Patents

Literature

72237results about How to "Avoid pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

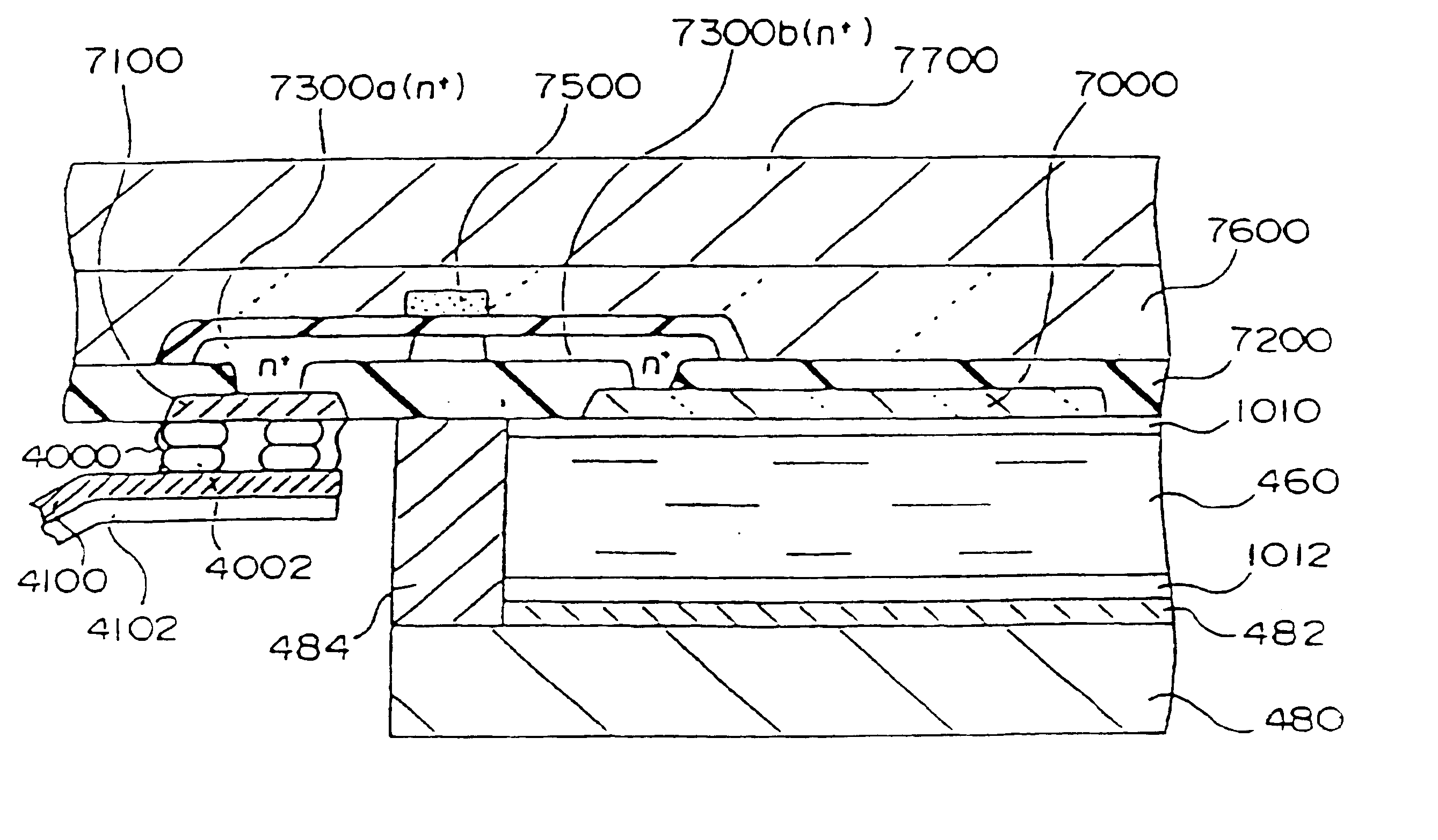

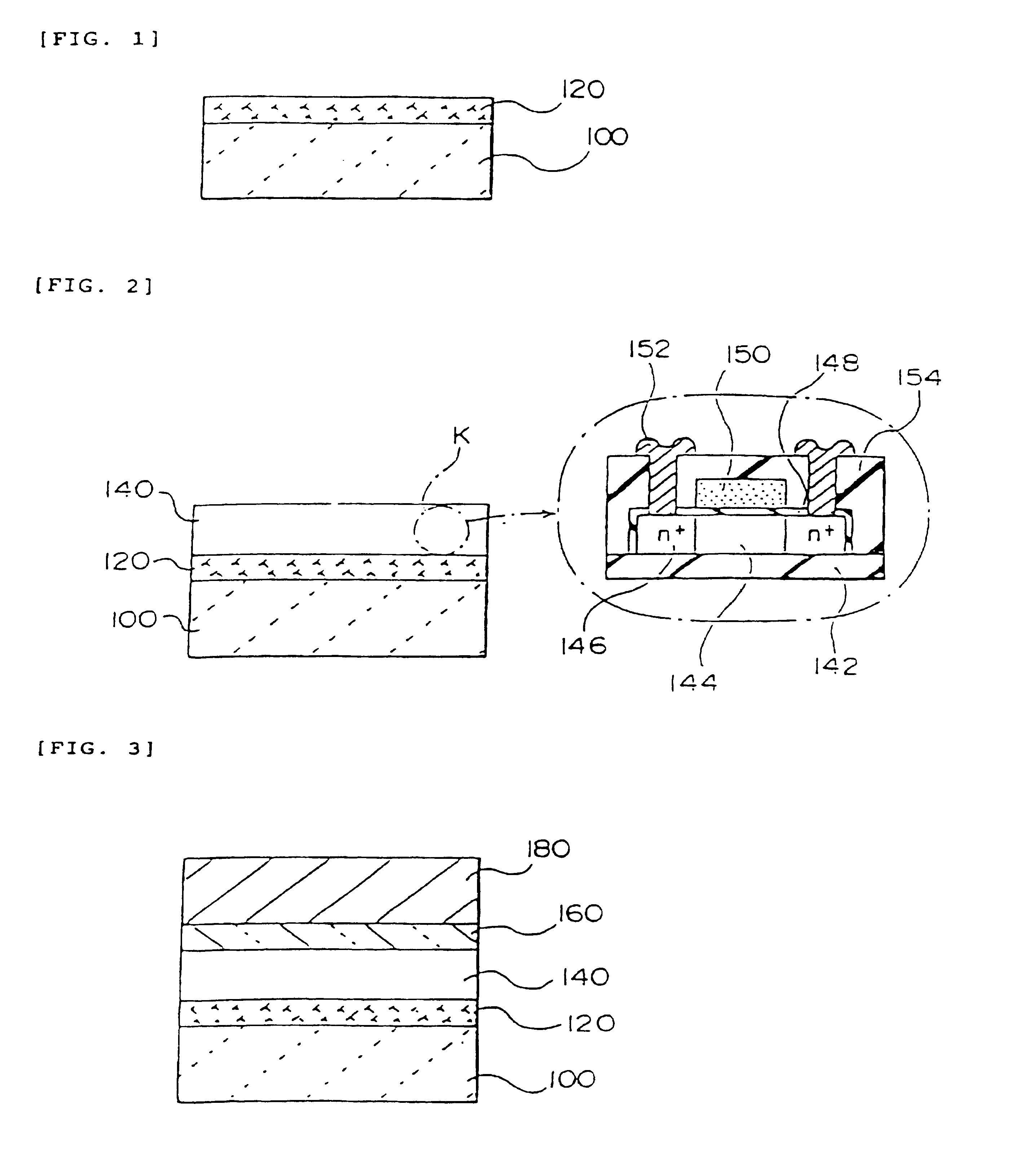

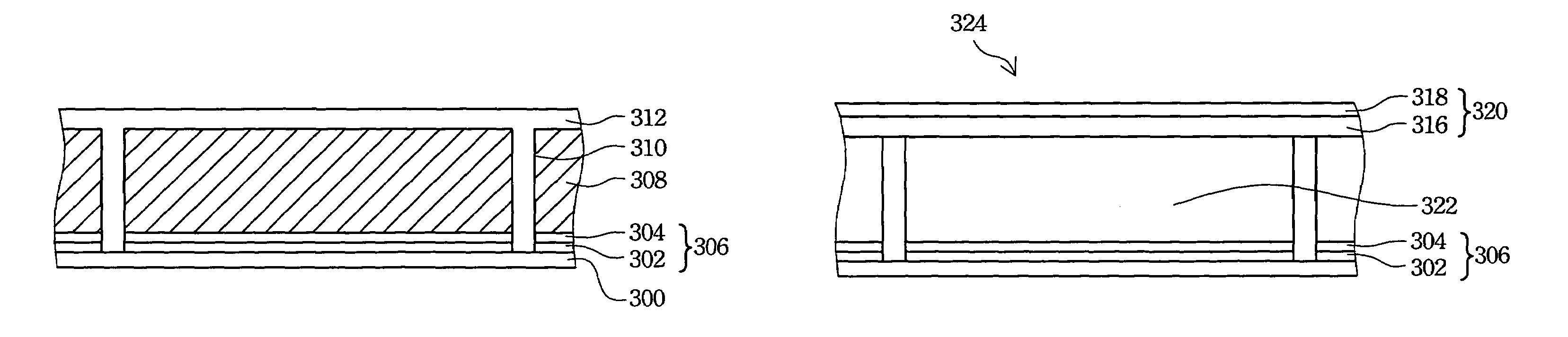

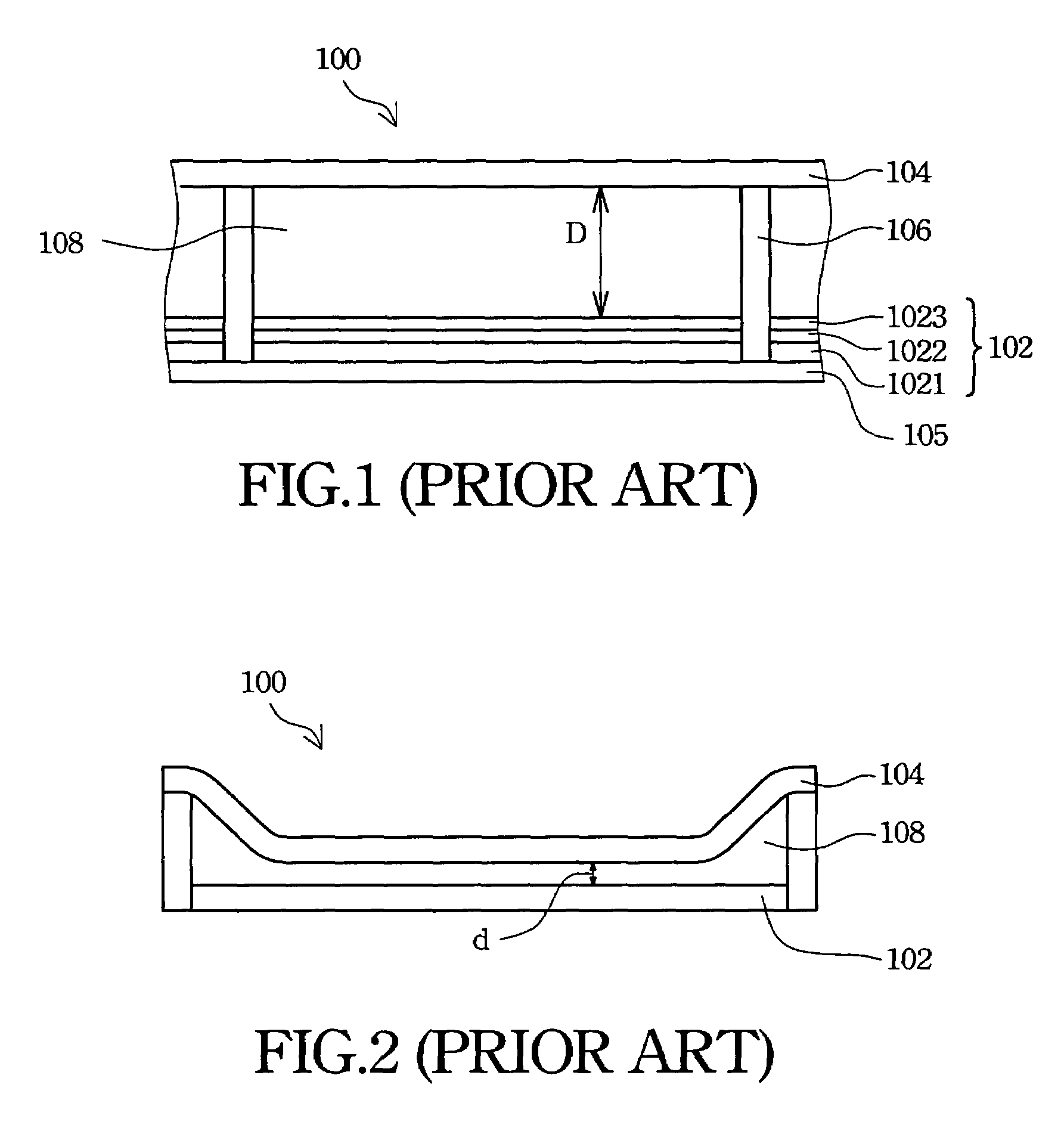

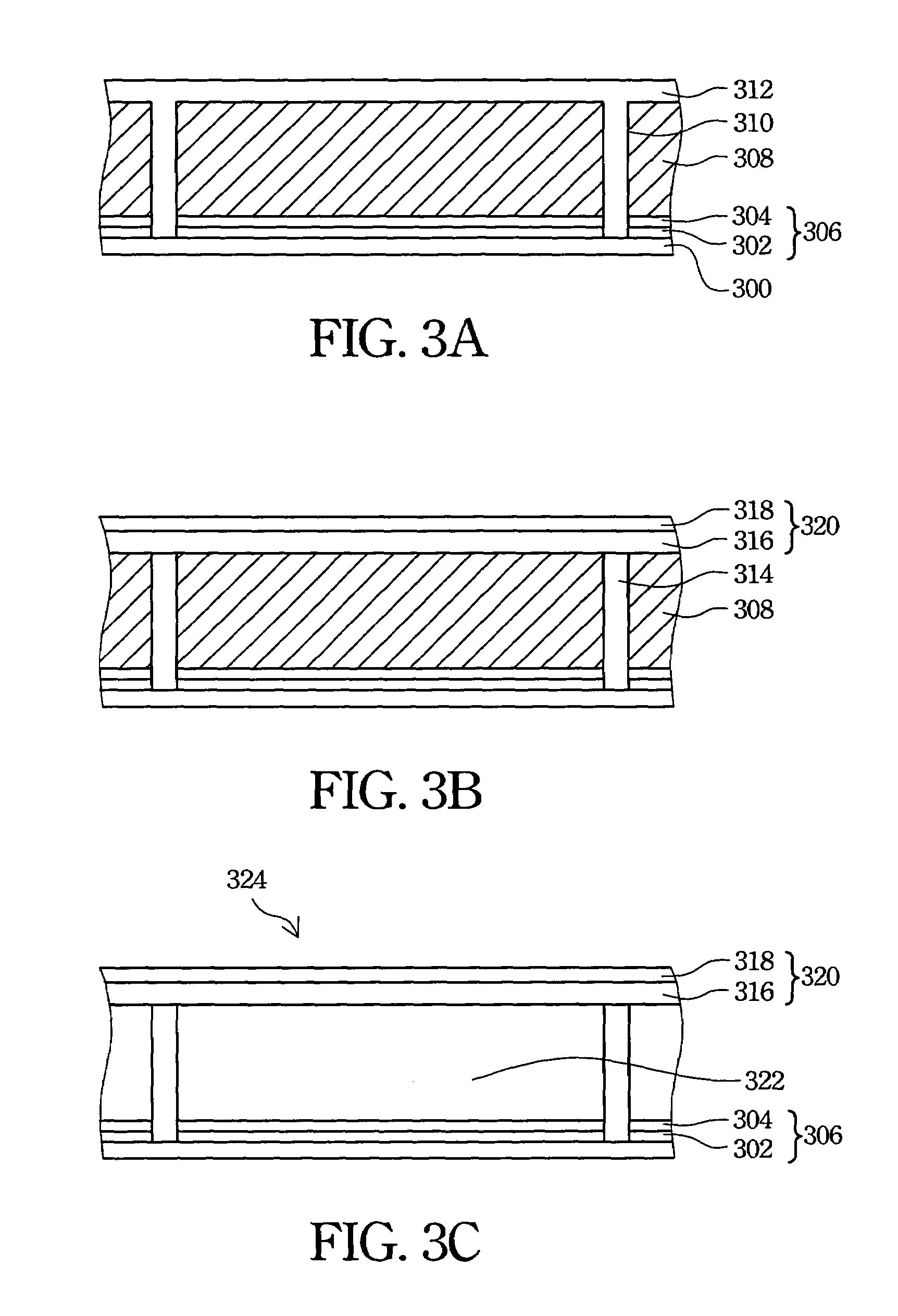

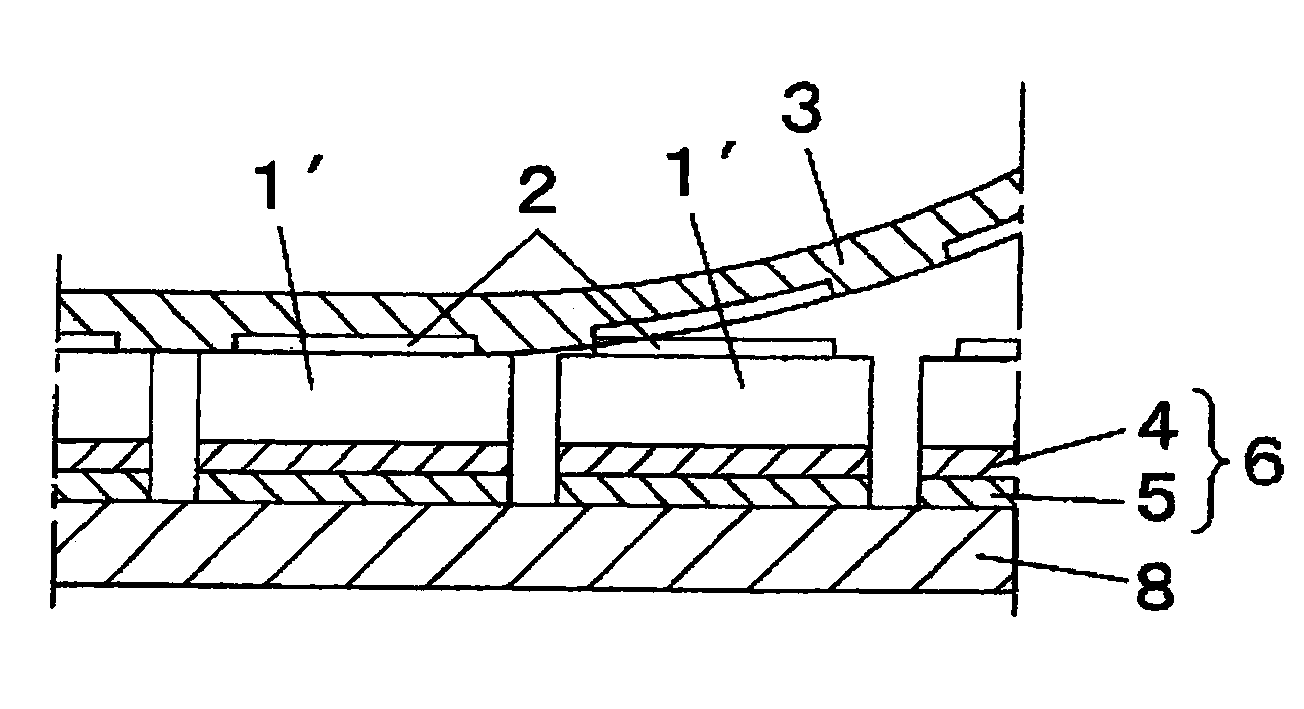

Manufacturing method of active matrix substrate, active matrix substrate and liquid crystal display device

InactiveUSRE38466E1Property for applicationMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayActive matrix

A method of manufacturing an active matrix substrate is provided that uses a technique of transferring a thin film device. In forming thin film transistors and pixel electrodes on an original substrate before transfer, an insulator film such as an interlayer insulation film or the like, is previously removed before the pixel electrodes are formed. Further, the original substrate is separated by exfoliation to transfer the device to a transfer material to cause the pixel electrodes to partially appear in the surface or the vicinity of the surface of the device. This portion permits application of a voltage to a liquid crystal through the pixel electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

