Patents

Literature

39results about How to "High-precision exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

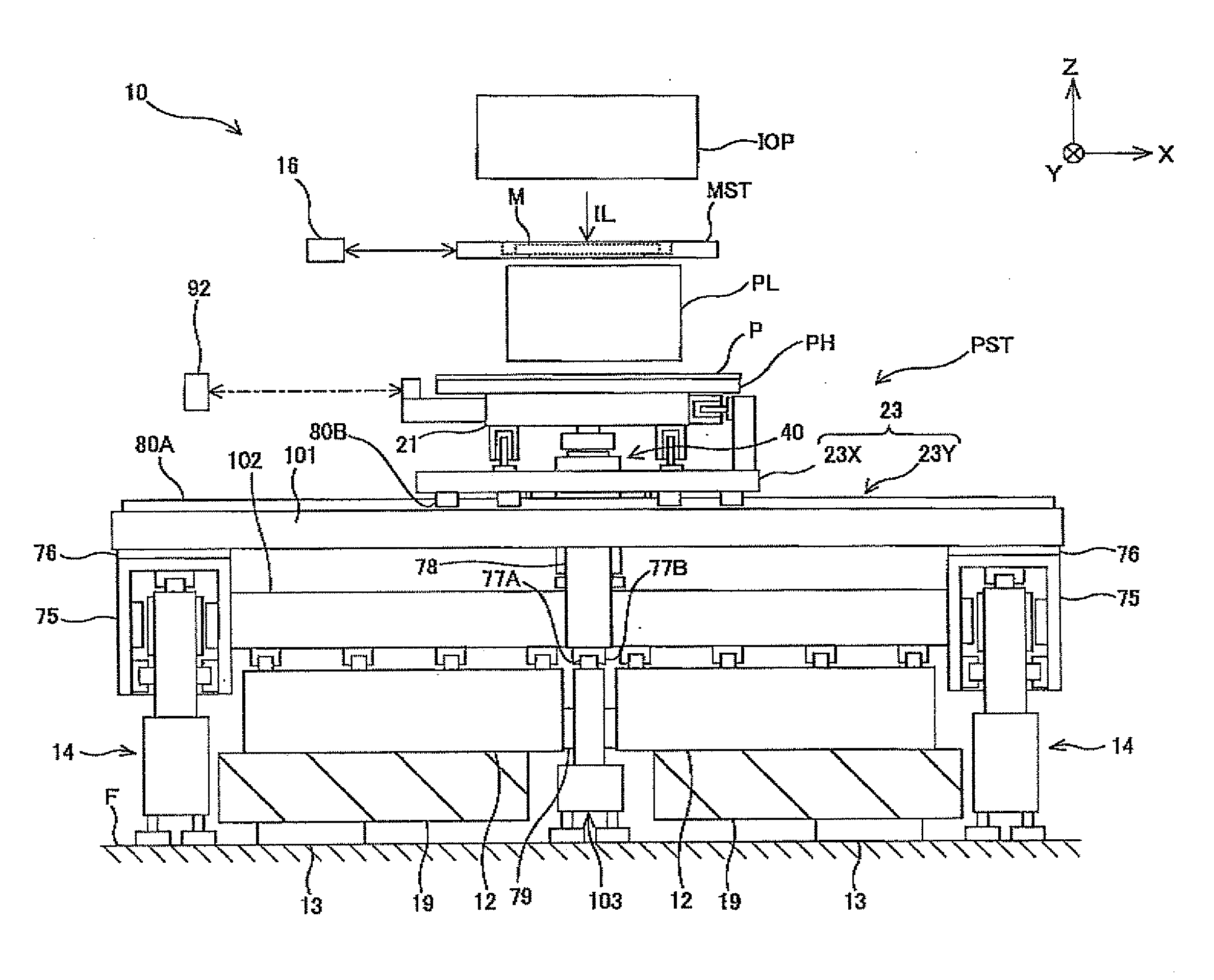

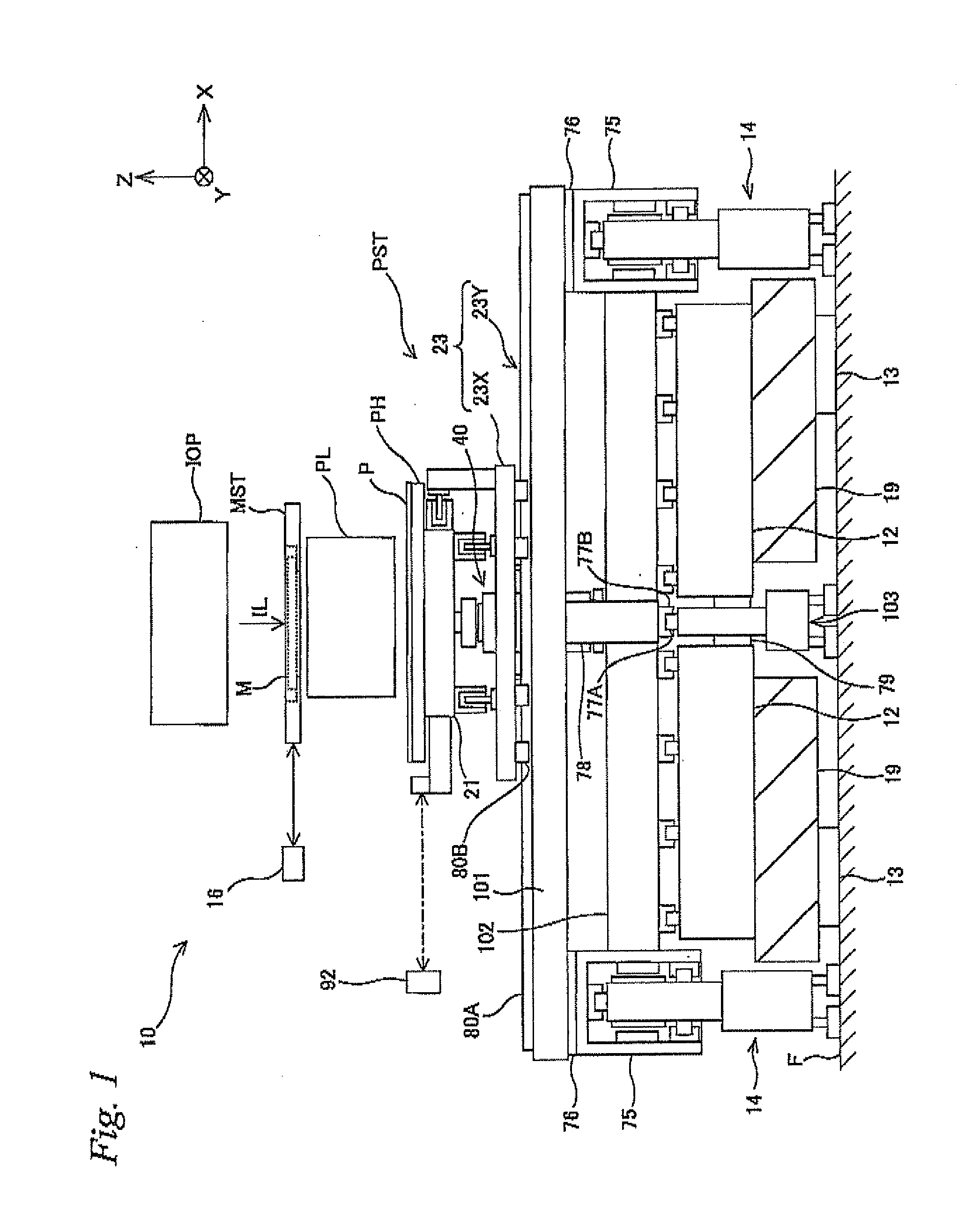

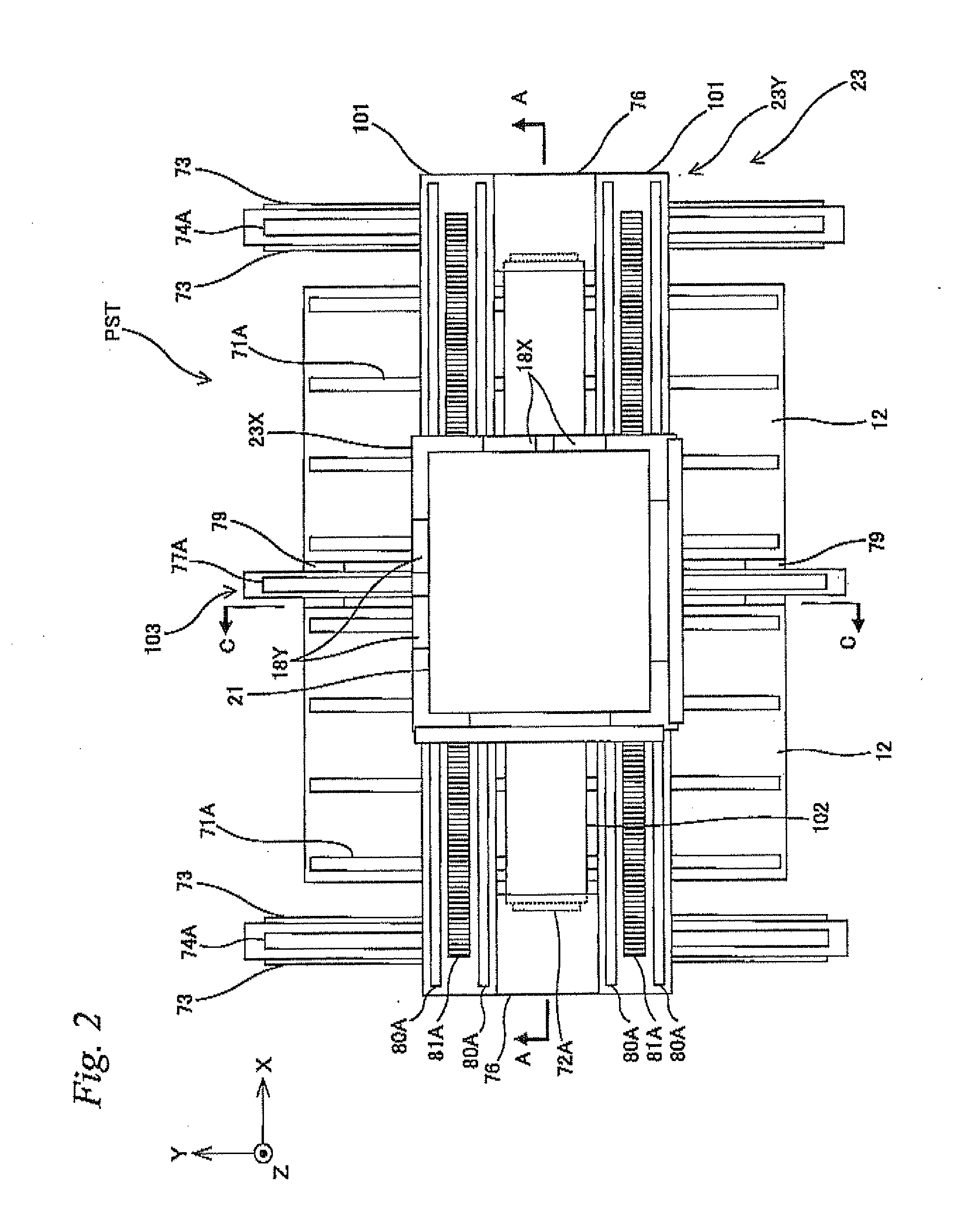

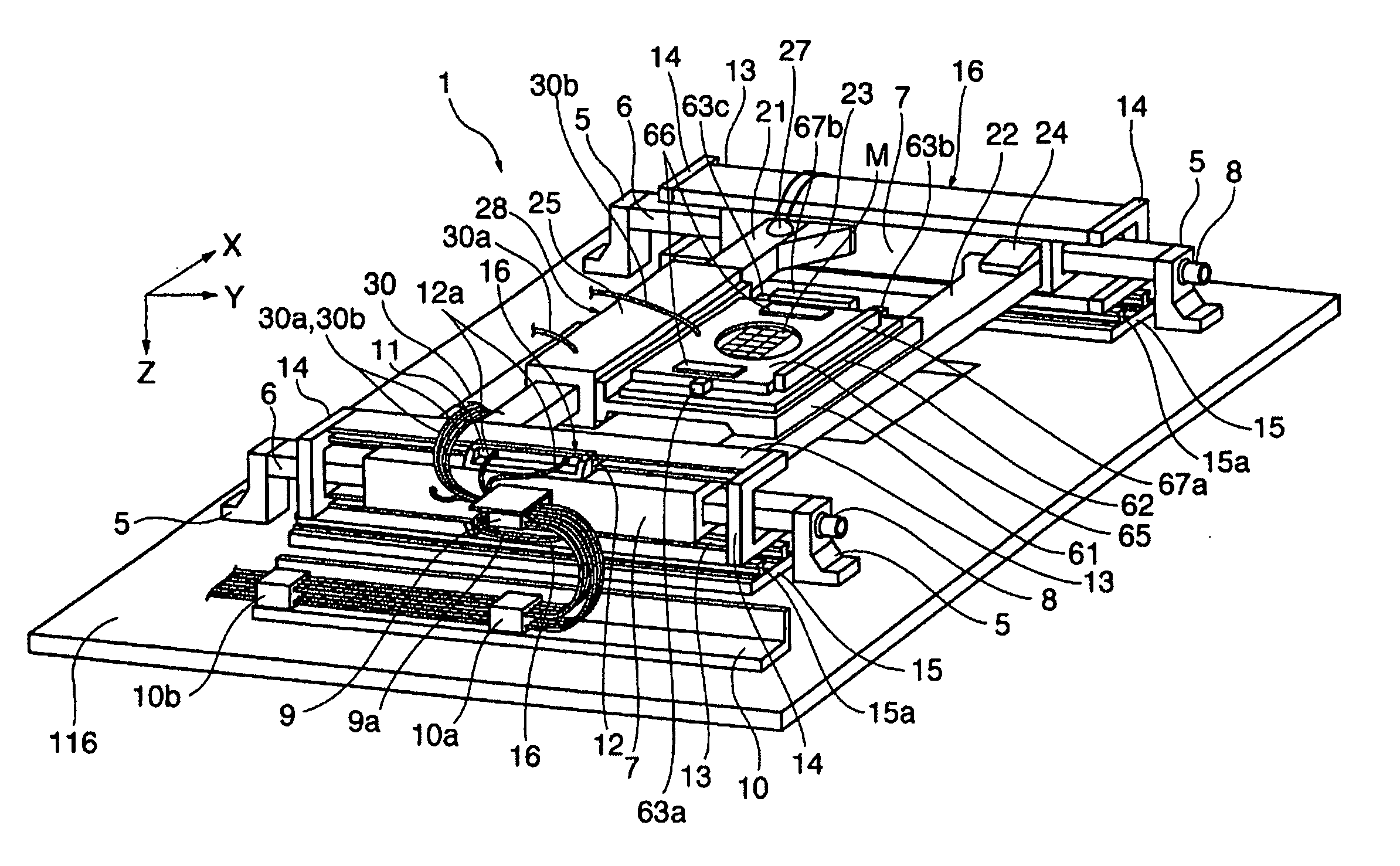

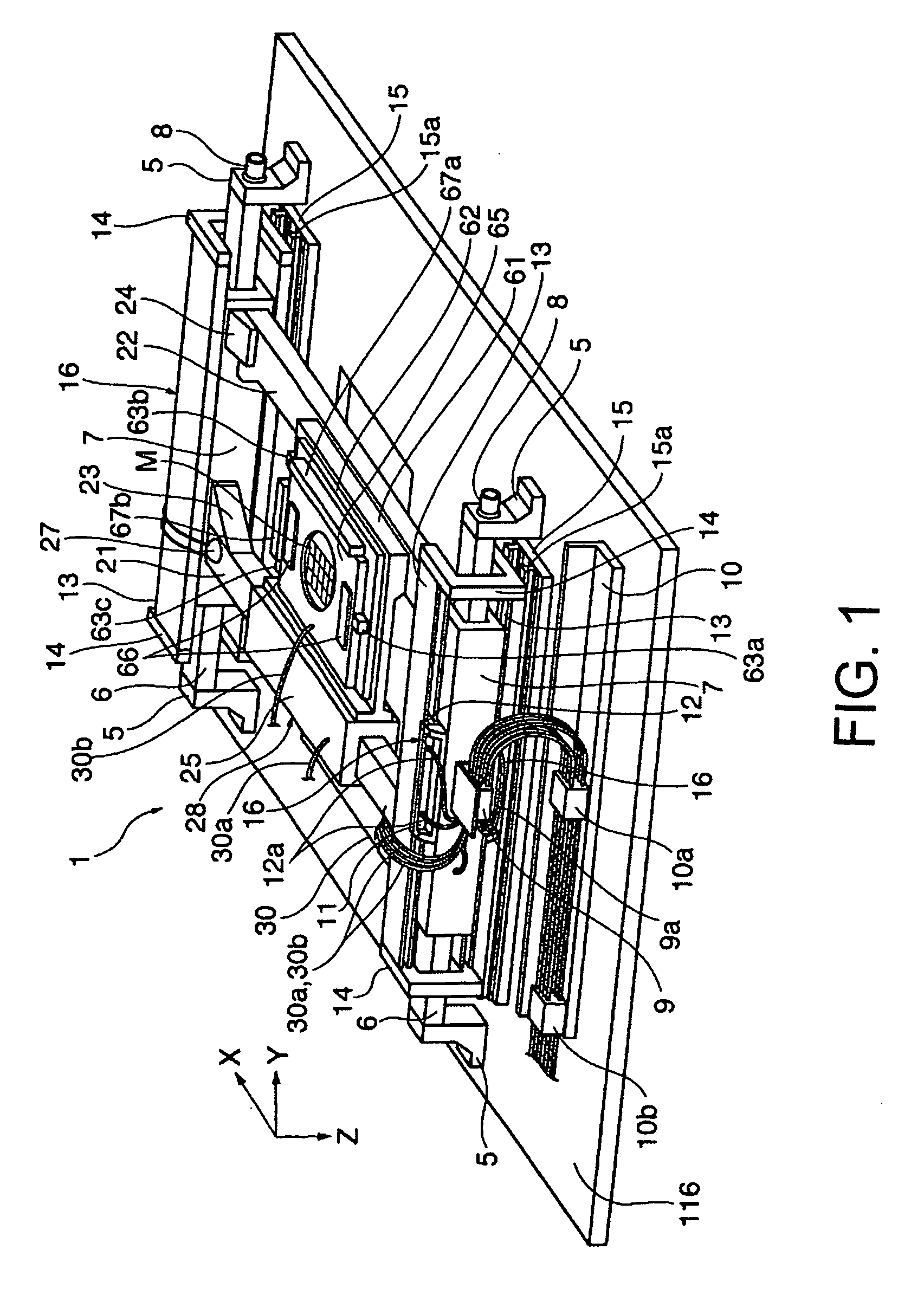

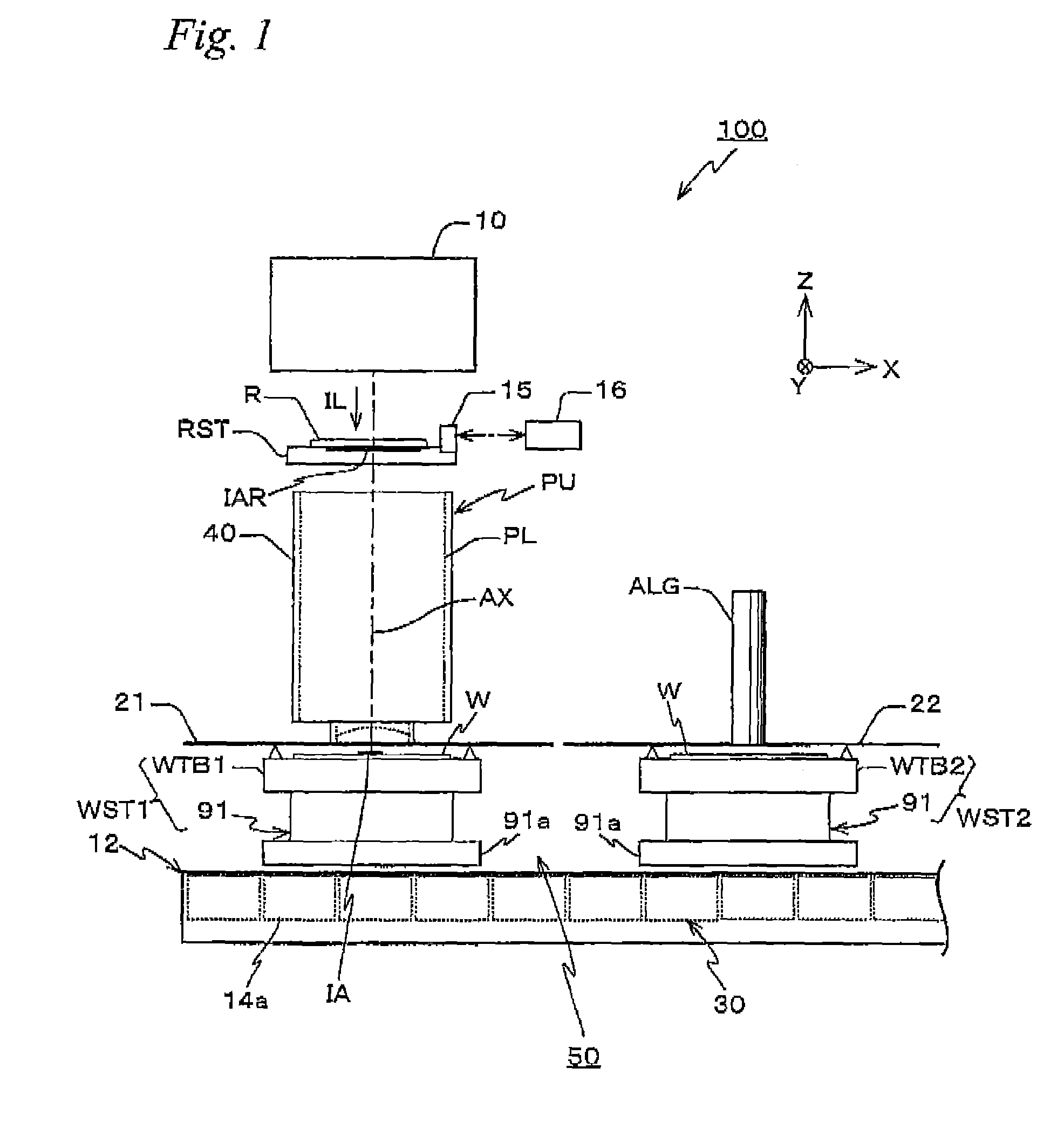

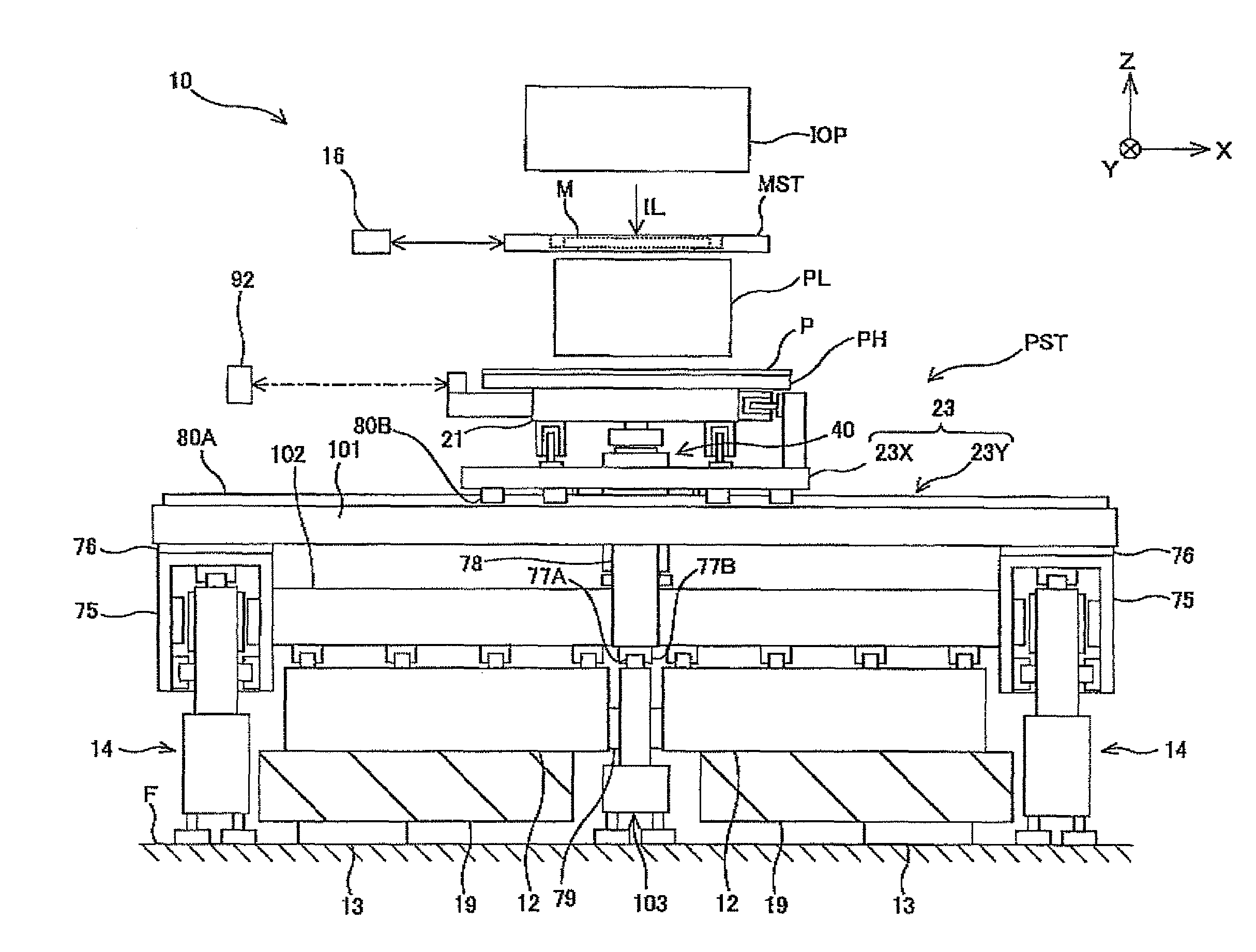

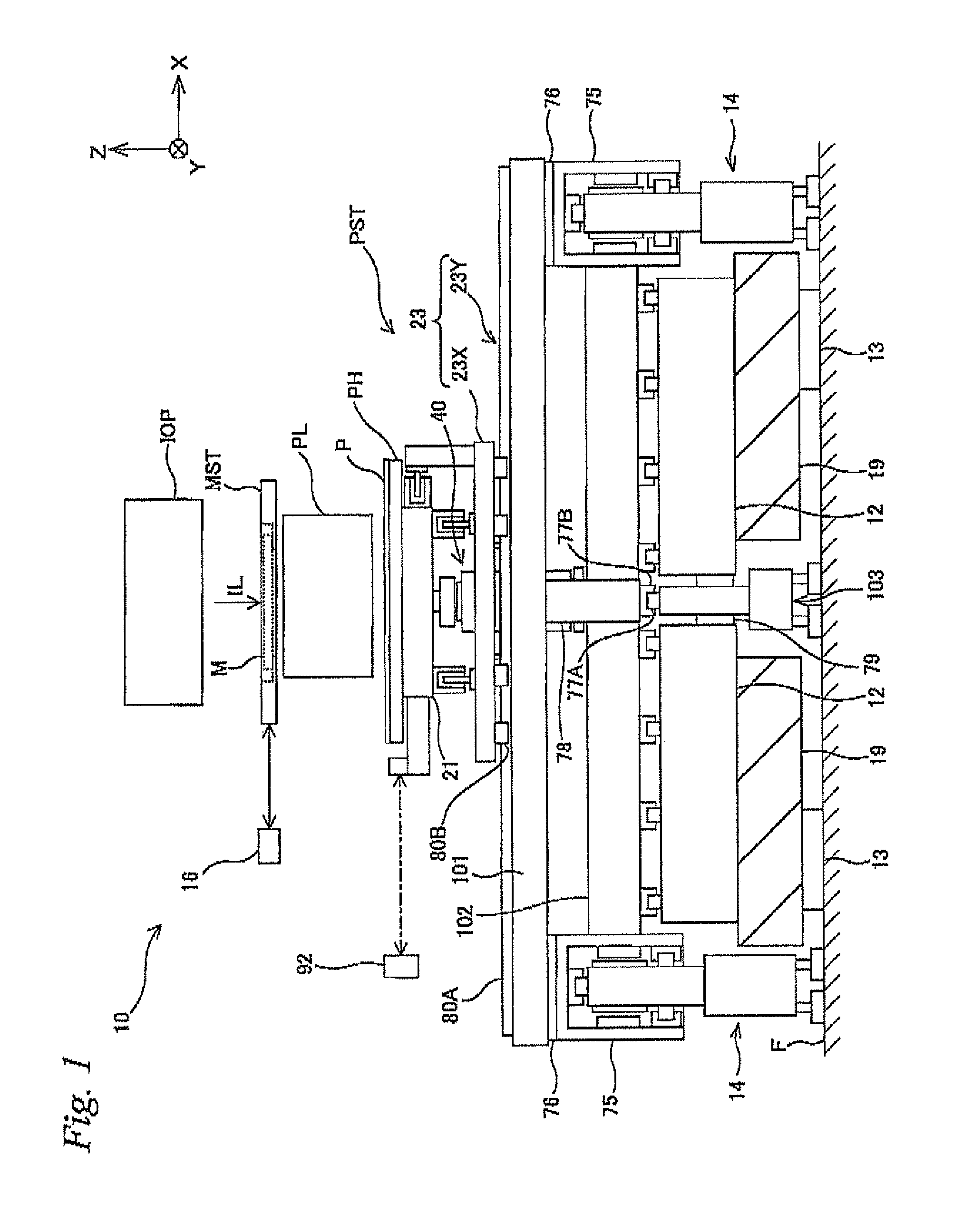

Exposure apparatus, movable body apparatus, flat-panel display manufacturing method, and device manufacturing method

In a substrate stage, when a Y coarse movement stage moves in the Y-axis direction, an X coarse movement stage, a weight cancellation device, and an X guide move integrally in the Y-axis direction with the Y coarse movement stage, and when the X coarse movement stage moves in the X-axis direction on the Y coarse movement stage, the weight cancellation device moves on the X guide in the X-axis direction integrally with the X coarse movement stage. Because the X guide is provided extending in the X-axis direction while covering the movement range of the weight cancellation device in the X-axis direction, the weight cancellation device is constantly supported by the X guide, regardless of its position. Accordingly, a substrate can be guided along the XY plane with good accuracy, even if a member (for example, a surface plate and the like) that has a guide surface large enough to cover the total movement range of the weight cancellation device is not provided.

Owner:NIKON CORP

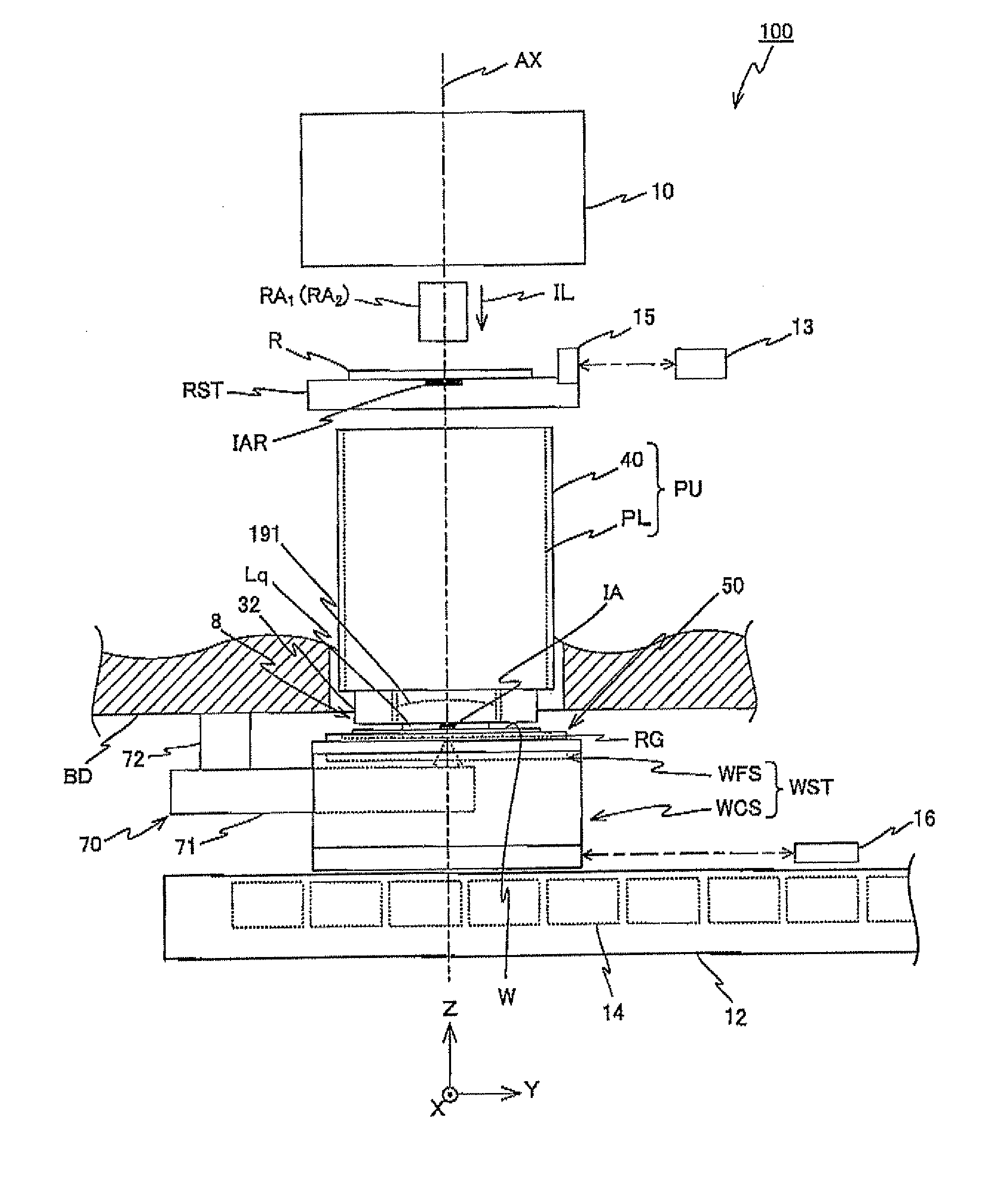

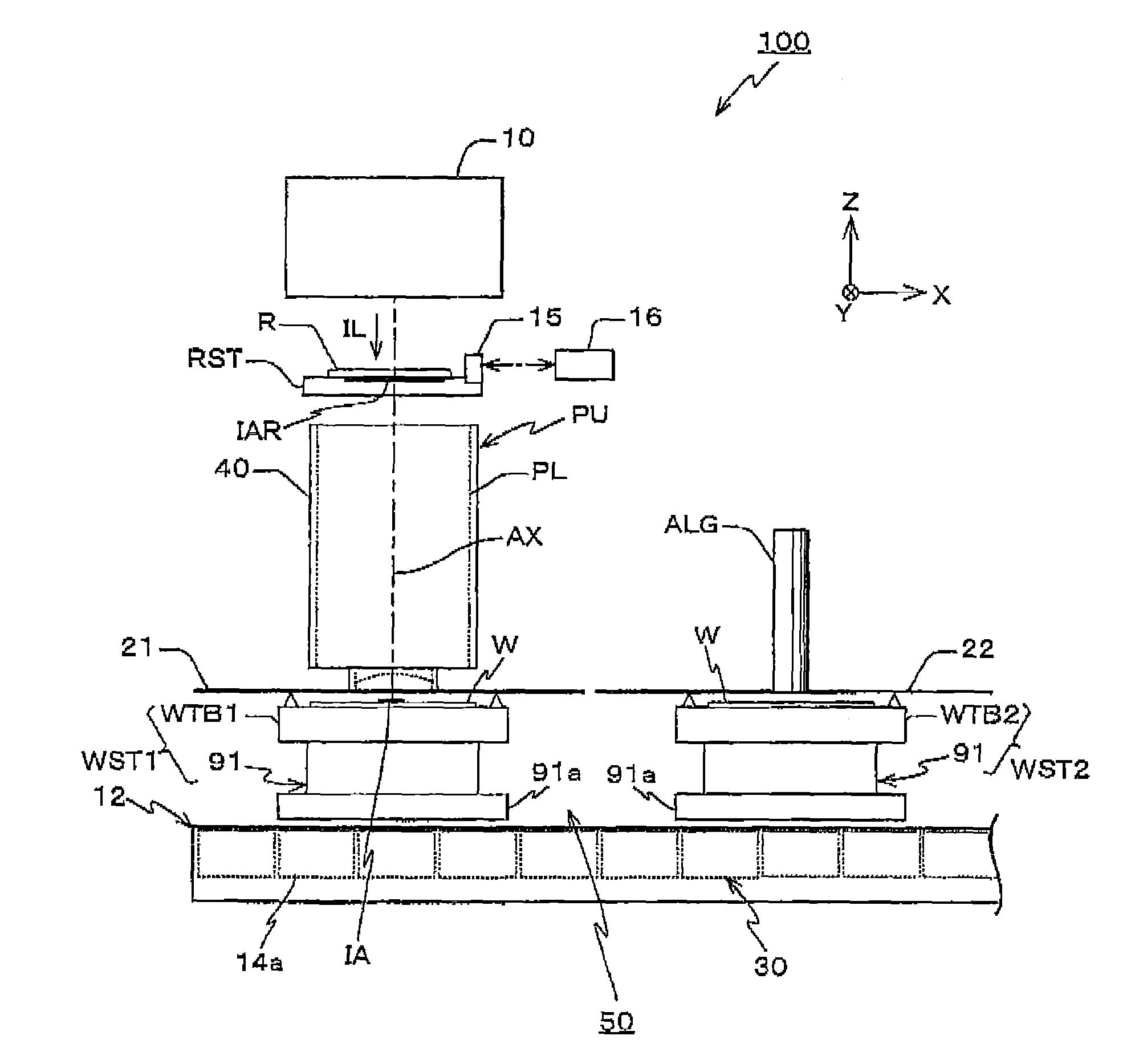

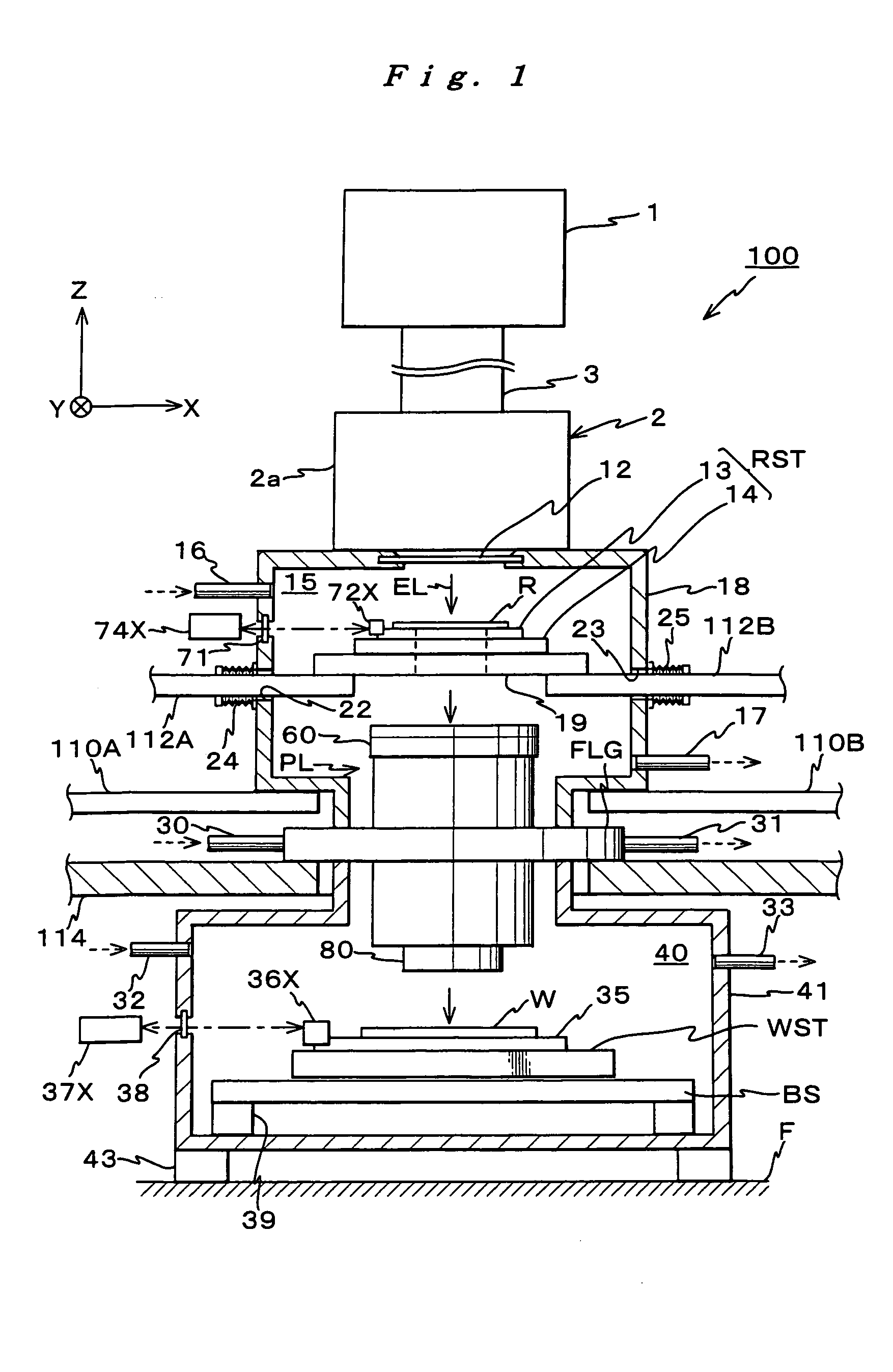

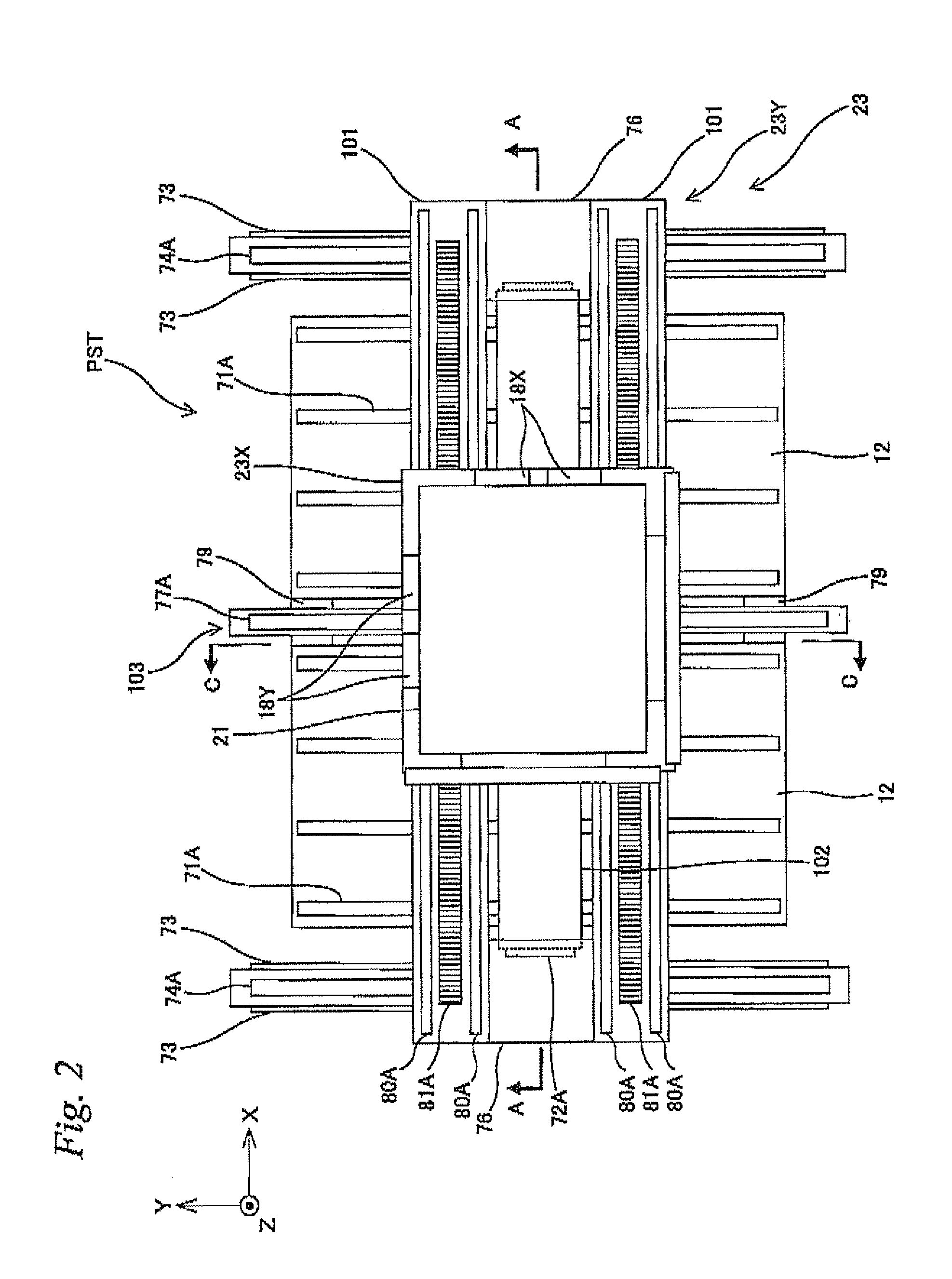

Movable body apparatus, exposure apparatus, exposure method, and device manufacturing method

