Patents

Literature

1945results about "Weighing apparatus testing/calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

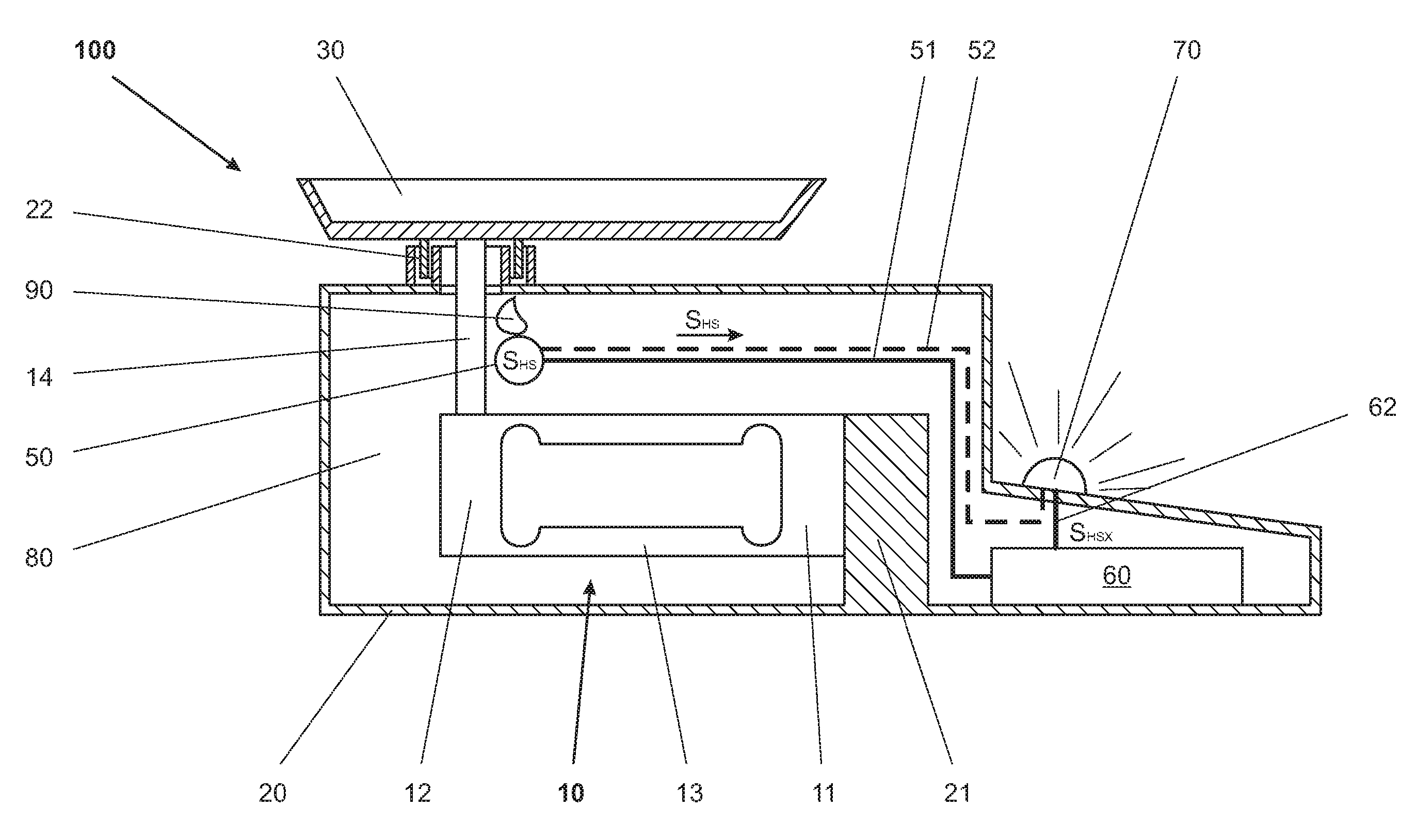

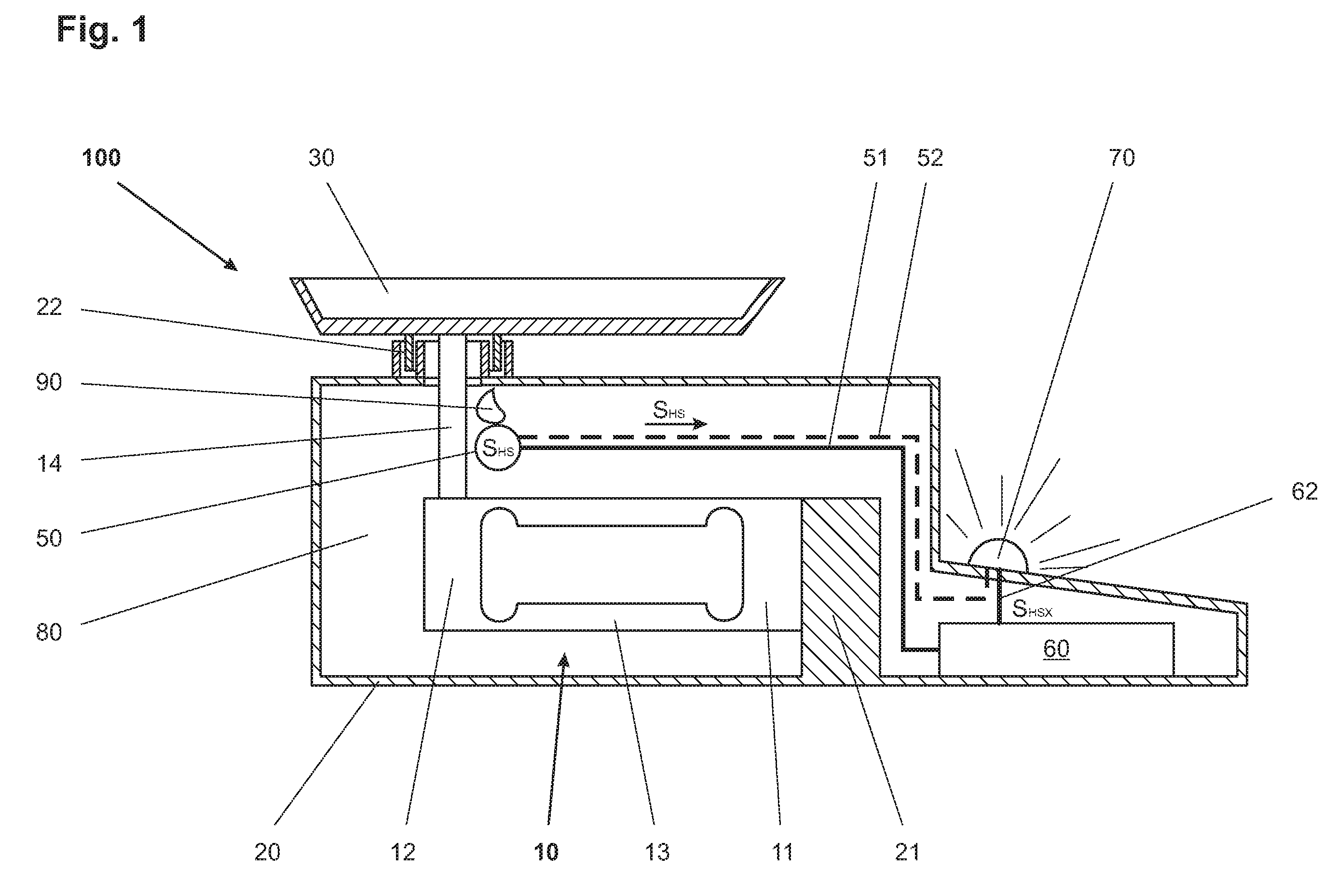

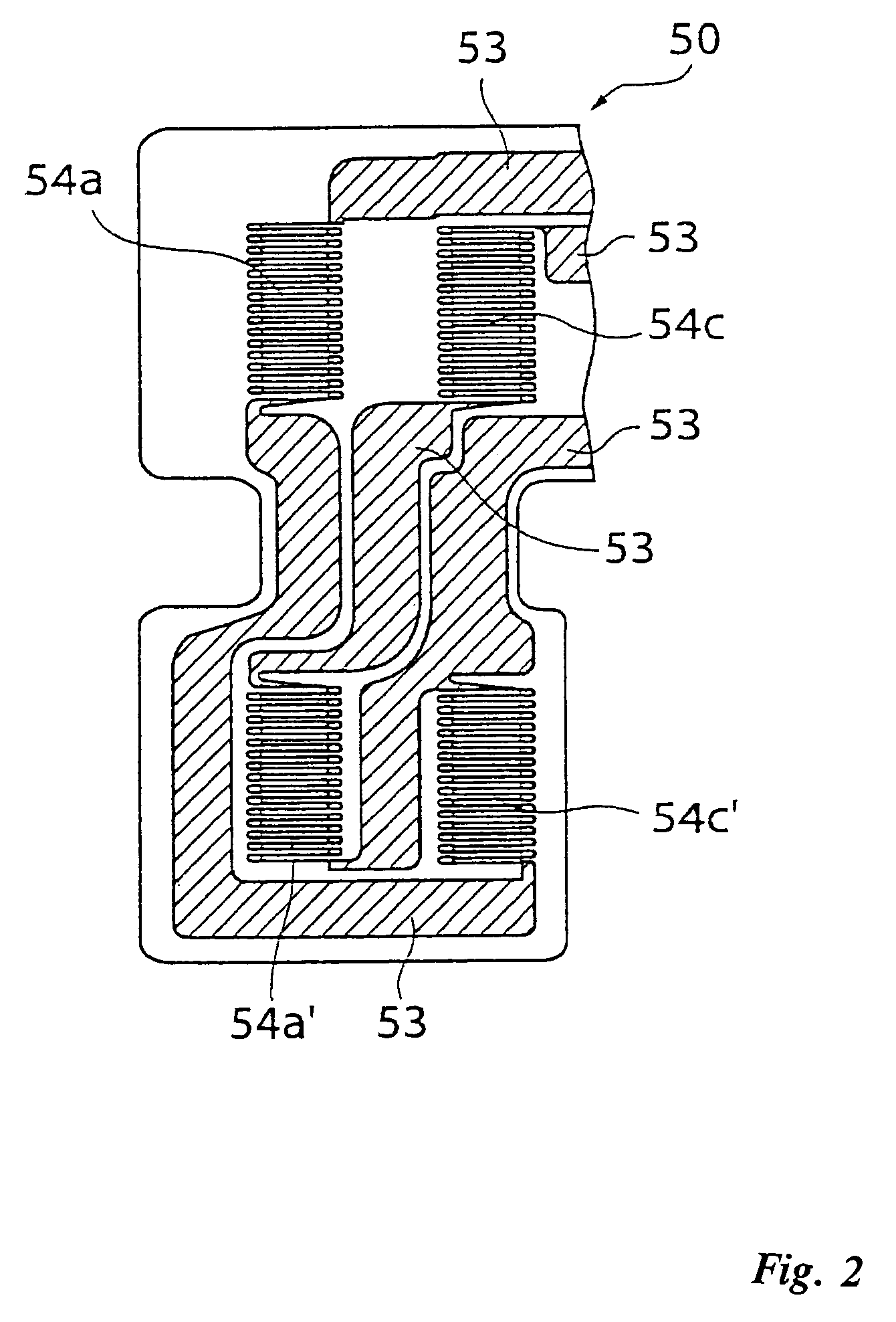

Method of monitoring and/or determining the condition of a force-measuring device, and force-measuring device

ActiveUS7497137B2Accurate calculationPlug gaugesWeighing apparatus testing/calibrationInterior spaceMeasurement device

In a method for monitoring and / or determining the condition of a force-measuring device with at least one housing that has an interior space and with at least one force-measuring cell installed in the interior space of the at least one housing, at least one parameter of the atmospheric climate of the interior space is measured with at least one sensor that is arranged in the interior space of the housing or with at least one sensor that is arranged at the housing, wherein said parameter is of a kind that has an influence on the operating lifetime of the force-measuring cell; and a sensor signal corresponding to the measured parameter of the atmospheric climate of the interior space is transmitted to a computing unit and / or to a data output device.

Owner:METTLER TOLEDO GMBH

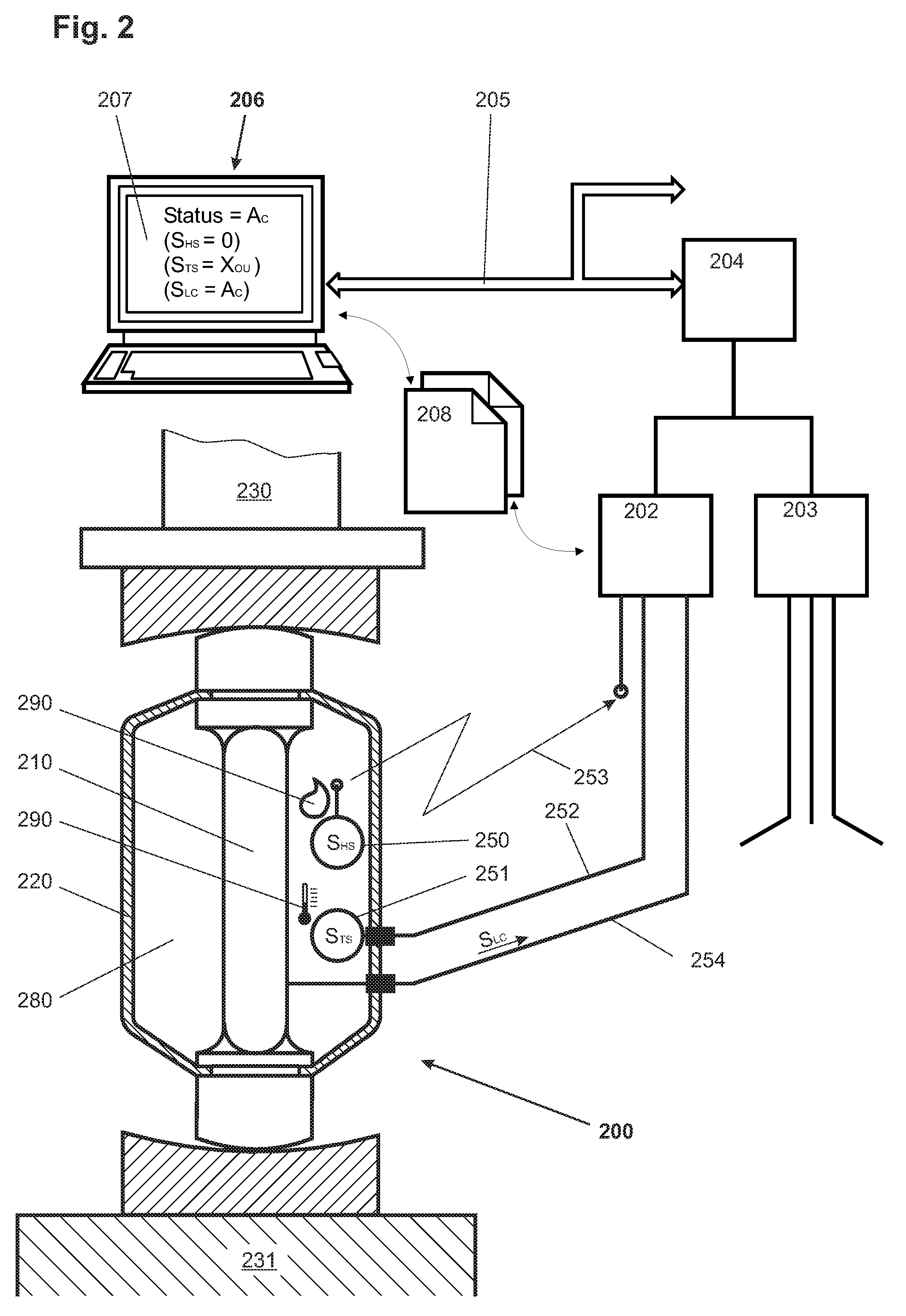

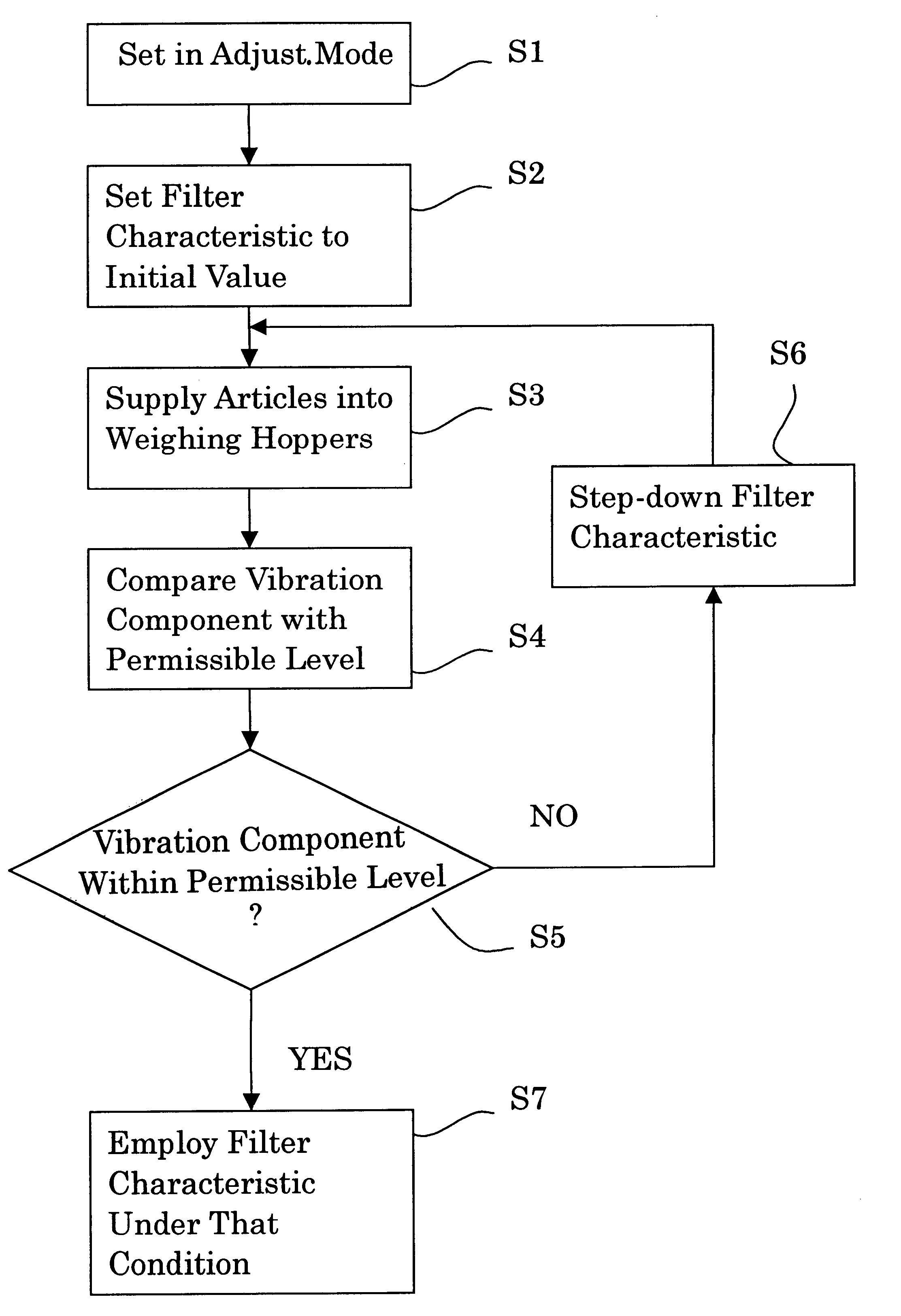

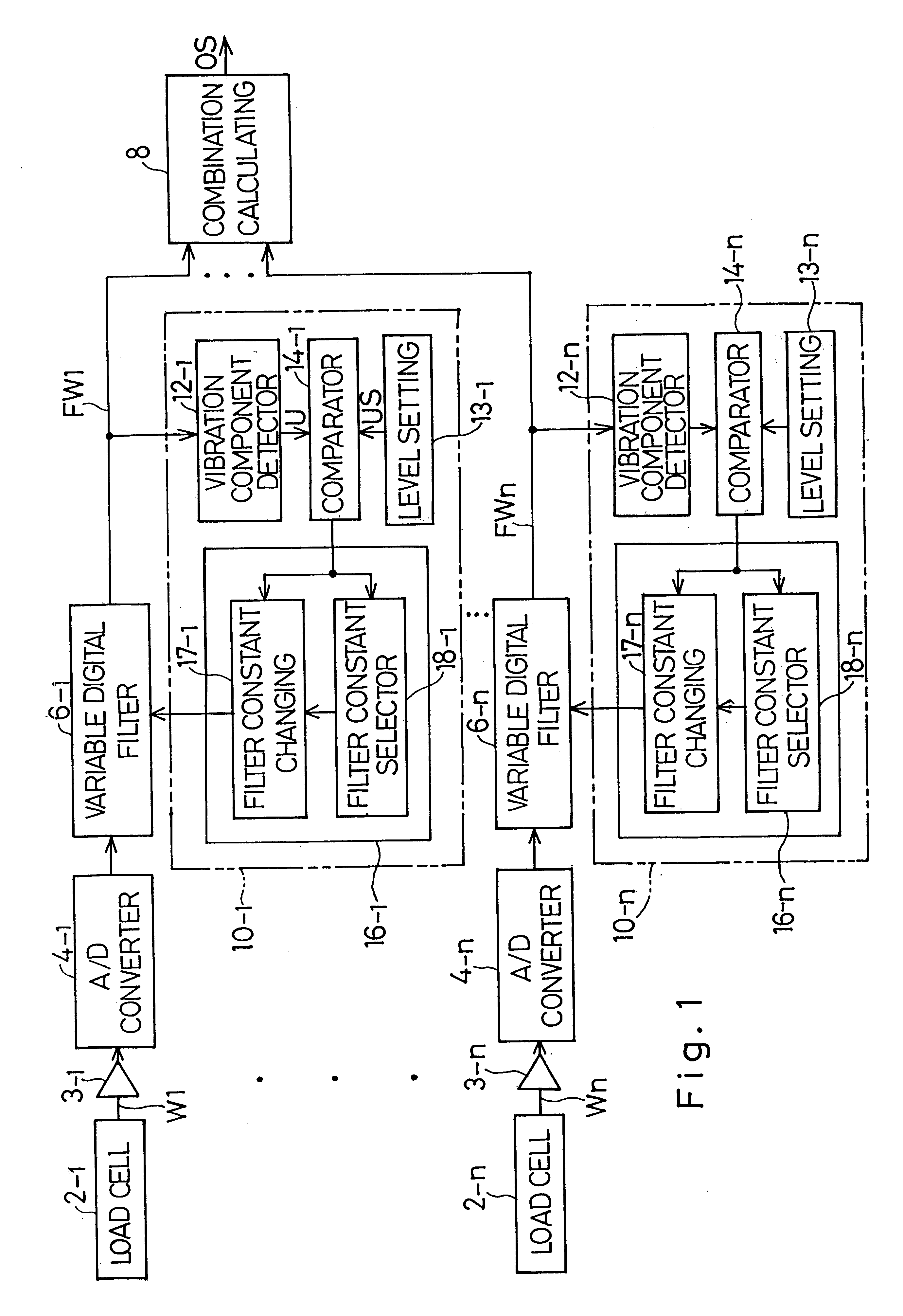

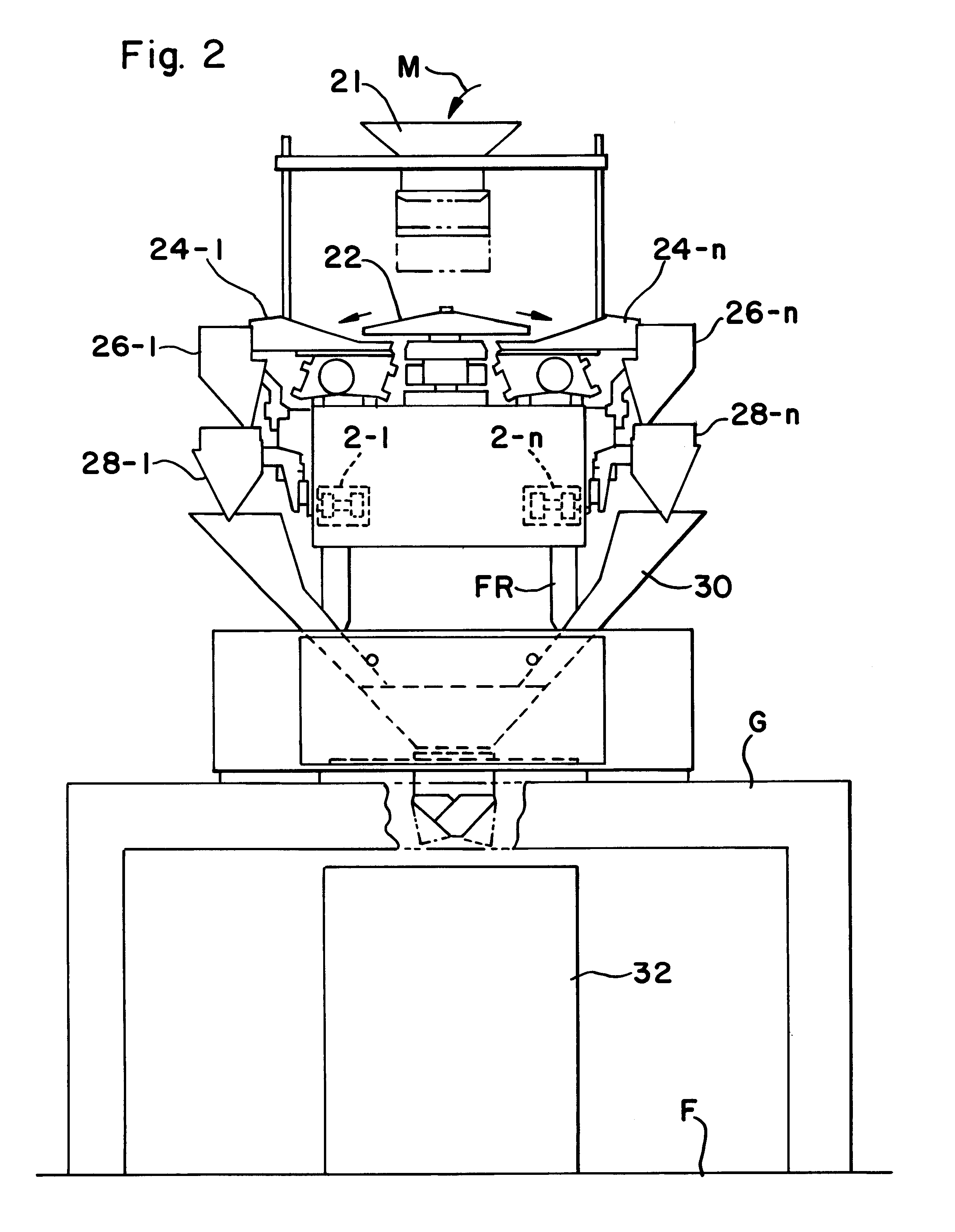

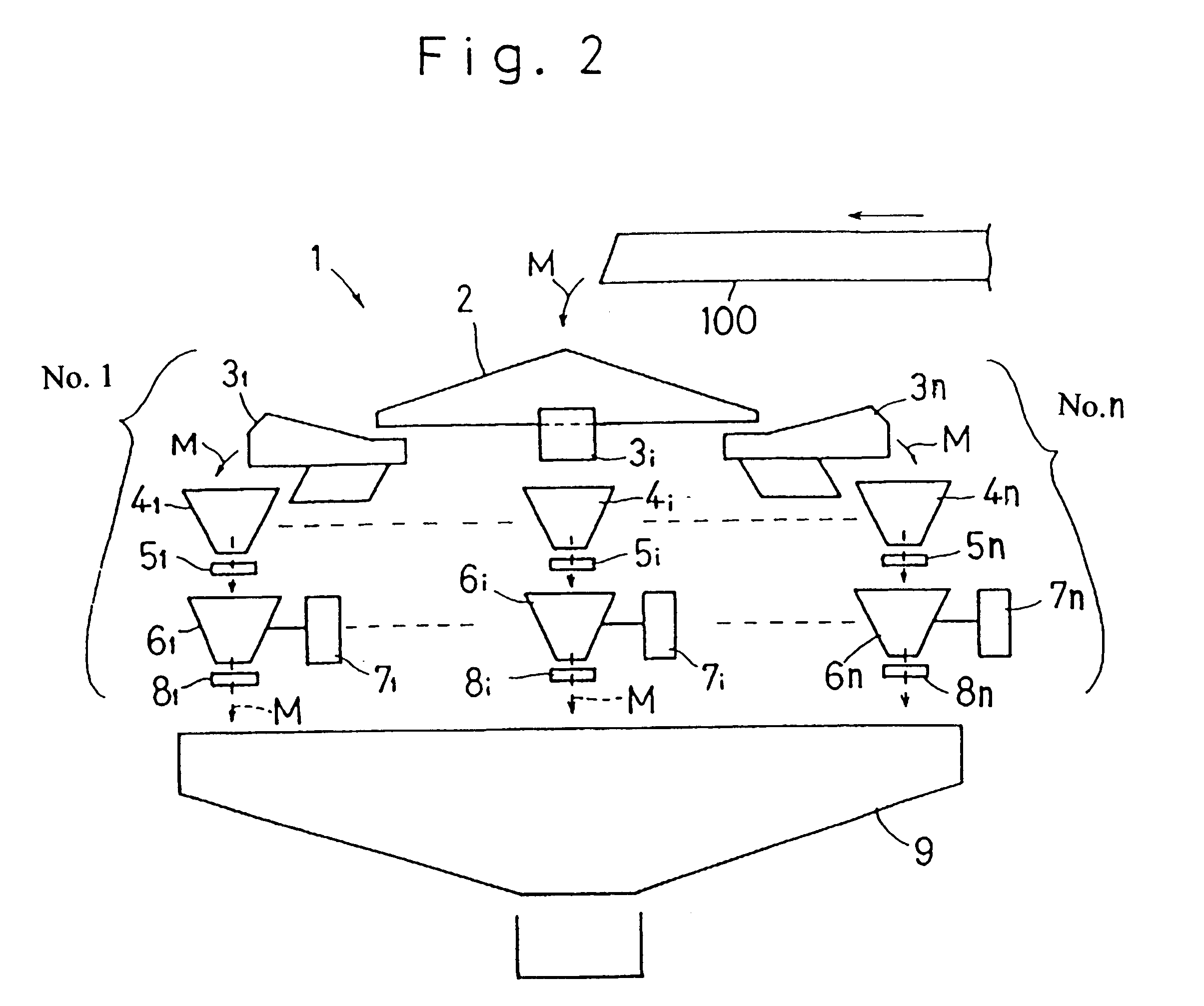

Weighing apparatus having an automatic filter adjusting capability

InactiveUS6271484B1Short response timeShort timeWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationDigital filterAutomatic filtering

In order to provide a combination weighing apparatus having an automatic filter adjusting capability which is effective to secure a weighing accuracy and also to adjust a filter characteristic of a digital filter having a short response time, the filter characteristic is automatically adjusted, based on a result of comparison of respective vibration components U of filtered weight signals FW1 to FWn with a permissible level US of the vibration components, so that the respective vibration components U of the filtered weight signals FW1 to FWn can attain a value approximating to the permissible level US, but not exceeding the permissible level US. In this way, by damping the vibration components U down to a value within the permissible level US, the weighing accuracy can be secured and, on the other hand, by damping the vibration components U down to a value approximating to the permissible level US, the filter characteristic can be obtained quickly in a short time.

