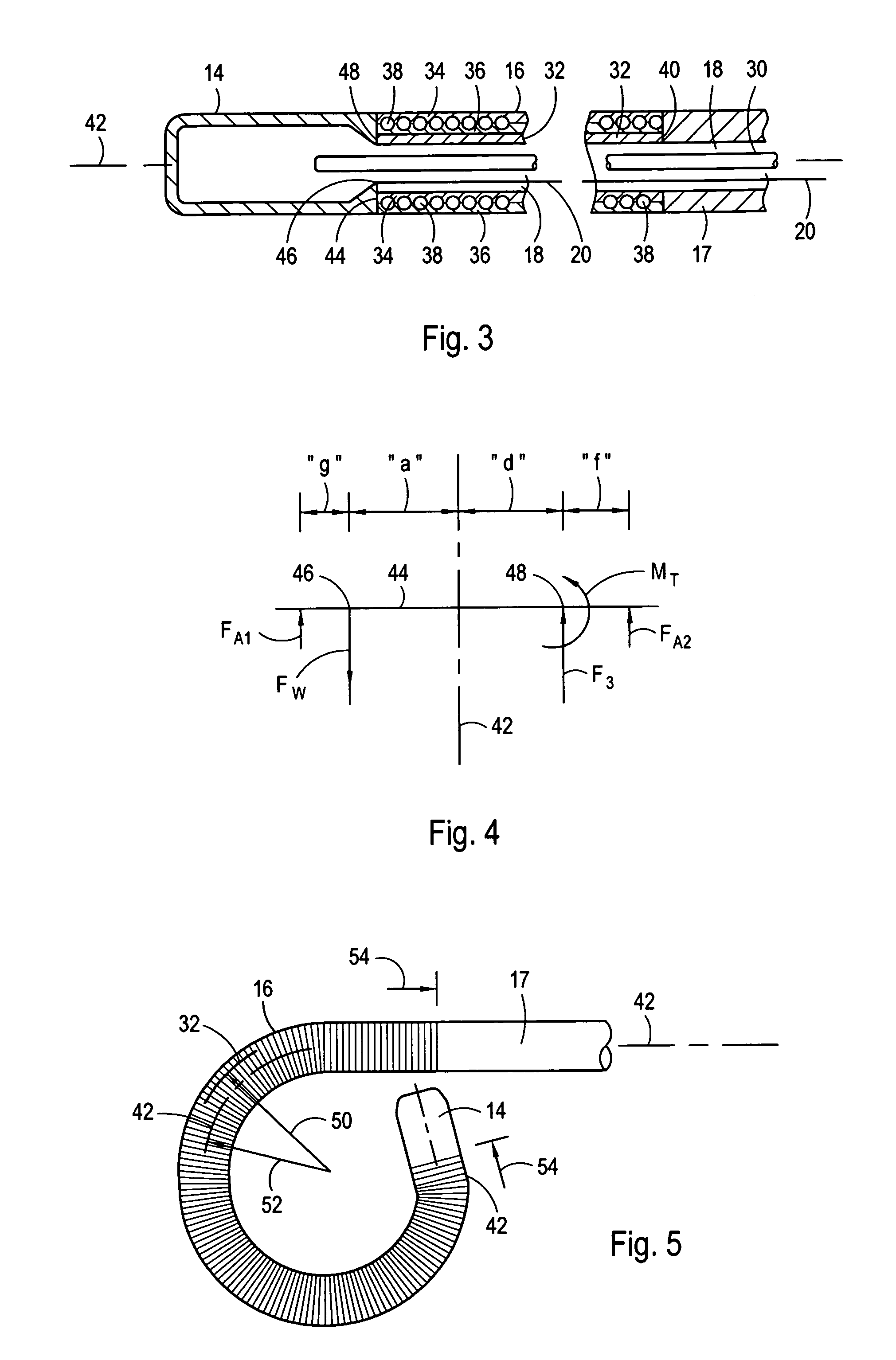

Wire reinforced articulation segment

A device for steering a cardiac cryoablation catheter through the vasculature of a patient includes separate first and second deflection members that connect a tip member to the distal end of a catheter tube. Importantly, the first deflection member has a first flexural modulus, and the second deflection member has a second flexural modulus that is greater than the first flexural modulus. Also included is a control wire for pulling the tip member toward the catheter tube. In response, the first and second deflection members differentially deflect, according to their respective flexural moduli, to move the tip member for steering the catheter through the vasculature.

Owner:CRYOCOR

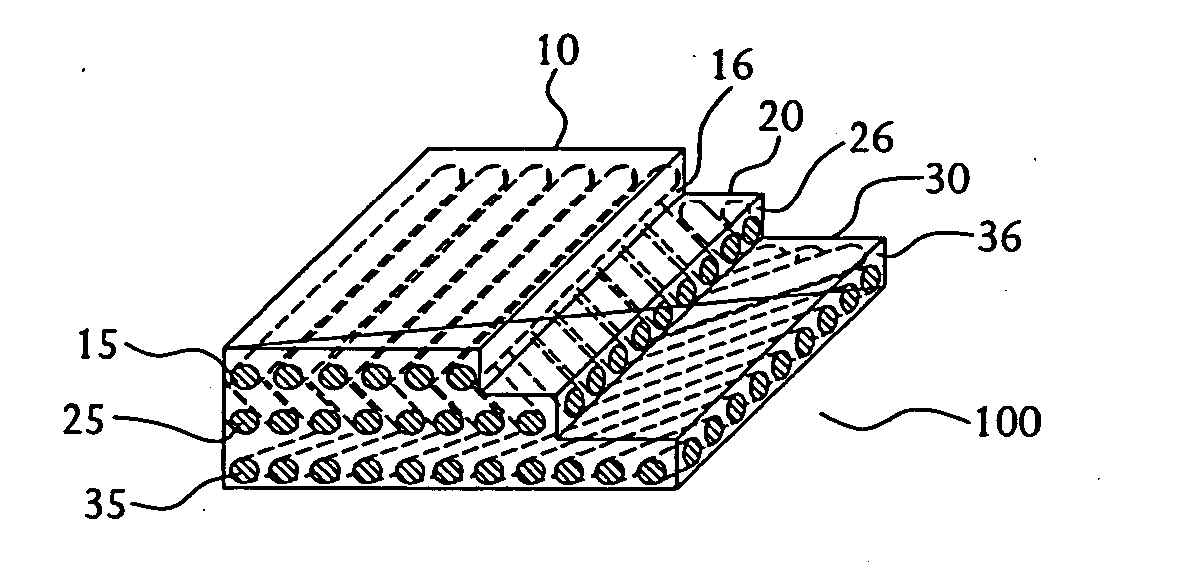

Energy absorbent laminate

InactiveUS20060135022A1Tensile modulusImprove toughnessSynthetic resin layered productsPrinted circuit aspectsFiberFlexural modulus