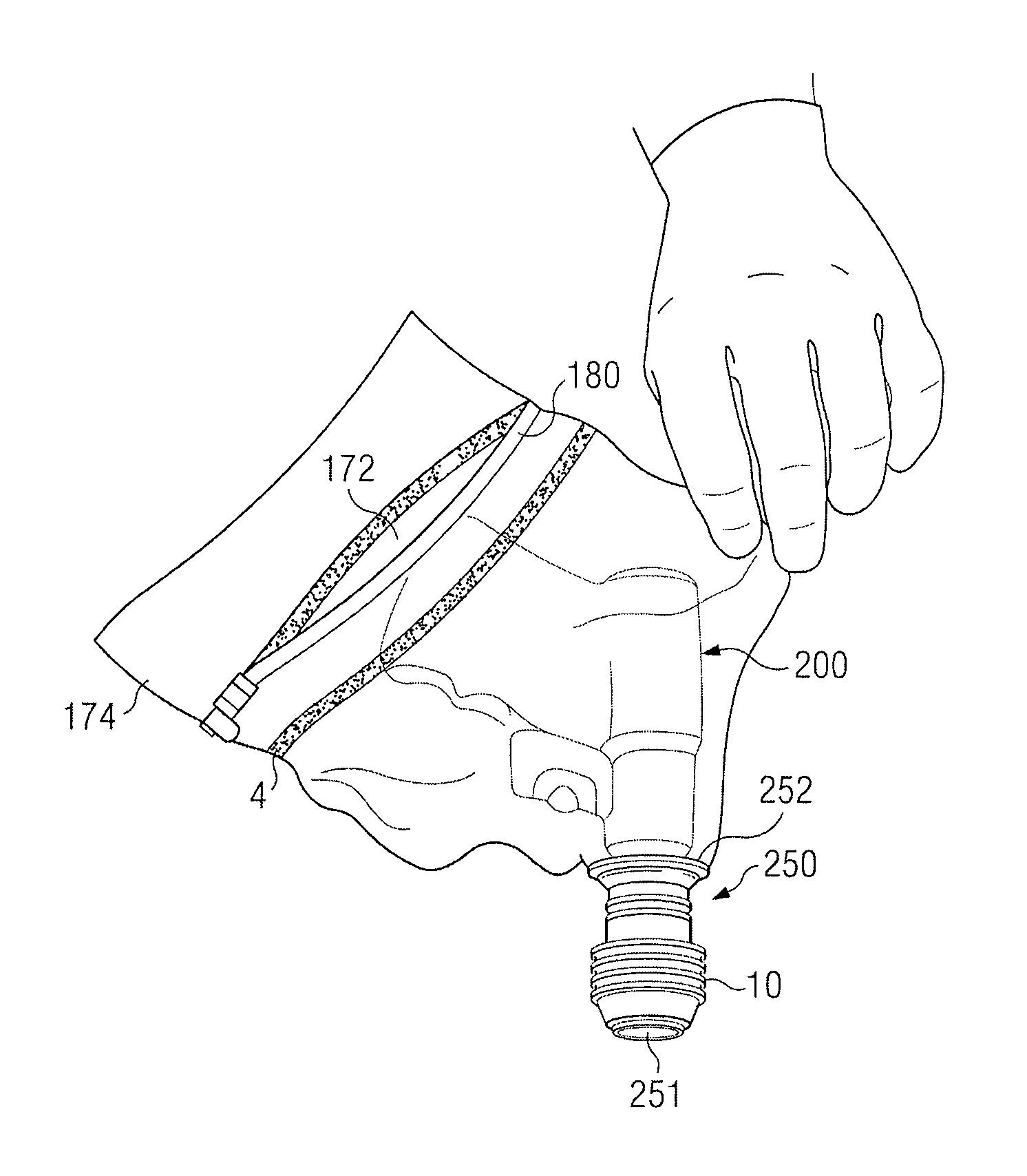

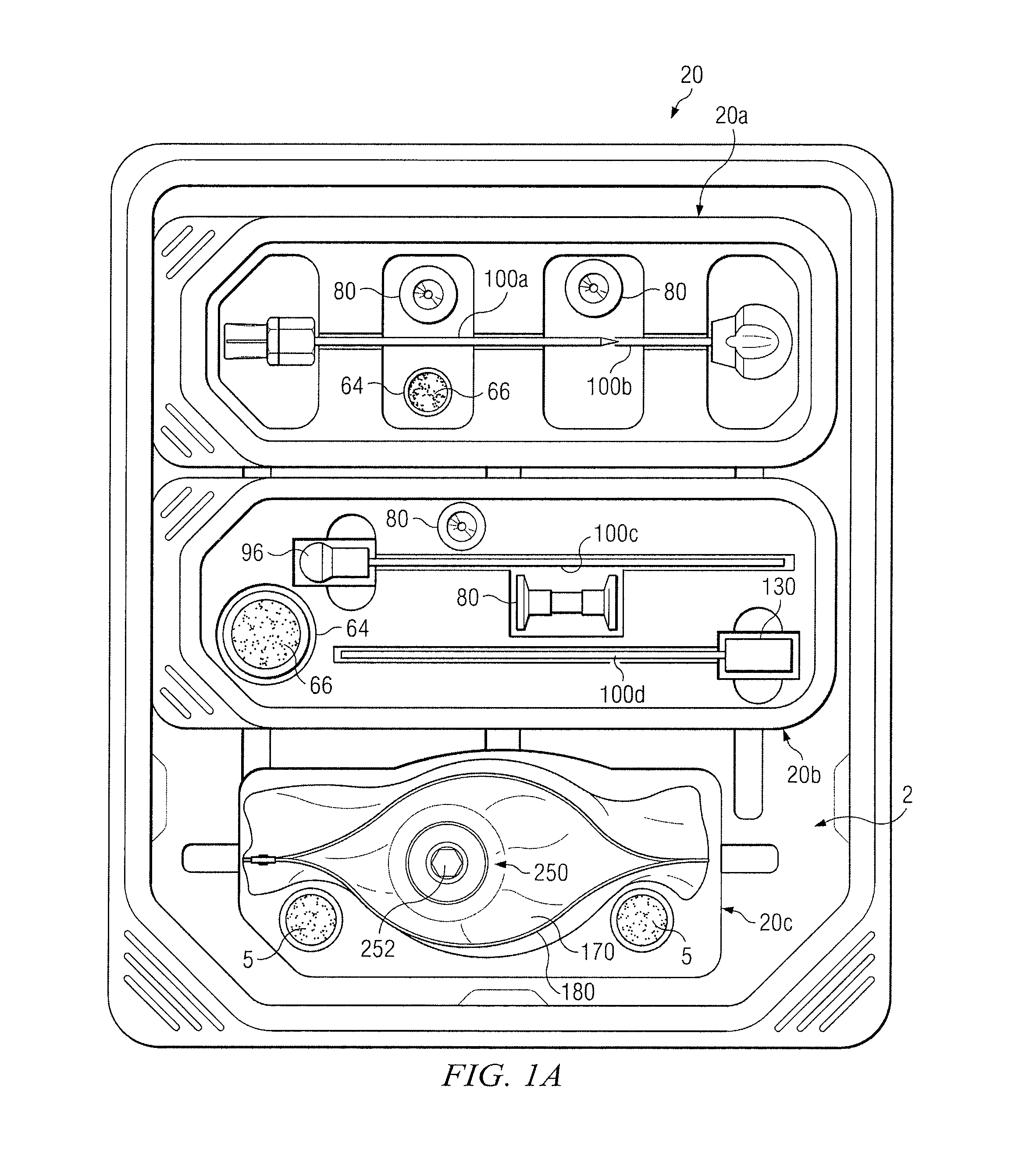

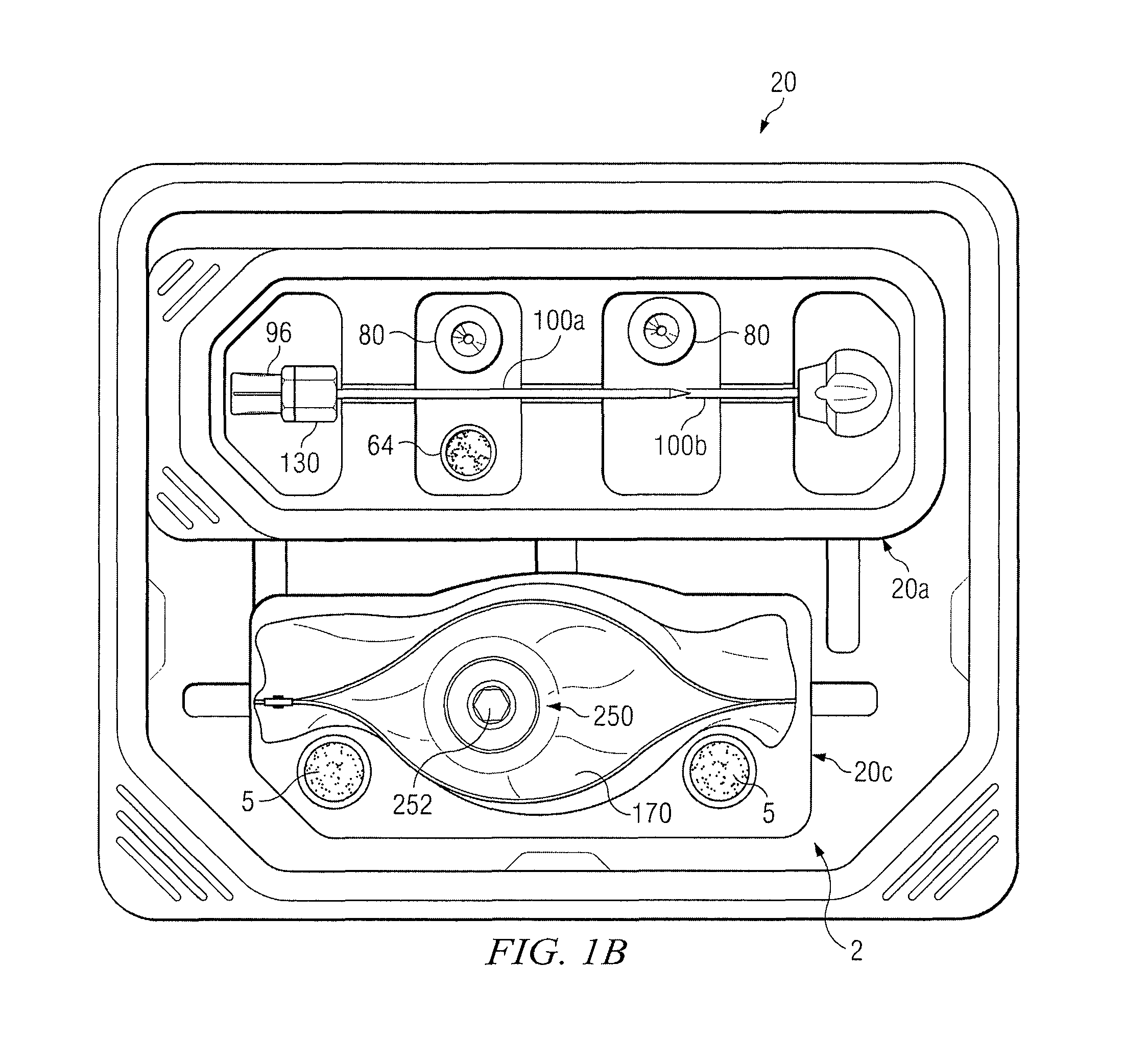

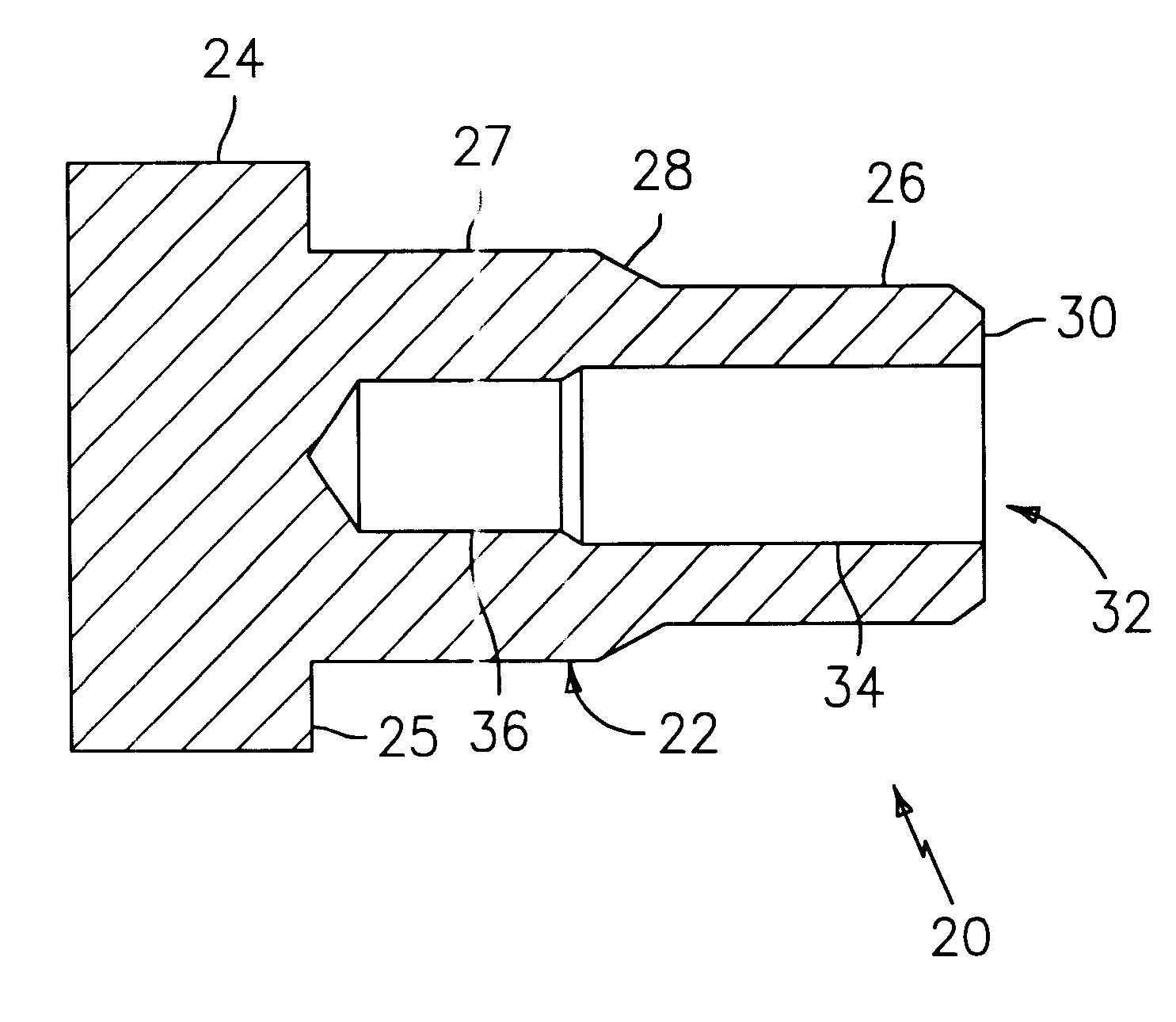

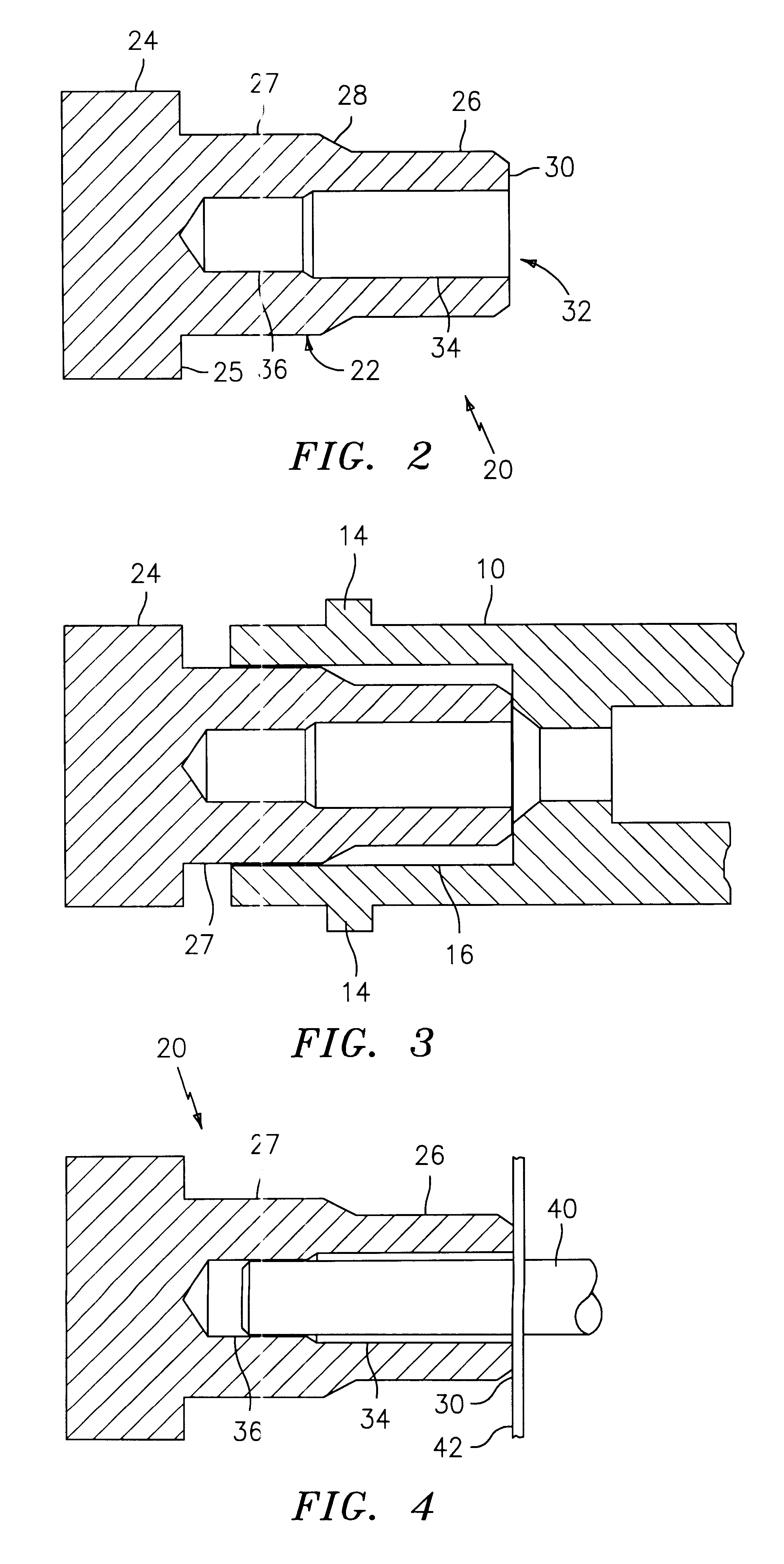

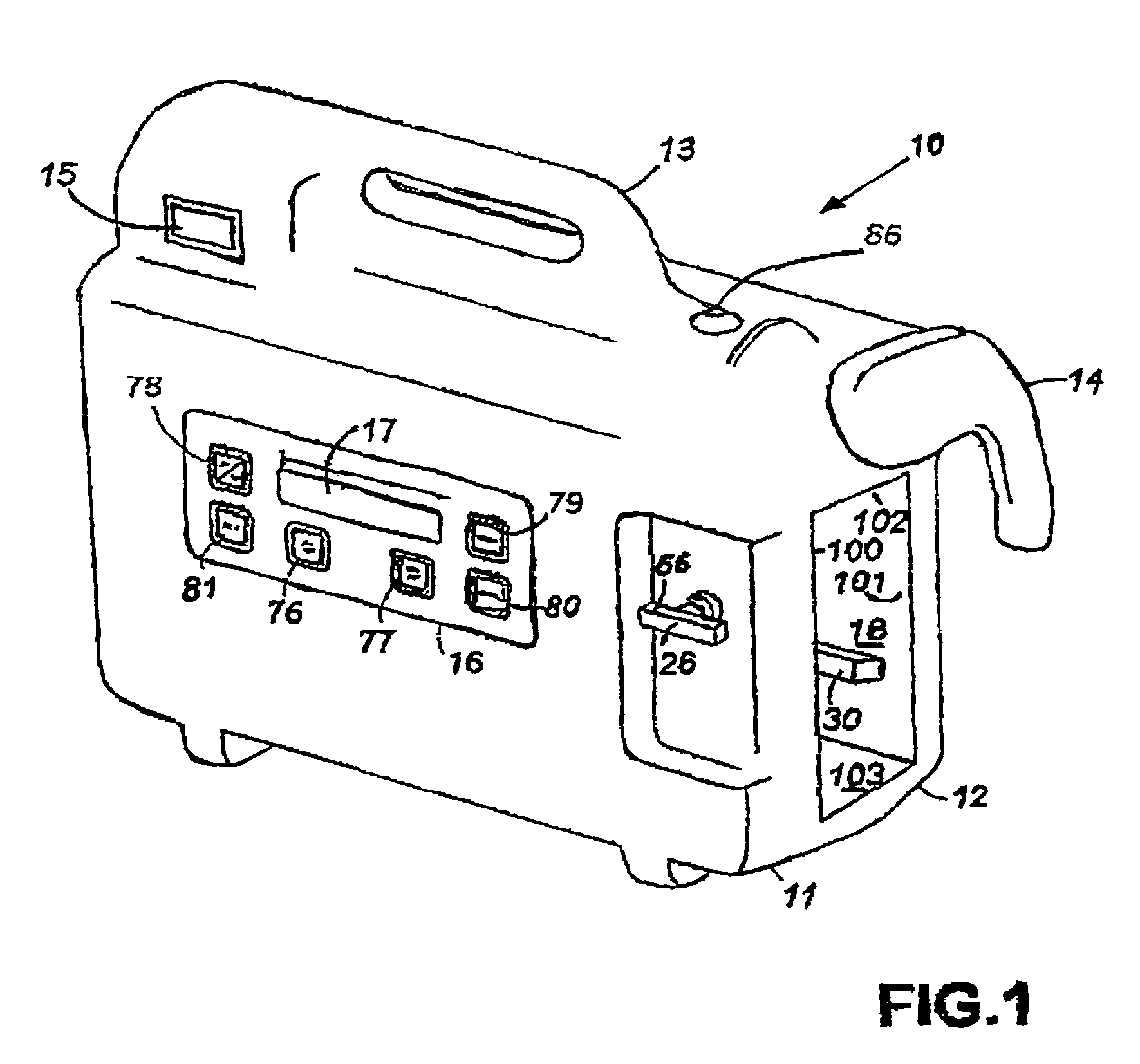

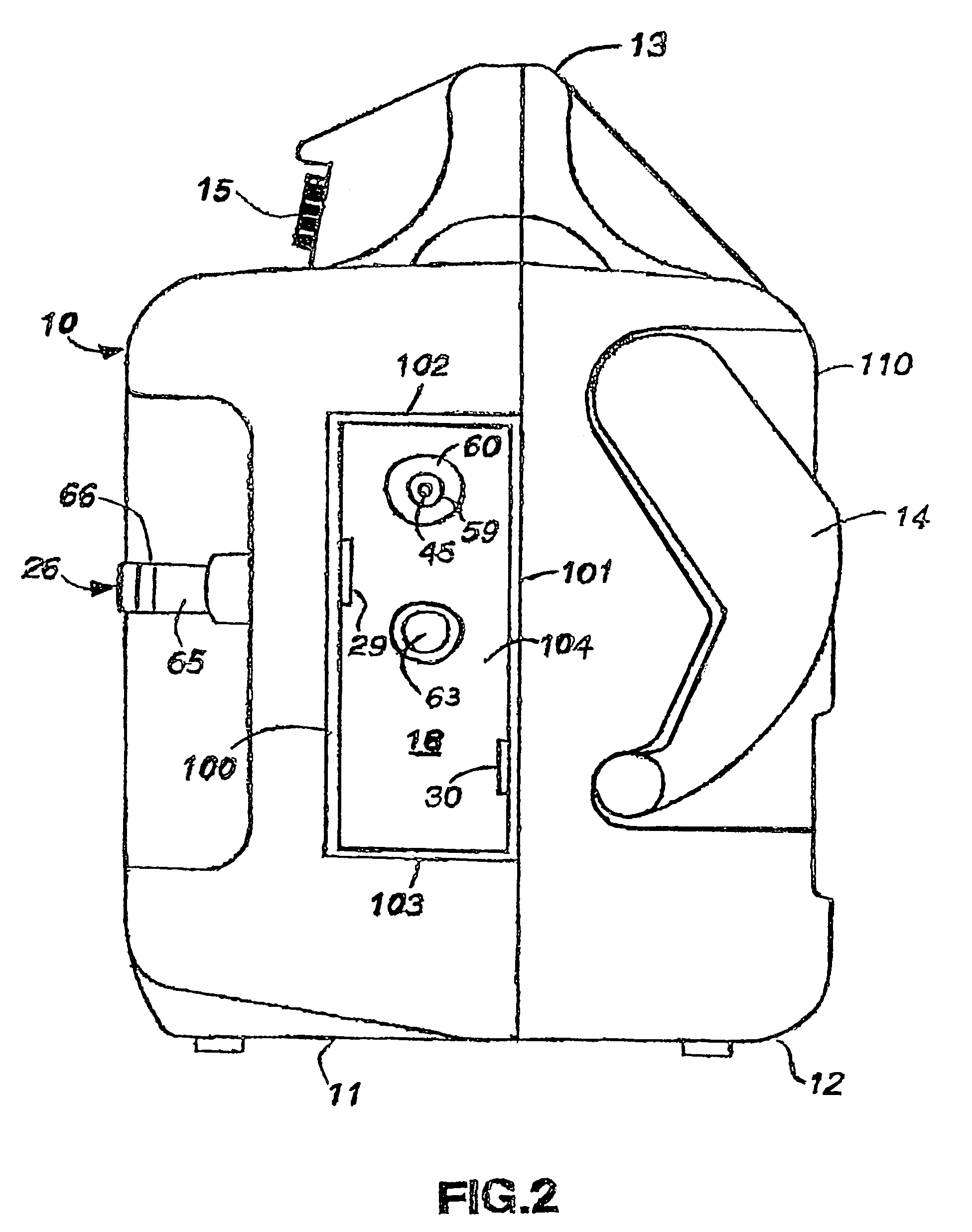

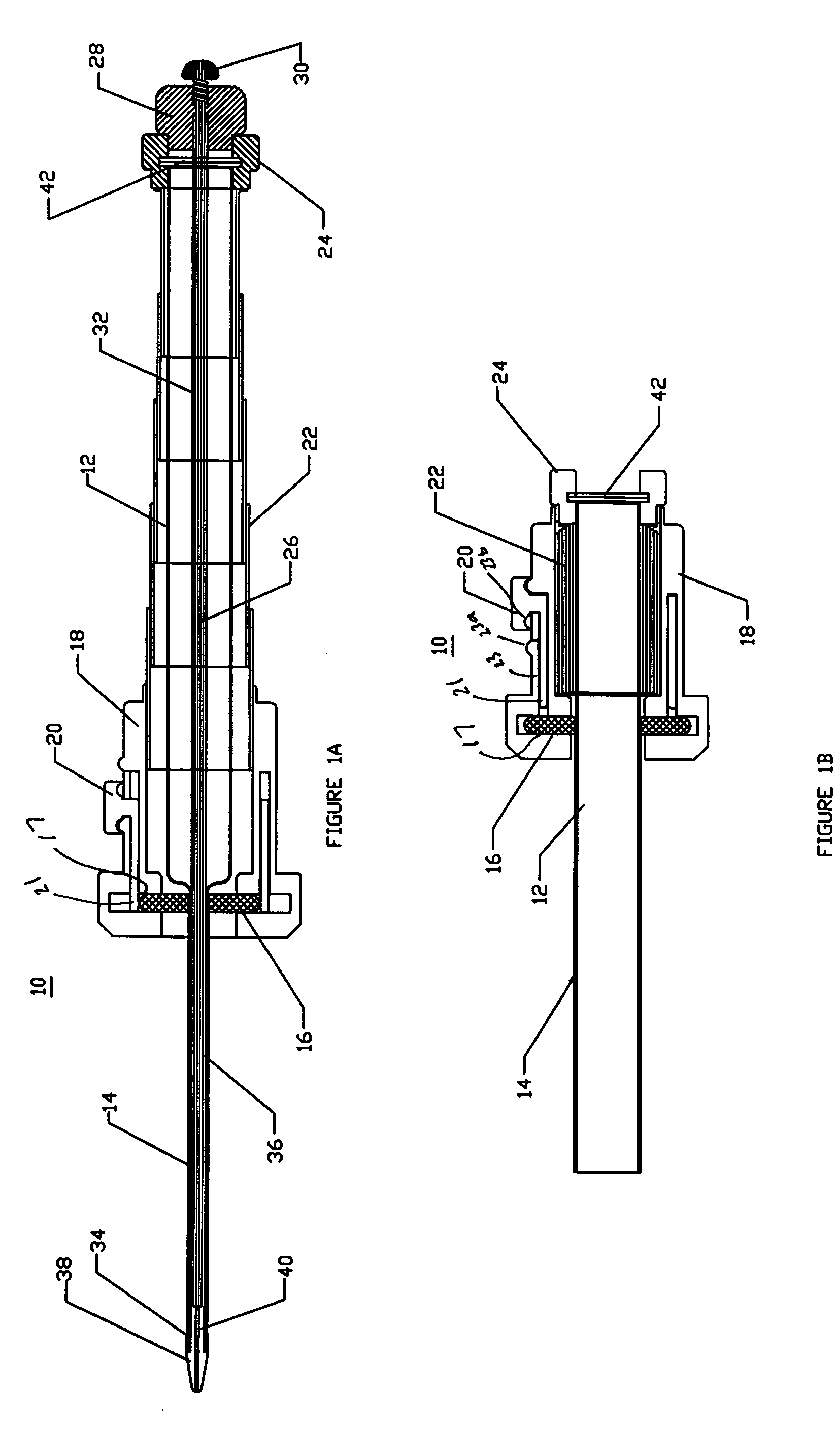

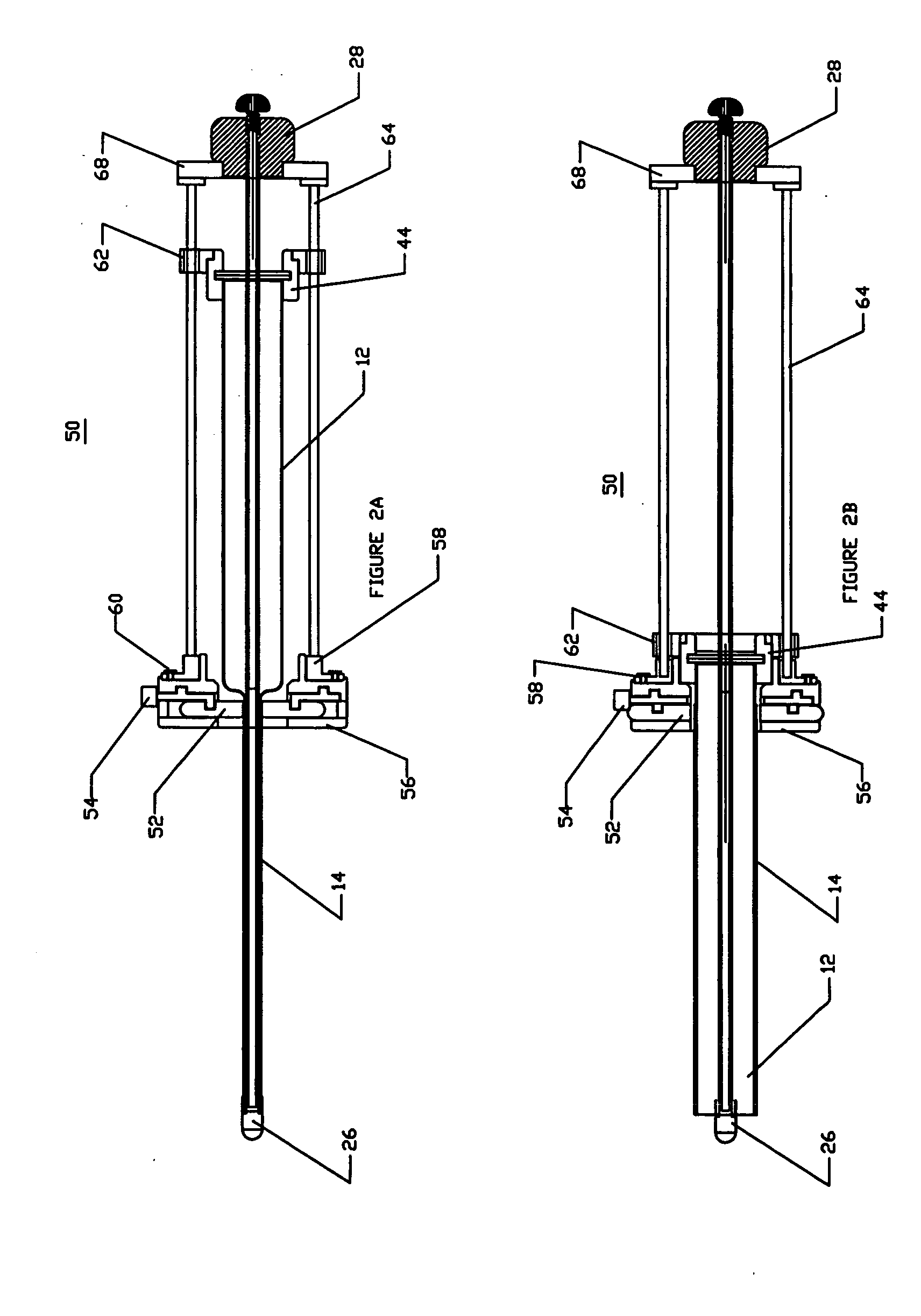

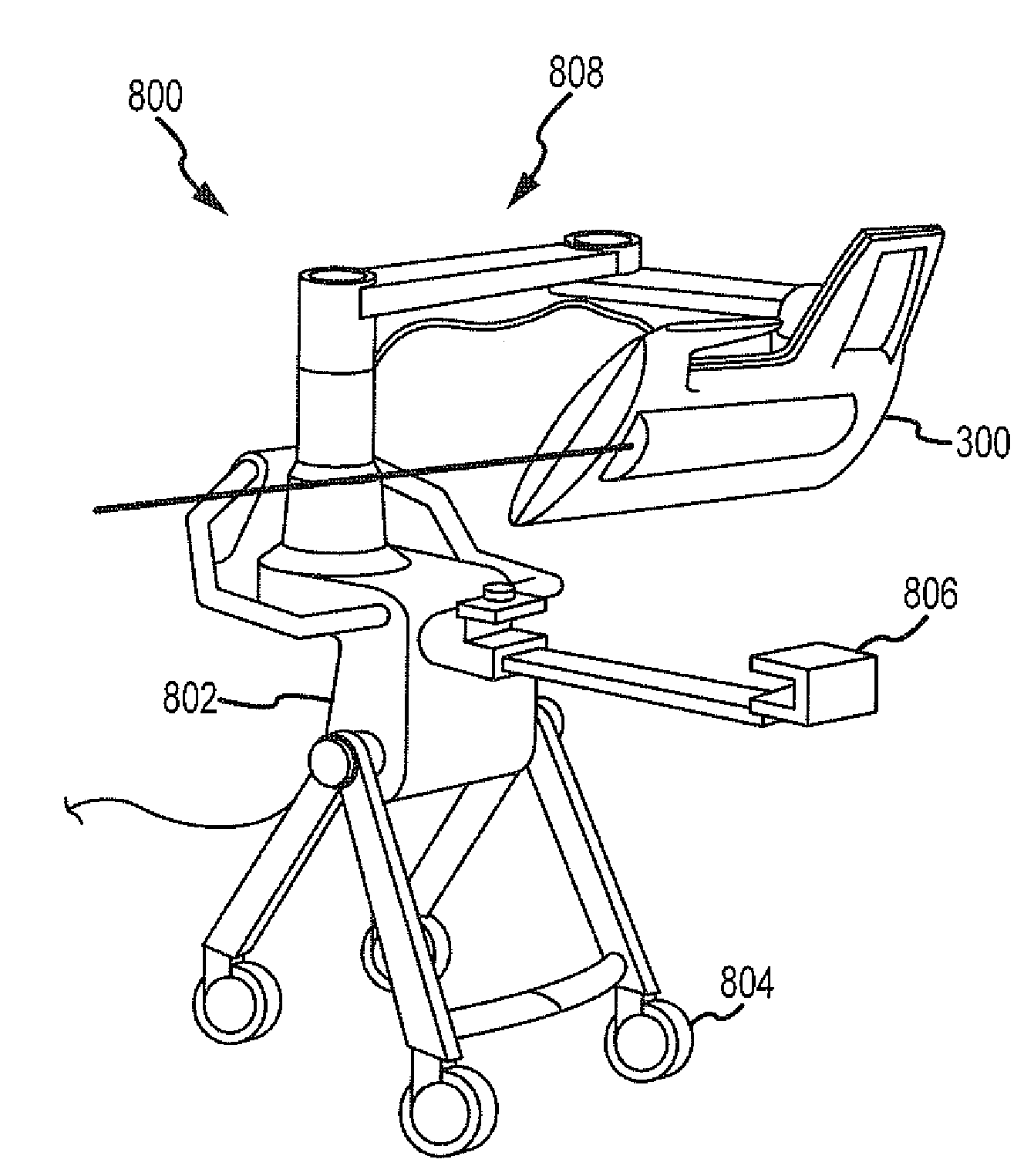

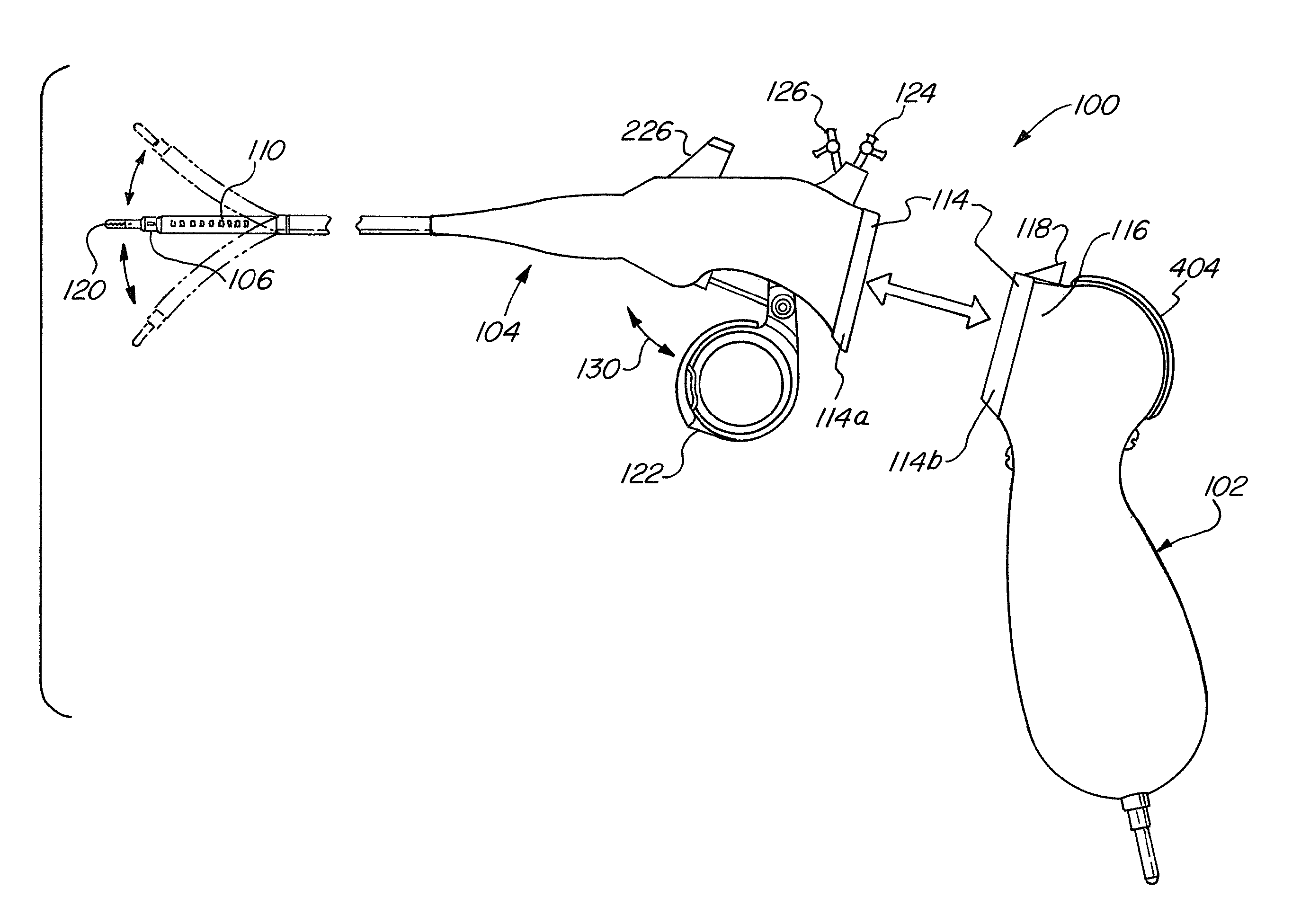

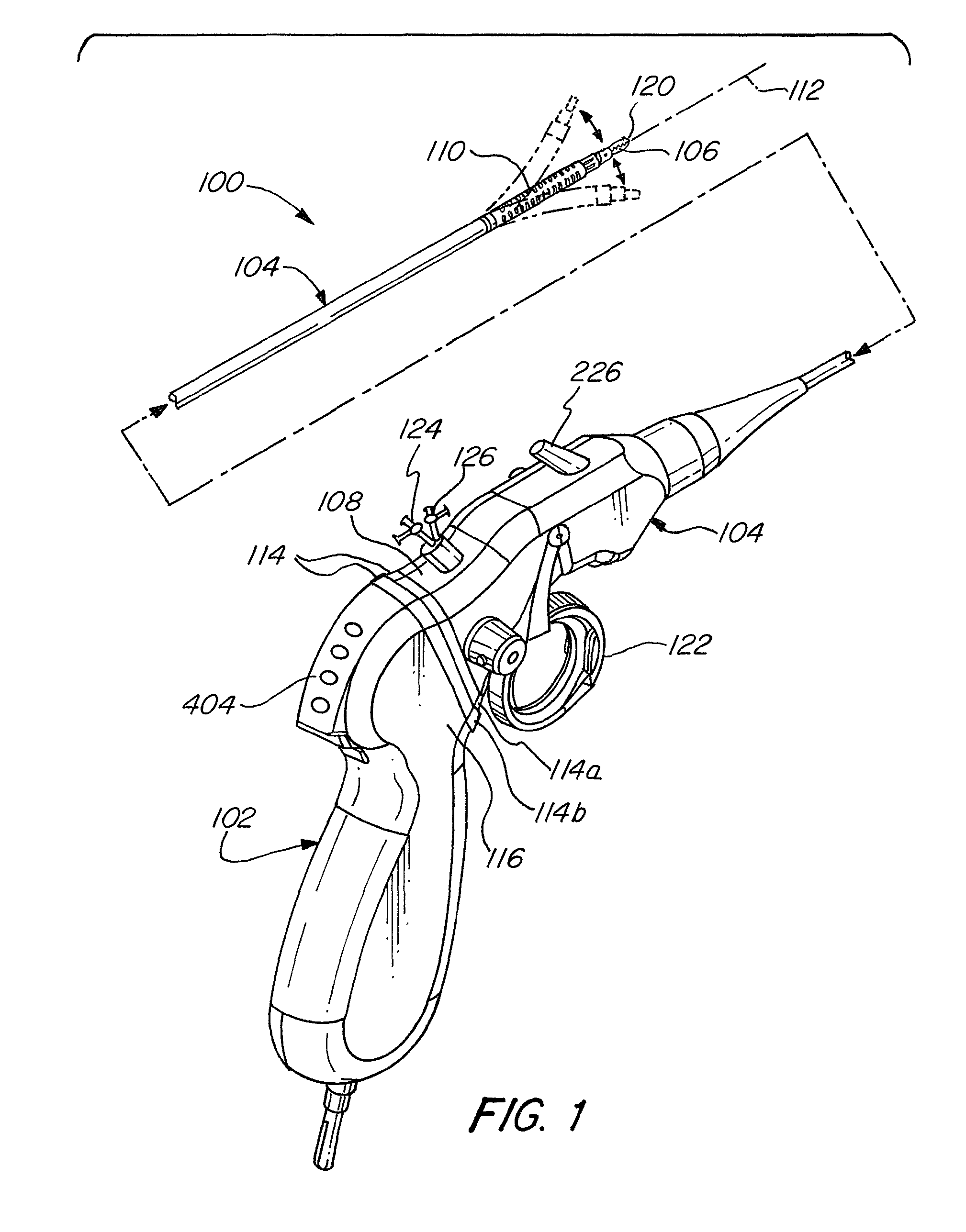

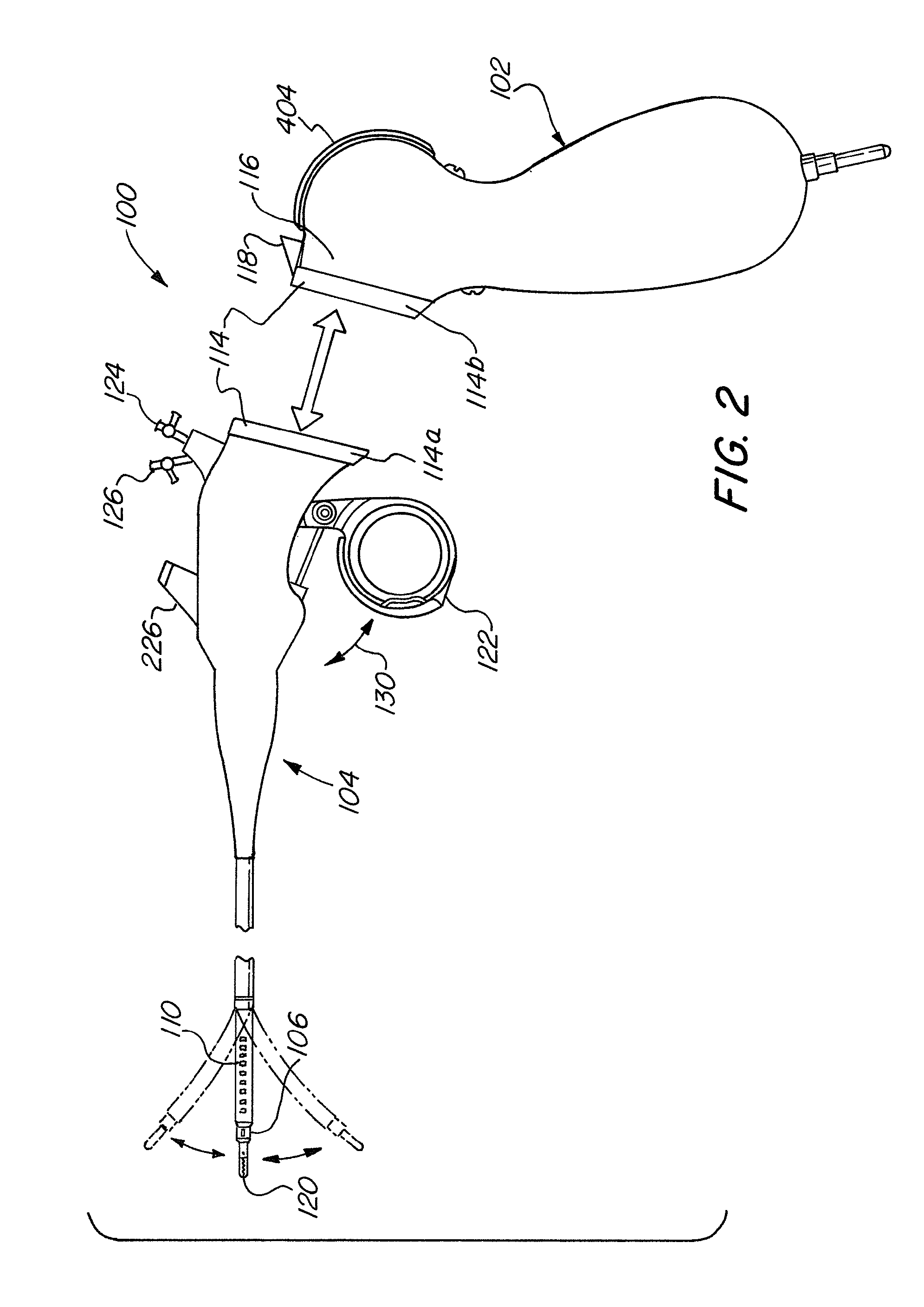

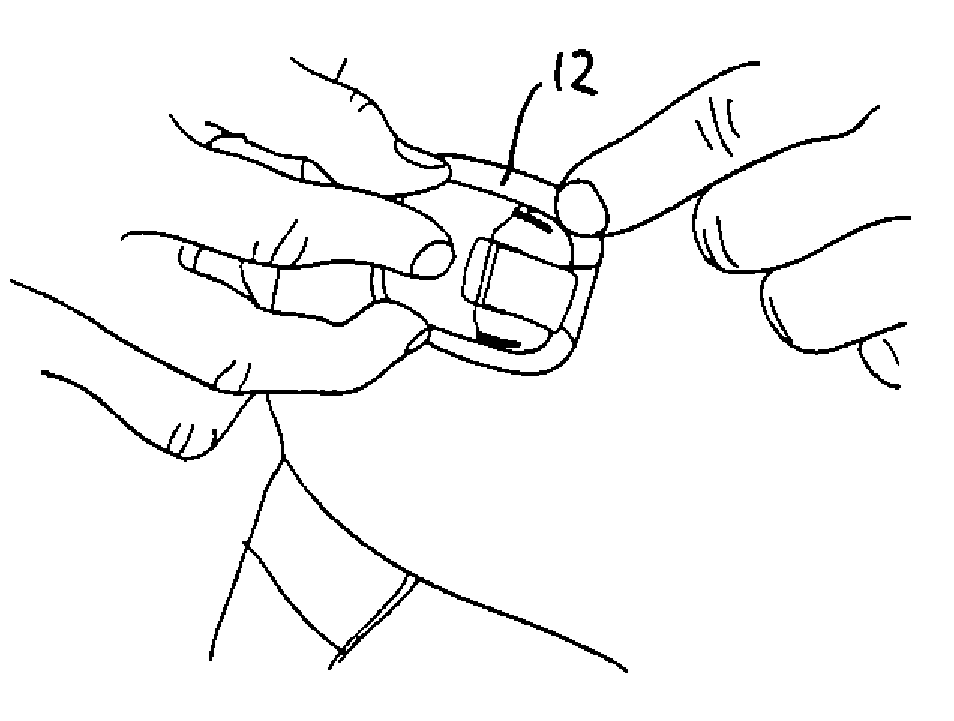

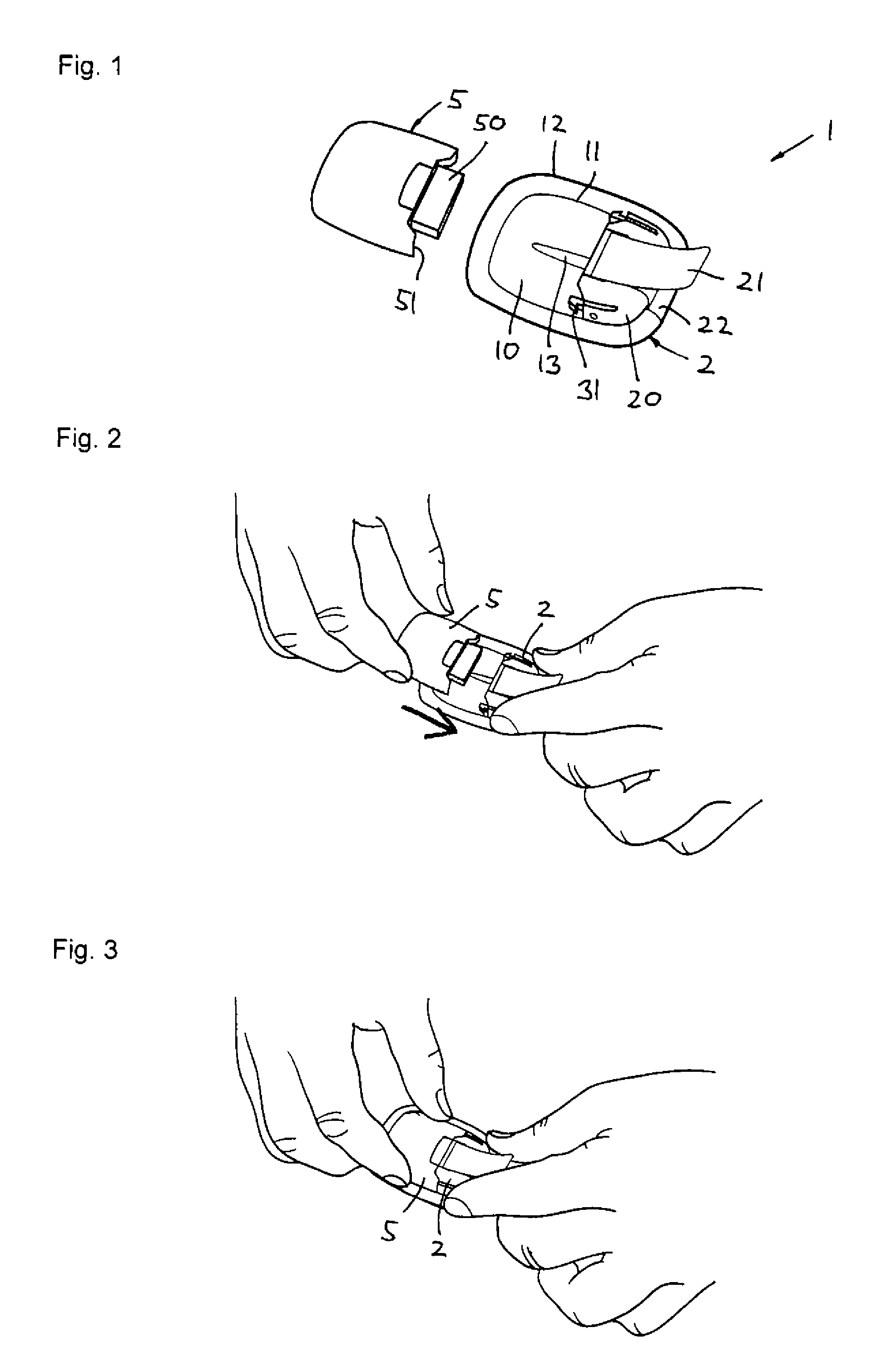

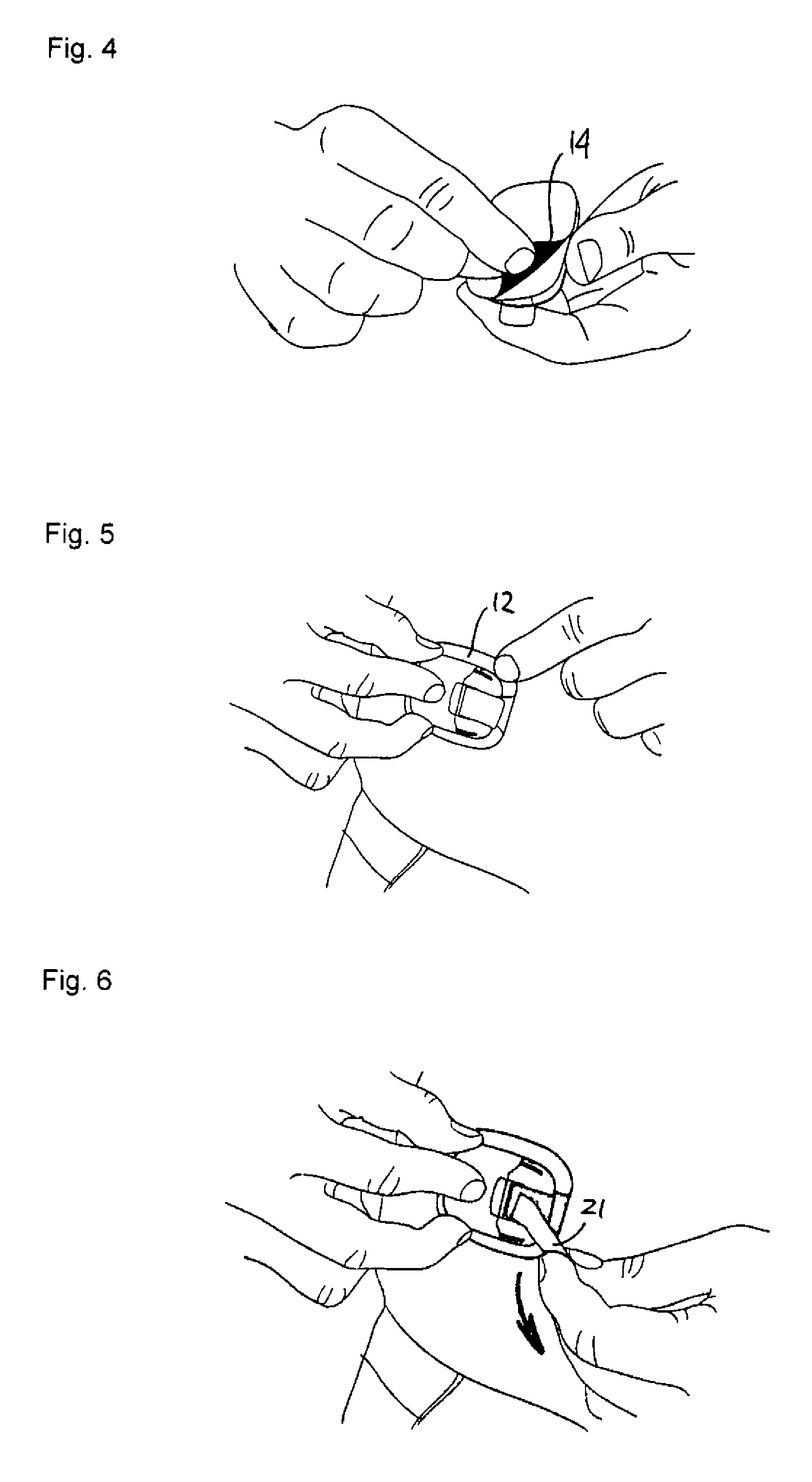

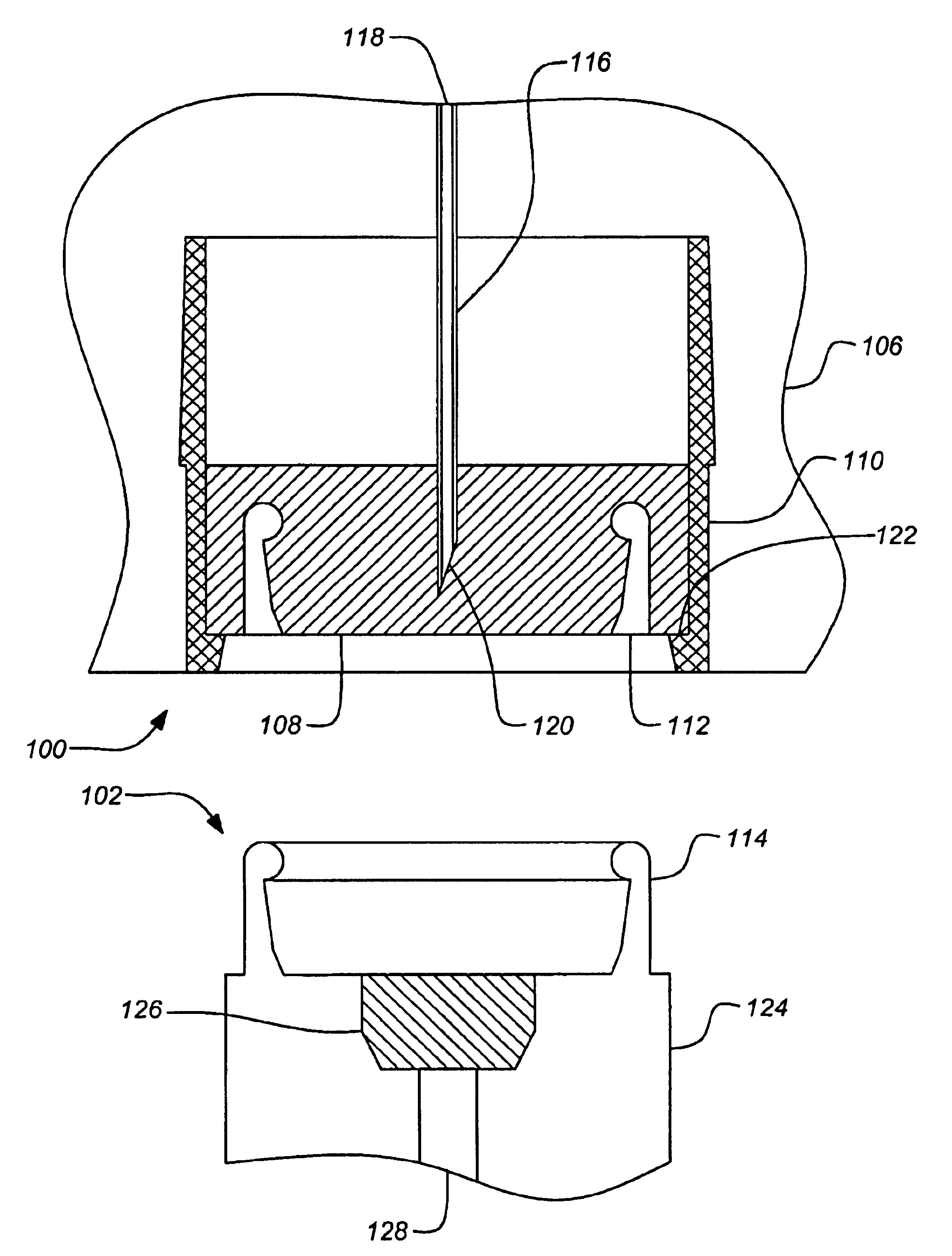

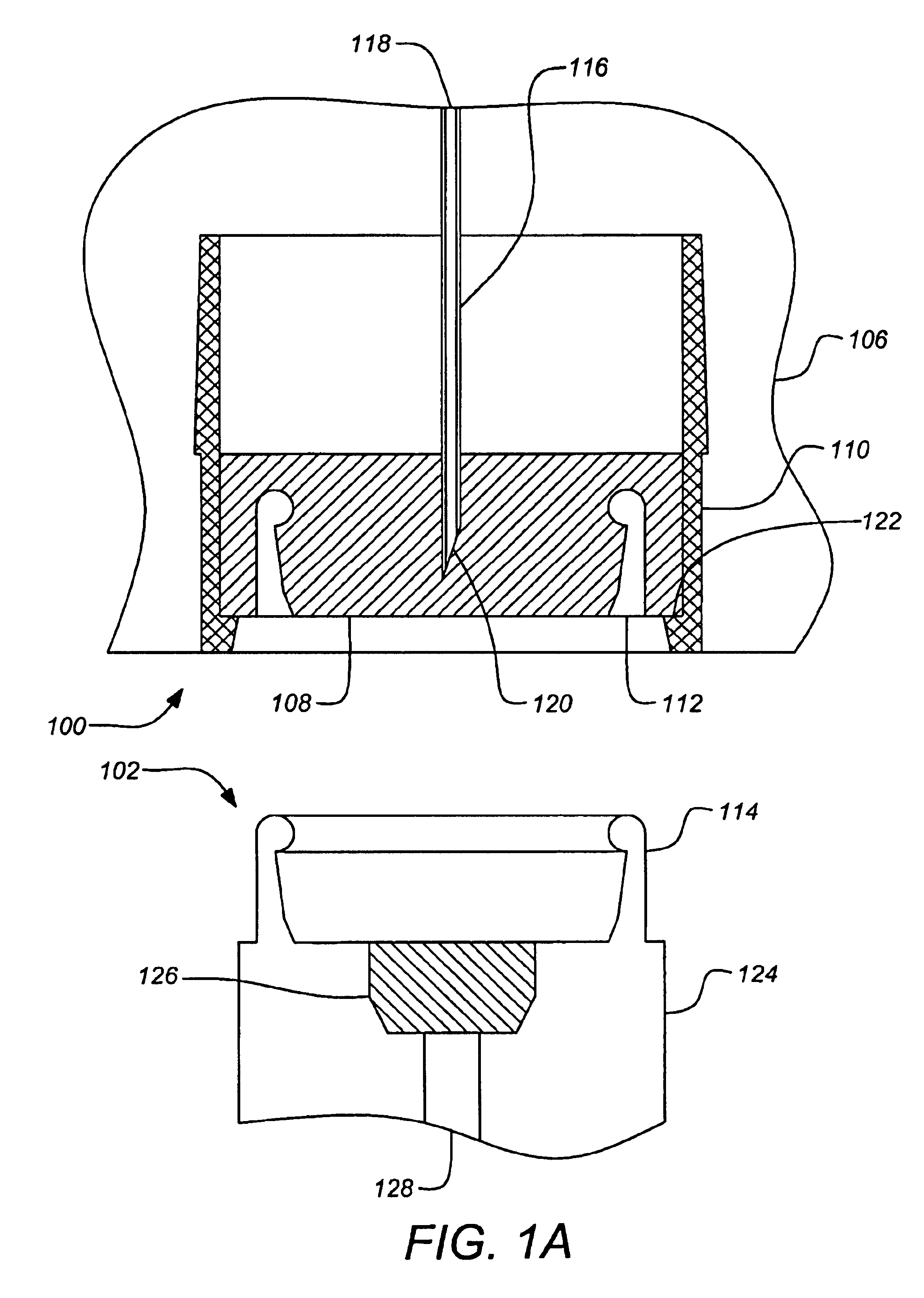

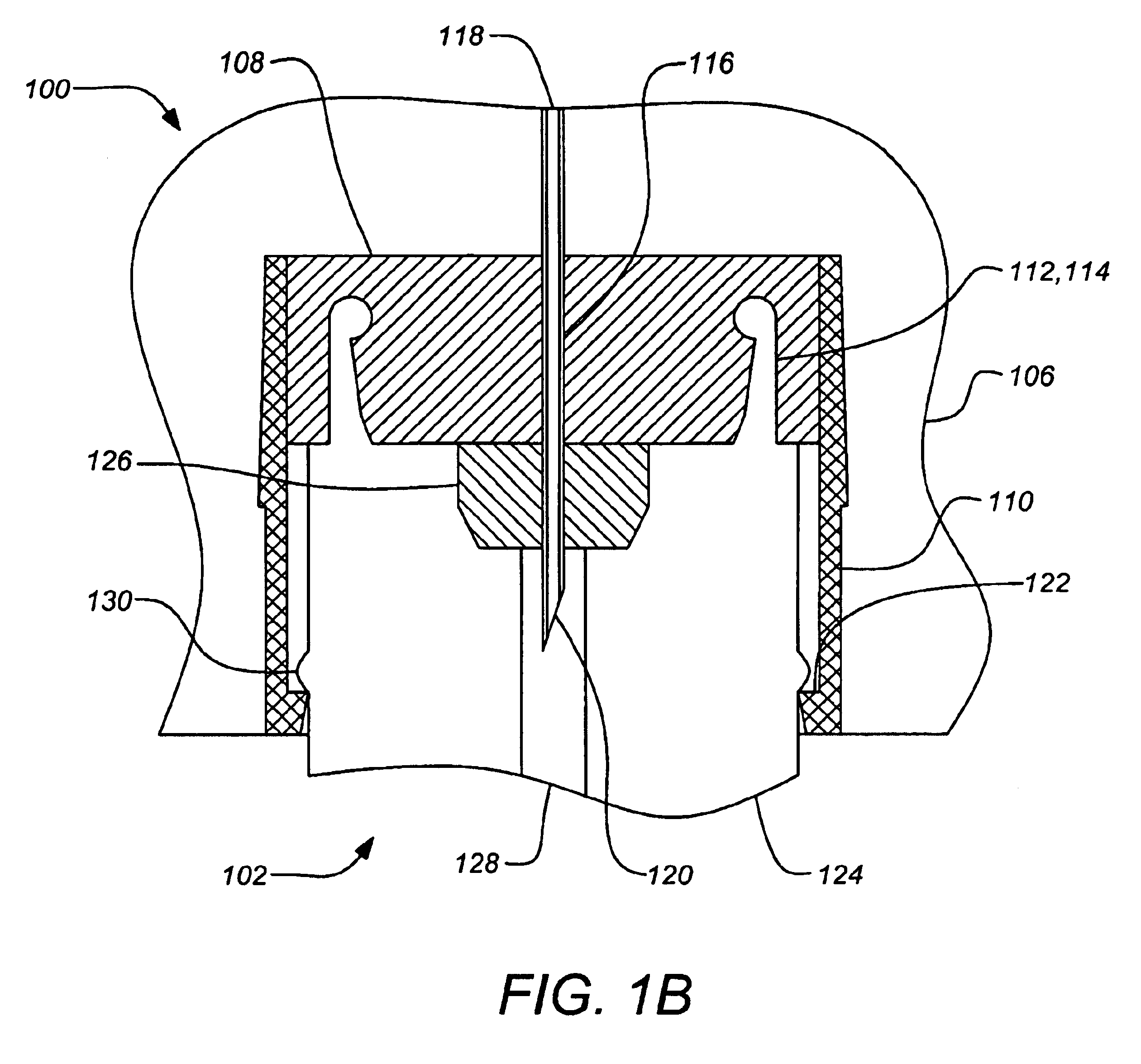

Assemblies for coupling intraosseous (IO) devices to powered drivers

ActiveUS8944069B2Easy to useDirect contact guaranteeSurgical furnitureSurgical needlesMultiple useBone marrow aspiration procedure

Medical devices, medical procedure trays, kits and related methods are provided for use to perform medical procedures that require access to the interior of a bone. The devices, trays and methods allow multiple use of non-sterile medical devices with sterile medical devices for performing medical procedures requiring sterile conditions. A coupler assembly, capable of releasably attaching to a non-sterile medical device at one end and releasably attaching to one or more sterile medical devices at another end, and further comprising a containment bag which allows maintaining sterility of a non-sterile medical device which may be used in conjunction with sterile medical devices