Patents

Literature

208results about How to "Solving Feed Problems" patented technology

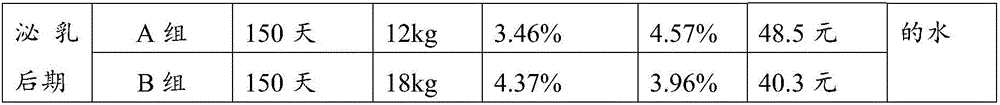

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

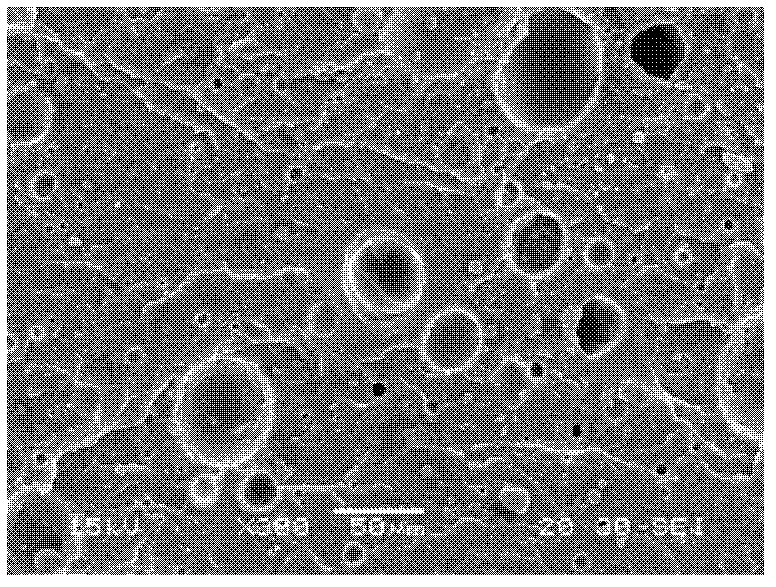

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

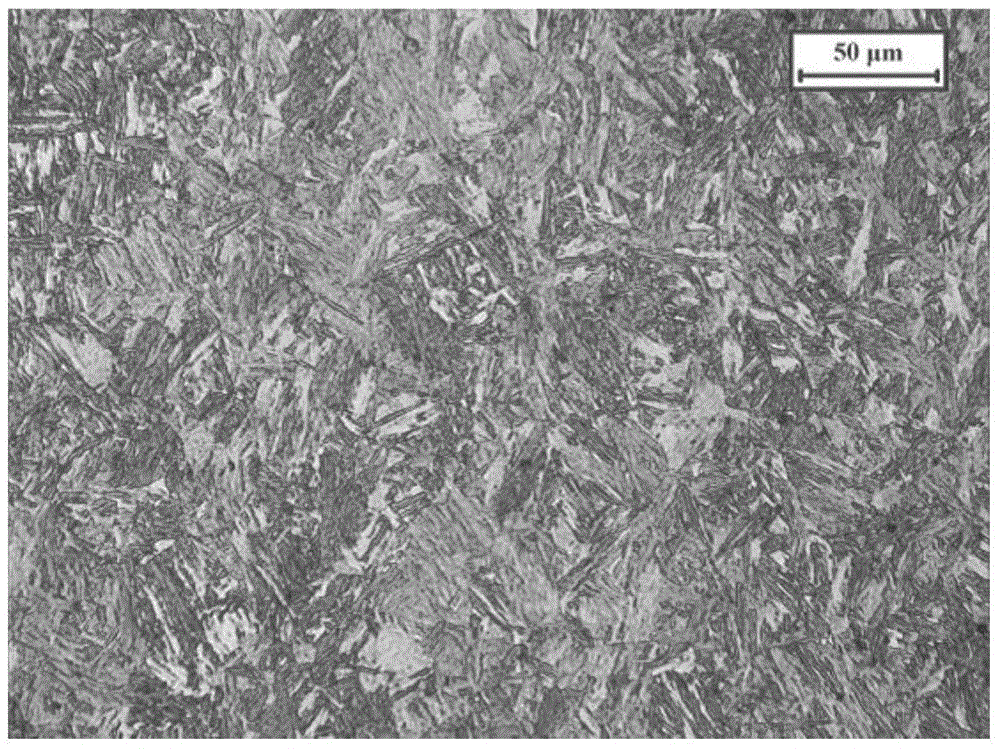

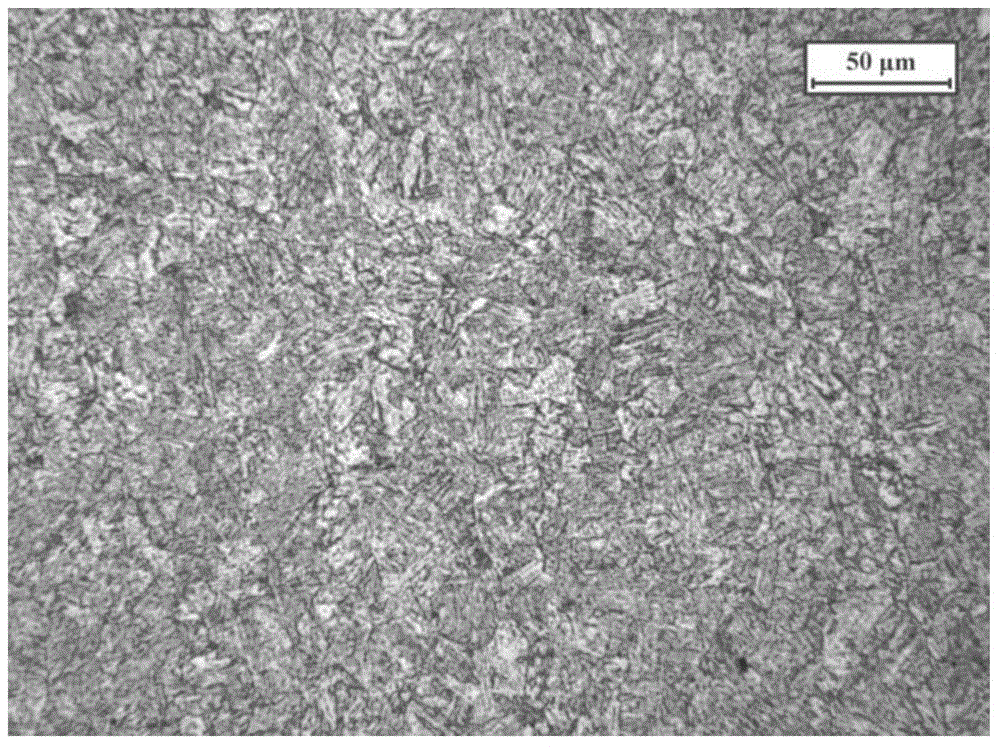

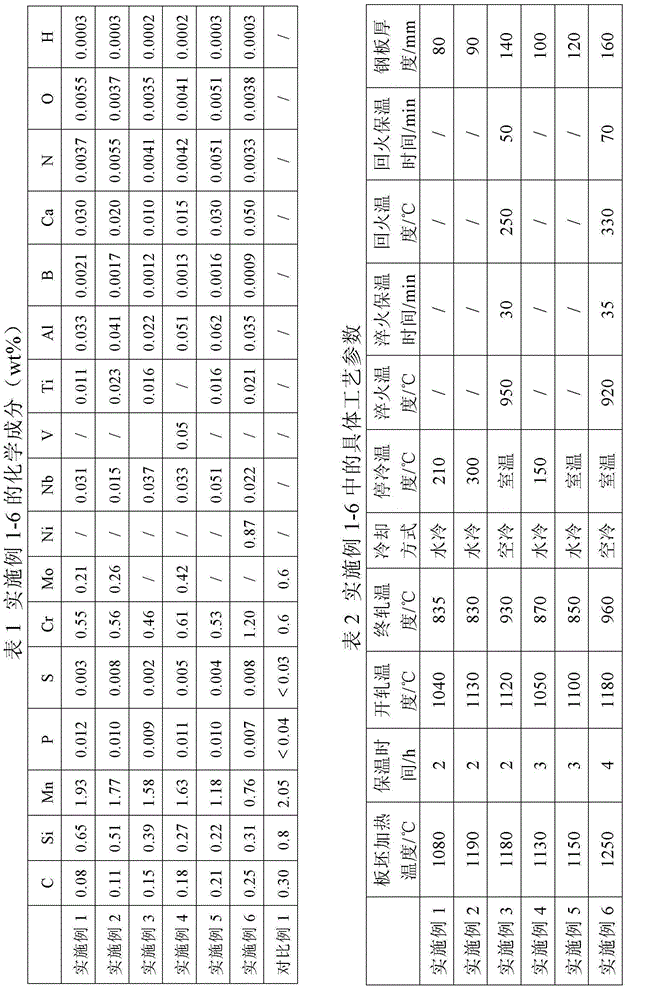

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

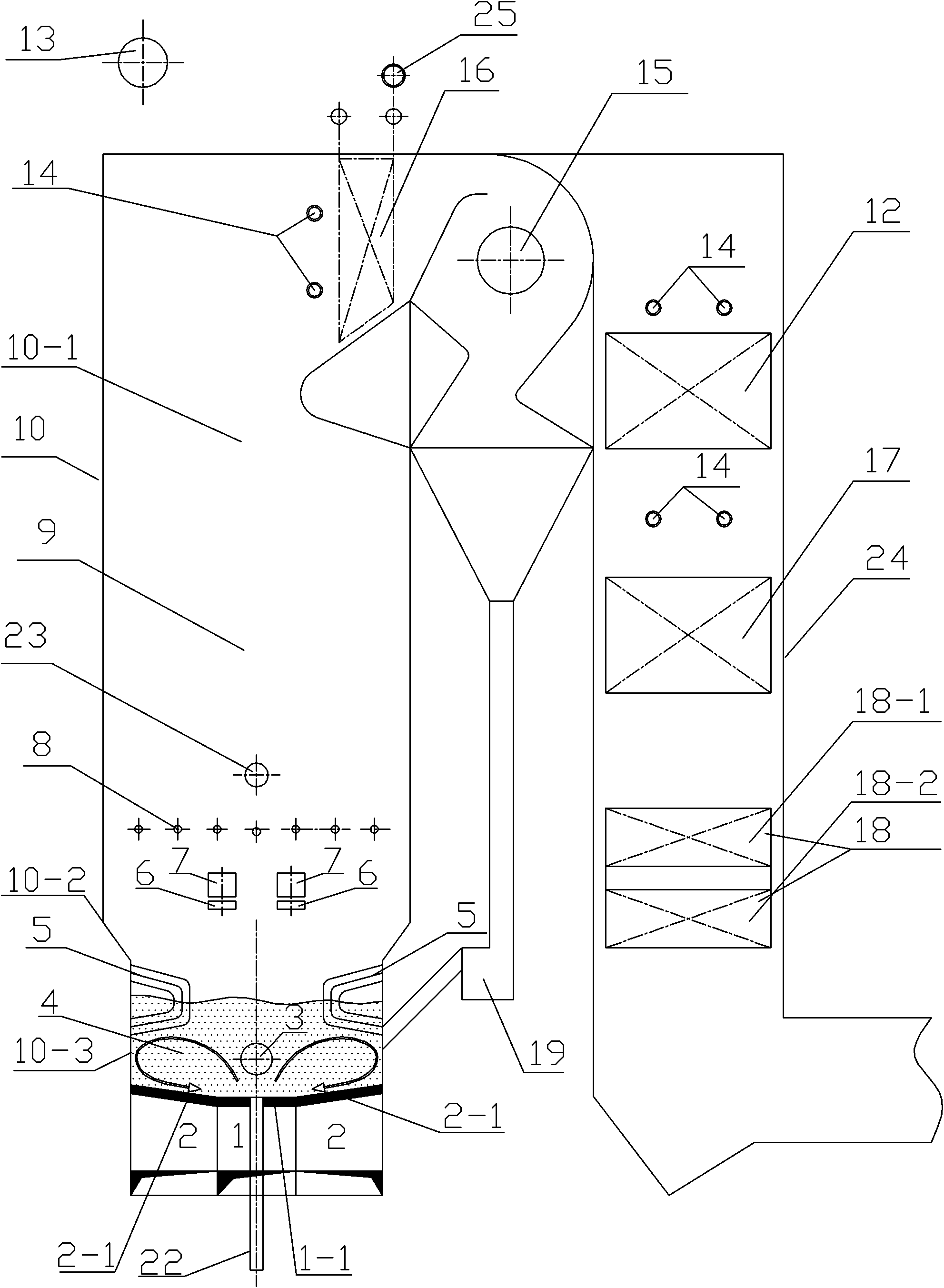

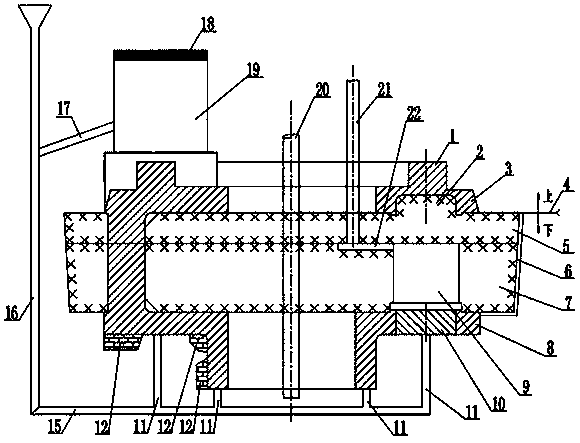

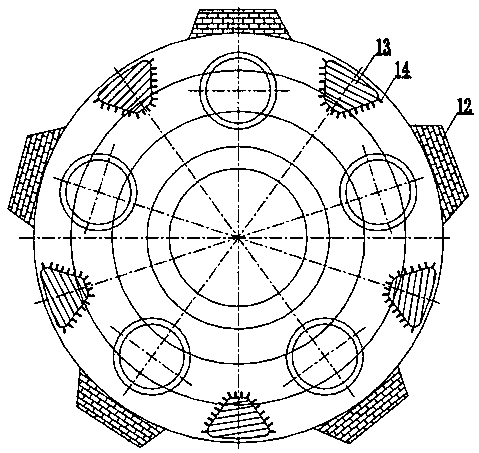

Low-ratio biomass circulating fluidized bed boiler and combustion method thereof

InactiveCN101949535AProlonged combustion residence timeSolve cokingFluidized bed combustionApparatus for fluidised bed combustionCombustionLow speed

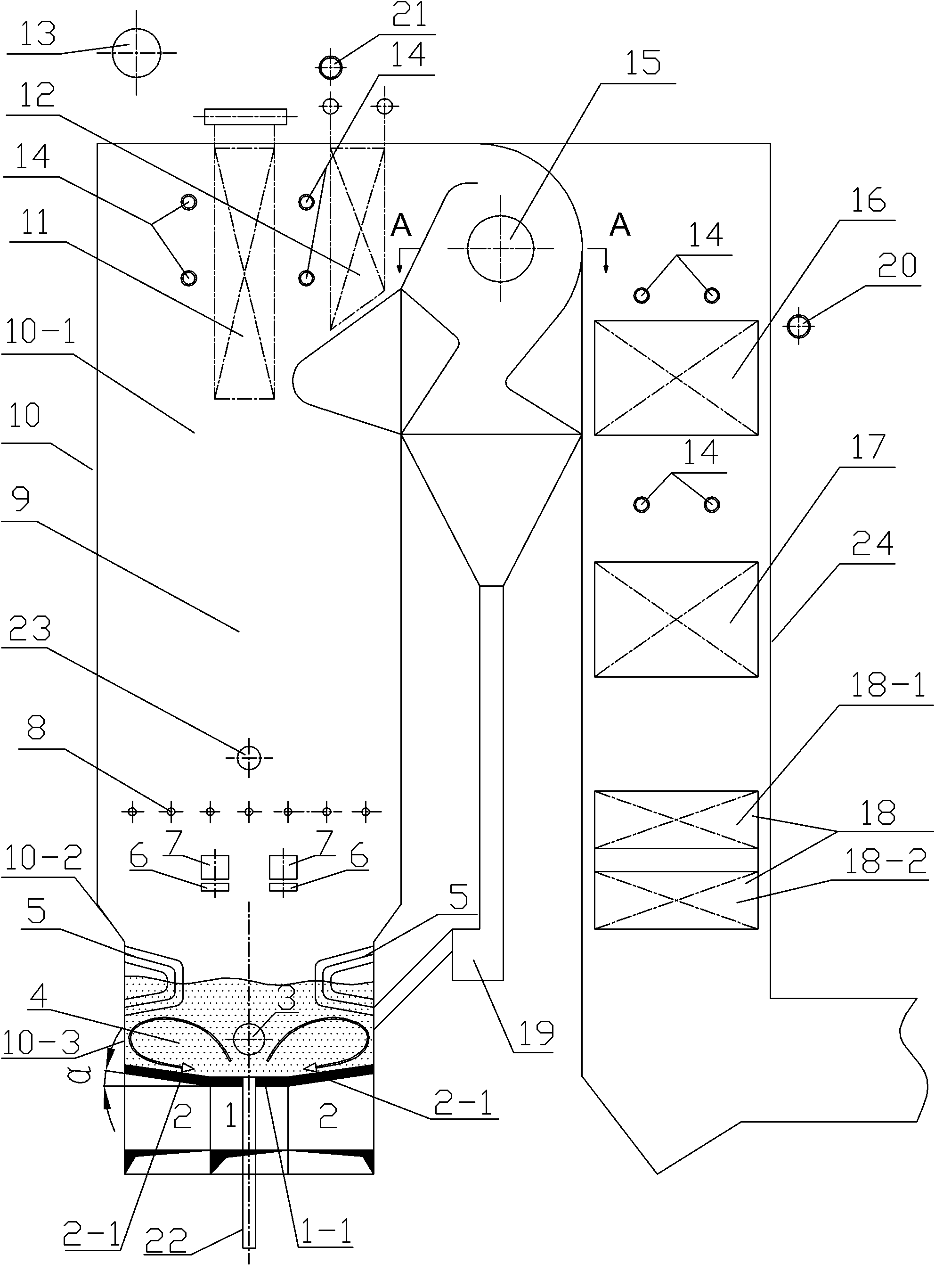

The invention relates to a low-ratio biomass circulating fluidized bed boiler and a combustion method thereof, relating to a circulating fluidized bed boiler and a combustion method thereof and solving the problems of difficult feeding, grate slagging, bed material coking, tempering and output reduction, and the like existing in the operation of traditional grate furnaces and circulating fluidized bed boilers. A middle air chamber corresponds to the middle of a dense-phase area at the lower part, lateral grid plates are arranged between a lateral air chamber and the dense-phase area at the lower part, and a medium-temperature steam-cooled cyclone separator is arranged at the joint between a flue shaft at the tail part and a health outlet of a boiler body, respectively communicated with the flue shaft and the health outlet and communicated with the dense-phase area at the lower part through a material returner. The method adopts a negative-pressure feeding manner so that the fluidization air velocity of a high-speed area of the dense-phase area at the lower part is 4-5 m / s, the fluidization air velocity of a low-speed area is 1.5-2.0 m / s, the temperature of the dense-phase area at the lower part is 650-780 DEG C, and the material circulation ratio is below 10. The invention is suitable for the biomass circulating fluidized bed boiler for an electric power plant.

Owner:湖南博茂节能环保科技有限公司

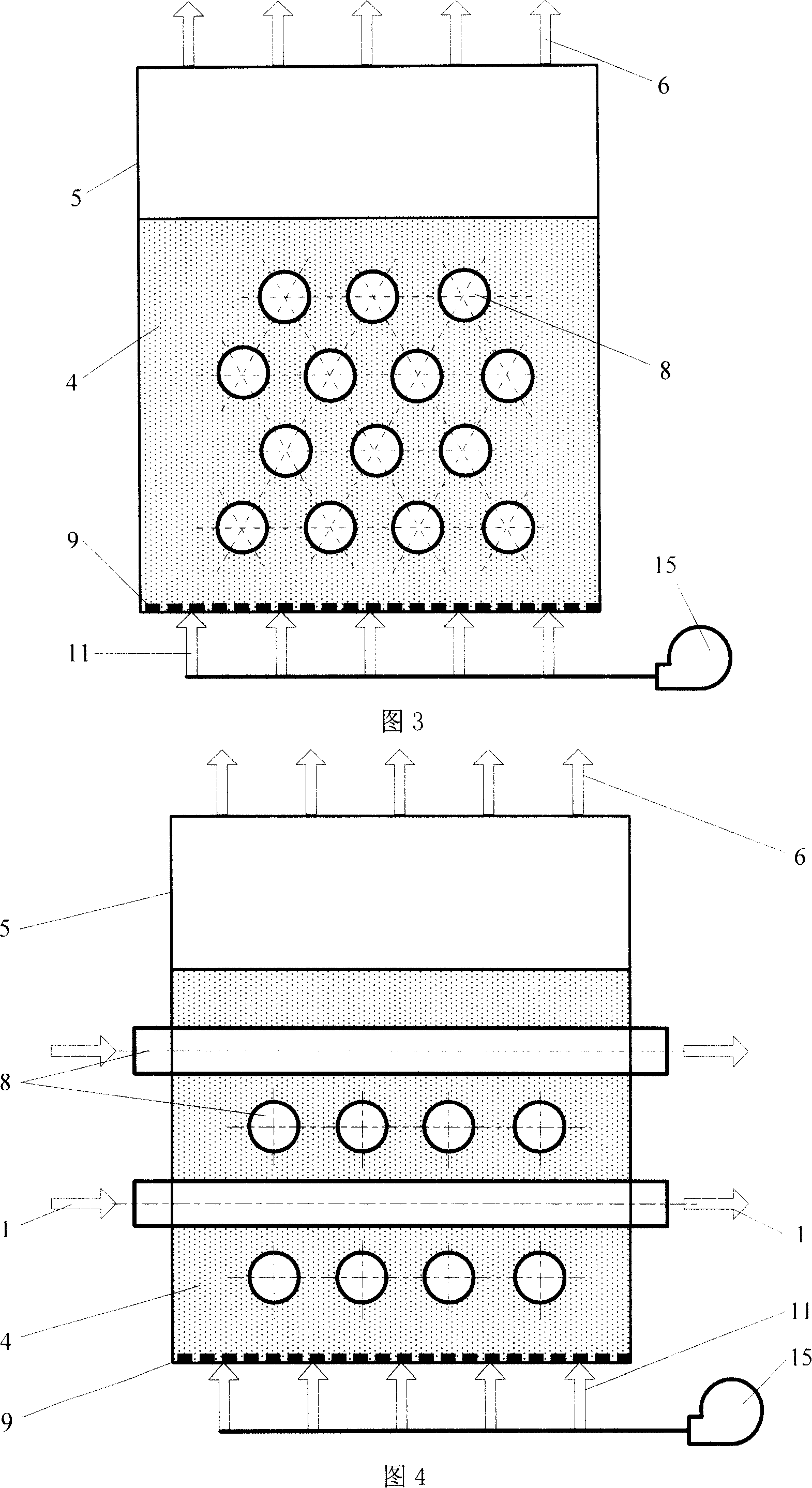

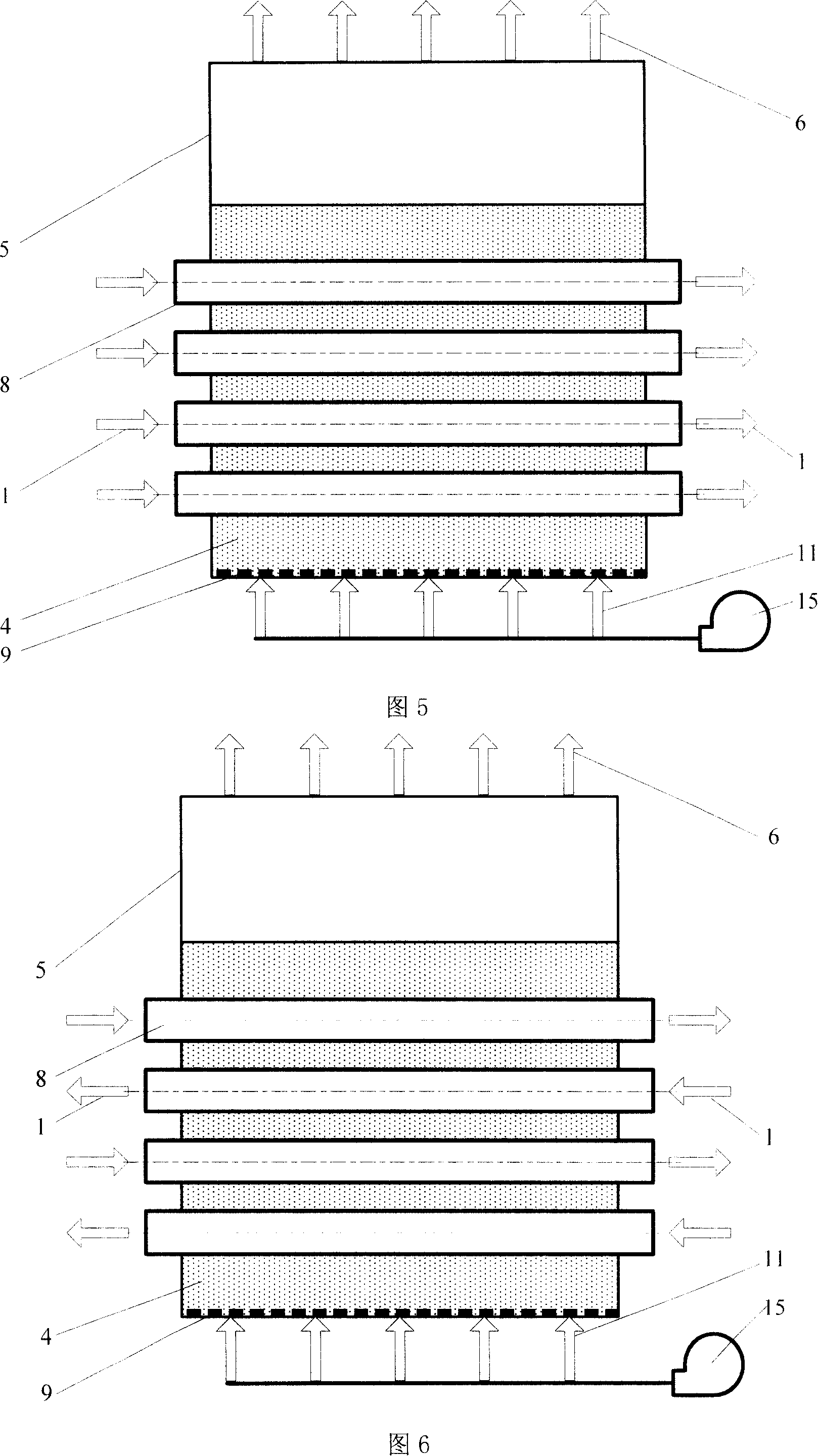

Fluid bed electrode direct carbon fuel cell device

InactiveCN102324539AImprove performanceEasy inflowCell electrodesFuel cell auxillariesElectrochemical responseSolid carbon

The invention discloses a fluid bed electrode direct carbon fuel cell device, which belongs to the technical field of clean energy. The device comprises a fluid bed, two or more tubular single cells, collector plates, a composite carbon fuel, a gas circulating device, a screw feeder and a fuel tank. In the device, a conductor catalyst is added into a solid carbon fuel on the basis of a solid oxide direct carbon fuel cell to expand a direct electrochemical reaction interface of carbon from a two dimension to a three dimension and promote the gasification reaction of the carbon, thereby improving the performance of the cell; the collector plates are distributed on the wall surface of a reactor, so current is convenient to collect; and simultaneously, a fluid bed reactor forms a fluid bed electrode to further enhance heat transfer and mass transfer in the electrode, so not only problems about feeding are solved, but also the performance of the solid oxide direct carbon fuel cell is further improved.