Owner:ISHIDA CO LTD

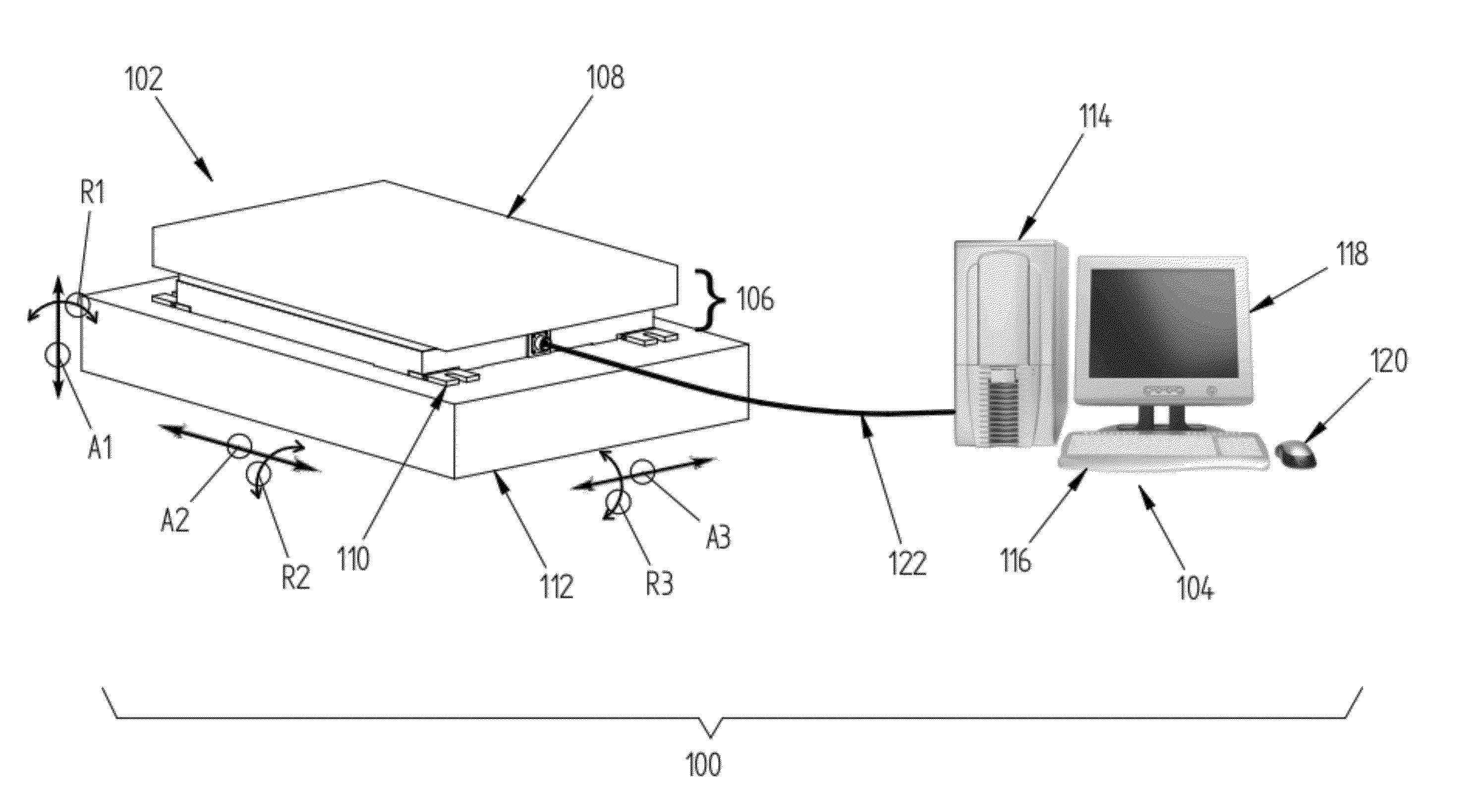

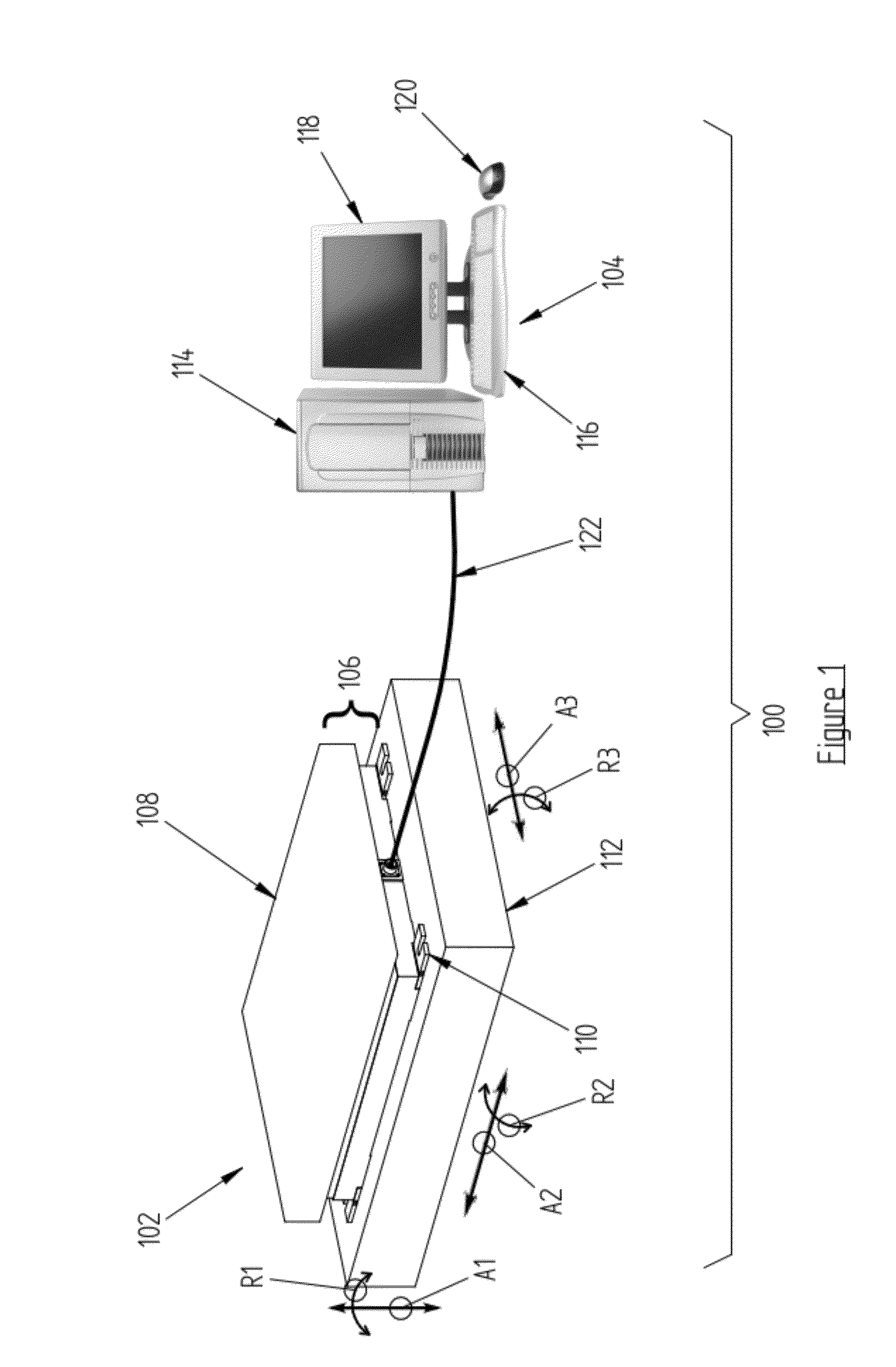

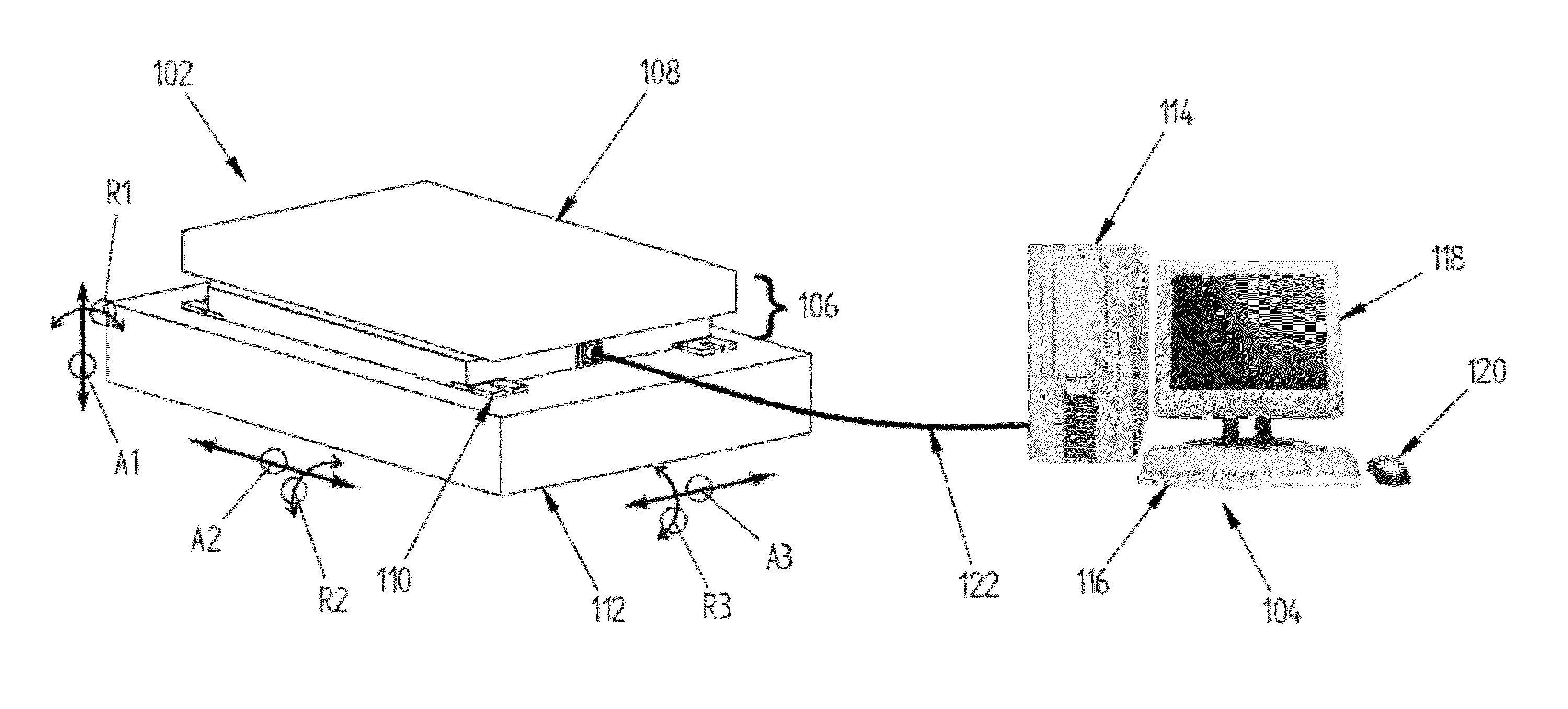

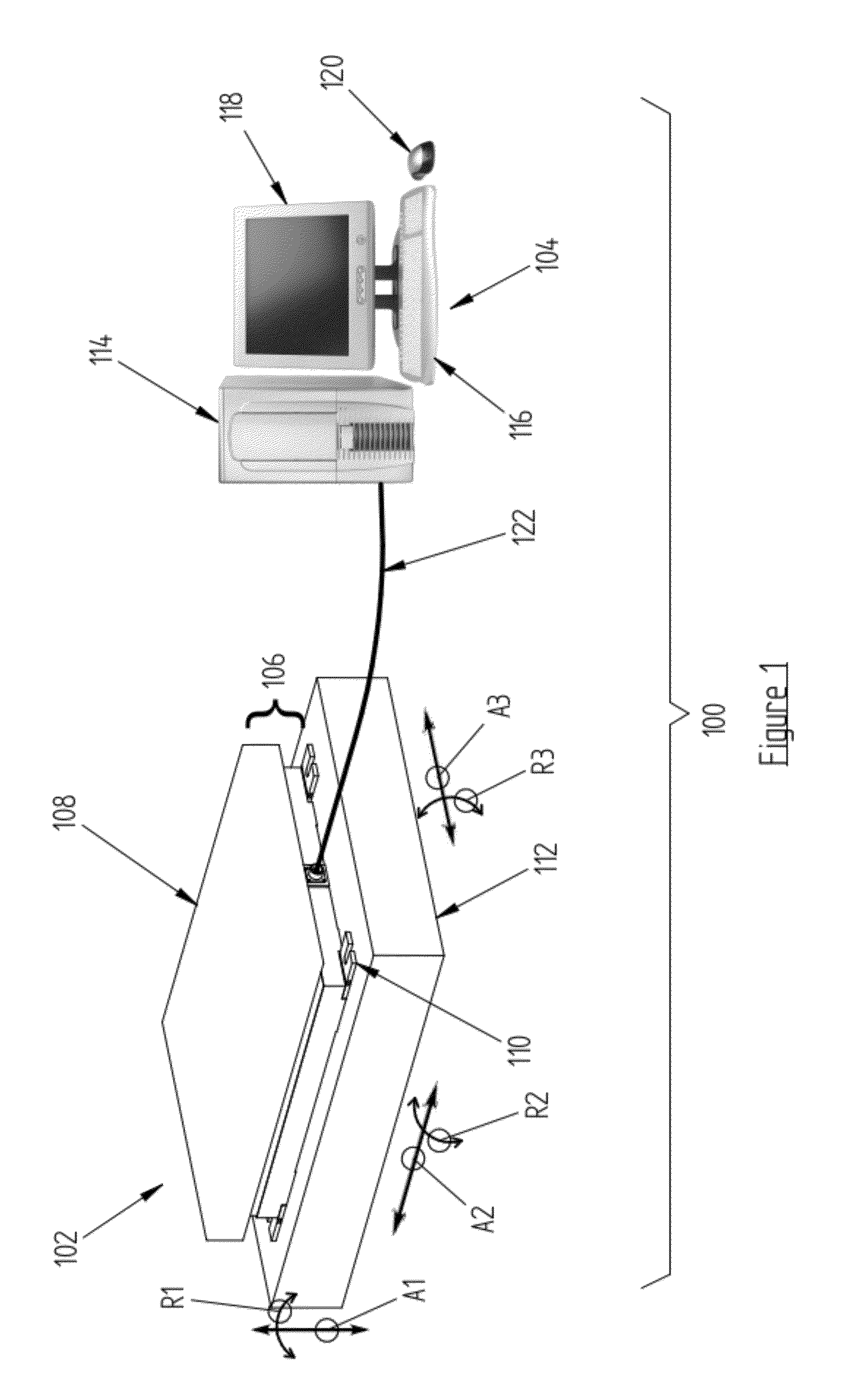

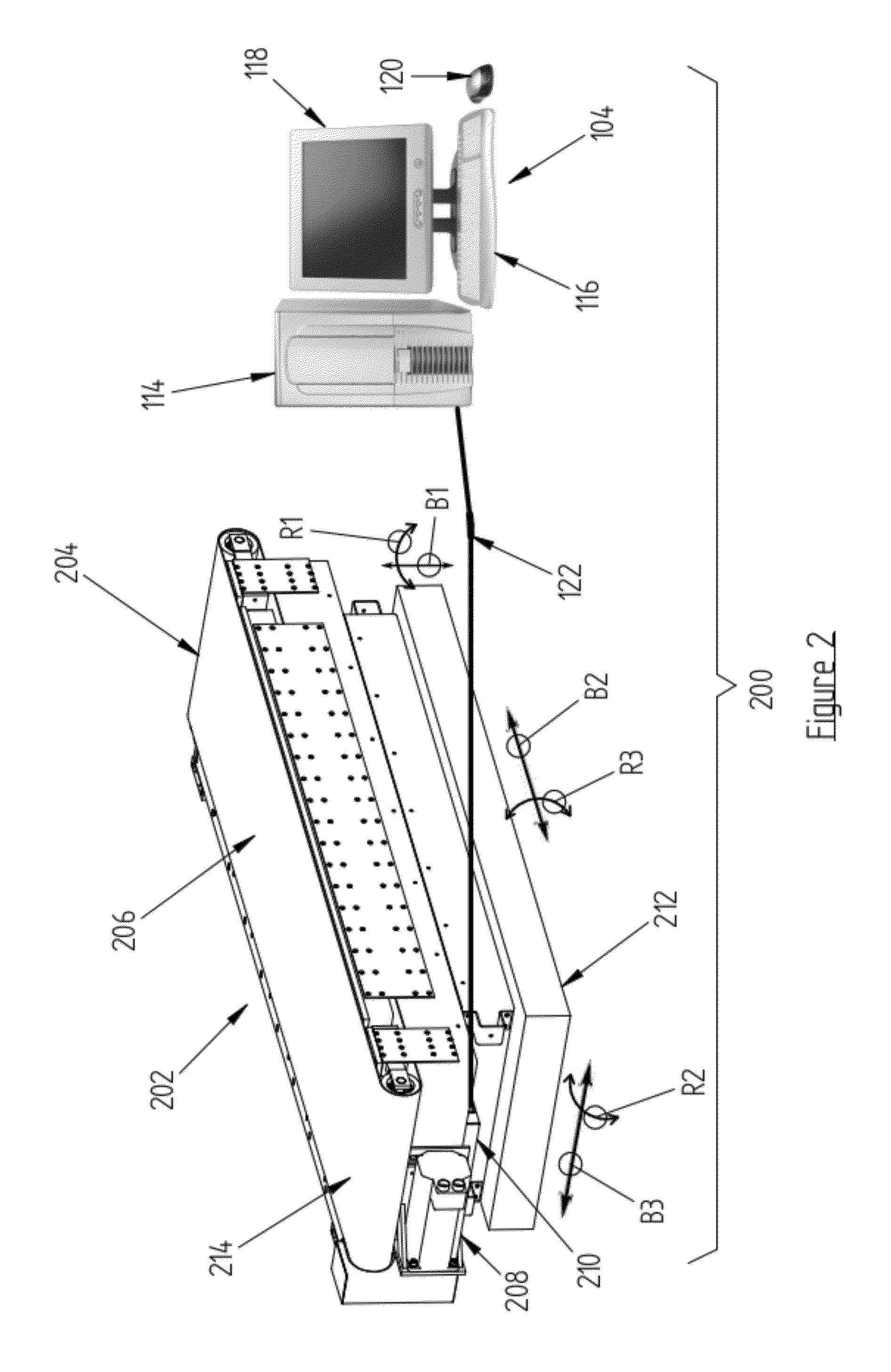

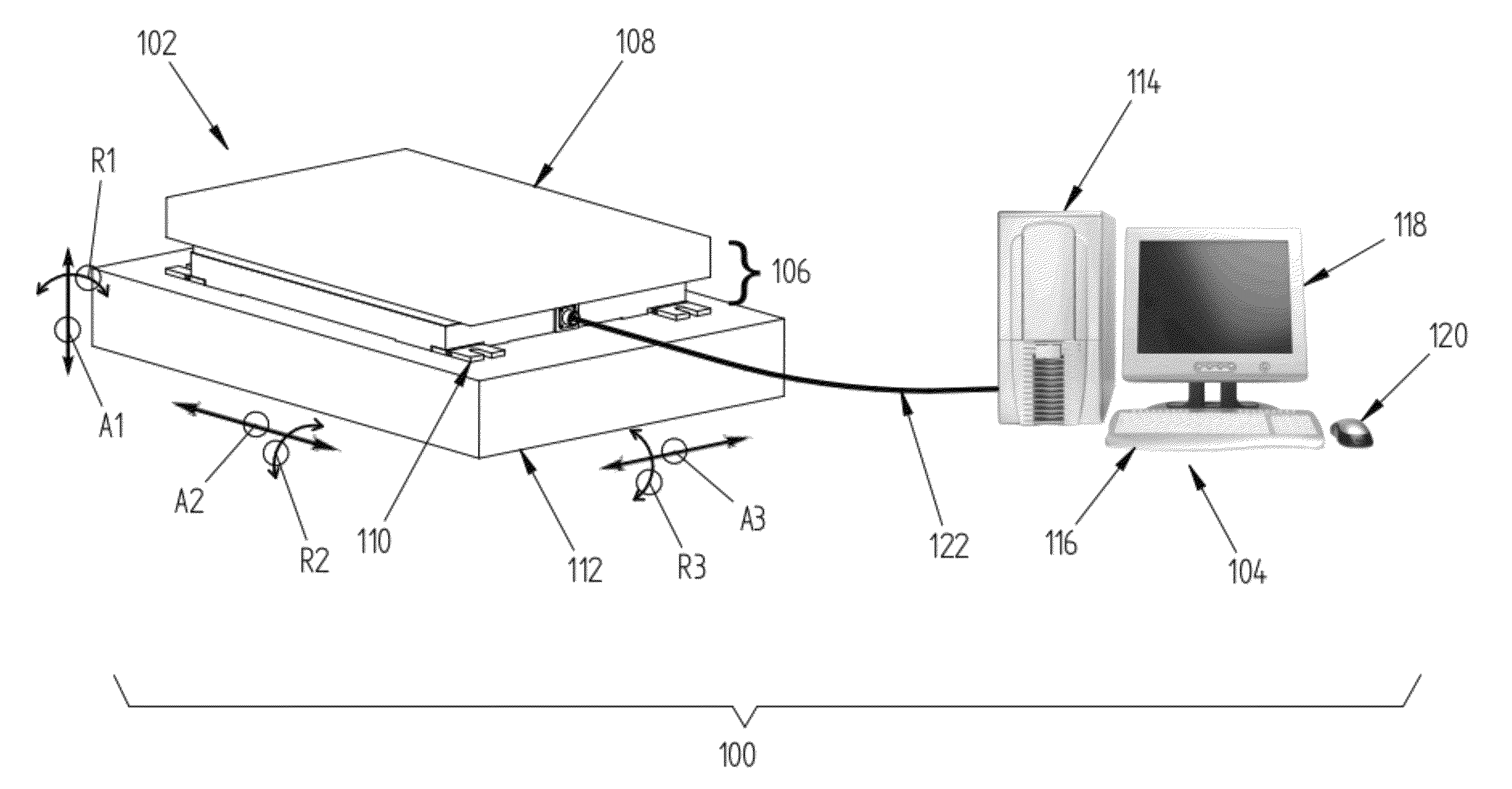

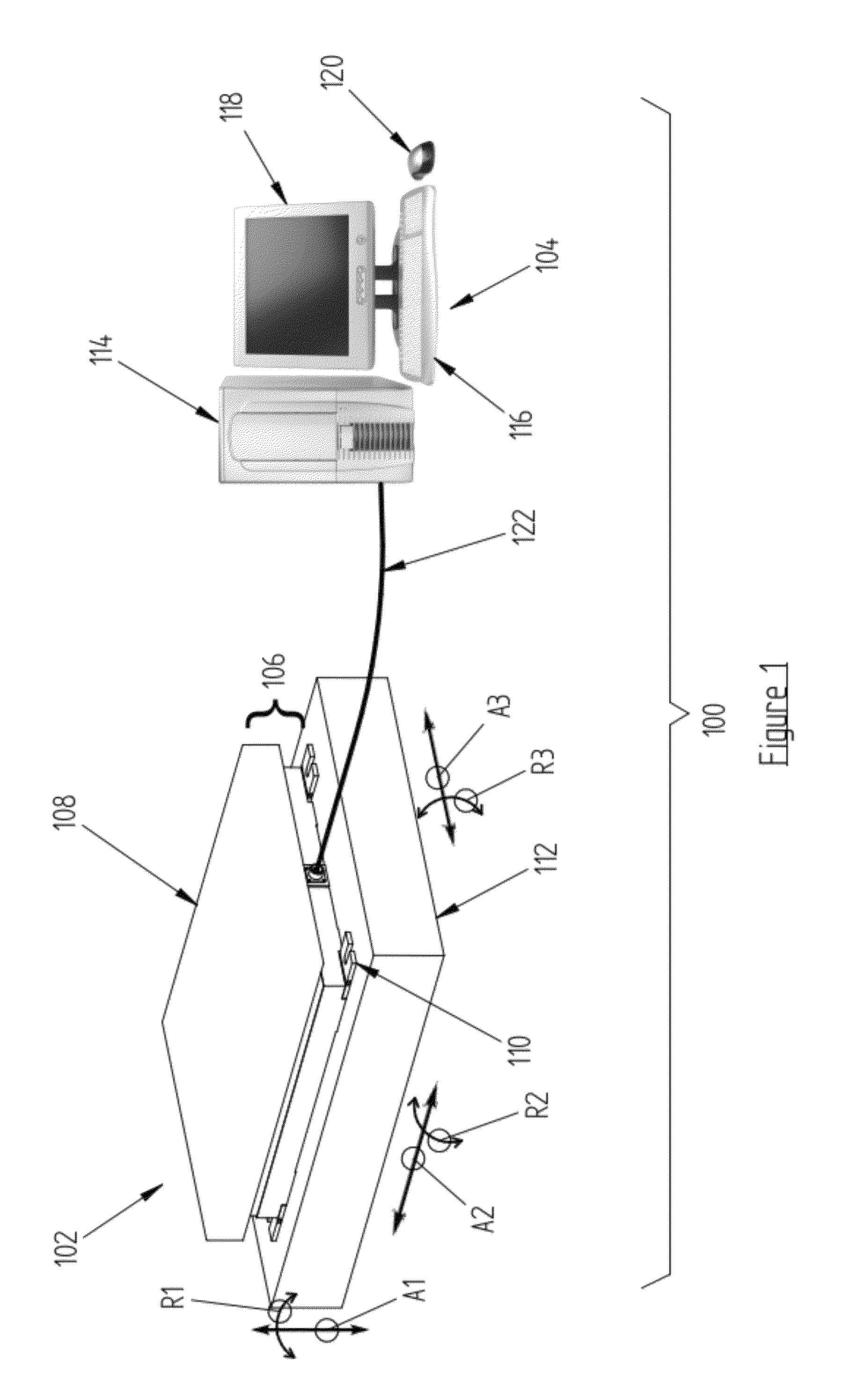

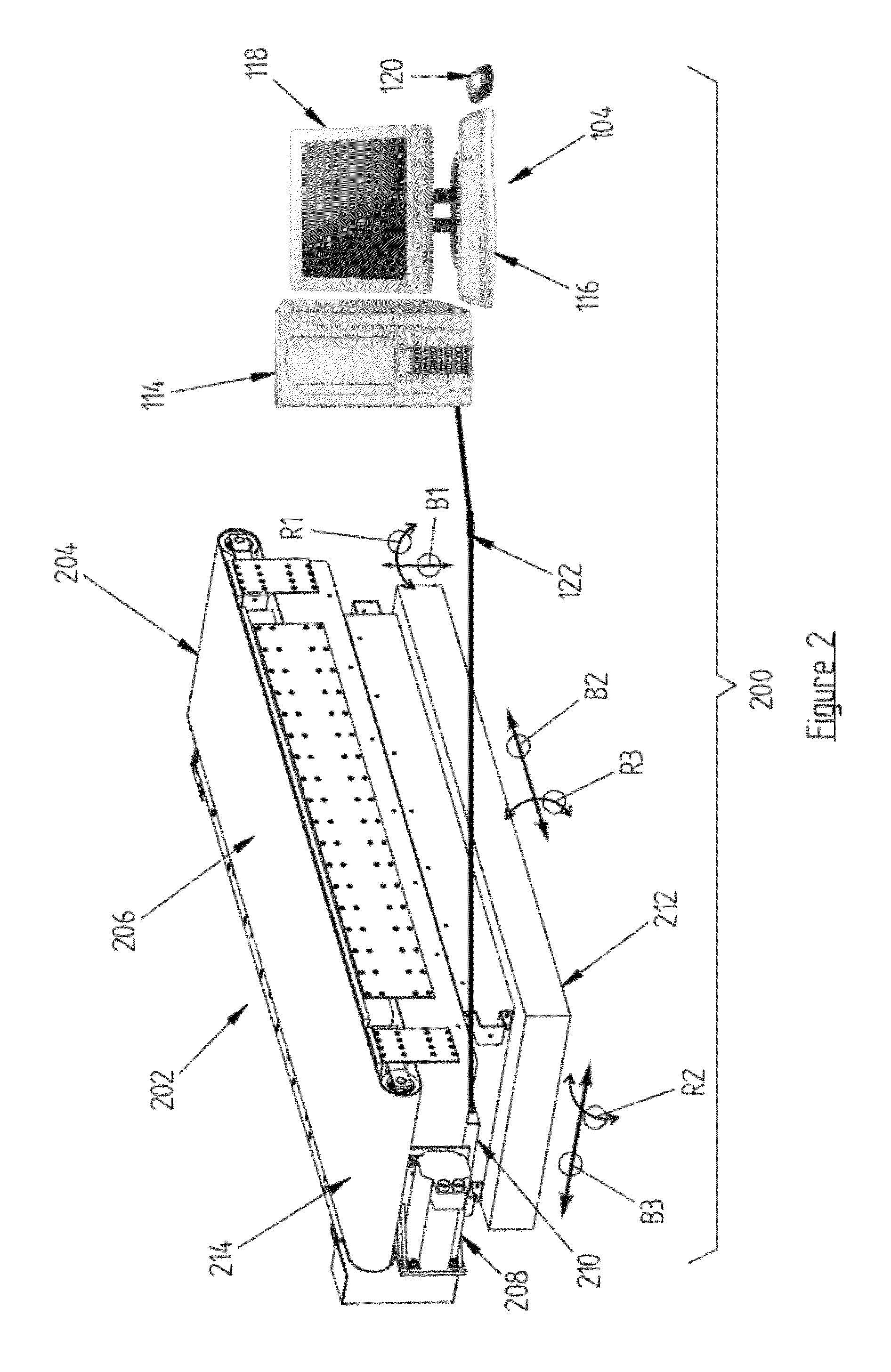

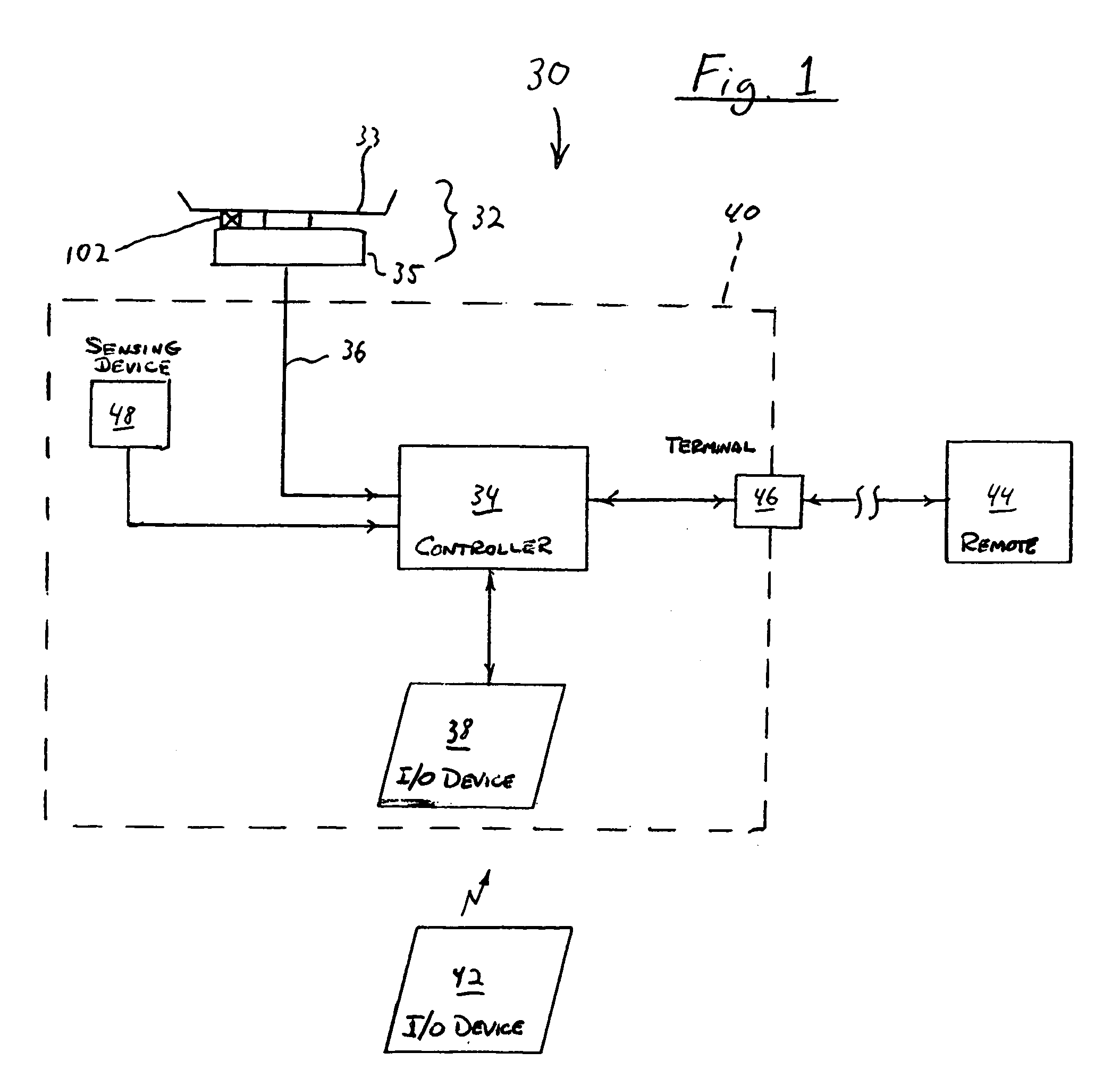

Force and/or motion measurement system having inertial compensation and method thereof

ActiveUS8315823B2Accurate compensationAccurately determineForce measurementDiagnostic recording/measuringMeasurement deviceSeries compensation

According to one aspect of the invention, a force measurement system includes a force measurement assembly, a motion base configured to displace the force measurement assembly, and an inertial compensation system configured to determine the inertial forces and / or moments resulting from the displacement of the force measurement assembly by the motion base. According to another aspect of the invention, a method for accurately determining the forces and / or moments applied to a surface of a force measurement device by a subject disposed thereon is disclosed, which includes the step of determining, by using an inertial compensation system, the inertial forces and / or moments resulting from the displacement of a force measurement assembly by a motion base. According to still another aspect of the invention, a force and / or motion measurement system having inertial compensation includes a motion acquisition system having a plurality of motion sensing devices configured to capture a subject's movement.

Owner:BERTEC

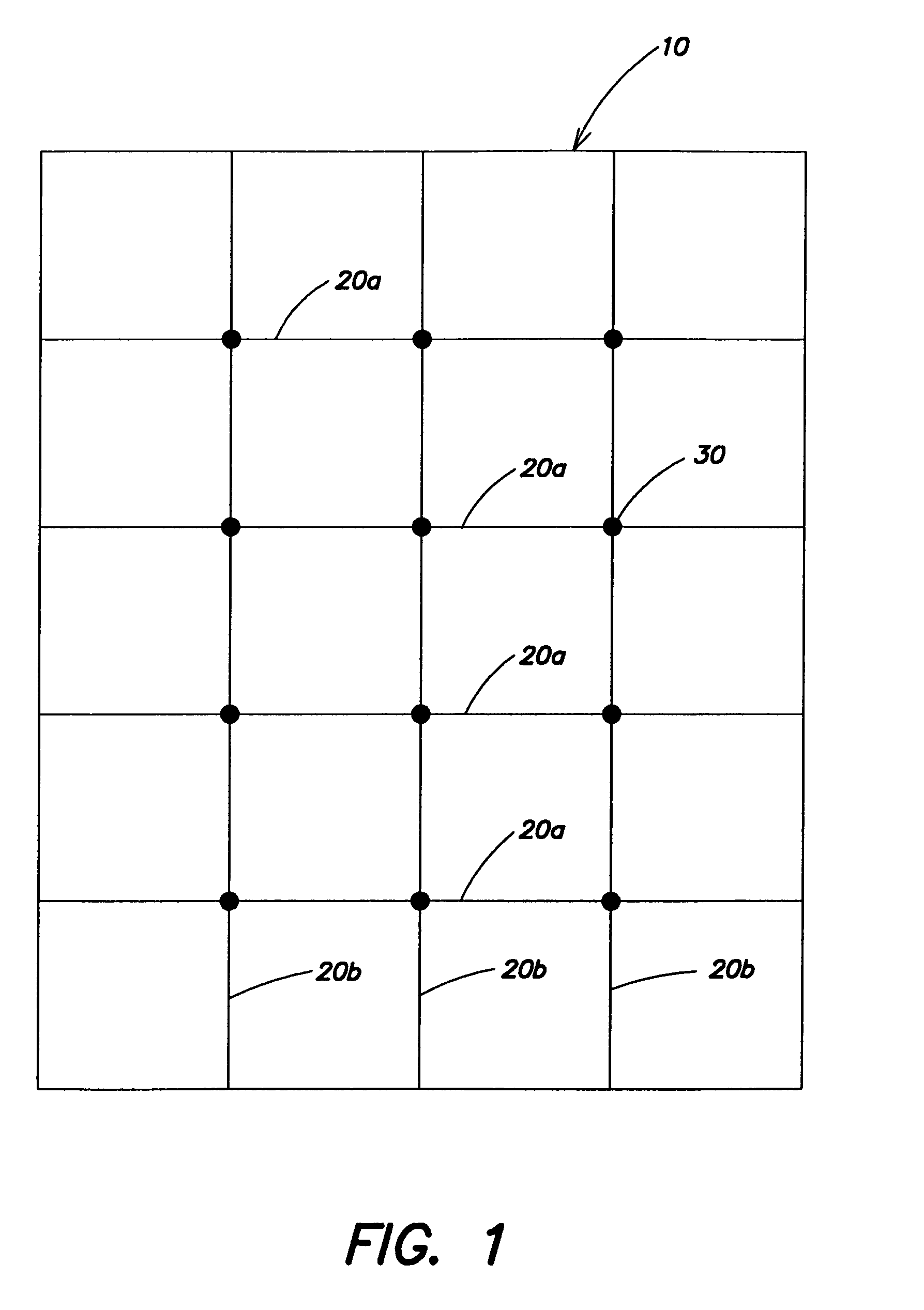

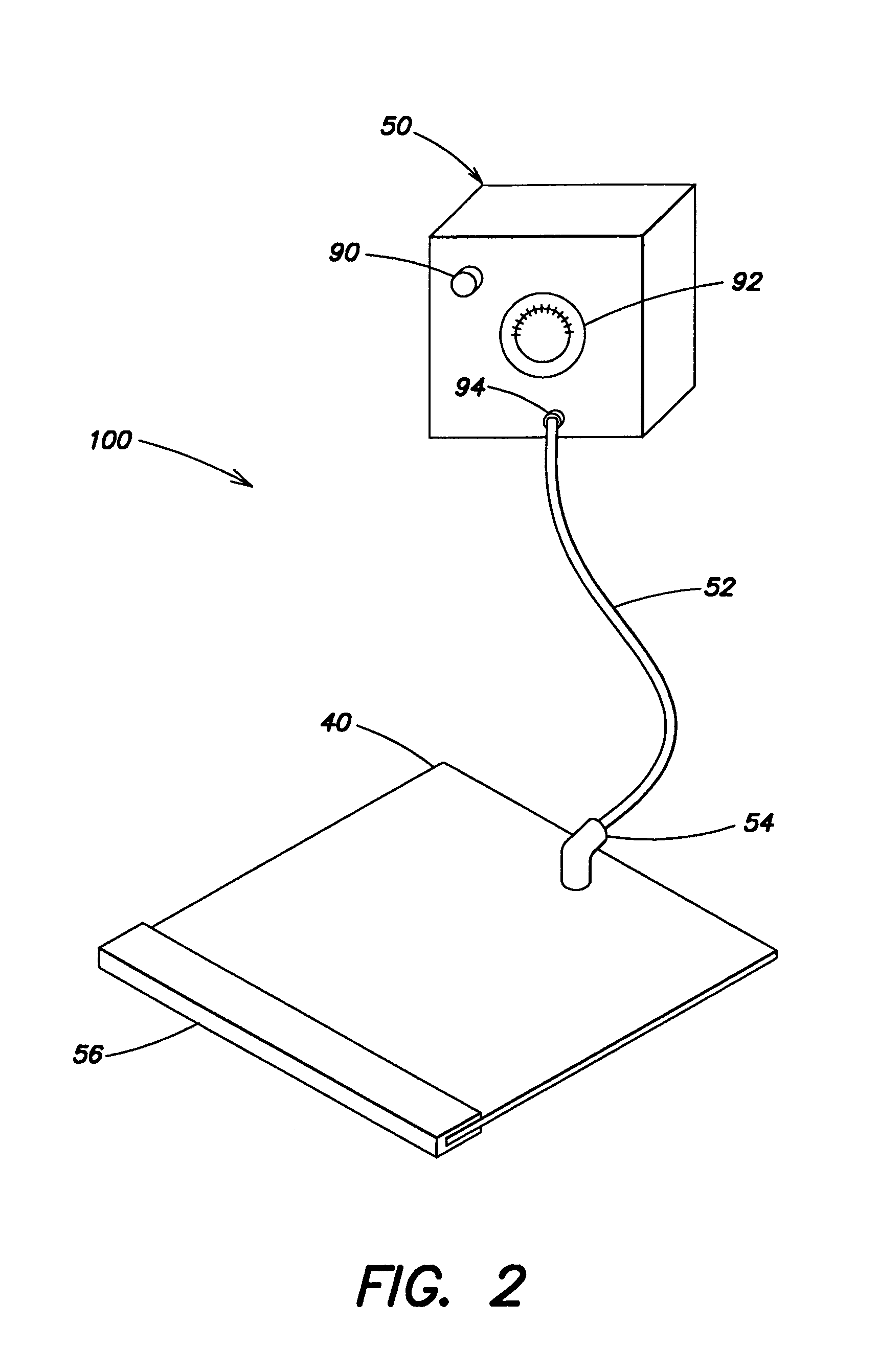

Sensor equilibration and calibration system and method

InactiveUS6993954B1Ease of evacuationWeighing apparatus testing/calibrationFluid pressure measurementDecreased pressureEngineering

Owner:TEKSCAN

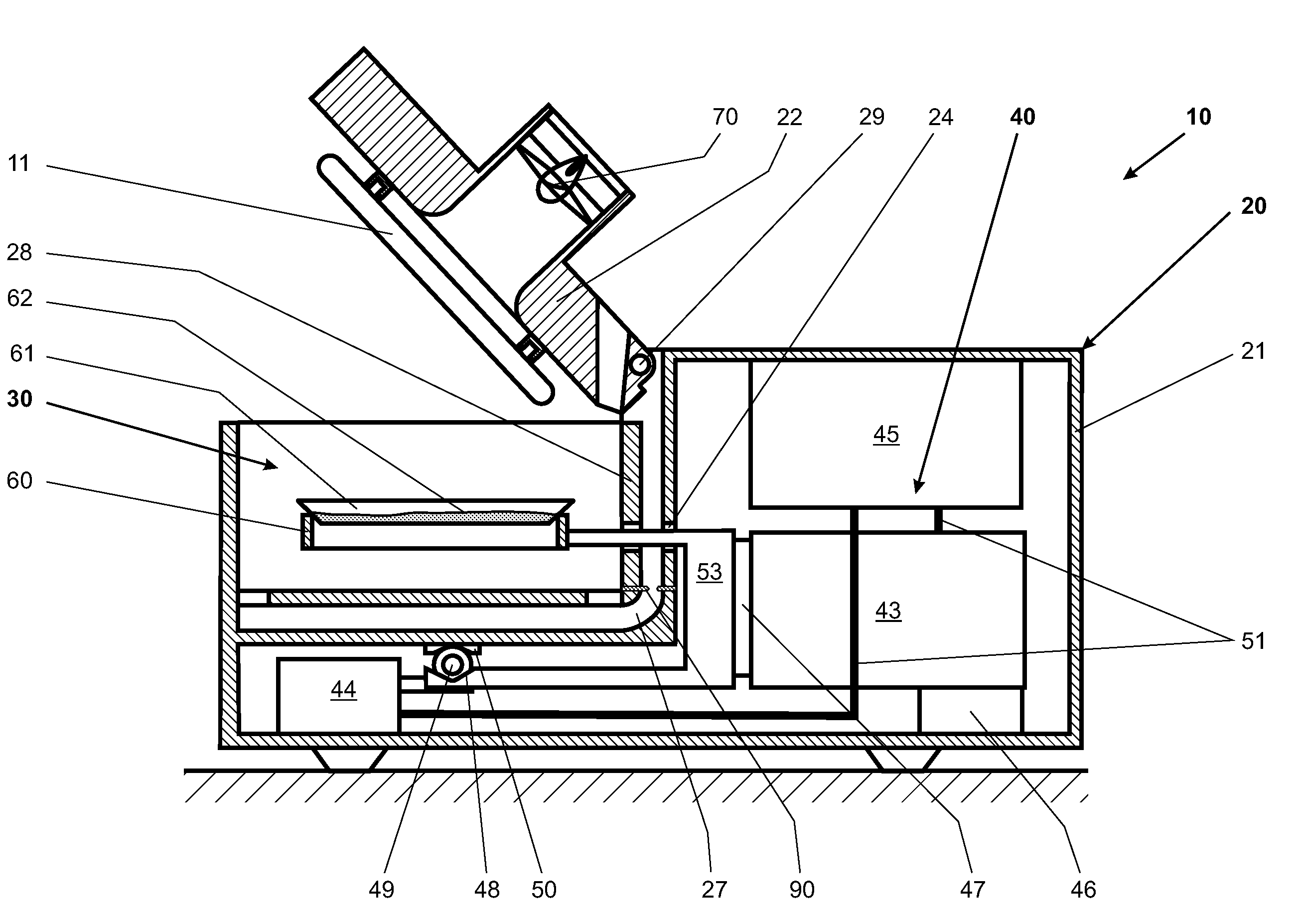

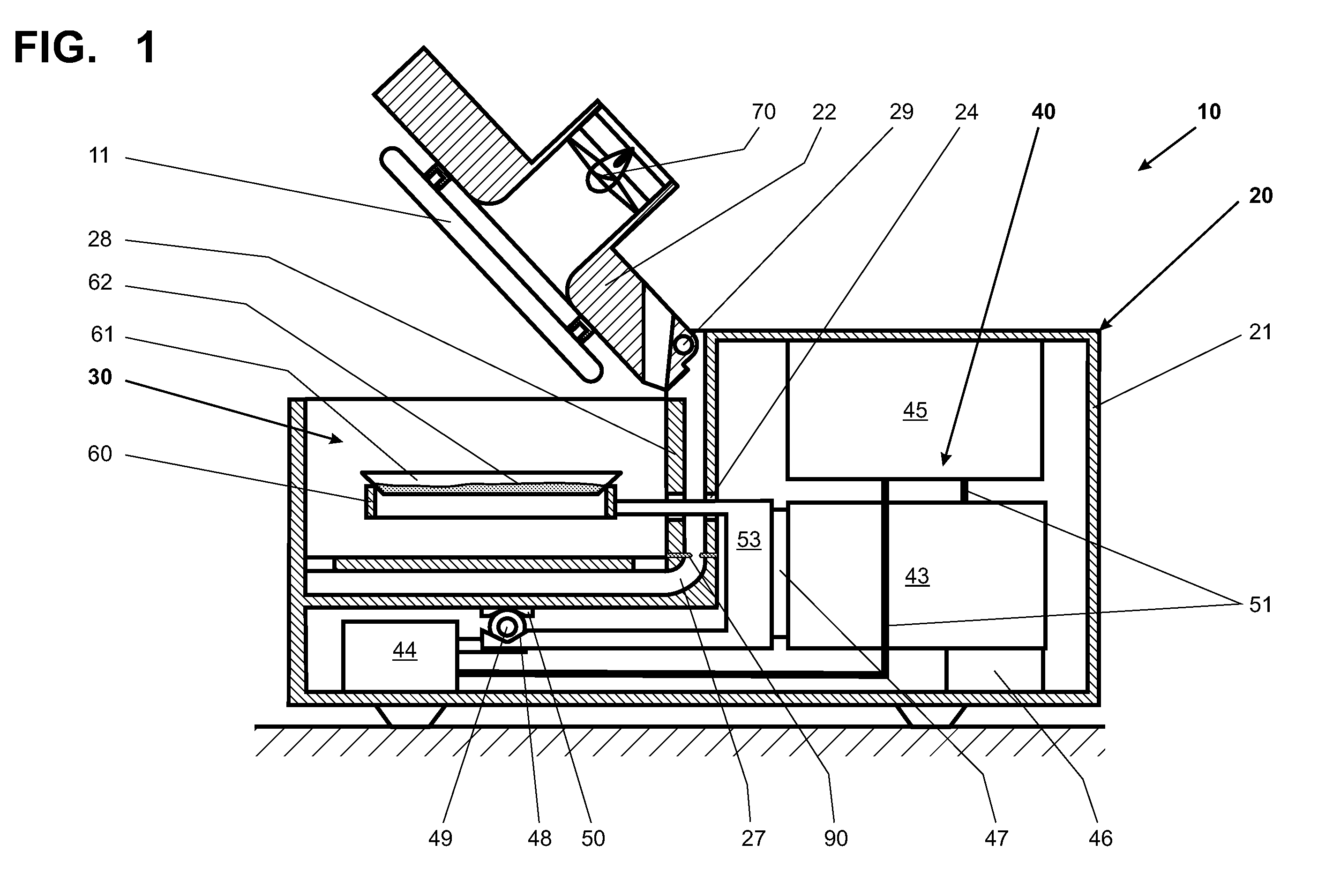

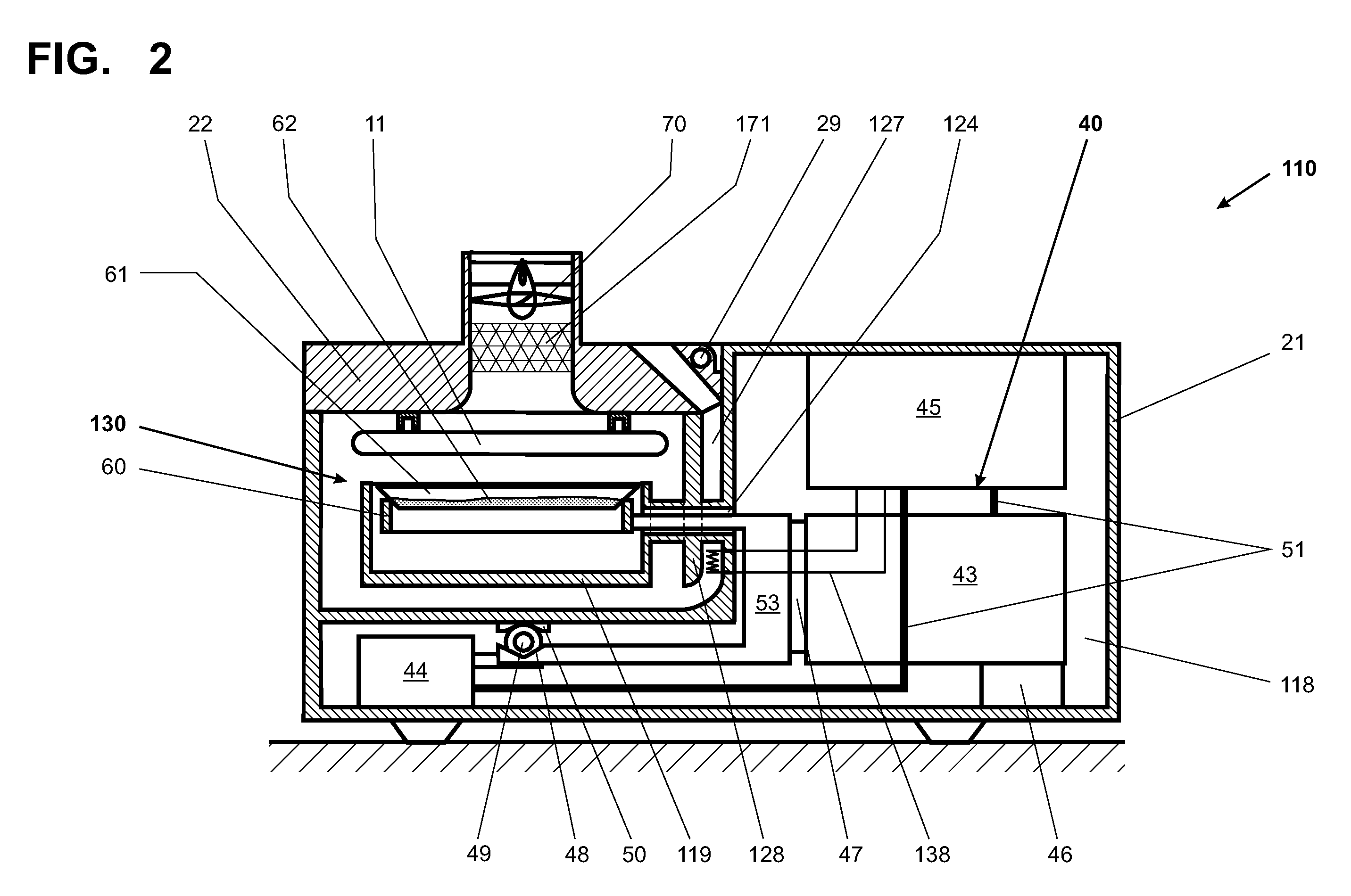

Force Measurement System Having Inertial Compensation

ActiveUS20120271565A1Accurate force measurementAccurate compensationForce measurementInertial sensorsAccelerometerAngular velocity

A force measurement system having inertial compensation includes a force measurement assembly with at least one accelerometer configured to measure the acceleration thereof. According to one aspect of the invention, the force measurement system additionally includes at least one angular velocity sensor configured to measure the angular velocity of the force measurement assembly. According to another aspect of the invention, the force measurement system additionally includes a data processing device with a computer-readable medium loaded thereon that is configured to execute a calibration procedure for determining the inertial parameters of the force measurement assembly by utilizing the measured acceleration of the force measurement assembly while the force measurement assembly is subjected to a plurality of applied linear and / or rotational motion profiles. According to still another aspect of the invention, the at least one accelerometer is disposed on the force transducer.