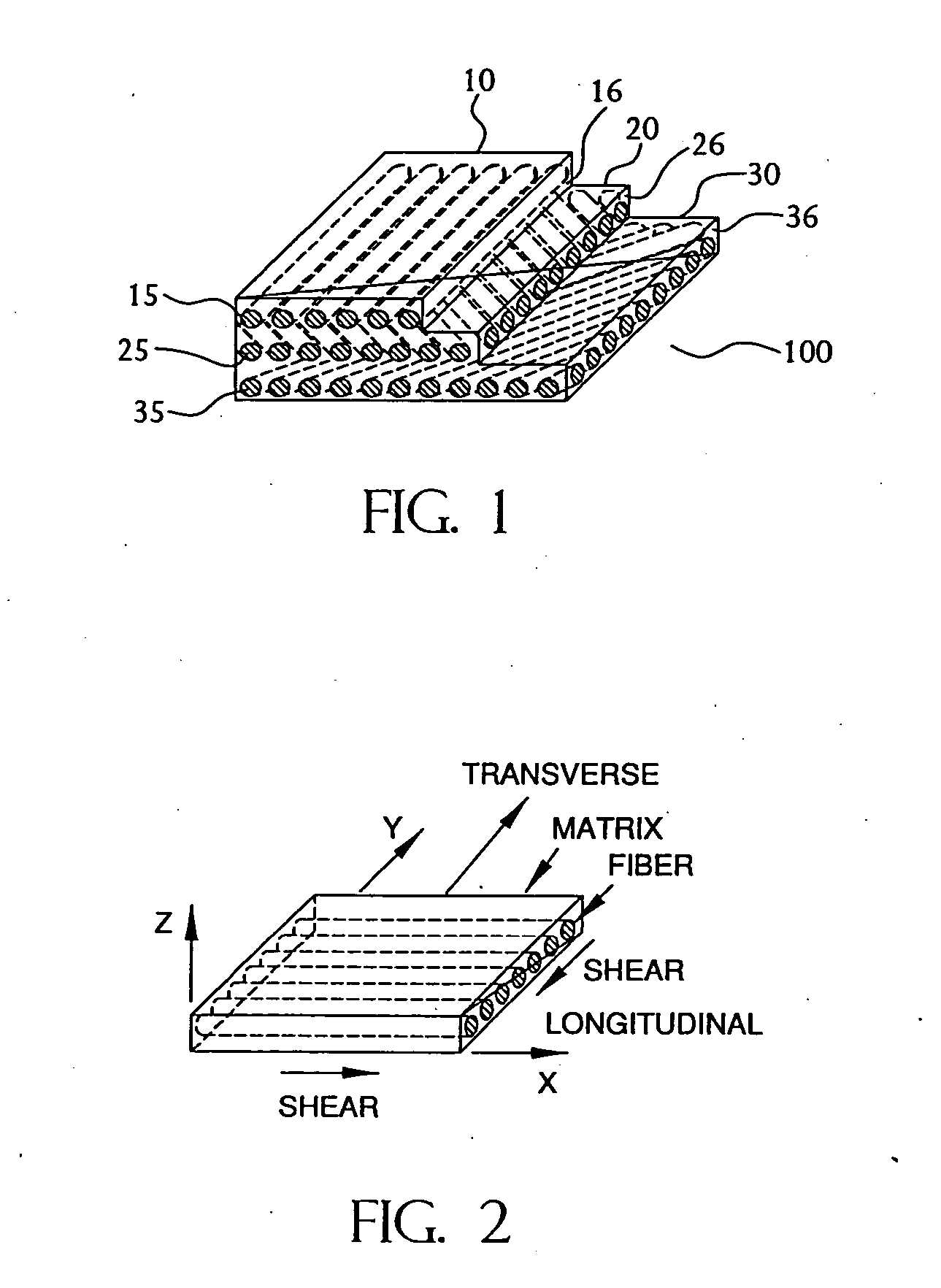

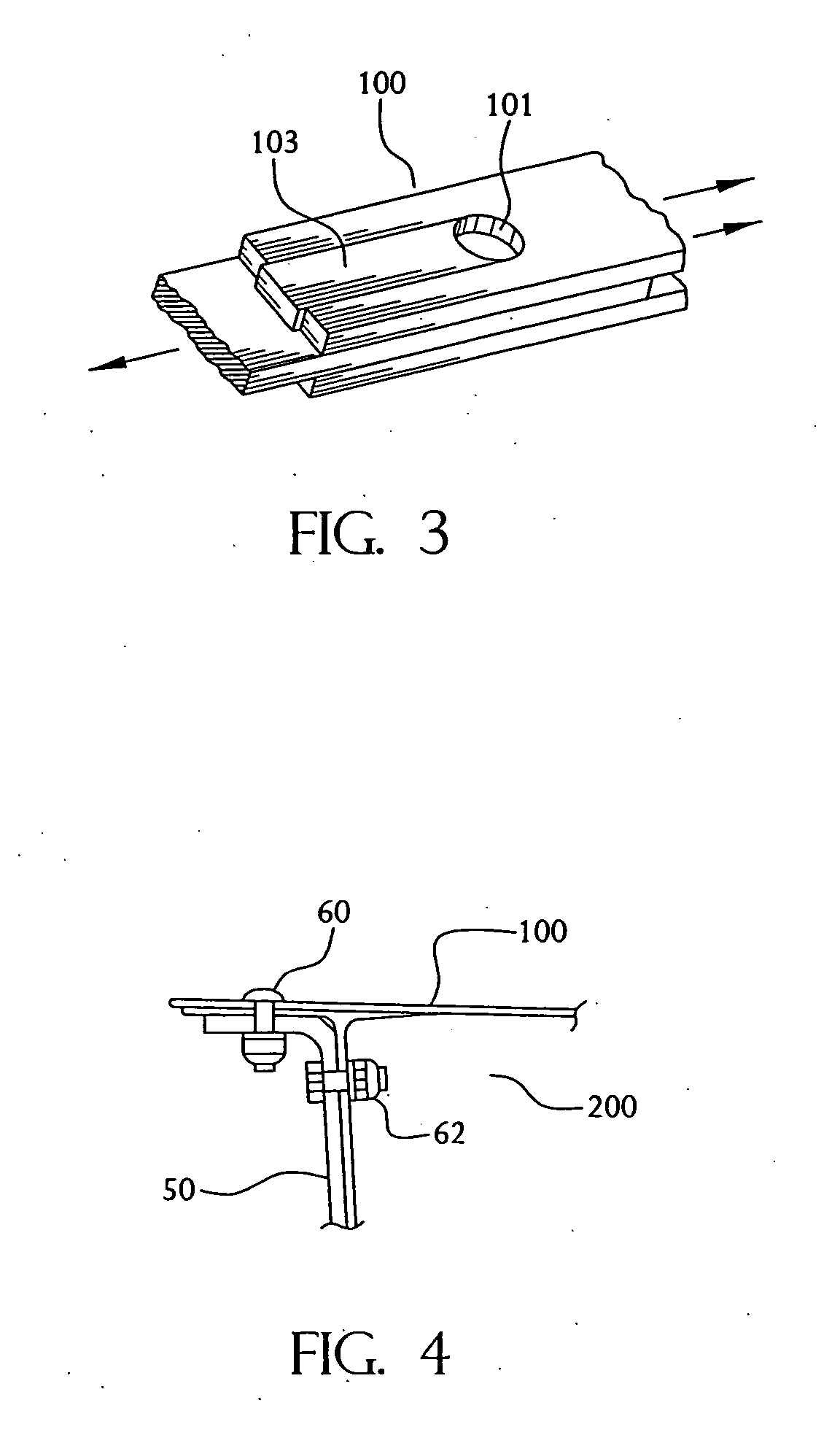

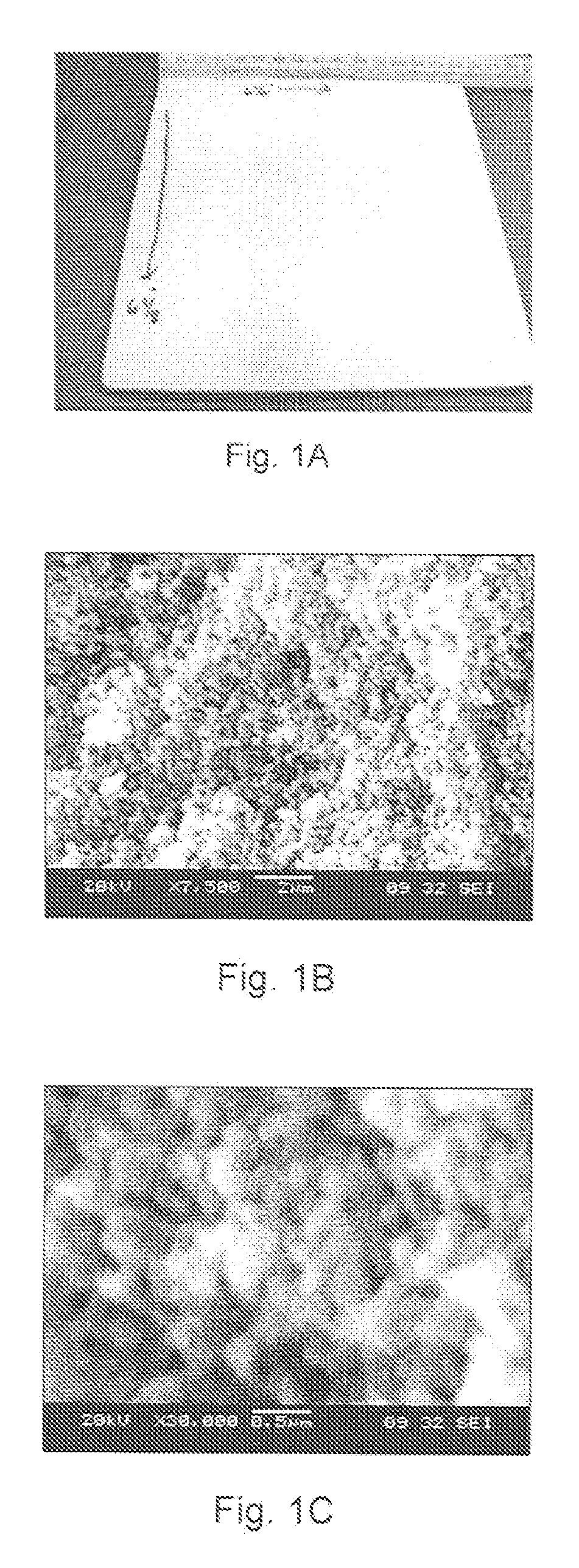

This invention provides multi-layered composites, laminates and composite joints in which at least one resin-impregnated, fiber-containing layer is joined or laminated to a core layer having a lower flexural modulus or higher elongation at break, higher toughness, or a combination of all or some of these properties. The multi-layer composite produced by laminating or joining these materials together has improved shearout, impact and cutting resistance, since stresses caused by outside forces can be more widely distributed throughout the composite.

