Patents

Literature

14359results about "Heating arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

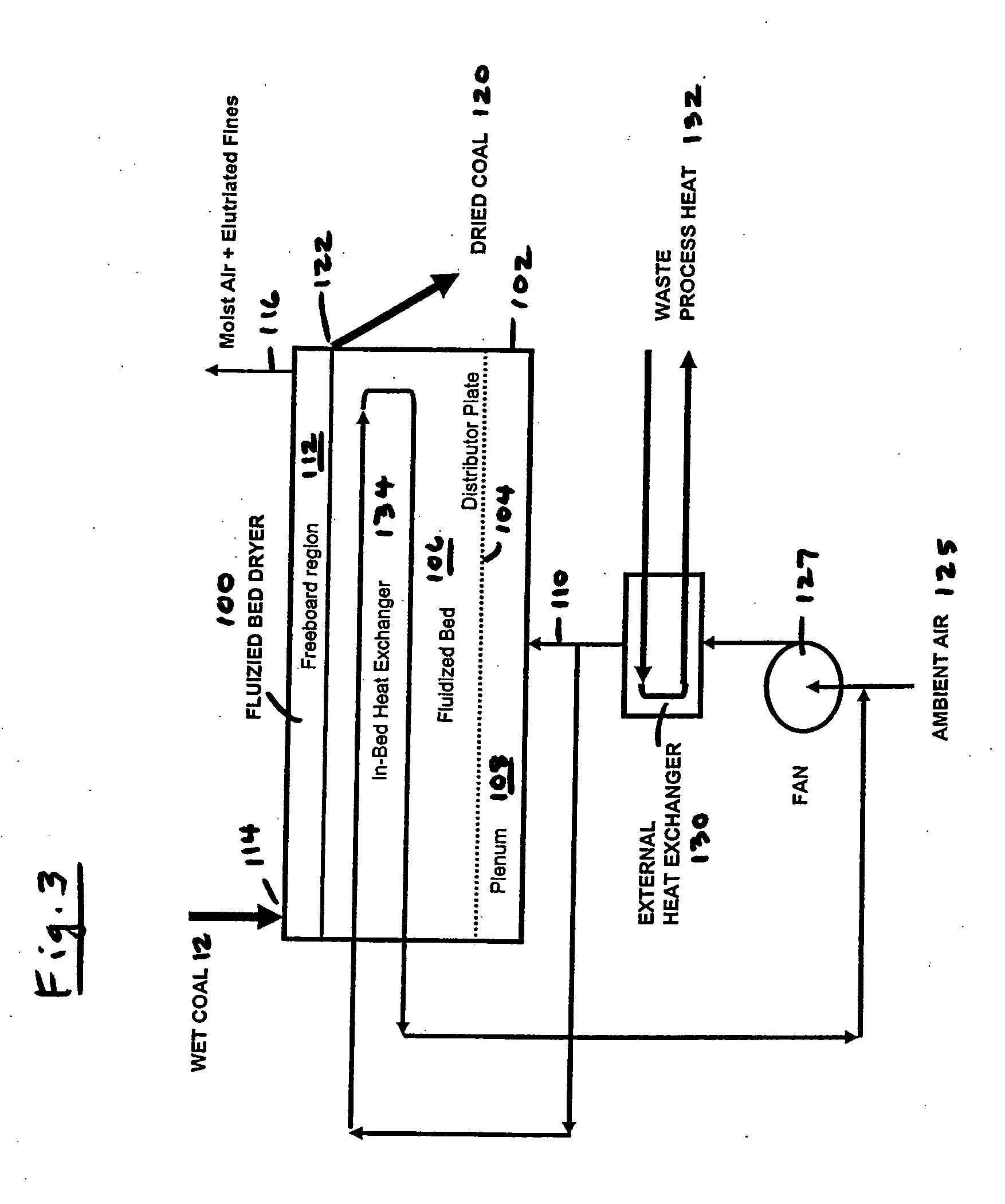

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

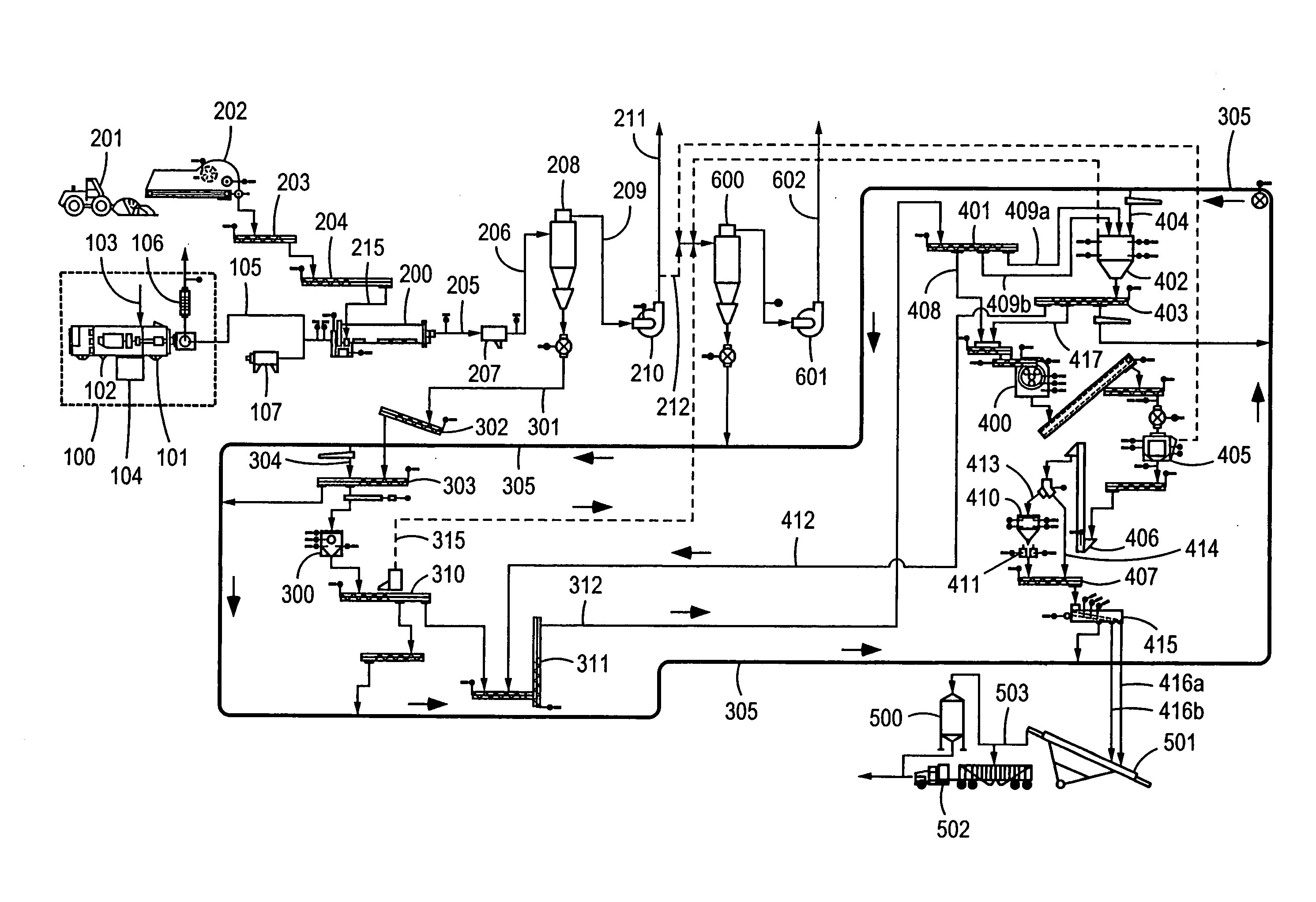

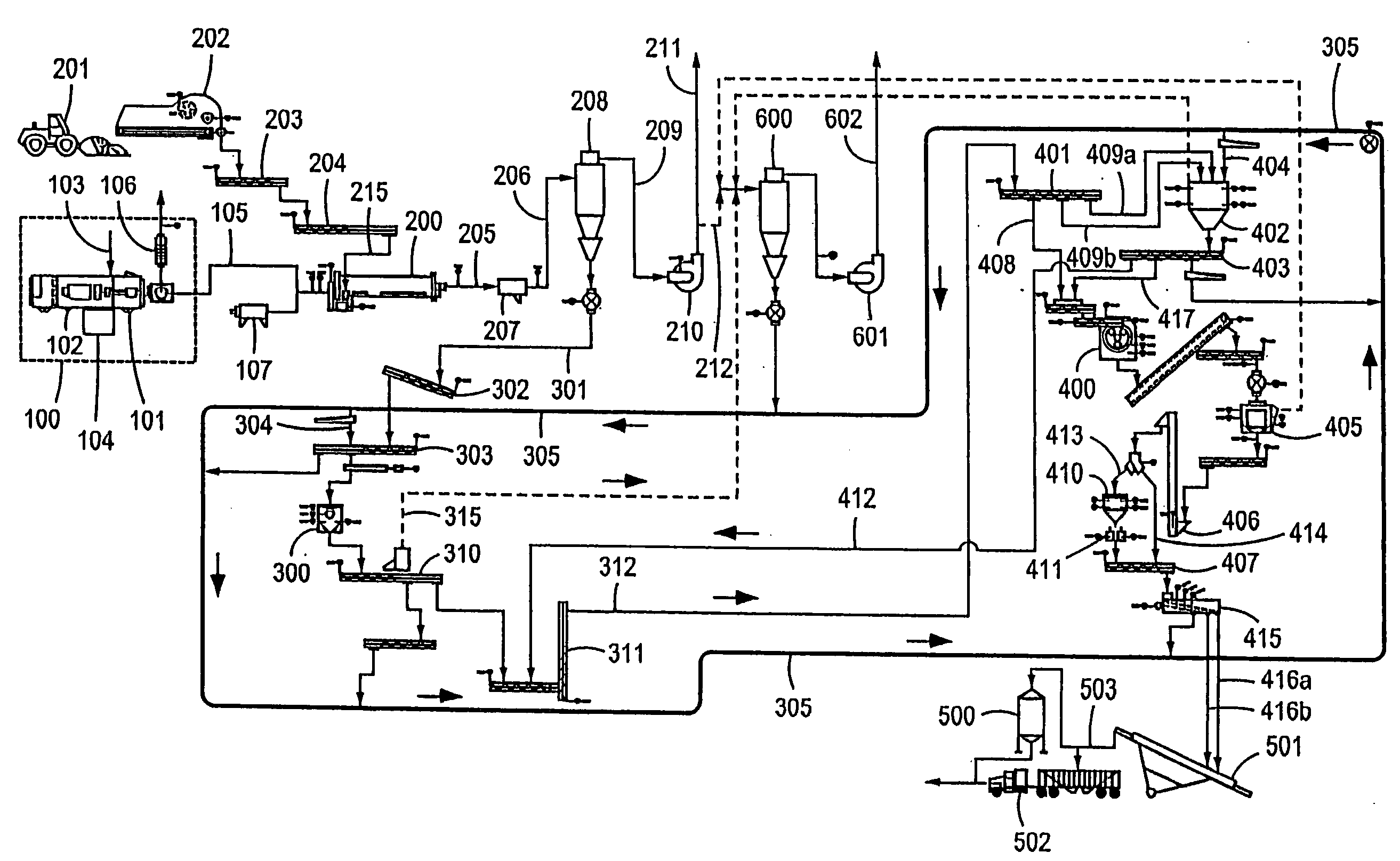

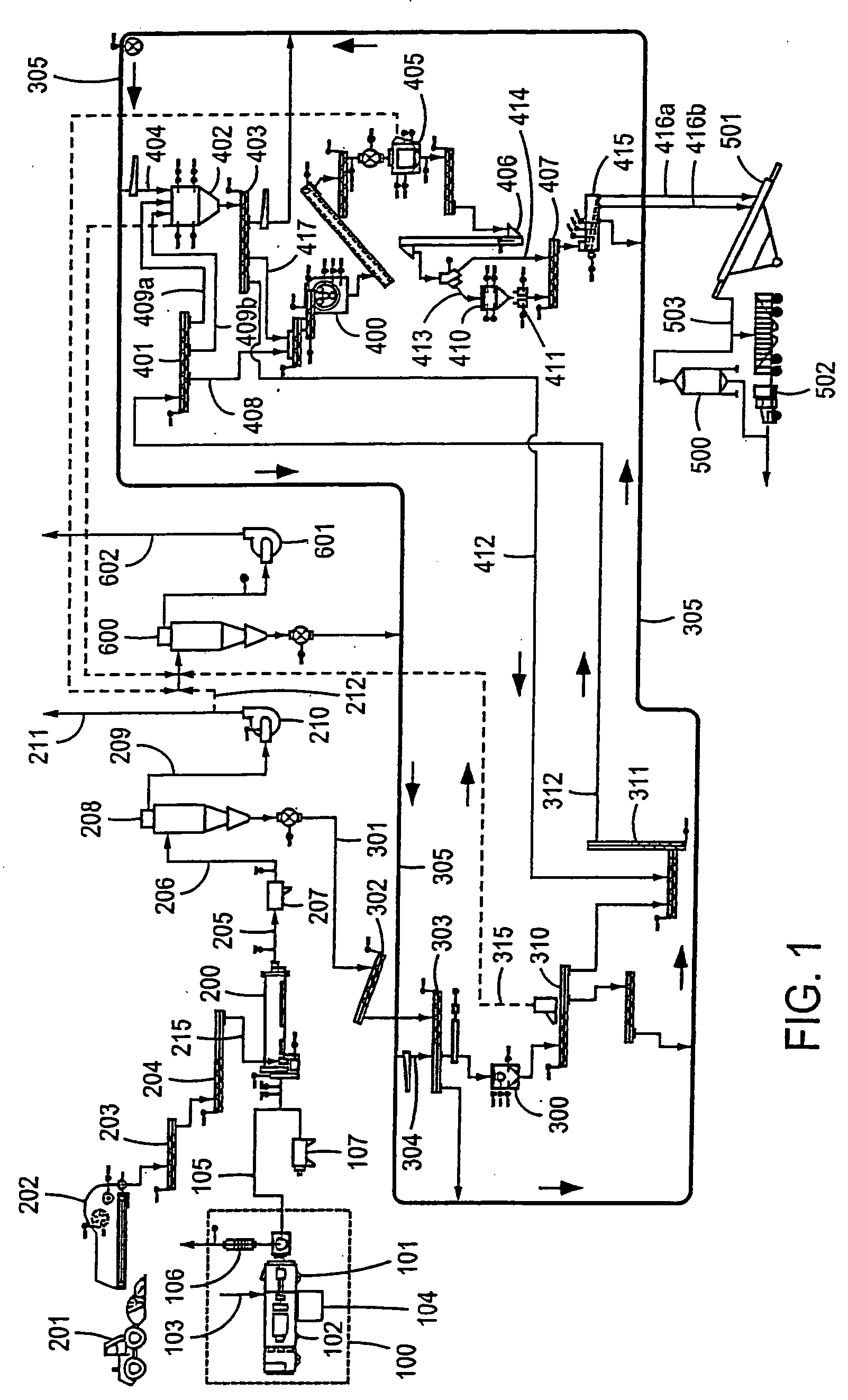

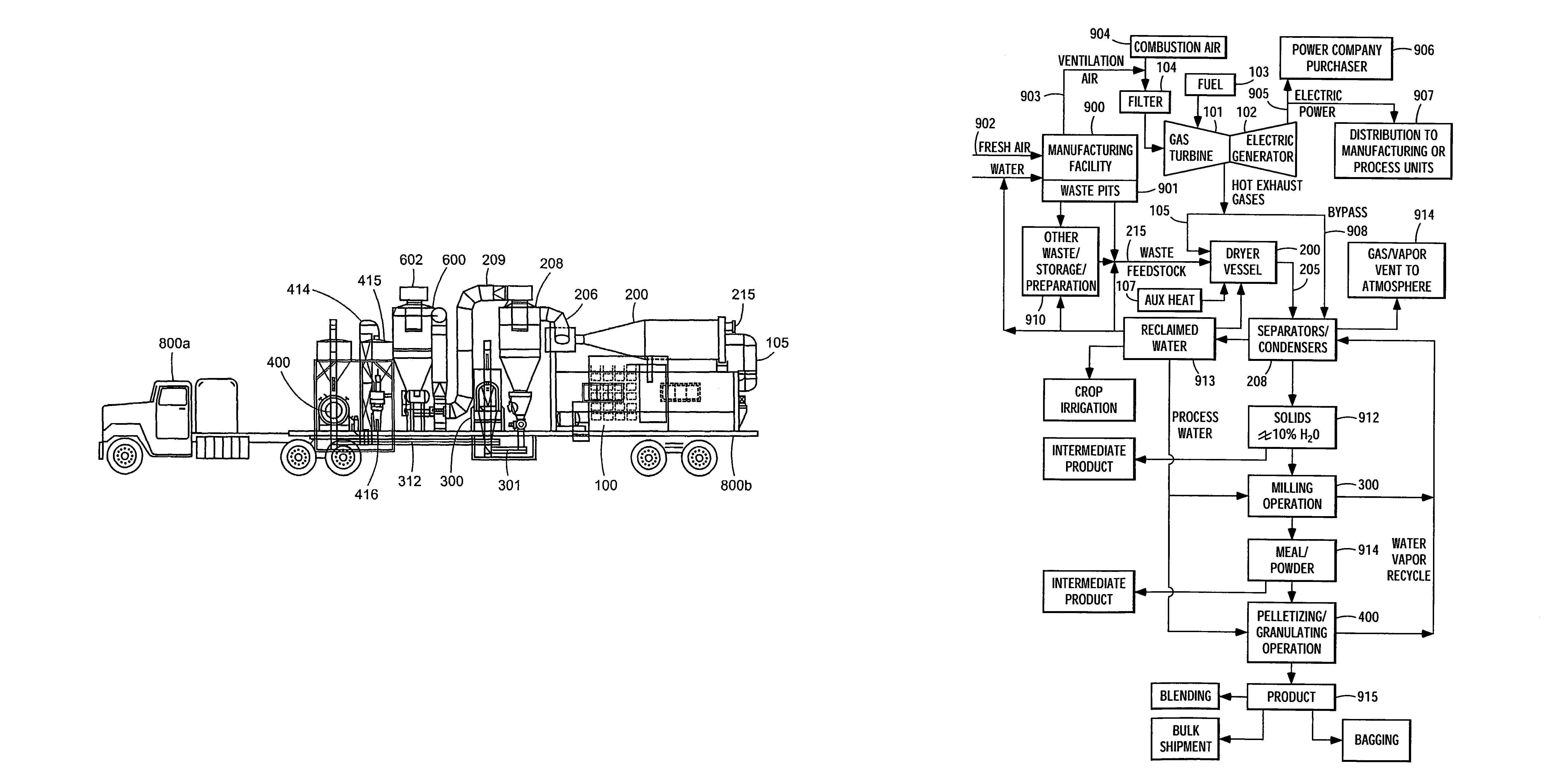

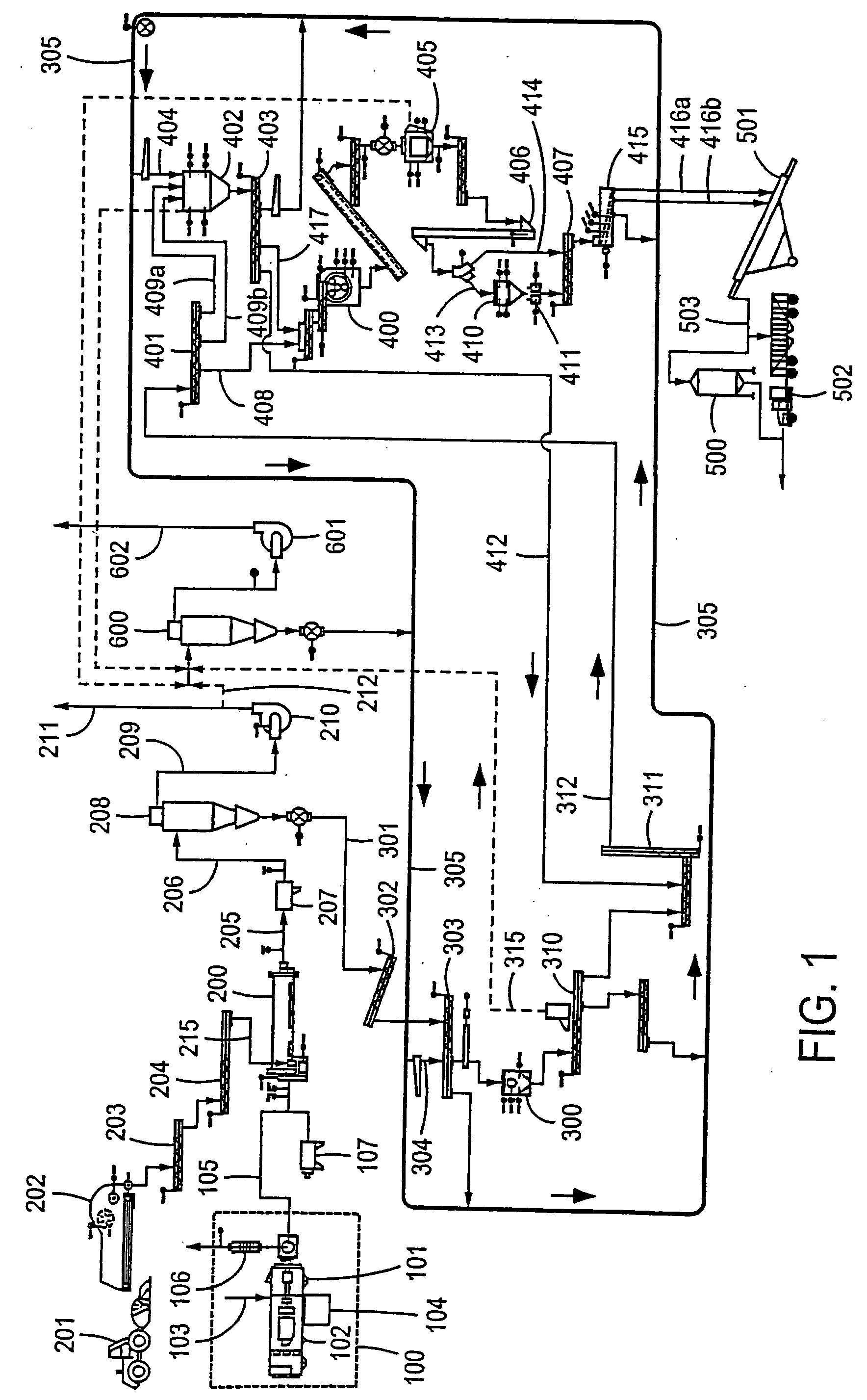

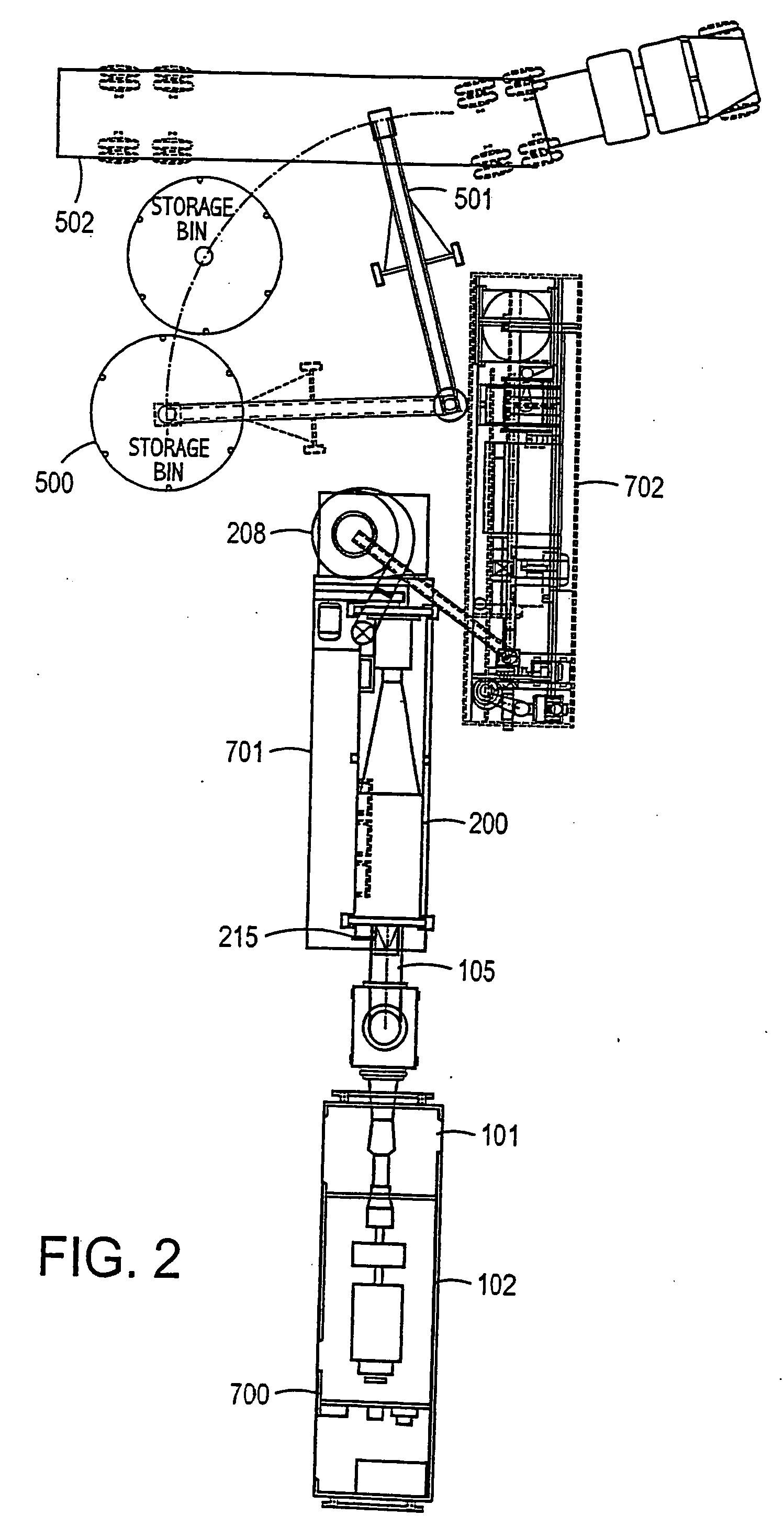

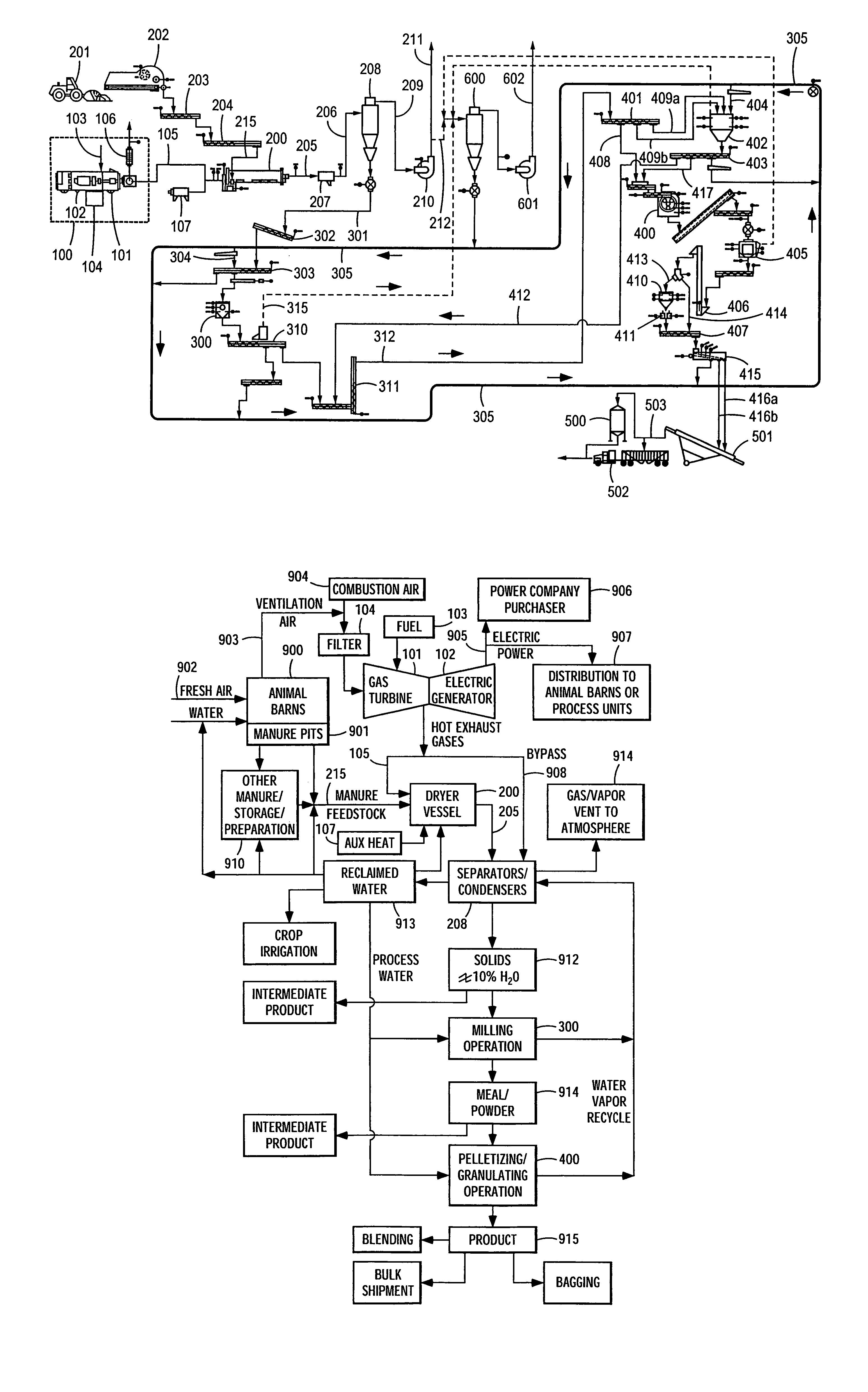

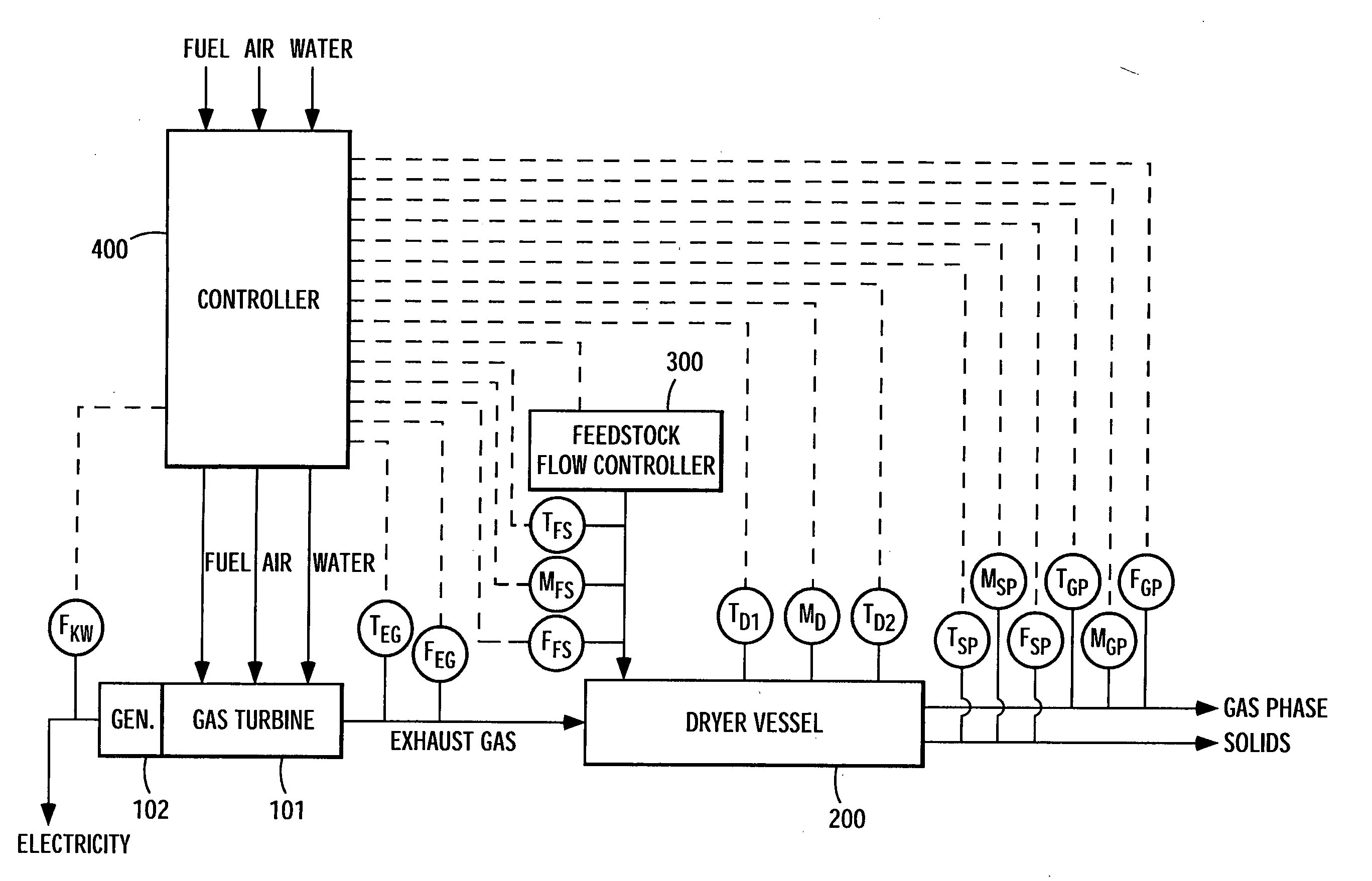

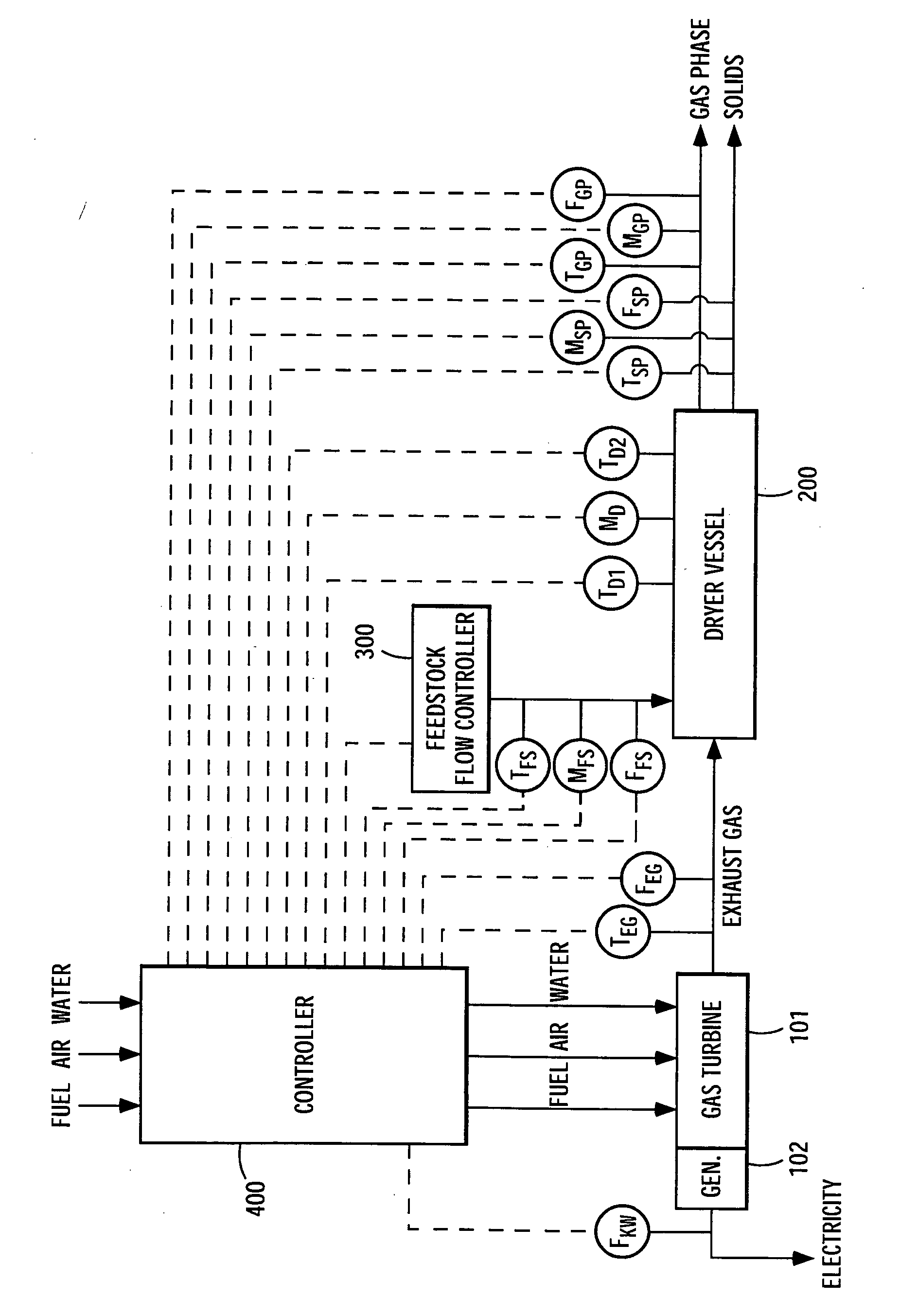

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS20060010712A1Drying using combination processesBio-organic fraction processingOrganic farmingSewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