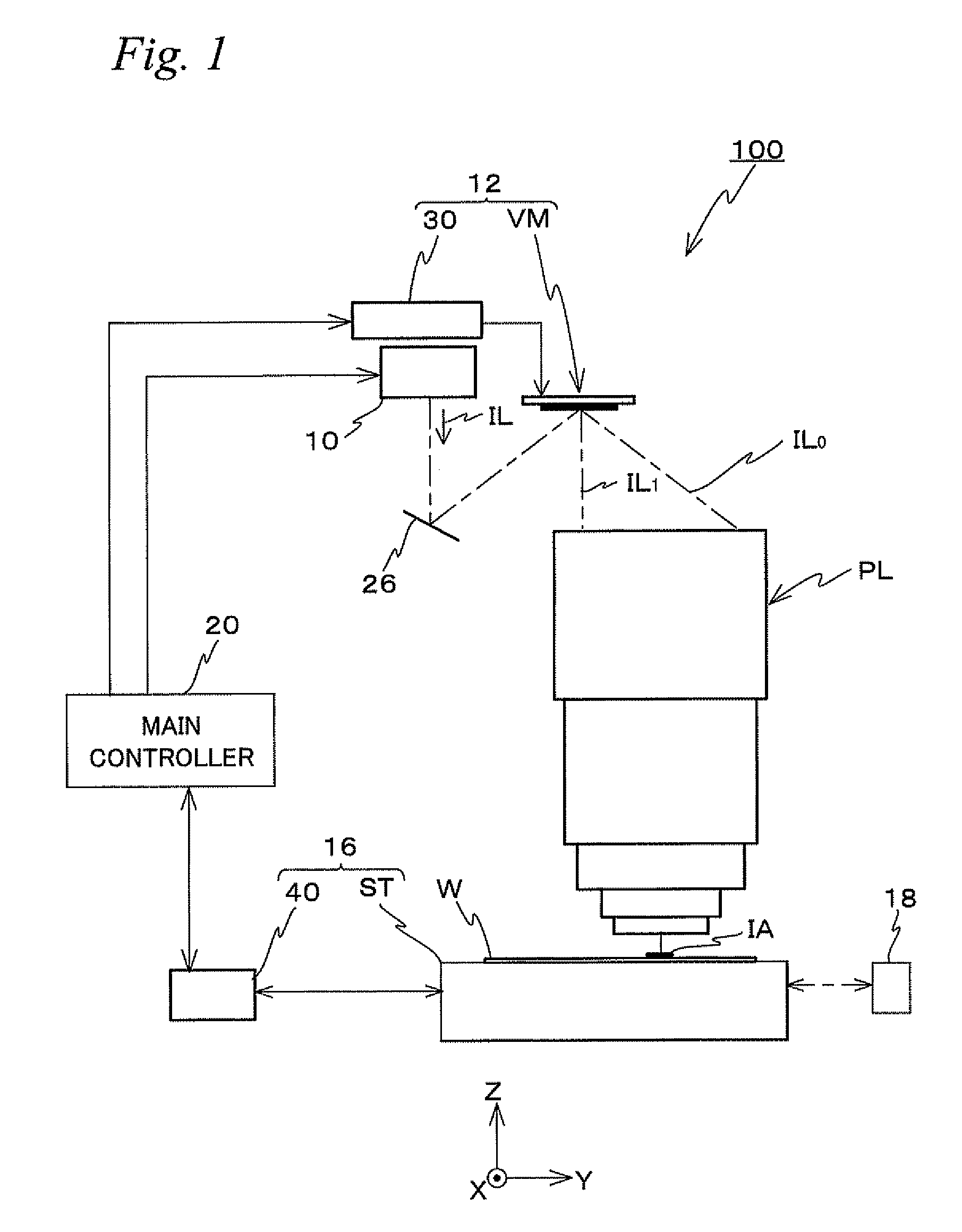

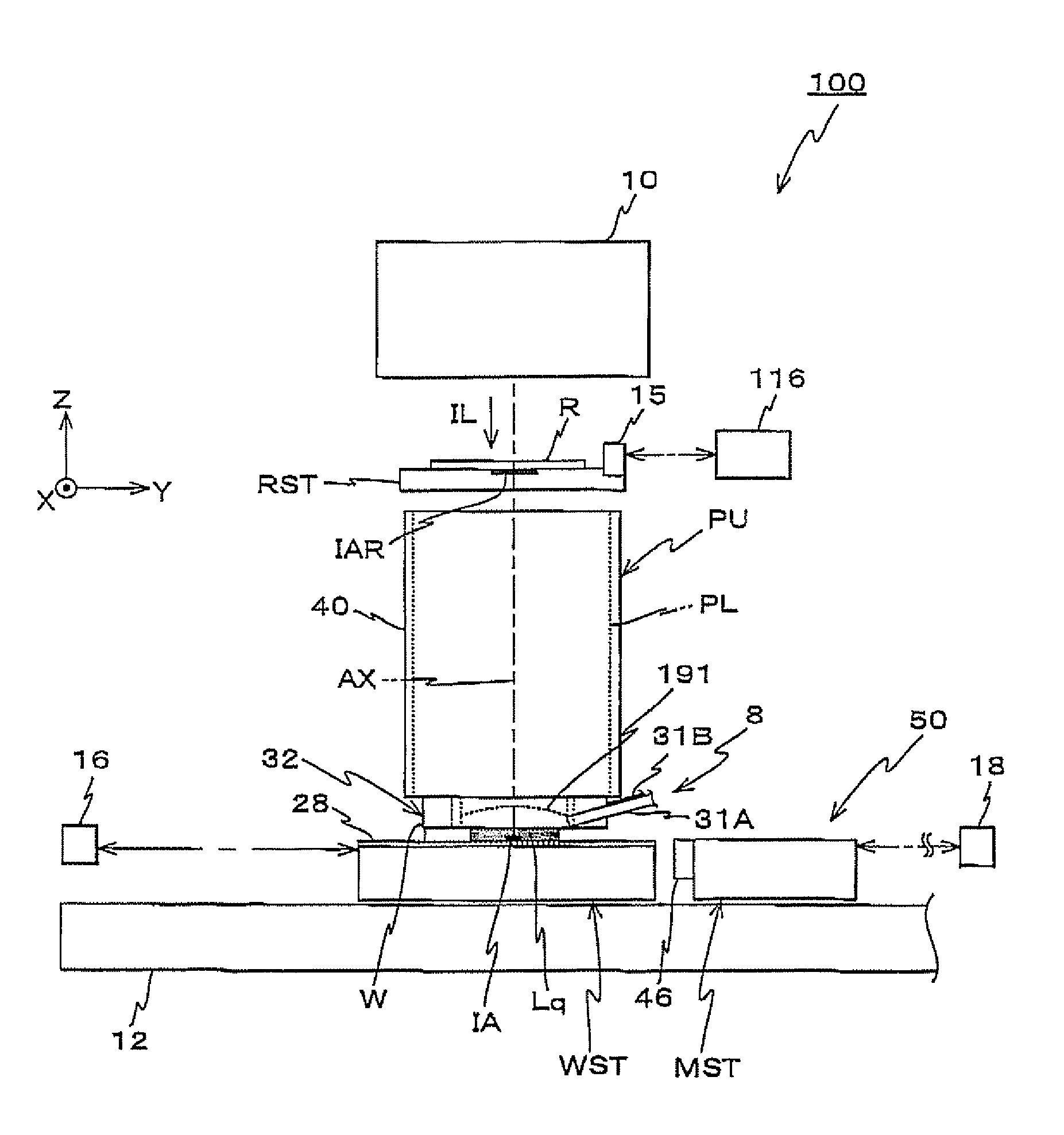

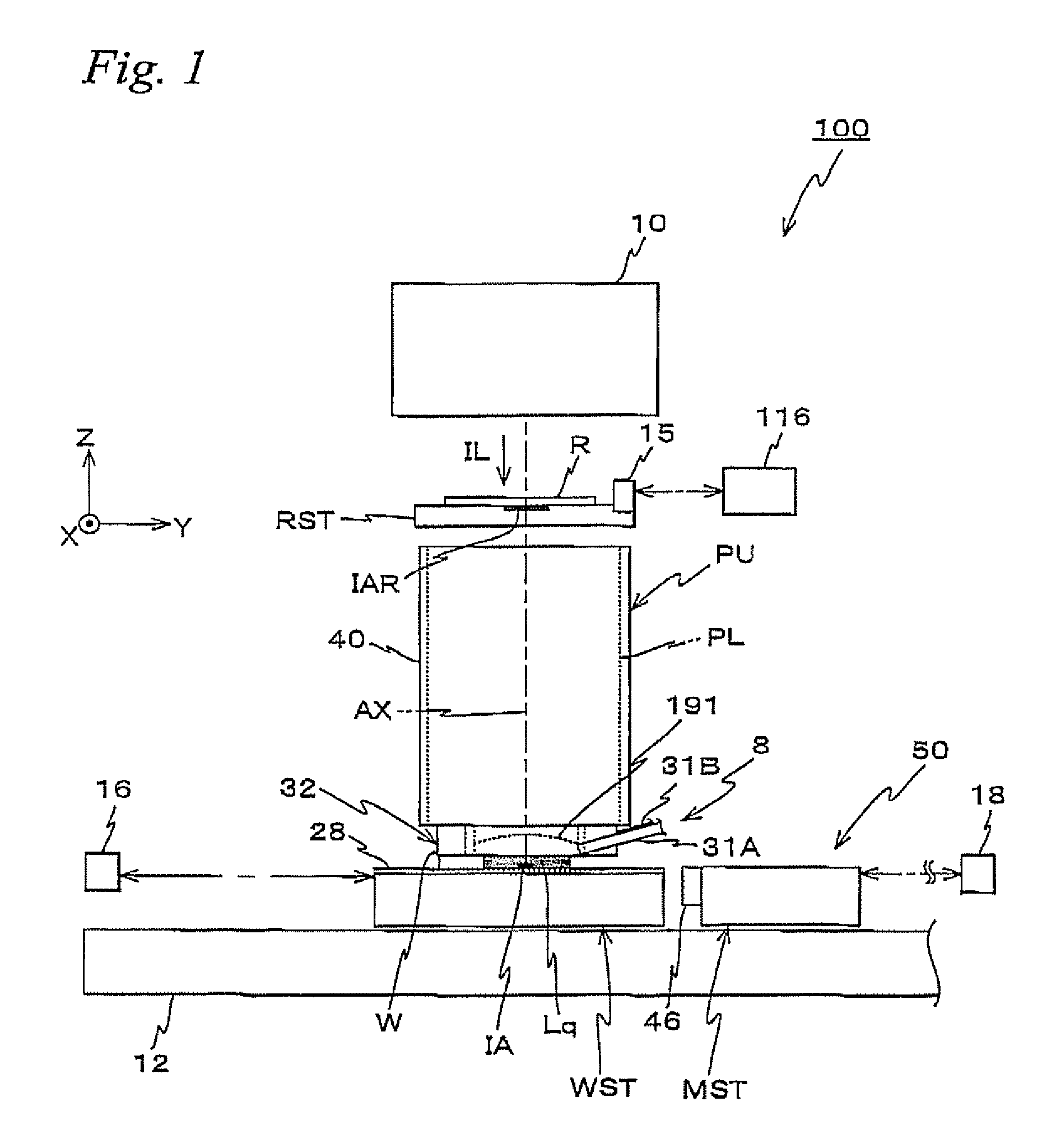

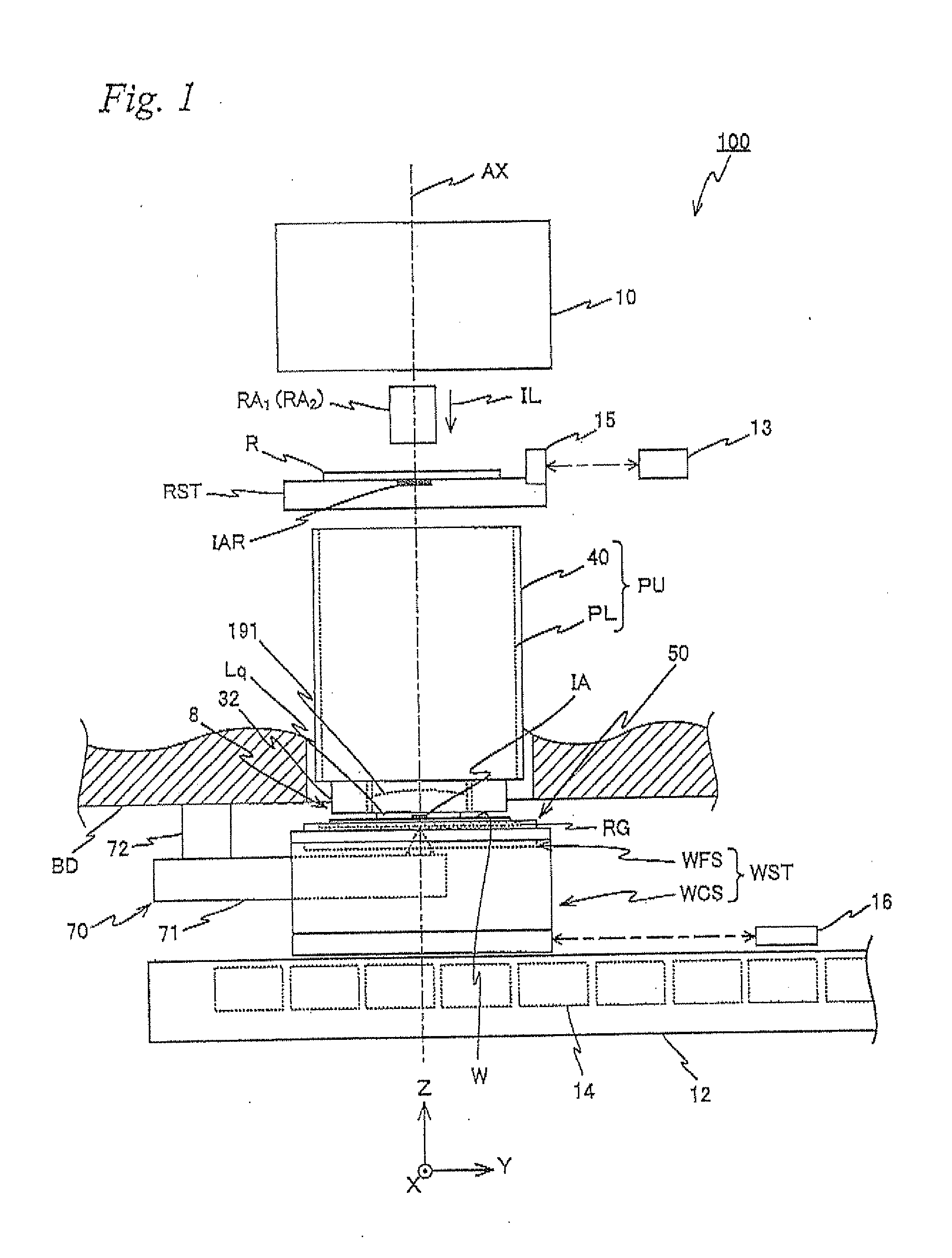

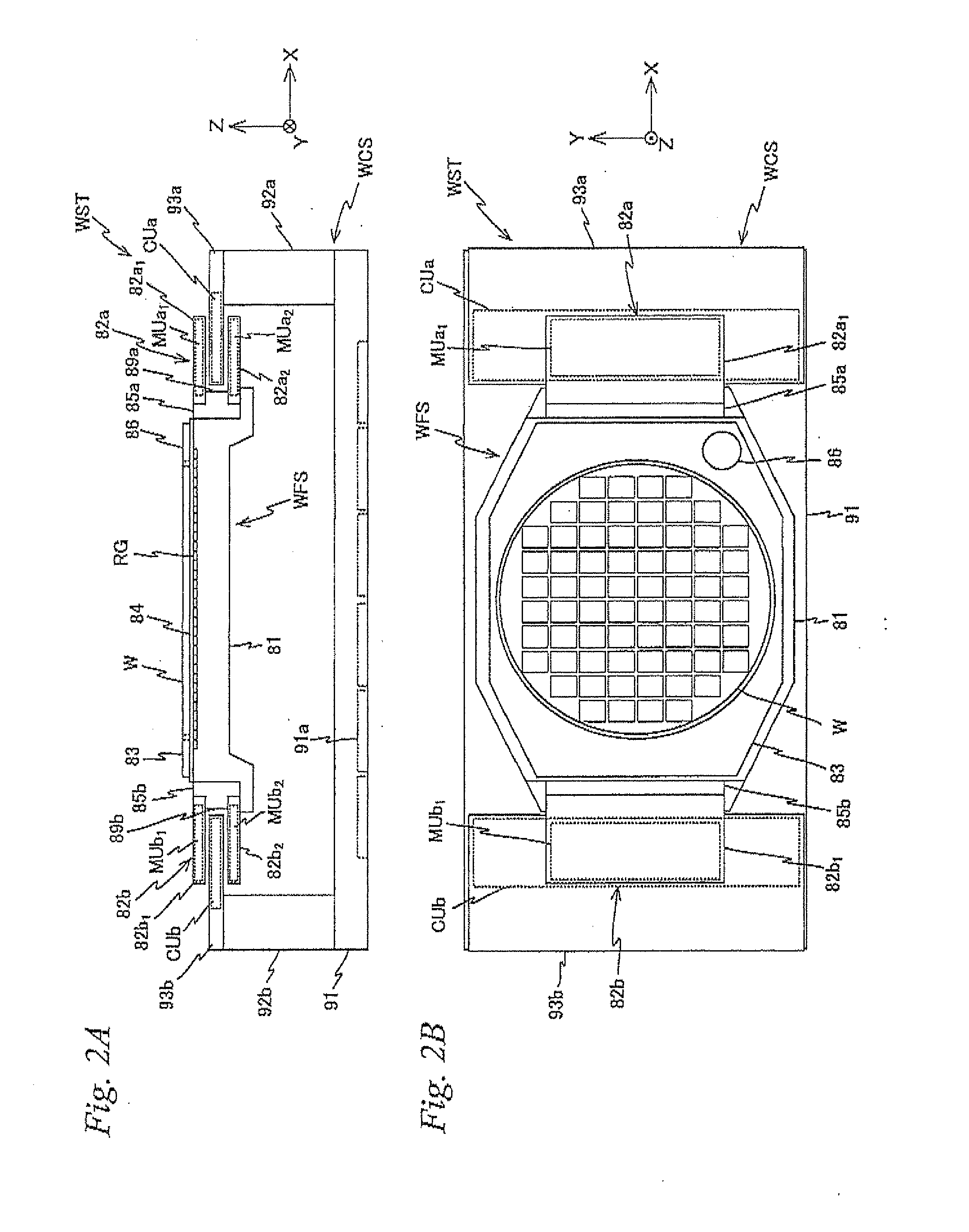

ActiveUS20100073653A1Improve accuracyGood precisionPhotomechanical apparatusSemiconductor/solid-state device manufacturingGratingLight beam

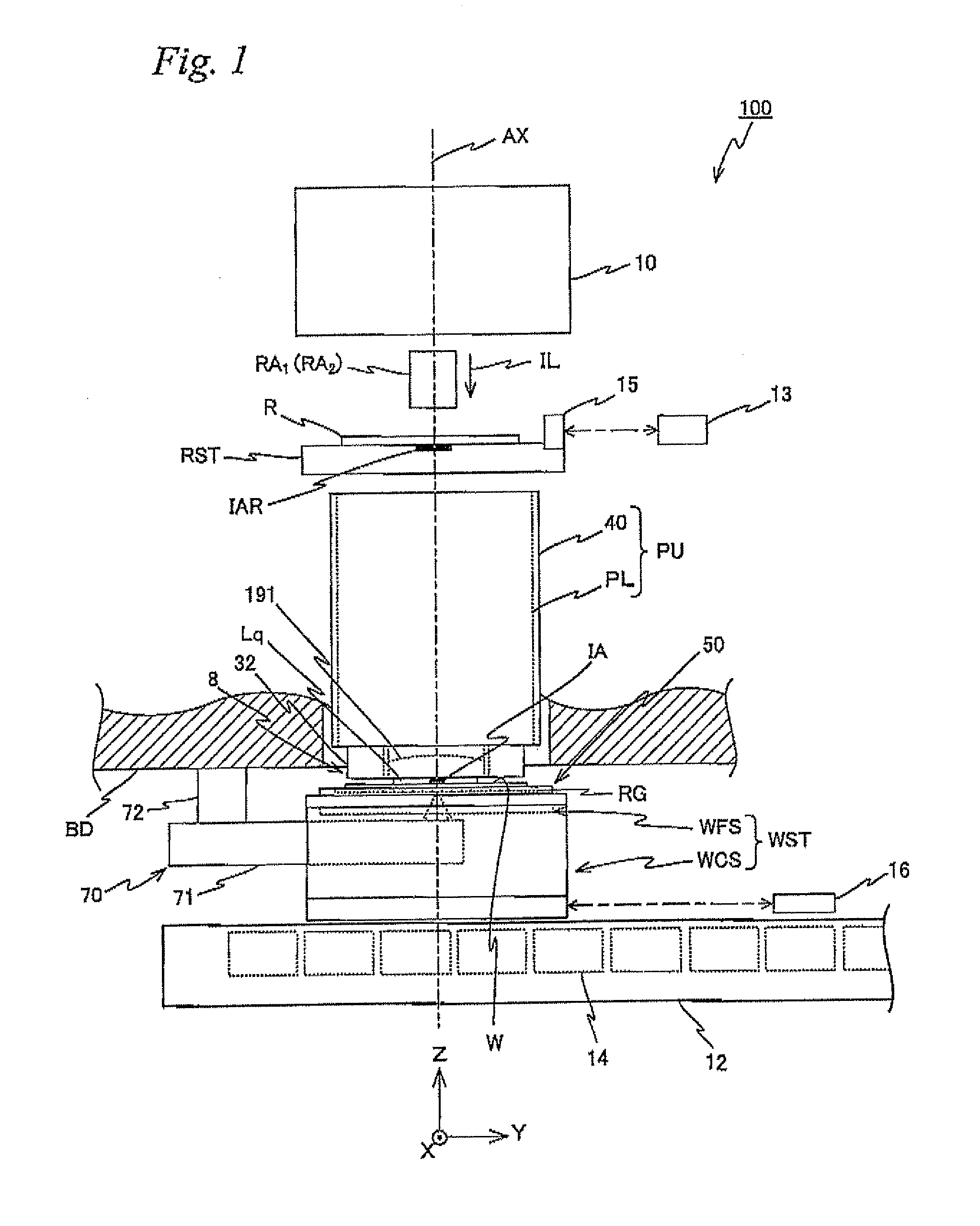

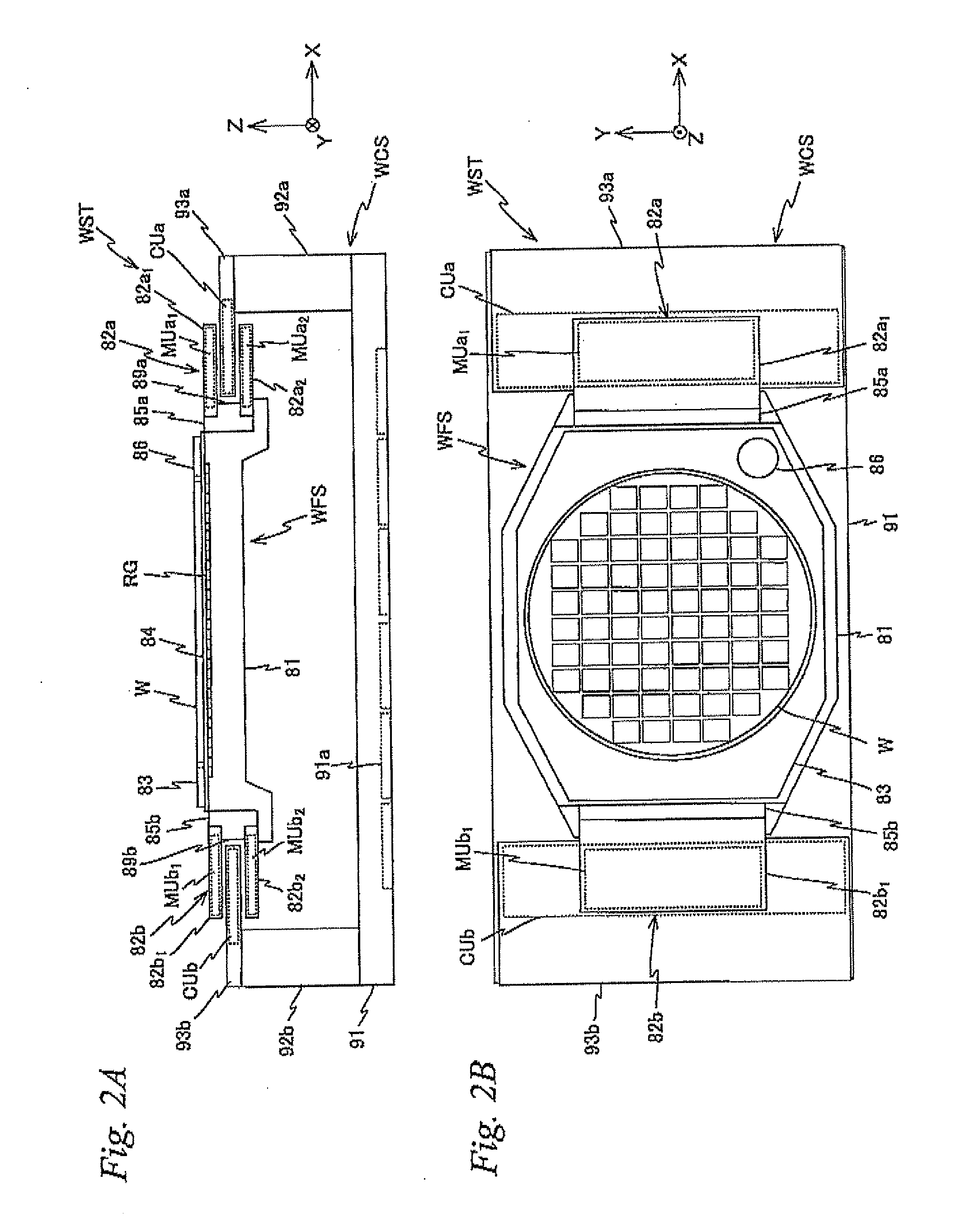

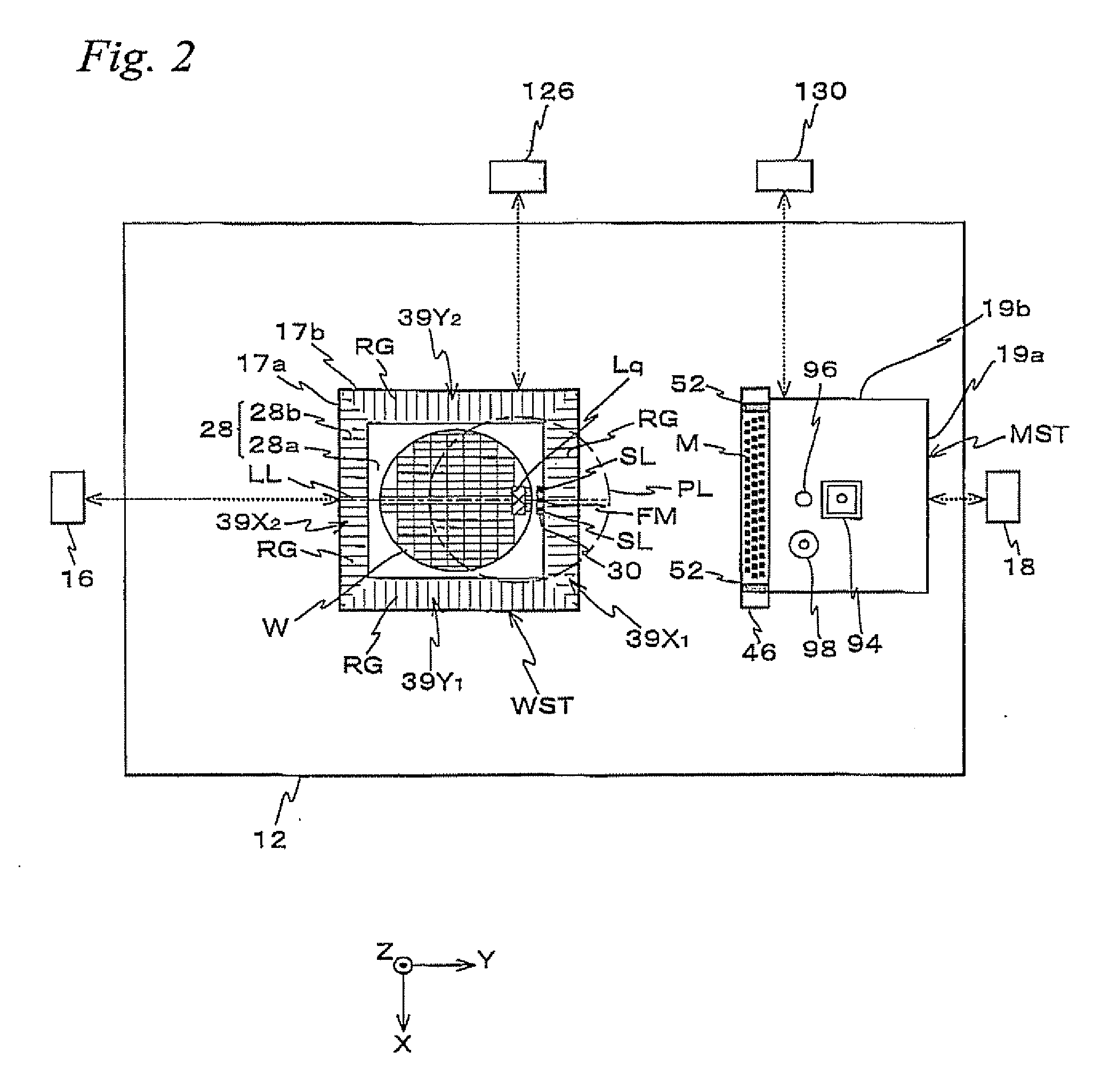

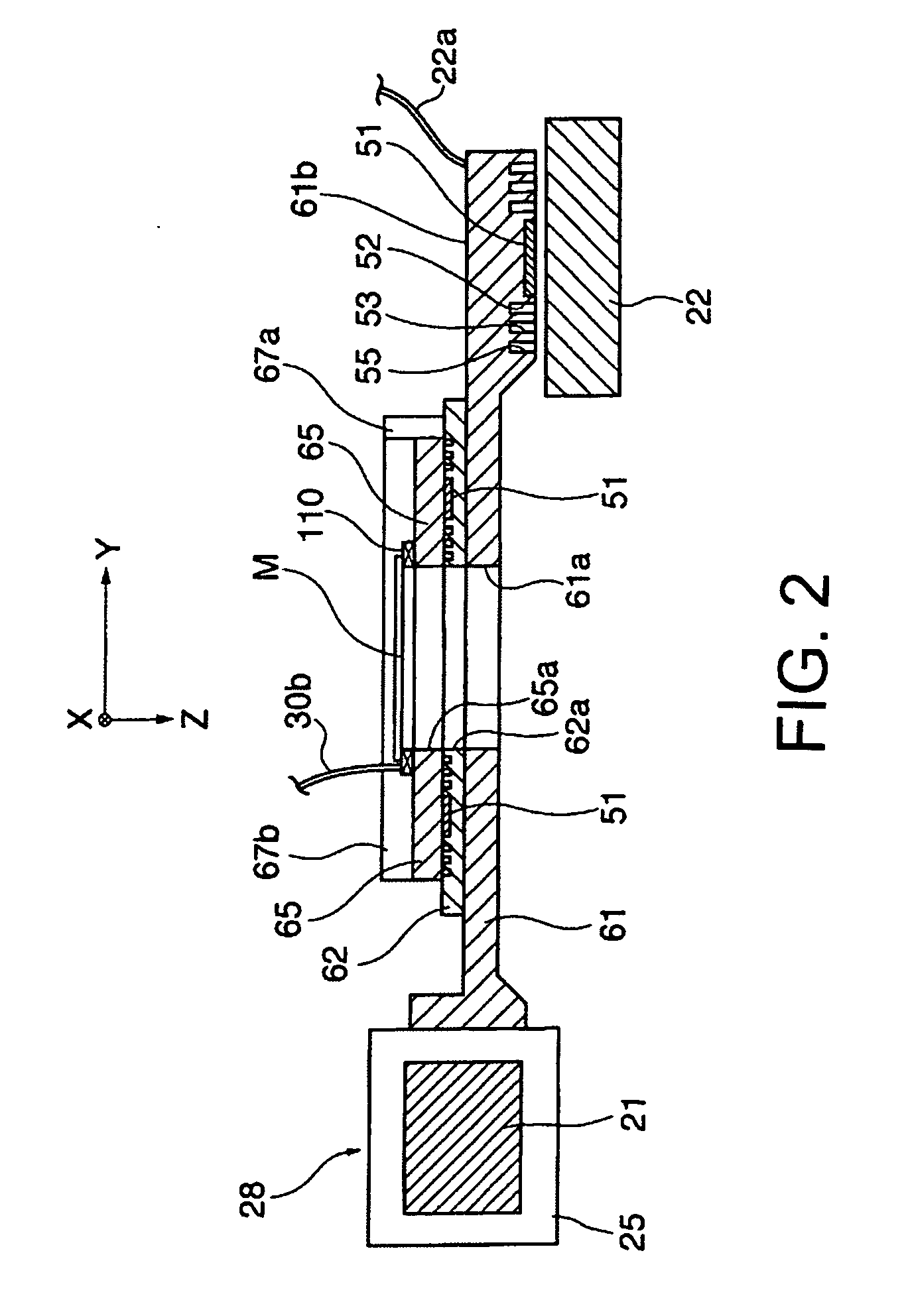

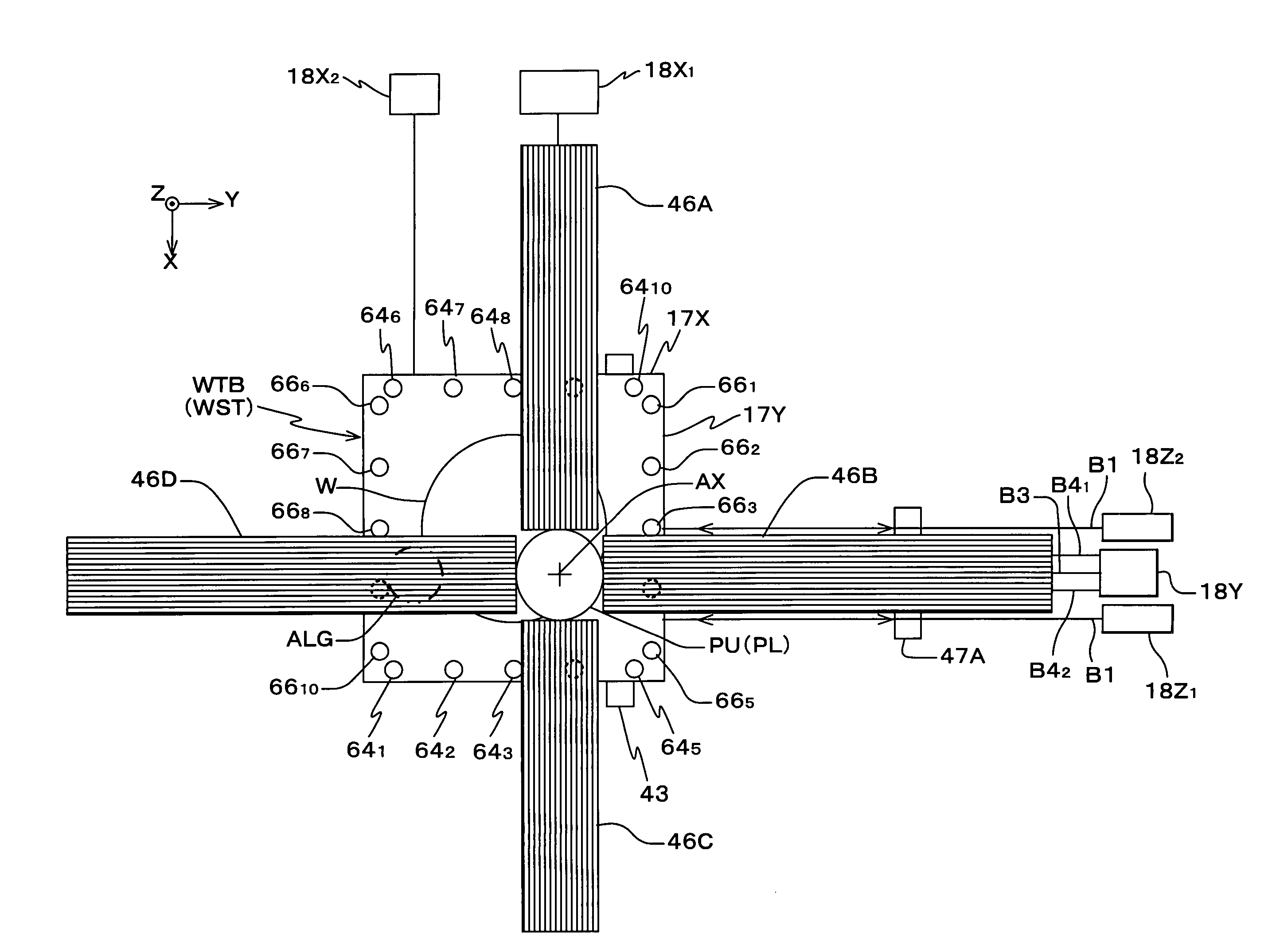

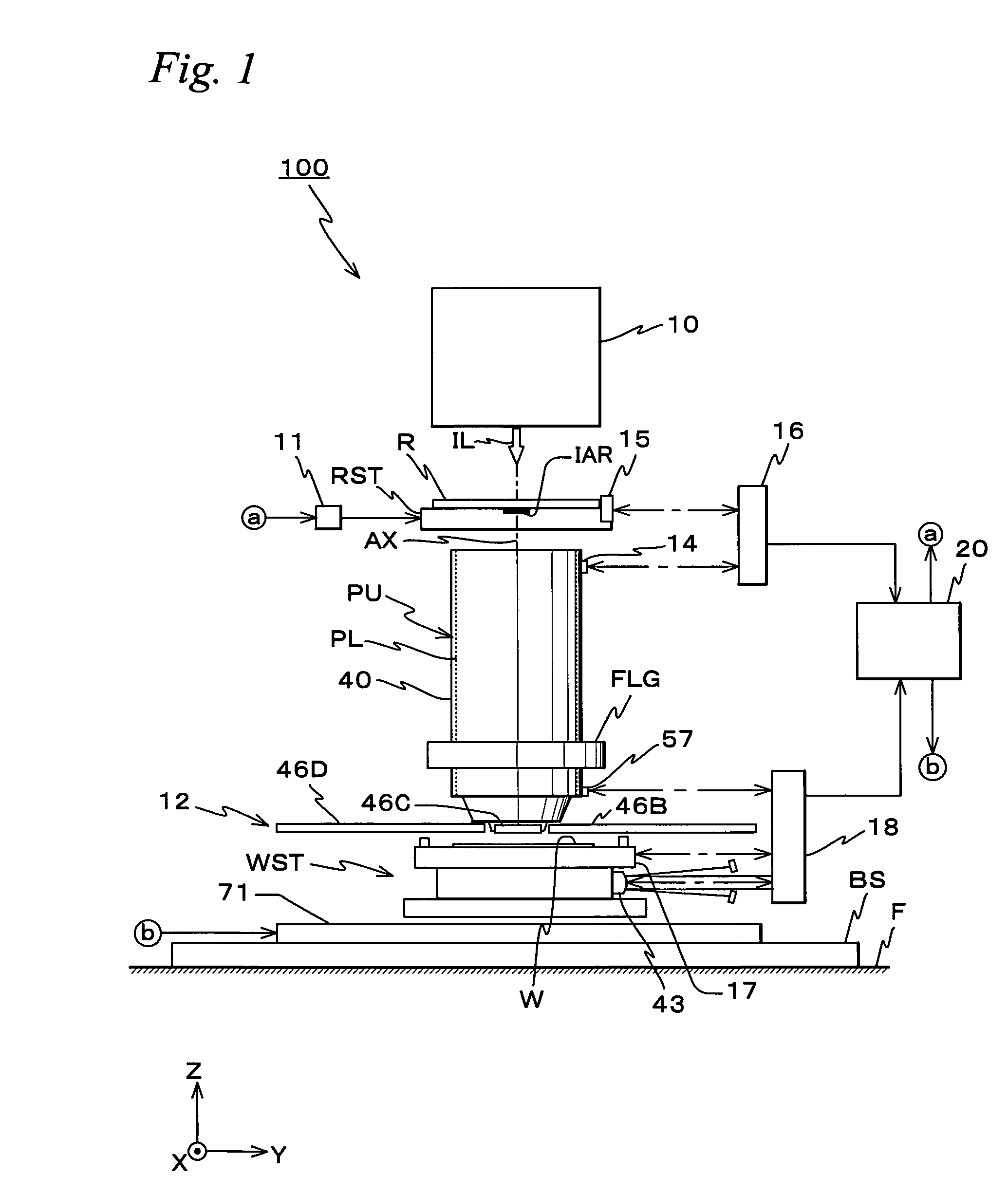

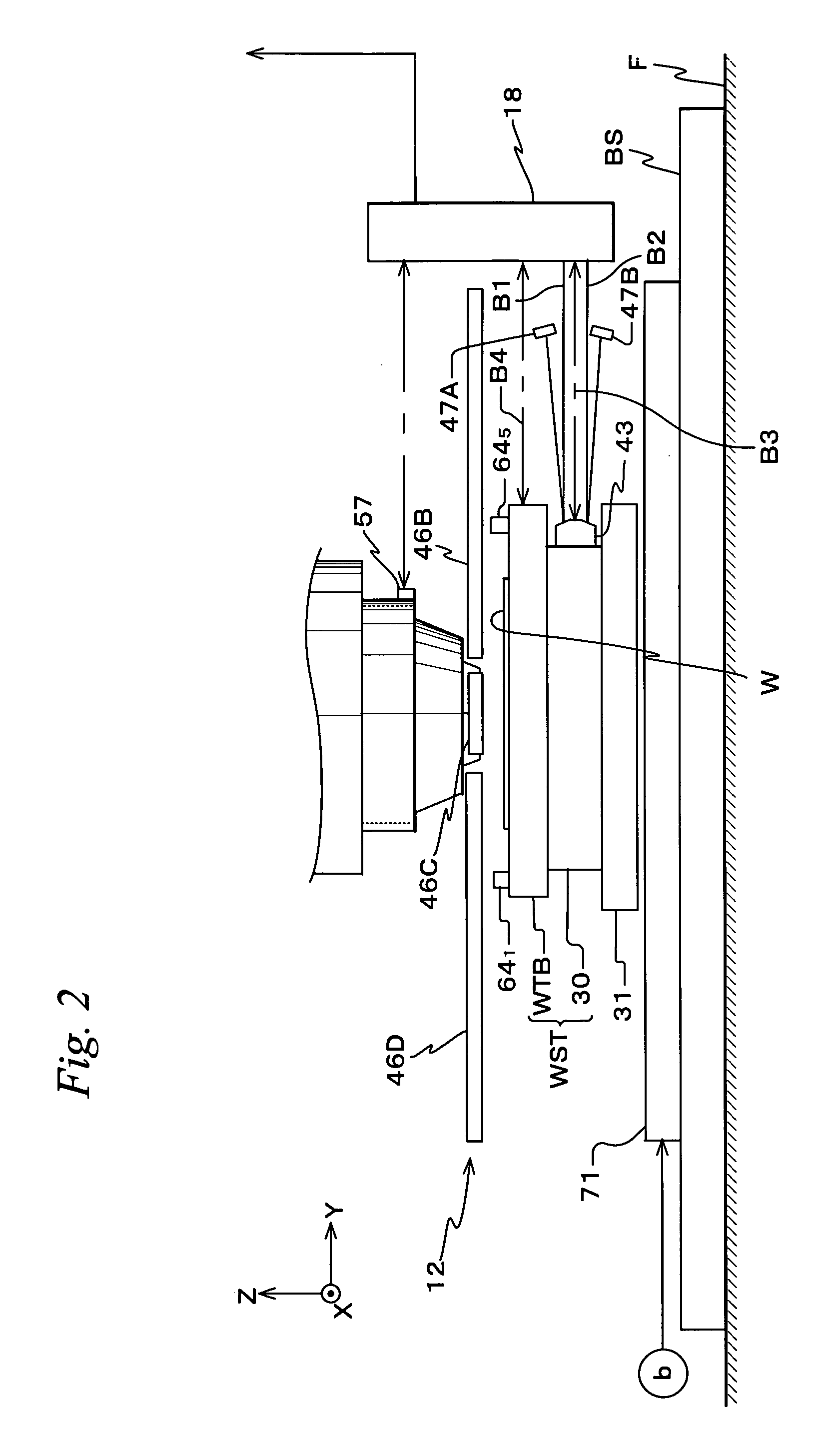

In measurement of a positional information in the XY plane of a fine movement stage held by a coarse movement stage, an encoder system is used including a head which is placed facing a grating placed on a surface substantially parallel to the XY plane of the fine movement stage and irradiates a measurement beam on the grating. Then, the fine movement stage is driven individually or integrally with the coarse movement stage by a drive system, based on the positional information measured by the encoder system. In this case, the head of the encoder system can be placed in proximity to the fine movement stage (the grating), which allows a highly precise measurement of the positional information of the fine movement stage by the encoder system.