Owner:BERTEC

Force measurement system having inertial compensation

ActiveUS8315822B2Accurate compensationAccurate force measurementForce measurementInertial sensorsAccelerometerAngular velocity

A force measurement system having inertial compensation includes a force measurement assembly with at least one accelerometer configured to measure the acceleration thereof. According to one aspect of the invention, the force measurement system additionally includes at least one angular velocity sensor configured to measure the angular velocity of the force measurement assembly. According to another aspect of the invention, the force measurement system additionally includes a data processing device with a computer-readable medium loaded thereon that is configured to execute a calibration procedure for determining the inertial parameters of the force measurement assembly by utilizing the measured acceleration of the force measurement assembly while the force measurement assembly is subjected to a plurality of applied linear and / or rotational motion profiles. According to still another aspect of the invention, the at least one accelerometer is disposed on the force transducer.

Owner:BERTEC

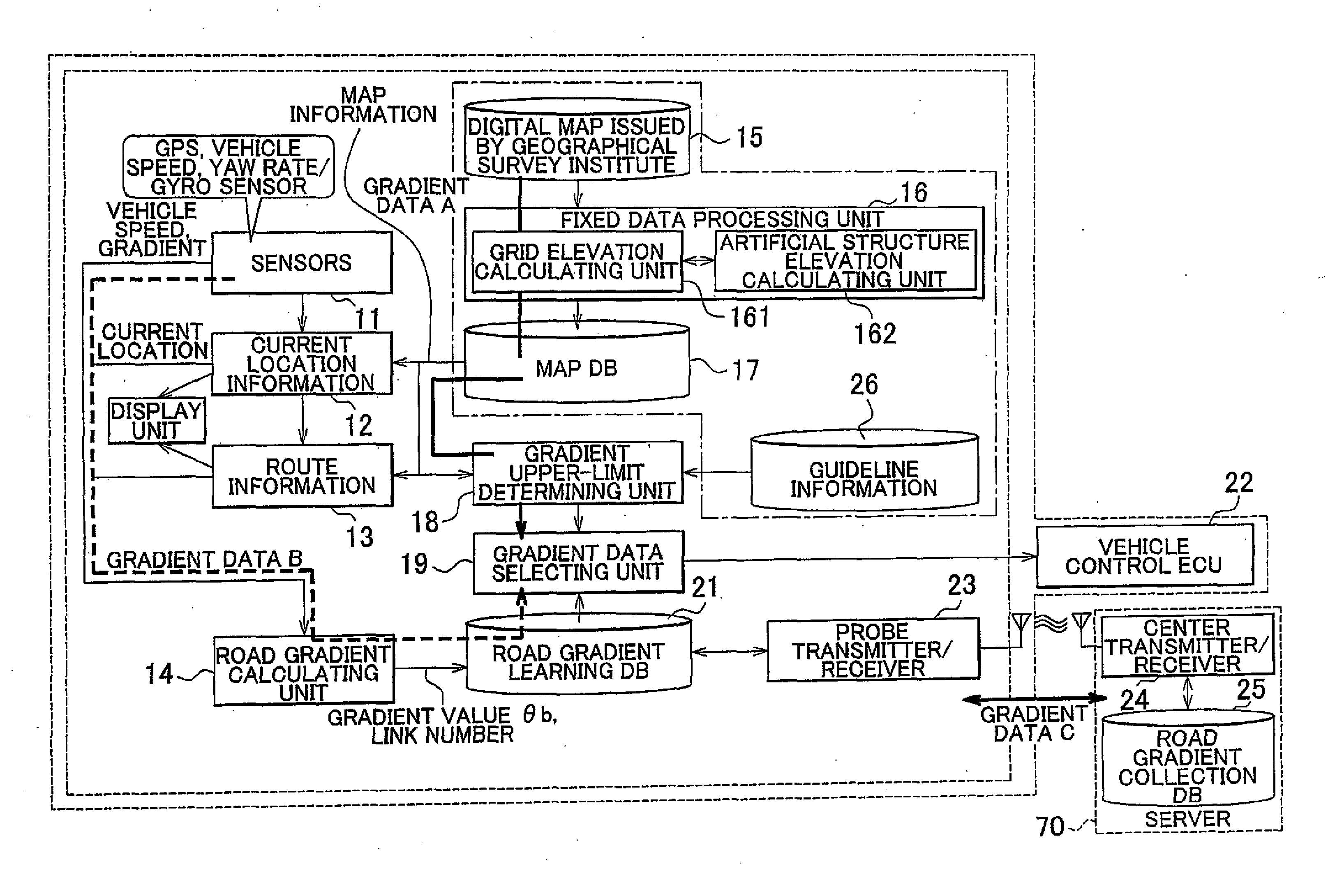

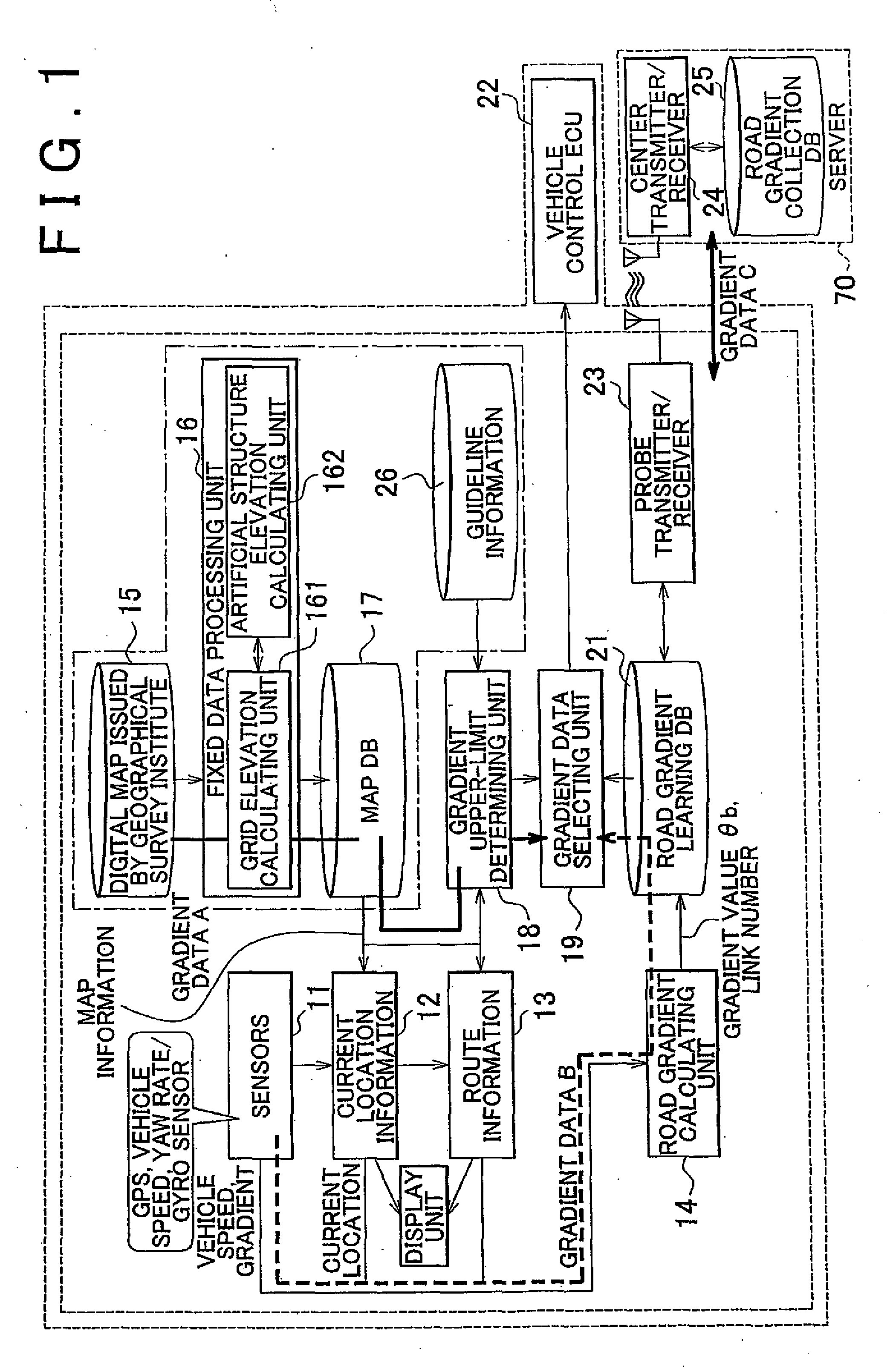

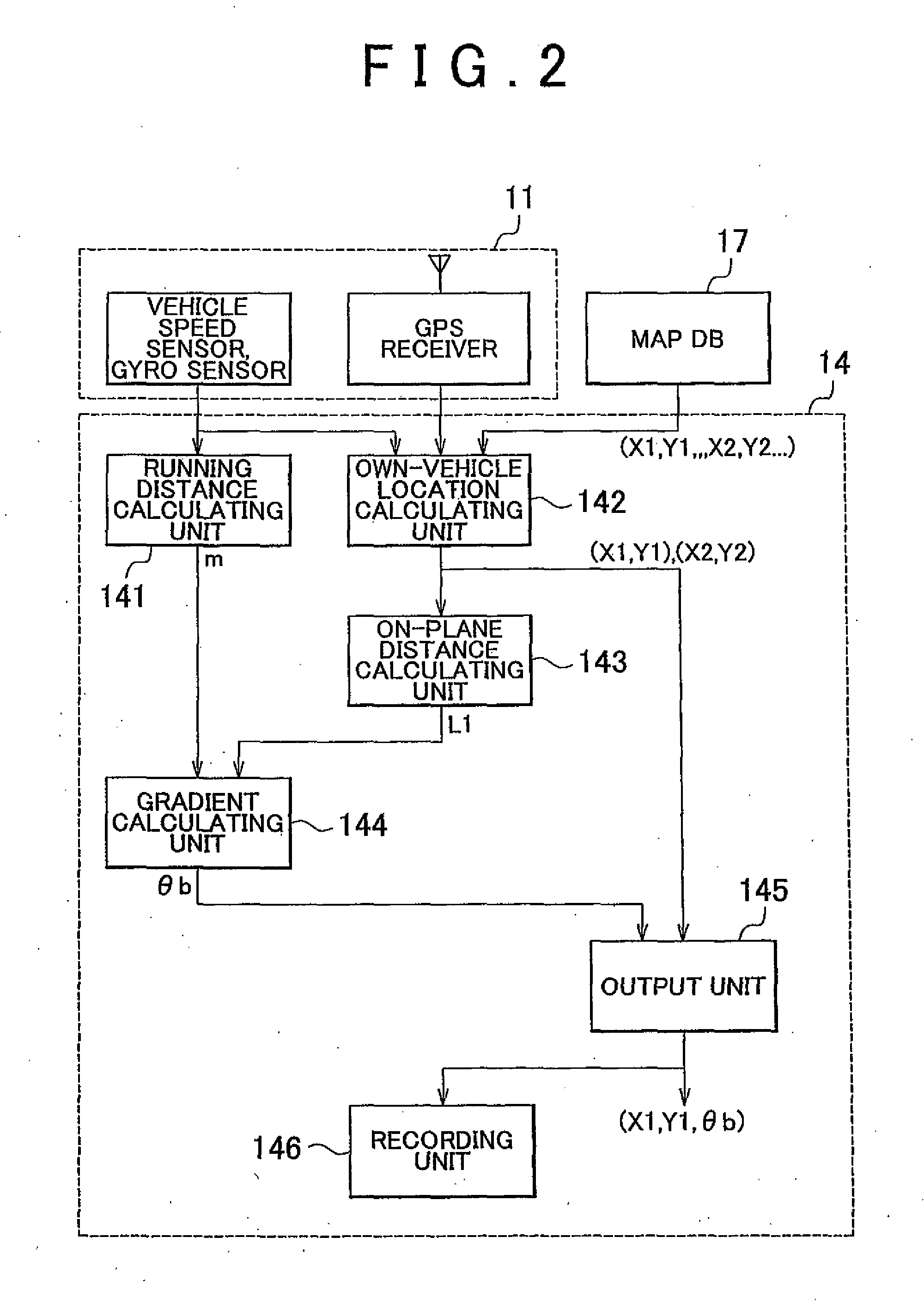

Gradient information calculating system, vehicle running control system, navigation system, and gradient information calculating method

ActiveUS20100324752A1High densityInstruments for road network navigationDigital data processing detailsControl systemData selection

A gradient information calculating system includes a first calculating unit (14) that detects three-dimensional location information through autonomous navigation, and calculates a first gradient value (θb, B), based on a distance (m) traveled, and an on-plane distance (L1) obtained by projecting the distance (m) traveled on a horizontal plane, a road map information storing unit (17) that stores road map information that represents each road by nodes of which the location information is known, and a link that connects the nodes, a second calculating unit (16) that estimates elevations of the nodes from previously measured elevation data, and calculates a second gradient value (A), based on a difference in elevation between the nodes and the length of the link, and a gradient data selecting unit (19) that selects one of the first and second gradient values to be adopted as a gradient value of the link, according to a difference between the first and the second gradient values.

Owner:TOYOTA JIDOSHA KK

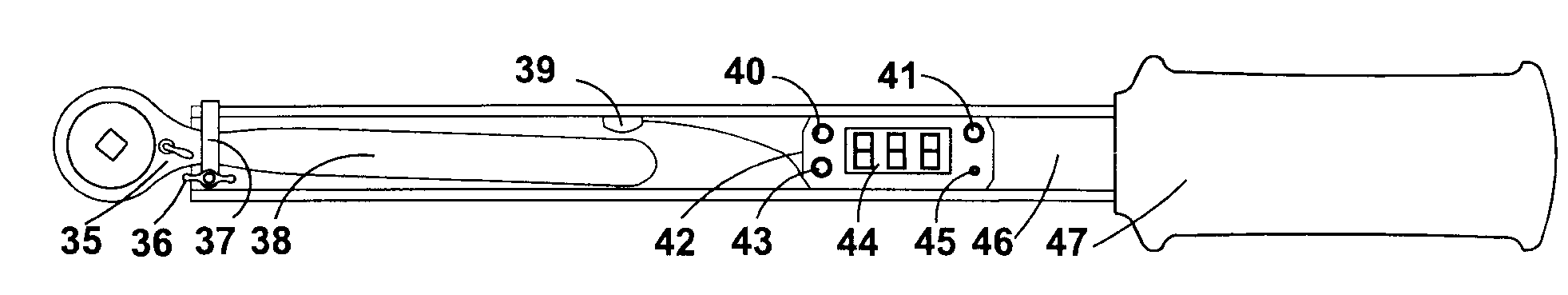

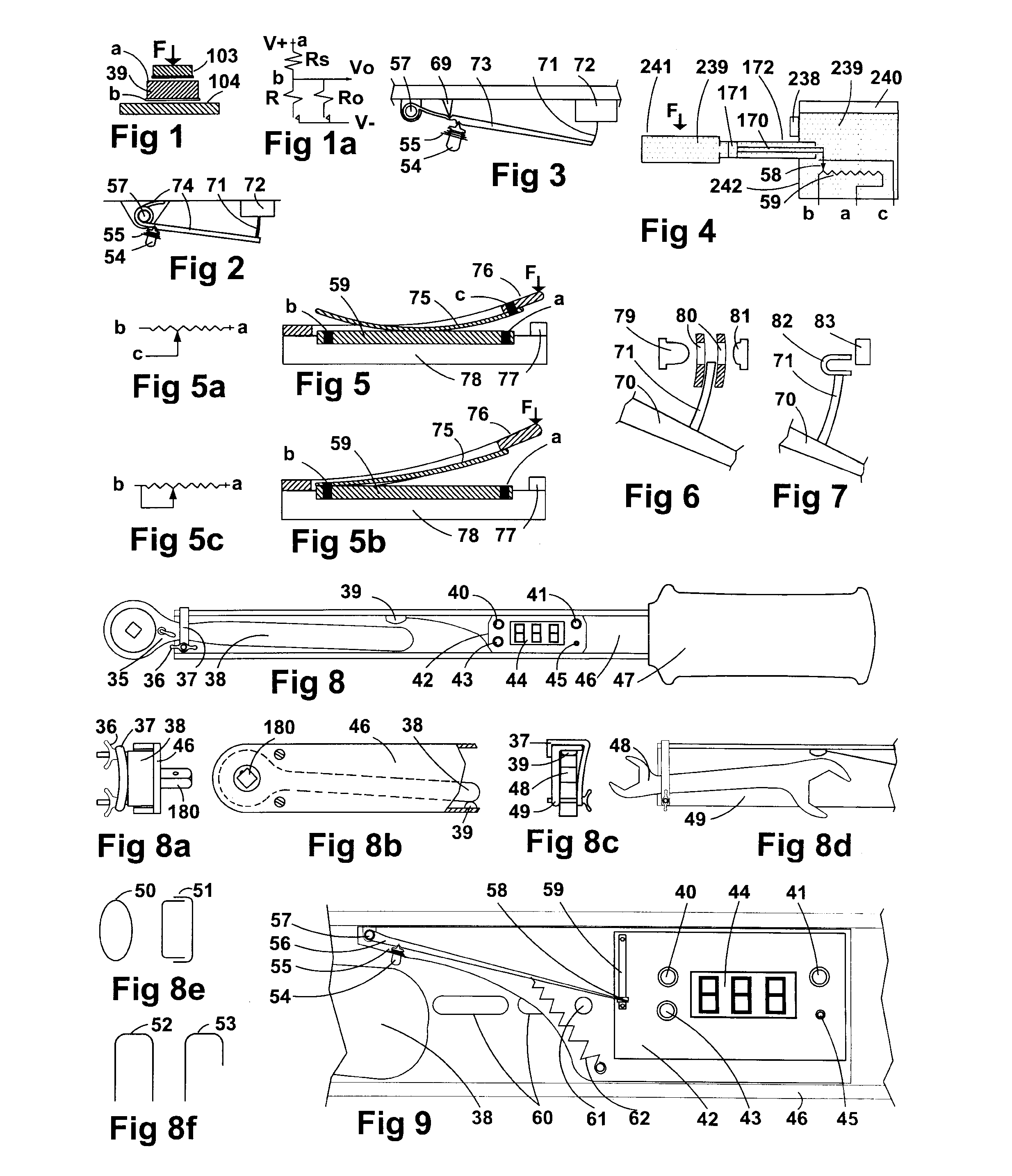

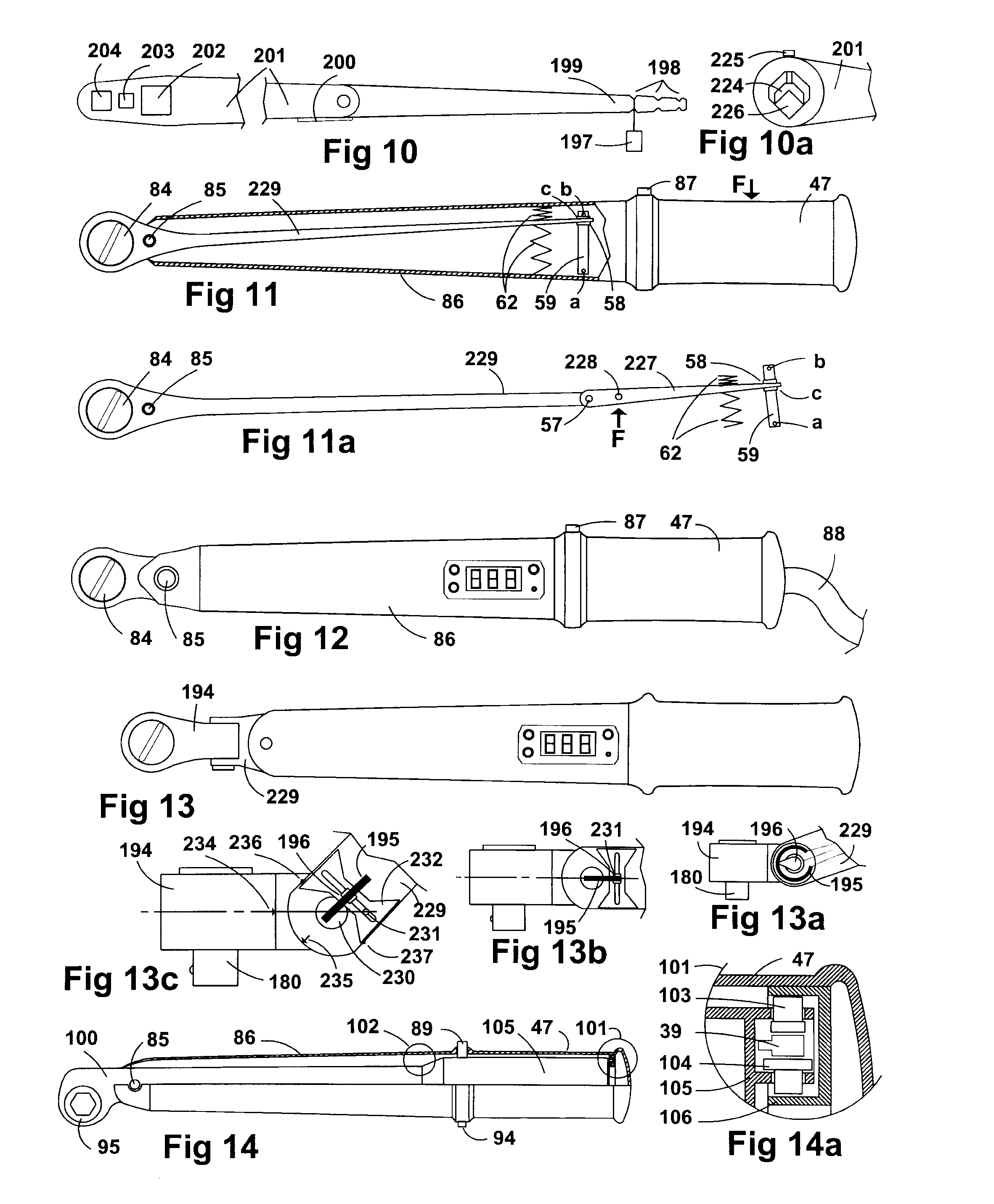

Force and Torque Measurements with Calibration and Auto Scale

InactiveUS20080127711A1Low costImprove reliabilityWeighing apparatus testing/calibrationSpannersPeak valueBiological activation

This invention is device and method for electronic measurements of the force and torque applied to a work piece. The measured values are visually displayed, audibly indicated, and / or transferred in electronic formats to other controlling devices. The values could be displayed in different physical measuring units, and as an average or peak. The device produces different output signals when the torque applied equals or exceeds predetermined values. This device and method provide an automatic, accurate, and easy calibration, which could be self-calibration or in-the-field calibration. It has protection from accidental activation of the switches, and provides a permanent record of the incidents in which the device was operated at conditions beyond its specifications. It provides a manual and / or automatic scale selection to improve the accuracy.

Owner:FARAG TAREK A Z

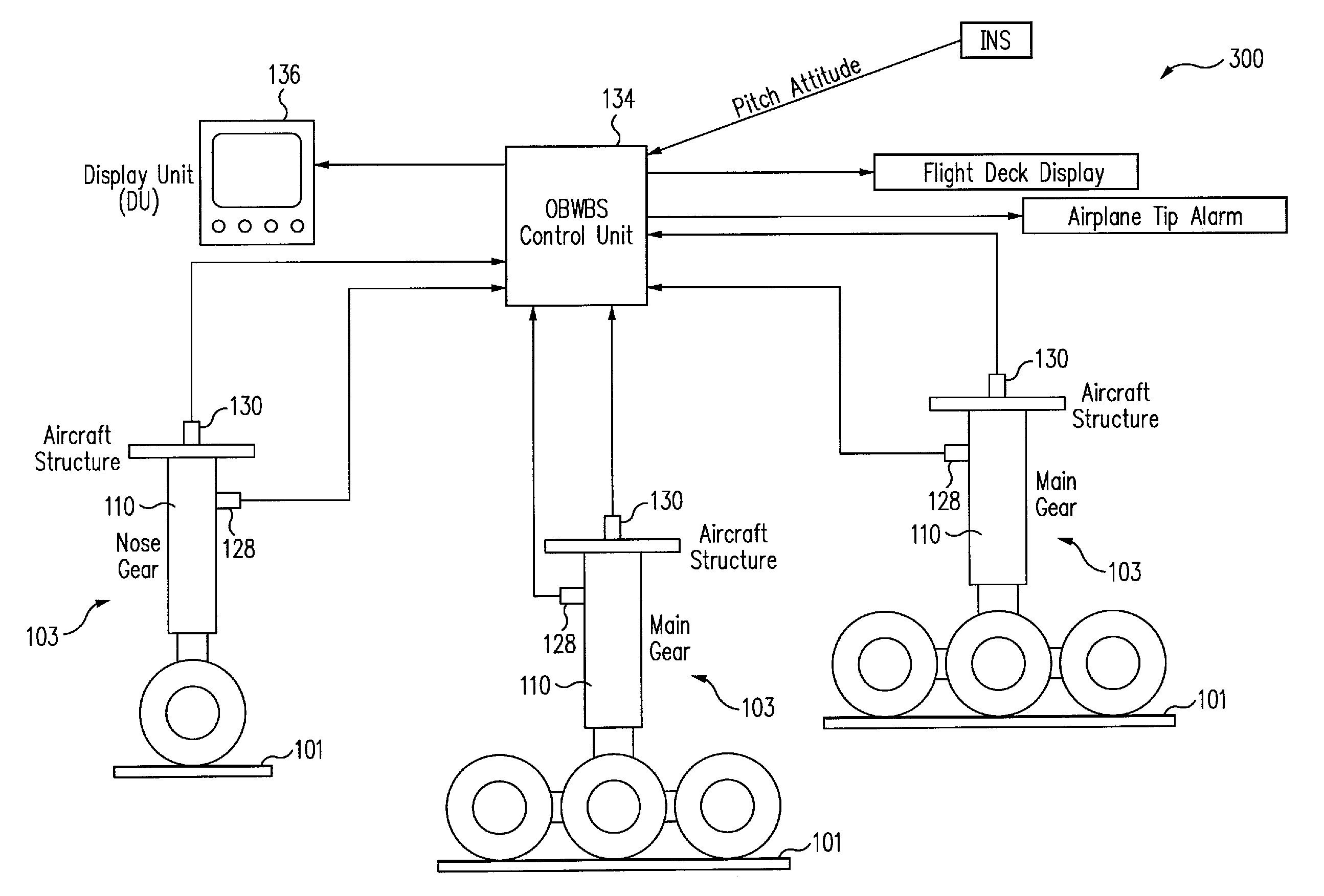

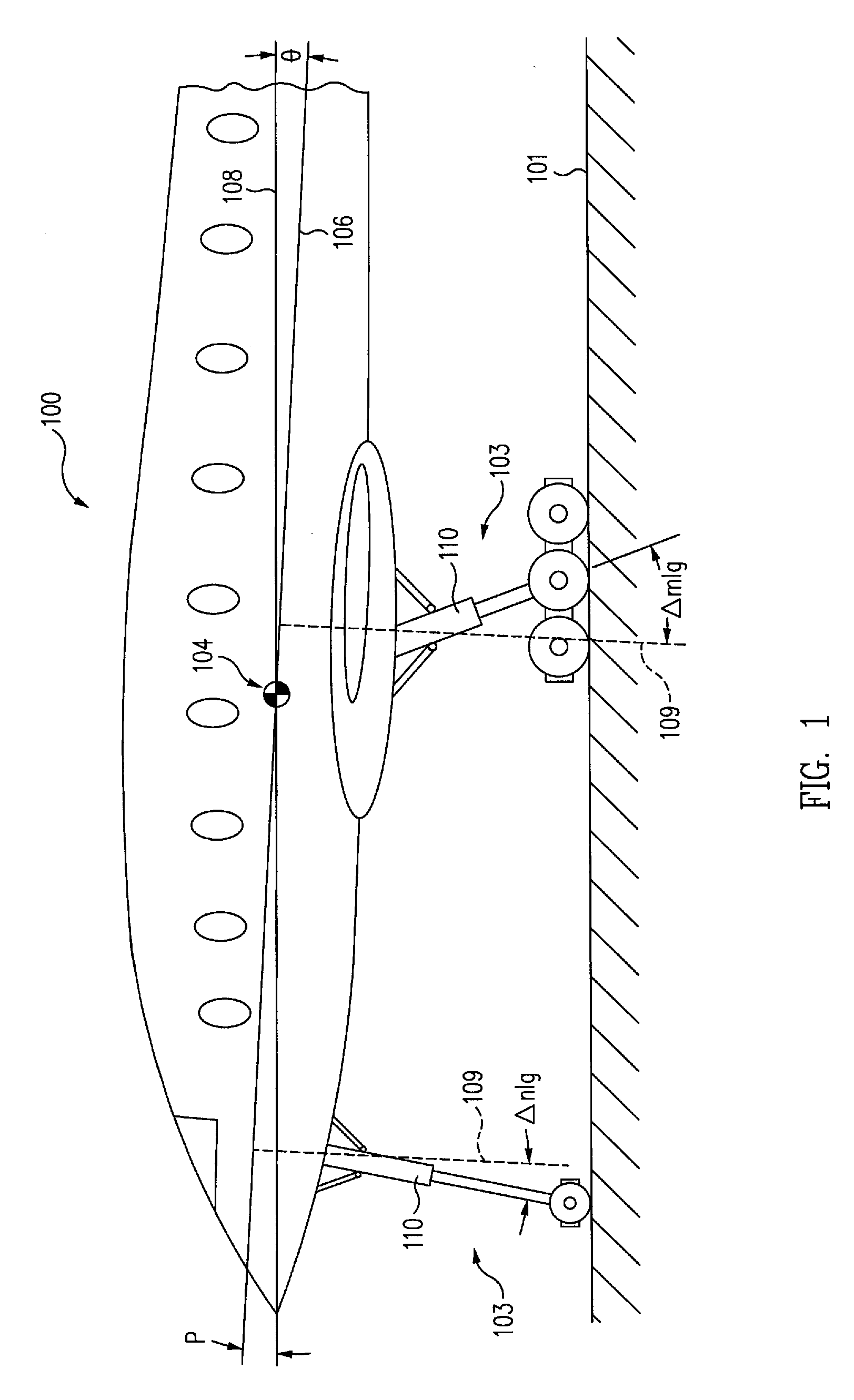

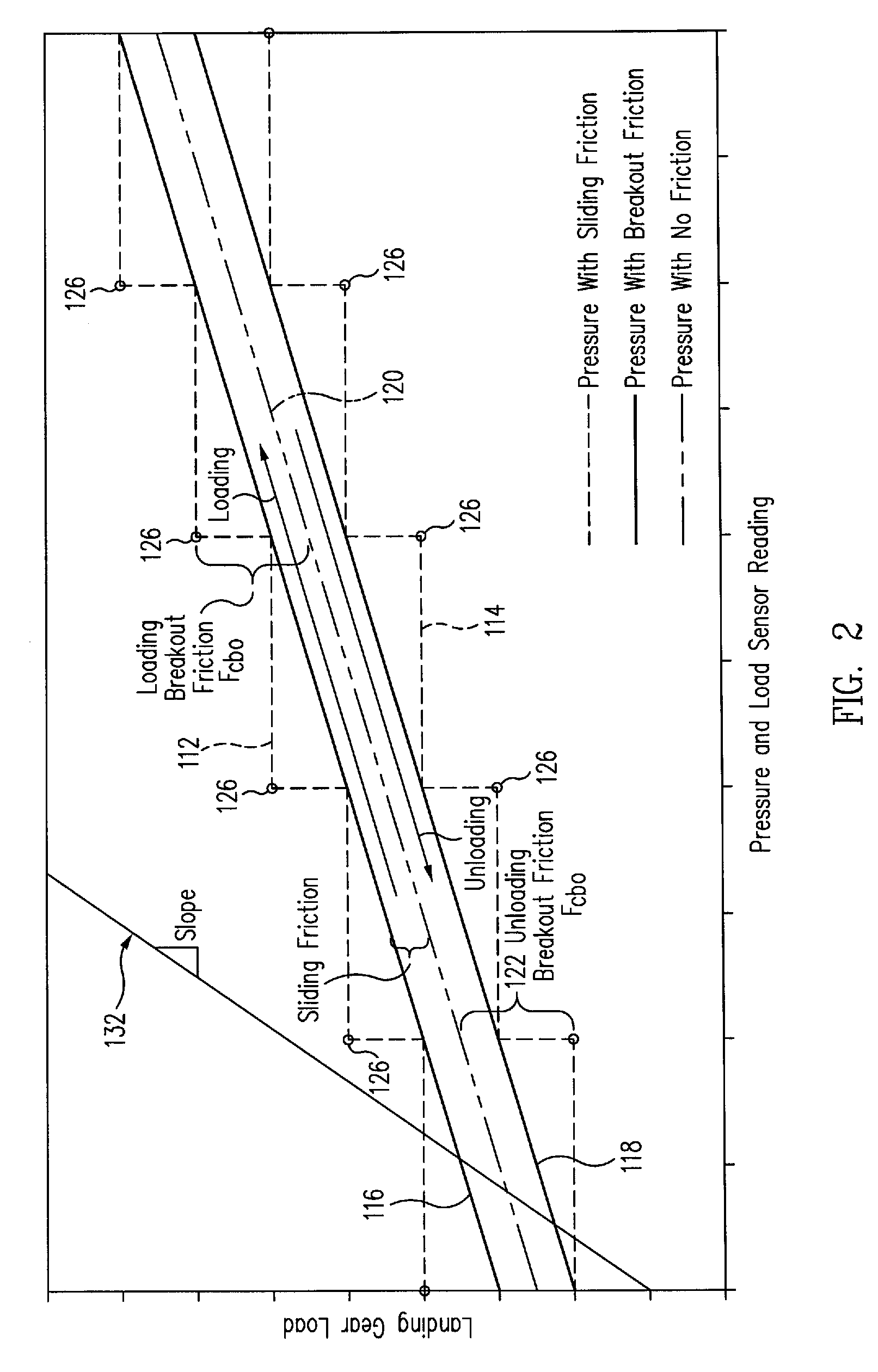

Onboard Aircraft Weight And Balance System

ActiveUS20080119967A1Easy CalibrationEasy maintenanceDigital data processing detailsWeighing apparatus testing/calibrationVertical loadAirplane

An onboard system for determining the instantaneous weight and balance of an aircraft simply, reliably, accurately, and requiring a minimum amount of calibration includes a memory for storing previously determined breakout friction data of the aircraft's landing gear shock struts, sensors for sensing the pressures in the struts, the vertical loads exerted by the landing gear on the aircraft, and the attitude of the aircraft relative to the horizontal during loading or unloading thereof, and a computer for computing the vertical load in each of the landing gears from the stored calibration breakout friction data and the shock strut pressures, landing gear vertical loads and aircraft attitude sensed during the loading or unloading. The computer then computes the gross weight of the aircraft and the location of its center of gravity (CG) using the computed vertical loads in the landing gears.

Owner:THE BOEING CO

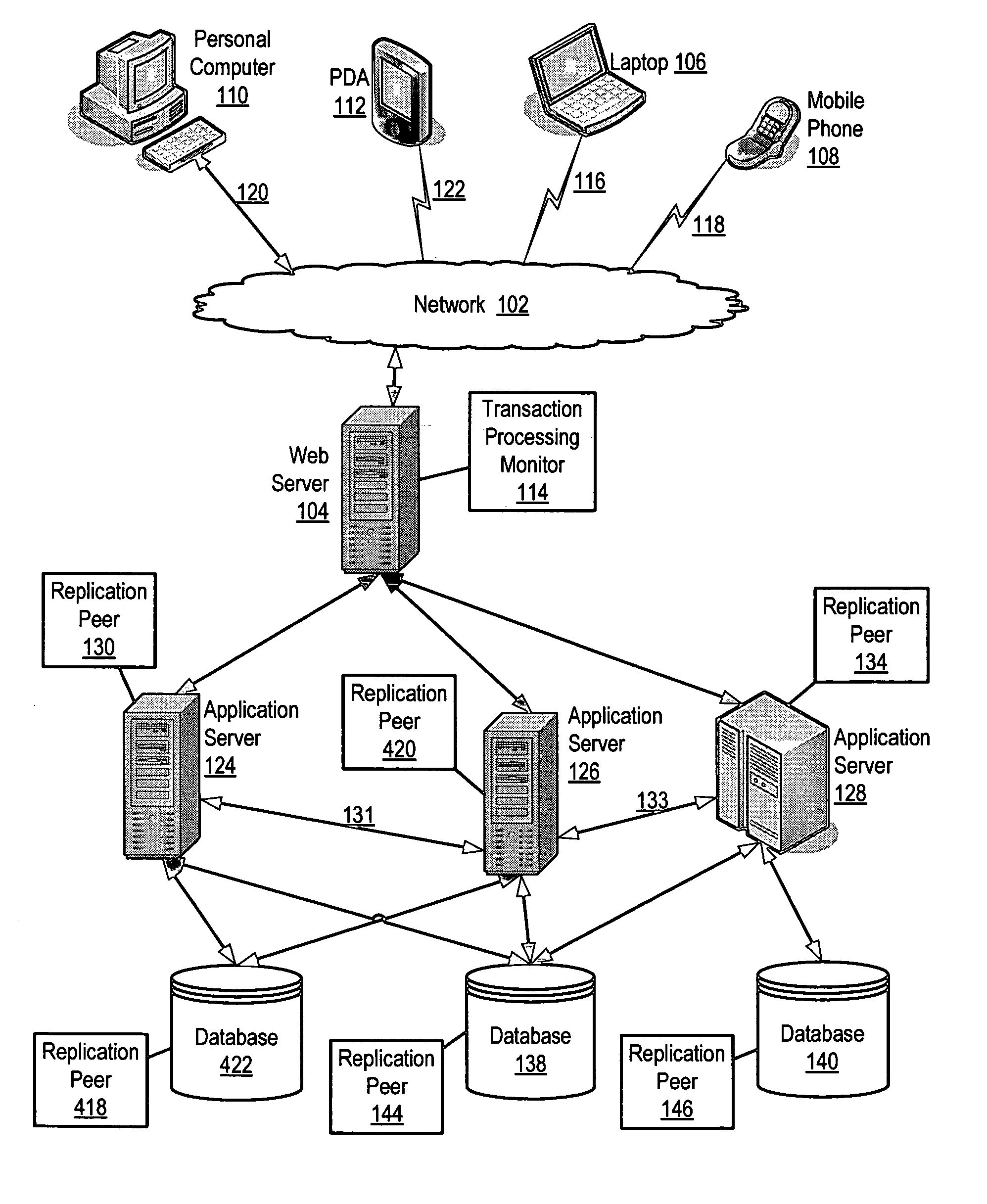

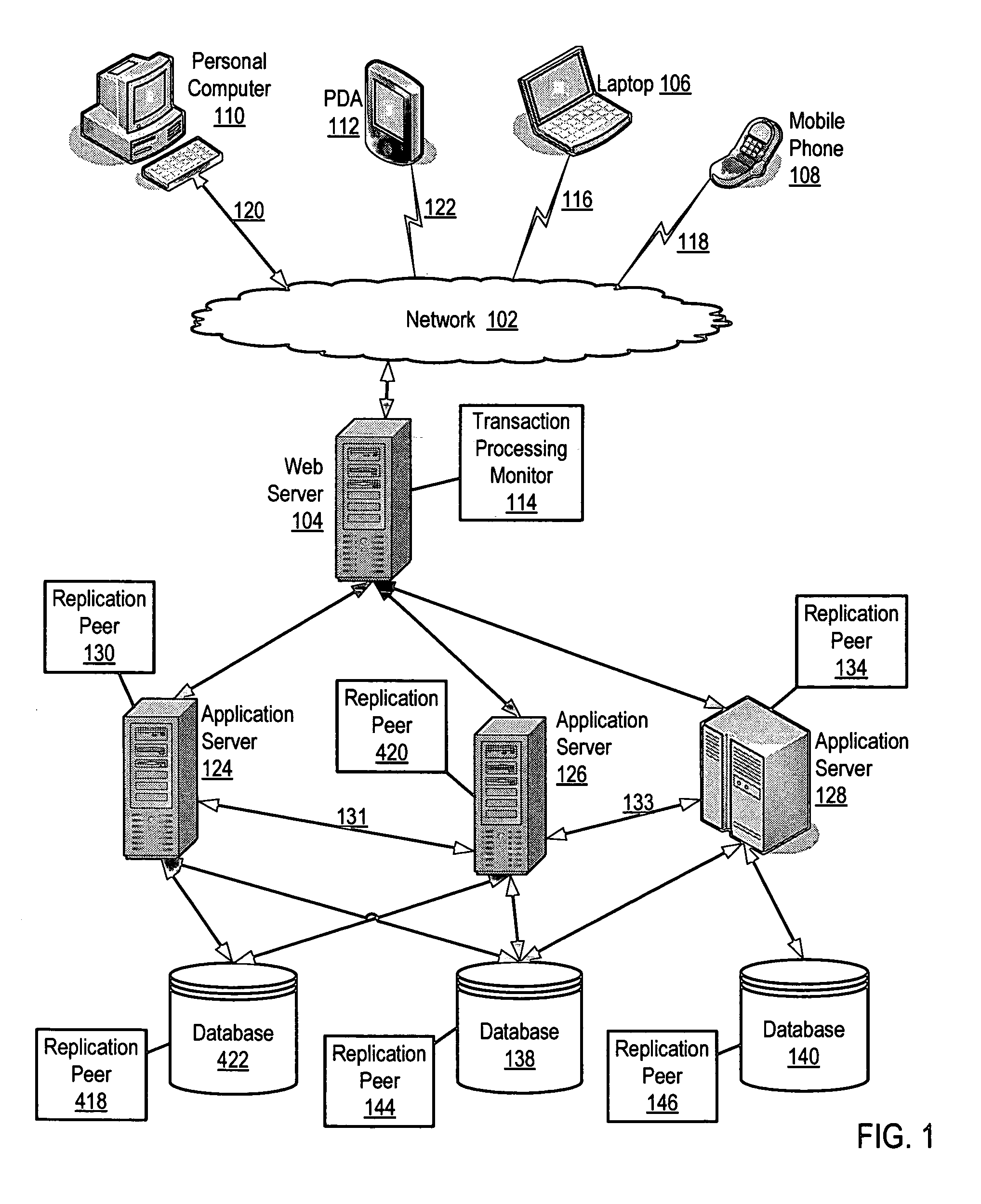

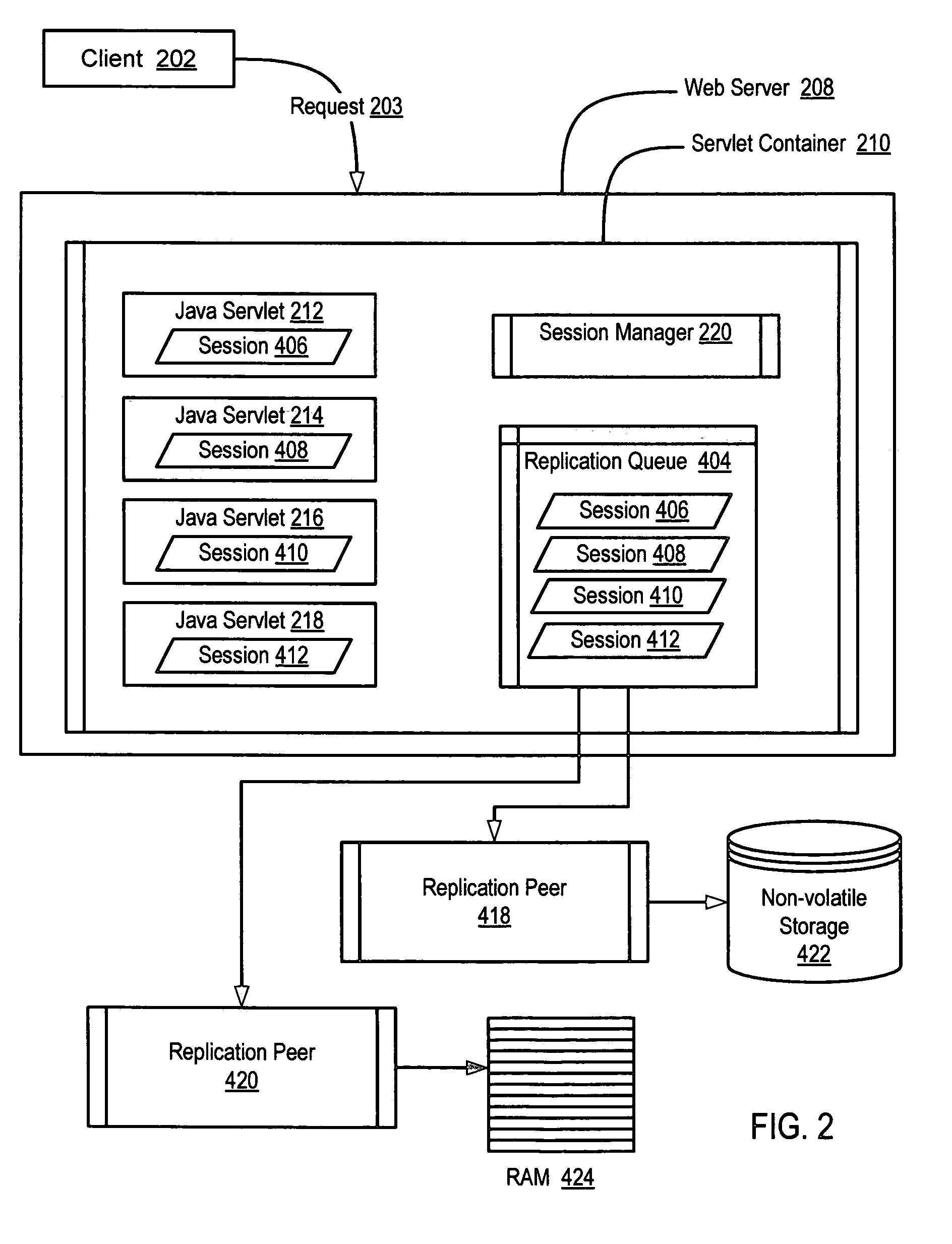

Session replication

InactiveUS20070027896A1Digital data processing detailsWeighing apparatus testing/calibrationDistributed computingNon-volatile memory

Methods, apparatuses, and products are disclosed for session replication that include enqueueing sessions on a replication queue and flushing enqueued sessions, from the replication queue to a replication peer, in dependence upon flushing criteria, for storage on a replication medium. The replication medium may be non-volatile storage in a database or remote random access memory. Flushing may be carried out periodically or in dependence upon replication queue depth. Flushing may include aggregating sessions from the replication queue for transmission to the replication peer.

