Patents

Literature

1372results about How to "Improve recycling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

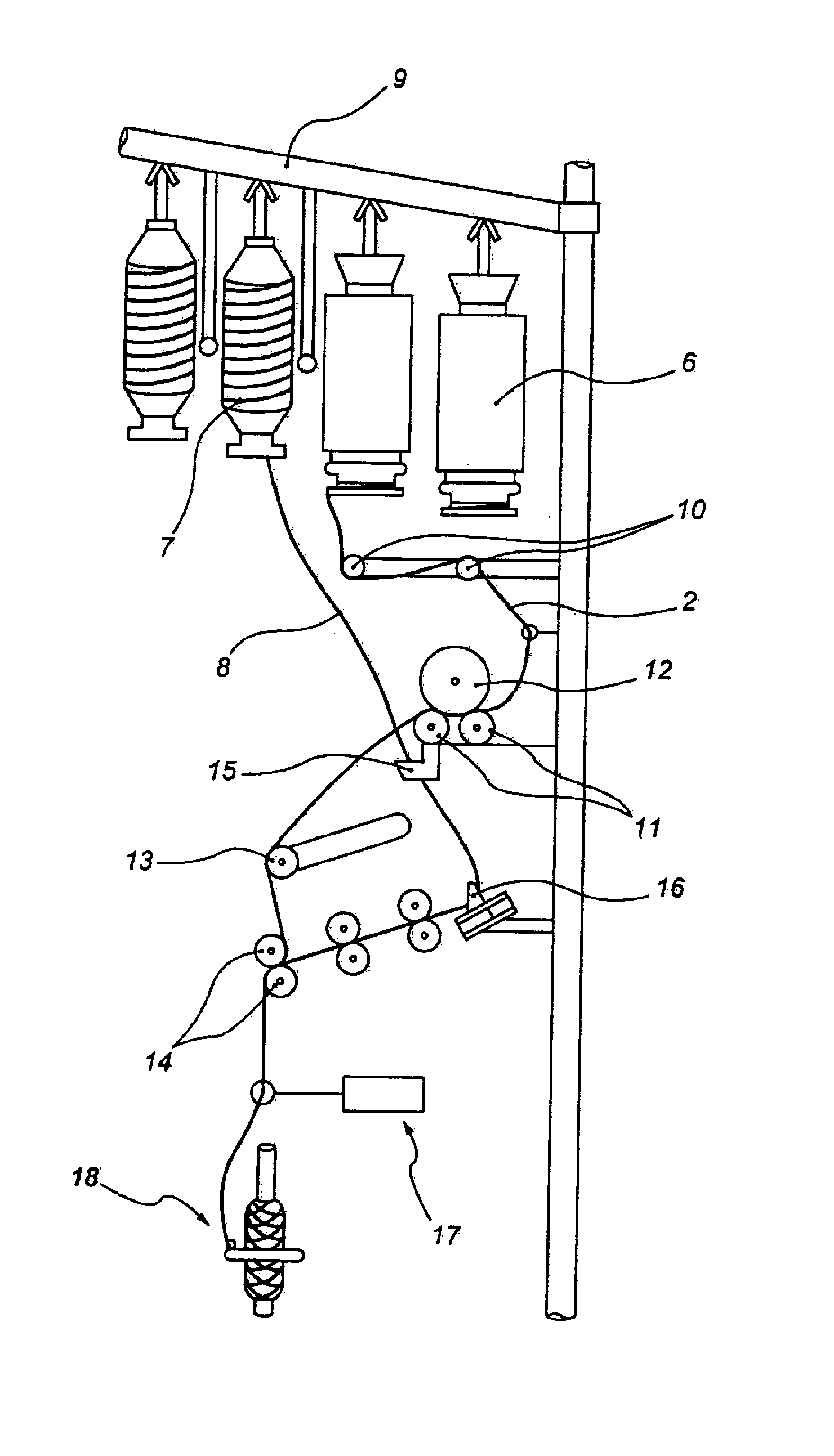

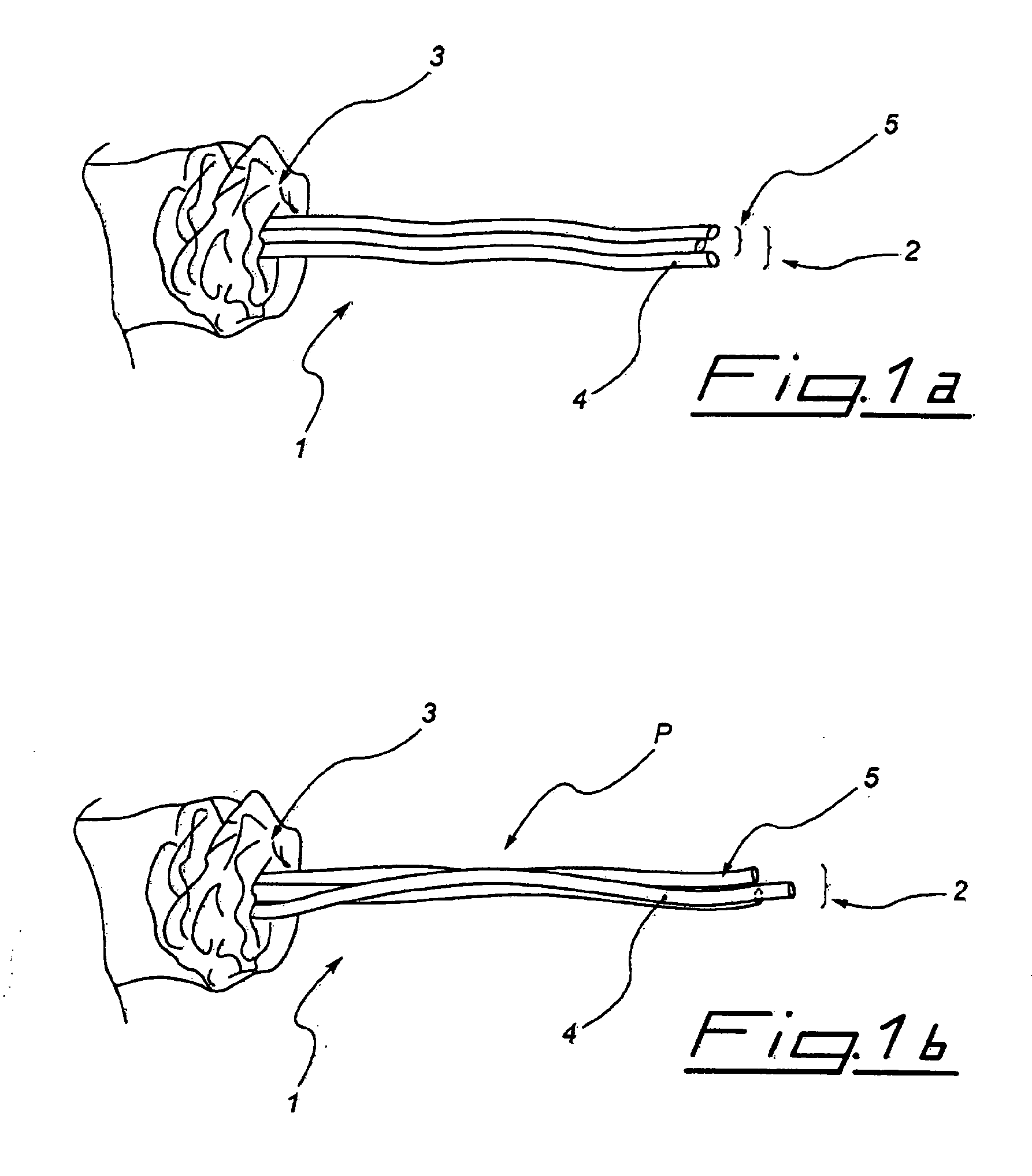

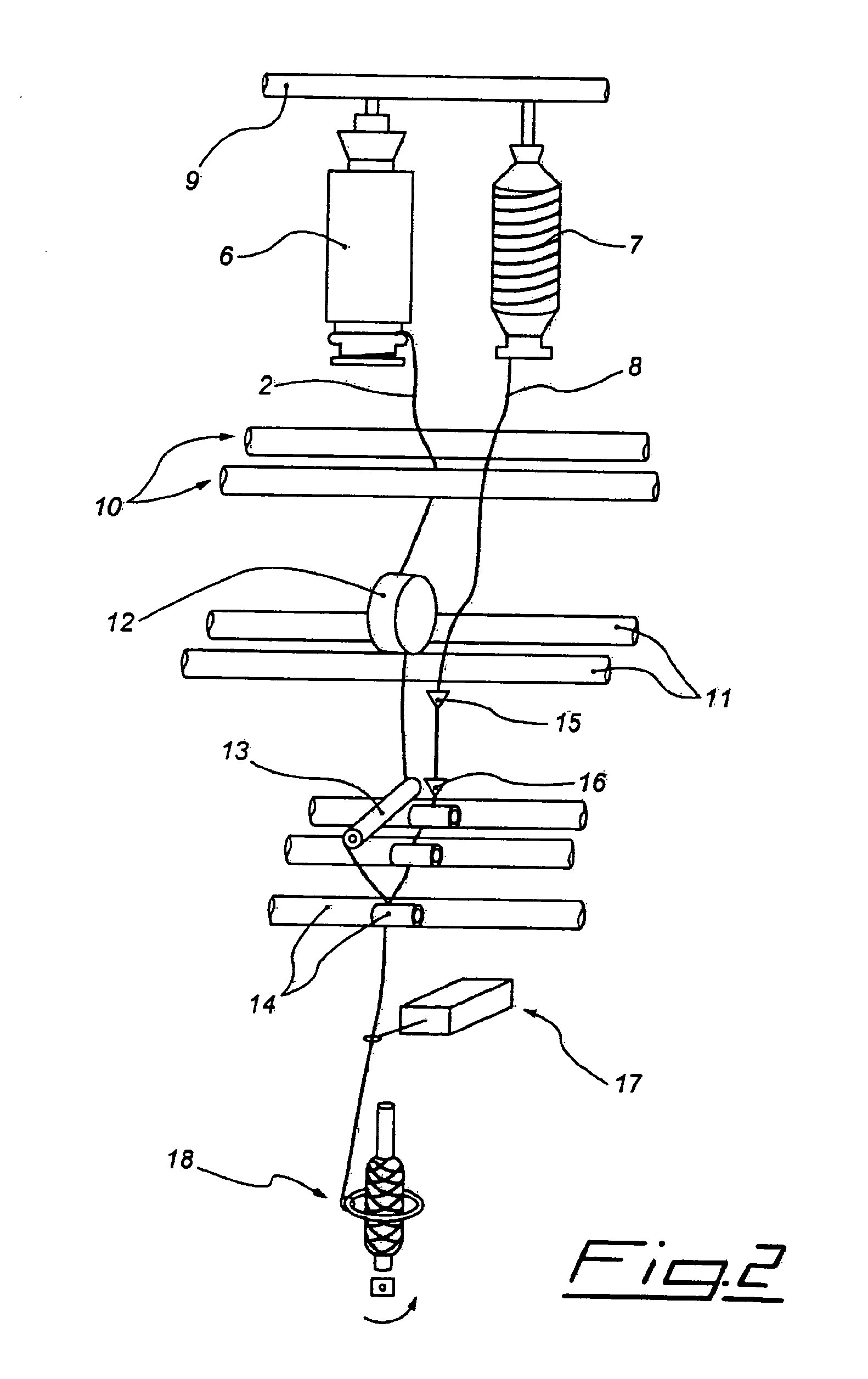

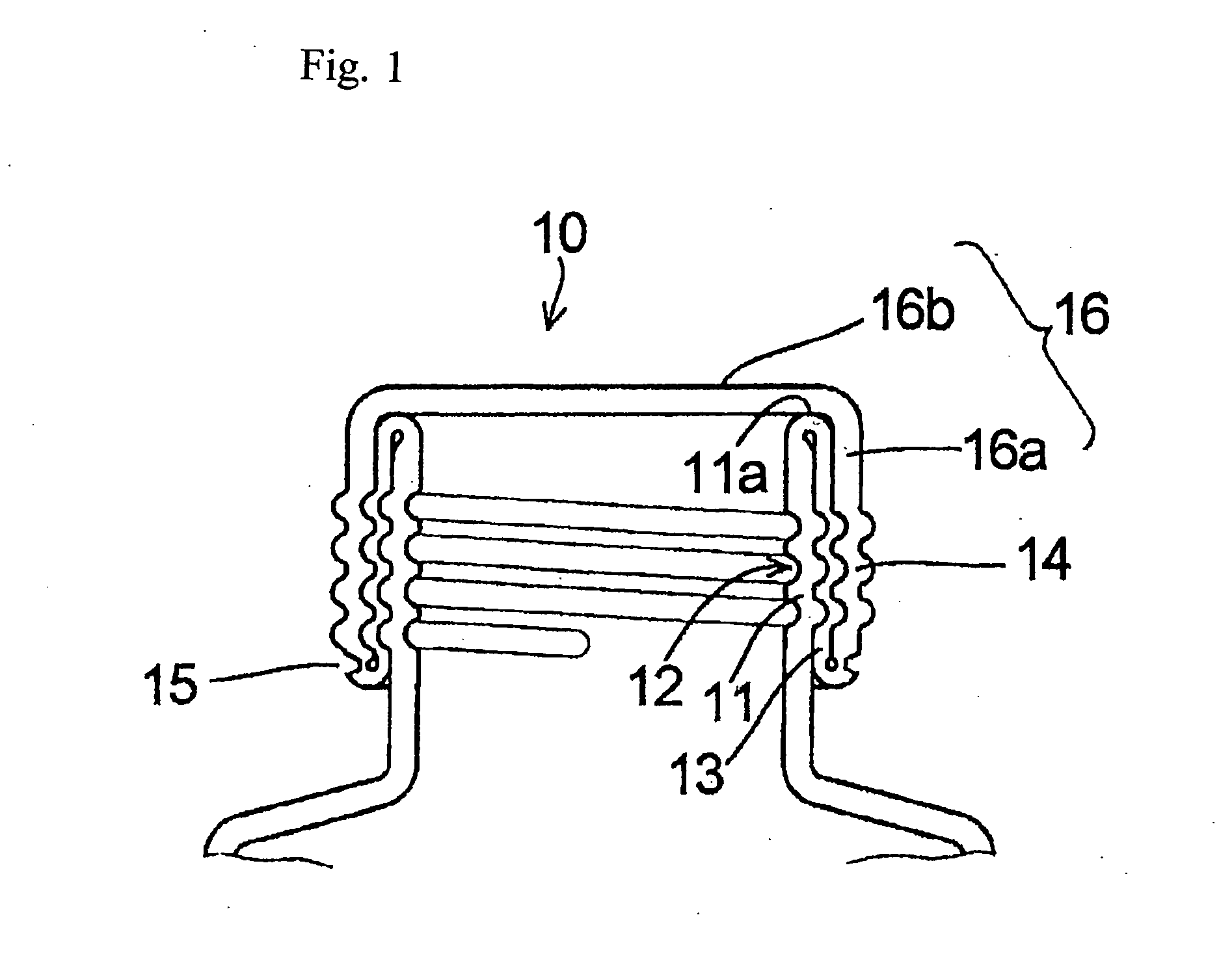

Composite stretch yarn, process and fabric

ActiveUS20130260129A1Increase elasticityGood stretch recoveryDrafting machinesAnimal housingElastomerYarn

In a stretch yarn (1) comprising a stretchable core (2) covered by an inelastic fibers sheath (3) the stretchable core (2) comprises first and second fibers (4, 5) that have elastic properties, the first fiber (4) is an elastomer and the second fiber (5) is a polyester based (co)polymer, the amount of the second fiber being in the range of 60-90% (w / w) of the total weight of the fibers of the stretchable core (2); the first and second fibers are connected together at least at a plurality of points (P).

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

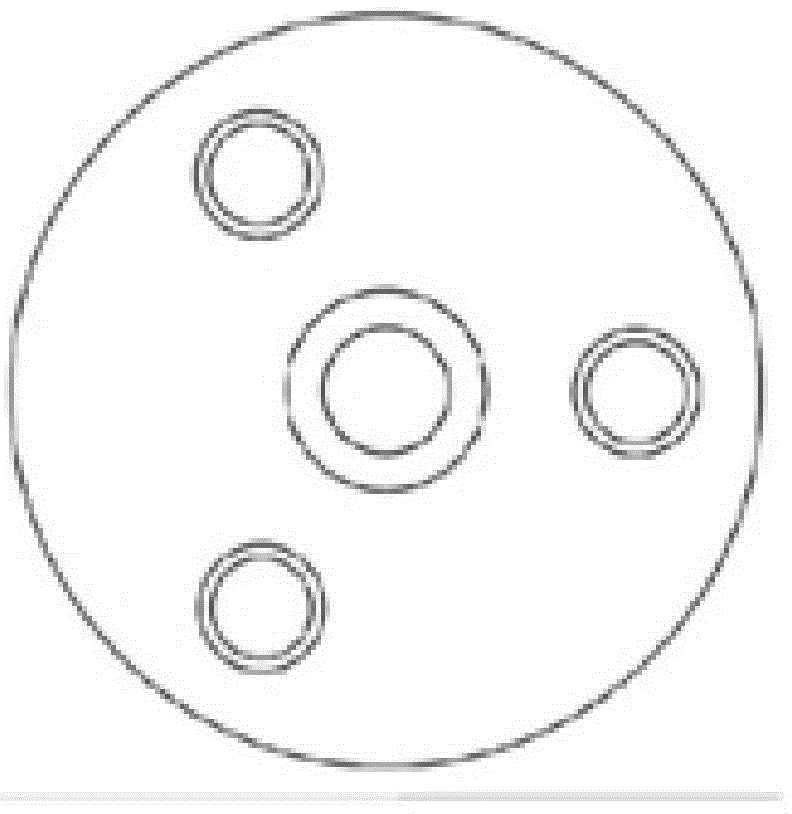

Container sealing structure, container with the sealing structure, and method of manufacturing the sealing structure

InactiveUS20050205575A1Easily breakableImprove tamper resistanceCapsThreaded caps applicationMechanical engineering

Owner:TOYO SEIKAN KAISHA LTD

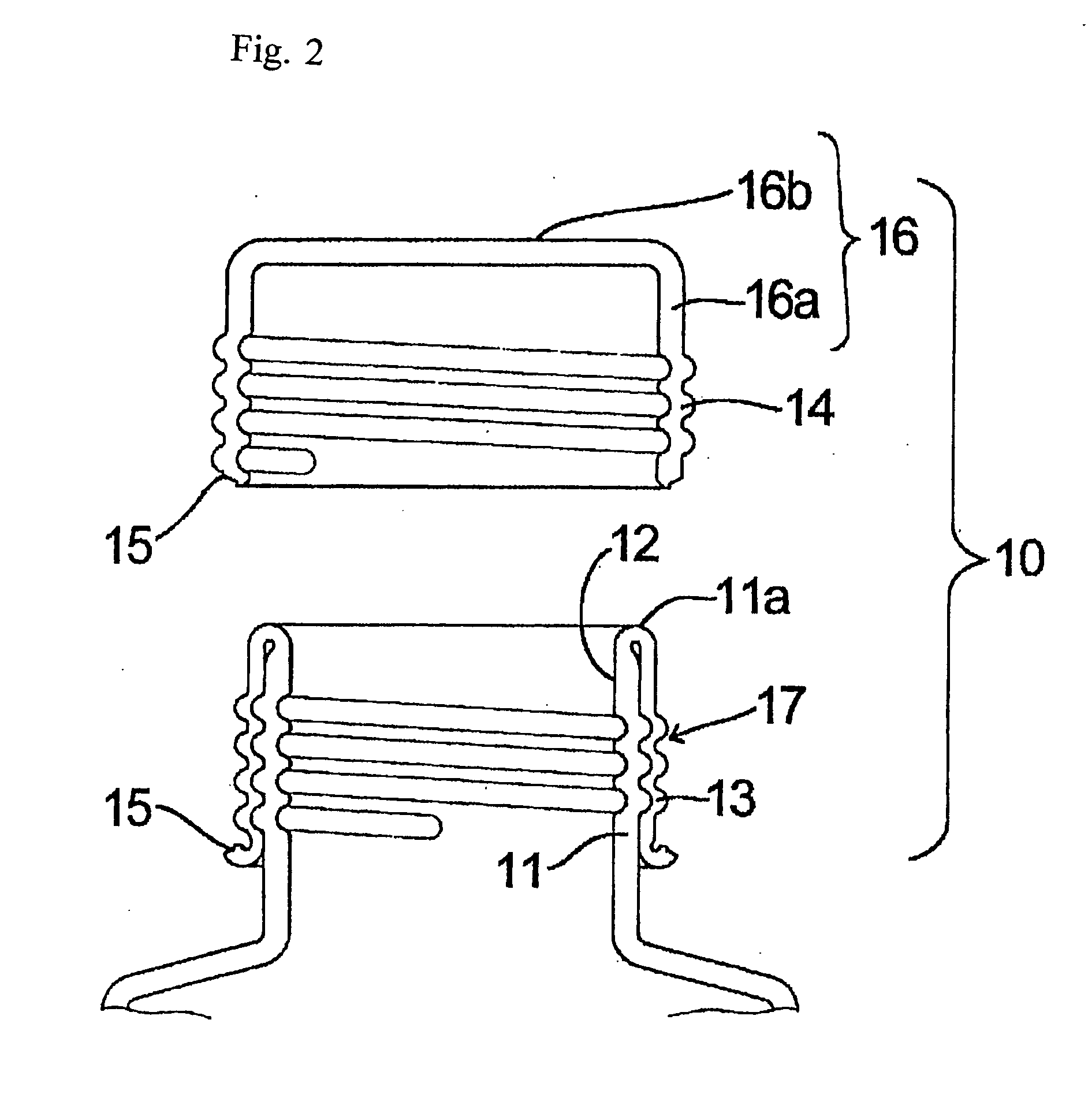

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

InactiveCN103418488ASolve the problems of low recovery rate, single beneficiation products, and poor economic benefitsRaise the gradeFlotationMagnetic separationLithiumNiobium

