Patents

Literature

1152 results about "Light attenuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

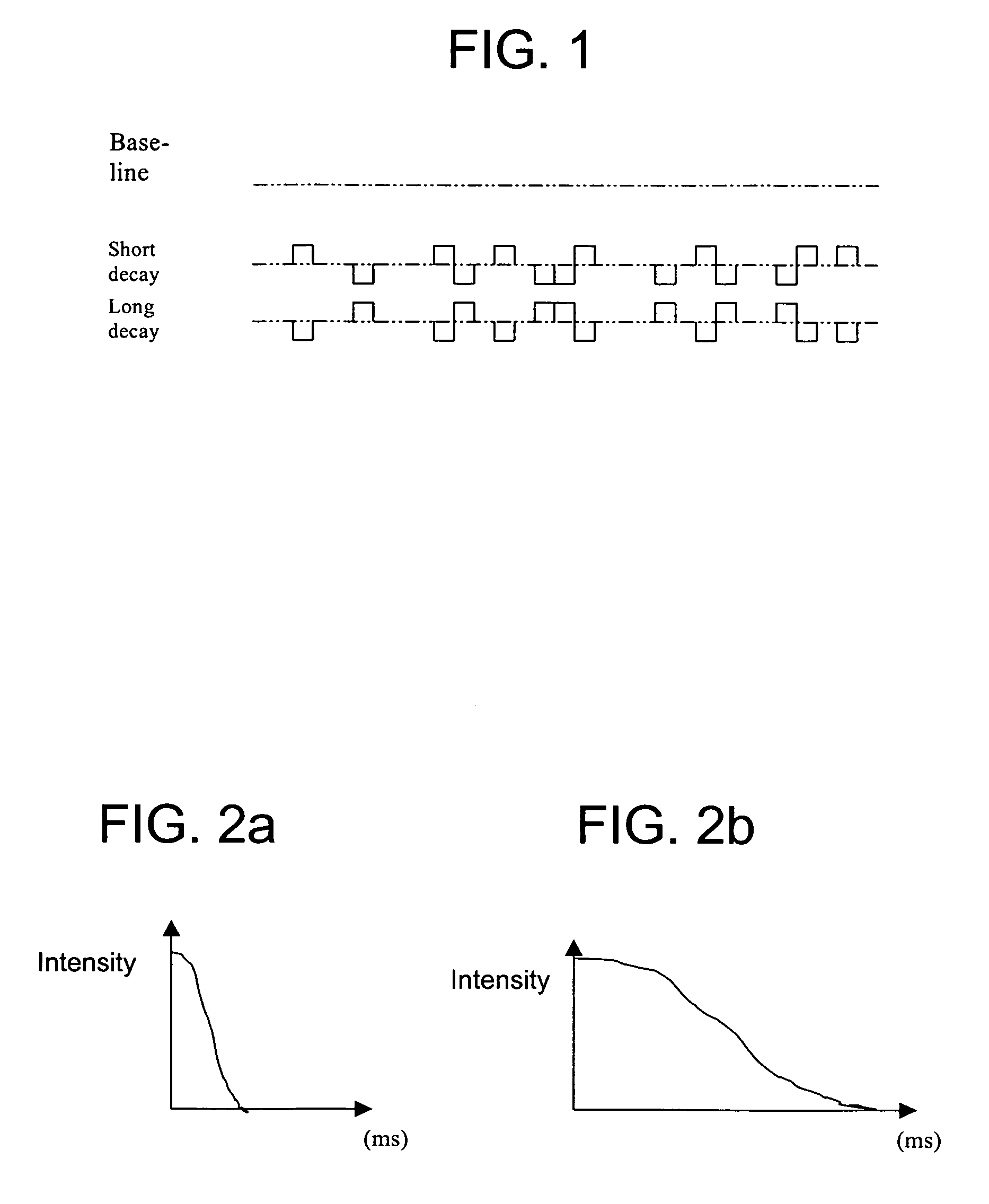

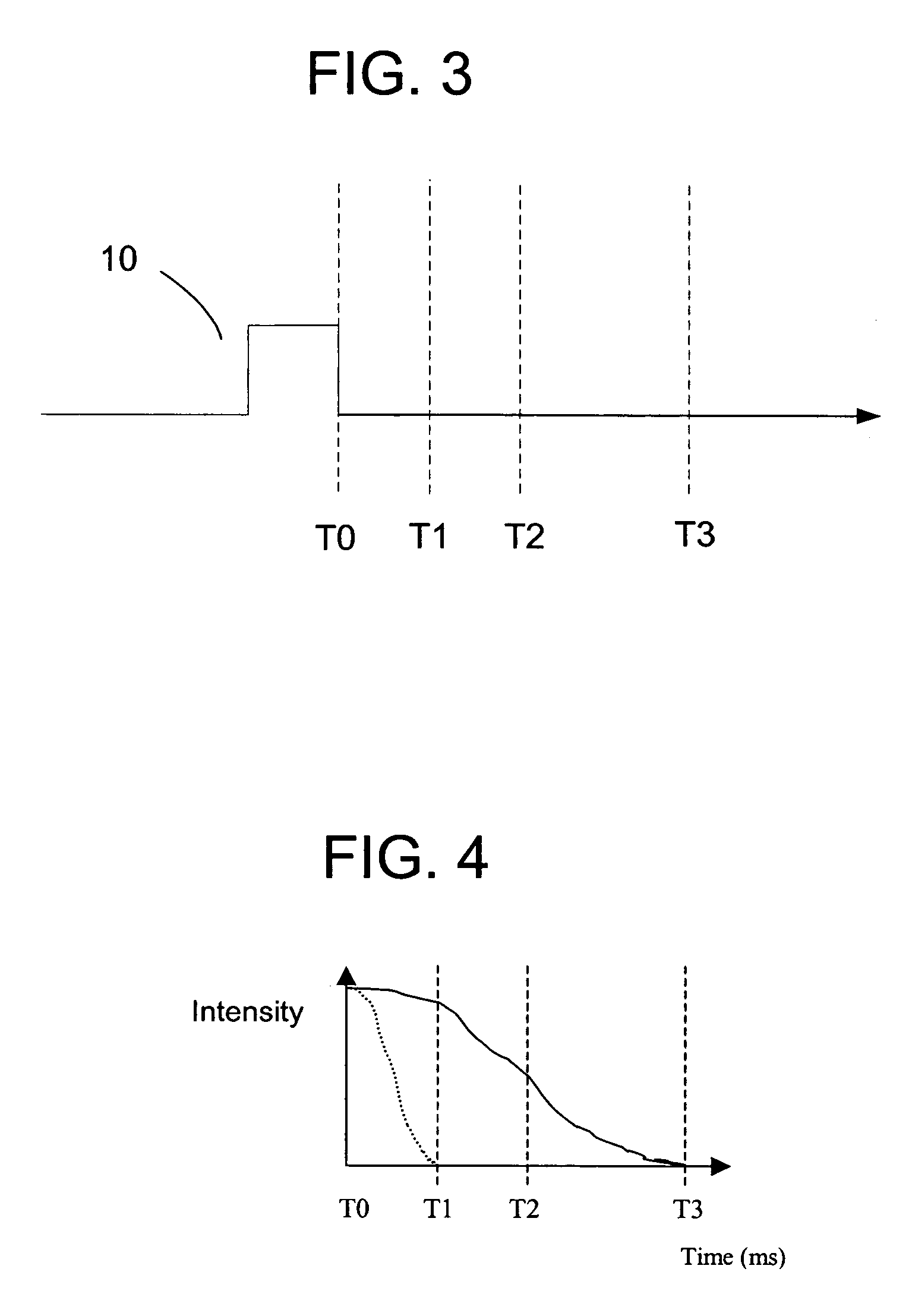

