Patents

Literature

155results about "Pneumatic tables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

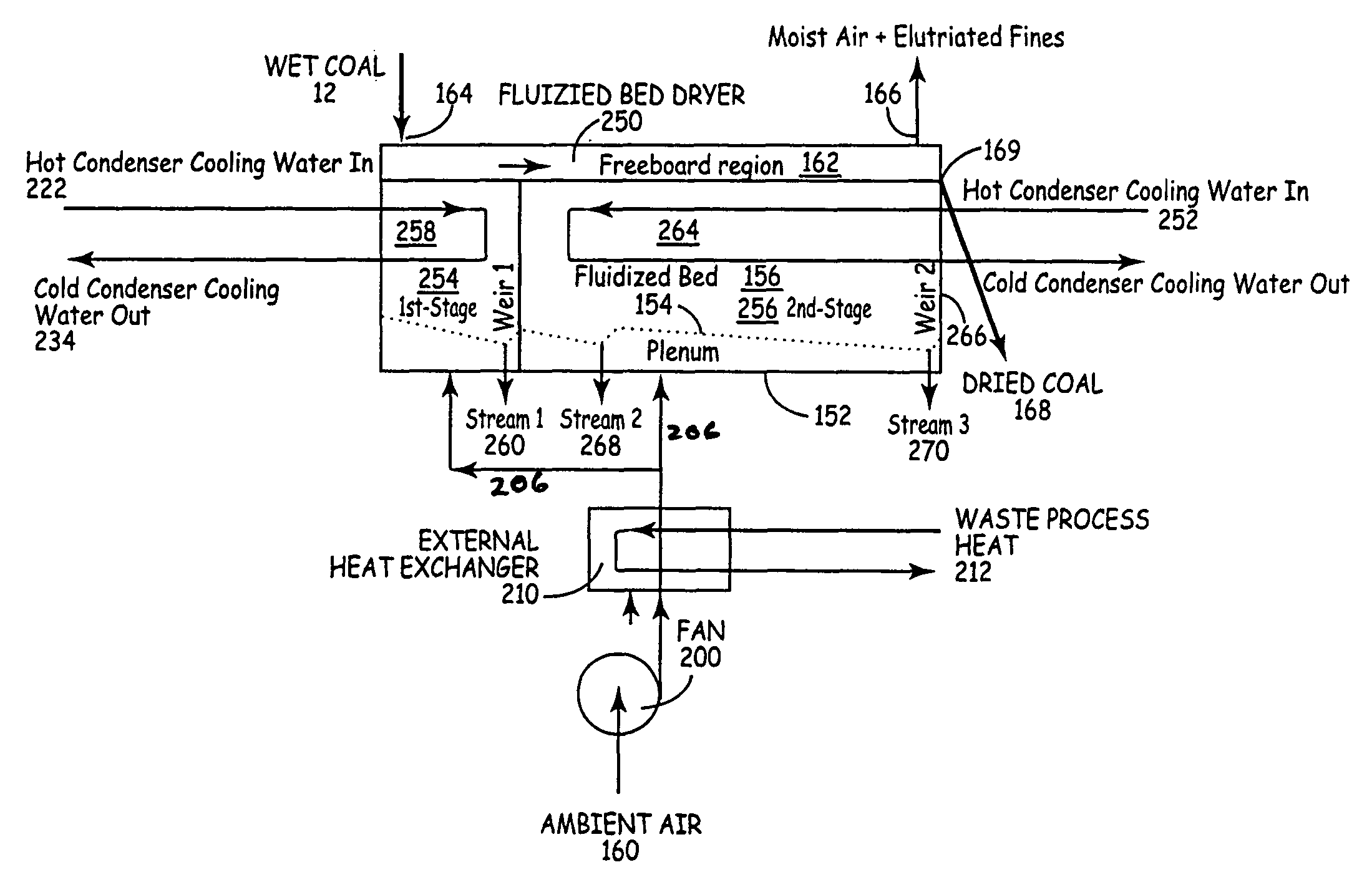

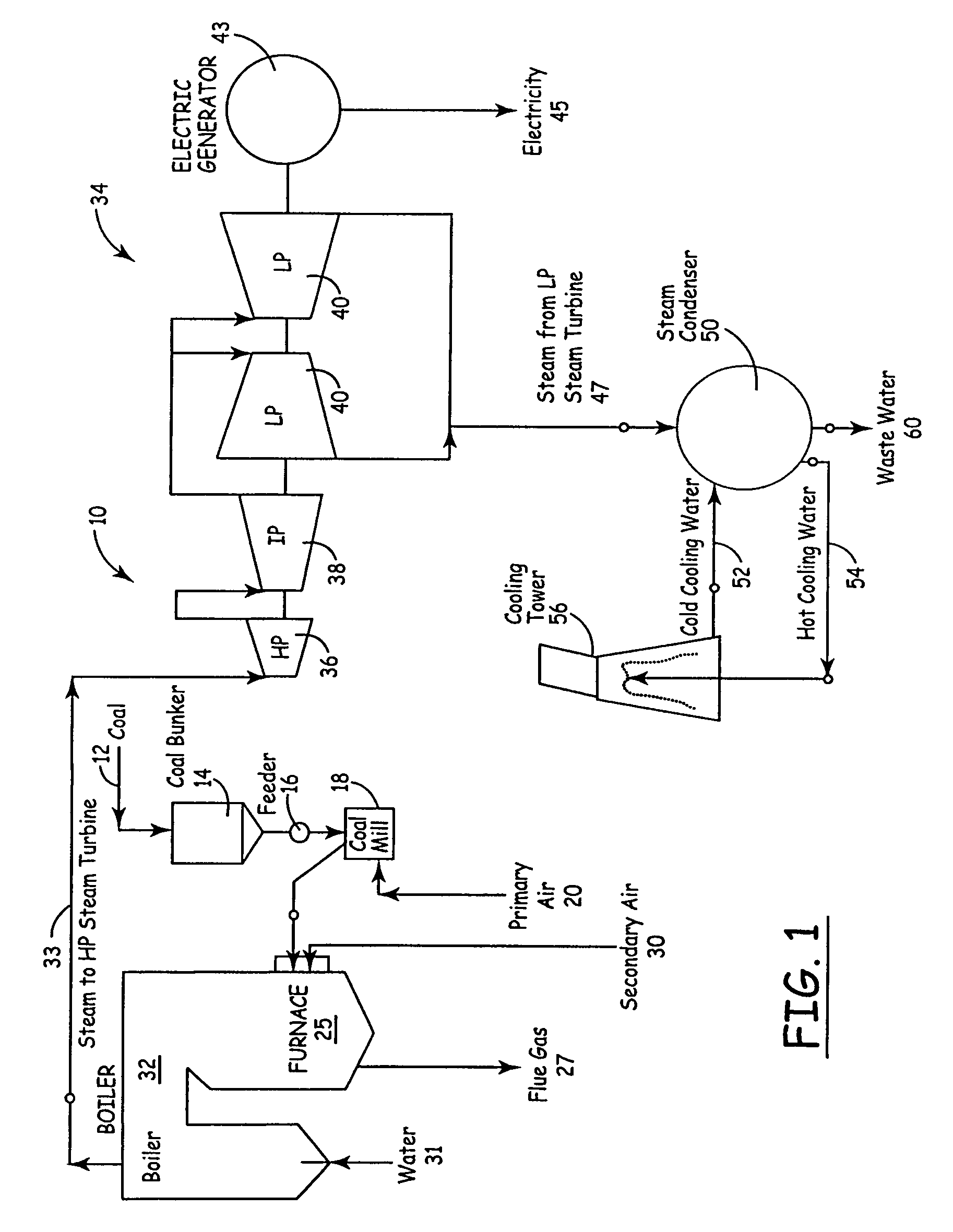

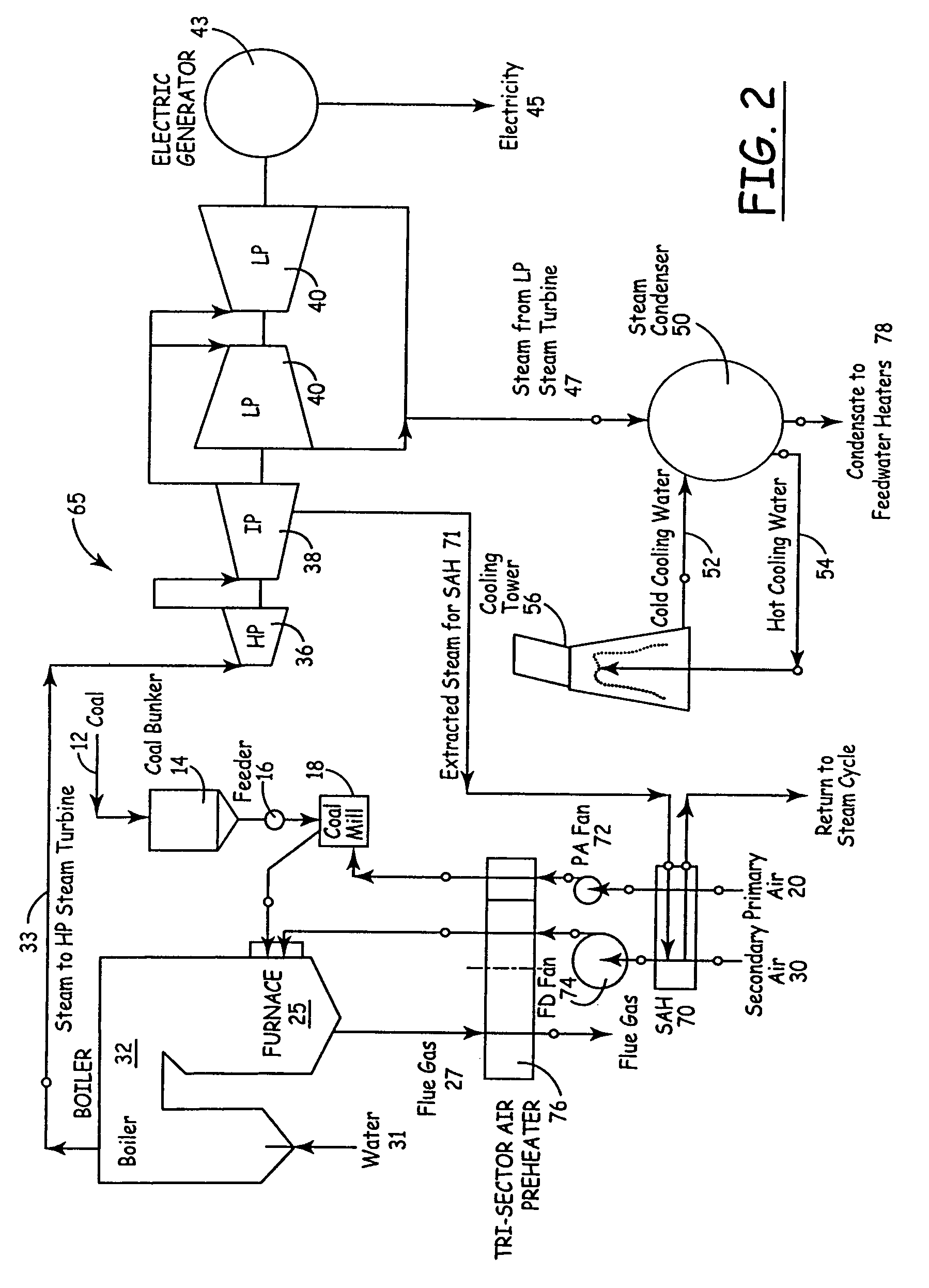

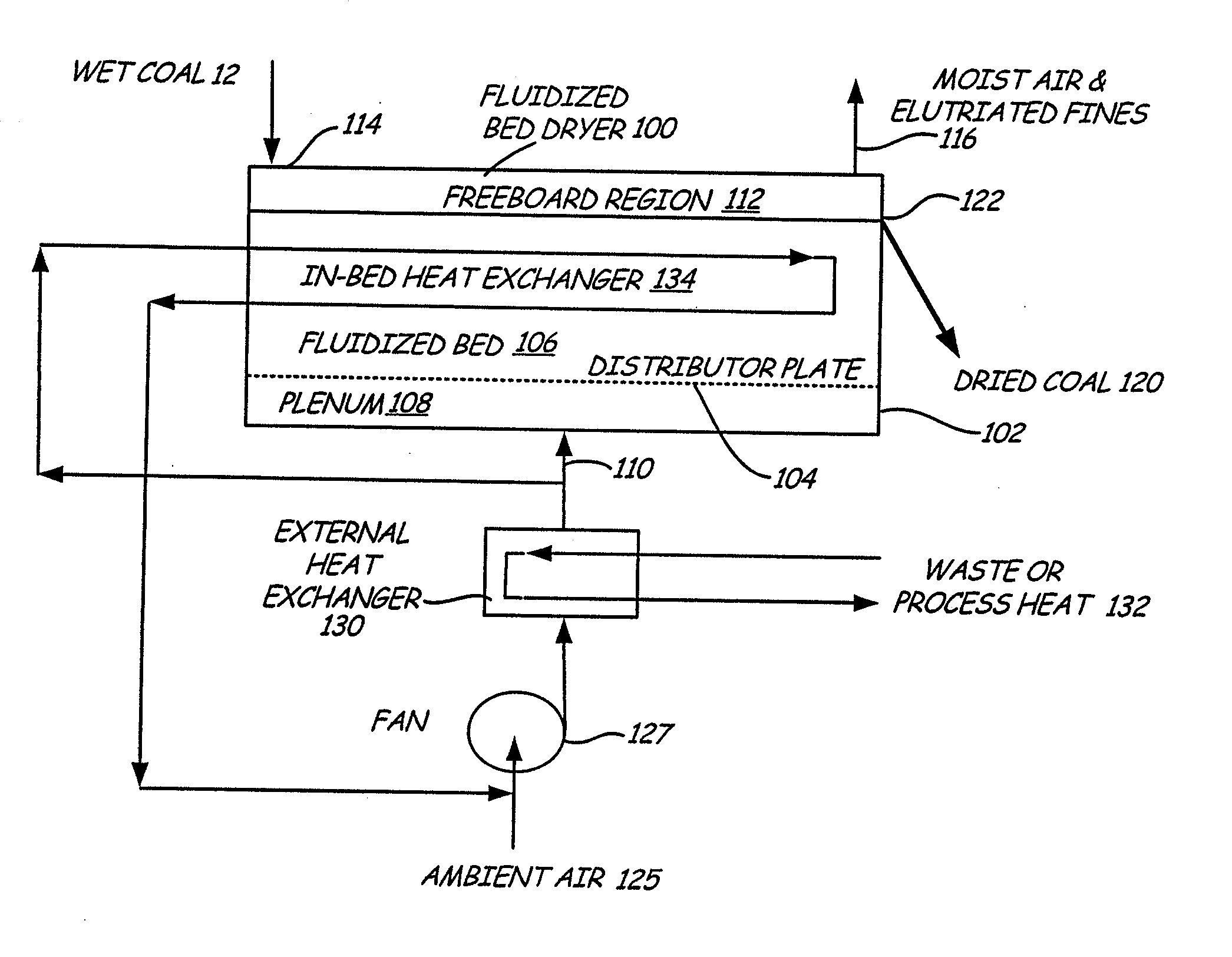

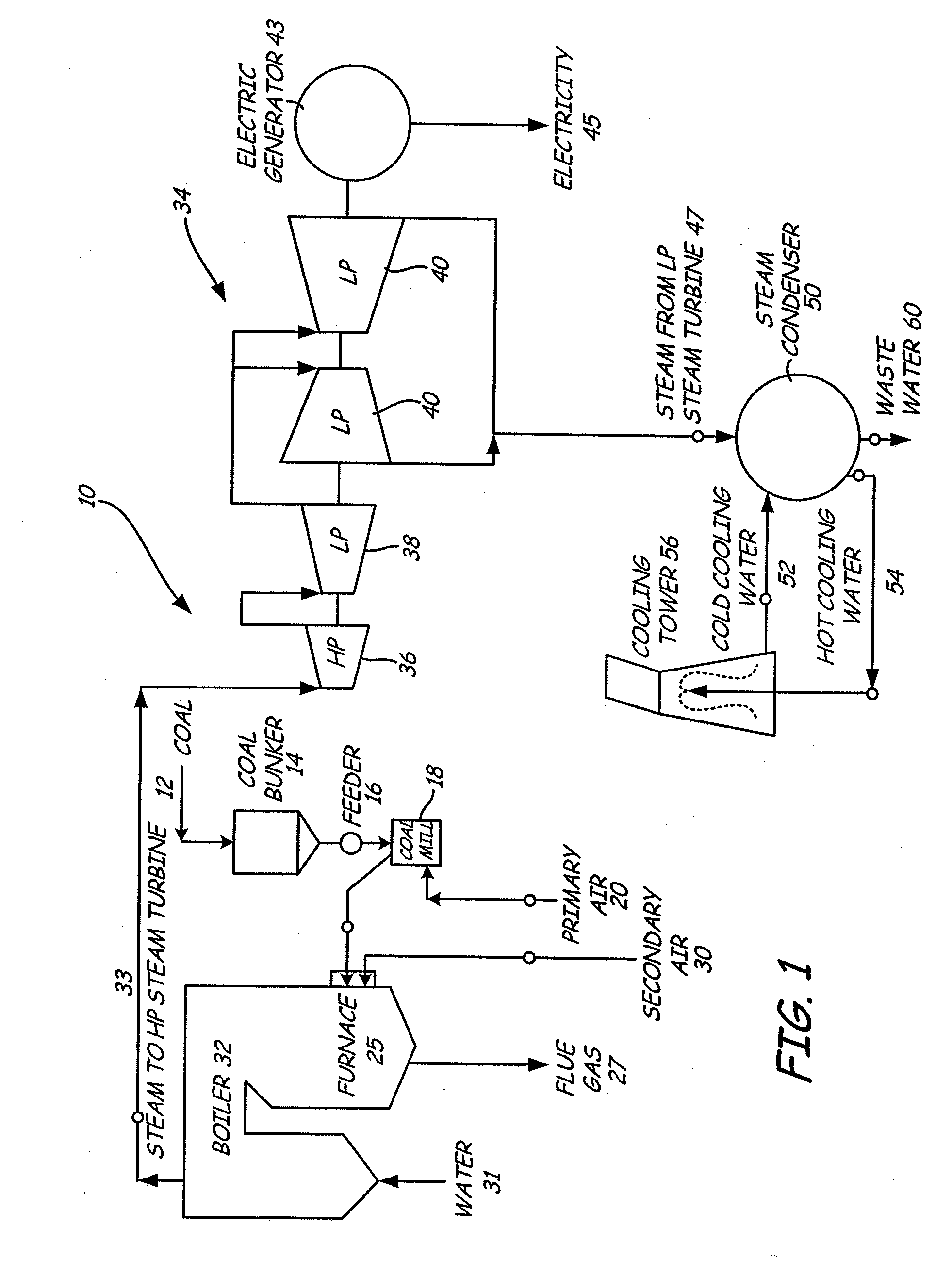

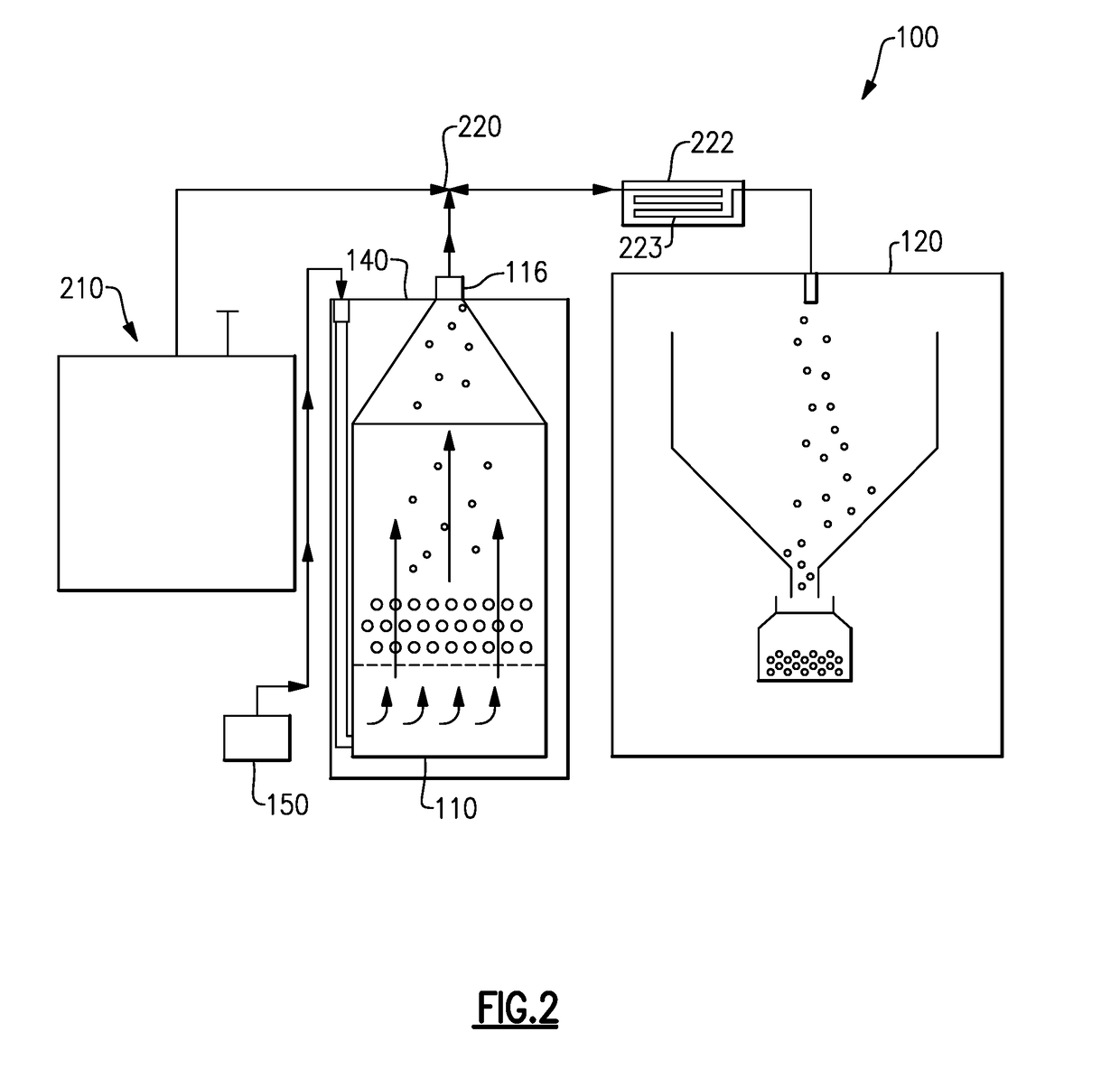

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

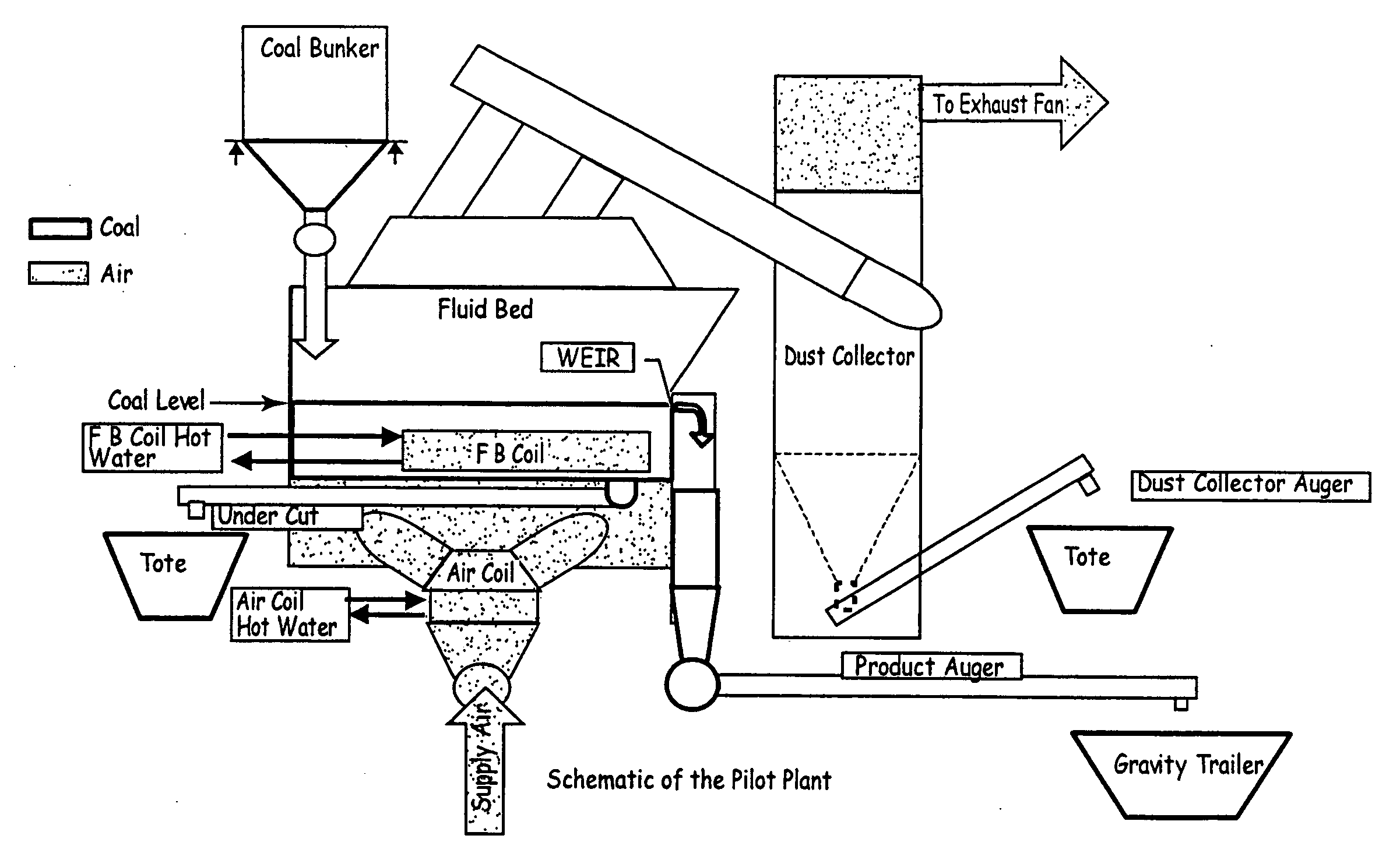

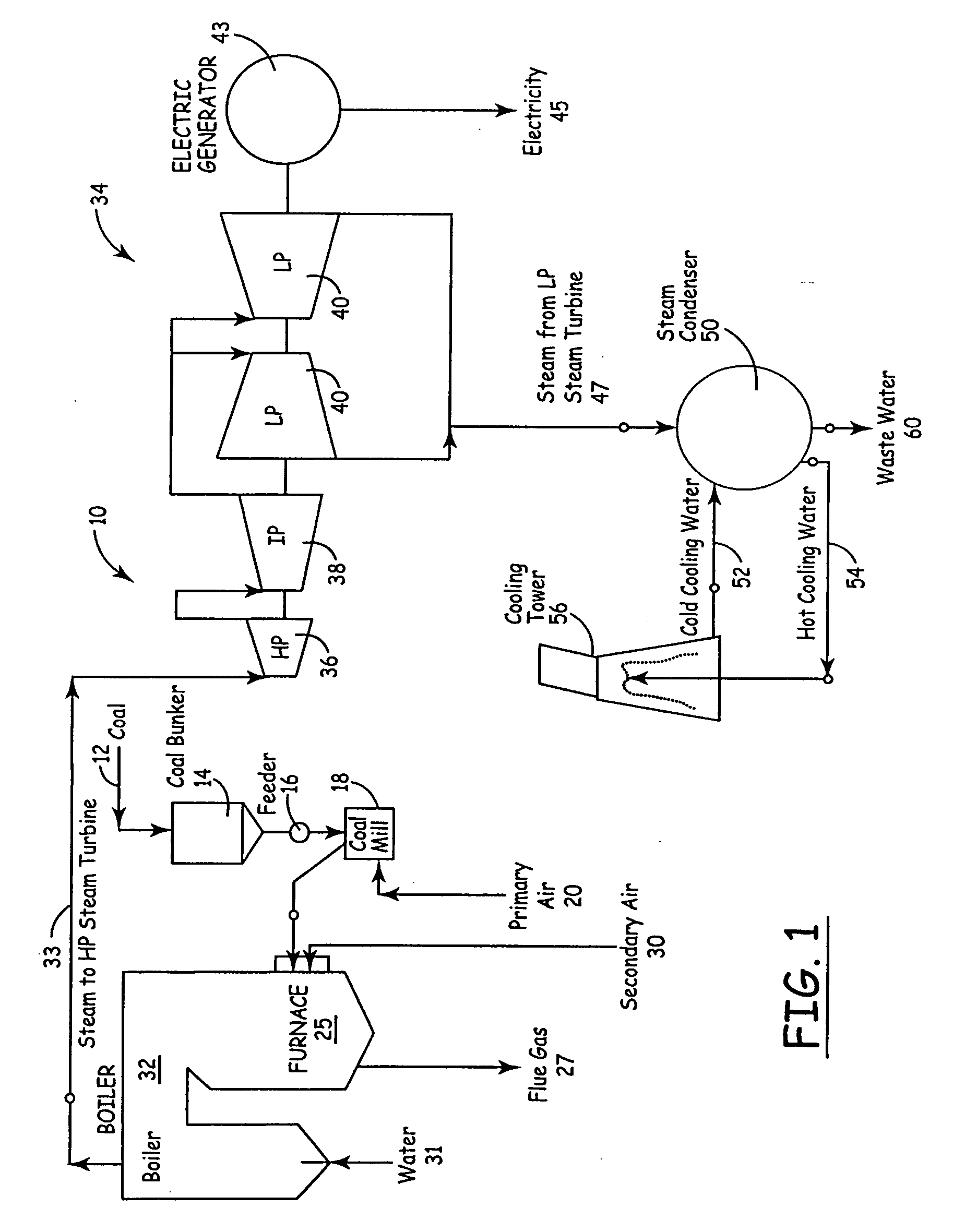

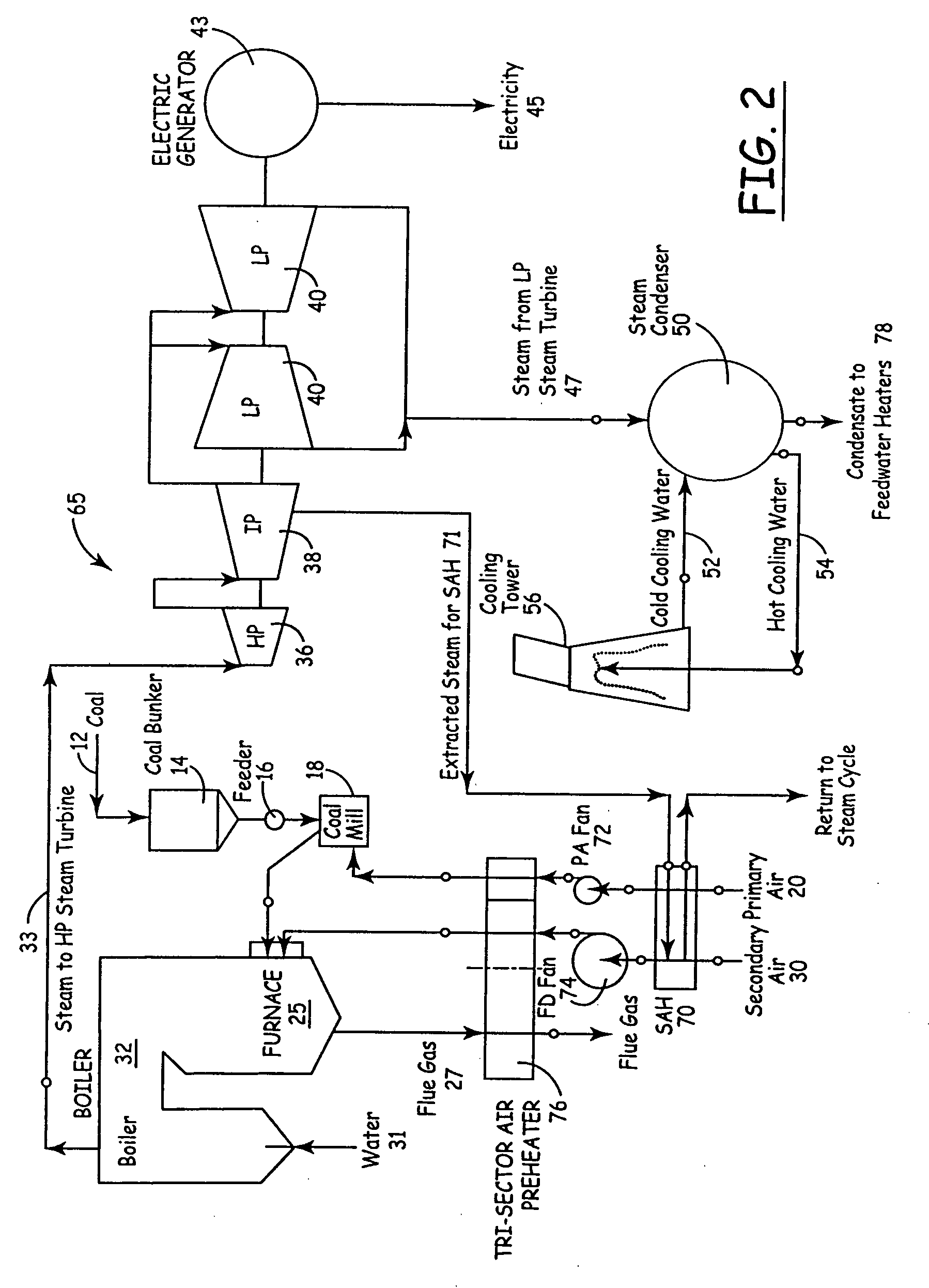

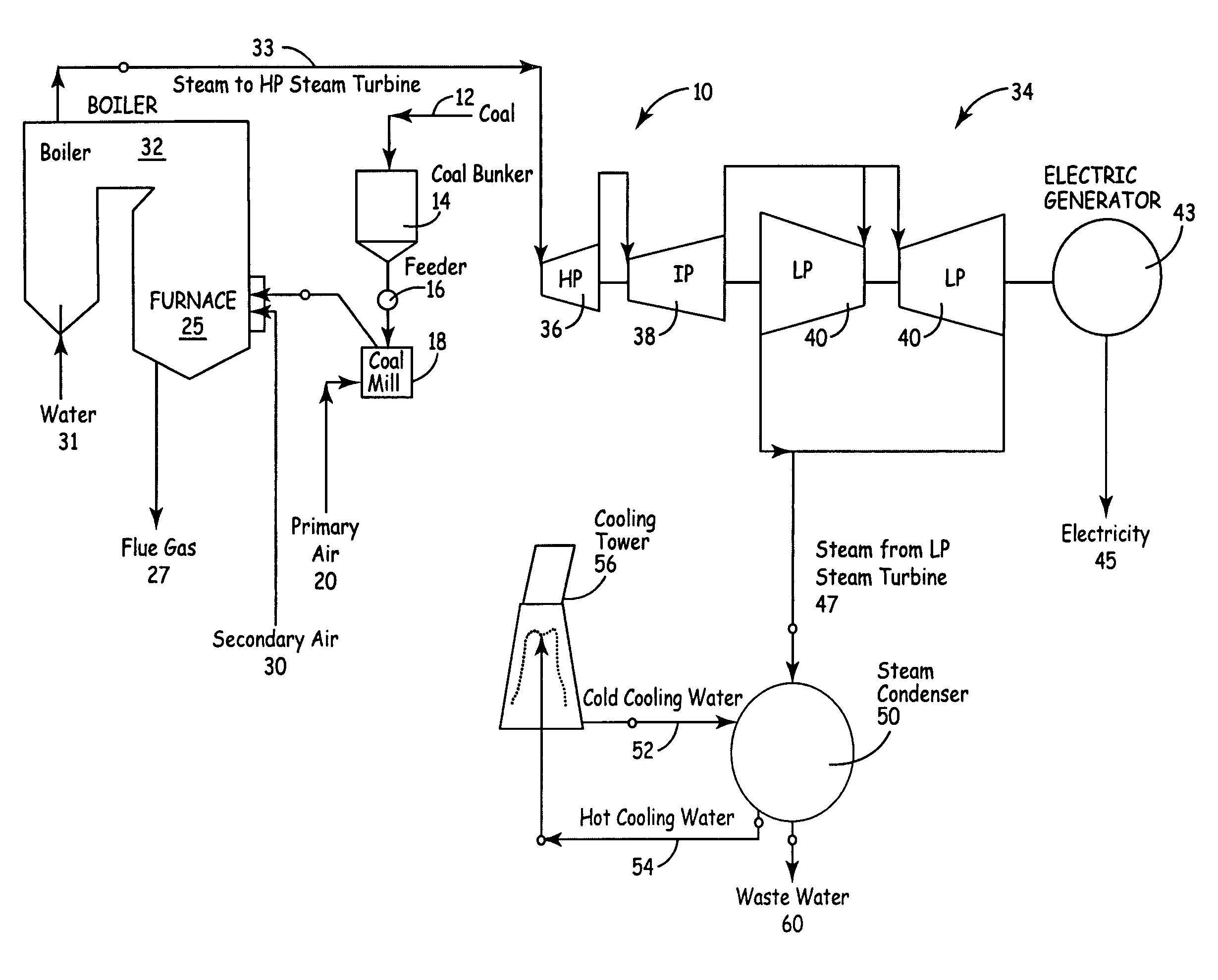

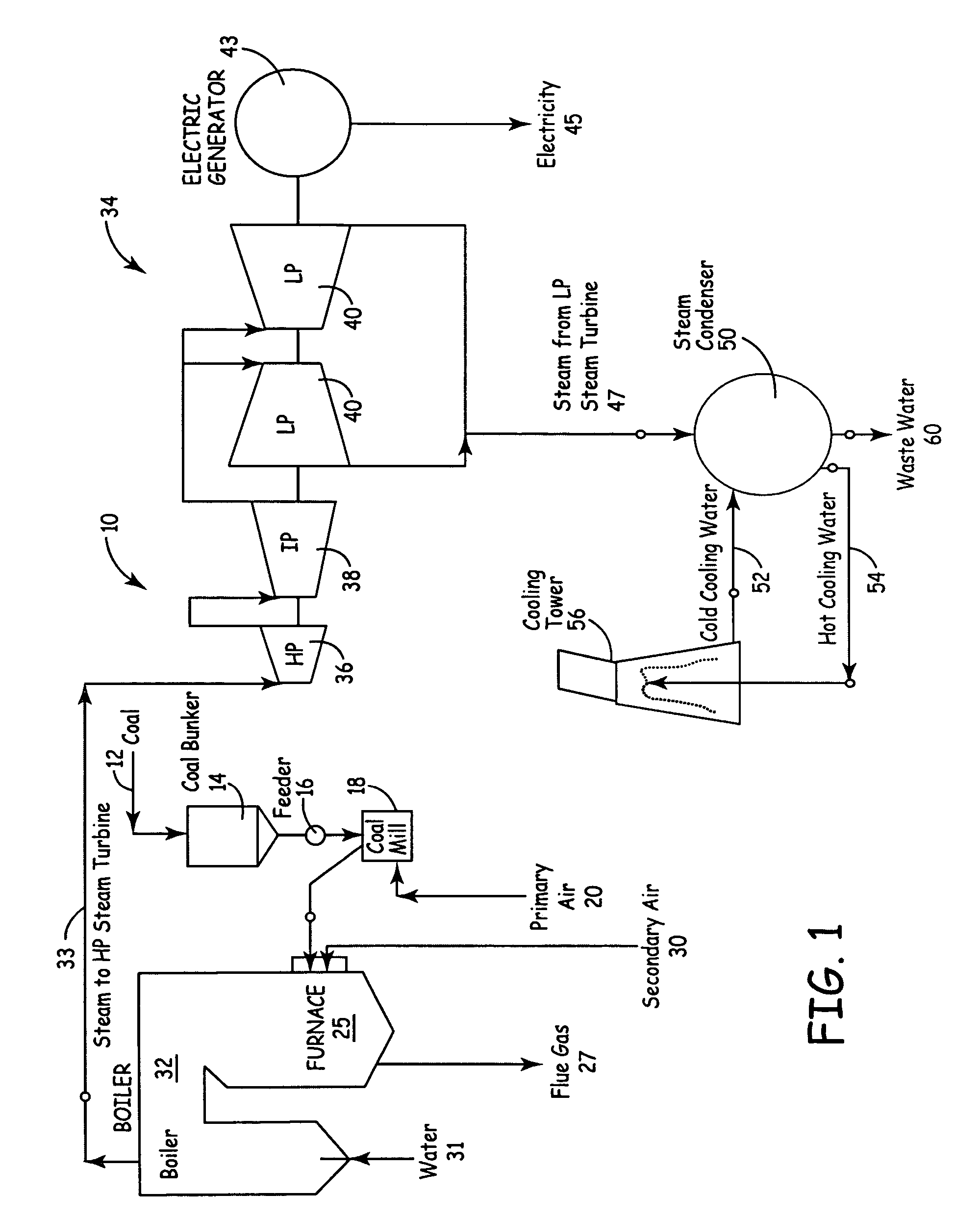

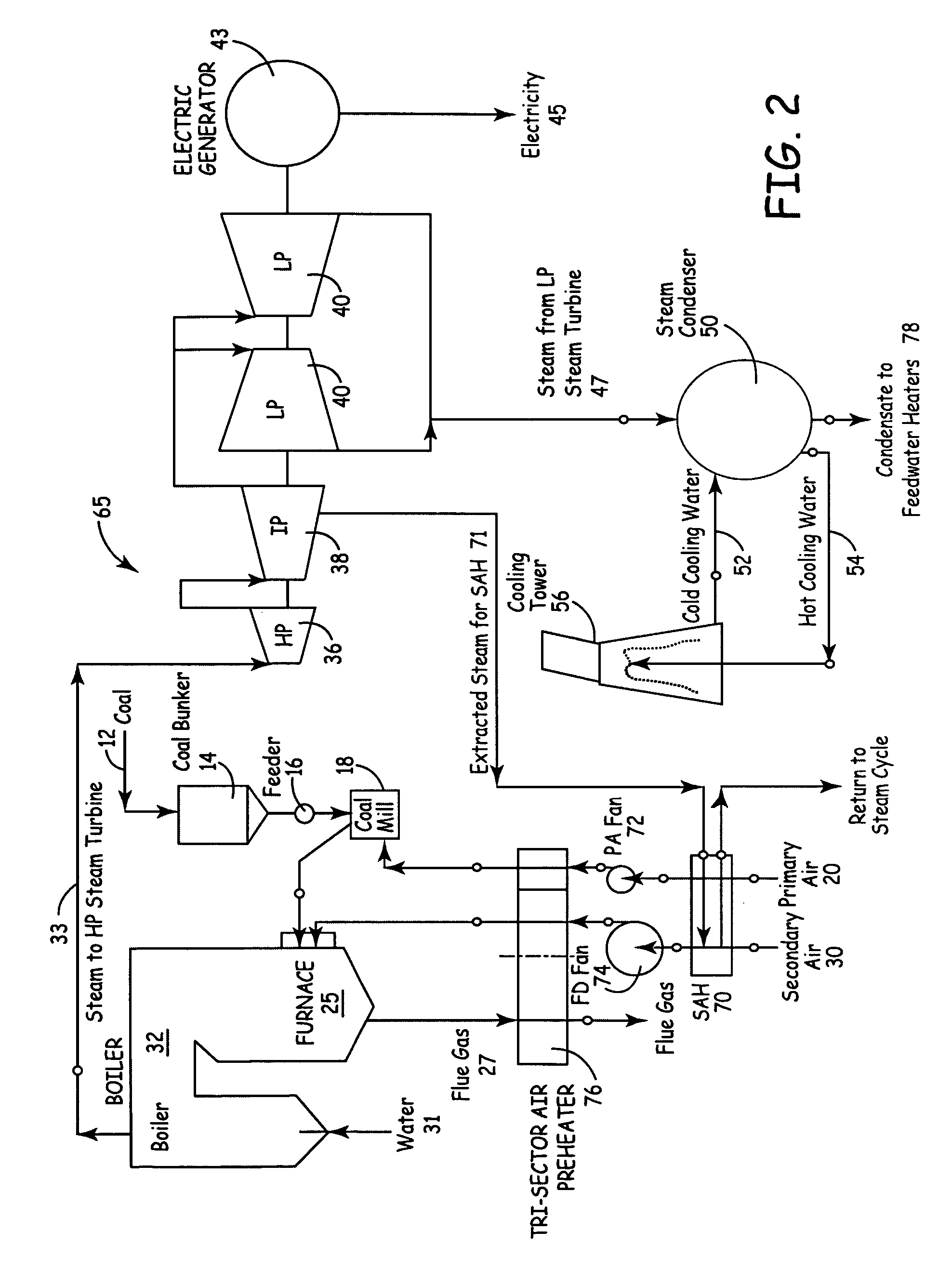

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

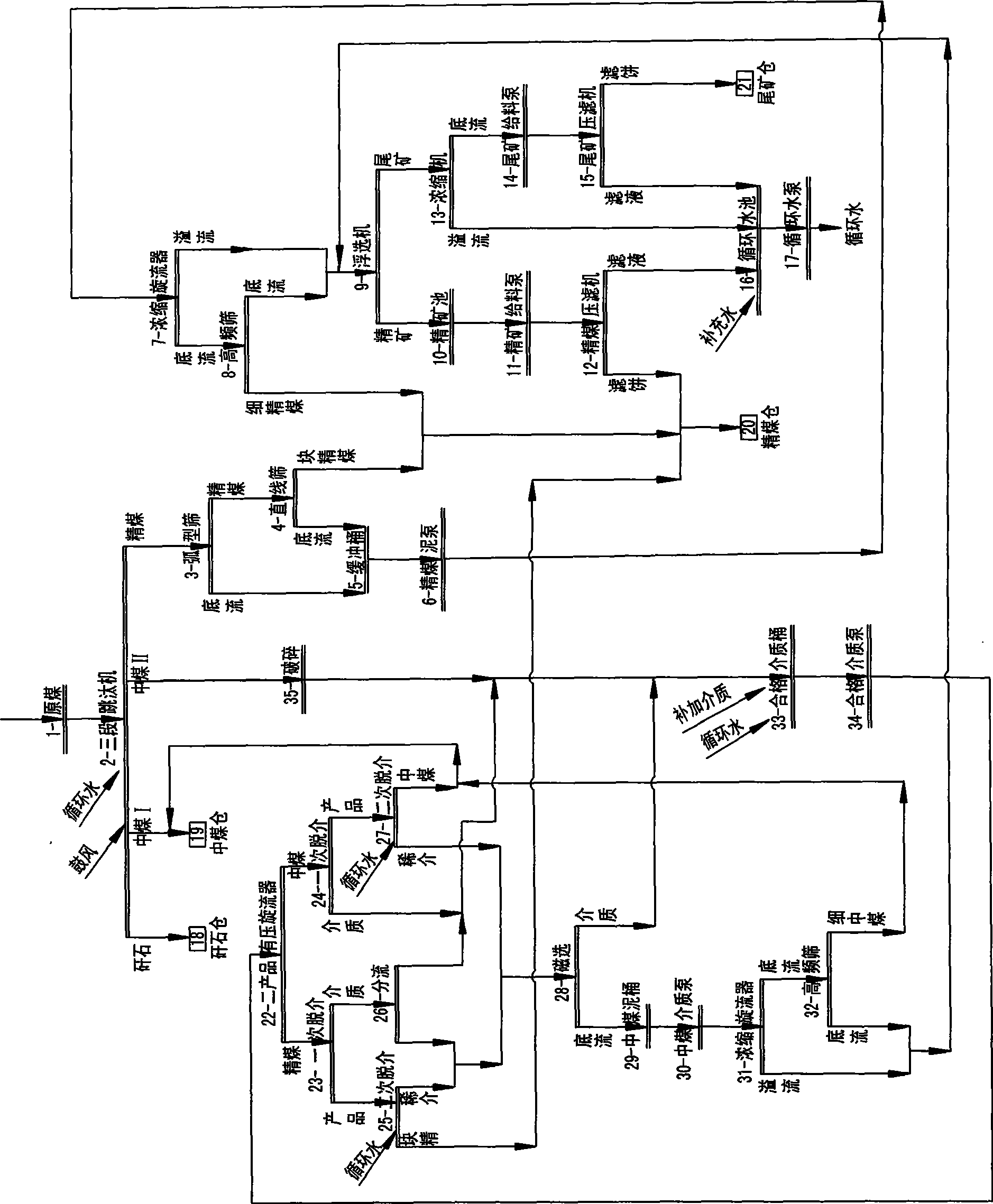

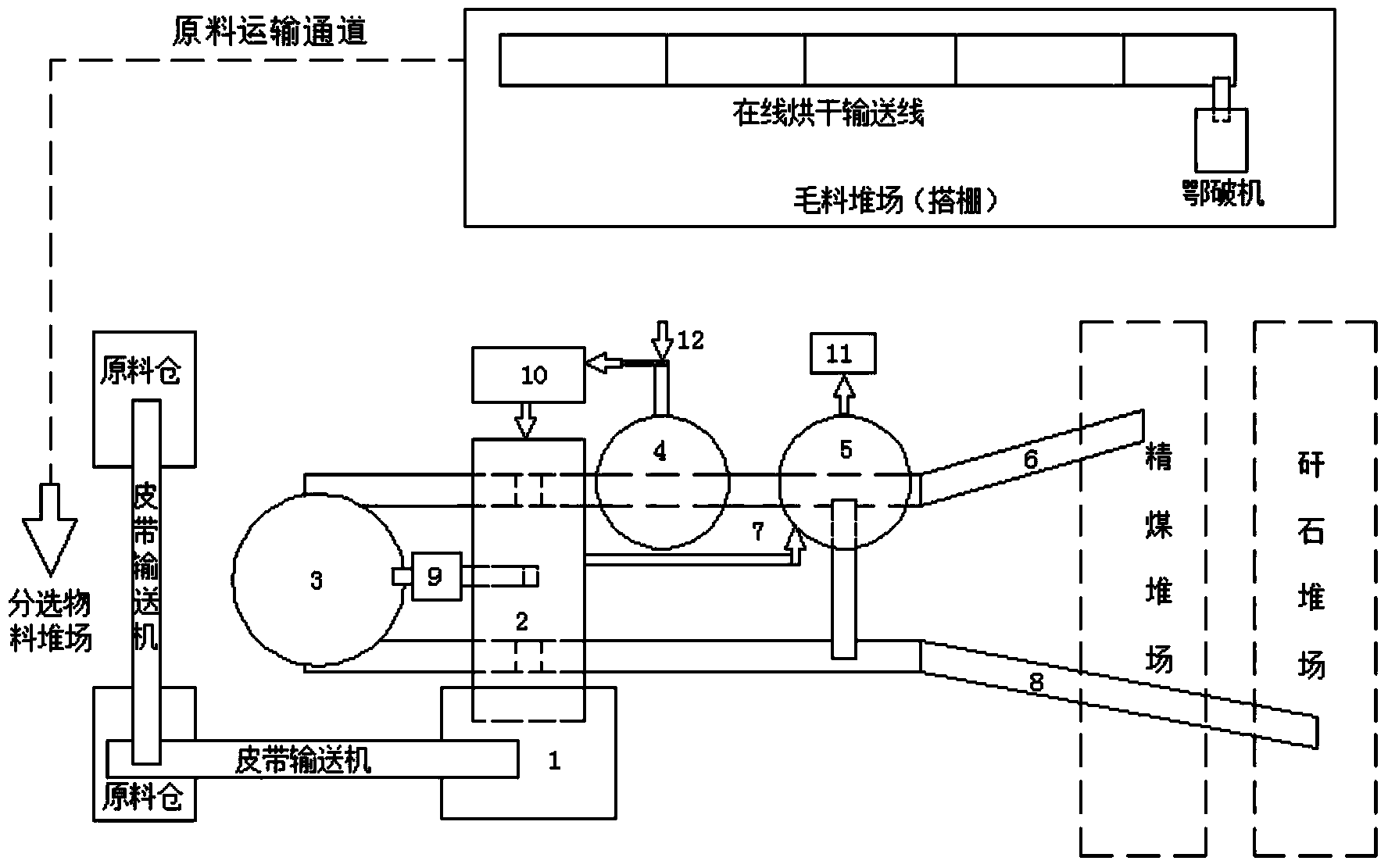

A coal dressing method and system of four-product jigging primary cleaning, secondary head coal small simplified heavy medium reelecting

ActiveCN101530824AReduce investmentLow operating costSievingScreeningTotal investmentSeparation technology

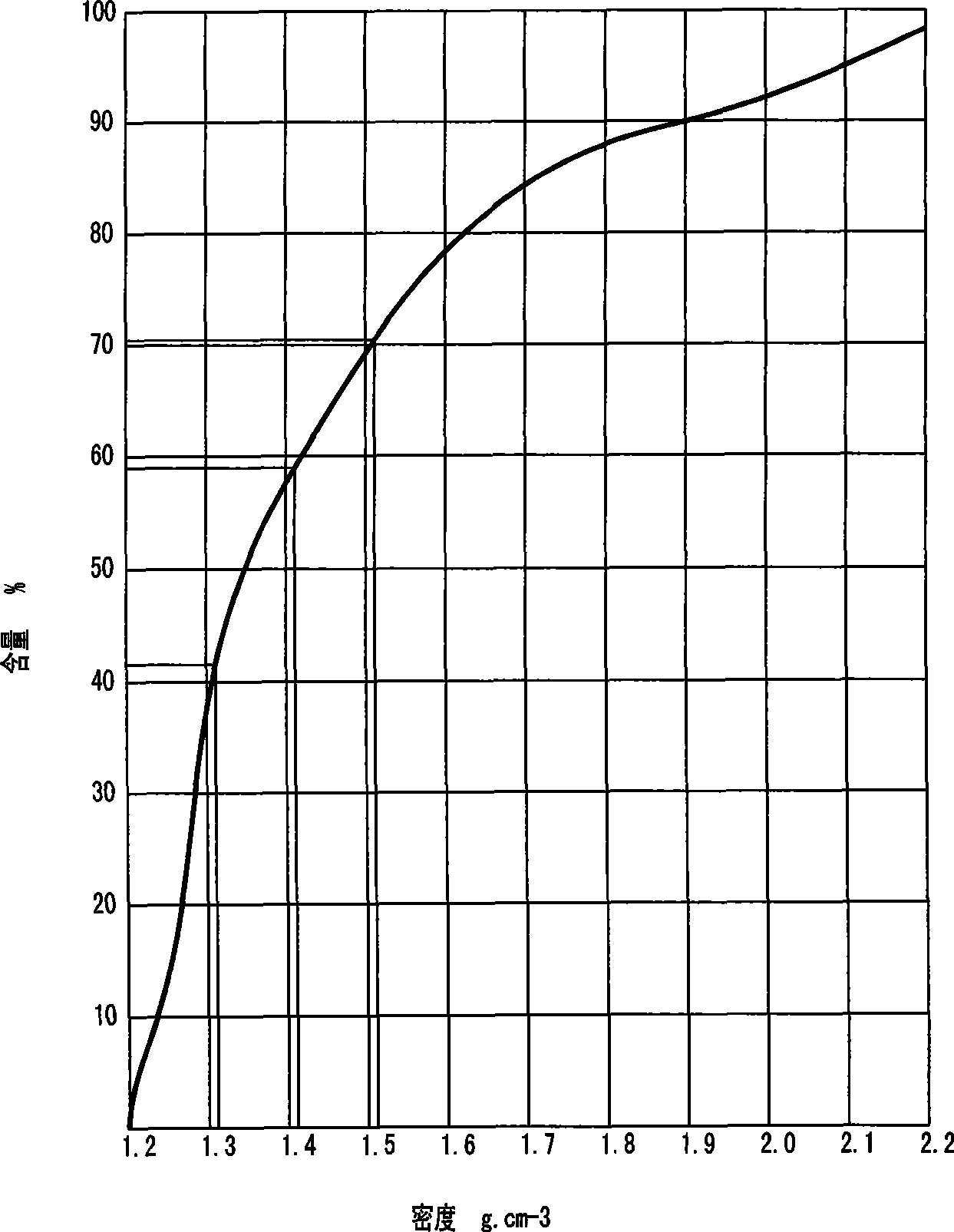

