Patents

Literature

1064 results about "Pattern formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The science of pattern formation deals with the visible, (statistically) orderly outcomes of self-organization and the common principles behind similar patterns in nature. In developmental biology, pattern formation refers to the generation of complex organizations of cell fates in space and time. Pattern formation is controlled by genes. The role of genes in pattern formation is an aspect of morphogenesis, the creation of diverse anatomies from similar genes, now being explored in the science of evolutionary developmental biology or evo-devo. The mechanisms involved are well seen in the anterior-posterior patterning of embryos from the model organism Drosophila melanogaster (a fruit fly), one of the first organisms to have its morphogenesis studied, and in the eyespots of butterflies, whose development is a variant of the standard (fruit fly) mechanism.

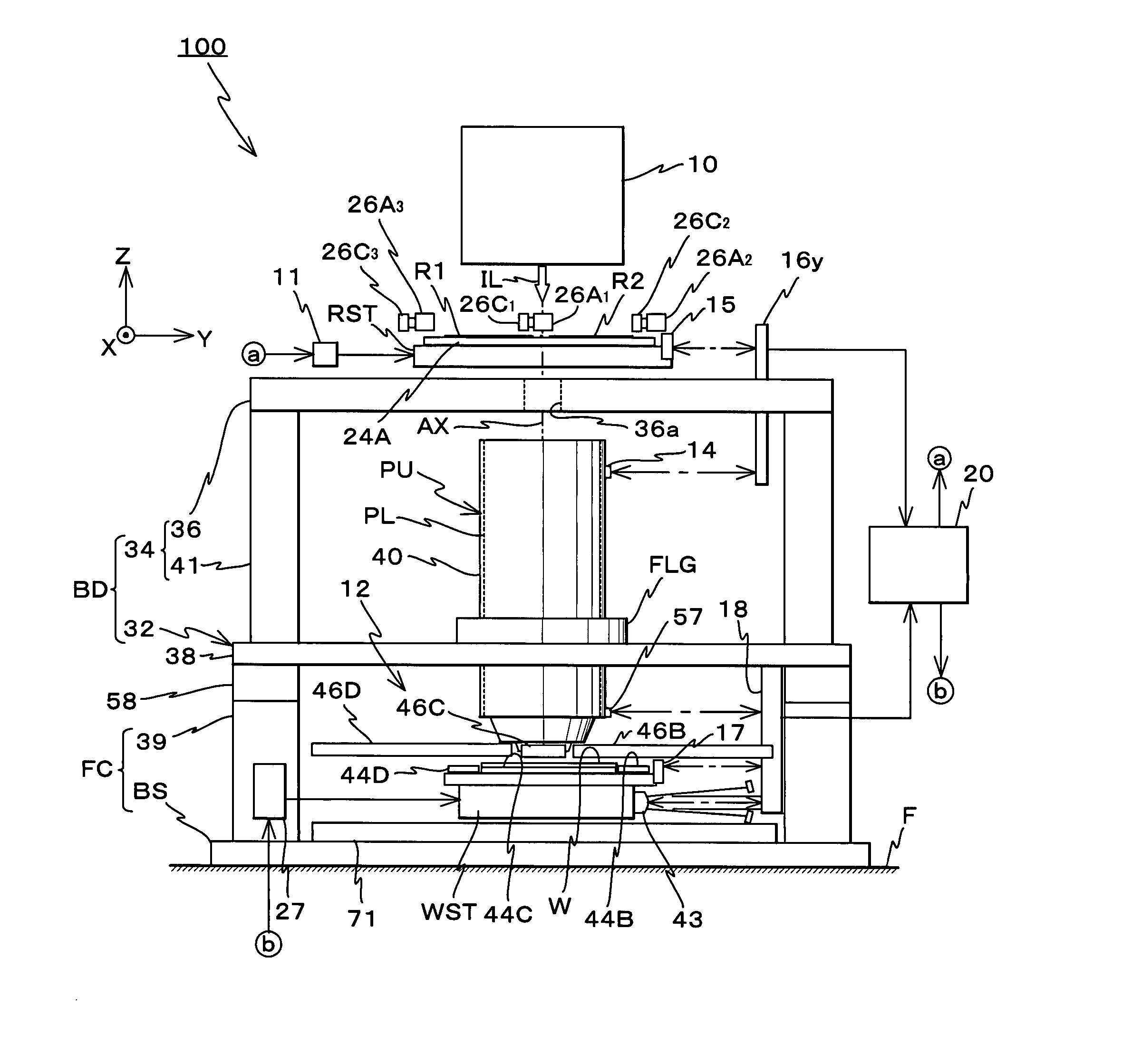

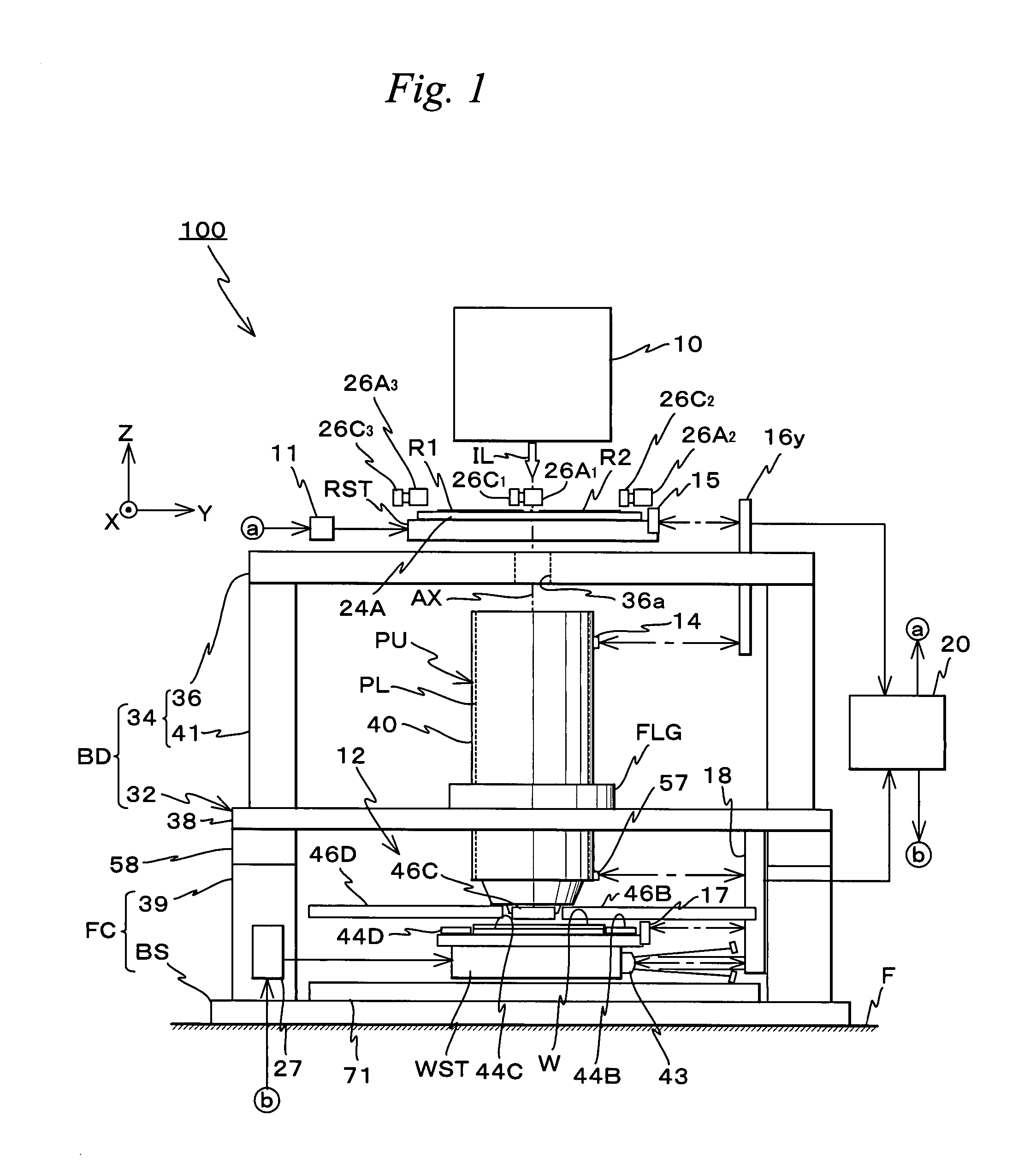

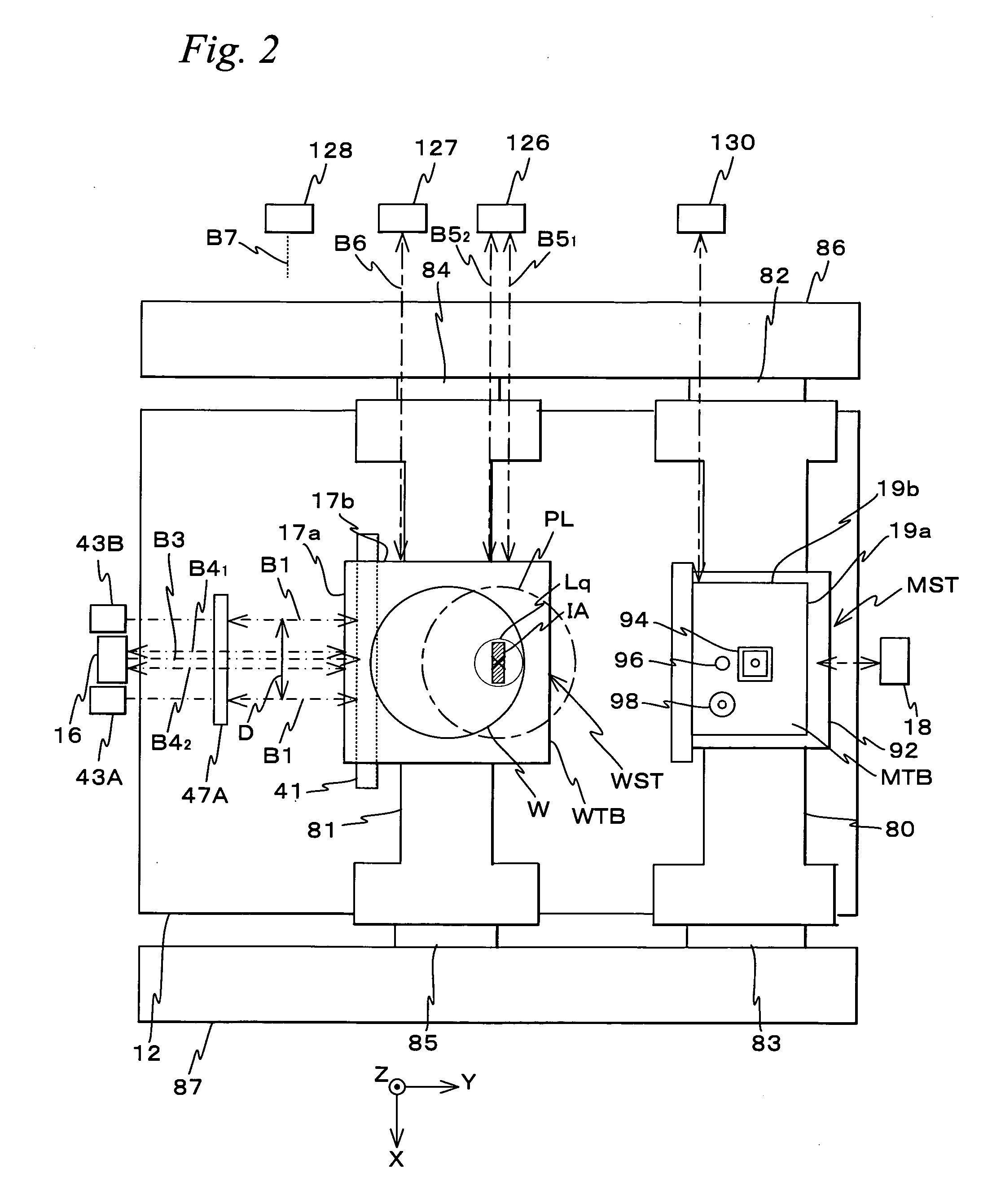

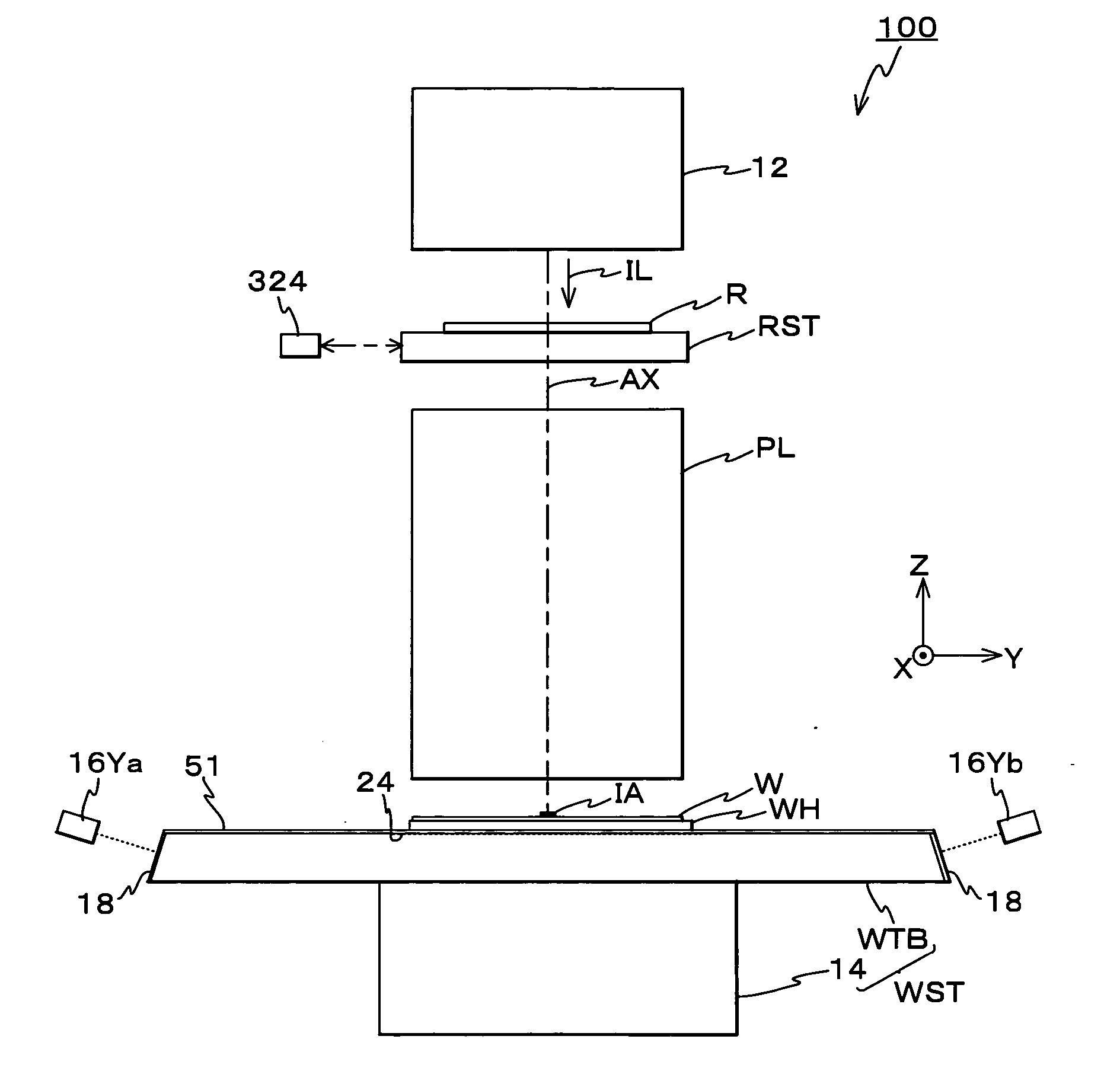

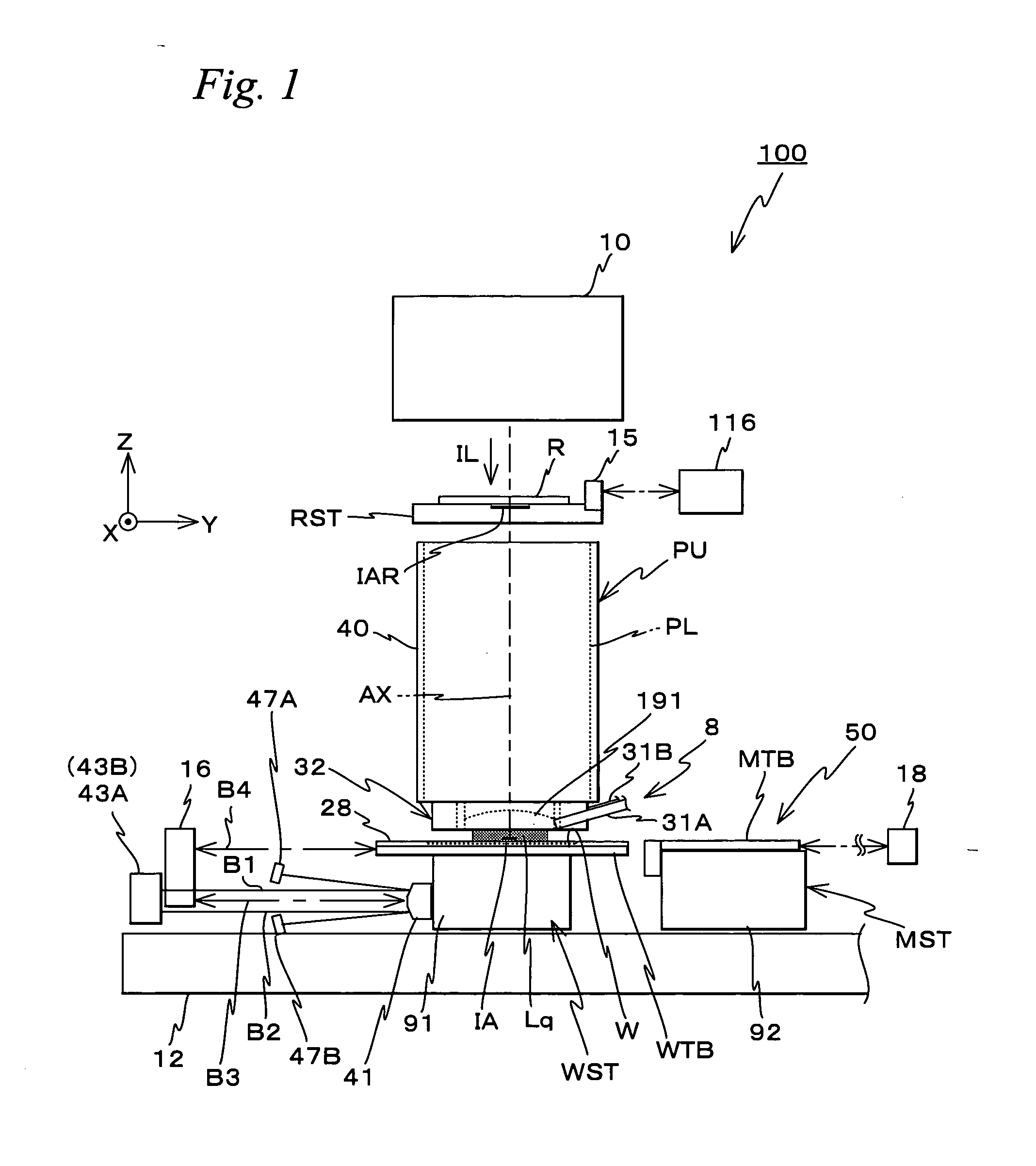

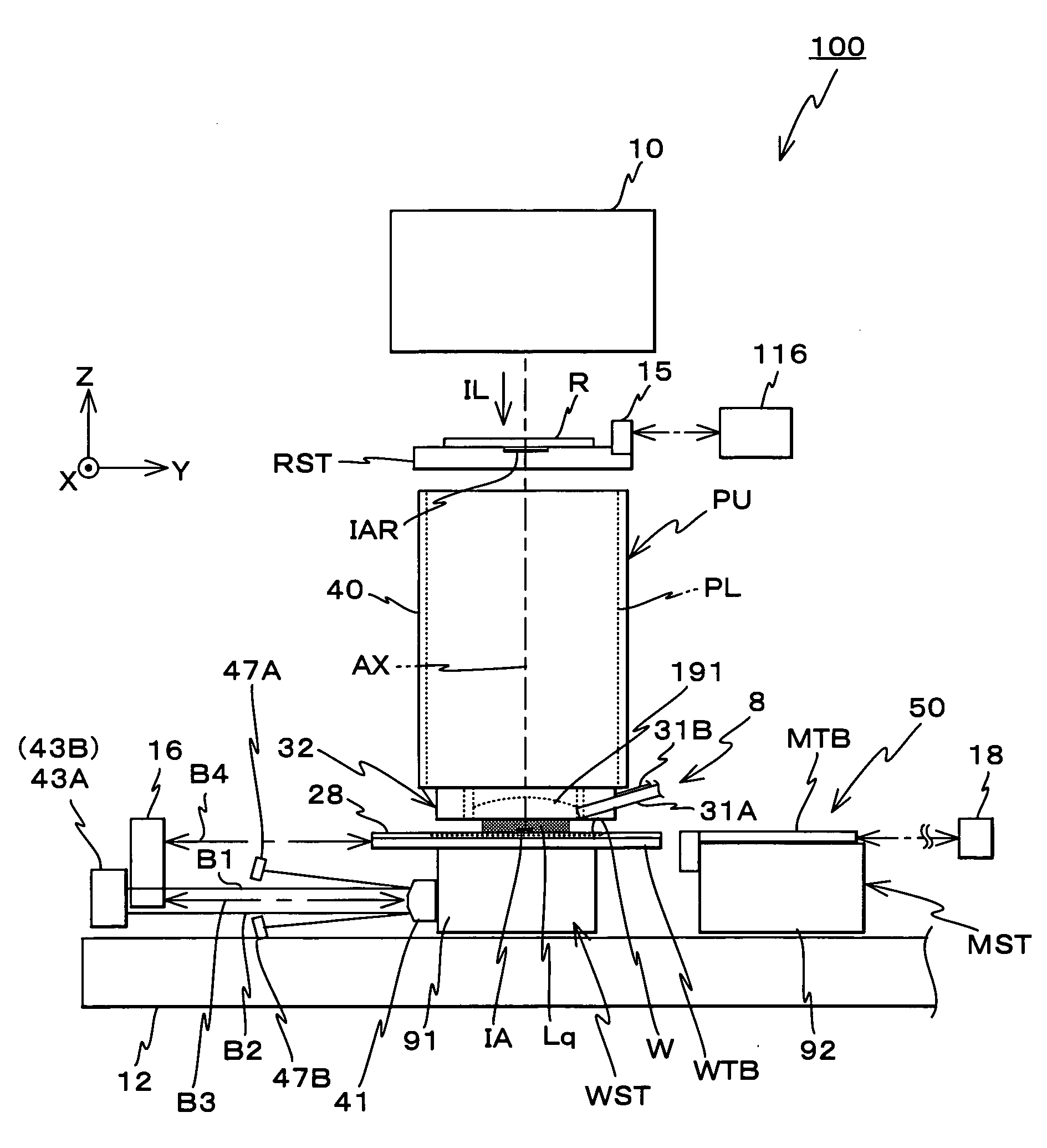

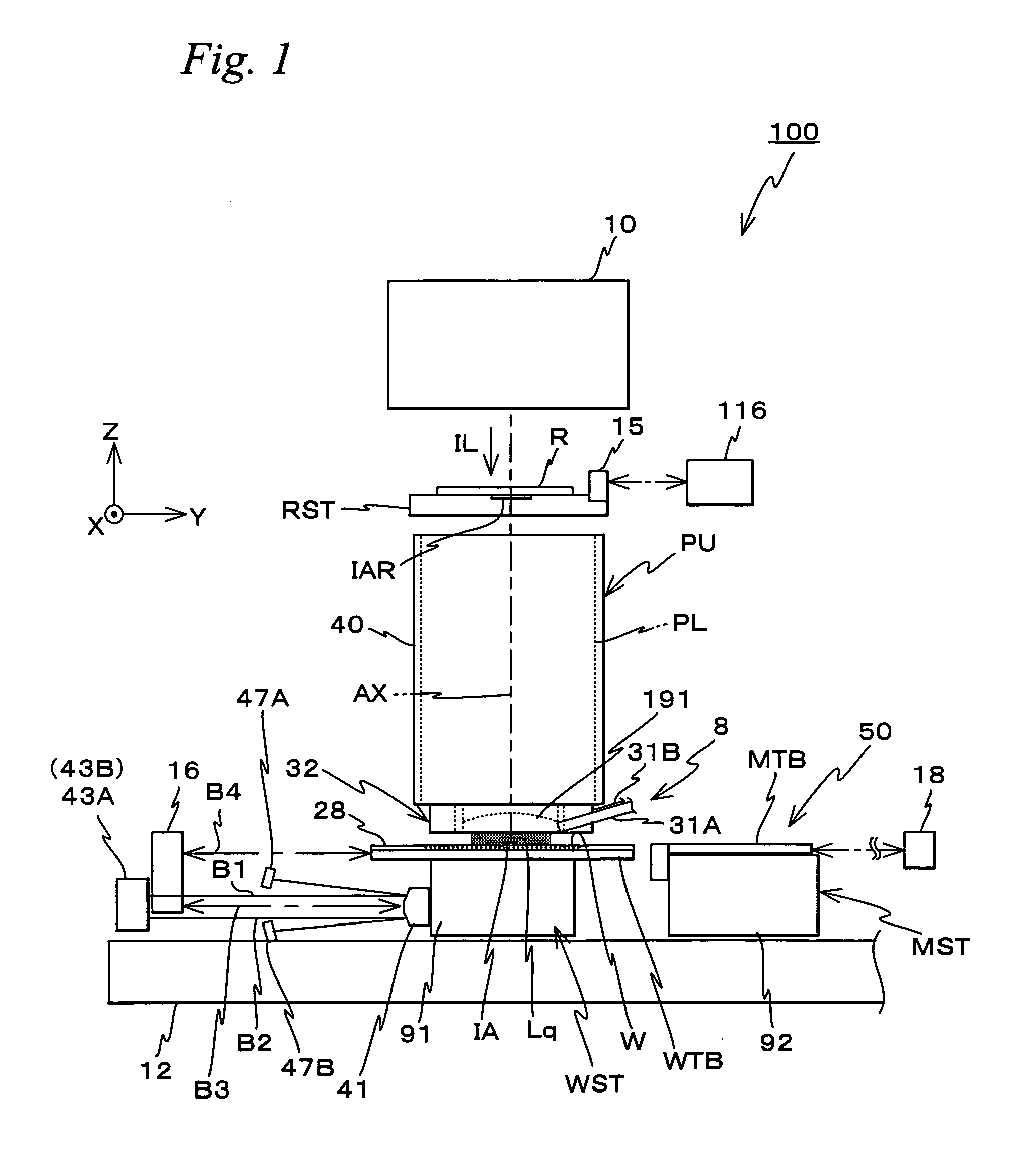

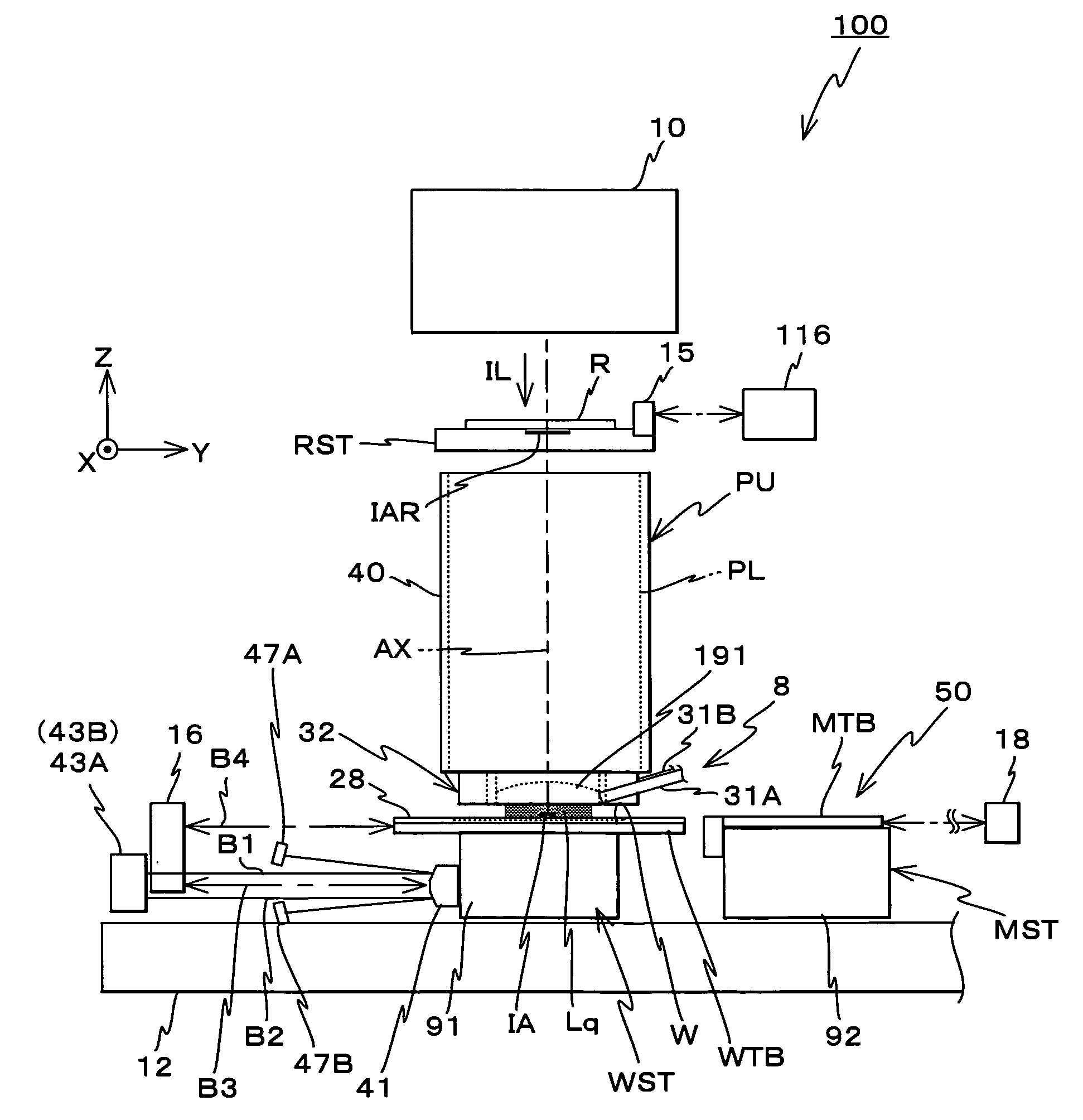

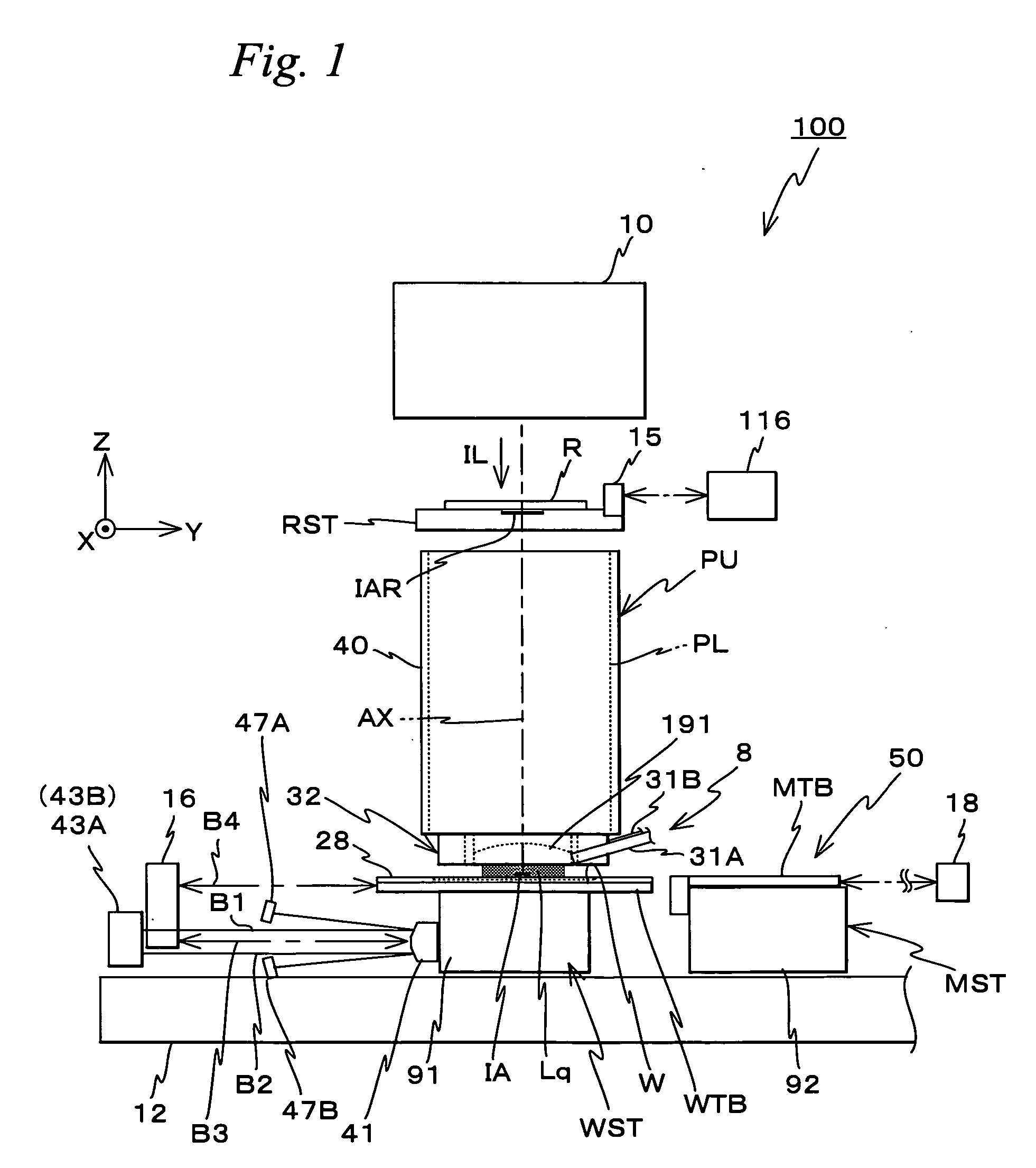

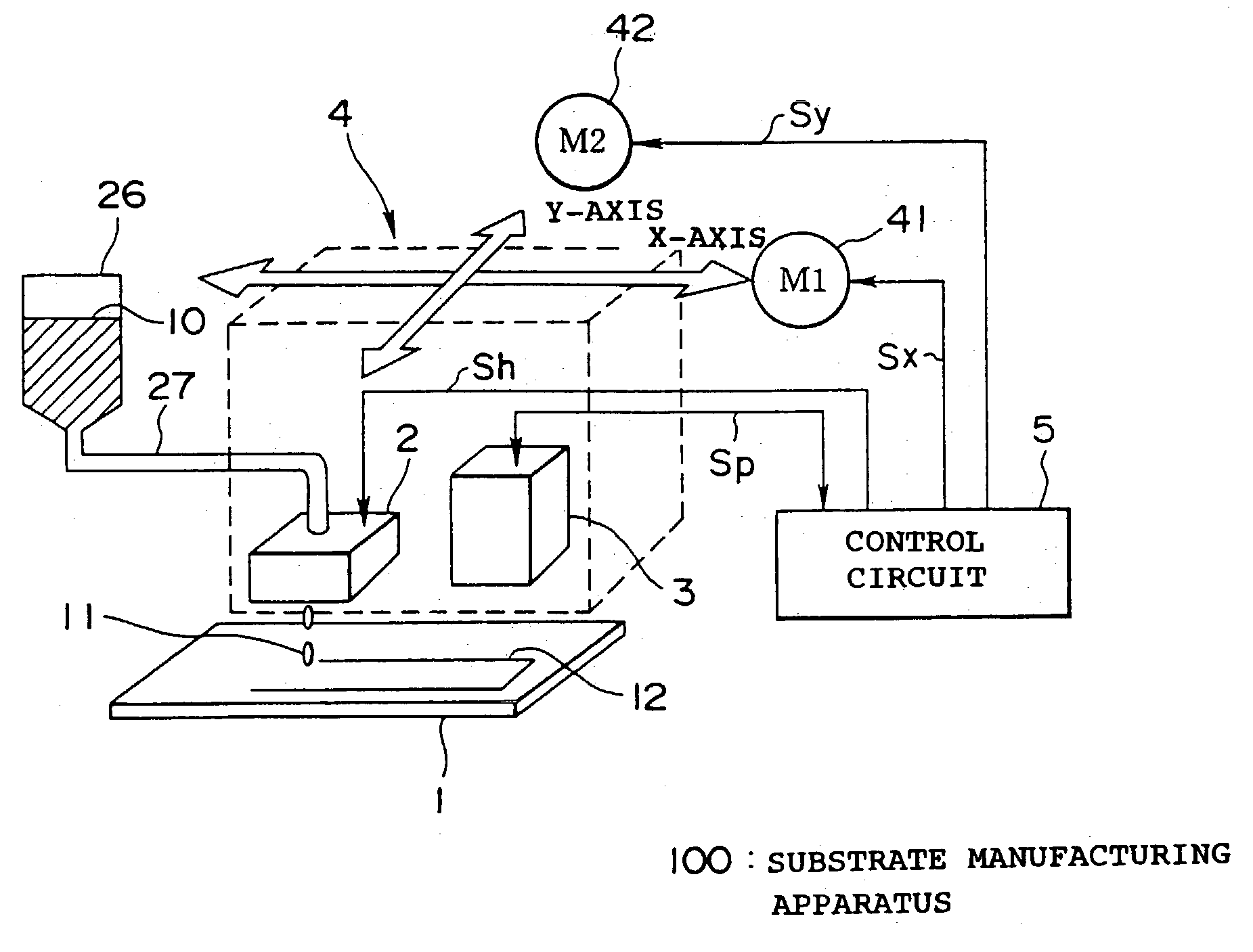

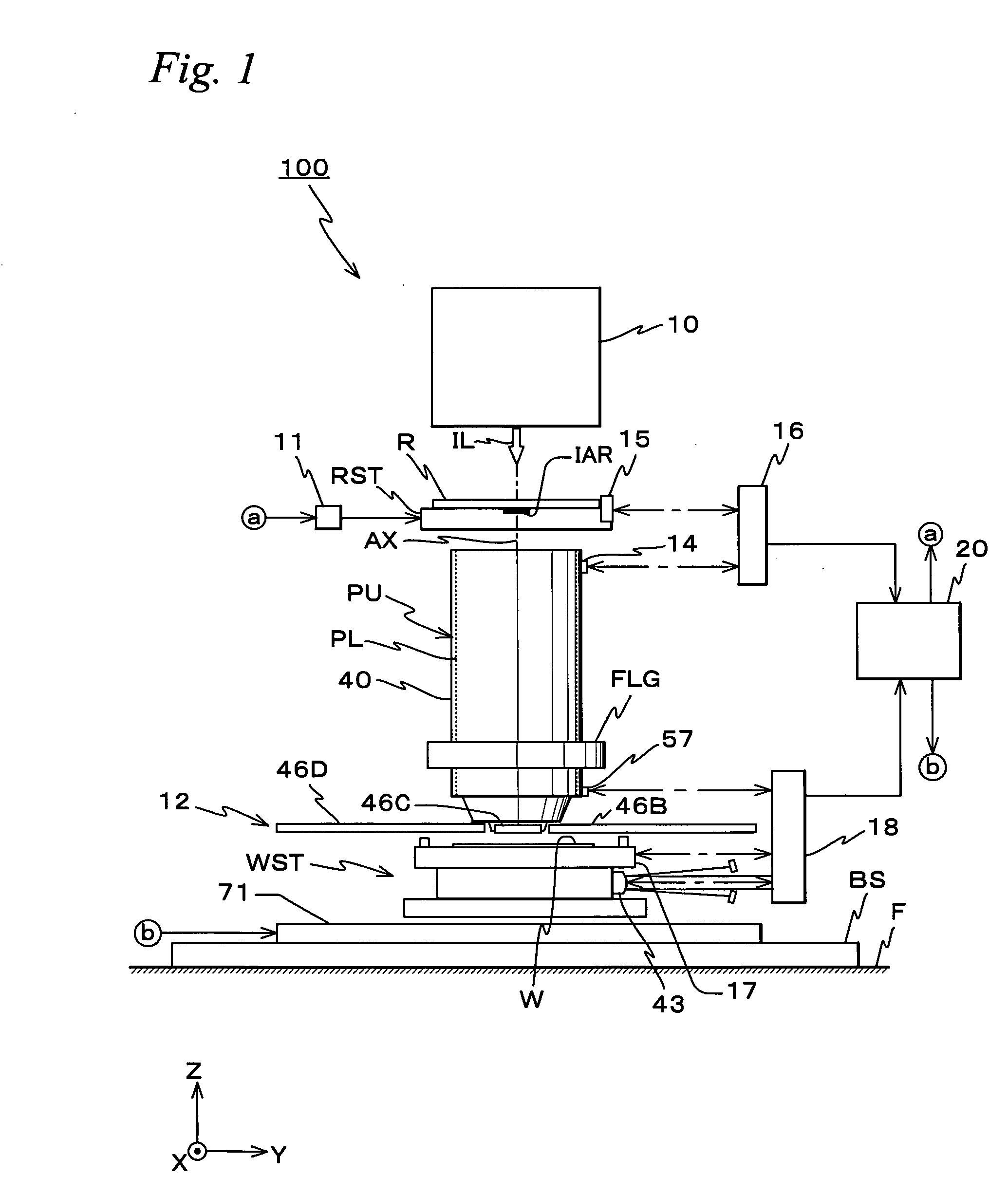

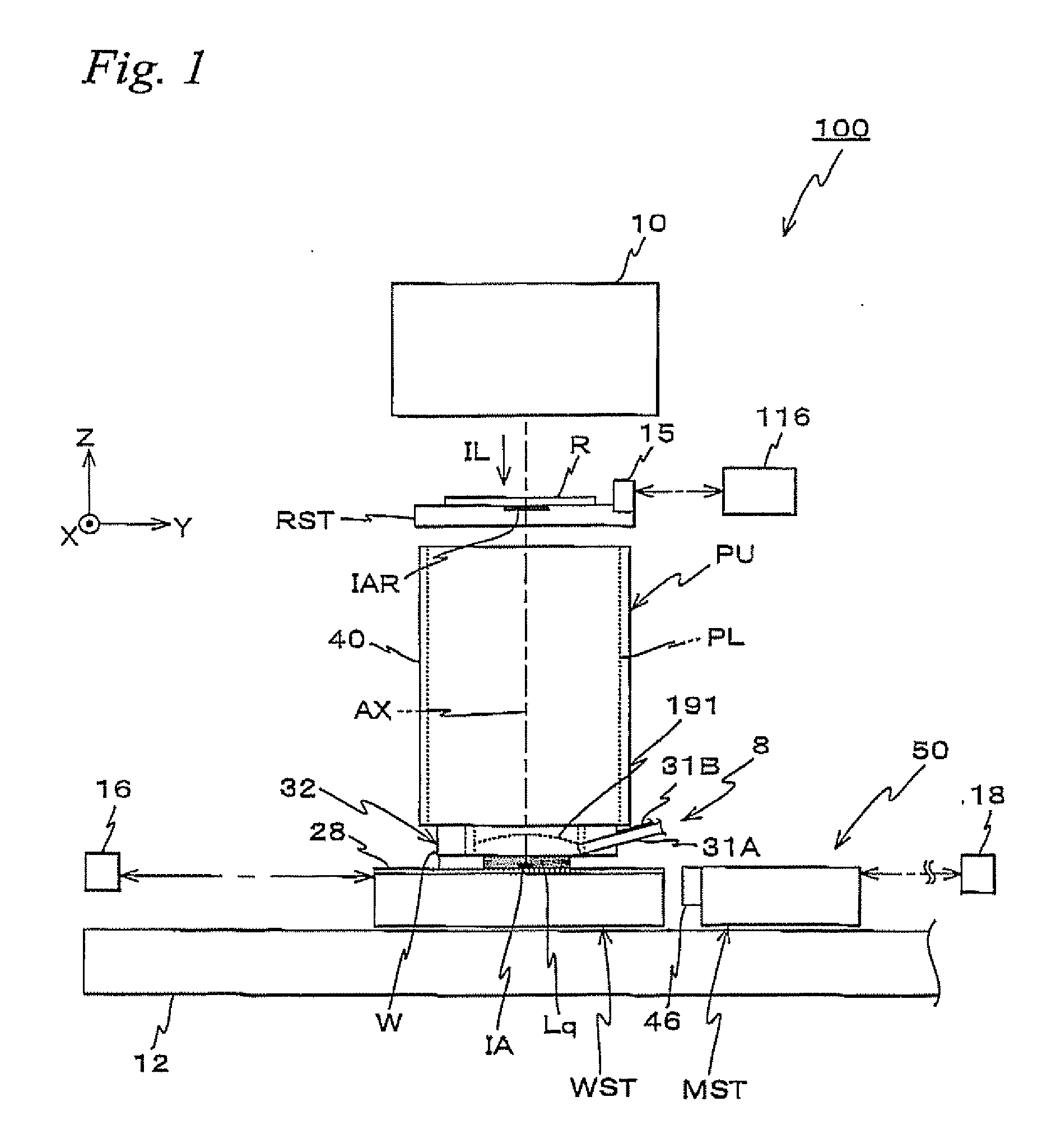

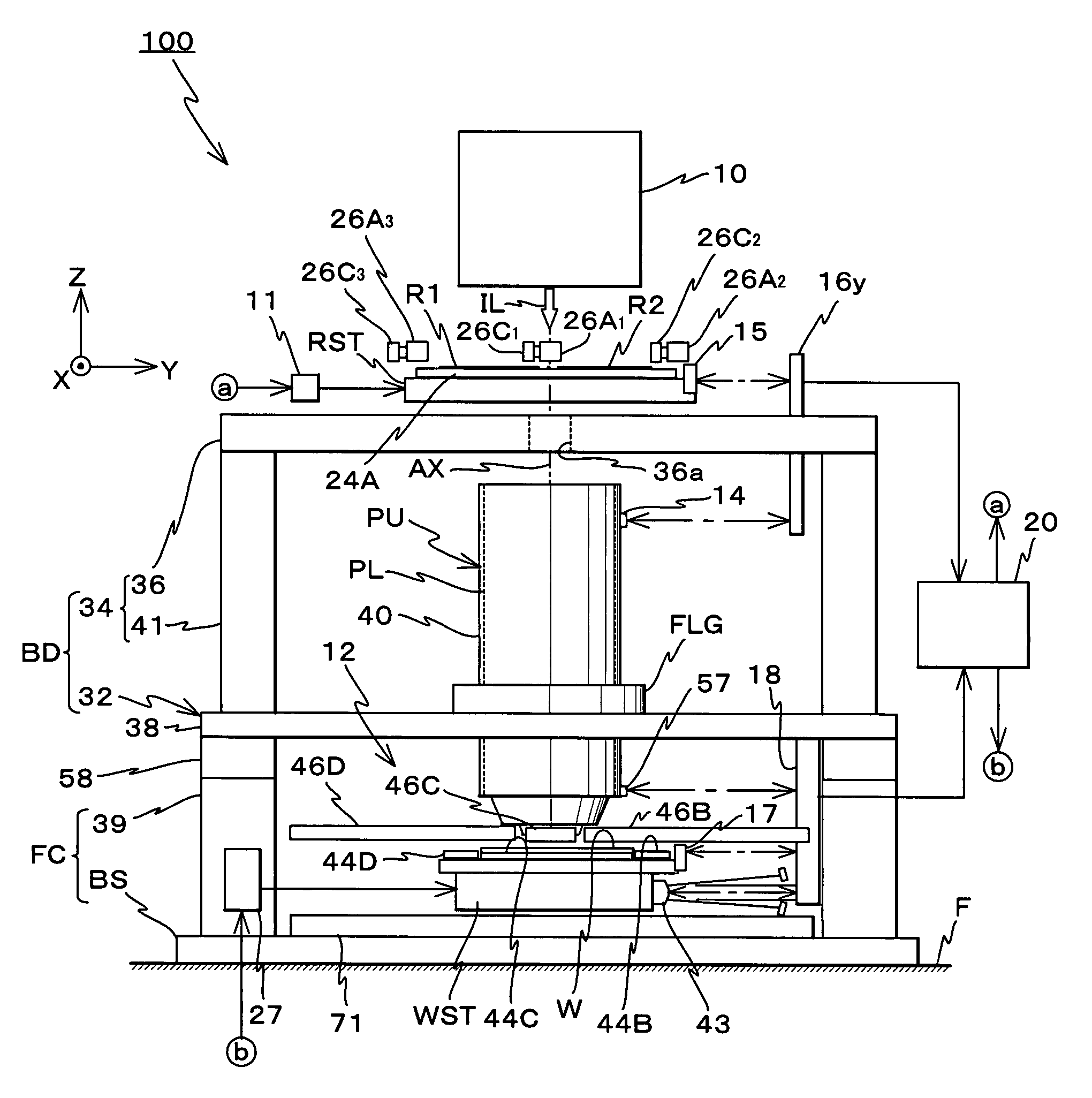

Movable body drive method, movable body drive system, pattern formation method, pattern forming apparatus, exposure method, exposure apparatus, and device manufacturing method

InactiveUS20070288121A1Improve accuracyScaling errorDigital data processing detailsSemiconductor/solid-state device manufacturingComputational physicsShort term stability

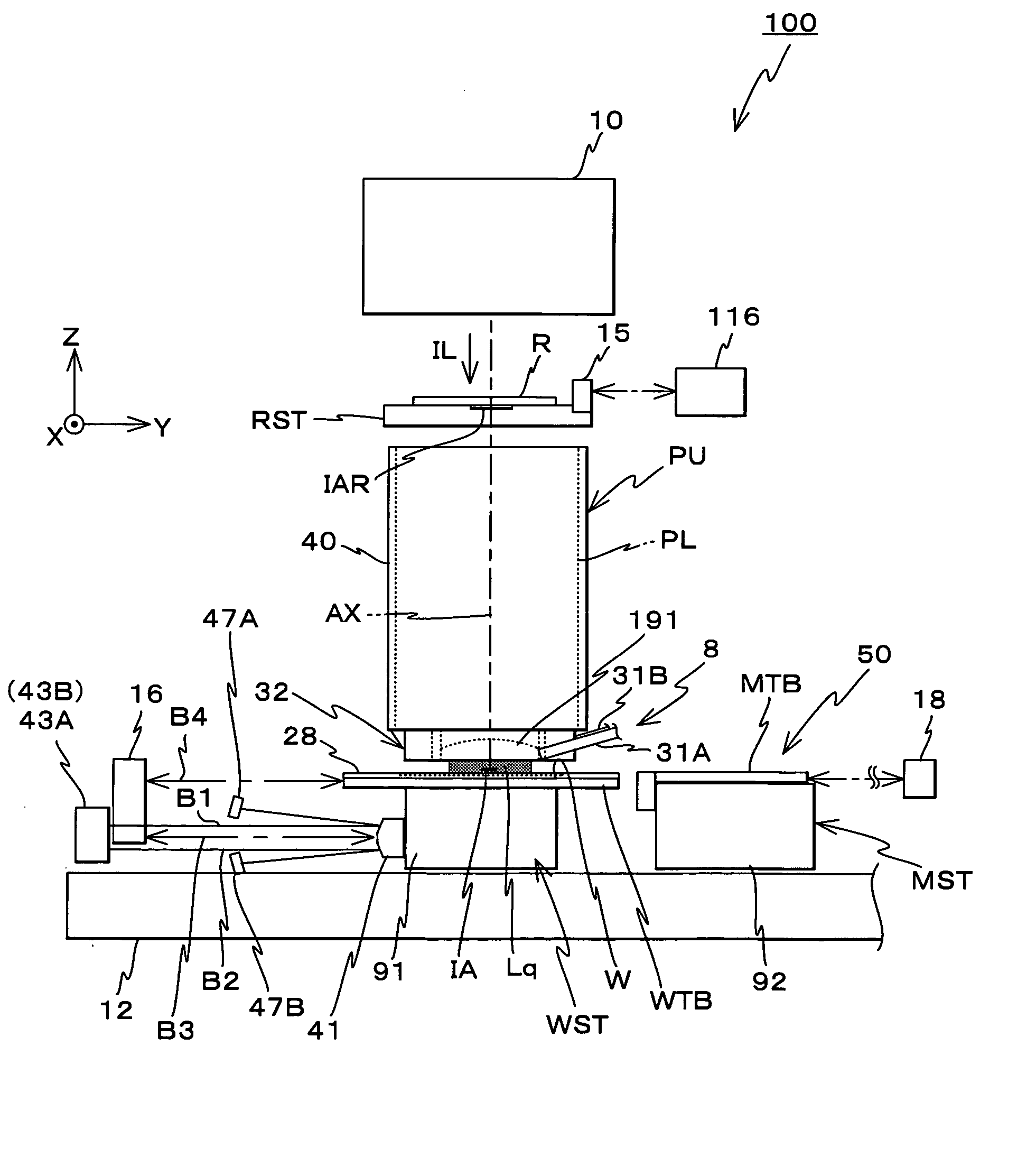