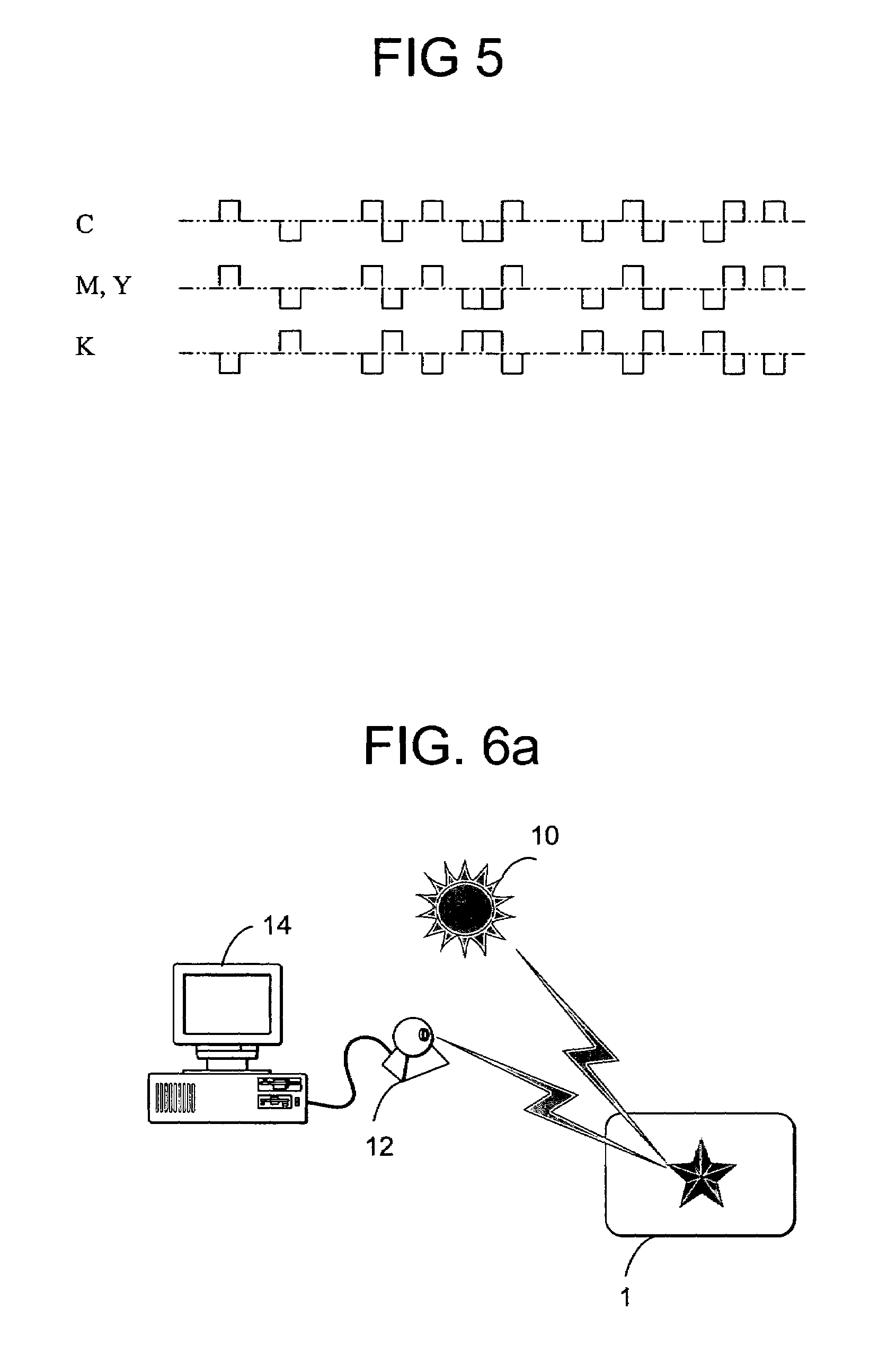

Low visibility watermark using time decay fluorescence

InactiveUS6996252B2Character and pattern recognitionSecret communicationFluorescenceComputer science