Owner:NIKON CORP

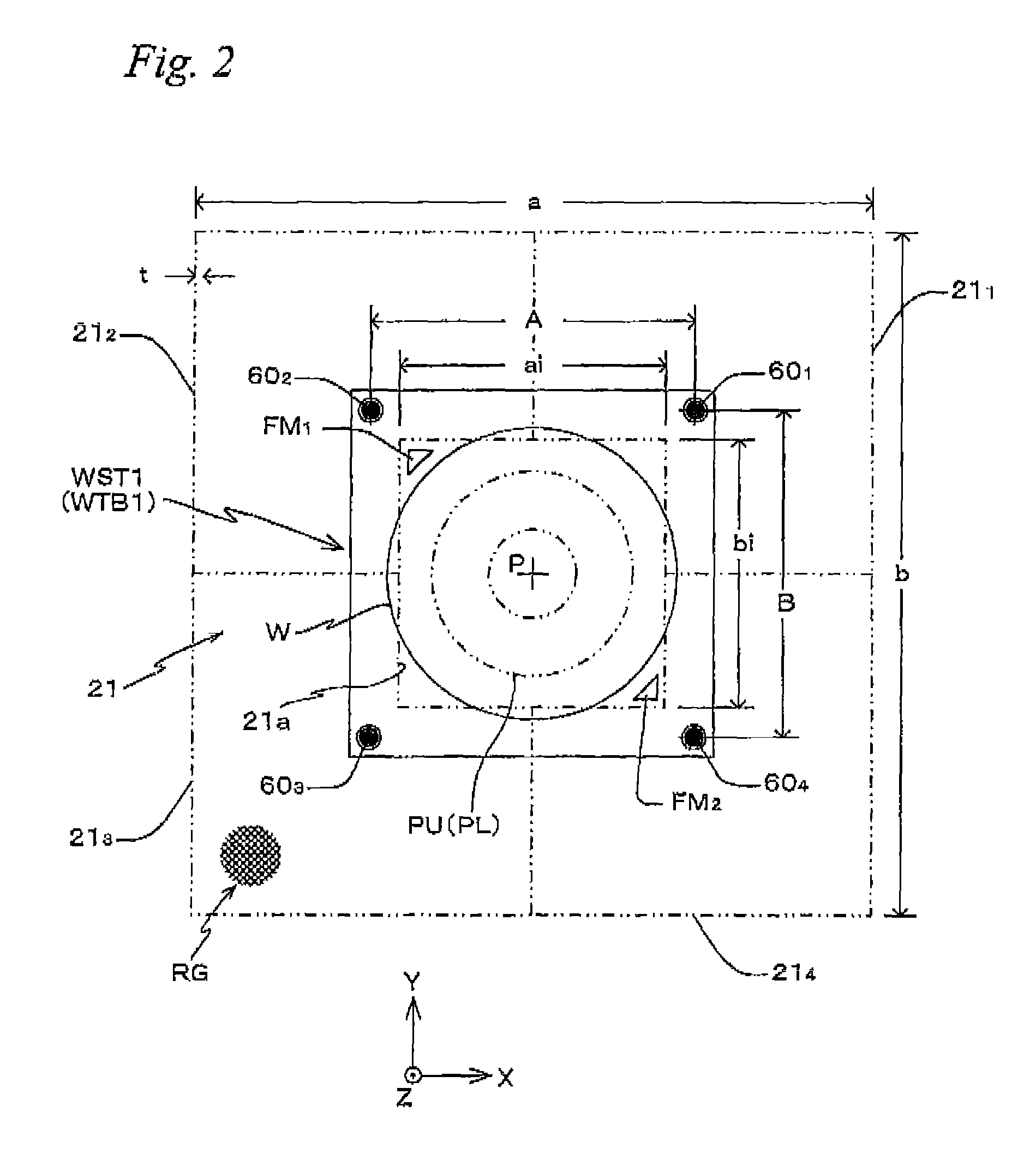

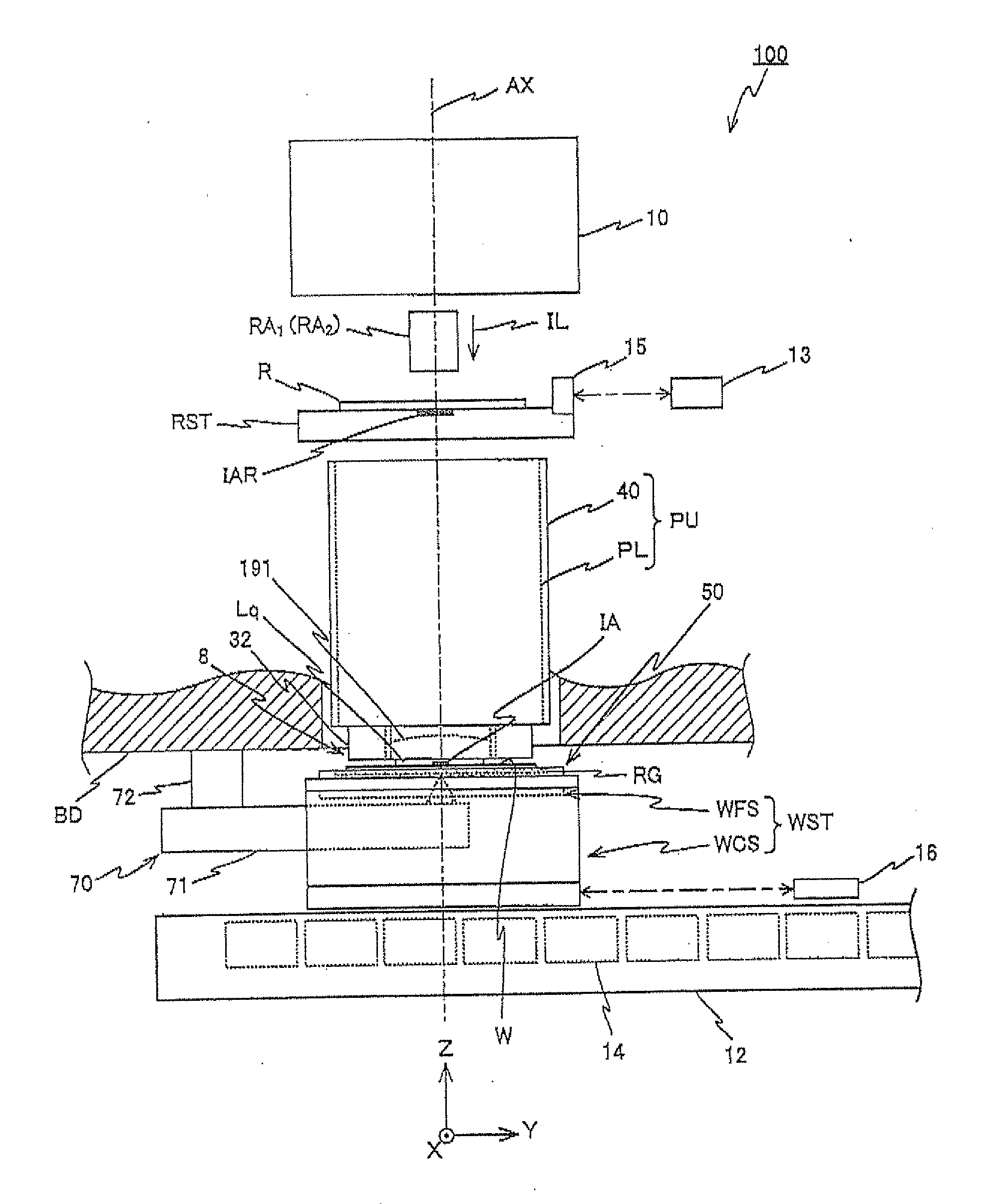

Detection device, movable body apparatus, pattern formation apparatus and pattern formation method, exposure apparatus and exposure method, and device manufacturing method

ActiveUS20090004580A1Improve accuracyHigh-precision exposurePhotomechanical apparatusUsing optical meansForeign matterLight beam

By irradiating a detection beam from an irradiation system of a detection device to a scale used for measuring the position of a wafer stage, and detecting the detection beam via the scale by a photodetection system, a surface state (an existence state of foreign substance) of the scale is detected. With this operation, detection of the surface state can be performed contactlessly with respect to the scale. Moreover, movement control of the wafer stage can be performed with high precision by taking the surface state into consideration.