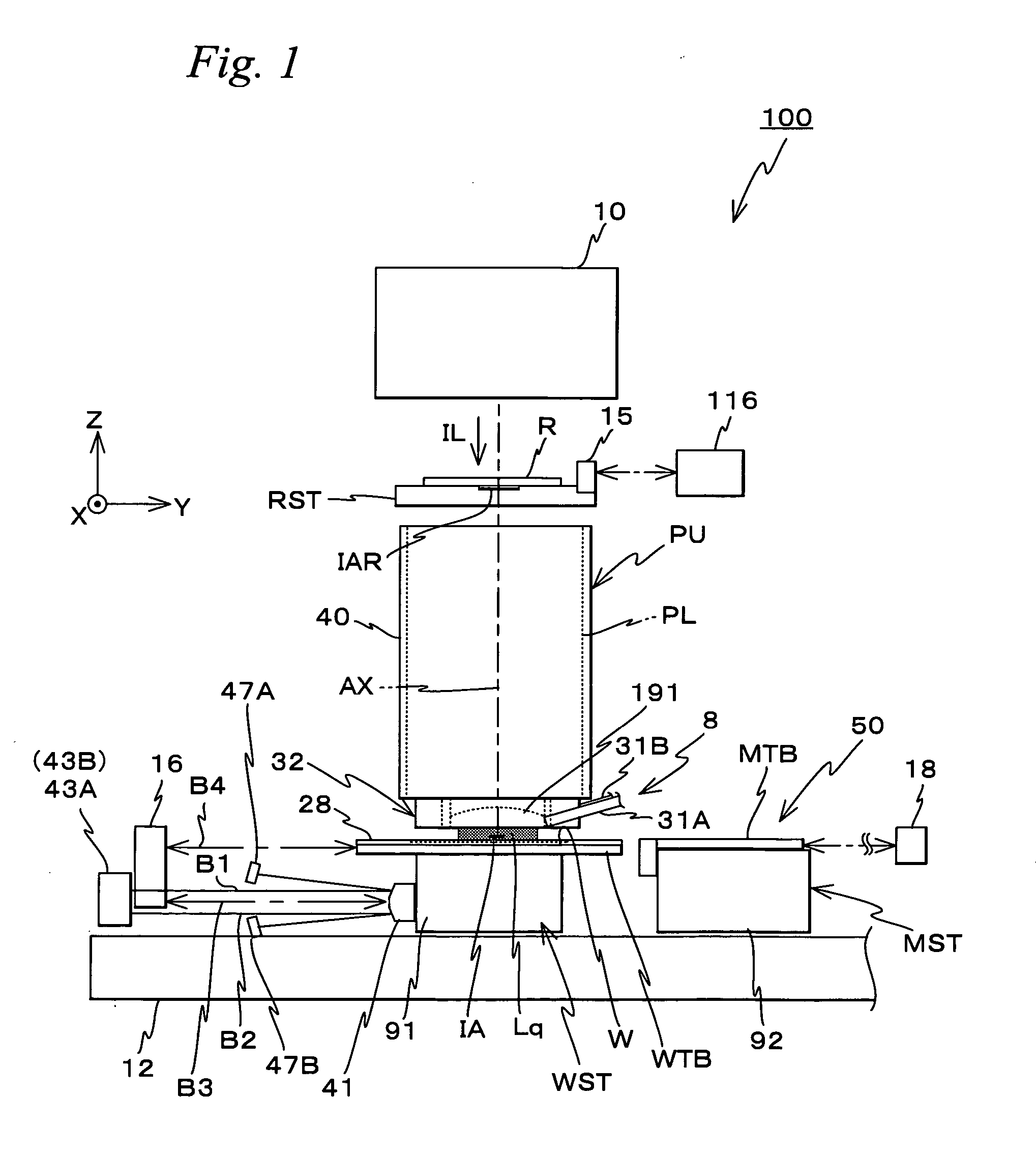

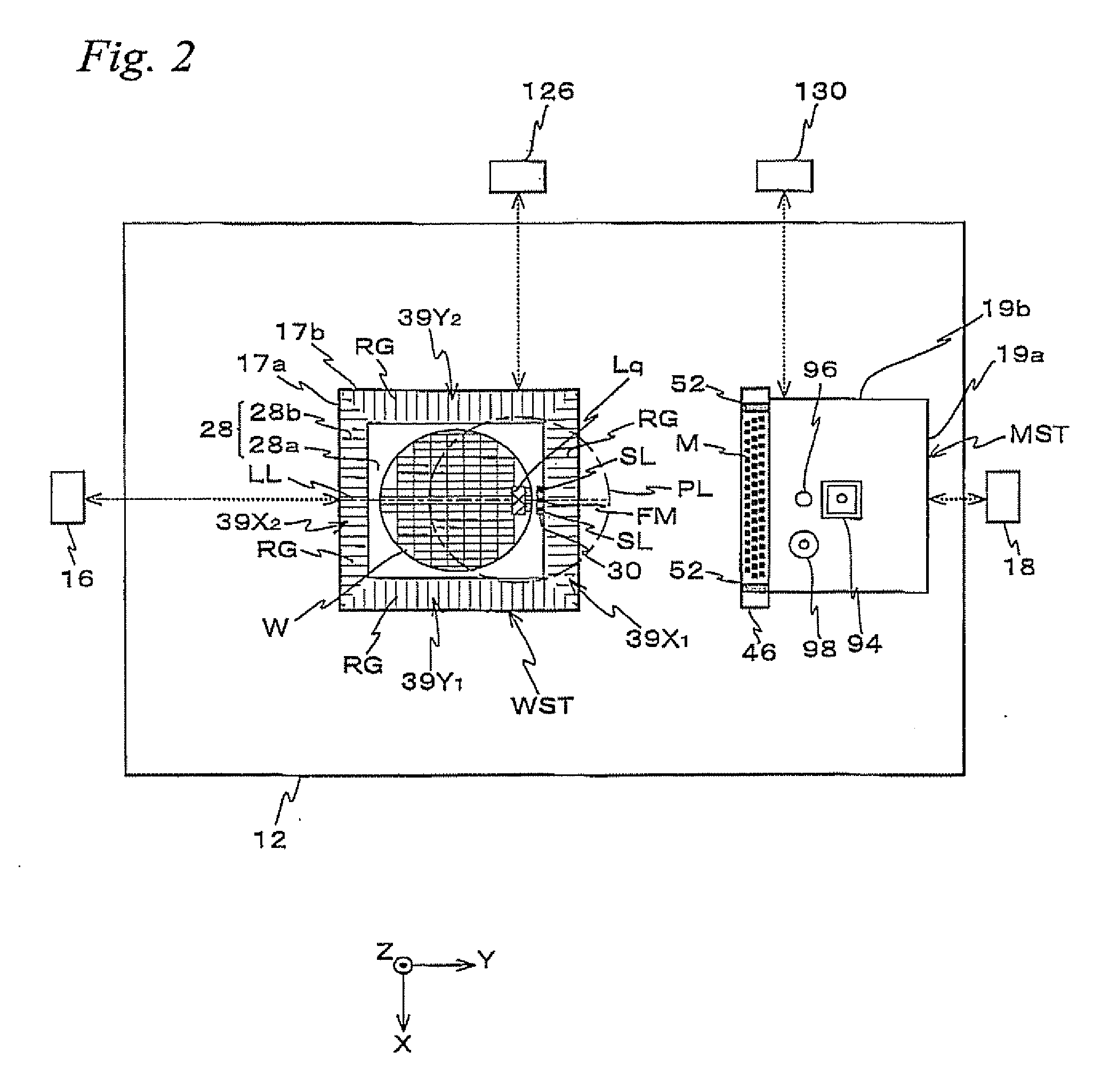

Positional information of a movable body in a Y-axis direction is measured using an interferometer and an encoder whose short-term stability of measurement values excels when compared with the interferometer, and based on the measurement results, a predetermined calibration operation for obtaining correction information for correcting measurement values of the encoder is performed. Accordingly, by using measurement values of the interferometer, correction information for correcting the measurement values of the encoder whose short-term stability of the measurement values excels the interferometer is obtained. Then, based on the measurement values of the encoder and the correction information, the movable body is driven in the Y-axis direction with good precision.

Owner:NIKON CORP

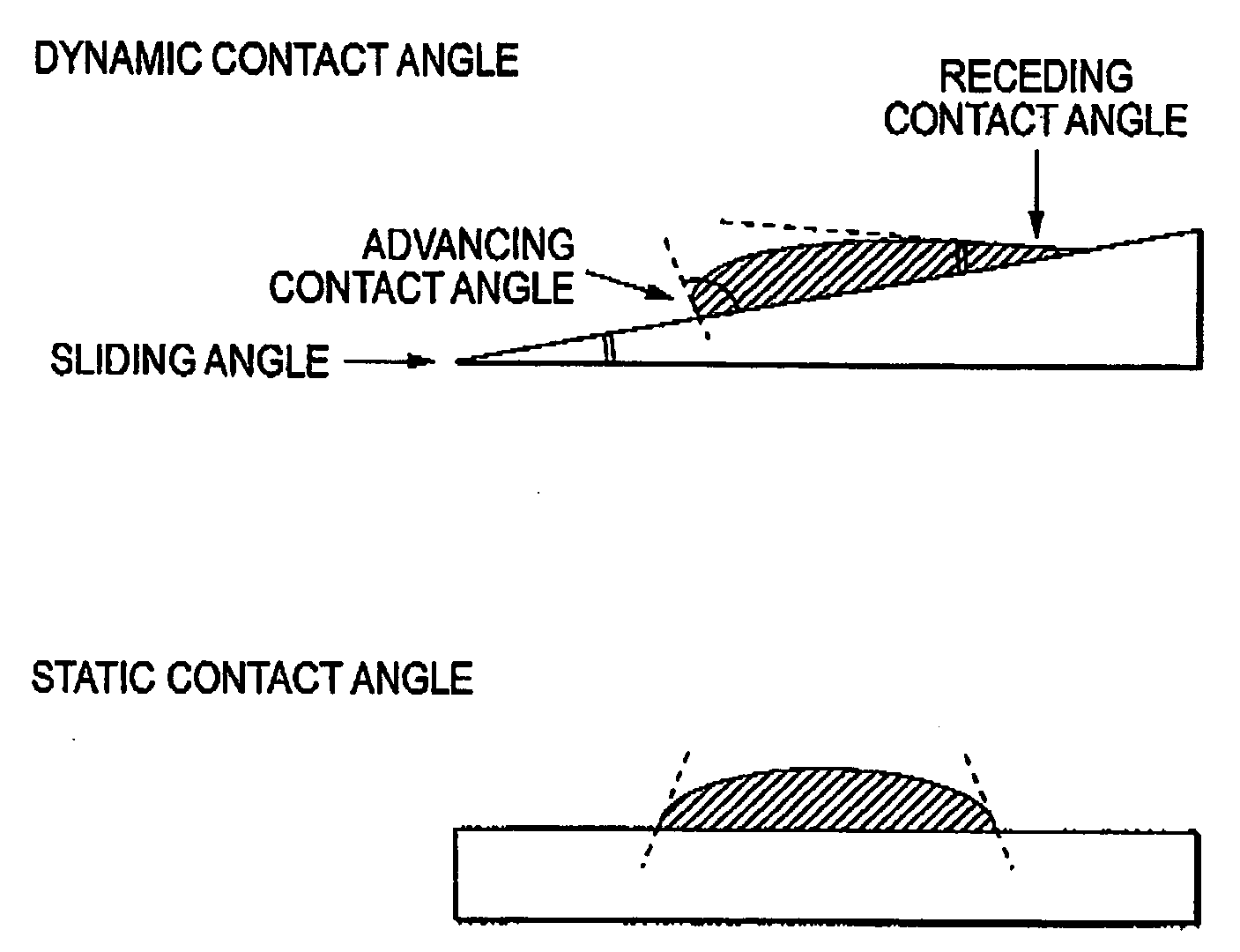

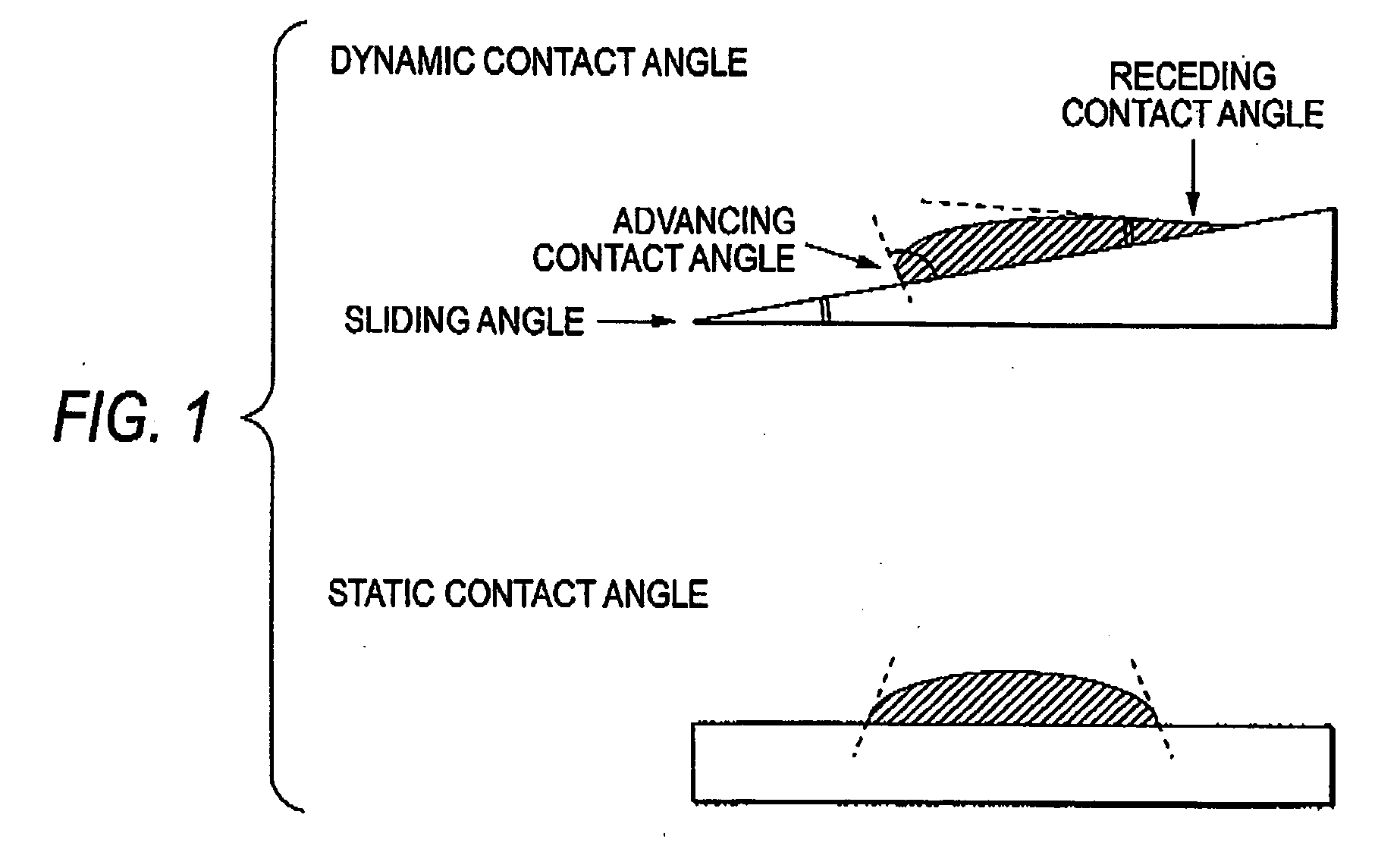

Cleaning solution for photoresist and method for forming pattern using the same

ActiveUS7238653B2Use cleanOrganic detergent compounding agentsTransportation and packagingResistAlcohol

Cleaning solutions for photoresist are disclosed which are useful for cleaning a semiconductor substrate in the last step of development when photoresist patterns are formed. Also, methods for forming photoresist patterns using the same are disclosed. The disclosed cleaning solution comprises H2O as a solution, a surfactant which is phosphate-alcoholamine salt represented by Formula 1, and an alcohol compound. The disclosed cleaning solution has lower surface tension than that of distilled water which has been used for conventional cleaning solutions, thereby improving resistance to photoresist pattern collapse and stabilizing the photoresist pattern formation.wherein R, x, y, z, a and b are as defined in the specification.

