Patents

Literature

5277results about How to "Reduce measurement error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

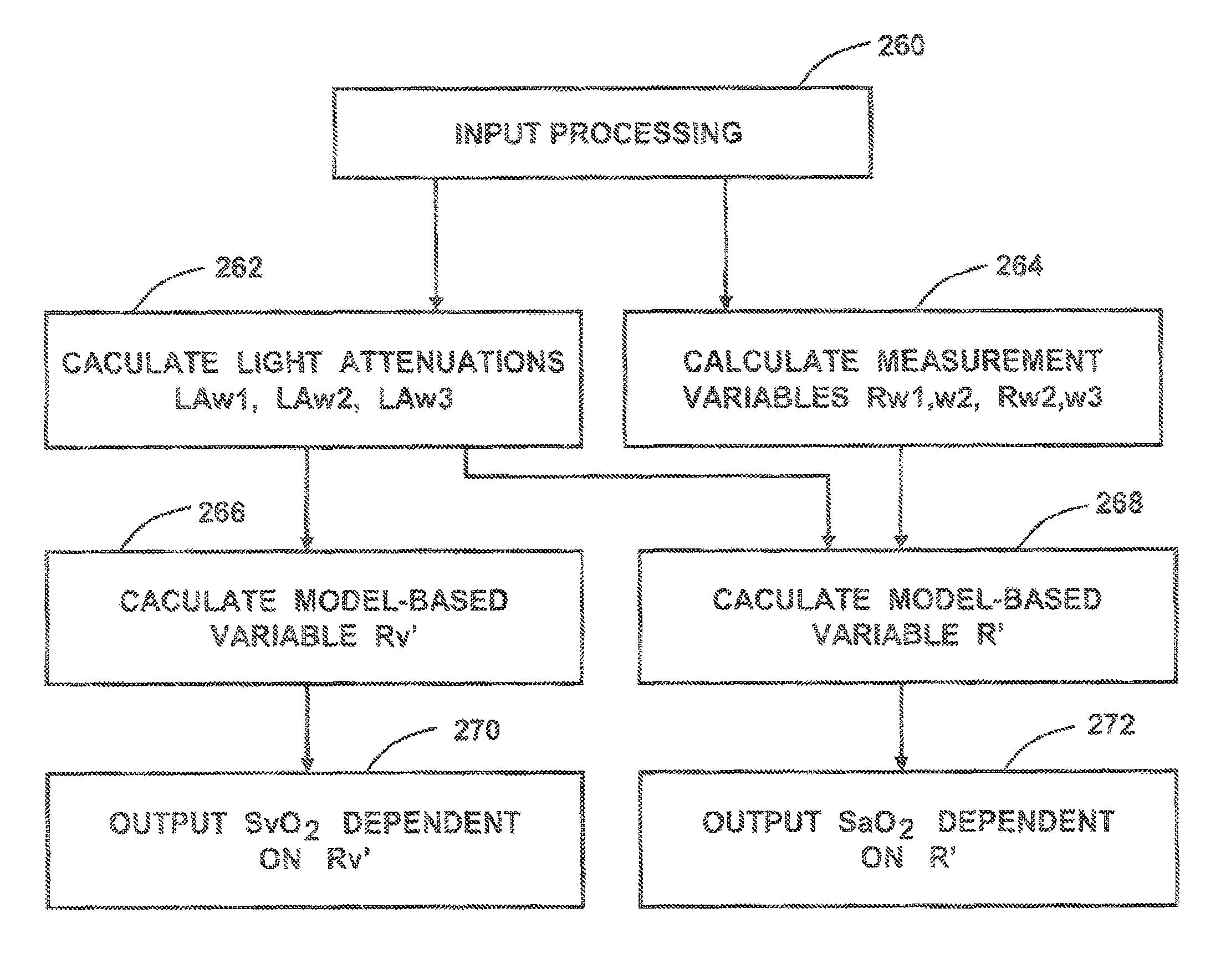

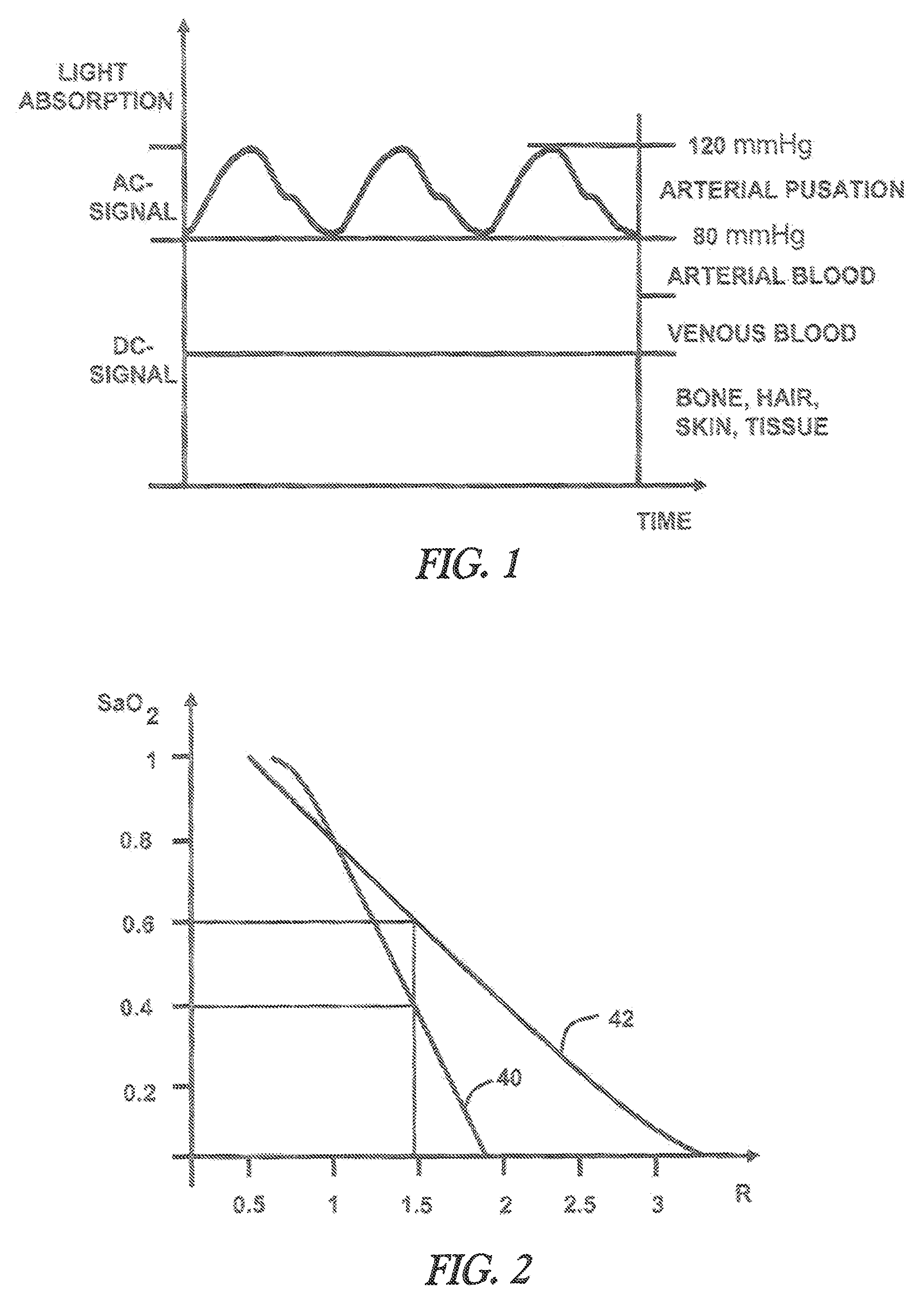

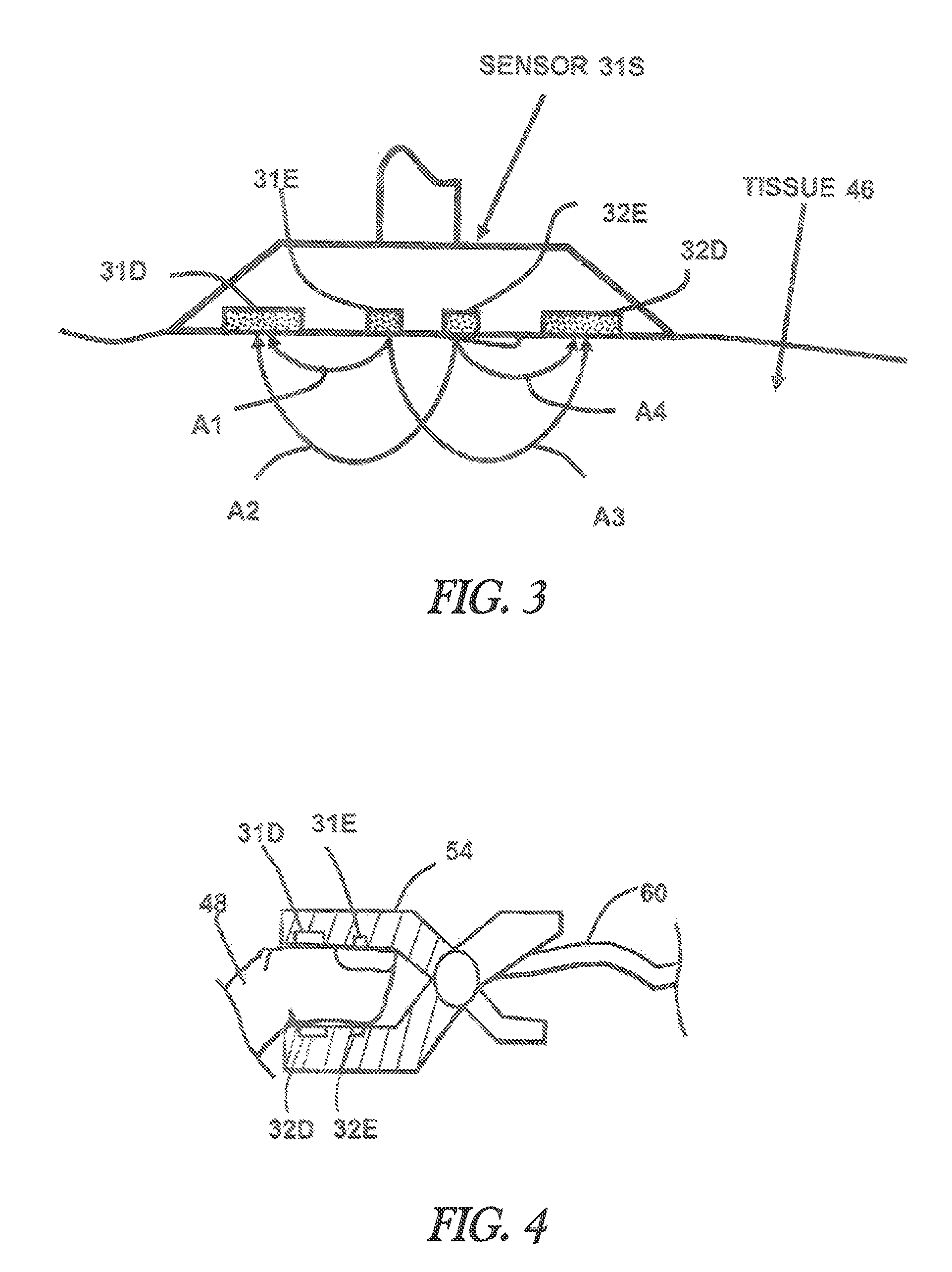

Tissue Oximetry Apparatus and Method

ActiveUS20080015424A1Exclude influenceHigh precisionDiagnostic signal processingOptical sensorsVeinOptical property

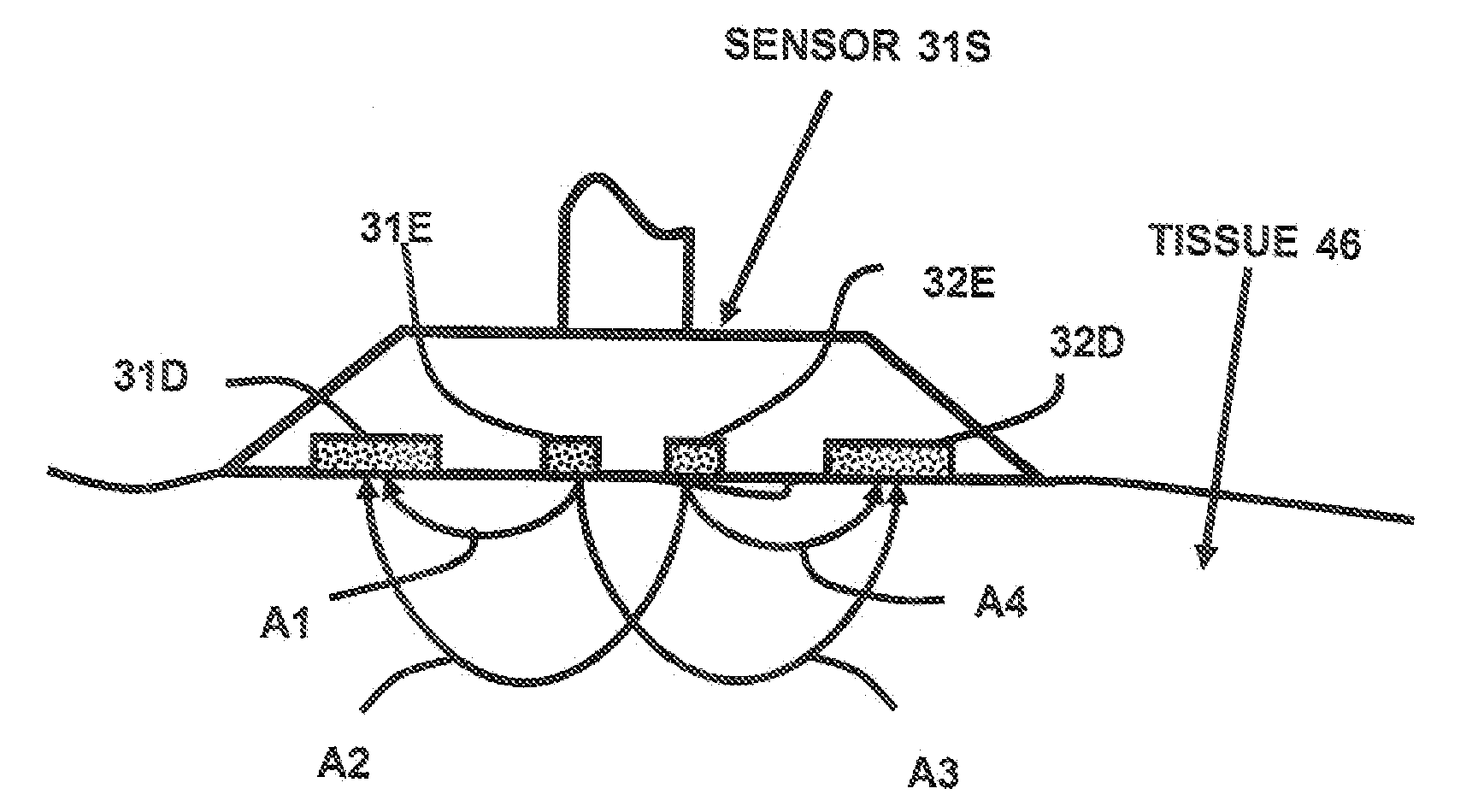

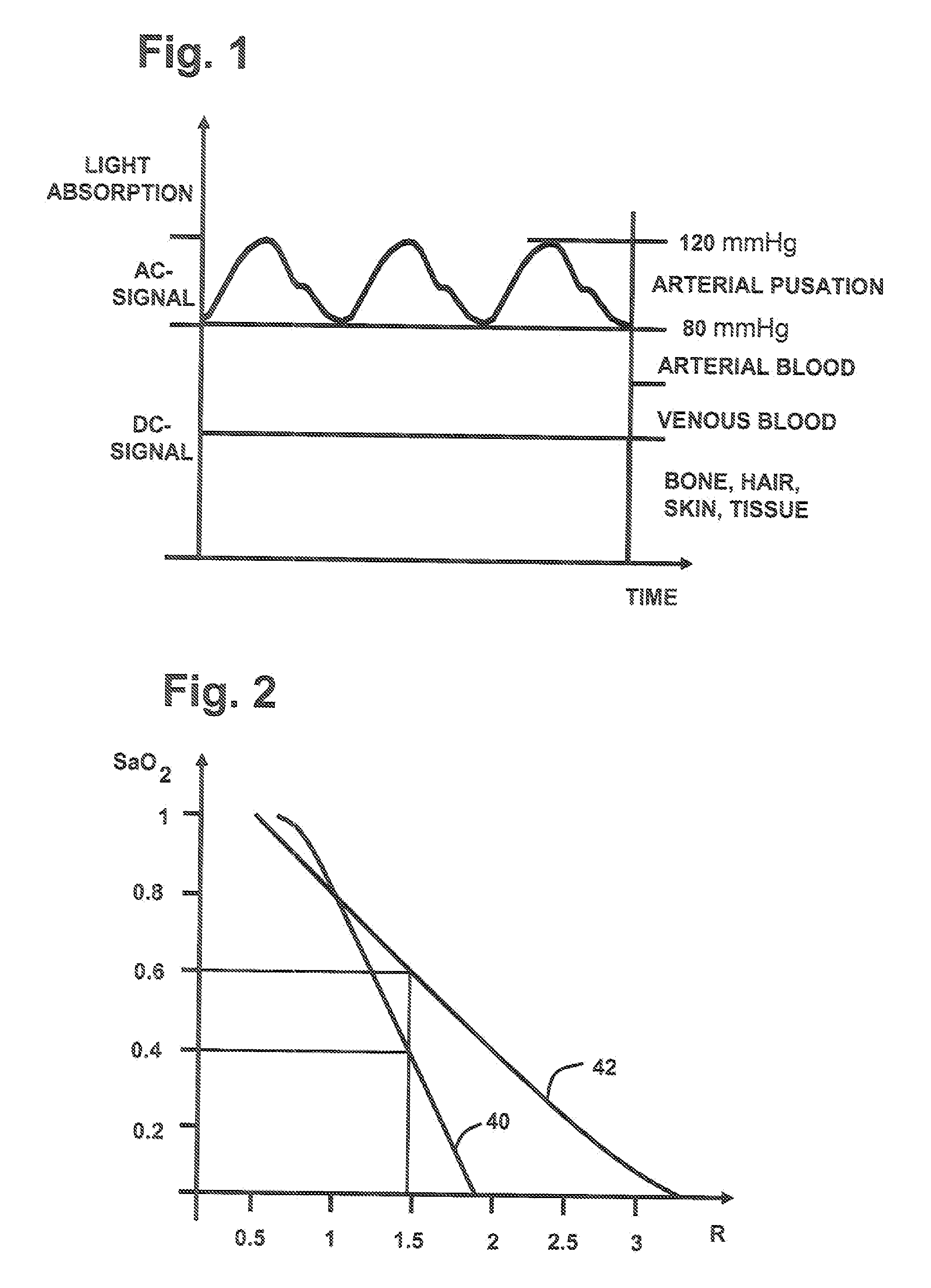

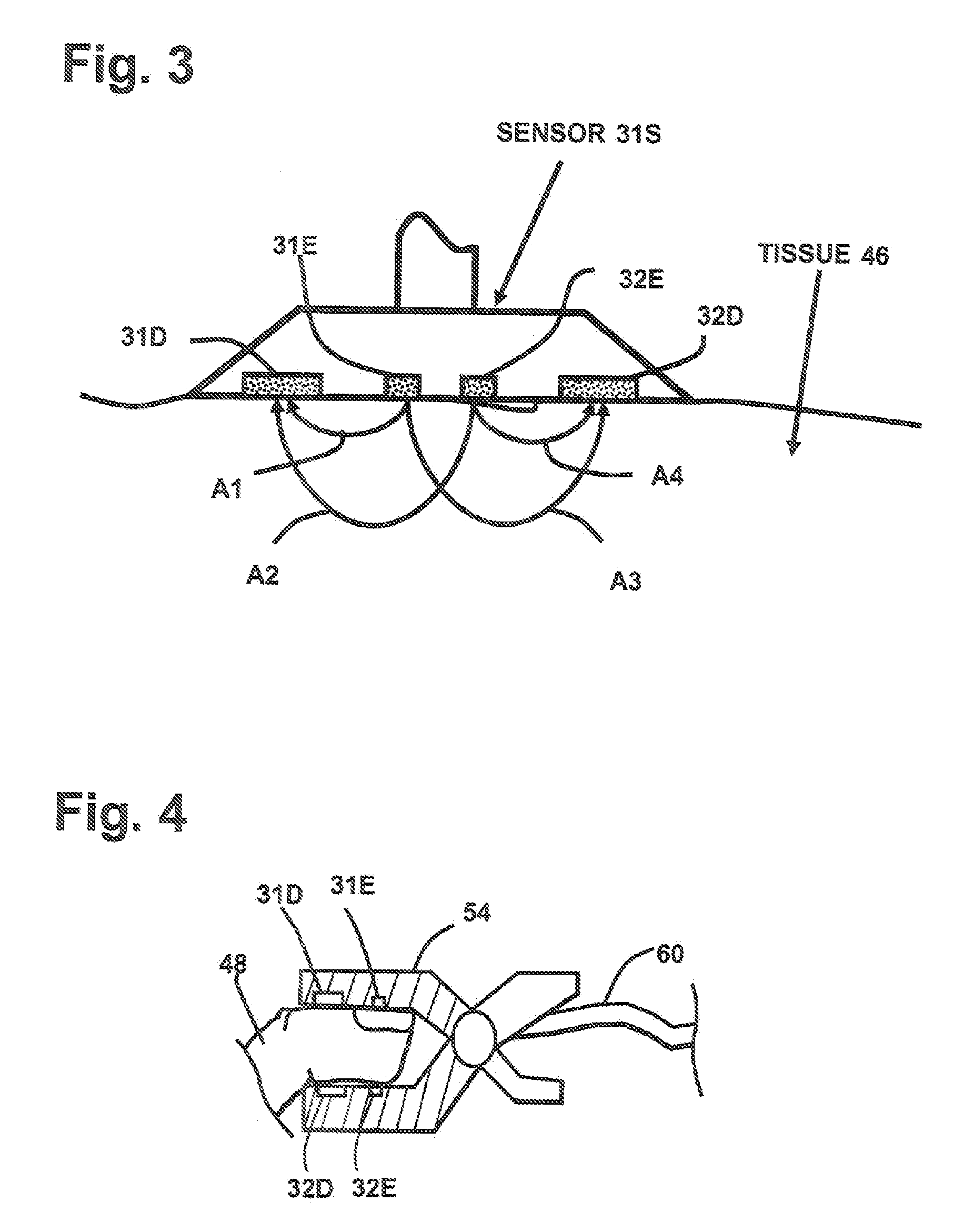

An apparatus and method for determining tissue oxygenation such as arterial and venous oxygenation and cerebral oxygenation. In one embodiment the optical properties of tissue are determined using measured light attenuations at a set of wavelengths. By choosing distinct wavelengths and using light attenuation information, the influence of variables such as light scattering, absorption and other optical tissue properties can be minimized.