and procedures. The devices, trays, kits and methods enable the performance of multiple medical procedures with a single insertion into bone. For example, a vertebral procedure such as a vertebroplasty may be performed along with biopsy and / or bone marrow aspiration procedures, thereby reducing patient trauma and costs.

Owner:TELEFLEX LIFE SCI LTD

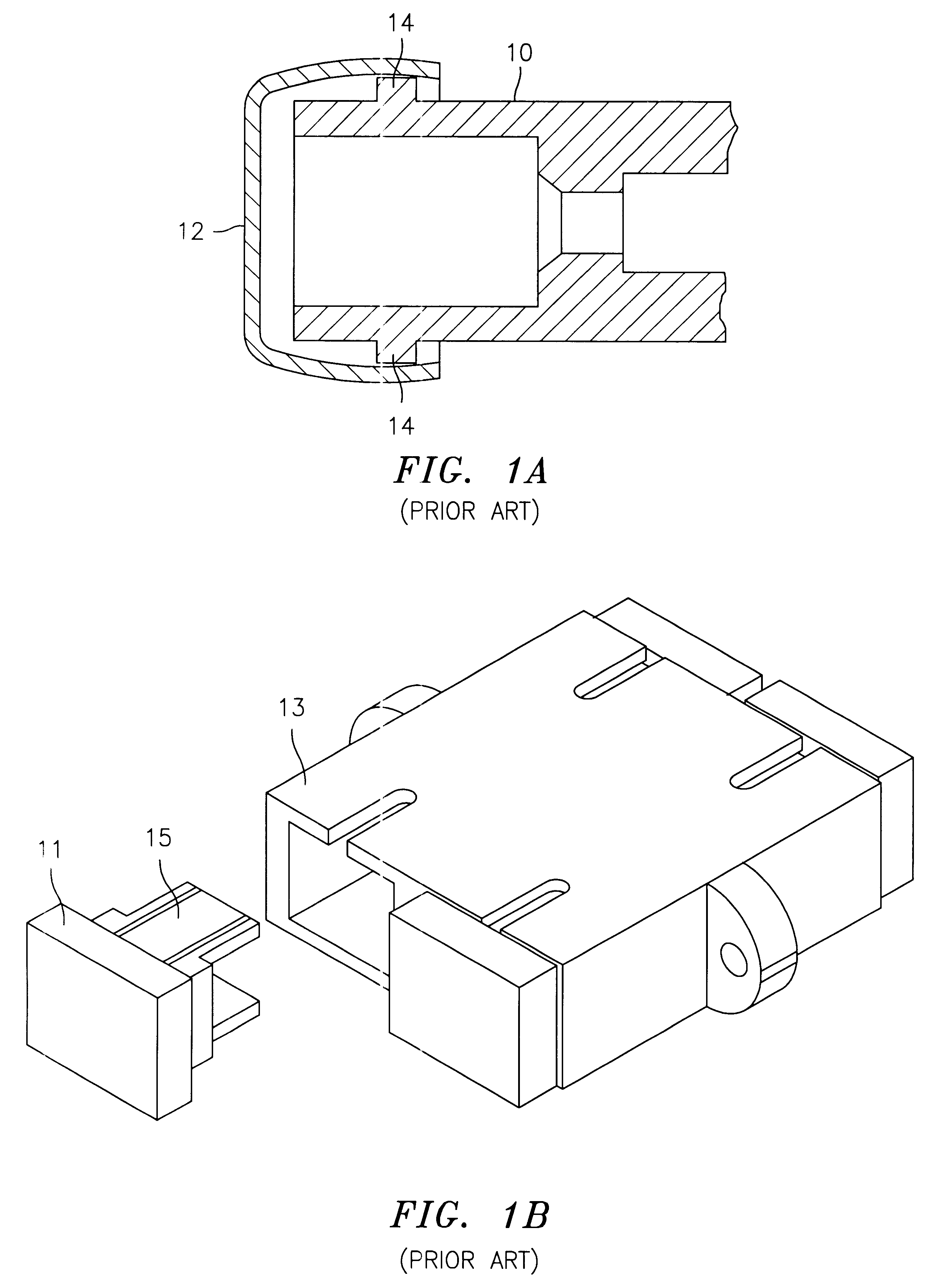

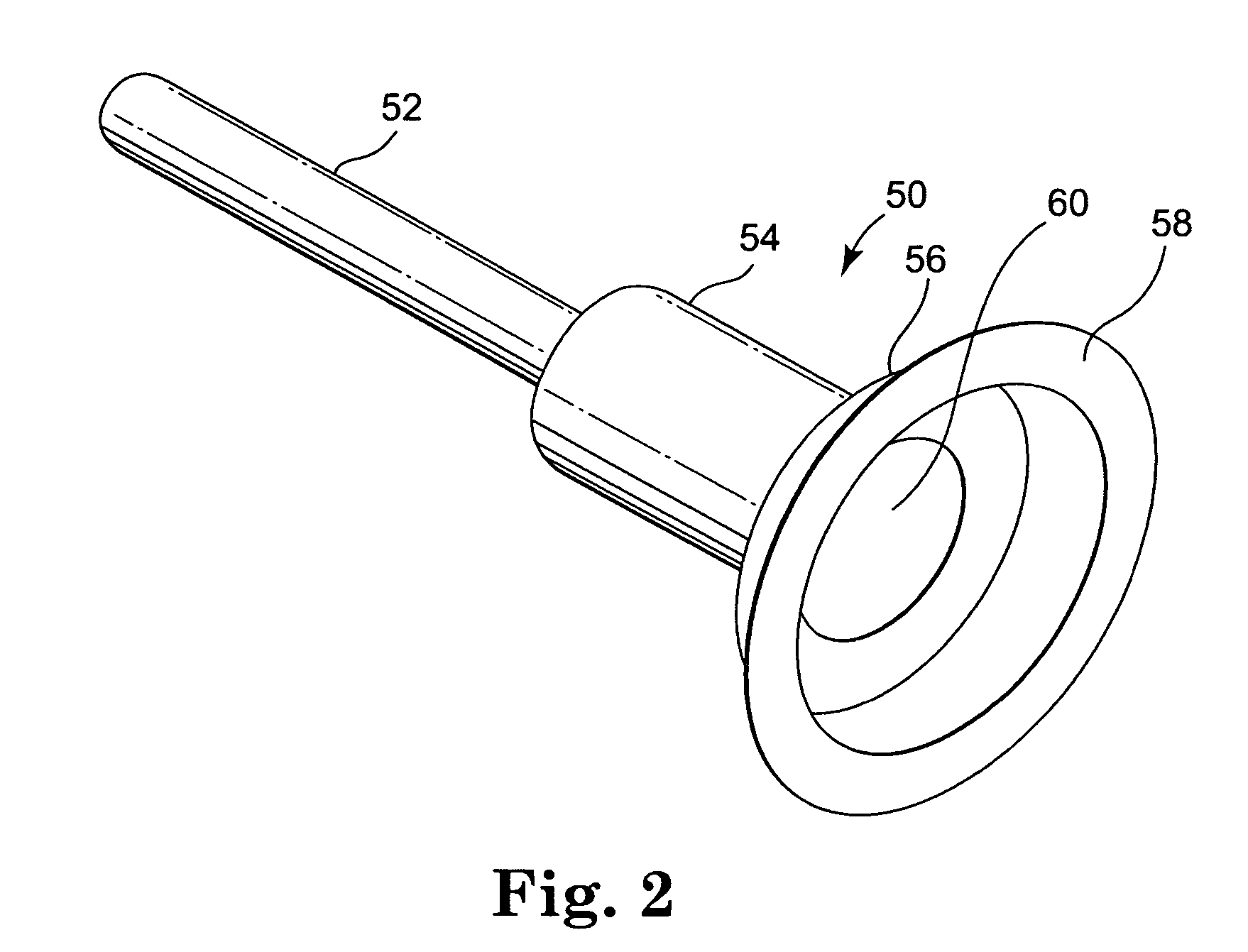

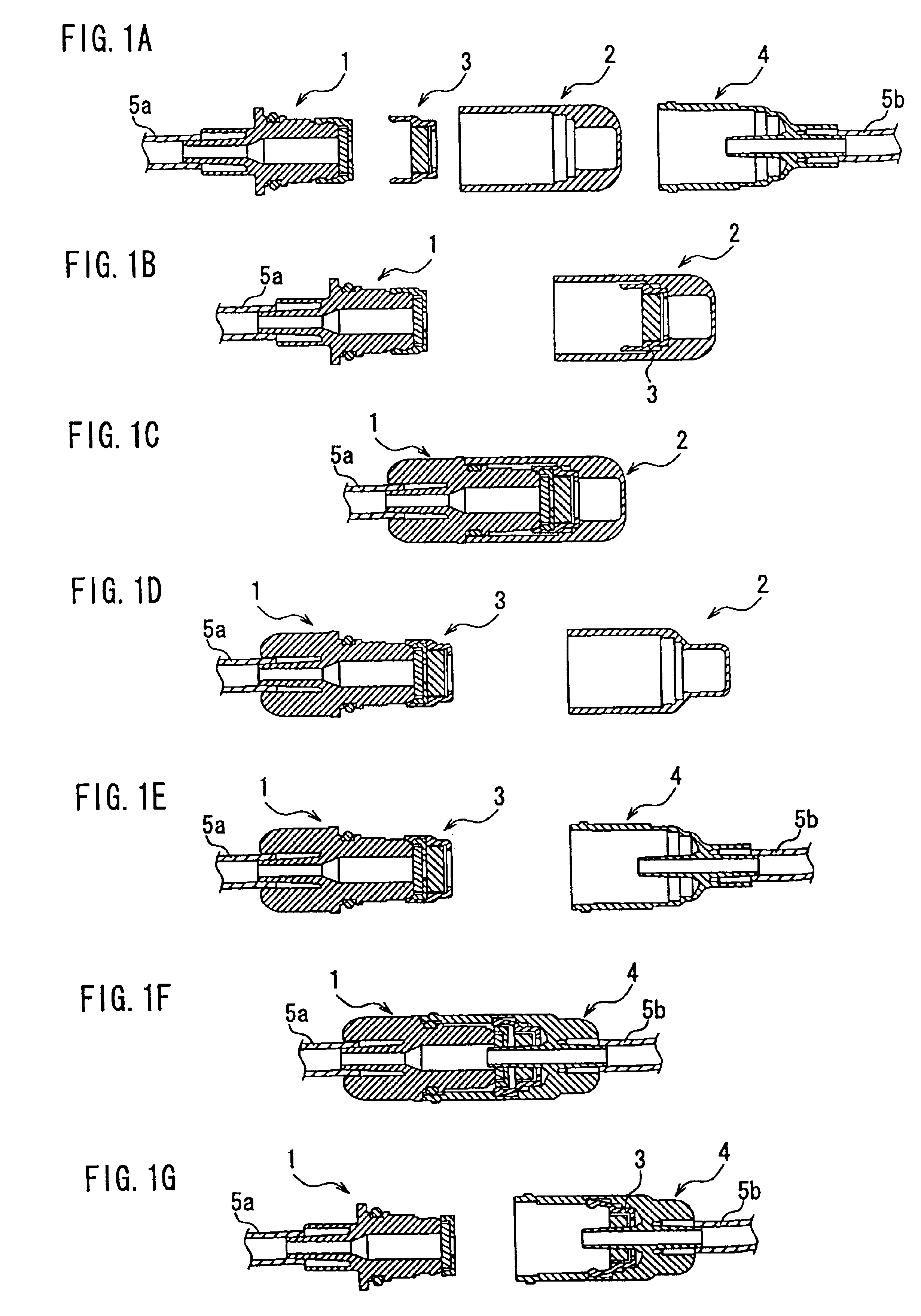

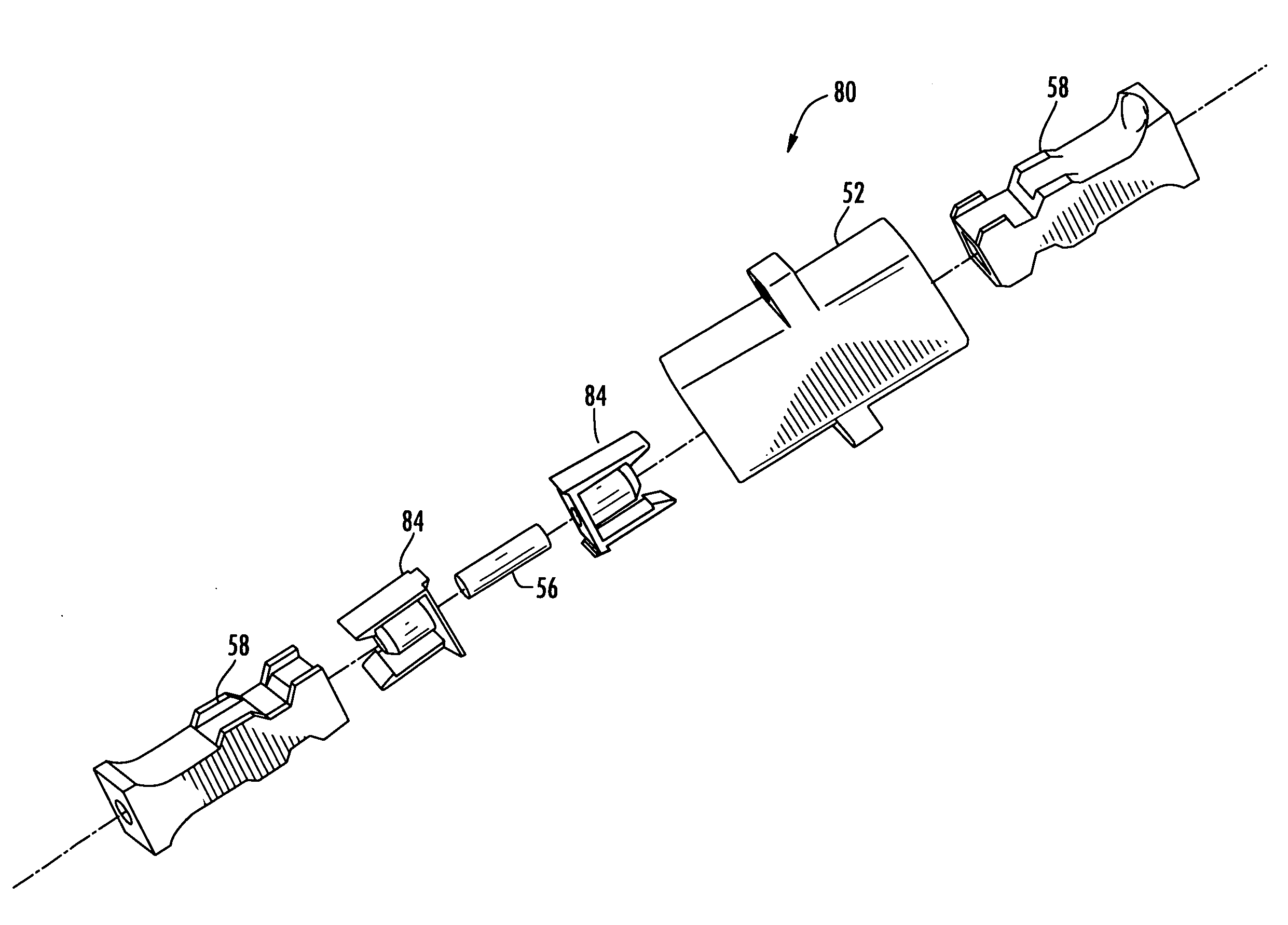

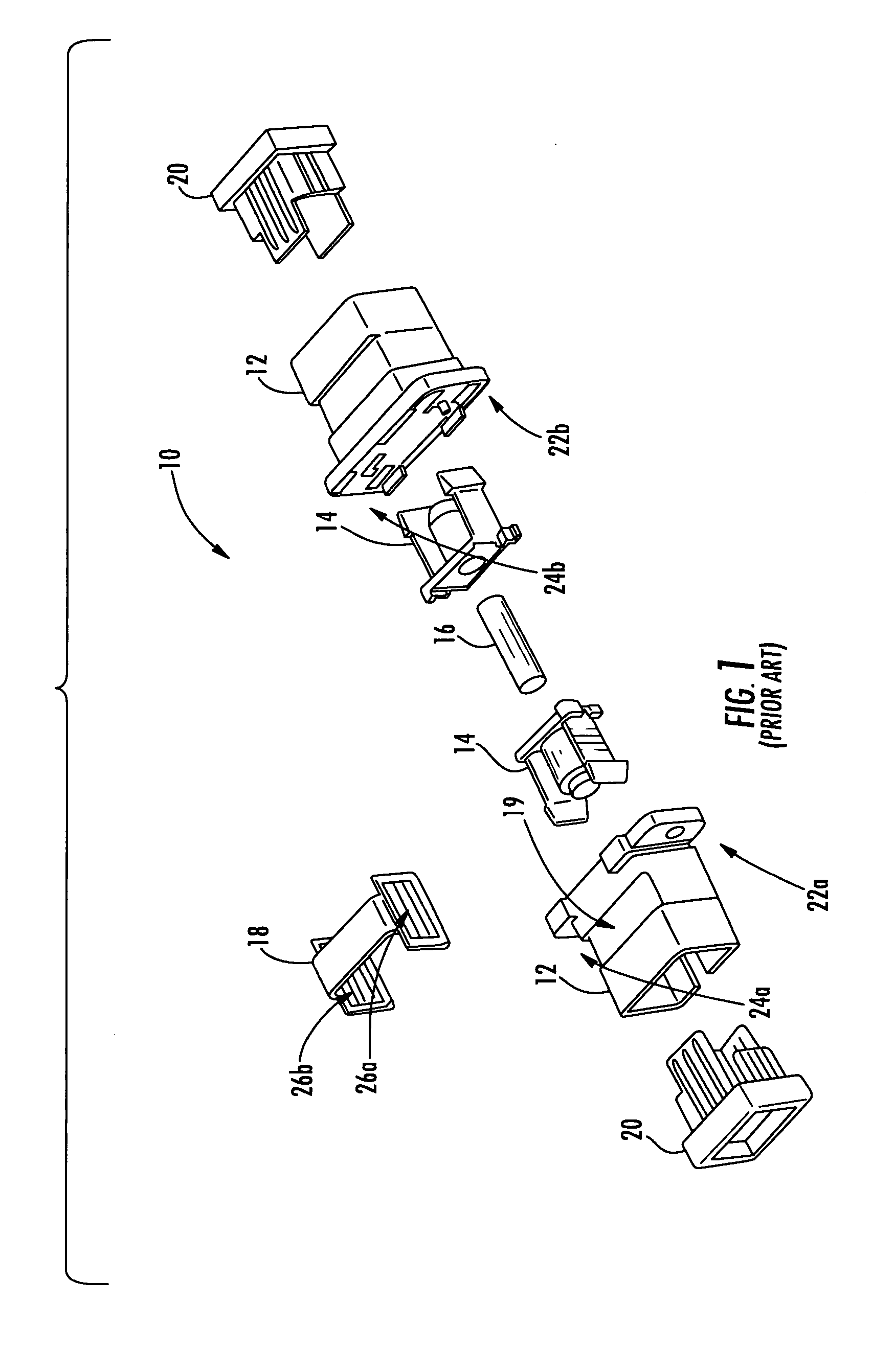

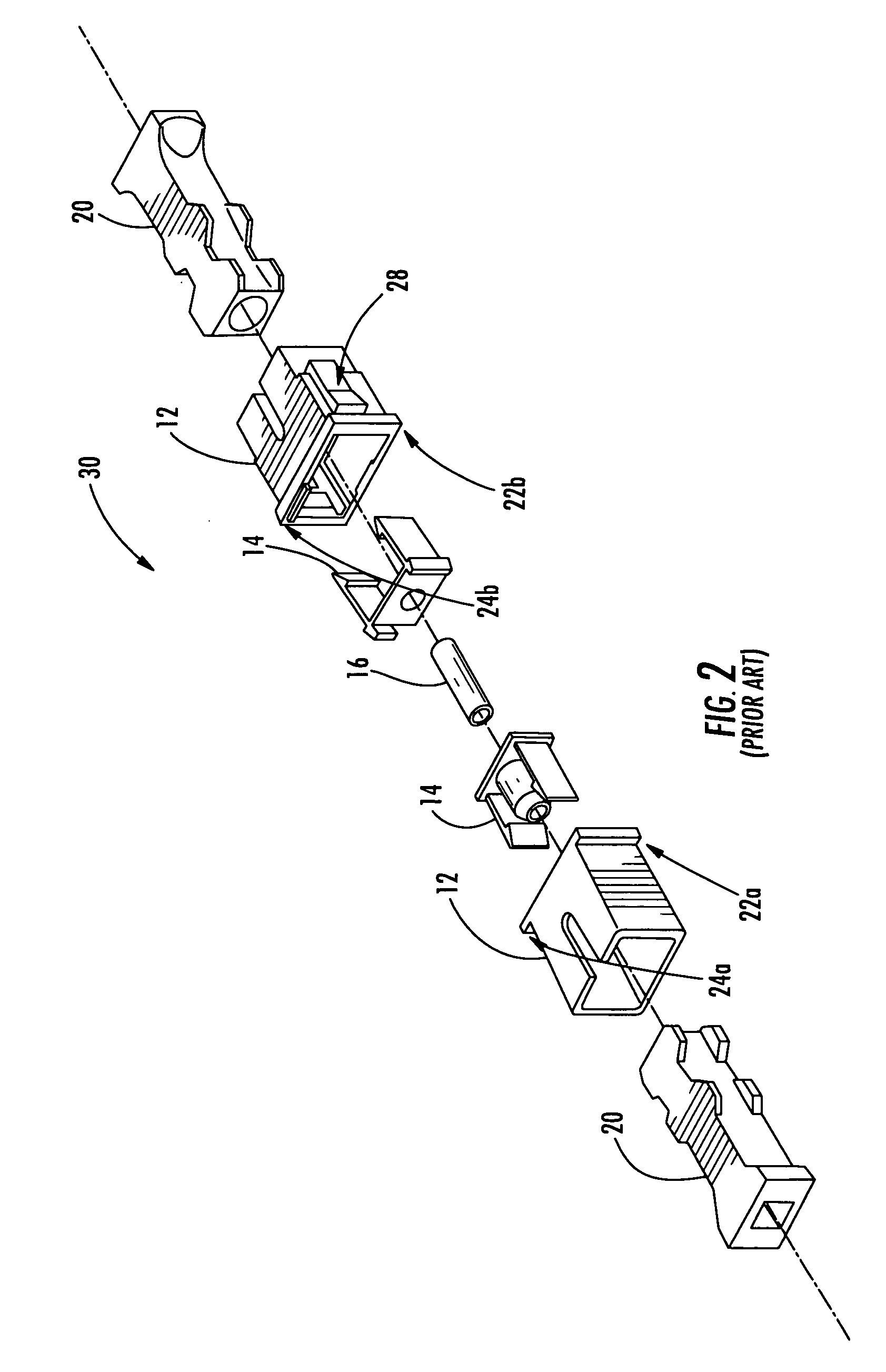

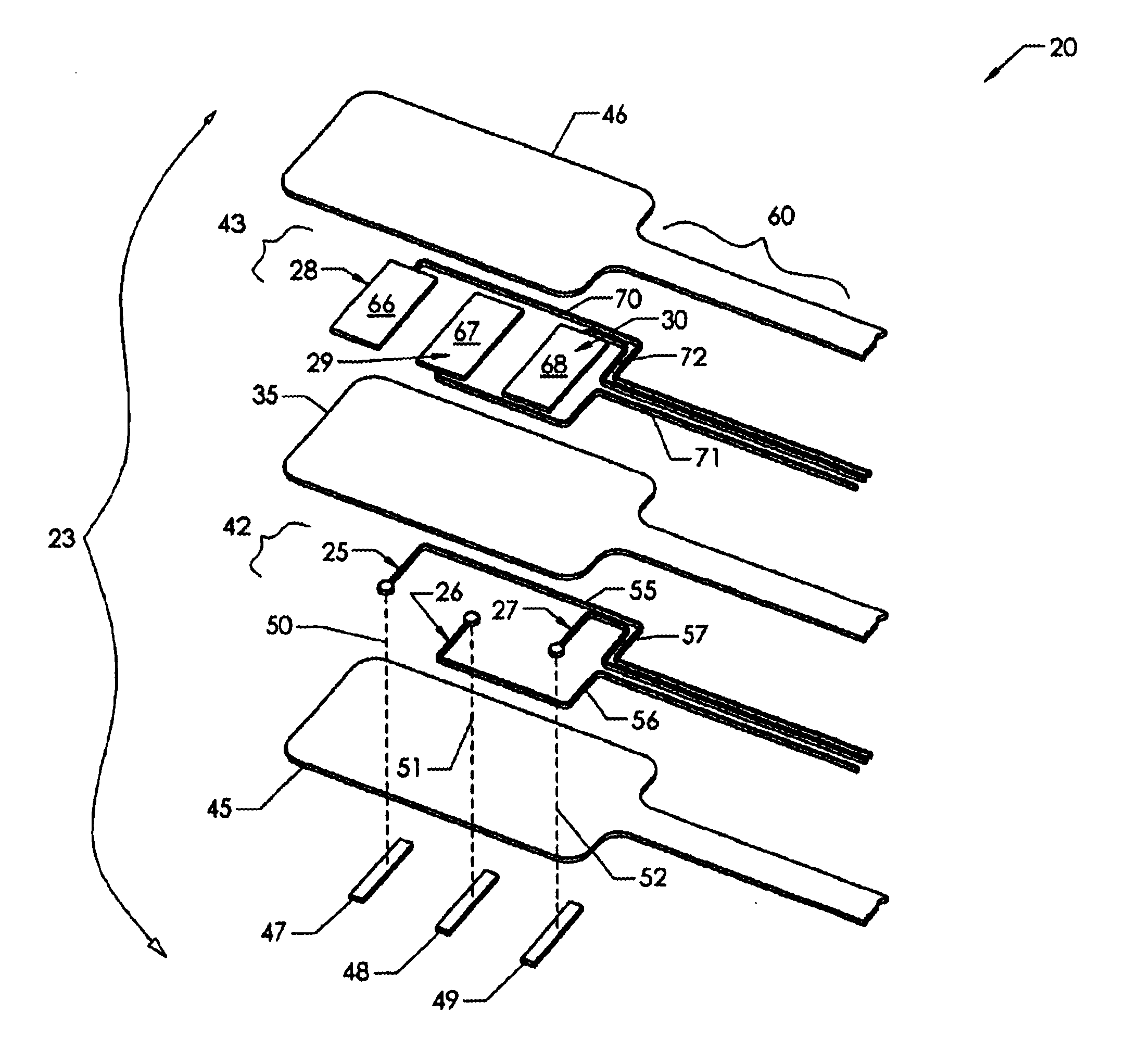

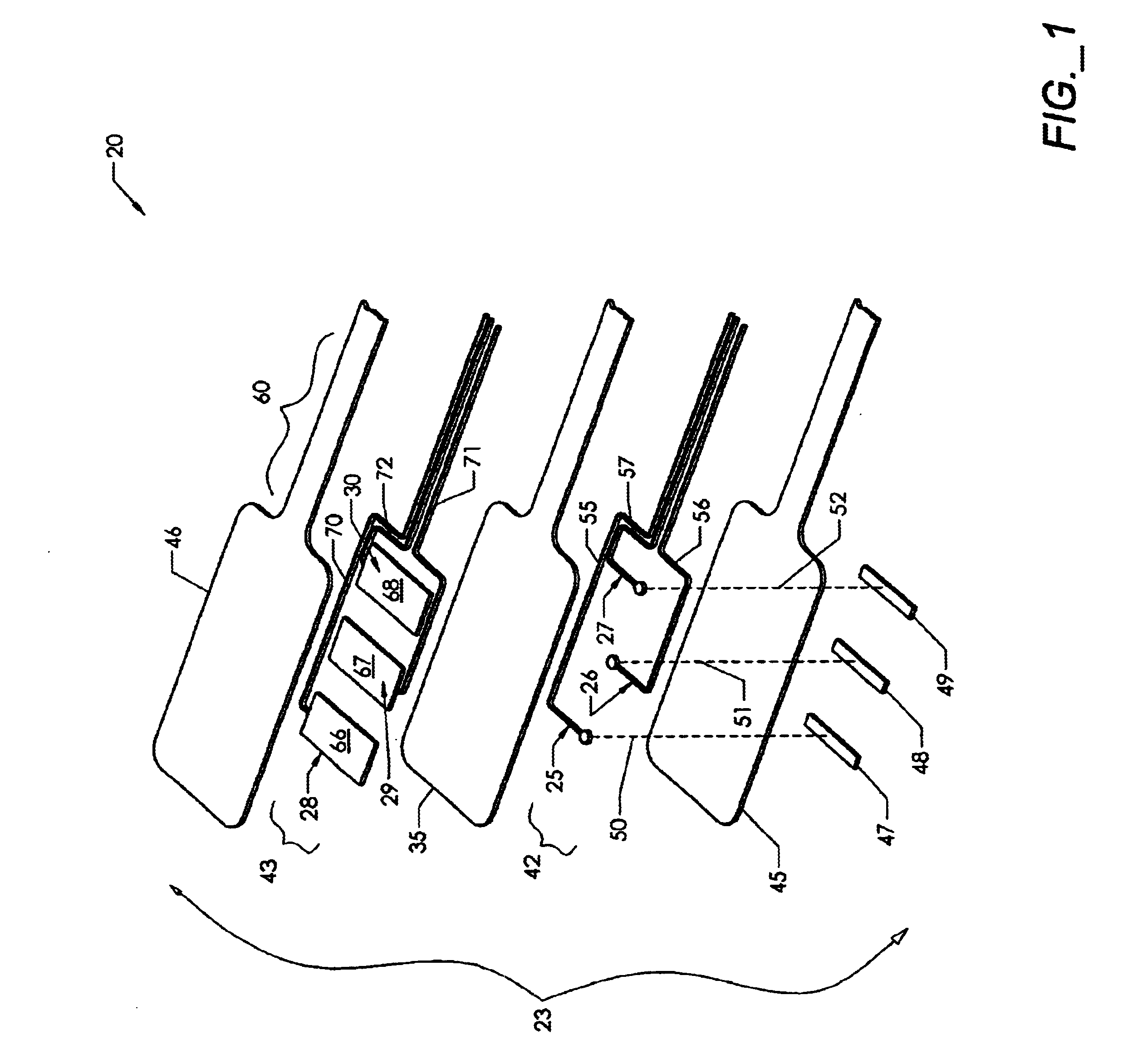

Dust caps for use with telecommunications adapters and connectors

InactiveUS6227717B1Avoid pollutionReduce the overall diameterCoupling device detailsCoupling light guidesEngineeringMechanical engineering

Dust caps for use with multiple optical fiber adapters and connectors. A first embodiment of the invention is a dust cap for use with ST adapters, ST connectors and SC connectors. The dust cap includes a sealing surface for contacting the bottom of an ST adapter for sealing the portion of the adapter containing the alignment sleeve. The dust cap also includes an opening having a reduced diameter to prevent contamination of the tip of the ferrule of an ST or SC connector. The dust cap may be formed in a duplex fashion and include a retaining strap for securing the dust cap to an ST adapter. An alternative embodiment of the invention is a dust cap having a first side for mating with either an SC or ST adapter and a second side for mating with either an SC or ST connector.