Owner:DIGIMARC CORP

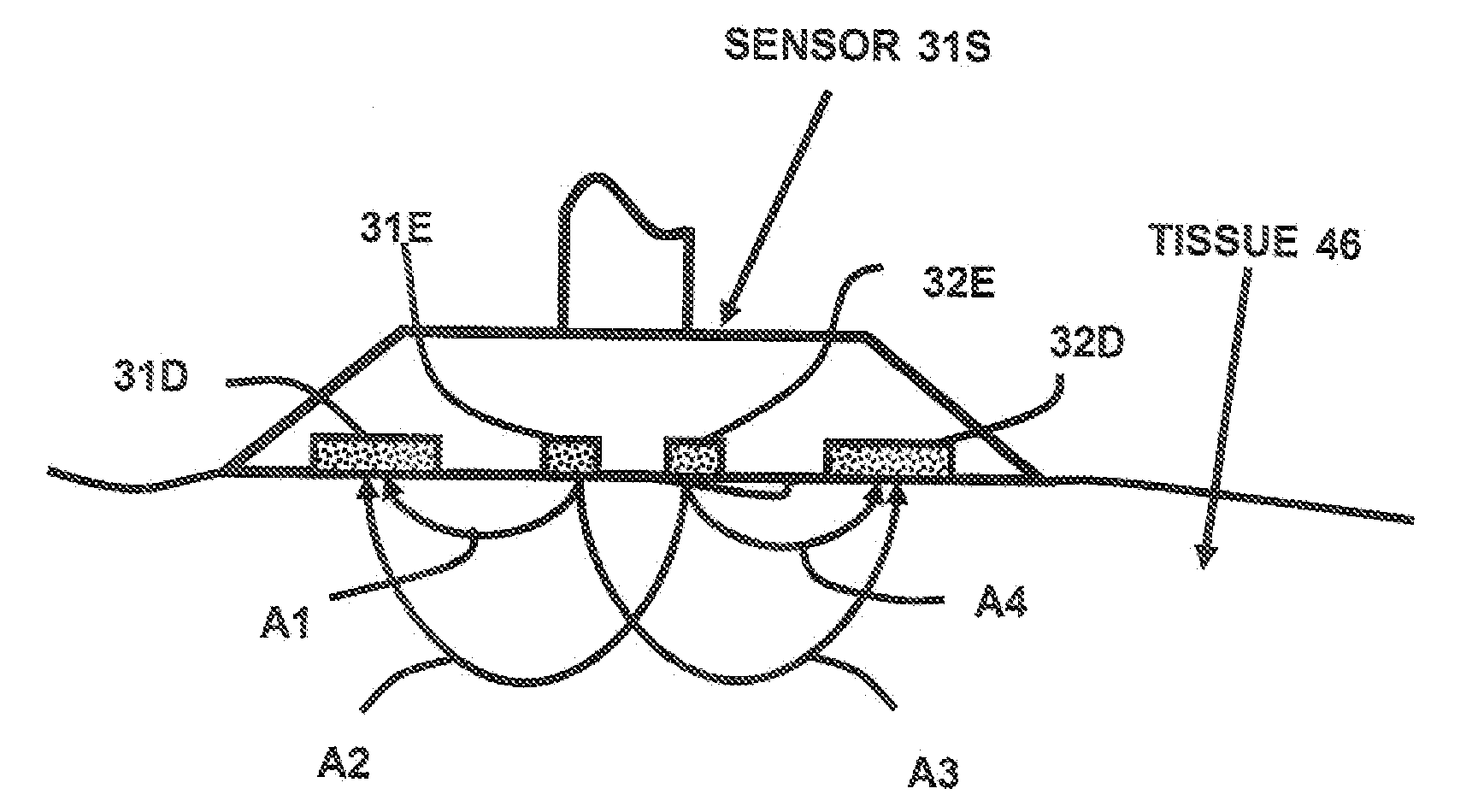

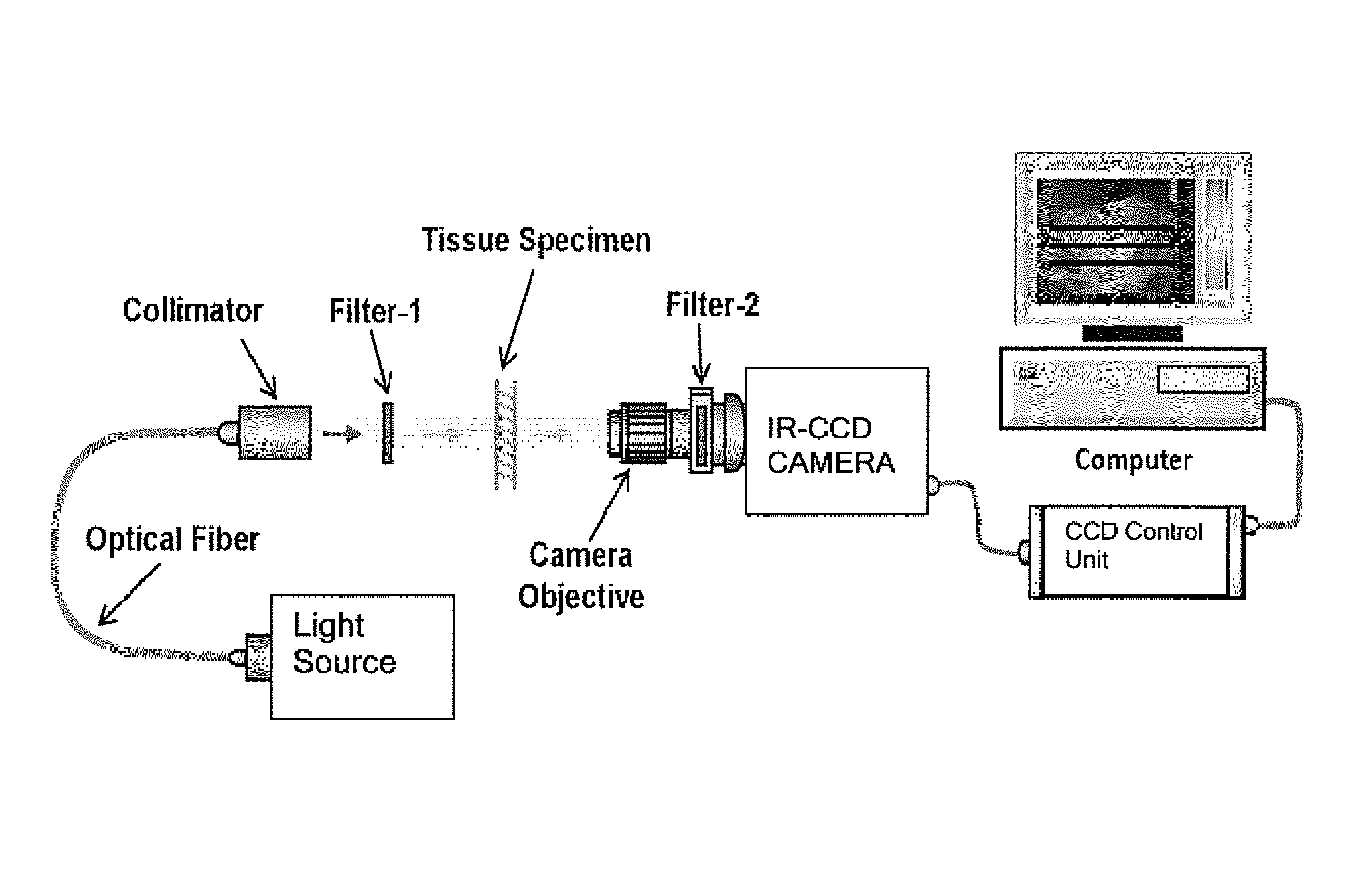

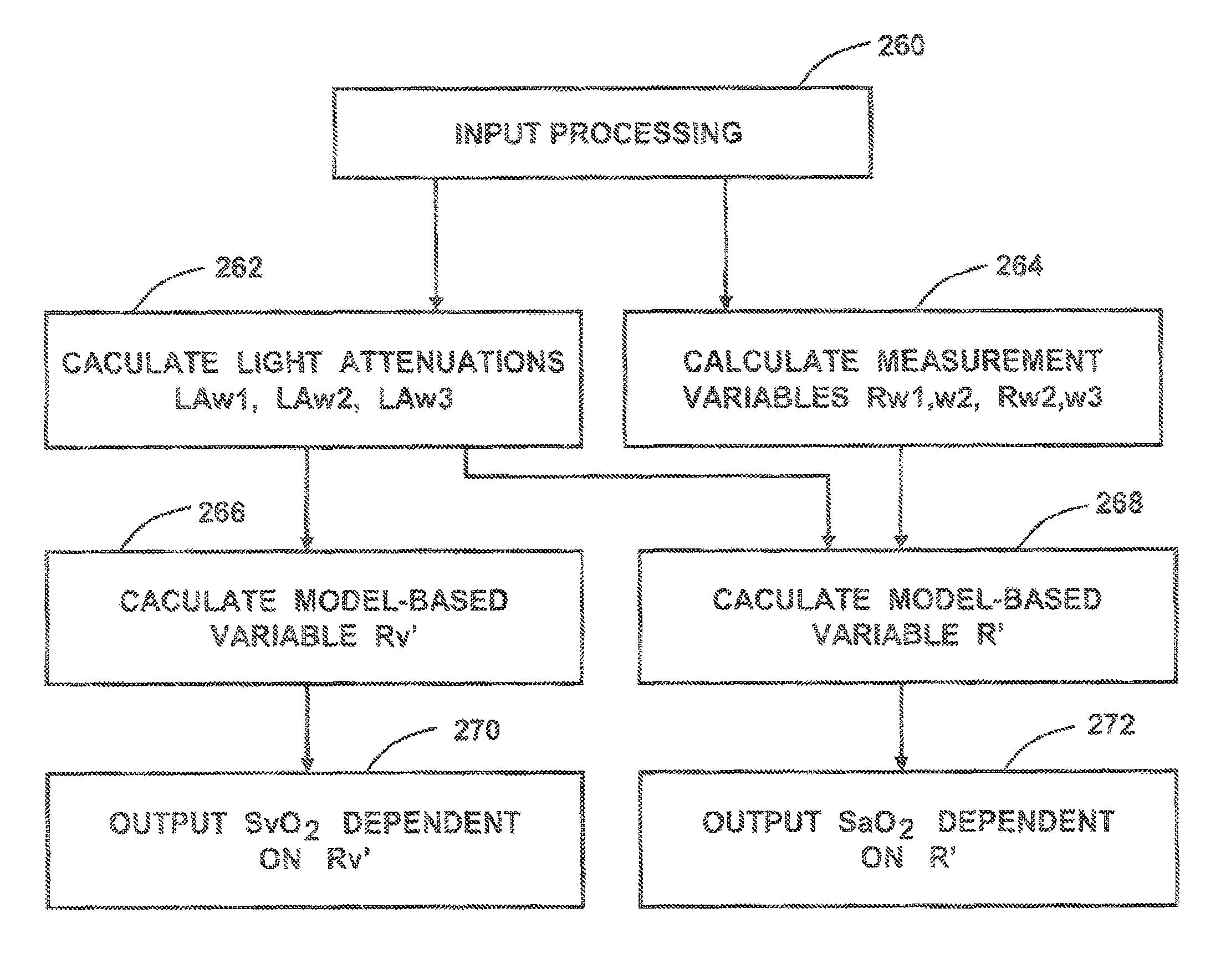