The invention relates to a comprehensive recovery process for lithium-containing polymetallic ores with associated fine-grained niobium-tantalum. The process comprises the steps of raw ore crude grinding, settlement for desliming, flotation, agglomeration and magnetic separation, gravity separation and the like. The process provided by the invention is particularly applicable to the comprehensive recovery of lithium-containing polymetallic ores which contain a great amount of slime, are located in mining areas at low temperature all through the year, are low in grade of associated niobium-tantalum minerals and are fine in disseminated grain size, the process is advanced, reliable, simple, reasonable and highly targeted, the requirement on raw ore grinding fineness is not high, the regrinding amount is small, the operation cost is low, the comprehensive recovery rate is higher and the industrialization prospect is good.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

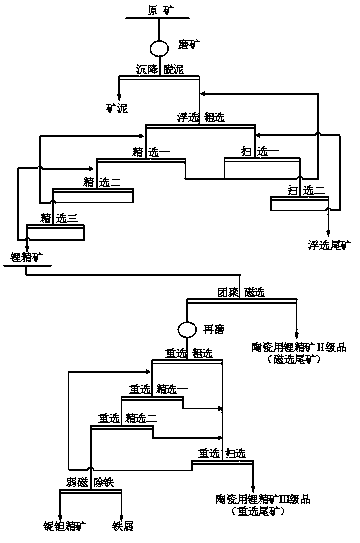

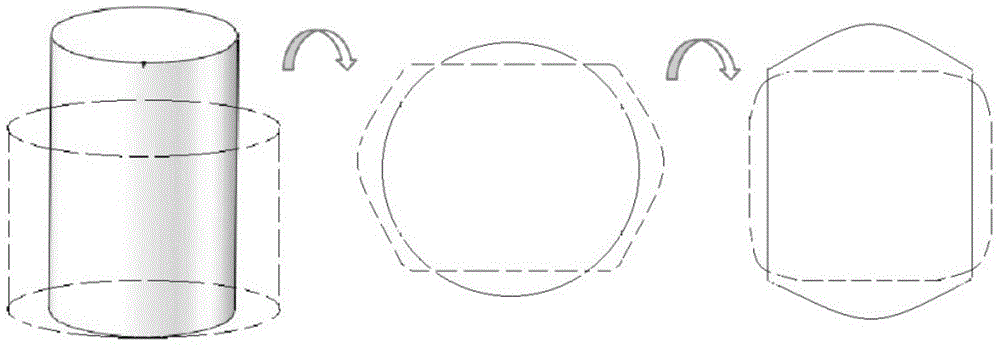

Thermoplastic elastomer composition

InactiveUS20040010090A1Improve recycling effectImproved compression setElastomerThermoplastic elastomer

Owner:YOKOHAMA RUBBER CO LTD

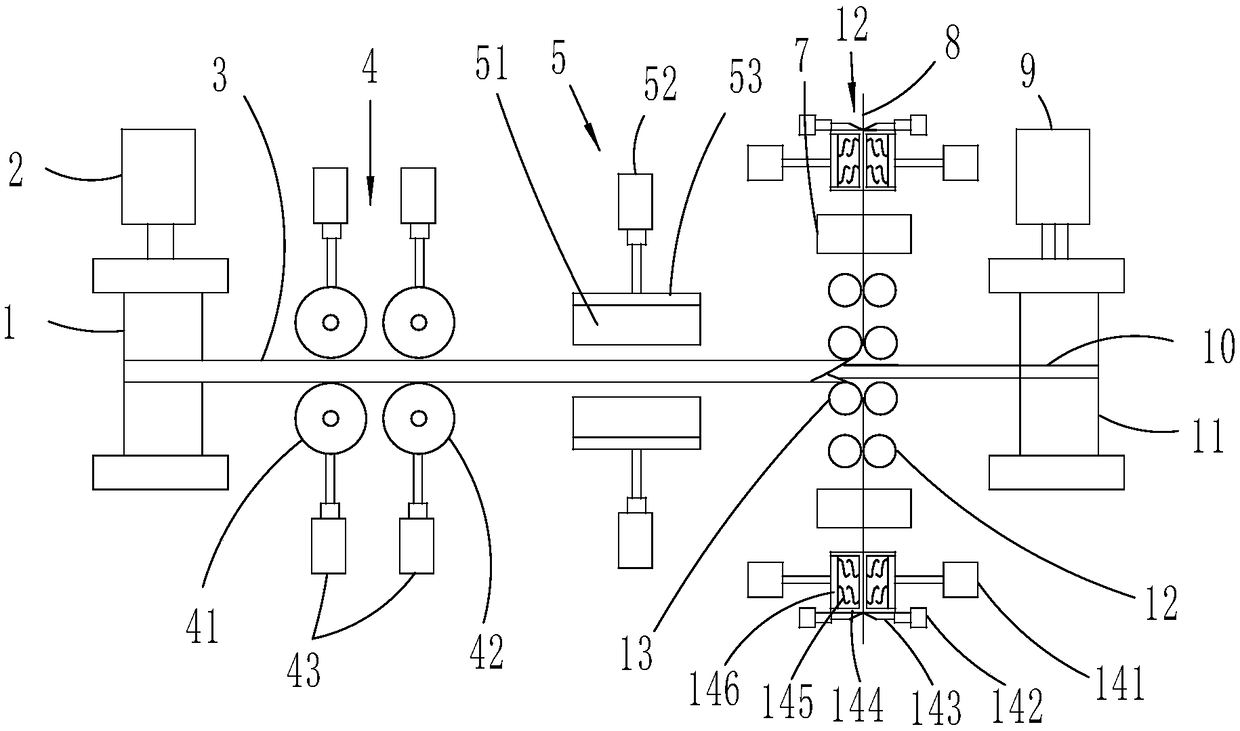

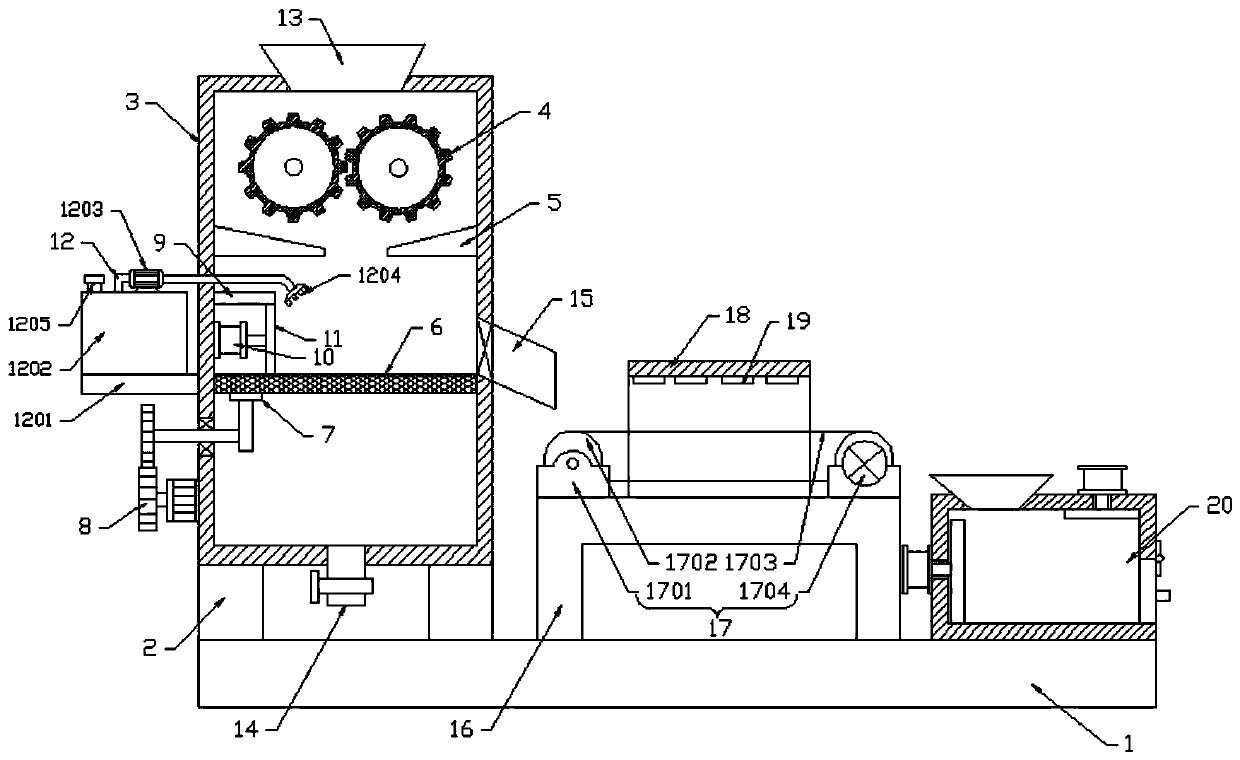

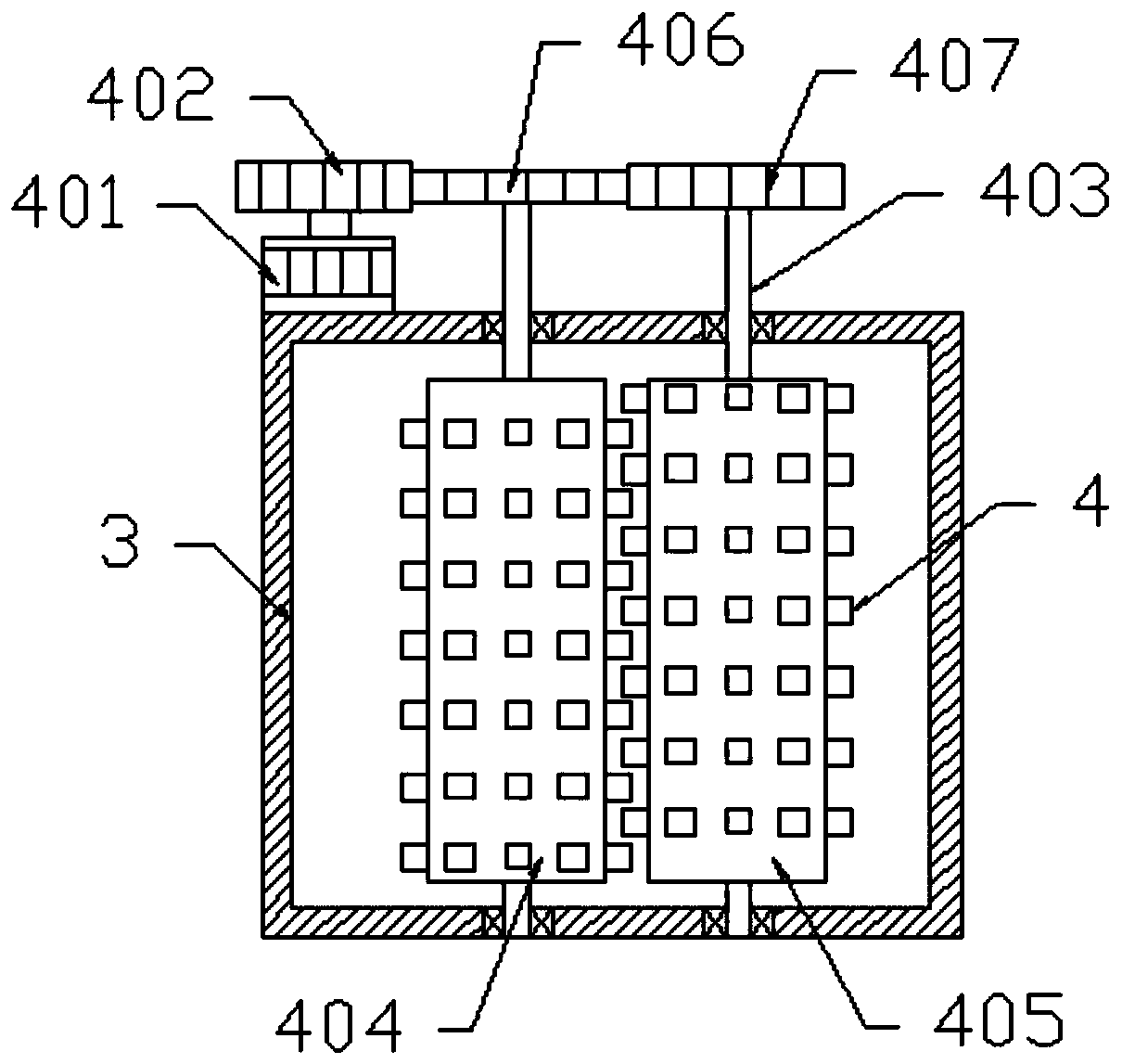

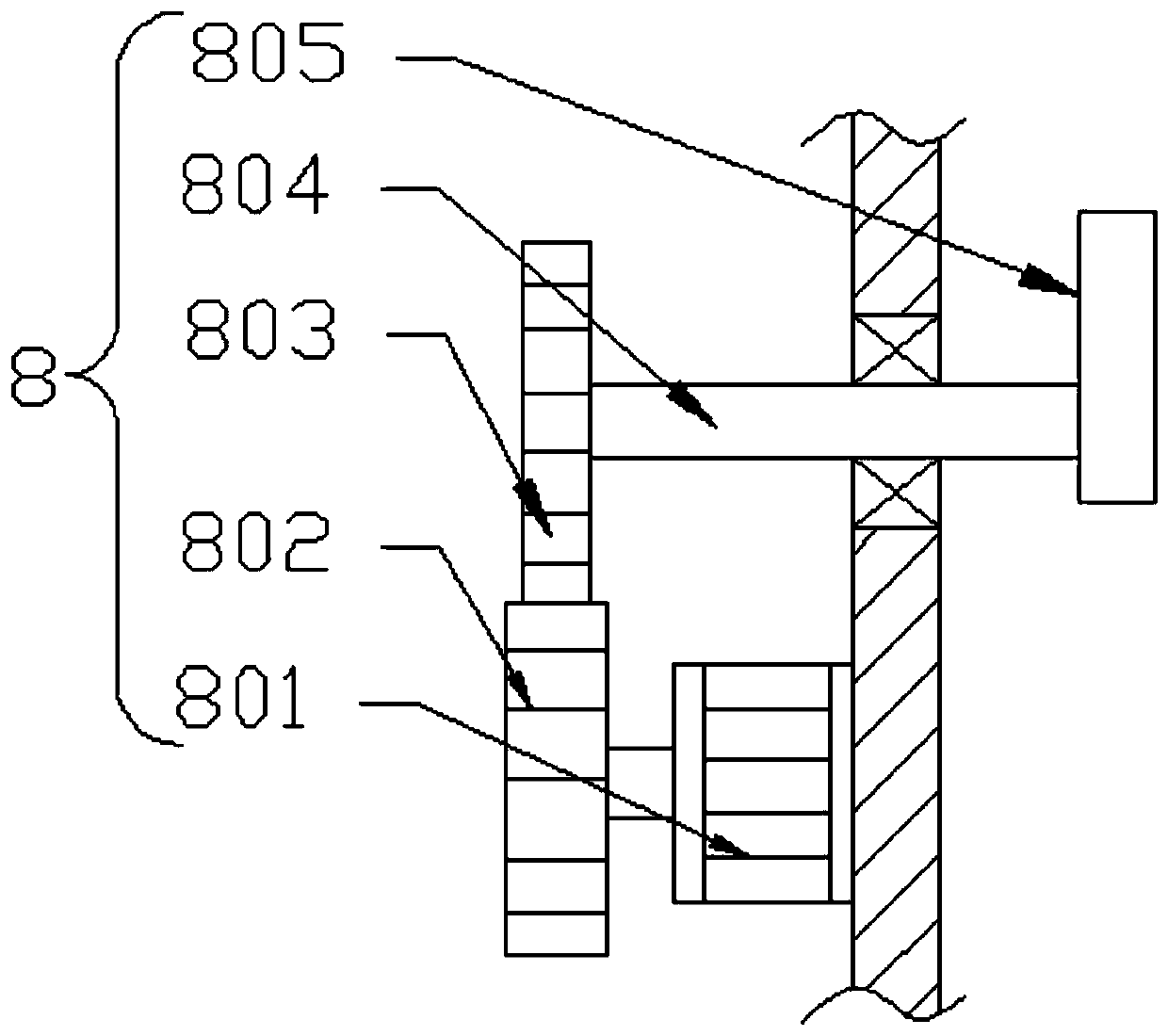

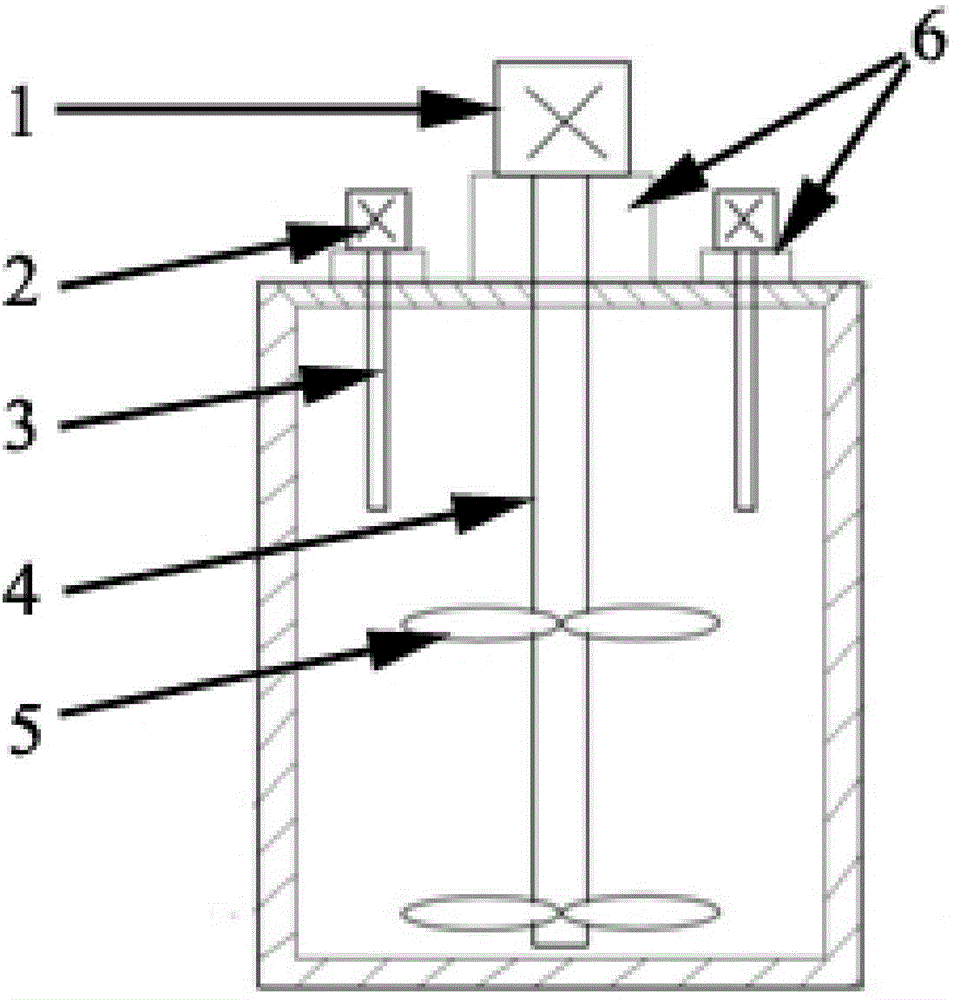

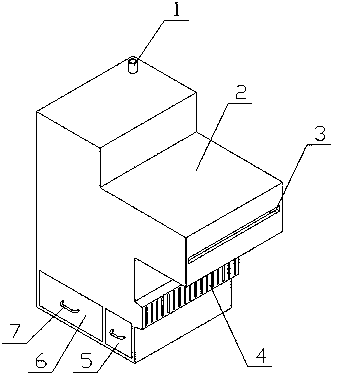

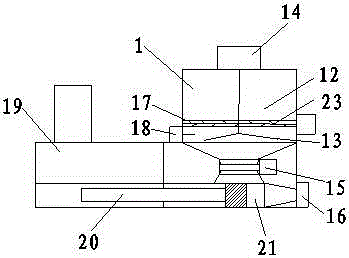

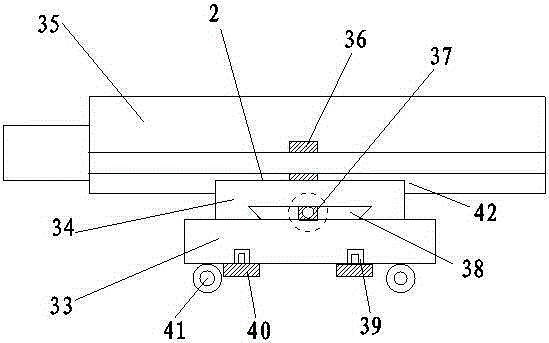

Waste Cable Recovery System

ActiveCN109036736AImprove recycling effectAvoid stickingBasic electric elementsApparatus for removing/armouring cablesEngineeringCopper

The invention provides a waste cable recovery system and belongs to the technical field of waste cable reuse. The system includes frame, pay-off roll, straightening device, cutting device, cop core winding roller, two cooling devices, two cutting devices and crushing device. A let-out roller, a straightening device, a cutting device and a cop core winding roller are arranged in sequence from one end of that frame, two cooling device and two cutting devices are arranged between the cutting device and the cop core winding roller and are symmetrically arranged on both sides of the frame, the cooling device is close to the frame, and the cutting device is far away from the frame. The invention provides a waste cable recovery system, by carrying out straightening first, and Cutting, Cut off thecable sheath after cooling, the cable sheath after the cutting-off falls into the lower crushing device for crushing, copper core is wound on the copper core winding roller along a straight line, after straightening the cable sheath, adhesion and incessant cutting of the cable sheath can be avoided, thereby avoiding scratching the copper core, the cable sheath is cut off after cooling, and is easy to cut and crushing.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