The invention discloses a coal dressing method and system of four-product jigging primary cleaning and secondary head coal small simplified heavy medium reelecting. The invention is a coal dressing method and system that selects the secondary head coal product through the four-product jigging technique and then reelects the secondary head coal with small simplify heavy medium separation technology. The adoption of the invention to select coal is characterized by less total investment, simpler system and lower operational expense, which can improve the stability of the system, reduce the powerconsumption, simplify the managing and maintaining work. The method can be easily realized with present technical merits, which is beneficial to be popularized in the middle and small coal washeries where the management level is low and if the method is used in oversize coal washeries, the cost for washing is lower.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

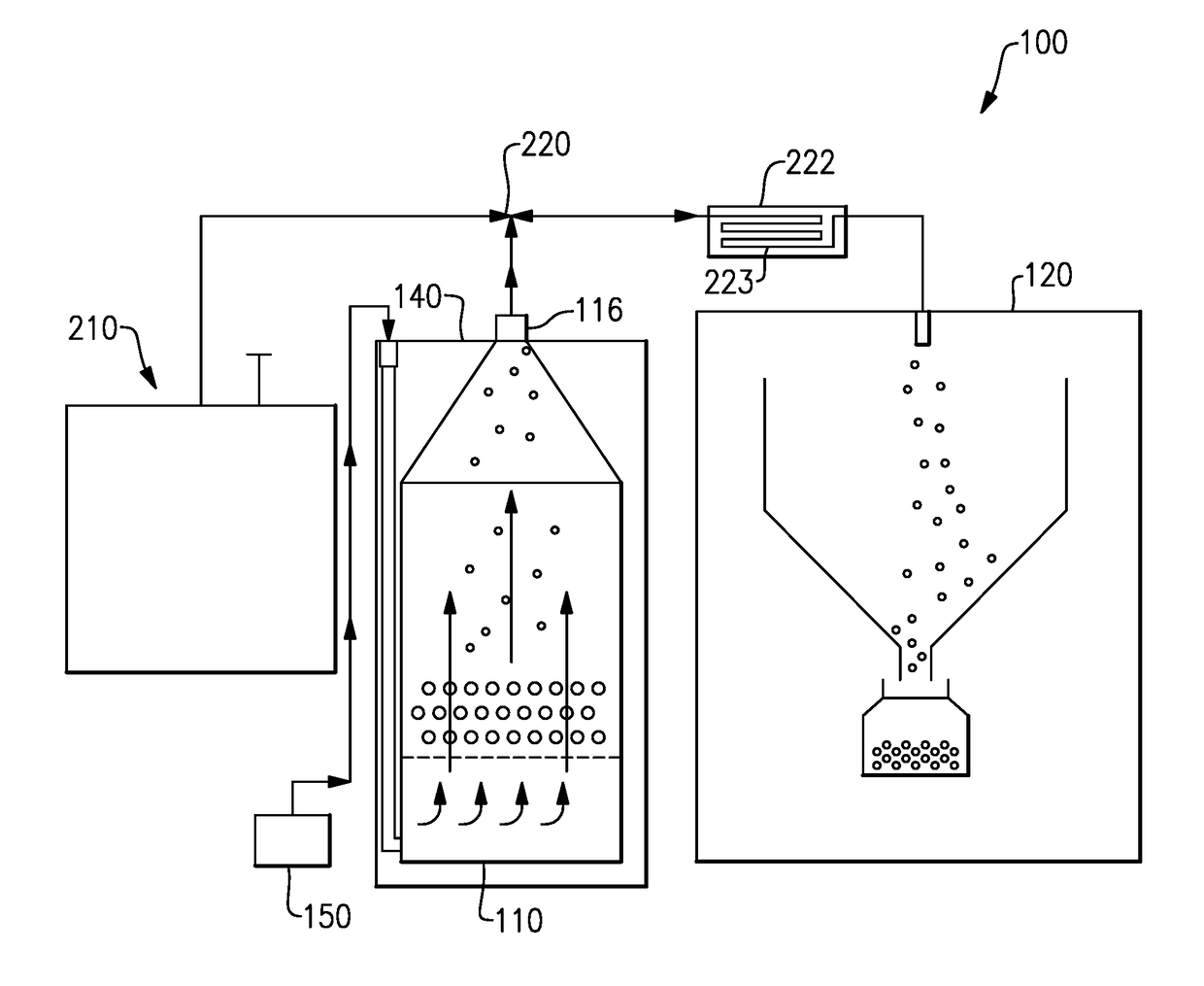

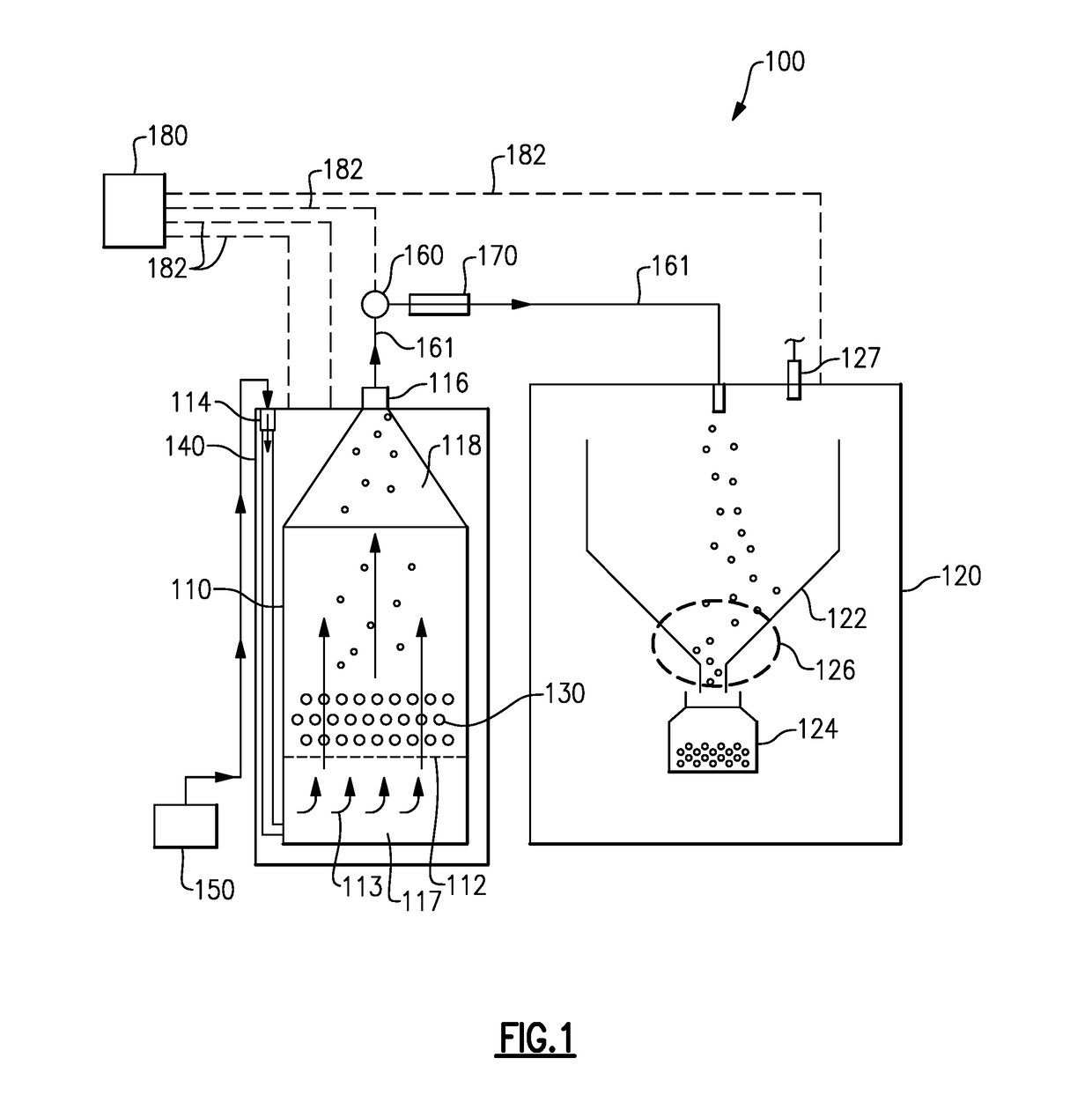

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS8062410B2Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatGas current separationParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