Owner:TSINGHUA UNIV

Full artificial compound feed for juvenilesea cucumbers

InactiveCN101099542AMeeting nutritional needsImprove conversion rateClimate change adaptationAnimal feeding stuffYeastStichopus

The present invention provides a complete artificial mixed feed for stichopus japonicus. Said feed composition includes (by weight portion) 60-30 portions of sargassum thunbergii powder, 15-25 portions of sea-verdure powder, 15-45 portions of degummed sea-tangle powder, 15-5 portions of spirulina princes powder, 10-5 portions of fermentation yeast, 0.6-0.2 portion of polyvitamin complex, 0.8-0.4 portion of compound mineral salt and 10-60 portions of dried dredge.

Owner:青岛浩然海洋科技有限公司

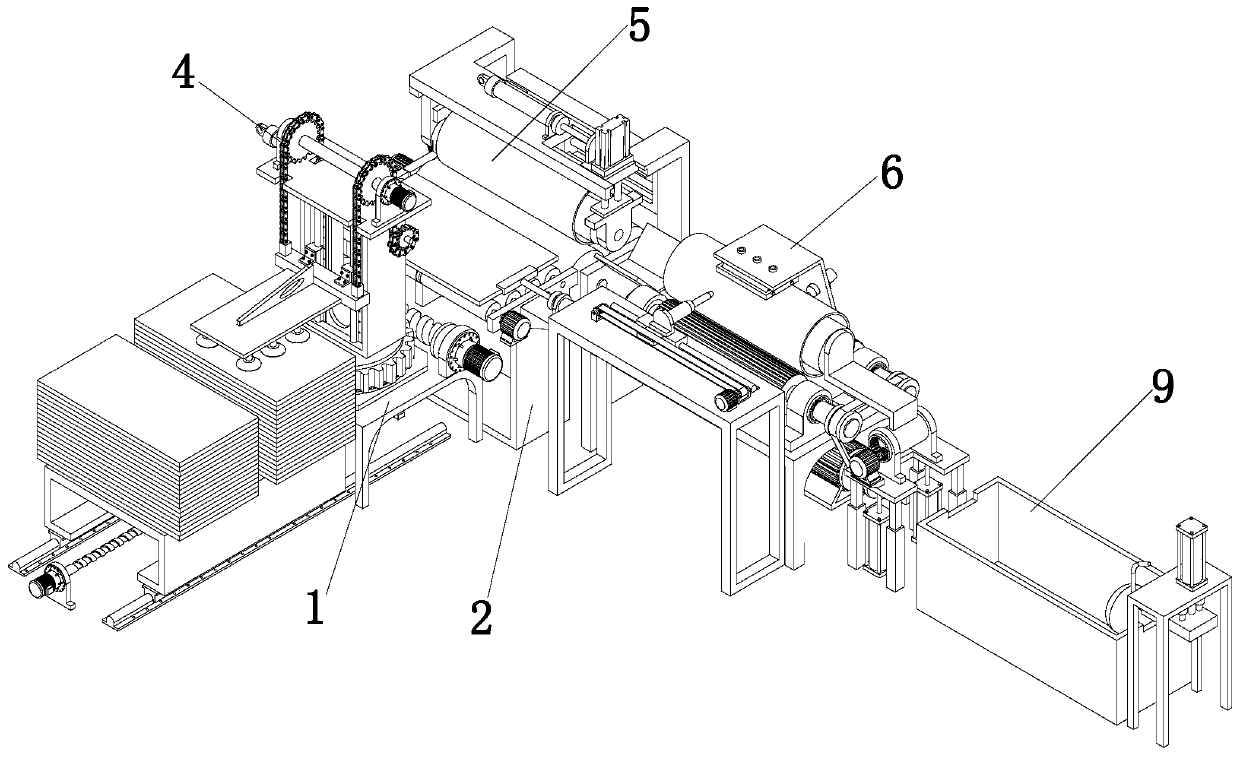

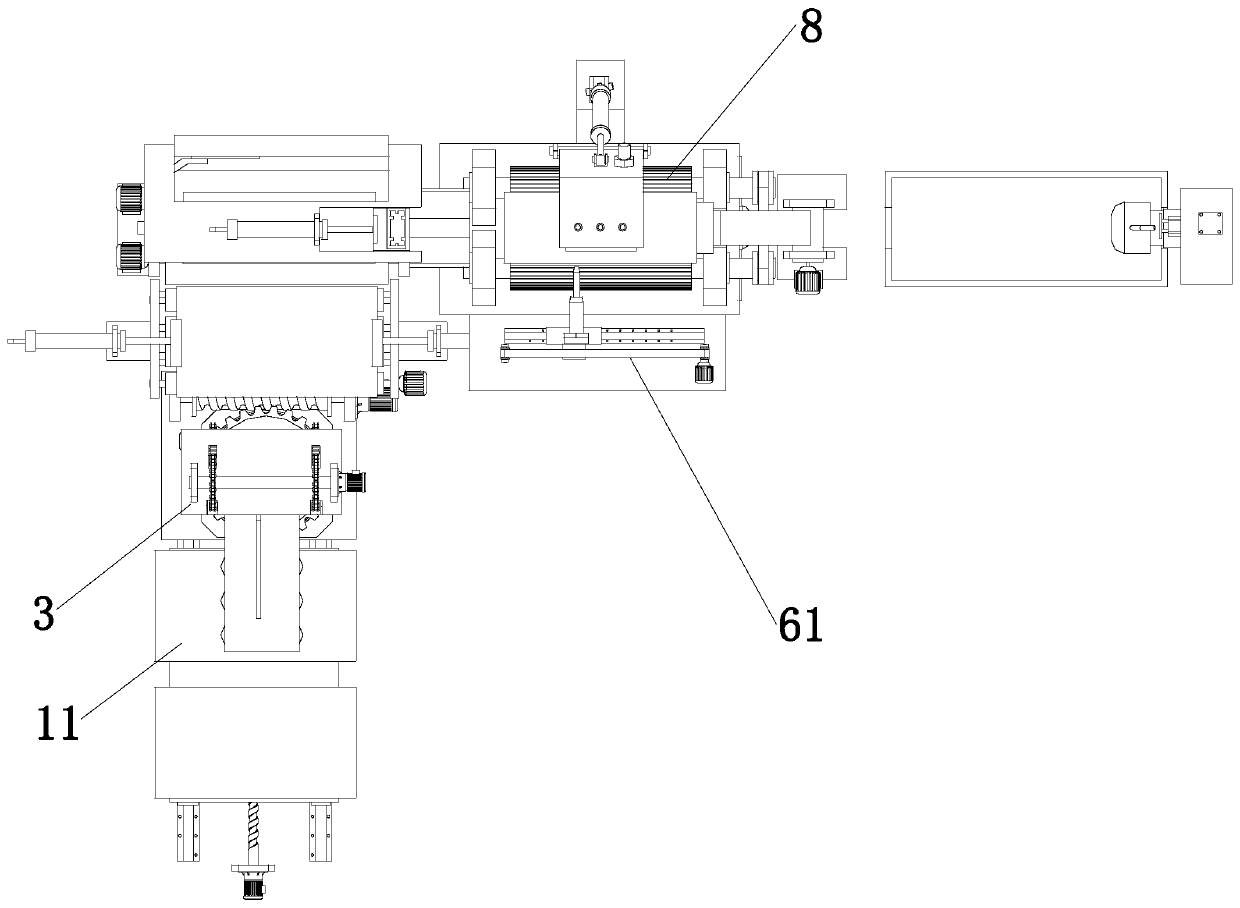

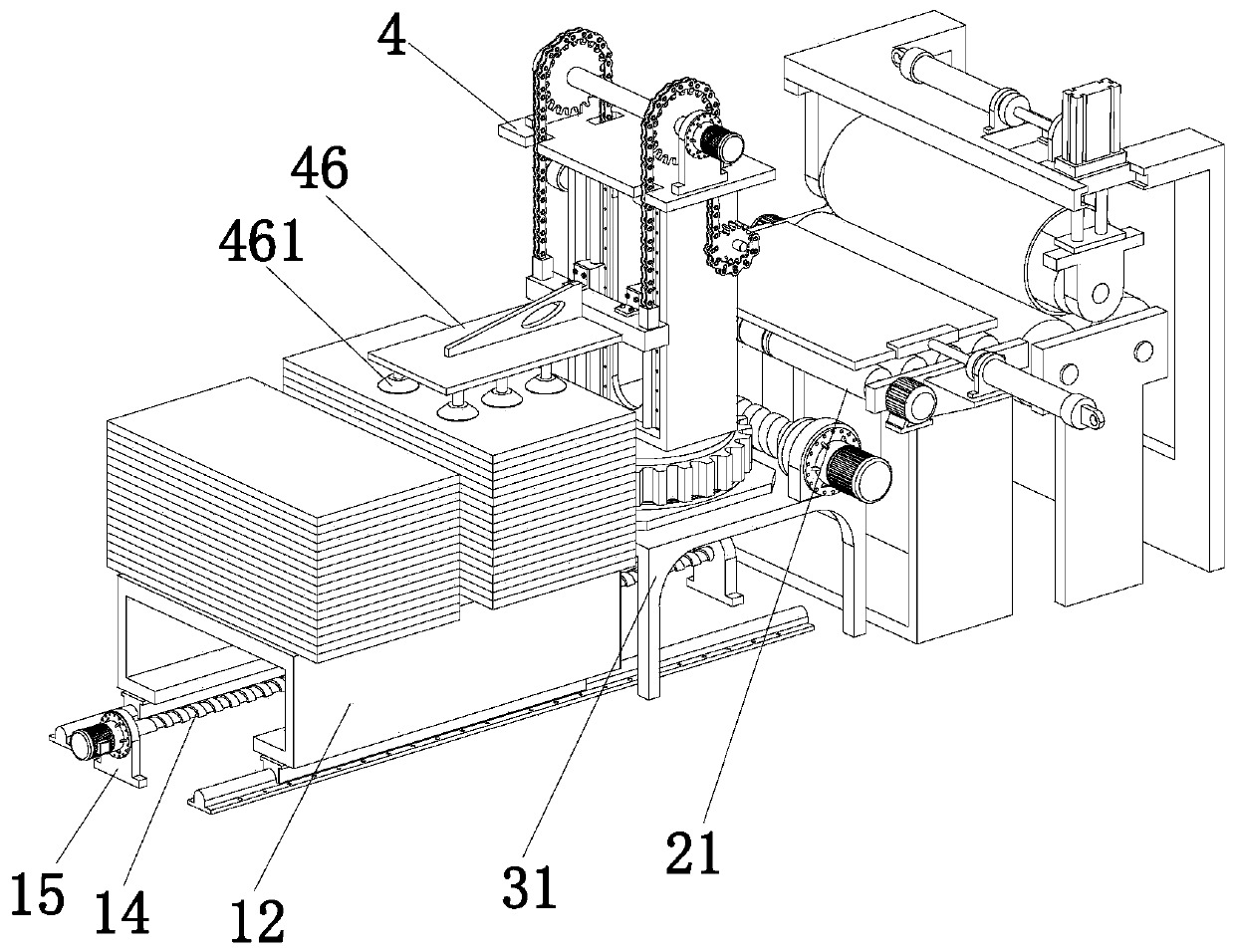

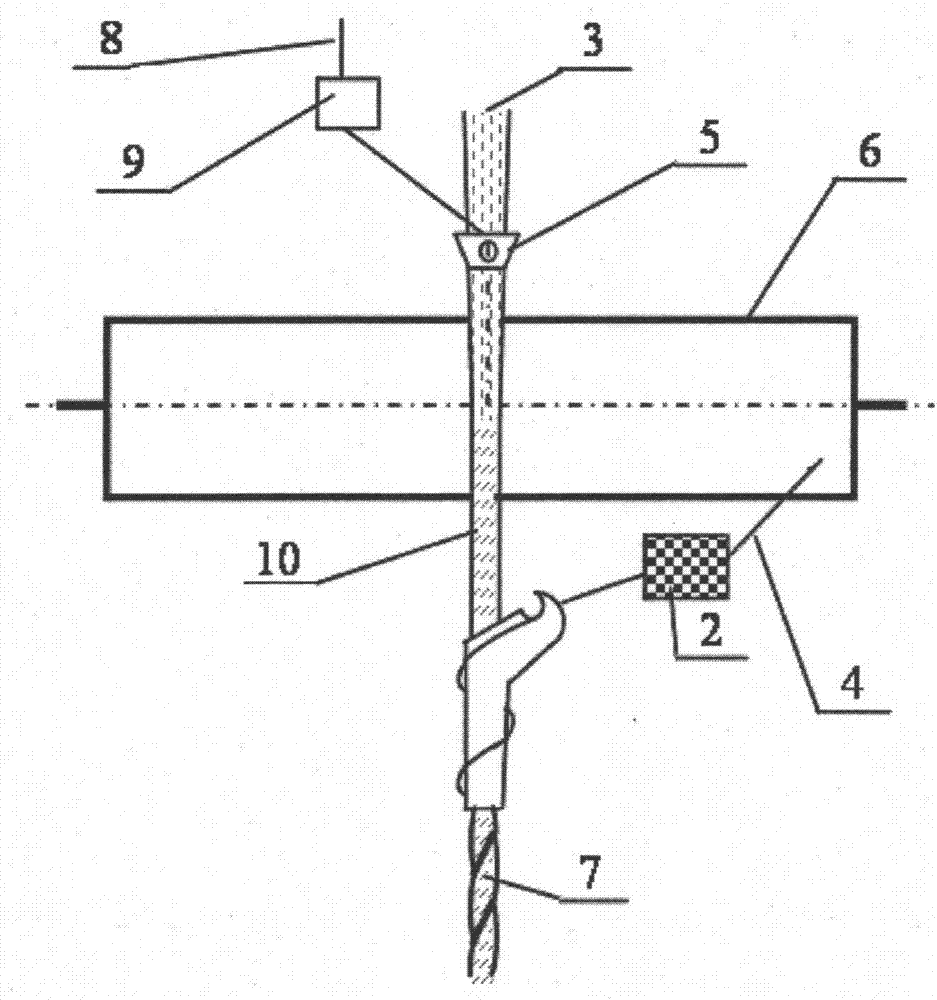

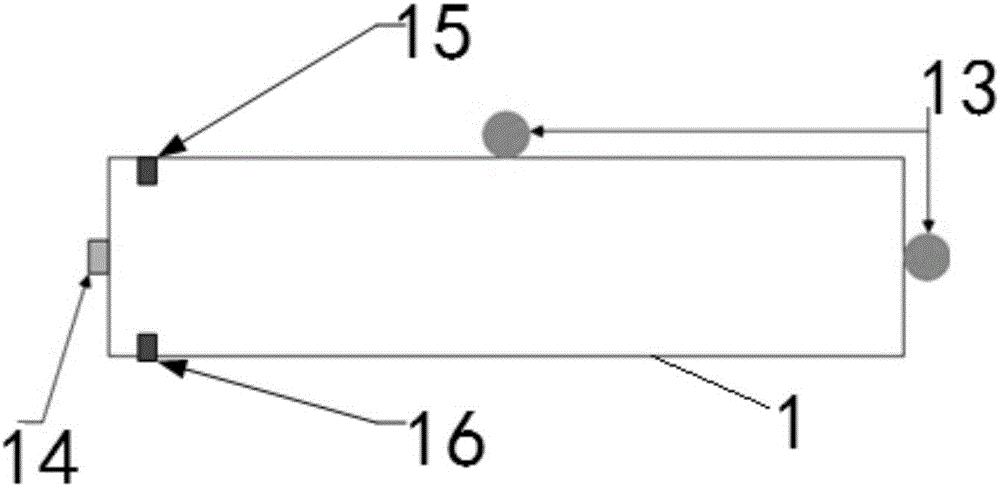

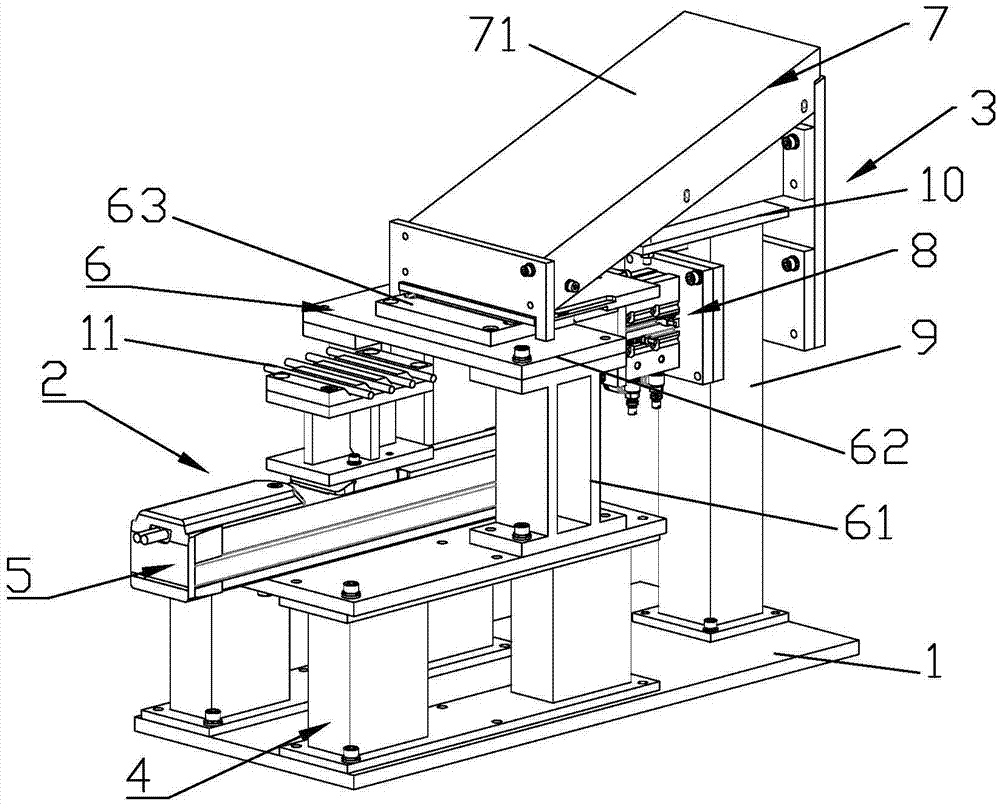

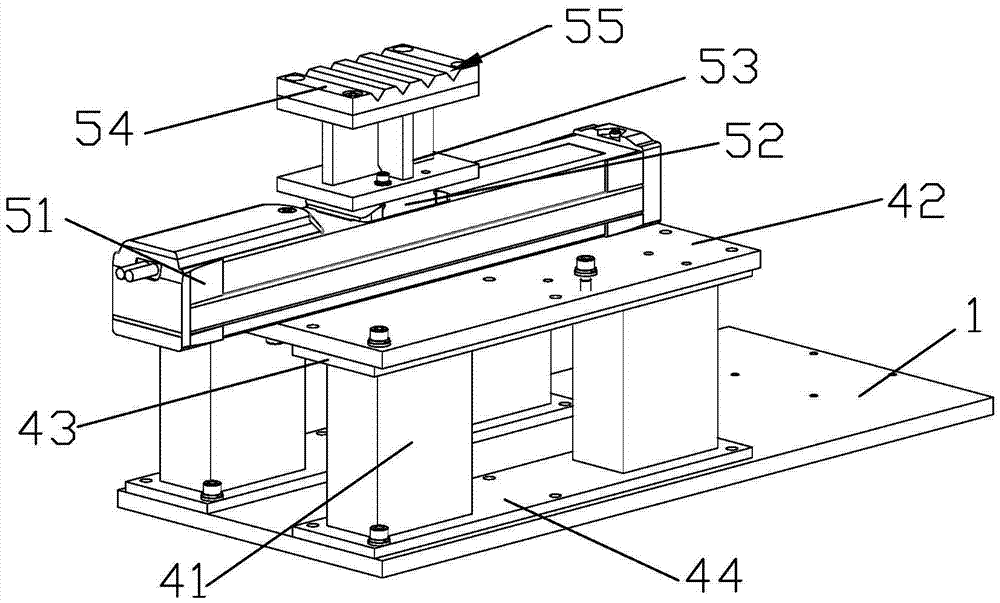

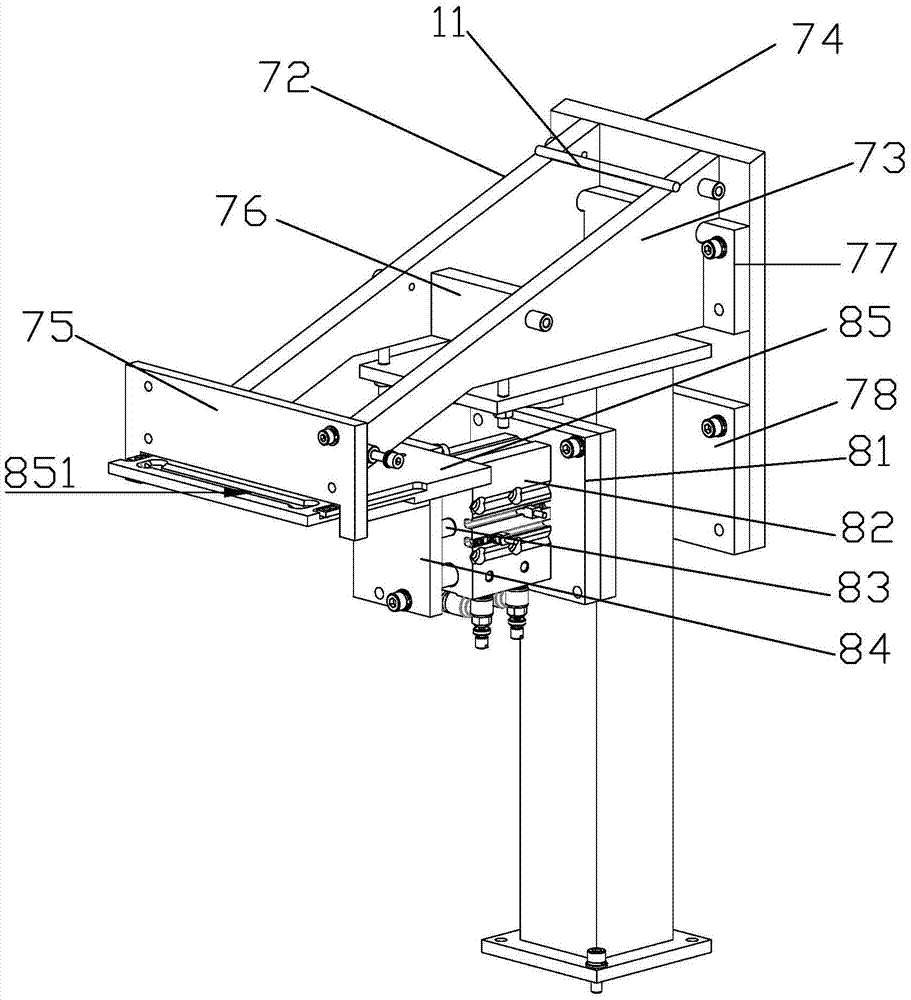

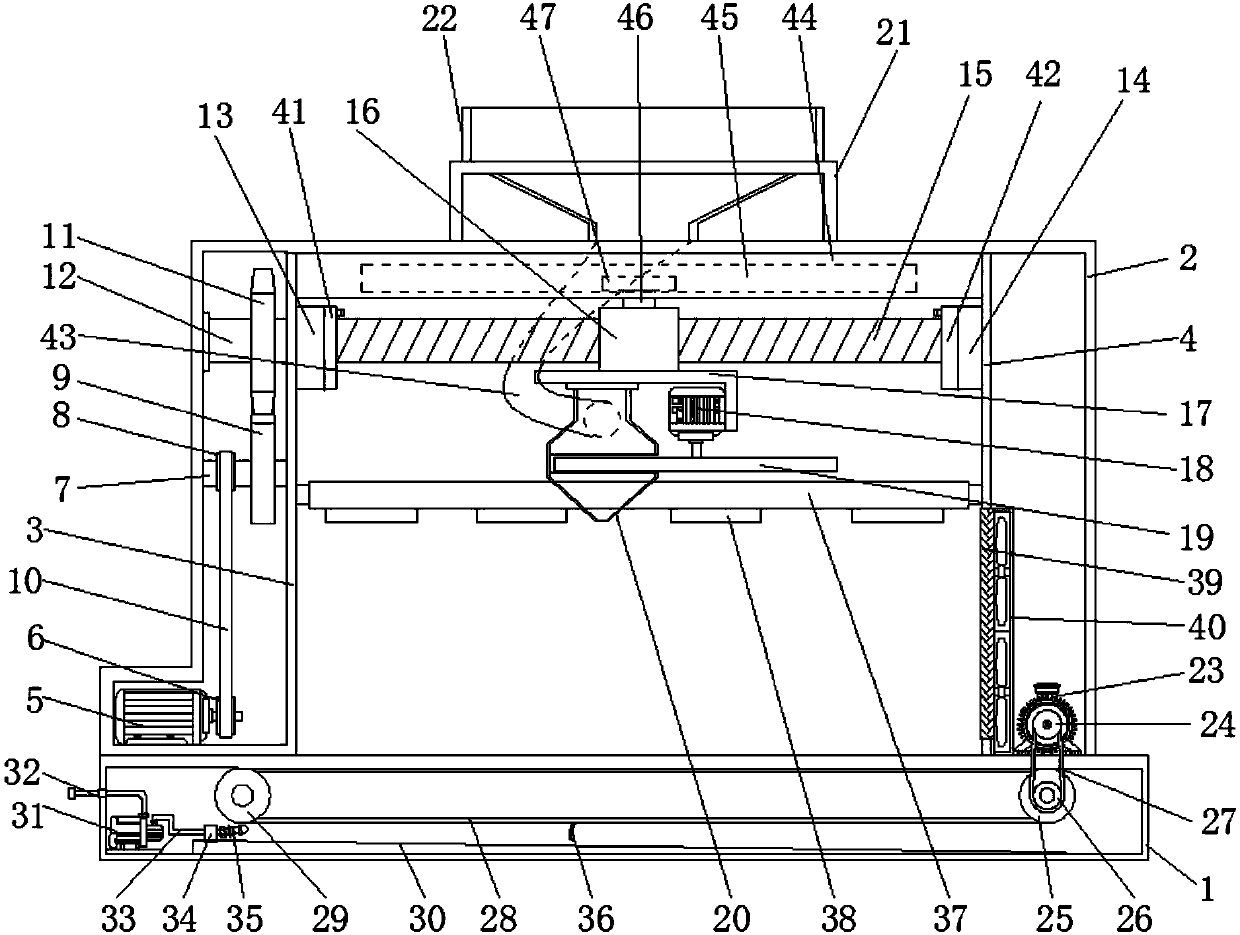

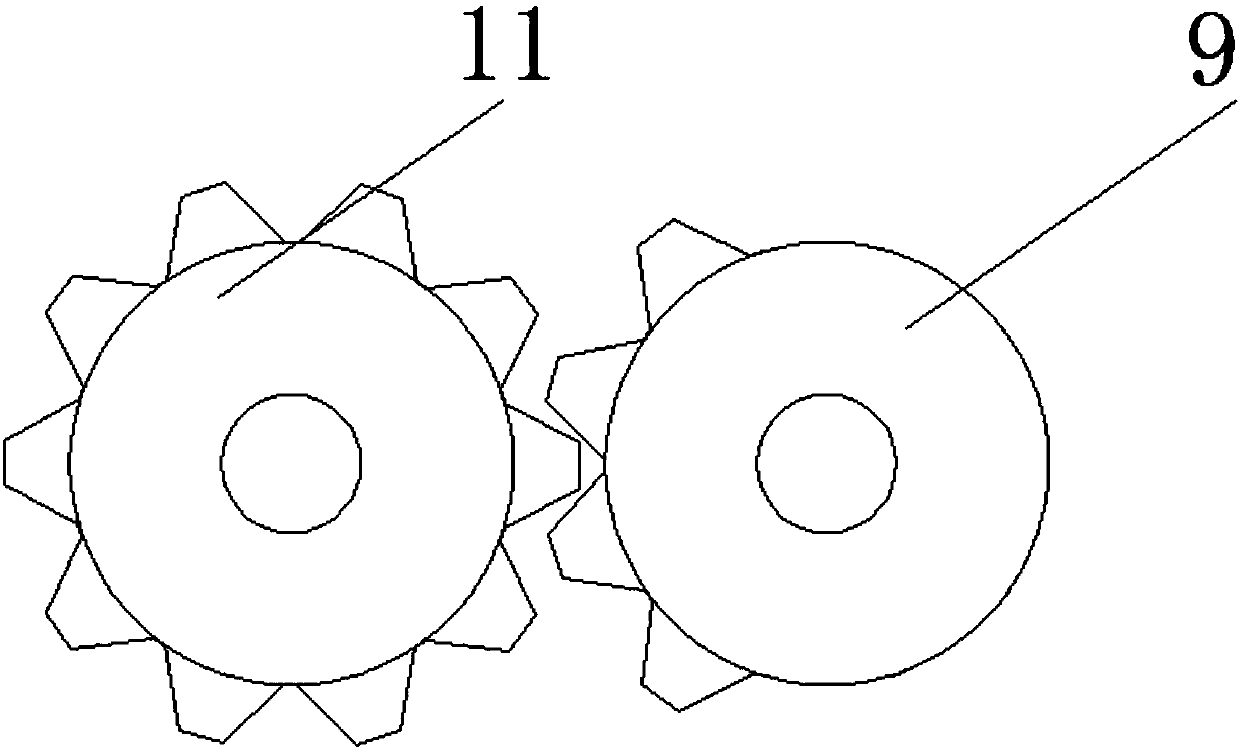

Solar water heater water tank inner container rounding welding machine

ActiveCN111185697ARealize roll forming operationAutomatically realize transportation and handlingWelding/cutting auxillary devicesAuxillary welding devicesThermodynamicsSolar water

The invention discloses a solar water heater water tank inner container rounding welding machine, and belongs to the technical field of water heater machining equipment. The solar water heater water tank inner container rounding welding machine comprises a plate feeding device, a plate rolling forming device and a welding leak checking device. The plate feeding device comprises a plate storing mechanism, an aligning feeding mechanism and a plate conveying mechanism. The aligning feeding mechanism comprises an aligning limiting assembly, a conveying assembly, a supporting frame, two conveying rollers and multiple supporting rollers. The two ends of each supporting roller and the two ends of each conveying roller are connected with a supporting frame through bearings. The solar water heaterwater tank inner container rounding welding machine has the beneficial effects that the solar water heater water tank inner container rounding welding machine is high in automation degree, plates canbe automatically subjected to transporting and carrying, plate rolling forming and leak checking welding operation, the plates can be sequentially conveyed into the plate rolling forming device underthe operation of the plate feeding device, and the plates can be limited at the middle-section positions of the supporting rollers through the aligning limiting assembly.

Owner:裘士兴

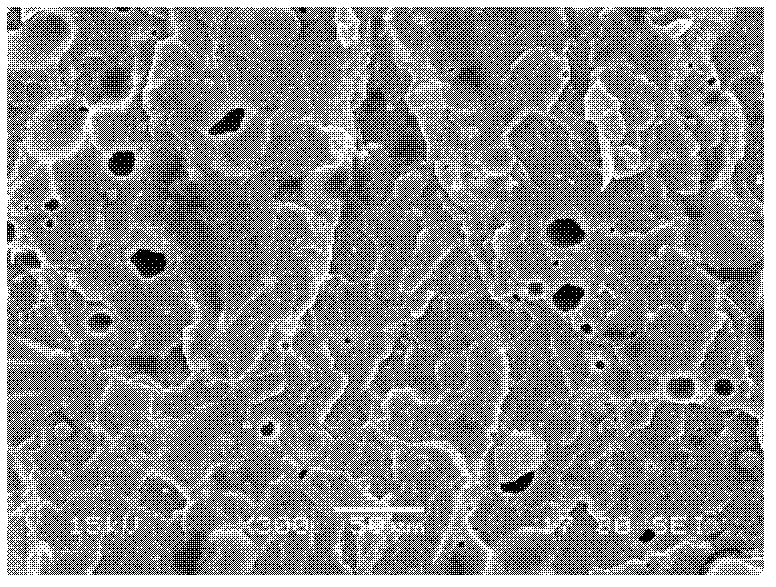

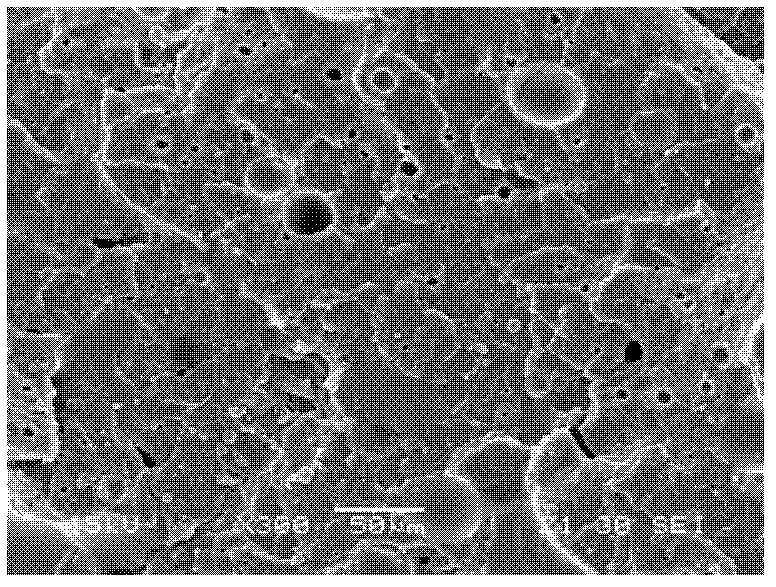

Halogen-free inflaming-retarding polypropylene composition and preparation method thereof

The invention provides a halogen-free inflaming-retarding polypropylene composition comprising the following components in parts by weight: 30-90 parts of polypropylene resin, 1-3 parts of compatilizer, 10-50 parts of fire retardant and 0.05-2 parts of antioxidant, wherein the compatilizer is a grafted object of low-molecular polyolefin and a polar monomer; and the fire retardant is the mixture of ammonium polyphosphate and polyatomic alcohol, and the mass ratio of the ammonium polyphosphate to the polyatomic alcohol is (0.1-12): 1. The preparation method of the halogen-free inflaming-retarding polypropylene composition comprises the following steps of: melting and commixing all the components including the polypropylene resin, the compatilizer, the fire retardant and the antioxidant in a high-speed mixing machine in parts by weight; and then, molding by a pressing plate or directing extruding and granulating in a screw extruding machine to prepare the halogen-free inflaming-retarding polypropylene composition. The composition disclosed by the invention has the advantages of good inflaming-retarding performance, low smoke and no toxin, and has good processing performance and mechanical property; and the preparation method is simple and reliable.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