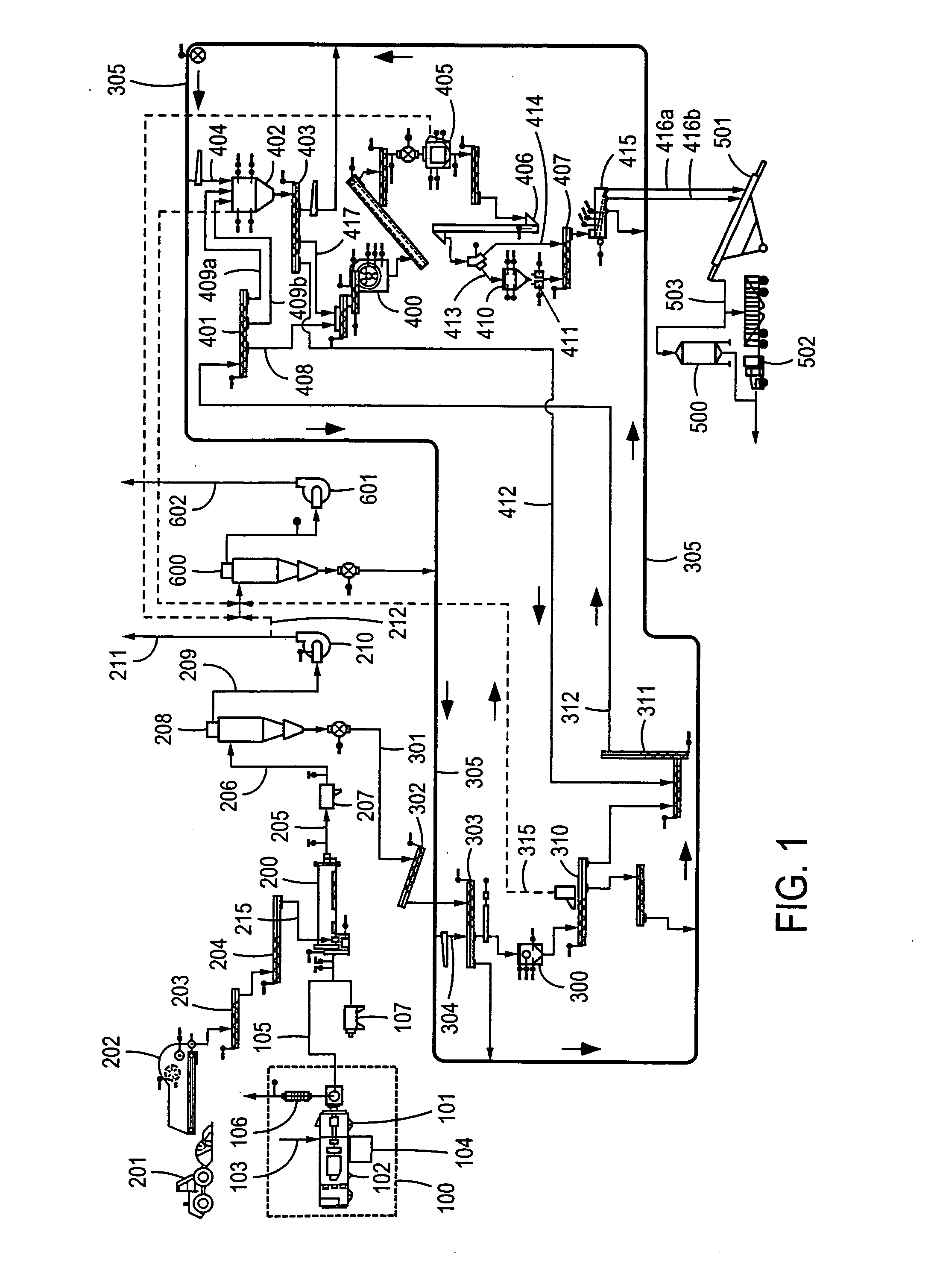

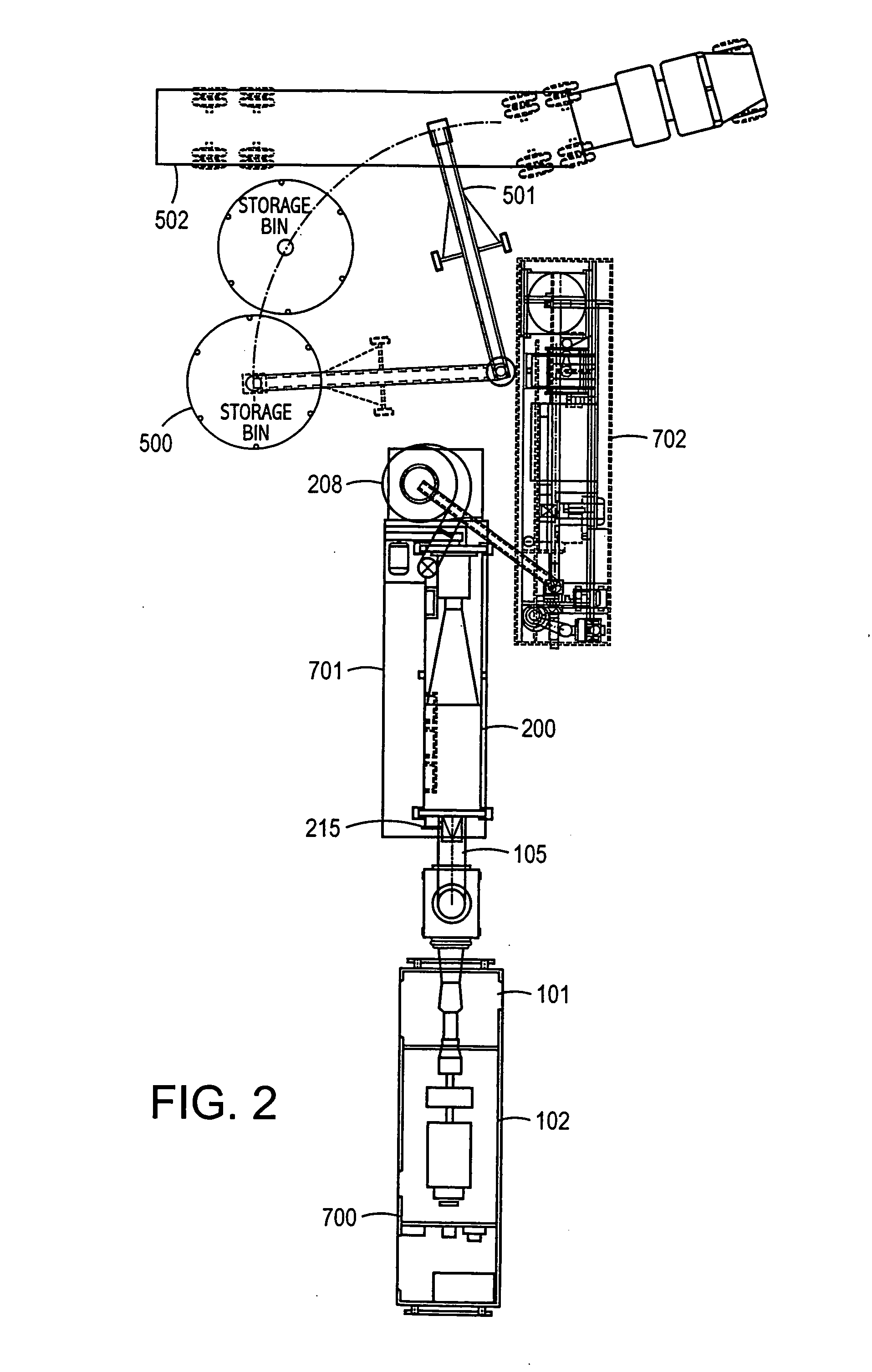

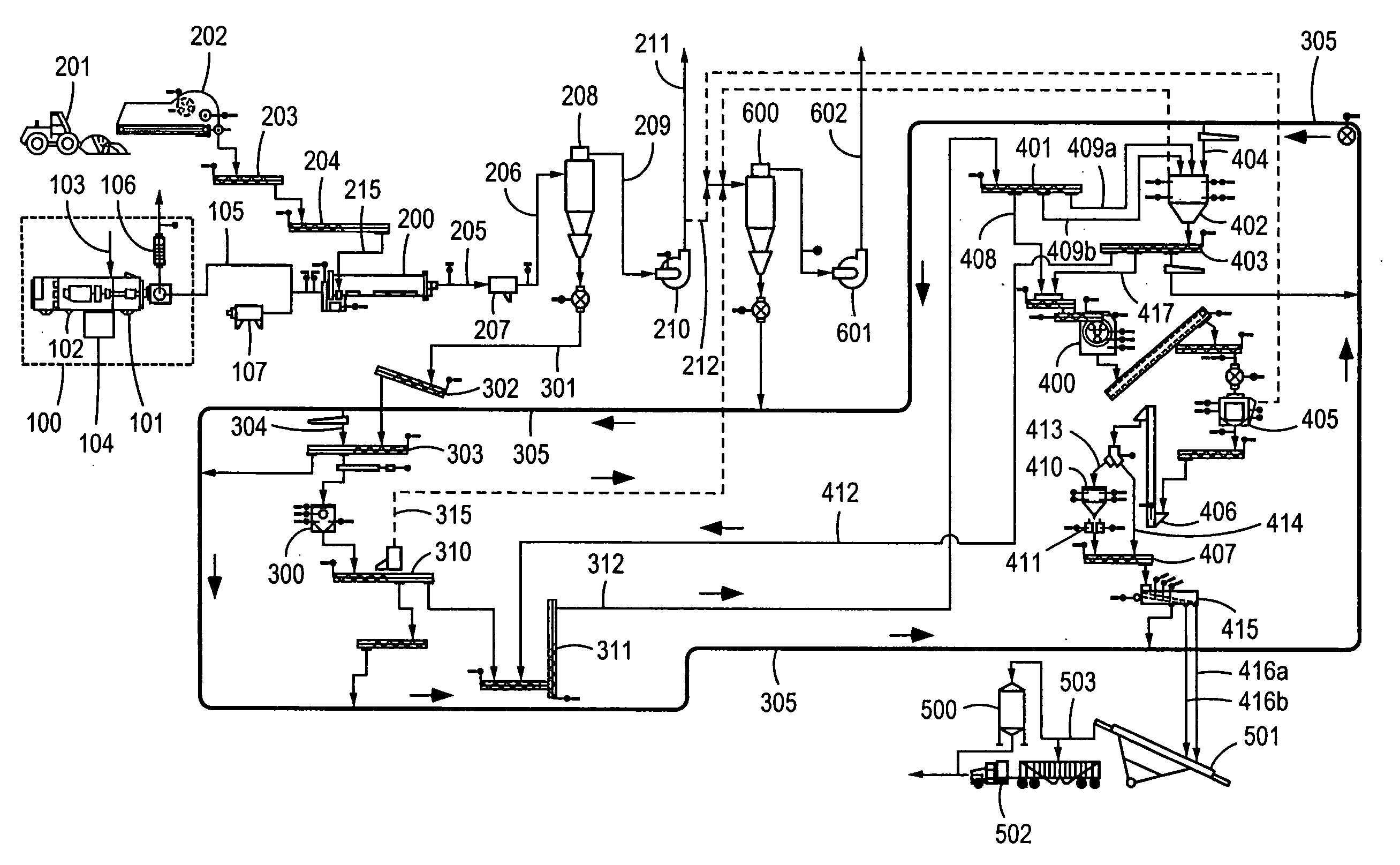

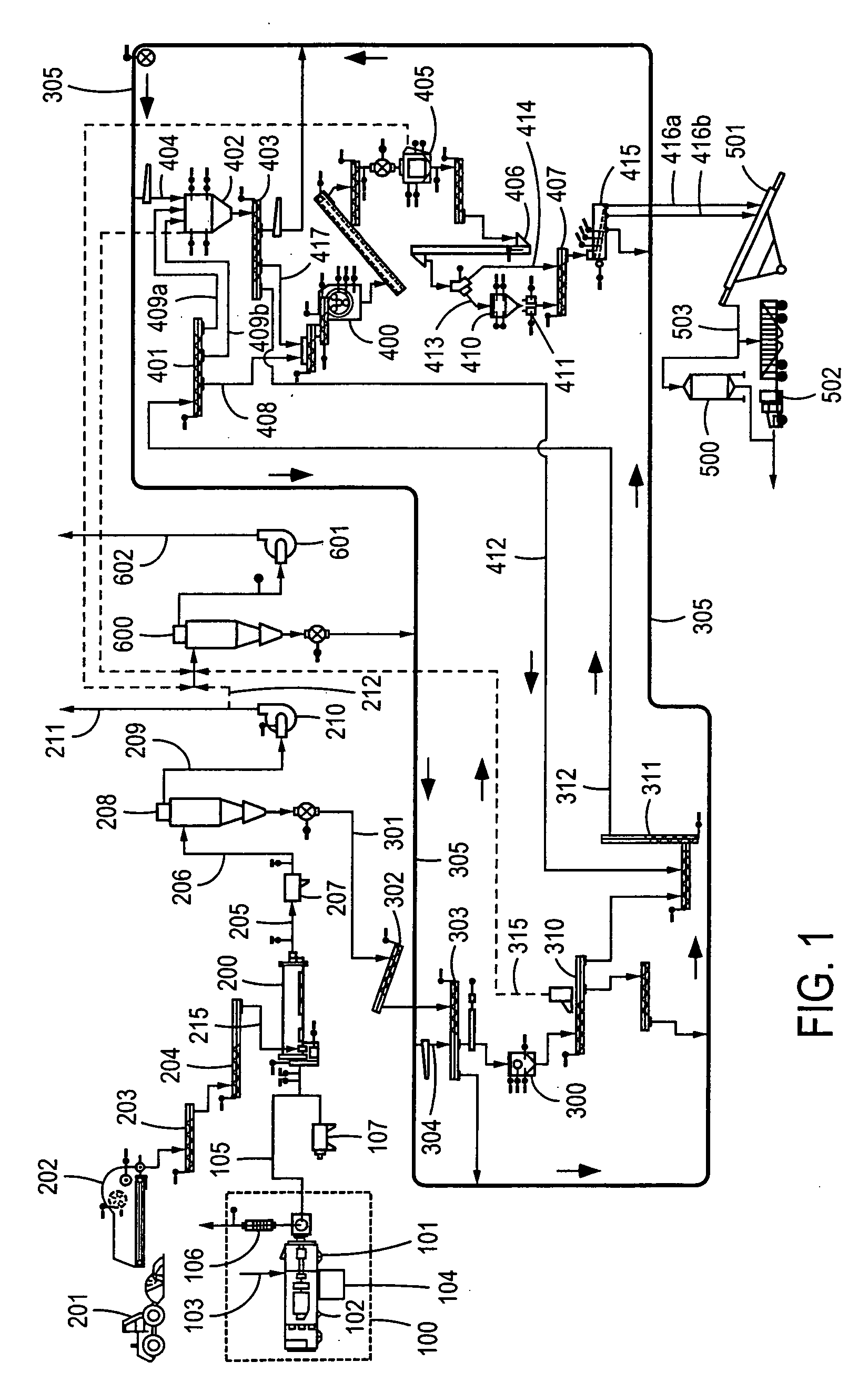

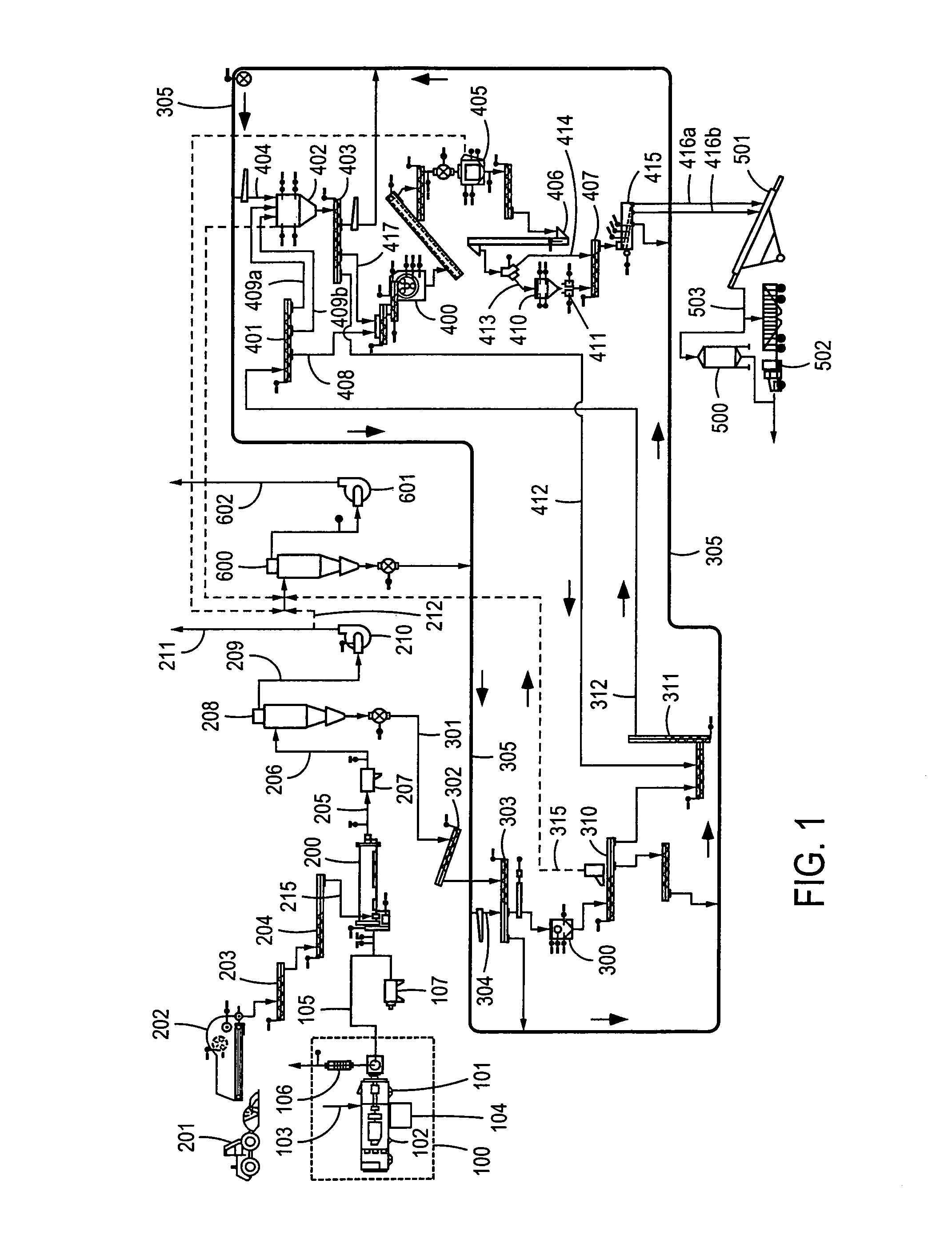

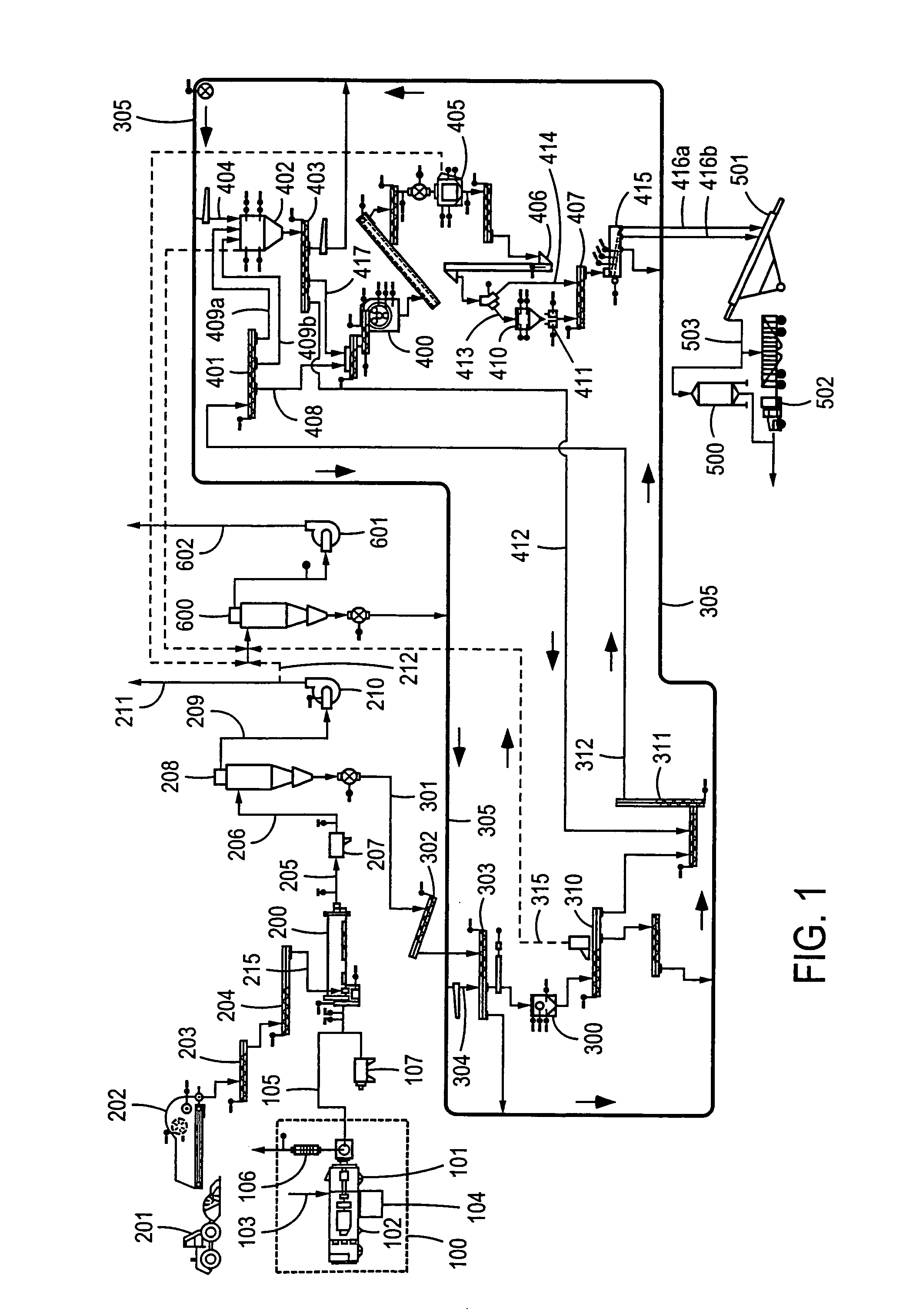

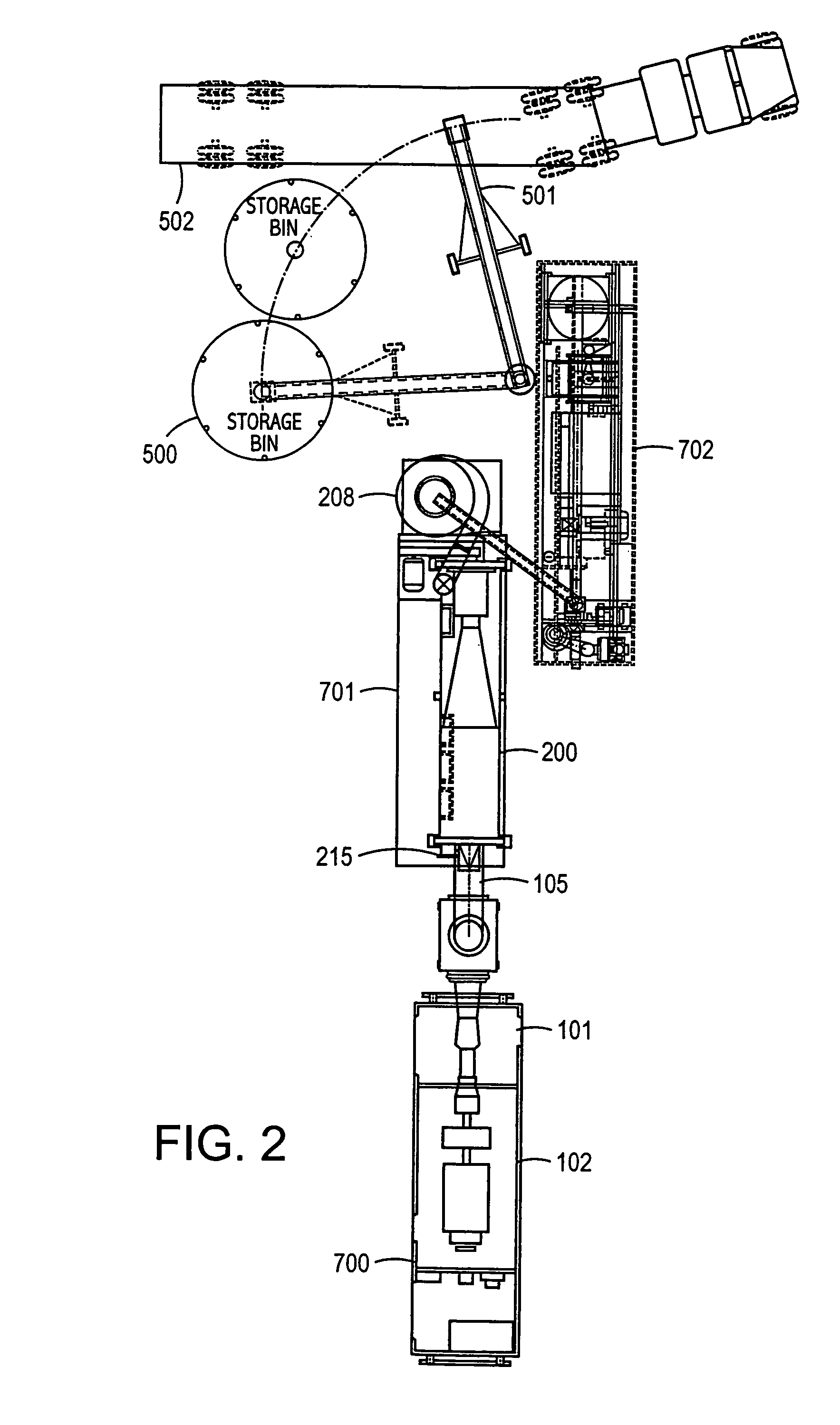

Process and system for drying and heat treating materials

InactiveUS20060010714A1Drying solid materials with heatExcrement fertilisersEngineeringProcess engineering

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

Process and system for drying and heat treating materials

InactiveUS20060101665A1Water/sewage treatment by centrifugal separationReversed direction vortexProcess engineeringMoisture

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

Aluminum chip dryers

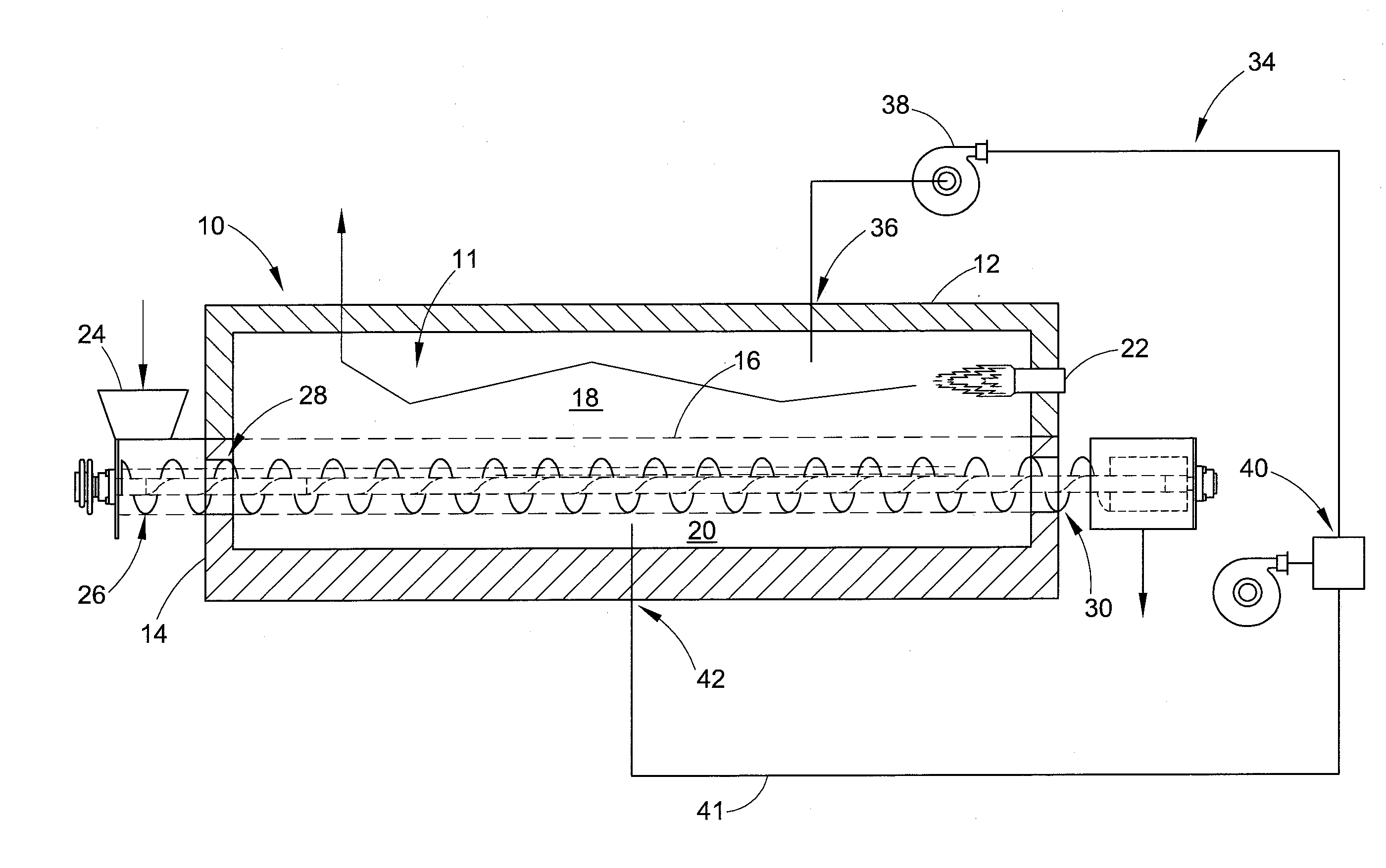

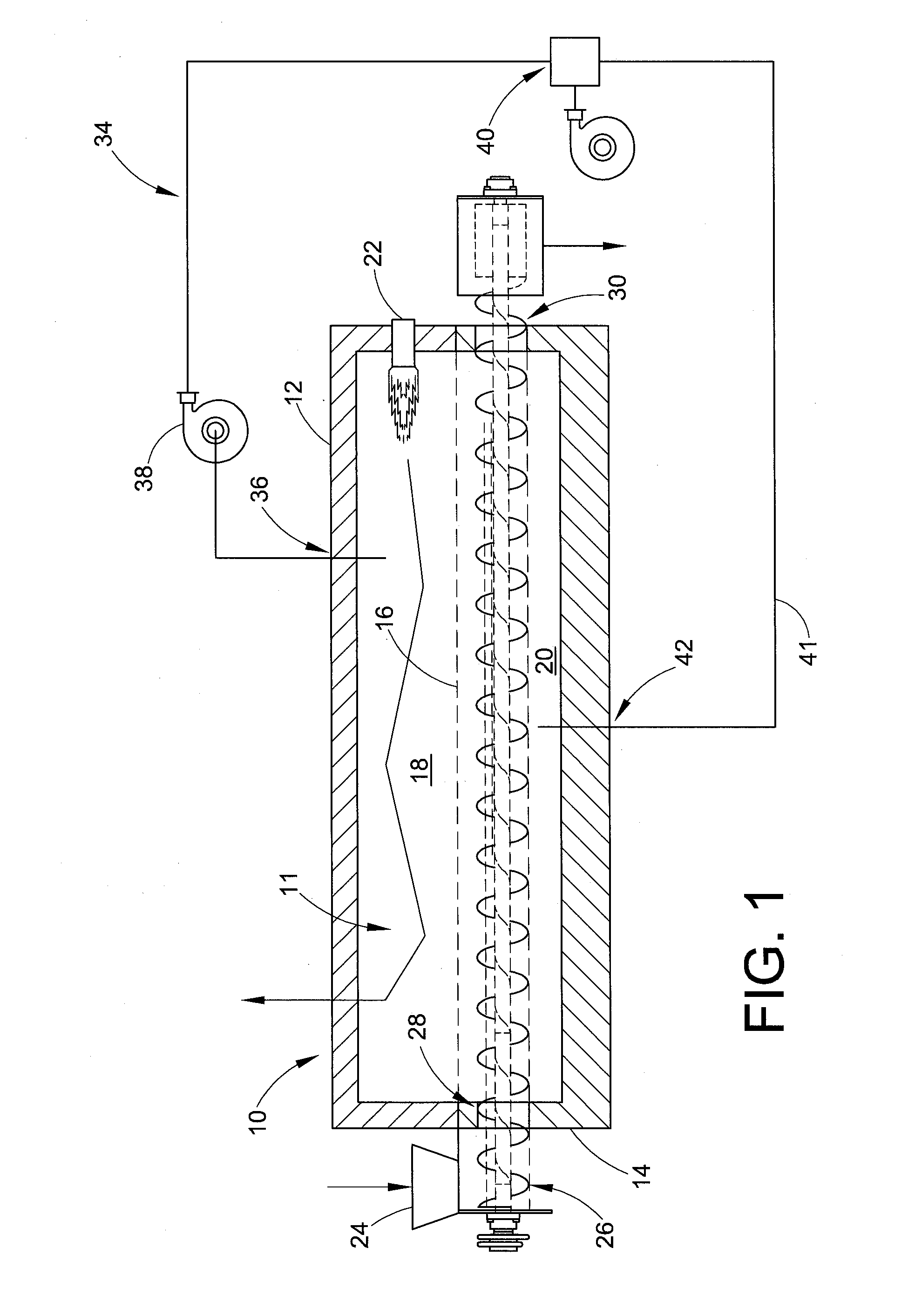

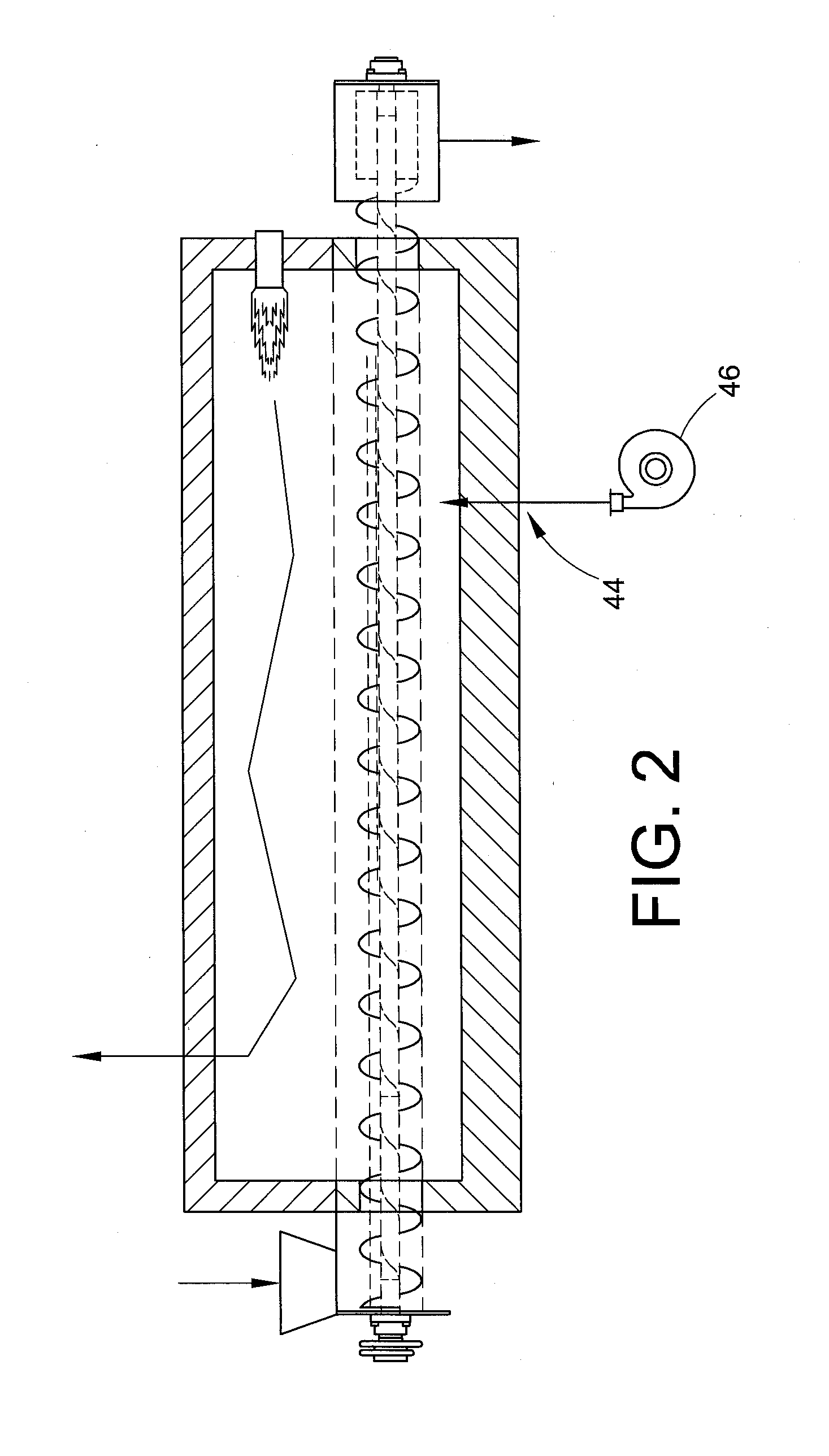

InactiveUS20140041252A1High emissivityDrying solid materials with heatDrying gas arrangementsEmissivityCombustor

In accordance with one aspect of an exemplary embodiment, a dryer for removing hydrocarbons and / or moisture from metal chips is provided. The dryer has a chamber including a top portion and a base portion. The top portion is comprised of a material having a higher emissivity than the material forming the base portion. A burner is provided which introduces heated gas into the top portion. A device for transporting the metal chips is provided in the base portion. The device receives the metal chips at an inlet and transporting the metal chips to an outlet.