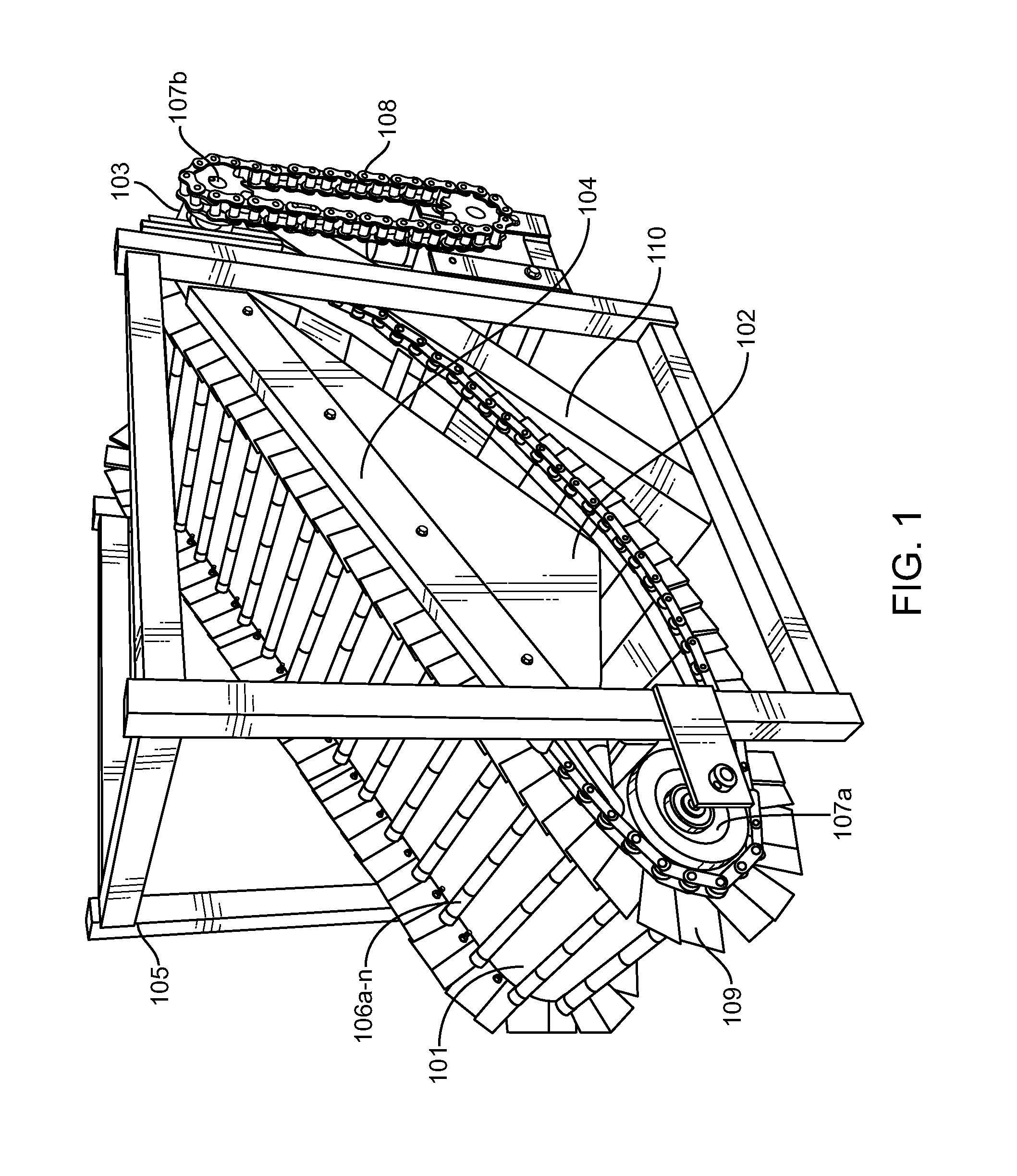

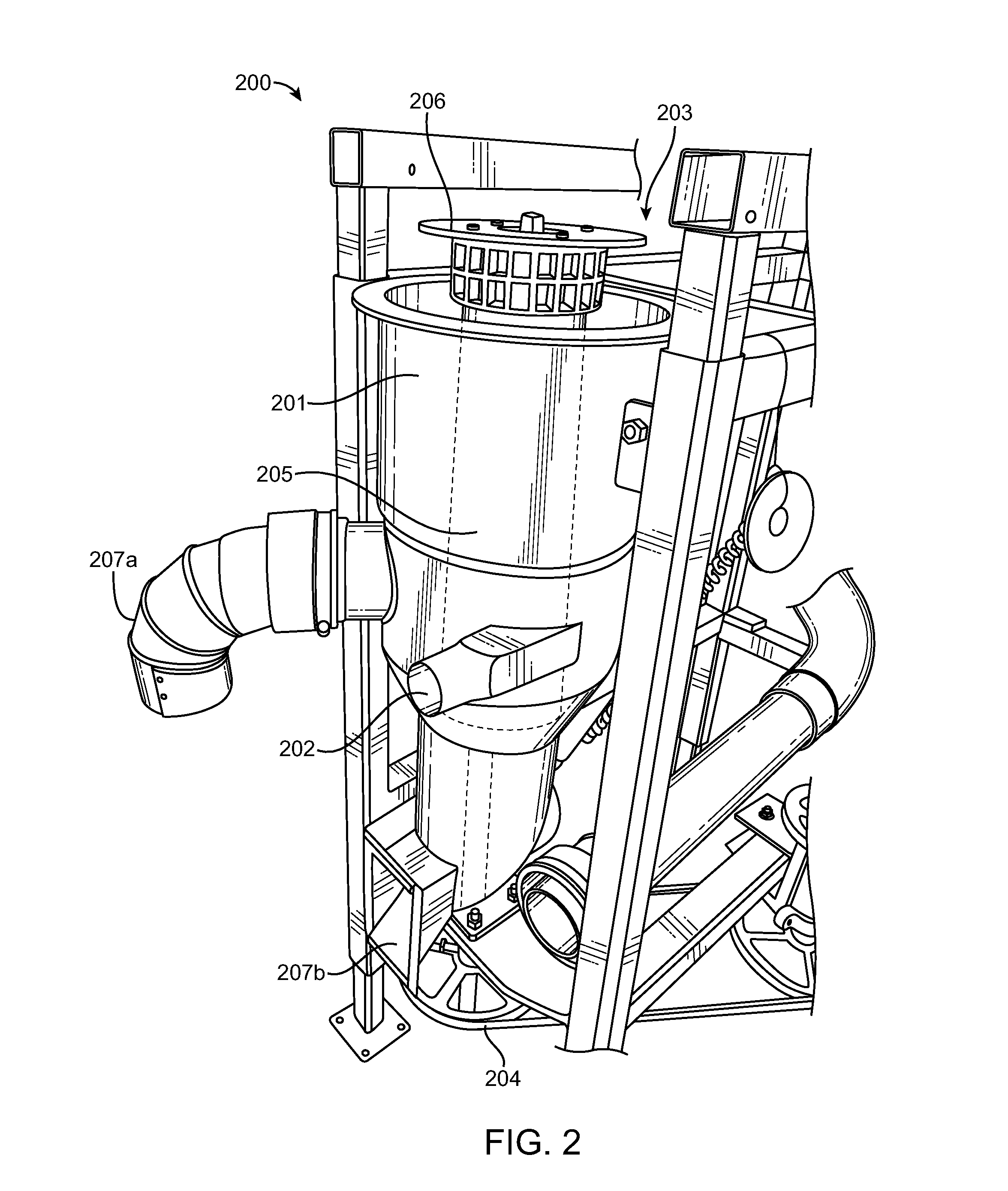

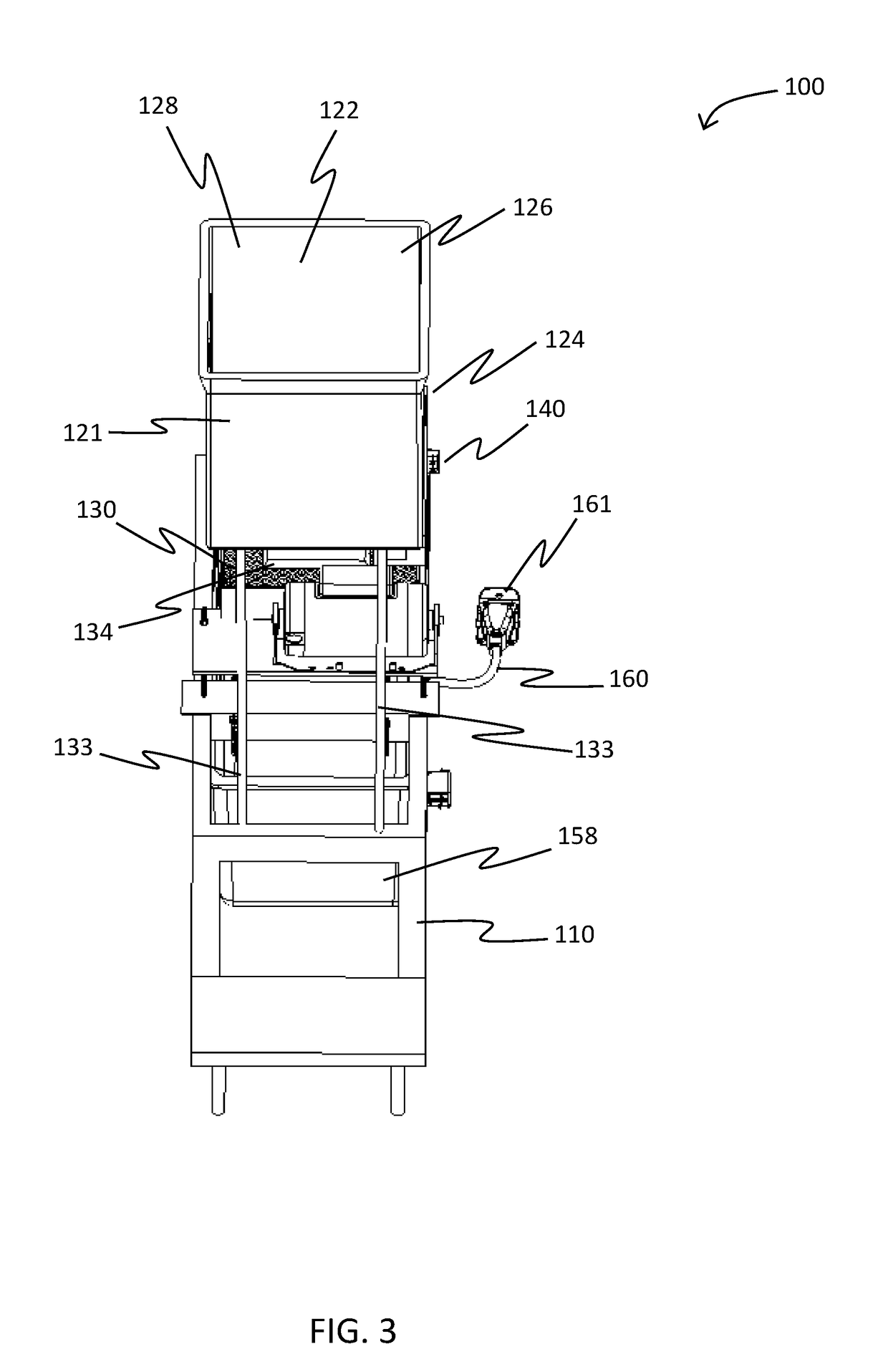

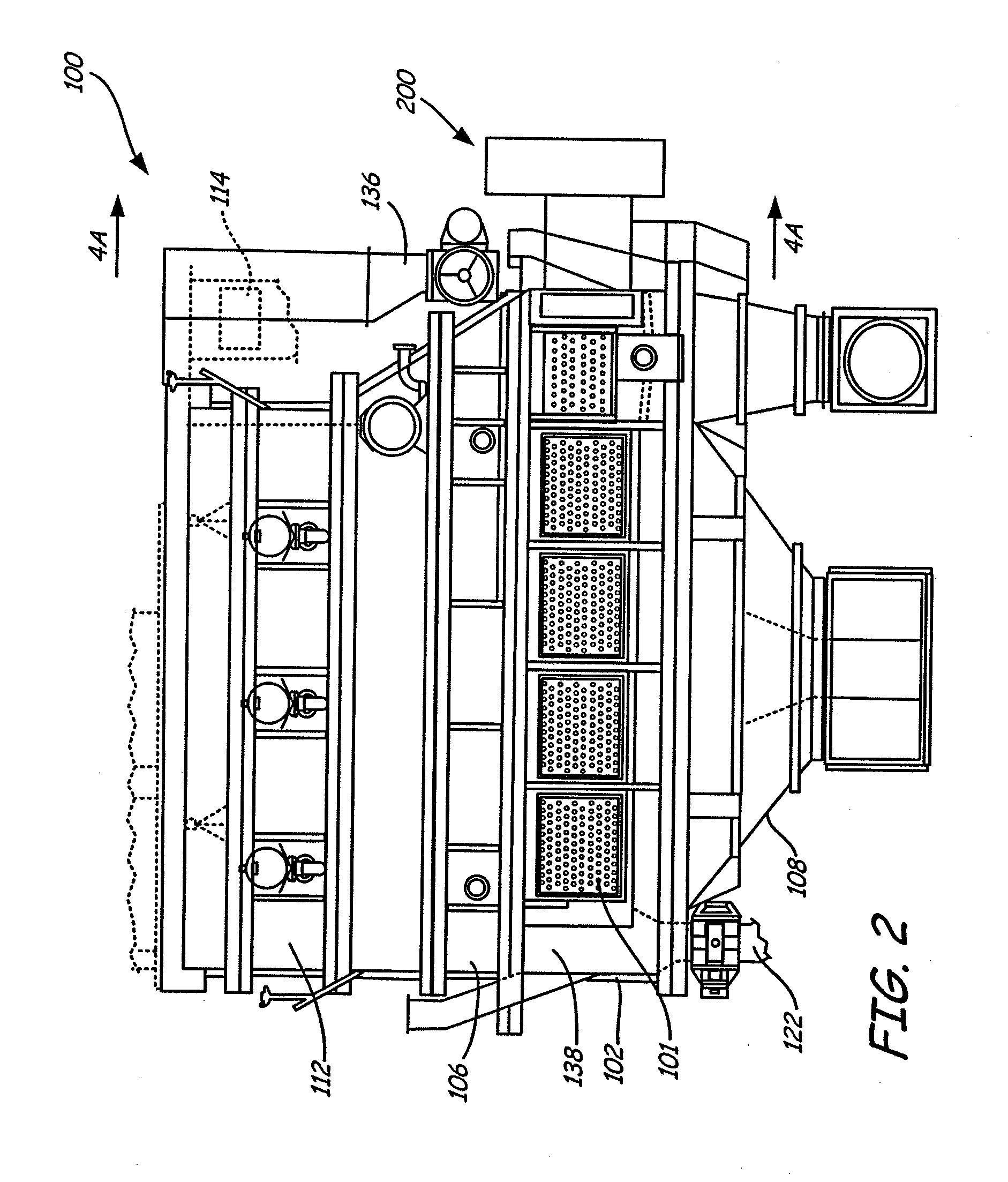

Apparatus and method of separating and concentrating organic and/or non-organic material

ActiveUS7540384B2Processed evenly and quicklySignificant environmental benefitsGas current separationSolid fuel pretreatmentParticulatesFluidized bed

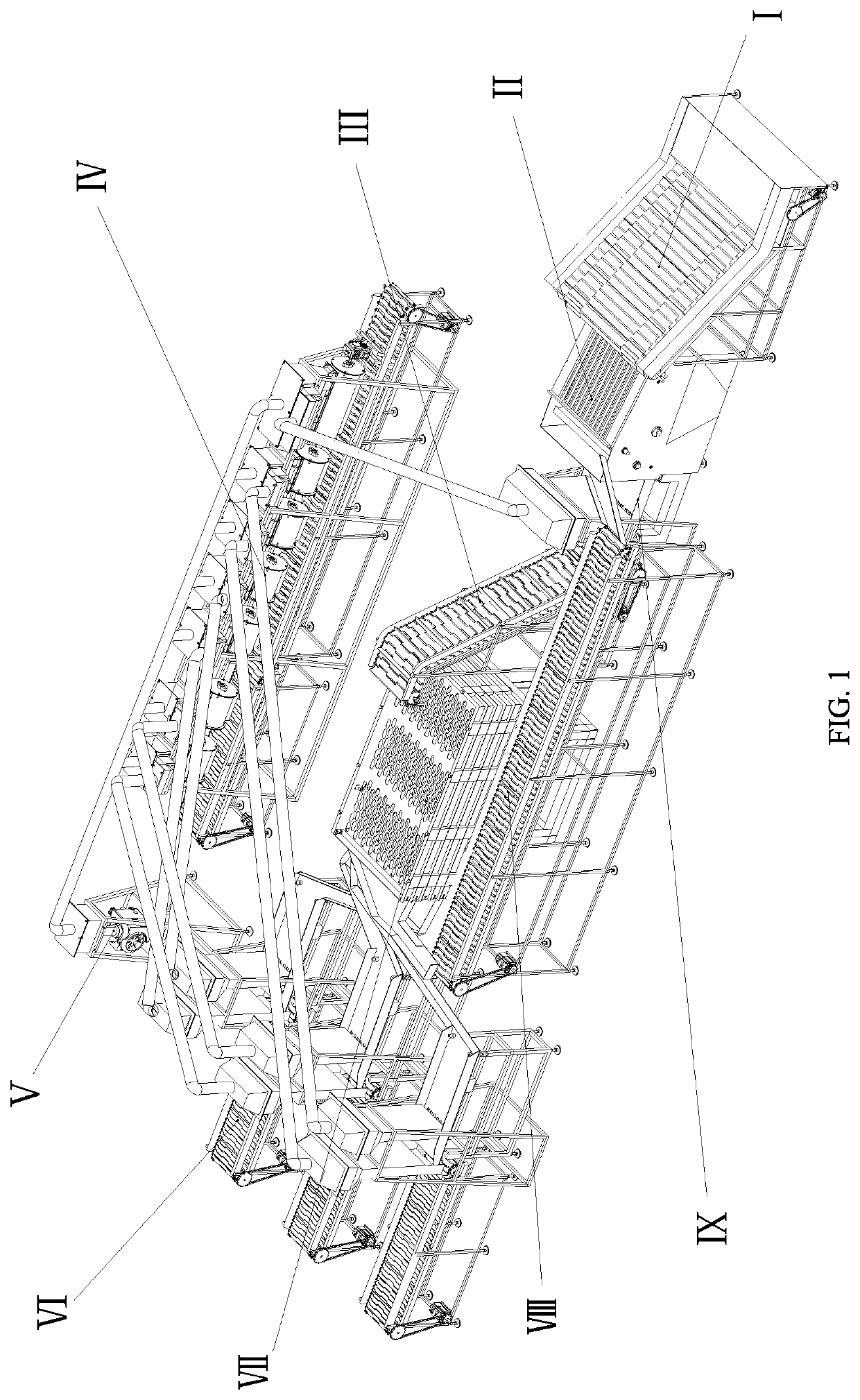

An apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. The fluidized bed also includes an opening for receiving a first fluidizing stream, an exit for fluidized particulate and at least one exit for non-fluidized particulate. A conveyor is operatively disposed in the fluidized bed for conveying the non-fluidized particulate to the non-fluidized particulate exit. A collector box is in operative communication with the fluidized bed to receive the non-fluidized particulate. There is a means for directing a second fluidizing stream through the non-fluidized particulate as while it is in the collector box to separate fluidizable particulate therefrom.

Owner:RAINBOW ENERGY CENT LLC

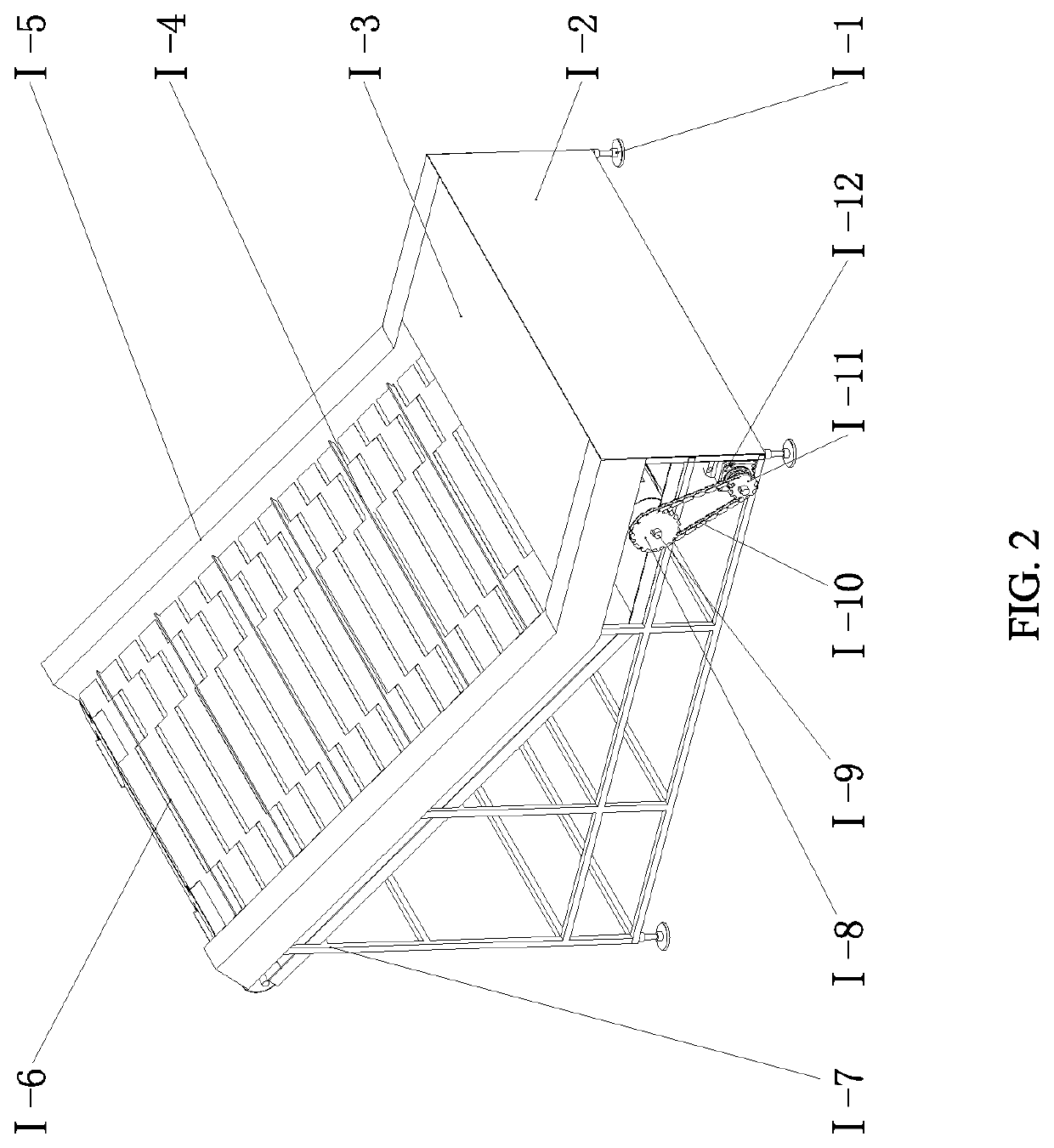

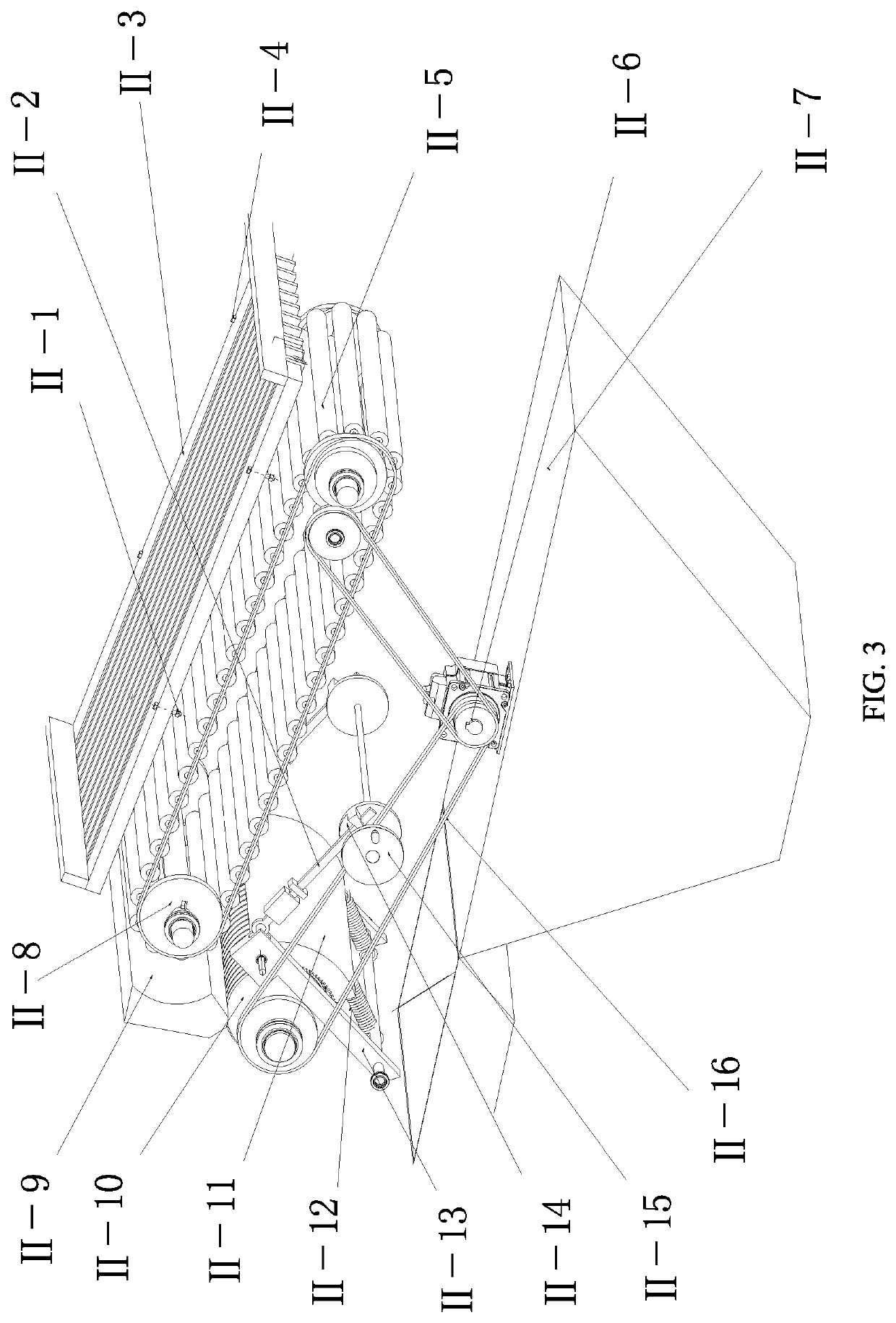

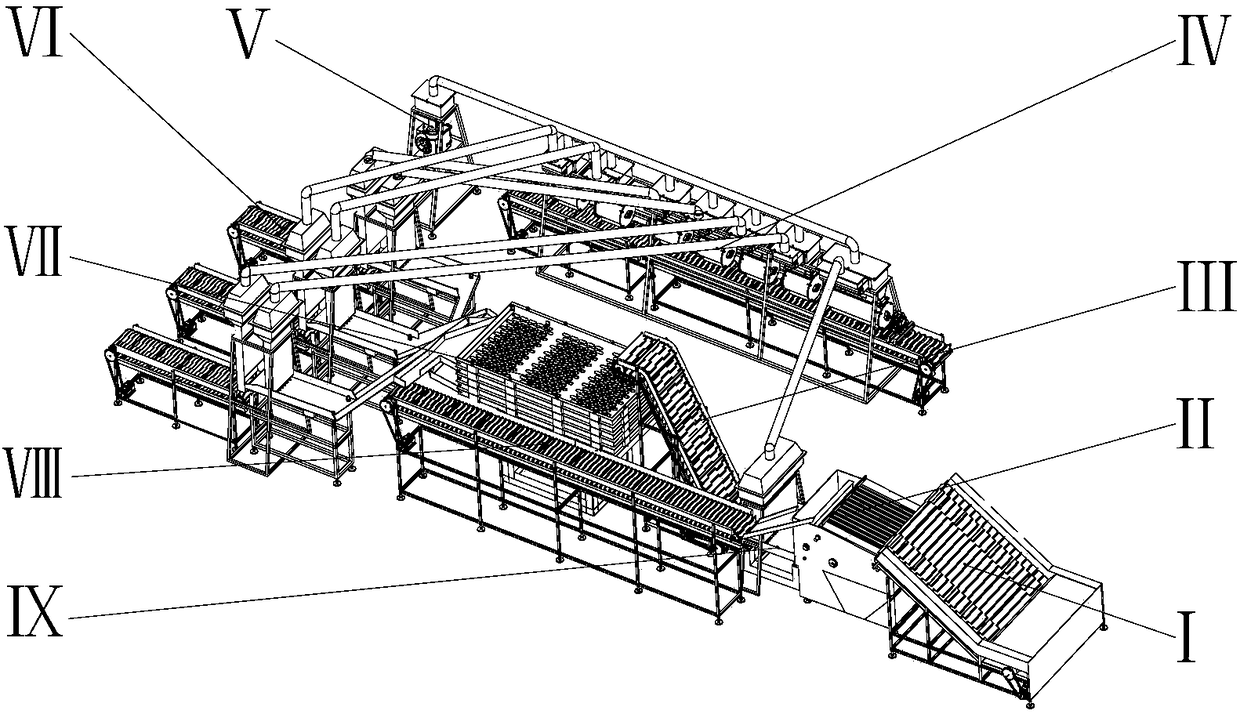

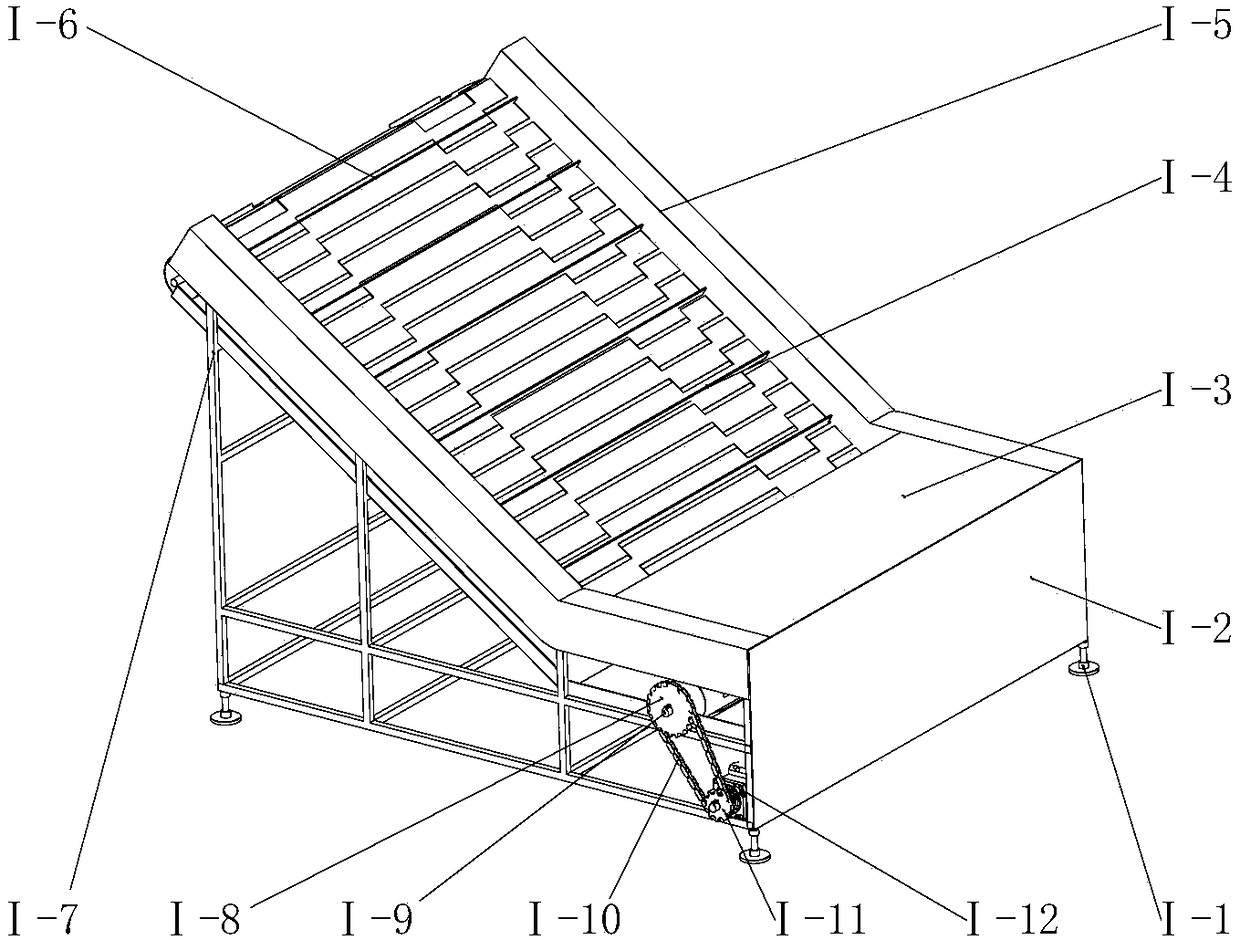

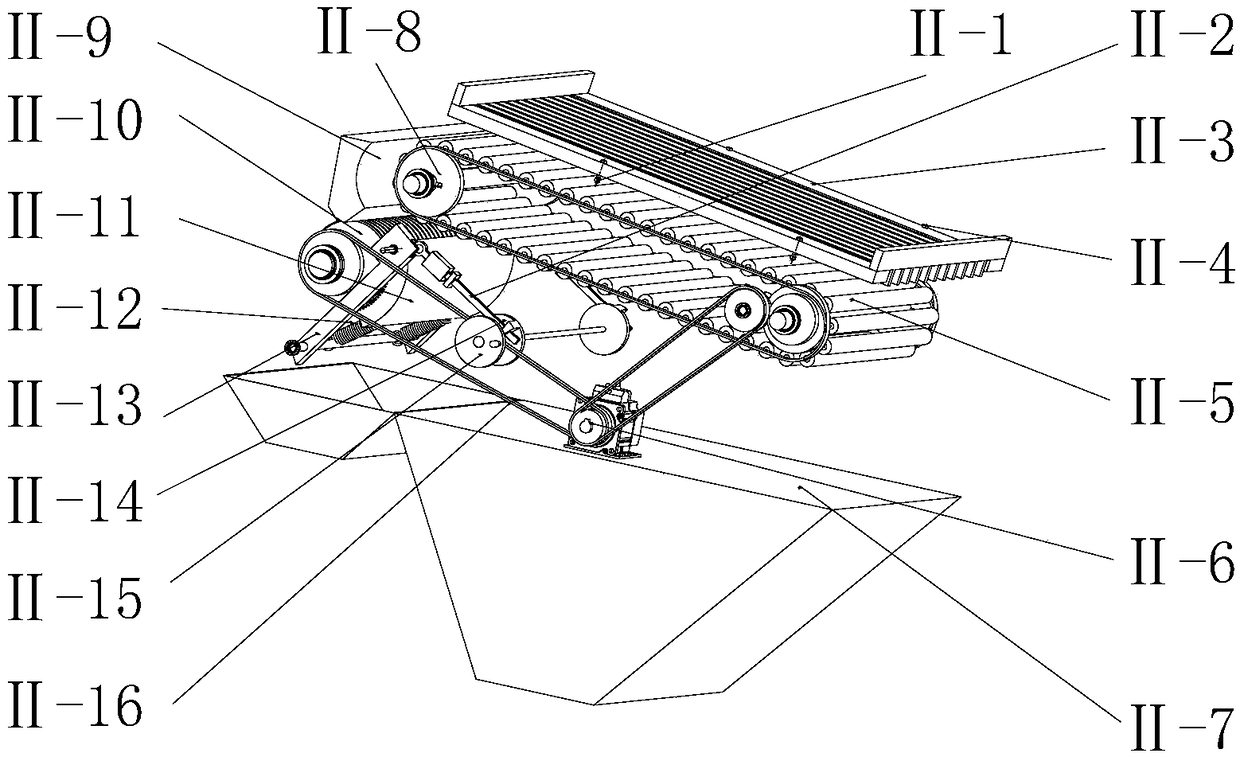

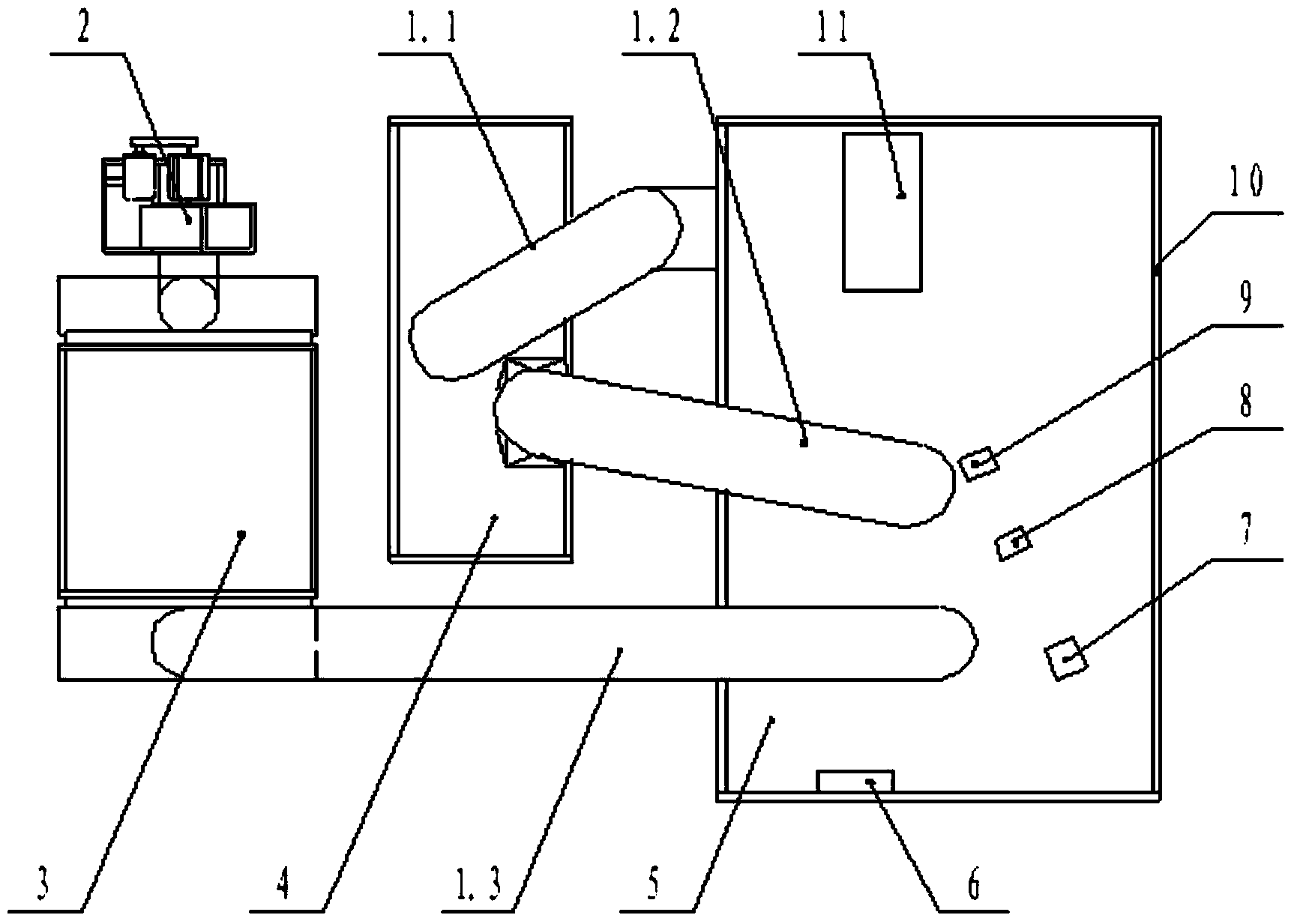

Automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation

PendingUS20200138083A1High speedHigh-efficiency walnut shell-breakingGas current separationHuskingWalnut NutProcess engineering

The disclosure discloses an automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation, solving the problem that the existing walnut shell breaking device cannot adapt to walnuts having different sizes and shell breaking rate and shell breaking efficiency cannot be ensured. The system can realize efficient shell-breaking, kernel-taking and shell-kernel separation on different varieties of walnuts, is quick in production speed and high in automation degree, and meanwhile is capable of improving entire kernel rate and kernel obtaining rate, reducing the damage rate of the walnut kernel and ensuring the high shell-breaking efficiency and thoroughness of shell and kernel separation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Automatic production system for highly-efficient walnut shell breaking and kernel obtaining and shell-kernel separation

PendingCN108576844AReduce manufacturing costSmall footprintGas current separationHuskingProduction rateSuction force

The invention discloses an automatic production system for highly-efficient walnut shell breaking and kernel obtaining and shell-kernel separation, and the automatic production system solves problemsthat the existing walnut shell breaking device can not adapt to walnuts in different sizes, and the shell breaking rate and the shell breaking efficiency can not be guaranteed. The automatic production system is capable of realizing highly-efficient shell breaking and kernel obtaining and shell-kernel separation for walnuts in different varieties, high in production rate and automation degree, improved in whole kernel rate and kernel obtaining rate, reduced in damage rate of walnut kernels and capable of ensuring high efficiency of shell breaking and thoroughness degree of shell-kernel separation. A technical scheme of the automatic production system is that: the automatic production system includes a shell breaking device: extruding components are arranged to extrude and break walnut shells; a walnut kernel vibrating and grading device: receiving shell-kernel mixture after shell breaking, subjecting the shell-kernel mixture to vibrating and grading, and conveying the graded shell-kernel mixture to each negative pressure shaking and sorting device, respectively; and the negative pressure shaking and sorting devices are connected to a negative pressure separation device, the negative pressure separation device sucks and stores the walnut shells through negative pressure suction force, and the walnut kernels are classified and stored through the negative pressure shaking and sorting devices.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