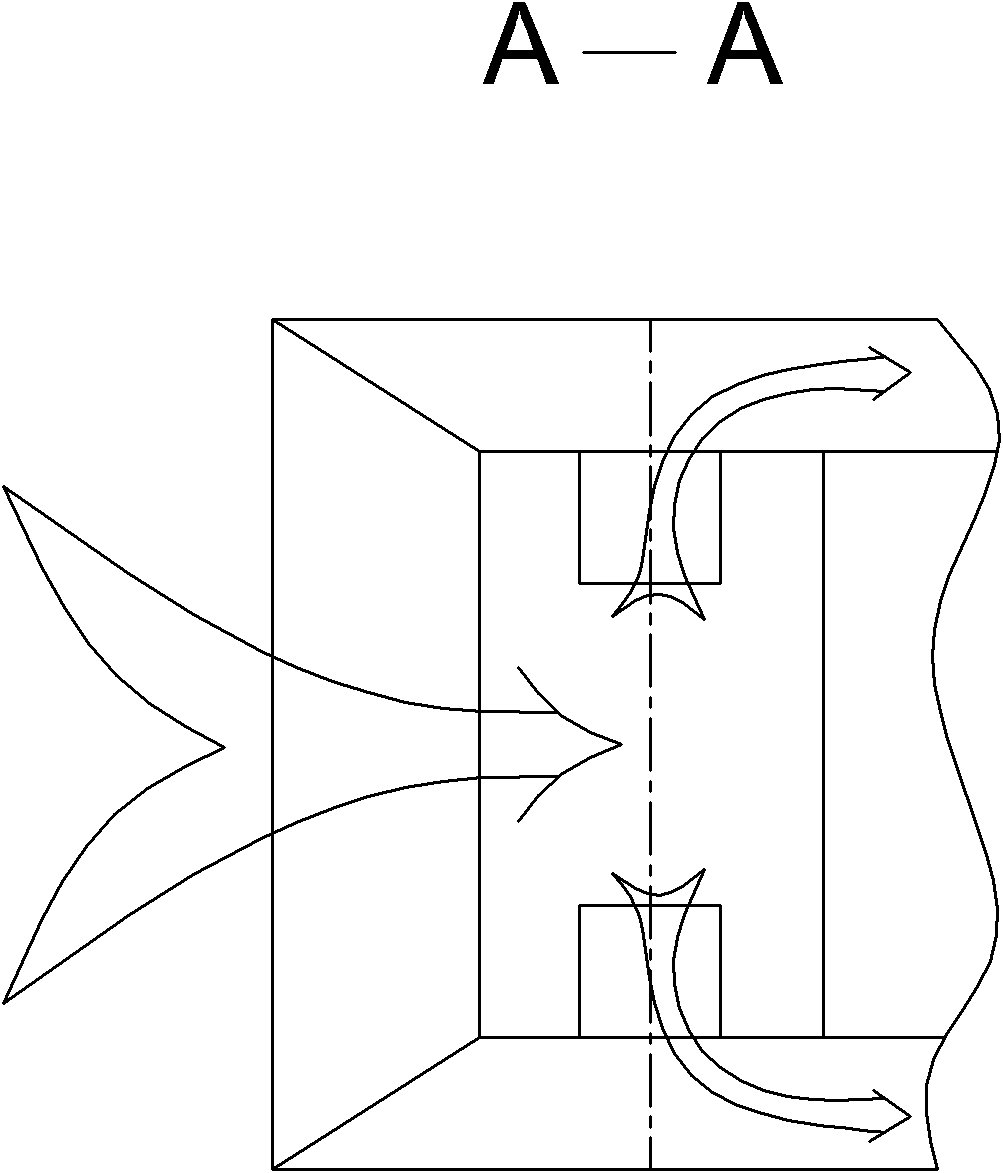

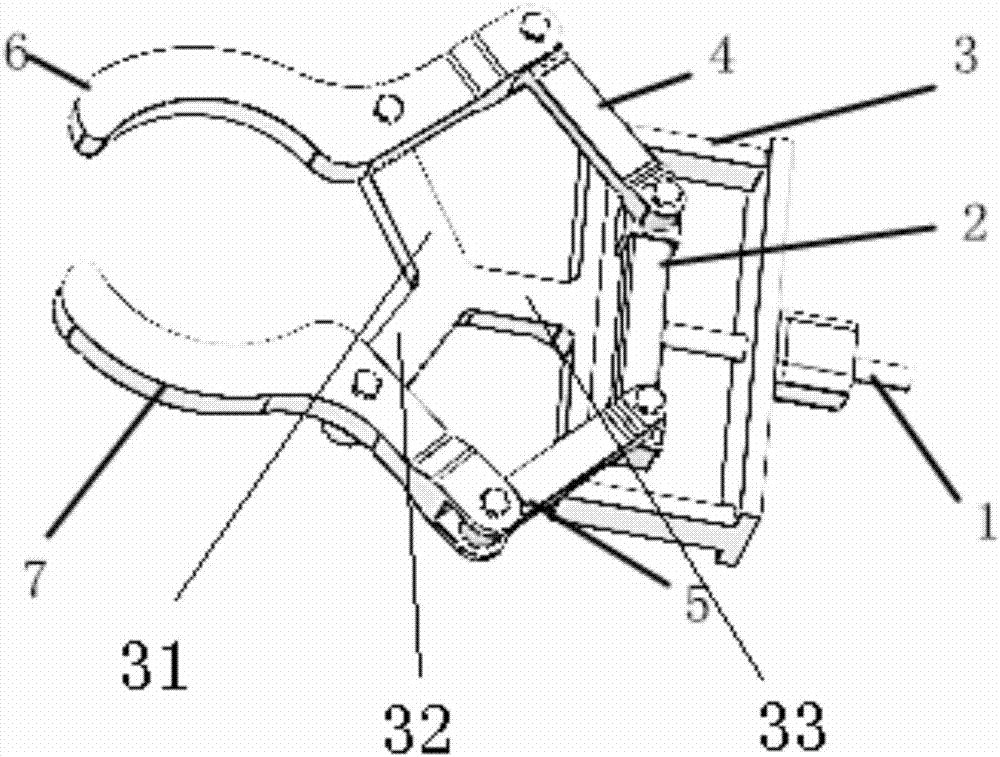

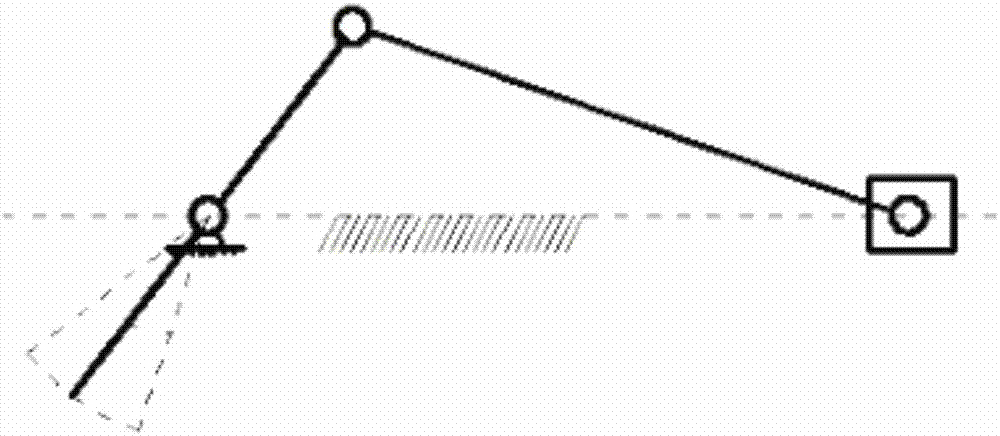

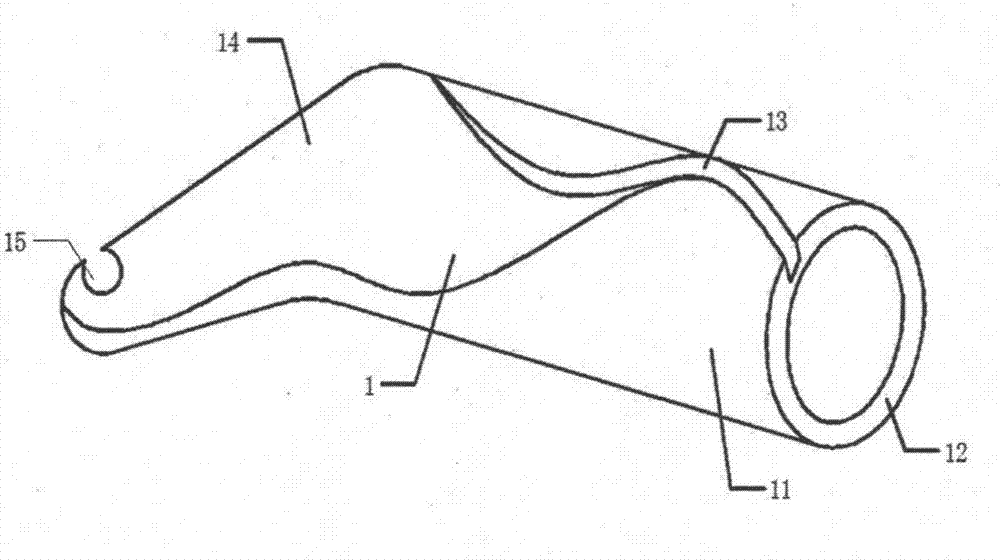

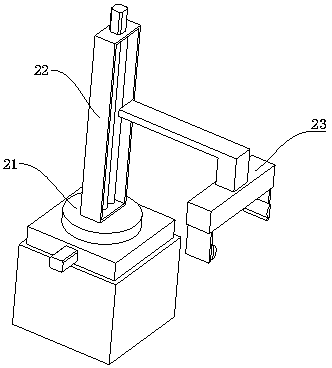

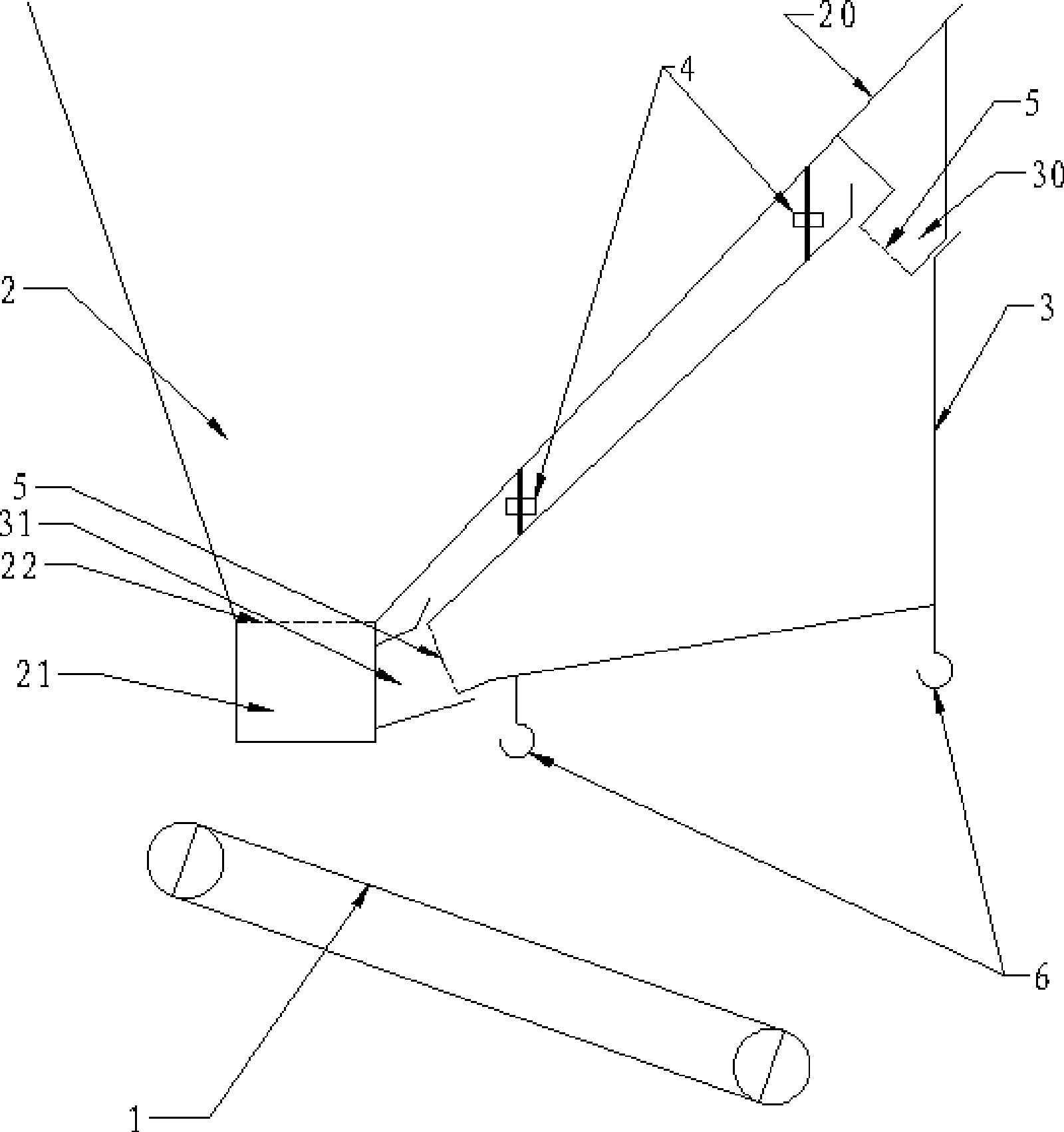

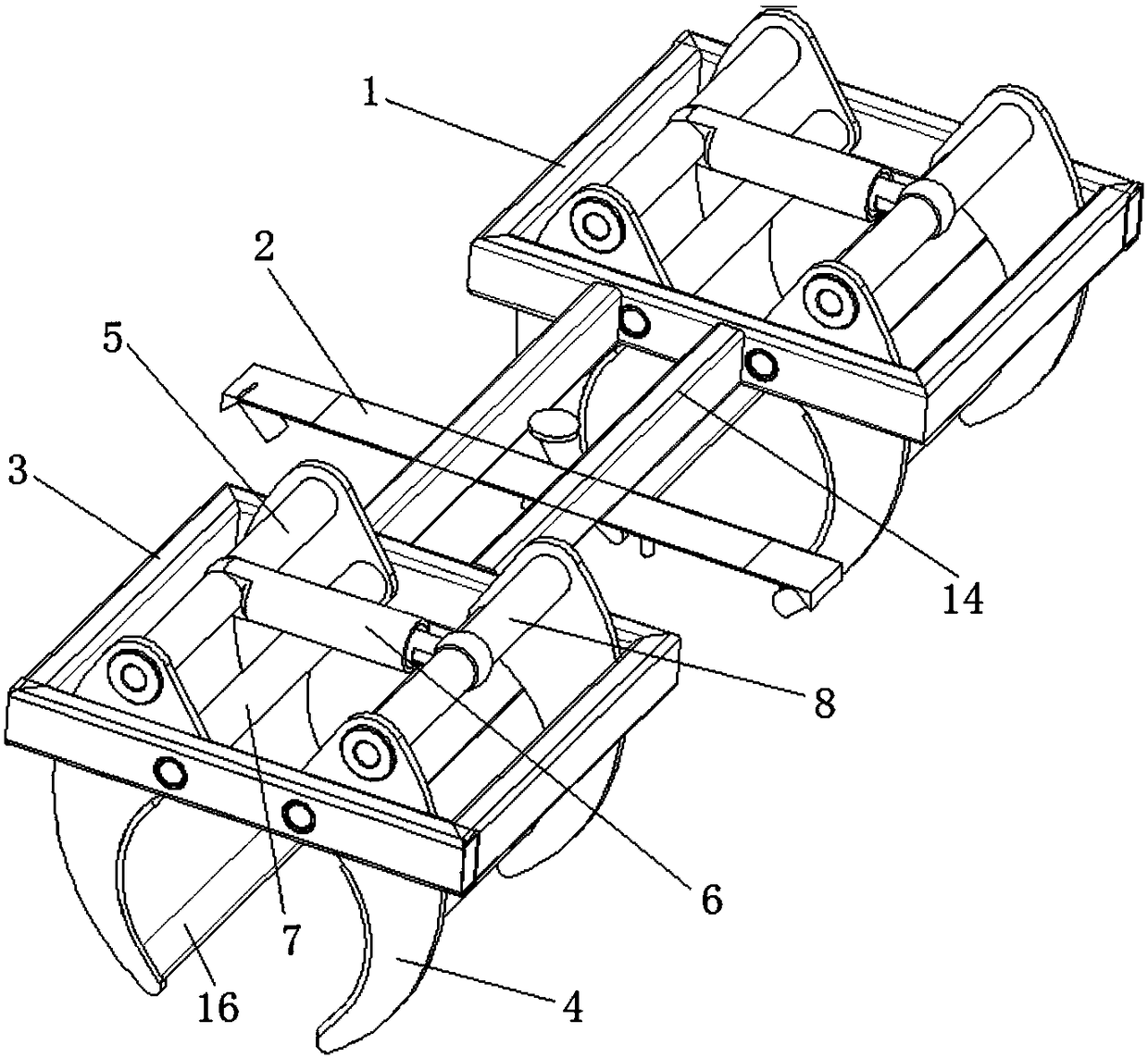

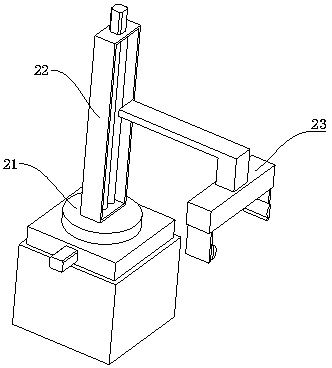

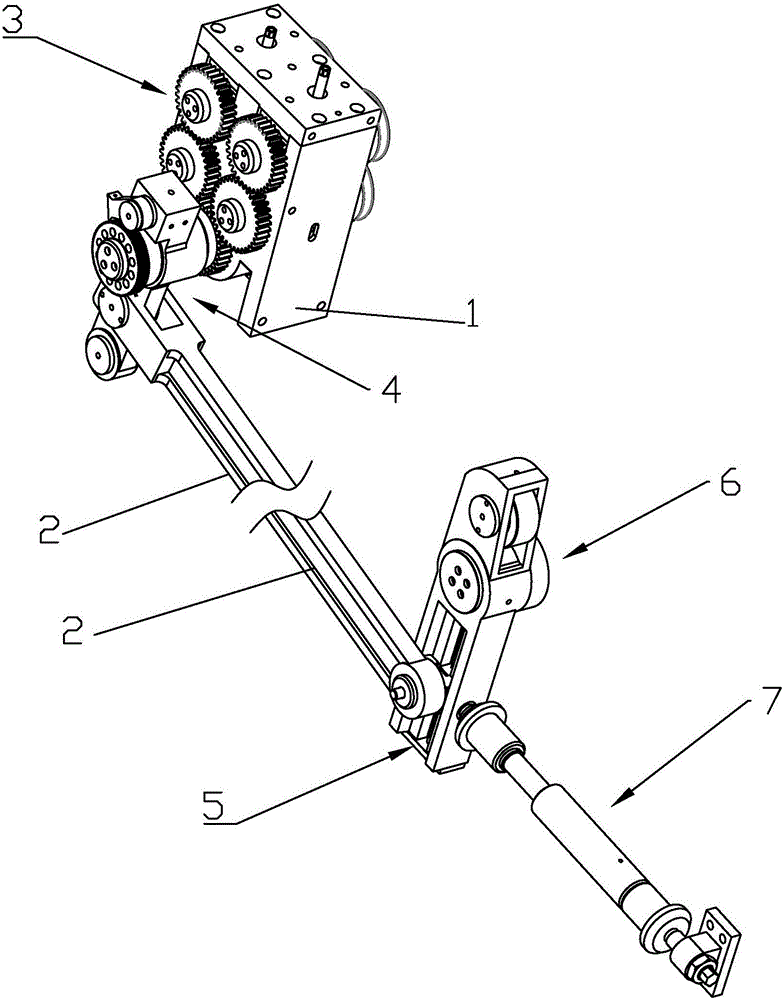

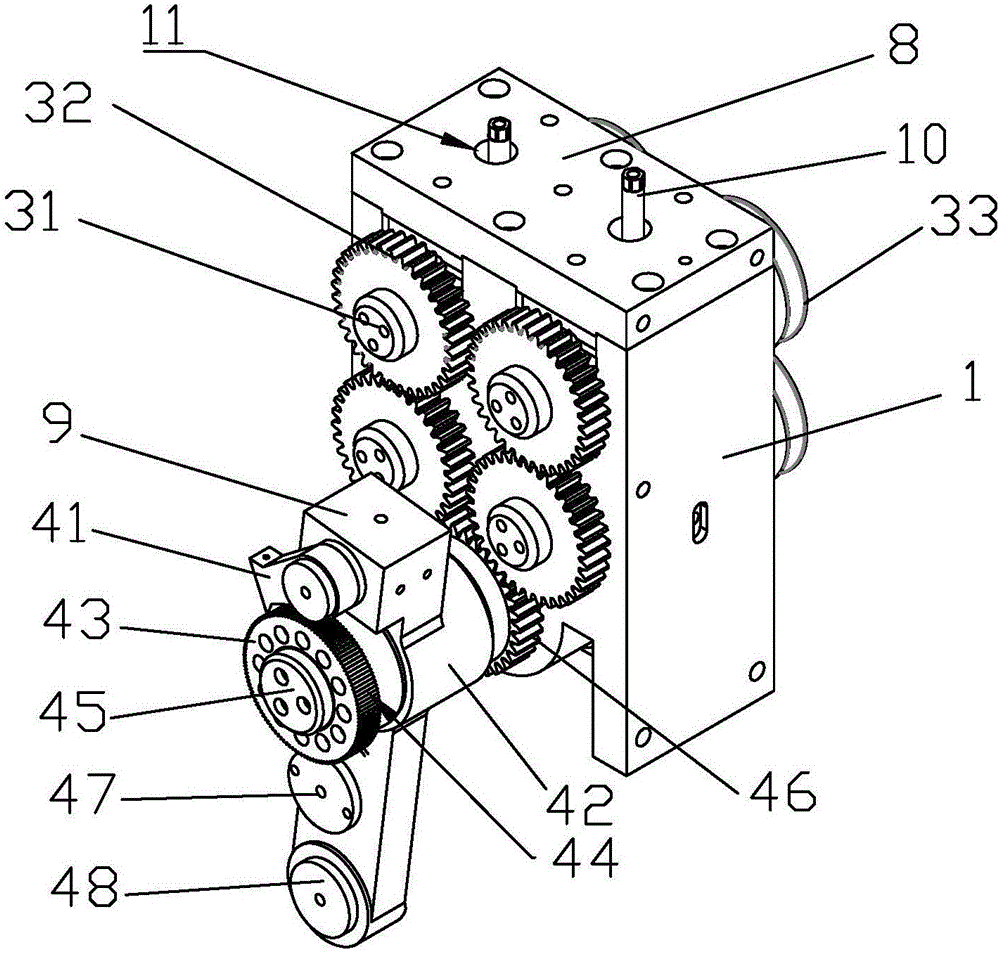

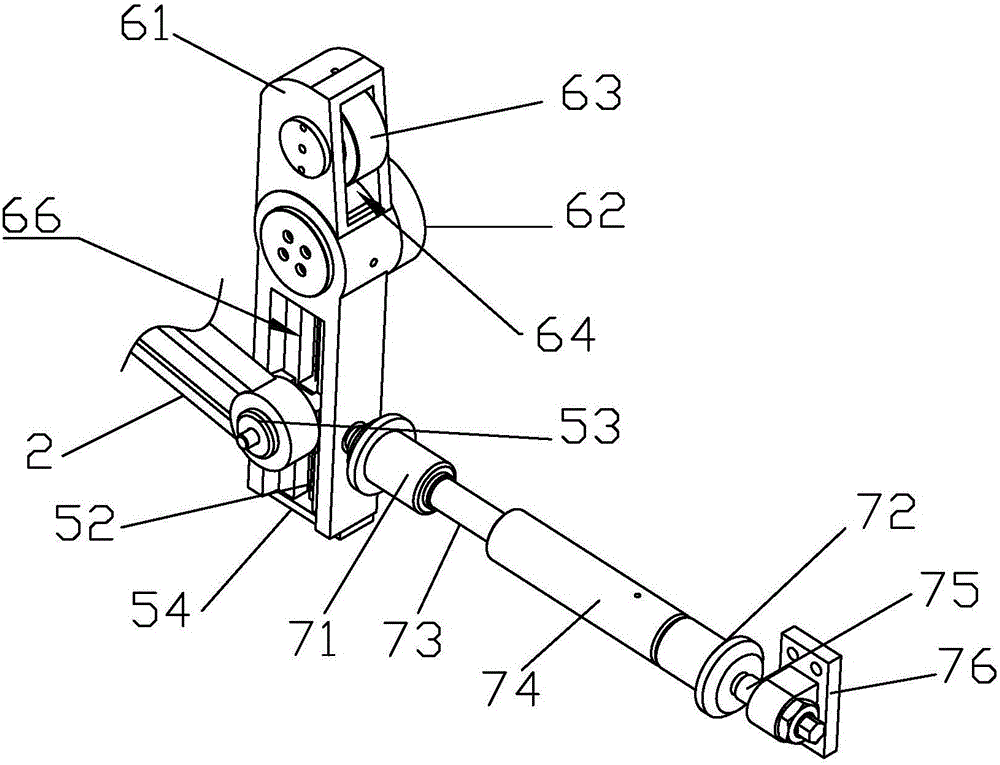

Feeding robot gripper for rod material

InactiveCN106945066ASolving Feed ProblemsProtection securityGripping headsConveyor partsEngineeringFeeding problems

The invention discloses a feeding robot gripper for a rod material. The feeding robot gripper comprises a base, a sliding block assembly, a first gripper finger, a first connecting rod, a second gripper finger and a second connecting rod. The sliding block assembly is slidably assembled on the base. The front portion of the first gripper finger is a first gripping part. The middle of the first gripper finger is hinged to the base. One end of the first connecting rod is hinged to the sliding block assembly, and the other end of the first connecting rod is hinged to the back portion of the first gripper finger. The front portion of the second gripper finger is a second gripping part. The middle of the second gripper finger is hinged to the base. One end of the second connecting rod is hinged to the sliding block assembly, and the other end of the second connecting rod is hinged to the back portion of the second gripper finger. The sliding block assembly acts on the base, so that the first gripping part of the first gripper finger and the second gripping part of the second gripper finger move in the opposite direction or in the backward direction. According to the feeding robot gripper for the rod material, the feeding problem of the rod material can be effectively solved; and in addition, the structure is simple, the time and effort are saved, the worker safety is protected, and the production cost is reduced.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

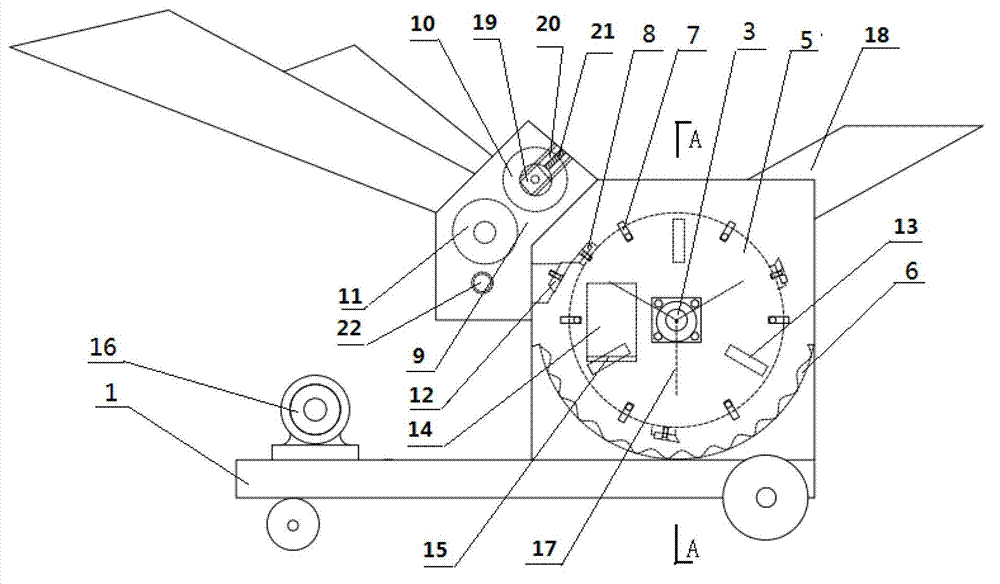

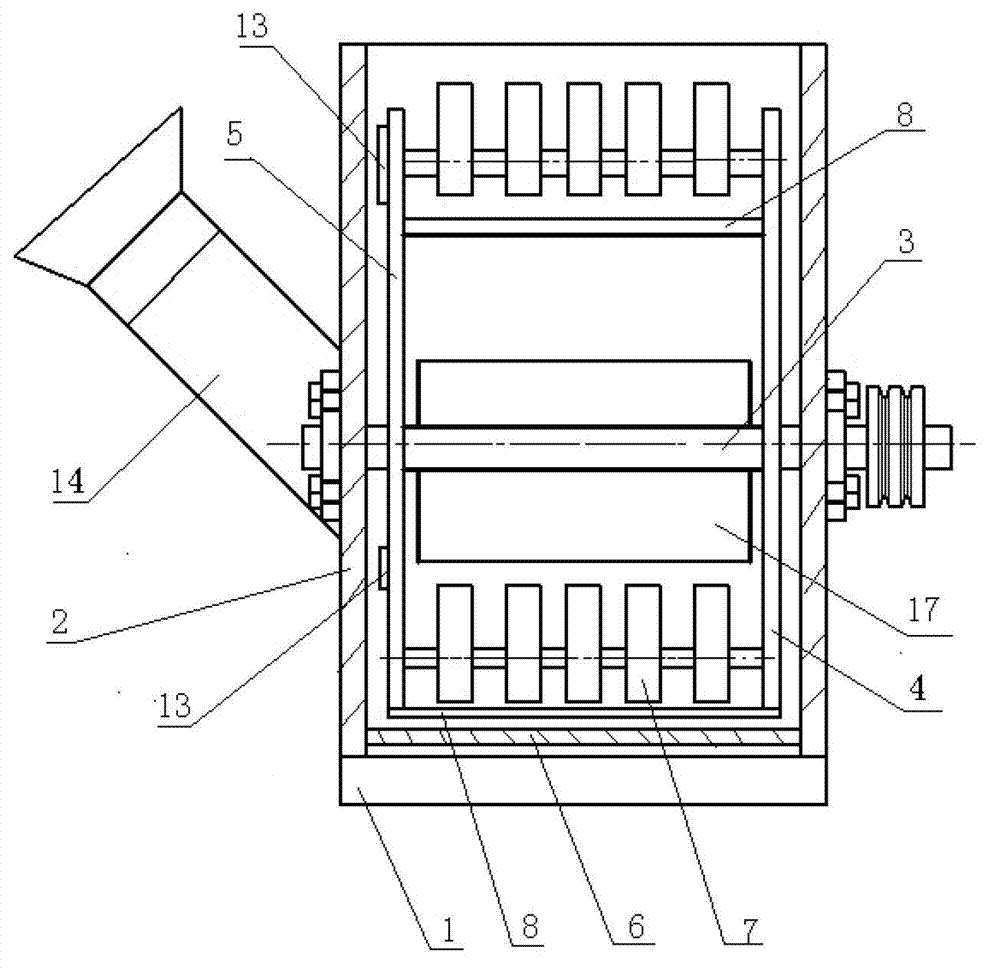

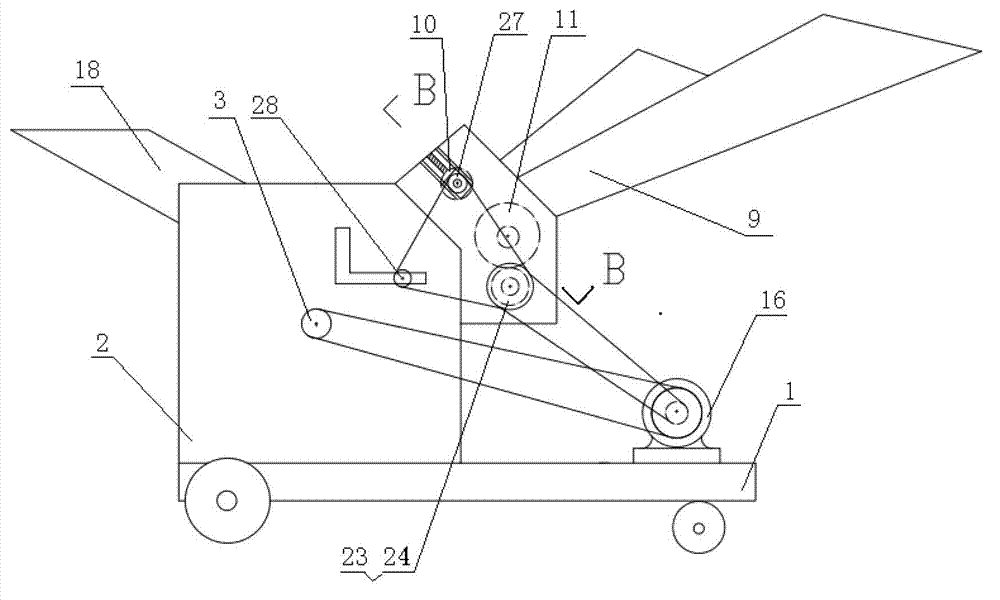

Branch slicing shredder