Owner:IBM CORP

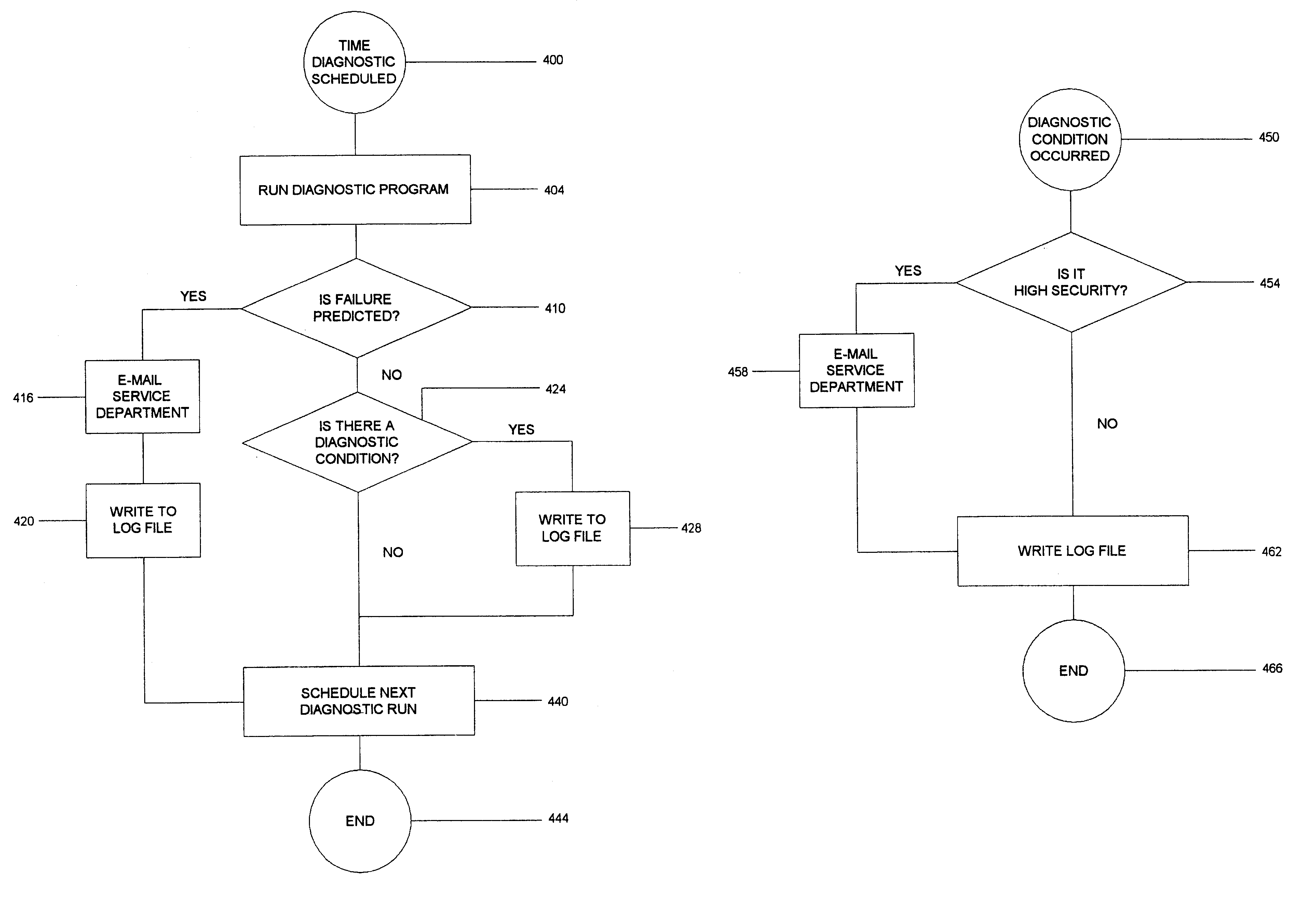

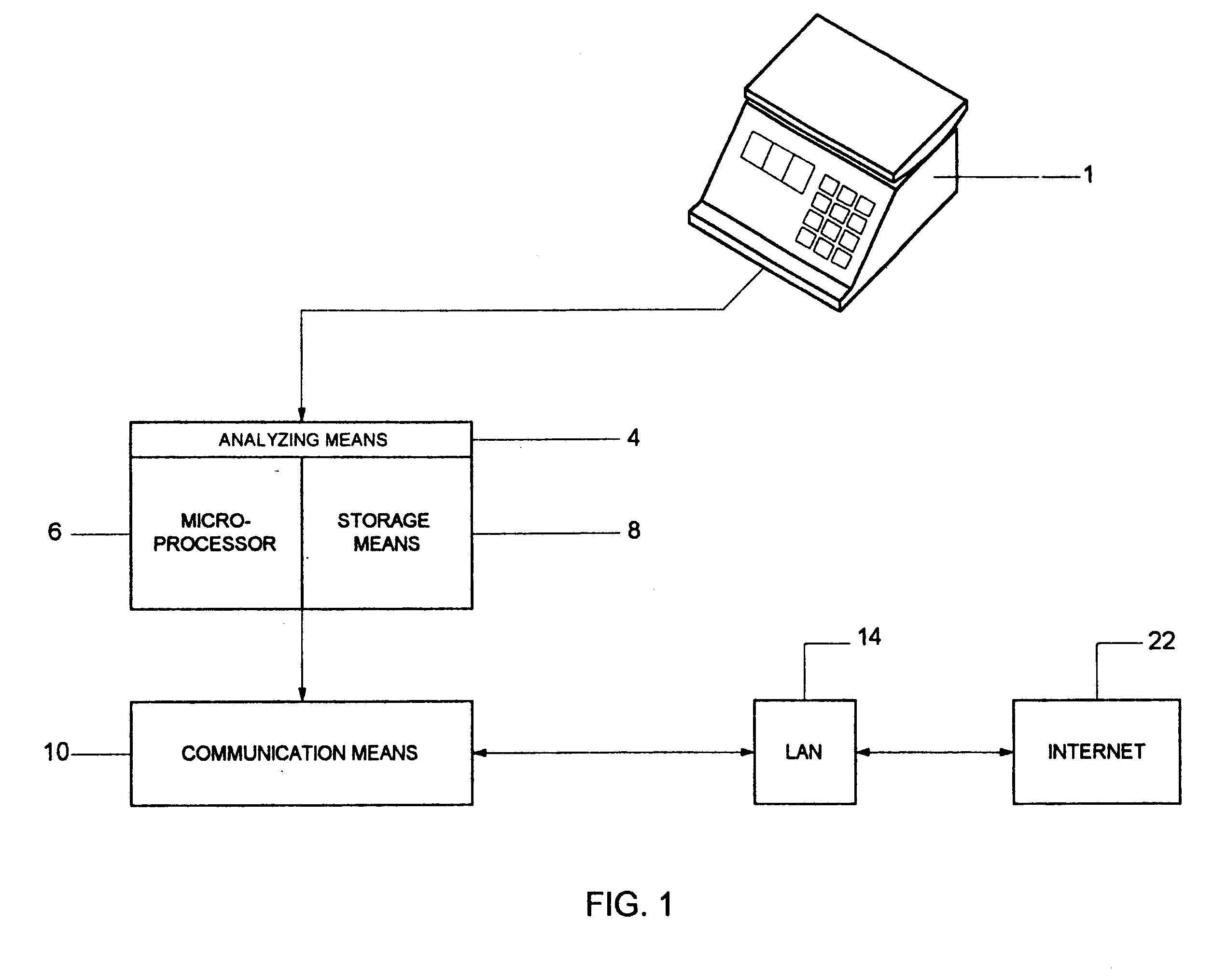

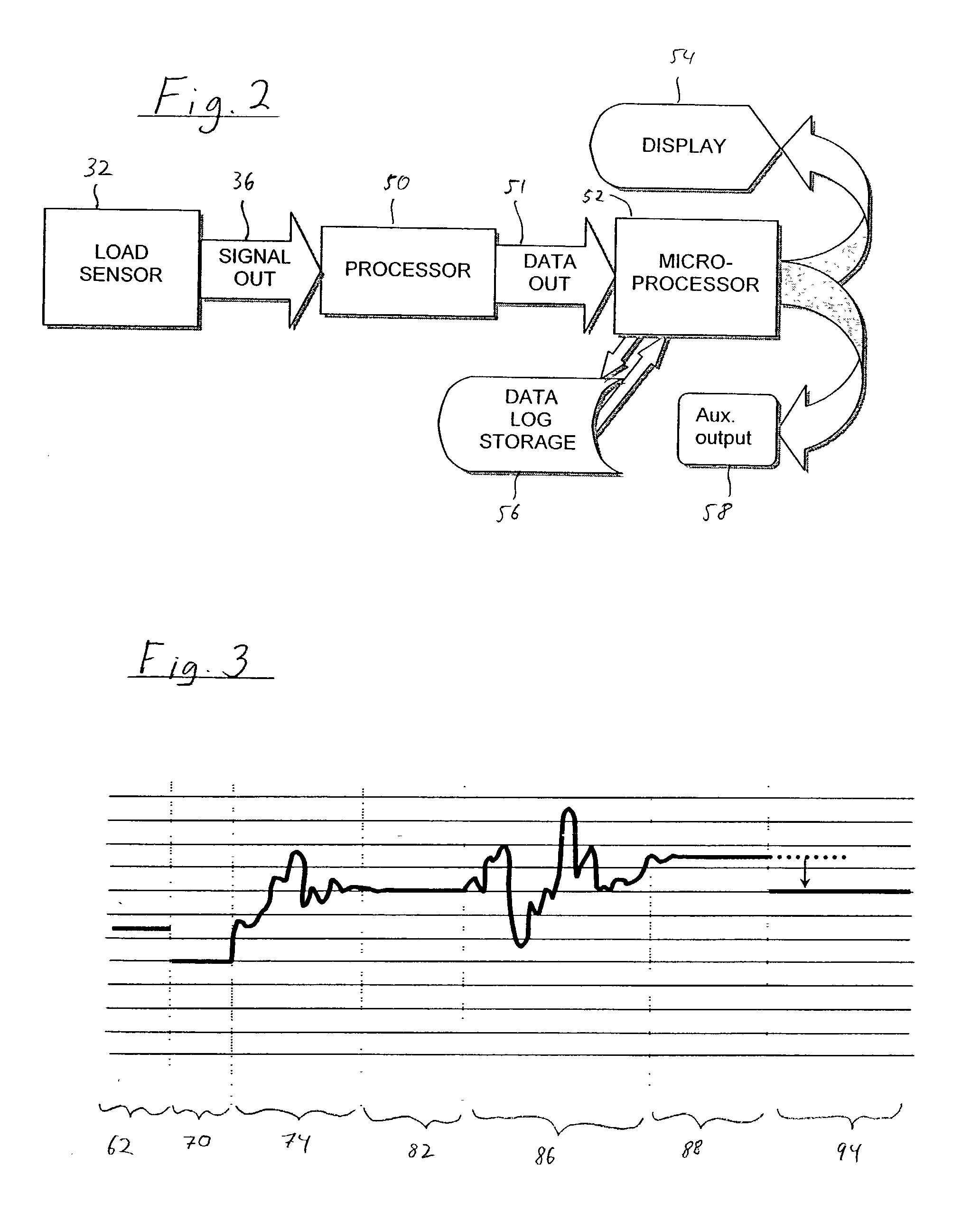

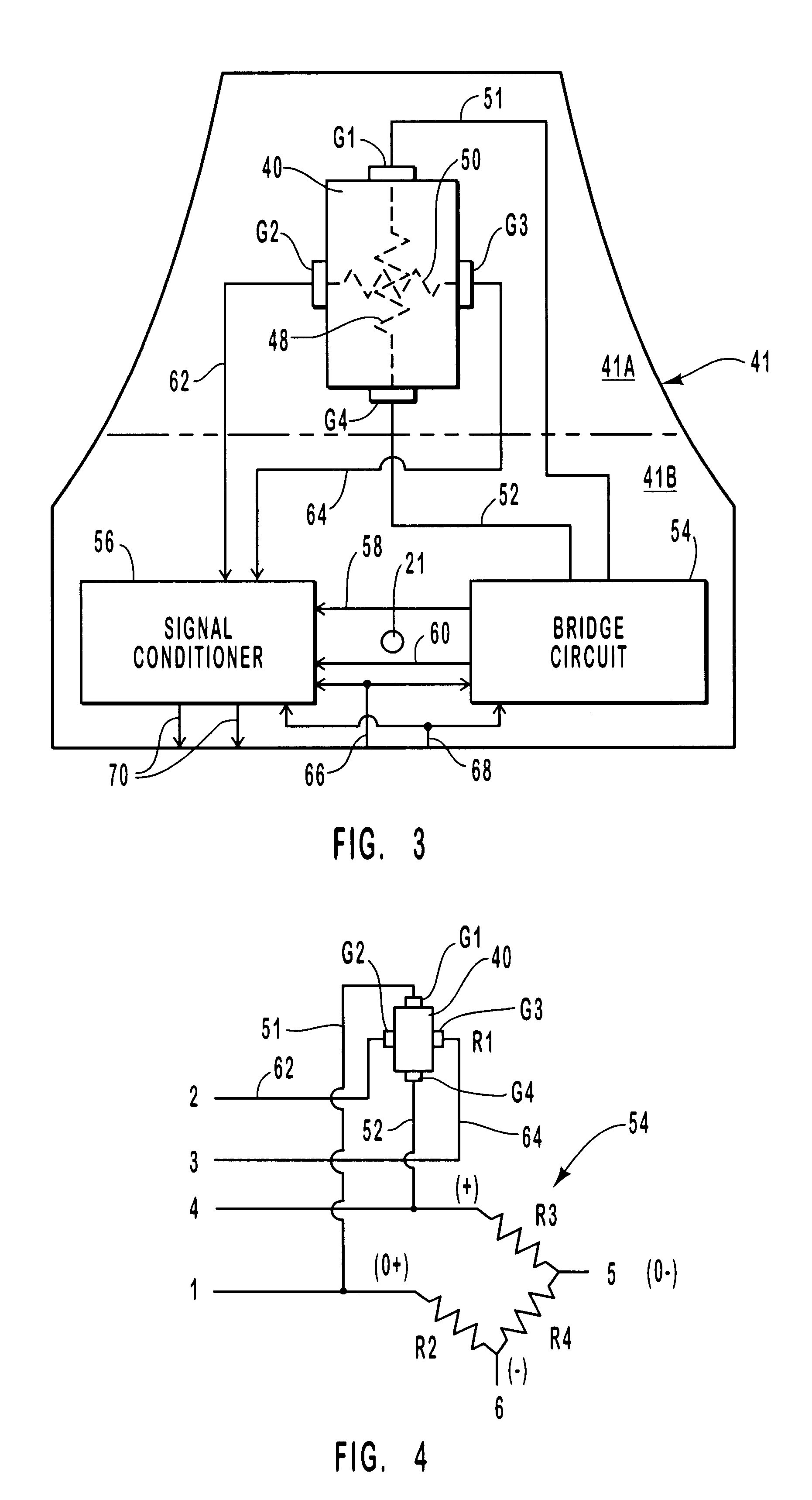

Load cell diagnostics and failure prediction weighing apparatus and process

InactiveUS6576849B2Provide compensationWeighing apparatus testing/calibrationWeighing indication devicesThe InternetLoad cell

The invention disclosed consists of weighing apparatus and process that includes a new Calibration management utility to automate compliance testing to ISO 9000 requirements and has the "load cell symmetry", "empty platform" and "test load" readings for each load stored on the weighing apparatus. This weighing apparatus makes periodic tests to determine the health of the load cells in the system, producing a log file to record events such as any detected failure, any suspicious reading, overload condition, or any user defined parameter, and is network enabled to be connected through a LAN via an Ethernet to the Internet.

Owner:METTLER TOLEDO INC

Intelligent load distribution system

InactiveUS7072763B2Improve performanceWeighing apparatus testing/calibrationDigital computer detailsLoad generationEngineering

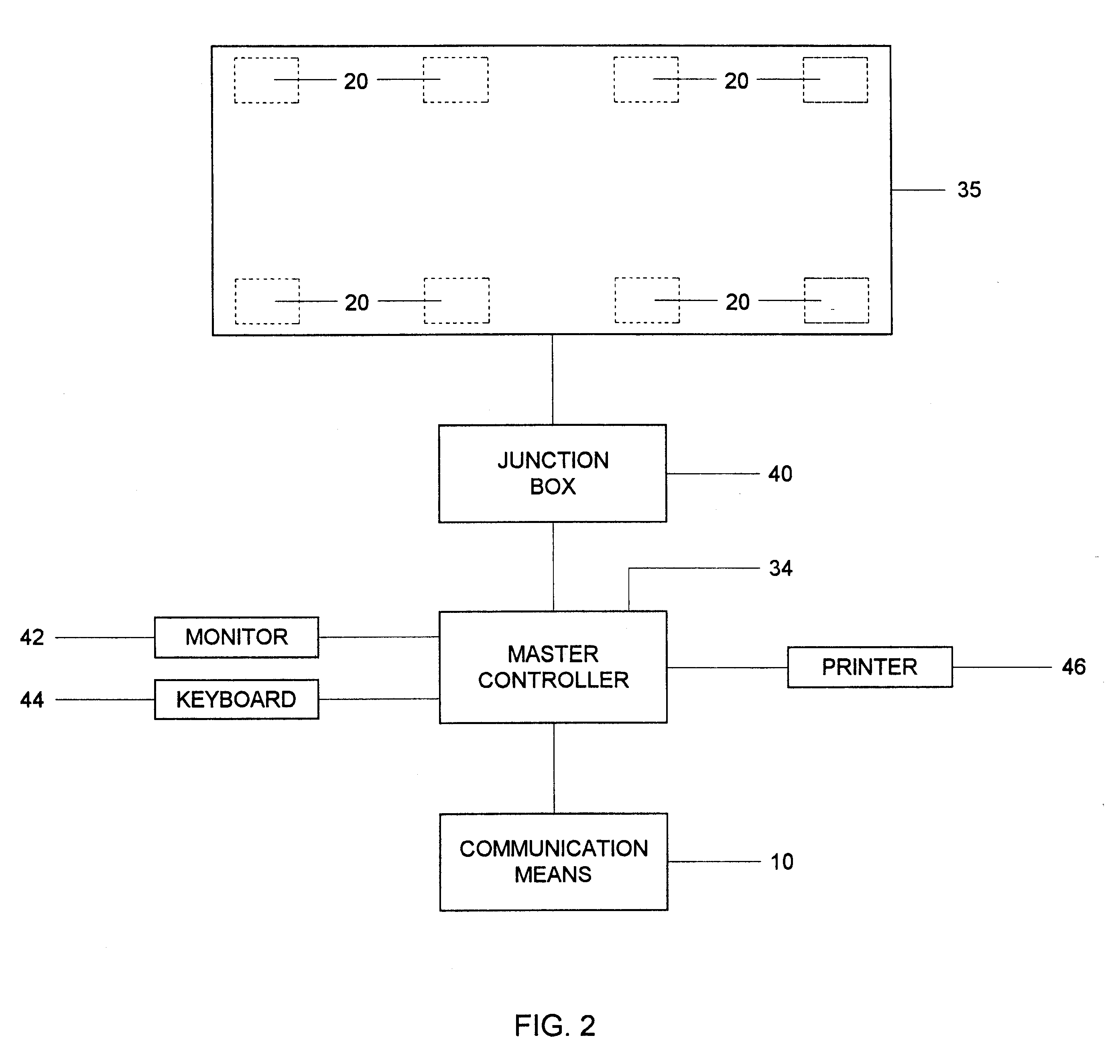

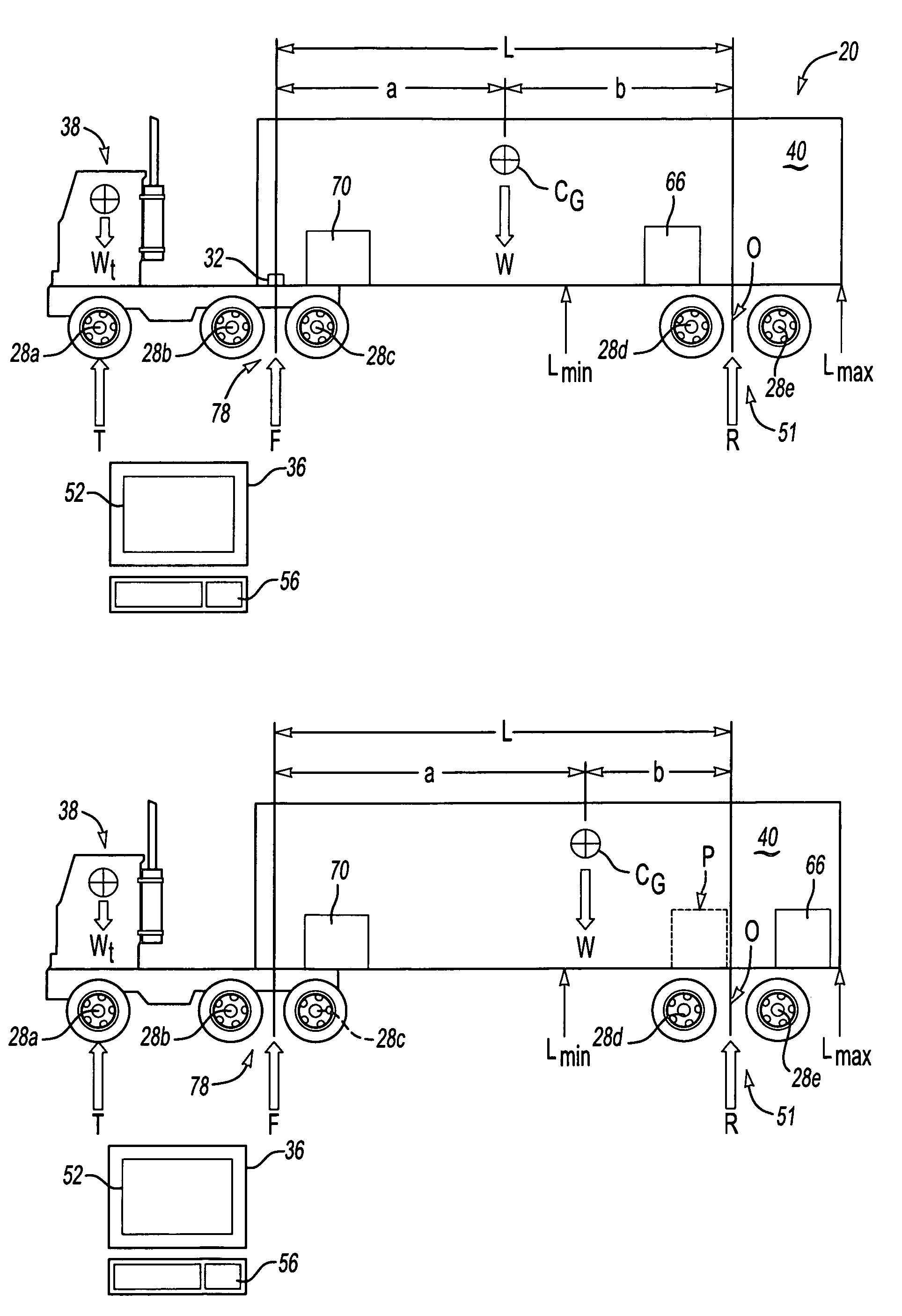

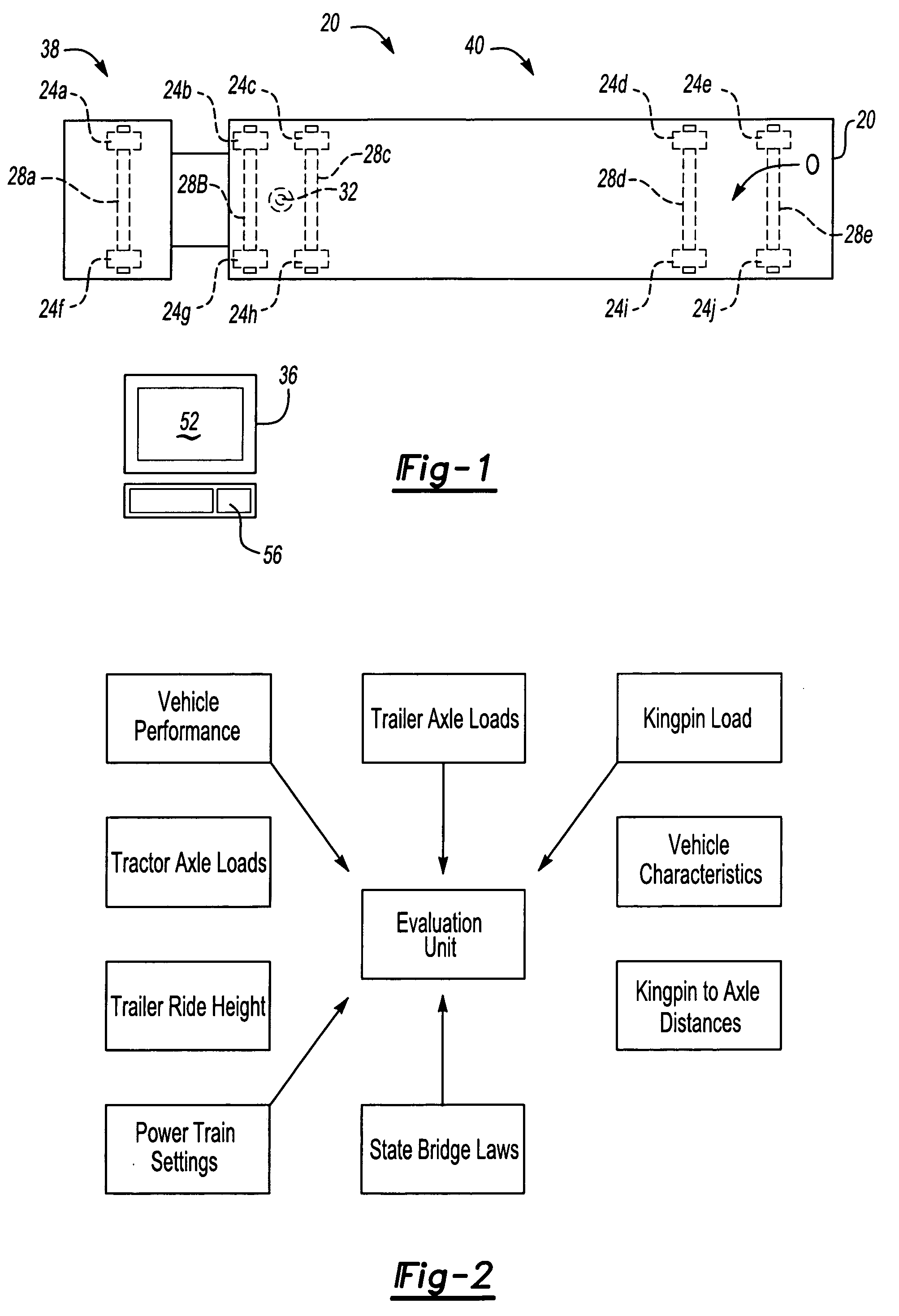

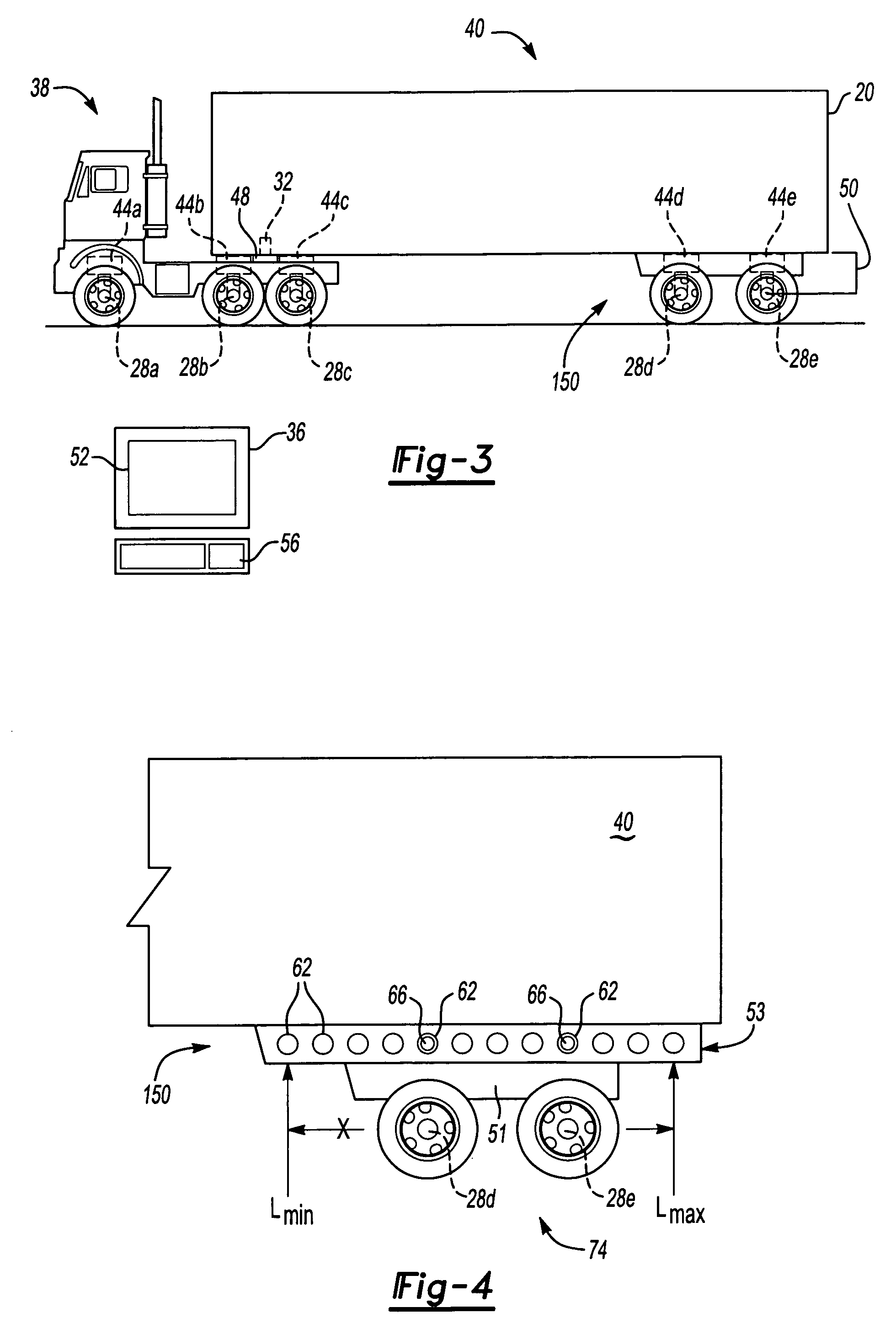

A vehicle information system has a first load sensor for generating a first load signal based on a first vehicle load. A first position sensor generates a first position signal based on a position of a vehicle axle. A second position sensor generates a second position signal based on a position of a vehicle kingpin. A memory unit stores vehicle optimization data. An evaluation unit is in communication with the first load sensor, the first position sensor, the second position sensor and the memory unit. A general user interface for receiving input is also in communication with the evaluation unit. The evaluation unit makes an evaluation of the first load signal, the first position sensor, the second position signal, and any input and generates a vehicle optimization instruction relating to a distance between the axle and the kingpin.

Owner:ARVINMERITOR TECH

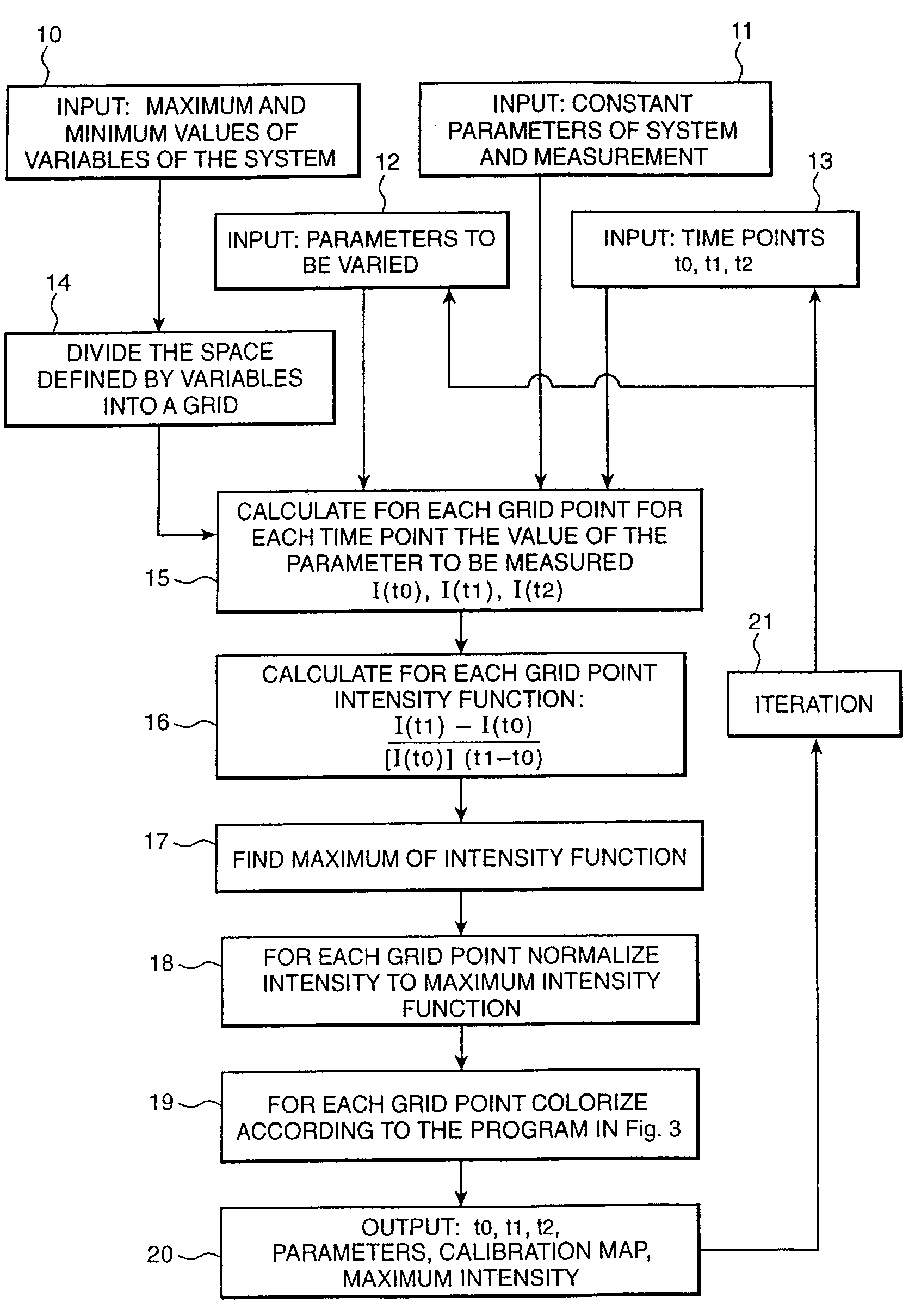

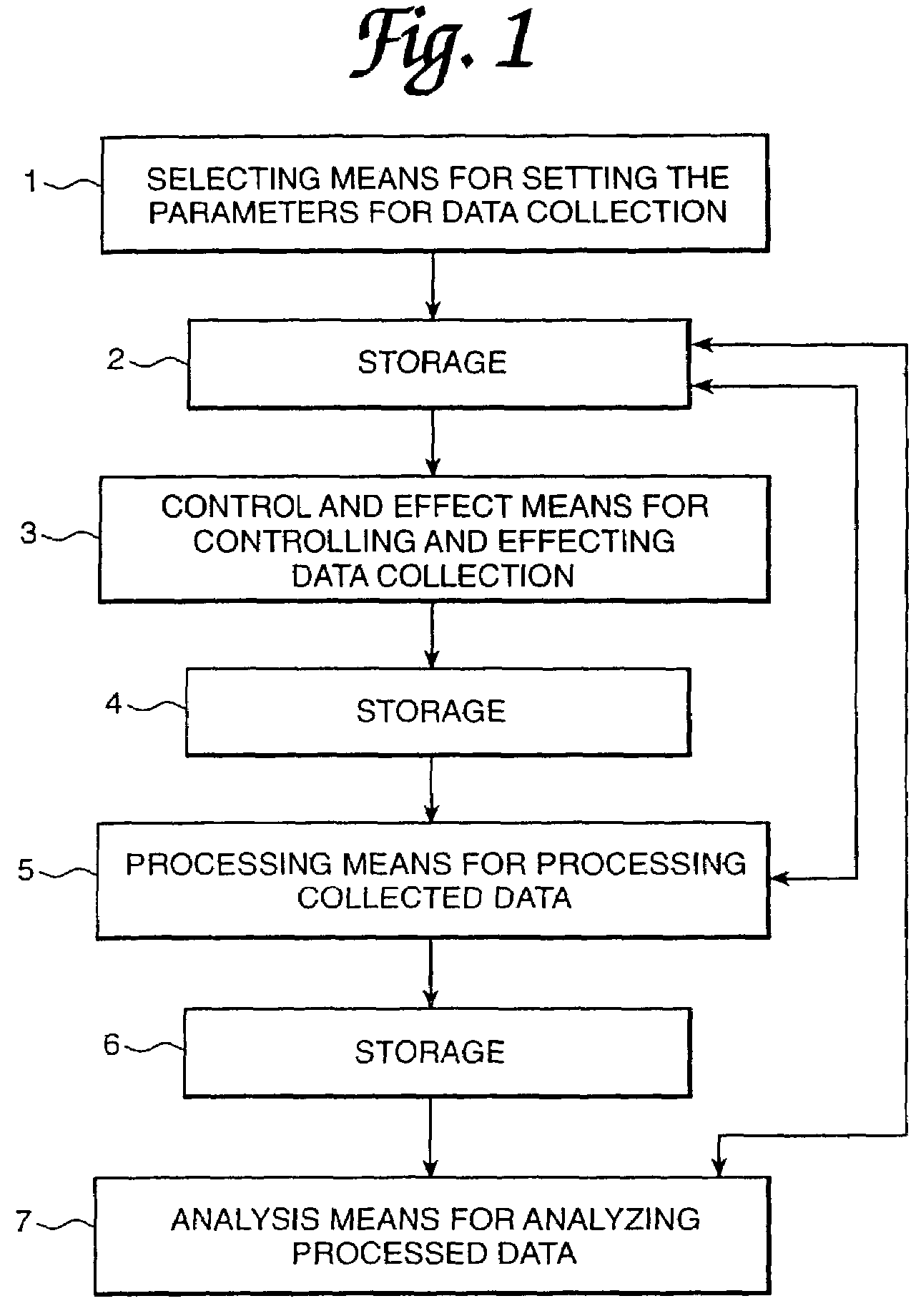

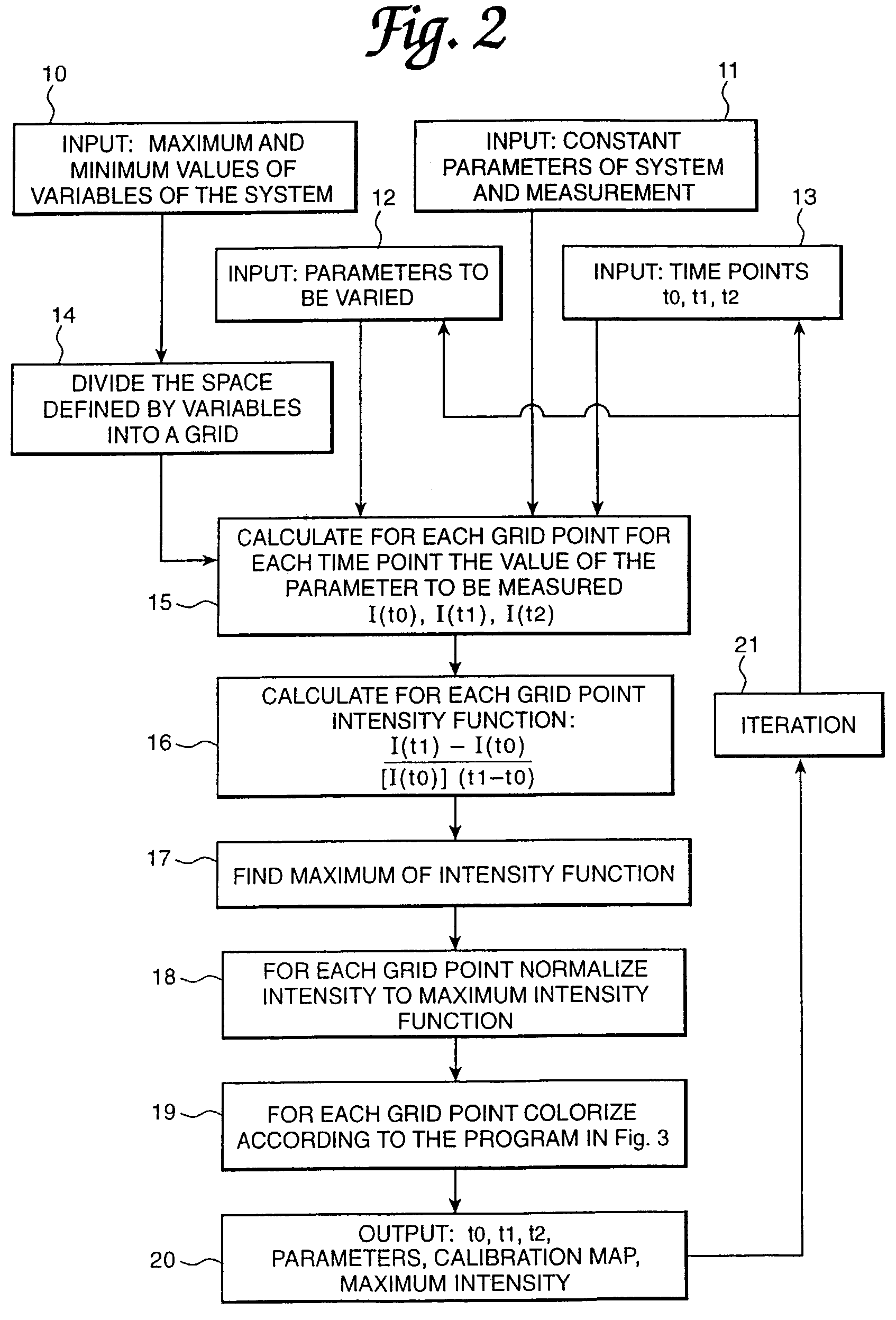

Apparatus for monitoring a system with time in space and method for diagnosing a condition of a prostate

InactiveUS7245748B2High angiogenicStrong specificityElectric/magnetic detection for well-loggingImage enhancementData processing systemVoxel

Apparatus and method for monitoring a prostate in a human body in which a fluid flows and which is characterized by a change in the prostate with time in space for the purpose of diagnosing a prostate condition, particularly cancer. A preselected place in the prostate is monitored to collect data at two or more time points correlated to a prostate event. The data is indicative of a prostate parameter that varies with time as a function of at least two variables related to prostate wash-in and wash-out behavior. A calibration map is made on a calculated basis with each pixel or voxel representative of a color hue indicative of wash-out behavior and a color intensity indicative of wash-in behavior. When a satisfactory map is obtained, the collected data is processed on the basis of the map to obtain an image of the preselected place with each spatial unit thereof correlated with a color hue and a color intensity. Software and a data processing system are provided to develop the calibration map. The calibration map and image of the preselected place are also novel implementations.