Owner:SAINT GOBAIN BRUNSWICK TECH

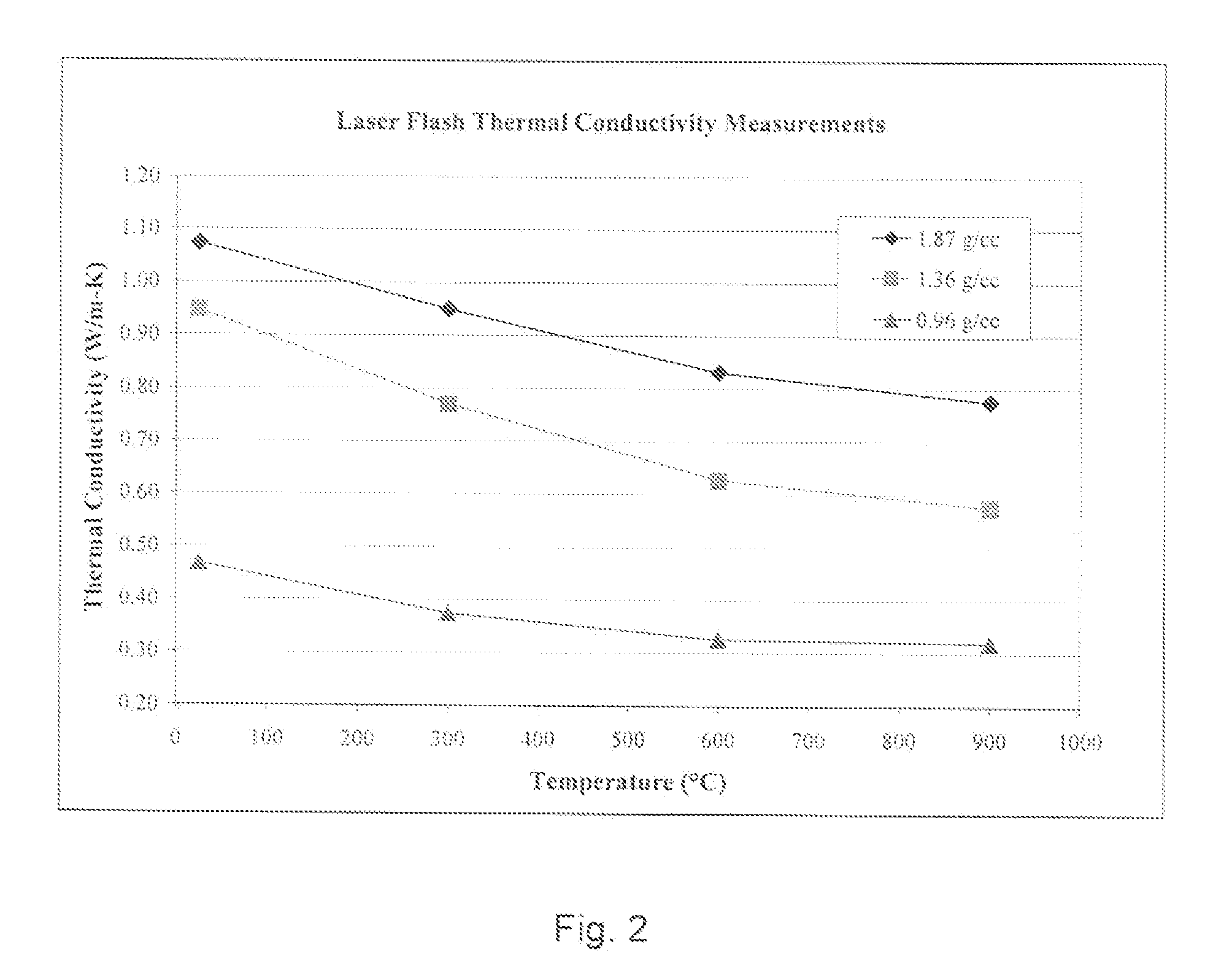

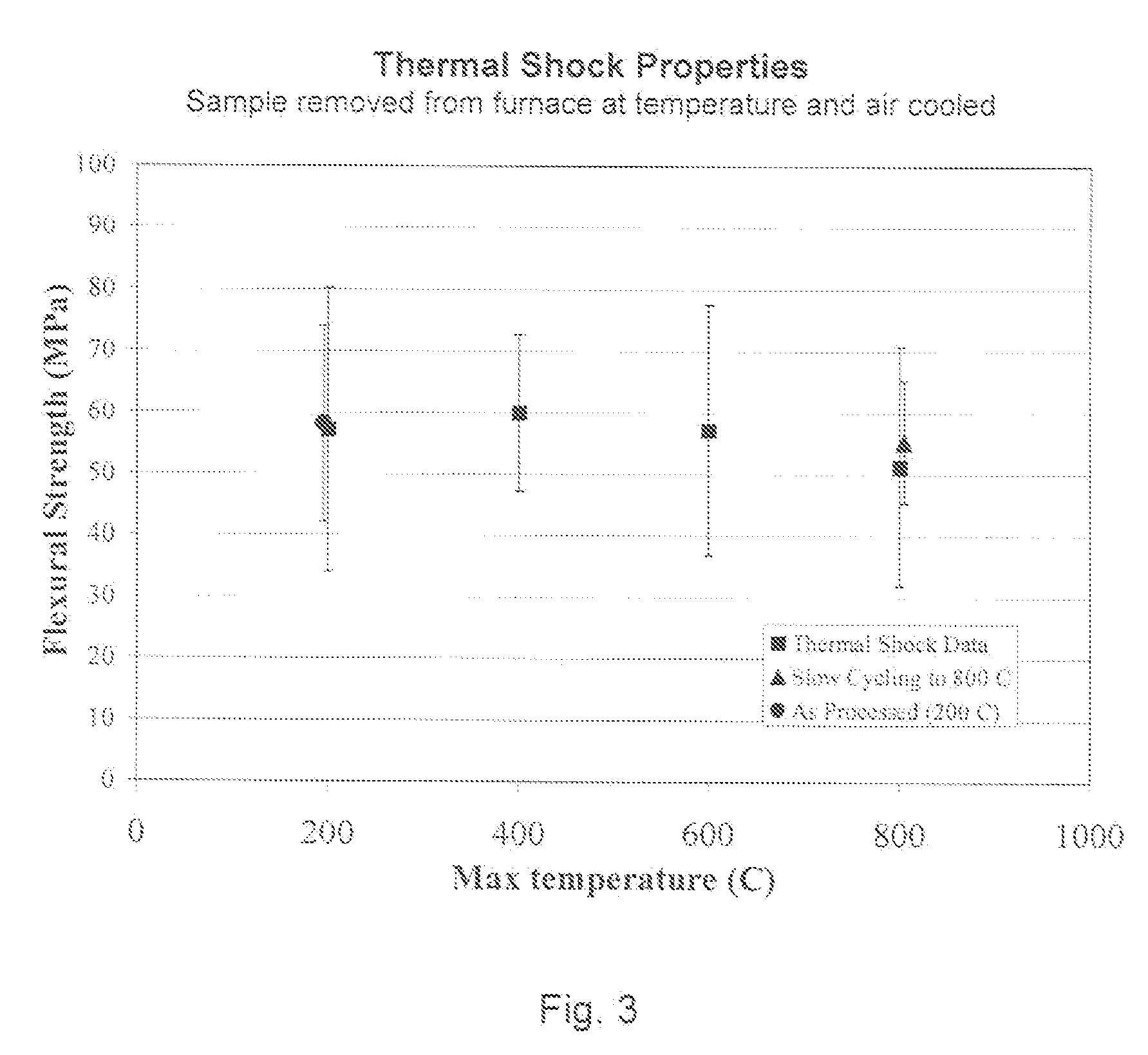

Process for making ceramic insulation

InactiveUS20090295045A1Low costImprove performanceFinal product manufactureCeramic shaping apparatusPorosityFuel cells

A method is provided for producing insulation materials and insulation for high temperature applications using novel castable and powder-based ceramics. The ceramic components produced using the proposed process offers (i) a fine porosity (from nano-to micro scale); (ii) a superior strength-to-weight ratio; and (iii) flexibility in designing multilayered features offering multifunctionality which will increase the service lifetime of insulation and refractory components used in the solid oxide fuel cell, direct carbon fuel cell, furnace, metal melting, glass, chemical, paper / pulp, automobile, industrial heating, coal, and power generation industries. Further, the ceramic components made using this method may have net-shape and / or net-size advantages with minimum post machining requirements.