Owner:SIEMON

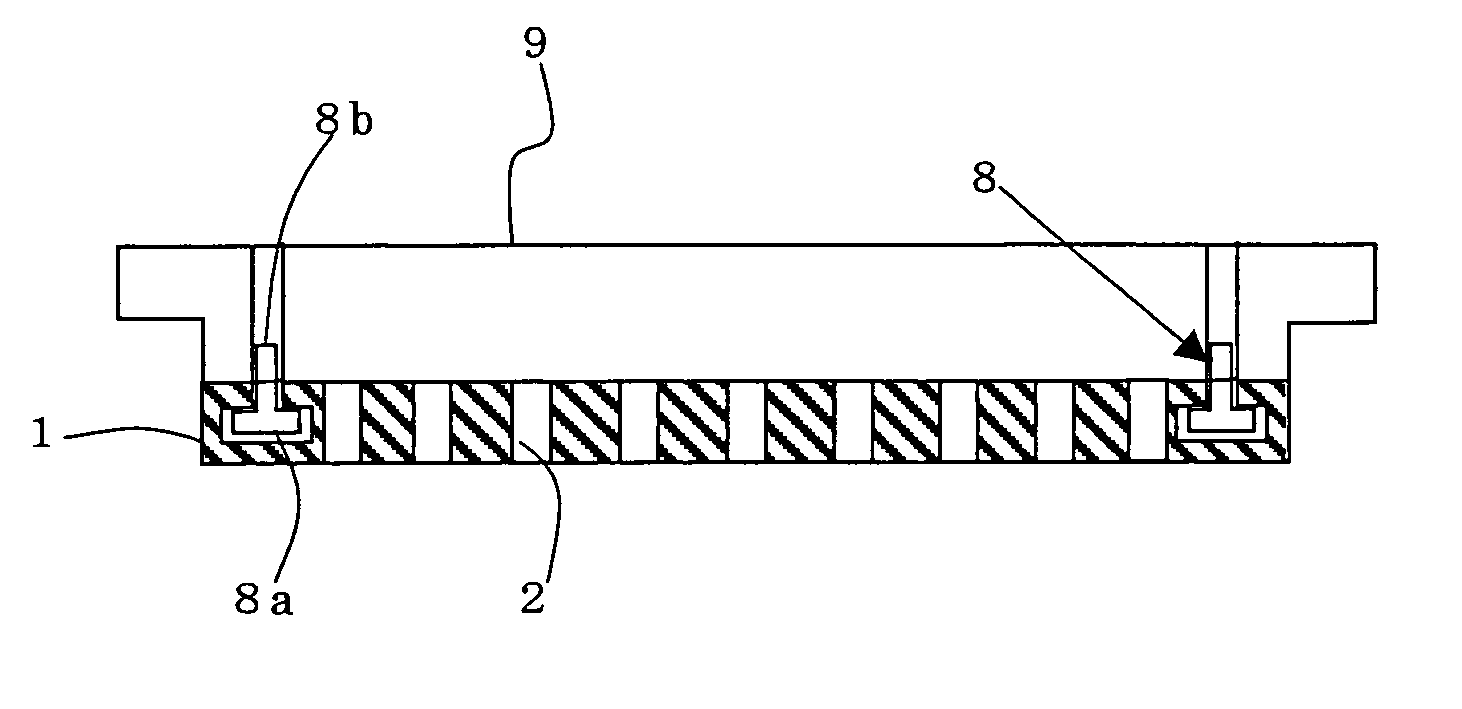

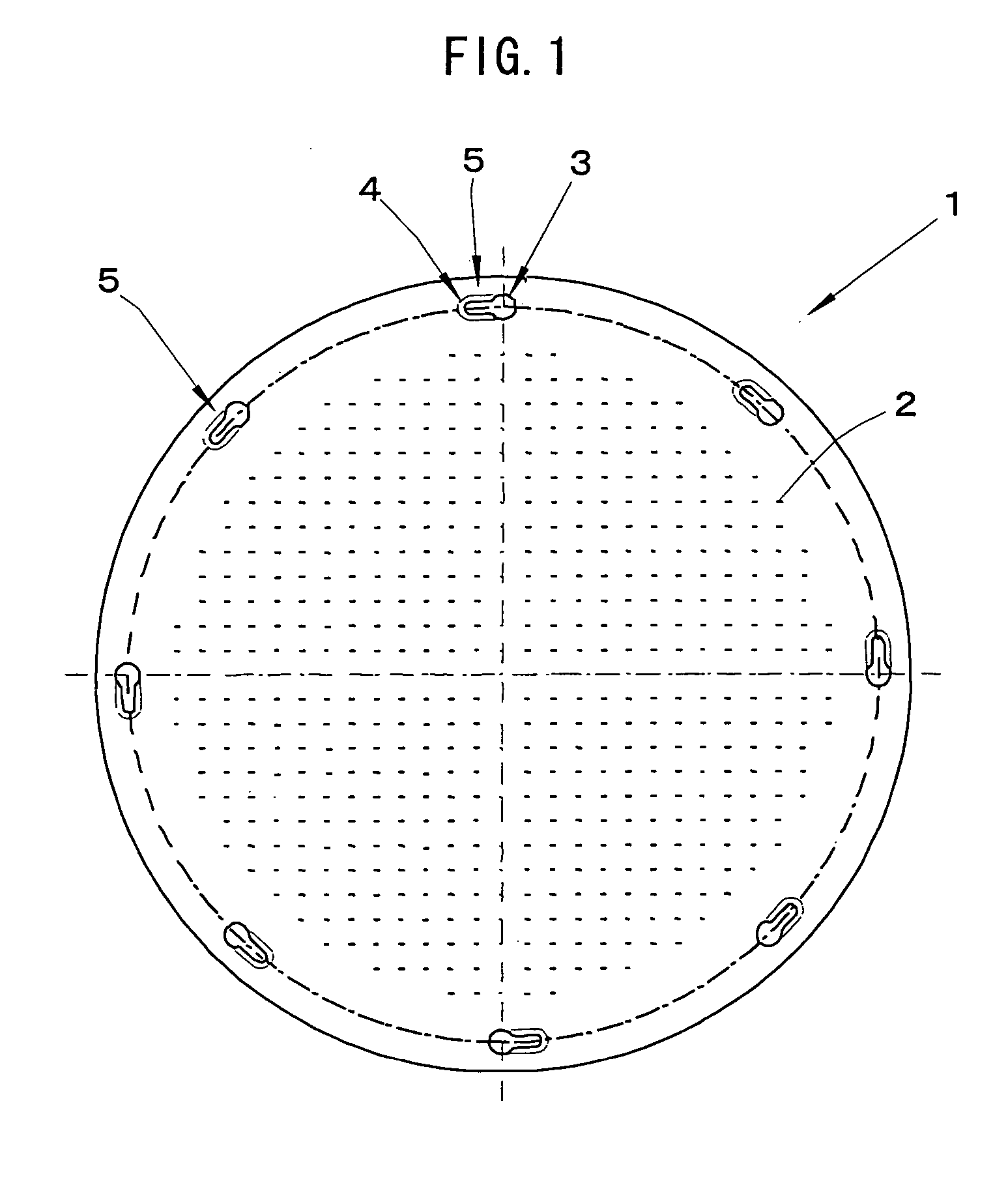

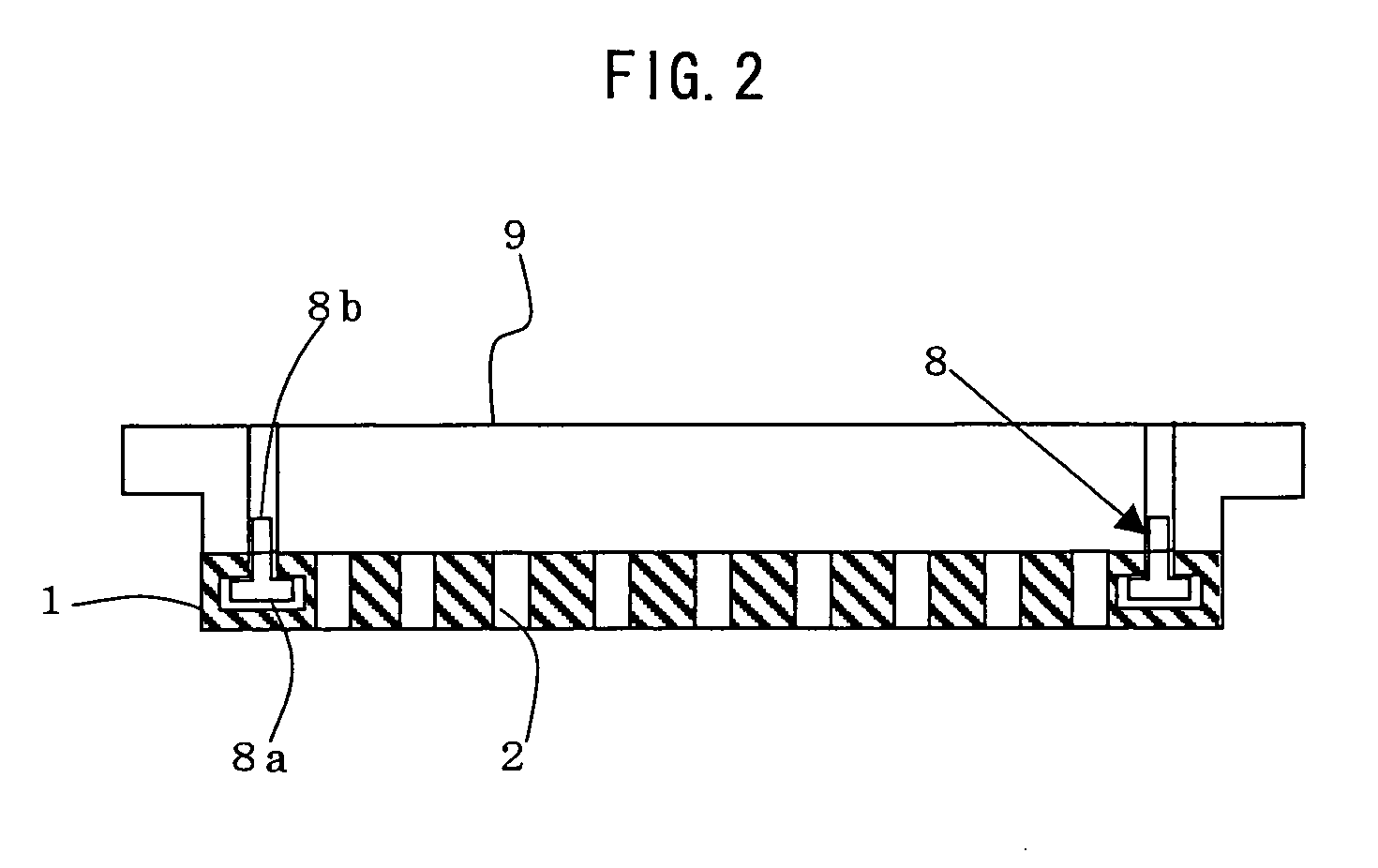

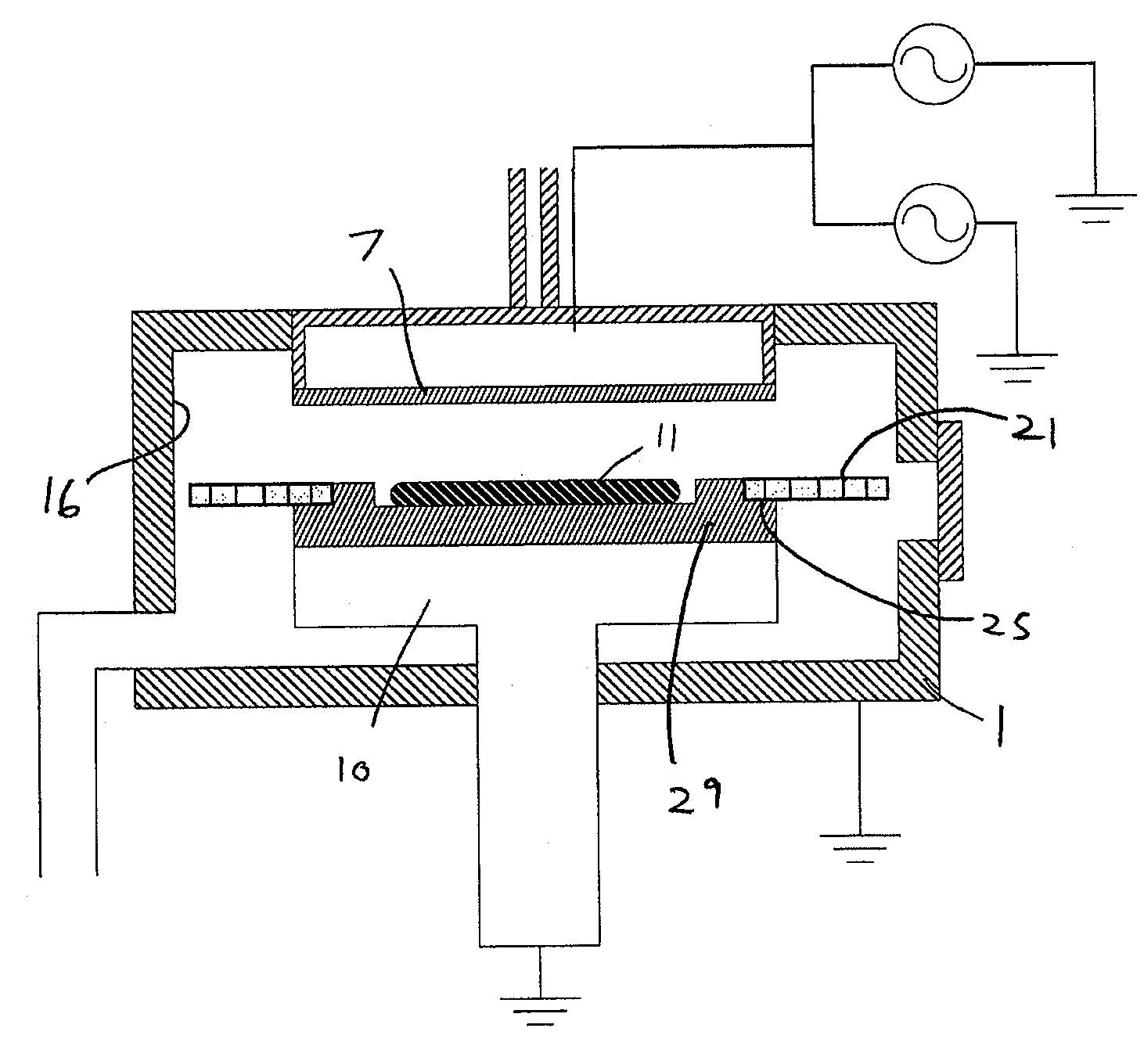

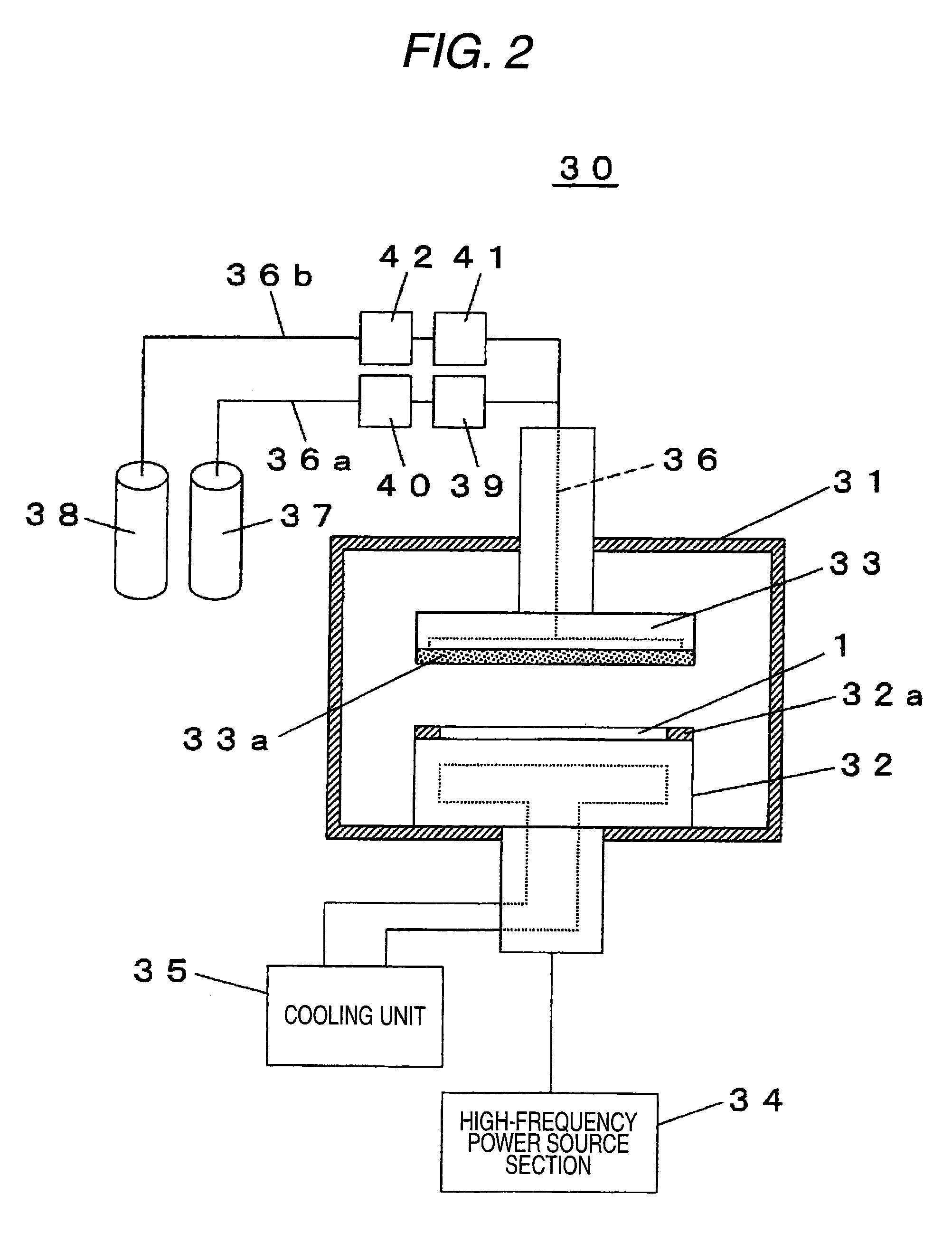

Shower plate for plasma processing apparatus and plasma processing apparatus

InactiveUS20050258280A1Easy to manufactureAvoid pollutionElectric discharge tubesMovable spraying apparatusEngineeringContamination

There is disclosed a shower plate 1, wherein the shower plate has a plurality of holes 3 for inserting the head of the fastening member and holes 4 for fitting the head are formed integrally along a concentric circle in the outside region of the gas feeding holes 2 on a side facing the supporting member, each hole for fitting extending in one direction of the concentric circle from each hole for insertion, each hole for fitting has a groove portion 4b through which the shank of the fastening member is to pass and a fitting portion 4a which is wider than the groove portion and in which the head of the fastening member is to be fitted, and the head of the fastening member fixed in the supporting member is inserted into the hole for insertion of the shower plate and the shower plate is turned so that the head of the fastening member is fitted in the fitting portion, and thereby the shower plate is supported by the supporting member without exposure of the fastening member. There can be provided a shower plate for a plasma processing apparatus, wherein effective diameter is large enough, contamination of a substrate to be treated can be prevented, it is easy to manufacture, and it is easy to fix to a supporting member.

Owner:SHIN ETSU CHEM IND CO LTD

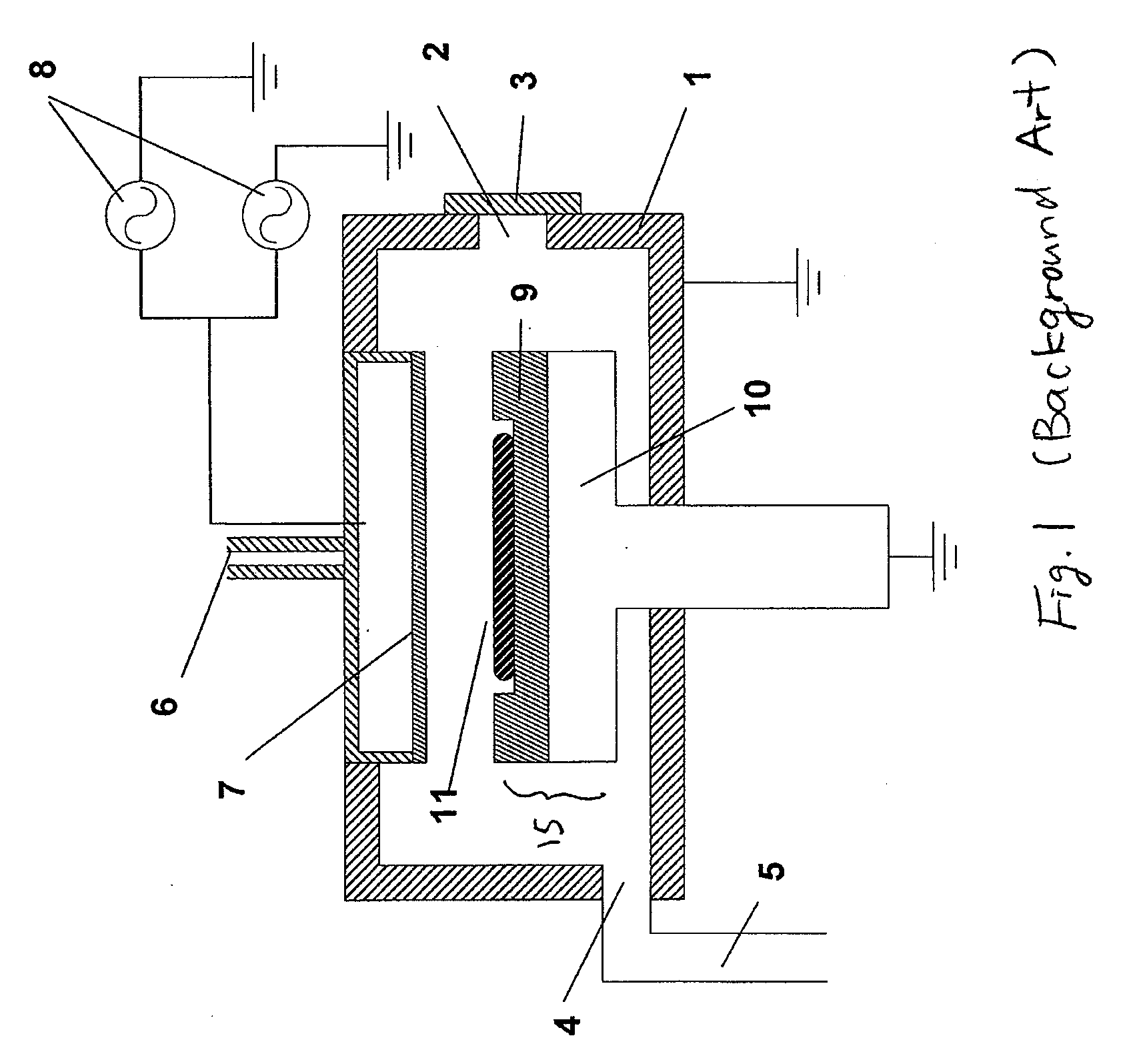

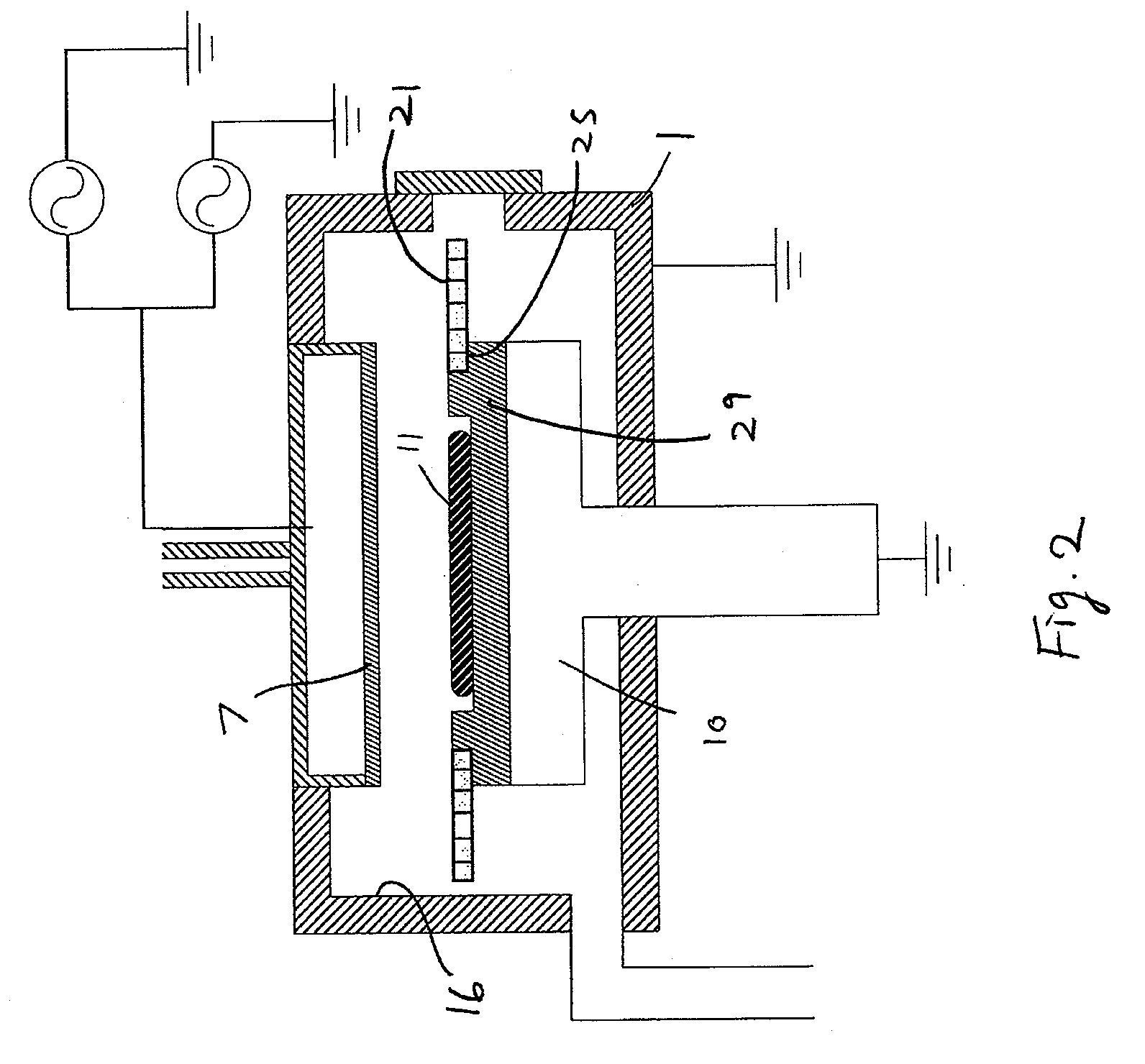

Plasma CVD apparatus equipped with plasma blocking insulation plate

InactiveUS20070266945A1Floating potentialControl areaElectric discharge tubesChemical vapor deposition coatingSusceptorEngineering

A plasma CVD apparatus for forming a thin film on a substrate includes: a vacuum chamber; an upper electrode; a susceptor as a lower electrode; and a ring-shaped insulation plate disposed in a gap between the susceptor and an inner wall of the chamber in the vicinity of or in contact with the susceptor to minimize a floating potential charged on the substrate while processing the substrate.

Owner:ASM JAPAN

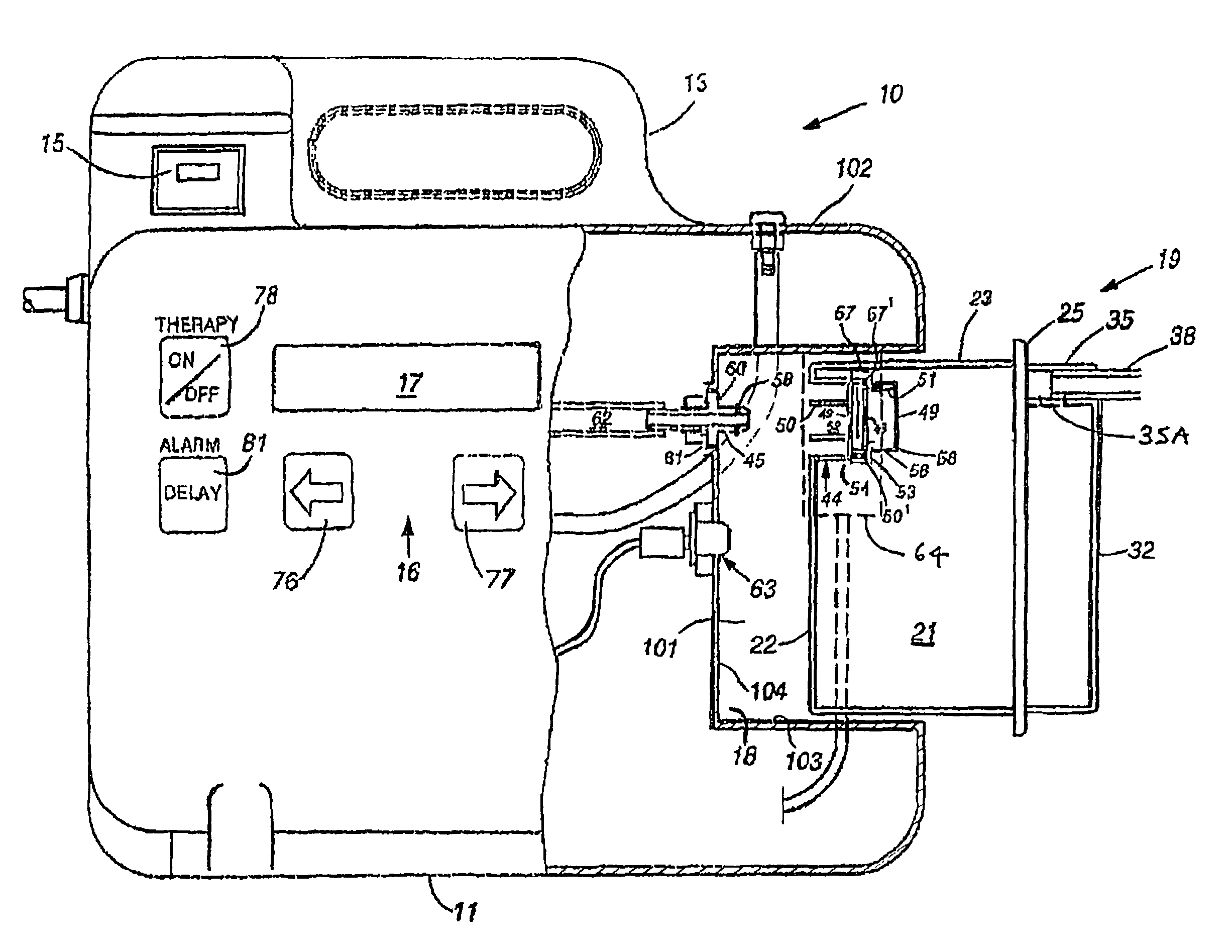

Wound therapy device and related methods

A wound closure apparatus is disclosed which includes a housing that contains a vacuum pump and a chamber for holding a disposable wound fluid collection canister. The canister resides within the chamber and connects at an outlet with the vacuum pump and at an inlet with a pad. The pad is placed over a wound and adhesively secured thereto. When the vacuum pump activates, it evacuates air from the canister resulting in wound fluids flowing from the wound into the canister. After the canister is filled, it is removed from the chamber and replaced with another canister to continue the removal of wound fluids.

Owner:KCI LICENSING INC

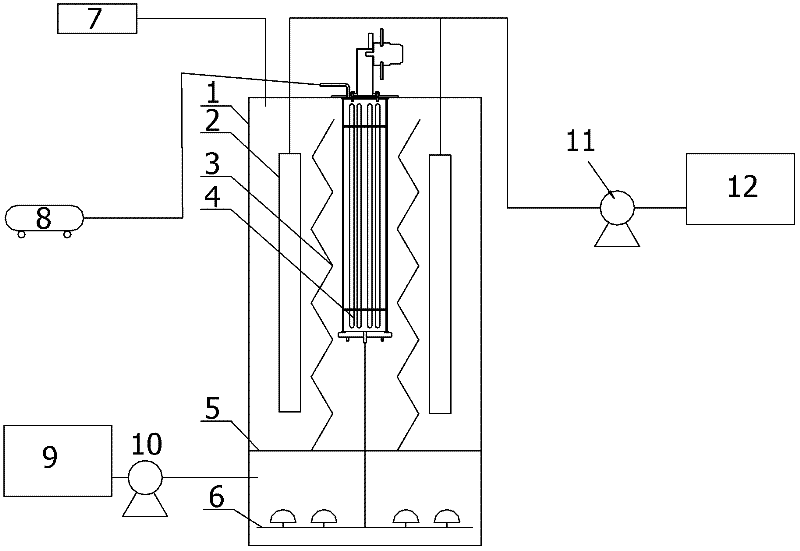

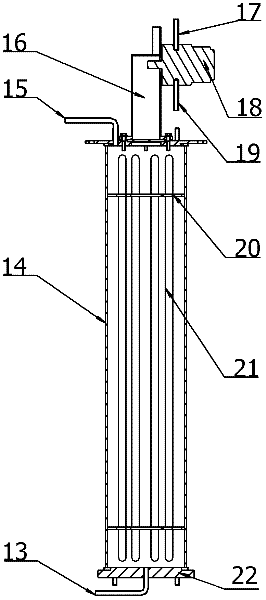

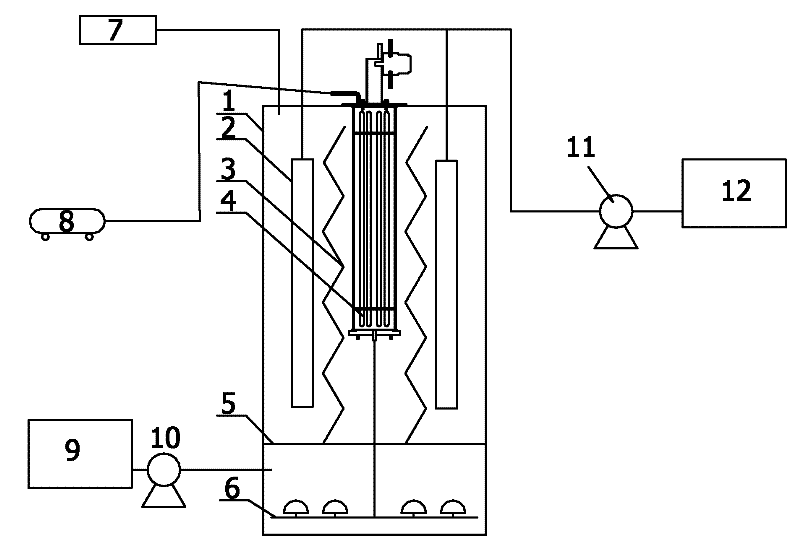

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

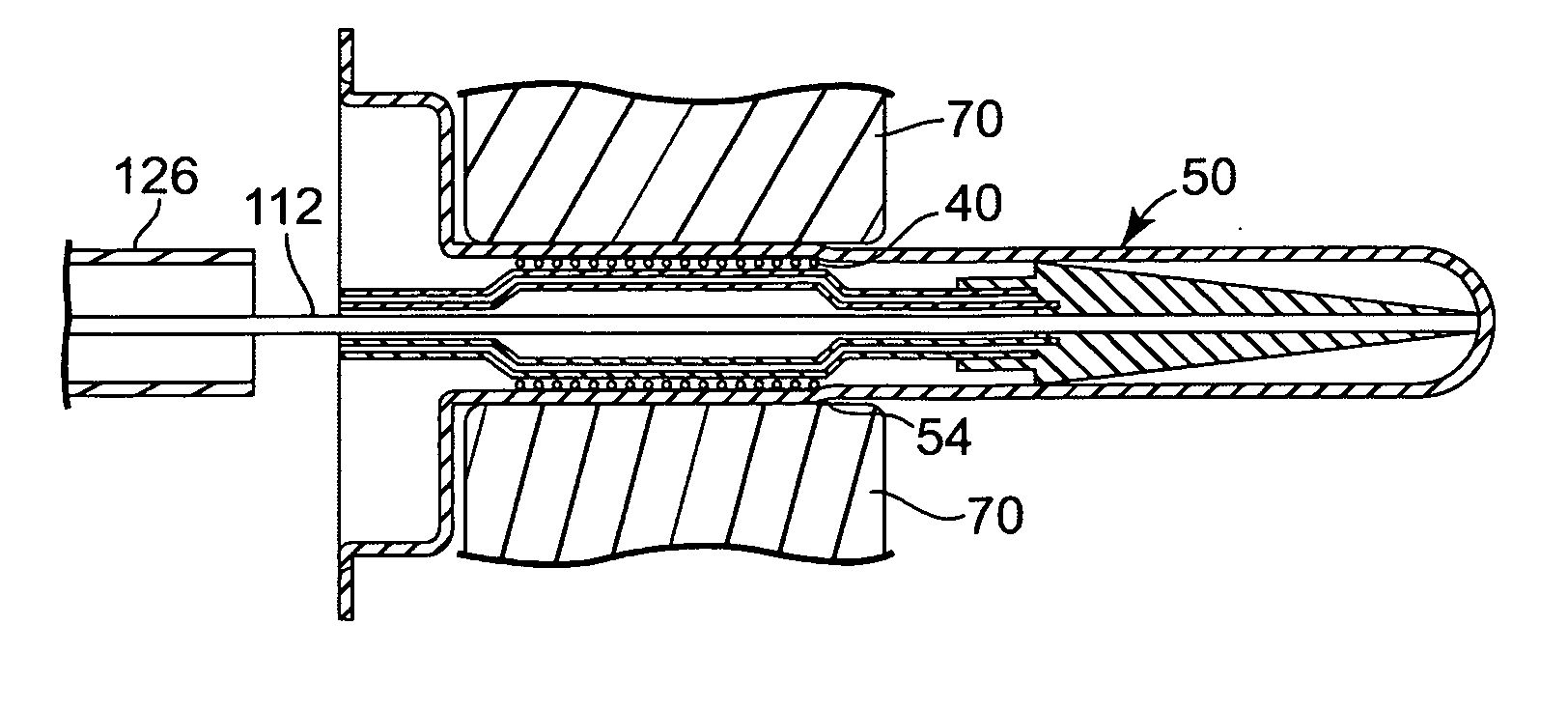

Sterile cover for compressible stents used in percutaneous device delivery systems

InactiveUS20070162102A1Avoid pollutionMinimize and eliminate contactStentsBlood vesselsInsertion stentDelivery system

A stent cover for enclosing a compressible stent during a stent crimping process, the stent cover having an outer sheath with a proximal end, a distal end, an end portion at the distal end of the sheath having a first diameter, and a stent-retaining portion adjacent to the end portion and having an uncompressed diameter that is larger than the first diameter of the end portion for retaining a stent in its uncompressed condition.