The invention relates to a branch slicing shredder. A shell and a motor are fixed on a base of the shredder, a round cutter I and a round cutter II are installed in the shell through a spindle, a jaw plate is fixed below the shell, hammer components uniformly distributed between the round cutter I and the round cutter II and a driving cutter are arranged in a stagger manner, an upper feed roller and a lower feed roller are installed on the main feed port of the shell, a main stationary knife is fixed below the main feed port, auxiliary moving cutters are uniformly distributed on the outer side surfaces of the round cutter II, a support plate is fixed below the side feed port of the shell, the motor is used for driving the spindle and the upper feed roller as well as the lower feed roller, and fan blades are installed in the shell through the spindle. According to the branch slicing shredder, the side plane of the round cutter II is used for locating so as to control the feeding length of a hard branch with large diameter, the moving cutters installed on the side plane of the round cutter II is used for planing and slicing, and both thick branches and thin branches can be fed smoothly through automatic regulation of the gap size of two feed rollers.

Owner:扶风永恒农牧机械制造有限责任公司

Technology for processing comprehensive waste water from acrylonitrile and acrylic fibers production

ActiveCN102190408AReduce refluxIncrease concentrationMultistage water/sewage treatmentNature of treatment waterAcrylonitrileOxygen

The invention relates to a technology for processing comprehensive chemical waste water from acrylonitrile and acrylic fibers production and is directed to the field of environment engineering technology. According to the invention, an aeration reaction, a biology hydrolysis acidification, a denitrification nitrogen removal and an aerobic biological treatment are adopted. The waste water is classified into C, N and S grade. The toxicity problem for microbes caused by the waste water is solved; the biological treatment capability and waste water processing effect are improved. The technology is characterized by simple and reasonable process flow. The operation cost is reduced. The technology is suited for industrial application and biology processing of high sulfur high nitrogen organic waste water of the same kind.

