Patents

Literature

235 results about "Coal product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A: Thousands of products are made with coal or coal by-products, including aspirins, soap, dyes, solvents, plastics, and fibers such as rayon or nylon. Coal is an important ingredient in production of products that require activated carbon, carbon fiber or silicon metal.

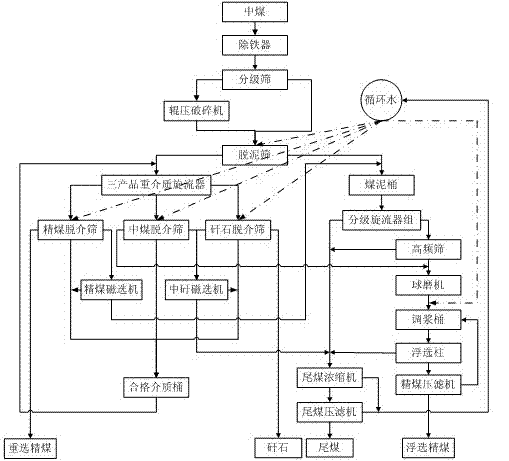

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

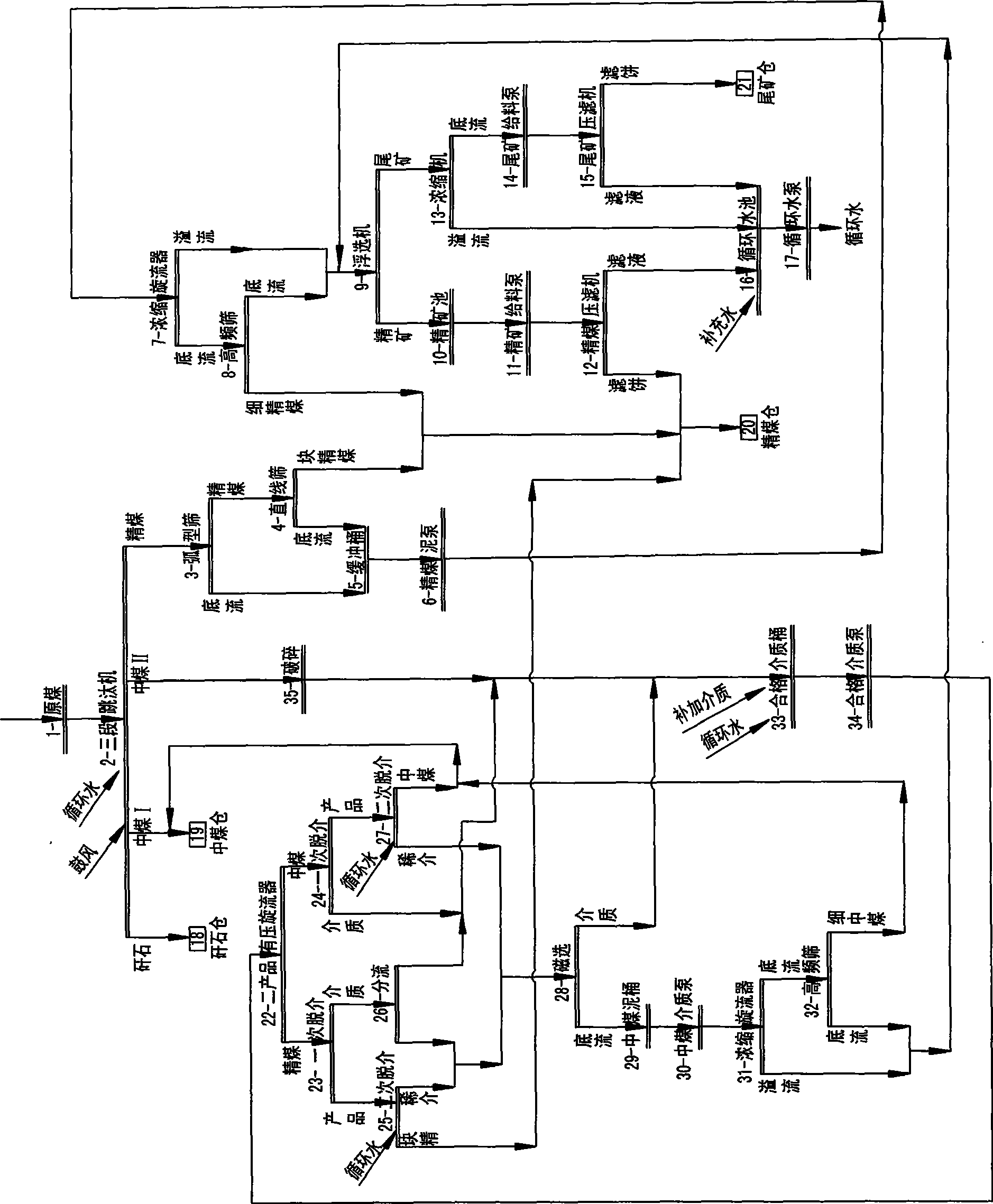

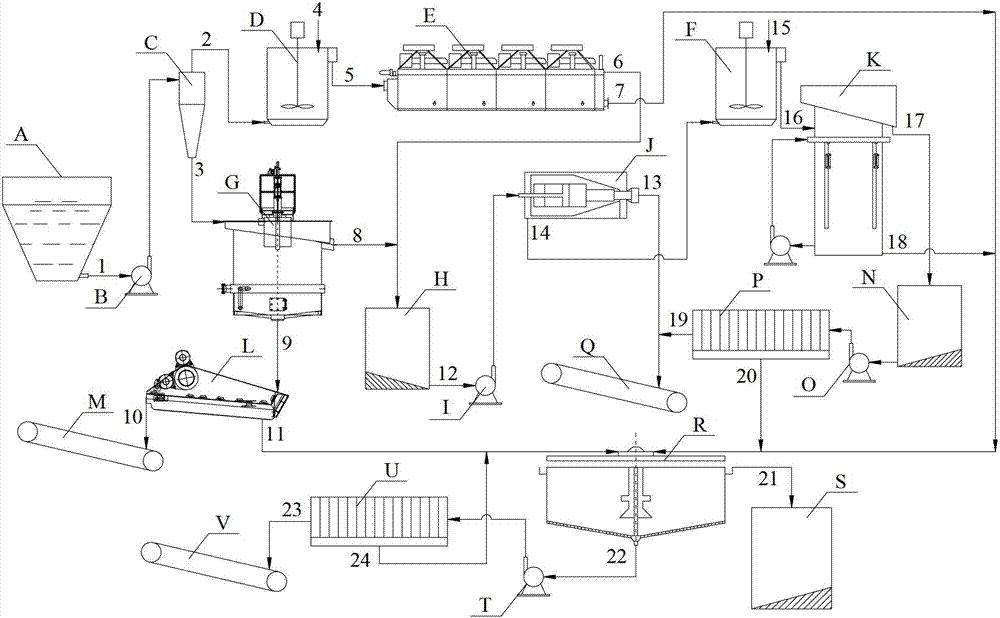

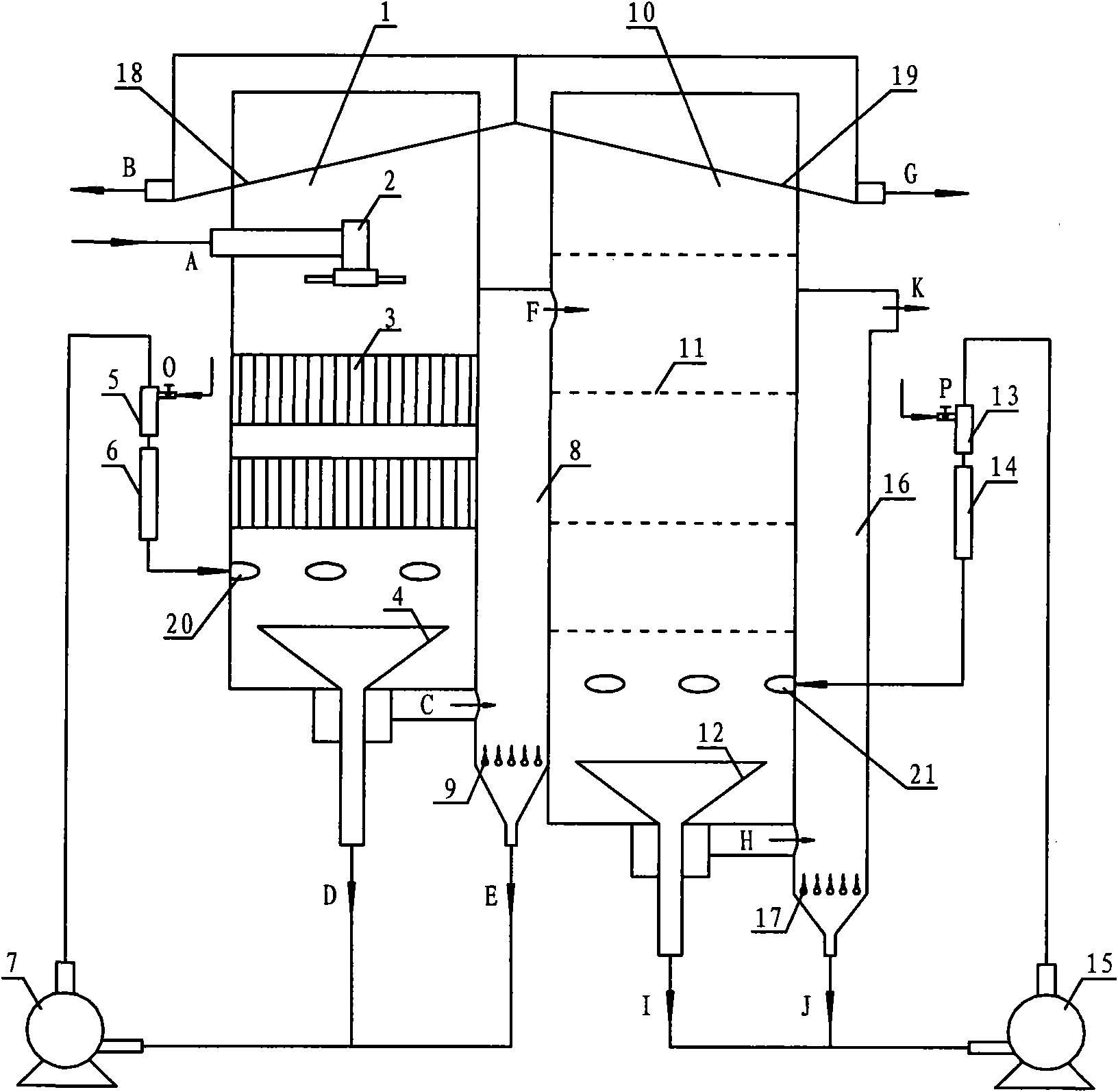

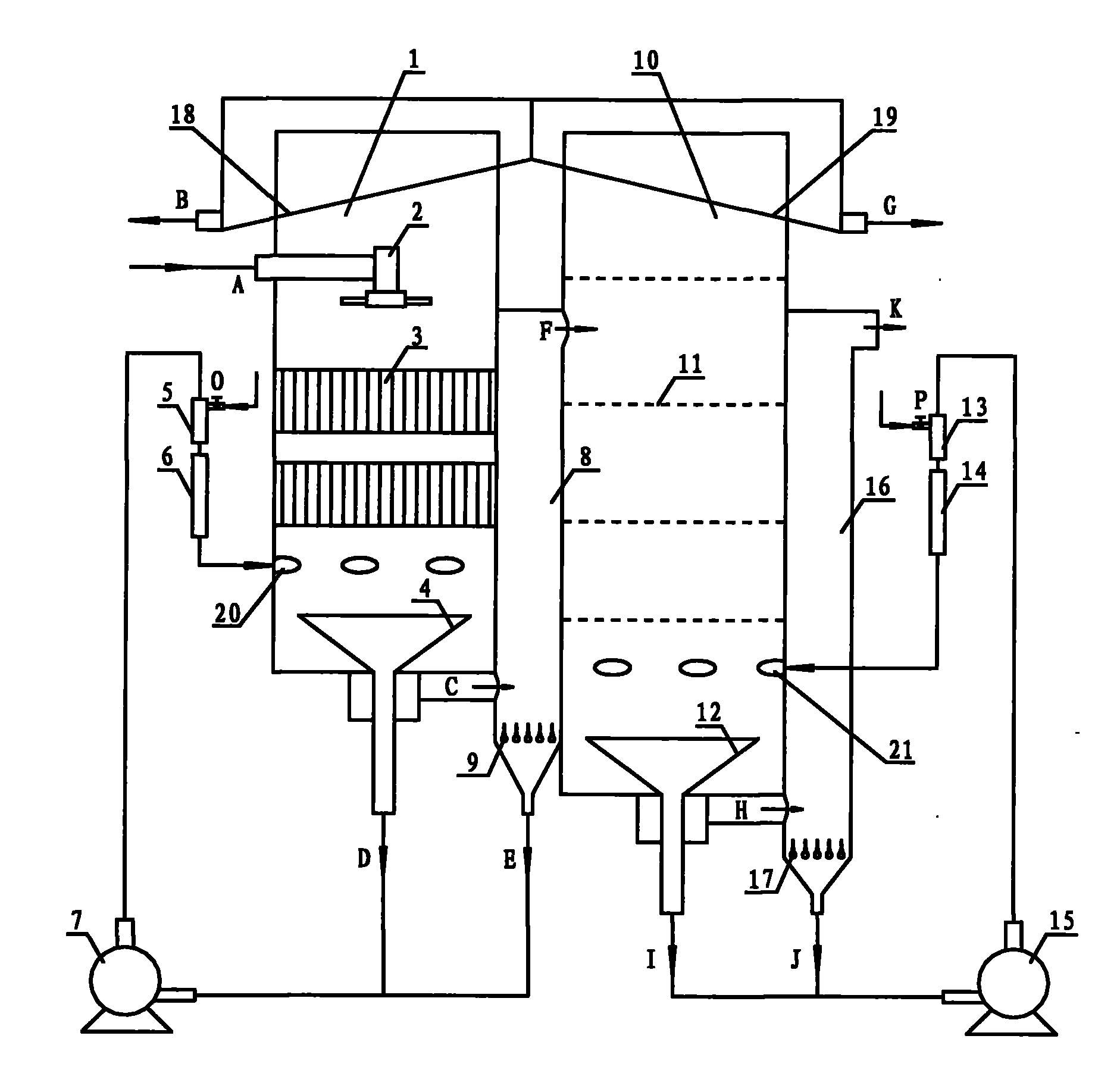

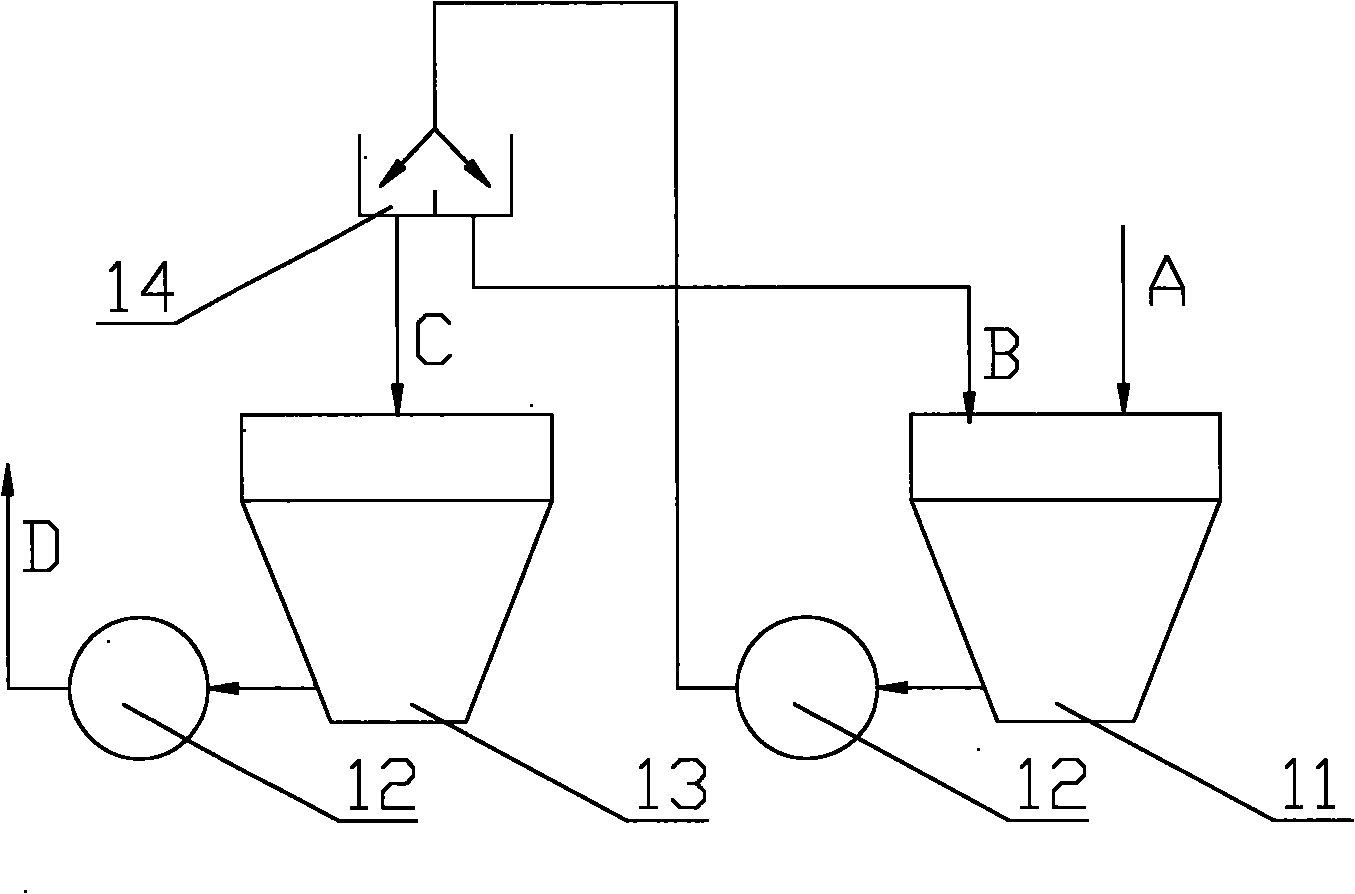

A coal dressing method and system of four-product jigging primary cleaning, secondary head coal small simplified heavy medium reelecting

ActiveCN101530824AReduce investmentLow operating costSievingScreeningTotal investmentSeparation technology

The invention discloses a coal dressing method and system of four-product jigging primary cleaning and secondary head coal small simplified heavy medium reelecting. The invention is a coal dressing method and system that selects the secondary head coal product through the four-product jigging technique and then reelects the secondary head coal with small simplify heavy medium separation technology. The adoption of the invention to select coal is characterized by less total investment, simpler system and lower operational expense, which can improve the stability of the system, reduce the powerconsumption, simplify the managing and maintaining work. The method can be easily realized with present technical merits, which is beneficial to be popularized in the middle and small coal washeries where the management level is low and if the method is used in oversize coal washeries, the cost for washing is lower.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

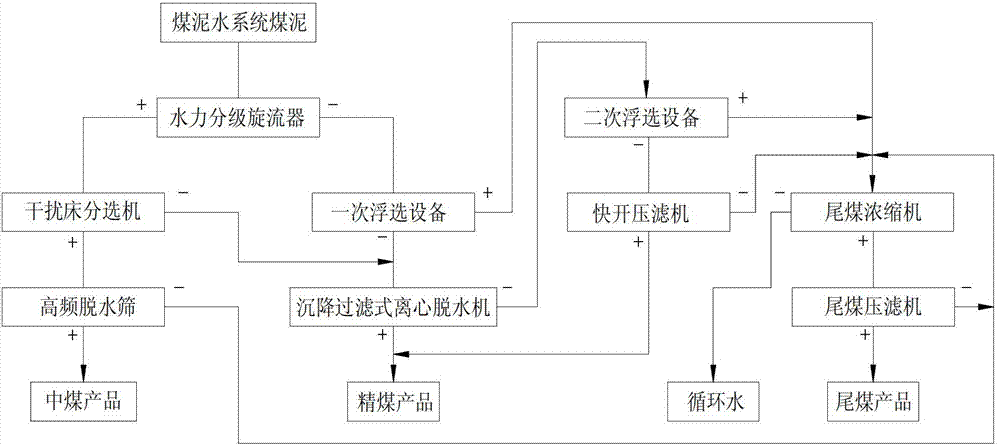

Classifying, separating and dewatering method for high-ash-content difficultly-separated coal slime

ActiveCN103240168AGive full play to the advantages of sortingRealize high-precision sortingFlotationWet separationCycloneFluidized bed

The invention discloses a classifying, separating and dewatering method for high-ash-content difficulty-separated coal slime. The classifying, separating and dewatering method includes: pumping a coal slime water system coal slime to a hydraulic classifying cyclone for classifying, enabling the coal slime to enter primary floatation equipment to separate by overflowing, subjecting bottom flow to entering a separating machine of a liquid-solid fluidized bed to separate, mixing and 'doping' primary floated fine clean coal and coarse-grain clean coal prior to entering a horizontal sedimentation perforated basket centrifuge to dewater and recycle, enabling filtrate and centrifugate of the horizontal sedimentation perforated basket centrifuge to enter secondary floatation equipment to separate, dewatering secondarily-separated clean coal by a quick-opening filter press, doping on-sieve products of coarse-grain tailing coal slime dewatered by a high-frequency sieve into coal products, and mixing backwater of the high-frequency sieve and primarily-separated tailing coal, the secondarily-separated tailing coal and filtrate of a clean coal quick-opening filter press into a tailing coal concentrator and the filter press to dewater and recycle. Therefore, high-quality clean coal low in ash content and water and high in recycling rate is obtained, the problem of 'loss of coarse coal' of floatation of tailing coal is solved, and the technical difficulty of high-precision separation of high-ash-content difficultly-separated coarse and fine coal slime is overcome.