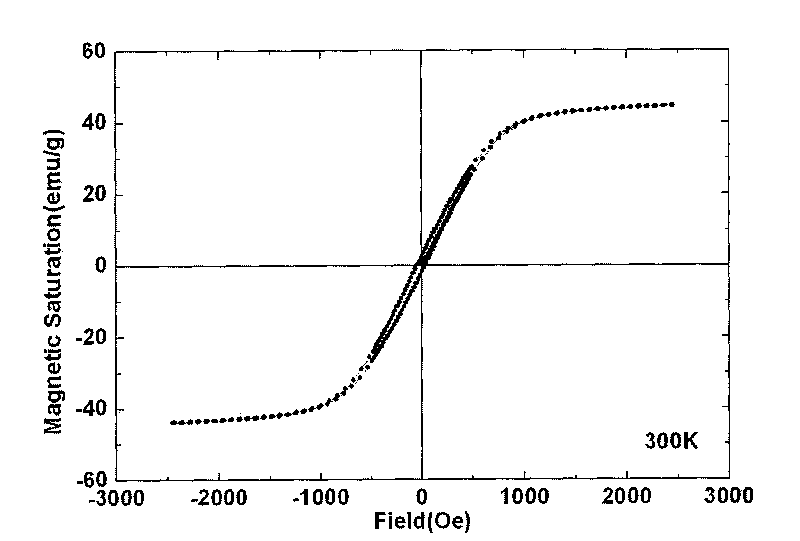

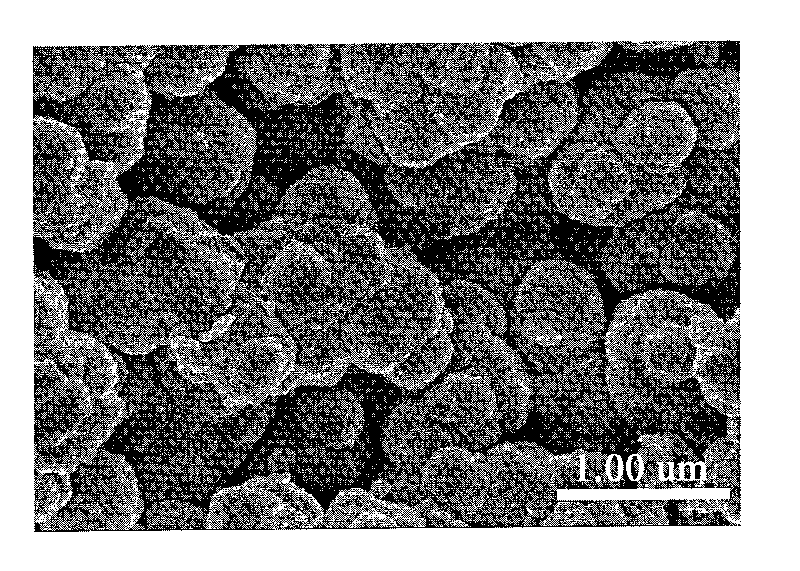

High-magnetic heavy-metal ion adsorbent carrying conductive high molecules and preparation method thereof

ActiveCN101708463AStable in natureHigh magnetic responsivenessOther chemical processesWater contaminantsMicrospherePolypyrrole

The invention discloses a high-magnetic heavy-metal ion adsorbent carrying conductive high molecules and a preparation method thereof. The adsorbent comprises high-magnetic microspheres carrying conductive high molecules, each of which comprises a Fe3O4 polycrystal sphere cluster, an amorphous SiO2 protective layer and a polypyrrole adsorption outer layer from inside to outside. The preparation method of the adsorbent is realized in a way that: carrying out a solvent thermal reduction reaction on soluble ferrites to obtain the Fe3O4 magnetic sphere cluster; carrying out the basic hydrolysis by using tetraethoxysilane to obtain the Fe3O4-SiO2 nuclear shell sphere cluster; and finally, carrying out the free radical polymerization reaction on the pyrrole monomers to obtain the Fe3O4-SiO2-polypyrrole functional particles. The heavy-metal ion adsorbent has the characteristics of stable property, high adsorption rate and reproducibility, has favorable adsorption and recovery properties on dichromic ions, and has the advantages of simple preparation process, low material price and no environmental pollution. Compared with the normal chemical absorbent, the product of the invention is convenient to use and achieves the effects of waste water treatment, pollution abatement and environment protection.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

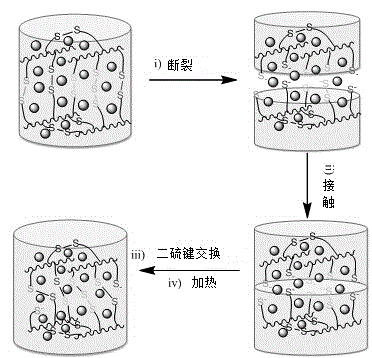

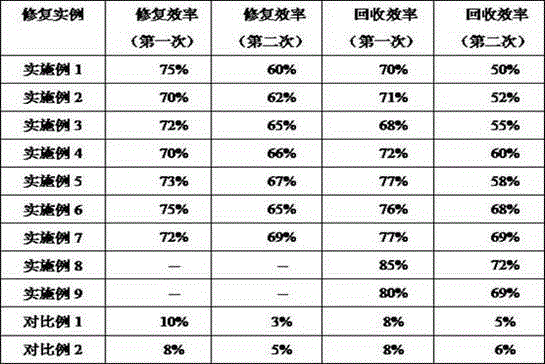

Vulcanized rubber with self-repairing and recyclability characteristics as well as preparation method and application thereof

The invention provides vulcanized rubber with intrinsic self-repairing and recyclability characteristics as well as a preparation method thereof. The vulcanized rubber comprises components in parts by weight as follows: 100 parts of a rubber matrix, 5-30 parts of nano-silica, 5-50 parts of carbon black, 1-20 parts of small liquid-state molecules containing disulfide bonds, 0.1-1 part of a disulfide bond exchange reaction catalyst, 0.5-5 parts of zinc oxide, 0.5-3 parts of stearic acid, 0.1-2 parts of an antioxidant, 0.1-2 parts of an anti-aging agent, 0.5-2 parts of an accelerant and 1-30 parts of sulfur. According to the vulcanized rubber, raw materials are easy to obtain, the preparation method is simple, repeated self-repairing and recycling can be realized, service lives of rubber products can be prolonged, the environmental pollution can be reduced, and petroleum resources can be saved.

Owner:SUN YAT SEN UNIV

Environmentally-friendly medical waste treatment device

InactiveCN111530547AReasonable structural designImprove crushing effectMagnetic separationGrain treatmentsMedical wasteSpray nozzle

An environmentally-friendly medical waste treatment device comprises a base, a treatment box is arranged on the upper end of a pillar, a crushing mechanism is arranged on the upper side of the inner part of the treatment box, a filter screen is arranged on the inner part of the treatment box, a vibration mechanism is arranged at the lower end of the filter screen, a cleaning mechanism is connectedto the left side wall of the treatment box, a conveying mechanism is installed on the upper end of a frame, and a collection mechanism is arranged on the right side of the upper end of the base. Thedevice is reasonable in structure and design, wherein a first crushing roller and a second crushing roller rotate relatively through a counterclockwise first motor to crush medical wastes; the filterscreen realizes solid-liquid separation, and a second motor drives a cam to rotate to slightly vibrate the filter screen, so that the efficiency of the solid-liquid separation is improved; a water pump sprays disinfectant through a spray nozzle to the medical wastes for disinfection treatment; an electromagnet in a sieving room can adsorb and screen some metal needles or scissors in the wastes, sothat the waste of resources is avoided, the rest of the wastes finally enter a collection box for compression, the volume of the wastes is reduced, and the transportation is convenient.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