Owner:SK HYNIX INC

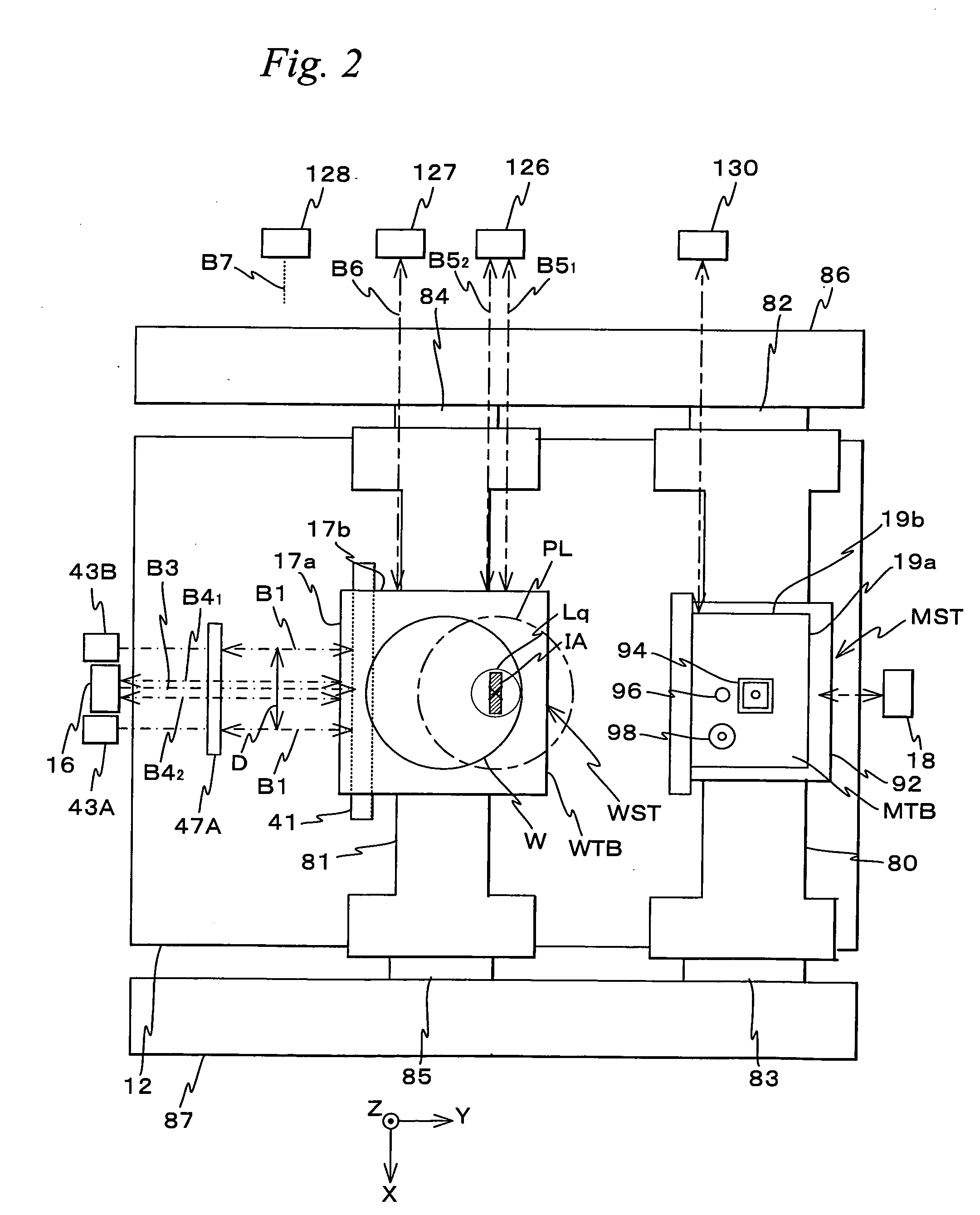

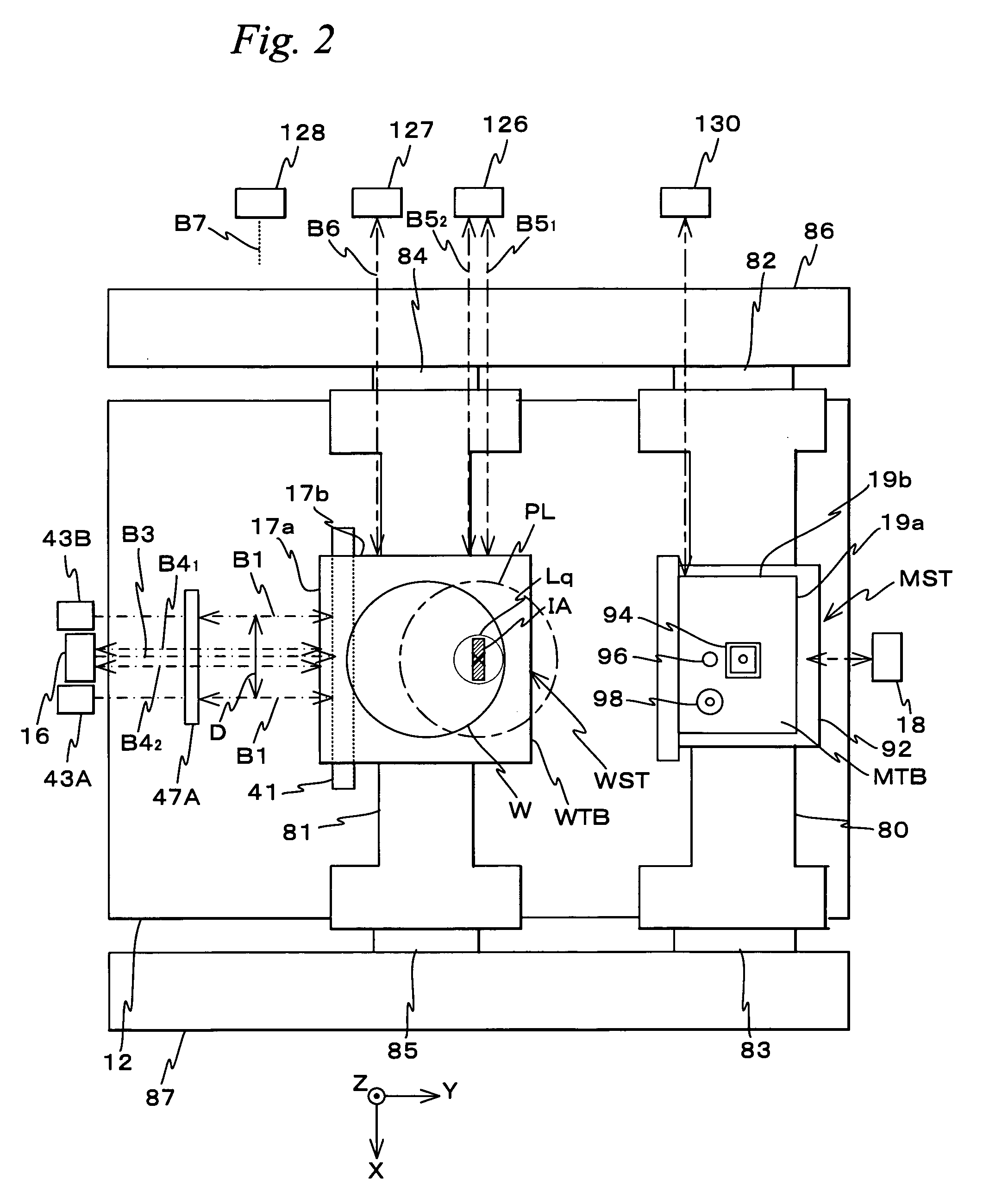

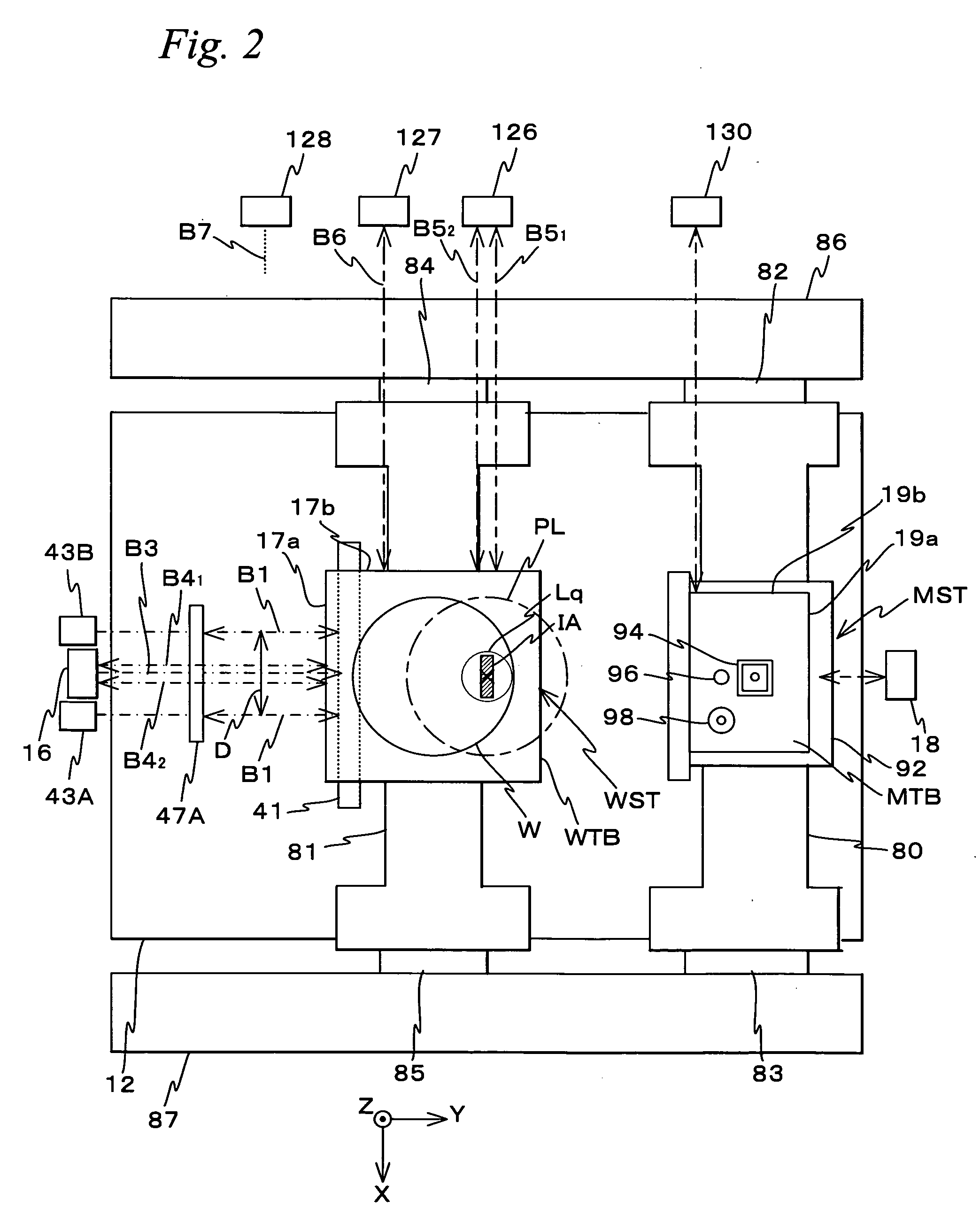

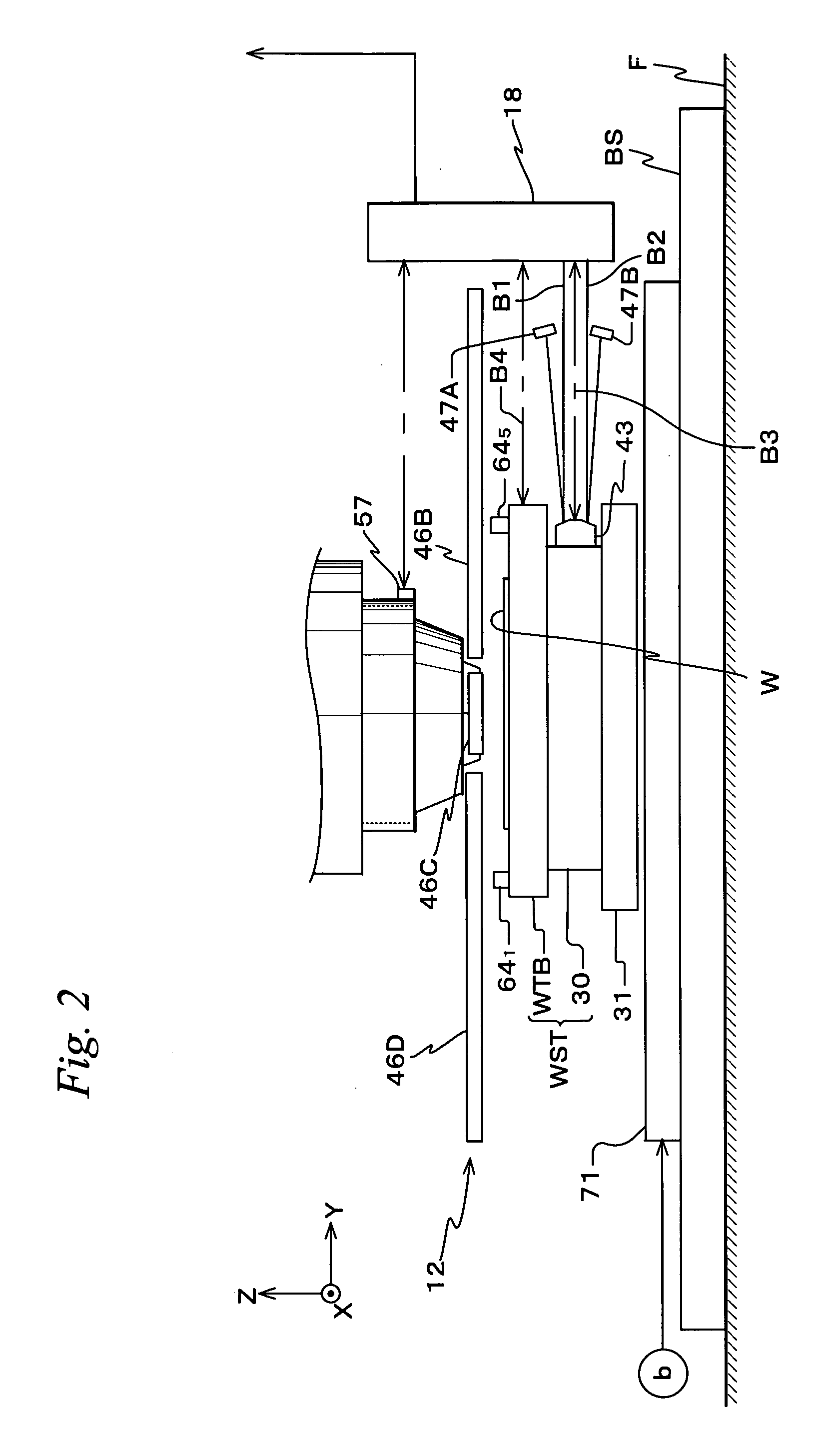

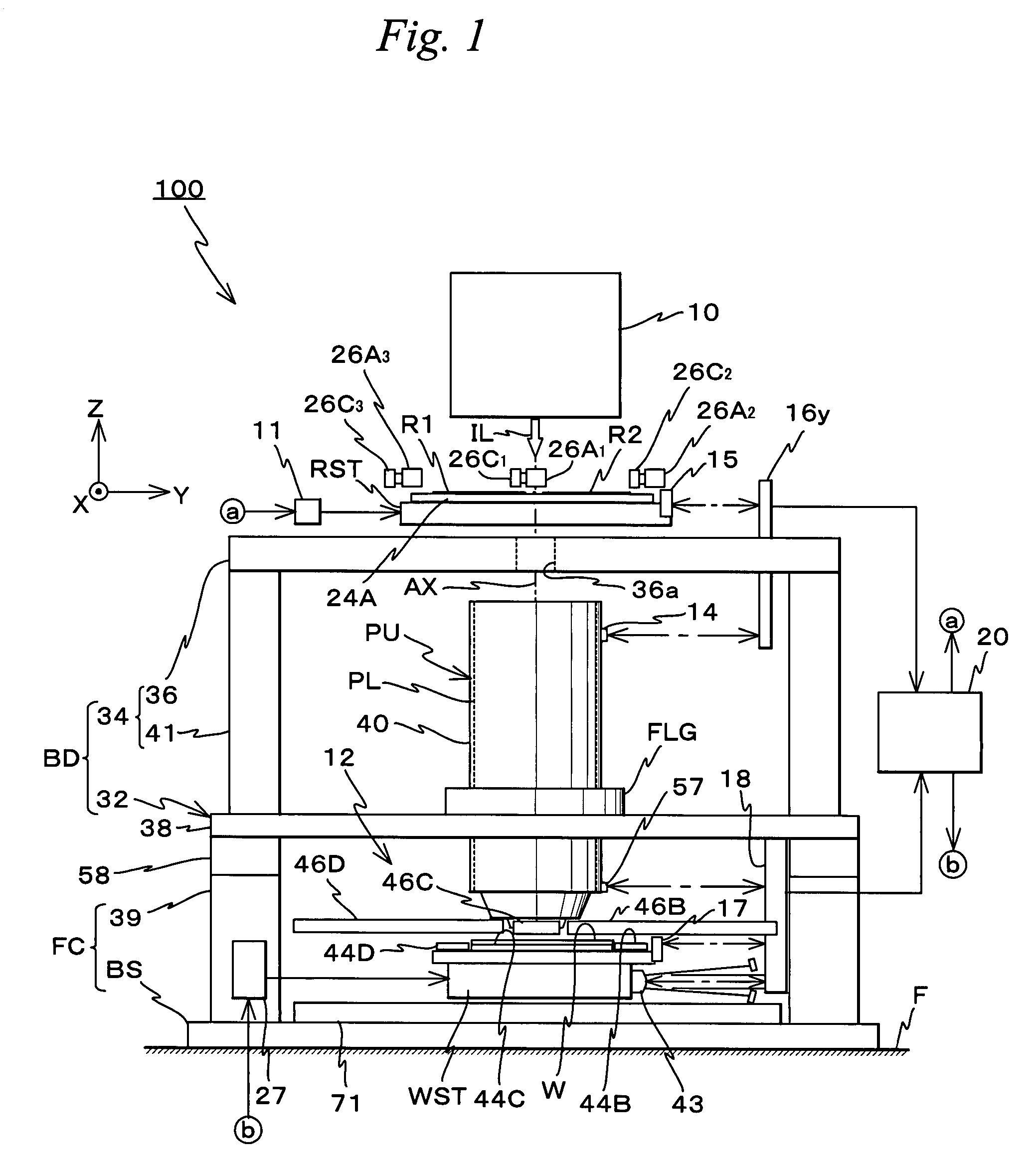

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, and device manufacturing method

InactiveUS20080094592A1Accurate linkageMaintain positionSemiconductor/solid-state device manufacturingUsing optical meansEngineeringEncoder

During the drive of a stage, positional information in a movement plane of a stage is measured by three encoders that include at least one each of an X encoder and a Y encoder of an encoder system, and a controller switches an encoder used for a measurement of positional information of a stage in the movement plane from an encoder to an encoder so that the position of the stage in the movement plane is maintained before and after the switching. Therefore, although the switching of the encoder used for controlling the position of the stage is performed, the position of the stage in the movement plane is maintained before and after the switching, and a correct linkage becomes possible.

Owner:NIKON CORP

Method for forming a photoresist pattern

InactiveUS20070163625A1Inhibition formationSurface-active detergent compositionsNon-surface-active detergent compositionsResistPhotoresist

A photoresist cleaning solution and method for forming photoresist patterns using the same. More specifically, disclosed are a photoresist cleaning solution comprising H2o and an ionic surfactant represented by Formula 1, and a method for forming a photoresist pattern using the same. By spraying the cleaning solution of the present invention over photoresist film before and / or after exposing step, pattern formation in an undesired region caused by ghost images can be removed.

Owner:SK HYNIX INC

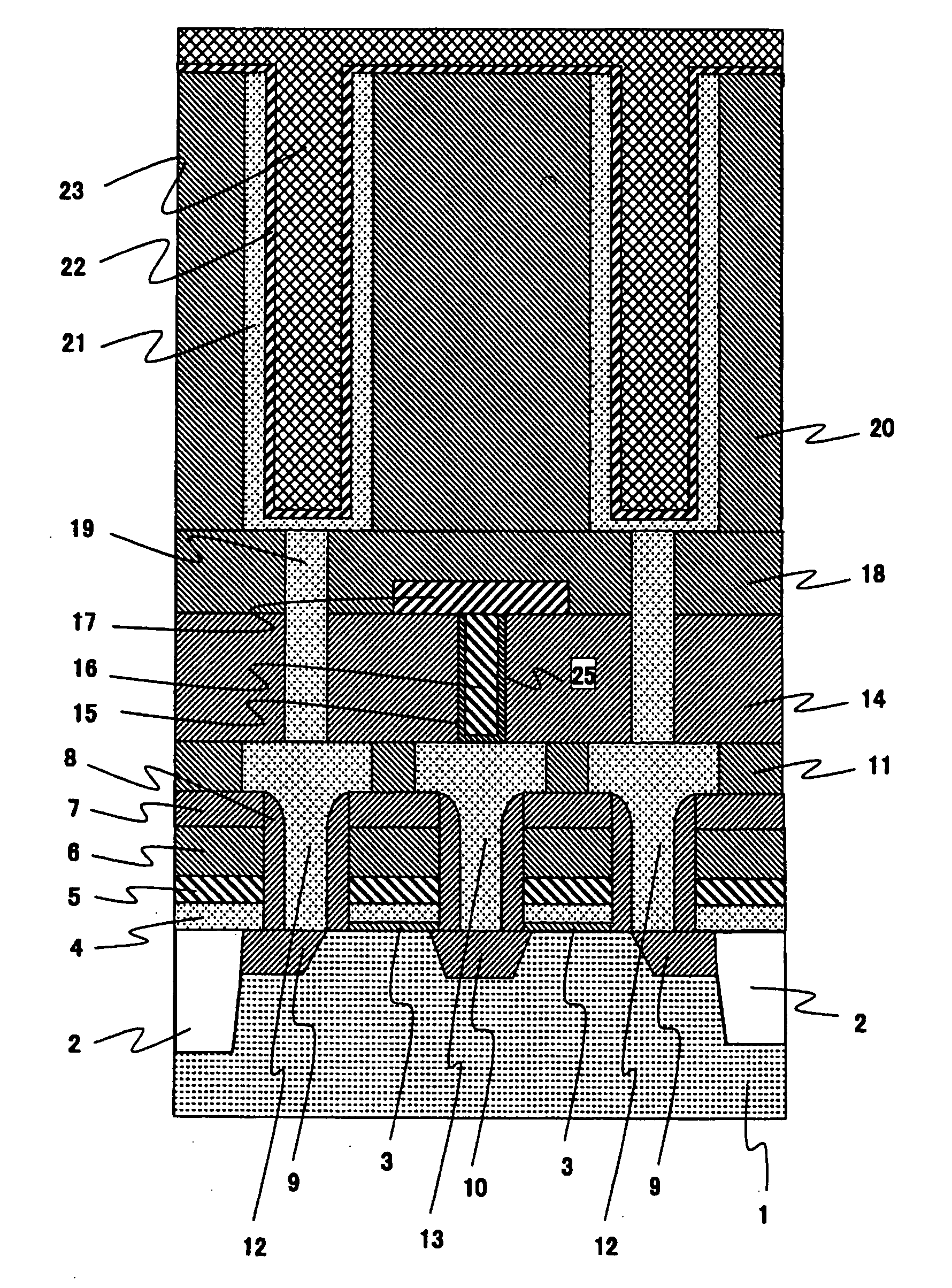

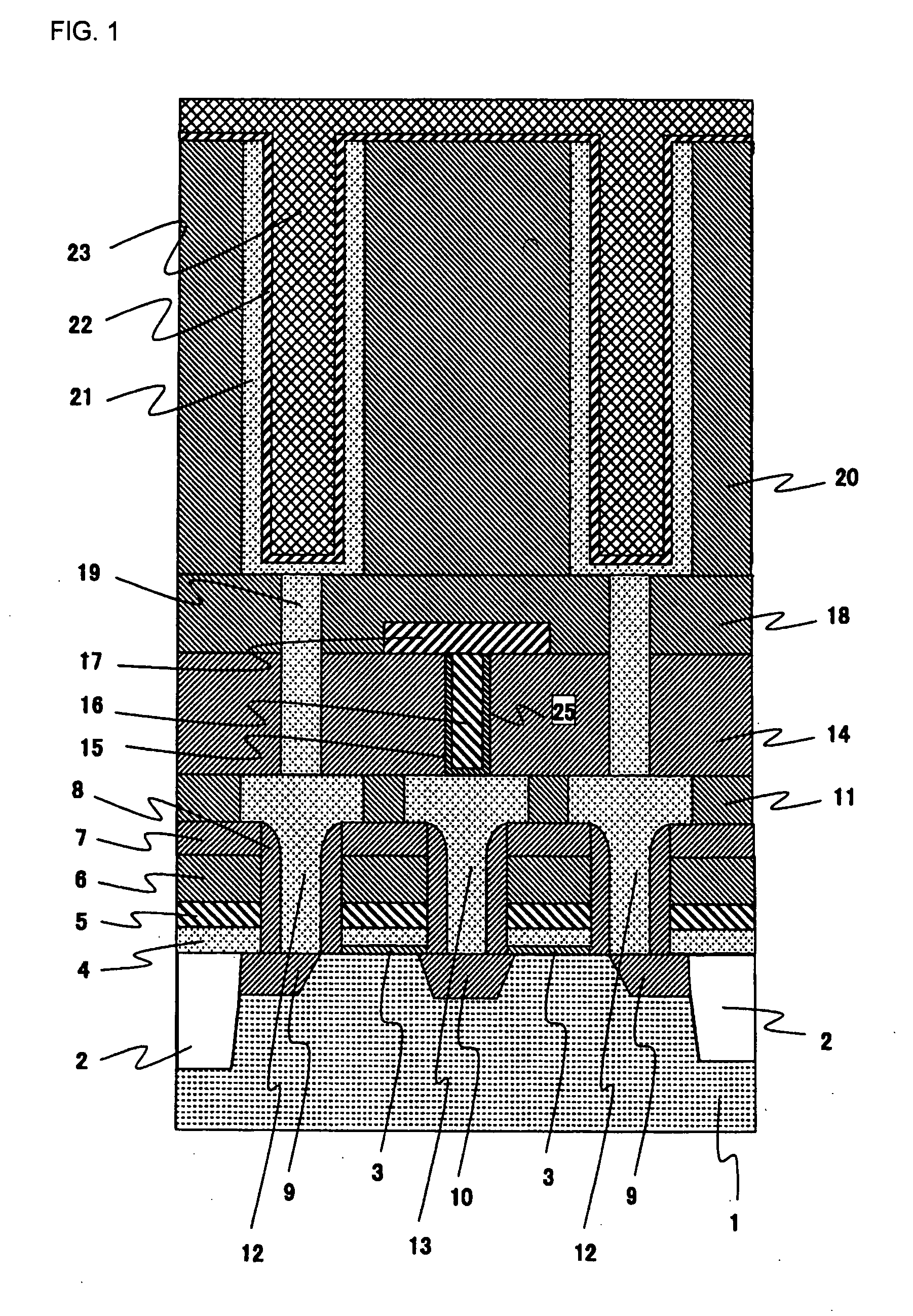

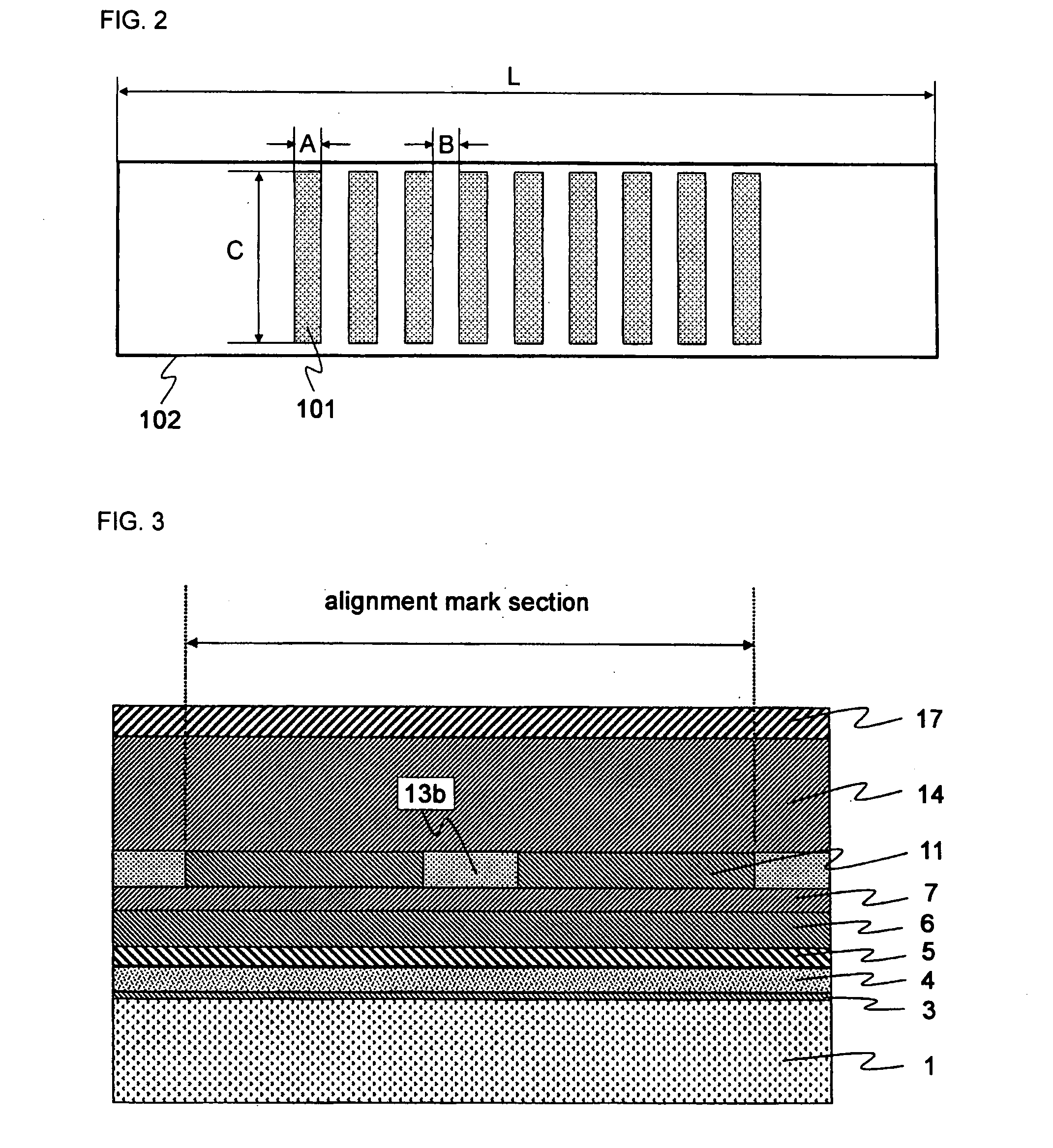

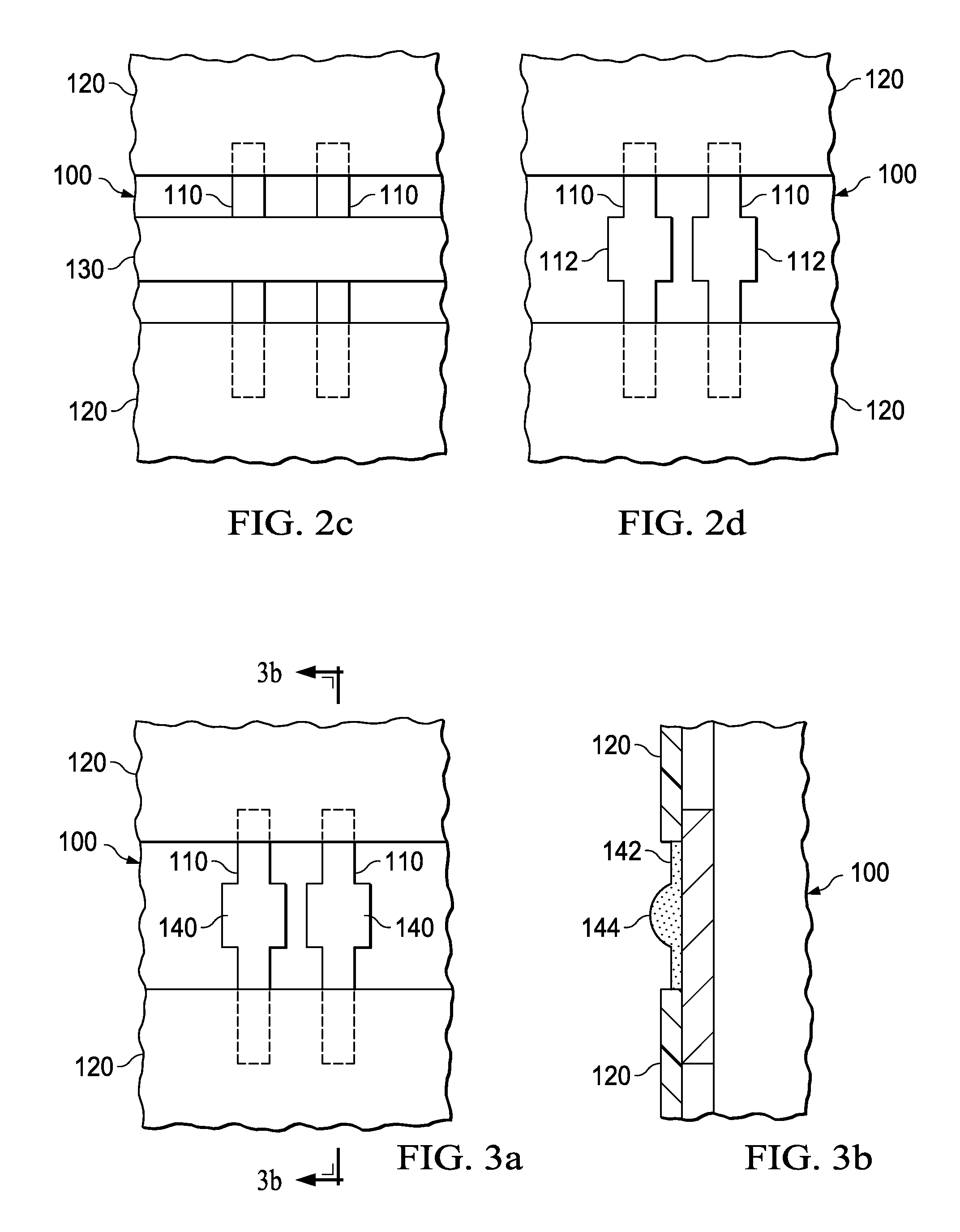

Method of manufacturing semiconductor device

InactiveUS20070275520A1Easy alignmentSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistSemiconductor

An object of the present inventions is to overcome a problem that the presence of a metal film, which is opaque to a visible light, between a lower layer alignment mark and a photoresist prevents the detection of the lower layer alignment mark, to make the pattern formation difficult. In the present inventions, an insulating film is placed beneath the alignment mark in structure; an alignment mark consisting of said multi-layered film comprising an alignment mark layer and the insulating film, which constitutes a stepped part with an increased difference in level, is first formed, inside a mark hole, in a manner of self-alignment; and then the metal film which is the very cause of the above problem is formed thereon. Since the metal film itself has a stepped shape corresponding to the alignment mark, alignment can be made with great accuracy.