Owner:MEDTRONIC INC

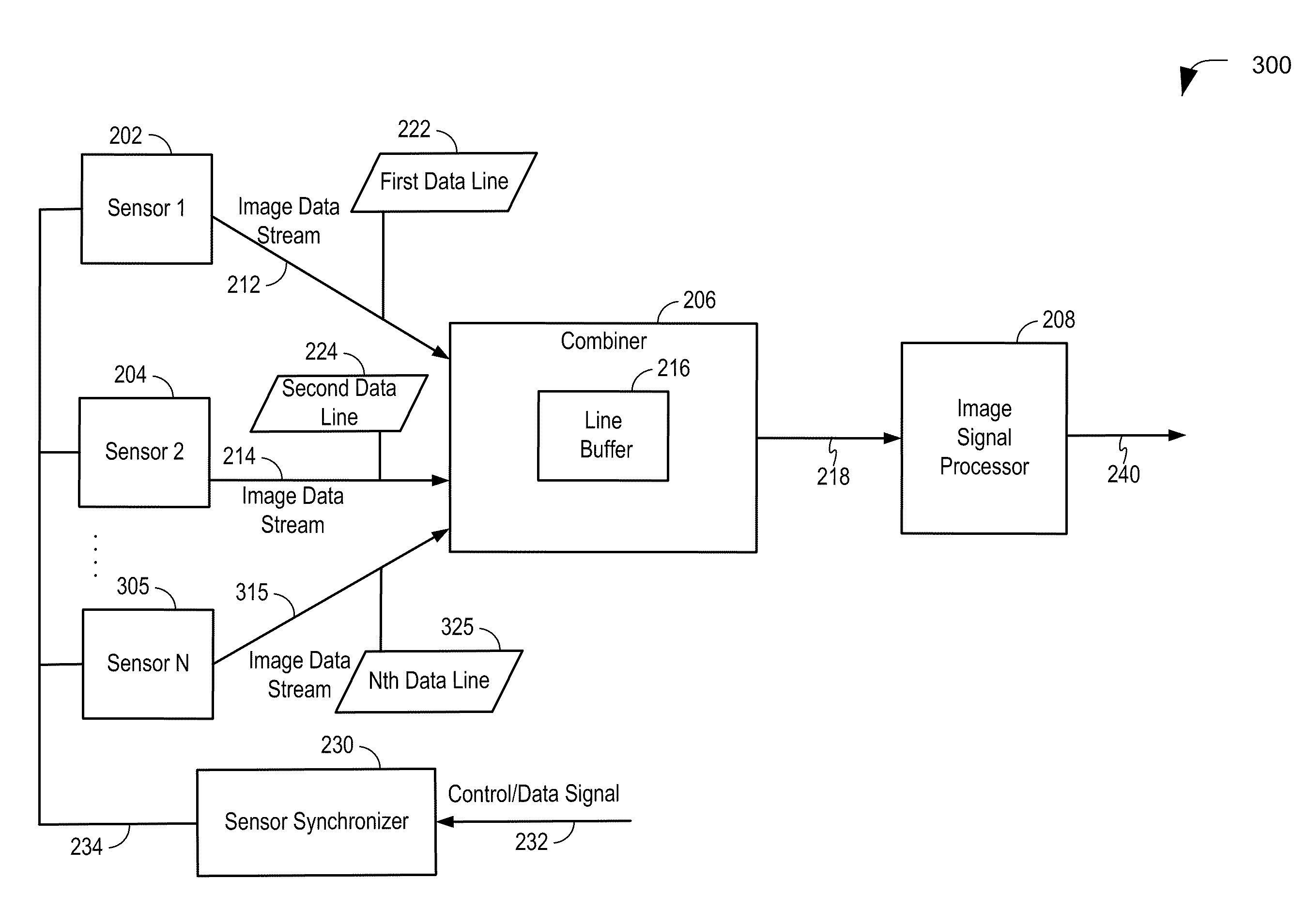

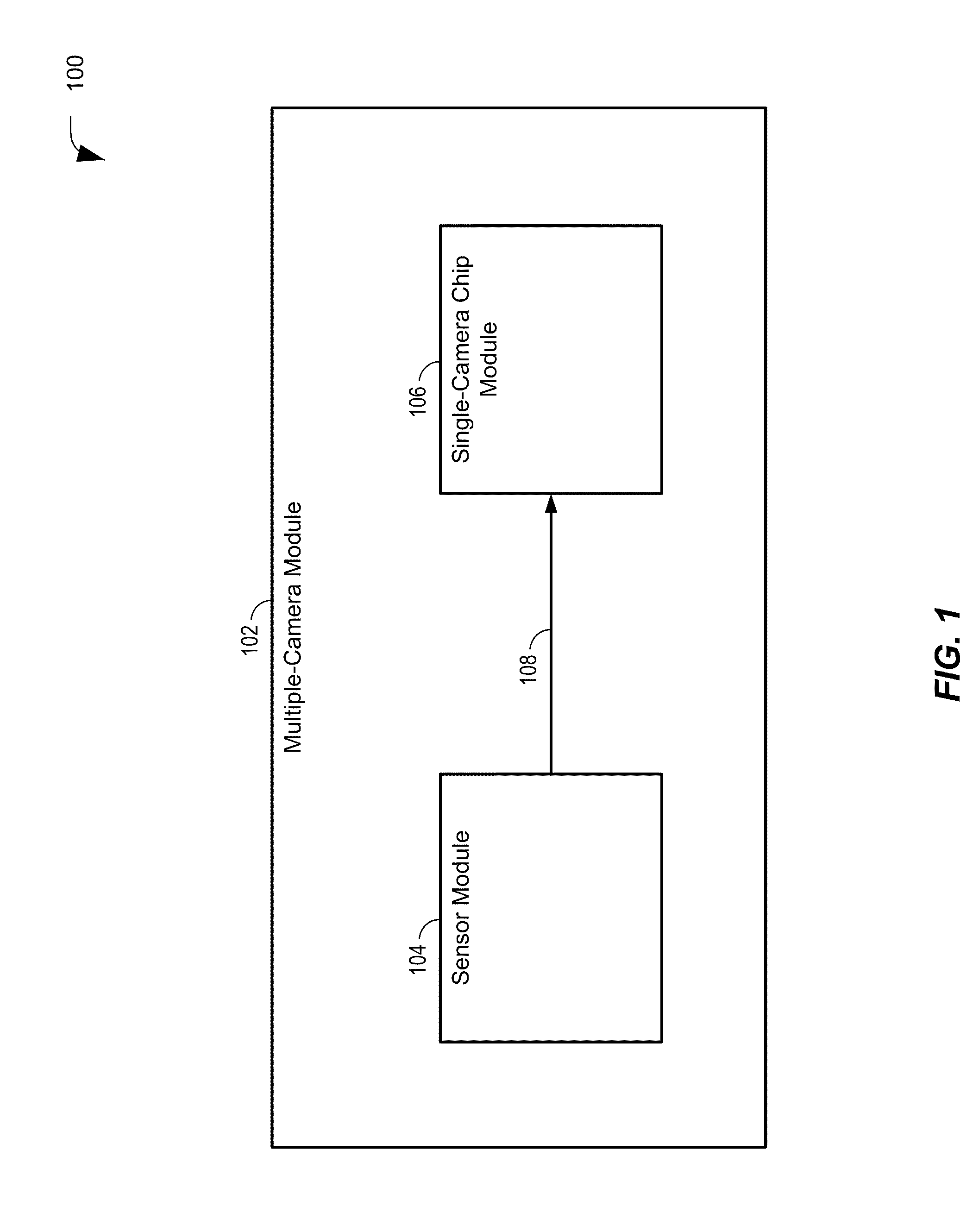

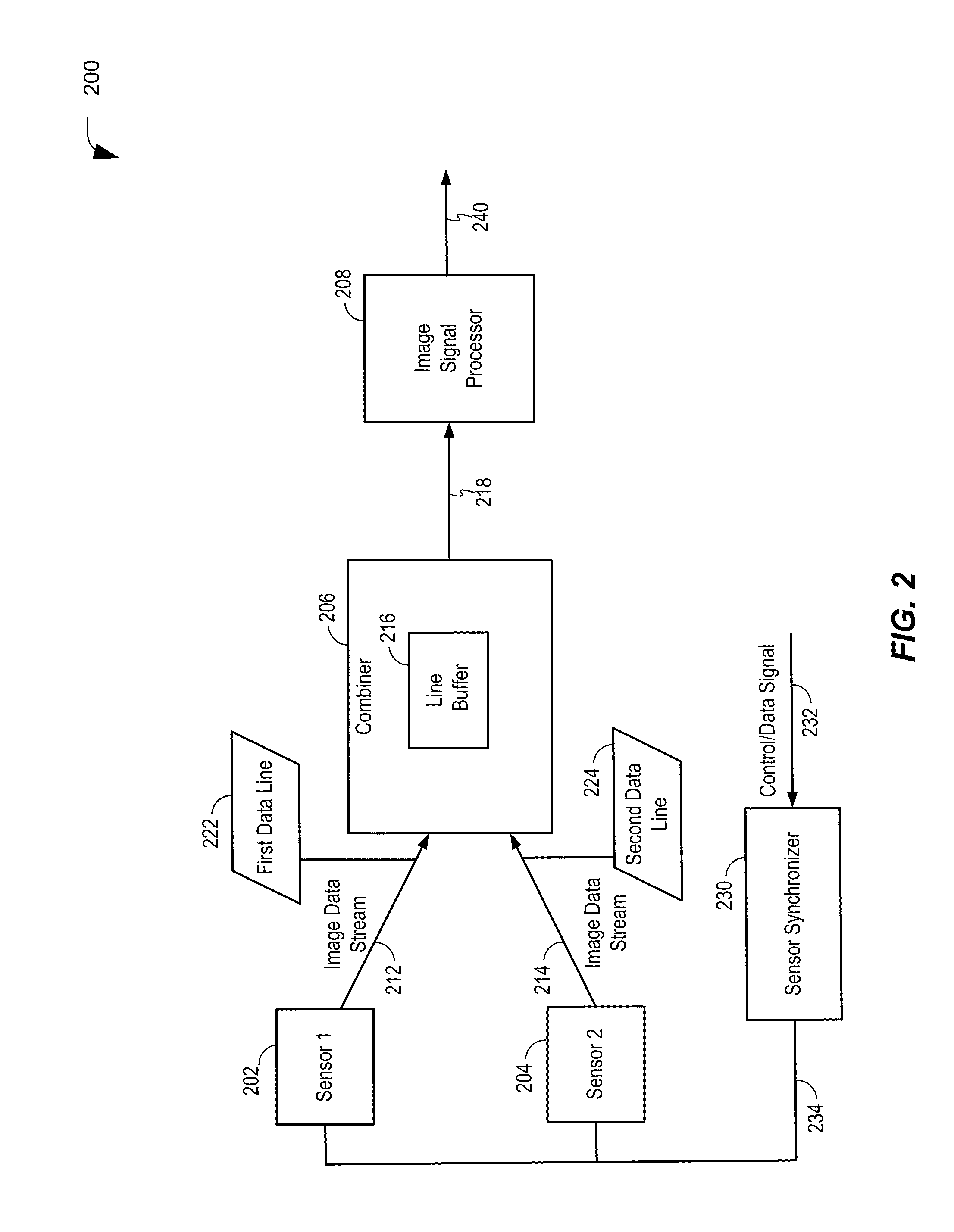

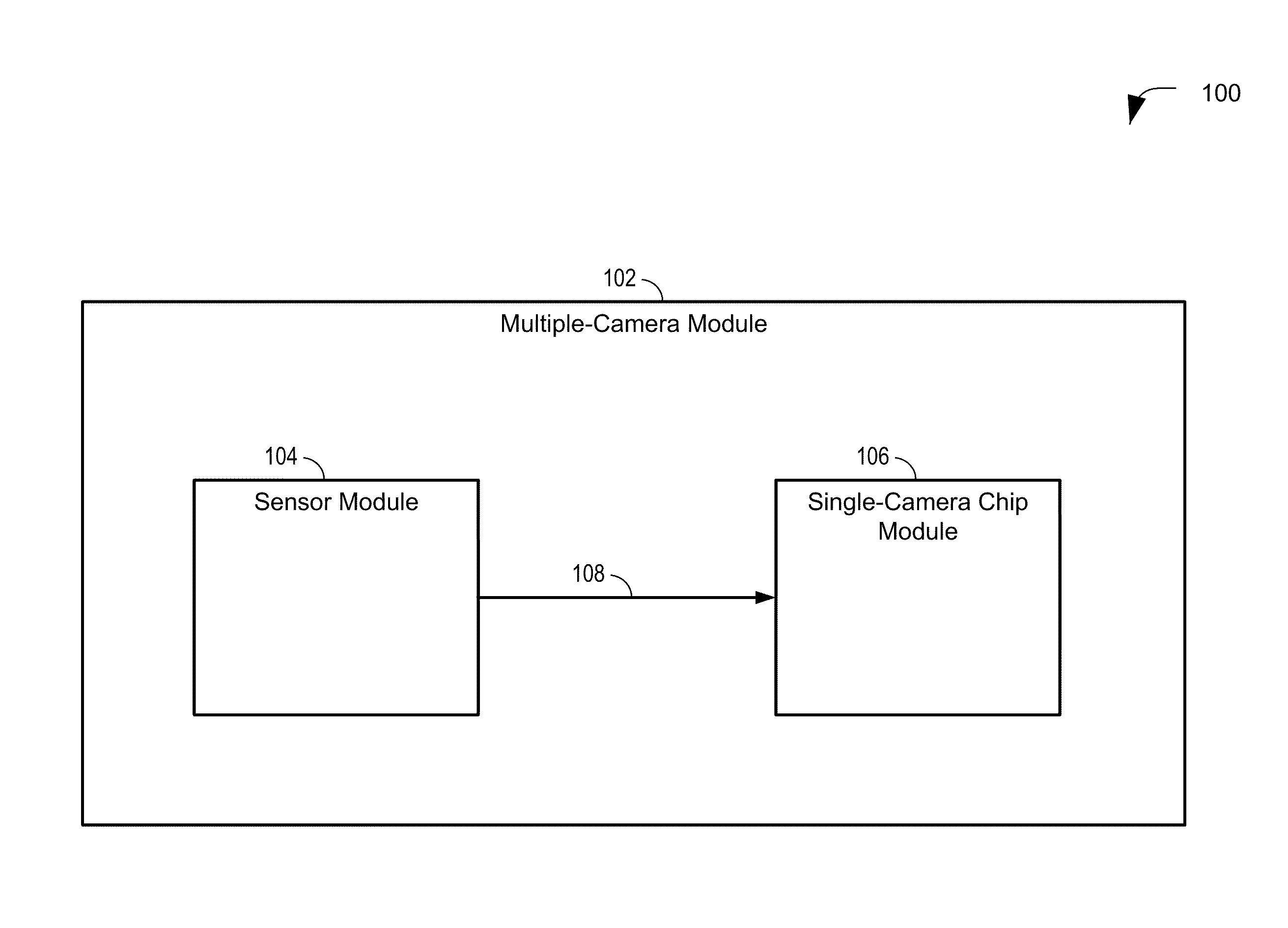

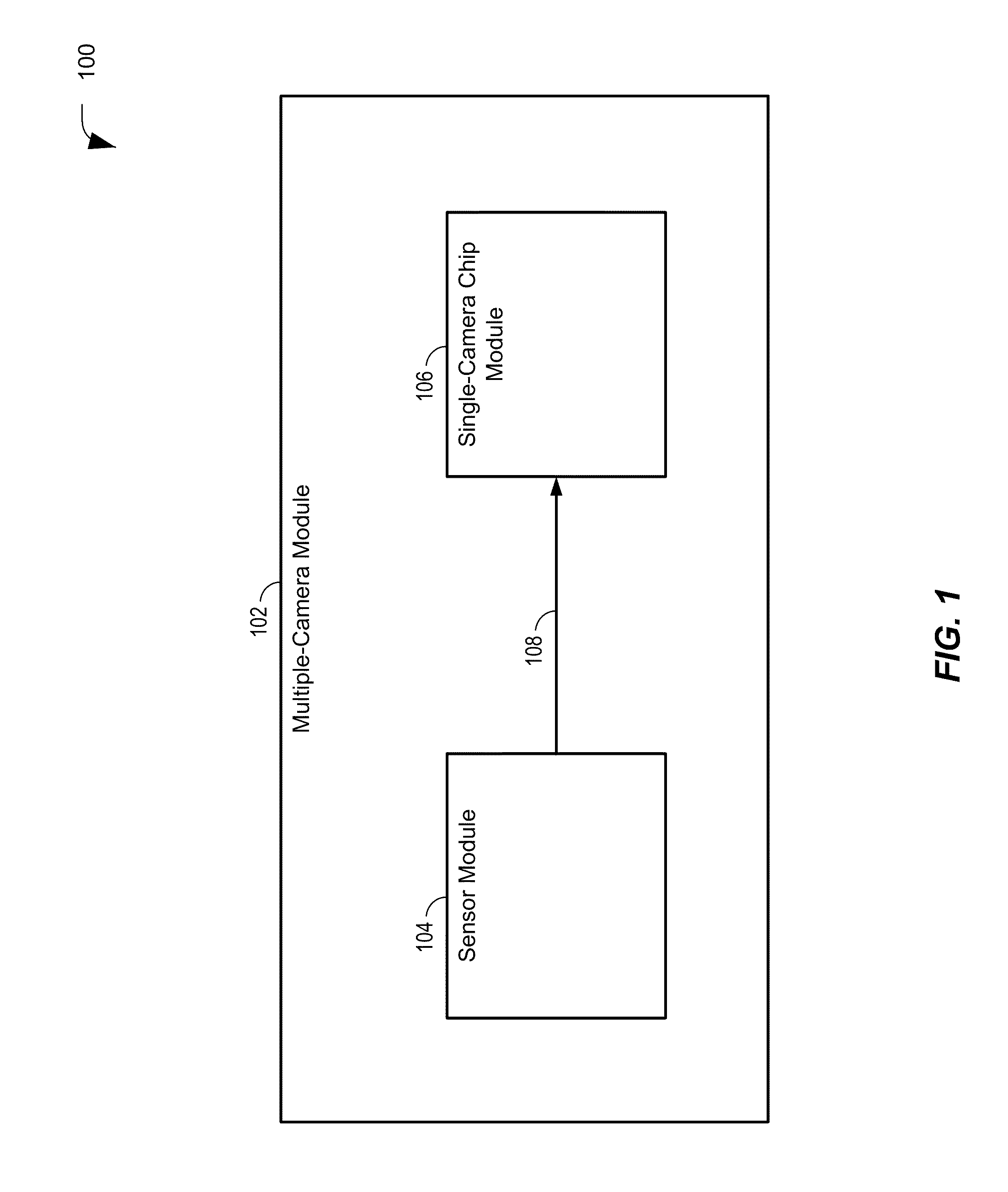

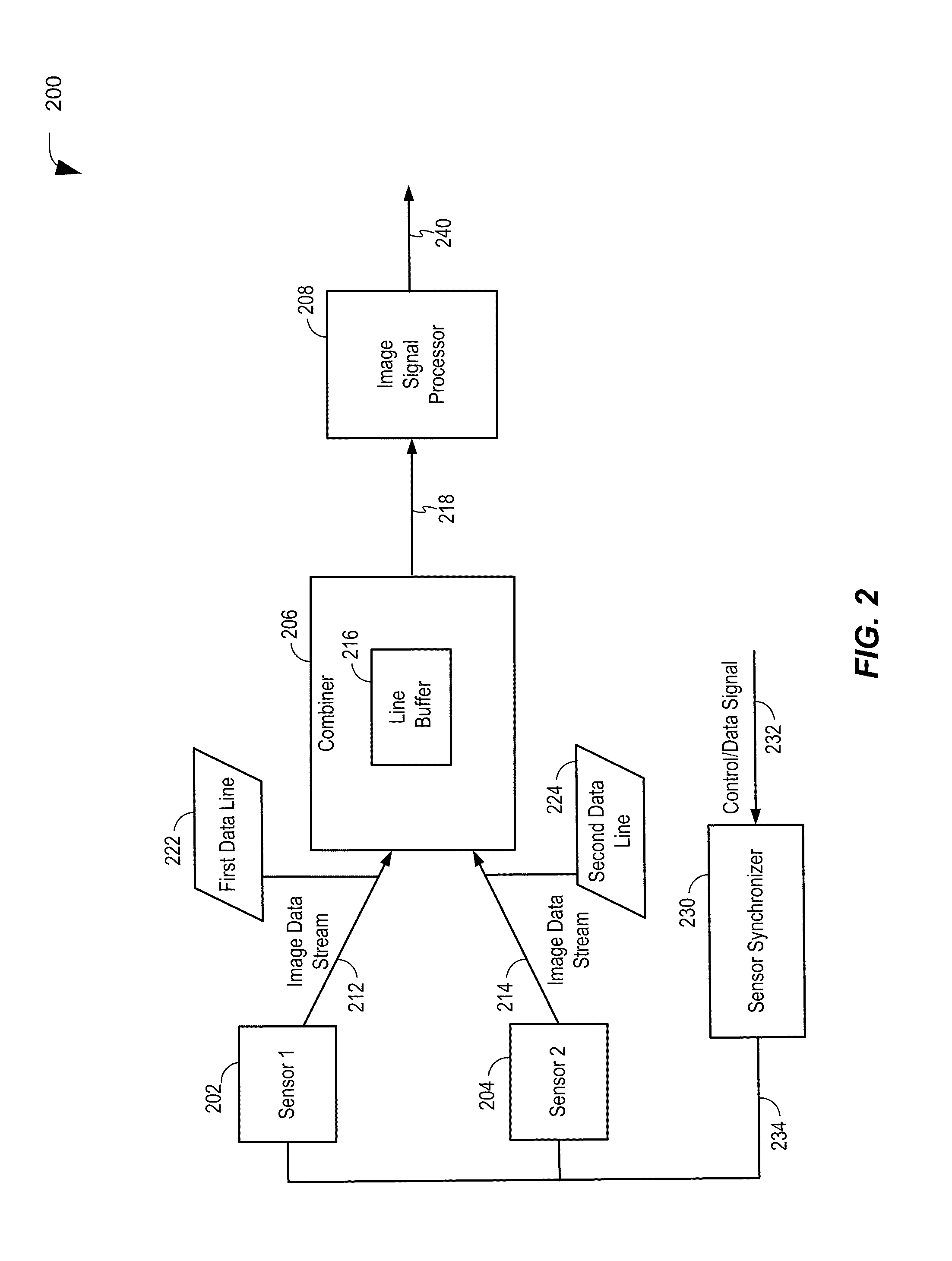

Combining data from multiple image sensors

InactiveUS20110242342A1Avoid pollutionTelevision system detailsSteroscopic systemsControl signalMultiple sensor

A method of combining data from multiple sensors is disclosed. The method includes providing a common control signal to multiple image sensors to be synchronized. The method further includes receiving a first data line from a first image sensor of the multiple image sensors, receiving a second data line from a second image sensor of the multiple image sensors, and combining the first data line and the second data line to generate a synchronized data line.

Owner:QUALCOMM INC

Combining data from multiple image sensors

InactiveUS20110242355A1Avoid pollutionTelevision system detailsSteroscopic systemsComputer graphics (images)Control signal

A method of combining data from multiple sensors is disclosed. The method includes providing a common control signal to multiple image sensors. Each of the multiple image sensors is responsive to the common control signal to generate image data. The method also includes receiving synchronized data output from each of the multiple image sensors, combining the synchronized data output from each of the multiple image sensors to generate a synchronized data line, and providing the synchronized data line to an image processor via a single camera input of the image processor.

Owner:QUALCOMM INC

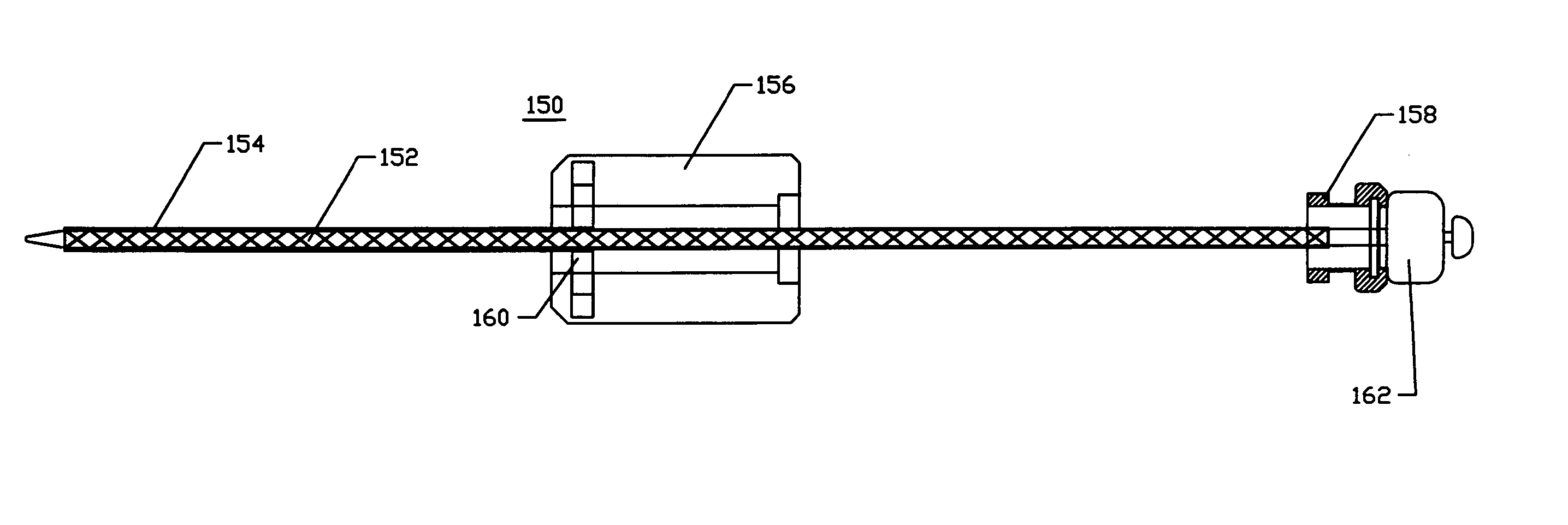

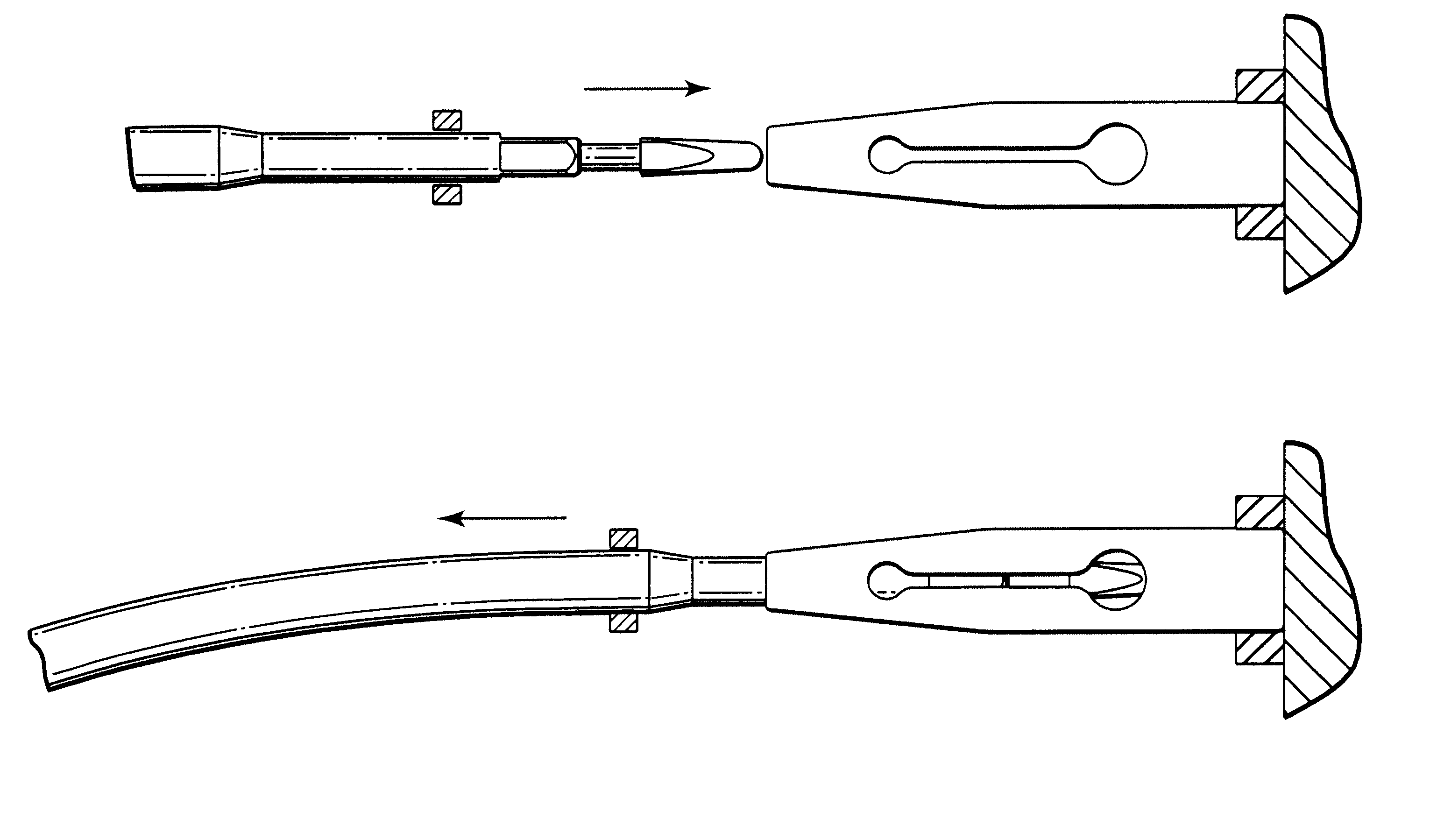

Medical access sheath

InactiveUS20060041270A1Shorten the axial lengthInhibit migrationCannulasDilatorsAxial compressionSurgical site

An expandable sheath is insertable into a patient through an incision. Once inserted and advanced to the target surgical site, the sheath can be expanded to an enlarged diameter. The wall of the sheath is fabricated from a tubular structure comprising filamentous elements that extend axially and at least partially circumferentially along the length of the sheath. The tubular filamentous material is drawn or expanded axially to create the small diameter configuration that is inserted into the patient. A standoff attaches the distal end of the tubular filamentous material to the sheath hub by way of radially movable anchors. Additional filamentous tubular material extends out the proximal end of the hub. A compression mechanism forces the additional filamentous tubular material in the distal direction which causes axial compression and radial or diametric dilation of the working length of the sheath, that part of the sheath that extends beyond the proximal end of the hub. Radial dilation is accomplished with no substantial change in sheath working length.