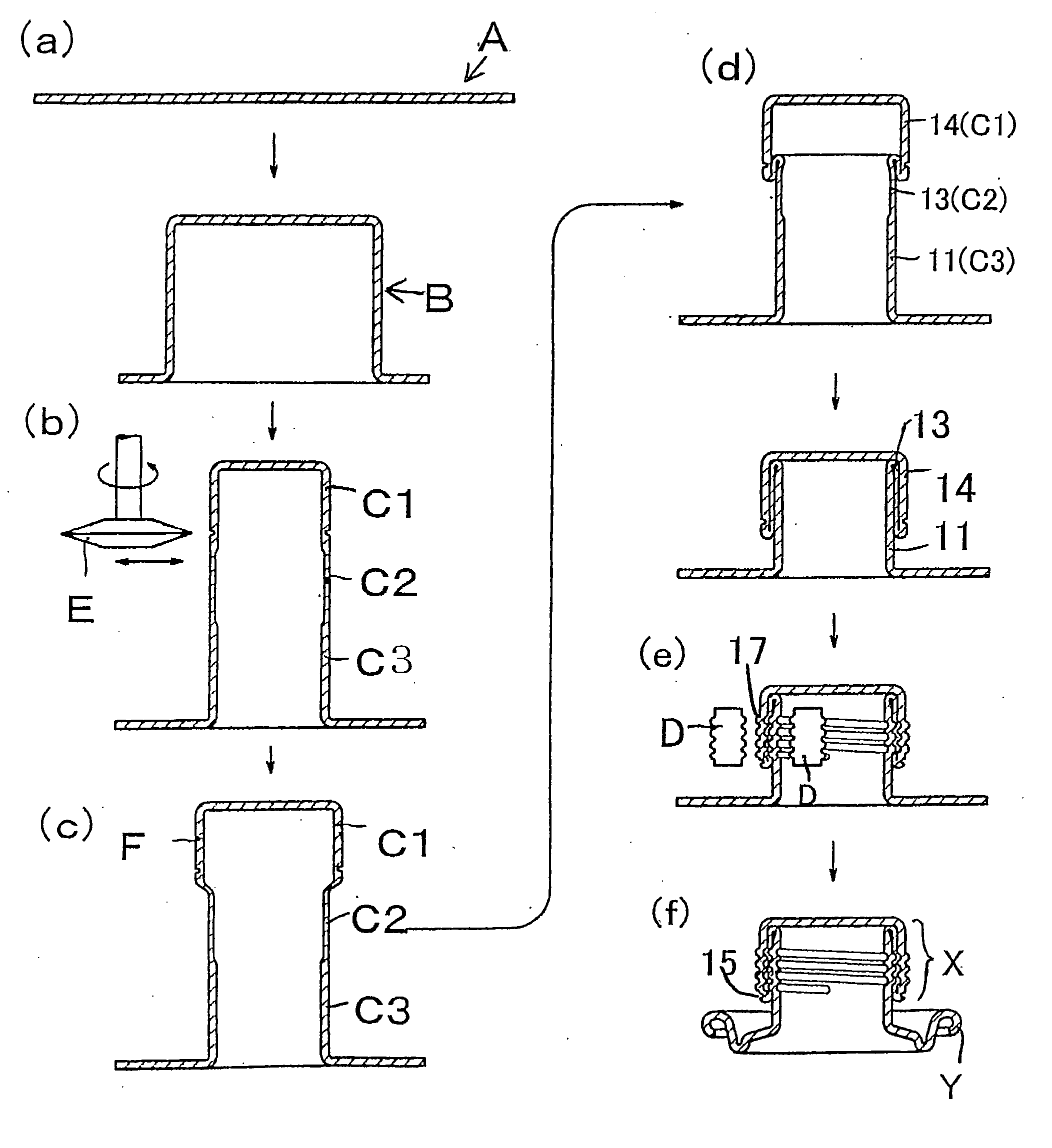

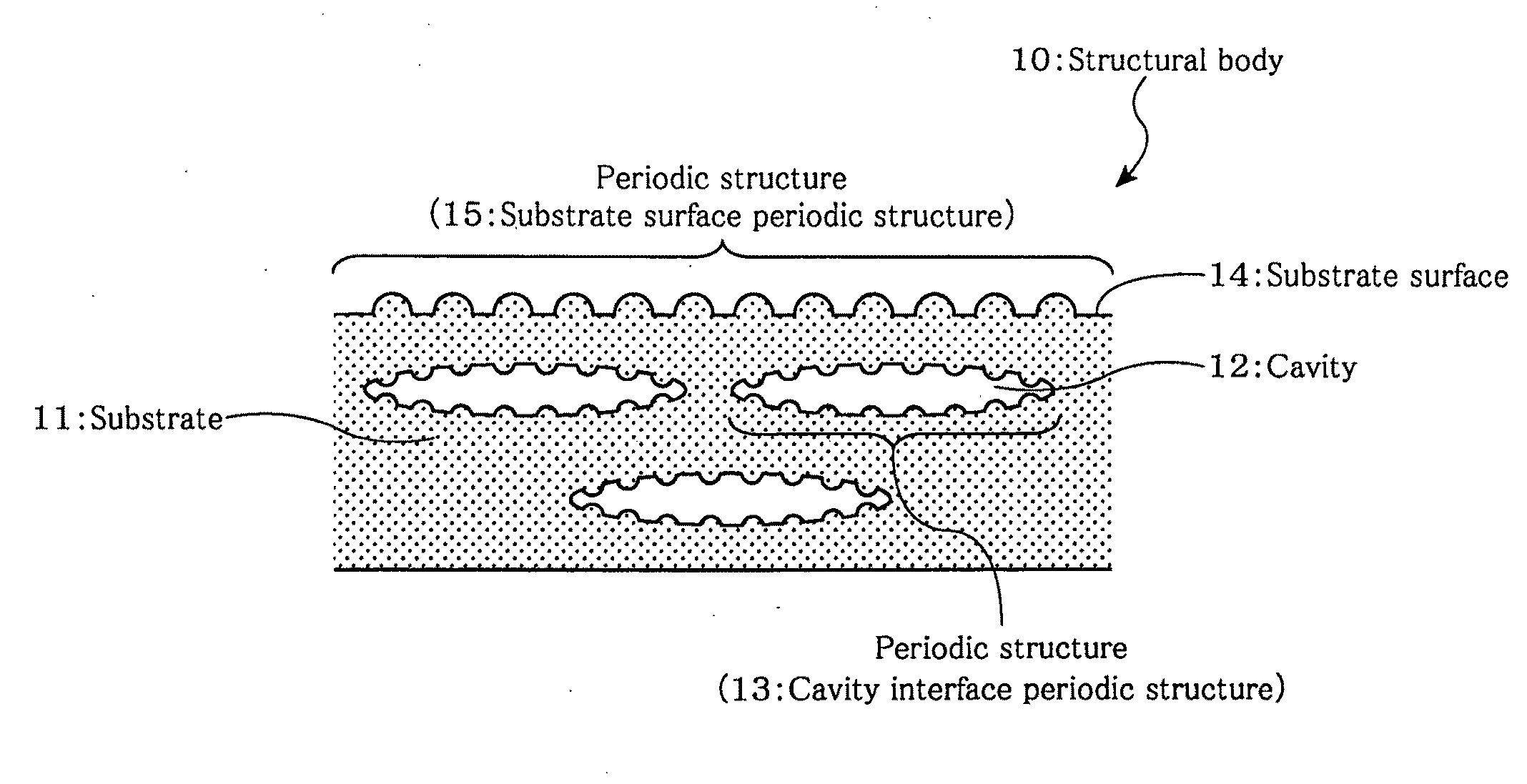

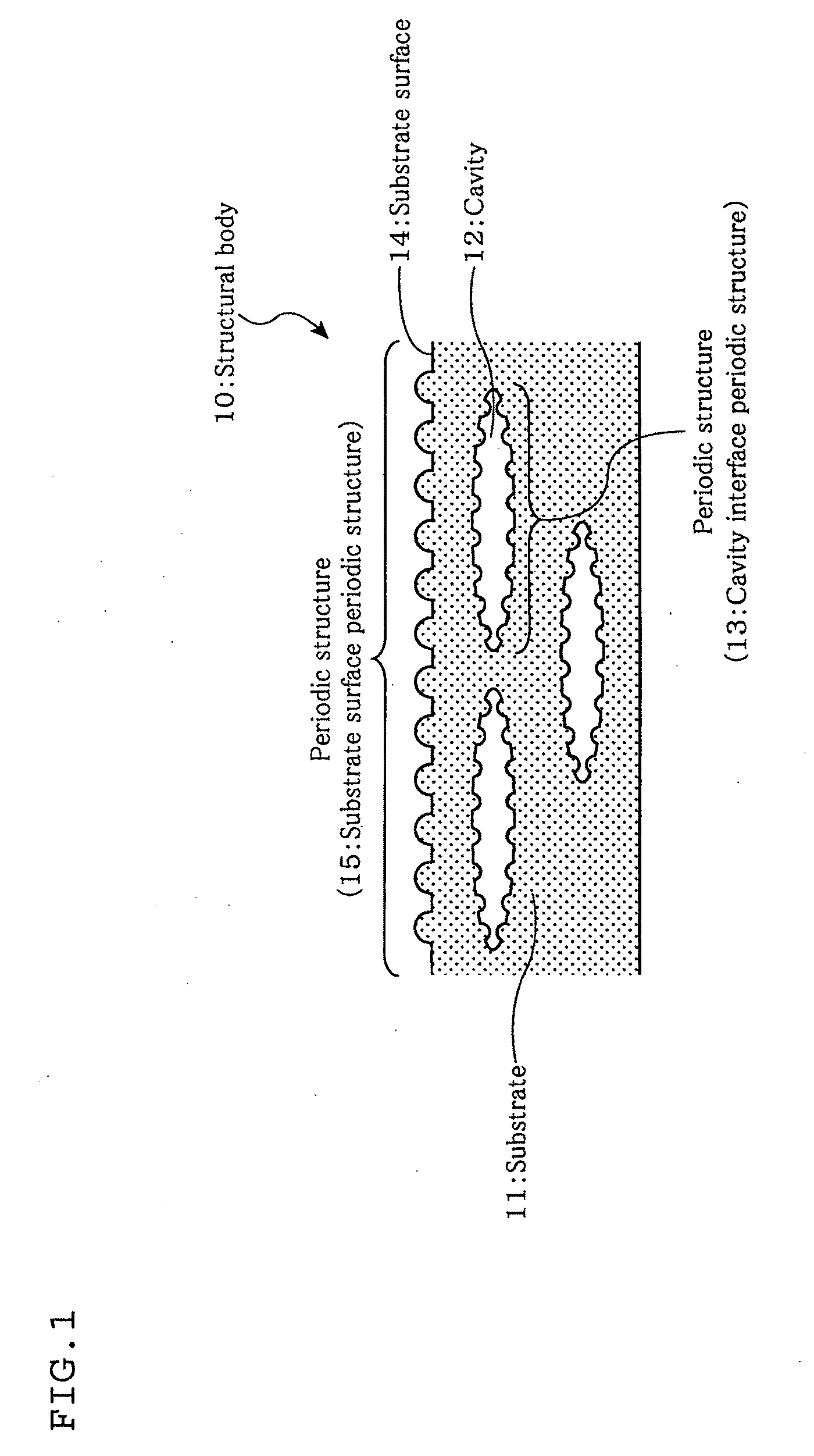

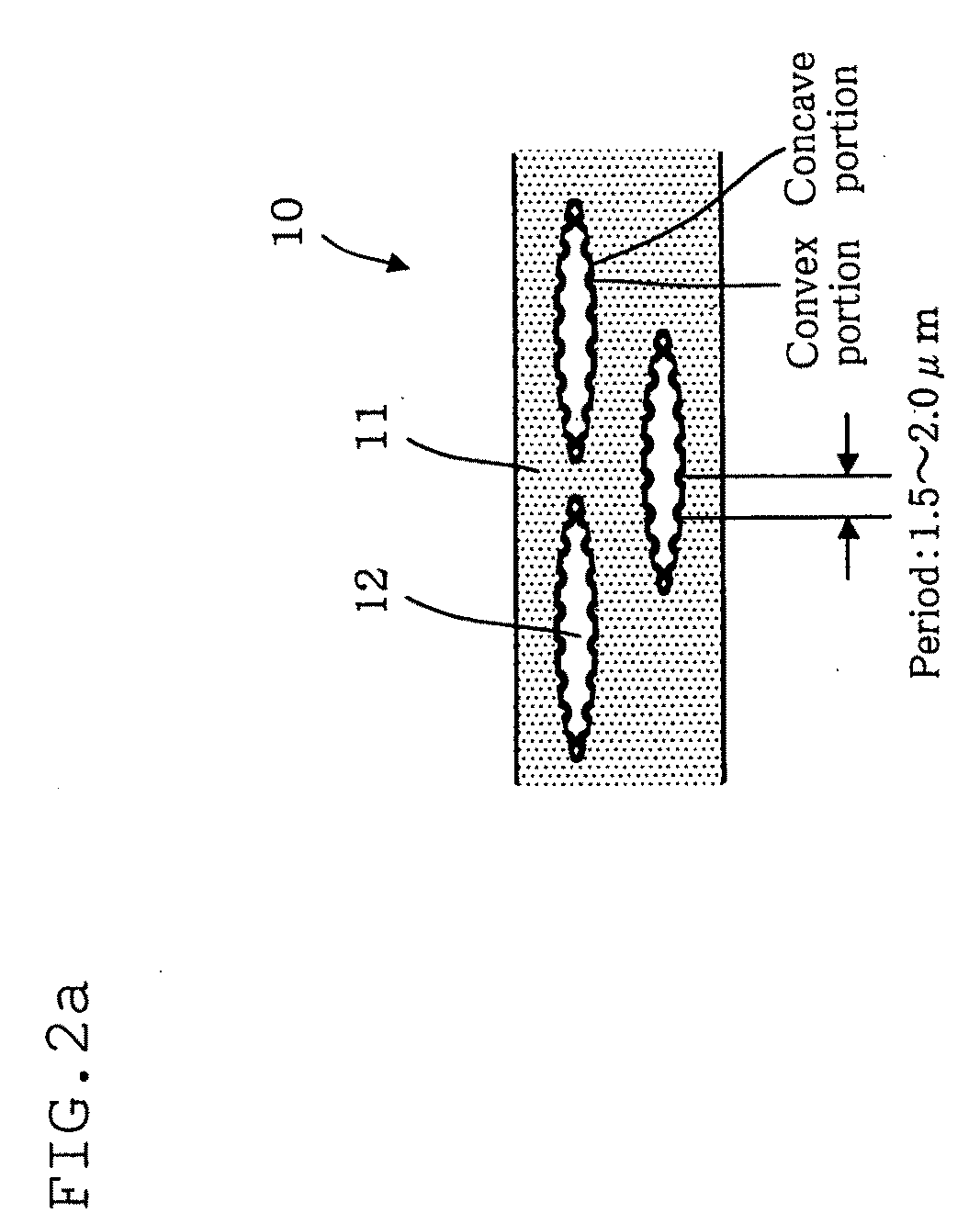

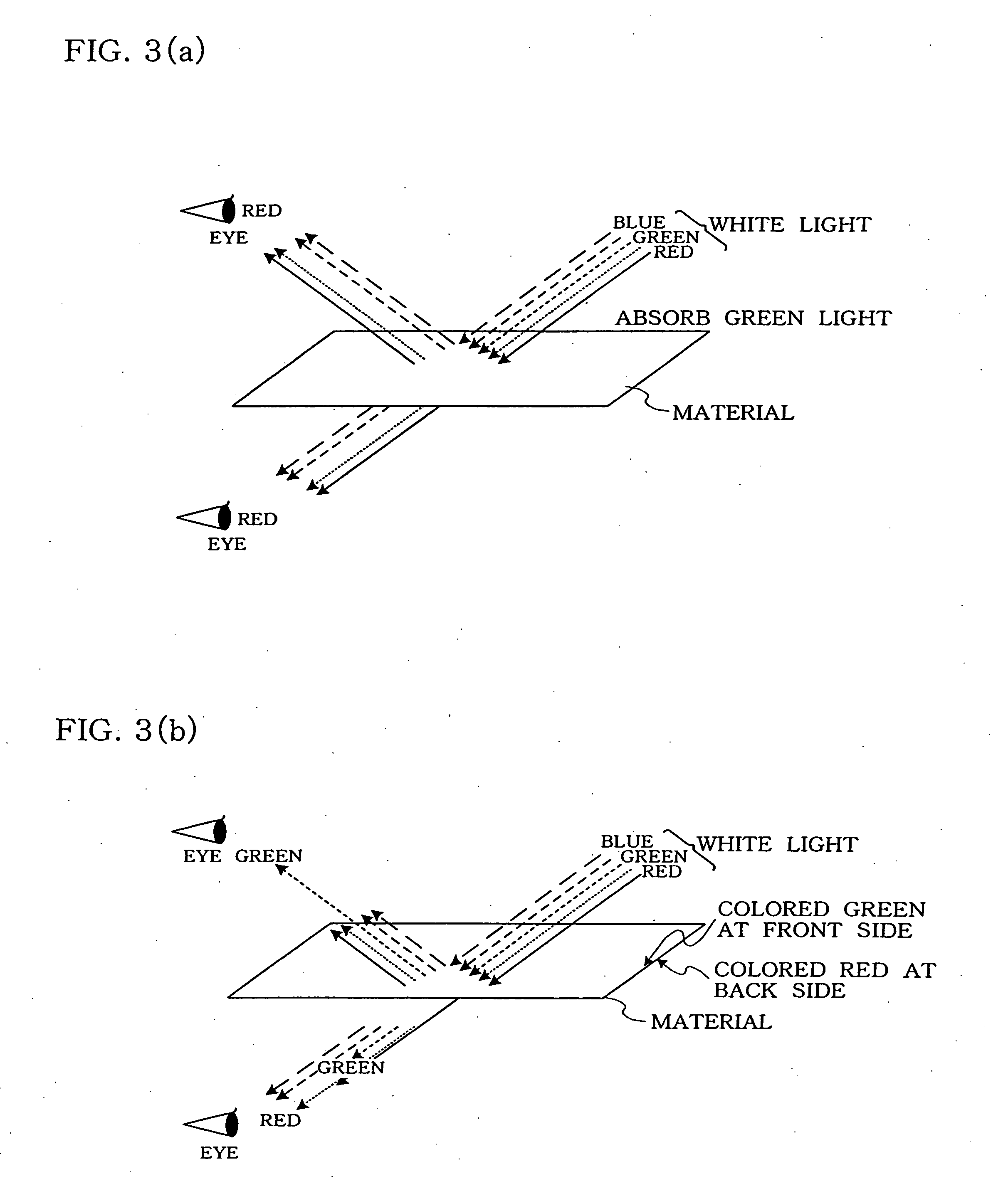

A Structural Body, a Method for Forming a Structural Body, an Apparatus for Forming a Structural Body, a Method for Reading a Structural Color and/or Diffraction Light, and a Truth/False Discriminating Method

InactiveUS20090174944A1Satisfies requirementImprove recycling effectPaper-money testing devicesAuxillary shaping apparatusOptical diffractionOptoelectronics

Decoration of a material is enabled with a high degree of recycling properties while satisfying the requirements for putting a structural color into practical use on the industrial scale. Furthermore, whether an object is genuine or not can be verified easily, and reusing by peeling as in the case of a hologram seal is prevented.A cavity 12 having a periodic structure 13 causing optical diffraction is formed in the inside of a substrate 11, and a periodic structure 15 causing optical diffraction is formed on part or the whole of the substrate 11. These cavity interface periodic structure 13 and the substrate surface periodic structure 15 have a regular arrangement developing a structural color. In addition, by bringing a functional material to be in contact with the substrate surface periodic structure 15, development of a structural color by the substrate surface periodic structure 15 is suppressed, thereby enabling a structural color developed by the cavity interface periodic structure 13 to be read.

Owner:TOYO SEIKAN KAISHA LTD

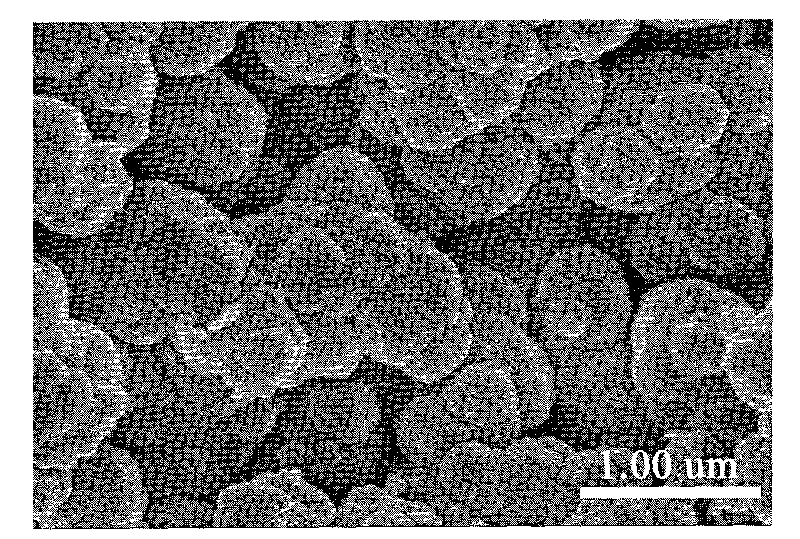

Microscale Al-containing rare earth wrought magnesium alloy and preparation method thereof

The invention relates to a microscale Al-containing rare earth wrought magnesium alloy and its preparation method and belongs to the scope of industrial magnesium alloy. The magnesium alloy comprises, by weight, 6.5-15.0% of Gd, 3.0-5.5% of Y, 2.0-4.0% of Zn, 0.3-1.5% of Nd, 0.3-0.9% of Zr, 0.4-1.0% of Al and the balance of Mg. The preparation method of the magnesium alloy comprises the steps as follows: raw material preparation, alloy melting, alloy semi-solid extrusion, homogenization treatment, redeformation, cooling and pre-stretching treatment, ageing strengthening treatment and the like. By fully utilizing the defect that Al is preferentially combined with rare earth and Zr in alloy to form a stable phase, Zn element is added to make up insufficiencies and the wrought magnesium alloy with high performance is prepared. The recovery effect of rare earth elements is enhanced, and semi-solid forming and solid plastic forming are combined.

Owner:GRIMAT ENG INST CO LTD

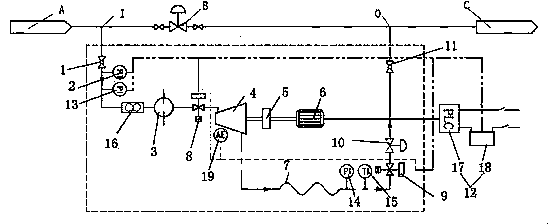

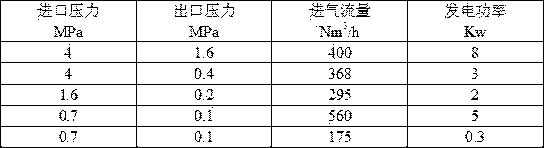

A pressure energy-recycling generation device for a natural gas pipe network

InactiveCN104213939AReduce wasteEnable recyclingMachines/enginesSafety/regulatory devicesElectricitySolenoid valve

The invention provides a pressure energy-recycling generation device for a natural gas pipe network. The device can efficiently transform the pressure energy in the natural gas pipe network into electricity, thereby realizing recycling. The operation state of the generation device can be automatically real-time monitored by combining a PLC and a solenoid valve, a pressure transmitter, a leakage detector and a sealing machine pry. The device can automatically forewarn and interlock to shut off when conditions like excess pressure and gas leakage occur, so the device has superior security and stability. The device can produce outstanding economic benefit, and has important meaning to reducing resource waste and accelerating establishment of resource-saving and environmentally friendly society.

Owner:JIANGSU AEROSPACE HEWLETT ENVIRONMENTAL PROTECTION TECH

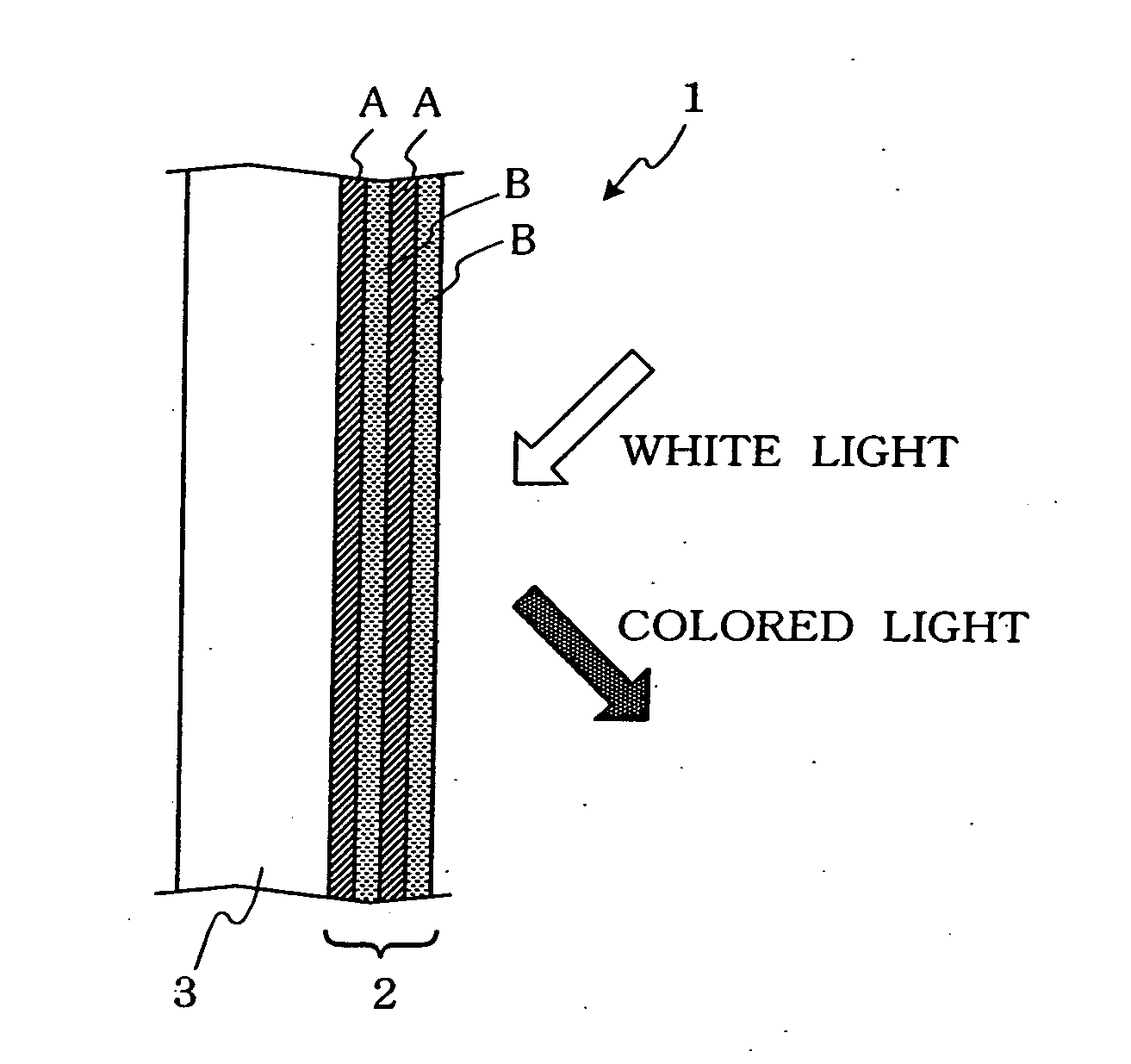

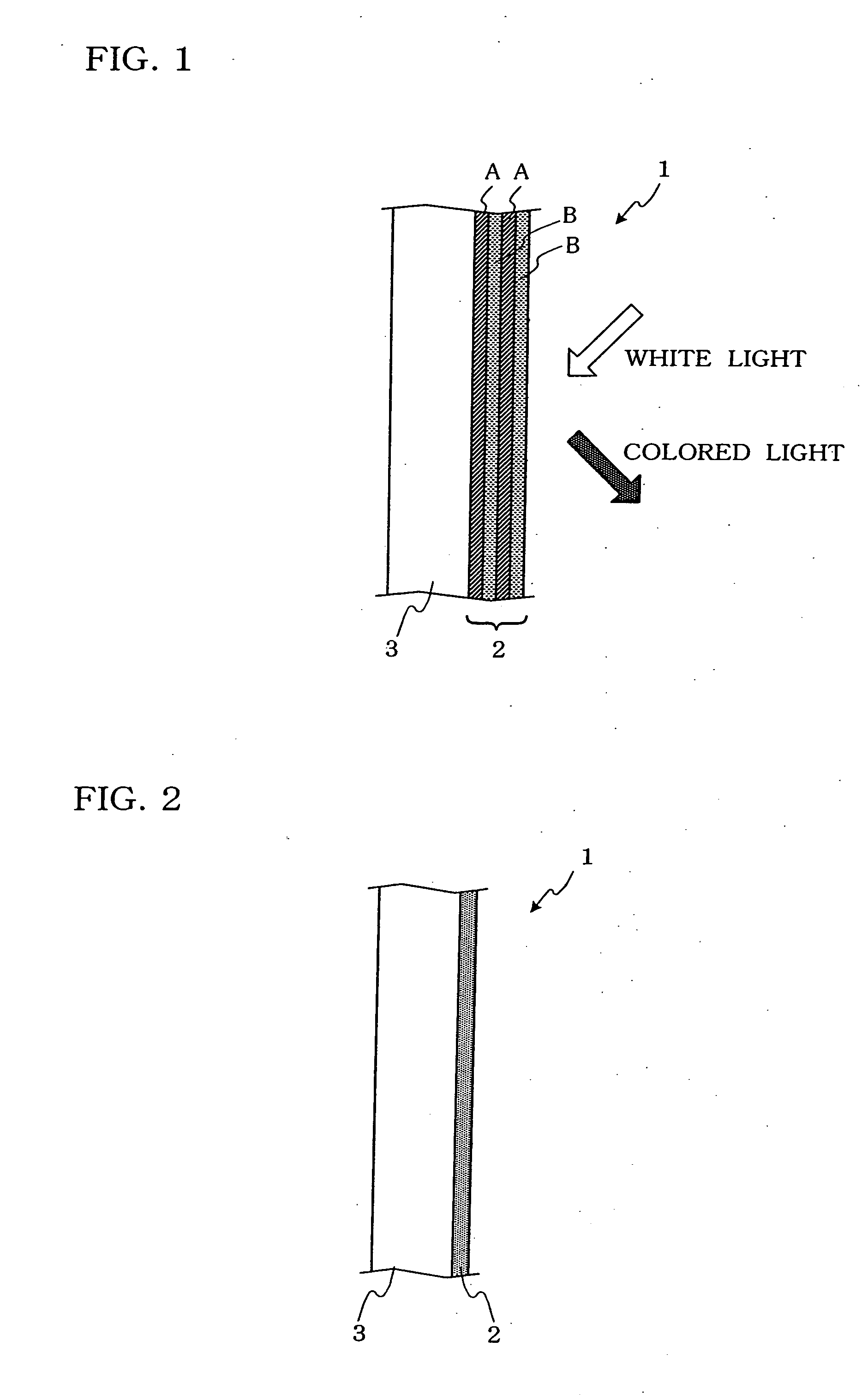

Decorated plastic package and method for reproduction

InactiveUS20060263554A1Reuse ratioMold growthWrappersDecorative surface effectsOptical propertyPlastic packaging

There is here disclosed a plastic package (1) which has a thin-film layered structure (2) constituted of substances having different refractive indices and which is colored by an interference effect due to the thin-film layered structure (2). The plastic package is characterized in that, on a part of the surface of the plastic package, portions which are different in optical characteristics from the surface are periodically arranged.