Owner:CERAMTEC

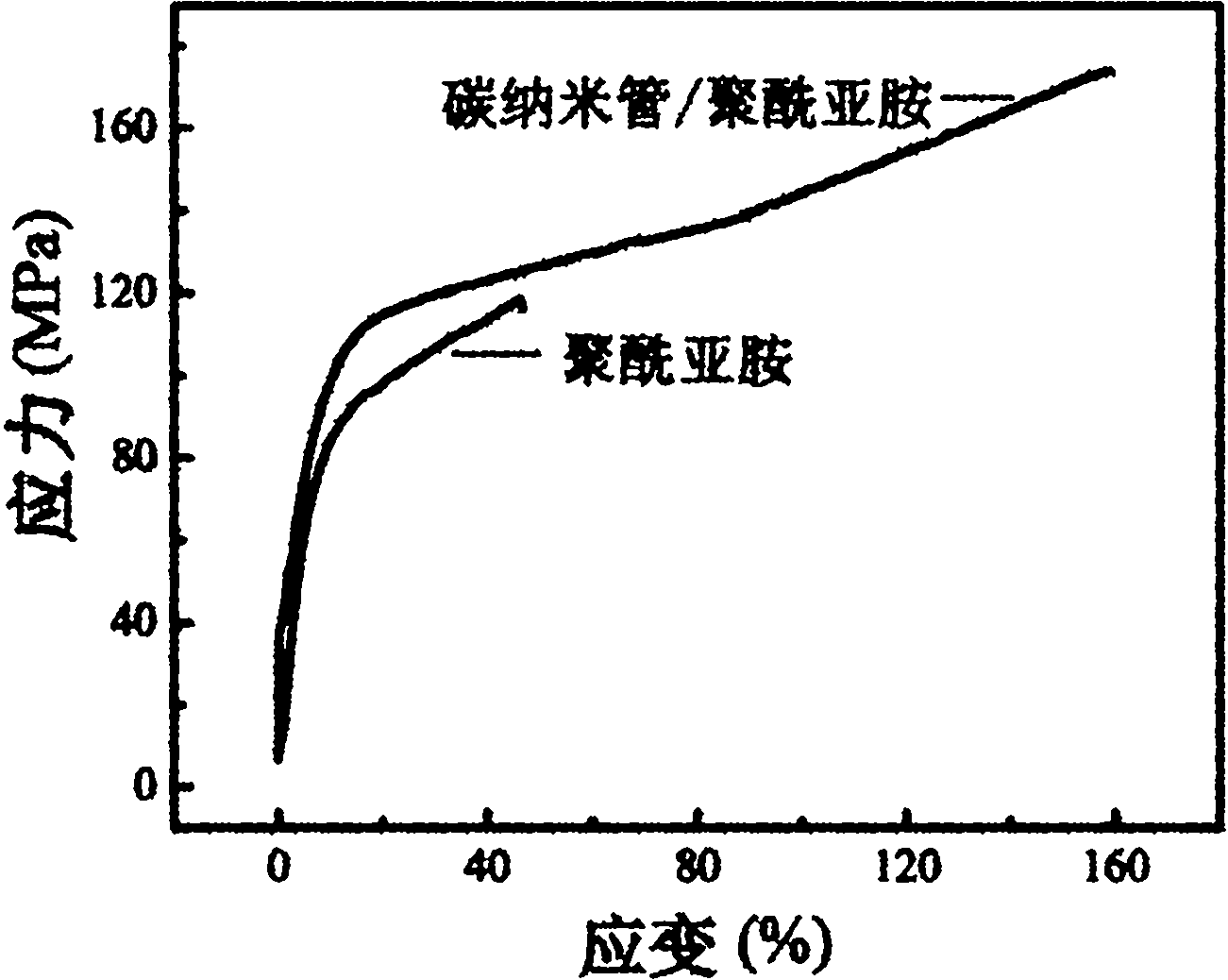

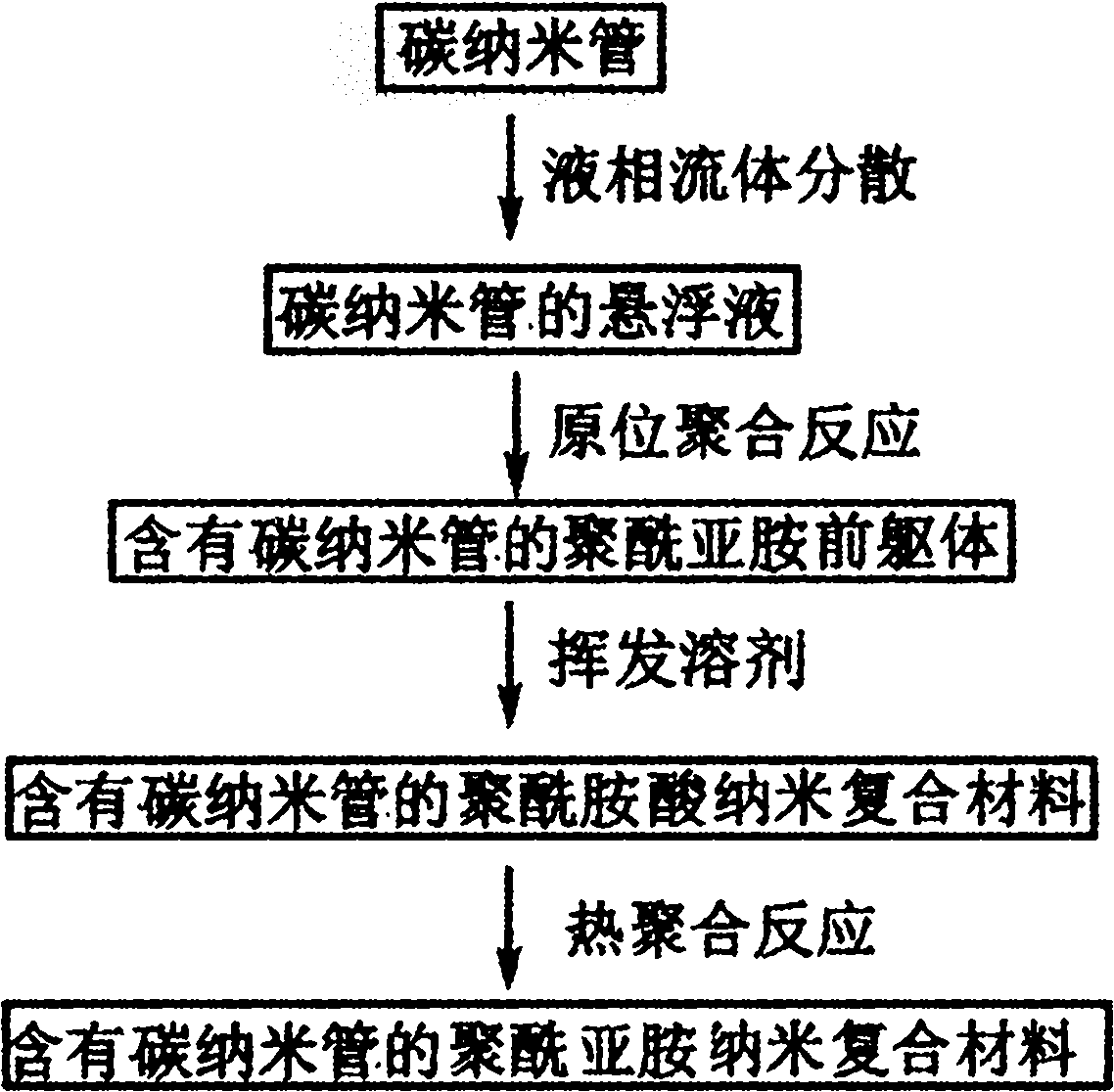

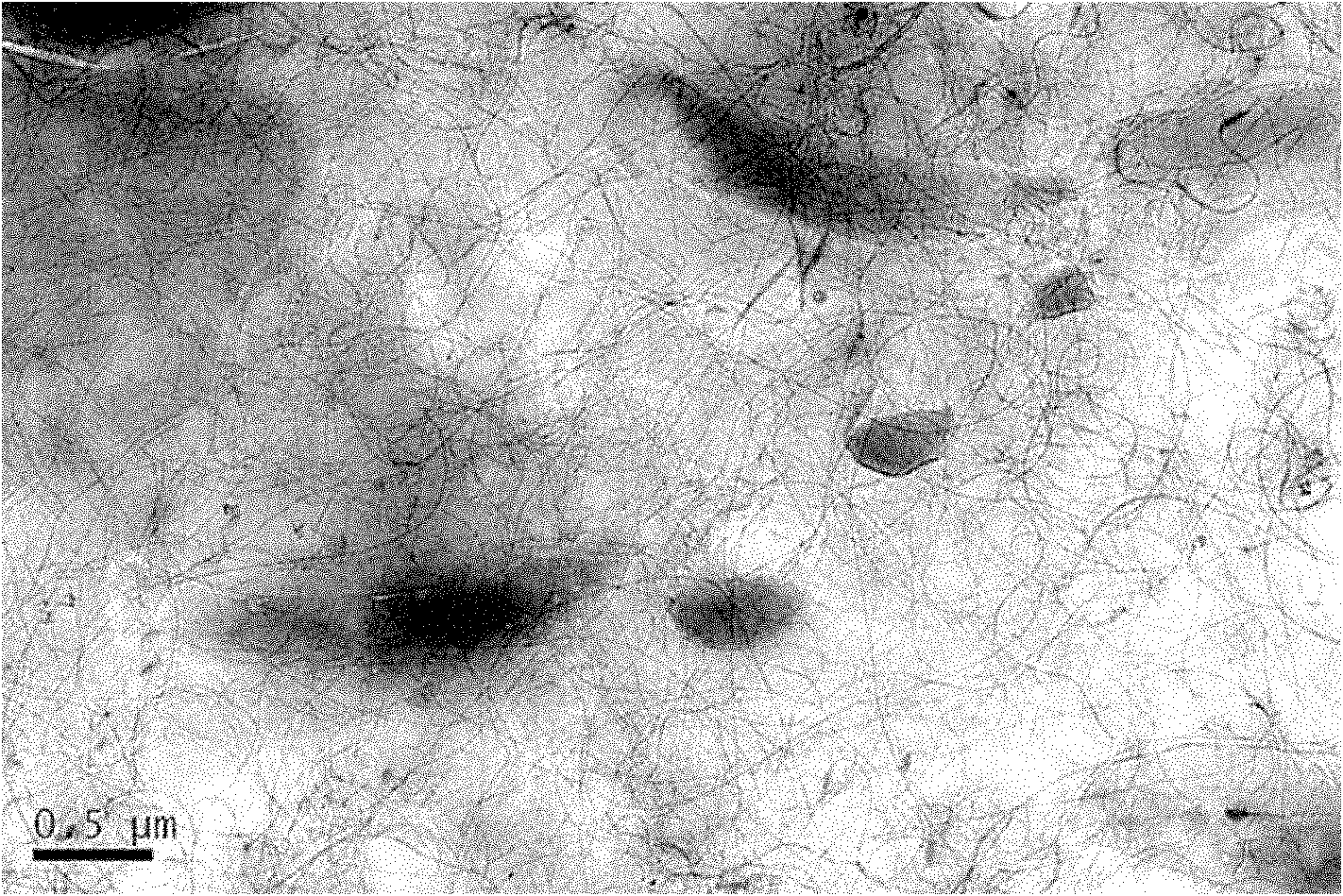

Preparation method of carbon nanotube reinforced polyimide nano composite material

ActiveCN102093715AImprove thermal stabilityIncrease contentMonocomponent synthetic polymer artificial filamentFiberImide

The invention relates to a preparation method of a carbon nanotube reinforced polyimide nano composite material, which comprises the following steps: carrying out liquid-phase shearing dispersion on 10-10000 micrometer long carbon nanotubes in an organic solvent; adding 4,4-diaminodiphenyl ether and pyromellitic dianhydride into the dispersed carbon nanotube slurry to carry out an in-situ polymerization reaction; and carrying out vacuum degasification to obtain a thin film or fibers, volatilizing the solvent, and carrying out heat treatment to obtain the carbon nanotube / polyimide nano composite material. By using the high-length-diameter ratio carbon nanotubes to provide interfaces for adequate slip of polyimide molecules and favorable interface combination, the composite material has excellent mechanical properties, thereby being hopefully applied to fields such as aerospace, automobiles, flexible substrates and the like.