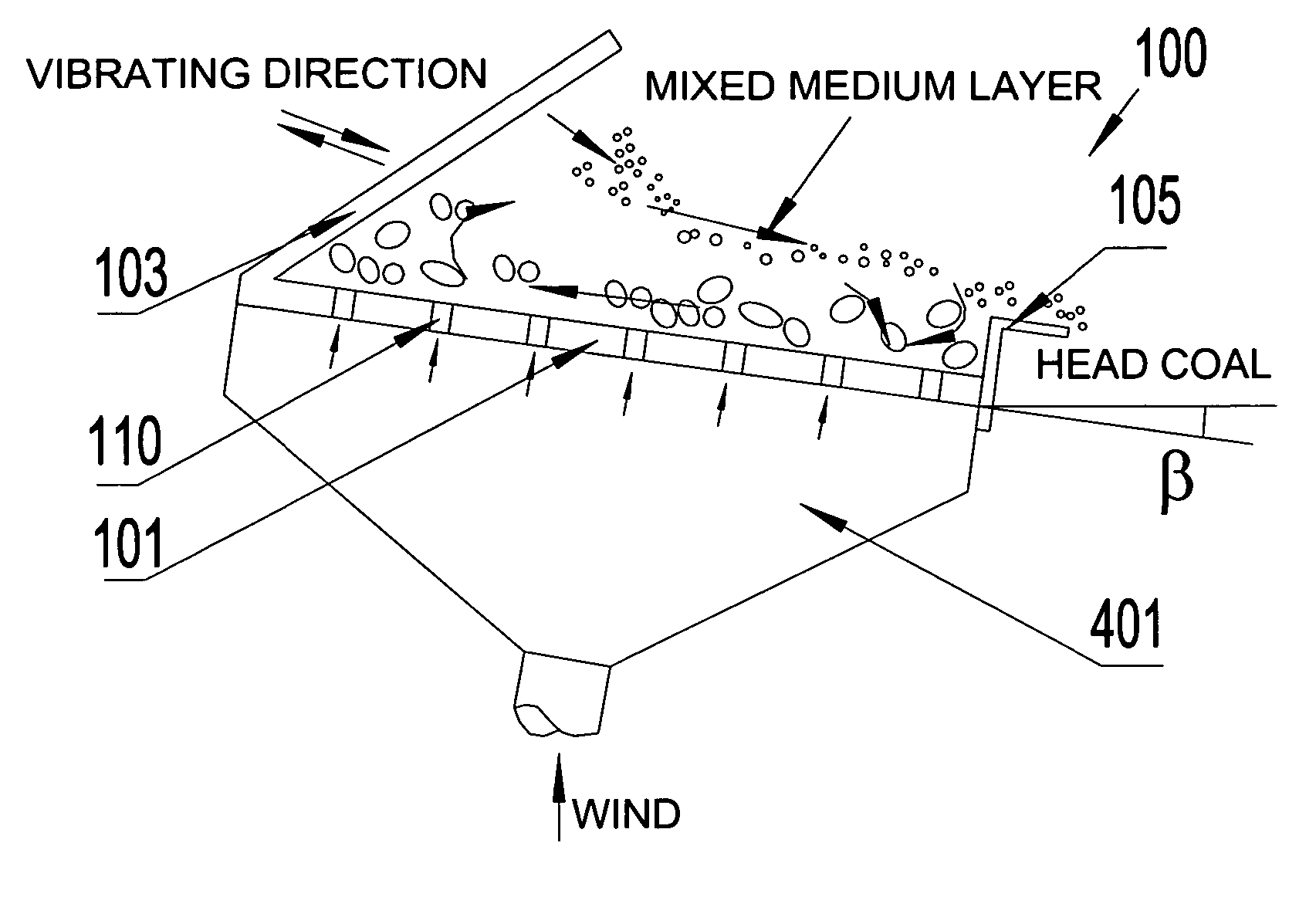

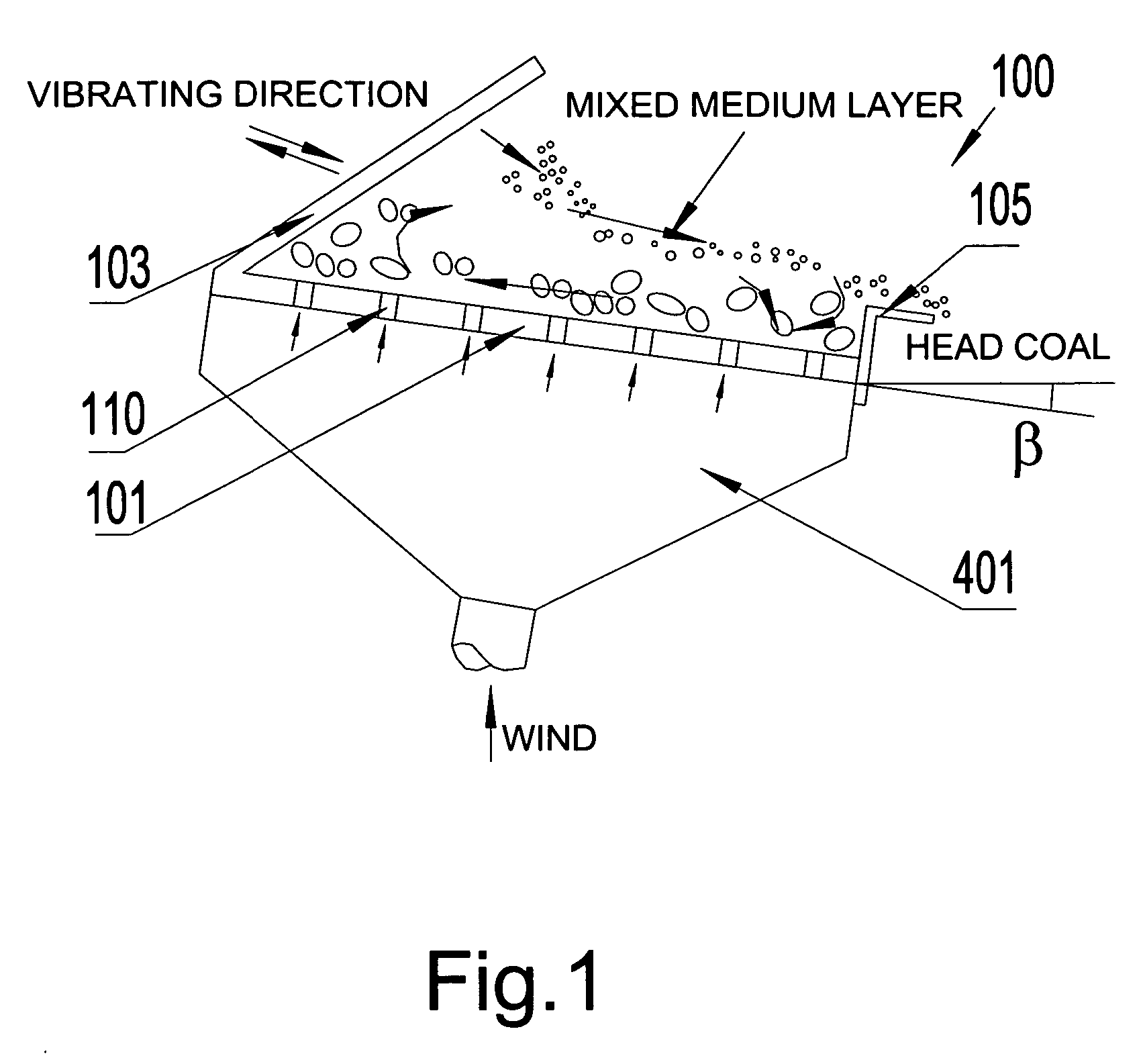

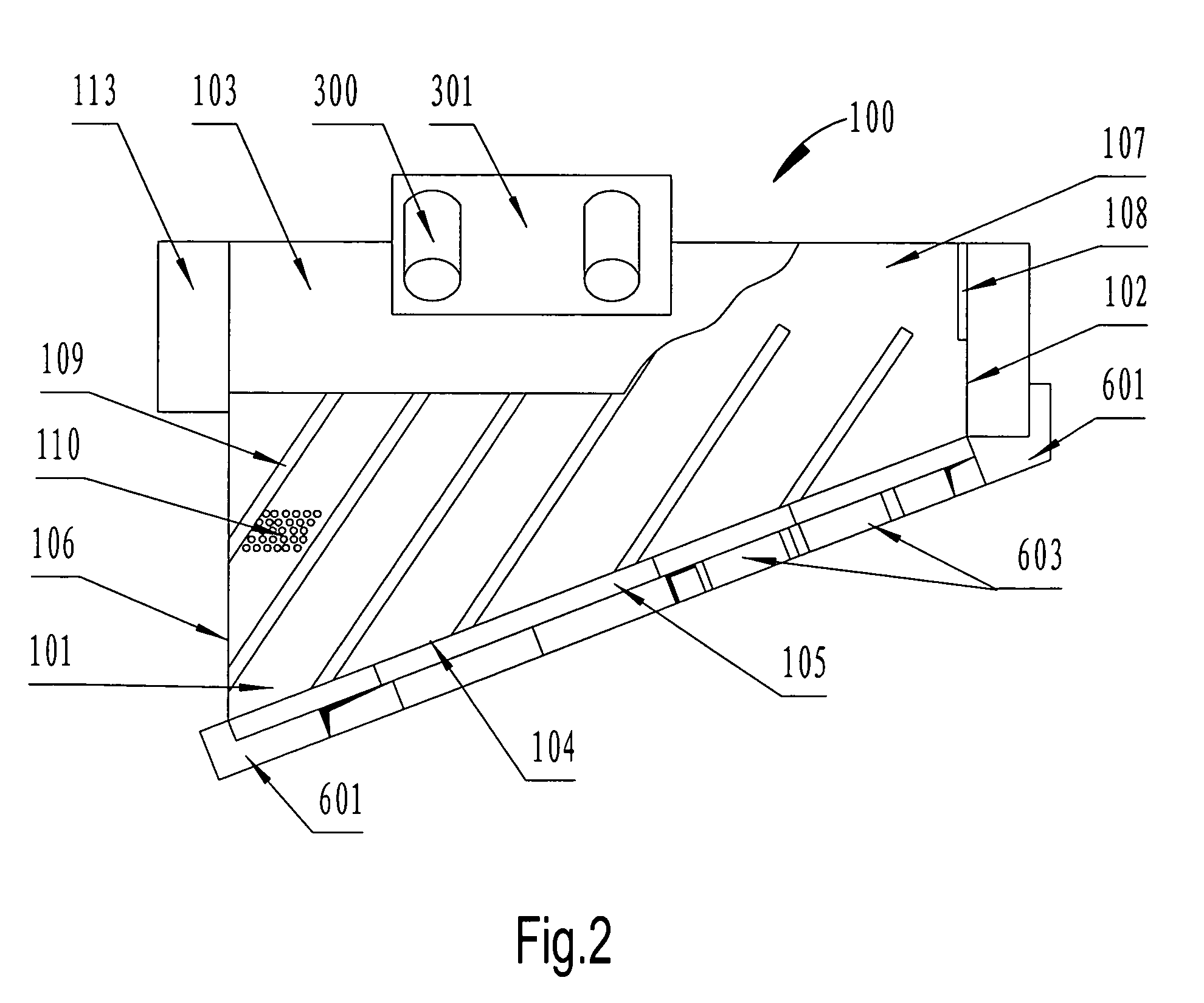

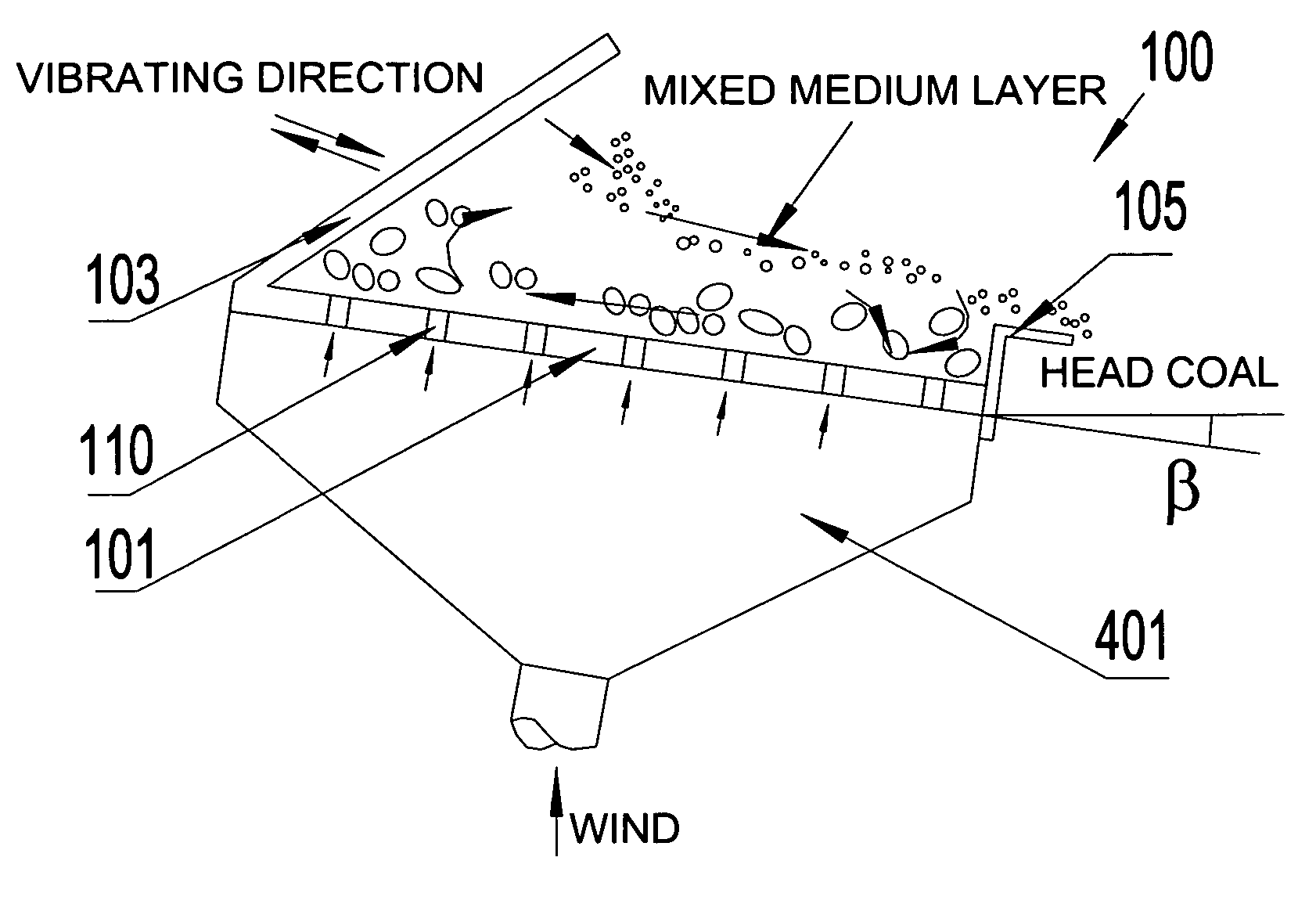

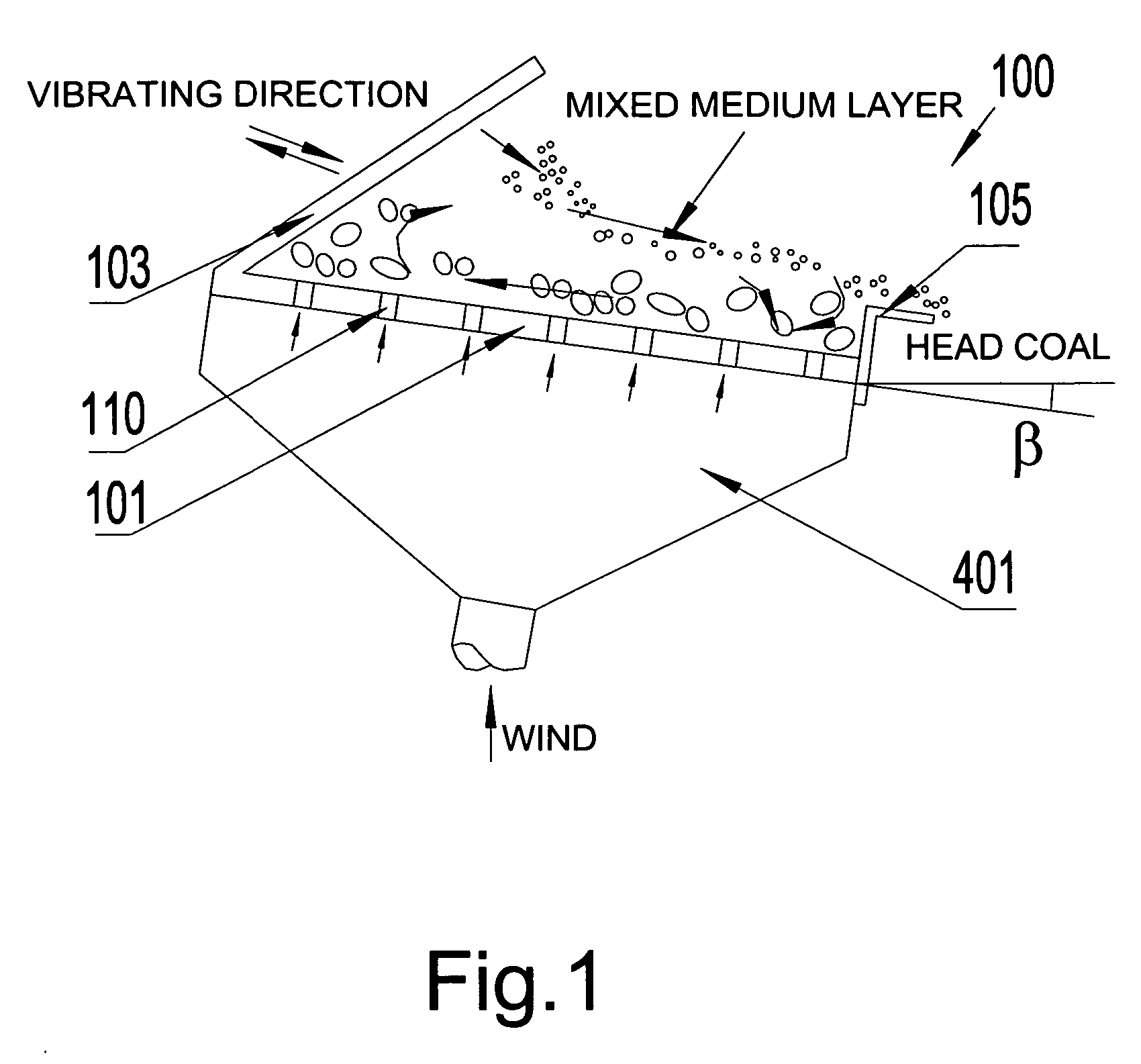

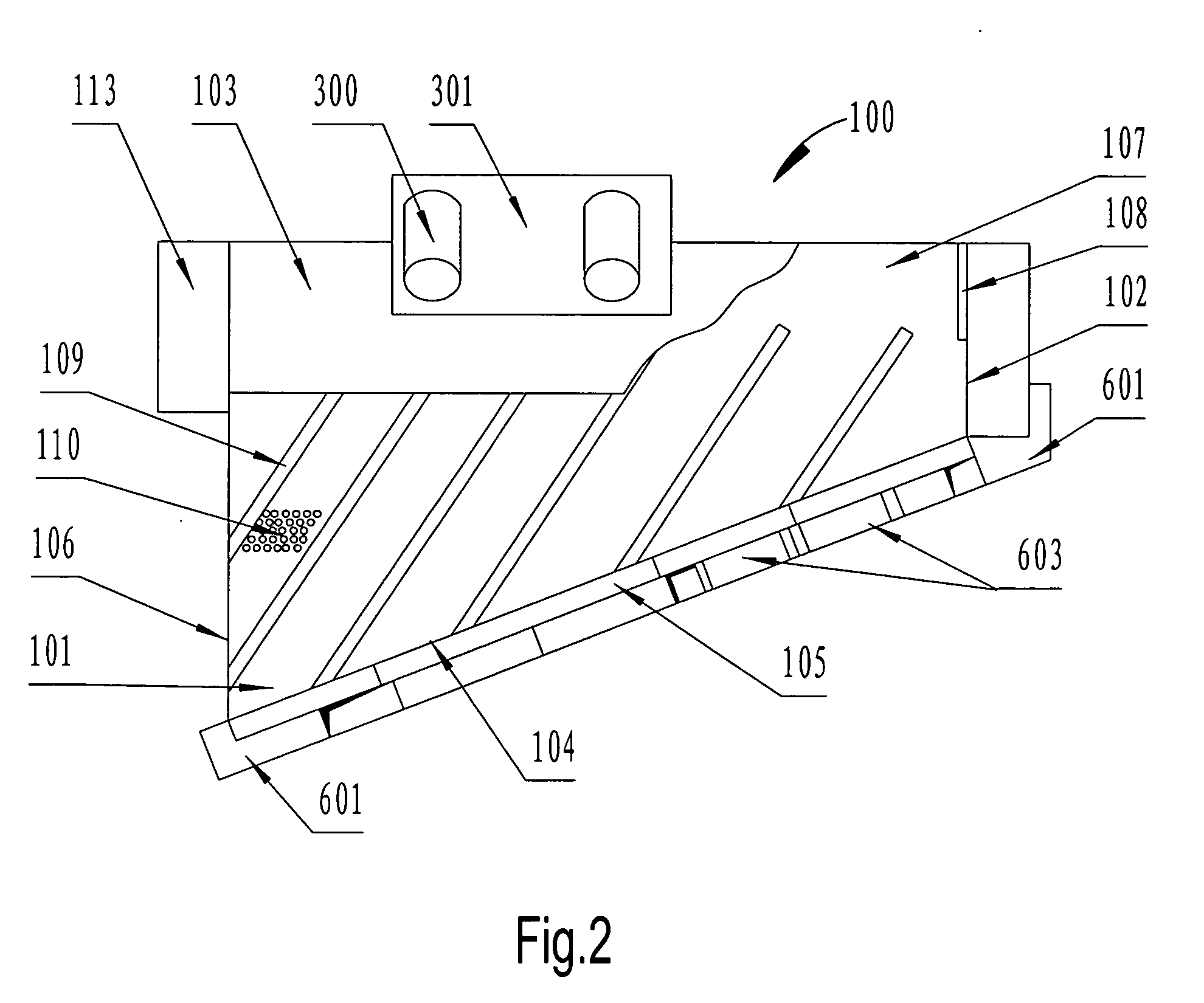

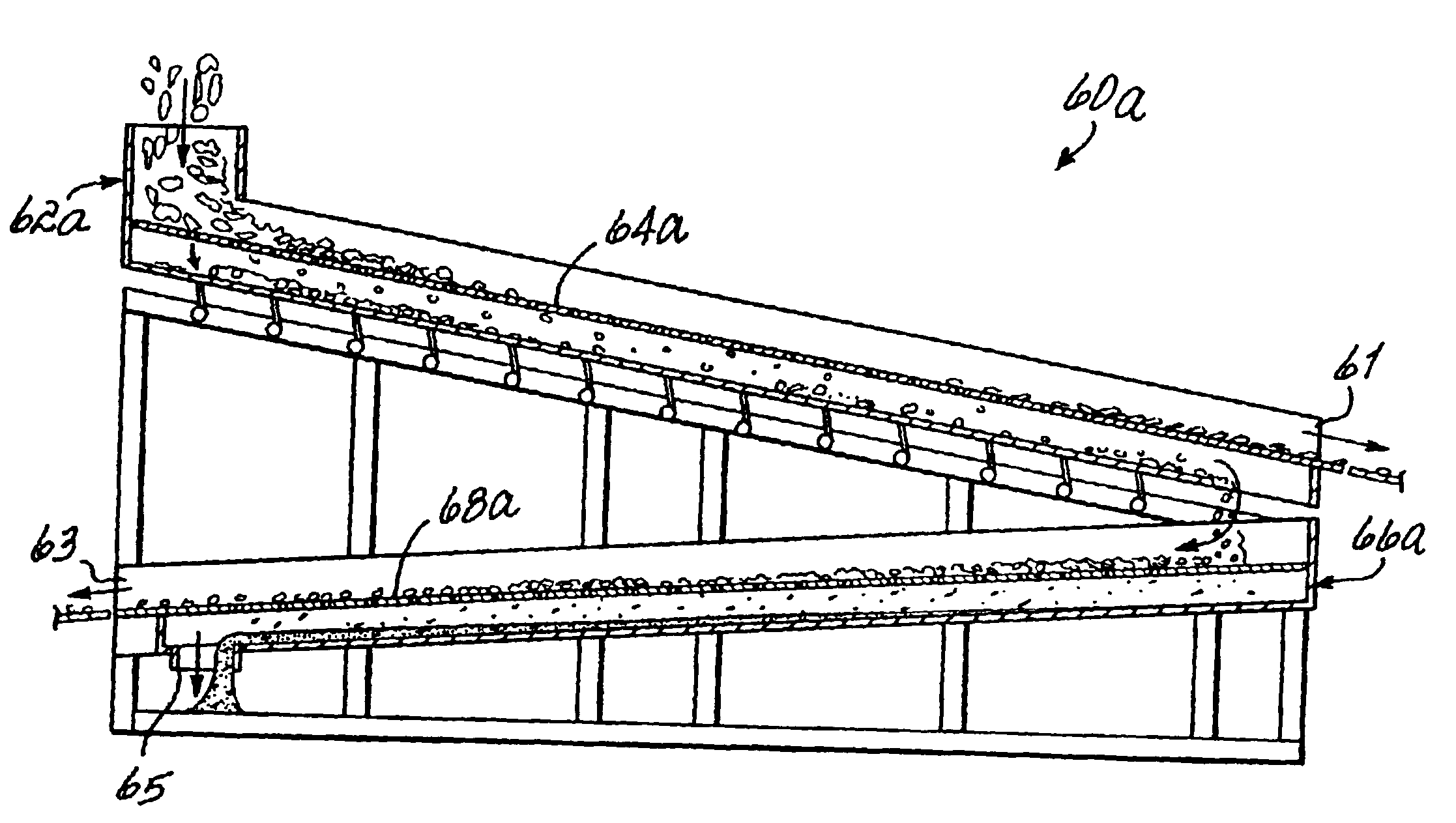

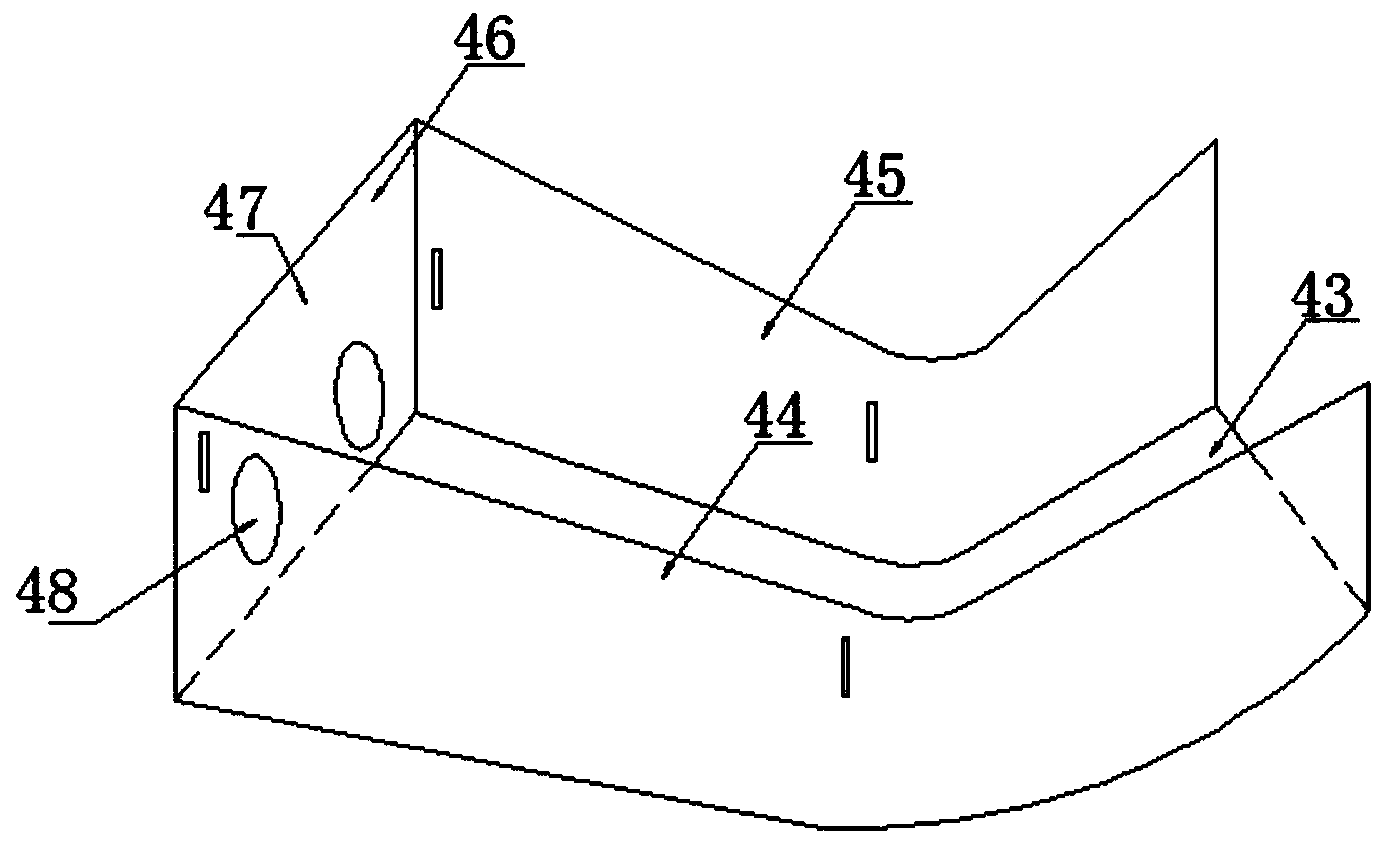

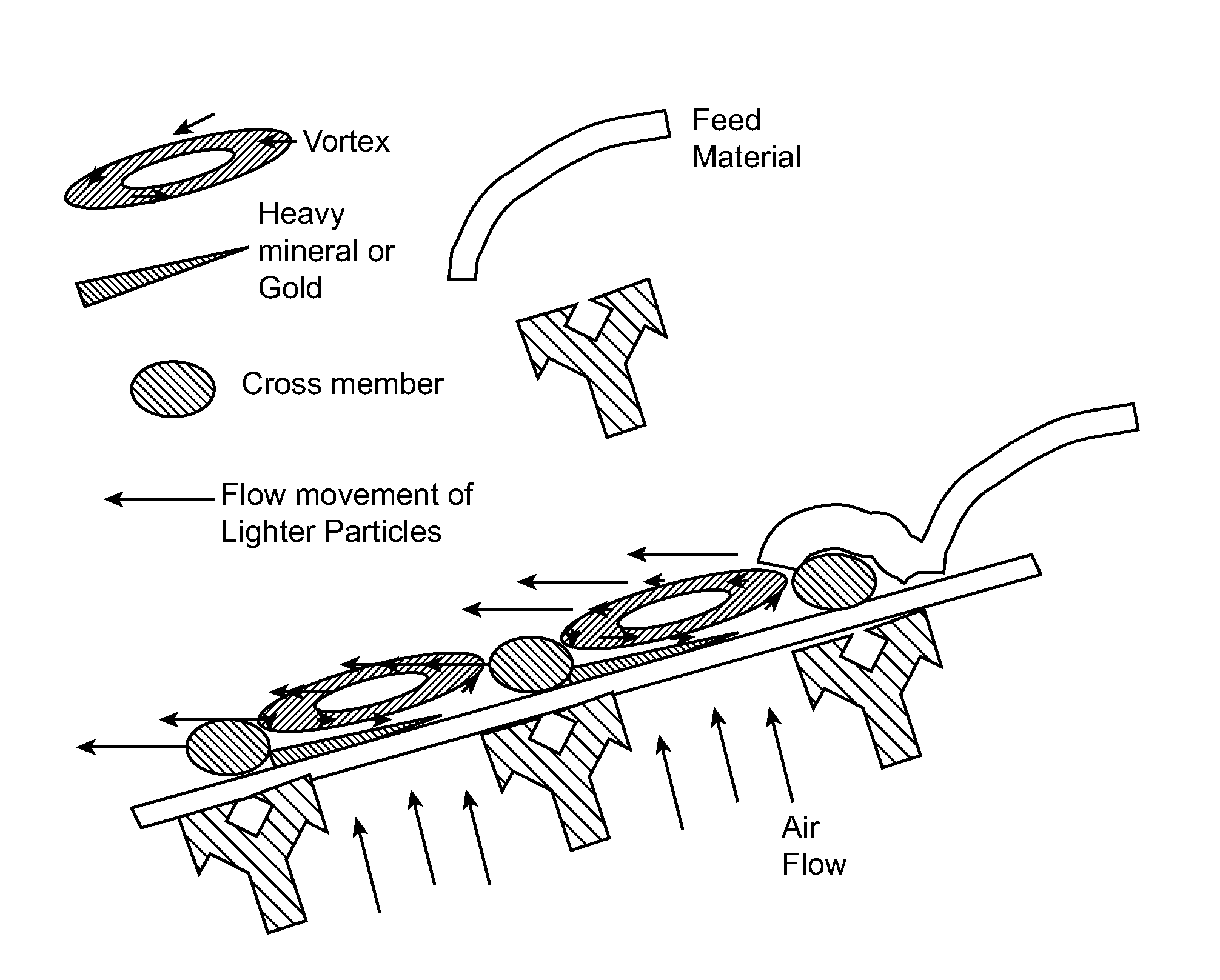

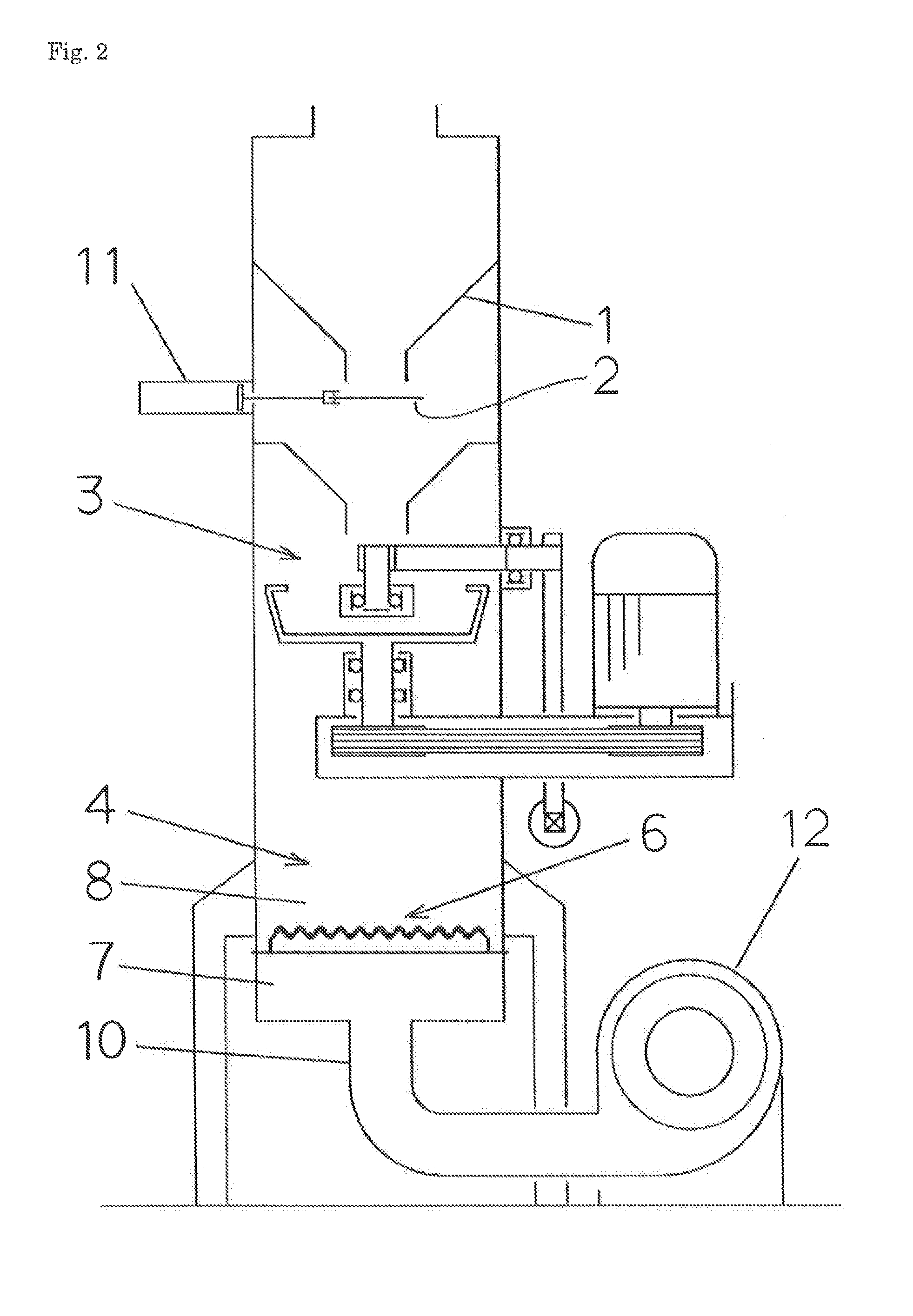

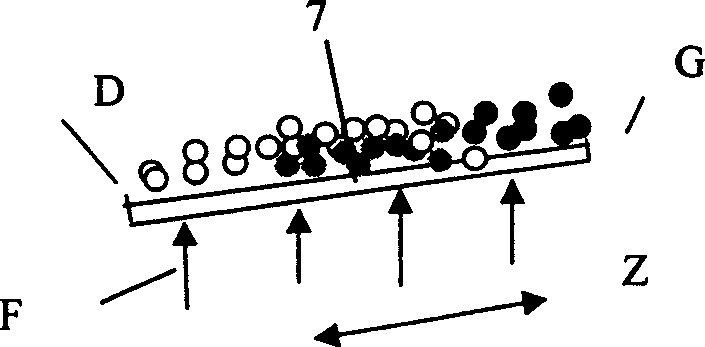

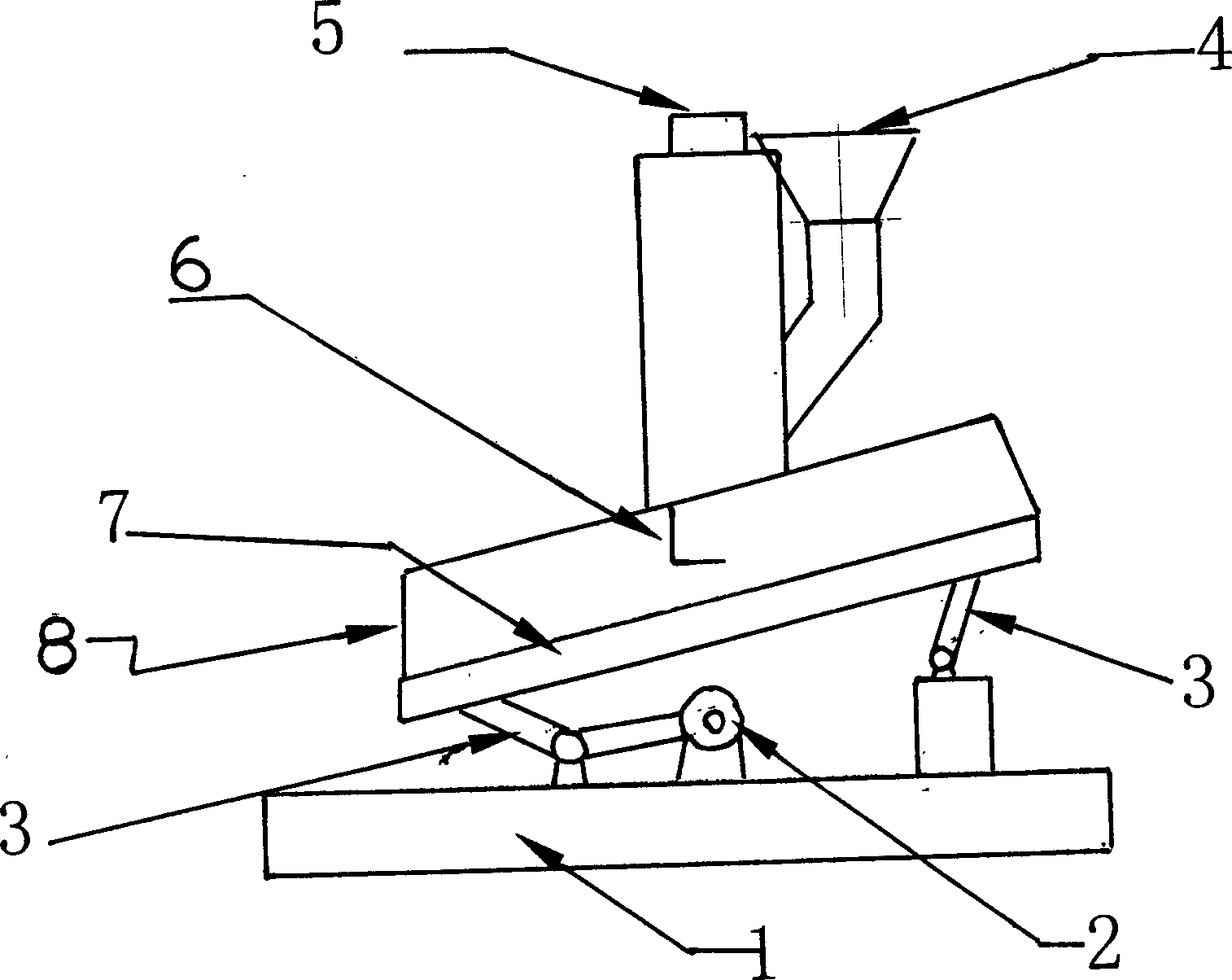

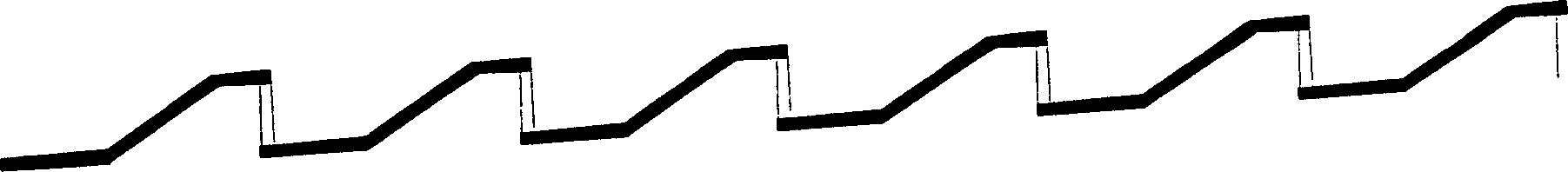

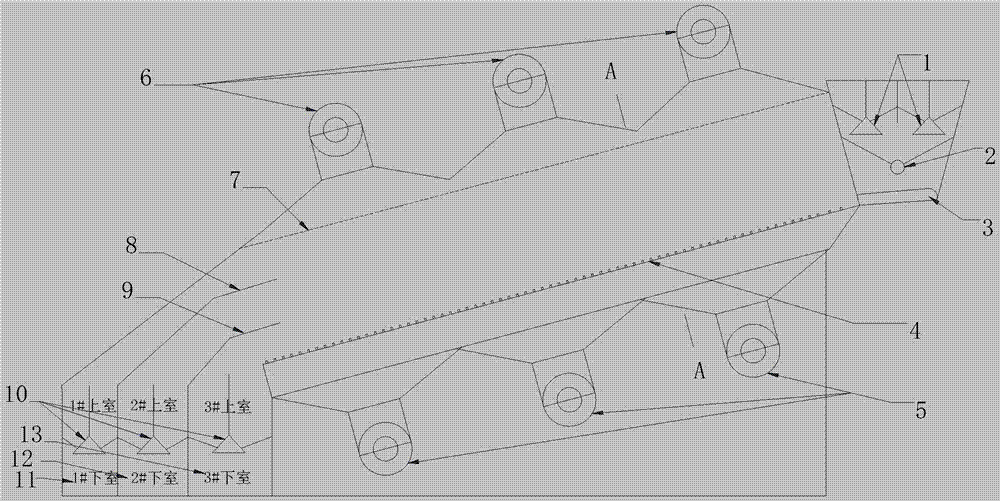

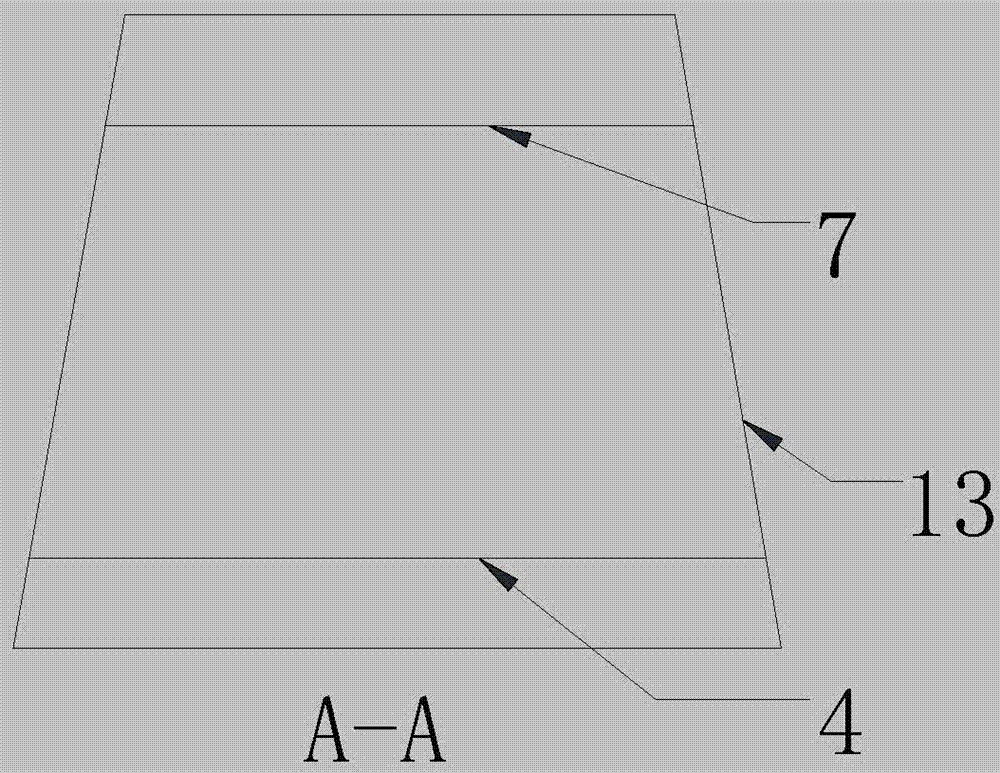

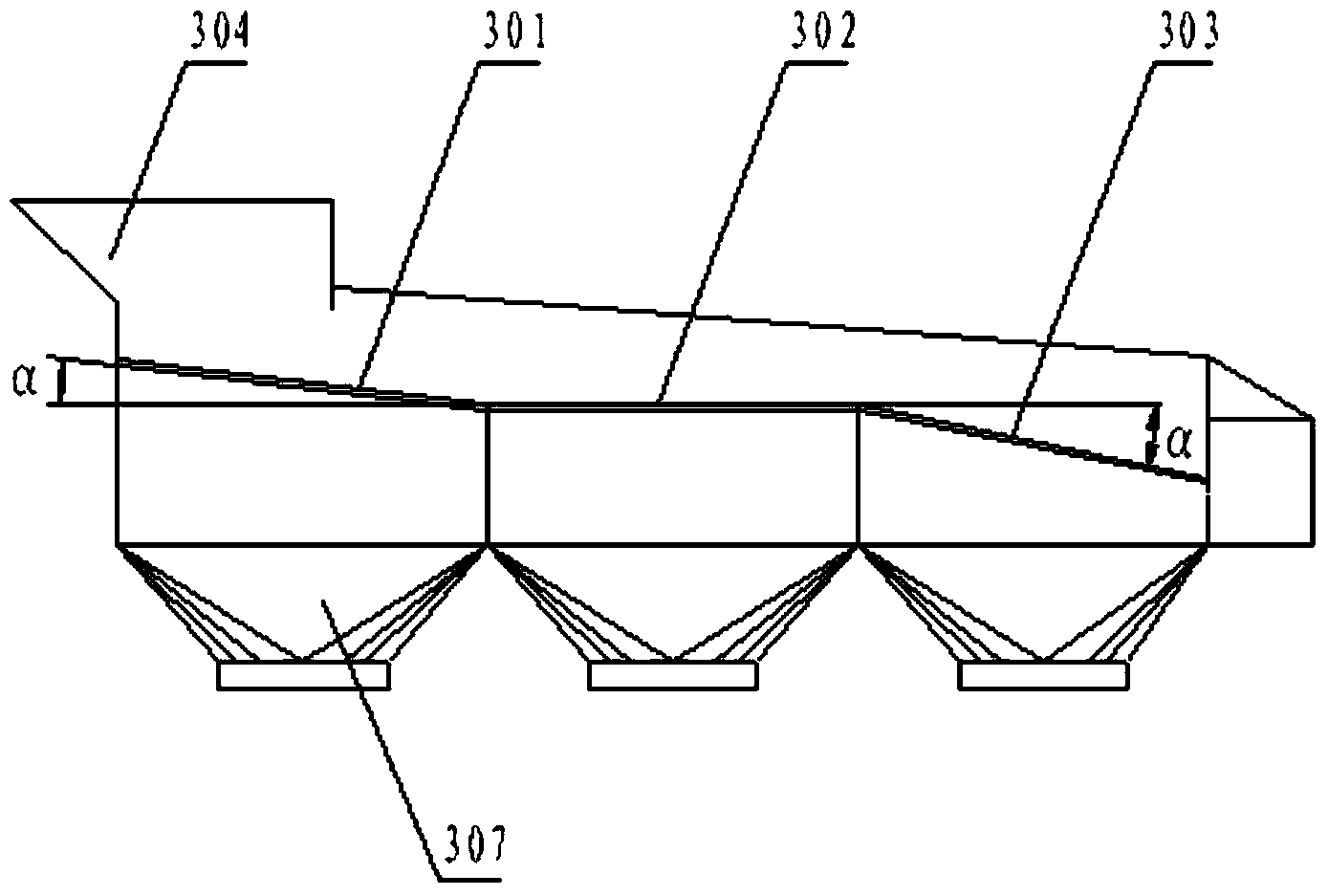

Dry separating table, a separator and equipment for the compound dry separation with this table

The present invention discloses a combined dry sorting bed, the sorting bed is arranged with an inclination, and the inclination between the longitudinal extending of said bed surface and horizontal plane is from −2° to +4°, and the inclination between the lateral extending of said bed surface and horizontal plane is from 0° to +15°. By reasonable setting of the angle of inclination, the material being separated spiral overturn continuously on the sorting bed under the influence of the rising air currents and the force of vibration, with the result that the light material in the upper layer is separated under the influence of weight. The material is sorted for many times during the circularly movements, the product with different content of ash can be obtained. This invention also relates to a combined dry sorting device that comprises frame, sorting bed, vibrator and air supply device. This invention further relates to an apparatus for separation that comprises a feeding device, an air supply and dedusting device and a separating device, the above mentioned sorting bed is used in the sorting device and apparatus, therefore different products with vary quantity of ash are generated according to the gravity of material, and the accuracy of separation is improved.

Owner:TANGSHAN SHENZHOU MFG

Dry separating table, a separator and equipment for the compound dry separation with this table

The present invention discloses a combined dry sorting bed, the sorting bed is arranged with an inclination, and the inclination between the longitudinal extending of said bed surface and horizontal plane is from −2° to +4°, and the inclination between the lateral extending of said bed surface and horizontal plane is from 0° to +15°. By reasonable setting of the angle of inclination, the material being separated spiral overturn continuously on the sorting bed under the influence of the rising air currents and the force of vibration, with the result that the light material in the upper layer is separated under the influence of weight. The material is sorted for many times during the circularly movements, the product with different content of ash can be obtained. This invention also relates to a combined dry sorting device that comprises frame, sorting bed, vibrator and air supply device. This invention further relates to an apparatus for separation that comprises a feeding device, an air supply and dedusting device and a separating device, the above mentioned sorting bed is used in the sorting device and apparatus, therefore different products with vary quantity of ash are generated according to the gravity of material, and the accuracy of separation is improved.

Owner:TANGSHAN SHENZHOU MFG

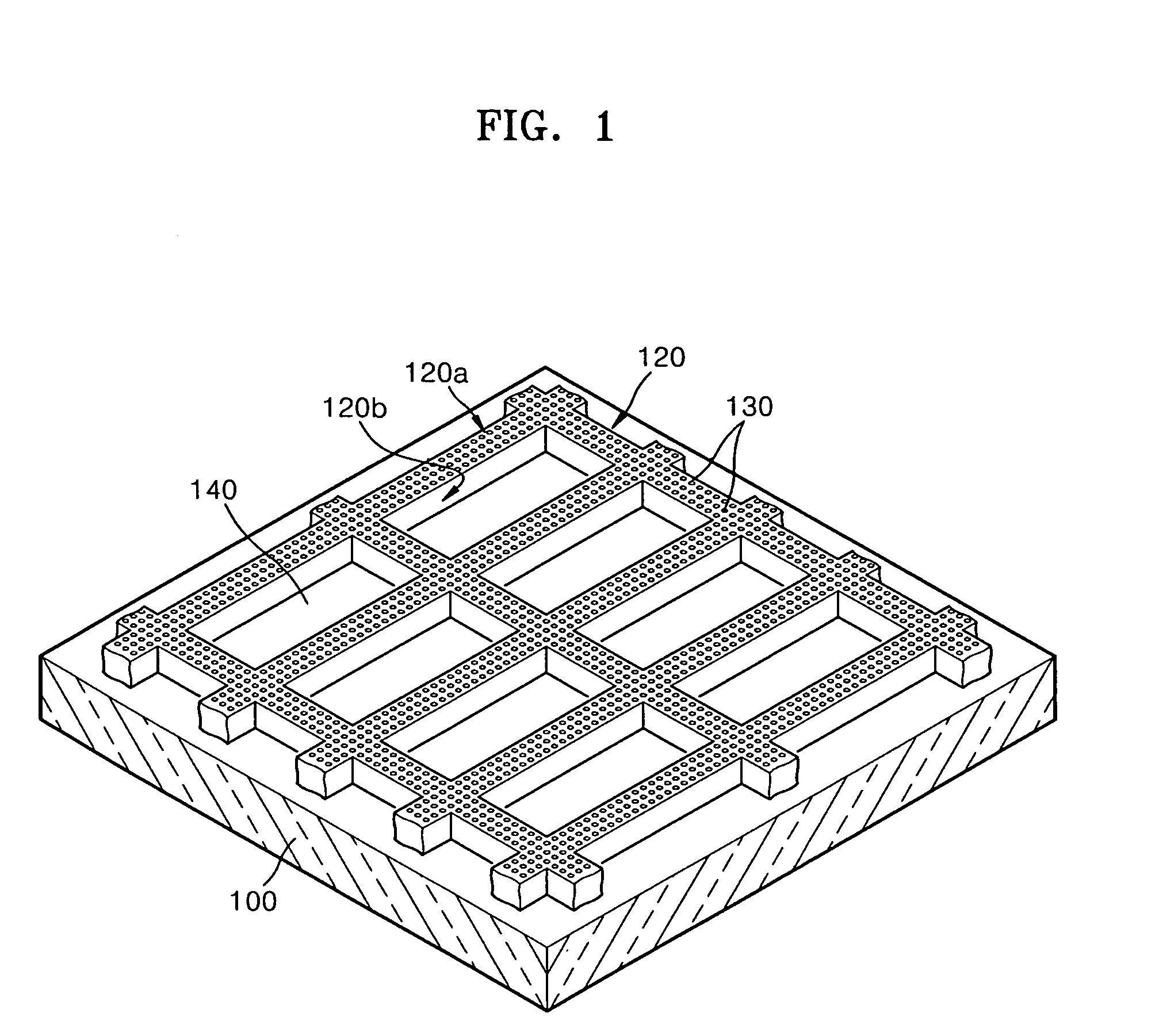

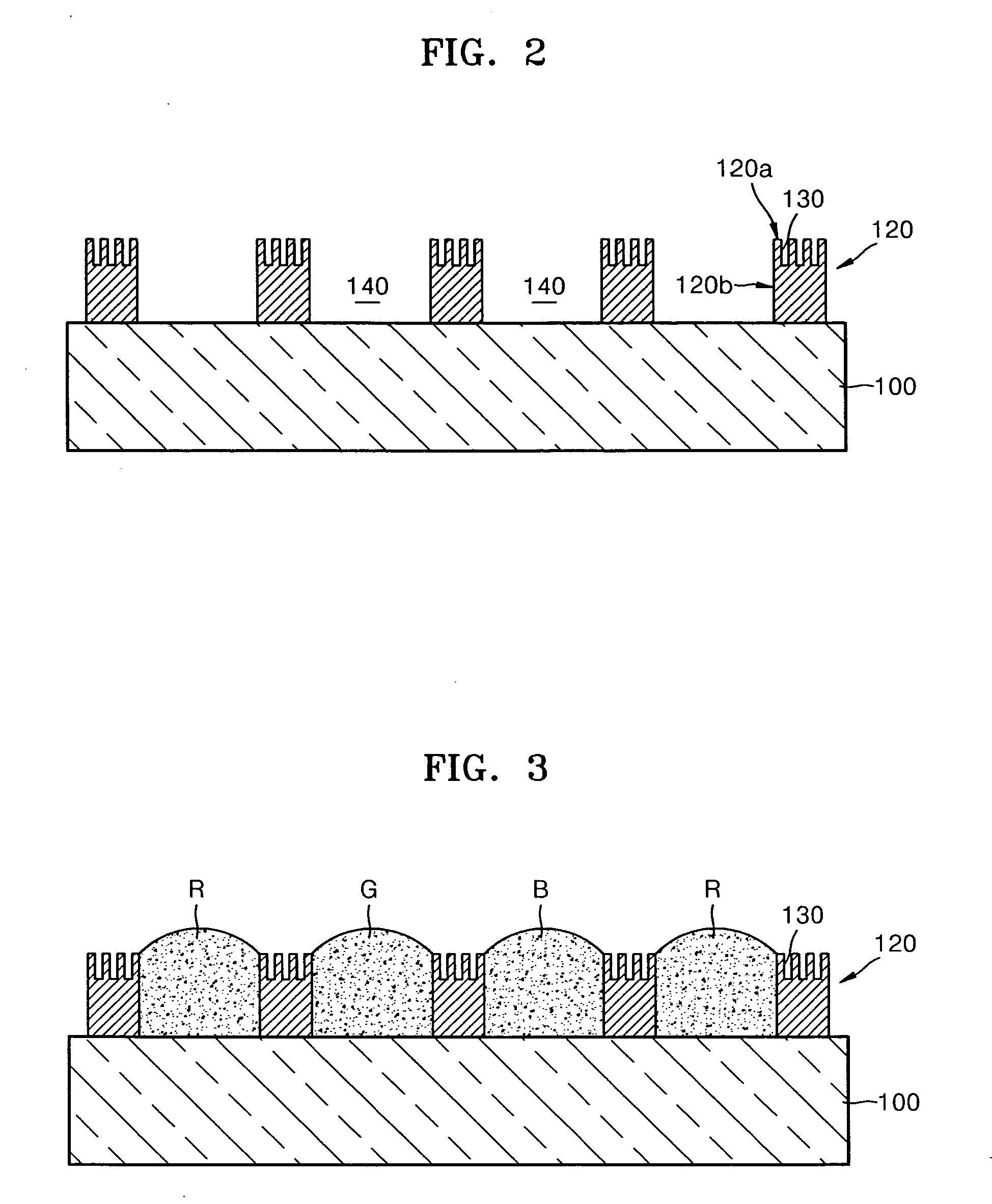

Black matrix of color filter and method of manufacturing the black matrix

InactiveUS20070157839A1Ink mixtureImprove color reproducibilityCathode ray tubes/electron beam tubesFlotationEngineeringNanometre

