Patents

Literature

82 results about "Direct carbon fuel cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

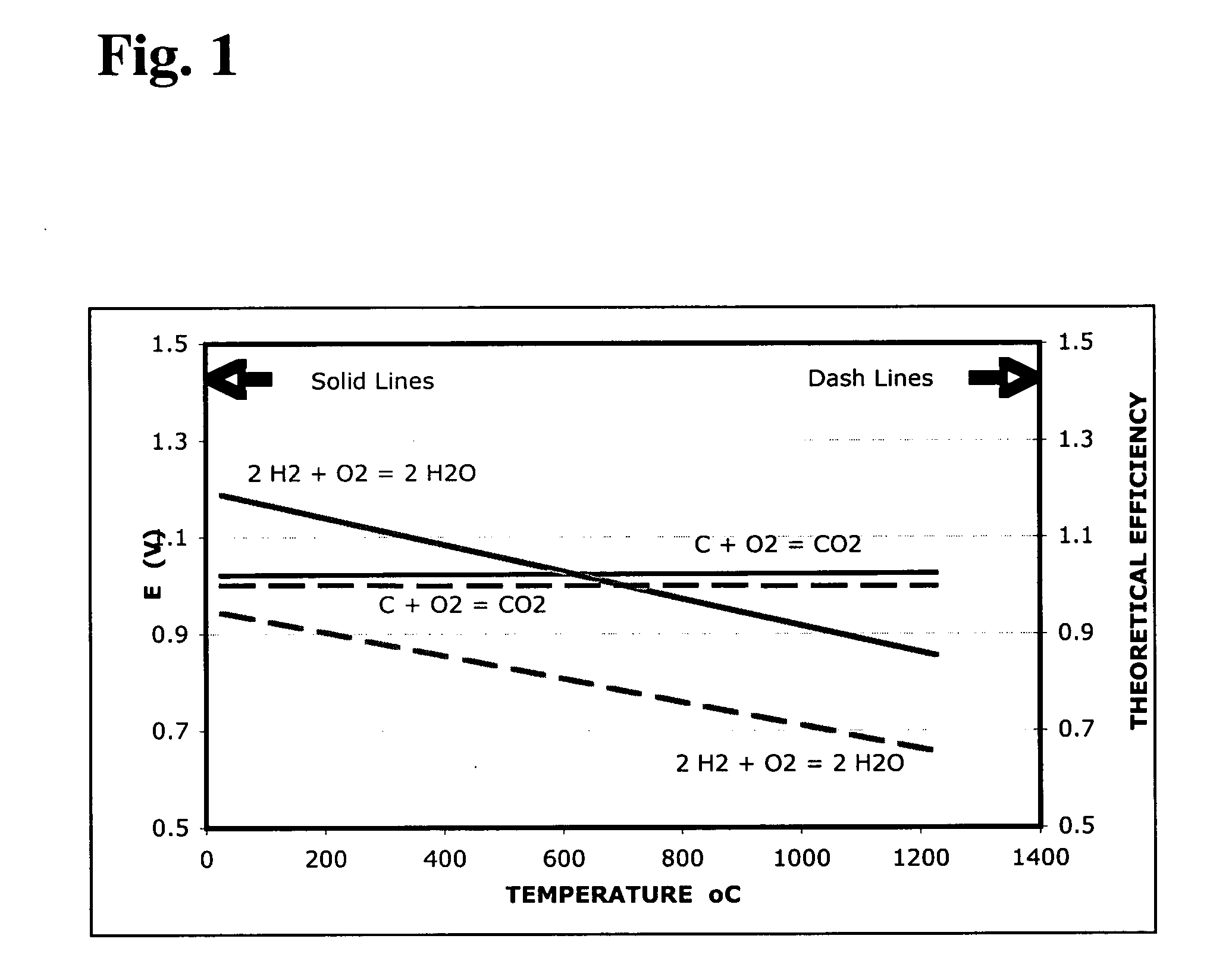

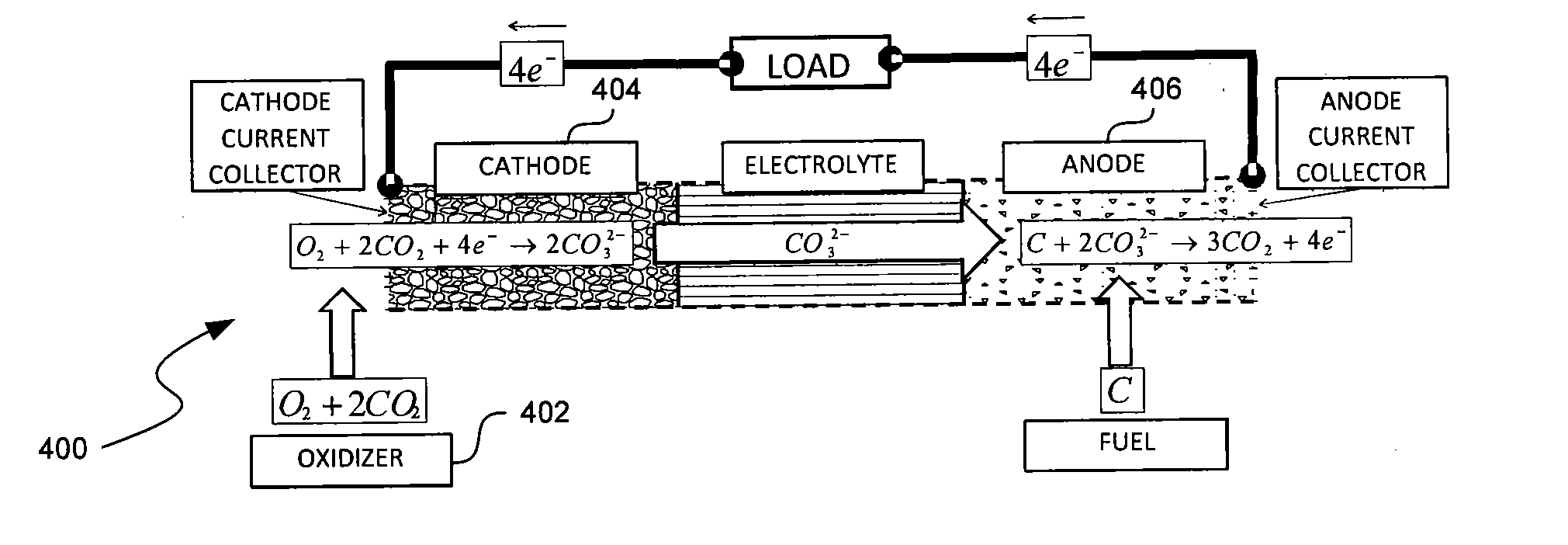

A Direct Carbon Fuel Cell (DCFC) is a fuel cell that uses a carbon rich material as a fuel such as bio-mass or coal. The cell produces energy by combining carbon and oxygen, which releases carbon dioxide as a by-product. It also called coal fuel cells (CFCs), carbon-air fuel cells (CAFCs), direct carbon/coal fuel cells (DCFCs), and DC-SOFC.

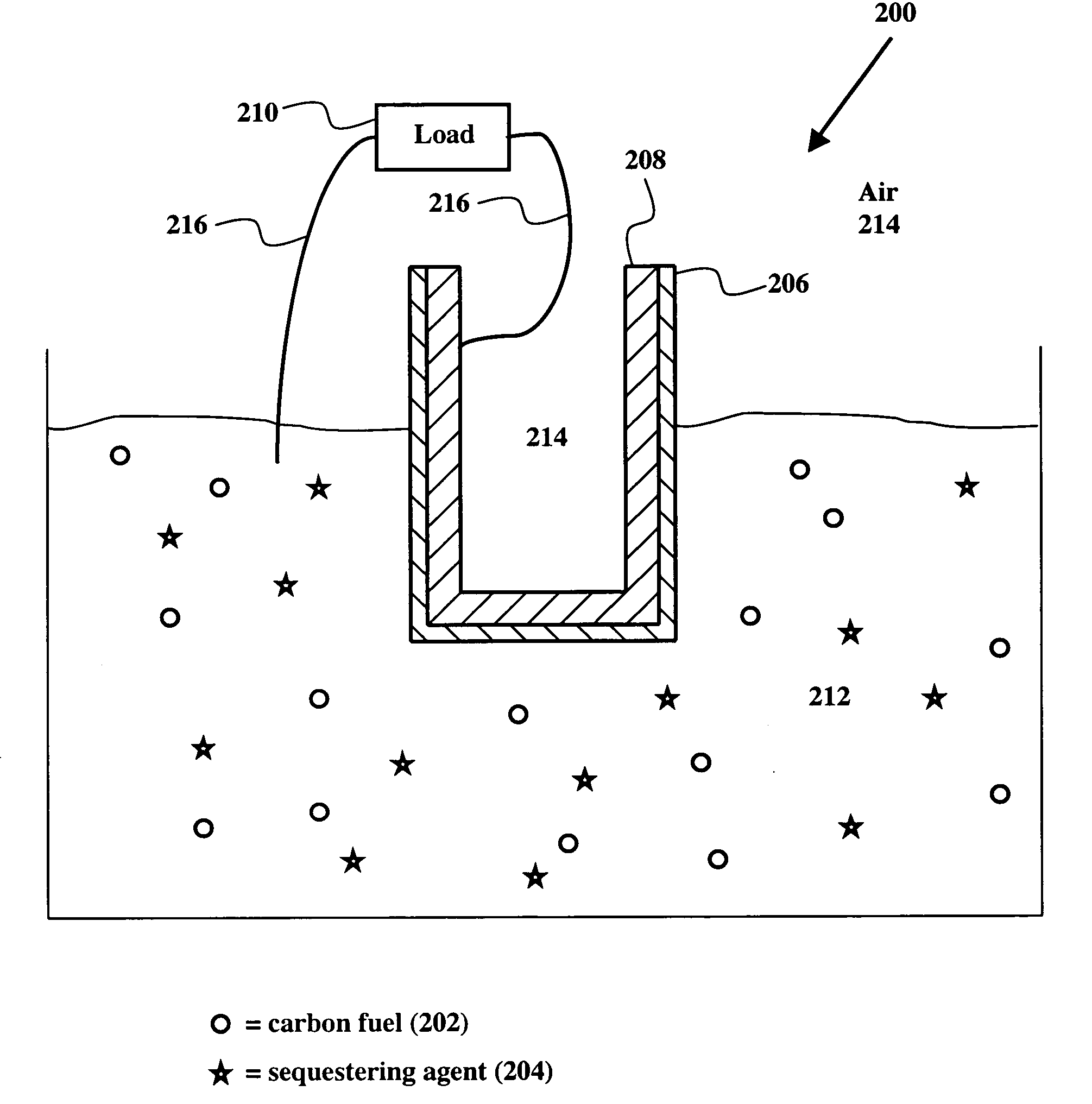

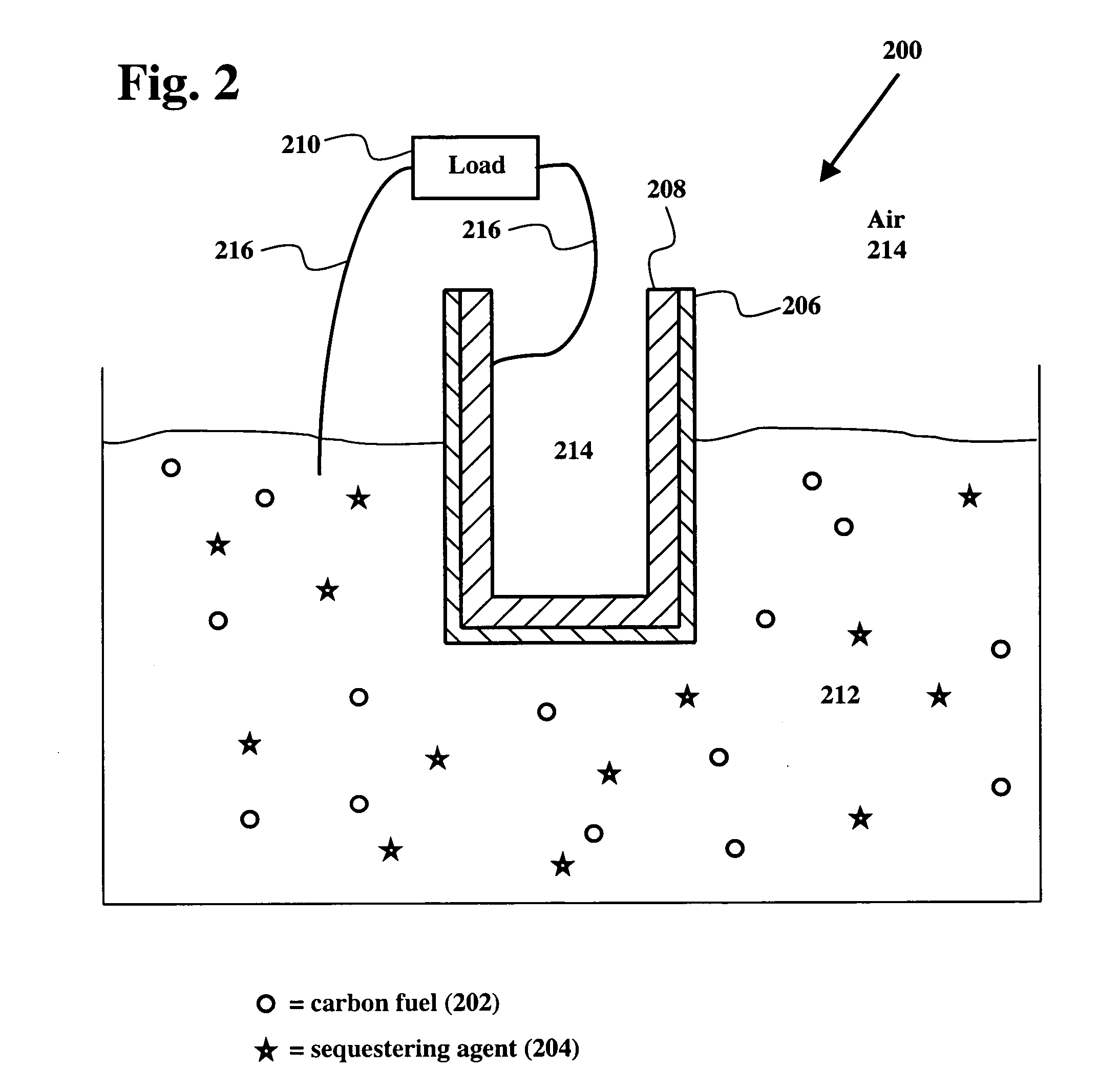

Direct carbon fuel cell with molten anode

This invention discloses a method of converting carbon-containing materials directly to electrical energy without the need for intermediate processing steps. An embodiment comprises the use of a conductive molten medium with dispersed particles of carbon material as the anode in a fuel cell with a solid oxide electrolyte which enables conversion of carbon-containing materials (such as pulverized coal, charcoal, peat, coke, char, petroleum coke, oil sand, tar sand, waste plastics, biomass, and carbon produced by pyrolysis of carbonaceous substance) directly into electrical energy in a single step process. The anode optionally may have a dispersed second solid phase that getters CO2 and SO2 gases that are produced during the anodic reaction. Hence, this invention facilitates near-zero emissions and dramatically reduces the release of environmentally harmful emissions. More importantly, this direct route to electrical energy eliminates Carnot cycle constraints and offers high thermodynamic efficiency.