Owner:CHINA UNIV OF MINING & TECH

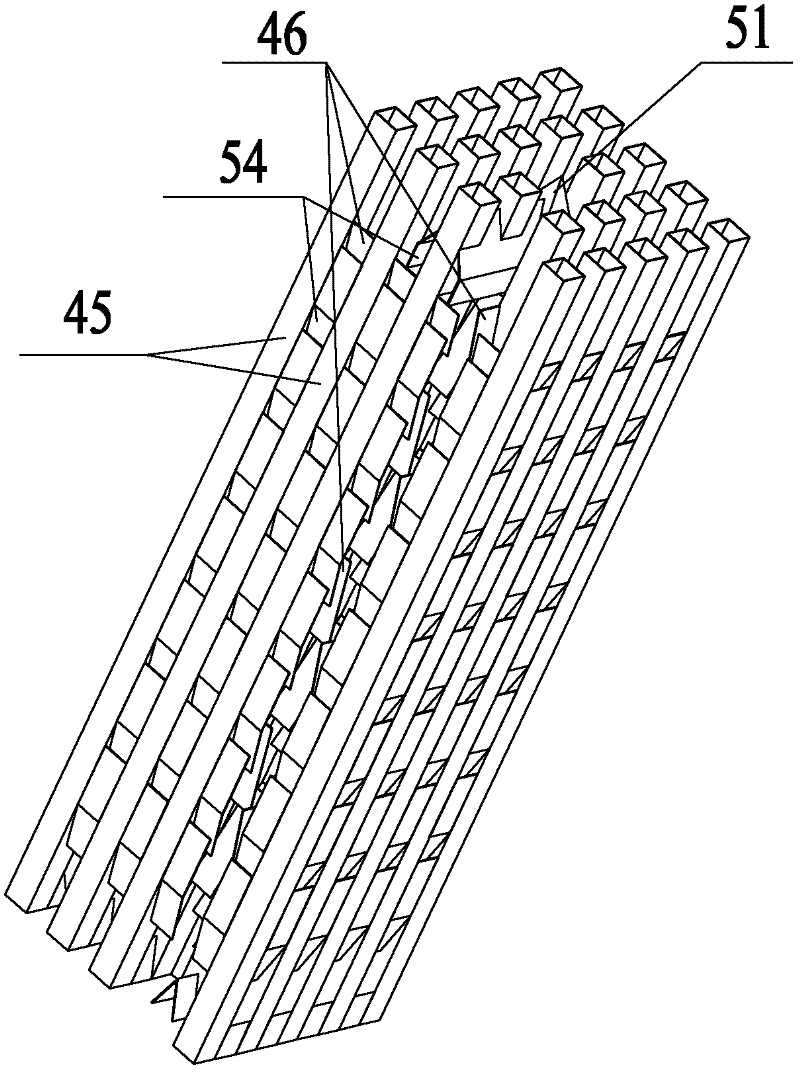

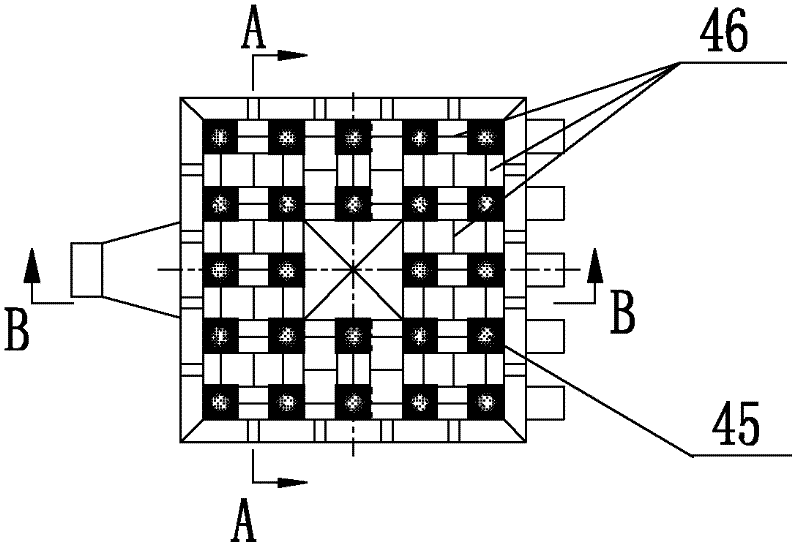

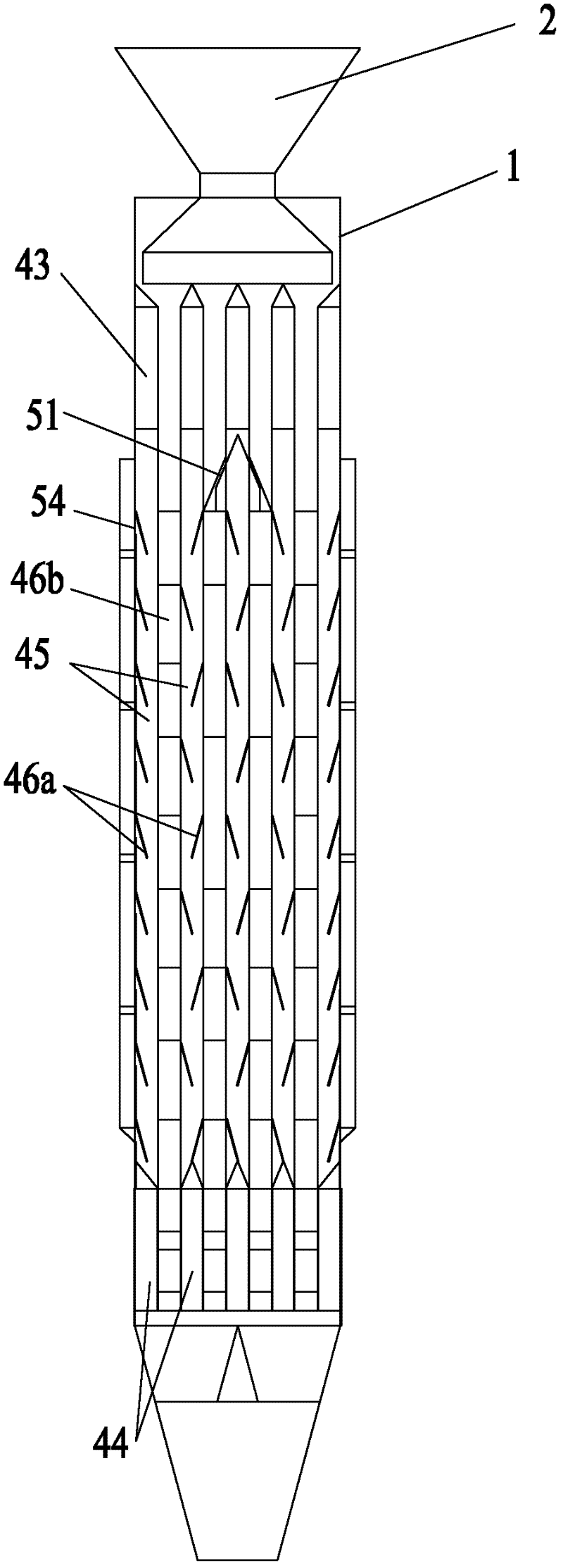

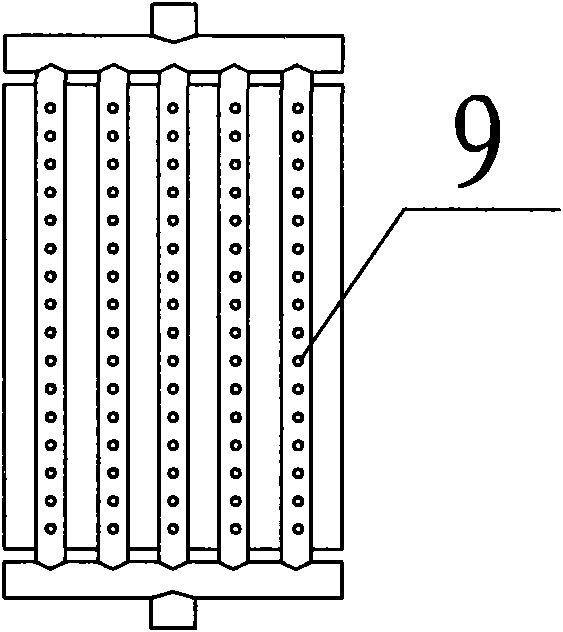

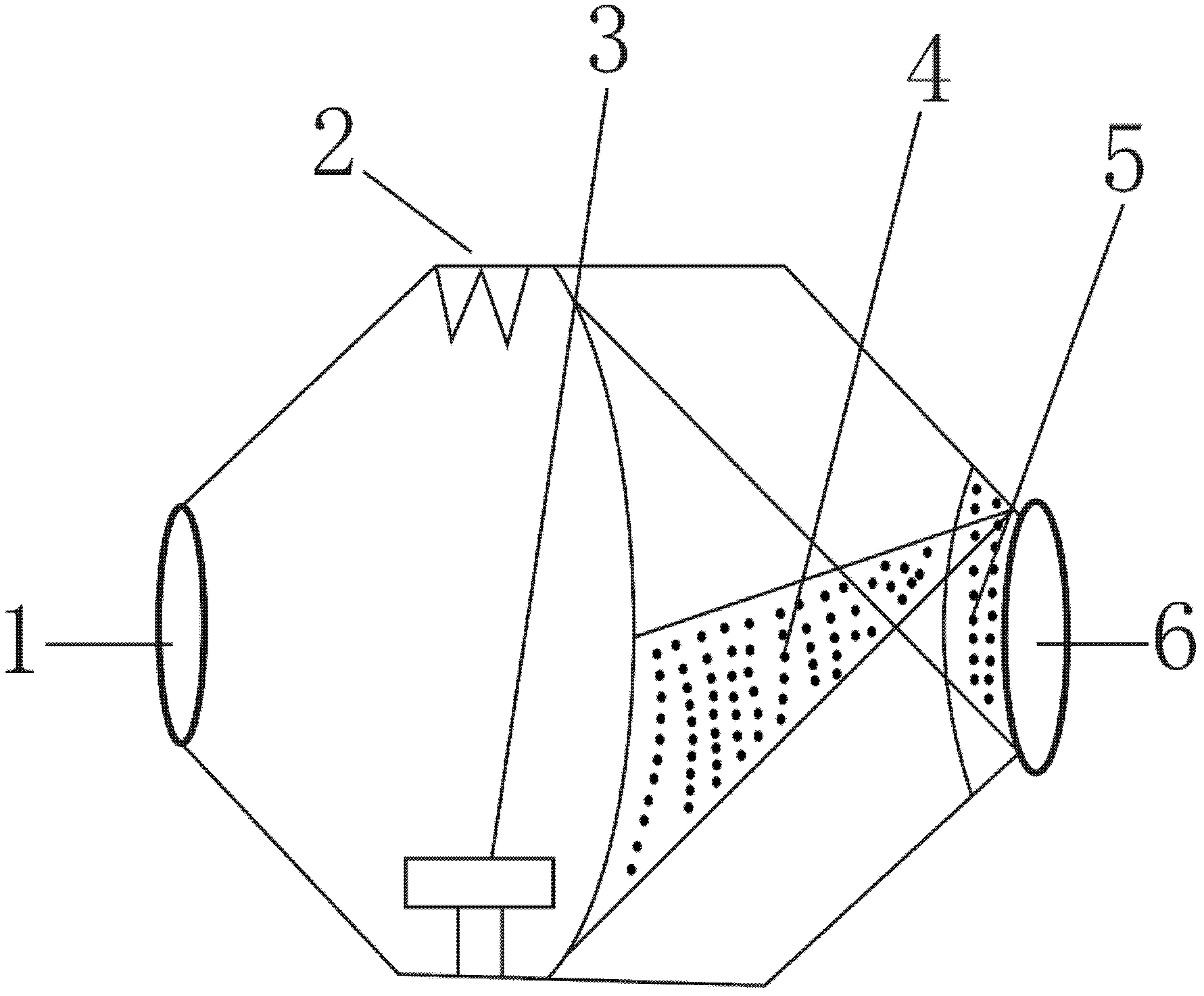

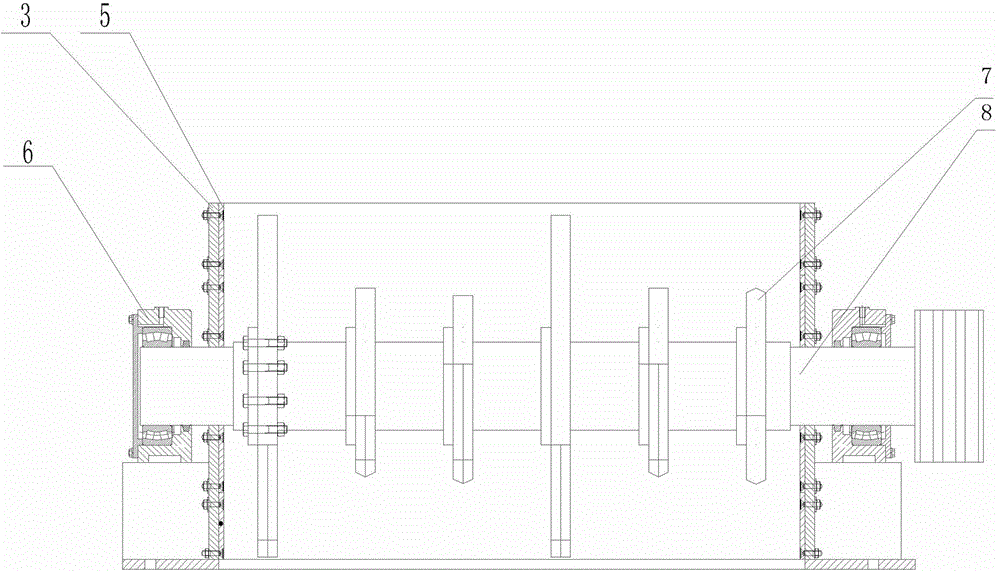

High-quality coal product production equipment and production system

InactiveCN102260559AHigh calorific valueContinuous operationDrying solid materials with heatEnergy inputProduct gasProcess engineering

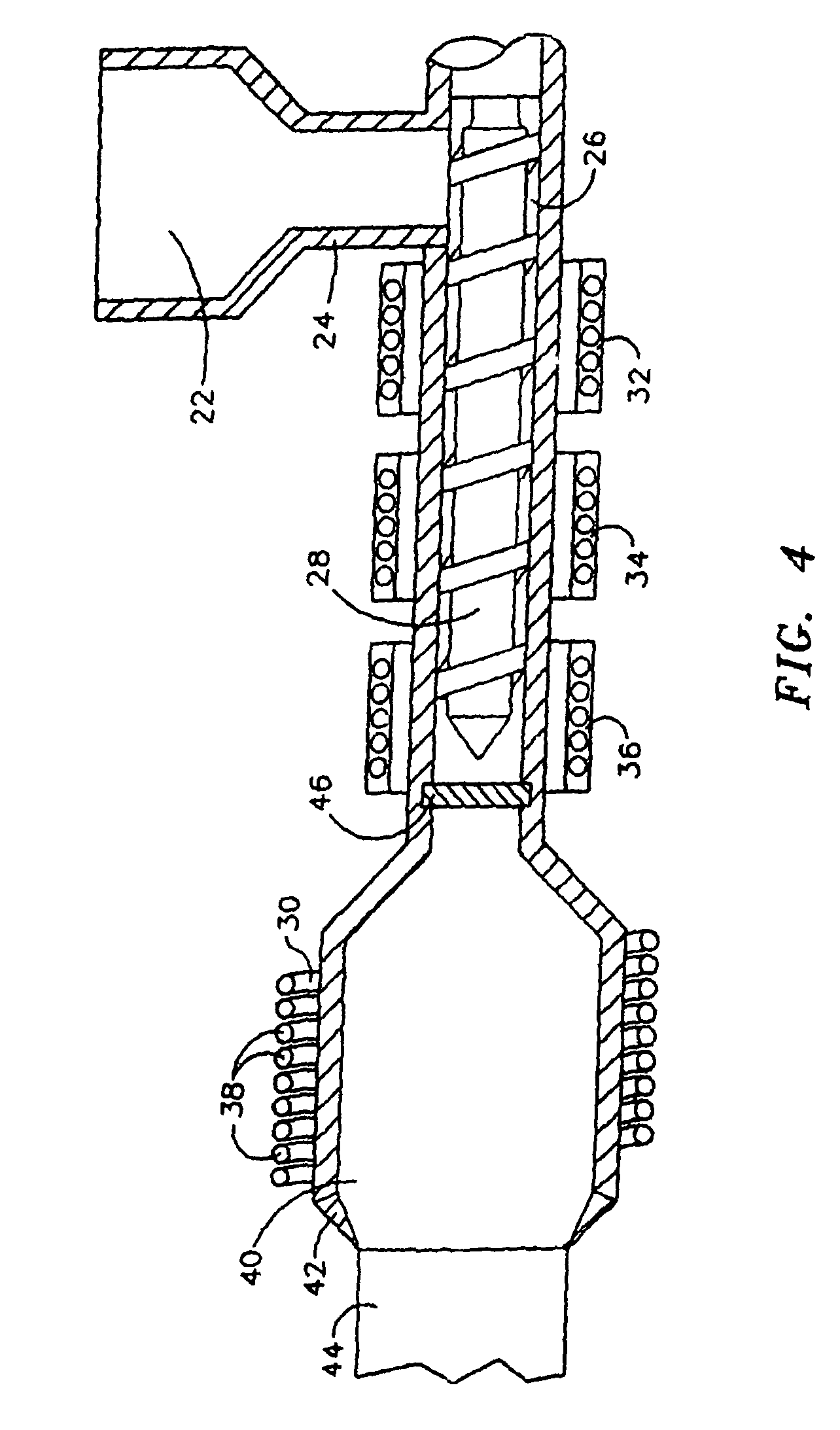

The invention discloses a high-quality coal product production plant which comprises a shell and a heat conduction mechanism arranged in the shell, wherein the heat conduction mechanism is provided with a heat conduction medium inlet near the discharge end, and provided with a heat conduction medium outlet near the feed end; the heat conduction mechanism comprises a plurality of sets of heat conduction units which are distributed at intervals; each heat conduction unit comprises a plurality of heat conduction tubes which are communicated with the heat conduction medium inlet and the heat conduction medium outlet; a plurality of fins, which slope downwards, are longitudinally arranged between adjacent heat conduction tubes; and the lower end of each fin arranged between the heat conduction tubes beside the exhaust passage slopes away from the exhaust passage, so as to shield the exhaust port arranged in the wall surface of the exhaust passage. Since the fins, which are arranged in the blanking space between the heat condition tubes, can turn over the material and discharge gas, the gas can be discharged in time, and heat can be transferred quickly, thereby obtaining the high-quality coal product. The invention also discloses a high-quality coal product production system.

Owner:QIANQIU ENERGY SHANGHAI

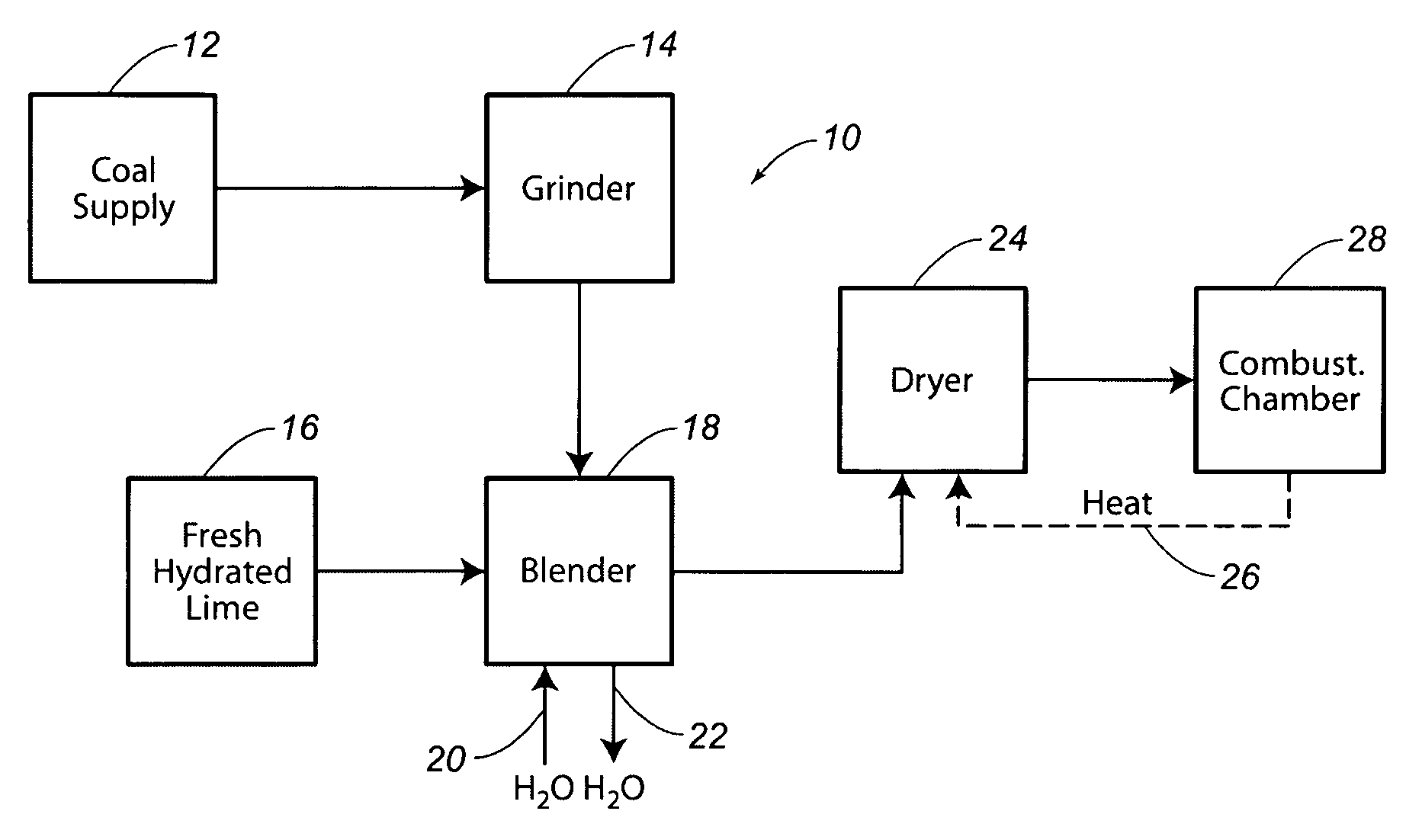

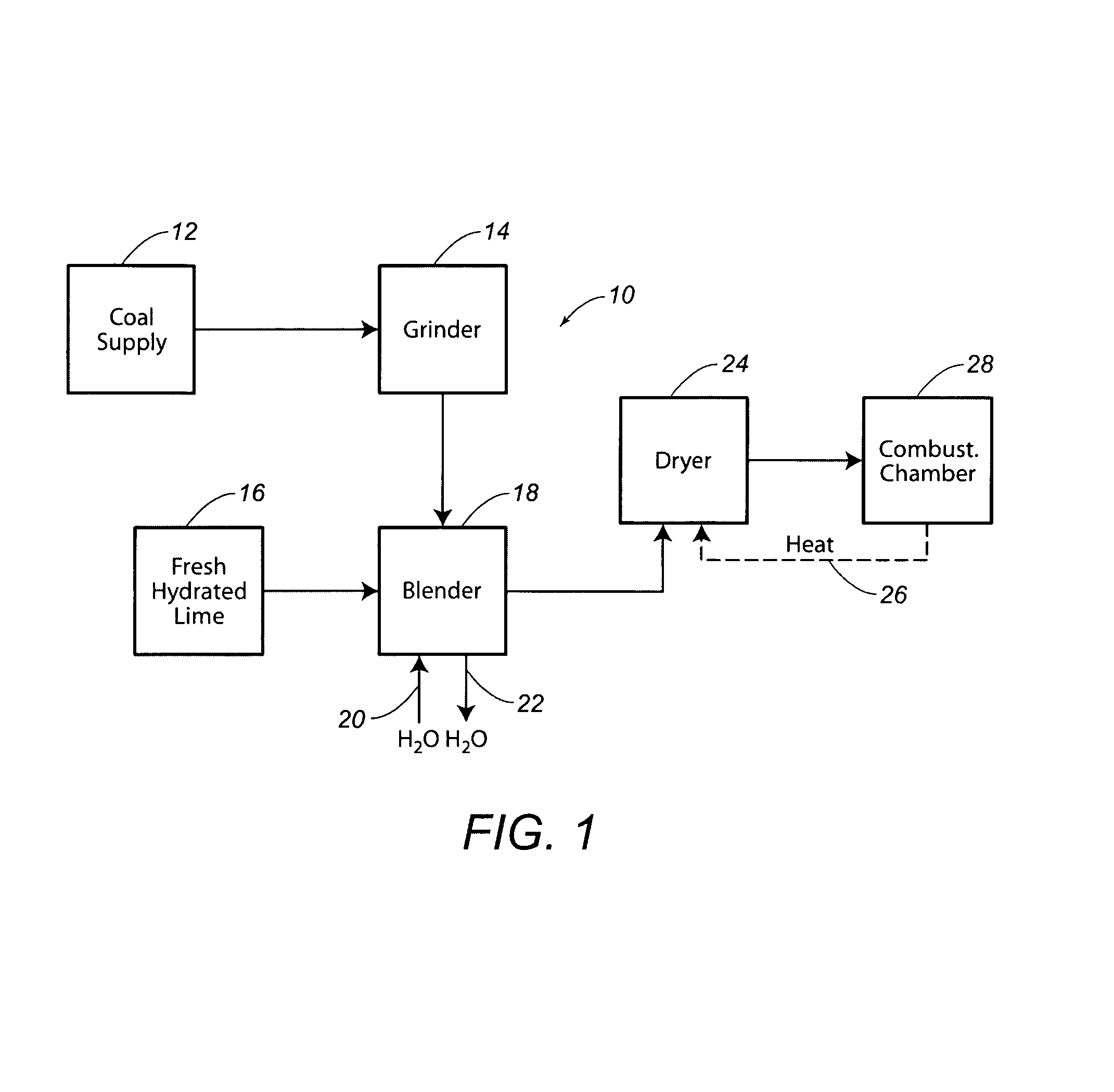

Process for modifying coal so as to reduce sulfur emissions

InactiveUS7056359B1Reduce sulfur emissionsEmission reductionSolid fuelsFuel additivesPower stationGranularity

A method of manufacturing a coal product having reduced sulfur emissions including the steps of grinding coal into a powder form having a desired particle size; blending the ground coal with hydrated lime; adding water to the blend so as to have a moisture content of between 10 and 30 weight percent and drying the water-added blend so as to have a desired reduced moisture content. The desired reduced moisture content is less than 1% of the total weight of the coal powder and the hydrated lime. The step of drying includes heating the water-added blend to a temperature of between 300 and 400° F. in an externally heated oven. Waste heat form a power plant can be used so as to head the blend.

Owner:WILSON GREATBATCH LTD

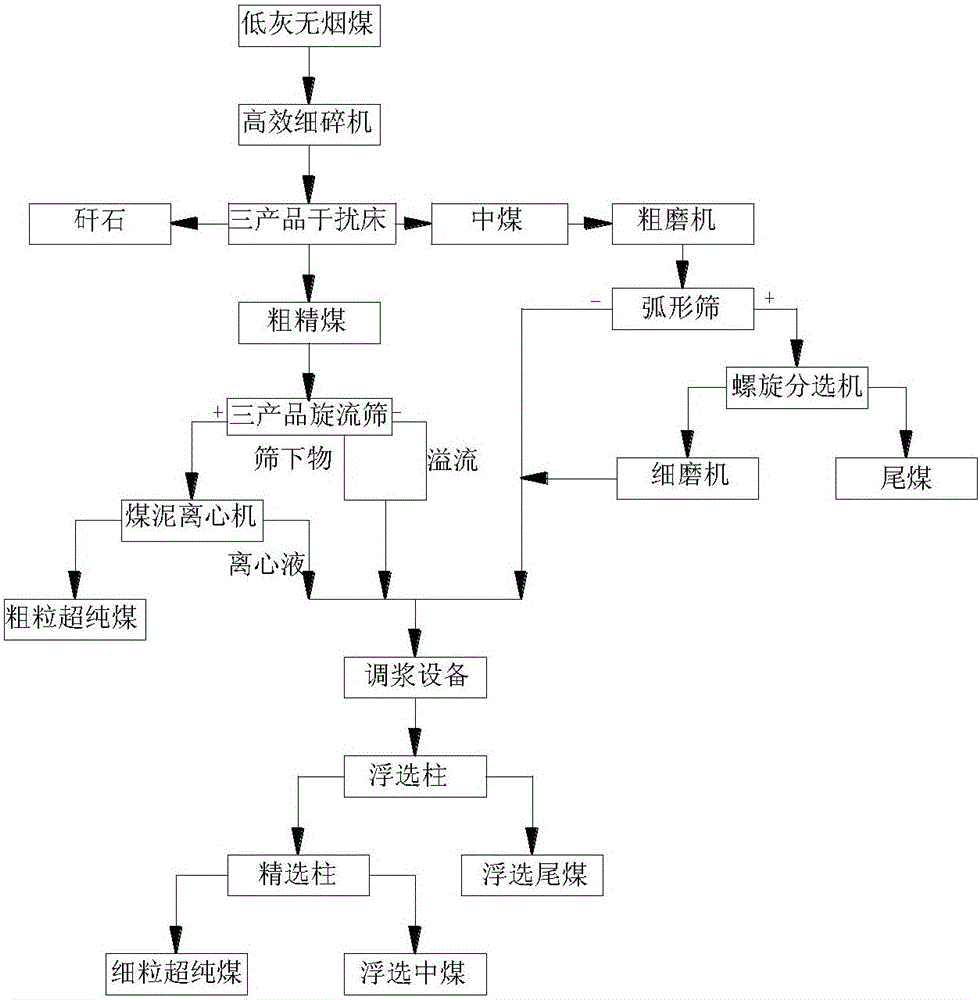

Preparation technology of super pure coal

ActiveCN105728156AAvoid enteringAvoid pollutionSolid separationGrain treatmentsSeparation technologyEngineering

The invention discloses a preparation technology of super pure coal, and is applicable to the technical field of mineral separation. The preparation technology comprises the steps that after minus 50 mm low-ash anthracite is crushed through a high-efficiency fine crusher, the crushed low-ash anthracite is introduced into a three-product interference bed for separation, and coarse clean coal, medium coal and recrement are obtained; coarse clean coal is classified through a three-product vortex sieve, and coarse clean coal remaining on the sieve is dehydrated through a coal slime centrifuge to obtain a coarse-particle super pure coal product; and after primary coarse grinding, medium coal is introduced into a sieve bend for classification, oversize material on the sieve bend is introduced into a spiral separator for tailing discharging, and after secondary fine grinding, a light product is introduced into a flotation device for flotation together with screen underflows of the three-product vortex sieve, overflows, the centrifugate of the coal slime centrifuge, and screen underflows of the sieve bend, and a fine-particle super pure coal product is obtained. According to the preparation technology, a two-stage ore grinding technology is adopted, so that an overgrinding phenomenon which often occurs during open-circuit grinding is avoided; tailings are discharged during primary ore grinding, so that efficiency and energy consumption are achieved; the two-stage floatation is adopted, so that low-ash clean coal can be obtained; and compared with a traditional separation technology, the preparation technology has the advantages that the principle of more crushing and less grinding is better met, efficiency and energy consumption are achieved, and the economic benefits are remarkable.

Owner:CHINA UNIV OF MINING & TECH

Slime separation method and equipment

InactiveCN101773873AImprove recycling effectSurface as soon as possibleFlotationEconomic benefitsEngineering

The invention relates to a slime separation method and equipment. The slime separation method adopts a one-piece double-flotation-column to carry out circulating flotation and classification for slime, and a flow stabilizer is arranged in a first flotation column; the flow stabilizer can eliminate large vortex, support a foam layer and increase the probability of collision between particles and bubbles, so that the slime easy to float can be floated out as soon as possible so as so reduce mix and pollution and play the role of flow stabilization; the material floated out through sedimentation is classified by a first sedimentation box and then enters a second floatation column to be floated again, and then enters a second sedimentation box to be classified again; and the number of the circulating separation of pulp is increased, and the recovery capabilities of coarse-fraction slime and difficultly floated fine-fraction slime are improved. The equipment has compact structure, large treating capacity, low production operation cost, and convenient installation and operation, improves the number and quality of fine coal products on the whole, and has marketable economic benefits.

Owner:CHINA UNIV OF MINING & TECH

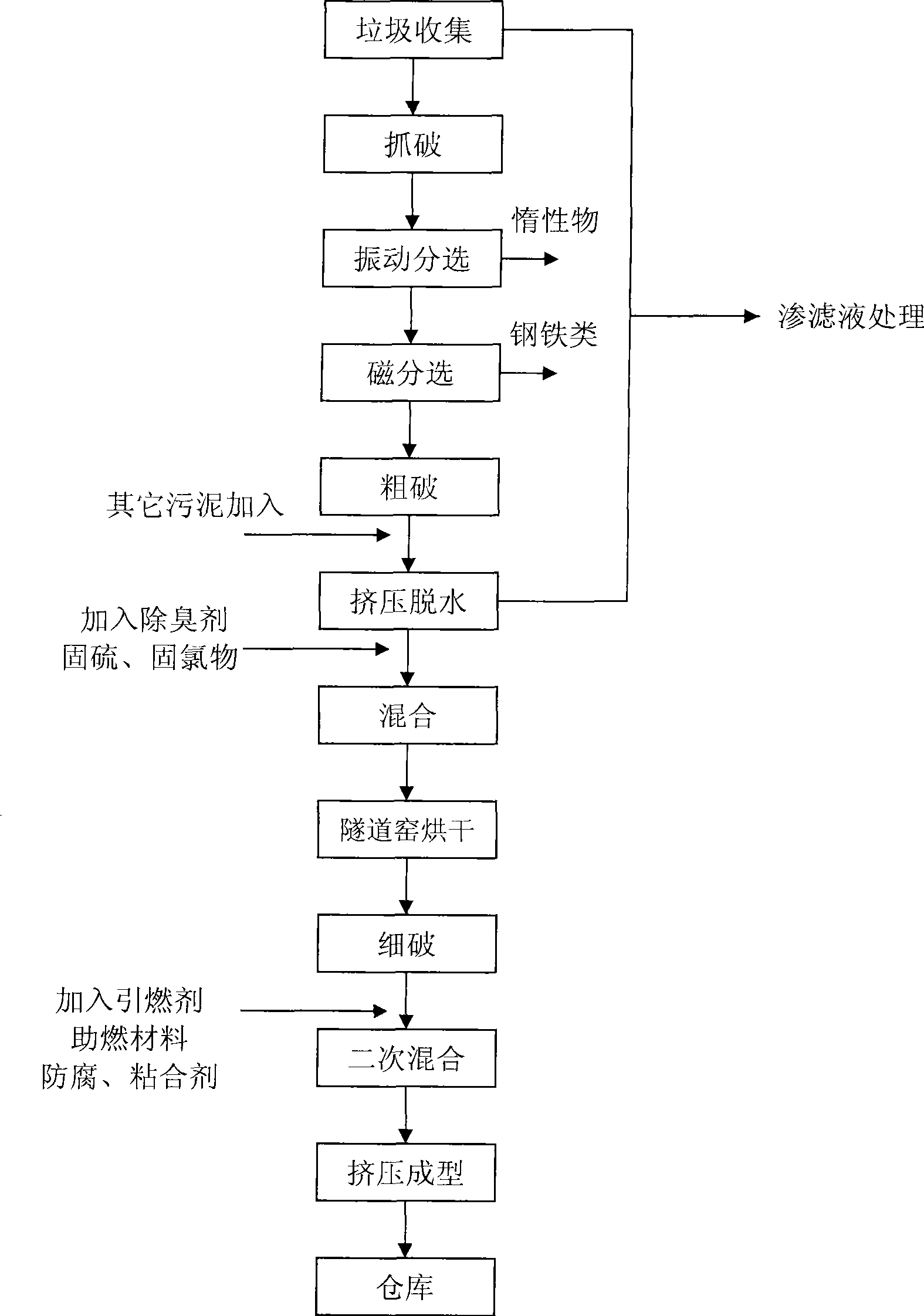

Technique for preparing consumer waste regenerated coal

InactiveCN101362977AEnsure resource utilizationGuaranteed to be harmlessBiofuelsSolid fuelsTunnel kilnAdhesive

The invention relates to a technology for treating living garbage, in particular to a complete production process for changing the living garbage to garbage renewable coal products. The urban living garbage is firstly sent to a designated garbage place for collection; then coarse visible inert materials and iron and steel metals are removed through the scratch, the vibration selection and the magnetic selection pre-treatment, after that, a coarse breaker is used for carrying out the coarse breaking of the garbage till less than 50mm; the coarsely broken garbage is extruded and dehydrated, a deodorant, a bactericide and sulfur fixing and chloride fixing substances are added after the dehydration, the even mixing is carried out in a stirrer; then the high-temperature drying by a tunnel kiln is carried out, the fine breaking is carried out after the drying, the particle size of the garbage is controlled to be within 20 meshes at the stage, an ignition agent, a combustion improver, a preservative, a adhesive, and the like, are added after the fine breaking, the even mixing with the garbage particles after the fine breaking is carried out in the stirrer; finally the coal is prepared by extrusion forming, the shape and the dimension can be achieved in the pass design of a template.