Owner:TSINGHUA UNIV

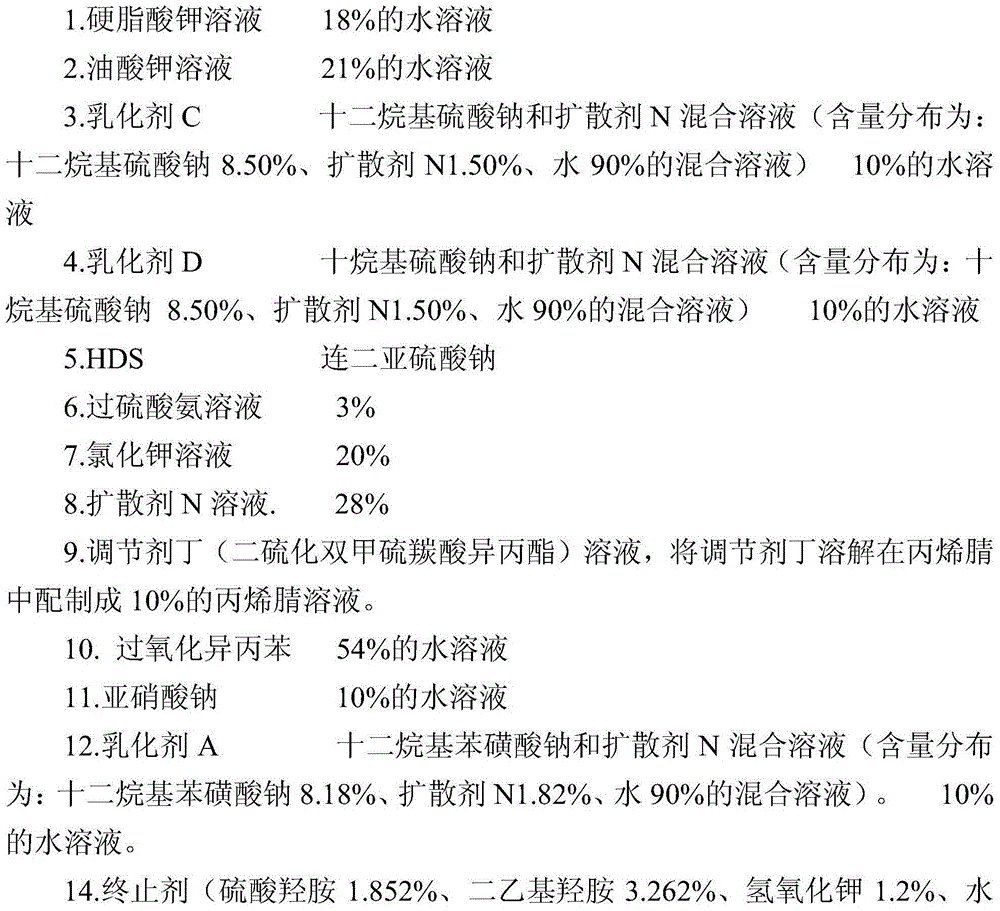

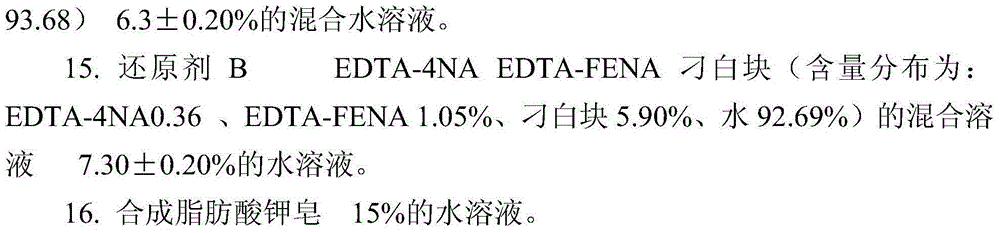

Preparation method of carboxyl nitrile rubber through emulsion polymerization

The invention relates to a preparation method of carboxyl nitrile rubber through emulsion polymerization. According to the preparation method, acrylonitrile, an emulsifier, an adjusting agent, and an initiator are added into a polymerization kettle, then butadiene is added, emulsion polymerization is carried out under stirring, and in the late phase of emulsion polymerization, unsaturated carboxylic acid and / or anhydride thereof is added into the polymerization kettle. The obtained carboxyl nitrile rubber has a low content of gel and a two-layer molecular structure, the index of conjugated acid is controllable; during the processing process, a three-dimensional network structure can be easily formed, thus the mechanical and physical properties of rubber products made of the carboxyl nitrile rubber are good; after processing, the Mooney viscosity is increased, the crosslinking degree of finished products is good, and especially, the elongation at break is prominently improved.