Owner:博瑞德环境集团股份有限公司

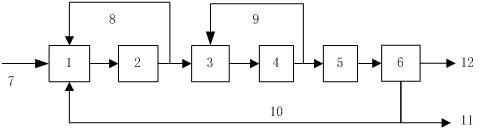

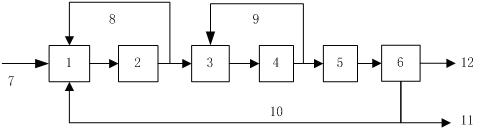

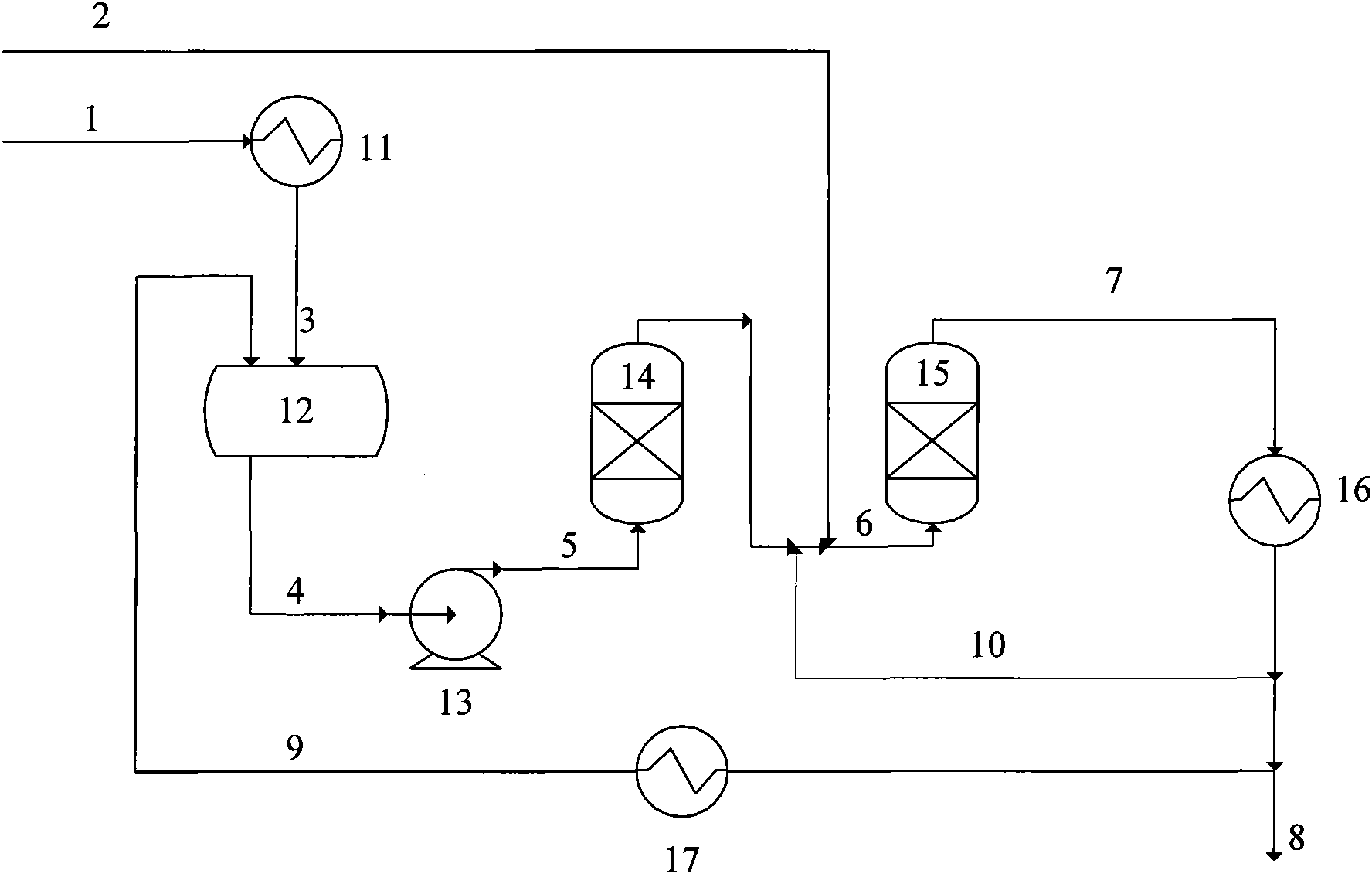

Method and equipment for using waste gas of butadiene extraction unit

ActiveCN101993323AIncrease profitAlkyne content decreasedHydrocarbon by hydrogenationGaseous mixture working upAlkaneNaphtha

The invention relates to a method for using waste gas of a butadiene extraction unit, comprising the following steps: (1) condensation and pressurization: introducing waste gas materials from the extraction unit to a condenser, condensing the materials to liquid phases to enter a mixing tank, completely mixing the liquid phases with diluted alkane from hydrogenated products of step (2) in the mixed tank, then entering to a pump, pressurizing by the pump; and (2) hydrogenation: mixing the mixed material flow pressurized in step (1) with cycling alkane from hydrogenated products, adding hydrogen in a certain ratio and then entering a hydrogenation reactor, cooling the hydrogenated products at the outlet of the reactor to normal temperature, and dividing the cooled products into three parts,wherein one part is taken as diluted alkane to enter the mixed tank in step (1), one part is taken as cycling alkane to enter inlet of the reactor, and the rest part is served as alkane products. Thehydrogenated products in the invention can be taken as the fuels, can be returned to a cracking furnace as cracking stocks to replace parts of naphtha, and also can be taken as high-purity alkane which is sent to a downstream unit for being a raw material, thereby reaching the purposes of saving resources and improving the rate of multipurpose utilization of C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

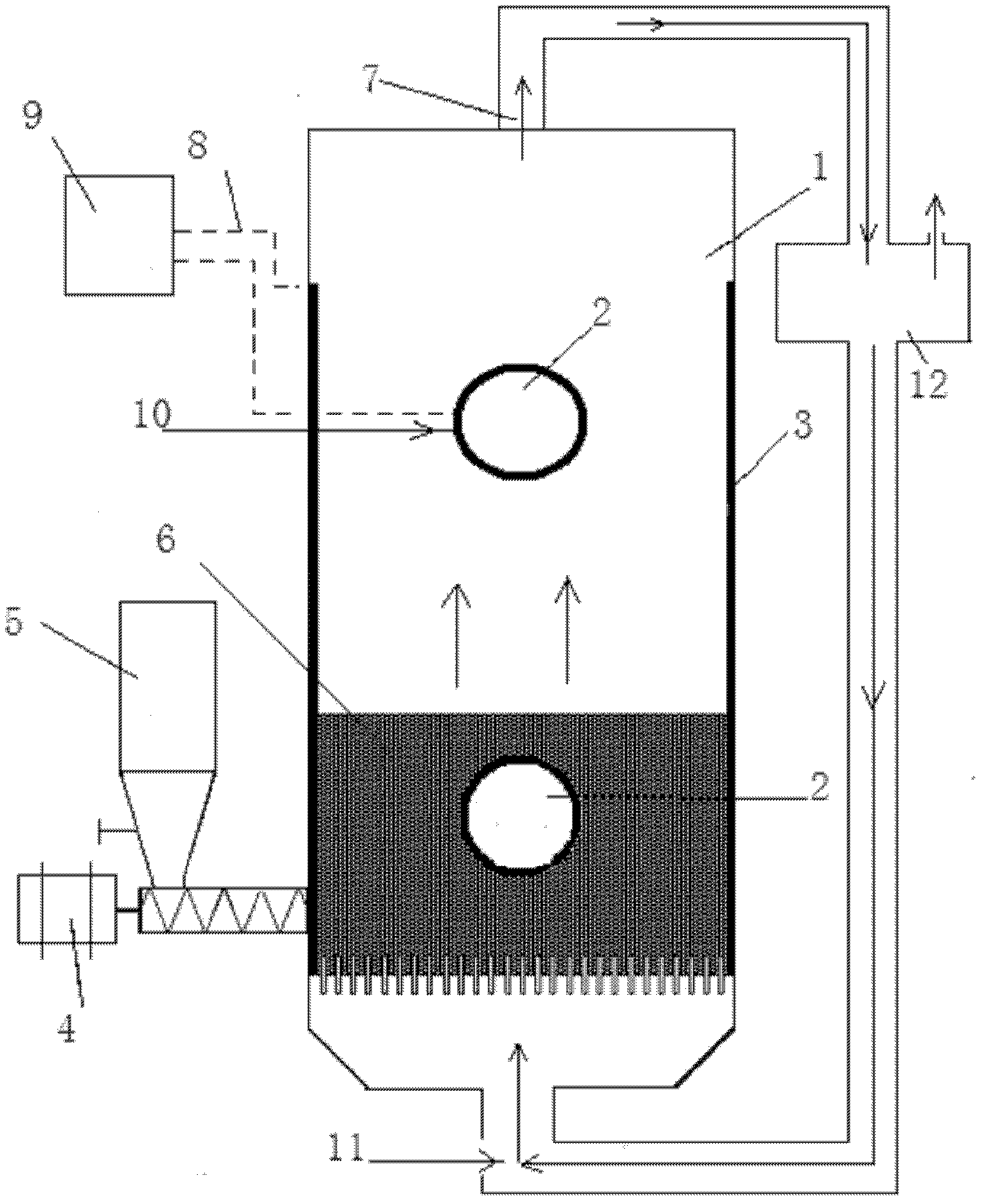

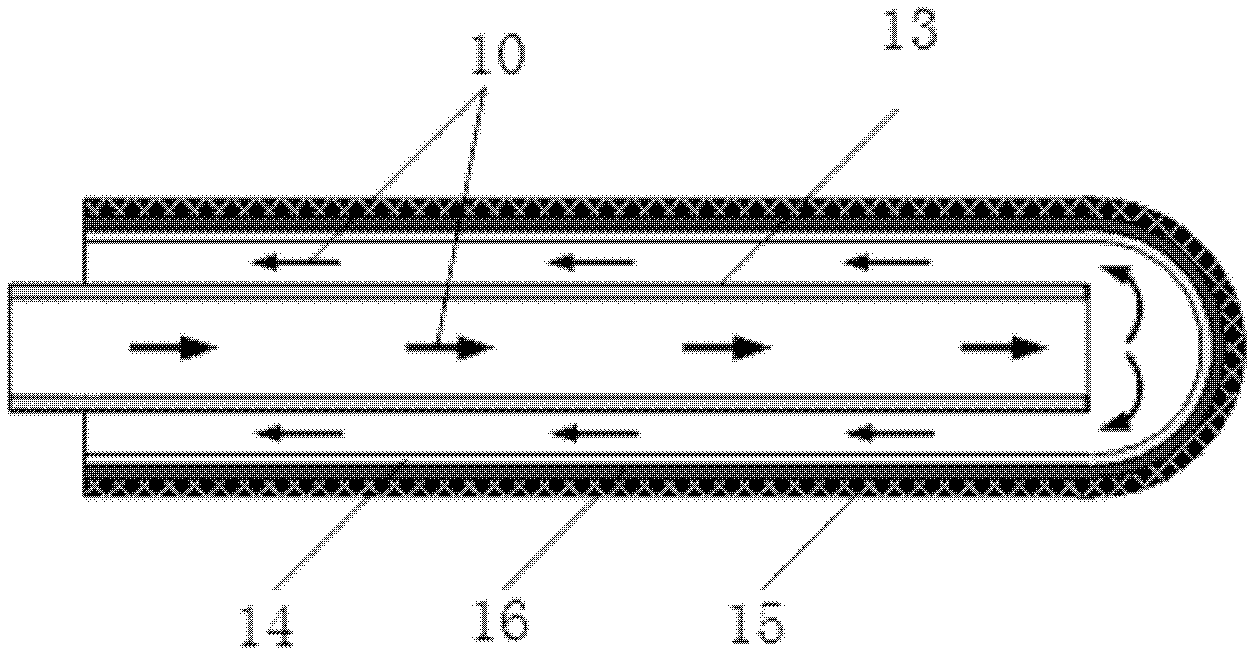

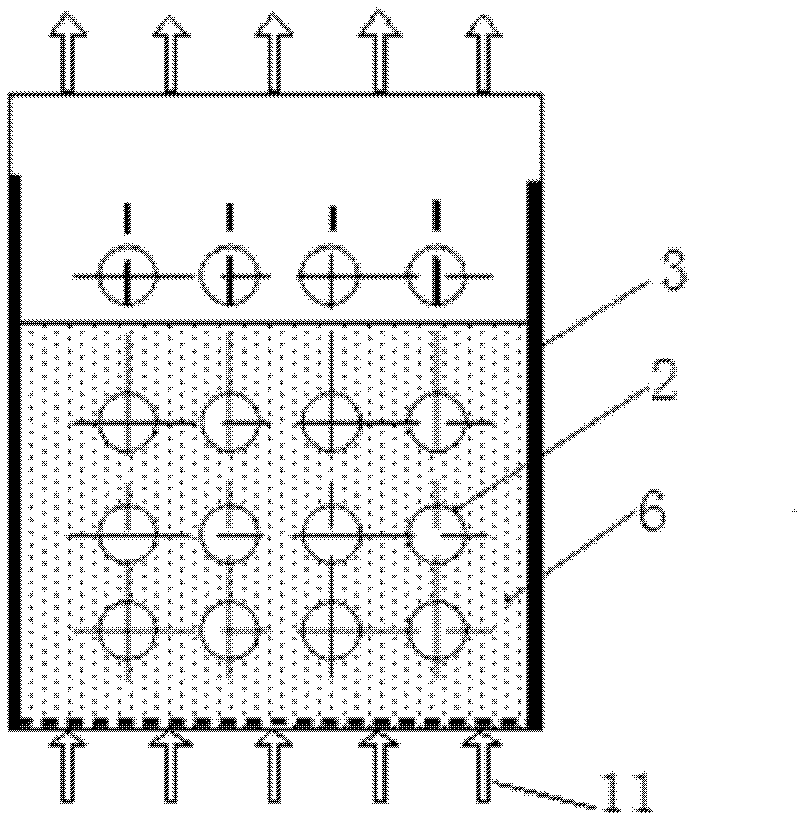

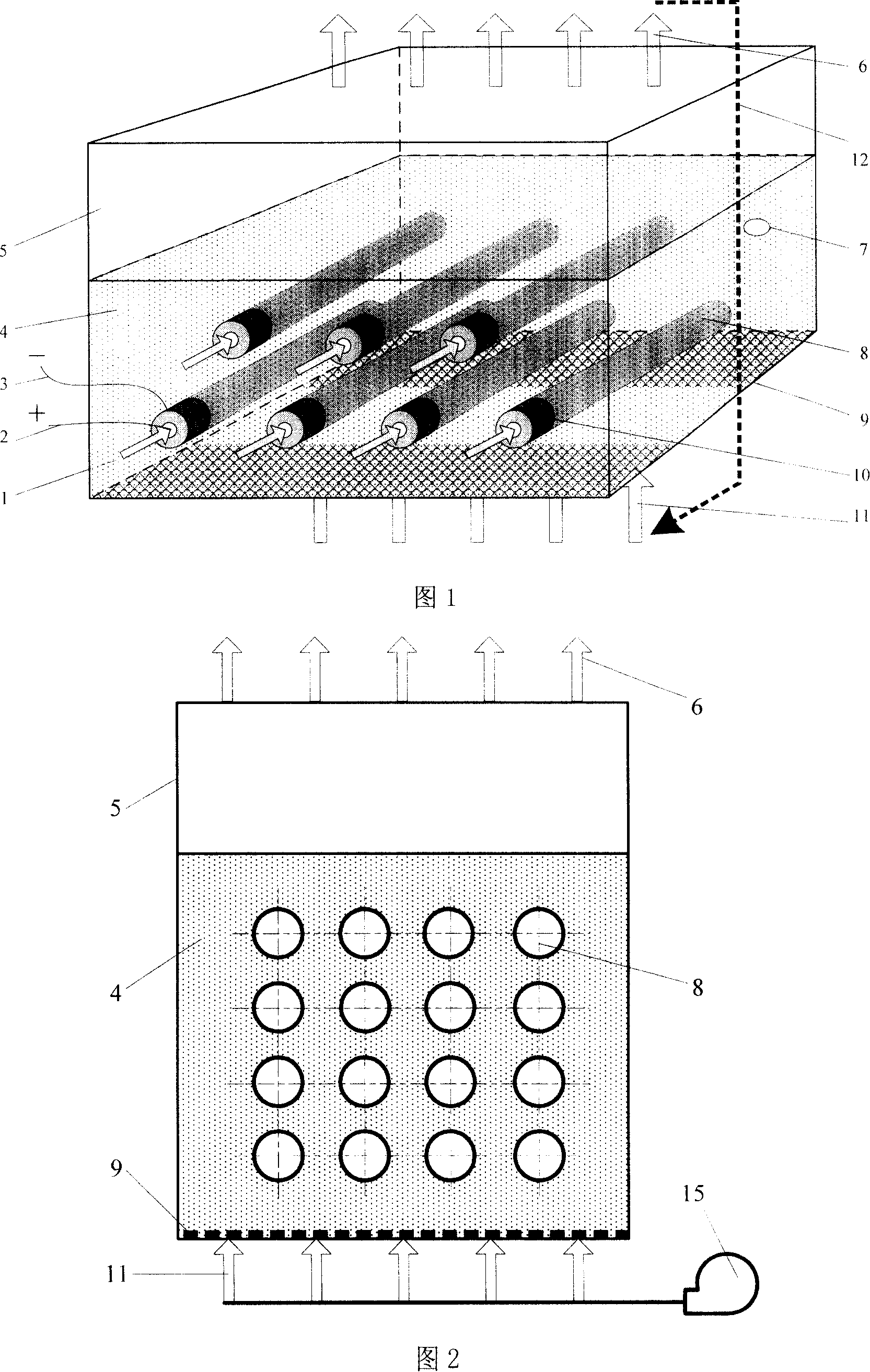

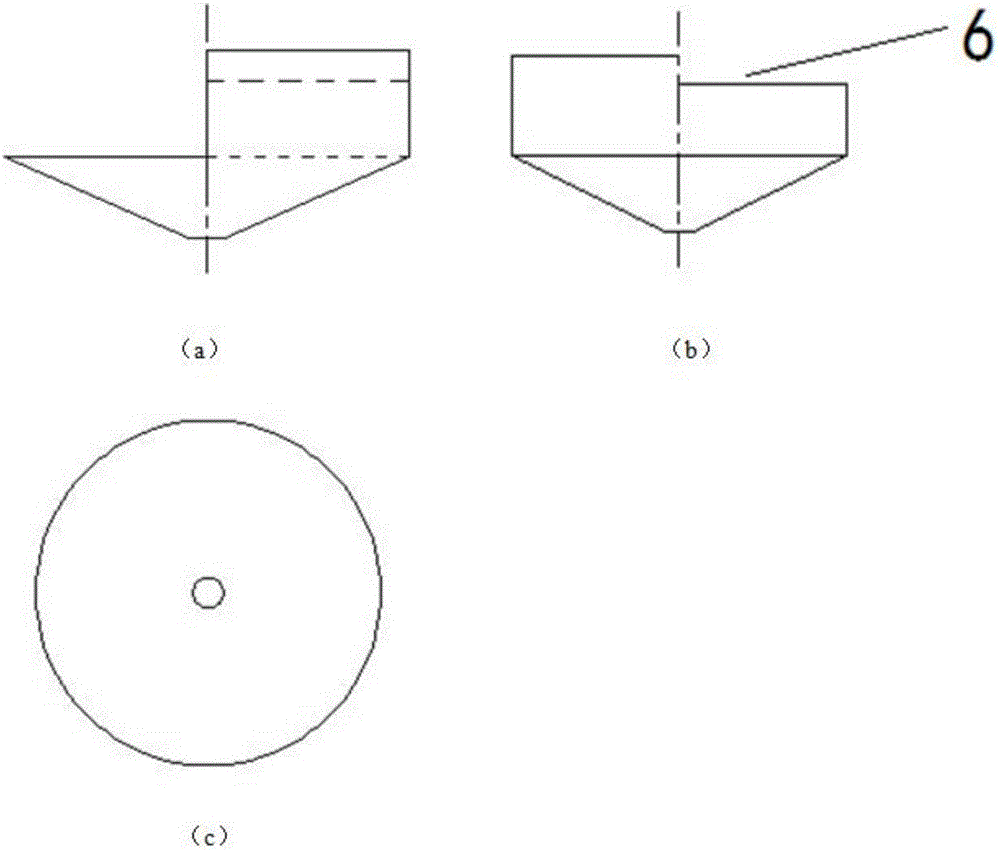

Buried tube type bubbling bed direct carbon fuel cell

ActiveCN1988229ASolving Feed ProblemsEasy to implementFuel cell auxillariesSolid electrolyte fuel cellsSolid carbonWorking temperature

This invention relates to a buried bubble bed direct carbon fuel cell including a bubble bed, tube solid oxide fuel cell monomers, an air distribution board and solid carbon fuel and wind feed device, in which, the monomers are arranged crossly, in sequence or in stagger to be plugged in the buble bed horizontally, the joint places of the monomers and the bed are sealed, the tube solid oxide electrolyte fuel battery is buried in the solid fuel to form a tube-buried structure, the wind feeding device sends gas into the bed via the distributing board to blow up solid carbon fuel particles, and the working temperature of the bed is 700-1000deg.C, the inside tube of the cell is output positive and the outside is output negative and the reacted anode gas is discharged from the top of the bed .

Owner:TSINGHUA UNIV

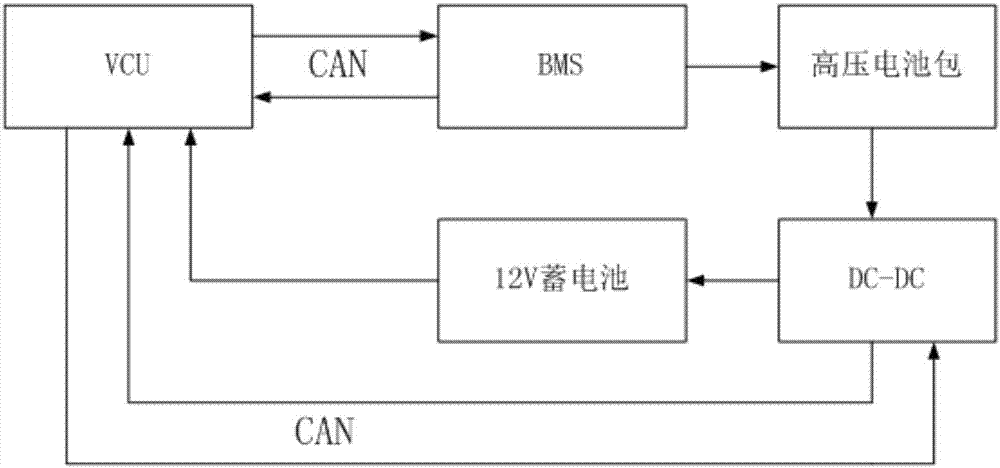

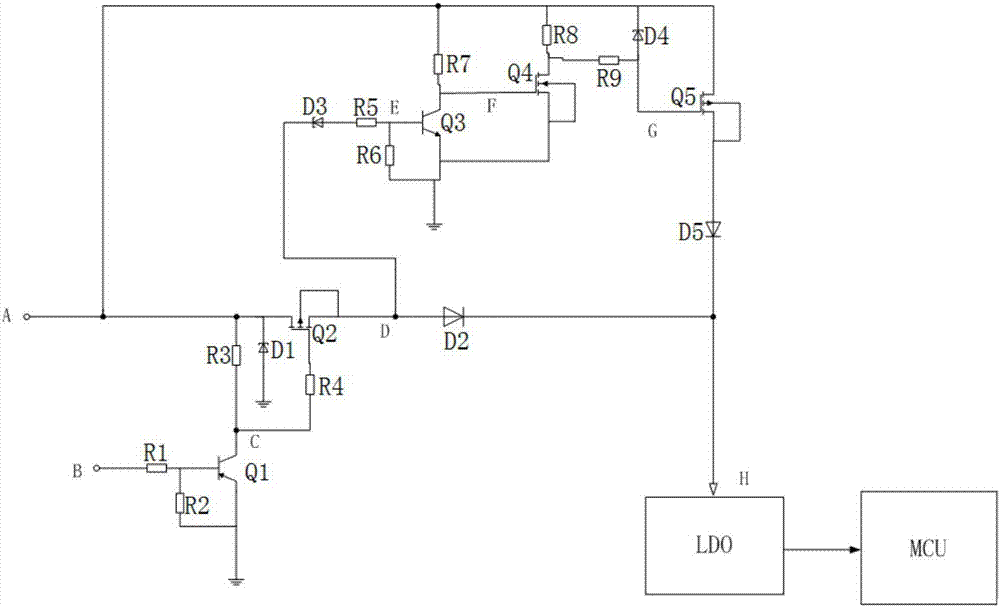

Electric automobile storage battery charging system and method

ActiveCN108001277ASolving Feed ProblemsSimple structureVehicular energy storageElectric energy managementDc dc converterControl signal

The invention discloses an electric automobile storage battery charging system. A VCU, a BMS, a high voltage battery pack and a storage battery are arranged on an electric automobile; the VCU communicates with the BMS through a CAN bus; the BMS outputs a control signal to the high voltage battery pack; the VCU receives a voltage signal of the storage battery; the VCU communicates with a DC-DC converter through a CAN bus; and the high voltage battery pack charges the storage battery through the DC-DC converter. The electric automobile storage battery charging system has the advantages that thestructure is simple and reasonable, the operation is stable and reliable and a feed problem of the storage battery caused by long-time parking of the electric automobile can be effectively solved.