Owner:周泽宇

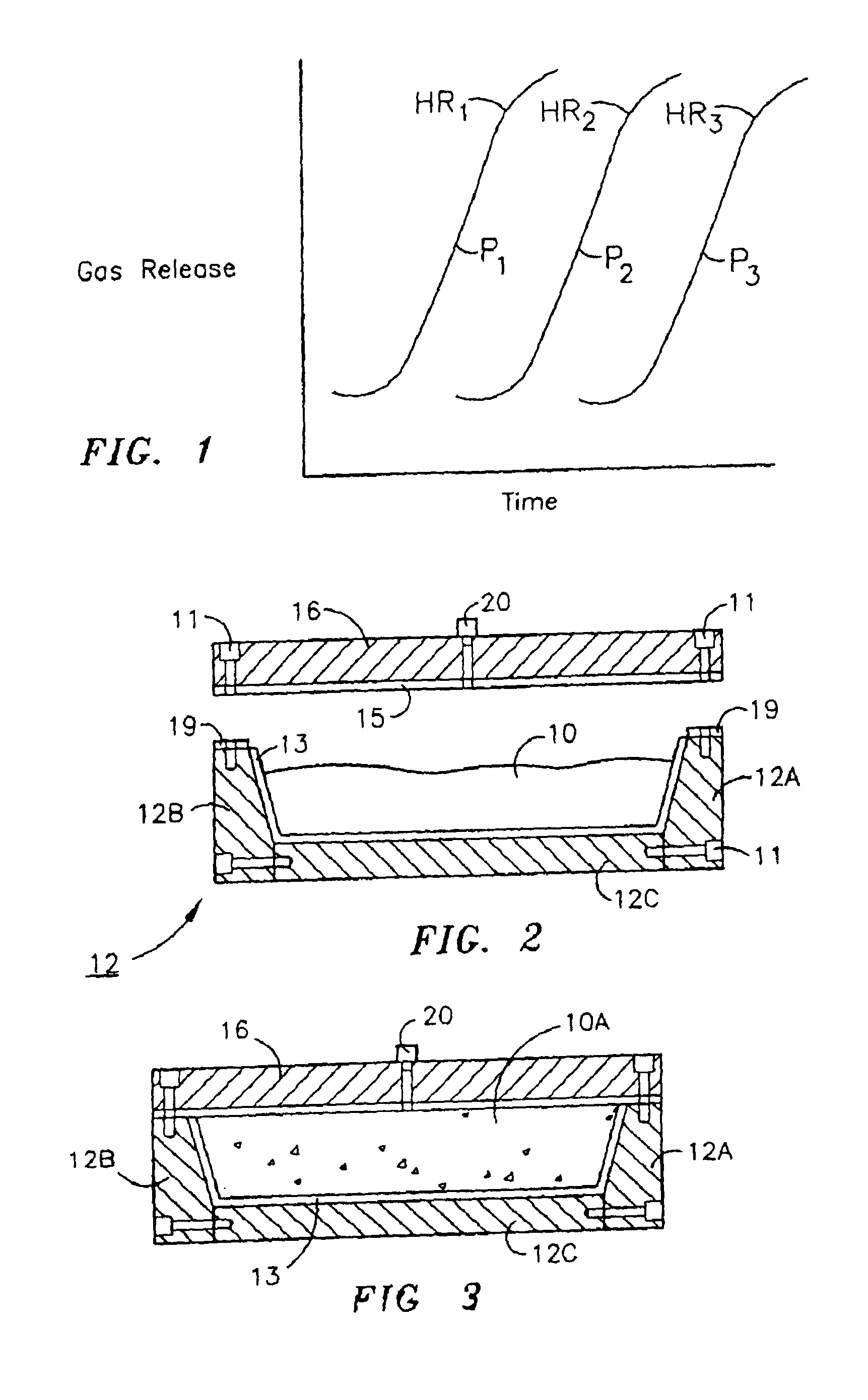

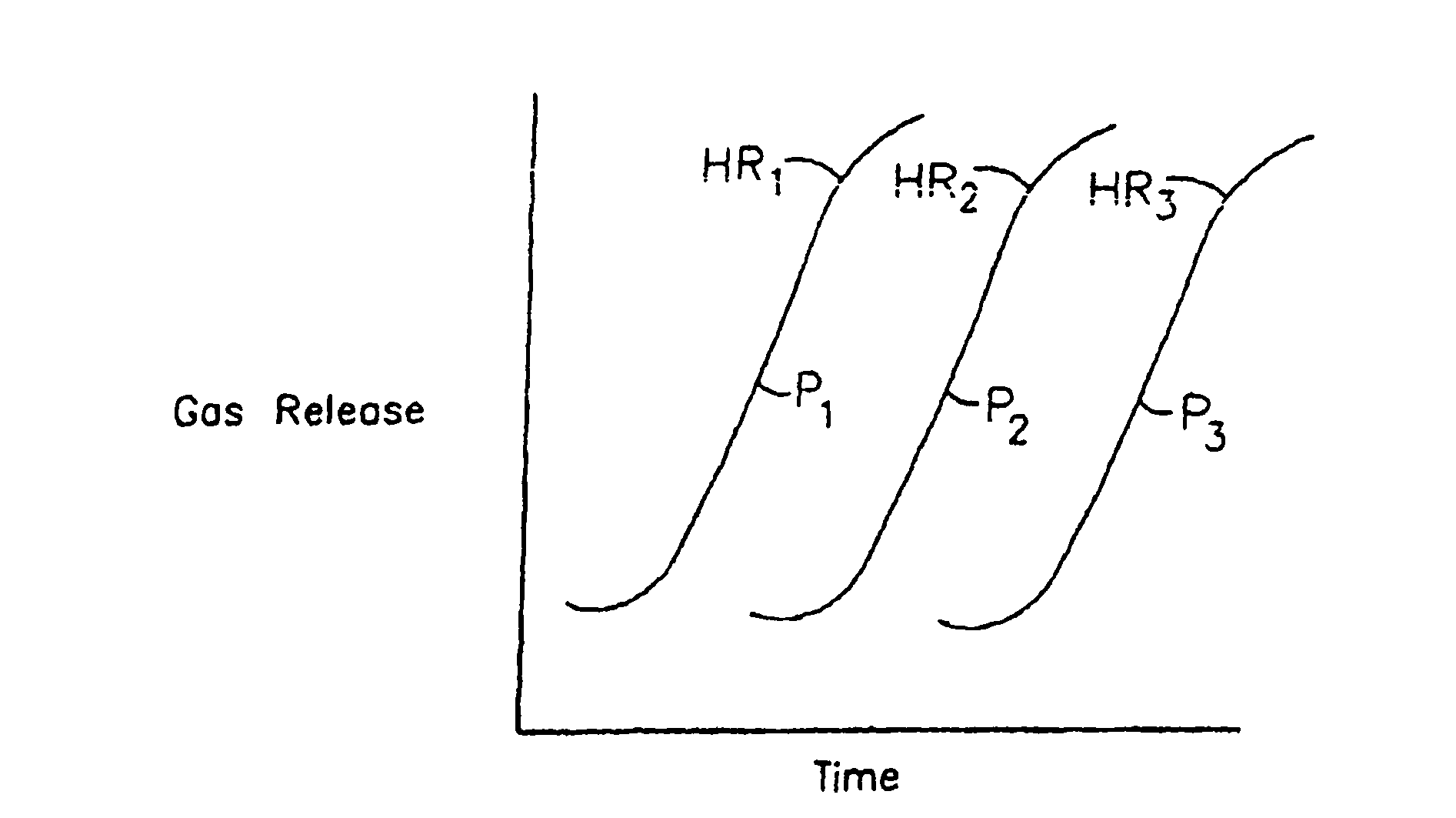

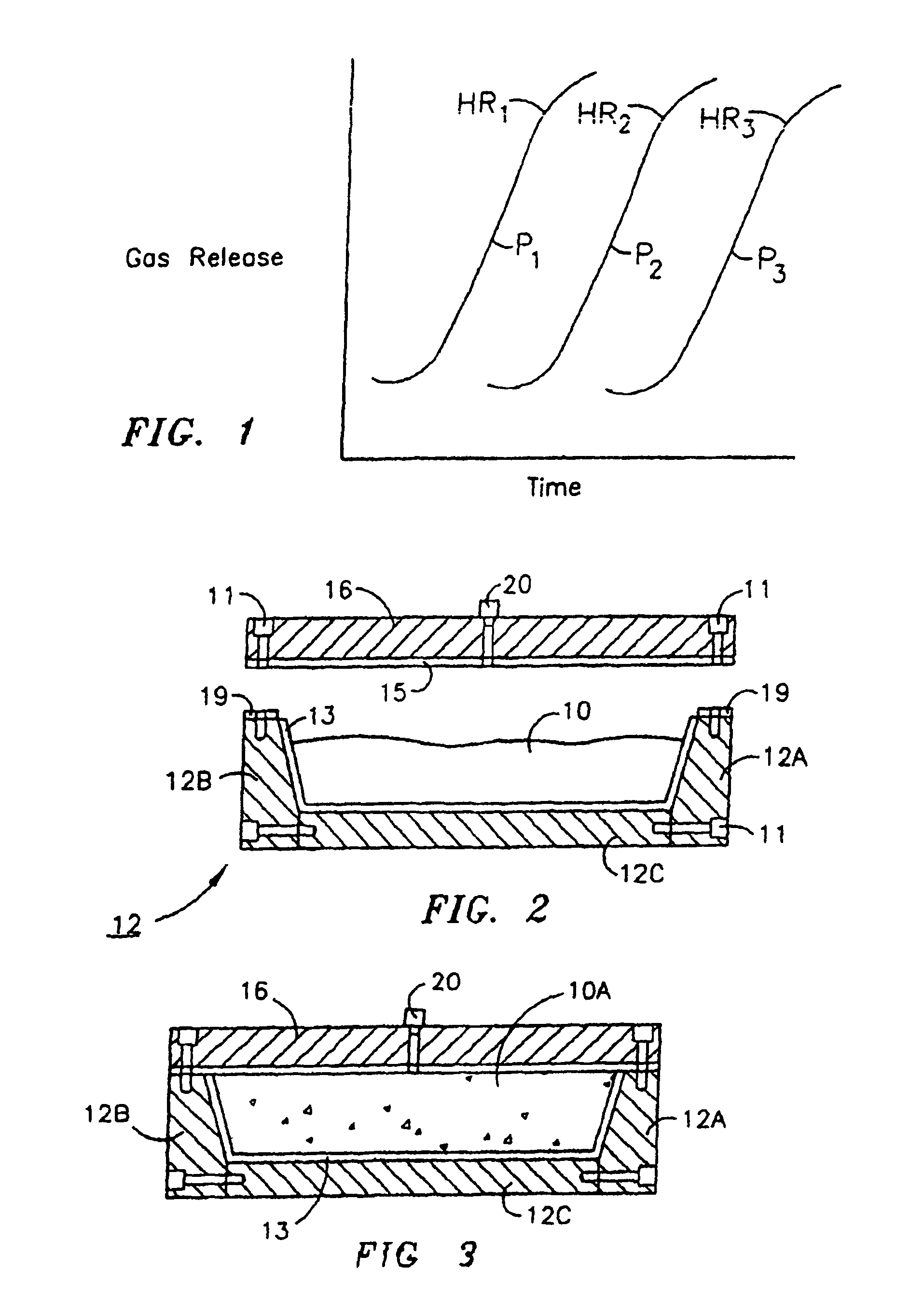

Cellular coal products and processes

InactiveUS6814765B1Low costLow densityPigmenting treatmentSolid fuelsParticulatesElectrical conductor

According to the present invention there is provided a coal-based carbon foam having a density of between about 0.1 g / cm<3 >and about 0.8 g / cm<3>, preferably between about 0.2 g / cm<3 >and about 0.6 g / cm<3 >and most preferably between about 0.3 g / cm<3 >and about 0.4 g / cm<3 >that is produced by the controlled heating of high volatile bituminous coal particulate in a "mold" and under a non-oxidizing atmosphere. The high volatile bituminous coal starting material preferably exhibits a free swell index of between about 3.5 and about 5.0 and most preferably between about 3.75 and about 4.5. A number of additional highly desirable characteristics of the high volatile bituminous coal starting material are also described. The carbon foam product thereby produced can be machined, adhered and otherwise fabricated to produce a wide variety of low cost, low density products, or used in its preformed shape as a filter, heat or electrical insulator etc. Such carbon foams, with treatment exhibit compressive strengths of up to about 6000 psi. Further treatment by carbonization or graphitization yields products that can be used as electrical or heat conductors. Methods for the production of these coal-based cellular products are also described.

Owner:TOUCHSTONE RES LAB

Cellular coal products and processes

InactiveUS6749652B1Low costLow densityPigmenting treatmentFoundry mouldsParticulatesElectrical conductor

Owner:CFOAM LLC

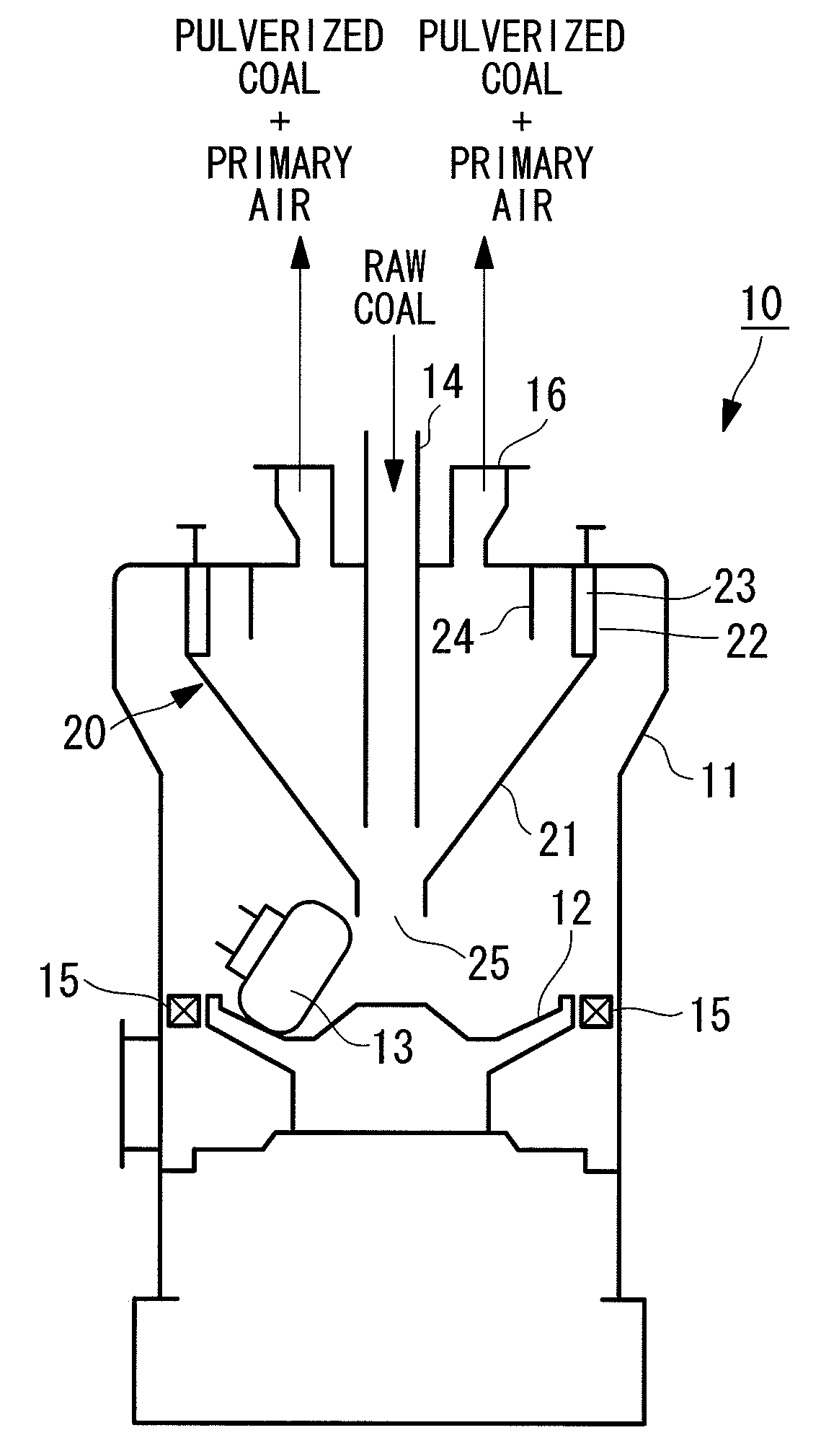

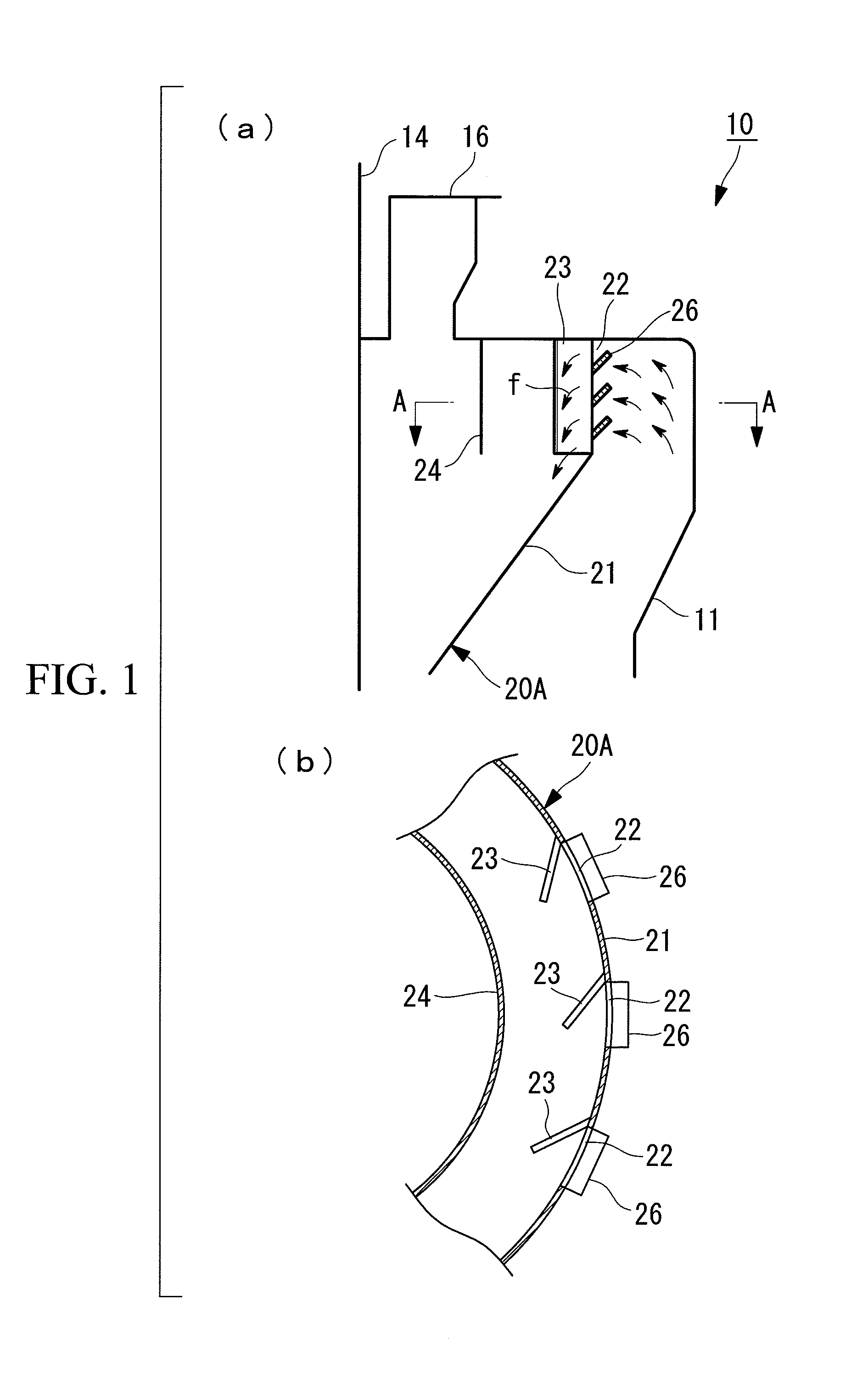

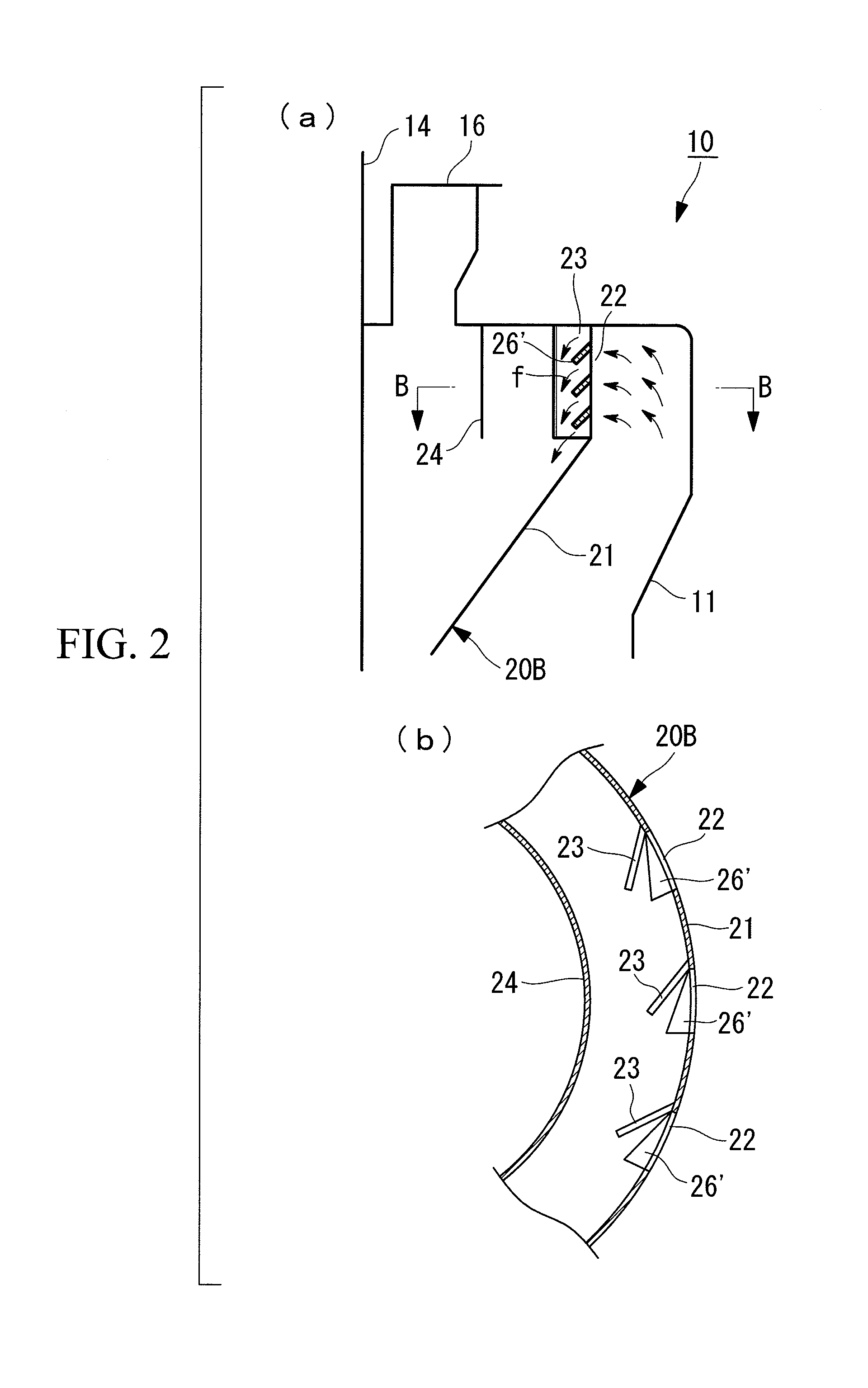

Vertical roller mill

InactiveUS20120138718A1Reduce contentEasy maintenanceGas current separationGrain treatmentsEngineeringCentrifugal force

In a vertical roller mill including a fixed classifier, a proportion of coarse particles in a pulverized coal product is reduced. The vertical roller mill (10) includes a cyclone-type fixed classifier (20A) provided within a casing (11) for classifying fine powder having a small particle diameter by centrifugal force and discharging the classified powder to the outside. The fixed classifier (20A) is adapted to discharge the fine powder to the outside from a pulverized coal outlet (16) at an upper side through a lower end portion of an inner cylinder (24) provided inside a cone (21) by introducing a solid-gas two-phase flow into the inside from a fixed vane inlet window (22) opened on the cone (21) and swirling the solid-gas two-phase flow using a fixed vane (23) arranged in the vicinity of the inner side of the fixed vane inlet window (22). A deflector (26) is provided in the vicinity of the fixed vane inlet window (22) for strengthening the solid-gas two-phase flow delivered into the inside of the cone (21) from the fixed vane inlet window (22) in the downward direction.