Owner:ONSET MEDICAL CORP

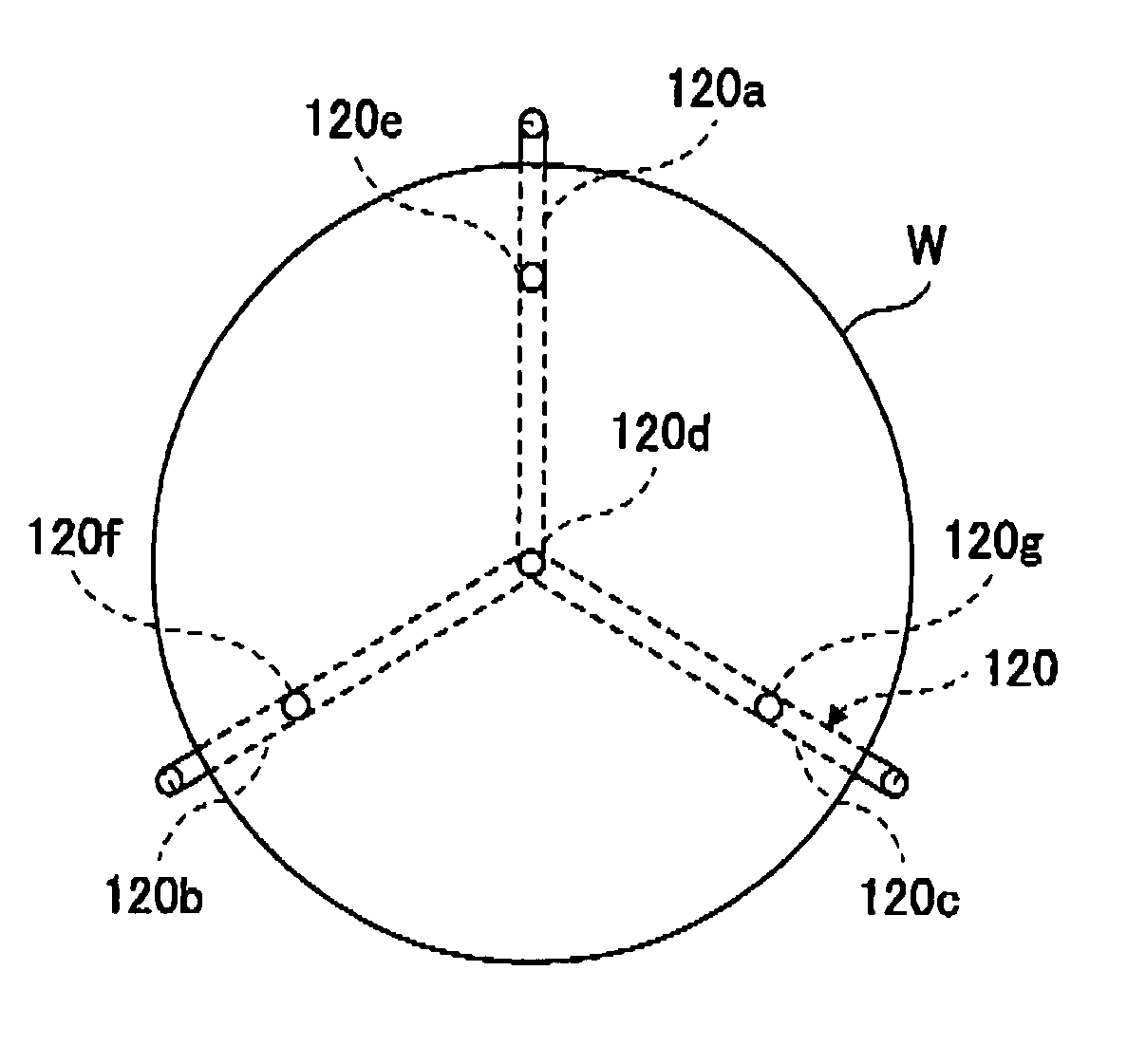

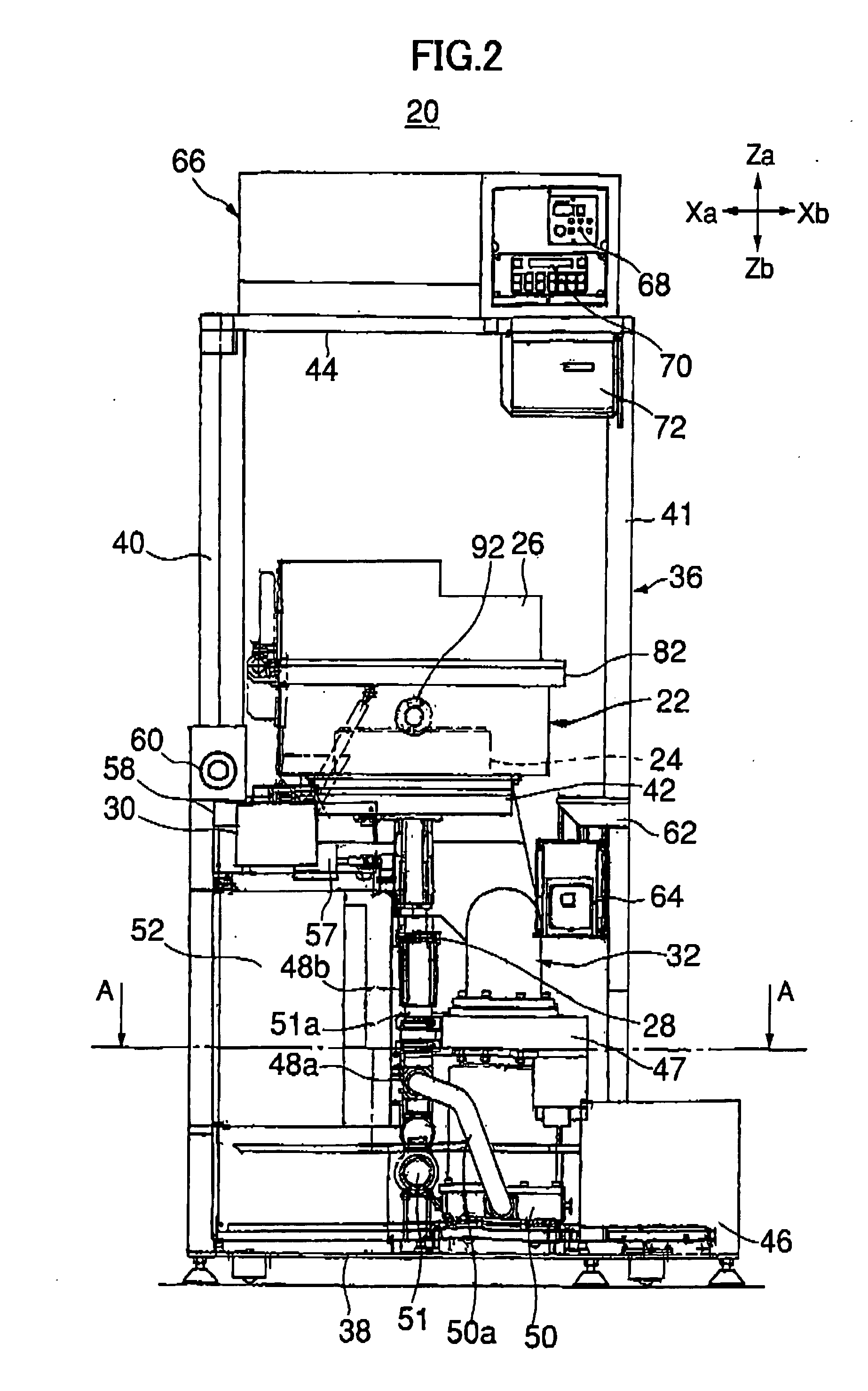

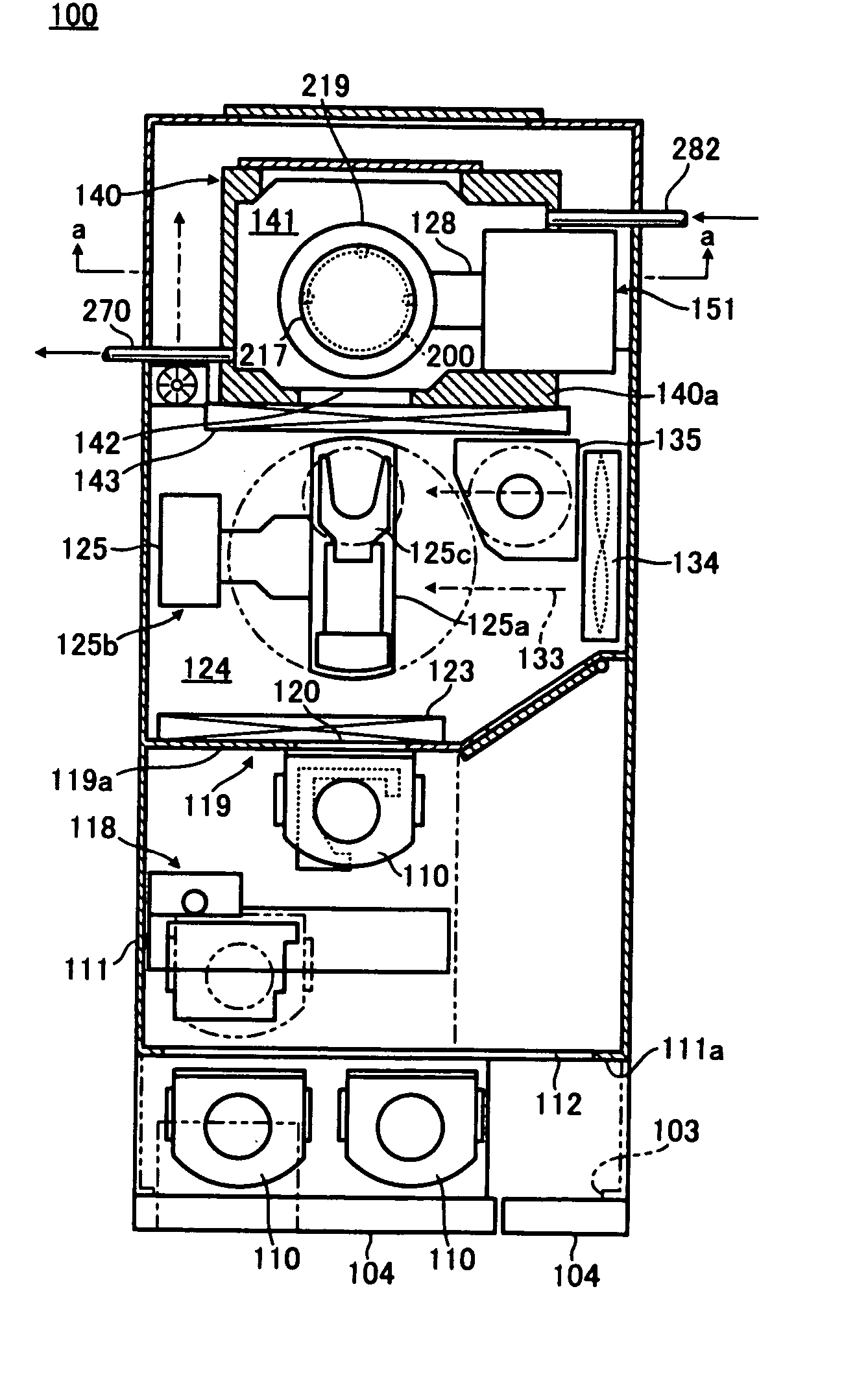

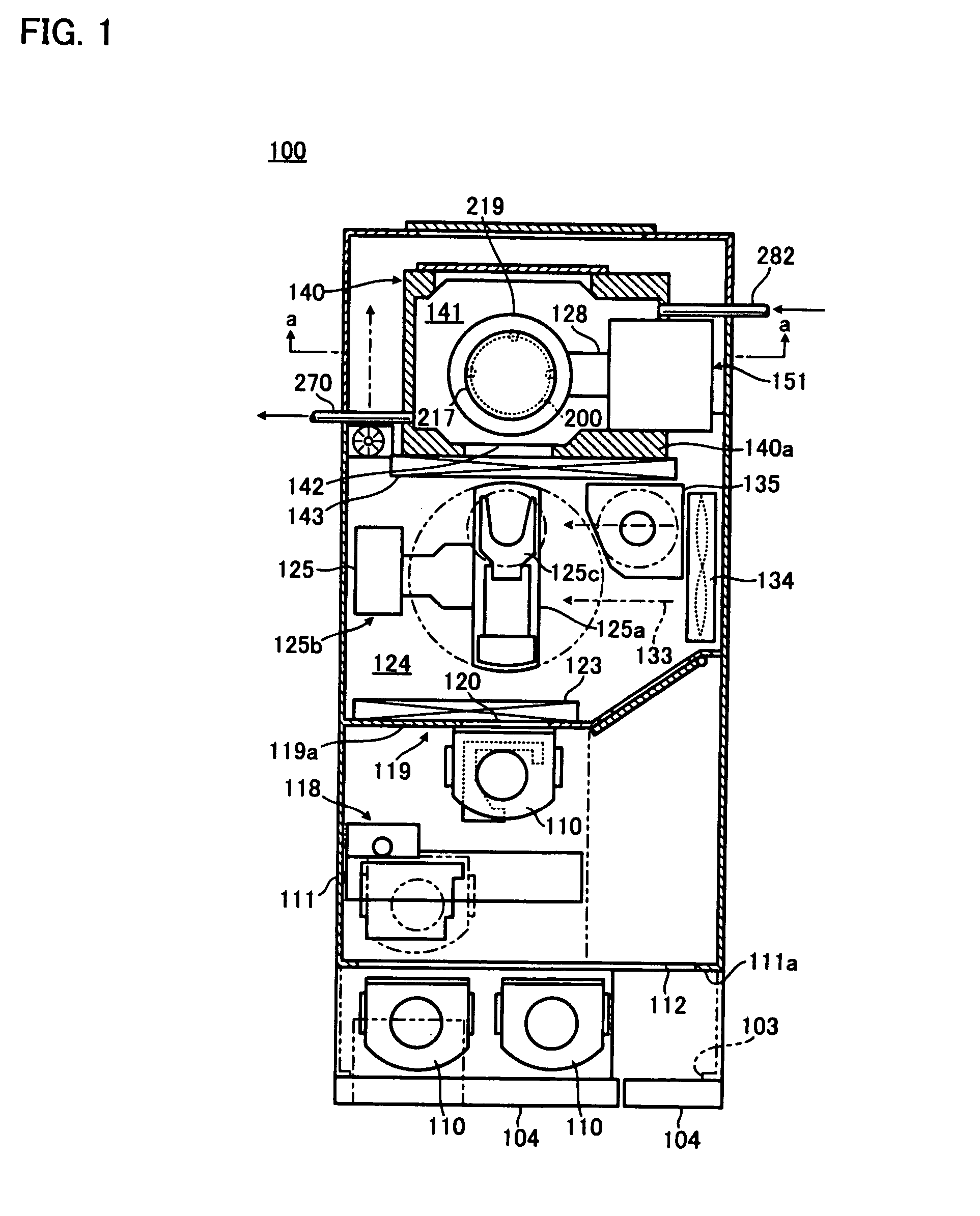

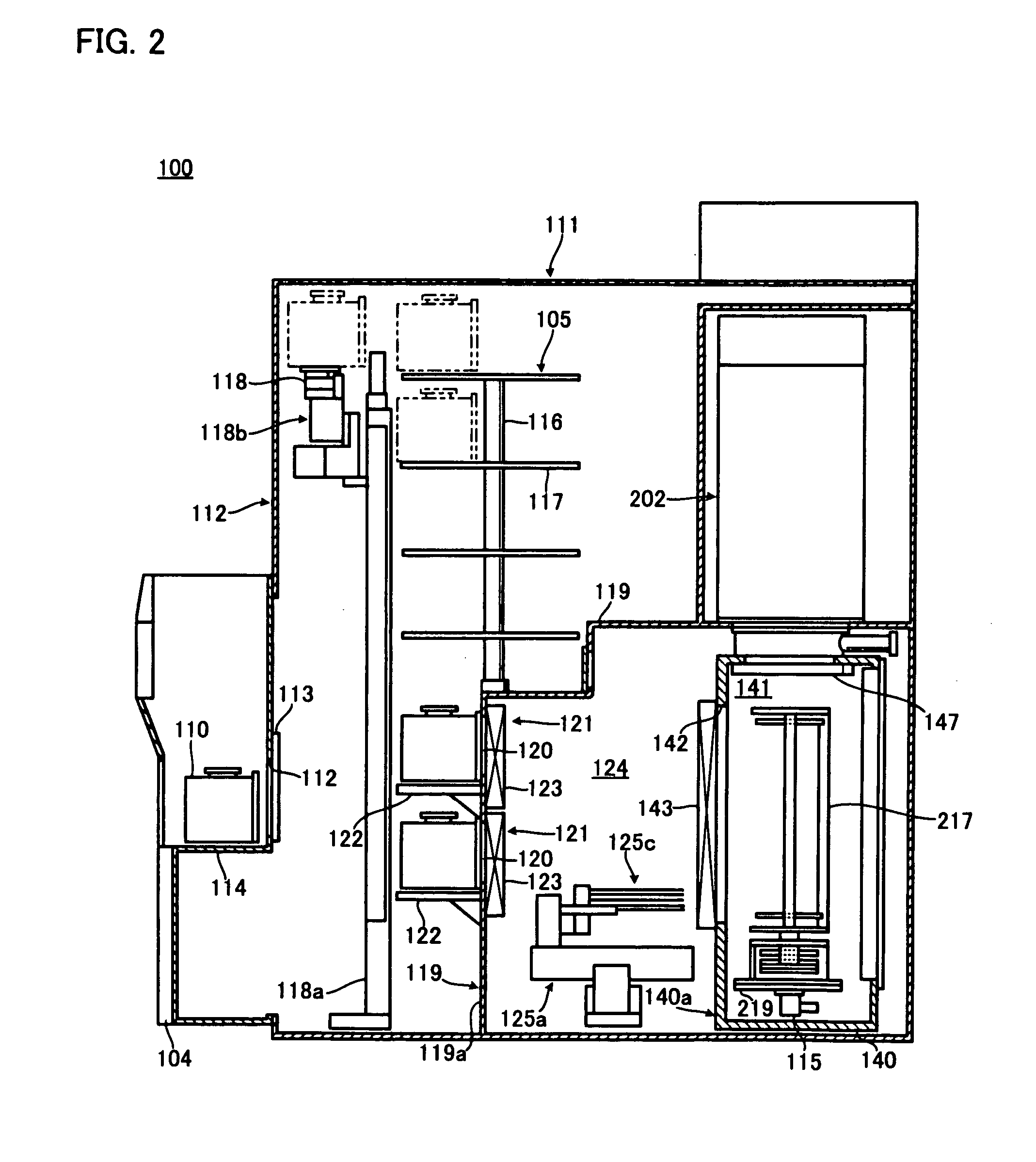

Substrate processing apparatus

ActiveUS20060048710A1Avoid pollutionUniform temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

The substrate processing apparatus according to the present invention is aimed to stably and efficiently perform a deposition process on a substrate W. The substrate processing apparatus supports the substrate W in a position facing a heater portion and thus rotates a holding member holding the substrate W. Furthermore, the heating portion houses a SiC heater and a heat reflecting member in an internal portion of a quartz bell jar made of transparent quartz, and depressurizes an internal space of a processing vessel and an internal space of the quartz bell jar at the same time; thereby allowing the thickness of the quartz bell jar to be thinner, and thus improving thermal conductivity of heat from the SiC heater and preventing contamination by the SiC heater.

Owner:TOKYO ELECTRON LTD

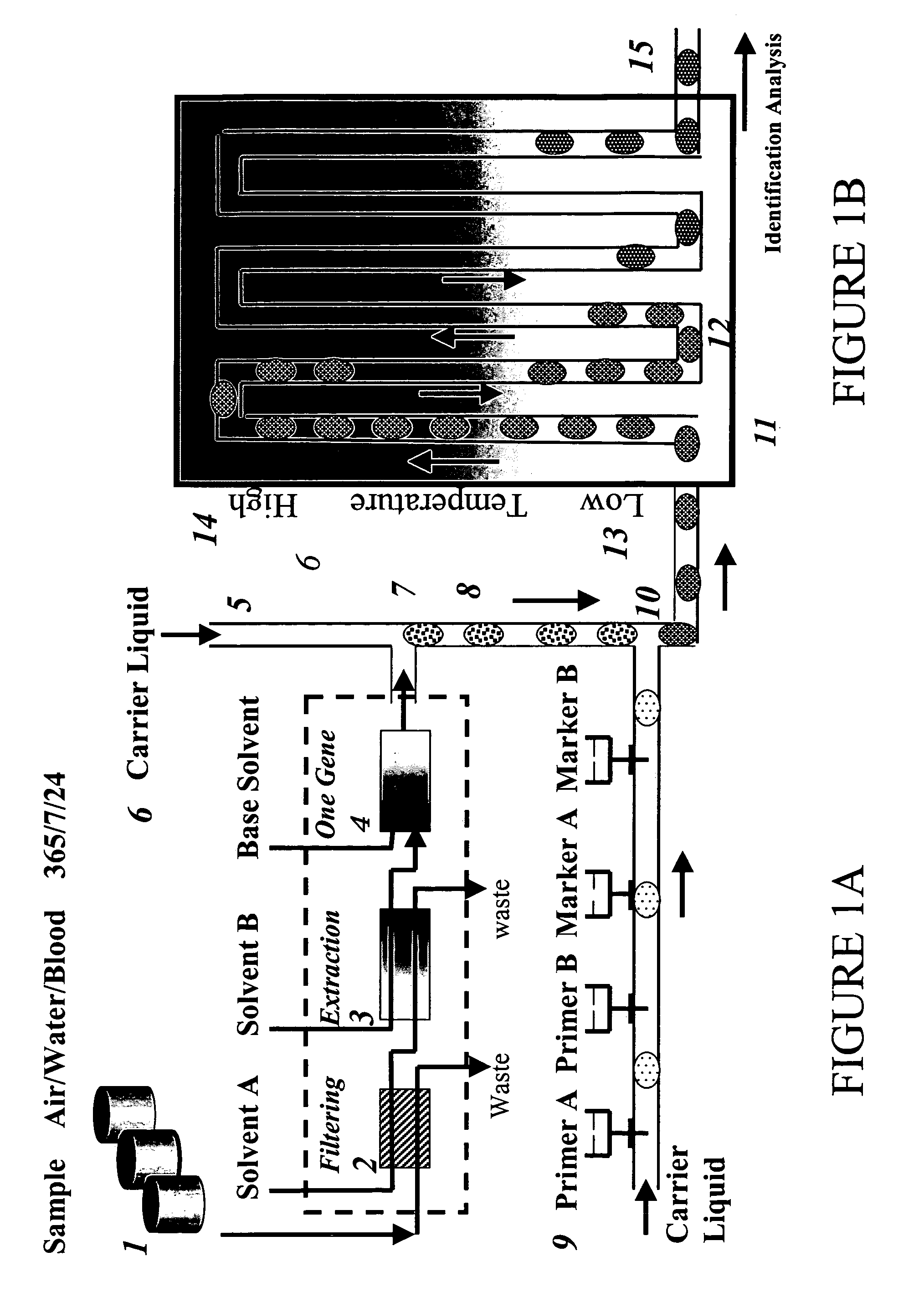

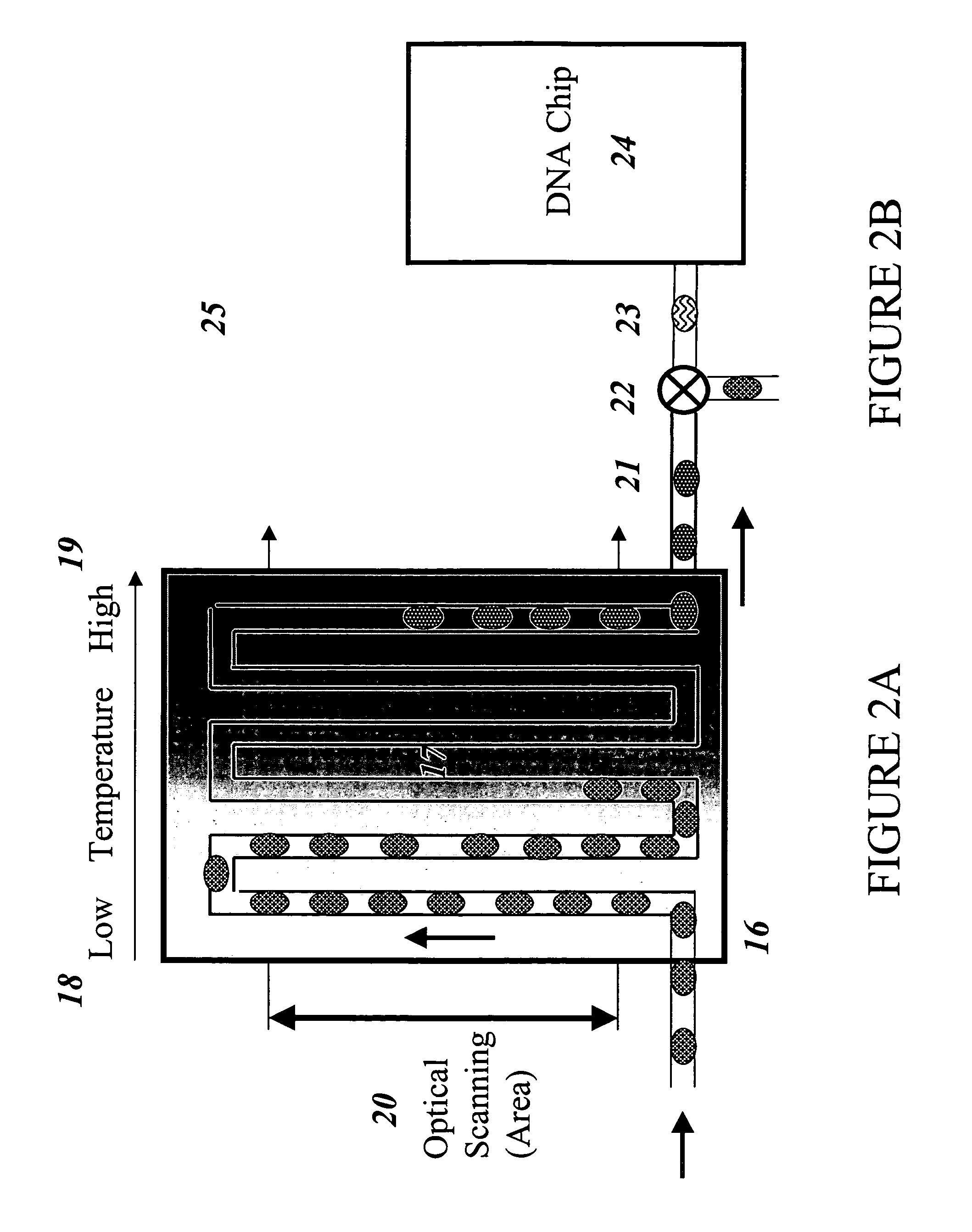

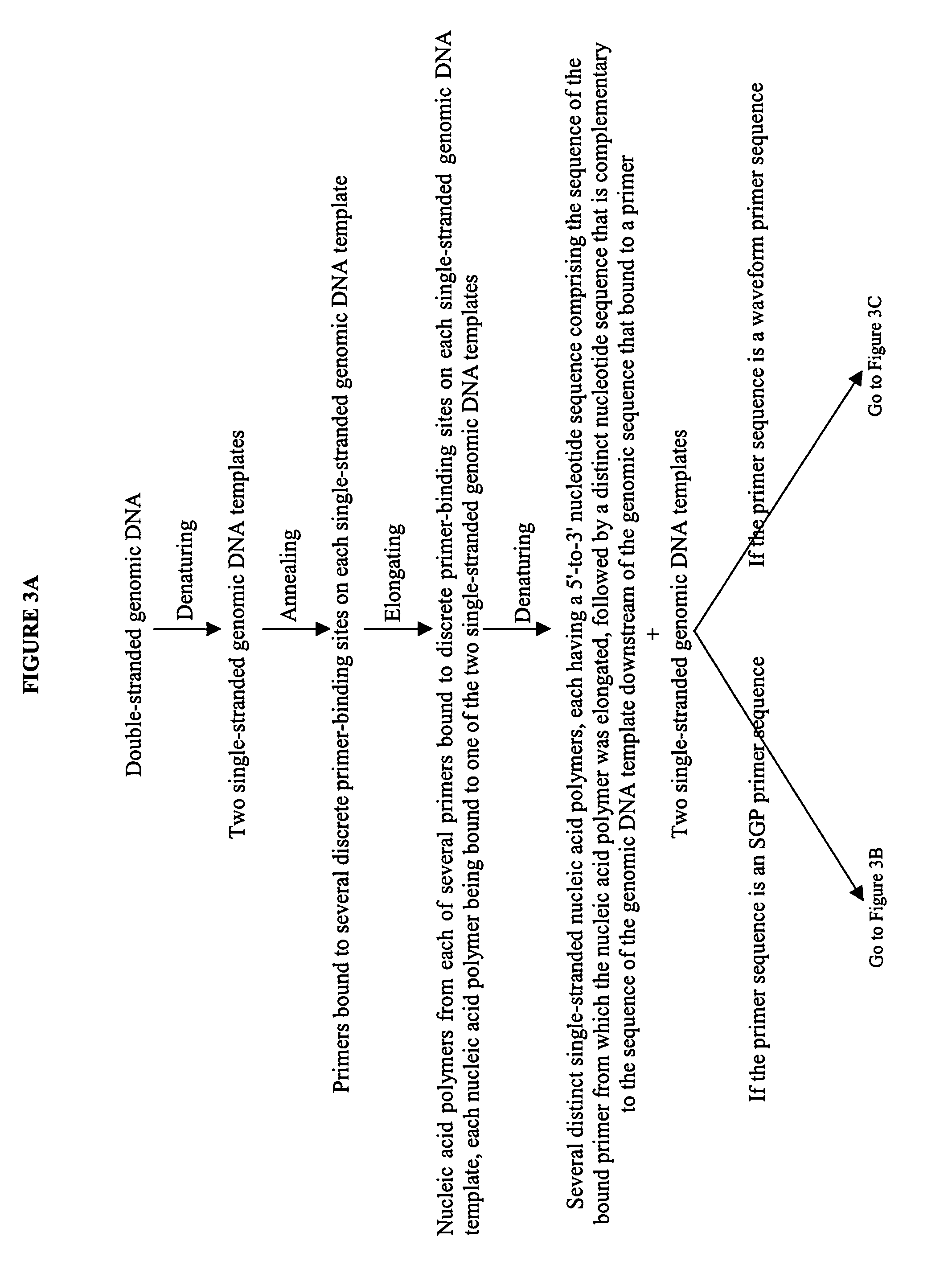

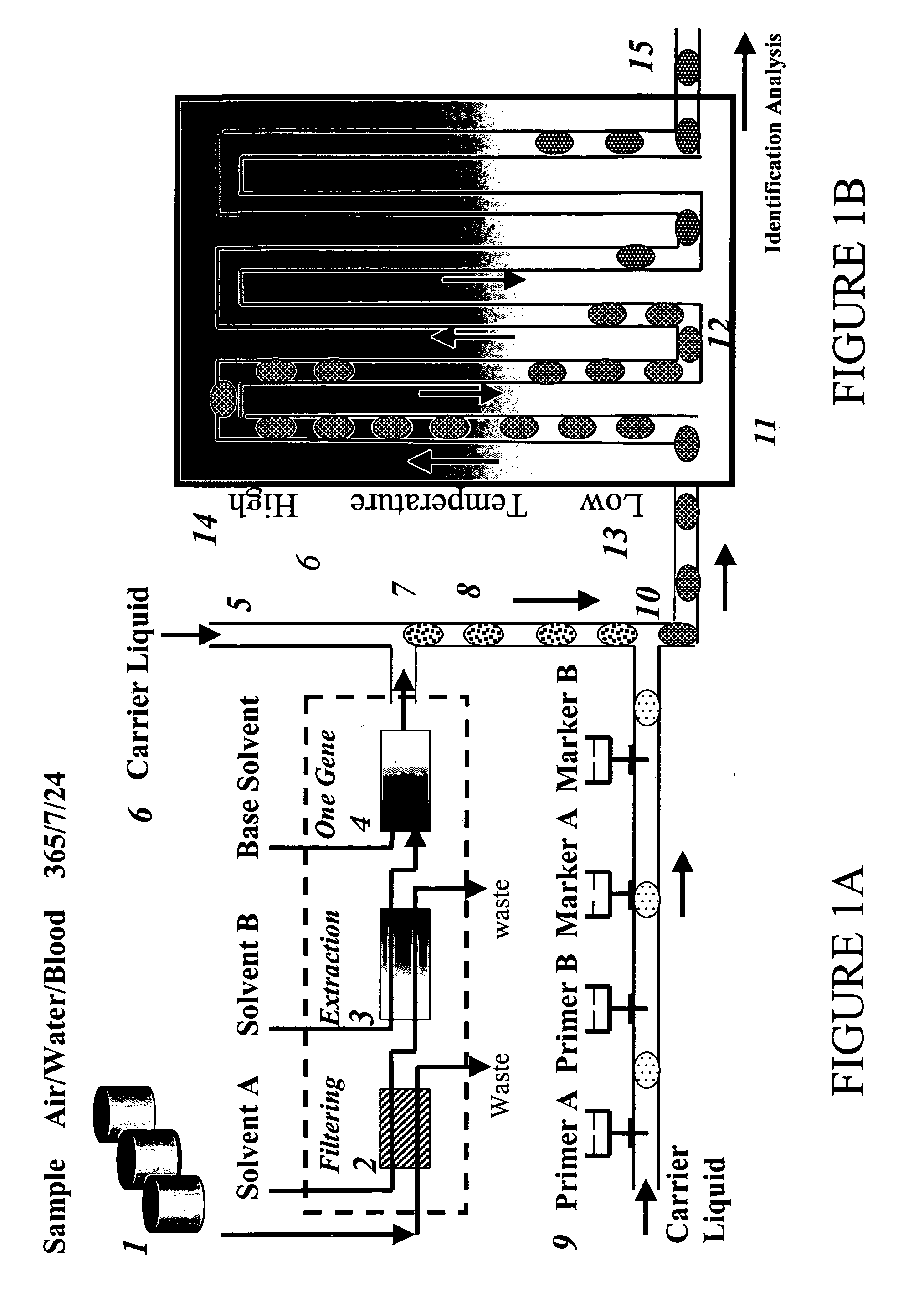

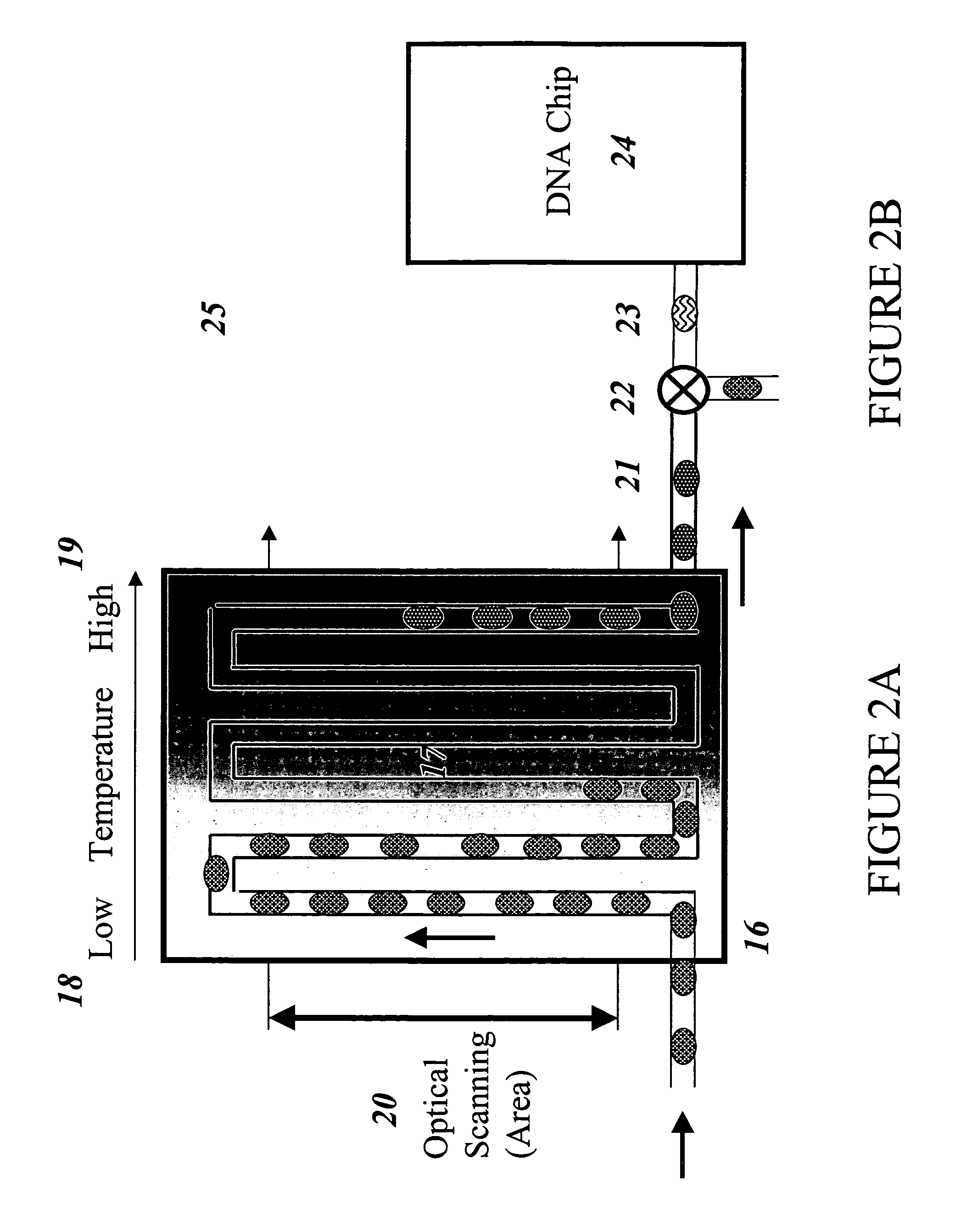

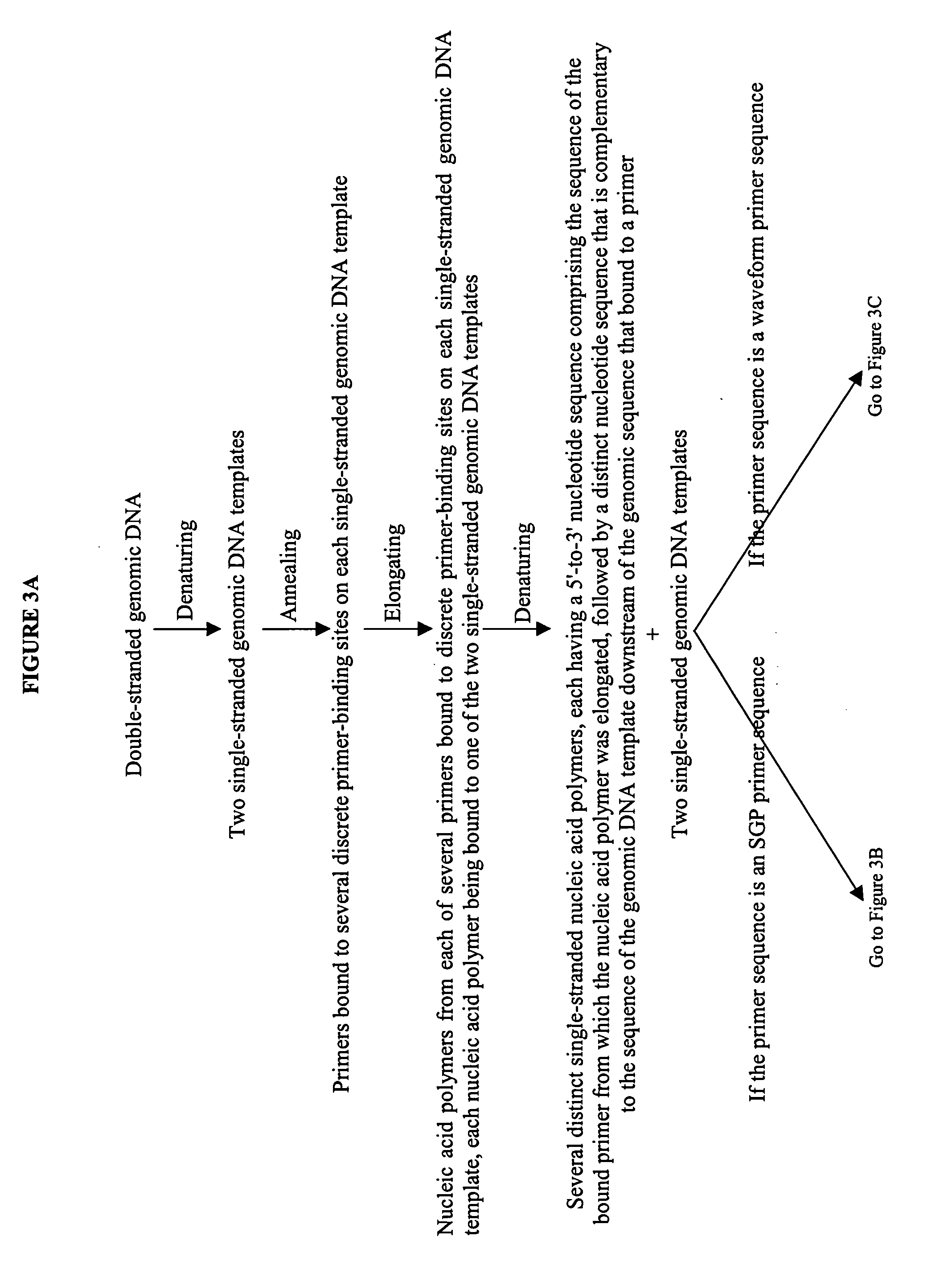

Devices and methods for monitoring genomic DNA of organisms

InactiveUS7604938B2Low costAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsGenomic DNADna amplification

The invention provides an apparatus that can be used in methods of preparing, amplifying, detecting, and / or optionally selecting for further analysis the genomic material from an organism for the rapid detection and / or classification of an organism in a sample (e.g., screening for, identifying, quantifying, and / or optionally further analyzing, e.g., sequencing, the genomic material of the organism). The invention further provides methods of using the apparatus, e.g., in combination with novel SGP primers for improved use in waveform-profiling methods of DNA amplification. It is an object of the invention to provide an apparatus for fully automated analysis of genomic material, and multiple methods of using the apparatus that are beneficial to society, e.g., the apparatus may be used in methods of screening for, identifying, quantifying, and / or selecting genomic material for further analysis (e.g., sequencing) in relation to monitoring a source for the presence of contaminating organisms.

Owner:CANON US LIFE SCIENCES INC

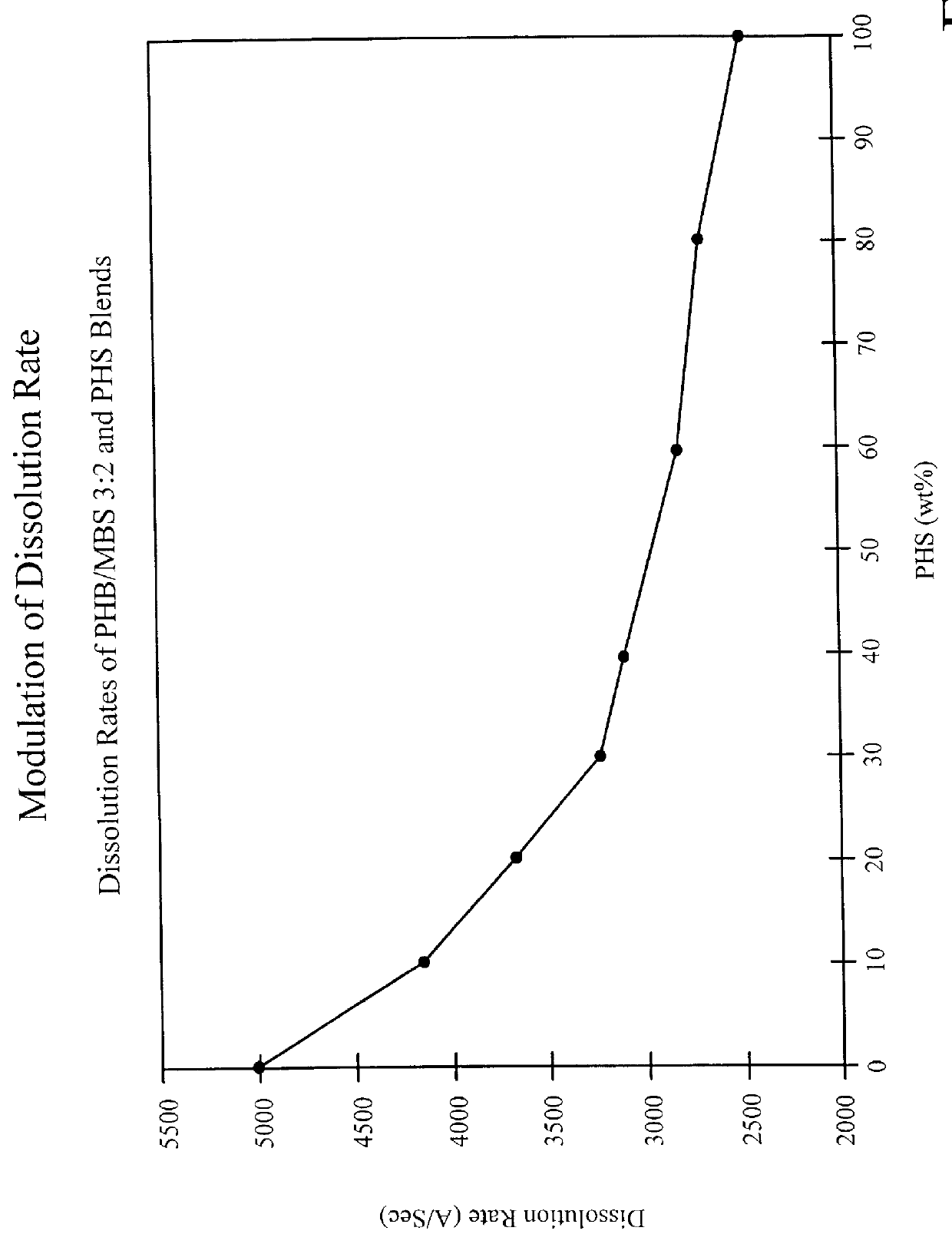

Silsesquioxane polymers, method of synthesis, photoresist composition, and multilayer lithographic method

InactiveUS6087064AReduce usageAvoid pollutionPhotosensitive materialsRadiation applicationsResistPolymer science

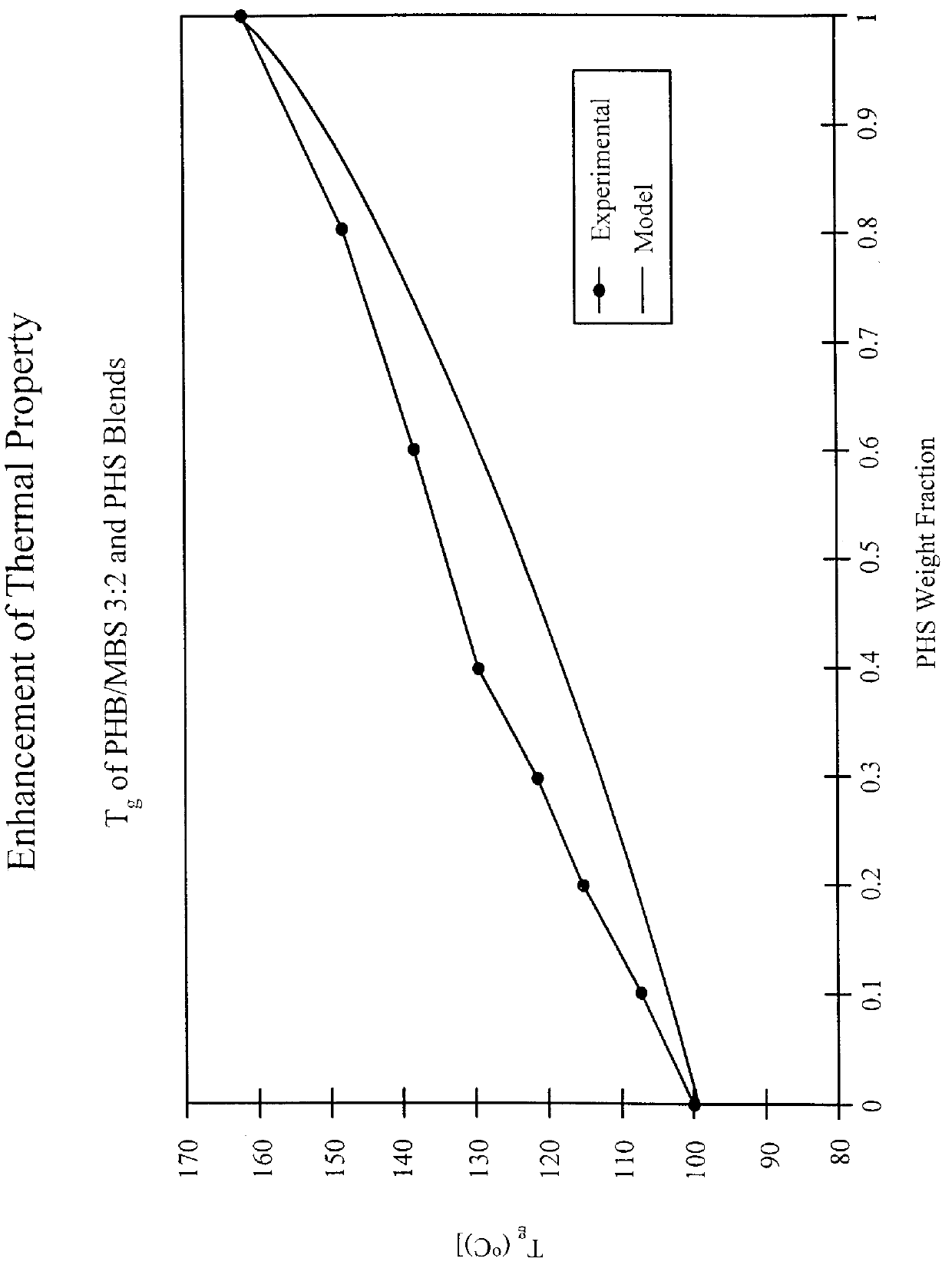

Novel silsesquioxane polymers are formed by methods which avoid the use of BBr3. The novel silsesquioxane polymers are especially useful in negative photoresist compositions and photolithographic processes. Alternatively, improved silsesquioxane polymer-containing negative photoresist compositions are obtained by using a polymer component containing a blend of silsesquioxane polymer and non-silsesquioxane polymer. The photoresist compositions provide improved dissolution characteristics enabling the use of 0.26 N TMAH developer. The photoresist compositions also provide improved thermal characteristics enabling use of higher processing temperatures. The photoresist compositions are especially useful in a multilayer photolithographic processes and are capable of producing high resolution.