Owner:BERNREUTER PETER

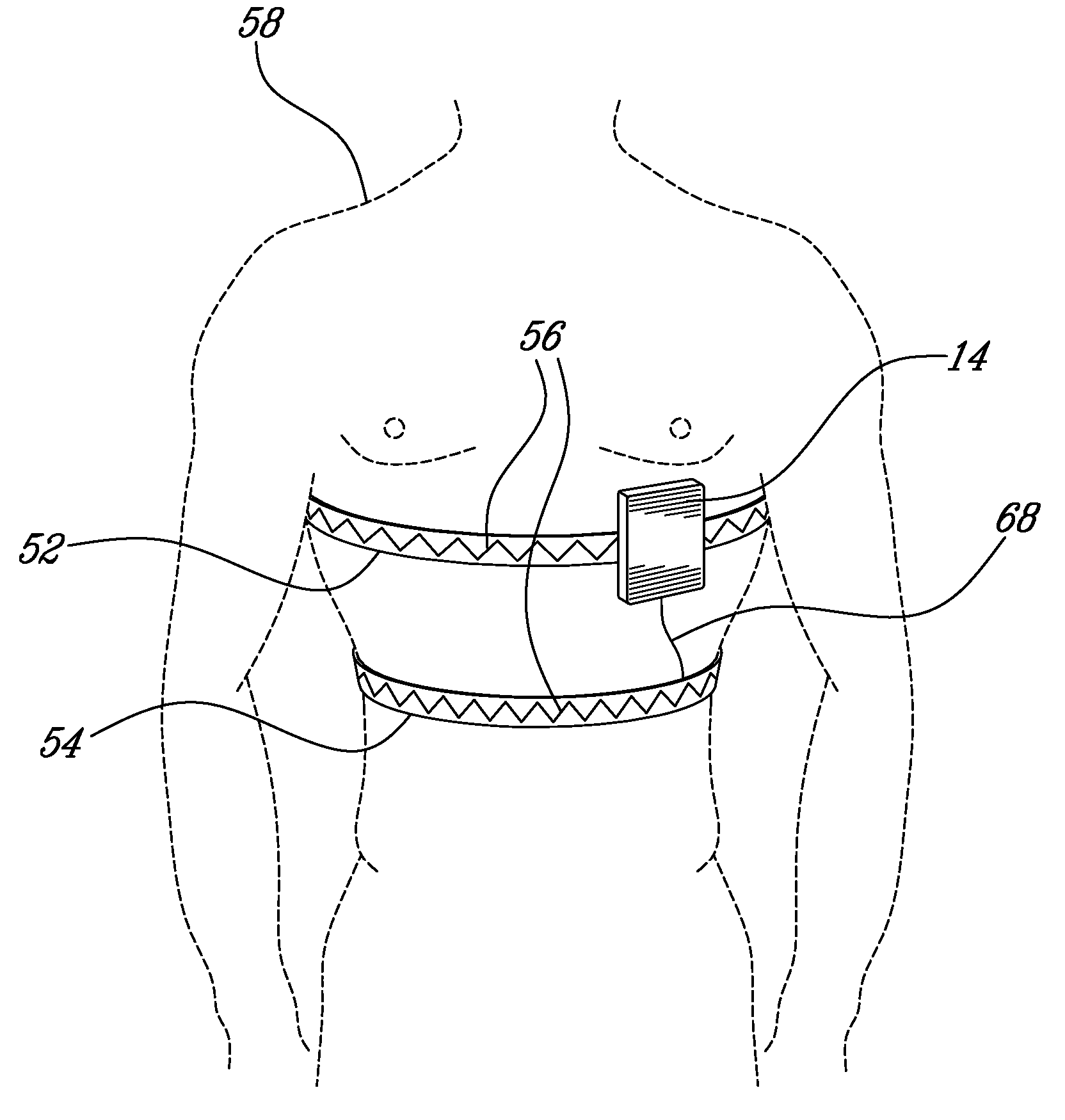

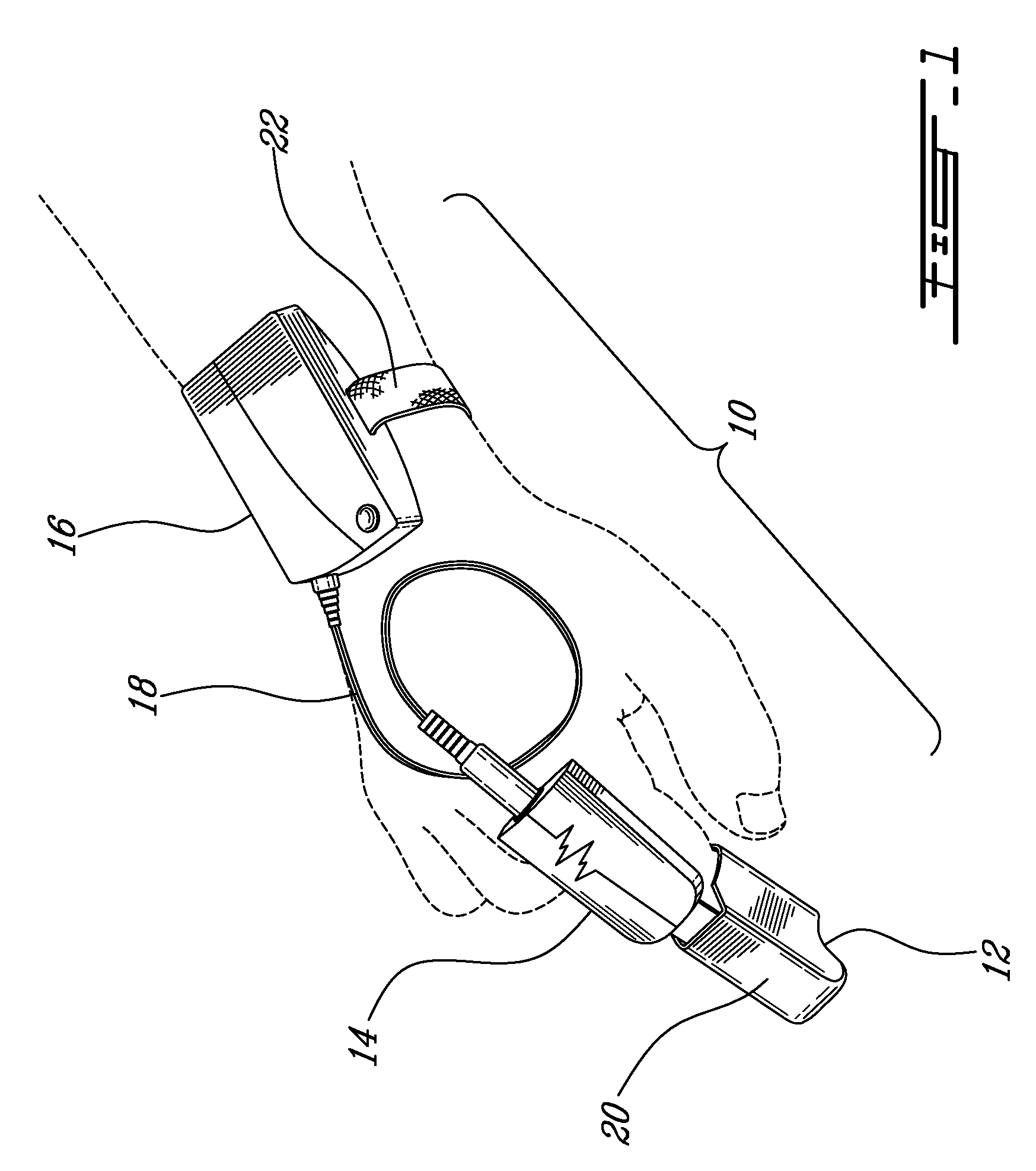

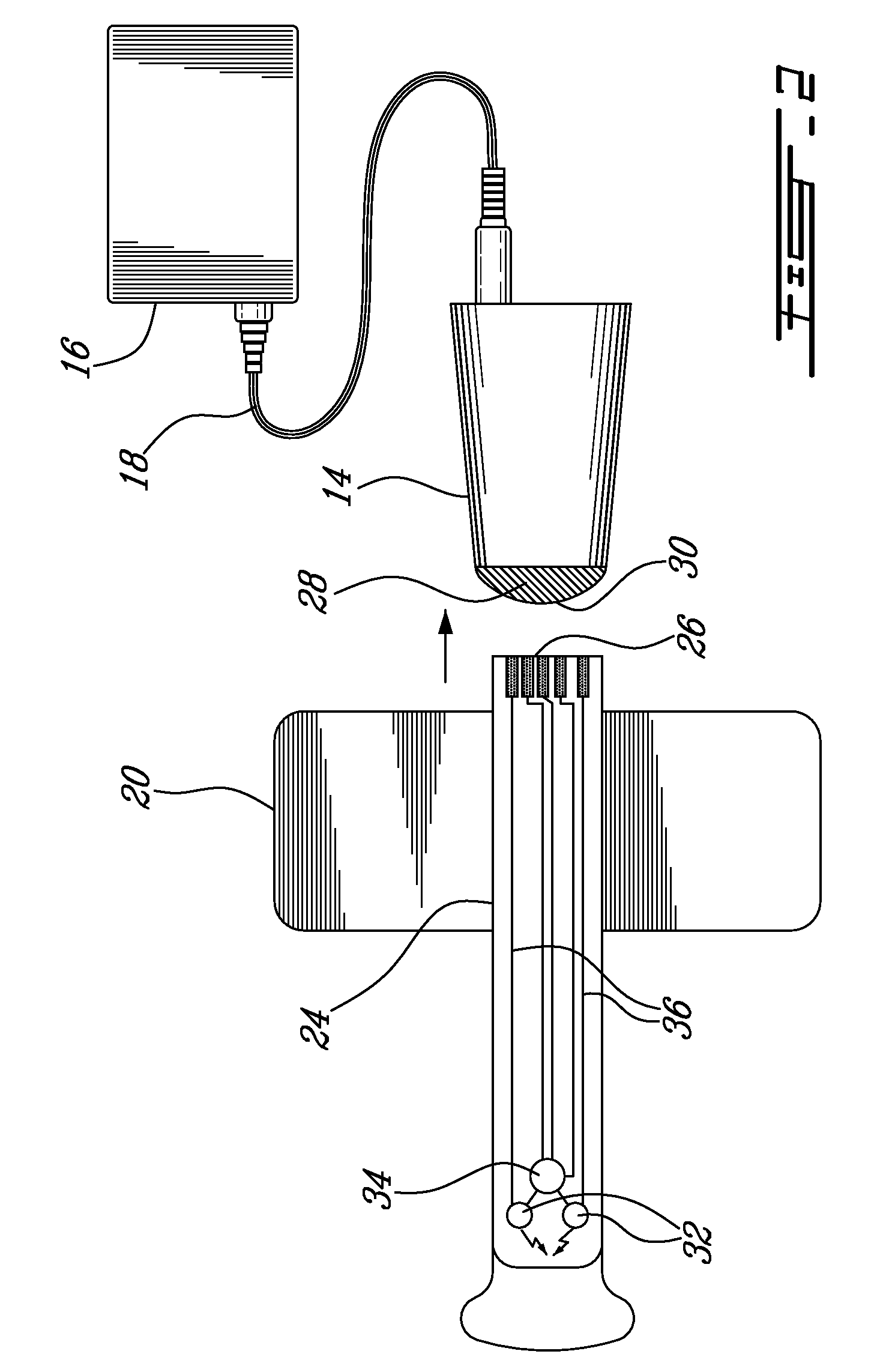

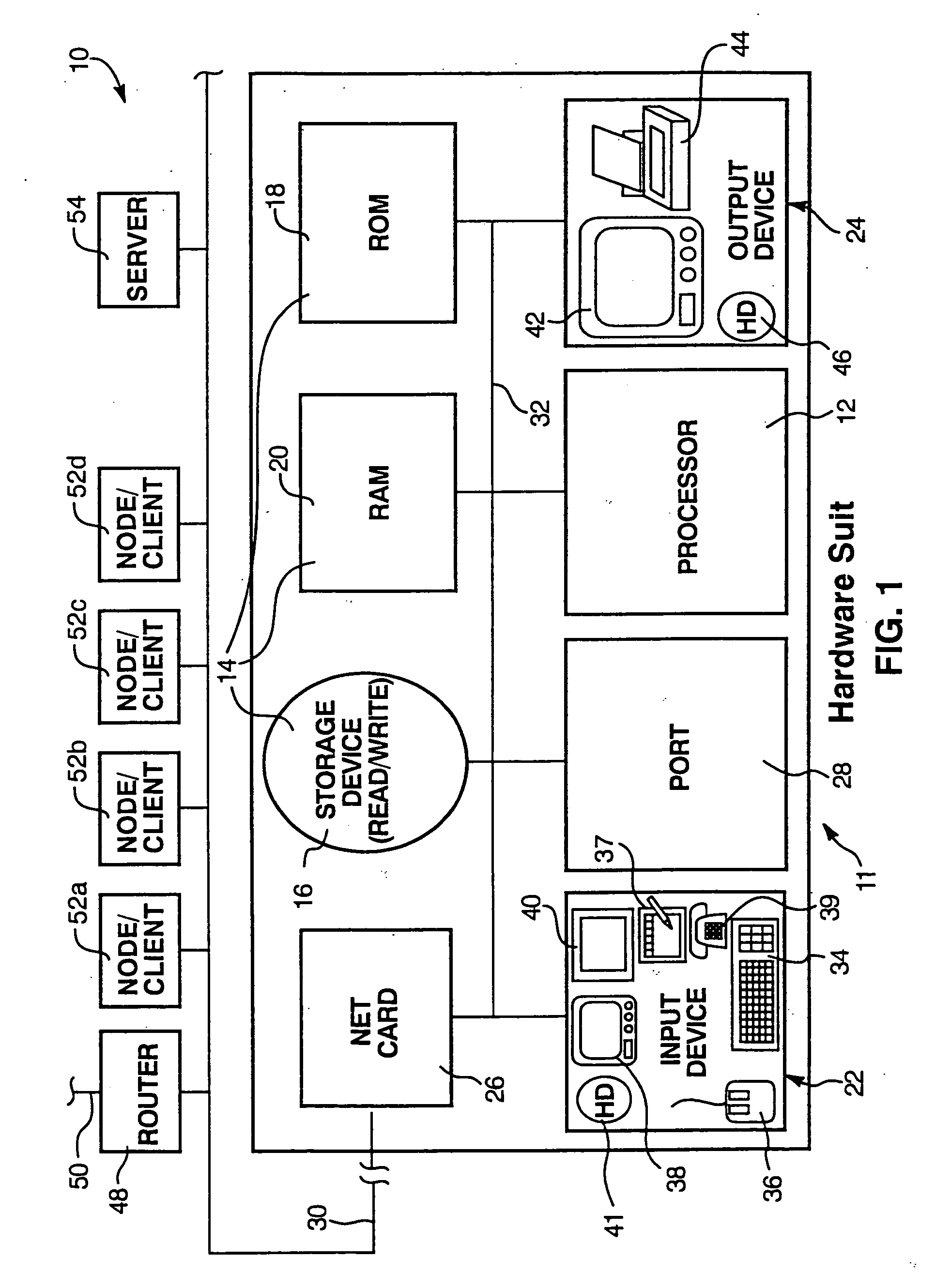

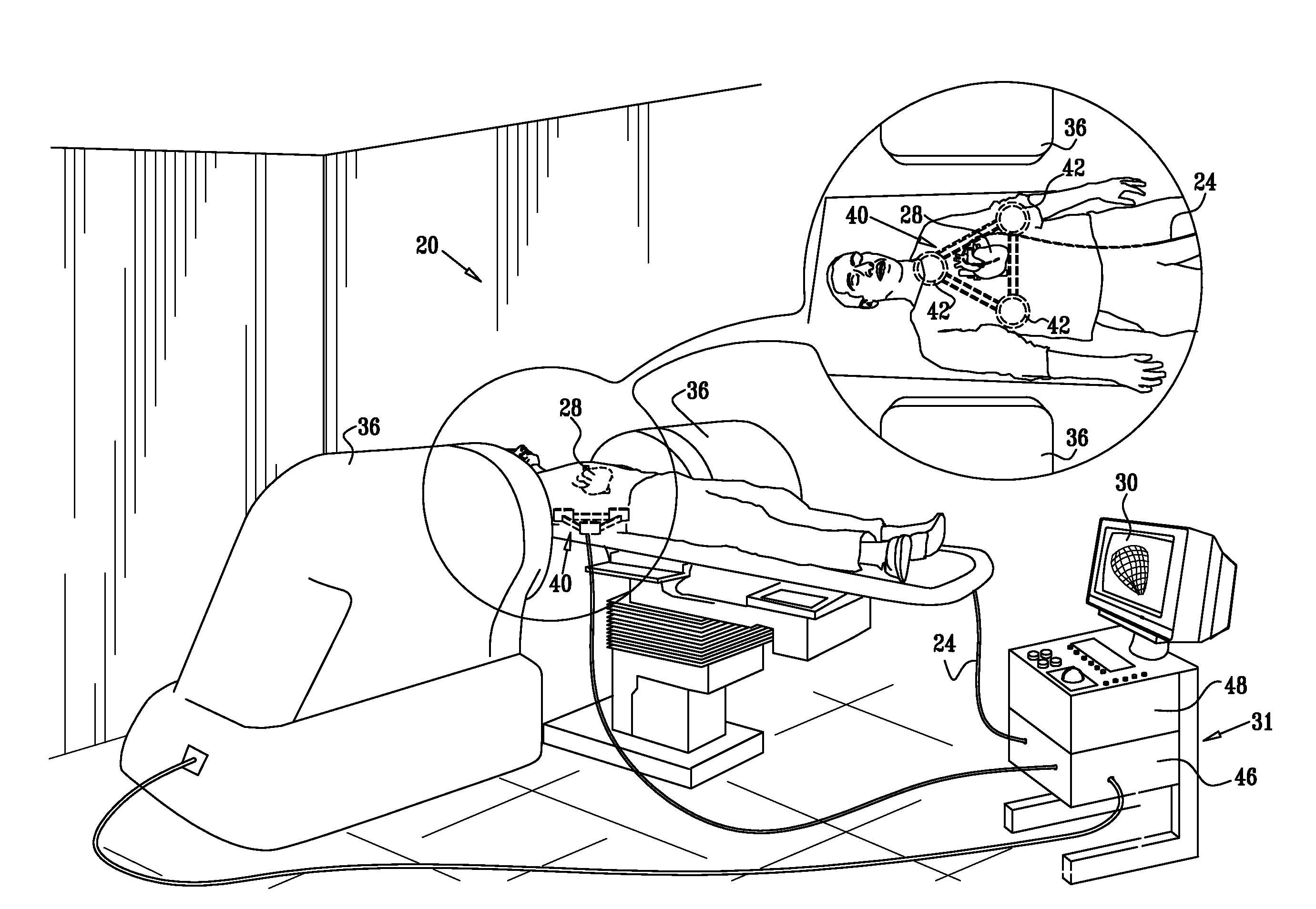

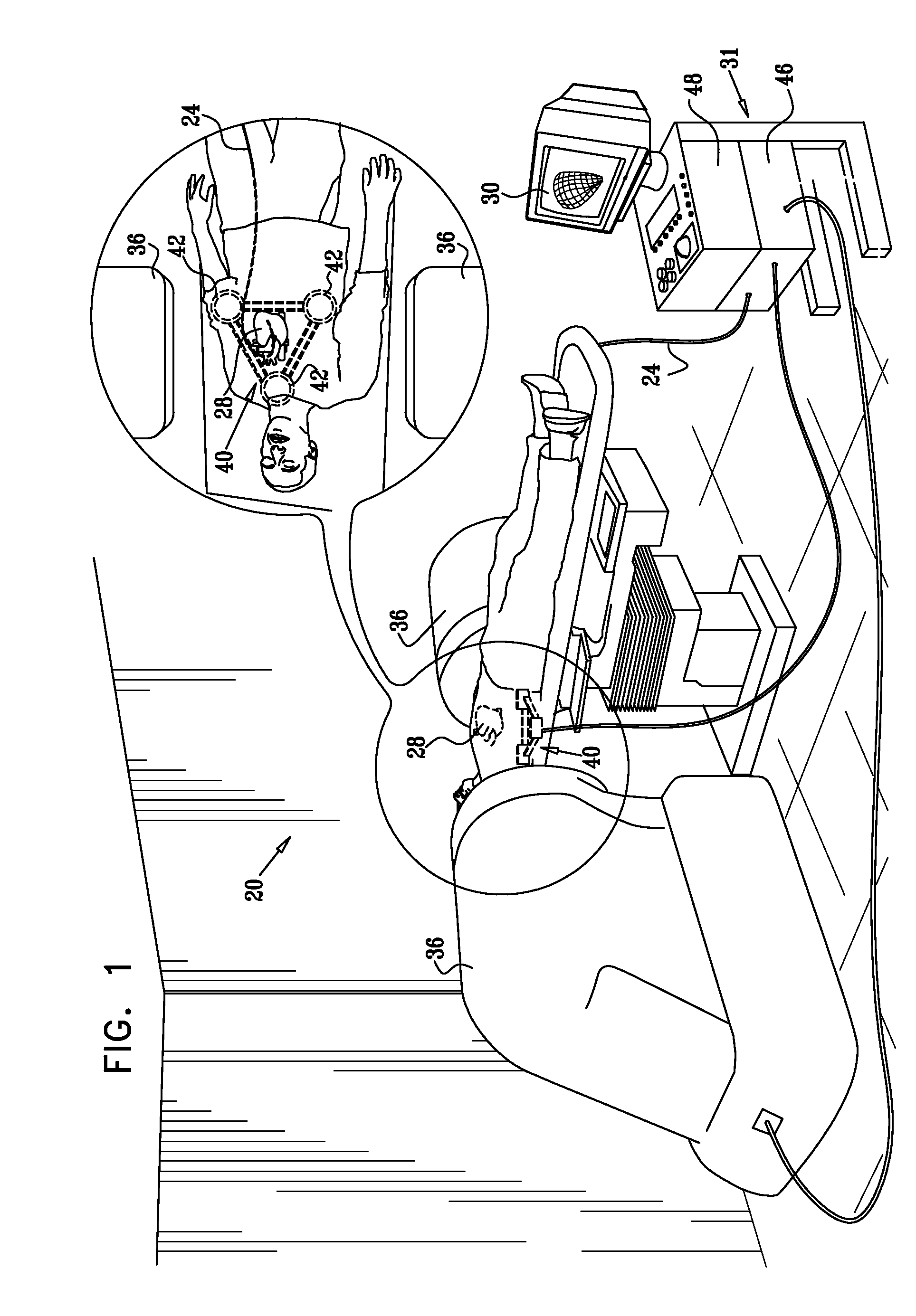

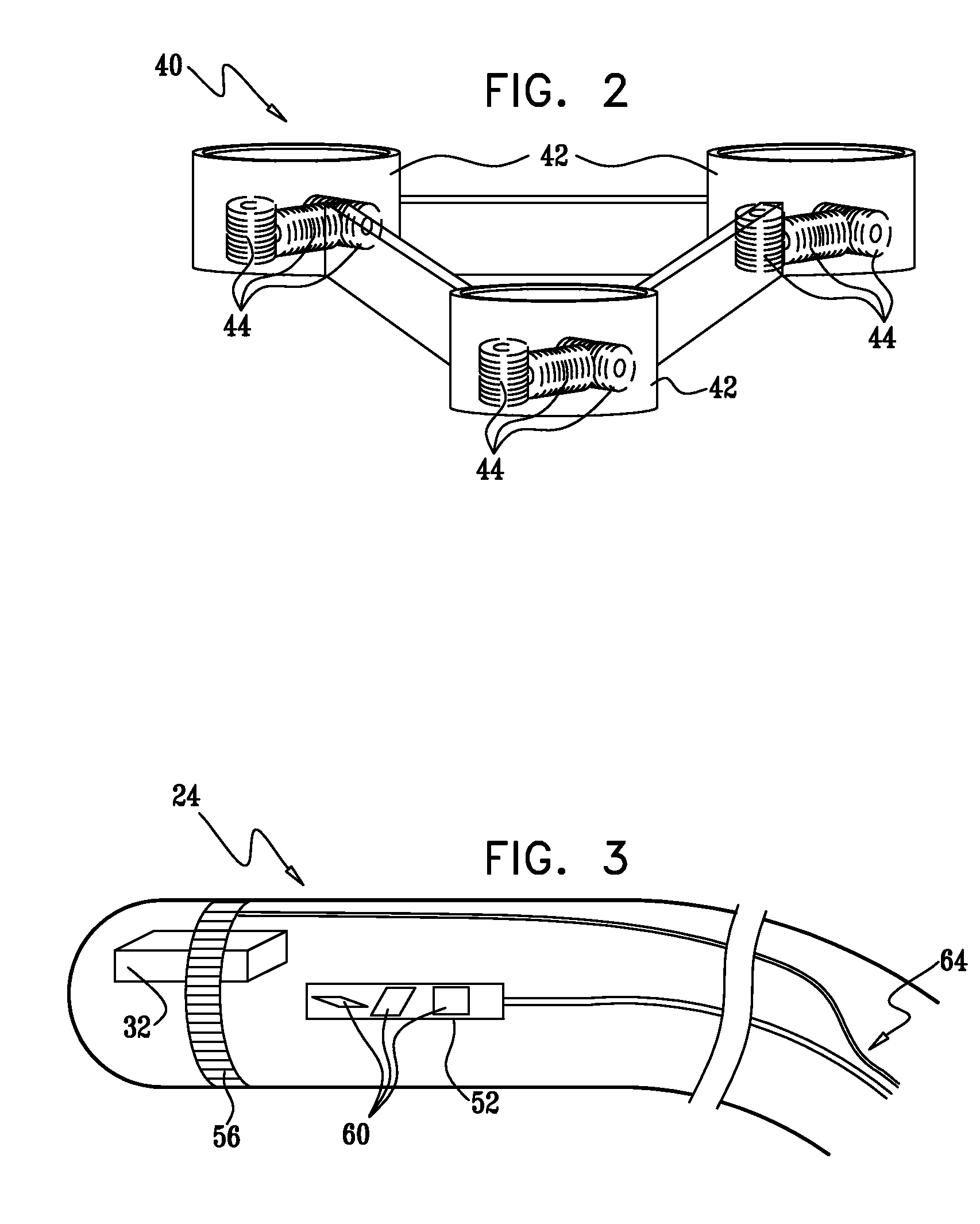

Physiologic sensor apparatus

InactiveUS20060282001A1Shorten the timeEasy data accessElectrocardiographyRespiratory organ evaluationEngineeringPeripheral

An apparatus for sensing at least one physiological parameter of a patient and transmitting data related to the sensed physiological parameter to an external device. The apparatus comprises a detecting portion comprising at least one sensor interconnected with a connector, an acquisition portion comprising a connector interface configured to receive the connector, electronics for controlling the at least one sensor via the connector interface, receiving data related to the at least one physiological parameter from the at least one sensor via the connector interface and processing the received data, and a wireless interface for transmitting the processed data to the external device, and a power source for supplying energy to the acquisition module.

Owner:SCOPRA SCI & GENIE SEC

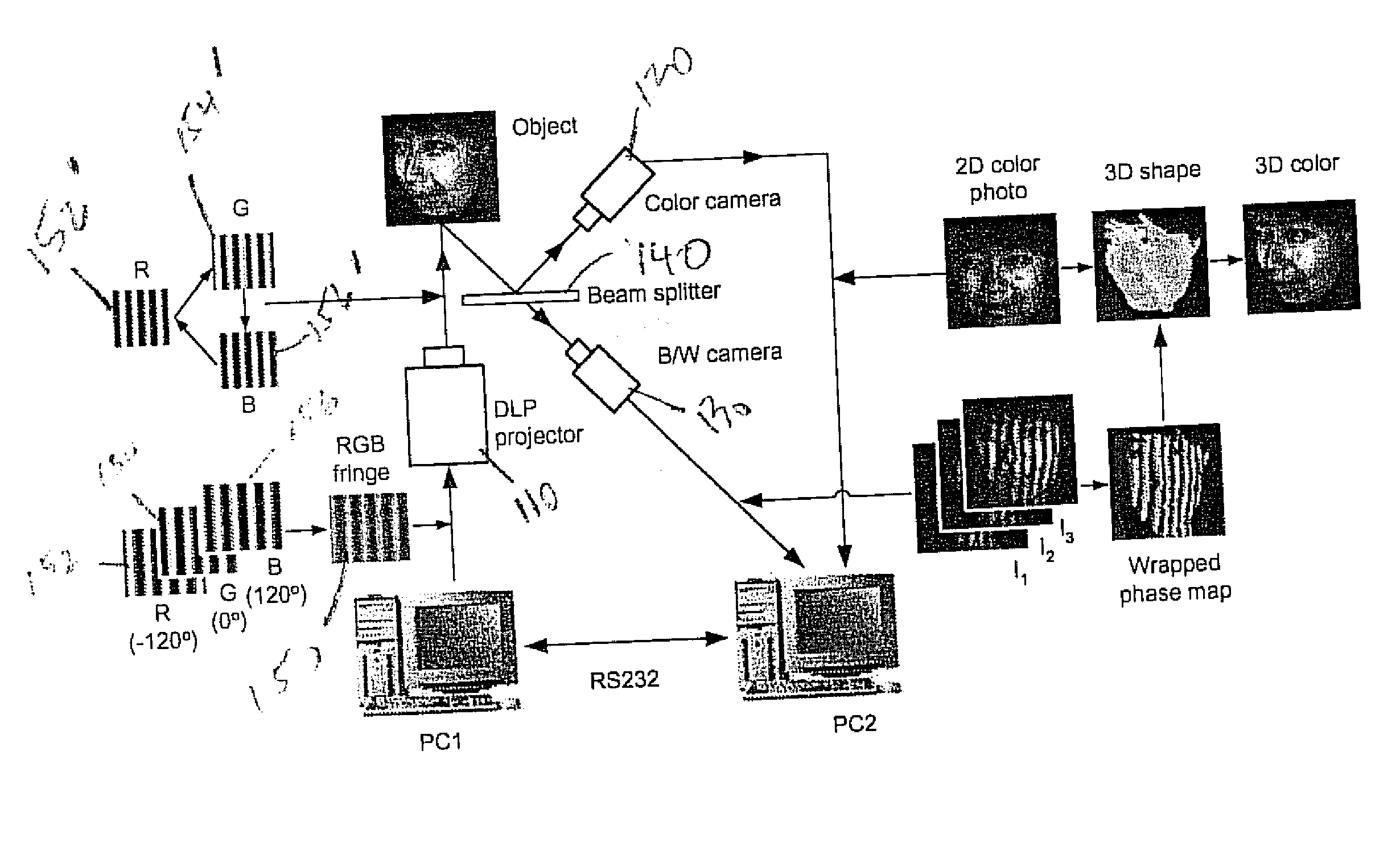

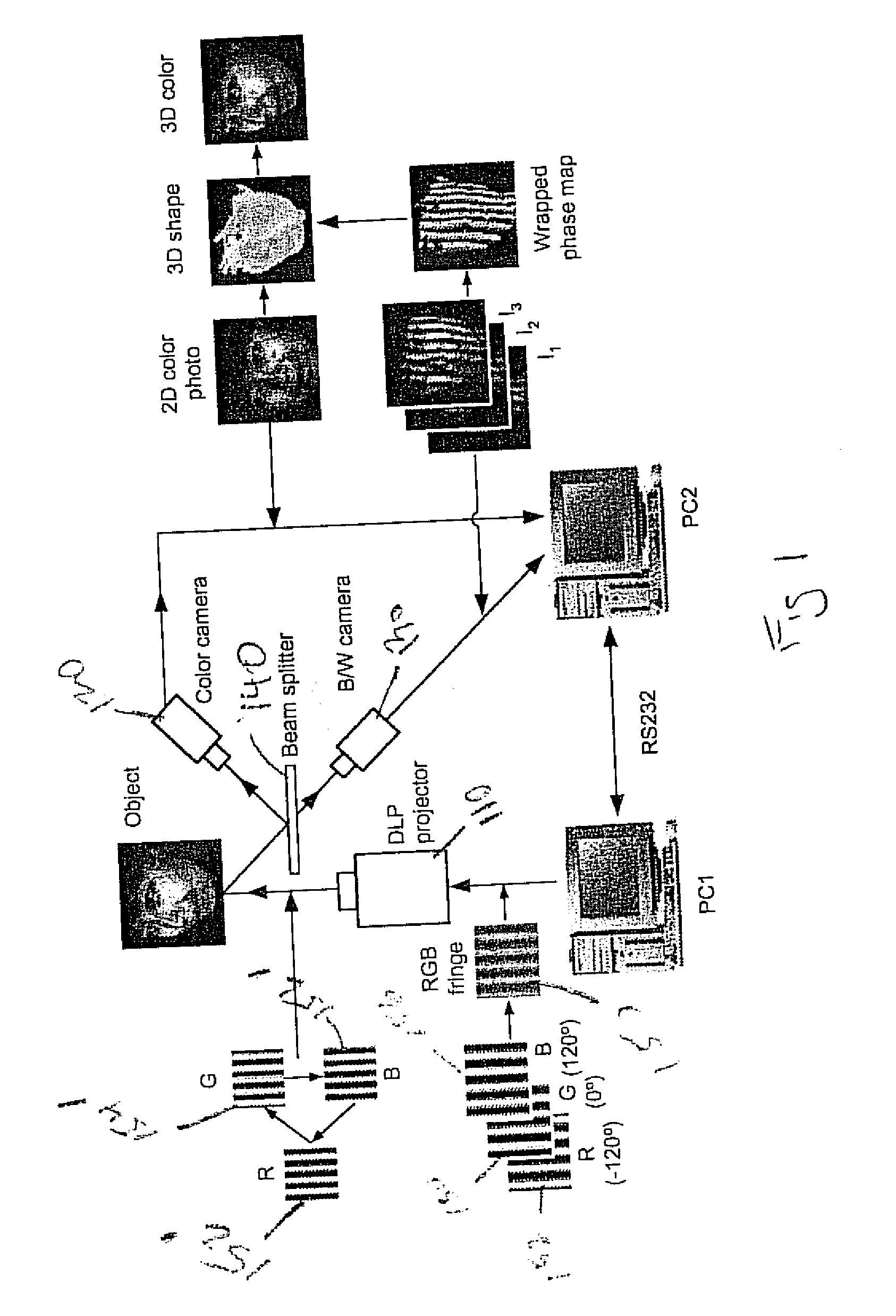

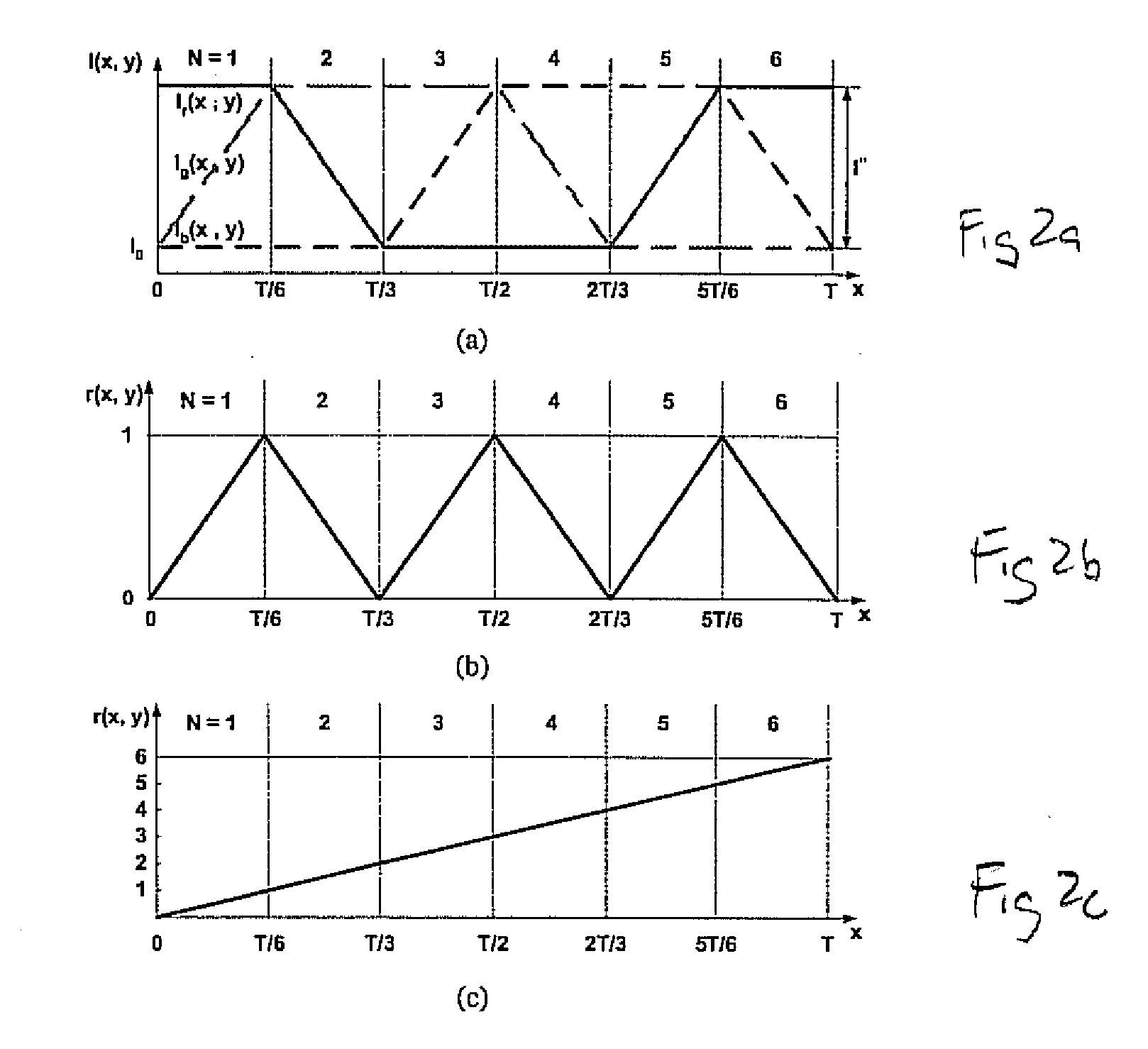

3D shape measurement system and method including fast three-step phase shifting, error compensation and calibration

InactiveUS20070115484A1Improve system speedFacilitates establishment of coordinate relationshipUsing optical means3d shapesPhase shifted

A structured light system for object ranging / measurement is disclosed that implements a trapezoidal-based phase-shifting function with intensity ratio modeling using sinusoidal intensity-varied fringe patterns to accommodate for defocus error. The structured light system includes a light projector constructed to project at least three sinusoidal intensity-varied fringe patterns onto an object that are each phase shifted with respect to the others, a camera for capturing the at least three intensity-varied phase-shifted fringe patterns as they are reflected from the object and a system processor in electrical communication with the light projector and camera for generating the at least three fringe patterns, shifting the patterns in phase and providing the patterns to the projector, wherein the projector projects the at least three phase-shifted fringe patterns sequentially, wherein the camera captures the patterns as reflected from the object and wherein the system processor processes the captured patterns to generate object coordinates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

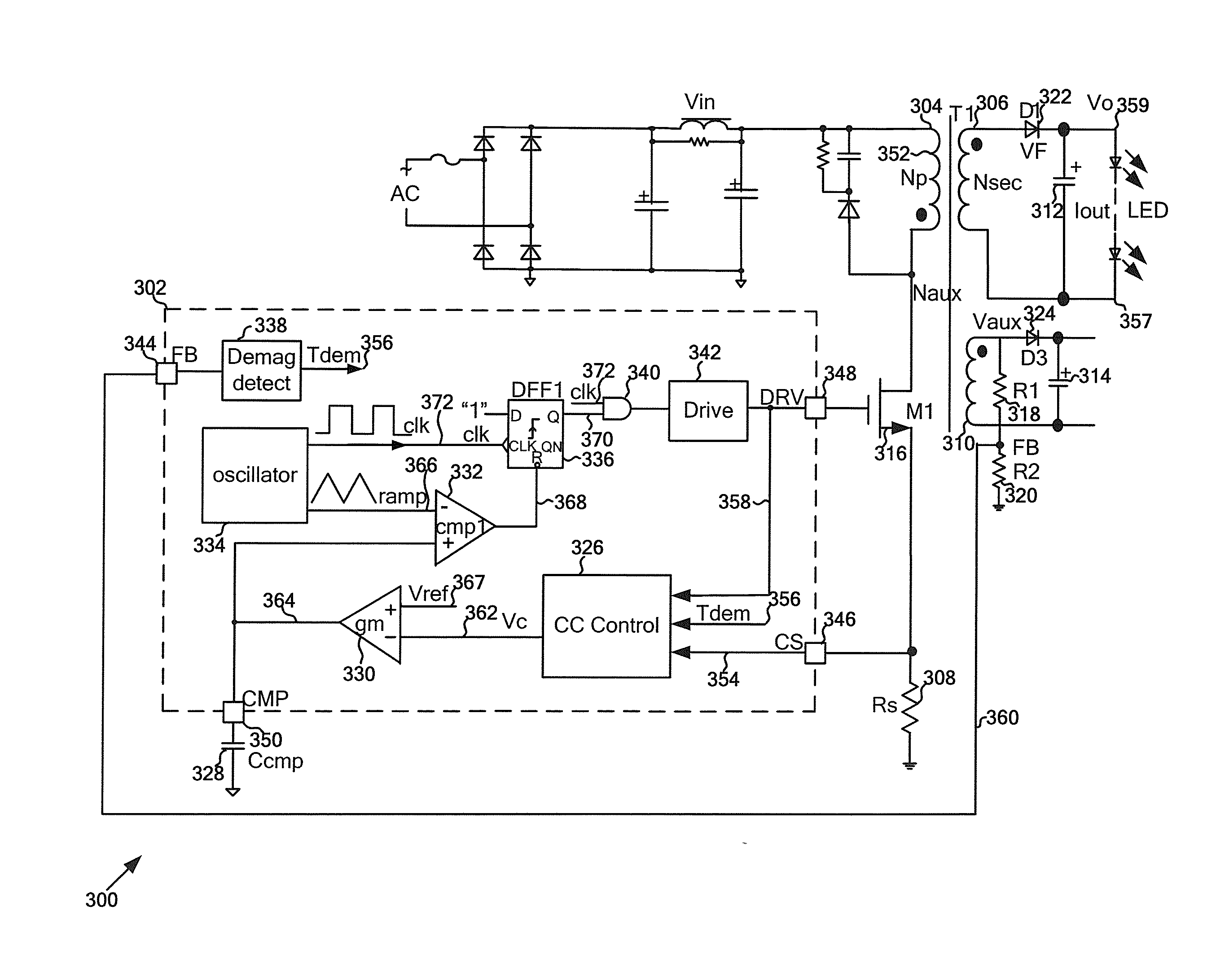

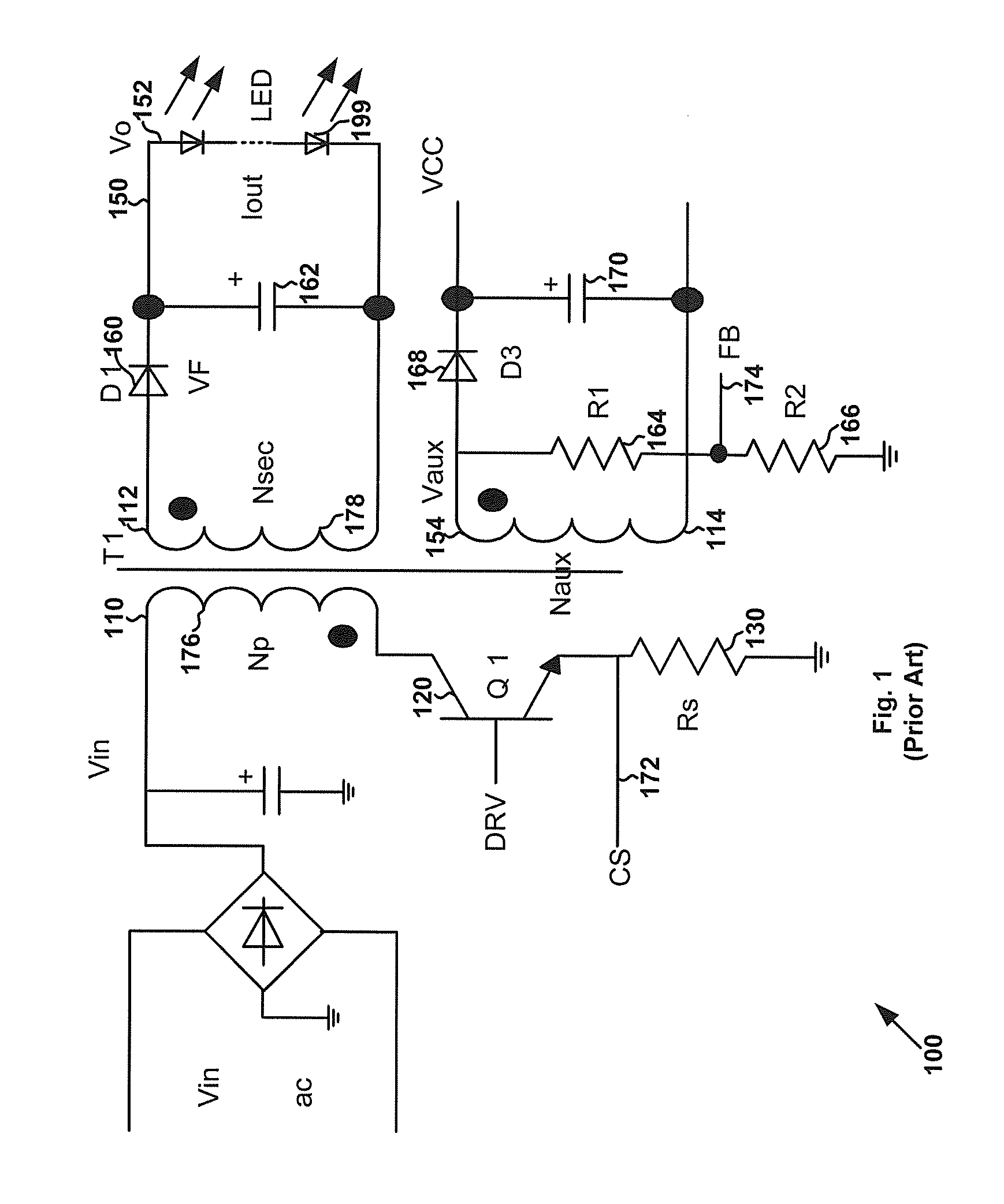

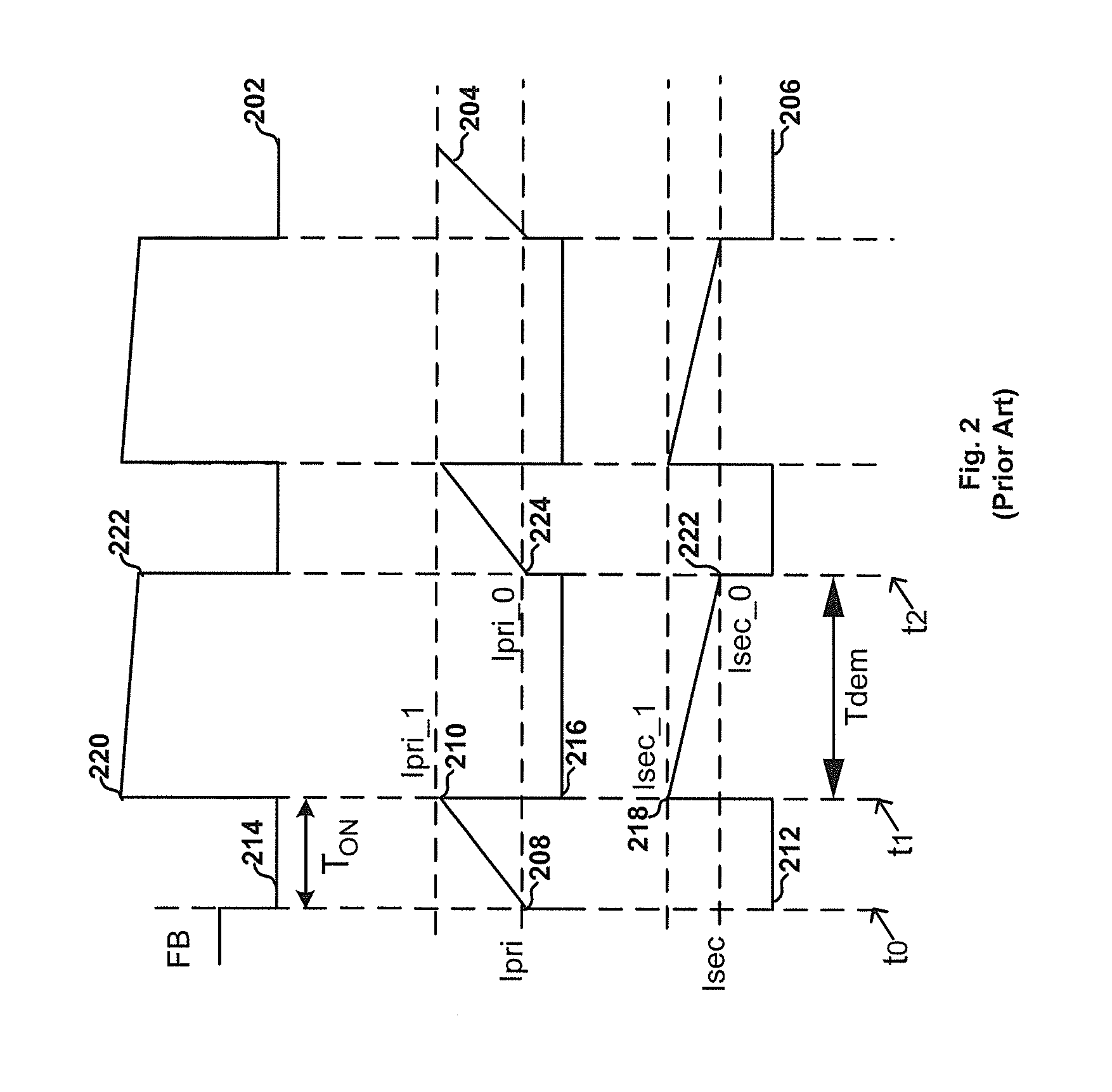

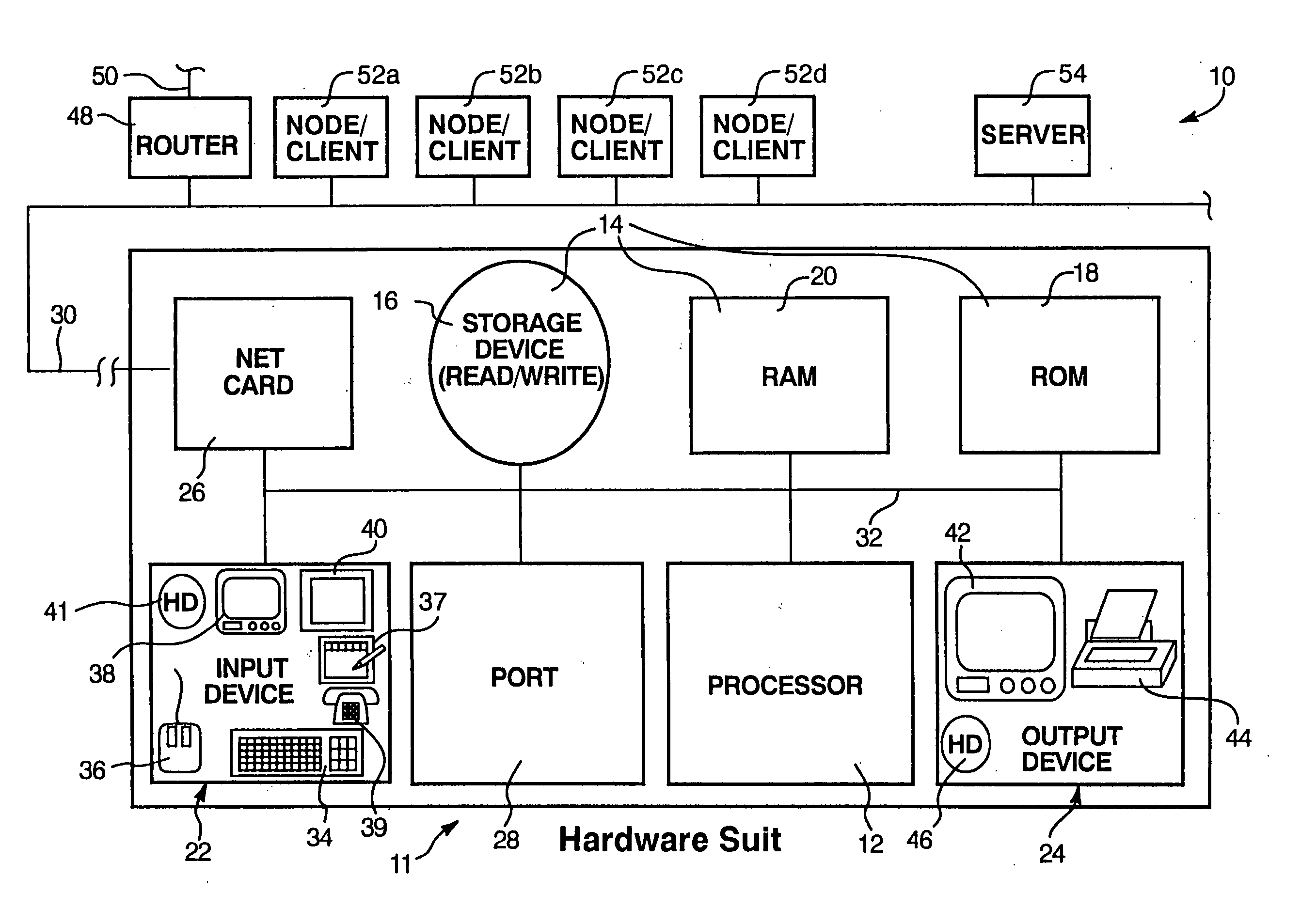

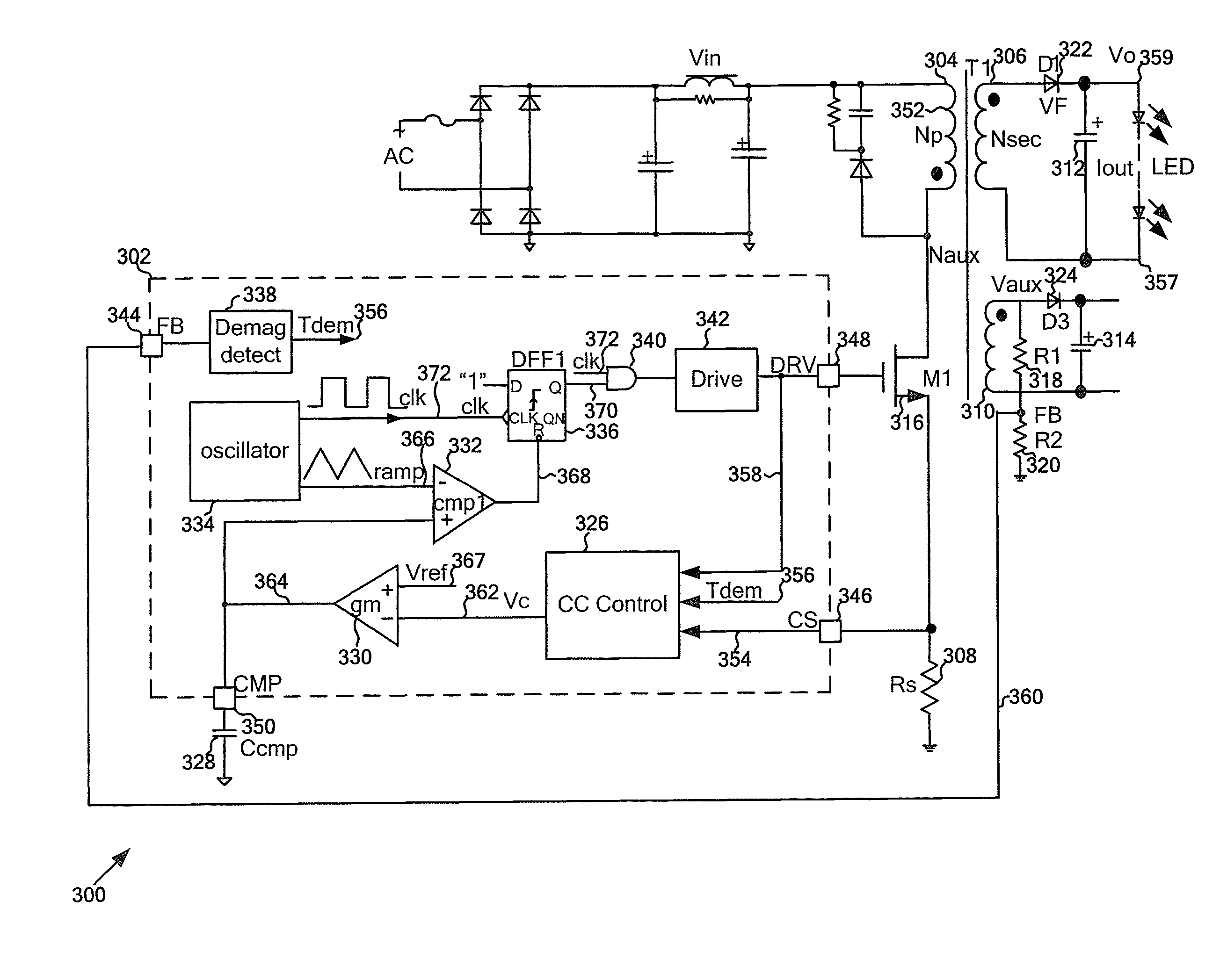

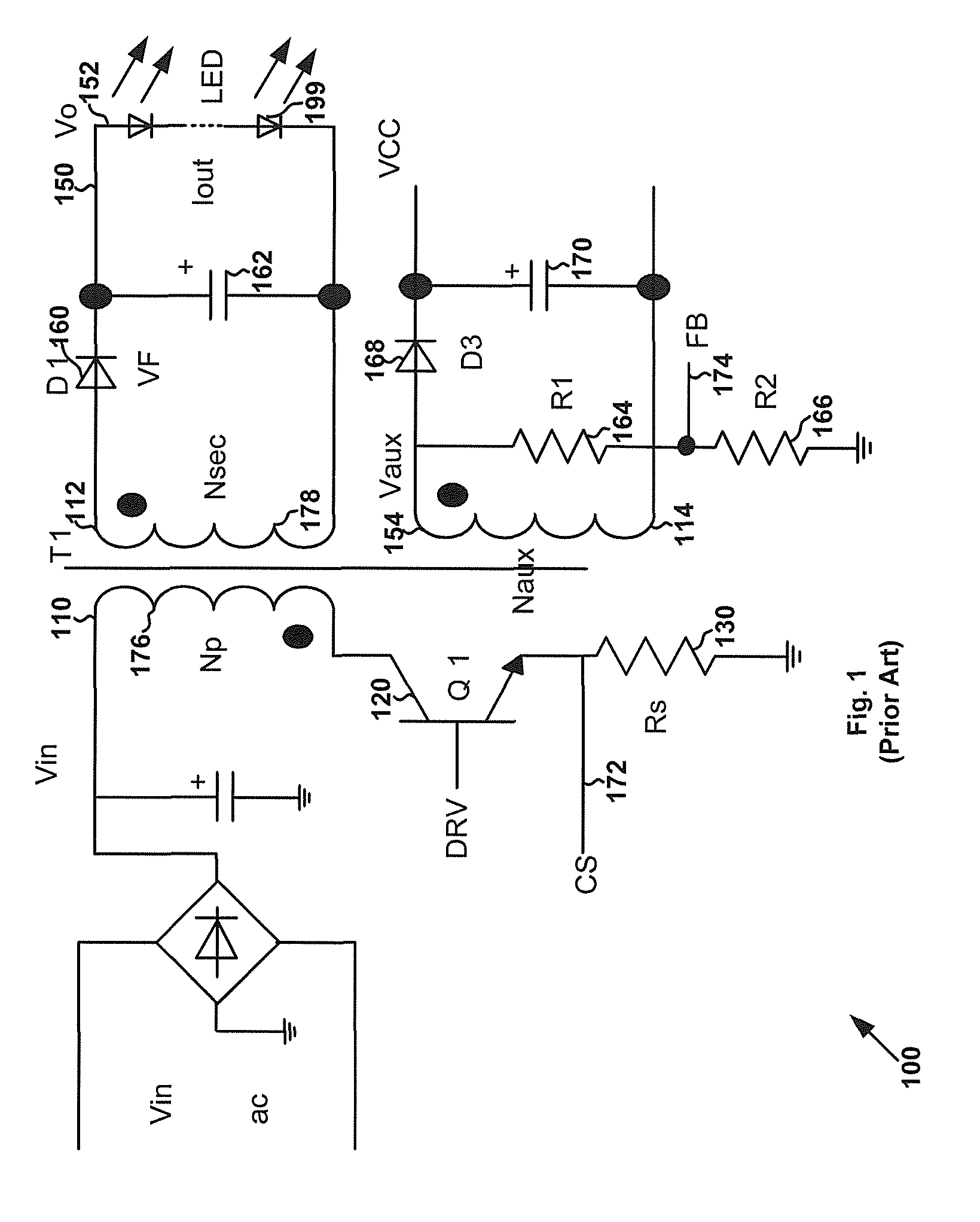

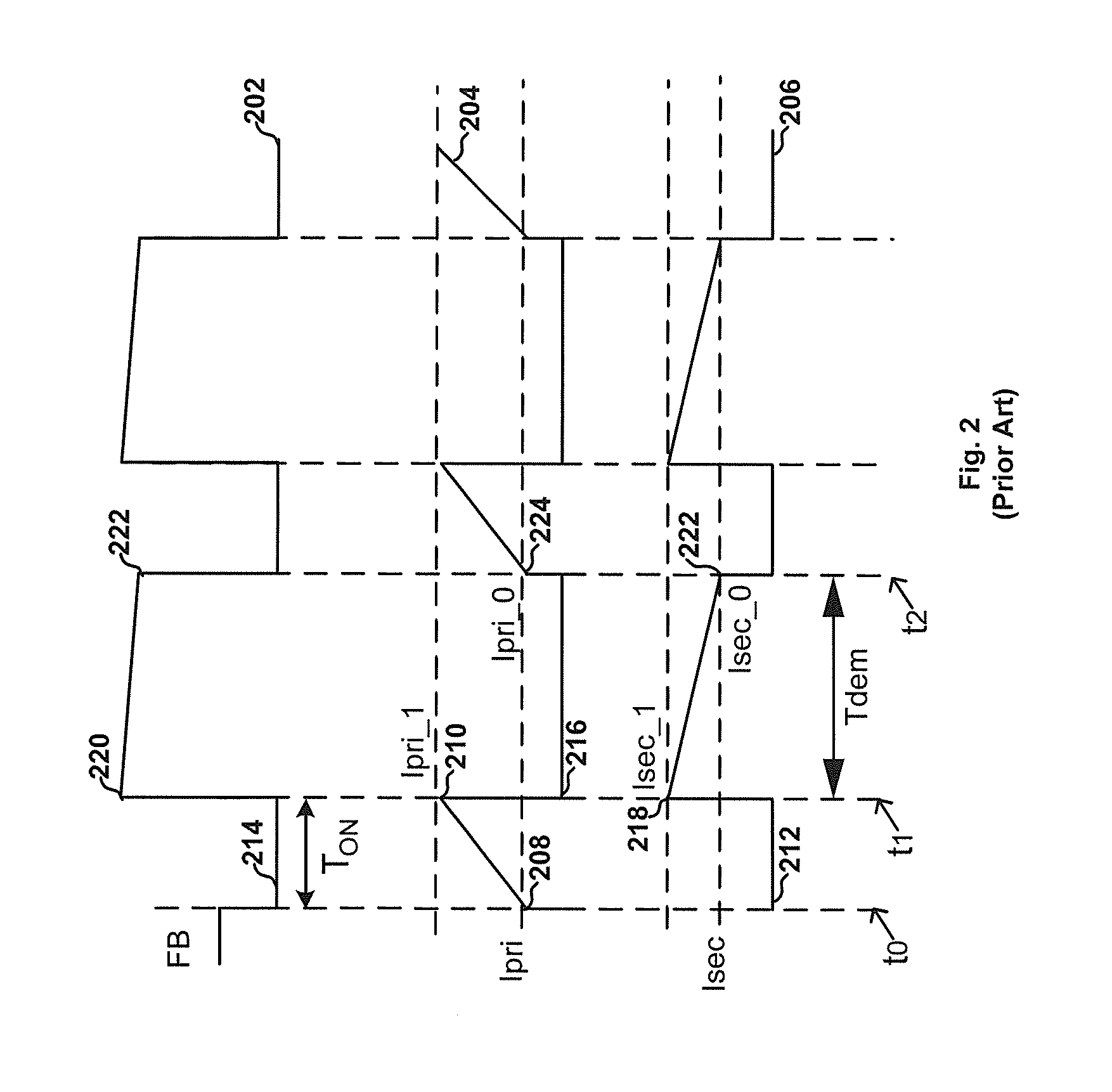

Systems and methods for current control of power conversion systems

ActiveUS20140029315A1Reduce errorsReduce measurement errorElectroluminescent light sourcesDc-dc conversionEngineeringConductor Coil