Owner:MITSUBISHI HEAVY IND LTD

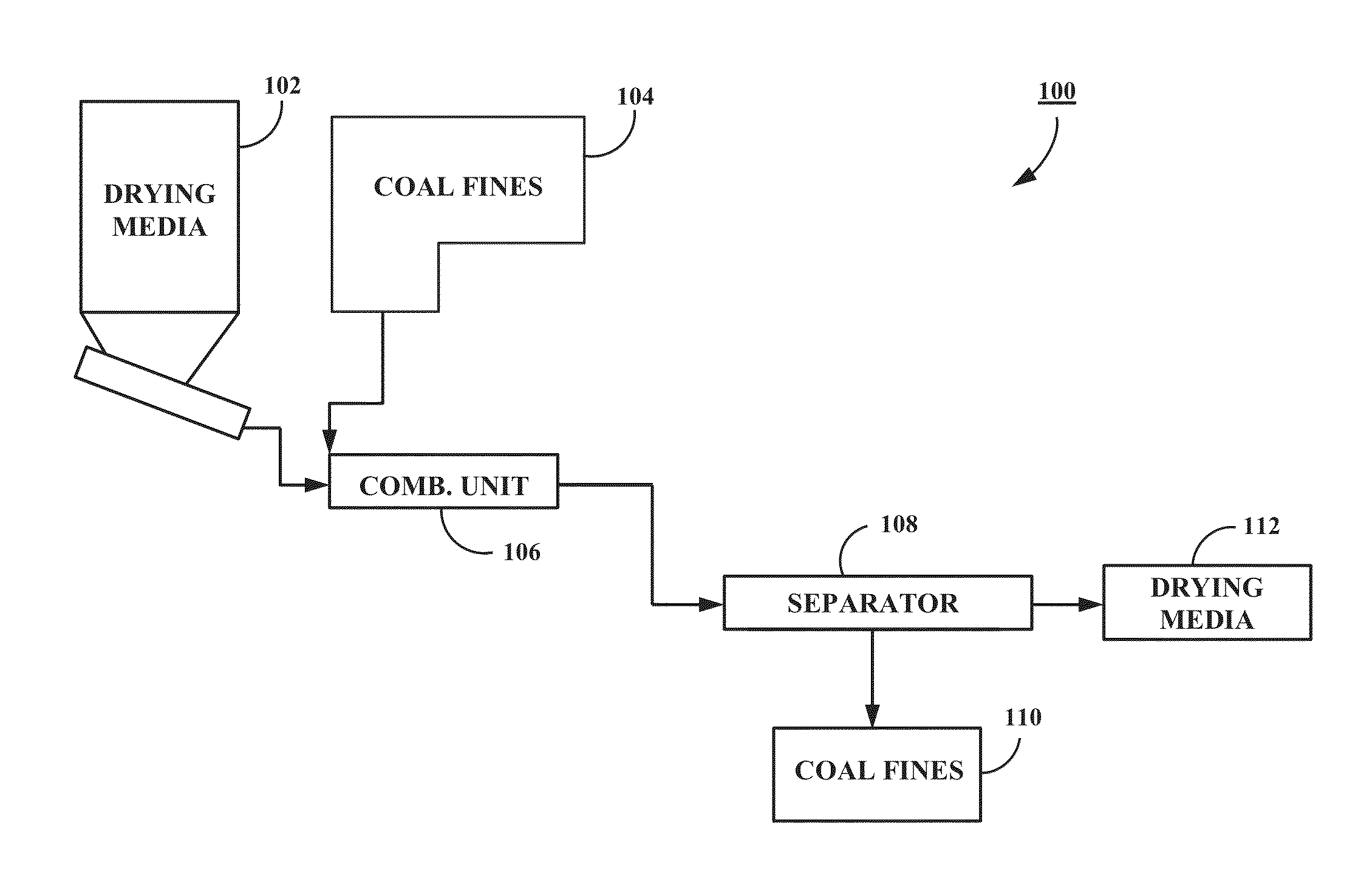

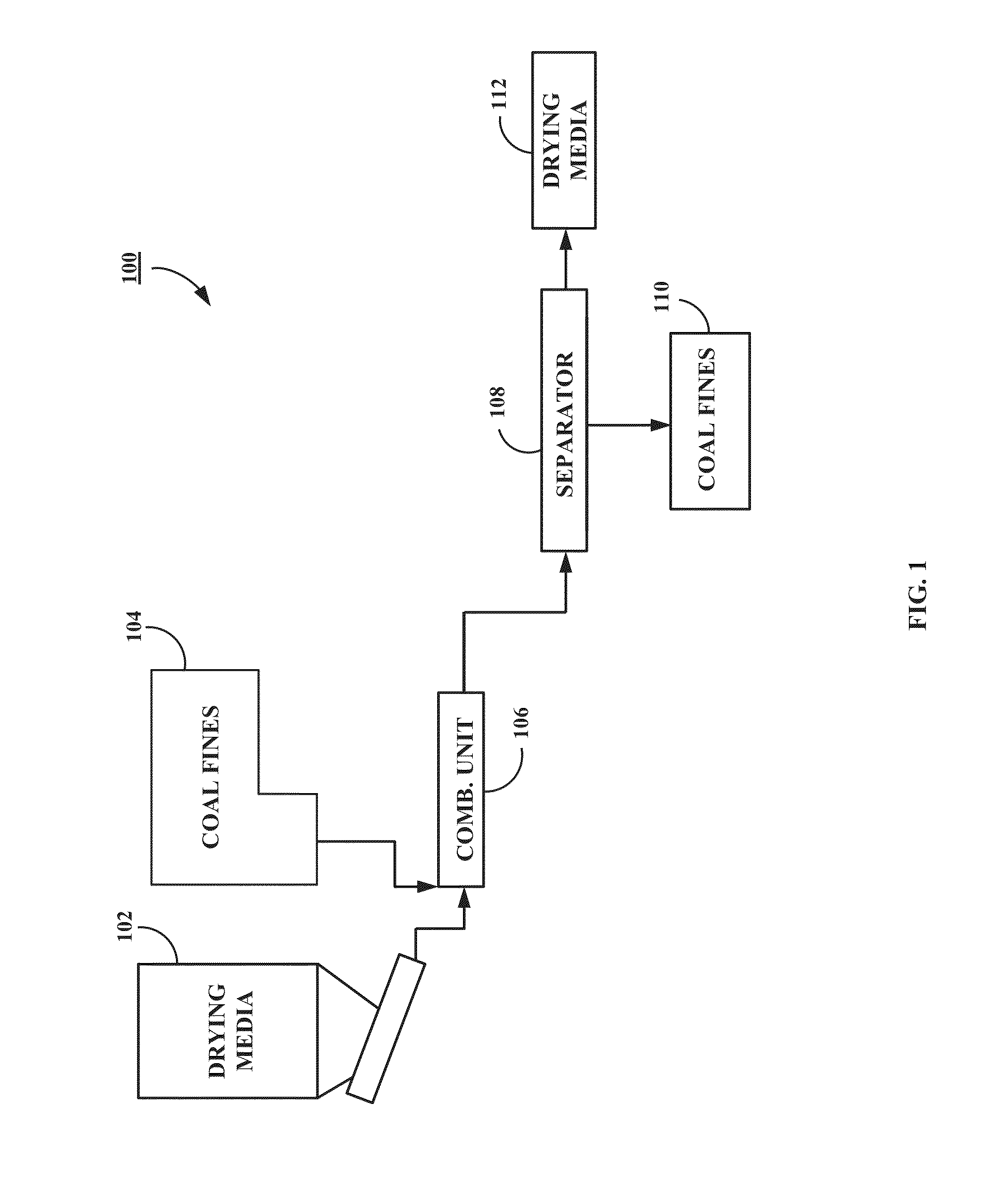

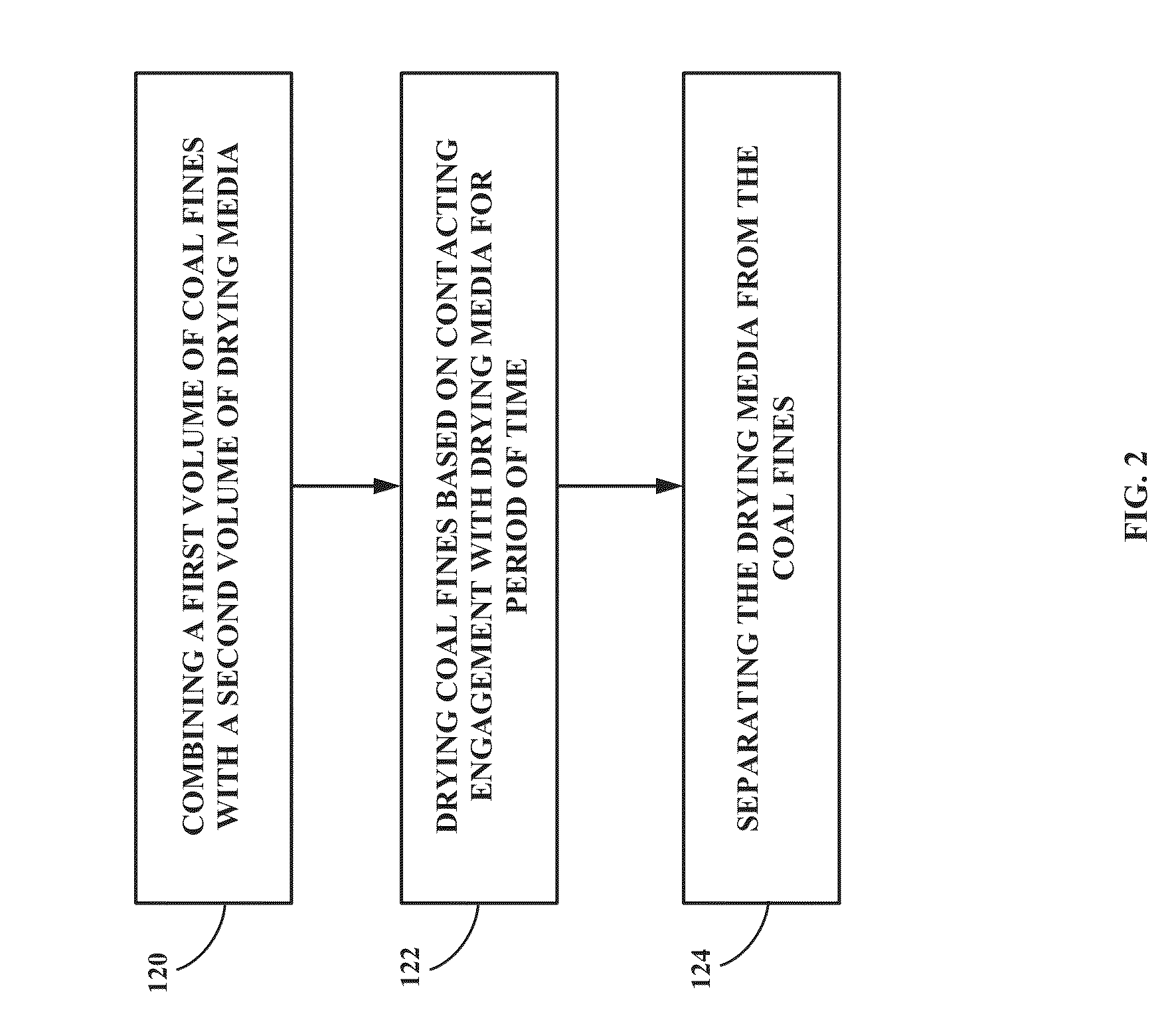

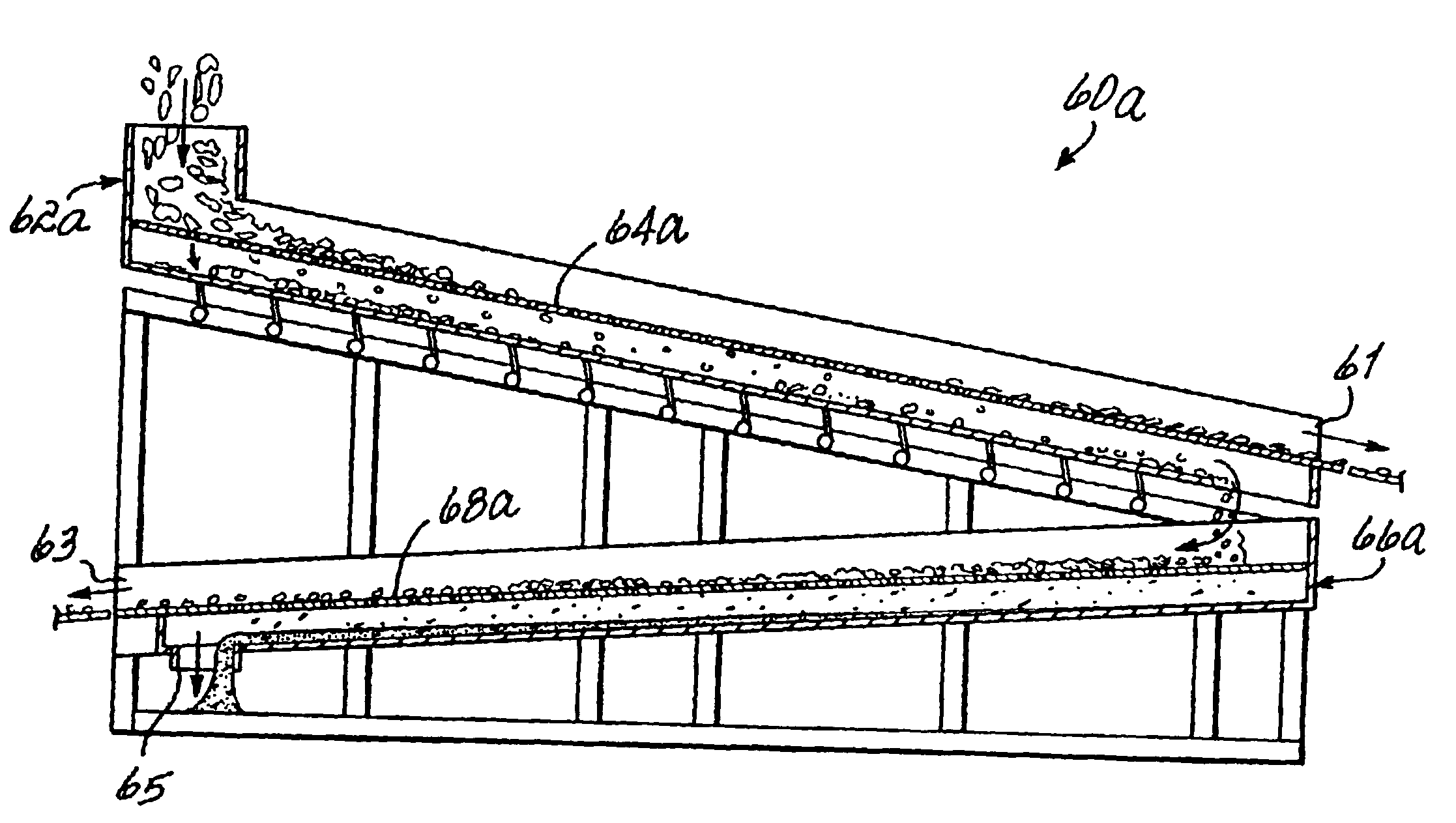

Coal drying method and system

InactiveUS20140144072A1Maximize surface contactLarge capacityCoke ovensDrying solid materials without heatProcess engineeringMoisture

The present invention provides methods and systems for reducing moisture in coal, particularly coal fines and other coal streams comprising small diameter particles, using a granular drying material. The invention also relates to novel coal products and intermediates useful in connection with the process. The method and system reduced moisture by contacting the coal with the granular drying material. The granular drying material is selected to be readily separated from the coal fines using a size separation technique such as a sieve screen. The granular drying material is the regenerated, preferably using a process involving heat exchange and cross-flow air. The granular drying material is preferably capable of regeneration and recycling in a continuous process with minimal attrition.

Owner:VITRINITE SERVICES

Method for producing carbonized coal with coal material

InactiveCN101550372AGenerate reduction and overcomeAdjustable generationSolid fuelsIndirect heating destructive distillationPorosityPolymer science

A method for producing carbonized coal with coal material comprises the following components: after adding additive into the coal material and mixing to uniform, mixing in a temperature of 50 DEG C to 250 DEG C, and simultaneously adding nodulizing agent; then shaping in a pressure of 300-1000KN; increasing the temperature and charring according to a program for generating the carbonized coal. According to the invention, the coal material is added with adhesive and nodulizing agent. Furthermore the granularity and matching parameter of coal material are adjusted. Through adjusting the dimension and connecting characteristic of spherule and furthermore controlling the crackle generation and shrinkage characteristics, the performance index controlling of intensity and granularity of product is realized. The whole-ball rate and strength of carbonized coal are increased. The apparent porosity is improved. The high-quality carbonized coal product is obtained.

Owner:山西中元煤洁净技术有限公司

Cellular coal products

According to the present invention there is provided coal-based cellular or porous products, also referred to herein as “carbon foams”, having a density of preferably between about 0.1 g / cm3 and about 0.8 g / cm3 and most preferably between about 0.3 and about 0.4 g / cm3 that are produced by the controlled heating of coal particulate preferably up to ¼ inch in diameter in a “mold” and under a non-oxidizing atmosphere. The coal-based cellular or porous products of the present invention have ash contents typically greater than about 1%. More typically these coal-based cellular or porous products have ash contents greater than about 3%, with ash contents in the range of about 7% to 15% being most typical. The ash residue remaining after essentially complete combustion / oxidation of these coal-based cellular or porous products is predominately composed of oxides of aluminum and silicon. Additionally, the cellular coal-based products of the present invention have relatively low overall B.E.T. surface areas. Such surface areas are typically less than about 5 m2 / g and are commonly in the range of about 1 m2 / g to about 2 m2 / g.

Owner:CFOAM LLC

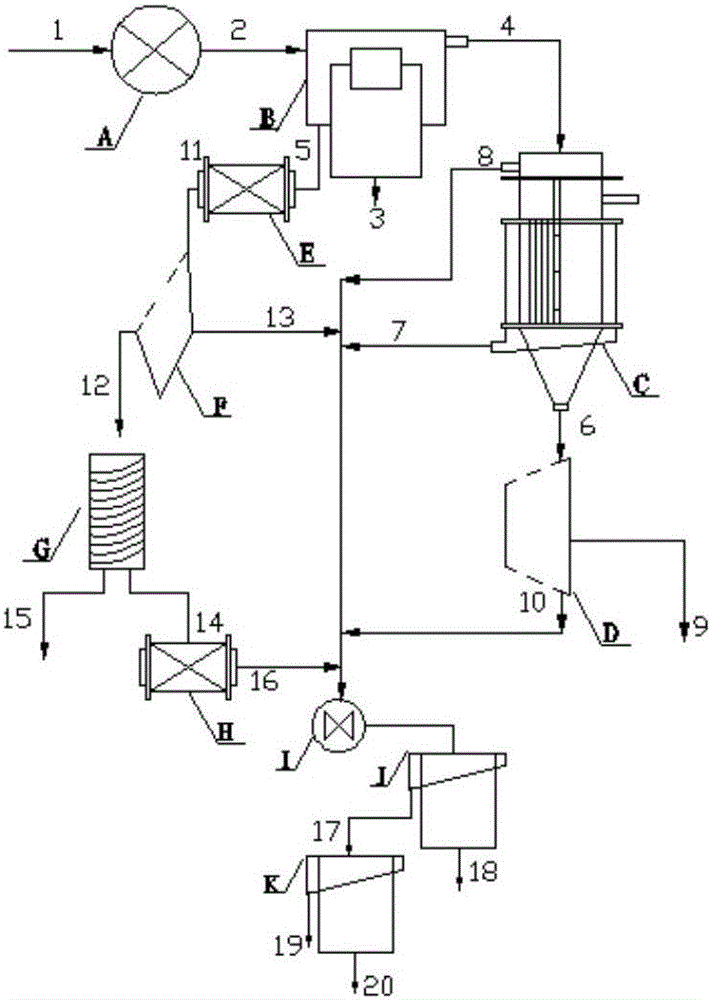

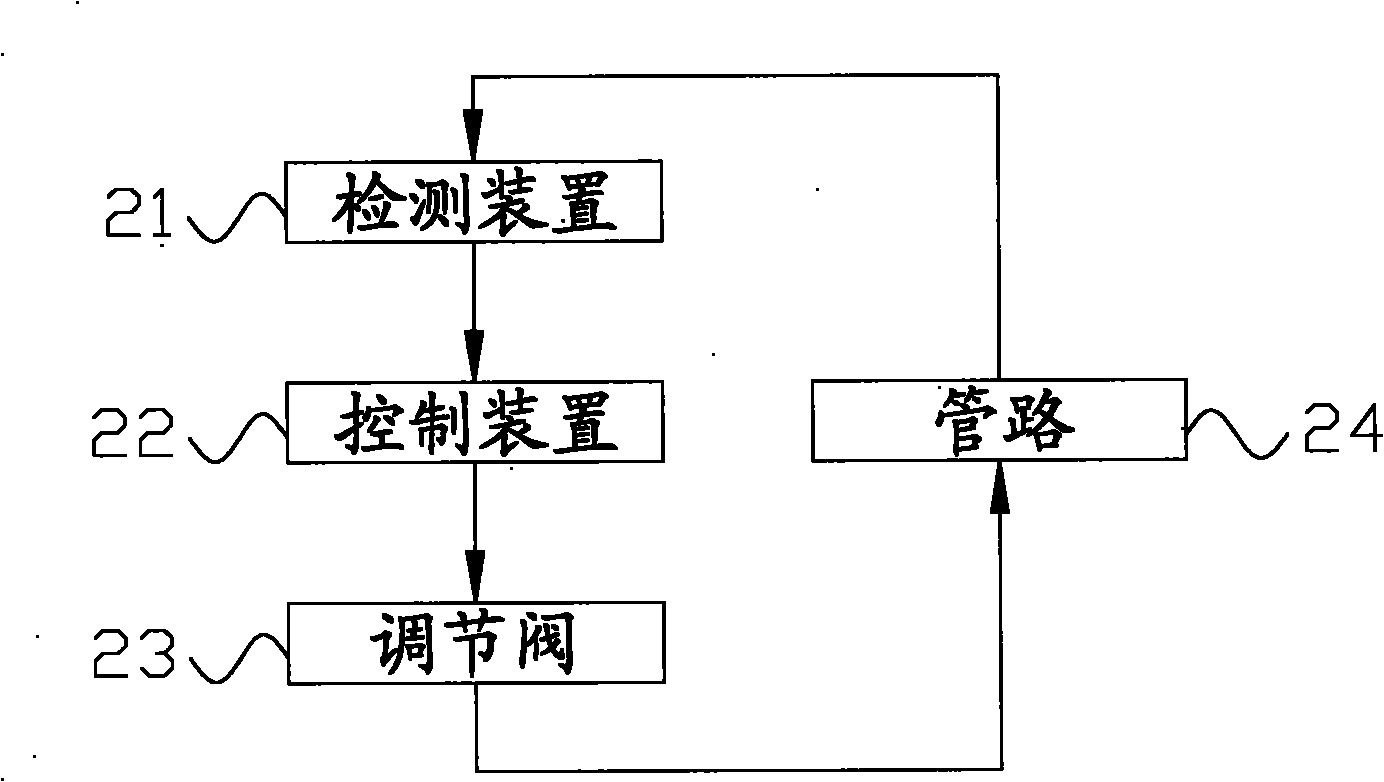

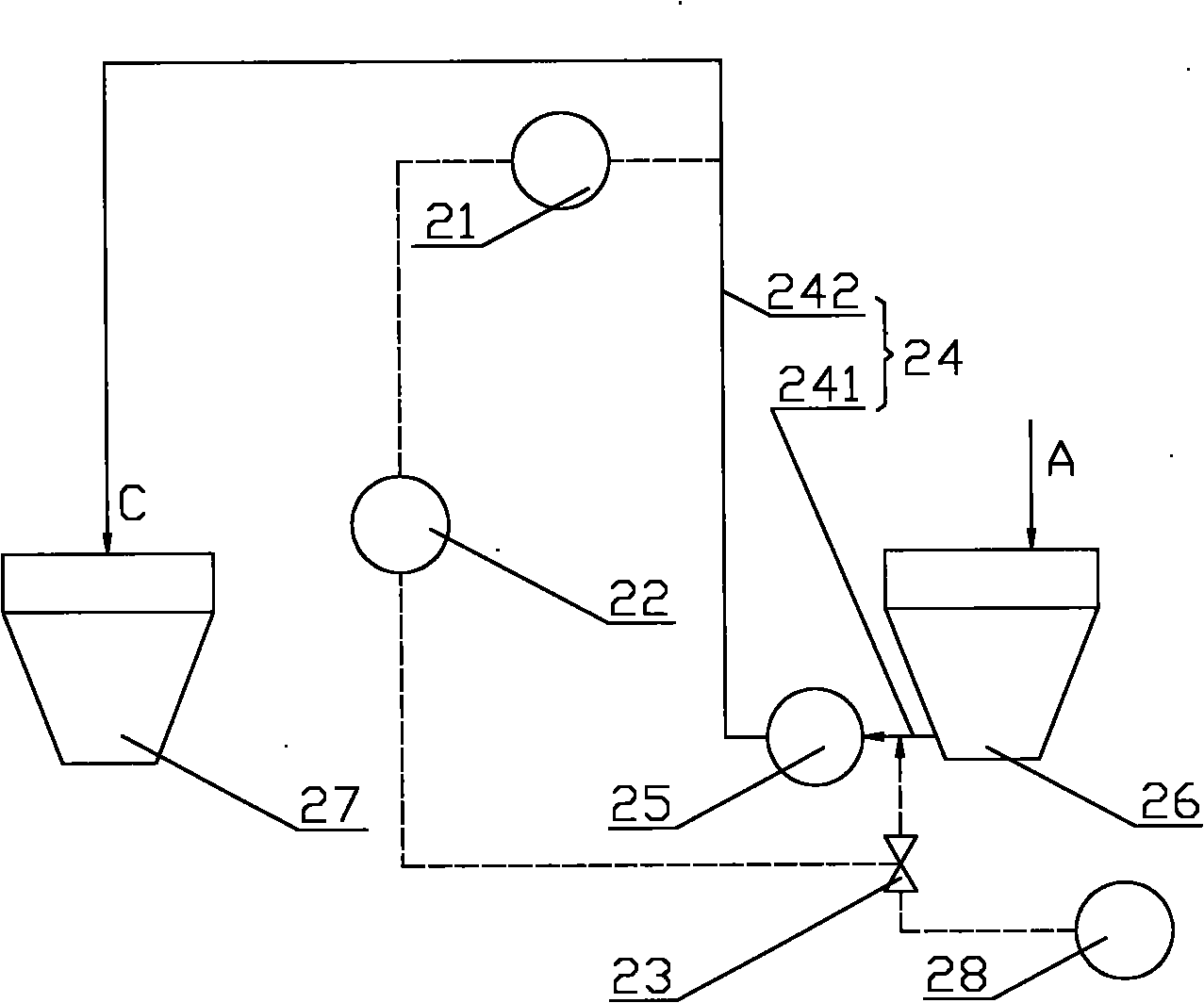

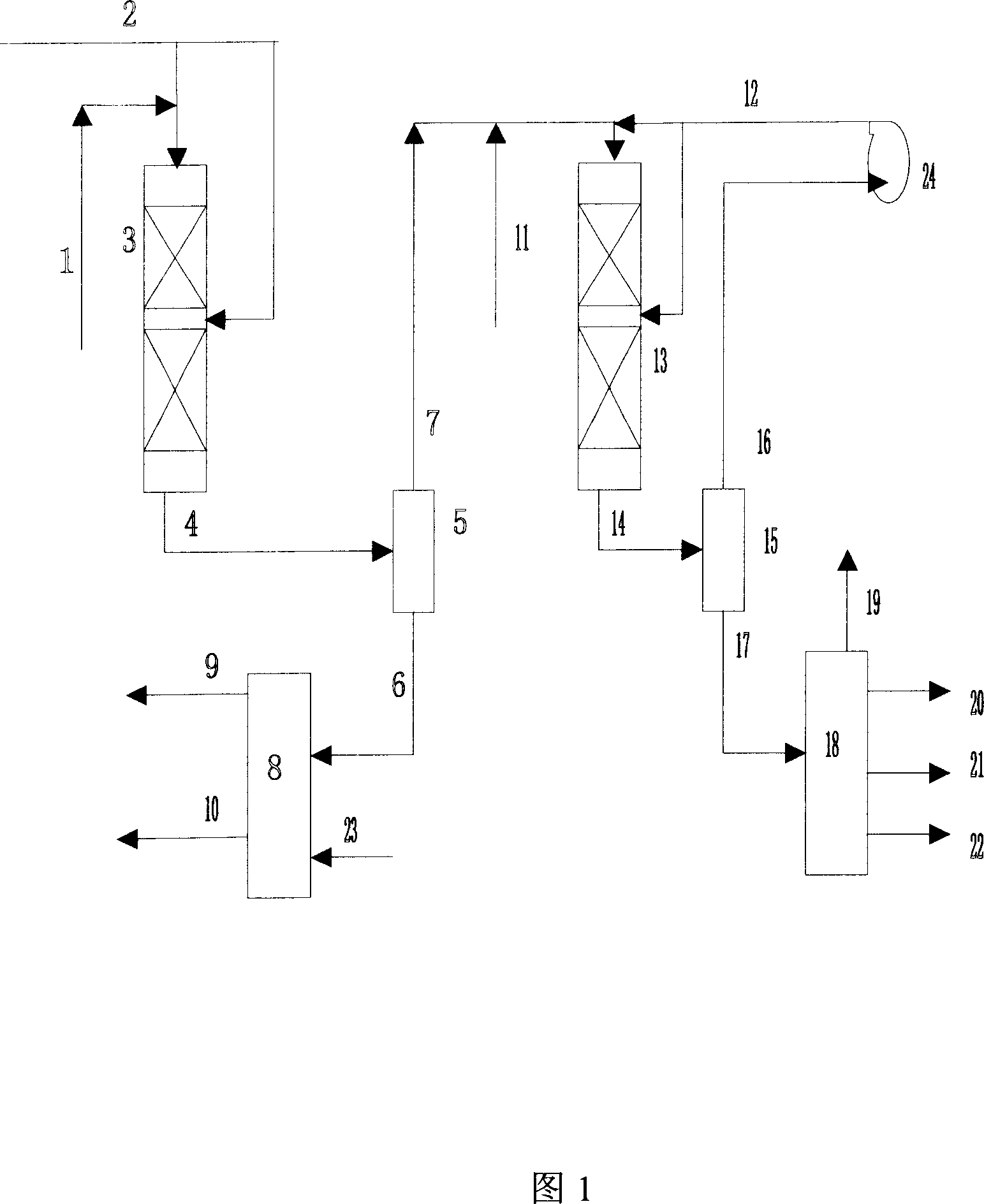

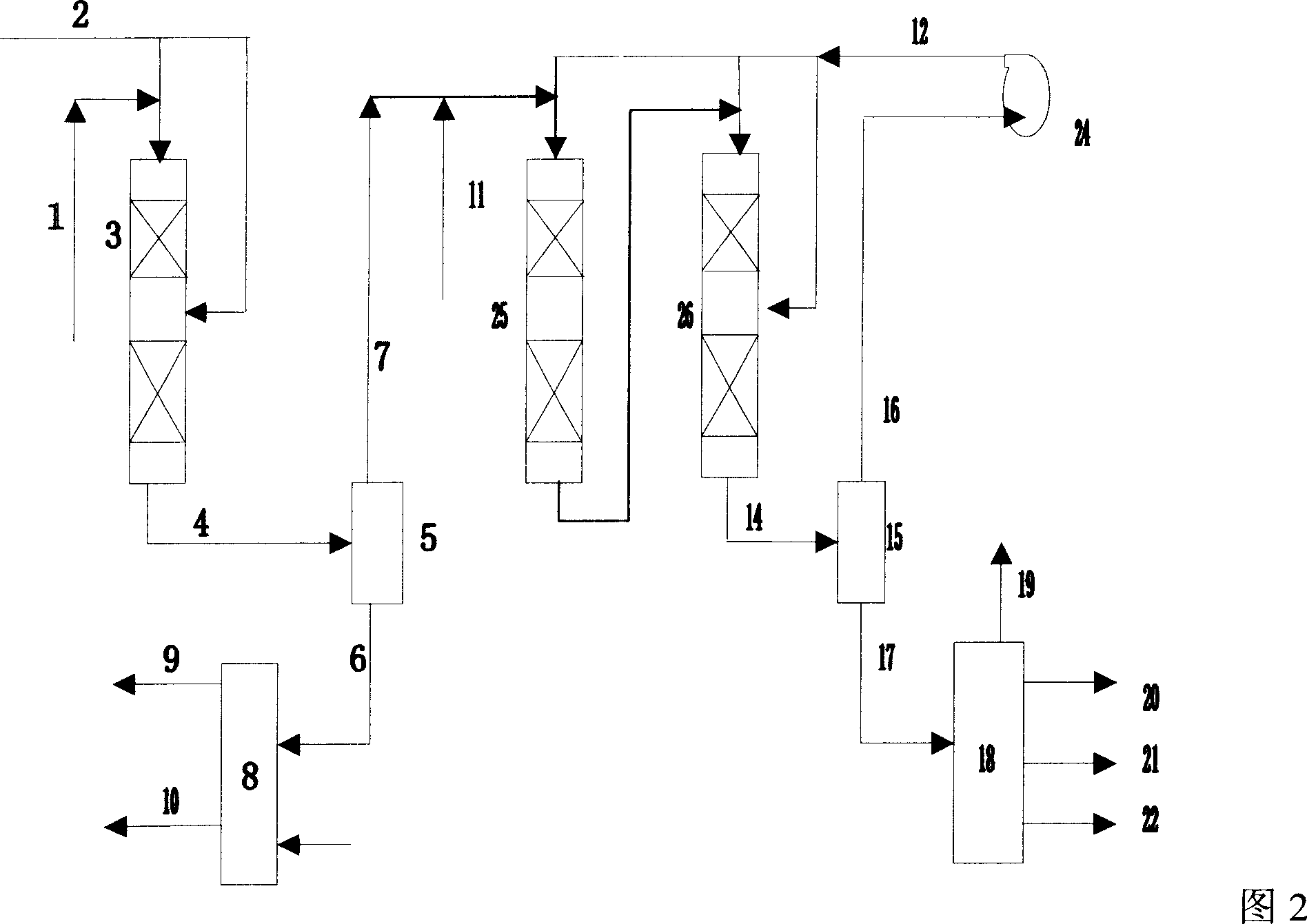

Heavy medium coal preparation control equipment, density control system thereof and density control method

The invention discloses a density control system of heavy medium coal preparation control equipment. The heavy medium coal preparation control equipment comprises a medium barrel (26) and separation equipment, wherein the medium barrel (26) and the separation equipment are communicated by a pipe (24). The density control system comprises a detection device (21), a control device (21) and a regulation valve (23), wherein the regulation valve (23) is communicated with a water source (28) and a pipe (24); the detection device (21) detects the density of suspension in the pipe (24) between the regulation valve (23) and the separation equipment; the control device (22) receives a detected density signal and compares a detected density with a preset density; when the detected density is smallerthan the preset density, the opening of the regulation valve (23) is controlled to reduce; when the detected density is equal to the preset density, the opening of the regulation valve (23) is controlled to be constant; and when the detected density is greater than the preset density, the opening of the regulation value (23) is controlled to increase. The density control system can reduce power consumption and production cost and can ensure the quality stability of a screen out concentrate coal product. The invention also discloses the heavy medium coal preparation control equipment and a density control method.