Owner:PYROTECK INC

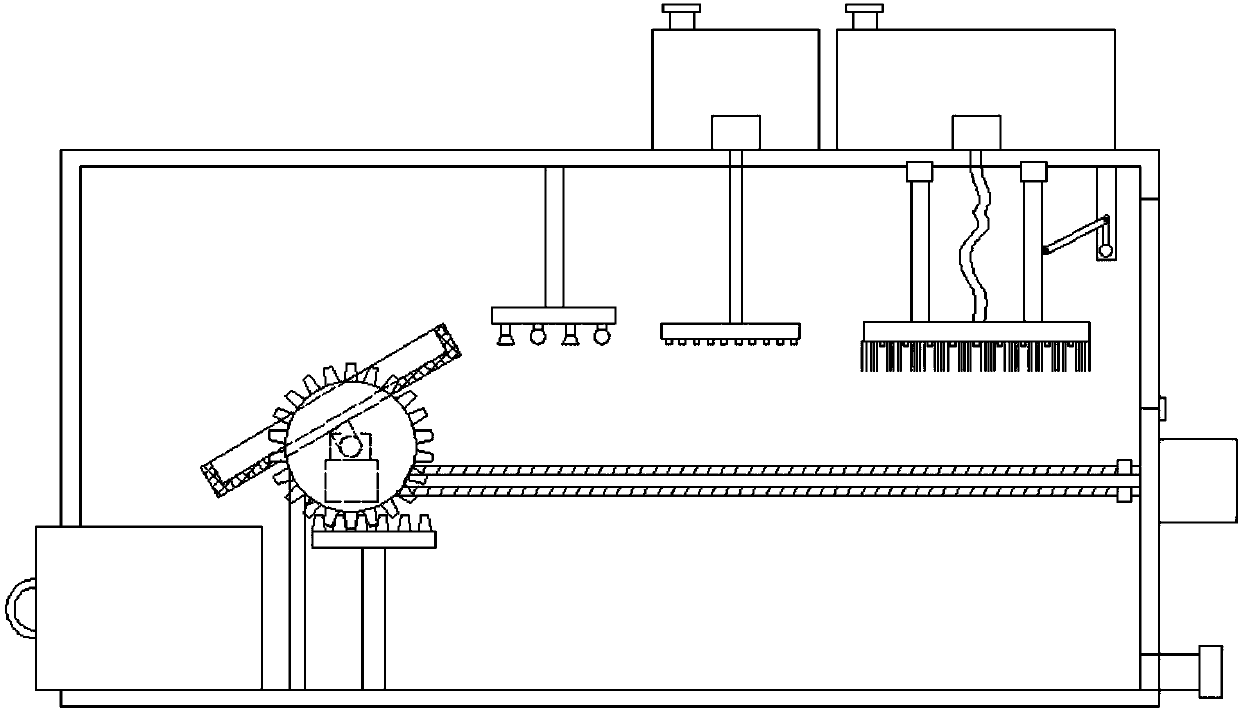

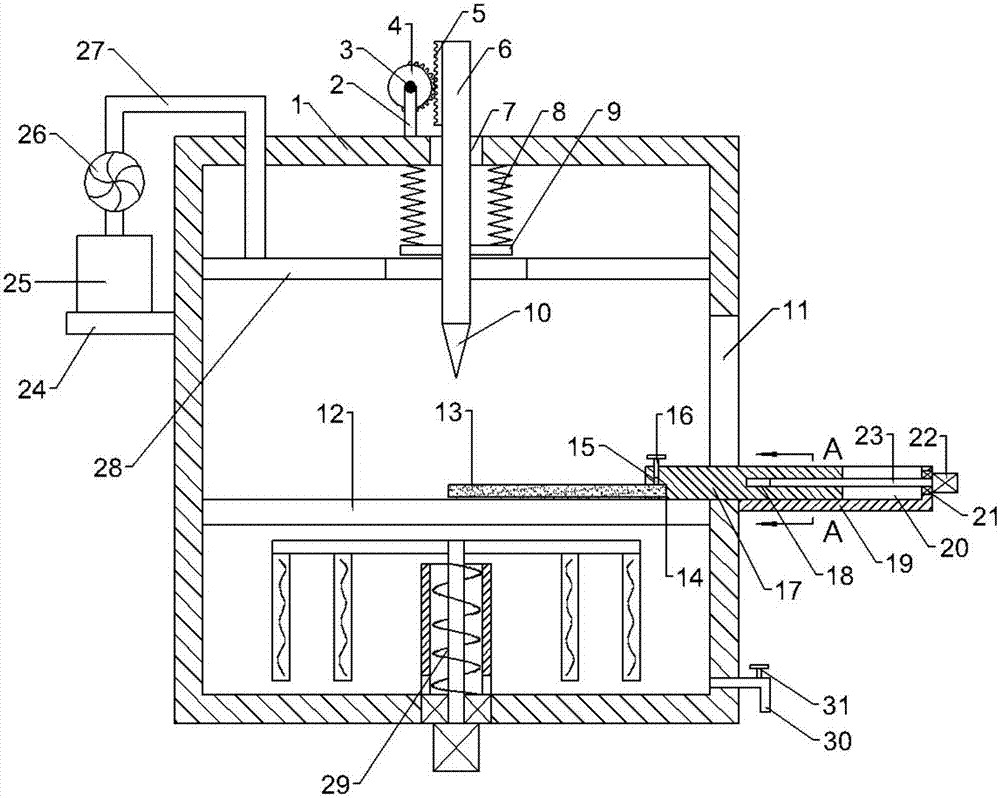

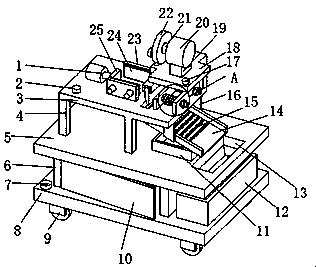

Medical instrument sterilization, cleaning and drying integral equipment

InactiveCN107899042AAvoid harmAvoid contactDrying gas arrangementsLavatory sanitoryDisinfectantUltraviolet

The invention discloses medical instrument sterilization, cleaning and drying integral equipment which comprises a tank body, a threaded rod, a first motor, a movable block, a rotating shaft, a spring, a holding frame, a gear, a sterilization device, a cleaning device, a drying device, a collecting frame and a rack, wherein the sterilization device comprises a disinfectant tank, a first pump body,a second motor and a brush plate; the cleaning device comprises a water tank, a second pump body and a cleaning plate; the drying device comprises a drying plate, a drying lamp and an ultraviolet raysterilization lamp. Due to adoption of the sterilization device, a disinfectant can be sprayed while a medical instrument is brushed, so that the sterilization effect is improved; due to adoption ofthe cleaning device, the disinfectant is prevented from being retained on the medical instrument to do harm to skin of medical operators; due to adoption of the drying machine, two drying modes are implemented simultaneously, so that a rapid drying speed and a good drying effect are achieved; due to adoption of the gear and the rack, a medical instrument in the holding frame can automatically slide into the collecting frame conveniently and rapidly, and meanwhile the consequence that the medical instrument is contaminated again as operators contact the medical instrument is avoided.

Owner:黄莉

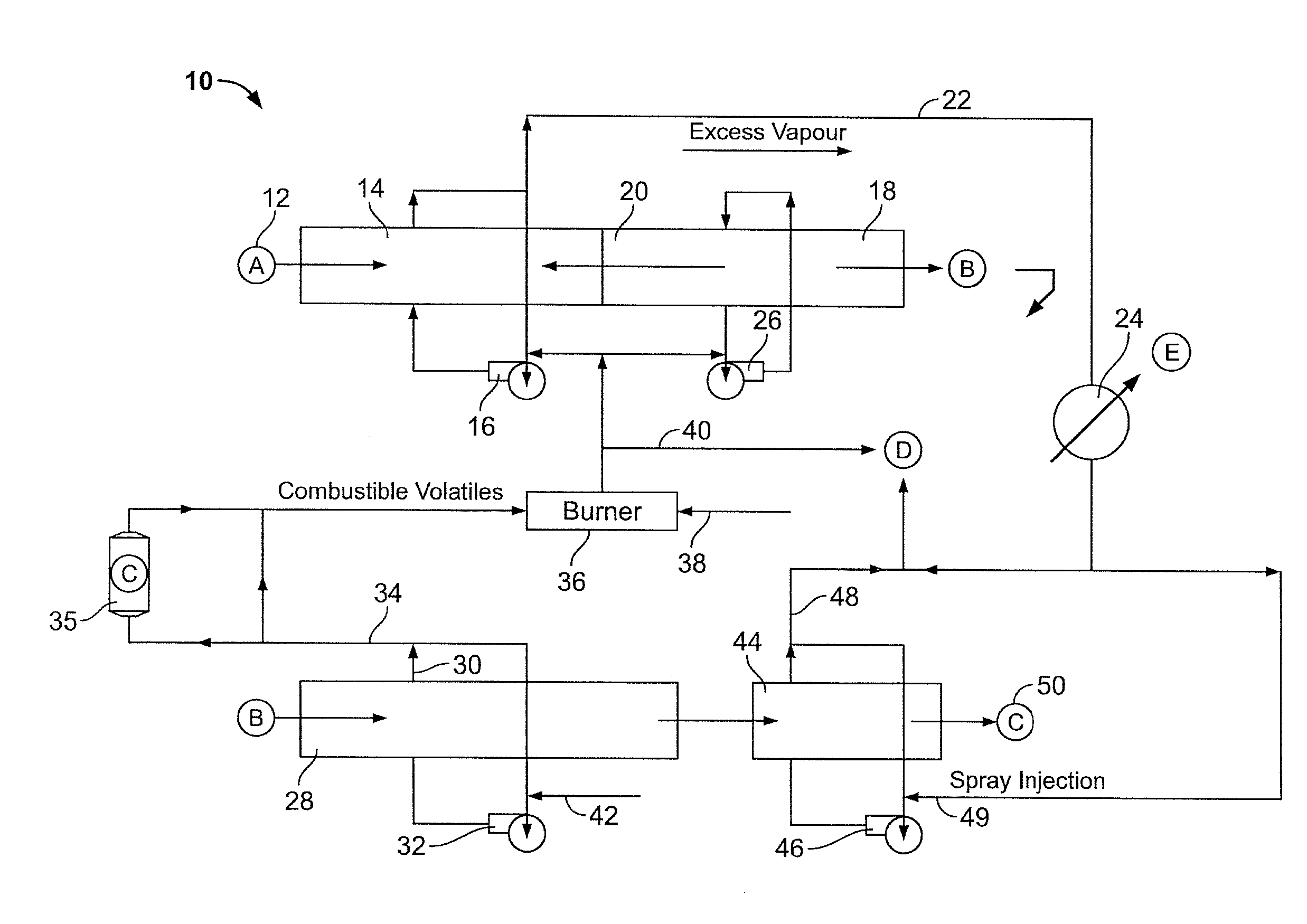

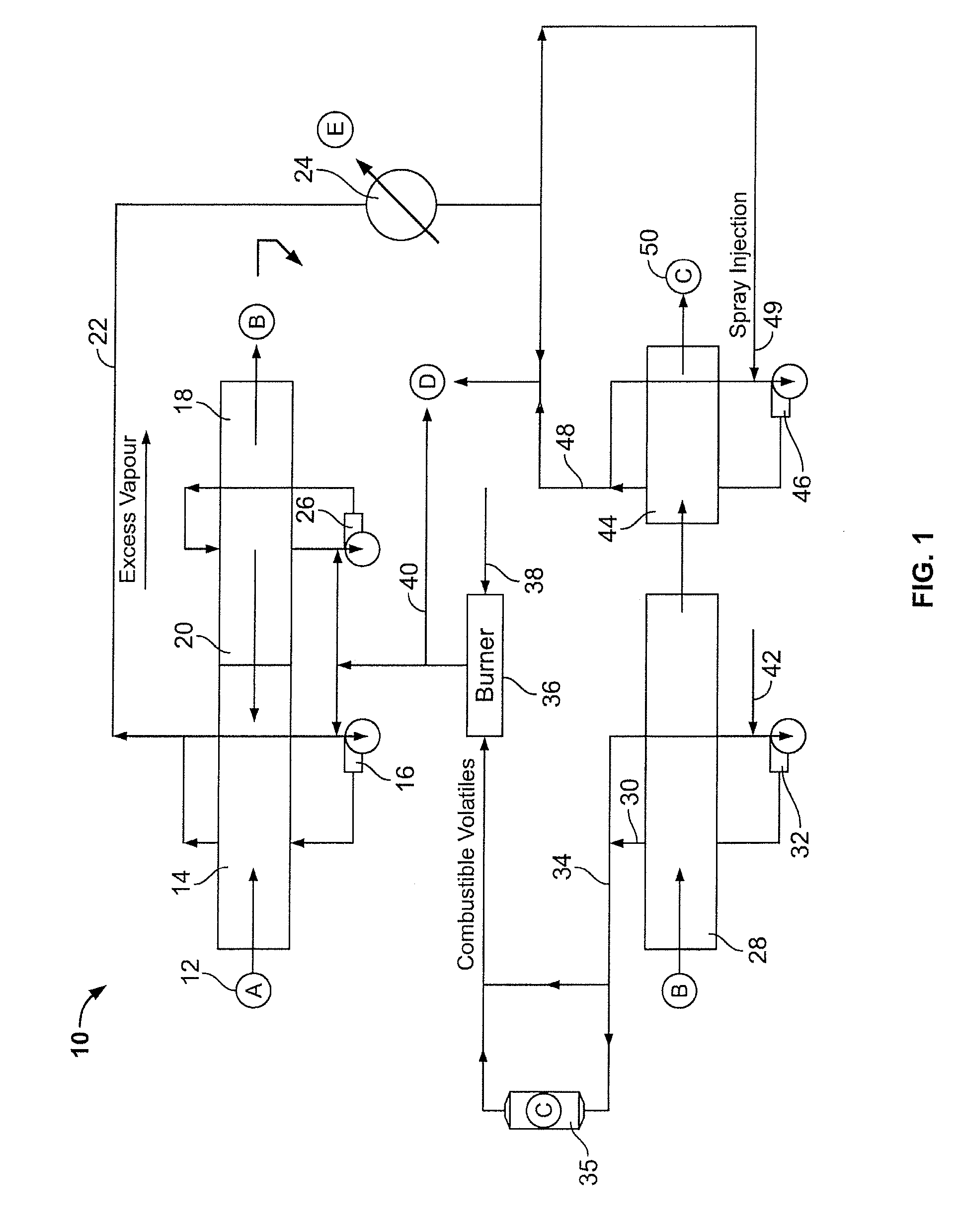

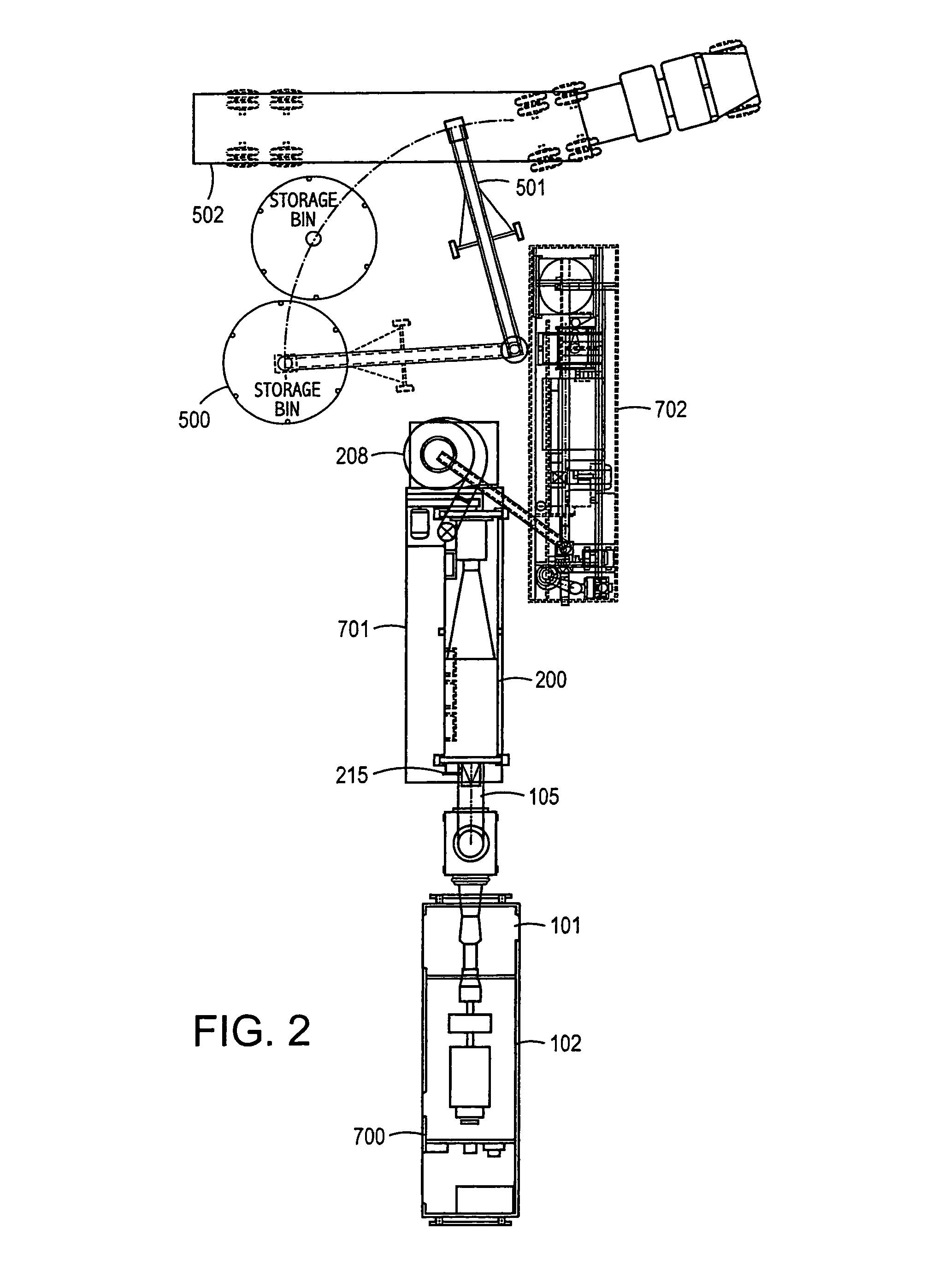

Autothermal and mobile torrefaction devices

ActiveUS20090250331A1Increased cost-effectivenessLow costCombustible gas coke oven heatingCharging-discharging device combinationsCombustorEngineering

The present invention provides an autothermal torrefaction device, which can be either stationary of mobile. Embodiments of the present invention include a torrefaction chamber having a chamber inlet for receiving biomass and at least one chamber outlet. The torrefaction chamber can be substantially surrounded by an exterior housing defining an outer jacket and having a jacket inlet and a jacket outlet. The outer jacket and torrefaction chamber define a space therebetween such that a burner unit including an inlet operatively connected to the chamber outlet and an outlet operatively connected to the jacket inlet allows vapors produced or released from within the torrefaction chamber to travel into the burner unit for combustion of at least a portion of the vapors and subsequently travel through the space between the jacket and the torrefaction chamber to provide heat necessary for autothermal torrefaction of biomass.

Owner:NORTH CAROLINA STATE UNIV

Method of converting pyrolyzable organic materials to biocarbon

InactiveUS20100300866A1Simple methodWidespread benefit to the efficiency of the method and the biocarbon qualityCombustible gas coke oven heatingCarbon compoundsVolatilesCarbonization

A method of forming a pyrolysed biocarbon from a pyrolyzable organic material is delineated. The method involves the conversion of pyrolyzable organic materials to biocarbon for subsequent use. A carbonization circuit is employed with individual feedstock segments being advanced through the circuit. The method facilitates user manipulation of rate of advancement of the feedstock through the circuit, selective collation of volatiles from pyrolyzing feedstock, selective exposure of predetermined feedstock segments to collated volatiles as well as thermal recovery and redistribution as desired by the user. This results in the capacity for a customizable biocarbon product, the latter being an auxiliary feature of the methodology.