Owner:LONGITUDE SEMICON S A R L

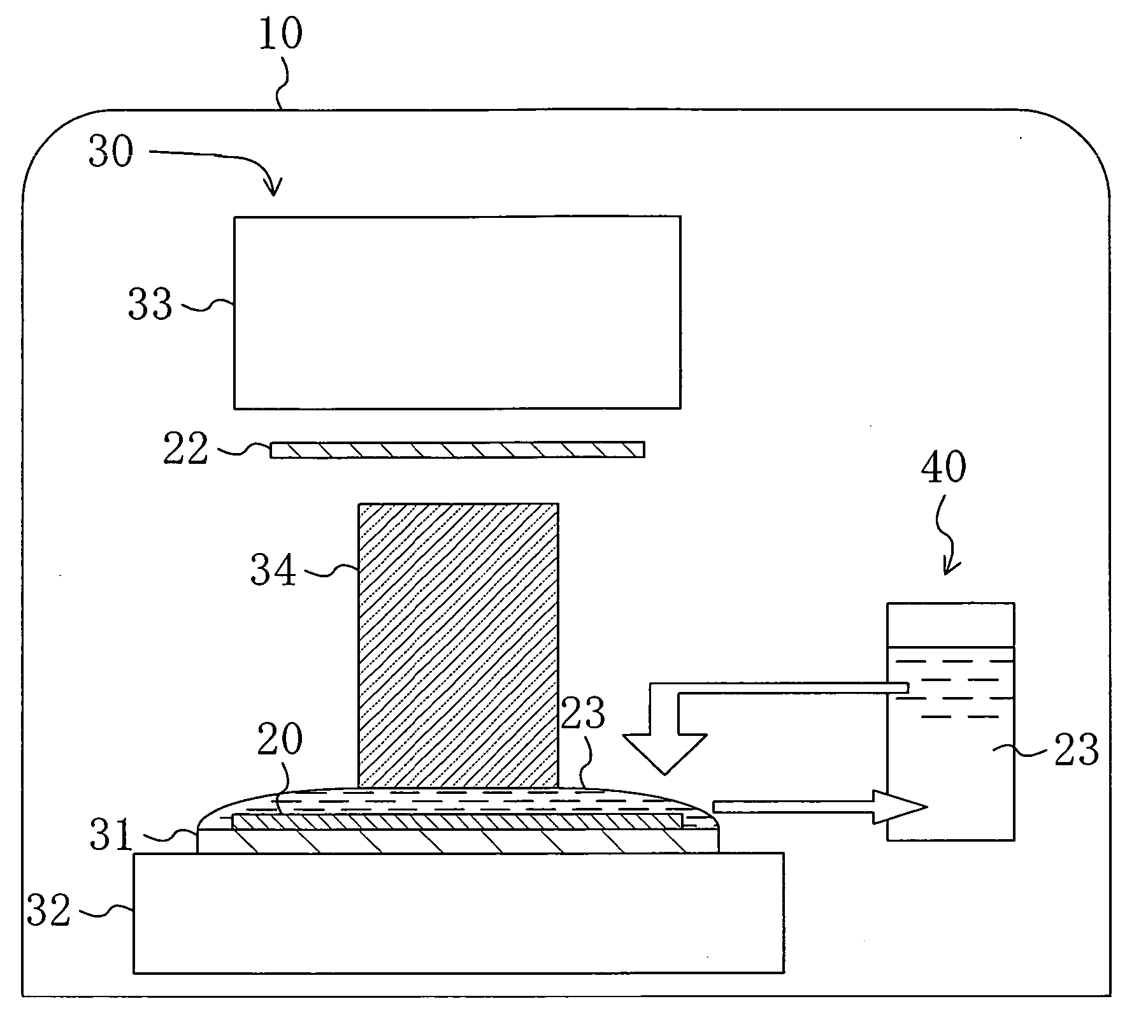

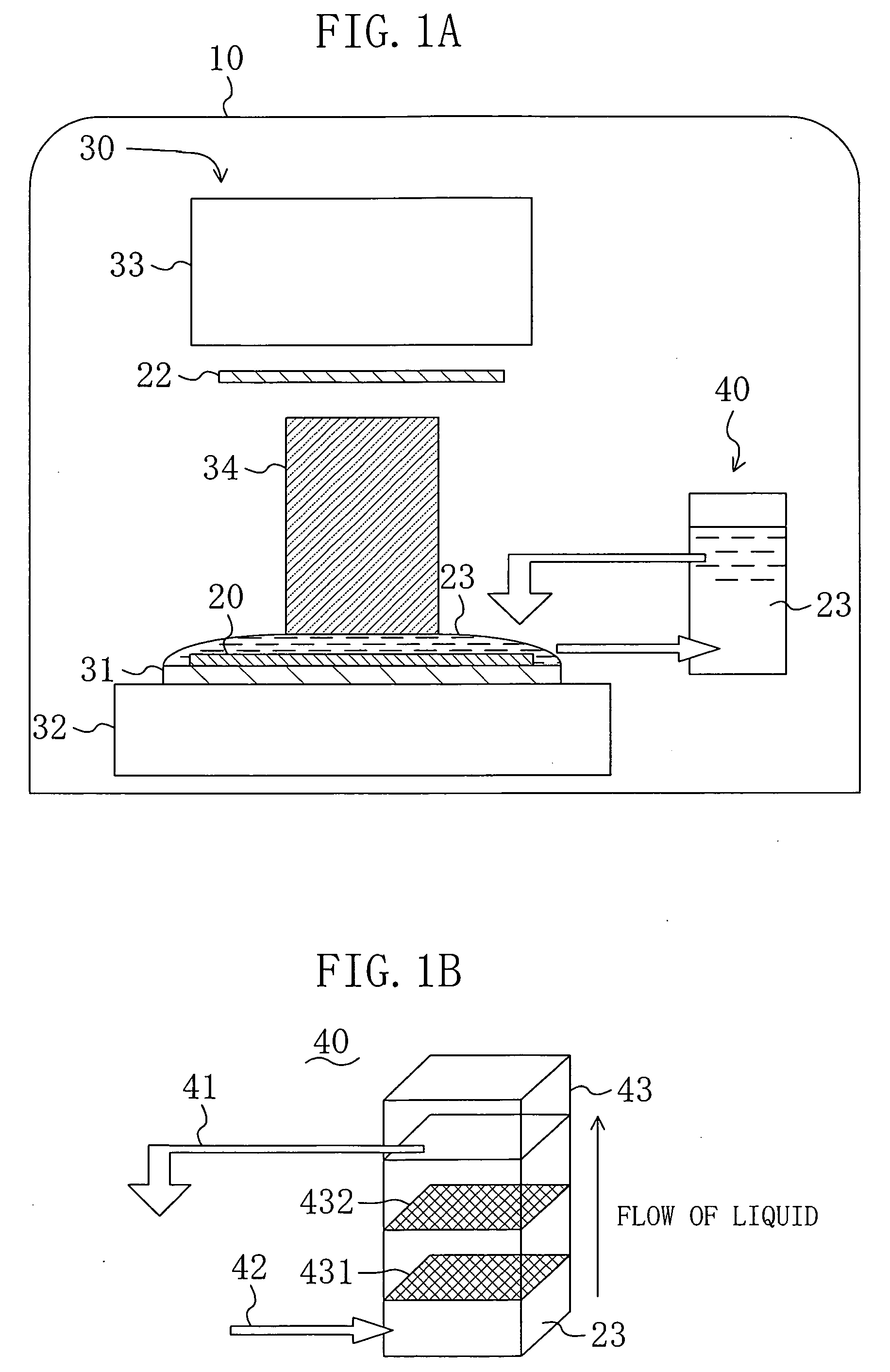

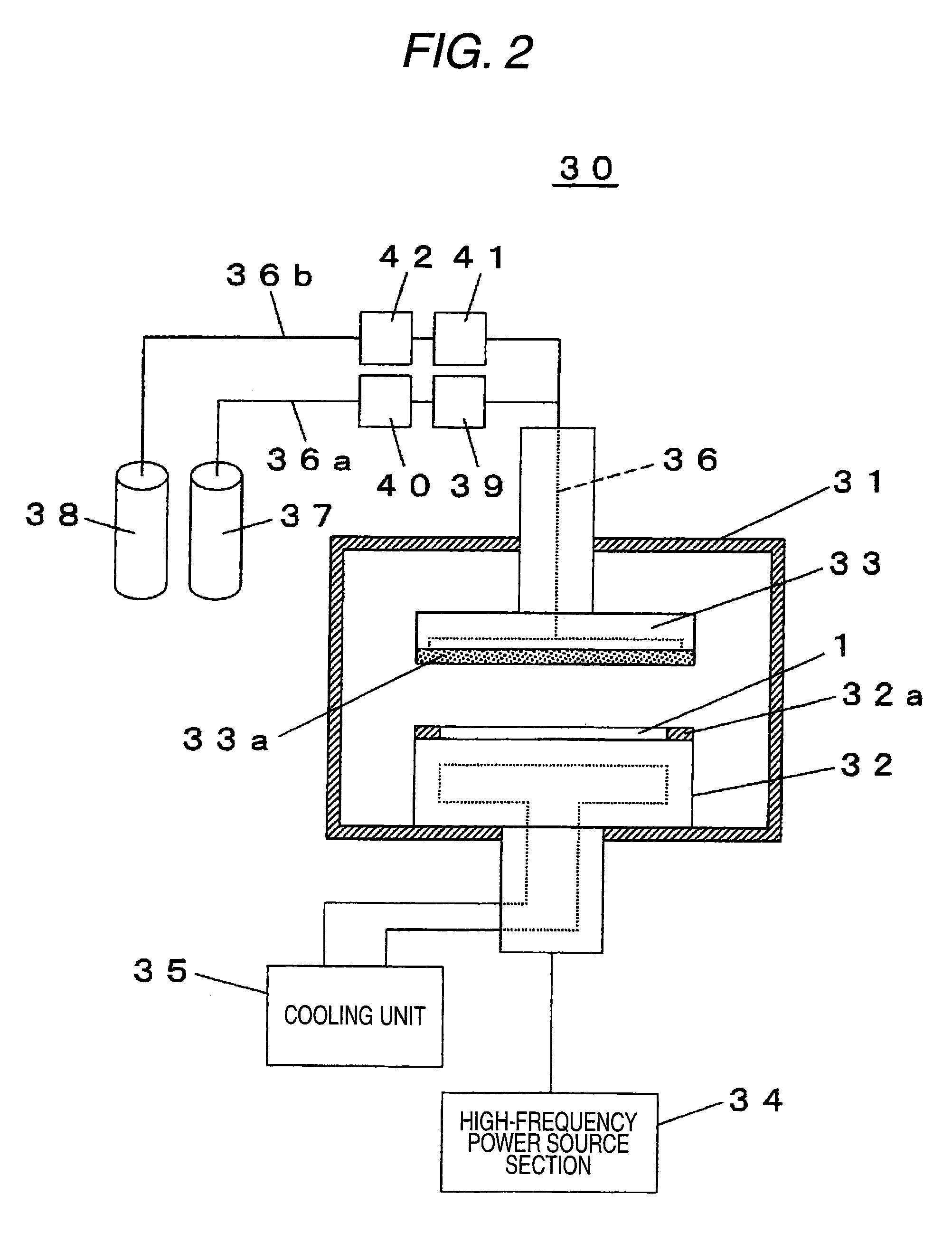

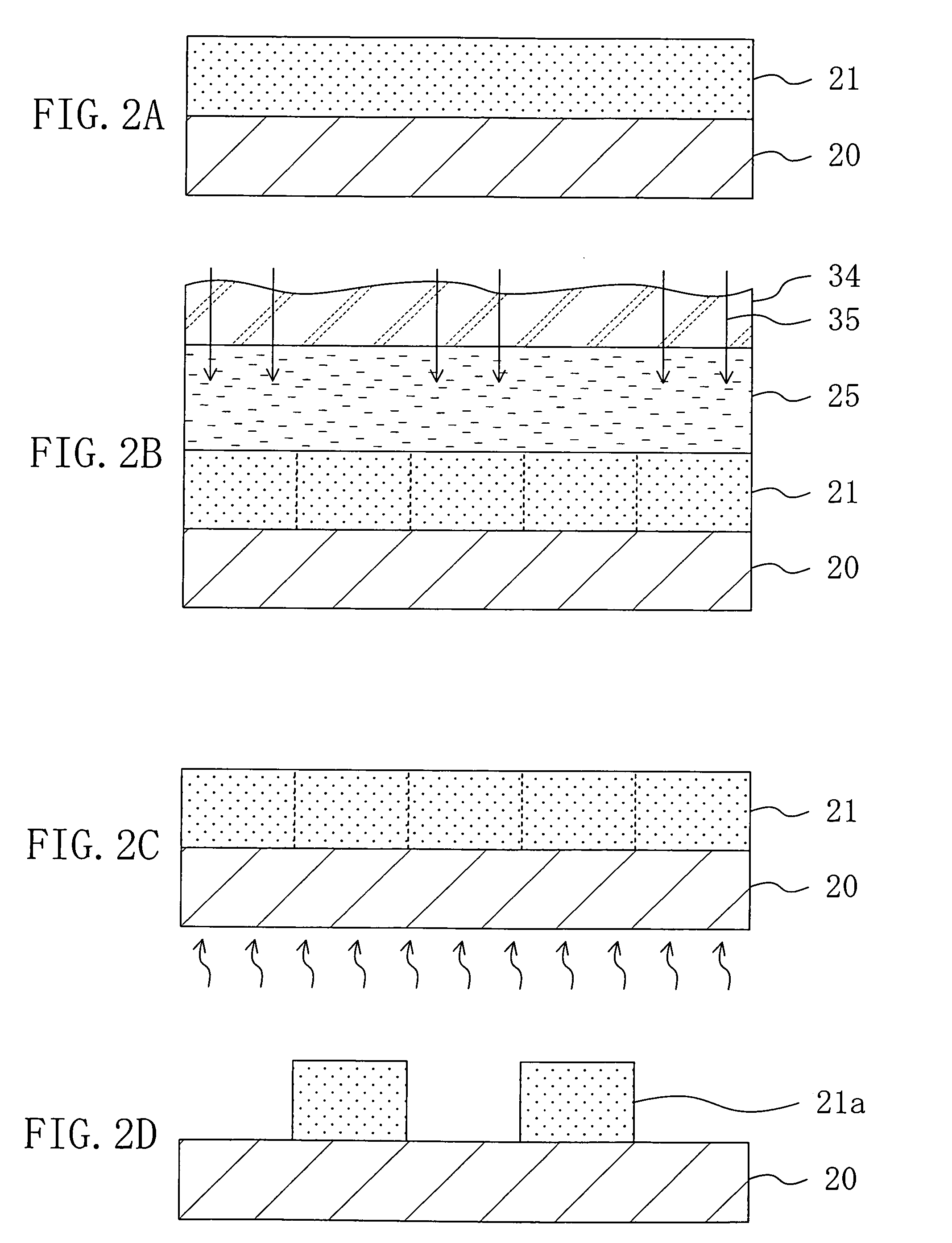

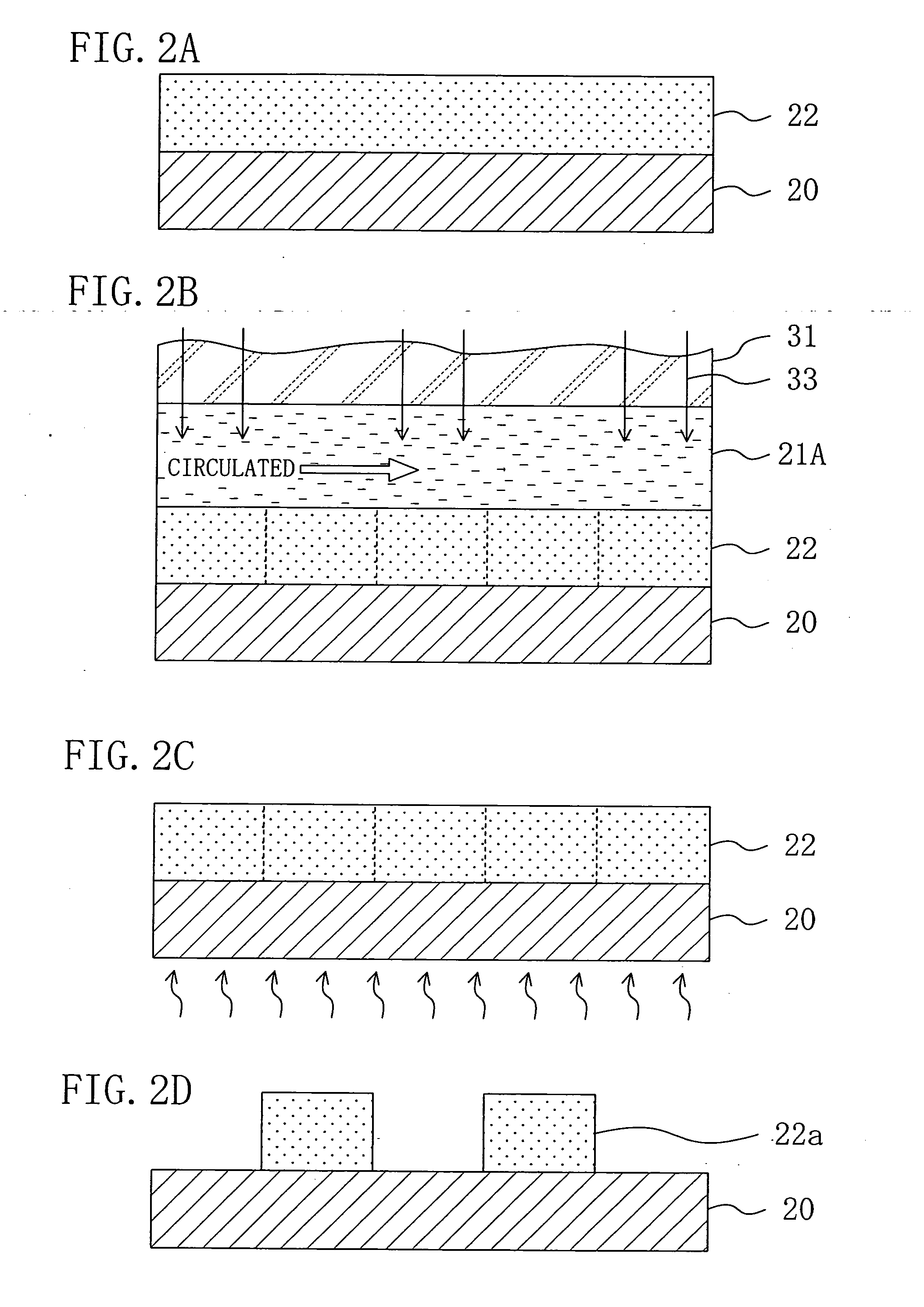

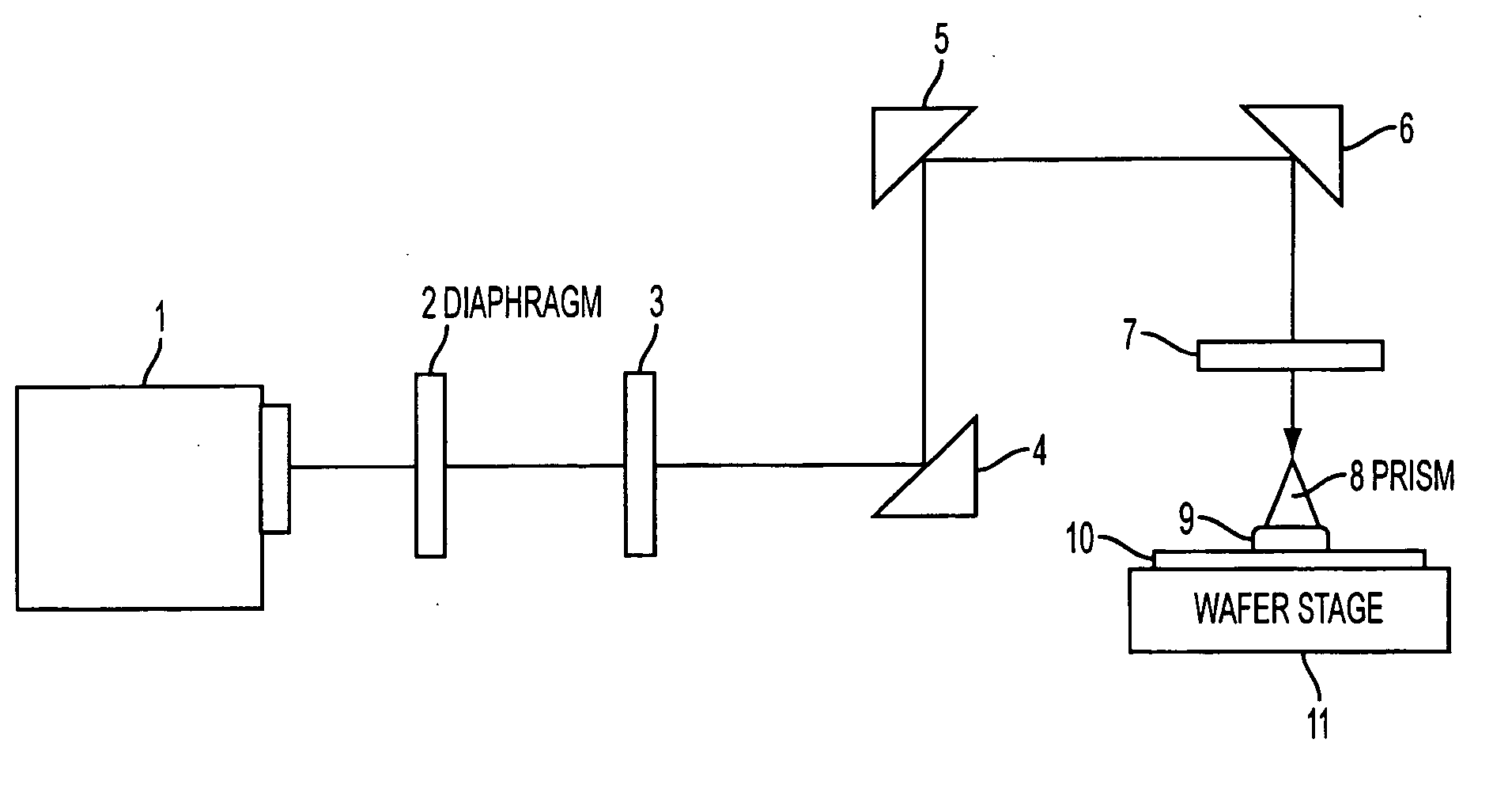

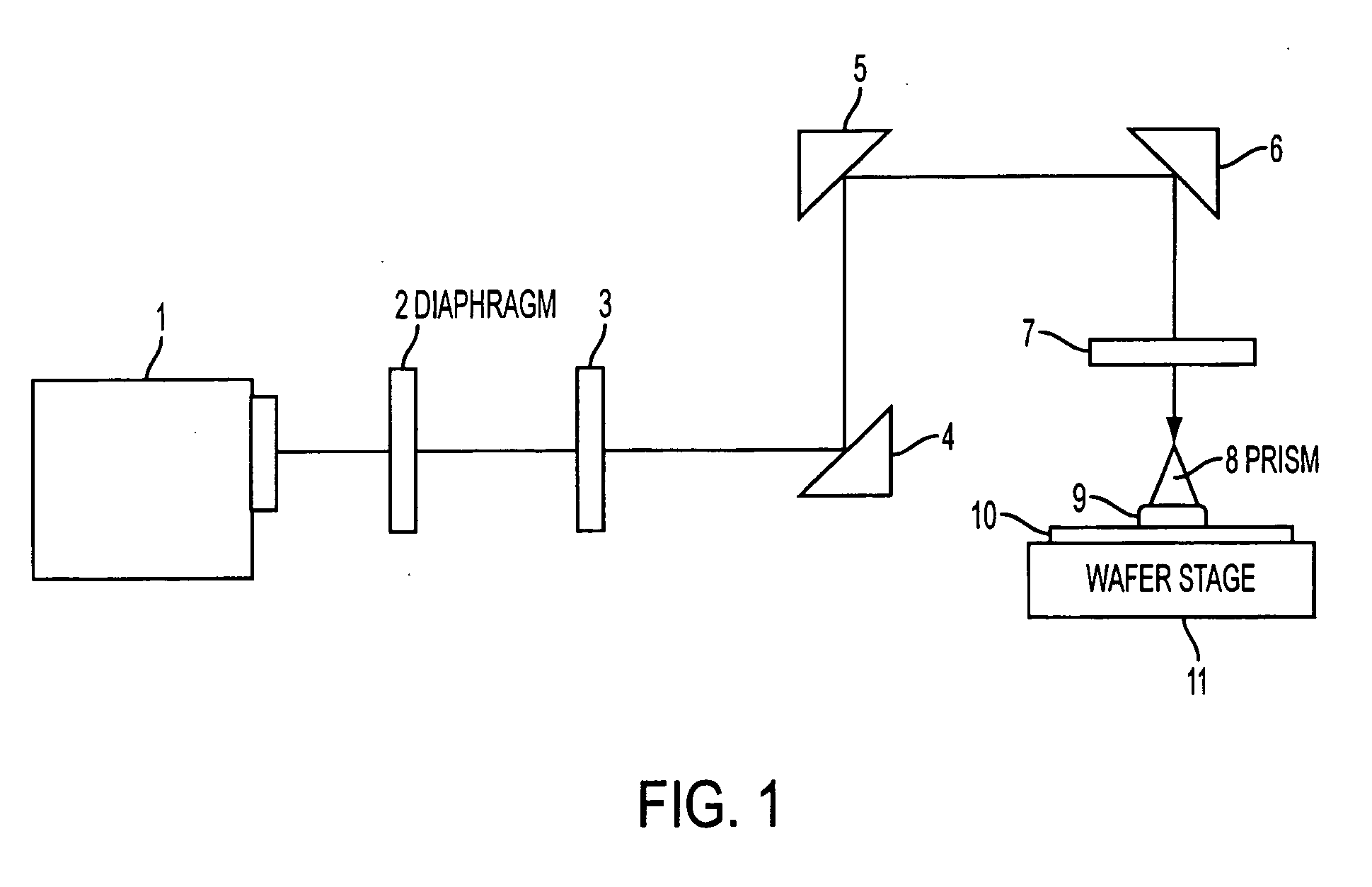

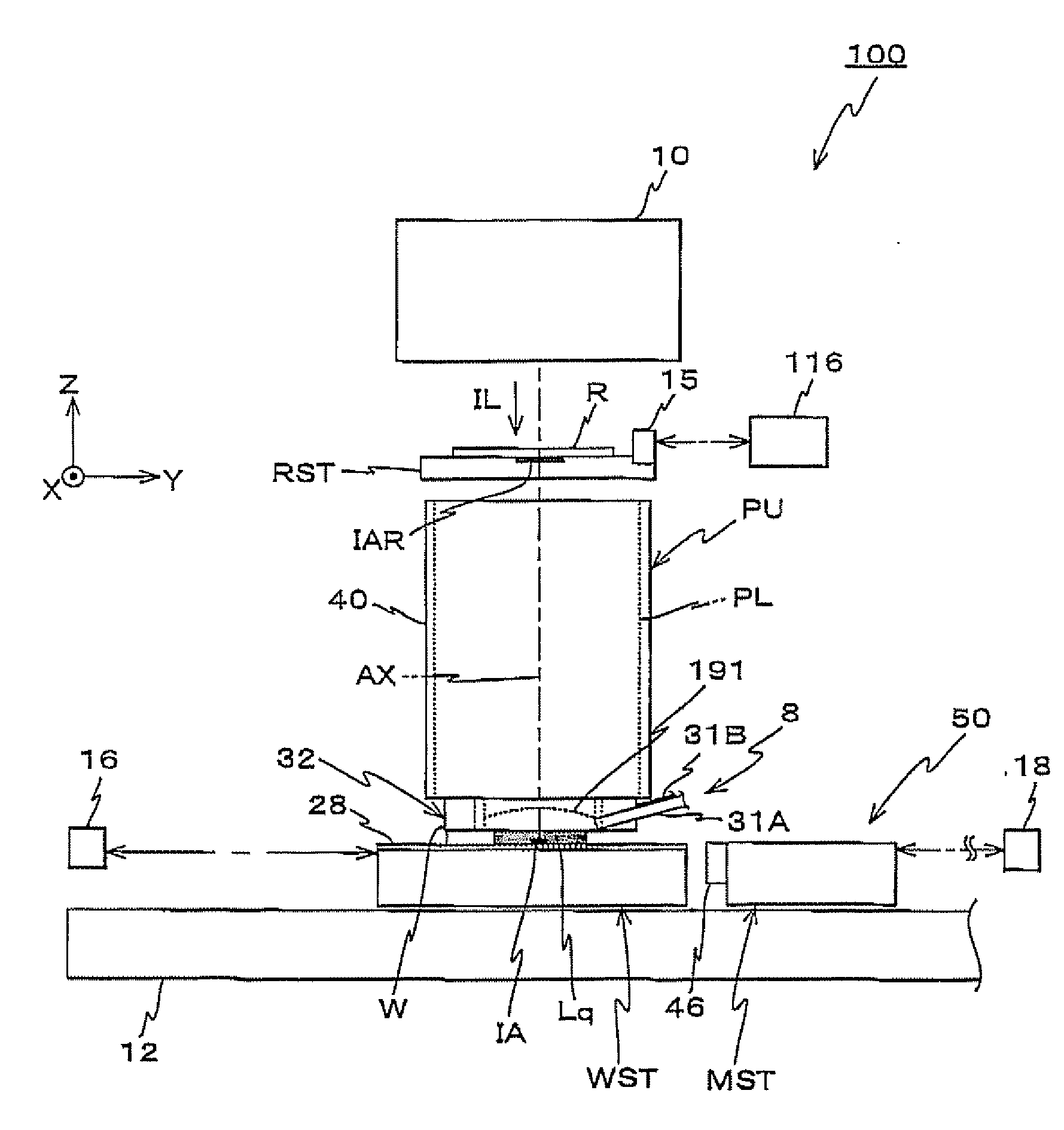

Semiconductor fabrication apparatus and pattern formation method using the same

InactiveUS20050074704A1Low costAvoid distractionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImpurity

The semiconductor fabrication apparatus of this invention includes an exposure section provided within a chamber for exposing a design pattern on a resist film applied on a wafer, and a liquid recycle section for supplying, onto the wafer, a liquid for use in immersion lithography for increasing the numerical aperture of exposing light during exposure while recycling the liquid. The liquid recycle section includes a liquid supply part for supplying the liquid onto the resist film of the wafer, a liquid discharge part for discharging and recovering the liquid from above the wafer, and an impurity removal part for containing the liquid and removing an impurity included in the liquid.

Owner:PANASONIC CORP

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, device manufacturing method, and calibration method

ActiveUS20080094593A1Good precisionPhotomechanical apparatusSemiconductor/solid-state device manufacturingArtificial intelligenceEncoder

A controller measures positional information of a stage within an XY plane using three encoders which at least include one each of an X encoder and a Y encoder of an encoder system, and the stage is driven in the XY plane, based on measurement results of the positional information and positional information (p1, q1), (p2, q2), and (p3, q3) in a surface parallel to the XY plane of a head (an encoder) used for measurement of the positional information. Accordingly, it becomes possible to control the movement of the stage with good precision, while switching the head (the encoder) used for control during the movement of the stage using the encoder system which includes a plurality of heads.

Owner:NIKON CORP

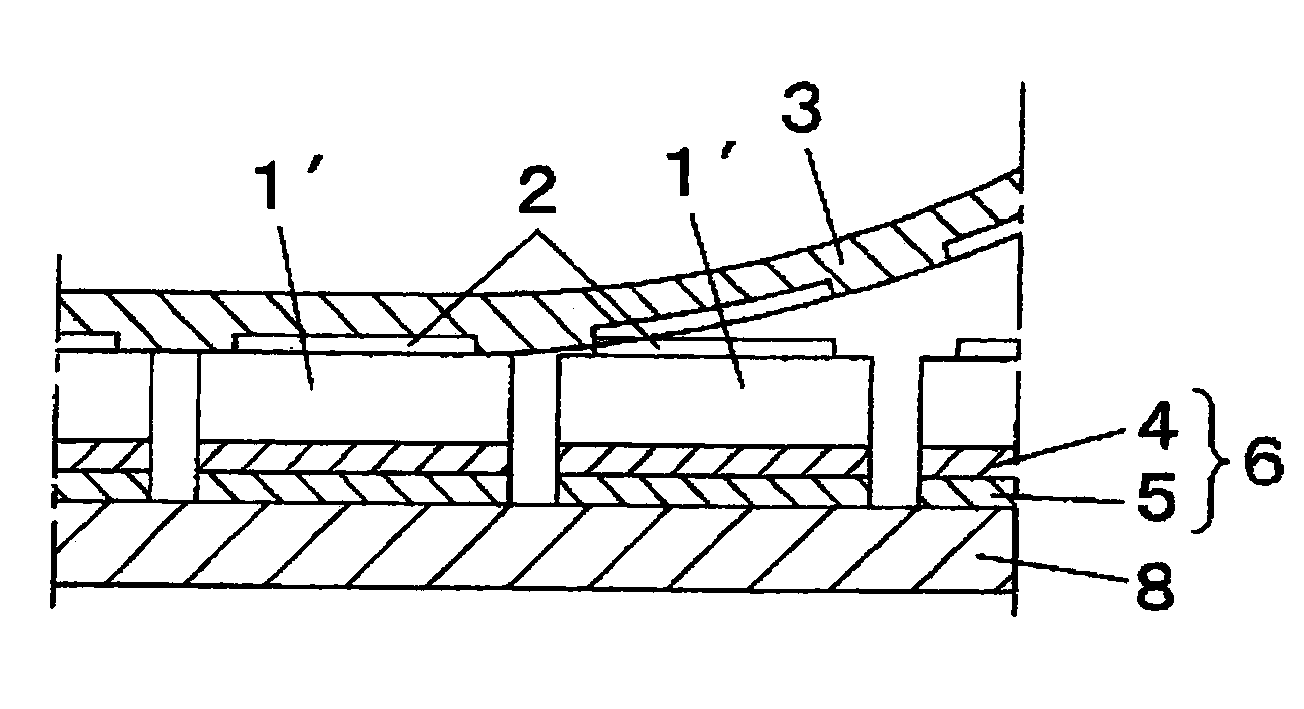

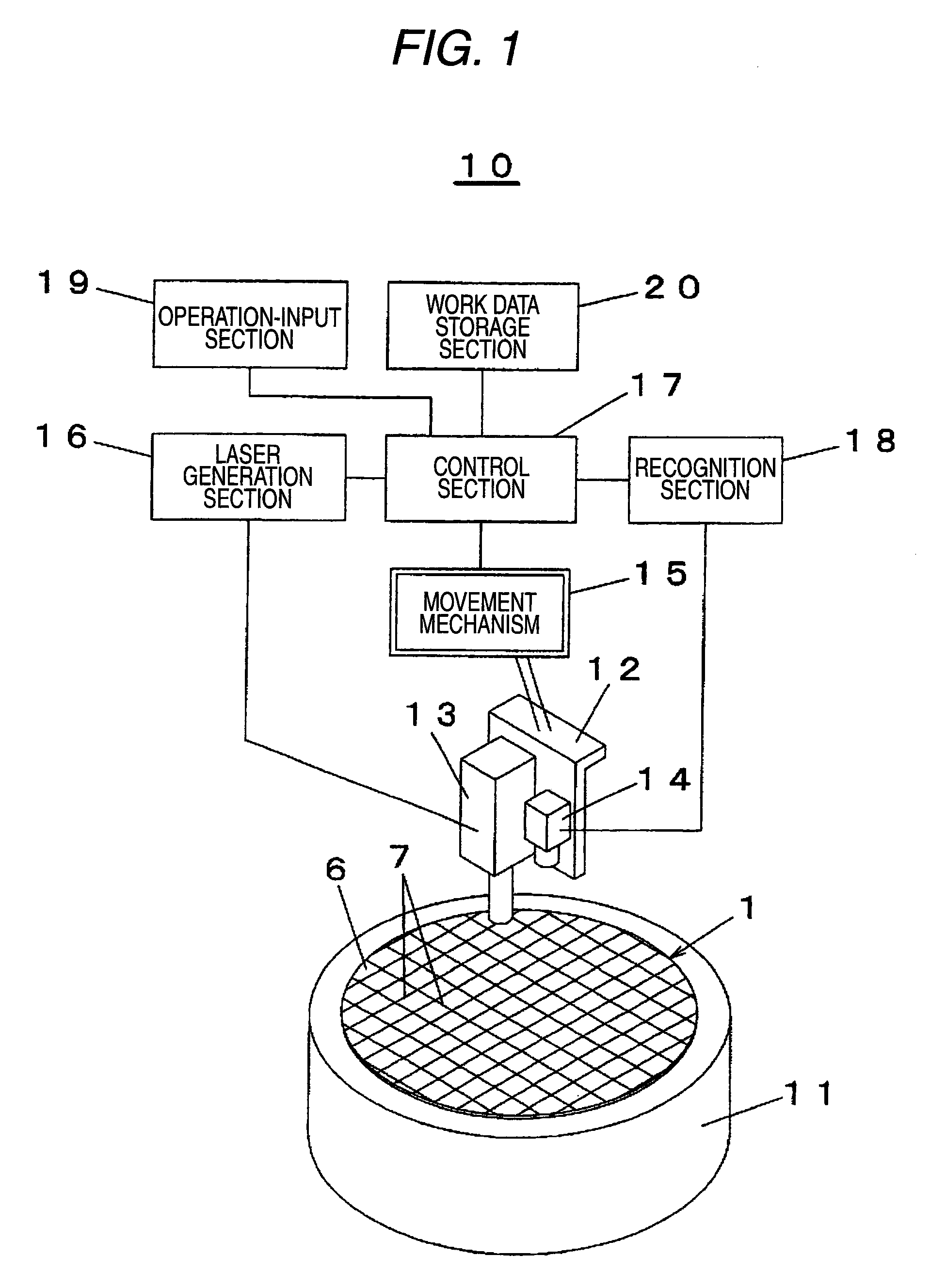

Method for fabricating semiconductor chip

ActiveUS7767551B2Avoid pollutionUnnecessary removalSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

After a film layer 6 formed from a die attach film 4 and a UV tape 5 has been provided as a mask on a semiconductor wafer 1, boundary trenches 7 for partitioning semiconductor elements 2 formed on a circuit pattern formation surface 1a are formed in the film layer 6, thereby making a surface 1c of a semiconductor wafer 1 exposed. The exposed surface 1c of the semiconductor wafer 1 in the boundary trenches 7 is etched by means of plasma of a fluorine-based gas, and the semiconductor wafer 1 is sliced into semiconductor chips 1′ along the boundary trenches 7.

