Patents

Literature

1759results about How to "Promote escape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

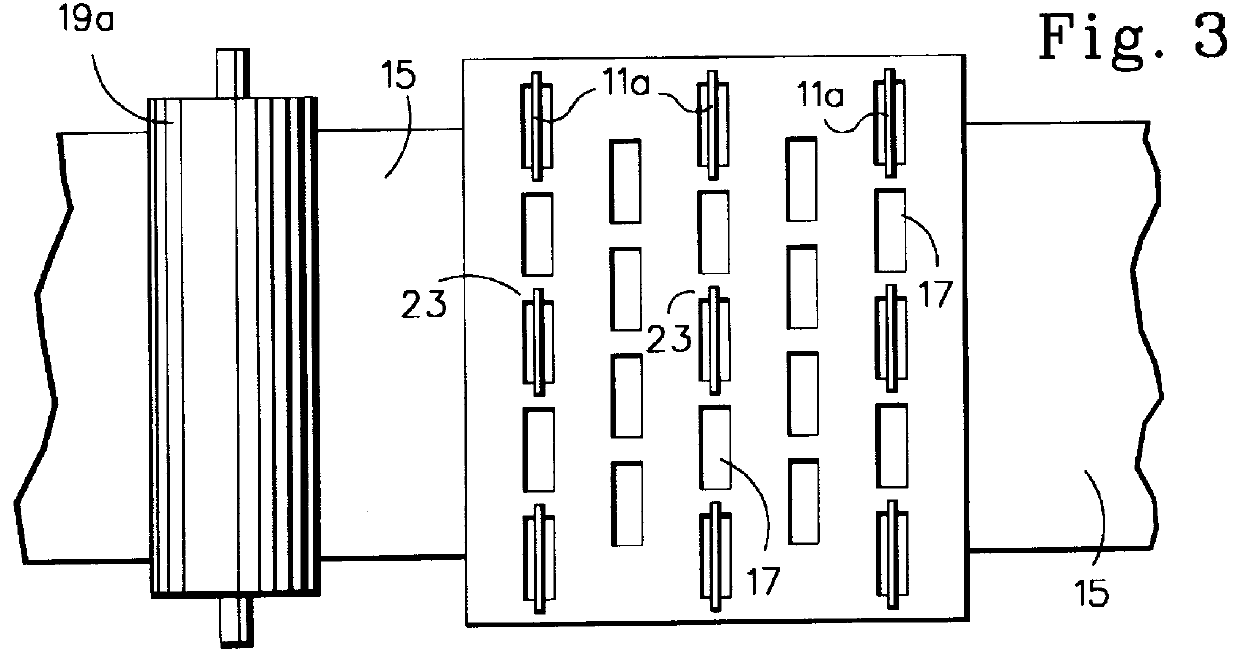

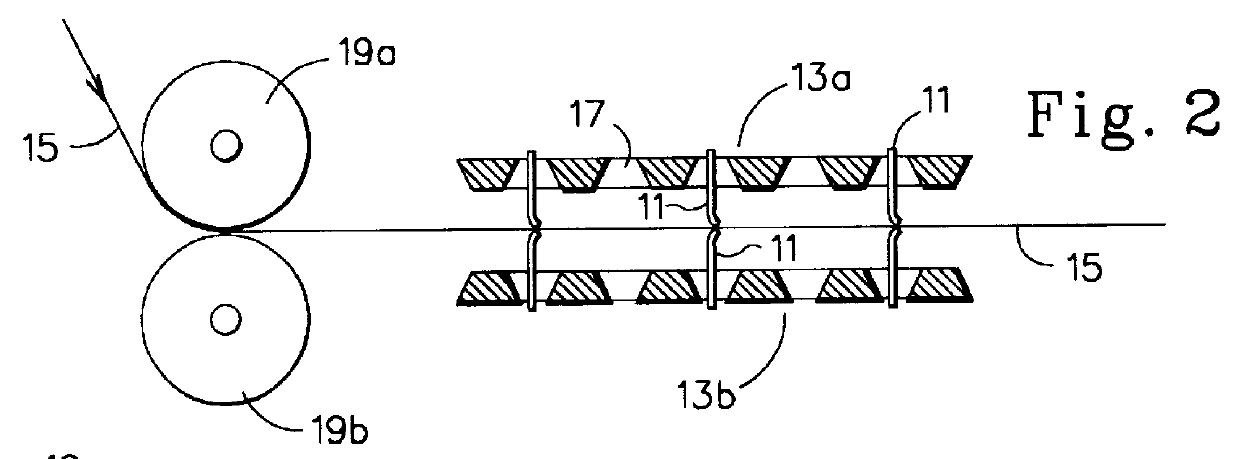

Method and apparatus for electrochemical processing

InactiveUS6149781AEffective expansionPreventing gradual depletionElectrolysis componentsDielectricAnodizing

A continuous strip is electrochemically processed in an electrolytic processing bath using either a thin flexible or resilient dielectric wiping blade or an open web, plastic mesh to wipe bubbles of gas from the surface, sever dendritic material, if such is present, and to remove a surface layer of partially depleted electrolytic solution in the form of a barrier or depletion layer including a heat zone, replacing with fresh cooler solution and to stabilize strip portions extending between support rolls. The resilient dielectric wiper blade is preferably used with perforated anodes which allow fresh electrolytic solution to flow into the space between the anodes and the strip surface after being expelled by passage of the strip past the wiping blade. It may also be used with electrode baskets in electroplating, however. The open web, plastic mesh wiper is particularly effective as a separator to provide the best spacing between the strip and the electrodes to prevent arcing and also prevents any filter cloth used over the electrodes in electroplating from catching upon the strip. The resilient wiper blade and open web, plastic mesh are preferably used in combination, but may also be used separately in electroplating, anodizing or electrolytic cleaning.

Owner:ELECTROPLATING TECH

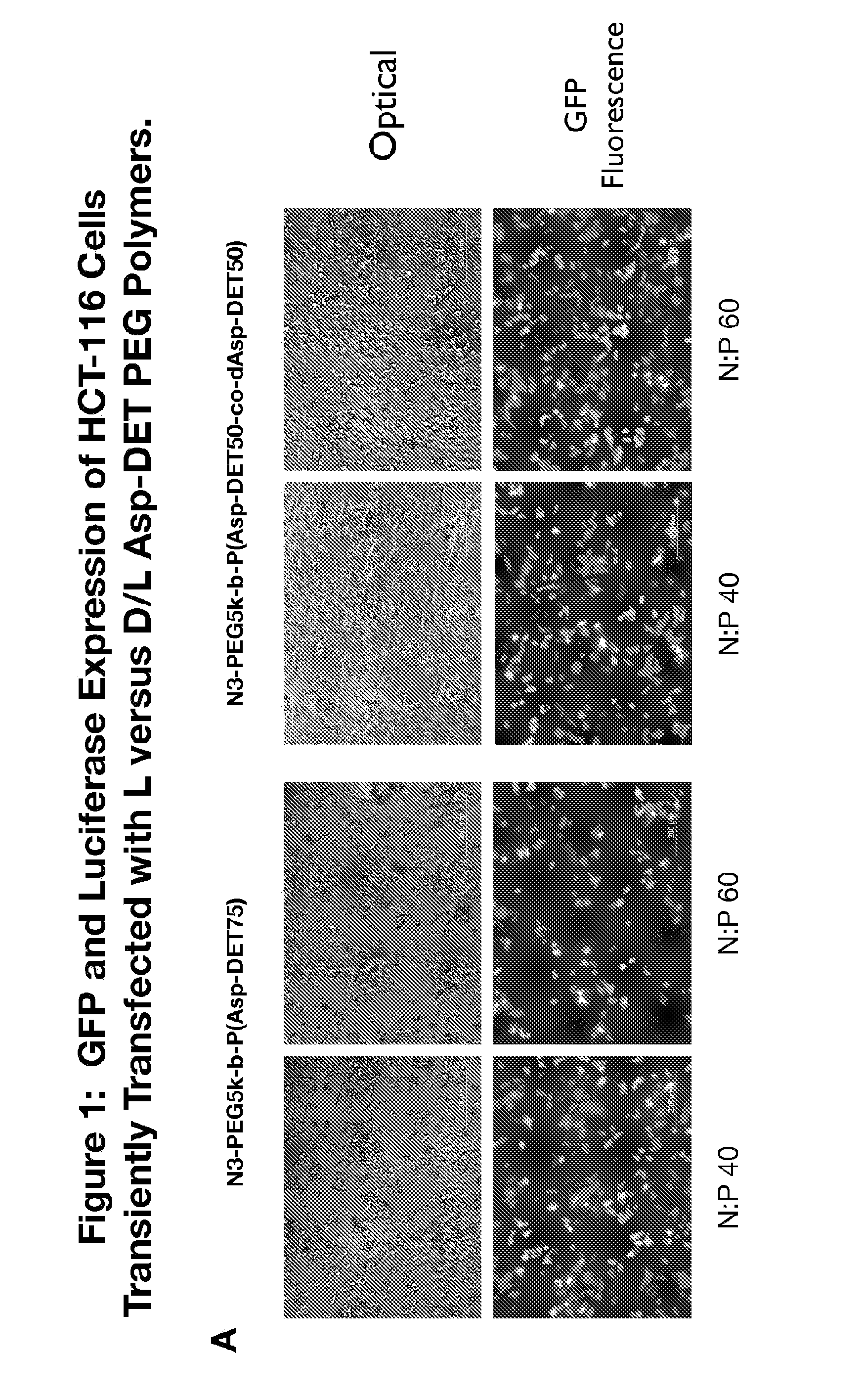

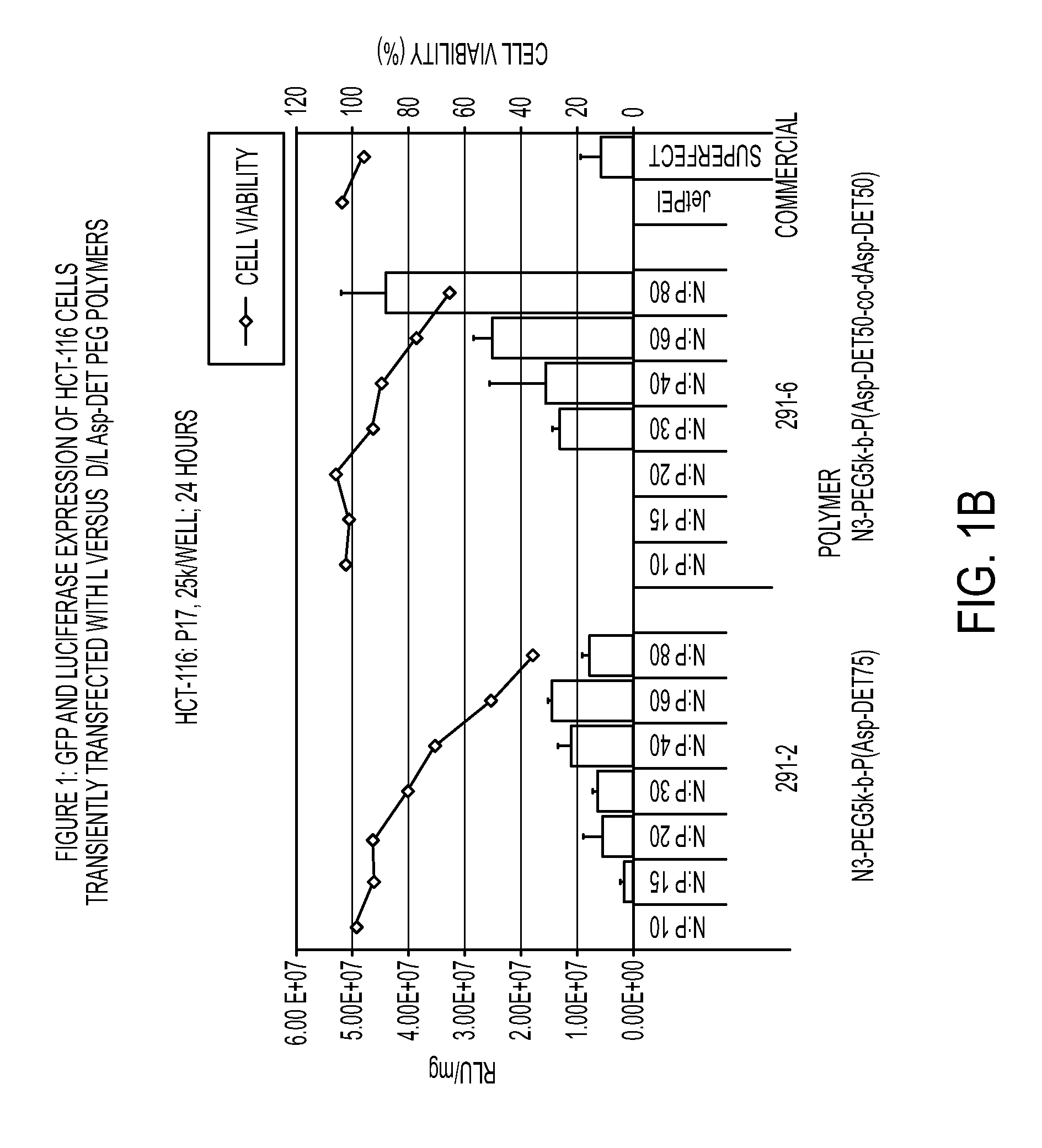

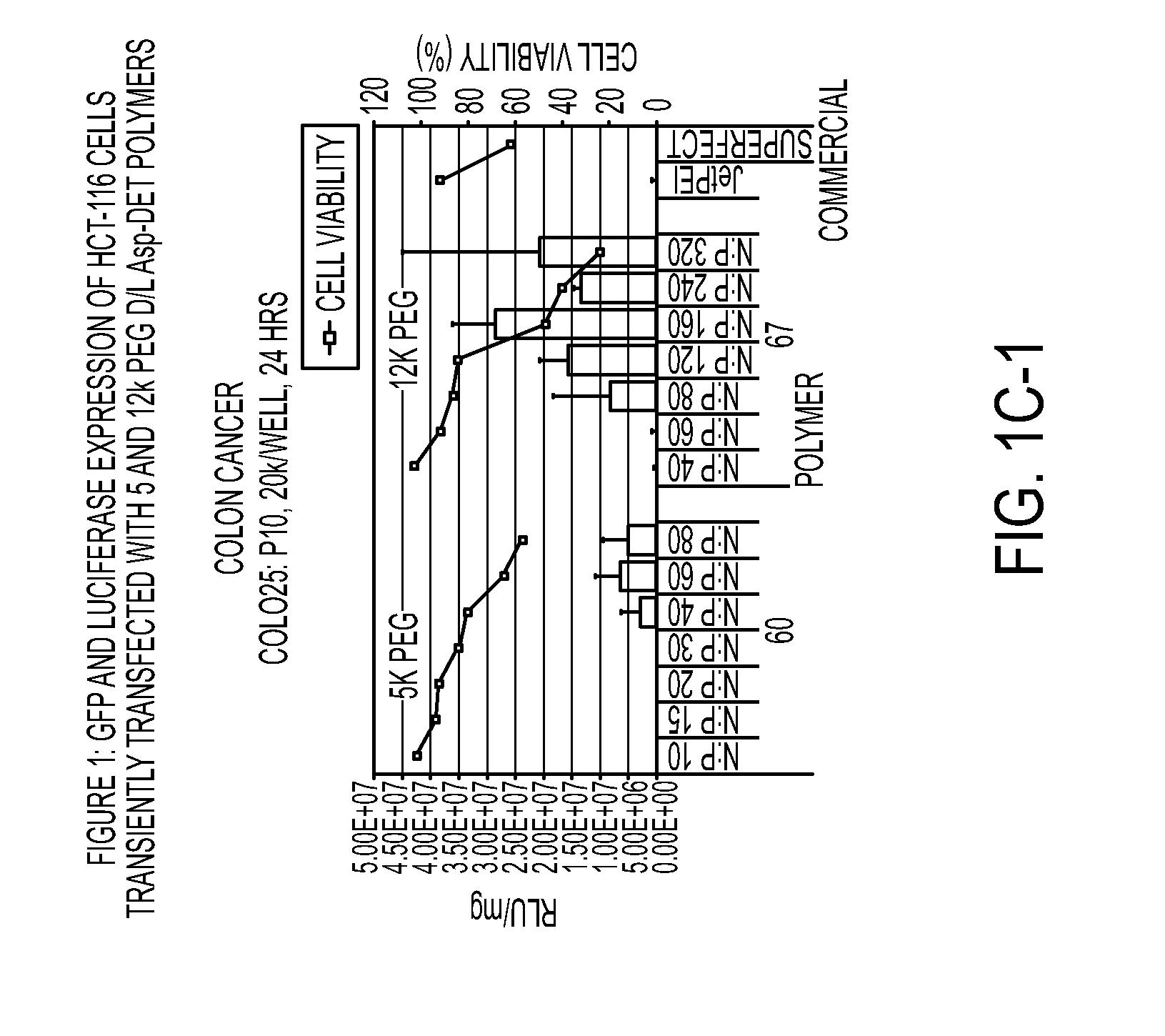

Polymeric micelles for polynucleotide encapsulation

InactiveUS8287910B2Enhance endolysosomal escapePrevent degradationPowder deliveryPharmaceutical non-active ingredientsPolymer sciencePolynucleotide

The present invention provides micelles having a polynucleotide encapsulated therein, the micelle comprising copolymers comprising hydrophobic moieties in a cationic complexing block. The invention further provides methods of preparing and using said micelles, and compositions thereof.