Owner:ALTERNA ENERGY

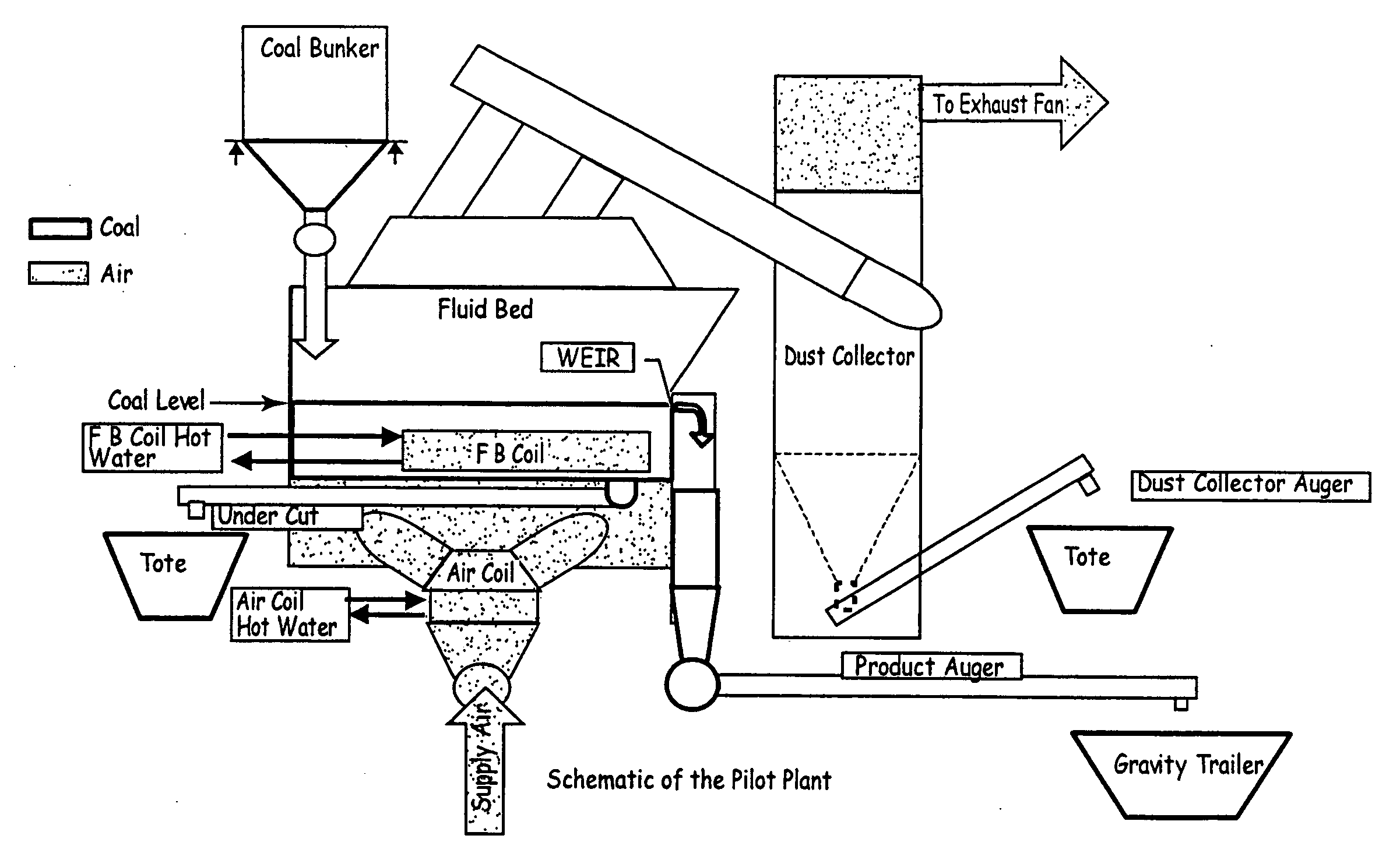

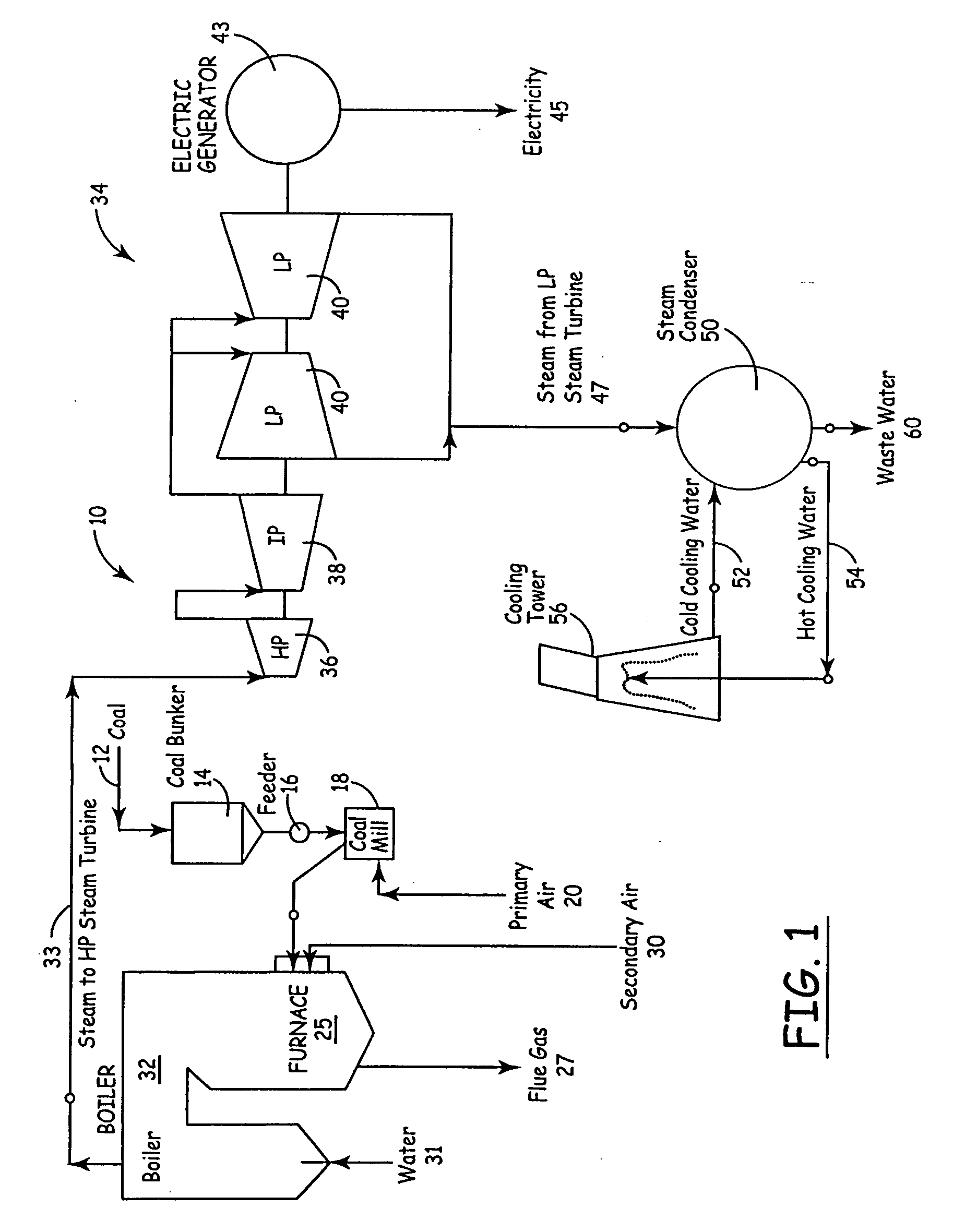

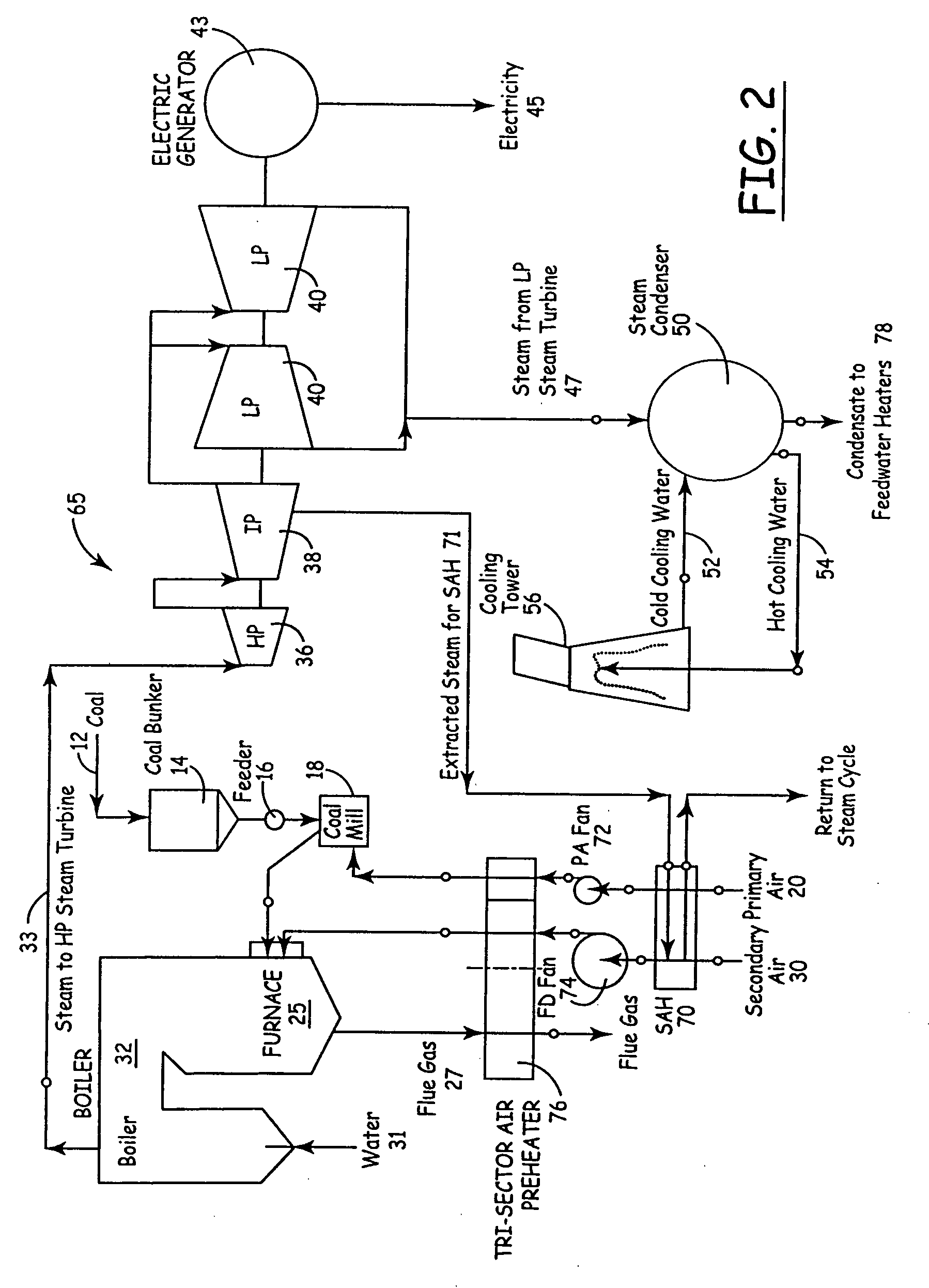

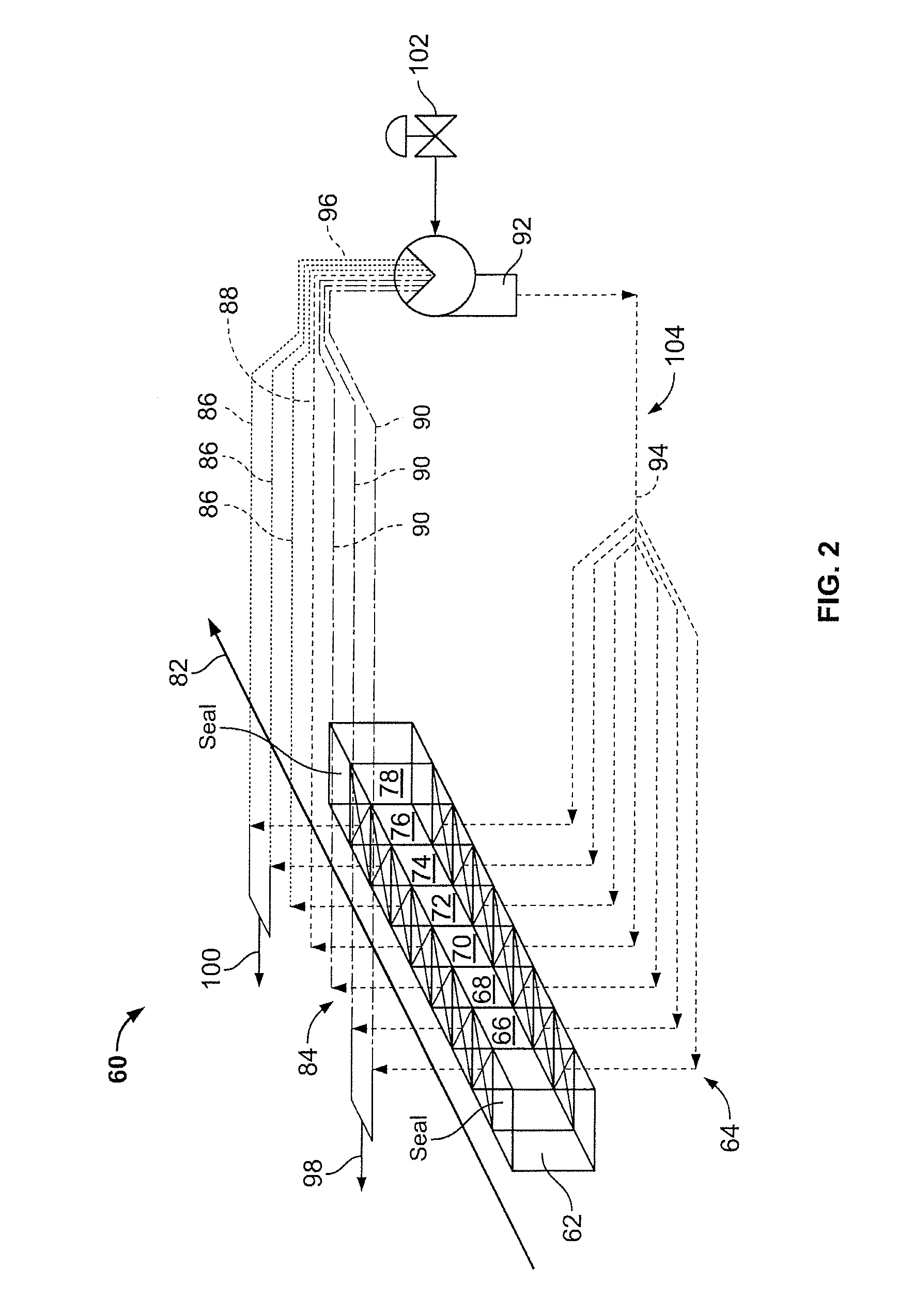

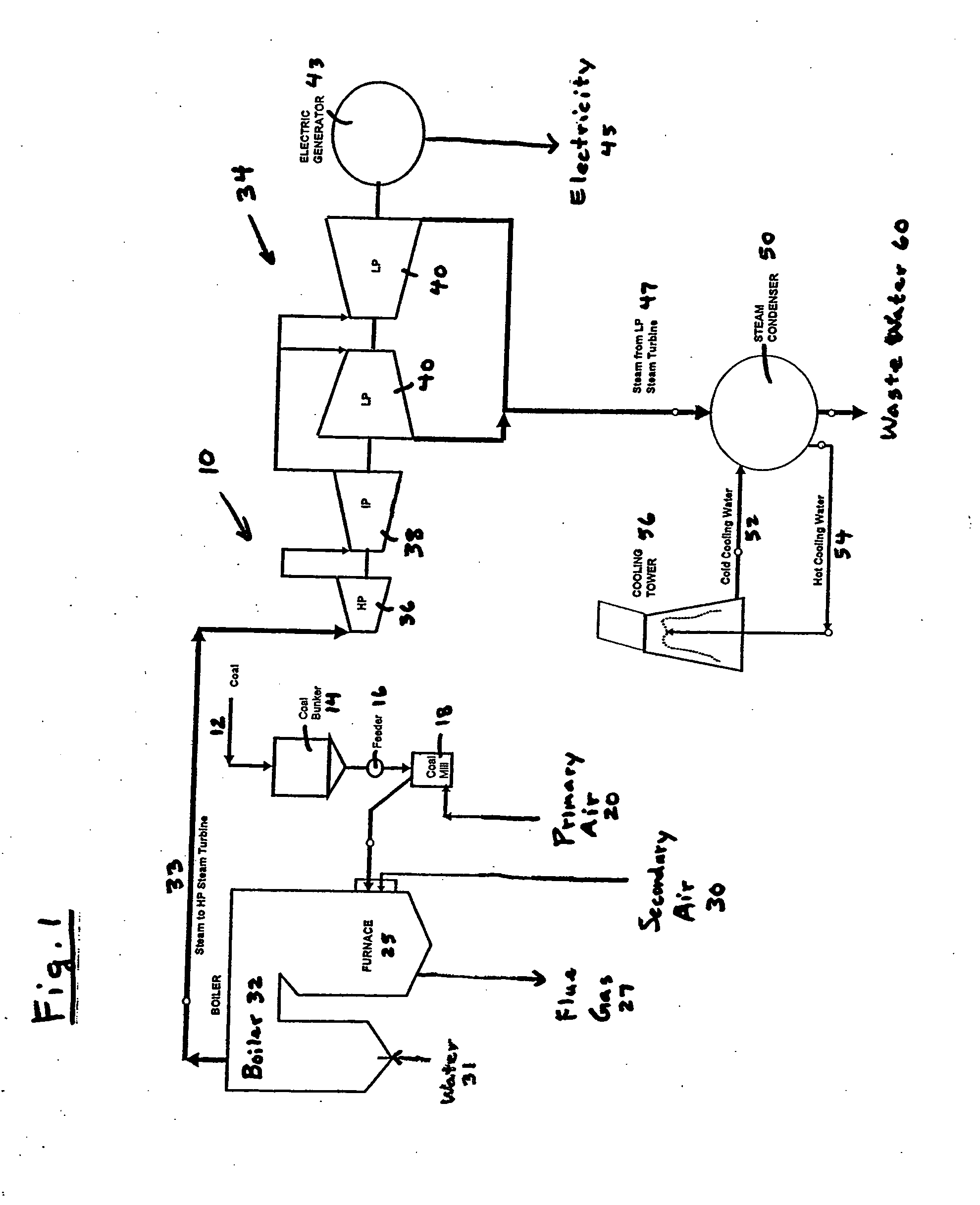

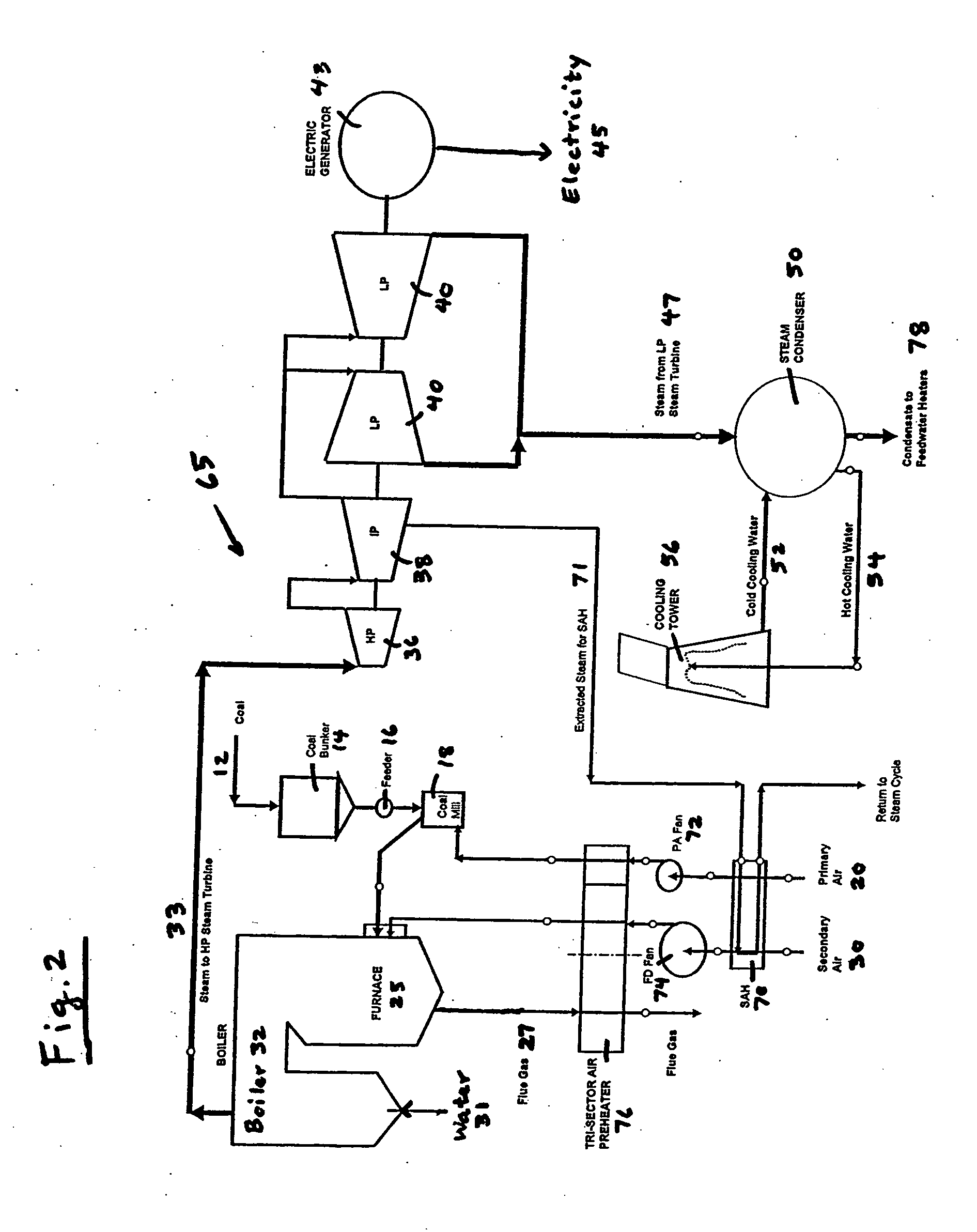

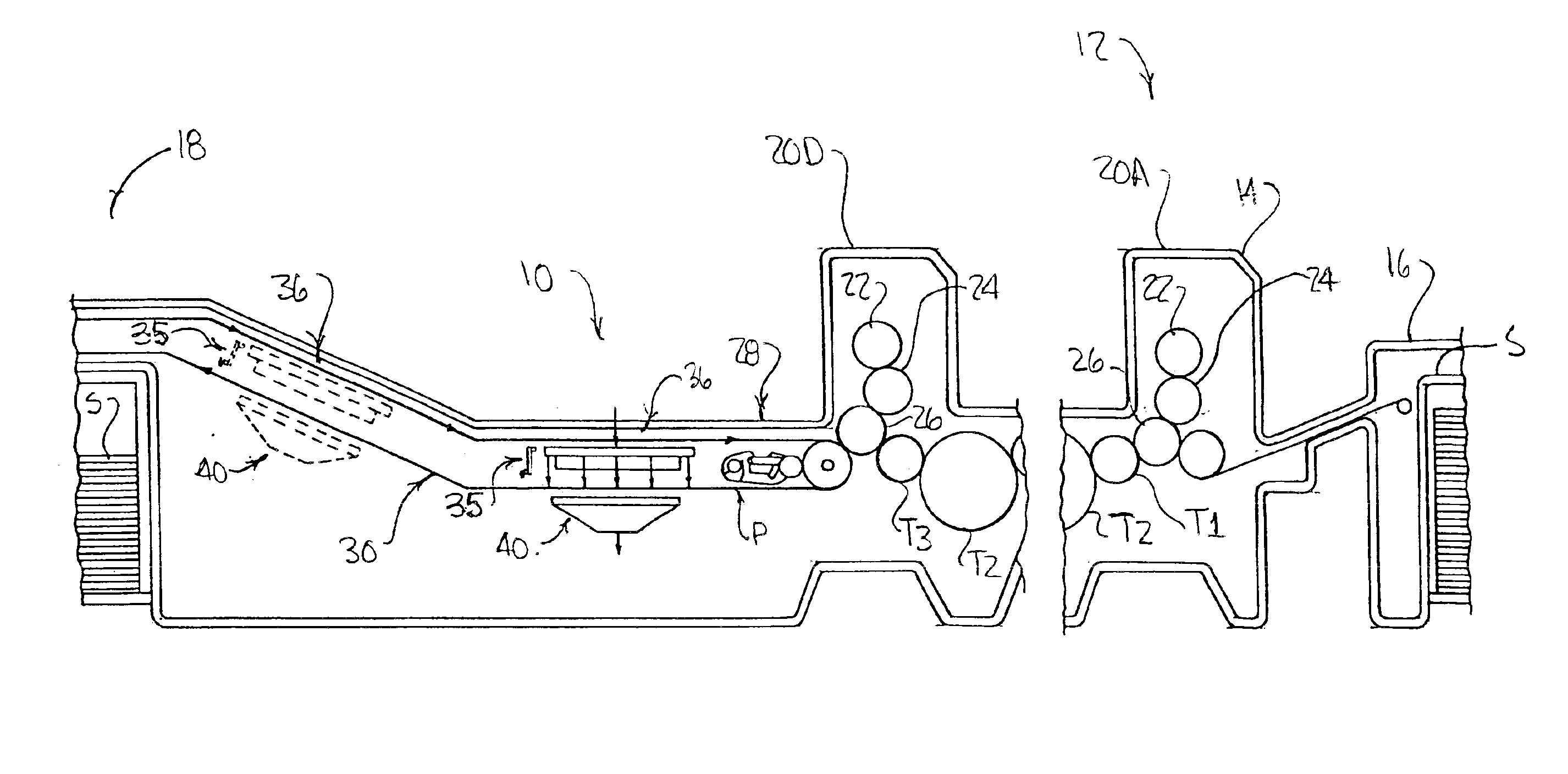

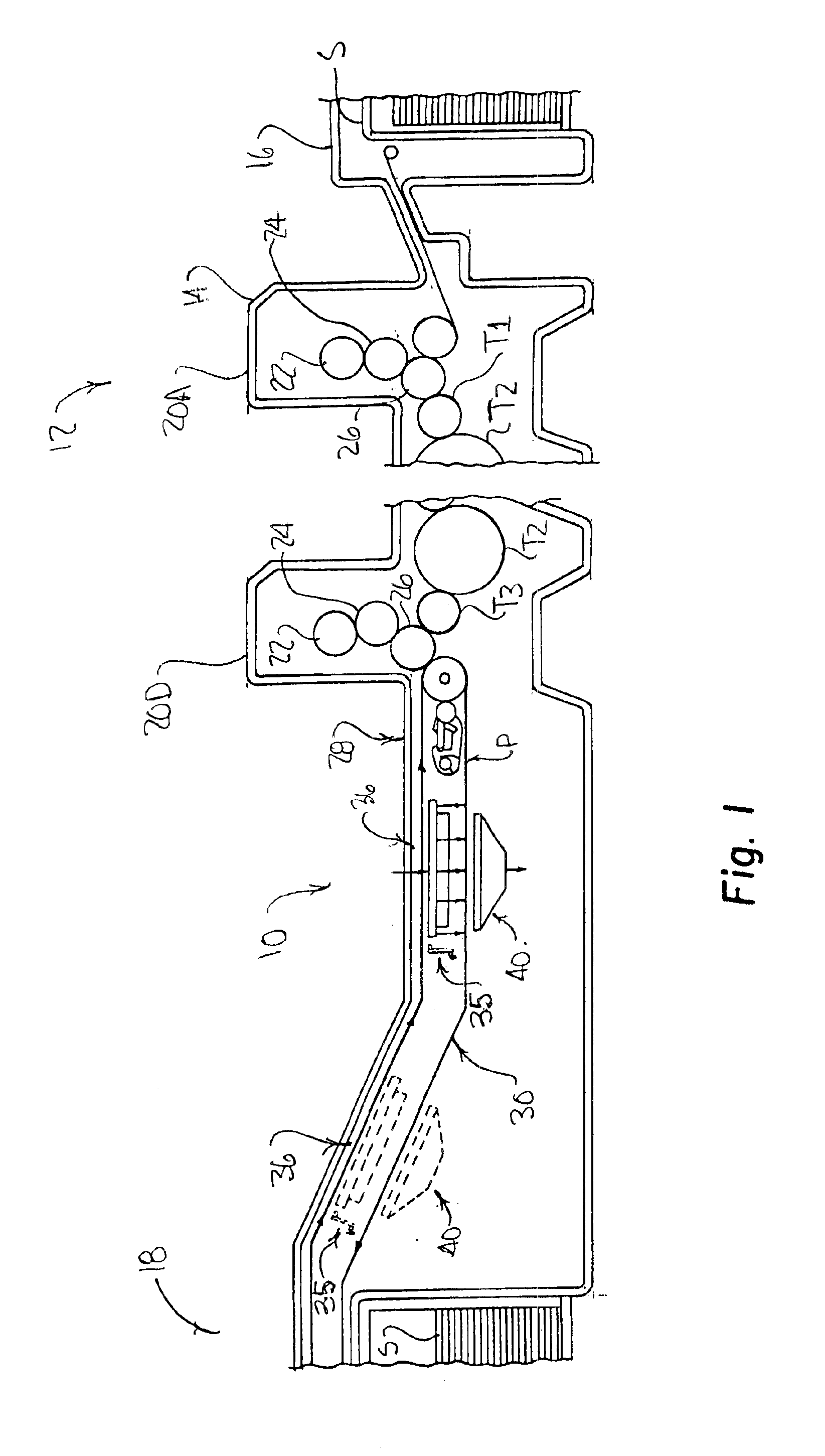

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

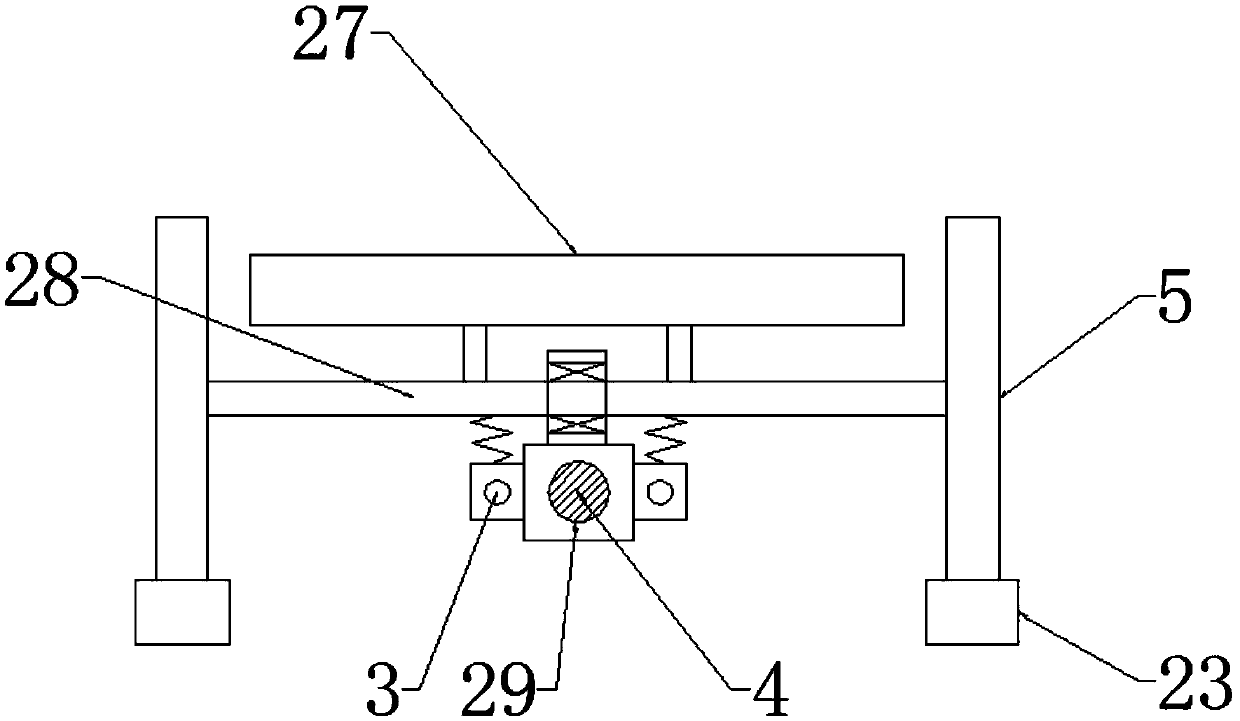

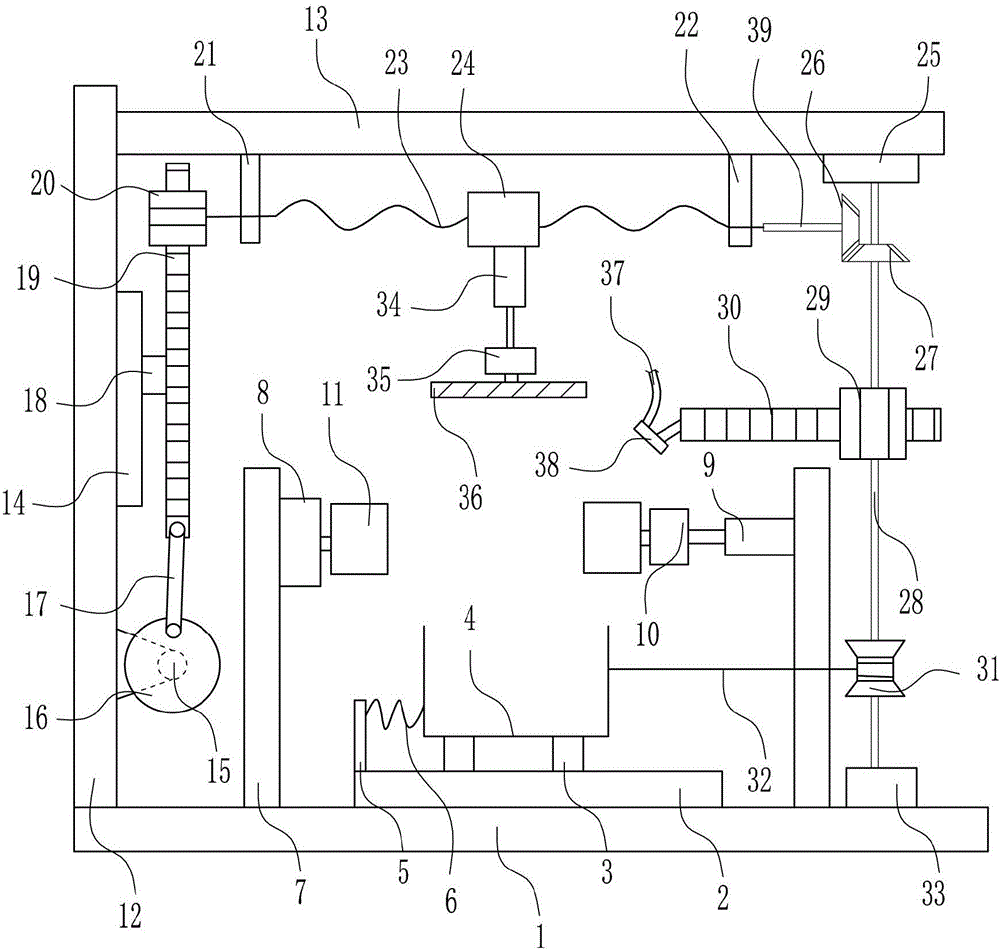

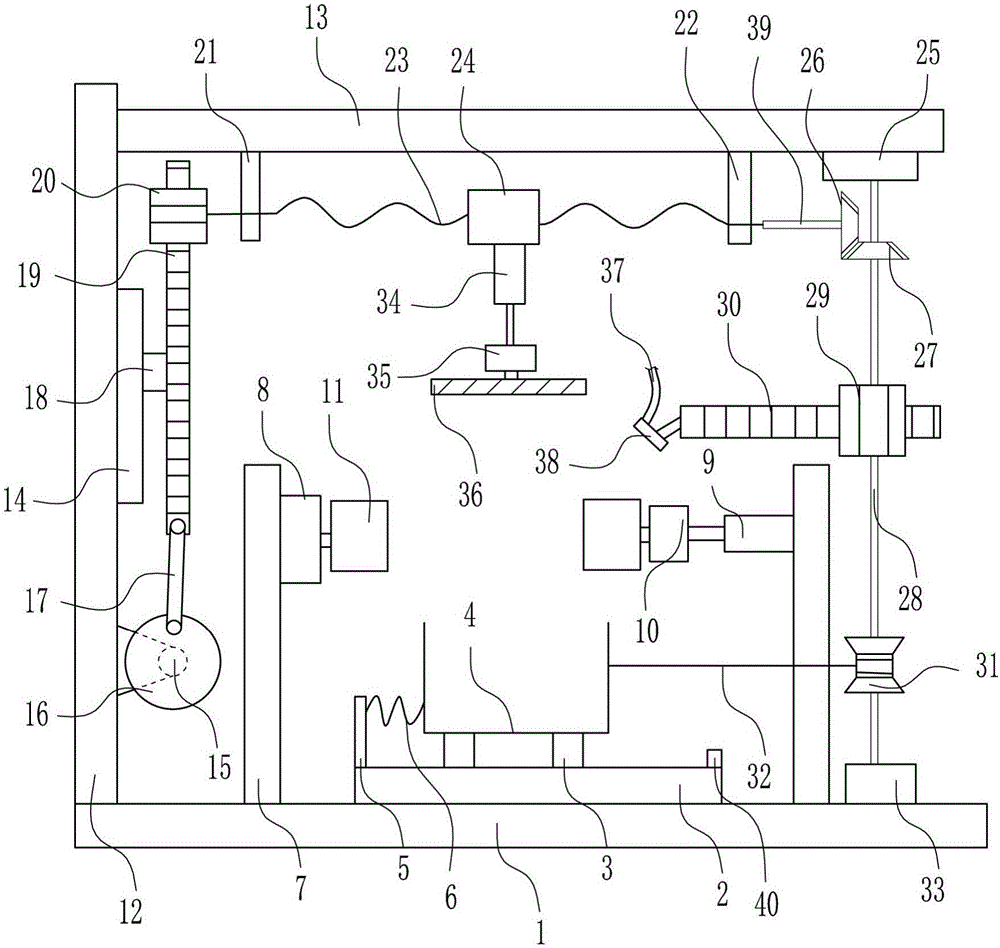

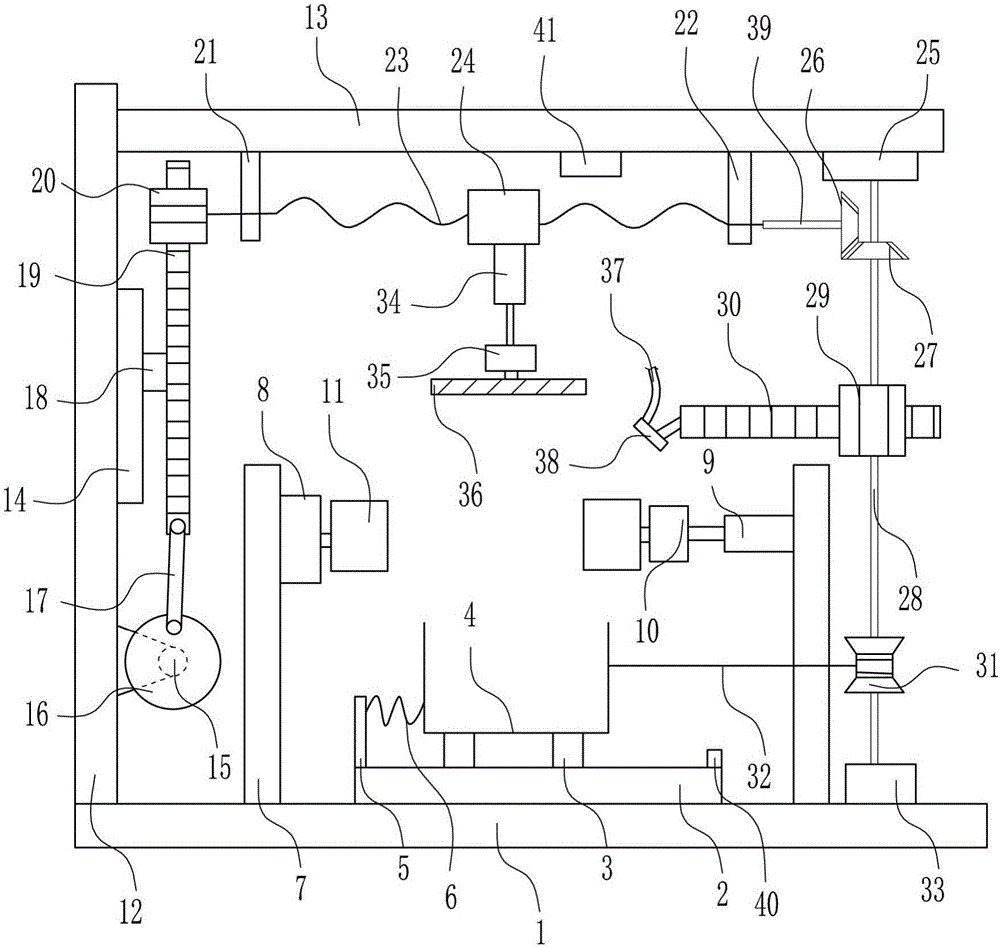

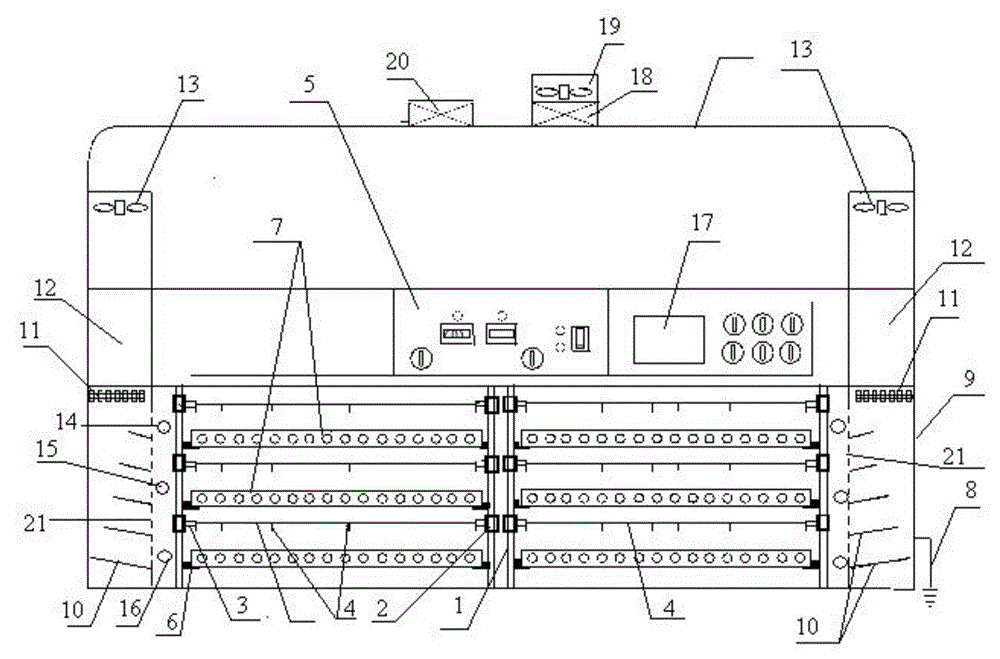

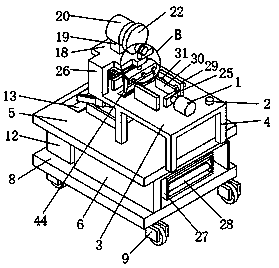

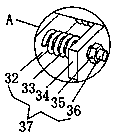

Steel plate surface polishing device for hardware machining

ActiveCN106141875AImprove corrosion resistanceHigh strengthGrinding carriagesPolishing machinesSheet steelMachining

The invention relates to a steel plate surface polishing device, in particular to a steel plate surface polishing device for hardware machining. The steel plate surface polishing device for hardware machining aims to achieve the technical purposes that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of operators is small. In order to achieve the technical purposes, the steel plate surface polishing device for hardware machining comprises a bottom plate, a first sliding rail, a first sliding block, a collection tank, a fixing stop block, a spring, a supporting rod, a first bearing pedestal, a first air cylinder, a disc and the like, wherein the first sliding rail is arranged in the middle of the top of the bottom plate. Through ingenious cooperation of the components, the effects that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of the operators is small are achieved.

Owner:如皋市通城冲压机械制造有限公司

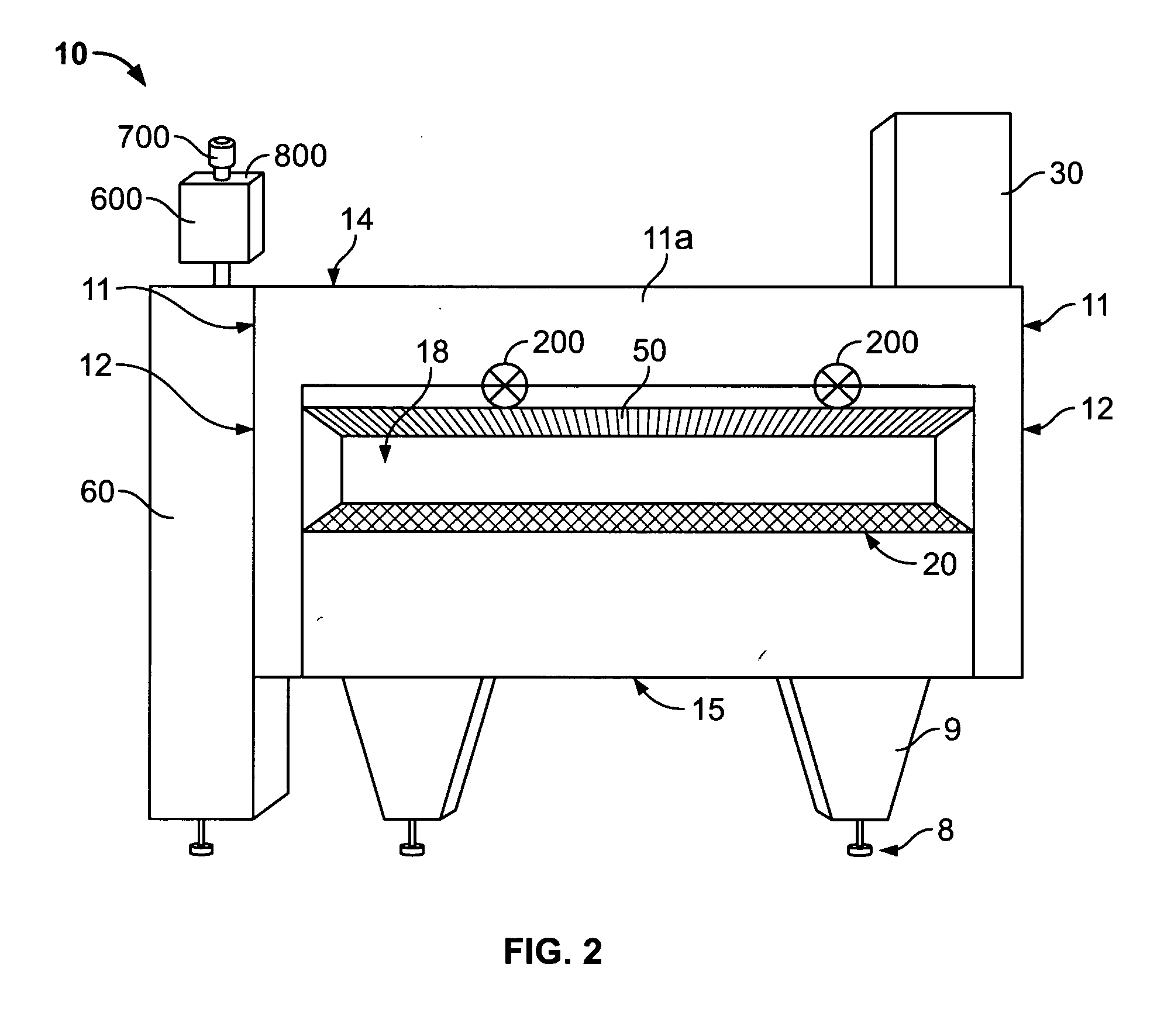

Power saving automatic zoned dryer apparatus and method

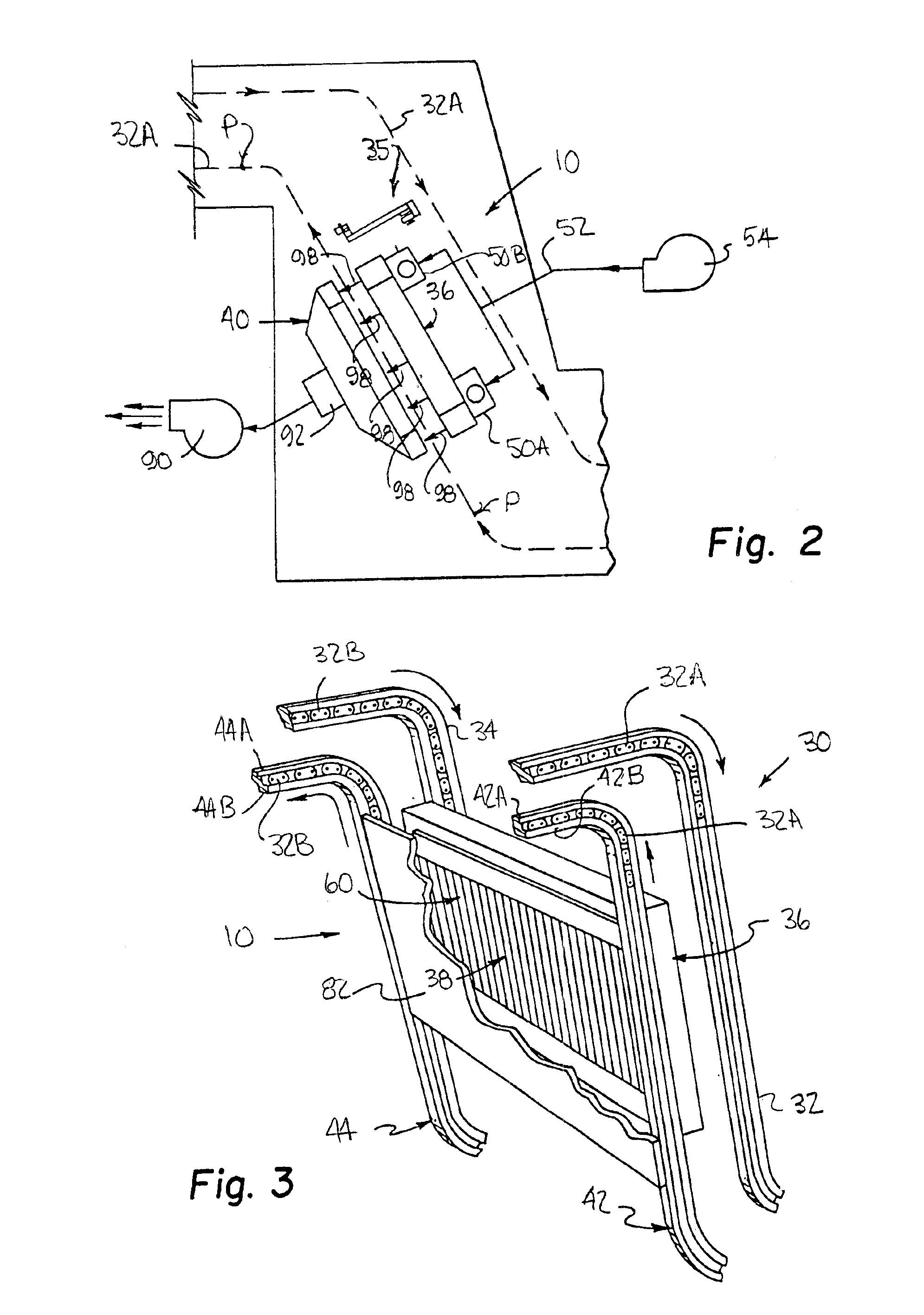

InactiveUS6877247B1Eliminates and greatly reduces needImprove paper qualityDrying solid materials with heatDrying gas arrangementsAuto regulationEngineering

A computer controlled power saving automatic zoned dryer for a printing press has a dryer head facing the substrate travel path, having a multiplicity of IR lamps connected individually or in groups to form a plurality of heating zones running longitudinally and each extending laterally side by side across the substrate travel path. The radiant heat output of each heating zone is controlled separately by means of a control unit connected to a power supply. The control unit individually regulates output of the heating zones. Unneeded zones are turned off to reduce cost of power and conserve energy. A plurality of heat sensors spaced laterally across the substrate path measure the surface temperature of substrate heated areas corresponding to the heating zones being operated and maintain an automatic set point temperature. The temperature of each individual heated area can be regulated automatically by adjusting the output of its heating zone whereby printed substrates having a more even temperature profile are delivered. In an alternate manual mode any zone can be set independently to operate at any percentage of full available power from zero to 100%. Separate high velocity air scrubbers and additional air extraction are used to enhance the total drying effect of the zoned dryer assembly.