Owner:DIRECT CARBON TECH

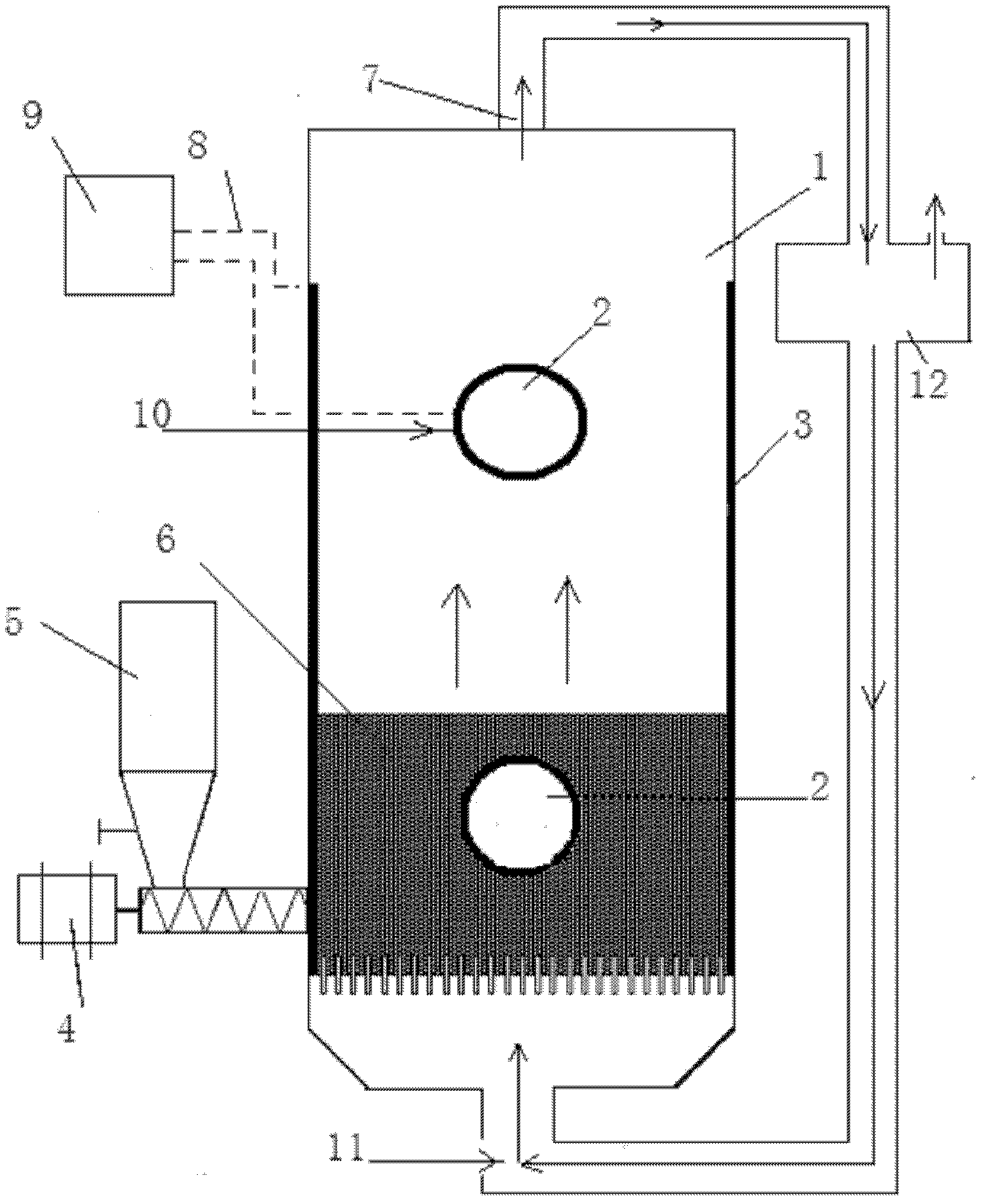

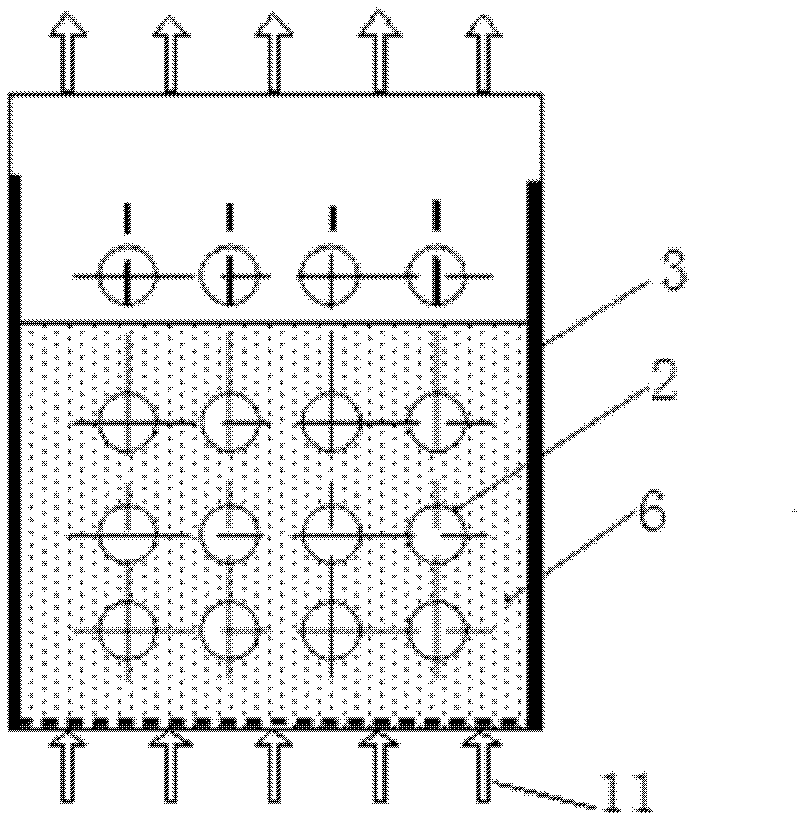

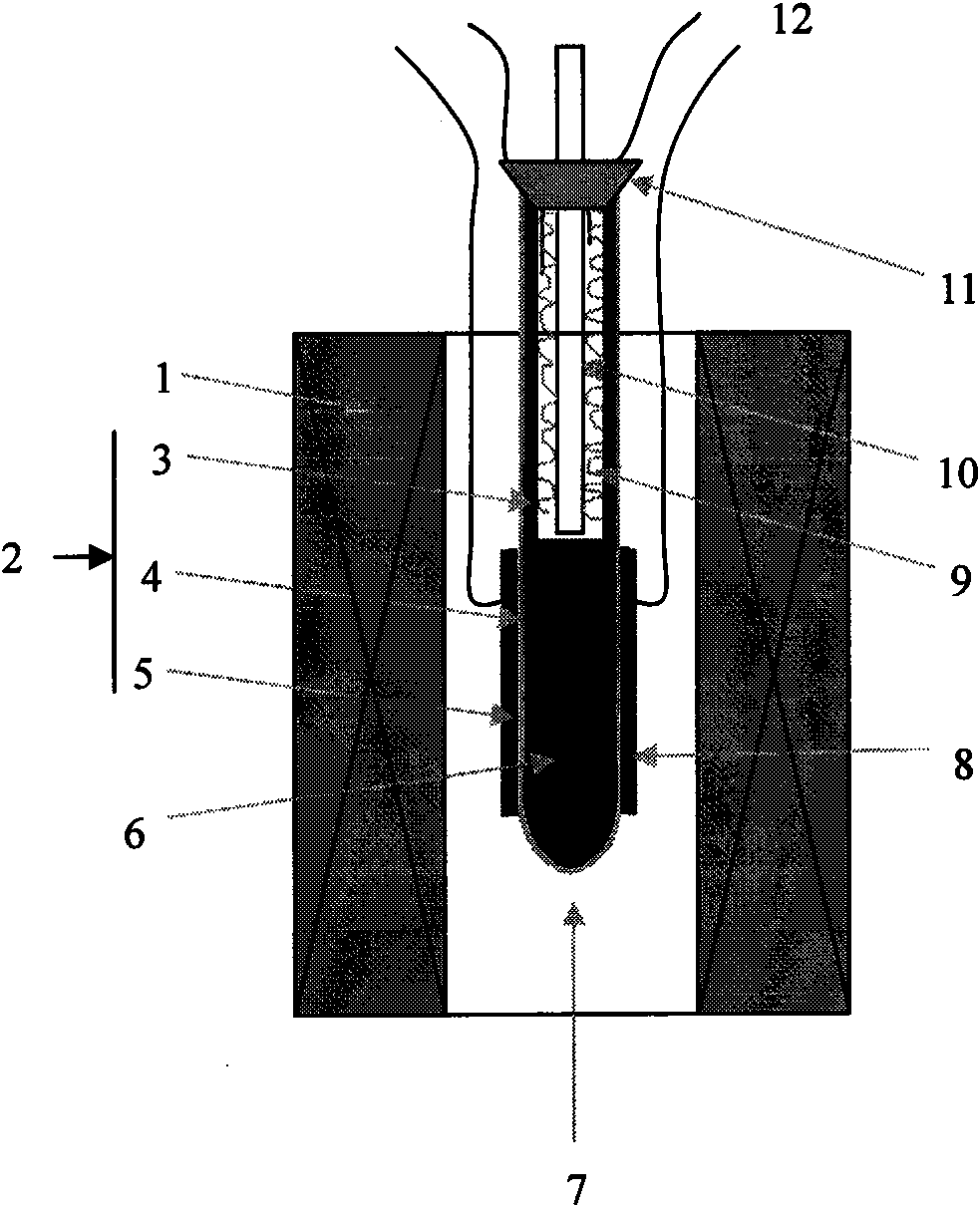

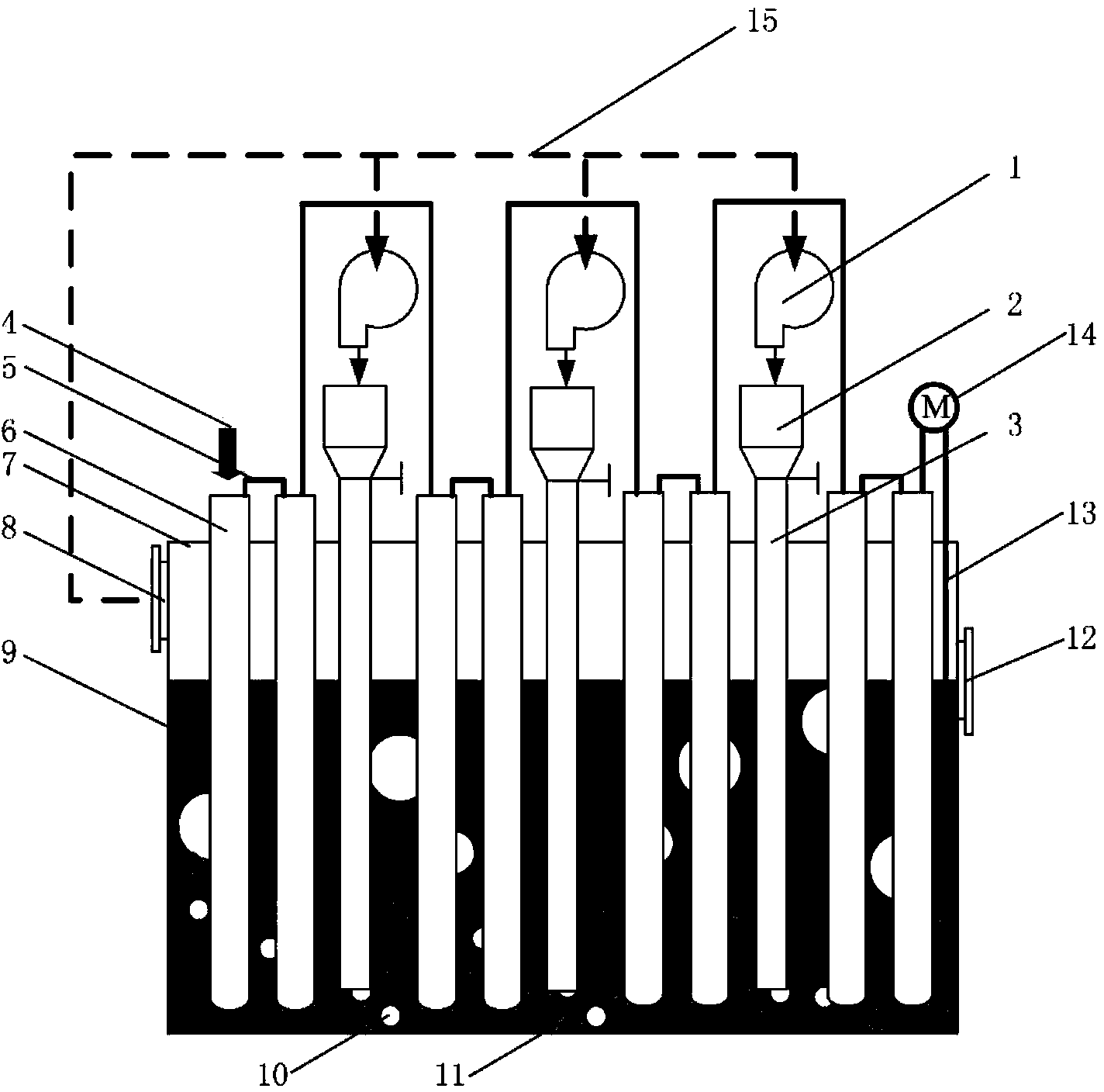

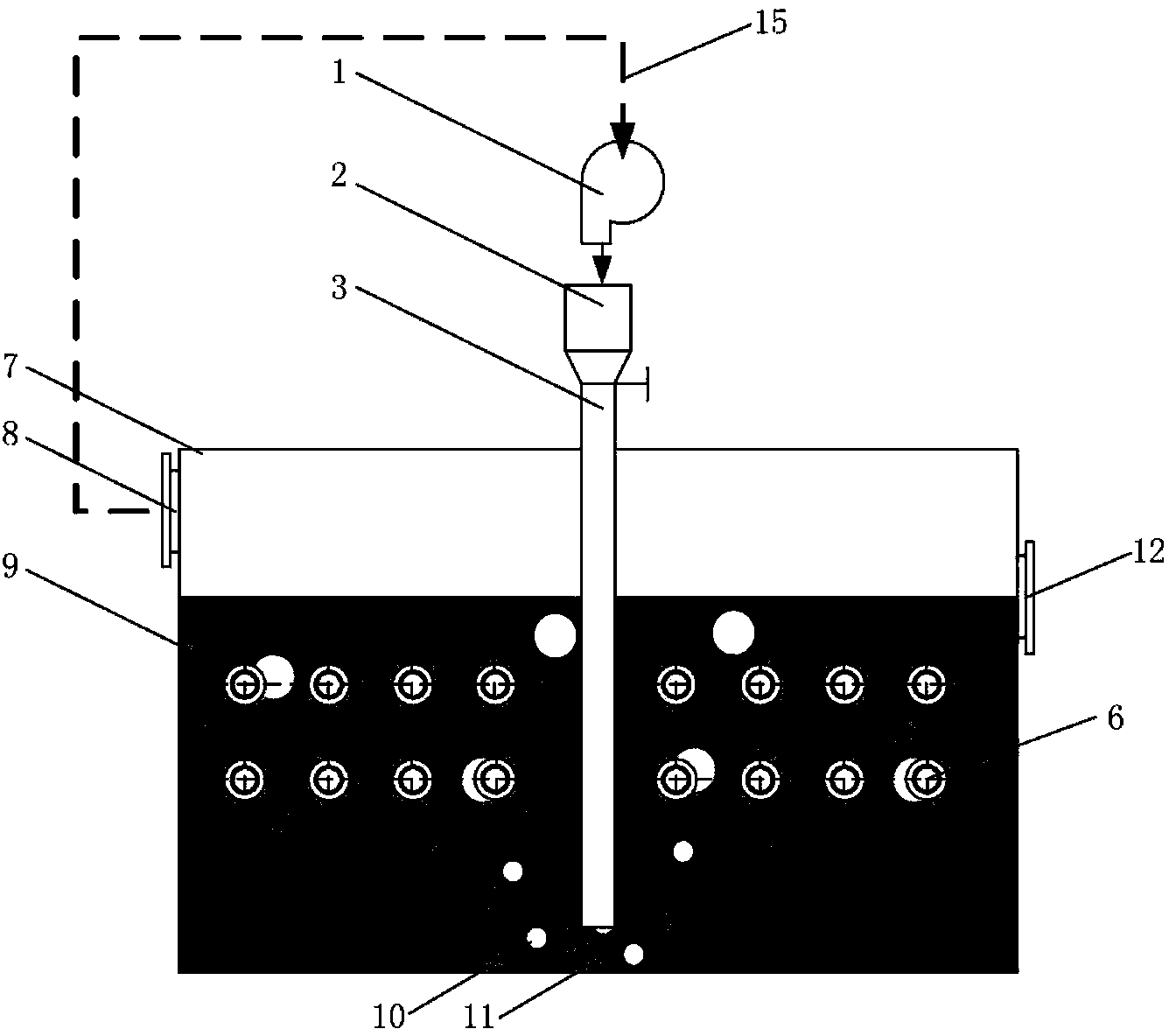

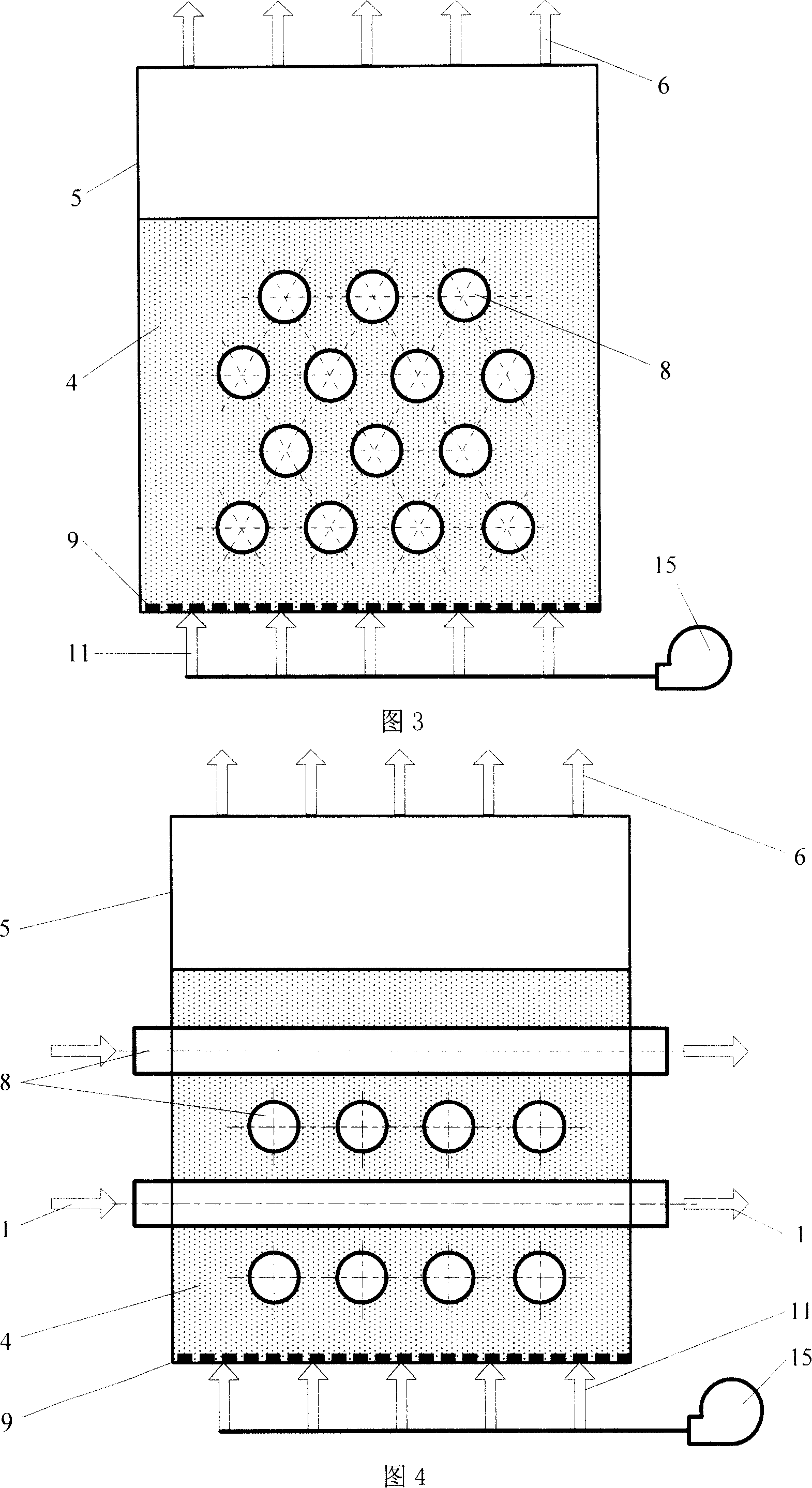

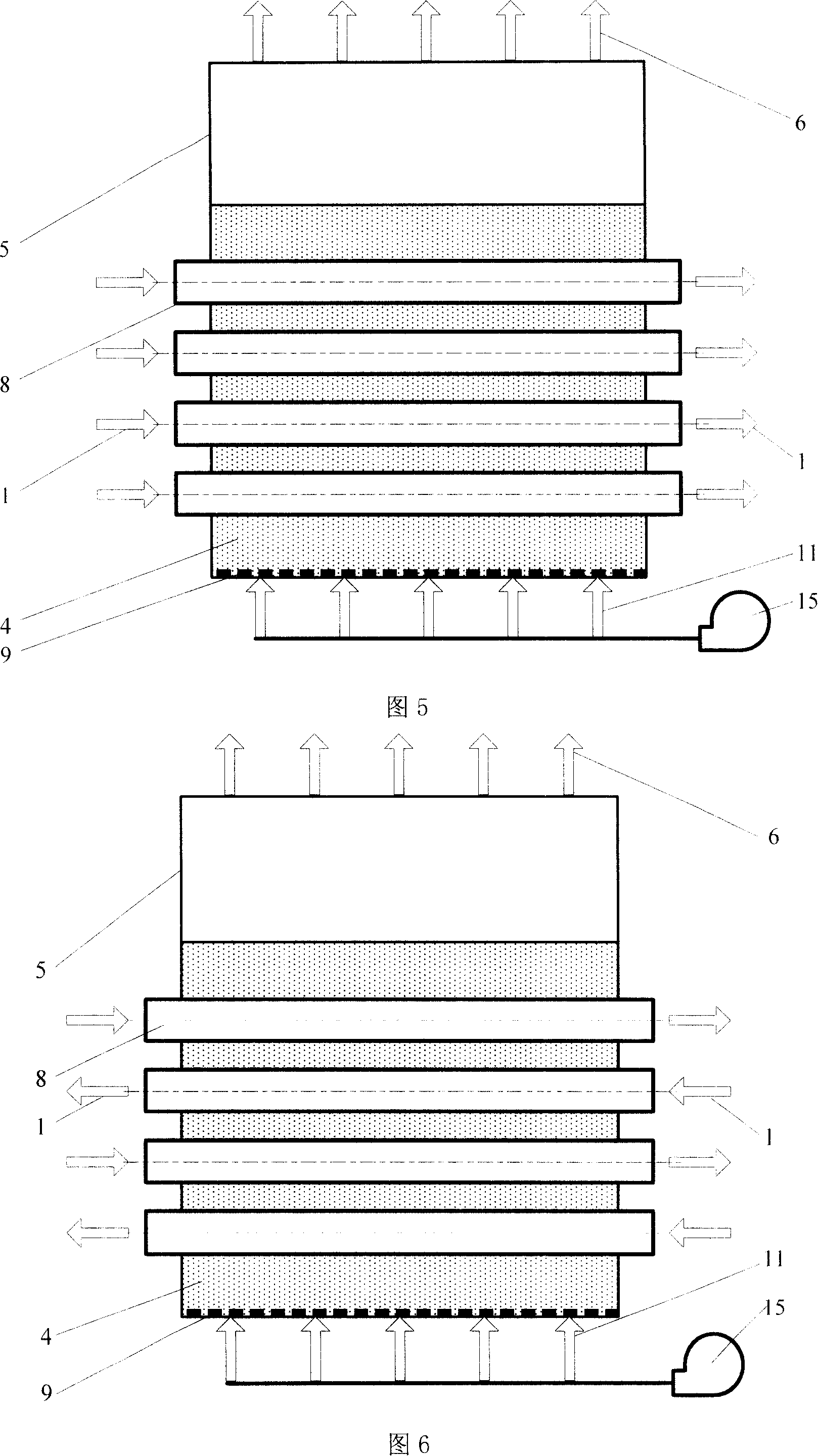

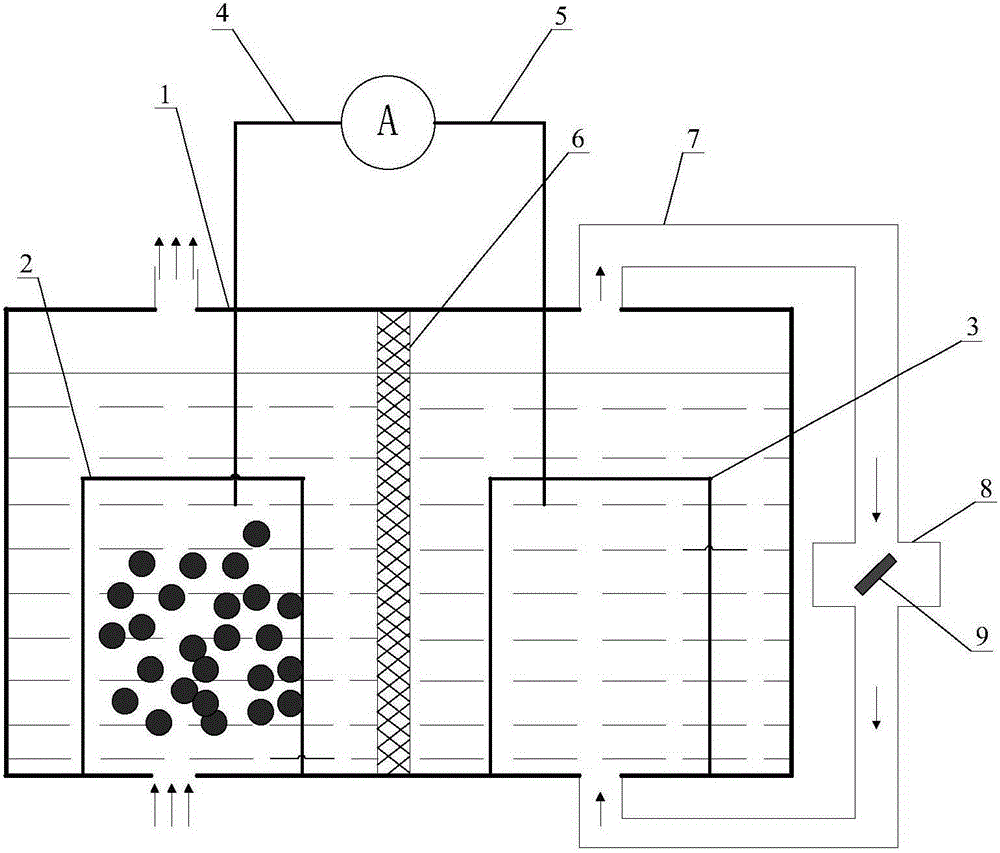

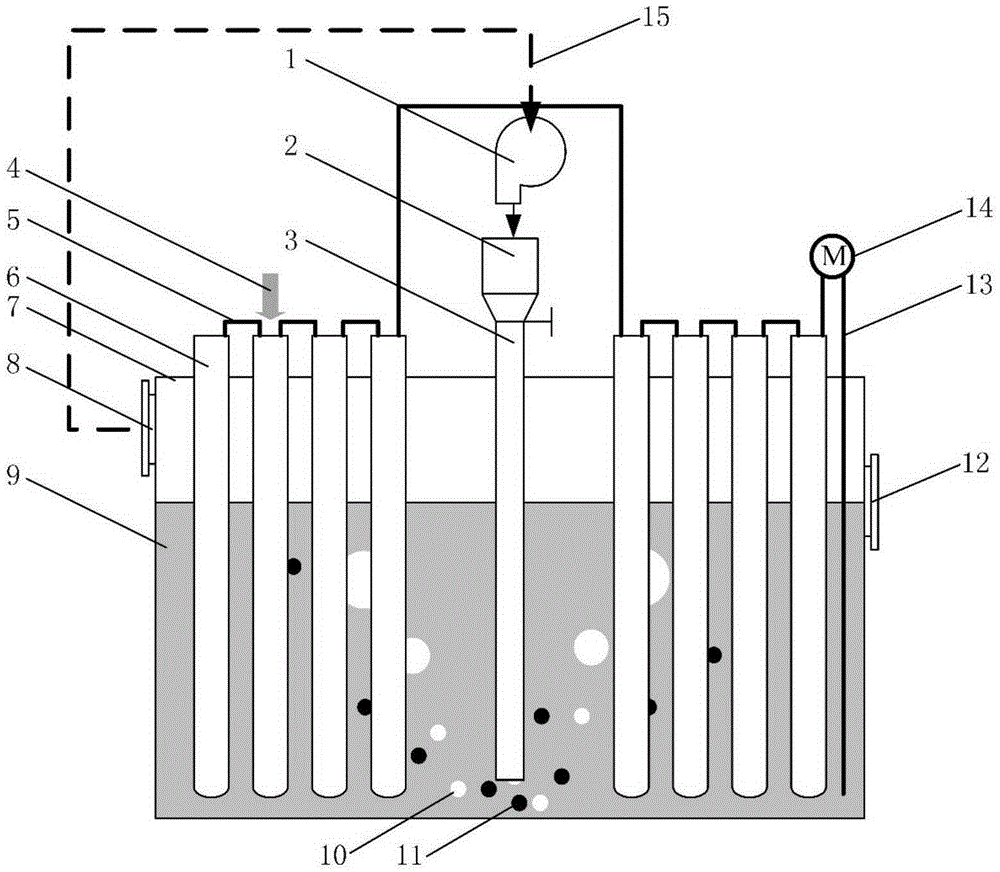

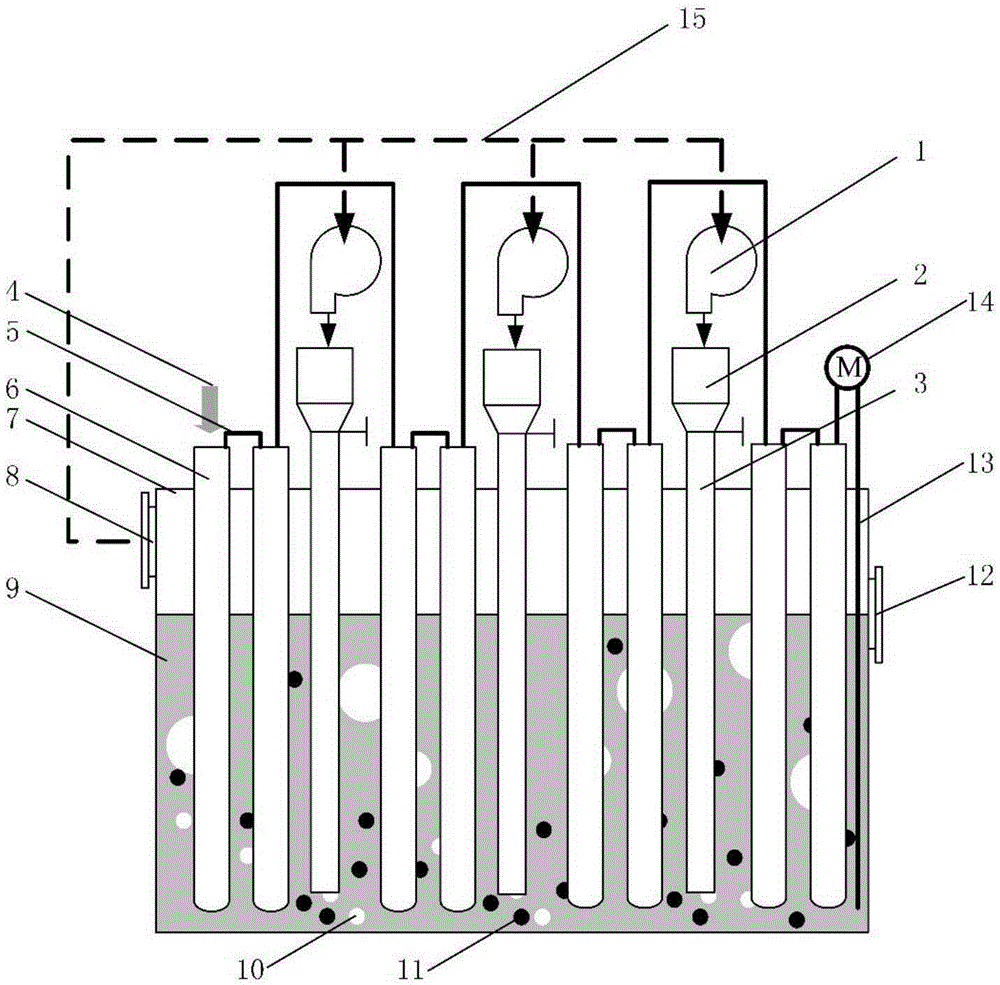

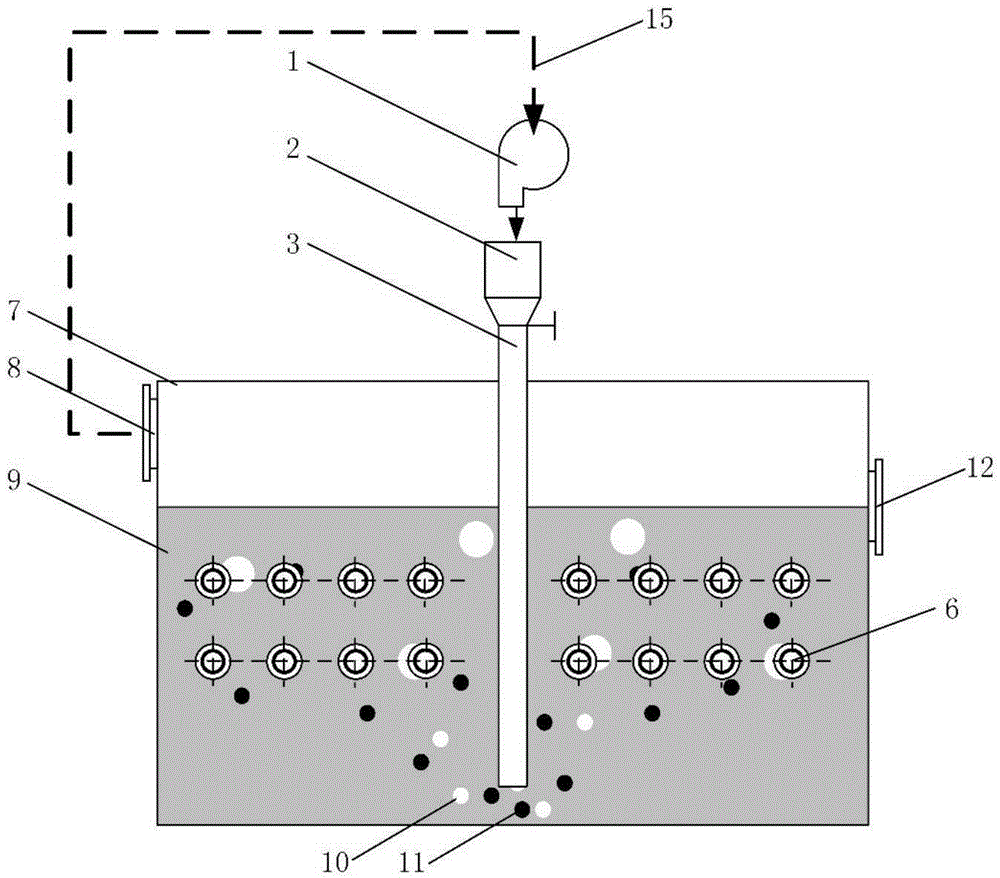

Fluid bed electrode direct carbon fuel cell device

InactiveCN102324539AImprove performanceEasy inflowCell electrodesFuel cell auxillariesElectrochemical responseSolid carbon

The invention discloses a fluid bed electrode direct carbon fuel cell device, which belongs to the technical field of clean energy. The device comprises a fluid bed, two or more tubular single cells, collector plates, a composite carbon fuel, a gas circulating device, a screw feeder and a fuel tank. In the device, a conductor catalyst is added into a solid carbon fuel on the basis of a solid oxide direct carbon fuel cell to expand a direct electrochemical reaction interface of carbon from a two dimension to a three dimension and promote the gasification reaction of the carbon, thereby improving the performance of the cell; the collector plates are distributed on the wall surface of a reactor, so current is convenient to collect; and simultaneously, a fluid bed reactor forms a fluid bed electrode to further enhance heat transfer and mass transfer in the electrode, so not only problems about feeding are solved, but also the performance of the solid oxide direct carbon fuel cell is further improved.