Owner:TOYO SEIKAN KAISHA LTD

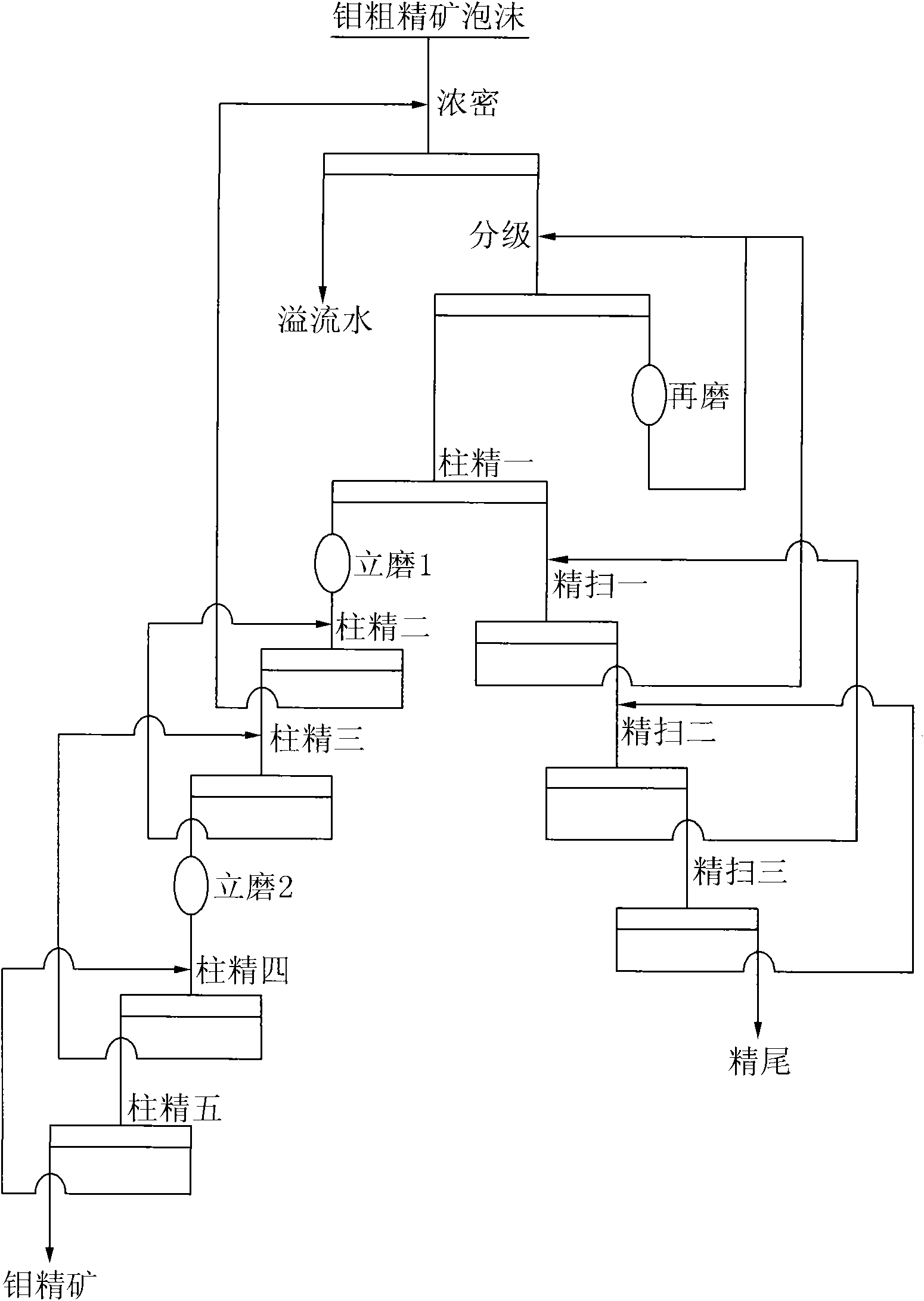

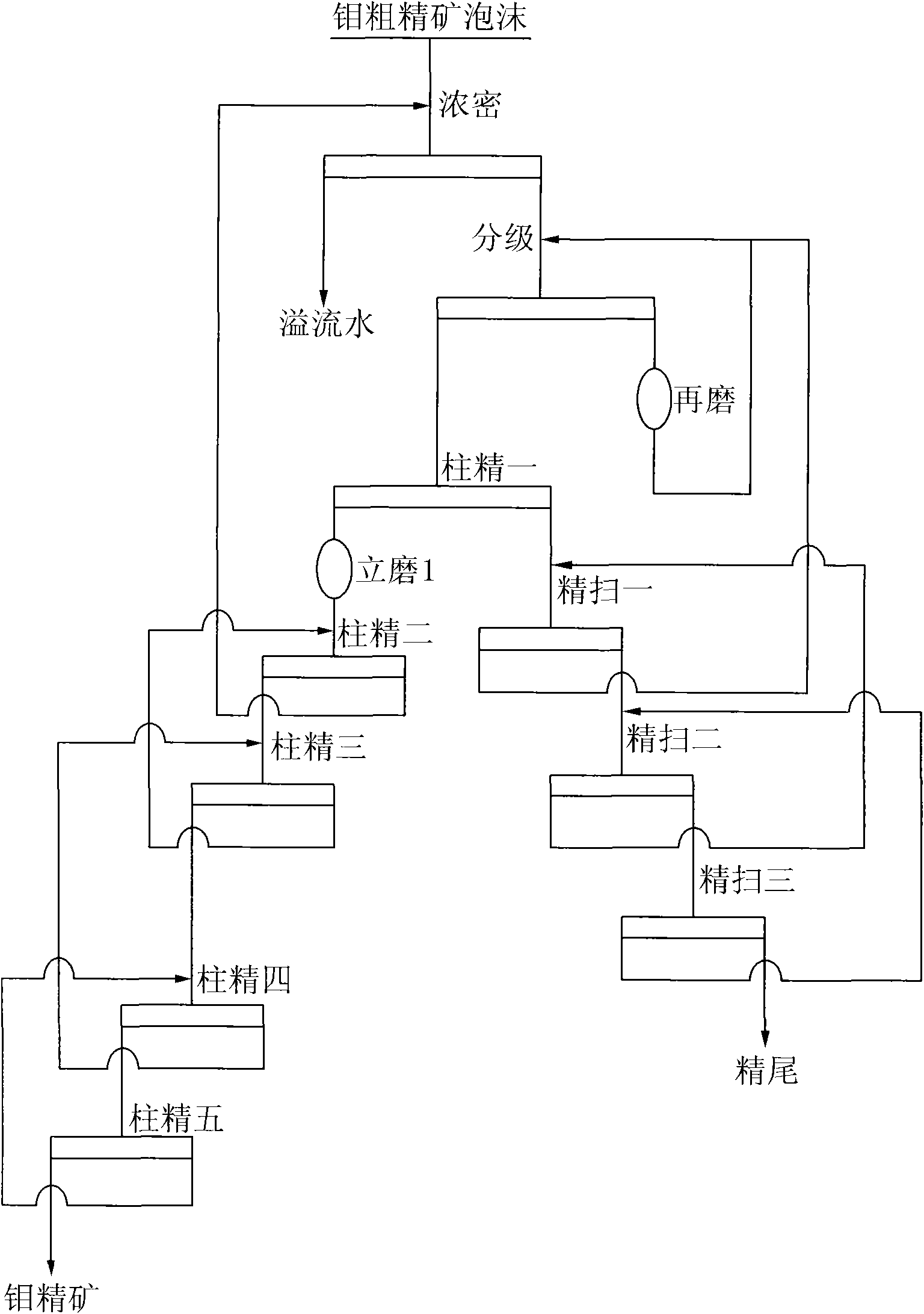

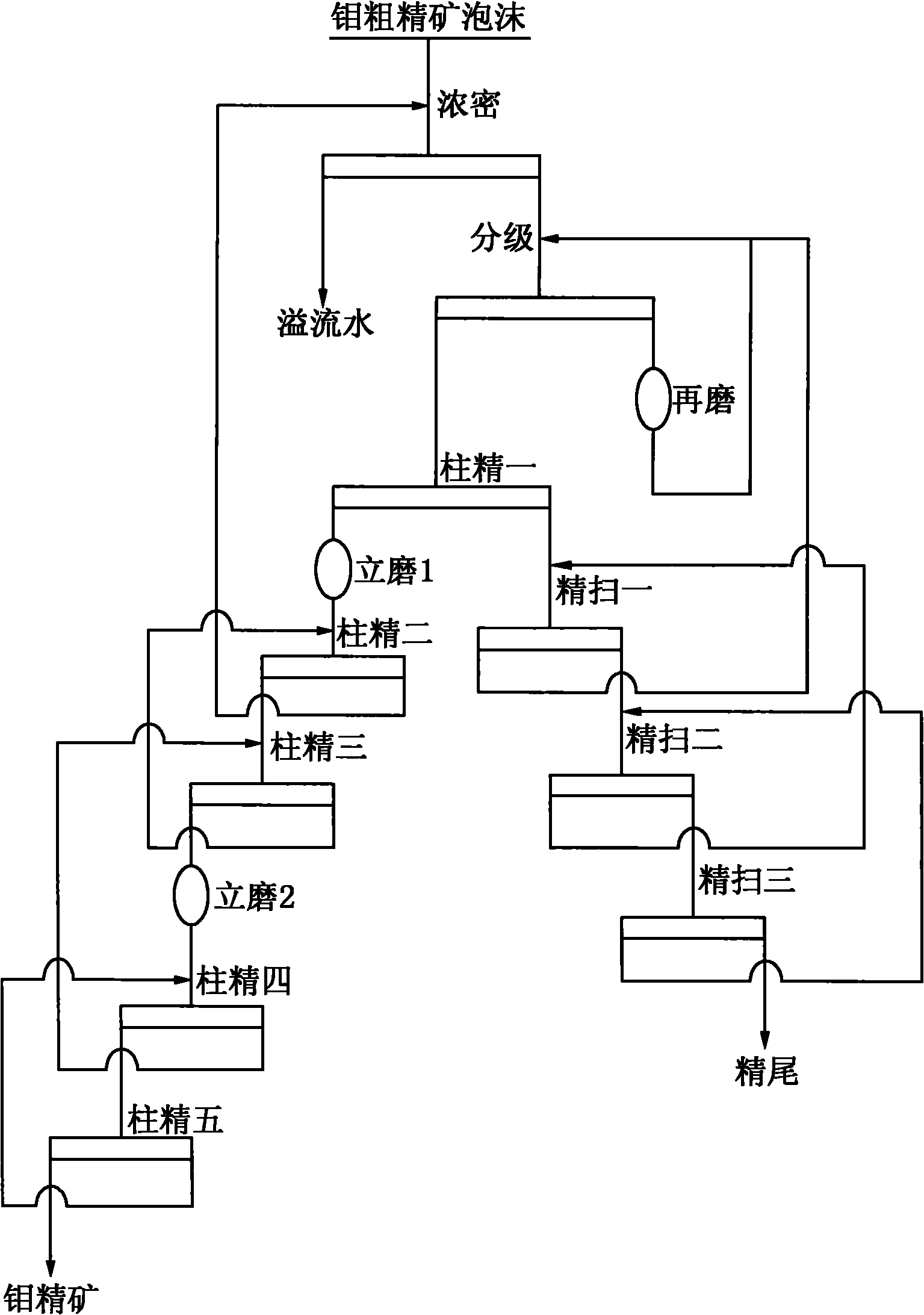

Production technology of high-grade molybdenum concentrate

ActiveCN101773871AReduce pollutionIncrease feed concentrationFlotationWet separationBall millReagent

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

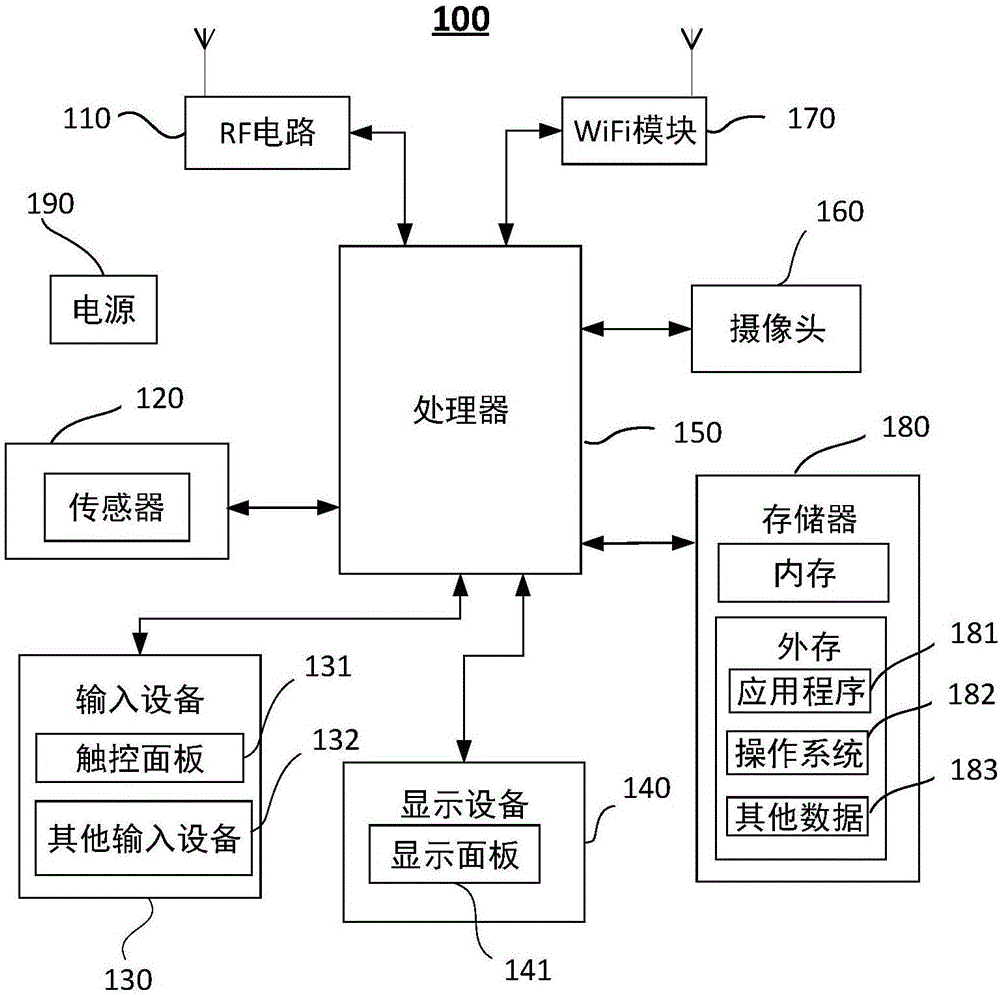

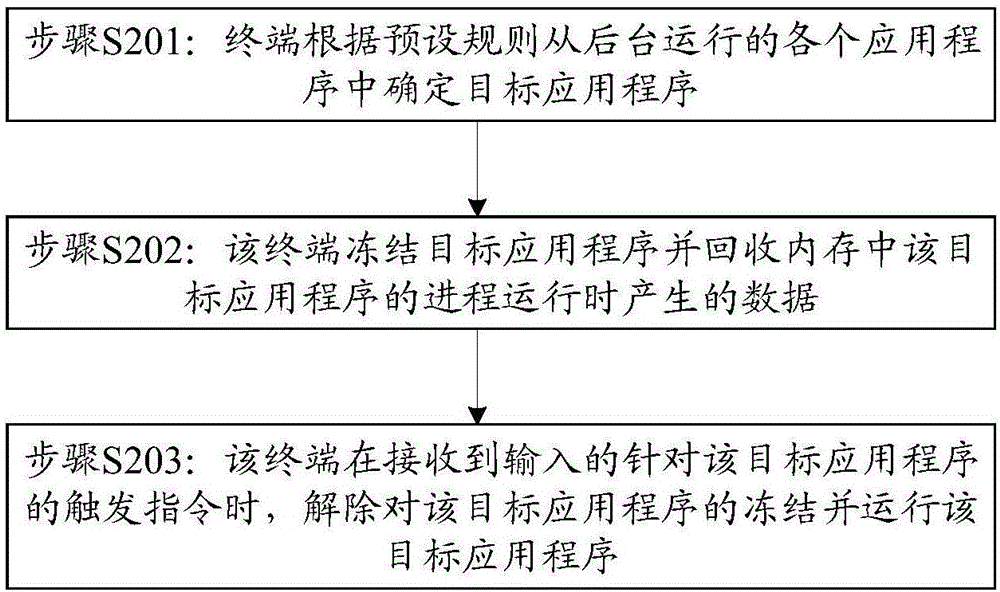

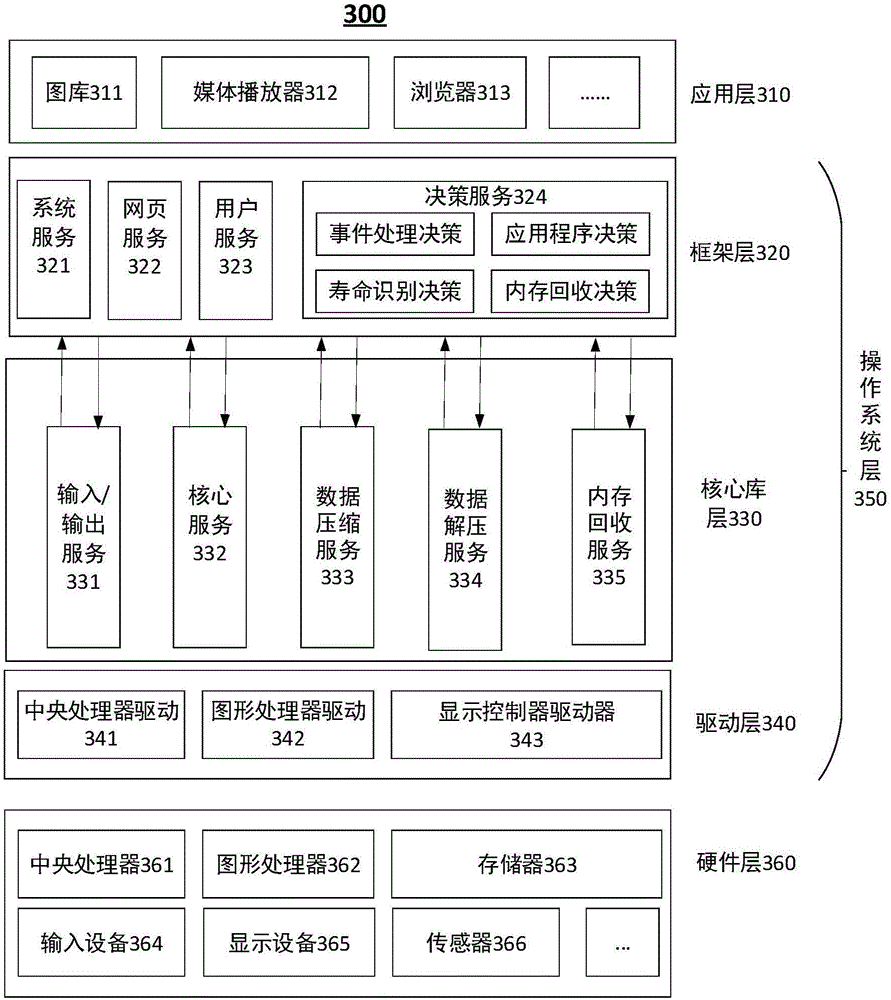

Memory recovery method and terminal

ActiveCN106484472AAvoid reoccupyingImprove the effect of memory recoveryMemory adressing/allocation/relocationProgram loading/initiatingRecovery methodOperating system

Embodiments of the invention disclose a memory recovery method and a terminal. The method comprises the steps that the terminal determines a target application from applications running in a background according to a preset rule, wherein the target application is an application needed to be cleared; the terminal freezes the target application and recovers data generated during running of a process of the target application in a memory; and the terminal unfreezes the target application and runs the target application when receiving an input triggering instruction for the target application. By adopting the method and the terminal provided by the embodiments of the invention, the memory recovery effect can be improved.

Owner:HUAWEI TECH CO LTD

Corundum-mullite honeycomb ceramic heat accumulator

The invention belongs to the inorganic nonmetal field, and relates to a corundum-mullite honeycomb ceramic heat accumulator for waste heat recovery of high-temperature kiln tail gas. The honeycomb ceramic heat accumulator is prepared by the following steps of: forming ceramic powder from corundum, mullite, alumina, clay and the like; adding cellulose, glycerol, glue and water to prepare plastic mud; and mixing, mixing mud, performing vacuum pug, forming, drying and performing high-temperature sintering. The honeycomb ceramic heat accumulator prepared by the method has the characteristics of superior high temperature strength, high heat accumulation capacity, high heat exchange speed, high thermal shock stability, low cost, easiness in operation and adaptation to industrial production.

Owner:晋城市富基新材料股份有限公司

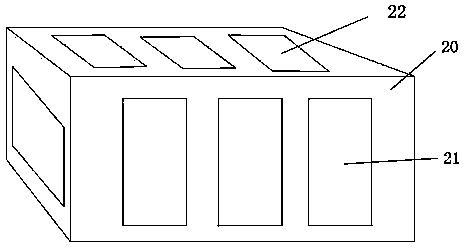

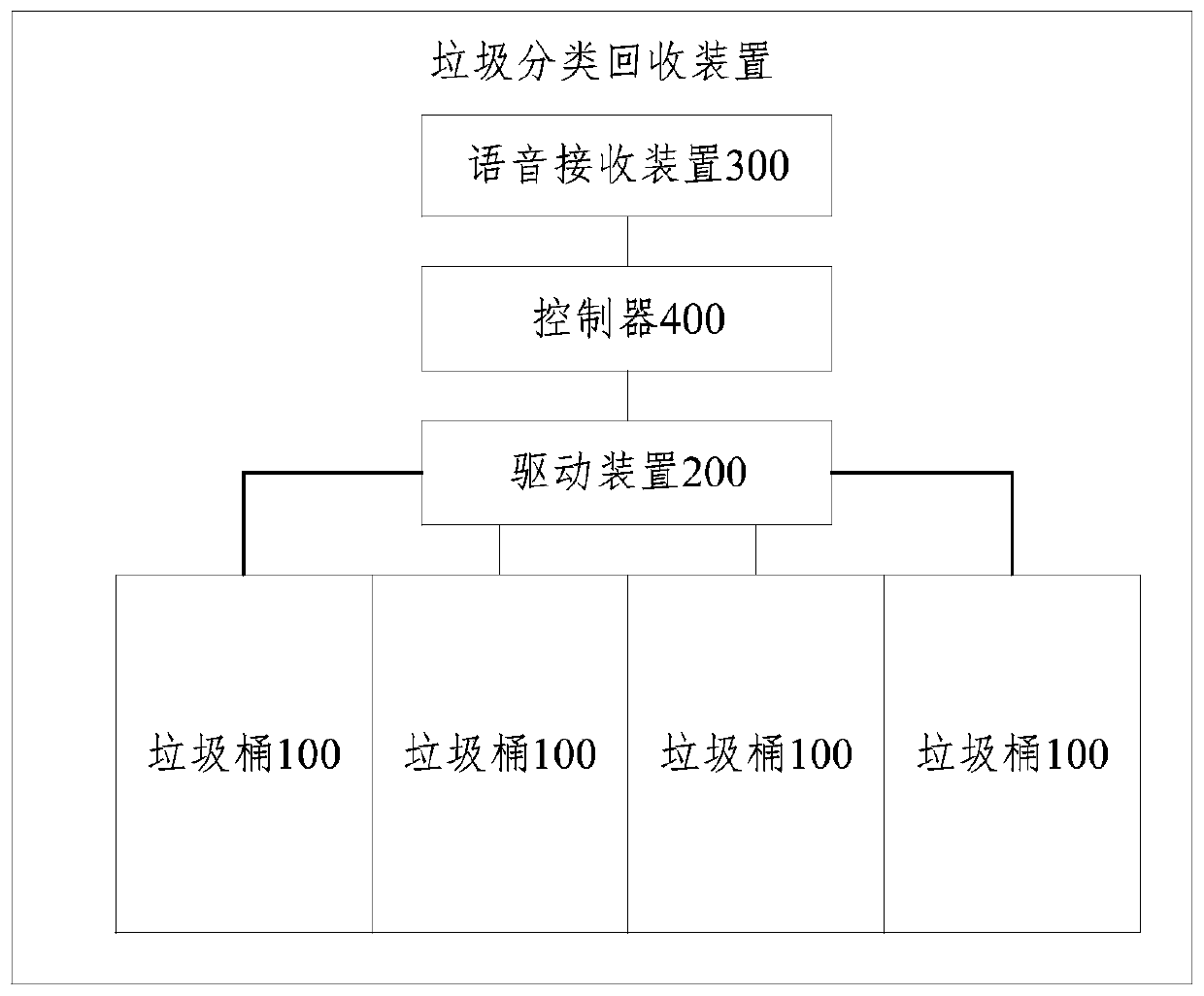

Garbage classification collection device

InactiveCN110194338AImprove recycling effectWaste collection and transferRefuse receptaclesEngineeringWaste sorting

The embodiment of the invention discloses a garbage classification collection device. The garbage classification collection device comprises multiple garbage cans, a driving device used for driving can covers of the garbage cans to be opened or closed, a voice receiving device used for receiving a garbage putting voice instruction and a controller. The garbage cans are used for recycling garbage of multiple recycling kinds in a one-to-one corresponding manner, can covers capable of being opened are arranged on the garbage cans in a one-to-one corresponding manner, the driving device is used for driving the can covers of the garbage cans to be opened or closed, the controller is used for carrying out recognizing treatment on the garbage throwing voice instruction, according to the recognizing processing result, matching with the pre-stored information of a garbage classifying warehouse is carried out to obtain garbage matching recycling kinds, and according to the garbage matching recycling kinds, through the driving device, the can covers of the corresponding garbage cans can be opened. According to the garbage classification collection device, a user can be helped to carry out garbage classifying, and the garbage recycling effect can be improved.