Owner:NIKON CORP

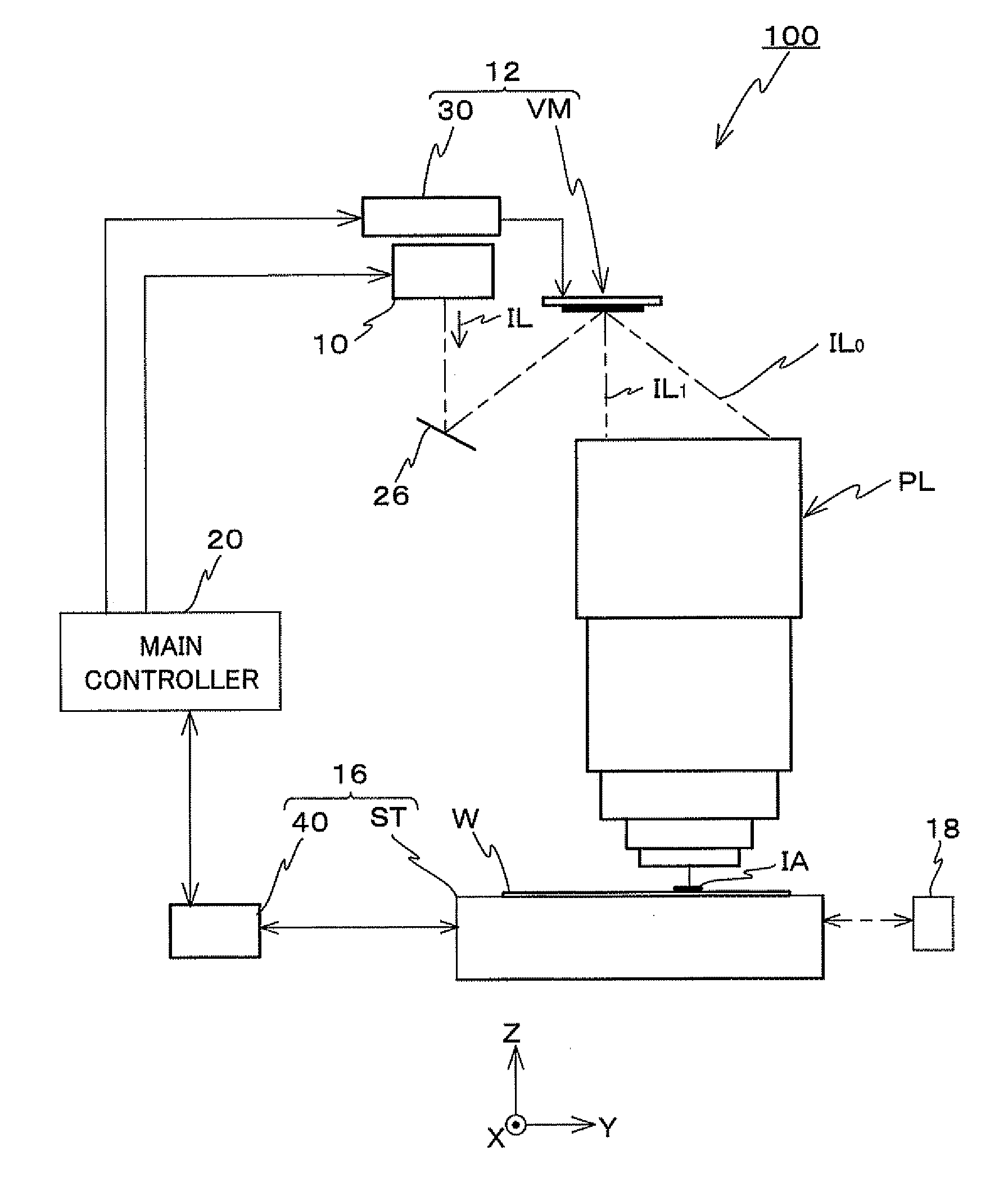

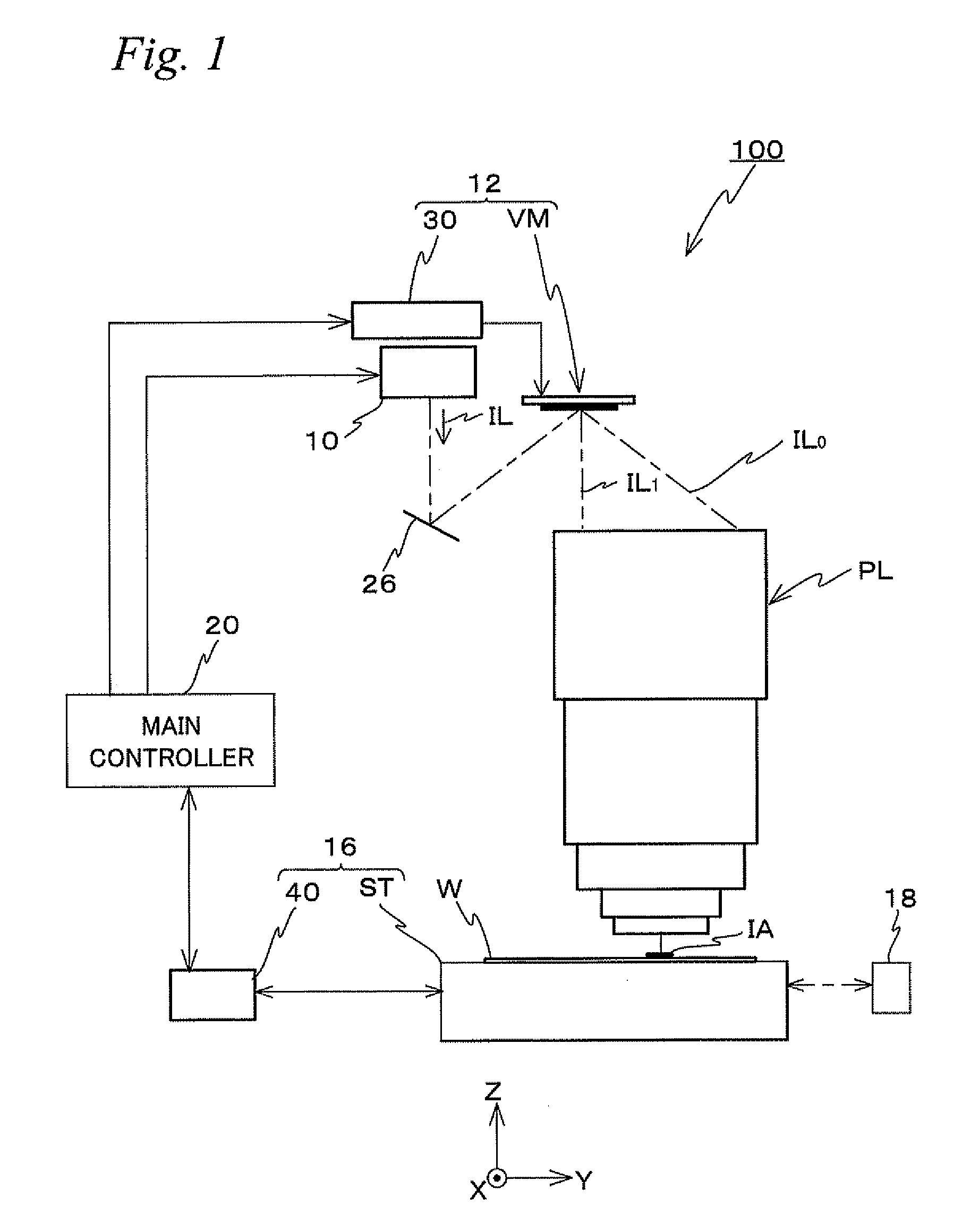

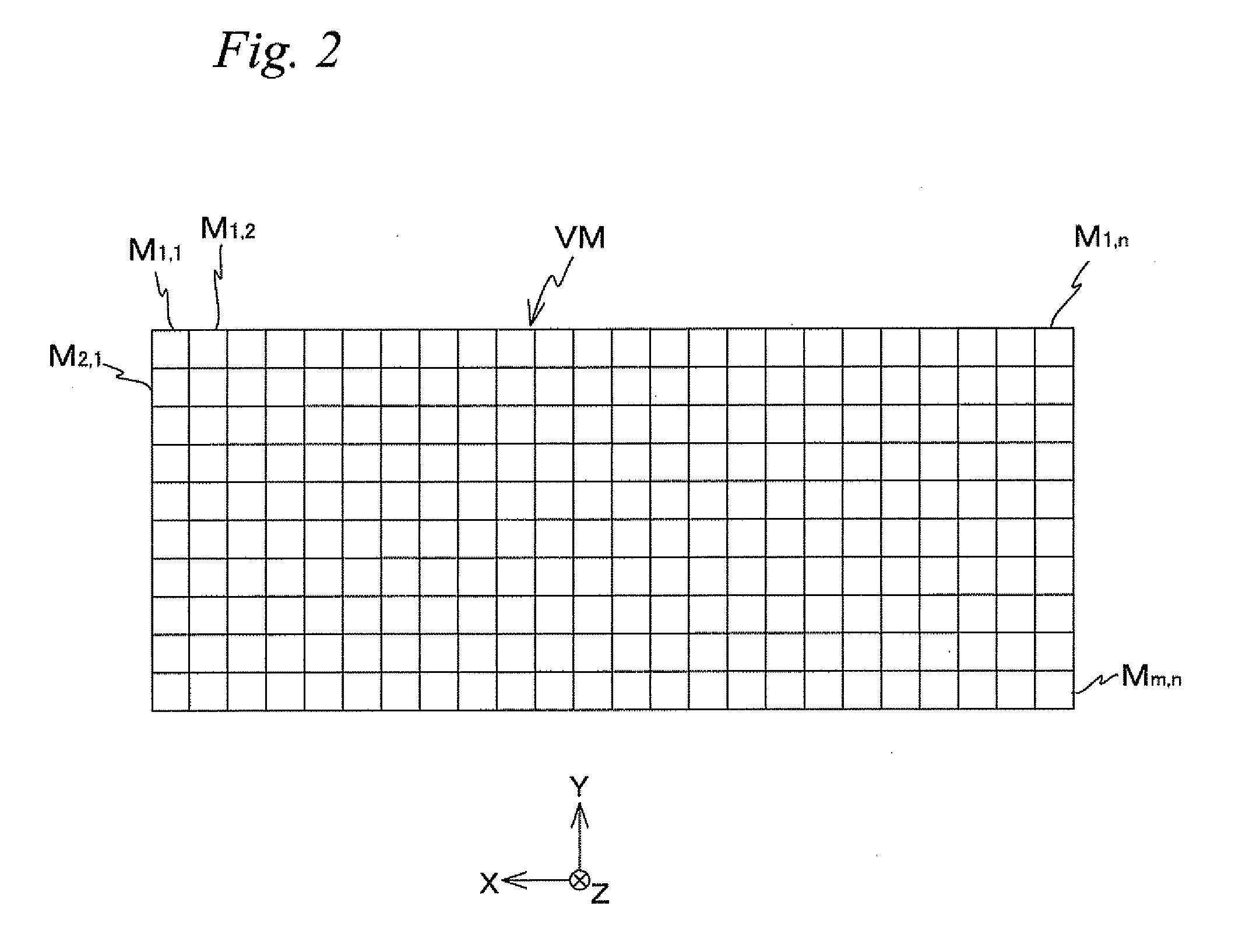

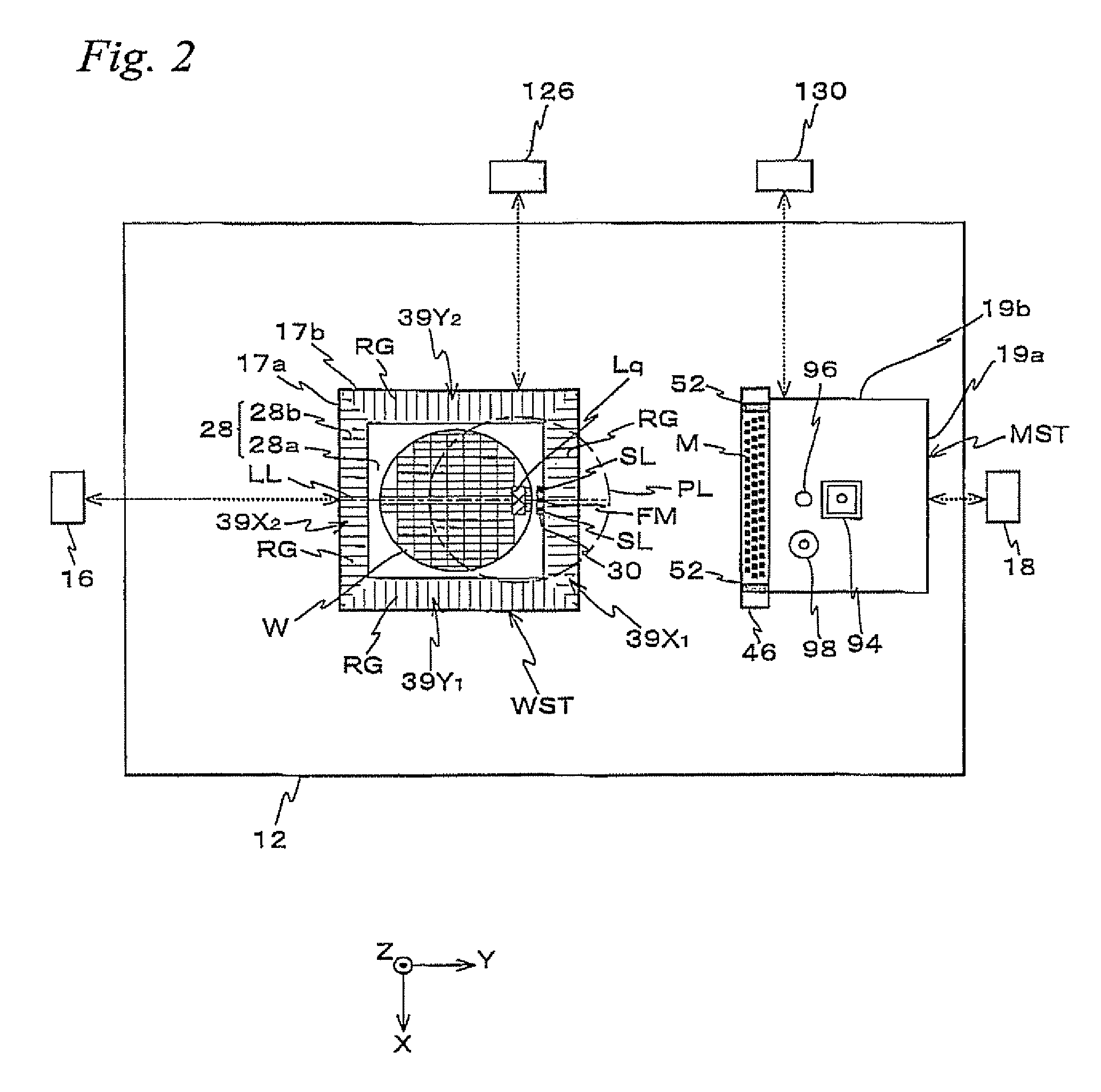

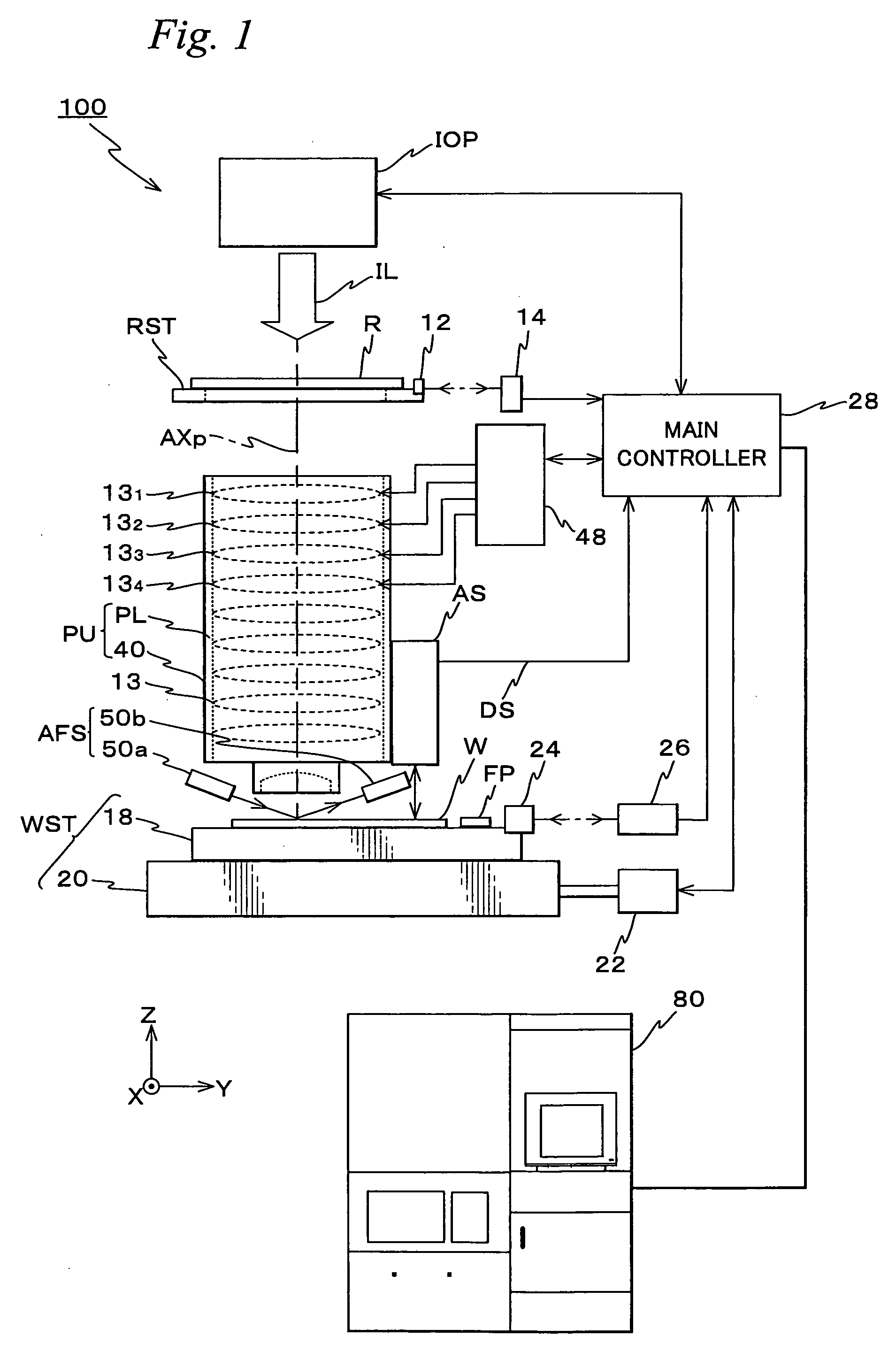

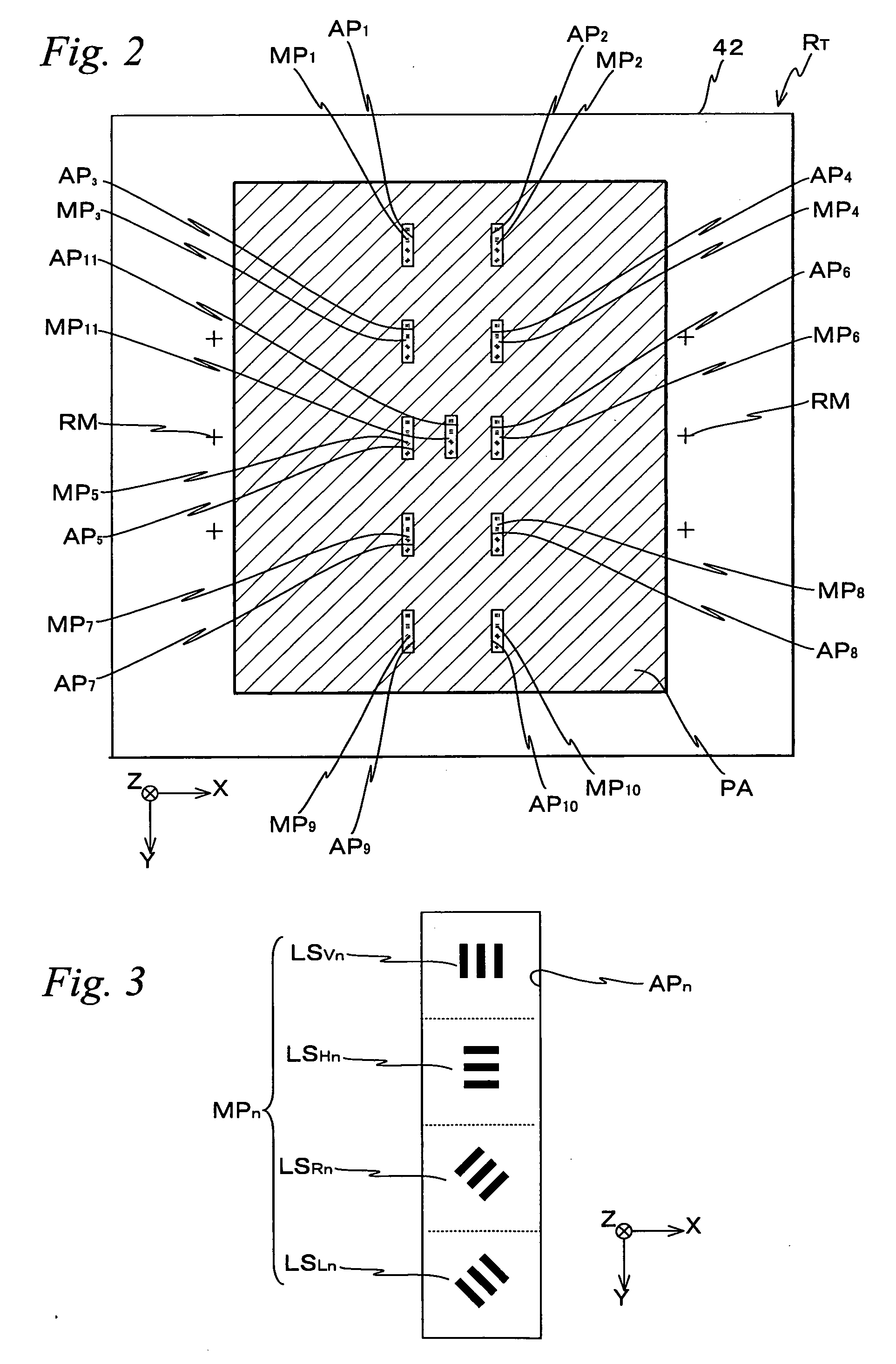

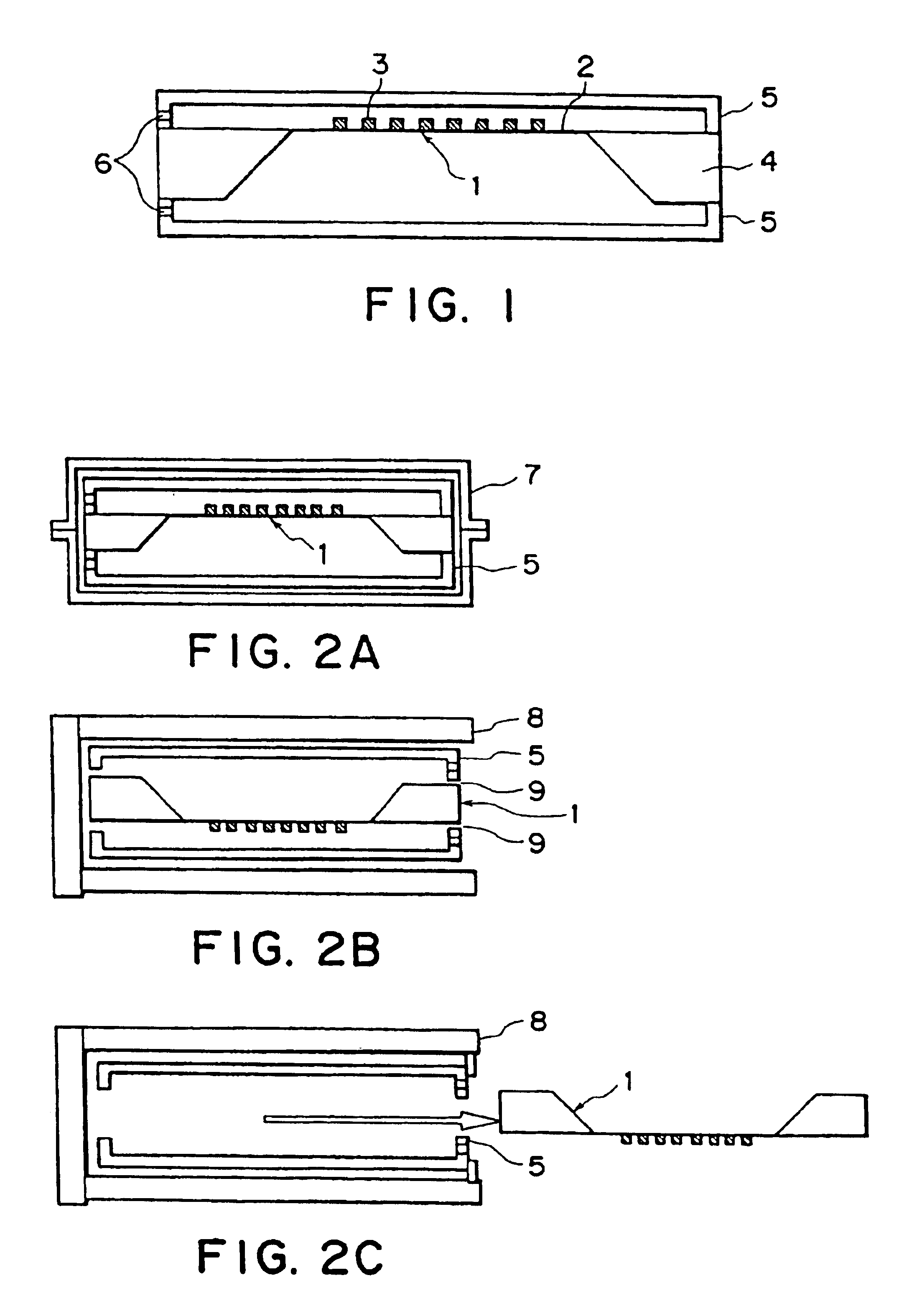

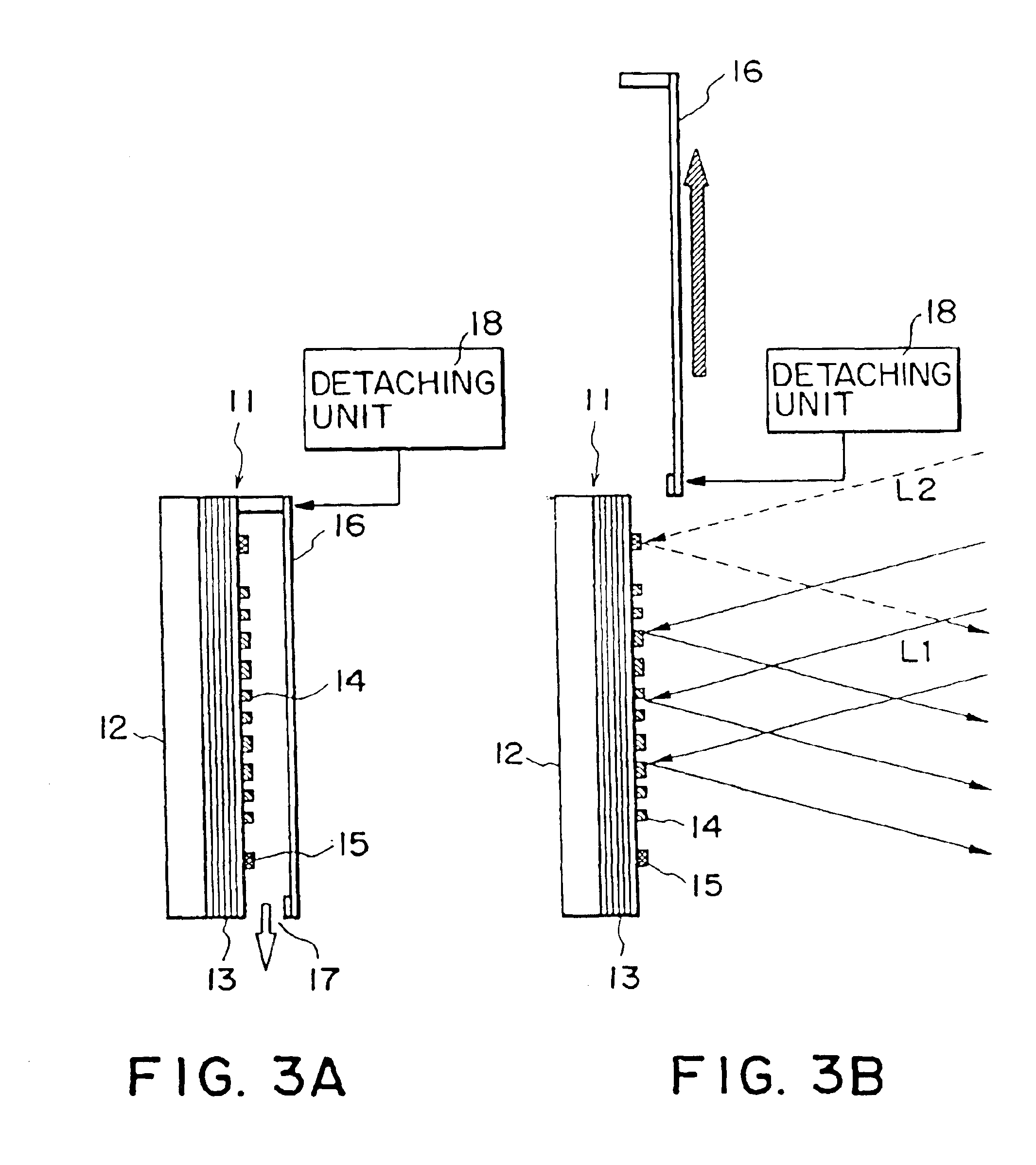

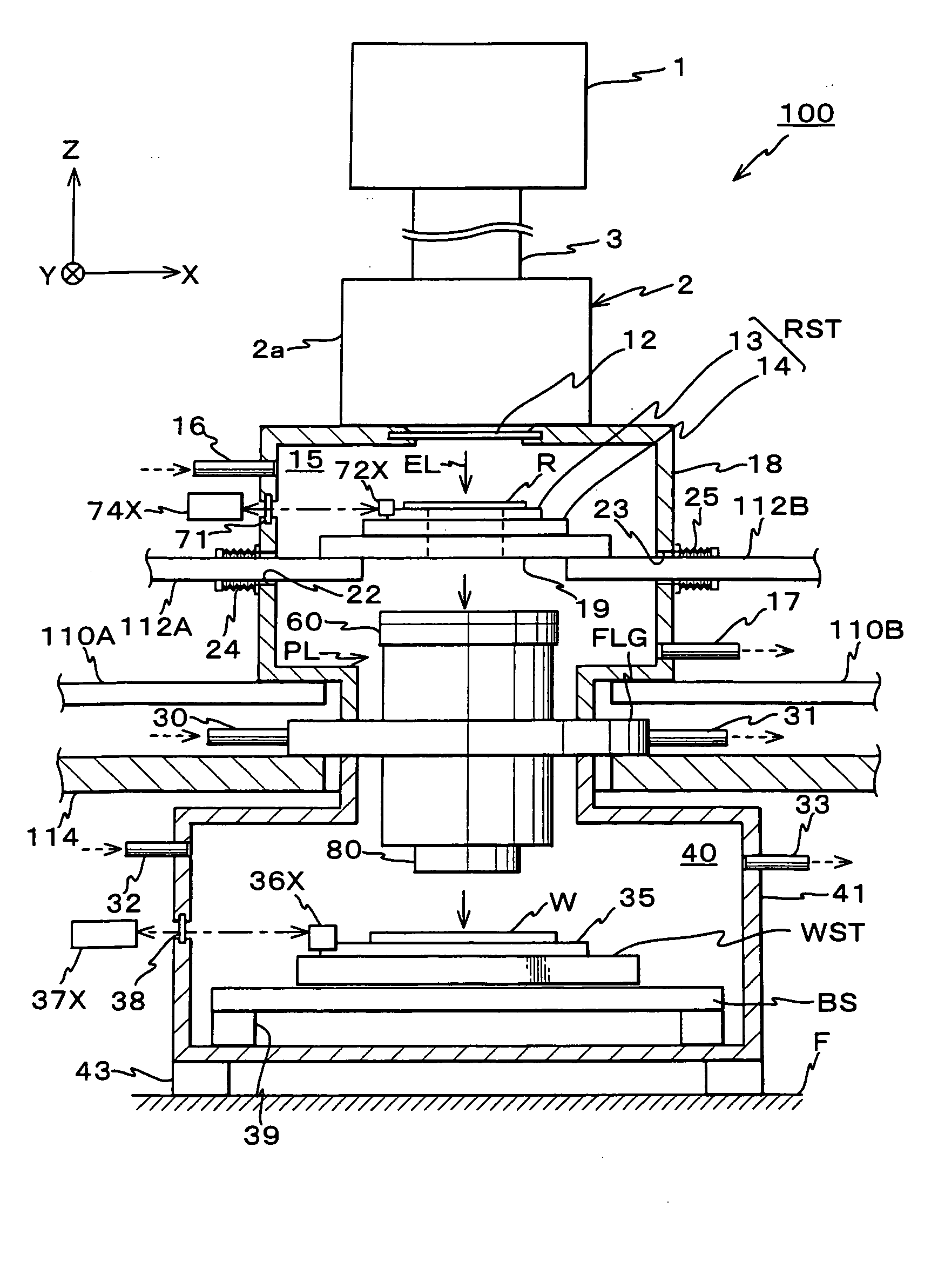

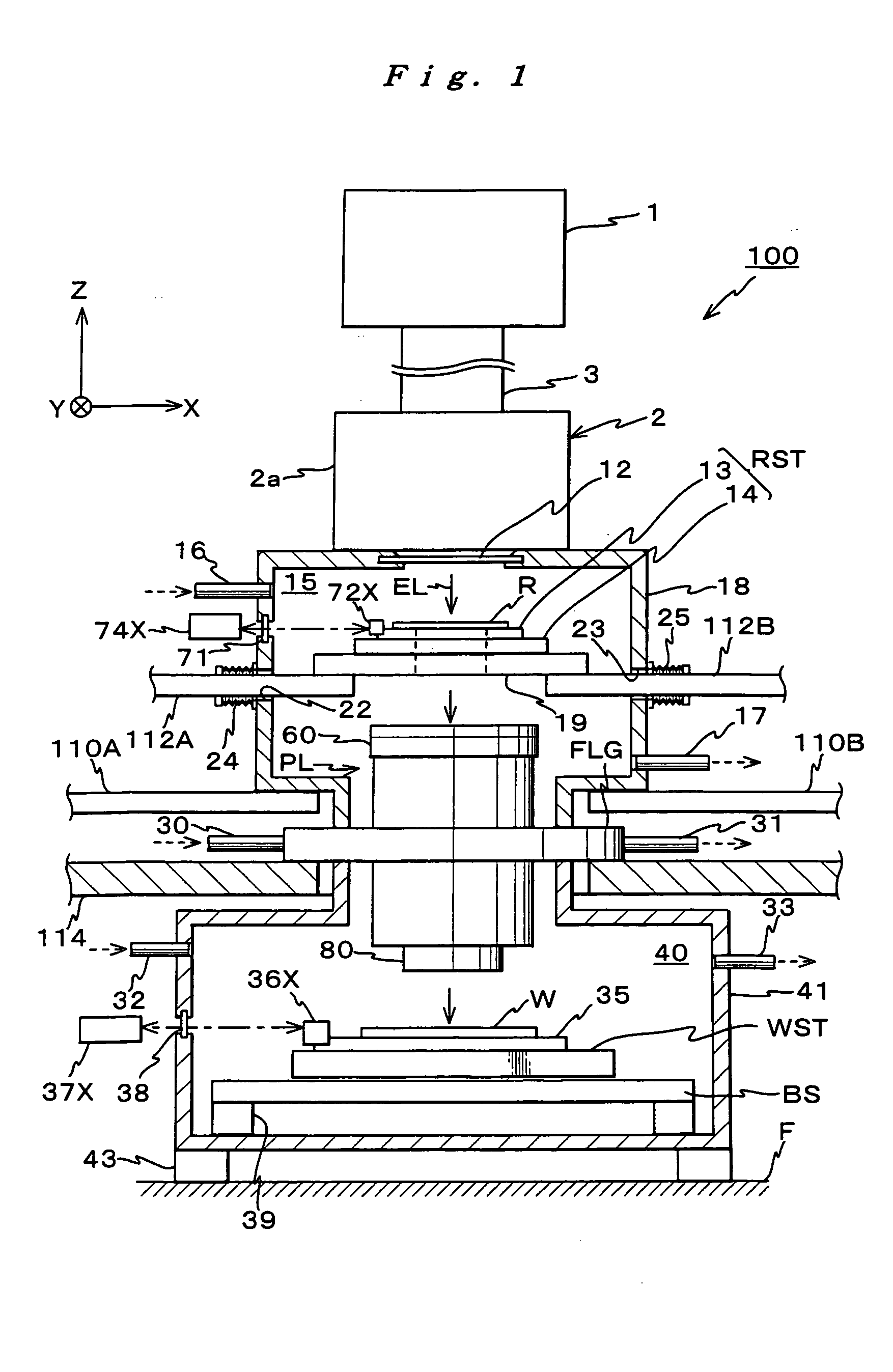

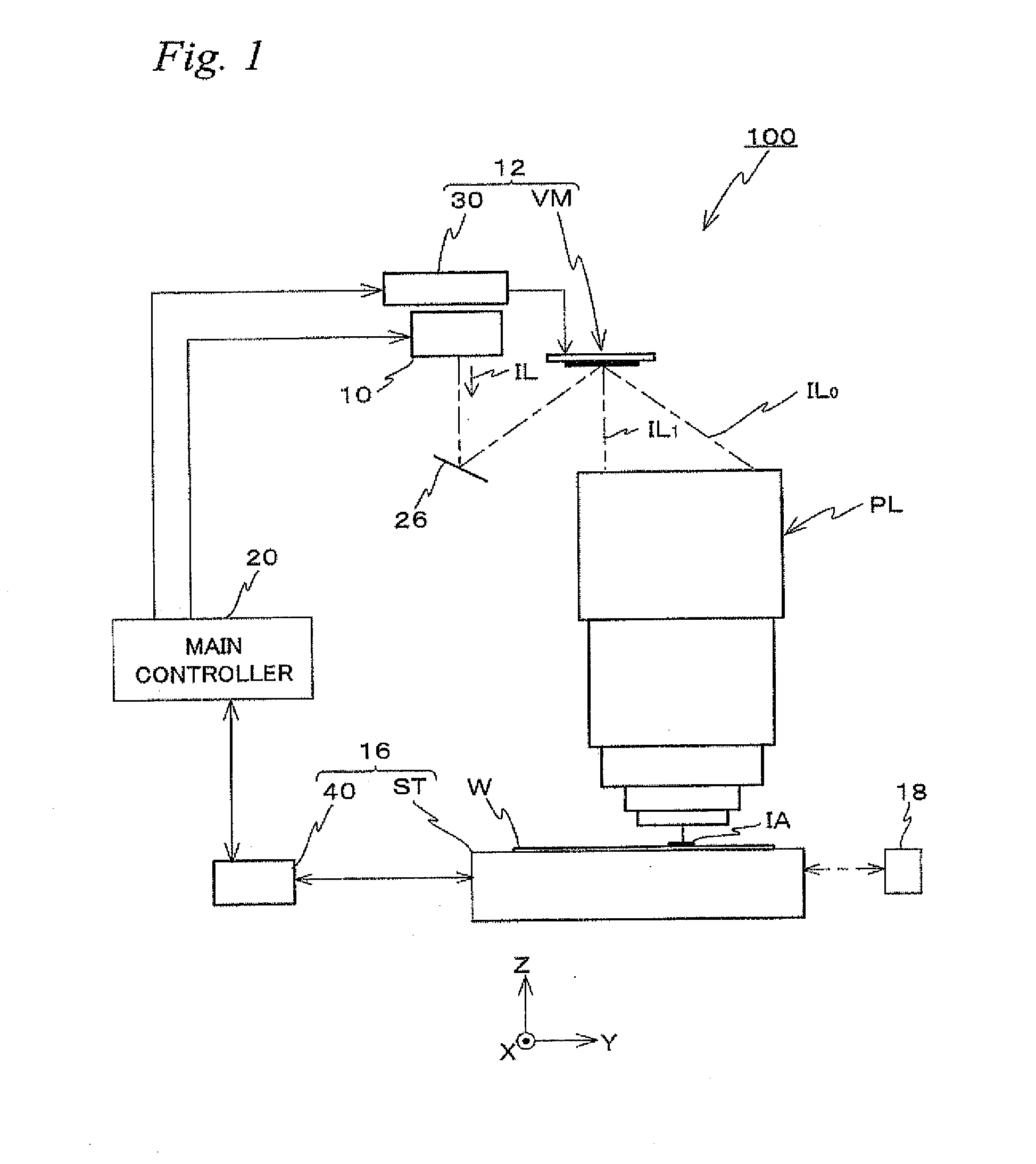

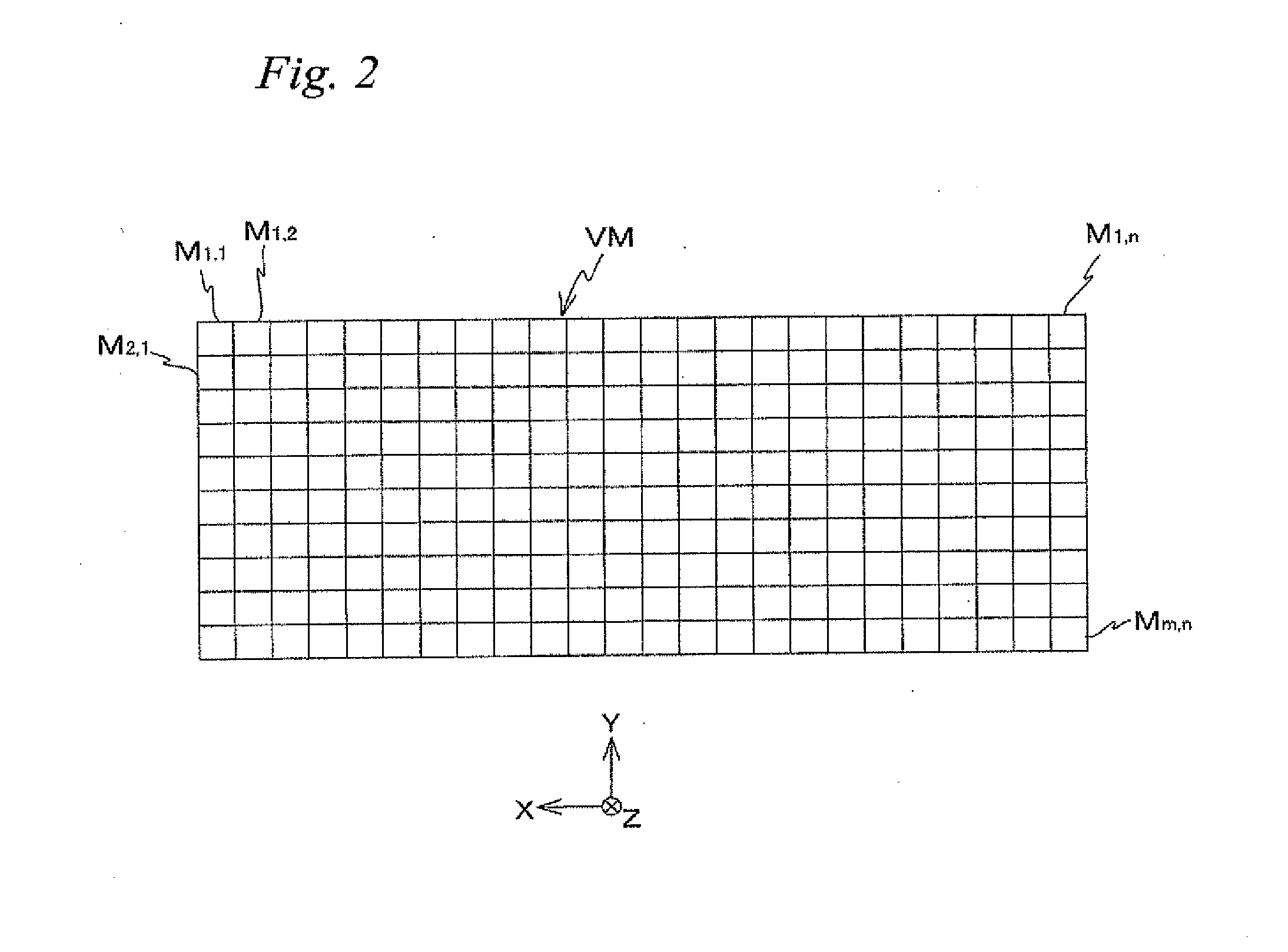

Pattern forming method and apparatus, exposure method and apparatus, and device manufacturing method and device

ActiveUS8089616B2High-precision exposureImprove productivityPhotomechanical apparatusUsing optical meansOptoelectronics

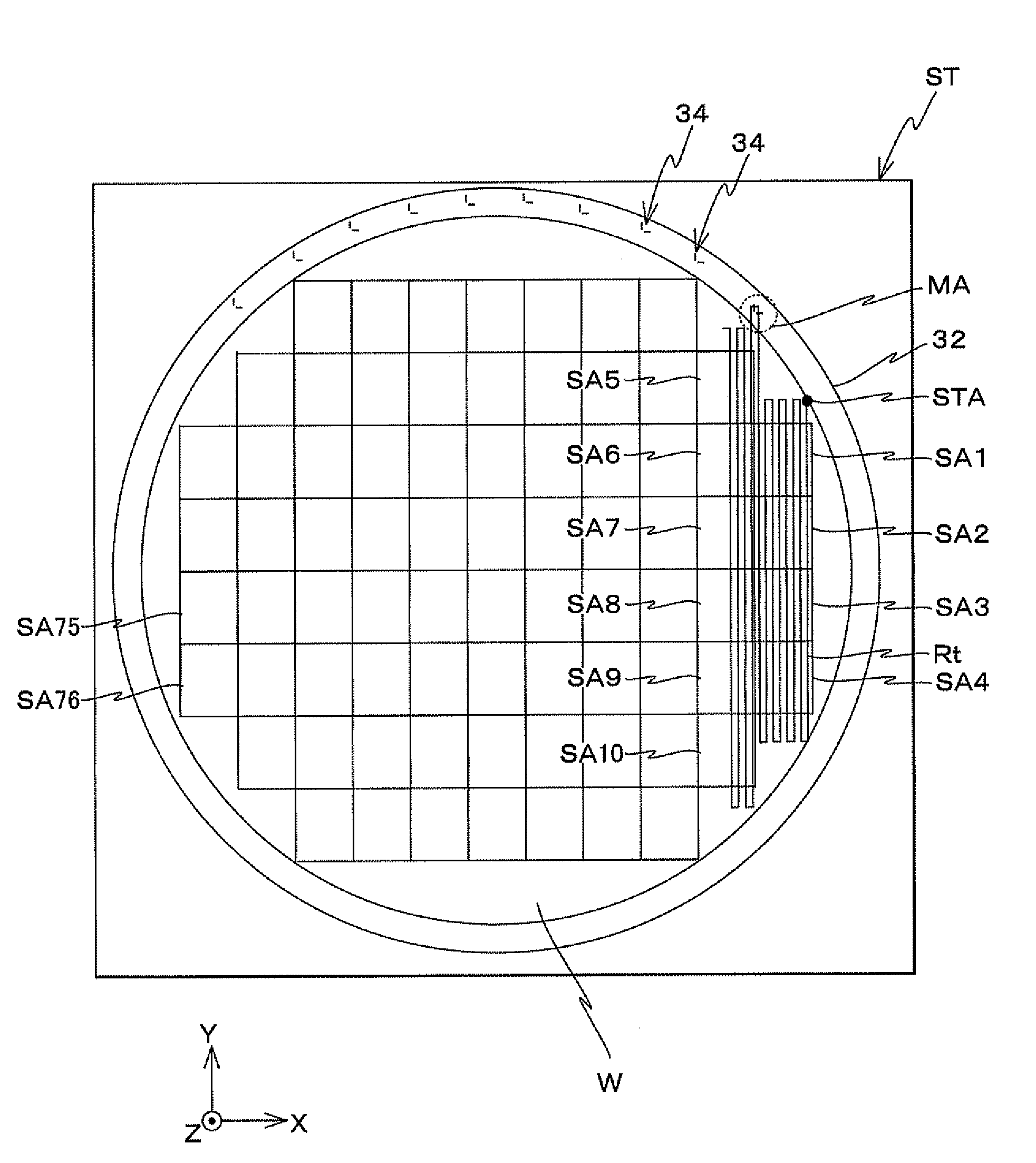

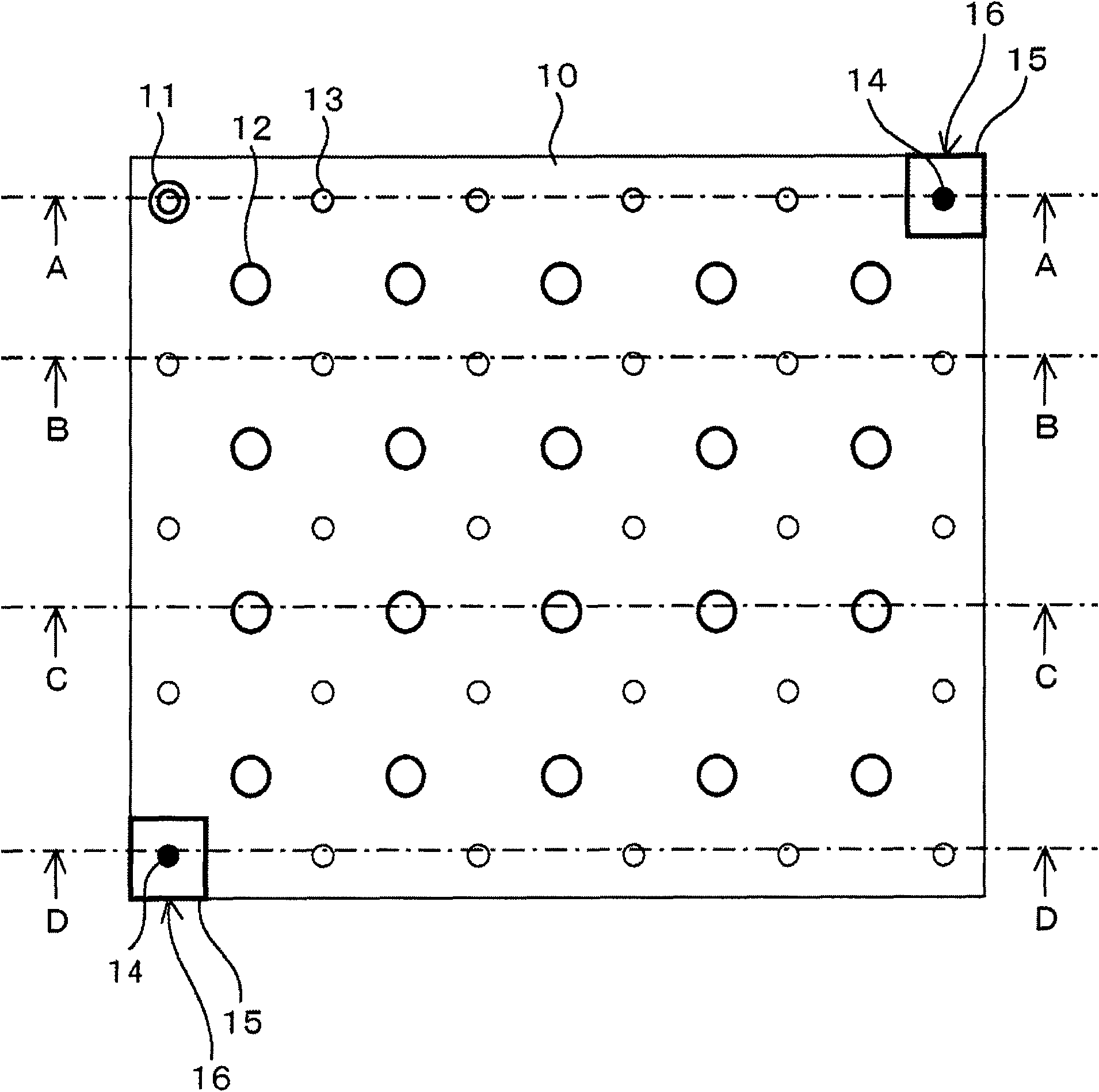

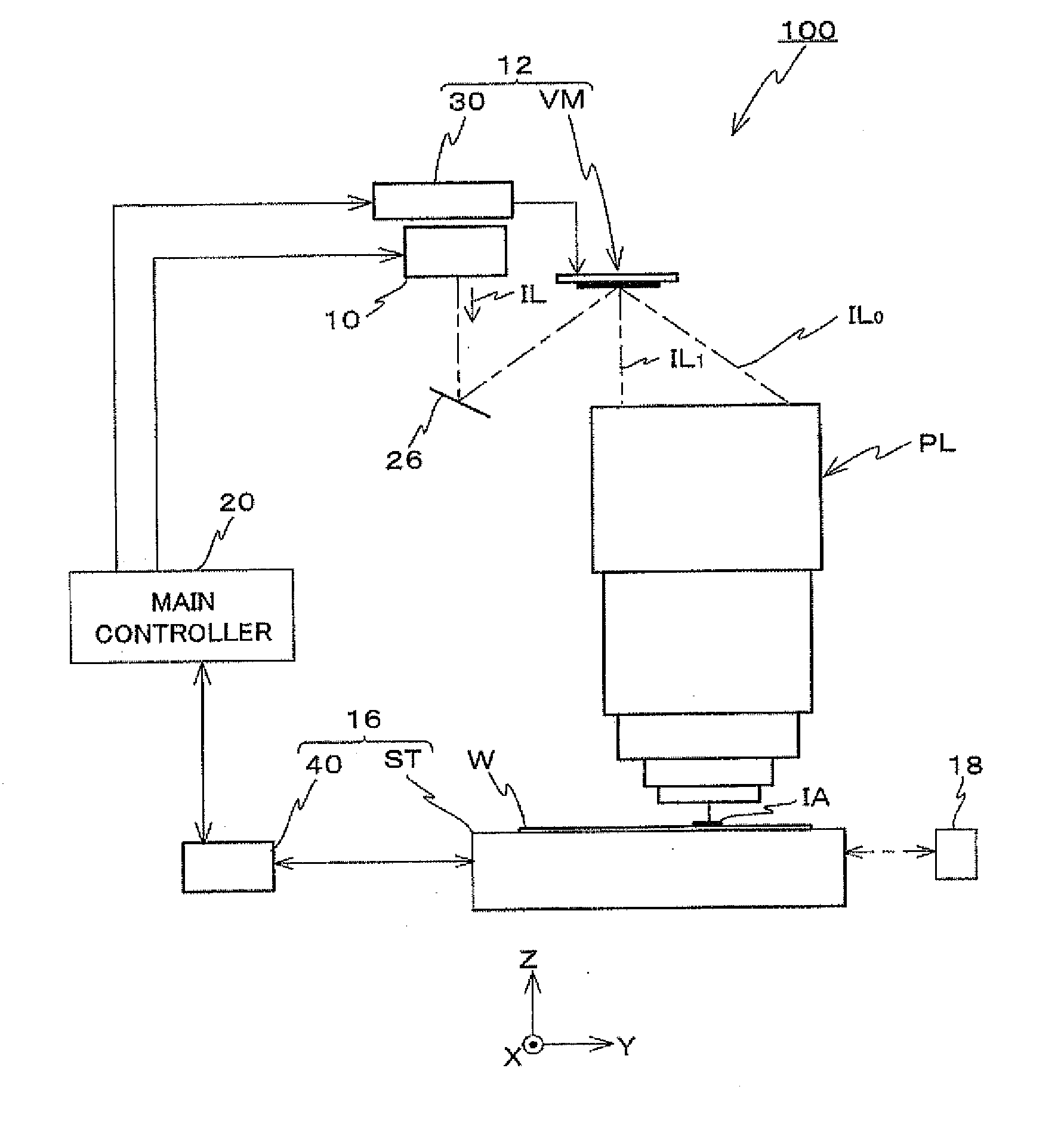

During a period after starting exposure to a plurality of shot areas subject to exposure on a wafer until completing the exposure, a light via a slit pair arranged on a stage that holds the wafer, of illumination light via a pattern generating device, is received, and information on a positional relation between an illumination light and the stage (and hence a positional relation between the illumination light and the wafer) is detected. With this operation, even if the information on the positional relation between the illumination light and the wafer varies due to some reason, information on the variation can be detected while performing the exposure to the plurality of shot areas. Accordingly, high-precision exposure can be achieved in an exposure operation, by considering this detection results.

Owner:NIKON CORP

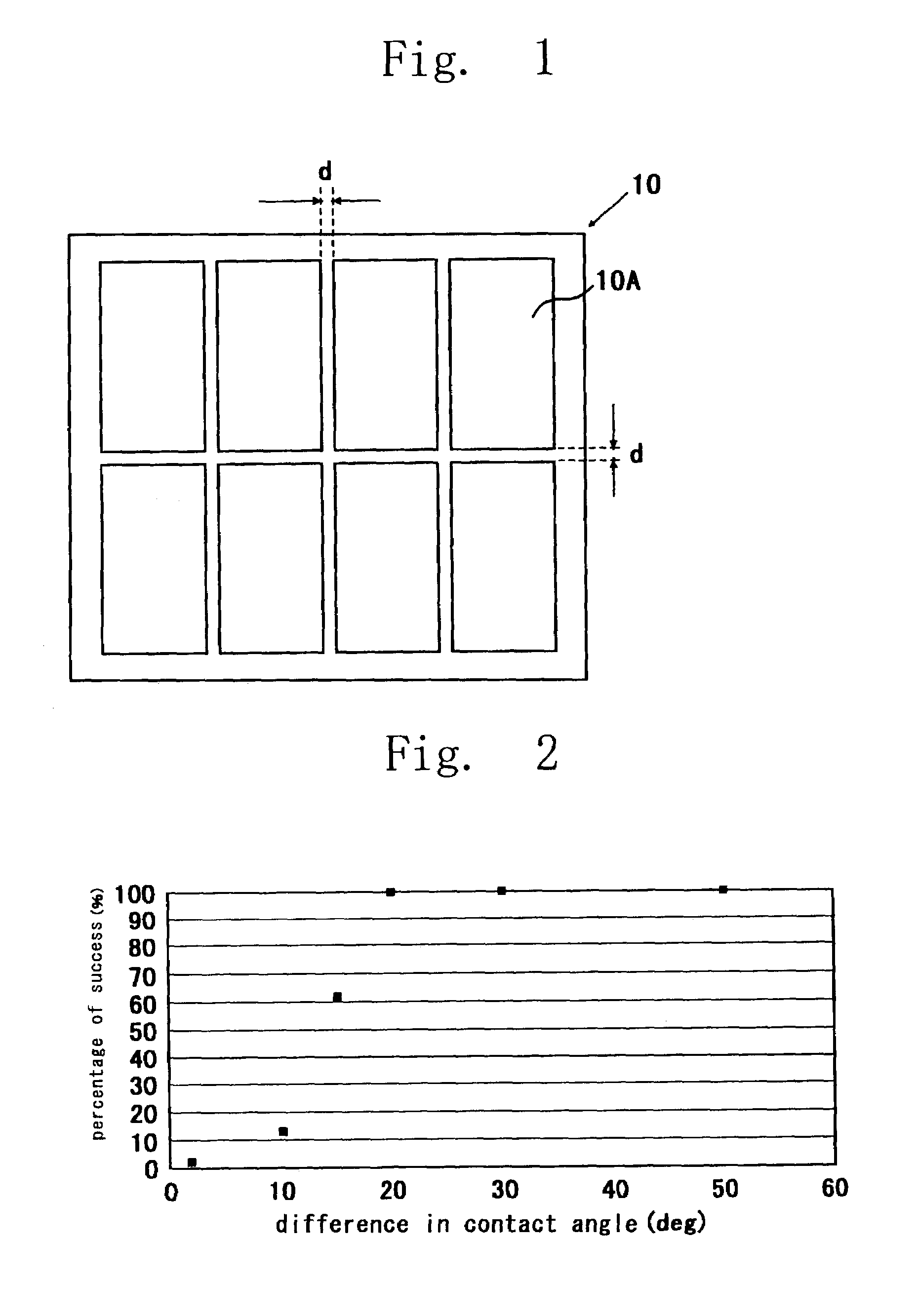

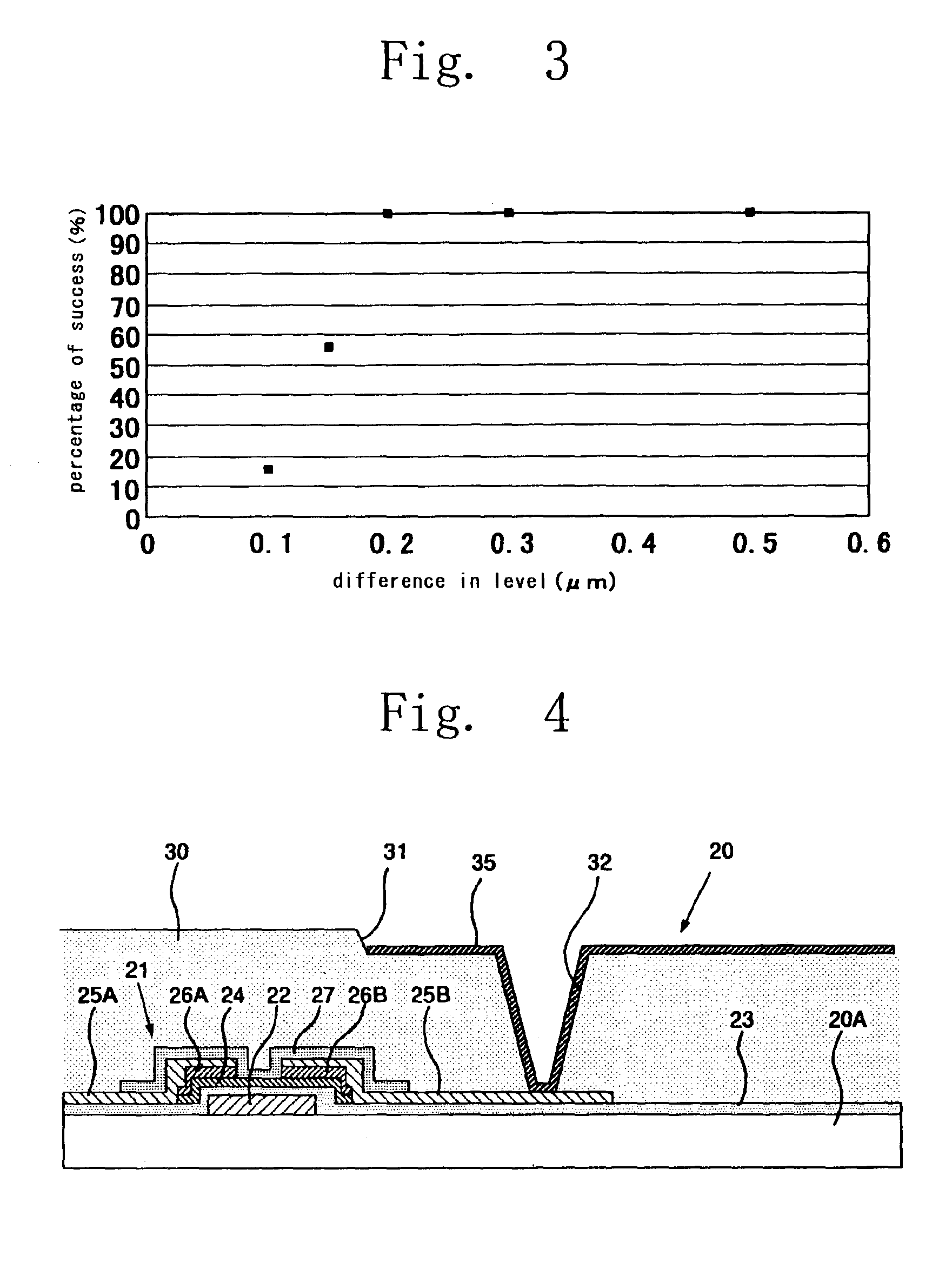

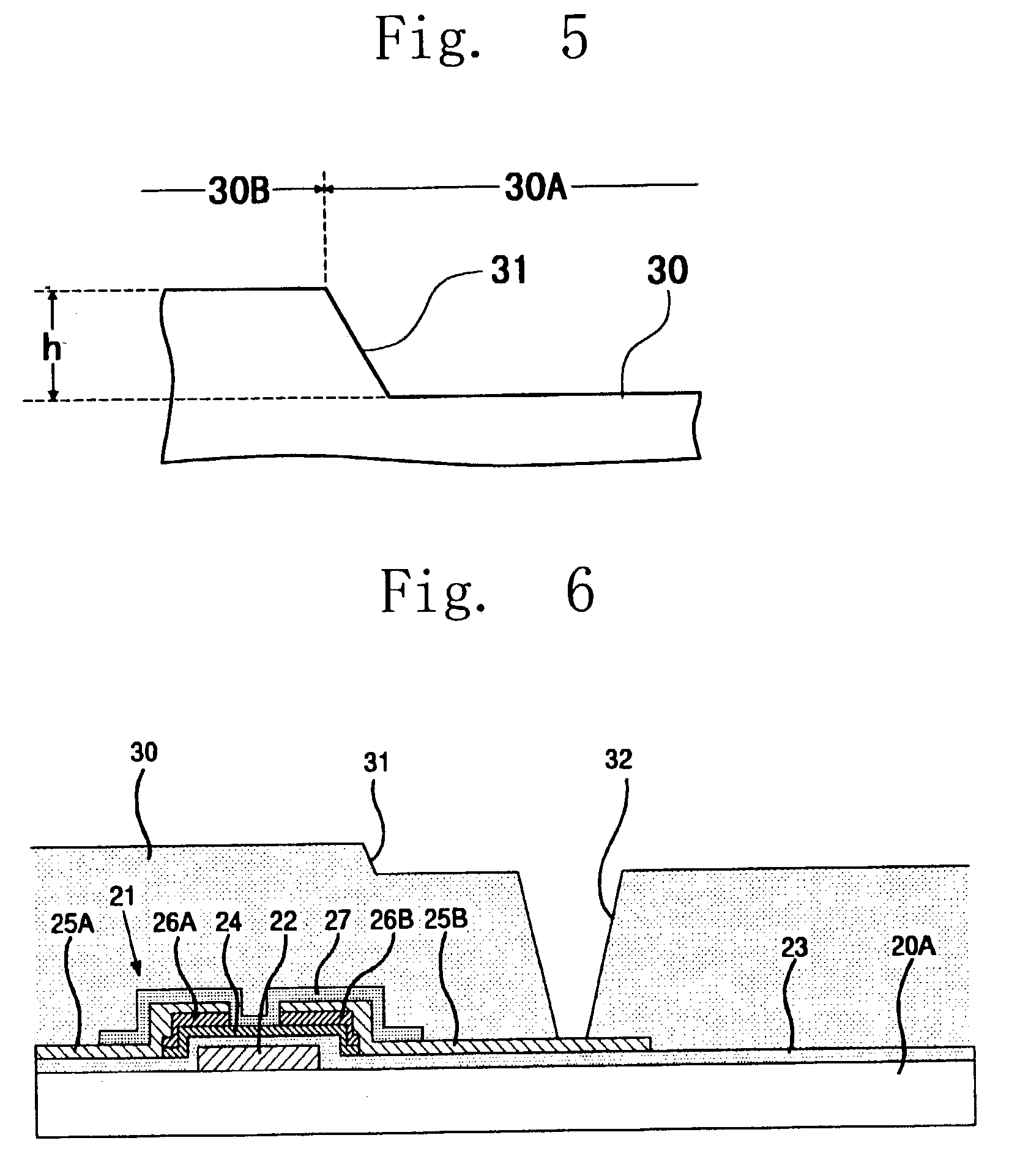

Radiation-sensitive resin composition, forming process for forming patterned insulation film, active matrix board and flat-panel display device equipped with the same, and process for producing flat-panel display device

InactiveUS6984476B2Less treatment stepFormed with easeVessels or leading-in conductors manufactureDiazo compound compositionsElectrical conductorRadiation sensitivity

The invention provides a radiation-sensitive resin composition, by which a patterned insulation film whose water repellency varies is easily formed with high precision, a process for forming a patterned insulation film using this composition, a display element and an flat-panel disply device using the composition, and a process for producing the flat-panel disply device.The resin composition comprises (A) an alkali-soluble copolymer, (B) a 1,2-quinonediazide compound and (C) a water-repellent siloxane resin in particular proportions. In the production process of the patterned insulation film, patterning exposure and development are conducted on a coating formed of the resin composition. The display element and flat-panel disply device are equipped with an interlayer insulation film formed by the resin composition. The production process of the flat-panel disply device comprises an interlayer insulation film-forming step including a treatment of patterning exposure exposing conductor layer-forming regions in an exposure that only surface layer portions are cured in one part thereof, and the whole in the thickness-wise direction thereof is cured in the other parts, and a conductor layer-forming step of forming conductor layers on the surface of the interlayer insulation film with a liquid material.

Owner:SHARP KK +1

Pattern forming method and apparatus, exposure method and apparatus, and device manufacturing method and device

ActiveUS20100099049A1Improve productivityHigh-precision exposurePhotomechanical apparatusUsing optical meansOptoelectronics

During a period after starting exposure to a plurality of shot areas subject to exposure on a wafer until completing the exposure, a light via a slit pair arranged on a stage that holds the wafer, of illumination light via a pattern generating device, is received, and information on a positional relation between an illumination light and the stage (and hence a positional relation between the illumination light and the wafer) is detected. With this operation, even if the information on the positional relation between the illumination light and the wafer varies due to some reason, information on the variation can be detected while performing the exposure to the plurality of shot areas. Accordingly, high-precision exposure can be achieved in an exposure operation, by considering this detection results.

Owner:NIKON CORP

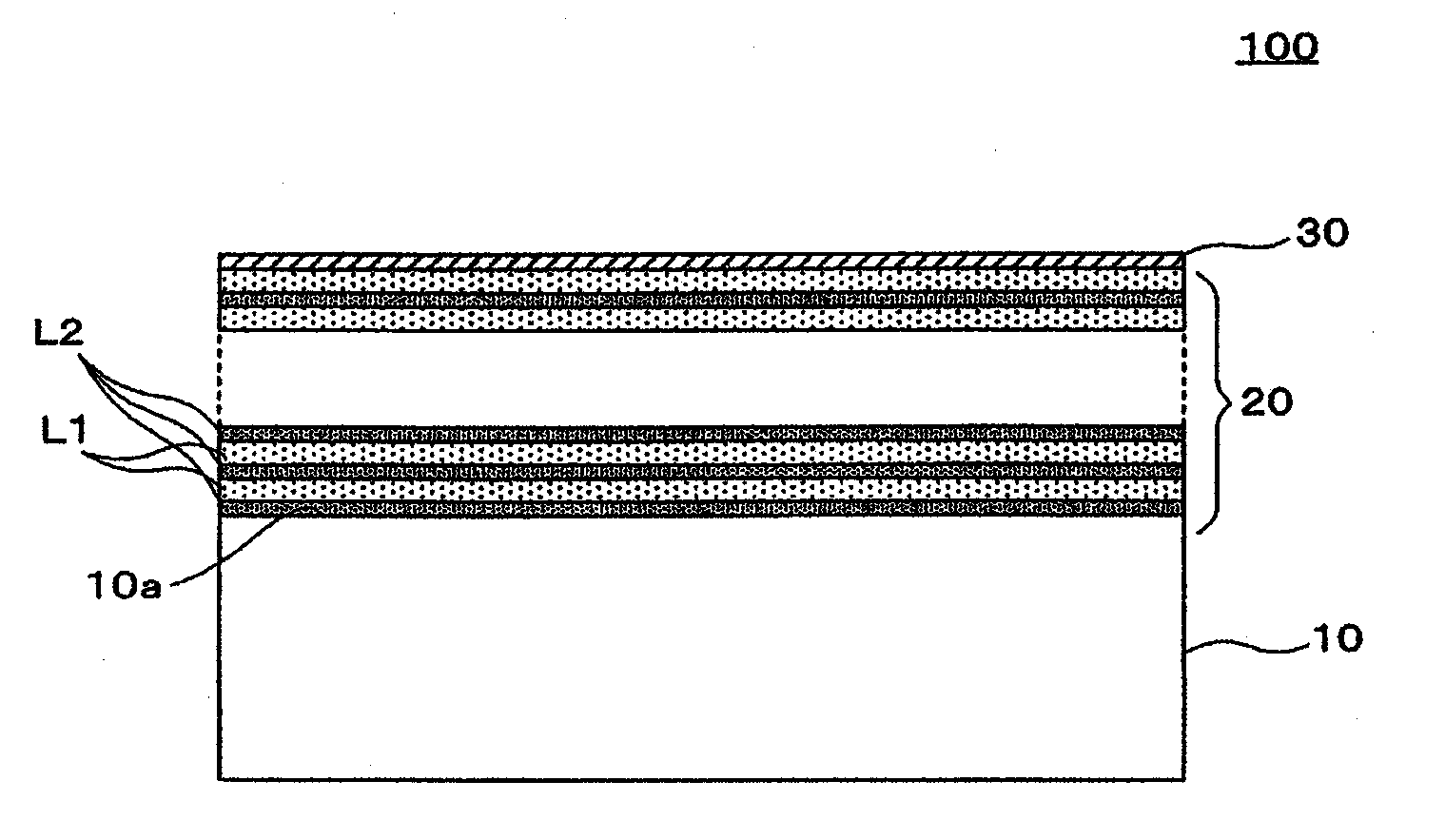

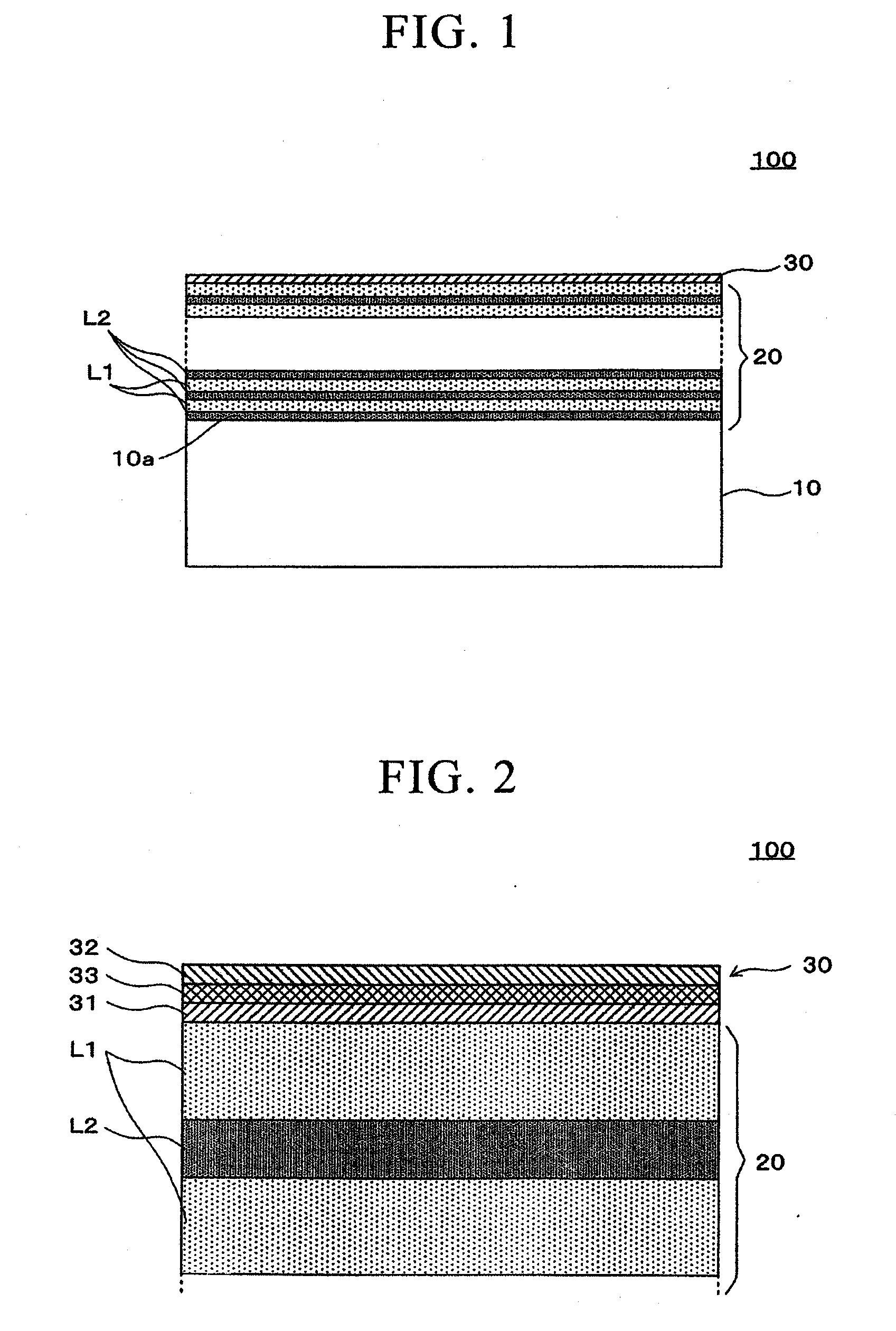

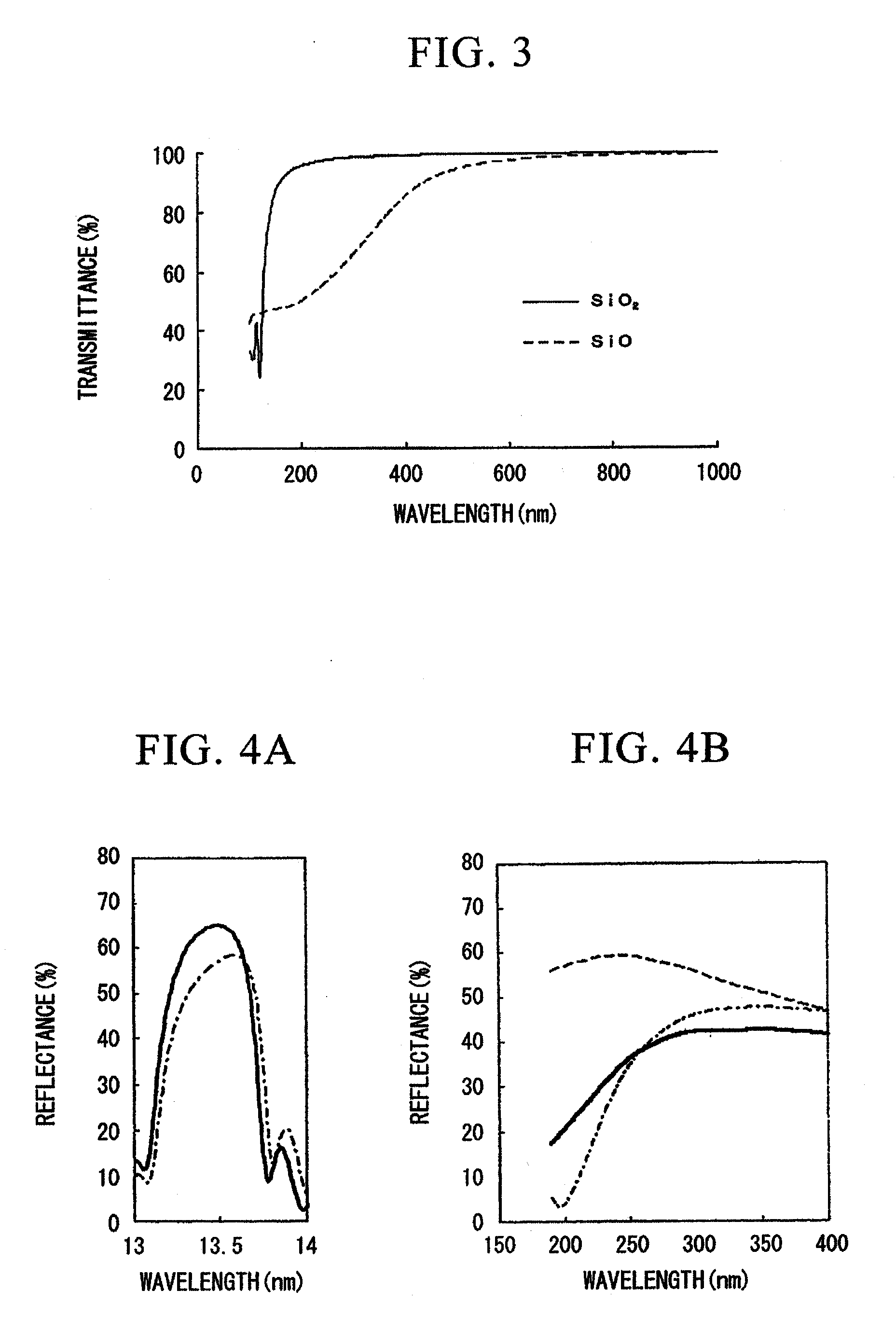

Optical element, exposure apparatus using this, and device manufacturing method

ActiveUS20100190113A1Maintained relatively longReduce non-exposure lightNanoinformaticsHandling using diffraction/refraction/reflectionInter layerOptoelectronics

On a multilayer film mirror, a protective layer is formed having a varied composition in the depth direction. The protective layer includes an interface side layer formed on a thin film layer, i.e., the outermost layer of a multilayer film, a surface side layer provided on the interface side layer as the outermost surface of an optical element, and an intermediate layer. The interface side layer has properties such as providing relative absorption of non-exposure light from a light source. The surface side layer suppresses oxidation of the surface of the multilayer film.