Owner:PANJI BRANCH OF FINLAY COAL DRESSING ENG & TECH BEIJING CO LTD

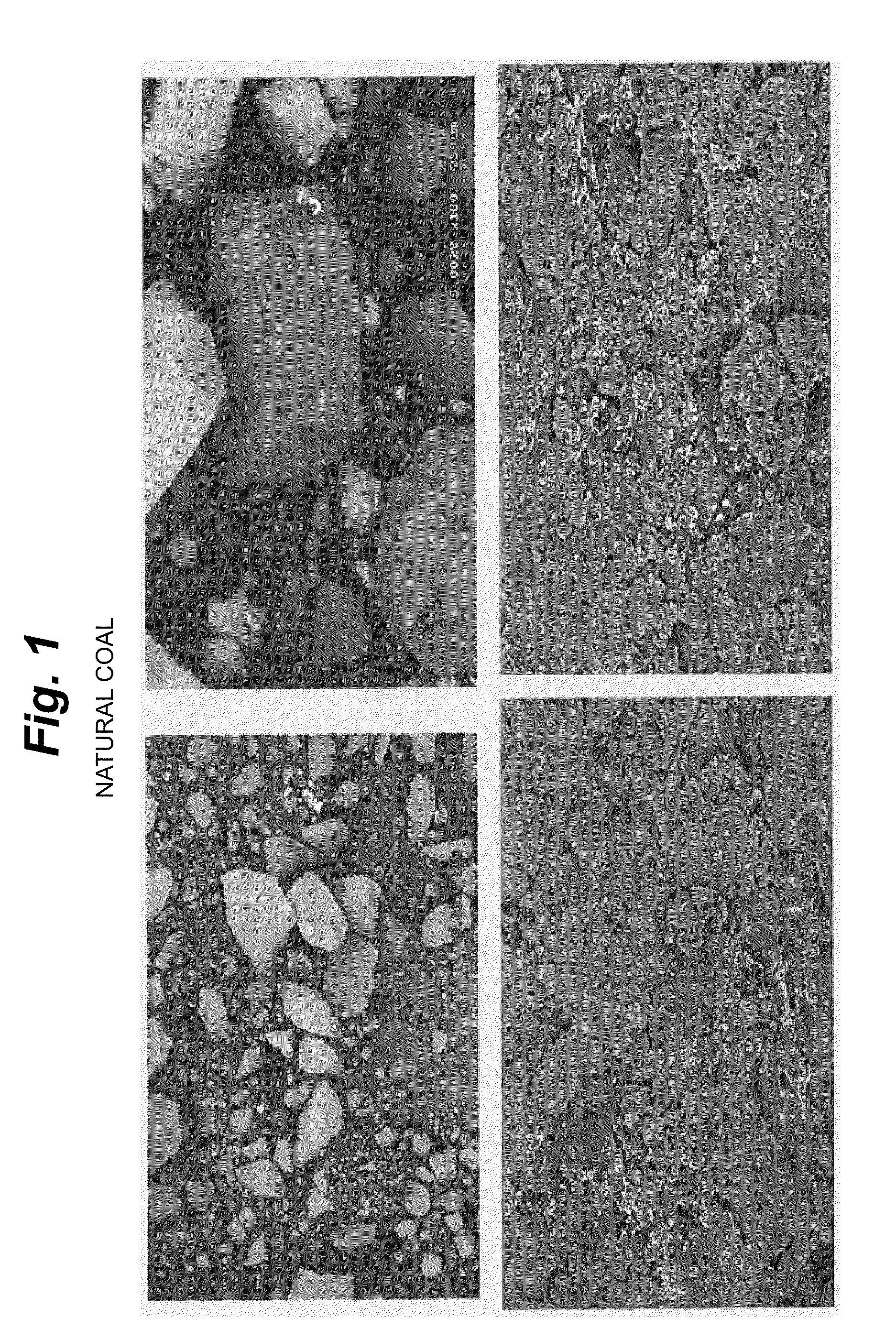

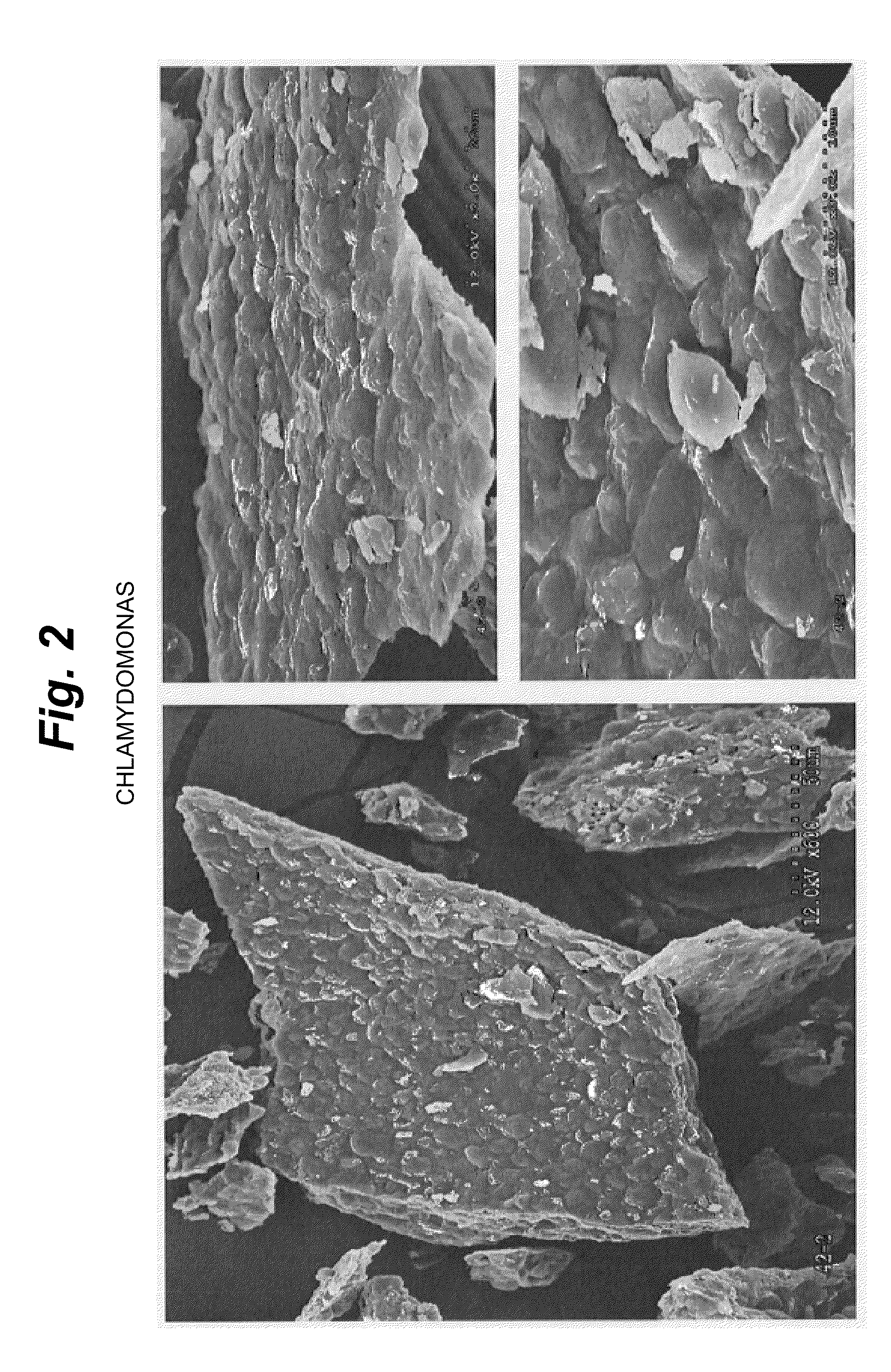

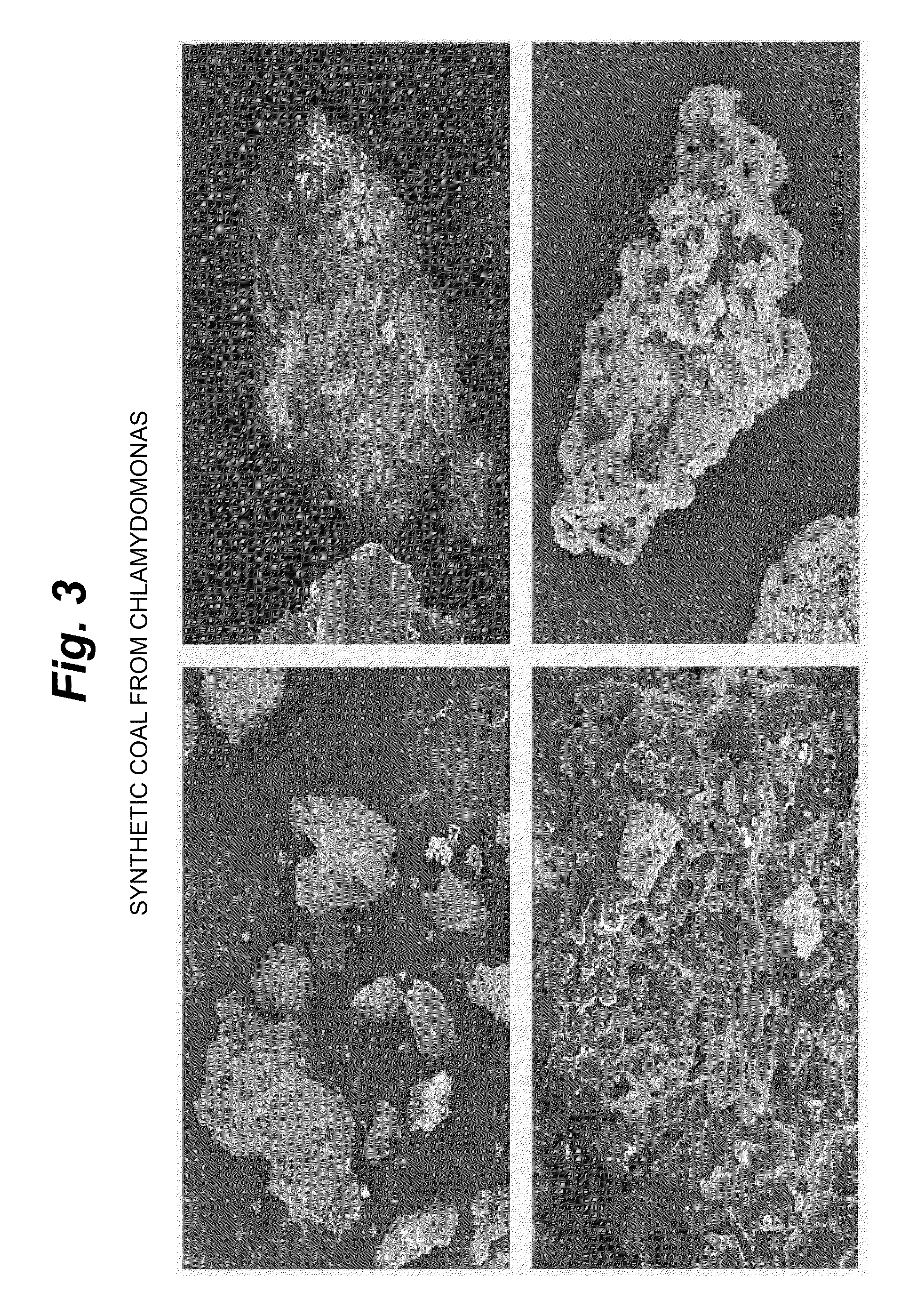

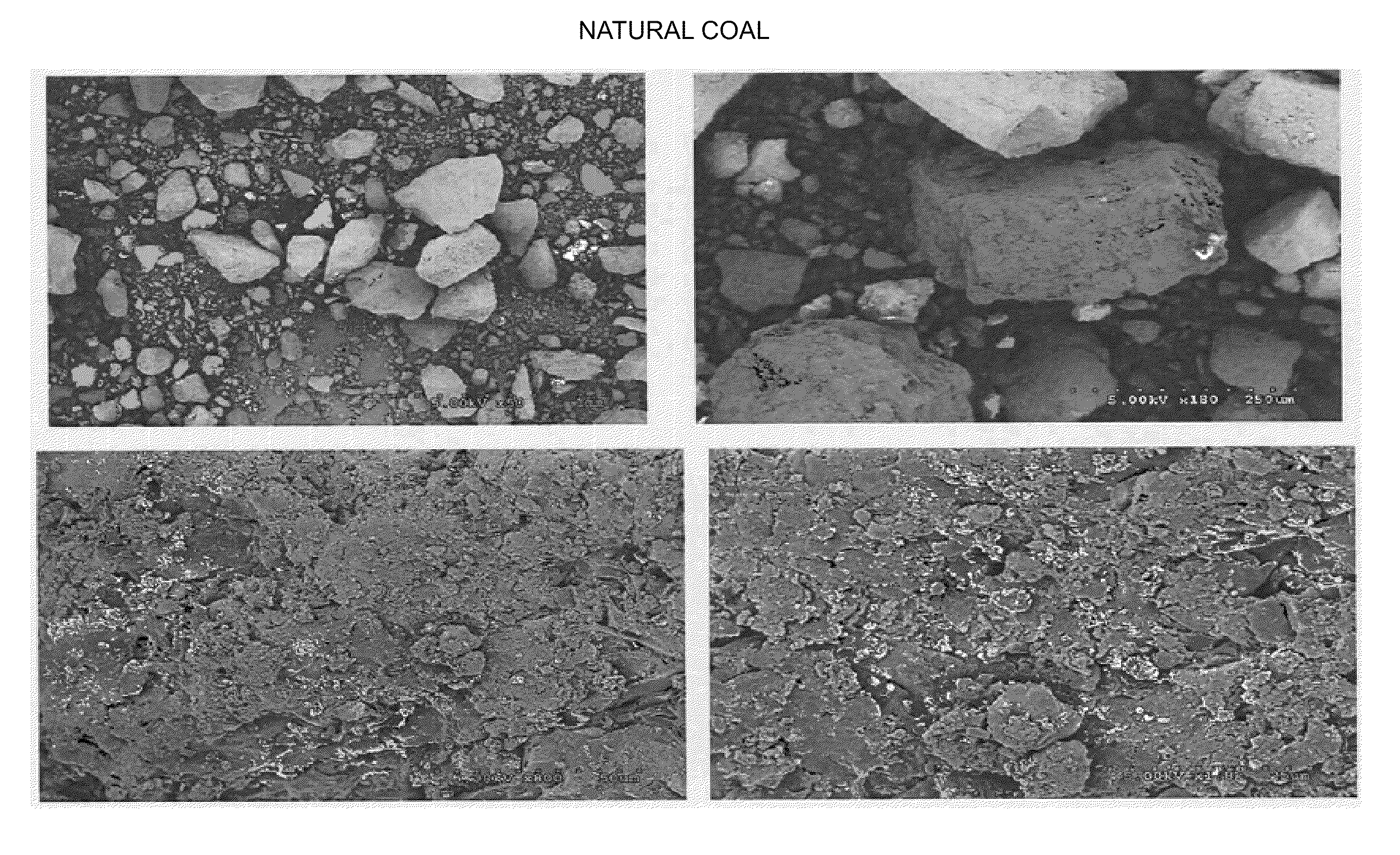

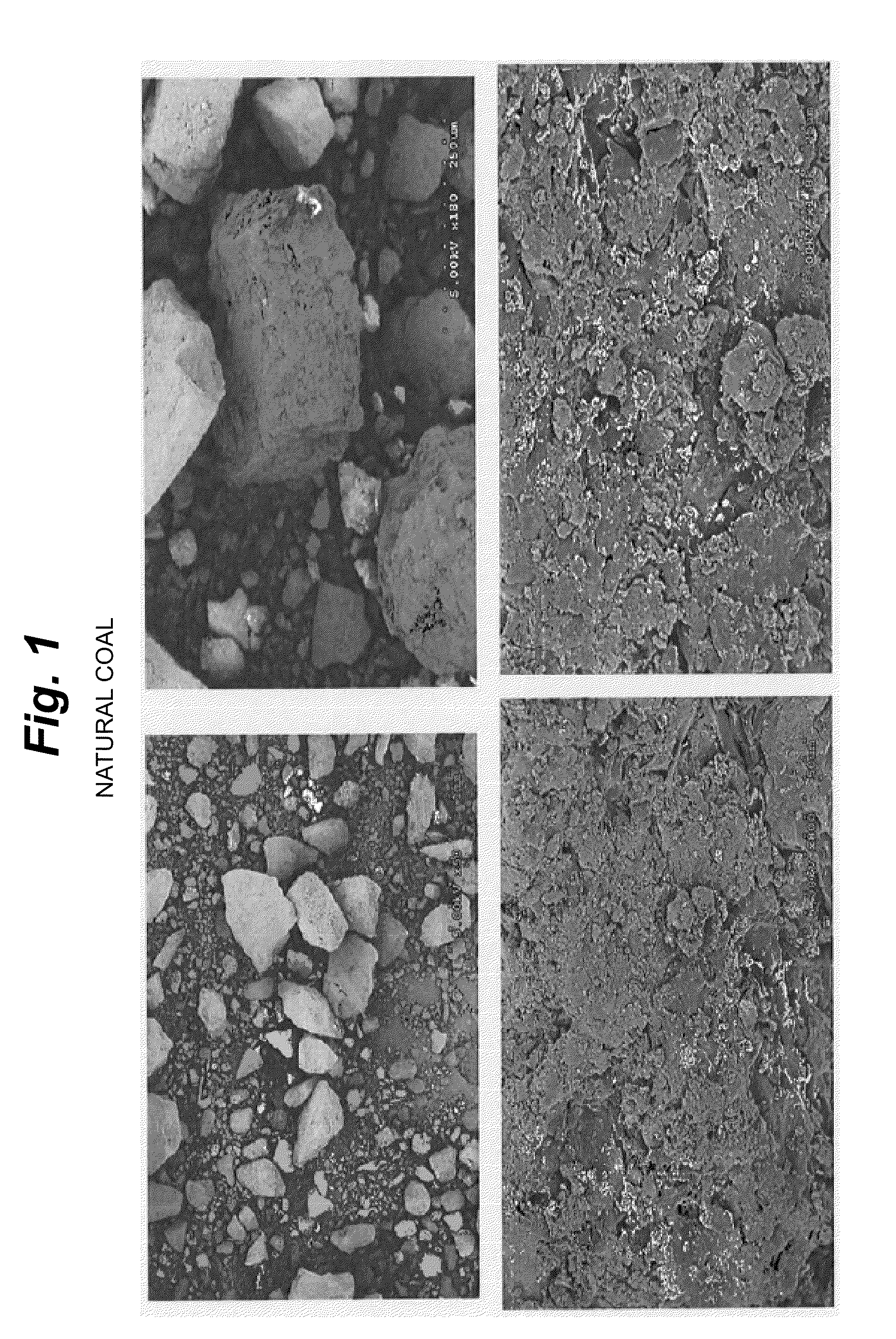

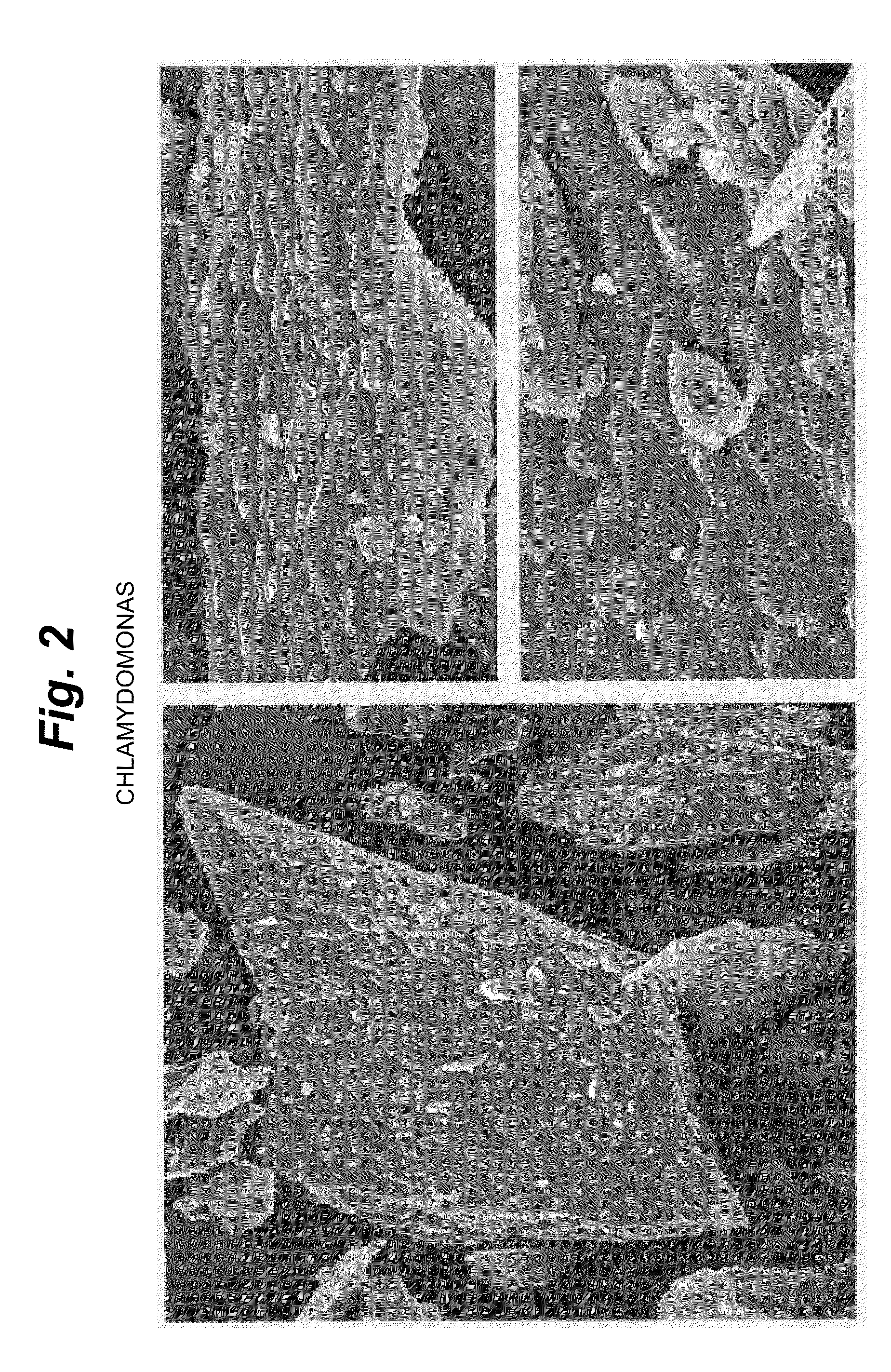

Algal Coal and Process for Preparing Same

InactiveUS20110056124A1Reduce environmental impactLow toxicityBiofuelsSolid fuelsSulfurBituminous coal

Algae-derived synthetic coal and filtrates. The invention described herein provides an algae-derived synthetic coal product and filtrates and process for preparing the same using an improved hydrothermal carbonization process. The synthetic coal product is similar to natural bituminous coal in terms of percent carbon content and energy equivalency while at the same time containing relatively low levels of sulfur and contaminant heavy metals. Unlike natural coal and other fossil fuels, because the carbon of the biomass is formed through photosynthesis, carbon dioxide formed during combustion is a “carbon neutral” event with little or no “new” carbon dioxide being added to the earth's atmosphere. The algae-derived filtrates contain useful constituents.

Owner:BIOCHAR

Non-bonder forming method for lignite

The invention discloses a non-bonder forming method for lignite, which belongs to processing and utilization technologies for lignite, relates to a forming method for lignite, and in particular to a forming method for weak lignite containing a high ash content and gel substances. The forming method disclosed by the invention is performed according to the following steps: (1) screening out lignite with a particle size of 0-5 mm by sieving, and drying the lignite until the water content is 5-30%; (2) preheating the dried lignite to 30-60 DEG C, and hydraulically forming the preheated lignite under 50-180 MPa; and (3) drying the formed lignite again for 1.0-6.0 hours at 50-100 DEG C to obtain a final briquette coal product. According to the forming method disclosed by the invention, the purpose of non-bonder forming for middle-aged and old lignite, in particular, weak lignite is realized; moreover, the obtained lignite is very high in cold and heat intensity, and the industrialized application range of low-value lignite is expanded.

Owner:YUNNAN CHEM RES INST

Flexible coal powder foam concrete and preparation thereof

The invention discloses a flexible coal dust foam concrete and a method for preparing the same, and in particular relates to a concrete. The concrete comprises the following main components by weight percentage: 10 to 15 percent of cement; 35 to 65 percent of coal dust; 20 to 45 percent of medium coarse sand; 3 to 4.5 percent of water; 0.1 to 0.3 percent of waterproofing agent; and 1 to 1.5 percent of foaming agent. A mode for blocking the wall surface of a heading by using the concrete is a concrete spraying mode, or a concrete lining mode, or a concrete curtain grouting mode. The flexible coal dust foam concrete is prepared from local materials, makes full use of the coal dust accumulated in the heading by underground drilling to reduce the transportation and construction cost of a supporting material and improve the efficiency and the progress of coal mining excavation, and has small impoverishment effect on coal products; a structural body has excellent impermeability, good leakproofness and integrity; besides, the concrete can be widely used for blocking and preventing seepage for the wall surface of a gas displacement coal-bed methane gas tunnel in coal mines, and also can be applied to supporting surrounding rocks of complex rock stratums or other dynamic pressure tunnels with the characteristics of softness, expansion, rheological performance and the like.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Regenerative coal produced by multiple kinds of oily sludge in oil refinery and preparation method thereof

InactiveCN101962590AMake up for the shortageFully embersSolid fuelsWaste based fuelSludgePolyacrylamide

The invention relates to regenerative coal produced by multiple kinds of oily sludge in an oil refinery and a preparation method thereof. The method is characterized by comprising the following steps of: stirring multiple kinds of oily sludge, coal gangue, refuse burning fly ash, quick lime powder, calcium sulfate, ferric trichloride, aluminum sulfate, polyacrylamide, a combustion improver, ferrous sulfate, magnesium sulfate, a Li macromolecule collection agent, water and the like serving as raw materials into a wet state by using a double-shaft mixing blender and extruding to prepare block, rod or spherical regenerative coals by using a vacuum extruder; and naturally drying at normal temperature to prepare various mixed oily sludge regenerative coal products. The regenerative coal has the advantages of high heat value, application of the burned ash to raw materials of production and construction materials, waste recycling, capacity of meeting national regulation on energy conservation, emission reduction and environmental protection, no pollution, low cost and high benefit.