Owner:GLOBALFOUNDRIES INC

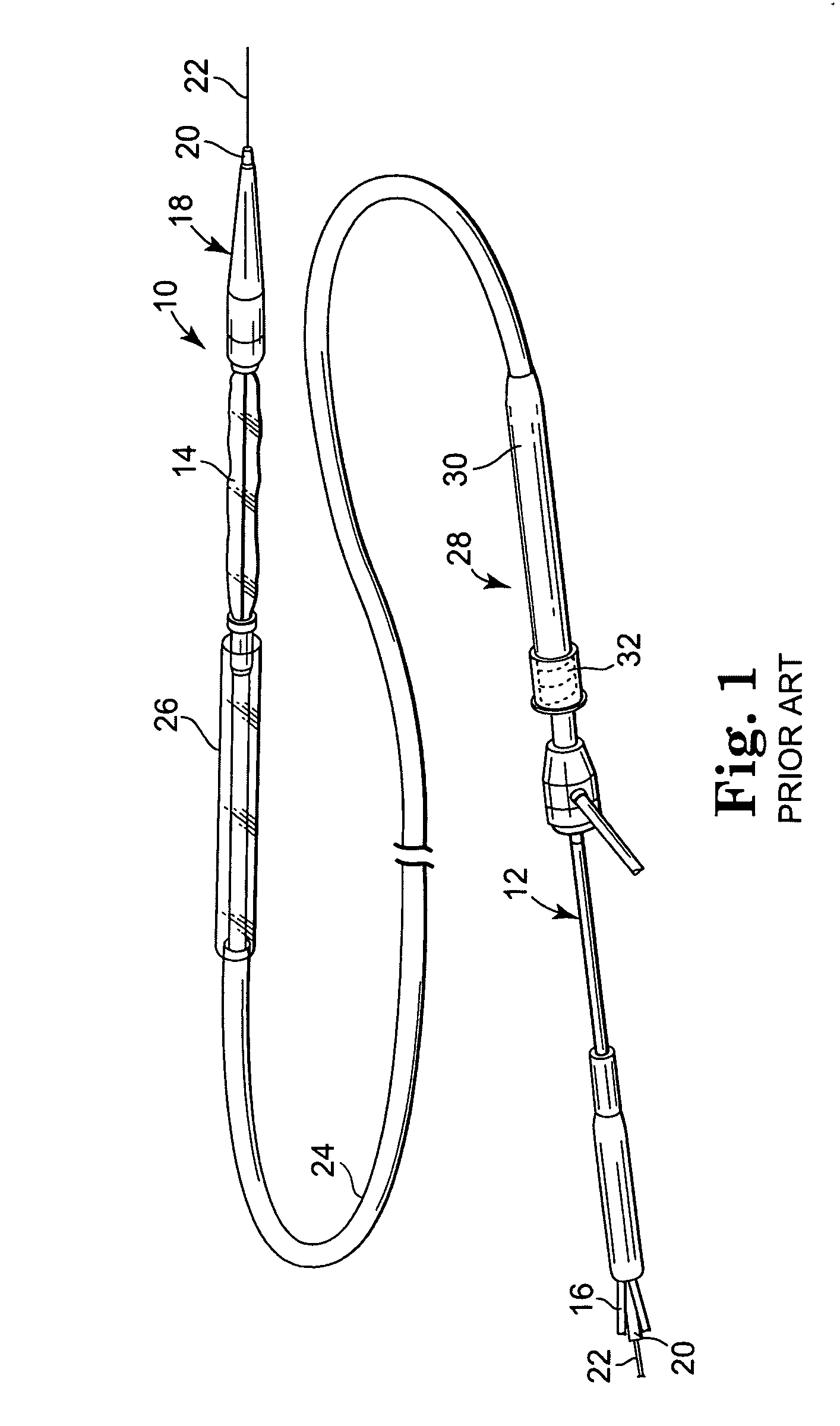

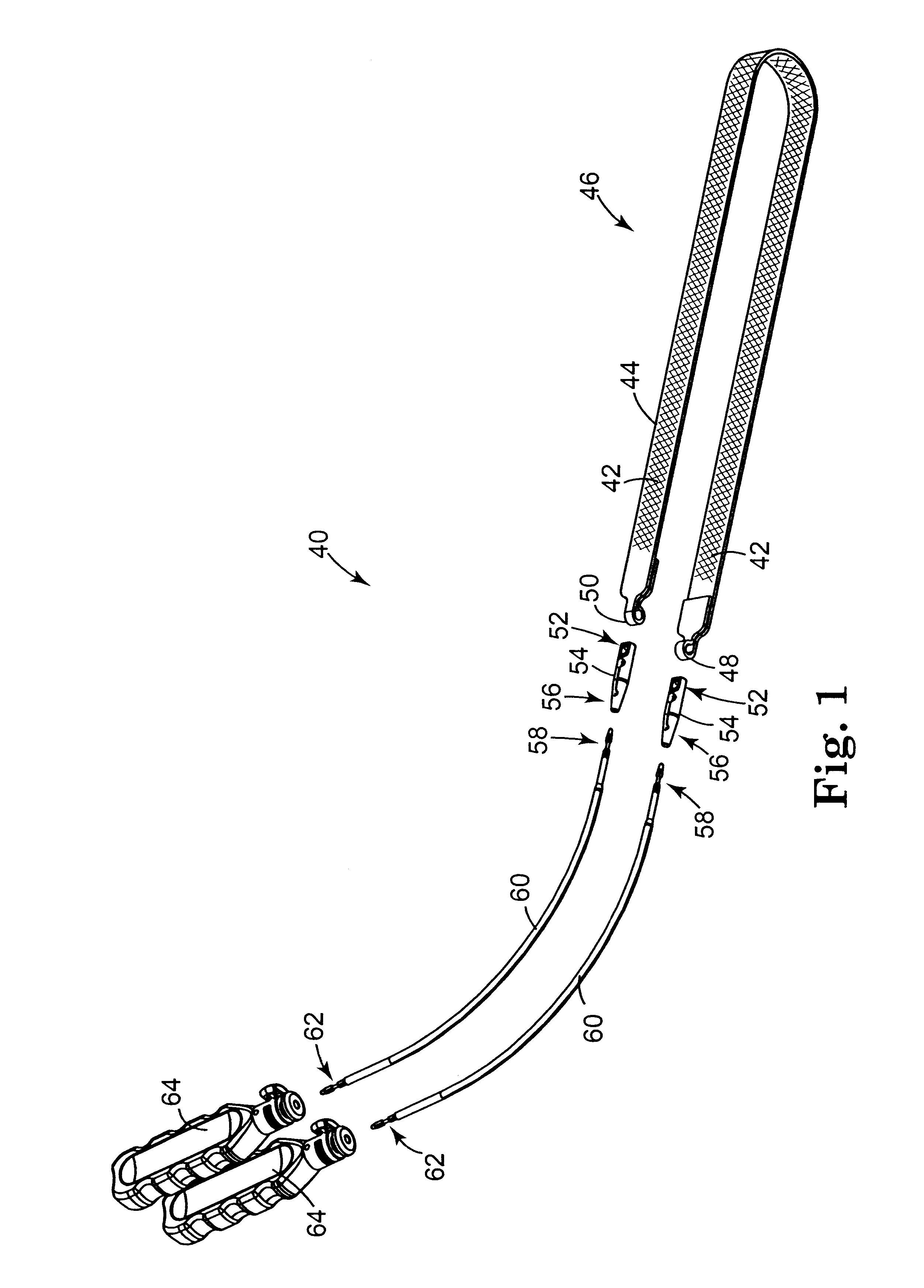

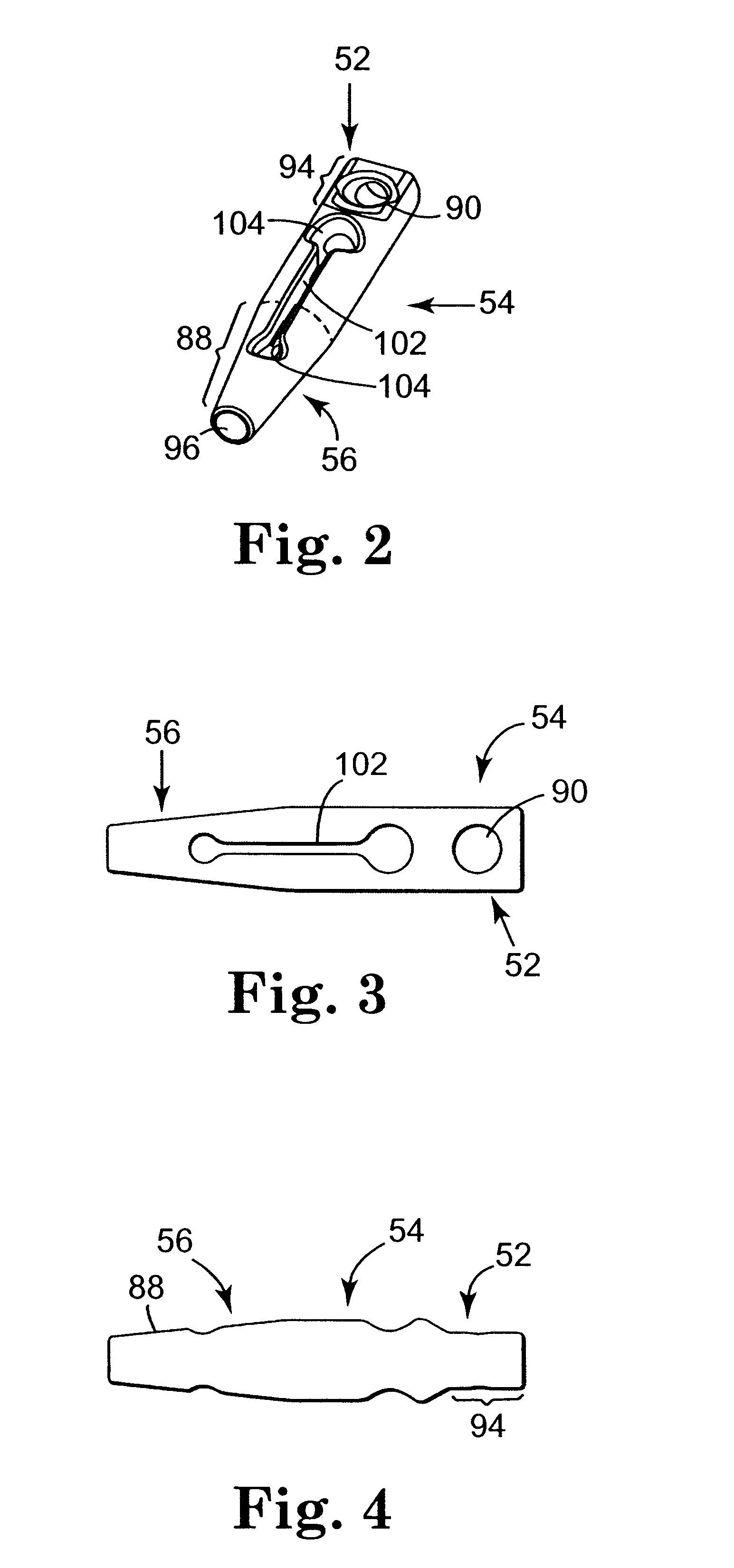

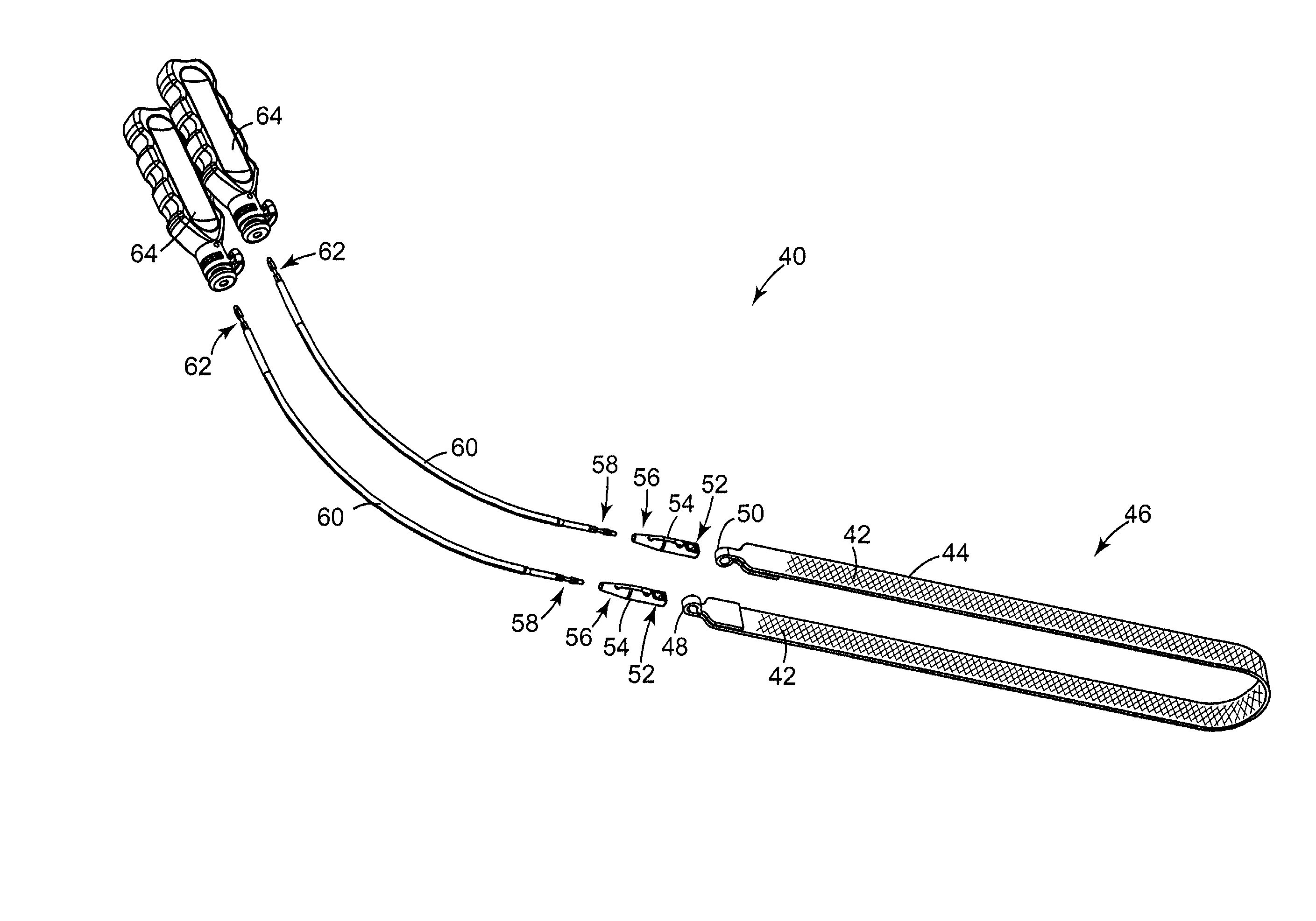

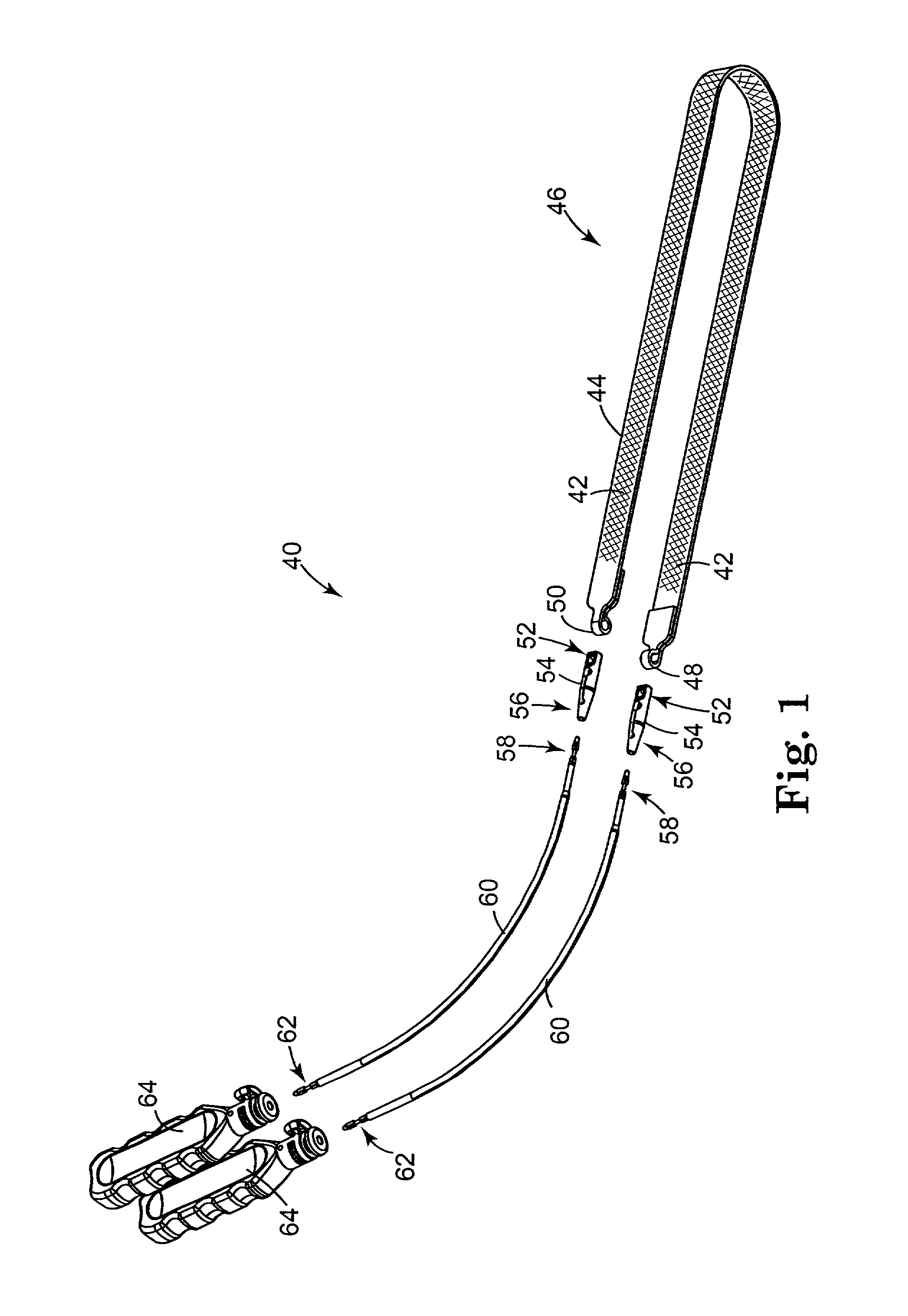

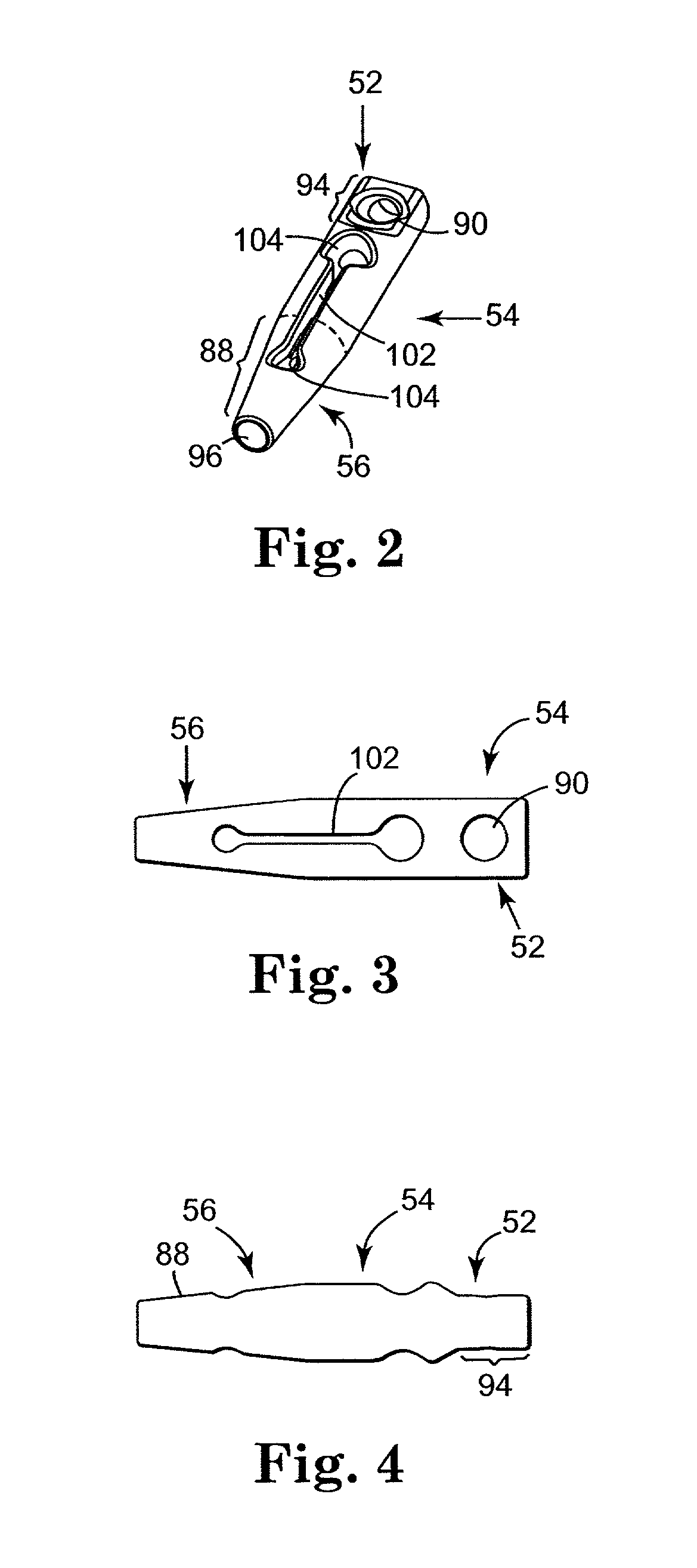

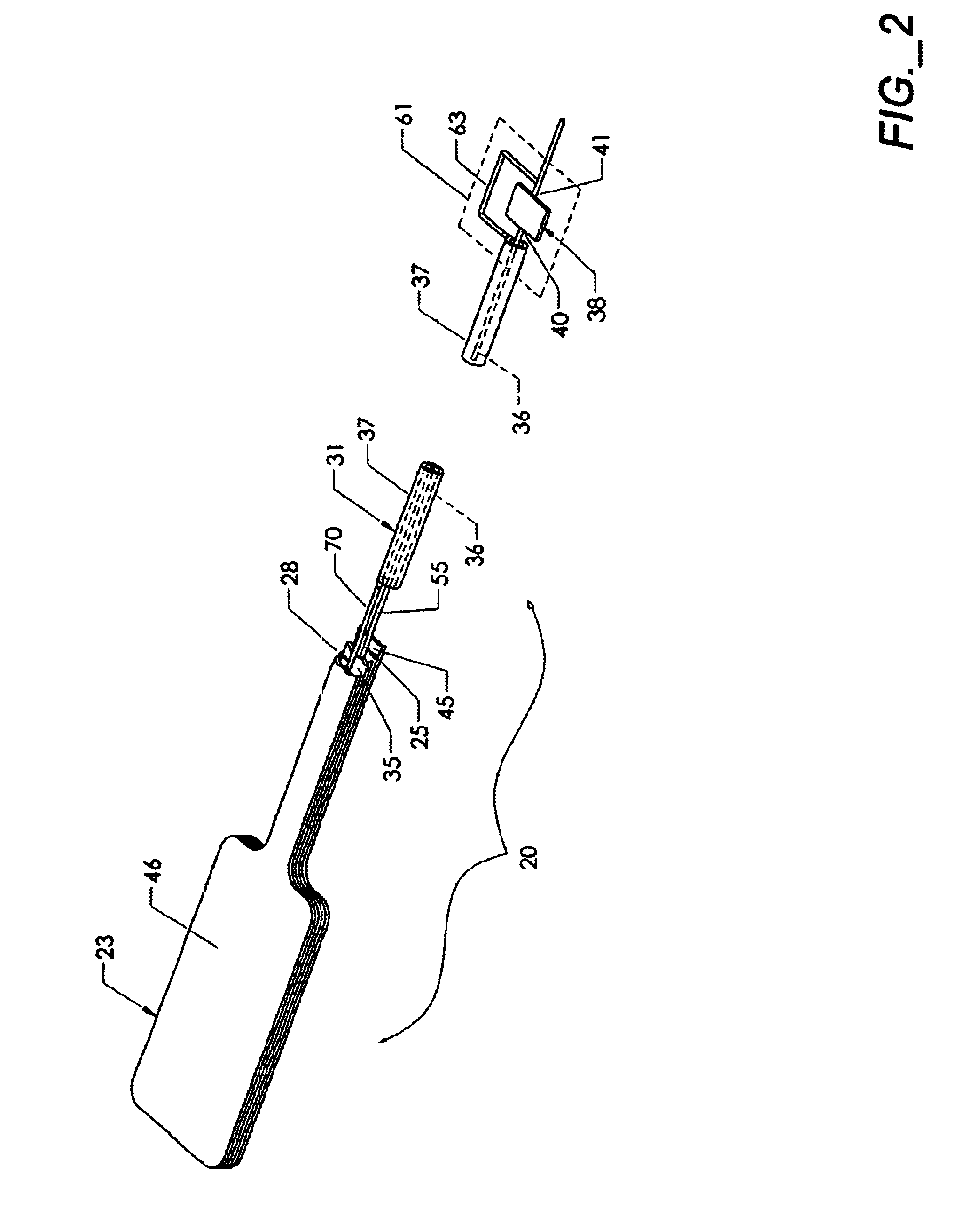

Sling assembly with secure and convenient attachment

InactiveUS6641525B2Eliminate cross-contaminationAvoid pollutionSuture equipmentsSurgical furnitureOperative Surgical ProceduresSurgical department

Surgical articles that are conveniently and securely coupled are disclosed. Improved surgical procedures are also disclosed.

Owner:STASKIN DAVID MD DR

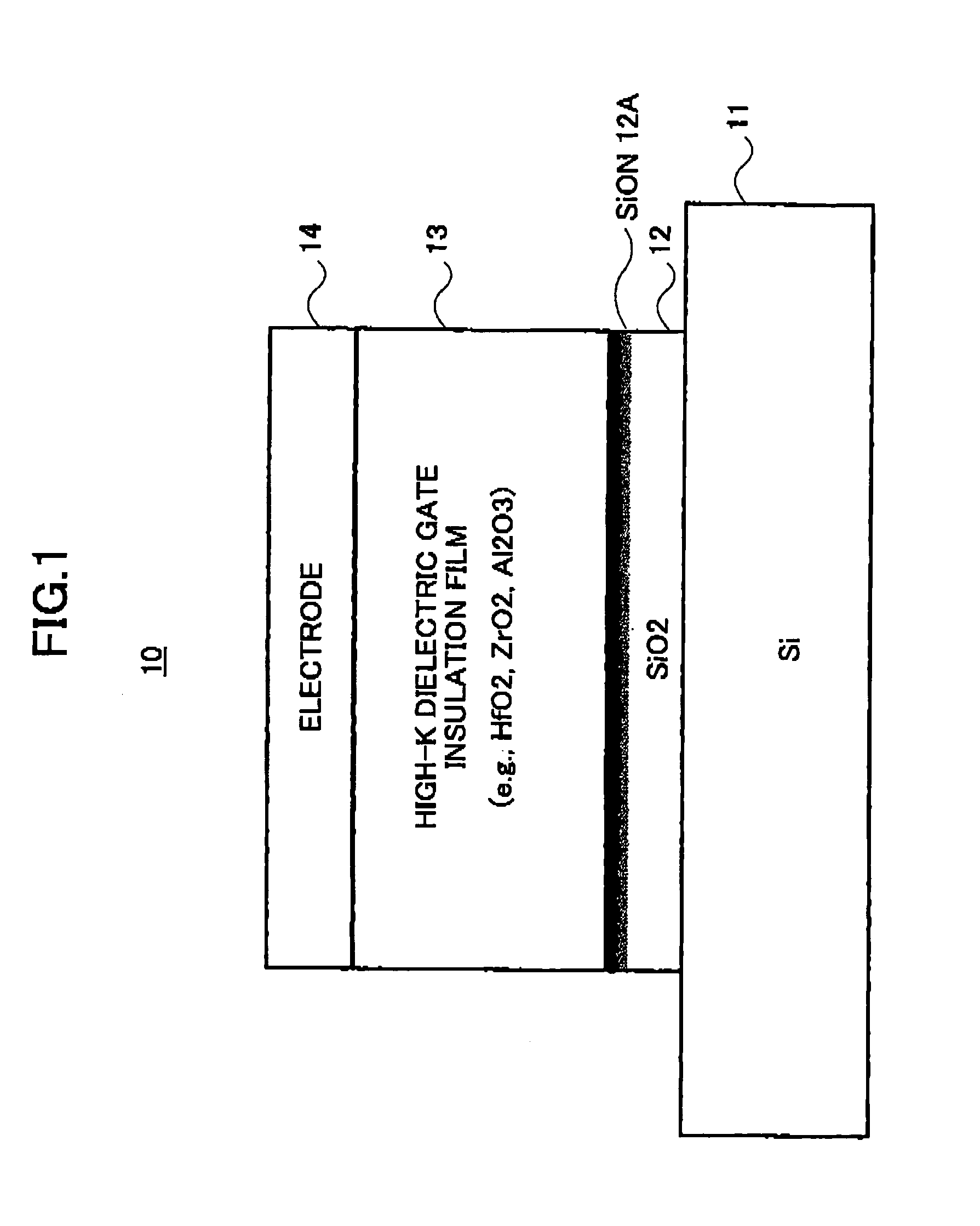

Board processing apparatus and method of fabricating semiconductor apparatus

InactiveUS20080087218A1Rapid gas flowReduce pressure differenceLiquid surface applicatorsSemiconductor/solid-state device manufacturingFast flowEngineering

A board processing apparatus and a method of fabricating a semiconductor apparatus for reducing a pressure difference between a preparing chamber and a processing chamber and restraining a rapid flow of a gas caused by the pressure difference to thereby prevent a board from being contaminated by a particle are disclosed.

Owner:NTT MOBILE COMM NETWORK INC

Structure of an optical interference display unit

InactiveUS6958847B2Avoid pollutionIncreased process complexityTelevision system detailsColor television detailsLight reflectionReflective layer

Owner:SNAPTRACK

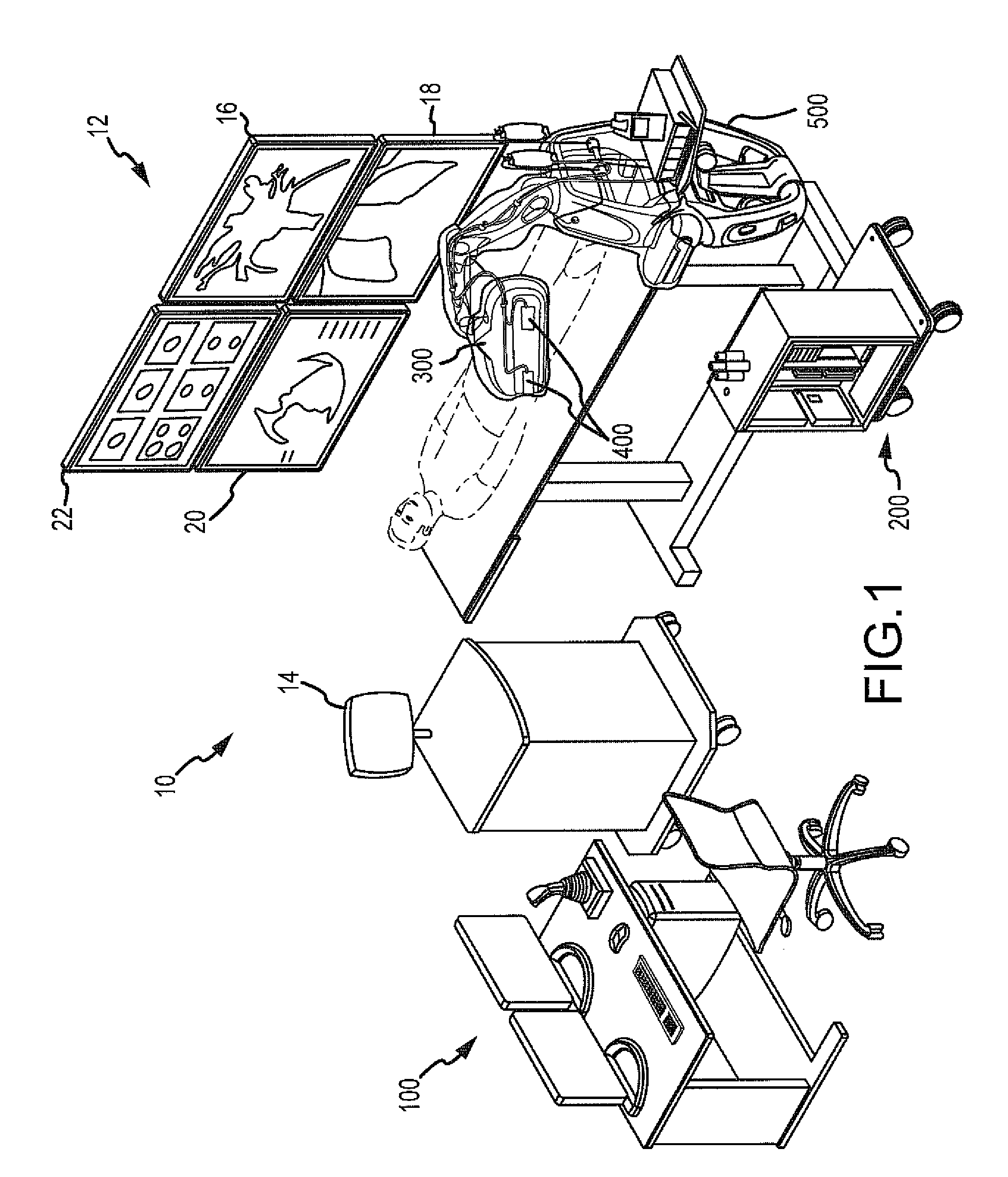

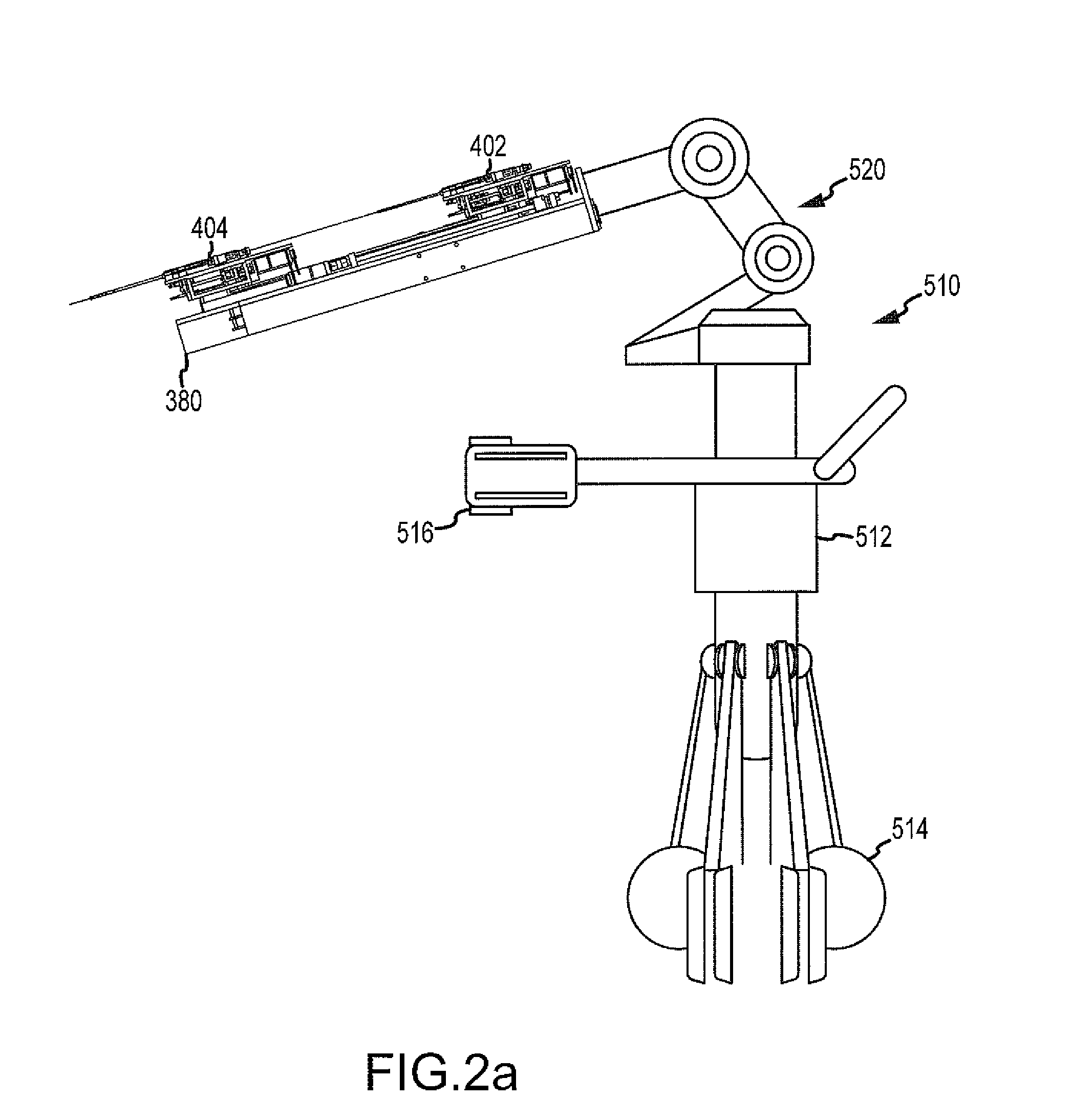

Robotic catheter system

ActiveUS20090247993A1Minimize and eliminate procedural variabilityEasy to transportDiagnosticsSurgical navigation systemsControl systemInput control

A robotic catheter system including one or more robotic catheter manipulator assemblies supported on a manipulator support structure. The robotic catheter manipulator assembly may include one or more removably mounted robotic catheter device cartridges and robotic sheath device cartridges, with each cartridge being generally linearly movable relative to the robotic catheter manipulator assembly. An input control system may be provided for controlling operation of the robotic catheter manipulator assembly. A visualization system may include one or more display monitors for displaying a position of a catheter and / or a sheath respectively attached to the robotic catheter and sheath device cartridges.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Sling assembly with secure and convenient attachment

InactiveUS20020151762A1Decrease rigidity and resistanceReduce amountSuture equipmentsSurgical furnitureSurgical departmentSurgical procedures

Surgical articles that are conveniently and securely coupled are disclosed. Improved surgical procedures are also disclosed.