Owner:PANASONIC CORP

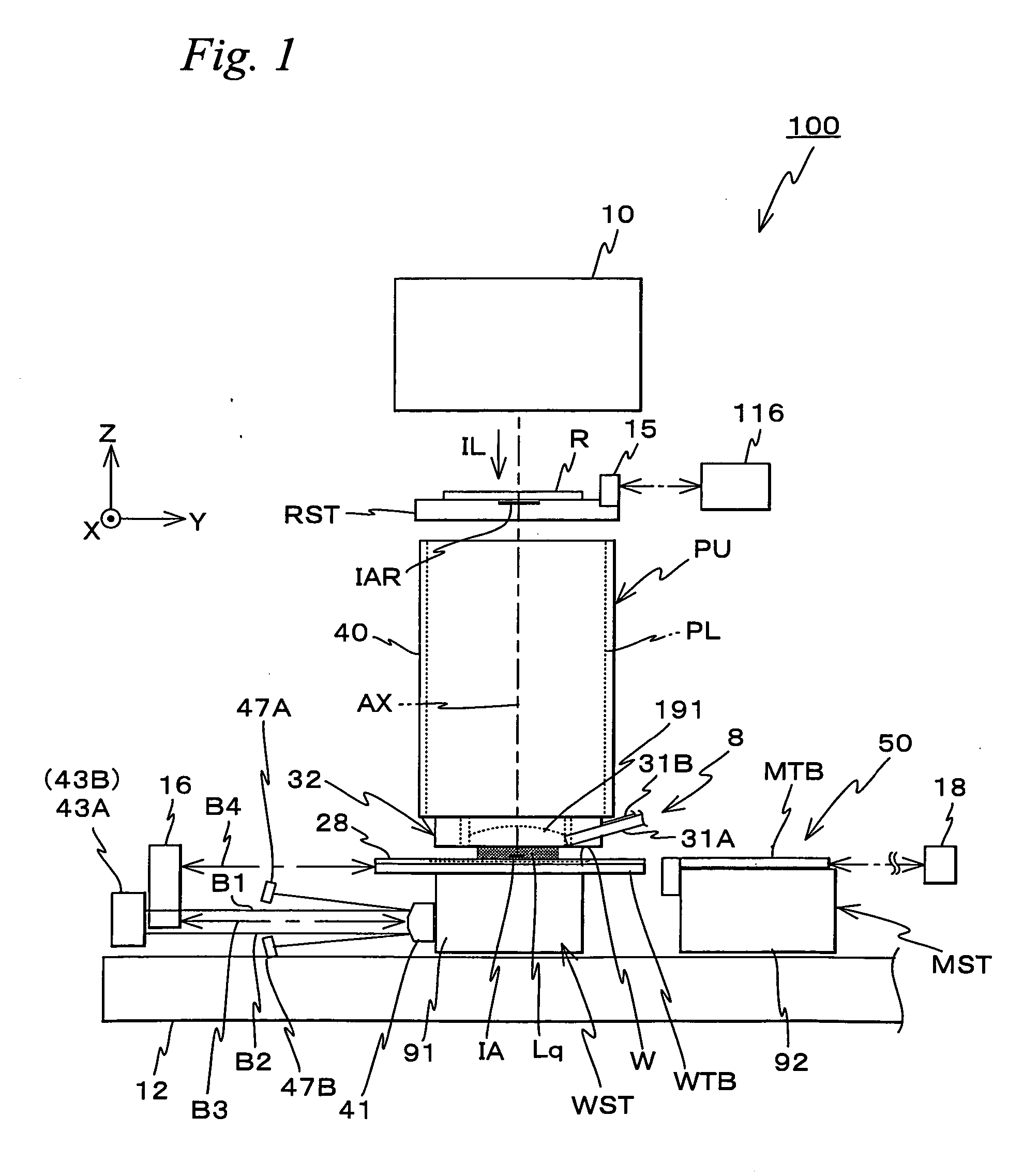

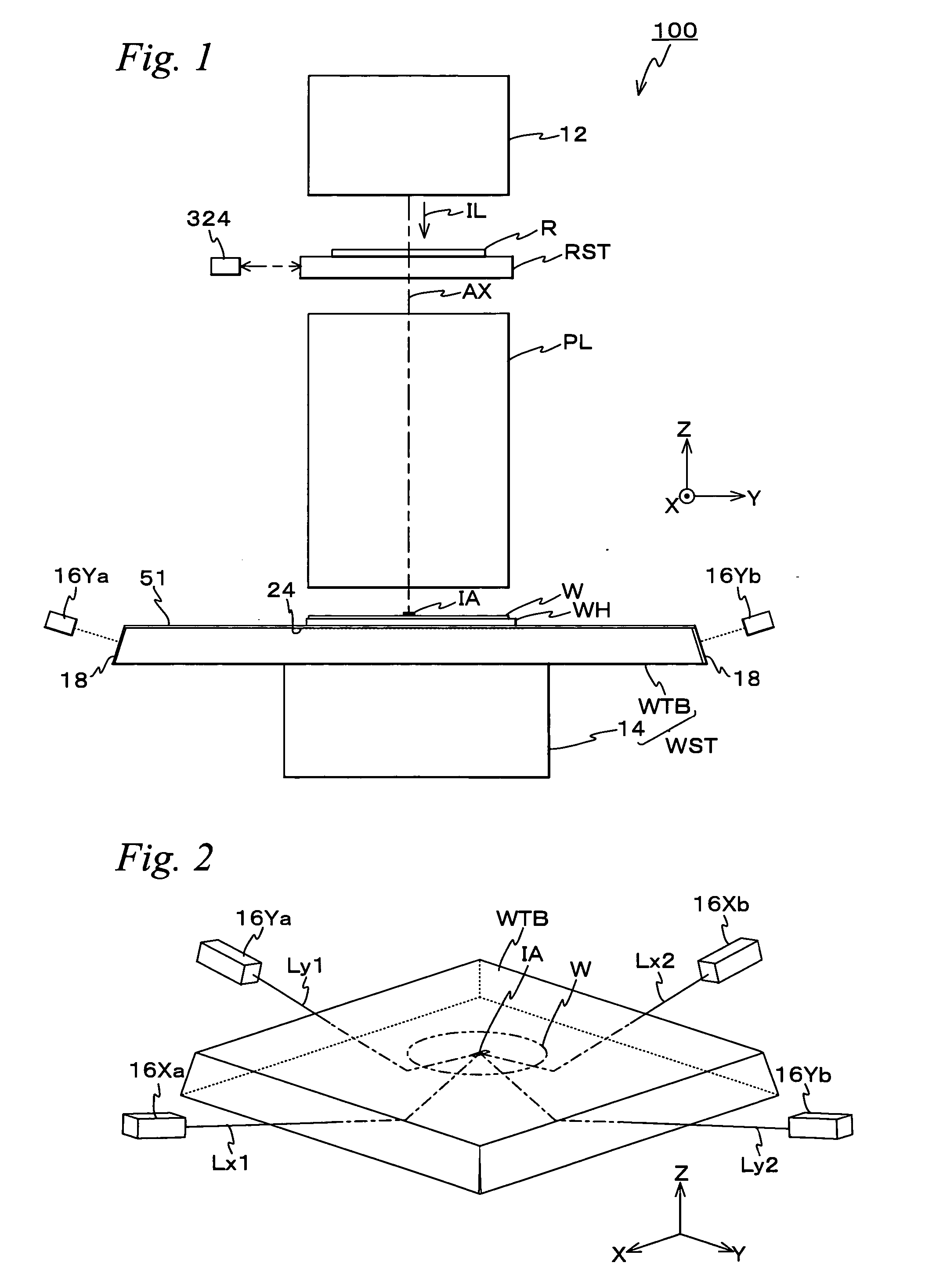

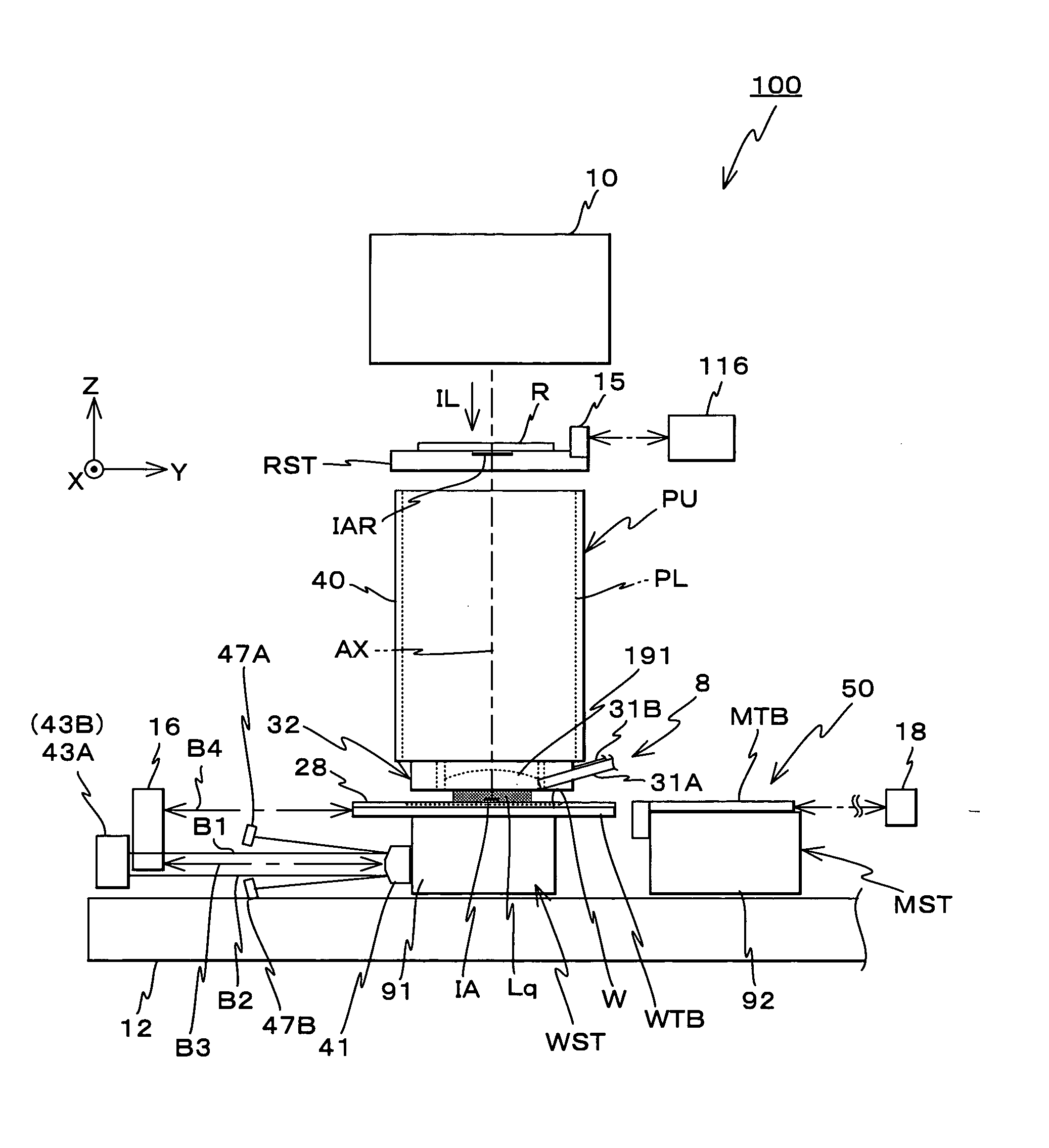

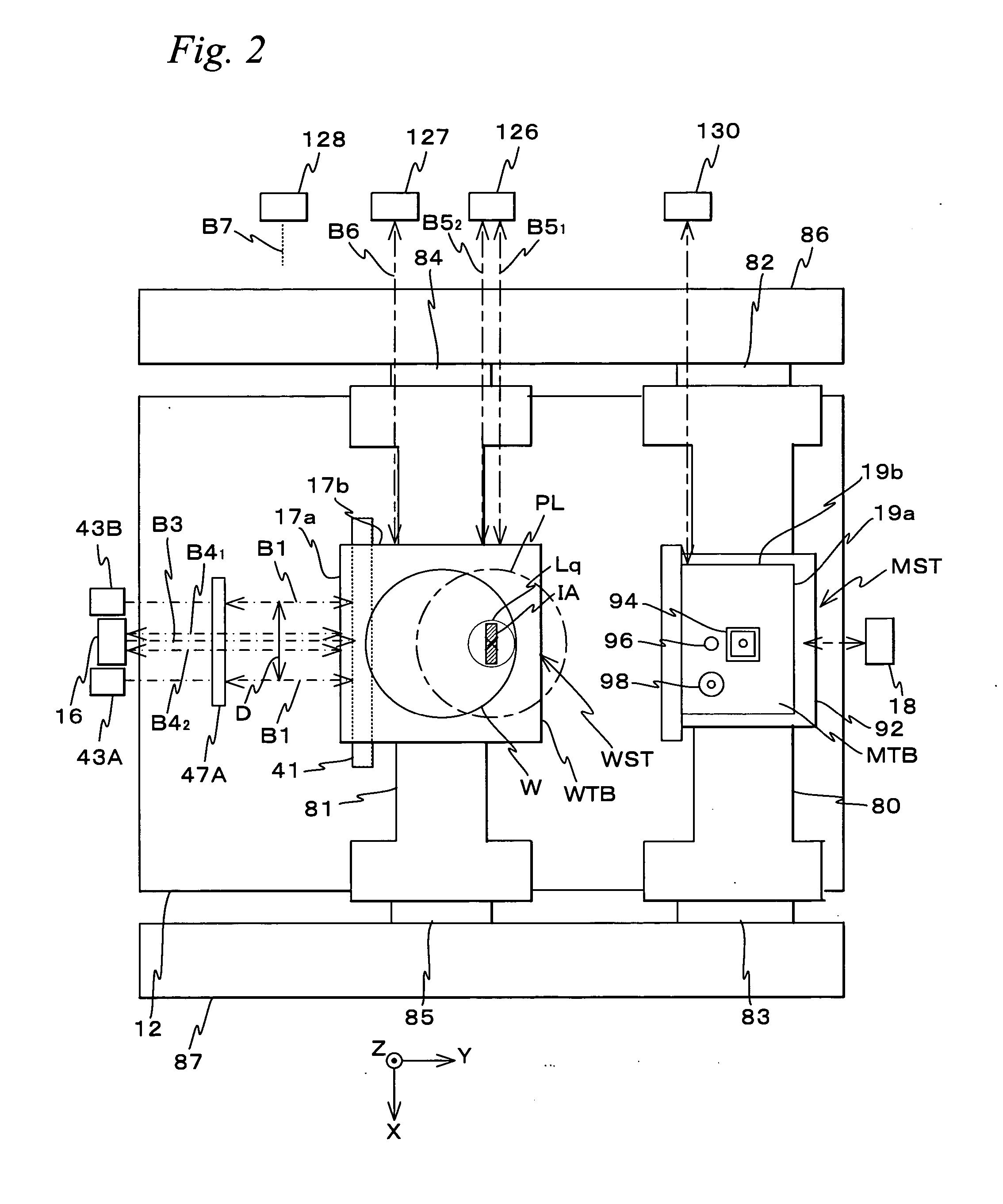

Movable body system, pattern formation apparatus, exposure apparatus and exposure method, and device manufacturing method

InactiveUS20080094594A1Small sizeImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingGratingLight beam

A laser beam emitted by an encoder main body enters a wafer table via a PBS from the outside, and reaches a grating at a point that is located right under exposure area, and is diffracted by the grating. Then, by receiving interference light of a first polarized component that has returned from the grating and a second polarized component reflected by the PBS, positional information of the wafer table is measured. Accordingly, because the first polarized component, which has passed through PBS passes through the wafer table until it is synthesized with the second polarized component again, does not proceed through the atmosphere outside, position measurement of the wafer table can be performed with high precision without the measurement beam being affected by the fluctuation of the atmosphere around the wafer table.

Owner:NIKON CORP

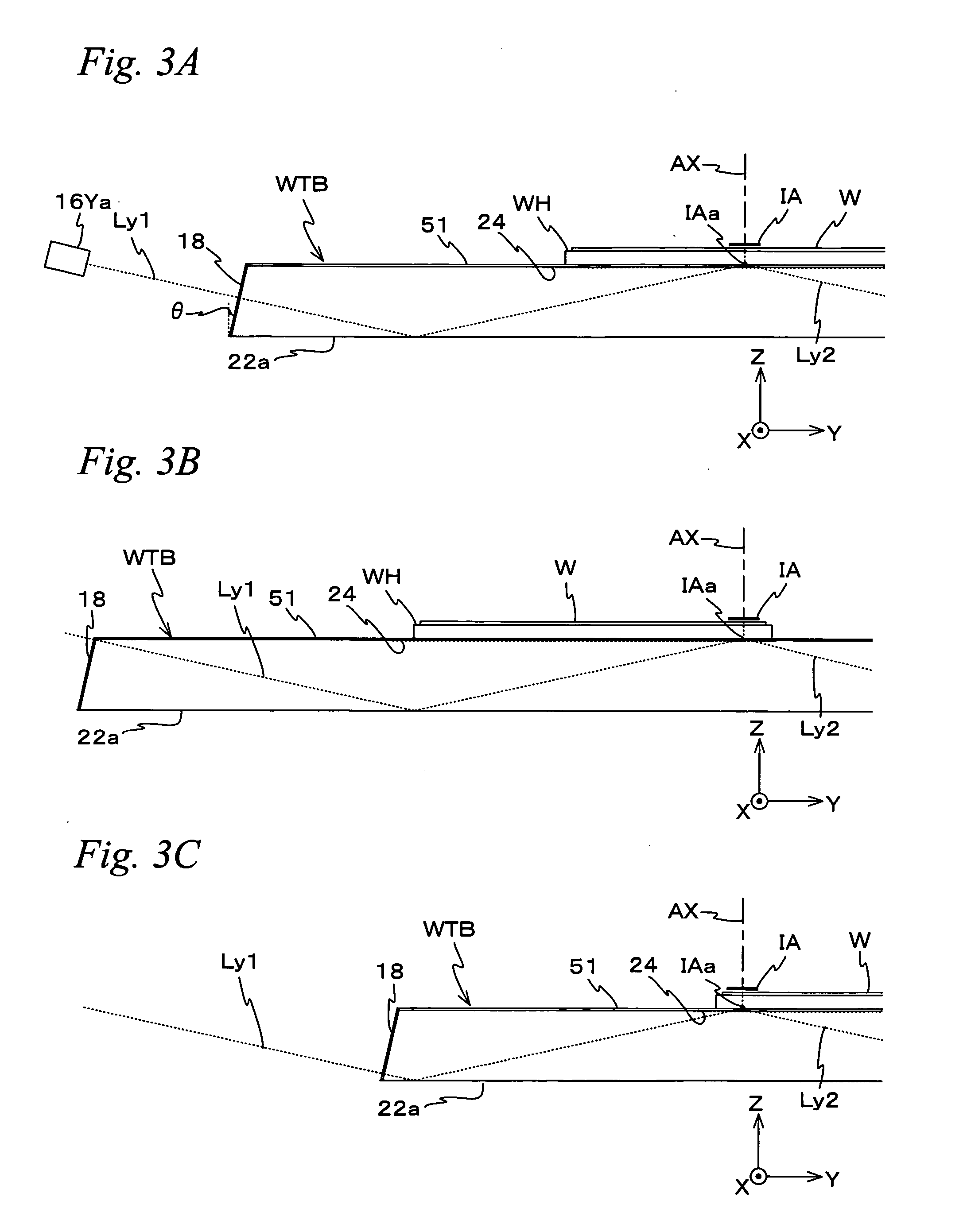

Movable body drive system and movable body drive method, pattern formation apparatus and method, exposure apparatus and method, device manufacturing method, and decision-making method

InactiveUS20080106722A1Improve accuracyDrive precisionBeam/ray focussing/reflecting arrangementsSemiconductor/solid-state device manufacturingRelative displacementEngineering

A drive unit drives a wafer table in a Y-axis direction based on a measurement value of an encoder that measures position information of the wafer table in the Y-axis direction and based on known correction information in accordance with position information of the wafer table in a non-measurement direction (e.g. Z, θz and θx directions) that is measured by an interferometer at the time of the measurement by the encoder. That is, the wafer table (a movable body) is driven in the Y-axis direction based on the measurement value of the encoder that has been corrected by correction information for correcting a measurement error of the encoder that is caused by a relative displacement of a head and a scale in the non-measurement direction. Accordingly, the movable body can be driven with high accuracy in a desired direction while measuring the position by the encoder, without being affected by the relative motion between the head and the scale in directions other than a direction to be measured (measurement direction).

Owner:NIKON CORP

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, and device manufacturing method

InactiveUS20080218713A1Improve accuracyEasy to controlPhotomechanical apparatusSemiconductor/solid-state device manufacturingObservational errorEngineering

A drive unit drives a wafer stage in a Y-axis direction based on a measurement value of an encoder that measures position information of the wafer stage in the Y-axis direction and based on information on the flatness of a scale that is measured by the encoder. In this case, the drive unit can drive the wafer stage in a predetermined direction based on a measurement value after correction in which a measurement error caused by the flatness of the scale included in the measurement value of the encoder is corrected based on the information on the flatness of the scale. Accordingly, the wafer stage can be driven with high accuracy in a predetermined direction using the encoder, without being affected by the unevenness of the scale.

Owner:NIKON CORP

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, and device manufacturing method

InactiveUS20080094604A1Good precisionImprove accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGratingEngineering

A controller inclines a movable body with respect to an XY plane at an angle α in a periodic direction of a grating, based on a measurement value of an interferometer which measures an angle of inclination of the movable body to the XY plane, and based on a measurement value of an encoder system and information of angle α before and after the inclination, and computes an Abbe offset quantity of the grating surface with respect to a reference surface (e.g., an image plane of a projection optical system) which serves as a reference for position control of the movable body in the XY plane. Then, the controller drives the movable body, based on positional information of the movable body in the XY plane measured by the encoder system and a measurement error of the encoder system corresponding to an angle of inclination of the movable body to the XY plane due to the Abbe offset quantity of the grating surface.

Owner:NIKON CORP

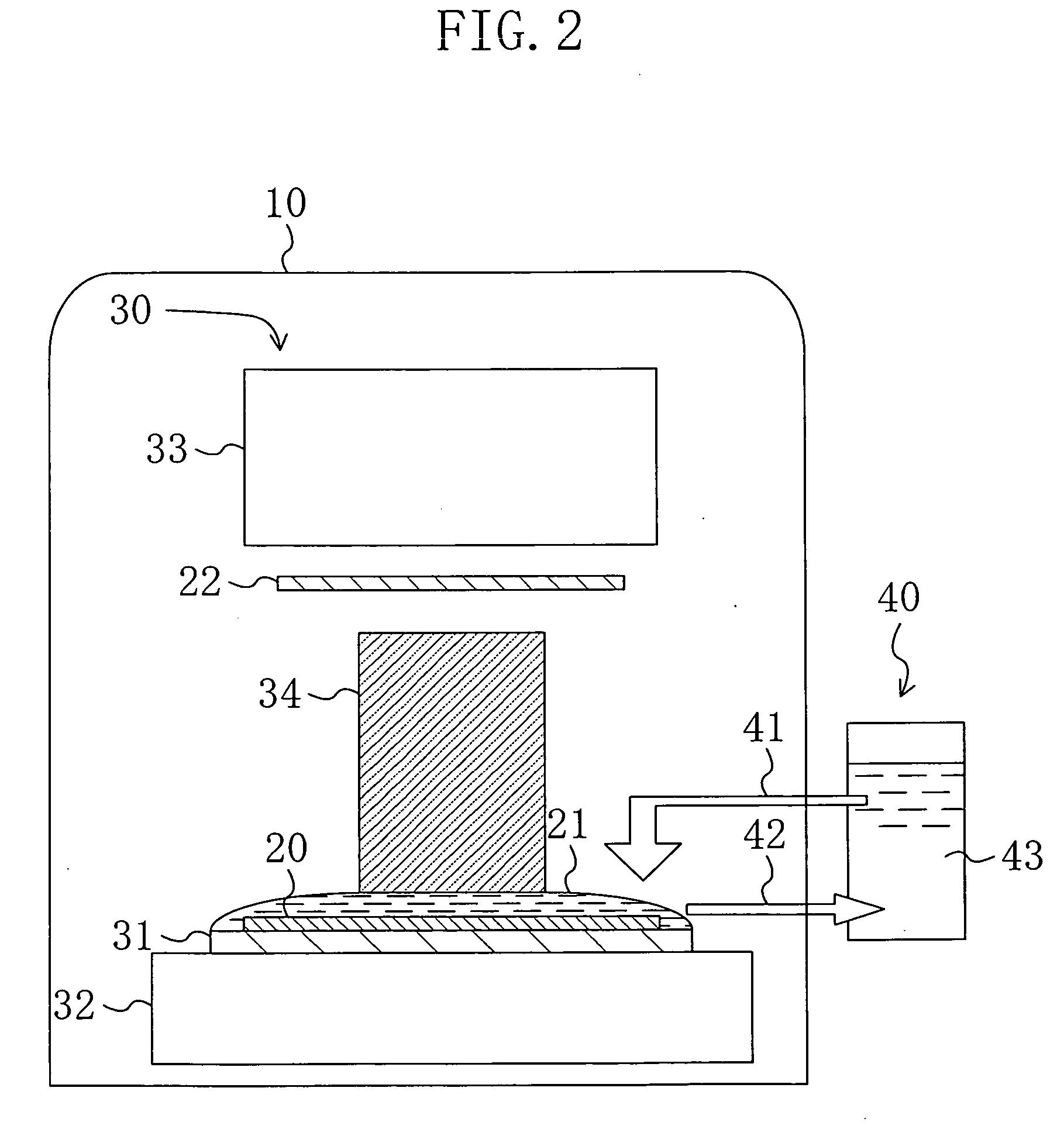

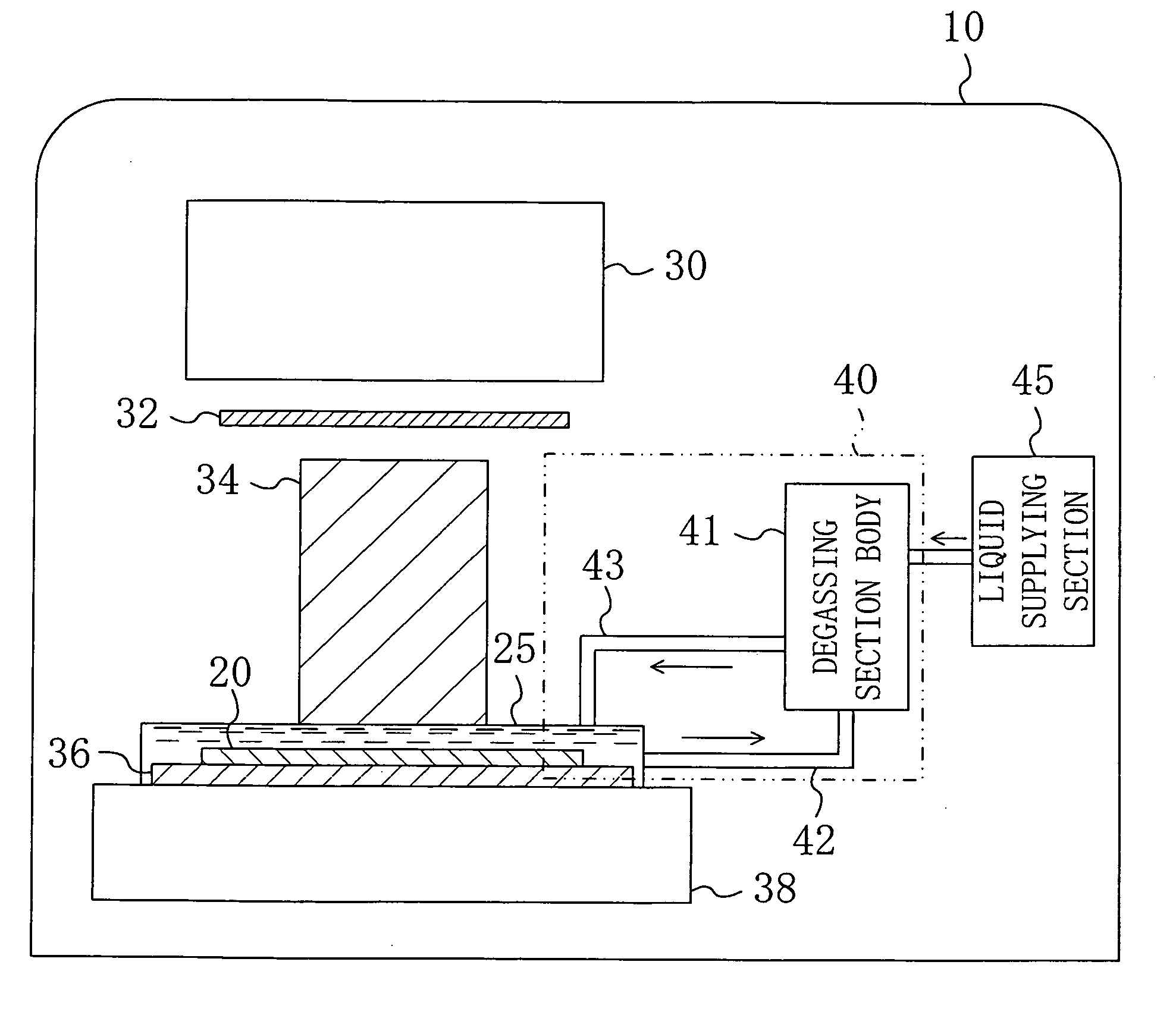

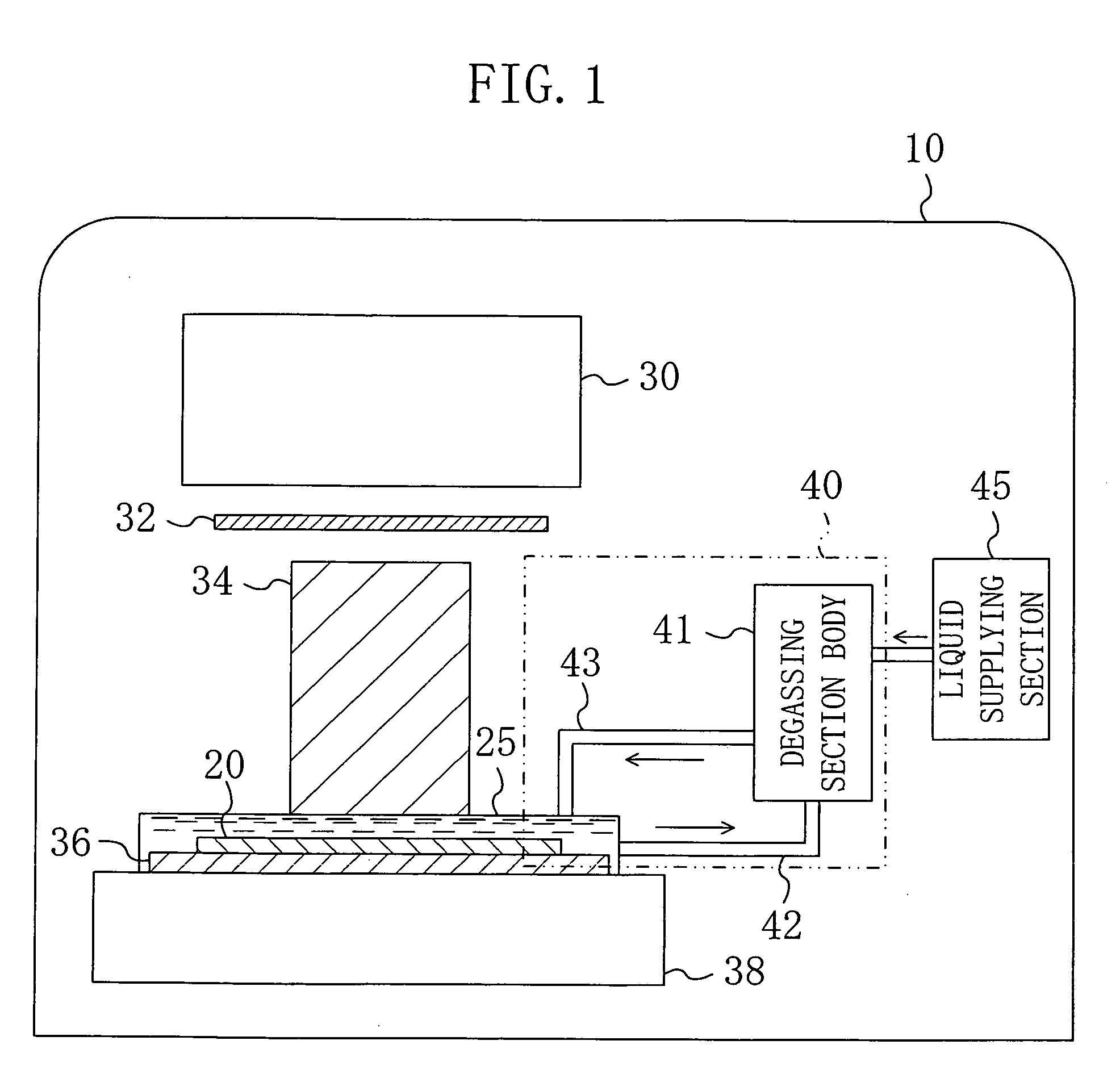

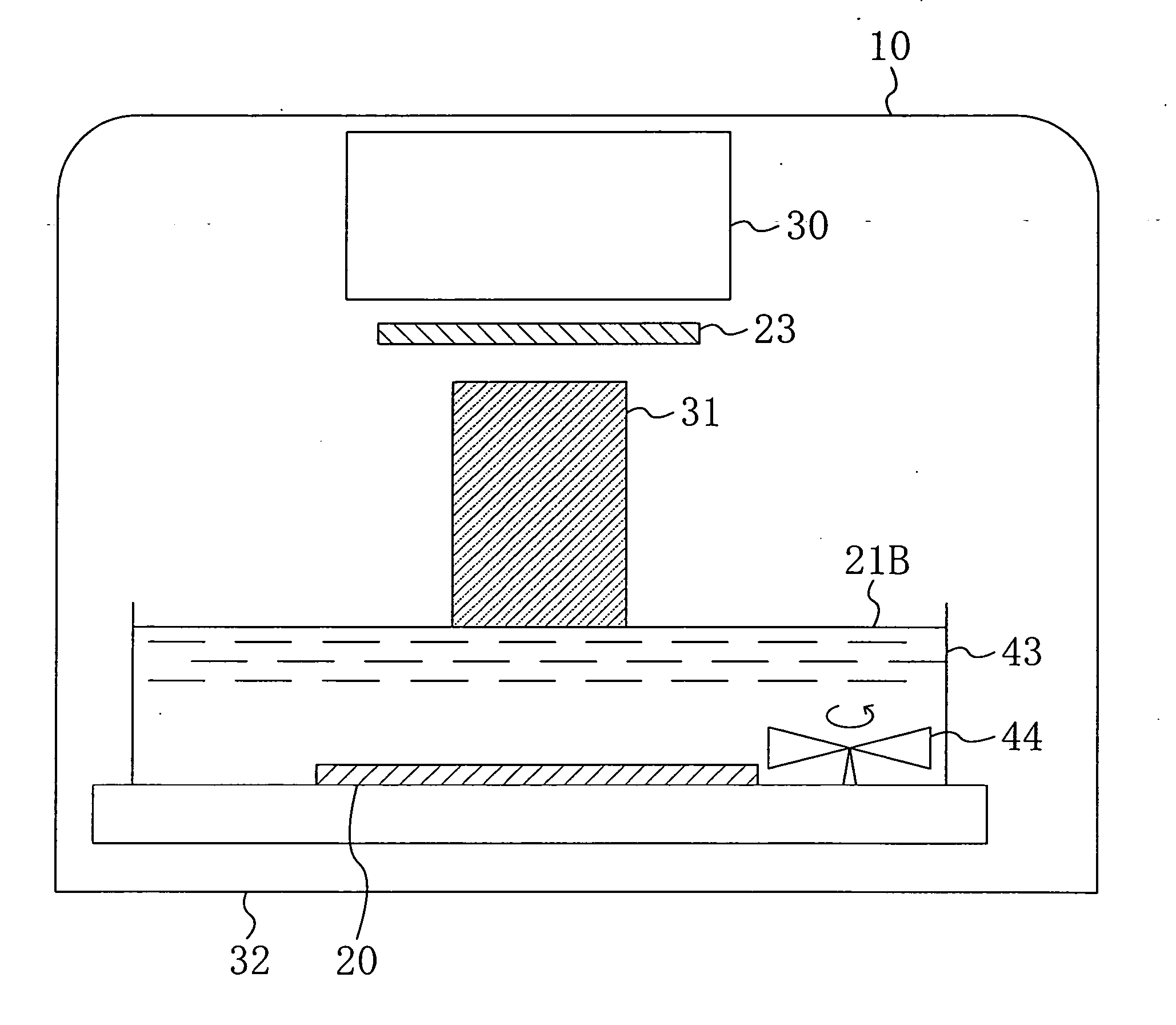

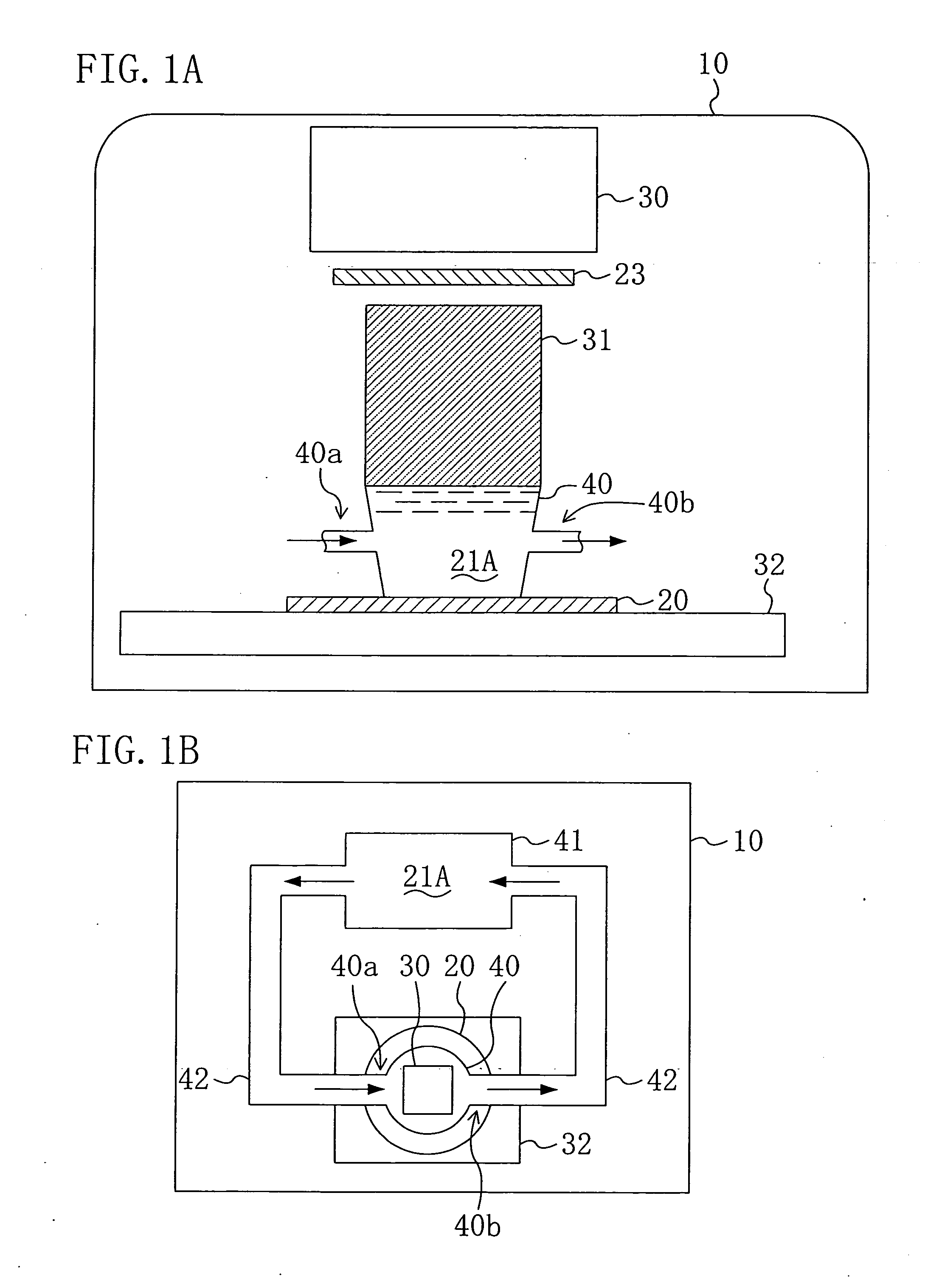

Semiconductor manufacturing apparatus and pattern formation method

InactiveUS20050106512A1Good body shapeAvoid focusPhotosensitive materialsSemiconductor/solid-state device manufacturingResistManufactured apparatus

A semiconductor manufacturing apparatus includes a liquid supplying section for supplying a liquid onto a stage for holding a wafer on which a resist film is formed; an exposing section for irradiating the resist film with exposing light through a mask with the liquid provided on the resist film; and a removing part for removing, from the liquid, a gas included in the liquid. Thus, the liquid from which the gas has been removed is provided on the resist film, and therefore, foams included in the liquid or formed during the exposure can be removed. Accordingly, exposure abnormality such as diffraction abnormality can be prevented, resulting in forming a resist pattern in a good shape.