Owner:TSINGHUA UNIV

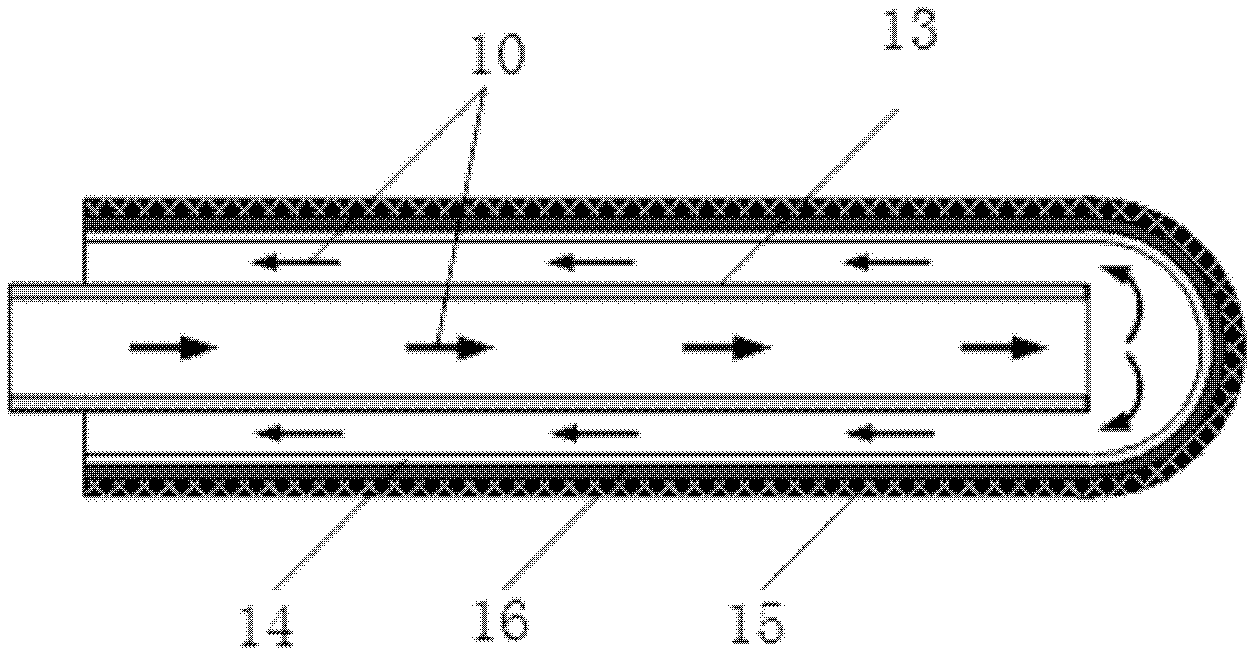

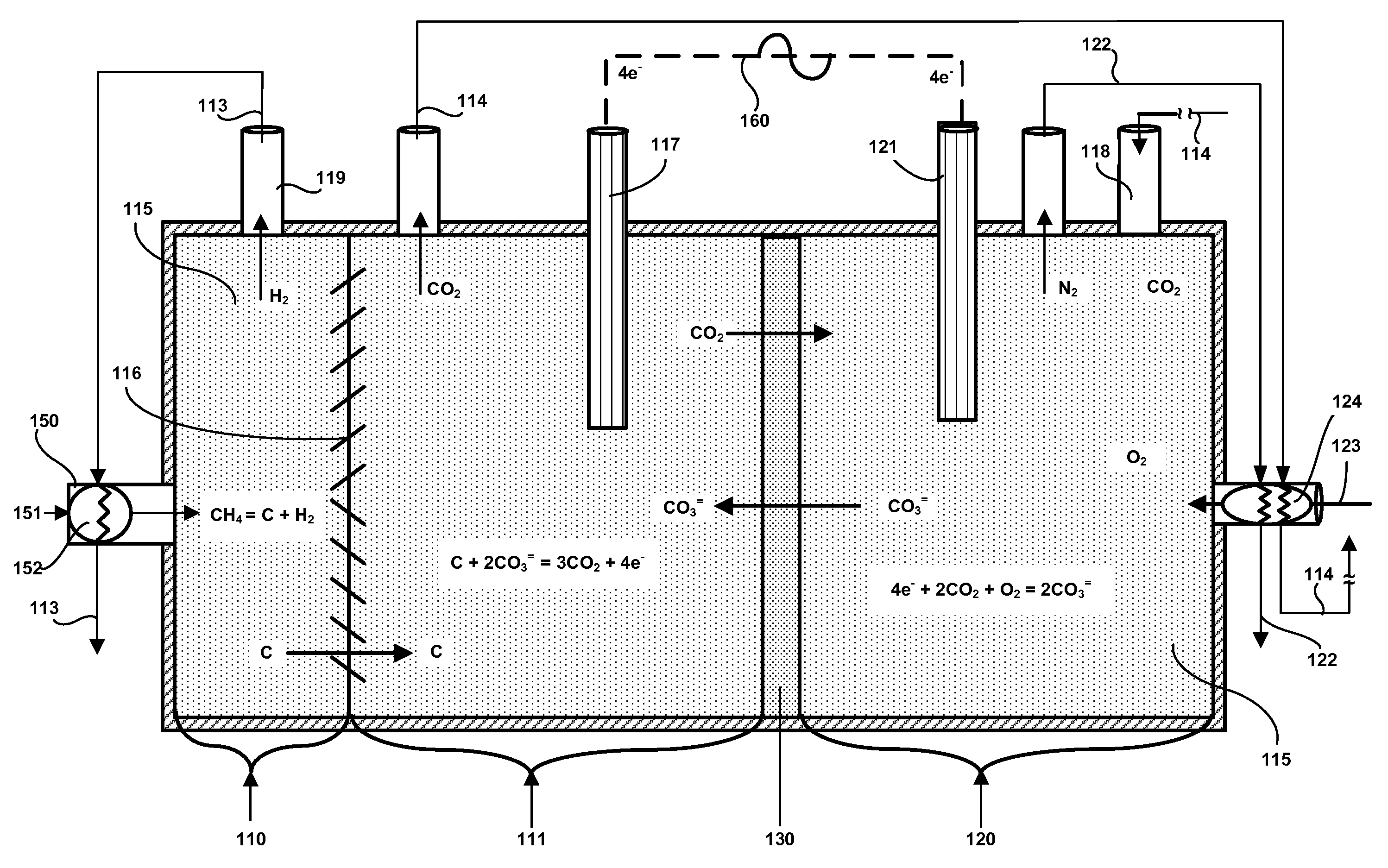

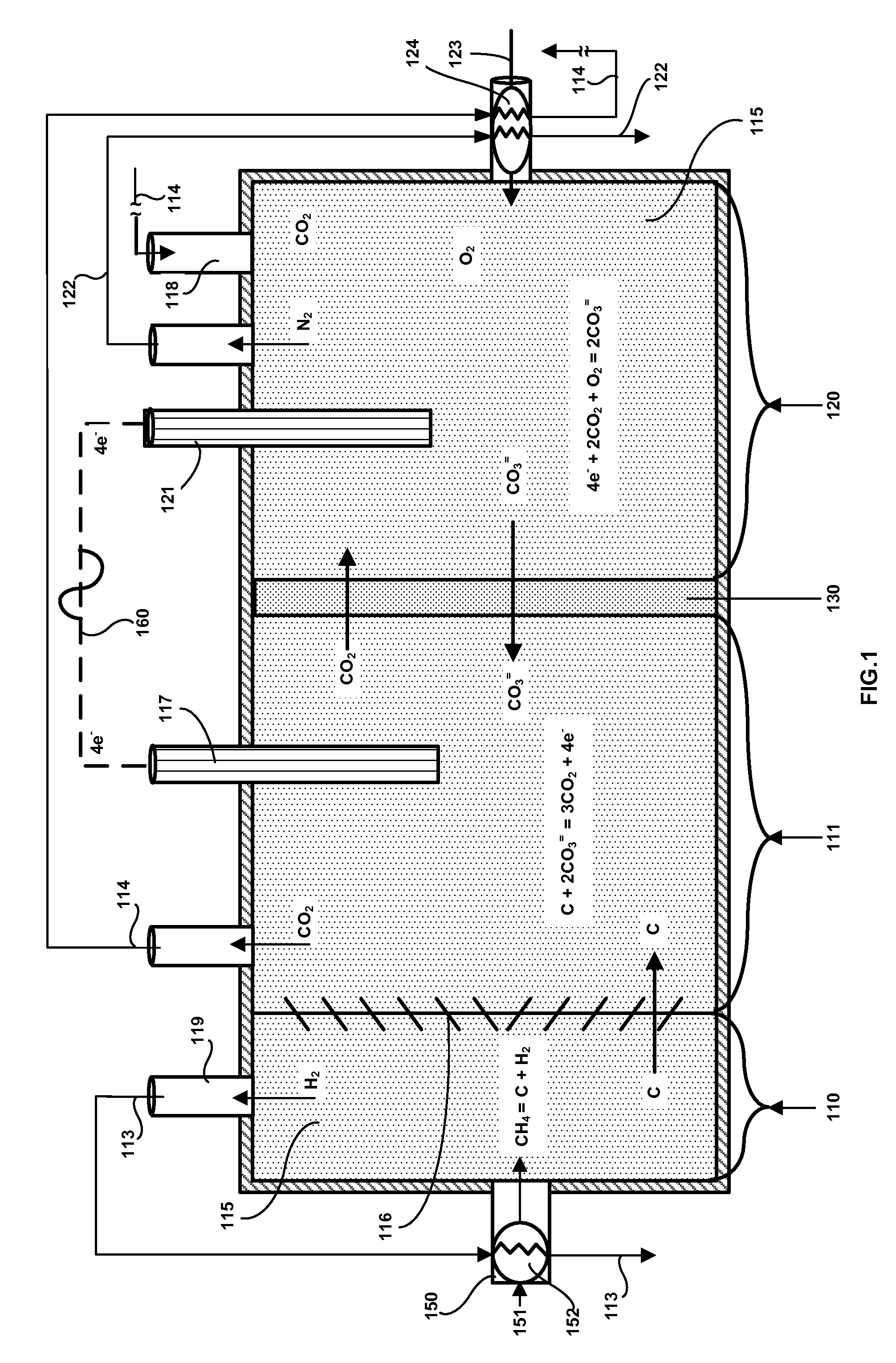

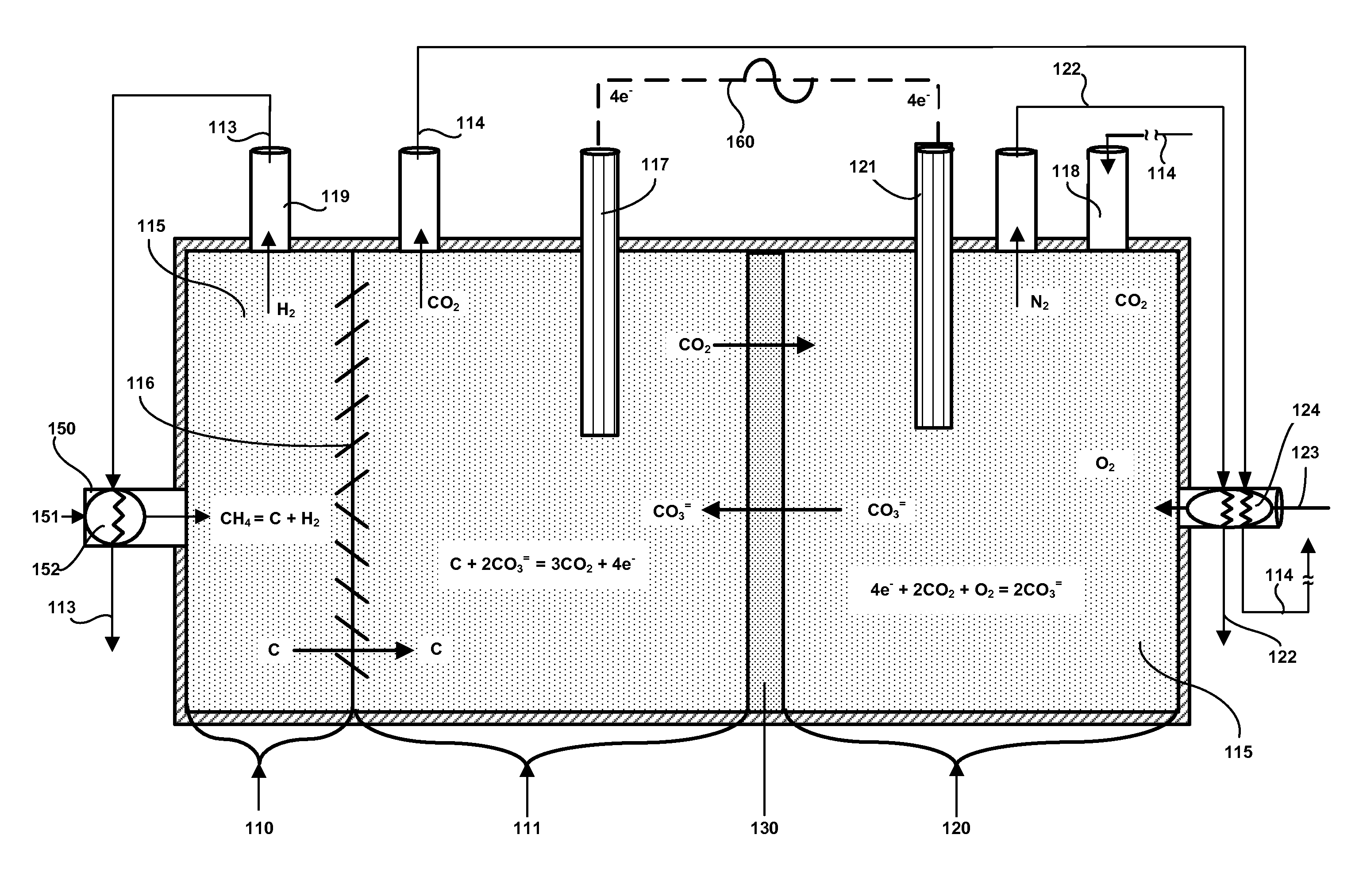

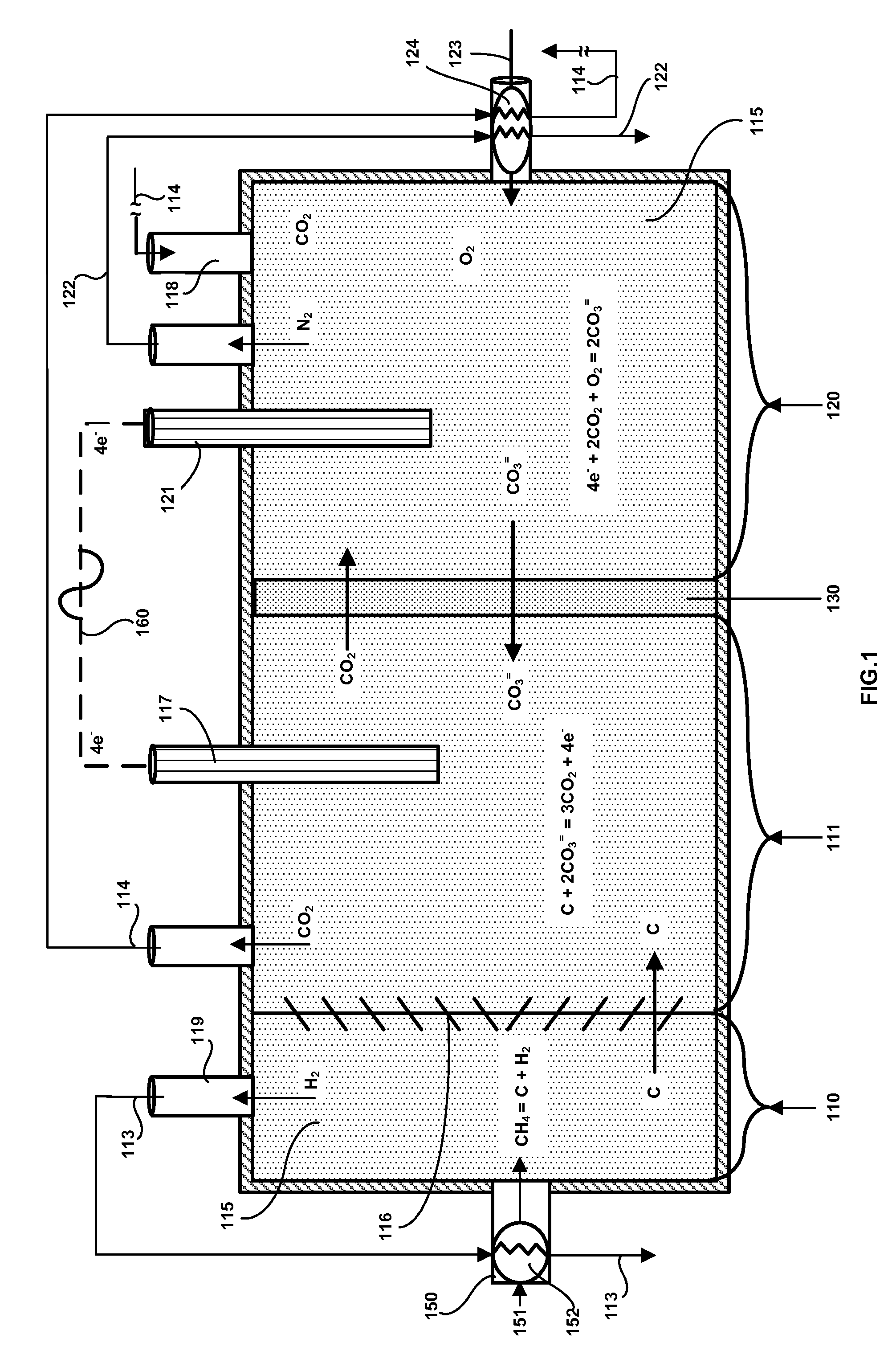

Natural gas direct carbon fuel cell

InactiveUS20090258278A1Improve hydrogen production efficiencyImprove power generation efficiencyFuel cell auxillariesFused electrolyte fuel cellsOxygenDirect carbon fuel cell

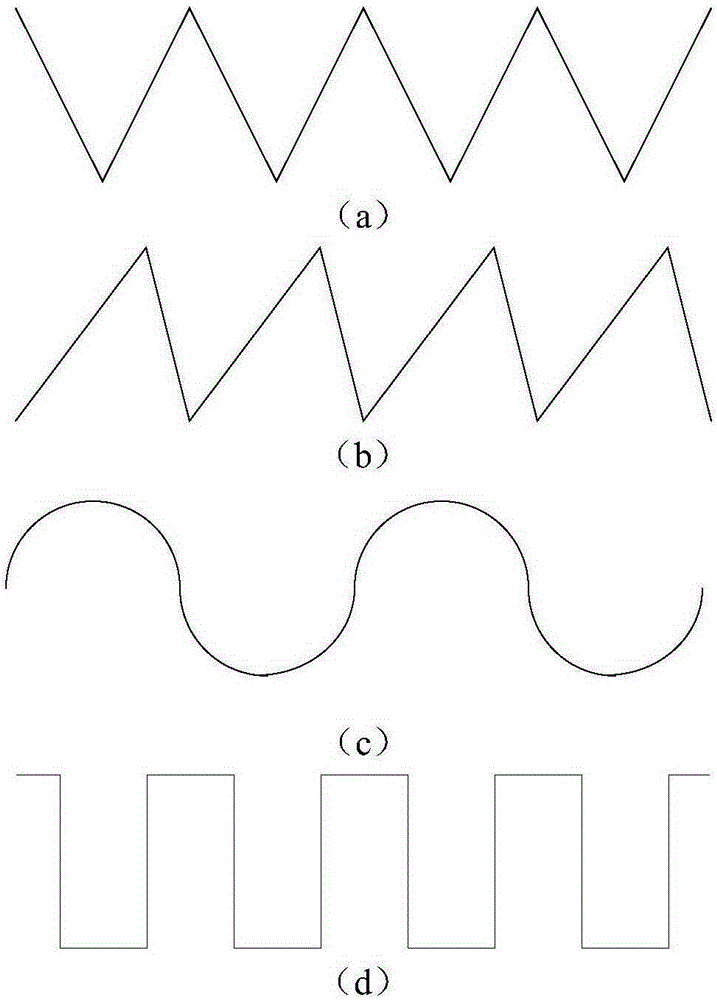

A natural gas fueled, direct carbon fuel cell produces electricity and hydrogen. It adds to an existing direct carbon fuel cell a carbon dioxide injection port to the cathode compartment; a natural gas feed port to the anode compartment, a hydrogen extraction port from the anode compartment, and a carbon dioxide extraction port from the anode compartment. To improve hydrogen generation efficiency, the anode compartment may have a louvered baffle dividing the anode compartment into an ante-chamber and a main chamber. The louvered baffle preferably has an upper section with slats angled from bottom to top and a lower section with slats angled from top to bottom. A heat exchanger is preferably included to pre-heat natural gas feed from hot hydrogen effluent. A second heat exchanger is preferably included to pre-heat oxygen-containing gas with hot nitrogen and carbon dioxide effluents.

Owner:HCE

Solid electrolyte direct carbon fuel cell

InactiveCN101540411AEasy to operateImprove energy efficiencySolid electrolyte fuel cellsElectrochemical responseHigh energy

The invention relates to solid electrolyte direct carbon fuel cell. In the invention, tube-type batteries serve as the electrochemical reaction device, the inner layer of the batteries is anode, the intermediate layer is the electrolyte and the outer layer is cathode, carbon fuel is filled in the tube-type batteries. The carbon fuel cell of the invention features high energy efficiency, sound environmental protection property, a theoretic efficiency being 2-3 times of the generating efficiency of the existing coal power plants, reduction of discharge of greenhouse gas CO2, no generation of acidic gases such as nitrogen oxide and sulfide, no possible danger of liquid leakage and gas explosion and fine electrochemistry property.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

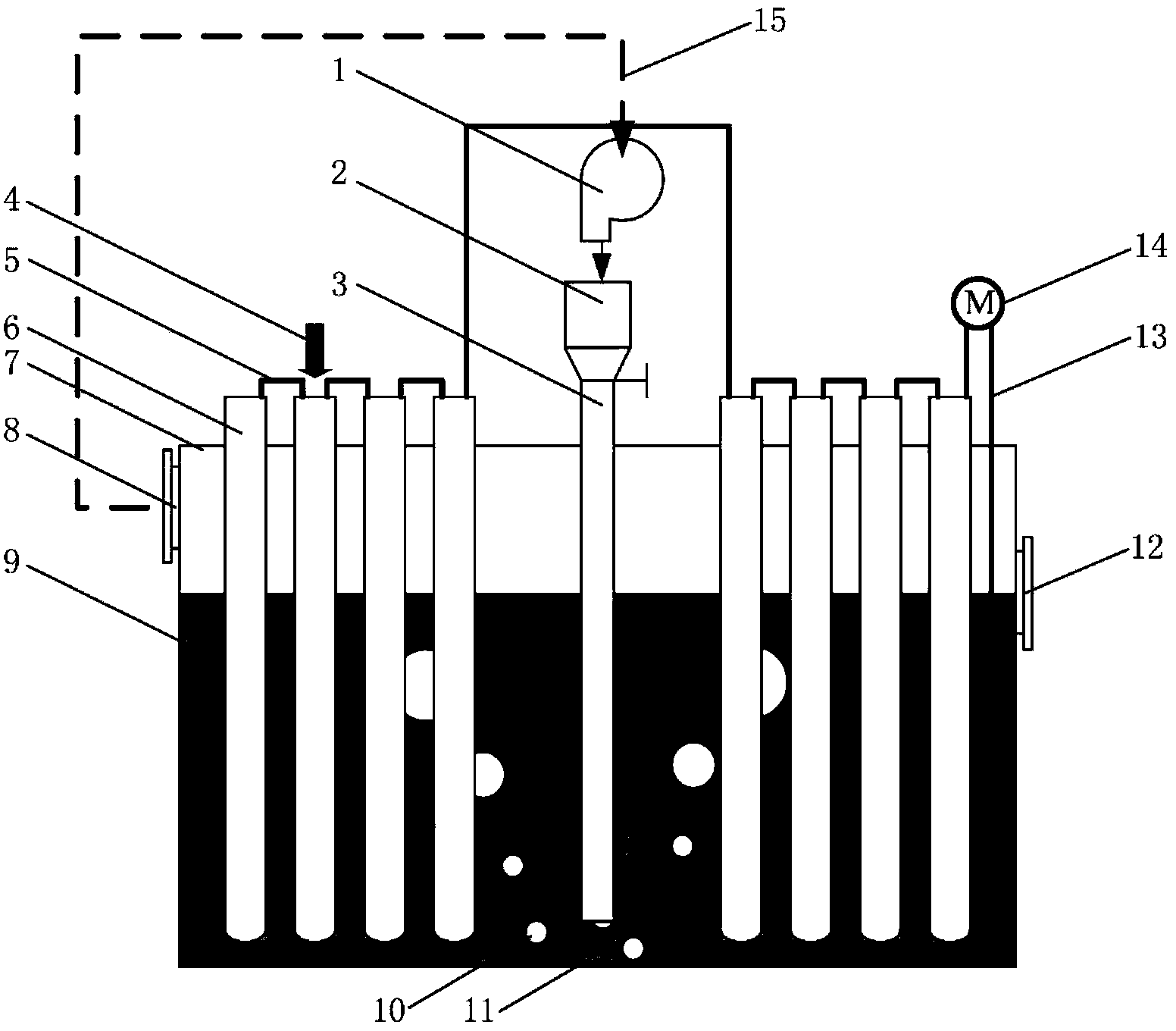

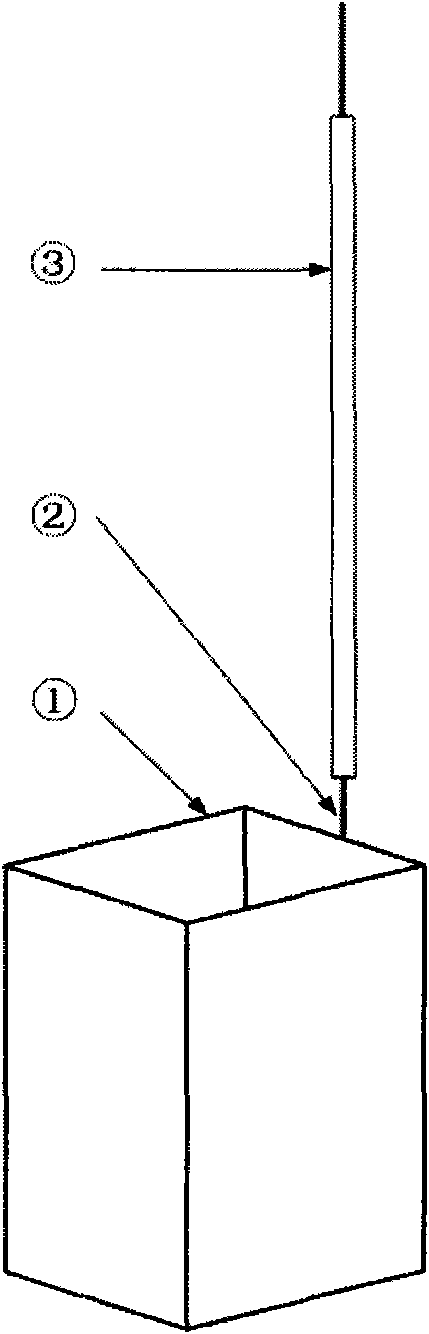

Generating and energy storage integrated device based on direct carbon fuel cells (DCFCs) with liquid metal positive electrode

ActiveCN103972526AMeet peak shaving needsGuaranteed power supplyReactant parameters controlCell electrodesElectrical batteryEngineering

The invention belongs to the field of fuel cells, and particularly relates to a generating and energy storage integrated device based on direct carbon fuel cells (DCFCs) with a liquid metal positive electrode. The generating and energy storage integrated device comprises a metal molten pool, the liquid metal positive electrode, the tubular solid oxide direct carbon fuel cells (SO-DCFCs) and a fluidization air distributing feeding system, wherein the tubular SO-DCFCs can be blind pipes and through pipes and can be inserted into the metal molten pool vertically or horizontally; the feeding system carries a fuel and a positive electrode material into the metal molten pool by virtue of carrier gas, and substances in the molten pool are stirred. The generating and energy storage integrated device provided by the invention has the advantages that chemical energy in the fuel and surplus electric energy in an power grid are changed into chemical energy in the liquid metal positive electrode to be stored, and the integration of a generating device and an energy storage device is realized; the integrated device is simple and compact, the reactivity of the carbon fuel and the metal positive electrode is high, the property of the cell is good, the friction of the cell caused by liquid state positive electrode fluidization is small, the service life of the cell is long, the seal is easy, the collection is convenient, and a large-scale electric pile is convenient to form.

Owner:TSINGHUA UNIV

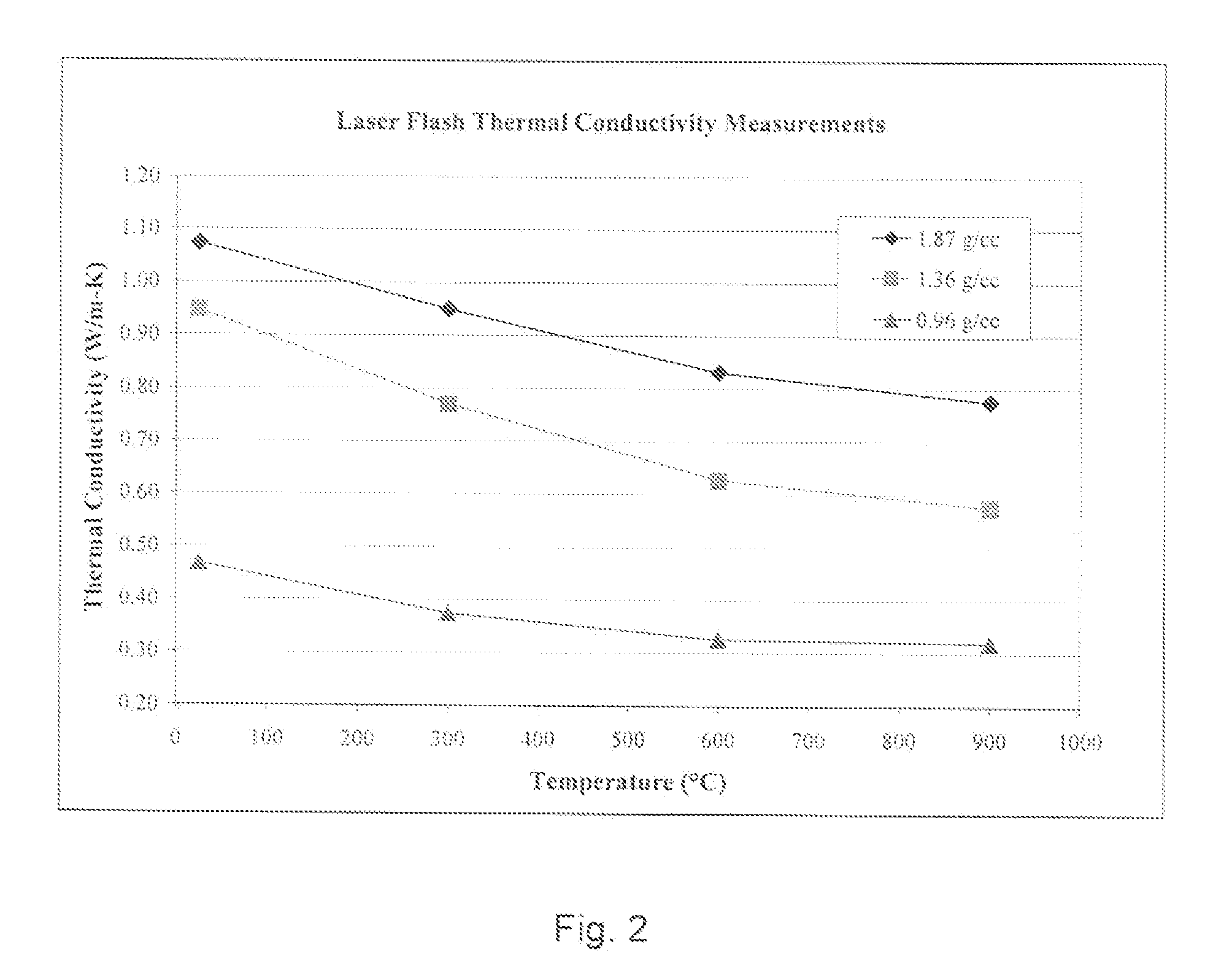

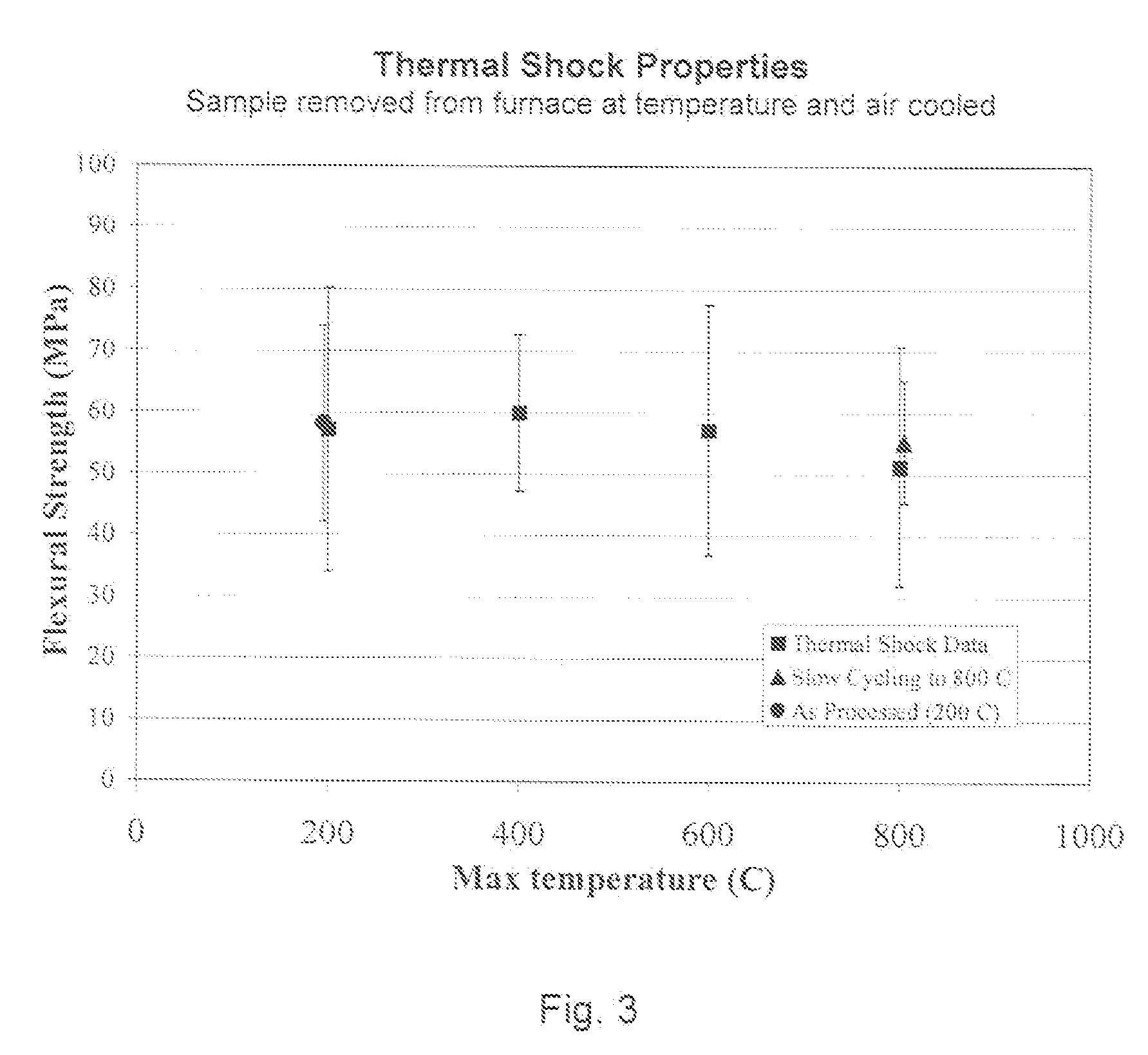

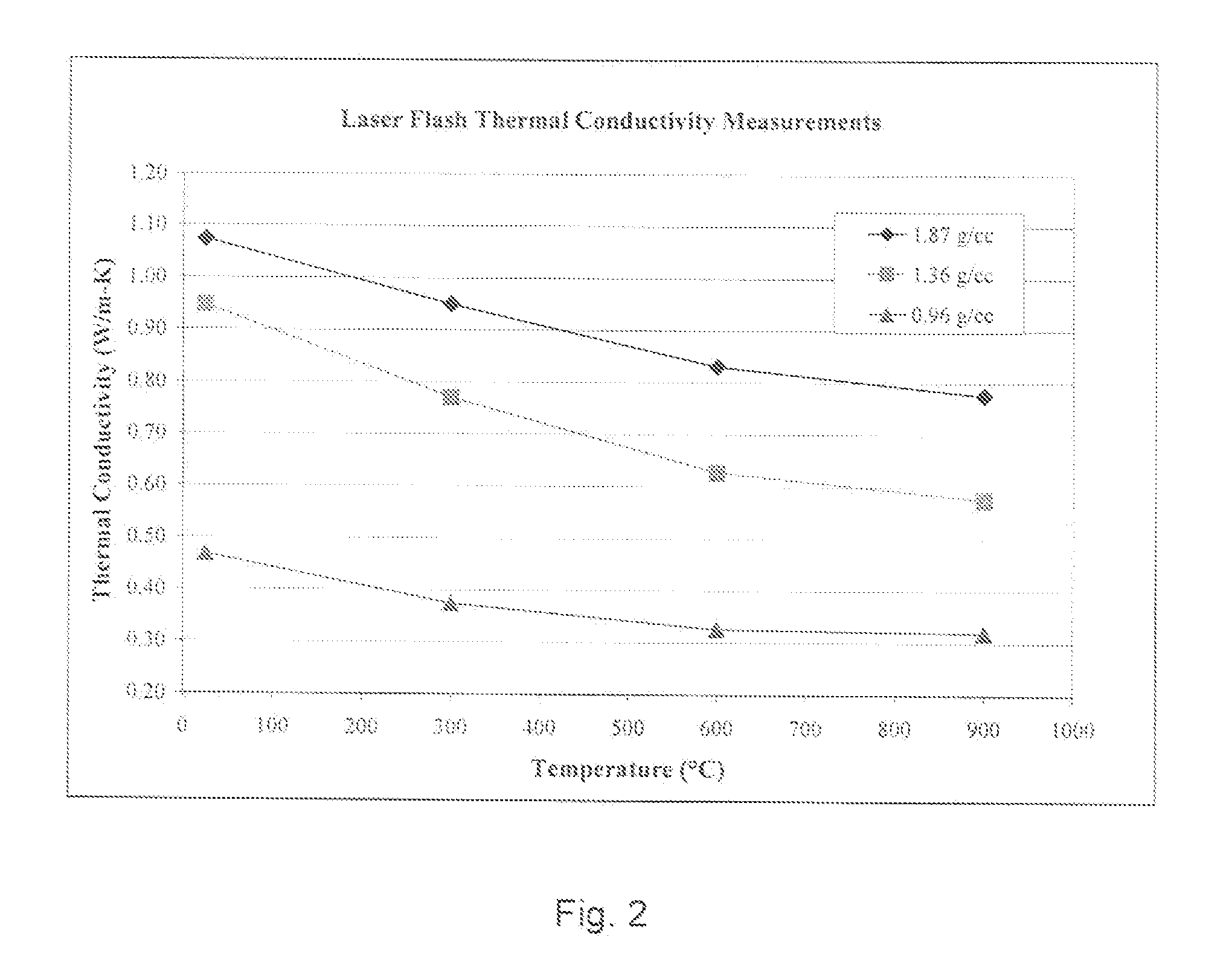

Process for making ceramic insulation

InactiveUS20090295045A1Low costImprove performanceFinal product manufactureCeramic shaping apparatusPorosityFuel cells

A method is provided for producing insulation materials and insulation for high temperature applications using novel castable and powder-based ceramics. The ceramic components produced using the proposed process offers (i) a fine porosity (from nano-to micro scale); (ii) a superior strength-to-weight ratio; and (iii) flexibility in designing multilayered features offering multifunctionality which will increase the service lifetime of insulation and refractory components used in the solid oxide fuel cell, direct carbon fuel cell, furnace, metal melting, glass, chemical, paper / pulp, automobile, industrial heating, coal, and power generation industries. Further, the ceramic components made using this method may have net-shape and / or net-size advantages with minimum post machining requirements.