Owner:CHERY AUTOMOBILE CO LTD

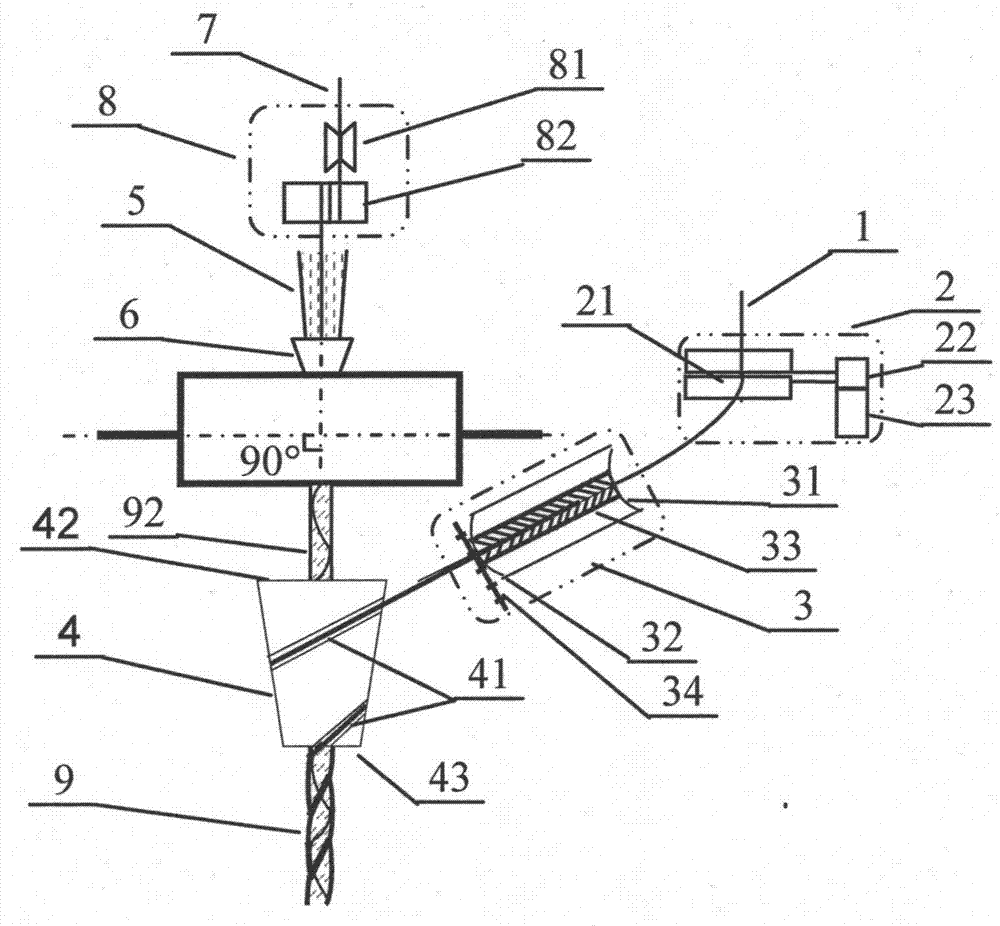

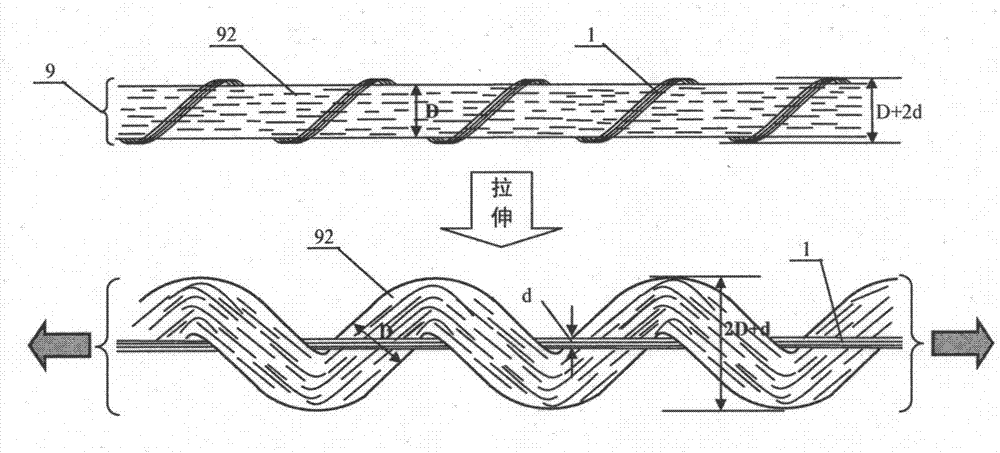

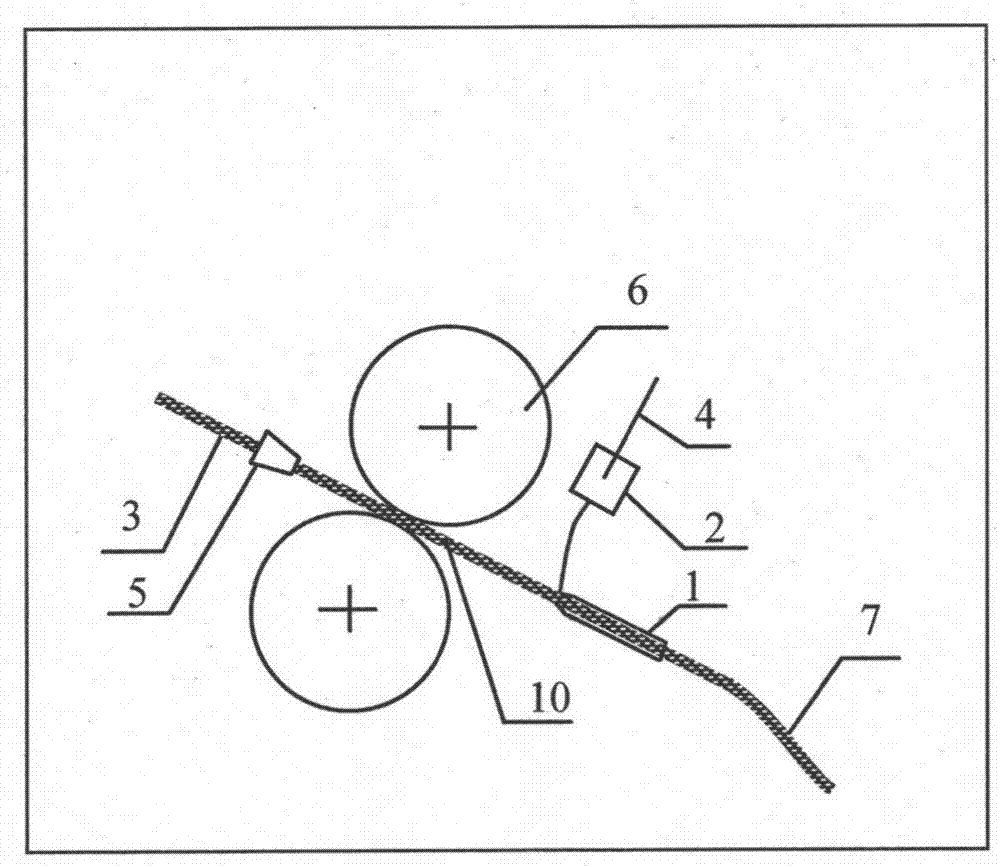

Three-axis system cone cylinder type composite spinning device and method of negative poisson ratio yarn

ActiveCN107254724ABig upload twistEasy to twistDrafting machinesContinuous wound-up machinesFiberYarn

The invention provides a three-axis system cone cylinder type composite spinning device of negative poisson ratio yarn. The three-axis system cone cylinder type composite spinning device comprises a ring spinning frame, and the rear side of a front roller of the ring spinning frame is provided with a bundler and an under-feeding elasticity enhancing device, wherein the bundler is used for positioning and bundling short fiber strands, and the under-feeding elasticity enhancing device is used for controlling the pre-tension and position of stretch yarn, feeding the stretch yarn into the bundler and making the stretch yarn and the short fiber strands wrapped to form stretch yarn with a rebounding function; a flattening plate used for unfolding rigid filament tows is and a cone cylinder are arranged on the front side of the front roller of the ring spinning frame, wherein the cone cylinder is used for continuously unfolding the rigid filament tows and feeding the wrapped rigid filament tows at a set wrapping angle, so that the stretch yarn is wrapped with the rigid filament tows to form a cone cylinder of the negative poisson ratio yarn; an overfeeding device used for enabling the rigid filament tows to generate the required overfeeding amount due to a yarn forming spiral track is arranged on the upstream of the flattening plate. The composite spinning device is simple in structure and convenient to operate, and the obtained negative poisson ratio yarn can be used for a fabric with a negative poisson ratio and has a more obvious negative poisson ratio effect.

Owner:DONGHUA UNIV

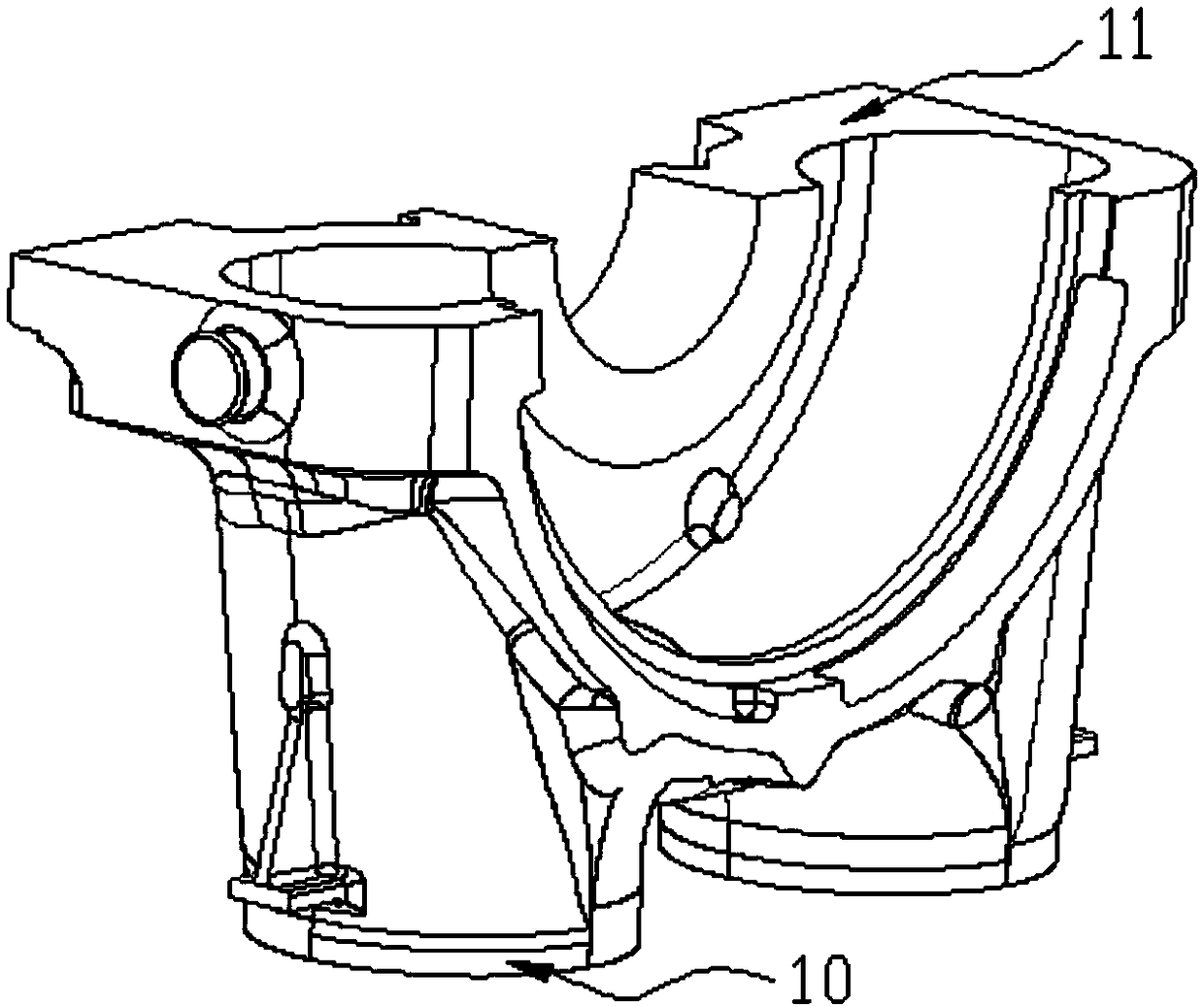

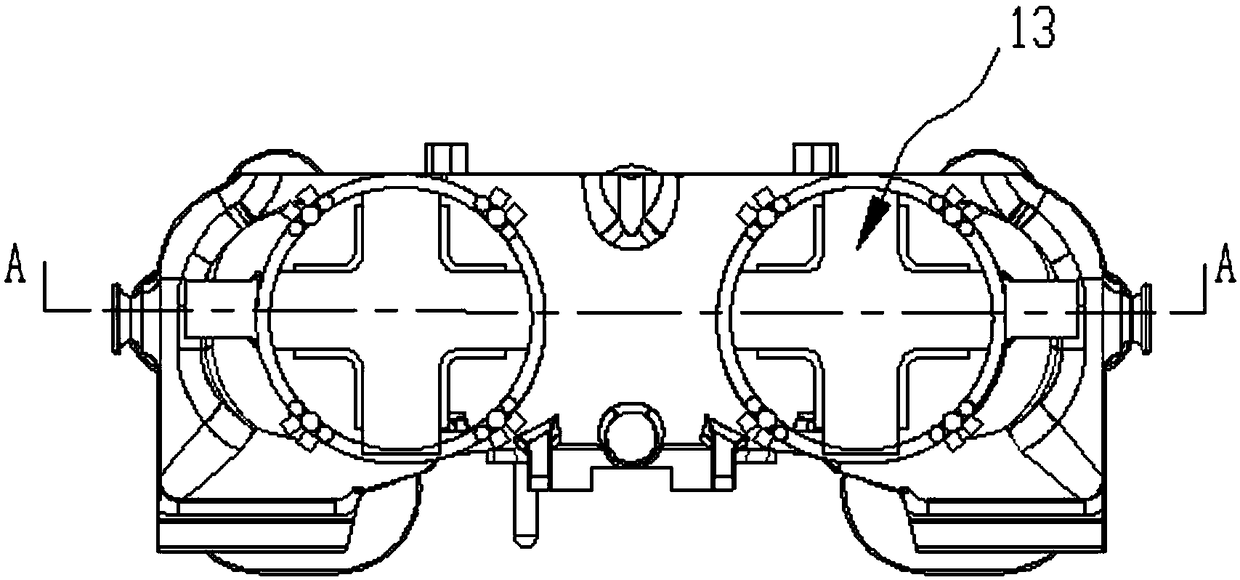

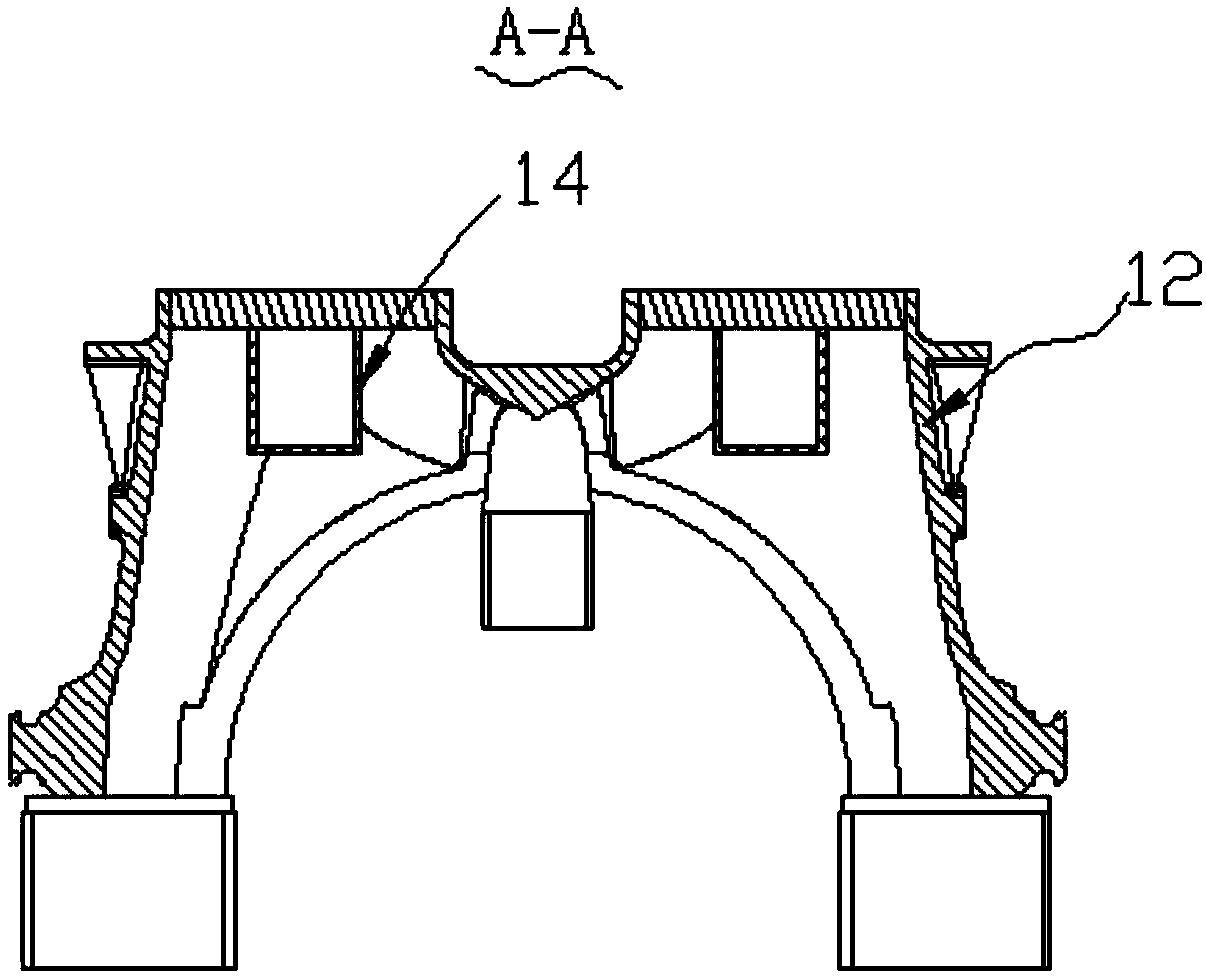

Casting forming process for large wind power planetary carrier

ActiveCN107790641ASmall size deviationEasy to operateFoundry mouldsFoundry coresElectricityEconomic benefits

The invention discloses a casting forming process for a large wind power planetary carrier casting. The planetary carrier casting comprises an upper annular plate and a lower annular plate which are vertically connected with triangular vertical columns, and a parting face of the planetary carrier casting is arranged on the interfaces of the upper annular plate and the triangular vertical columns;a first sand core and a second sand core are arranged between the upper annular plate and the lower annular plate, a triangular air outlet channel is formed in the outer sides of the sand cores, and vertical air outlet channels are formed in the centers of the sand cores; open risers are arranged right above the intersections of the upper annular plate and the triangular vertical columns, blinderrisers are arranged on the lower annular plate, and external chills are arranged under the lower annular plate. Pouring is carried out by adopting combined pouring mode of bottom-back pouring gates and stepped pouring gates. The planetary carrier produced by the method is good in forming and qualified in size, the matric structure of the casting is compact, joint parts of the triangular verticalcolumns and the upper annular plate and the lower annular plate has no crack defect, the other parts only need to undergo modification repair welding, the production cost of the casting is reduced, and higher economic benefits are achieved.

Owner:兰州兰石铸锻有限责任公司

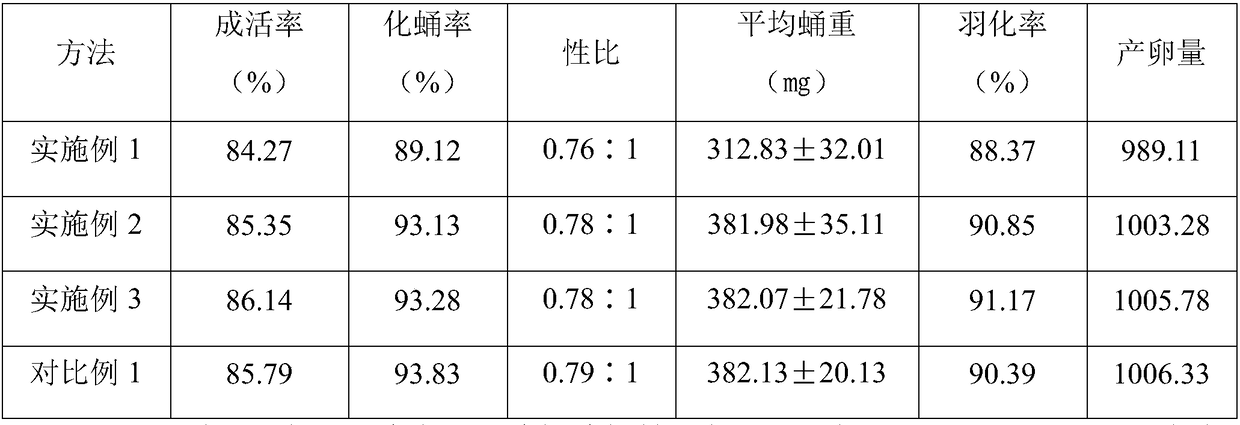

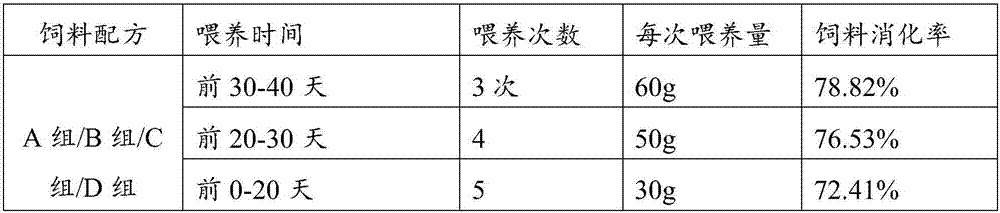

Prodenia litura fabricius larva group breeding method

InactiveCN108077191ASuitable for growth and developmentSimple and fast operationAnimal feeding stuffAccessory food factorsOrder LepidopteraSpodoptera

The invention discloses a prodenia litura fabricius larva group breeding method, and provides an artificial breeding method according to the problems in current artificial breeding process of prodenialitura fabricius larva. The method is suitable for growth and development of the prodenia litura fabricius larva and solves the problems of easily declination of insects, weak vigor and breeding of dog-eat-dog lepidoptera insects such as prodenia litura fabricius and the like. The method includes the steps: (1) larva breeding; (2) pupa management; (3) adults to eggs; (4) egg management. The method is simple and convenient to operate, low in breeding cost, good in breeding effect and suitable for large-scale breeding, and the prodenia litura fabricius is bred in a group manner at a larval stage.