System and method for regulating an output current of a power conversion system. An example system controller for regulating an output current of a power conversion system includes a driving component, a demagnetization detector, a current-regulation component, and a signal processing component. The driving component is configured to output a drive signal to a switch in order to affect a primary current flowing through a primary winding of the power conversion system. The demagnetization detector is configured to receive a feedback signal associated with an output voltage of the power conversion system and generate a detection signal based on at least information associated with the feedback signal. The current-regulation component is configured to receive the drive signal, the detection signal and a current-sensing signal and output a current-regulation signal based on at least information associated with the drive signal, the detection signal, and the current sensing signal.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

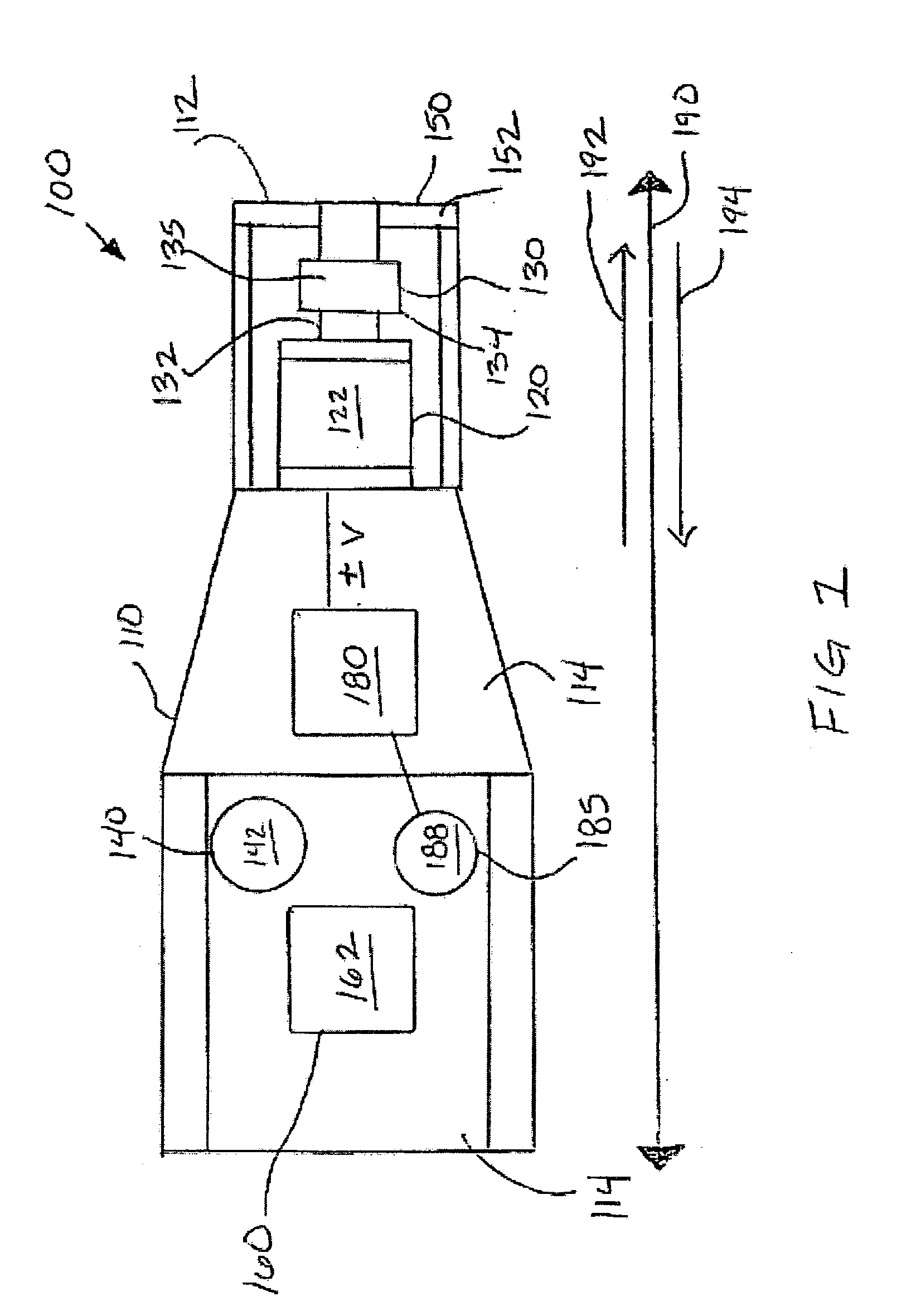

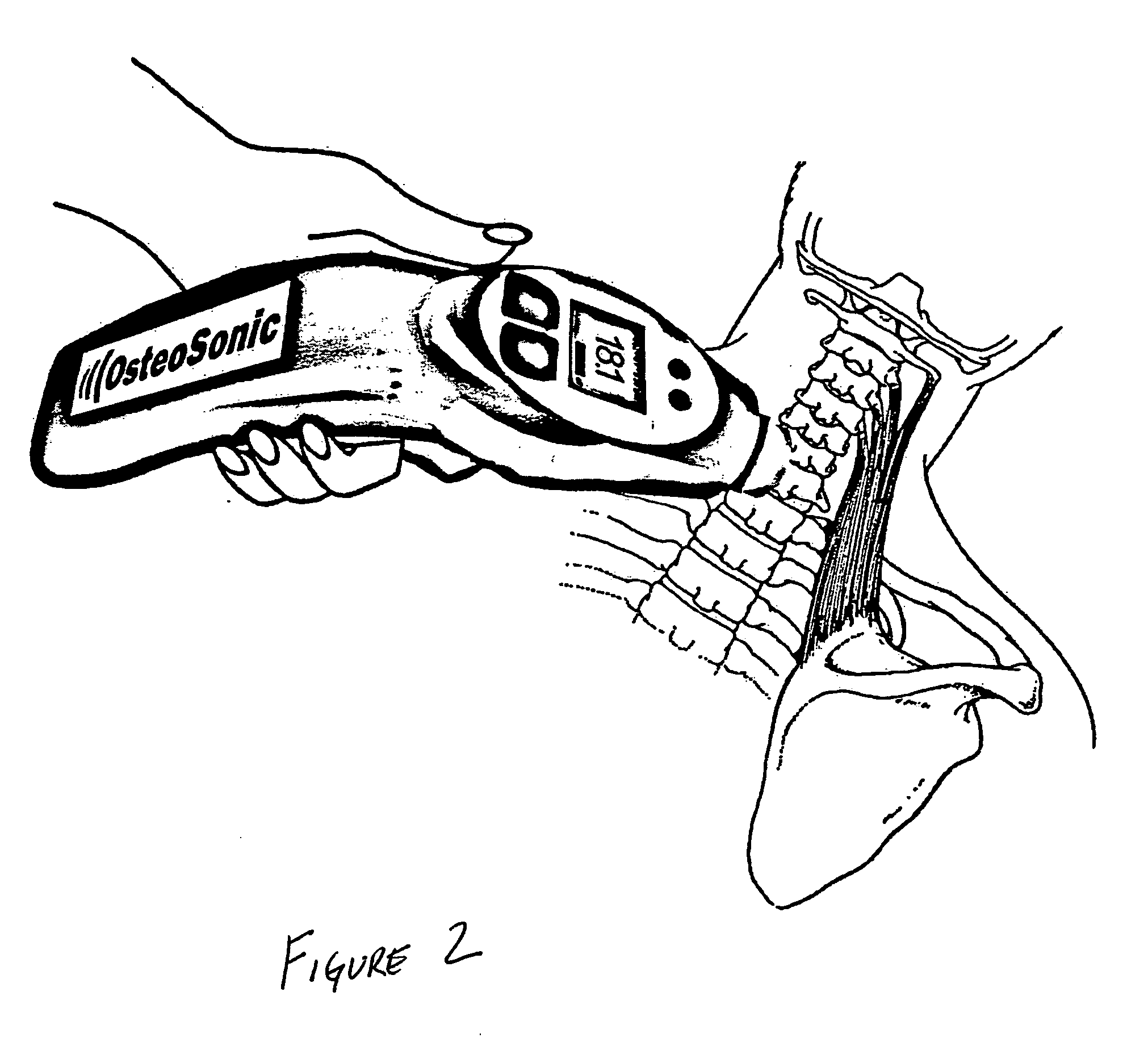

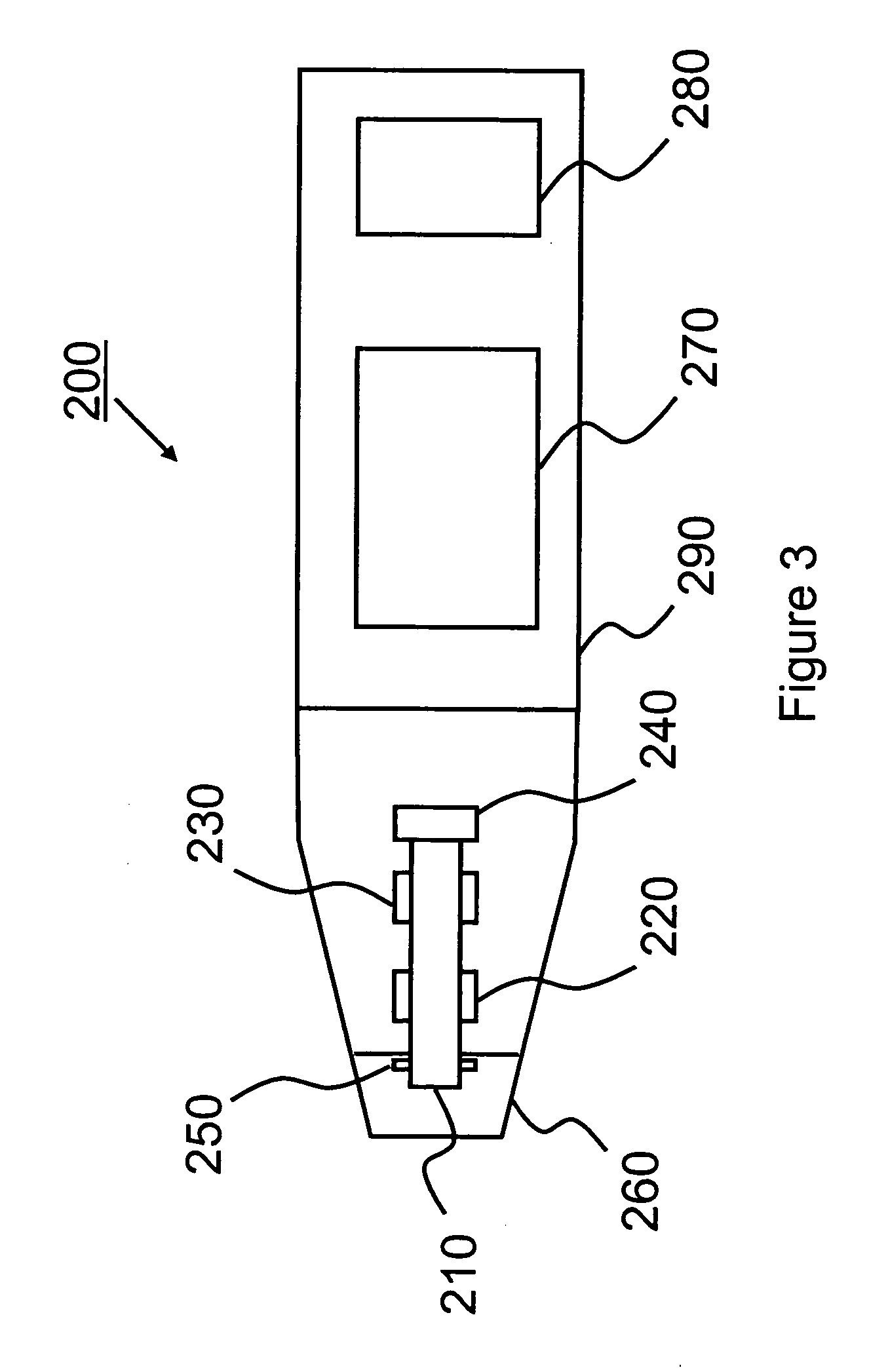

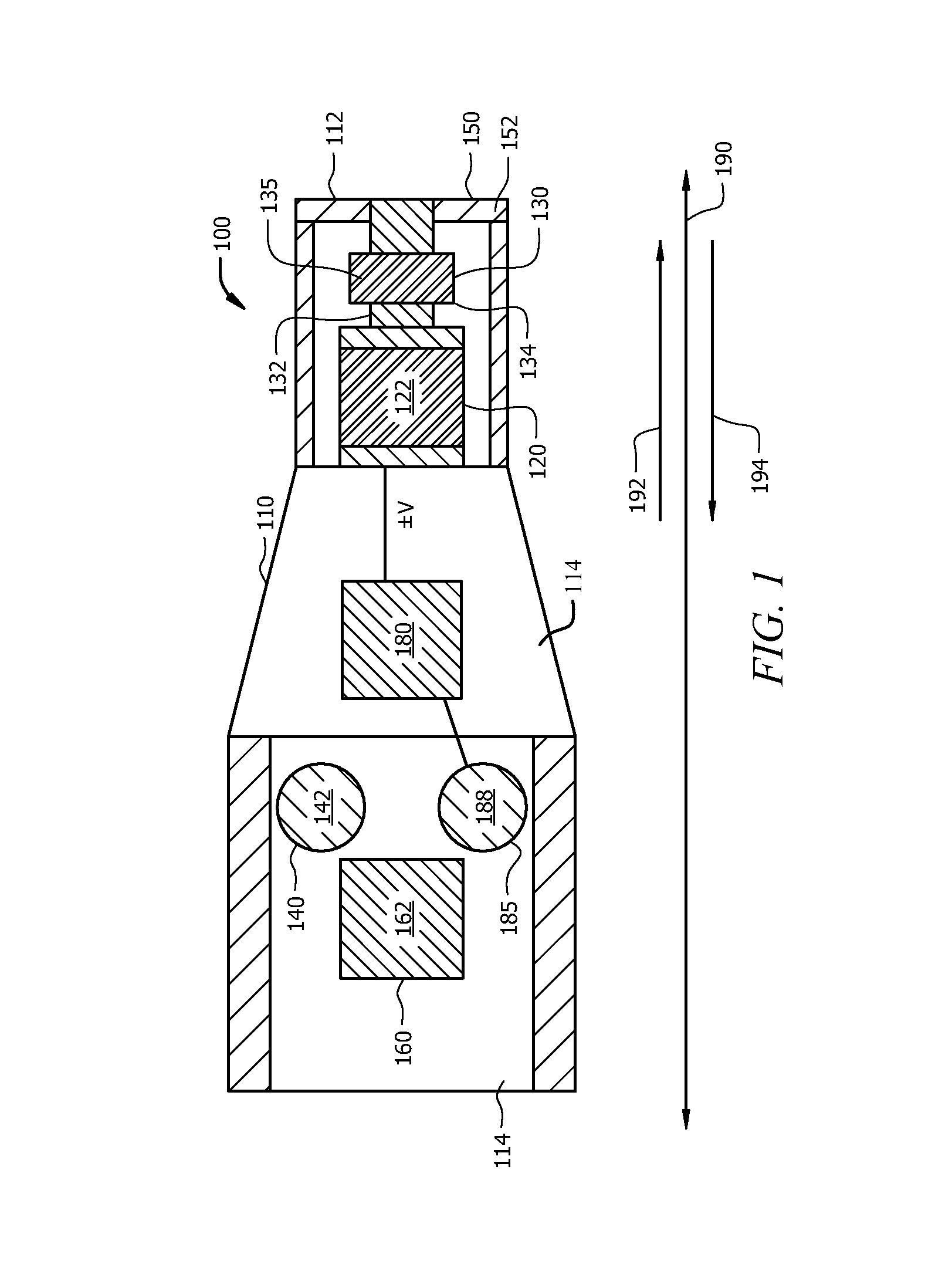

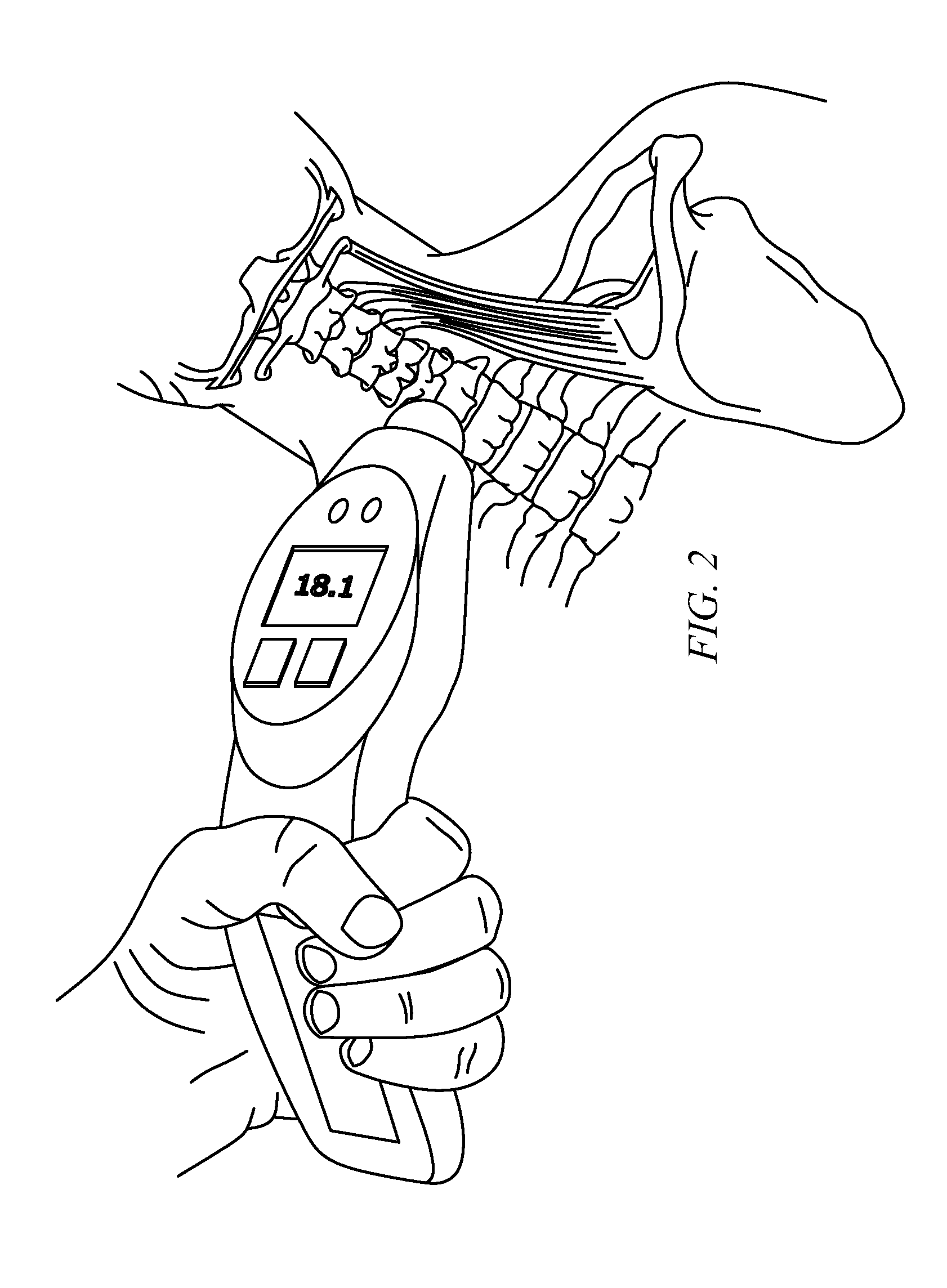

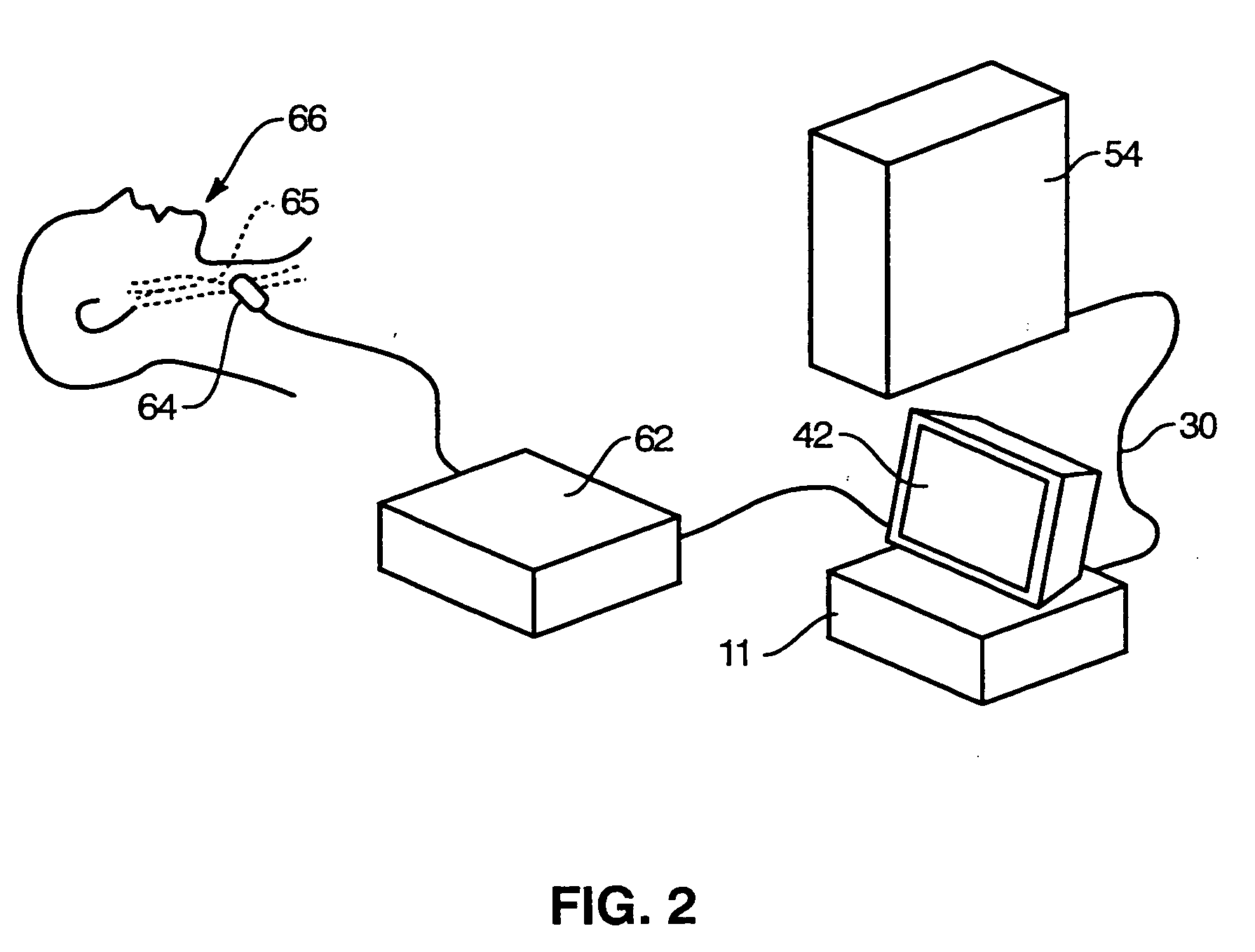

Noninvasive tissue assessment

InactiveUS20050113691A1Reduce measurement errorSufficient pressureUltrasonic/sonic/infrasonic diagnosticsBioreactor/fermenter combinationsFrequency spectrumPost operative

Methods and apparatus for non-invasively assessing physiological hard of soft tissue of human and other species are described. In a preferred embodiment, tissue is vibrationally stimulated in vivo through a frequency spectrum. The tissue reacts against the stimulus and the reaction is preferably measured and recorded. Based on analytical algorithms or comparisons with previously taken measurements, changes within the tissue can be detected and used for diagnostic purposes. Further embodiments describe the usage of the device and methods for in vivo intra-operative and post-operative implant evaluations and as a therapeutic tool.