Owner:CERAMTEC

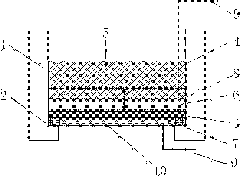

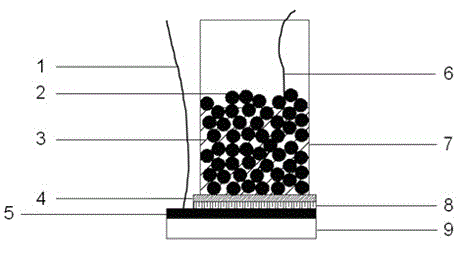

A cathode-supported direct carbon fuel cell

ActiveCN102290589ASimple structureImprove energy efficiencyElectrolyte holding meansFused electrolyte fuel cellsSolid carbonHigh energy

The invention discloses a cathode-supported direct carbon fuel cell, which comprises a fuel bin, an anode side collector layer, an anode layer, an electrolyte layer, a cathode active layer, a cathode-supporting layer, a cathode side collector layer, a carbon fuel layer, a porous ceramic layer, a carbon fuel input tube, a carrier gas intake tube, a carrier gas output tube and an oxygen or air intake tube, a cell is arranged in the fuel bin, the anode side collector layer, the anode layer, the electrolyte layer, the cathode active layer, the cathode-supporting layer and the cathode side collector layer are arranged sequentially from the outside to the inside, and moreover, the anode side collector layer, the carbon fuel layer and the porous ceramic layer are superposed in the fuel bin sequentially from the top down. Since the cell is a cathode-supported cell which directly utilizes solid carbon as fuel and the outside of the cell is provided with the fuel input tube, the cell has the advantages of simple structure, high energy efficiency, environment-friendliness, no leakage, corrosion and explosion dangers and the like, can realize the continuous feeding of fuel and the diversity of the fuel electrode, and is convenient and easy to operate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

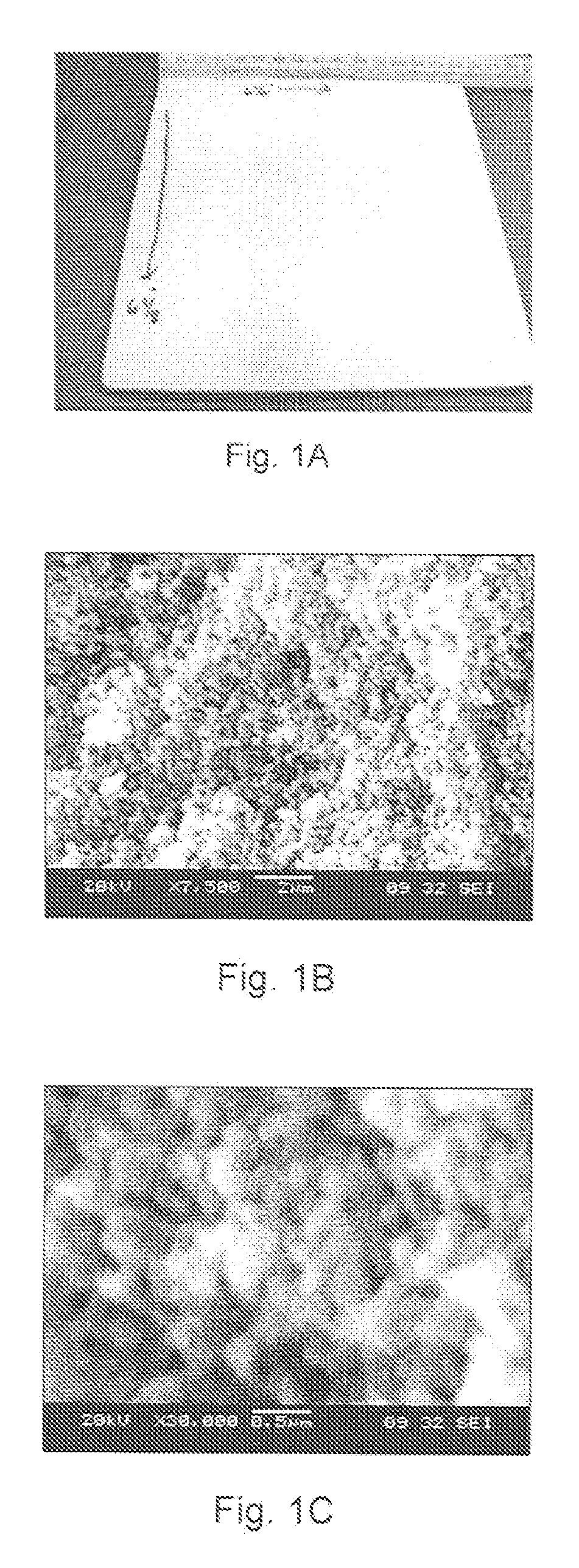

Multi-functional cermet anodes for high temperature fuel cells

An anode in a Direct Carbon Fuel Cell (DCFC) is provided. The anode includes a cermet anode that can be made of nickel-copper / yttria-stabilized zirconia oxide (Ni—Cu / YSZ) or nickel-copper / gadolina-doped ceria (Ni—Cu / GDC). The surface of the cermet anode is functionalized by decorating it with dispersed catalytic particles. The particles can be made of various materials such as ruthenium (Ru), rhodium (Rh), palladium (Pd), rhenium (Re), osmium, (Os), iridium (Ir), platinum (Pt), gold (Au), or any combination of the particles' alloys and mixtures. Decorating is a process where discrete particles are deposited to the anode surface. In general the particles are not able to contact each other and have a well-defined separation. The cermet anode has a graded porous microstructure spanning from a macropore outer region to a submicron inner region, where the pore span is from tens of microns to hundreds of nanometers.

Owner:DIRECT CARBON TECH

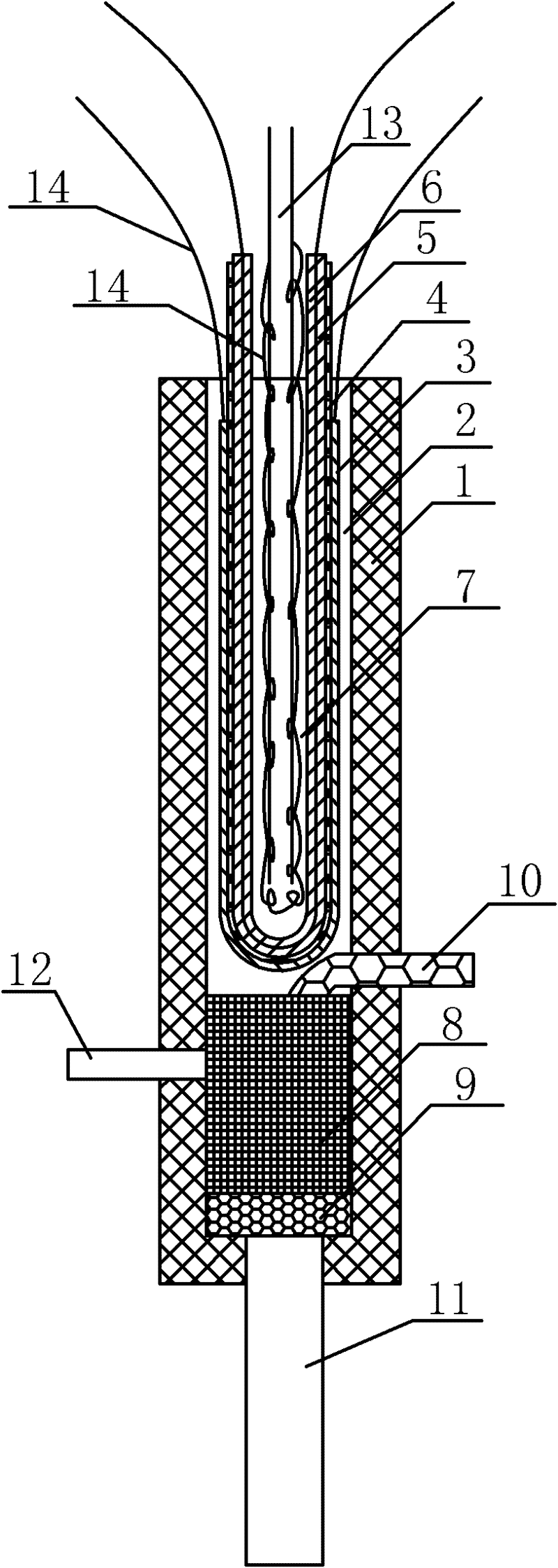

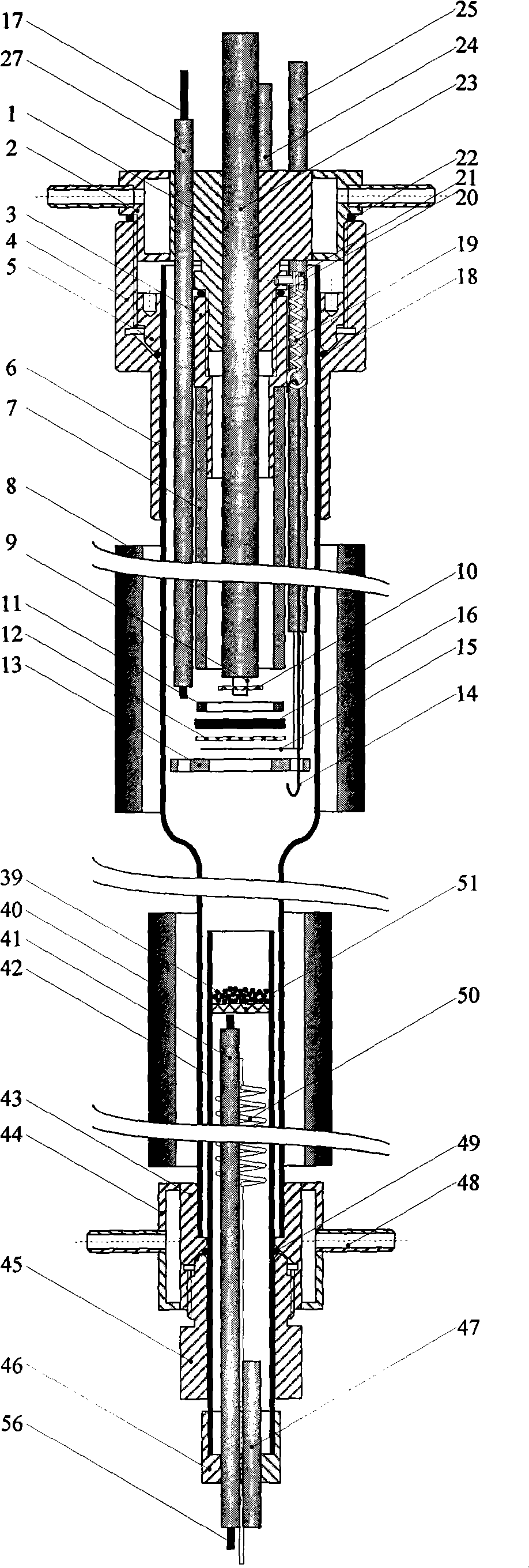

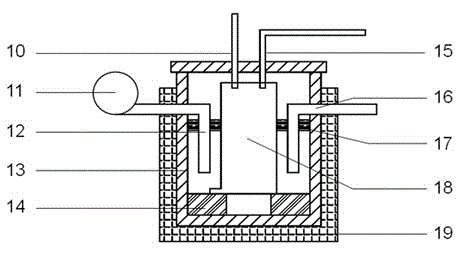

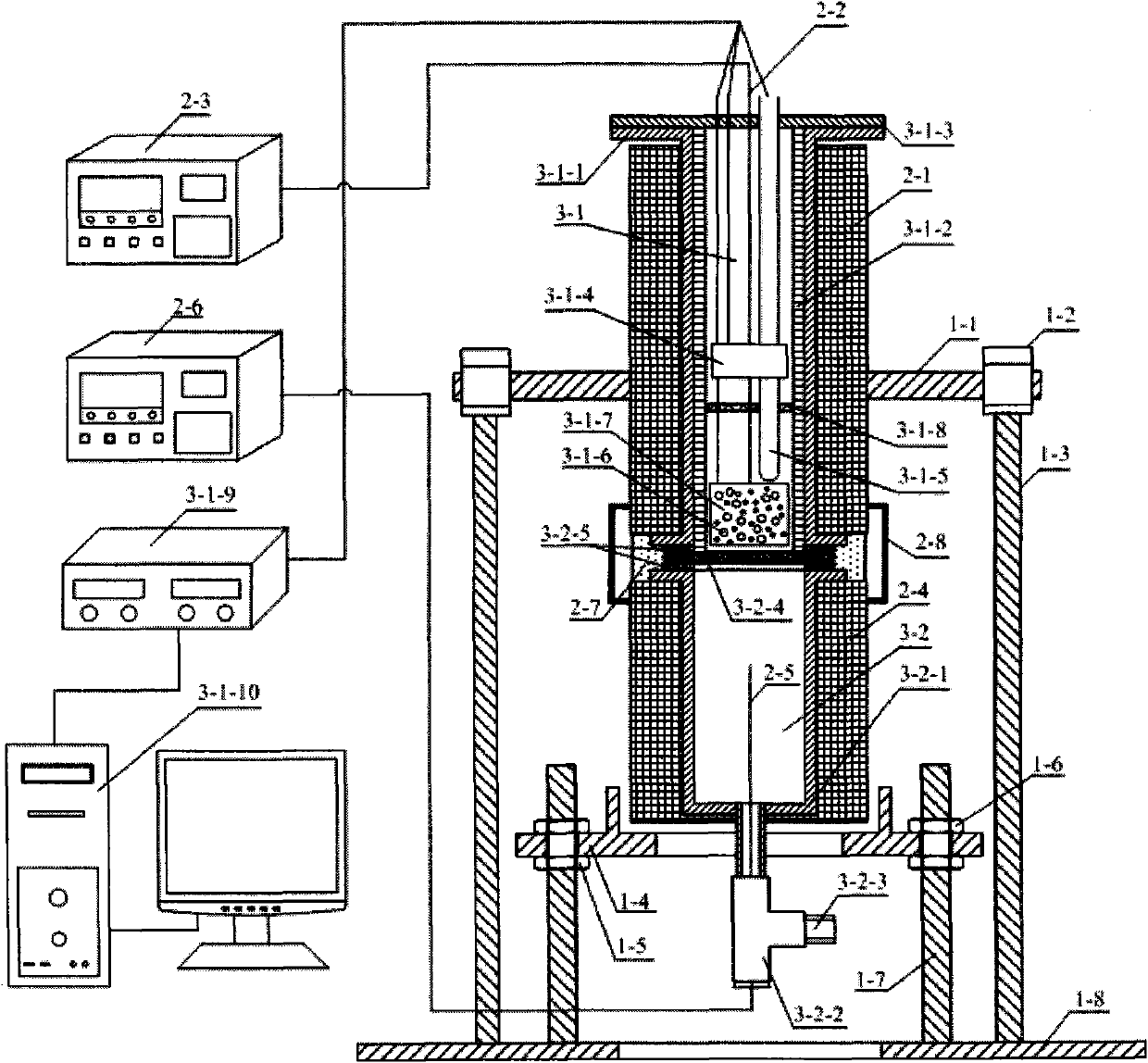

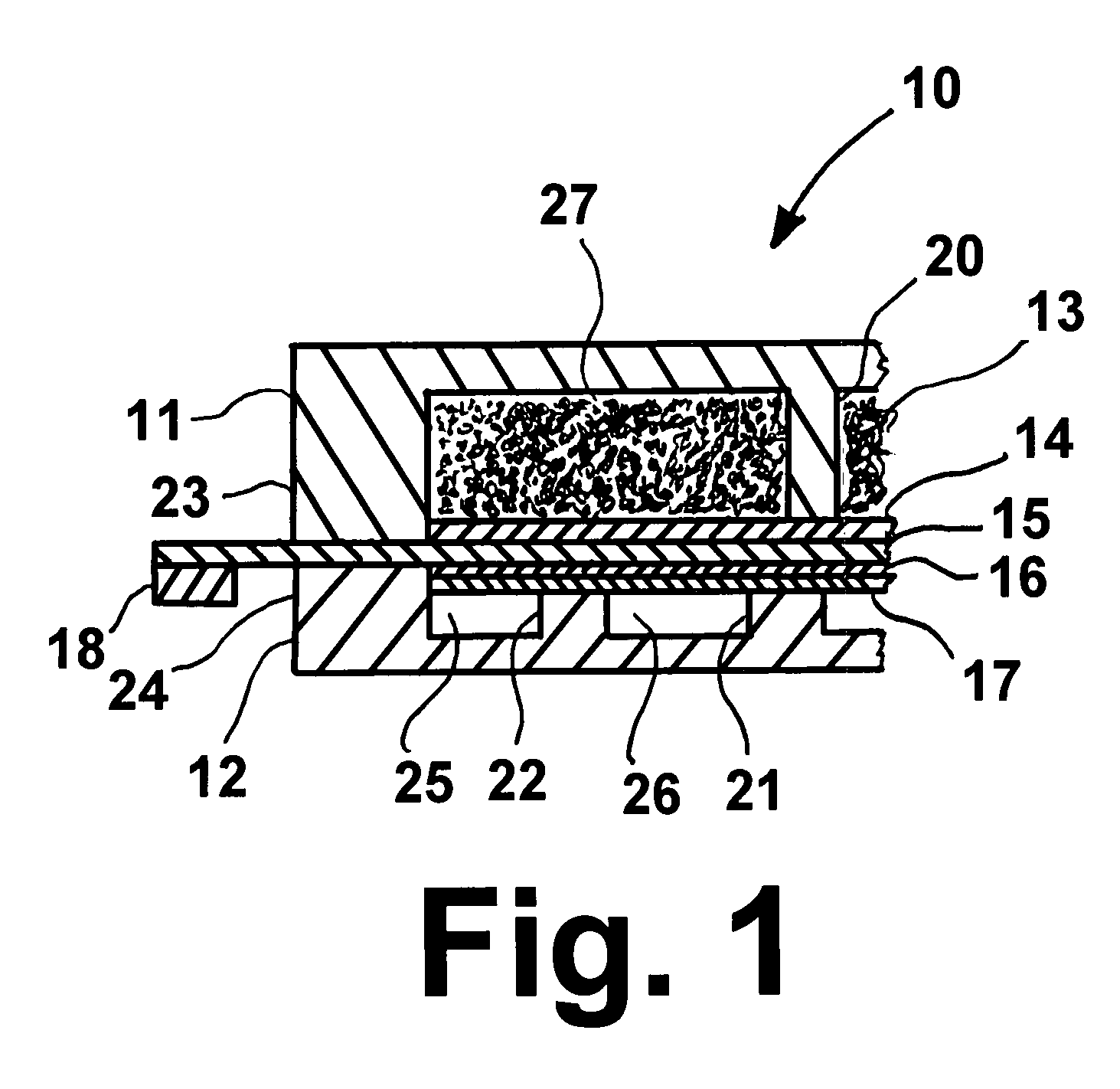

Direct carbon fuel cell reaction device

ActiveCN101345315AImprove performanceSolve adding waterFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsEngineering

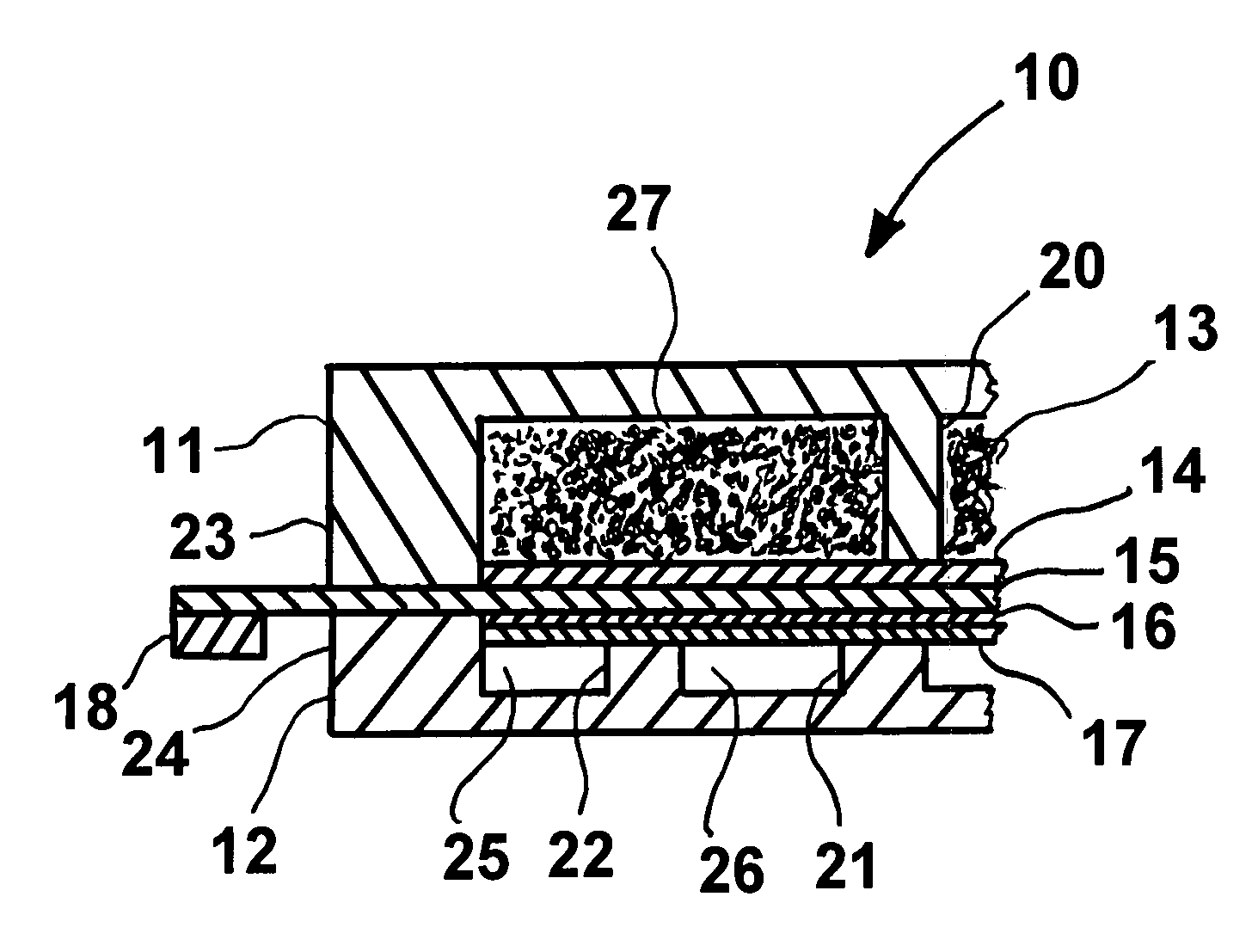

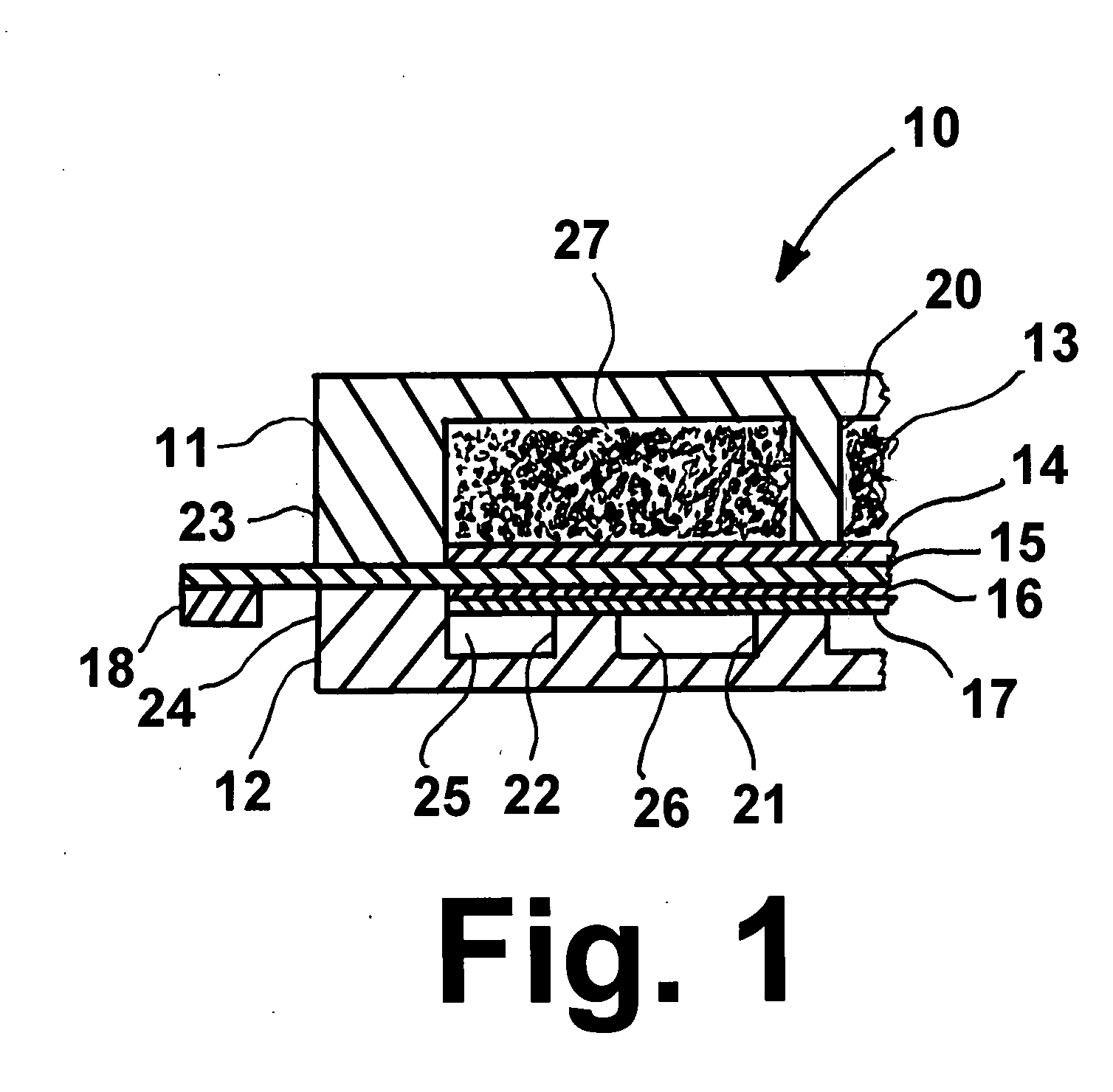

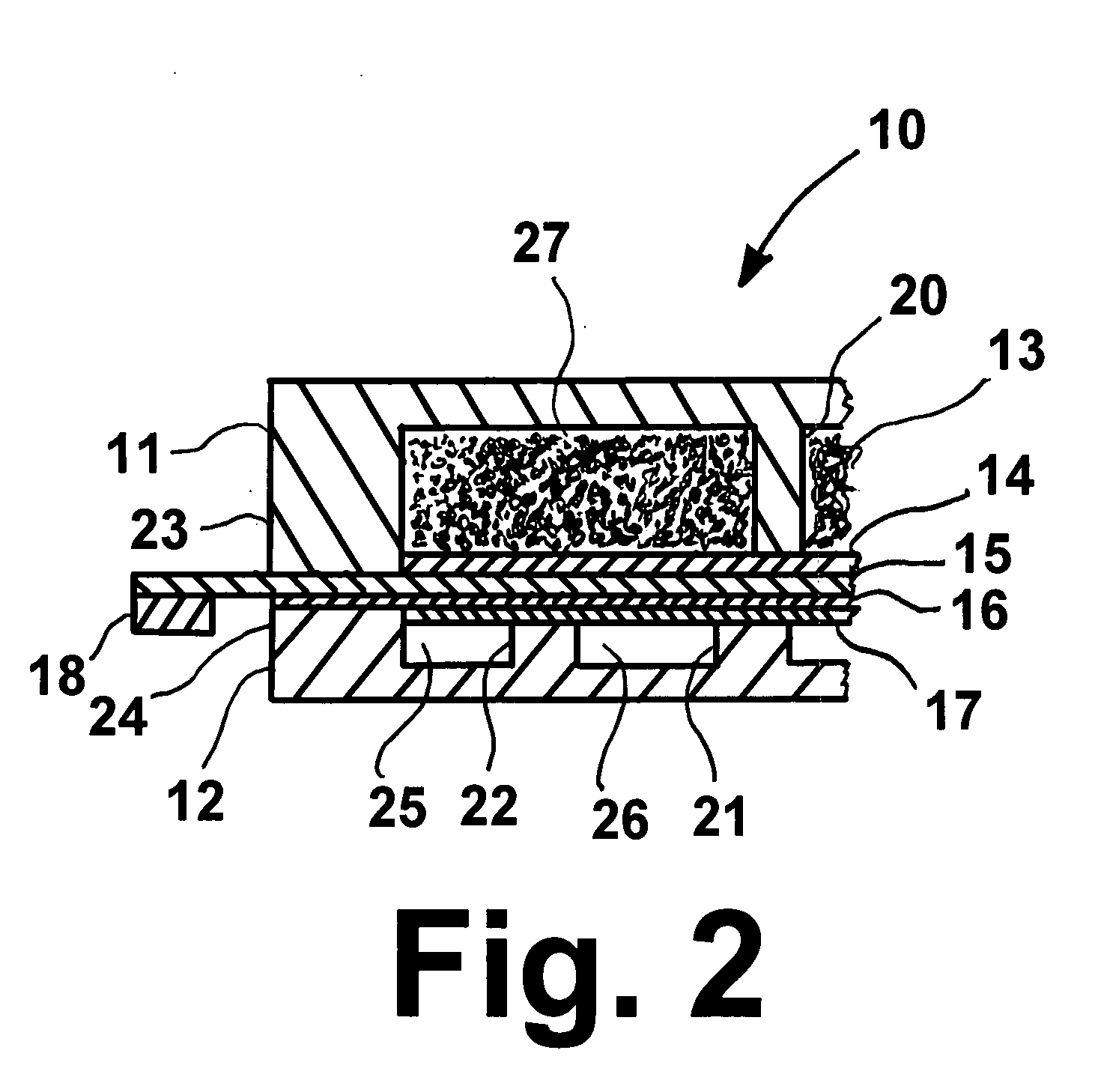

The invention provides a direct carbon fuel battery reaction device, belonging to the field of direct carbon fuel battery technique. An upper base (1) of the reaction device is coaxially arranged into a water cooling sleeve (2); the connection of the upper base and the water cooling sleeve is welded and sealed to form a water cooling chamber; an anode current collecting Pt net (12) is used for collecting current from the anode of a button-typed solid oxide fuel battery (16); two ends of an anode current collecting Pt wire (15) are respectively used as an reference electrode and a testing electrode; the temperature measuring point of a temperature measuring thermal-couple (17) and the button-typed solid oxide fuel battery (16) keep in the same height; the bottom of an anode chamber pipe (6) is inserted into the upper hole of a lower base (43); the lower surface of a quartz sand sintering plate (42) is provided with a carbon fuel thermal-couple (56); all pipes and sealing heads (46) are hermetically connected with each other. The direct carbon fuel battery reaction device of the invention solves the problem of water adding of anode chamber and the arranging of carbon fuel, realizes that the temperatures required by the running of fuel battery and the reacting of the carbon fuel are respectively controlled, avoids complex disassembly / assembly process and personnel scald, prevents the sealing invalidity and reduces the cost.