Owner:INST OF PLANT PROTECTION SICHUAN ACAD OF AGRI SCI

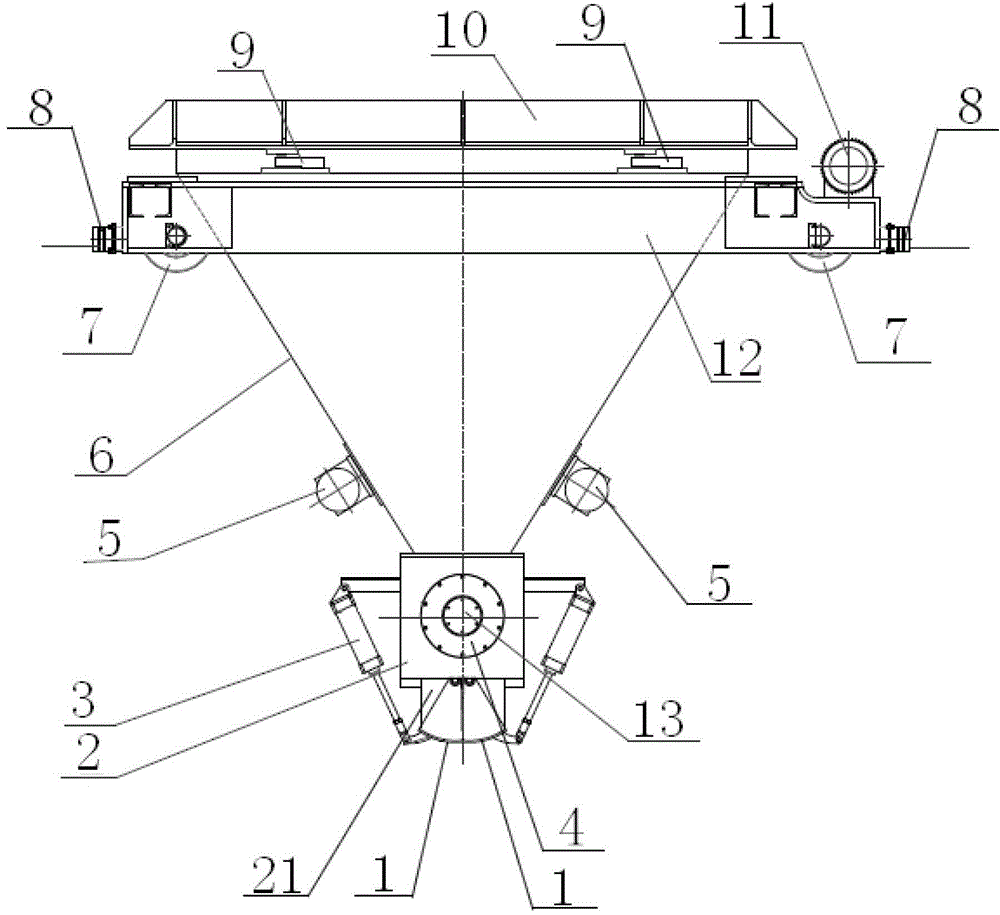

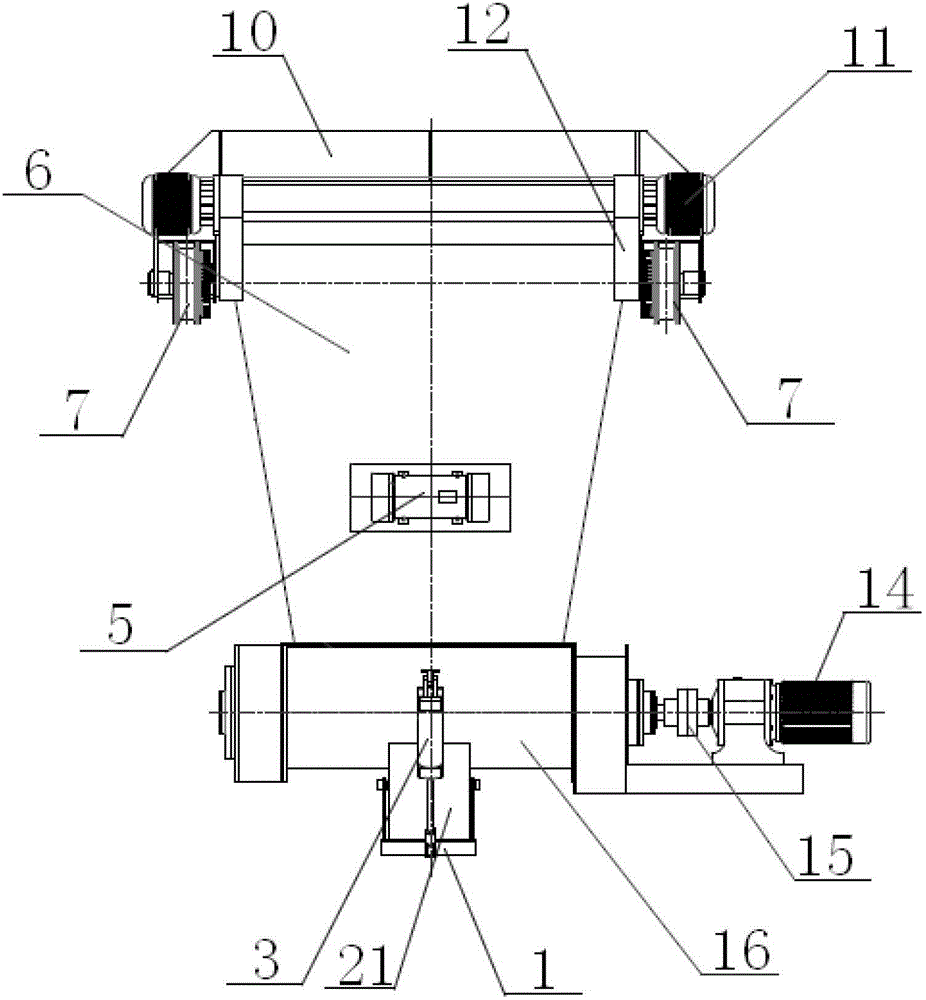

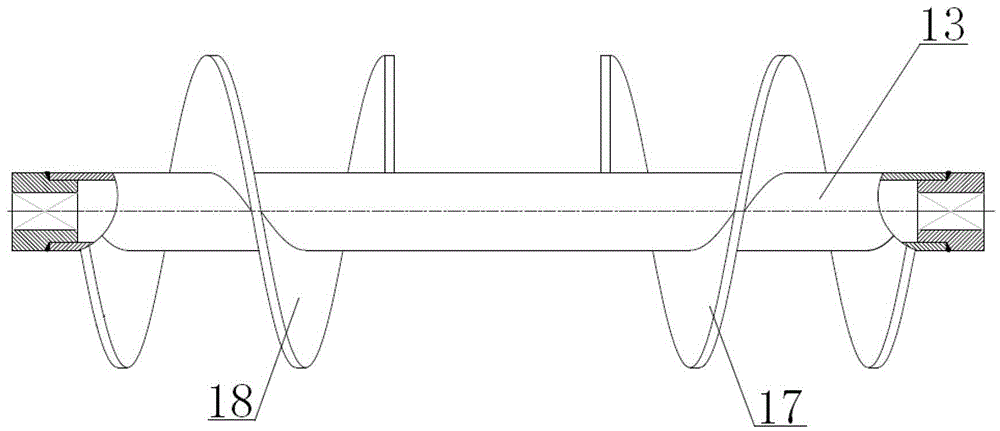

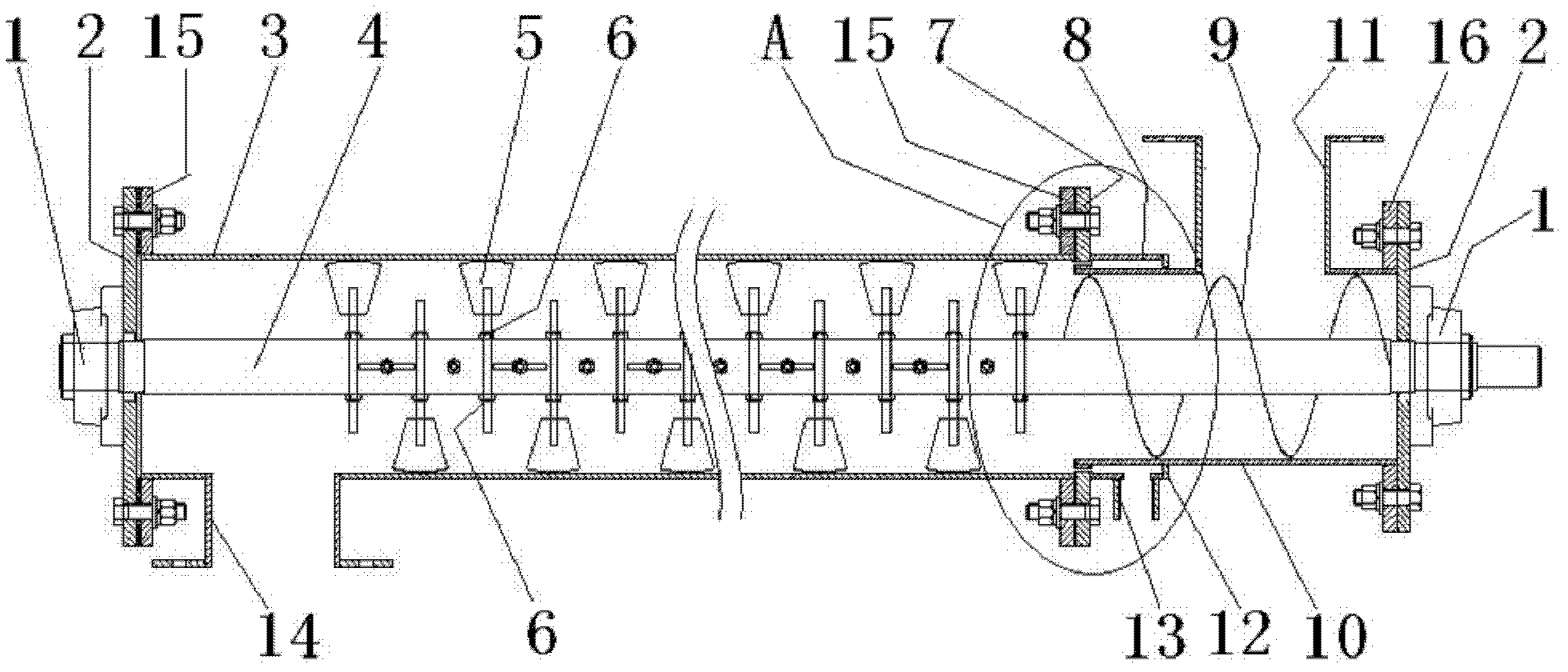

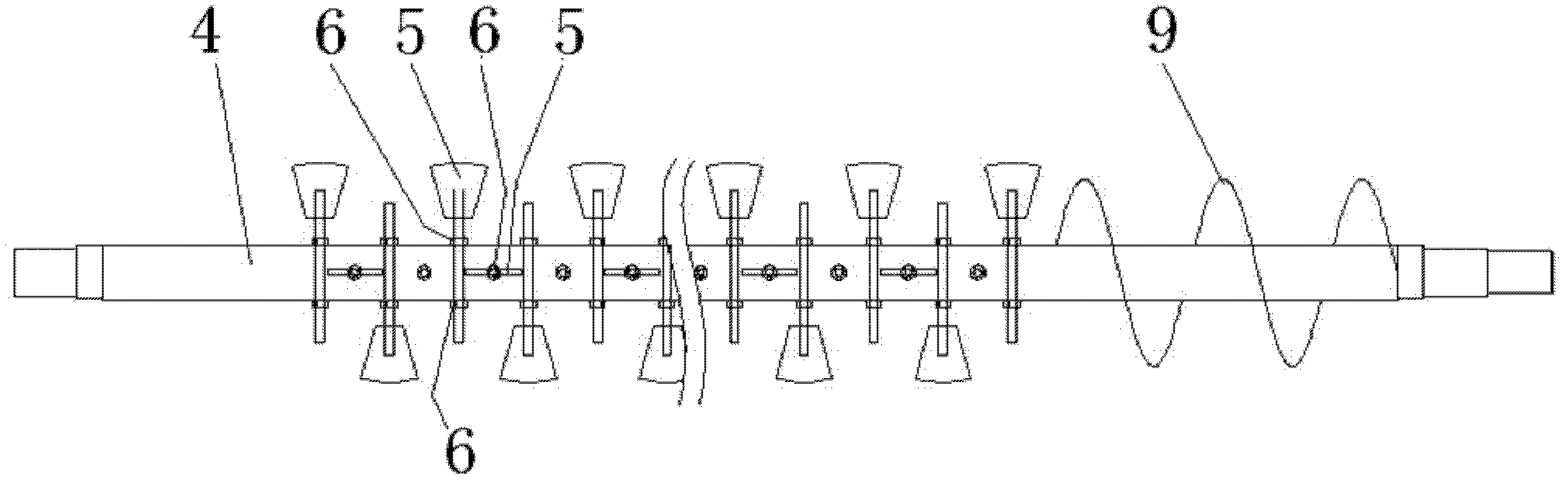

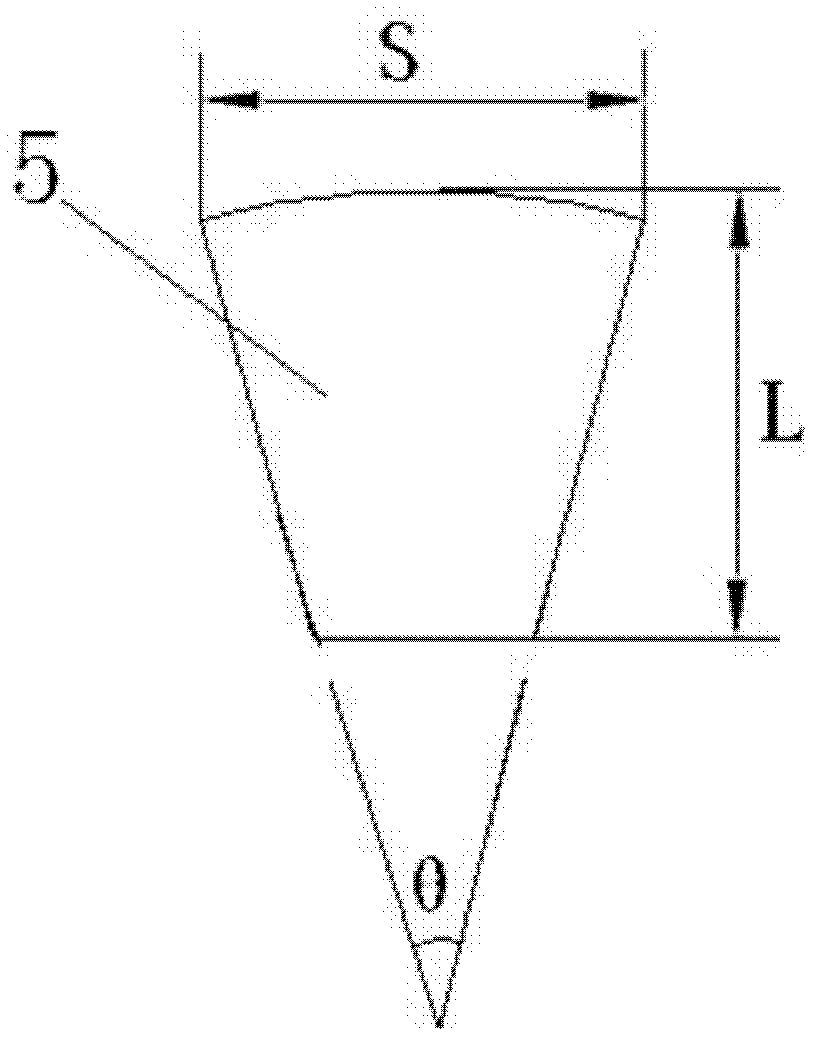

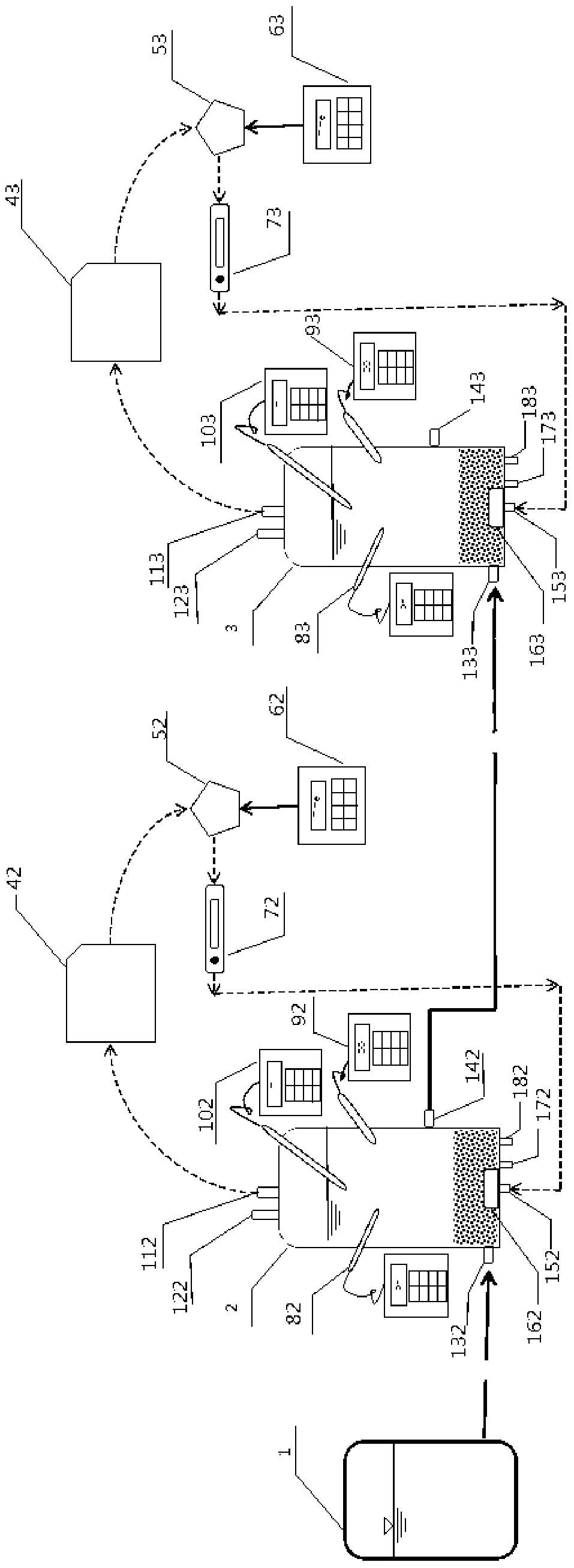

Feeding device for U-shaped pre-stress concrete pile plank and control method

InactiveCN102909782ASolve feeding problemsIncrease productivityCeramic shaping apparatusProgramme control in sequence/logic controllersProduction lineStopped work

The invention discloses a feeding device for a U-shaped pre-stress concrete pile plank and a control method. A proportion integration differentiation (PID) controller transmits an instruction to a variable-frequency motor and a servo electric cylinder according to a preset flow value, the variable-frequency motor drives a two-directional helical shaft to rotate, and the servo electric cylinder controls a radian discharging door to be opened to a certain degree; a weighing sensor collects a weight signal of a material in real time and transmits the weight signal to the PID controller; the PID controller transmits a processed result to the variable-frequency motor and the servo electric cylinder; the variable-frequency motor controls the two-directional helical shaft to be roughly adjusted; when the real flow of the material does not stay within a set threshold value range, the PID controller controls the servo electric cylinder to change the openness of the radian discharging door so as to perform the fine adjustment; and when the real flow reaches a feeding target value or a minimal alarming value, the PID controller controls the variable-frequency motor and the servo electric cylinder to stop working. One hopper is used for feeding different production lines, and the discharging speed is controlled in a closed-loop way, so that the production efficiency is improved, the labor is saved, the cost is reduced, and the feeding accuracy and uniformity can be guaranteed.

Owner:SHANGHAI ZHONGJI PILE IND

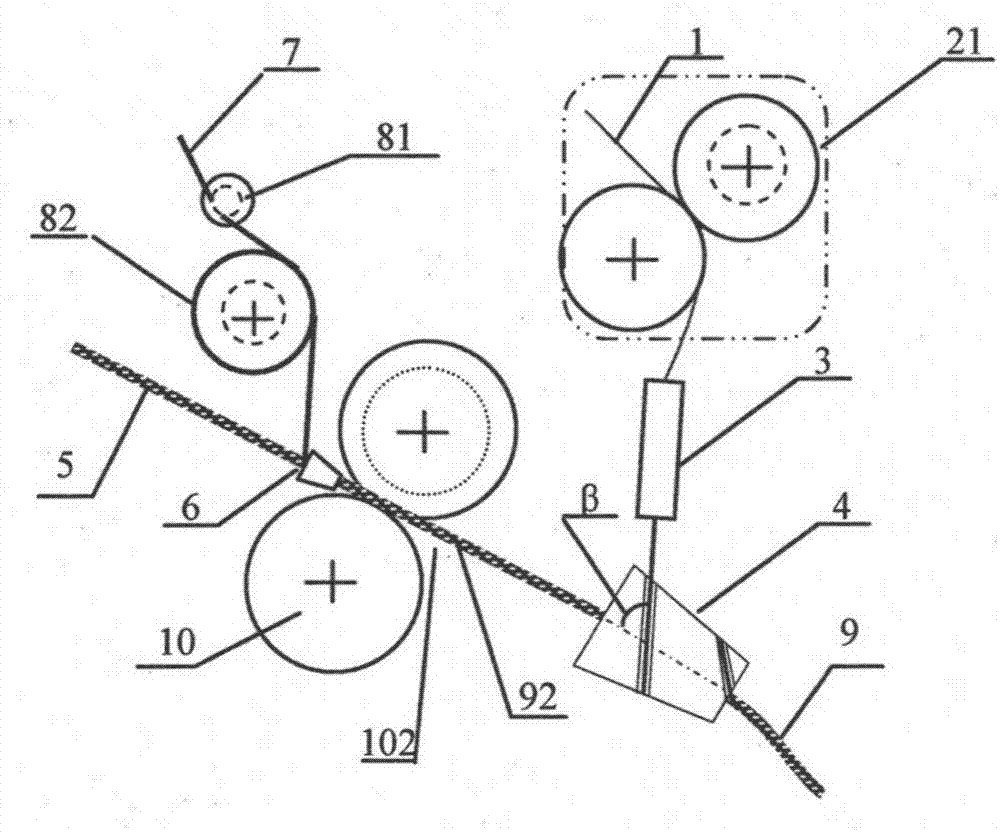

Pre-wrapping-pipe-front-mounted composite negative-poisson's-ratio-yarn spinning device and method and application

ActiveCN107245786AEasy to installSignificantly negative Poisson's ratio effectDrafting machinesYarnYarnEngineering

The invention provides a pre-wrapping-pipe-front-mounted composite negative-poisson's-ratio-yarn spinning device. The device comprises a pre-wrapping pipe for allowing a rigid filament to be in set feeding angle positioning, a yarn feeding device for stable overfeeding of the rigid filament and a buncher for accurate positioning and bundling of a short fiber strand, wherein stable wrapping is formed between the pre-wrapping pipe and the short fiber strand with the twisting degree. The pre-wrapping pipe and the yarn feeding device are installed on the output side of a front roller nip on a ring spinning frame, and the buncher is installed on the input side of the front roller nip on the ring spinning frame. The invention also provides a composite pre-wrapping-pipe negative-poisson's-ratio-yarn spinning method and application of the composite spinning device. The short fiber strand is output from the front roller nip to be twisted to be a high-twisting fiber strand; the rigid filament is fed through the yarn feeding device, and is wrapped through the pre-wrapping pipe and the high-twisting fiber strand in certain tension, and the negative poisson's ratio yarn is formed in the mode that the rigid filament is slightly embedded into the high-twisting fiber strand. The structure of the device is simple, the cost is low, operation is convenient, and the negative poisson's ratio yarn prepared with the method has the more obvious negative poisson ' s ratio effect.