Owner:NIKON CORP

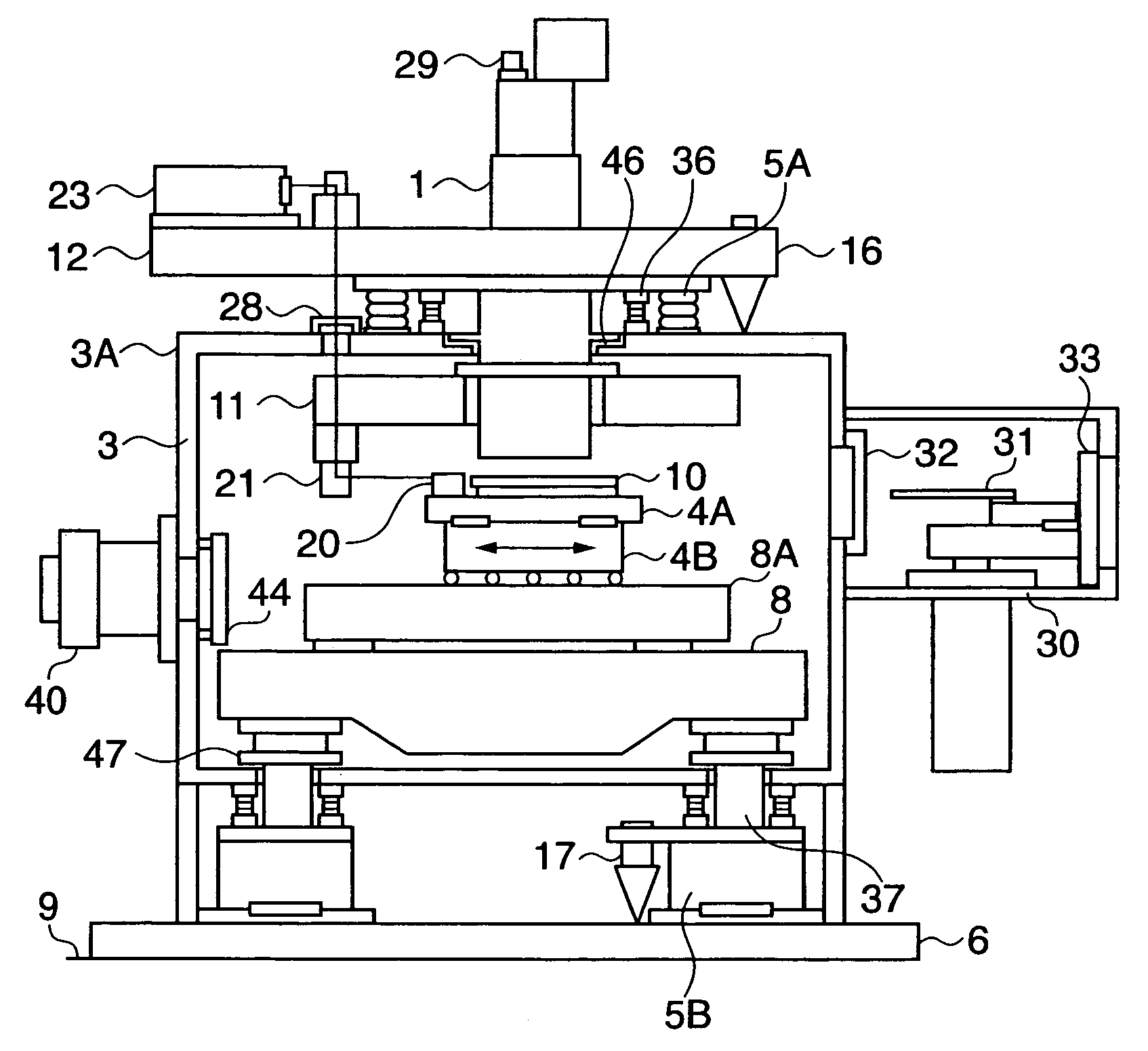

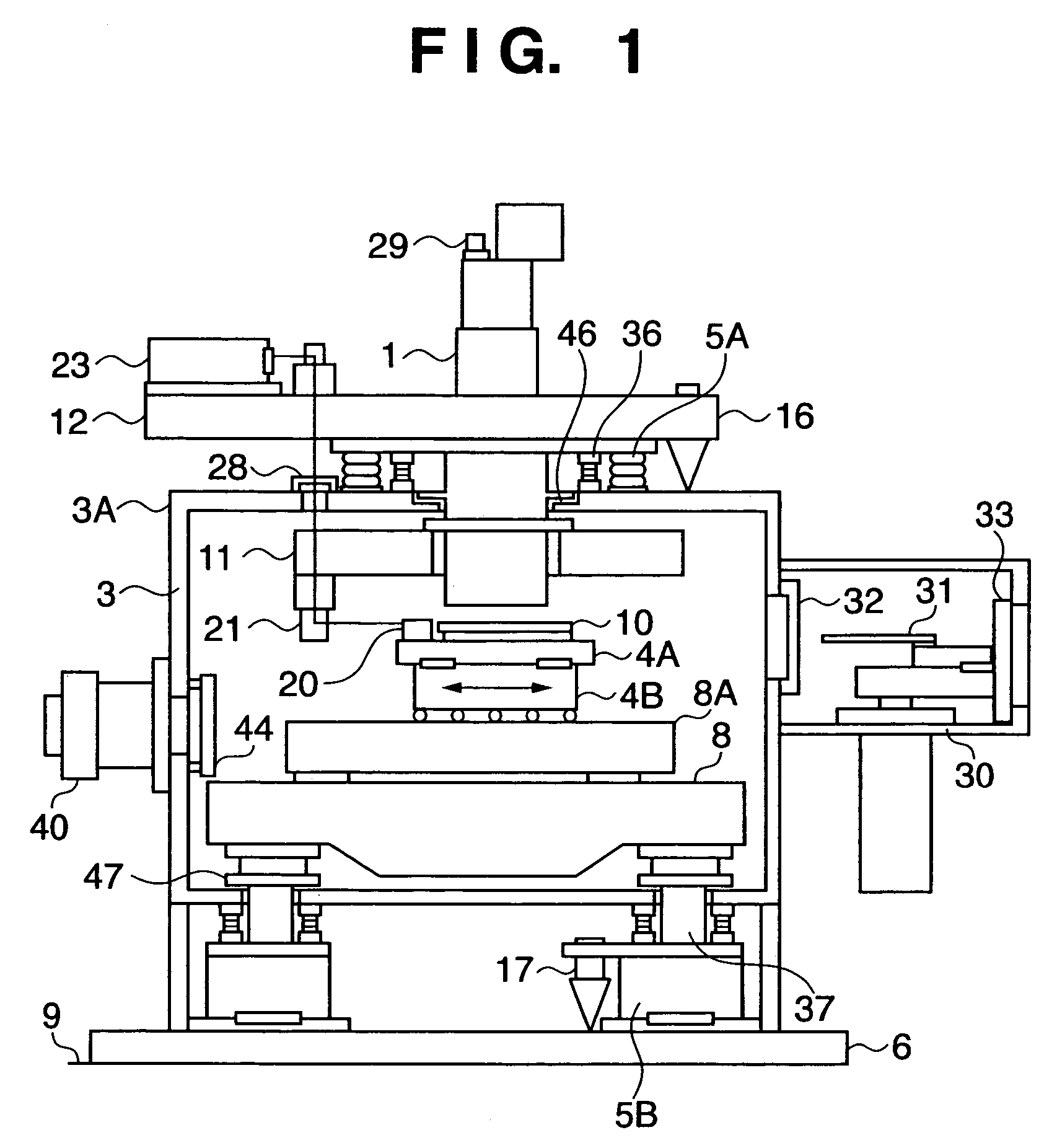

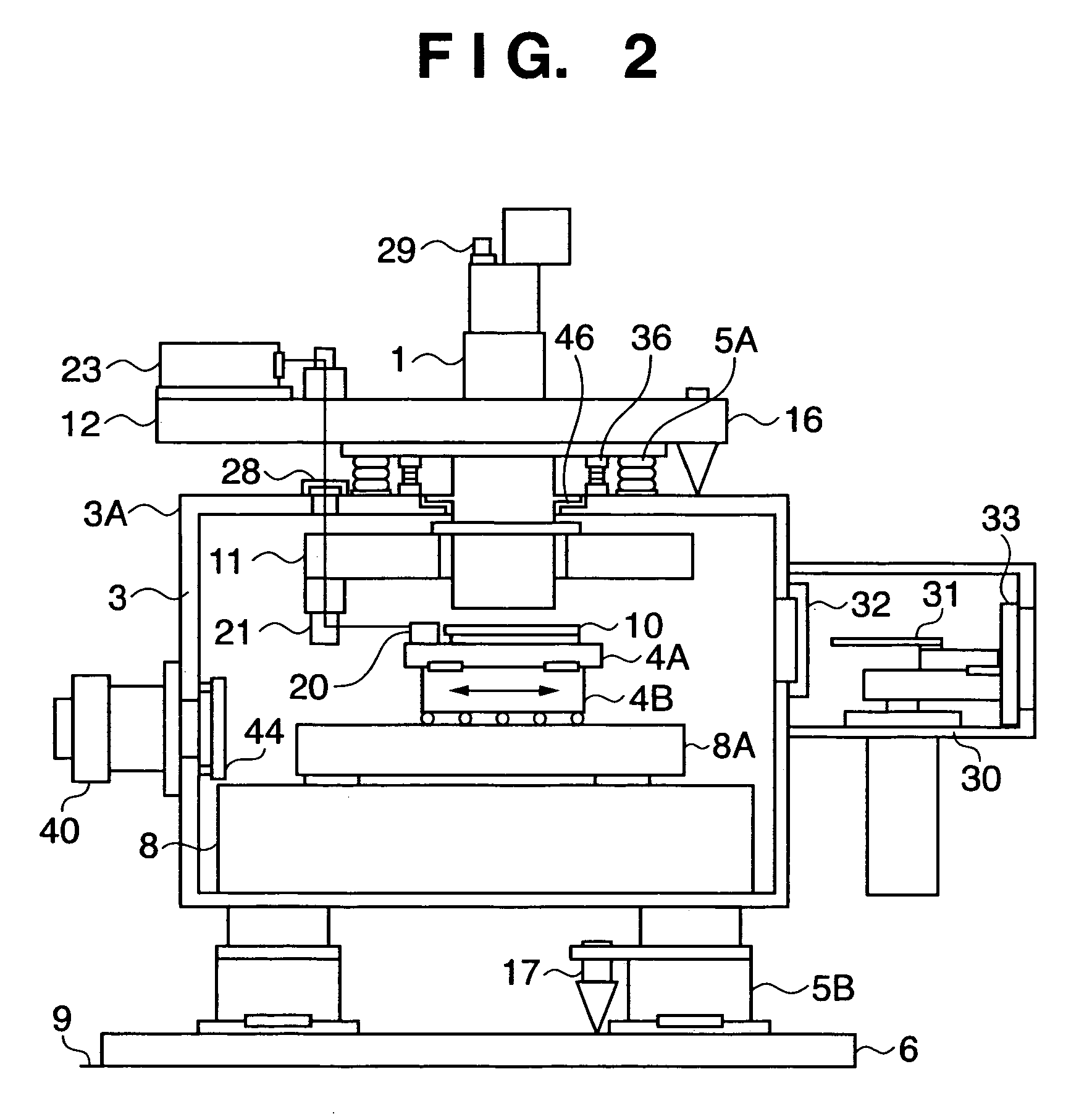

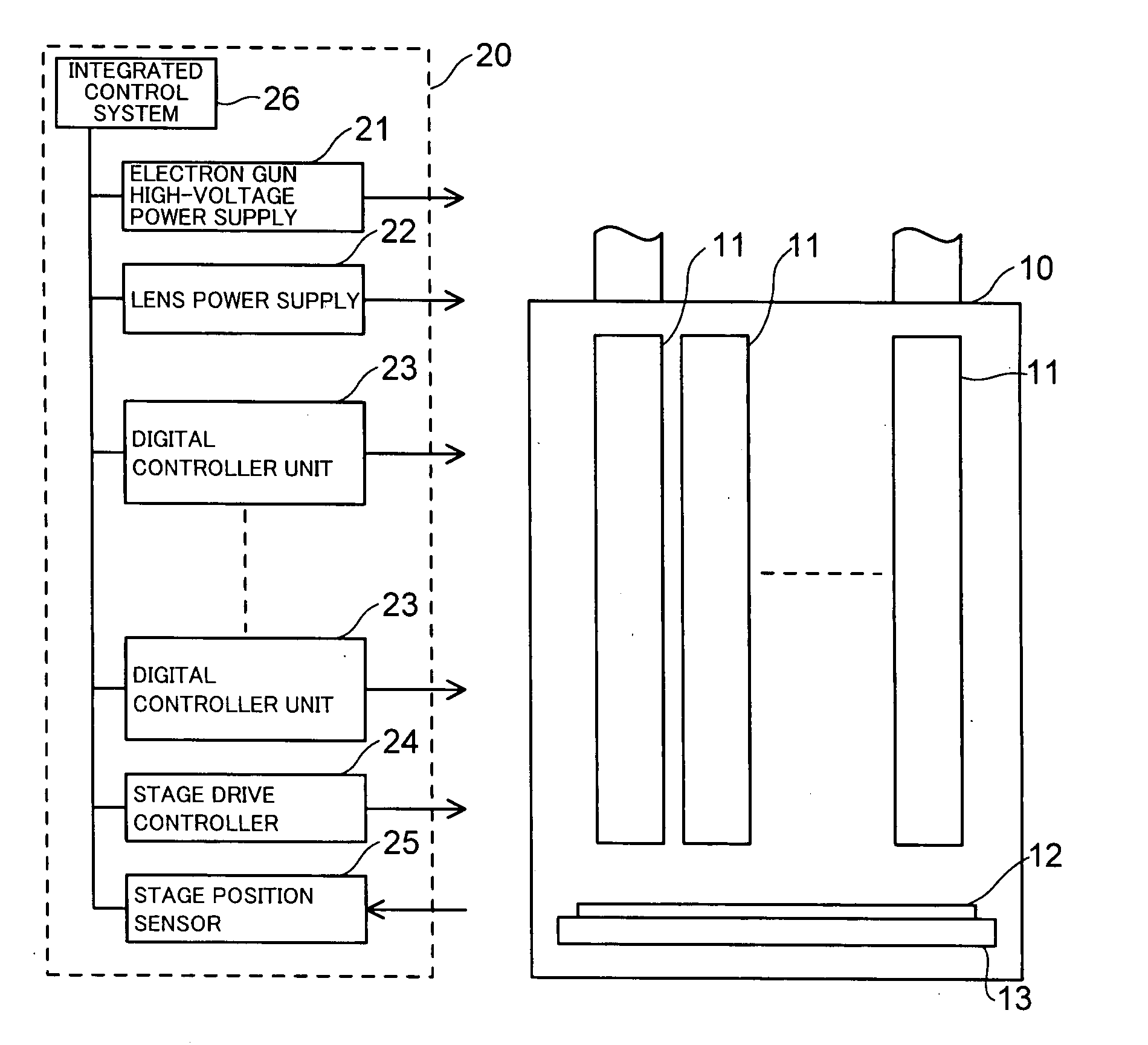

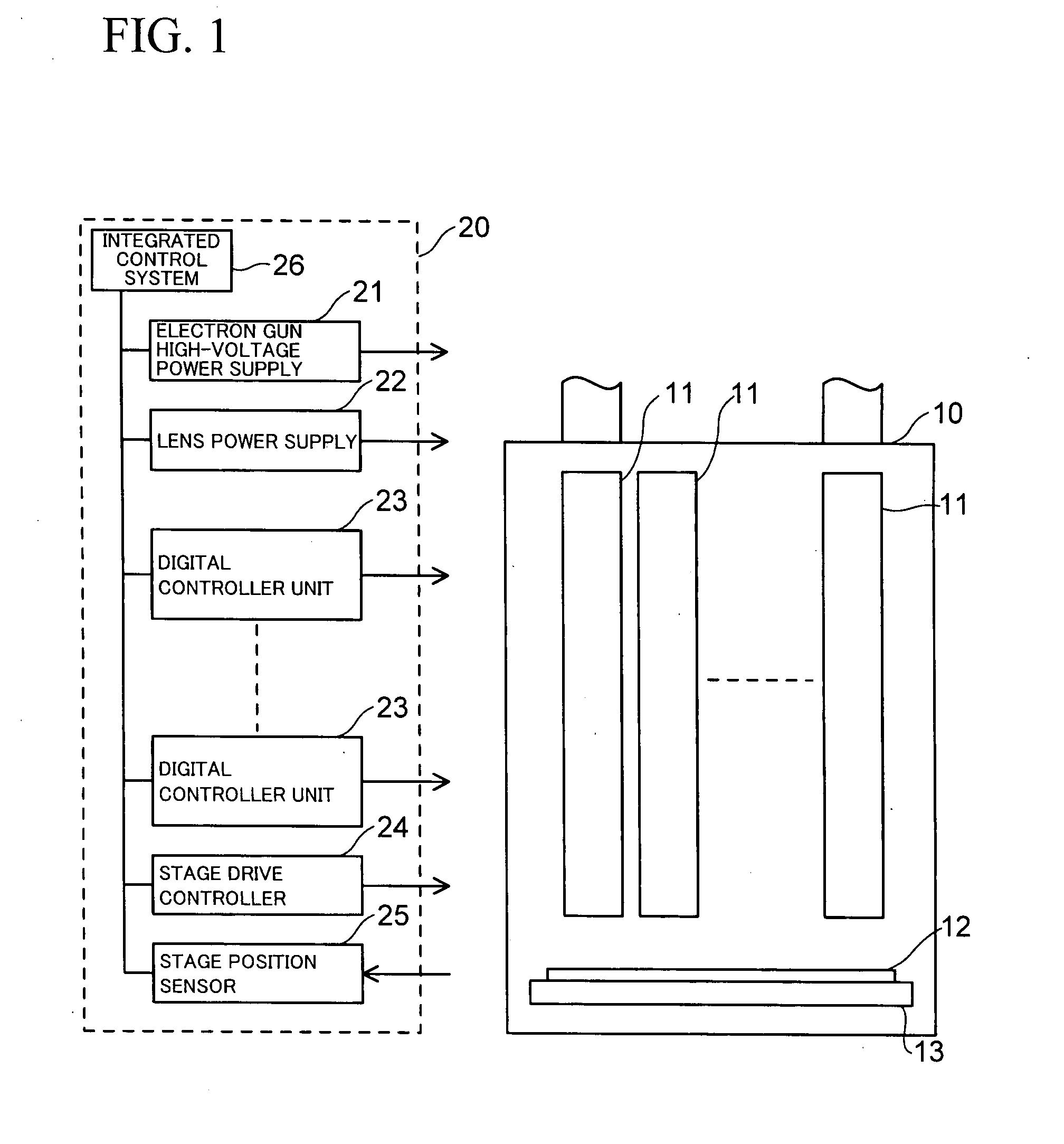

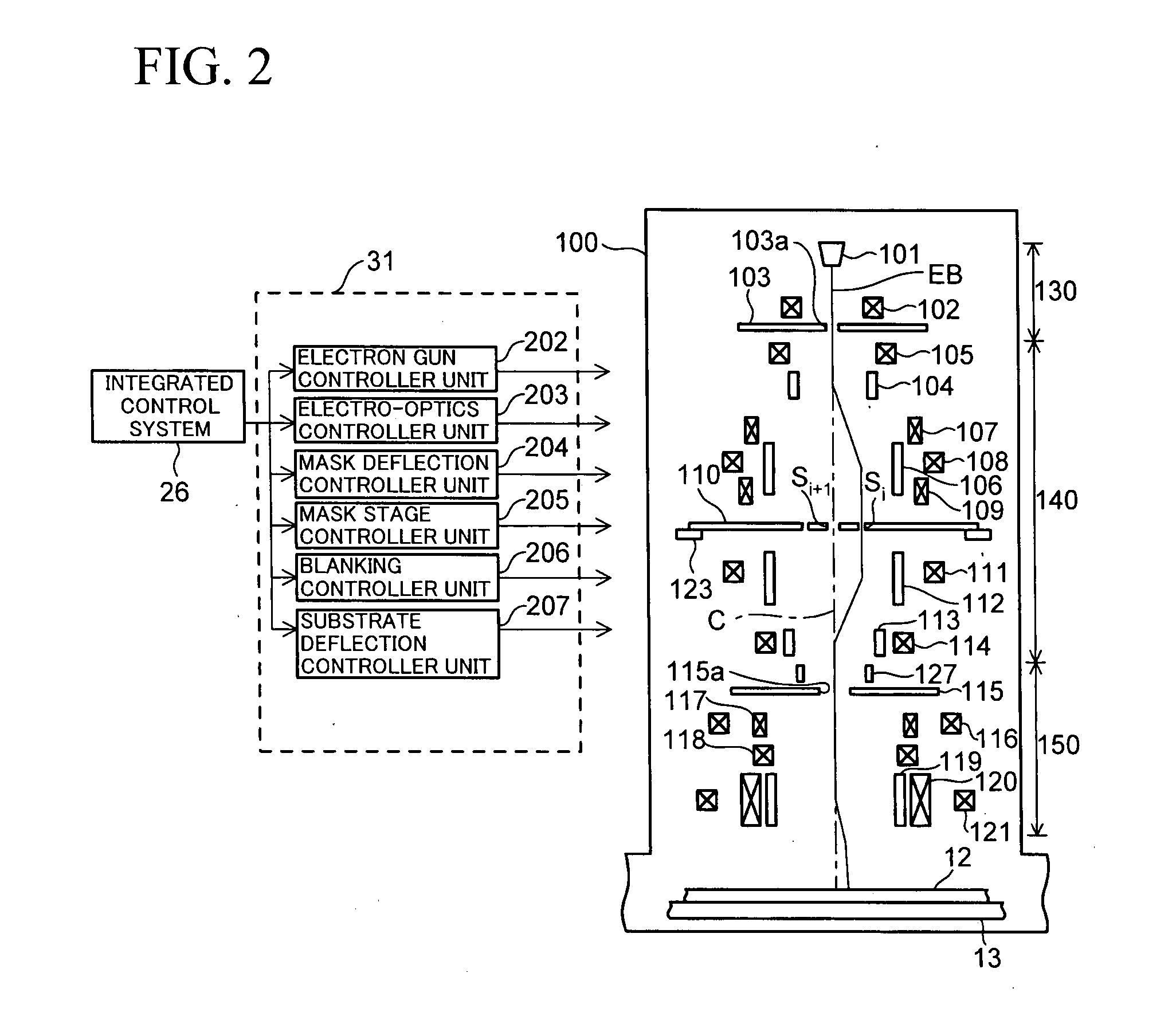

Electron beam exposure apparatus

InactiveUS7230257B2Reduce measurement errorAccurate exposureThermometer detailsStability-of-path spectrometersElectron-beam lithographyVacuum pump

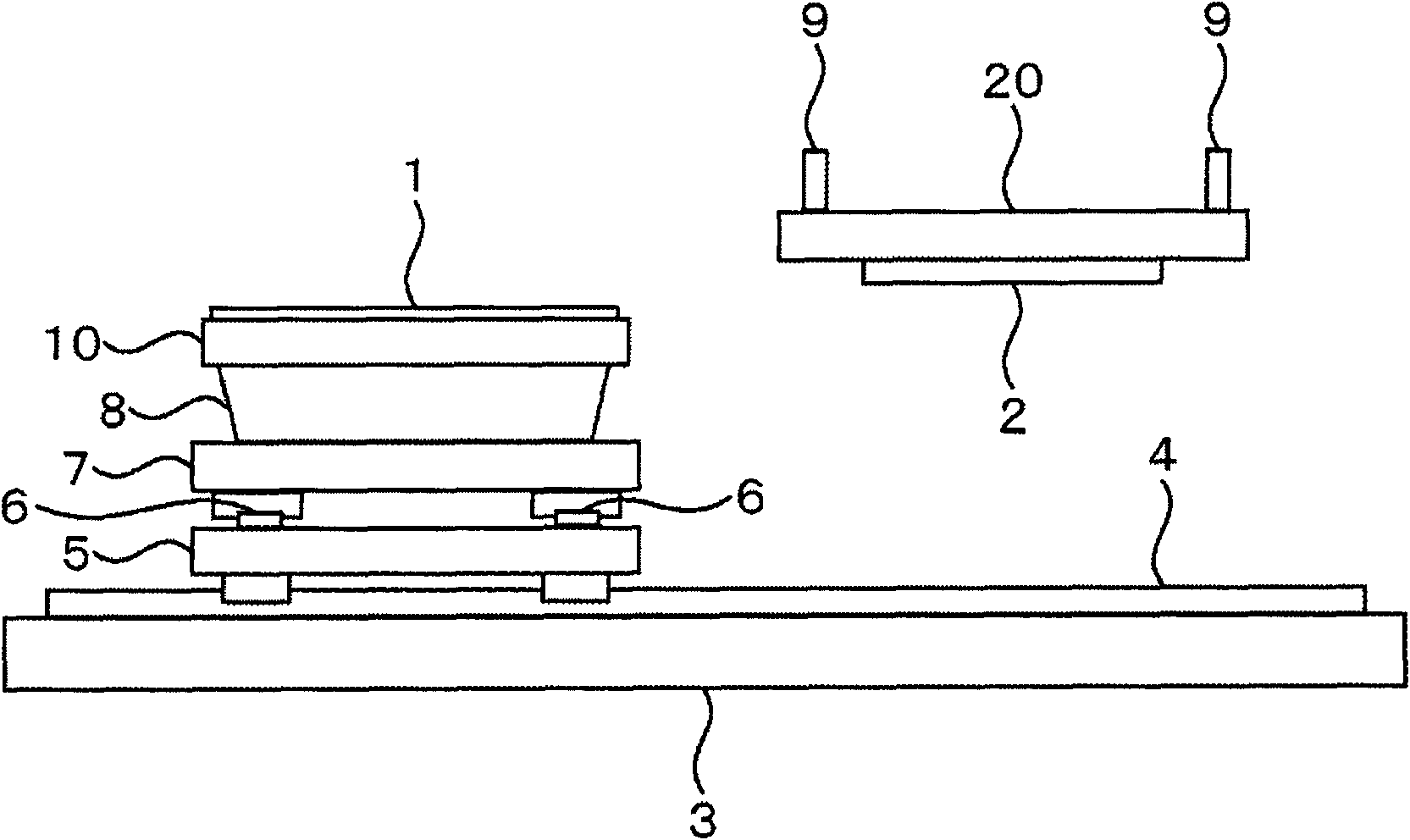

An electron beam exposure apparatus comprising: column 1 for irradiating an electron beam to wafer 10 serving as a sample; sample chamber 3 having vacuum pump 40 as a vacuum exhaustion unit for controlling the internal unit to a vacuum atmosphere; stage 4A arranged in the sample chamber 3 for holding and moving the wafer 10; and first mounting 5A for elastically supporting the column 1 with respect to the sample chamber 3.

Owner:CANON KK

Stage devices and exposure systems comprising same

InactiveUS20050189901A1Improve linearityStable positionElectric discharge tubesNanoinformaticsEngineeringLinear motor

Stage devices are disclosed that can be made small and lightweight and that produce little magnetic-field disturbance. As a result, high-precision scan positioning can be performed using them. In an exemplary configuration, a Y-slider driven by a linear motor is deployed on each of two fixed guides that extend in the Y-direction. Between the two Y-sliders are suspended two movement guides that extend in the X-direction. On the movement guide is an X-slider driven by an air cylinder. A stage projects from the X-slider. On the stage is a table driven in the O,-direction (about the Z-axis). The stage device is configured so that a continuous movement (scan) requiring precise positioning is achieved in the Y-direction by linear motors, and intermittent movement and stopping in the X-direction is achieved using an air cylinder.

Owner:NIKON CORP

Exposure method, exposure apparatus, and device manufacturing method

ActiveUS8514395B2Good precisionImprove accuracySemiconductor/solid-state device manufacturingUsing optical meansObservational errorEngineering

Within area where of four heads installed on a wafer stage, heads included in the first head group and the second head group to which three heads each belong that include one head different from each other face the corresponding areas on a scale plate, the wafer stage is driven based on positional information which is obtained using the first head group, as well as obtain the displacement (displacement of position, rotation, and scaling) between the first and second reference coordinate systems corresponding to the first and second head groups using the positional information obtained using the first and second head groups. By using the results and correcting measurement results obtained using the second head group, the displacement between the first and second reference coordinate systems is calibrated, which allows the measurement errors that come with the displacement between areas on scale plates where each of the four heads face.

Owner:NIKON CORP

Multi-column type electron beam exposure apparatus

InactiveUS20080049204A1Keep for a long timeData being receivedElectric discharge tubesNanoinformaticsPhysicsData conversion

A multi-column type electron beam exposure apparatus includes: plural column cells disposed over a wafer, each including an electron gun, deflector for deflecting an electron beam emitted by the electron gun, and exposure data receiving unit for receiving exposure data; and correction computing unit for calculating the exposure data for use in the column cells. The correction computing unit includes exposure data controlling unit and exposure data transmitting unit for each of the column cells. The exposure data transmitting unit encodes the exposure data corrected by the exposure data controlling unit to convert the data into serial data, converts the serial data into a light signal, and transmits the light signal. The exposure data receiving unit converts the light signal into an electric signal, and decodes the encoded exposure data to convert the data into parallel data.

Owner:ADVANTEST CORP

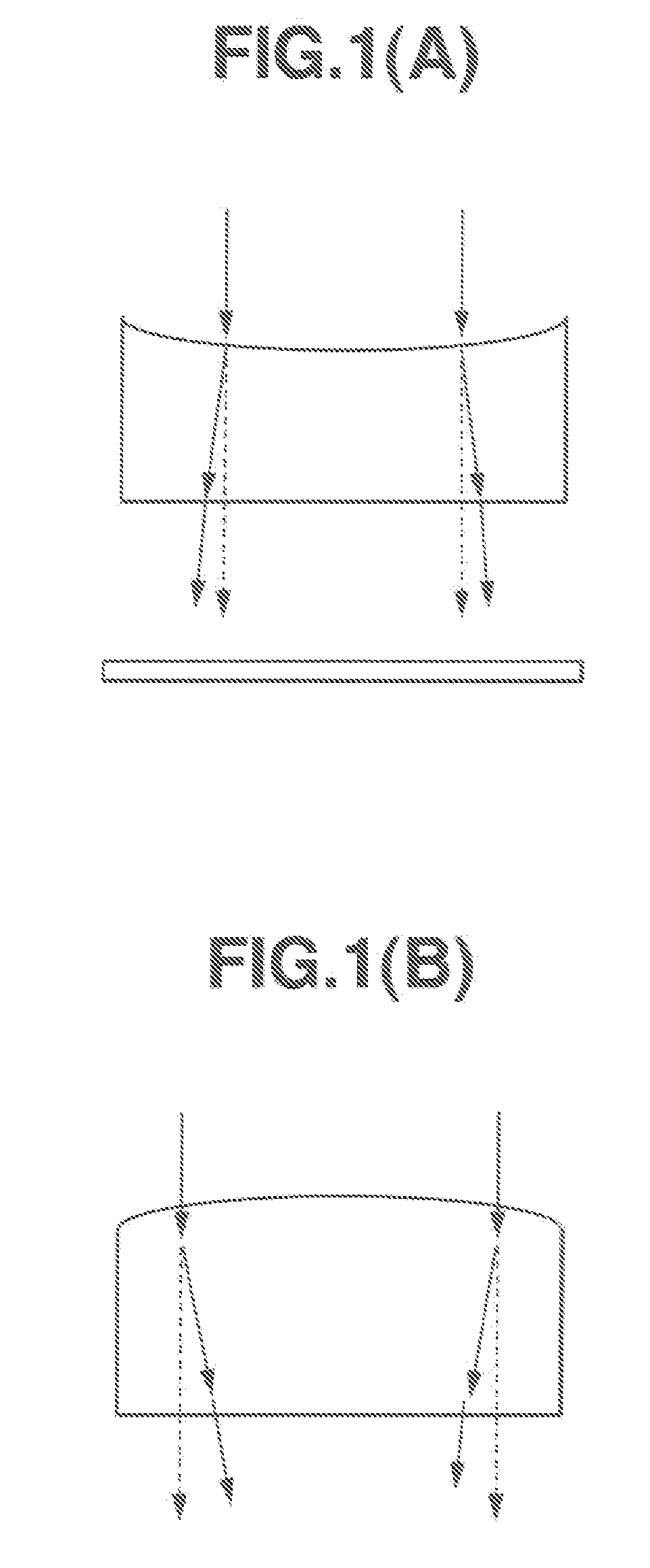

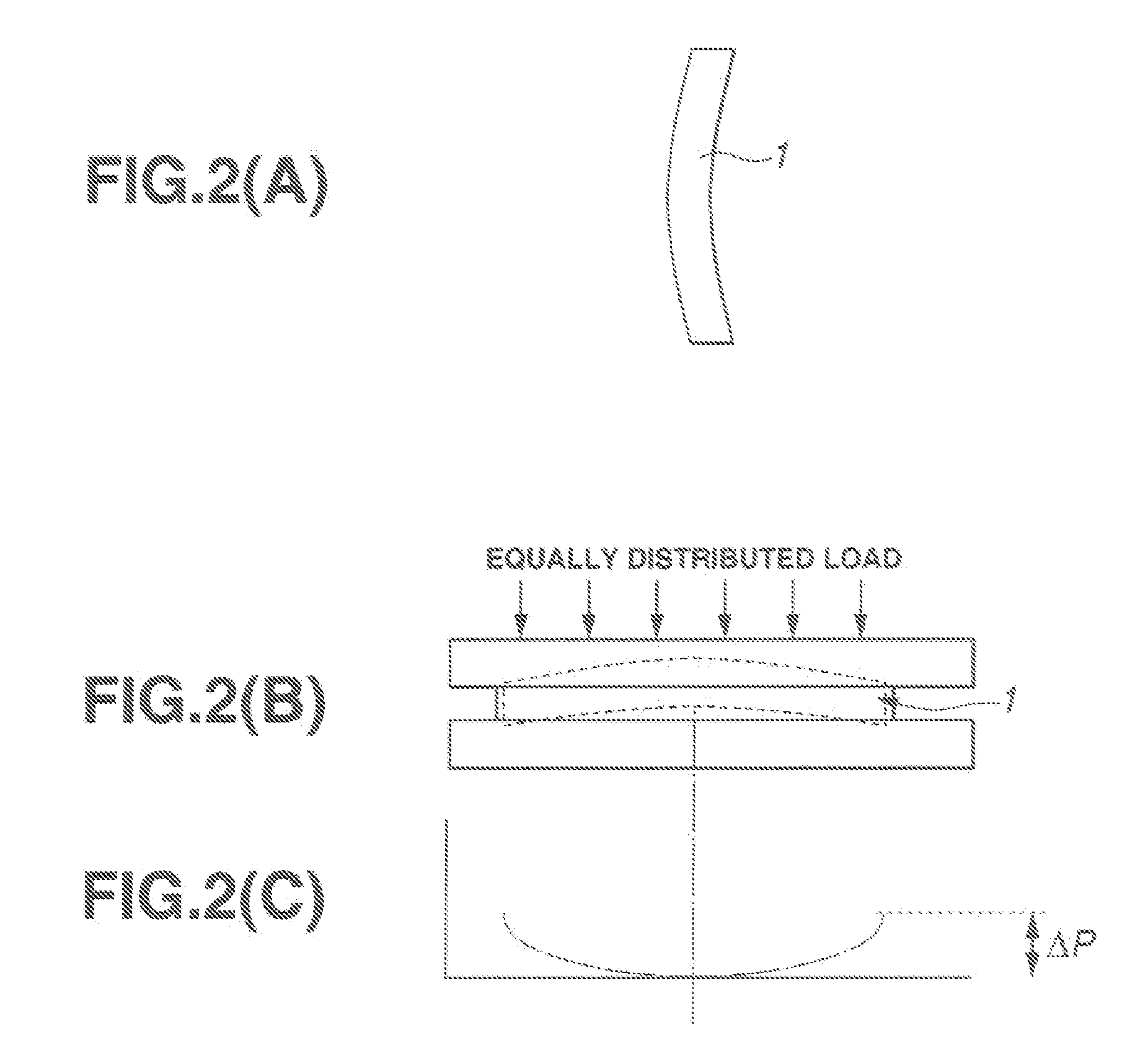

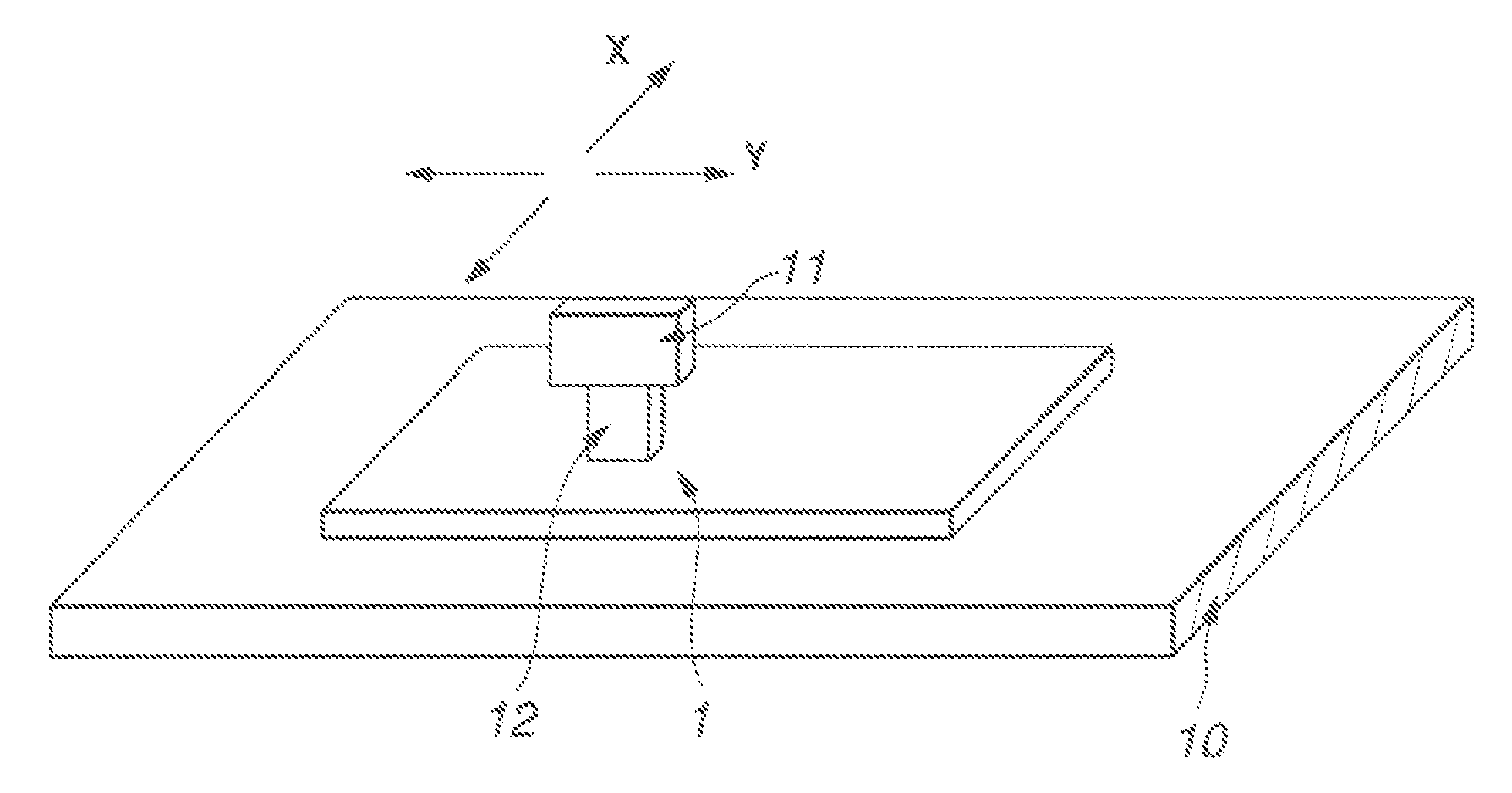

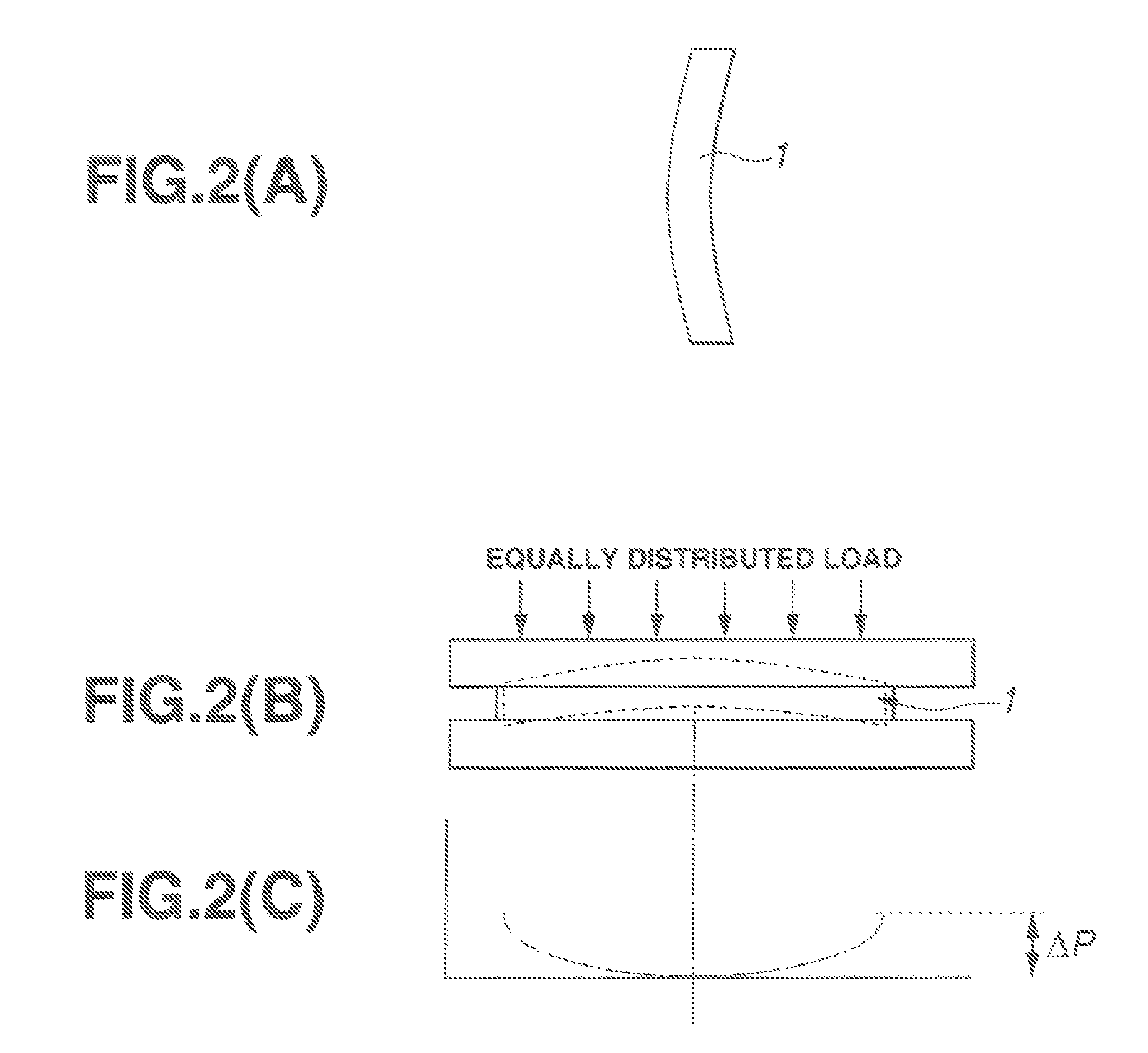

Large-sized substrate and method of producing the same

ActiveUS20070132068A1Improve flatnessEnhance flatness and parallelnessSemiconductor/solid-state device detailsSolid-state devicesImage resolutionDiagonal

A large-sized substrate having a diagonal length of not less than 500 mm and a ratio of flatness / diagonal length of not more than 6×10−6 is disclosed. By use of the large-sized substrate for exposure of the present invention, the exposure accuracy, particularly the register accuracy and resolution are enhanced, so that it is possible to achieve high-precision exposure of a large-sized panel. With the processing method according to the present invention, it is possible to stably obtain a large-sized photomask substrate with a high flatness, and since the CD accuracy (dimensional accuracy) at the time of exposure of the panel is enhanced, it is possible to perform exposure of a fine pattern, leading to a higher yield of the panel. Furthermore, by applying the processing method according to the present invention, it is also possible to create an arbitrary surface shape.