Owner:TSINGHUA UNIV

Process for making ceramic insulation

InactiveUS7628951B1Low costImprove performanceFinal product manufactureCeramic shaping apparatusPorosityDirect carbon fuel cell

A method is provided for producing insulation materials and insulation for high temperature applications using novel castable and powder-based ceramics. The ceramic components produced using the proposed process offers (i) a fine porosity (from nano-to micro scale); (ii) a superior strength-to-weight ratio; and (iii) flexibility in designing multilayered features offering multifunctionality which will increase the service lifetime of insulation and refractory components used in the solid oxide fuel cell, direct carbon fuel cell, furnace, metal melting, glass, chemical, paper / pulp, automobile, industrial heating, coal, and power generation industries. Further, the ceramic components made using this method may have net-shape and / or net-size advantages with minimum post machining requirements.

Owner:CERAMTEC

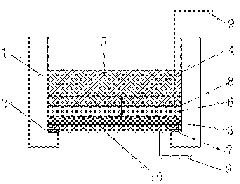

Two-electrolyte direct carbon fuel cell and assembling method thereof

InactiveCN101800326AAvoid Corrosion HazardsInhibit migrationFused electrolyte fuel cellsSolid electrolyte fuel cellsFuel cellsDirect carbon fuel cell

The invention discloses a two-electrolyte direct carbon fuel cell and an assembling method thereof, which relate to the technical field of fuel cells. The two-electrolyte direct carbon fuel cell comprises an anode part, a cathode part, and a carbonate layer and a solid oxide layer which are positioned between the anode part and the cathode layer and serve as two electrolytes, wherein the anode part comprises a carbon substrate layer and a porous anode plate; the cathode part is a porous cathode plate; the solid oxide layer is positioned between the porous anode plate and the porous cathode plate; and the carbonate layer is positioned between the solid oxide layer and the porous anode plate. The two-electrolyte direct carbon fuel cell and the assembling method thereof realize a device using the solid oxide layer and the molten carbonate layer at the same time in the same DCFC battery and increase the area of an anode reaction, and simultaneously, the anode carbon substrate layer can be supplied continuously.

Owner:SHANGHAI JIAO TONG UNIV

Direct carbon fuel cell device with liquid metal tin serving as anode

ActiveCN102723516AImprove anode mass transfer performanceCell electrodesSolid electrolyte fuel cellsHeat conductingEngineering

The invention relates to a direct carbon fuel cell device with liquid metal tin serving as an anode. A cover is arranged at the top of a cylindrical container externally wrapped by a heating ring, a cell monomer is arranged on a heat conducting gasket which is arranged at the inner bottom of the cylindrical container, a channel for cathode gas to flow through is reserved to enable the cathode gas to contact with a cathode through pore passages on ceramic, and the cylindrical container is partitioned into a cathode area and an anode area by a sealing washer. The cathode area is arranged on the lower portion of the cylindrical container, the cathode gas is led in by a gas pump via a cathode gas inlet guide tube, and cathode tail gas is led out through a cathode gas outlet guide tube. The anode area is arranged on the upper portion of the cylindrical container, and anode carrier gas is led in through an anode gas inlet tube and led out through an anode gas outlet tube. The direct carbon fuel cell device has the advantages that anode mass transfer performance is improved by using the liquid metal tin as the anode instead of an existing anode structure consisting of carbon-containing fuel mixture and a current collector; and further, study and development on high-power direct carbon fuel cell stacks can be conducted on basis of the novel structure.

Owner:江苏华昌铝厂有限公司

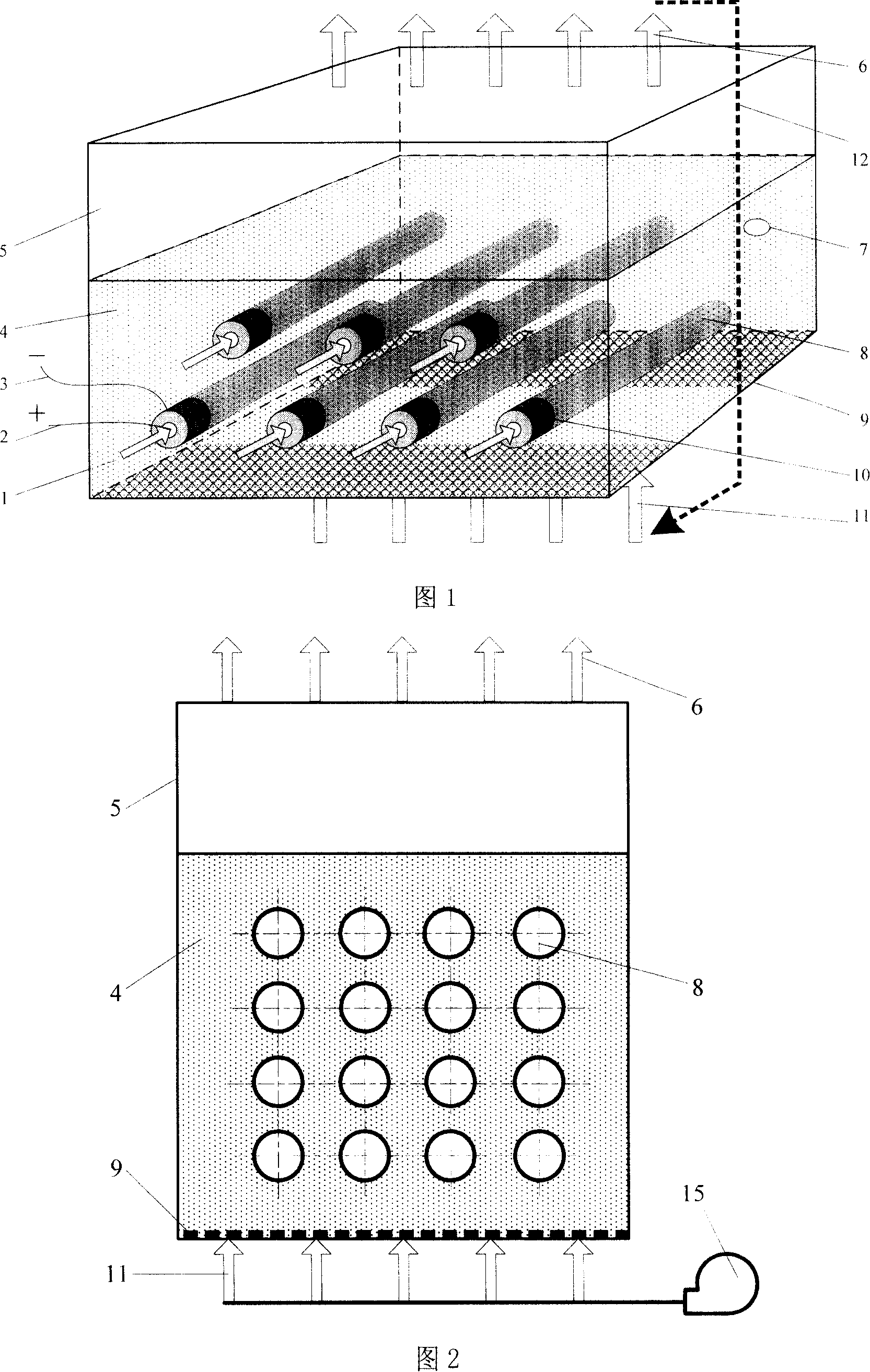

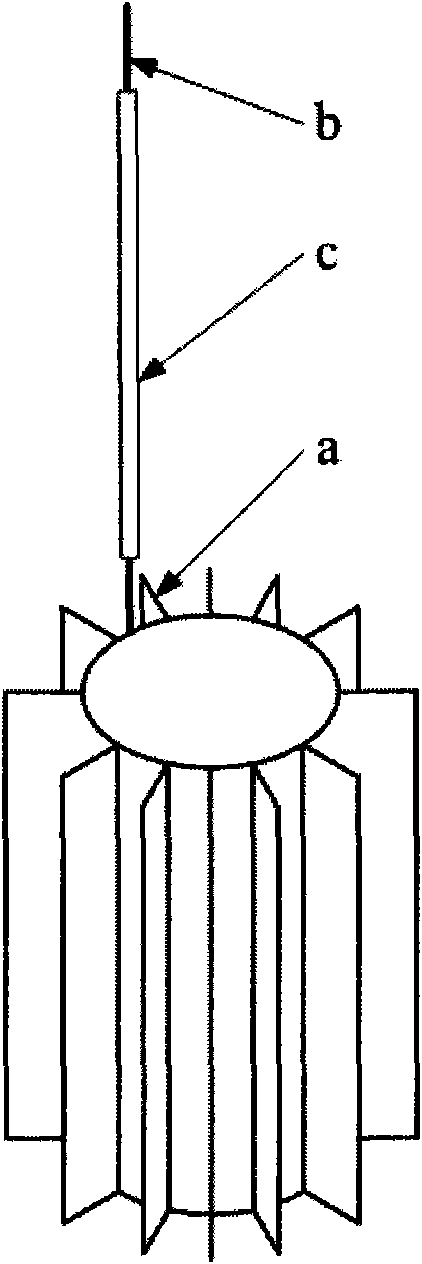

Buried tube type bubbling bed direct carbon fuel cell

ActiveCN1988229ASolving Feed ProblemsEasy to implementFuel cell auxillariesSolid electrolyte fuel cellsSolid carbonWorking temperature

This invention relates to a buried bubble bed direct carbon fuel cell including a bubble bed, tube solid oxide fuel cell monomers, an air distribution board and solid carbon fuel and wind feed device, in which, the monomers are arranged crossly, in sequence or in stagger to be plugged in the buble bed horizontally, the joint places of the monomers and the bed are sealed, the tube solid oxide electrolyte fuel battery is buried in the solid fuel to form a tube-buried structure, the wind feeding device sends gas into the bed via the distributing board to blow up solid carbon fuel particles, and the working temperature of the bed is 700-1000deg.C, the inside tube of the cell is output positive and the outside is output negative and the reacted anode gas is discharged from the top of the bed .

Owner:TSINGHUA UNIV

Natural gas direct carbon fuel cell

InactiveUS7910258B2Improve power generation efficiencyFuel cell auxillariesFused electrolyte fuel cellsOxygenDirect carbon fuel cell

A natural gas fueled, direct carbon fuel cell produces electricity and hydrogen. It adds to an existing direct carbon fuel cell a carbon dioxide injection port to the cathode compartment; a natural gas feed port to the anode compartment, a hydrogen extraction port from the anode compartment, and a carbon dioxide extraction port from the anode compartment. To improve hydrogen generation efficiency, the anode compartment may have a louvered baffle dividing the anode compartment into an ante-chamber and a main chamber. The louvered baffle preferably has an upper section with slats angled from bottom to top and a lower section with slats angled from top to bottom. A heat exchanger is preferably included to pre-heat natural gas feed from hot hydrogen effluent. A second heat exchanger is preferably included to pre-heat oxygen-containing gas with hot nitrogen and carbon dioxide effluents.

Owner:HCE

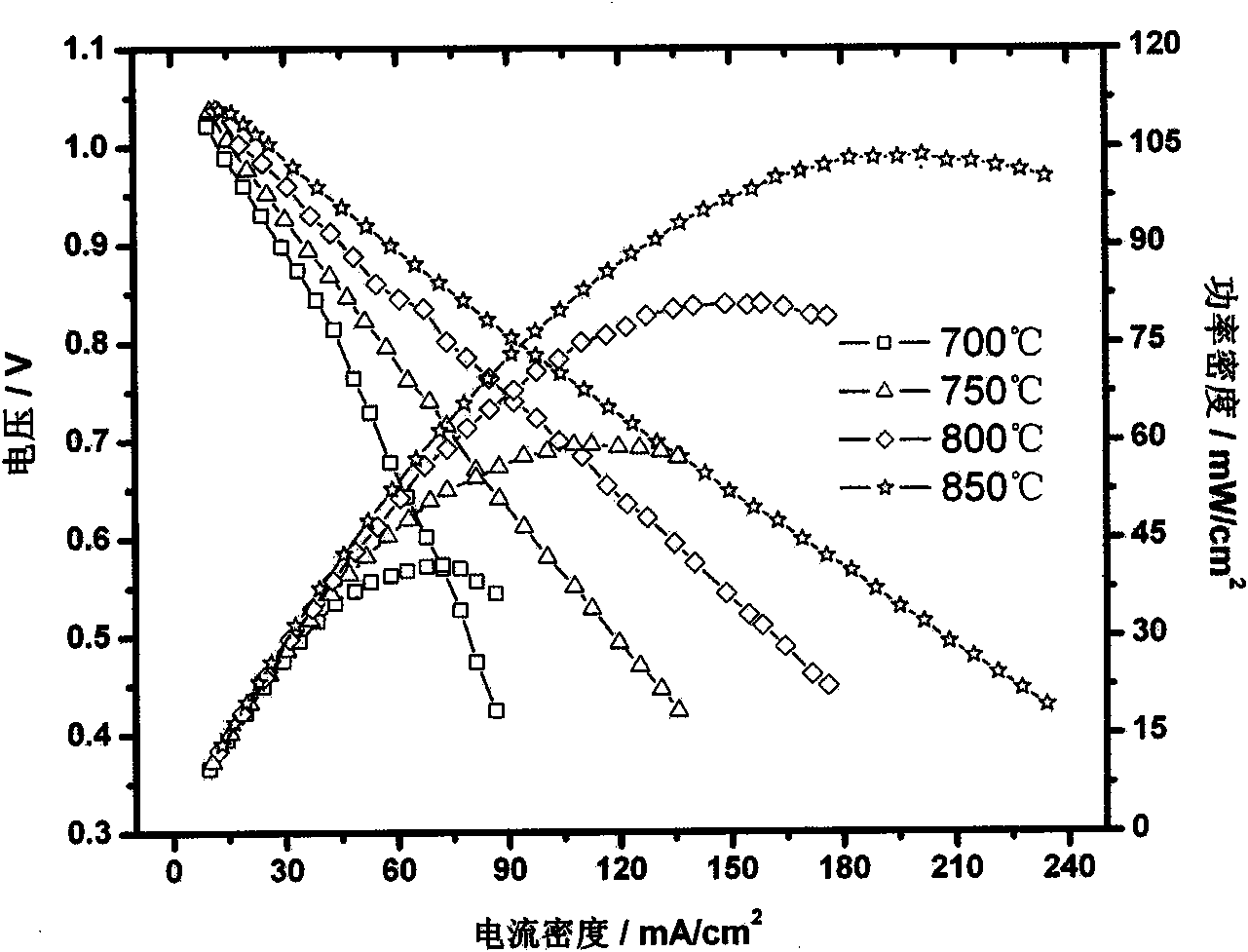

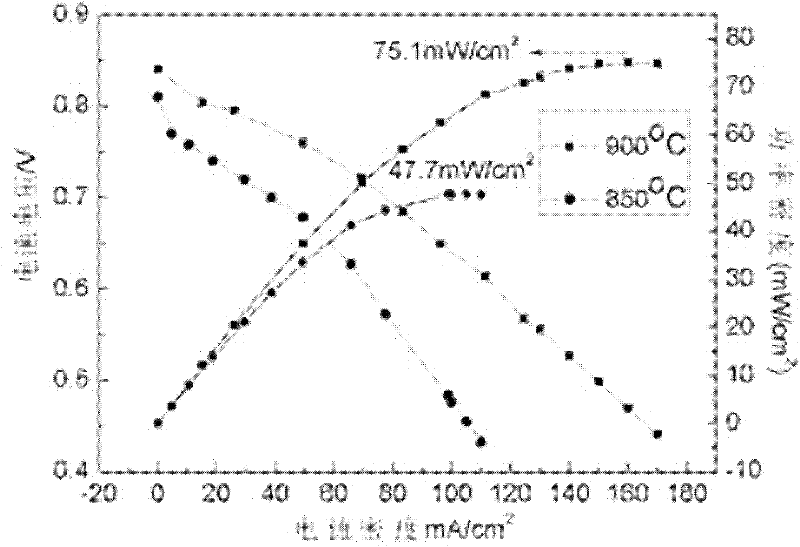

A cathode material for direct carbon fuel cell and its manufacture method

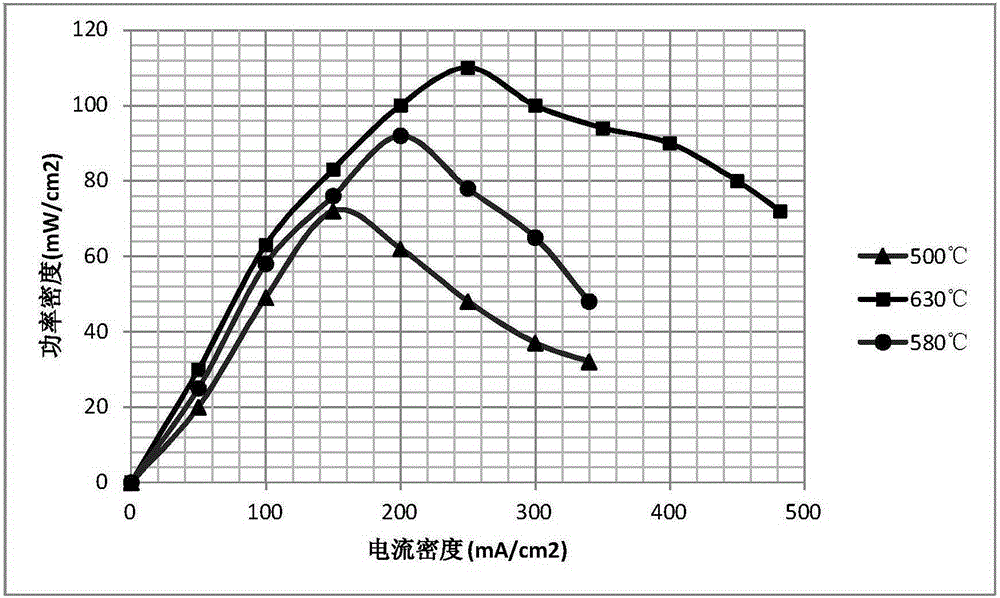

InactiveCN1964112AImprove power densityIncrease current densityCell electrodesDirect carbon fuel cellWorking temperature

The rare earth oxide composite cathode material for direct carbon fuel battery comprises following ingredients as mole percent content: 50-90% Ni, 1-18% Gd2O3, 1-20% CeO2, 0.5-7% La2O3, 1-7% Nd2O3, 0.5-7% Yb2O3, 1-4% ZrO2, and 1-4% MgO. This invention can increase the power density and current density of fuel battery, and reduces battery working temperature.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

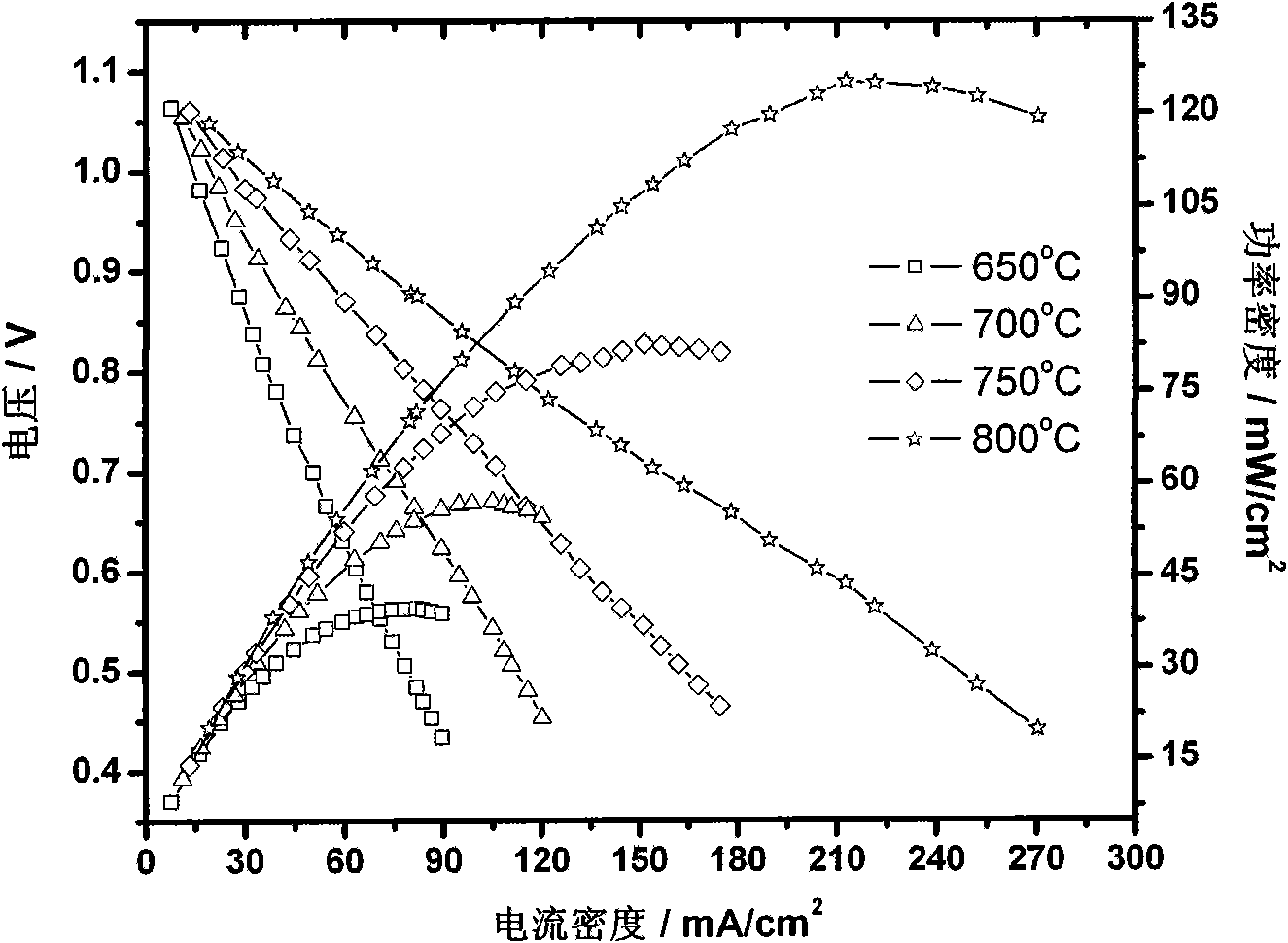

Method for improving performance of direct carbon fuel cell of solid oxide

InactiveCN102088100AImprove performanceIncrease current densityFuel cell auxillariesSolid carbonWorking temperature

The invention discloses a method for improving the performance of a direct carbon fuel cell of solid oxide, belonging to the technical field of clean energy. On the basis of the direct carbon fuel cell of the solid oxide, a metal salt is added into the solid carbon fuel to serve as a catalyst; the solid carbon added with the metal salt serves as a fuel and is put in the anode cavity of the direct carbon fuel cell; meanwhile, an anode carrier gas is introduced in to keep the anode reaction atmosphere; air or oxygen is introduced into the cathode to serve as an oxidant; and the working temperature range of the cell is 600-1000DEG C. On the basis of the prior art, the reaction activity of the solid carbon fuel is further improved by the method, the cell working temperature is lowered, and the cell performance is improved.