Owner:RICE UNIV

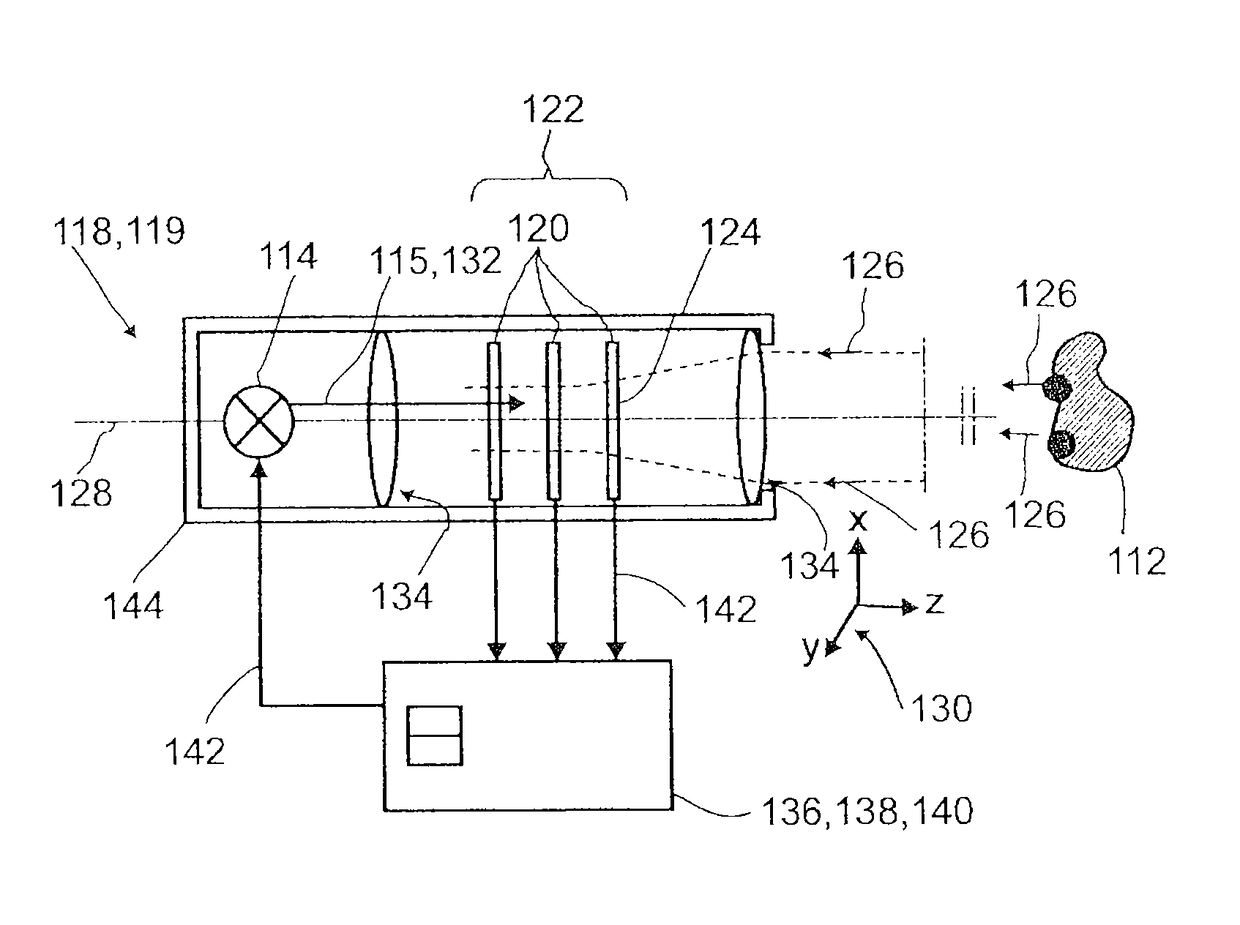

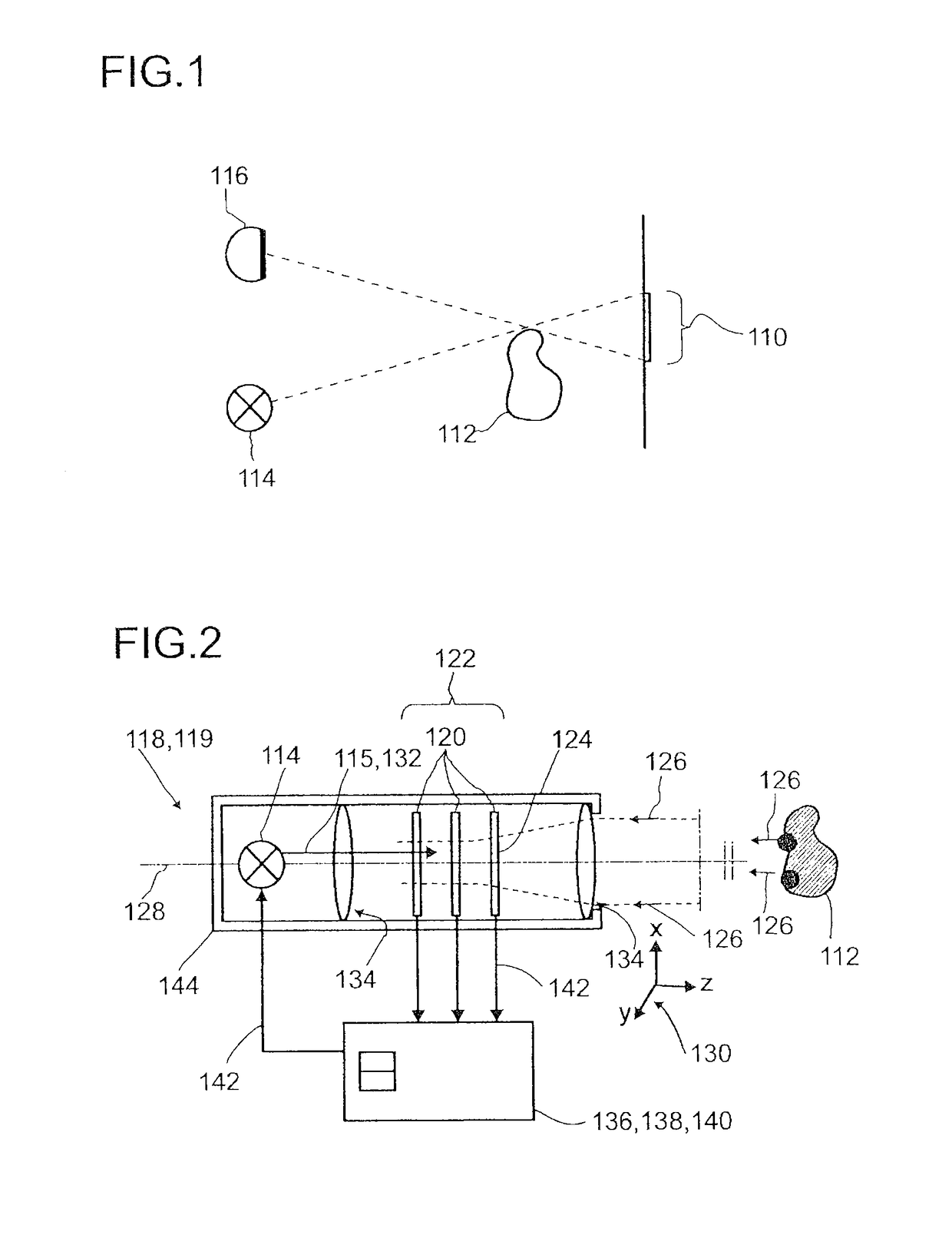

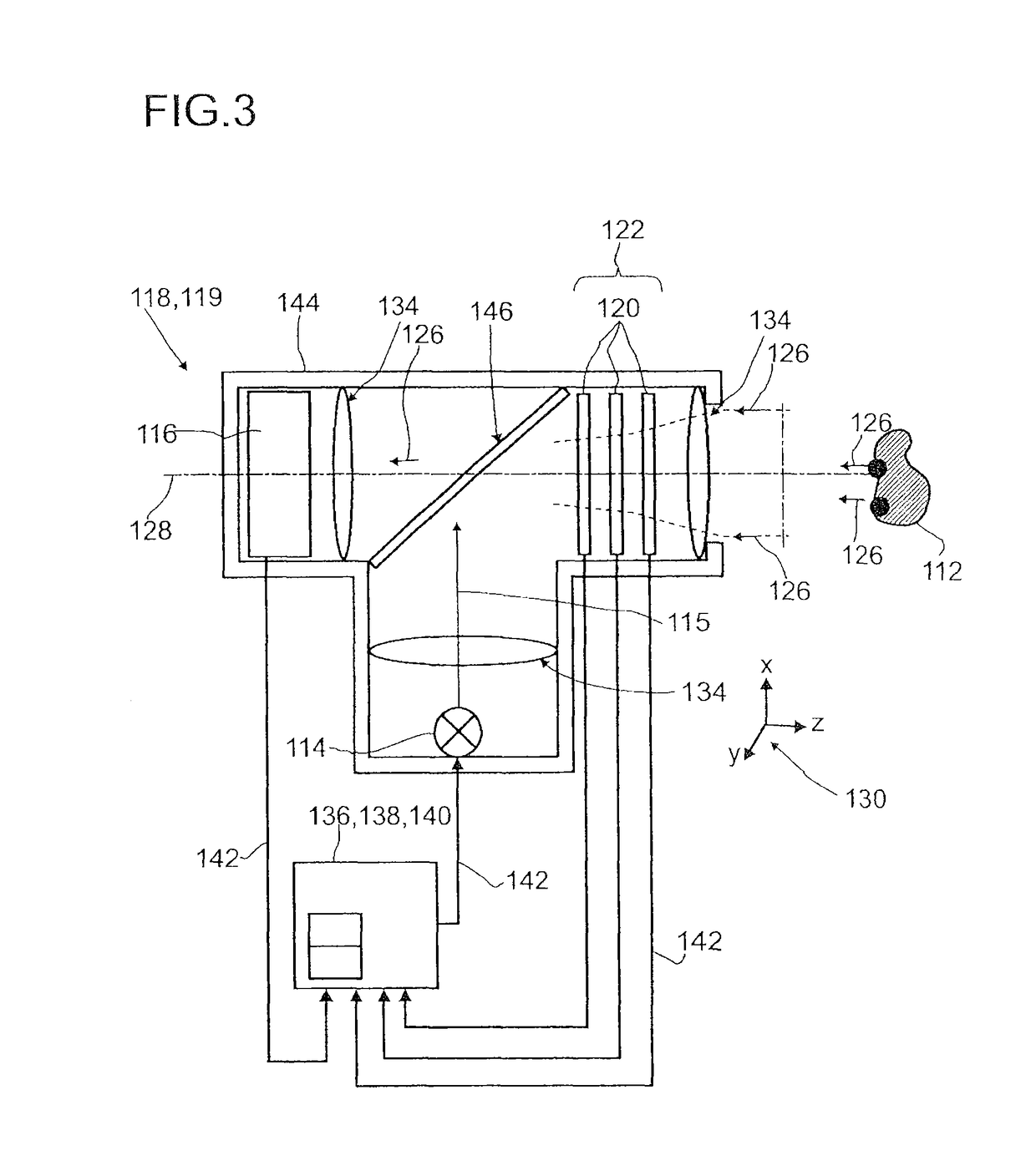

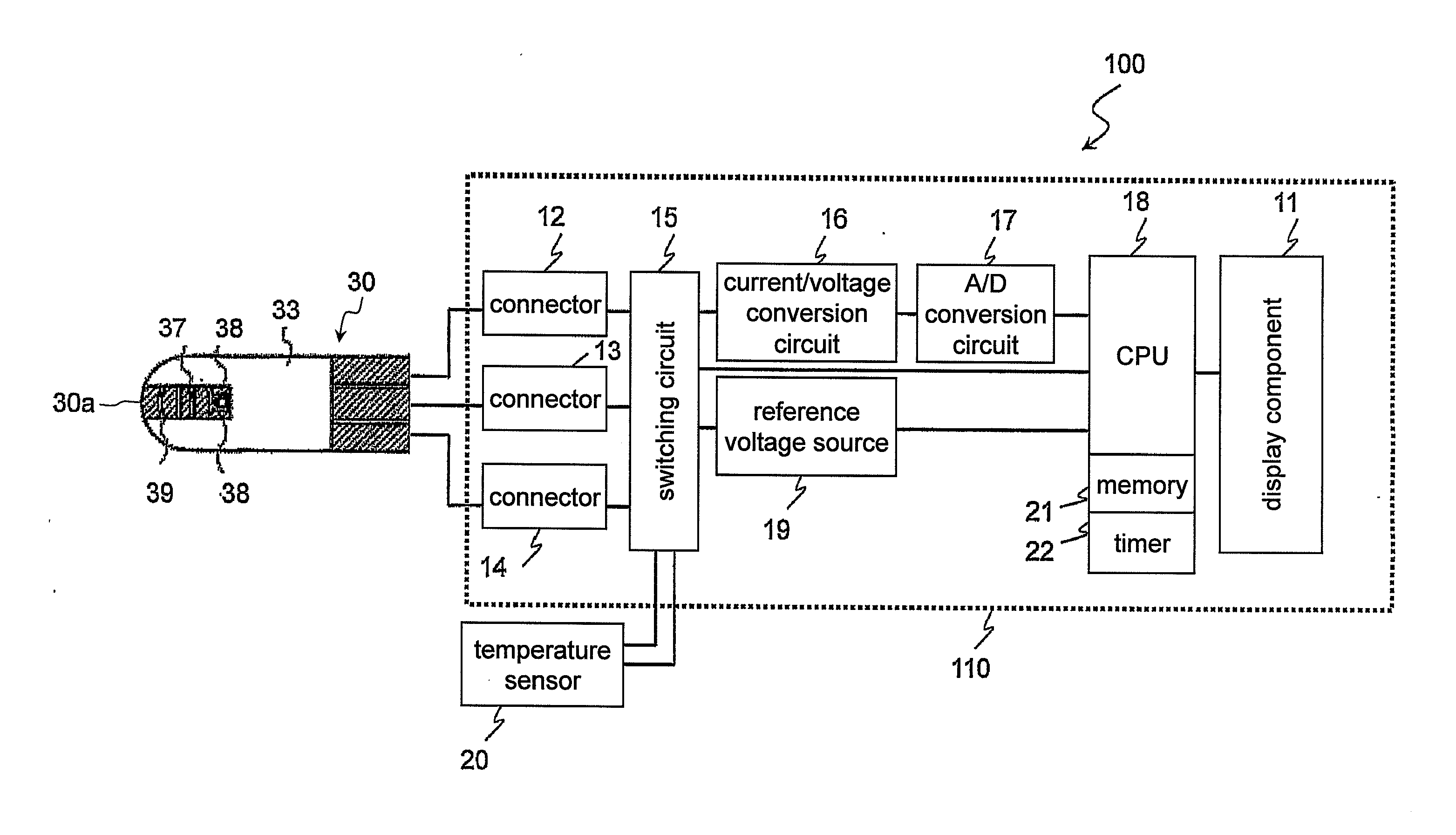

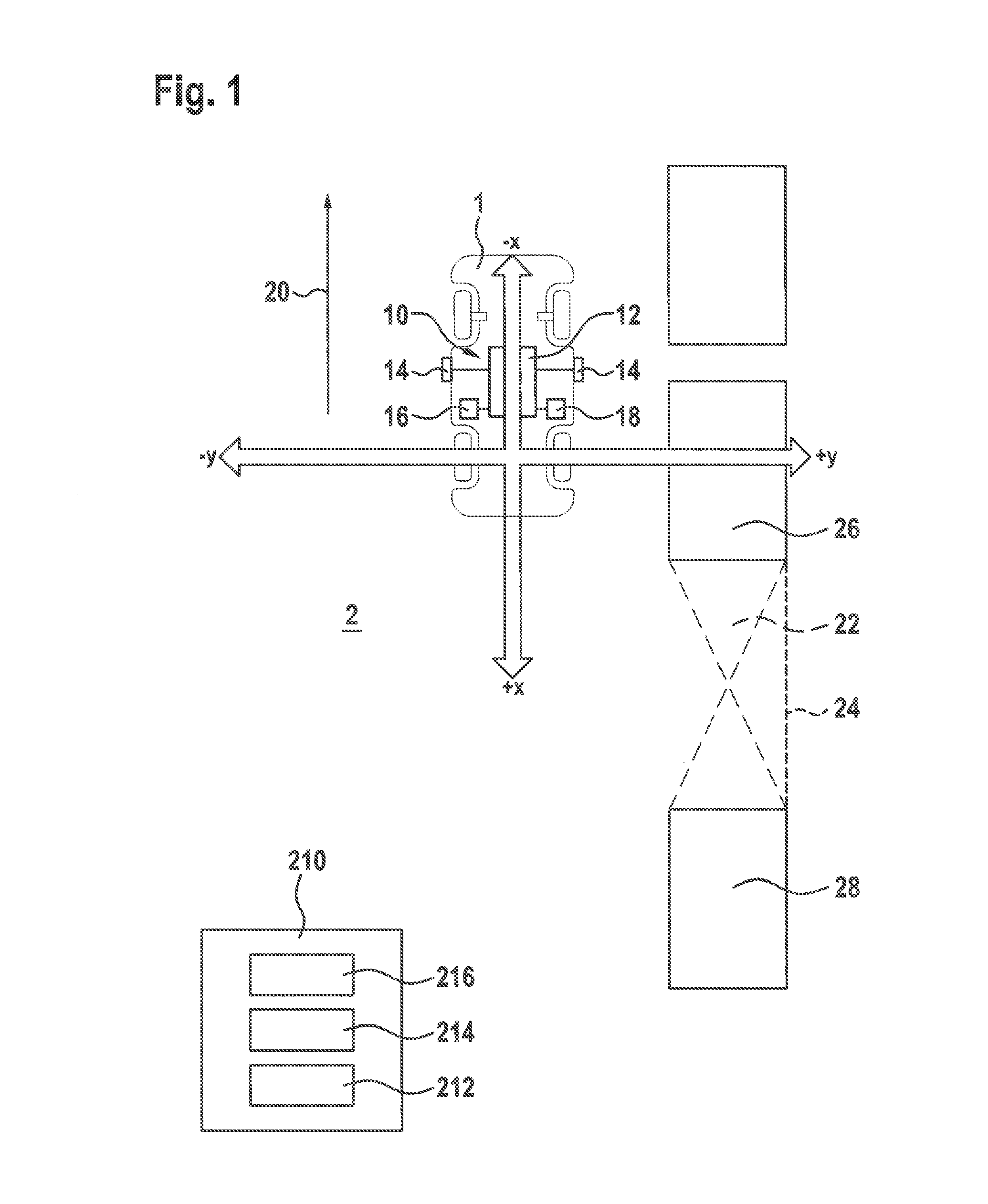

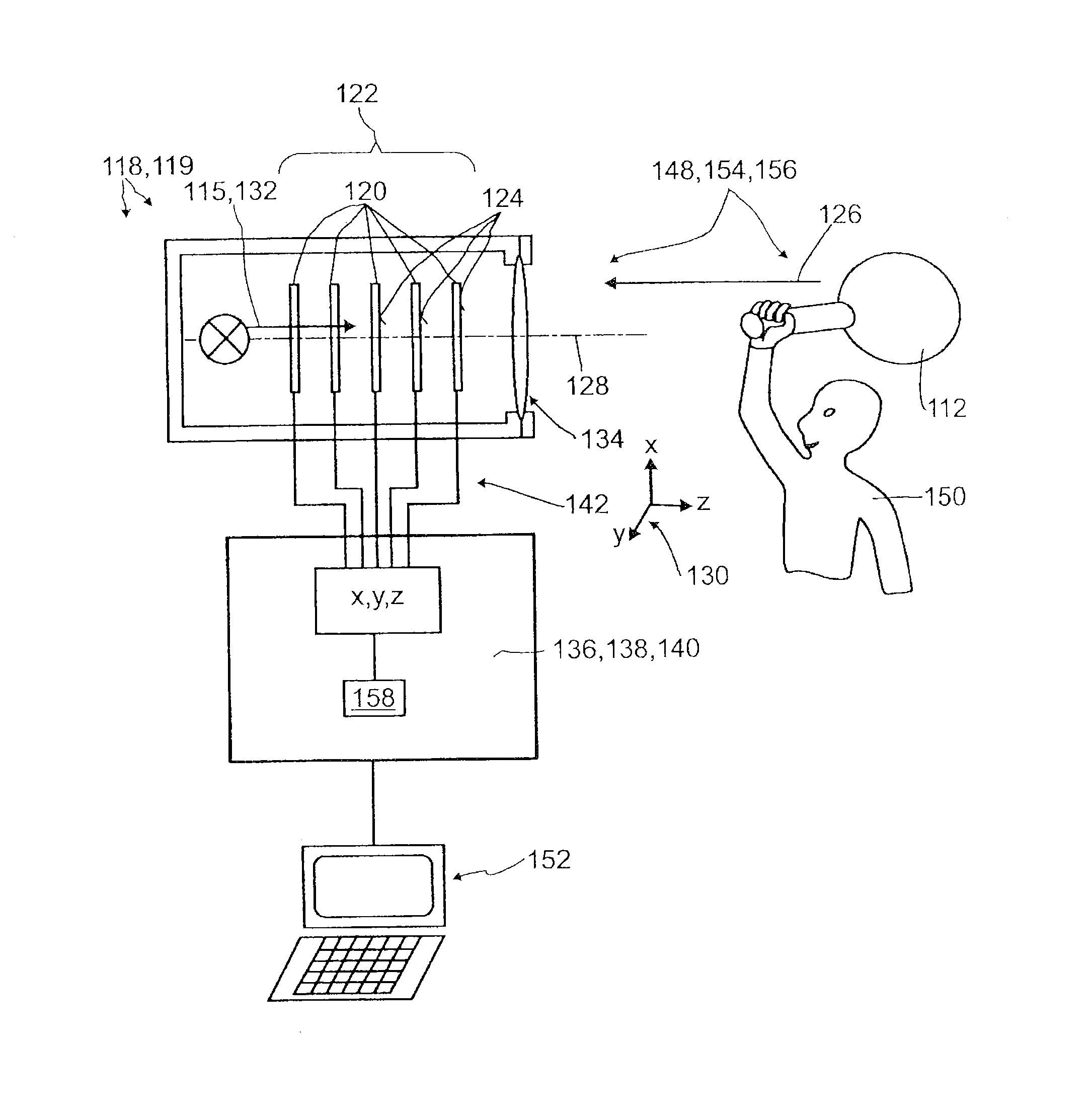

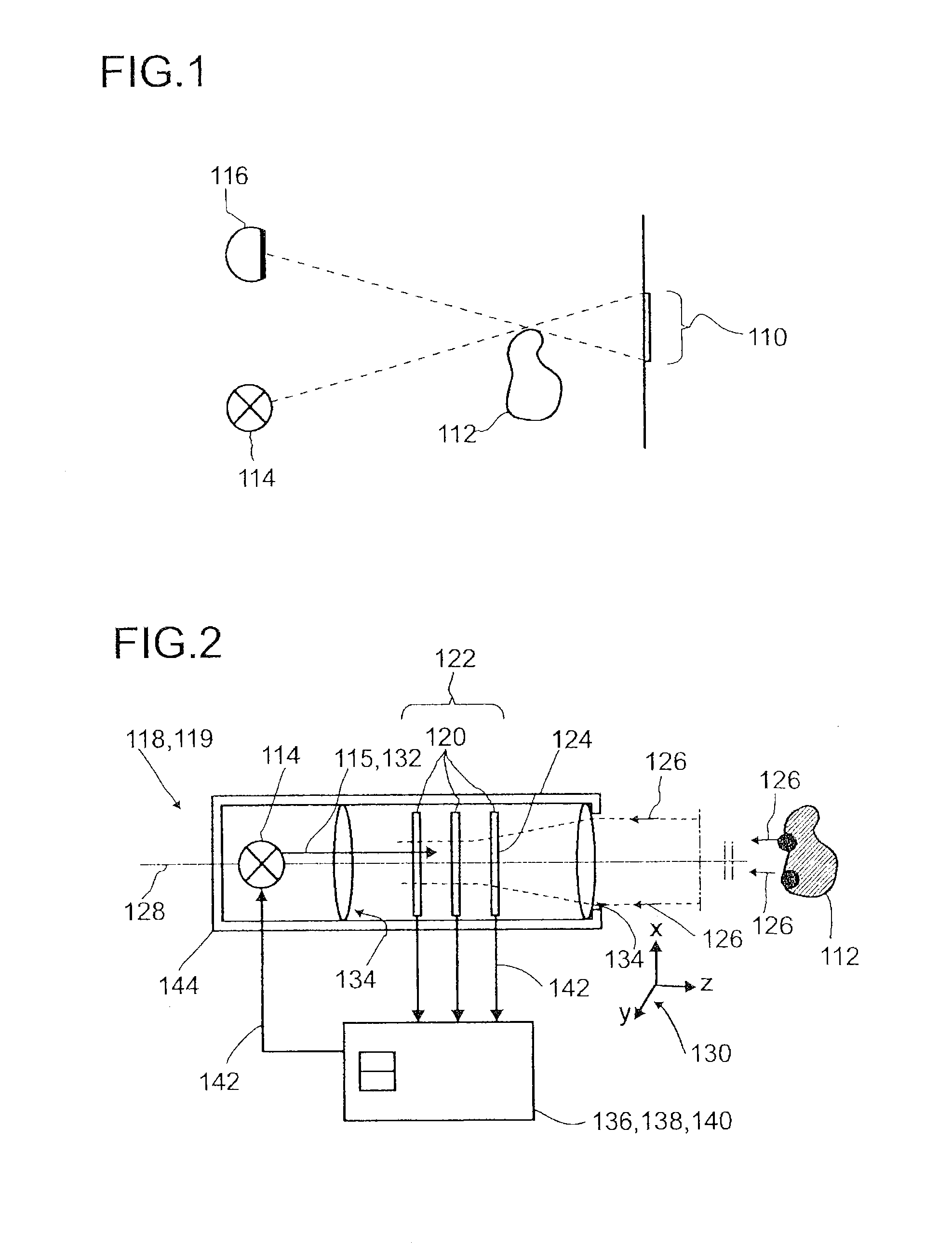

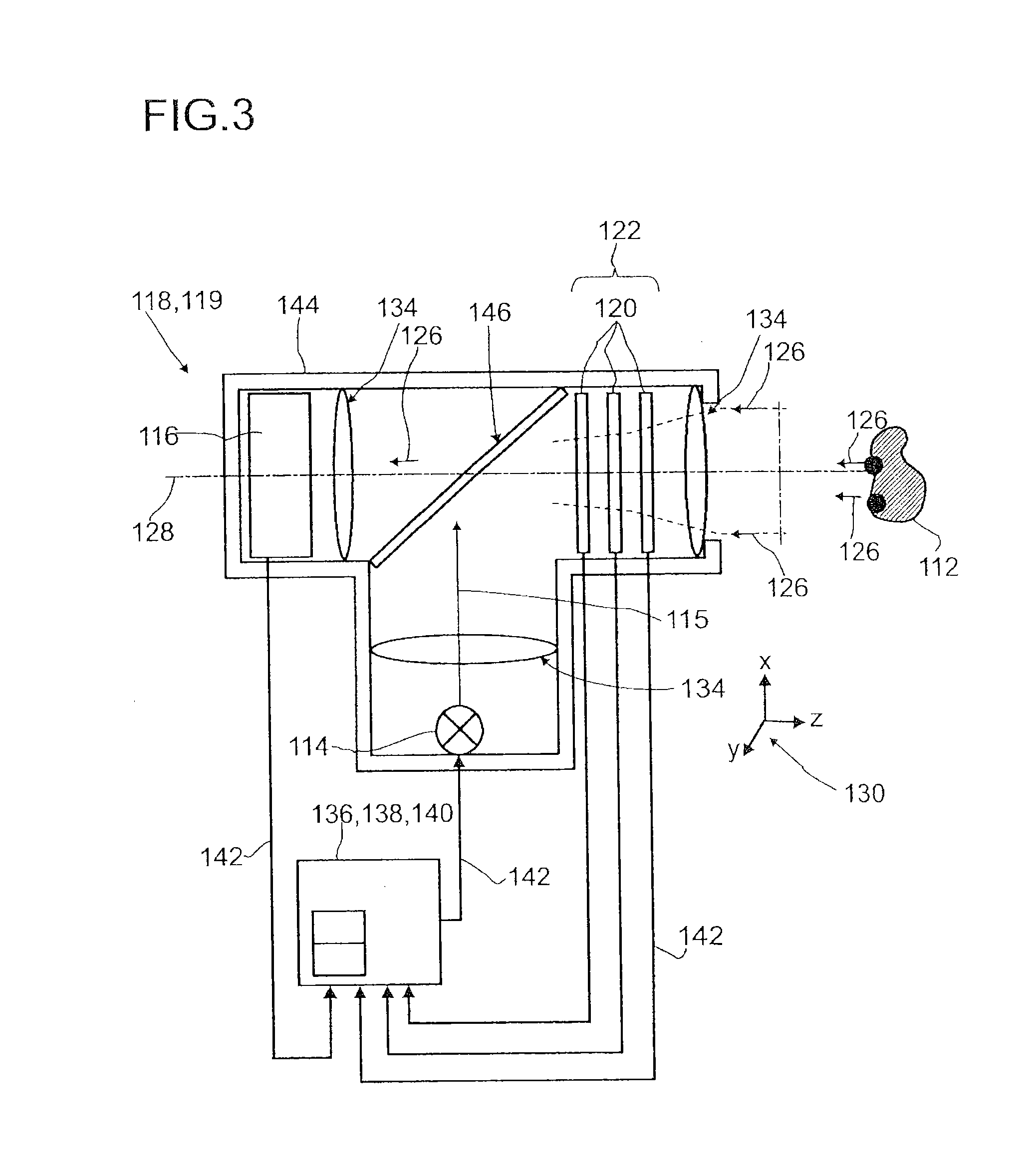

Detector for determining a position of at least one object

ActiveUS9665182B2Reduce measurement errorInput/output for user-computer interactionDirection/deviation determining electromagnetic systemsLight beamBeam cross section

A detector (118) for determining a position of at least one object (112) is disclosed, the detector (118) comprising:at least one longitudinal optical sensor (120), wherein the longitudinal optical sensor (120) has at least one sensor region (124), wherein the longitudinal optical sensor (120) is at least partially transparent, wherein the longitudinal optical sensor (120) is designed to generate at least one longitudinal sensor signal in a manner dependent on an illumination of the sensor region (124) by at least one light beam (126) traveling from the object (112) to the detector (118), wherein the longitudinal sensor signal, given the same total power of the illumination, is dependent on a beam cross-section of the light beam (126) in the sensor region (124);at least one illumination source (114) adapted to illuminate the object (112) with illumination light (115) through the longitudinal optical sensor (120); andat least one evaluation device (136), wherein the evaluation device (136) is designed to generate at least one item of information on a longitudinal position of the object (112) by evaluating the longitudinal sensor signal.

Owner:BASF SE

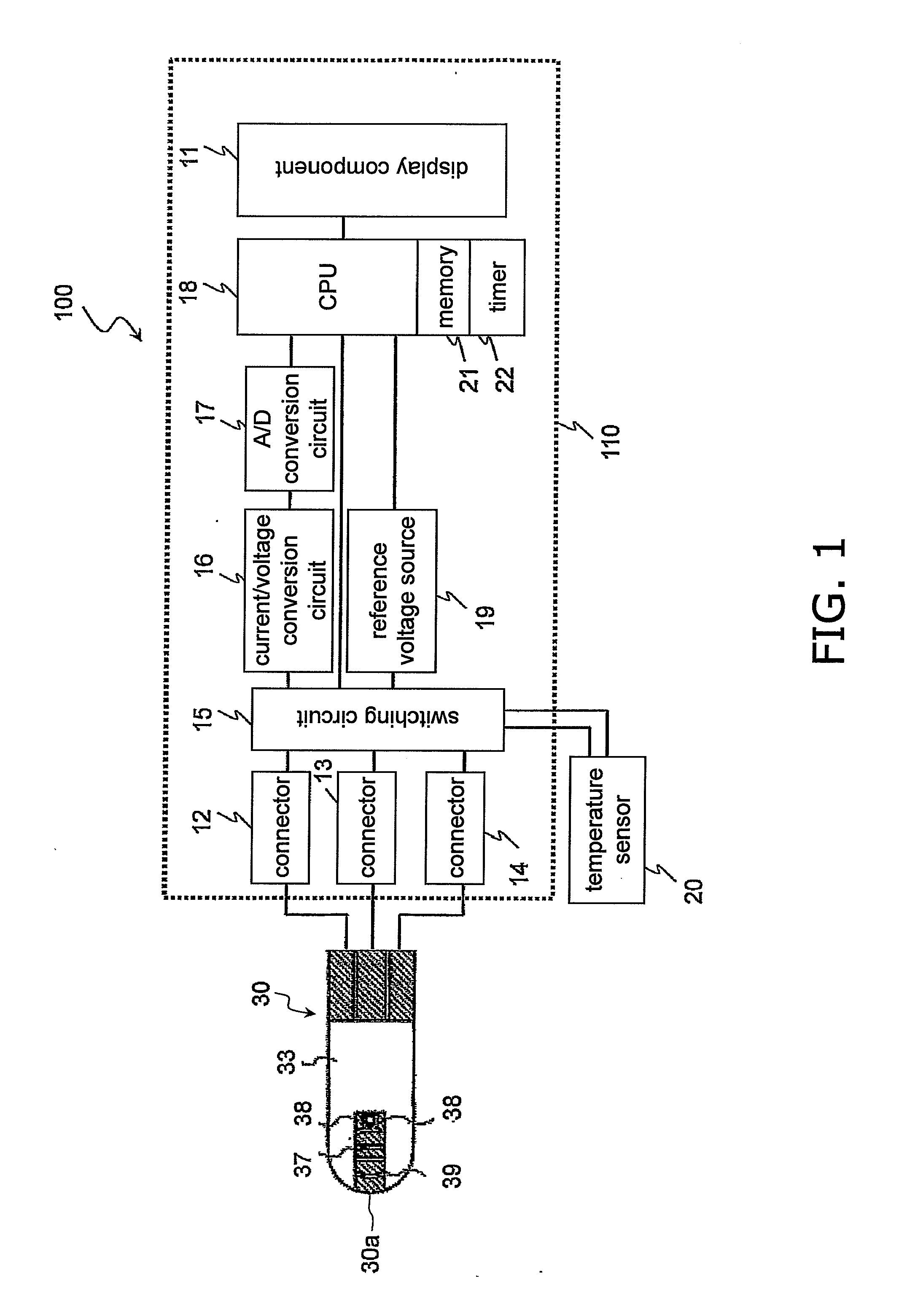

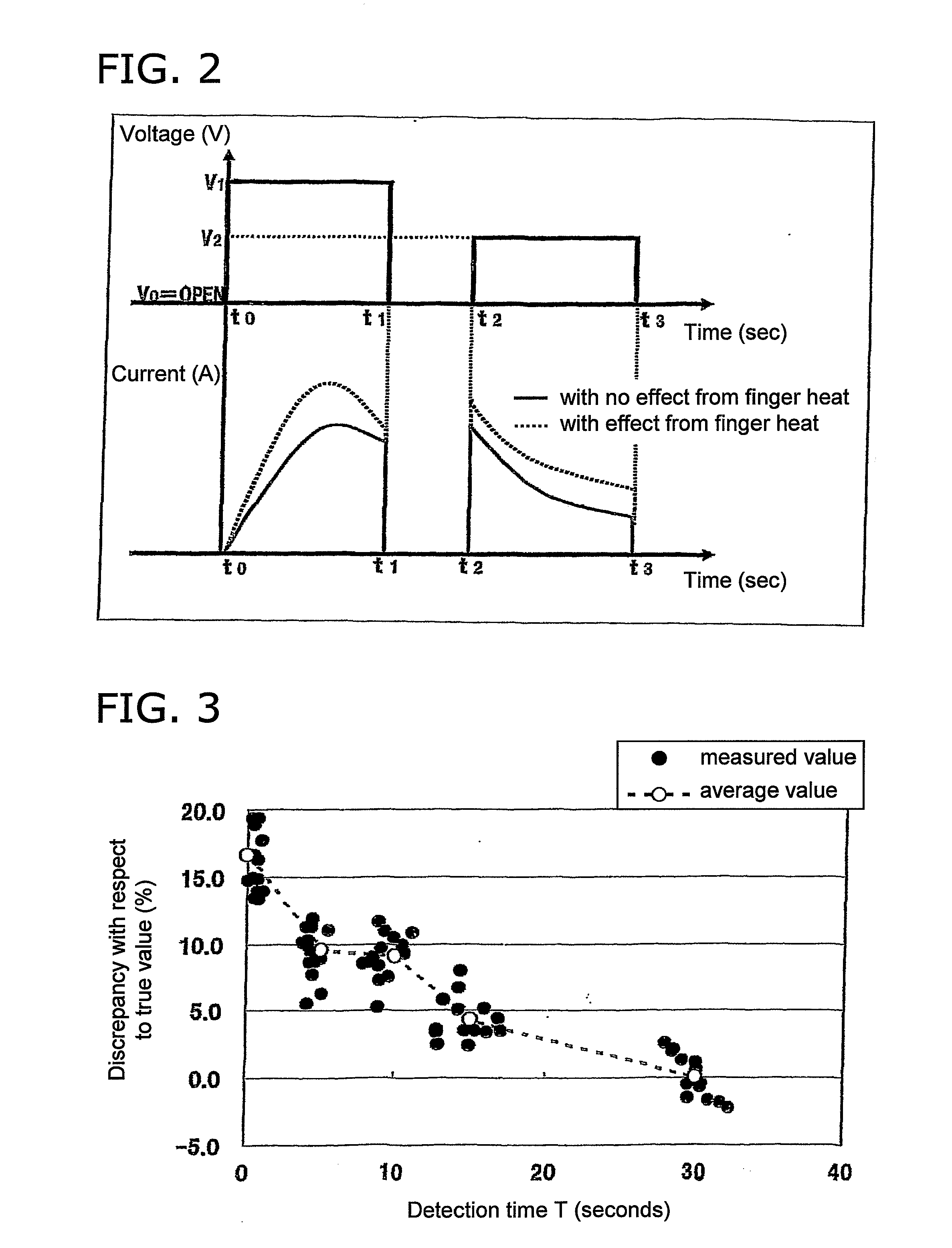

Sample measurement device, sample measurement system and sample measurement method

ActiveUS20100283488A1Reduce measurement errorImmobilised enzymesBioreactor/fermenter combinationsPhysicsMeasurement device

A sample measurement device (110), in which a biosensor (30) having an electrode is mounted, voltage is applied to the electrode, and the concentration of a specific component in a sample deposited on the biosensor (30) is measured, comprises a voltage source (19) configured to apply voltage to the electrode, a time measurement component (22), and a controller (18) configured to control the voltage to be applied and measure the concentration of the specific component. The time measurement component (22) measures a detection time, which is the length of time between the mounting of the biosensor (30) and the deposition of a sample on the biosensor (30). The controller (18) changes a set value for measuring the concentration of a specific component according to the detection time. Consequently, measurement accuracy can be improved regardless of the temperature of the biosensor (30).

Owner:PHC HLDG CORP

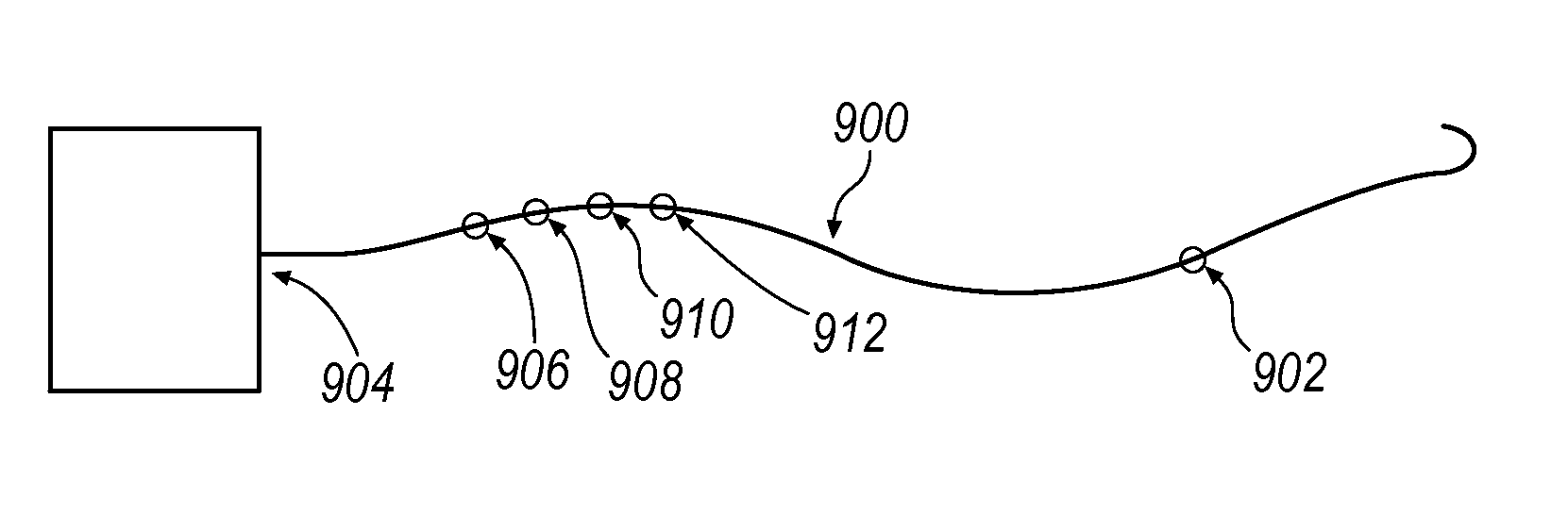

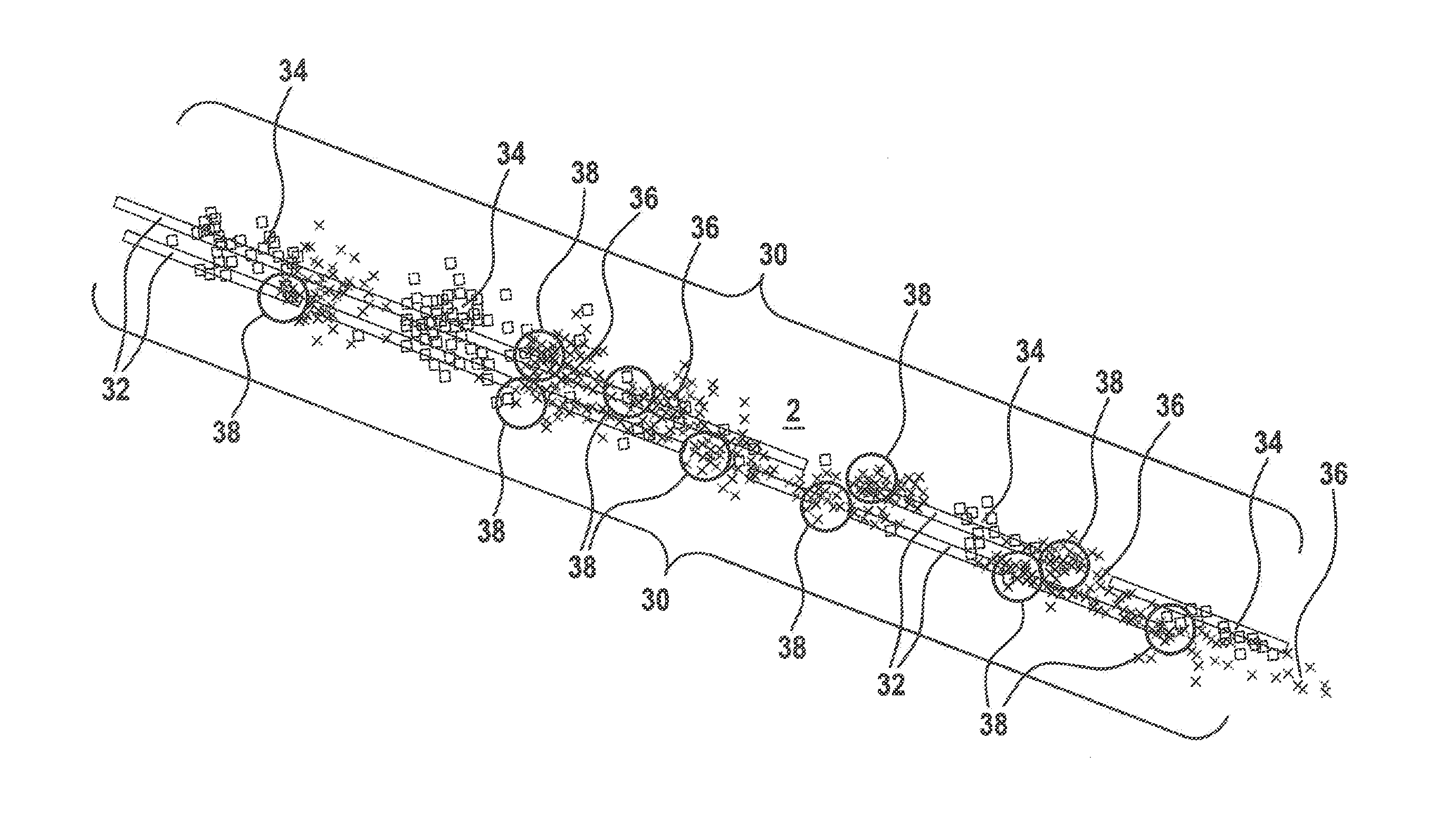

Reducing incremental measurement sensor error

ActiveUS20140264081A1Reduce measurement errorReduce volatilityOptical radiation measurementRadiation measurementFiberOrientation measurement

For position sensors, e.g., a fiber-based system, that build a shape of an elongated member such as a catheter using a sequence of small orientation measurements, a small error in orientation at the proximal end of the sensor will cause large error in position at distal points on the fiber. Exemplary methods and systems are disclosed which may provide full or partial registration along the length of the sensor to reduce the influence of the measurement error. Additional examples are directed to applying selective filtering at a proximal end of the elongated member to provide a more stable base for distal measurements and thereby reducing the influence of measurement errors.

Owner:AURIS HEALTH INC

Noninvasive tissue assessment

InactiveUS7435232B2Reduce measurement errorUltrasonic/sonic/infrasonic diagnosticsBioreactor/fermenter combinationsFrequency spectrumNon invasive

Methods and apparatus for non-invasively assessing physiological hard of soft tissue of human and other species are described. In a preferred embodiment, tissue is vibrationally stimulated in vivo through a frequency spectrum. The tissue reacts against the stimulus and the reaction is preferably measured and recorded. Based on analytical algorithms or comparisons with previously taken measurements, changes within the tissue can be detected and used for diagnostic purposes. Further embodiments describe the usage of the device and methods for in vivo intra-operative and post-operative implant evaluations and as a therapeutic tool.

Owner:RICE UNIV

Ultrasonic blood vessel measurement apparatus and method

ActiveUS20050096528A1Effective filteringAccurate representationImage enhancementImage analysisTissue architectureMedicine

Disclosed are systems and methods for identifying various tissue structure aspects, such as boundaries of arterial walls, within an image, such as an ultrasound image. Various measurements may be made using information with respect to the identified aspects of tissue structure. For example, intima-media thickness measurements may be made. Additionally or alternatively, tissue structure aspects, such as plaque within an artery, may be characterized, such as by determining a density thereof. Various information, such as measurement datums, used in identification of aspects of tissue structure in one image may be stored and applied to subsequent images, such as images of a video sequence.