Owner:PRINTING RES

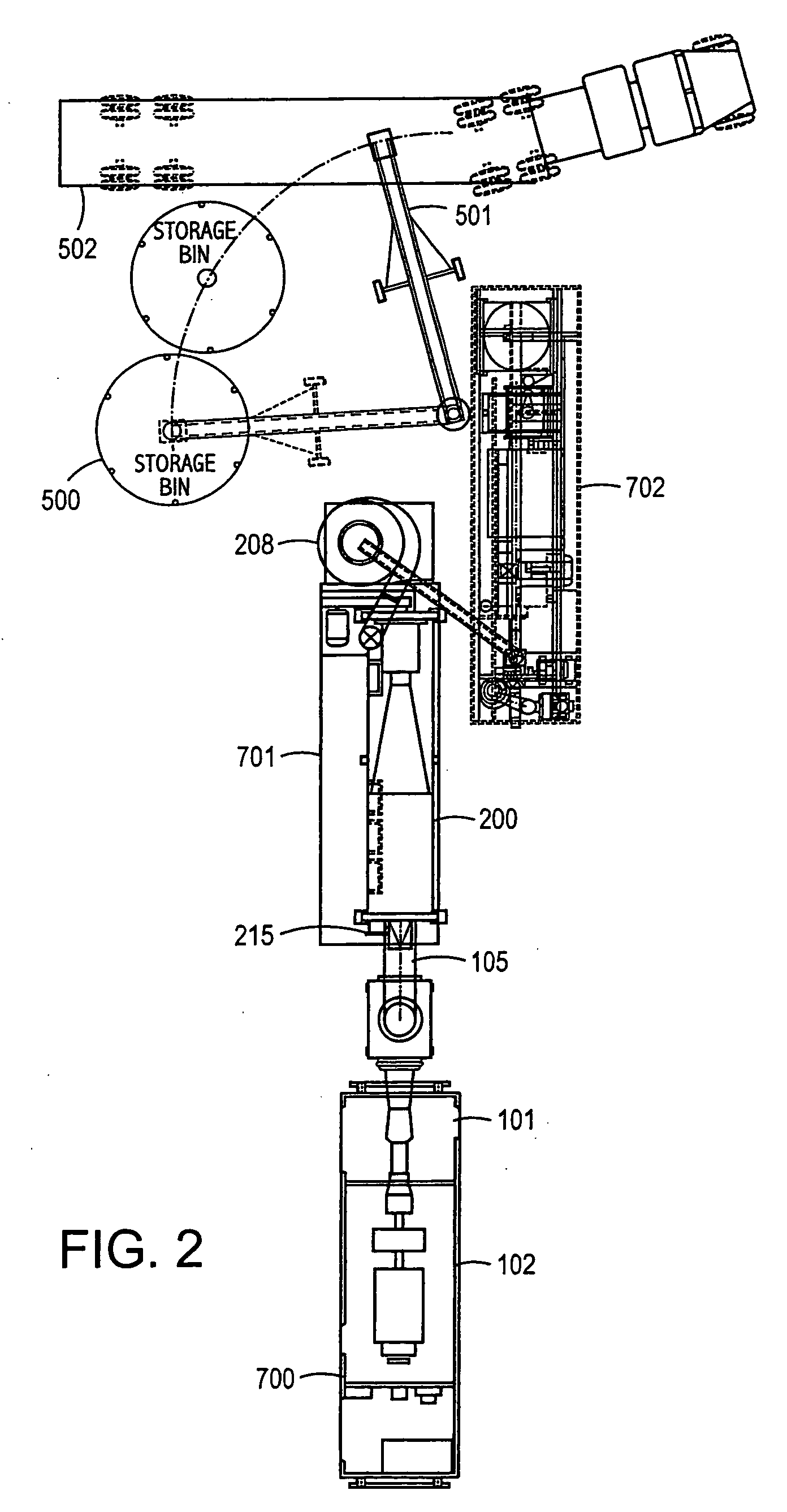

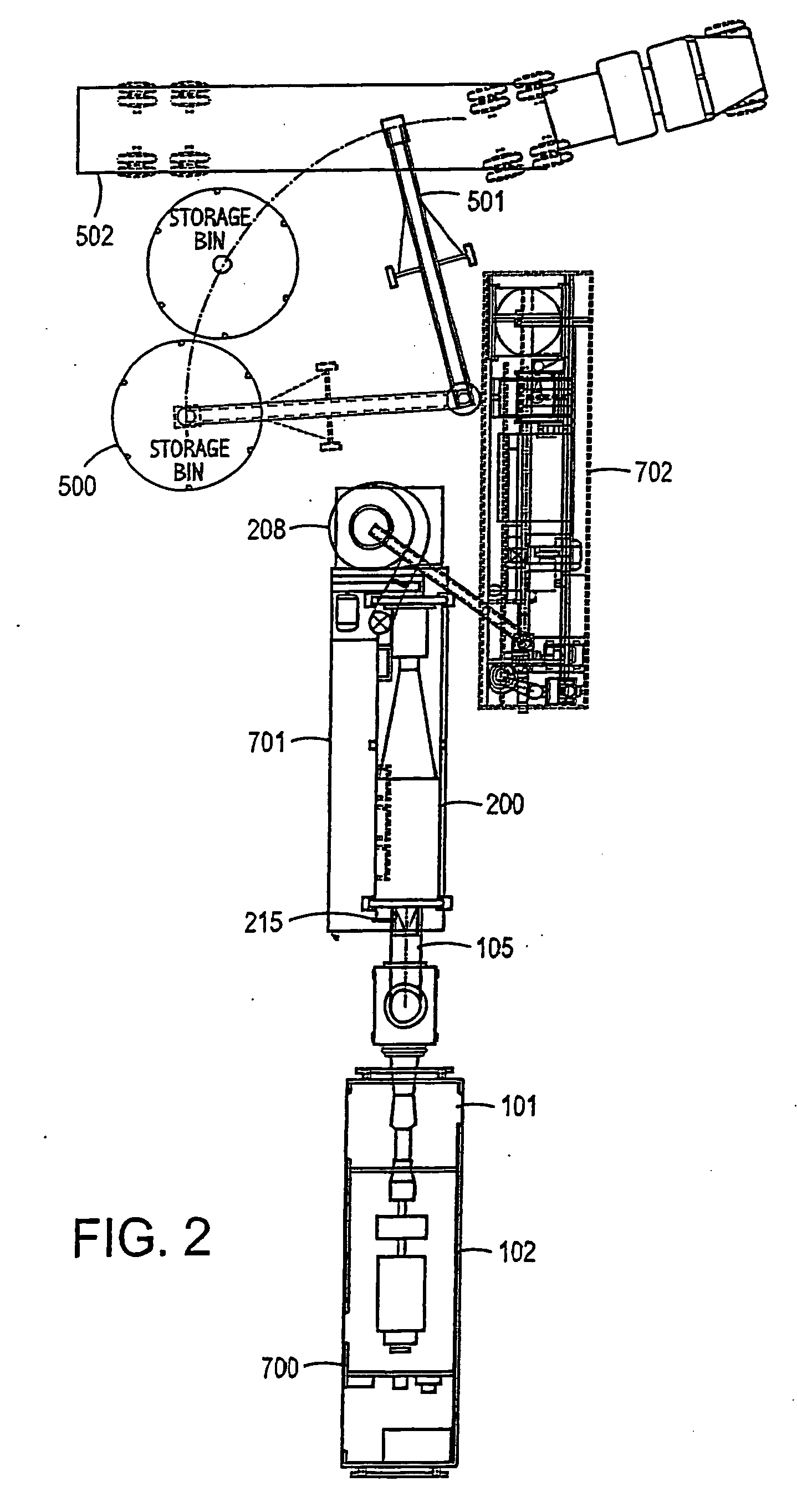

Process and system for drying and heat treating materials

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

Process and apparatus for manufacture of fertilizer products from manure and sewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

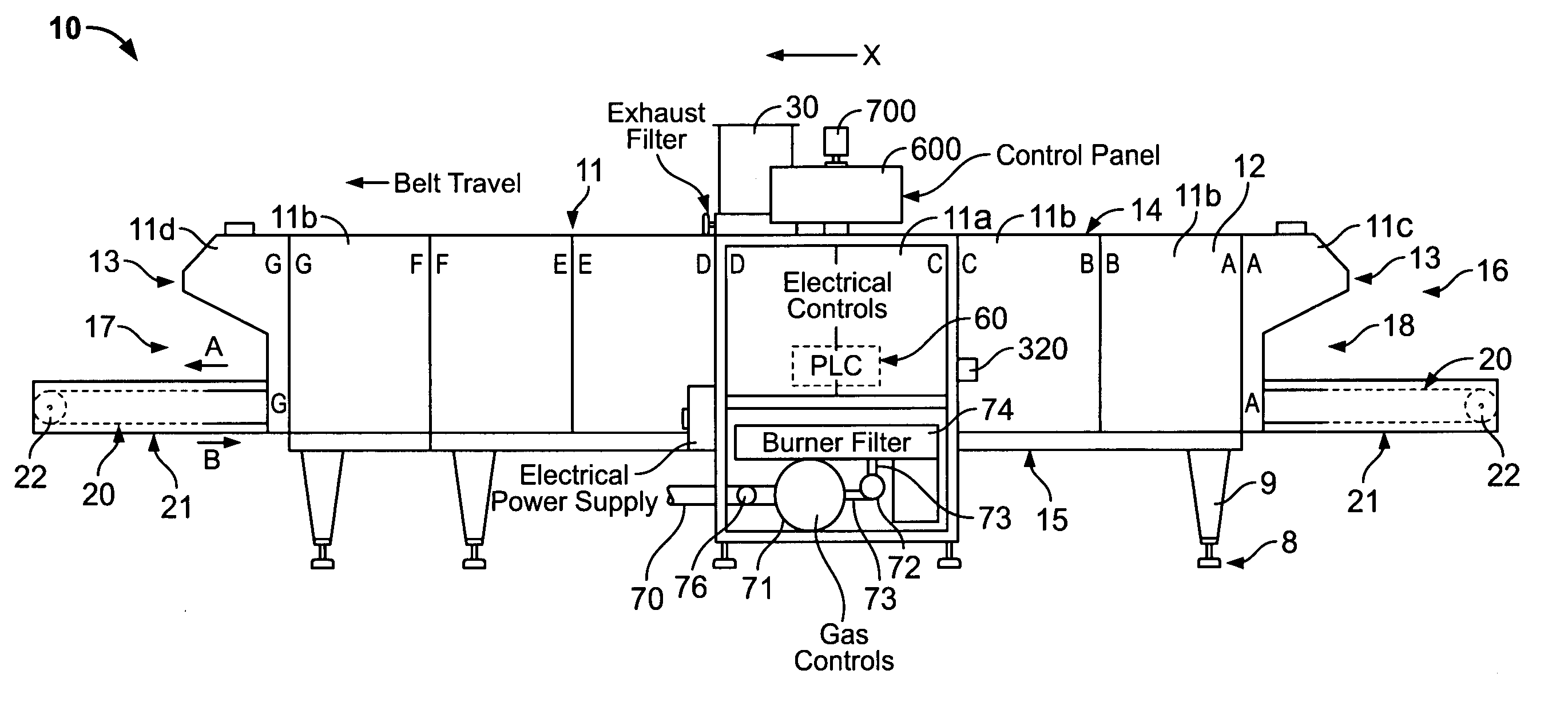

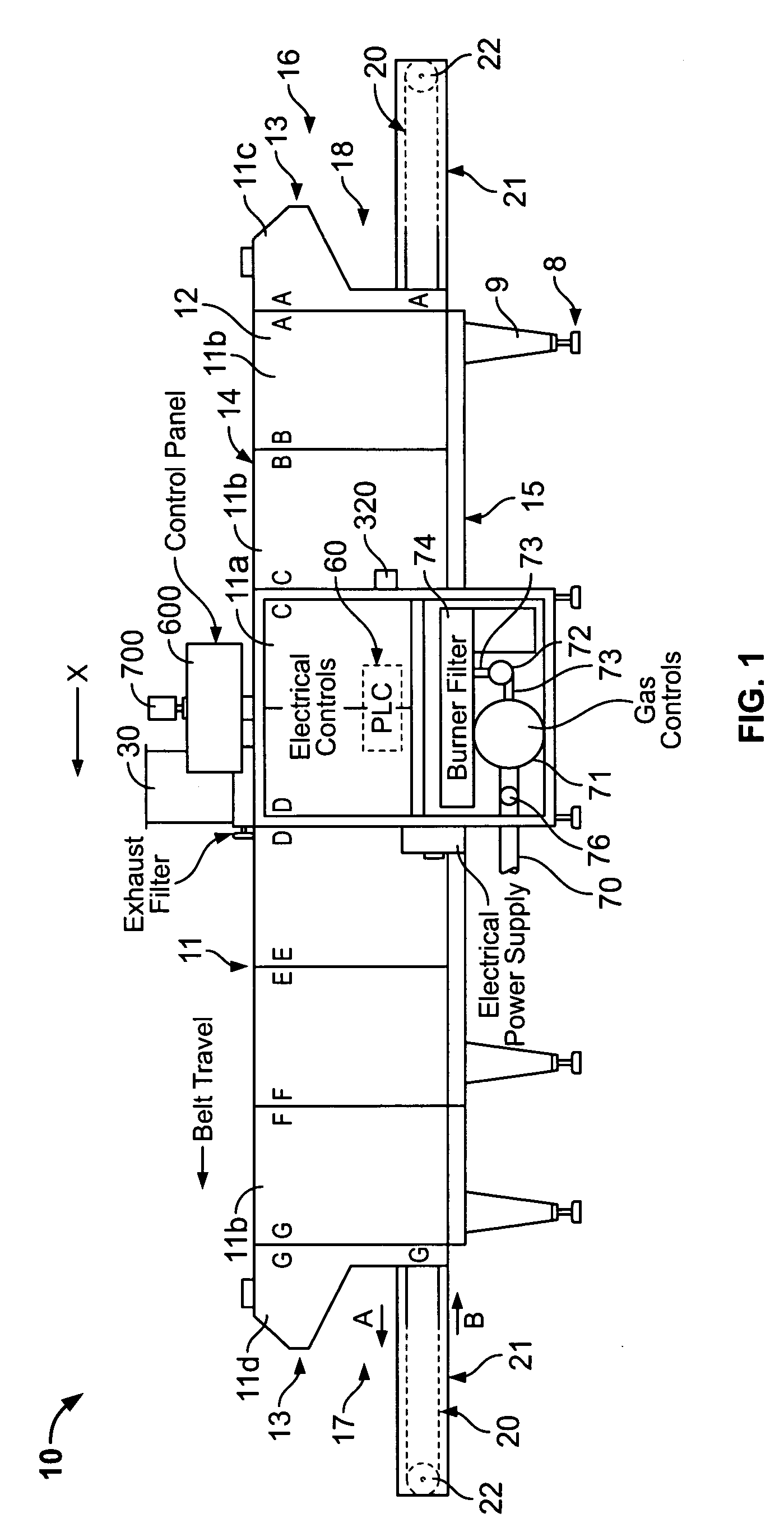

Dryer assembly

InactiveUS20070193056A1Large capacityFast curingDrying solid materials with heatDrying gas arrangementsProcess engineeringThermocouple

A textile dryer capable of monitoring heating chamber temperature (internal thermocouple), peak ink temperature (absorption infrared probe at exit), real-time ink temperature (donut thermocouple) as the textile travels through the chamber, and gas consumption is disclosed. A controller permits one to set numerous parameters and view graphs of the monitored variables over time. Recipes or job settings can be stored for recall and use later. In addition, visual and audible warnings and alarms are incorporated into the system.

Owner:M&R PRINTING EQUIP

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS7024796B2Drying using combination processesBio-organic fraction processingAgricultural scienceOrganic farming

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

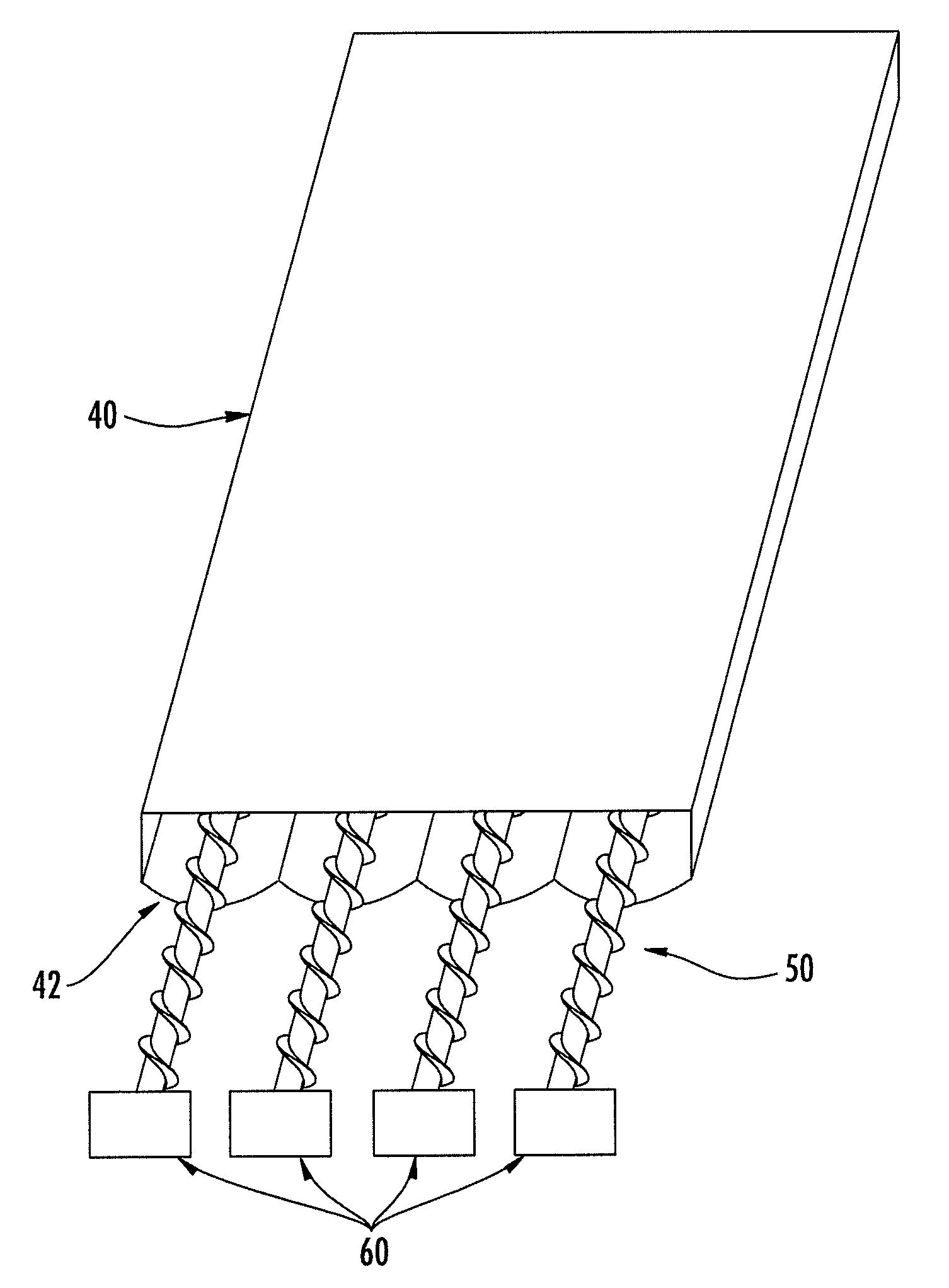

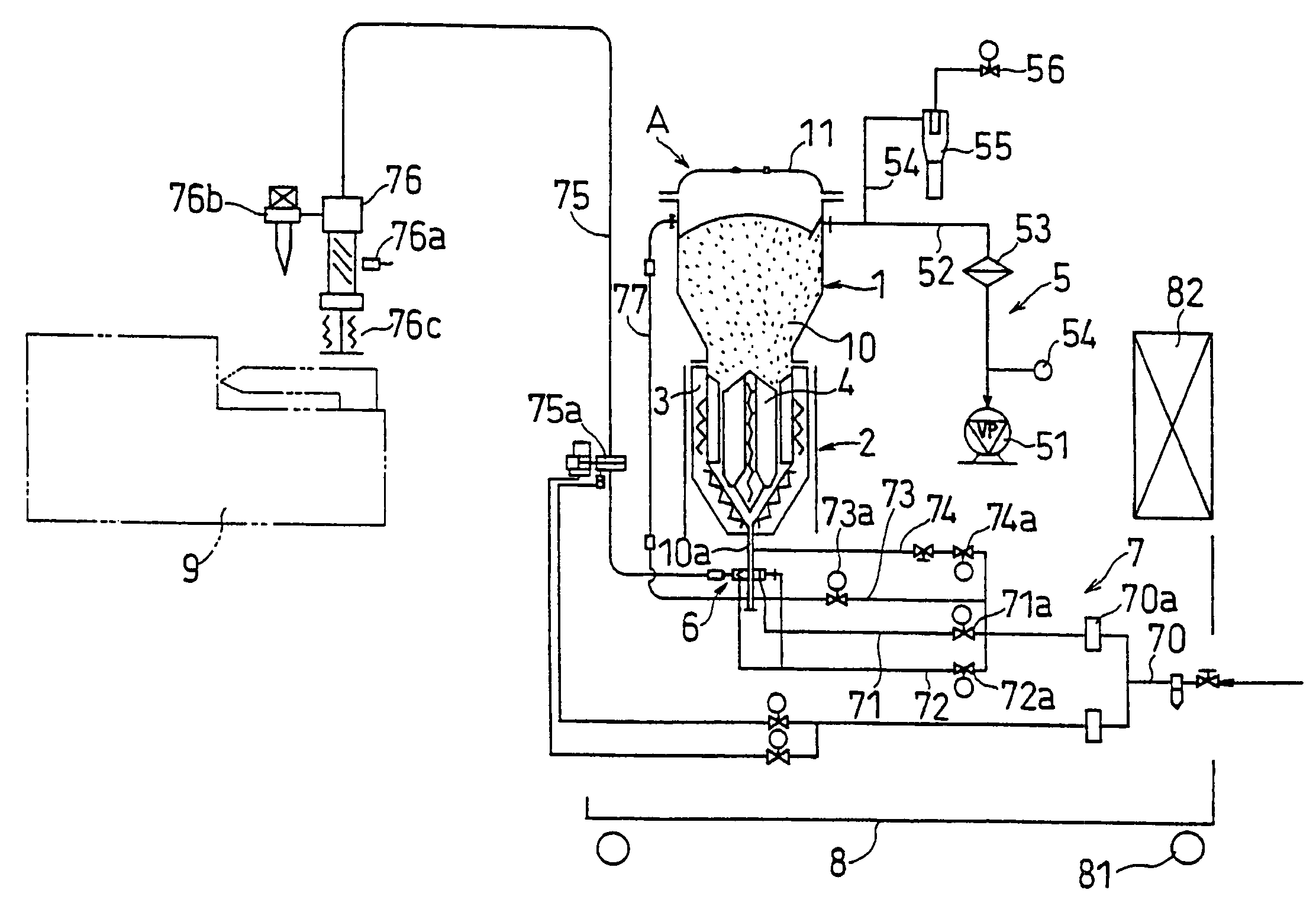

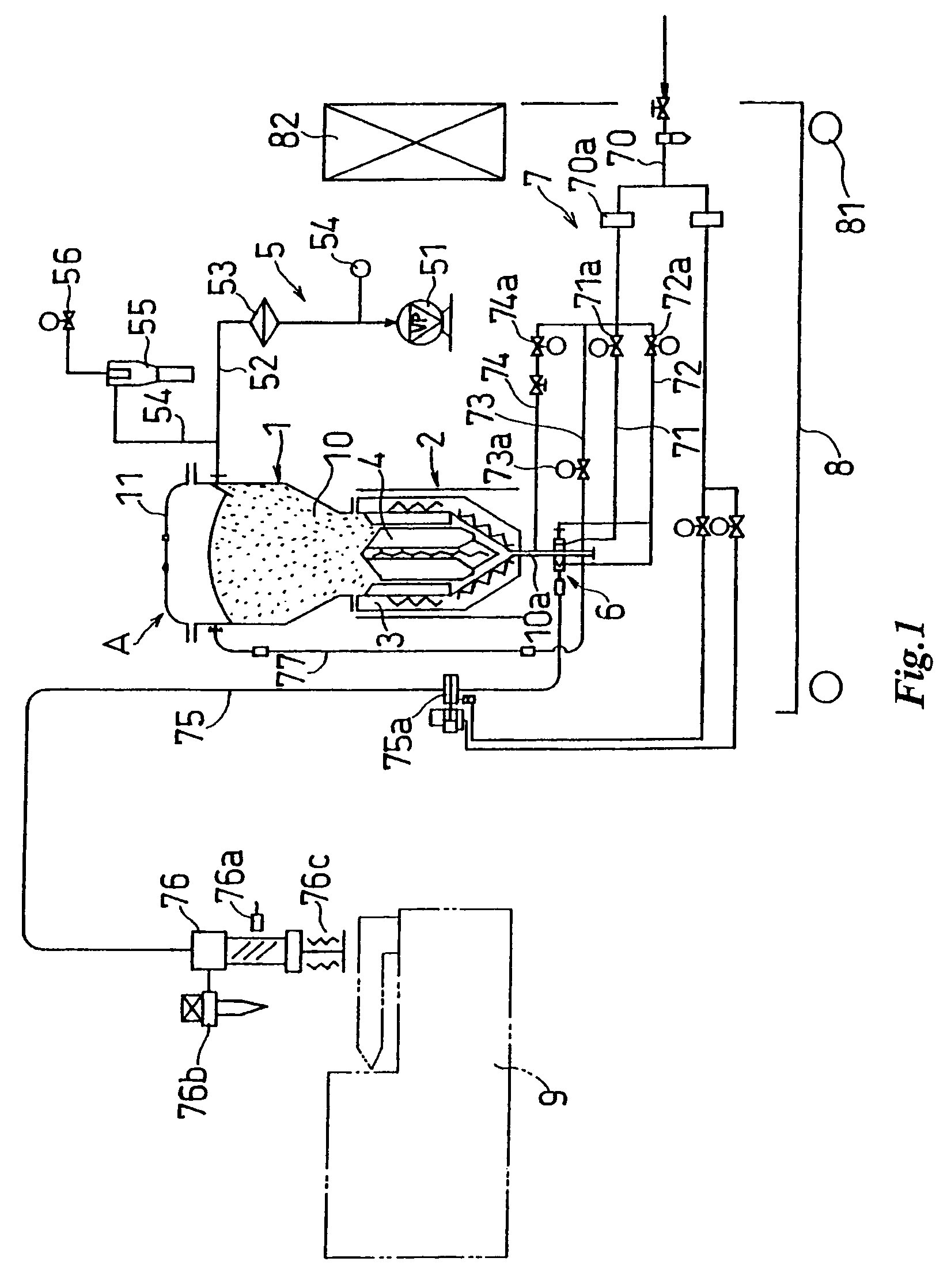

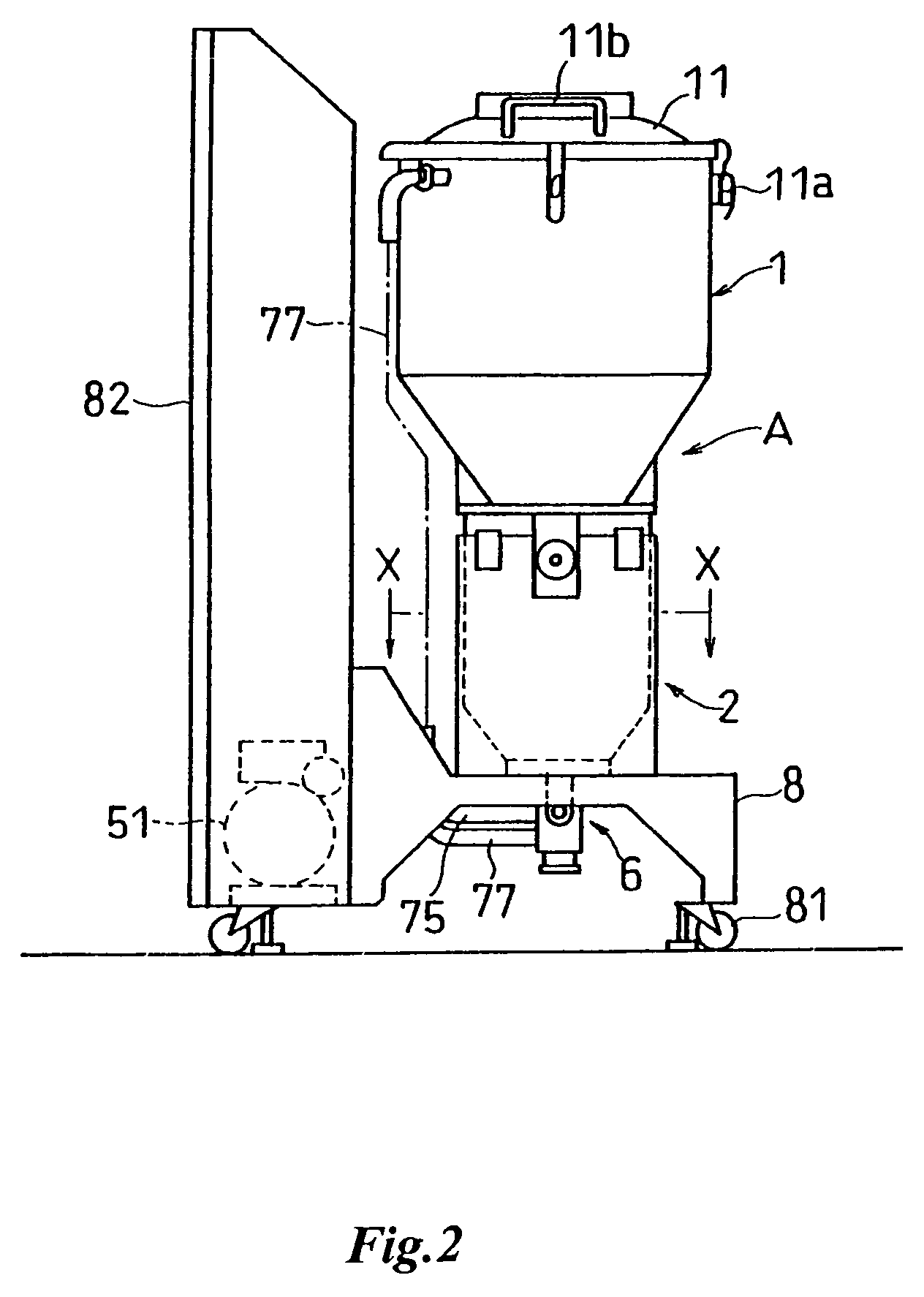

Drying-storing apparatus for powdered or granular material and feeding system for powdered or granular material

InactiveUS7703217B2Improve efficiencySimple materialDrying using combination processesDrying solid materials with heatProcess engineeringMaterial storage

A drying and storing apparatus for powdered or granular material and a feeding system for powdered or granular material. The apparatus comprises a heating and drying chamber having a discharge port at its lower end and a thermal conductive heating means therein and a hopper chamber connected to the upper end of the heating and drying chamber, in which the heating and drying chamber and the hopper chamber constitute a integrally combined material storage processing tank for powdered or granular material.