Owner:DONGHUA UNIV

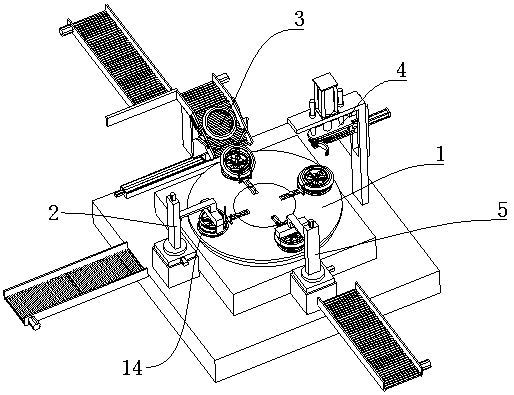

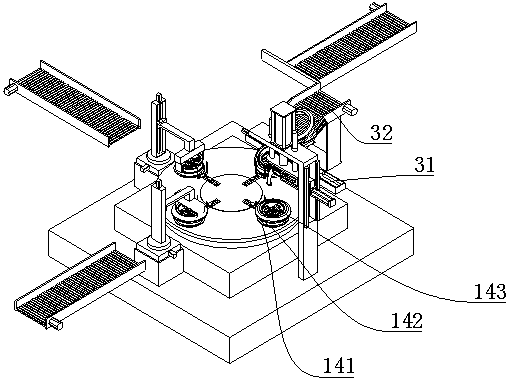

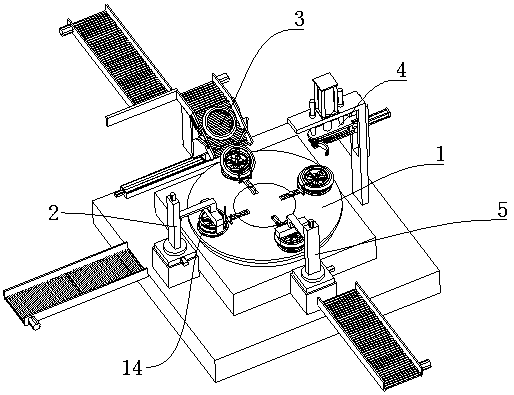

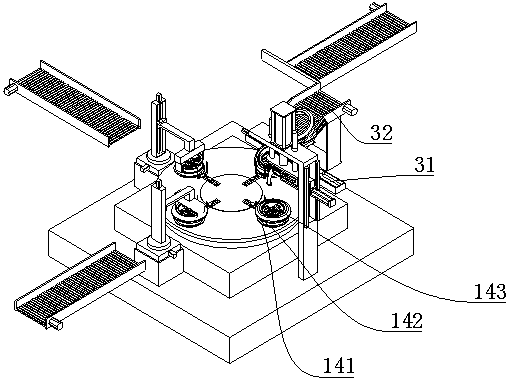

Tire and wheel hub assembling line

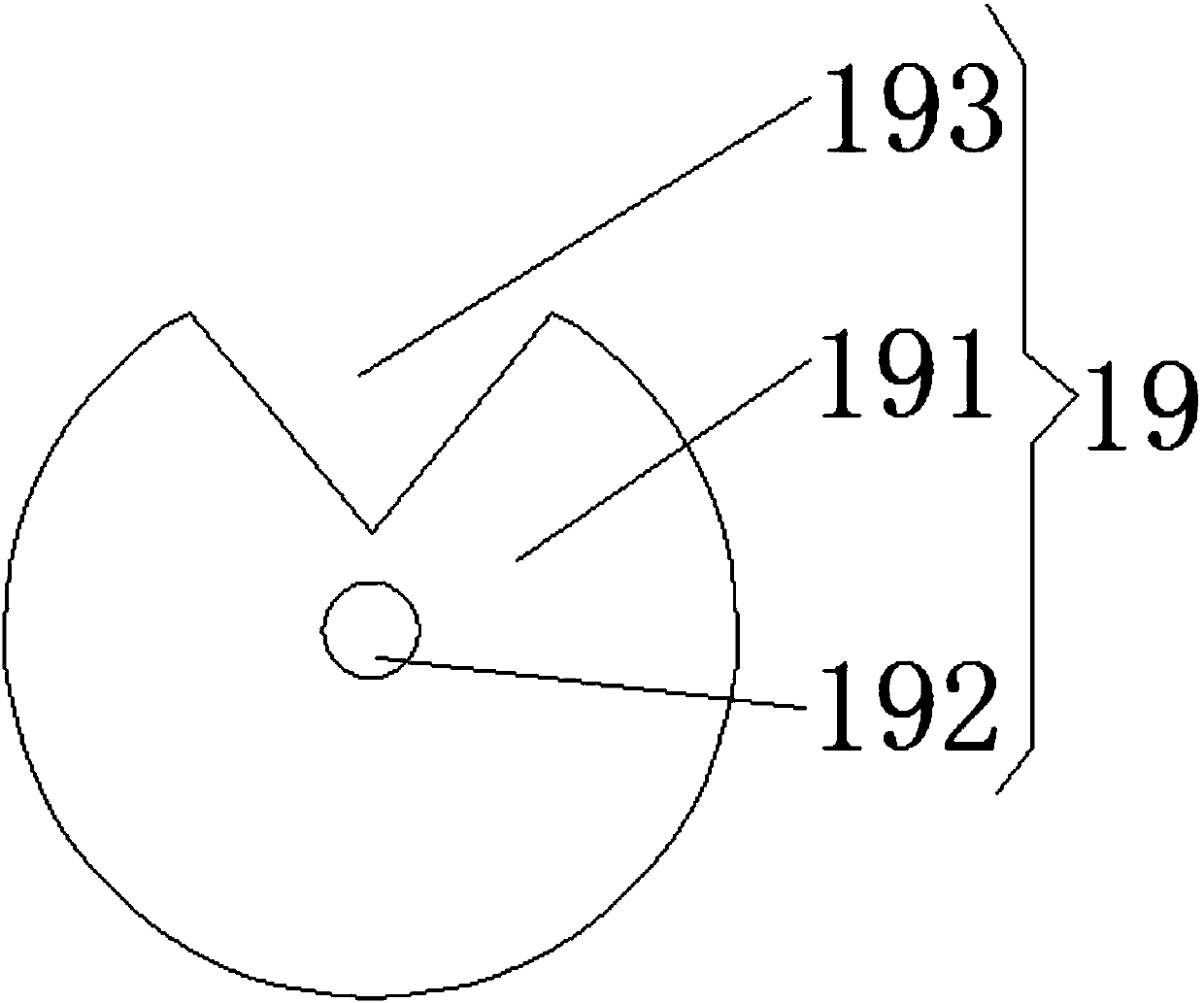

InactiveCN108890249ASolving knowing assembly workSolving Feed ProblemsMetal working apparatusCircular discEngineering

The invention relates to the field of vehicle wheel assembling, in particular to a tire and wheel hub assembling line which comprises a base, a rotary device, a wheel hub loading station, a tire loading station, an assembling station and an unloading station. A boss is arranged in the middle of the base, the rotary device is mounted on the base and comprises a rotary disc, workpieces can move by the aid of the rotary disc, the wheel hub loading station, the tire loading station, the assembling station and the unloading station are fixedly mounted on the base and are sequentially equidistantlyarrayed along the circumferential direction of the rotary disc, four workpiece jigs for carrying the workpieces are equidistantly arranged on the rotary disc, and the wheel hub loading station, the tire loading station, the assembling station and the unloading station are in one-to-one correspondence to the workpiece jigs when the tire and wheel hub assembling line is in working states. The tire and wheel hub assembling line has the advantages that the rotary device, the wheel hub loading station, the tire loading station, the assembling station and the unloading station work with one another,accordingly, the problems in the aspect of tire assembling work can be solved by the aid of the tire and wheel hub assembling line, the work efficiency can be improved, and the labor cost can be reduced.

Owner:赵广朔

High efficiency dirt collection and intelligent feeding system for fishpond recirculating aquaculture

ActiveCN106614243AEasy to separateSolve efficiency problemsClimate change adaptationPisciculture and aquariaFecesEngineering

The invention discloses a high efficiency dirt collection and intelligent feeding system for fishpond recirculating aquaculture which includes a breeding pond, a sump, a dirt auxiliary device, a feeding device and the like. The system mainly utilizes the sump and the dirt auxiliary device to separate the feces in the breeding pond with the fluid characteristic, and uses the computer vision technology to estimate and control the feeding quantity and feeding range of the breeding pond. The high efficiency dirt collection and intelligent feeding system for fishpond recirculating aquaculture has the advantages of novel structure and simple principle. The high efficiency dirt collection and intelligent feeding system is suitable for the fishpond recirculating aquaculture mode, which is capable of effectively solving the problems of low efficiency in debris separating, easy in breaking and difficult in feeding of the existing fishpond recirculating aquaculture system.

Owner:ZHEJIANG UNIV

Small-sized conditioner for testing

InactiveCN102511906AInhibit refluxReduce wear and tearFeeding-stuffHelical bladePulp and paper industry

The invention belongs to the technical field of food feed machinery, and relates to a small-sized conditioner for testing. The small-sized conditioner is formed by a conditioner shell and a conditioner rotor, wherein the conditioner rotor is arranged in the conditioner shell. In the invention, the diameter of a feed cavity is smaller than the diameter of a conditioning cavity, a feed section adopts a helical blade propelling mode, the adding for steam is carried out by adopting an axial multipoint adding mode, the steam can be added into materials in the conditioning cavity from steam adding holes which are annularly distributed on a steam adding flange after the steam enters into a steam cavity, the adding direction of the steam and the advancing direction of the materials are consistent, material seal is formed at the position of the steam adding holes, the backflow of the steam is prevented, and the materials can be preheated by the steam in the steam cavity. Compared with the conditioner in the prior art, more steam can be used for carrying out the transmission of heat and water with the materials, the consumption of the steam can be reduced, and the conditioning efficiency and the conditioning quality are increased; and the angle of a helical blade is adjustable, and thus parameter related to a conditioning technology of feed or food can be optimized. The small-sized conditioner disclosed by the invention is suitable to be used for a scientific test and research in feed or food industry.

Owner:CHINA AGRI UNIV

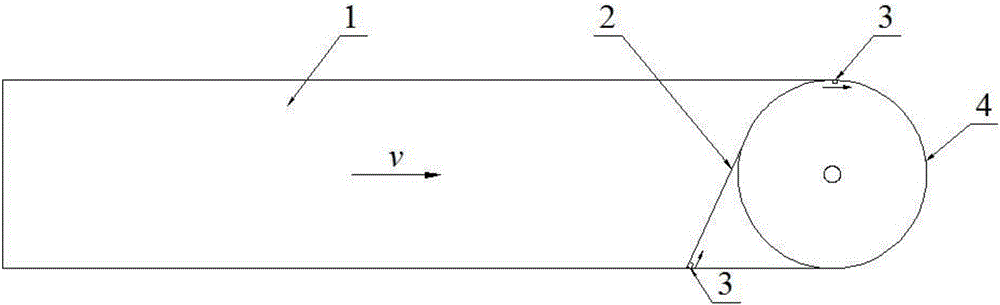

On-line matter verifying device and method for belt feed weigher

ActiveCN101398327AEasy to checkSolving Feed ProblemsWeighing apparatus testing/calibrationControl engineeringMachine

The invention discloses a belt feeding balance online object calibration device with simple operation and a method; the device comprises a static weighing device which is arranged in arranged in a free suspension state; the material inlet of the static weighing device is communicated with the a material storage bin; the material outlet of the static weighing device is arranged above a belt feeding balance; the static weighing device used in the calibration method is arranged in the free suspension state, the material inlet of the static weighing device is communicated with the material storage bin; and the material outlet of the static weighing device is arranged above the belt feeding balance. The calibration device and the method calibrate the static weighing device firstly carry out the online object calibration on the belt feeding balance by the static weighing device, solve the problem that the material supply of a calciner which is affected by the belt feeding balance online calibration, improve the calibration precision, and can be widely applied to the online object calibration of various belt feeding machines.

Owner:四川启明星铝业有限责任公司

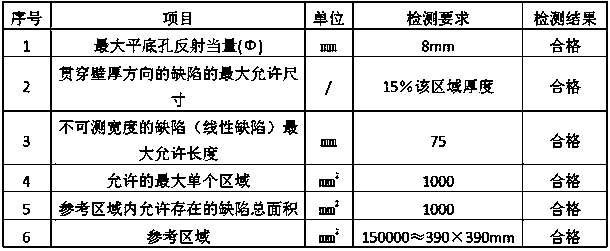

Casting method capable of preventing defects of air cylinder casting pipe orifice

ActiveCN109128046APrevent inflowSolve the problem that the gate cannot be set when the wall thickness is thinFoundry mouldsFoundry coresSlagCasting defect

The invention belongs to the field of casting and mainly relates to a casting method capable of preventing defects of an air cylinder casting pipe orifice. When the pipe orifice part is casted in theprior art, one loop of cold iron is adopted, and the casting defects such as shrinkage porosity and slag inclusion exist among the cold iron through RT ray detection; in consideration of the above problem, the invention provides a casting method capable of preventing casting defects for an air cylinder casting pipe orifice part. The casting method comprises: a casting process scheme of placing theair cylinder casting with the upward combined surface and the downward pipe orifice is selected, a crossed riser neck is arranged at the radial part of the air cylinder casting pipe orifice, a blindriser is arranged at the middle position of the crossed riser neck, and partitioned cold iron is arranged on the end face part of a crossed riser neck feeding superposed area of the air cylinder casting pipe orifice, so that the casting defects such as shrinkage porosity, slag inclusion and crack on the air cylinder casting pipe orifice part are effectively avoided, the quality of the air cylindercasting is improved, and the standard requirement for the RT ray detection first level of the air cylinder casting pipe orifice part is met.

Owner:KOCEL STEEL

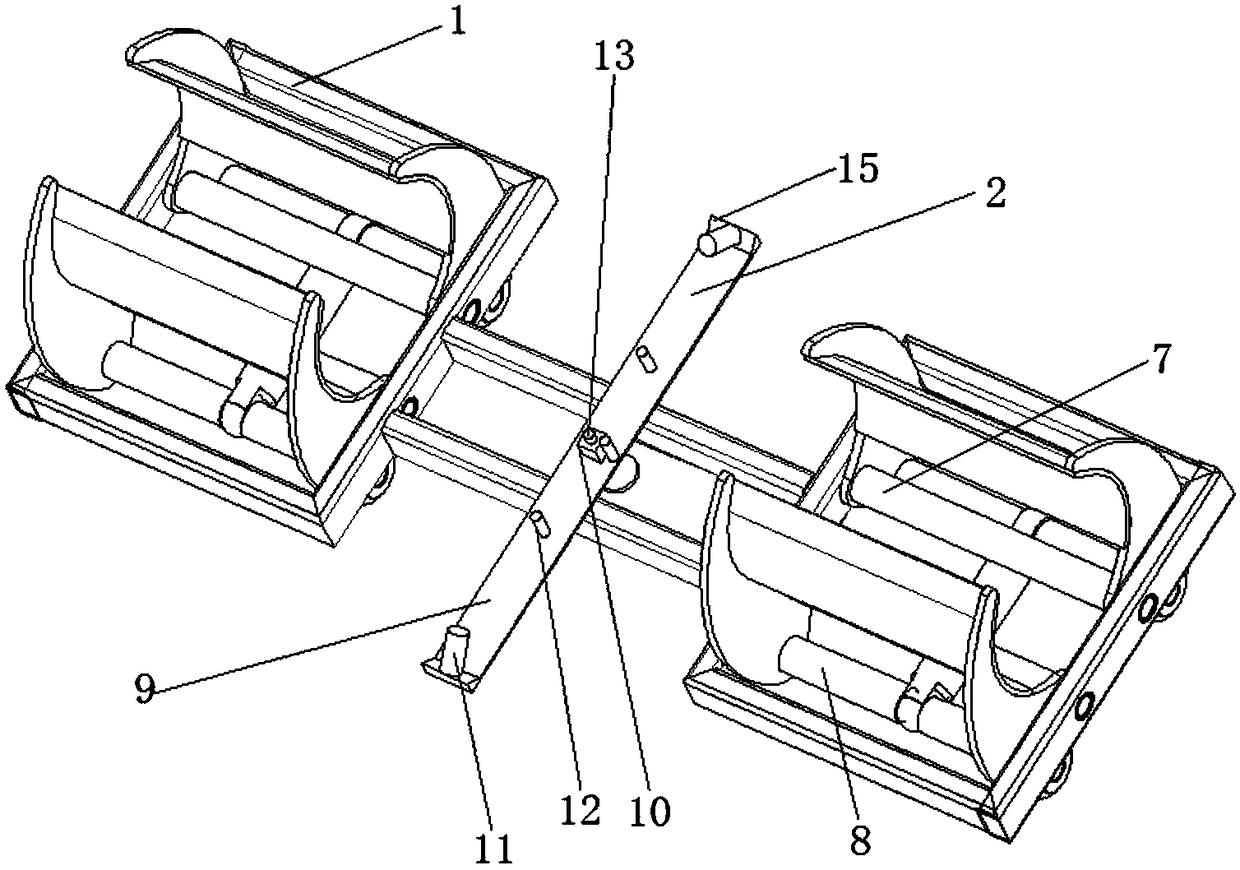

Hydraulic mechanical gripper having identification positioning function and capable of grabbing rods of various sizes

PendingCN108058182AHigh degree of automationAccurate captureGripping headsHydraulic cylinderMotor drive

The invention belongs to the technical field of industrial automation equipment and particularly relates to a hydraulic mechanical gripper having an identification positioning function and capable ofgrabbing rods of various sizes. The hydraulic mechanical gripper comprises two clamping mechanisms and a positioning mechanism, and the two clamping mechanisms are symmetrically arranged on the two sides of the positioning mechanism correspondingly. Each clamping mechanism comprises a supporting frame, two clamping jaws, rotating shafts and a hydraulic cylinder, wherein the rotating shafts comprise the first rotating shaft and the second rotating shaft which are arranged on the two clamping jaws correspondingly; the left and right ends of the first rotating shafts are fixed to the supporting frames; the two second rotating shafts are connected through the hydraulic cylinders; the positioning mechanism comprises a fixing frame, and the fixing frame is provided with an industrial camera, twoline lasers and three point lasers; and the industrial camera is provided with a lighting light source. The hydraulic mechanical gripper is simple in structure, the time and labor are saved, the hydraulic mechanical gripper can replace a traditional motor-driven manipulator, replaces workers to complete the task efficiently and adapts to the harsh working environment, the safety of the workers can be guaranteed, and the production cost is reduced.

Owner:INST OF INTELLIGENT MFG TECH JITRI

Method for producing pellet feed for sheep from peanut straw

InactiveCN106900996APromote growth and developmentImprove disease resistanceFood processingAnimal feeding stuffCelluloseAdditive ingredient

The invention relates to the technical field of peanut straw feed processing, in particular to a method for producing pellet feed for sheep from peanut straw. The pellet feed for the sheep is prepared from raw materials by weight as follows: 53%-65% of peanut straw, 2%-5% of pine needle powder, 4.7%-8% of soybean meal, 4%-7% of corn flour, 4%-8% of Pennisetum sinese, 5%-8% of carrots, 2%-4% of yeast powder, 1%-3% of cane sugar molasses, 2%-5% of a compound premix, 0.2%-0.3% of monensin sodium, 0.1%-0.2% of bacitracin zinc, 1.0%-2.0% of table salt and the balance of distillers' grain powder. The pellet feed for the sheep has comprehensive nutritional ingredients and high benefits and is low in cost, high in cellulose content, good in palatability, proper in energy content, high in digestion rate, convenient to transport and long in storage time and cannot easily deteriorate.

Owner:GUANGXI UNIV

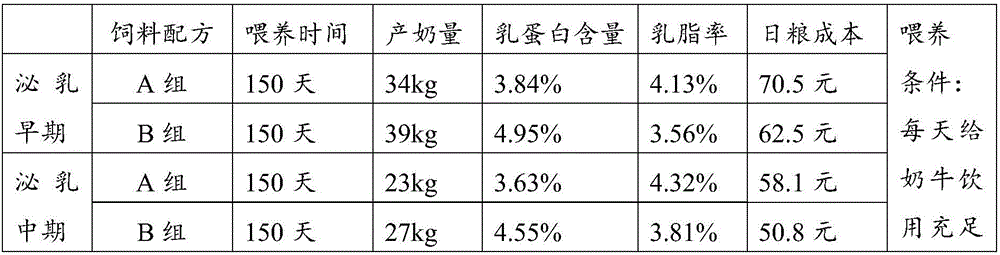

Herbivorous animal mixed feed and preparation method thereof

The invention belongs to the technical field of feed processing, and particularly relates to herbivorous animal mixed feed which comprises, by weight, 120-140 parts of straw, 10-18 parts of corn flour, 8-15 parts of bean pulp, 5-12 parts of vinasse powder, 6-10 parts of pine needles, 4-8 parts of yeast powder, 2-6 parts of sucrose molasses, 2-6 parts of premix and 0.2-0.8 part of rumen protected methionine. The invention further discloses a preparation method of the mixed feed. Raw materials of the mixed feed are weighed in parts by weight, and then straw pretreatment, mixing treatment, mixed powder curing, granulation and packaging are sequentially performed to obtain finished mixed feed. The mixed feed is low in cost, high in benefit, comprehensive in nutrient value, high in cellulose content, good in palatability, easy to store and transport and free from deterioration.

Owner:GUANGXI UNIV

Automatic assembly machine for tire wheel hubs

InactiveCN108859626ASolving knowing assembly workSolving Feed ProblemsTyre repairingEngineeringCooperative work

The invention relates to the field of wheel assembly, in particular to an automatic assembly machine for tire wheel hubs. The automatic assembly machine comprises a base, a rotating device, a wheel hub feeding station, a tire feeding station, an assembling station and an unloading station, wherein a boss is arranged at the middle position of the base; the rotating device is installed on the boss;the rotating device comprises a rotary disc used for moving a workpiece; the wheel hub feeding station, the tire feeding station, the assembling station and the unloading station are fixedly installedon the base and are sequentially arranged at equal intervals along the circumferential direction of the rotary disc; four workpiece fixtures used for bearing the workpiece are arranged on the rotarydisc at equal intervals; in a working state, the wheel hub feeding station, the tire feeding station, the assembling station and the unloading station separately correspond to one workpiece fixture; by means of the cooperative work of the rotating device, the wheel hub feeding station, the tire feeding station, the assembling station and the unloading station, the problem of automatic assembly work of a tire is solved, the work efficiency is increased, and the labor cost is lowered.

Owner:赵广朔

Sequential feeding device for barrel-shaped workpiece

InactiveCN105438766ASolving Feed ProblemsSimple structureConveyorsConveyor partsPass rateEngineering

The invention discloses a sequential feeding device for a barrel-shaped workpiece. The device comprises a base, a conveying device and a feeding device, wherein the conveying device and the feeding device are both mounted on the base; the conveying device comprises a conveyor base assembly, a conveying transmission assembly and a feeding conveying assembly; the conveying transmission assembly and the feeding conveying assembly are mounted on the conveyor base assembly; the feeding device is arranged at the upper end of the feeding conveying assembly, comprising a feeding base rack, a feeding chute assembly and a feeding transmission assembly; the feeding base rack is fixedly mounted on the base; a feeding base plate on which the feeding chute assembly is mounted is arranged on the feeding base rack; a conveyed workpiece is arranged on the feeding chute assembly; the lower end of the feeding chute assembly is connected to the conveying transmission assembly which is connected to the feeding conveying assembly. The device is applied to the feeding processing of the barrel-shaped workpiece, is wide in operation scope, high in working efficiency, and simple in operation, and can greatly improve the working efficiency and the passing rate of finished products.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Feeding device of eight-station cold header

The invention discloses a feeding device of an eight-station cold header. The feeding device comprises a feeding box and a feeding connection rod. A feeding transmission mechanism is disposed in the feeding box, one end of the feeding connection rod is connected with a ratchet wheel rocker mechanism, the ratchet wheel rocker mechanism is connected with the feeding transmission mechanism, a height adjusting mechanism is connected with the other end of the feeding connection rod and connected with a feeding rocker arm mechanism, and the feeding rocker arm mechanism is connected to a spring return mechanism. The feeding length is adjusted by adjusting the height adjusting mechanism on a feeding rocker arm and adjusting the positions of the feeding connection rod and a ratchet wheel rocker so that whole feeding work can be quickly, accurately, stably and orderly conducted. The feeding device is simple in structure, scientific and convenient to use, high in automation degree, safe and reliable in feeding, good in equipment reliability and long in service life, and well solves the feeding problem of the cold header.

Owner:浙江东雄机床有限公司

Automatic-feeding live poultry breeding device

The invention discloses an automatic-feeding live poultry breeding device which comprises a bottom box, wherein the top of the bottom box is fixedly connected with a frame body; a first vertical plateand a second vertical plate are sequentially, vertically and fixedly connected between the bottom box and the top of the inner wall of the frame body; one side of the top of the bottom box is fixedlyconnected with a first motor; an output shaft end of the first motor is connected with a drive shaft in a drive mode through belt-gear drive; a screw rod is rotatablely connected between the two opposite sides of the first vertical plate and the second vertical plate; the surface of the screw rod is fixedly connected with an L-shaped fixed plate through a slider; one side of the L-shaped fixed plate is fixedly connected with a second motor; an output shaft end of the second motor is fixedly connected with a discharge plate; one side of the L-shaped fixed plate is fixedly connected with a scattering hopper; and the top of the frame body is fixedly connected with a material hopper through a supporting frame. The automatic-feeding live poultry breeding device relates to the technical field of live poultry breeding. The automatic-feeding live poultry breeding device solves the following problems: live poultry breeding has a demand for feeding manually, and the existing feeding machine cannot implement fixed-point fixed-quantity feeding.

Owner:奉节县王子林黑豚饲养专业合作社

Device using AB-ASBR reactors to start anaerobic ammonia oxidation

ActiveCN105502664AImmobilizationAchieving AnammoxWater treatment parameter controlBiological treatment apparatusHigh concentrationMeasuring instrument

The invention discloses a device using AB-ASBR reactors to start anaerobic ammonia oxidation. The device comprises a sewage tank, a front-section reaction device and a rear-section reaction device. Each of the front-section reaction device and the rear-section reaction device comprises an ASBR reactor, a gas collecting device, a miniature vacuum pump, a time-control switch, a gas flowmeter, a pH measuring instrument, a dissolved oxygen measuring instrument and a temperature control device. The water outlet of the front-section ASBR reactor is connected with the water inlet of the rear-section ASBR reactor. The height ratio and diameter ratio of the front-section ASBR reactor to the rear-section ASBR reactor are 2-3. A gas outlet and a trace element adding port are formed in the top end of each of the front-section ASBR reactor and the rear-section ASBR reactor. A water inlet and a water outlet are respectively formed in the bottom side of each of the front-section ASBR reactor and the rear-section ASBR reactor. The bottom center of each of the front-section ASBR reactor and the rear-section ASBR reactor is provided with a gas circulation inlet and an aeration head, and the gas circulation inlet is arranged below the aeration head. An emptying valve and a mud discharging valve are further arranged at the bottom of each of the front-section ASBR reactor and the rear-section ASBR reactor. By the device, high-concentration organic matter can be degraded under an anaerobic condition while ammonia and nitrogen in sewage can be removed, sewage treatment efficiency is increased evidently, and treatment cost is lowered.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com