A black matrix used with color filters and a method of manufacturing the black matrix. The black matrix is formed on a substrate and defines a plurality of pixel regions. The black matrix has an ink-phobic upper surface having a plurality of nano-sized grooves formed therein, and ink-philic lateral surfaces.

Owner:SAMSUNG ELECTRONICS CO LTD

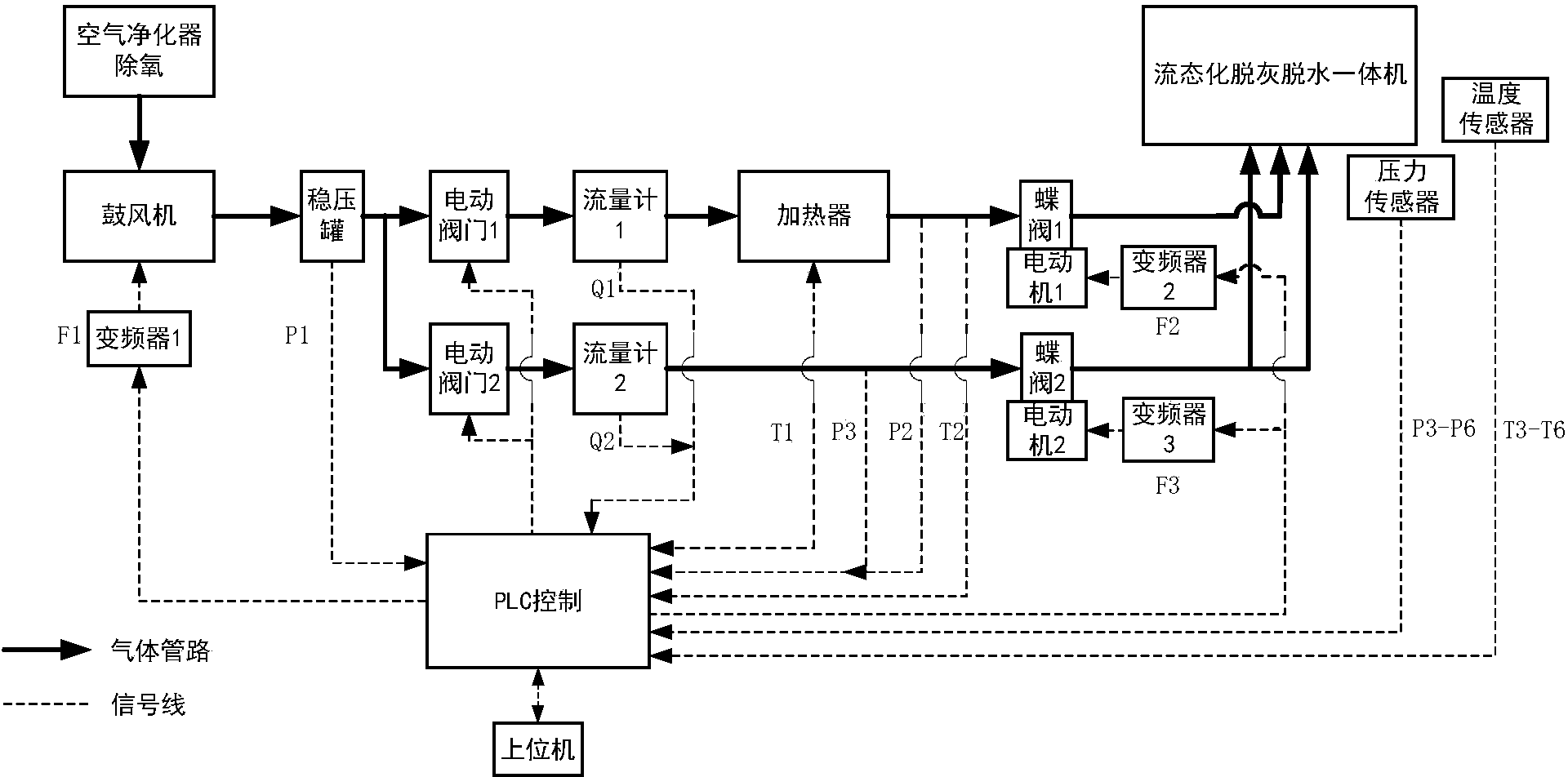

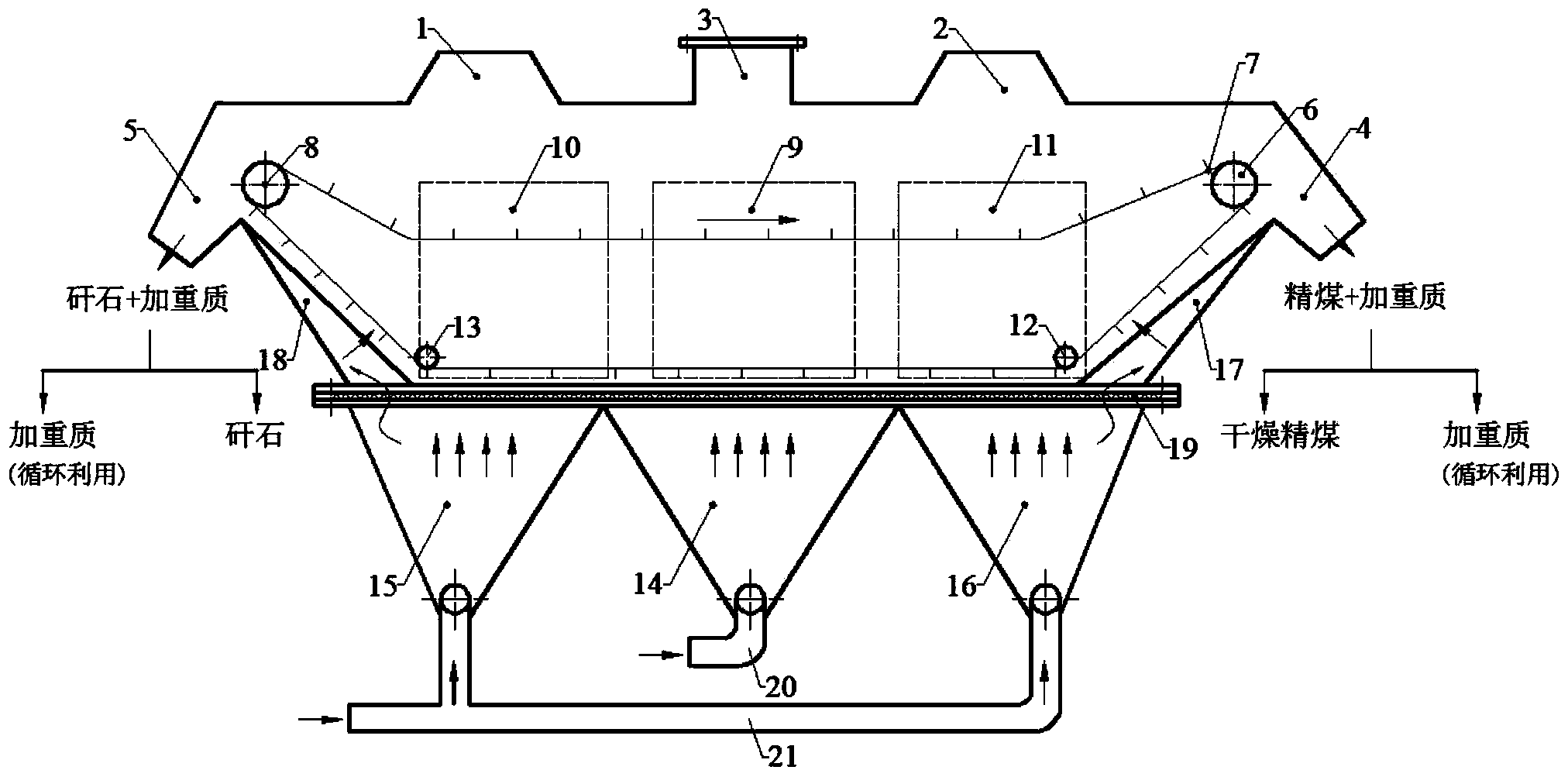

Pulse fluidization-based integrated de-ashing and dehydrating method and equipment of brown coal

ActiveCN103773544AEasy to adjustKeep dryDrying solid materials with heatDrying gas arrangementsBrown coalProgrammable logic controller

The invention provides a pulse fluidization-based integrated de-ashing and dehydrating method and equipment of brown coal, belonging to the integrated de-ashing and dehydrating method and equipment of brown coal. The method comprises the following steps that a pulse air flow generating and controlling system automatically carries out feedback control in real time by a PLC (Programmable Logic Controller) aiming at properties of dried and sorted materials in a sorting bed body and product indexes; in the sorting bed body, the to-be-sorted material first enters into a pulse hot wind drying section to dry and extract mass under the hot wind effect of a large air flow at a higher temperature, materials enter into a pulse cold wind sorting section under the effect of scraper conveyers which are parallely arranged up and down inside, and light and heavy products sorted and layered are respectively conveyed to fine coal and gangue discharge openings of a sorting machine; floats and hypostasis at corresponding discharge openings are respectively discharged through a light product discharge wheel and a heavy product discharge wheel; and at the discharge openings, media in the sorted light and heavy materials are removed and purified and recycled, and dried and sorted vapor and dust containing air is purified and circulated through a subsequent dedusting process.

Owner:CHINA UNIV OF MINING & TECH

Ecological treating method for blast furnace slag containing titanium

InactiveCN1775957ASimple processing methodShort processRecycling and recovery technologiesMagnetic separationSlagFree cooling

The invention relates to biology process method for titanium contained blast furnace slag that the TiO2 is over 16.03% titanium contained as raw material. After crashing, magnetic separation, pulverizing, and baking for 1 hour under the condition of 800 degree centigrade and strong magnetic field of 0.8-4.0, tesla cooling naturally, the ZnO, CeO2, or AgCl could be mixed in it. The invention has simple process, low cost and could be used in kinds of fields.

Owner:NORTHEASTERN UNIV

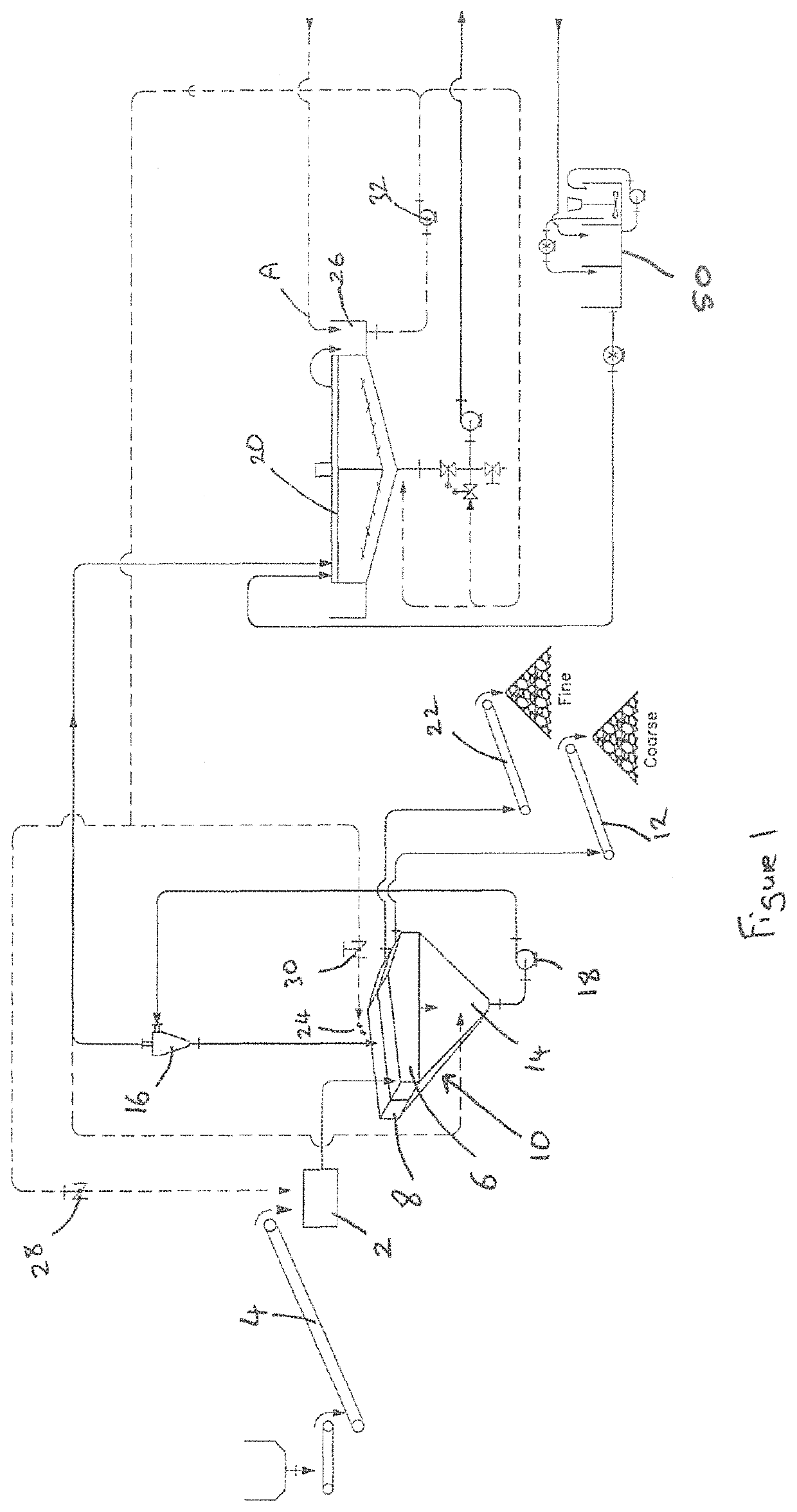

Method and apparatus for washing and grading sand

An apparatus for washing and grading sand includes a first vibrating screen having a deck arranged to receive a feed material. Oversize material passes over the deck of the first vibrating screen for collection as a first product, and undersize material and water are collected in a sump of the first vibrating screen before being pumped to a hydrocyclone. A second vibrating screen receives an underflow from the hydrocyclone upon a deck thereof, with oversize material passing over the deck of the second vibrating screen for collection as a second product. An overflow from the hydrocyclone passes into a settling tank, and a water storage reservoir receives water overflowing from the settling tank while sludge is collected and removed from a lower end of the settling tank. Water is passed from the water storage reservoir to the first and second vibrating screens to wash and fluidise material thereon.