Owner:SHIN ETSU CHEM IND CO LTD

Detection device, movable body apparatus, pattern formation apparatus and pattern formation method, exposure apparatus and exposure method, and device manufacturing method

ActiveUS8098362B2Improve accuracyHigh-precision exposurePhotomechanical apparatusUsing optical meansForeign matterMovement control

By irradiating a detection beam from an irradiation system of a detection device to a scale used for measuring the position of a wafer stage, and detecting the detection beam via the scale by a photodetection system, a surface state (an existence state of foreign substance) of the scale is detected. With this operation, detection of the surface state can be performed contactlessly with respect to the scale. Moreover, movement control of the wafer stage can be performed with high precision by taking the surface state into consideration.

Owner:NIKON CORP

Linewidth measuring method, image-forming-state detecting method, adjustment method, exposure method, and device manufacturing method

InactiveUS20090233195A1Low costImprove throughputElectric discharge tubesMaterial analysis by optical meansImage resolutionLine width

A pattern area that includes a plurality of line patterns with a predetermined spacing therebetween formed on a wafer is imaged, and based on the imaging results, a contrast value of an image of the pattern area is computed, and the computed contrast value is converted into the linewidth of the line pattern based on known conversion information. Therefore, even if the pattern area is imaged using a microscope having a low resolving power, e.g. an image-forming type alignment sensor or the like, without using the SEM, the linewidth of the line pattern can be measured with high precision. Accordingly, linewidth measurement with low cost and high throughput becomes possible.

Owner:NIKON CORP

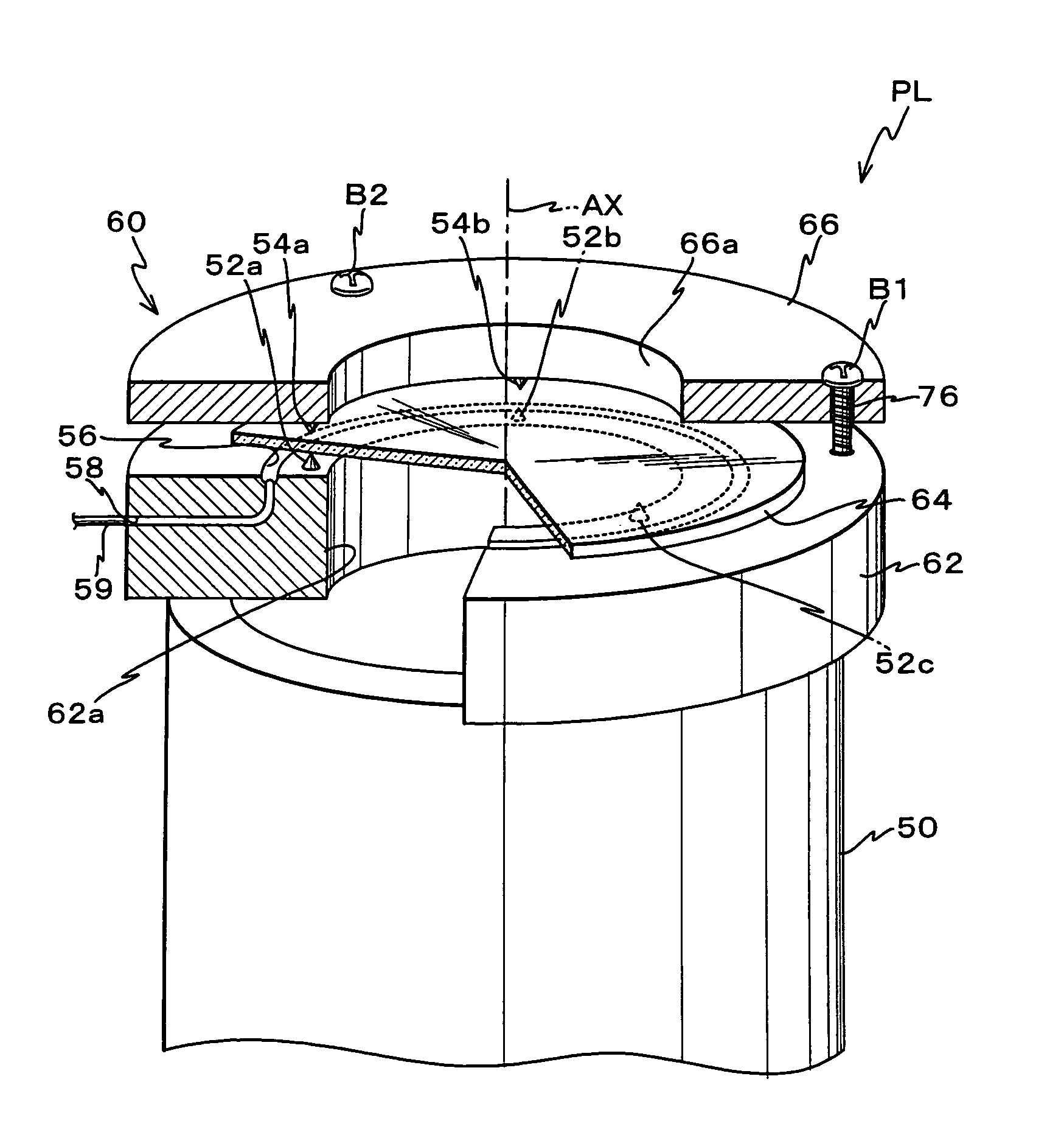

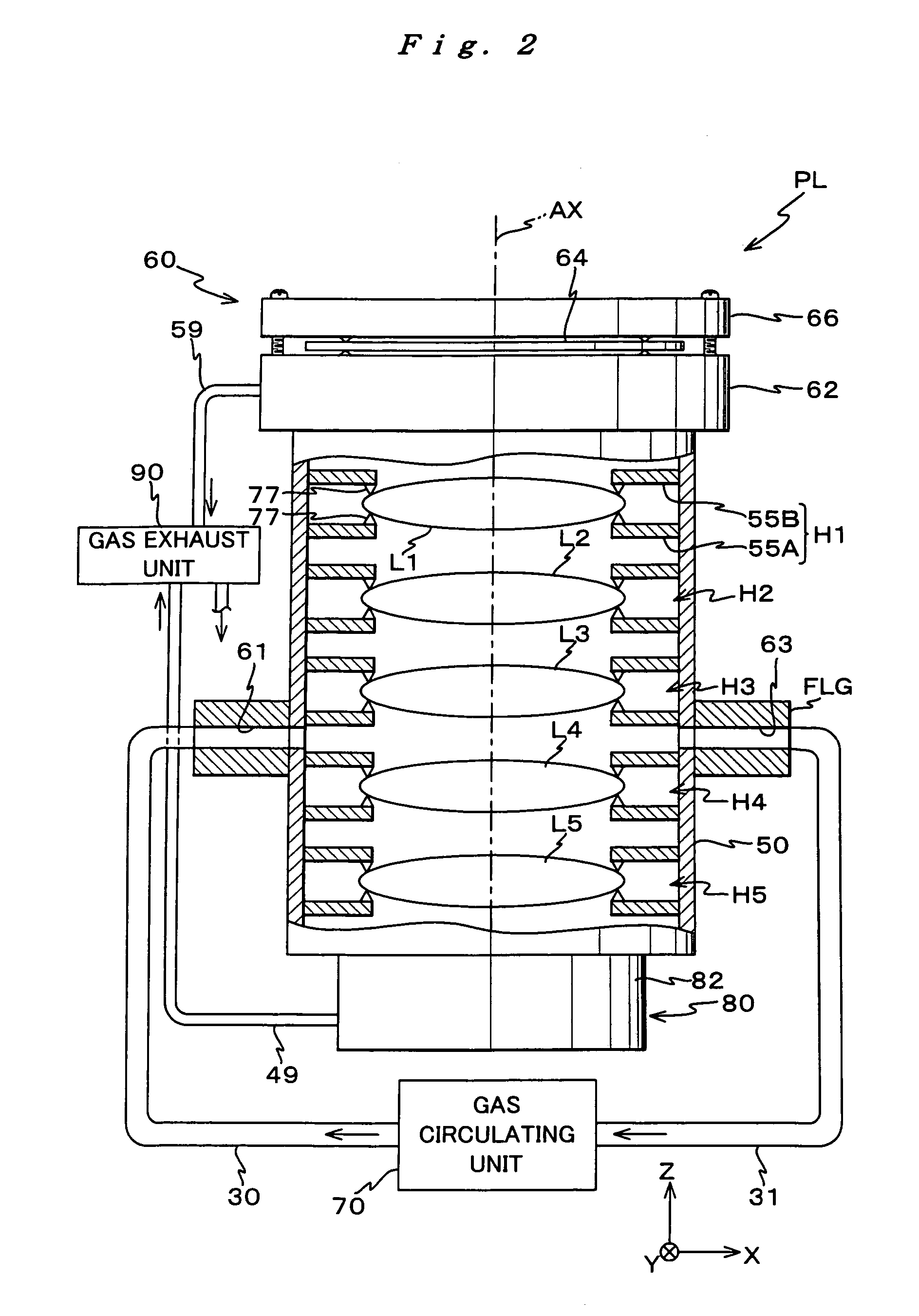

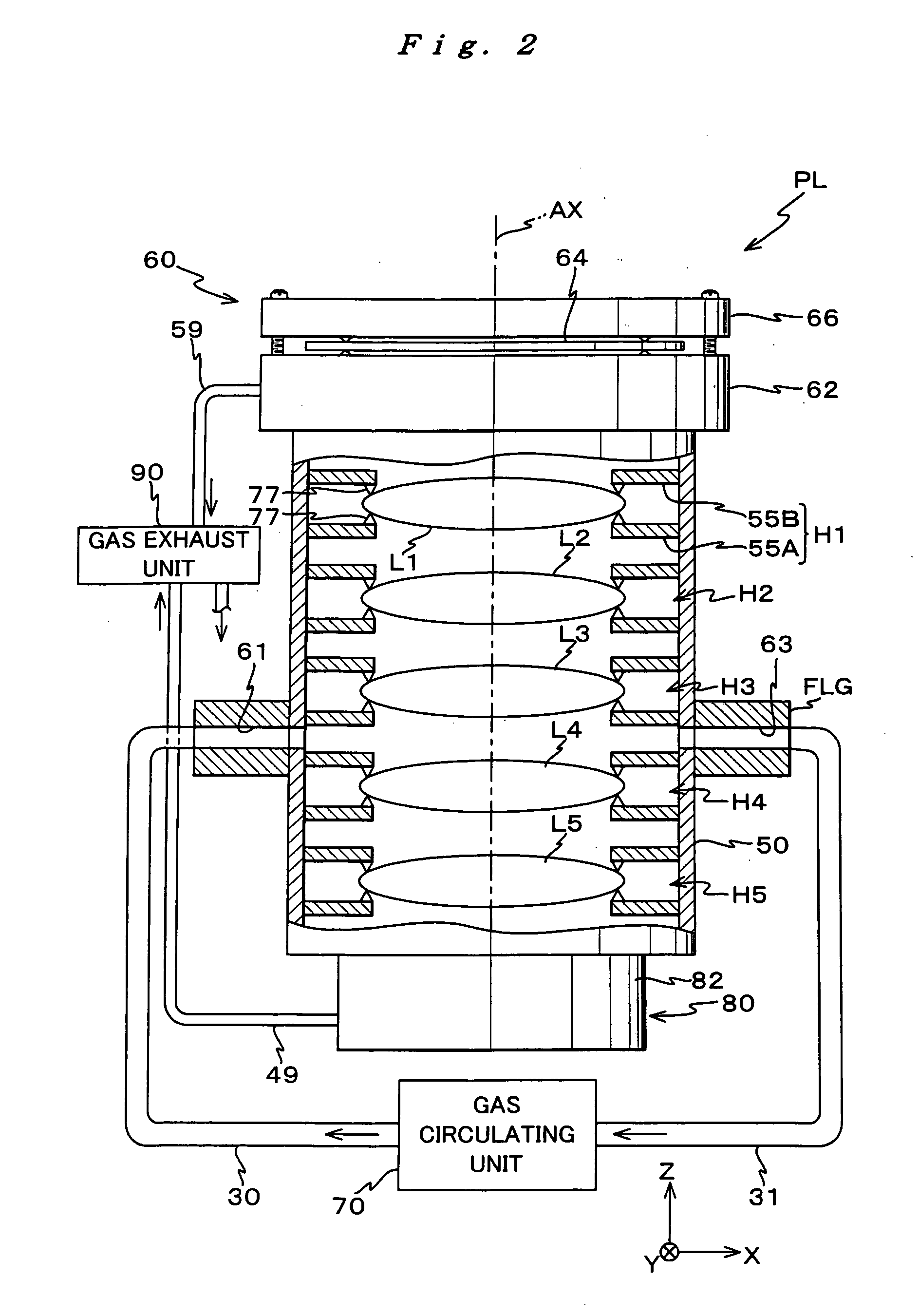

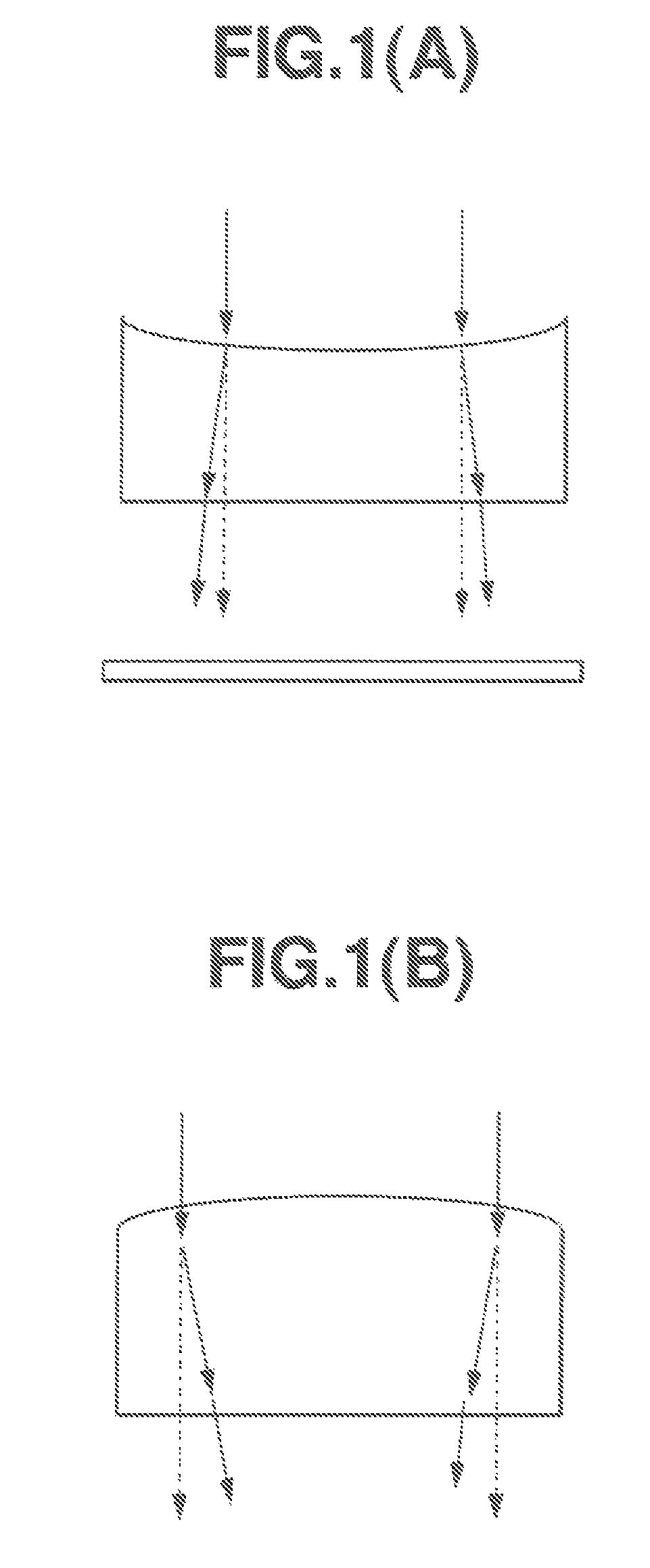

Optical unit, exposure apparatus, and device manufacturing method

InactiveUS7050148B2Improve accuracyHigh-precision exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusParallel plateRefractive index

In a barrel of an optical unit a ring shaped support member is integrally arranged, and three projected portions are arranged on the upper surface of the support member. The projected portions support a lower surface of a parallel flat plate supported in direct contact. In this supported state, the parallel flat plate opposes a surface of the support member with a clearance of several μm in between. With this arrangement, the space in one side of the parallel flat plate is substantially isolated from the space in the other side. Accordingly, for example, even if gas environment in the space on one side of the parallel flat plate is different from the other side, gases can be effectively kept from mixing. In addition, since the parallel flat plate is supported at three coplanar points, deformation of the parallel flat plate can be suppressed due to the force supporting the parallel flat plate, thereby suppressing the index of refraction from varying.

Owner:NIKON CORP

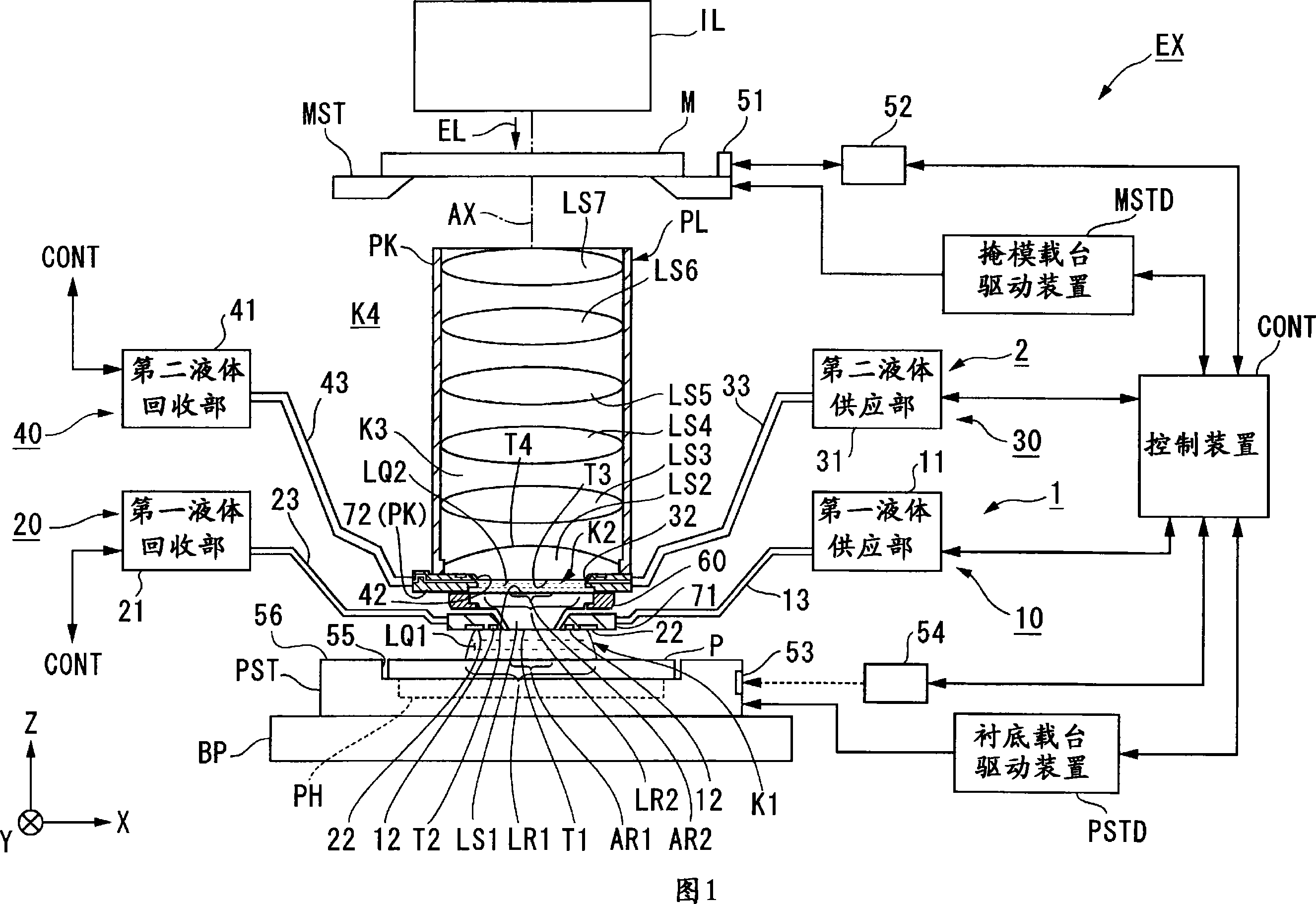

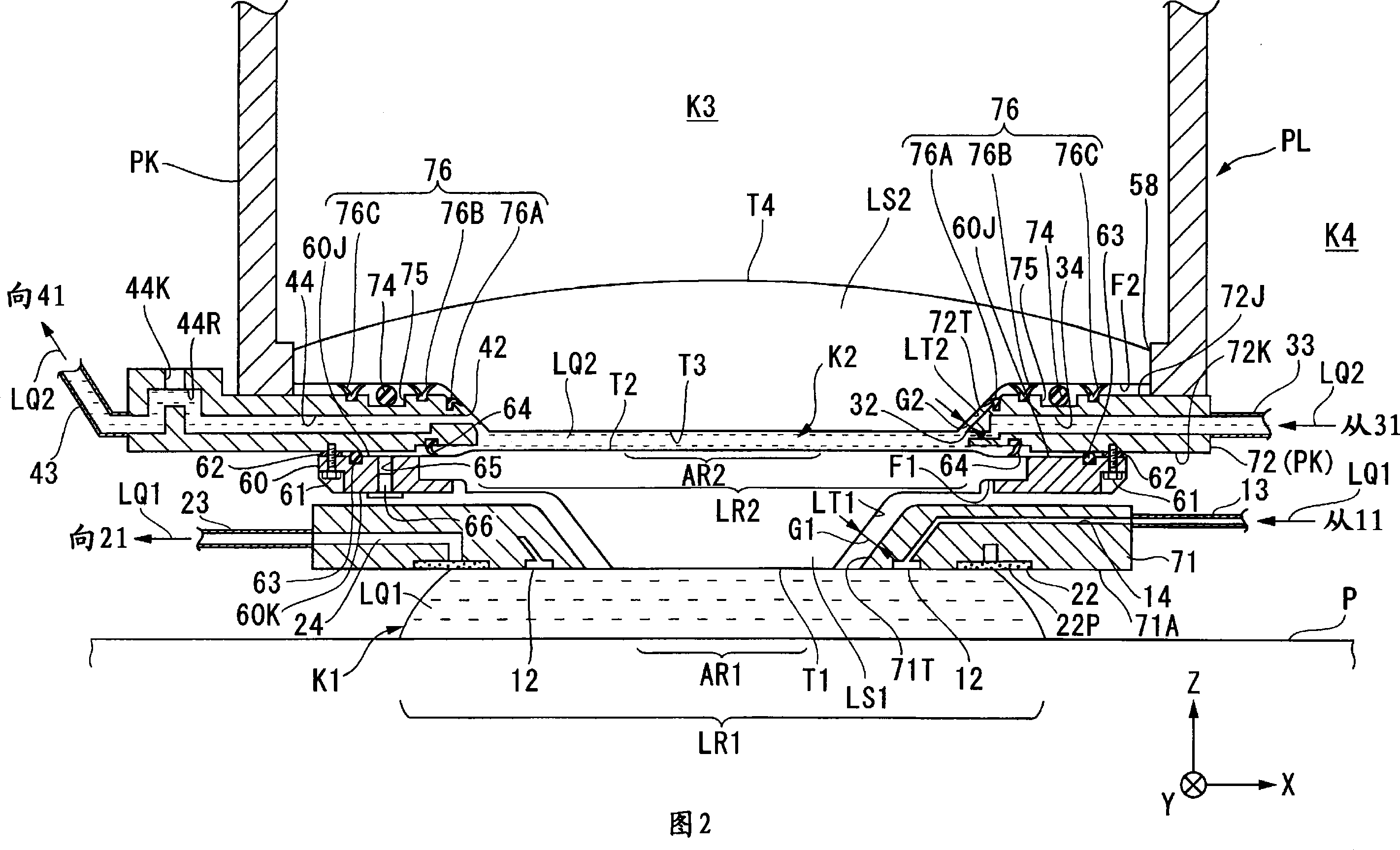

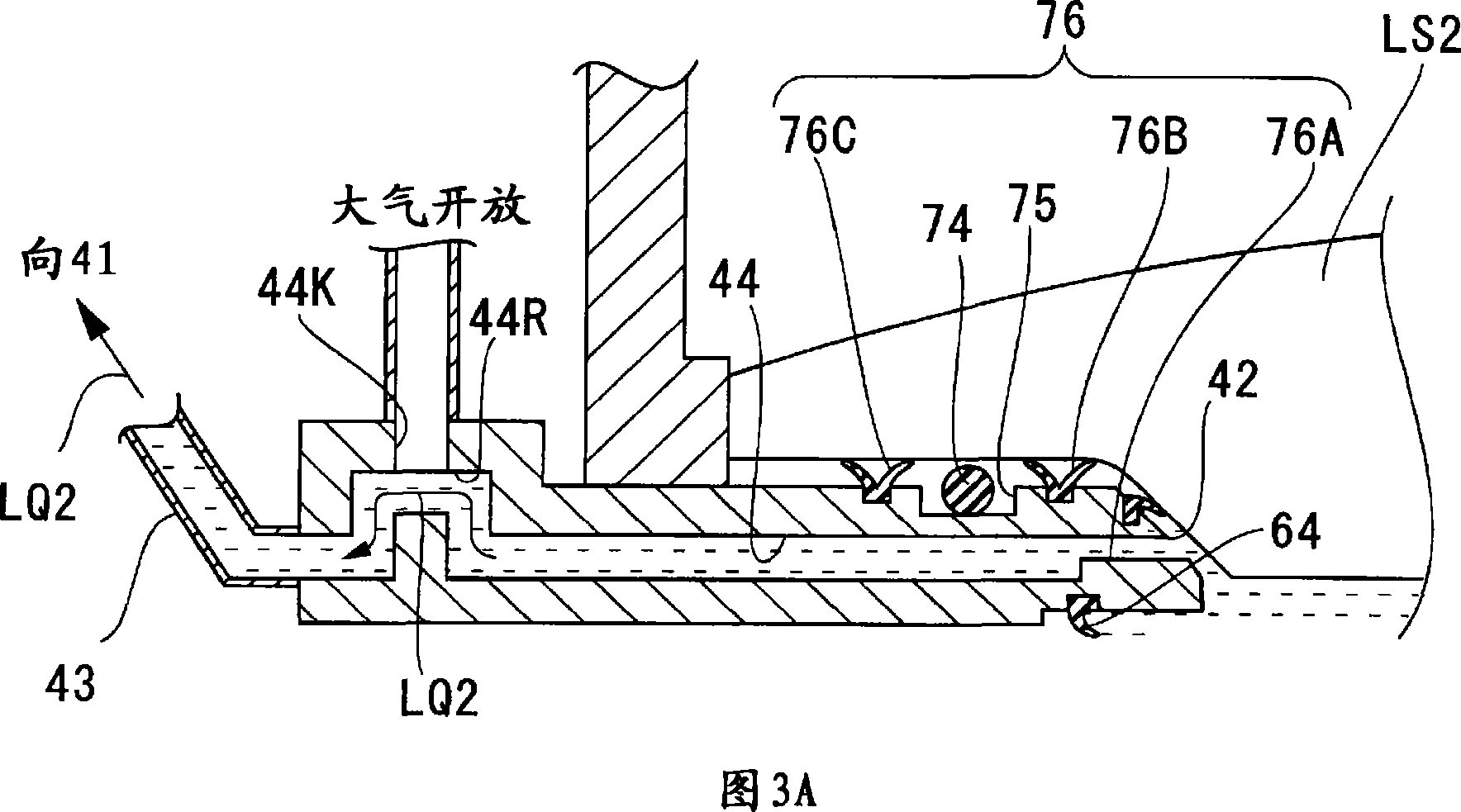

Exposure device and device manufacturing method

InactiveCN101069266APrevents deterioration of exposure accuracyHigh precision exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImage plane

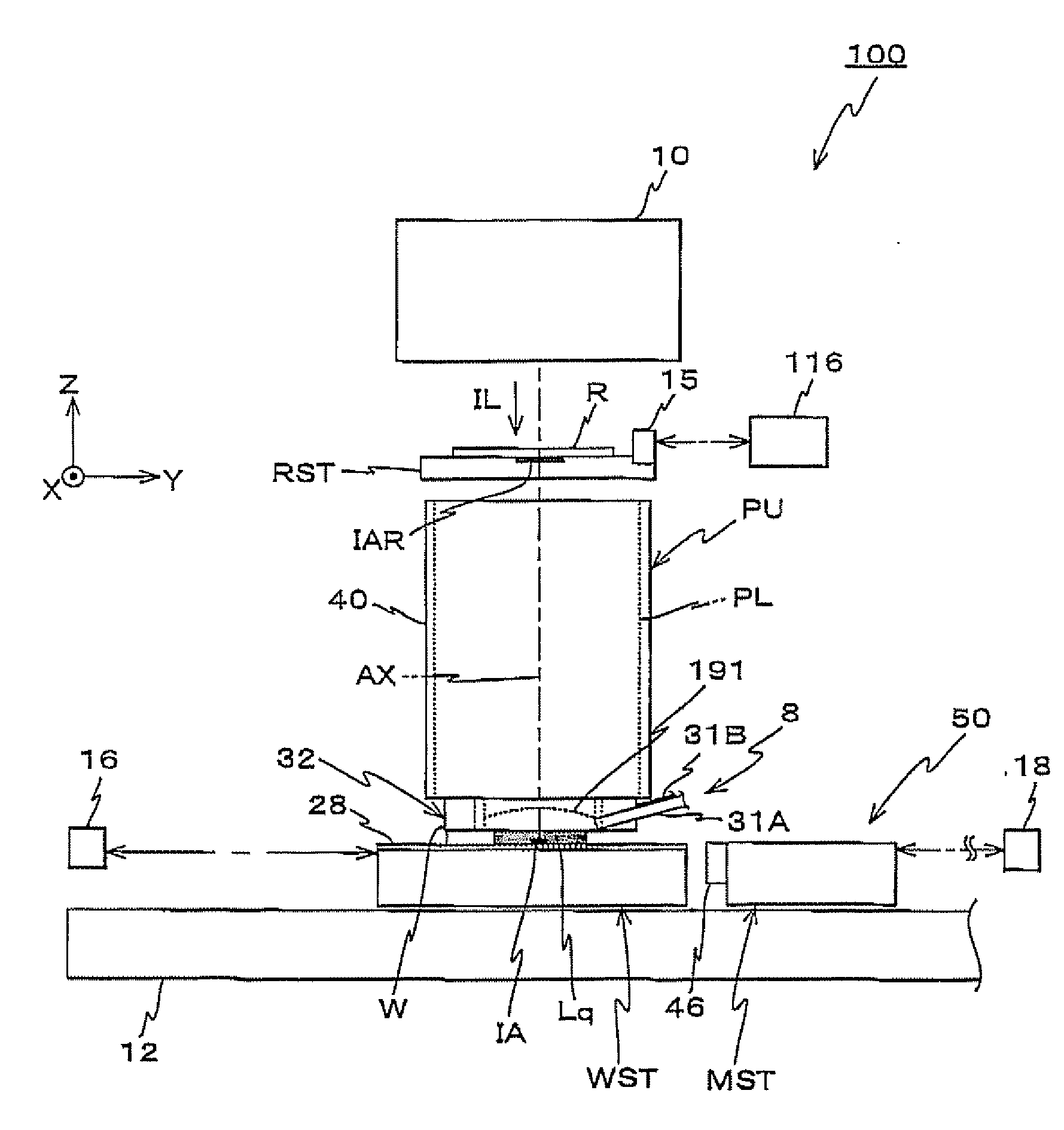

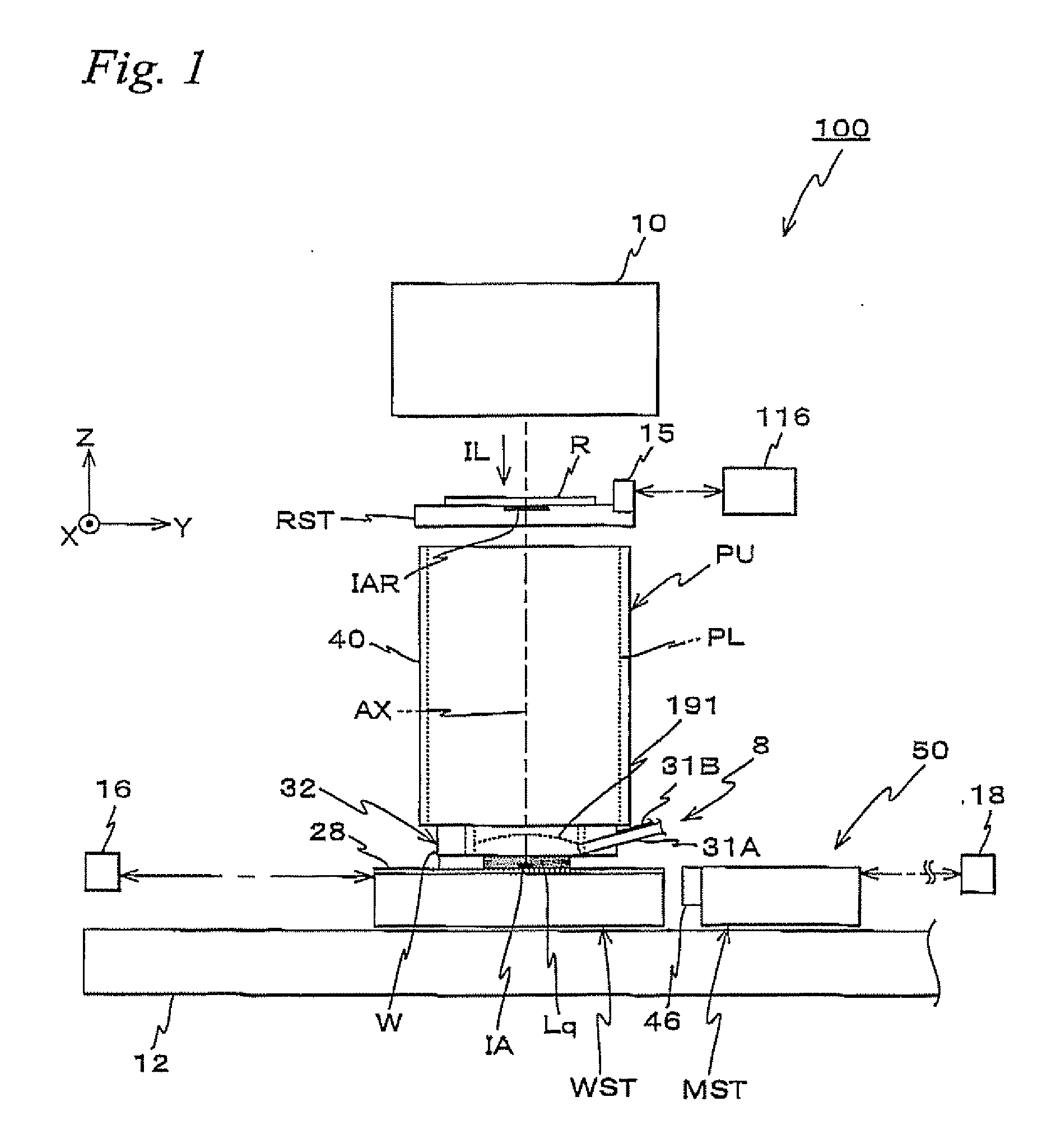

The invention provides an exposure device which applies an exposure light to a substrate (P) via a projection optical system (PL) so as to expose the substrate (P). The projection optical system (PL) includes a first optical element (LS1) nearest to the image plane of the projection optical system (PL) and a second optical element (LS2) arranged near to the image plane next to the first optical element (LS1). The exposure device further includes a second collection opening (42) arranged at a position higher than a lower surface (T3) of the second optical element (LS2) for collecting second liquid (LQ2) contained in a second space (K2) between an upper surface (T2) of the first optical element (LS1) and the lower surface (T3) of the second optical element (LS2).

Owner:NIKON CORP

Reflection type mask

InactiveUS7072438B2Reduce possibilityHigh-precision exposureNanoinformaticsSolid-state devicesSoft x rayOptoelectronics

Owner:CANON KK

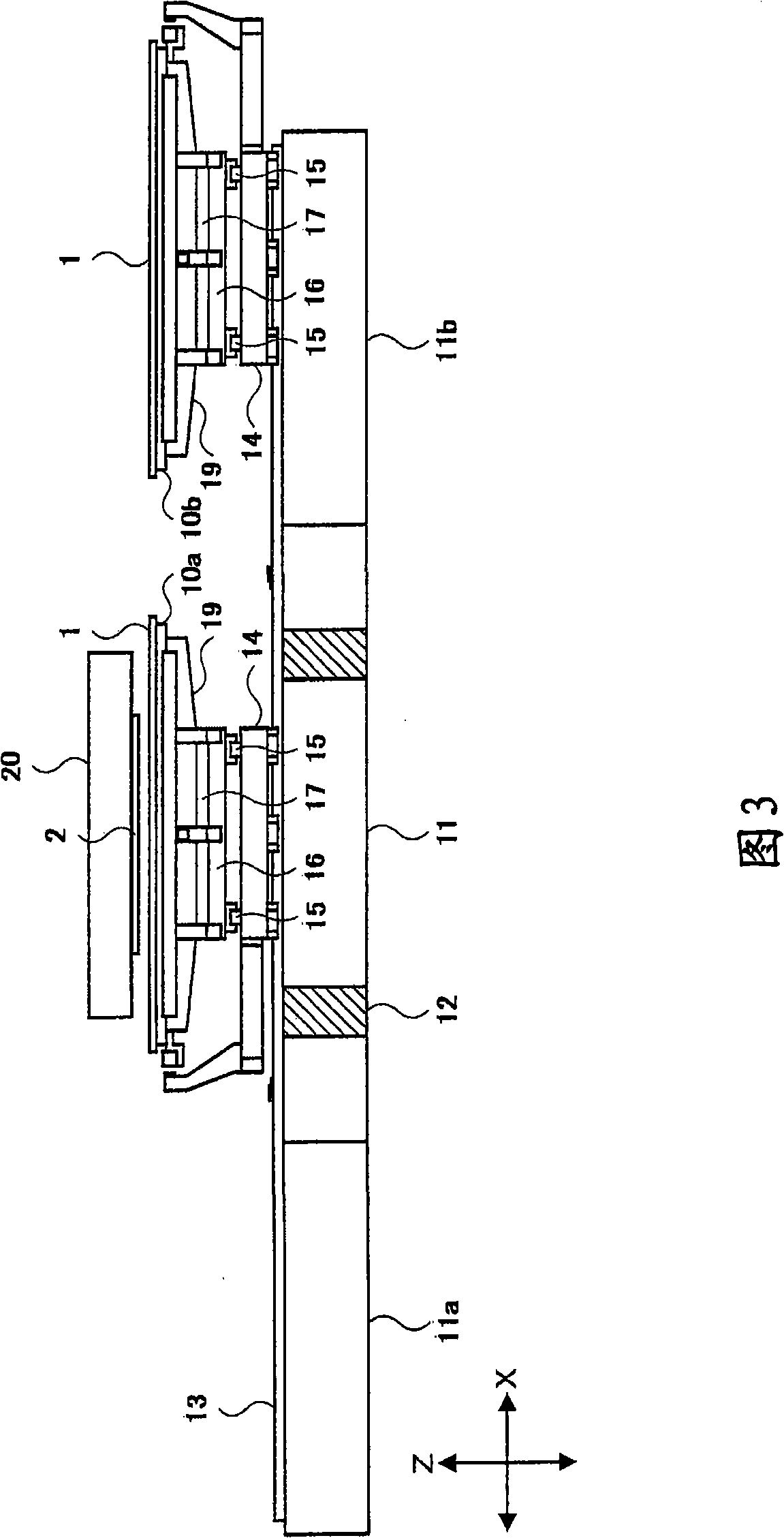

Exposure apparatus, movable body apparatus, flat-panel display manufacturing method, and device manufacturing method

In a substrate stage, when a Y coarse movement stage moves in the Y-axis direction, an X coarse movement stage, a weight cancellation device, and an X guide move integrally in the Y-axis direction with the Y coarse movement stage, and when the X coarse movement stage moves in the X-axis direction on the Y coarse movement stage, the weight cancellation device moves on the X guide in the X-axis direction integrally with the X coarse movement stage. Because the X guide is provided extending in the X-axis direction while covering the movement range of the weight cancellation device in the X-axis direction, the weight cancellation device is constantly supported by the X guide, regardless of its position. Accordingly, a substrate can be guided along the XY plane with good accuracy, even if a member (for example, a surface plate and the like) that has a guide surface large enough to cover the total movement range of the weight cancellation device is not provided.