Owner:YEDA RES & DEV CO LTD

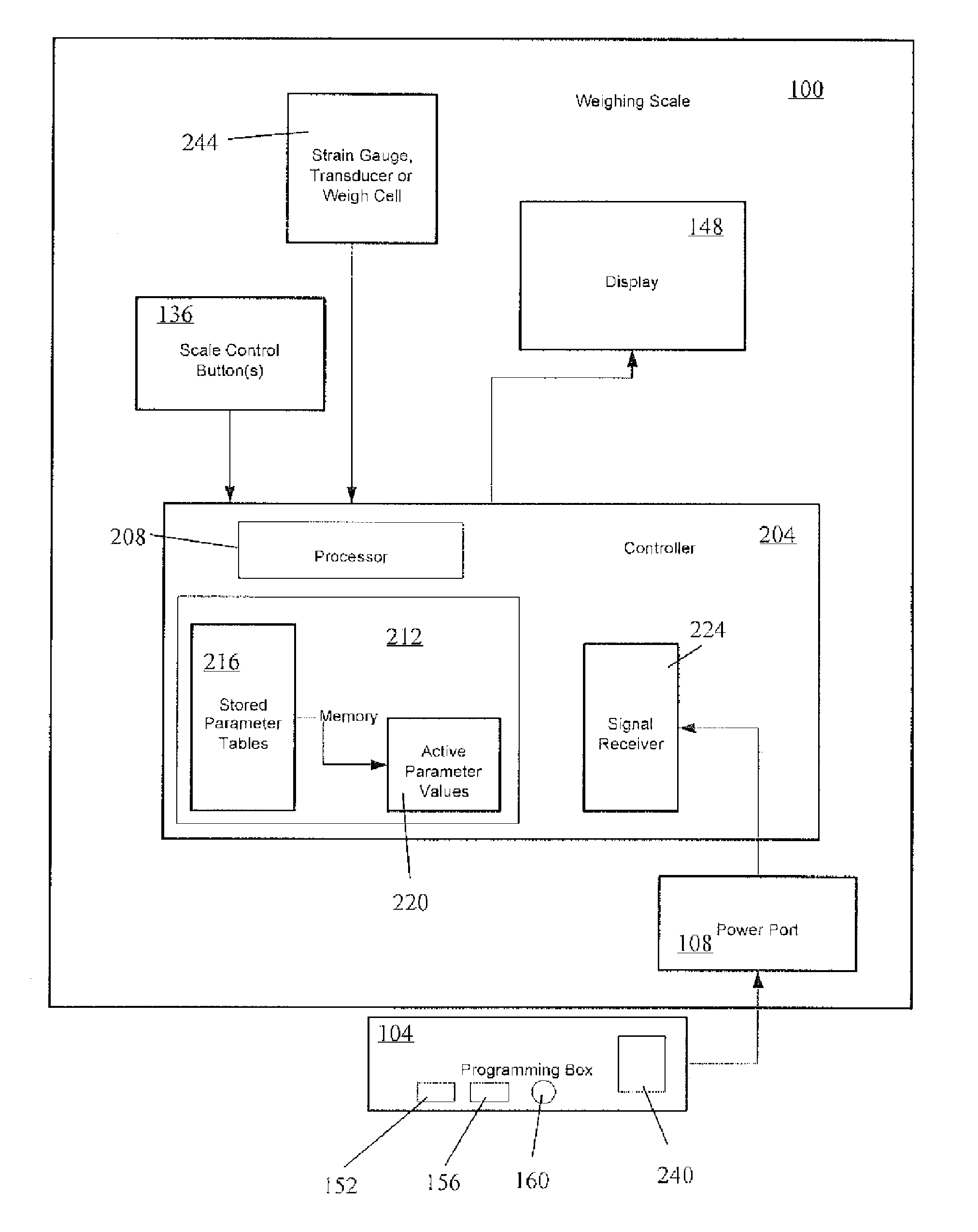

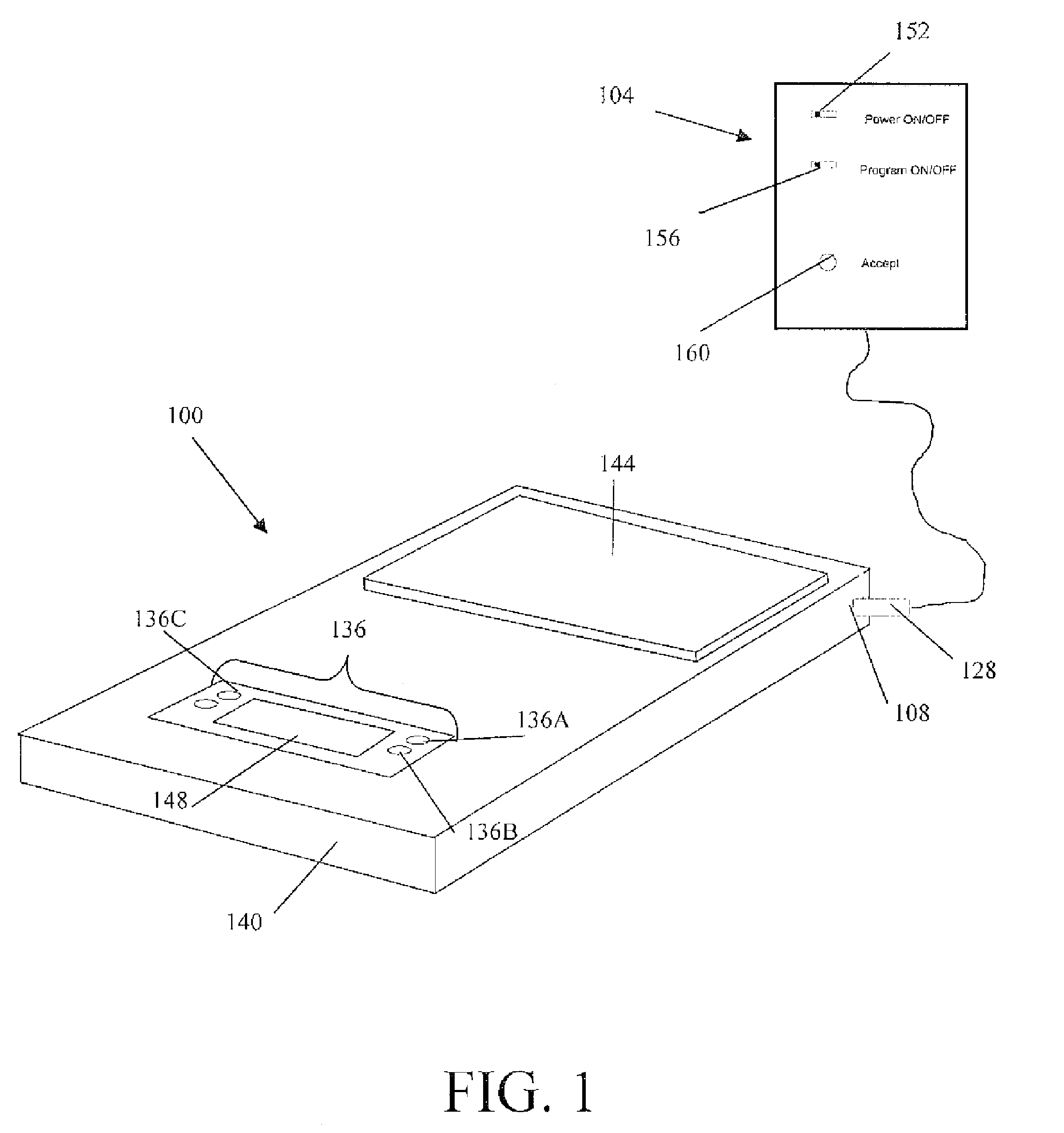

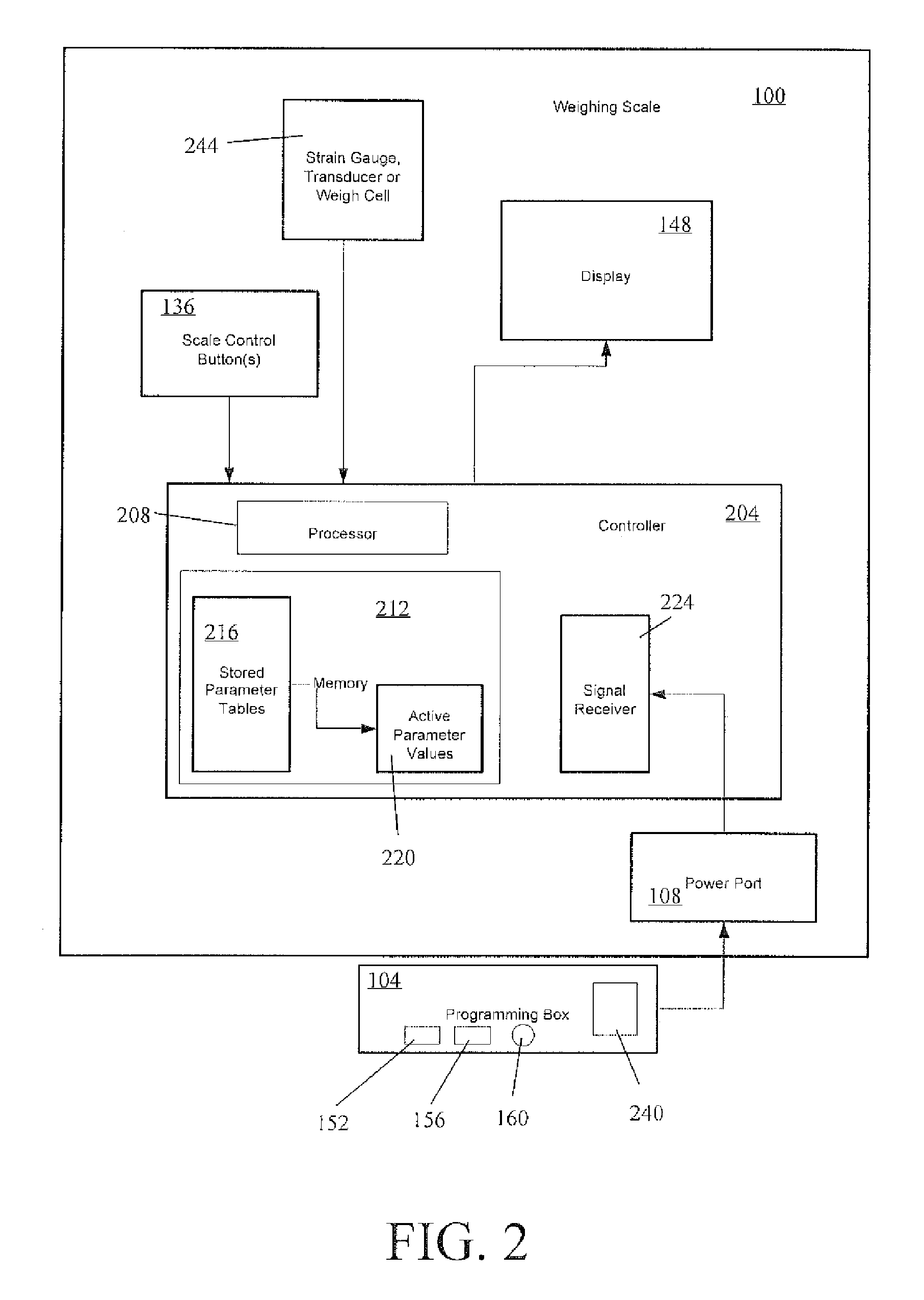

System and method for programming a weighing scale using a key signal to enter a programming mode

ActiveUS7872201B1Weighing apparatus testing/calibrationWeighing indication devicesElectricityReprogramming

A programmable weighing scale and a system and method for programming values of adjustable operating parameters used in generating the displayed output from the weighing scale. The weighing scale is placed into a restricted-access programming mode, which allows an authorized programmer to select values of operating parameters that allow the programmer to initially set or change the service characteristics of the scale. Operating parameters that can be varied include variables used in sampling the weighing scale's transducer electrical output, mathematically processing that output, and displaying the results. Once the operating parameter values have been selected, the weighing scale will utilize those values until the weighing scale undergoes a subsequent reprogramming.

Owner:EDLUND CO INC

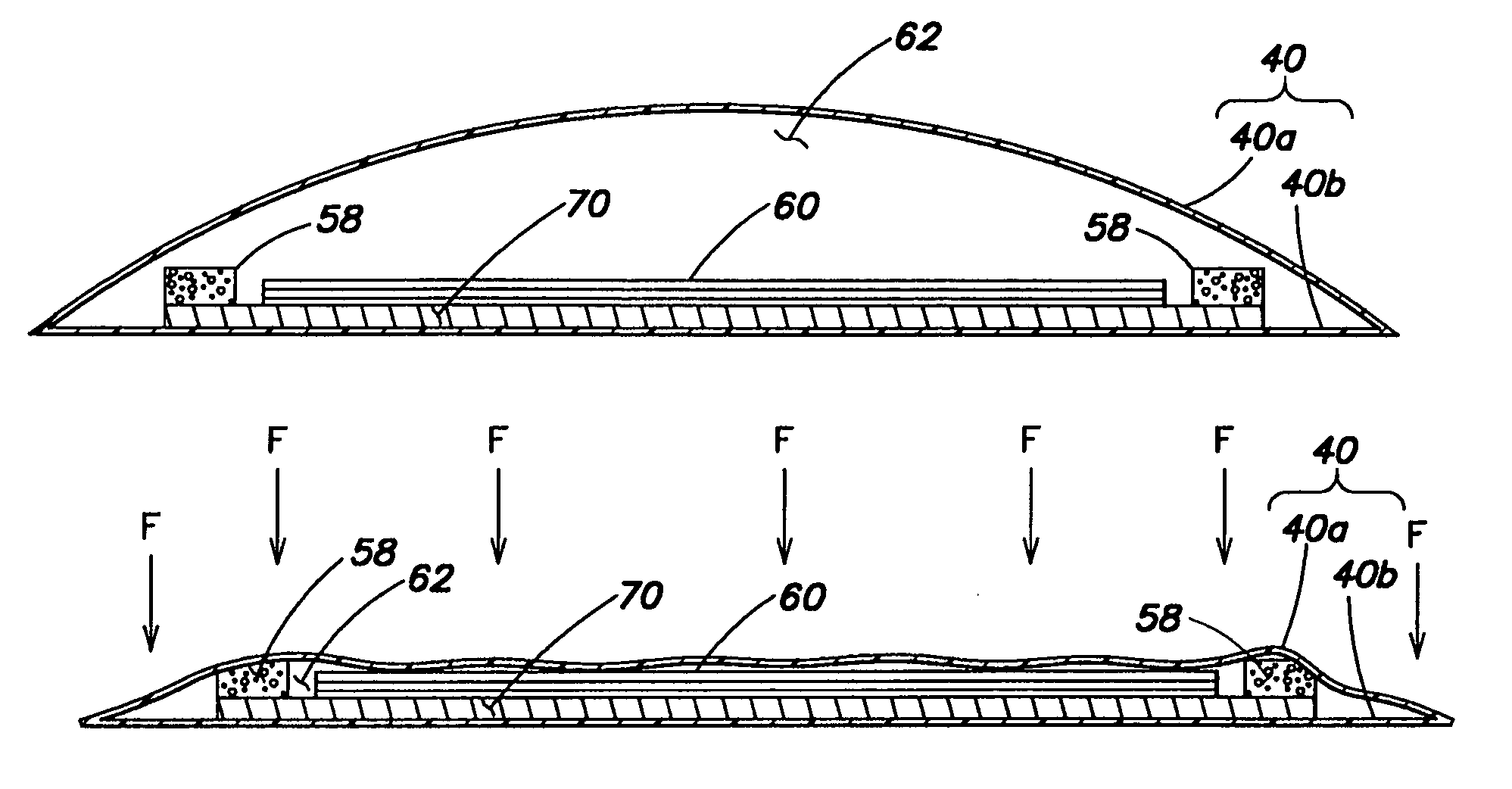

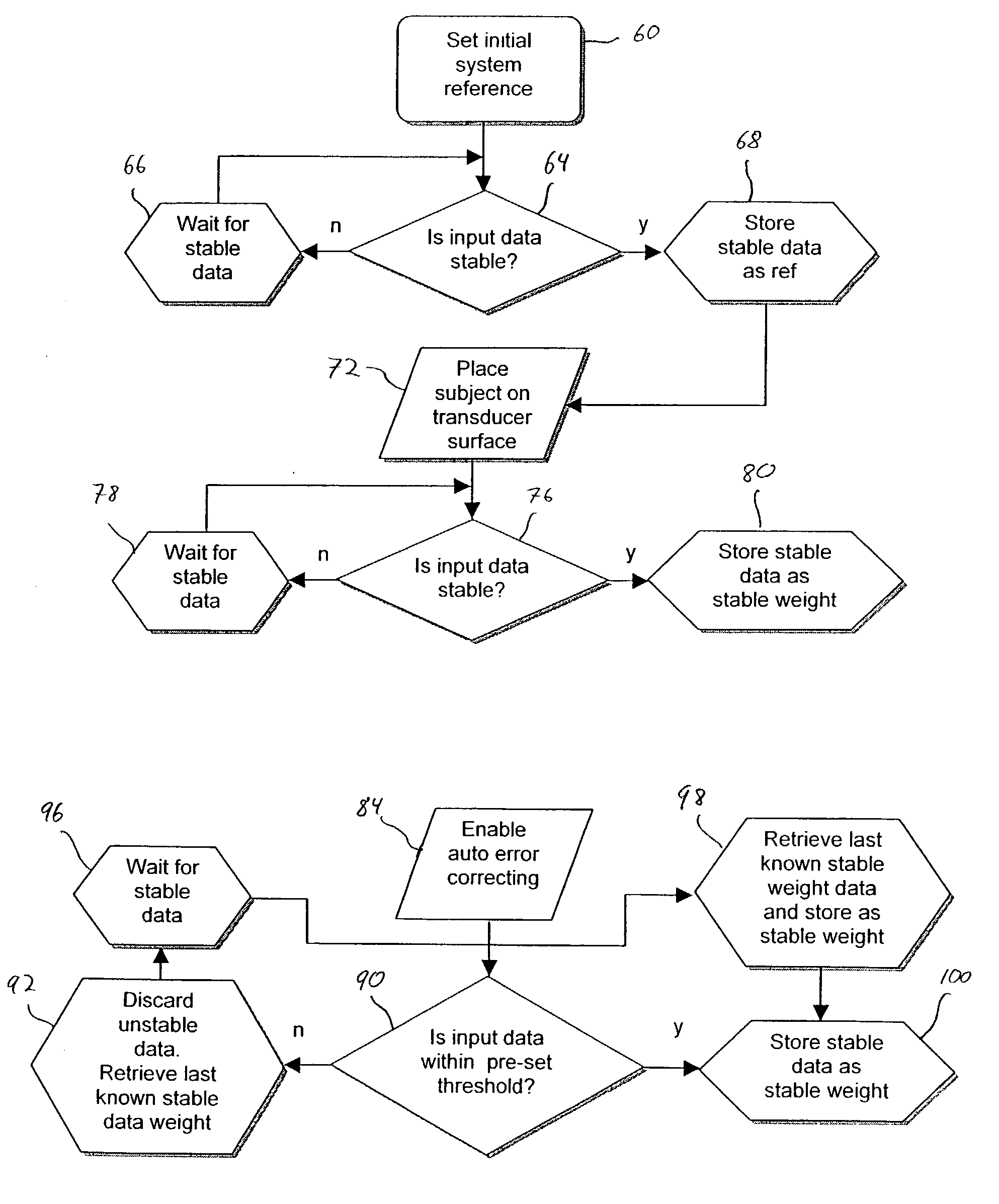

Weighing apparatus and method

InactiveUS6956175B1Reduce decreaseEliminate the problemWeighing apparatus testing/calibrationOscillations damping for weighingWeight shiftCollection system

A scale including an event data discrimination and collection system for continuously monitoring a weight of an infant placed on the scale platen, which may be configured as a bed. Load cells are used to continuously monitor infant weight from time placed on the scale platen, so that sudden apparent weight spikes sensed by the load cells but attributable to events involved in patient care may be discarded as artifact, while gradual weight changes reflective of infant physiology are accumulated by the scale controller and used to provide a current weight for the infant.

Owner:DALY PAUL C +1

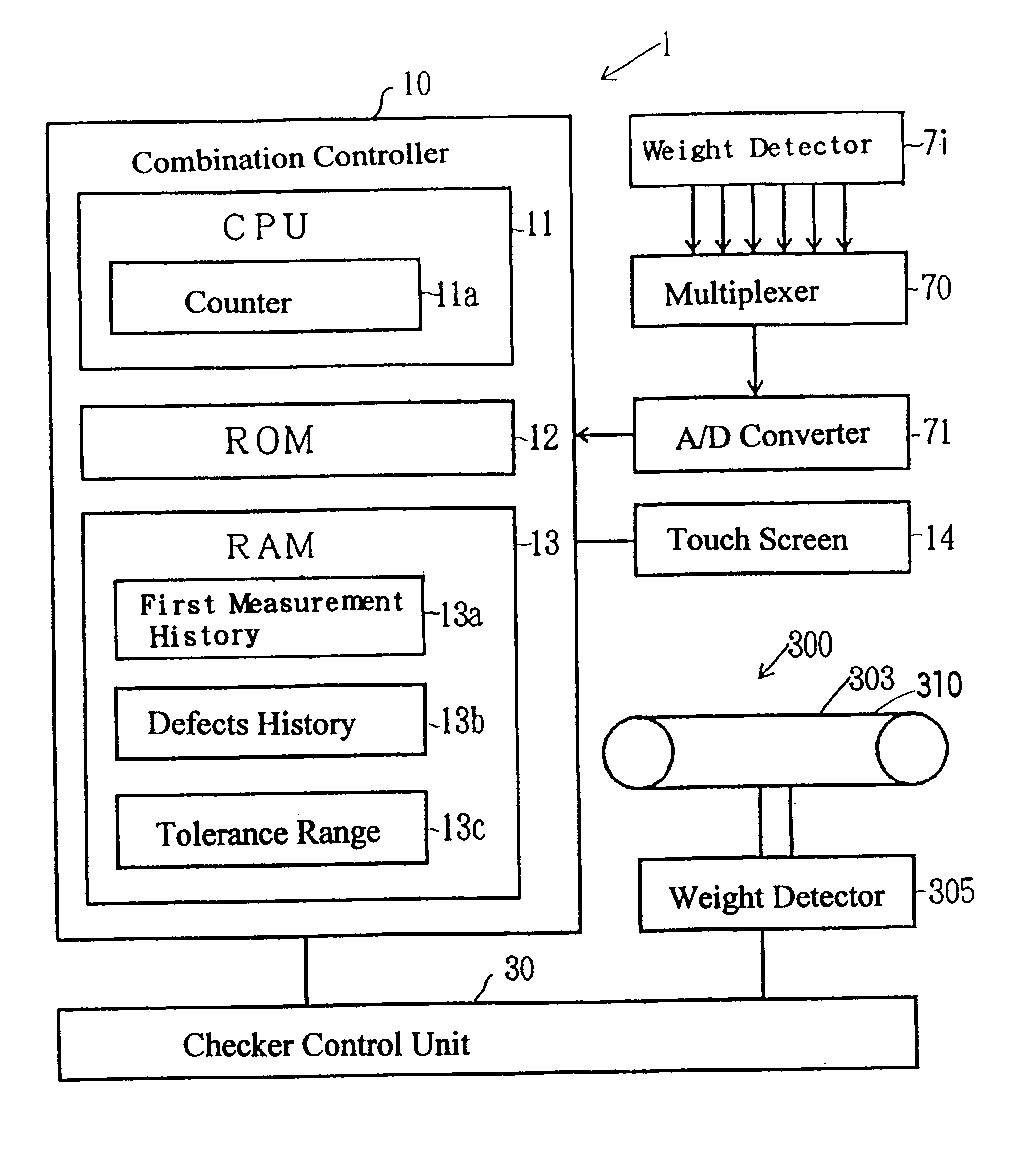

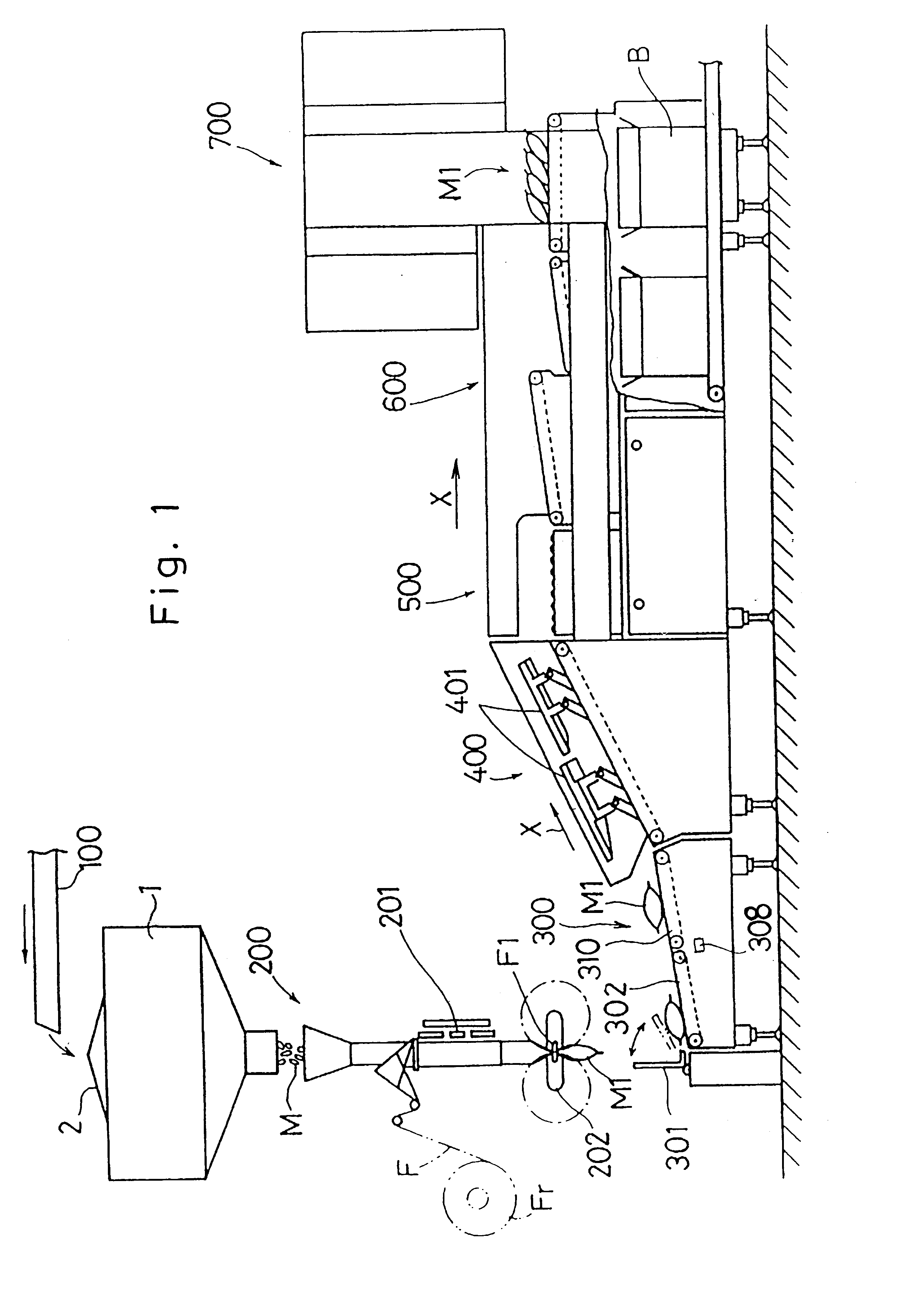

Weighing, packaging and inspecting system

InactiveUS6373001B1Weighing apparatus testing/calibrationWeighing indication devicesDisplay devicePost discharge

There is provided an abnormal device determining means (CPU 51) which reads a tendency of displacement between the combination calculated weight Wc of the contents M and the post-discharge Ws measured value of the same contents M measured after such contents M have been bagged and which, based on the tendency of displacement so read, determines which one of the combination calculated value Wc and the post-discharge measured value Ws is abnormal, and a display device (54) for displaying a result of the determination. Thus, since based on the displacement tendency of the combination calculated value Wc and the post-discharge measured value Ws, which one of the combination calculated value Wc and the post-discharge measured value Ws is abnormal is determined, it can readily and easily grasped which one of the combination weighing apparatus (1) and the weight checker (300) suffers from a trouble.

Owner:ISHIDA CO LTD

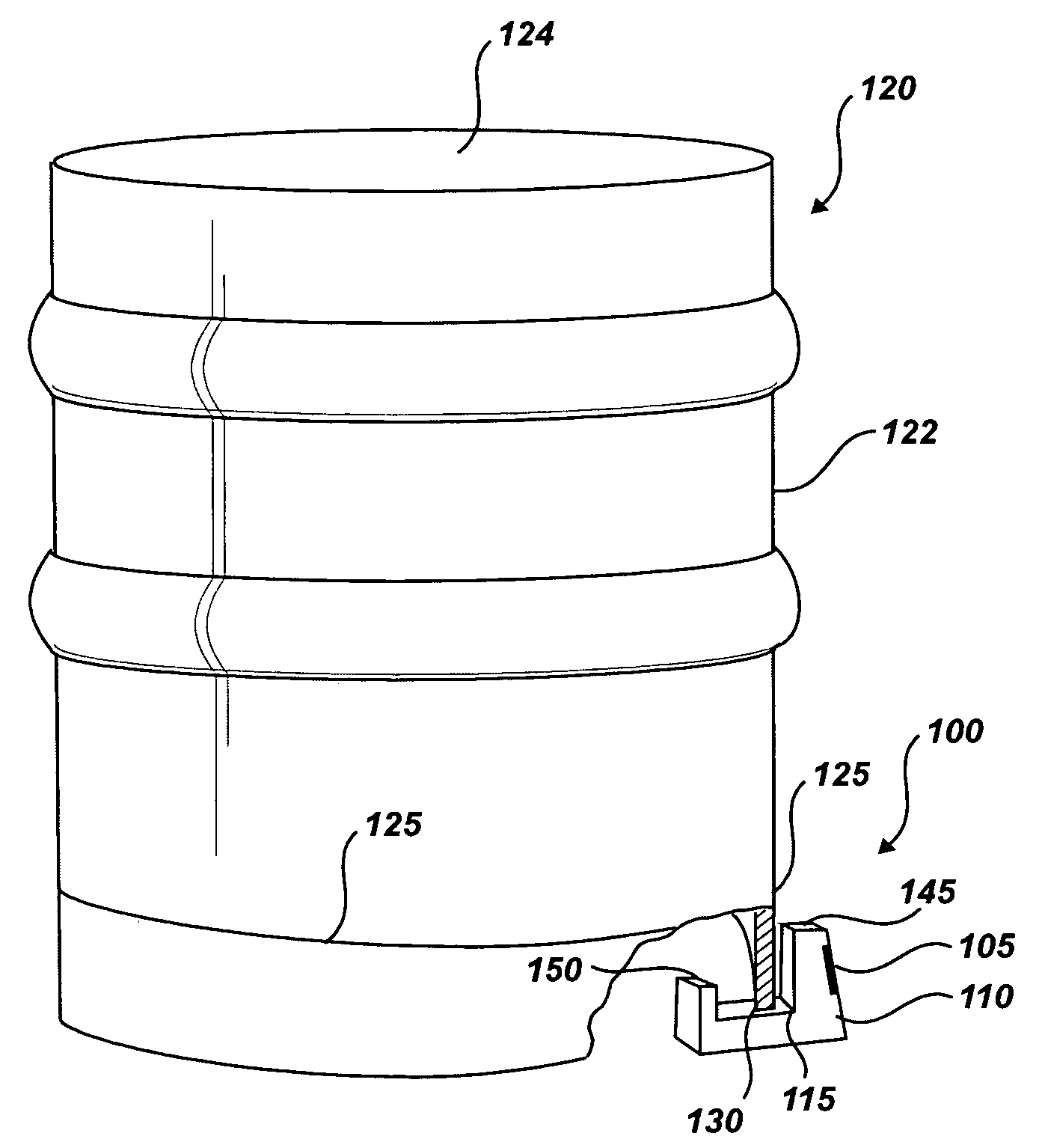

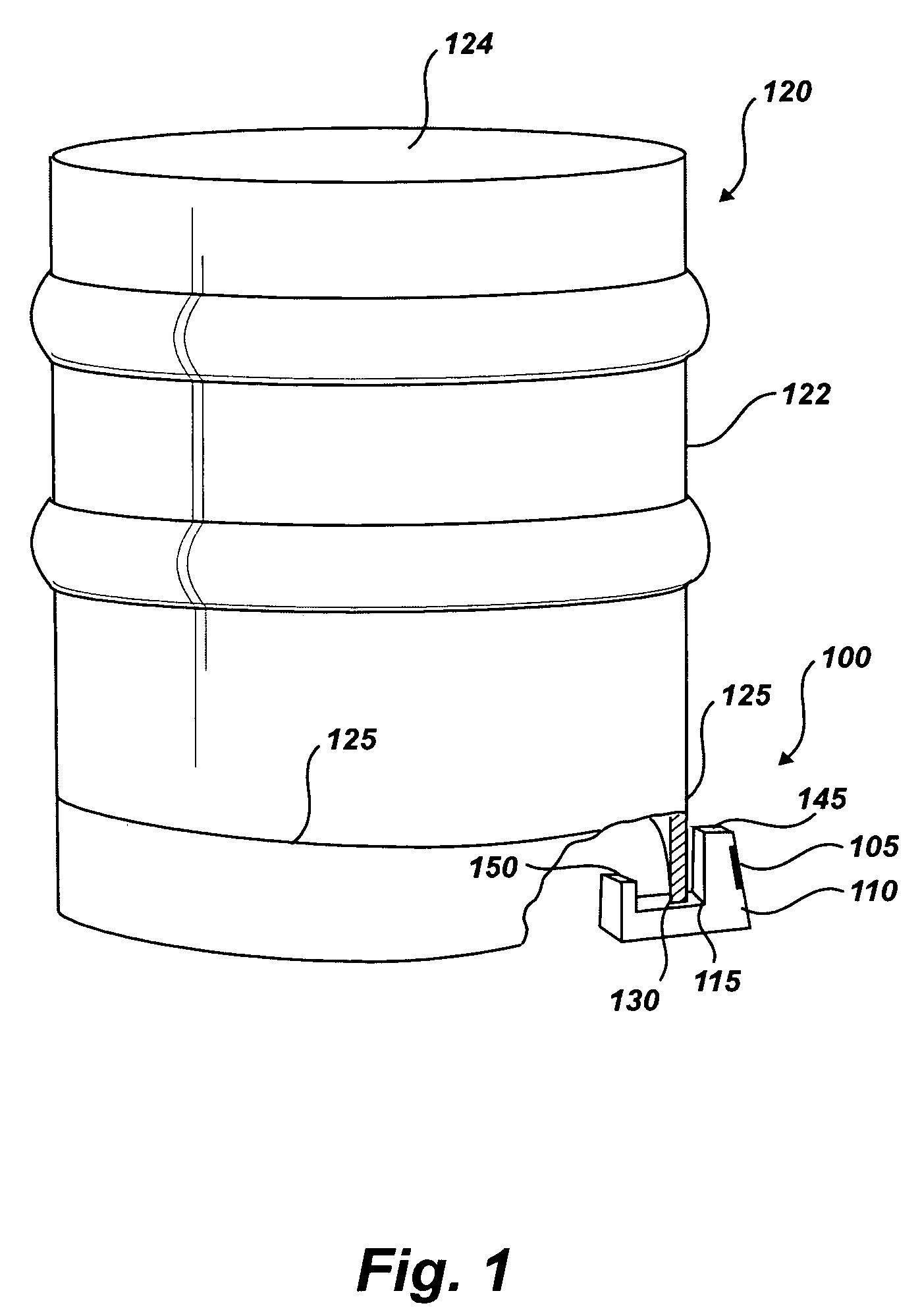

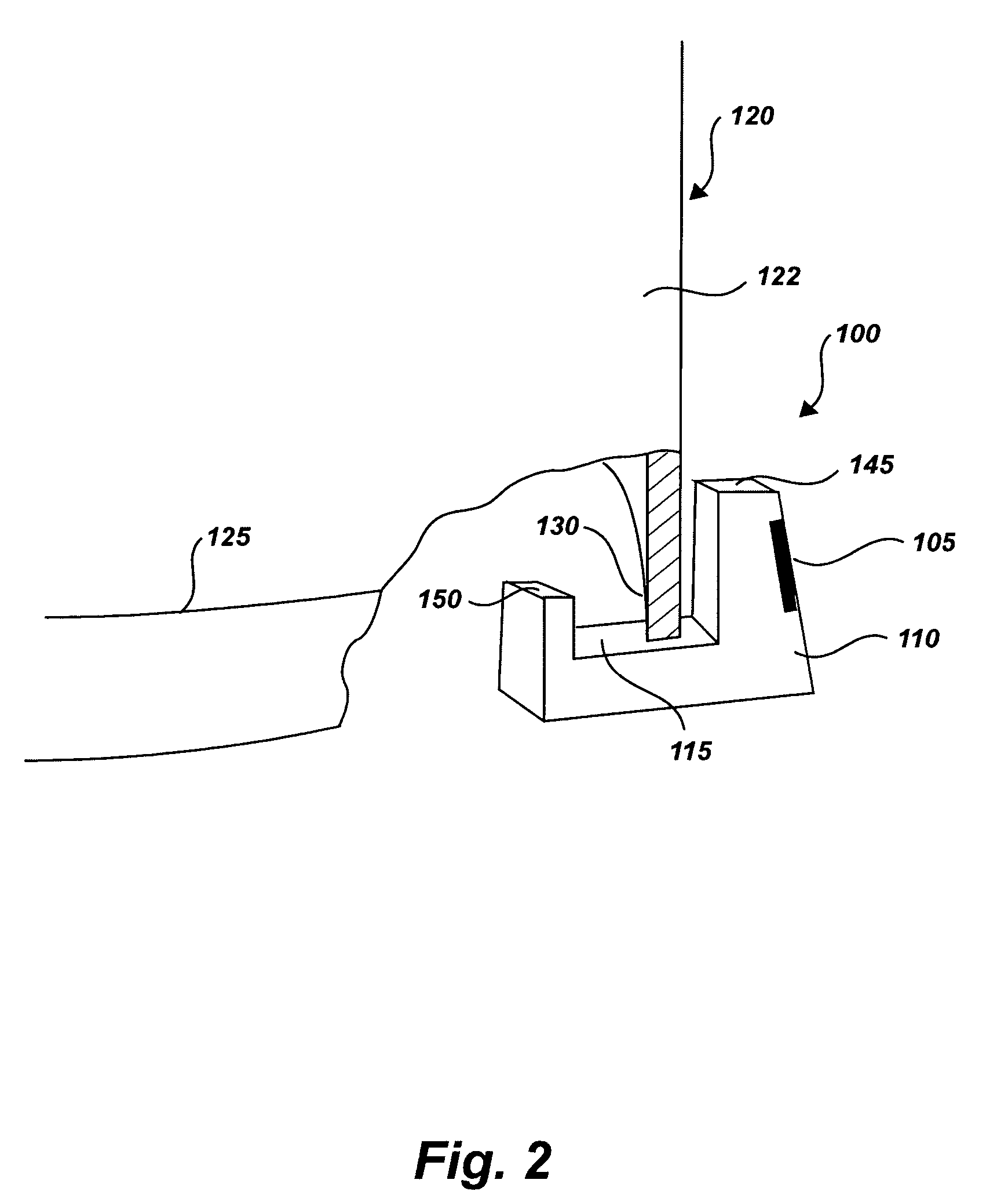

Device for measuring and displaying the amount of beer in a keg

InactiveUS7255003B2Weighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationDisplay deviceEngineering

A scale for determining a quantity of material in a container such as a keg. The scale may include a support member configured to be placed under a portion of the container, a display to indicate the quantity of material in the container, and a weight sensor positioned underneath the support member to determine the quantity of material in the container and to provide a signal to the display.