Owner:INTEZYNE TECH INC

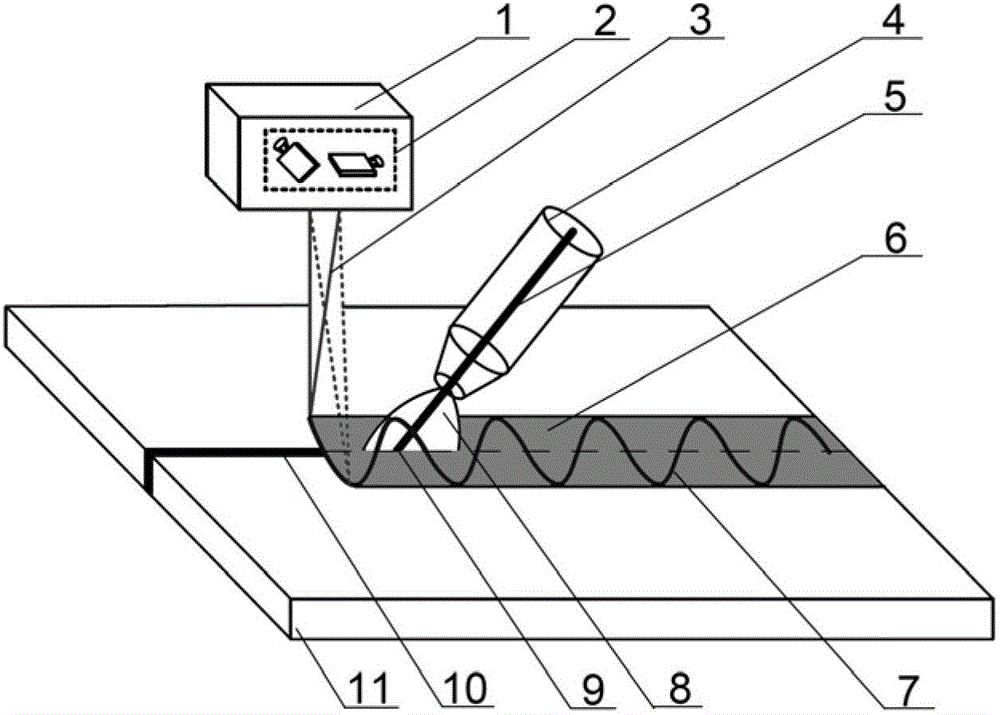

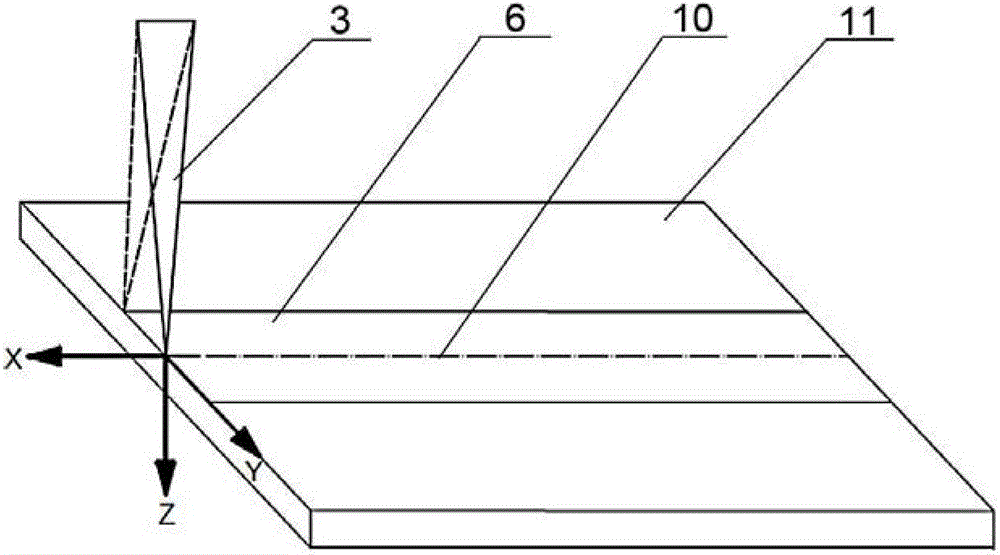

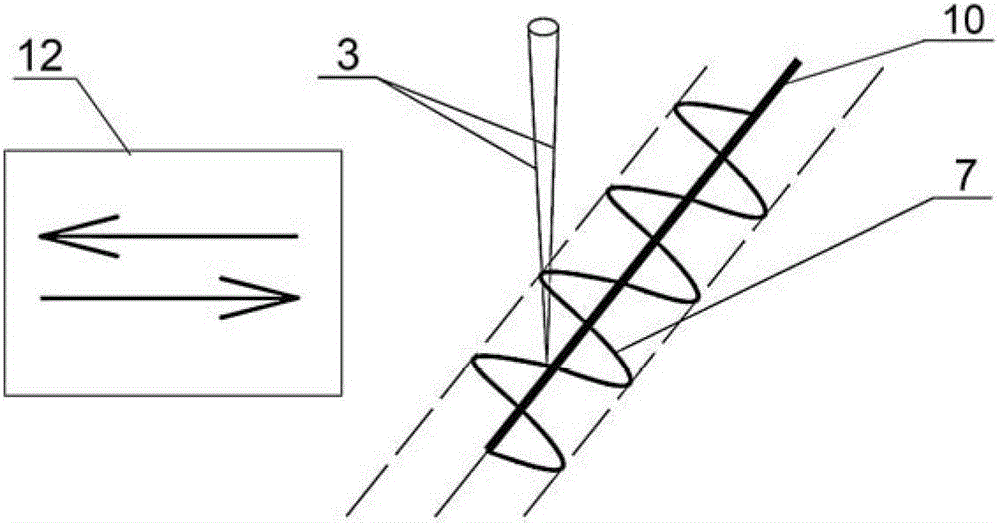

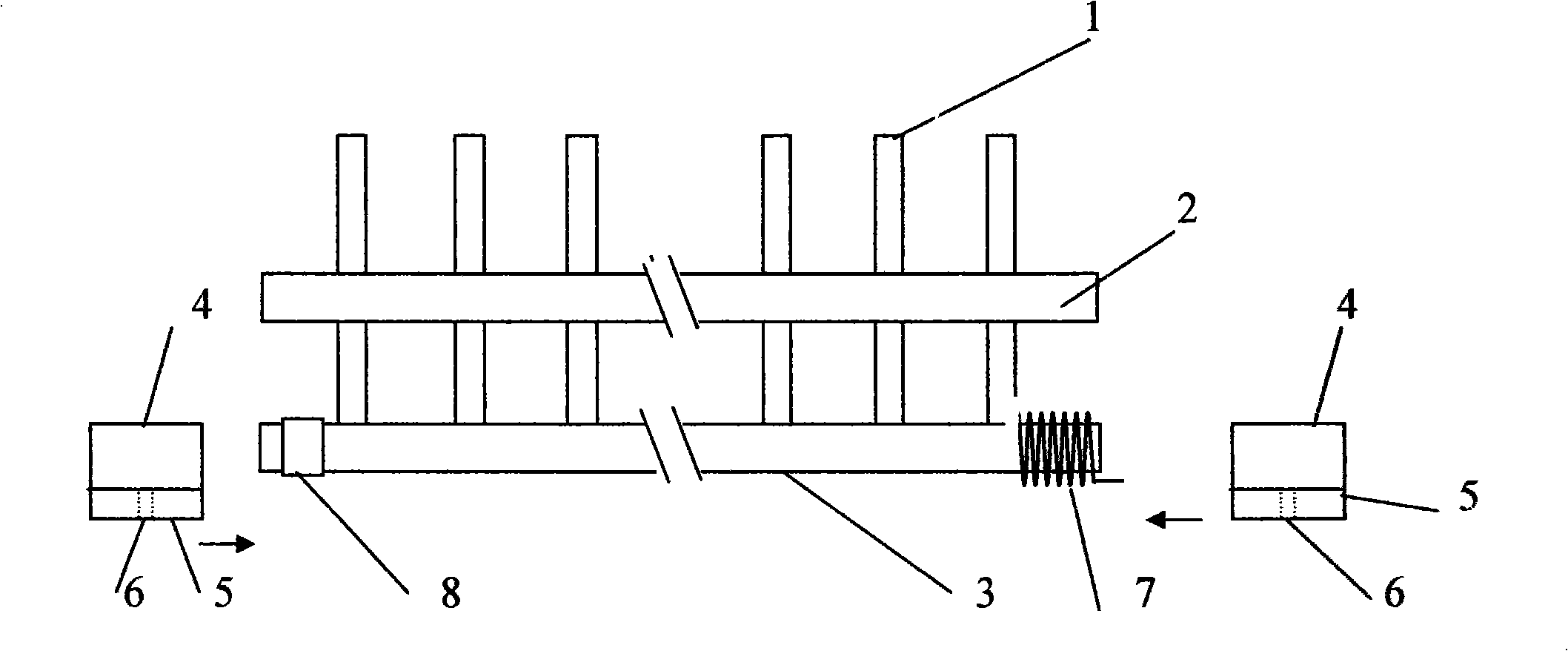

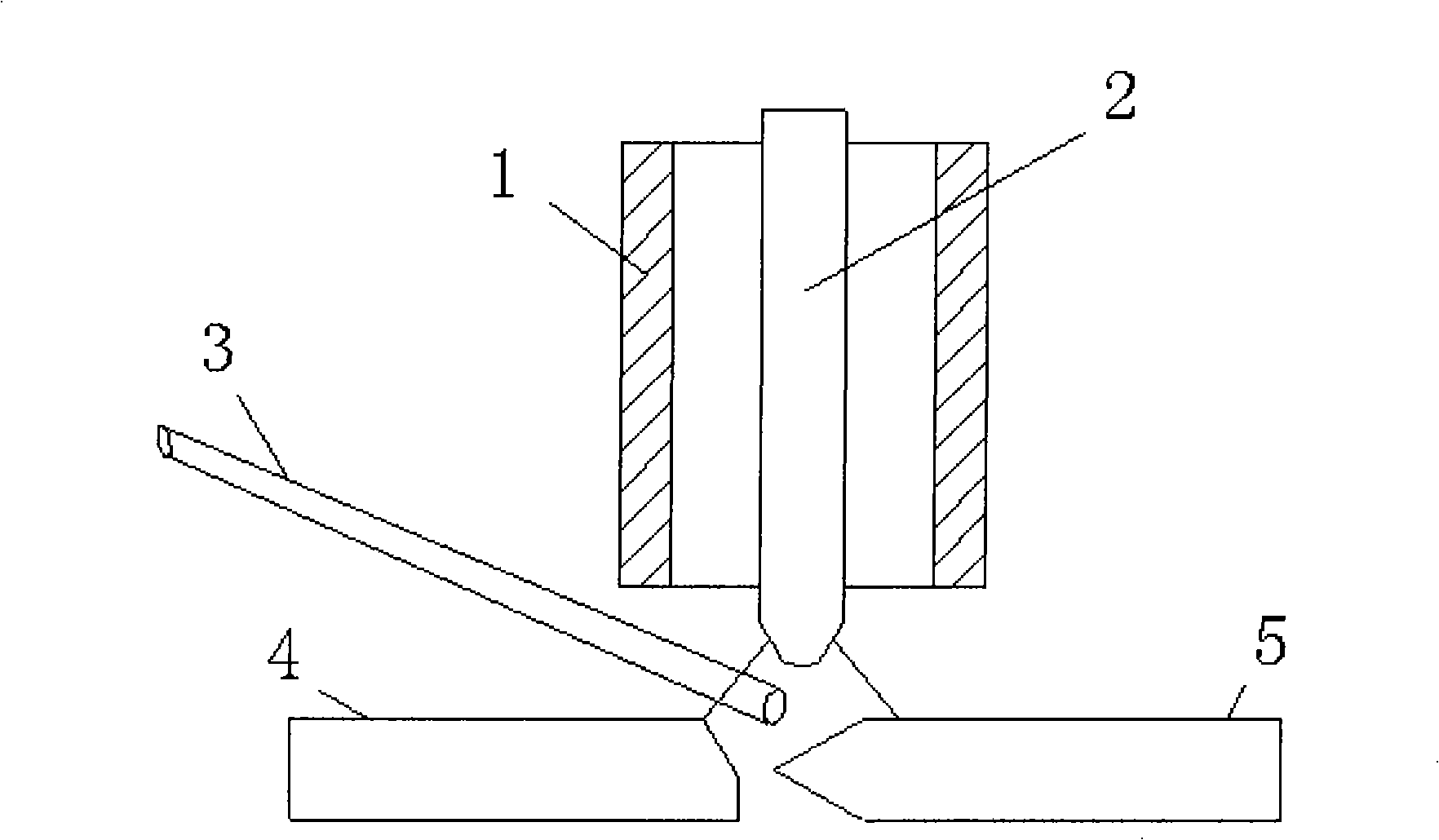

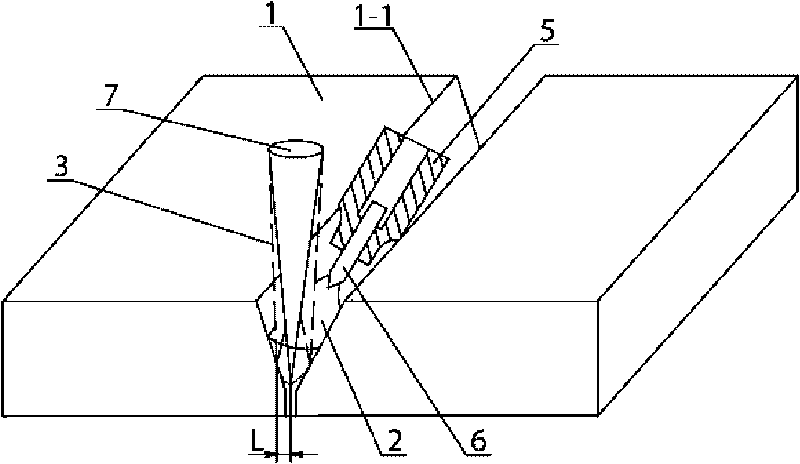

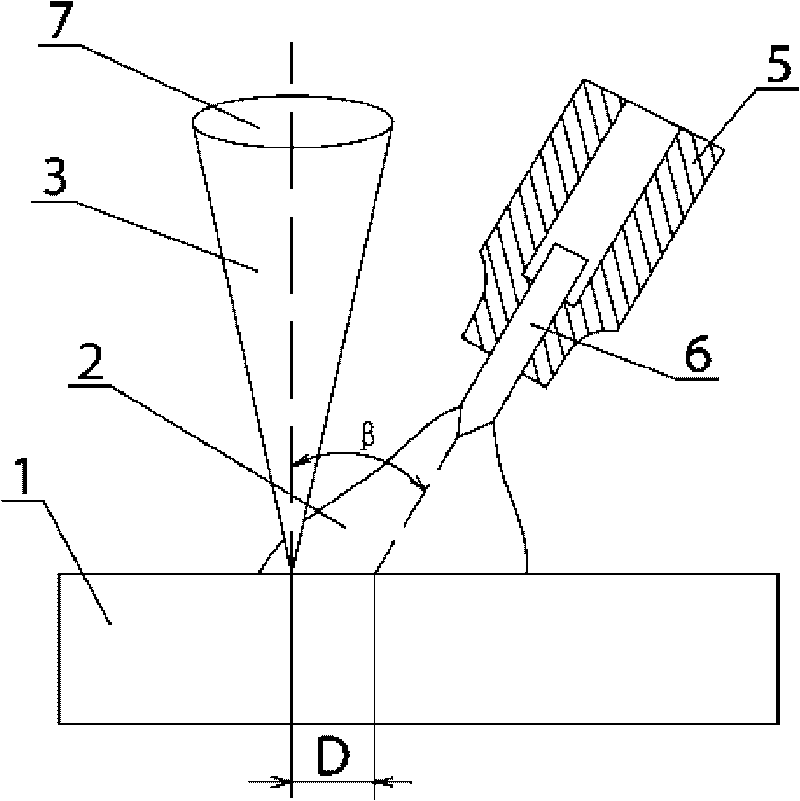

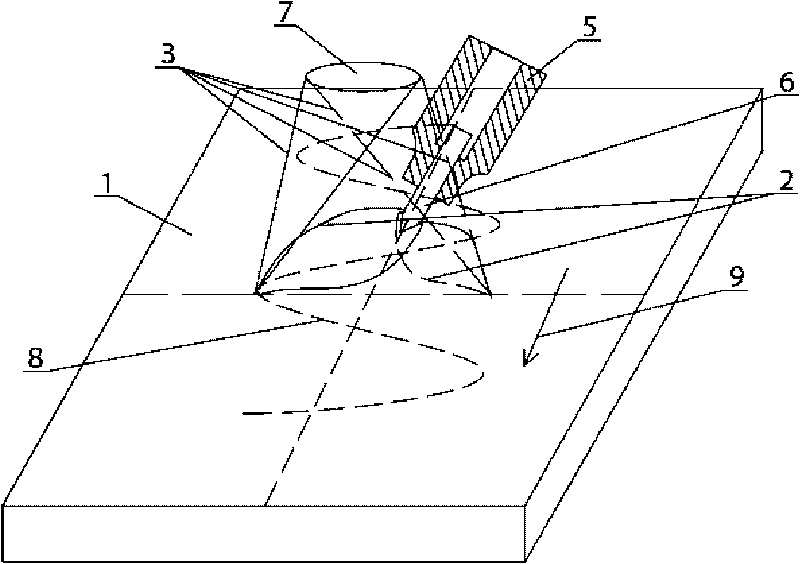

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

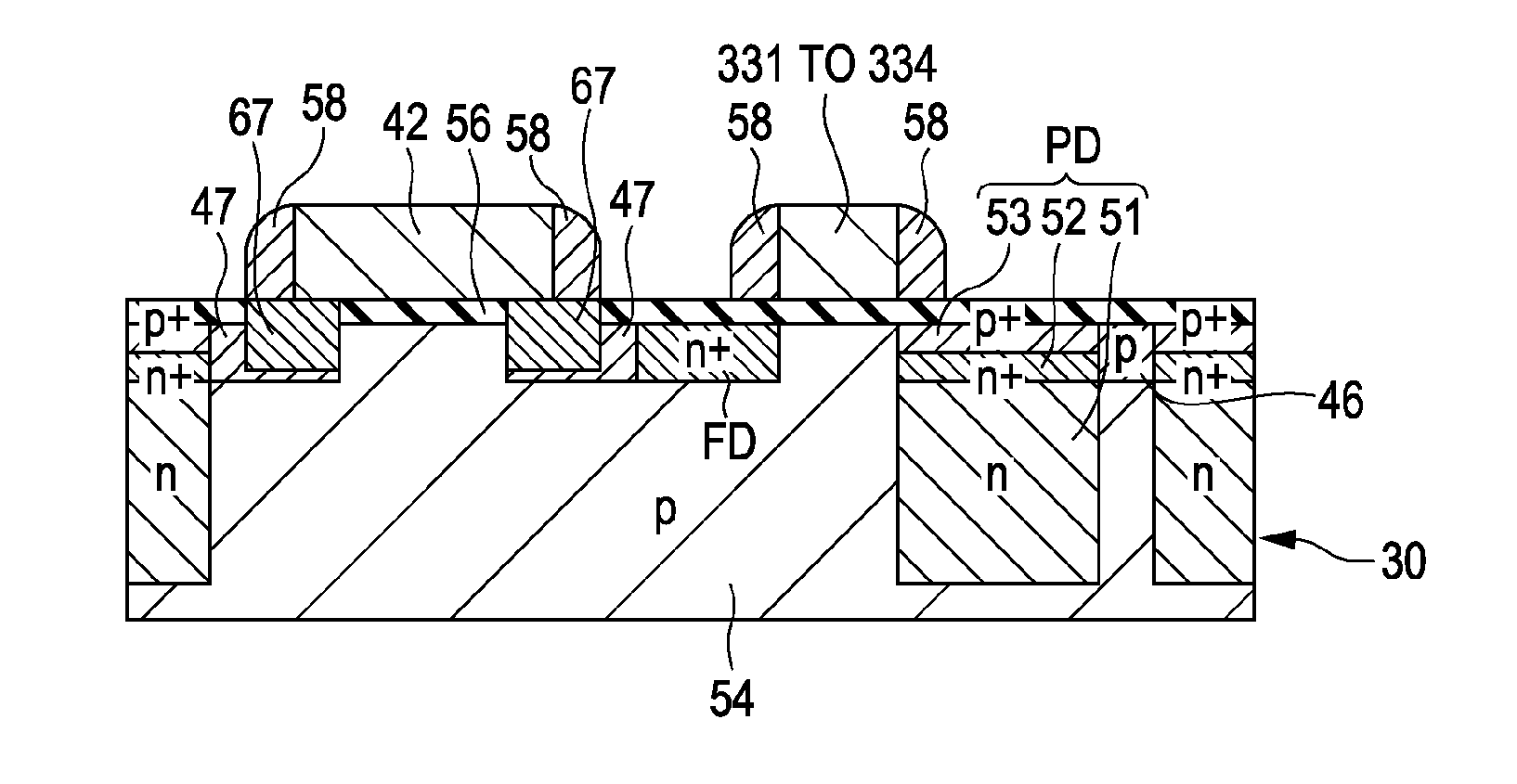

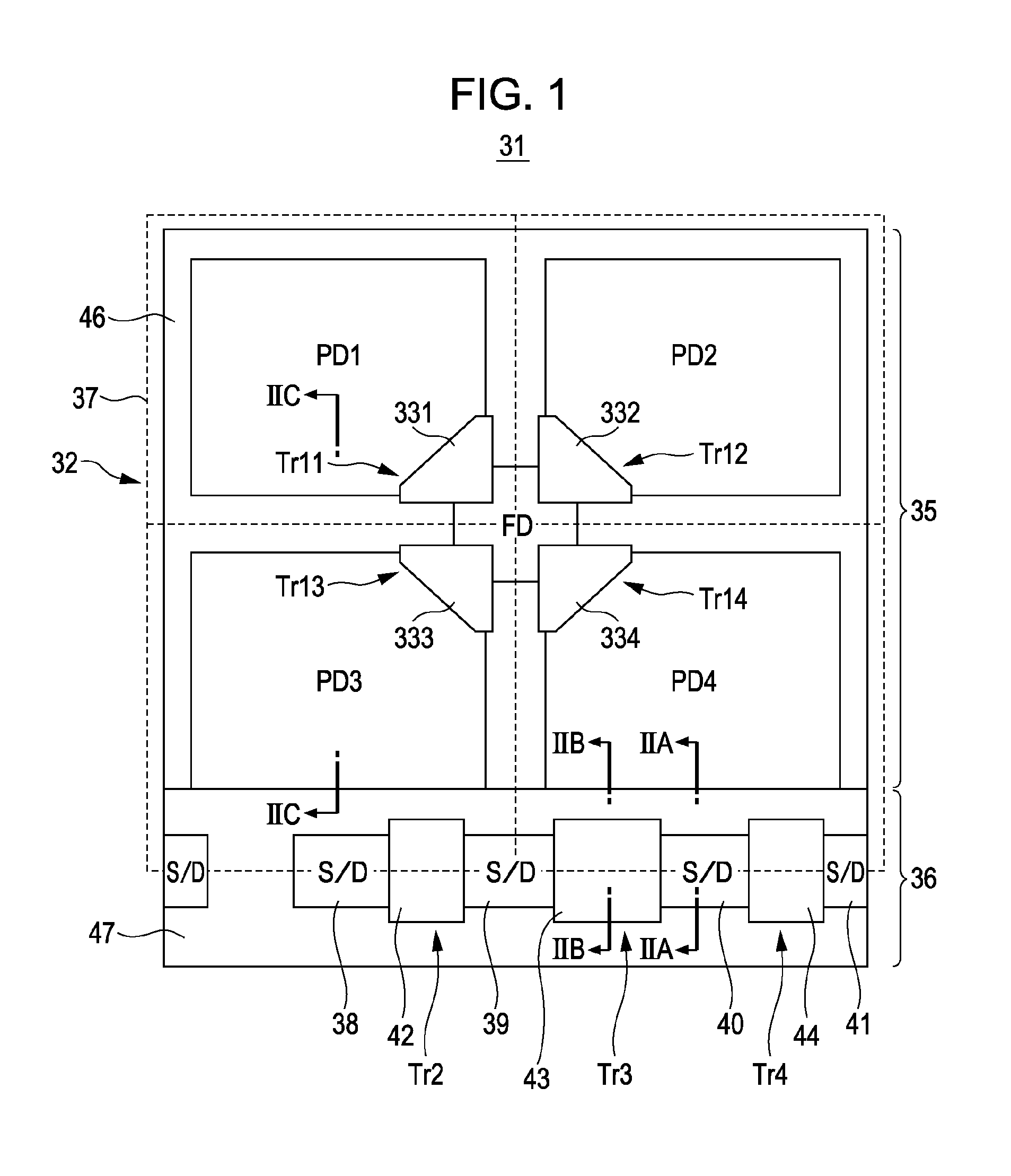

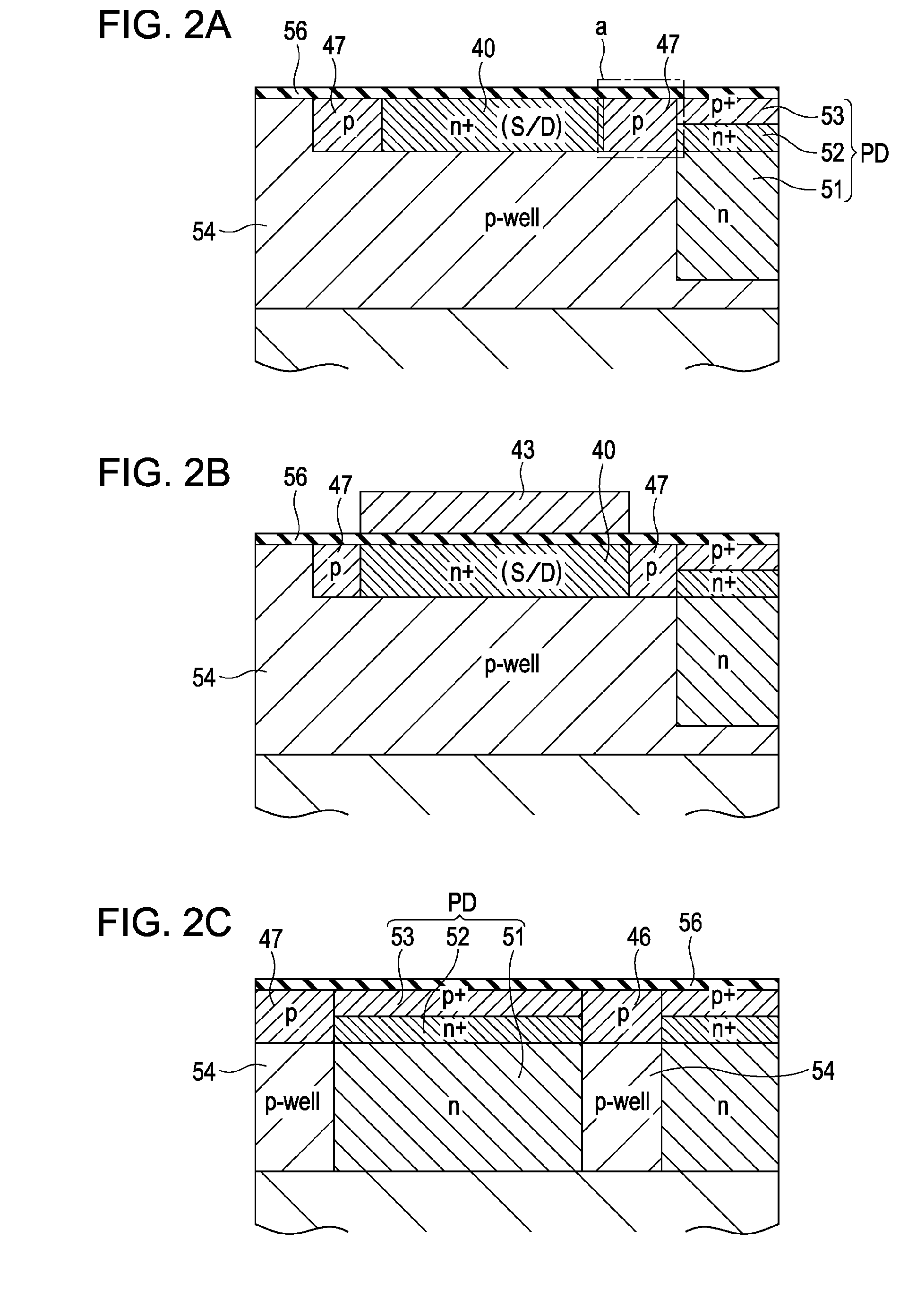

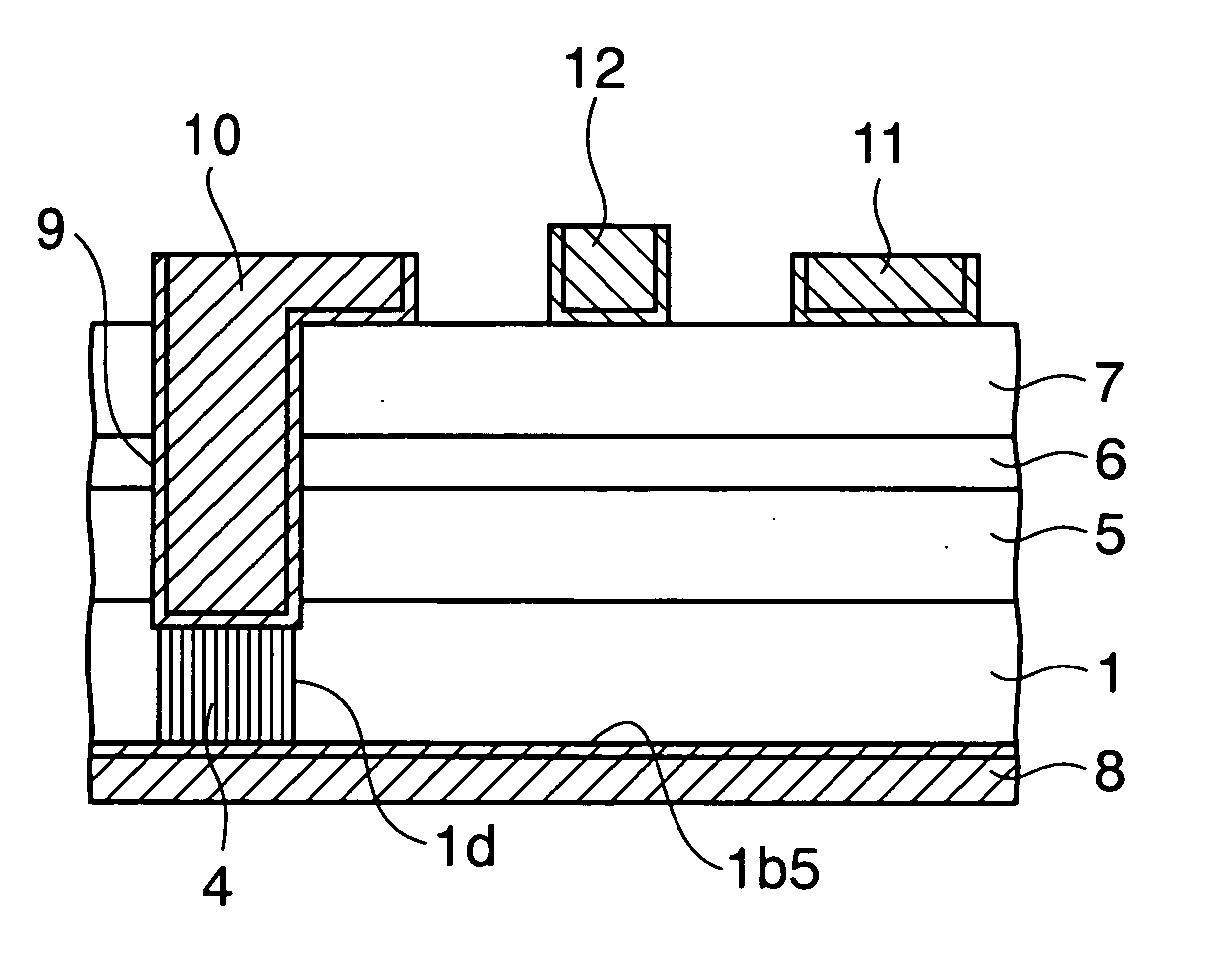

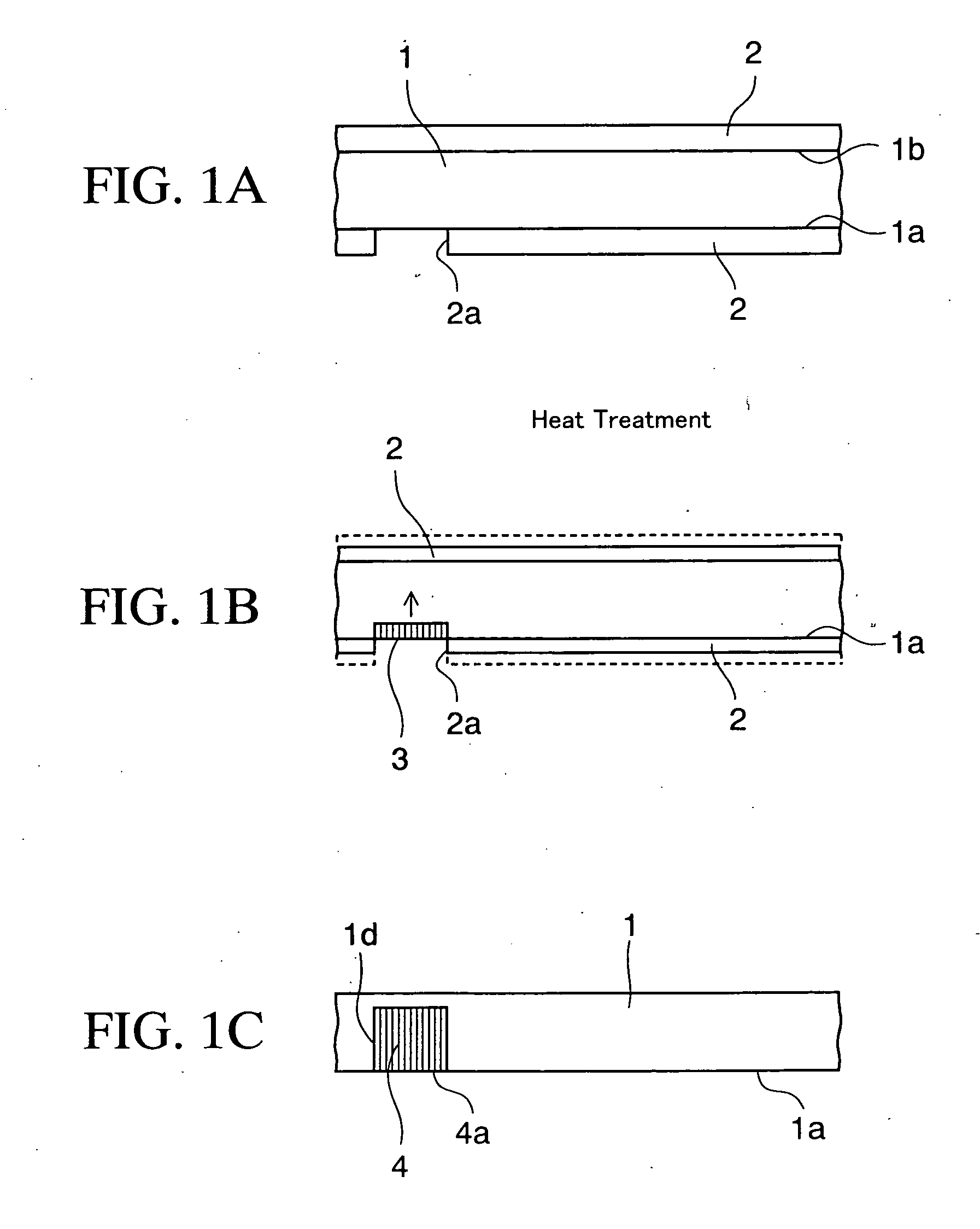

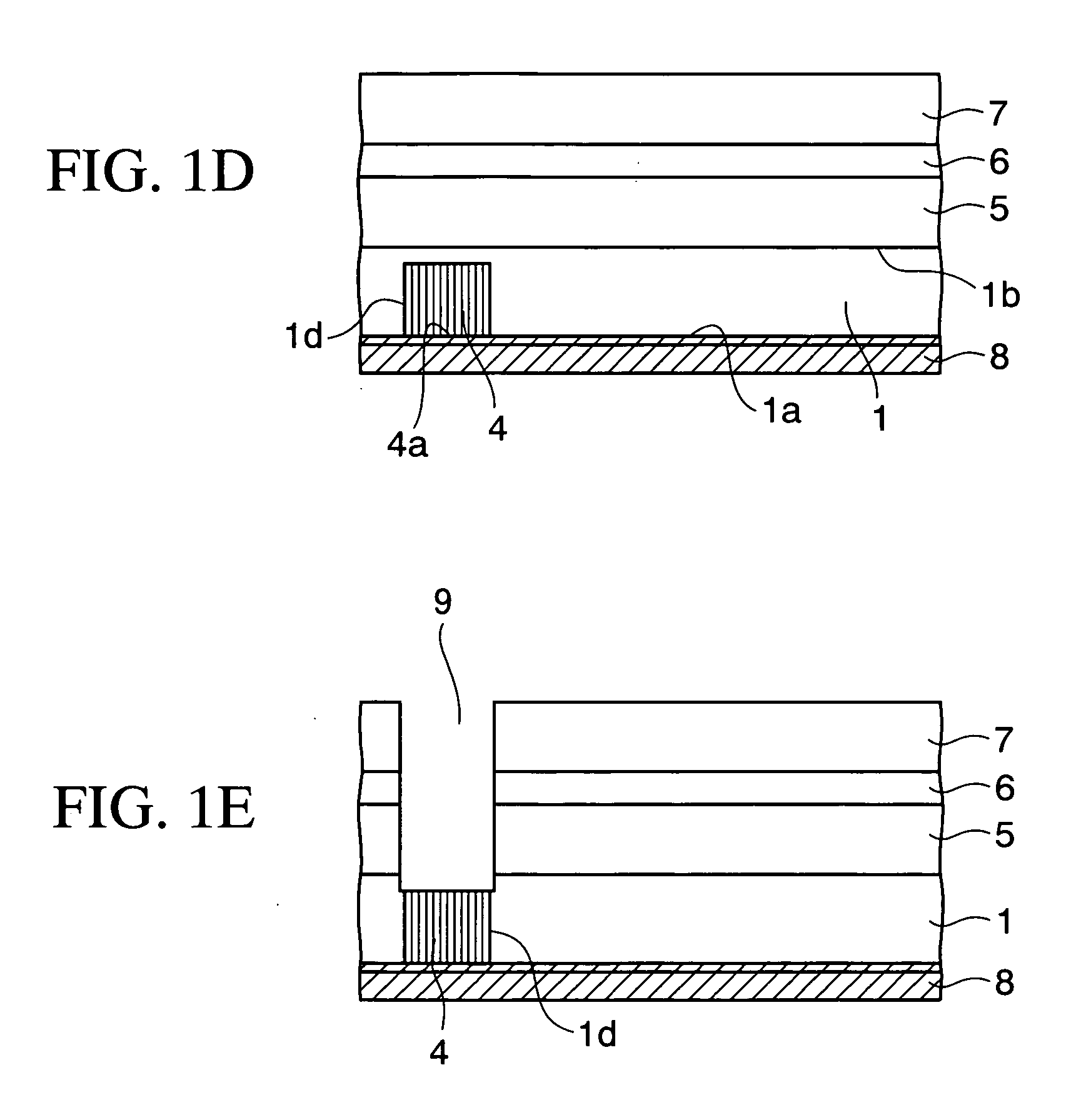

Solid-state imaging device, method of manufacturing the same, and electronic apparatus

ActiveUS20110127408A1Promote escapeReduce the effective areaTransistorSolid-state devicesEngineeringPhotodiode

A solid-state imaging device includes: a pixel having a photodiode and a pixel transistor; a first isolation region using a semiconductor region containing impurities formed between neighboring photodiodes; and a second isolation region using an semiconductor region containing impurities formed between the photodiode and the pixel transistor, wherein an impurity concentration of the first isolation region is different from an impurity concentration of the second isolation region.

Owner:SONY CORP

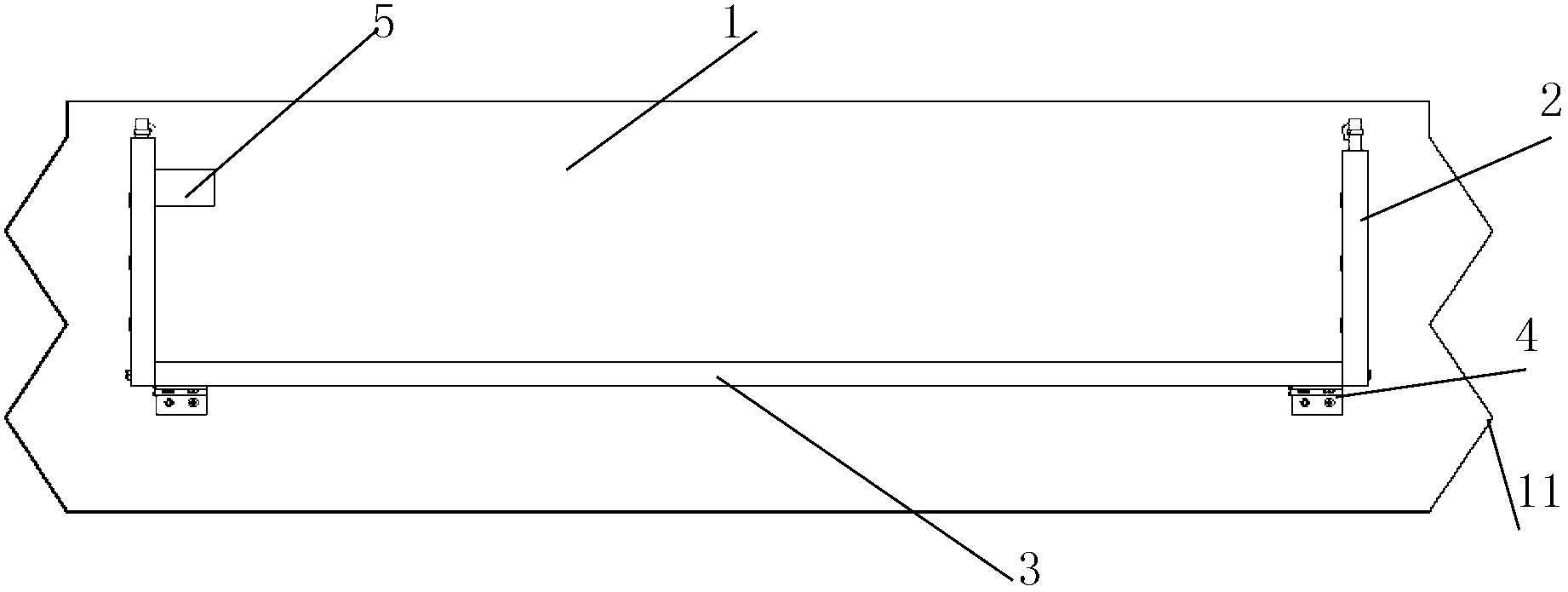

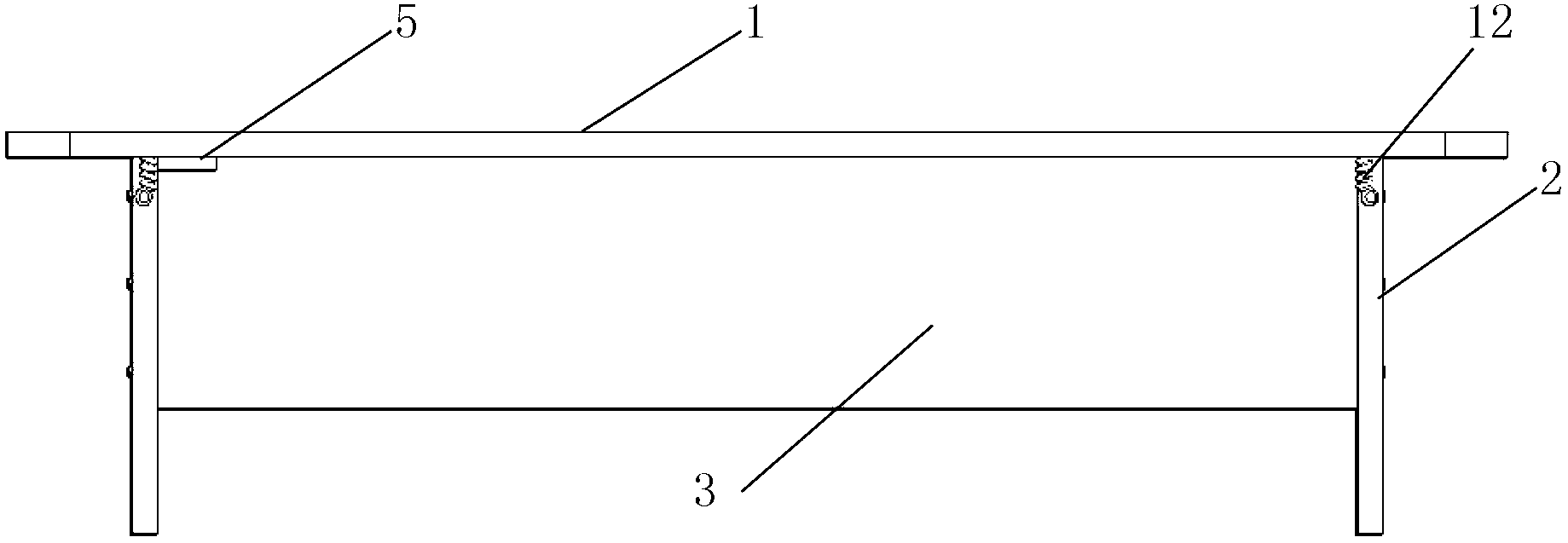

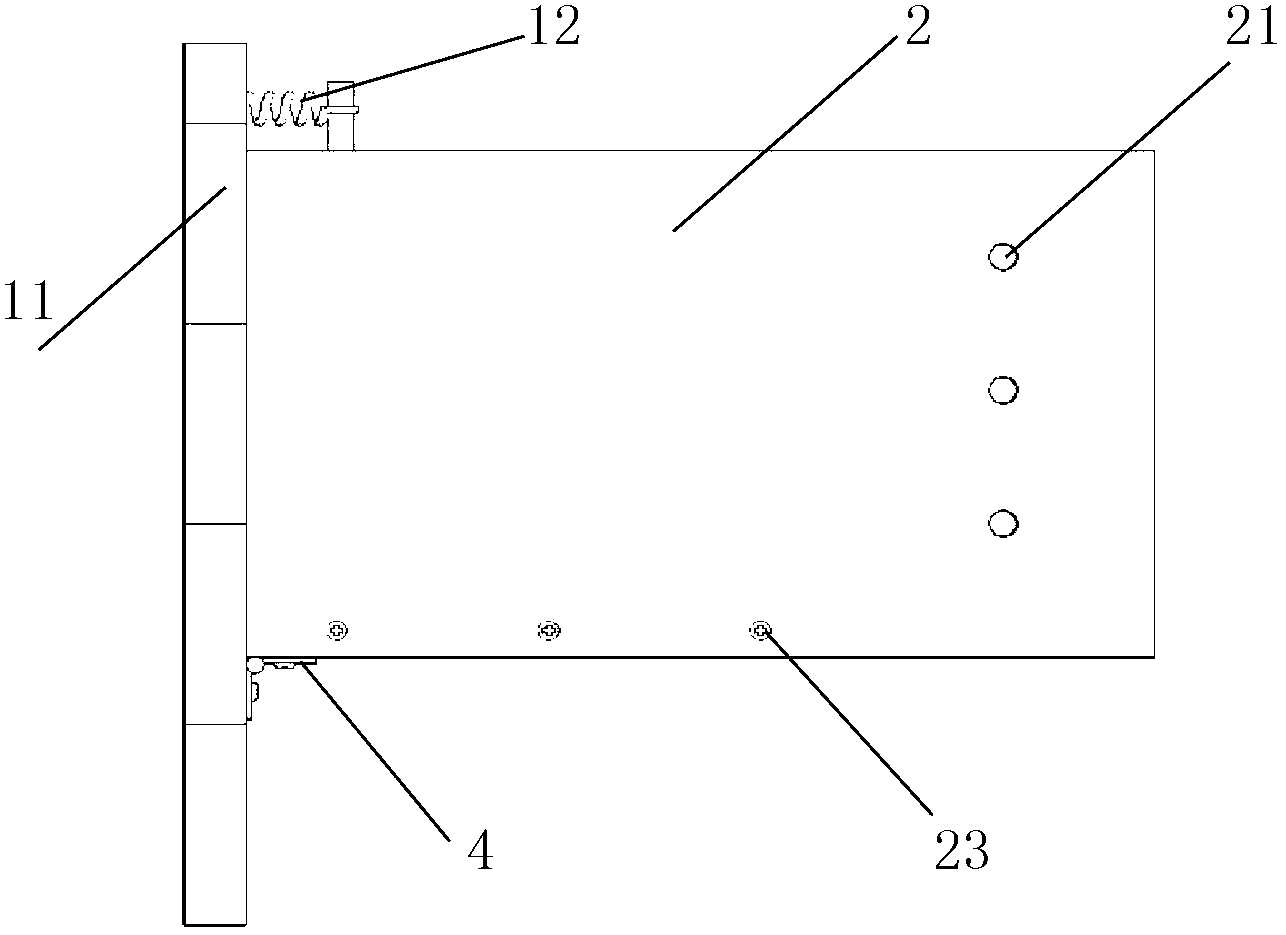

Window-plate type alarming rail and manufacturing method thereof

ActiveCN102704820AWill not affect daylightingNice appearanceSills/thresholdBurglar alarm mechanical actuationFloor levelAgricultural engineering

The invention discloses a window-plate type alarming rail and a manufacturing method thereof. The window-plate type alarming rail mainly comprises a front plate, side plates and a bottom plate, and is characterized in that the side plates are upwards arranged at two ends of the bottom plate; the movable front plate is arranged at the front sides of the bottom plate and the side plates; the rear sides of the two side plates protrude out of the rear side of the bottom plate by a certain distance; the front plate, the bottom plate and the left and the right side plates form a semienclosed basket body; the basket body is also provided with an electronic switch which is connected with alarming equipment. The window-plate type alarming rail disclosed by the invention is arranged at the outer side of the window, has anticlimbing and antitheft functions, also can prevent persons and objects at high altitude from falling accidentally, has no influence on life escape and disaster relief, and can be widely used for various building floors.

Owner:TAICANG CITY LVDIAN INFORMATION TECH CO LTD

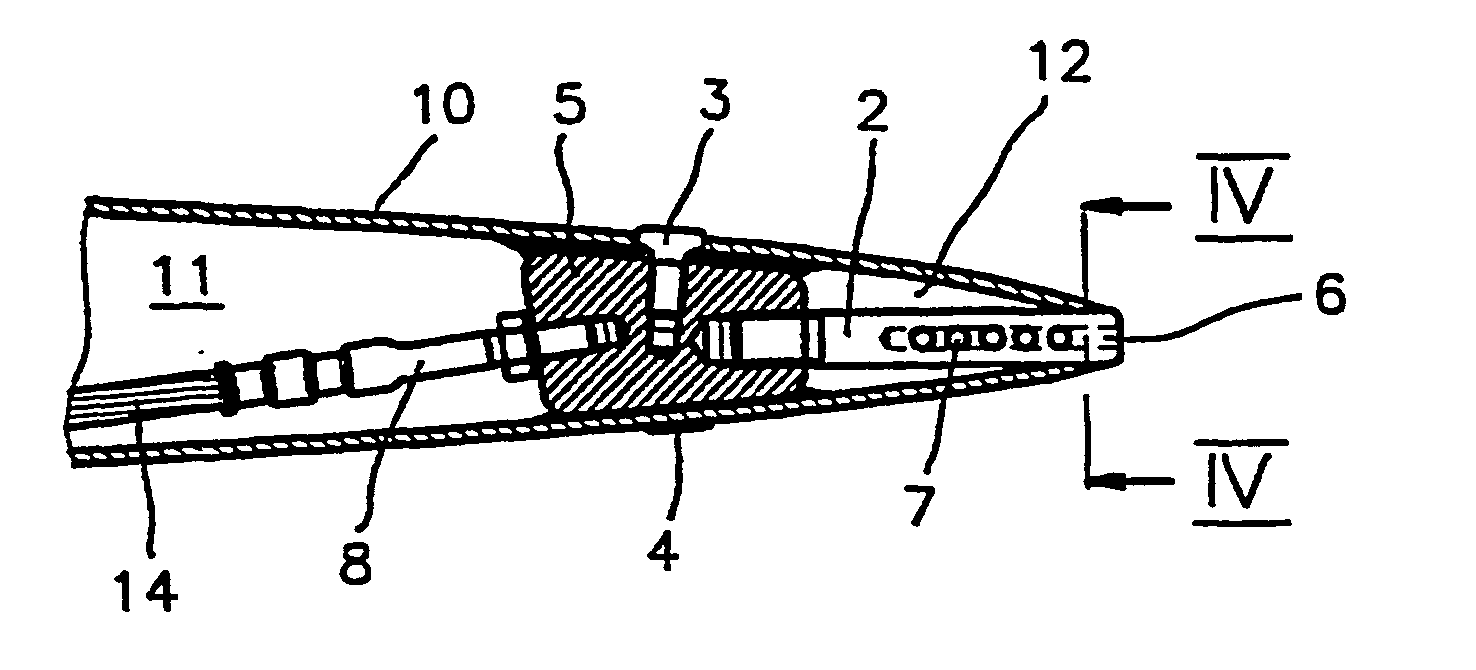

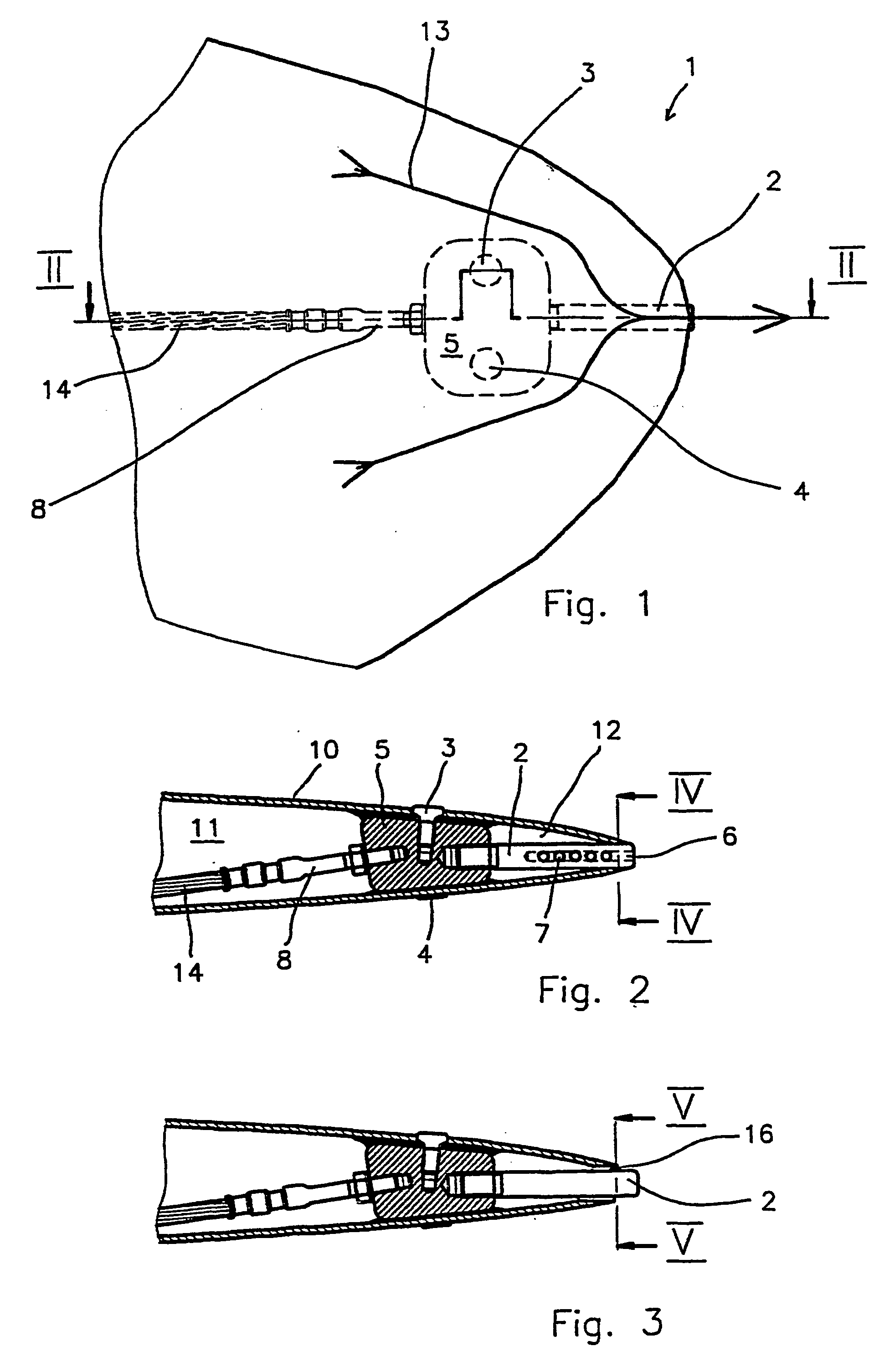

Wind turbine rotor blade with combined lighting receptor and drain passage and lighting receptor with drain passage

The invention relates to a wind turbine rotor blade which in its tip (1) is provided with a lightning receptor (2) and a drain passage (6; 16; 26; 36; 46; 56) connecting the blade interior (11, 12) with the blade exterior, the drain passage (6; 16; 26; 36; 46; 56) and the lightning receptor (2) having a common interface. The invention further relates to a lightning receptor provided with a drain passage (6; 36; 46; 56).

