Method for recycling micro-particle ilmenite through vanadium-titanium magnetite titanium beneficiation main tailings

A technology of vanadium-titanium magnetite and fine particles, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of high yield of fine particles and high distribution rate of fine particle grade TiO, and achieve good recovery effect , strong applicability, and the effect of improving the enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

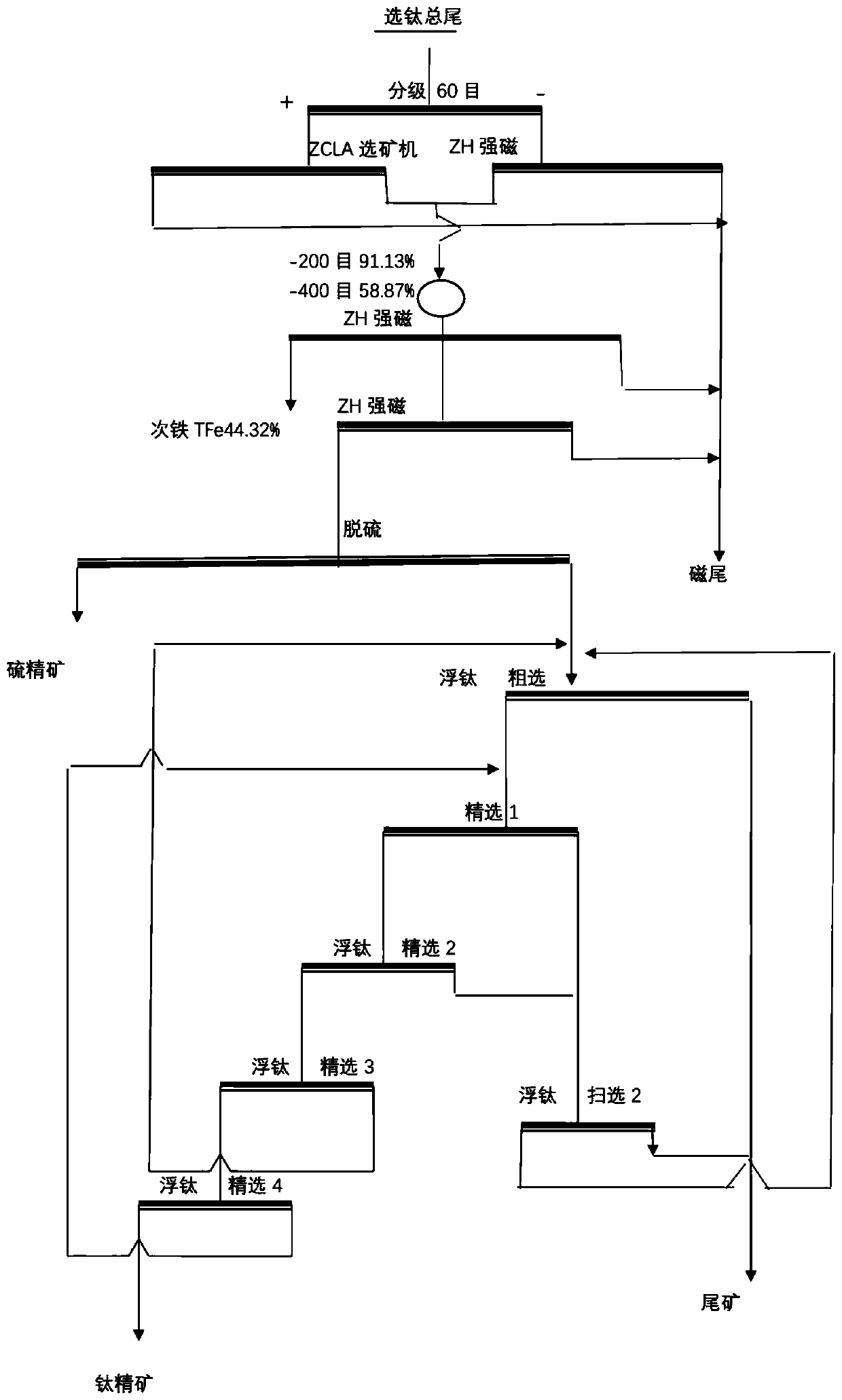

[0060] to TiO 2 The total tailings with a grade of 3.83% are classified with a 60-mesh sieve; 2 Grade 2.35%, under-sieve -0.35mm particle size TiO 2 Grade 4.57%;

[0061] +0.35mm particle size is pre-enriched by ZCLA separator, the ore concentration is 50%, the magnetic field strength is 8500Gs, and TiO can be obtained 2 Grade 5.85% coarse concentrate; -0.35mm particle size ZH combined magnetic separator feed concentration is 35%, magnetic field strength is 8500Gs, TiO can be obtained 2 Grade 6.61% rough concentrate;

[0062] The mixed concentrate of ZCLA concentrator and ZH combined magnetic separator enters the ball mill and grinds to -200 mesh, accounting for 91%;

[0063] Grinding products adopt ZH combined magnetic separator with one coarse and one fine separation, the ore concentration is 35%, the medium flushing water pressure is 0.3MPa, the rough separation and concentration adopt the magnetic field strength of 8000Gs and 10000Gs respectively, and TiO can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com