Owner:TSINGHUA UNIV

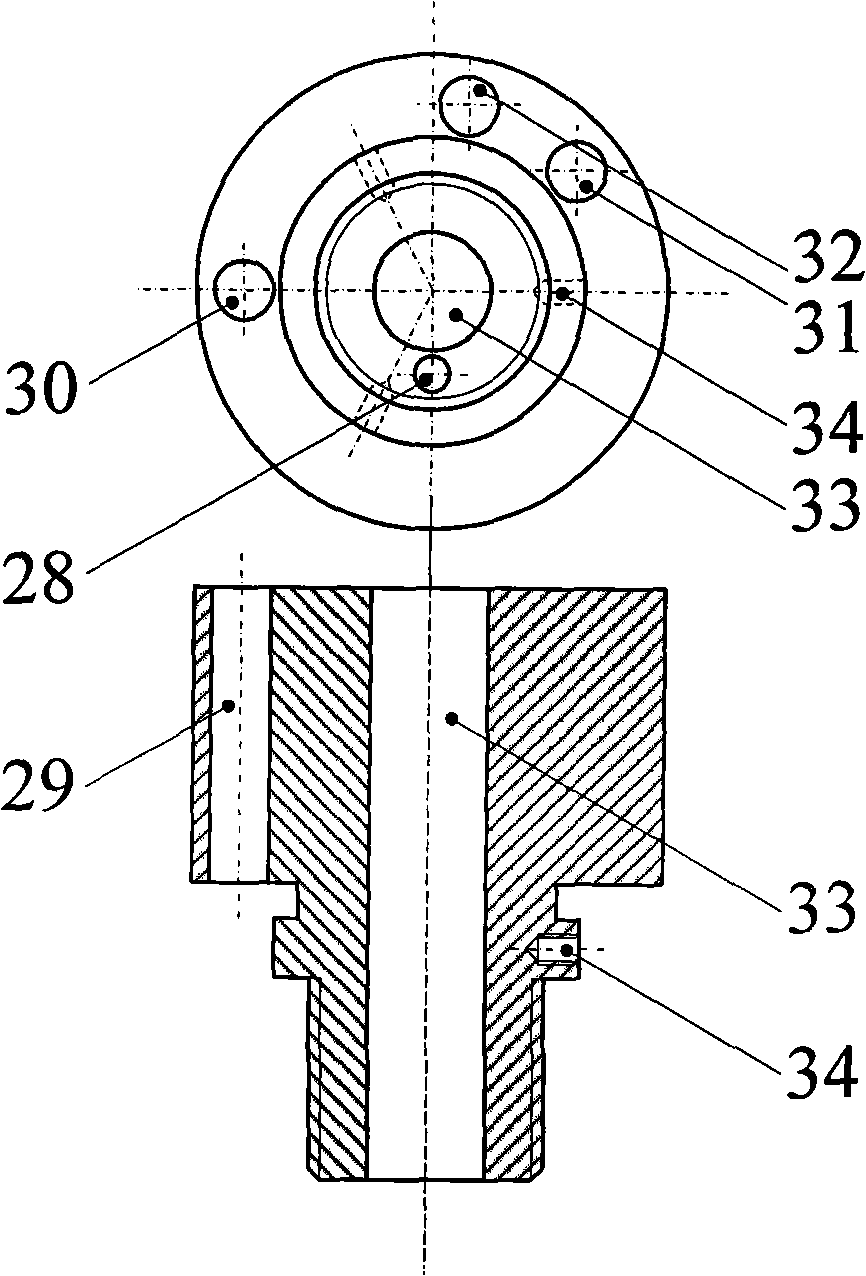

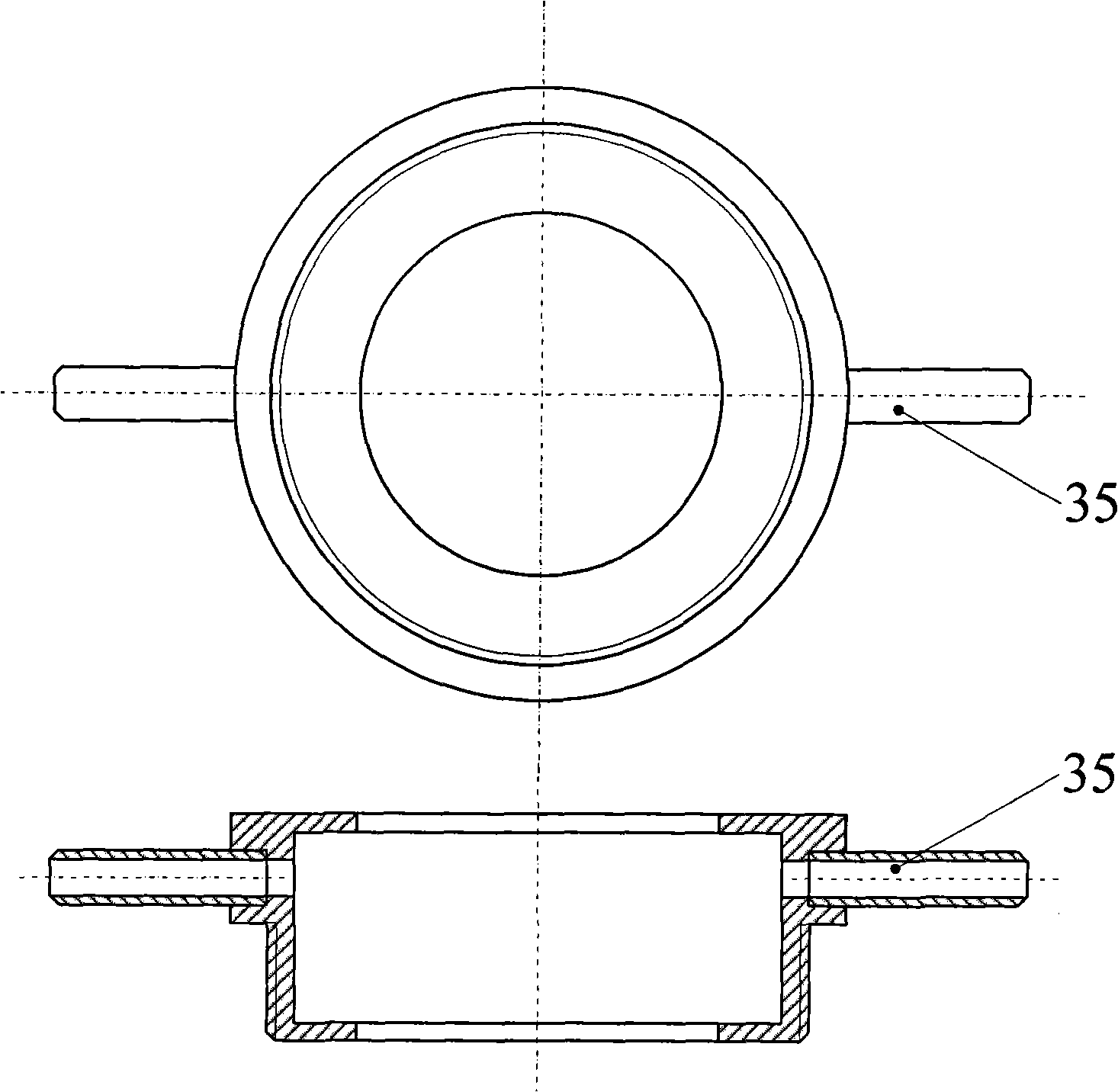

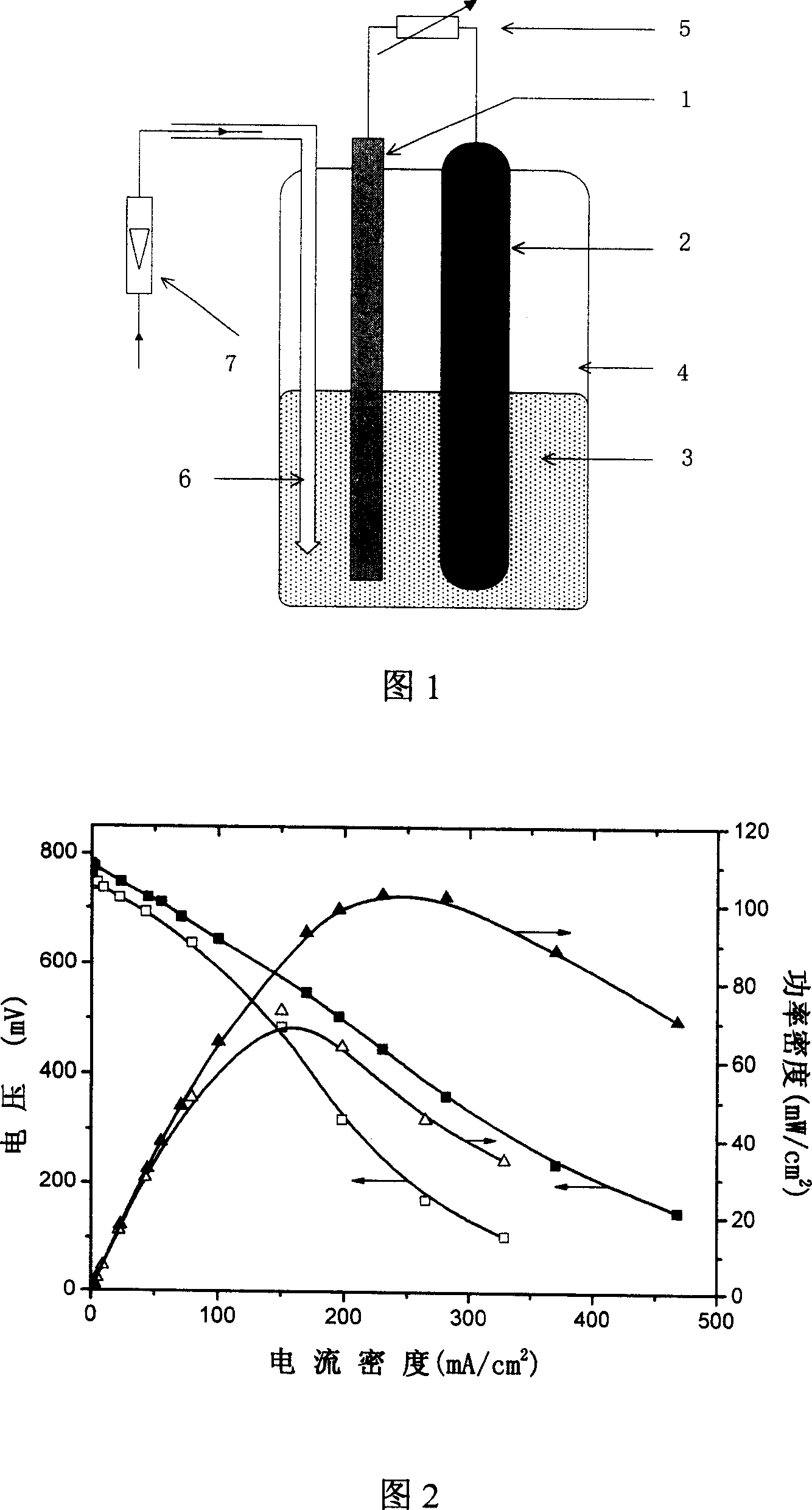

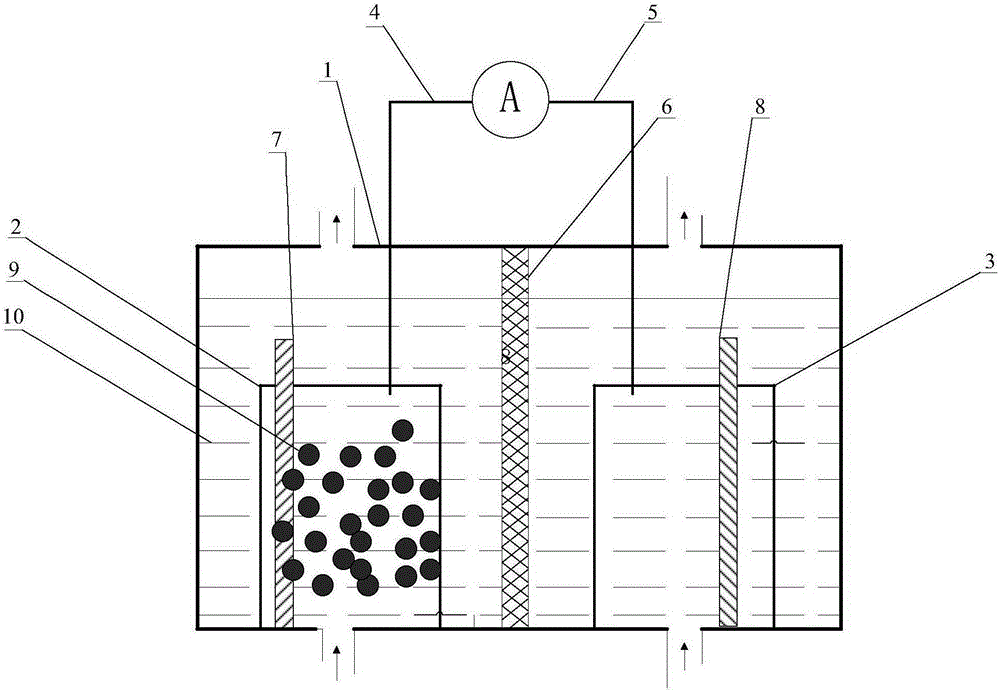

Test method and device for half cell of fluid bed electrode direct carbon fuel cell

InactiveCN102004225AHigh activitySimple structureFuel cell auxillariesElectrical testingPtru catalystElectrical battery

The invention provides a test method and device for half cell of fluid bed electrode direct carbon fuel cell. The method comprises the following steps: firstly, arranging a current collector and the mixture of carbon fuel and catalyst granules in a half cell; secondly, fixing a porous plate in a preset position, and sequentially adding an auxiliary electrode, a reference electrode and carbonate; then, introducing nitrogen gas into the half cell, heating the nitrogen gas to a preset reaction temperature, regulating the flow of the nitrogen gas, and introducing oxygen gas and carbon dioxide into the reference electrode to balance the gas; and finally, connecting to an external circuit to start experiment. The device for realizing the testing method is a half-cell reaction device and comprises a half-cell reactor and a gas preheater, two electric heating devices are respectively used for carrying out temperature control on the half-cell reactor and the gas preheater, and a rotatable support structure is used for supporting and fixing the half-cell reaction device and the electric heating devices and realizing the dumpage of molten carbonate in the half cell. By making full use of theadvantages of the fluid bed electrode and the direct carbon fuel cell, the performance of the cell can be improved.

Owner:SOUTHEAST UNIV

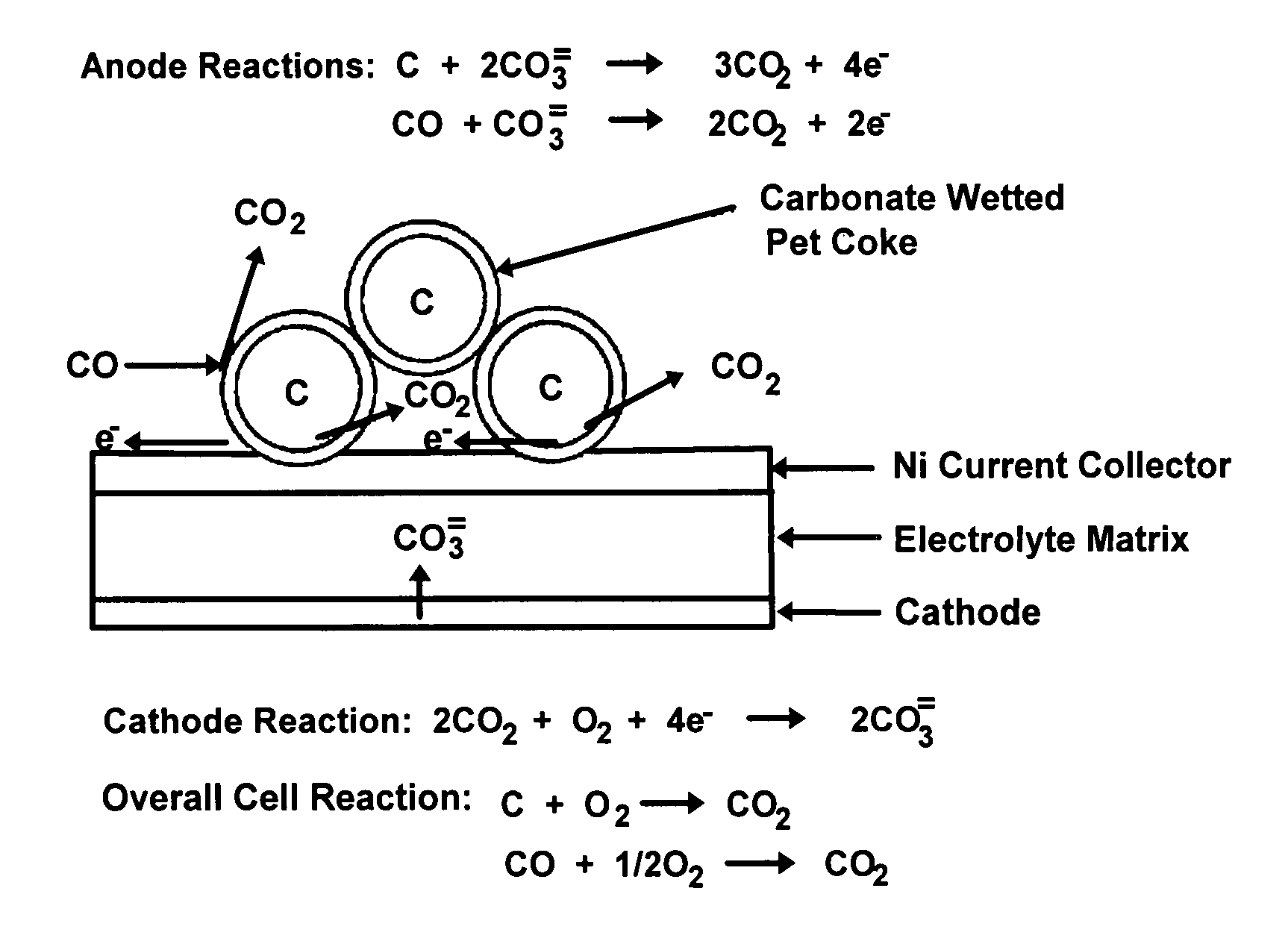

Direct carbon fuel cell with pre-wetted carbon particles

A direct carbon fuel cell having an anode electrode of carbon particles pre-wetted with carbonate, a cathode electrode, and an electrolyte layer disposed between the anode electrode and the cathode electrode and containing a molten carbonate. The fuel cell includes a wicking feature whereby excess carbonate produced during the operation of the fuel cell is removed. The use of carbonate pre-wetted carbon particles as the anode provides a network of empty voids, facilitating the removal of CO2 gas from the cell, thereby enhancing fuel cell performance.

Owner:GAS TECH INST

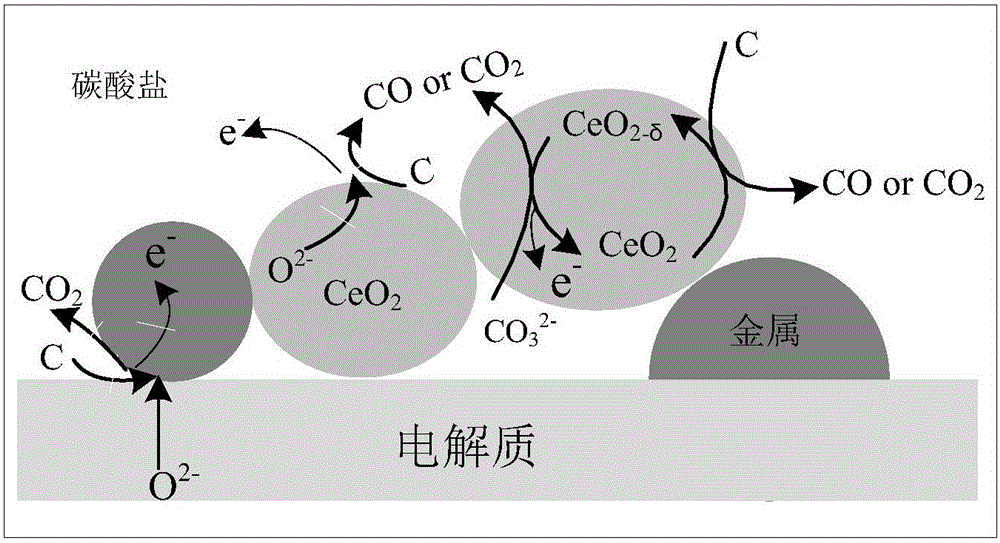

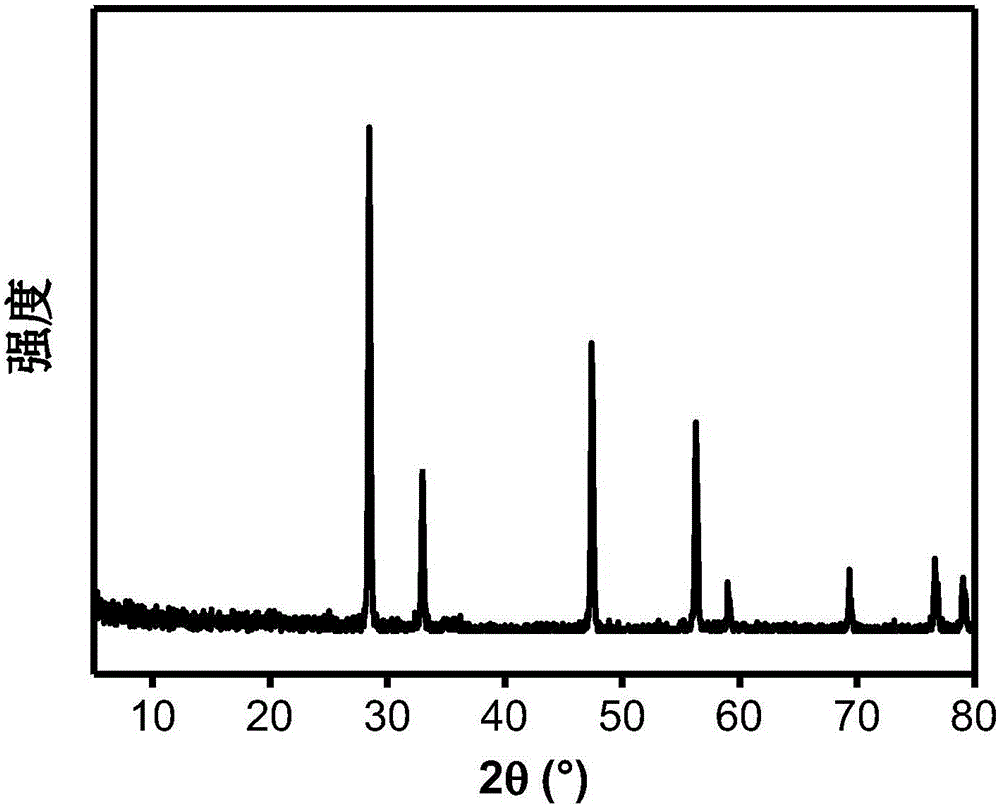

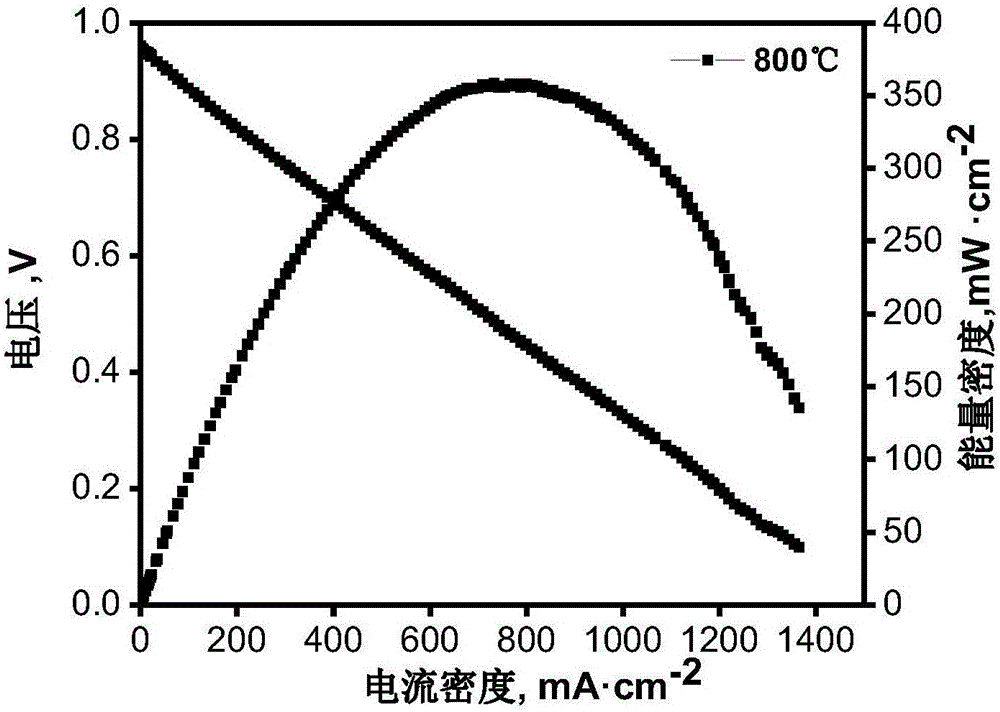

Direct carbon fuel cell anode with dual electric catalytic functions

ActiveCN105742653AImprove output performanceIncreased reactive sitesCell electrodesElectrical conductorReaction rate

The invention relates to a direct carbon fuel cell anode with dual electric catalytic functions, and belongs to the technical field of clean energy. The anode material is prepared by compounding nanoparticle as a conductive phase on the inner and outer parts of transition element-codoped CeO2 as a catalytic active phase of the anode and a porous framework. The prepared anode material has dual electrocatalysis effects on carbon fuel, can be used as an excellent ion conductor, transfers O<2-> generated by a cathode to the electrode surface and increases the electrode reaction active sites; the anode material can be applied to electrochemical oxidation of an intermediate catalytic carbon; and the power output of the cell is improved. The anode material disclosed by the invention is assembled into a direct carbon fuel cell for power generation, so that the three-phase interface length is prolonged; the fuel gasification reaction rate is improved; corrosion of molten carbonate to an electrolyte is avoided; and the lifetime of the cell is prolonged.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

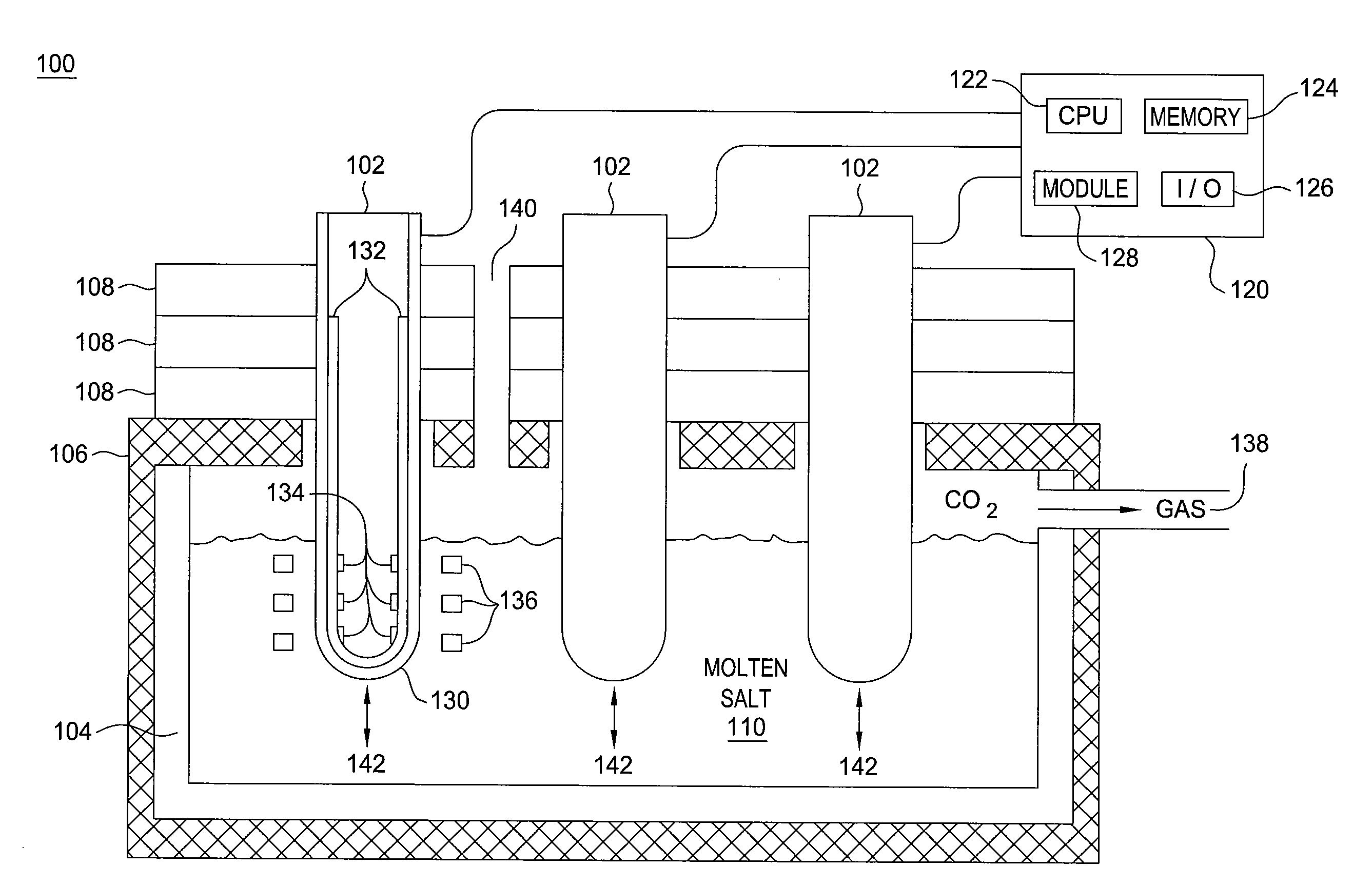

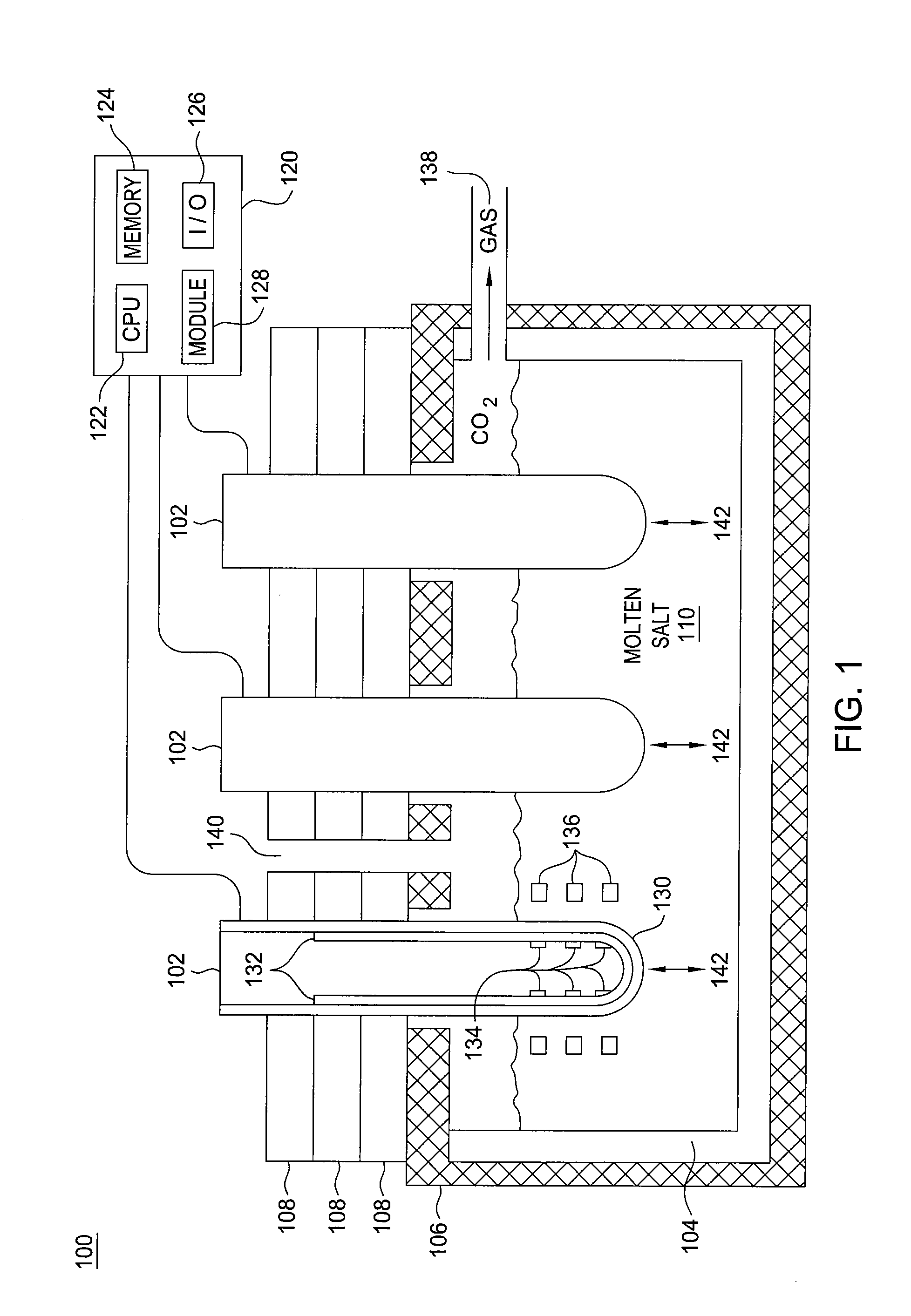

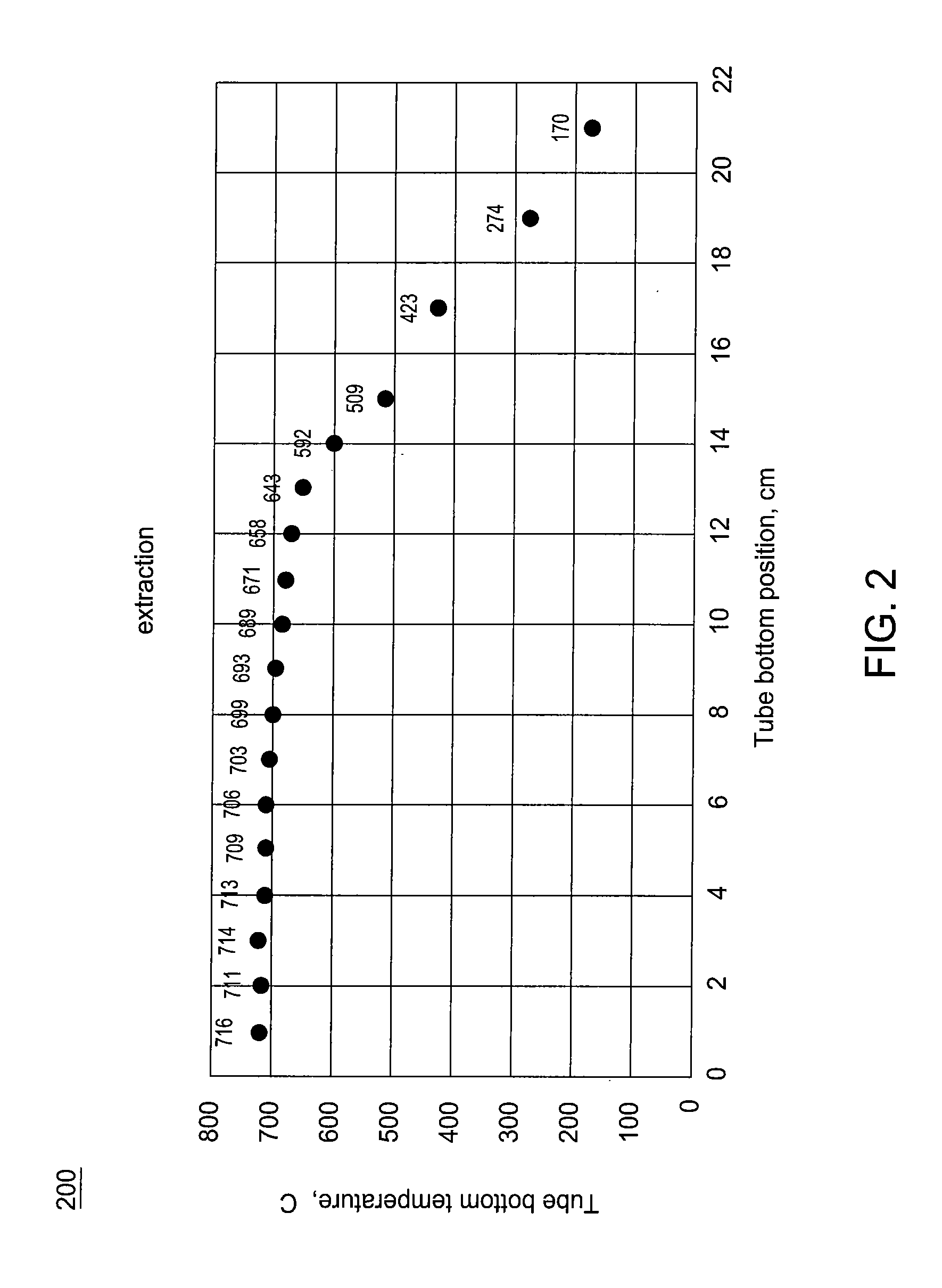

On-line replacement of dcfc tubular elements

In one embodiment, the present invention relates generally to a method for replacing at least one direct carbon fuel cell (DCFC) tube of a plurality of DCFC tubes in a fuel cell on-line. In one embodiment, the method includes detecting a degradation in performance of the at least one DCFC tube, removing the at least one DCFC tube while the fuel cell is still operating and providing a replacement DCFC tube while the fuel cell is still operating.