Owner:LM GLASSFIBER

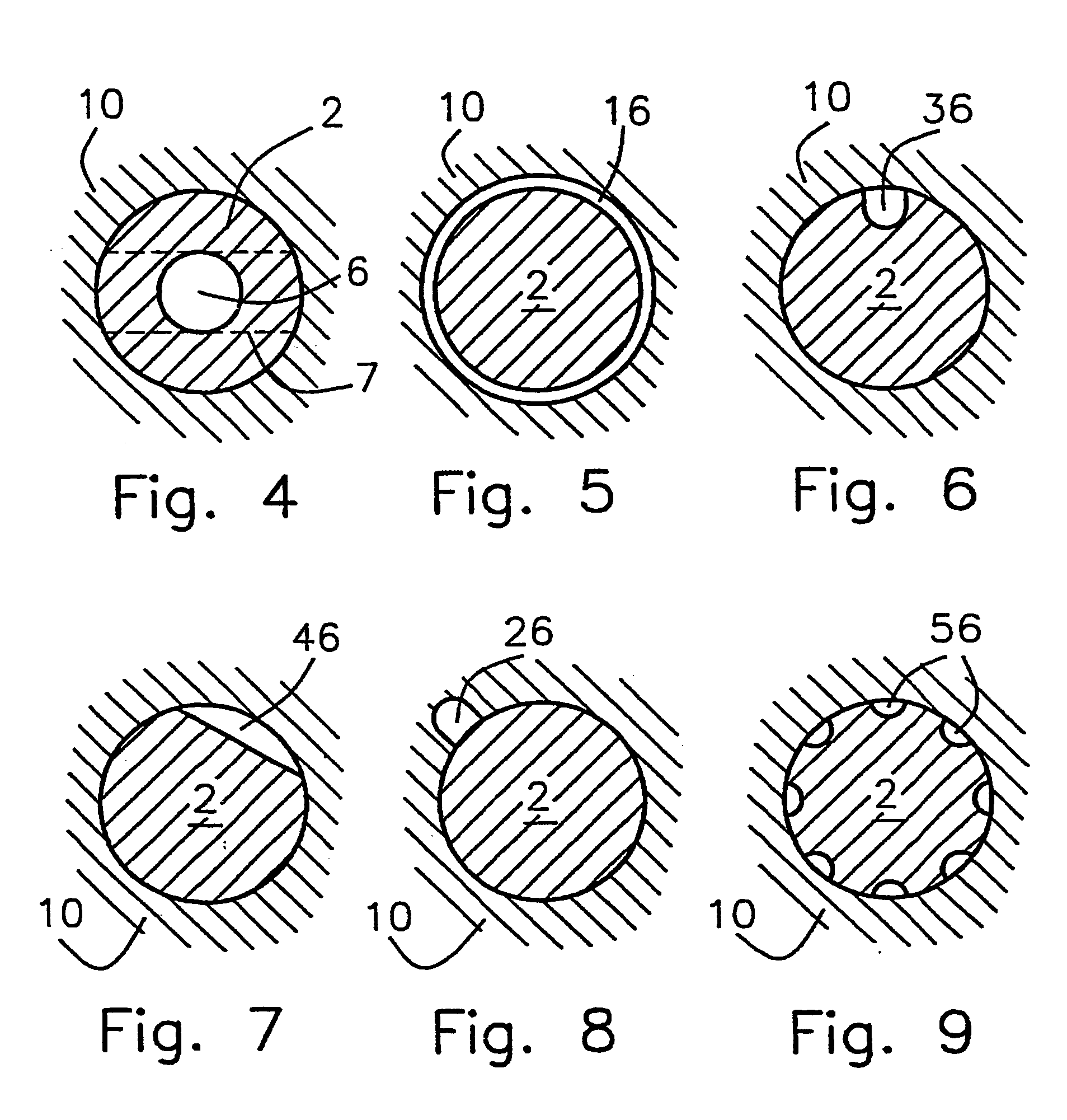

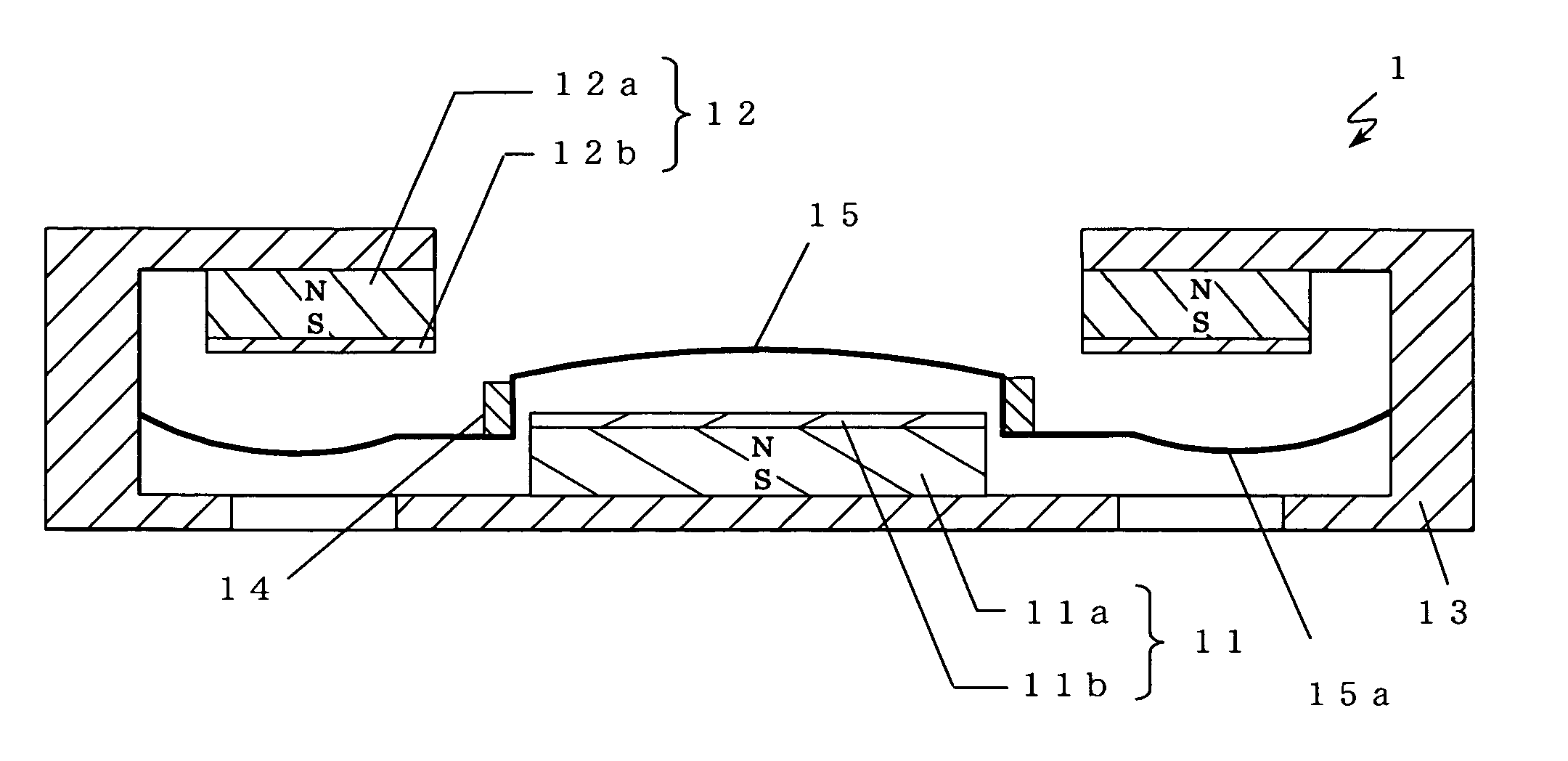

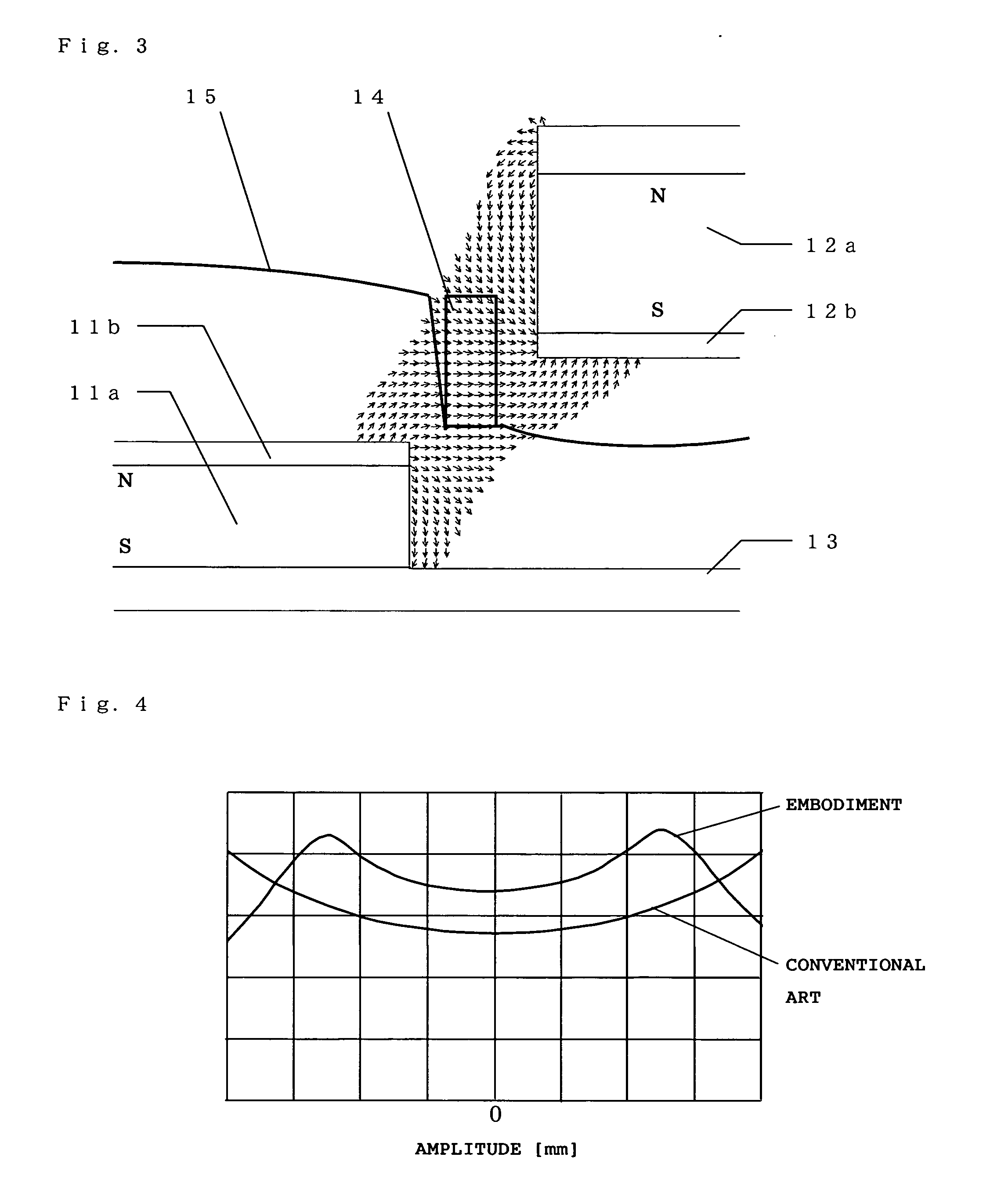

Electrodynamic electroacoustic transducer and electronic device

ActiveUS20070165902A1High magnetic flux densityImprove performanceTransducer detailsTransducerMagnetic poles

An electrodynamic electroacoustic transducer comprises: a first magnetic pole; a second magnetic pole that forms a magnetic gap between itself and the first magnetic pole and is arranged in a space excluding spaces in upper and lower face directions of the first magnetic pole; a yoke; a diaphragm; and a voice coil. The yoke magnetically couples one magnetic pole face of the first magnetic pole with one magnetic pole face of the second magnetic pole so as to support them. The diaphragm is arranged in a space in an upper face direction of the first magnetic pole and in a space in a lower face direction of the second magnetic pole, while its outer periphery is supported by the yoke. The voice coil is arranged in the magnetic gap and adhered to the diaphragm. At least one of the first magnetic pole part and the second magnetic pole part includes a magnet.

Owner:PANASONIC CORP

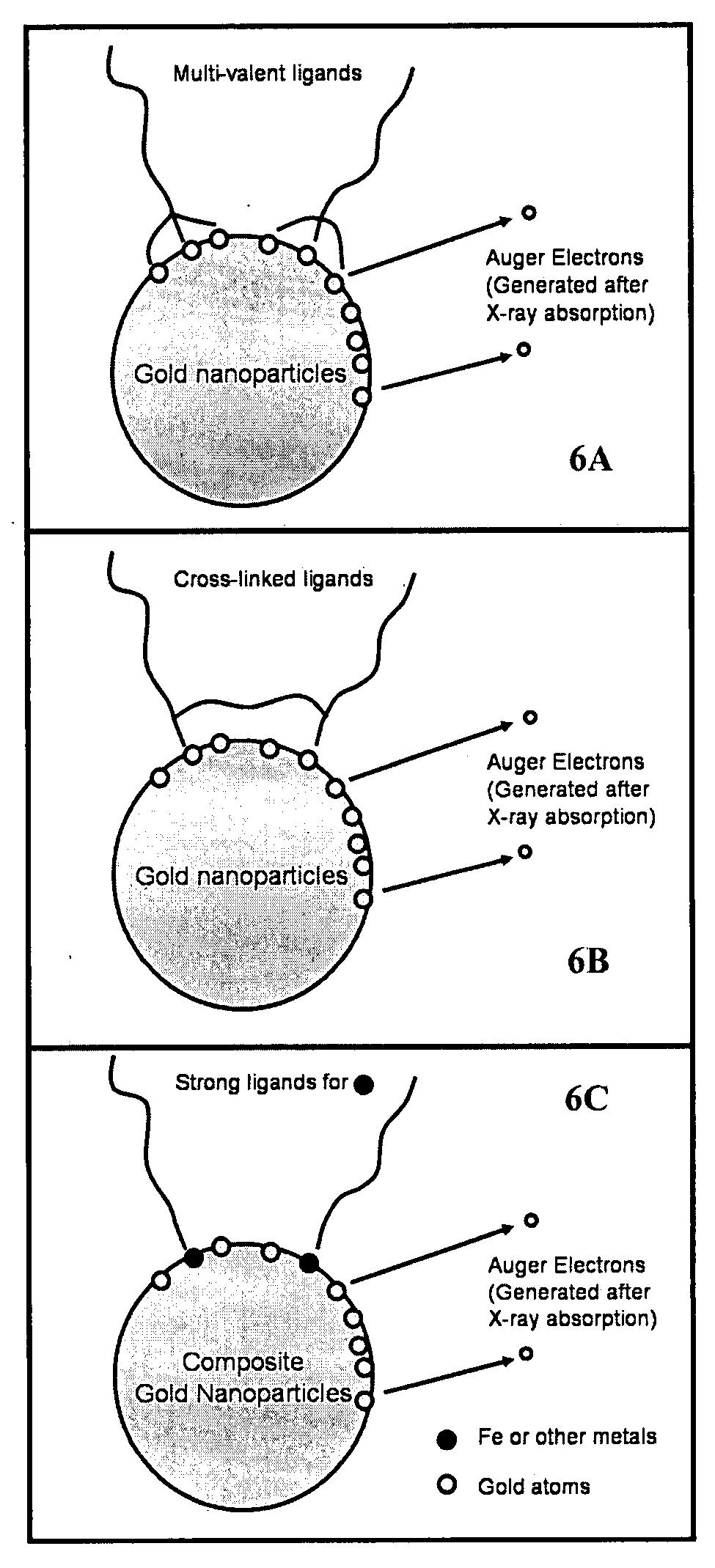

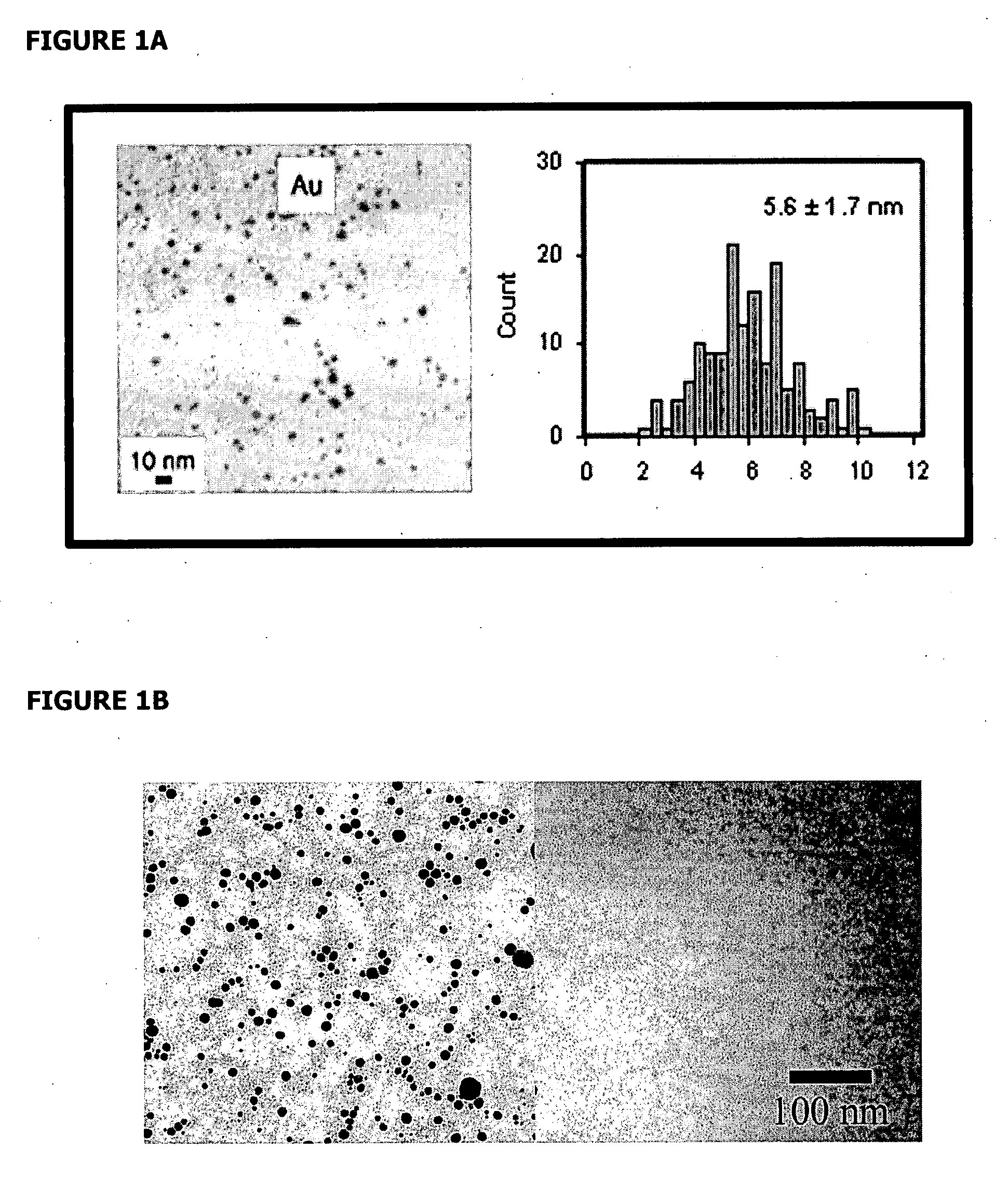

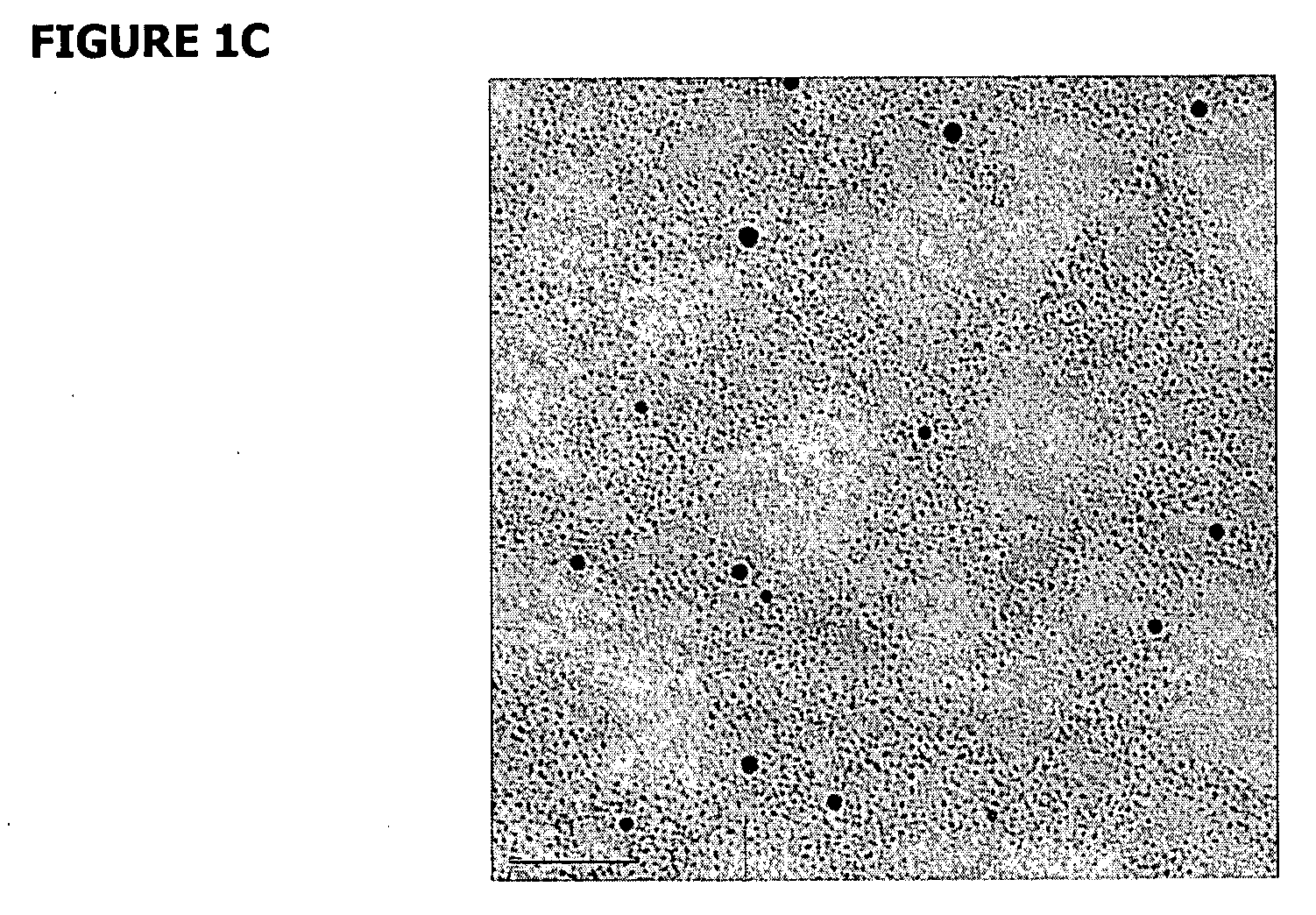

Nanoparticle radiosensitizers

InactiveUS20080003183A1Strong specificityPromote absorptionBiocideHeavy metal active ingredientsSolubilityCell membrane

Herein is described Nanostructure Enhanced X-ray Therapy (NEXT), which uses nanomaterials as radiosensitizers to enhance electromagnetic radiation absorption in specific cells or tissues. The nanomaterial radiosensitizers emit Auger electrons and generate radicals in response to electromagnetic radiation, which can cause localized damage to DNA or other cellular structures such as membranes. The nanomaterial radiosensitizers contain moieties for specific targeting to molecules or structures in a cell or tissue, and can be functionalized for increased stability and solubility. The nanomaterial radiosensitizers can also be used as detection agents to help in early diagnosis of disease. Together with known techniques such as Computed Tomography or Computerized Axial Tomography (CT or CAT scan), these nanomaterial radiosensitizers could allow early diagnosis and treatment of diseases such as cancer and HIV.

Owner:RGT UNIV OF CALIFORNIA

Semiconductor device and manufacturing method thereof

InactiveUS20050067693A1Improve thermal conductivityAvoid temperature riseMaterial nanotechnologySemiconductor/solid-state device detailsElectrical conductorSic substrate

Disclosed is a semiconductor device including a SiC substrate and a heat conductor formed in a hole in the SiC substrate and made of a linear structure of carbon elements.

Owner:FUJITSU LTD

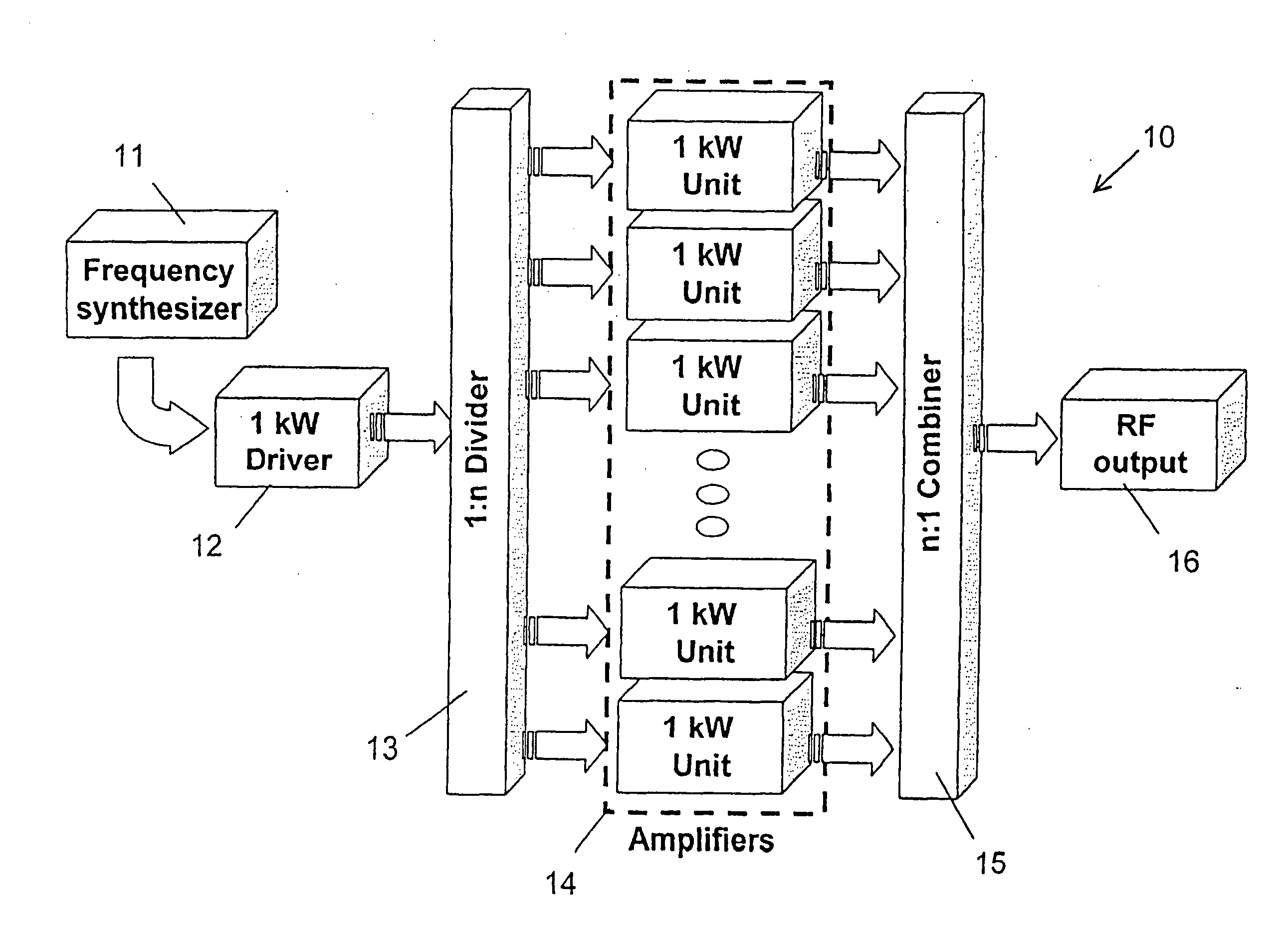

Radio frequency textile drying machine

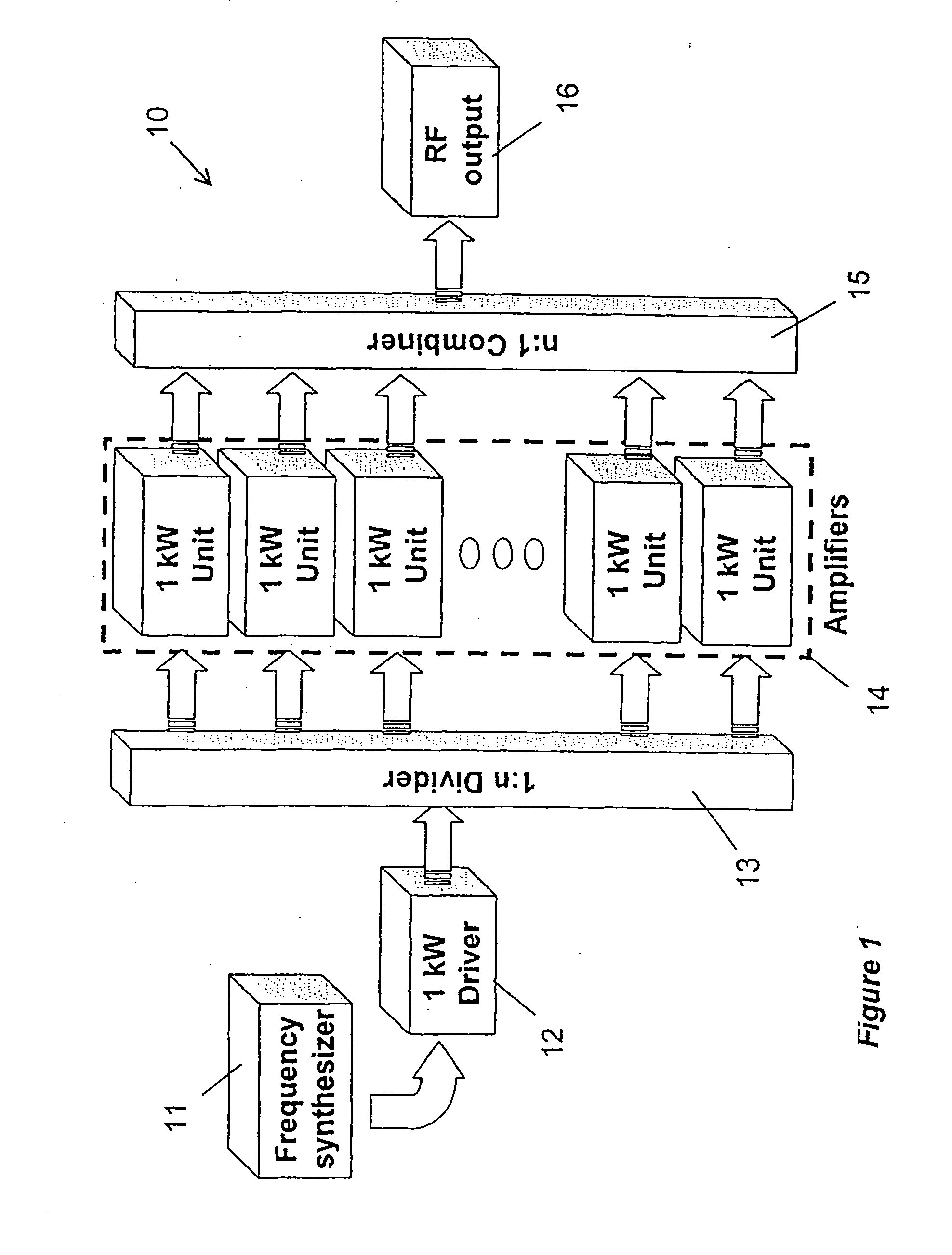

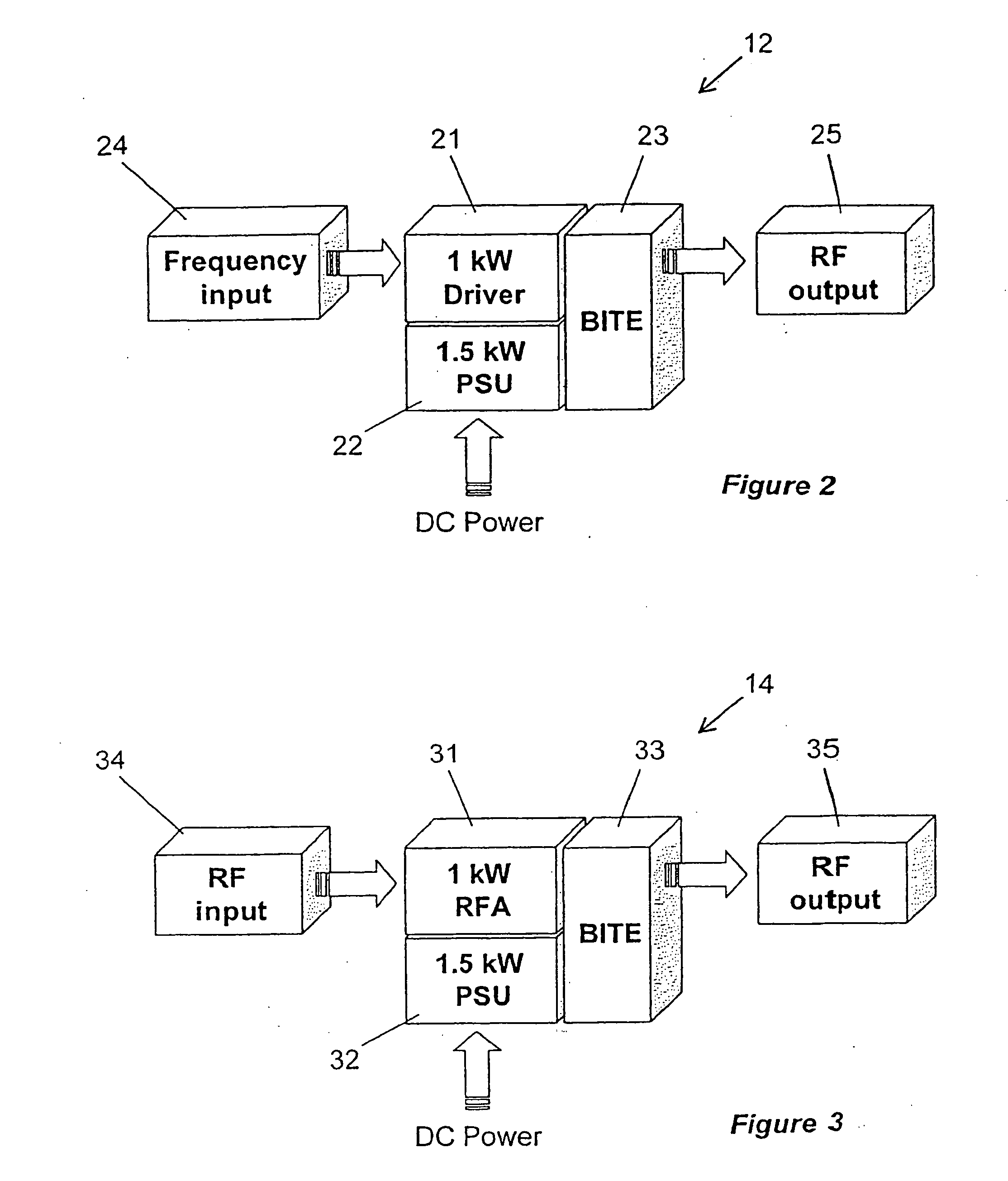

InactiveUS20070045307A1Reduce maintenance costGood efficiencyDielectric heatingDrying solid materials with heatRadio frequencySolid-state

A textile drying machine comprises a tank for receiving textiles with a spindle inside the tank for supporting the textiles, and a solid-state radio frequency generator. The generator is connected to the spindle and the tank is earthed so that when the generator is operated an oscillating electric field is generated between the spindle and the tank, and hence applied to textiles on the spindle. The electric field heats water molecules in the textiles by molecular vibration so that evaporation occurs, and the water vapor is removed from the tank by an extractor fan. The machine may also be used to dye the textiles prior to drying, thus providing an integrated dyeing / drying machine.