Owner:简科宇

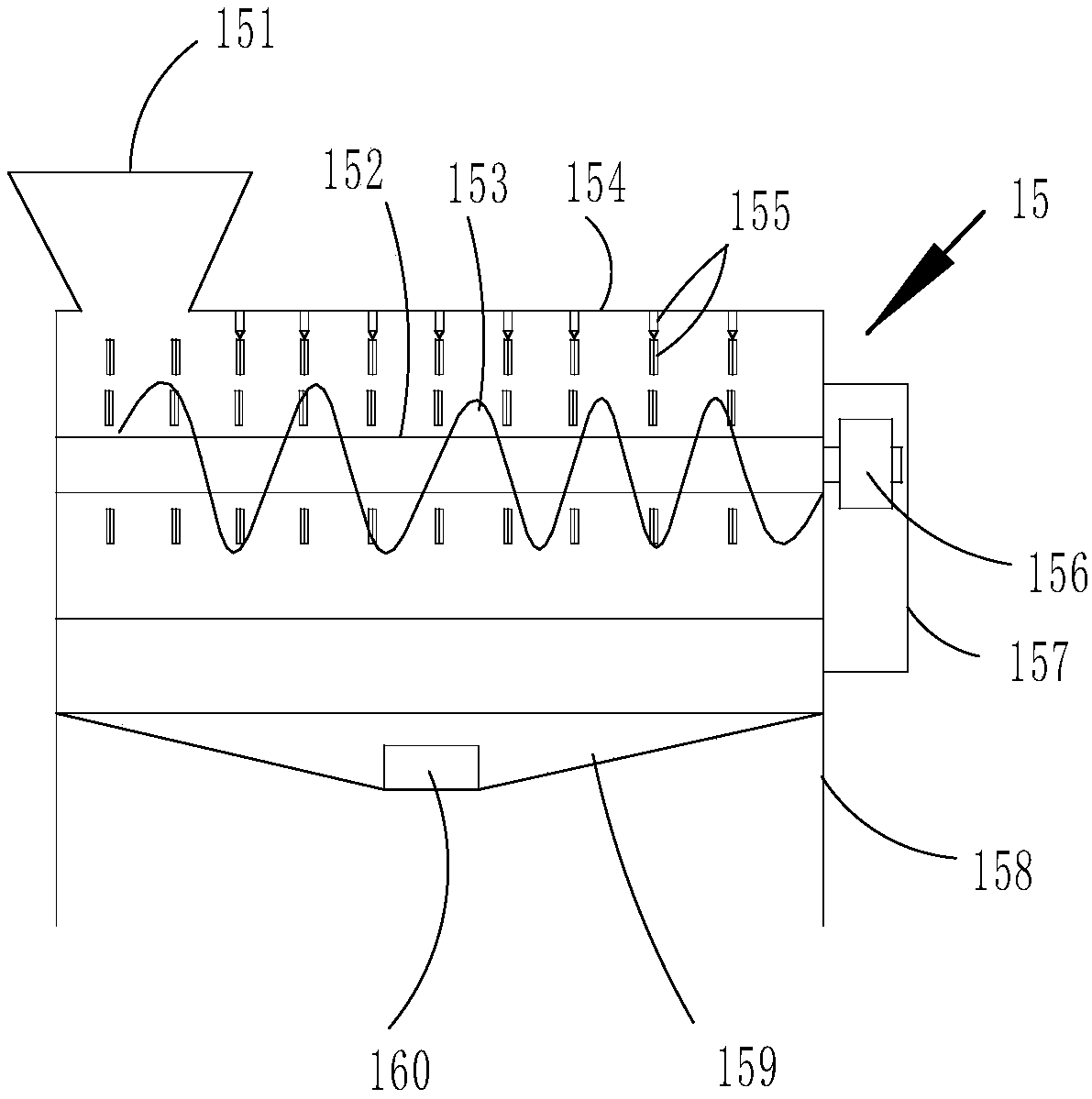

Plastic film scrap online recycling system

The invention relates to an online recycling system for plastic film trim, which includes a leading pipe connected to a suction side wind bag, a crusher connected to the suction side wind bag through an auxiliary wind bag, a discharge hopper, a suction fan, The first cyclone separator, hopper and extruder; the invention can recycle all the side materials produced in the plastic film production process on-line, and after crushing, they can be extruded by the extruder for recycling to avoid waste of resources; the recycling process is fully closed The side material is not polluted by the environment and does not pollute the environment; the continuous operation of the system of the present invention is stable and reliable, the labor cost is reduced, and the side material recycling effect is good.

Owner:XINLE HUABAO PLASTIC MACHINERY

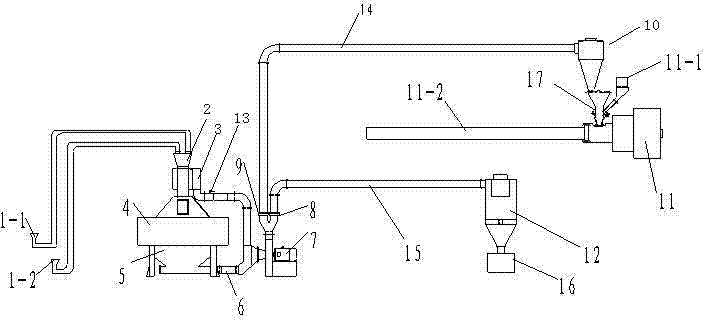

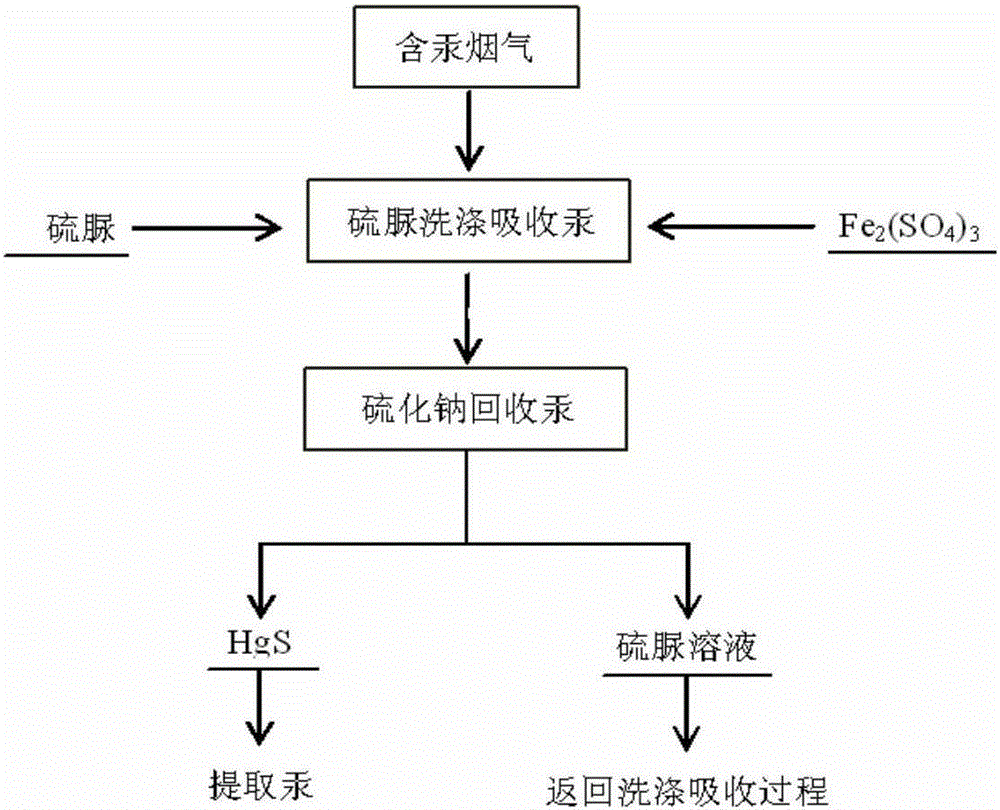

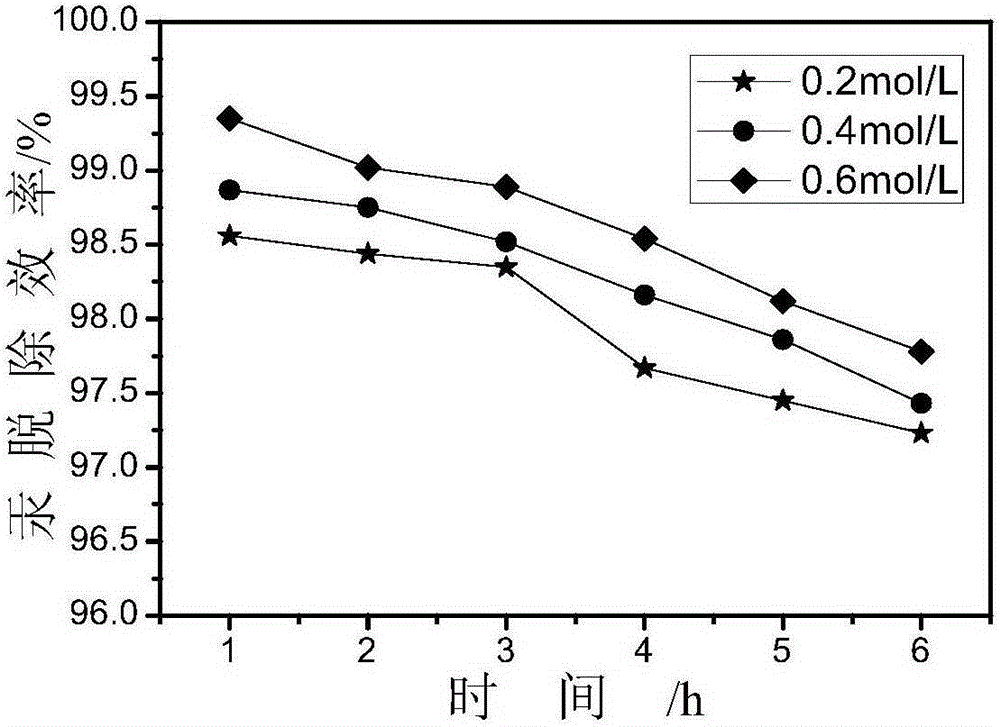

Washing liquid for eluting mercury in mercury-containing flue gas and method for recovering mercury form mercury-containing flue gas

ActiveCN105289261AEasy to precipitate and recoverImprove absorption efficiencyDispersed particle separationMercury compoundsRecovery methodThiourea

The invention disclose a washing liquid for eluting mercury in mercury-containing flue gas and a method for recovering mercury form mercury-containing flue gas. The washing liquid is a sulfuric acid solution containing thiourea and trivalent iron ions, and is especially suitable for removing mercury from smelting flue gas with a high content of sulfur dioxide. The mercury recovery method comprises the following steps: introducing mercury-containing flue gas into a washing reactor to fully contact the washing liquid, which flows in an opposite direction, wherein during the process the elemental mercury and oxidation-state mercury in the flue gas are purified and absorbed, then using a sulfurized salt precipitant to recover mercury form the washing liquid, and returning the washing liquid to the washing tower. The method can well remove mercury from flue gas, the recovery efficiency is high, and the comprehensive recovery rate of mercury from flue gas can reach 95% or more.

Owner:CENT SOUTH UNIV

Laminated film and molding and reflector

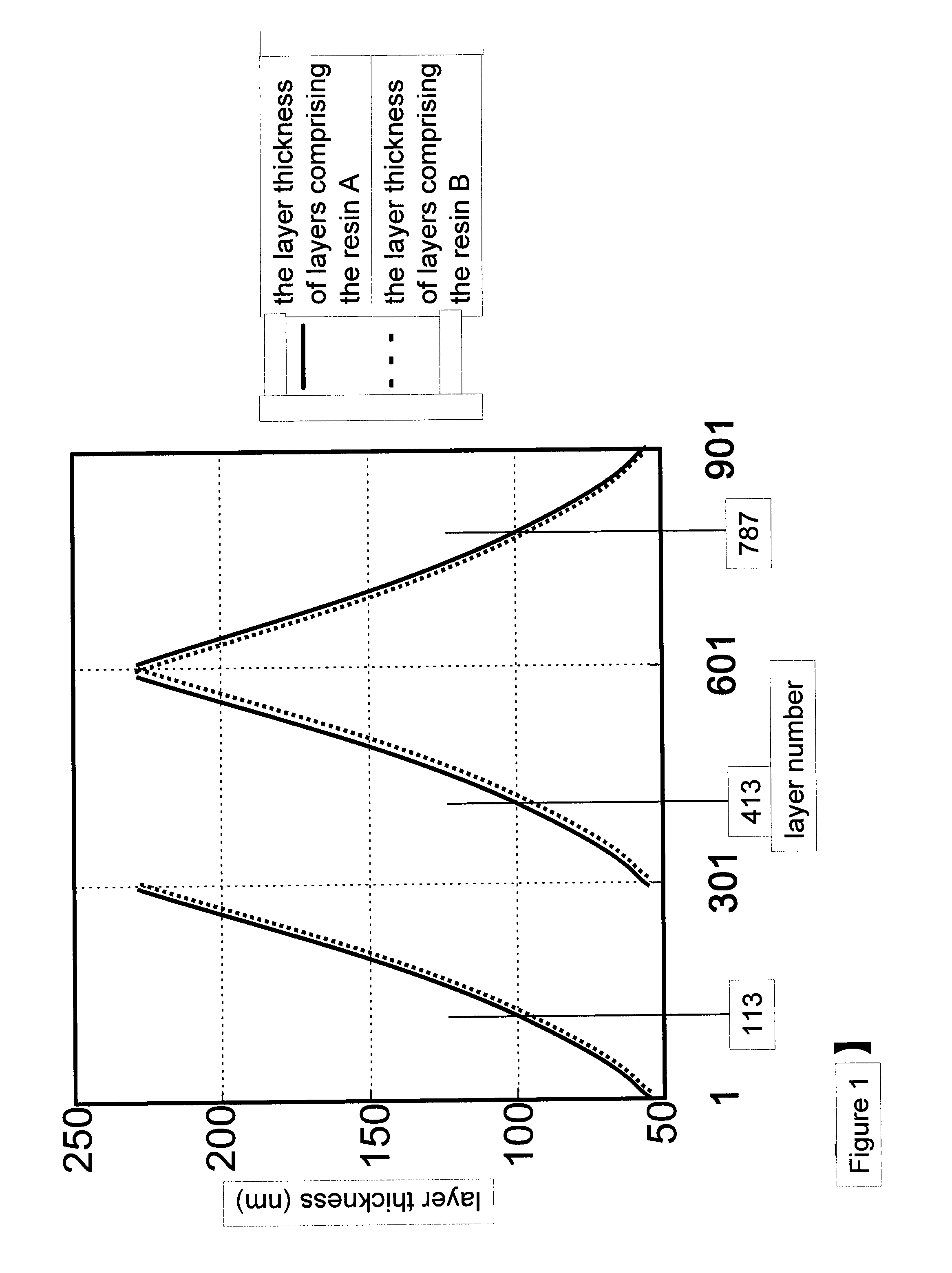

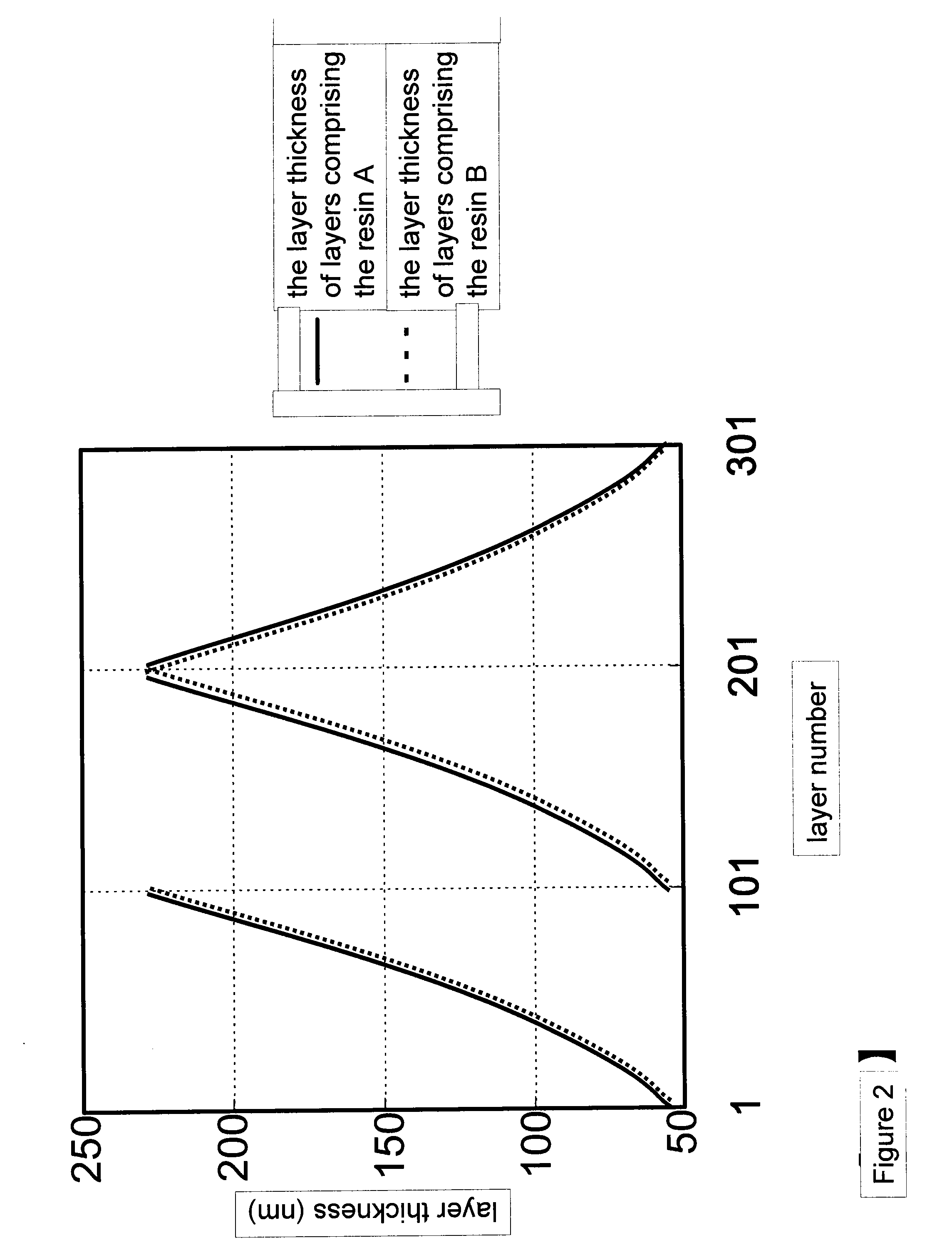

ActiveUS20100330350A1Improve recycling effectLow environmental burdenSynthetic resin layered productsLabelsLayer thicknessLayer group

A laminated film with 200 or more laminated layers which include at least layers comprising a resin A and layers comprising a resin B where, taking the layers comprising the resin A having a layer thickness from 10 nm to 1000 nm as a layer group L, the layer group L has layers La, Lb and Lc and, in the direction from one surface to the other, these are arranged in the order of the layer La, the layer Lb, and the layer Lc, the thicknesses of the layers La and Lc are the same and at least 30 layers, each layer comprising the resin A, are included between the layer La and the layer Lc, and the thickness of the layer La is at least 1.4-fold or more and 0.7-hold or less the thickness of the layer Lb.

Owner:TORAY IND INC

Basic copper chloride production method

ActiveCN103351020AImprove recycling effectSimplified processing stepsCopper chloridesAmmoniacal nitrogenTribasic copper chloride

The invention discloses a method for producing tribasic copper chloride. The method for producing the tribasic copper chloride includes the following steps of: (1) removing impurities from an acidic etching waste solution; (2) adding clean water or a tirbasic copper chloride production mother solution to a synthesis reactor, performing preheating, and then, preheating the acidic etching waste solution whose impurities have been removed and an alkaline solution of sodium hydroxide and mixing the two solutions for a reaction with the pH value and temperature of the reaction being controlled so as to gradually form the tribasic copper chloride, and discharging partial materials after a certain amount of reaction time; (3) filtering the materials discharged from the reaction system, and performing washing, suction filtration, centrifugation and drying on the filtrated residues to obtain the tribasic copper chloride; and (4) performing ammonia nitrogen removal treatment on filtrated liquid. By adopting the method for producing the tribasic copper chloride in the invention, continuous production can be achieved and the tribasic copper chloride with large particle size and high purity can be produced; further, production cost can be reduced and overall process can be integrated; and the method for producing the tribasic copper chloride is advantaged in simple ultimate steps of ammonia nitrogen removal, easiness in operation as well as reduced difficulty and cost of ammonia nitrogen treatment.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

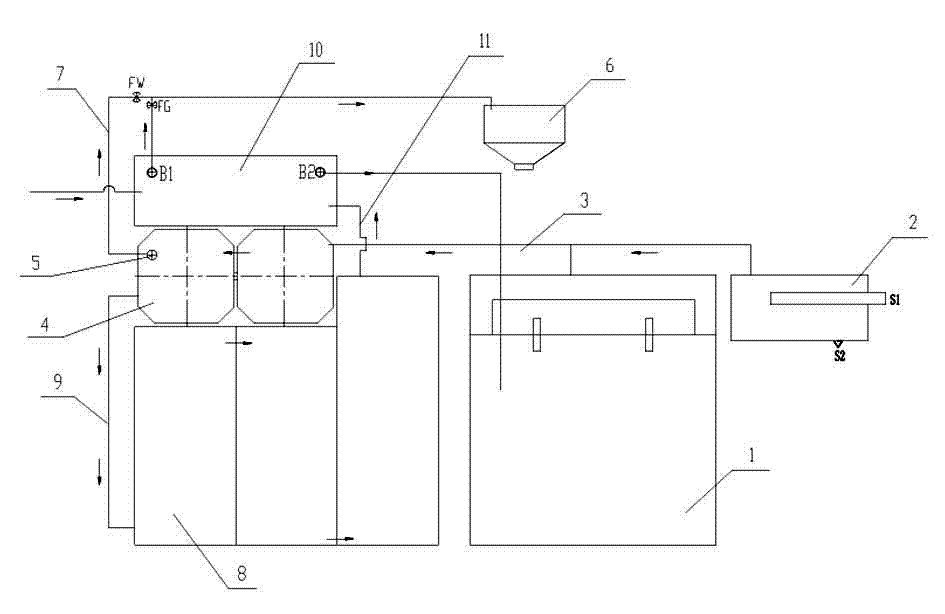

Recovering system for concrete cement mortar

InactiveCN102826668AReduce wearExtended service lifeMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationEngineeringSewage

The invention discloses a recovering system for concrete cement mortar. The recovering system comprises a service rack and a sand and stone separating machine, wherein a mortar water outlet of the sand and stone separating machine is communicated with a mixing tank; a sewage pipeline extending to the upper side of a metering hopper is connected to a sewage pump water outlet arranged in the mixing tank; a setting pond is arranged on one side of the mixing tank; the mixing tank is communicated with the setting pond through an overflowing pipeline; a clean water reservoir is arranged beside the mixing tank; a water outlet pipe of a clean water pump B1 arranged in the clean water reservoir is communicated with a sewage pipe through a one-way valve FG; a one-way valve FW is arranged on the sewage pipe on a front section at the intersection joint of the water outlet pipe of the clean water pump B1; a water outlet pipe of a clean water pump B2 arranged in the clean water reservoir extends to the service rack; and a water pouring pipe is arranged between the setting pond and the clean water reservoir. The recovering system disclosed by the invention has the advantages that the structure is simple and reasonable; and the clean water pump and the sewage pump are adopted for simultaneously supplying materials, so that the wear to the pump body is reduced, the service life of the pump body is prolonged, the recovering effect of mortar water generated by washing a vehicle is remarkably improved and the maintenance cost is greatly reduced.