Owner:FUJIFILM SONOSITE

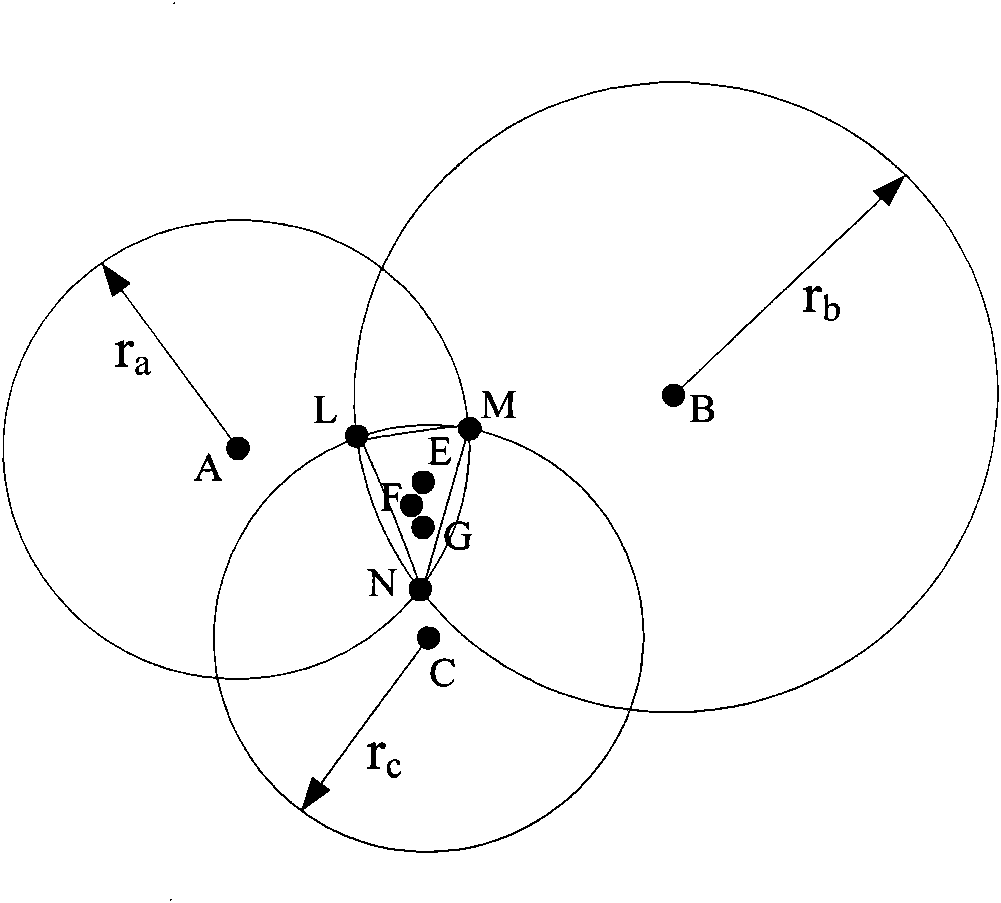

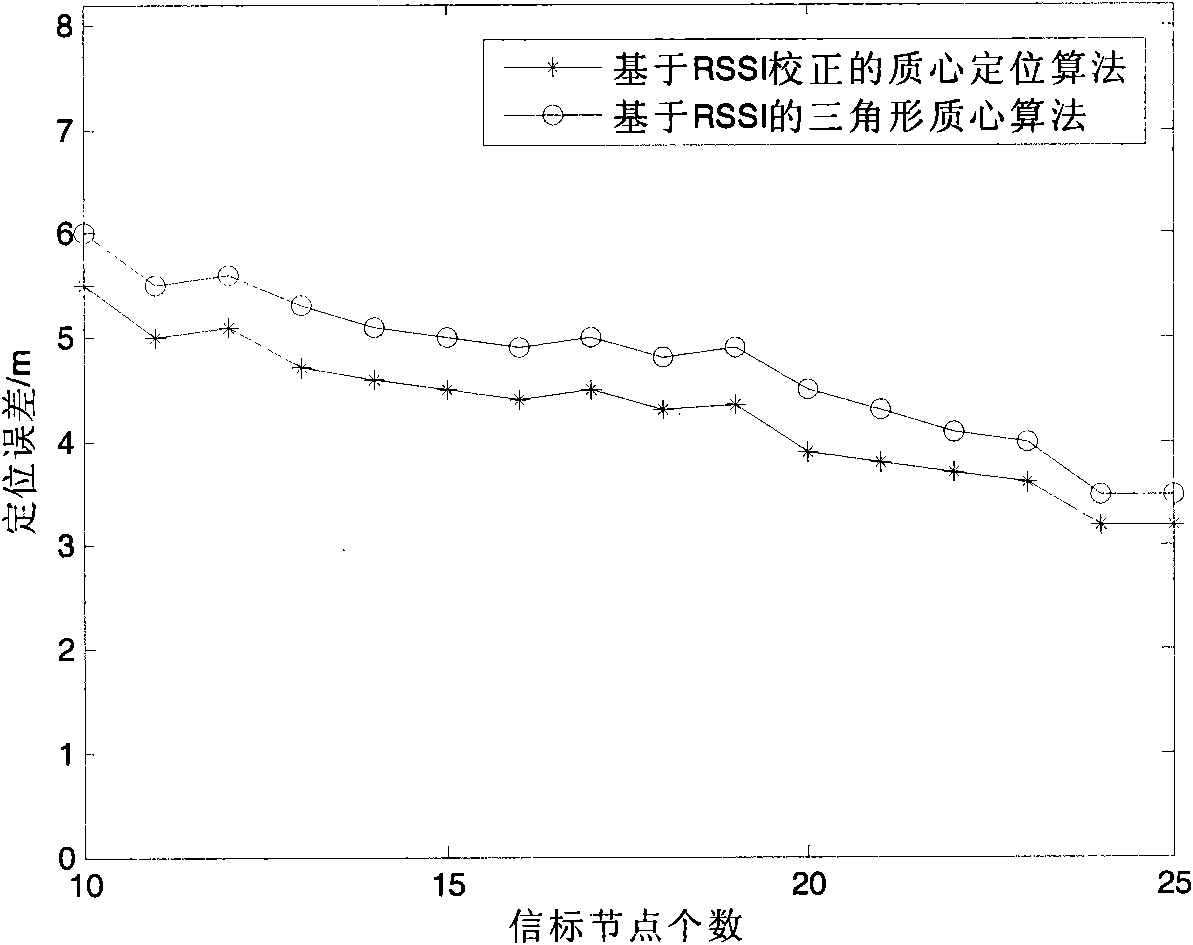

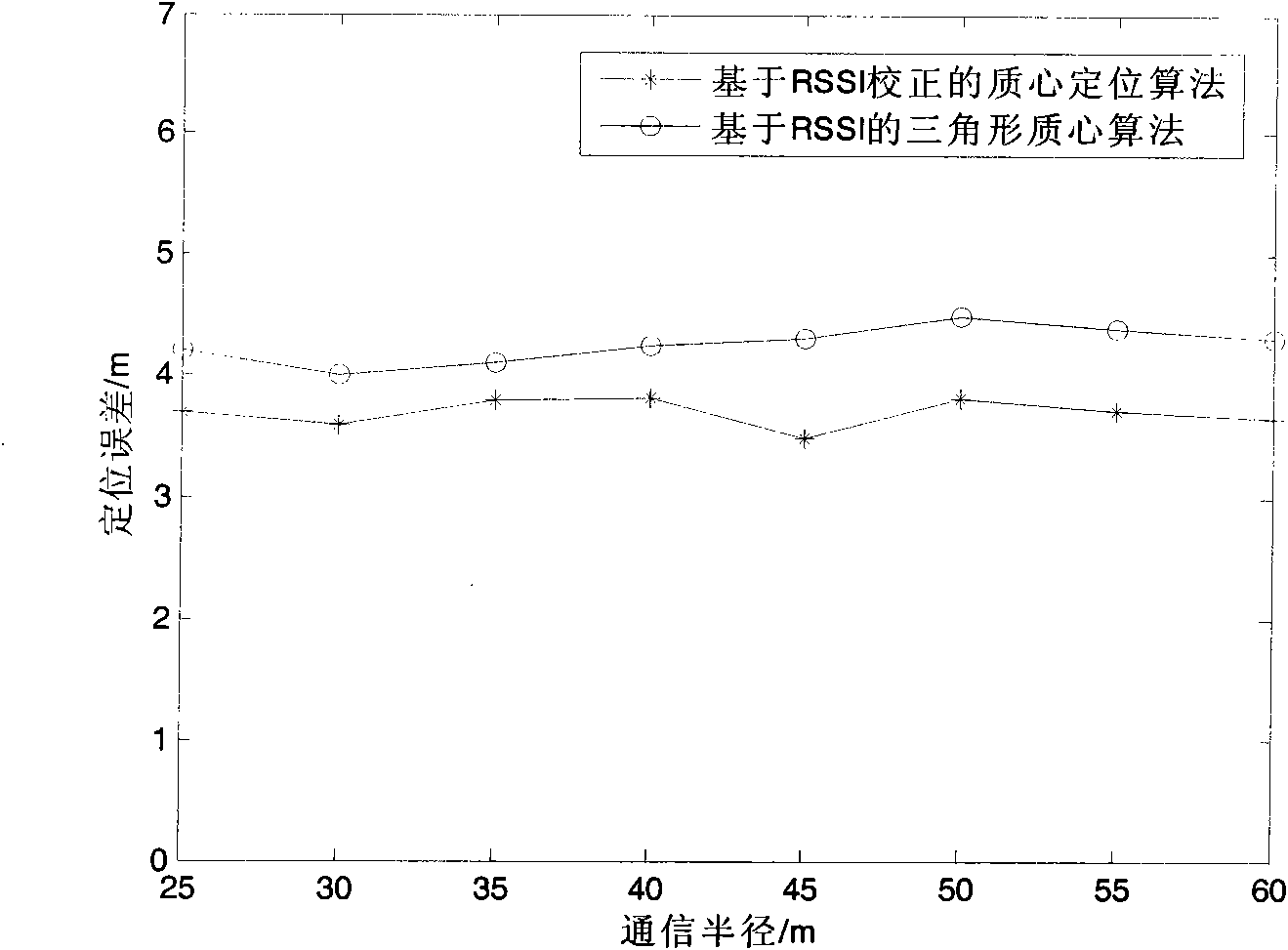

Centroid location algorithm based on RSSI (Received Signal Strength Indication) correction for wireless sensor network

InactiveCN102123495AReduce measurement errorHigh positioning accuracyTransmission monitoringWireless communicationObservational errorWireless mesh network

The invention discloses a centroid location algorithm based on RSSI (Received Signal Strength Indication) correction for a wireless sensor network, and the centroid location algorithm comprises: (1) anchor nodes periodically broadcast information around, wherein the information contains respective node ID (identity) and coordinates; and ordinary nodes average the RSSI of the same anchor node after receiving the information; (2) the ordinary nodes do not receive new information any more after collecting the information of n anchor nodes, wherein n is greater than 3 and less than or equal to 100; the ordinary nodes sort the anchor nodes according to the RSSI from strong to weak and establish mapping of the RSSI value and the distance from the nodes to the anchor nodes; (3) the anchor nodes with the RSSI value greater than or equal to minus 93dbm and less than or equal to minus 113dbm is selected for self-location calculation; and (4) the calculated unknown node coordinate set is aggregated and averaged to obtain the unknown node coordinates. In the invention, the point-to-point distance between the nodes is measured by correcting an RSSI ranging technology, and a triangle centroid location algorithm is adopted for location, thus the measurement error of the RSSI is reduced. Compared with the triangle centroid location algorithm based on the RSSI, the centroid location algorithm provided by the invention has the advantage that the location accuracy is greatly improved.

Owner:SHANDONG UNIV

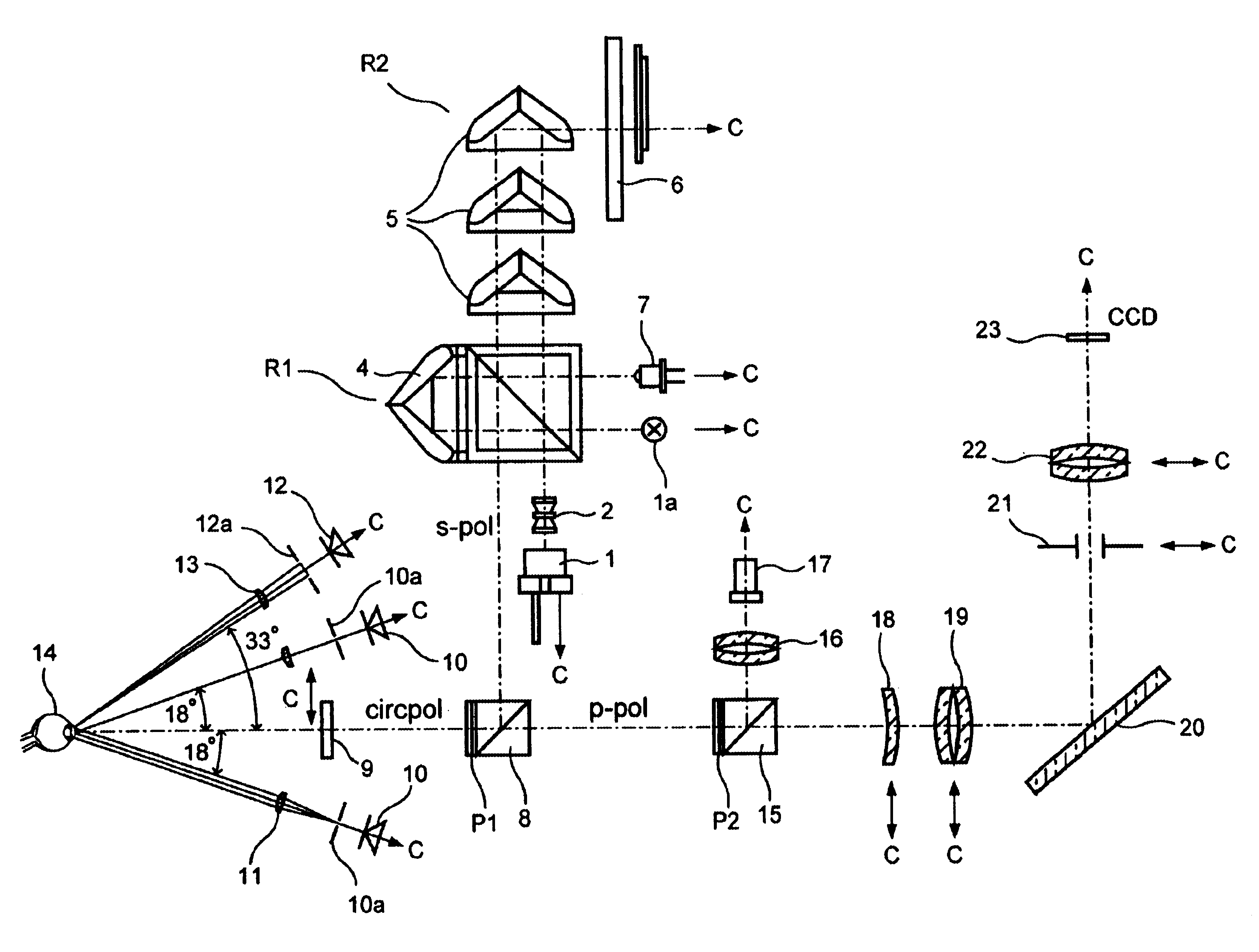

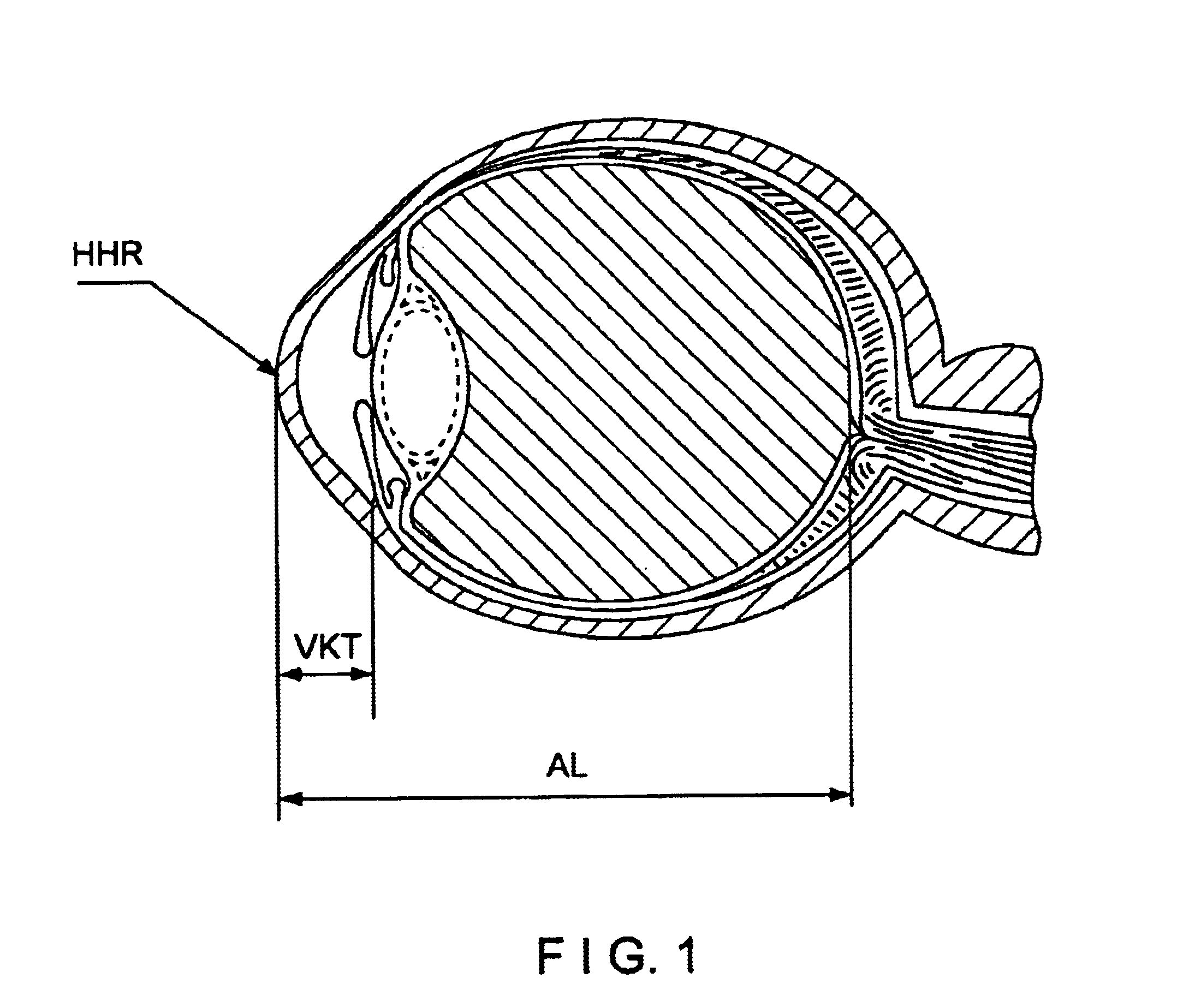

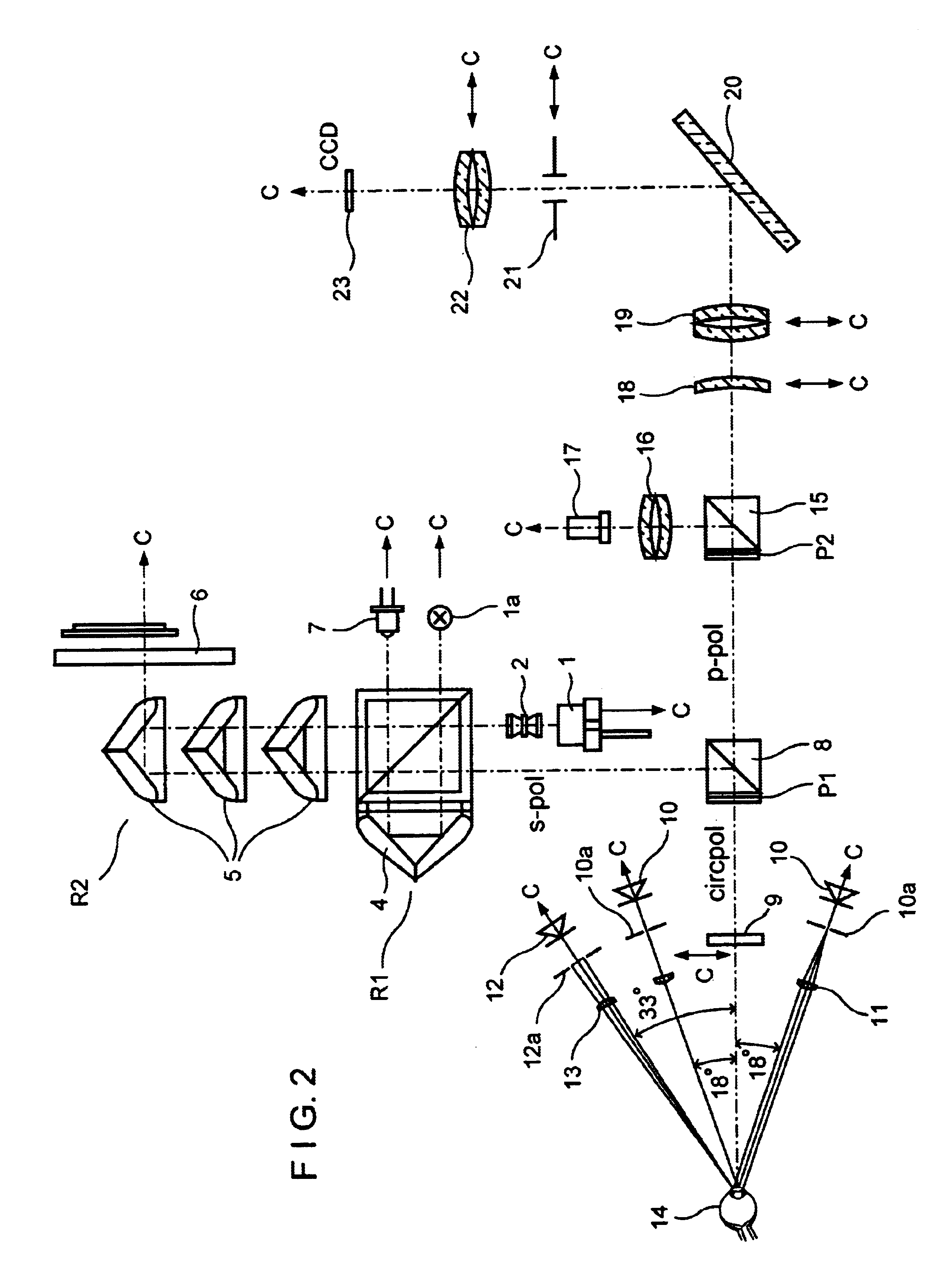

System and method for non-contacting measurement of the eye

InactiveUS6779891B1Reduce device-dependent measurement errorReduce measurement errorEye inspectionGonioscopesCorneal curvatureIntraocular lens

Combined equipment for non-contacting determination of axial length (AL), anterior chamber depth (VKT) and corneal curvature (HHK) of the eye are also important for the selection of the intraocular lens IOL to be implanted, particularly the selection of an intraocular lens IOL to be implanted, preferably with fixation of the eye by means of a fixating lamp and / or illumination through light sources grouped eccentrically about the observation axis.

Owner:CARL ZEISS JENA GMBH

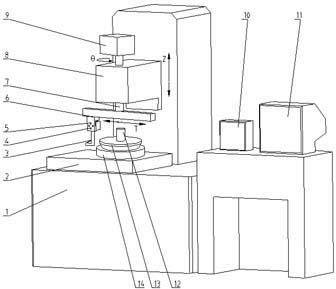

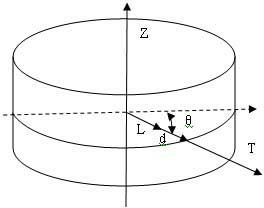

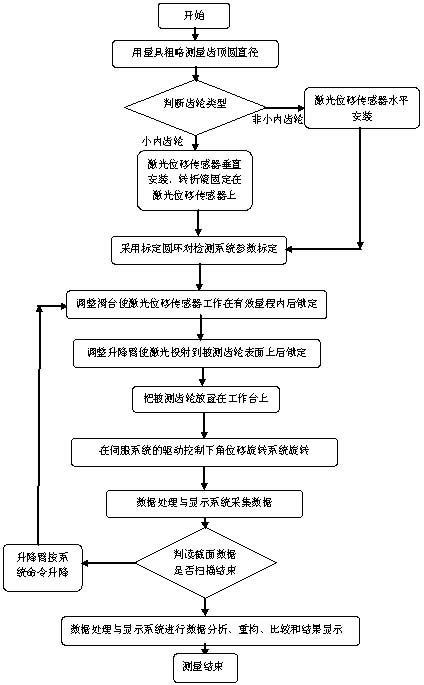

Laser detection device and method for gear parameters

InactiveCN102322796ADetection speedReduce measurement errorUsing optical meansPhysicsElectric machinery

The invention relates to a laser detection device and method for gear parameters. The laser detection device is characterized in that a worktable is provided with an internal point; a laser displacement sensor is arranged on a bracket; the bracket is arranged on a linear motor sliding block of a sliding table; the sliding table is arranged on an angular displacement rotating system and is fixedlyconnected to a rotating disk together with a rotating shaft; a casing of the angular displacement rotating system is arranged on a lifting arm through screws; the lifting arm is connected with the vertical surface of a machine body through a high-precision linear guide rail and a sliding block; a servo motor drives a ball screw which is fixedly connected to the vertical surface of the machine body to rotate; and a data acquisition and communication system is arranged on a rotating shaft upper plane of the angular displacement rotating system. Tested workpieces are subjected to data measurement, acquisition, transmission, reconstruction, separation, comparison and display to finish the full process of detection. According to the laser detection device and method, the non-contact and blind spot-free measurement is realized, the detection speed and measurement precision are improved; the difficult problem that a pinion is difficult to detect is solved; and in the measuring process, the gear is stationary and a measuring head does measuring movement, thus the measuring error caused by mounting the gear is reduced.

Owner:唐大春

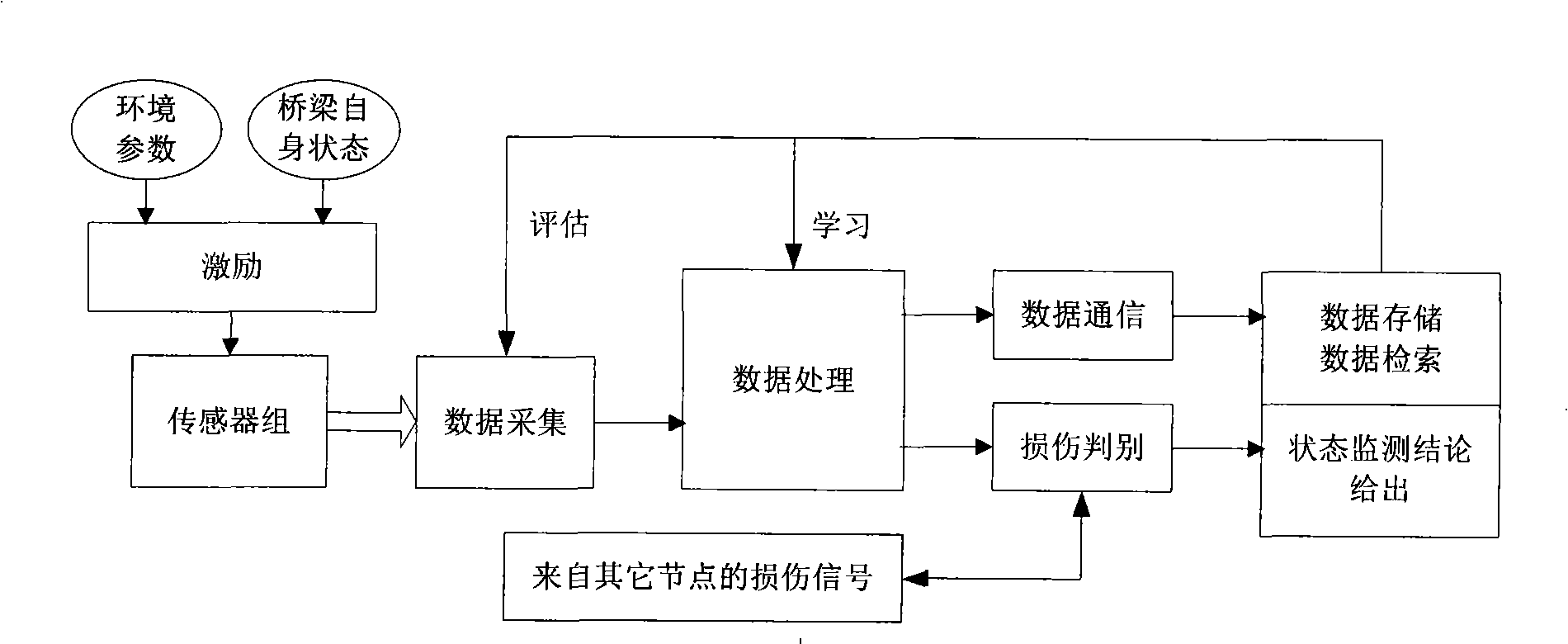

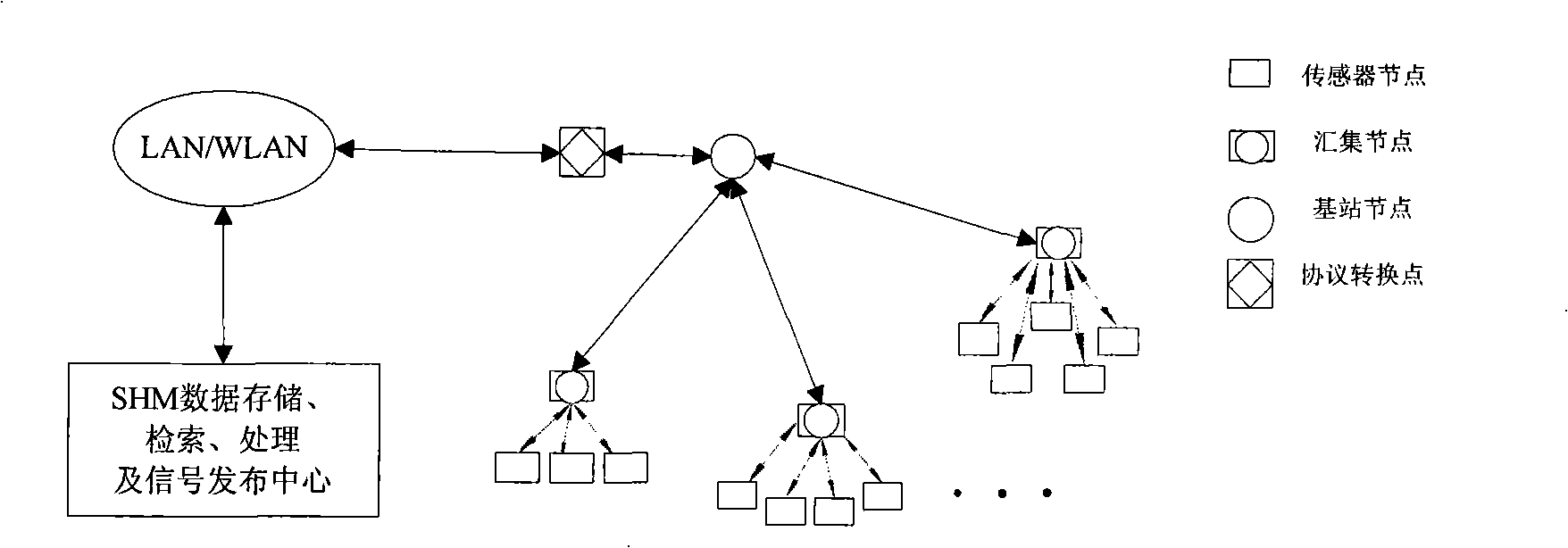

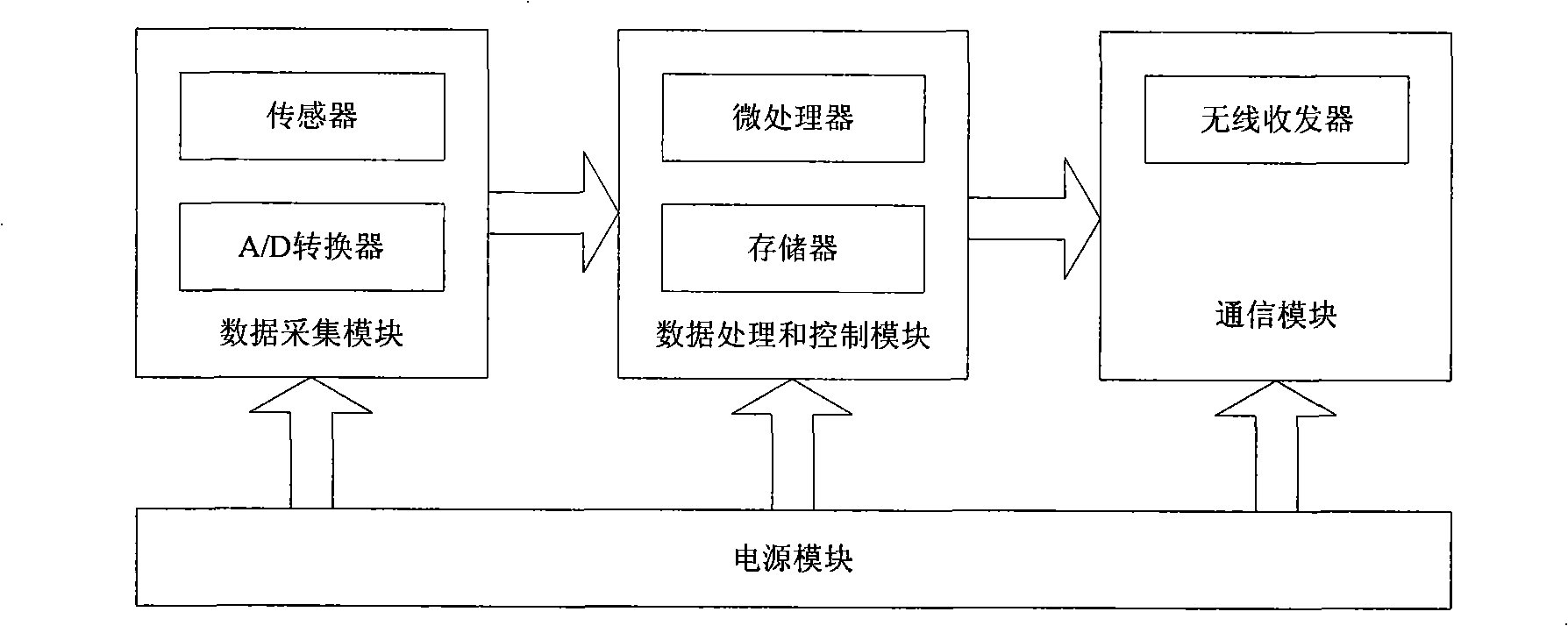

Bridge structure safe state emergency monitoring and early warning method and system based on wireless sensor network

InactiveCN101408487AAvoid Field Wiring WorkEasy to install and maintainStructural/machines measurementUsing mechanical meansStress pointWireless sensor networking

The invention discloses a bridge structure safe state emergency monitoring and pre-warning method based on a wireless sensor network. The network with a sensor module which is arranged on the two sides or bottom stress point of the bridge or stress bearing parts of beams and columns is used for collecting bridge temperature and humidity, vibration amplitude, stress strain data of the beams and the columns, and data of the frequency and the amplitude of the bridge structure change. The sensor module wirelessly receives and sends with a collection node and a base station node by a wireless communication module, and sends the collected and processed data; the wireless receiving and sending collection node is connected with the base station node, and the base station node is connected with a computer by the network. The wireless sensor network realizes bridge structure safe state emergency monitoring and pre-warning, the sensor system processes, systematically decomposes and transforms the data to obtain the required parameters, and is connected to the computer by the network, and various software and hardware with realizable diagnostic function diagnose the received data.

Owner:常州赛杰电子信息有限公司 +2

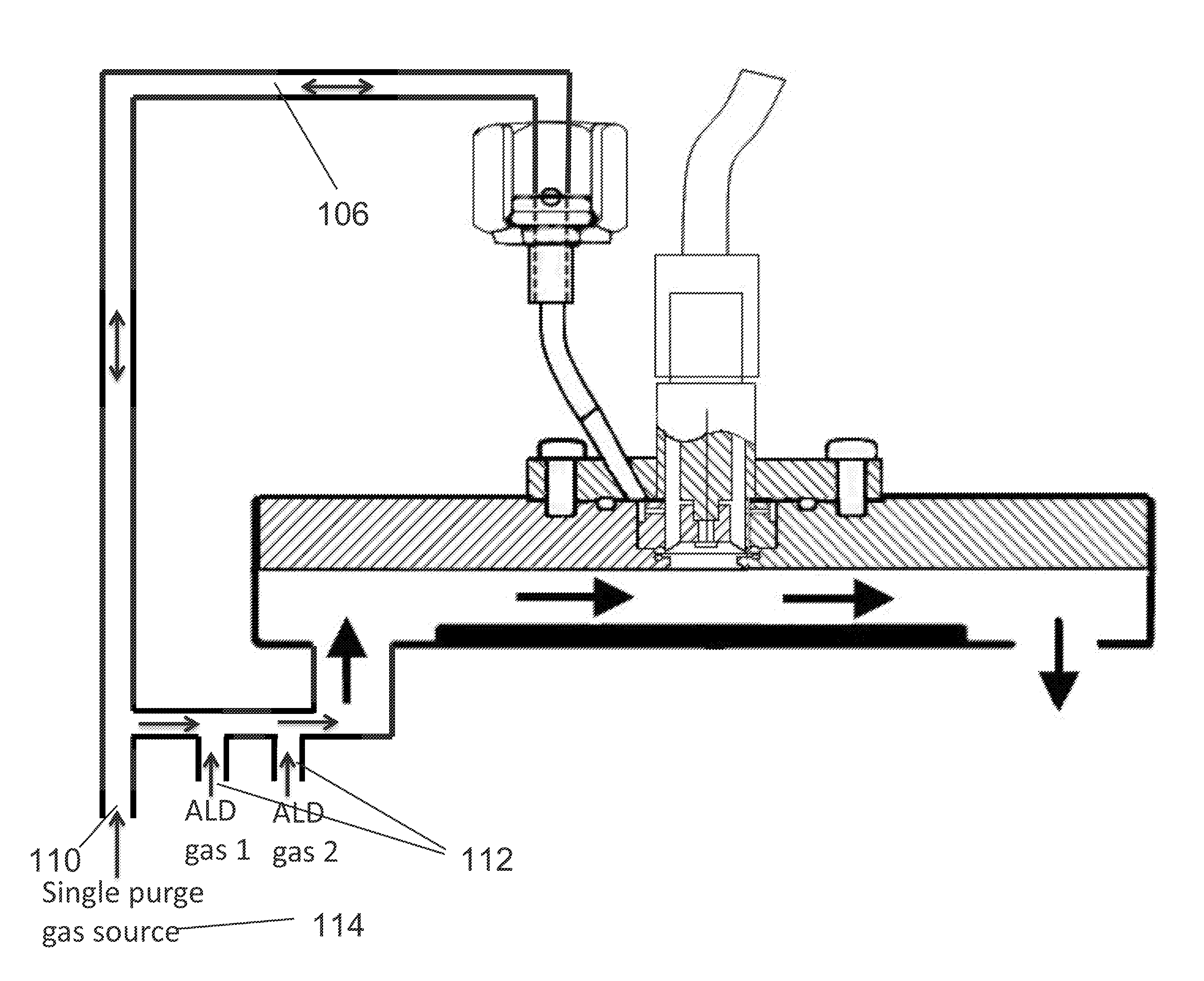

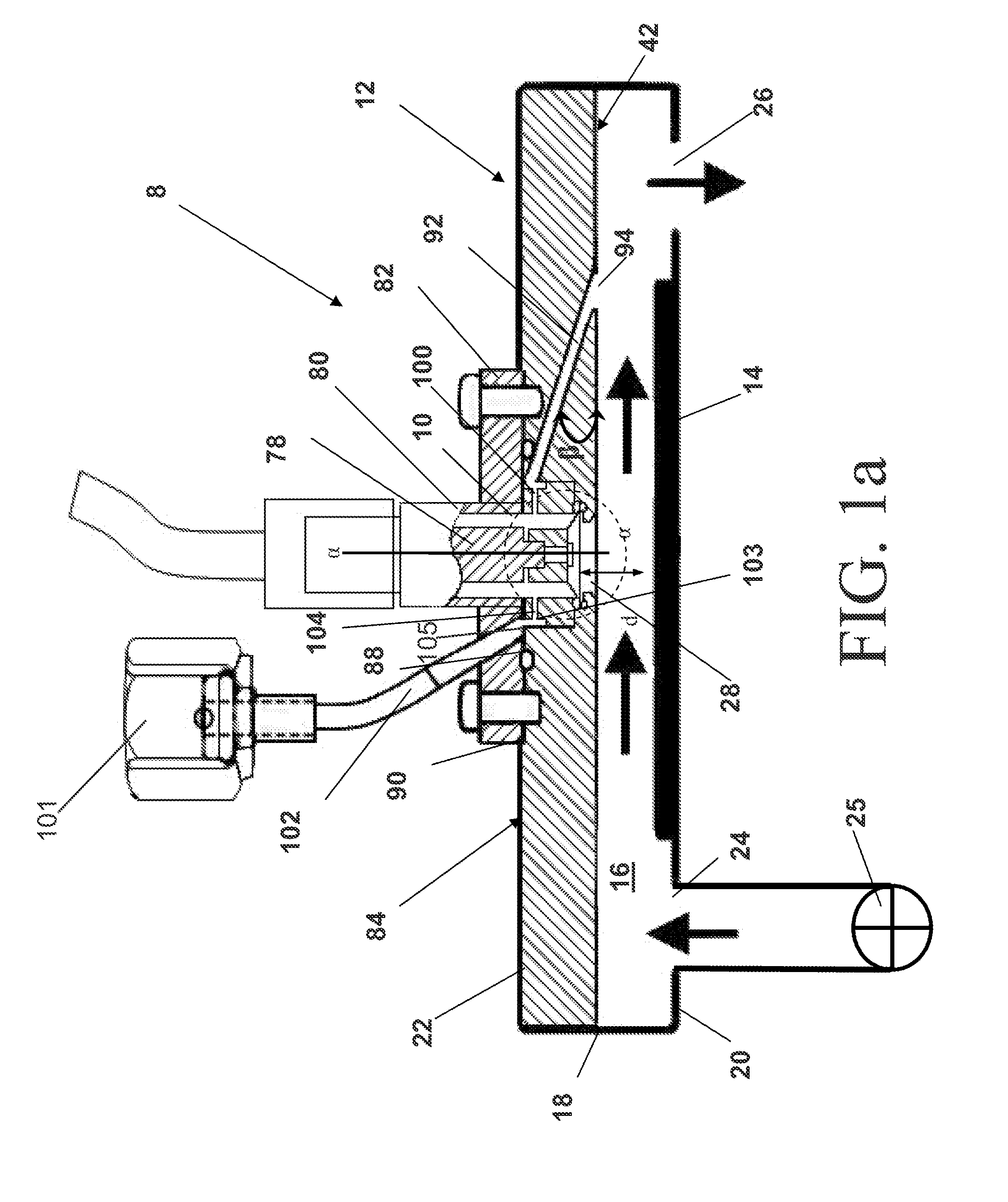

Micro-balance sensor integrated with atomic layer deposition chamber

ActiveUS20140053779A1Easy to installMinimal modificationChemical vapor deposition coatingThermal equilibrationEngineering

The invention is directed to QCM measurements in monitoring ALD processes. Previously, significant barriers remain in the ALD processes and accurate execution. To turn this exclusively dedicated in situ technique into a routine characterization method, an integral QCM fixture was developed. This new design is easily implemented on a variety of ALD tools, allows rapid sample exchange, prevents backside deposition, and minimizes both the footprint and flow disturbance. Unlike previous QCM designs, the fast thermal equilibration enables tasks such as temperature-dependent studies and ex situ sample exchange, further highlighting the feasibility of this QCM design for day-to-day use. Finally, the in situ mapping of thin film growth rates across the ALD reactor was demonstrated in a popular commercial tool operating in both continuous and quasi-static ALD modes.