Owner:SCHNEITER CALVIN R

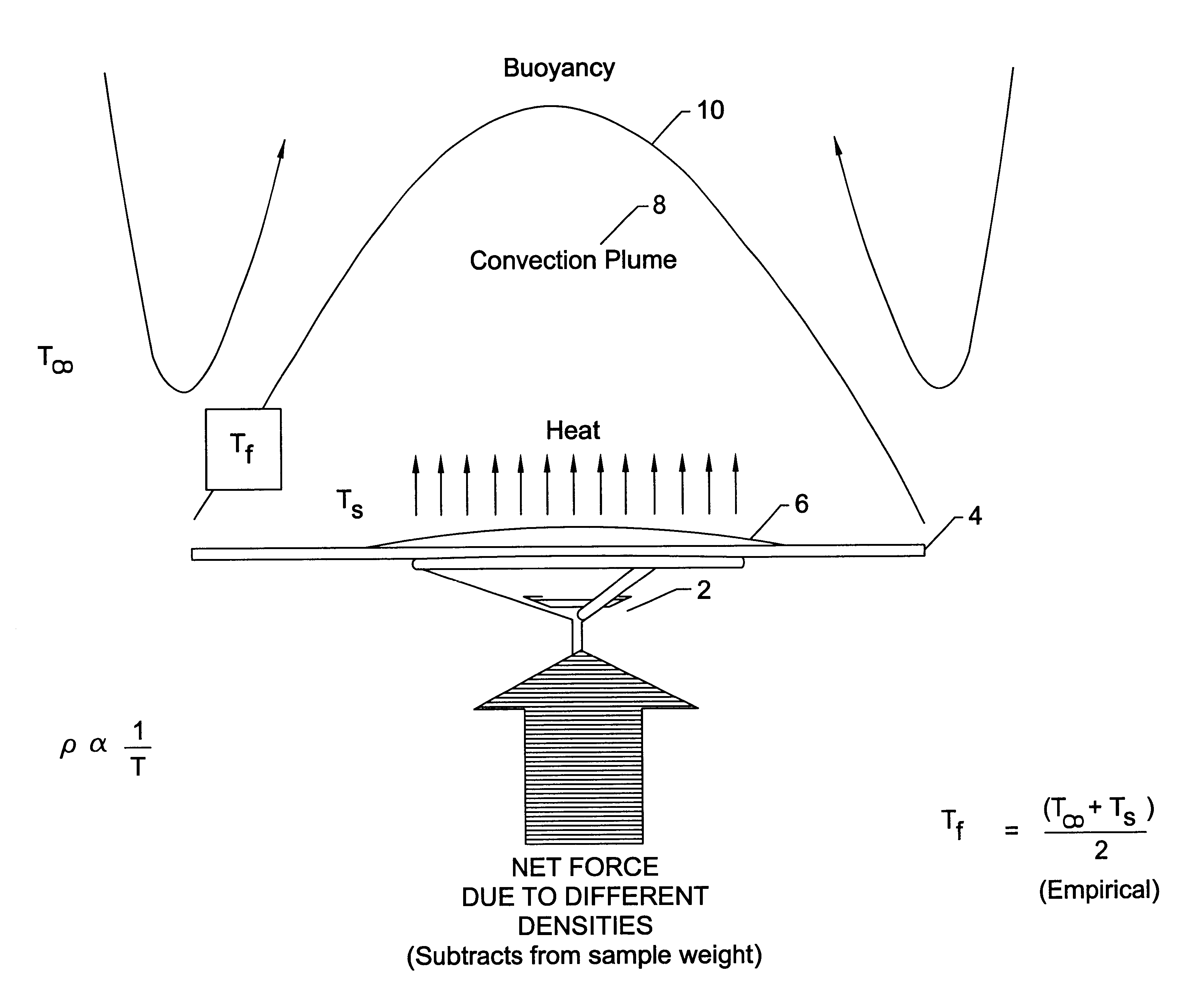

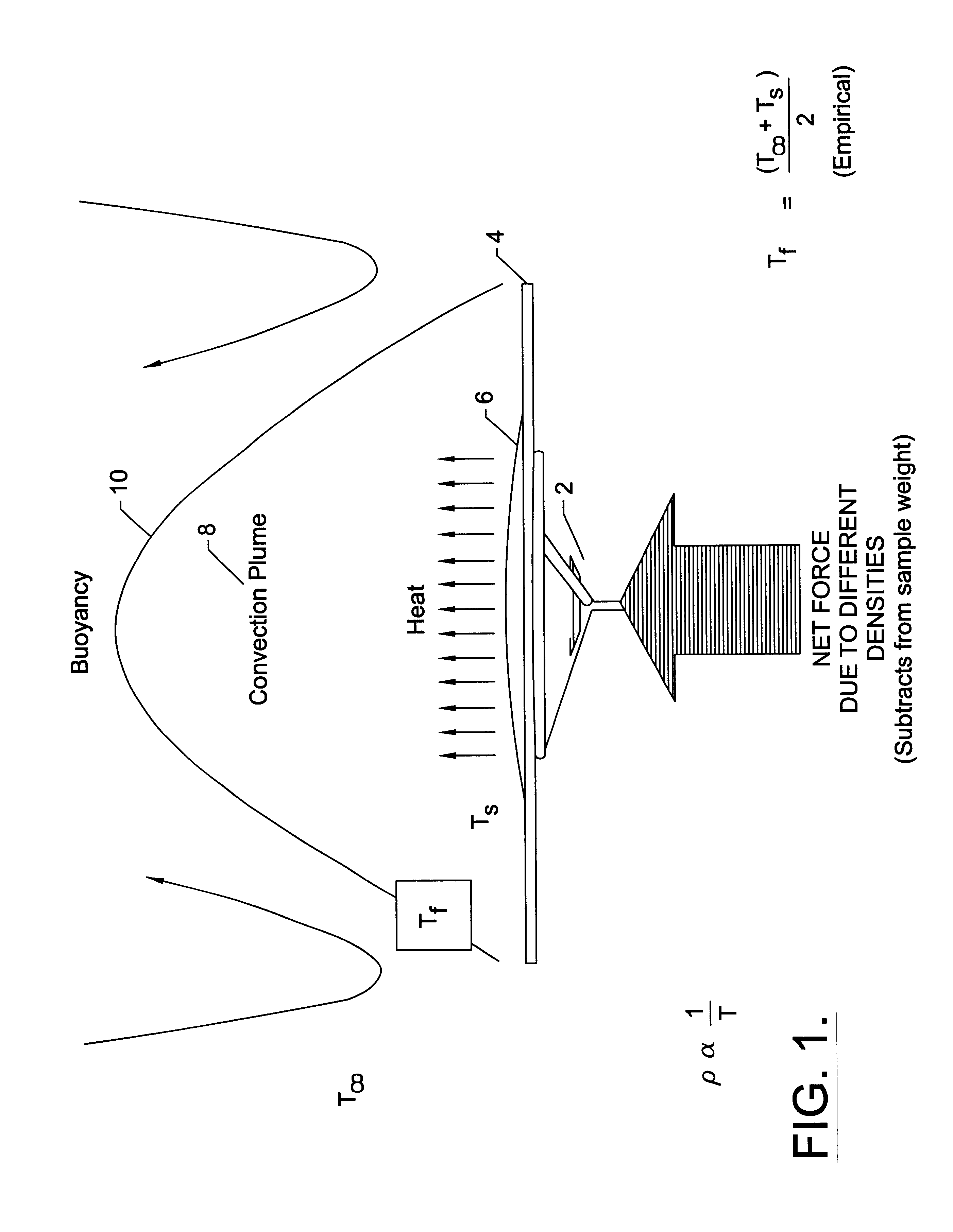

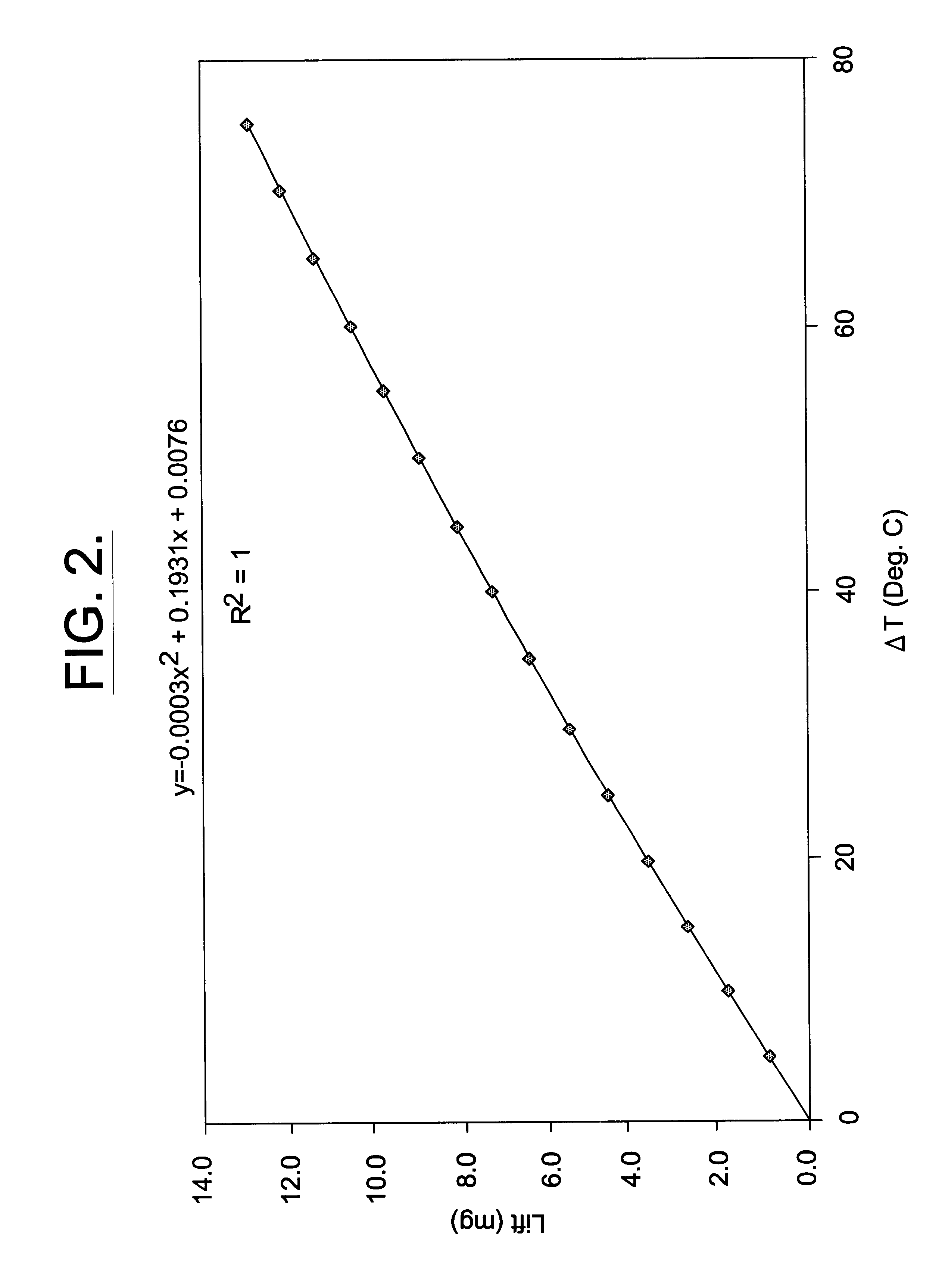

Method for correcting weight measurement errors during microwave heating

InactiveUS6268570B1Accurate sample weight measurementAccurate weighingWeighing apparatus testing/calibrationMaterial moisture contentObservational errorMicrowave

The invention is a method of measuring an apparent weight of a substance, while concurrently measuring a surface temperature of the substance and an ambient air temperature surrounding the substance, then predicting buoyancy forces acting upon the substance based on these temperature measurements. Thereafter, the true weight of the substance can be determined by correcting the apparent weight by the predicted buoyancy forces acting upon the substance.

Owner:CEM CORP

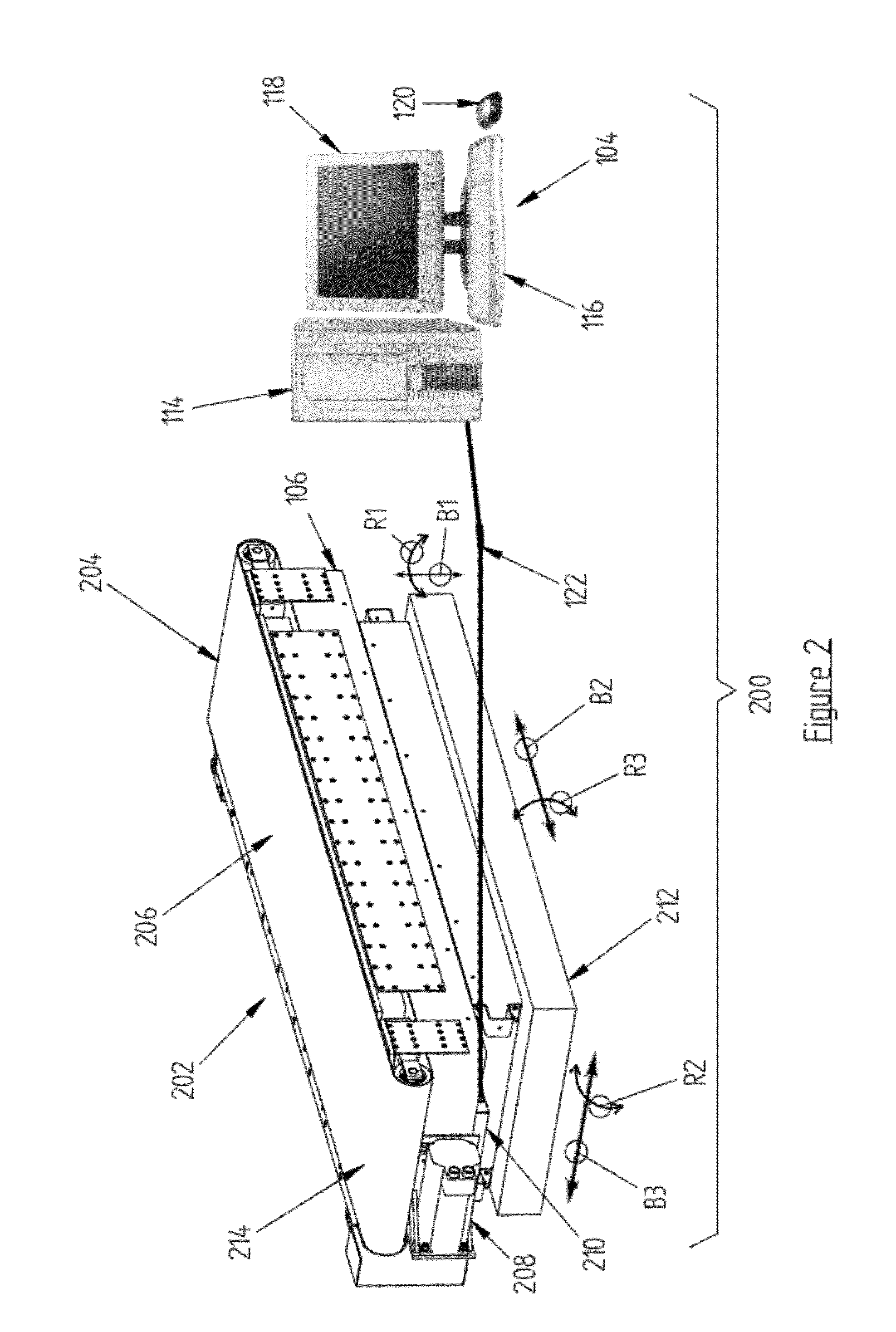

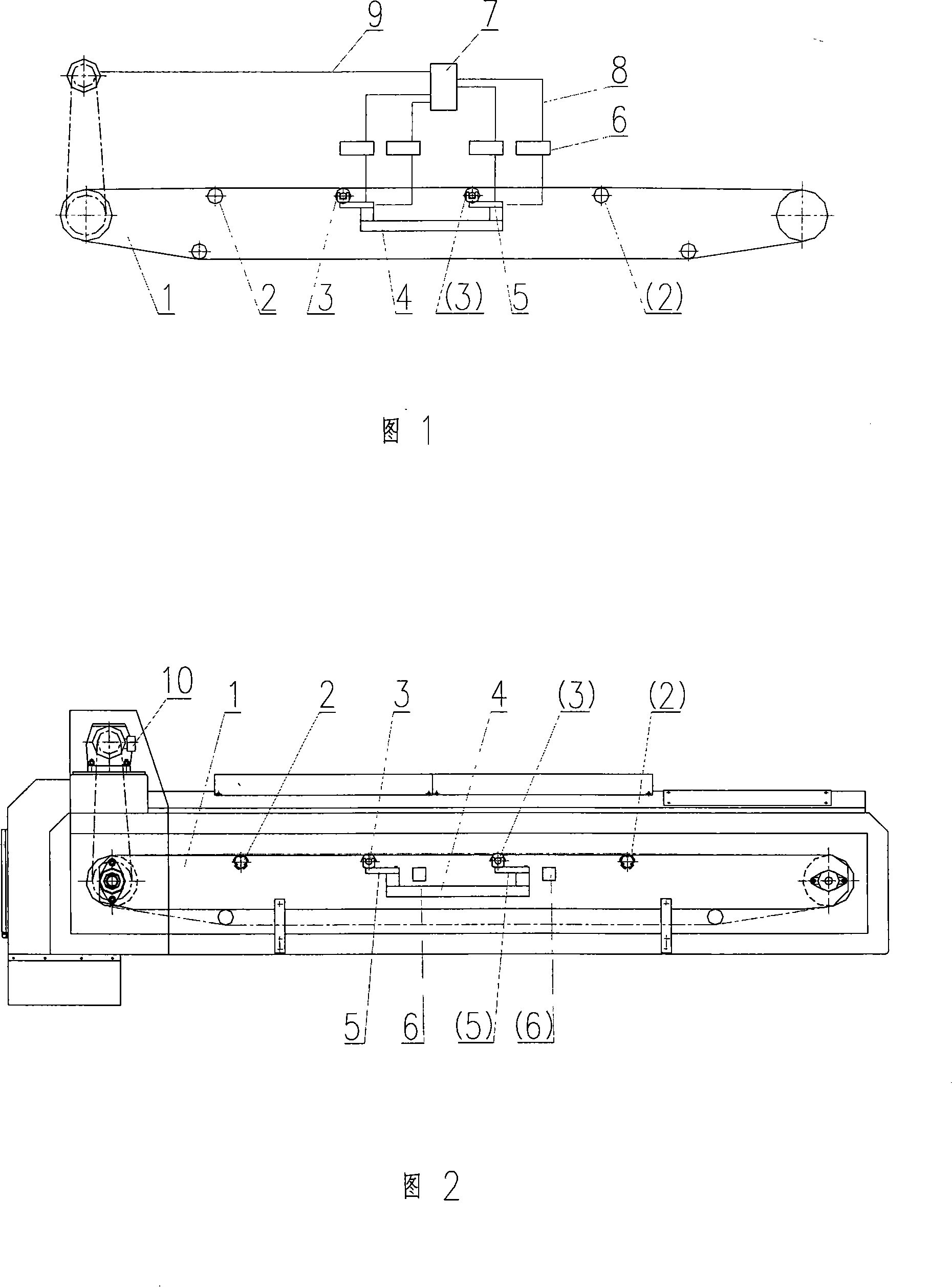

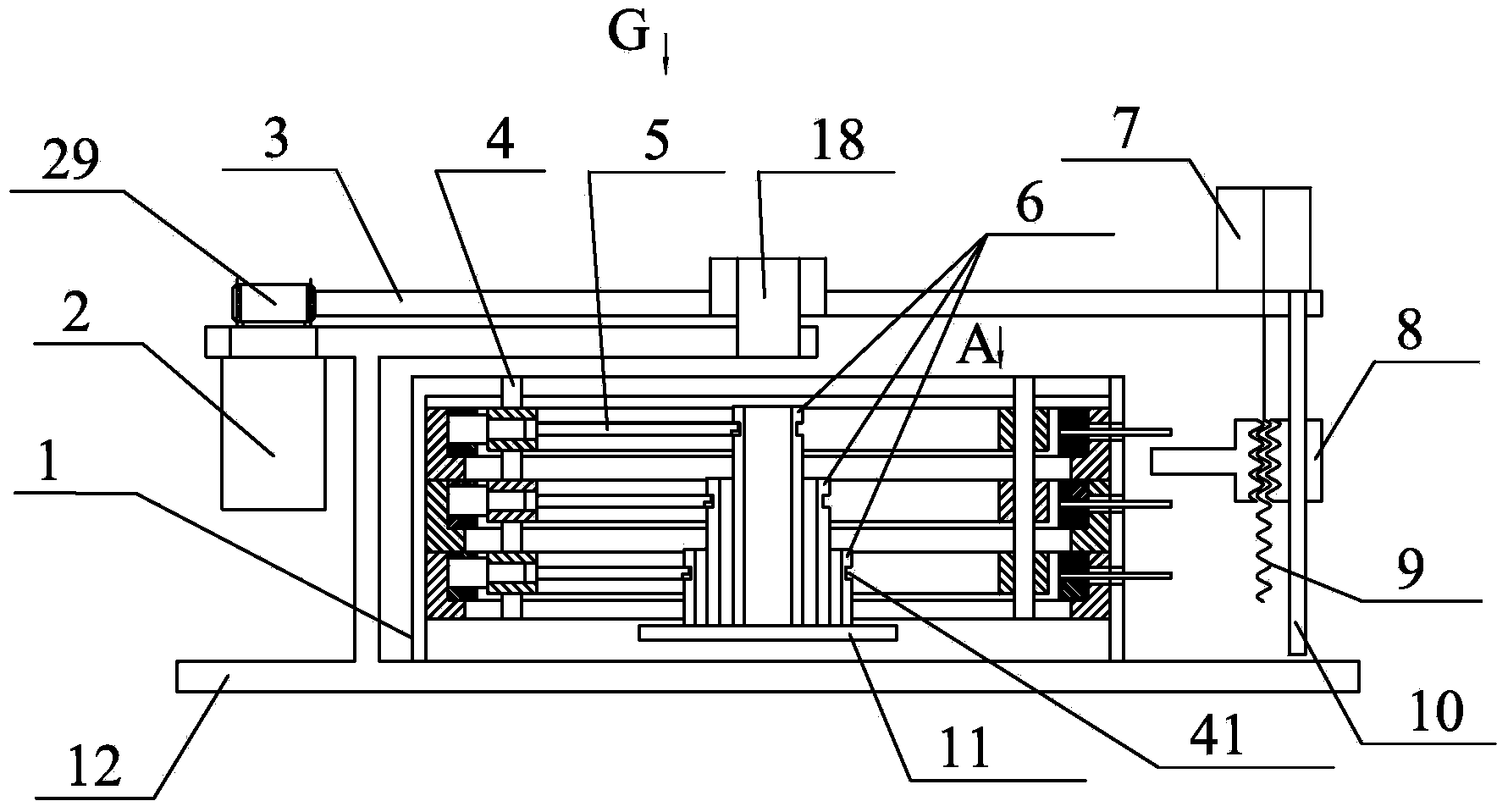

Weighing method of electronic belt conveyor scale capable of checking automatically

ActiveCN101206136AImprove anti-interference abilitySignal transmission distance is longWeighing apparatus testing/calibrationWeighing apparatus for continuous material flowEngineeringLoad cell

The invention relates to a weighing method for an electronic belt scale capable of self-check, more than two weighing carrier rollers (3) form into a weighing device of the electronic belt scale, each weighing carrier roller is supported by more than two weighing sensors (5), each weighting sensor is respectively connected with a PLC (7) through an individual signal transmission line (8), the PLC can directly acquire an output weighing signal of each weighing sensor to monitor and diagnose each weighing carrier roller and weighing sensor on real-time in the weighing process. During a normal weighing, the method measures according to a multiple carrier roller mode. The PLC monitors, recognizes, diagnoses, groups and compares the weight signals after A / D transition on real-time, and calculates the material weight after integral arithmetic with speed signals of a motor or the belt. During thediagnosis, the weighing device treat according to more than two single carrier roller manners, and each weighing carrier roller is measuring cup for each other. The invention has strong ability of disturbance resistance, and can find out failures such as poor measuring accuracy, damaged weighing sensor, etc., the performance is stable and reliable, the failure point can be quickly checked out so as to be maintained conveniently, the maintenance capacity and component replacement quantity are in a small quantity.

Owner:云南昆船电子设备有限公司

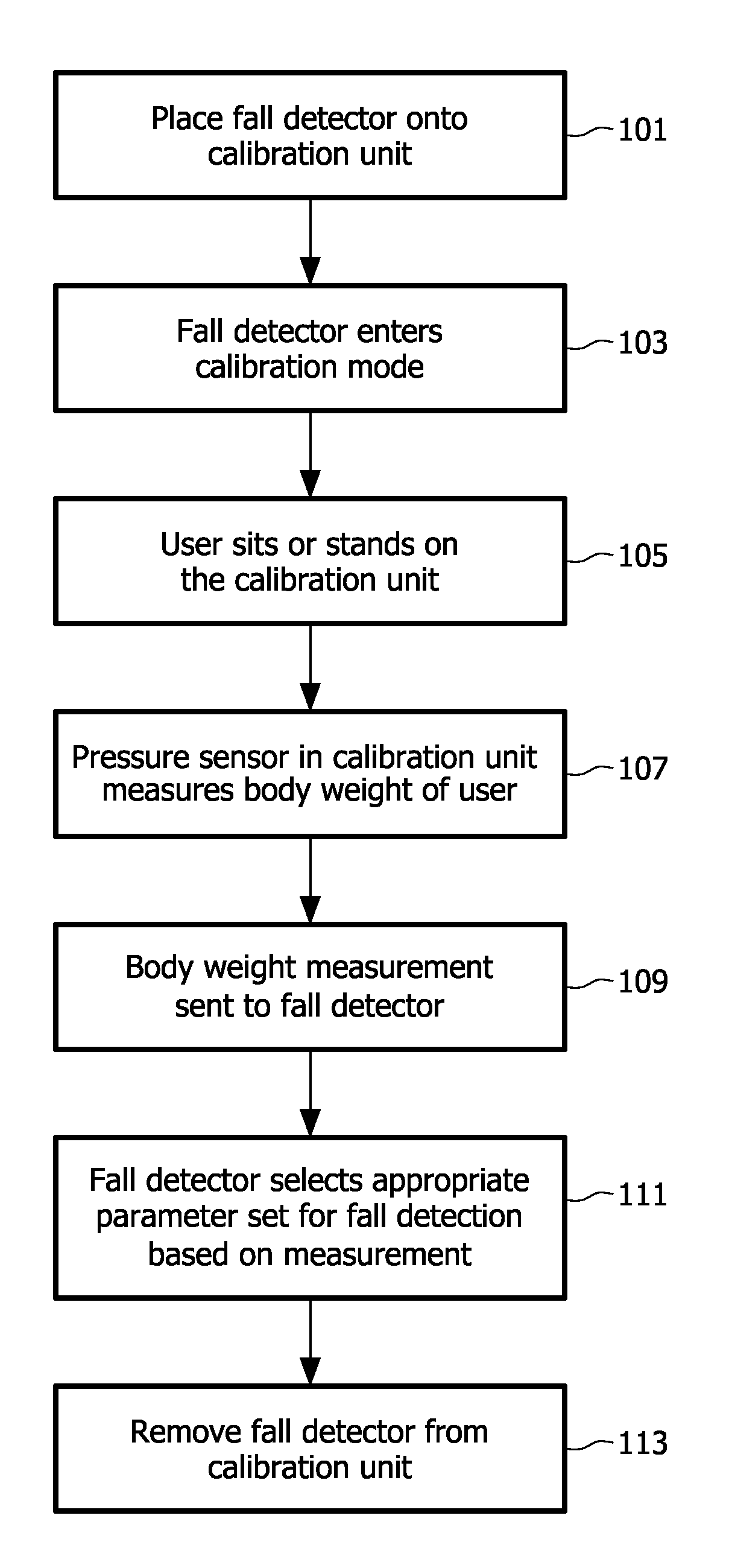

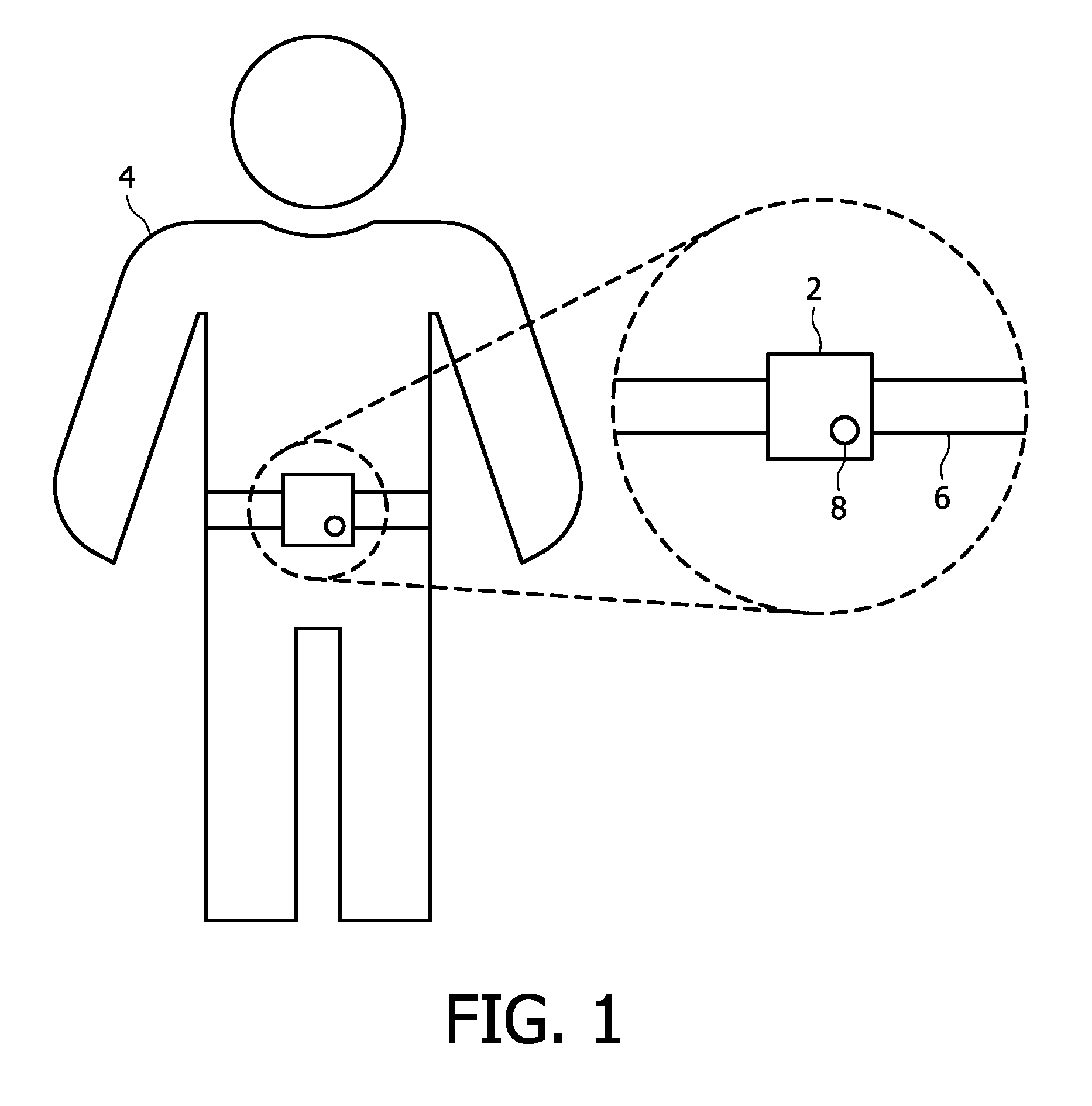

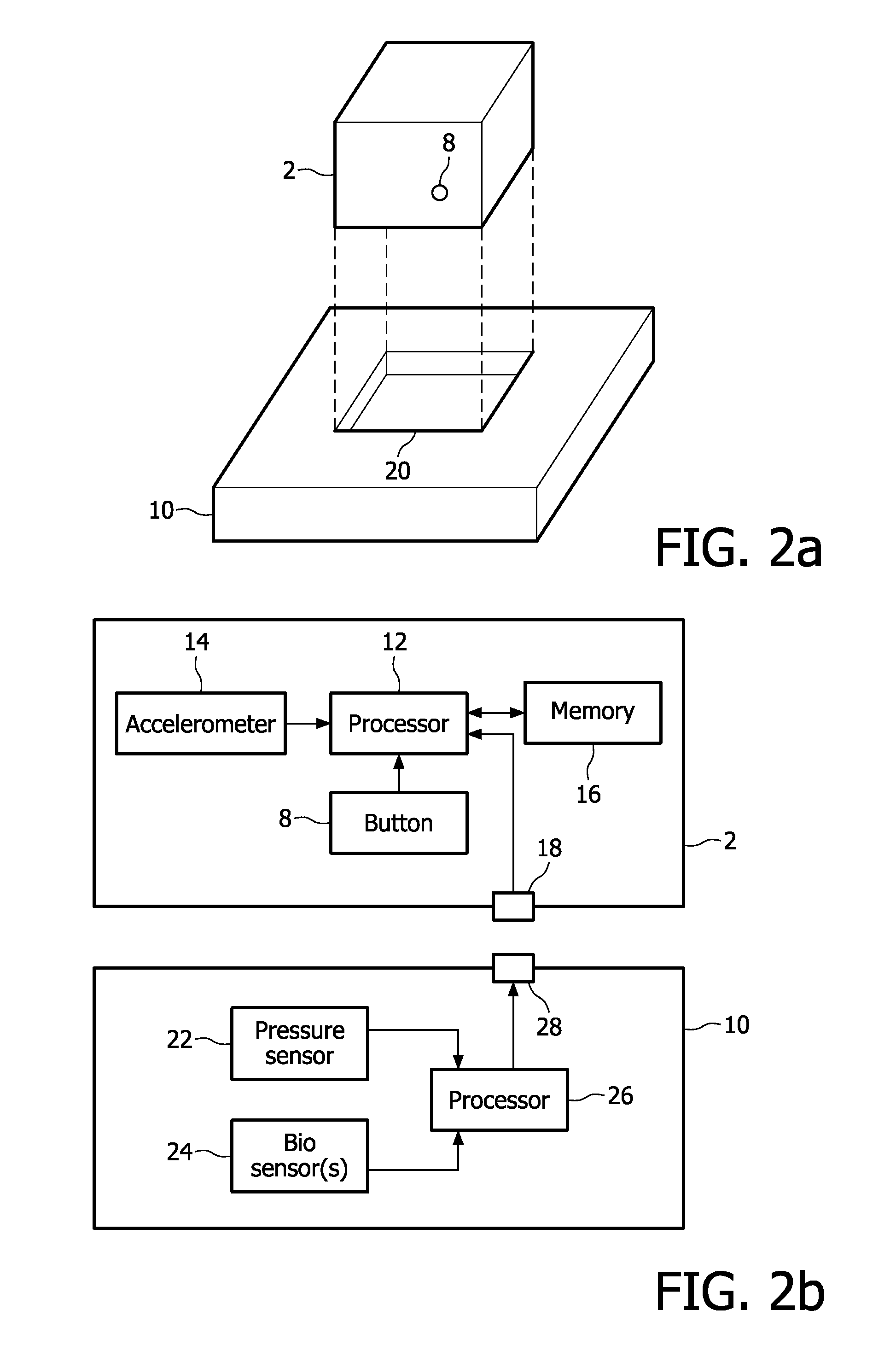

Fall detection system

ActiveUS8381603B2Improve reliabilityDesired level of detection accuracyForce measurement by permanent gauge deformationPerson identificationEngineeringFall detector

Owner:KONINK PHILIPS ELECTRONICS NV

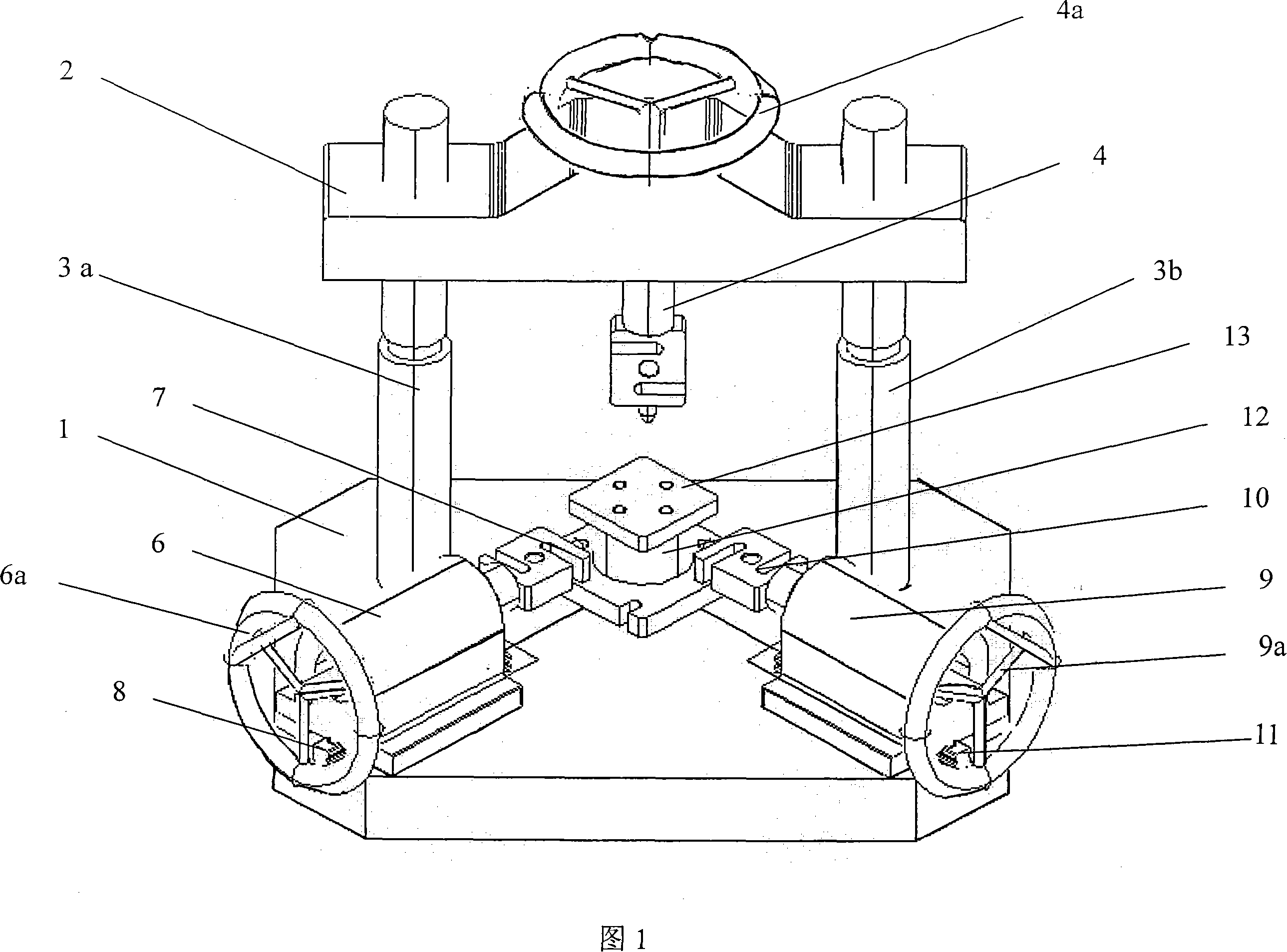

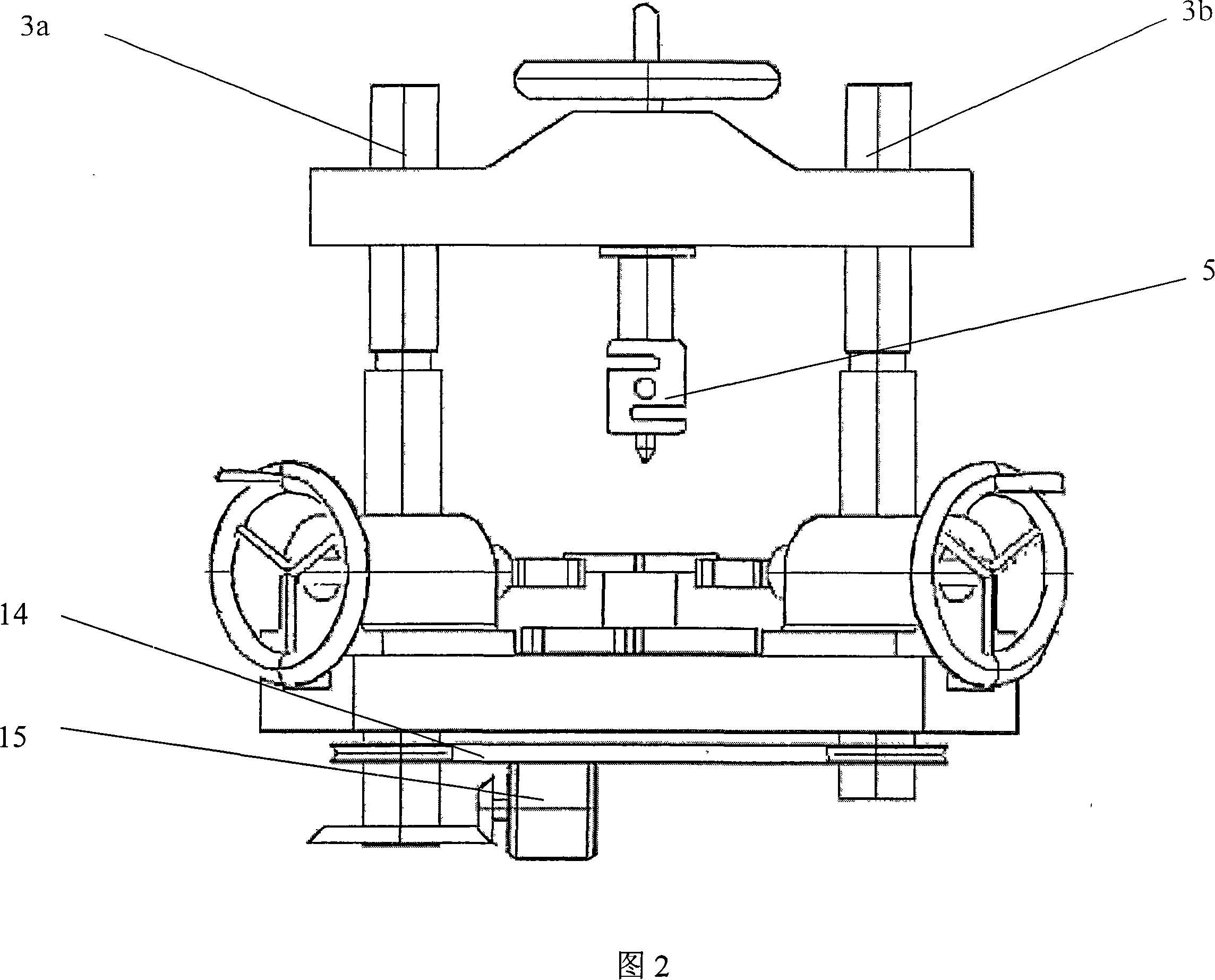

Three-dimensional force transducer calibration device

InactiveCN101109670AHigh force measurement accuracyImproved force performanceWeighing apparatus testing/calibrationFluid pressure measurementMotor driveBall screw