Owner:FALMER INVESTMENTS LTD

Window multifunction guard rail and manufacturing method and application thereof

InactiveCN101270631AWill not affect daylightingNice appearanceFixed grillesBurglar alarm mechanical actuationSOCKSElectronic switch

The invention relates to a multi-function window guardrail and a manufacturing method and application, which belongs to the anti-creep, burglary-prevention and protecting device of the wall, the balcony and the window of a building. The invention comprises a fender bracket that is characterized in that the fender bracket is provided with a setting spring and an electronic switch. The electronic switch is connected with an alarm. The fender bracket is a mobile part. When external force acts, the fender bracket rotates to an angle and the electronic switch is turned on. Meanwhile, the alarm gives warning and the external force is lost. With the aid of the spring, the fender bracket is reset and the alarm stops giving warning. The multi-function window guardrail is installed outside the balcony and the window to be used for guarding against being climbed and theft, giving shoes and socks an airing and actively giving the warning. In addition, the multi-function window guardrail is also used for guarding against the creeper and the theft and protection for the pipes of the building and wall.

Owner:张朝峰

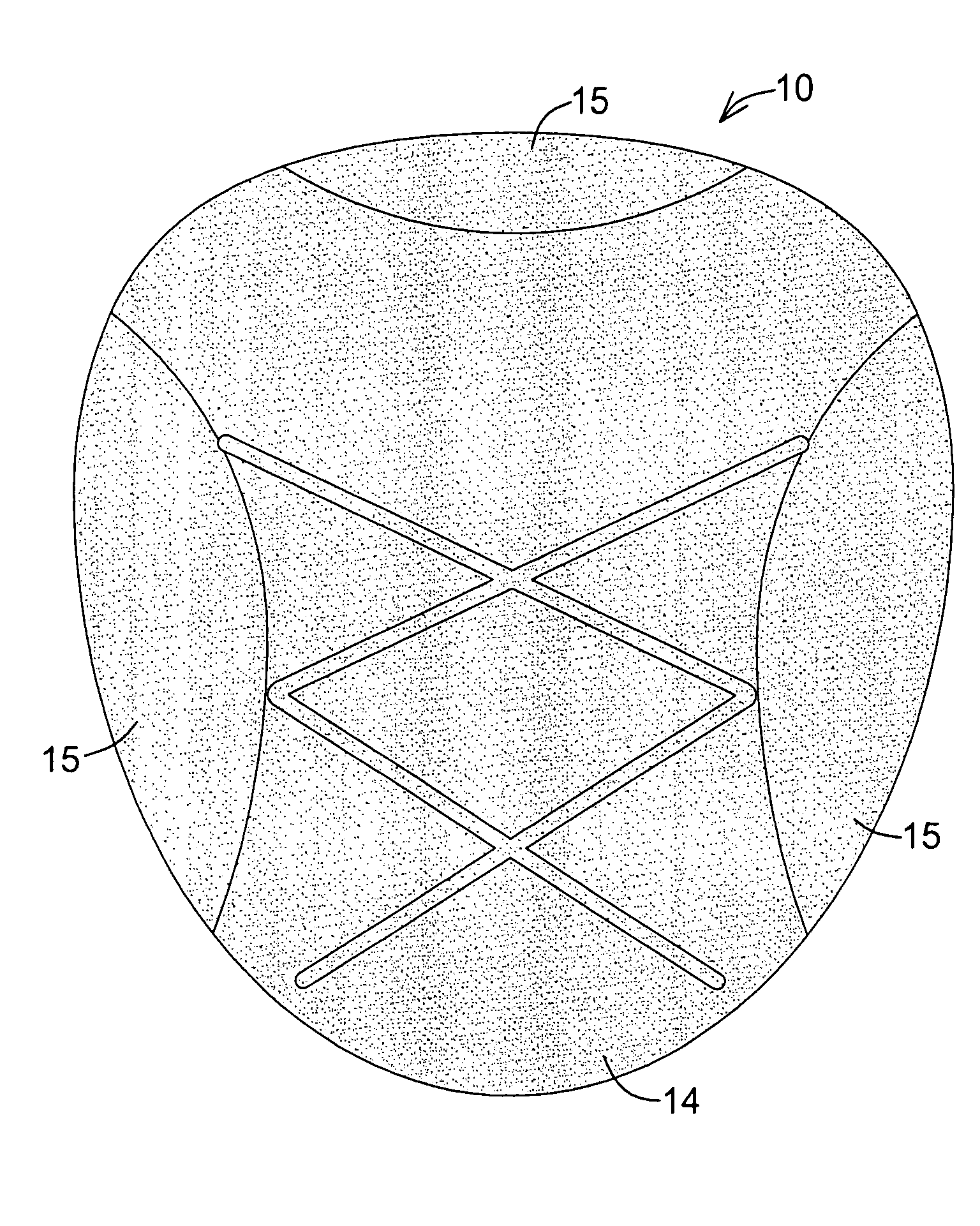

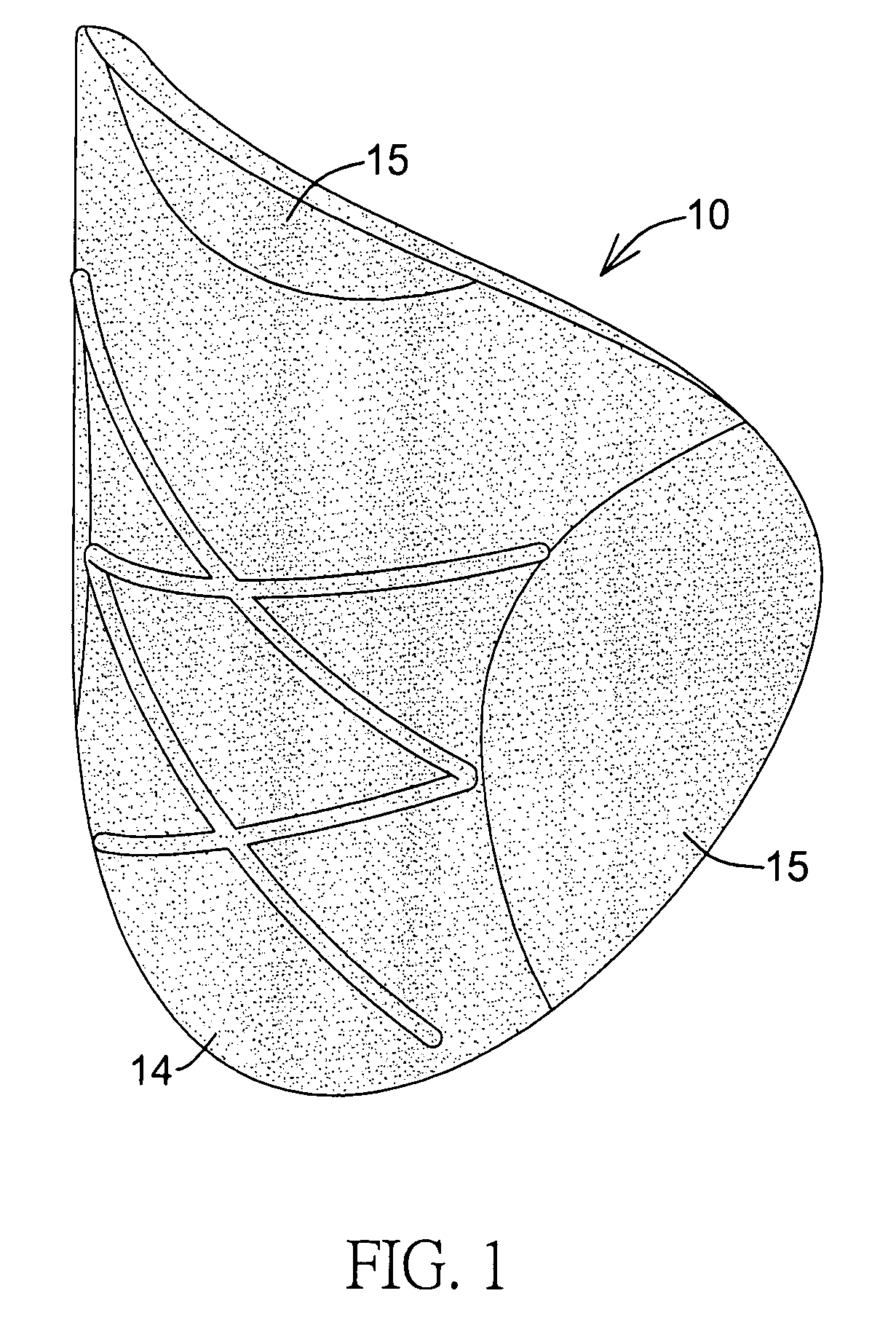

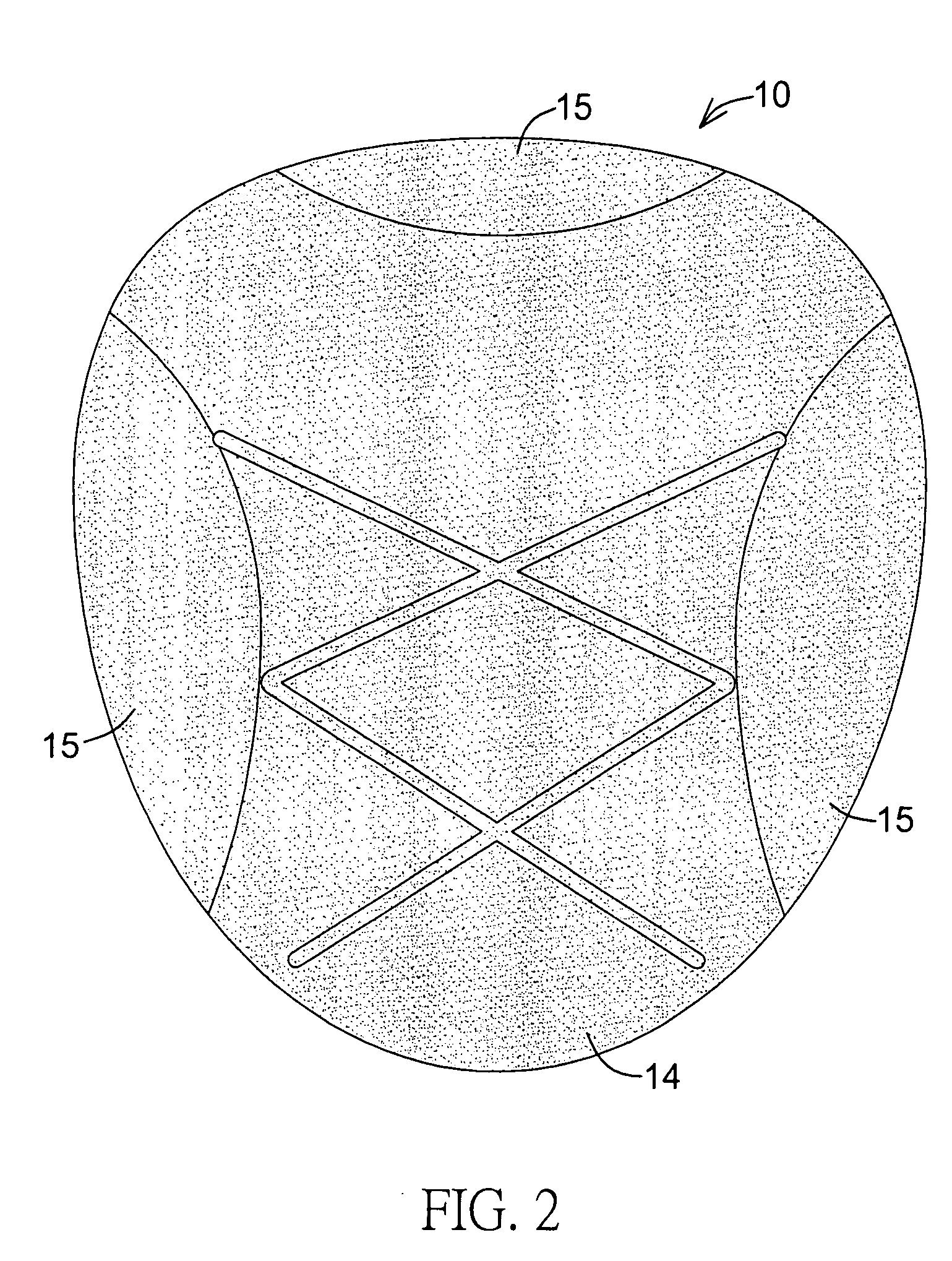

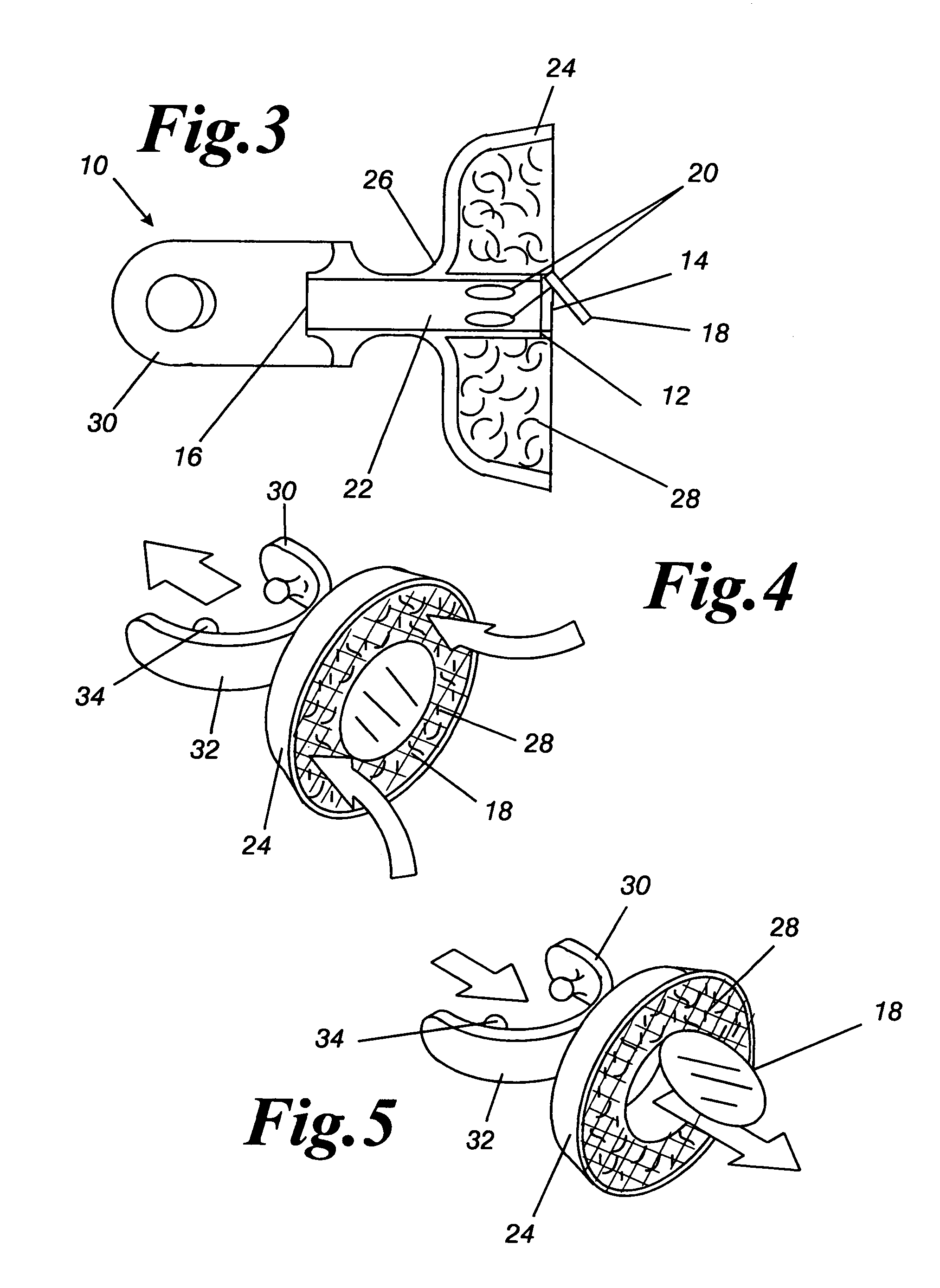

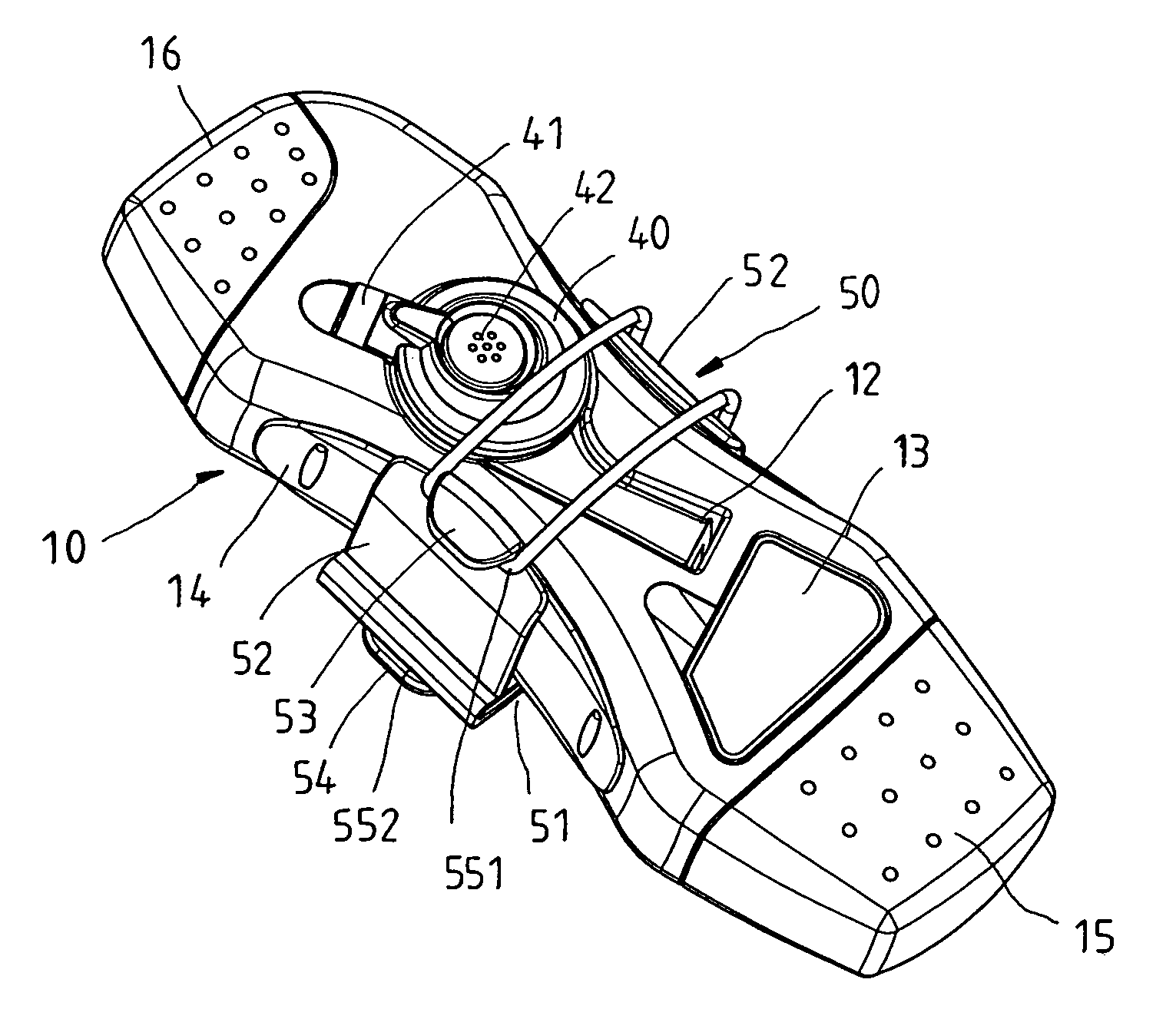

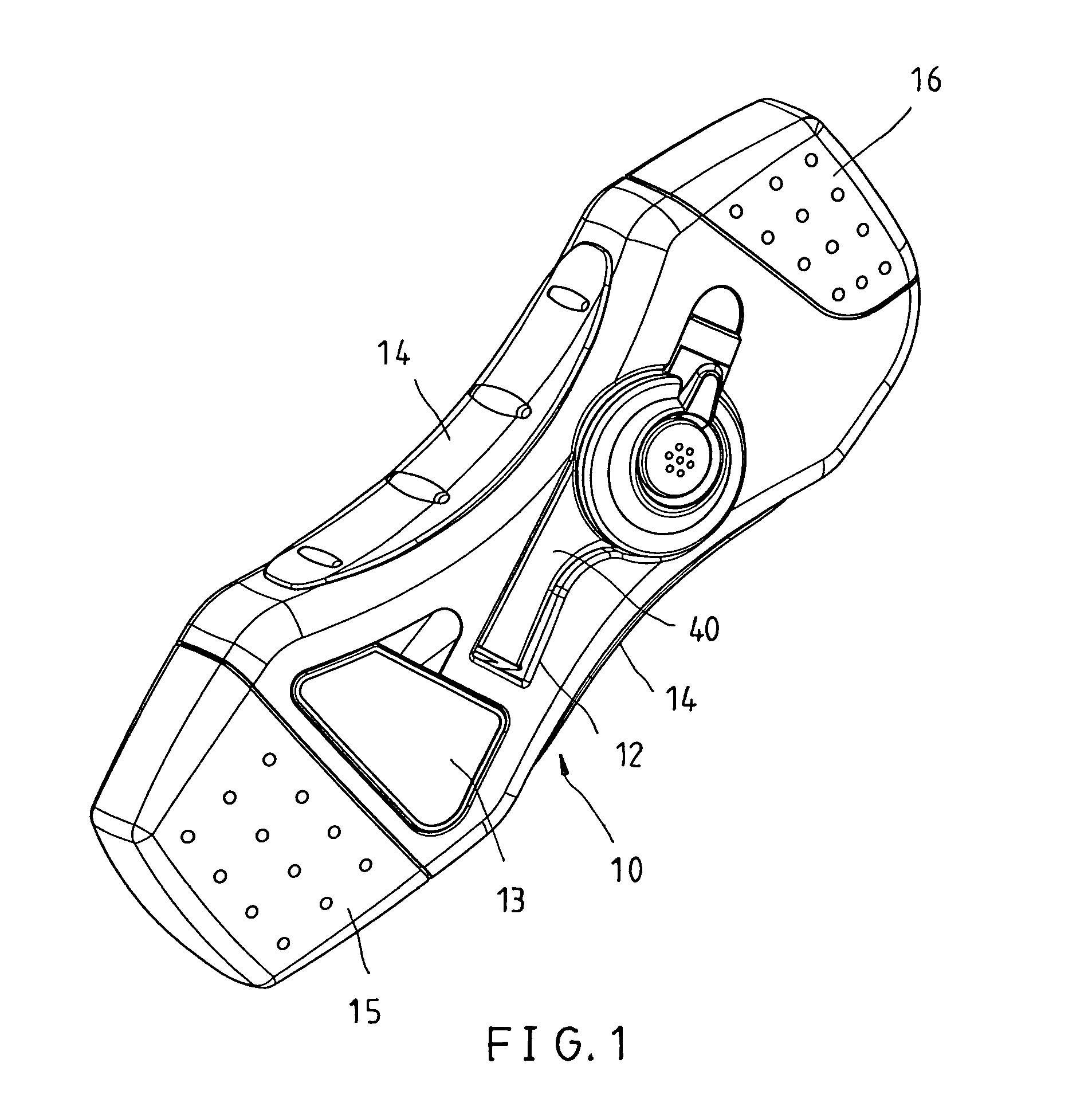

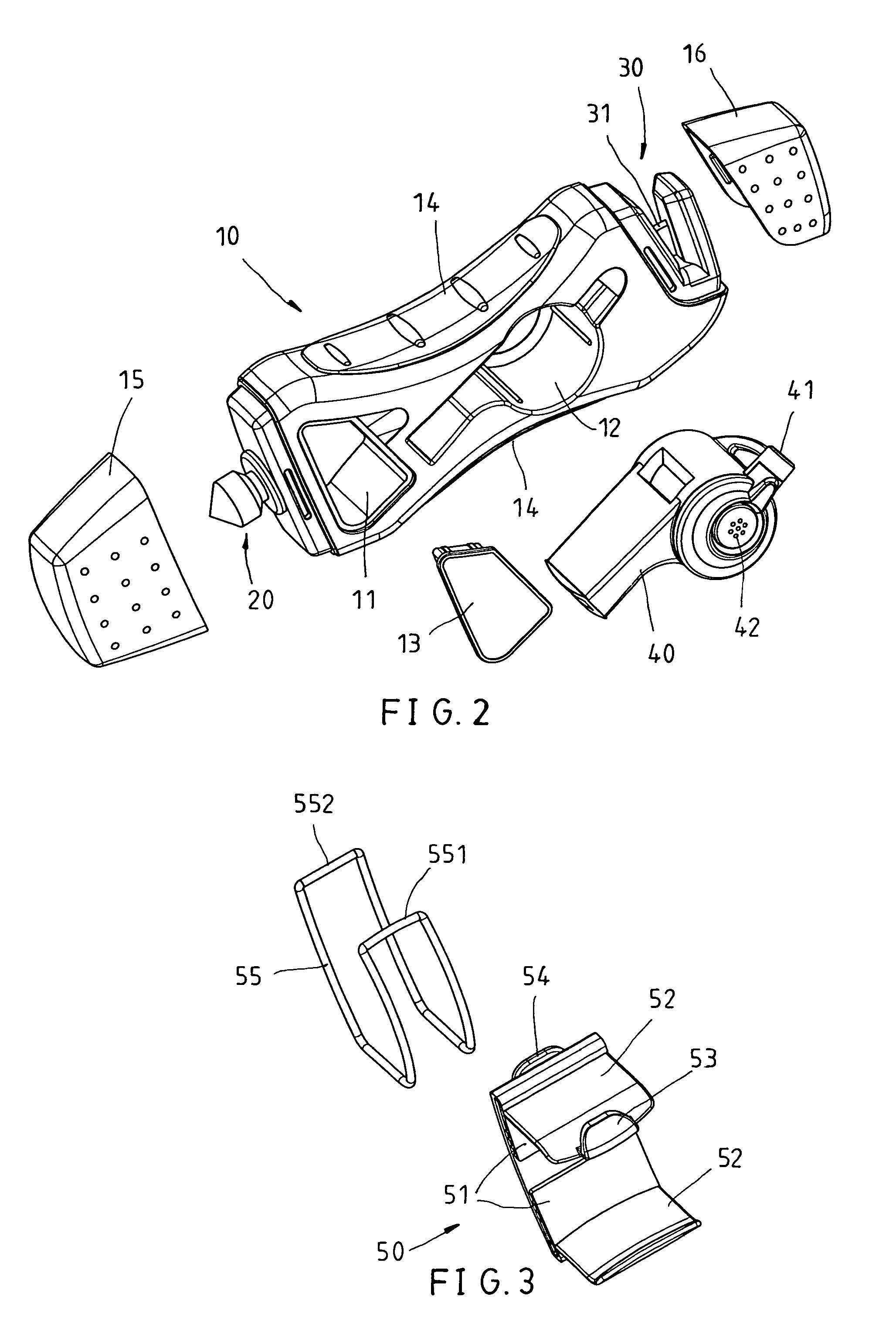

Protective sports-pad

InactiveUS20090070911A1Promote escapeComfortable to wearChemical protectionGarment special featuresEngineeringElectrical and Electronics engineering

A protective sports-pad has an outer surface, an inner surface, a recess, multiple protrusions and multiple airways. The recess is formed in the inner surface of the protective sports-pad. The protrusions are formed on and protrude from the inner surface in the recess. The airways are formed between adjacent protrusions. The airways between the protrusions allow heat to escape easily and moisture and sweat in the airways to evaporate. Consequently, the protective sports-pad does not form a breeding ground for germs, does not irritate a person's skin and is comfortable to wear.

Owner:CHANG GIN RUEY

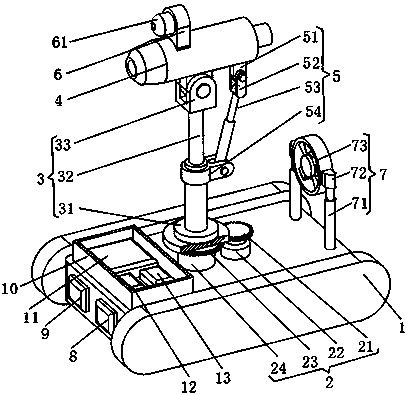

Multifunctional firefighting robot

InactiveCN108379762ASimple structureImprove fire extinguishing effectFire rescueFirefightingFire - disasters

The invention relates to a multifunctional firefighting robot which comprises a tracked robot. A rotary device is arranged in the middle of the upper surface of the tracked robot; an adjusting frame is arranged on the upper surface of a rotary shaft of the rotary device; a high pressure nozzle is arranged at the upper end of a first connecting piece of the adjusting frame; an adjusting device is arranged at the lower end of the right end of the high pressure nozzle; an installation plate is arranged at the upper end of the side surface of the high pressure nozzle; a camera is arranged on the side surface of the installation plate; a smoke dispersing device is arranged at the right end of the upper surface of the tracked robot; a temperature detector and a smoke detector are arranged on theleft side surface of the tracked robot; and a heat insulation box is arranged at the left end of the upper surface of the tracked robot. The multifunctional firefighting robot is simple in structure,capable of detecting and feeding back information of temperature and smoke concentration of a fire disaster zone, entering the fire disaster zone for multi-angle fighting fire, and dispersing dense smoke produced after firefighting, convenient for patients to escape, high in safety, diverse in functions, and convenient to use.