Owner:MATSUI MFG

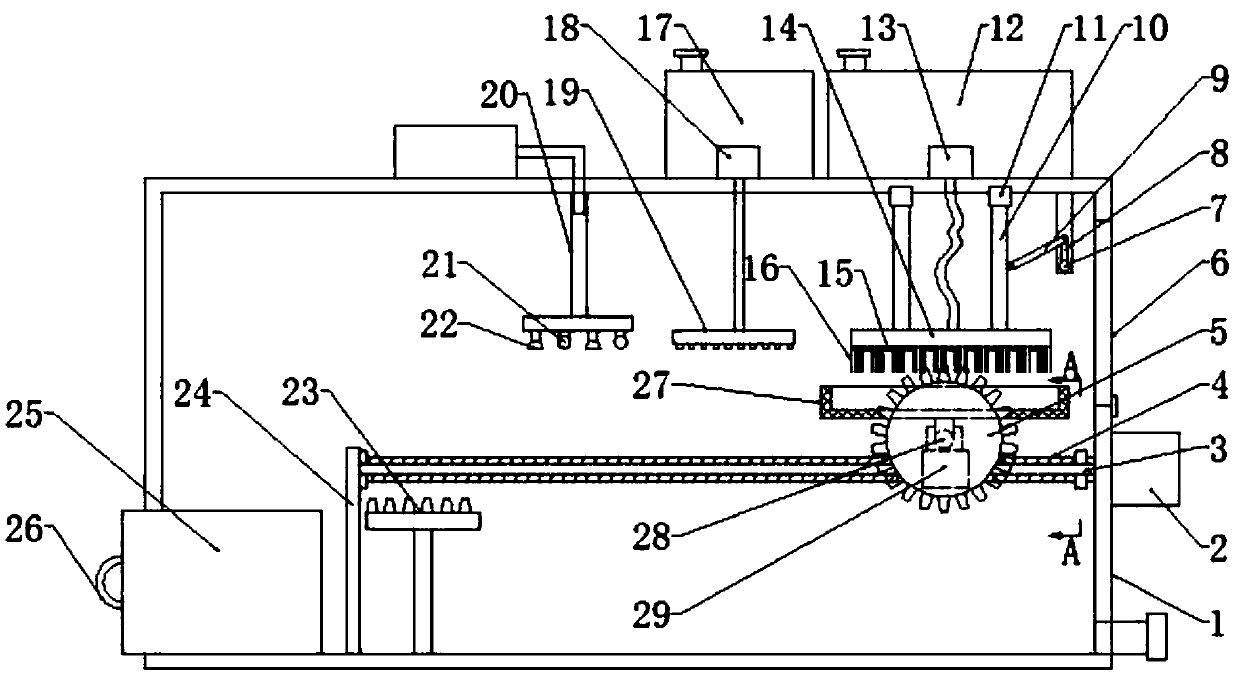

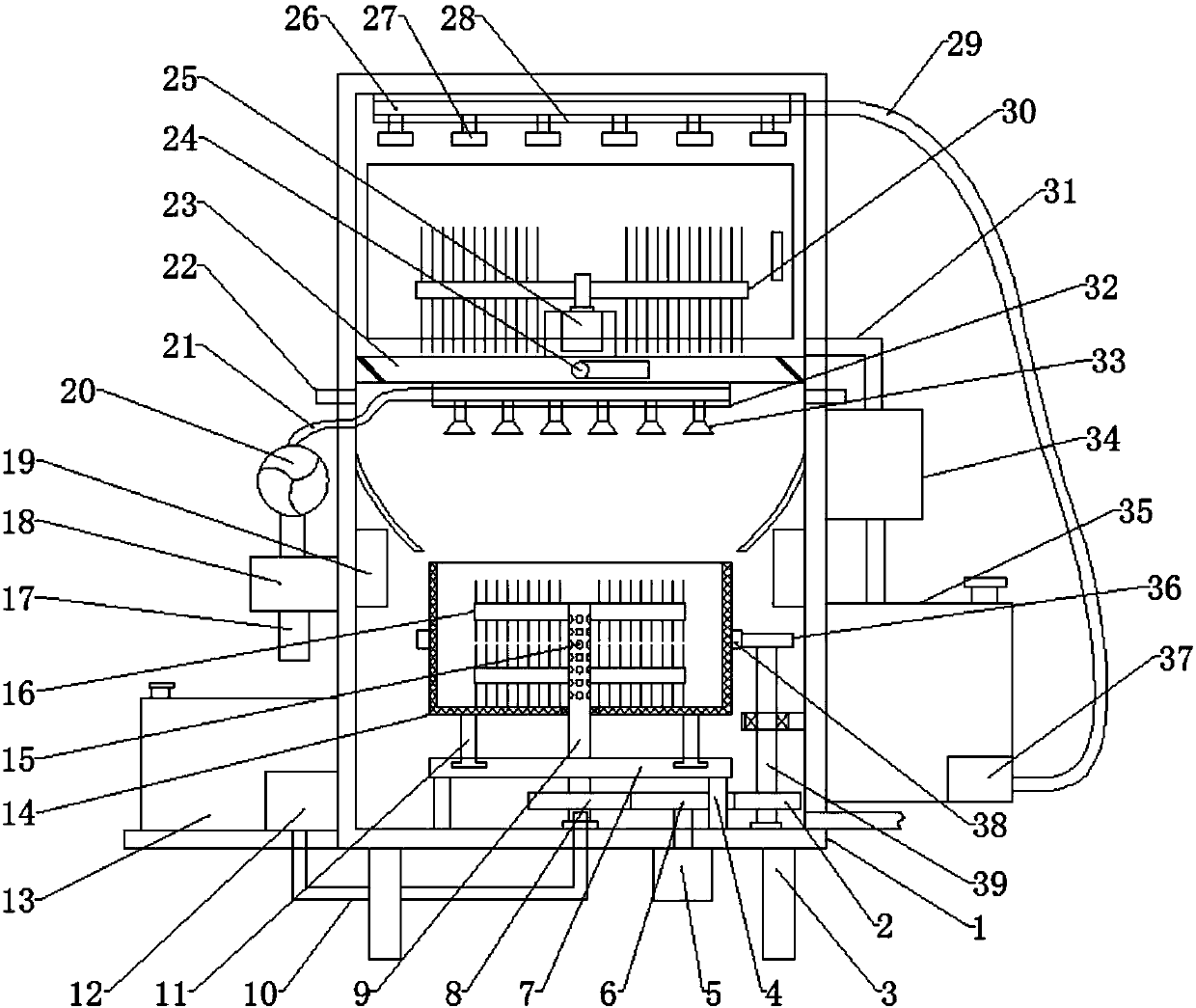

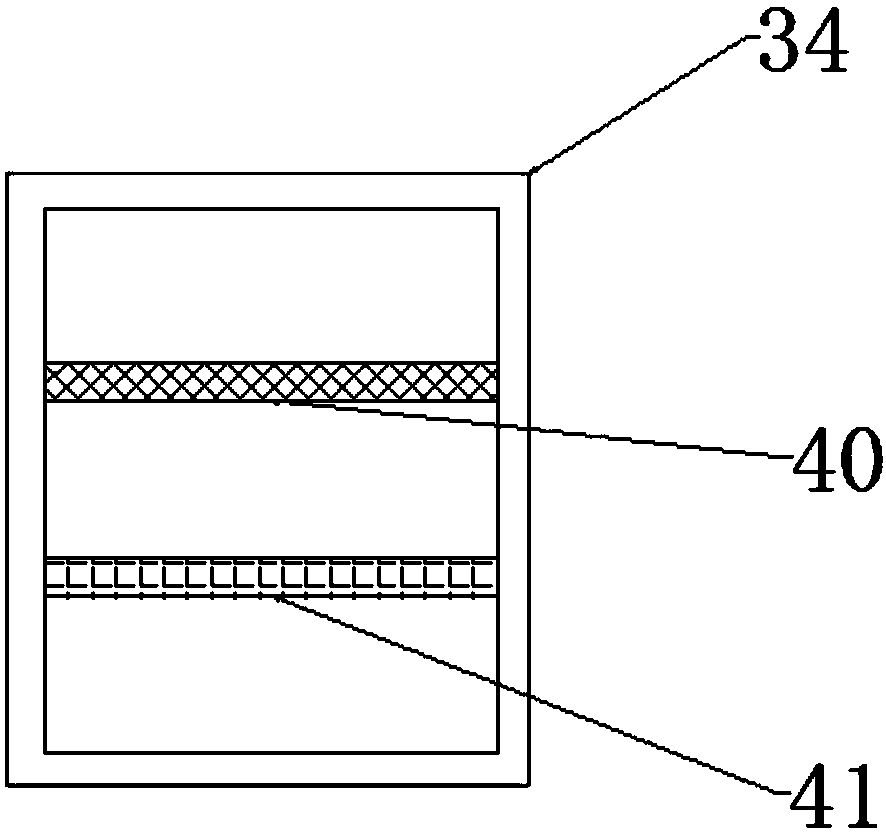

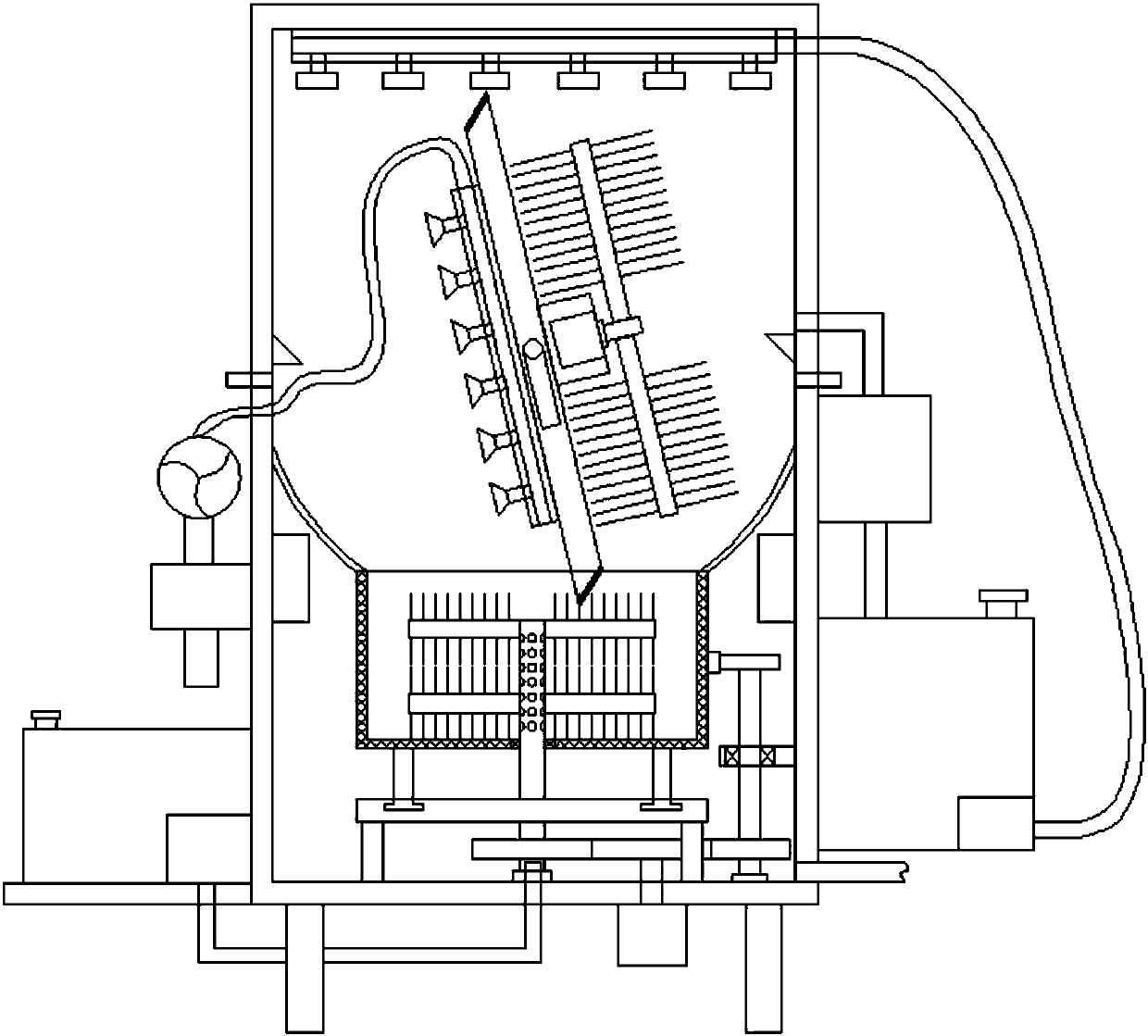

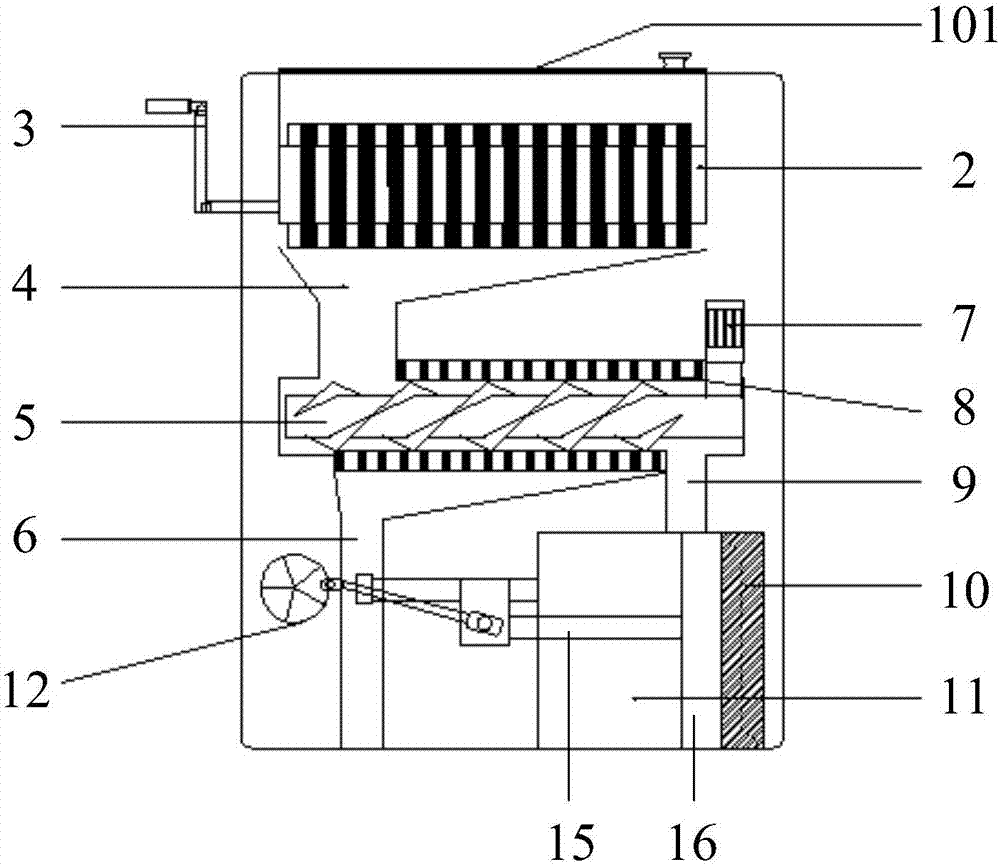

Medicinal material processing device for producing traditional Chinese medicine (TCM) decoction pieces, with dust removal and drying functions

InactiveCN107139234AGuaranteed uniformityImprove processing qualityUsing liquid separation agentDirt cleaningSlice thicknessInstability

A device for processing medicinal materials for the production of decoction pieces of traditional Chinese medicine with the function of dust removal and drying, comprising a shell, a through hole is opened in the middle of the top of the shell, and a lifting plate passes through the through hole, and the upper left side wall of the lifting plate is fixedly connected There is a rack, and the top of the housing on the left side of the lifting plate is fixedly connected with two support frames, and the top of the support frame is rotatably connected with a first rotating shaft, and one end of the first rotating shaft is fixedly connected with the output shaft of the first motor, and the first rotating shaft The upper part is fixedly connected with a half gear, and half of the gear teeth are arranged on the half gear, and the half gear is meshed with the rack. The invention has the beneficial effects of ensuring the uniformity of slice thickness, making the processing quality of medicinal materials better, meeting the requirements of production specifications, reducing the quality instability during manual slicing, and having certain application value; at the same time, it can also be processed The adsorption of dust ensures the life safety of the operators; the drying device is used to fully dry the sliced medicinal materials.

Owner:许晶

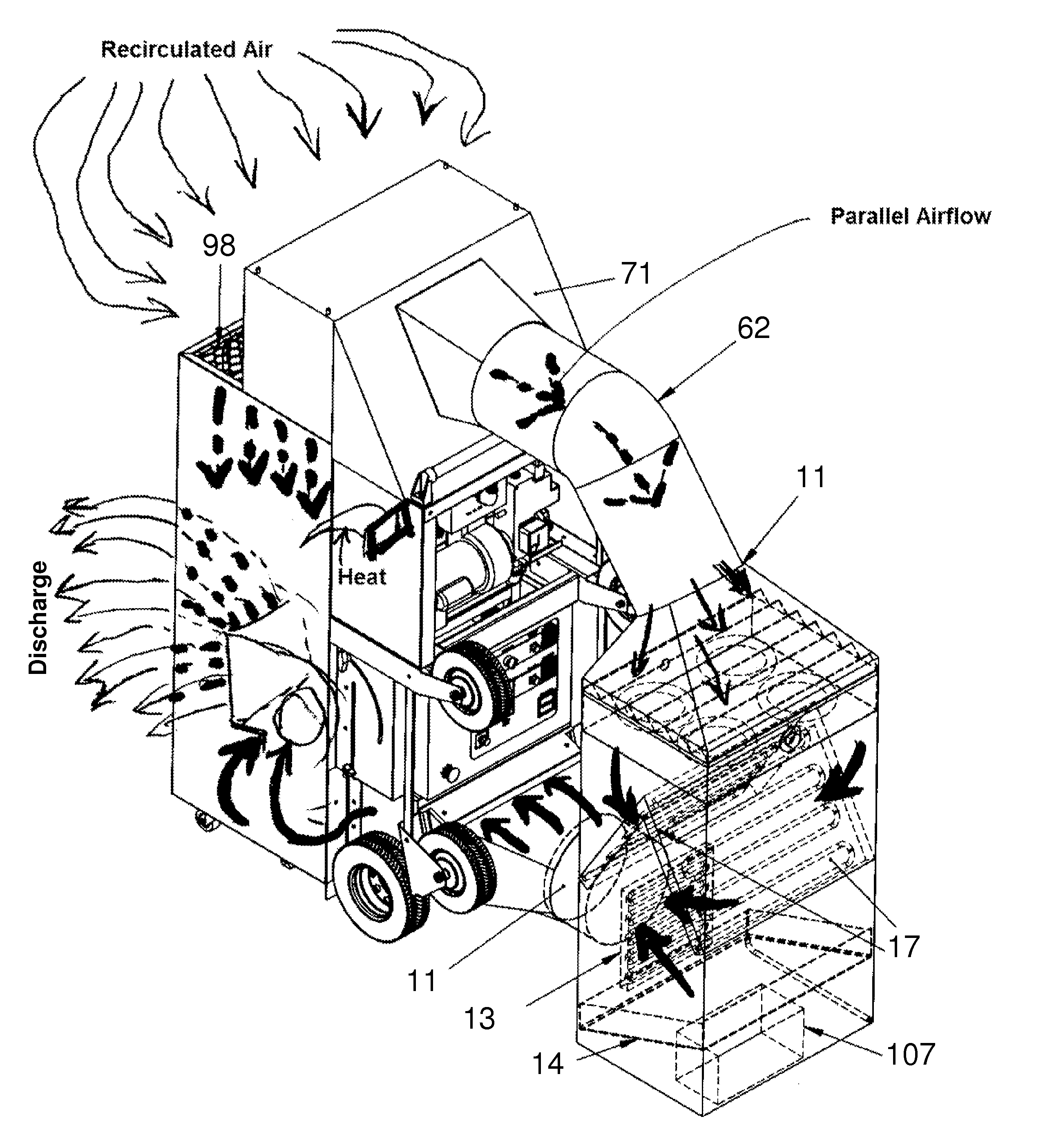

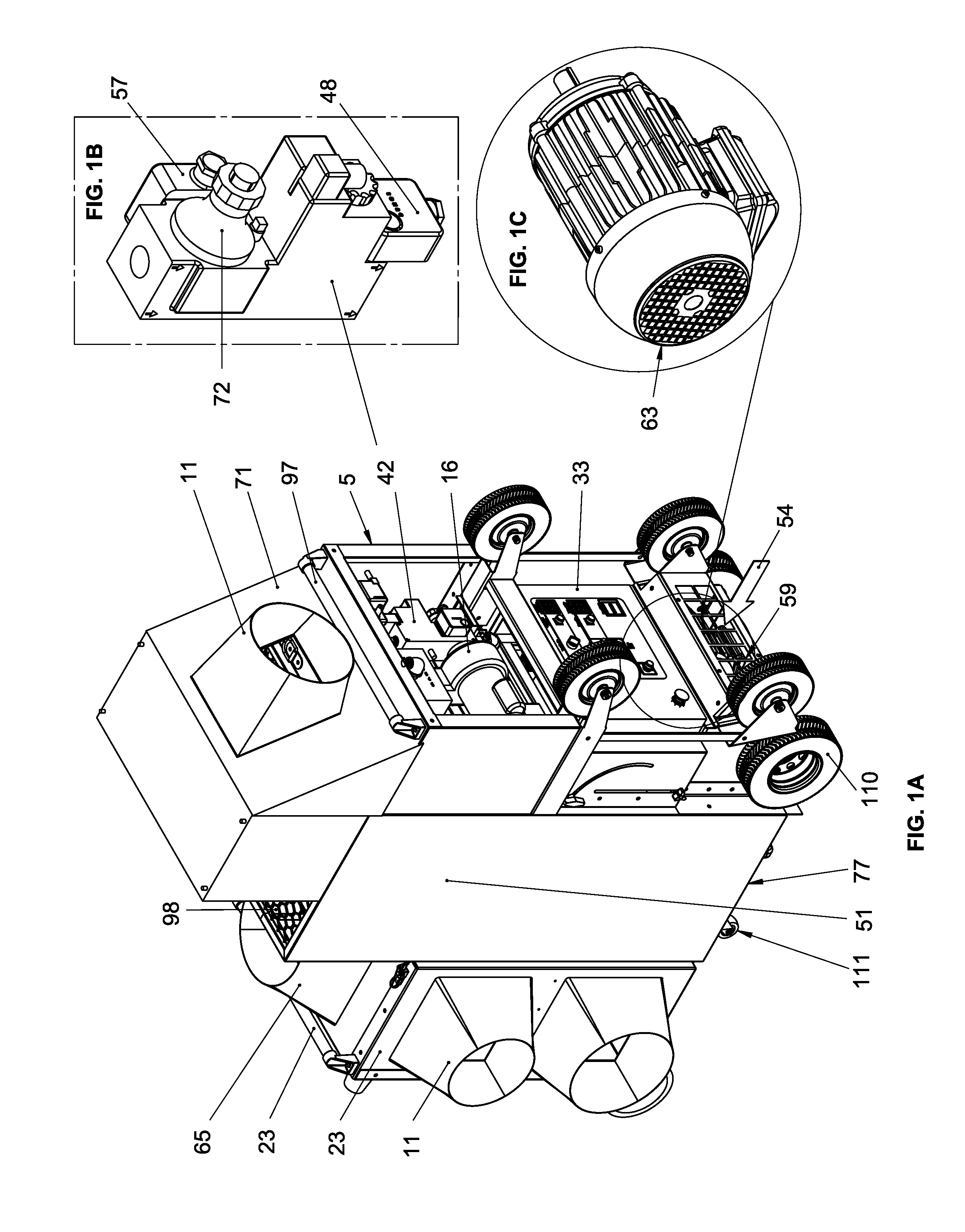

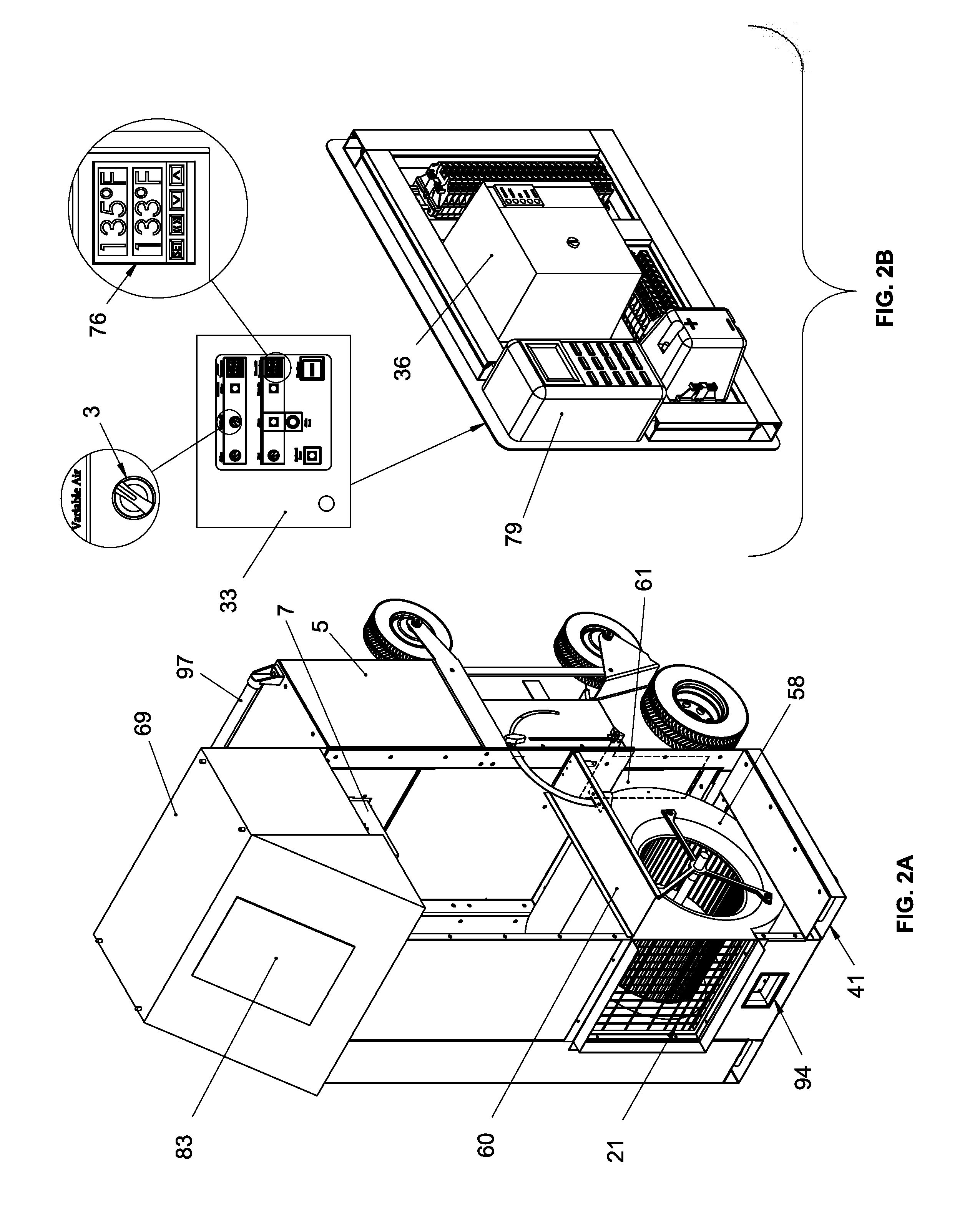

Multi-Component System for Treating Enclosed Environments

ActiveUS20150128483A1Eradicate smoke and water damageStructural damageHot-air central heatingDrying solid materials with heatComputer moduleEngineering

Described herein is a heating system where air is drawn into a system where hot gas is injected into it. The air is then discharged at a regulated temperature into an environment through ductwork to heat environments to elevated temperatures and employing functional modules to further condition the air to humidify, dehumidify, decontaminate with airborne free-radicals, and filtrate in both stationary and portable applications. The system is useful to eradicate pests, disease germs, bacteria, viruses, and mold. The system is also useful in water remediation and comfort heating. The system can be configured to create a parallel path to both heat and dehumidify the airflow blended and discharged at the operator-chosen set-point temperatures.

Owner:SUPPLIER SUPPORT INT

Medical device disinfection, washing and drying integrated equipment

InactiveCN107552429AAvoid wastingSimple structureDrying gas arrangementsCleaning using toolsDisinfectantSpray nozzle

The invention discloses an integrated equipment for disinfection, cleaning and drying of medical instruments, which includes a box body, a disinfection chamber, a cleaning and drying chamber, a rotating plate, a first motor, a pole, a brush, a hard water pipe, a nozzle, a filter device, a trachea, Nozzle, hot air blower, cleaning frame, electric heating element, hollow pipe, third water pipe, second water pump, water tank, first gear, second gear, third gear, rotating shaft, fourth gear and ring gear, the present invention has The disinfection chamber is equipped with a first motor, a pole and a brush, which can fully sterilize medical instruments. It is equipped with a filter device, which can recycle the disinfectant and avoid wasting the disinfectant. It is equipped with a rotating plate. It can quickly transfer medical instruments from the disinfection chamber to the cleaning and drying chamber. It has a simple structure and is easy to operate. It is equipped with a cleaning frame and a hollow tube, which can efficiently scrub medical instruments. It is equipped with a hot air blower, nozzles and electric heating elements. Medical equipment is dried, which is convenient and practical.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

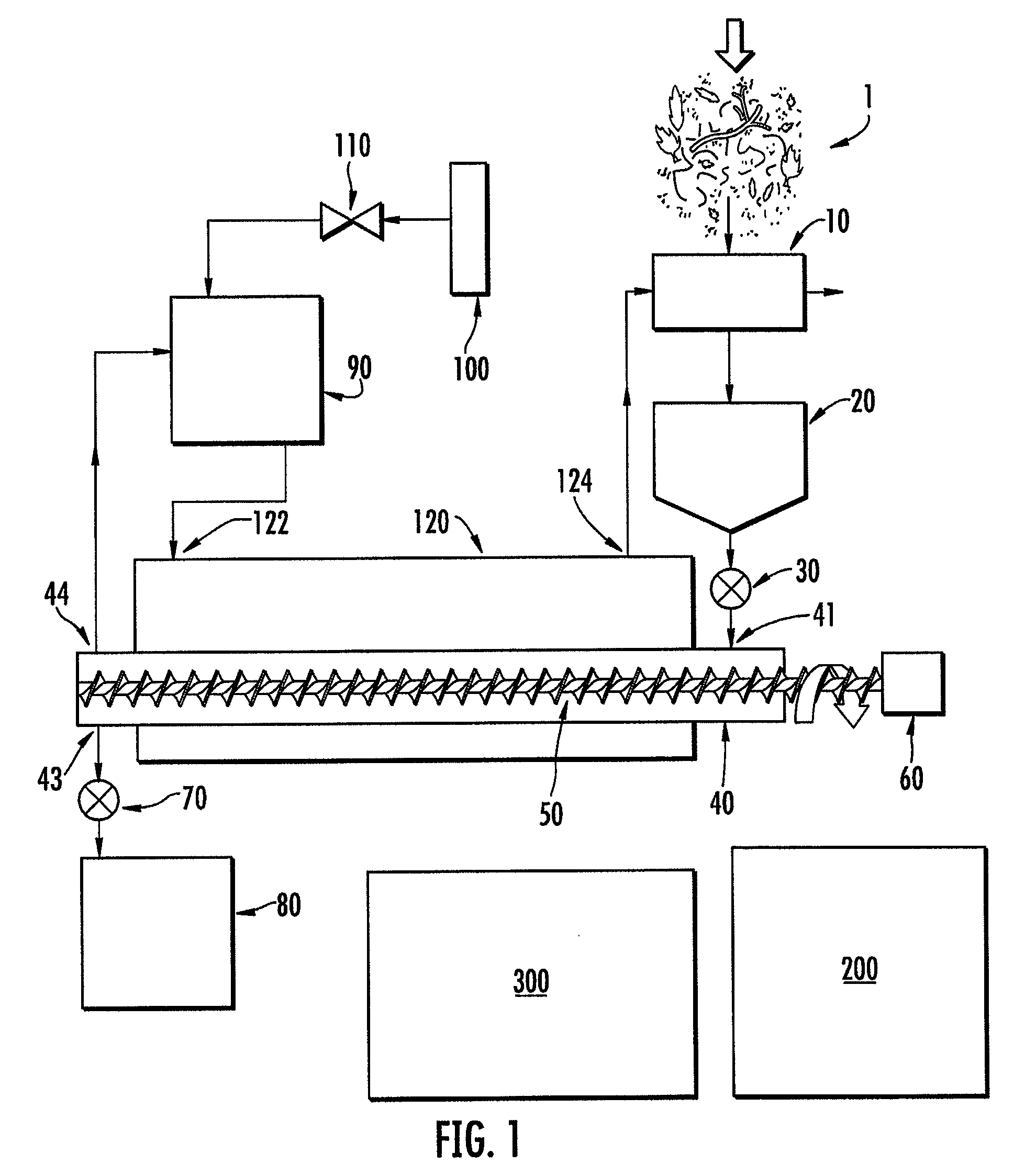

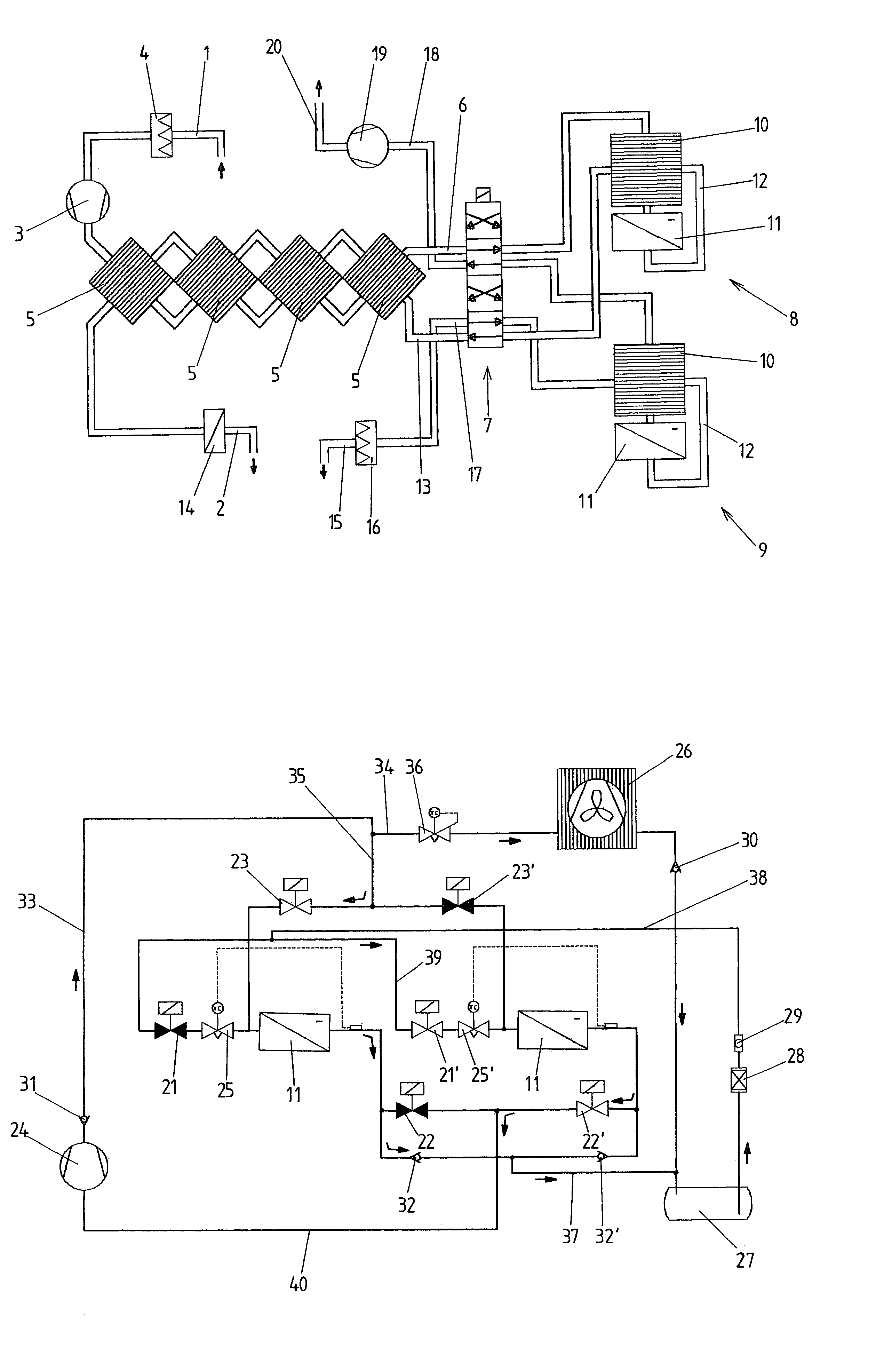

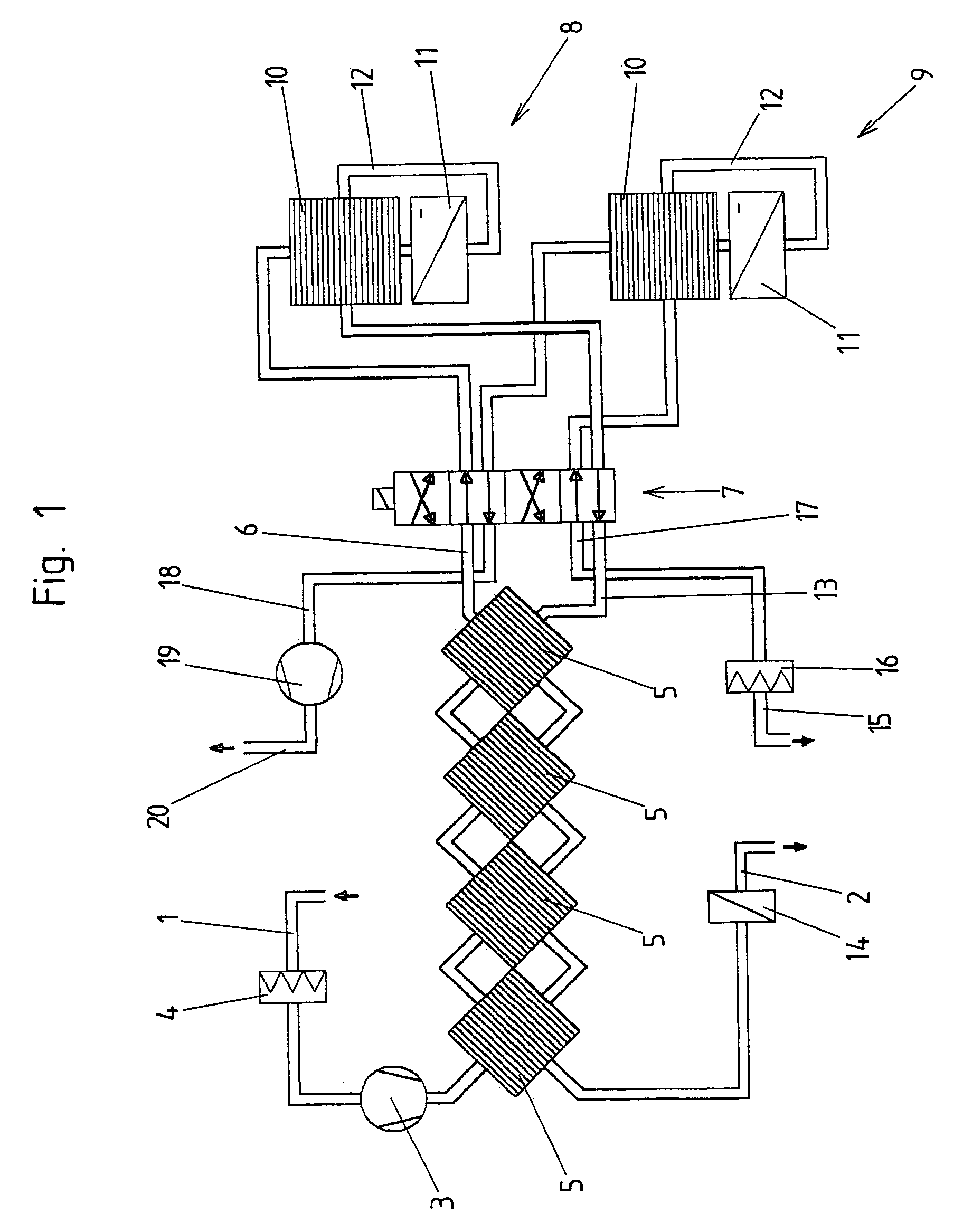

Control system for gas turbine in material treatment unit

InactiveUS20060010708A1Avoid introducingEmission reductionDrying solid materials with heatGas turbine plantsControl systemLiquid fuel

This invention discloses systems and methods for control of a gas turbine or a gas turbine generator, where the gas turbine is connected to a dryer vessel in which gas turbine exhaust gases are used to heat treat a material in the dryer vessel. The control system comprises one or more sensors for temperature, moisture and / or flow rate in the dryer vessel and / or of the material inside, entering and / or exiting the dryer vessel and a controller responsive to the sensor for controlling the fuel and / or air flow into the gas turbine. This control system and method enables providing the appropriate heat output from the gas turbine to meet the process heat required for the desired material treatment. Optionally, the gas turbine can be a liquid fuel turbine engine, or a reciprocating engine can be substituted for the turbine engine.