Owner:UCHICAGO ARGONNE LLC

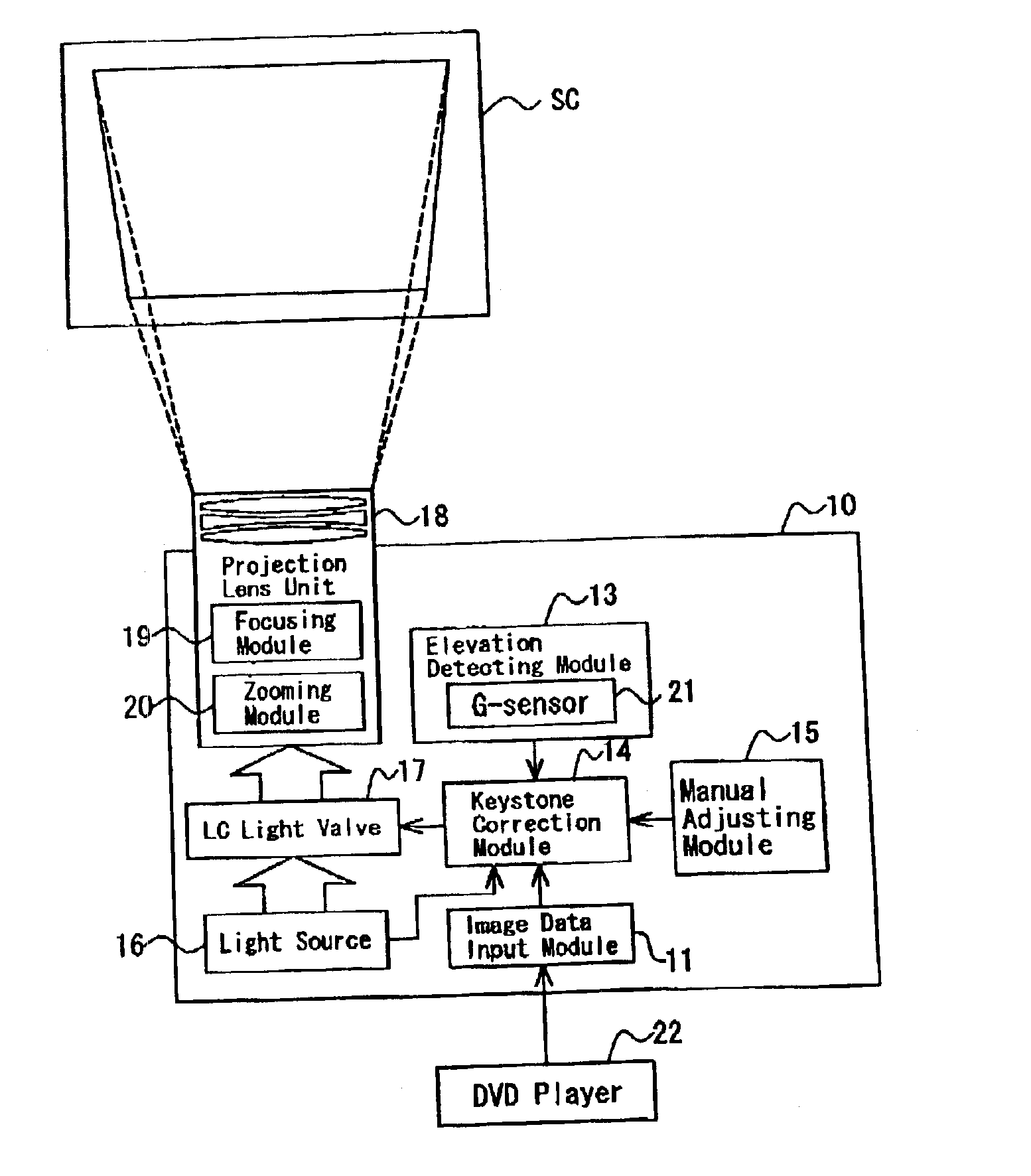

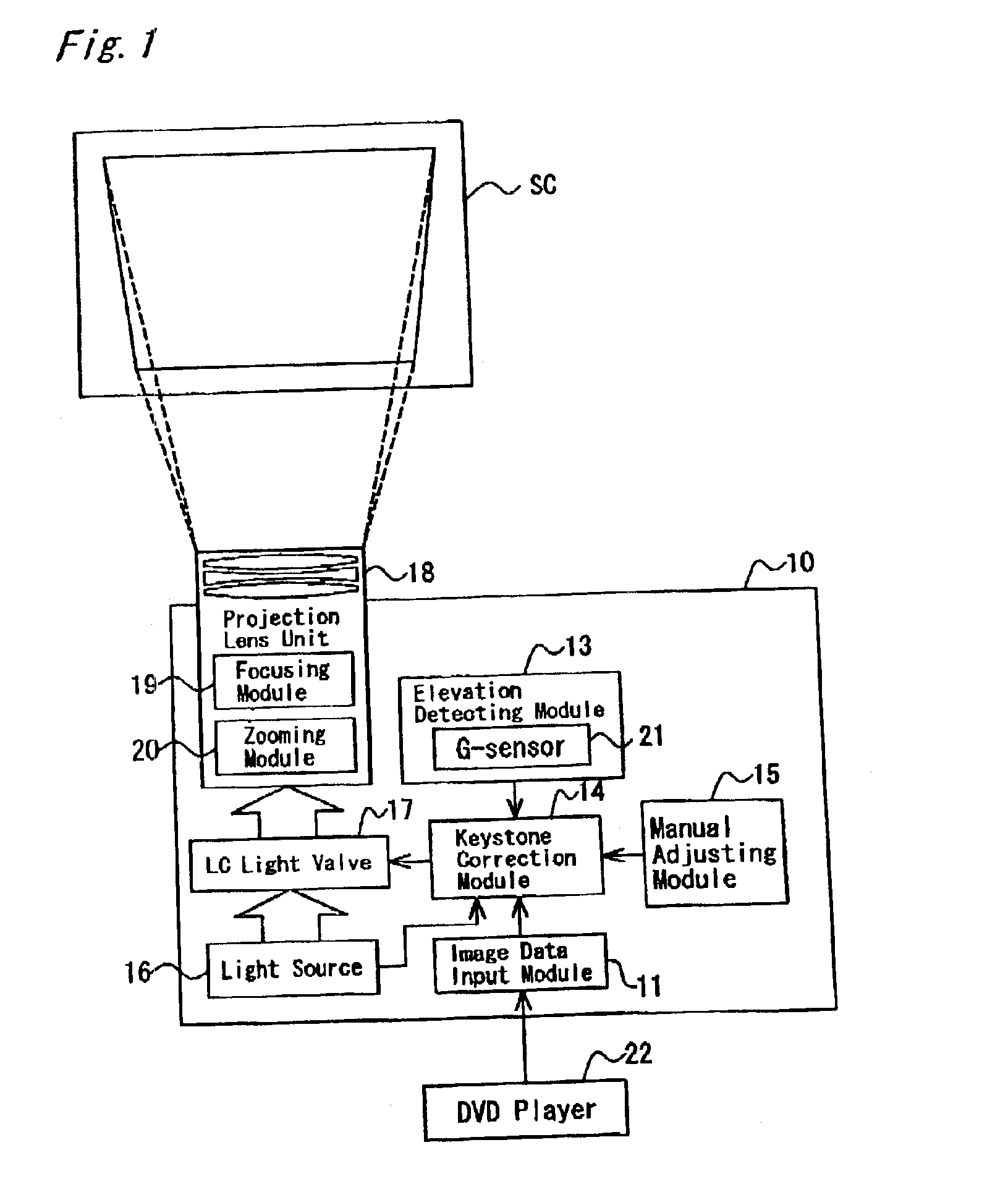

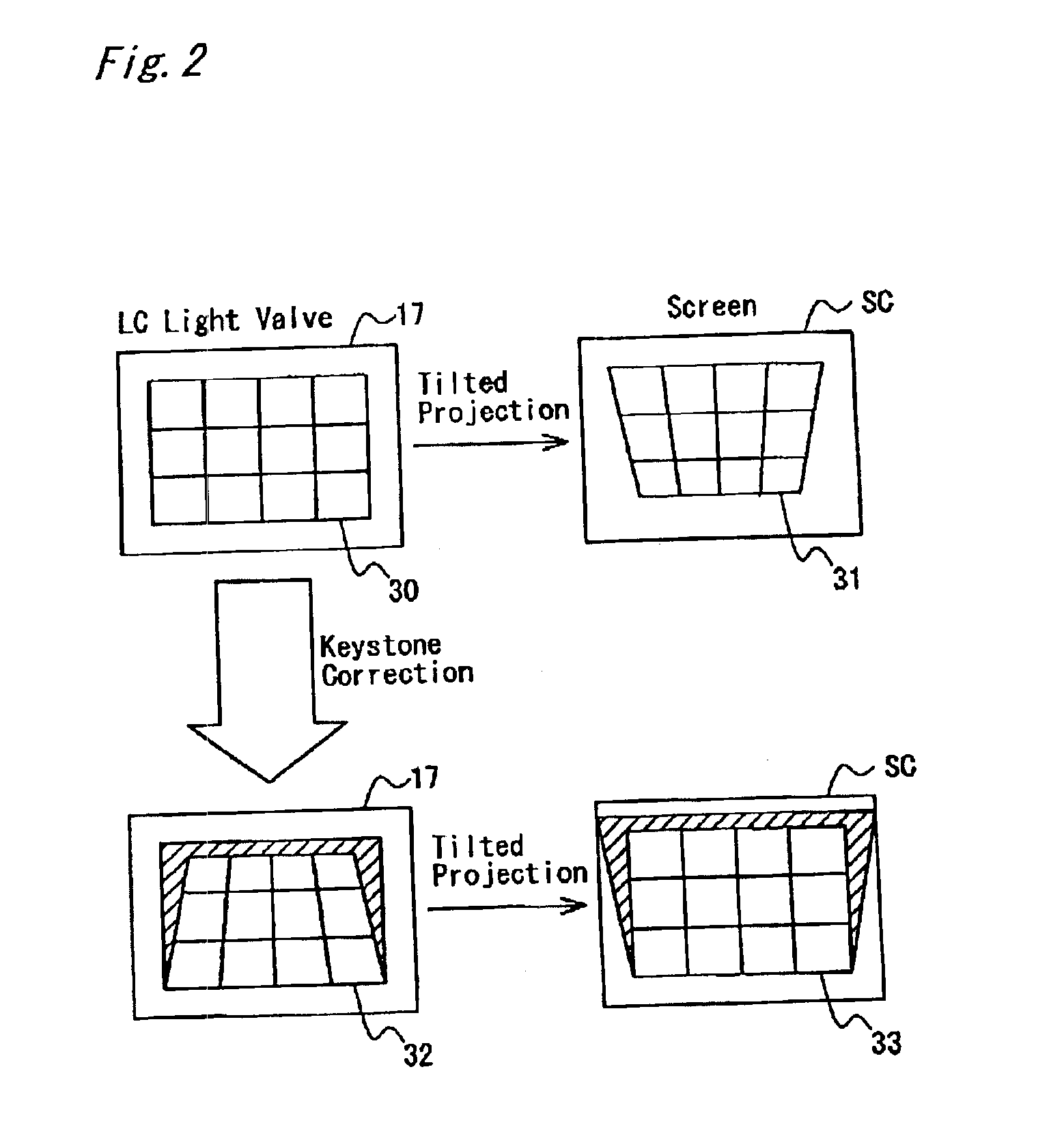

Projector executing keystone correction

InactiveUS6974217B2Reduce measurement errorStabilizing correctionProjectorsColor television detailsElevation angleComputer graphics (images)

An automatic keystone correction which enables even an inexperienced user to easily obtain an image corrected using the keystone distortion during a tilted projection. The projector detects varying of its elevation angle by using an elevation detecting module. When the angle stops varying, the projector determines that the elevation adjustment by the user ends, and executes auto keystone correction of the input image according to the elevation angle.

Owner:SEIKO EPSON CORP

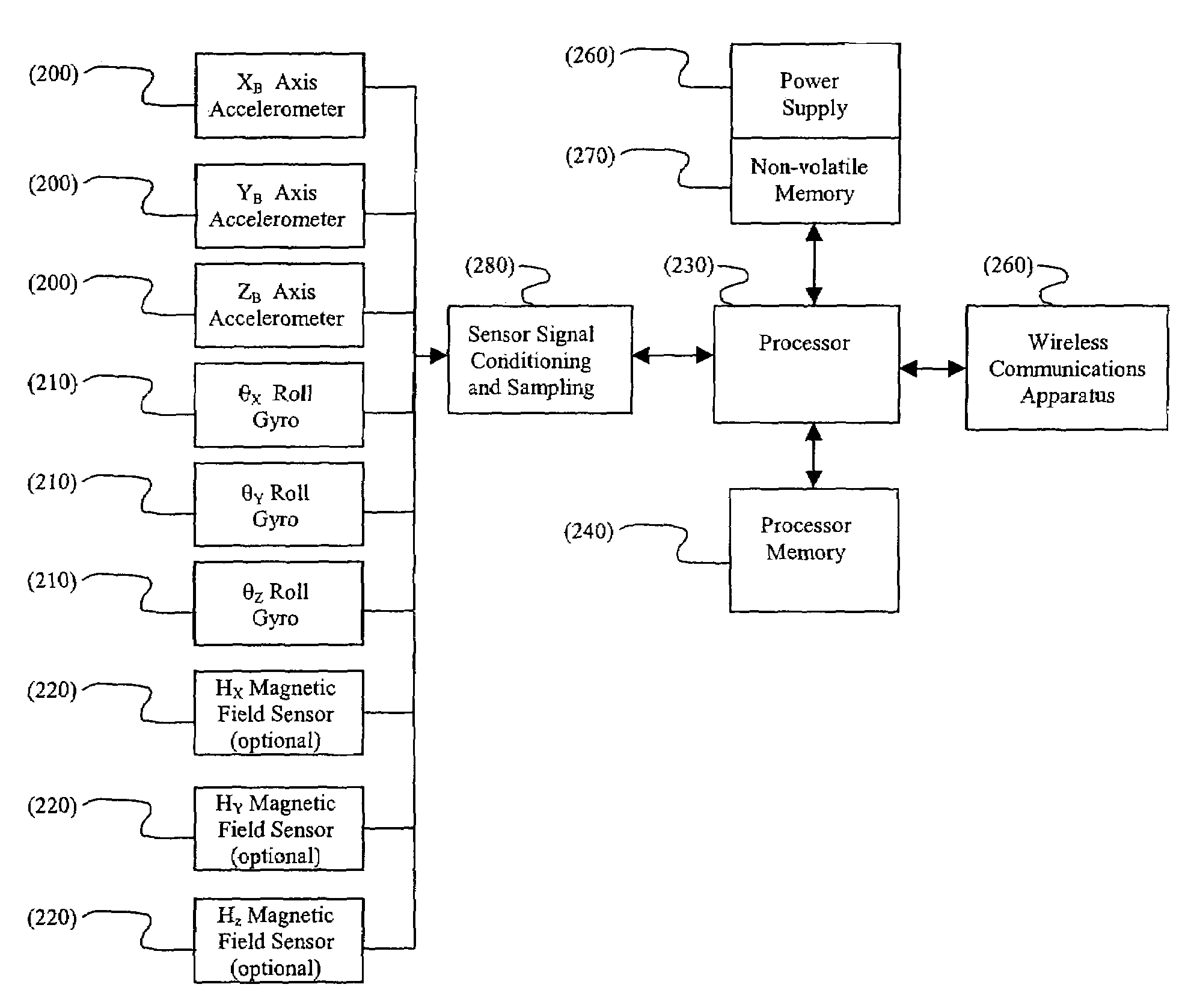

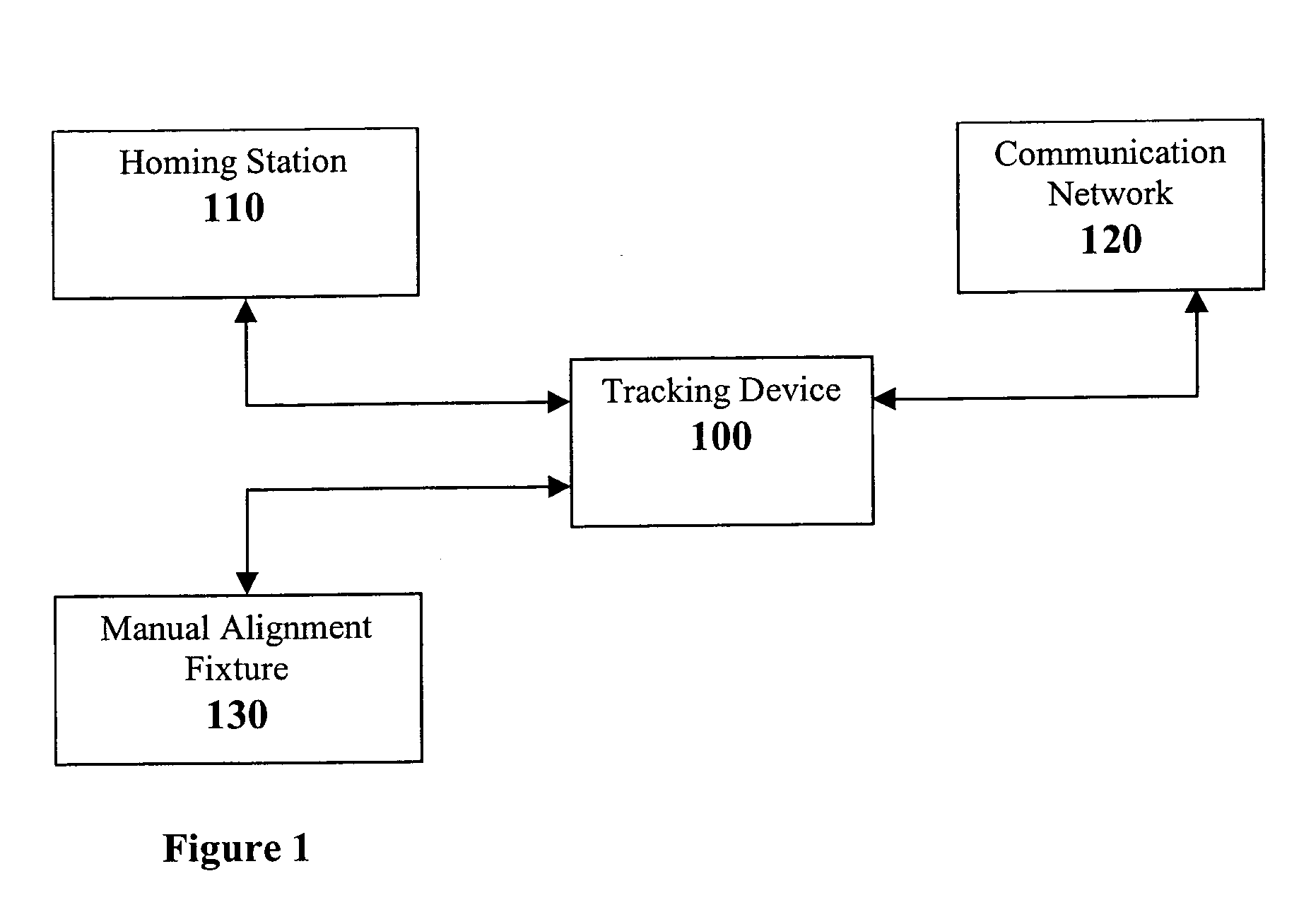

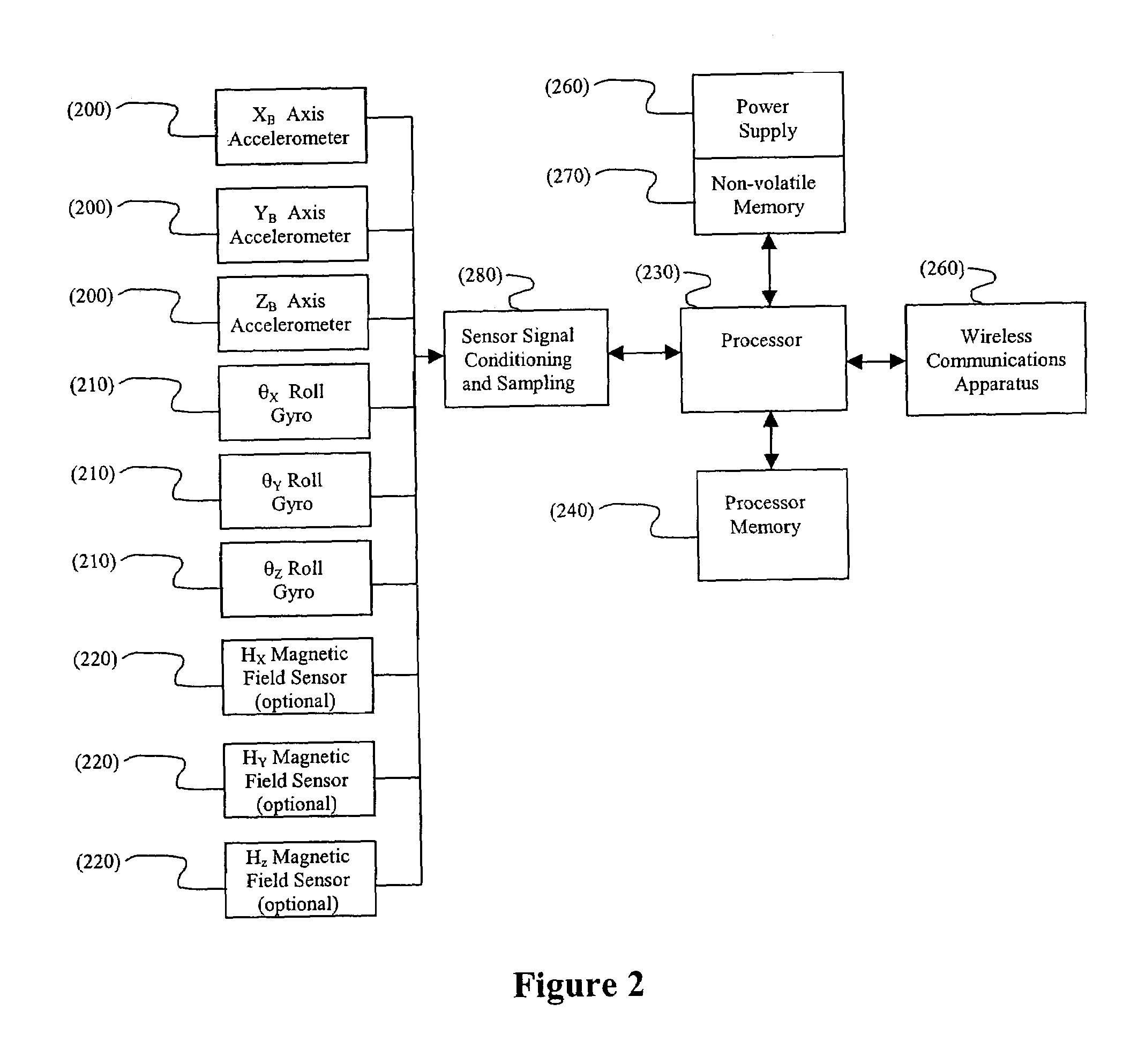

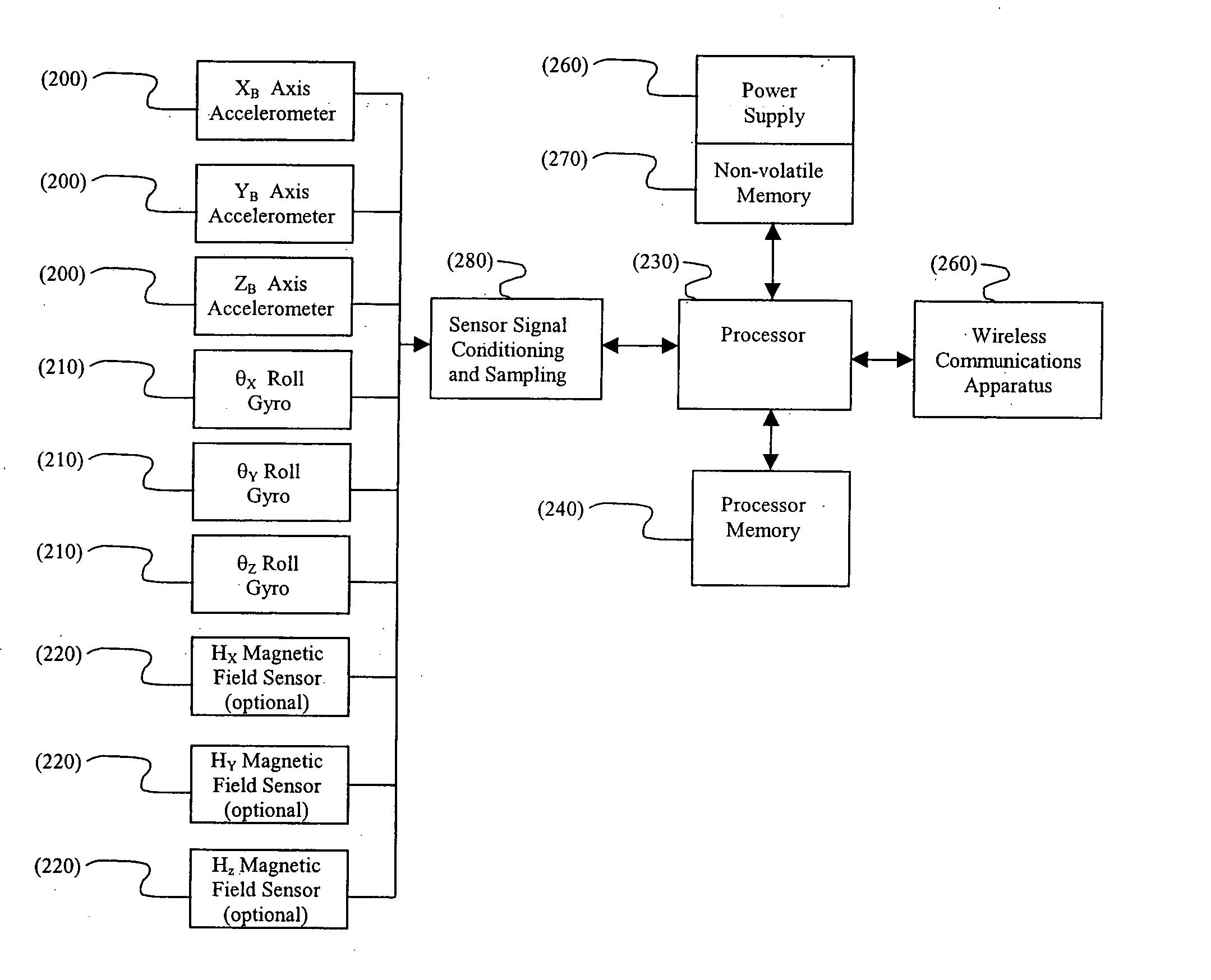

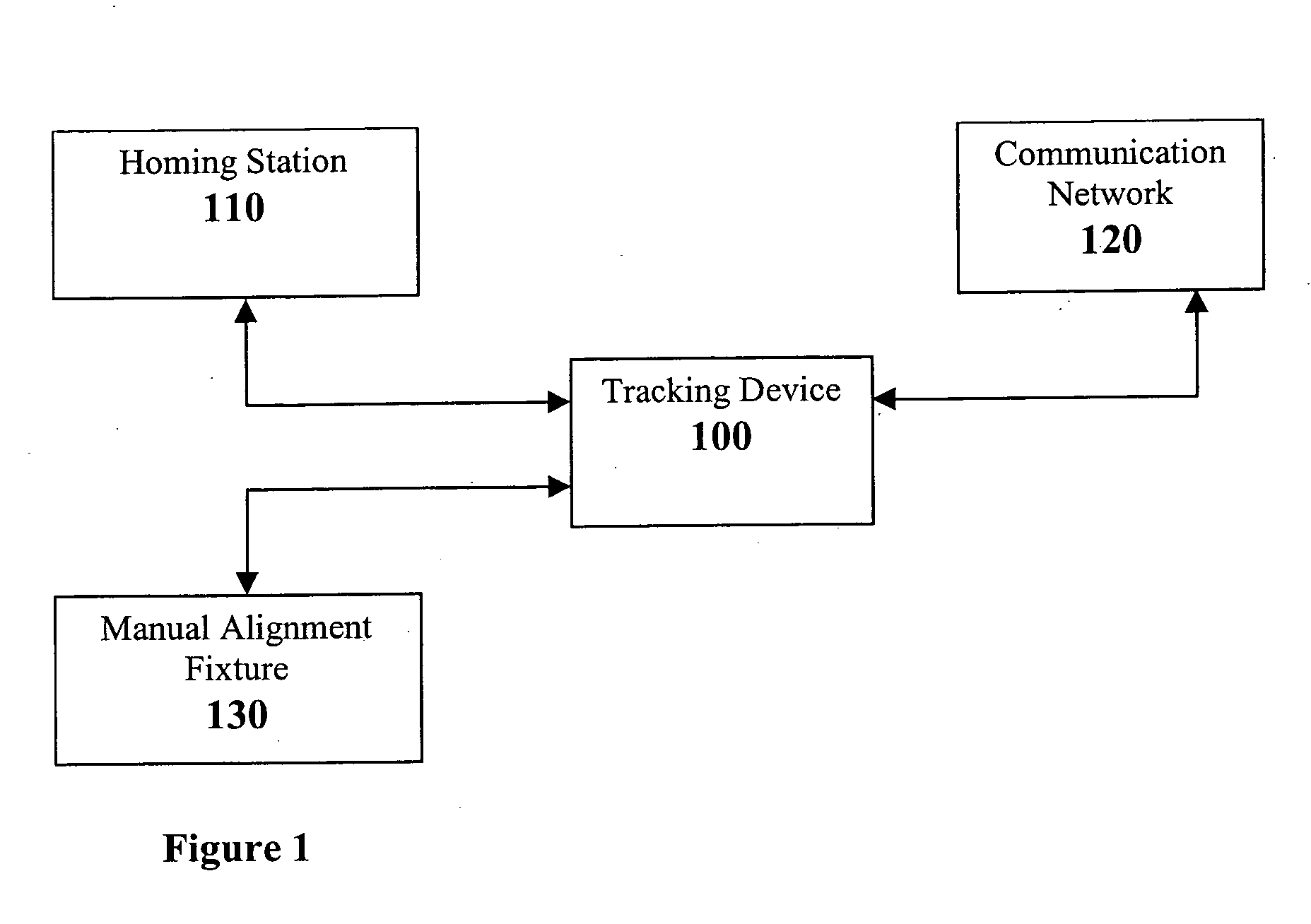

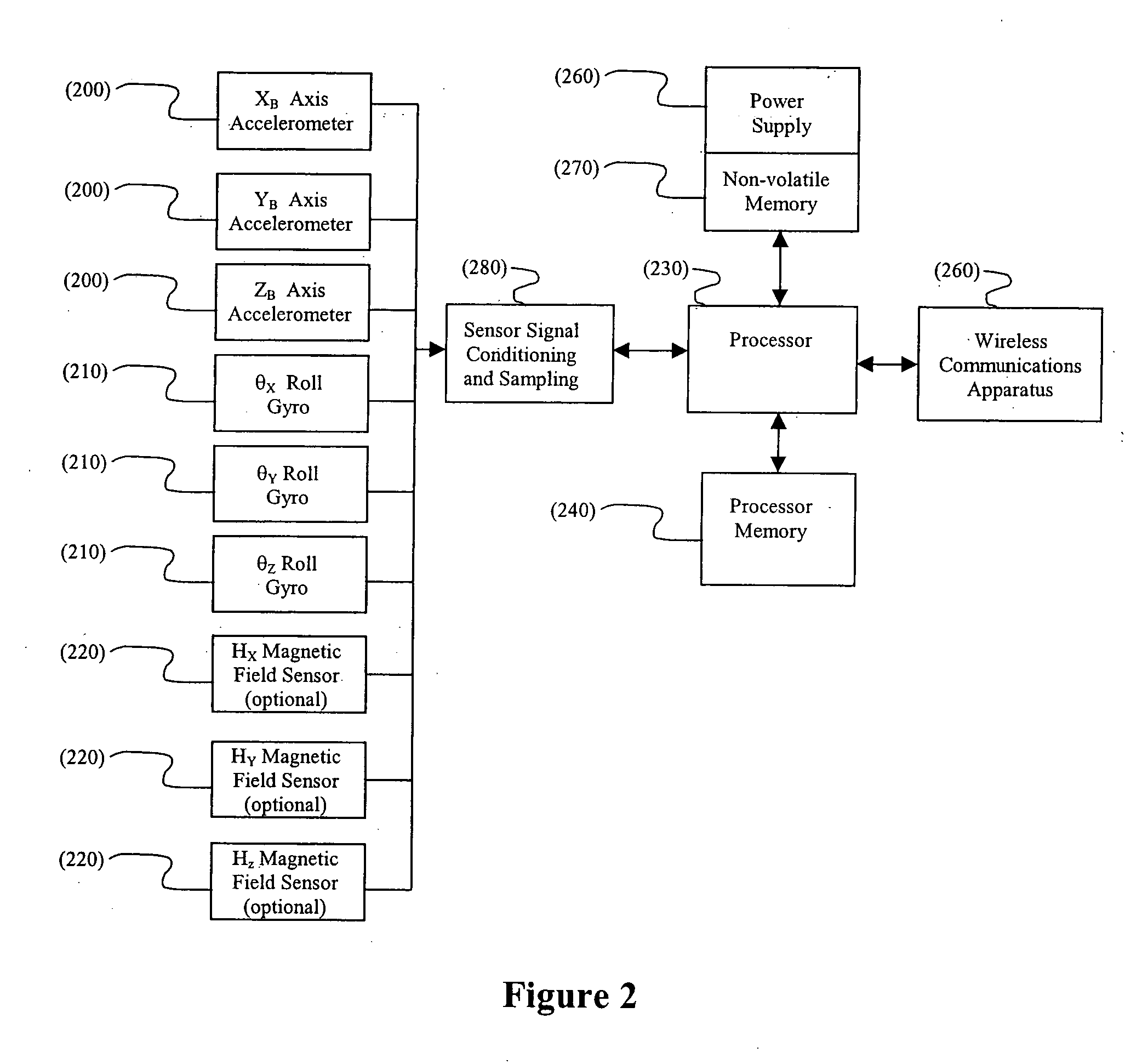

Tracking system and methods thereof

ActiveUS7106189B2Reduce measurement errorElectric/electromagnetic visible signallingNavigation instrumentsData miningData science

Owner:INTELLECTUAL VENTURES ASSETS 180 LLC

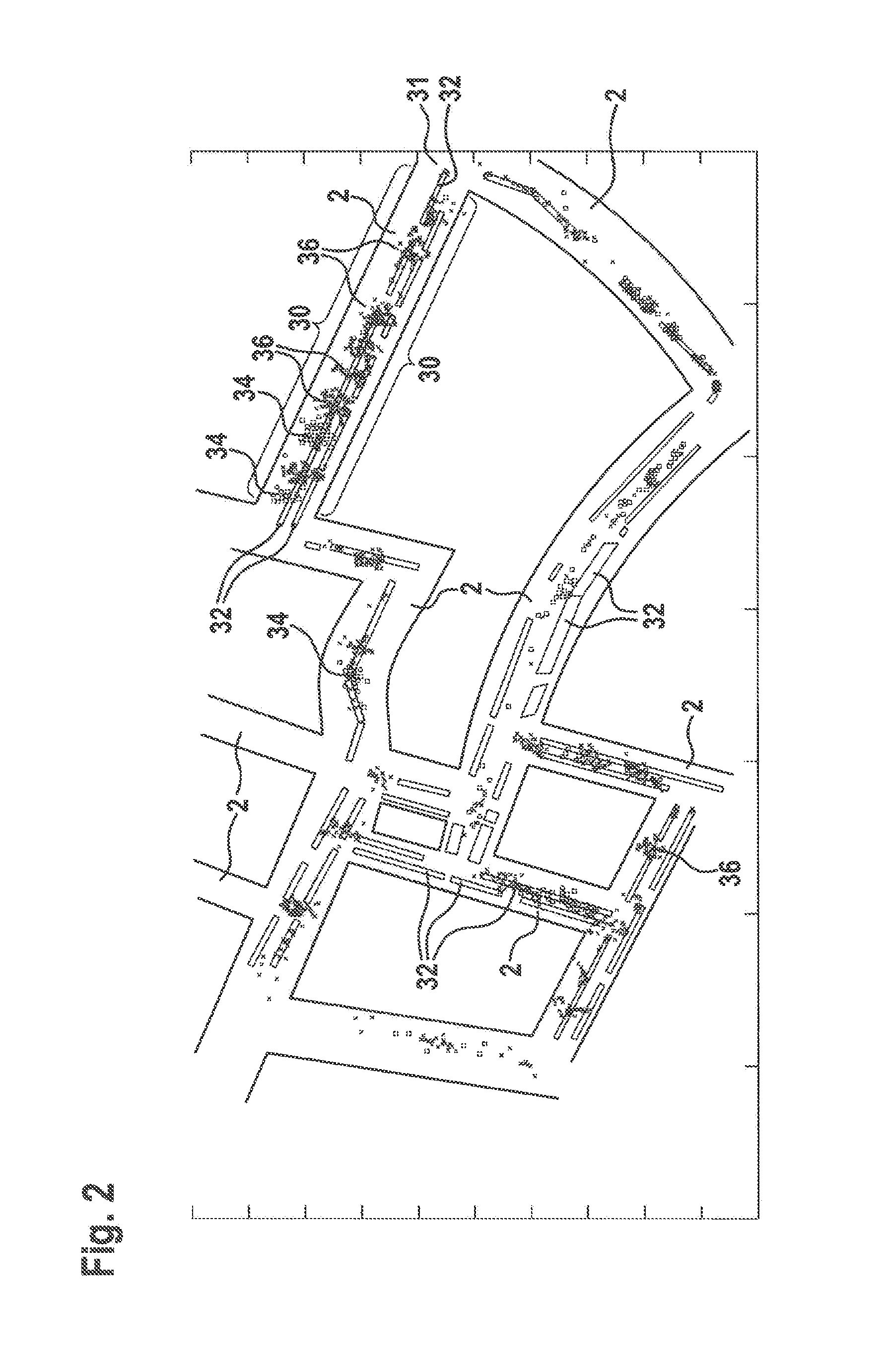

Method for identifying parking areas and/or free spaces--

ActiveUS20160321926A1Short timeQuick updateIndication of parksing free spacesAnti-collision systemsParking areaDriver/operator

A method for identifying free spaces (parking not permitted) and / or permitted parking areas, vehicles transmitting pieces of information about possible parking spaces (PPS) to a central computer facility (CCF). Positions of PPS are detected with vehicle surroundings sensors, and the detected PPS are evaluated based on the data collected, a categorization being performed for recording the PPS, with positions, in a CCF database and evaluating the data using a cluster analysis. When the analysis is performed, PPS are assigned to a street portion, a function is assigned to the street portion, which is given by the quotient of the frequency of PPS detections in a certain position along the street portion and the number of vehicle passages through the street portion and a weighting factor from the evaluation. A free space is inferred when the function value is greater than a predefined second limiting value and / or a parking area is inferred when the function value is within a predefined range. Also described is a device for assisting a driver, a central computer facility, and a related computer program.