Owner:梁慧薇

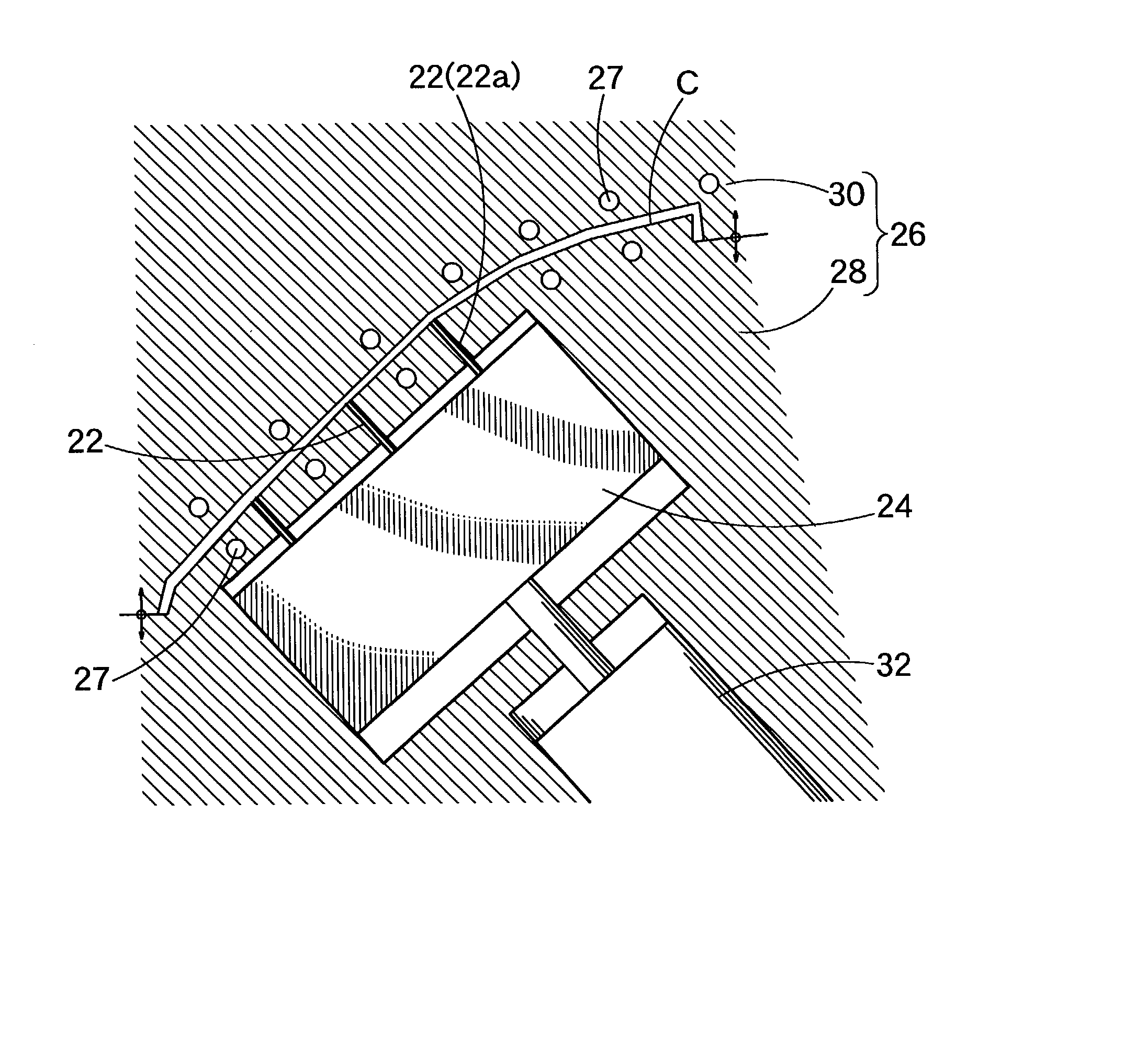

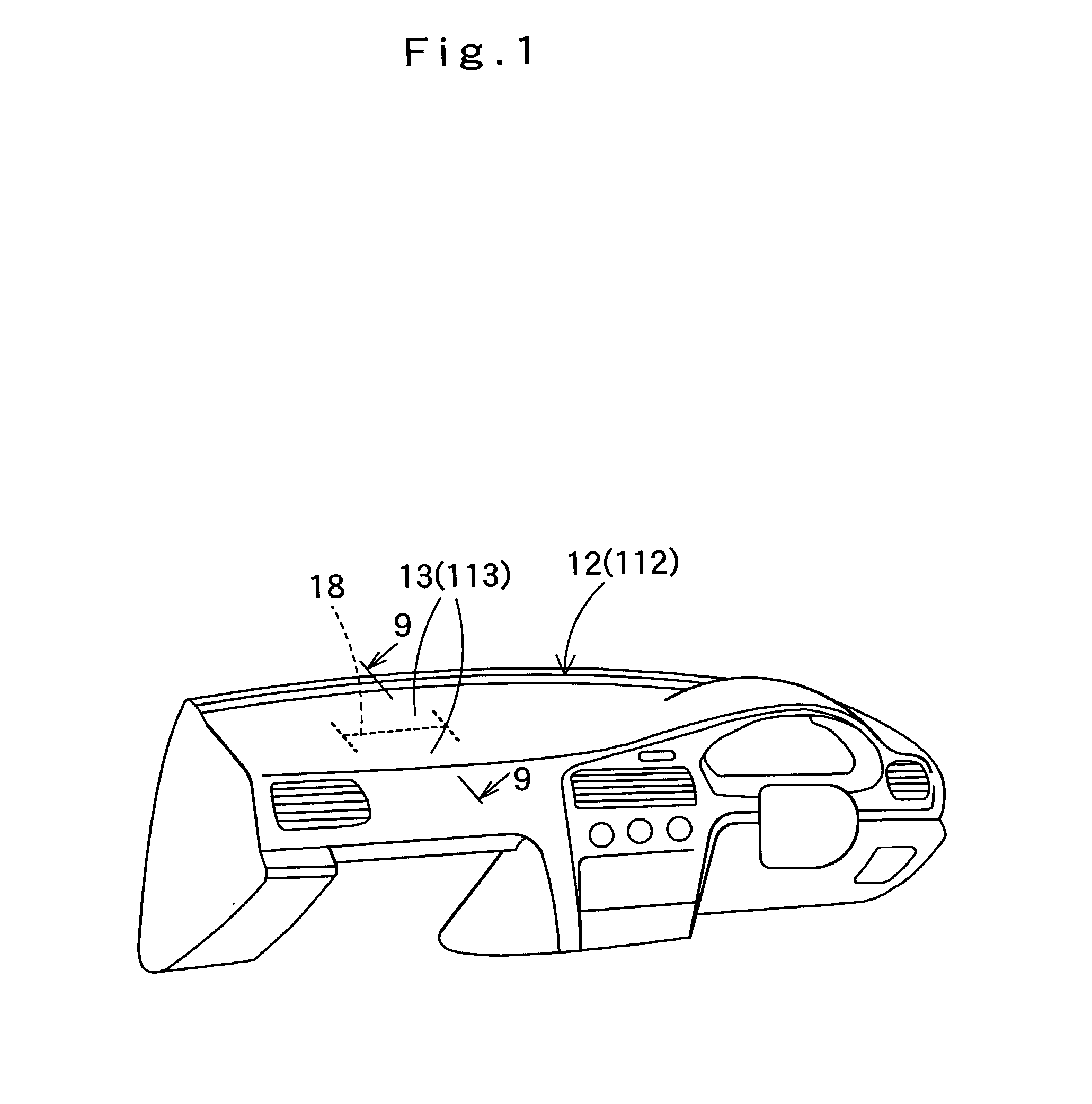

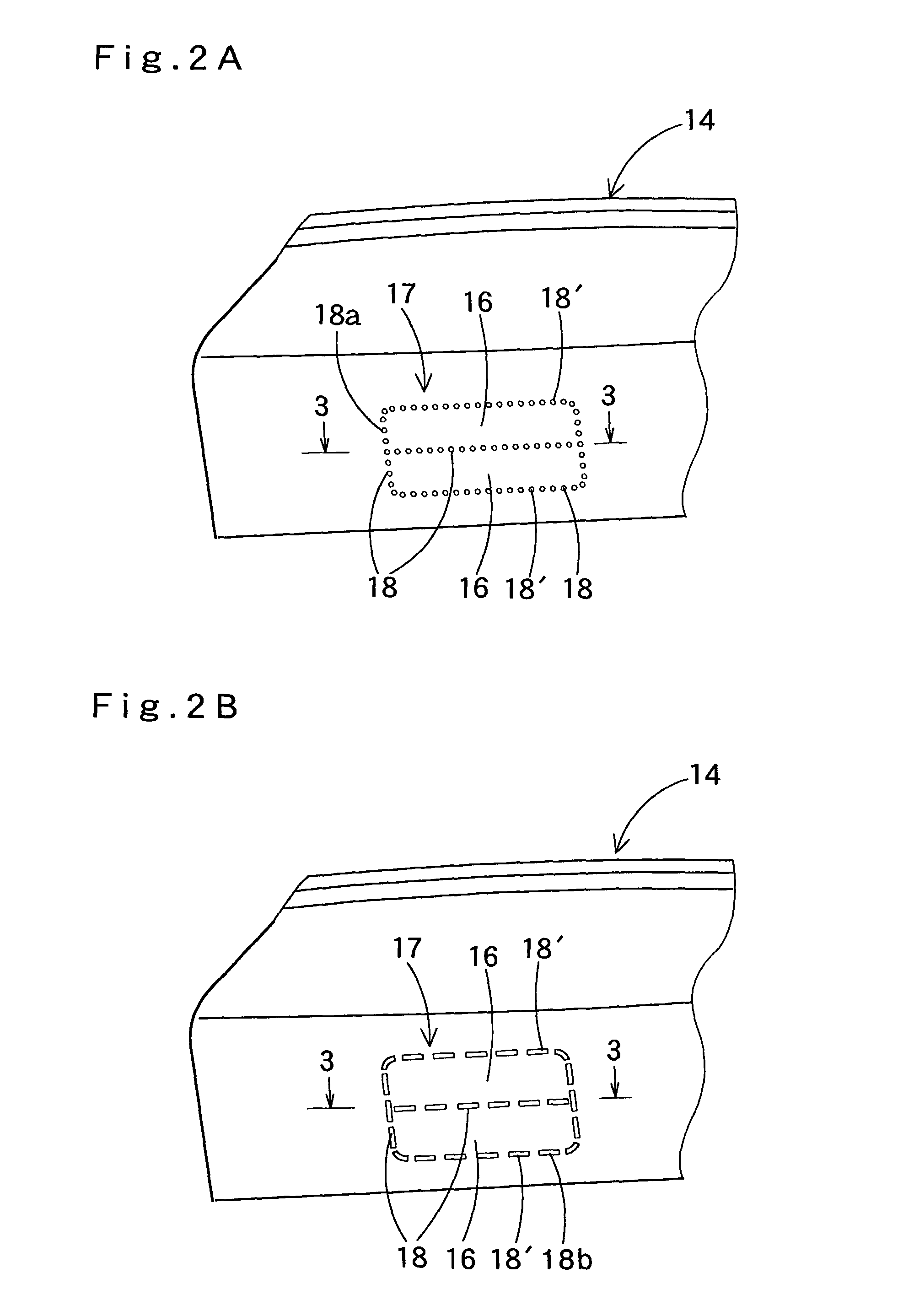

Method for manufacturing automobile interior article

InactiveUS20030020202A1Poor reproductionImprove productivityButtonsMouldsEngineeringAirbag deployment

A method for forming tear lines in the rear side of an automobile interior article having a cover portion being developed from which an airbag inflates. When either an automobile interior article body having an integrally molded surface portion or an automobile interior article surface portion is to be molded, the mold is opened after tear line forming projections are moved forward and backward with the mold closed. Thus, the tear lines can be formed at the molding time without any visible extrusion marks of the tear line forming projections on the front surface side (the design face).

Owner:TOYODA GOSEI CO LTD

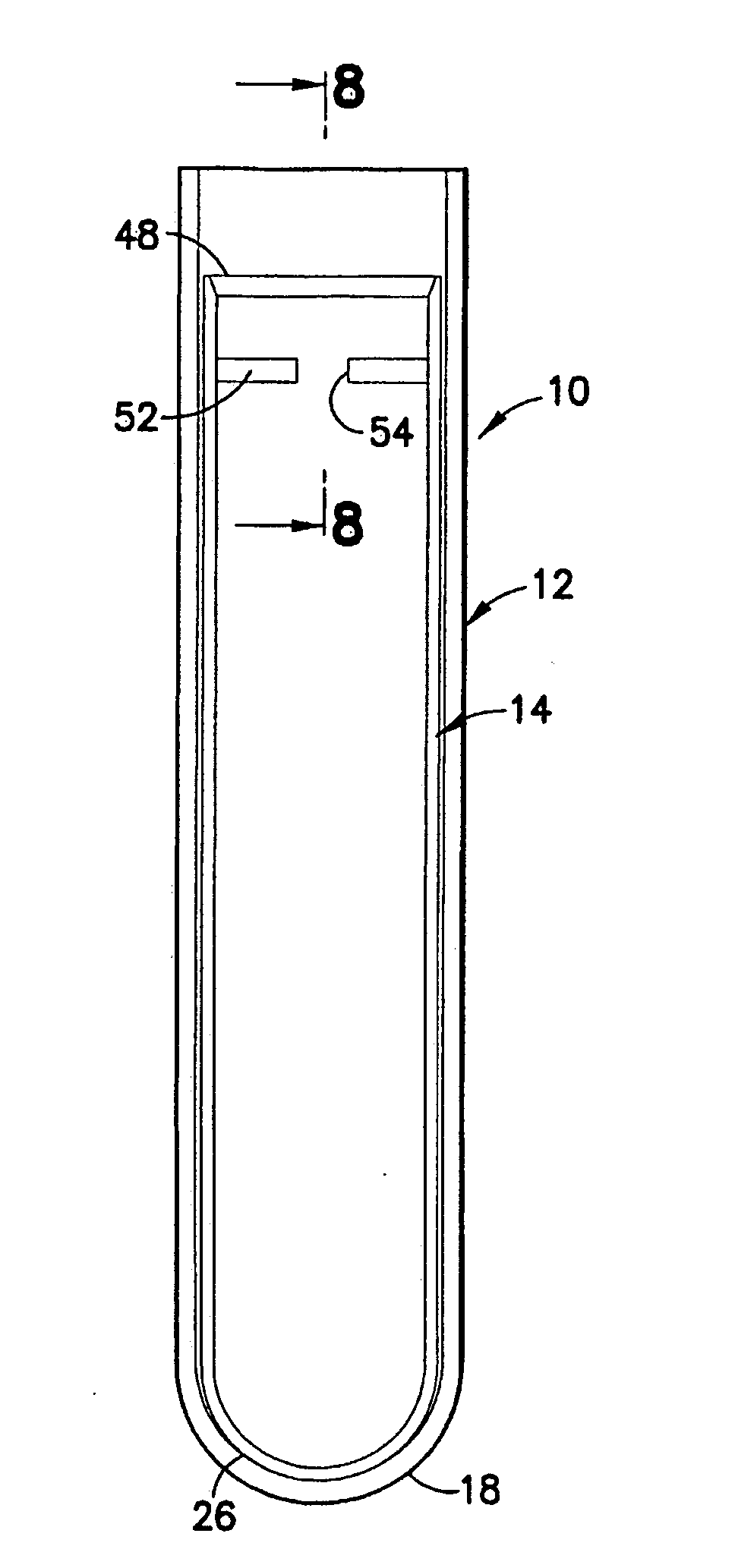

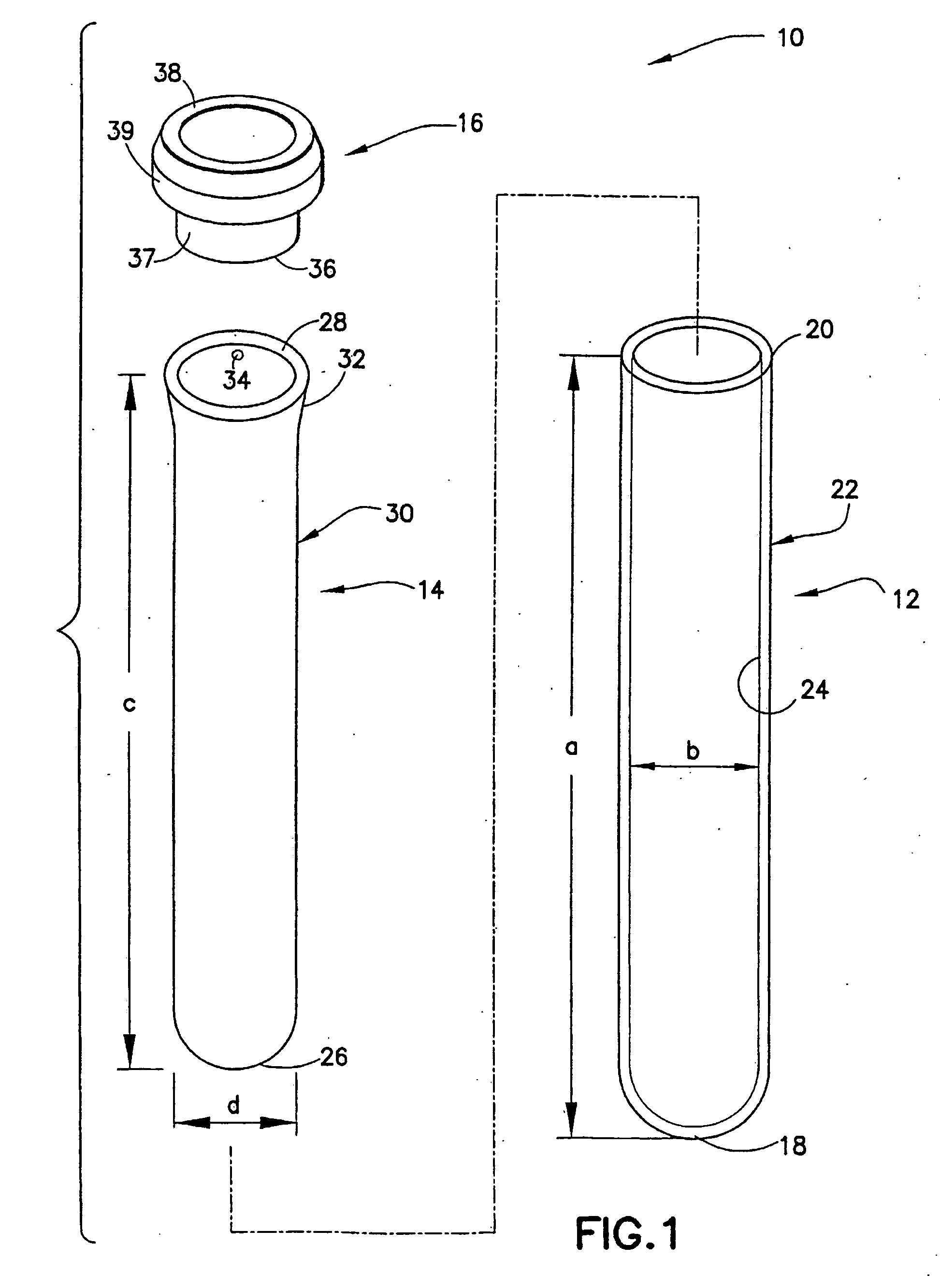

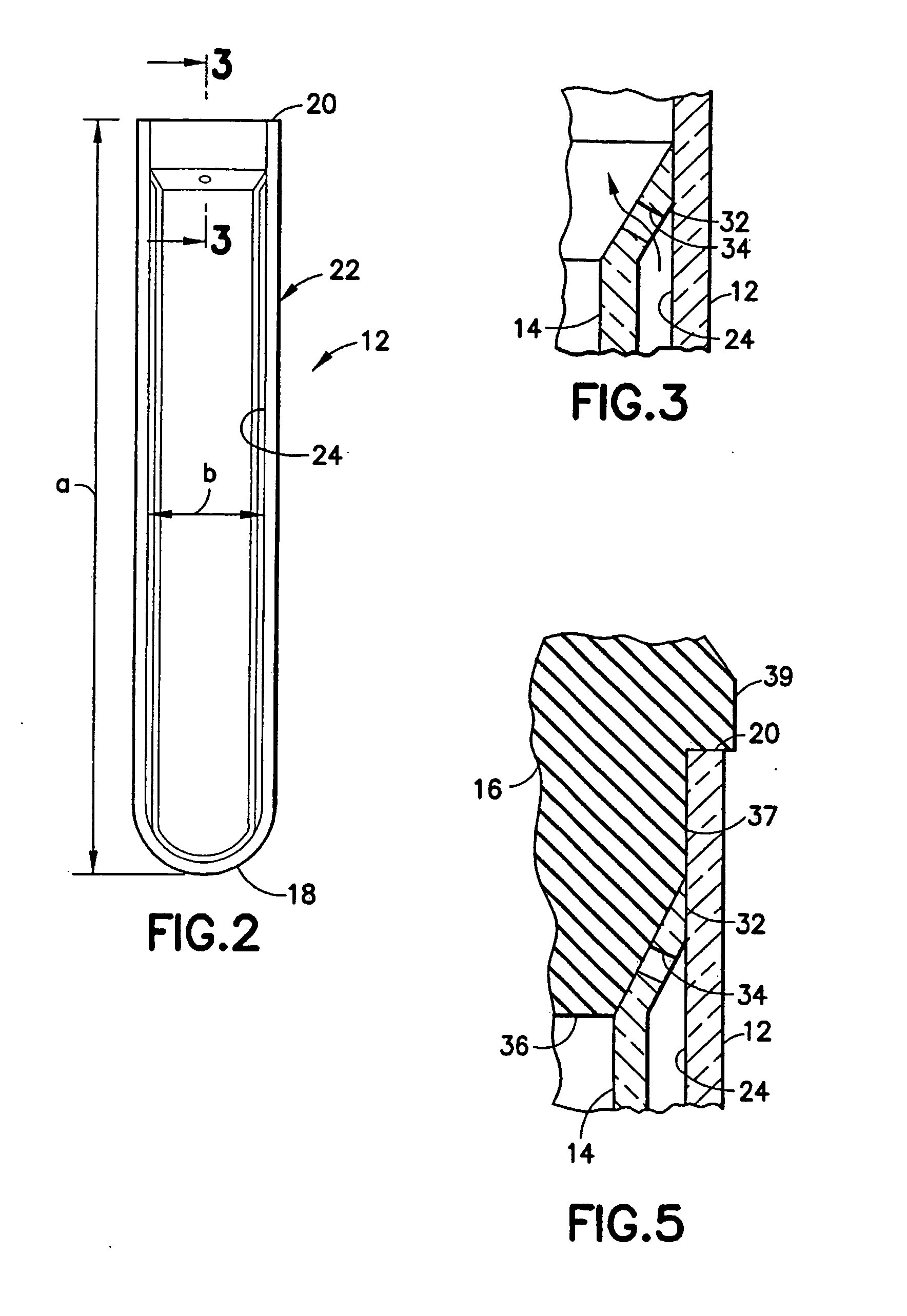

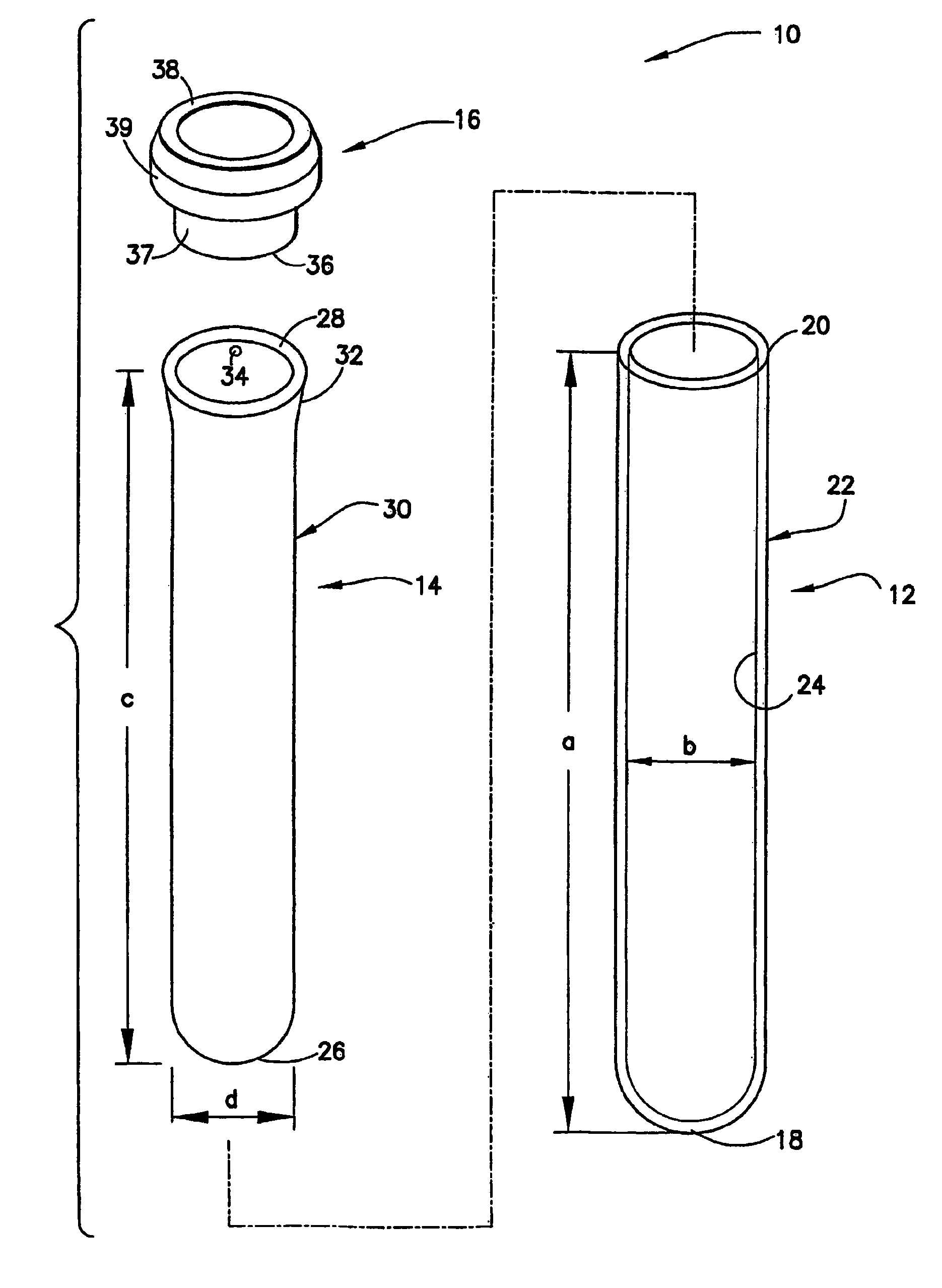

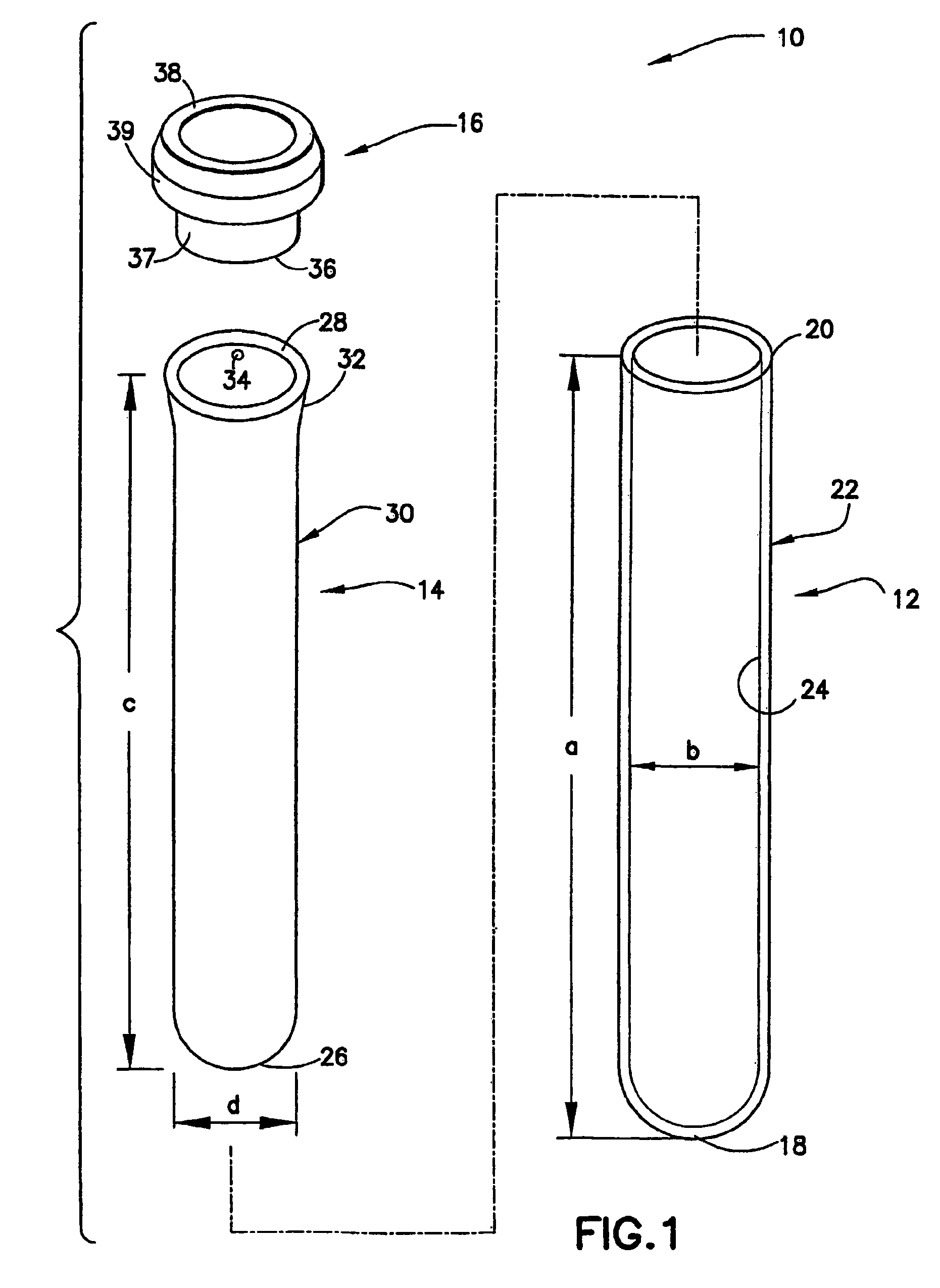

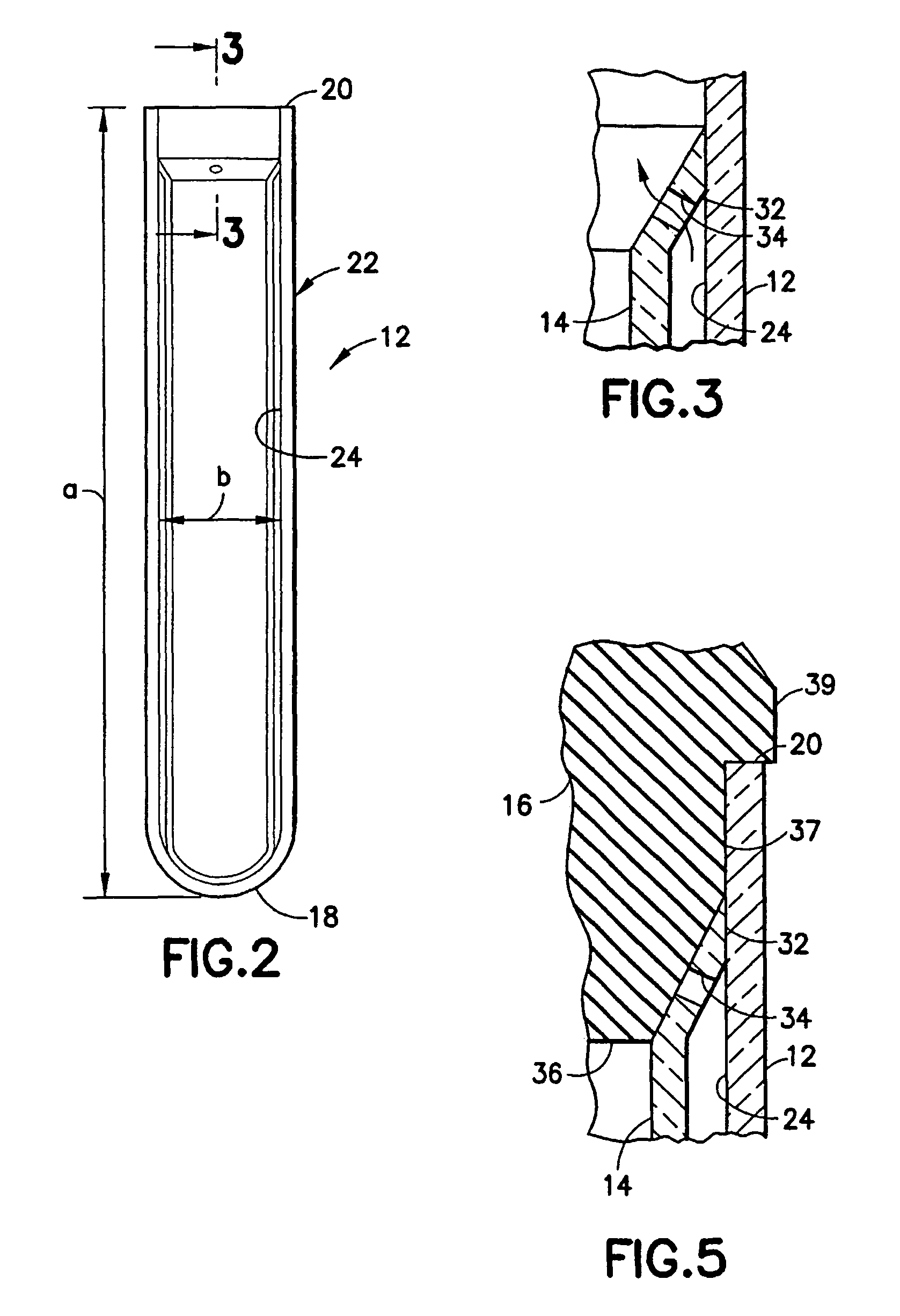

Collection assembly

InactiveUS20050000962A1Promote escapeSealing is reliableTable equipmentsLaboratory glasswaresEngineering

A tube assembly includes an inner tube telescoped into an outer tube. The inner tube is dimensioned to define a substantially annular space between the inner and outer tubes. Portions of the inner tube near its open top are configured to permit venting as the inner tube is inserted into the open top. However, the vent is closed during insertion of a closure into the tube assembly or prior to inserting a closure into the tube assembly.