Owner:NIKON CORP

Optical unit, exposure apparatus, and device manufacturing method

InactiveUS20050068512A1Improve accuracyImprove productivitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRefractive indexEngineering

In a barrel of an optical unit a ring shaped support member is integrally arranged, and three projected portions are arranged on the upper surface of the support member. The projected portions support a lower surface of a parallel flat plate supported in direct contact. In this supported state, the parallel flat plate opposes a surface of the support member with a clearance of several μm in between. With this arrangement, the space in one side of the parallel flat plate is substantially isolated from the space in the other side. Accordingly, for example, even if gas environment in the space on one side of the parallel flat plate is different from the other side, gases can be effectively kept from mixing. In addition, since the parallel flat plate is supported at three coplanar points, deformation of the parallel flat plate can be suppressed due to the force supporting the parallel flat plate, thereby suppressing the index of refraction from varying.

Owner:NIKON CORP

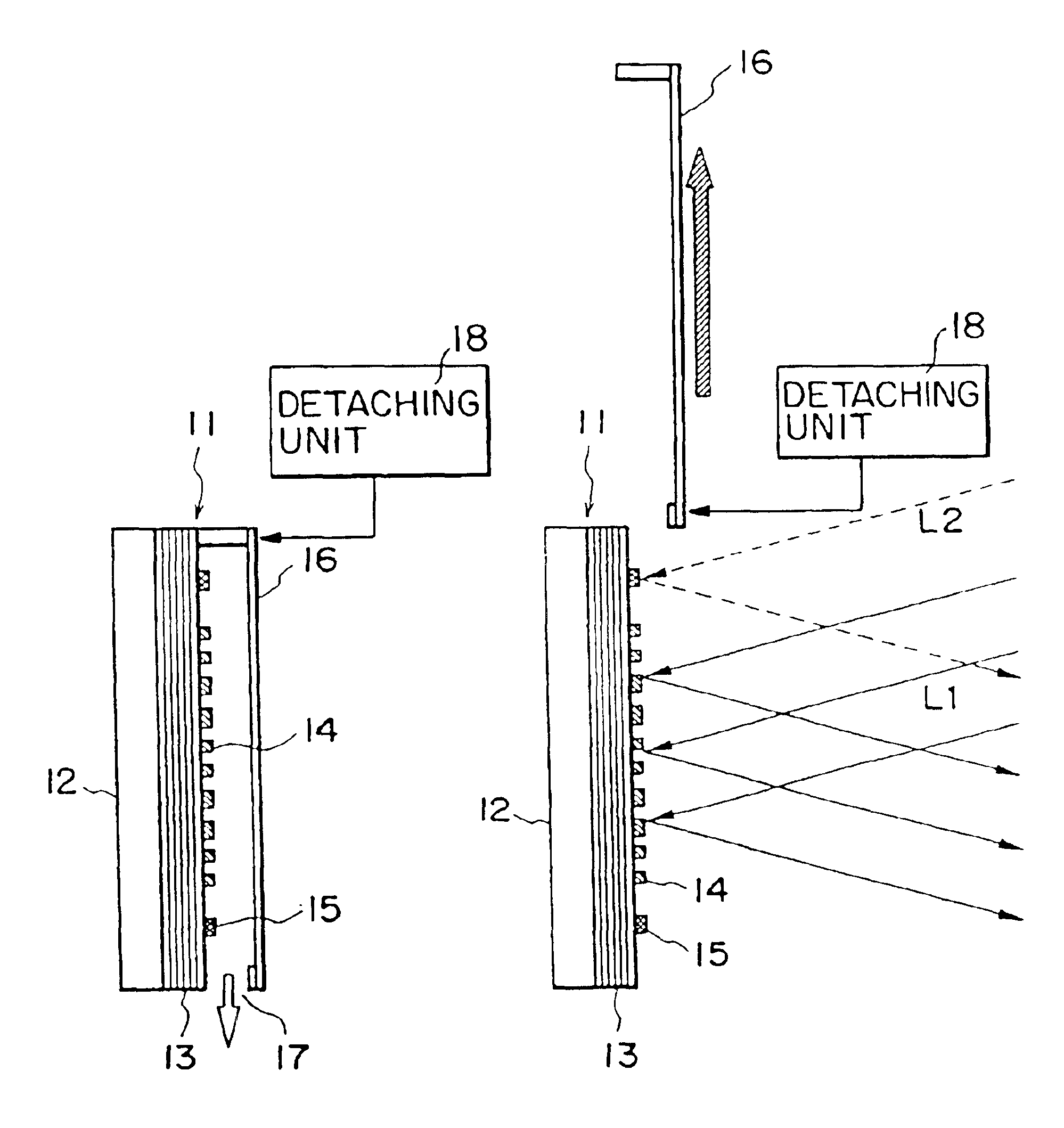

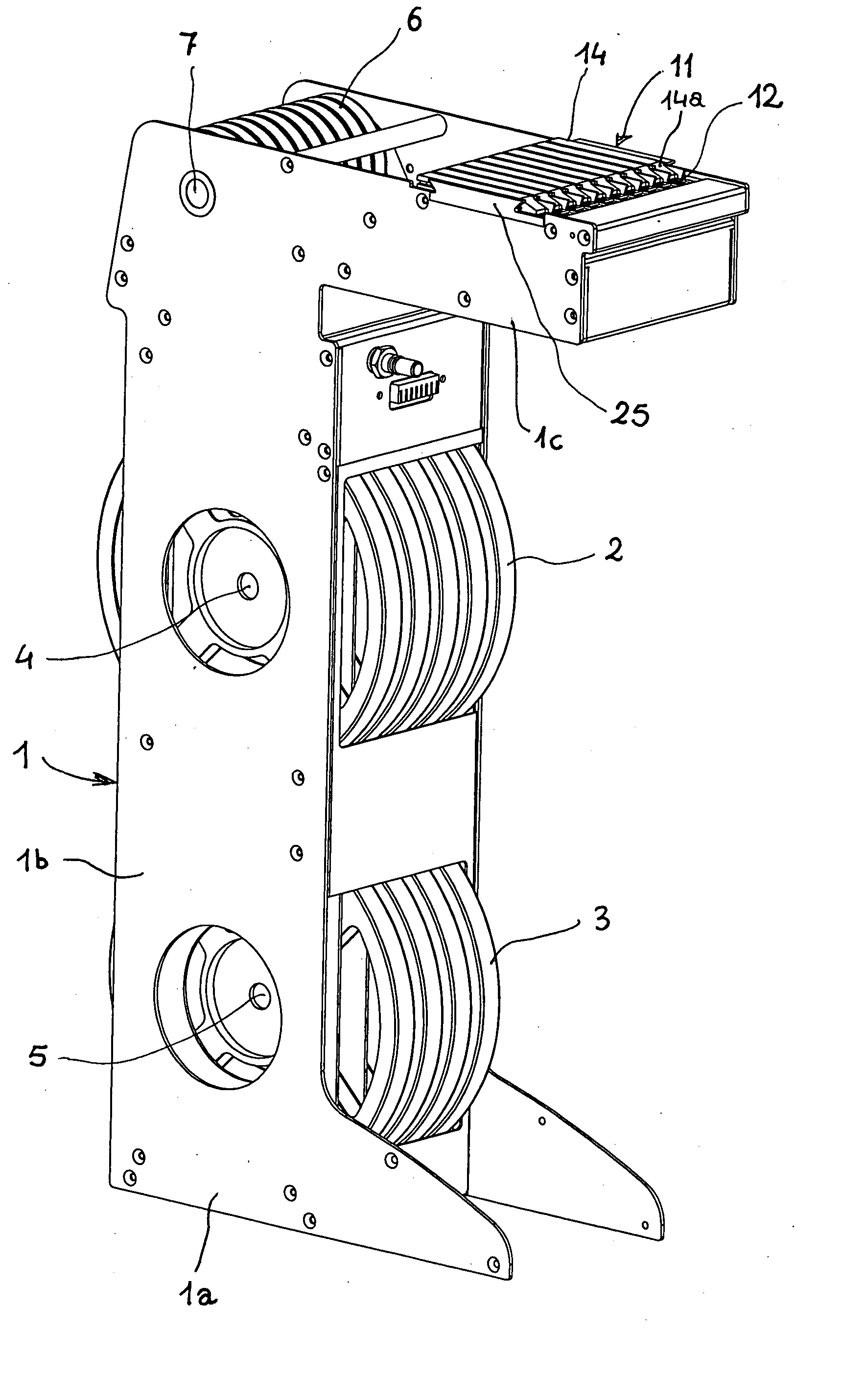

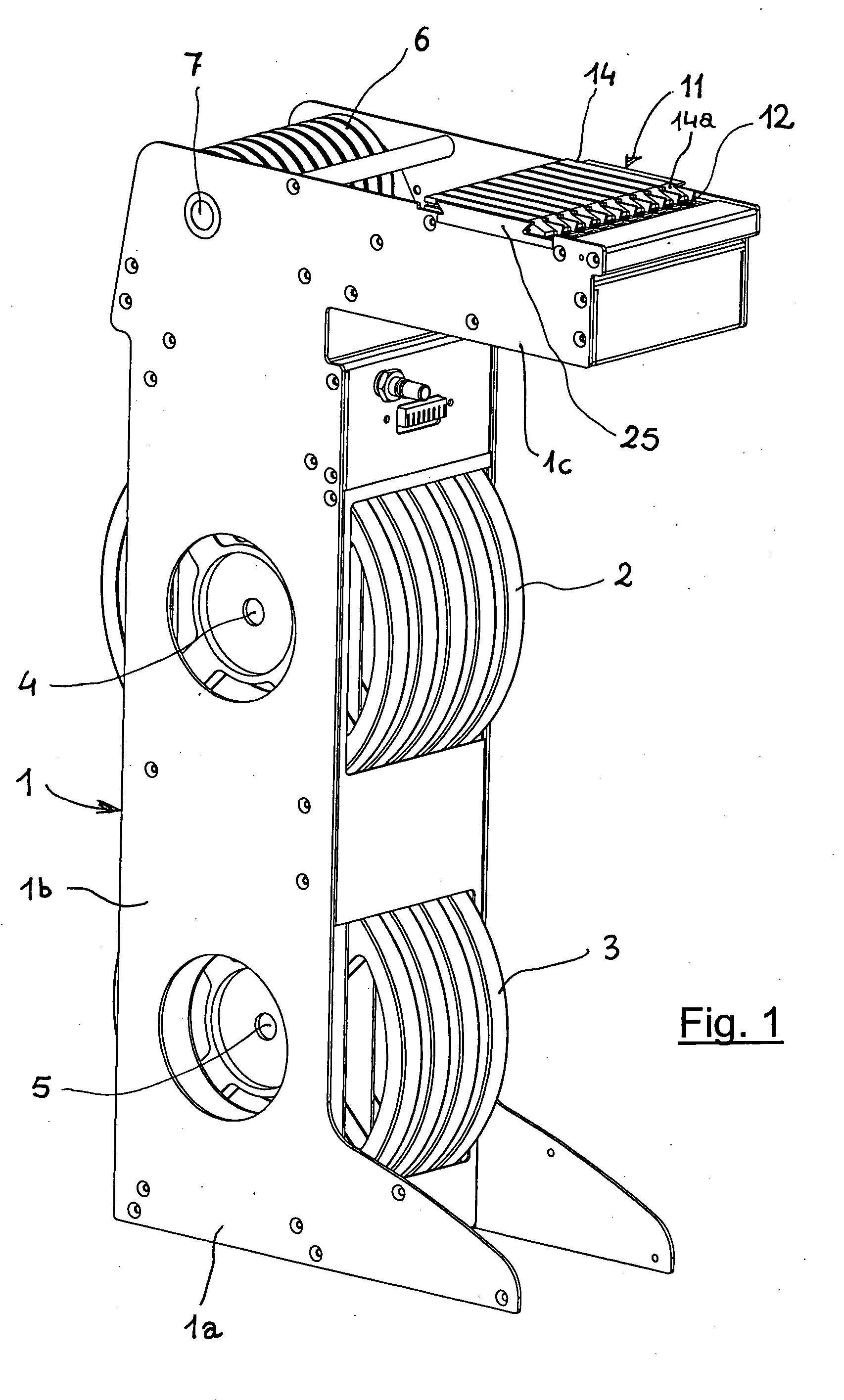

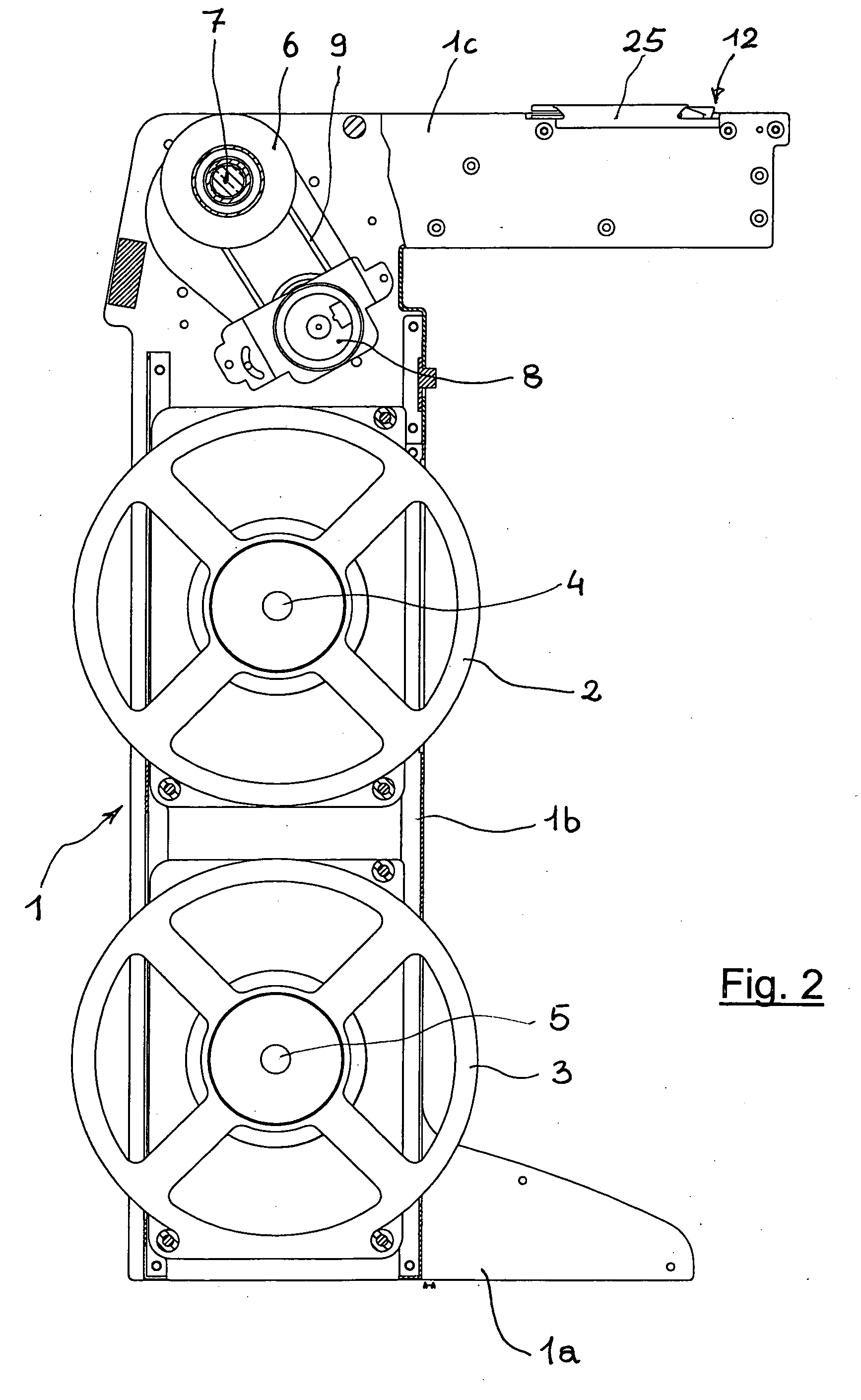

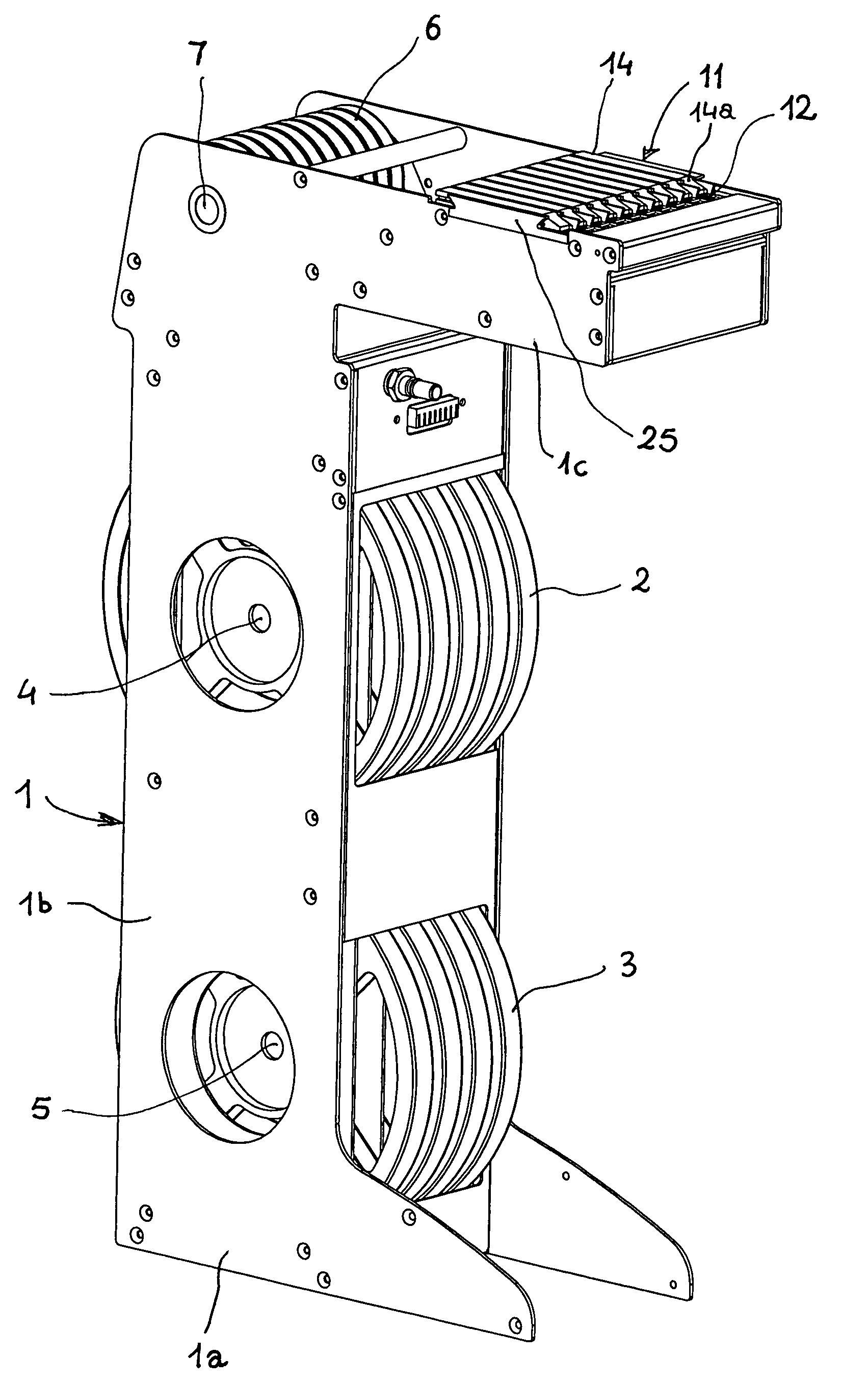

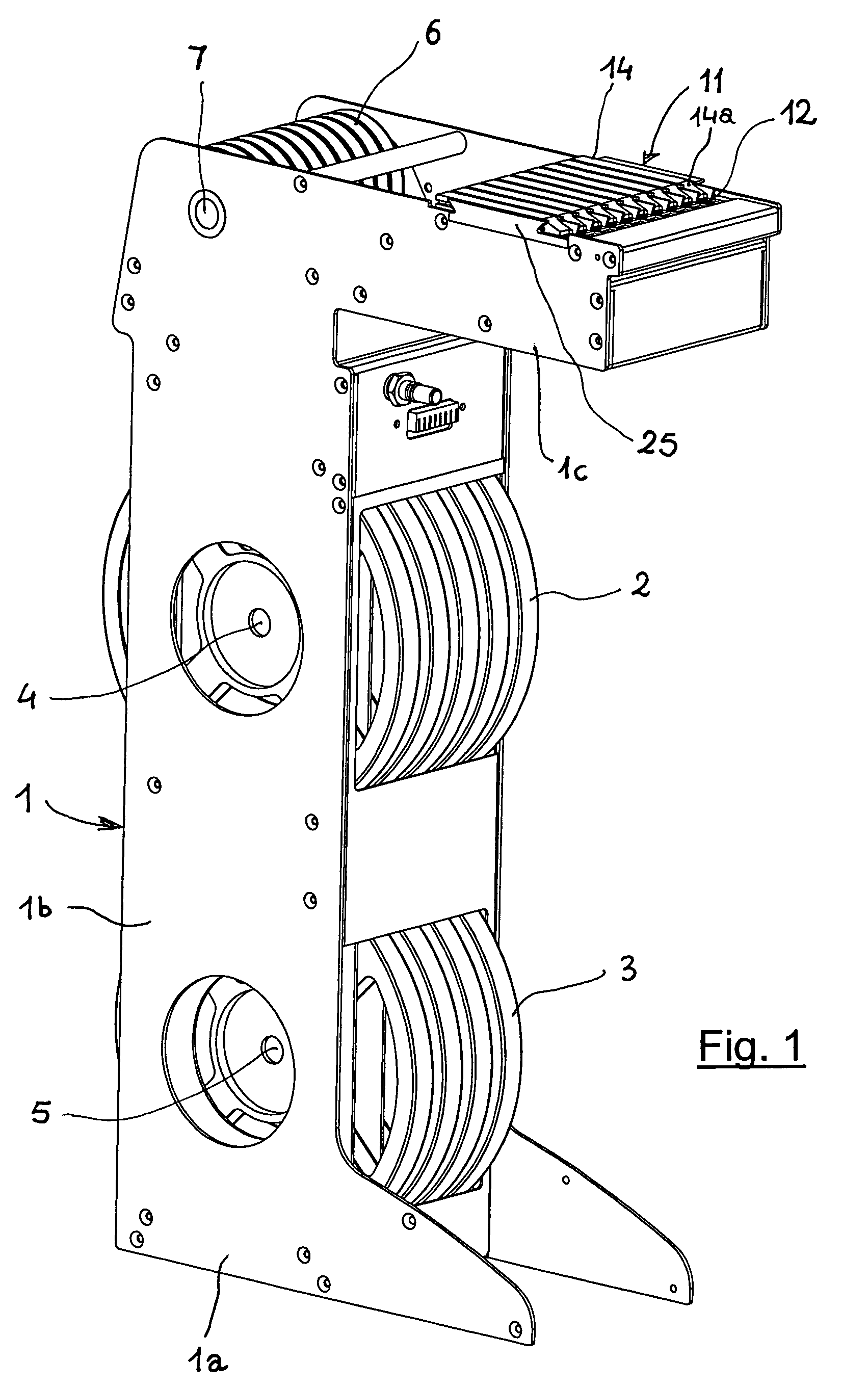

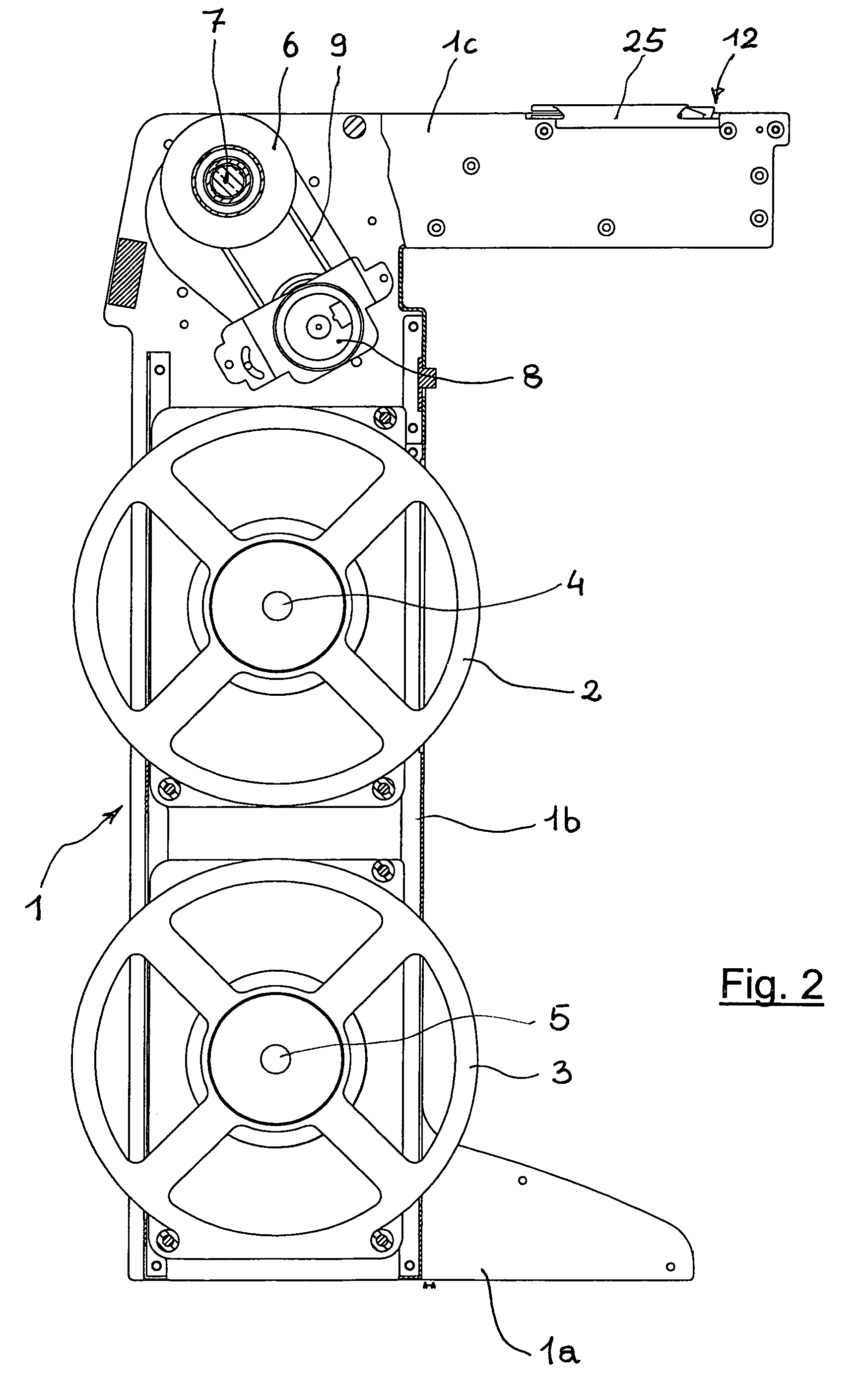

Linear multiple feeder for automatic surface-mounting device positioning apparatuses

InactiveUS20070169436A1High exposureHigh-precision exposureLayered productsSemiconductor/solid-state device detailsElectric machineryEngineering

A linear multiple feeder for use with machines for automatically positioning surface-mounted devices (SMDs) collected from a tape wound on a reel. The tape has a protective film coating removably attached thereto, and detachable therefrom for enabling the device to be picked-up. The feeder comprises a support structure, a plurality of reels of tape carrying the device revolvingly mounted to the structure, motor-driven wheels for retrieving the protective film being detached from the tape to expose those components that are ready for collection, a plurality of relatively parallel lanes on the support structure, downstream from the film-retrieving wheels. Also provided is a device for forward linear delivery of the tape along the lanes. The delivery device includes a carriage moving alternately between two stops and carrying a row of tape-entraining pins selectively engageable with holes in the tape and inside the lanes so as to induce forward motion of only those tapes selected. The lanes are provided with respective elements for separating the film coating entrained axially by the film-retrieving wheels in a direction opposite to that of forward feed delivery of the corresponding tape, thereby detaching the film coating from the tape as the latter moves forward by forcing it against the separator elements. The tension induced in the film coating by the film-retrieving wheels biases the separators against the bottom of their respective lanes so as to prevent movement of any tape(s) that have not been selected by blocking them between the separators and the bottom of the lanes.

Owner:L C M SRL

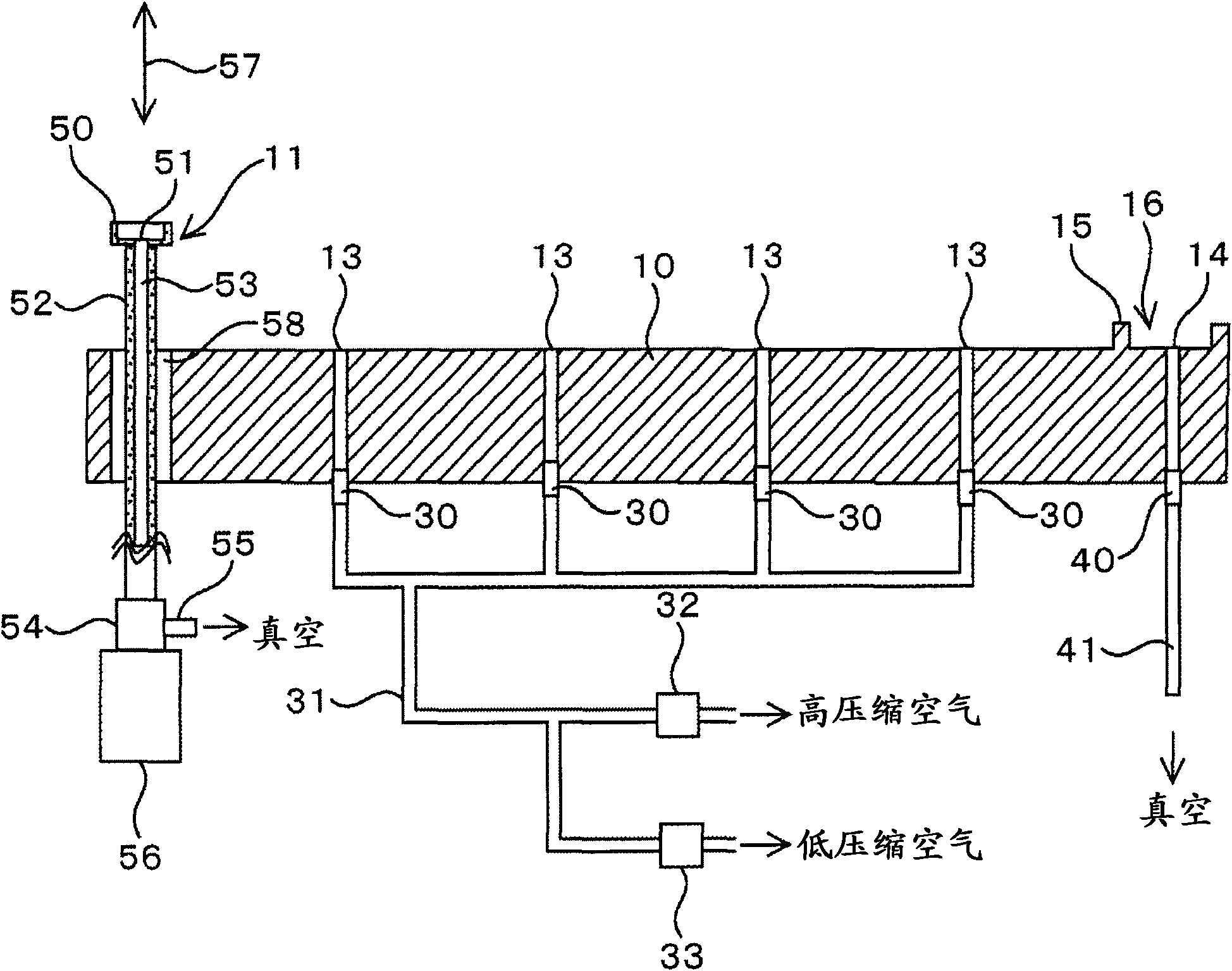

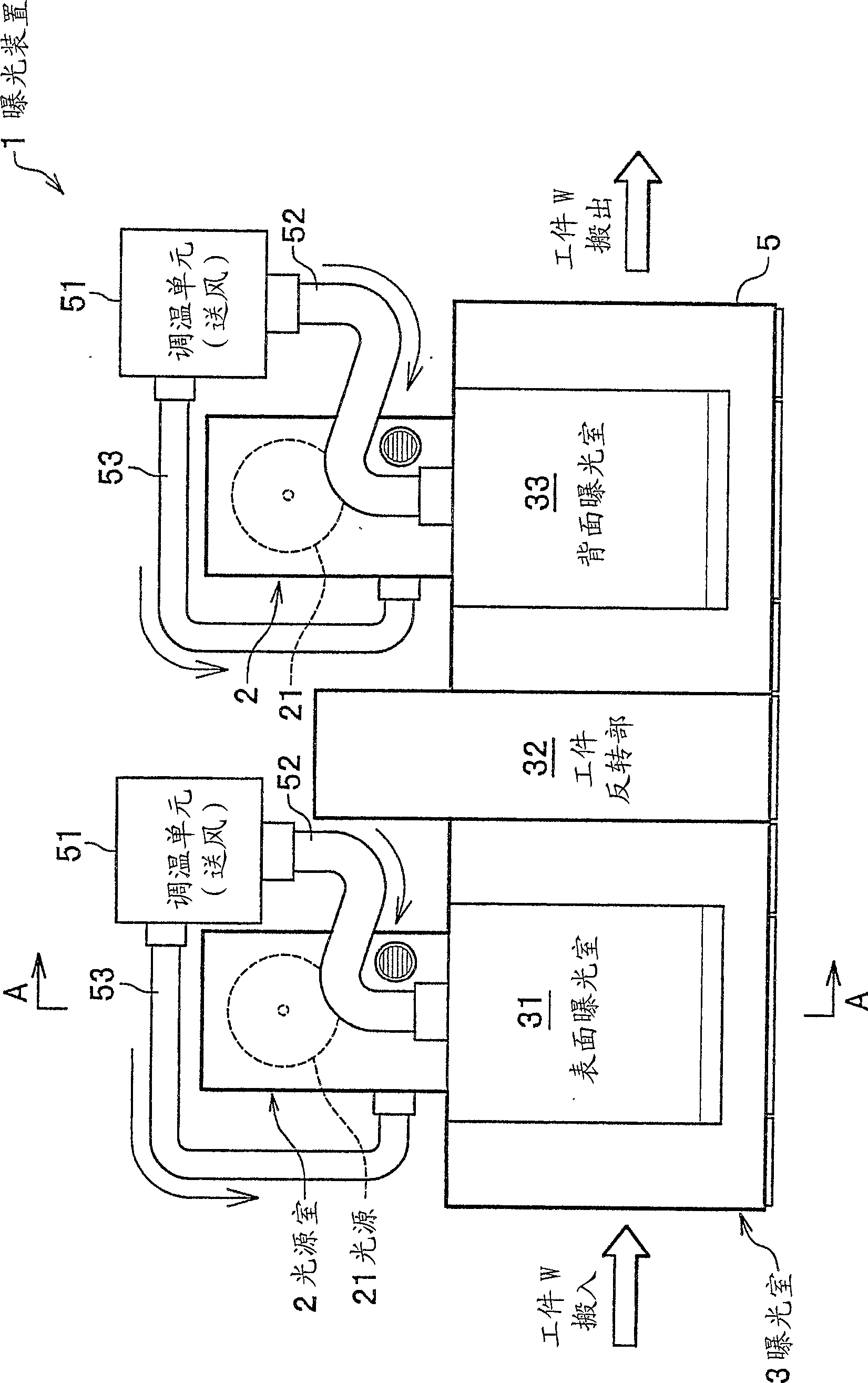

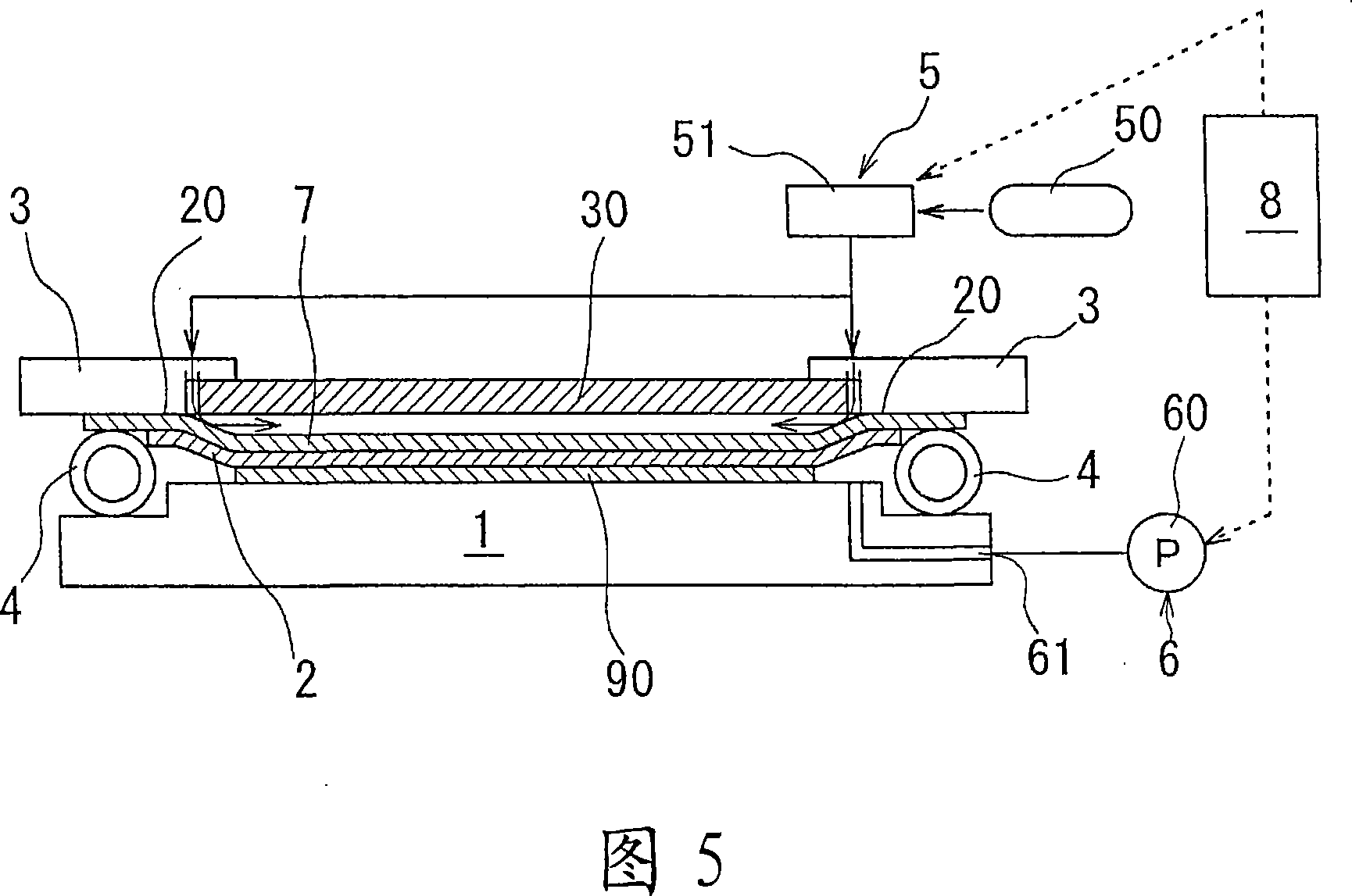

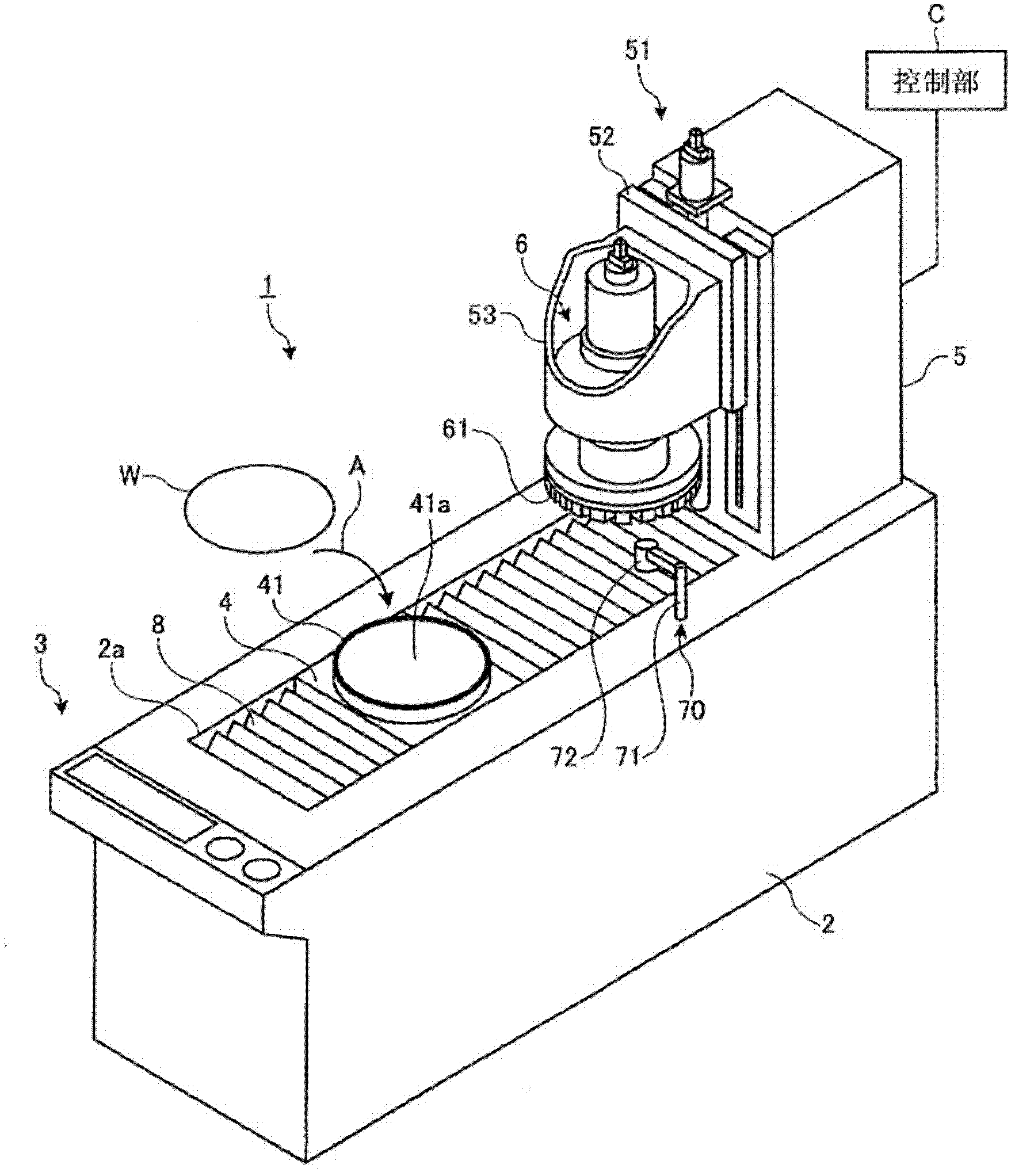

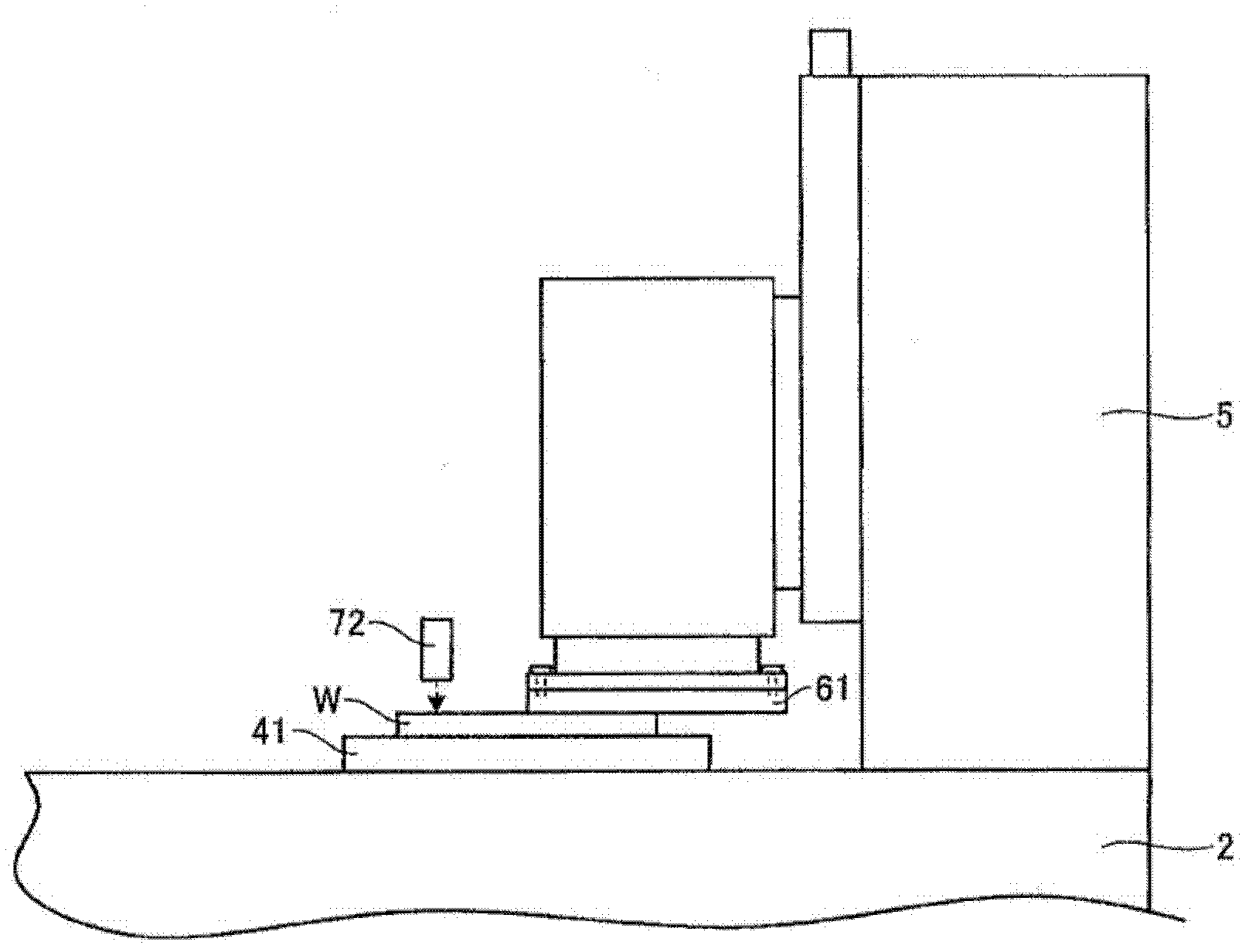

Liquid crystal exposure device

InactiveCN102375346AReduce foulingShorten takt timePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringLiquid crystal

By adopting he method of contacting and supporting a chuck with a substrate in an exposure device, inside reversion of maintaining the substrate shape caused by dust adhered to the substrate can occur, and due to the contacting sequence of the substrate or the chuck, the substrate can be creased, the flatness can be damaged, and the exposure is bad. Thus, through a part which is arranged on the chuck and used for enabling the substrate to float with an air force, the substrate is maintained in a non-contact way, the flatness damage and creasing caused by the contact state can be prevented, and exposure images can be exposed on the substrate precisely. Moreover, through arranging a constant temperature part, the temperature change of the floating substrate can be prevented, and color inferiority caused by the floating exposure of the substrate can be avoided.