Owner:CDE GLOBAL

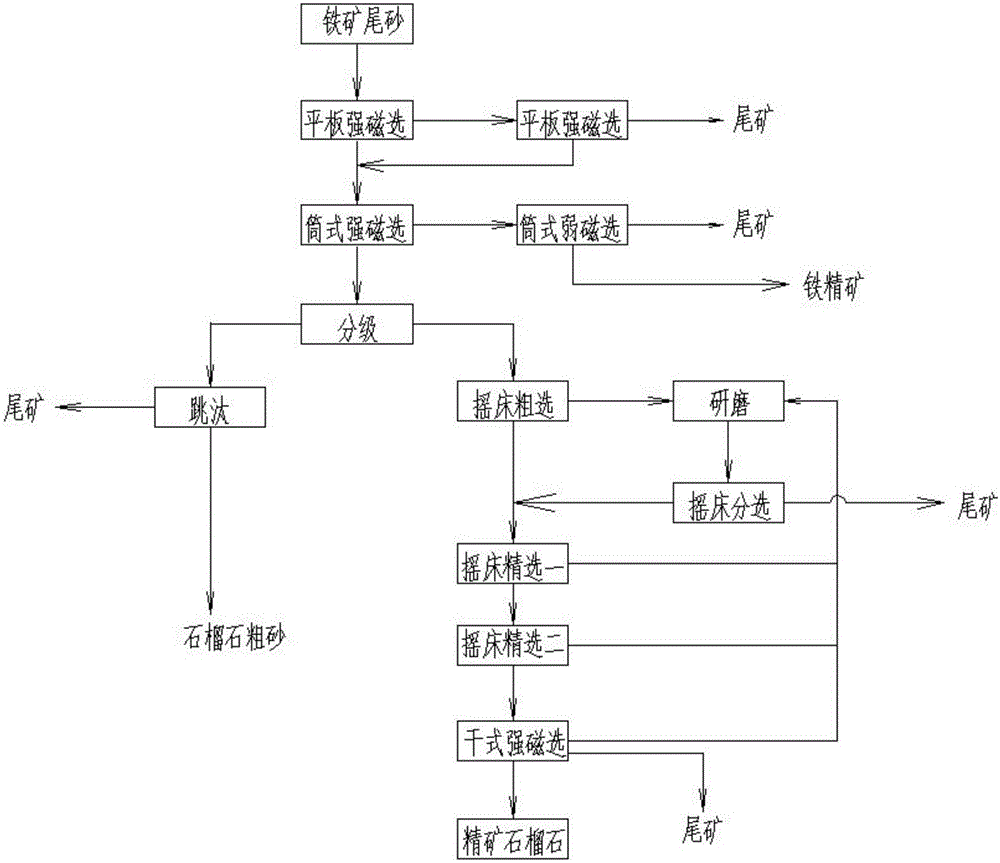

Separation and purification method for garnets of iron ore tailings and product of method

ActiveCN106000627AReduce the difficulty of separation and purificationLong-term retention of characteristicsSievingScreeningPurification methodsMagnetization

Owner:河源紫金天宏科技有限公司

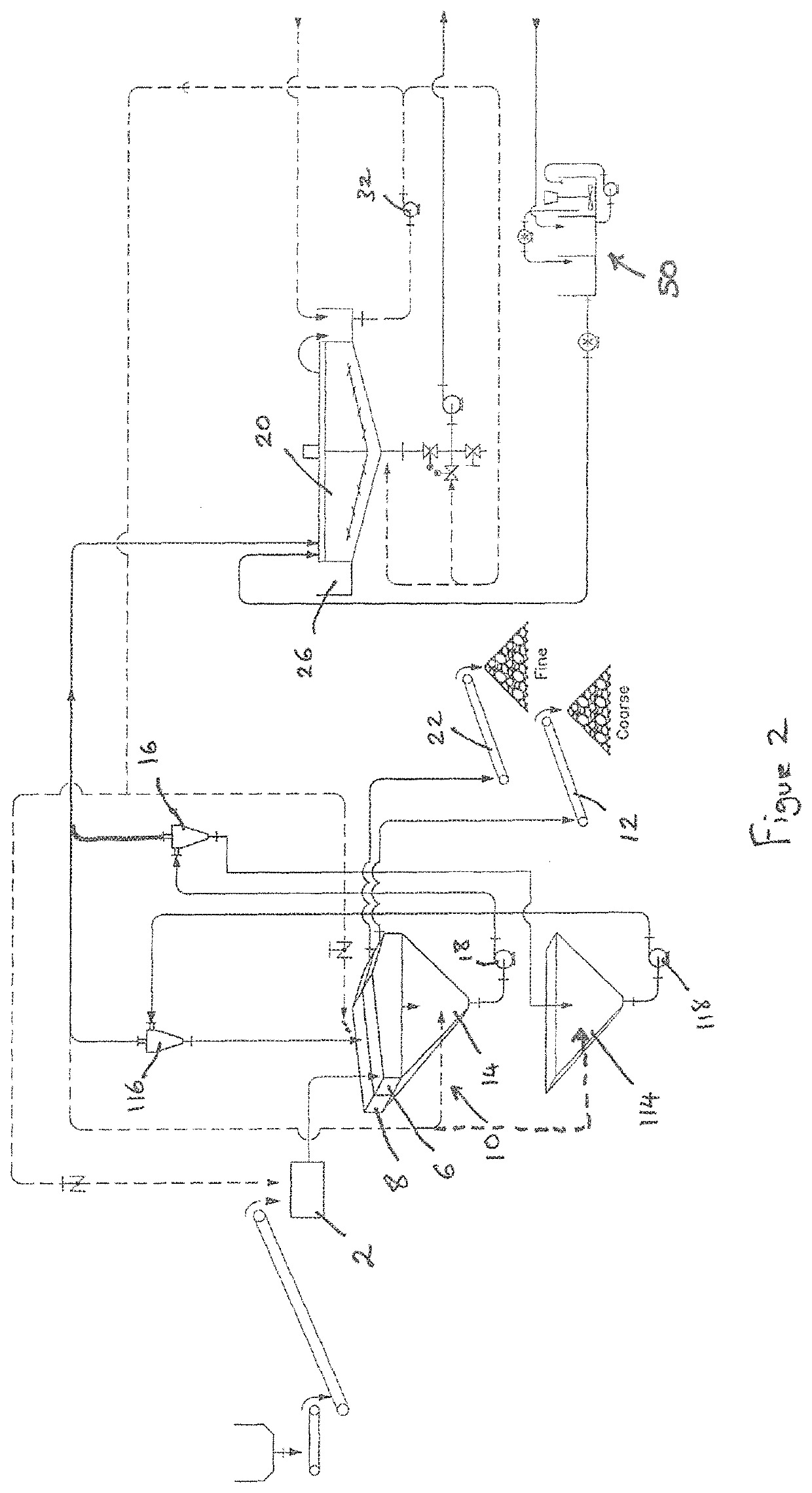

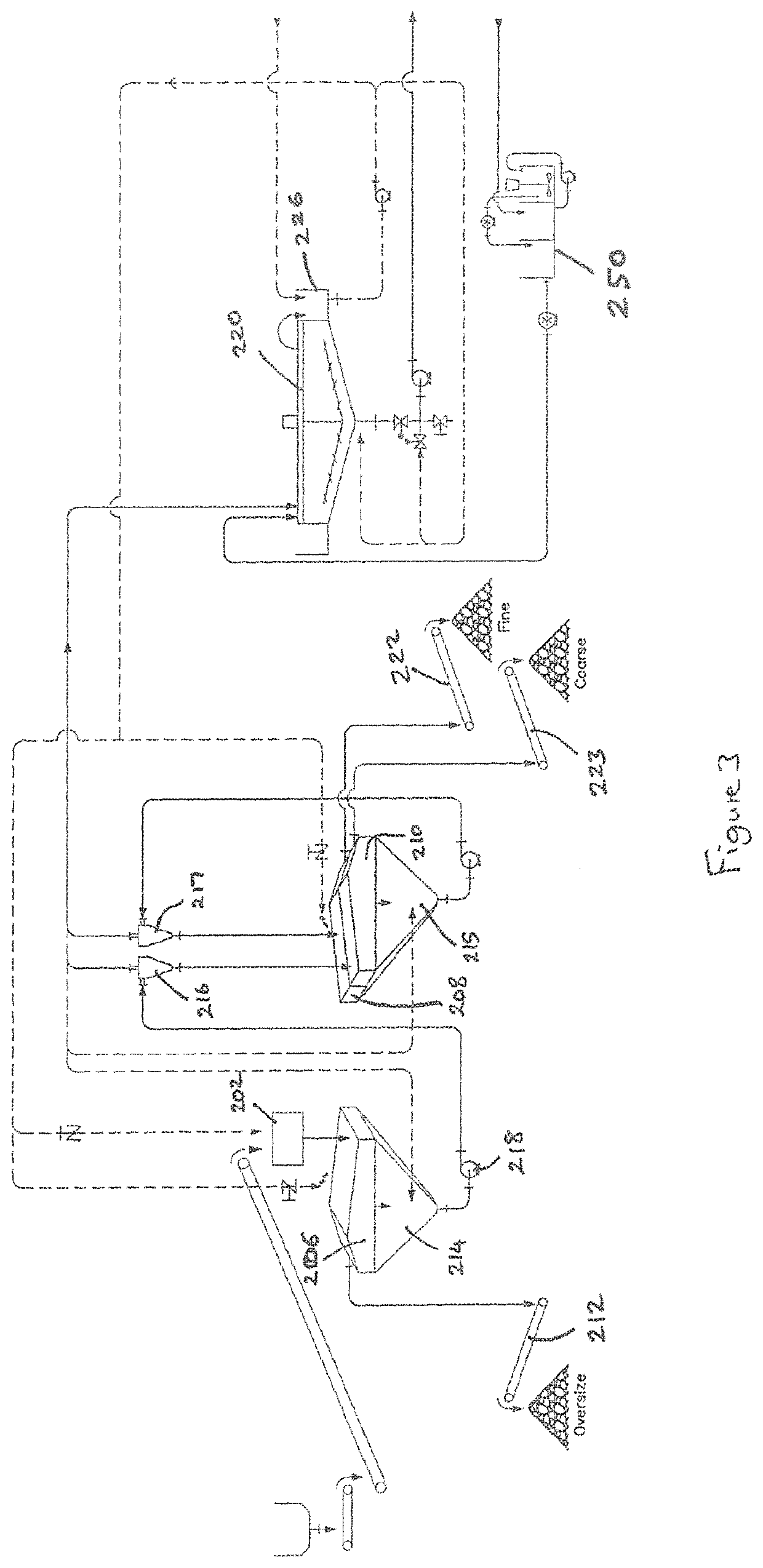

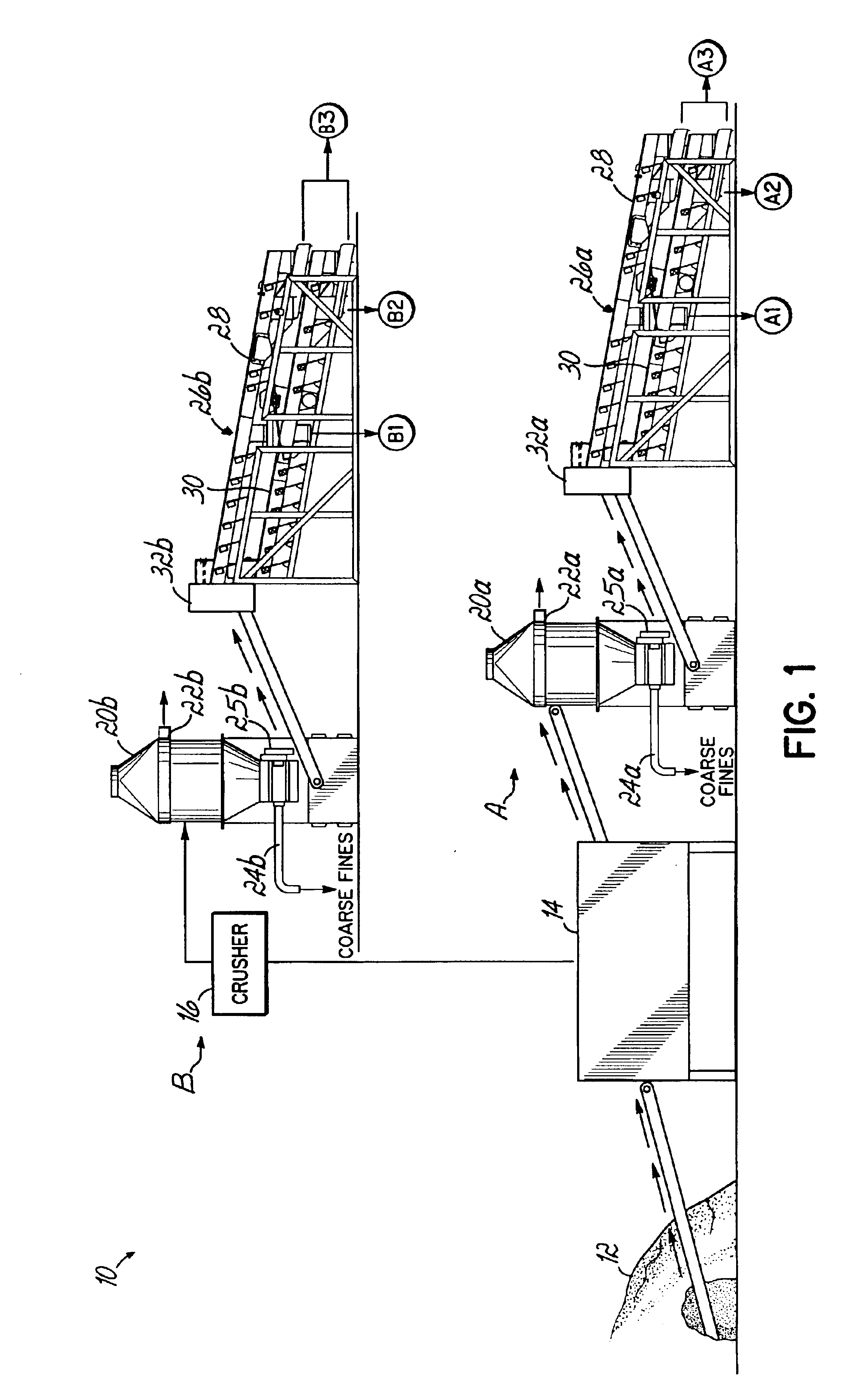

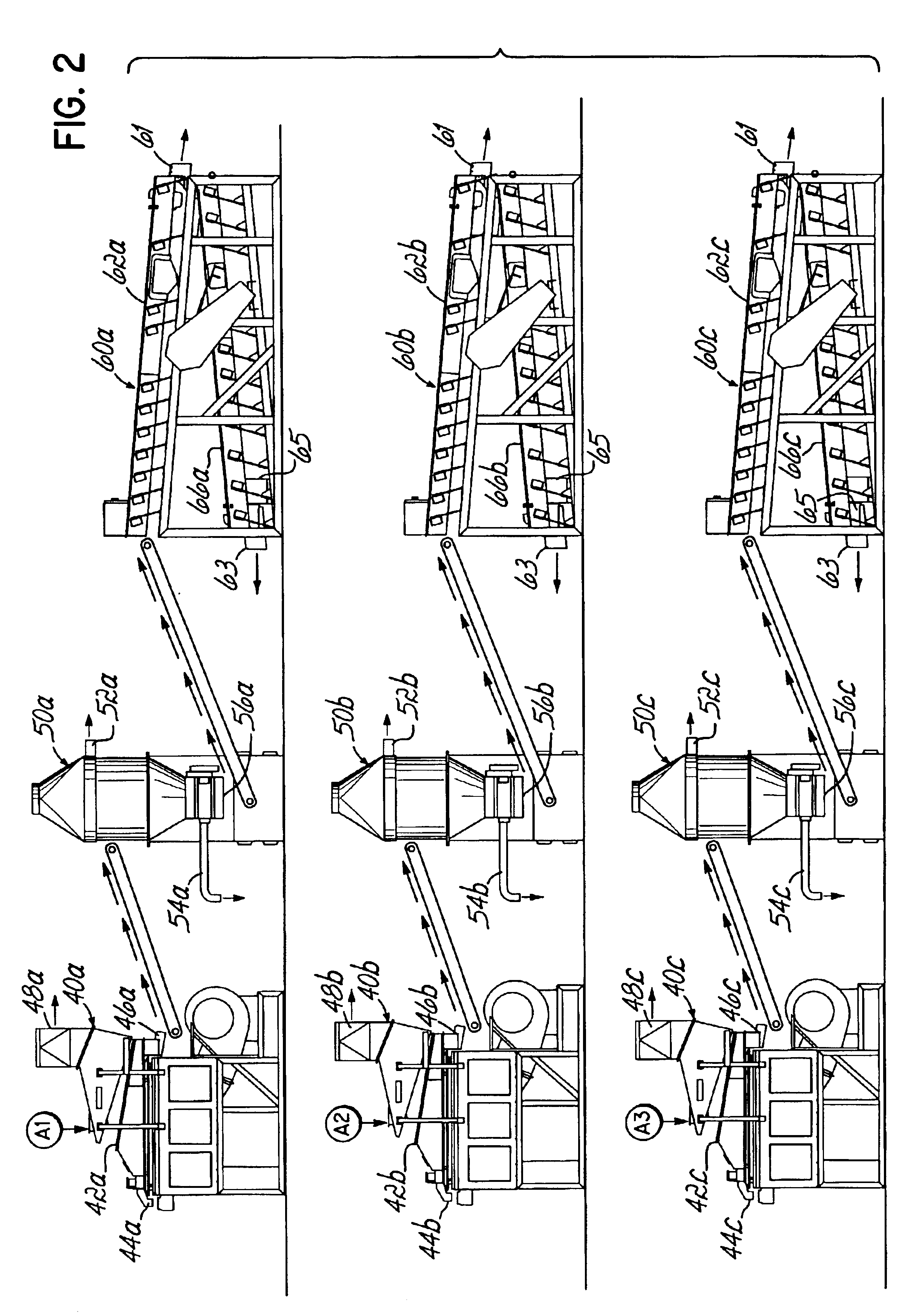

Apparatus and method for dry beneficiation of coal

A method of beneficiating coal in a dry process includes separating raw coal from a coal mine into coal fines and larger pieces of coal using pressurized air, separating the larger pieces of coal according to size, removing ash from the larger pieces of coal on an air table, and further removing ash from the larger pieces of coal using a size-discriminating device to obtain a beneficiated coal product. The invention also includes an apparatus for the dry beneficiation of coal. The apparatus includes at least one air separating device, at least one air table, and at least one first and second shakers which separate the coal by size and remove ash from the coal. The air table effectively removes ash from infed coal without the need for a fluidizing media.

Owner:LEWIS M CARTER MFG

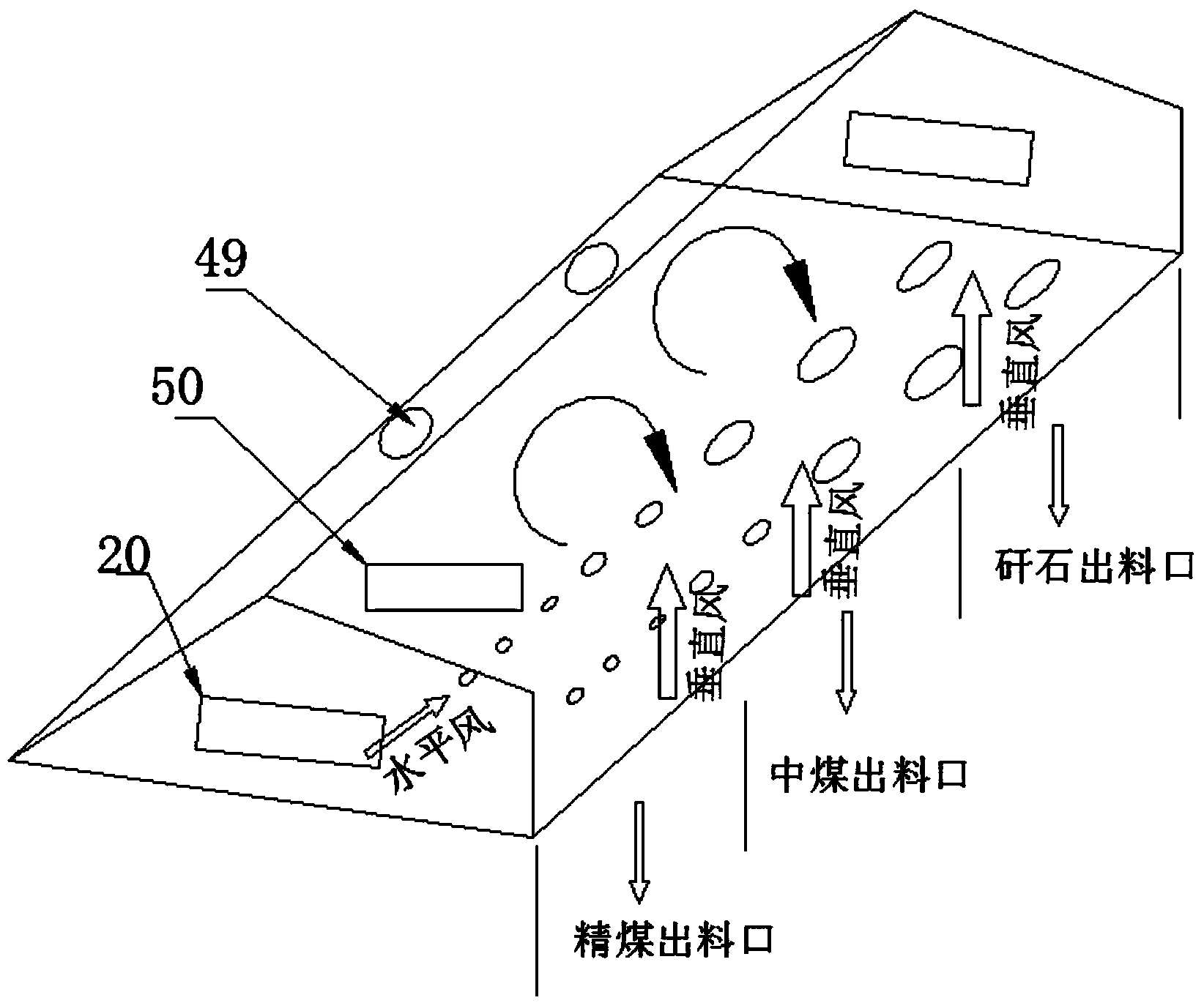

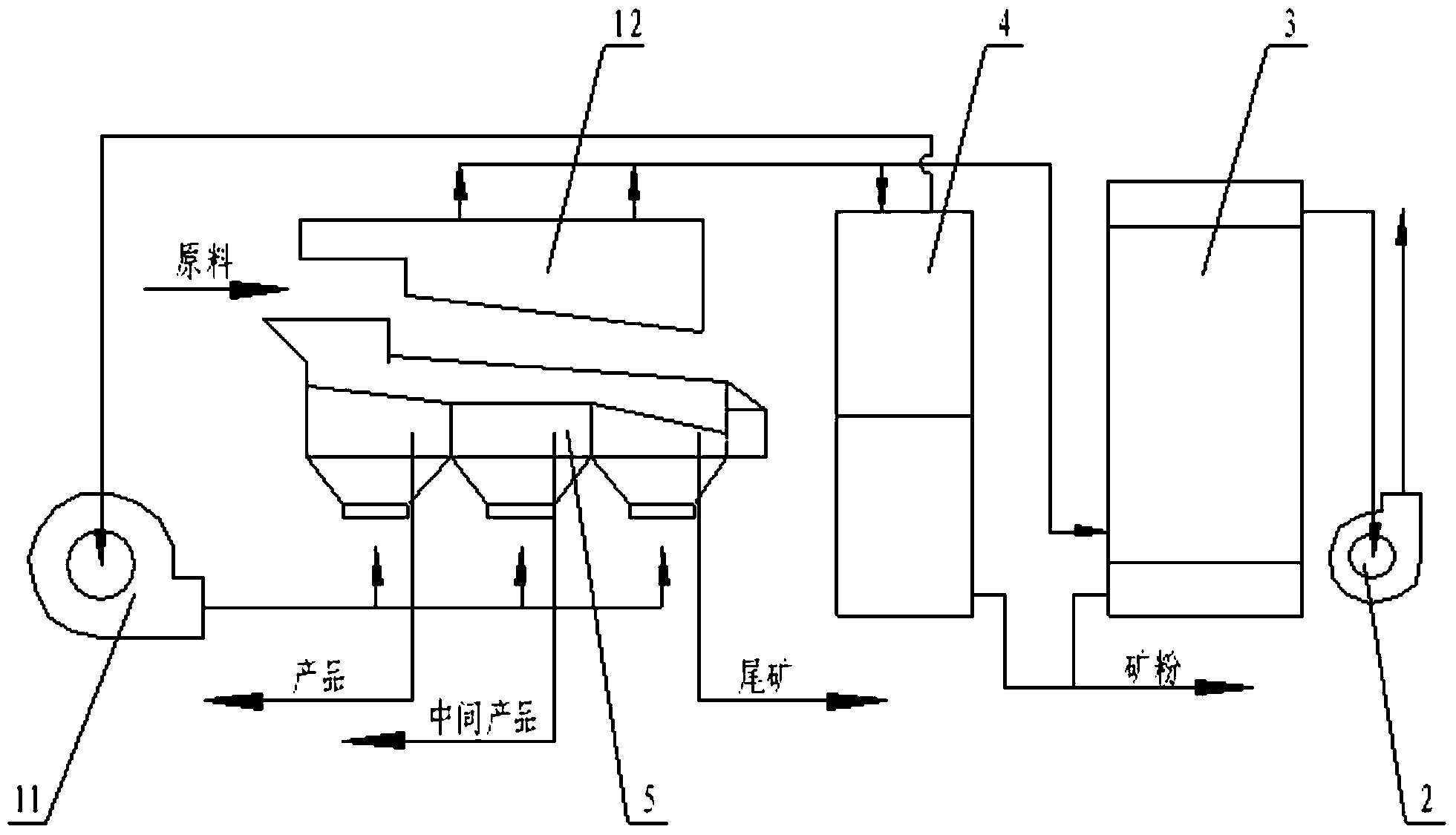

Multistage combined type dry method coal dressing system and method

InactiveCN104138797ARealize multi-level sortingHigh precisionSingle direction vortexPneumatic tablesFlueHeat distribution

The invention provides a multistage combined type dry method coal dressing system and method. In a traditional combined type dry method coal dressing system combined type dry method vertical sorting machine, a vertical sorting bed material feeding elevator connected to be below the middings discharging hole of a combined type dry method horizontal sorting machine is connected with the combined type dry method horizontal sorting machine to realize the vertical sorting of the middings from the combined type dry method horizontal sorting machine; the combined type dry method horizontal sorting machine and the combined type dry method vertical sorting machine are combined to realize multistage sorting so as to improve a coal dressing precision and a production rate and simultaneously improve a coal dressing yield; a horizontal air flue is arranged on a horizontal sorting bed, so that a sorting lower limit is eliminated. According to a heat distribution pipeline, high-temperature smoke generated by a combustion furnace is transported to each piece of sorting equipment in a whole sorting process, the on-line drying of sorted materials and the circular drying of a whole system are formed, all-weather dry method sorting production is guaranteed, and the sorting efficiency and yield are improved.

Owner:SHAANXI GELIEFULAI ENTERPRISE DEV CO LTD

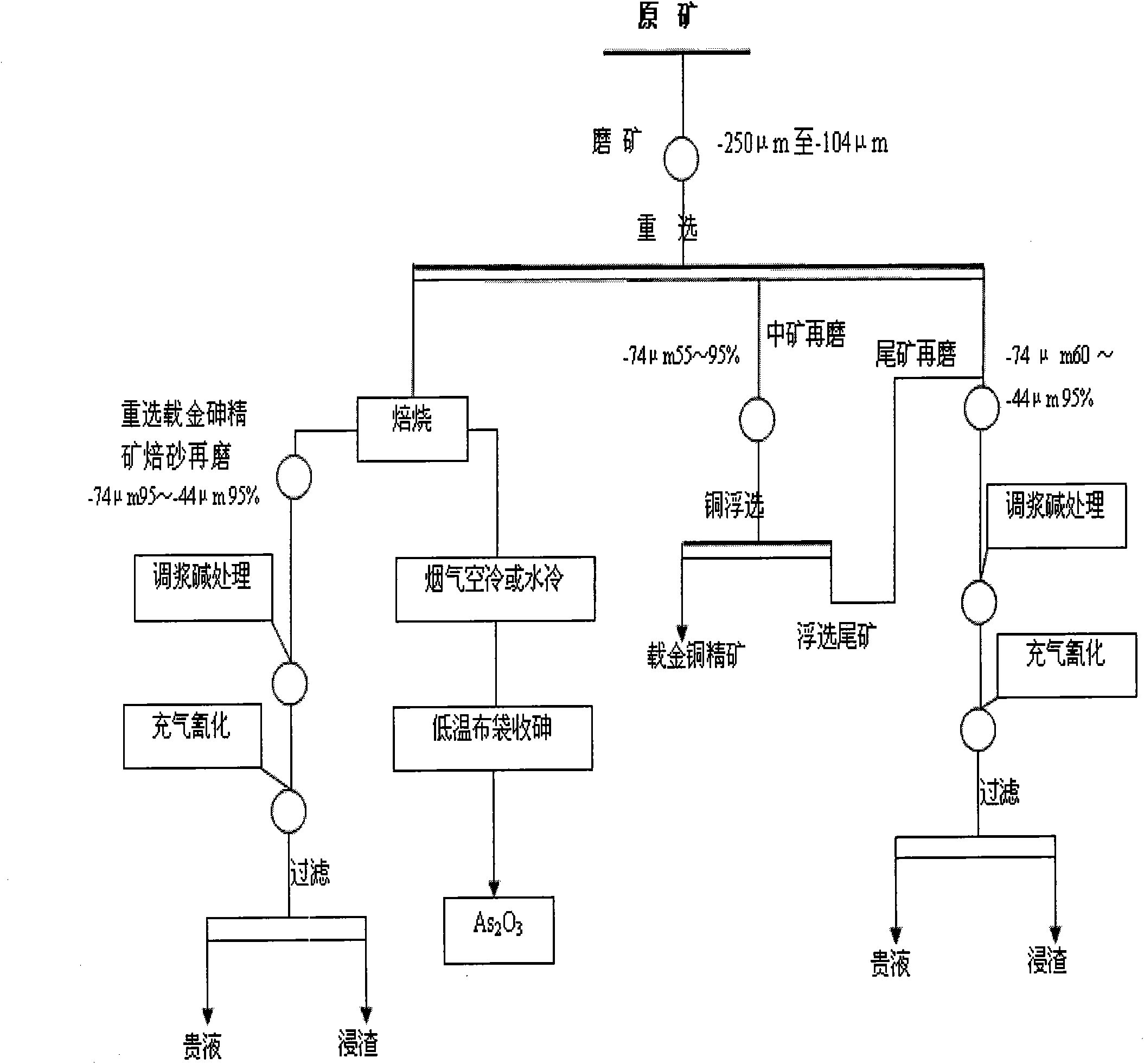

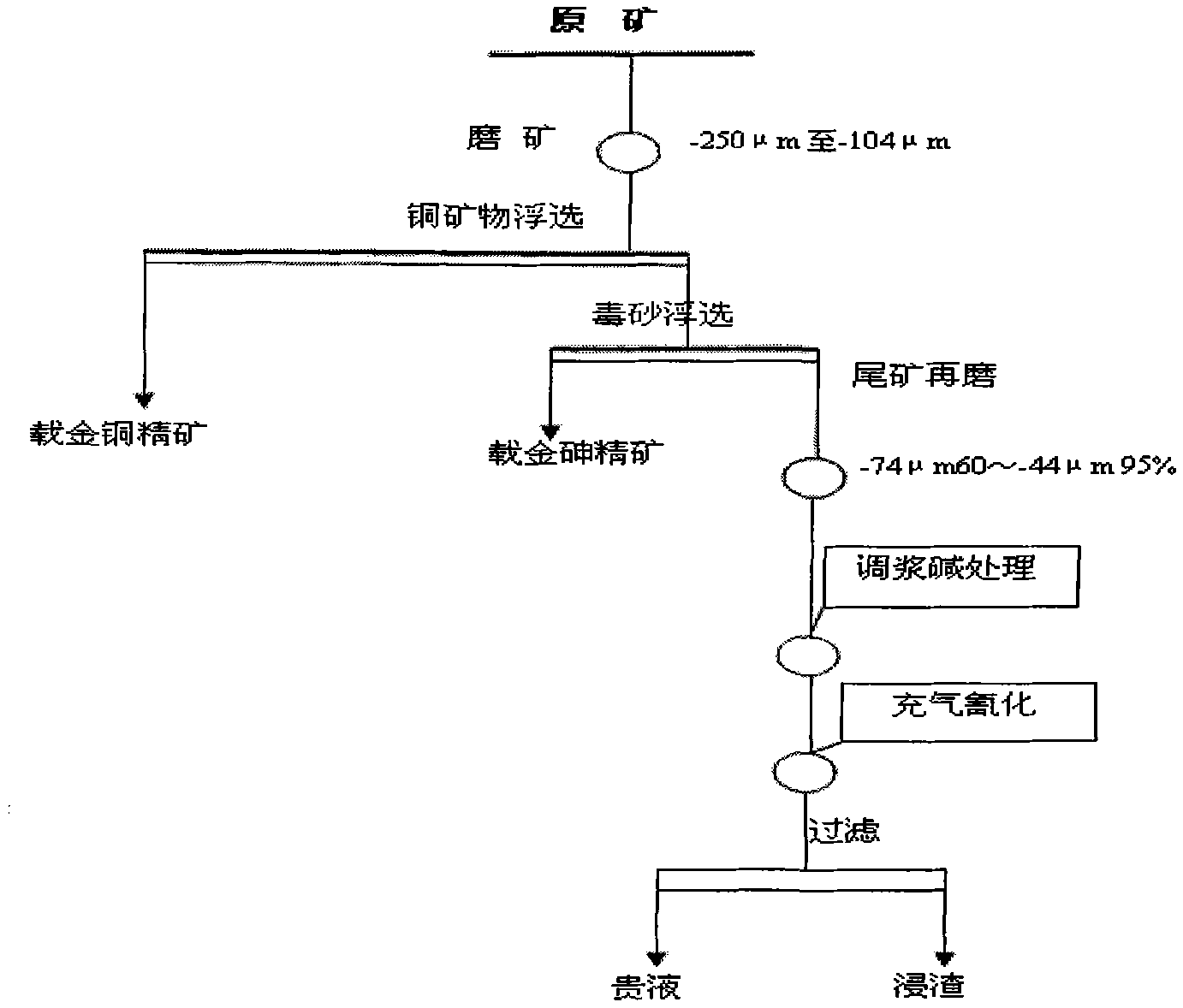

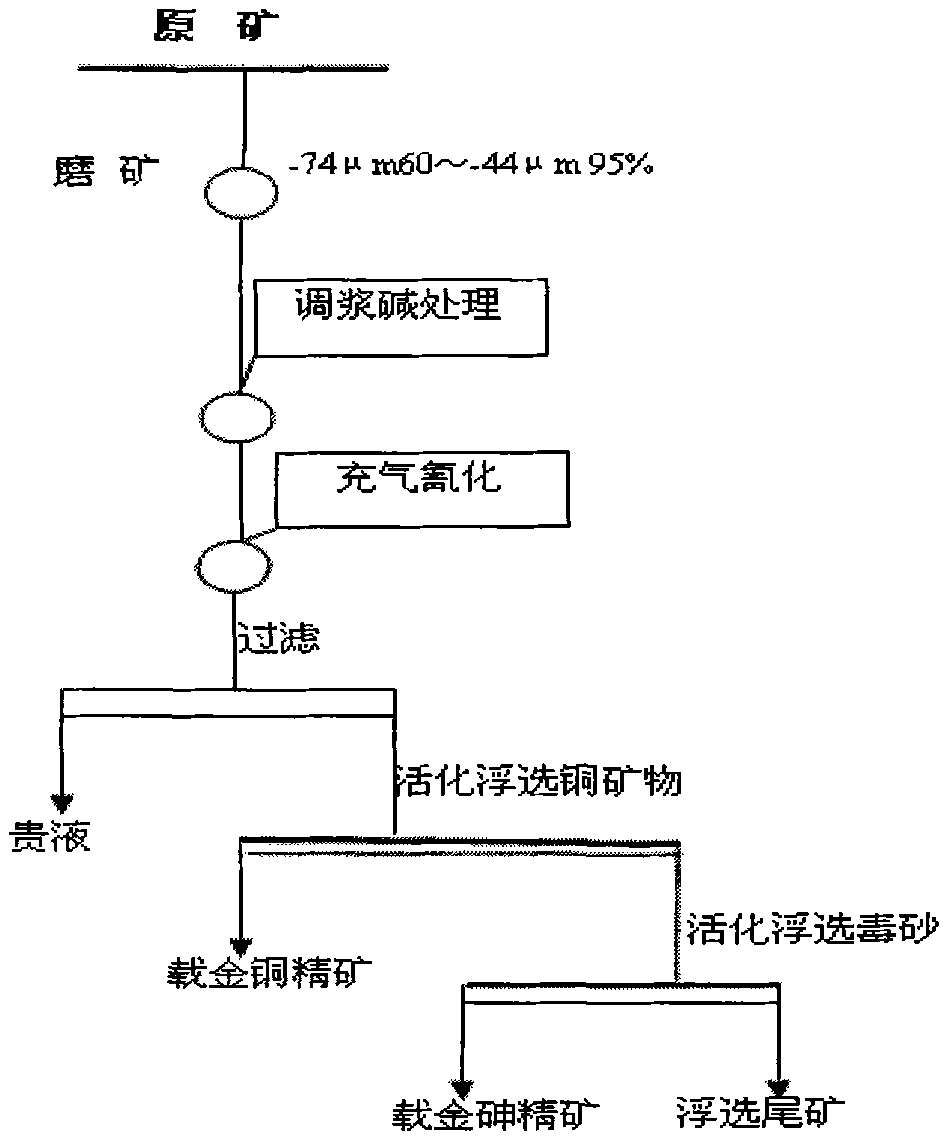

Process for processing complex gold ore containing copper and arsenic

InactiveCN102373337AEasy to recycleImprove technical indicatorsFlotationProcess efficiency improvementMaterials scienceMonomer