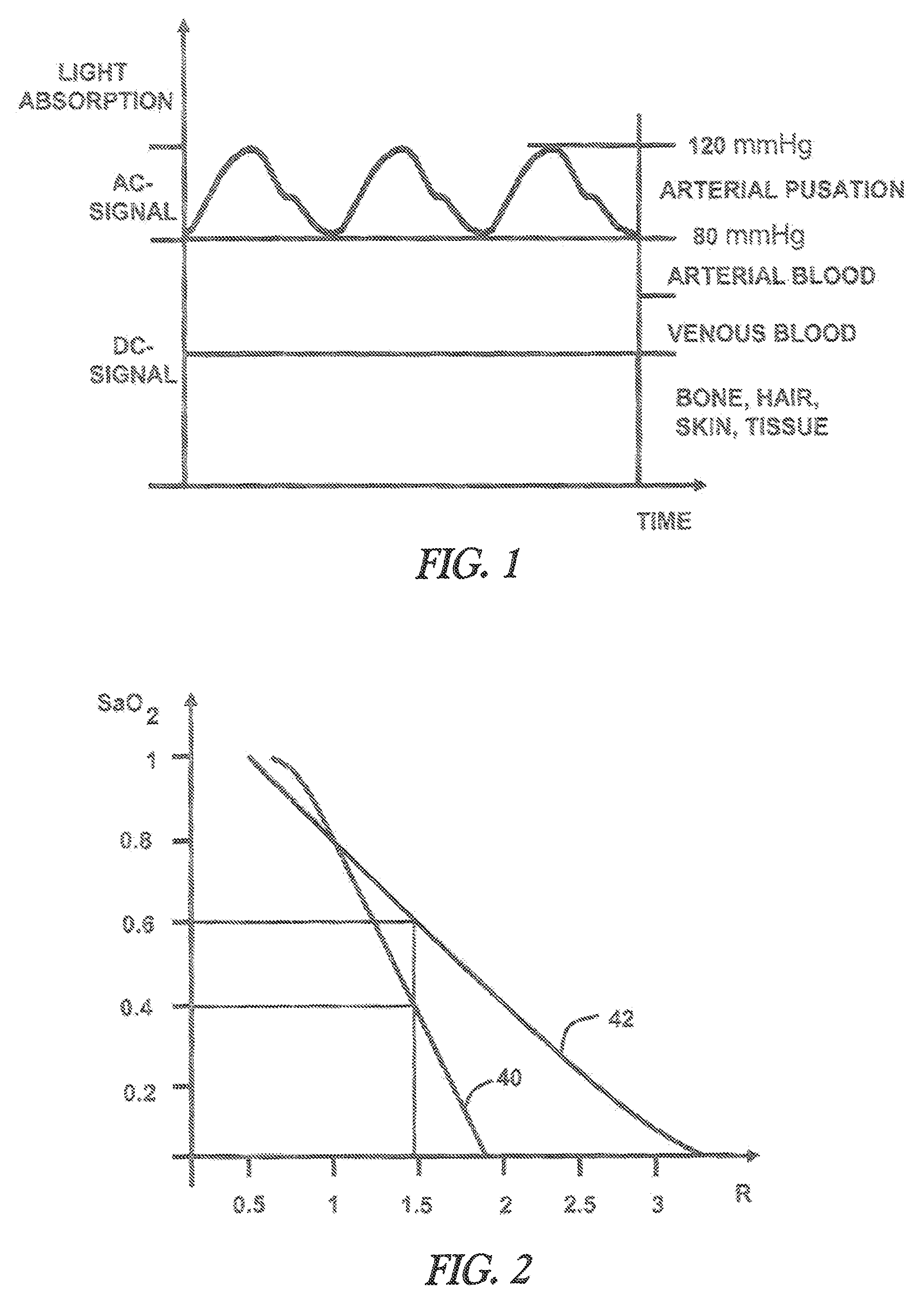

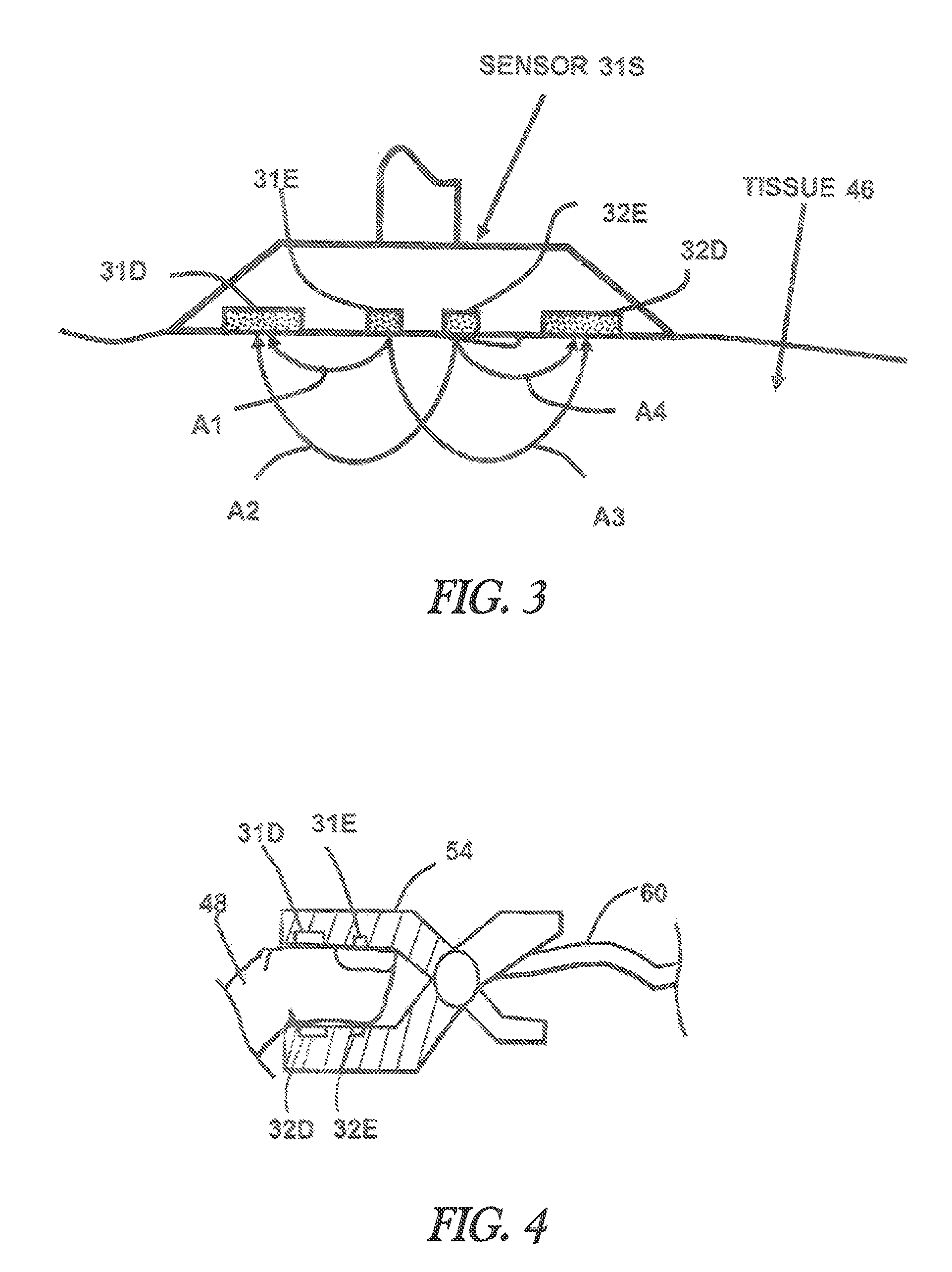

Tissue Oximetry Apparatus and Method

ActiveUS20080015424A1Exclude influenceHigh precisionDiagnostic signal processingOptical sensorsVeinOptical property