Owner:ROBERT BOSCH GMBH

Systems and methods for current control of power conversion systems

ActiveUS9088218B2Reduce errorsReduce measurement errorElectroluminescent light sourcesDc-dc conversionPower flowEngineering

System and method for regulating an output current of a power conversion system. An example system controller for regulating an output current of a power conversion system includes a driving component, a demagnetization detector, a current-regulation component, and a signal processing component. The driving component is configured to output a drive signal to a switch in order to affect a primary current flowing through a primary winding of the power conversion system. The demagnetization detector is configured to receive a feedback signal associated with an output voltage of the power conversion system and generate a detection signal based on at least information associated with the feedback signal. The current-regulation component is configured to receive the drive signal, the detection signal and a current-sensing signal and output a current-regulation signal based on at least information associated with the drive signal, the detection signal, and the current sensing signal.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

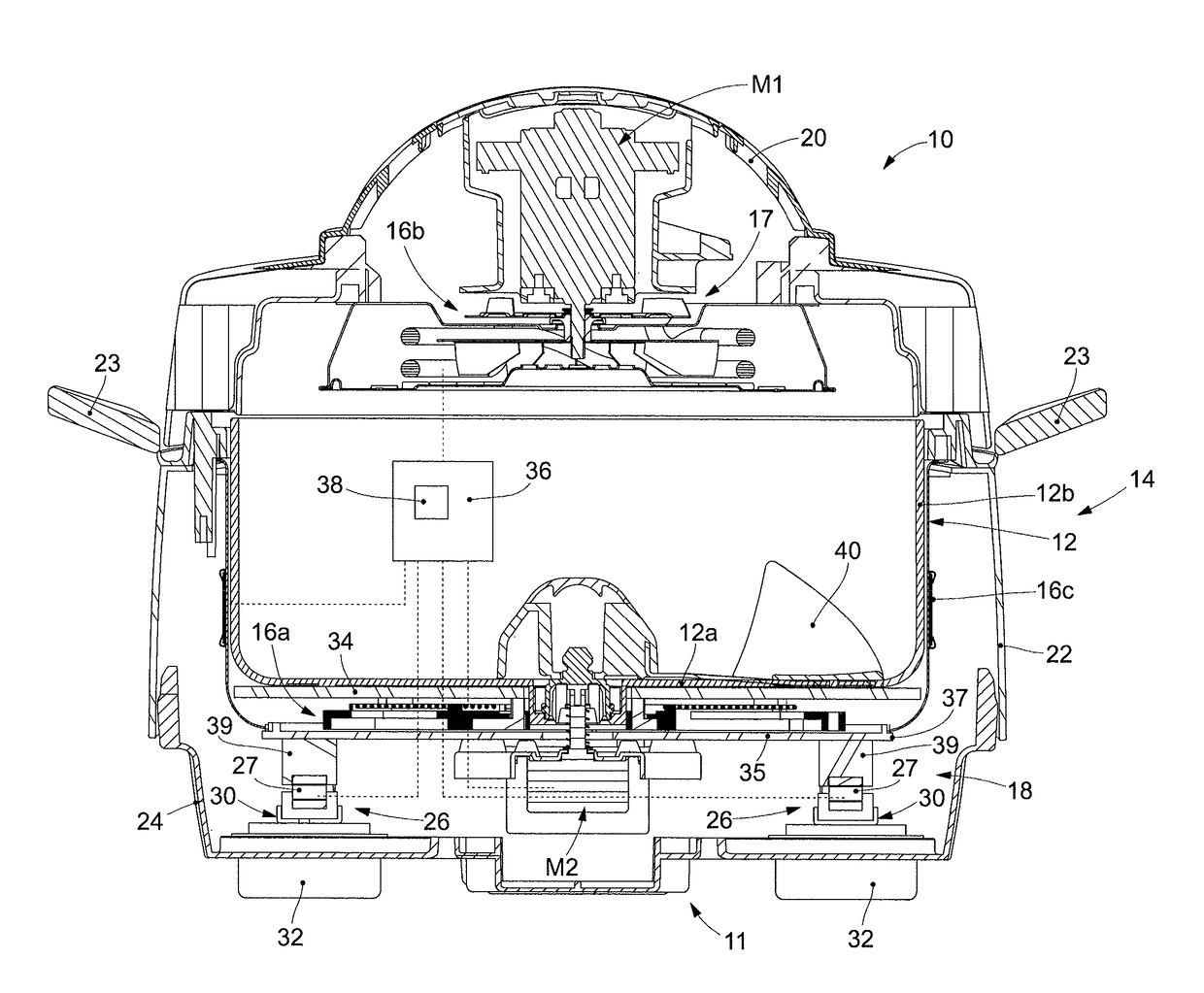

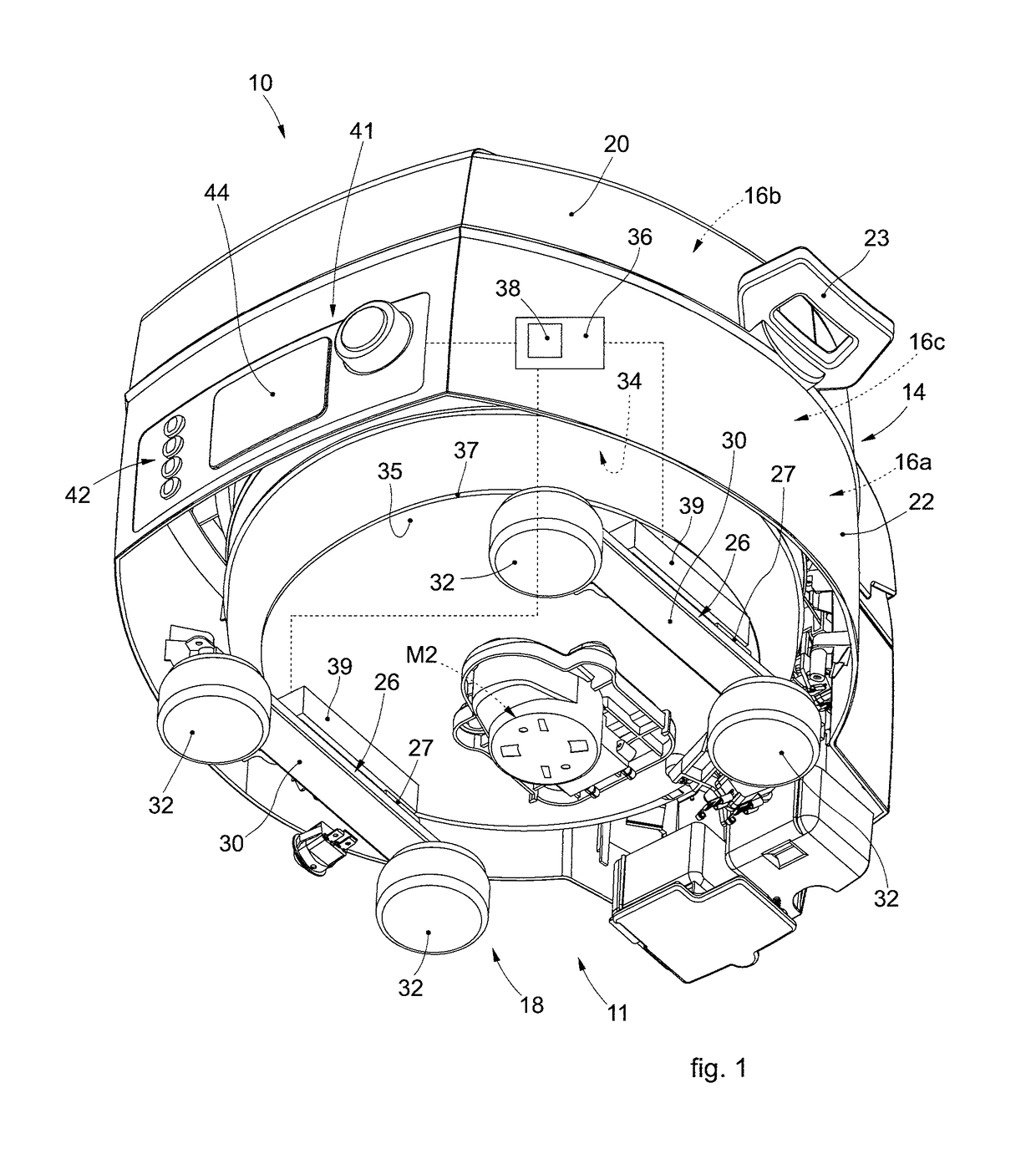

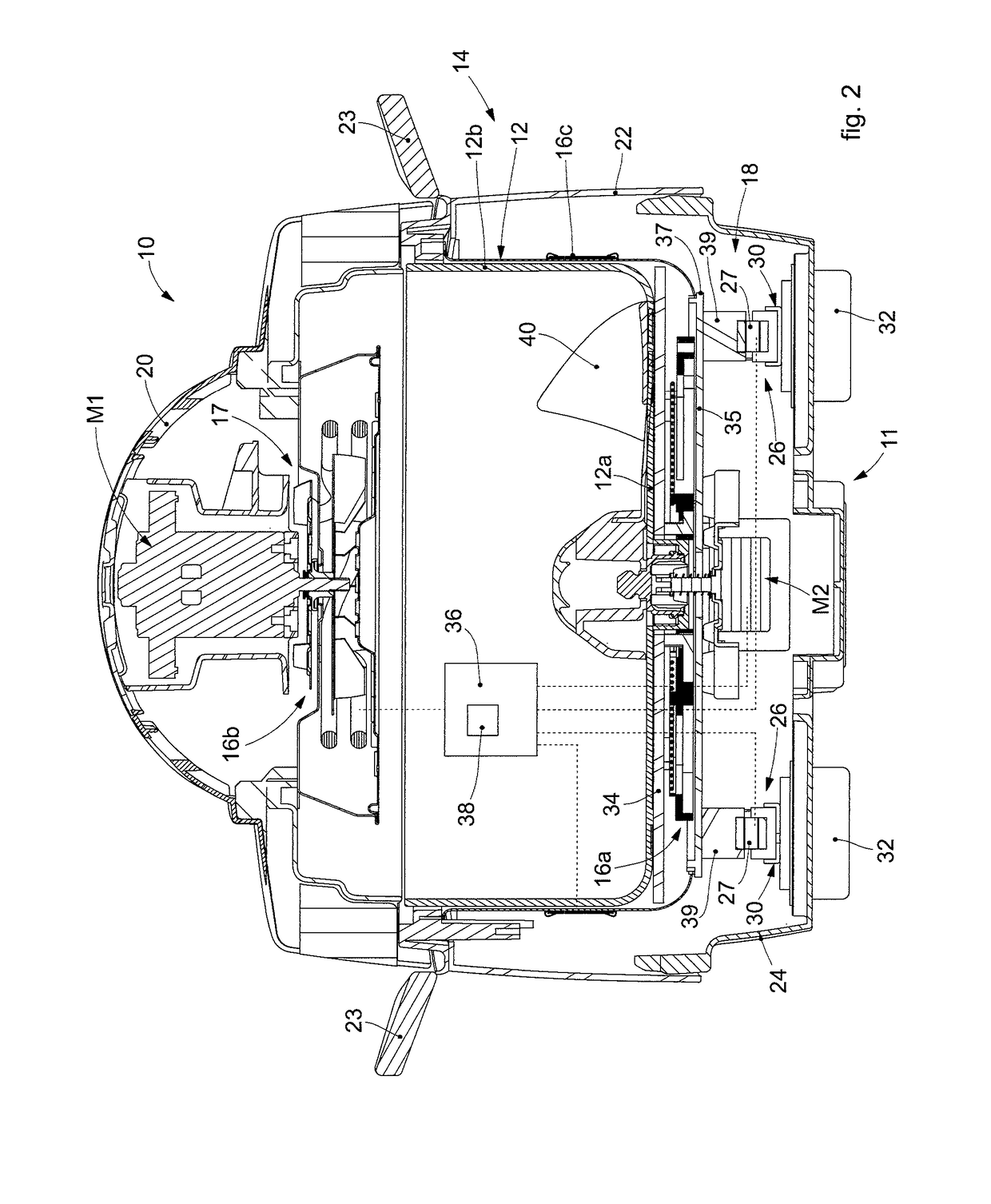

Apparatus for cooking food

ActiveUS20180325318A1Precise weightReduce measurement errorDomestic stoves or rangesLighting and heating apparatusEngineeringControl unit

An apparatus for cooking food (10) includes a casing (14), a lid (20) and at least a support unit (11). The casing (14) has a compartment in which to insert a container (12) which may be temporally associated with the support unit (11), and the support unit (11) may be configured to temporally support the container (12) with respect to a support plane. The apparatus for cooking food (10) also includes a first heating unit (16a), a second heating unit (16b), a third heating unit (16c) and a weighing unit (18) associated with a control unit (36).

Owner:DELONGHI APPLIANCES S R L CON UNICO SOCIO

Tracking system and methods thereof

ActiveUS20050242947A1Reduce measurement errorElectric/electromagnetic visible signallingNavigation instrumentsData miningData science

Owner:INTELLECTUAL VENTURES ASSETS 180 LLC

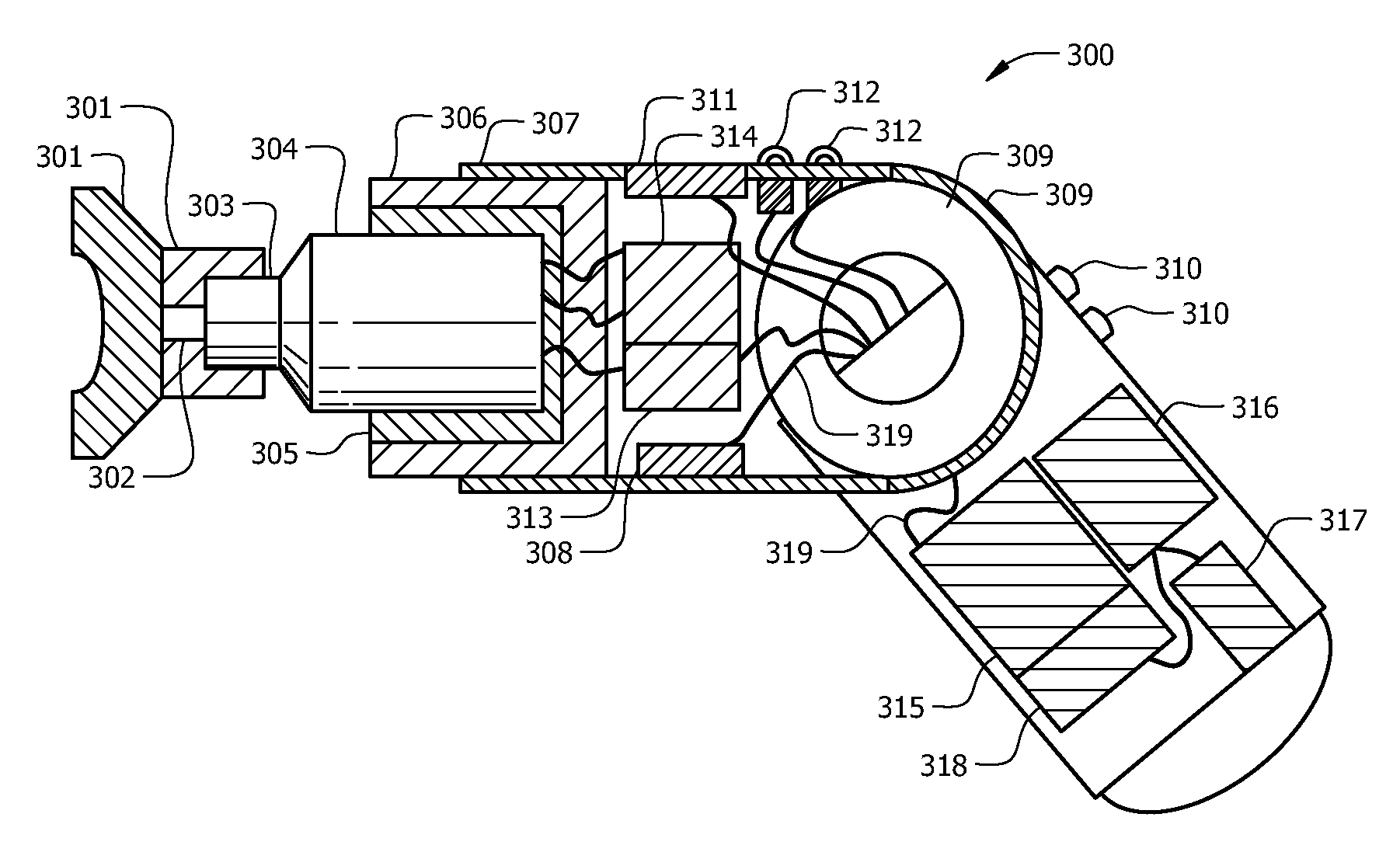

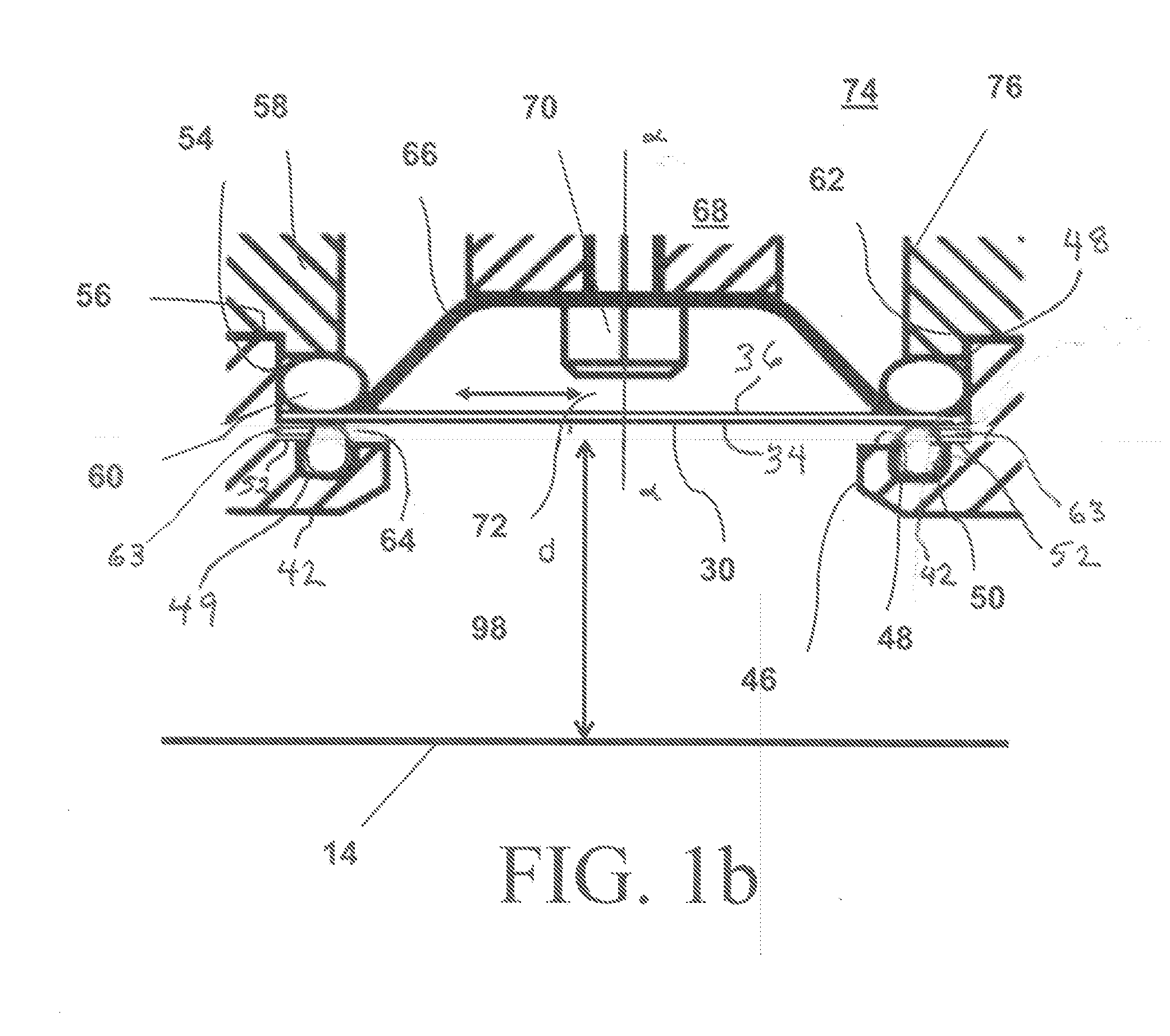

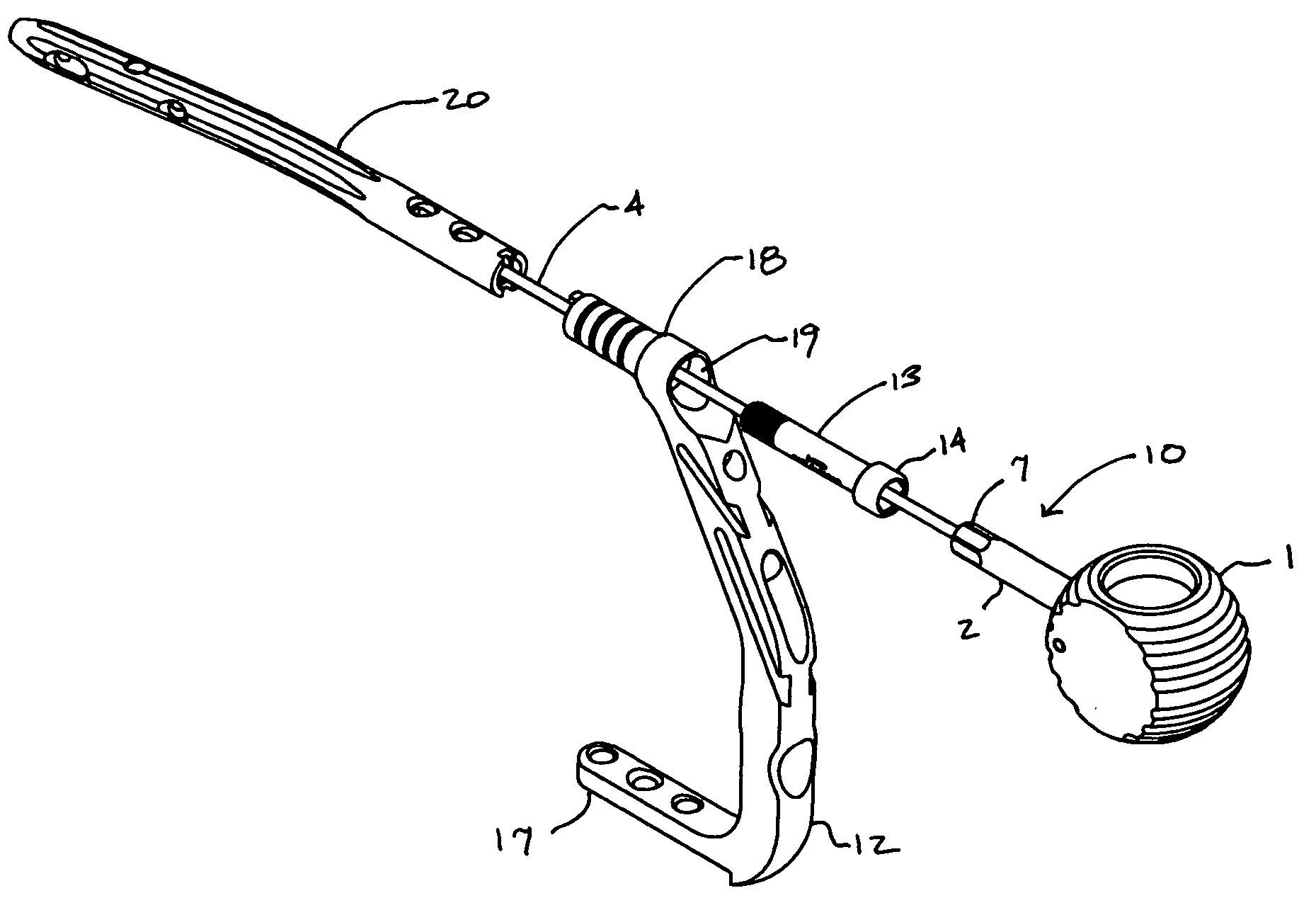

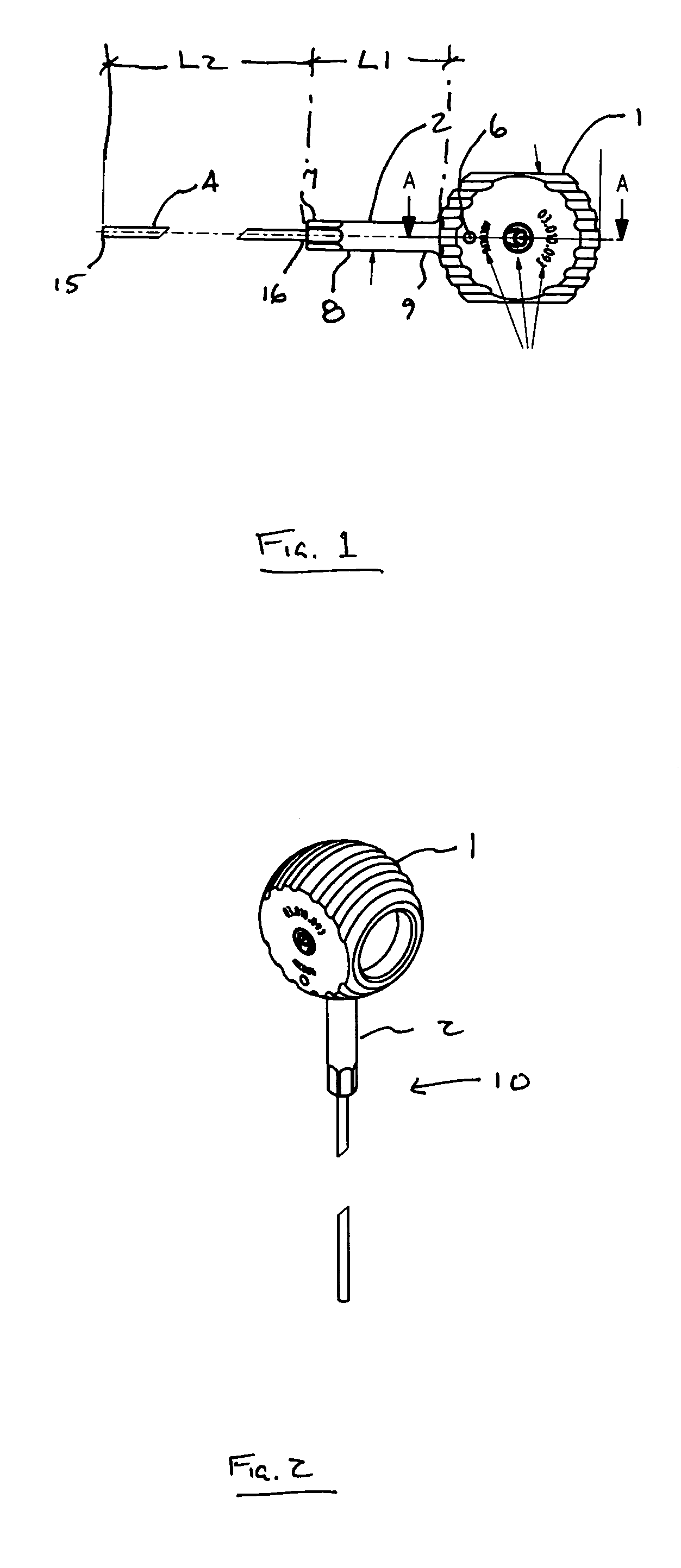

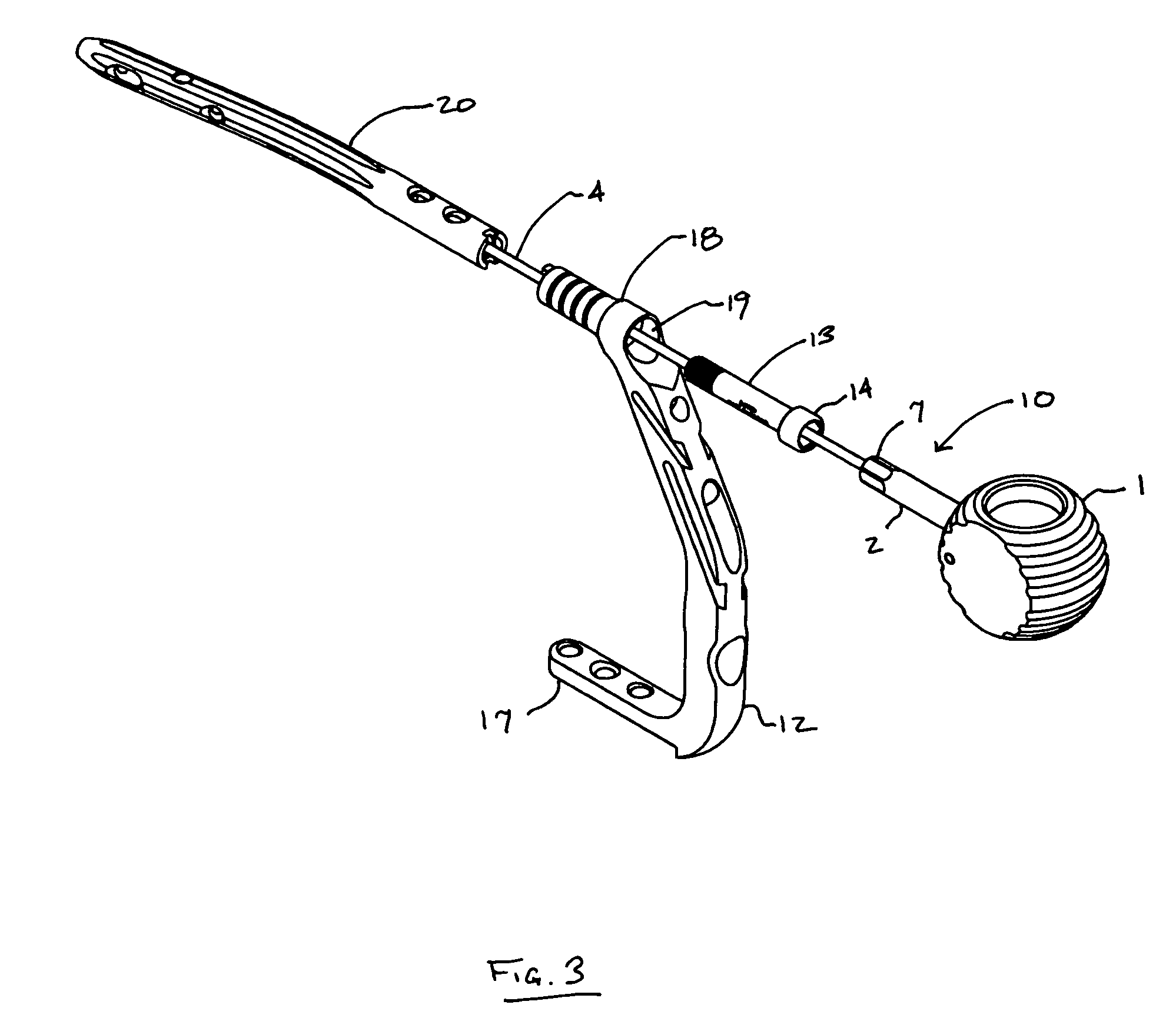

Implant assembly device

ActiveUS7033365B2Reduce measurement errorEasily and securely attachInternal osteosythesisJoint implantsTibiaLONG BONE FRACTURE

This invention relates generally to systems for the internal fixation of bone fractures, and particularly, to equipment associated with the insertion of intramedullary fracture fixation devices such as those used in the treatment of long bone fractures, such as for example fractures of the femur, tibia, humerus, etc. An implant assembly device of the present invention may comprise a handle, a shaft with a first end and a second end, and an elongated rod extending from the shaft. The first end of the shaft is connected to the handle and the second end of the shaft is configured to engage the head of a connecting screw. The device can be held with one hand while the various components are placed one by one into their proper position onto the rod, leaving the other hand free to manipulate the other components.

Owner:SYNTHES USA

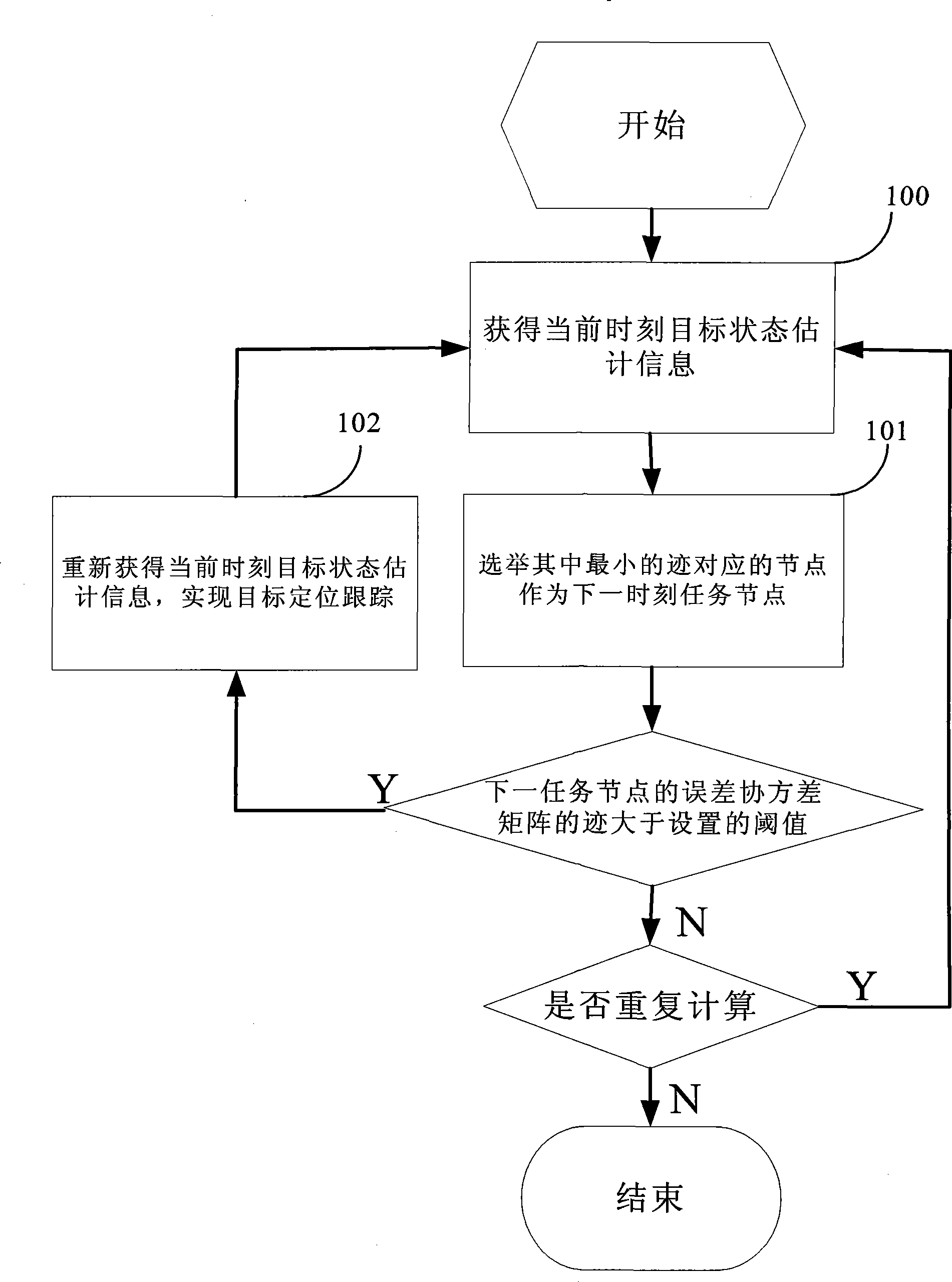

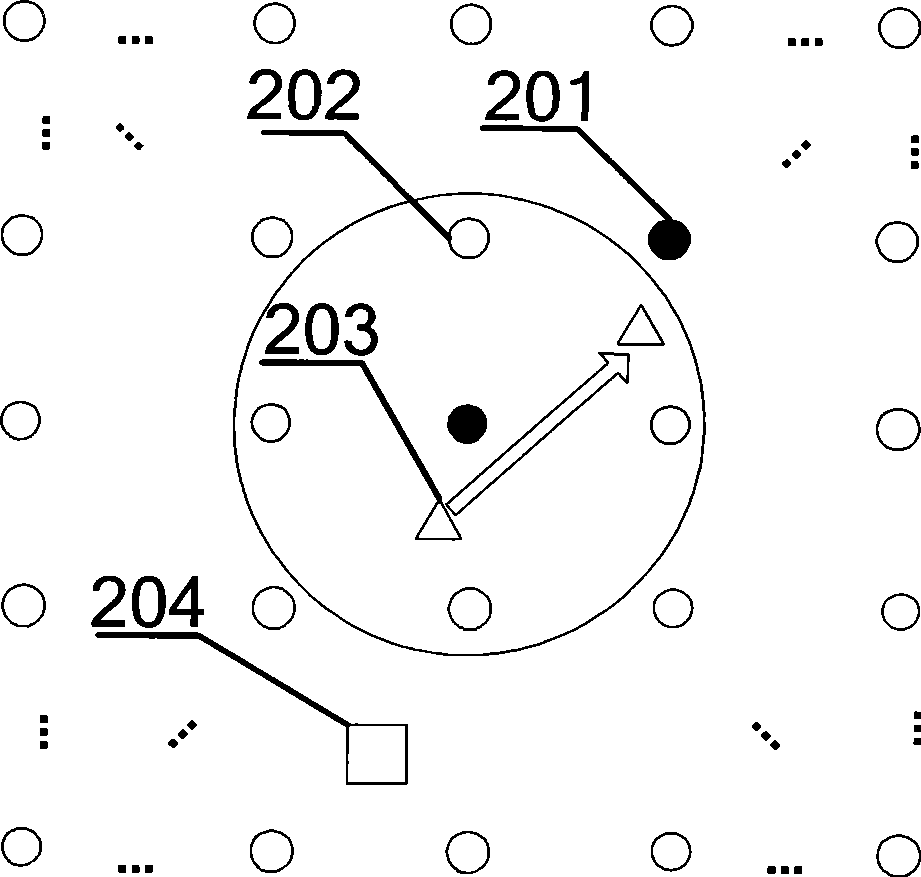

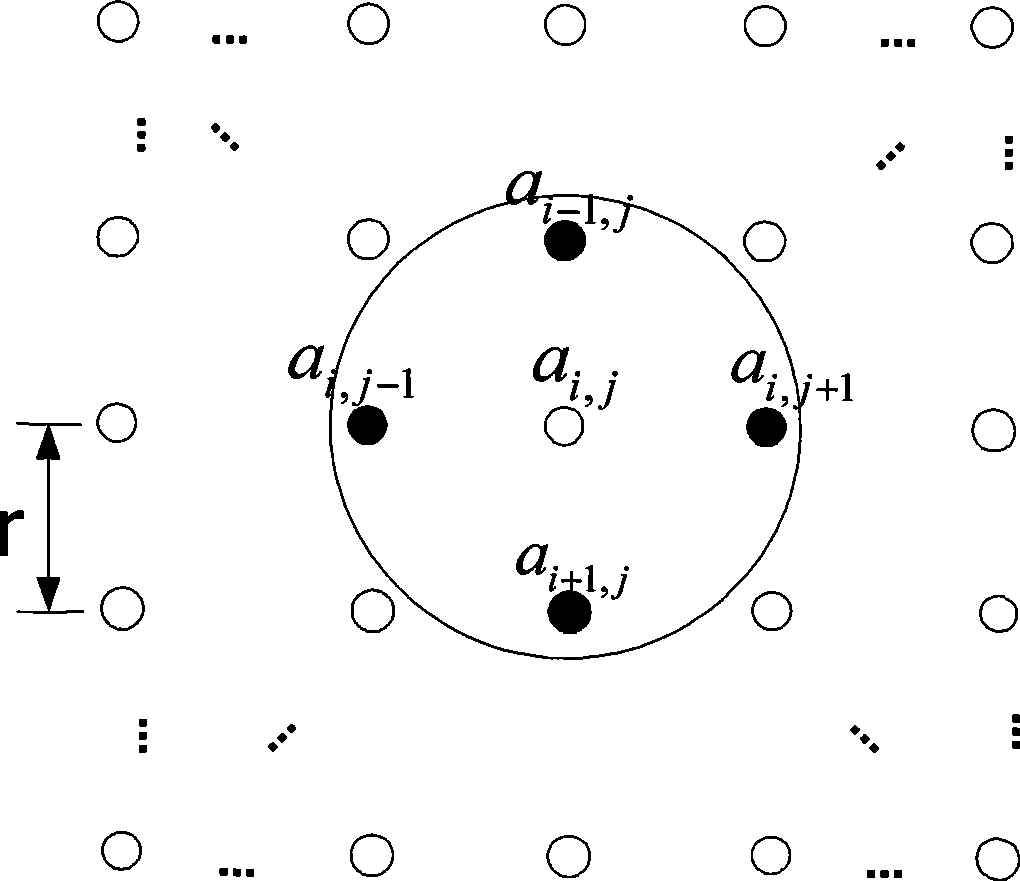

Wireless sensor network target tracking method based on distributed processing

InactiveCN101505532ASave energyReduce measurement errorEnergy efficient ICTBaseband system detailsCorrection algorithmReal-time computing

The invention discloses a target tracking method based on a distributed processing wireless sensor network, which comprises the following steps: observing data by utilizing last moment target state estimation information and current moment task nodes, and performing extended Kalman filter to obtain current moment target state estimation information; calculating to obtain a prior estimation error covariance matrix track of a next moment candidate task node according to the current moment target state estimation information, and comparing and selecting a node corresponding to the minimum track as a next moment task node; and when the prior estimation error covariance matrix track corresponding to the next moment task node is greater than a set threshold, adopting a target track correction algorithm to acquire the current moment target state estimation information again to realize the target positioning and tracking. The method can effectively reduce communication between nodes, save energy resources and communication resources of the nodes, and meet the requirements of accuracy, real-time and robustness of node positioning simultaneously.

Owner:SOUTH CHINA UNIV OF TECH

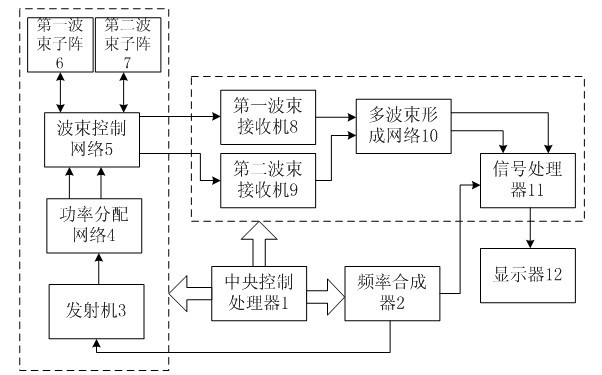

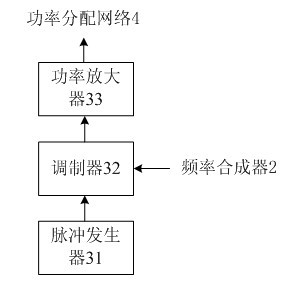

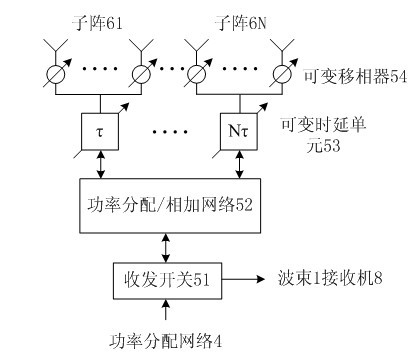

Multifrequency phased array ultrasonic Doppler flow detection system and method

InactiveCN101936756AReduce noiseHigh measurement accuracyVolume/mass flow measurementDisplay deviceBeam scanning

The invention discloses a multifrequency phased array ultrasonic Doppler flow detection system and a multifrequency phased array ultrasonic Doppler flow detection method. The system comprises a central control processor, a frequency synthesizer, a transmitting part, a receiving part and a display, wherein the transmitting part comprises a transmitter, a power distribution network, a beam control network, a first beam subarray and a second beam subarray; the receiving part comprises a first beam receiver, a second beam receiver, a multi-beam forming network and a signal processor. The system is characterized in that the central control processor is respectively connected with the frequency synthesizer, the transmitter, the power distribution network, the beam control network, the first beam receiver, the second beam receiver, the multi-beam forming network and the signal processor. In the detection method of the system, beam deflection and dynamic focusing are realized through the phased array technology, multi-directional and multi-depth positions can be measured on the cross section of an integral pipeline, and by a mode of adjusting beam scanning dynamically, the processing timeof the beam scanning is reduced, and the measuring accuracy is improved.