The invention relates to a process for processing a complex gold ore containing copper and arsenic. The complex gold ore containing copper and arsenic is processed by combining the steps of reselecting, floating, cyaniding and leaching, calcinating arsenic ore concentrate. The process of the invention comprises the following steps: grinding the raw ore to certain granularity, by using the specific gravity difference of mispickel, copper sulphide and gold, separating mispickel and coarse monomer gold with high specific gravity (gold loading or gold unloading) by using reselection, enriching middling by using flotation to obtain (gold loading or gold unloading) copper concentrate, leaching tailing (if gold-loading gangue ) by cyaniding and stirring to extract fine particle gold in gangue, reselecting arsenic concentrate to calcinate, recovering As2O3 by using low temperature cloth bag arsenic collection technology through air cooling or water cooling, and leaching calcine (if gold-loading calcine) by stirring and cyaniding. The process of the invention has simple device, obtains high technical index, and provides good economic benefit to mine.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

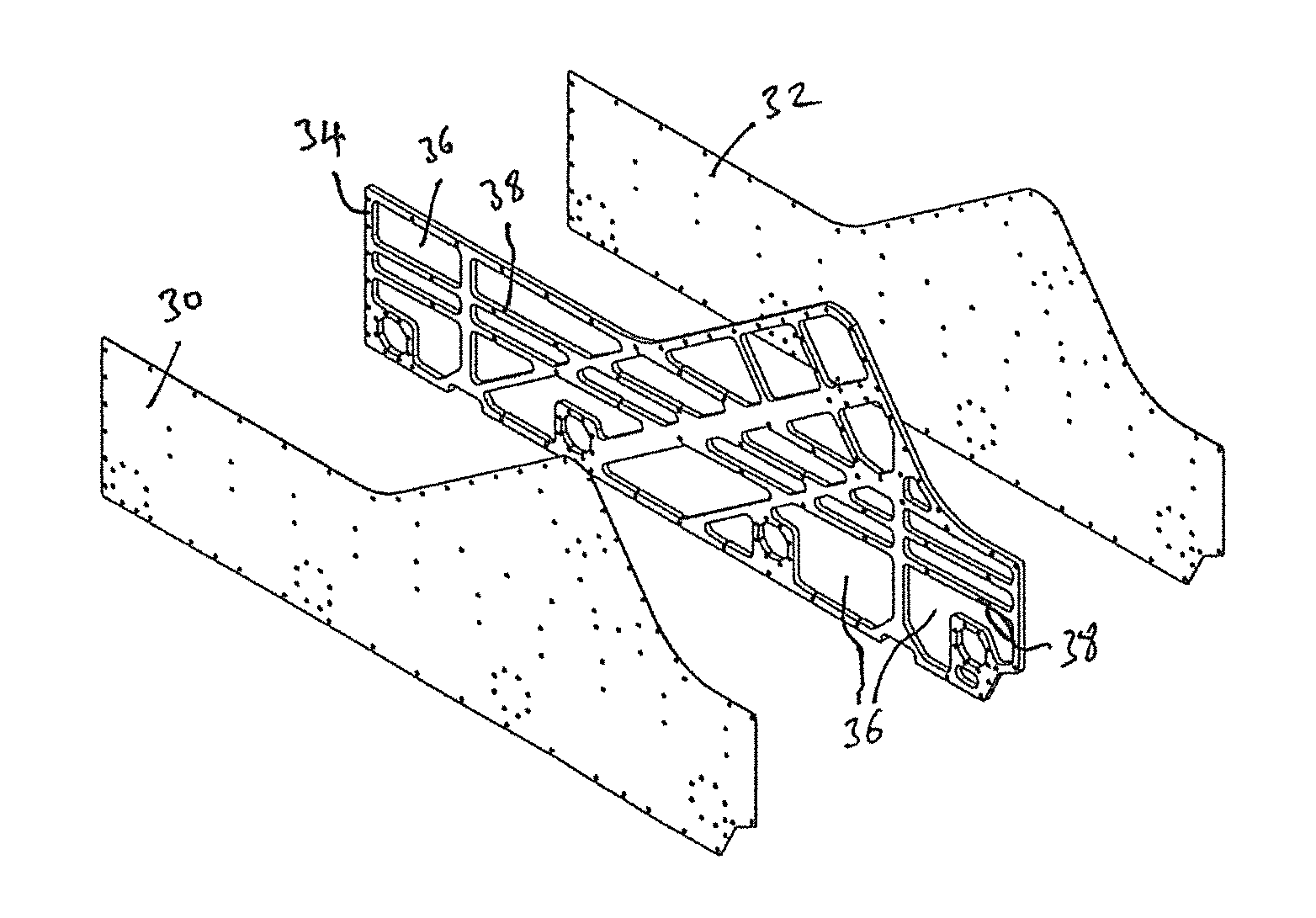

Vibrating screen

A vibrating screen is provided for separating excess water from particulate materials such as sand, gravel, iron ore, sludge or other particulate material and / or for grading, classifying or sorting particulate material by size. The vibrating screen includes a frame upon which is mounted a deck having a plurality of apertures therein, the frame being mounted on a base and being provided with vibration generating means for imparting vibration to the deck, wherein the frame includes pair of substantially parallel side walls between which the screen is mounted, each side wall including a pair of spaced apart side members defining outer faces of the side wall, at least one intermediate member being located between the side members, wherein the at least one intermediate member incorporates a plurality of apertures and / or cut-outs therethrough.

Owner:CDE GLOBAL

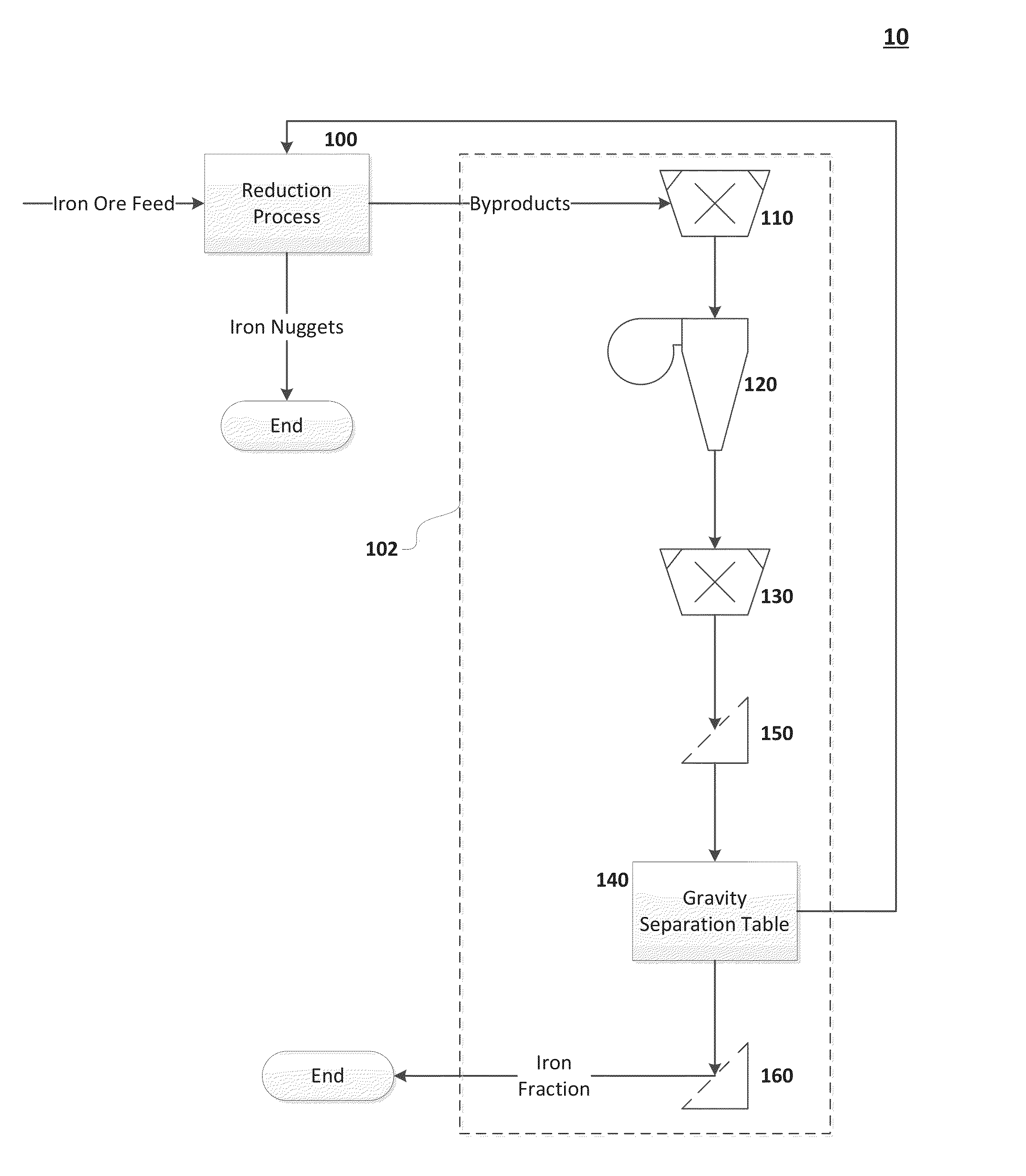

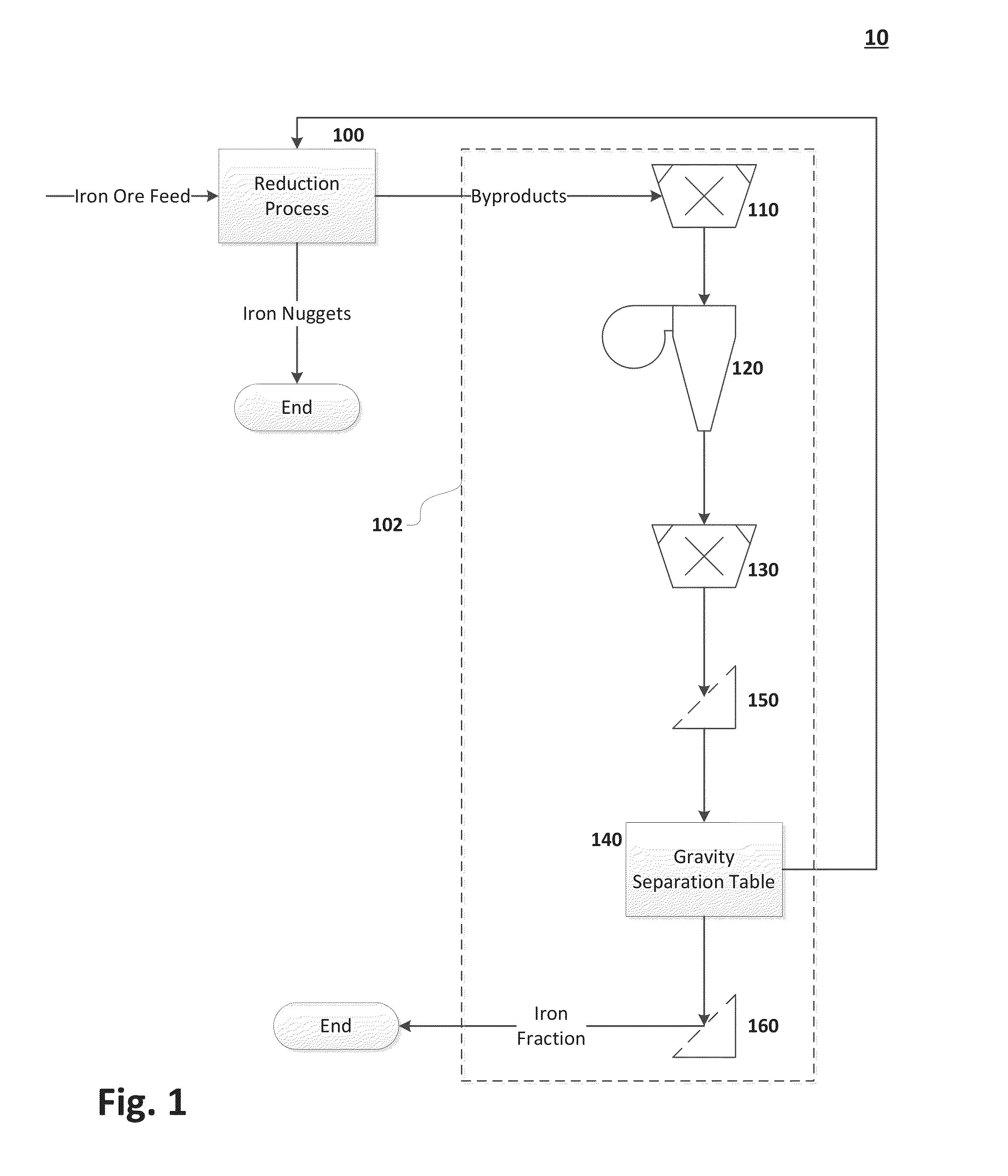

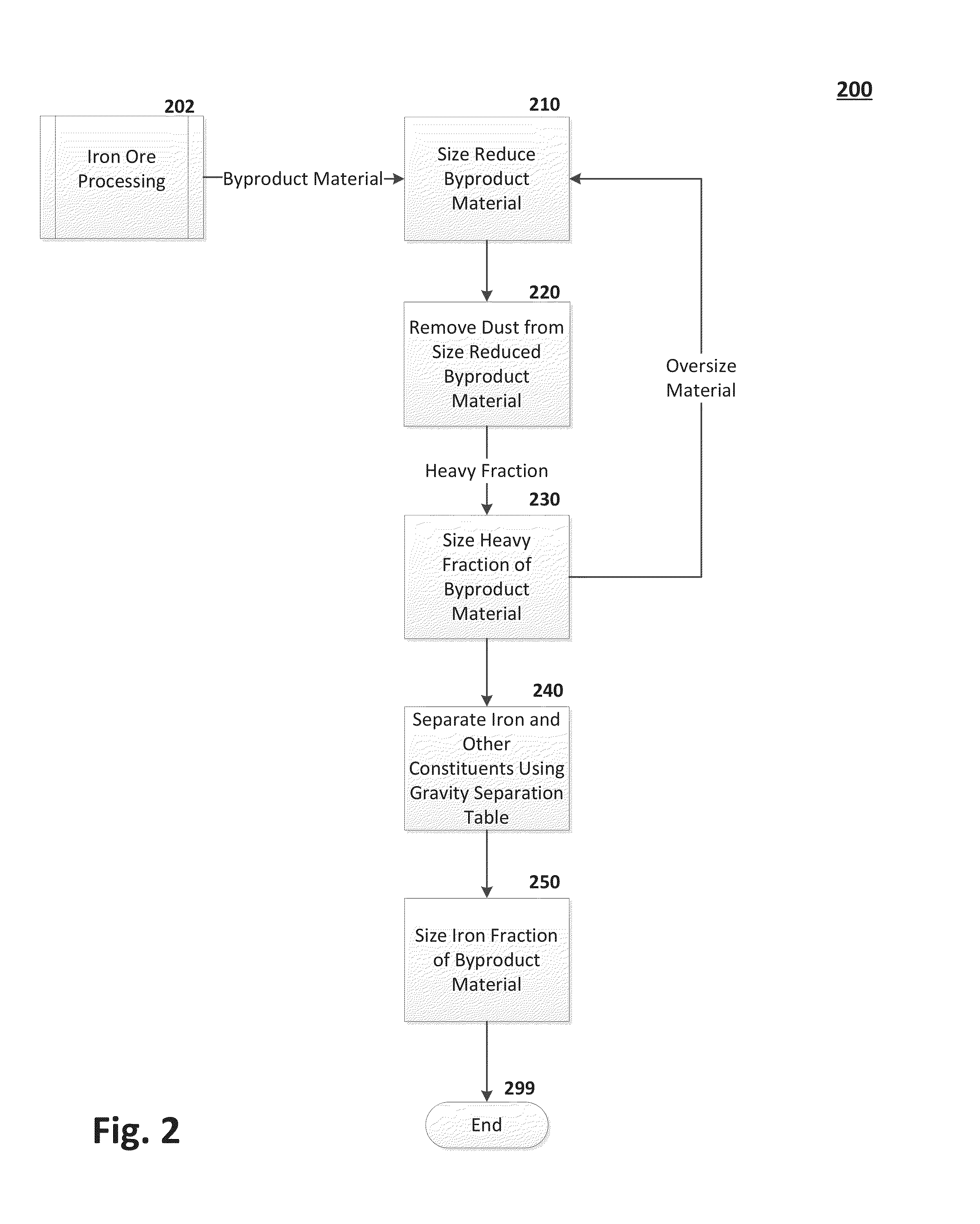

System and method for iron ore byproduct processing

ActiveUS20140077008A1Efficient and cost-effectiveGas current separationCocoaGravity separationFerric

Processing byproduct material from a direct reduction process of iron ore to reclaim iron and other materials from the byproduct. The systems and methods employ gravity separation tables to separate the iron from other byproduct material constituents. The byproduct material constituents may be size reduced, processed to remove dust, and sized prior to processing by the gravity separation.

Owner:VALERIO THOMAS A

Systems and methods for the environmental remediation of materials contaminated with heavy minerals

ActiveUS20160067744A1Prevent escapeSievingGas current separationEnvironmental engineeringEnvironmental remediation

The invention relates to a method and system for the environmental remediation of materials that are contaminated with heavy minerals, such as heavy metals. The invention finds utility in removing heavy minerals from materials such as soils, sediments, mine tailings and ores. The invention provides a means for removing heavy minerals from contaminated materials without the use of water while reducing the generation of dust. Thus, the invention provides an environmentally friendly method for the remediation of sites that are contaminated with heavy minerals.

Owner:VORTEX TECH LLC

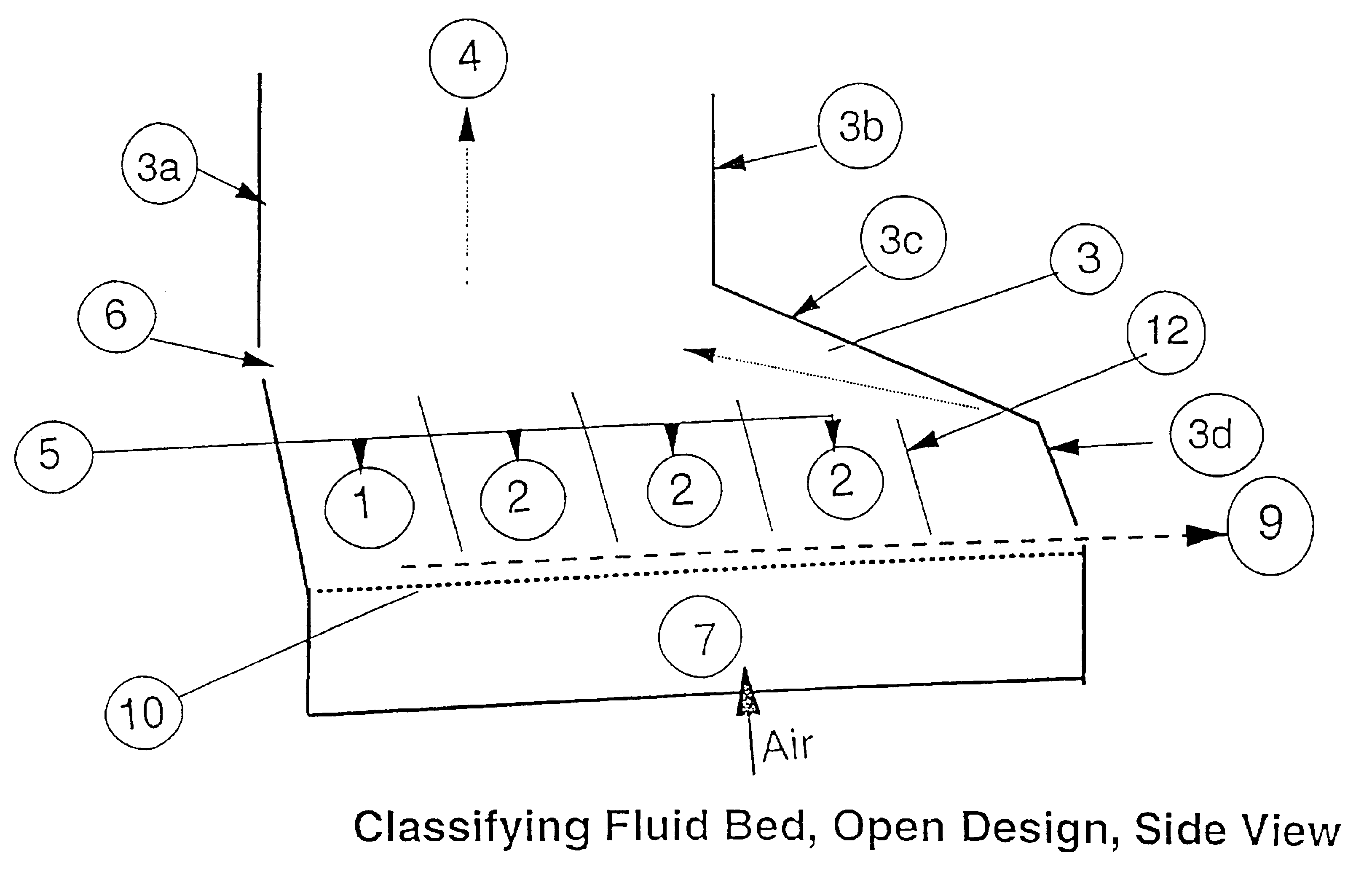

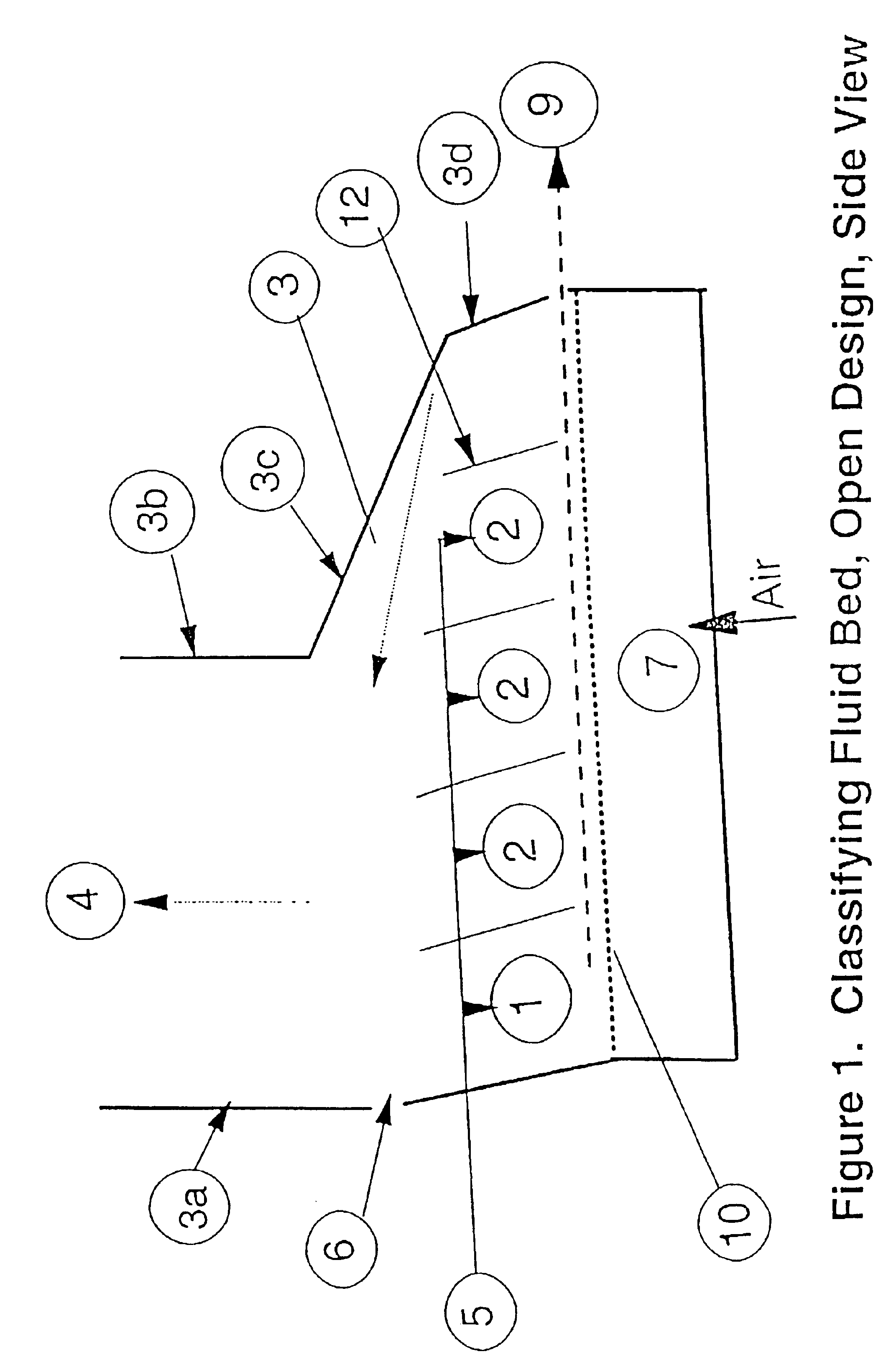

Method and a device for processing a solution, melt, suspension, emulsion, slurry or solids into granules

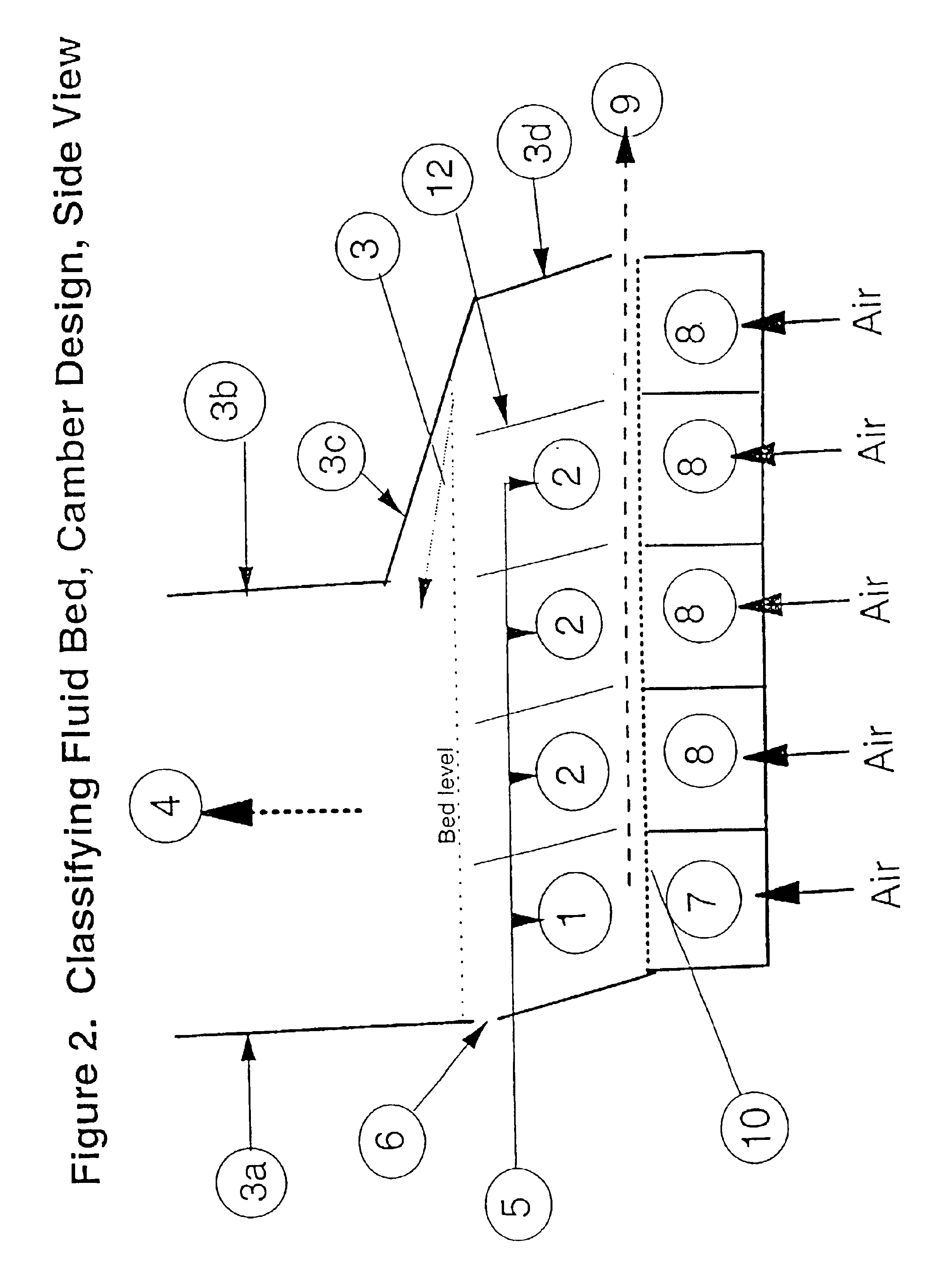

A classifying fluid bed granulator includes a granulation chamber including a fluidizing air chamber (7) with a bed floor (10), a ceiling (3c), an end wall (3d), and a feed inlet (5), a seed inlet (6), an air outlet (4) defined by walls (3a, 3b) and an outlet (9) for produced granules. The granulation chamber is divided into an agglomeration and seed control section (1) and a granulation and classification section (2), and the section (2) includes one or more consecutive compartments having an asymmetric design.

Owner:YARA INT ASA

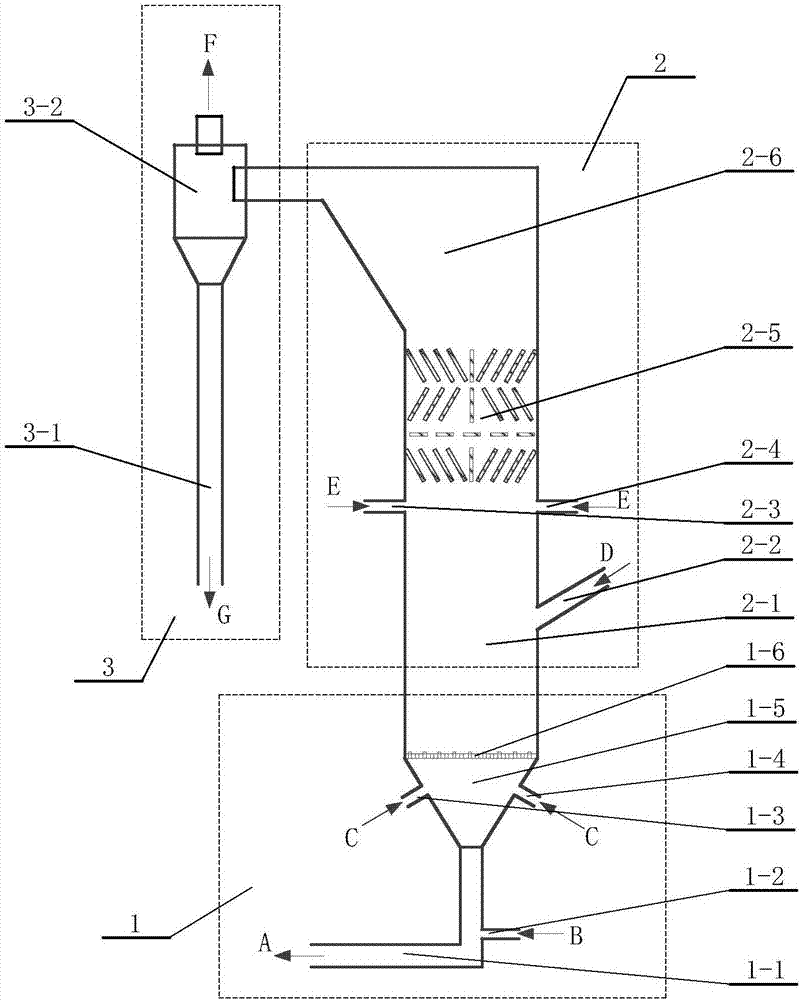

Coke and oxygen carrier particle separation device and method

InactiveCN107020195AEfficient separationVortex flow apparatusPneumatic tablesParticulatesChemical physics

The present invention discloses a coke and oxygen carrier particle separation device and method. The device is composed of an oxygen carrier recovery zone, a turbulence separation zone and a coke recovery zone. A mixture of coke and oxygen carrier particles enters into a fluidized bed, and the coke and oxygen carrier particles are separated in turn by a free space, turbulence plates and a divergent separation section in the turbulence separation zone. Ultimately, coke particles with a small specific gravity are discharged from the lower end of a cyclone separator and collected, and oxygen carrier particles with a large specific gravity fall into an oxygen carrier recovery tube at the lower end, thereby realizing separation and reutilization of the coke and oxygen carrier particles.