Owner:HITACHI HIGH-TECH CORP

Pattern forming method and apparatus, exposure method and apparatus, and device manufacturing method and device

ActiveUS20120057141A1High-precision exposureImprove productivityPhotomechanical apparatusPhotographic printingOptoelectronics

During a period after starting exposure to a plurality of shot areas subject to exposure on a wafer until completing the exposure, a light via a slit pair arranged on a stage that holds the wafer, of illumination light via a pattern generating device, is received, and information on a positional relation between an illumination light and the stage (and hence a positional relation between the illumination light and the wafer) is detected. With this operation, even if the information on the positional relation between the illumination light and the wafer varies due to some reason, information on the variation can be detected while performing the exposure to the plurality of shot areas. Accordingly, high-precision exposure can be achieved in an exposure operation, by considering this detection results.

Owner:NIKON CORP

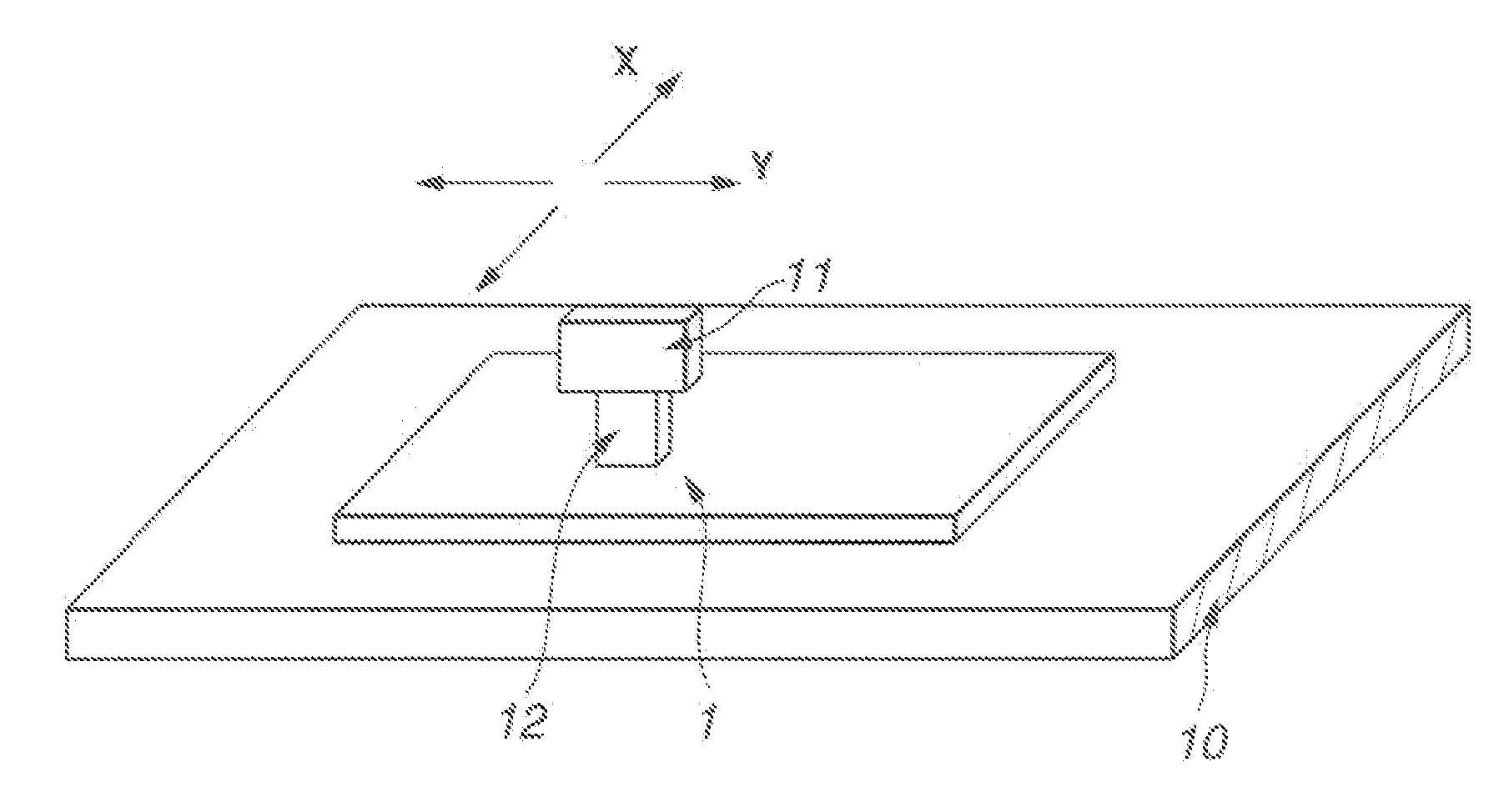

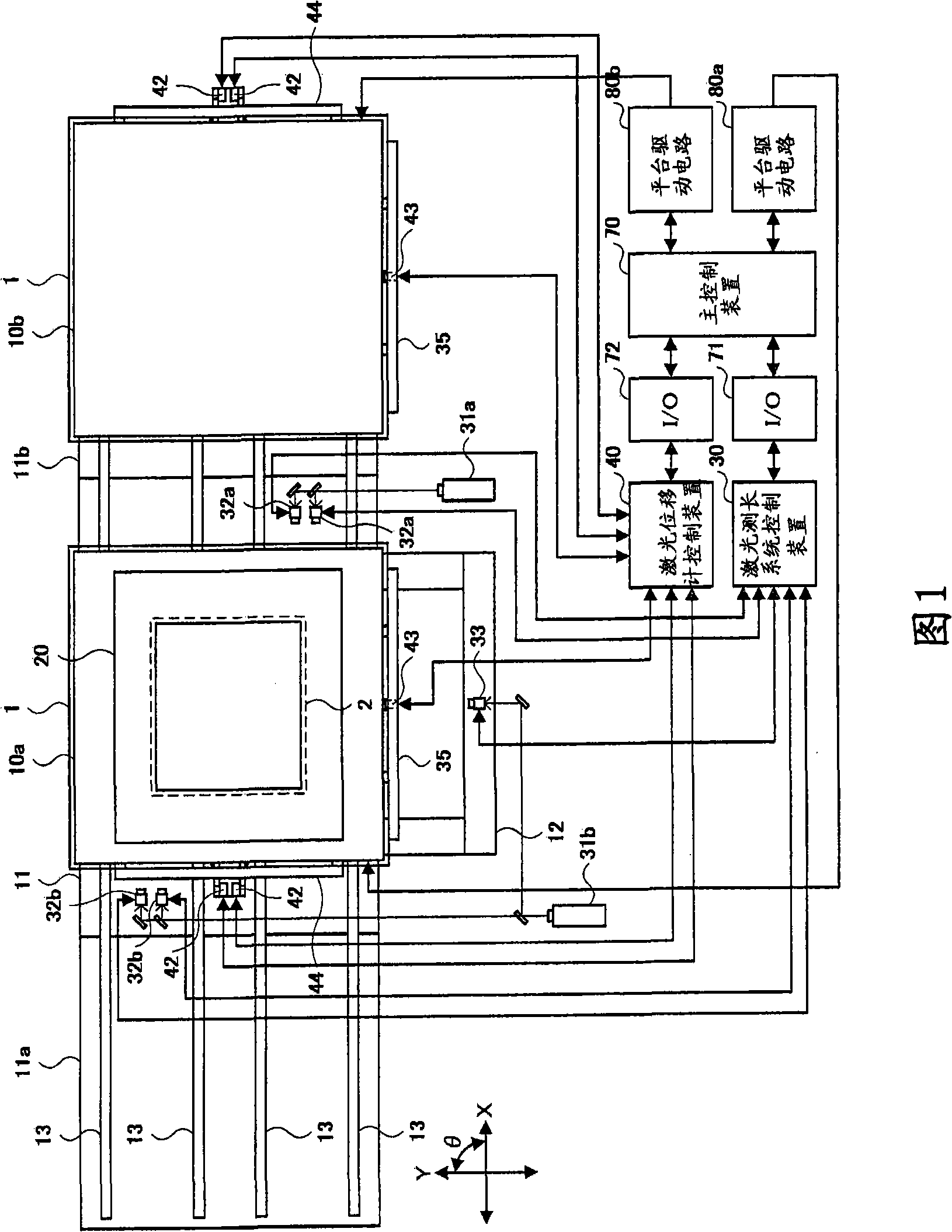

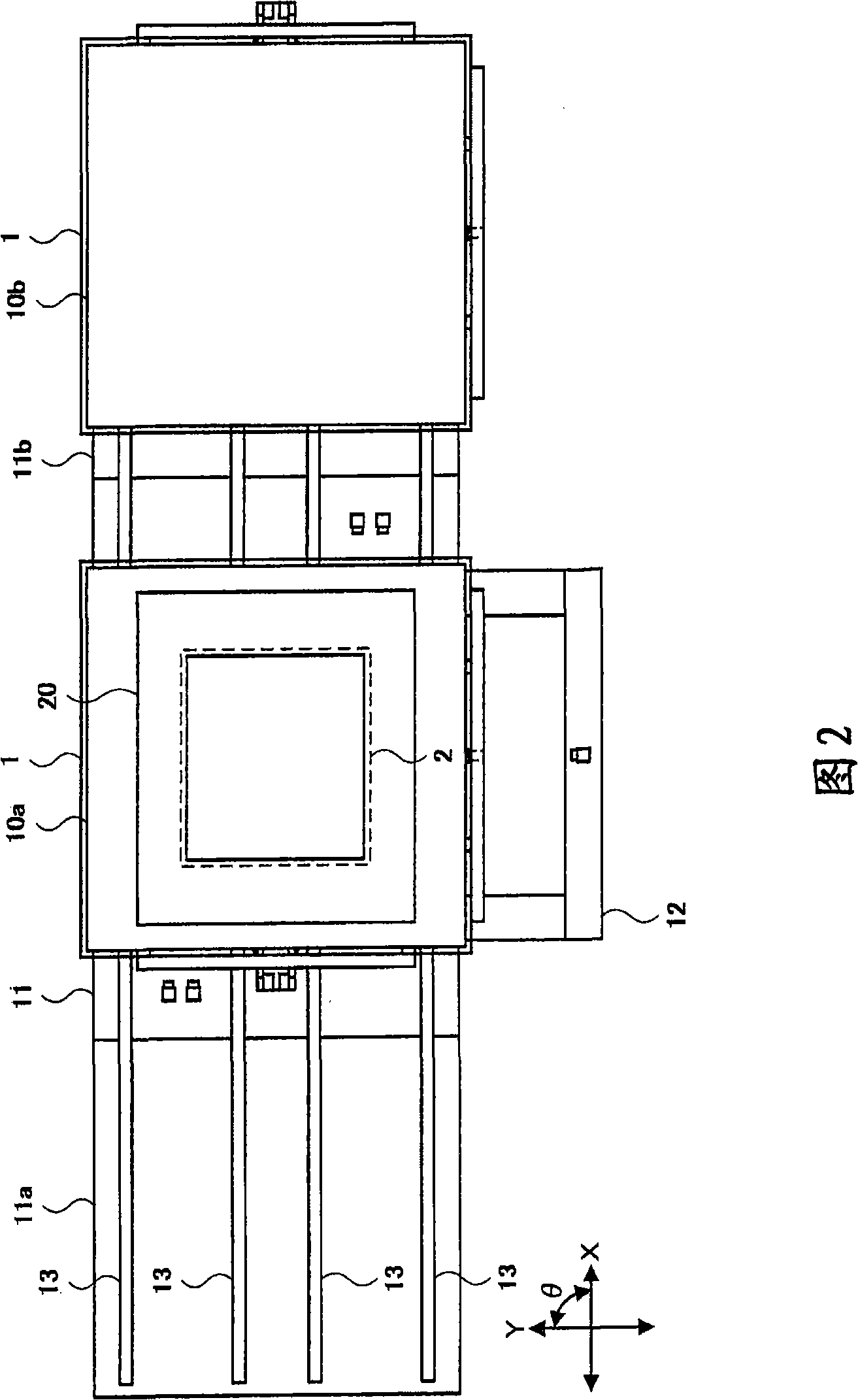

Exposure apparatus, exposure method, and method for manufacturing display panel substrate

InactiveCN101359185APrecise positioningImprove qualitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMeasurement deviceSecondary stage

In exposure in an approximate method by using a plurality of mobile states, a laser distance-to-coupling measurement device is used, to perform position of the sustrate in exposure with high precision. The movable stages carry chucks 10a and 10b and move towards secondary stage bases 11a and 11b and a primary stage base 11, thereby positioning the substrate 1 on the primary stage base 11. Each first laser length-measuring system includes laser sources 31a and 31b, bar mirrors 34a and 34b mounted below X stages 14 of the movable stages, and laser interferometers 32a and 32b disposed at positions deviated from X guide rails 13 on the primary stage base 11, so as to detect positions of the movable stages in X direction. The laser interferometers 32a and 32b will not be influenced by the vibration of the secondary stage bases 11a and 11b. Meanwhile, the measuring distance from the laser interferometers 32a and 32b to the movable stages on the primary stage base 11 is reduced.

Owner:HITACHI HIGH-TECH CORP

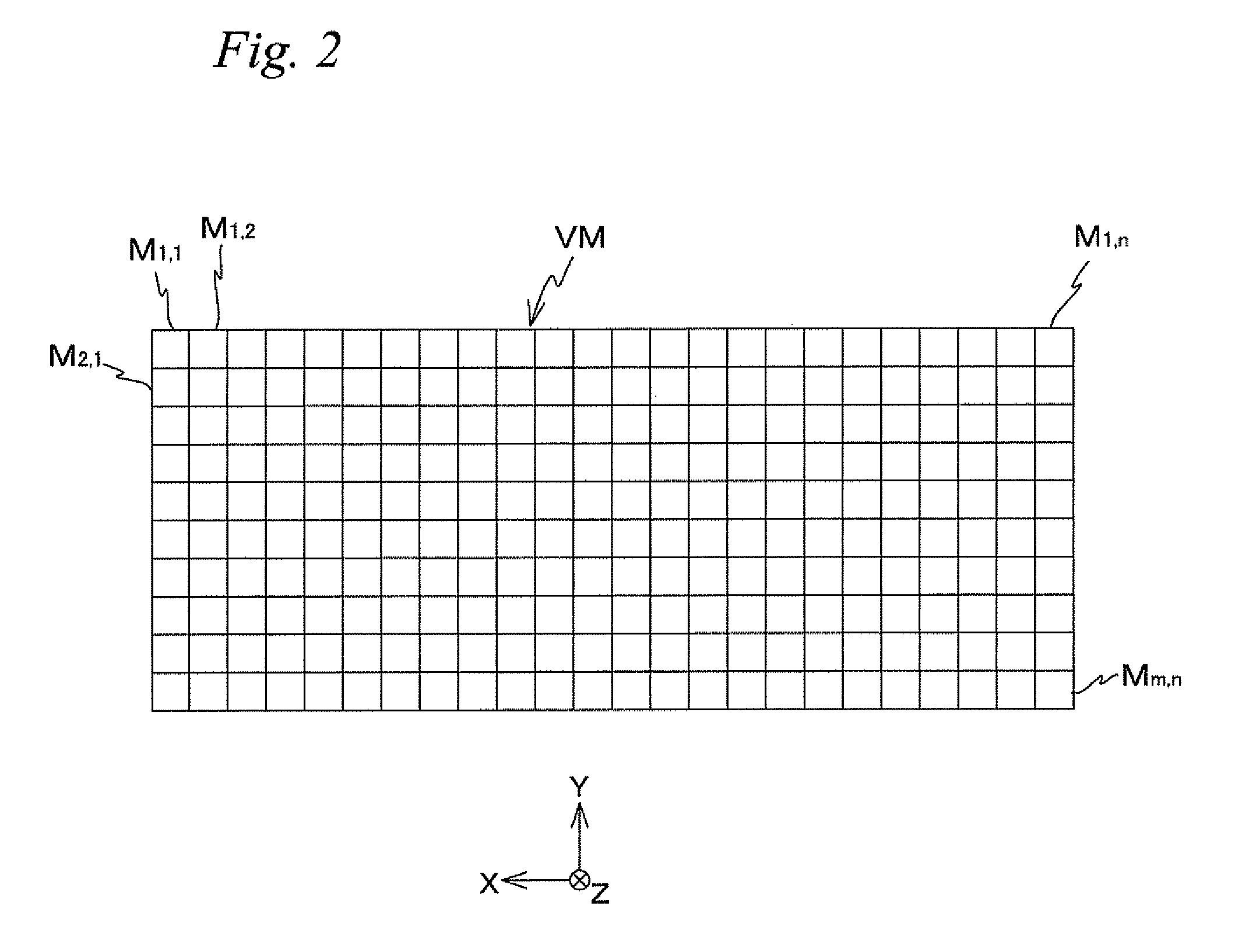

Movable body drive system, pattern formation apparatus, exposure apparatus and exposure method, and device manufacturing method

InactiveUS8237916B2Improve accuracyHigh precision formingWalking sticksPhotomechanical apparatusGratingEncoder

A stage device is equipped with a first scale which is placed with a Y-axis direction serving as its longitudinal direction and in which a first grating whose periodic direction is in an X-axis direction is formed and a second scale which is placed with the X-axis direction serving as its longitudinal direction and in which a second grating whose periodic direction is orthogonal to the periodic direction of the first grating is formed, the first scale and the second scale being placed on a plane which a wafer stage faces. Further, on the upper surface of the wafer stage, a plurality of X heads placed at different positions in the X-axis direction and a plurality of Y heads placed at different positions in the Y-axis direction are arranged. An encoder system that has these heads measures positional information of the stage within an XY plane, based on an output of the X head facing the first scale and an output of the Y head facing the second scale.

Owner:NIKON CORP

Linear multiple feeder for automatic surface-mounting device positioning apparatuses

InactiveUS7681617B2High-precision exposureSmall and less-expensiveLamination ancillary operationsCoin-freed apparatus detailsTectorial membraneMotor drive

A linear multiple feeder for use with an apparatus for automatically positioning surface-mounted devices (SMDs) collected from a tape wound on a reel. The tape has a protective film coating removably attached thereto, for enabling the device to be picked-up. The feeder comprises a support structure, a plurality of reels of tape carrying the device or component rotatably mounted to the structure, motor-driven wheels for retrieving the protective film being detached from the tape to expose those devices or components that are ready for collection, and a plurality of relatively parallel lanes on the support structure. Also provided is a device for forward linear delivery of the tape along the lanes. The lanes are provided with respective elements for separating the film coating entrained axially by the film-retrieving wheels in a direction opposite to that of delivery of the corresponding tape, thereby detaching the film coating from the tape as the latter moves forward.

Owner:L C M SRL

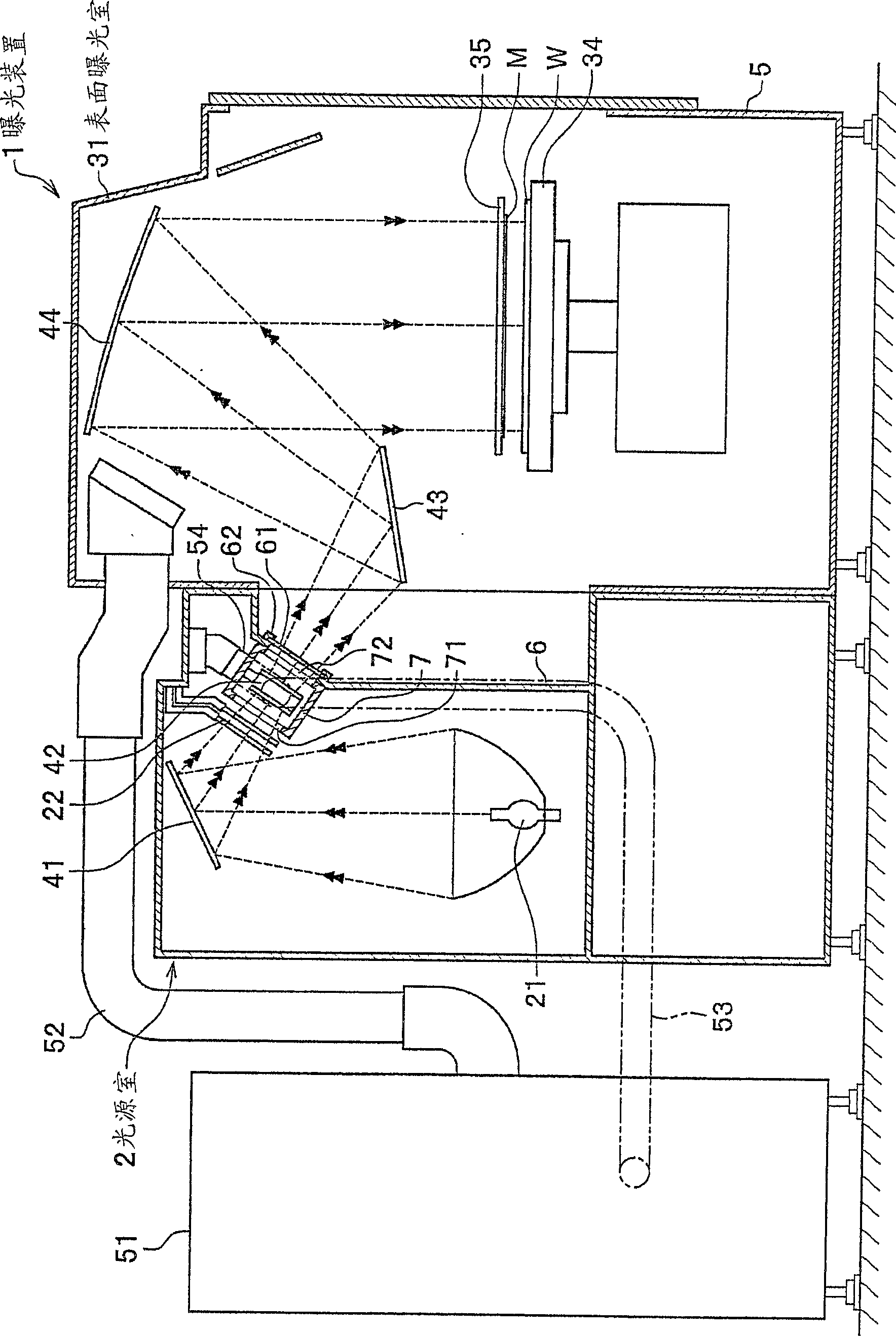

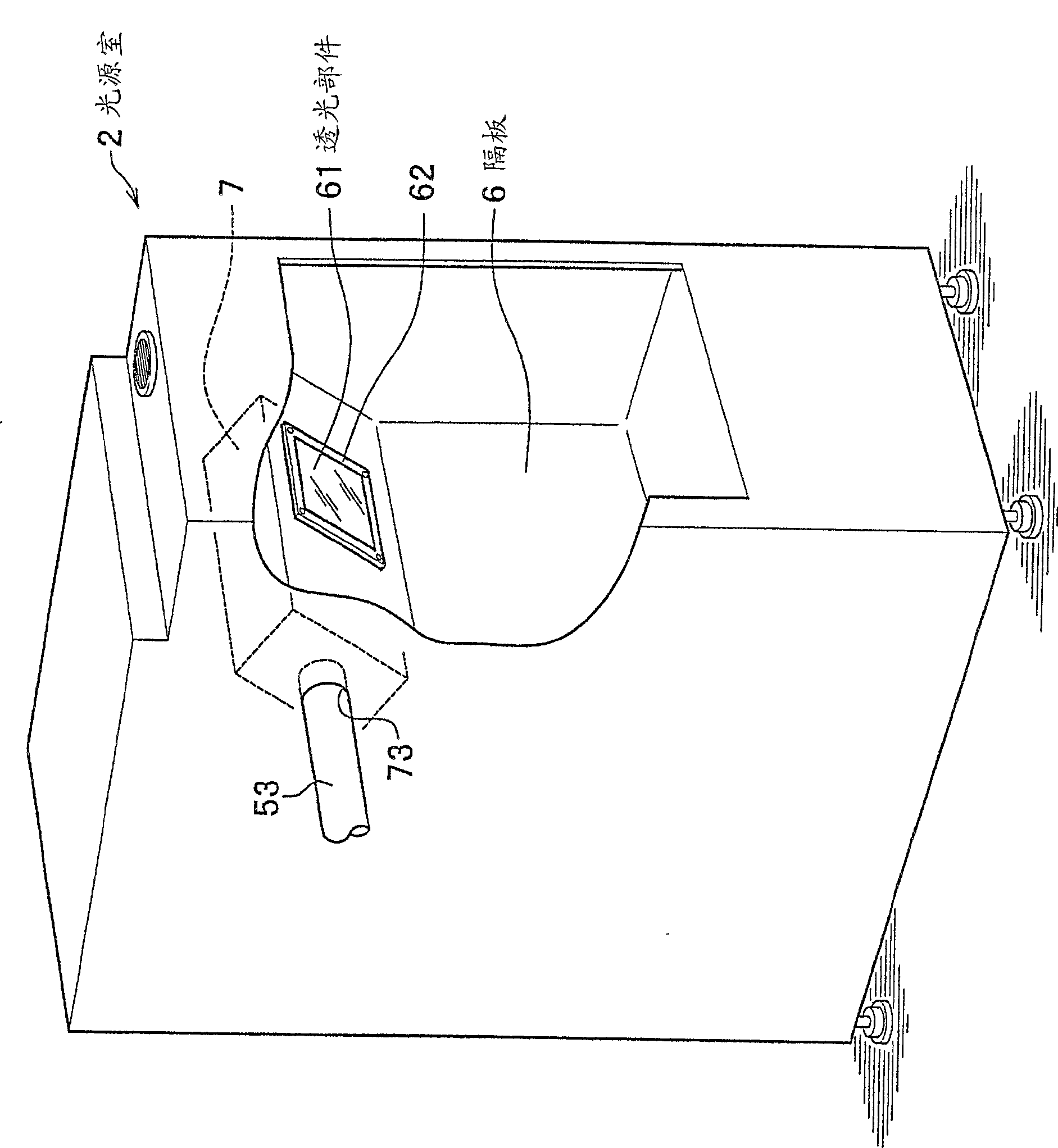

Exposure device

ActiveCN100533274CPrevent uneven illuminationHigh precision exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptoelectronicsEye lens

The invention provides an exposure device, which prevents the contamination of the surface of the fly-eye lens caused by the volatile matter produced by the photosensitive resin with a simple structure. The exposure device includes: a light source chamber having a light source, a reflector, and a fly-eye lens; and an exposure chamber separated from the light source chamber through a partition plate, including: a casing for accommodating the fly-eye lens; and an air blower for cooling The wind is sent to the fly-eye lens contained in the above-mentioned casing; the above-mentioned casing has: an opening formed at a position corresponding to the incident light path and the outgoing light path of the light from the above-mentioned light source; the air inlet is formed The above-mentioned blower device is connected at a position perpendicular to the opening direction of the opening; and the exhaust port is formed at a position facing the air intake port, thereby forming a straight line of blowing air in the above-mentioned housing. Path; on the partition plate, a light-transmitting member for transmitting the irradiated light is provided at a position corresponding to the optical path of the irradiated light.

Owner:ORC MFG

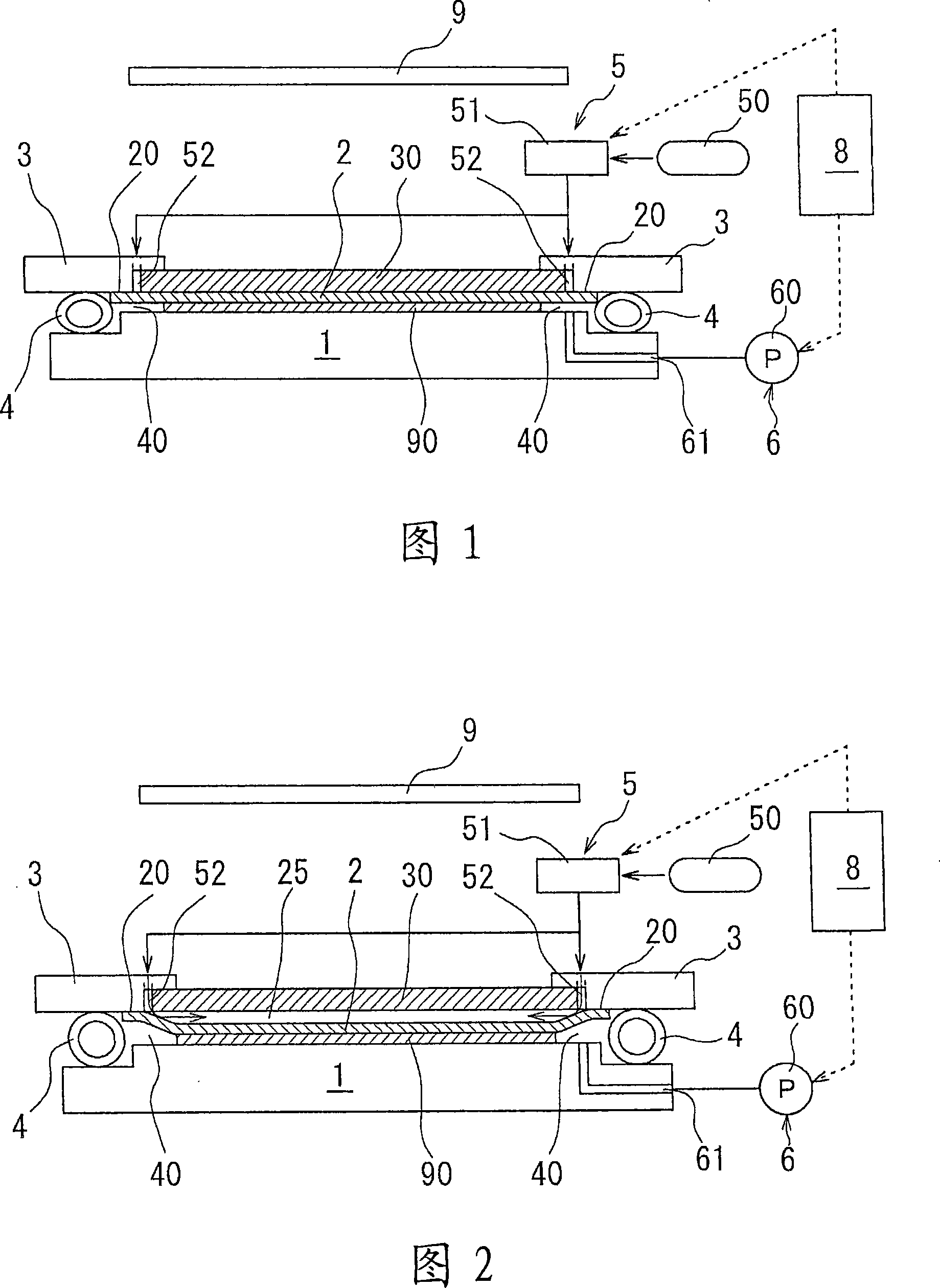

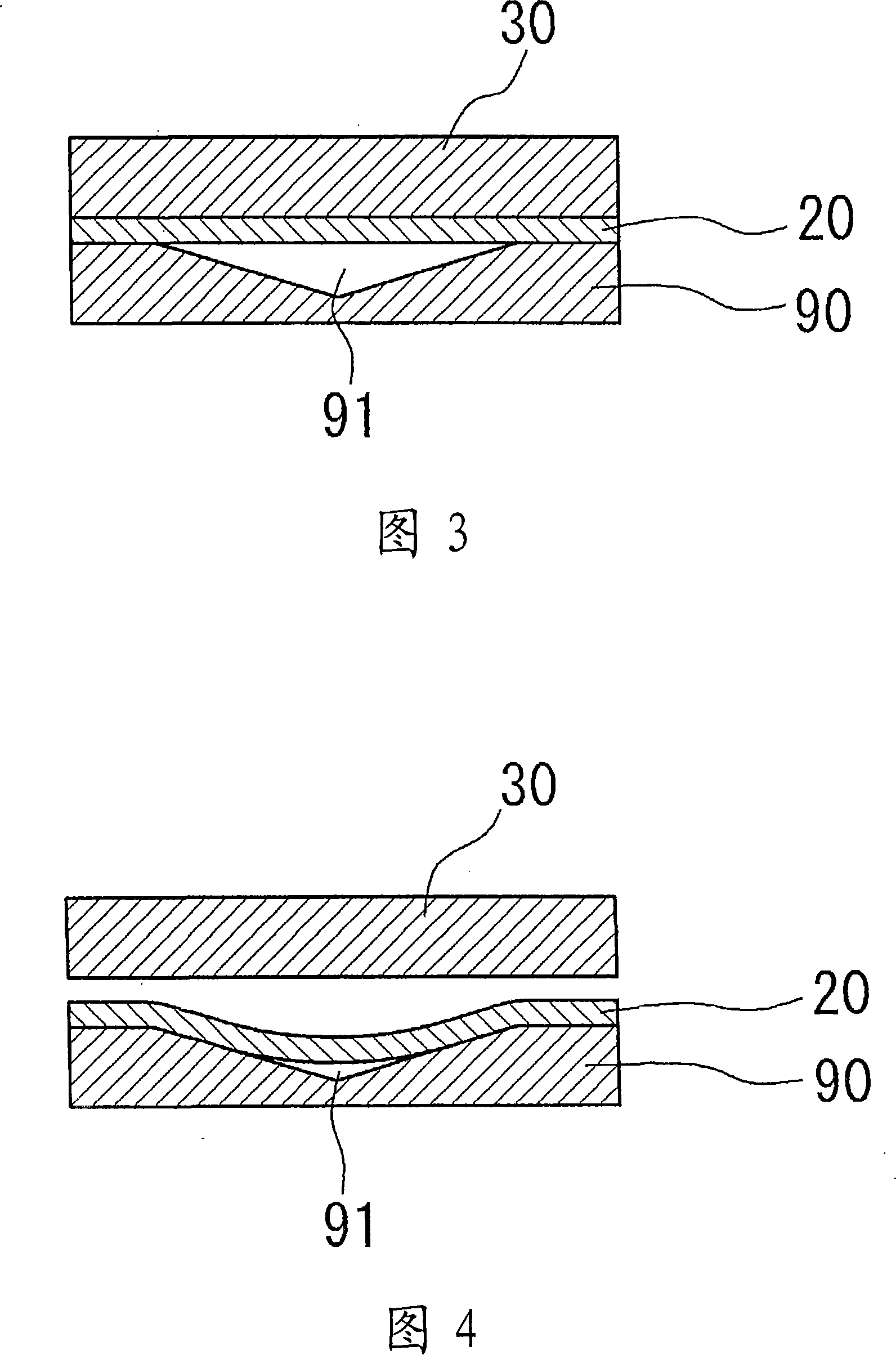

Exposure device

InactiveCN101174102AGood adhesionNot prone to elongationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusBlow outElectrical and Electronics engineering

The invention provides an exposure device which is high in accuracy and can have the exposure time shortened. A lighthouse (1) is elevated so as to contact a film mask (2) to a substrate (90) and then to form an enclosed place (40). A pressure reducing pump (60) is used for reducing the pressure. A one-time enclosure between the film mask (2) and the substrate (90) is conducted. Then, a pressurized air with a pressure ranging from 1kPa to 20kPa is led in from a guide hole (52), thus forming a pressuring space (25) between the film mask (2) and a piece of glass (30). The film mask (2) and the substrate (90) are further sealed, thus completing a second enclosure. As the first enclosure has made the film mask (2) and the substrate (90) sealed, a small amount of air in the guide hole (52) can be led in, and also a small amount of air is blown out under the inflation during the pressurizing. So the inside guide of the air can be fulfilled in a short period of time, without such defect as the deformation due to the inflation of the film mask (2).

Owner:ADTEC ENG

Large-sized glass substrate

ActiveUS7745071B2Improve flatnessEnhance flatness and parallelnessSemiconductor/solid-state device detailsSolid-state devicesImage resolutionDiagonal

A large-sized substrate having a diagonal length of not less than 500 mm and a ratio of flatness / diagonal length of not more than 6×10−6 is disclosed. By use of the large-sized substrate for exposure of the present invention, the exposure accuracy, particularly the register accuracy and resolution are enhanced, so that it is possible to achieve high-precision exposure of a large-sized panel. With the processing method according to the present invention, it is possible to stably obtain a large-sized photomask substrate with a high flatness, and since the CD accuracy (dimensional accuracy) at the time of exposure of the panel is enhanced, it is possible to perform exposure of a fine pattern, leading to a higher yield of the panel. Furthermore, by applying the processing method according to the present invention, it is also possible to create an arbitrary surface shape.

Owner:SHIN ETSU CHEM CO LTD

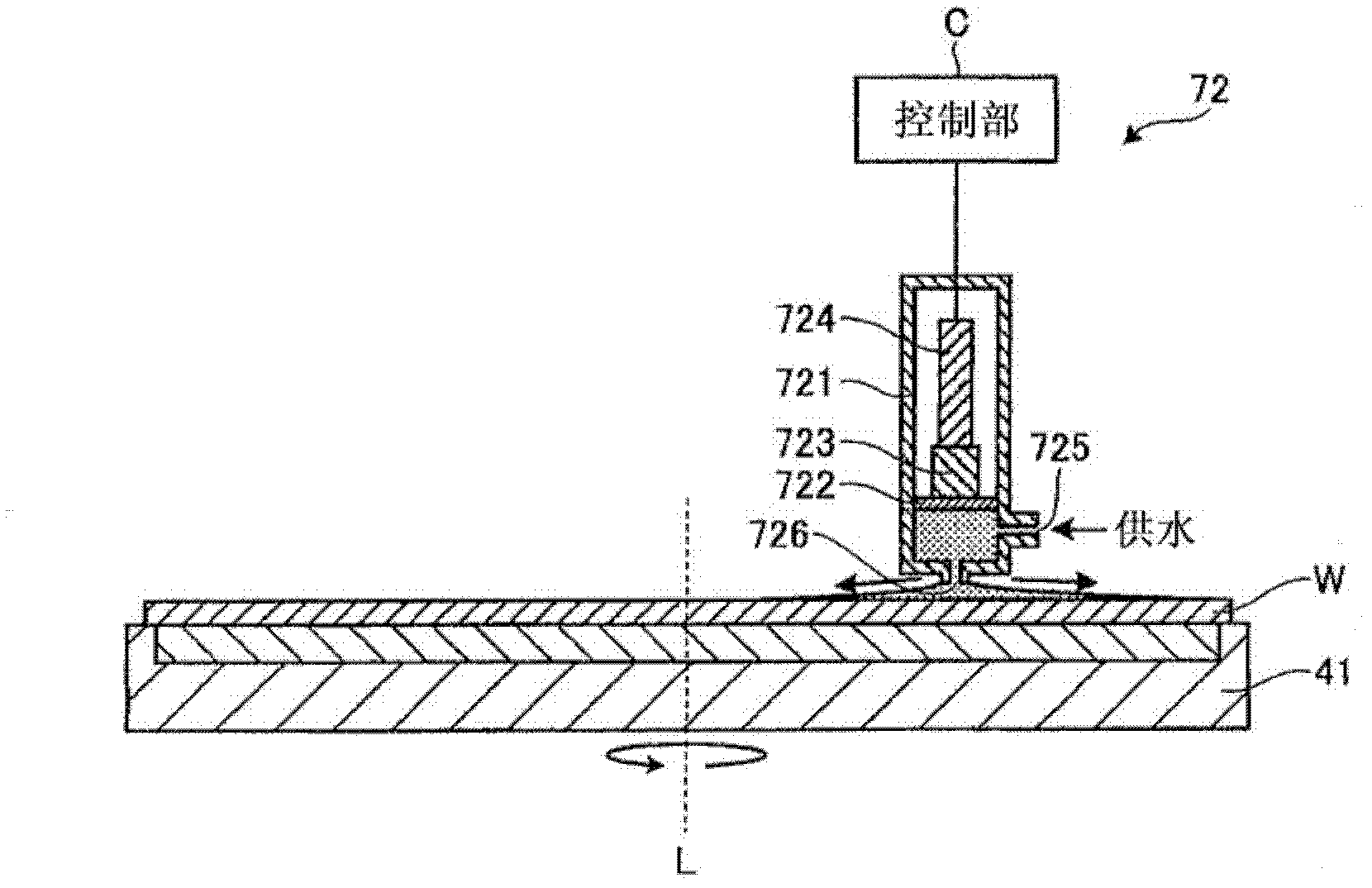

Grinding apparatus

ActiveCN102615585AHigh precision exposureSemiconductor/solid-state device manufacturingLapping machinesMechanical engineeringReflectivity

Provided is a grinding apparatus, comprising a maintaining member having a maintaining surface, a processing member used for grinding a member kept by the maintaining member, and a control member used for controlling the motion of the processing member, with the member being formed by a first member having its reflectivity as the first reflectivity and a second member having its reflectivity as the second reflectivity, wherein the control member has a detecting portion used for irradiating detecting light over the to-be-grinded surface of the member receiving grinding treatment, receiving the reflected light from the to-be-grinded surface, and stopping the grinding over the member when the light-receiving amount detected by the detecting portion is determined to be exposed by the first member covered by the second member.

Owner:DISCO CORP

Movable body apparatus, movable body drive method, exposure apparatus, exposure method, and device manufacturing method

ActiveUS20130293863A1Good precisionHigh-precision exposureSemiconductor/solid-state device manufacturingManufacturing dynamo-electric machinesObservational errorGrating

A drive system drives a movable body, based on measurement results of a first measurement system which measures the position of the movable body in an XY plane by irradiating a measurement beam from an arm member on a grating placed on a surface parallel to the XY plane of the movable body and measurement results of a second measurement system which measures a variance of the arm member using a laser interferometer. In this case, the drive system corrects measurement errors caused due to a variance of the arm member included in the measurement results of the first measurement system, using the measurement results of the second measurement system.

Owner:NIKON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com