Owner:SRI INTERNATIONAL

Nickel-lanthanum composite material cathode and direct carbon fuel cell and preparation method thereof

ActiveCN105206846AComposition is easy to controlSimple production processFinal product manufactureCell electrodesAlloyLanthanum

The invention discloses a nickel-lanthanum composite material cathode and a direct carbon fuel cell and a preparation method thereof. The nickel-lanthanum composite material cathode includes two materials, wherein the first material is nickel, and the second material is lanthanide metal or lanthanum oxide La2O3. The nickel-lanthanum composite material cathode facilitates manufacture of an amorphous-state nanocrystalline thin-film material which is large in area and complicated in shape and is suitable for continuous operation and large-scale production. In addition, the composition of an alloy film is easy to control, a production process is simple, the cost is lower and the like. The direct carbon fuel cell (DCFC) adopting the nickel-lanthanum composite material cathode has stable discharge performance at intermediate temperature, outputs higher power density and current density and has higher fuel conversion efficiency. A nickel-lanthanum composite material adopted by the nickel-lanthanum composite material cathode is indissoluble and does not pollute a molten alkali electrolyte and a molten carbonate electrolyte.

Owner:SHANXI YUXIANG INFORMATION TECH CO LTD +2

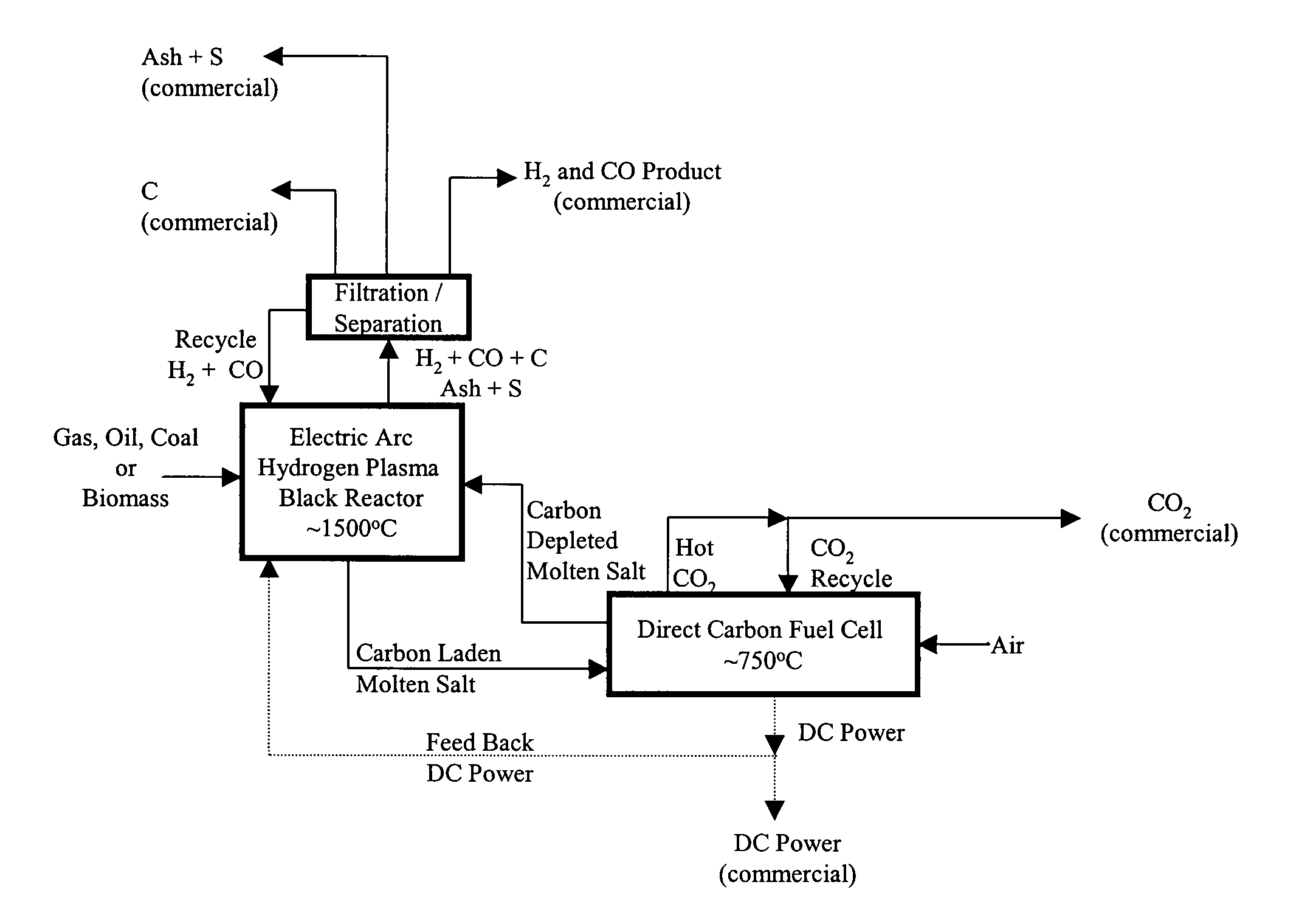

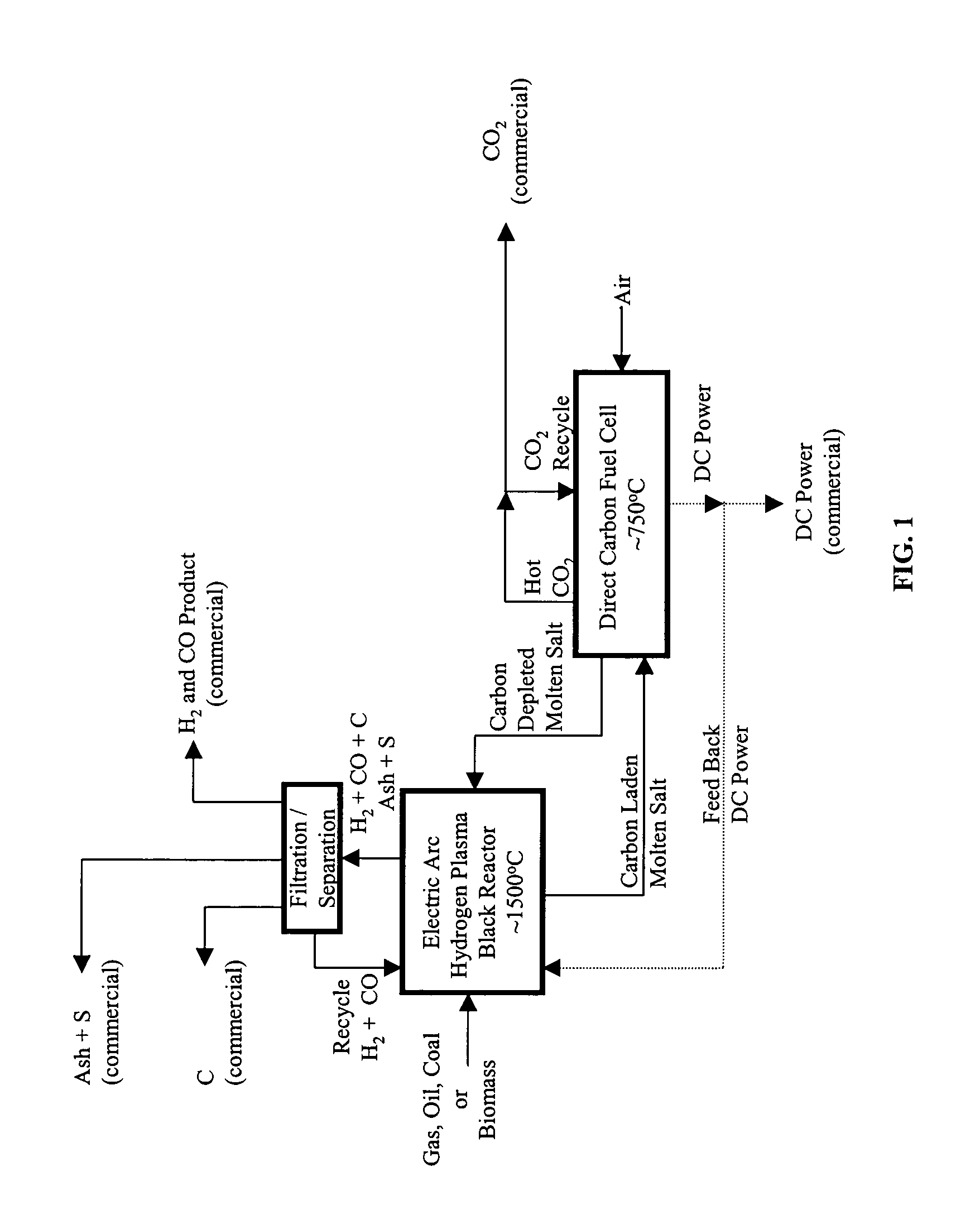

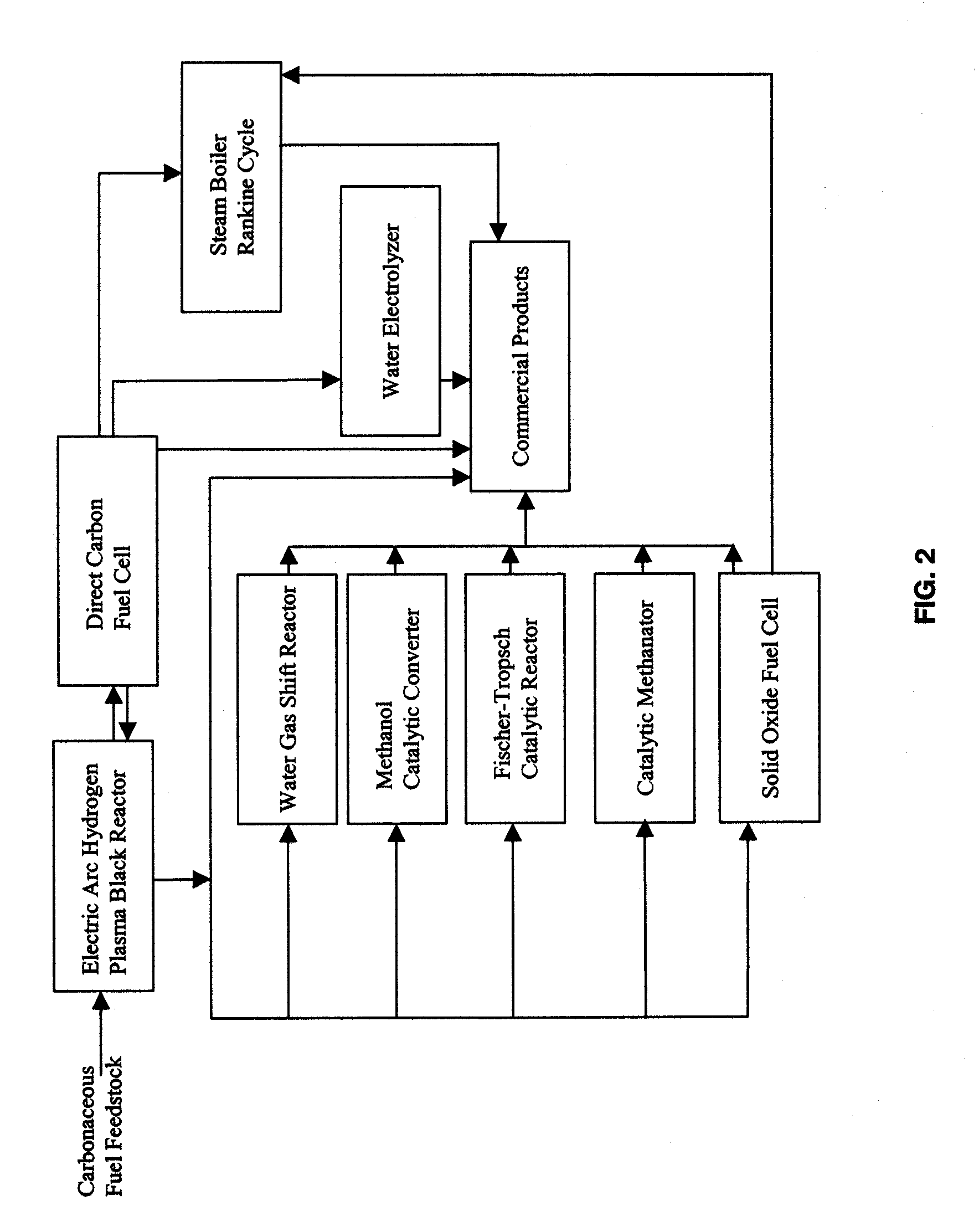

Integrated plasma fuel cell process

InactiveUS7163758B2Efficient productionMinimum carbon dioxide emissionFuel cell auxillariesFused electrolyte fuel cellsElectricityFuel cells

Owner:HCE

Direct carbon fuel cell using eutectic fusible hydroxide mixture as electrolyte

ActiveCN105186024AImprove conductivityFacilitate strippingCell electrodesFused electrolyte fuel cellsElectrochemical responseThree dimensional shape

The invention discloses a direct carbon fuel cell using a eutectic fusible hydroxide mixture as electrolyte. The direct carbon fuel cell comprises a reaction apparatus, an anode plate cabin, a cathode plate cabin, an anode, a cathode, an anode collector plate, a cathode collector plate, a micropore partition plate, a cathode pipeline, an air circulating apparatus, a gas-saving sheet, electrolyte and carbon fuel; the electrolyte adopts the eutectic fusible hydroxide mixture, so that the conductivity of the whole electrolyte can be improved, the activity of the electrolyte is improved, the full contact between electrode interfaces and reaction interfaces, and the stripping of the interface solid products are facilitated, and the ohmic resistance and the activation resistance are reduced; the cathode adopts a nickel lanthanum composite material and is processed into a multi-dimensional three-dimensional shape, so that the electrochemical reaction within unit space can be effectively improved; and a mixed gas of oxygen including no less than 35 % of vapor based on concentration, or a mixed gas of air including no less than 35 % of vapor based on concentration is adopted for the cathode air intake, so that the hydroxyl consumption in the electrolyte can be effectively avoided.

Owner:SHANXI YUXIANG INFORMATION TECH CO LTD +2

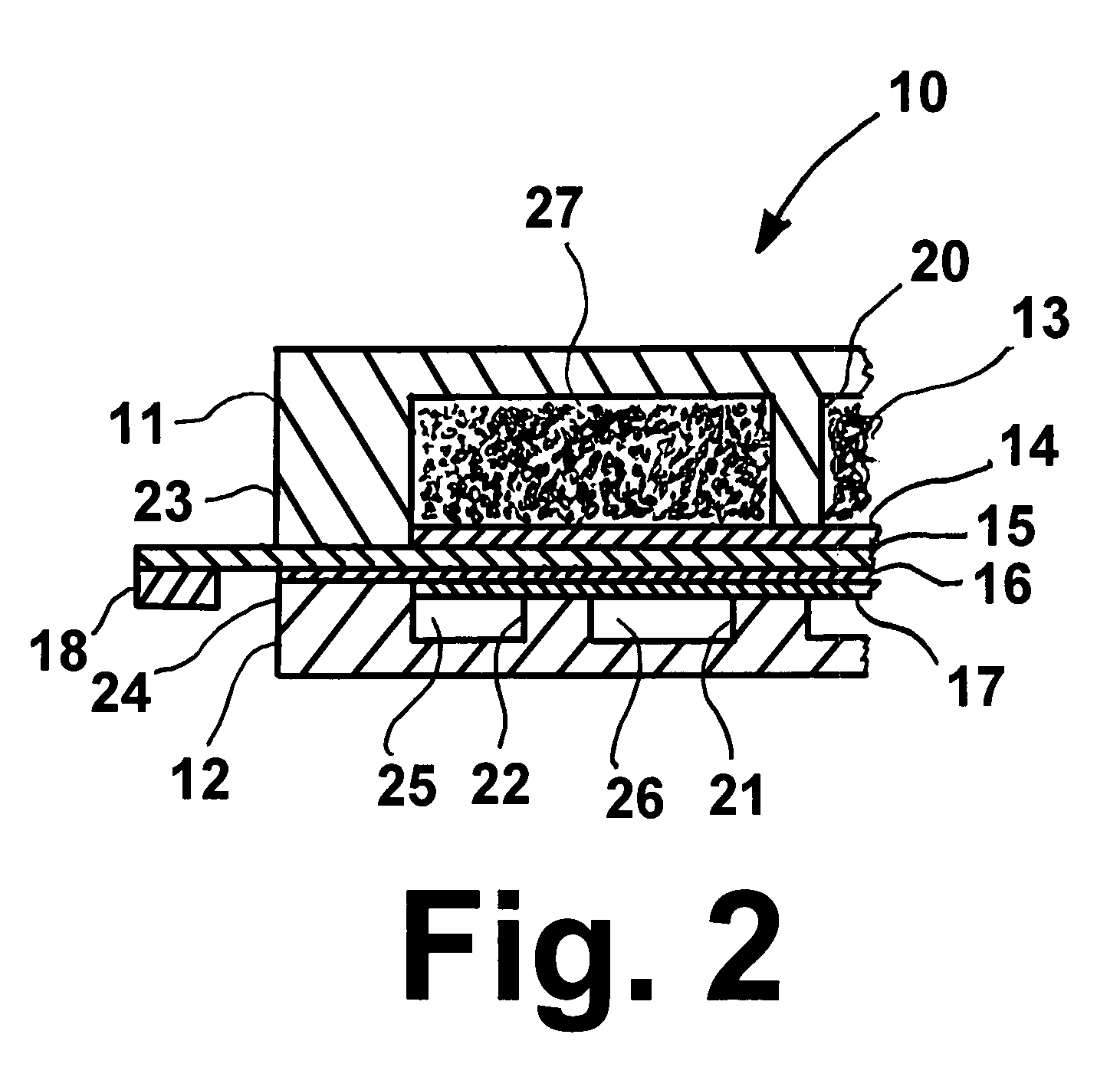

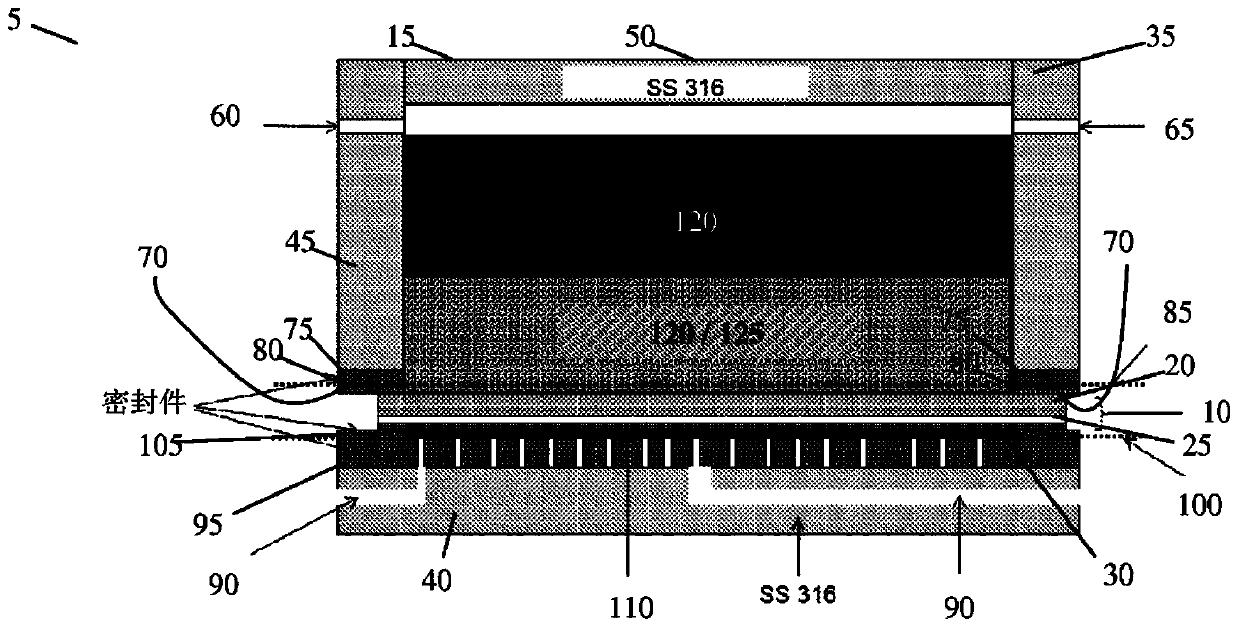

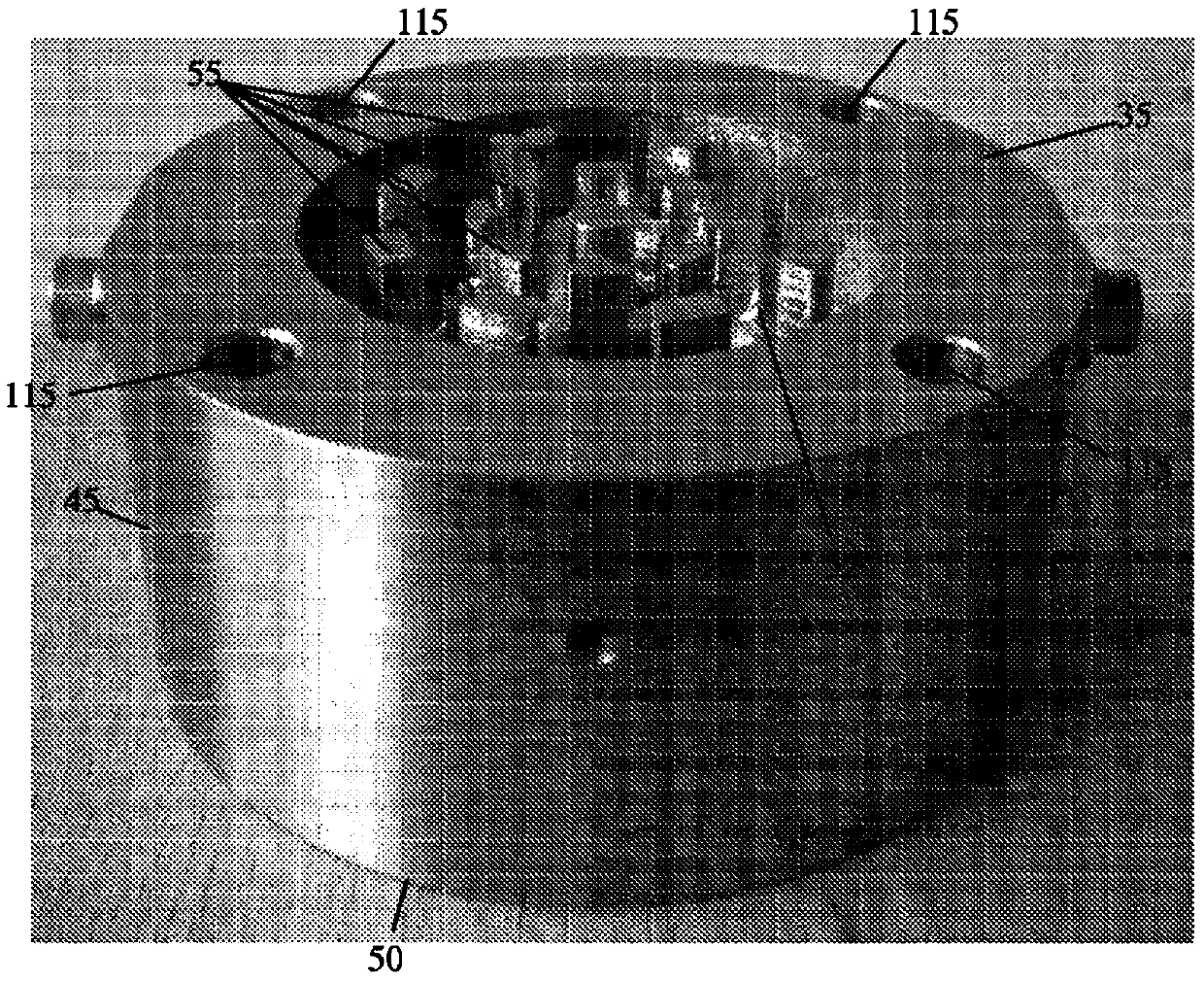

Direct carbon electrochemical cell

ActiveCN104011932AFuel and primary cellsFuel cells groupingElectrochemical cellDirect carbon fuel cell

A direct carbon fuel cell DCFC system (5), the system comprising an electrochemical cell, the electrochemical cell (10) comprising a cathode (30), a solid state first electrolyte (25) and an anode (20), wherein, the system further comprises an anode chamber containing a second electrolyte (125) and a fuel (120). The system, when using molten carbonate as second electrolyte, is preferably purged with CO2 via purge gas inlet (60).

