Plastic film scrap online recycling system

A recycling system and plastic film technology, applied in the field of plastic film scrap online recycling system, can solve the problems of incompatibility with large-scale industrial production, easy breakage of scraps, waste of resources, etc., to achieve stable and reliable continuous work and reduce labor costs. , the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

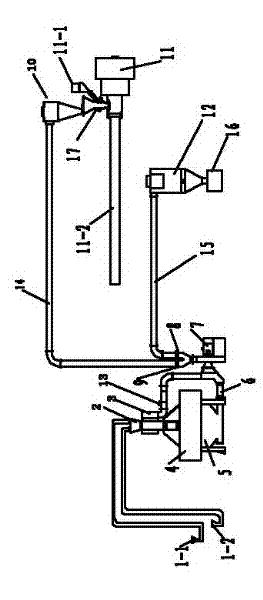

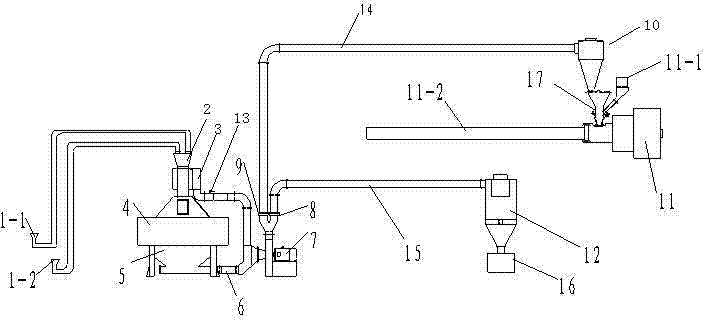

[0011] Such as figure 1 As shown, the system of the present invention includes a first lead pipe 1-1 and a second lead pipe 1-2 connected to the suction side wind bag 2, and a suction side wind bag 2 connected with the suction side wind bag 3 through the auxiliary wind bag 3. Crusher 4, suction fan 7, the first cyclone separator 10 and extruder 11; the suction edge air bag 2 and the auxiliary air bag 3 communicate with the suction fan 7 respectively, and the suction fan 7 passes through the suction pipe ( 6) Connected to the discharge hopper 5 of the crusher 4, the extruder 11 is connected to the first cyclone separator 10 through the stirring hopper 17, and the stirring hopper 17 is connected to the raw material hopper 11-1 of the extruder 11 connect. The suction blower 7 is also connected with a second feeding pipeline 15 with a second valve 8 and a second cyclone separator 12 , and the second cyclone separator 12 is connected with a storage tank 16 .

[0012] The trim cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com