Owner:EARTHRENEW INC

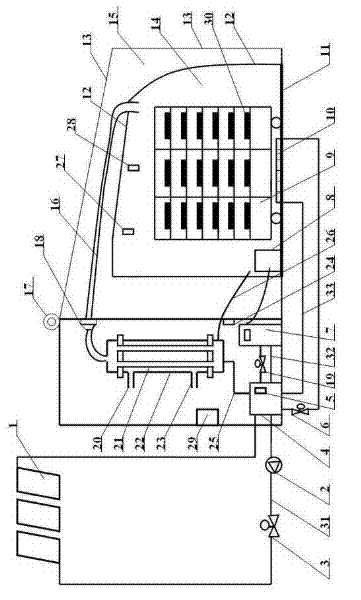

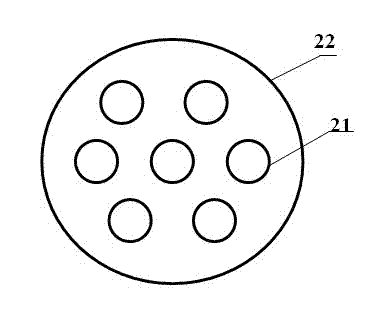

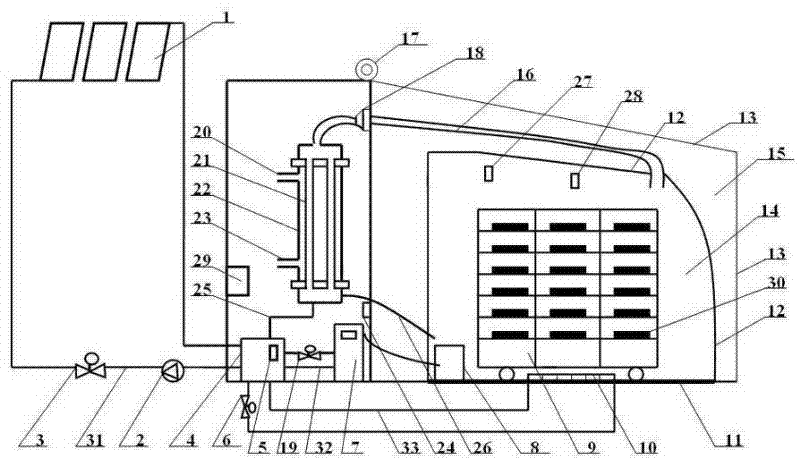

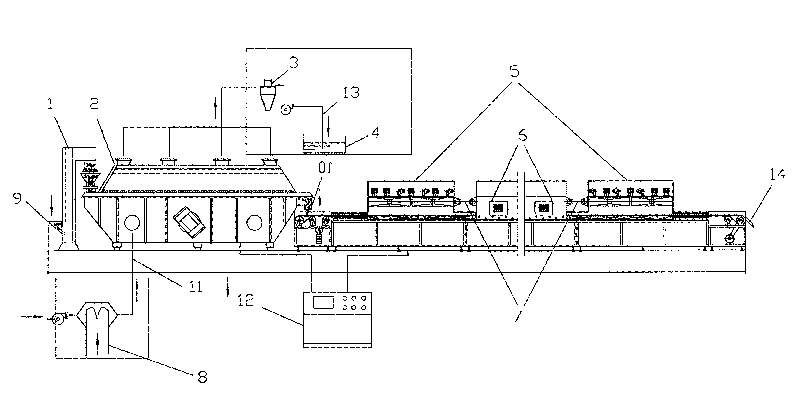

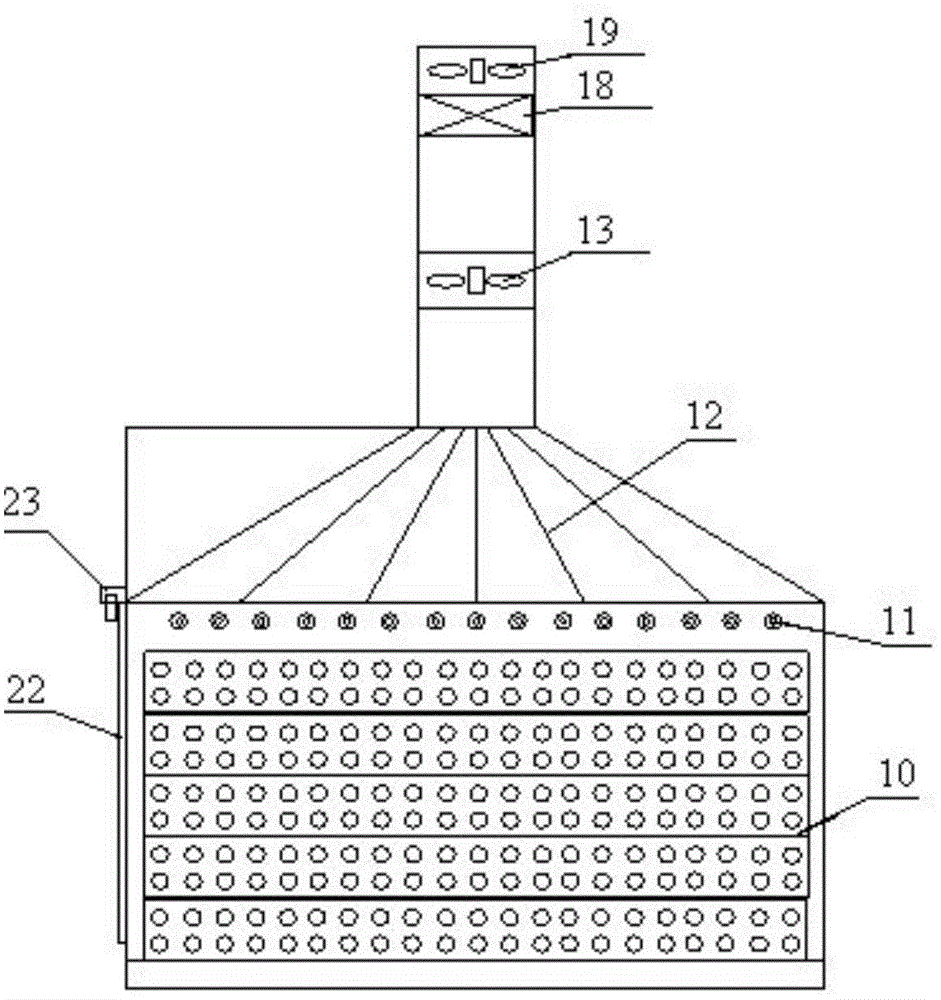

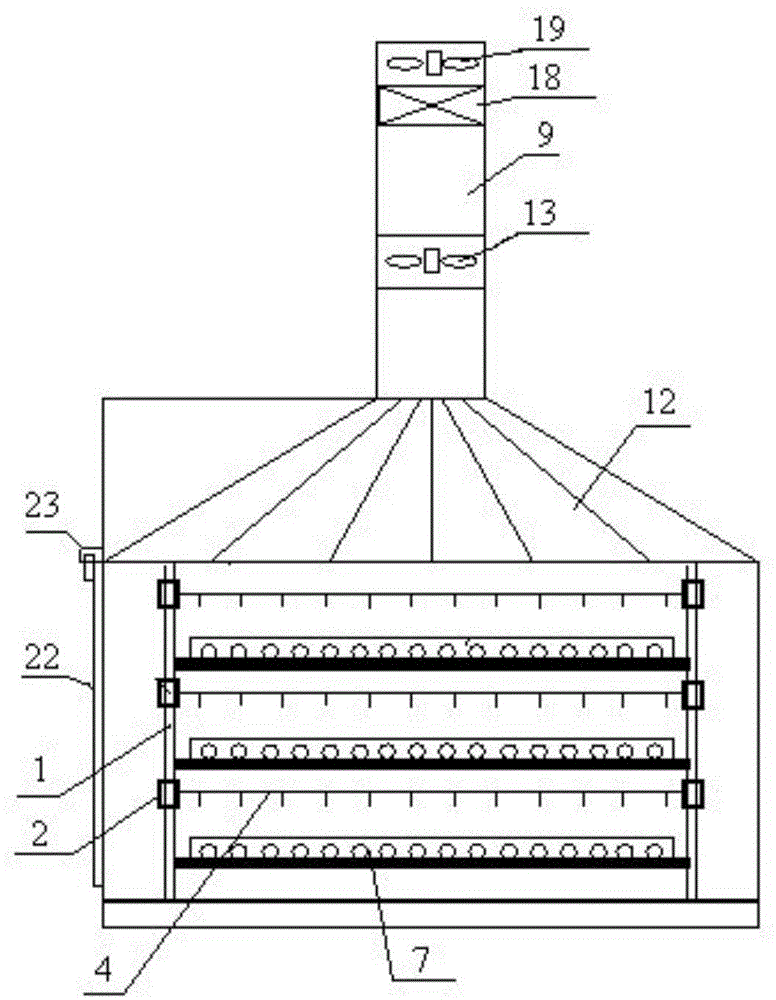

Greenhouse-type double-heat-collecting double-heat-preserving solar-energy heat-pump drying device

InactiveCN102393136AIncrease profitAvoid instabilitySolar heat devicesDrying machines with progressive movementsEcological environmentNew energy

The invention provides a greenhouse-type double-heat-collecting double-heat-preserving solar-energy heat-pump drying device for drying materials by utilizing solar energy, which comprises a drying unit, a solar-energy heat-collecting unit, an auxiliary heating unit, a condensing and dehumidifying residual-heat recovering unit and an automatic monitoring control unit, wherein the solar-energy heat-collecting unit is formed by a self-heat-collecting unit and an outer heat-collecting unit, and the auxiliary heating unit is formed by a heat pump. Through the drying device, the utilization ratio of the solar energy is effectively improved, the instability of the solar energy is overcome, the continuity of the drying process is ensured, and the drying efficiency is improved. The drying and dewatering processes are clean, sanitary and energy-saving, and the defects of pollution, decoloring, deterioration and energy consumption caused by adopting the conventional sun insolation and the traditional energy-source drying of farm and sideline products and the like can be effectively overcome. The greenhouse-type double-heat-collecting double-heat-preserving solar-energy heat-pump drying device has positive significance for developing new energy sources, improving the processing quality of the farm and sideline products, promoting the recycling economy and protecting the ecological environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

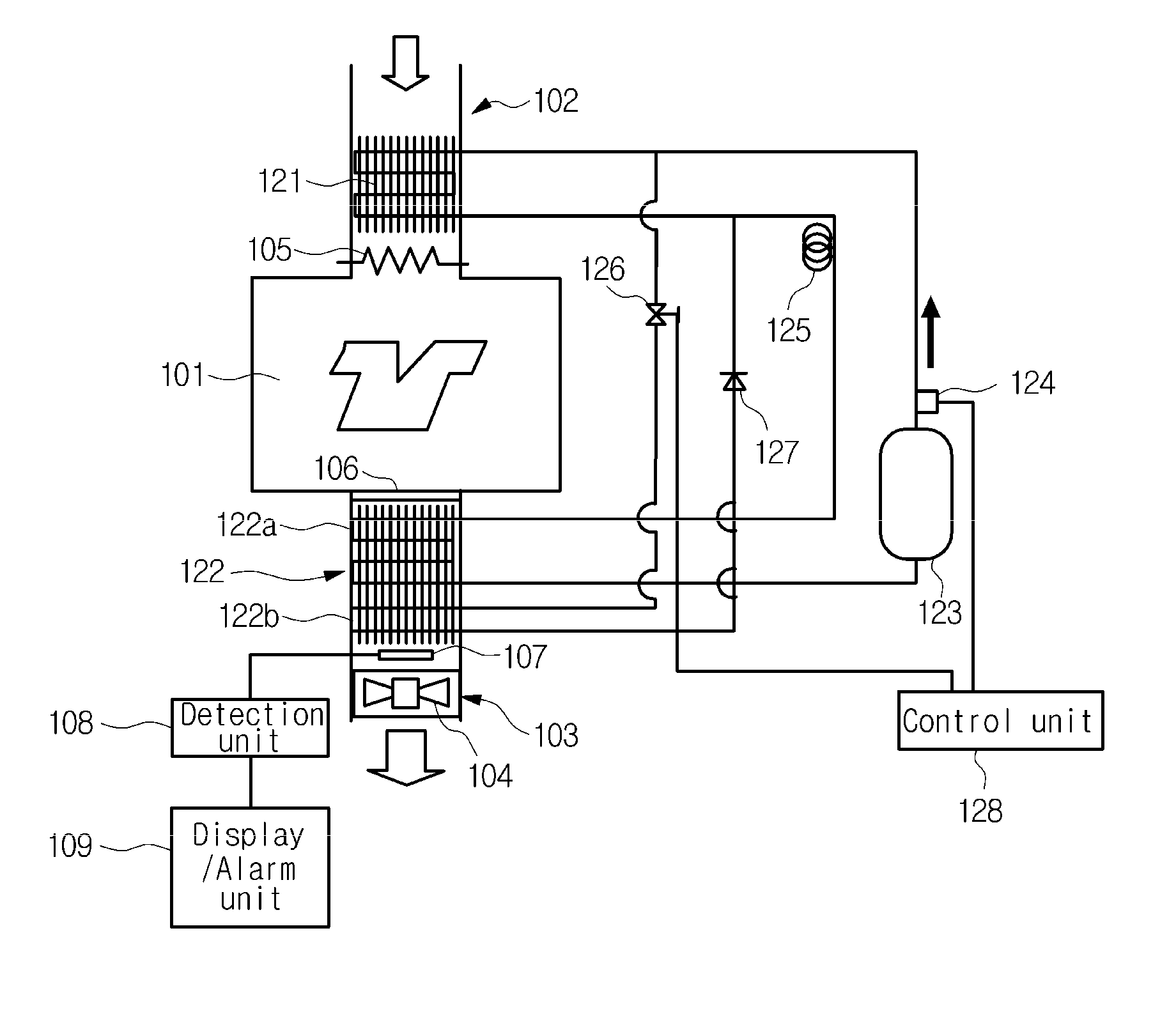

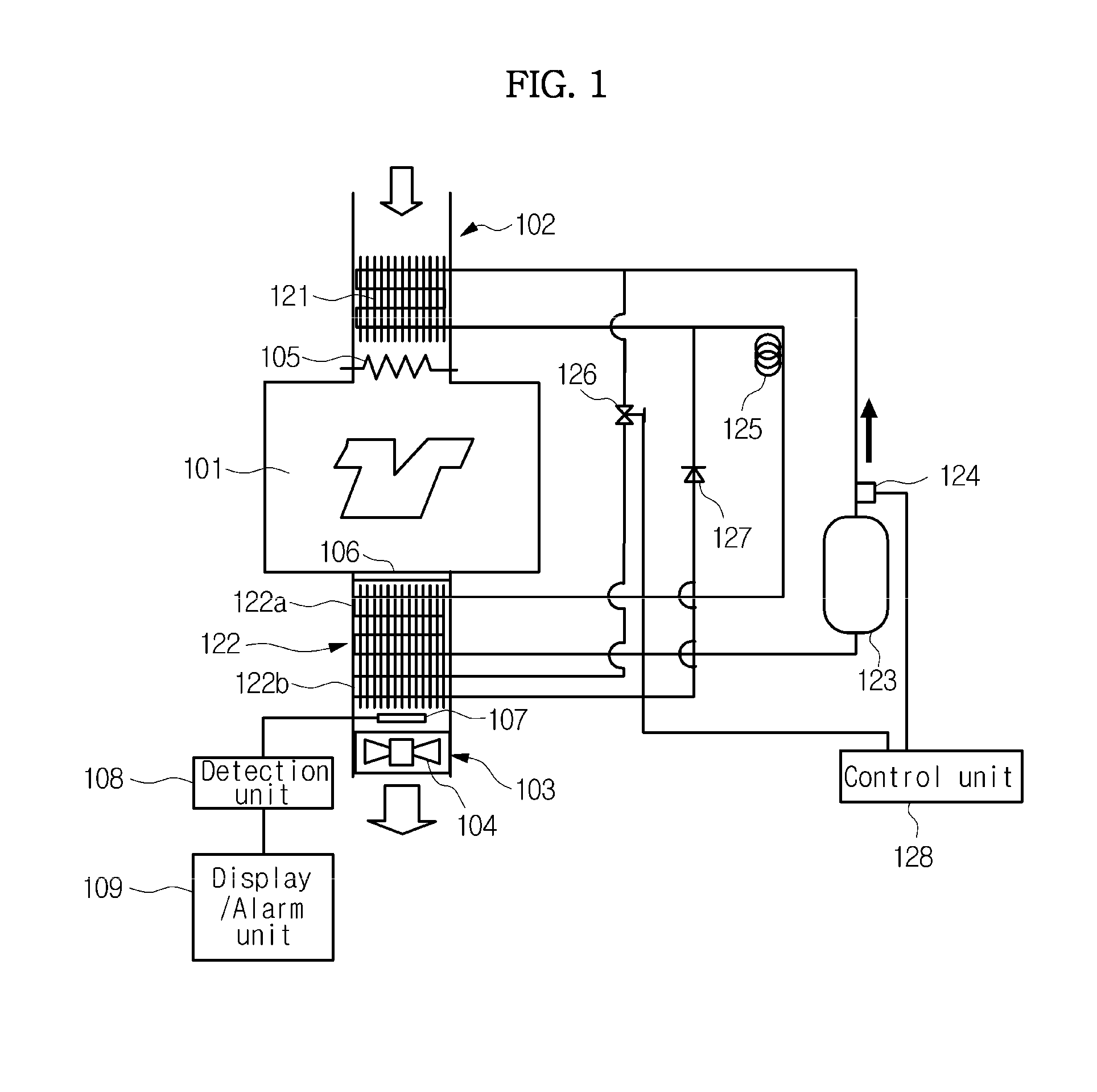

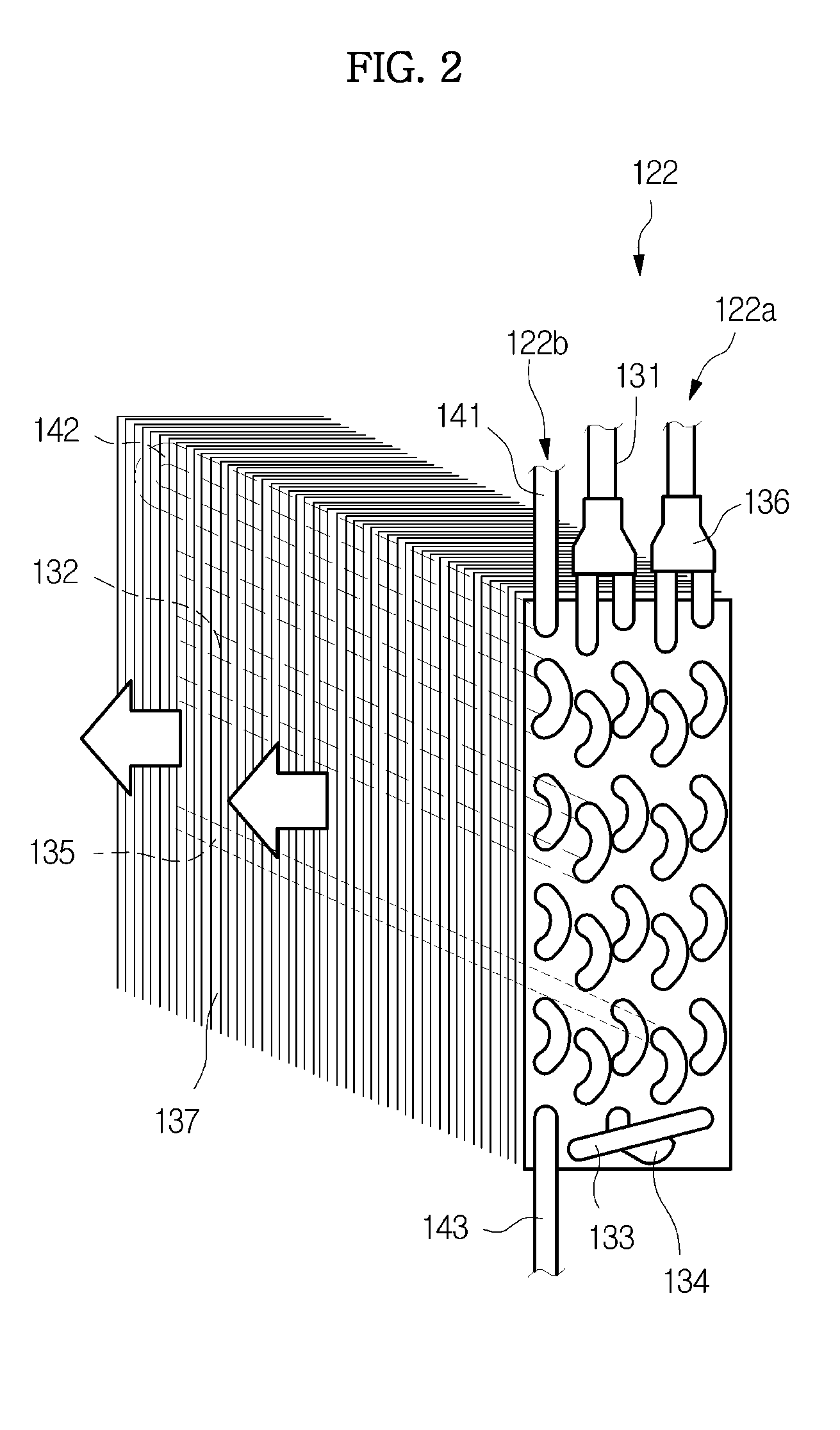

Clothes dryer

InactiveUS20140366397A1Avoid frostSimple configurationDrying gas arrangementsDrying machines with progressive movementsEngineeringThermistor

A clothes dryer configured to cause air to flow through a drying chamber, an exhaust passage (an air passage) 103 and a filter by a blower to dry clothes includes a heat pump installed in the exhaust passage (103) and having a heat exchanger (122) including a refrigerant pipe (132) and a pin, and a flow velocity sensor (107) of airflow having a hot thermistor (a heat generating body) 107a and a temperature compensation thermistor (a temperature detecting body) 107b and installed downstream from the heat exchanger (122), wherein the thermistors (107a and 107b) are disposed at a refrigerant pipe (132) of the heat exchanger (122) in parallel.

Owner:SAMSUNG ELECTRONICS CO LTD

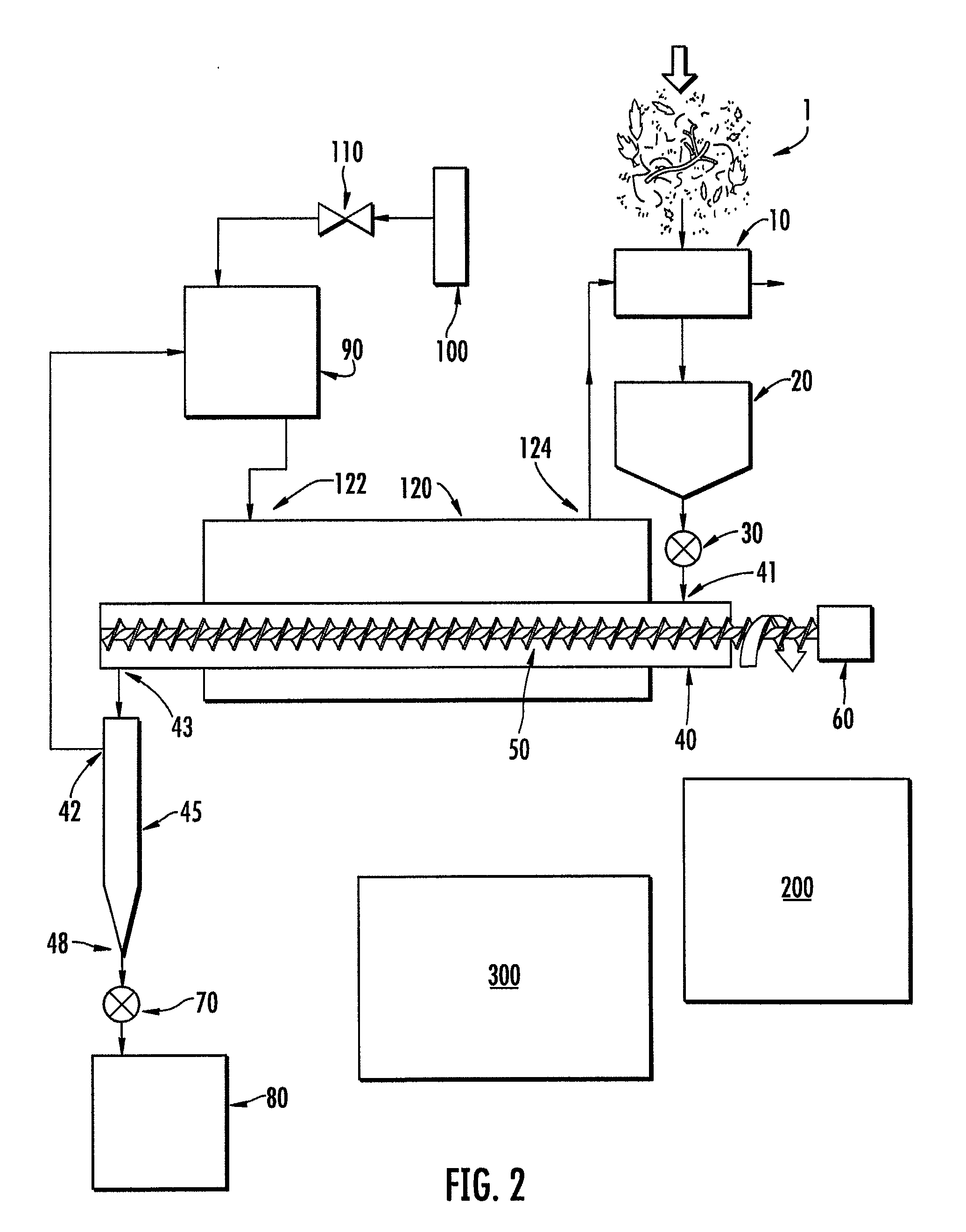

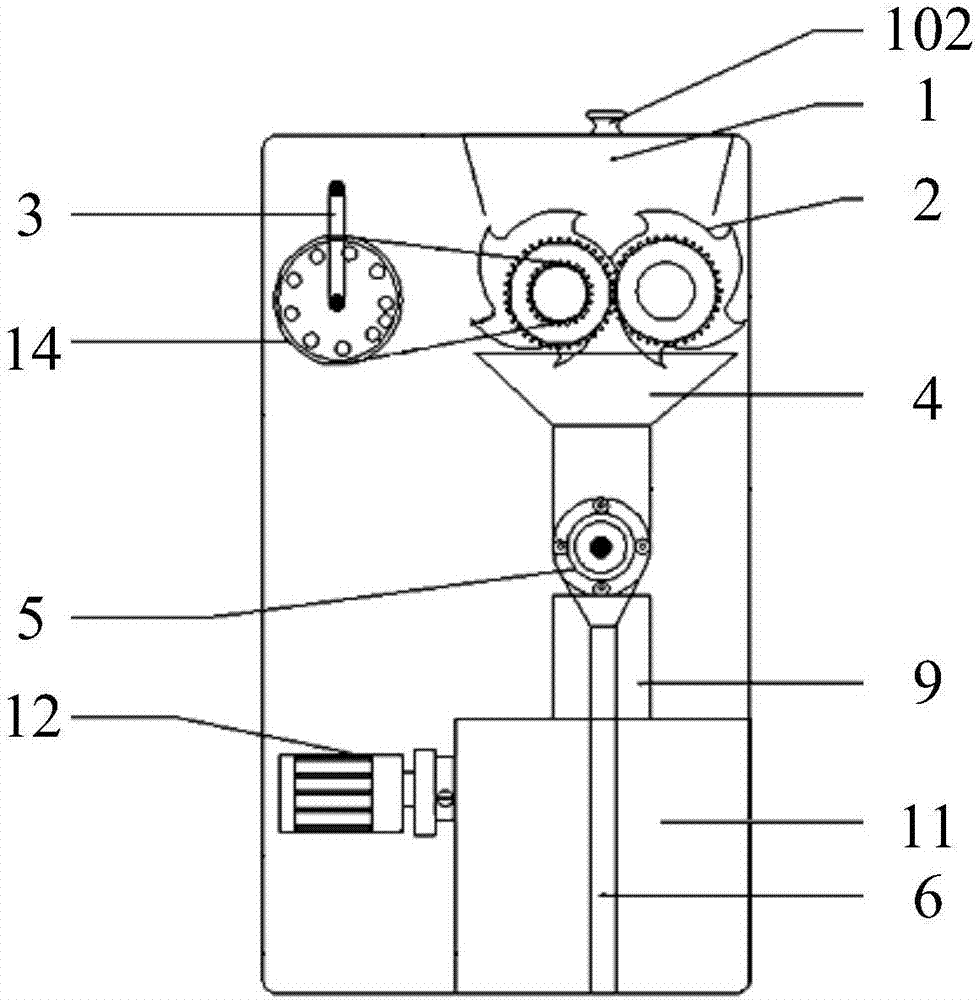

Household kitchen waste disposal device

PendingCN107321768AImprove processing efficiencyReduce wasteTransportation and packagingSolid waste disposalLitterPollution

The invention discloses a household kitchen waste disposal device. The device comprises a casing, a crushing assembly which is arranged in the casing and is used for crushing waste into preliminary residues, a dehydration assembly used for dehydrating the crushed waste to form dehydrated residues and waste liquids, a drying assembly used for drying the residues as well as a compression assembly used for compressing the residues; and the crushing assembly, the dehydration assembly, the drying assembly and the compression assembly are connected sequentially. With the household kitchen waste disposal device, the crushing assembly, the dehydration assembly, the drying assembly and the compression assembly are arranged, and crushing, dehydration, drying and compression operations can be performed on the waste sequentially, so that repeated pollution is no longer caused during centralized disposal of the waste, and the kitchen waste disposed by the disposal device is small in size, low in water content and convenient to transport and recycle.

Owner:GUANGDONG UNIV OF TECH

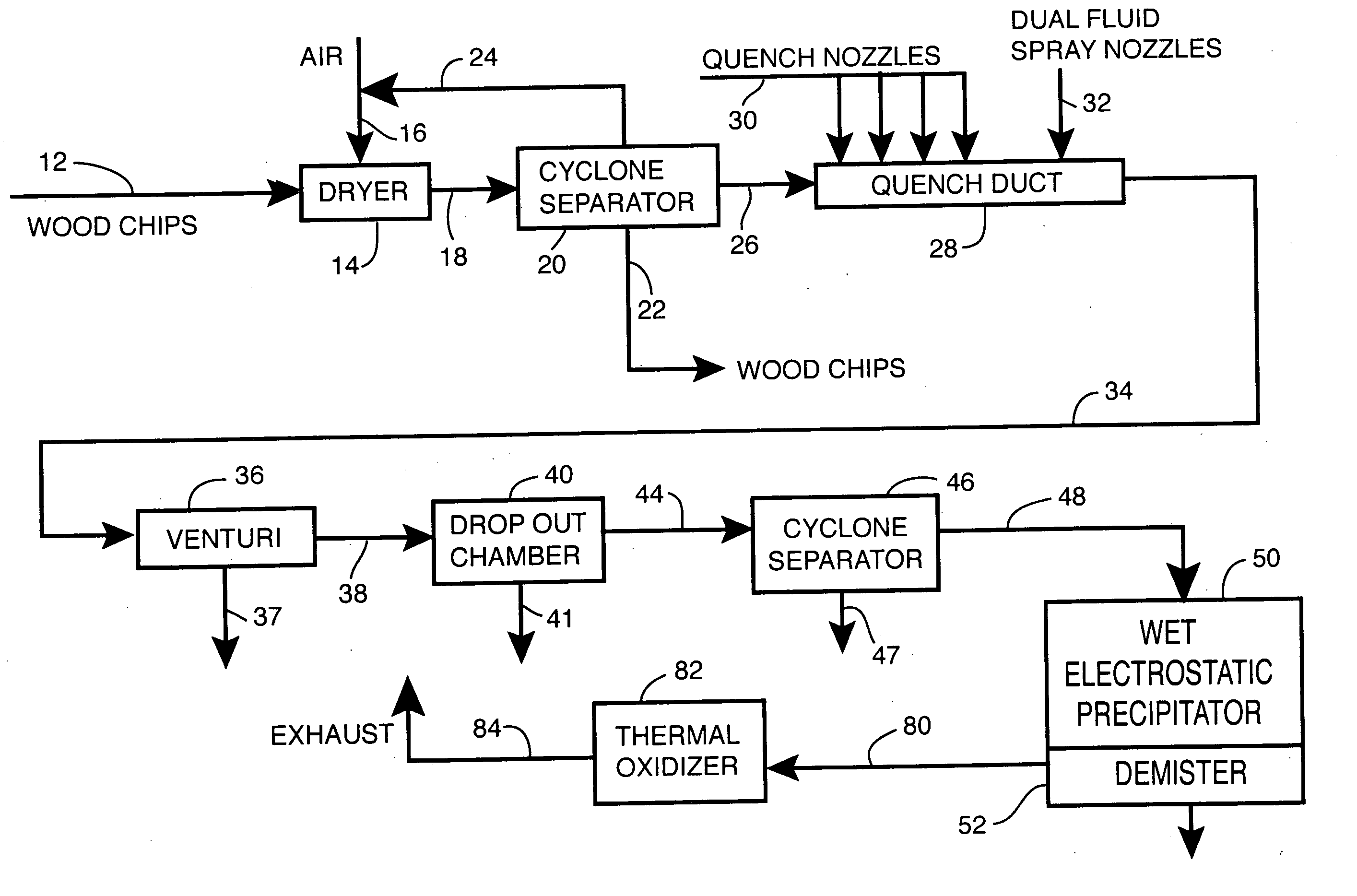

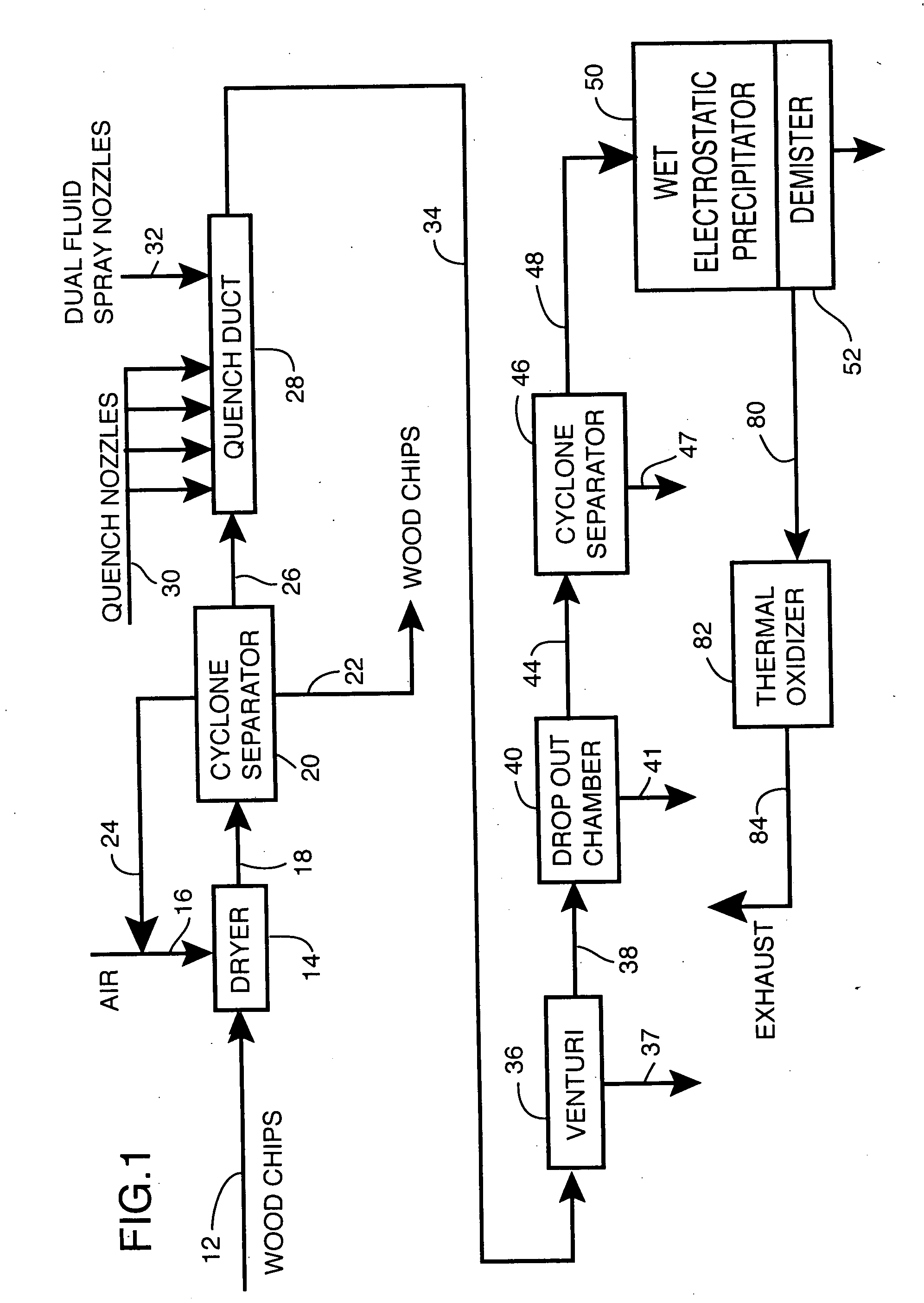

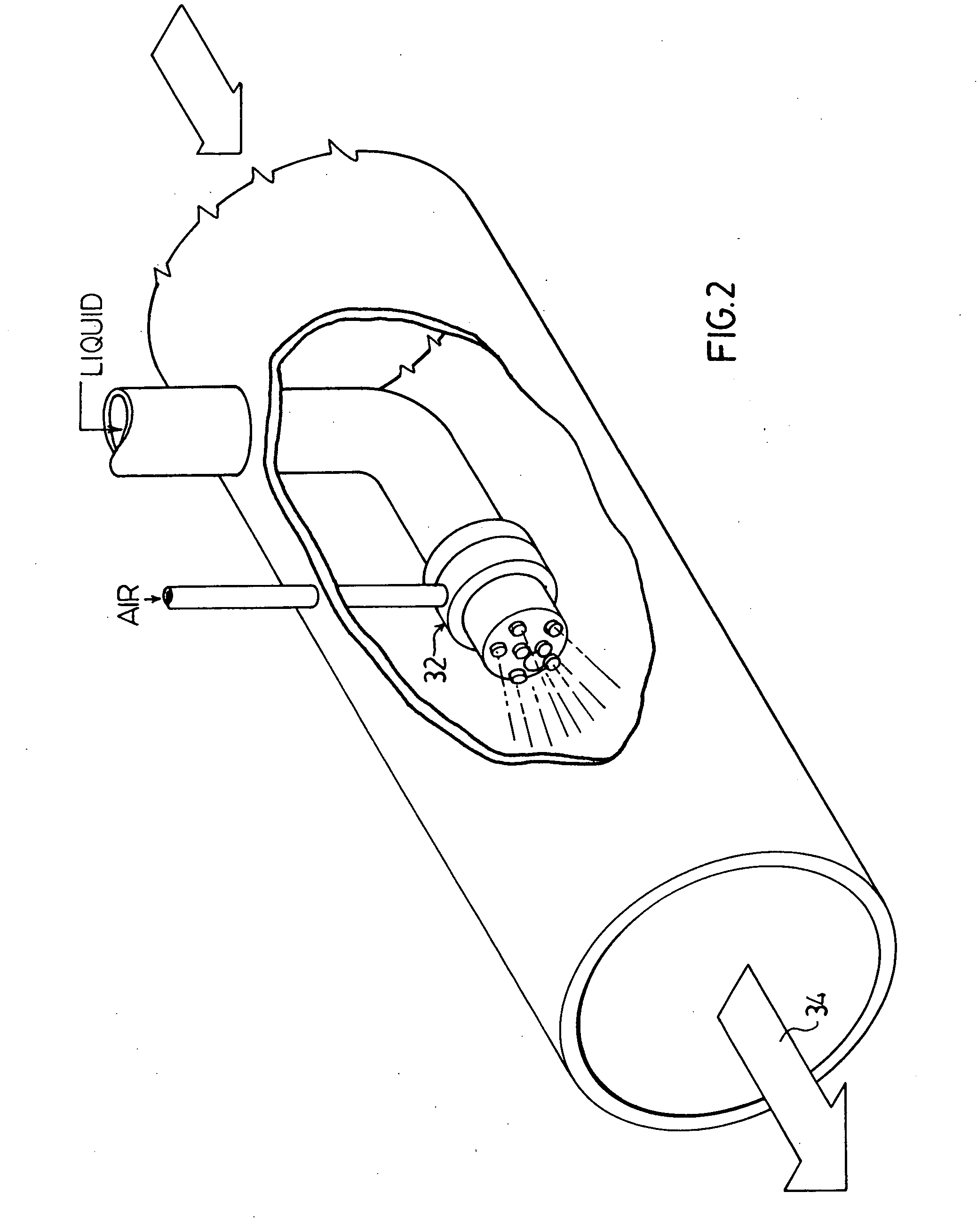

Pollution control in wood products dryer

InactiveUS20050229780A1Reduce gas flowEmission reductionCombination devicesDrying solid materials with heatParticulatesCombustor

Contaminant laden gas streams from wood product dryer operations, and other sources, are purified. The gas stream first is saturated with moisture by contacting the gas stream with fine liquid droplets which entrain particulates. The gas stream then is subjected to a plurality of separate particulate and liquid droplet removal steps before a droplet-free gas stream having substantially reduced particulate contaminant levels is passed to a burner for removal of volatile organic compounds from the gas stream.