Owner:SOUTHEAST UNIV

Separation process of coarse quartz grain and feldspar

InactiveCN1421274AReduce separation costsNo pollution in the processFlotationMagnetic separationMagnetic separatorSlurry

The separation process of coarse quartz and feldspar includes the steps of: crushing in a crusher; separating in shaking table to obtain light ore while eliminating heavy ore; magnetic separation of the light ore in magnetic separator to eliminate magnetic ore and electromagnetic separation to eliminate electromagnetic ore while obtaining quartz and feldspar; soaking quartz and feldspar in hydrochloric acid inside a container; stirring the soaked material in flotation machine at ore slurry temperature of 30-40 deg.c; and final air flotation after adding hydrochloric acid, citric acid and lauric acid and through stirring. The said process can separate quartz and feldspar effectively to reach quartz purity product of 95-98% and feldspar product purity of 92-95%.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

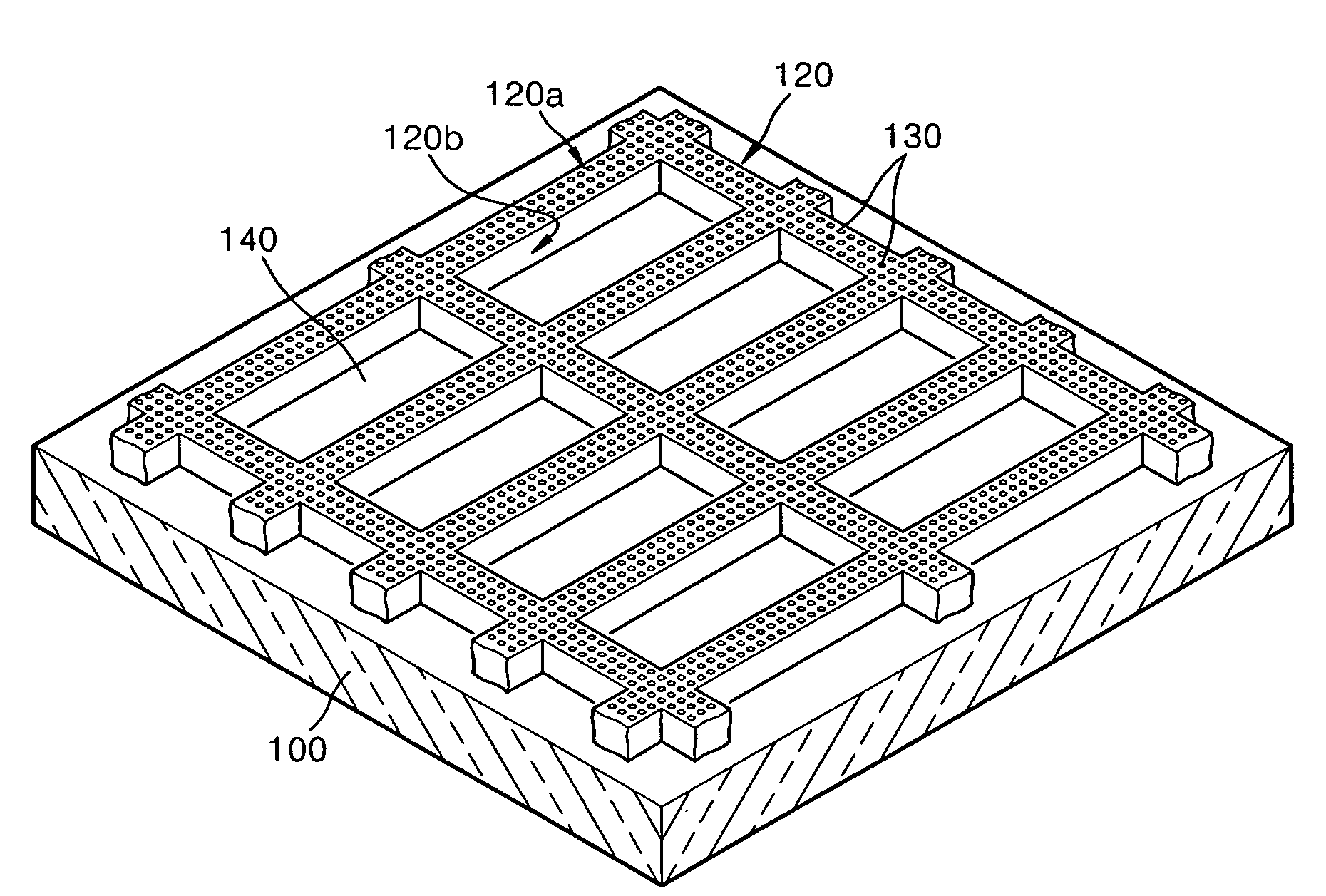

An Apparatus for Reclaiming Foundry Sand

ActiveUS20150183025A1Fully understandConvenient lightingGas current separationMould handling/dressing devicesFoundryFine powder

To provide an apparatus for reclaiming foundry sand that has a fluidized bed that prevents slits from being clogged. The apparatus comprises a tank (3) for reclaiming the foundry sand, a tank (4) for fluidization, an upper portion of which in an upstream side is connected to a bottom of the tank for reclaiming the foundry sand, the tank for fluidization transporting the reclaimed foundry sand and fine powder that drop from the tank for reclaiming the foundry sand, a dust hood (5), and a lower portion of which communicates with an upper portion of the tank for fluidization in a downstream side, the dust hood collecting the fine powder in the tank for fluidization, wherein a fluidized bed (6) in the tank for fluidization has a plurality of inverted. V-shaped covering members (13) and a plurality of V-shaped flooring members (14), wherein the inverted V-shaped covering members and the V-shaped flooring members are horizontally and alternately provided so that the inverted V-shaped covering members are at any point above a vertically corresponding point of the V-shaped flooring members, and wherein gaps between end portions of the inverted V-shaped covering members and end portions of the V-shaped flooring members are formed as inclined slits (15) for supplying air.

Owner:SINTOKOGIO LTD

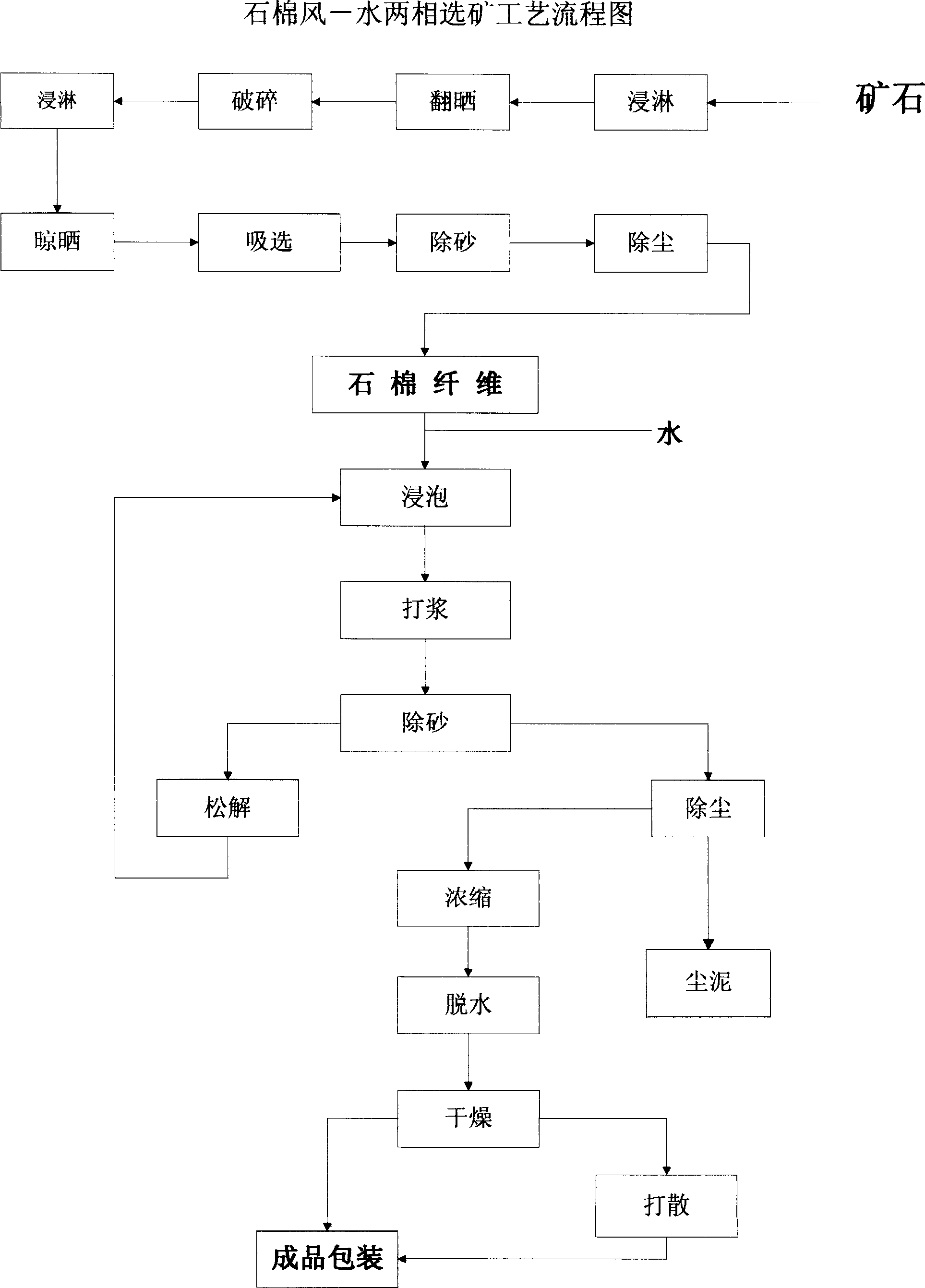

Asbestos wind-water two-phase concentrating technology

The present invention relates to a mineral separation process of asbestos mine, combining dry pneumatic separation and wet separation, which is characterized by that it makes the ore undergo the processes of soaking, showering, stacking, airing and breaking in dampness so as to implement its preparation process, in which dry pneumatic separation can obtain crude concentrate asbestos, most of sand and dust can be removed, then it makes wet separation operation, incluidng, removing sand, removing dust, opening and die-pressing and dewatering to obtain the invented high-quality asbestos with high yield and good degree of opening of fiber.

Owner:XIANYANG NONMETALLIC ORE CHEM

Vibration fluidizing density grading device for granular catalyst

InactiveCN1554486ASimple structureEasy to operateCatalyst regeneration/reactivationPneumatic tablesHigh carbonEngineering

The vibration fluidizing density grading device for granular catalyst includes one inclined sieve plate, motor connected to the sieve plate via vibrating link rod and transmitting part, sealing hood on the sieve plate, induced draft fan connected to the sealing hood via induced draft pipeline, and feeding bin over the sieve plate with bottom pipe connected to the sealing hood via the induced draft pipeline. After the motor and the induced draft fan are on, the catalyst to be graded and fed via the feeding bin is fluidized on the vibrating sieve plate so that catalyst grains with high carbon content is exhausted from the upper end while catalyst grains with low carbon content is exhausted from the lower end. The present invention can realize grading of granular catalyst with density difference as low as 3%, and the low carbon content catalyst with average carbon content of 1.5-3.5 5 is recovered in the recovering rate of 90-95 vol%.

Owner:SINOPEC YANGZI PETROCHEM +1

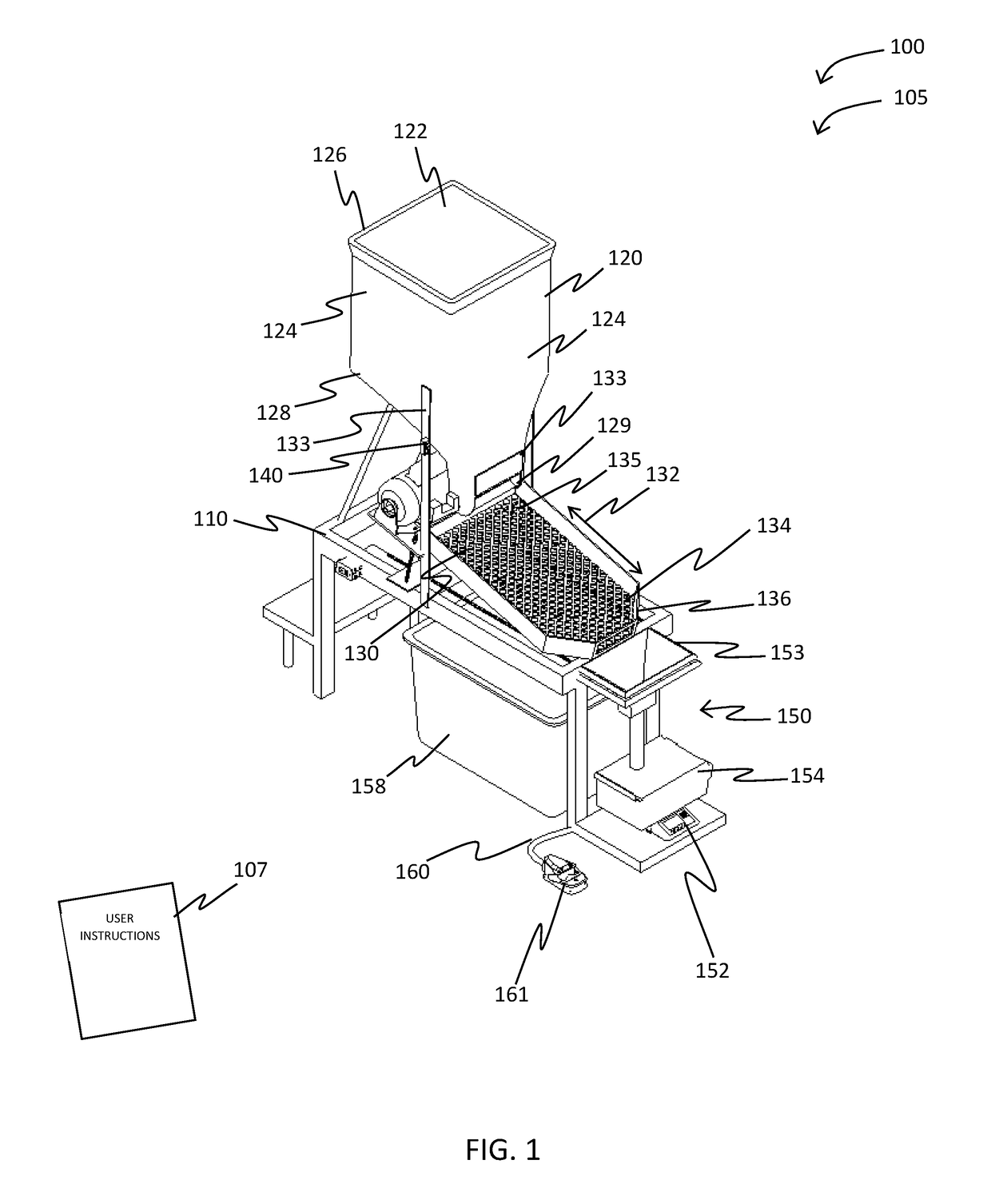

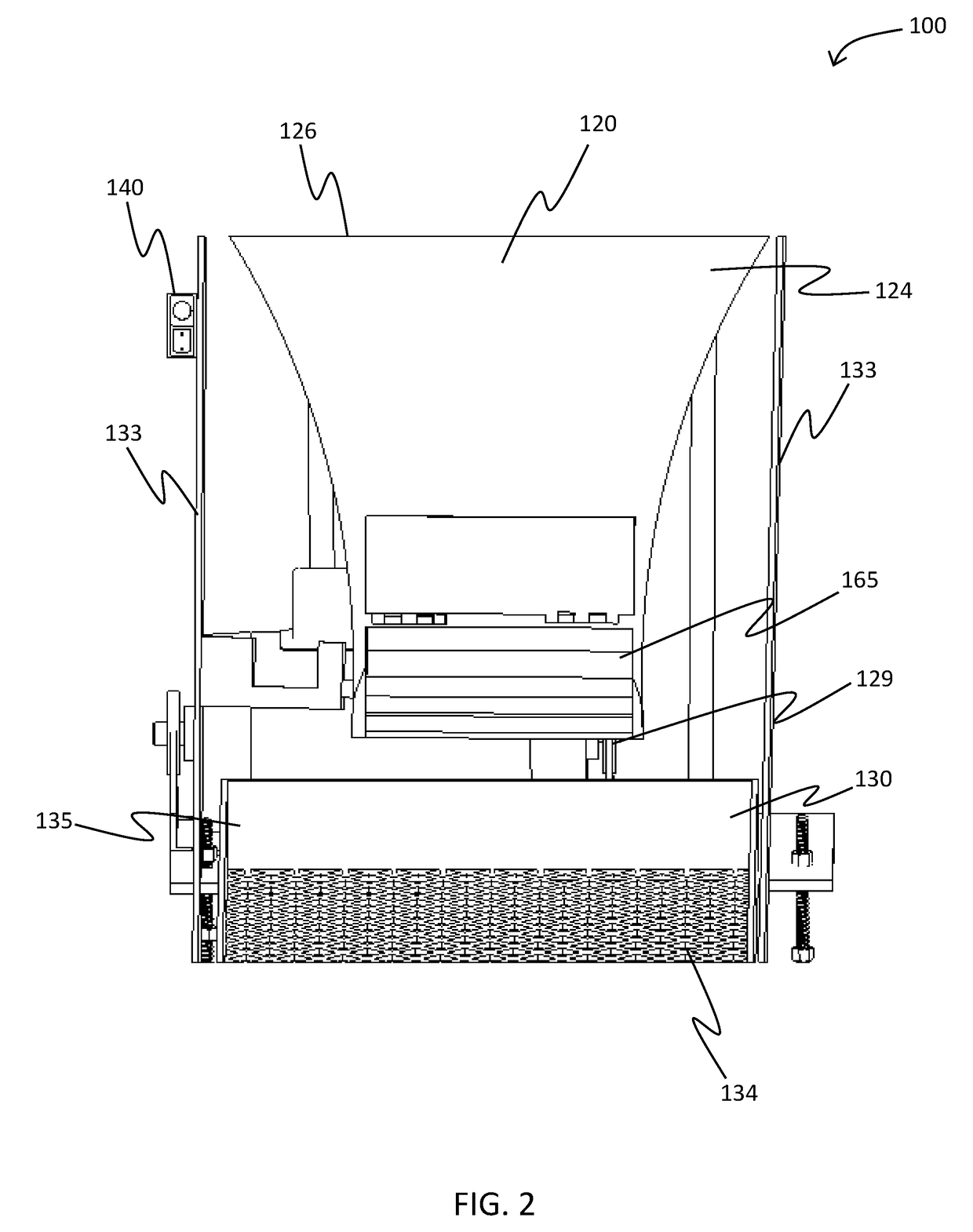

Apparatus for processing cannabis

InactiveUS20180339298A1Weighing apparatus for materials with special property/formGrain treatmentsCannabisEngineering

An apparatus for processing cannabis plants includes a support-frame, a hopper, a filter-tray, an oscillation means, a weighing station and a power supply. The apparatus for processing cannabis plants is useful for processing, weighing and packaging cannabis after the cannabis has flowered and is harvested.

Owner:MAYERS RACE

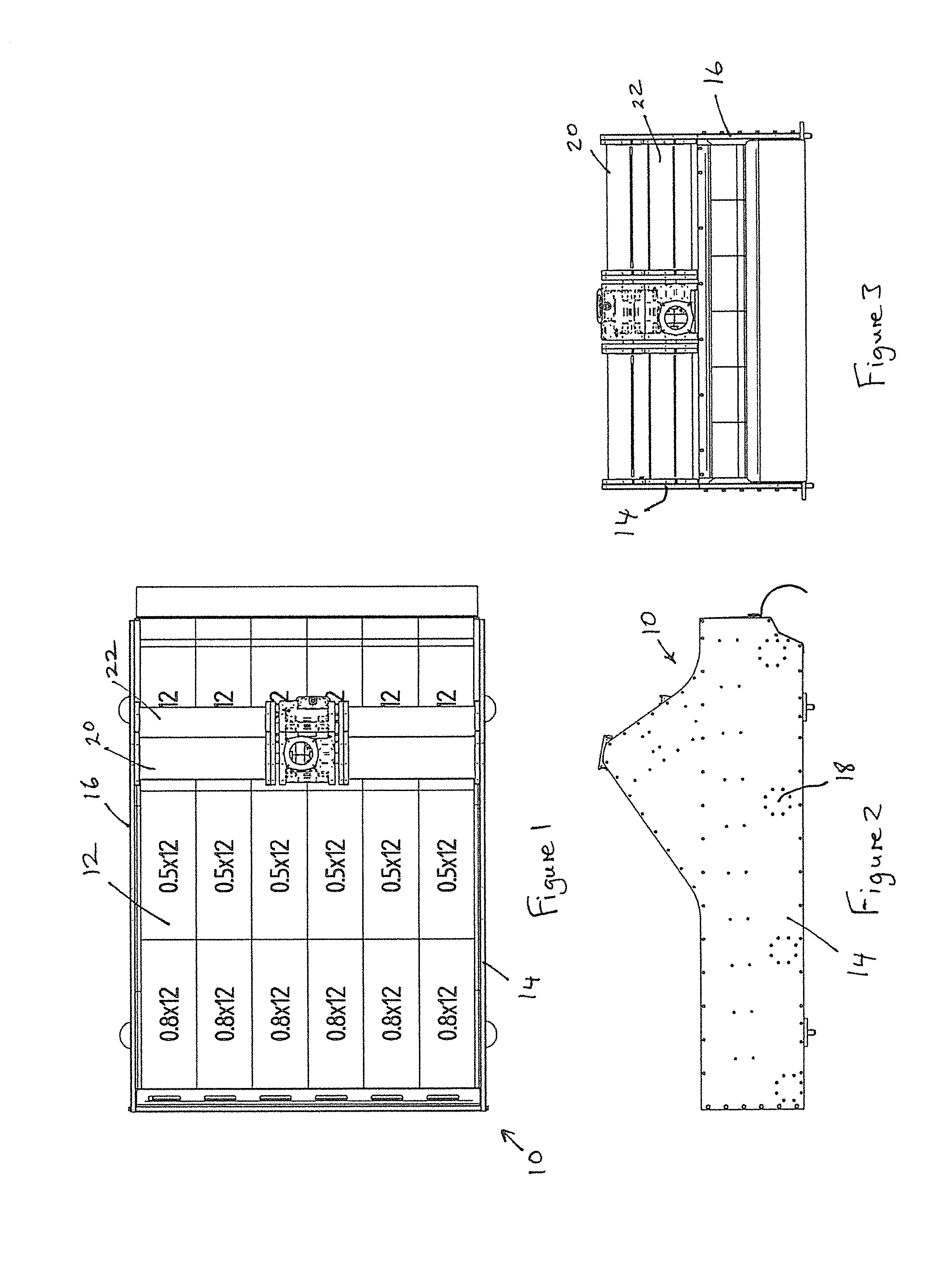

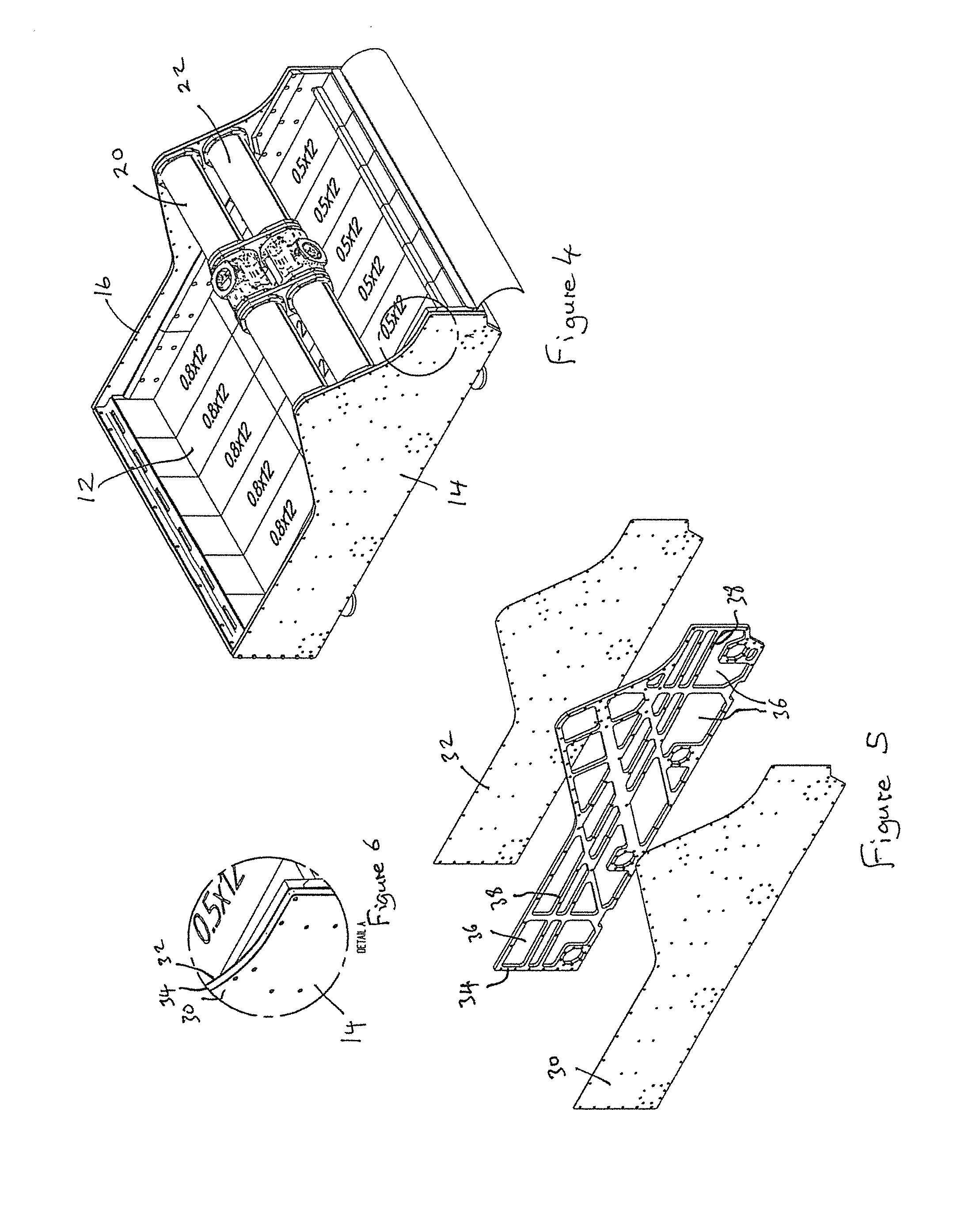

Apparatus and method of separating and concentrating organic and/or non-organic material

ActiveUS20070193926A1Processed evenly and quicklyReduce the amount of solutionGas current separationDrying solid materials with heatParticulatesFluidized bed

An apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. The fluidized bed also includes an opening for receiving a first fluidizing stream, an exit for fluidized particulate and at least one exit for non-fluidized particulate. A conveyor is operatively disposed in the fluidized bed for conveying the non-fluidized particulate to the non-fluidized particulate exit. A collector box is in operative communication with the fluidized bed to receive the non-fluidized particulate. There is a means for directing a second fluidizing stream through the non-fluidized particulate as while it is in the collector box to separate fluidizable particulate therefrom.

Owner:RAINBOW ENERGY CENT LLC

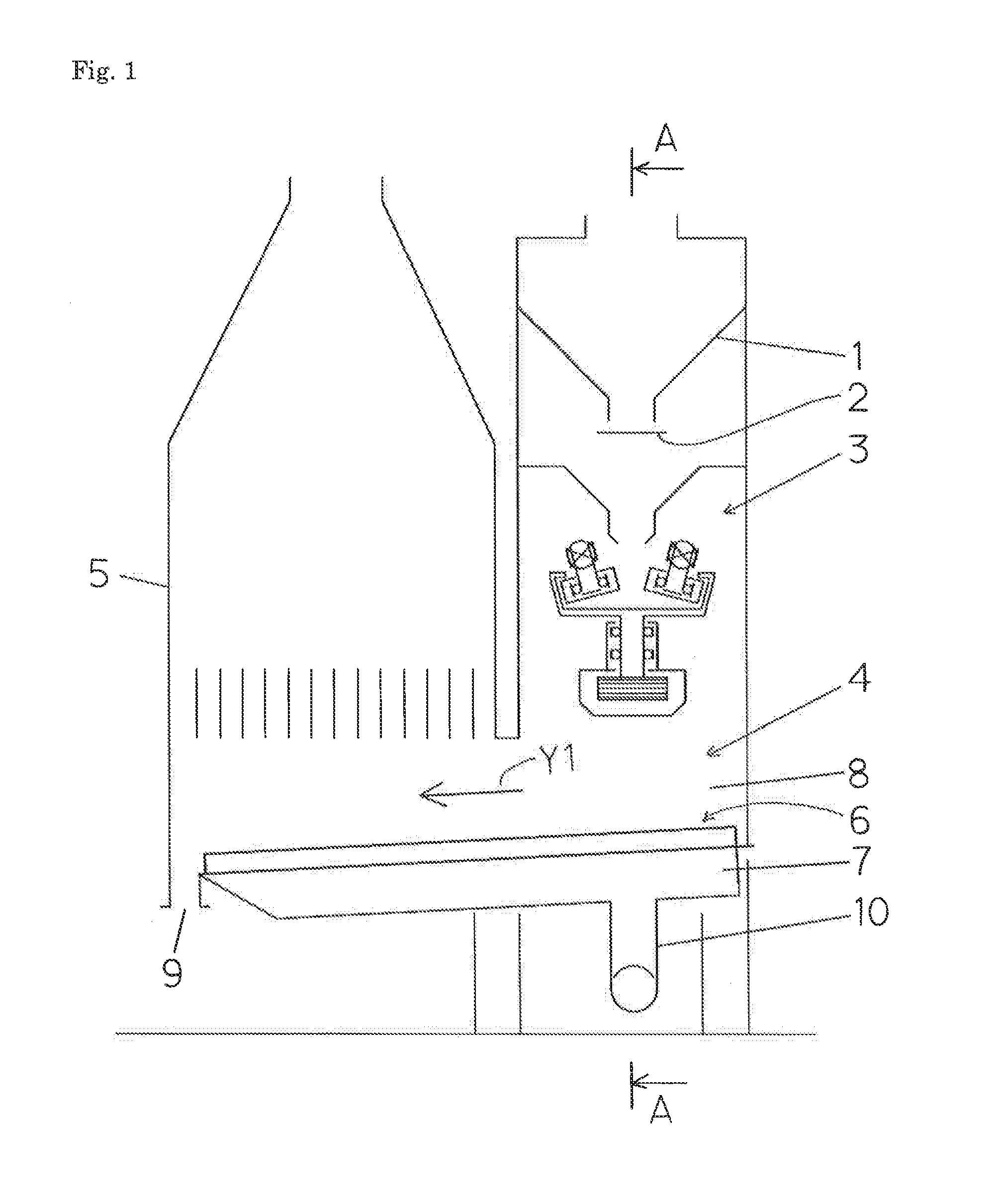

Auto-medium gas-solid two-phase fluidized bed dry coal separator based on bed layer partition plates

PendingCN107233995AAchieve the purpose of sortingApplicable to a wide range of mineralsPneumatic tablesCollection systemWater source

The invention discloses an auto-medium gas-solid two-phase fluidized bed dry coal separator based on bed layer partition plates. The auto-medium gas-solid two-phase fluidized bed dry coal separator comprises a feed system, a gas-solid fluidized bed and a sorting product collection system. The feed system is connected with the gas-solid fluidized bed to achieve feeding on the gas-solid fluidized bed. The sorting product collection system is connected with the gas-solid fluidized bed to achieve sorting collection. The gas-solid fluidized bed comprises an air distribution plate. Air blowers are arranged below the air distribution plate, a dust isolation plate is arranged above the air distribution plate, and exhaust fans are arranged above the dust isolation plate. The air distribution plate is arranged obliquely, the upper portion of the air distribution plate is used for receiving fed materials, the multiple parallel bed layer partition plates are arranged between the lower portion of the air distribution plate and the dust isolation plate, and the bed layer partition plates extend downwards to the sorting product collection system. According to the auto-medium gas-solid two-phase fluidized bed dry coal separator, the density variation between coal and impurity gangue is utilized, the coal, the impurity gangue and the like are fluidized in the fluidized bed so as to be stably layered, and finally the coal, the impurity gangue and the like are separated. The auto-medium gas-solid two-phase fluidized bed dry coal separator has the beneficial effects that sorting efficiency and sorting precision are high; the same coal sorting density level range adaptability is large; the equipment investment and construction cost is low; operation and maintenance are convenient; energy consumption is low; dependence on water sources is avoided; and high efficiency and energy saving are achieved.

Owner:LIUPANSHUI NORMAL UNIV

System for powder heat treatment and classification via fluidized bed

ActiveUS20170173591A1Gas current separationTransportation and packagingFluidized bedMechanical engineering

A fluidized powder heat treatment classification assembly includes a gas source. A fluidized bed is connected to the gas source via a metered connection. The fluidized bed includes a first output connected to a powder classifier via at least a first valve. The powder classifier includes a catch container operable to decelerate a gas flow from the output and operable to catch particles entrained in the gas flow.

Owner:RTX CORP

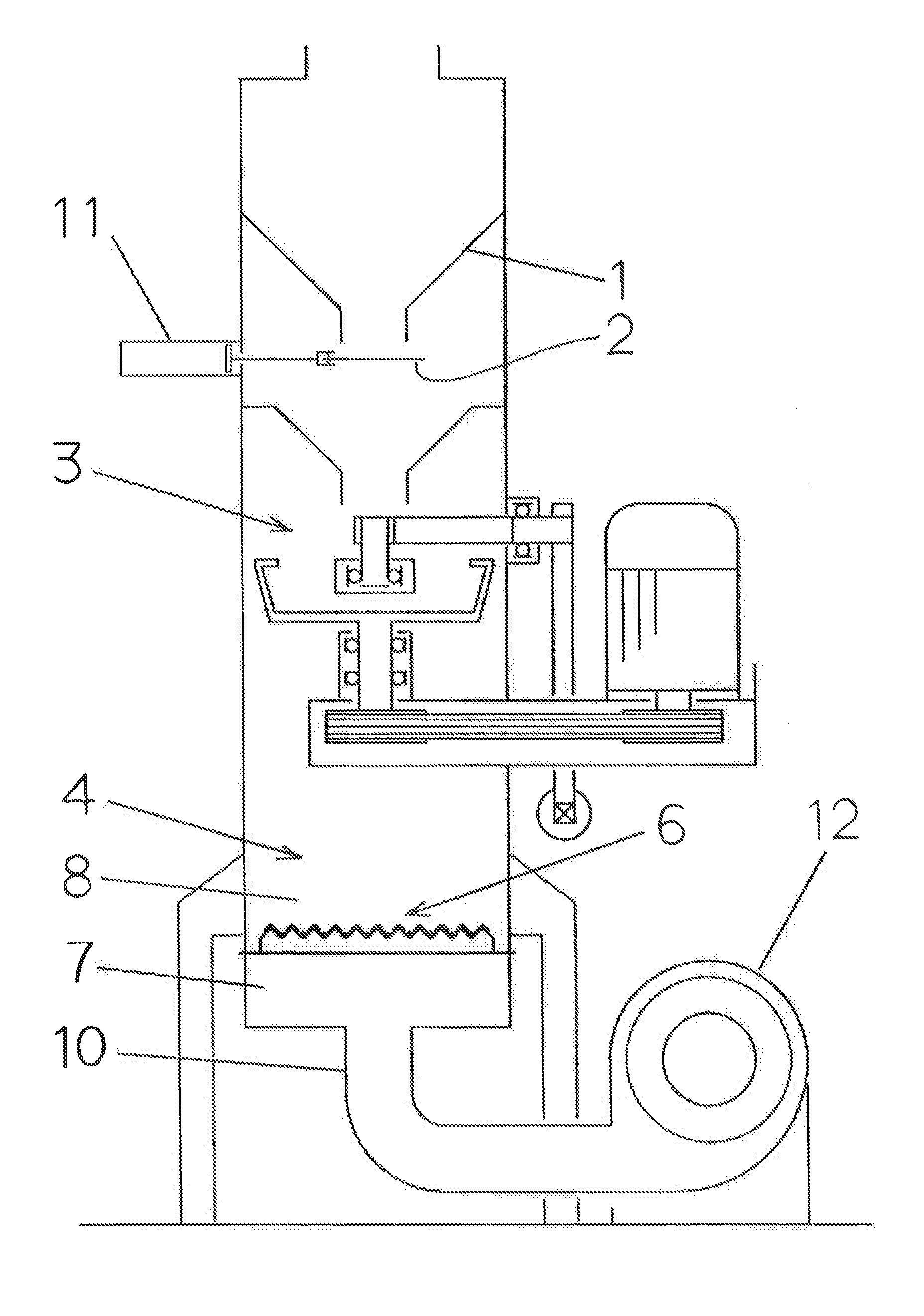

Mineral separator and use method thereof

InactiveCN104001613ANo longer dustyProtection of interestsVortex flow apparatusPneumatic tablesBaghouseMonitoring system

The invention discloses a mineral separator and a use method thereof. The mineral separator comprises an electric hoist hanger, a separating bed of the mineral separator, a gas-solid mixture gathering device, a cyclone separator, a bag-type dust collector, a main fan, a dust removing draft fan, a spray dust suppression system, an electric appliance controller, a monitoring system, an external heat source system and a mineral separator enclosing framework; the separating bed of the mineral separator and a vibrator are hung on the electric hoist hanger, the vibrator is connected with the separating bed of the mineral separator, and an air chamber at the bottom of the separating bed of the mineral separator is connected with an air supply device; the separating bed of the mineral separator comprises an approximately right trapezoid-shaped bed surface, the beveled edge of the right trapezoid is the discharge edge of the separating bed, a discharge baffle plate is arranged at the side of of the discharge edge, and the side of the right-angle edge opposite to the discharge edge is provided with a backboard for guiding materials to turn upwardly. The mineral separator and the use method thereof effective overcome the problem of narrow application range of an existing separating bed surface, is capable of selecting a reasonable bed surface inclination angle, enables the separation quantity to be improved, and enables the separating precision to be improved.

Owner:TANGSHAN SHENZHOU MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com