Owner:SOUTH CHINA UNIV OF TECH

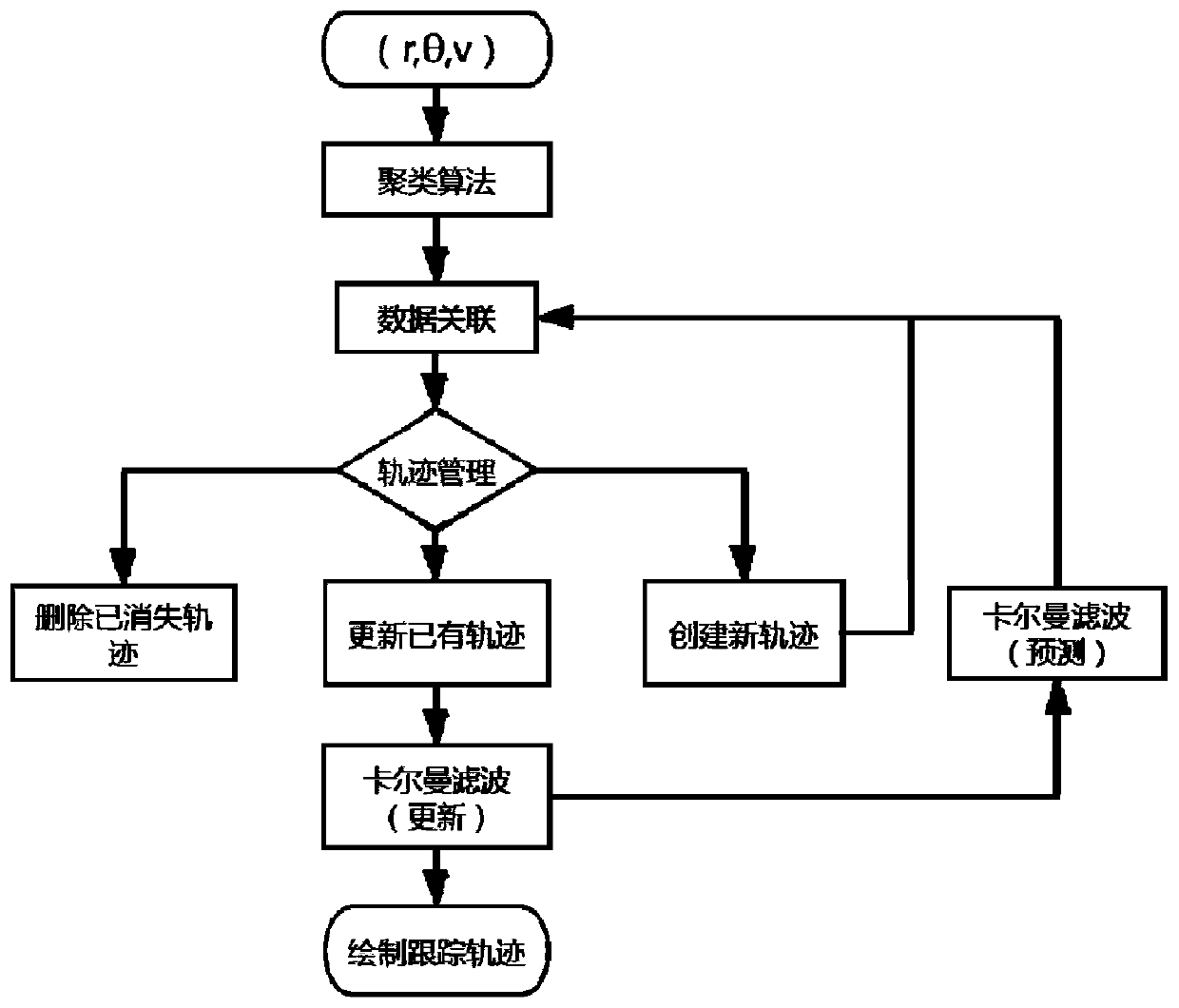

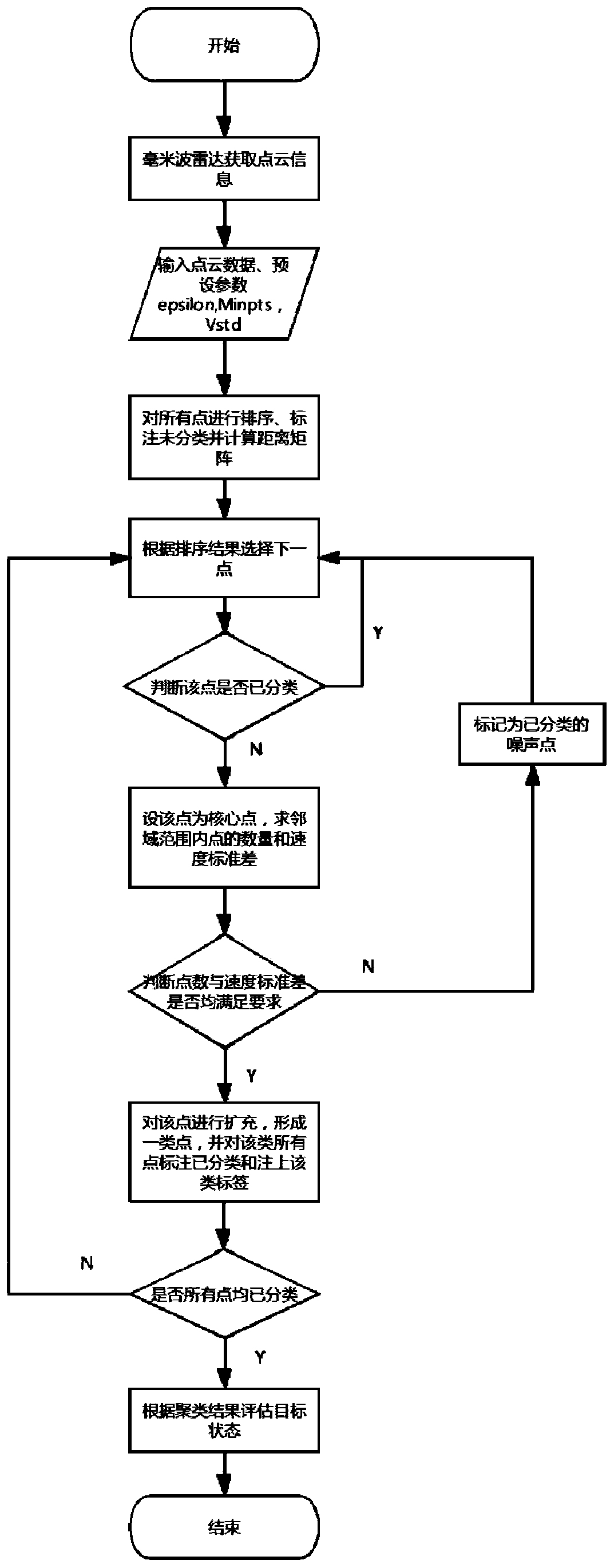

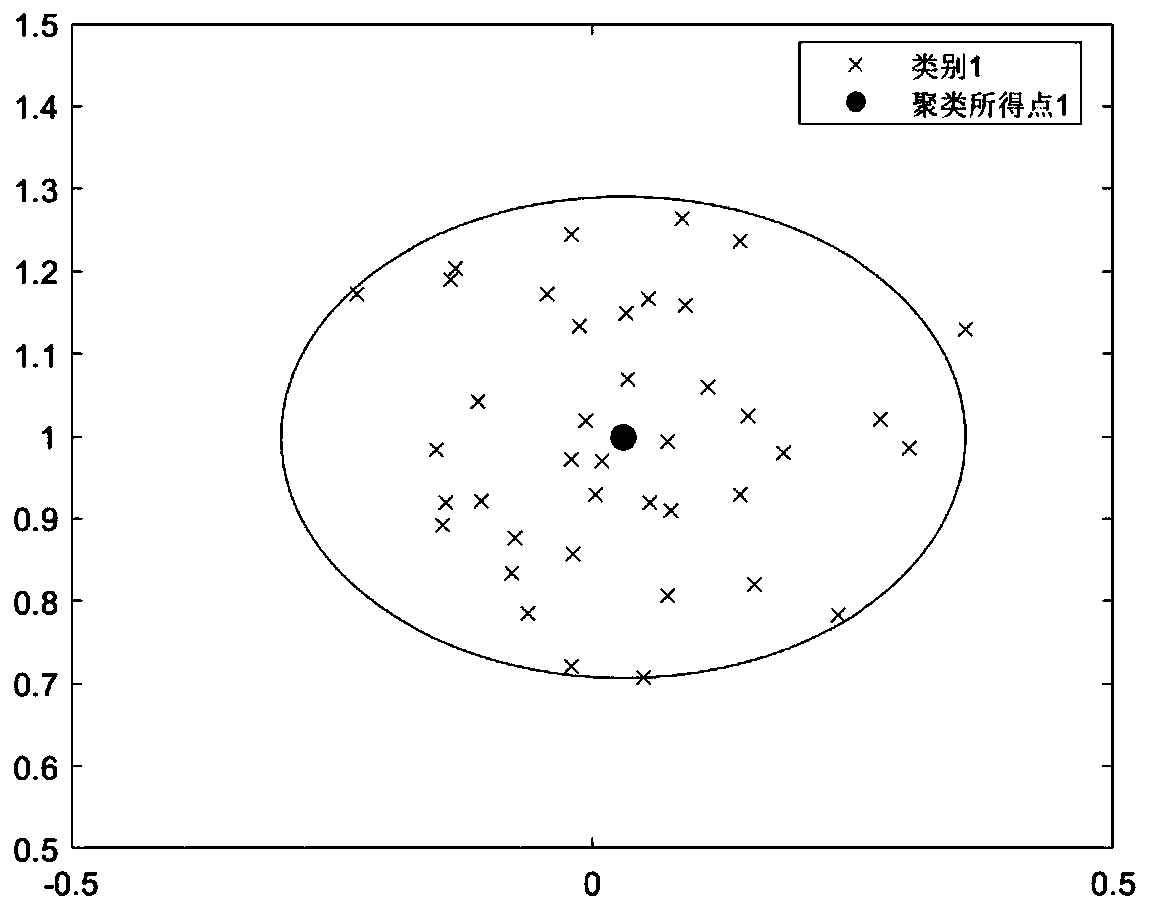

Multi-target tracking method based on millimeter-wave radar

InactiveCN110361727AAchieve perceptionImprove accuracyRadio wave reradiation/reflectionPattern recognitionCluster algorithm

The invention discloses a multi-target tracking method based on millimeter-wave radar. The method comprises acquiring point cloud data by millimeter-wave radar; clustering the point cloud data to distinguish the echo signals of different targets; and estimating the state information of multiple observed targets according to a clustering result so as to track the multiple targets. The method improves a DBSCAN clustering algorithm according to the characteristics of the millimeter-wave radar, improves the accuracy of esimating the number of the targets and the states of the targets, and predictsand tracks the trajectories of the multiple targets in a complex environment by using a Kalman filter and data association algorithm.

Owner:ZHEJIANG UNIV

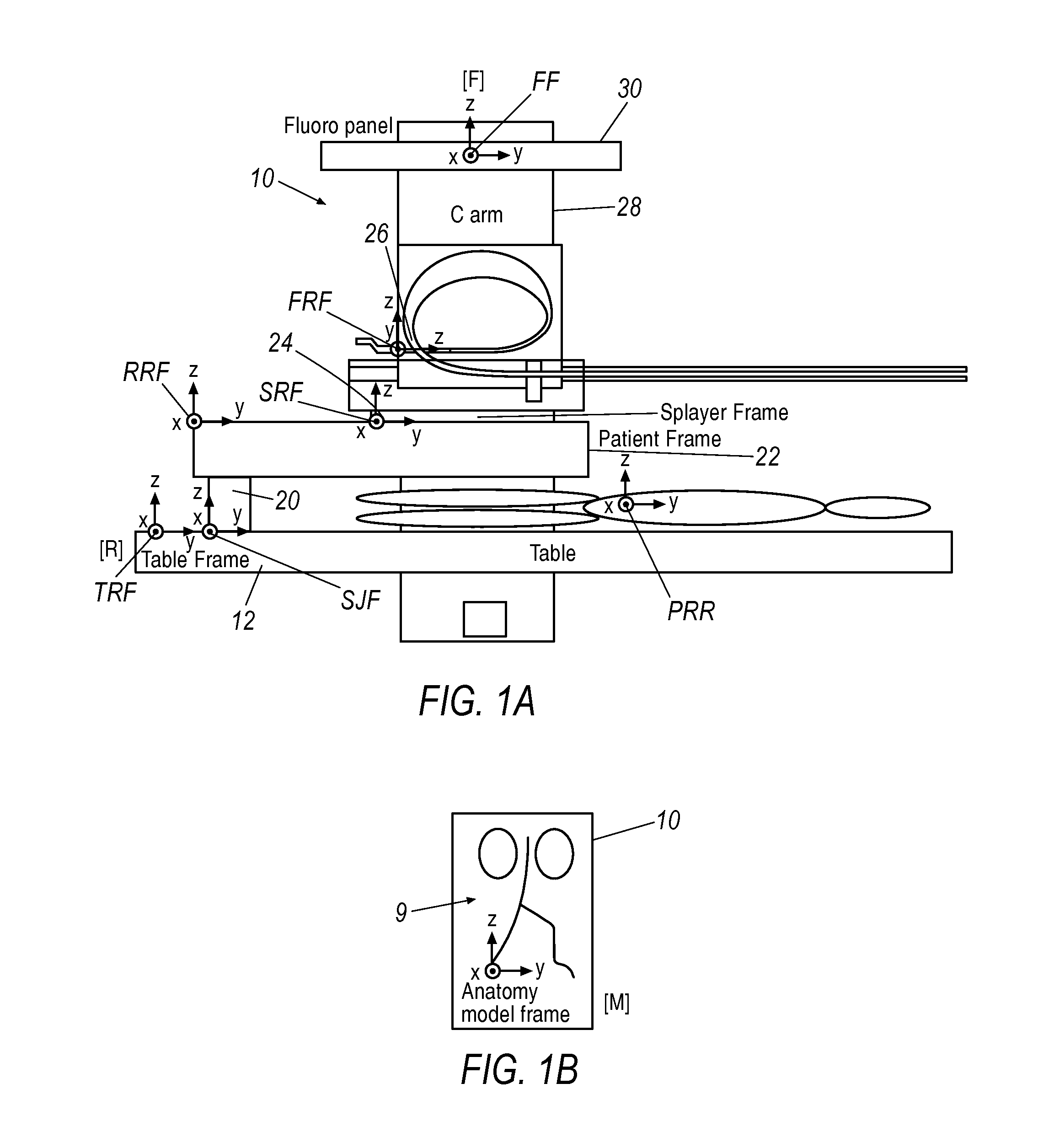

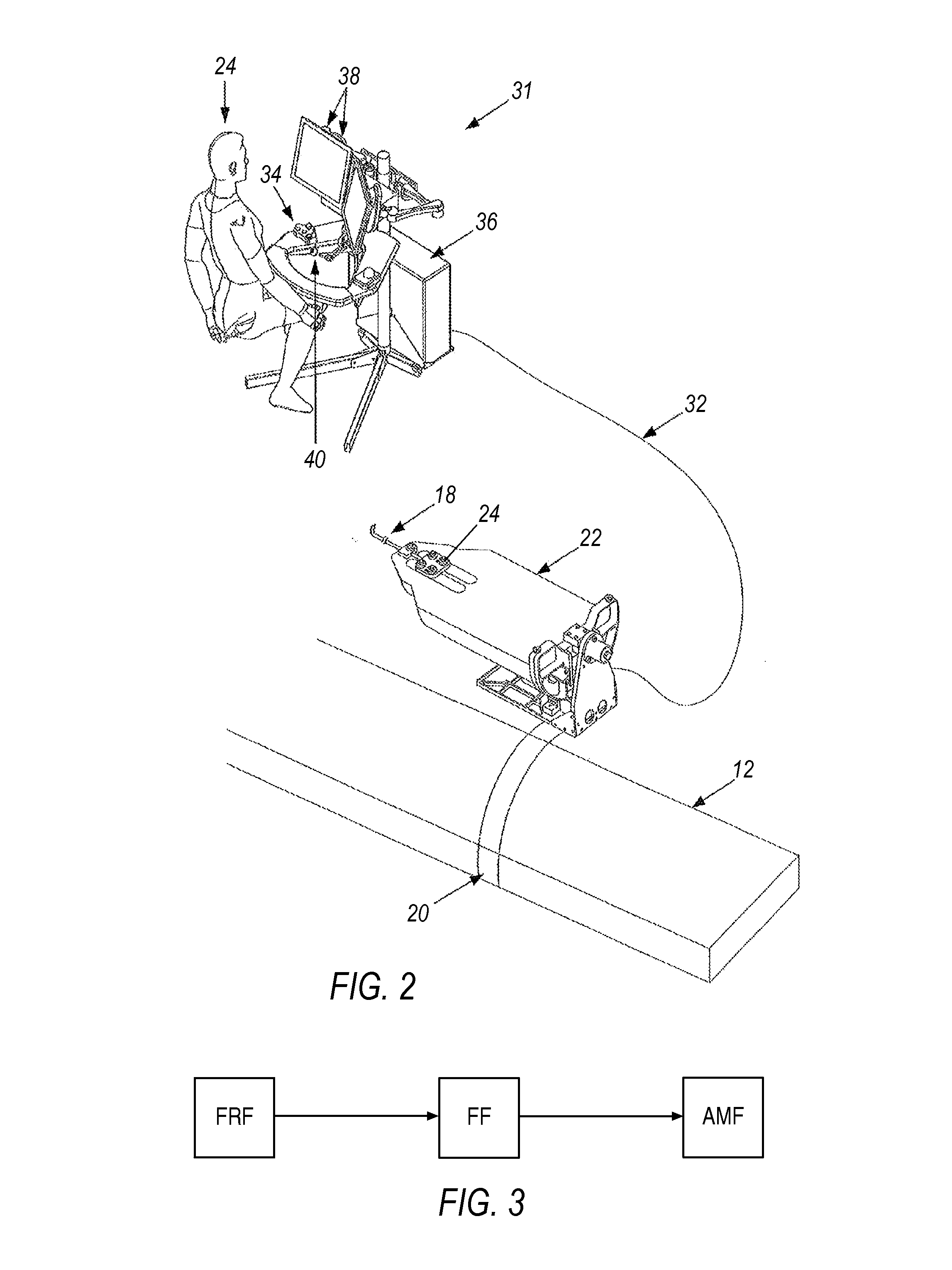

Distortion-immune position tracking using redundant measurements

ActiveUS20080033282A1Reduce measurement errorReduce impactElectrotherapyDiagnostic recording/measuringLocation trackingCondensed matter physics

A method for tracking a position of an object includes using a field sensor associated with the object to measure field strengths of magnetic fields generated by two or more field generators, wherein a measurement of at least one of the field strengths is subject to a distortion. Rotation-invariant location coordinates of the object are calculated responsively to the measured field strengths. Corrected location coordinates of the object are determined by applying to the rotation-invariant location coordinates a coordinate correcting function so as to adjust a relative contribution of each of the measured field strengths to the corrected location coordinates responsively to the distortion in the measured field strengths.

Owner:BIOSENSE WEBSTER INC

Tissue oximetry apparatus and method

ActiveUS8055321B2High precisionExclude influenceDiagnostic signal processingOptical sensorsOptical propertyMedicine

An apparatus and method for determining tissue oxygenation such as arterial and venous oxygenation and cerebral oxygenation. In one embodiment, the optical properties of tissue are determined using measured light attenuations at a set of wavelengths. By choosing distinct wavelengths and using light attenuation information, the influence of variables such as light scattering, absorption and other optical tissue properties can be minimized.

Owner:BERNREUTER PETER

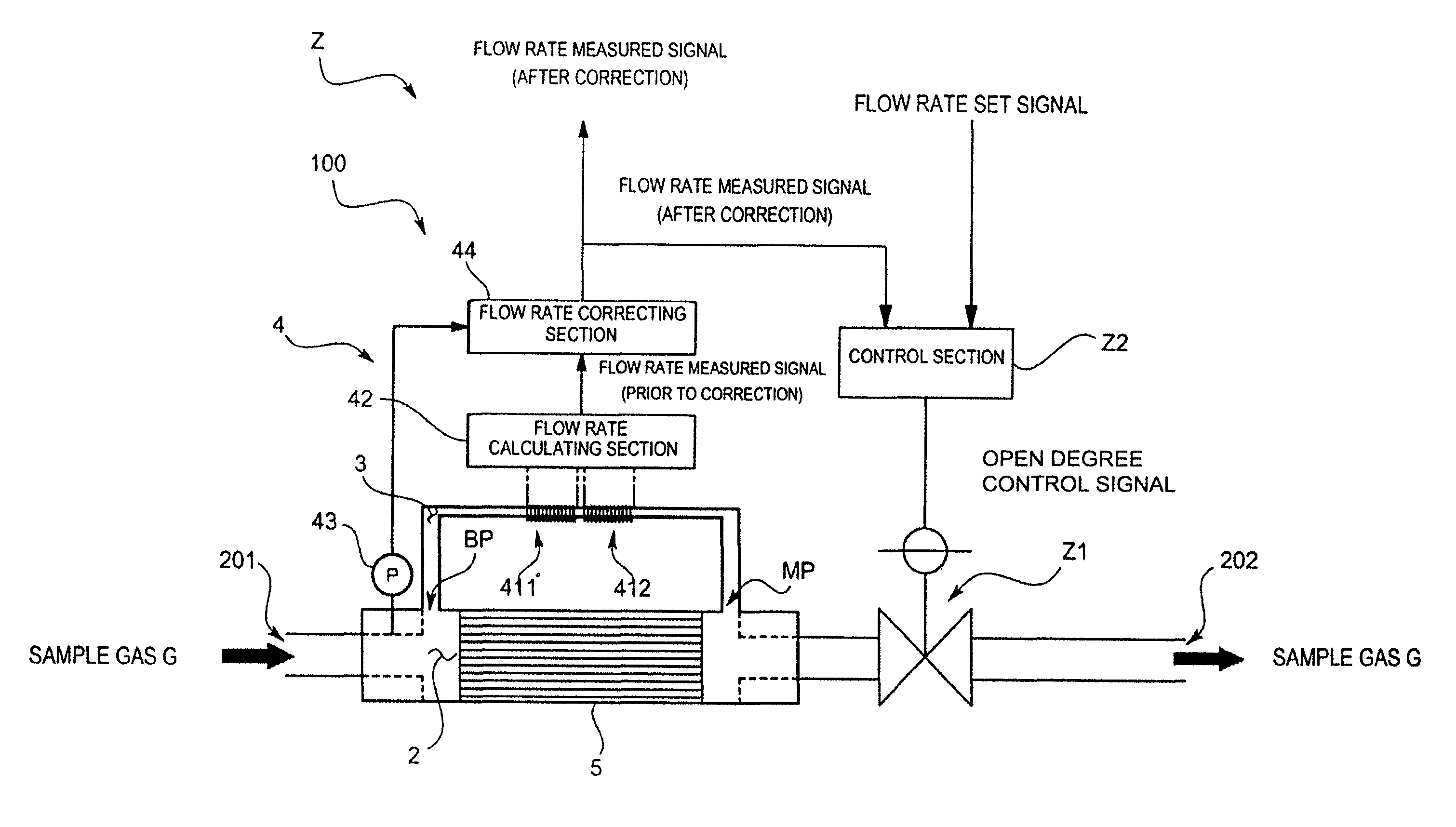

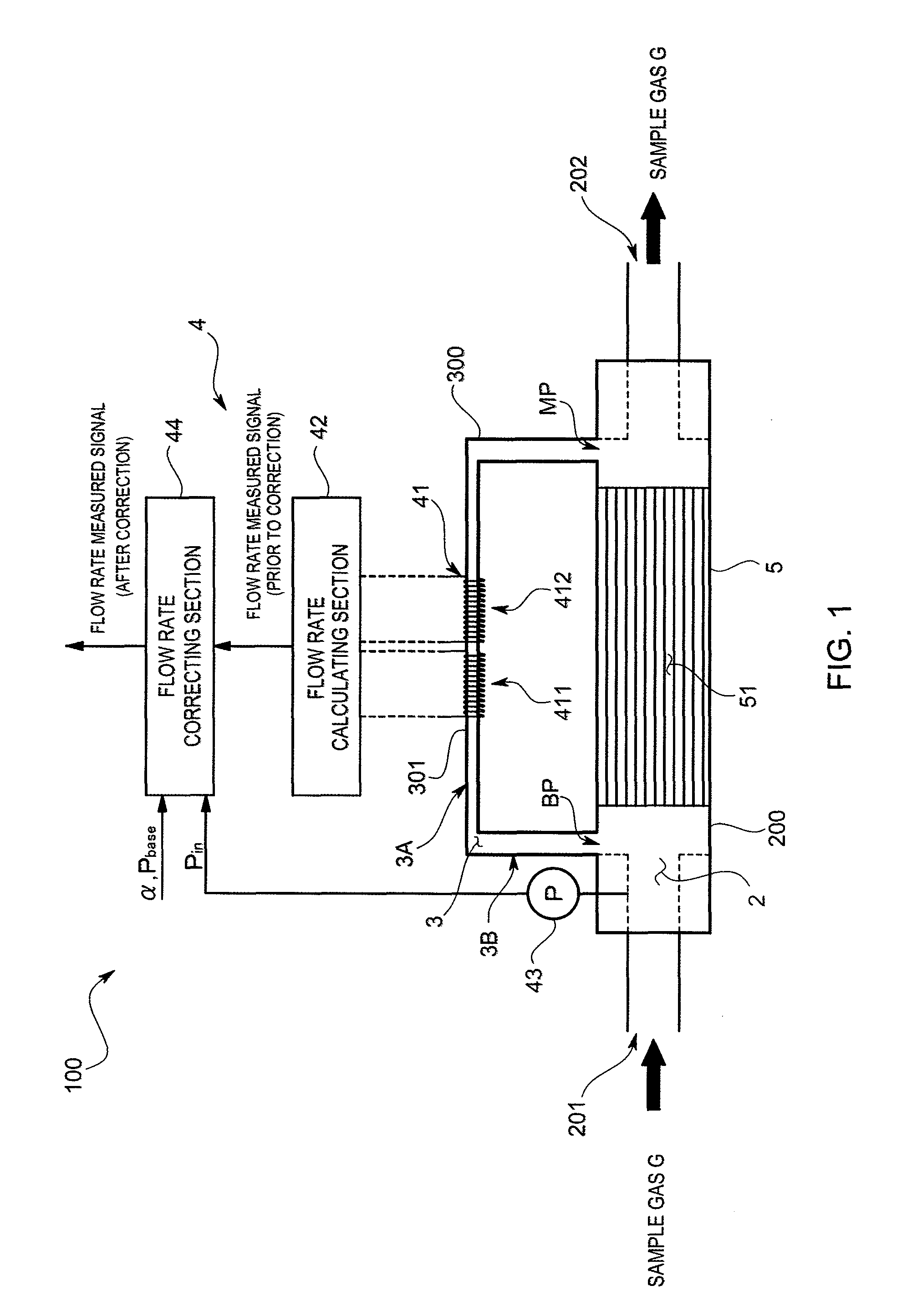

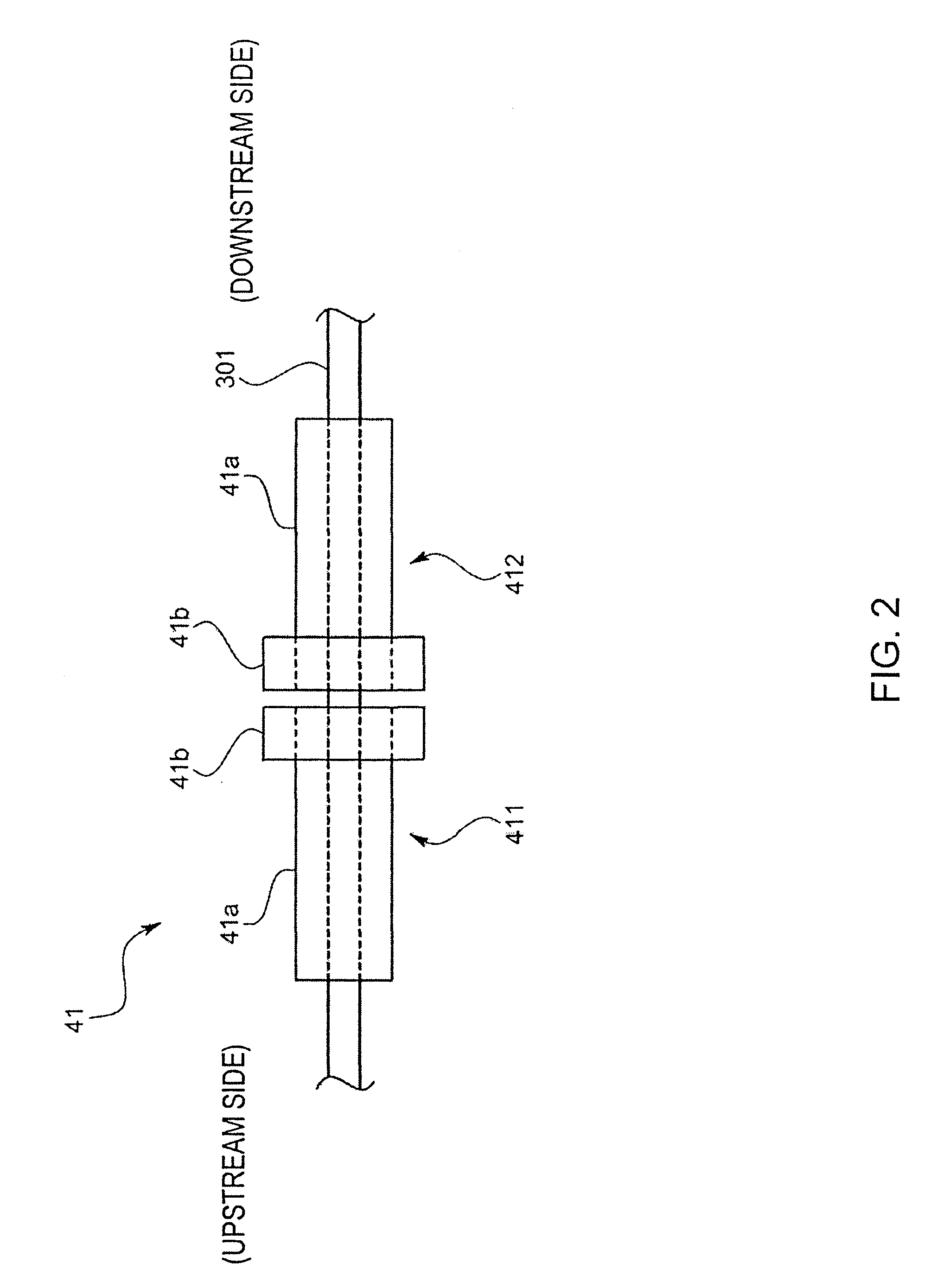

Mass flow meter and mass flow controller

ActiveUS8356623B2Reduce measurement errorHigh flow accuracyOperating means/releasing devices for valvesVolume/mass flow by thermal effectsEngineeringStreamflow

In order to improve a measurement accuracy of a mass flow meter, the mass flow meter comprises a flow rate calculating section that obtains an output signal from a sensor section having a thermosensitive resistive element arranged in a flow channel where a sample gas flows and that calculates a flow rate of the sample gas, a pressure measuring section that measures a primary side pressure in the flow channel, and a flow rate correcting section that corrects the measured flow rate obtained by the flow rate calculating section by the use of the primary side pressure obtained by the pressure measuring section and a gas coefficient determined by an isobaric specific heat of the sample gas.

Owner:HORIBA STEC CO LTD

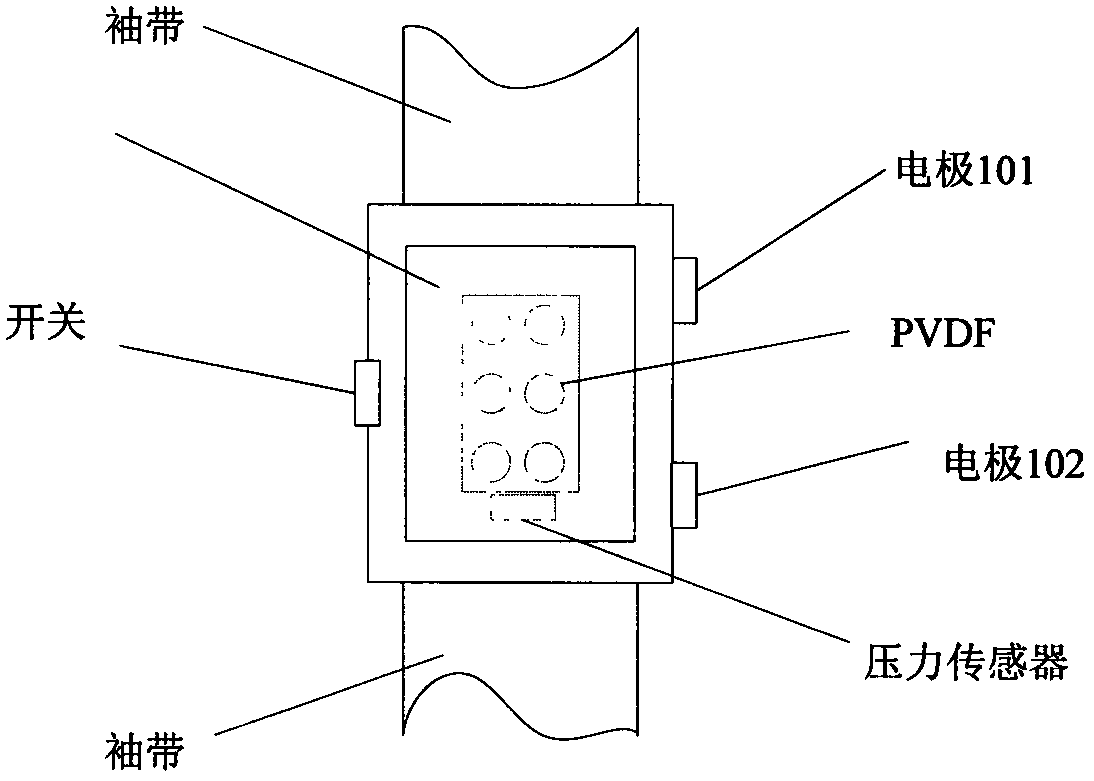

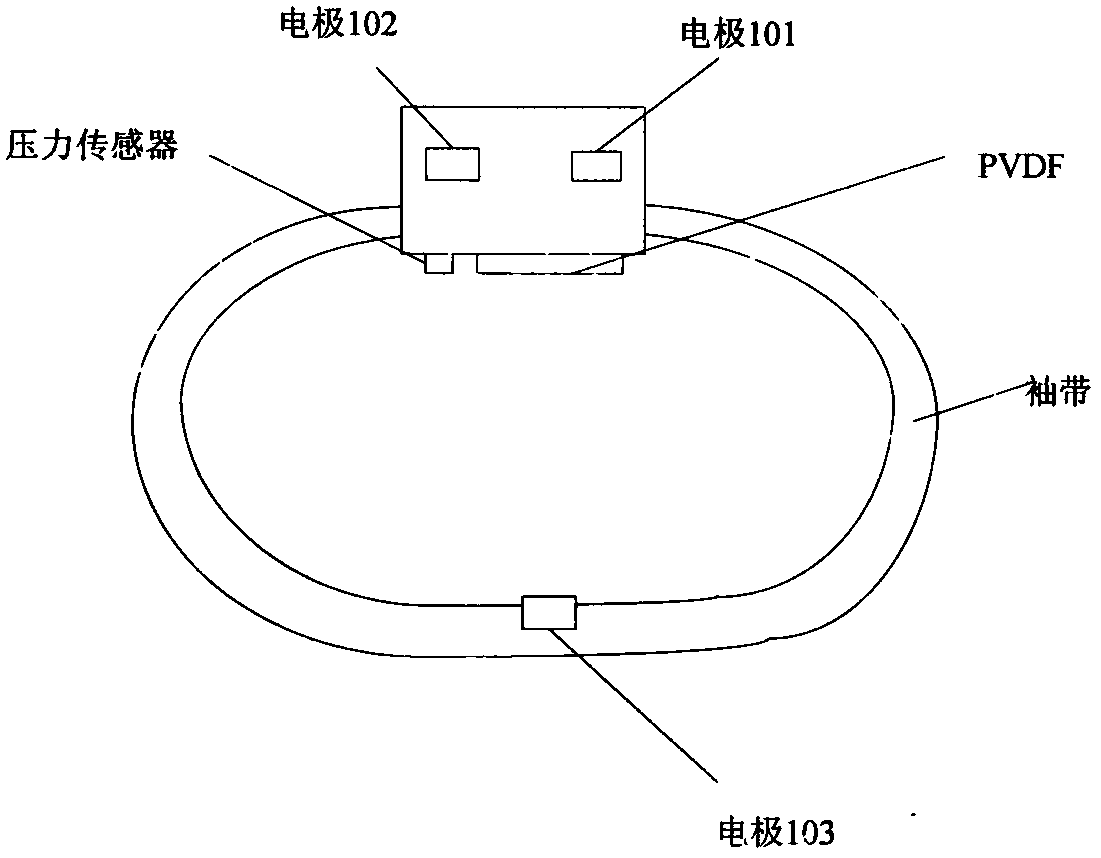

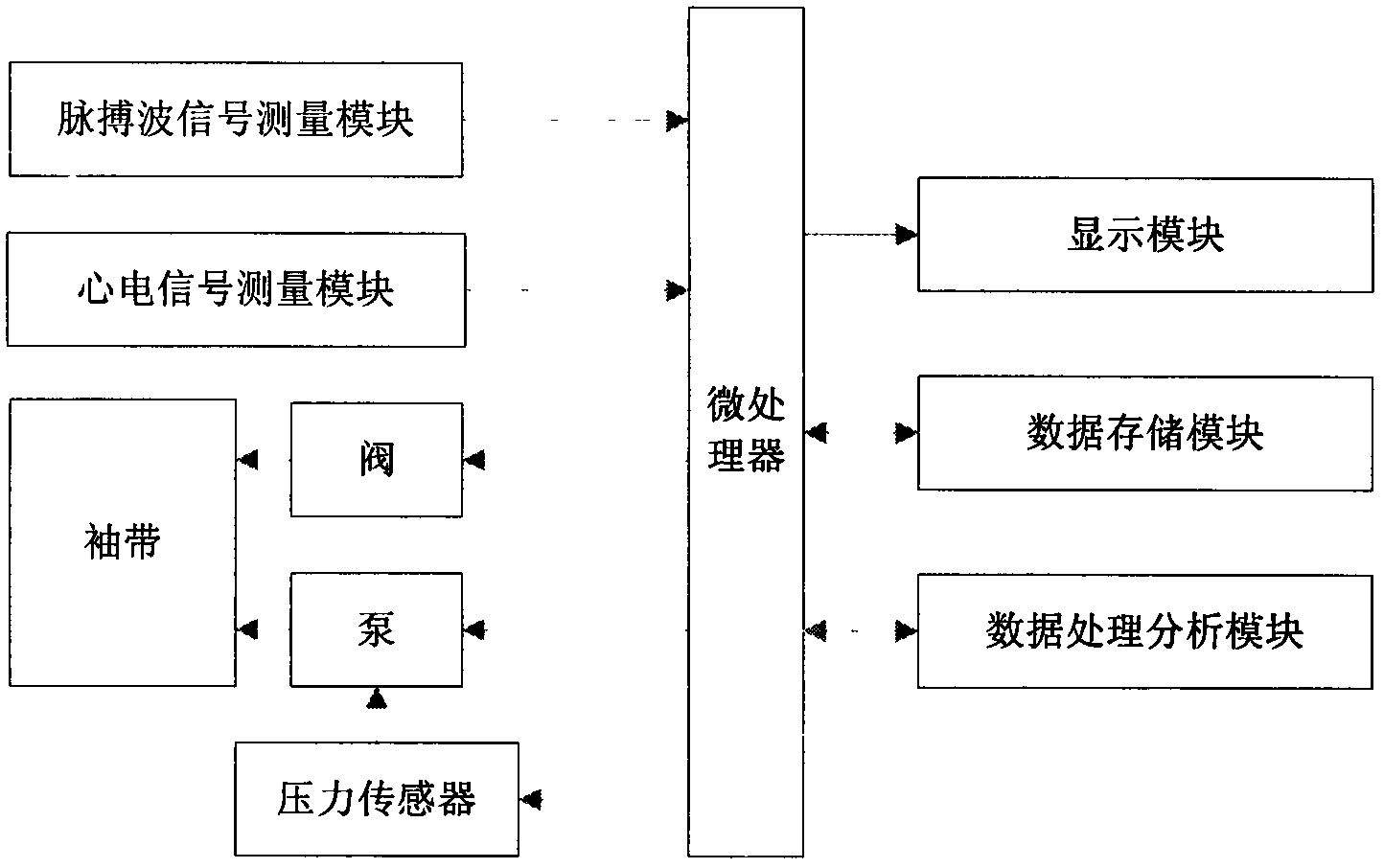

Research of dynamic blood pressure detection and calibration method of radial artery

InactiveCN104257371AImprove comfortSmall changes in body positionDiagnostic recording/measuringSensorsOscillometryEcg signal

The invention relates to a dynamic blood pressure detection and calibration method of a radial artery. The method comprises the following steps: measuring a blood pressure value BP1 to perform first calibration by using oscillography; measuring a blood pressure value BP2 to perform second calibration by using correlation of an electrocardiosignal, a pulse wave signal and human arterial pressure; finally performing continuous monitoring of blood pressure by using the linear relation between pulse wave transmission time difference PWT of two different parts on a wrist and the human arterial blood pressure which are measured at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

Detector for determining a position of at least one object

ActiveUS20160364015A1Sufficient electrical conductivityReduce measurement errorInput/output for user-computer interactionDirection/deviation determining electromagnetic systemsIlluminanceLight beam

A detector (118) for determining a position of at least one object (112) is disclosed, the detector (118) comprising:at least one longitudinal optical sensor (120), wherein the longitudinal optical sensor (120) has at least one sensor region (124), wherein the longitudinal optical sensor (120) is at least partially transparent, wherein the longitudinal optical sensor (120) is designed to generate at least one longitudinal sensor signal in a manner dependent on an illumination of the sensor region (124) by at least one light beam (126) traveling from the object (112) to the detector (118), wherein the longitudinal sensor signal, given the same total power of the illumination, is dependent on a beam cross-section of the light beam (126) in the sensor region (124);at least one illumination source (114) adapted to illuminate the object (112) with illumination light (115) through the longitudinal optical sensor (120); andat least one evaluation device (136), wherein the evaluation device (136) is designed to generate at least one item of information on a longitudinal position of the object (112) by evaluating the longitudinal sensor signal.

Owner:BASF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com