Owner:广州中滔绿由环保科技有限公司

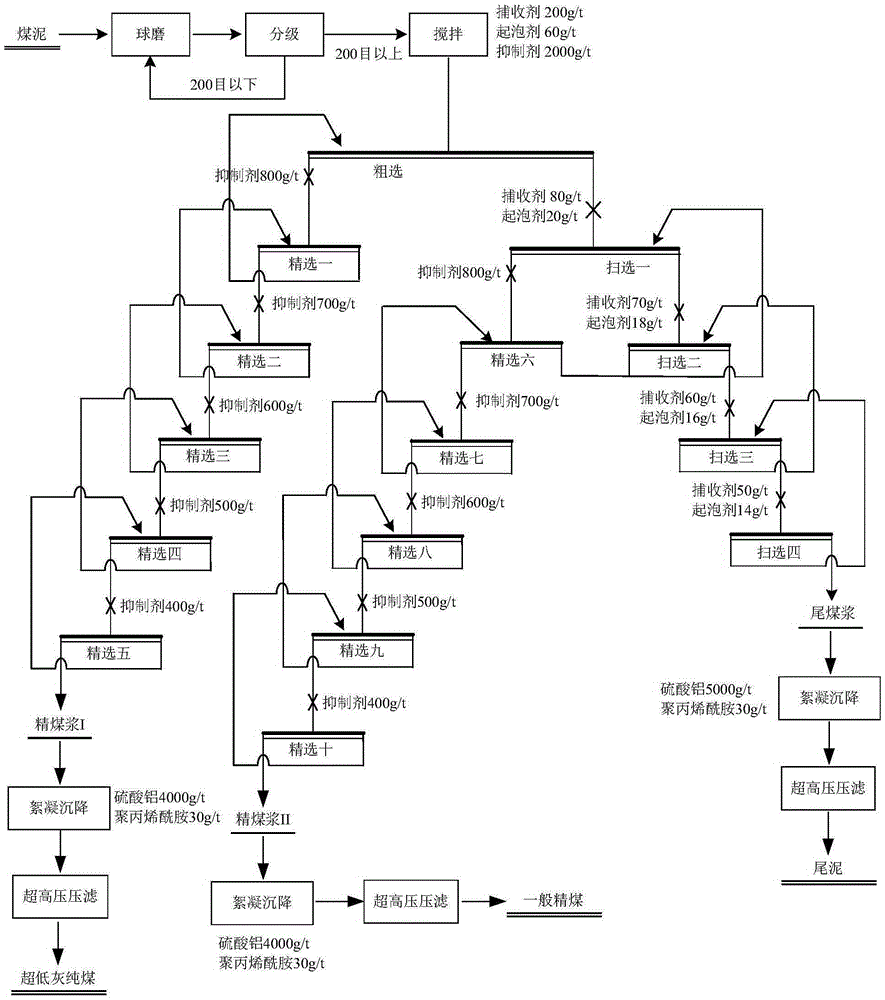

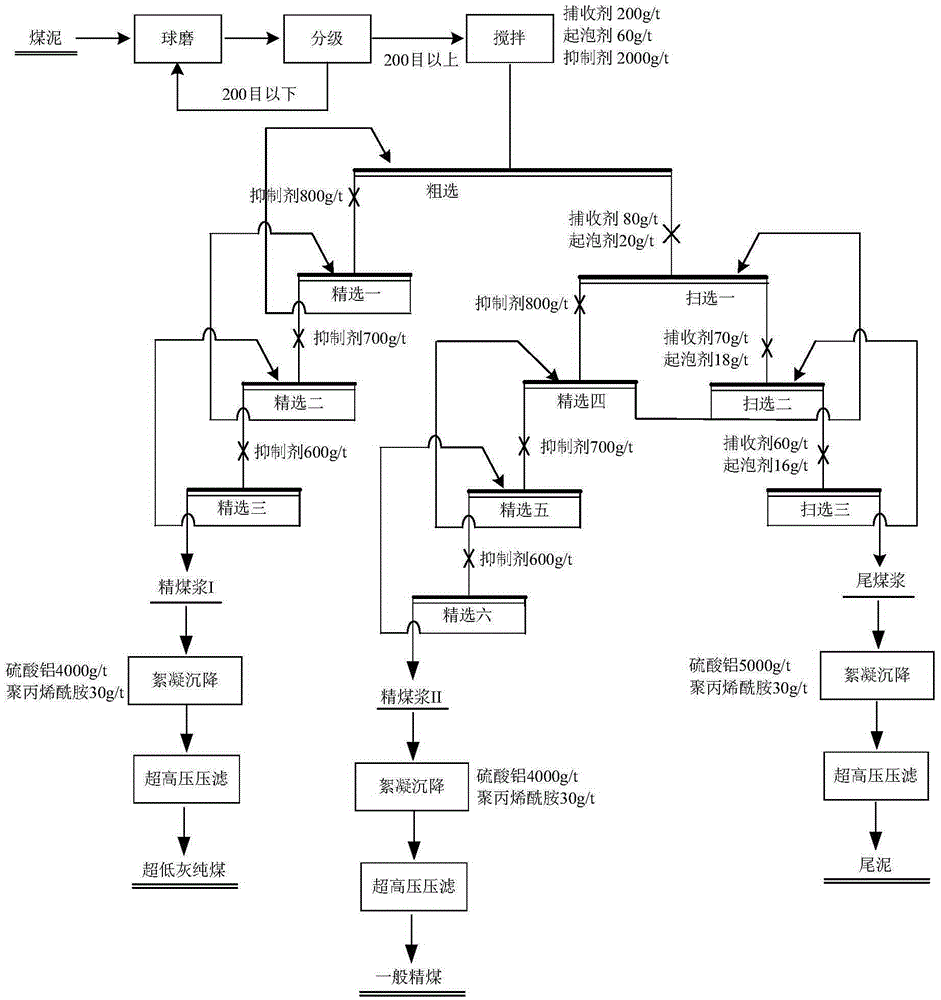

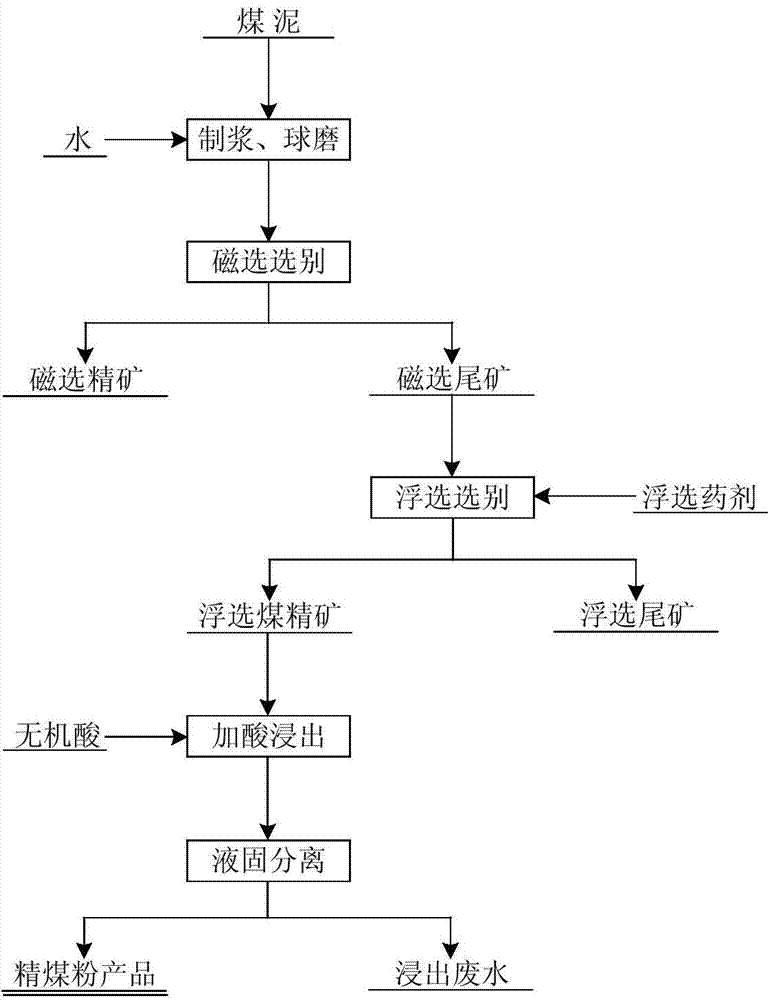

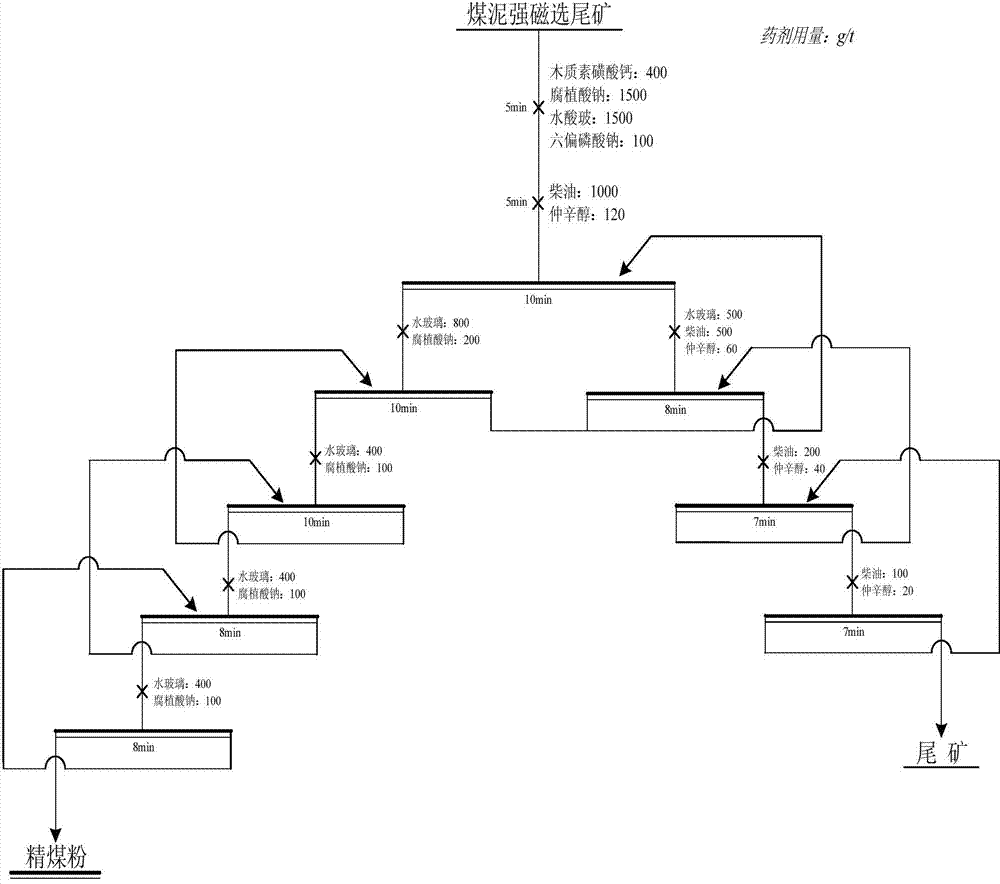

Method for extracting ultra-low-ash-content pure coal from coal slime

InactiveCN105396684ALow recovery rateGood technical effectDifferential sedimentationFlotationFlocculationFoaming agent

The invention discloses a method for extracting ultra-low-ash-content pure coal from coal slime. The method comprises the following steps: ball-milling slurrying, specifically, milling coal slime until particles with less than 200 meshes occupy more than 90%, and controlling the mass percent concentration of the coal slime slurry to be 10-35%; grading, specifically, conveying the particles with less than 200 meshes to a flotation step; flotation, specifically, adding a collecting agent, a foaming agent and an inhibitor in the obtained coal slime slurry, uniformly mixing, and carrying out one-time rough flotation, two sections of three-to-six-time fine flotation and one section of three-to-six-time scavenging to obtain refined coal slurry I, refined coal slurry II and tailing coal slurry respectively; and dehydration, specifically, adding a flocculant in the refined coal slurry I, the refined coal slurry II and the tailing coal slurry which are obtained through the flotation, carrying out flocculation settling, then dehydrating by virtue of an ultrahigh-pressure pressure filter, and controlling a pressure filter pressure to be 4.5-5.5Mpa, thus obtaining ultra-low-ash-content pure coal products, common refined coal products and tailing coal products. The method disclosed by the invention is simple in process flow, and capable of efficiently extracting the ultra-low-ash-content pure coal products from the coal slime; and moreover, the water contents of the obtained coal products are low and can achieve less than 15%, thus the coal products have remarkable economic benefits and environmental protection value.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

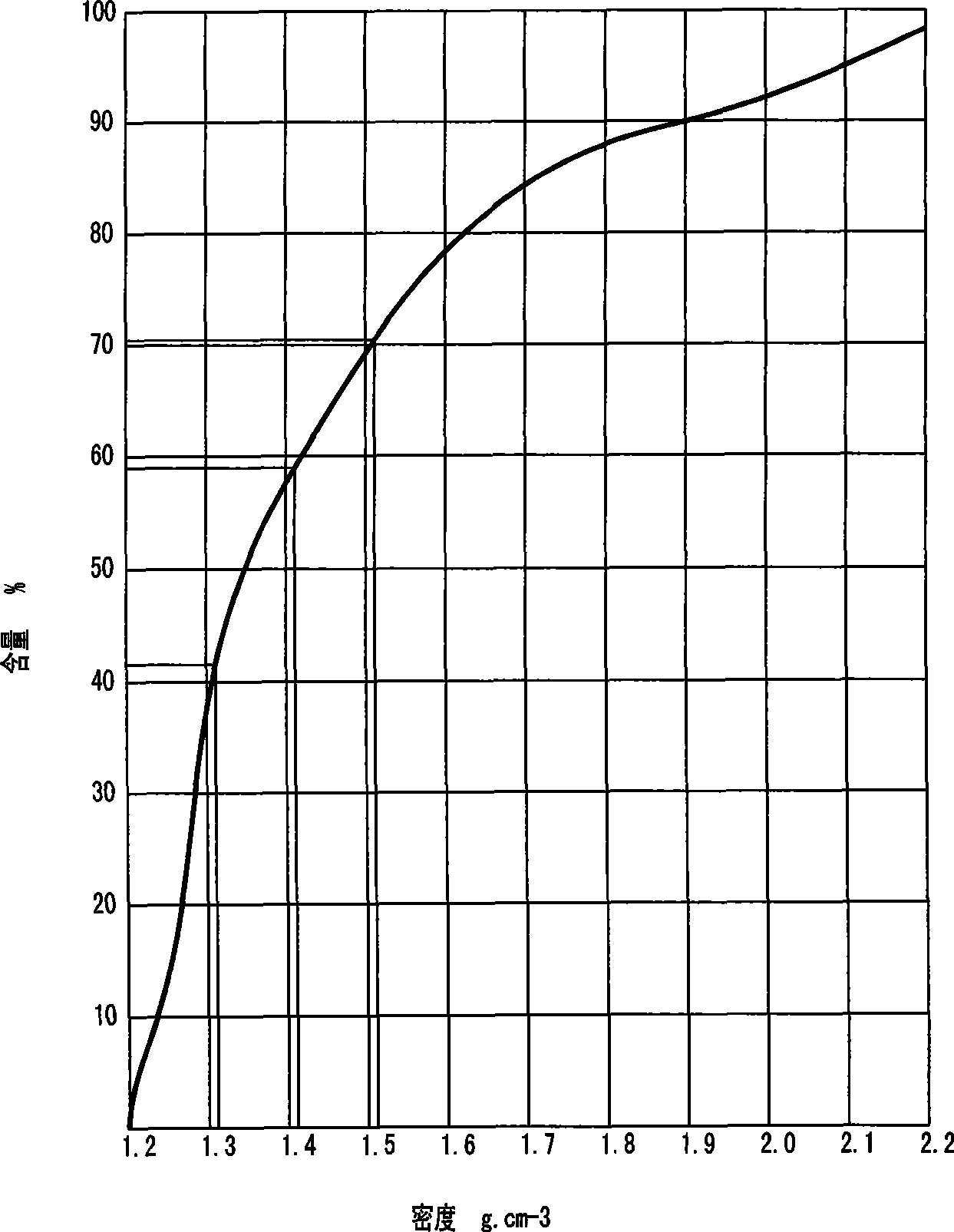

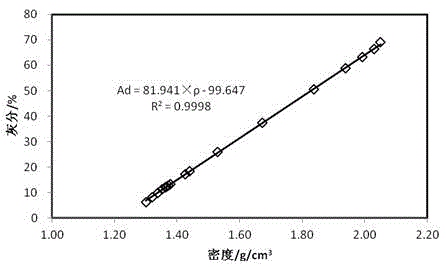

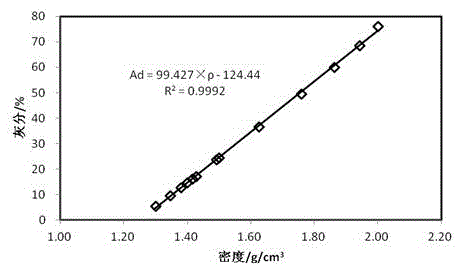

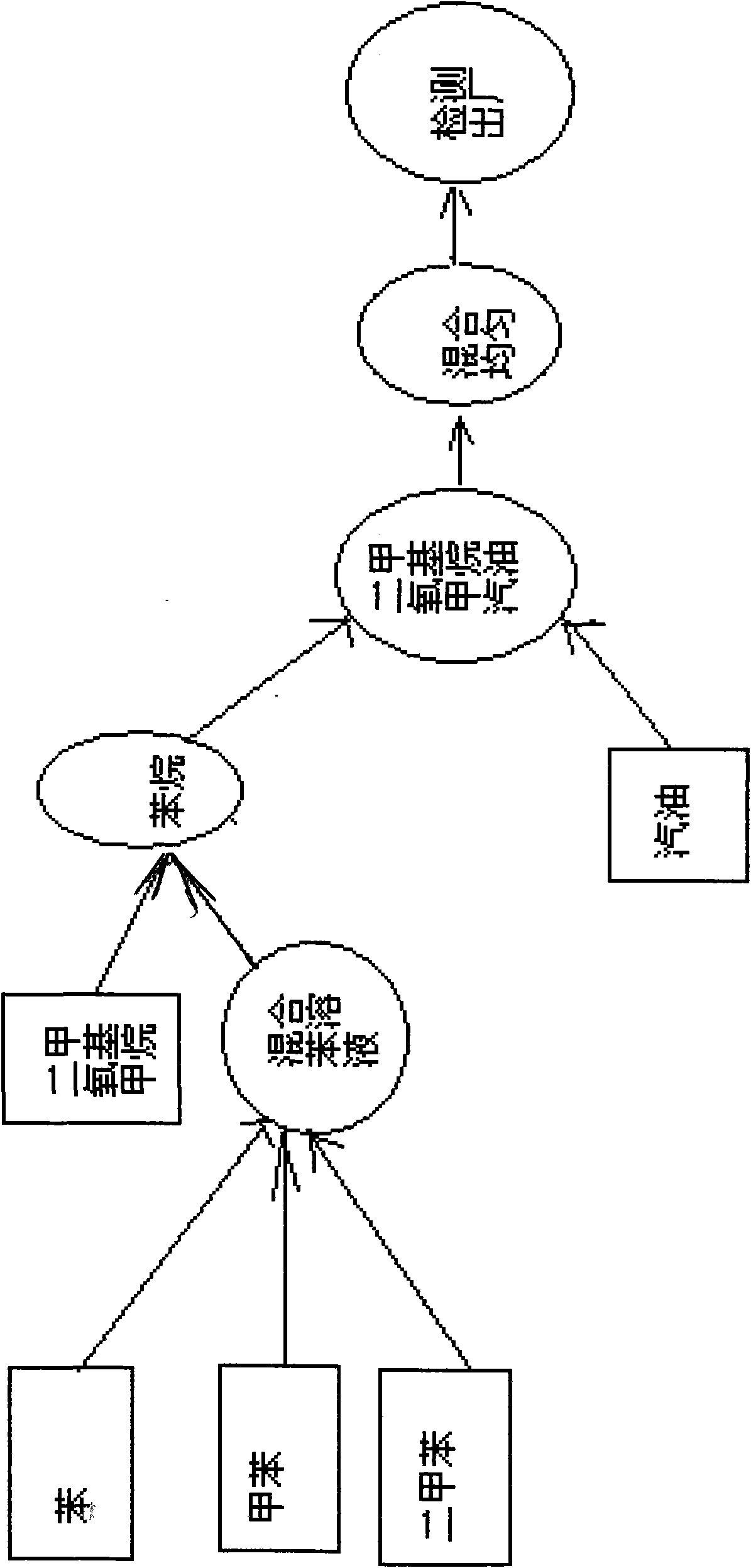

Automatic detection method for coal product ash content

InactiveCN105547917ASolve the problem of online real-time detectionLess investmentSpecific gravity measurementEconomic benefitsComputer science

The invention discloses an automatic detection method for the coal product ash content and belongs to the technical field of coal dressing detection methods. The automatic detection method is used for performing on-line ash content detection on a coal product. According to the technical scheme, in the process of conveying coal through a belt, a high-precision belt weigher and a volume scanner are used for determining the quality and volume of the coal product in real time; the density of the product is calculated through a computer, a density-ash content relation curve of the coal product is input into the computer, and then the computer automatically calculates the ash content of the product according to the density and the density-ash content relation curve of the product. The method is a brand-new detection method for the coal product ash content and is an innovation in the field of coal detection, on-line real-time detection of the coal ash content is achieved, the simple, rapid and accurate on-line detection method for the ash content is provided for the coal product, can achieve continuous and rapid detection on a coal conveying line, quite facilitates guiding of the production process in time and improves product quality through continuous detection and has remarkable economic benefits.

Owner:TIANDI TANGSHAN MINING TECH

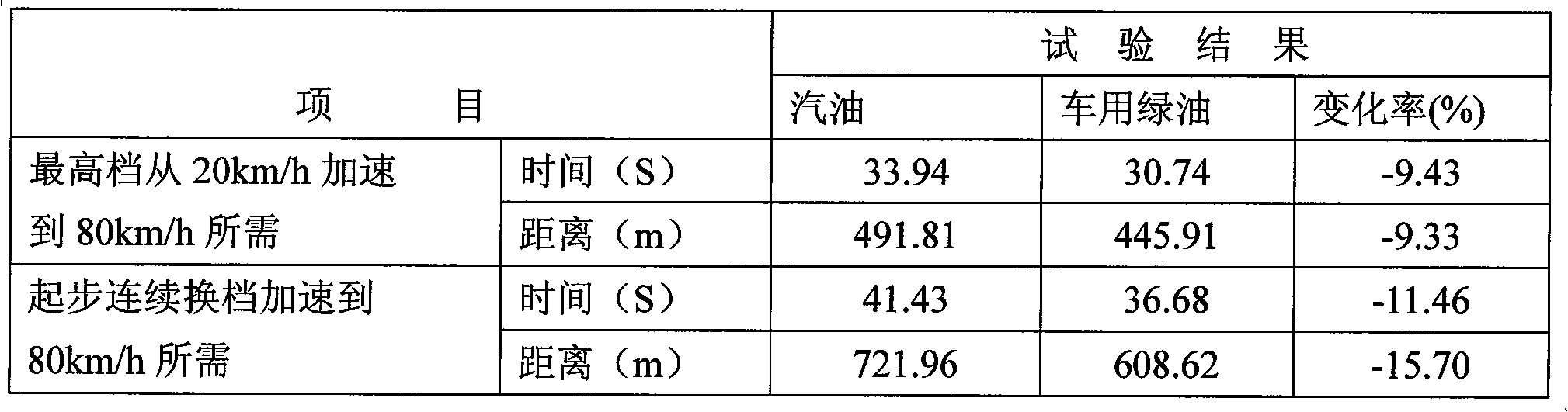

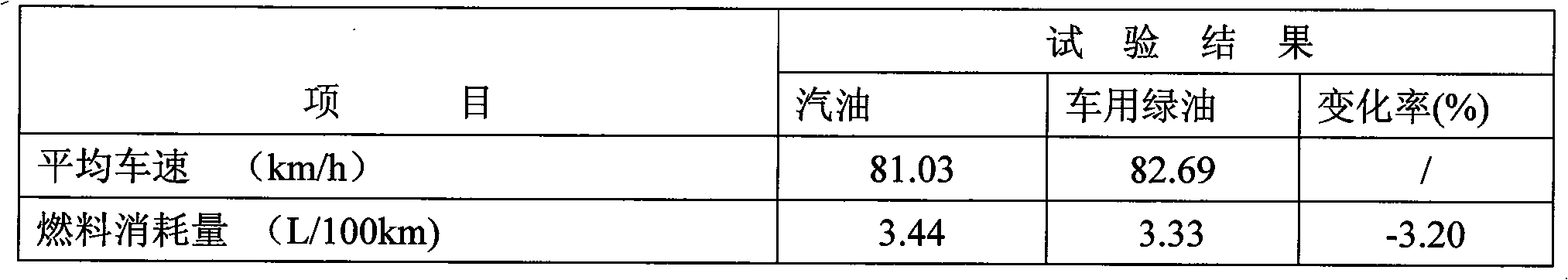

Dimethoxymethane gasoline

The invention relates to dimethoxymethane gasoline, which consists of dimethoxymethane, benzene, methylbenzene, dimethylbenzene and gasoline, wherein the benzene, the methylbenzene and the dimethylbenzene can be replaced by coked mixed benzene; the dimethoxymethane gasoline is not added with methanol and alcohol; and the dimethoxymethane and the gasoline are not delaminated at low temperature or delaminated when meeting water. The dimethoxymethane gasoline has high combustion efficiency and prevents the automobile power from falling. A coal product is applied to the dimethoxymethane gasoline so as to develop a novel kind of gasoline. The dimethoxymethane in the dimethoxymethane gasoline has a high component ratio and is used as a fuel so as to save the gasoline and reduce the cost.