Owner:RPX CORP

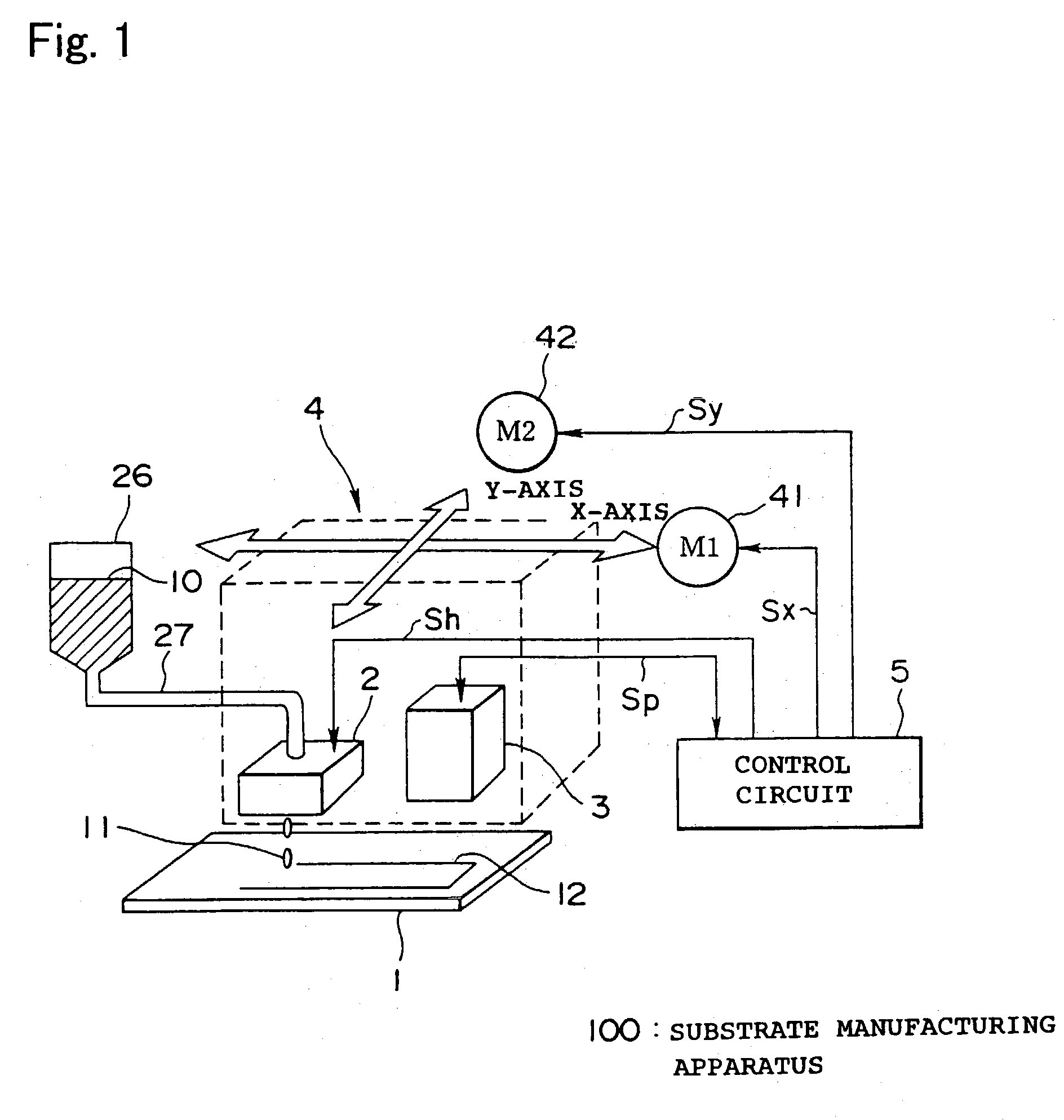

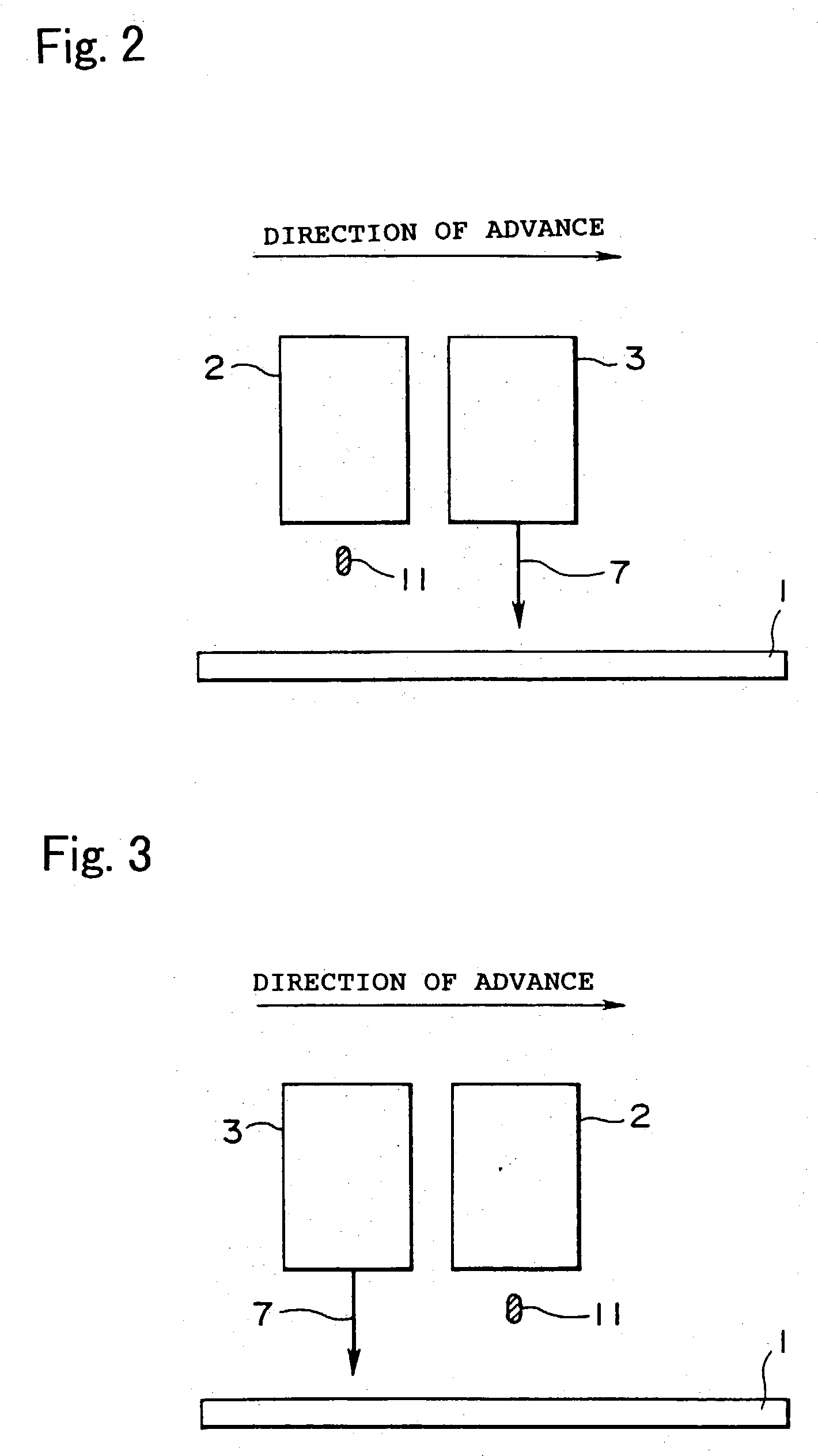

Pattern formation method and substrate manufacturing apparatus

InactiveUS20040048001A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringPattern formation

A pattern formation method for discharging a prescribed fluid onto a substrate form an ink-jet head and forming an arbitrary pattern. The method including the steps of discharging the fluid onto the substrate from an ink jet head and defining a pattern-forming region by subjecting the substrate to a specific treatment to prevent the fluid from spreading. The pattern forming region is formed after the fluid has been ejected so that the arbitrary pattern is formed in the fluid corresponding to the pattern-forming region. The treatment is one in which banks for preventing the fluid from flowing out are formed around the pattern-forming region. The method also includes removing the banks following the formation of the pattern.

Owner:SEIKO EPSON CORP

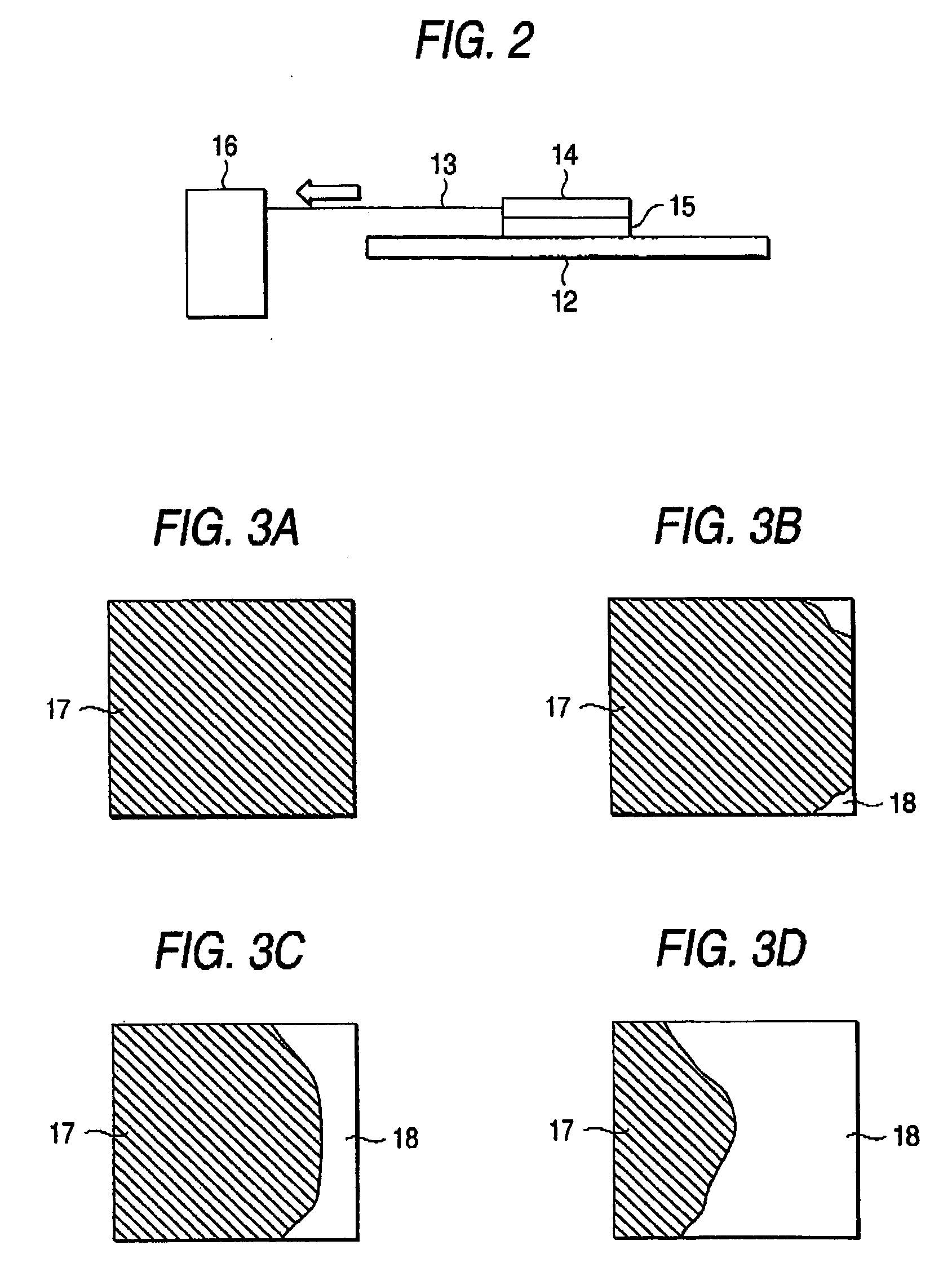

Exposure system and pattern formation method using the same

InactiveUS20050136361A1Good body shapeAbnormal exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistEngineering

An exposure system includes a liquid supply section for supplying an immersion liquid onto a resist film formed on a substrate; and an exposure section for irradiating the resist film with exposing light through a mask with the immersion liquid provided on the resist film. The liquid supply section includes an immersion liquid tank for circulating the immersion liquid during exposure.

Owner:RPX CORP

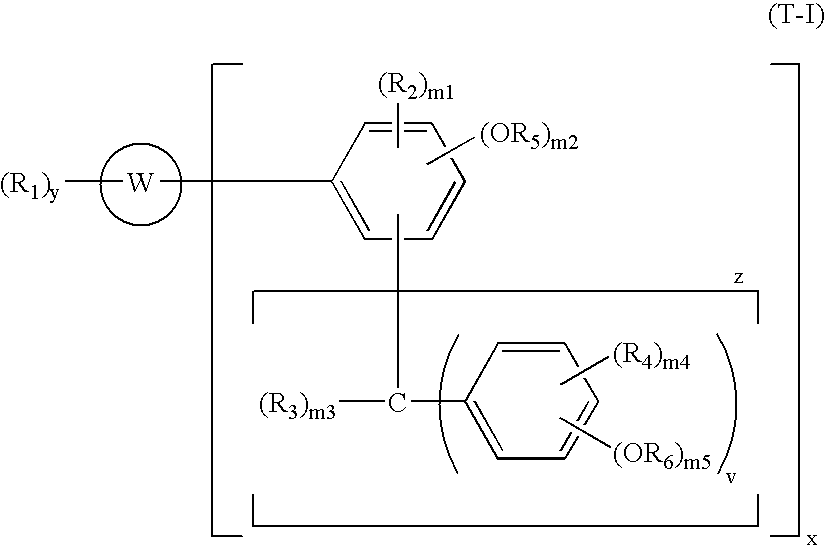

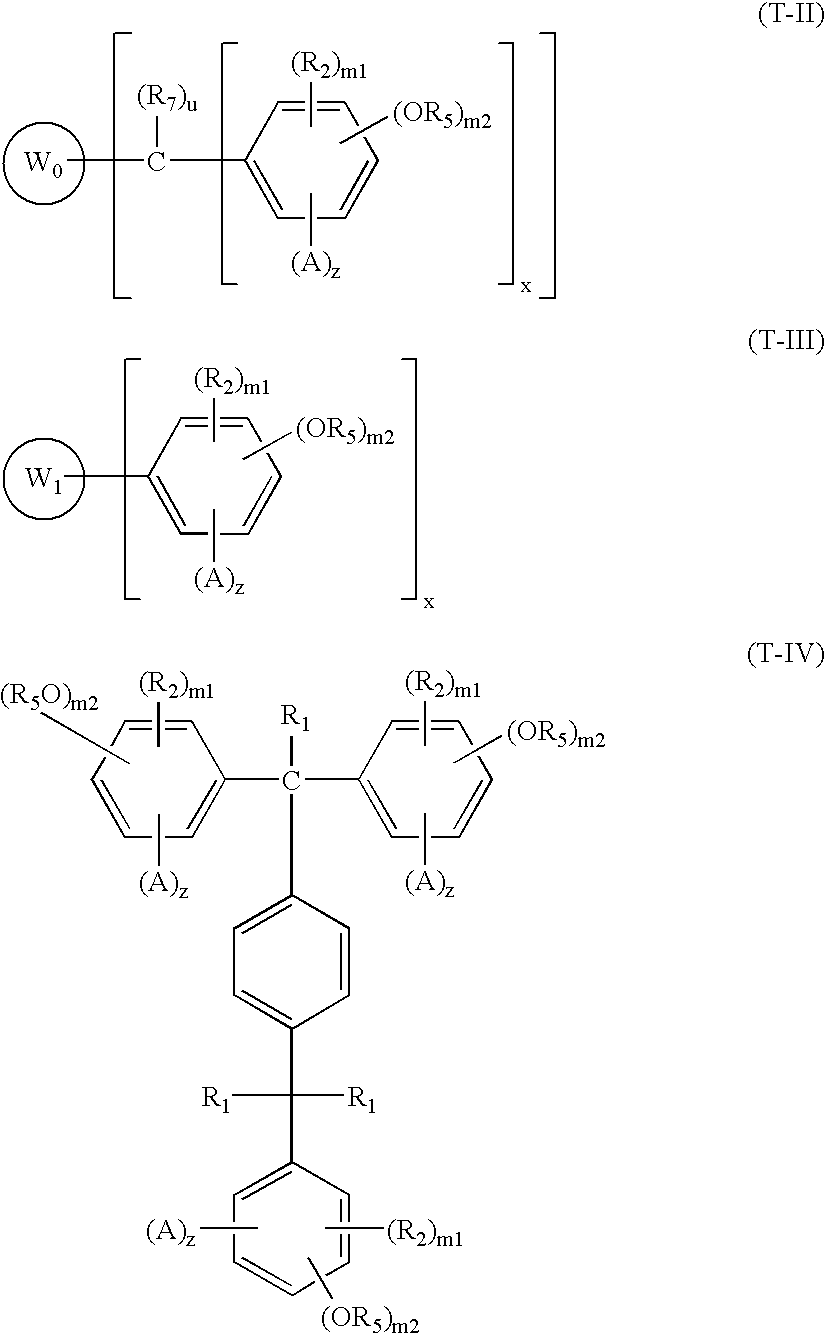

Positive resist composition and method of pattern formation with the same

ActiveUS20070178405A1Improved in pattern profile patternImproved in pattern pattern fallingPhotosensitive materialsSemiconductor/solid-state device manufacturingActinic RaysCompound (substance)

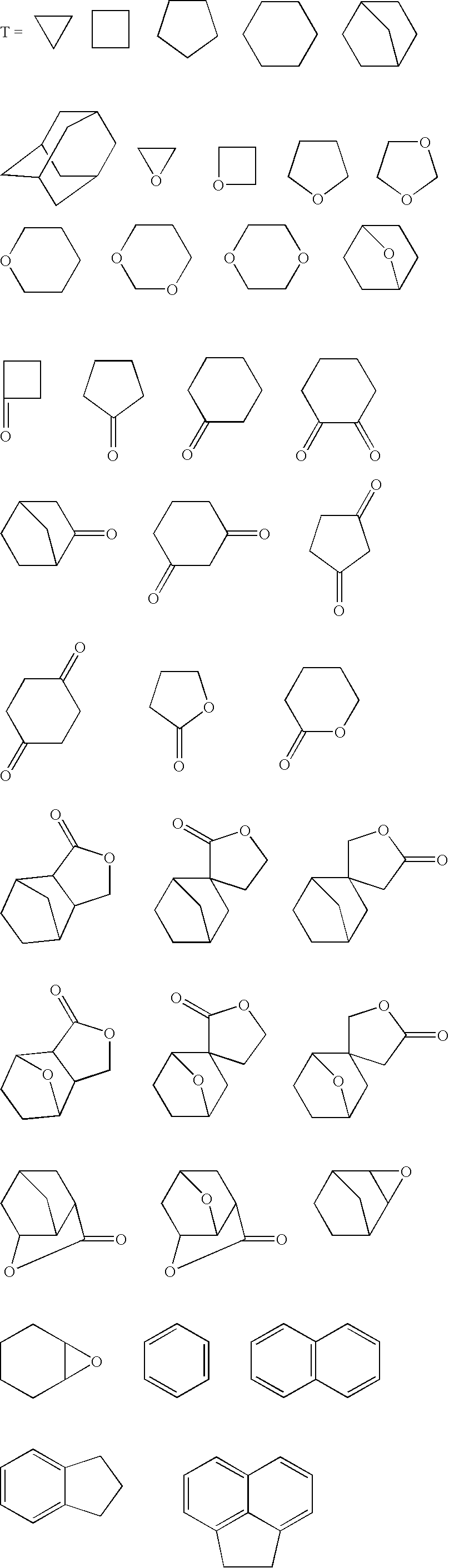

A positive resist composition comprising: (A) a resin which comes to have an enhanced solubility in an alkaline developing solution by an action of an acid; (B) a compound which generates an acid upon irradiation with actinic rays or a radiation; (C) a fluorine-containing compound containing at least one group selected from the groups (x) to (z); and (F) a solvent, and a method of pattern formation with the composition: (x) an alkali-soluble group; (y) a group which decomposes by an action of an alkaline developing solution to enhance a solubility in an alkaline developing solution; and (z) a group which decomposes by an action of an acid.

Owner:FUJIFILM HLDG CORP +1

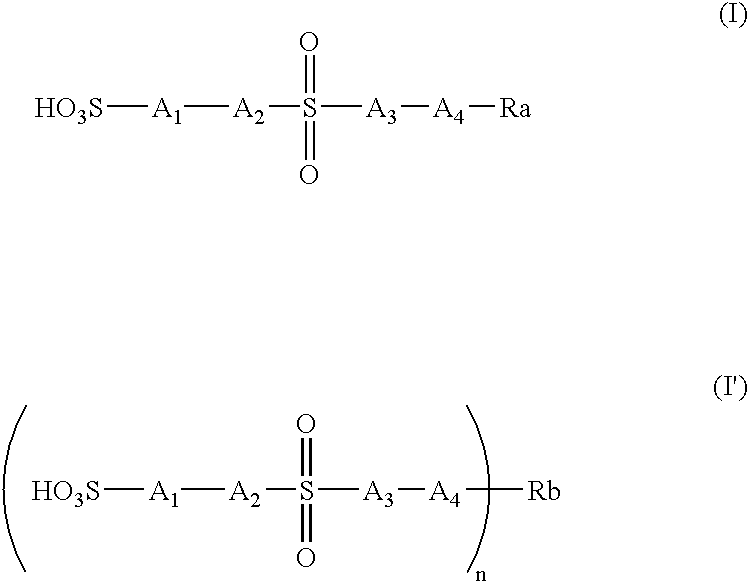

Photosensitive composition, compound for use in the photosensitive composition, and method of pattern formation with the photosensitive composition

ActiveUS20060040203A1Less apt to suffer pattern fallingReduce roughnessOrganic chemistryRadiation applicationsActinic RaysRadiation exposure

A compound which generates a sulfonic acid having one or more —SO3H groups and one or more —SO2— bonds upon irradiation with an actinic ray or a radiation; a photosensitive composition containing the compound; and a method of pattern formation with the photosensitive composition.

Owner:FUJIFILM HLDG CORP +1

Metal oxide-containing film-forming composition, metal oxide-containing film, metal oxide-containing film-bearing substrate, and patterning method

ActiveUS20090136869A1Sufficient etching resistanceImprove accuracySilicon organic compoundsOther chemical processesOrganic acidOrganic solvent

A metal oxide-containing film is formed from a heat curable composition comprising (A) a metal oxide-containing compound obtained through hydrolytic condensation between a hydrolyzable silicon compound and a hydrolyzable metal compound, (B) a hydroxide or organic acid salt of Li, Na, K, Rb or Cs, or a sulfonium, iodonium or ammonium compound, (C) an organic acid, and (D) an organic solvent. The metal oxide-containing film ensures effective pattern formation.

Owner:SHIN ETSU CHEM IND CO LTD

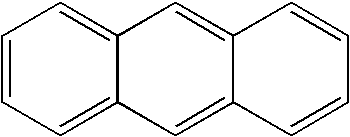

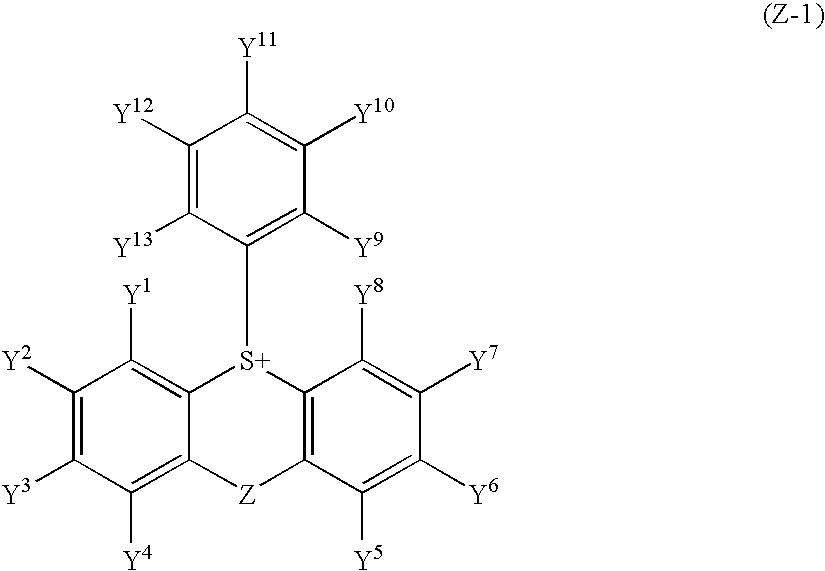

Positive resist composition and pattern formation method using the same

InactiveUS20070224540A1Improve performanceHigh sensitivityPhotosensitive materialsRadiation applicationsActinic RaysSulfonium

A positive resist composition containing a compound including a sulfonium cation having a structure represented by the formula (Z-I) as defined herein, a low molecular weight compound which increases solubility in an alkali developing solution by an action of an acid, and a compound which generates a compound having a structure represented by the formula (A-I) as defined herein upon irradiation of an actinic ray or a radiation.

Owner:FUJIFILM CORP

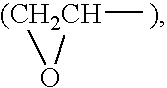

Method for pattern formation

InactiveUS20080041818A1Satisfactory etching resistanceHigh aspect ratioDecorative surface effectsNanoinformaticsOxygen plasmaSolvent

There is provided a method for pattern formation, including a step of coating a composition comprising a block copolymer, a silicon compound, and a solvent for dissolving these components onto an object to form a layer of the composition on the object, a step of subjecting the layer of the composition to self-organization of the block copolymer to cause phase separation into a first phase, in which the silicon compound is localized, having higher etching resistance by heat treatment or / and oxygen plasma treatment, and a second phase comprising a polymer phase and having lower etching resistance by heat treatment or / and oxygen plasma treatment, and thereby forming a pattern layer with a fine pattern, and a step of etching the object using as a mask the thus formed pattern layer.

Owner:KK TOSHIBA

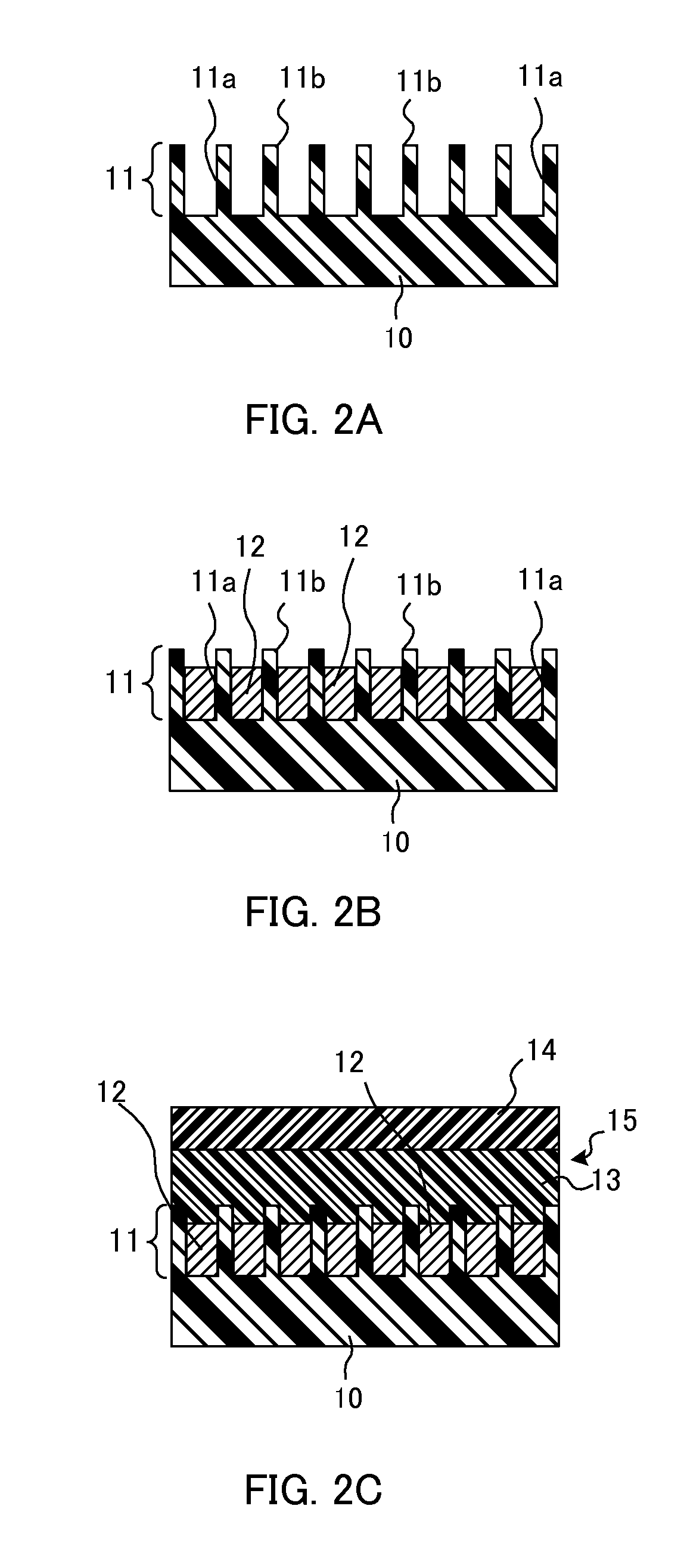

Method of nanopatterning, a resist film for use therein, and an article including the resist film

InactiveUS20070122749A1Surface energy is lowEasy to demouldNanoinformaticsPhotomechanical apparatusResistOxygen plasma etching

A method of nanopatterning includes the steps of providing a resist film (12) and forming a pattern in the resist film (12). The resist film (12) includes a copolymer consisting of an organosilicone component and an organic component. An article (10) includes a substrate (14) and the resist film (12) disposed on the substrate (14). The copolymer of the organosilicone component and the organic component is sufficiently elastic, due to the presence of the organosilicone component, to be capable of resisting fracture and delamination during mold release. Furthermore, during pattern formation, the copolymer develops relatively low surface energy at an interface with the surface of a mold, as compared to conventional polymeric materials, and preferentially adheres to the substrate (14) rather than the mold, which provides for relatively easy mold release. The presence of the organosilicone component in the copolymer also allows the resist film (12) to exhibit excellent resistance to oxygen plasma etching.

Owner:DOW CORNING CORP

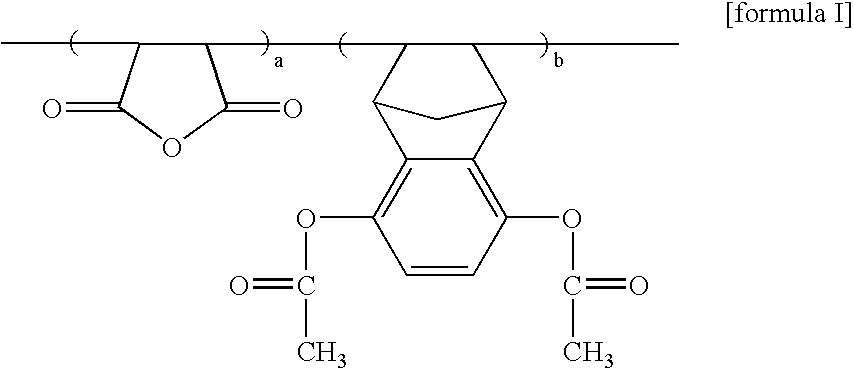

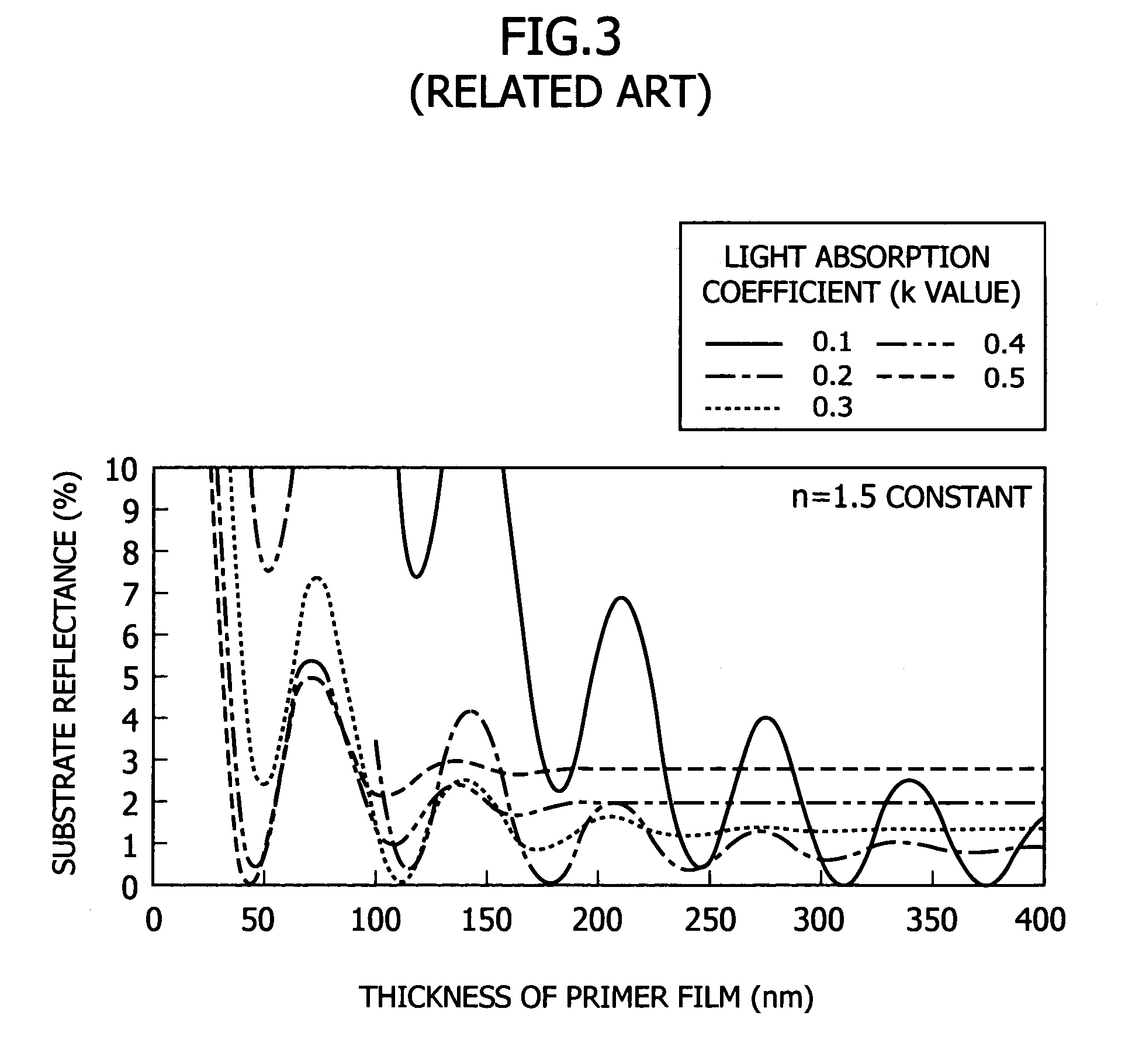

Light absorbent agent polymer for organic anti-reflective coating and preparation method and organic anti-reflective coating composition comprising the same

InactiveUS7033729B2Well formedSolvent-resistant abilityPhotosensitive materialsRadiation applicationsAnti-reflective coatingDiffuse reflection

Disclosed are a light absorbent agent polymer for organic anti-reflective coating which can prevent diffused reflection of lower film layer or substrate and reduce standing waves caused by variation of thickness of the photoresist itself, thereby, increasing uniformity of the photoresist pattern, in a process for forming ultra-fine patterns of photoresist for photolithography by using 193 nm ArF among processes for manufacturing semiconductor device, and its preparation method. Also, the present invention discloses an organic anti-reflective coating composition comprising the light absorbent agent polymer for the organic anti-reflective coating and a pattern formation process using the coating composition.