Owner:郑州新水工机械有限公司

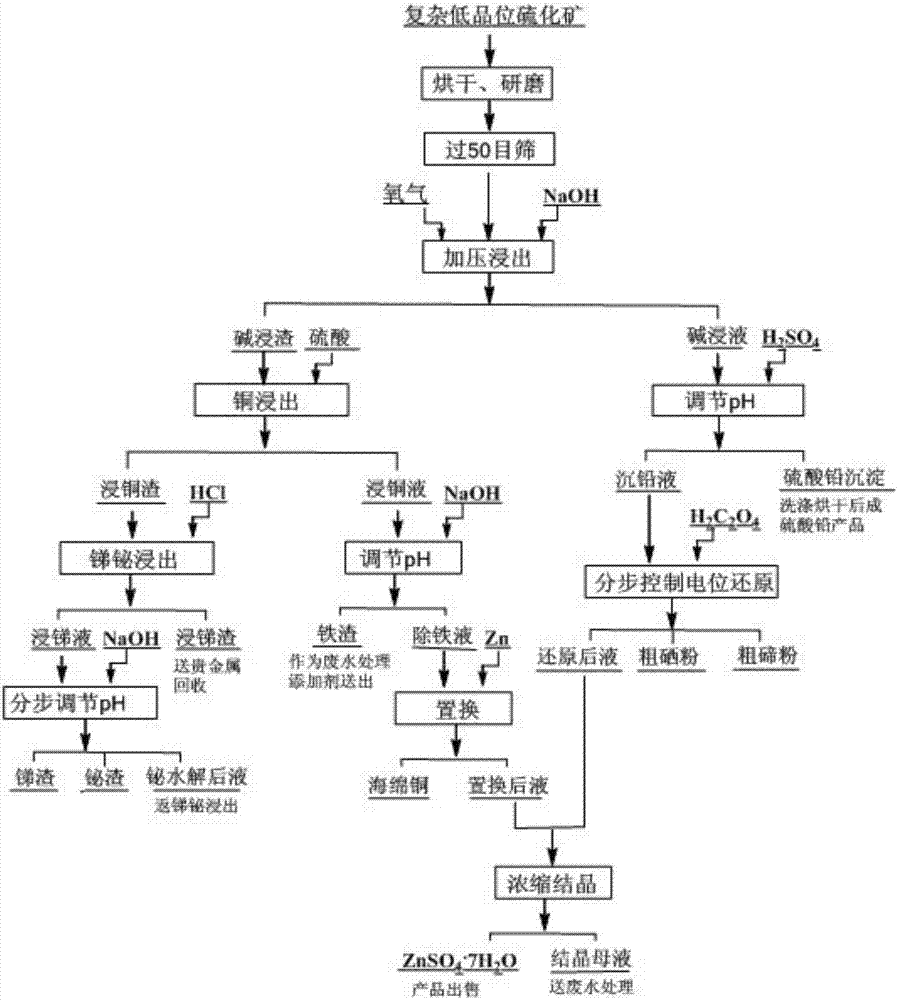

Process for all-wet recovery of valuable elements in complex low-grade sulphide ore

ActiveCN107190143AImprove recycling effectLow investment requirementProcess efficiency improvementSlagLead sulfate

A process for all-wet recovery of valuable elements in a complex low-grade sulphide ore comprises the following steps: crushing and grinding a raw material, sieving the crushed and ground raw material, performing size mixing by use of a sodium hydroxide solution, and after that, performing pressurized oxidizing leaching to obtain an alkaline-leached solution and alkaline-leached residues; acidizing the alkaline-leached solution to obtain a lead sulfate product and a heavy lead solution, and performing potential reduction control step by step on the heavy lead solution to obtain crude selenium powder, crude tellurium powder and a post-reduction solution; performing copper-soaking on the alkaline-leached residues by use of a sulfuric acid solution to obtain copper-leached residues and a copper-leached solution; performing antimony and bismuth soaking on the copper-leached residues by use of an acid liquor containing chloride ions to obtain an antimony-leached solution and antimony-leached residues, feeding the antimony-leached slags to noble metals for recovery, and adjusting the pH of the antimony-leached solution step by step to obtain antimony residues and bismuth residues; adjusting the pH of the copper-leached solution to obtain iron residues and an iron-removed solution, wherein the iron residues serve as a waste water treatment additive, and the iron-removed solution is subjected to zinc dust replacement to obtain copper powder and a post-replacement solution; and merging the post-reduction solution and the post-replacement solution, and performing concentration and crystallization to obtain heptahydrate. The process is good in comprehensive recovery effect, strong in adaptation to the raw material, clean and environment-friendly in process, low in demand on equipment, adjustable in implementation scale and high in practicability.

Owner:JIANGXI COPPER CORP

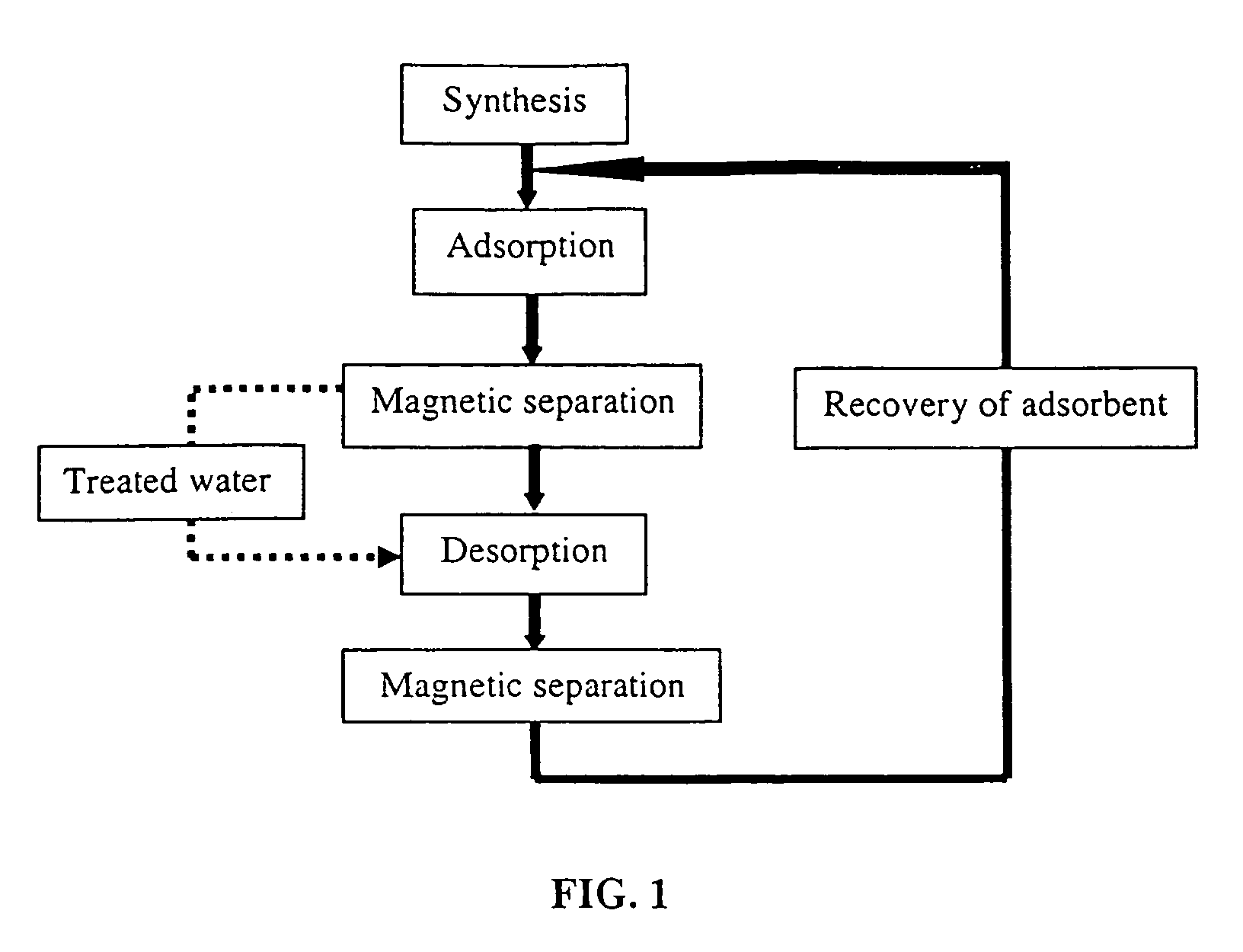

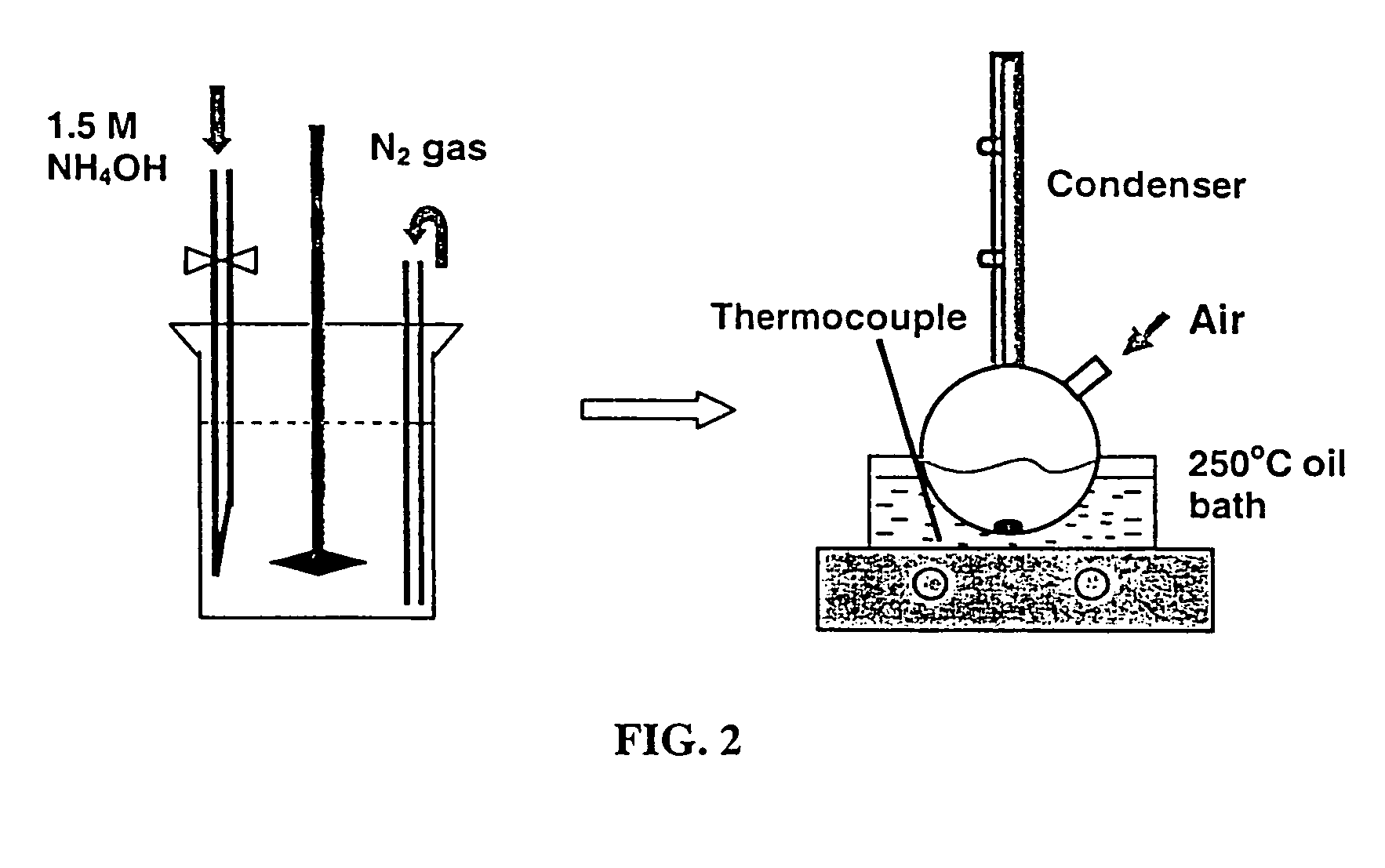

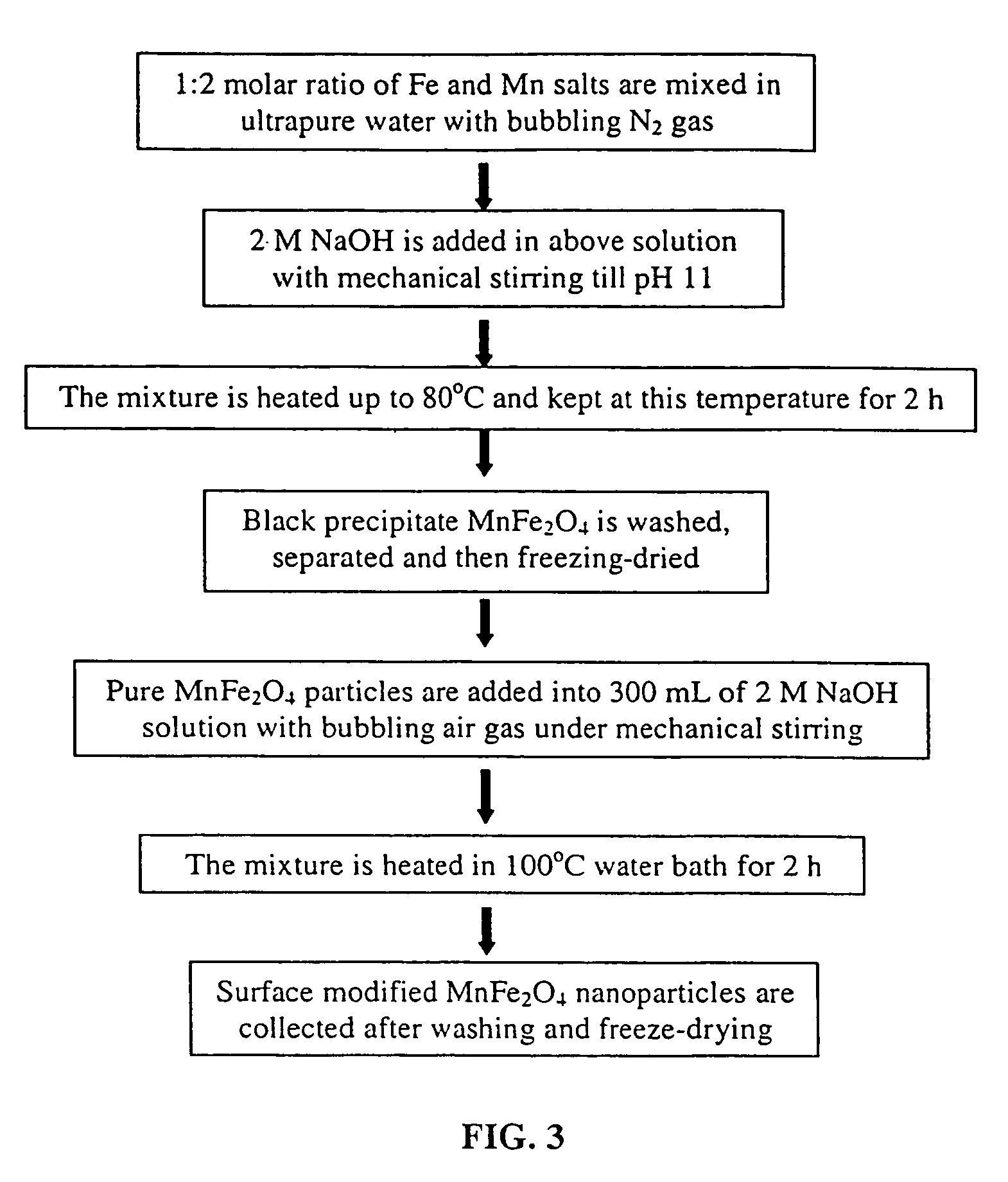

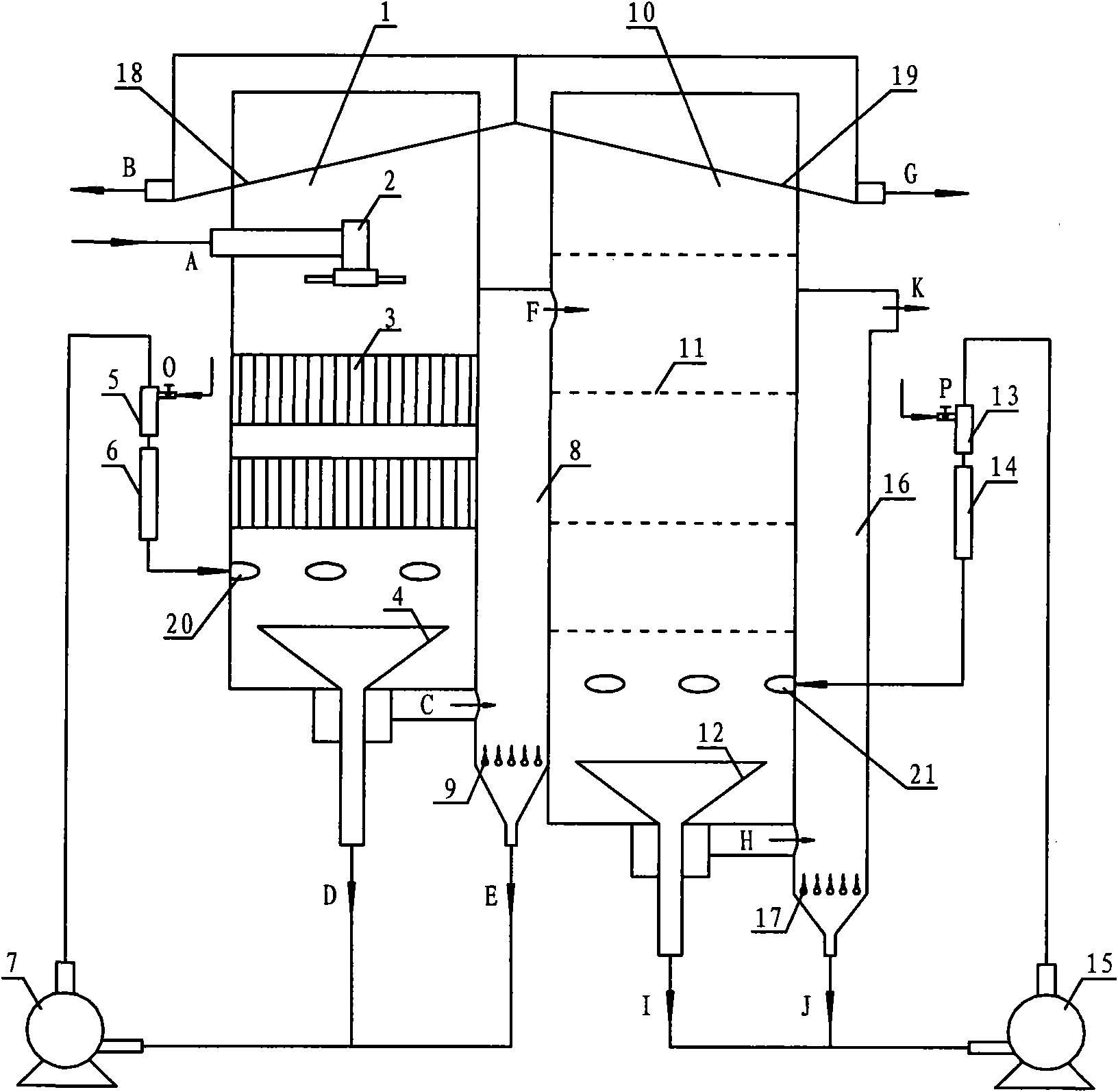

Synthesis of modified maghemite and jacobsite nanoparticles

ActiveUS7622423B1Good removal effectEfficient removalMaterial nanotechnologyOther chemical processesMaghemiteMagnetite Nanoparticles

The present invention provides a method for making modified jacobsite, Al-doped maghemite or modified maghemite nanoparticles that can be used to adsorb heavy metals, such as Cr(VI), found in wastewater. The magnetic nanoparticles can be separated using a magnetic field after adsorbing heavy metals from wastewater, and processed for reused.

Owner:THE HONG KONG UNIV OF SCI & TECH

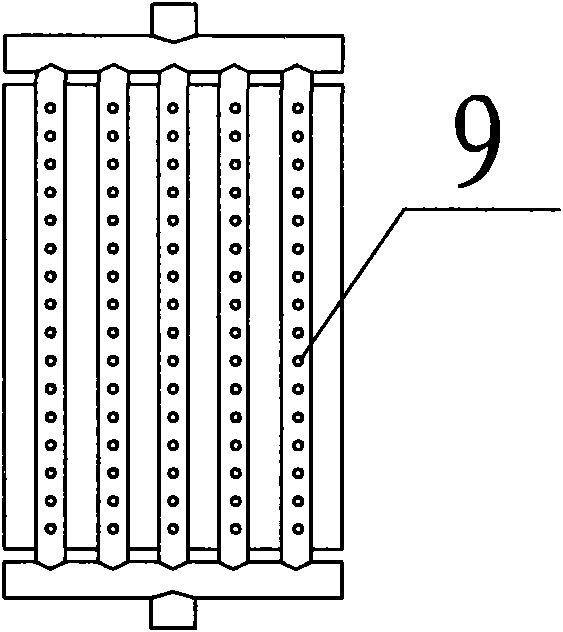

Slime separation method and equipment

InactiveCN101773873AImprove recycling effectSurface as soon as possibleFlotationEconomic benefitsEngineering

The invention relates to a slime separation method and equipment. The slime separation method adopts a one-piece double-flotation-column to carry out circulating flotation and classification for slime, and a flow stabilizer is arranged in a first flotation column; the flow stabilizer can eliminate large vortex, support a foam layer and increase the probability of collision between particles and bubbles, so that the slime easy to float can be floated out as soon as possible so as so reduce mix and pollution and play the role of flow stabilization; the material floated out through sedimentation is classified by a first sedimentation box and then enters a second floatation column to be floated again, and then enters a second sedimentation box to be classified again; and the number of the circulating separation of pulp is increased, and the recovery capabilities of coarse-fraction slime and difficultly floated fine-fraction slime are improved. The equipment has compact structure, large treating capacity, low production operation cost, and convenient installation and operation, improves the number and quality of fine coal products on the whole, and has marketable economic benefits.