Owner:SICHUAN JUNHONG ENVIRONMENTAL PROTECTION TECH +1

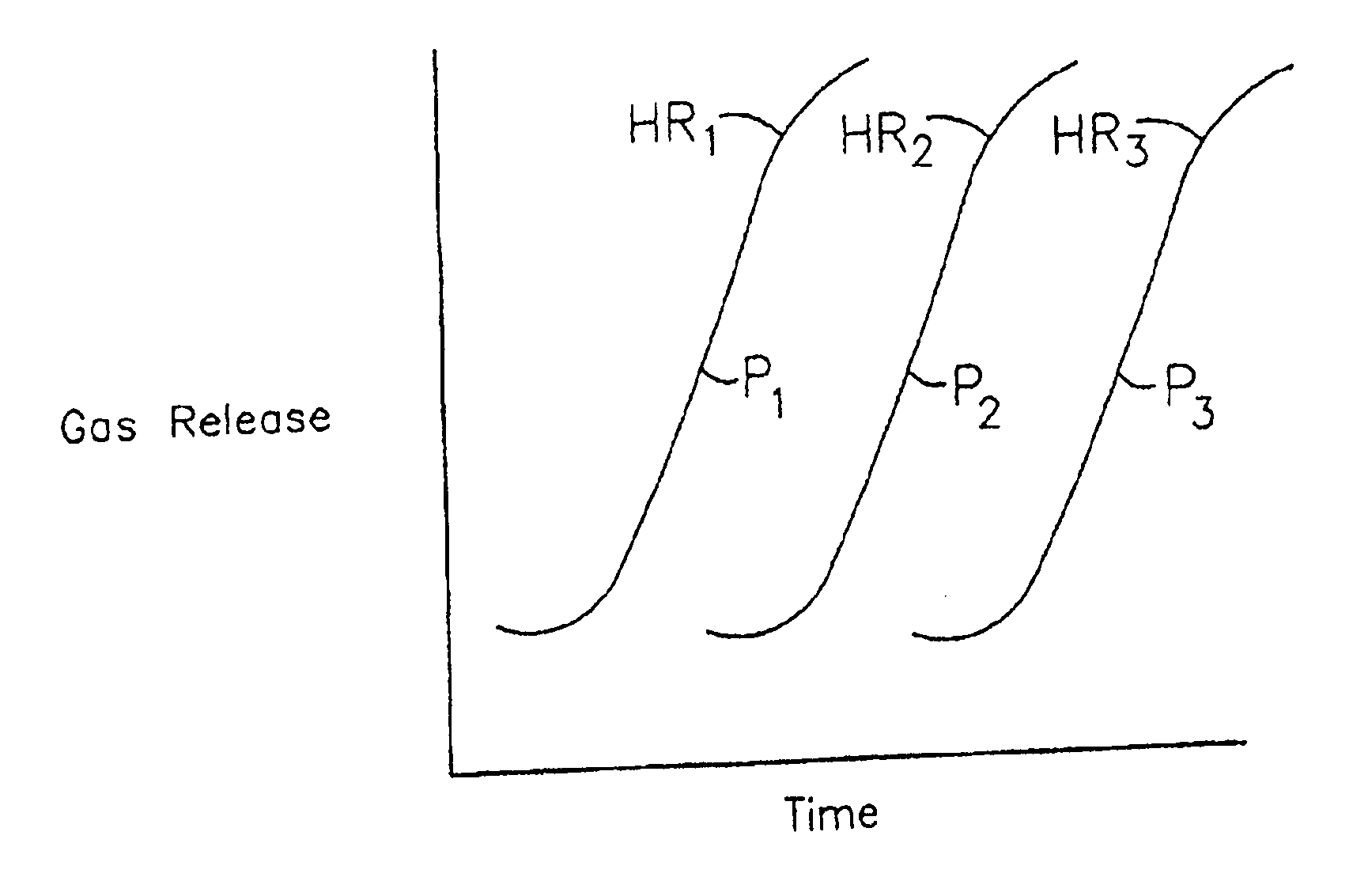

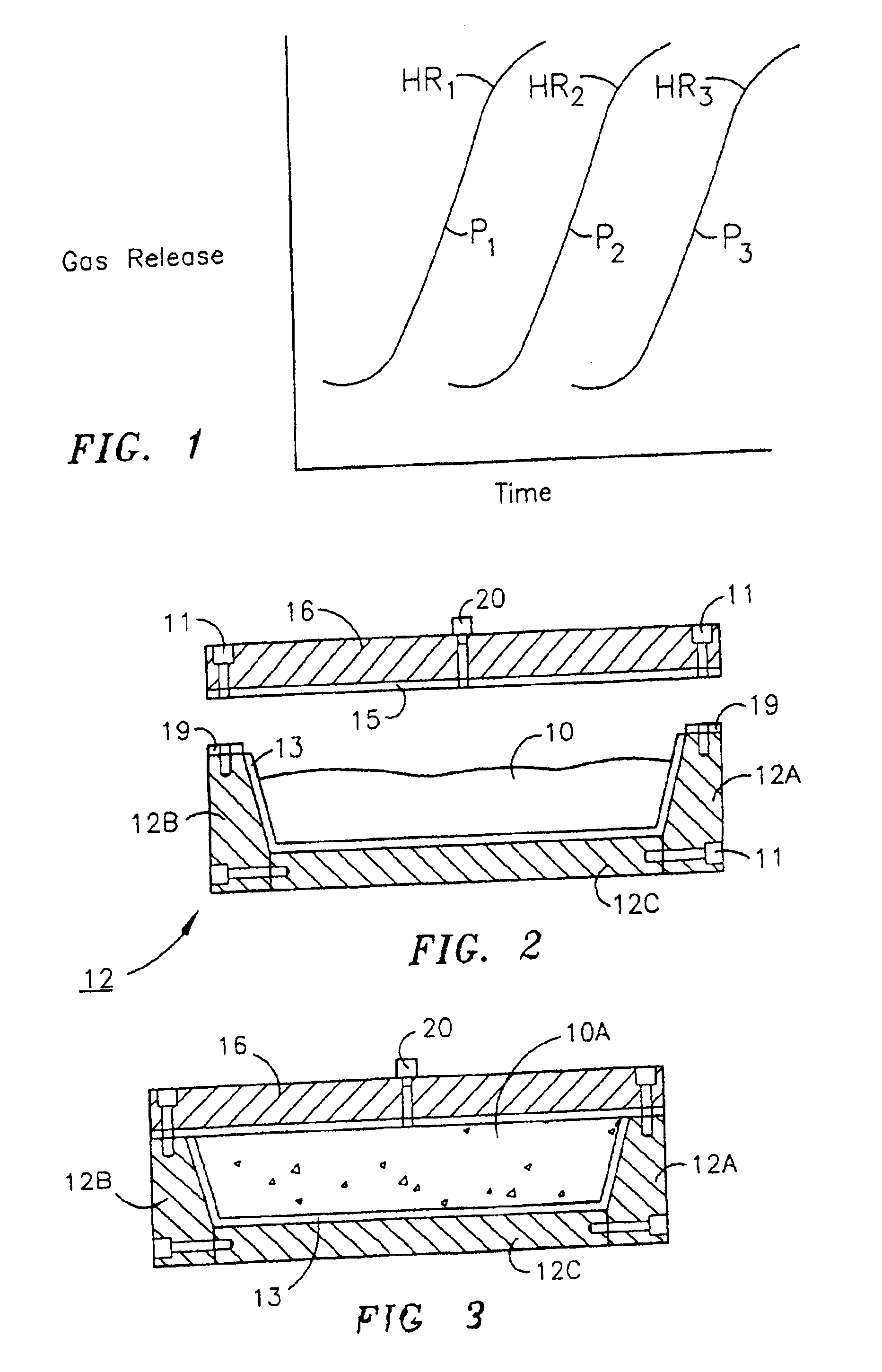

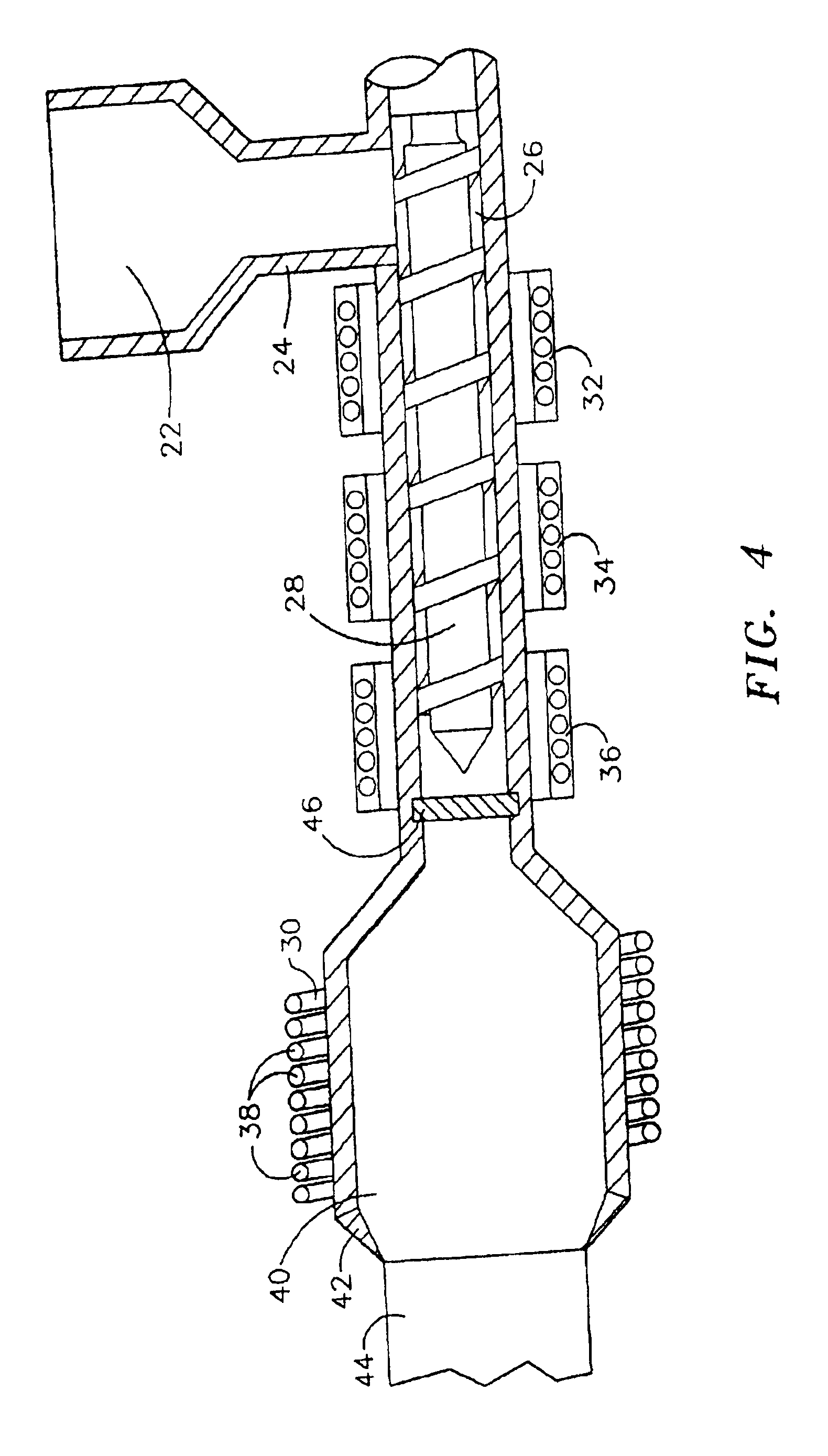

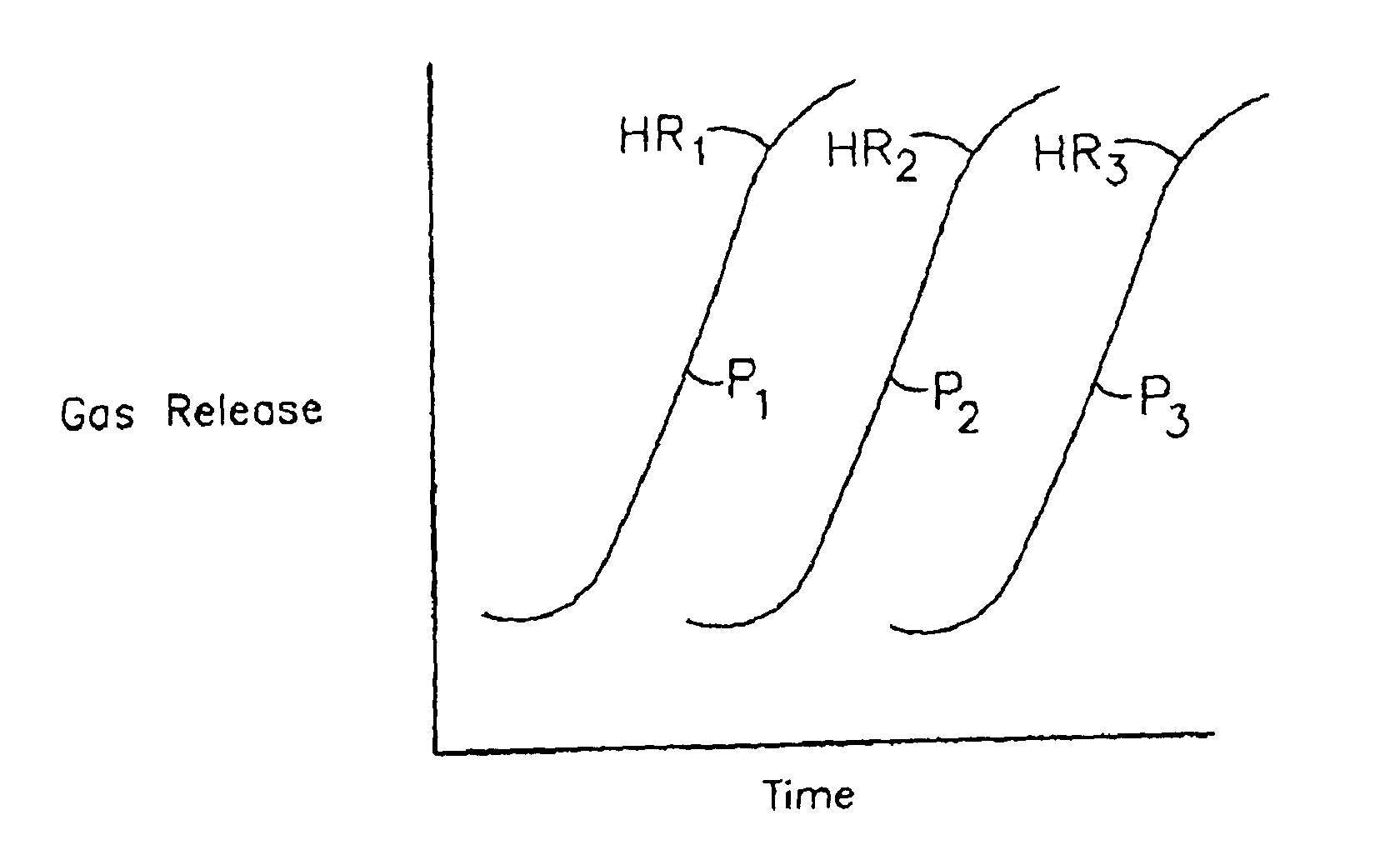

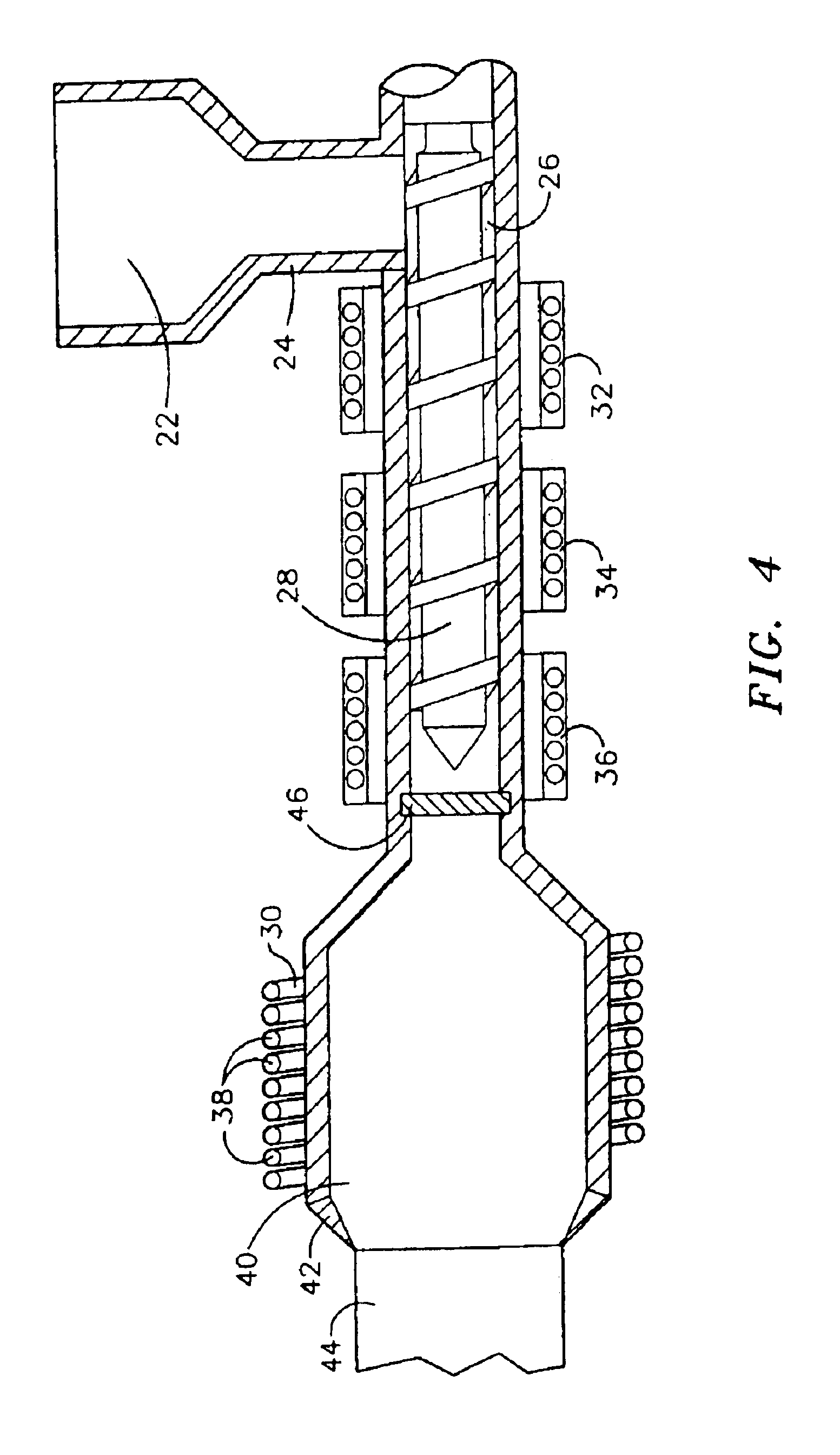

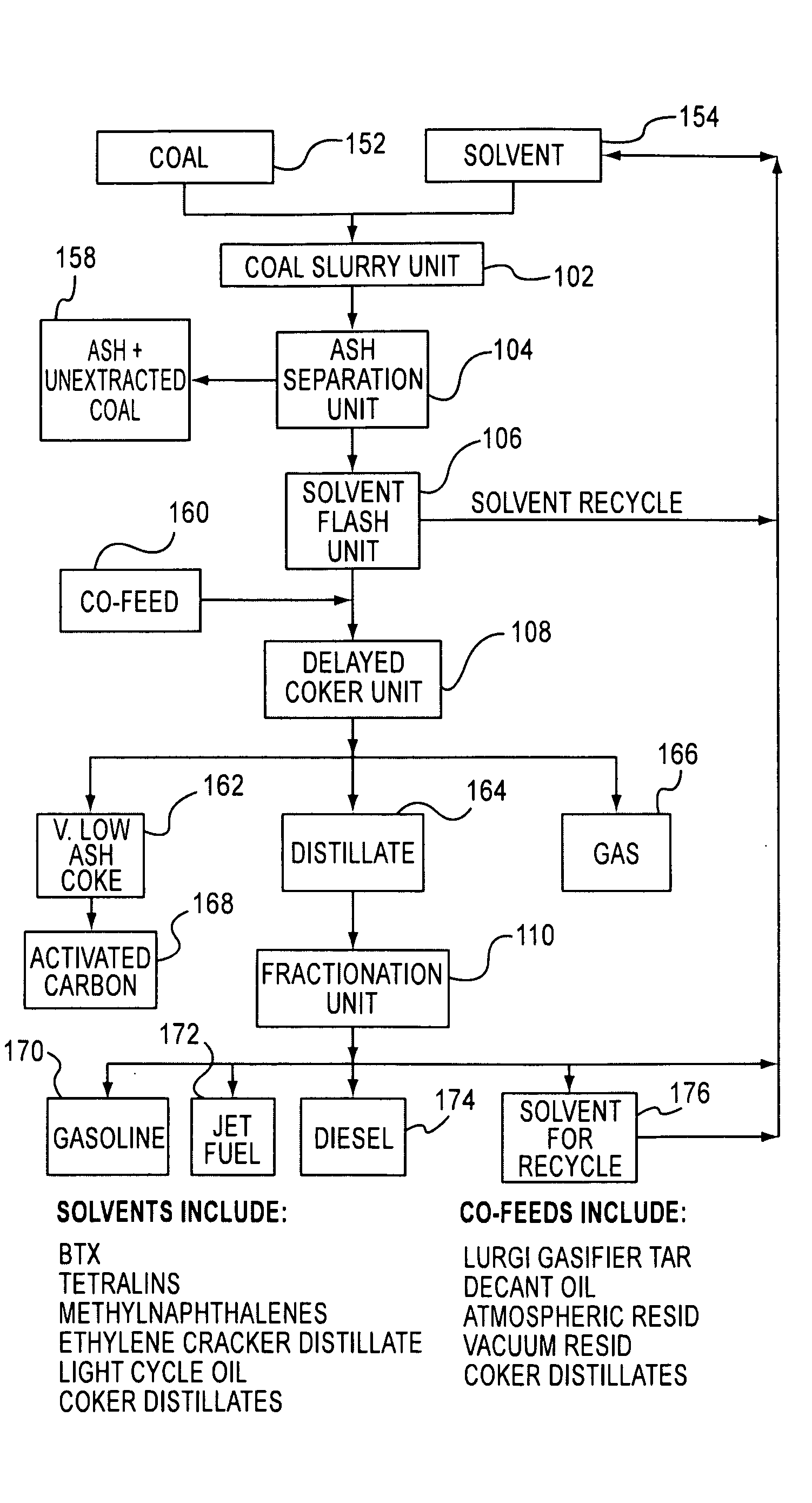

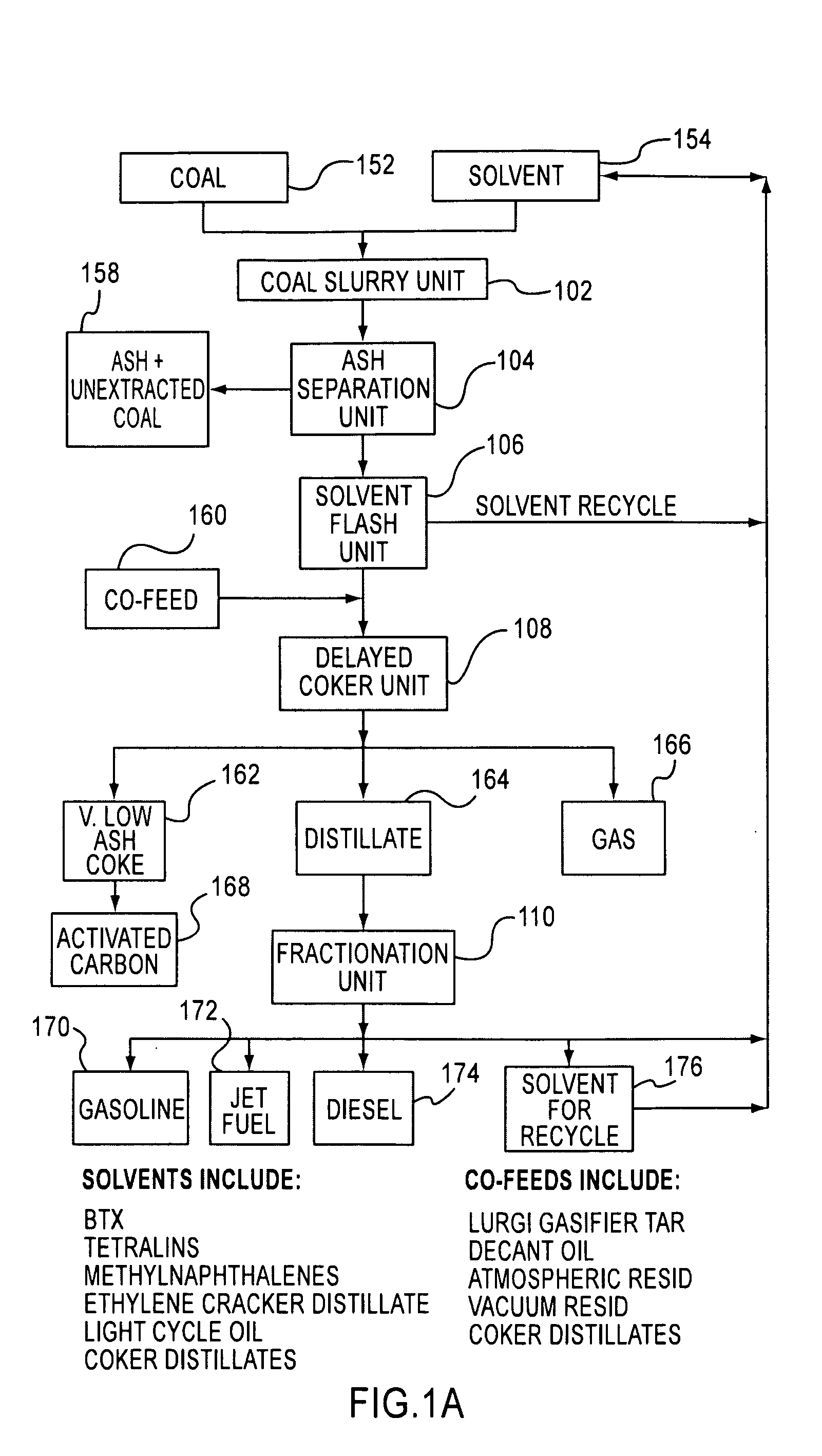

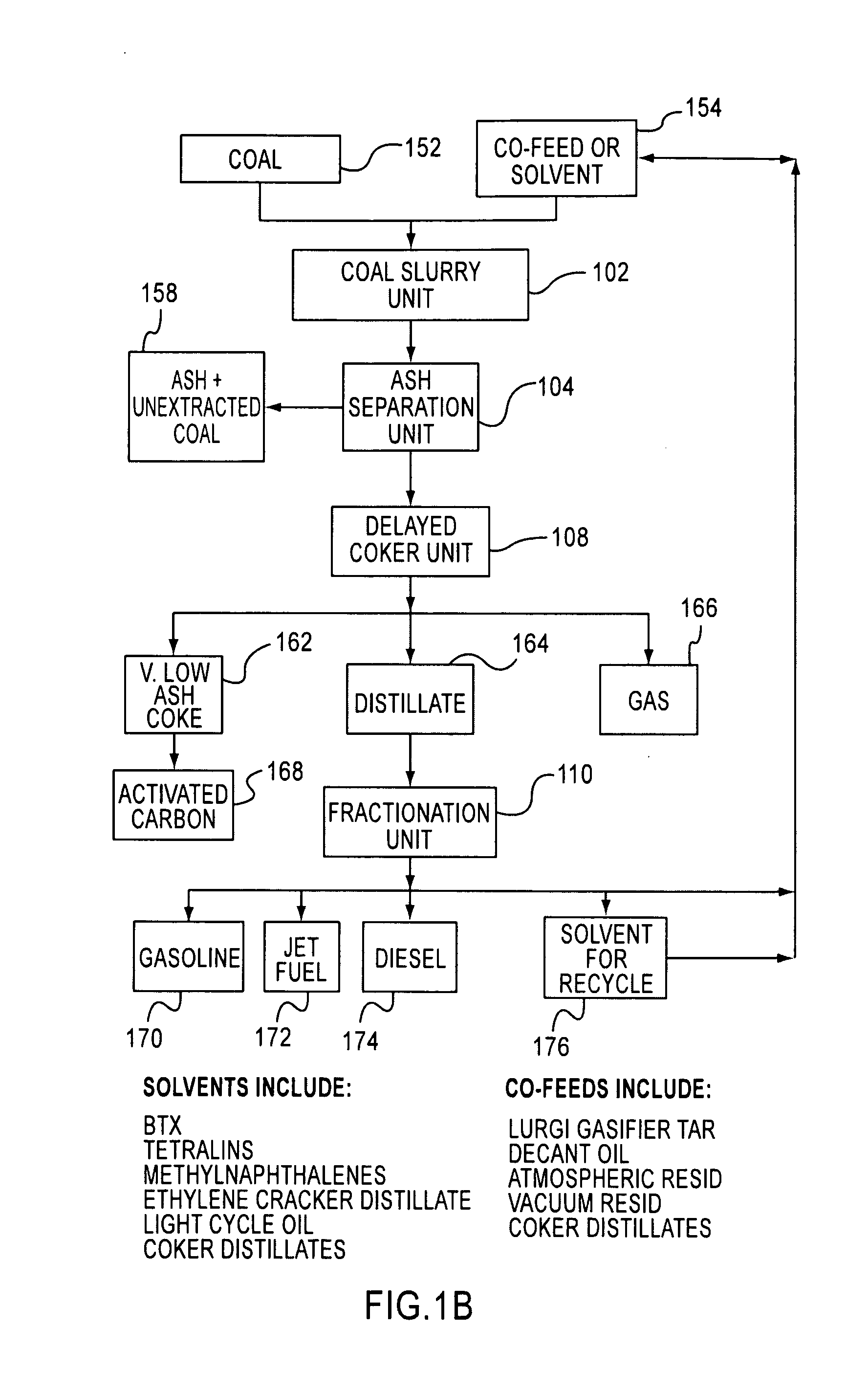

Apparatus and processes for production of coke and activated carbon from coal products

InactiveUS20090229463A1Easy to operateReducing objectionable emissionThermal non-catalytic crackingProductsActivated carbonCoal product

Production of coke and activated carbon from coal products, including the production of low ash coal and activated carbon products from coal products, and the production of very low ash coke and activated carbon products from coal products.

Owner:COALSTAR INDS

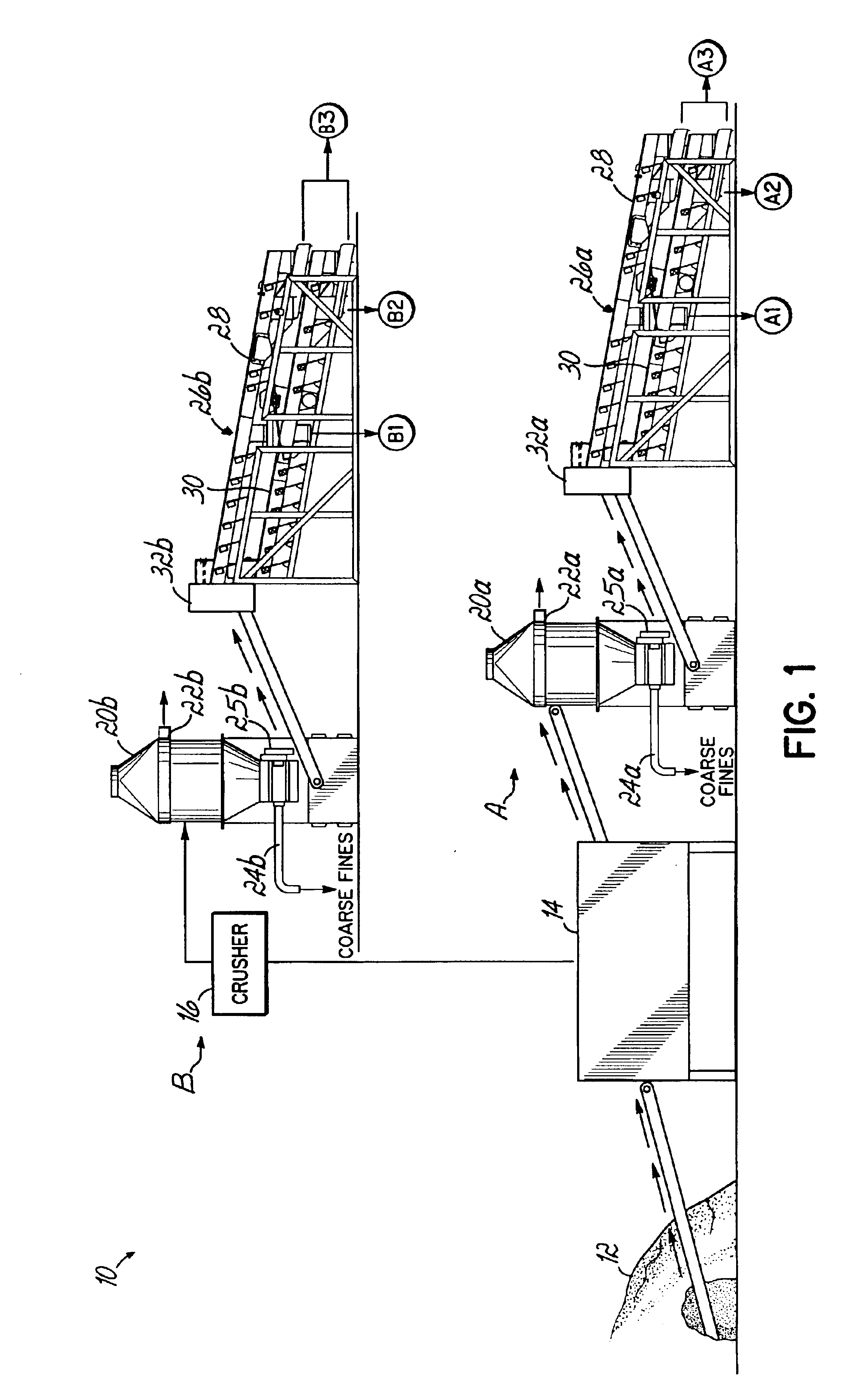

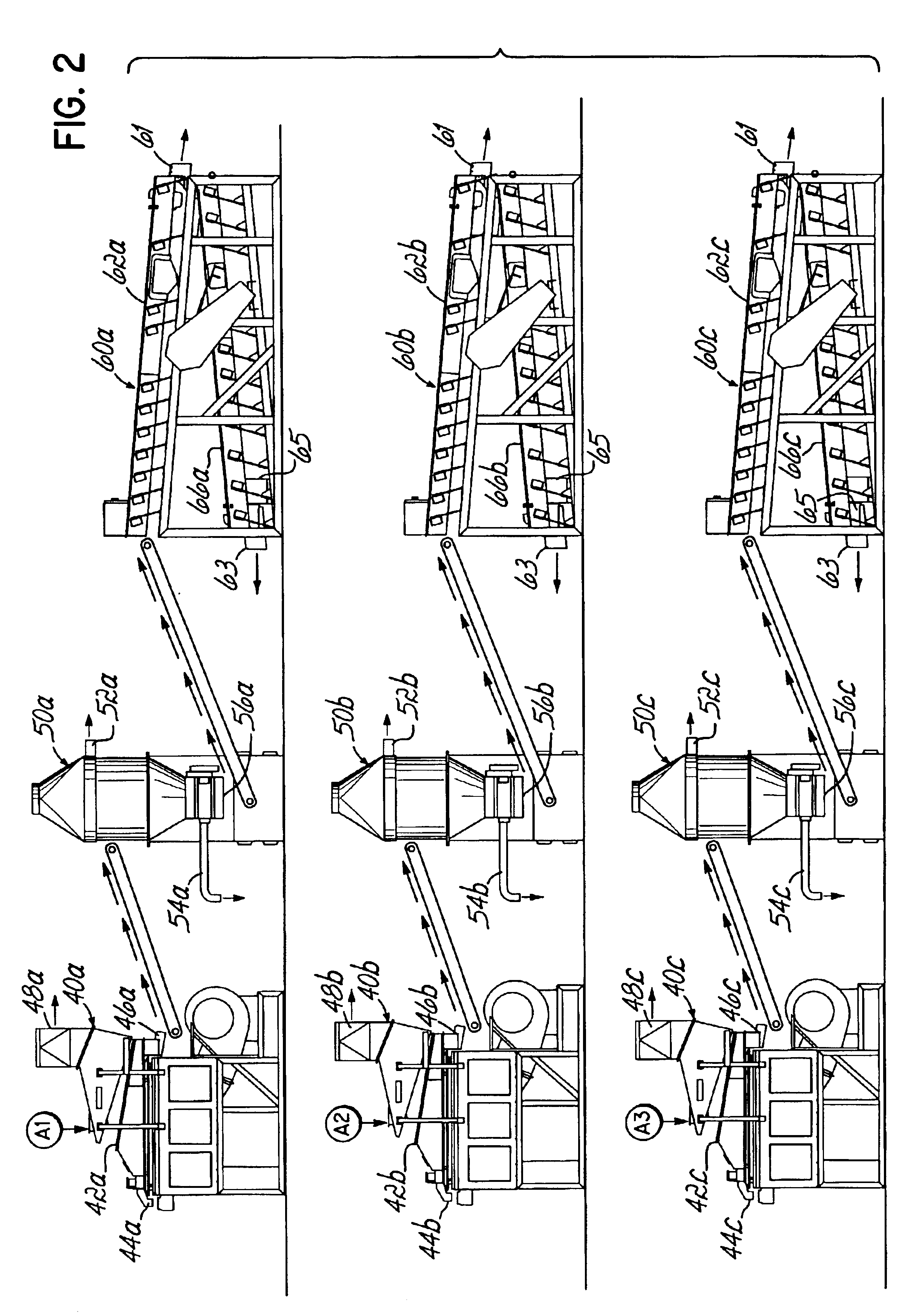

Apparatus and method for dry beneficiation of coal

A method of beneficiating coal in a dry process includes separating raw coal from a coal mine into coal fines and larger pieces of coal using pressurized air, separating the larger pieces of coal according to size, removing ash from the larger pieces of coal on an air table, and further removing ash from the larger pieces of coal using a size-discriminating device to obtain a beneficiated coal product. The invention also includes an apparatus for the dry beneficiation of coal. The apparatus includes at least one air separating device, at least one air table, and at least one first and second shakers which separate the coal by size and remove ash from the coal. The air table effectively removes ash from infed coal without the need for a fluidizing media.