Owner:PETROCHINA CO LTD

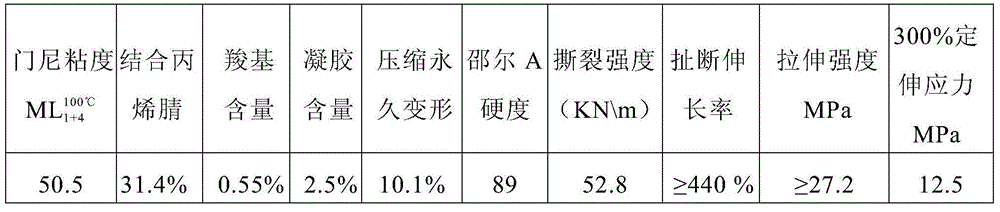

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

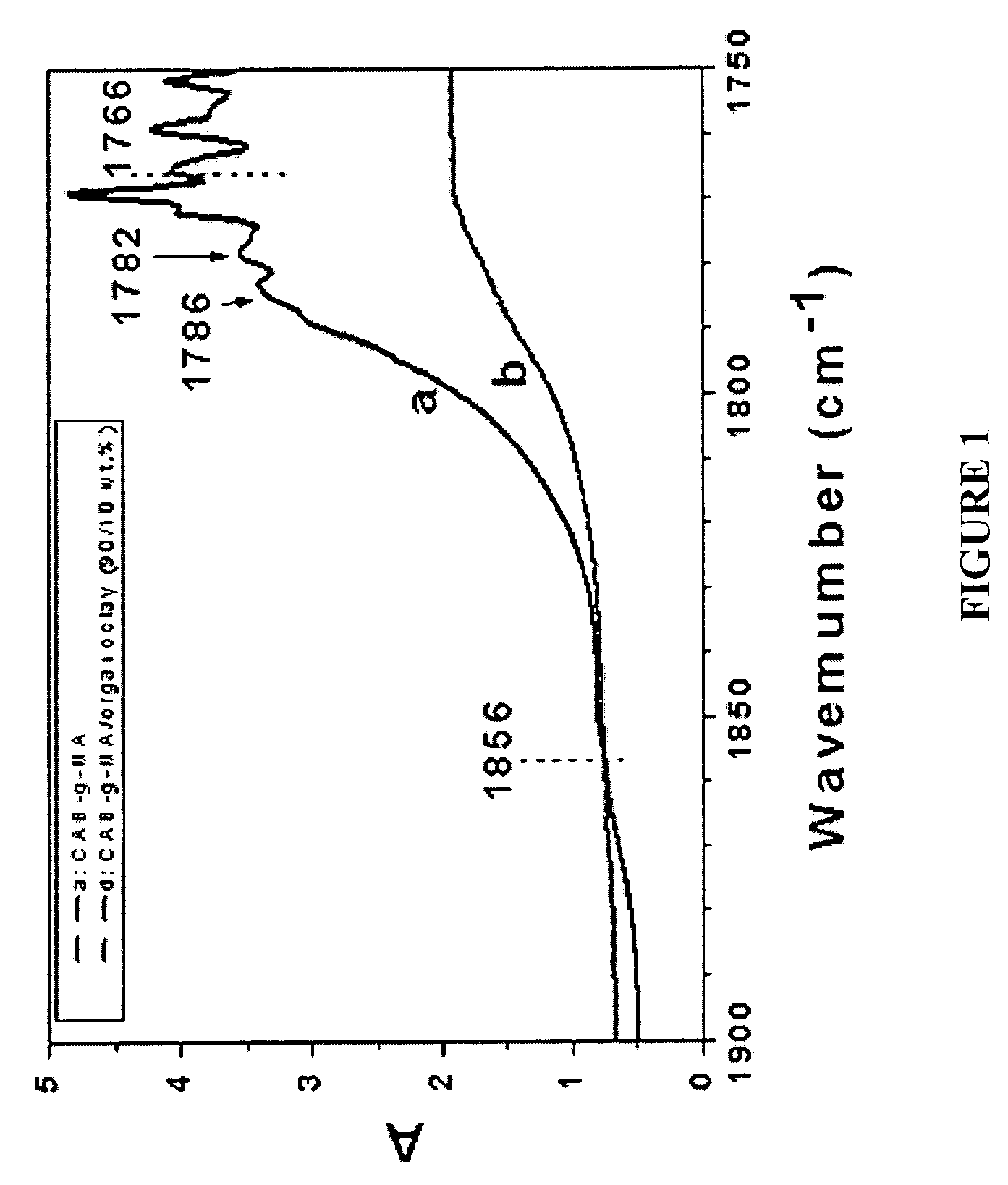

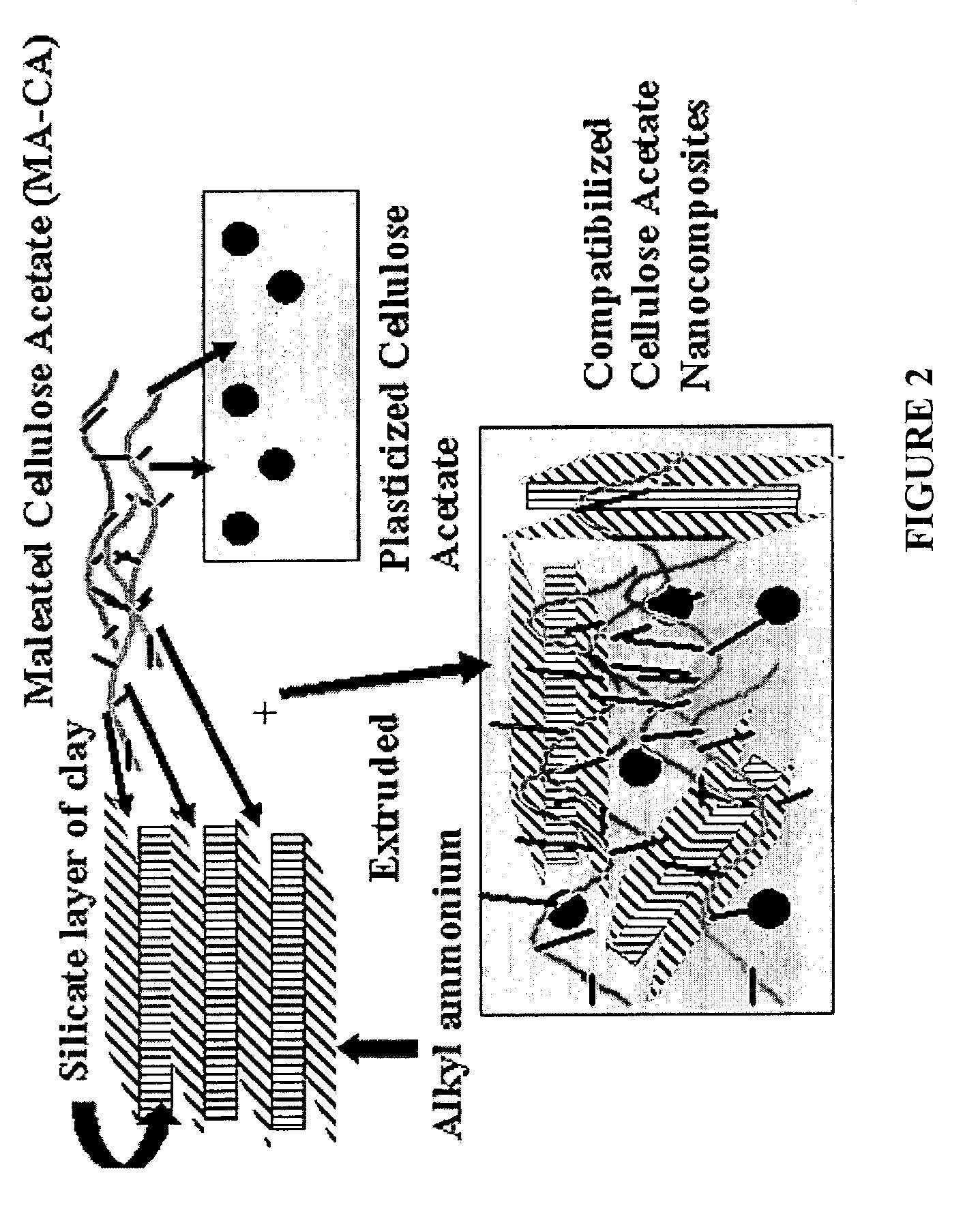

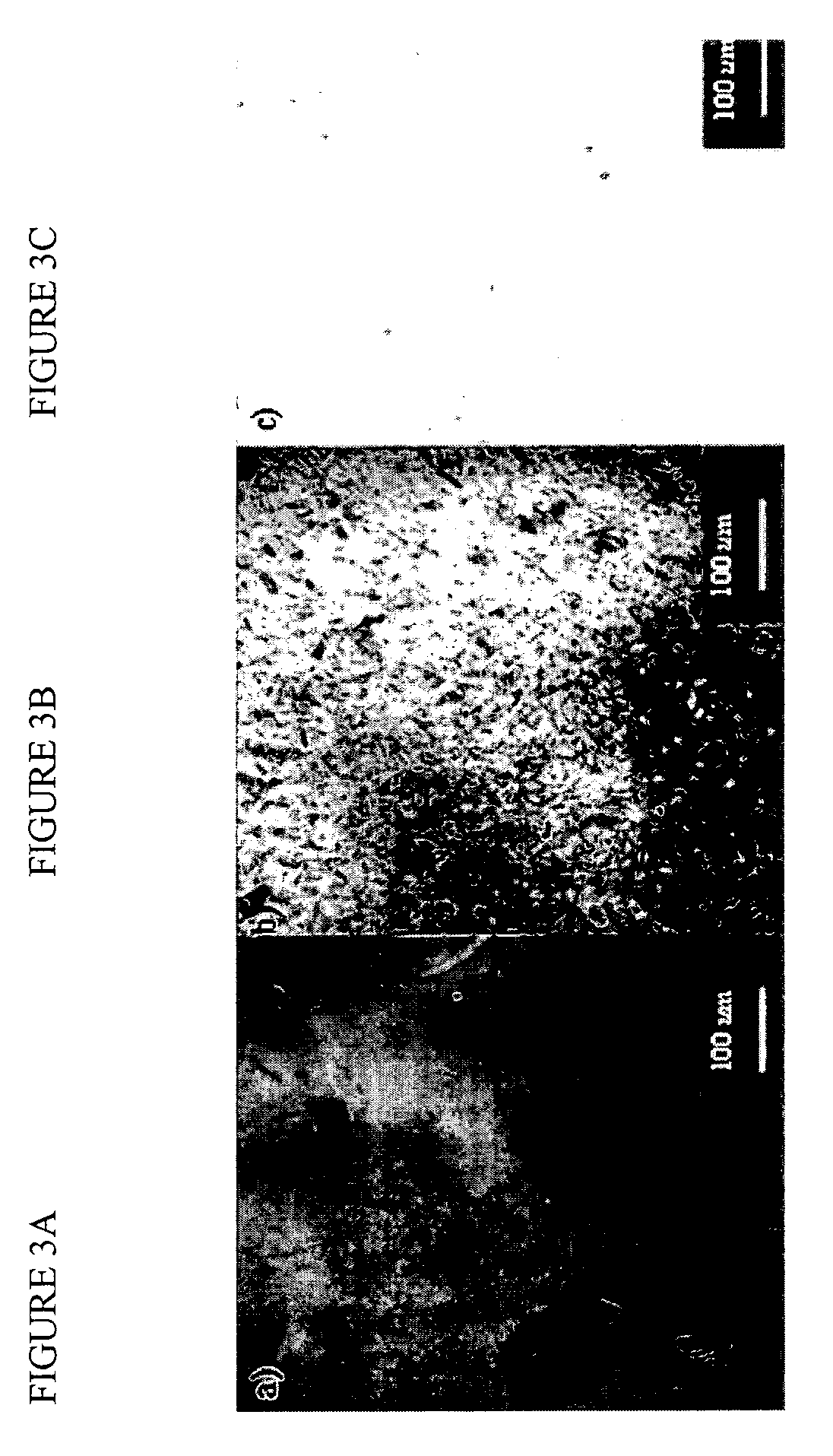

Compositions of cellulose esters and layered silicates and process for the preparation thereof

InactiveUS7253221B2Increase modulusImprove propertiesSurface-active detergent compositionsCoatingsCelluloseHeat deflection temperature

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Advanced polymer wood composite

InactiveUS20040126568A1High modulusHigh compressive strengthFibreboardWood working apparatusThermoplasticFiber

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm<3>. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

Resin composition

Provided is a resin composition having excellent bending strength, tensile strength, and bending elastic modulus suitable for use in molded articles for vehicle interiors, molded articles for home appliance exteriors, etc.The resin composition comprises the following (1) to (3):(1) a polyolefin;(2) an epoxy-modified polyolefin; and(3) cellulose fiber.

Owner:TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com