Owner:BECTON DICKINSON & CO

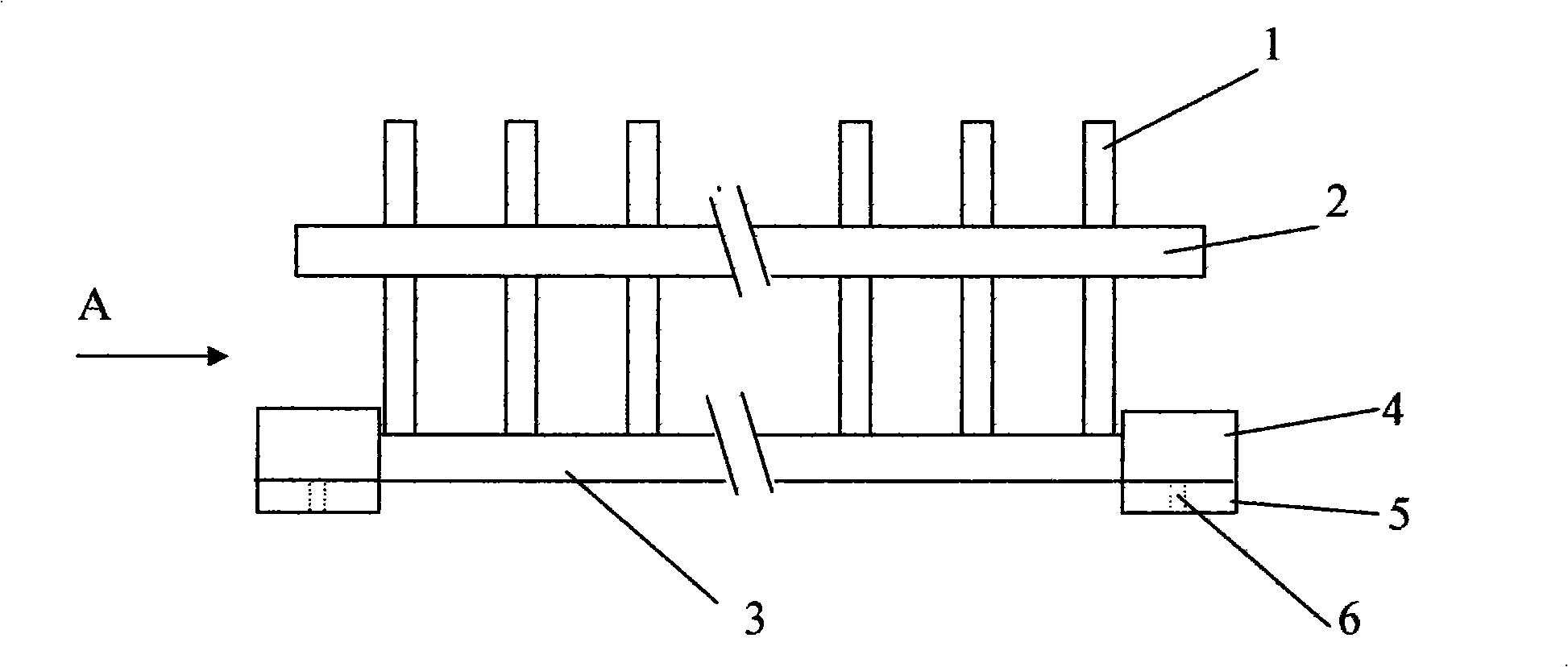

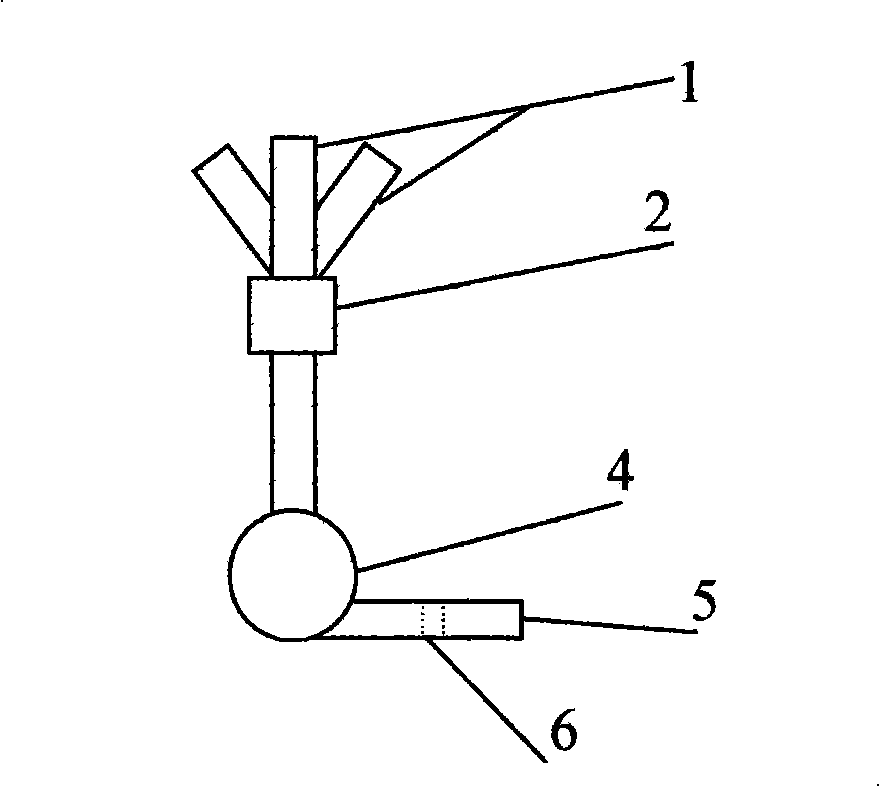

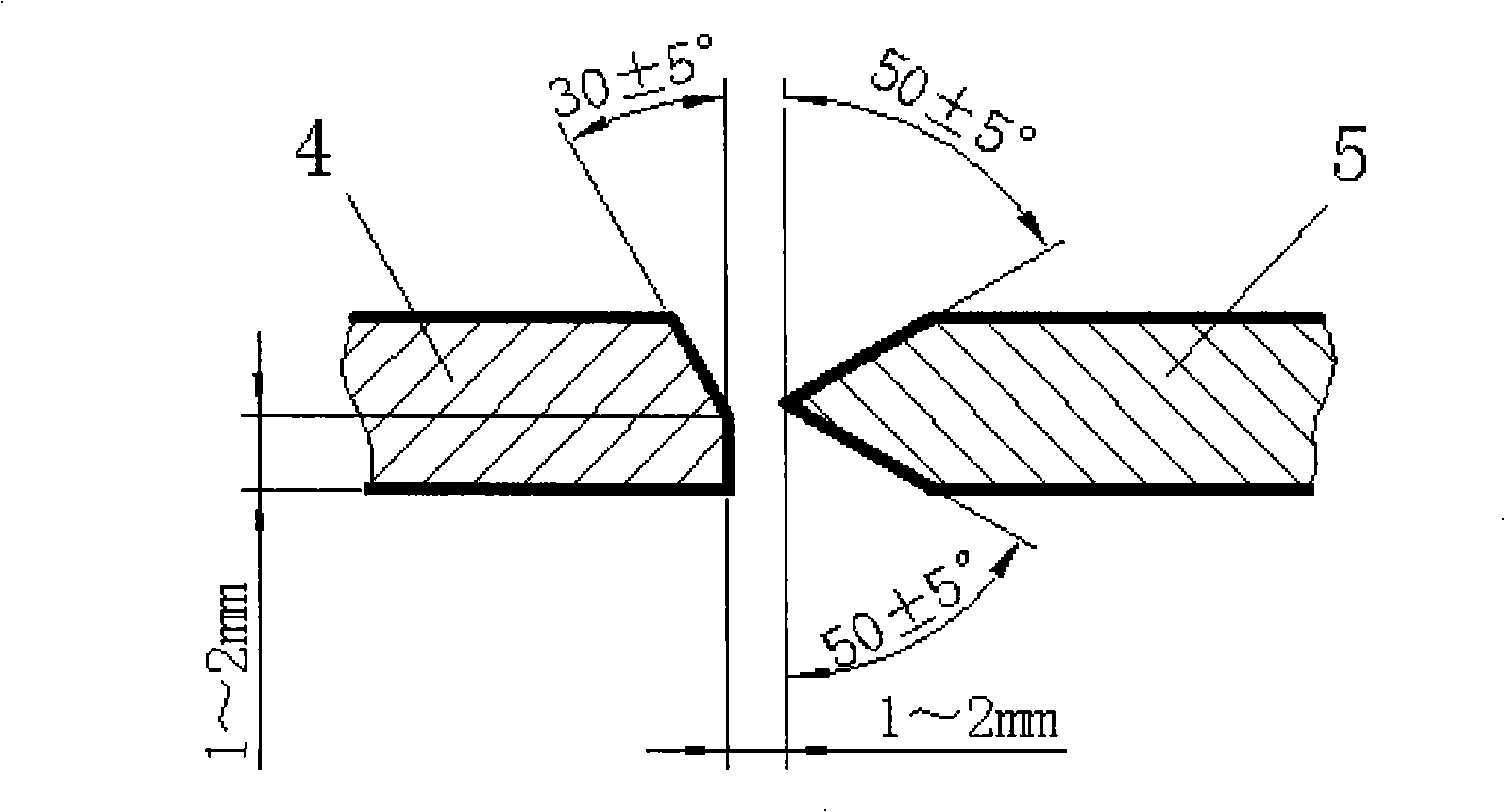

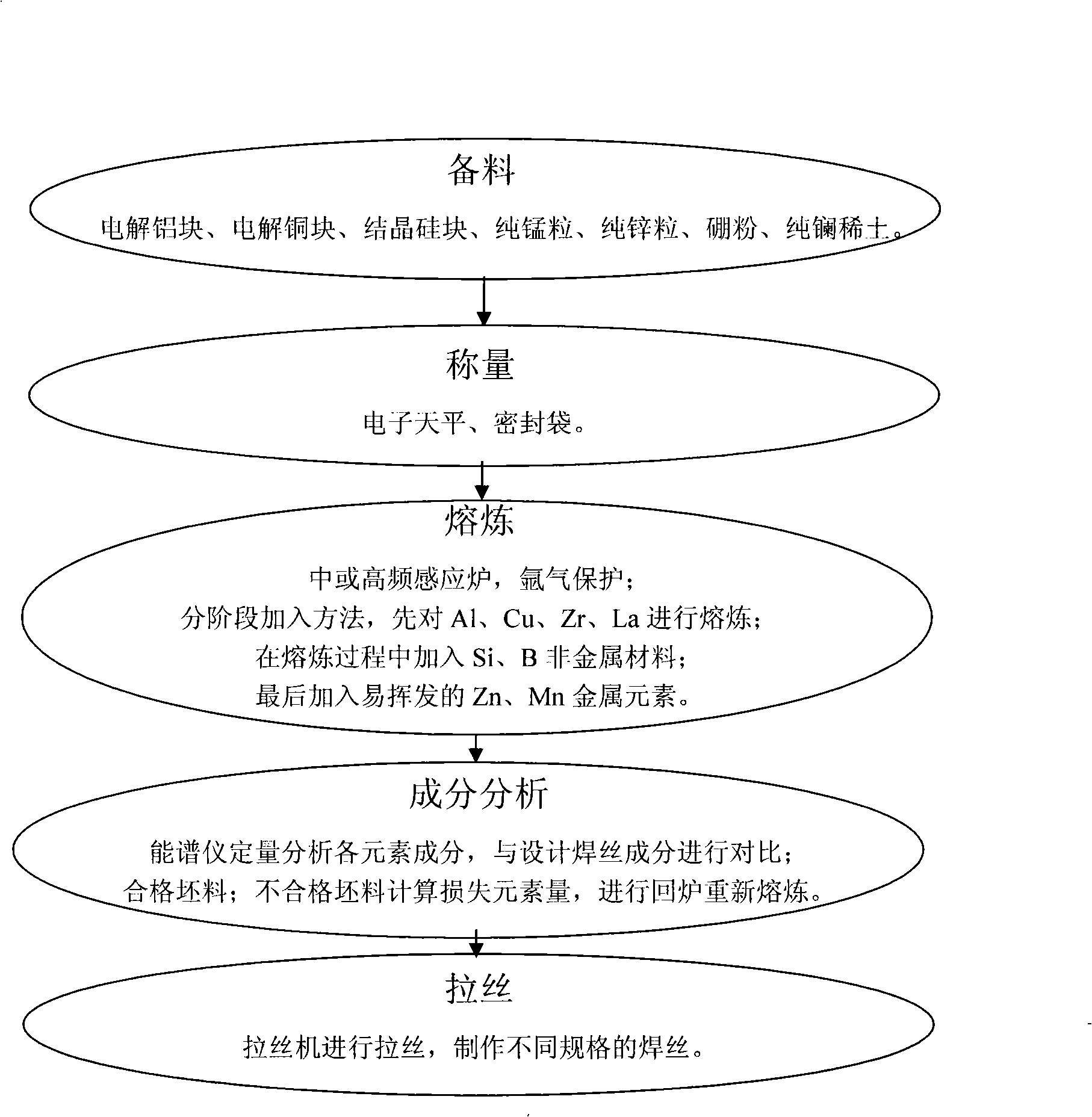

Welding wire and method for welding the aluminum and aluminum alloy and steel

InactiveCN101284339AImprove crack resistanceSuppresses the formation of intermetallic compoundsArc welding apparatusWelding/cutting media/materialsAlloy elementElectric arc

The invention discloses a welding wire and a method for applying the welding wire on aluminum and aluminum alloy to be welded with steel. The welding wire (3) takes Al-Si solder as matrix, and then alloying elements of Cu, Mn, Zn and microelements of B, Zr and La are added to form a dedicated welding wire. The method comprises the following steps: K-shaped divided edges are formed on both ends of the aluminum and aluminum alloy (5); the angle of the divided edges is 50 plus or minus 5DEG C; a divided edge of 30 plus or minus 5 and a truncated edge of 1.0-2.0mm are formed on the side of a steel piece (4); the steel piece (4) is fixed on a chucking tool with a cooling device; the butt clearance between the aluminum and aluminum alloy (5) and the steel piece (4) is 1.0-2.0mm; a small-scaled pulse AC TIG welding method is adopted for single-side welding to realize double side shaping; a tungsten electrode (2) is hemispherical; the nozzle (1) of a welding gun is inclined to the aluminum side; and the welding wire (3) is continuously fed. The method can successfully realize the effective and fine quality connection of the aluminum and the dissimilar steel material by electric arc braze welding without clad layer, and has the advantages of simple operation, low welding cost, and stable and reliable welding process.

Owner:HARBIN INST OF TECH

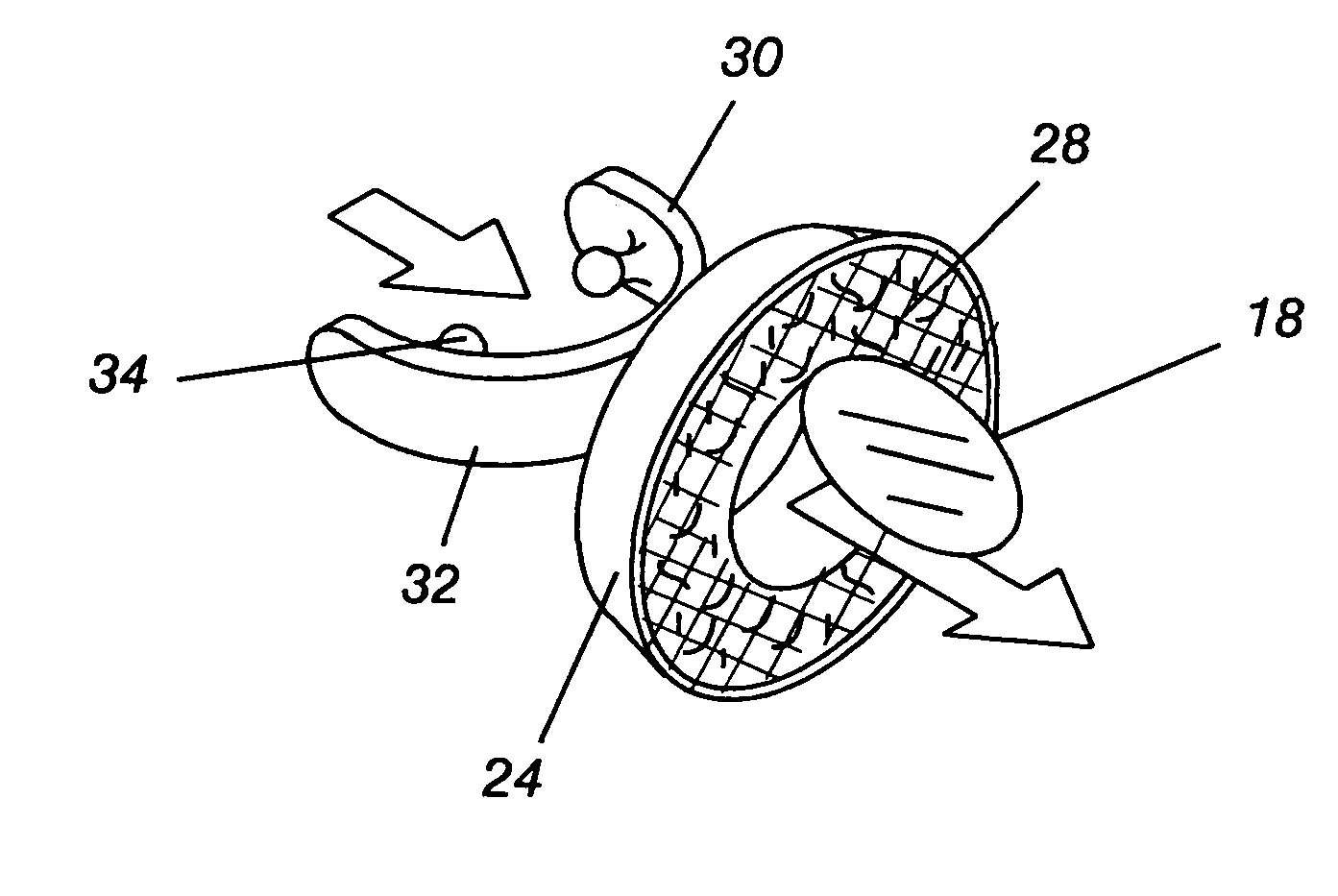

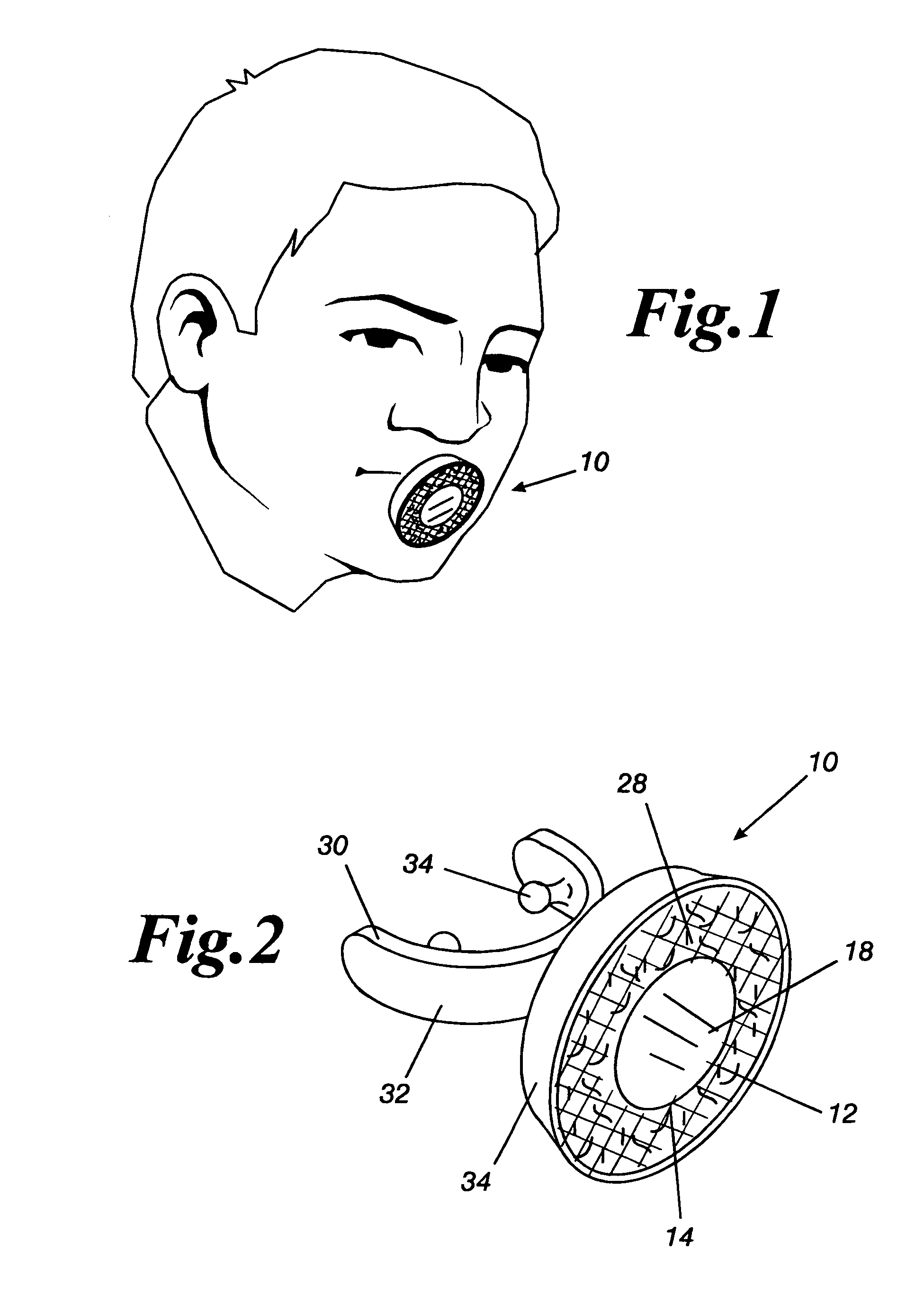

Personal breathing filter

ActiveUS7025060B1Easy to carryAvoid problemsBreathing filtersTeeth fillingAir filtrationFilter media

A personal air filtration device has a cylindrical exhalation tube, with a one-way valve thereon. Concentric around the periphery of the exhalation tube and integrally connected to the exhalation tube rearward (proximate the user's mouth) of the one-way valve is a filter media housing. Filter media is contained between the housing and the tube. A plurality of perforations in the exhalation tube, rearward of the one way valve but forward from the housing connection ring, provide inhaled air ingress to the exhalation tube. Inhaled air forces the one-way valve closed, so that air is directed through the filter media, passes through the perforations and into the exhalation tube where the user can take in the cleansed air. The pressure of the exhaled air through the exhalation tube causes the one-way valve to open, so that exertion by the user is minimized.

Owner:NICHOLSON ALEXANDER J G

Gravimetric moisture measurement instrument

ActiveUS7851712B2Lower Level RequirementsPromote escapeWeighing apparatus testing/calibrationMaterial moisture contentMeasuring instrumentEngineering

Owner:METTLER TOLEDO GMBH

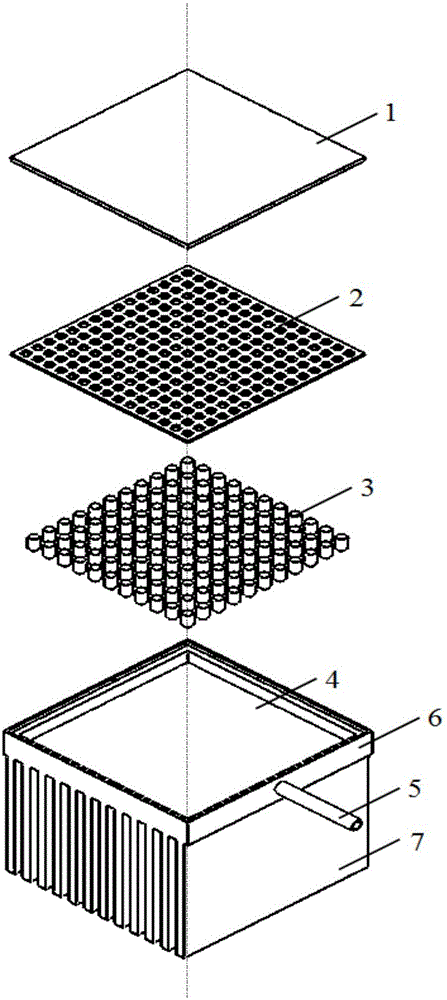

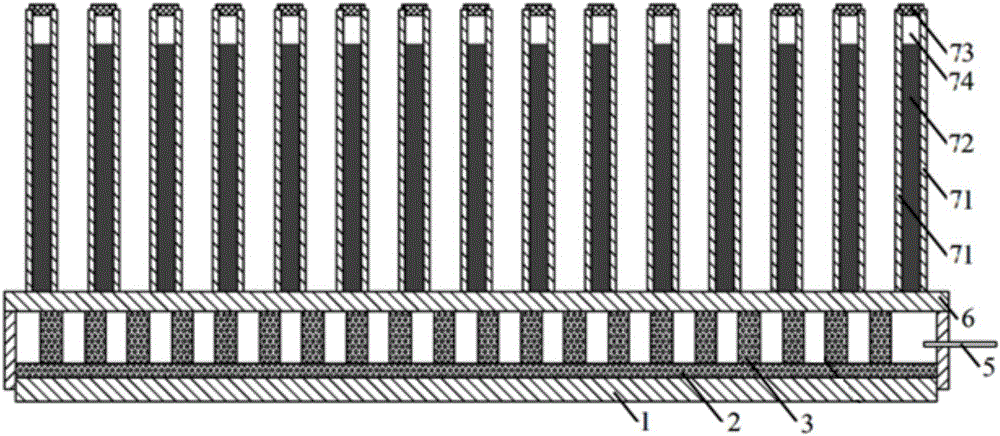

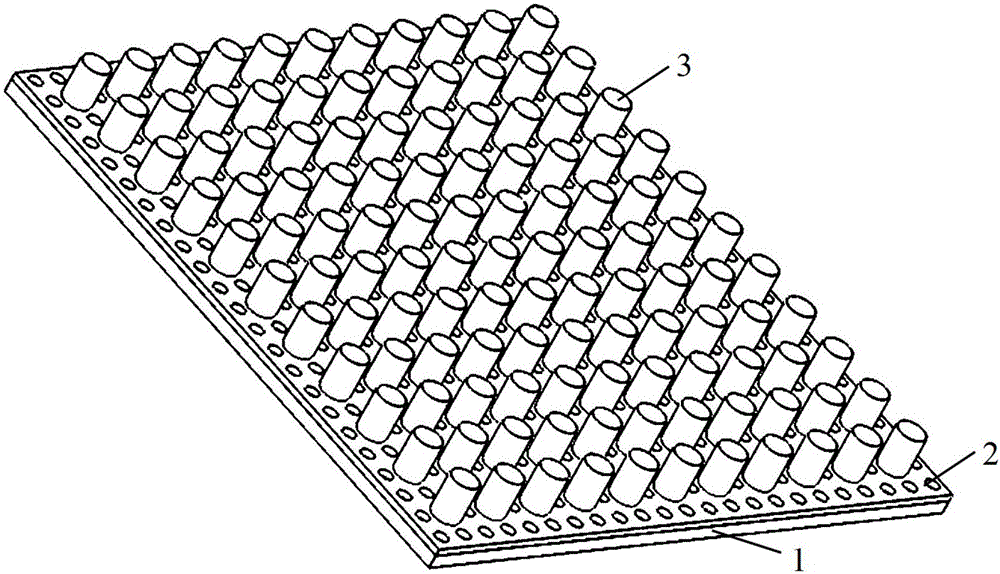

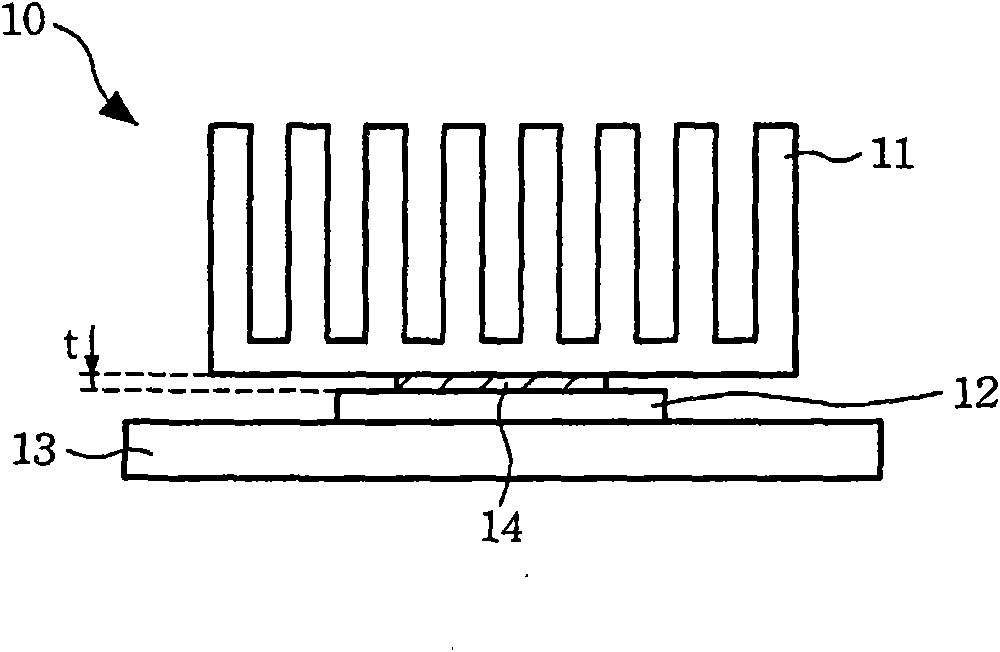

Composite heat dissipation device

InactiveCN106793685AImprove performancePromote escapeHeat storage plantsMachines using electric/magnetic effectsEvaporationIntegrated design

The invention discloses a composite heat dissipation device. The device comprises a flat plate heat tube and multiple sandwiched phase transition material composite boards. The evaporation end of the flat plate heat tube is used for taking heat from a heating element. The condensation end of the flat plate heat tube is connected with base parts of the sandwiched phase transition material composite boards. A multi-hole capillary liquid adsorbing core layer is arranged on the inner wall of the evaporation end. A bionic capillary liquid adsorbing core is arranged on the multi-hole capillary liquid adsorbing core layer. Each sandwiched phase transition material composite board comprises an enclosed inner cavity. Phase transition materials are arranged in each inner cavity. The side wall of each inner cavity is a metal plate. According to the invention, the flat plate heat tube with the capillary liquid adsorbing core has good temperature averaging ability; through the phase transition materials, temperature peaks are inhibited, so normal work of the whole electronic device is ensured; and through the integrated design of the flat plate heat tube and the sandwiched phase transition material composite boards, contact thermal resistance between a traditional flat plate heat tube and a heat sink is eliminated. In one word, the heat dissipation device is better in temperature averaging ability, stronger in heat dissipation ability, high in safety and simple to process.

Owner:淳铭散热科技股份有限公司 +1

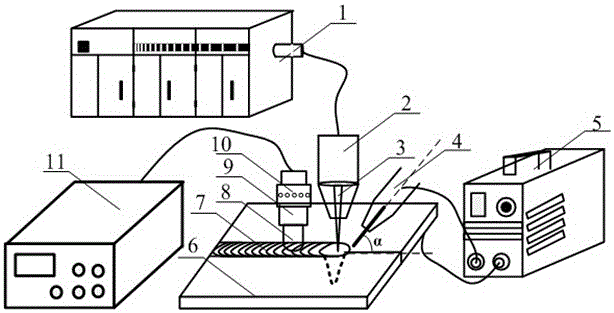

Ultrasonic assistec laser electric arc composite welding method of aluminum alloy

InactiveCN105710537AEfficient weldingPromote escapeWelding/soldering/cutting articlesLaser beam welding apparatusCavitationWelding residual stress

The invention relates to an ultrasonic assisted laser electric arc composite welding method of an aluminum alloy. On the basis of carrying out a welding scheme by combining TIG electric arc welding and laser welding, ultrasonic vibration pressure is introduced into a welding seam, wherein a designed vibration head is in direct contact with the welding seam, so that ultrasonic resources can be more sufficiently utilized, and gas in the welding seam can be rapidly escaped; most of gas in the welding seam is removed so that welding seam gas pore defects are reduced or avoided; tissue crystal grains of the welding seam are remarkably refined by utilizing cavitation effect and acoustic streaming effect caused by the fact that ultrasonic waves are transmitted in liquid, and furthermore, tissue alloy elements of the welding seam are more uniform, segregation is reduced, the strength and corrosion resistance performance of the welding seam are improved, and the performance of a welding connector is improved; and welding residual stress is effectively eliminated or reduced and the strength and corrosion resistance performance of the connector are enhanced, so that the efficient welding of the aluminum alloy is realized.

Owner:北京隆源自动成型系统有限公司

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

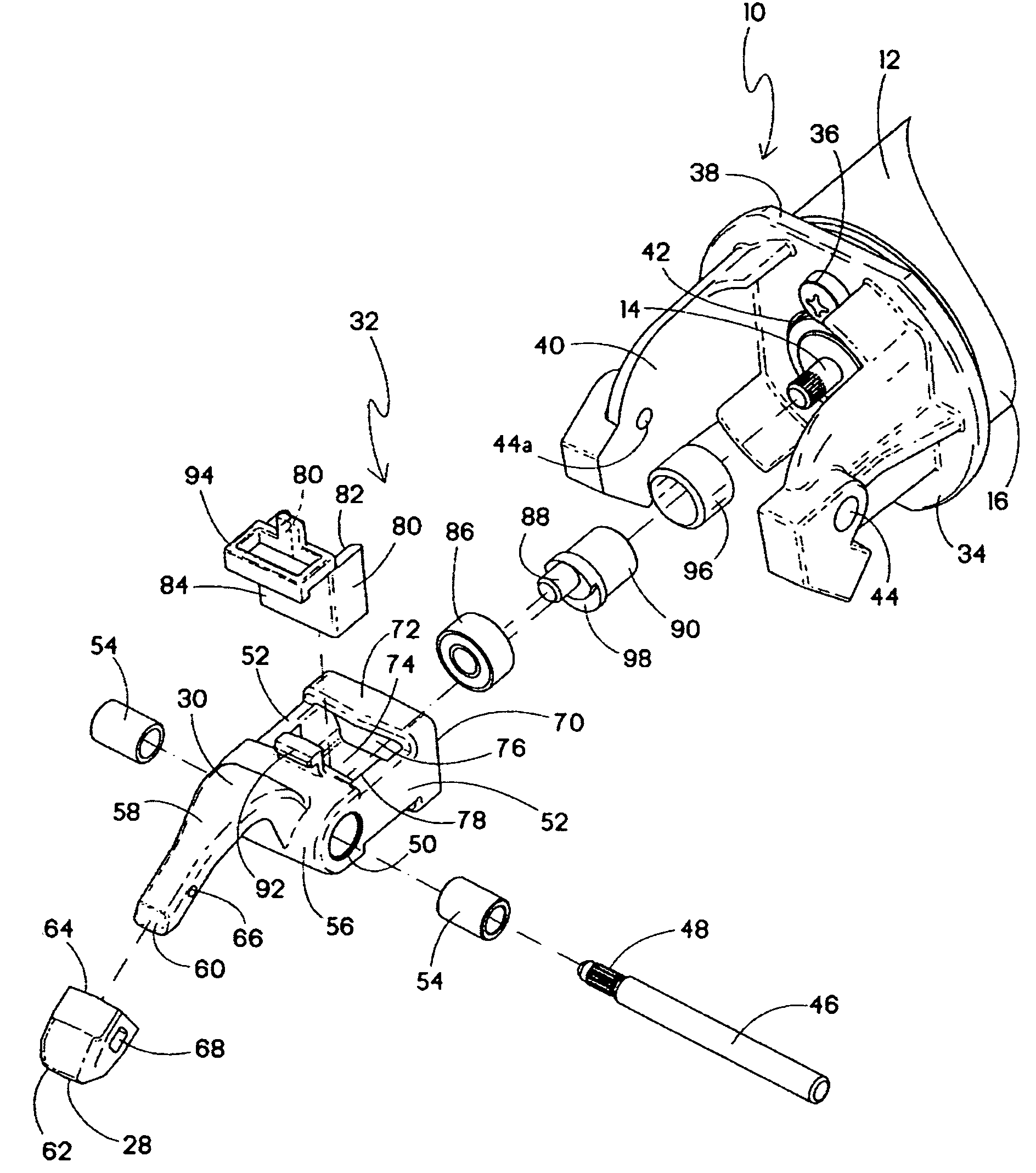

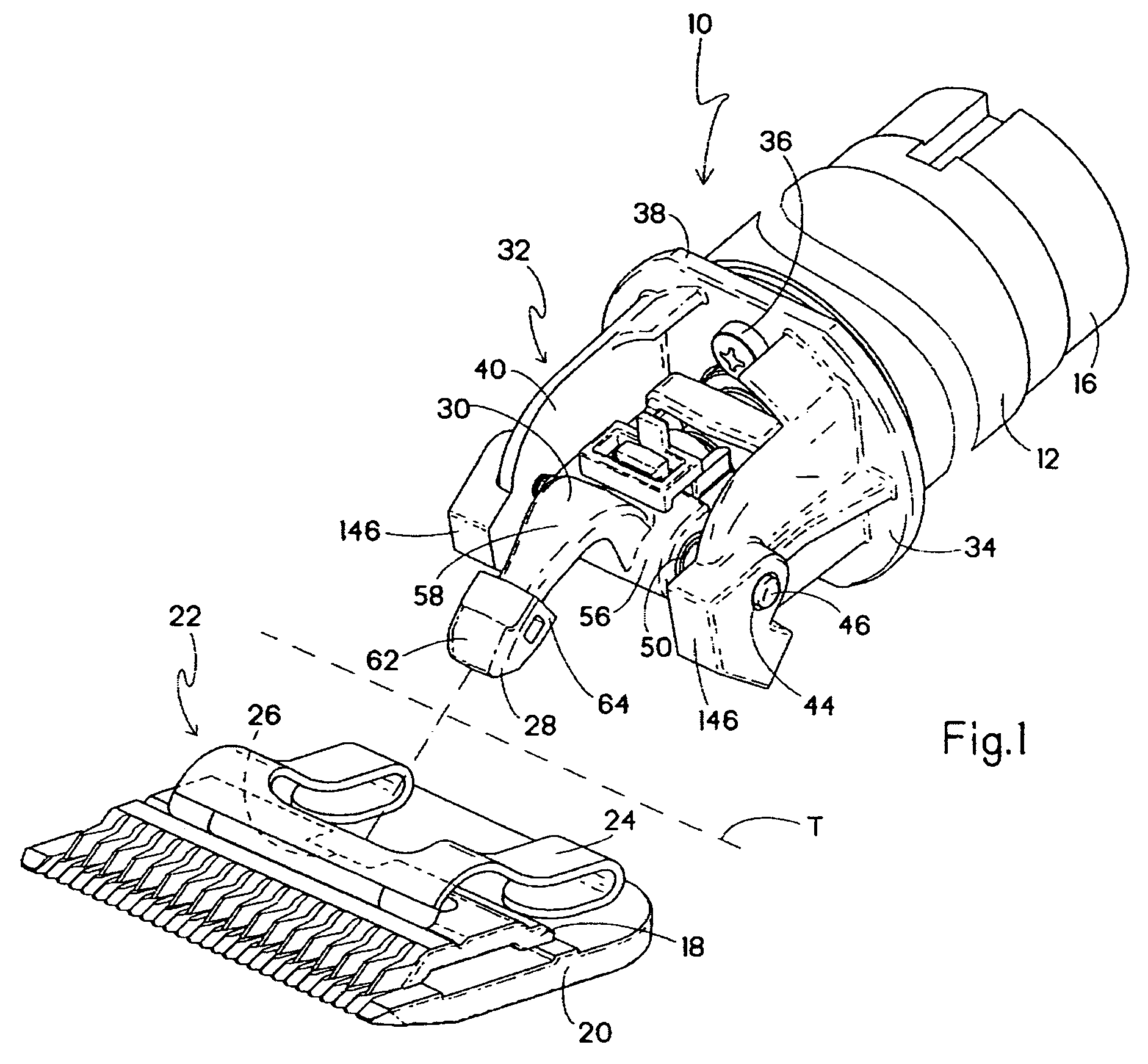

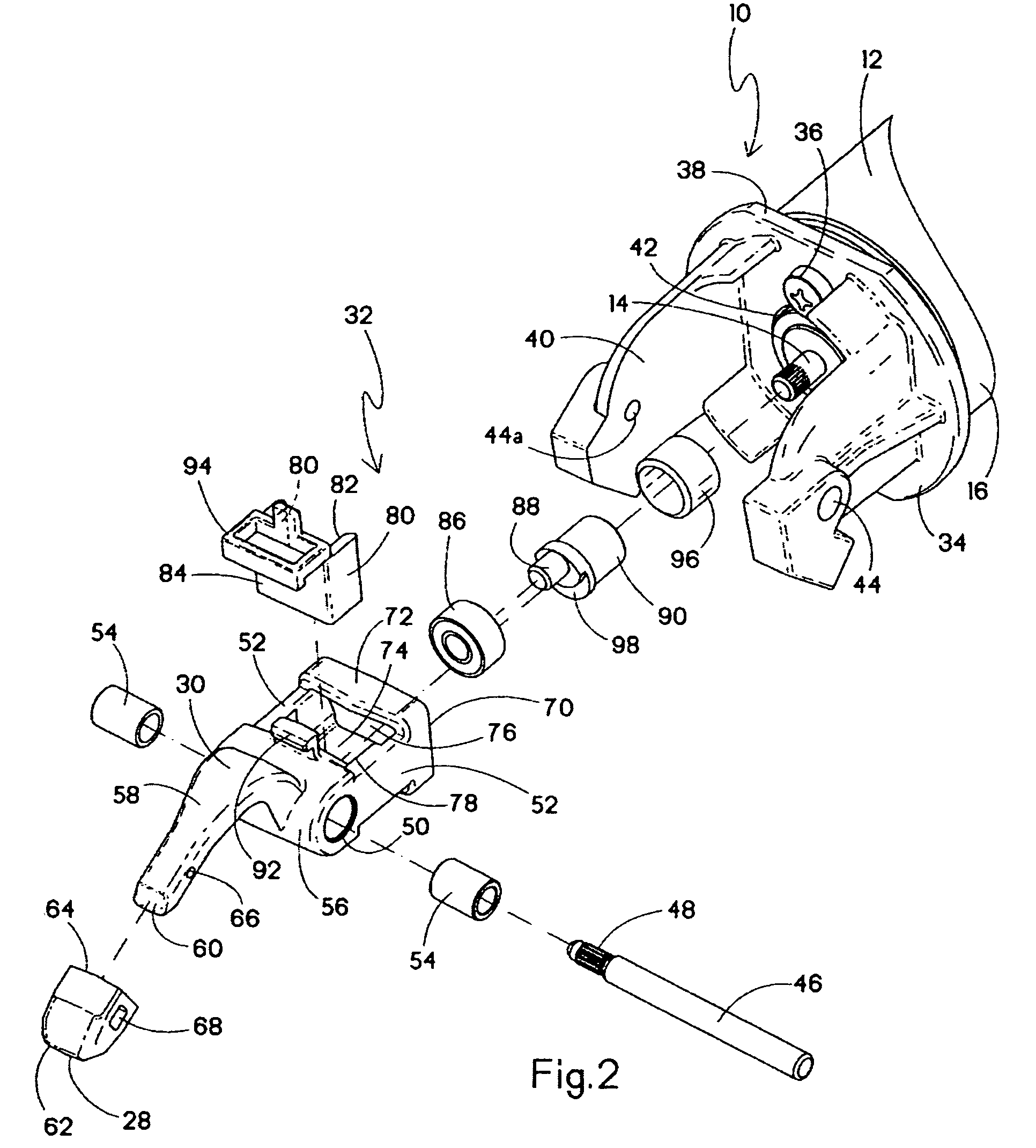

Rotary motor clipper with linear drive system

InactiveUS7346990B2Reduce accumulationSubject to movementMetal working apparatusReciprocating motionEngineering

A hair clipper includes a motor with a rotary output shaft, a bladeset including a stationary blade and a moving blade configured for reciprocation relative to the stationary blade, a drive system configured for transferring motion from the output shaft to the bladeset, and including a driving member moving linearly along an axis transverse to a longitudinal axis of the clipper.