The invention relates to a calibrator for a 3-way force sensor. Wherein, a X-way linear guideway for translating with a X-way loader and a Y-way linear guideway for translating with a Y-way loader are fixed perpendicular to each other on a calibrating worktable; the two ends of a beam are fixed on two ball screw for lifting the beam; the ball screws are installed vertically on the calibrating worktable; a Z-way loader is fixed on the beam; the standard force sensors that are respectively mounted on the X-, Y- and Z-way loader are intersected; an orientedly loading clamp clamps the 3-way force sensor to be calibrated, is placed on the calibrating worktable and located at the intersection of the three sensors; a motor drives the two ball screw for lifting the beam to move linearly and synchronously in Z direction. The weighing, 3-way force sensor is calibrated by a measurement comparison method. While detecting the force-measuring performance of the 3-way force sensor in any direction, one can observe the disturbance on the force measuring in another two directions, thereby the interference of forces in different directions can be reduced.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

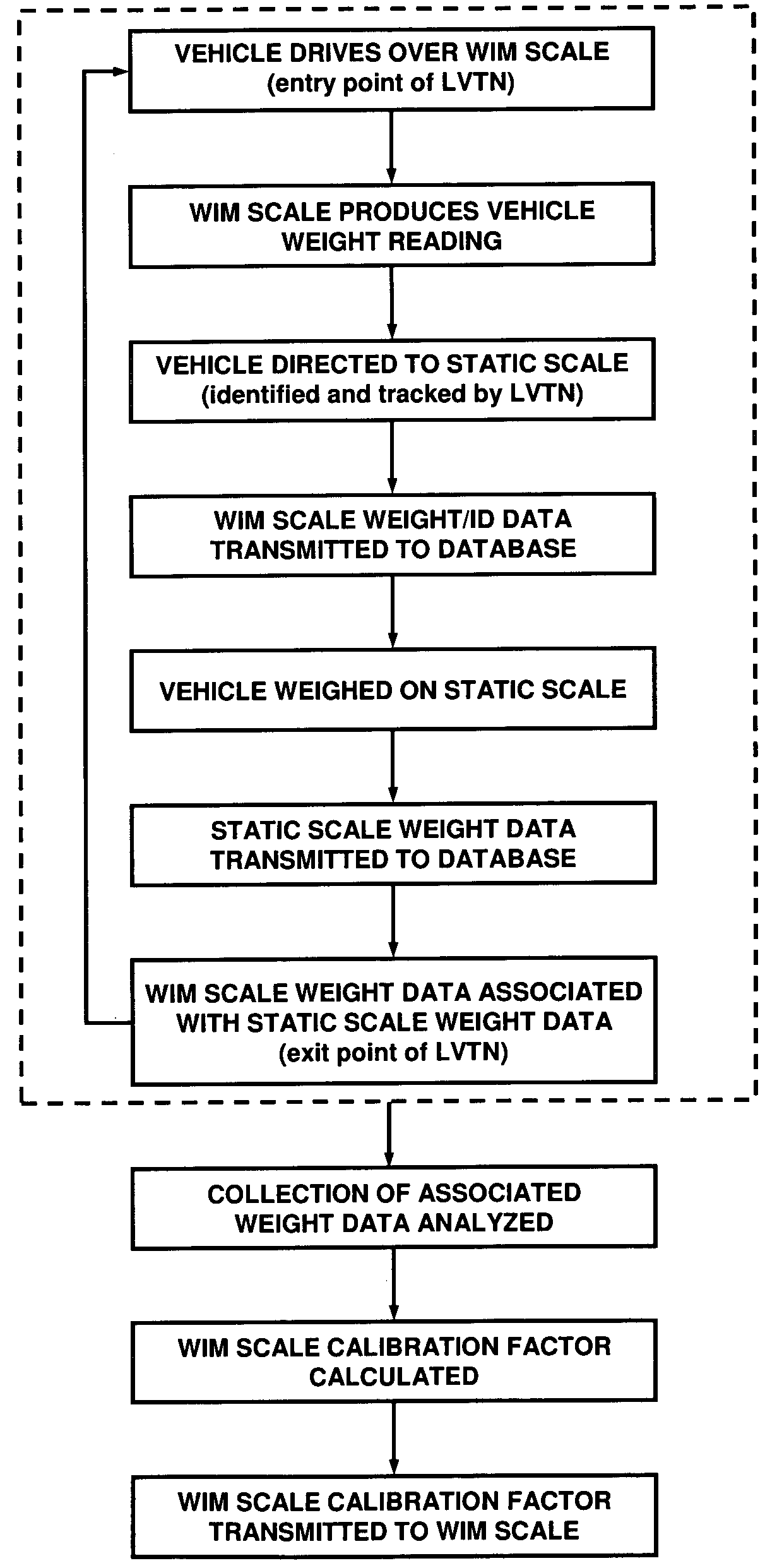

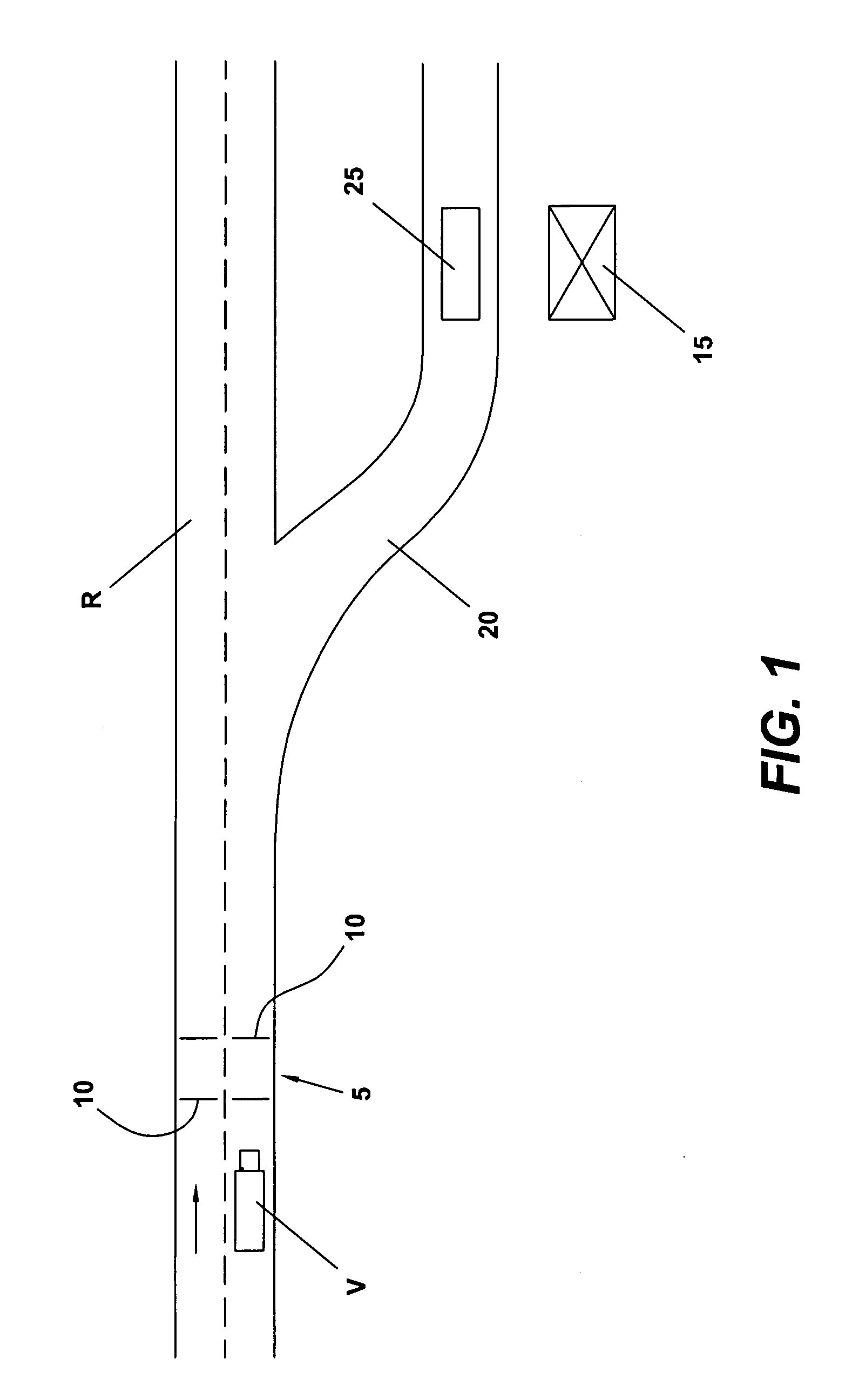

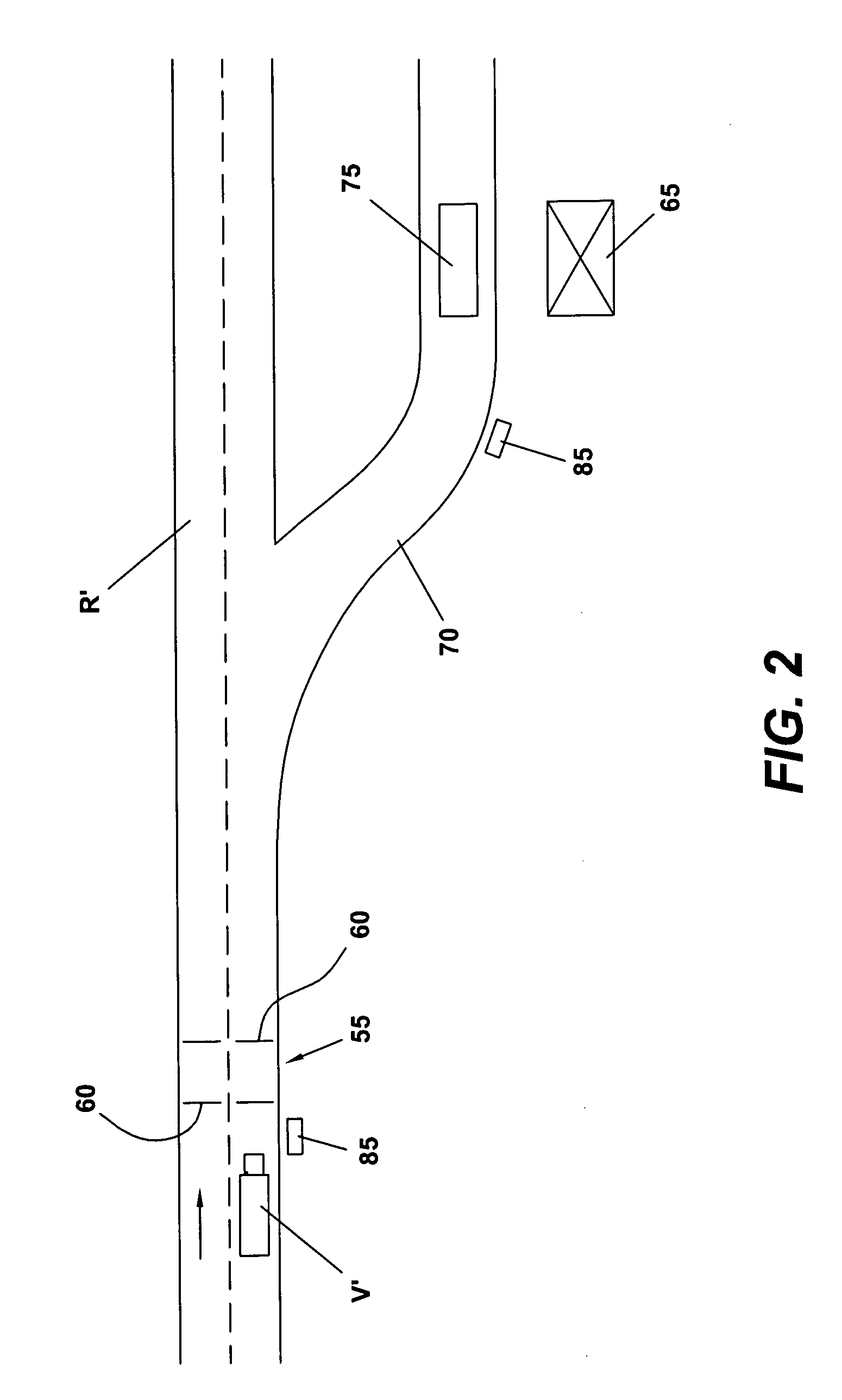

Weigh-in-motion system with auto-calibration

ActiveUS20090151421A1Accurate readingWeighing apparatus testing/calibrationSpecial data processing applicationsMobile vehicleComputer science

Weigh-in-motion (WIM) systems for weighing moving vehicles, the systems having the ability to automatically determine and periodically apply calibration factors to WIM scale readings. Auto-calibration may include transferring both WIM and static weight readings for the same vehicle to a database, associating the weight readings, collecting a number of such weight readings, and analyzing the differences between the WIM and static weight readings to calculate WIM scale calibration factors. The calibration factors may be based on vehicle characteristics such as vehicle weight, vehicle class and / or vehicle speed at the WIM scale.

Owner:METTLER TOLEDO INC

Gravimetric moisture measurement instrument

ActiveUS7851712B2Lower Level RequirementsPromote escapeWeighing apparatus testing/calibrationMaterial moisture contentMeasuring instrumentEngineering

Owner:METTLER TOLEDO GMBH

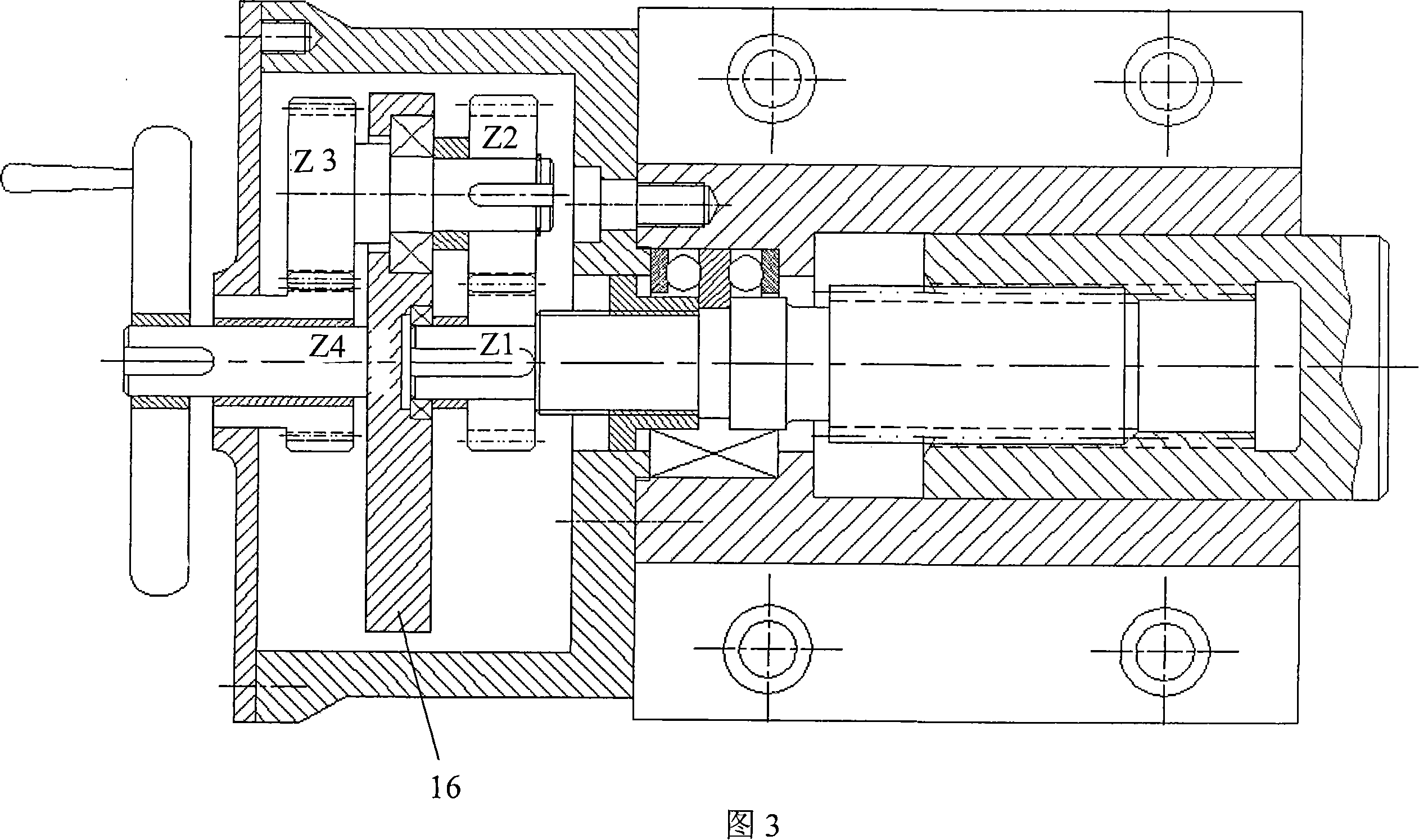

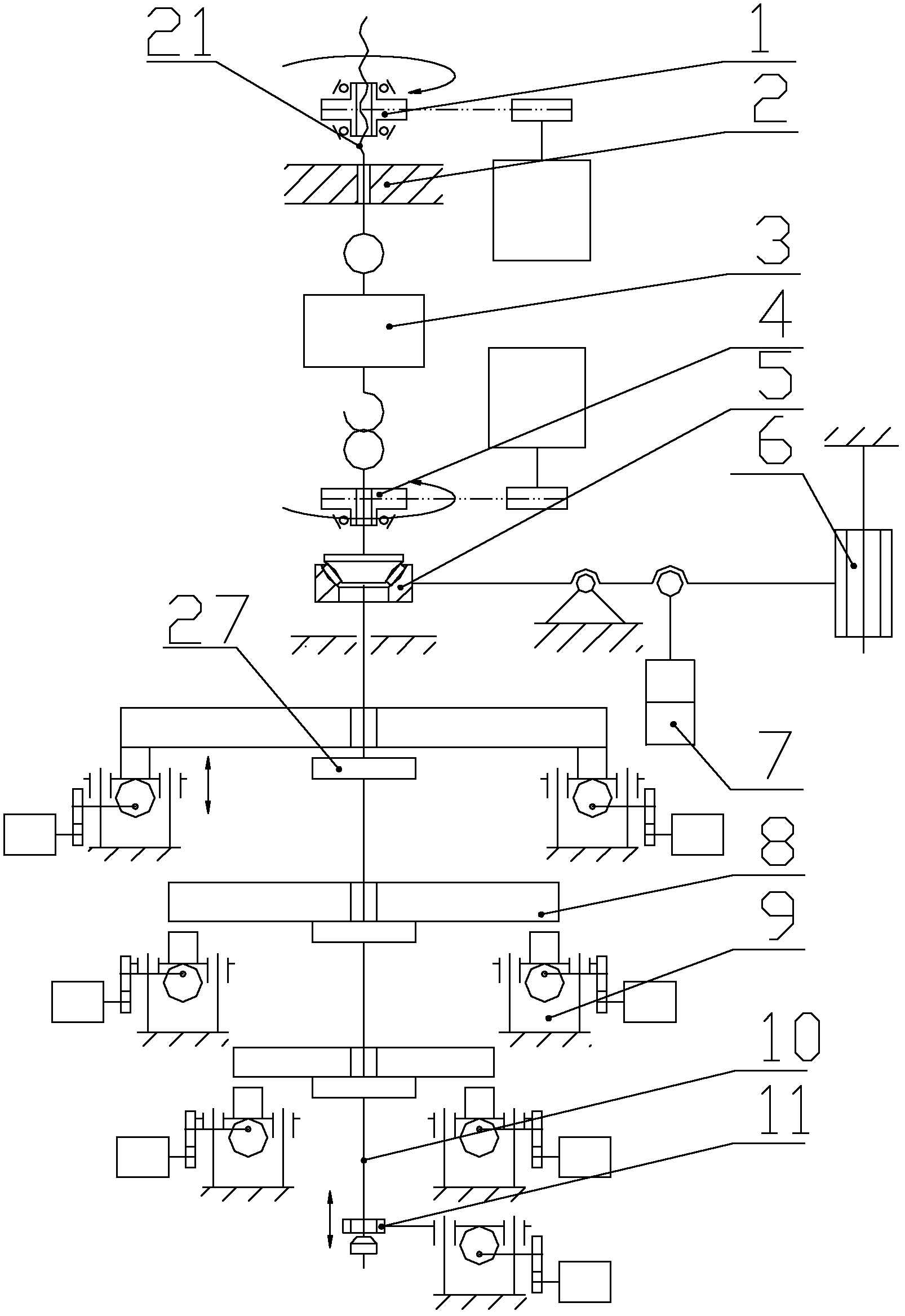

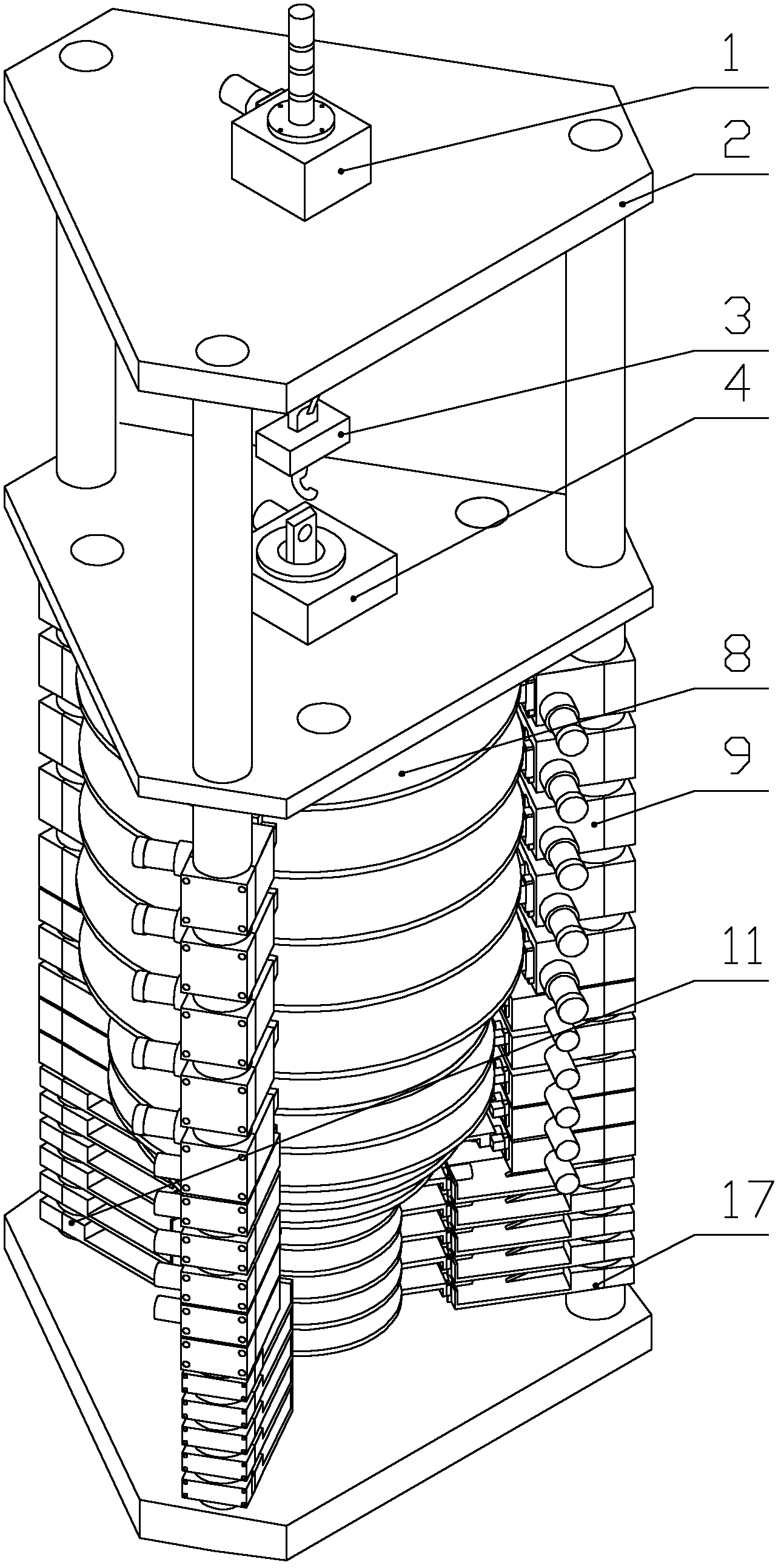

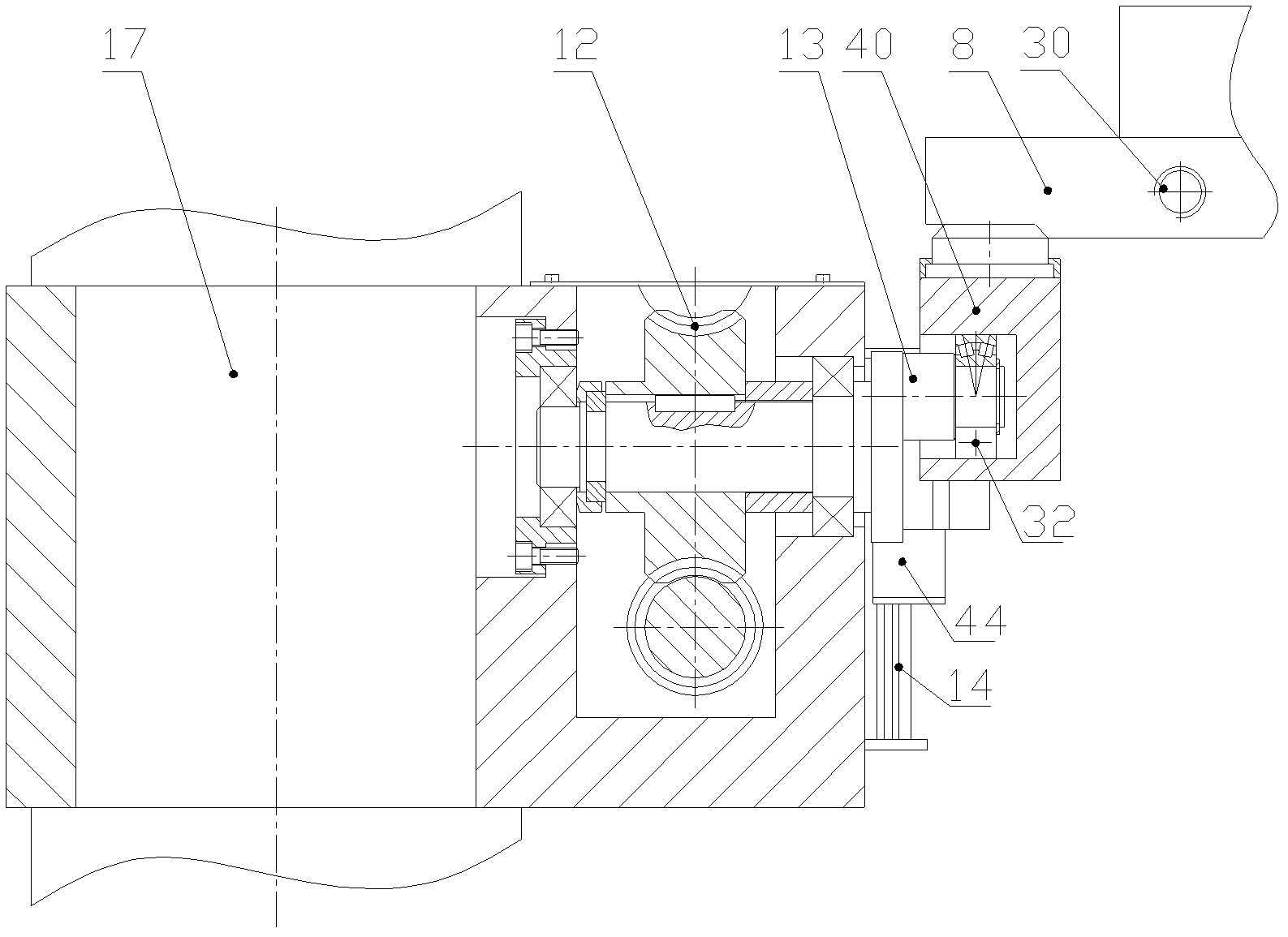

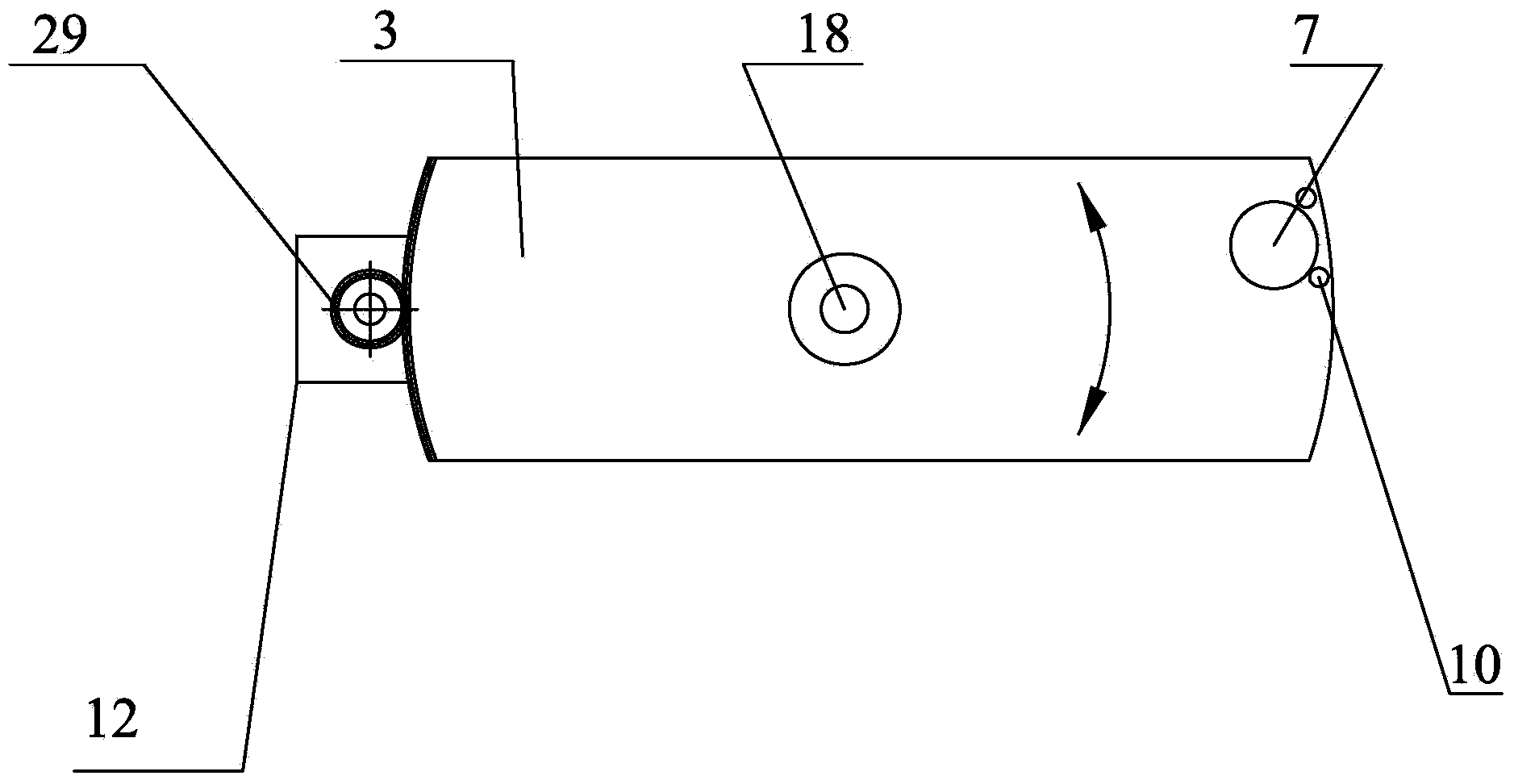

Testing machine for testing crane scale and method for disassembling and assembling weight thereof

InactiveCN102426051AImprove working precisionEasy accessWeighing apparatus testing/calibrationEngineeringMechanical engineering

The invention discloses a testing machine for testing a crane scale and a method for disassembling and assembling a weight thereof. The testing machine for testing a crane scale comprises a position adjustment control device, a rack, a weight, a weight drive mechanism, a weight swing mechanism, a suspender and an anti-swing mechanism, wherein the weight swing mechanism comprises a weight swing mechanism shell, a motor No.3, a stop dog, a worm, a worm gear and a weight swing mechanism driving part, the worm and the weight swing mechanism driving part are installed in the weight swing mechanismshell and are in rotating connection, the worm gear is sleeved on the weight swing mechanism driving part and is fixedly connected with the weight swing mechanism driving part, and the worm and the worm gear are engaged with each other, the output shaft of the motor No.3 fixed on the weight swing mechanism shell is fixedly connected with the worm, the stop dog is installed in a through groove of the weight swing mechanism driving part, the weight swing mechanism is installed at the center of a middle cross beam of the rack, the weight swing mechanism driving part is sleeved on the suspender, and a through hole on the weight swing mechanism driving part is in clearance fit with the suspender. The invention also provides a method for disassembling and assembling the weight in the testing machine.

Owner:JILIN UNIV

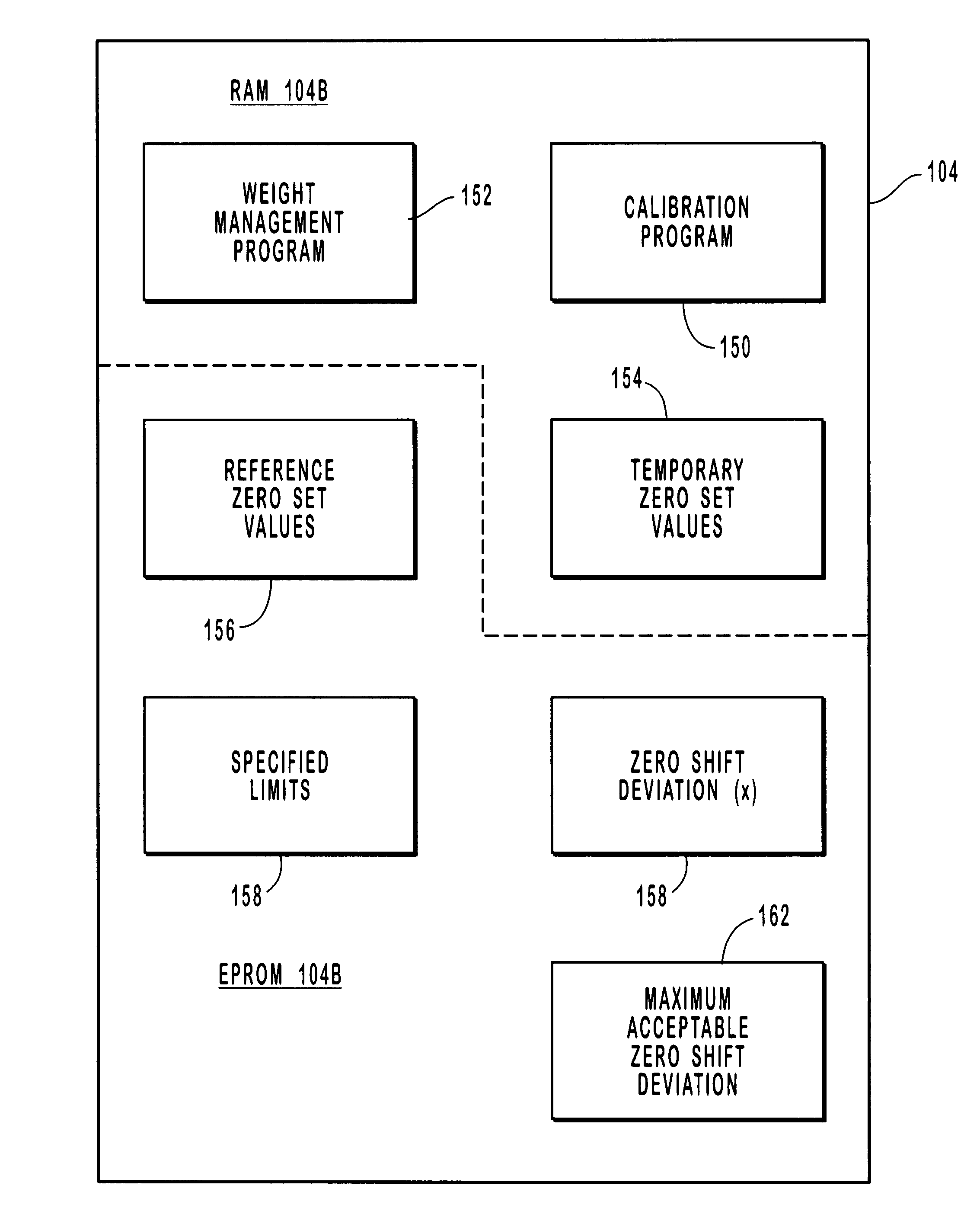

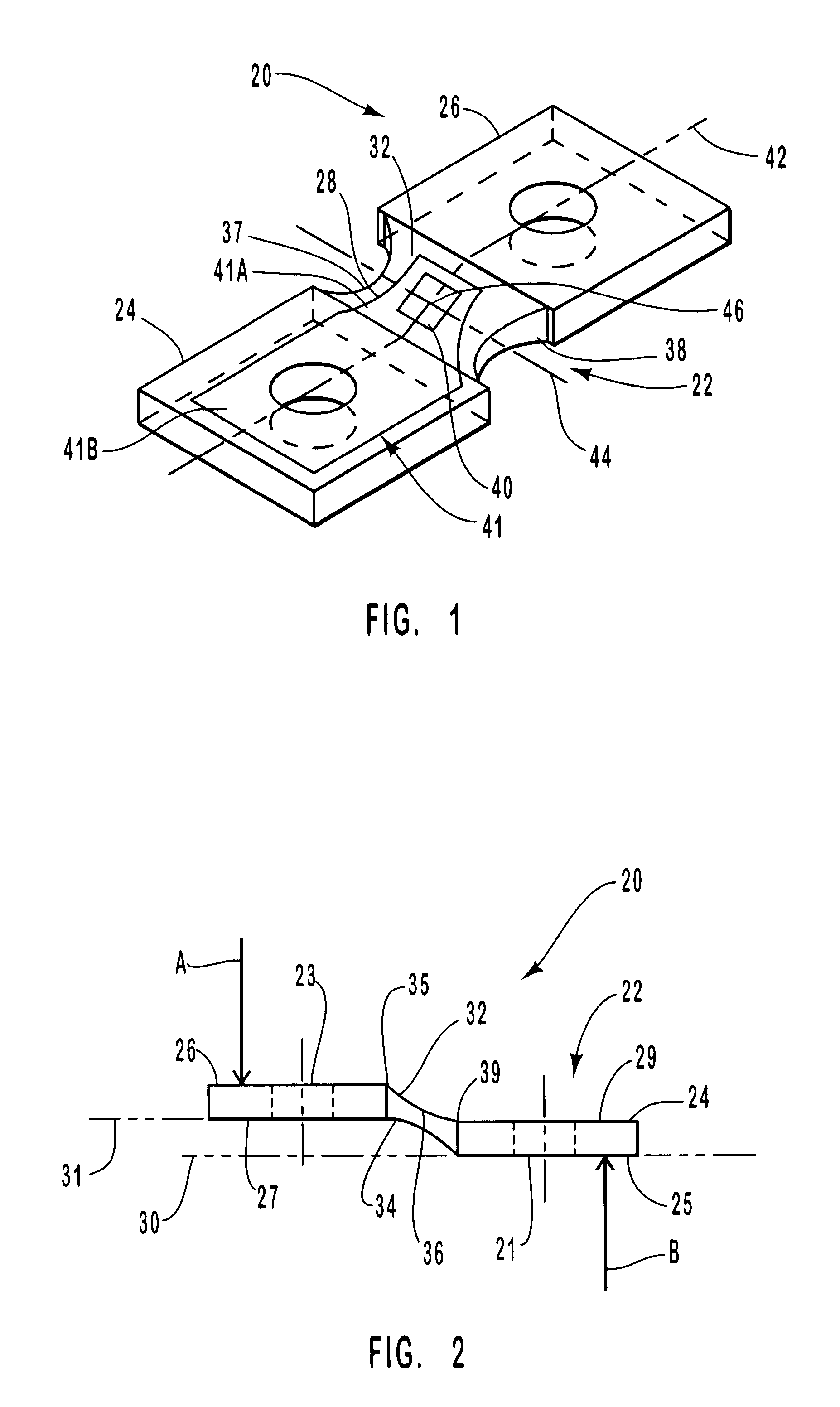

Weight measurement system, method and weight sensor

A weight measurement system for automatically calibrating weight sensors installed on a motor vehicle seat. The system performs a calibrate operation whenever a valid weight measurement window is found. A valid weight measurement window is defined by the seat being empty, an associated door being open and an associated seat buckle being unlatched. The system operates in a factory install mode to establish a reference zero set value and in a diagnostic mode to establish a temporary zero set value that reflects drift of the weight sensors. The temporary zero set value is used by a weight management program to control occupant restraint devices. The weight sensor has an integral body with two lands connected by an elastomeric beam. The elastomeric beam has a pair of opposed surfaces that define a region of minimum thickness and one or more regions of maximum thickness. A resistive strain gauge element is disposed on the region of minimum thickness. The system measures changes in the resistance of the weight sensor caused by weight of the seat.