Owner:SK HYNIX INC

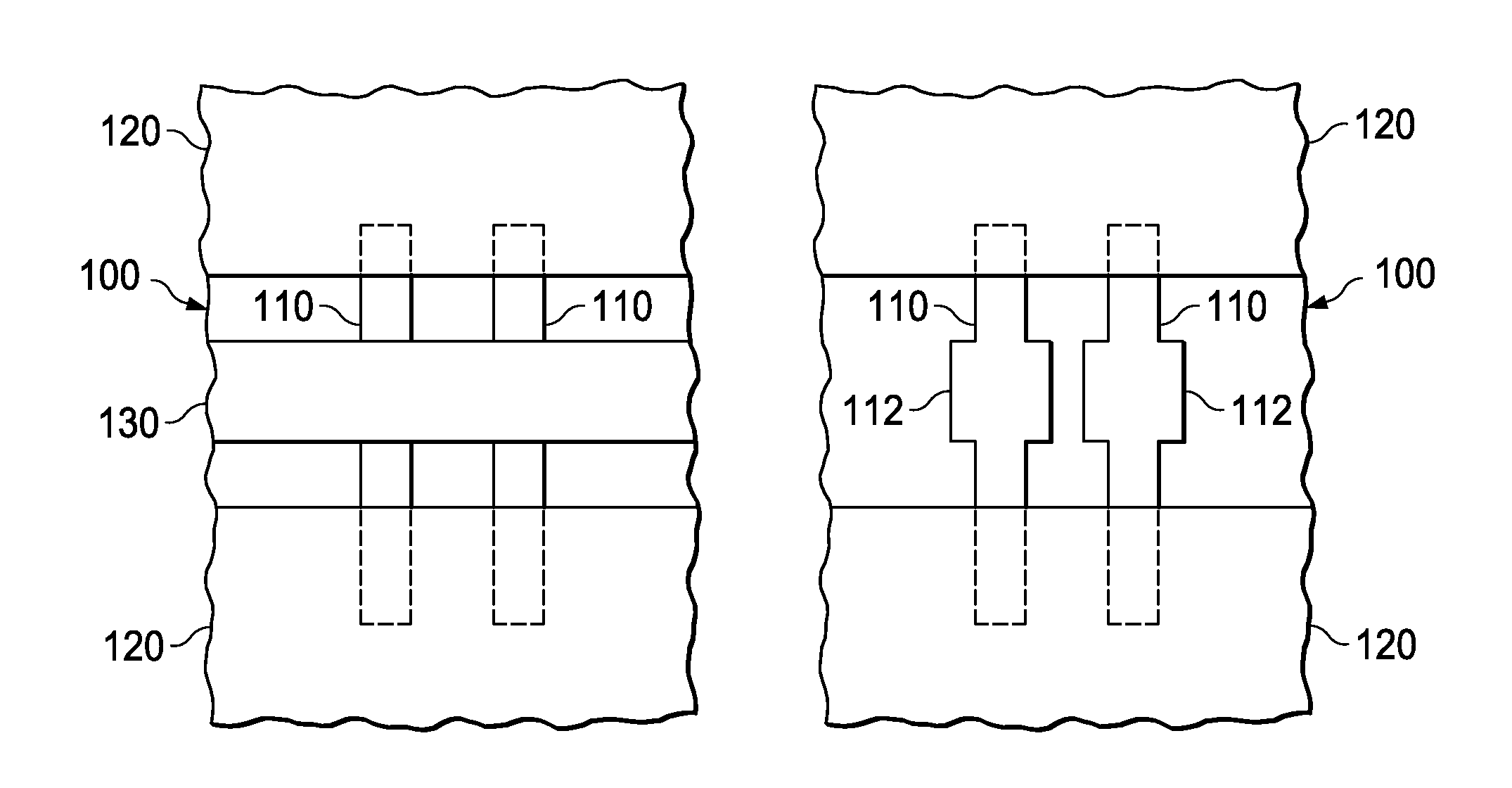

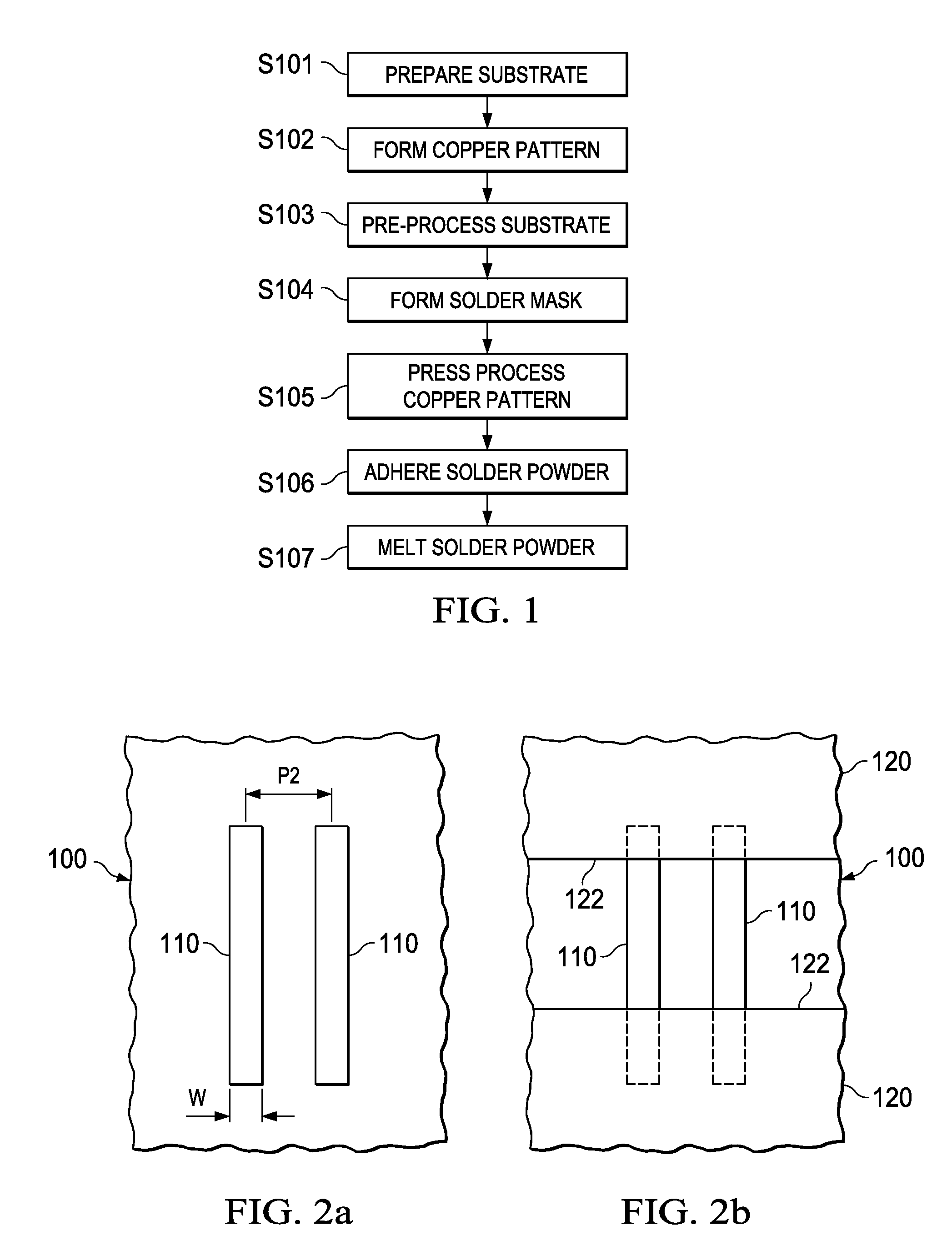

Conductive pattern formation method

ActiveUS7947602B2Electrically conductive connectionsFinal product manufactureSemiconductor chipPattern formation

The objective of the present invention is to offer a method for forming a conductive pattern on a substrate and solder protrusions on the conductive pattern. The pitch of the conductive pattern corresponds to the pitch of electrodes on a semiconductor chip.

Owner:TEXAS INSTR INC

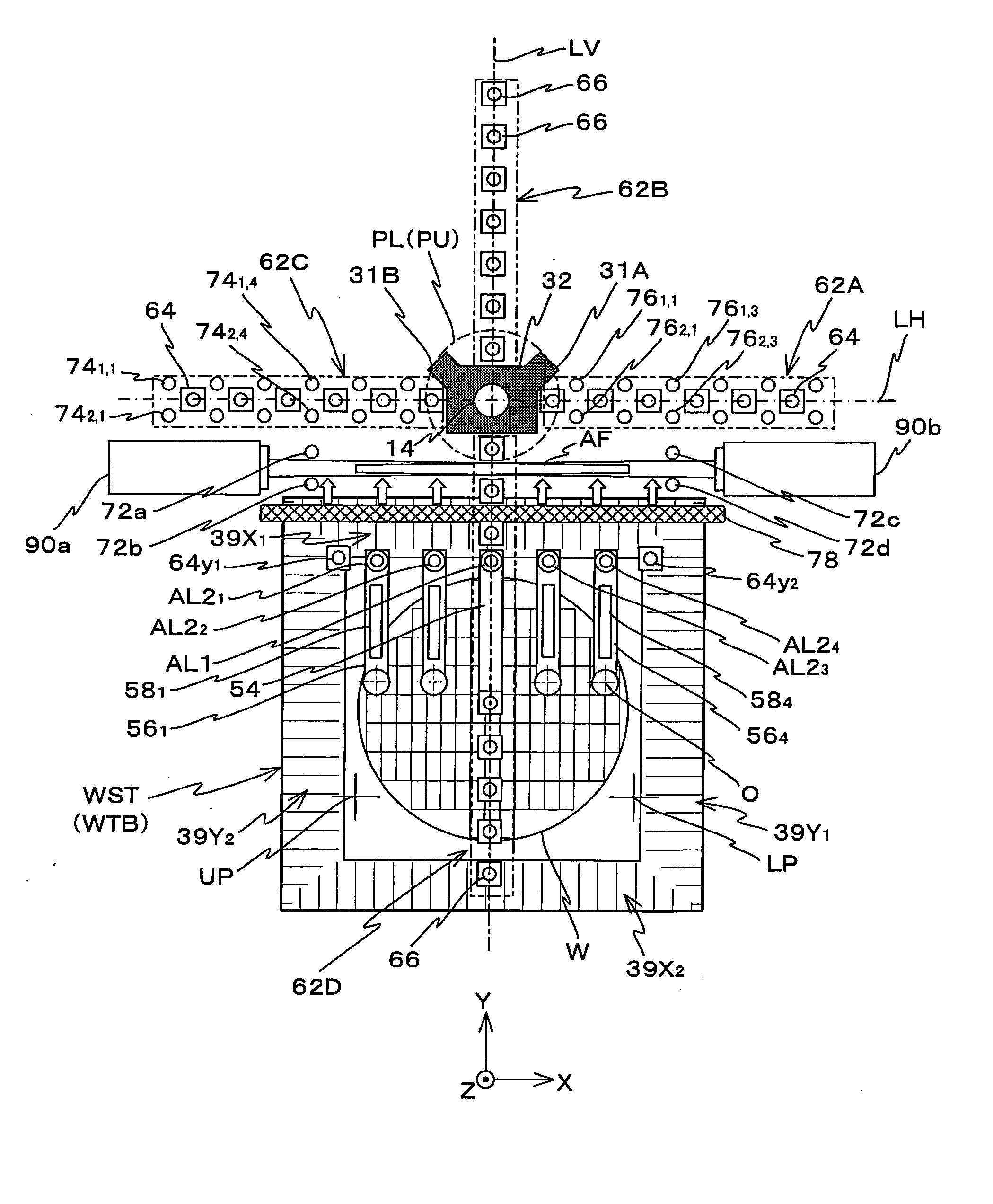

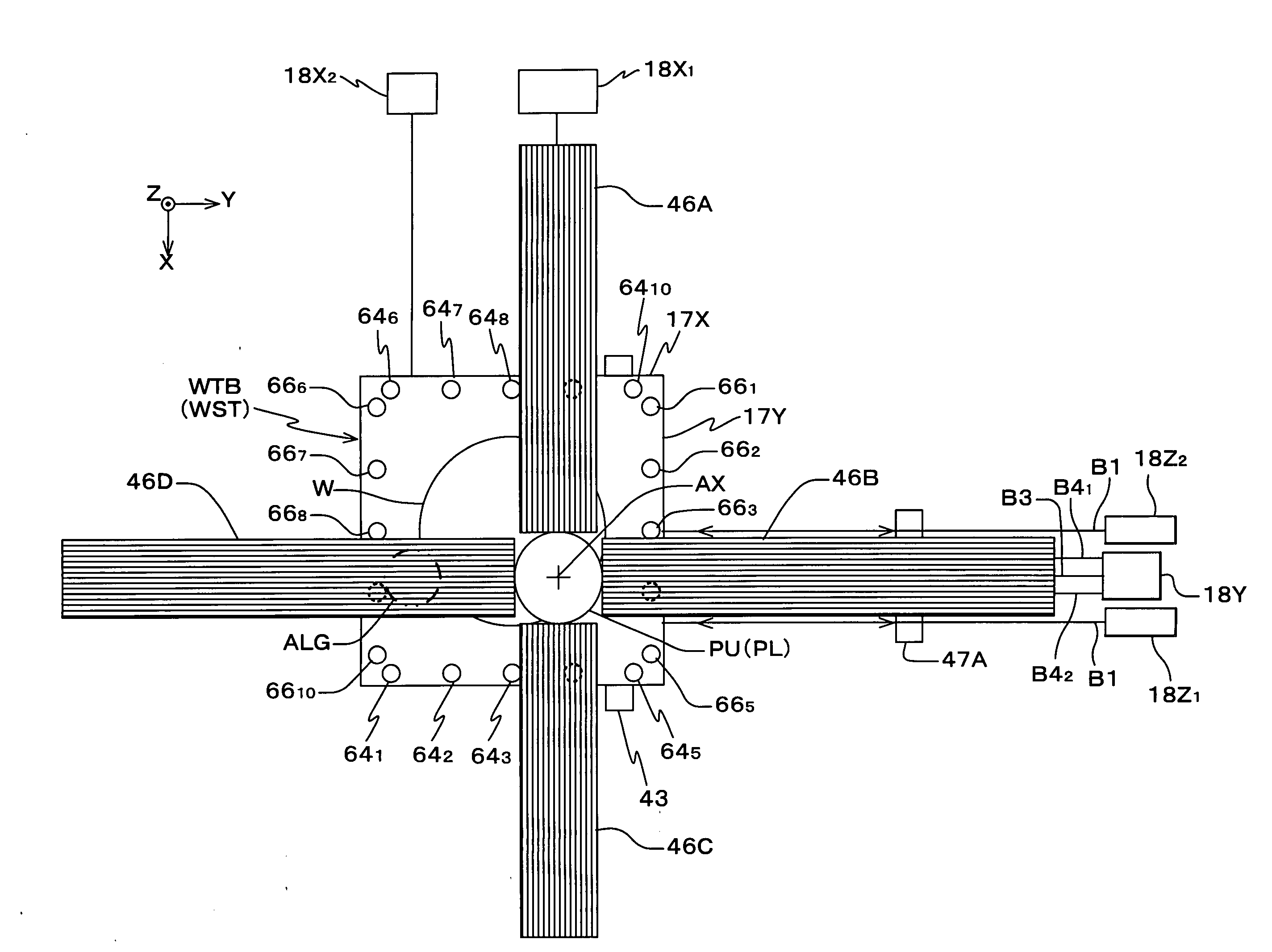

Movable body drive system, pattern formation apparatus, exposure apparatus and exposure method, and device manufacturing method

InactiveUS20090190110A1High-precision exposureImprove accuracyWalking sticksPhotomechanical apparatusGratingEncoder

A stage device is equipped with a first scale which is placed with a Y-axis direction serving as its longitudinal direction and in which a first grating whose periodic direction is in an X-axis direction is formed and a second scale which is placed with the X-axis direction serving as its longitudinal direction and in which a second grating whose periodic direction is orthogonal to the periodic direction of the first grating is formed, the first scale and the second scale being placed on a plane which a wafer stage faces. Further, on the upper surface of the wafer stage, a plurality of X heads placed at different positions in the X-axis direction and a plurality of Y heads placed at different positions in the Y-axis direction are arranged. An encoder system that has these heads measures positional information of the stage within an XY plane, based on an output of the X head facing the first scale and an output of the Y head facing the second scale.

Owner:NIKON CORP

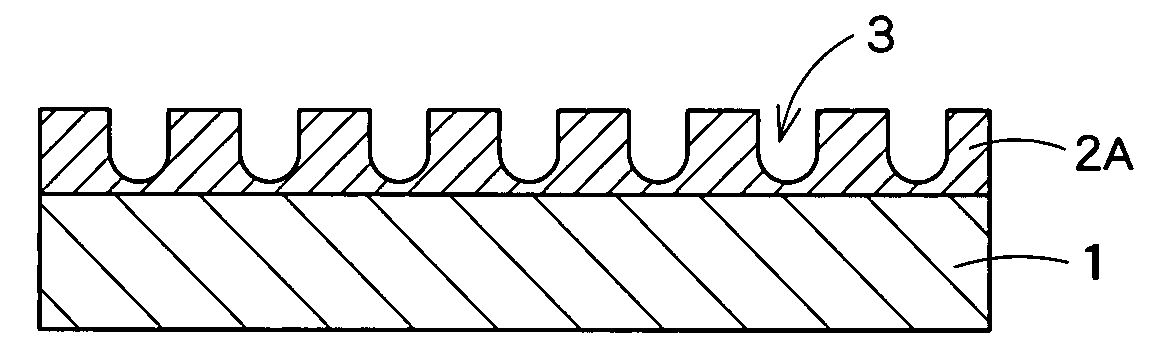

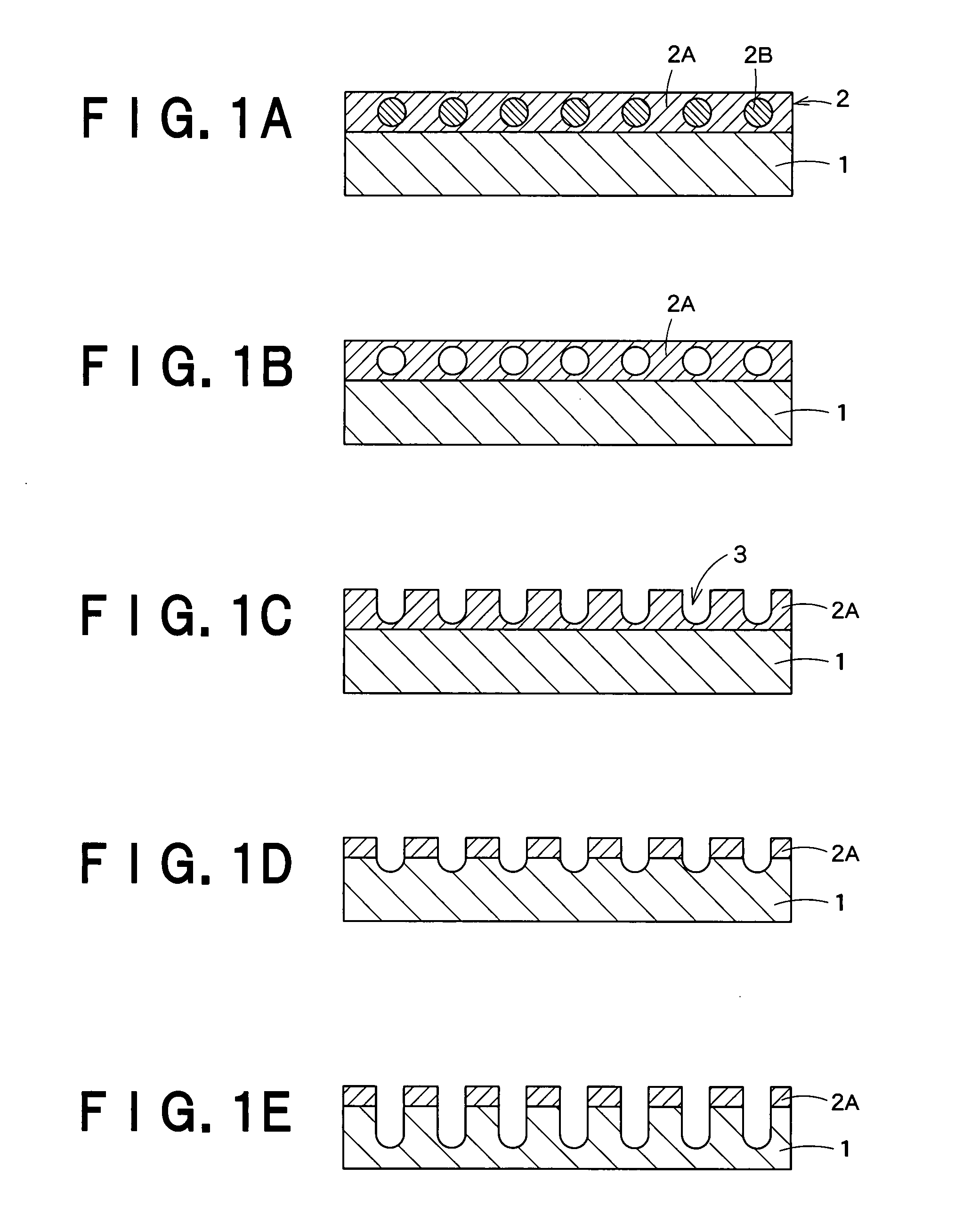

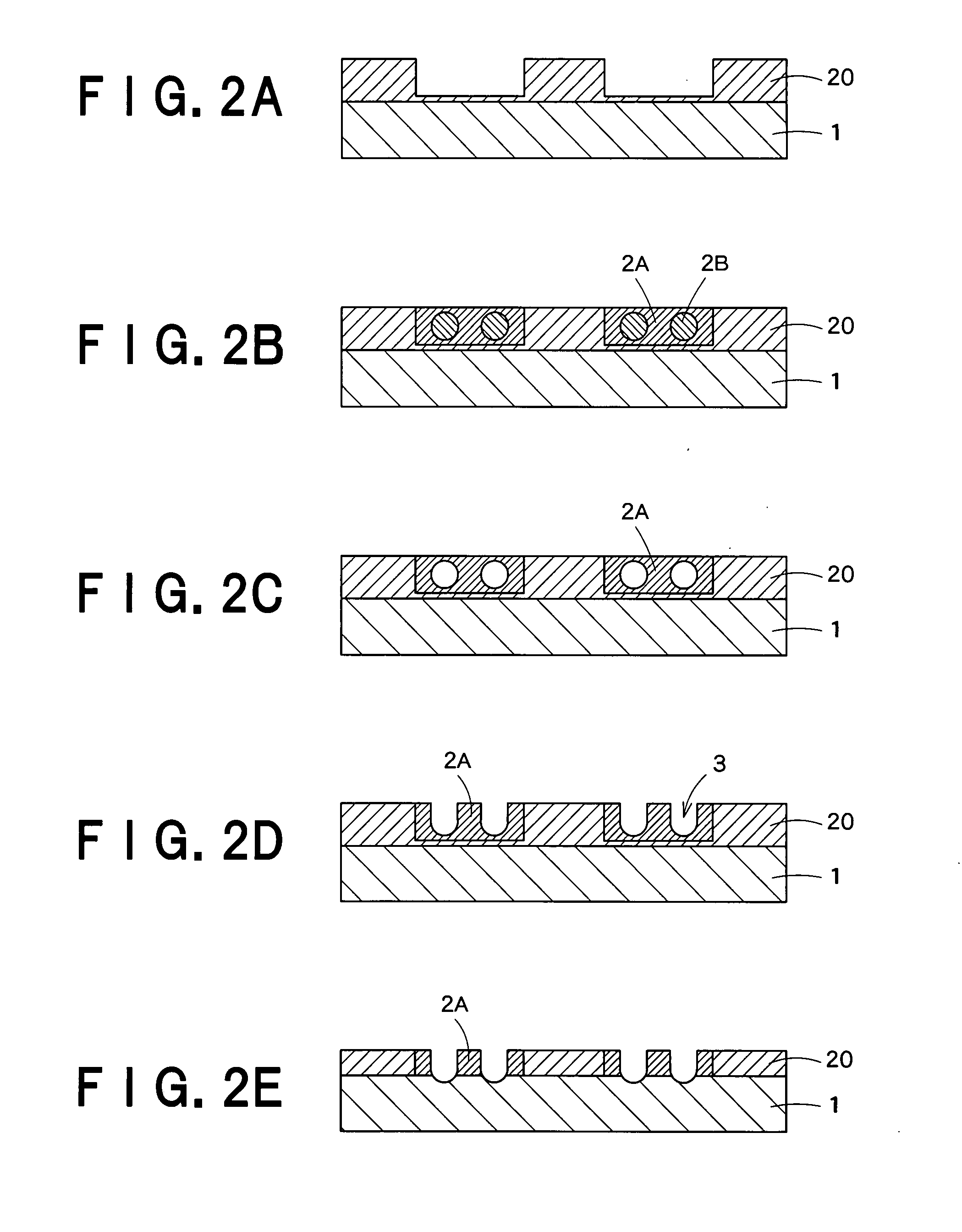

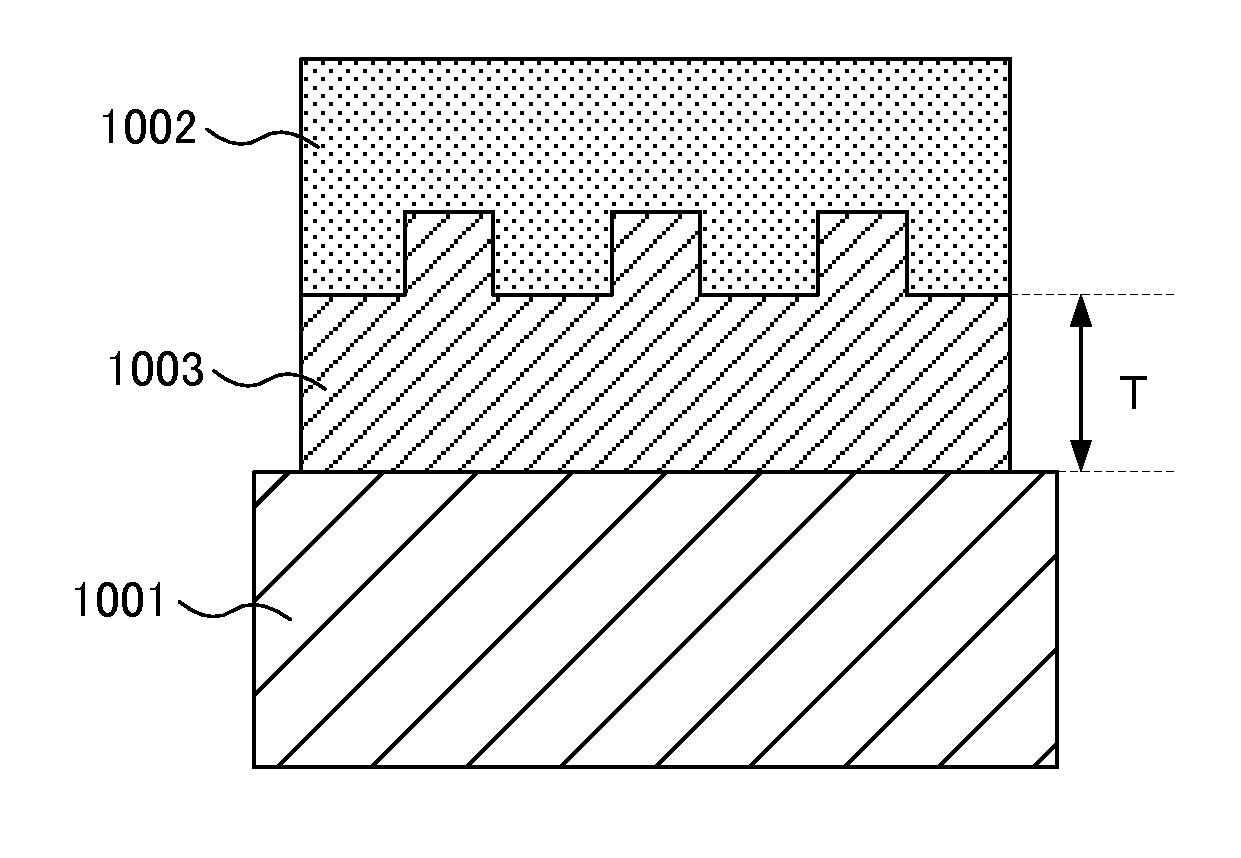

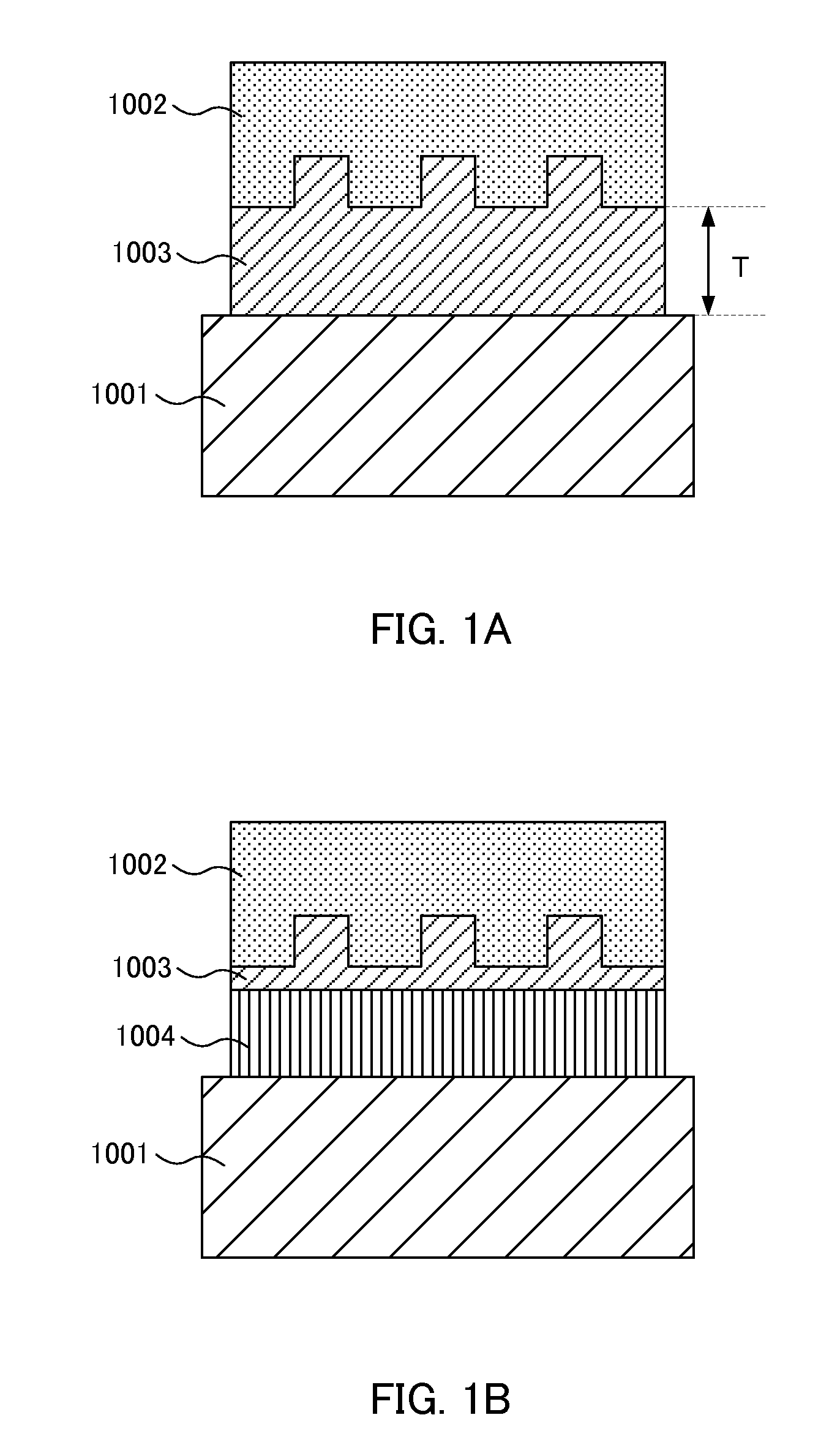

Layered product for fine pattern formation and method of manufacturing layered product for fine pattern formation

ActiveUS20140151733A1High aspect ratioWell formedConfectioneryNanoinformaticsConvex structureMaterials science

Disclosed is a layered product for fine pattern formation and a method of manufacturing the layered product for fine pattern formation, capable of easily forming a fine pattern having a thin or no remaining film in order to form a fine pattern having a high aspect ratio on a processing object. The layered product for fine pattern formation (1) of the present invention used to form a fine pattern (220) in a processing object (200) using a first mask layer (103) includes: a mold (101) having a concavo-convex structure (101a) on a surface; and a second mask layer (102) provided on the concavo-convex structure (101a), wherein in the second mask layer (102), a distance (lcc) and a height (h) of the concavo-convex structure (101a) satisfy Formula (1) 0<lcc<1.0 h, and a distance (lcv) and the height (h) satisfy Formula (2) 0≦lcv≦0.05 h.