Owner:WAHL CLIPPER

Emergency escape tool for vehicle

An emergency escape tool for helping people escaping from a vehicle while emergency has a member on which has a hole and a recess. The main member is provided with a hammer and a cutting device respectively at opposite ends thereof and two covers detachably mounted on the main member to shield the hammer and the cutting device. A whistle is received in the hole of the main member on which has a light emitting device. A clip and a holder are mounted on the main member to fasten the main member on a seat belt of the vehicle.

Owner:WANG LO PIN

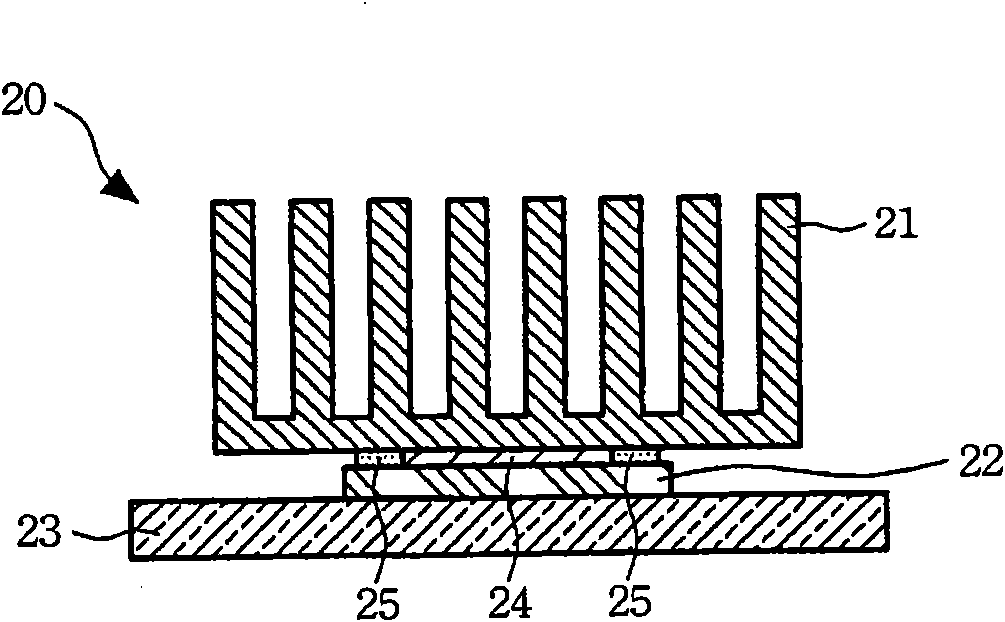

Heat radiation die set and radiation system applying phase change metal thermal interface material

InactiveCN101557697AAvoid the problem of liquid phase spillageAvoid spillingSemiconductor/solid-state device detailsSolid-state devicesElectronic componentPhase change

The invention relates to a heat radiation die set and a radiation system applying a phase change metal thermal interface material. The heat radiation die set and the heat radiation system can ensure that heat generated by the operation of an electronic element can be rapidly transmitted to outside environments. The heat radiation die set comprises a radiator and a phase change metal thermal interface material (TIM), wherein the radiator is arranged above the electronic element, and the bottom surface of the radiator is at least provided with a slot. The phase change metal thermal interface material is arranged between the electronic element and the bottom surface of the radiator, and is used as a thermal interface material between the electronic element and the radiator. When the phase change metal thermal interface material is melted by heating, part of hot melting liquid can flow into the slot so as to prevent the superfluous hot melting liquid from leaking out of a thermal interface.

Owner:萧复元

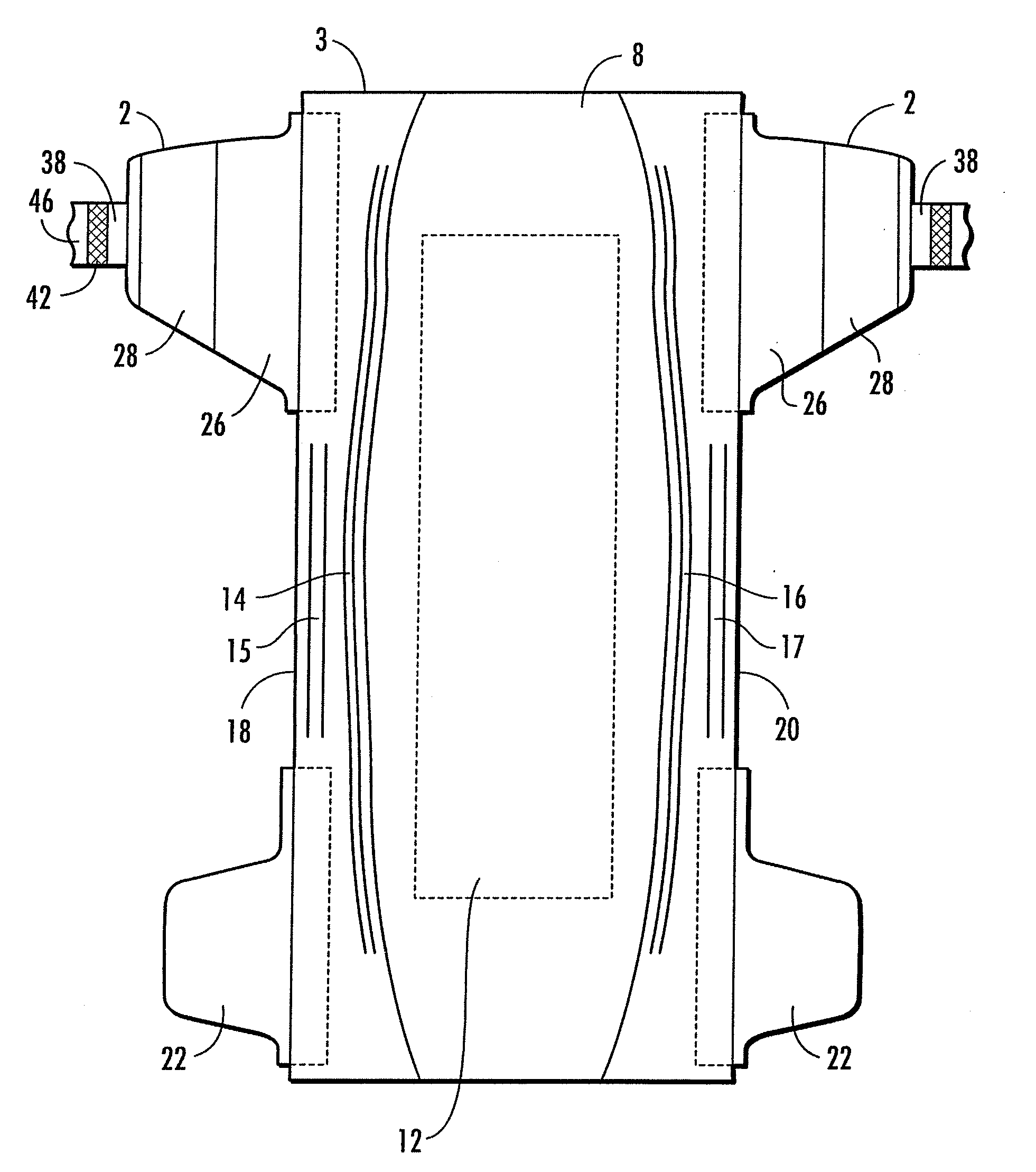

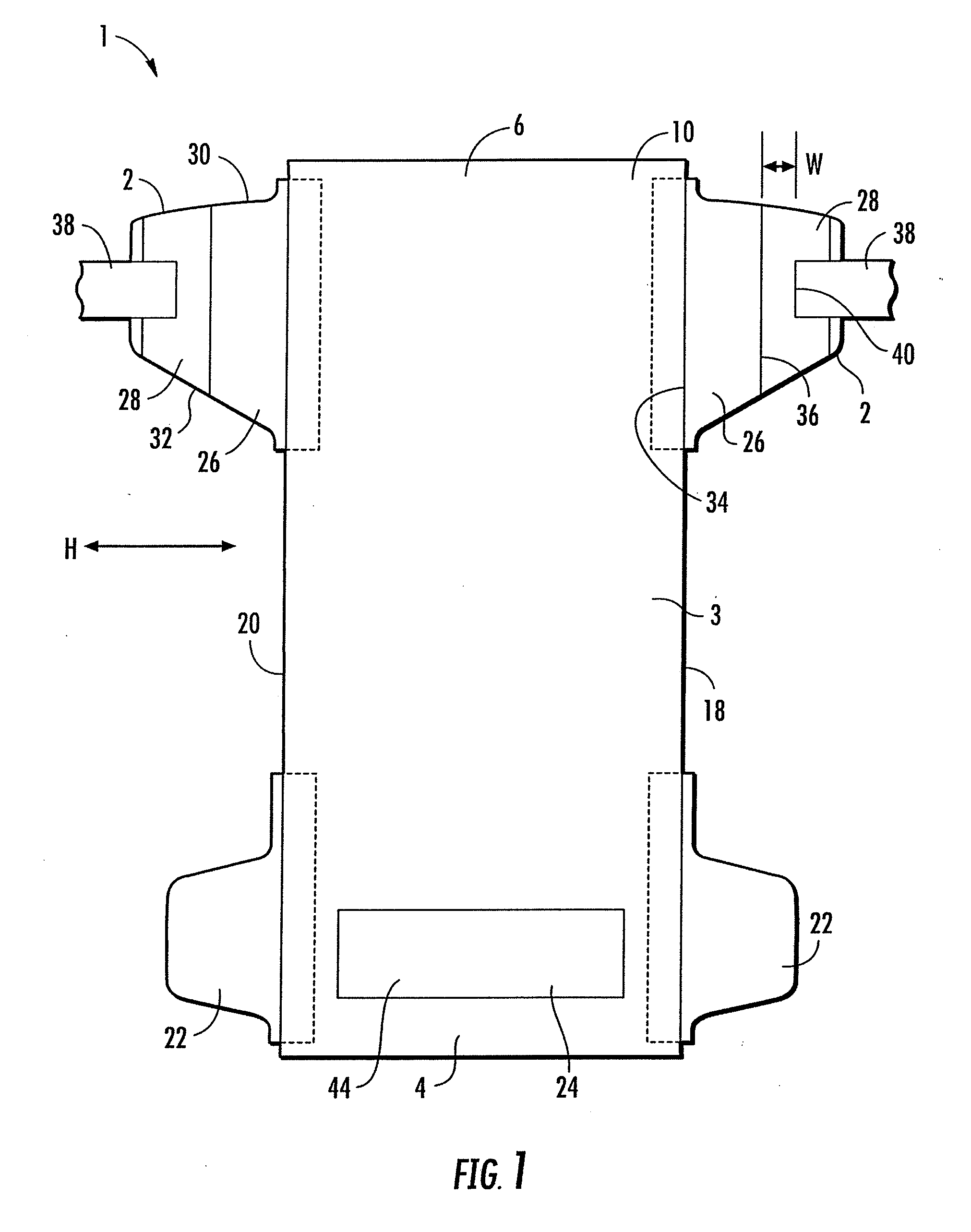

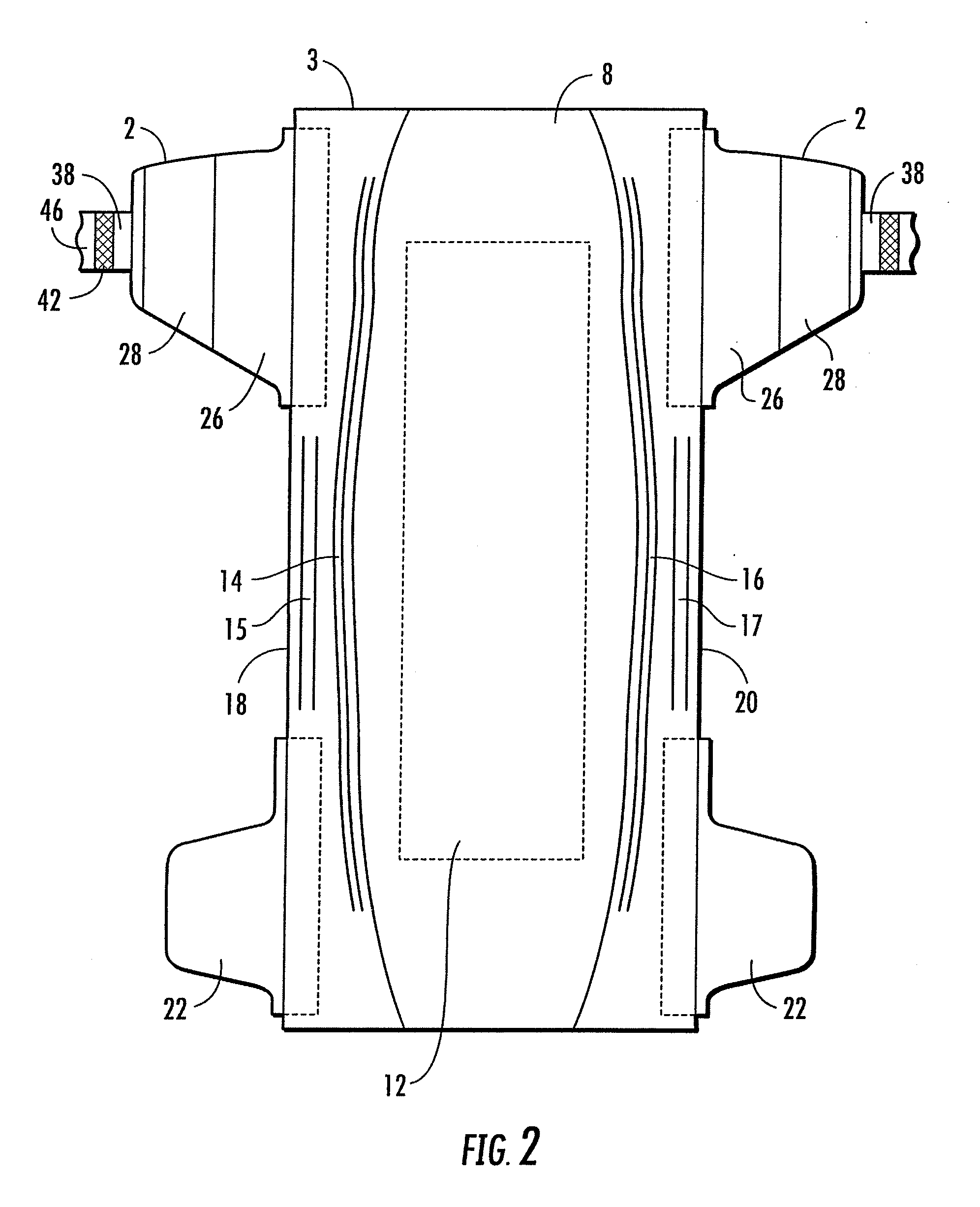

Hybrid stretch ear and absorbent article including the same

An absorbent article having a chassis with a front section, a rear section and opposed lateral side edges. A pair of hybrid stretch ears are attached to one of the front section and the rear section of the chassis. Each of the hybrid stretch ears include a non-elastic portion and an elastic portion, the non-elastic portion of each hybrid stretch ear being attached to one of the opposed lateral side-edges of the chassis. The non-elastic portion and the elastic portion of each hybrid stretch ear are sized and positioned relative to one another such that the elastic portion is positioned outside of respective leg opening areas defined by the opposed lateral side edges of the chassis when the absorbent article is secured to the torso of a wearer.