Owner:MEGTEC TURBOSONIC

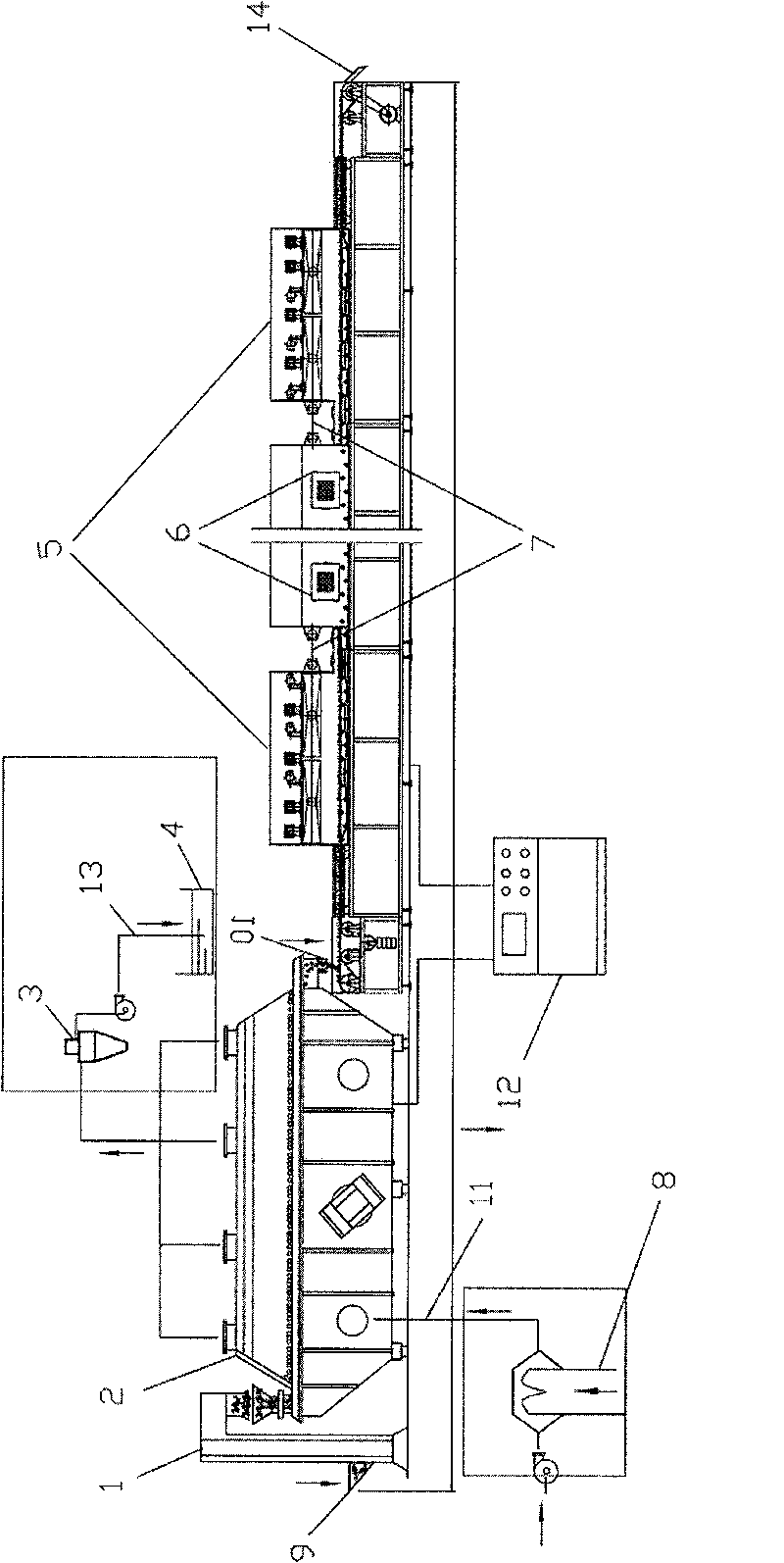

Brown coal drying and dehydrating device

InactiveCN101738077AAchieve dryingImprove coal qualityDrying solid materials with heatDrying machine combinationsComing outBrown coal

The invention relates to a brown coal drying and dehydrating device and an application method. The hot-air drying and dehydrating device dries and dehydrates brown coal at high speed and low energy consumption by main means of high-power microwaves and infrared. The application method for the device comprises the steps of: crushing raw coal; pretreating the coal through a hot-air drying system to remove external water; and then drying and dehydrating the coal further by microwaves, wherein an infrared scanning system is adopted in the drying and dehydrating process in order to prevent the brown coal from backwater. By applying the device, the water in the brown coal can be removed by over 98 percent in short time. The brown coal drying and dehydrating device has the advantages of simpleness and easy operation of process flow, quick dehydration and low energy consumption. The device and the method have no negative effect on the environment, the water coming out through drying can also be recycled, and the device and the method are economic and effective.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH +1

Apparatus and methods for improving the energy efficiency of dryer appliances

InactiveUS20090100702A1Improve efficiencyReduce operating costsDrying solid materials with heatDrying gas arrangementsResidenceProcess engineering

Apparatus for improving the efficiency of dryer appliances that utilize heated air for drying and are disposed within a residence or other closed conditioned space includes an intake air duct connected between the dryer appliance and a source of intake air outside the conditioned space, an exhaust outlet diverter valve to receive exhaust air from the dryer and direct the exhaust air for release within the conditioned space or alternatively outside the conditioned space. Alternative embodiments provide for drawing intake air from more than one source, with and without heat exchange, for releasing heated air to more than one location, including into a heating system return air duct, either directly or through a heat exchanger. A method of controlling the operation of the apparatus is also provided.

Owner:FAIR ROBERT WOOD

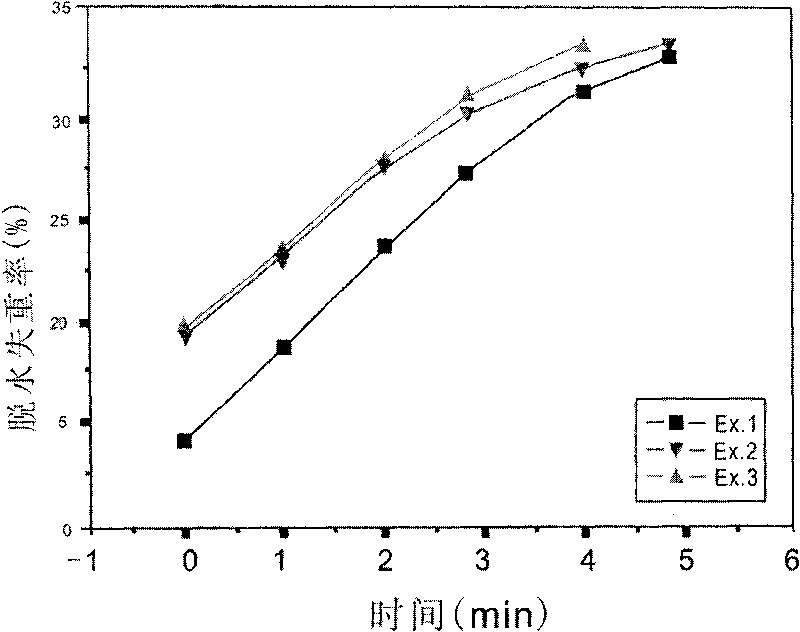

High-voltage electric field and hot air combined drying device

ActiveCN103983091AImprove retentionGood appearanceDrying gas arrangementsDrying chambers/containersThermal instabilityOperability

The invention discloses a high-voltage electric field and hot air combined drying device. The high-voltage electric field and hot air combined drying device comprises a box body, a high-voltage electric field drying system, a hot air circulation drying system and a monitoring control system, wherein the high-voltage electric field drying system, the hot air circulation drying system and the monitoring control system are arranged on the box body. According to the high-voltage electric field and hot air combined drying device provided by the invention, the structural design is reasonable, the operability is strong, and the use is convenient; compared with traditional hot air drying, the drying efficiency is high, the drying temperature is low, the drying time can be shortened by 50% than the drying time of drying by pure hot air under the same temperature, the drying energy consumption can be reduced by 51.9%, the high-voltage electric field and hot air combined drying device is particularly suitable for drying materials containing thermal-instability active components, for example, drying the materials of traditional Chinese medicine, medicinal slices, drug, agricultural products, food, biological products and the like, the appearance quality after the drying is good, the reservation degree of the active components is high, and the application range is very wide.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

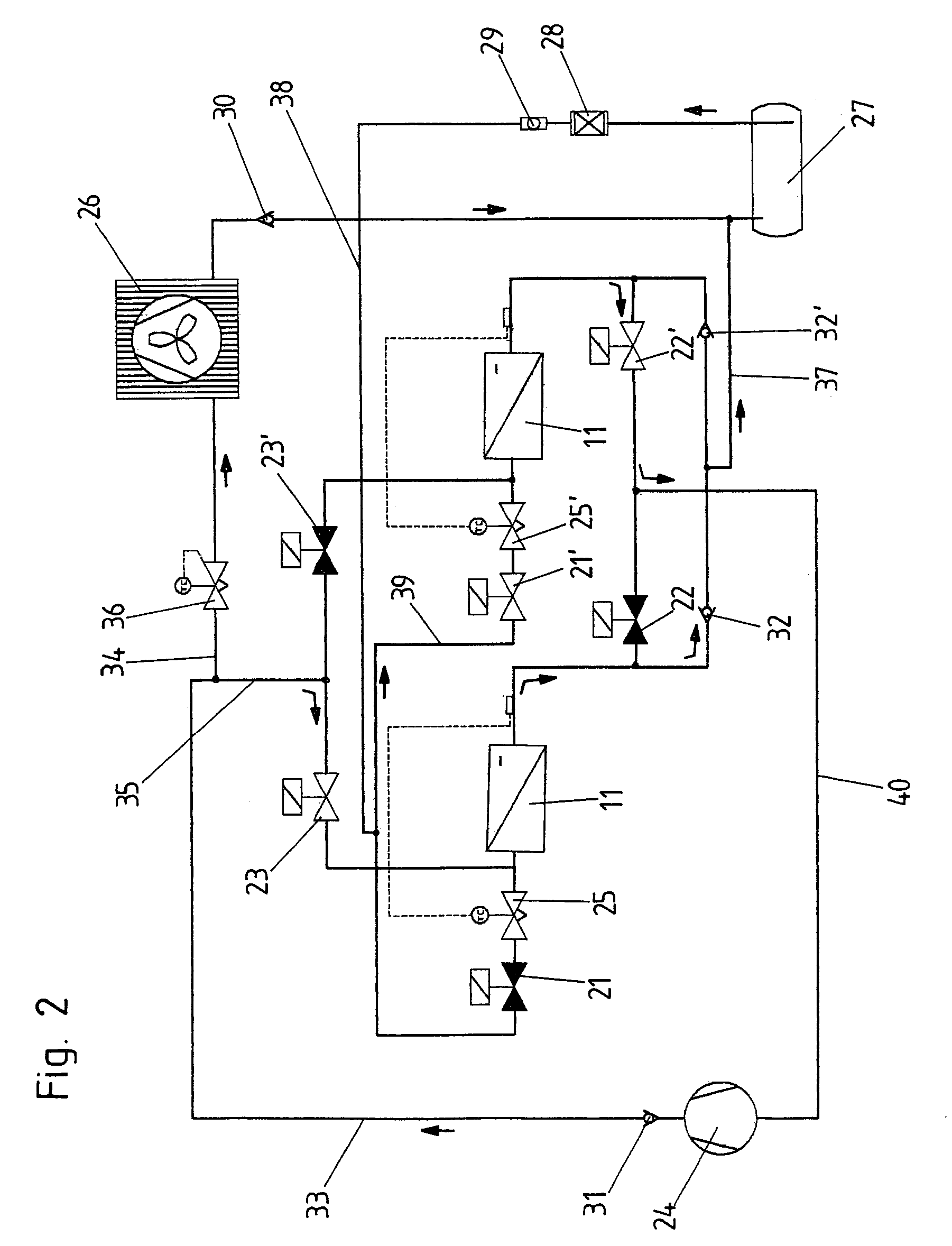

Drying device for drying a gas

InactiveUS7185447B2Lower dew point temperatureReduce energy consumptionDrying solid materials with heatDrying gas arrangementsLine tubingEngineering

A drying device for drying a gas comprises parallel cooling branches, at least one of which is in its active state at any given time. A gas-coolant heat exchanger arranged in each of the cooling branches has a first channel through which the gas to be dried flows in the active state of this cooling branch and a second channel which, in the active state of this cooling branch, forms an evaporator for a coolant circulating in at least one coolant circuit. The drying device further comprises an ambient-air input line, an ambient-air output line and an ambient-air conveyor. In the passive state of a respective cooling branch, the ambient-air input line and the ambient-air output line are connected, at least for a time, with this cooling branch by the switching device and the ambient-air conveyor conveys ambient air through the first channel of the gas-coolant heat exchanger arranged in this cooling branch.

Owner:ARBEITER PETER

Efficient slicing machine special for preparation of traditional Chinese medicine decoction pieces

InactiveCN108789581AAvoid uneven slice thicknessEasy to replaceMetal working apparatusHeating arrangementSlice thicknessEngineering

The invention discloses an efficient slicing machine special for preparation of traditional Chinese medicine decoction pieces. The efficient slicing machine comprises a machine seat. A drying box is arranged on the left side of the upper surface of the machine seat. A collecting box is arranged on the right side of the upper surface of the machine seat. A base is arranged on the upper surface of the drying box. A discharging port is formed in the right side of the upper surface of the base. Supporting columns are arranged on the left side of the upper surface of the base. A workbench is arranged at the upper ends of the four supporting columns. A slice thickness adjusting mechanism is arranged on the right side of the upper surface of the workbench. A pushing mechanism is arranged on the left side of the upper surface of the workbench. A first positioning clamp plate is arranged on one side of the middle of the upper surface of the workbench. A second positioning clamp plate is arranged on the other side of the middle of the upper surface of the workbench. Adjustable bolts are connected with threads of threaded holes in the side surface of the second positioning clamp plate. A clamping plate is arranged at the ends of the adjustable bolts. According to the efficient slicing machine special for preparation of the traditional Chinese medicine decoction pieces, moving is convenient, traditional Chinese medicine is convenient to clamp, it is guaranteed that slice thickness is uniform, the slice thickness can be adjusted, and chippings and slices are collected in a classified mode.

Owner:亳州市合七医药科技有限公司

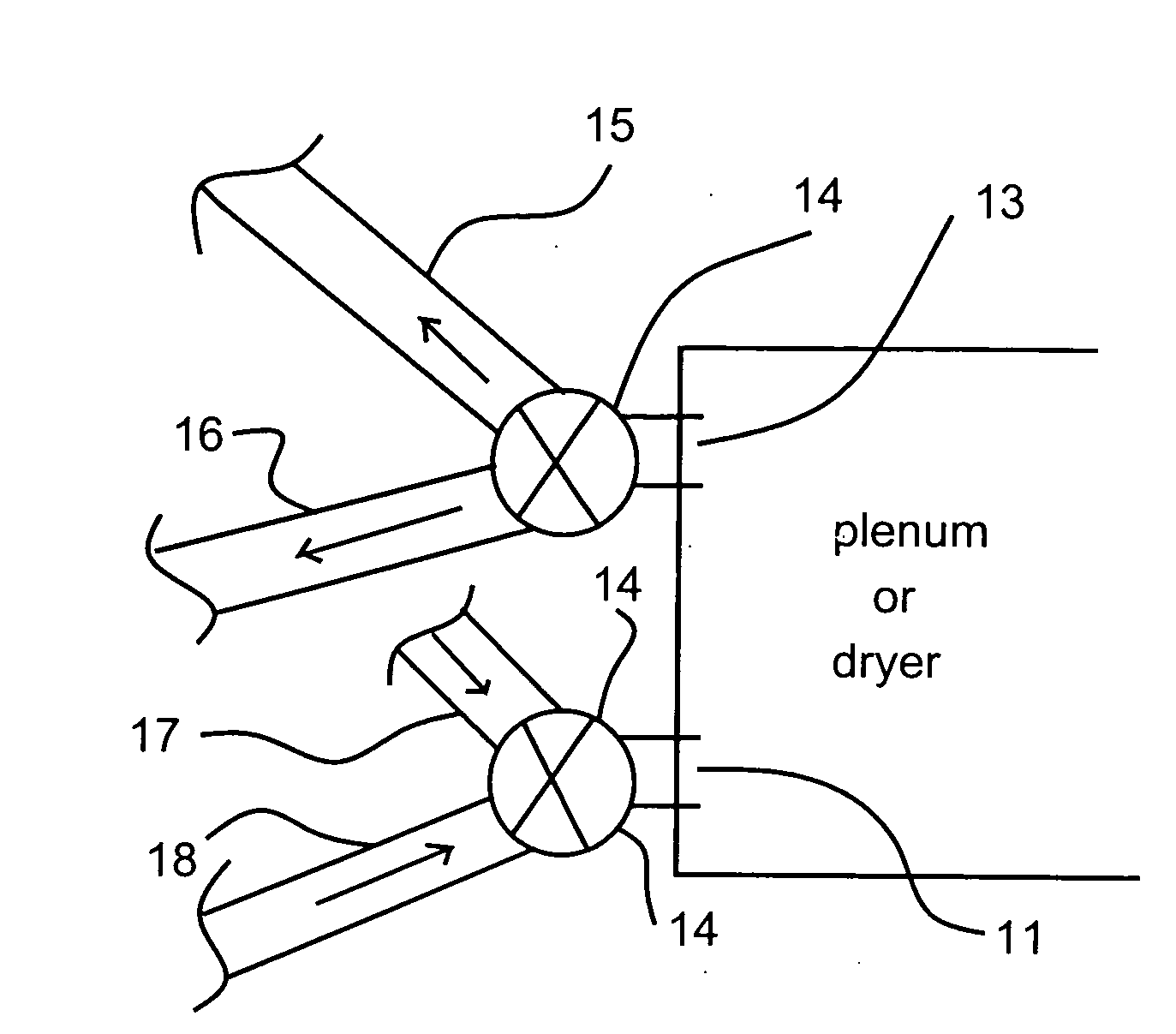

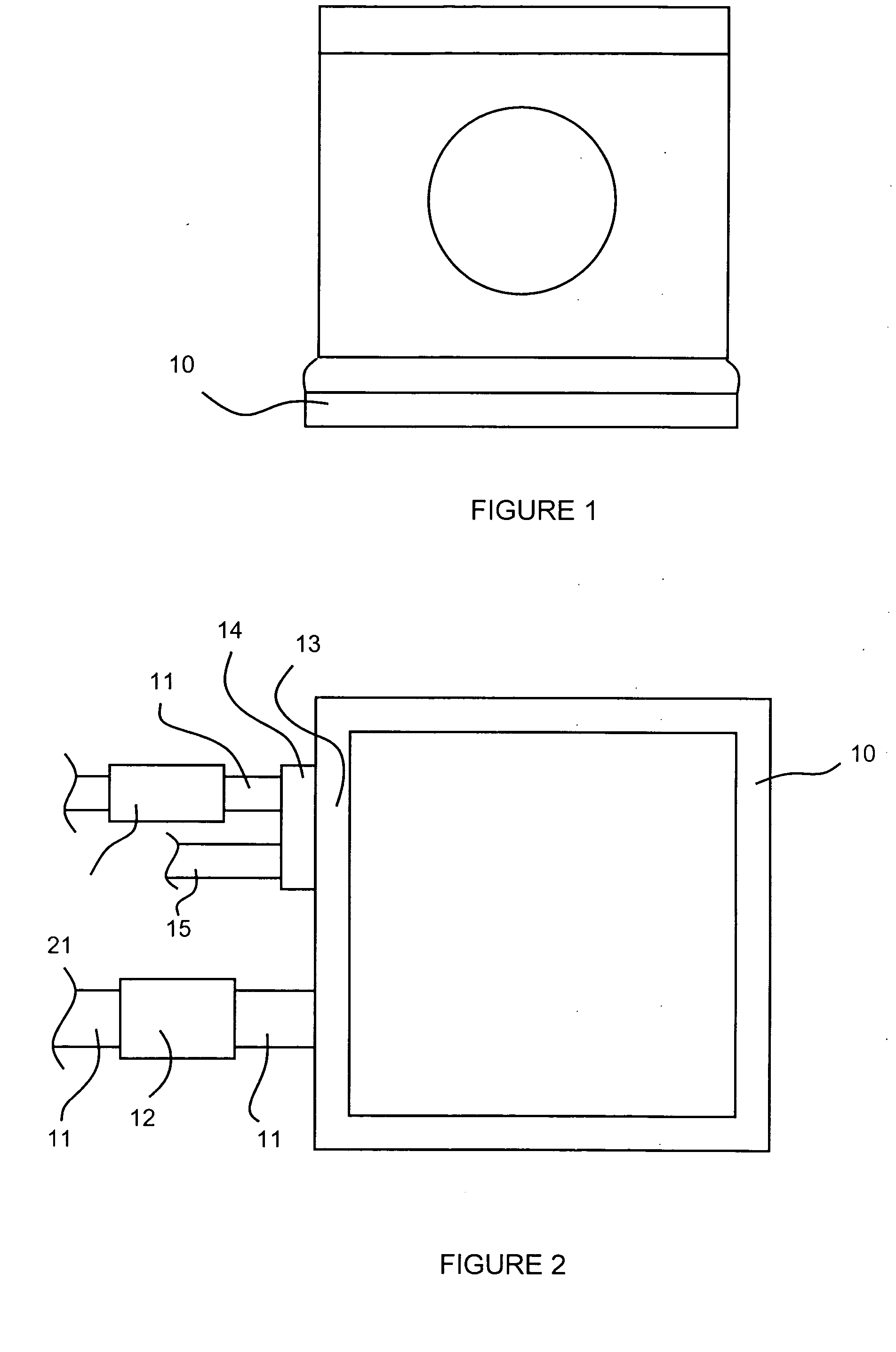

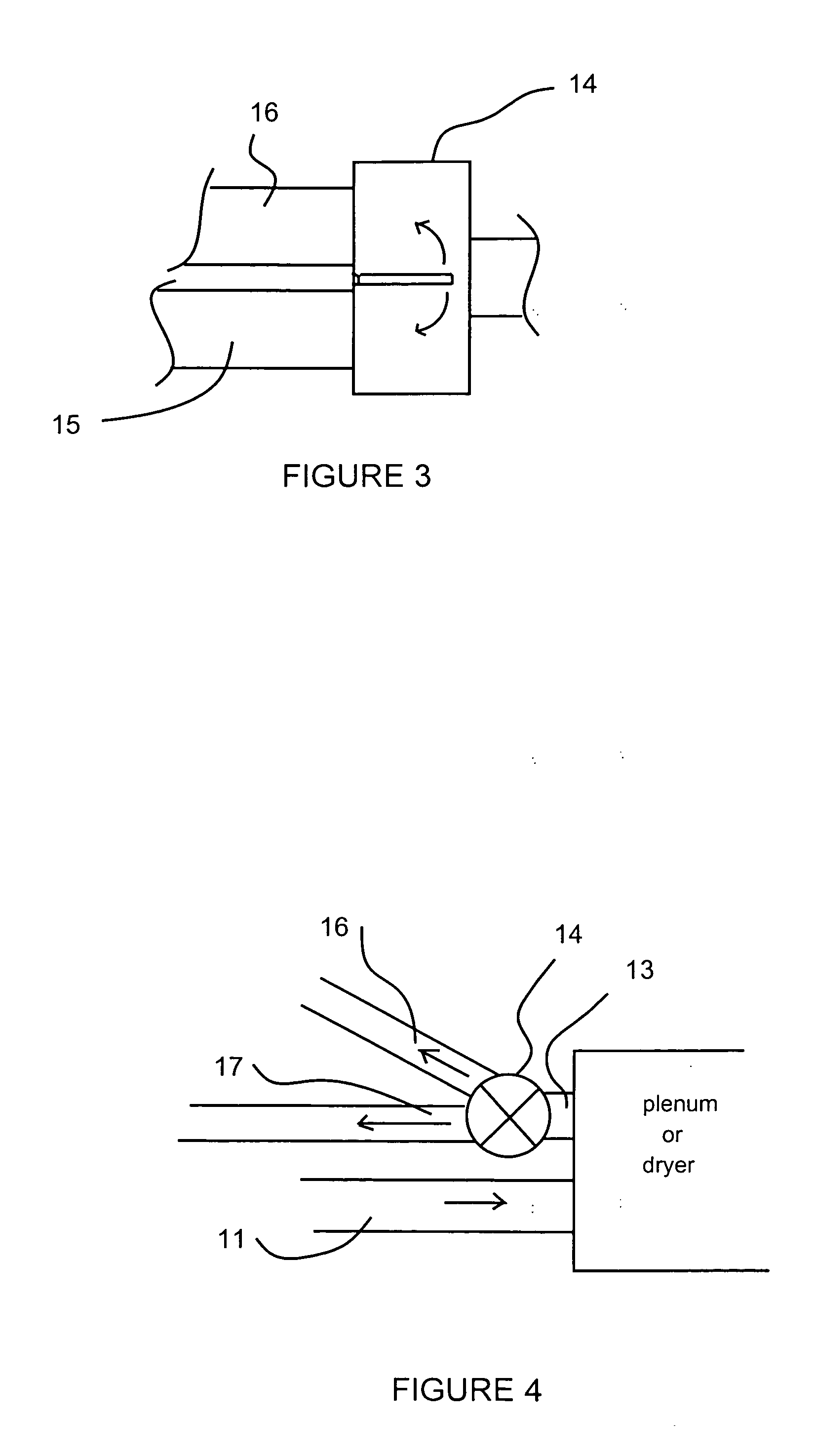

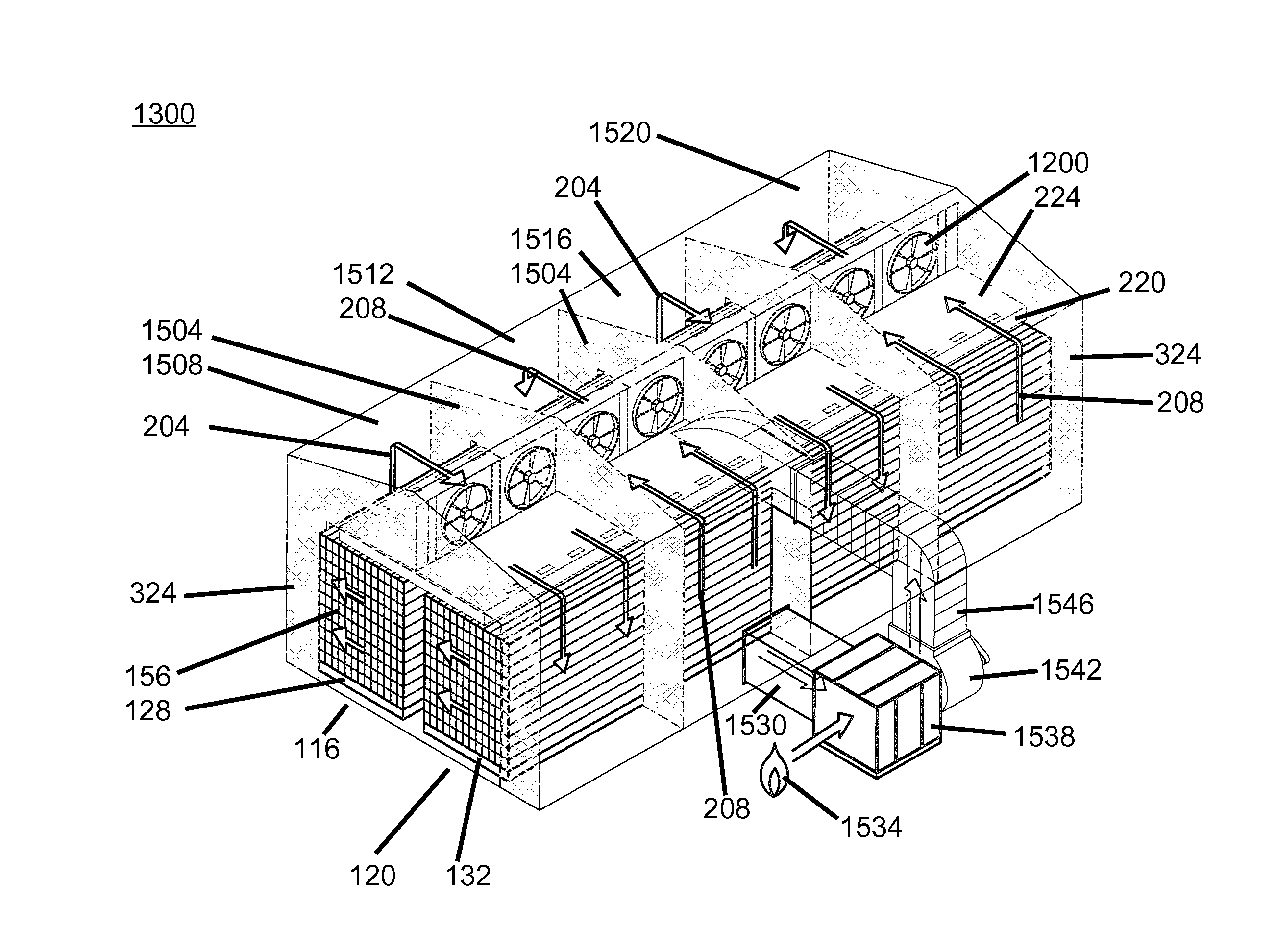

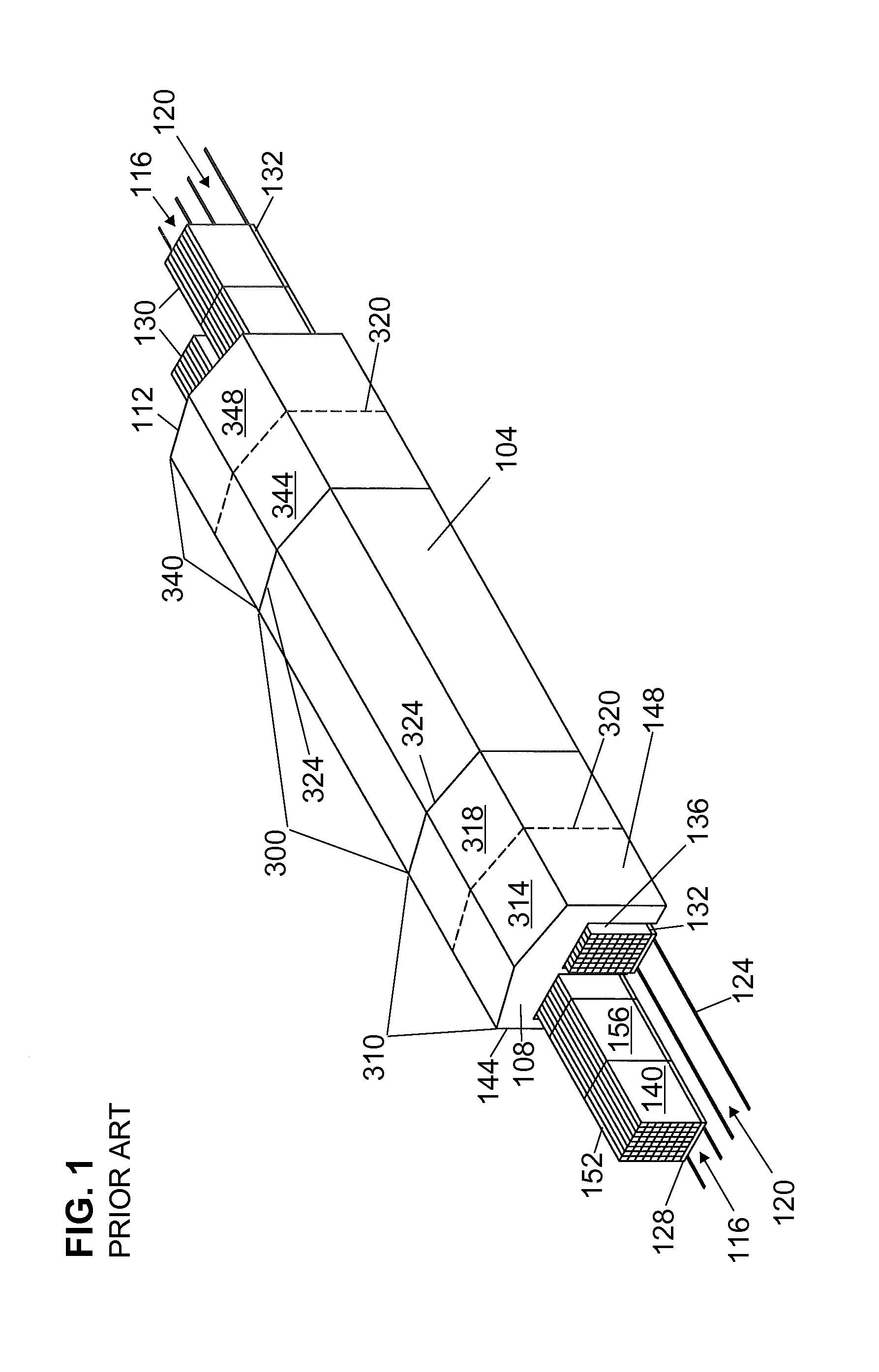

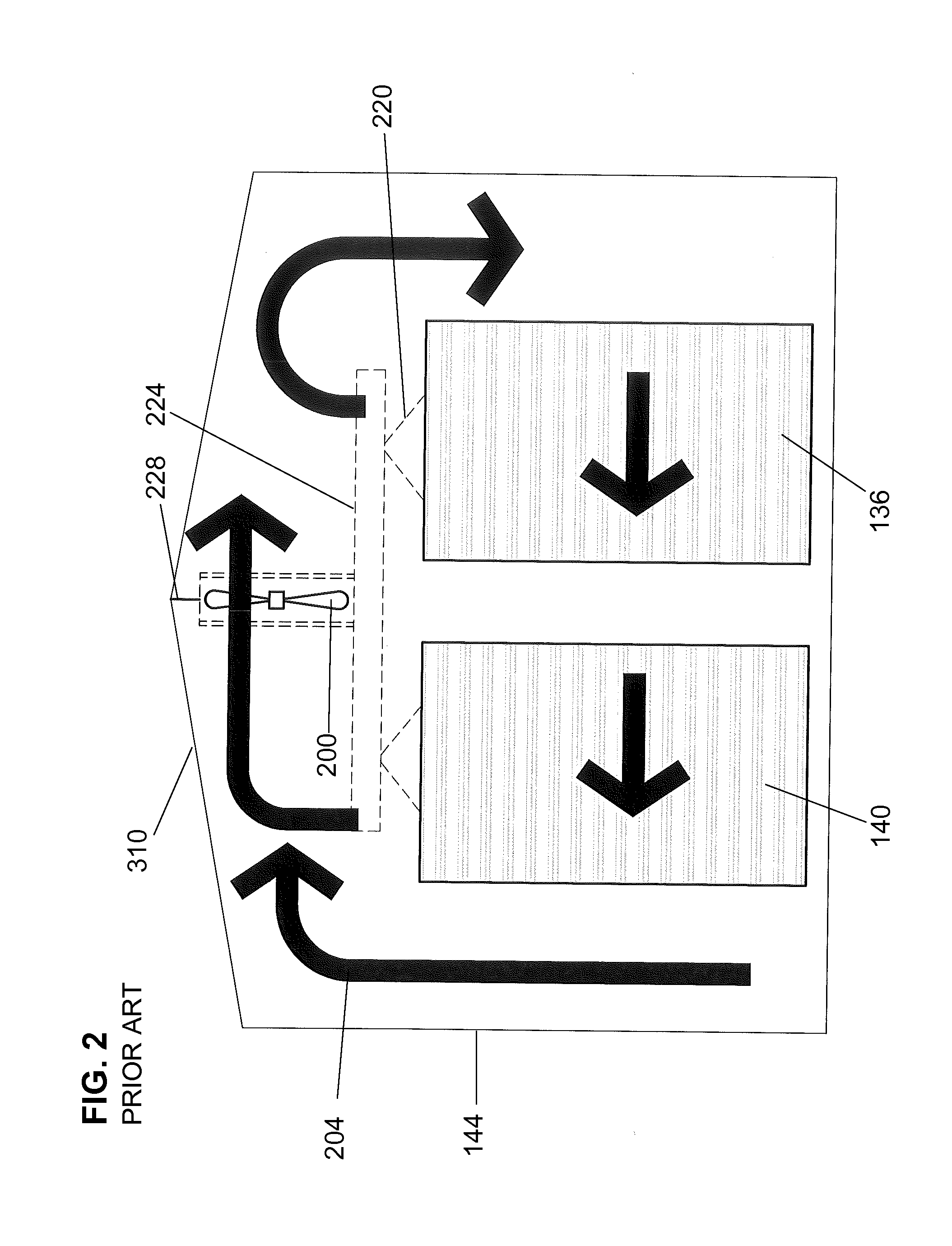

Uninterrupted alternating air circulation for continuous drying lumber kilns

ActiveUS9200834B1Quality improvementImprove uniformityDrying solid materials with heatDrying gas arrangementsKilnAerospace engineering

A continuous drying kiln (CDK) design, in which two sets of carriages carrying spaced stacks of lumber travel in opposite directions through a sequence of chambers in which green lumber is exposed to heated air to dry the lumber to desired conditions. The continuous drying kiln using fans in each chamber to circulate air across the stacked lumber on the two sets of carriages, orthogonal to the direction of carriage travel, in either a first circulation direction or in a second circulation direction. As a carriage moves from chamber to chamber, the circulation direction is reversed.

Owner:KILN DRYING SYST & COMPONENTS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com