Owner:CHINA UNIV OF MINING & TECH

Recyclable surfactant fracturing fluid and reutilization method

InactiveCN102851018AGood recycling of residual liquidGood technical prospectsDrilling compositionChemistryOil production

The invention discloses a recyclable surfactant fracturing fluid, relating to the technical field of fracturing fluids used in oil production. The recyclable surfactant fracturing fluid comprises the following components in parts by weight: 5-10 parts of recyclable surfactant fracturing fluid thickener and 100 parts of clear water or potassium chloride solution. The invention also provides a reutilization method of the fracturing fluid. After the fracturing fluid is used for fracturing construction, the viscosity breaking flow-back liquid can be used for fracturing fluid preparation again without chemical treatment, thereby developing a new way for fully utilizing the surfactant fracturing fluid.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

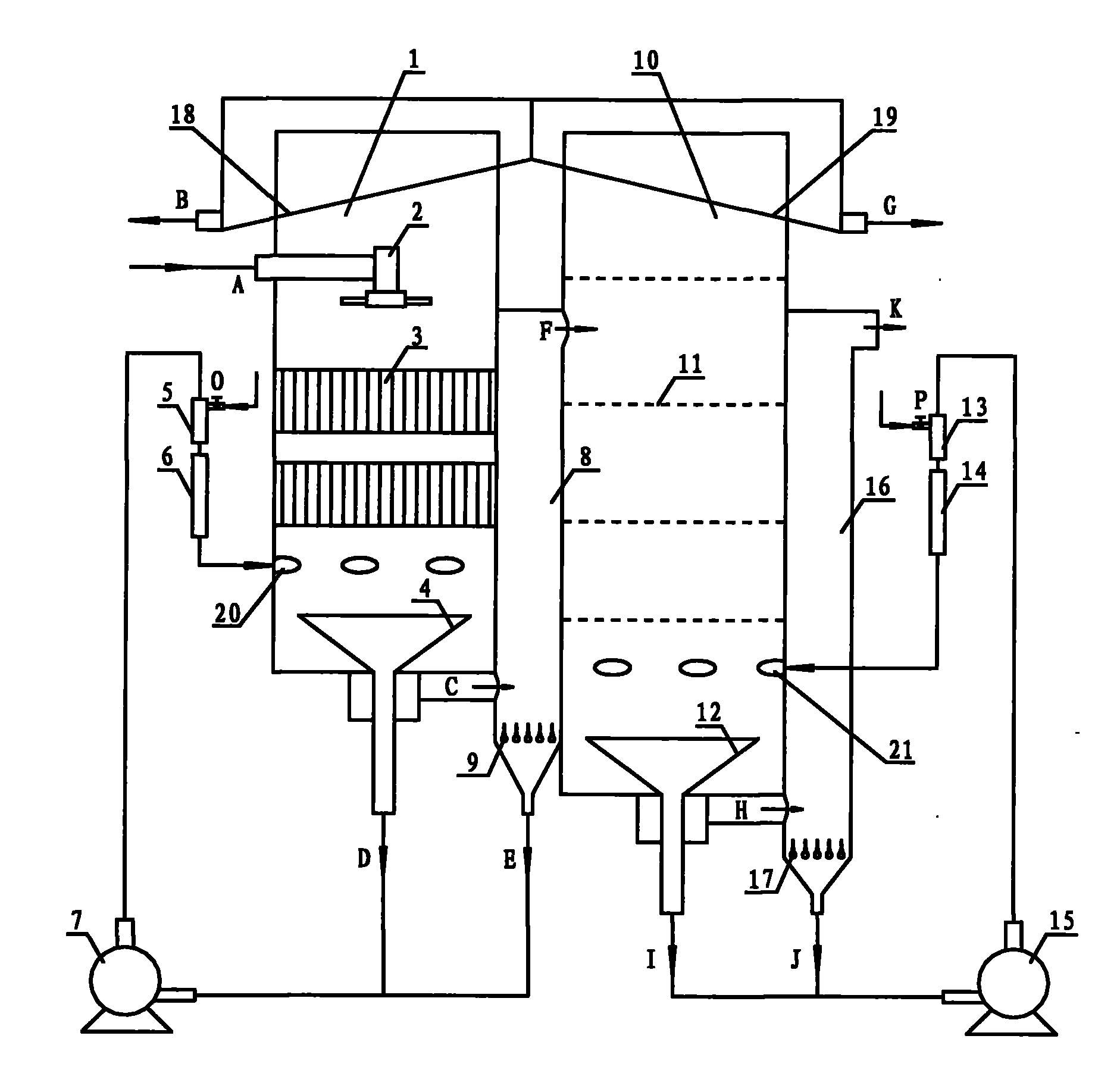

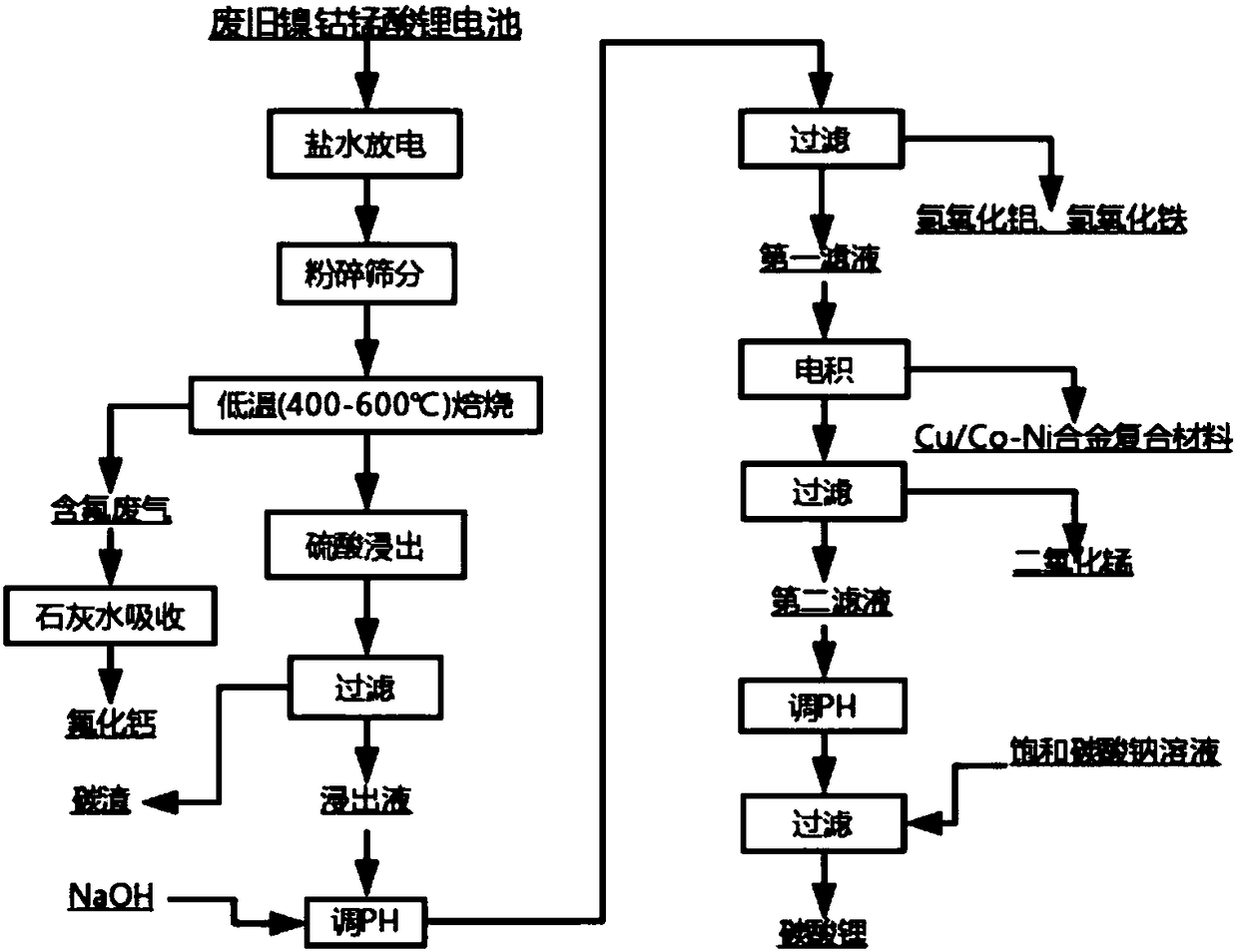

Method for recycling valuable metal in waste nickel-cobalt-manganese ternary lithium-ion battery

ActiveCN108470951AImprove current efficiencyImprove recycling effectPhotography auxillary processesWaste accumulators reclaimingLithium electrodeAlloy composite

The invention belongs to the field of recycling of valuable materials of waste lithium-ion batteries and particularly discloses a method for efficiently cleaning and recycling valuable metal in a waste ternary lithium-ion battery. The method comprises the following steps that (1) the waste ternary LNCM lithium-ion battery is subjected to short-circuit discharging, disassembly, stripping through abinding agent and smashing screening to obtain an electrode active material; the electrode active material is subjected to reduction-acid leaching, and solid-liquid separation is conducted to obtain acarbon material and an acid leachate containing Li+, Ni2+, Co2+, Mn2+, Fe3+, Al3+ and Cu2+; (2) the pH of the acid leachate is regulated and controlled within 3-5, and Fe3+ and Al3+ in the acid leachate are precipitated; then through solid-liquid separation, impurity-removal filtrate with Li+, Ni2+, Co2+ and Mn2+ is obtained; (3) the pH of the impurity-removal filtrate is adjusted to 1-6, then the filtrate is used as an electrolyte and subjected to rotational flow electrolysis, Cu / Co-Ni alloy composite film is collected at a negative electrode, and MnO2 is collected at a positive electrode. According to the method, a rotational flow electrolysis mode is innovatively adopted, and effective components in the leachate is efficiently recycled.

Owner:CENT SOUTH UNIV

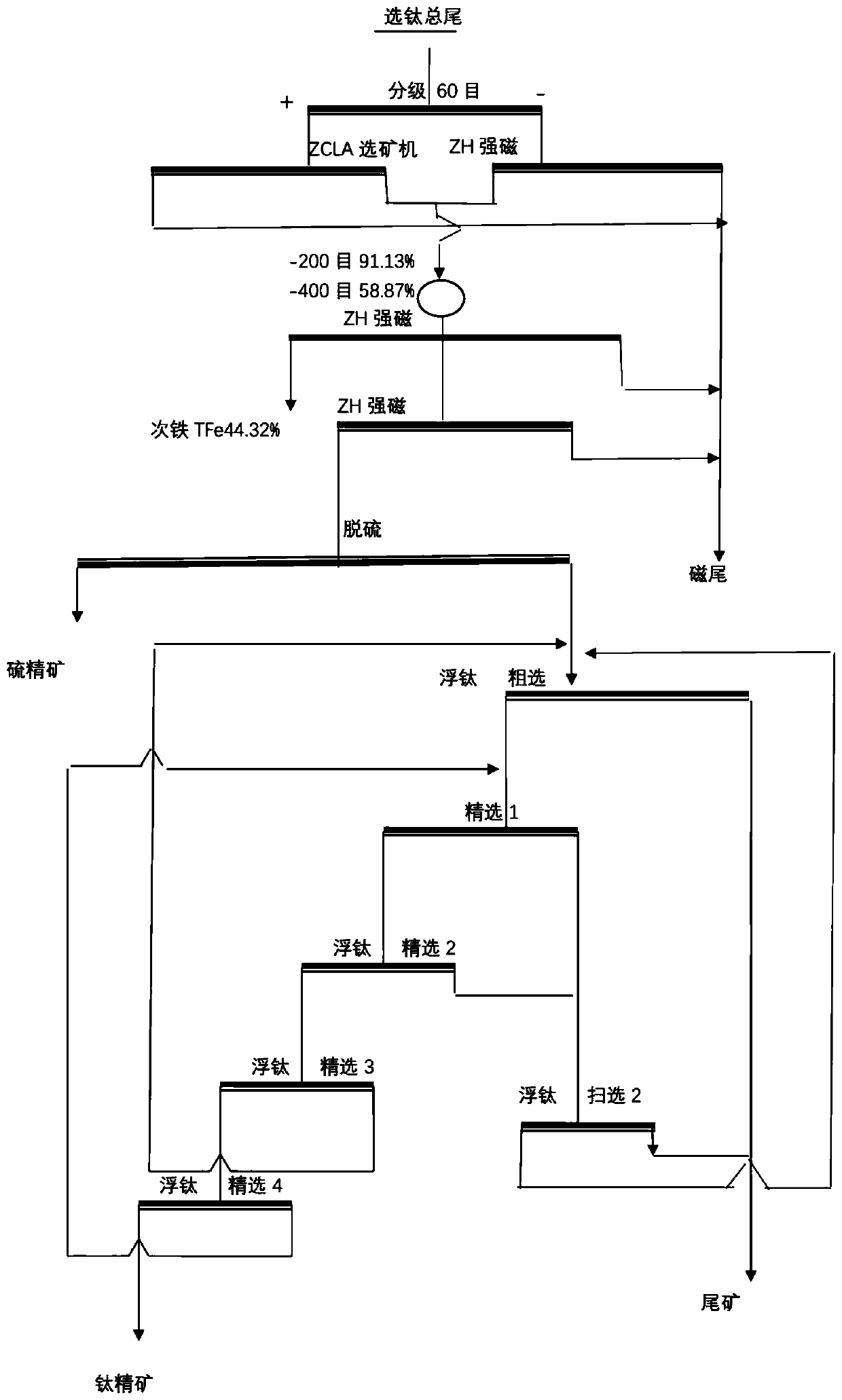

Method for recycling micro-particle ilmenite through vanadium-titanium magnetite titanium beneficiation main tailings

ActiveCN110882826AIncrease profitAvoid wastingFlotationMagnetic separationMagnetiteMagnetic separator

The invention belongs to the technical field of mineral processing, and particularly relates to a method for recycling micro-particle ilmenite through vanadium-titanium magnetite titanium beneficiation main tailings. For the problems that in the prior art, the micro-particle yield of micro-particle-level ilmenite in vanadium-titanium magnetite titanium beneficiation main tailings is large, and themicro-particle-level TiO2 distribution rate is high, according to the technical scheme of the method, classifying equipment is adopted for classifying the vanadium-titanium magnetite titanium beneficiation main tailings, a ZCLA concentrating machine is adopted for enrichment for the coarse fraction, a ZH combined magnetic separator is adopted for enrichment for the fine fraction, and after concentrates of two devices enter a ball mill for ore grinding, the ZH combined magnetic separator is adopted for one roughening and one refining, ZH concentrates with the TiO2 grade larger than 18% are obtained, then preselection desulfuration and one-roughening, four-refining and one-sweeping refining are conducted, and titanium concentrates with the TiO2 grade larger than 47% are obtained.

Owner:SICHUAN LOMON MINING & METALLURGY +1

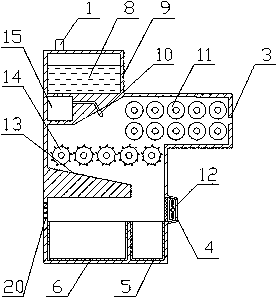

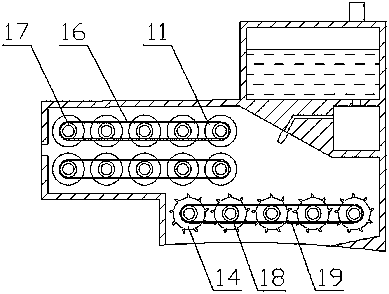

Medical mask recycling machine

PendingCN111151561APrevent reuseHarm reductionGas current separationSolid waste disposalSprocketIndustrial engineering

The invention discloses a medical mask recycling machine which can crush and sterilize recycled masks, carry out winnowing, distinguishing and collecting on the crushed masks through a draught fan andcan prevent the recycled masks from being reutilized by lawless persons. The medical mask recycling machine is characterized in that a device body is composed of a transverse shell and a vertical shell; the transverse shell is arranged on the top of the vertical shell; the position, corresponding to the vertical shell, of the transverse shell is provided with a communicating slot; the transverseshell communicates with the vertical shell through the communicating slot; one side of the transverse shell is provided with a charging slot; two sets of conveying rolls are arranged in the transverseshell; one set of conveying rolls is composed of at least five conveying rolls transversely and equidistantly distributed; the two sets of conveying rolls are located on the upper and lower sides ofthe charging slot correspondingly; the two ends of a shaft of each conveying roll are connected with the transverse shell through bearings; the shaft of each conveying roll is sleeved with a chain wheel I; the chain wheels I on one set of conveying rolls are connected through a chain I; and the gap between the two sets of conveying rolls communicates with the charging slot correspondingly.

Owner:XUZHOU CHUANGZHISHE GENERAL TECH IND RES INST CO LTD

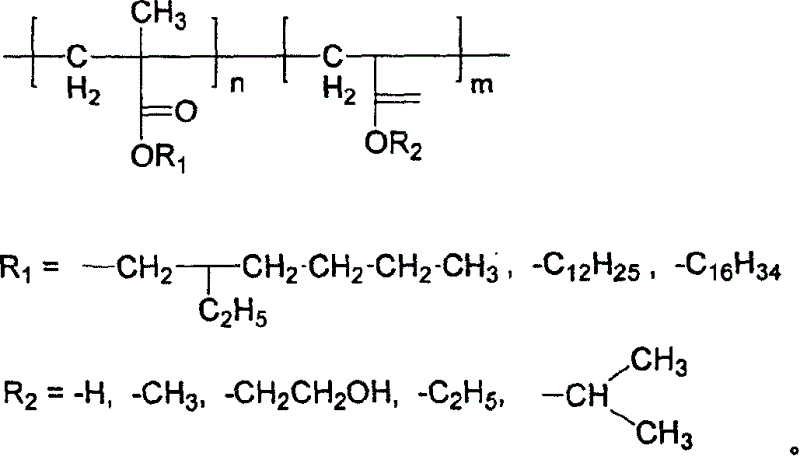

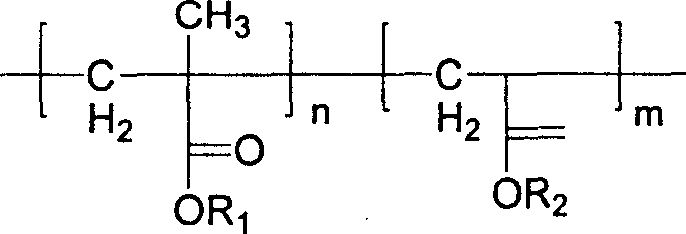

Porous high oil adsorption resin and its preparation method

InactiveCN1724575AIncreased contact surface areaMore oil-absorbing typesWater/sewage treatment by flocculation/precipitationSolventChemistry

The invention relates to a sewage treatment agent that uses methacrylic acid long chain ester and crylic acid short chain ester as monomer, and water as disperse phase, and adds dispersing agent, initiator agent, crosslink agent and organic solvent. The method is that: adding dispersing agent into water to make 0.3-5.0% aqueous solution and whisking under 30-50 degree centigrade for cooling; adding the mixture of 24-34% methacrylic acid long chain ester, 65-75%crylic acid short chain, 0.1-0.6% crosslink agent, and 0.5-1.6% initiator agent while whisking; under the protection of nitrogen gas, rising the temperature until reaching 70-100degree centigrade, the polymerization beginning and lasting for 7-9 hours; after reaction, cooling and filtrating the production, washing several times by 50-70 degree centigrade hot water, excerpting by methanol, putting into bake oven for baking, then the porosity high oil absorption rosin. It has high blotter scale factor and high blotter efficiency. Moreover, it could be used repeatedly, thus the secondary pollution would be avoided.

Owner:SUZHOU TIMEBLUE ENVIRONMENTAL TECH CO LTD

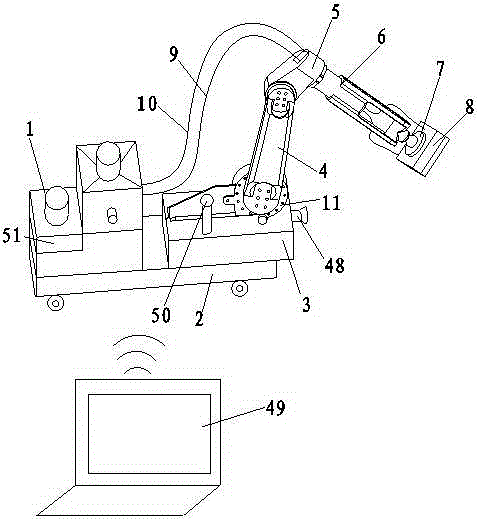

Spraying robot with automatic visual tracking function

The invention discloses a spraying robot with an automatic visual tracking function. The spraying robot comprises a conveying device, a moving device, an adjusting base, a large arm, a transition arm, a third arm, a rotary connector and a painting device. The adjusting base is mounted on the moving device, a mounting seat is mounted on the upper surface of the adjusting base and is hinged to the large arm, the large arm is hinged to the transition arm, the transition arm is hinged to the third arm, the rotary connector is arranged at the front end of the third arm, and the painting device is mounted at the front end of the rotary connector. The spraying robot has the advantages that tailing materials can be recycled, accordingly, the cost can be saved, surrounding edges can be fitted, and environmental pollution due to falling of the tailing materials in construction sites can be prevented; the spraying robot has the automatic visual tracking function, accordingly, construction personnel and equipment are separated from one another during site operation construction, and automatic construction can be implemented; fitting intensity of the painting device and walls can be adjusted at any time by the aid of load pressure sensors, and accordingly good plastering and tailing material recycling effects can be realized.

Owner:安徽东坚仓储货架制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com