Owner:ASAHI KASEI E-MATERIALS CORPORATION

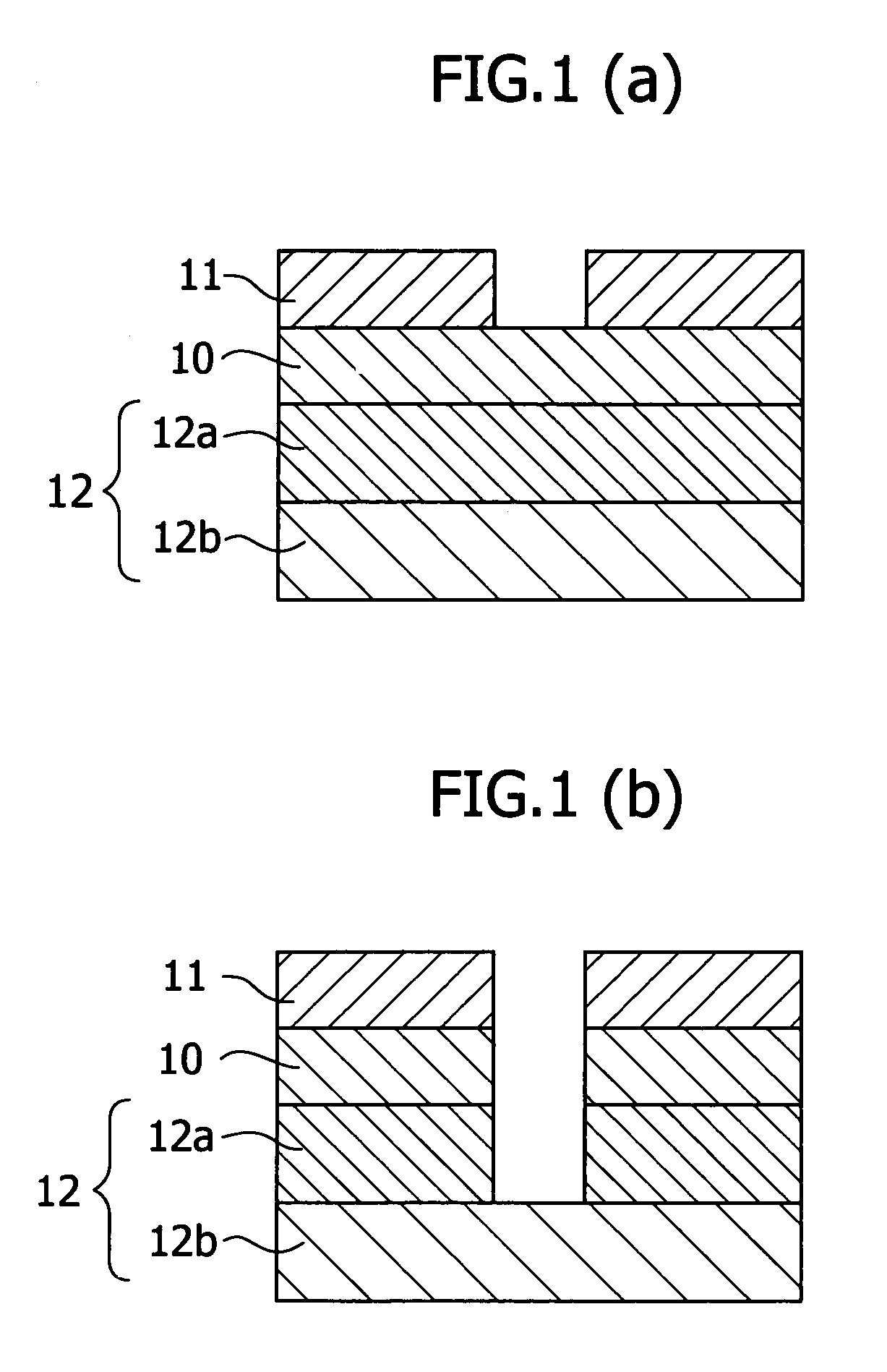

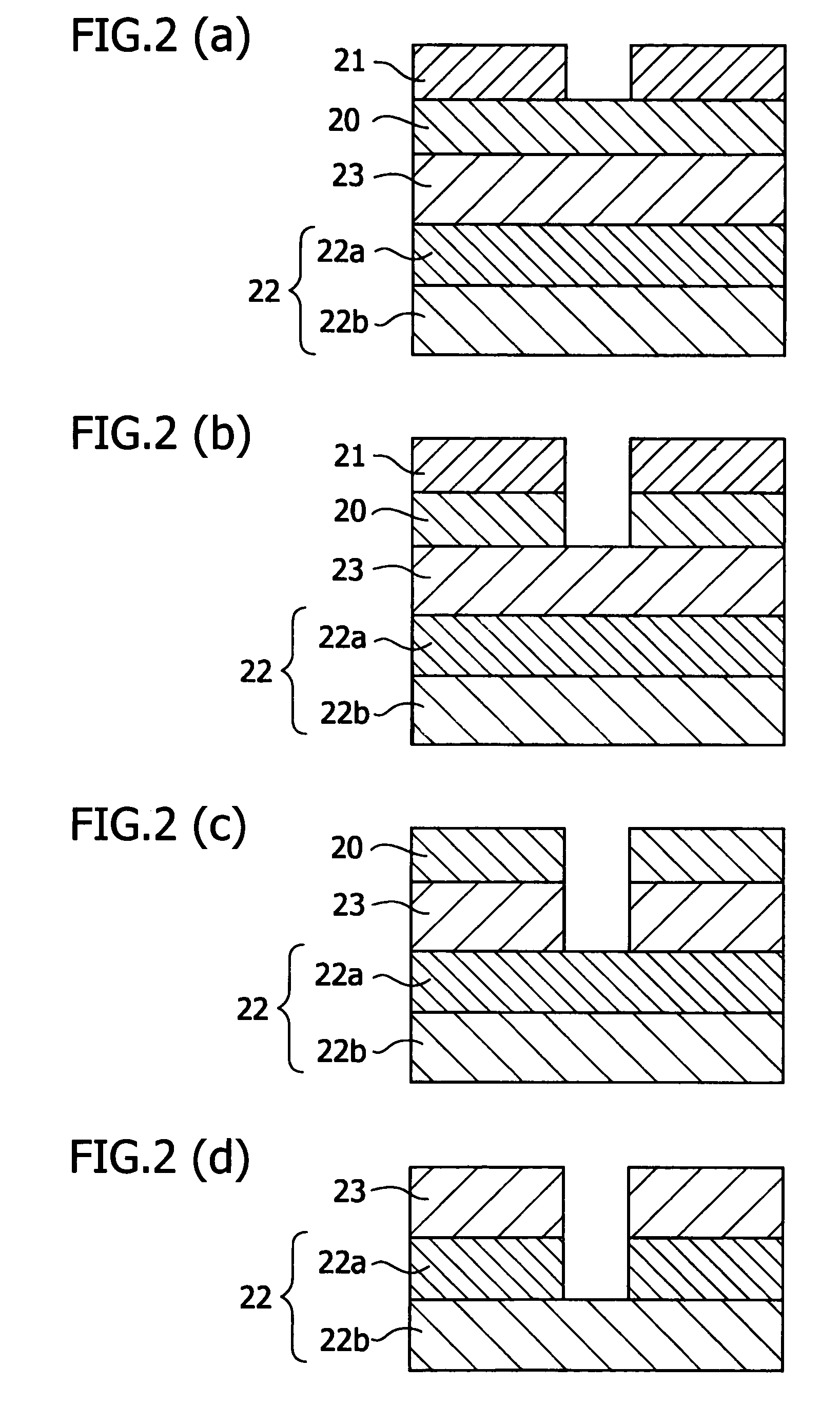

Antireflective film material, and antireflective film and pattern formation method using the same

ActiveUS7202013B2Sufficient antireflective effectImprove etch selectivityPhotosensitive materialsPhoto-taking processesResistOrganic solvent

It is an object of the present invention to provide a material for an antireflective film that has high etching selectivity with respect to the resist, that is, that has a faster etching speed than the resist, a pattern formation method for forming an antireflective film layer on a substrate using this antireflective film material, and a pattern formation method using this antireflective film as a hard mask for substrate processing.The present invention provides an antireflective film material comprising a polymer (A) comprising copolymerized repeating units expressed by the Formula (1) and / or the Formula (2), an organic solvent (B), an acid generator (C) and an optional crosslinking agent (D)

Owner:SHIN ETSU CHEM IND CO LTD

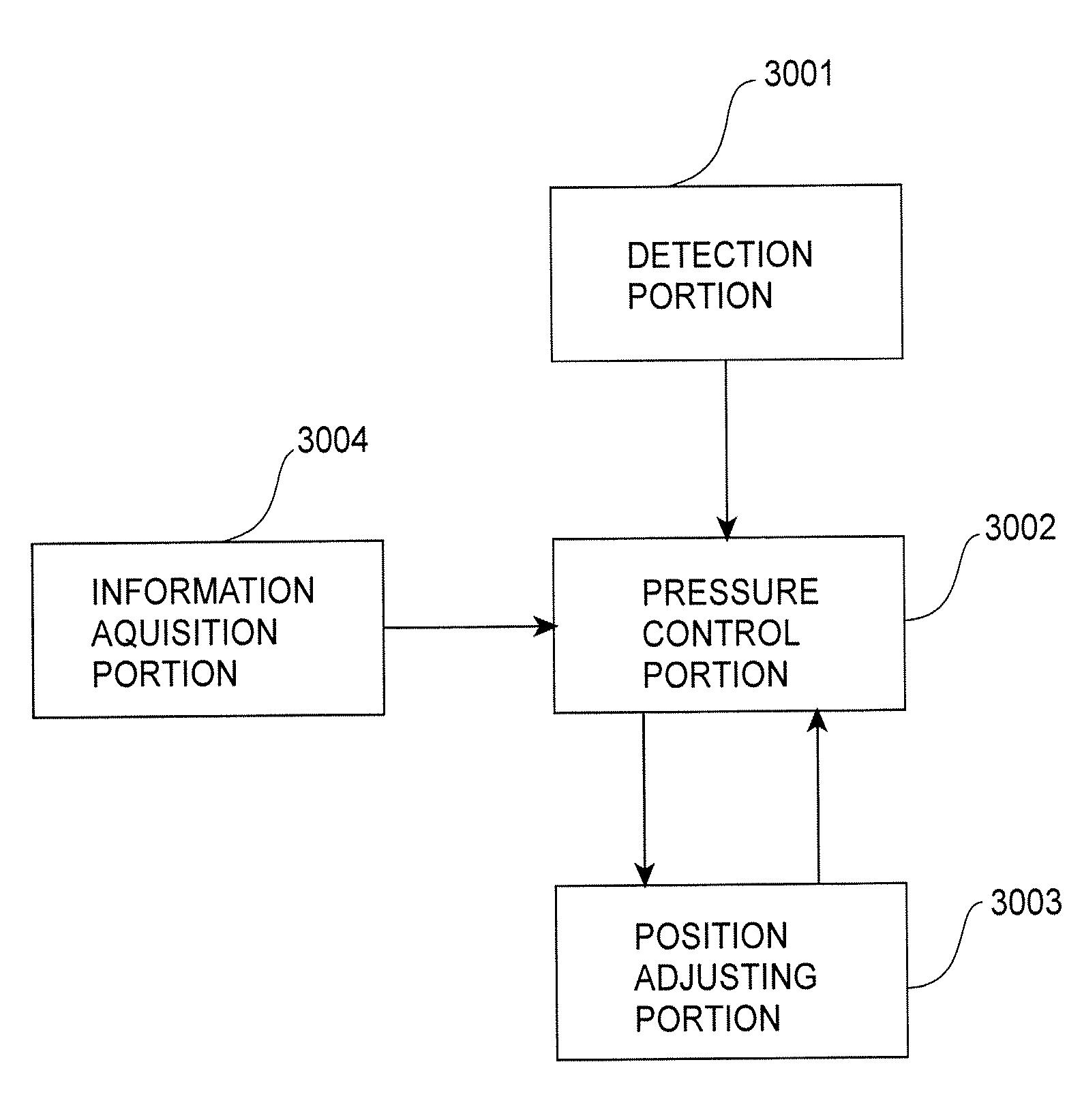

Detection device, movable body apparatus, pattern formation apparatus and pattern formation method, exposure apparatus and exposure method, and device manufacturing method

ActiveUS20090004580A1Improve accuracyHigh-precision exposurePhotomechanical apparatusUsing optical meansForeign matterLight beam

By irradiating a detection beam from an irradiation system of a detection device to a scale used for measuring the position of a wafer stage, and detecting the detection beam via the scale by a photodetection system, a surface state (an existence state of foreign substance) of the scale is detected. With this operation, detection of the surface state can be performed contactlessly with respect to the scale. Moreover, movement control of the wafer stage can be performed with high precision by taking the surface state into consideration.

Owner:NIKON CORP

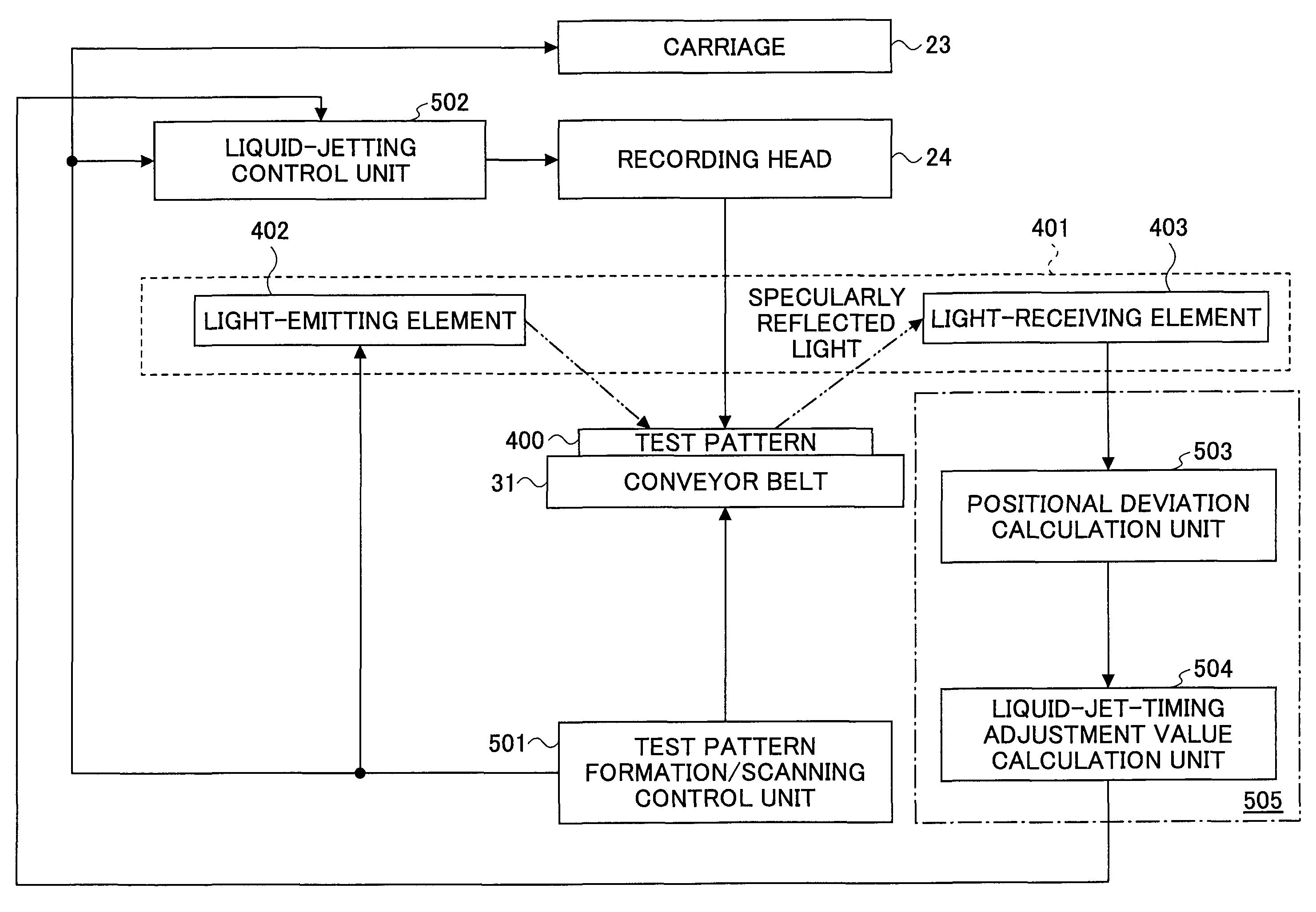

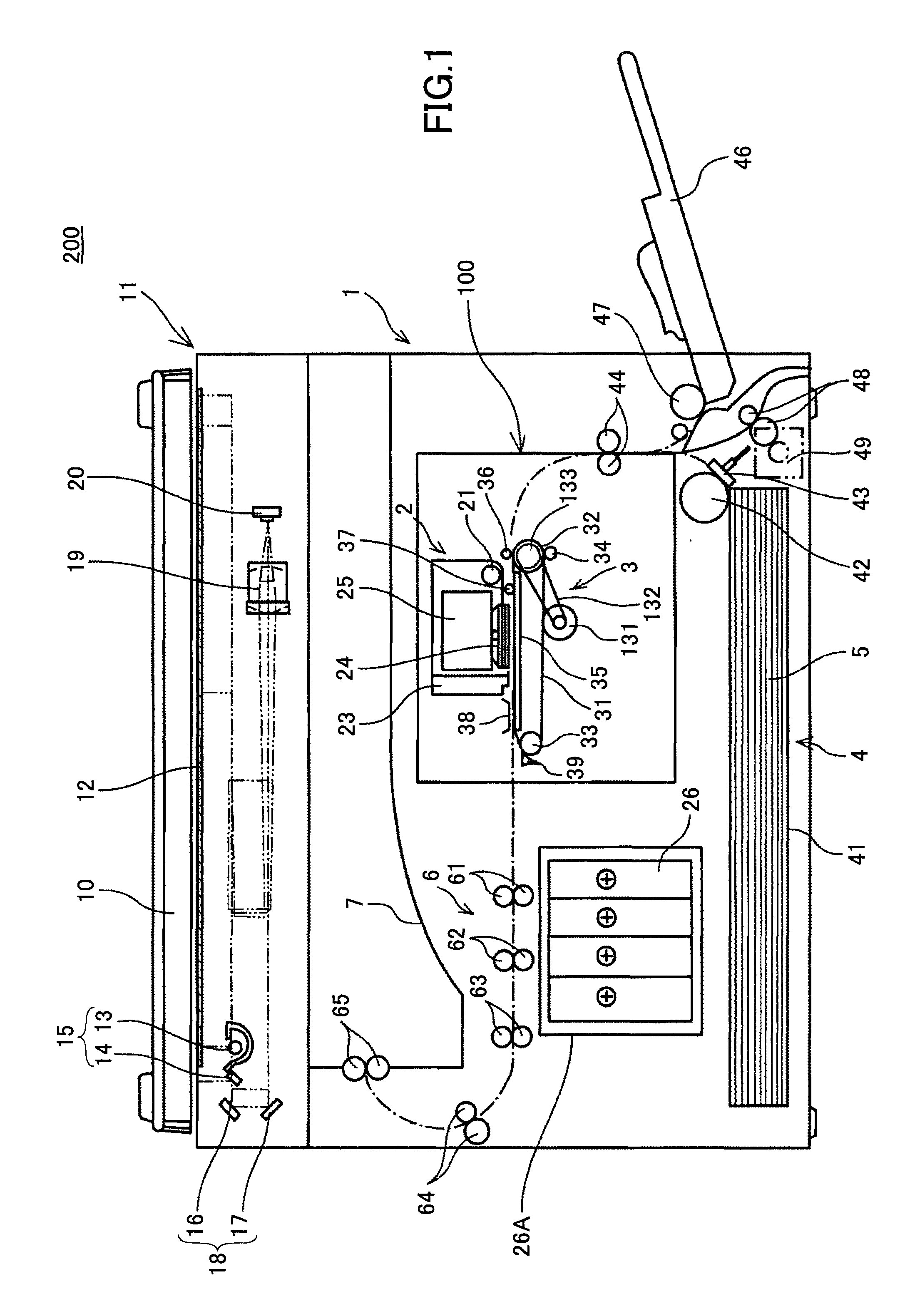

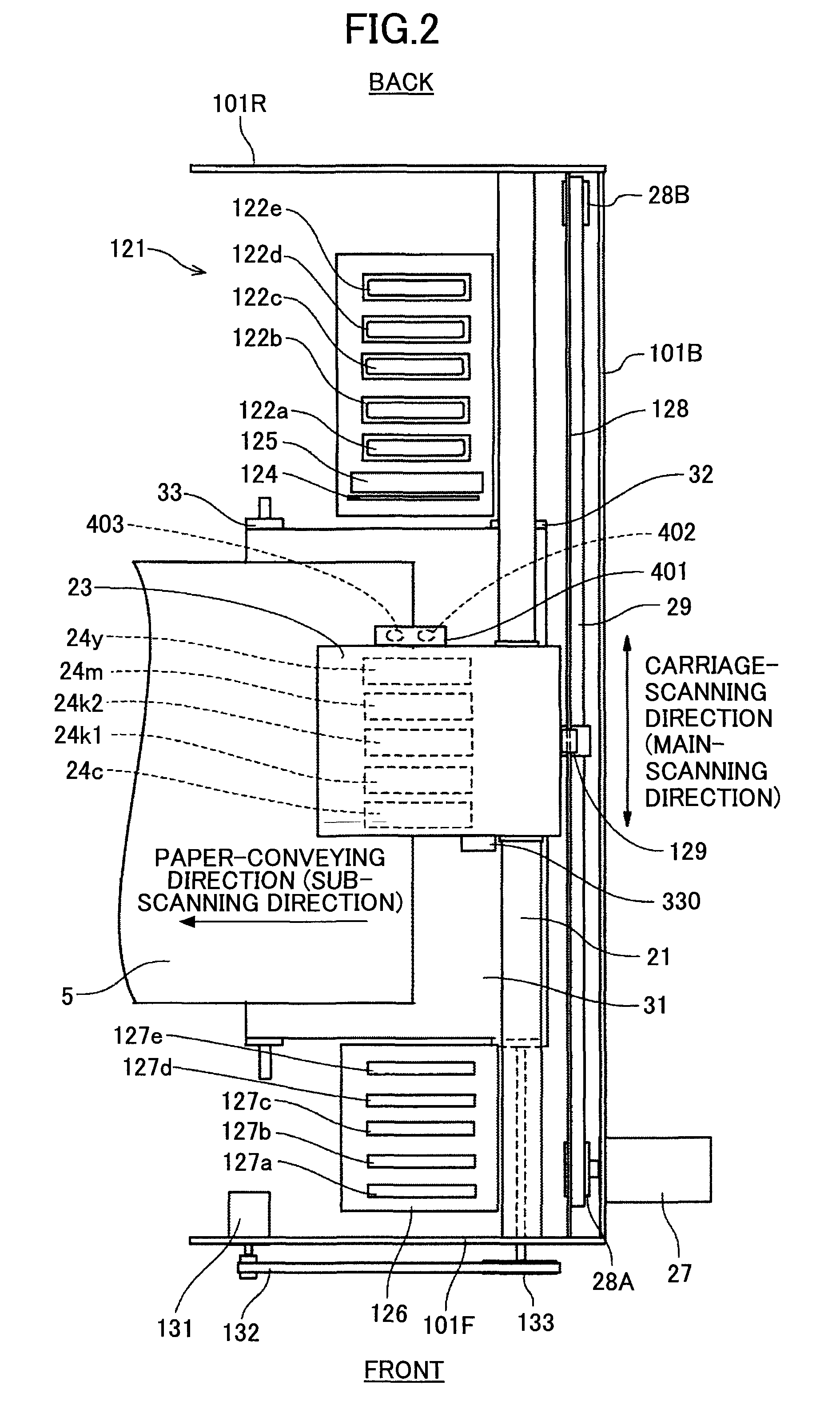

Liquid-jet device, image forming apparatus, and method for adjusting landing positions of liquid droplets

InactiveUS20080225068A1Solve or reduce one or more problemsSpacing mechanismsOther printing apparatusLiquid jetEngineering

A disclosed liquid-jet device includes a liquid-jet head configured to jet liquid droplets; a pattern formation control unit configured to control the liquid-jet head and thereby to form a test pattern composed of separate liquid droplets on a water-repellent part; a detecting unit including a light-emitting element configured to illuminate the test pattern on the water-repellent part and a light-receiving element configured to receive specularly reflected light from the illuminated test pattern and to output a detection signal proportional to the received specularly reflected light; and a landing position adjusting unit configured to adjust landing positions of the liquid droplets based on the detection signal from the light-receiving element.

Owner:RICOH KK

Movable body drive method, movable body drive system, pattern formation method, pattern forming apparatus, exposure method, exposure apparatus, and device manufacturing method

InactiveUS7839485B2Improve accuracyImprove long-term stabilityDigital data processing detailsSemiconductor/solid-state device manufacturingComputational physicsShort term stability

Positional information of a movable body in a Y-axis direction is measured using an interferometer and an encoder whose short-term stability of measurement values excels when compared with the interferometer, and based on the measurement results, a predetermined calibration operation for obtaining correction information for correcting measurement values of the encoder is performed. Accordingly, by using measurement values of the interferometer, correction information for correcting the measurement values of the encoder whose short-term stability of the measurement values excels the interferometer is obtained. Then, based on the measurement values of the encoder and the correction information, the movable body is driven in the Y-axis direction with good precision.

Owner:NIKON CORP

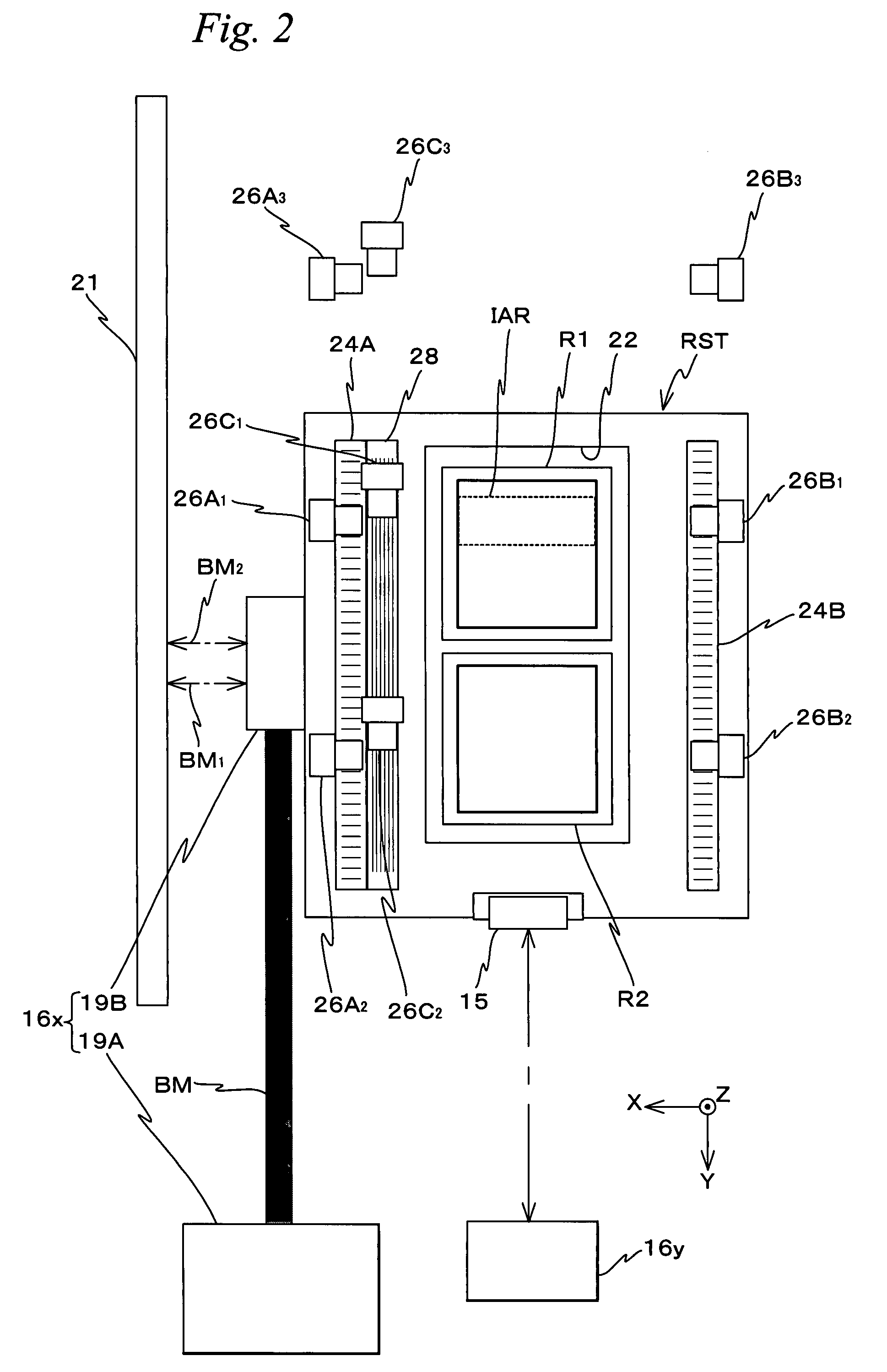

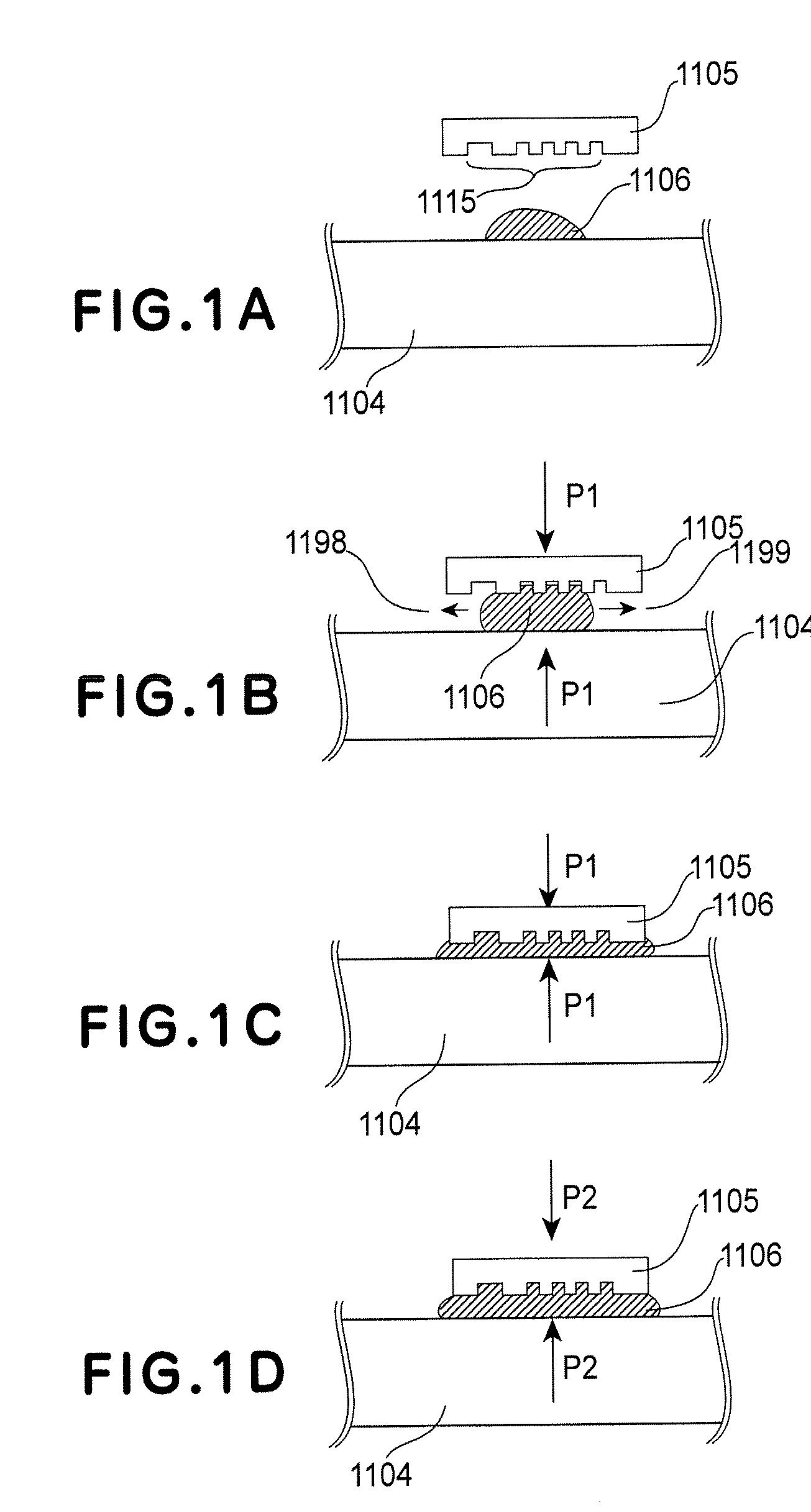

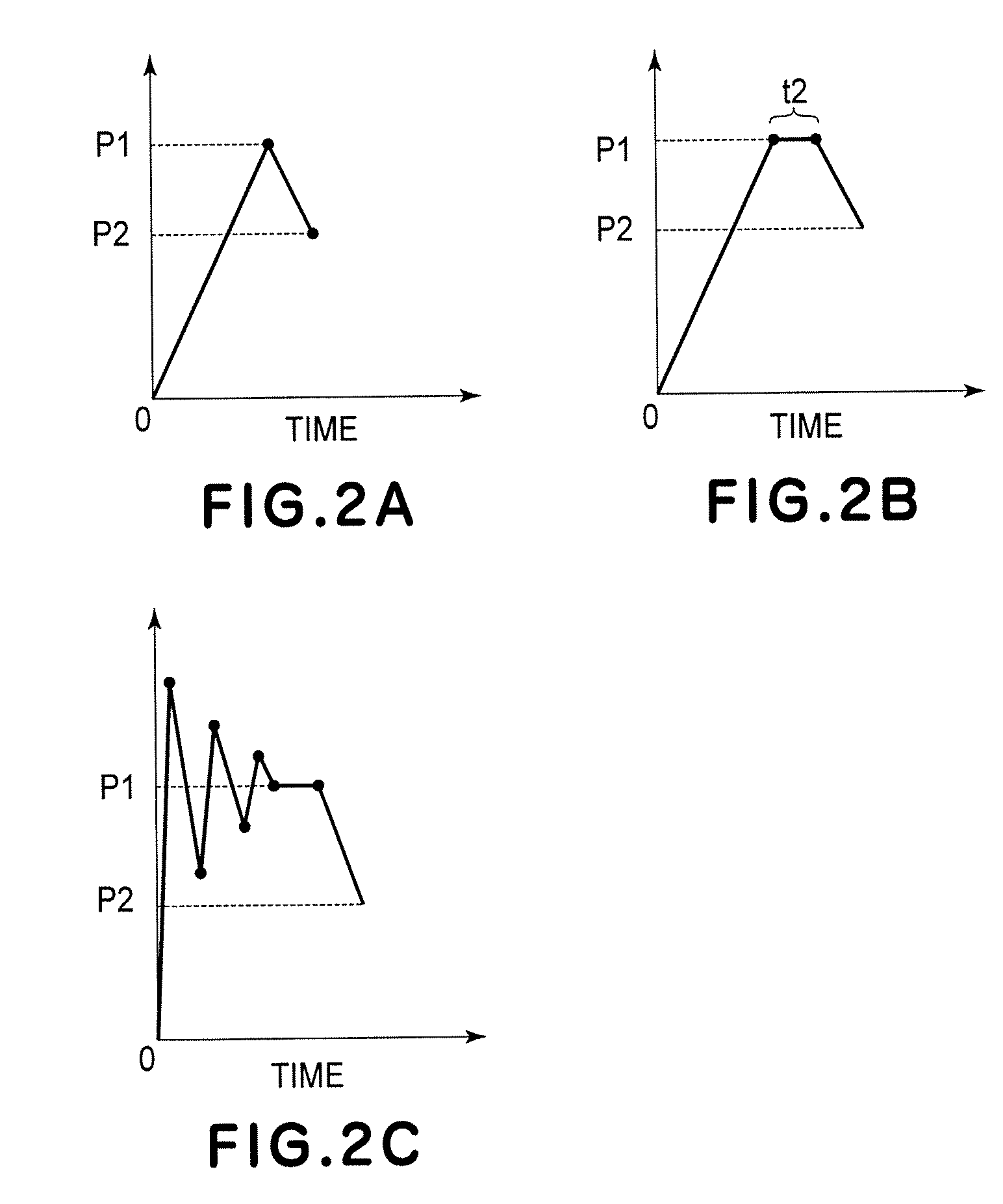

Imprint method, imprint apparatus, and process for producing chip

ActiveUS20070145639A1Improve throughputDecorative surface effectsConfectioneryEngineeringPattern formation

An imprint method for imprinting an imprint pattern of a mold onto a pattern formation material on a substrate so as to realize a high throughput includes the steps of bringing the imprint pattern and the pattern formation material into contact with each other; applying a first pressure between the mold and the substrate to increase a contact area between the imprint pattern and the pattern formation material; and adjusting a positional relationship between the mold and the substrate at a second pressure lower than the first pressure.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com