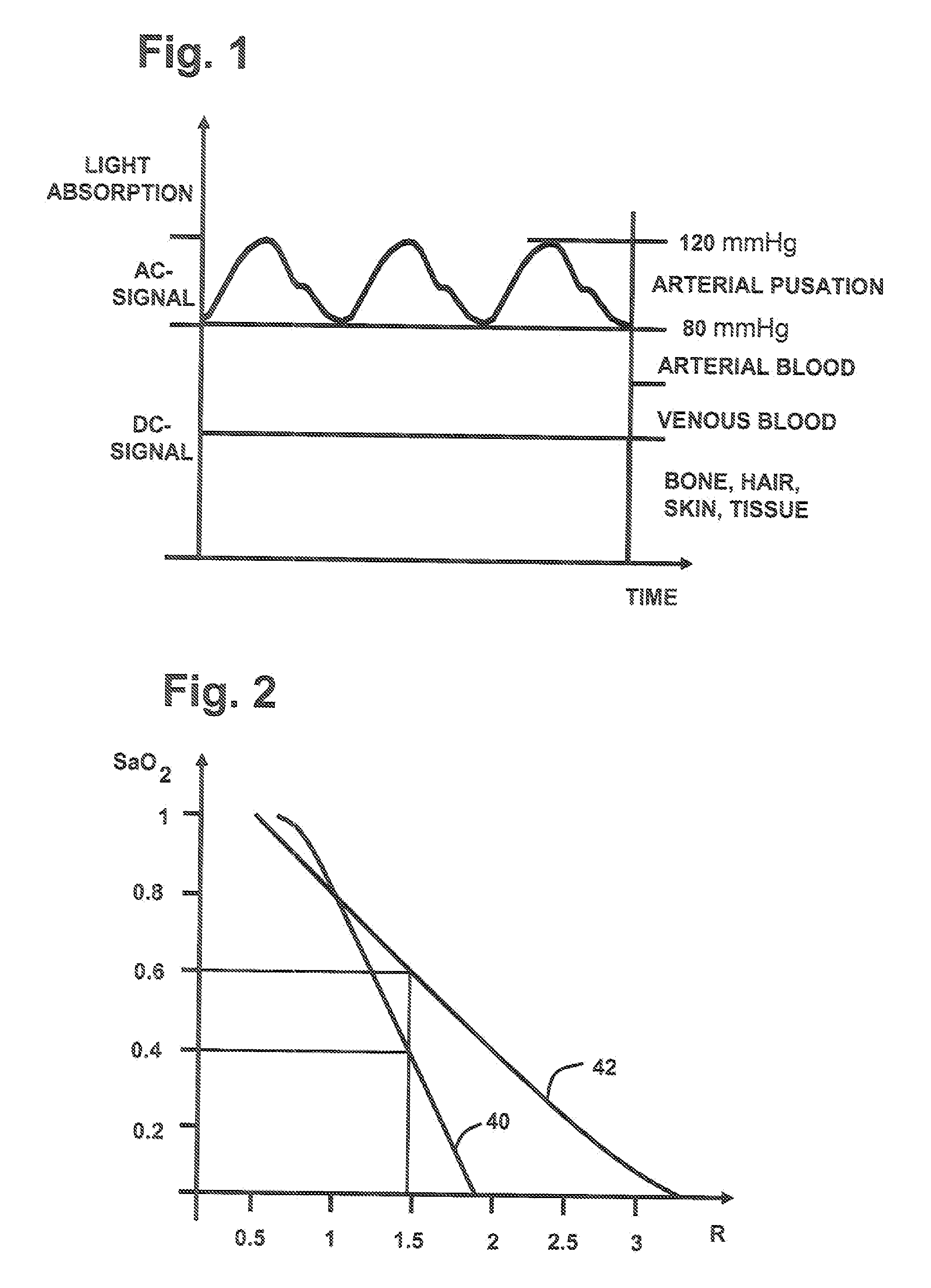

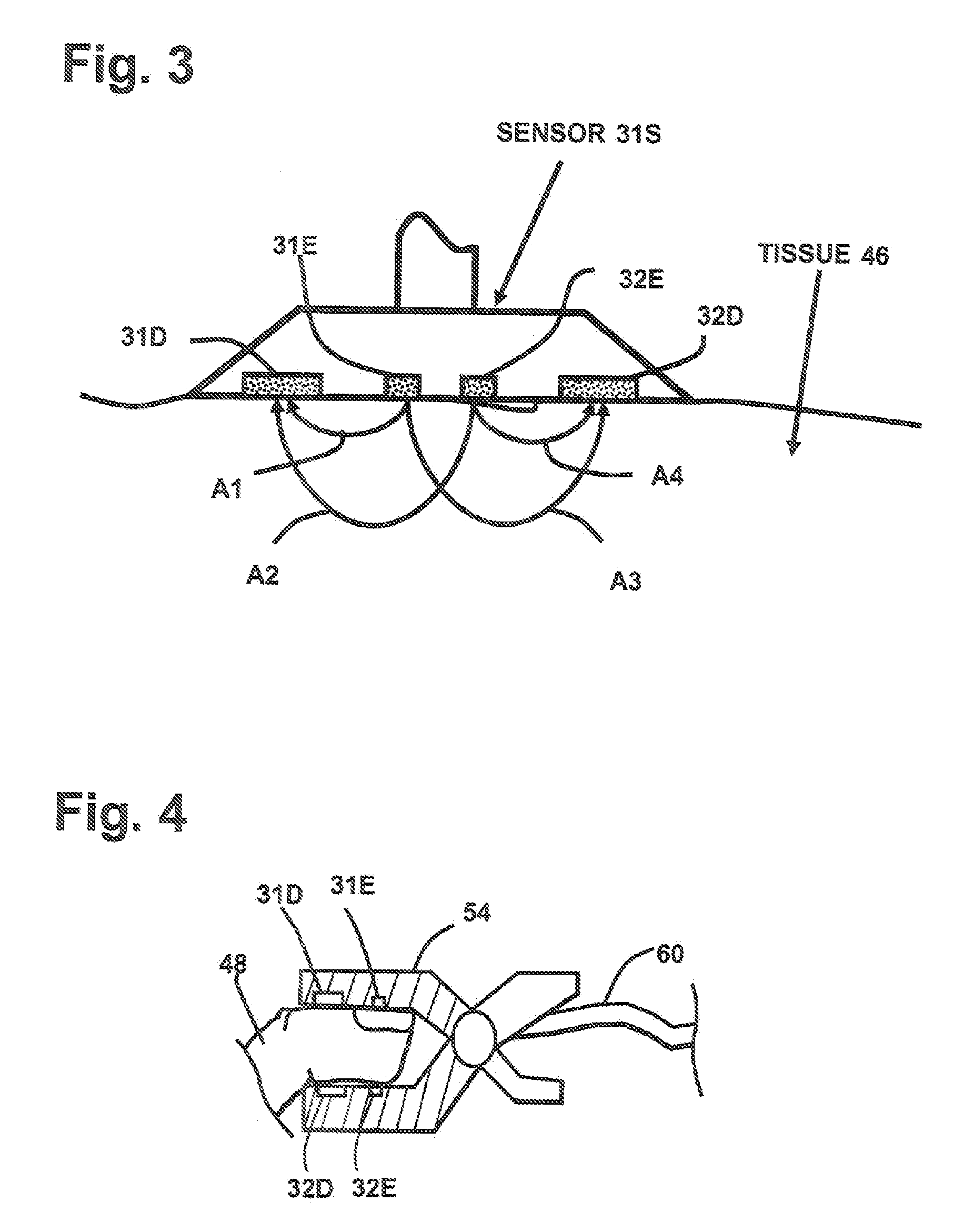

An apparatus and method for determining tissue oxygenation such as arterial and venous oxygenation and cerebral oxygenation. In one embodiment the optical properties of tissue are determined using measured light attenuations at a set of wavelengths. By choosing distinct wavelengths and using light attenuation information, the influence of variables such as light scattering, absorption and other optical tissue properties can be minimized.

Owner:BERNREUTER PETER

Multiple-wavelength spectroscopic quantitation of light-absorbing species in scattering media

InactiveUS6015969ASimplified determinationRadiation pyrometryPhotoelectric discharge tubesFiberMultiwavelength spectroscopy