Owner:LEWIS M CARTER MFG

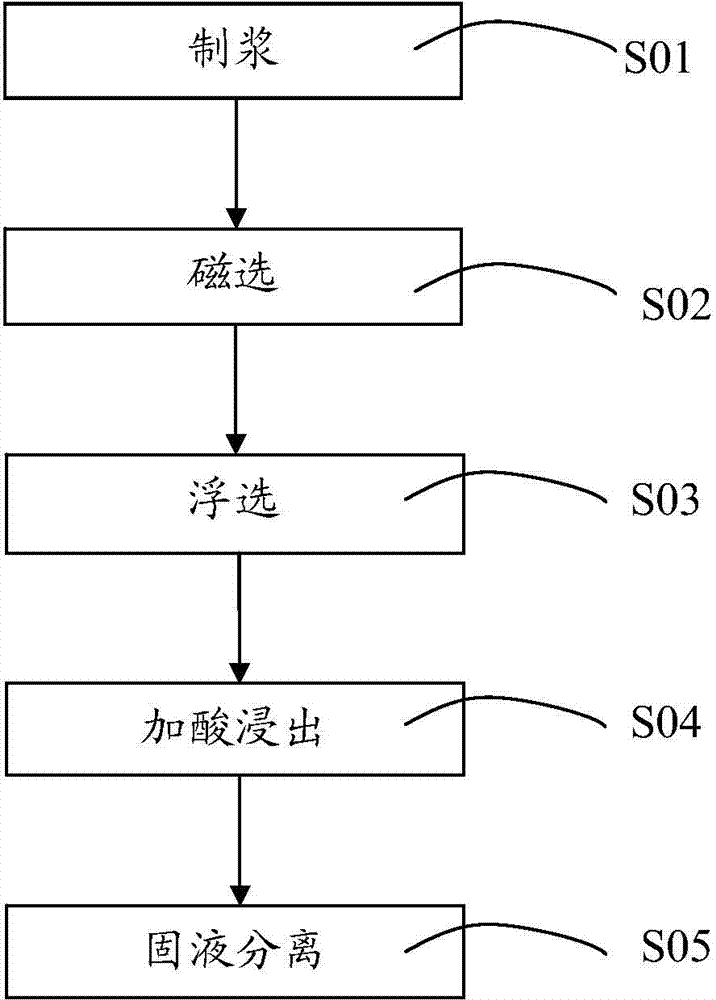

Method for recycling reduction coal from coal slime

The invention provides a method for recycling reduction coal from coal slime. The method includes: adding water into the coal slime for pulpify treatment and obtaining pulp whose concentration is 20-30%; conducting grading ball milling to enable the grains whose grain size is less than 0.074mm to take up 50% of the content of the pulp; conducting the magnetic separation on the pulp after the ball milling and obtaining the magnetic concentration and the magnetic tailings; adding water into the magnetic tailings for the pulpify treatment, adding the floatation reagent for the floatation treatment and obtaining the floatation coal concentrate and the floatation coal tailings; conducting the acid treatment on the floatation coal concentrate and conducting agitation leach for 0.2-4.0 hours; and adding the flocculating agent for flocculation and settlement, conducting filtering and obtaining the reduction coal. The ash content of the reduction coal is less than or equal to 5%, and the sulphur content is less than and equal to 0.1%. The method for recycling the reduction coal from the coal slime compositely uses the technology of magnetic separation-flocculation-chemical treatment so that advanced reduction coal products with the low ash content and suphur content can be obtained.

Owner:深圳市华天顿能源环保技术有限公司

Combined hydrogenation method

ActiveCN1952069AGood for deep saturationReduce loadTreatment with hydrotreatment processesNaphthaProduct gas

The invention disclosed an associated hydrogenating technology. The invention is about deep hydrogenationg refinement of poor quality ship-coal by neo-hydrogen (such as cyclane radical or cyclane intermediate radical). The gas which is rich in hydrogen is used as the supplementary gas in hydrocracking process of diesel oil; the invention adopts hydrocracking method to treat poor quality diesel oil; the gas which is rich in hydrogen can be recycled. In the invention, the poor quality ship-coal contacts the neo-hydrogen first so as to get the high-quality ship-coal products; by hydrocracking the diesel oil, the producer can produce high quality diesel oil directly, as well as some high quality ship-coal and high arene naphtha. The invention can save the investment of devices and equipments; it also has the advantage of less hydrogen consumption, less energy expenditure, and small circulated hydrogen compressor volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

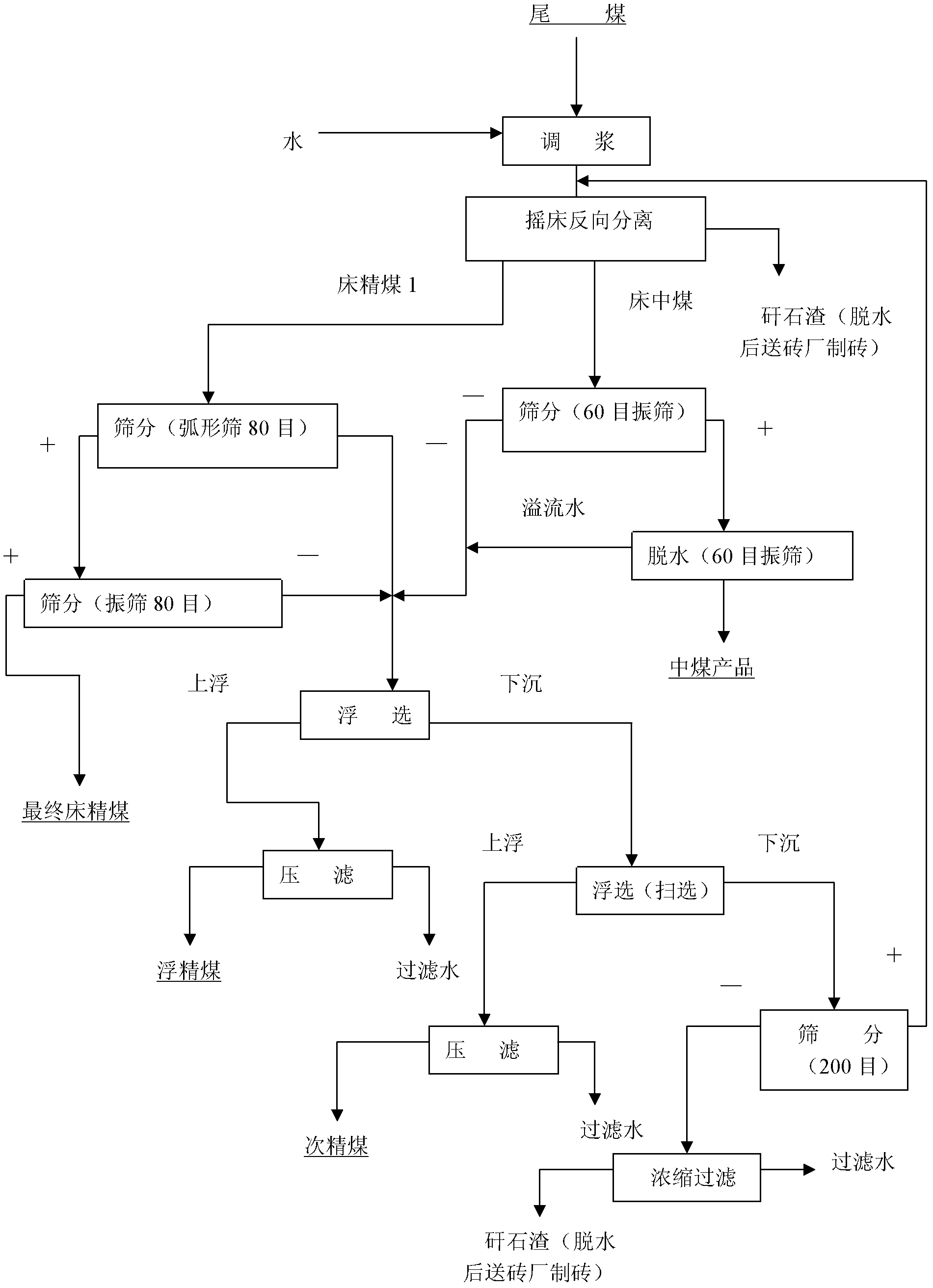

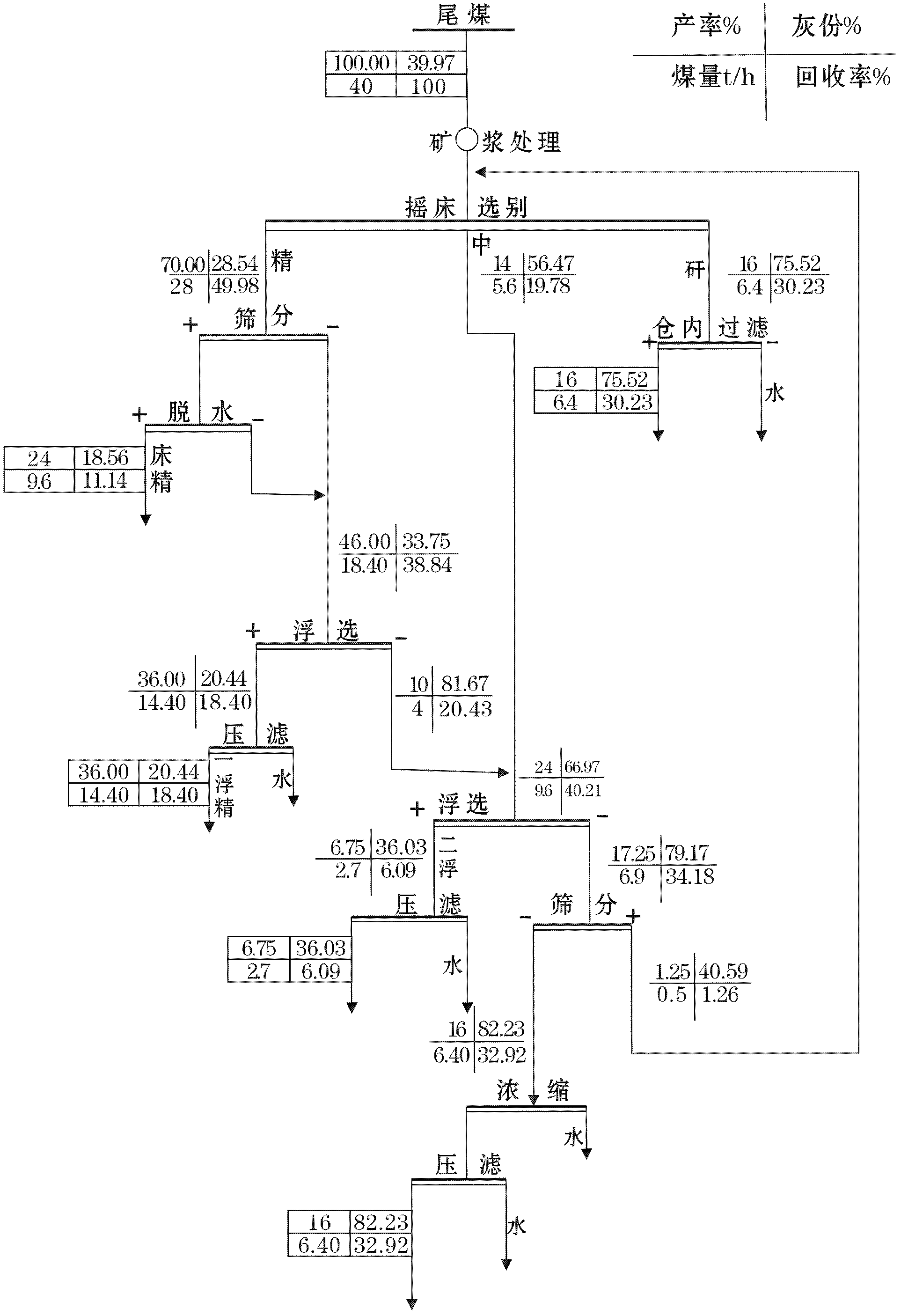

Technique for recycling cleaned coal from low-value gangue or tail coal of coal washery

The invention relates to a technique for recycling cleaned coal from low-value gangue or tail coal of a coal washery. The technique comprises the following steps of: crushing the gangue into powder with the grain size of 2mm, and dissociating coal from gangue mineral monomers; adding water into the powder or the tail coal of the coal washery to obtain ore pulp, carrying out reverse separation by virtue of a table concentrator, wherein light coal enters into a tailing slot to be prepared into a bed cleaned coal product, heavy gangue mineral enters into a concentrate slot to be prepared into gangue slag which can be used for making bricks, and an accretion body between the light coal and the heavy gangue mineral and a part of gangue mineral enter into a middling slot to be prepared into a bed midding coal product; screening the bed cleaned coal product to remove fine gangue component, dehydrating oversize products to obtain a final bed cleaned coal product; carrying out flotation separation on the bed middle coal product by adopting a flotation machine, and carrying out filter pressing on floating products to obtain a floating cleaned coal product, wherein a sink product is the gangue slag used for making bricks. By applying the technique provided by the invention, cleaned coal in the tail coal or gangue can be economically and reasonably recycled in a large scale, the reverse separation by using table concentrator is organically combined with certain flotation and the like, thus technological adaptability is high and technical index is good; coal gangue with ash content up to 62-72% can be processed into cleaned coal or secondary cleaned coal with the ash content of 27-40% only, technological process is simple and compact, operation cost is low, net profit created by each ton of the coal gangue is 50-80 yuan, no 'three wastes' pollution is produced, and the technique provided by the invention is safe and environmentally friendly.

Owner:高华

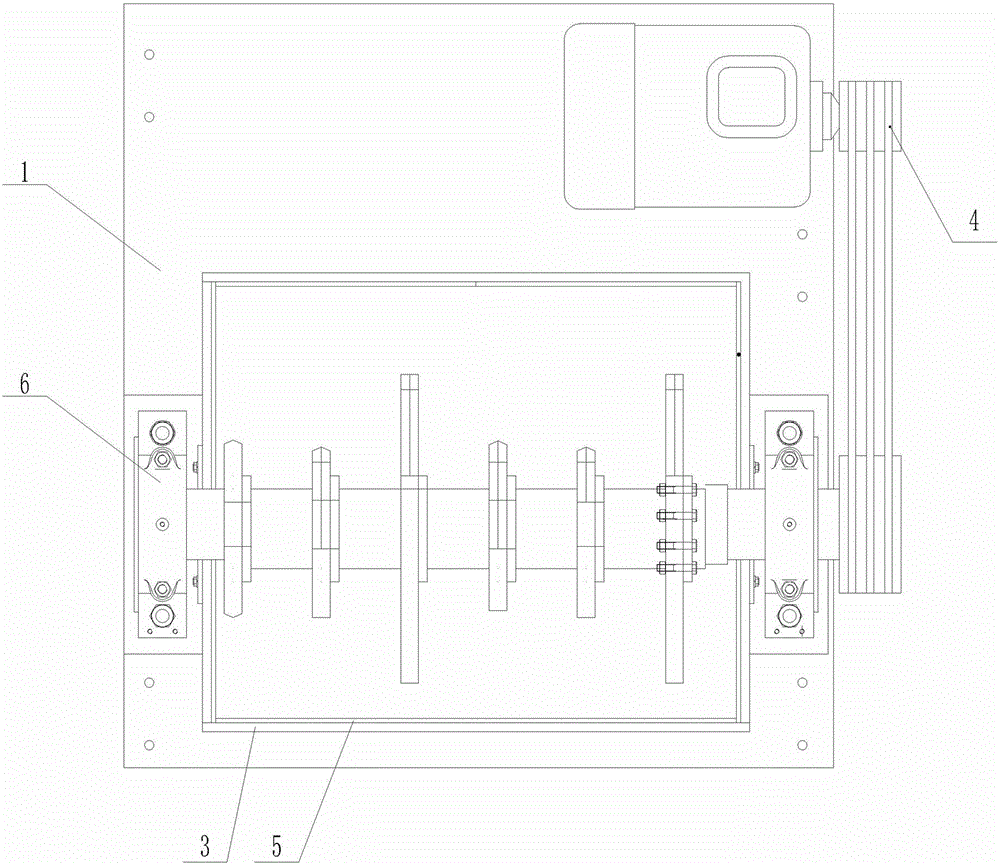

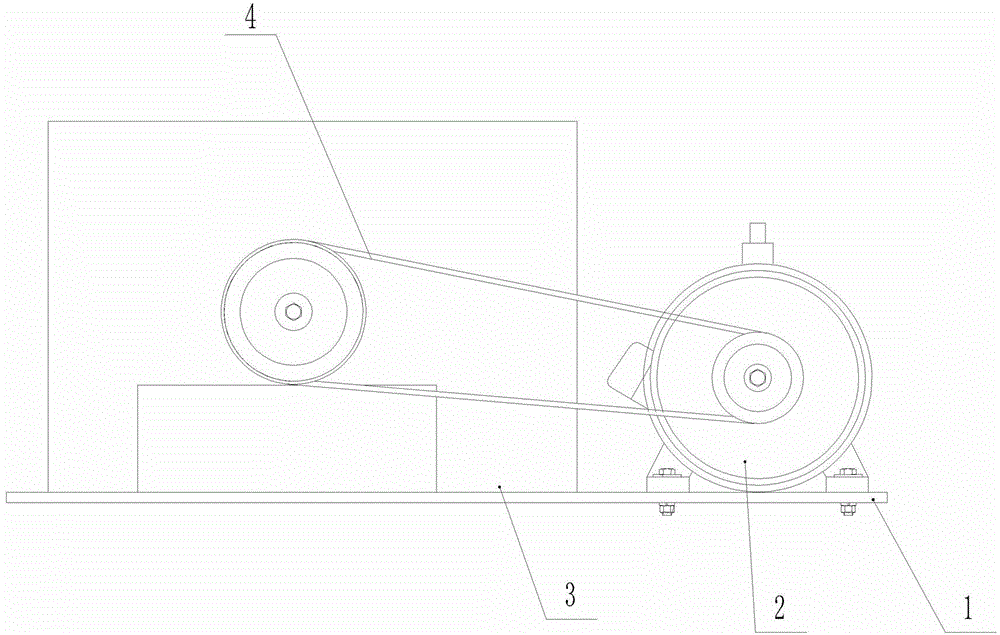

Toothed cutter type coal product breaking and mixing machine and clean coal and coal slime cake breaking and mixing method

InactiveCN104475211AAchieve the purpose of crushing and mixingGrain treatmentsEngineeringFilter press

The invention relates to a coal product breaking and mixing machine and is suitable for the breaking and mixing process of clean coal and filter-pressed coal slime cake in a coal preparation system. The toothed cutter type coal product breaking and mixing machine comprises a motor, a belt driving mechanism, a fixed foundation bed and a crushing box body of which two ends are communicated; the toothed cutter type coal product breaking and mixing machine is characterized in that a toothed cutter is arranged in the crushing box body, a wear-resisting plate is inlaid in the inner wall of the crushing box body, the communicating surface of the fixed foundation bed and the crushing box body is provided with discharging through holes with consistent size, and the lower through hole surface of the crushing box body is fixed on the fixed foundation bed and corresponds to the position of the discharging through hole; the toothed cutter type coal product breaking and mixing machine adopts the main principle as follows: an electric motor is utilized for driving a rotor to rotate at high speed, a blade designed to have special shape and mounting position is arranged on the rotor, coal and coal slime cake mixture charged above the blade is broken by the blade in a blade rotating process, and impart force during breaking can vibrate and mix the coal and the broken coal slime cake, and therefore, the purpose of breaking and mixing the coal and the coal slime cake can be achieved.

Owner:枣庄矿业(集团)有限责任公司蒋庄煤矿

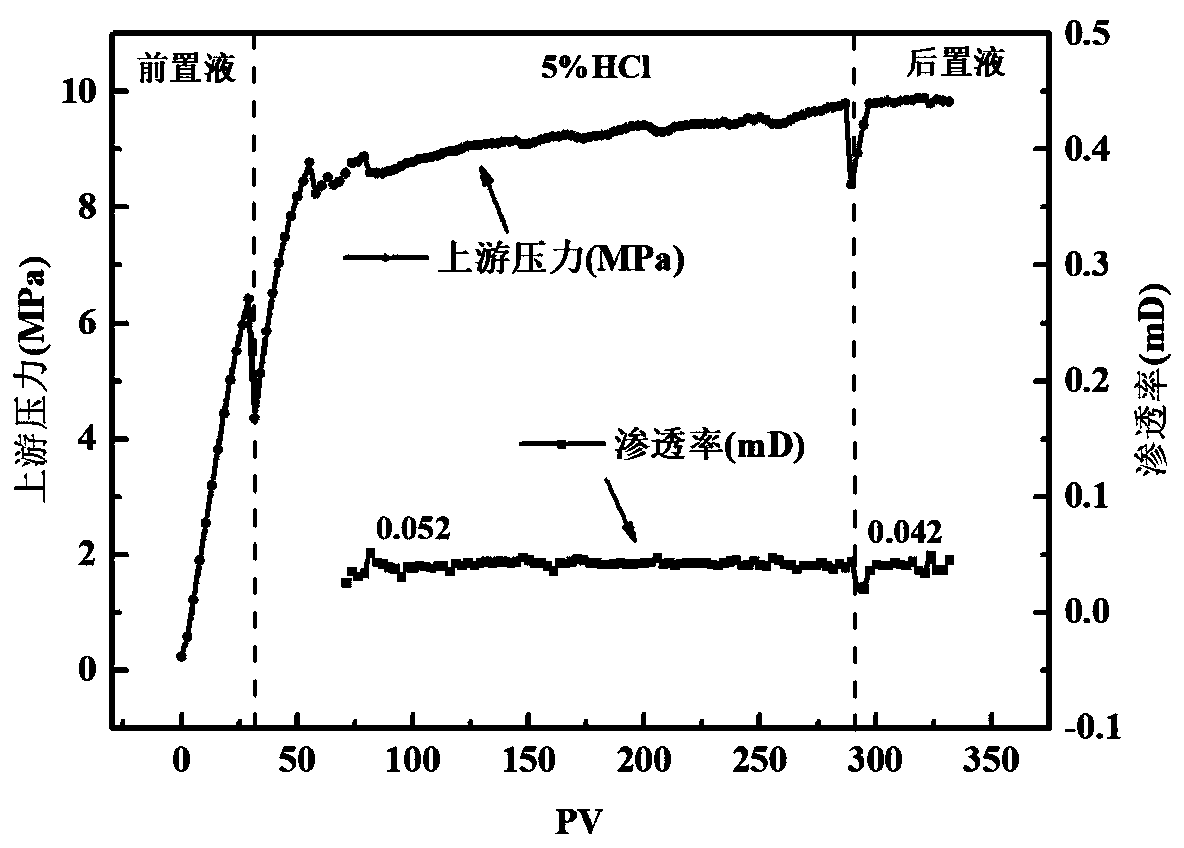

Environment-friendly acidizing working fluid suitable for low-permeability coalbed methane reservoir stimulation

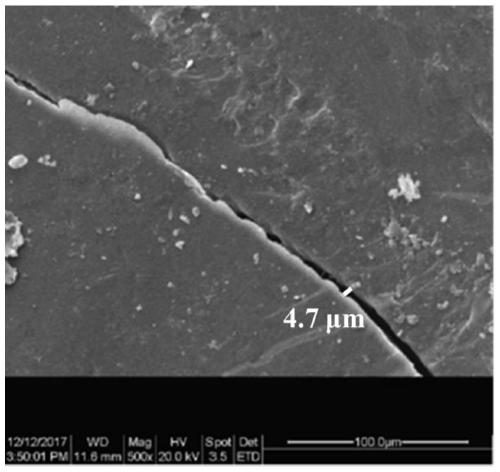

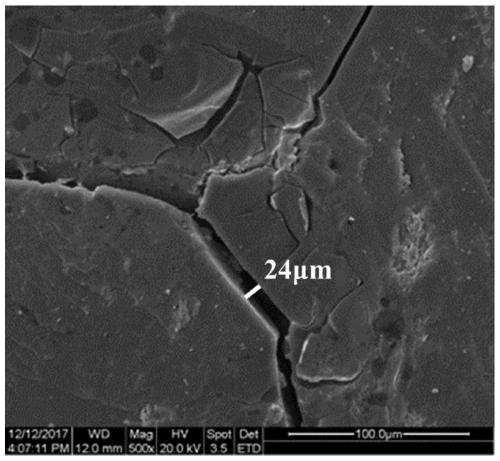

ActiveCN109810687ACreate pollutionQuality is not affectedDrilling compositionEthylenediaminePorosity

The invention provides environment-friendly acidizing working fluid suitable for low-permeability coalbed methane reservoir stimulation, and belongs to the technical field of coalbed methane development. The environment-friendly acidizing working fluid is composed of organic acid, a chelating agent, an anti-swelling agent and a corrosion inhibitor, and every 100 parts of water includes the following components in parts by mass: 7-9 parts of organic acid, 4-5 parts of the chelating agent, 4 parts of the anti-swelling agent and 0.5-1 part of the corrosion inhibitor; and the organic acid is composed of formic acid and citric acid, the chelating agent is composed of glutamic acid N,N-oxalic acid (GLDA) and N-beta-hydroxy ethyl ethylenediamine triacetic acid (HEDTA), and the anti-swelling agentis composed of potassium chloride and ammonium chloride. The environment-friendly acidizing working fluid has the good corrosion effect on crystalline minerals in coal rock, can increase the crack width and porosity of the coal rock, and thus increase the gasometry permeability; and meanwhile, the corrosivity of the environment-friendly acidizing working fluid to pipes is low, pollution to coal mine groundwater cannot be caused, the quality of coal products produced in the later period cannot be affected, and the environment-friendly acidizing working fluid has good application prospects in low permeability coalbed methane reservoir stimulation.

Owner:XIAN AODE PETROCHEM ENG TECH CO LTD

Algal coal and process for preparing same

InactiveUS8414664B2High hydrogen contentReduce environmental impactBiofuelsSolid fuelsEnvironmental engineeringBituminous coal

Algae-derived synthetic coal and filtrates. The invention described herein provides an algae-derived synthetic coal product and filtrates and process for preparing the same using an improved hydrothermal carbonization process. The synthetic coal product is similar to natural bituminous coal in terms of percent carbon content and energy equivalency while at the same time containing relatively low levels of sulfur and contaminant heavy metals. Unlike natural coal and other fossil fuels, because the carbon of the biomass is formed through photosynthesis, carbon dioxide formed during combustion is a “carbon neutral” event with little or no “new” carbon dioxide being added to the earth's atmosphere. The algae-derived filtrates contain useful constituents.

Owner:BIOCHAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com