Owner:UNIV COURT OF THE UNIV OF ST ANDREWS

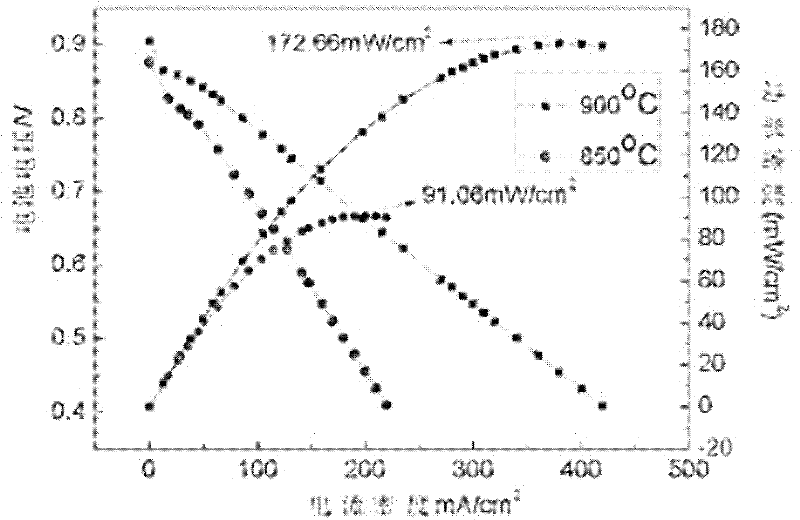

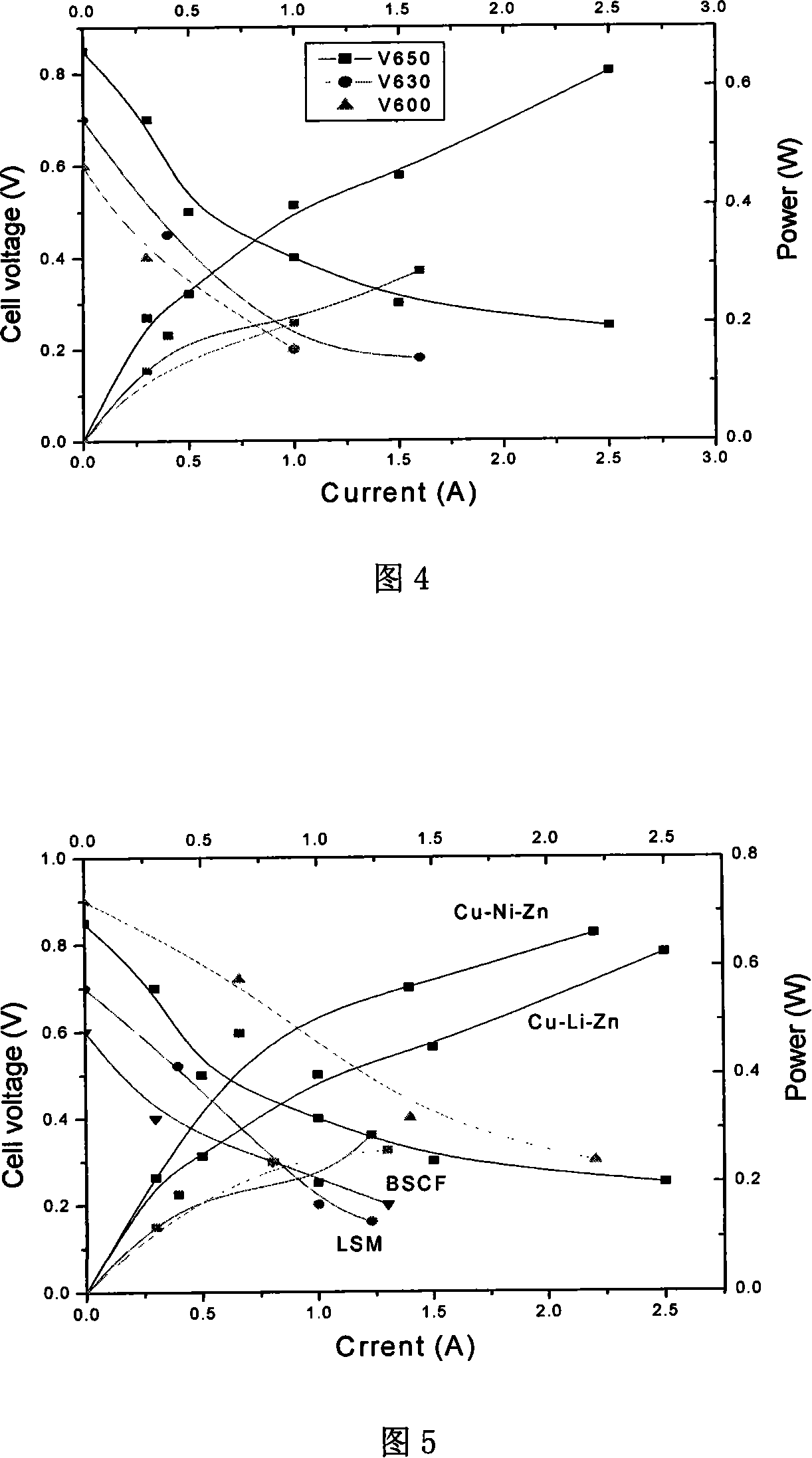

Direct carbon fuel battery

The invention relates to a direct carbon fuel cell, which provides a direct carbon fuel cell directly taking carbon or carbon composite as the anode, and metal oxide as the cathode, single or double phase low medium temperature ceria composite as the electrolyte. The direct carbon fuel cell is power molding button cell with electrolyte in the middle and the anode and cathode separately on each side. The pressed sheets of anode and cathode are one to two mm thick. The invention can get the best performance about 0.25 watts per square centimeter under the temperature of 600 to 650 degrees centigrade, which is two times above the performance of such fuel cell according to a report from USA and has reached the international leading level.

Owner:朱志刚

Catalytic oxide anodes for high temperature fuel cells

InactiveUS20080124265A1High activityImprove conductivityArsenites/arsenatesCell electrodesCelsius DegreeLanthanide

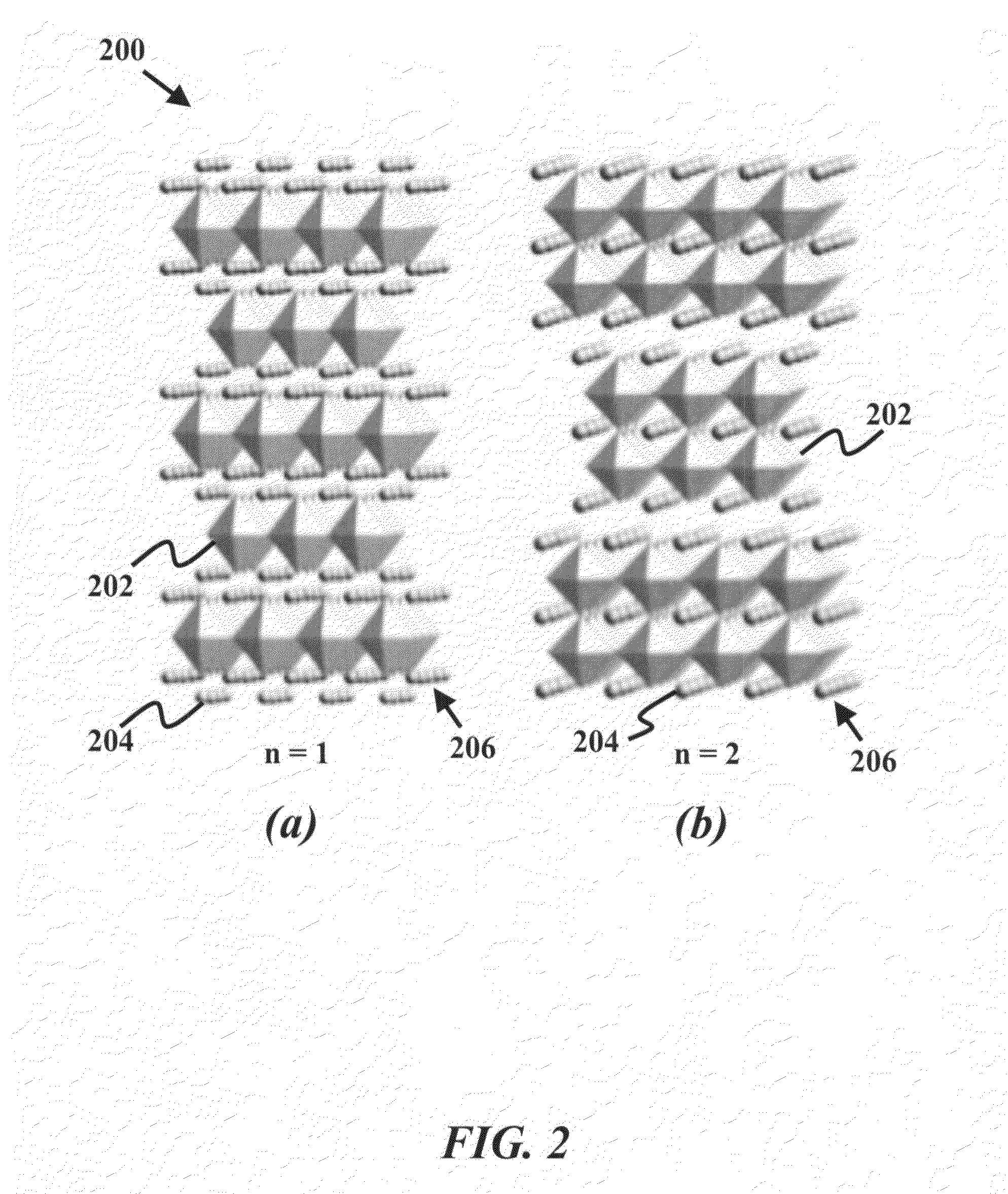

An anode in a Direct Carbon Fuel Cell (DCFC) operating in a temperature range between 500 and 1200 degrees Celsius is provided. The anode material has high catalytic activity and selectivity for carbon oxidation, sufficient oxygen non-stoichiometry, rapid oxygen chemical diffusion, wide thermodynamic stability window to withstand reducing environment, sufficient electronic conductivity and tolerance to sulfur and CO2 environments. The anode has doped ruthenate compositions A1−xA′xRuO3, AB1−yRuyO3, or A1−xA′xB1−yRuyO3. A and A′ may be divalent, trivalent, or tetravalent cation, and B is a multivalent cation. A is among lanthanide series elements La, Ce, Pr, Nd, Sm, Eu, Gd, Dy, Er or Yb, and dopant A′ is from Group IIA, IIIB, or IVB elements. The doped ruthenates can also be a (AB1−yRuyO3) structure or an ordered Ruddlesden-Popper series ((A1−xAx′)n+1(B1−yRuy)nO3n+1) structure where n=1 or 2. The dopant B is among Group IVB, VB, VIB, VIII, IB, and IIB elements.

Owner:DIRECT CARBON TECH

Direct carbon fuel cell

InactiveUS20090136797A1Avoid problemsCell electrodesFused electrolyte fuel cellsFuel cellsDirect carbon fuel cell

A direct carbon fuel cell having an anode electrode of carbon particles pre-wetted with carbonate, a cathode electrode, and an electrolyte layer disposed between the anode electrode and the cathode electrode and containing a molten carbonate. The fuel cell includes a wicking feature whereby excess carbonate produced during the operation of the fuel cell is removed. The use of carbonate pre-wetted carbon particles as the anode provides a network of empty voids, facilitating the removal of CO2 gas from the cell, thereby enhancing fuel cell performance.

Owner:GAS TECH INST

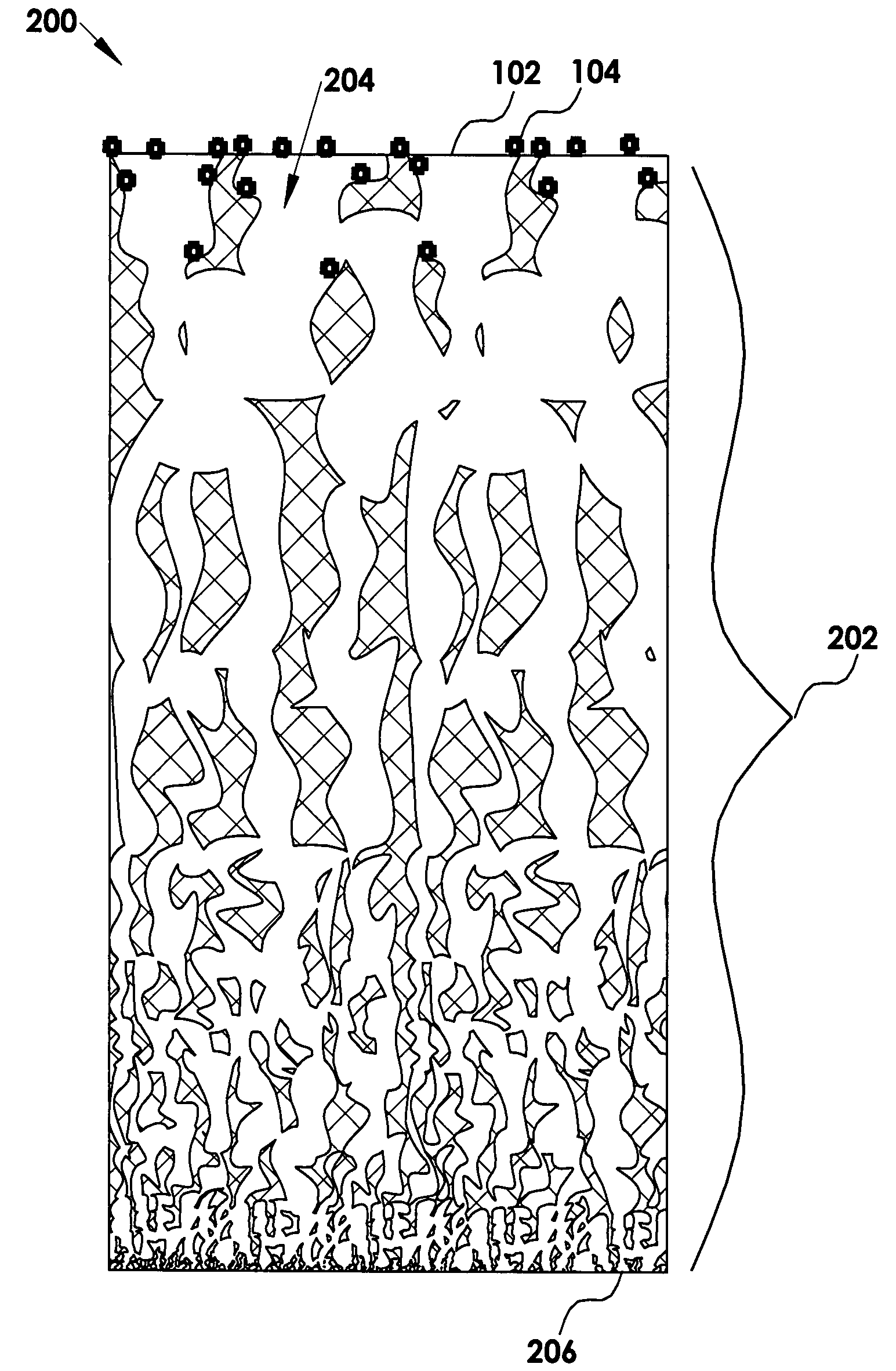

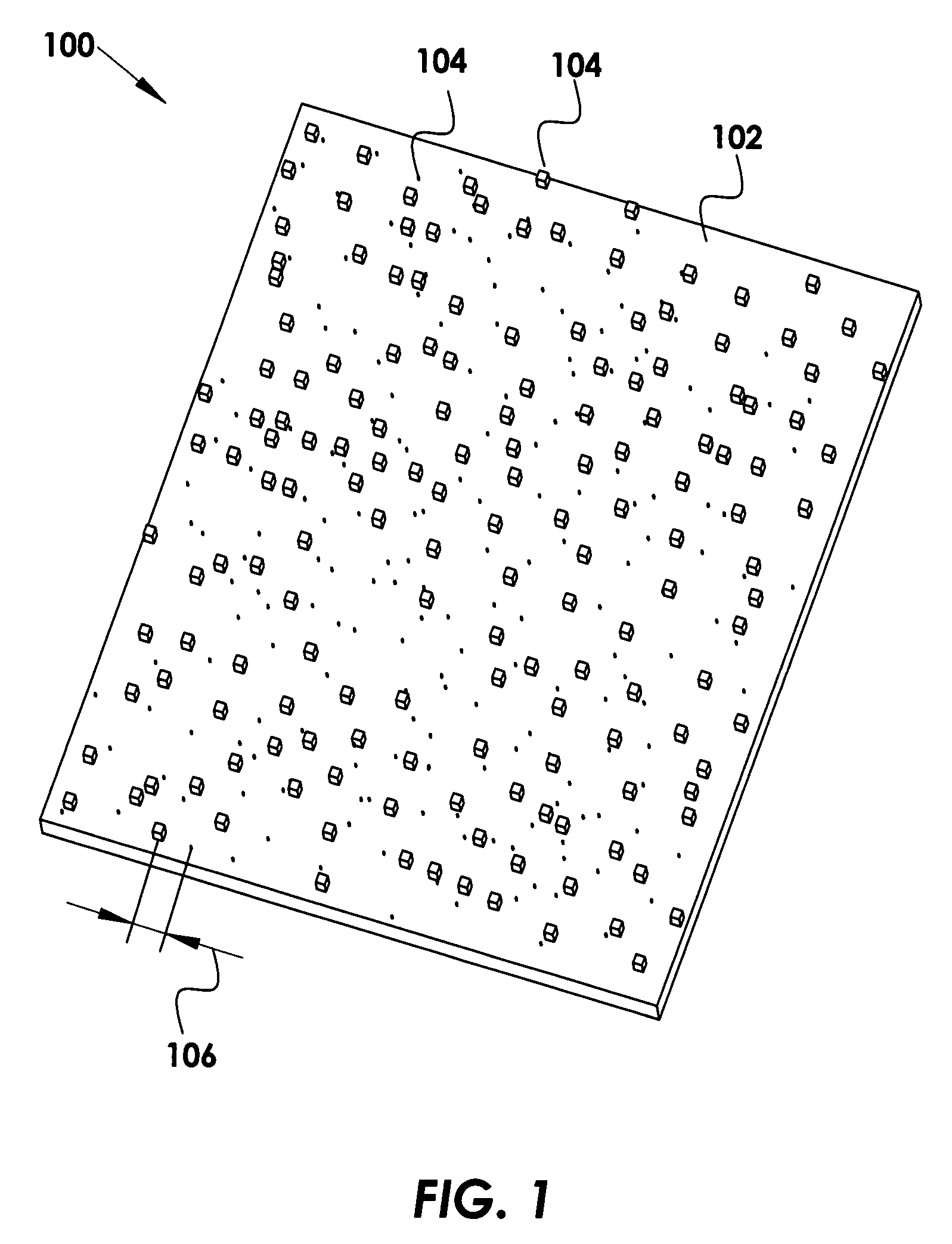

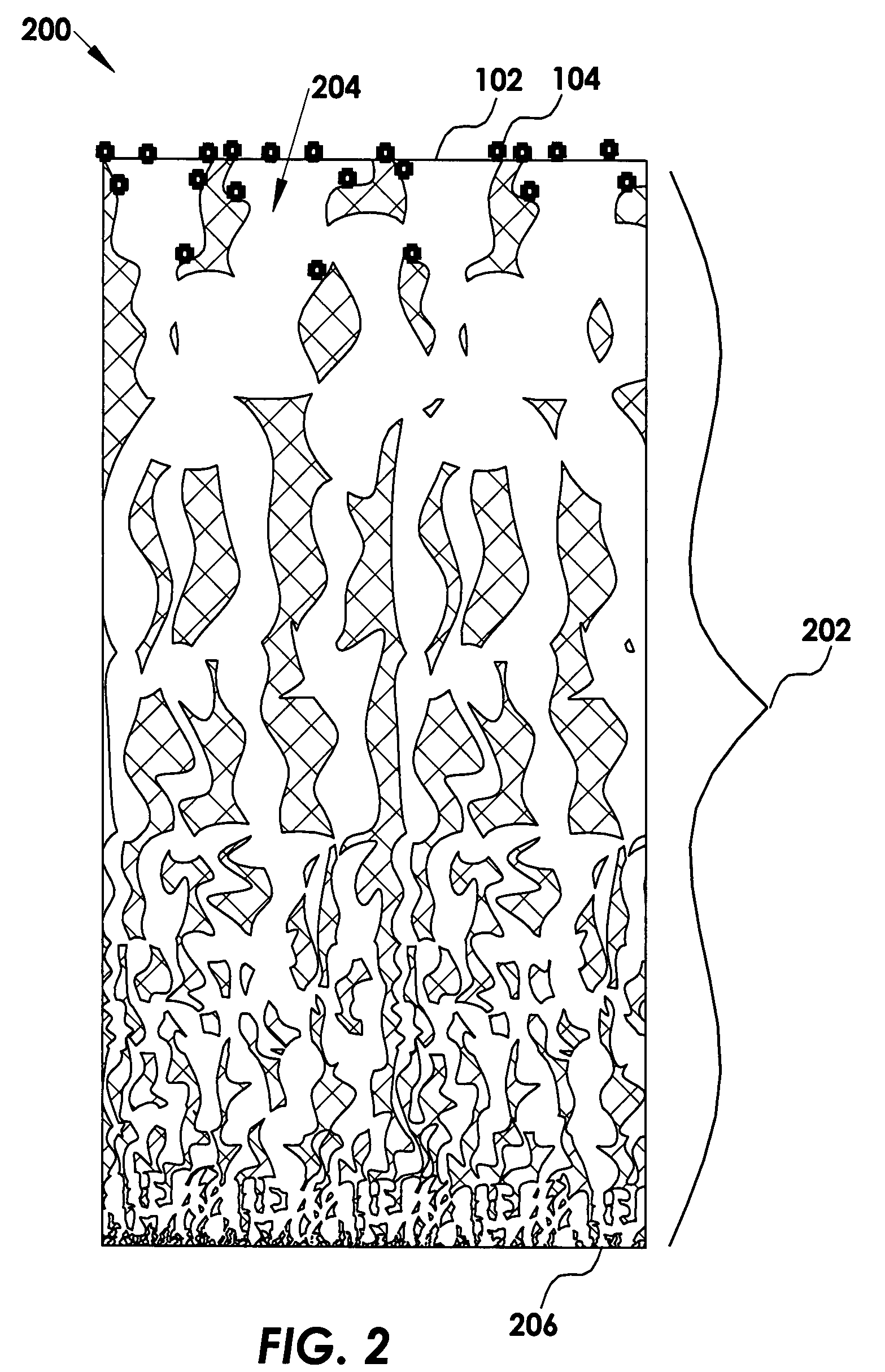

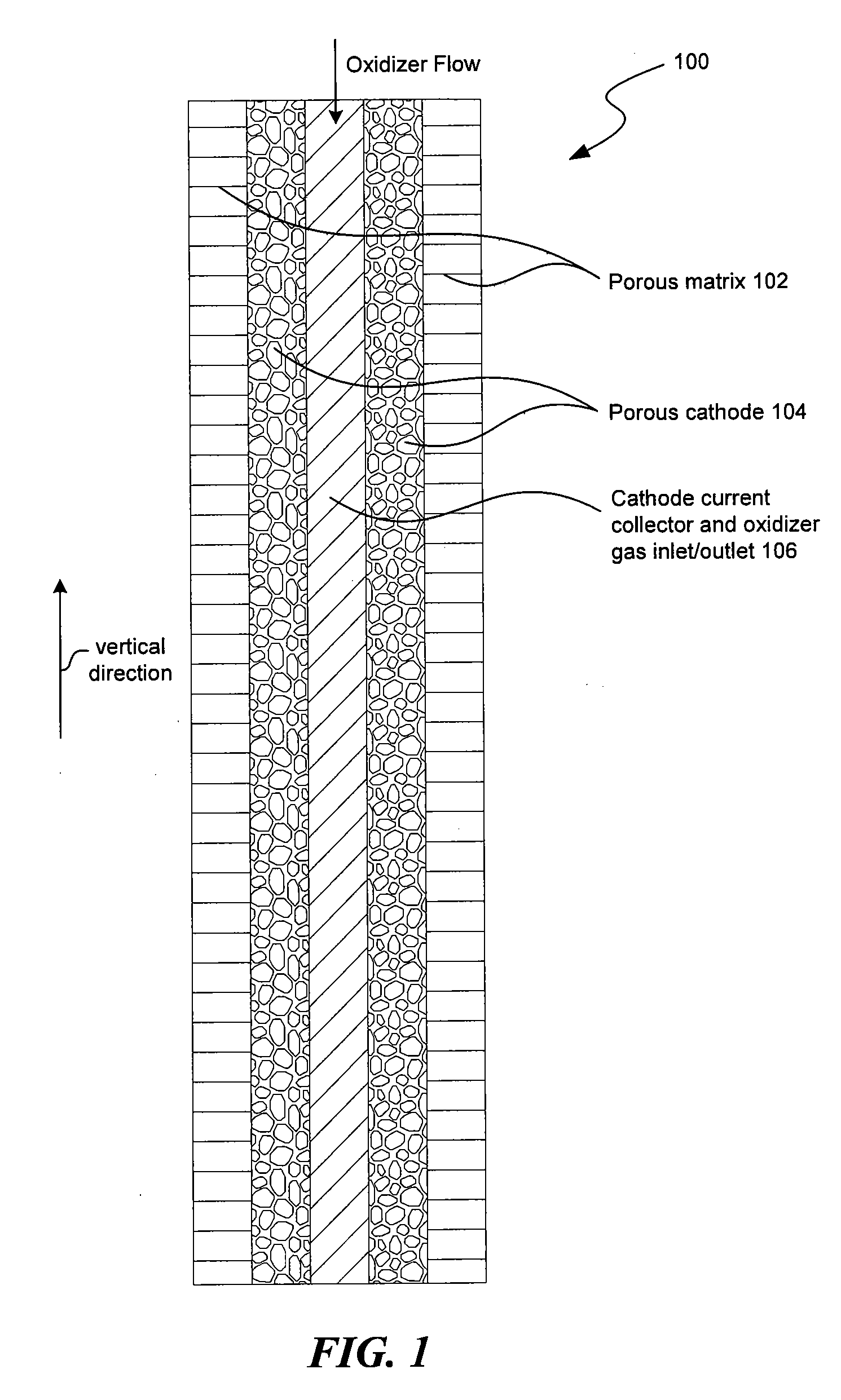

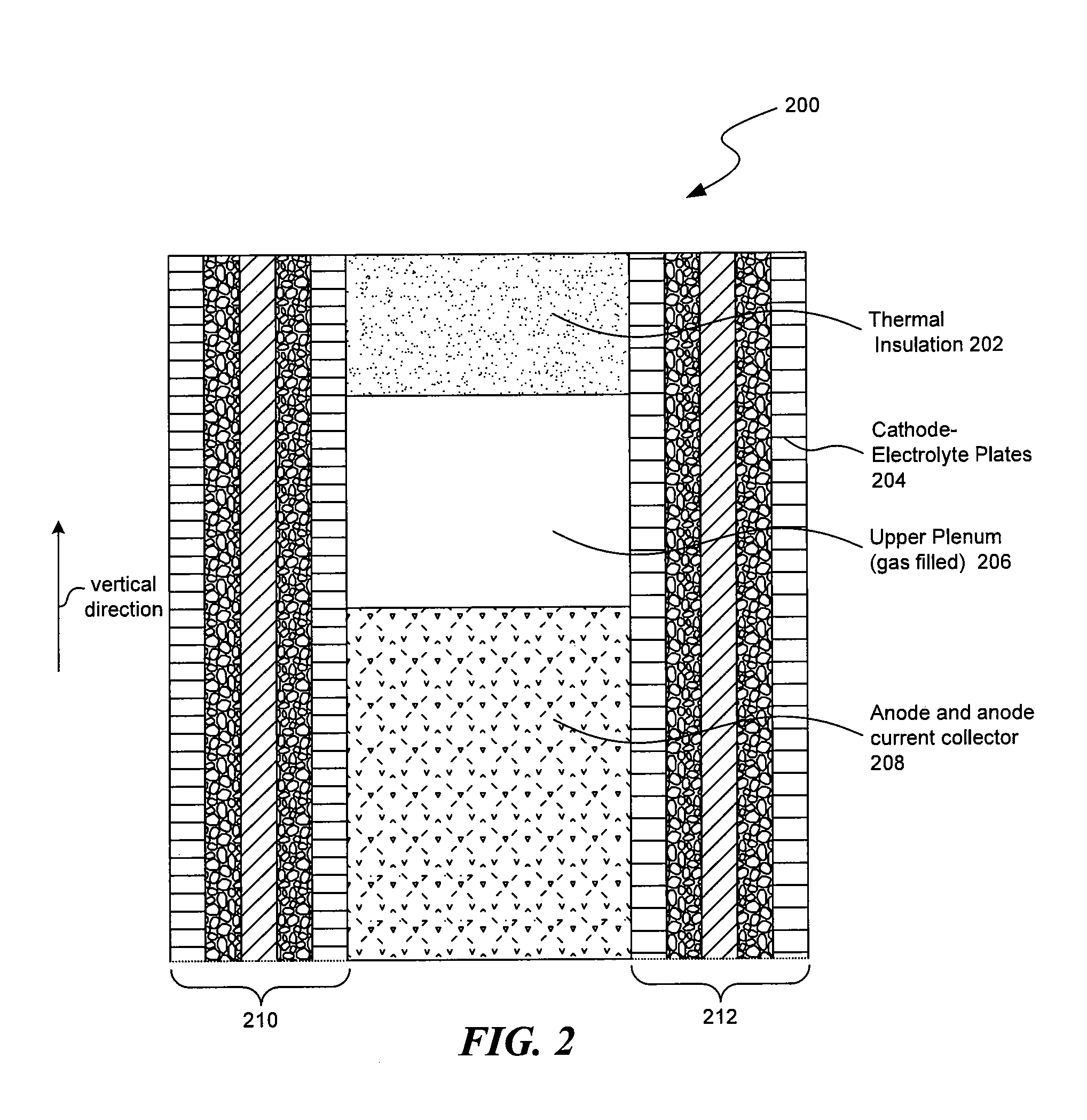

Scalable direct carbon fuel cell

InactiveUS20110177421A1Fuel cell heat exchangeReactant parameters controlFuel cellsComposite cathode

Fuel cells having cathode elements that are oriented such that dispersion of injected fuel through the fuel cell is caused at least in part by buoyancy force are disclosed. In one aspect of the present disclosure, the fuel cell includes a composite cathode element that is oriented such that dispersion of injected fuel through the fuel cell is caused at least in part by buoyancy force. For example, the composite cathode element and may be vertically oriented such that it is substantially parallel to the line of buoyancy. The composite cathode element further comprises, a porous matrix holding electrolyte, a cathode, and / or a cathode current collector. One embodiment of the fuel cell further includes, an anode chamber coupled to the composite cathode element. During operation, fuel injected into the fuel cell is oxidized in the anode chamber by oxidizer ions generated at the composite cathode element and transported to the anode chamber via the electrolyte in the porous matrix.

Owner:4D POWER

Conductor catalyst for enhancing performance of direct carbon fuel battery and method

InactiveCN102306809AIncrease direct electrochemical reactionImprove power densityPhysical/chemical process catalystsCell electrodesElectrochemical responseElectrical conductor

The invention discloses a conductor catalyst for enhancing the performance of a direct carbon fuel battery and a method, which relate to the technical field of cleaning energy. The conductor catalyst is prepared by mixing an ion conductor, an electronic conductor and a carbon gasification catalyst and then processing by a mechanical crushing method or a solid phase synthesizing method. The conductor catalyst provided by the invention is applied for generating power for the direct carbon fuel battery; a conductor network is formed in a battery anode; the direct electrochemical reaction of carbon is enlarged; the reaction speed of carbon gasification is enhanced through the carbon gasification catalyst; and the reaction speed of carbon gasification is enhanced.

Owner:TSINGHUA UNIV

Integrated device for power generation and energy storage based on liquid metal anode direct carbon fuel cell

ActiveCN103972526BPromote oxidationIncrease power generation capacityReactant parameters controlCell electrodesMelting tankEngineering

Owner:TSINGHUA UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com