Owner:AUTOLIV ASP INC

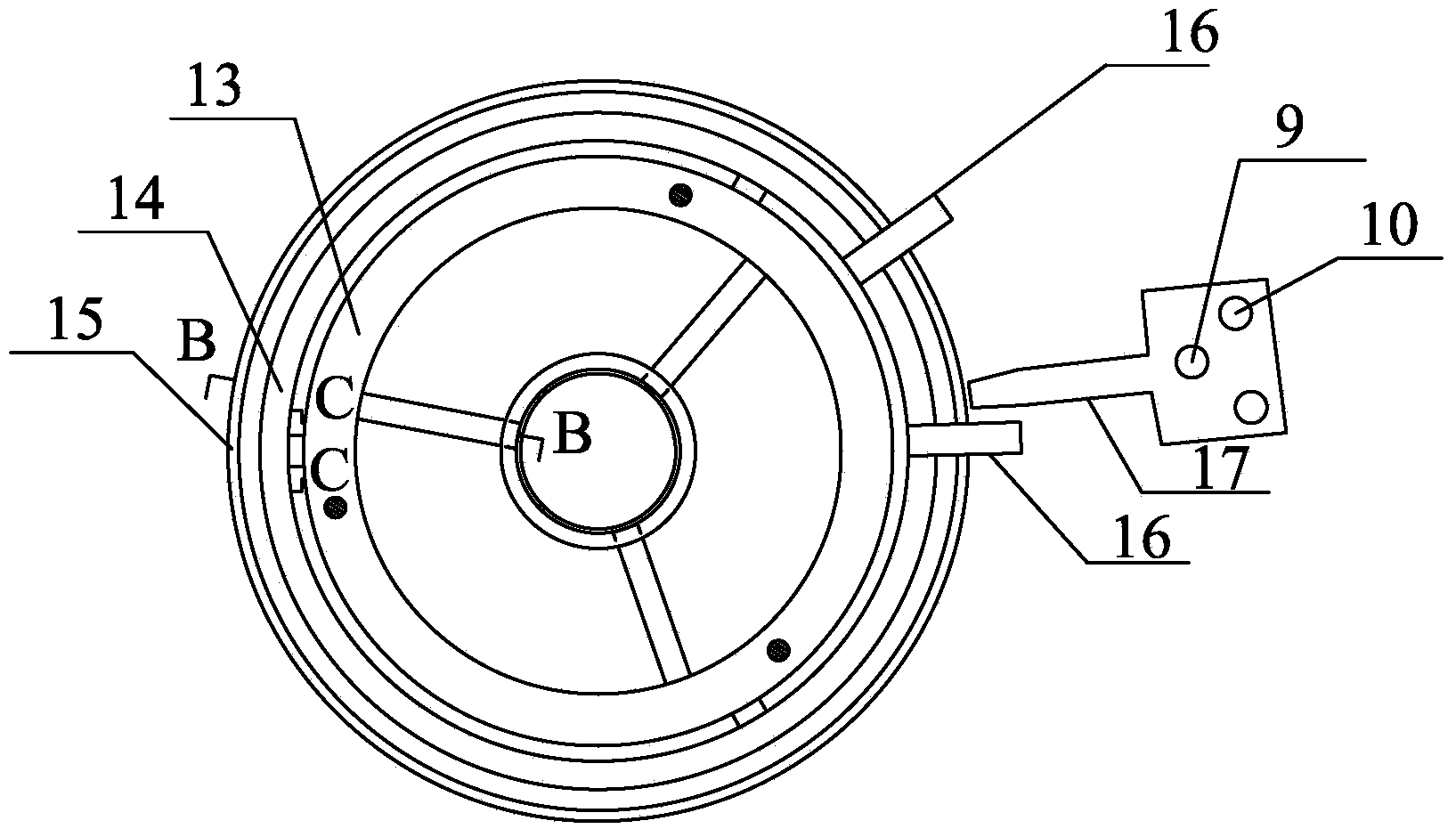

Free-combination automatic-weight adding device

ActiveCN104019938AEasy to operateAccurateWeighing apparatus testing/calibrationFluid pressure measurementEngineeringPressure detection

The invention discloses a free-combination automatic-weight adding device, which is used for automatic weight adding in the pressure detection field. The device comprises a group of cylindrical weights (6) arranged in a sleeving mode, and the upper end of each weight layer (6) is provided with a driving mechanism for driving the weight (6) to move up and down; and a weight tray (8) with a weighing or pressure detection mechanism additionally provided is arranged below the weight (6). Heights of the weights (6) are sequentially decreased from inside to outside, a supporting groove (41) is arranged in the exposed column surface of the upper end of each weight, and supporting rods, an inner ring (13), a middle ring (14) and an outer ring (15) are correspondingly arranged. The free-combination automatic-weight adding device is used in the pressure detection or weighing system, free combination and automatic weight adding of the weight adding operation can be realized, the operation is convenient, and weight adding is accurate.

Owner:DALIAN POLYTECHNIC UNIVERSITY

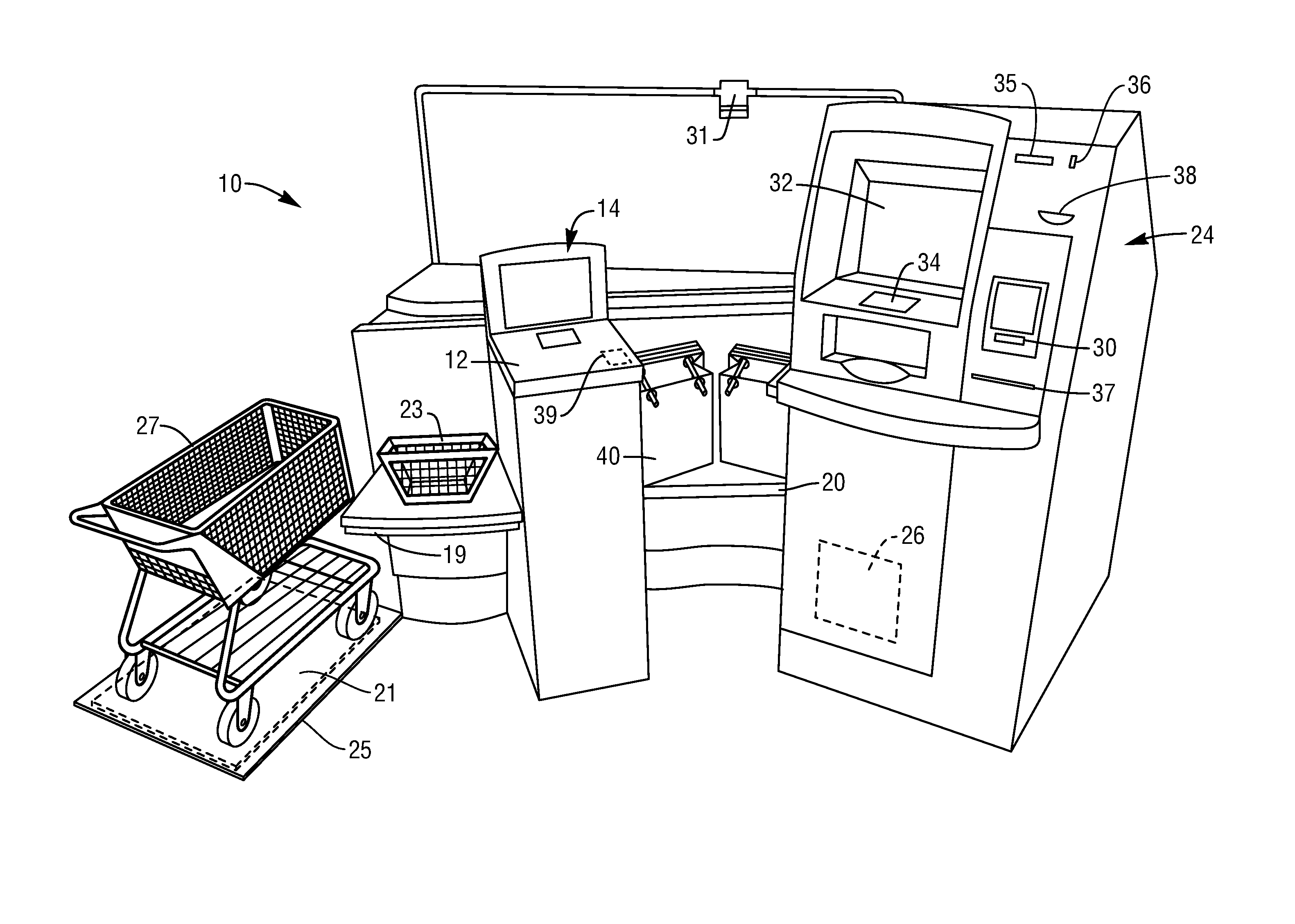

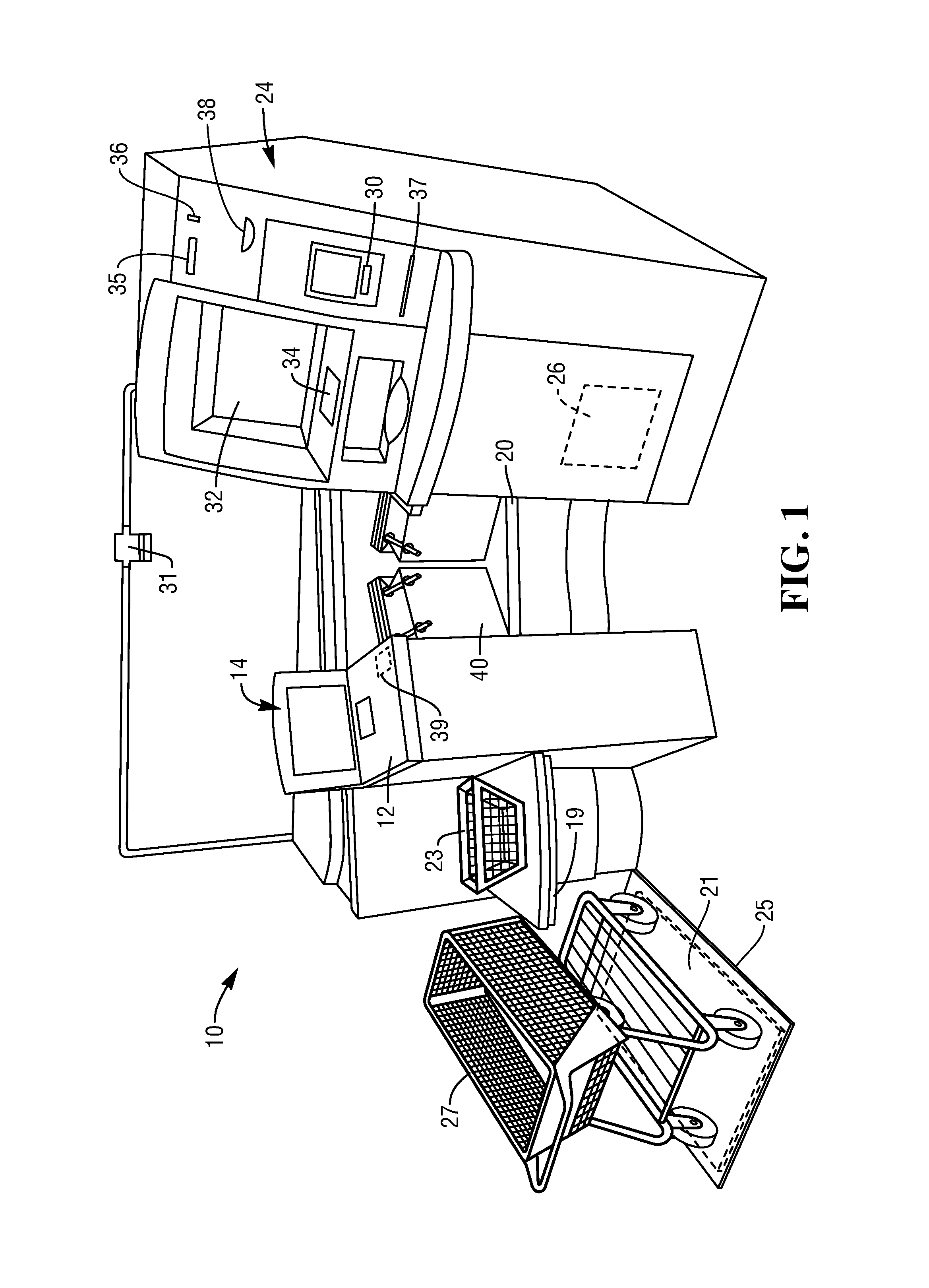

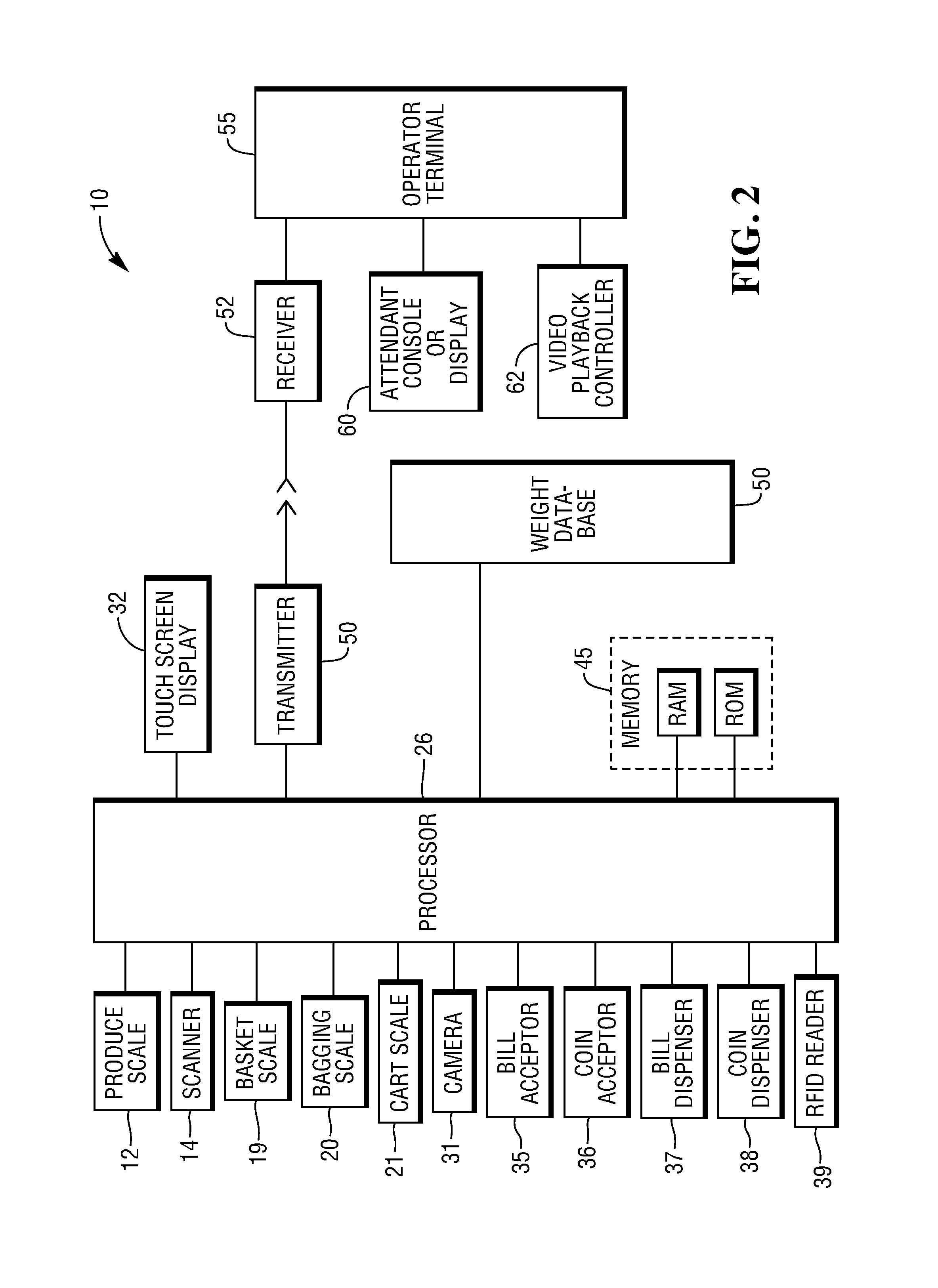

Checkout Methods and Apparatus

Owner:NCR CORP

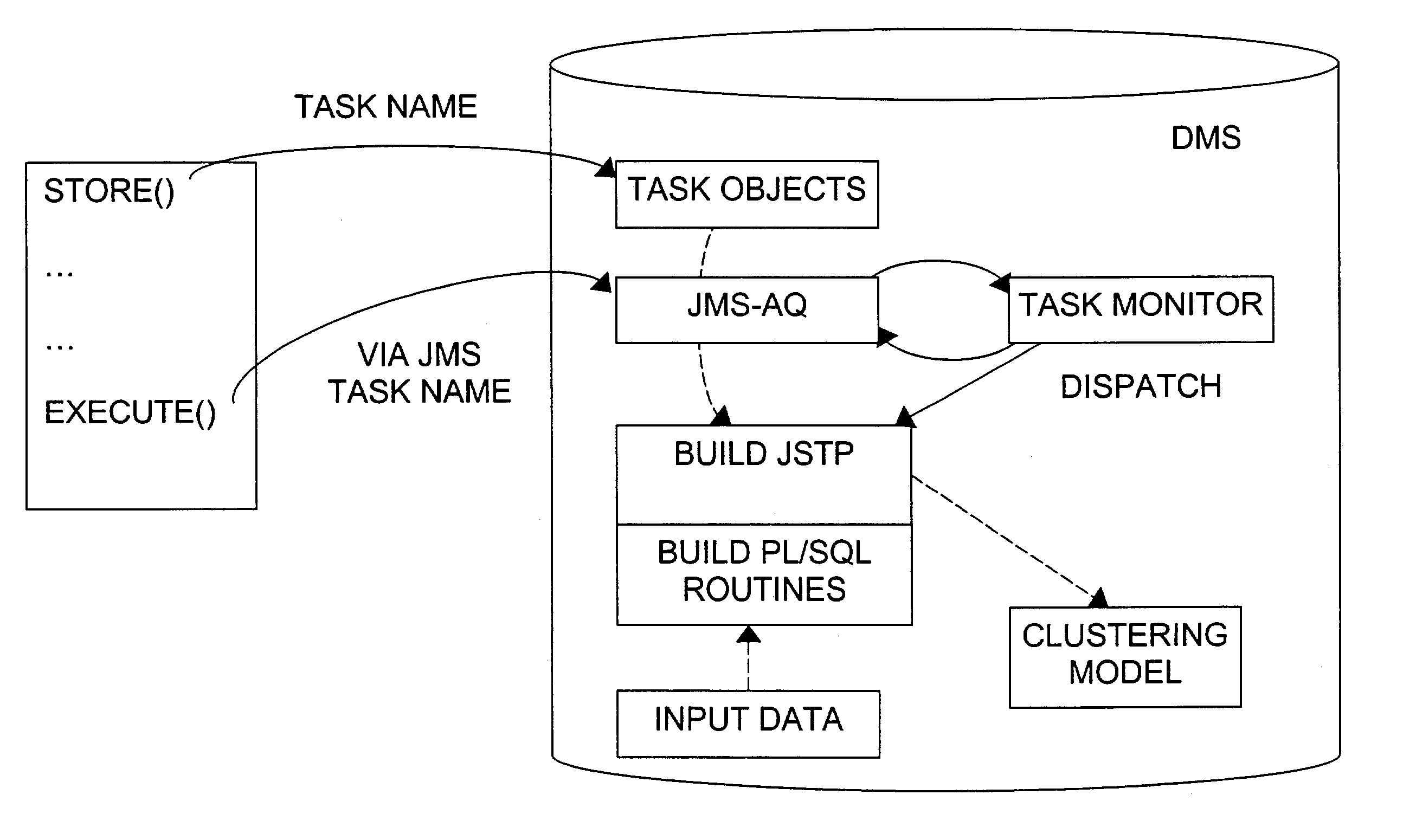

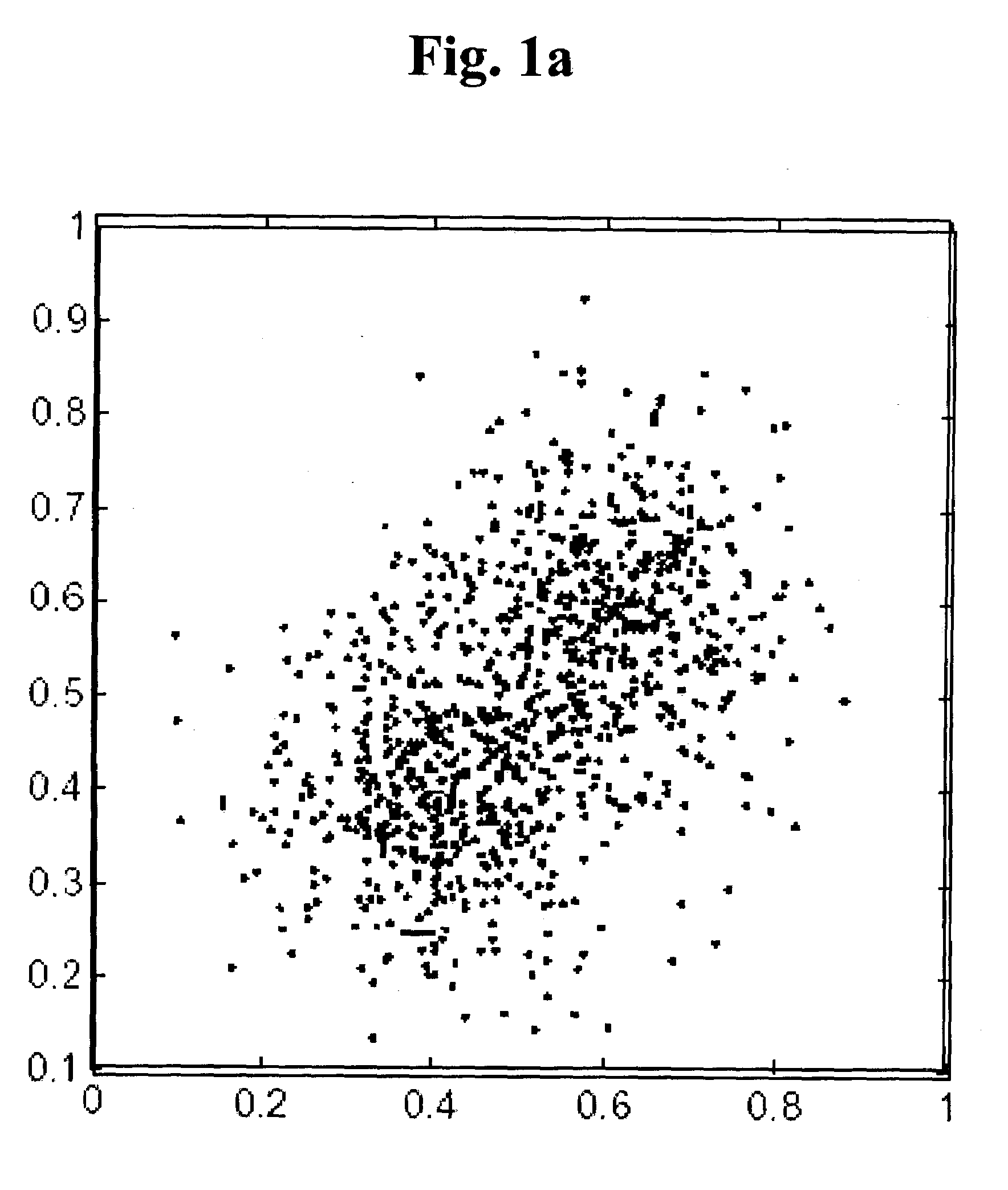

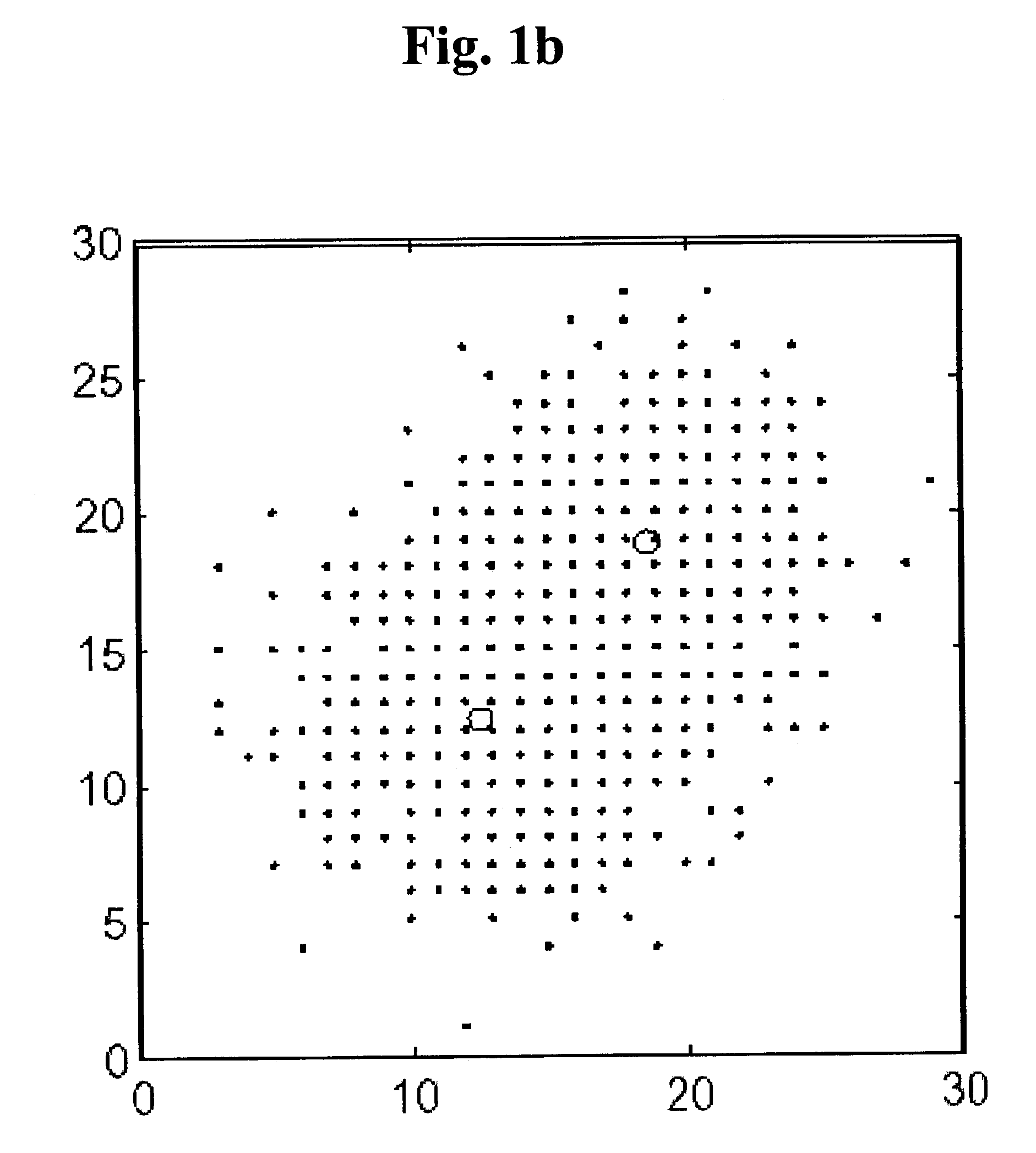

Probabilistic model generation

ActiveUS7080063B2Improve performanceEasy to integrateData processing applicationsWeighing apparatus testing/calibrationProbit modelData mining

A database management system provides the capability to perform cluster analysis and provides improved performance in model building and data mining, good integration with the various databases throughout the enterprise, and flexible specification and adjustment of the models being built, but which provides data mining functionality that is accessible to users having limited data mining expertise and which provides reductions in development times and costs for data mining projects. The database management system for in-database clustering, comprises a first data table and a second data table, each data table including a plurality of rows of data, means for building a clustering model using the first data table, means for building a probabilistic model using the clustering model, and means for applying the probabilistic model using the second data table to generate apply output data.

Owner:ORACLE INT CORP

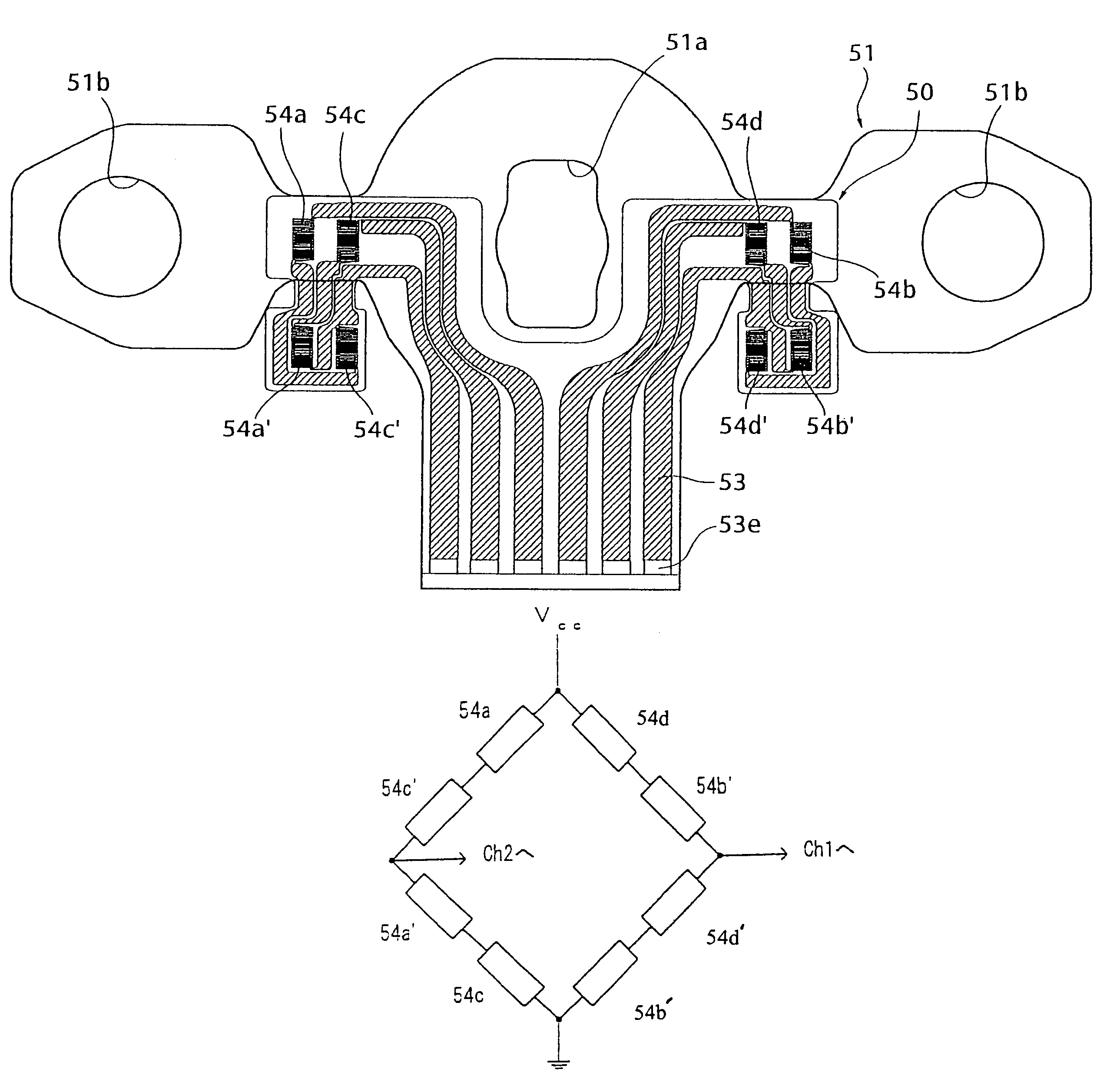

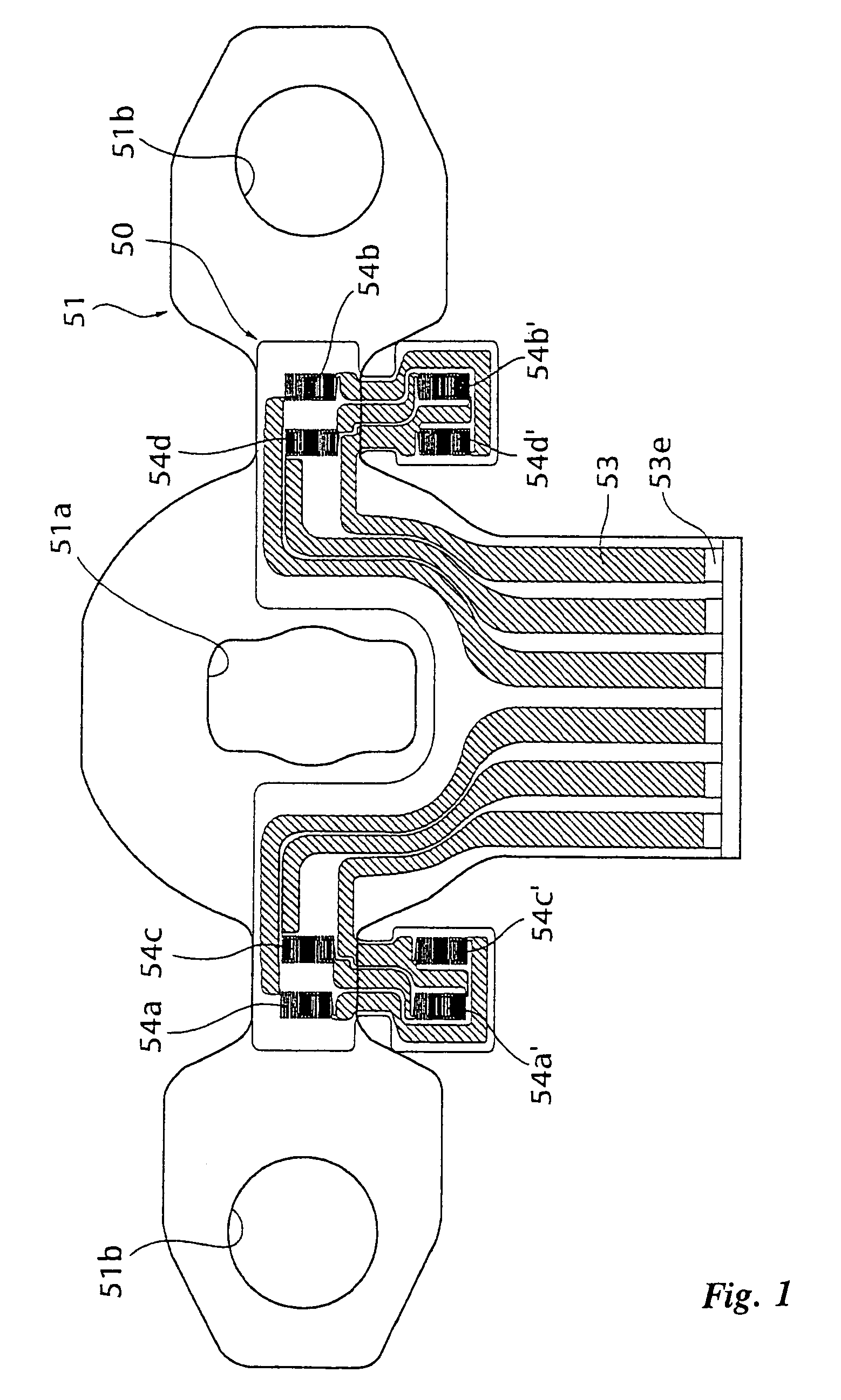

Load sensor and seat weight measuring apparatus with a plurality of strain gauges

InactiveUS7055365B2Vehicle seatsBelt control systemsElectrical resistance and conductanceMeasurement device

Owner:TAKATA CORPORATION

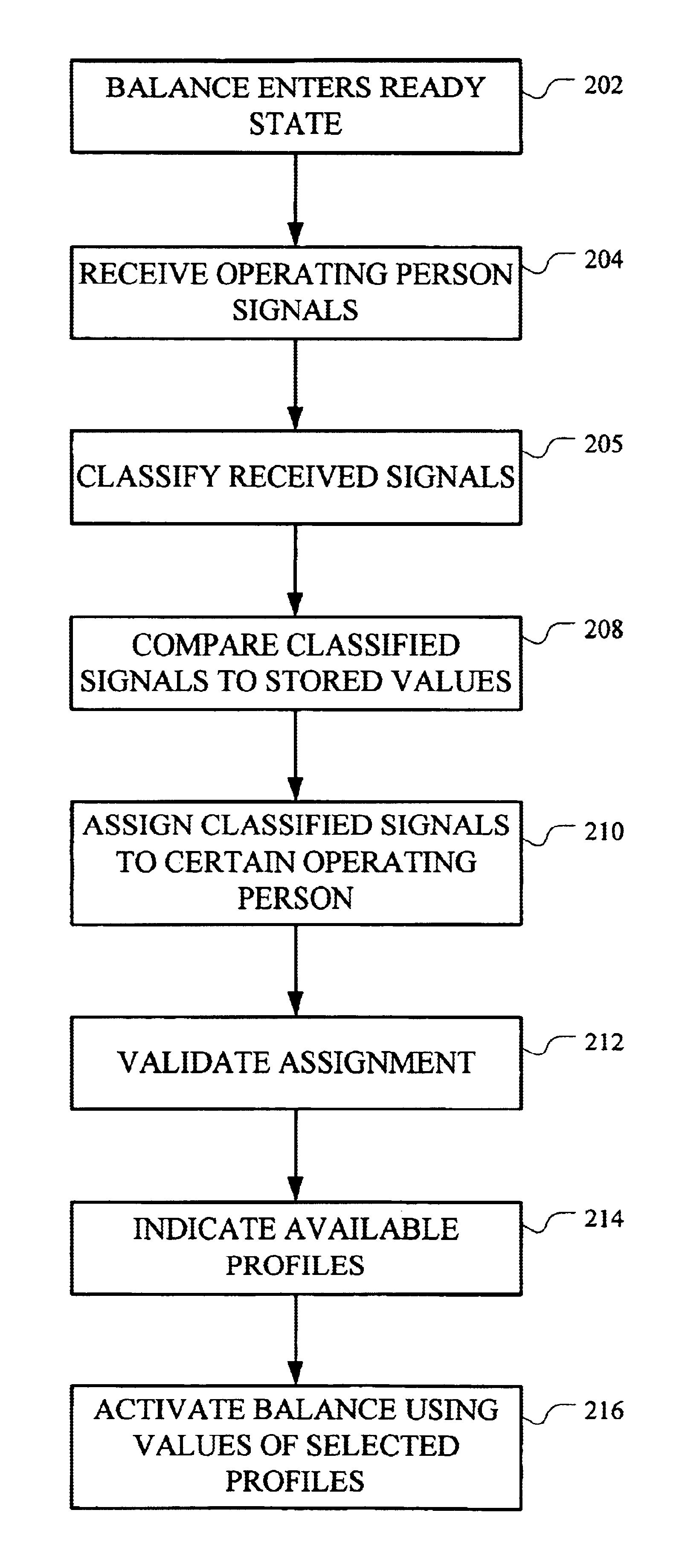

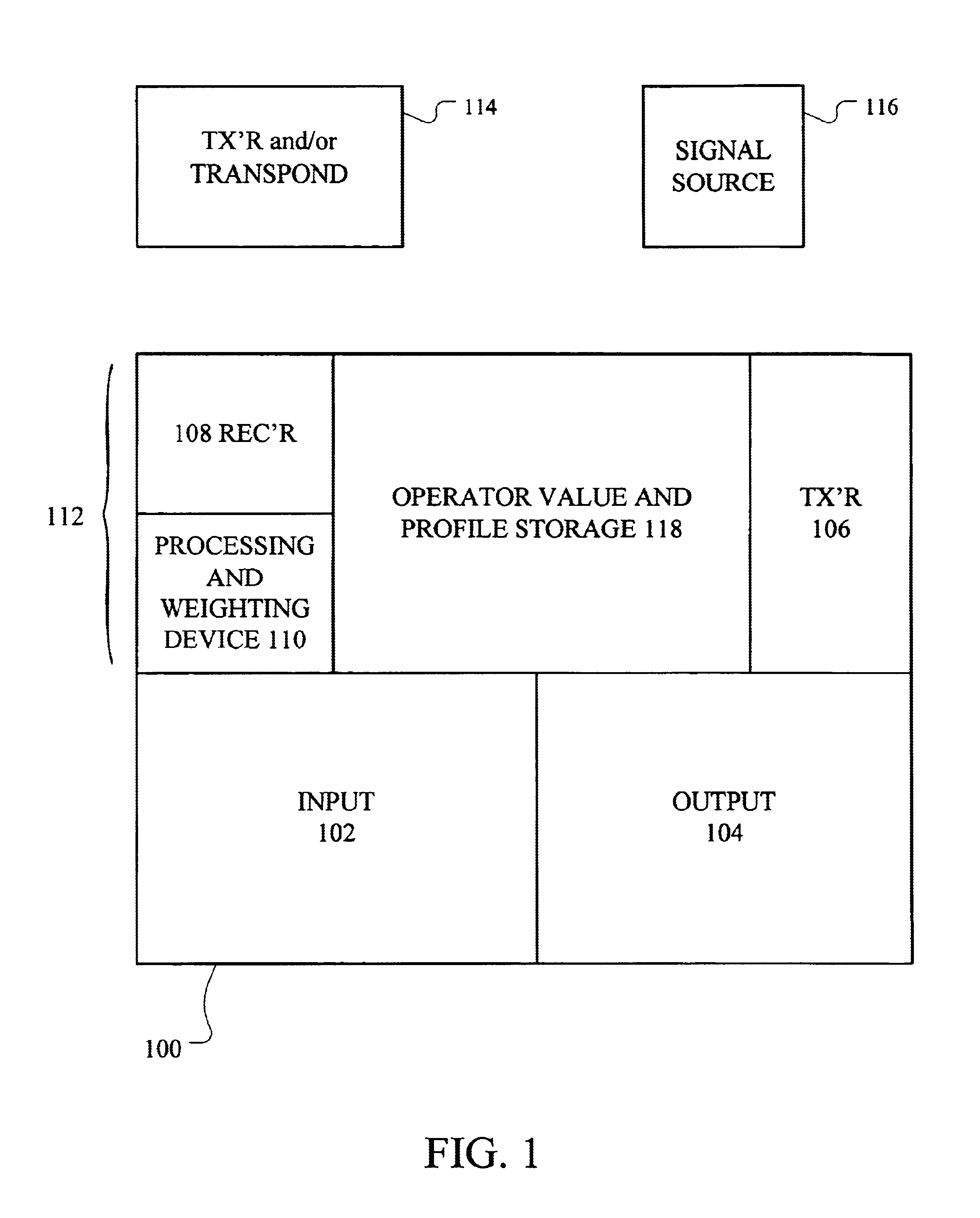

Measuring apparatus with user profile

InactiveUS6844506B2Easy to analyzeEasy to identifyElectric signal transmission systemsDigital data processing detailsPattern recognitionMeasurement device

Owner:METTLER TOLEDO GMBH

Popular searches

Weighing apparatus for materials with special property/form Gauges Special purpose weighing apparatus Material analysis Electrical measurements Testing/calibration of speed/acceleration/shock measurement devices Weighing apparatus with automatic feed/discharge Torque measurement Work measurement Sensors

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com