Slime separation method and equipment

A sorting and slime technology, applied in flotation, solid separation, etc., can solve the problems of inability to meet the needs of sorting, poor recovery of coarse particles, low ash content of flotation tailings, etc., to achieve enhanced secondary enrichment effect, reduction of mixing and pollution, and low production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

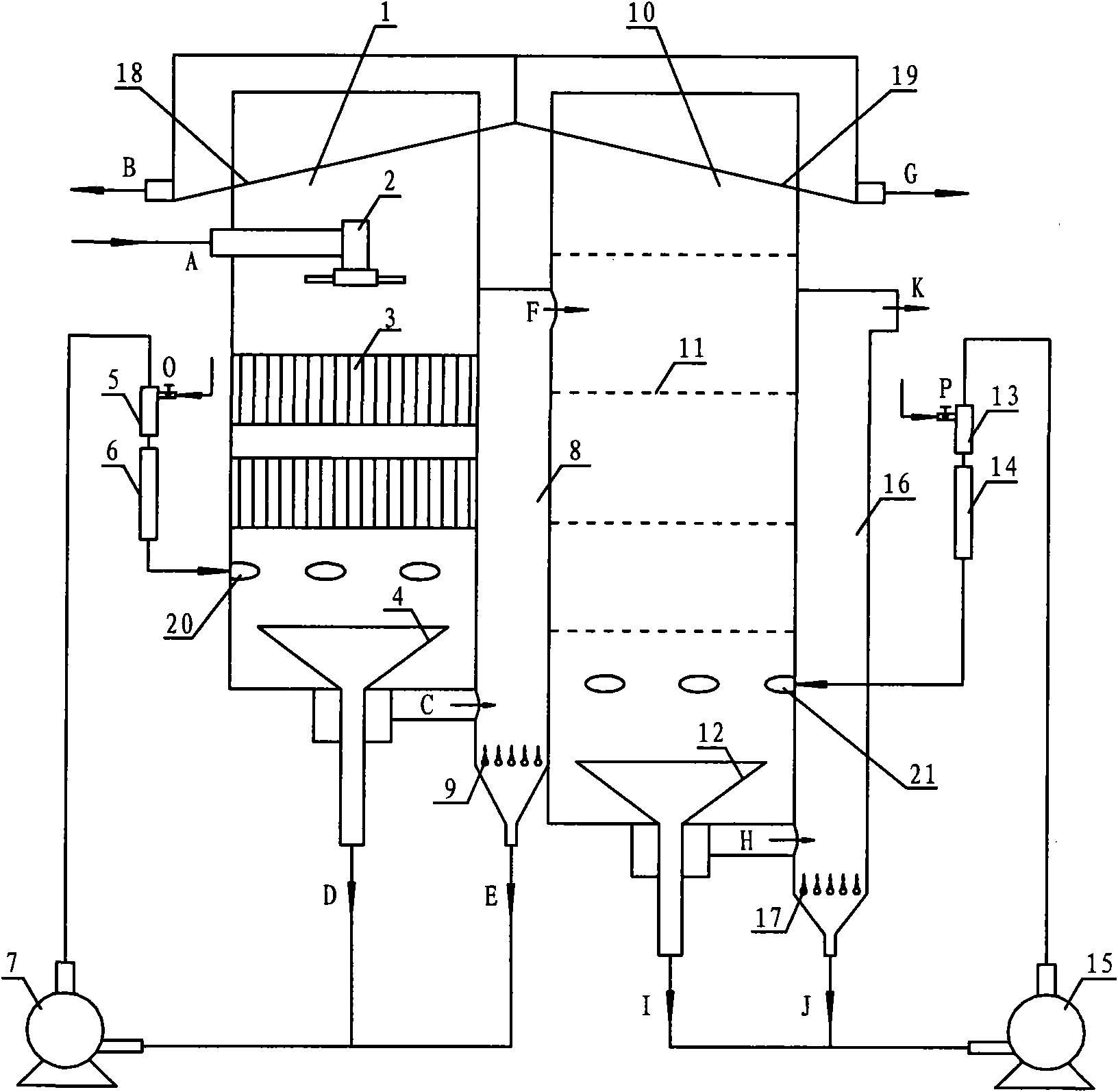

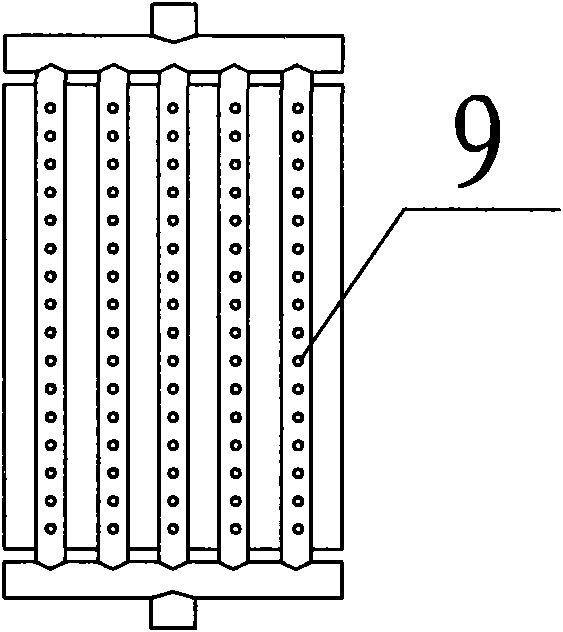

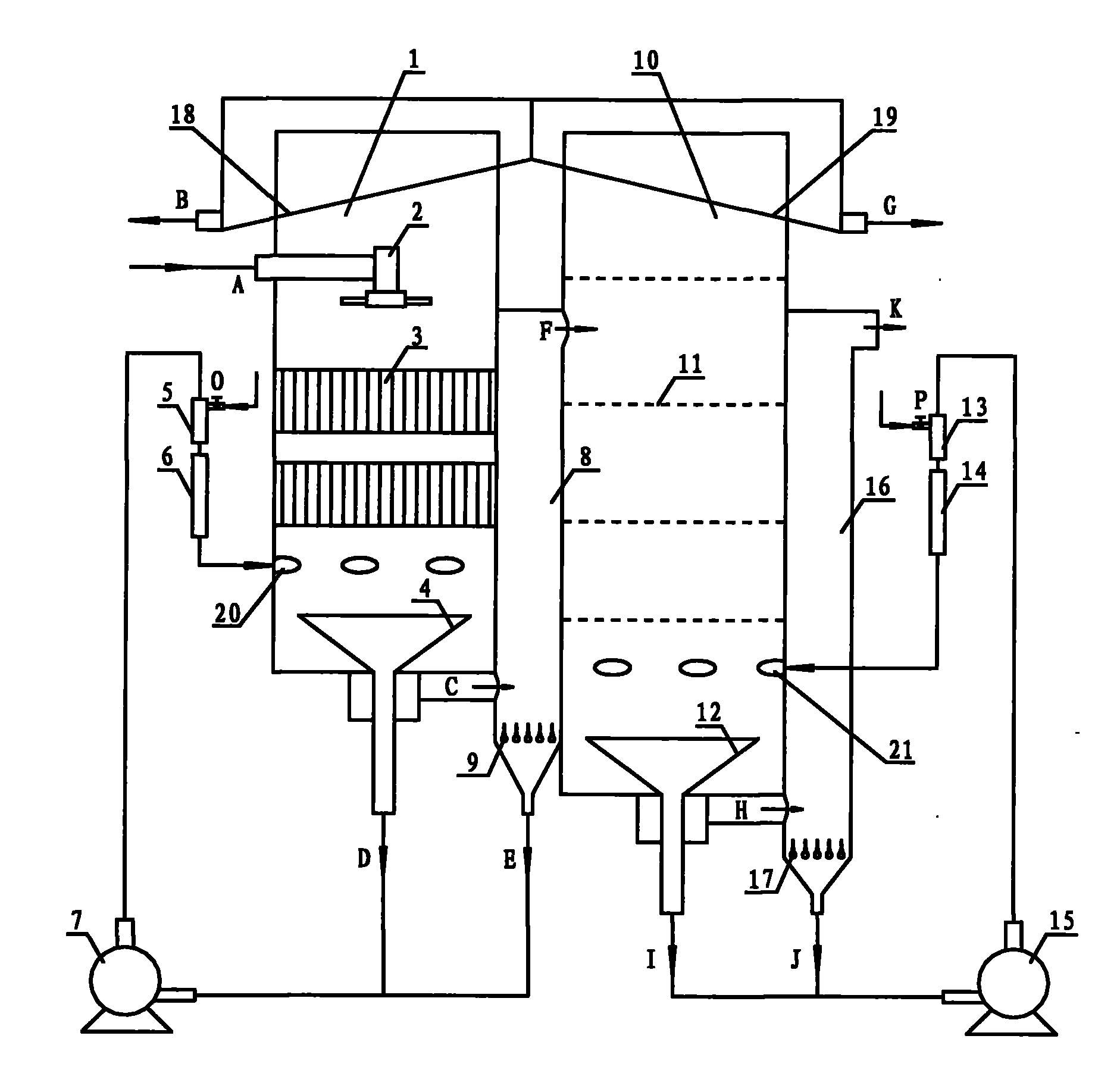

[0013] figure 1 As shown, the coal slime separation equipment of the present invention is mainly by flotation column, feed distributor 2, flow stabilizer 3, underflow bucket-shaped guide pipe, bubble generator, mineralization pipe, circulation pump, the first settling tank Body 8, the second settling tank body 16 constitutes. The flotation column is divided into the first flotation column 1 and the second flotation column 10, the feed distributor 2 is arranged on the upper part of the first flotation column 1, and the current stabilizer 3 is arranged on the top of the first flotation column 1. In the middle part, the flow stabilizer 3 is composed of upper and lower collars in the form of mesh plates and a plurality of pipe sections fixed between the upper and lower collars. According to the situation of the flotation material, the current s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com