Microwave vacuum freeze-drying apparatus for food and drug production

A technology of vacuum freeze-drying and drying equipment, applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

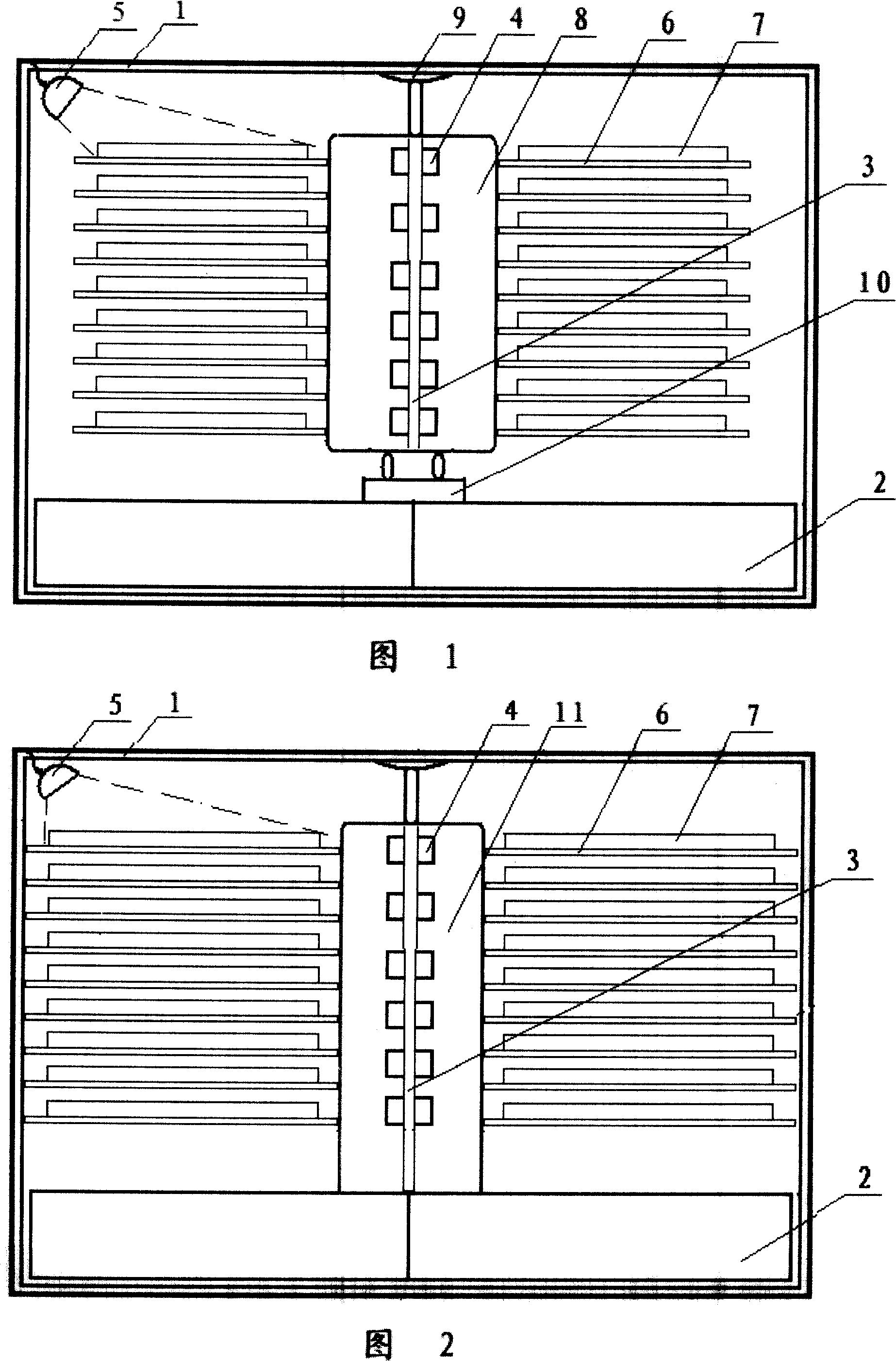

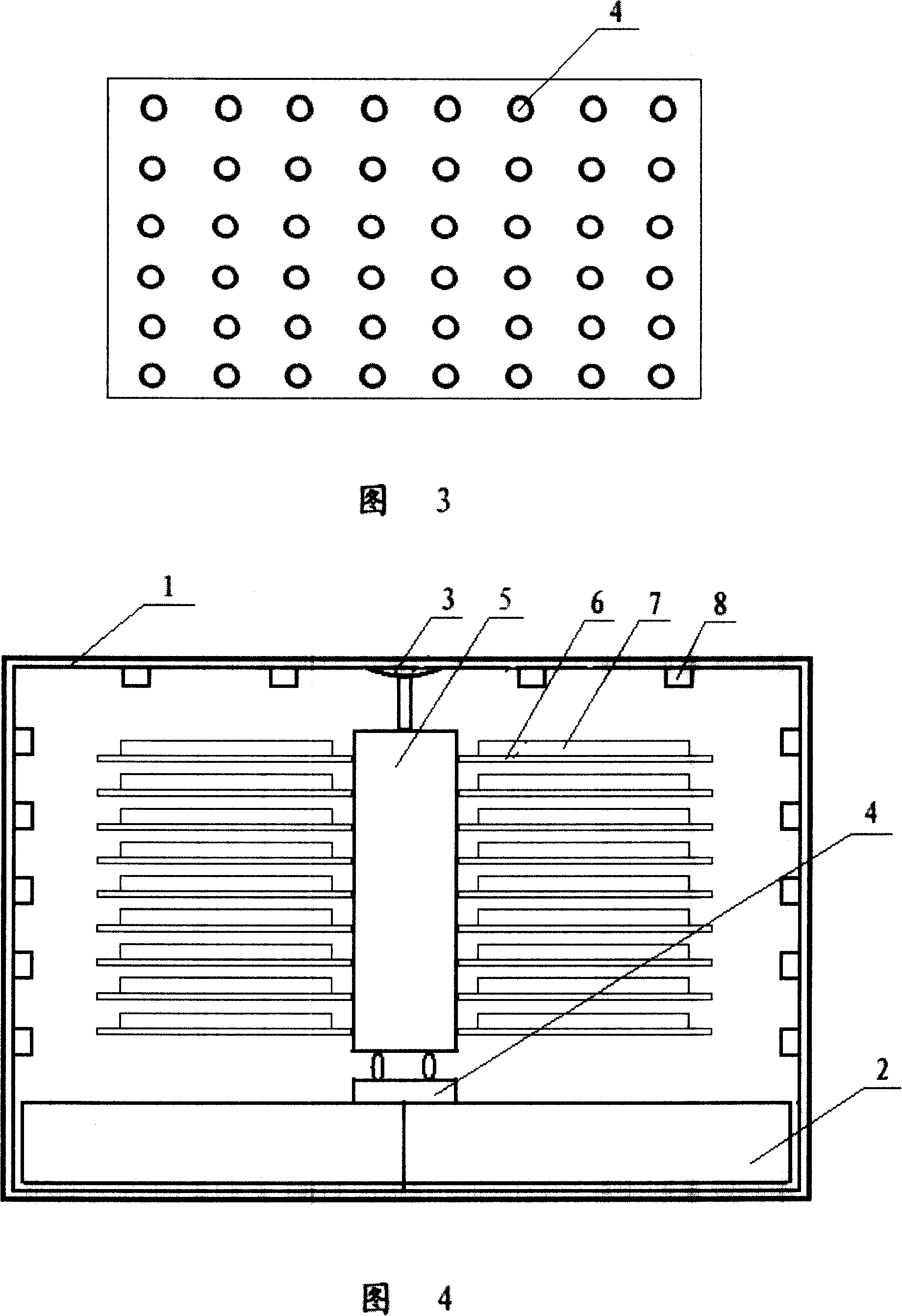

[0050] 1, structure, below in conjunction with accompanying drawing, the present invention is described in further detail.

[0051] As shown in Figure 1, Figure 2, and Figure 3, the microwave vacuum freeze-drying equipment that can be used for food and drug production includes a chamber body 1, a cold trap 2, a microwave magnetron support body 3, a microwave magnetron tube 4, and an infrared sensor 5 , a shelf 6, a material tray 7, a crane main body 8 with a built-in microwave magnetron support body, a guide rail 9, a slide rail 10, and a partition 11 with a built-in microwave magnetron support body. The warehouse body 1 is a rectangular parallelepiped vacuum container, and its size is length×width×height=4×3×3 meters, so as to adapt to large-scale industrial production. The front of storehouse door 1 is equipped with the translational storehouse door of the same size with storehouse body section, so that enter and exit crane.

[0052] Because the main heating source of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com