Owner:STASKIN DAVID MD DR

System and process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether

ActiveCN101823929AHigh yieldHigh selectivityHydrogen separation using liquid contactHydrocarbon from oxygen organic compoundsAromatizationAromatic hydrocarbon

The invention relates to a system and a process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether and belongs to the technical field of aromatic hydrocarbon production. The methanol or the dimethyl ether serving as a raw material firstly reacts in an aromatization reactor; a reaction product is separated; H2, methane, mixed C8 aromatic hydrocarbon and partial C9s + hydrocarbons serving as products are output from the system; and C2+ non-aromatic hydrocarbon and aromatic hydrocarbons except the mixed C8 aromatic hydrocarbon and the partial C9s + hydrocarbons are take as a circular material flow and return to corresponding reactors for further aromatization reaction. By separating and recycling the product obtained in the process of aromizing the methanol or the dimethyl ether, the system and the process improve the yield and selectivity of the aromatic hydrocarbon; and moreover, the process is flexible, and target products can be changed according to market demands.

Owner:TSINGHUA UNIV

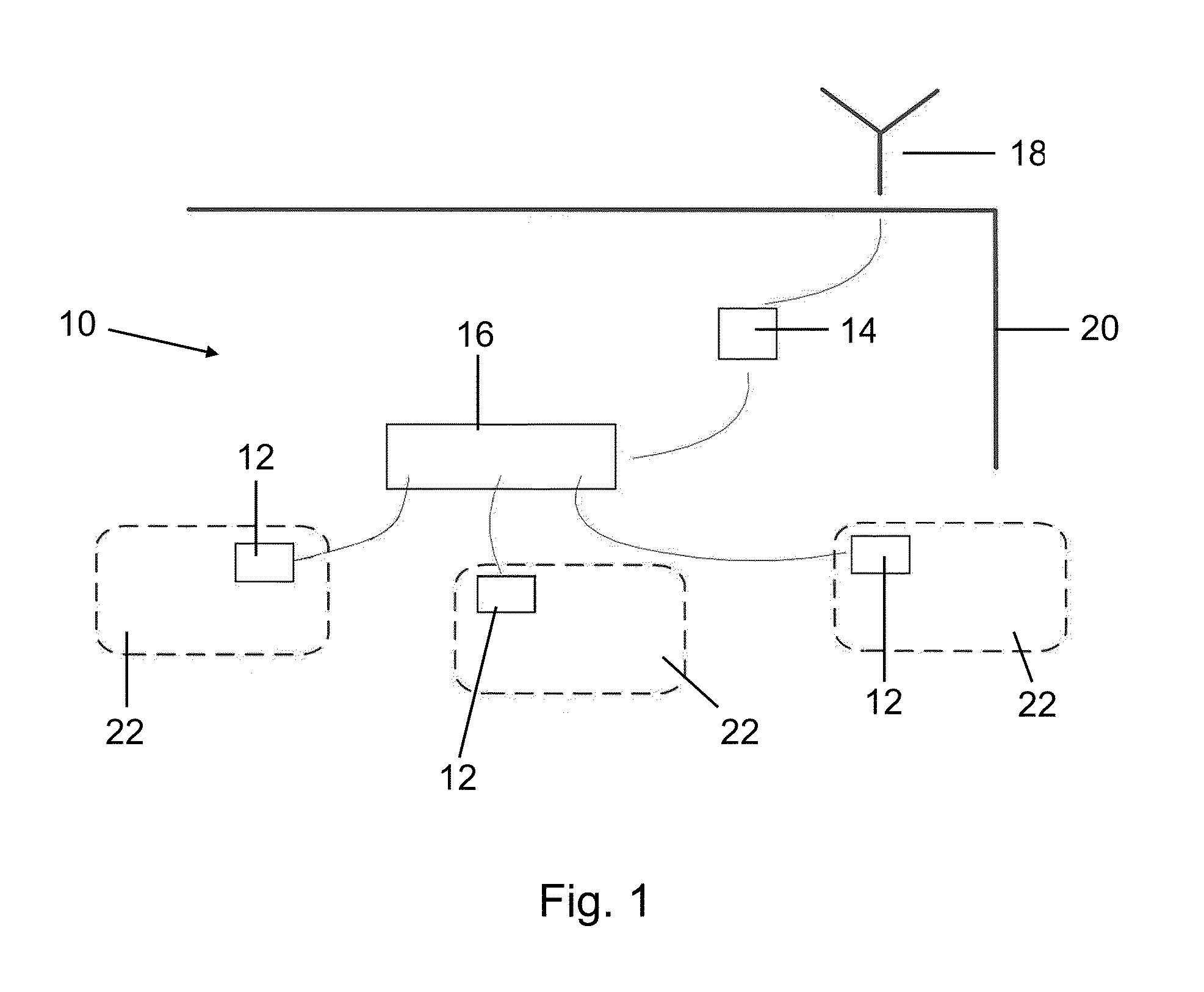

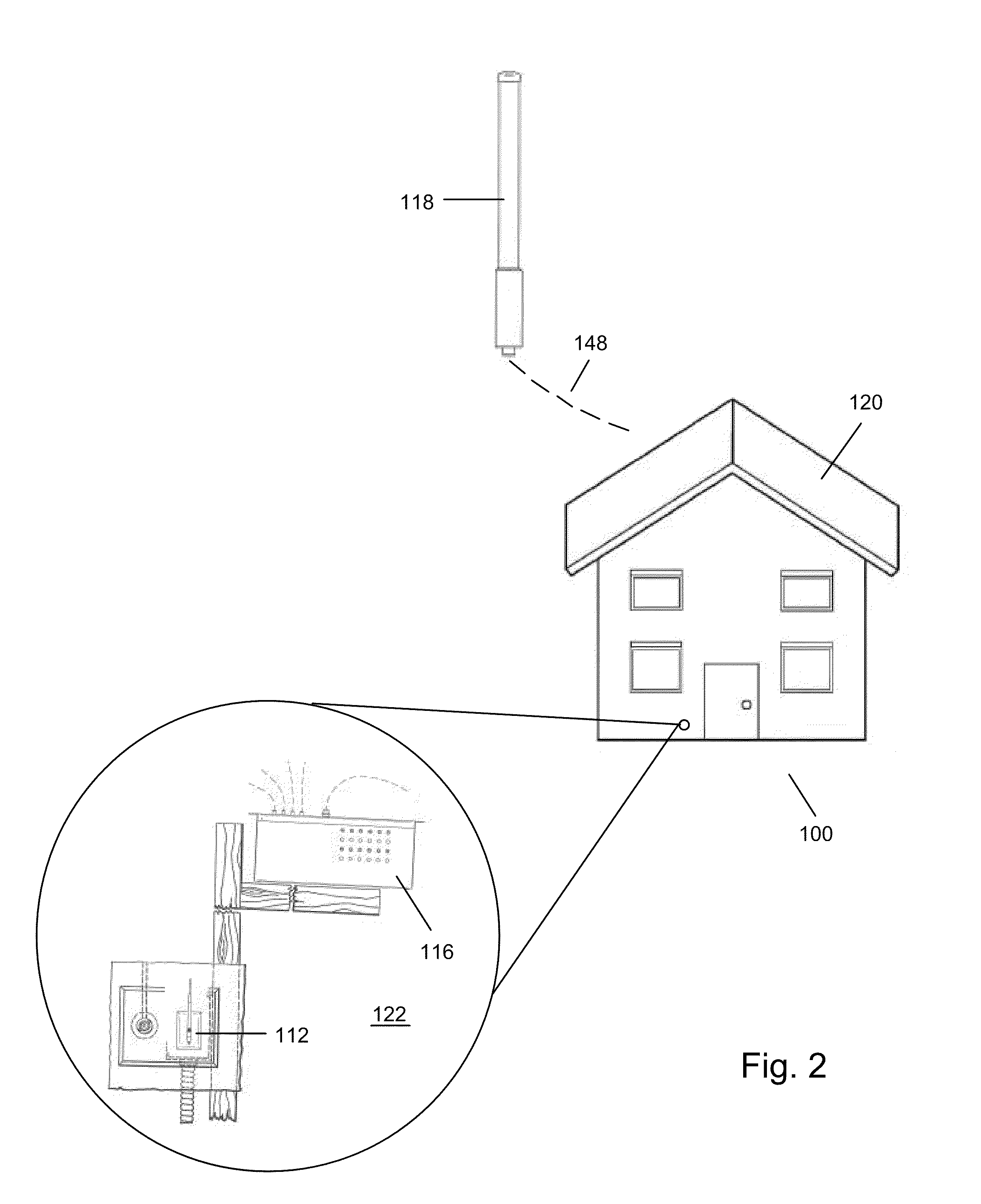

Method and Apparatus for Providing Wireless Communications Within a Building

ActiveUS20100080203A1Avoid pollutionSubstation equipmentRadio transmissionPatch panelStructured cabling

A wireless distribution secured cabling system includes faceplates, each of which contains an antenna or other radiating element and an active amplifier, which serves as a bi-directional repeater for the wireless communication system. The system further includes a patch panel or distribution module which connects multiple cables, which may be either twisted pair or coaxial, to amplifier, acting as a power divider and / or an impedance matching device. An antenna, which may be mounted either outside of a building structure or inside the building structure, provides communications between the structured cabling system and a service provider base station.

Owner:OPTICAL CABLE CORPORATION

Devices and methods for monitoring genomic DNA of organisms

InactiveUS20060257893A1Low costAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsGenomic DNADna amplification

The invention provides an apparatus that can be used in methods of preparing, amplifying, detecting, and / or optionally selecting for further analysis the genomic material from an organism for the rapid detection and / or classification of an organism in a sample (e.g., screening for, identifying, quantifying, and / or optionally further analyzing, e.g., sequencing, the genomic material of the organism). The invention further provides methods of using the apparatus, e.g., in combination with novel SGP primers for improved use in waveform-profiling methods of DNA amplification. It is an object of the invention to provide an apparatus for fully automated analysis of genomic material, and multiple methods of using the apparatus that are beneficial to society, e.g., the apparatus may be used in methods of screening for, identifying, quantifying, and / or selecting genomic material for further analysis (e.g., sequencing) in relation to monitoring a source for the presence of contaminating organisms.

Owner:CANON US LIFE SCIENCES INC

Detachable shaft flexible endoscope

ActiveUS9107573B2Good adhesionEasy detachmentSurgeryEndoscopesElectric power transmissionFlexible endoscopy

A flexible endoscope includes a handle, a flexible shaft having a distal end and a proximal end, a coupling mechanism releasably attaching the handle to the distal end of the flexible shaft, an illumination unit disposed in the flexible shaft, the illumination unit providing light to an area in front of the distal end of the flexible shaft, and an imaging unit disposed in the flexible shaft, the imaging unit generating image data of the area in front of the distal end of the flexible shaft, wherein the coupling mechanism includes an electrical channel for transmitting electrical power to the illumination unit and the imaging unit, and a data channel for transmitting the image data from the imaging unit.

Owner:KARL STORZ ENDOVISION INC

Medical Device with Transcutaneous Cannula Device

InactiveUS20080215006A1Avoid damagePrevent escapeMedical devicesPressure infusionCannula deviceMedical device

The present invention generally relates to the insertion of a transcutaneous device of the type comprising a cannula (651) and a therein moveably arranged insertion needle (661), as well as the connecting of such a transcutaneous device with a fluid supply. Thus, a device is provided comprising an insertion needle and a cannula disposed on and being axially moveable relative to the insertion needle, the insertion needle comprising a proximal fluid inlet, a seal (655) being provided between the cannula and the insertion needle allowing fluid to be transported from the fluid inlet to the distal fluid outlet, wherein the insertion needle after having been used to insert the cannula is arranged at a retracted position proximally of the initial position, thereby allowing the fluid inlet to be connected to a fluid supply when it is moved from its initial to its retracted position.

Owner:NOVO NORDISK AS

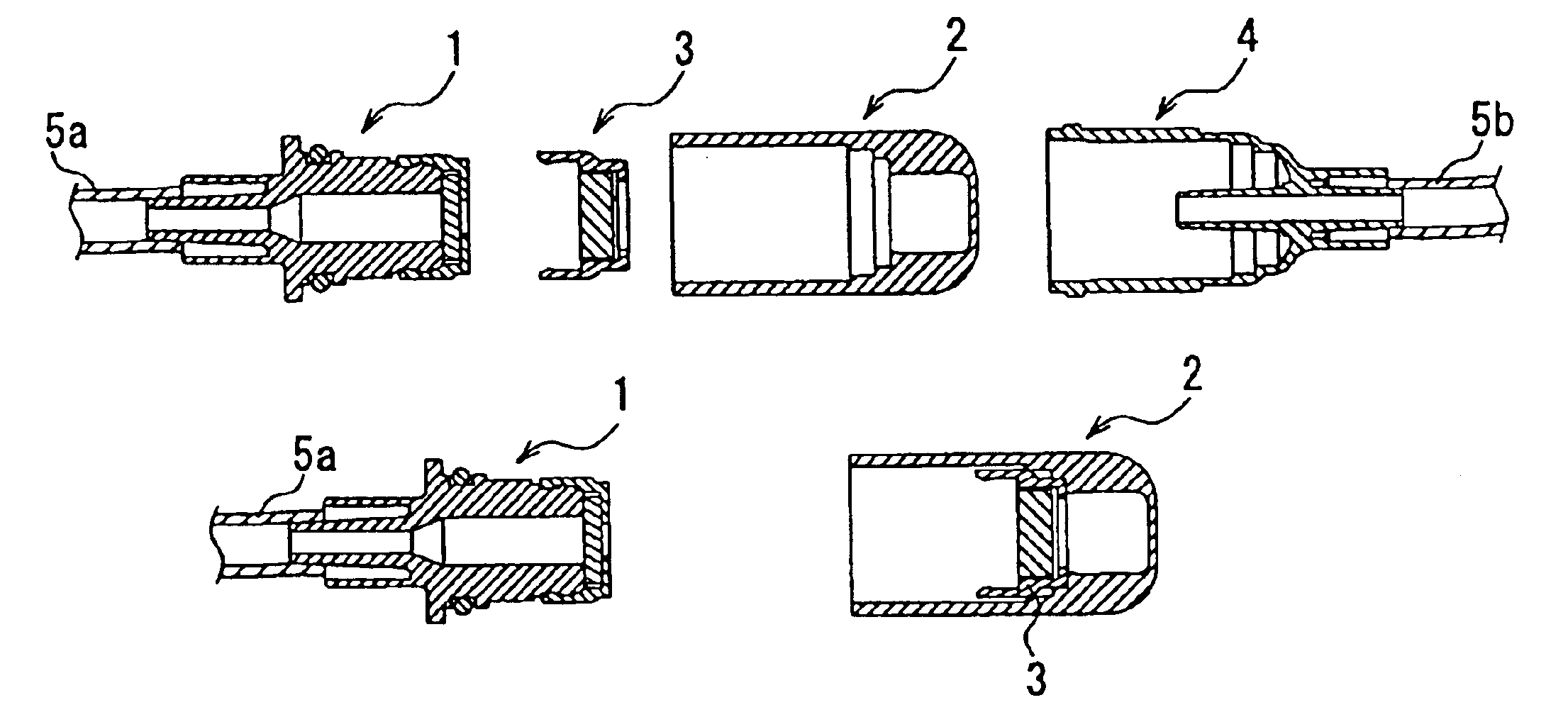

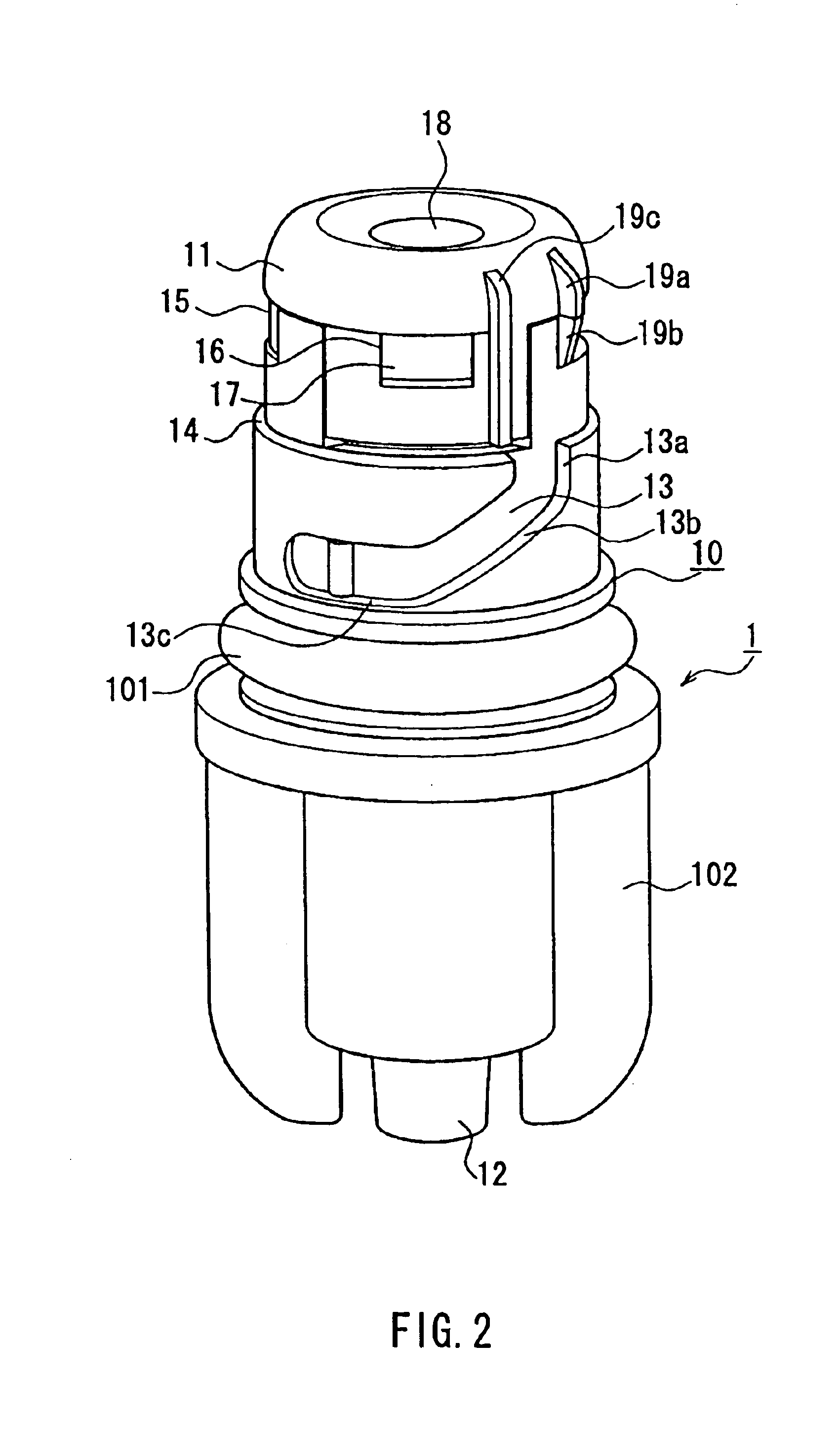

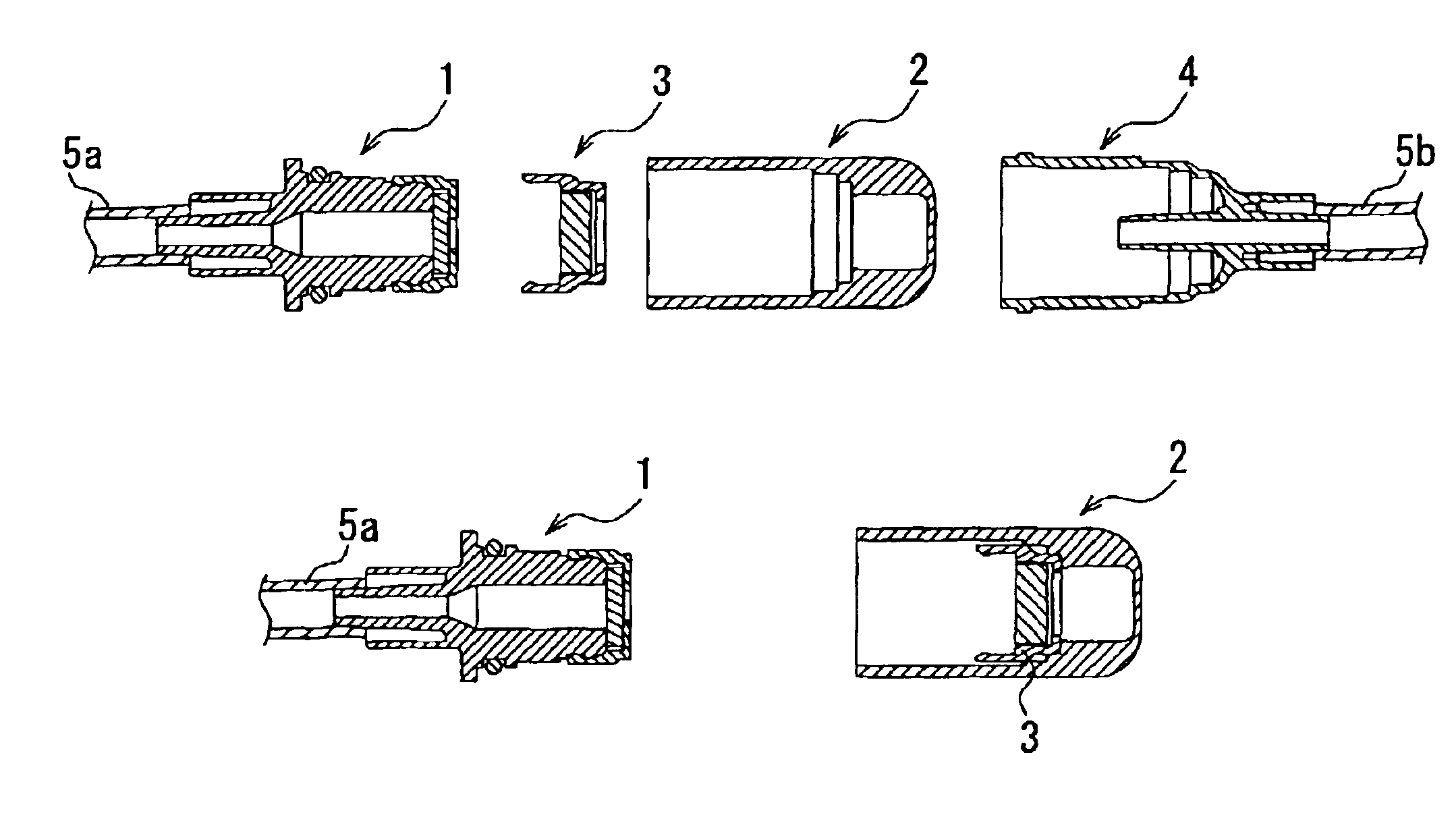

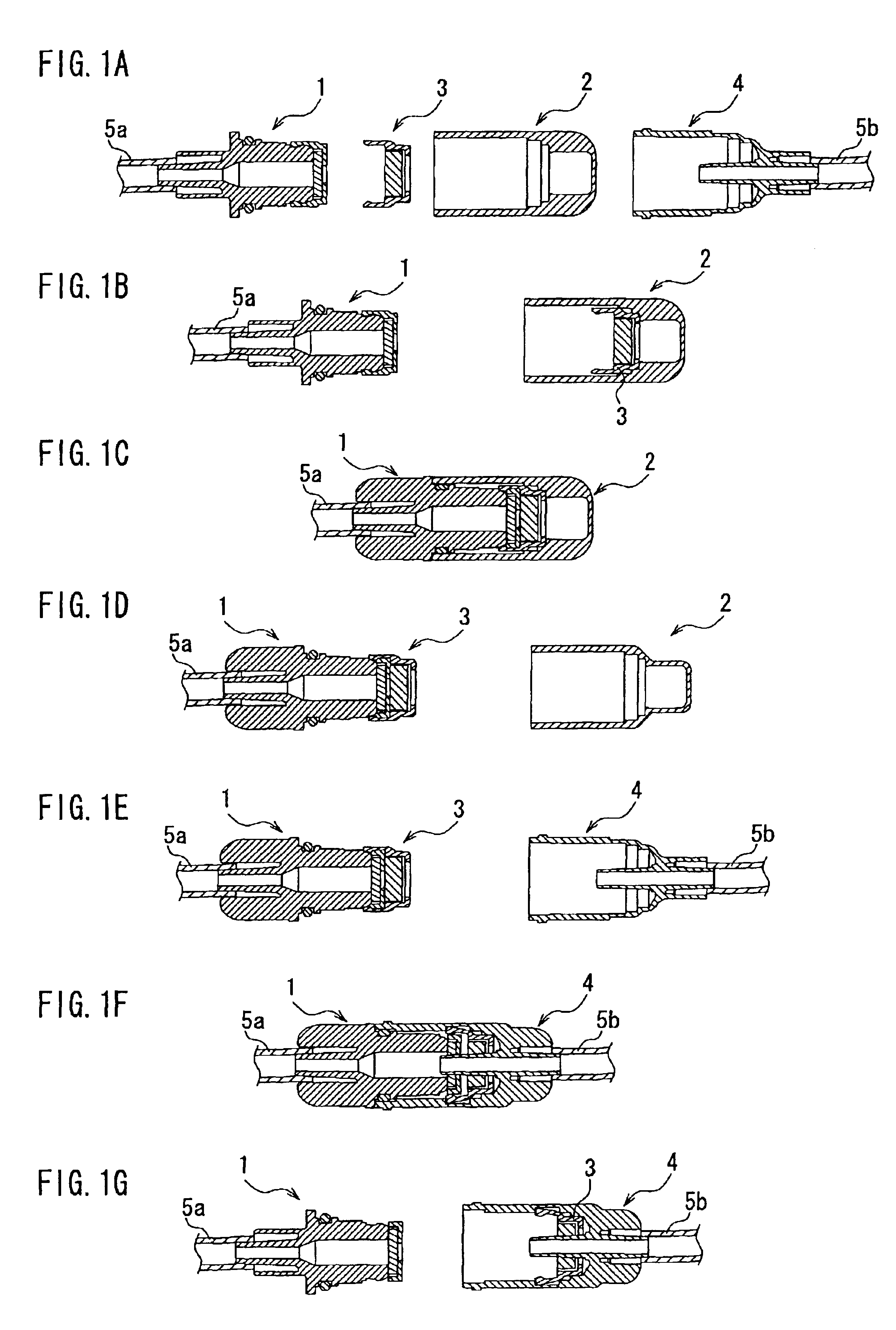

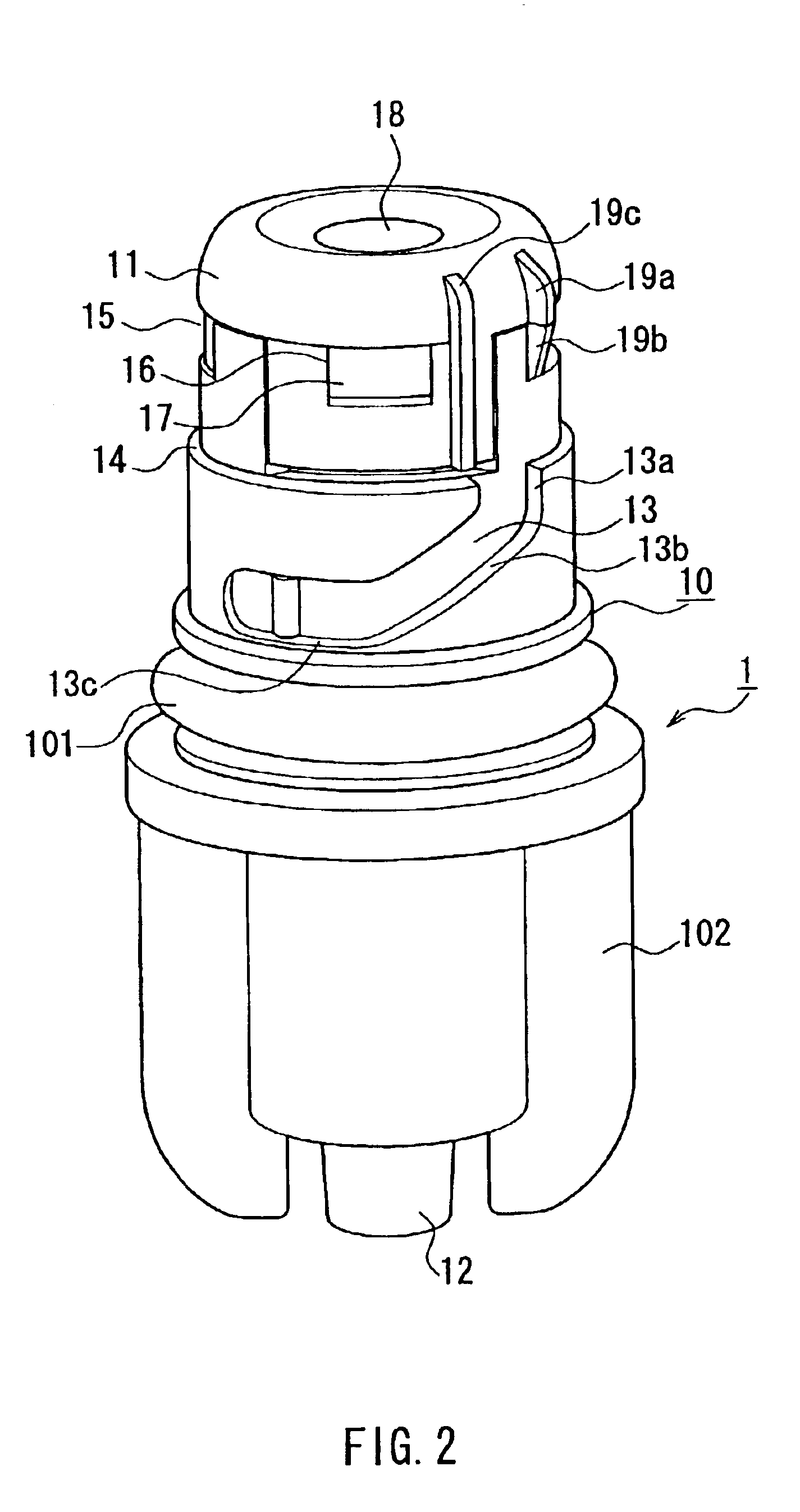

Connector system for sterile connection

A connector system for sterile connection includes a male type connector having a tube connecting portion at a rear end portion thereof, a protective cap for the patient side connector, an inner cap held in the protective cap and including a ring-shaped portion that supports a disinfectant-impregnated member therein, and a female type connector including an outer cylinder and an inner cylinder fixed at one end of the outer cylinder, where the inner cylinder includes an internal end portion located inside the outer cylinder and an external end portion exposed outside the outer cylinder. When the protective cap is fitted with the male type connector, the disinfectant-impregnated member contacts with the male type connector. When the protective cap is removed therefrom, the inner cap becomes retained in the male type connector. When such a male type connector is connected with the female type connector, the internal end portion of the inner cylinder penetrates through the disinfectant-impregnated member and a septum. When the connection is released, the inner cap is detached from the male type connector.

Owner:JMS CO LTD

Self sealing disconnect device

Owner:MEDTRONIC MIMIMED INC

Connector system for sterile connection

A connector system for sterile connection includes a male type patient side connector having a tube connecting portion at a rear end portion thereof, a protective cap for the patient side connector, an inner cap held in the protective cap and including a ring-shaped portion that supports a disinfectant-impregnated member therein, and a female type circuit side connector including an outer cylinder and an inner cylinder fixed at one end of the outer cylinder, where the inner cylinder includes an internal end portion located inside the outer cylinder and an external end portion exposed outside the outer cylinder. When the protective cap is fitted with the patient side connector, the disinfectant-impregnated member contacts with the patient side connector. When the protective cap is removed therefrom, the inner cap becomes retained in the patient side connector. When such a patient side connector is connected with the circuit side connector, the internal end portion of the inner cylinder penetrates through the disinfectant-impregnated member and a septum. When the connection is released, the inner cap is detached from the patient side connector.

Owner:JMS CO LTD

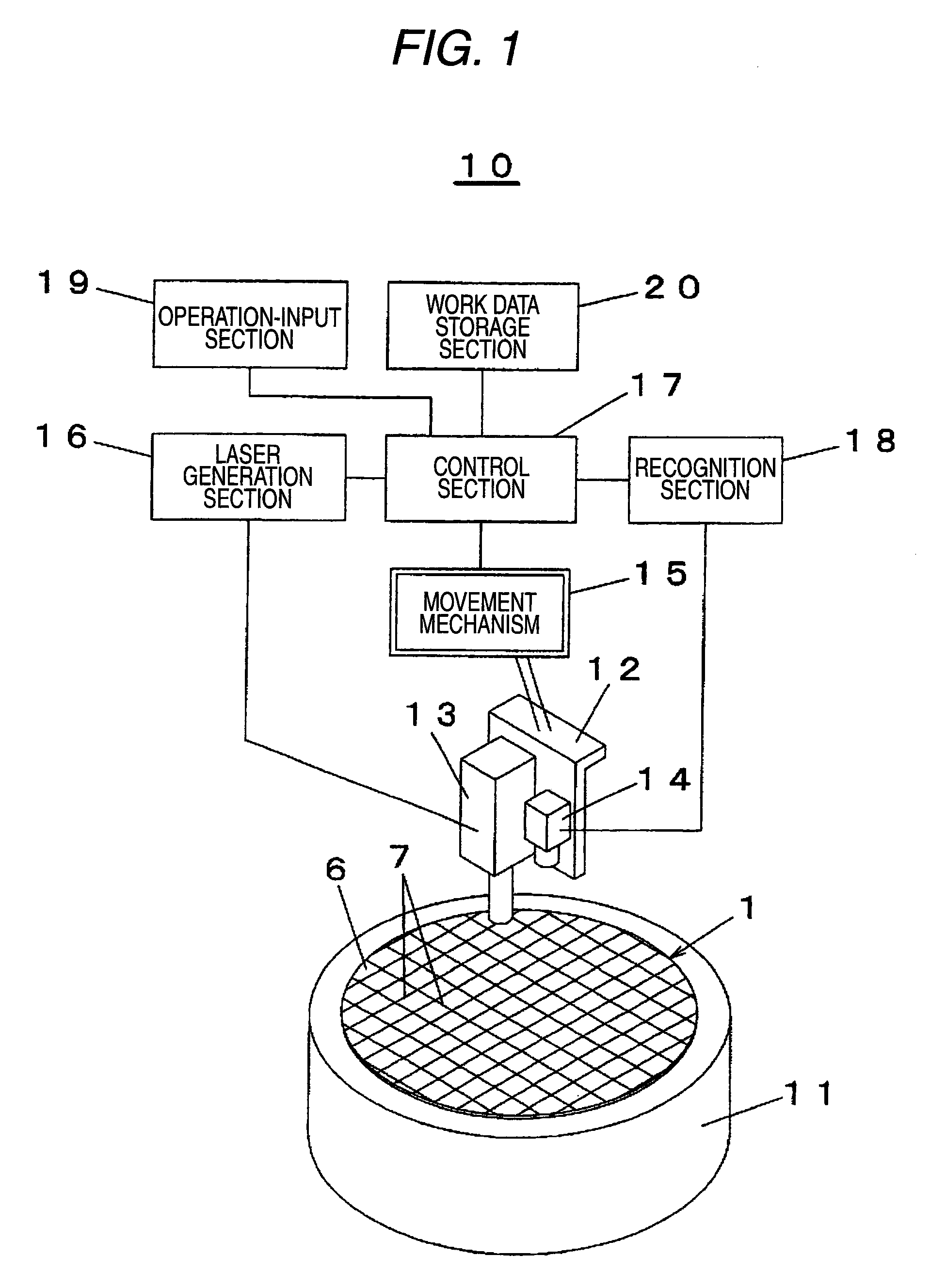

Method for fabricating semiconductor chip

ActiveUS7767551B2Avoid pollutionUnnecessary removalSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

After a film layer 6 formed from a die attach film 4 and a UV tape 5 has been provided as a mask on a semiconductor wafer 1, boundary trenches 7 for partitioning semiconductor elements 2 formed on a circuit pattern formation surface 1a are formed in the film layer 6, thereby making a surface 1c of a semiconductor wafer 1 exposed. The exposed surface 1c of the semiconductor wafer 1 in the boundary trenches 7 is etched by means of plasma of a fluorine-based gas, and the semiconductor wafer 1 is sliced into semiconductor chips 1′ along the boundary trenches 7.

Owner:PANASONIC CORP

Fiber optic adapter with integrated shutter

InactiveUS20090028507A1Reduce in quantityLower component costsCoupling light guidesFiberUltrasonic welding

The present invention relates generally to fiber optic connectors and adapters, and more specifically to a simplified fiber optic adapter assembly and integrated shutter mechanism. In various embodiments, the simplified fiber optic adapter assembly includes a one-piece outer housing, a one or two-piece inner housing, and several different clip arrangements, reducing the number of parts associated with conventional fiber optic adapter assemblies and eliminating the need for ultrasonic welding or the like. In various embodiments, the integrated shutter mechanism includes one or more shutter doors that are opened internally via the motion required for connector installation.

Owner:CORNING CABLE SYST LLC

Surface electromyographic electrode assembly

InactiveUS6865409B2Easily conform to body contourAvoid pollutionSurgeryDiagnostic recording/measuringElectrical conductorEngineering

An electrode assembly for use on a surface of biological tissue to measure bio-electric signals including an electrode apparatus having an electrode device adapted to directly contact the surface of the biological tissue. The electrode apparatus receives and transmits bio-electric signals measured across the biological tissue having a first voltage and a minute first current. A signal transmission line is included having a signal transmission conductor electrically coupled at one portion to the electrode device for transmission of the bio-electric signals. The transmission includes a second conductor electrically coupled to the amplifier apparatus and arranged to substantially shield the transmission conductor from ambient electric fields generated from sources external to the transmission line. A high impedance amplifier device is included having a signal input and a signal output. The signal input is electrically coupled to another portion of the signal transmission conductor for receipt of the transmitted bio-electric signals. The signal output is electrically coupled to the shield conductor, in a feedback loop, for receipt of at least a portion of the transmitted bio-electric signals, such that the voltage of the signals at the signal input of the high impedance amplifier device is maintained substantially equal to the voltage of the signals output from the signal output thereof.

Owner:KINESENSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com