Owner:ASSOCD HYGIENIC PRODS

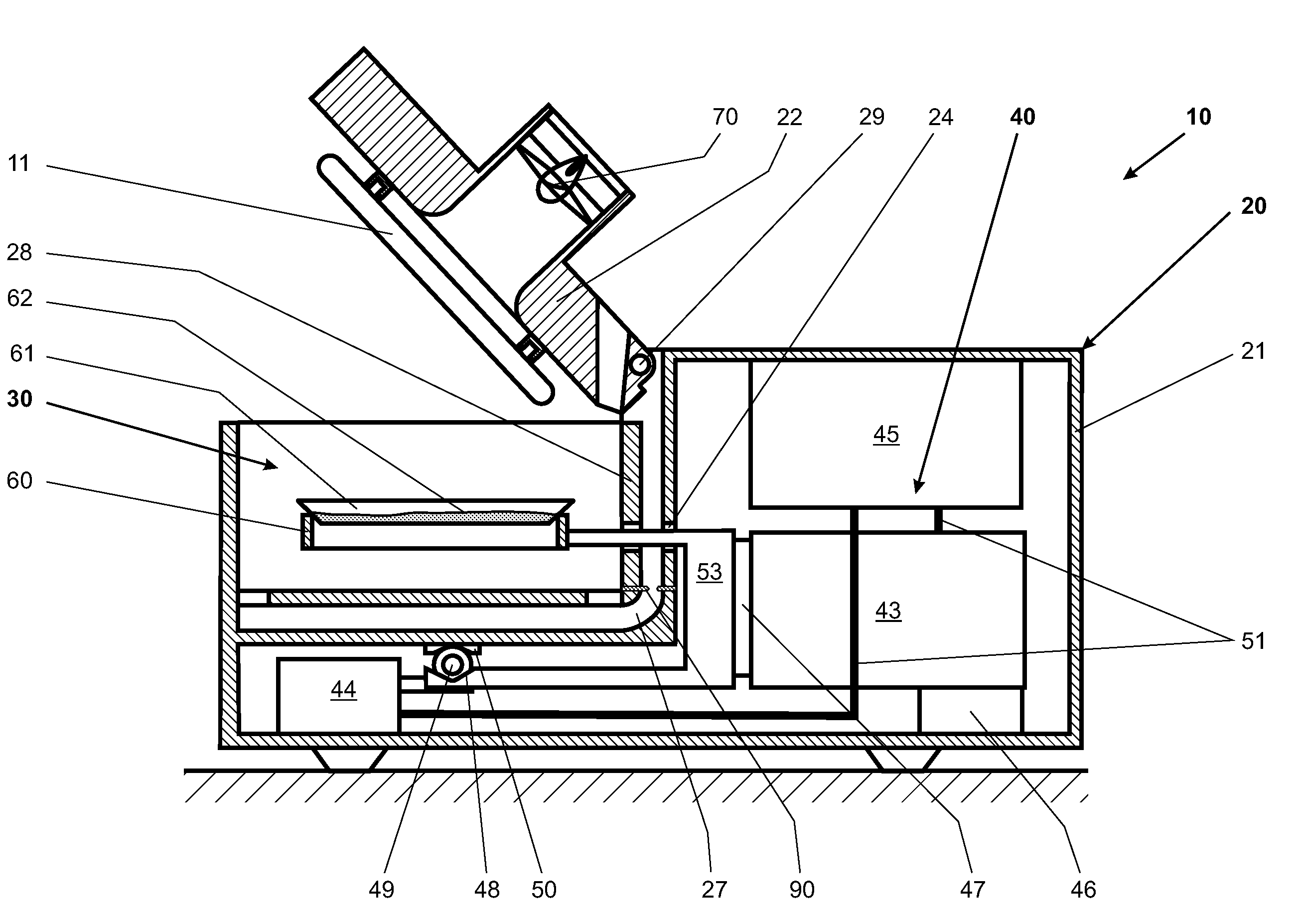

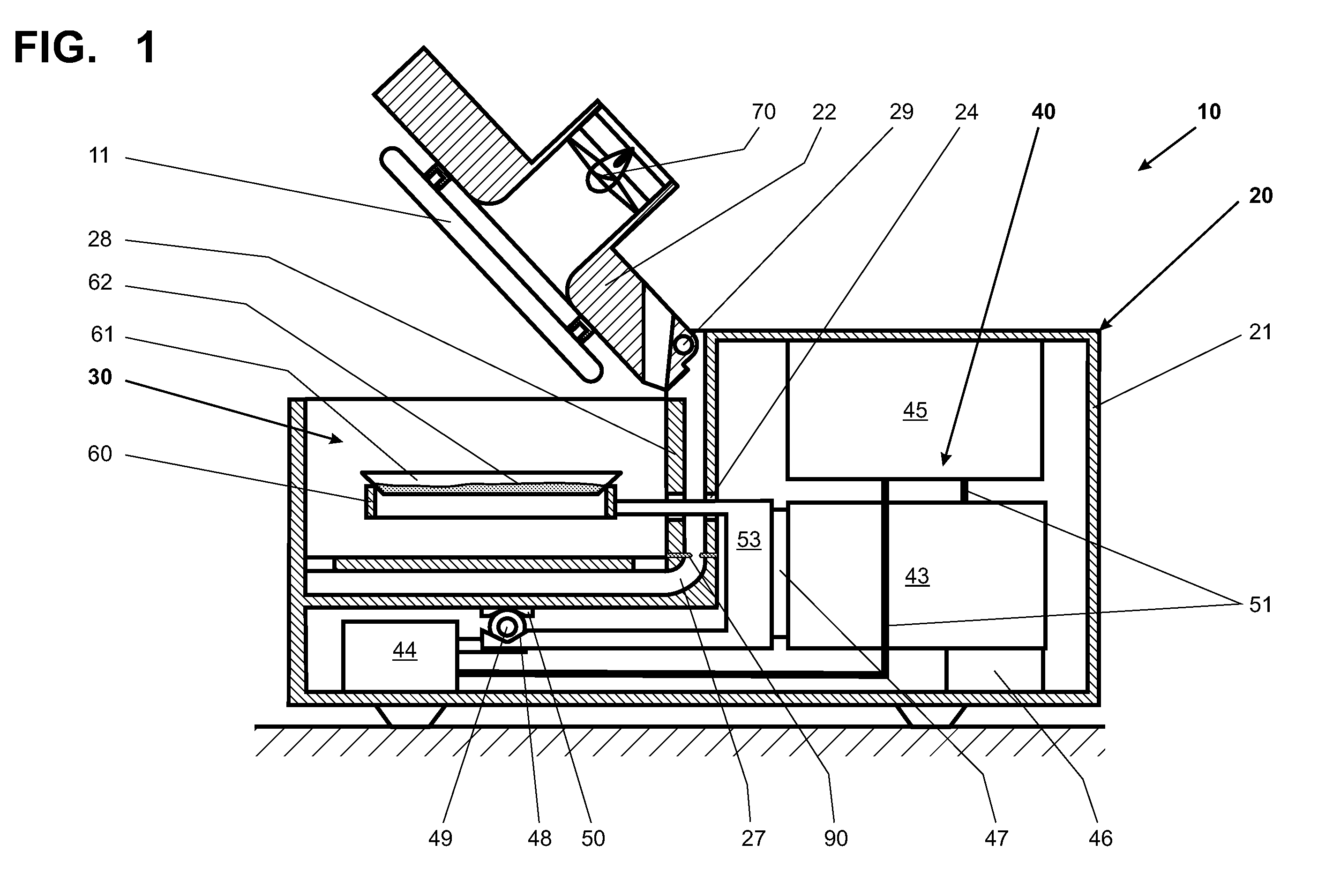

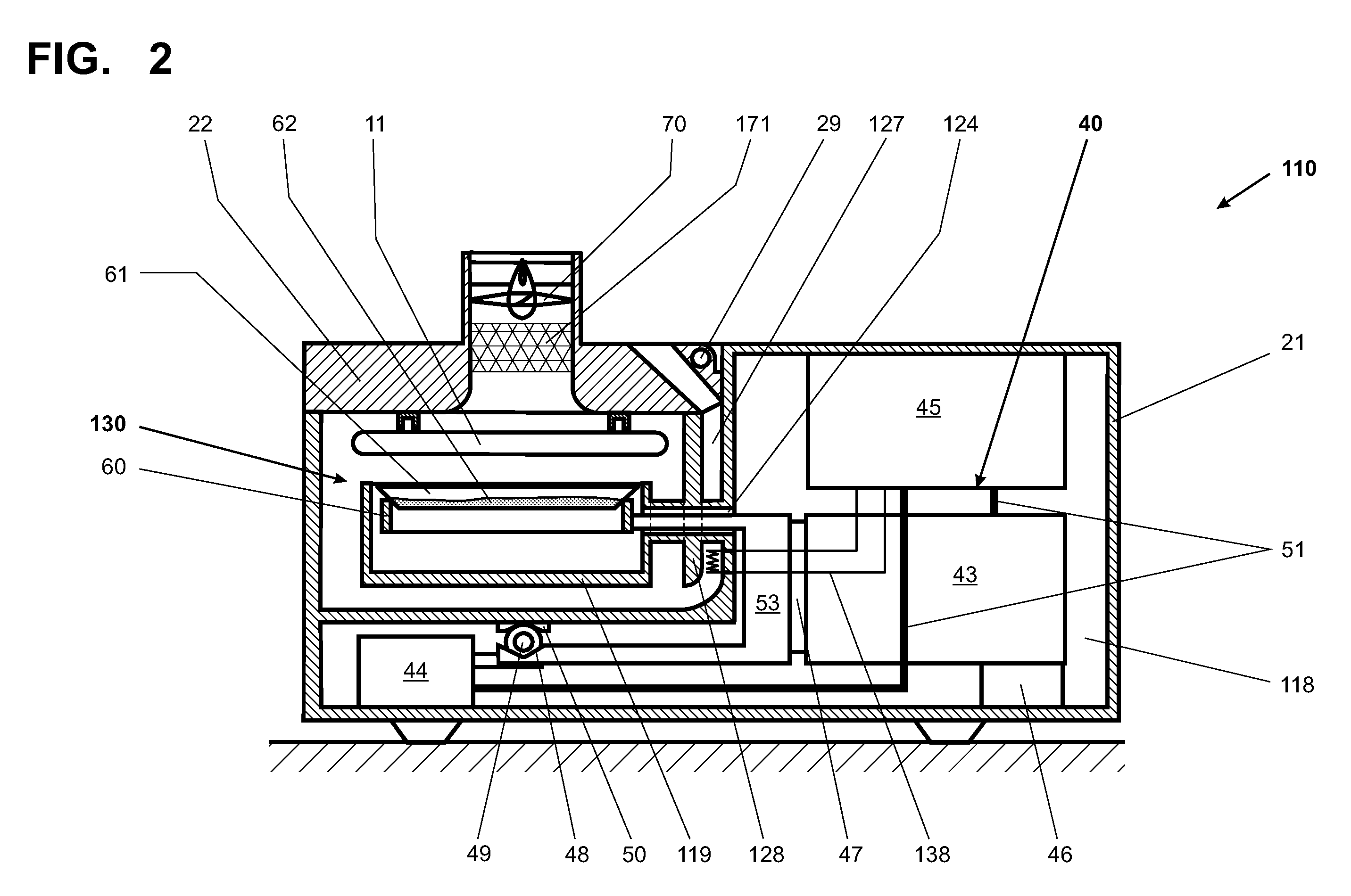

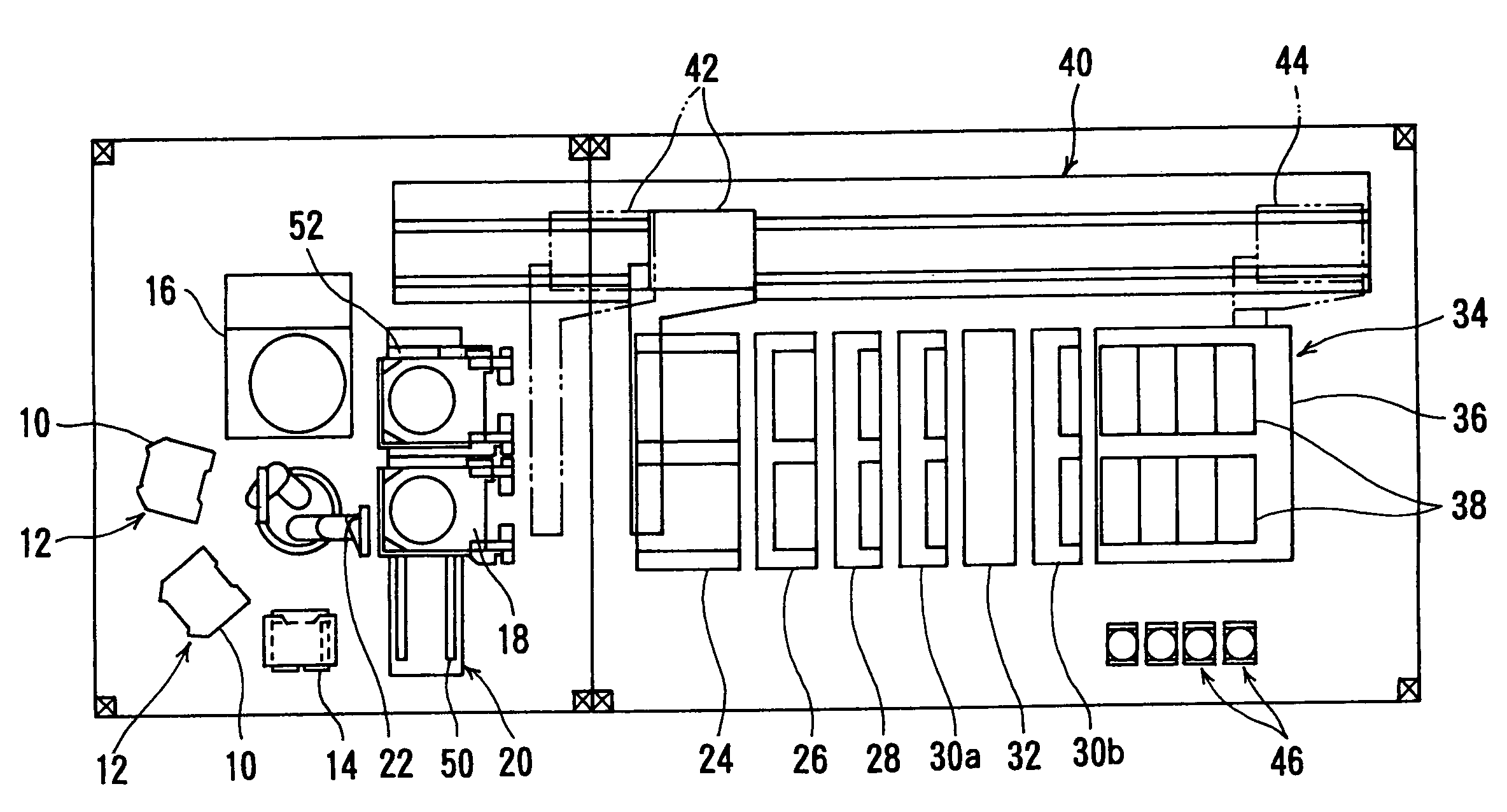

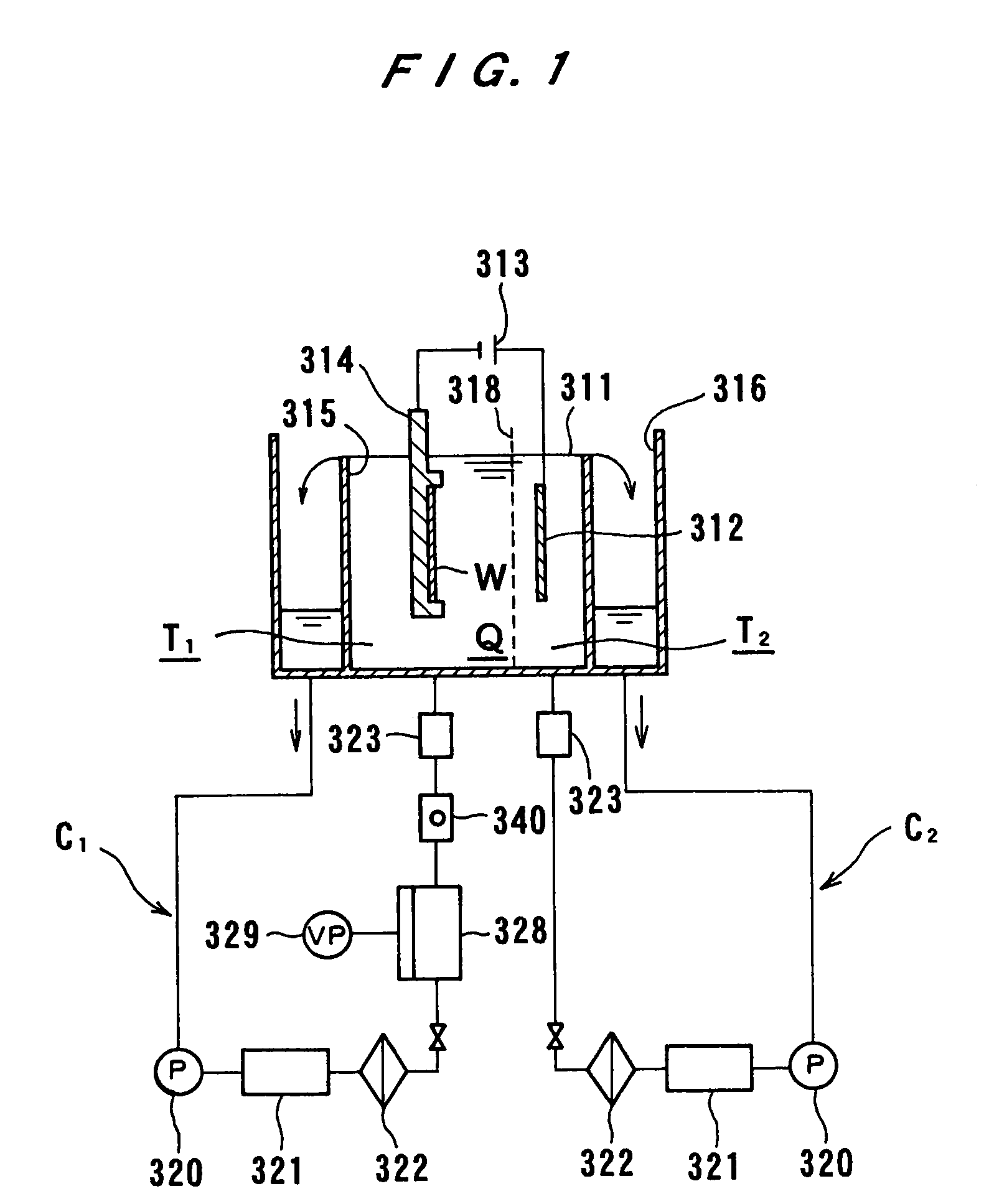

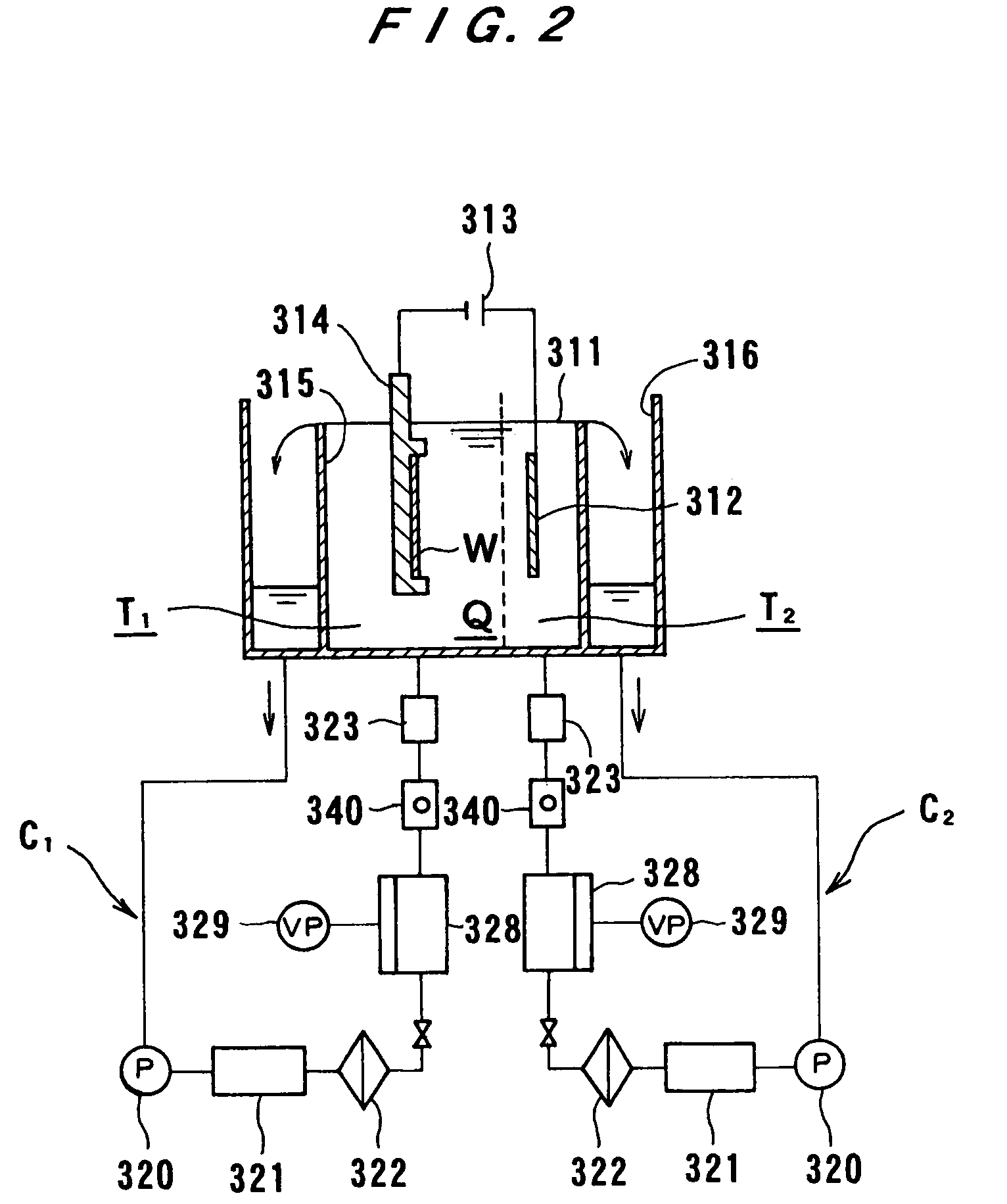

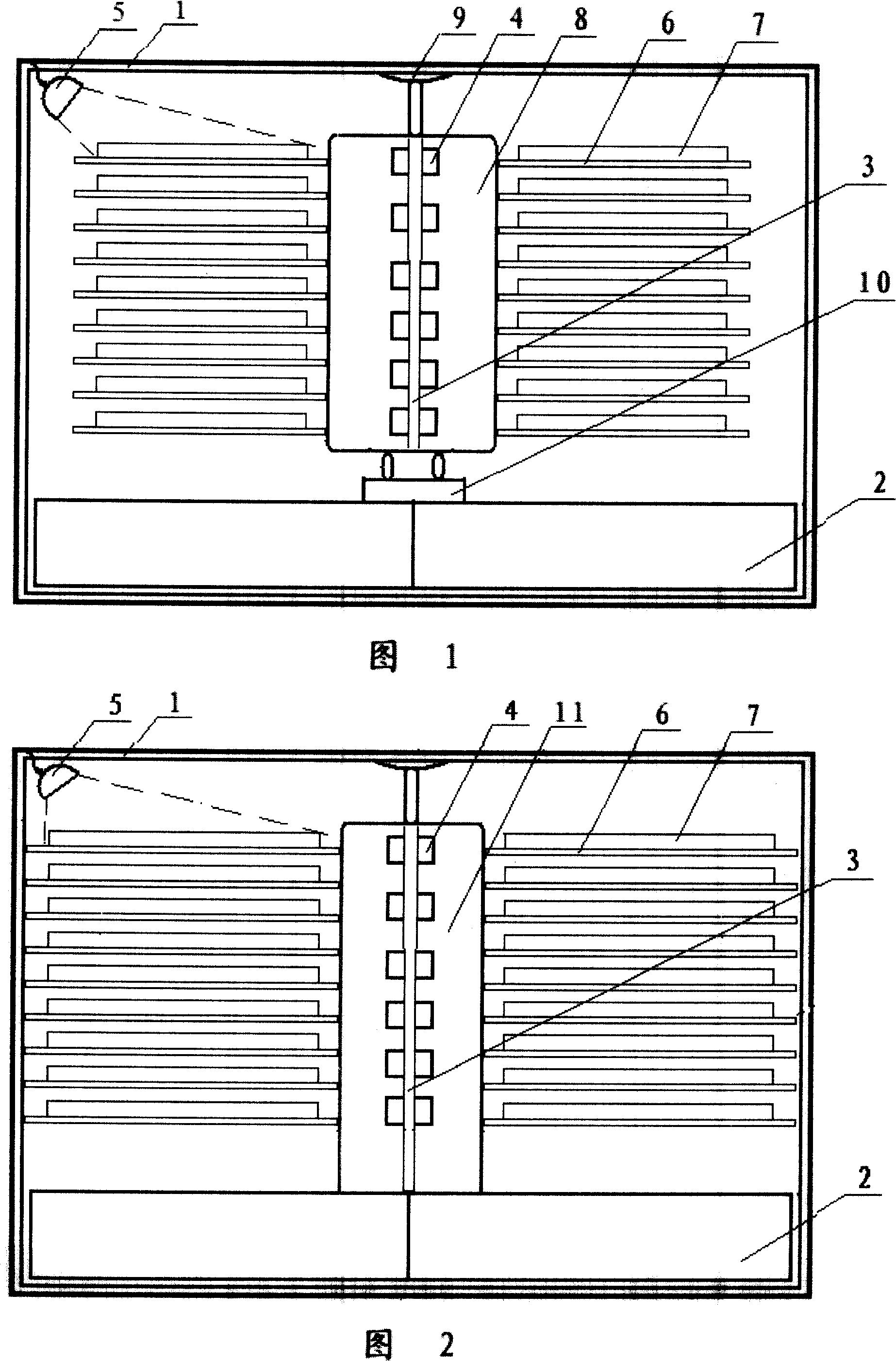

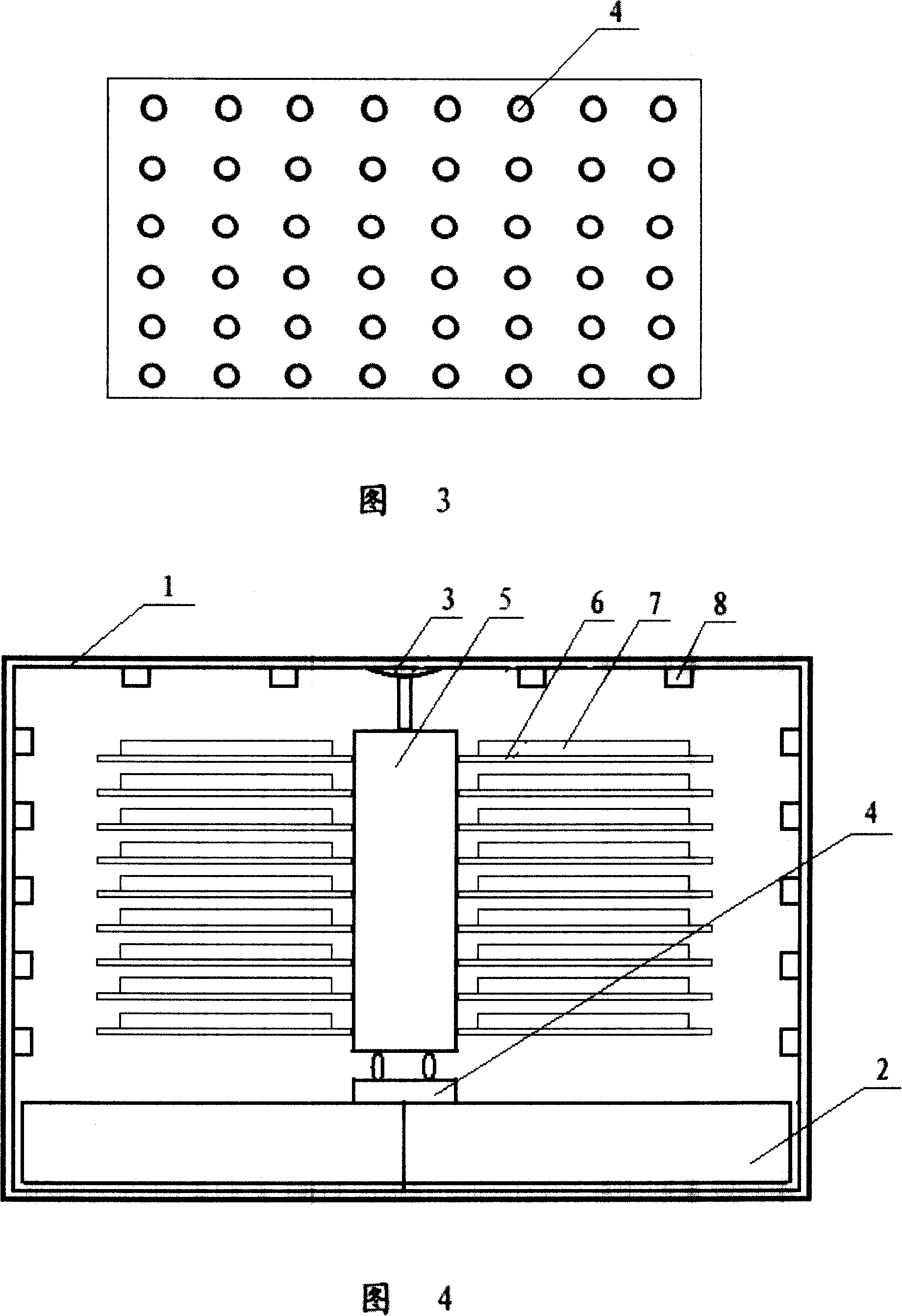

Plating apparatus and method

Owner:EBARA CORP

Microwave vacuum freeze-drying apparatus for food and drug production

InactiveCN101126596ABreak through the status quo of uneven heatingEvenly heatedDrying using combination processesDrying solid materials with heatFreeze-dryingProcess engineering

The utility model relates to a metal core which has replaced the traditional metal cores of the cold stores; after an access is opened in the microwave radiation of the heat energy in the vacuum freeze-drying, the microwave radiation provides energy directly to the material at low pressure or ultra low pressure, so as to make the water molecules in the internal and external parts of the ice crystal sublime rapidly; the change not only has an advantage that the microwave can heat the internal and external part of the material at the same time, but also reserves an advantages that the prior vacuum freeze-drying equipment can decrease temperature instantly when pre-freezing and maintain the temperature in the later period of the desorption. The main microwave heating source is arranged in the centre of the material with no metal wall in the utility model, which overcomes the insufficiency of heating way by the prior microwave and makes the material heated evenly; during the period of desorption, the utility model combines the microwave heating and the shelf silicone oil heating and makes the shelf silicone oil heating as the last safeguard for the dry quality of the products, which enables the microwave overheating never take effect on the quality of the products. The utility model introduces the infrared sensor to the microwave vacuum freeze-drying equipment, which can use the microwave energy scientifically, powerfully and accurately.

Owner:丛繁滋

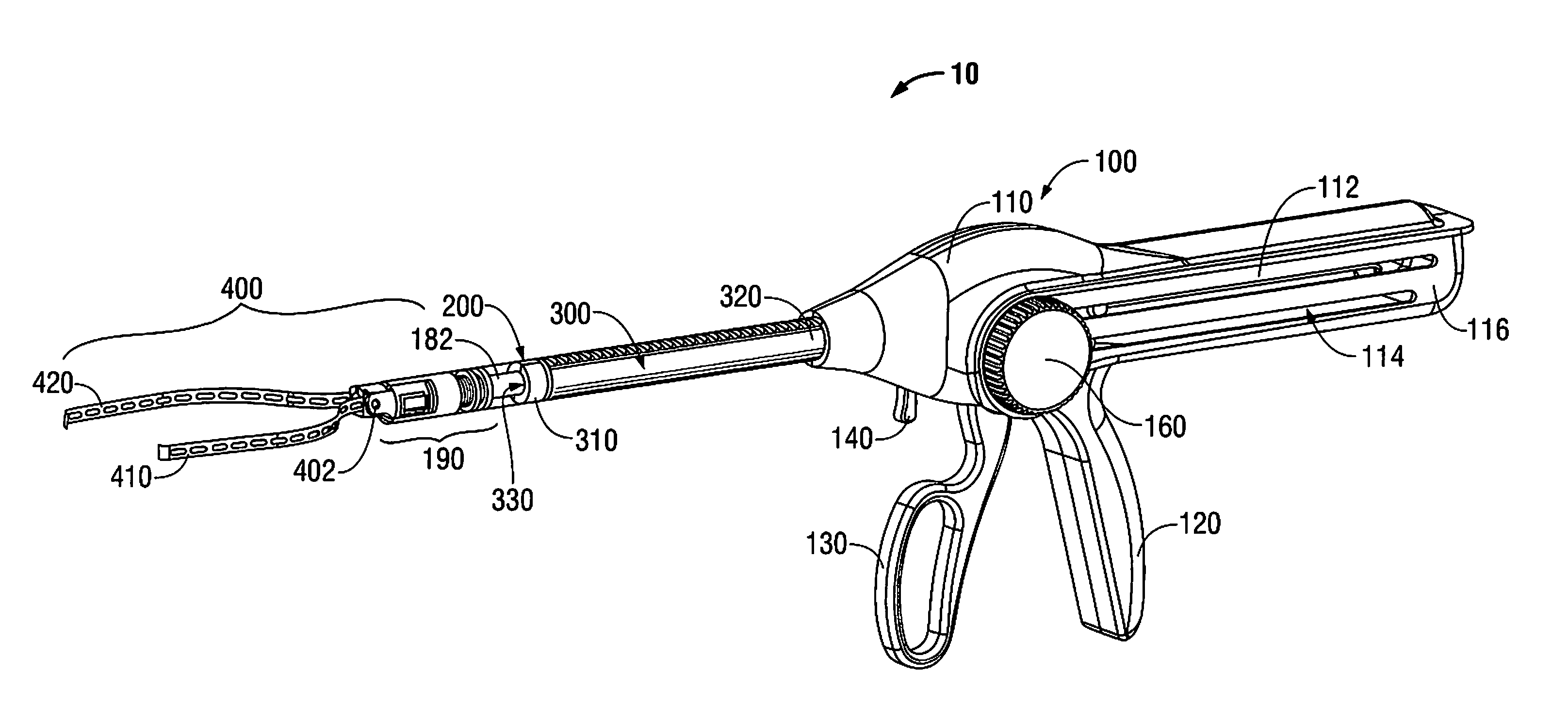

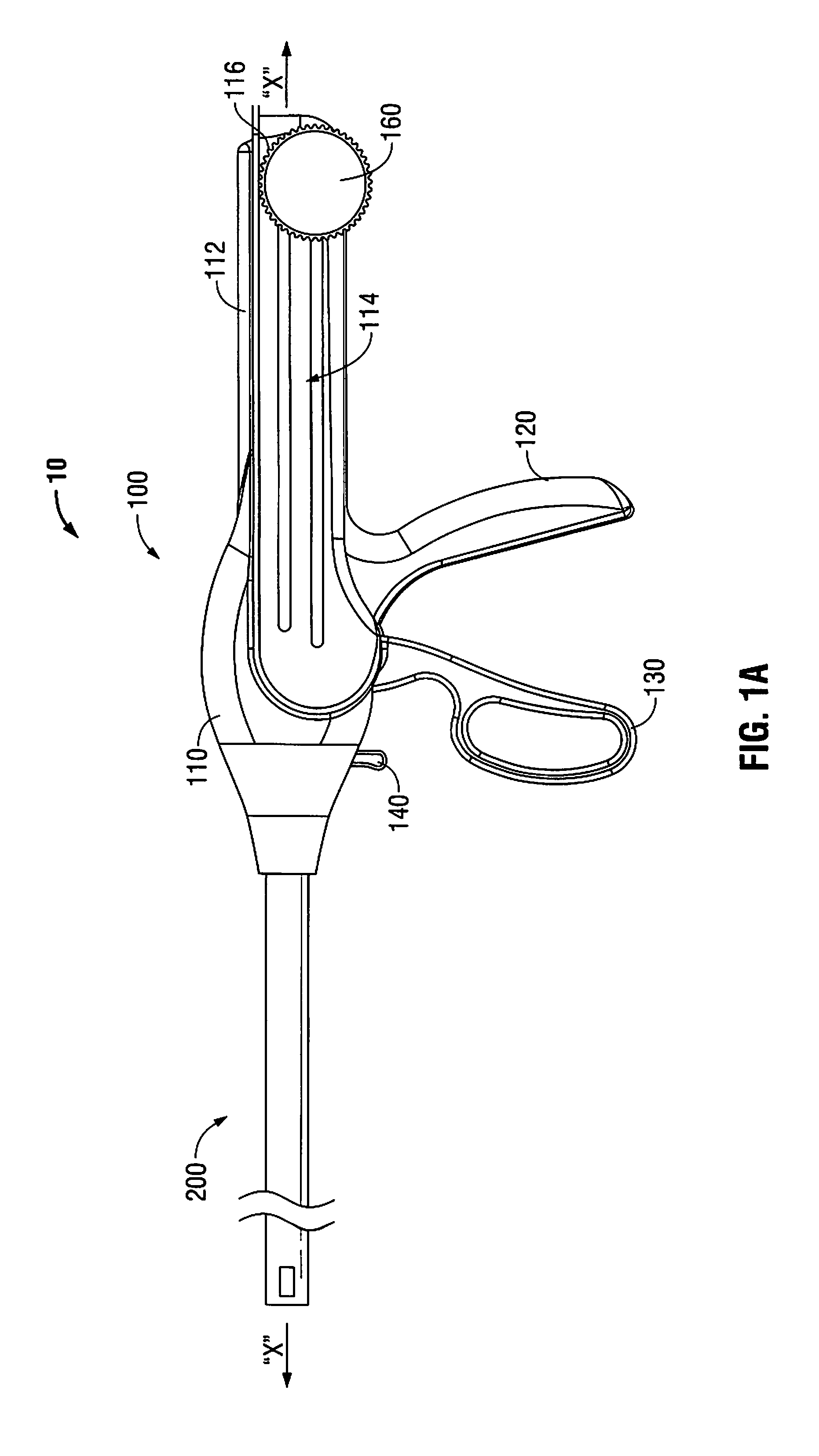

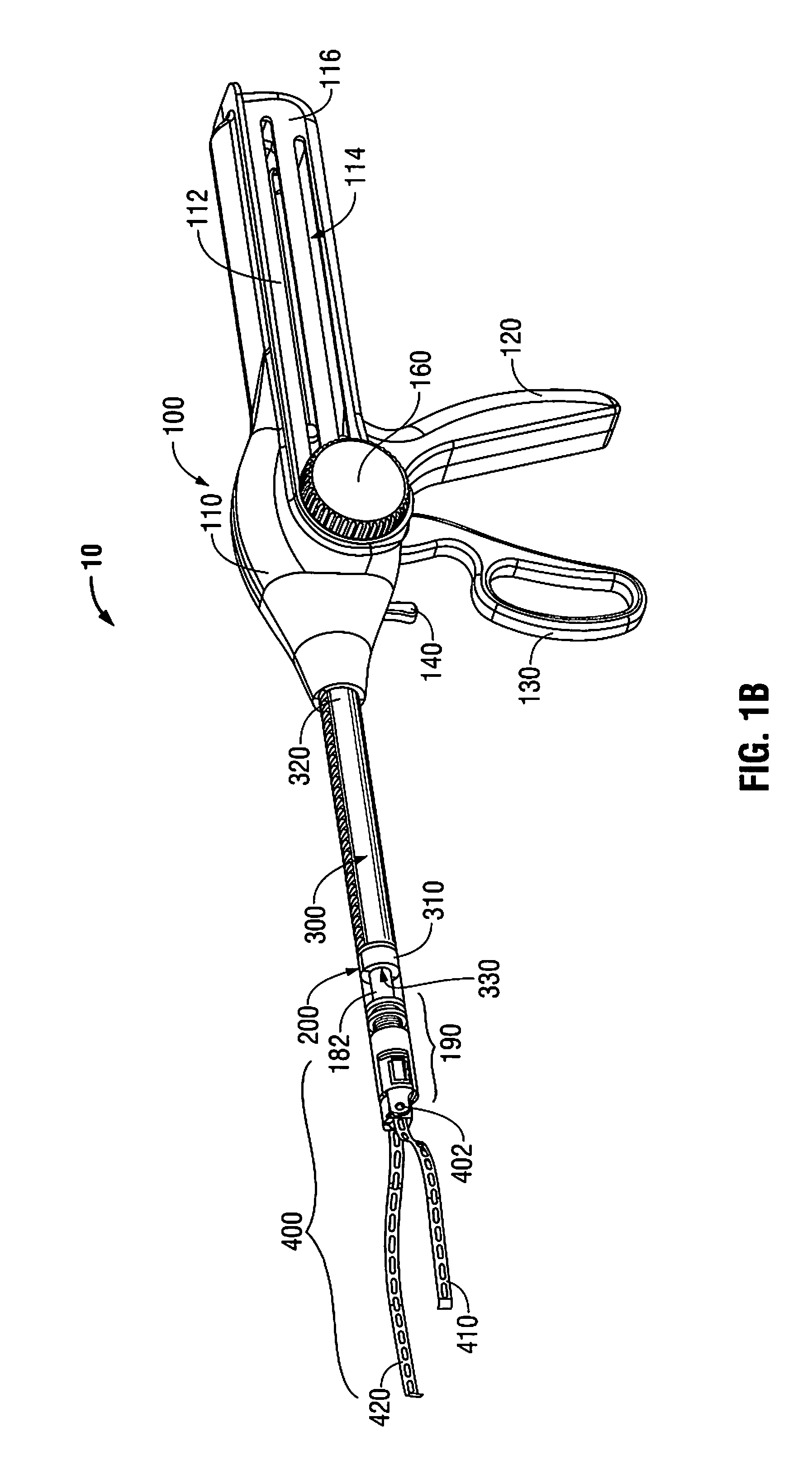

Specimen retrieval apparatus

A specimen retrieval apparatus includes a housing having an elongated tubular member extending distally therefrom. The elongated tubular member defines a longitudinal axis. An end effector assembly is coupled to a distal end of the elongated tubular member. The end effector assembly is configured to retain a specimen retrieval bag thereon. An articulation mechanism is operatively coupled to the elongated tubular member and the end effector assembly. The articulation mechanism is configured for selectively articulating the end effector assembly with respect to the longitudinal axis of the elongated tubular member.

Owner:COVIDIEN LP

Collection assembly

InactiveUS7959866B2Promote escapeSealing is reliableTable equipmentsLaboratory glasswaresEngineering

A tube assembly includes an inner tube telescoped into an outer tube. The inner tube is dimensioned to define a substantially annular space between the inner and outer tubes. Portions of the inner tube near its open top are configured to permit venting as the inner tube is inserted into the open top. However, the vent is closed during insertion of a closure into the tube assembly or prior to inserting a closure into the tube assembly.

Owner:BECTON DICKINSON & CO

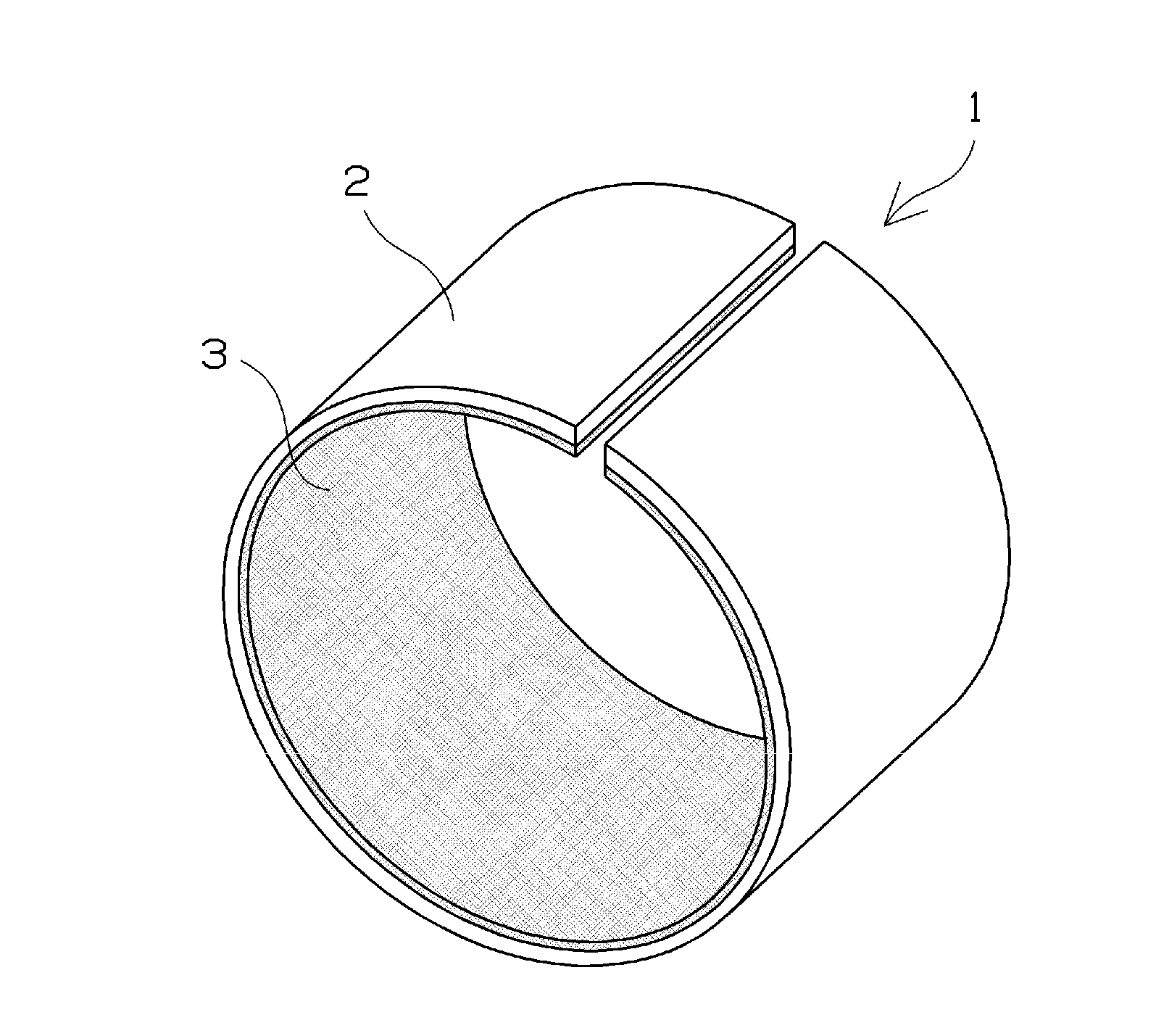

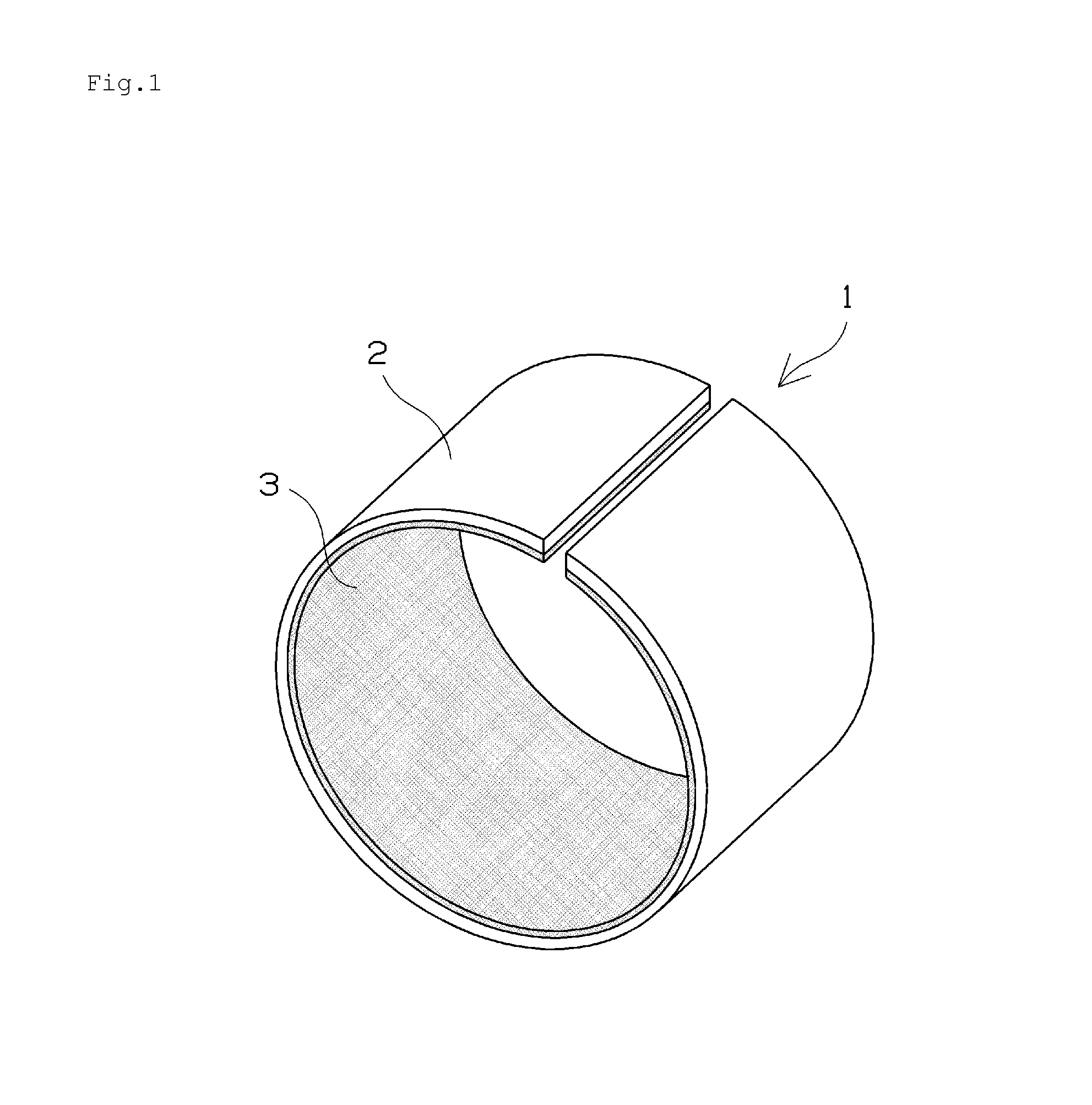

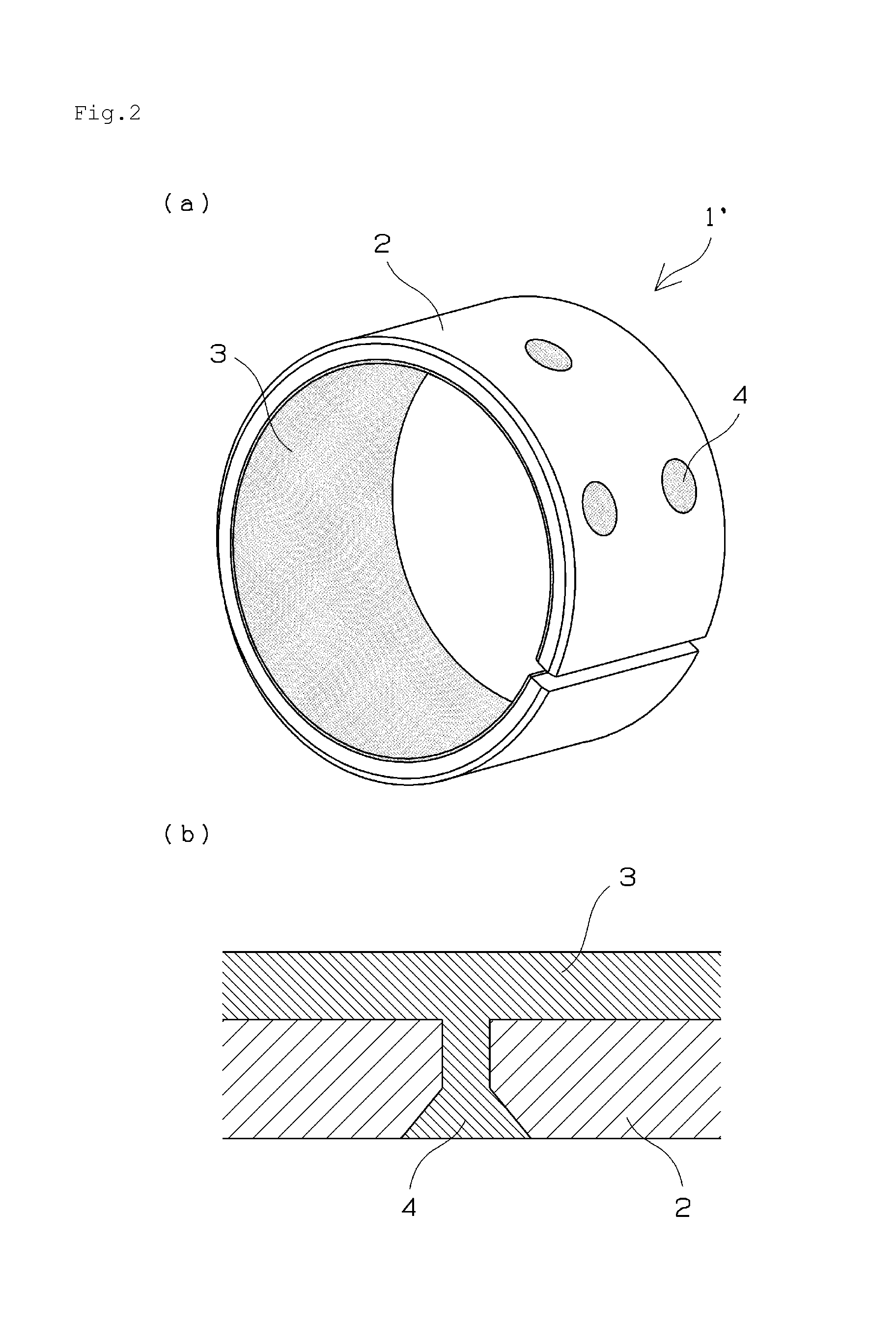

Composite plain bearing, cradle guide, and sliding nut

ActiveUS20150204383A1Improve load resistanceReduce the amount of deformationGearingSliding contact bearingsProduction rateHeat resistance

There is provided a composite plain bearing having excellent heat resistance, creep resistance under high surface pressure, low friction, abrasion resistance, and other characteristics while being capable of manufacture with high productivity. A composite plain bearing (1) comprising an ingot metal plate (2) and a resin layer (3) comprises a resin composition in which an aromatic polyether ketone resin or the like is used as a base resin, wherein the resin layer (3) is overlaid by injection molding and integrally provided on the surface on the surface of the ingot metal plate (2) to a thickness of 0.1 to 0.7 mm. The ingot metal plate (2) is chemically surface-treated on a face joined to the resin layer (3).

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com