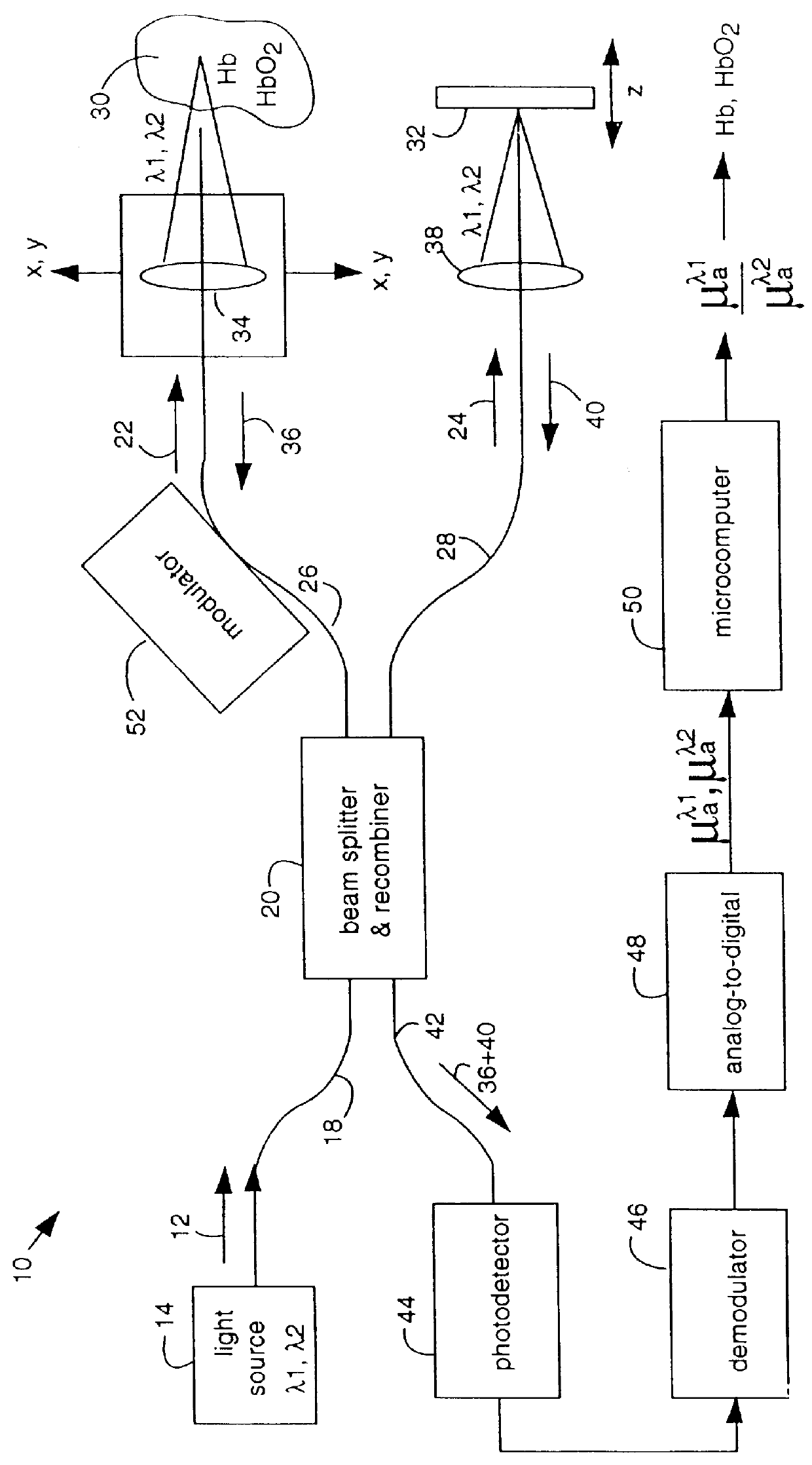

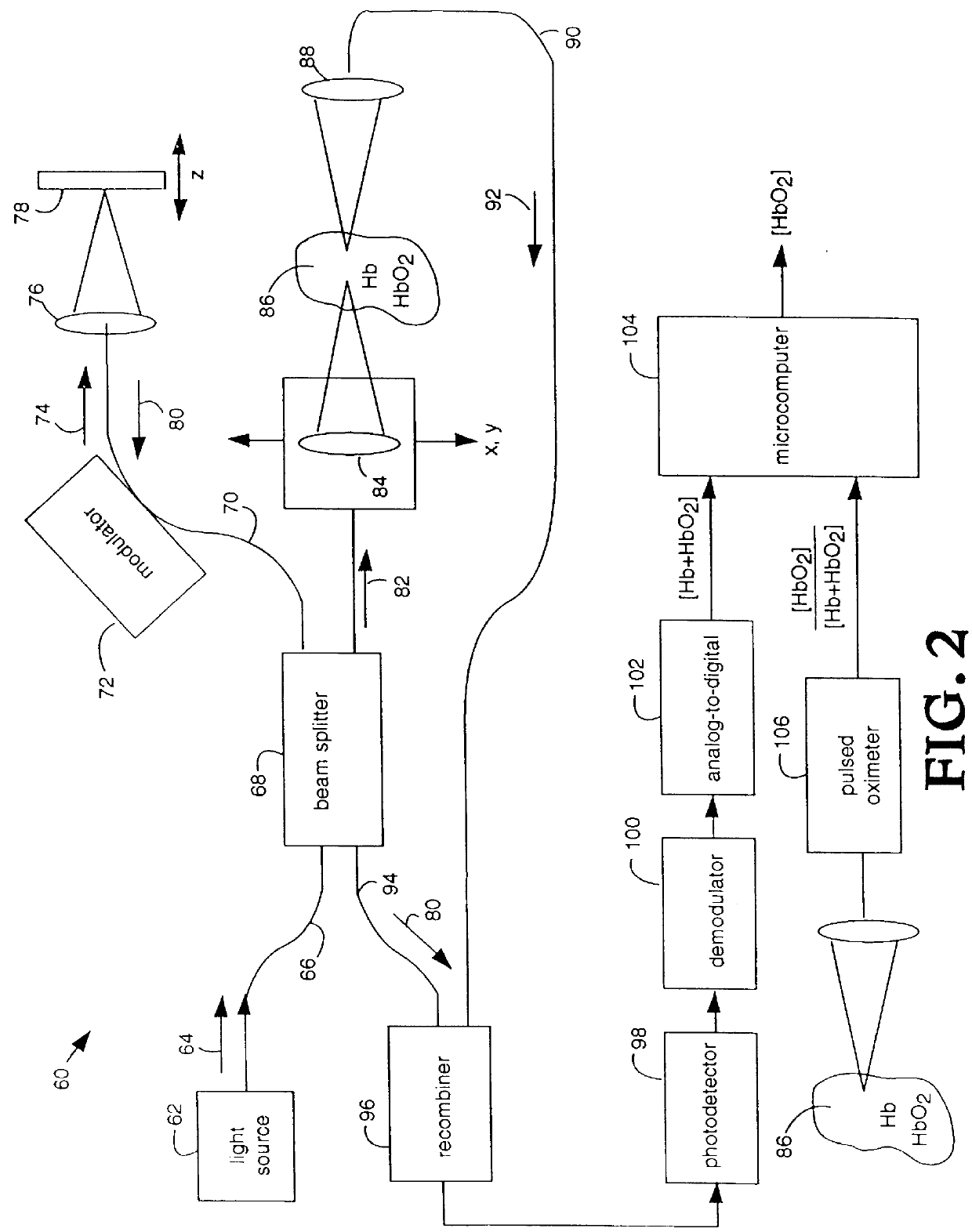

An oxygen concentration measurement system for blood hemoglobin comprises a multiple-wavelength low-coherence optical light source that is coupled by single mode fibers through a splitter and combiner and focused on both a target tissue sample and a reference mirror. Reflections from both the reference mirror and from the depths of the target tissue sample are carried back and mixed to produce interference fringes in the splitter and combiner. The reference mirror is set such that the distance traversed in the reference path is the same as the distance traversed into and back from the target tissue sample at some depth in the sample that will provide light attenuation information that is dependent on the oxygen in blood hemoglobin in the target tissue sample. Two wavelengths of light are used to obtain concentrations. The method can be used to measure total hemoglobin concentration [Hb.sub.deoxy +Hb.sub.oxy ] or total blood volume in tissue and in conjunction with oxygen saturation measurements from pulse oximetry can be used to absolutely quantify oxyhemoglobin [HbO.sub.2 ] in tissue. The apparatus and method provide a general means for absolute quantitation of an absorber dispersed in a highly scattering medium.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

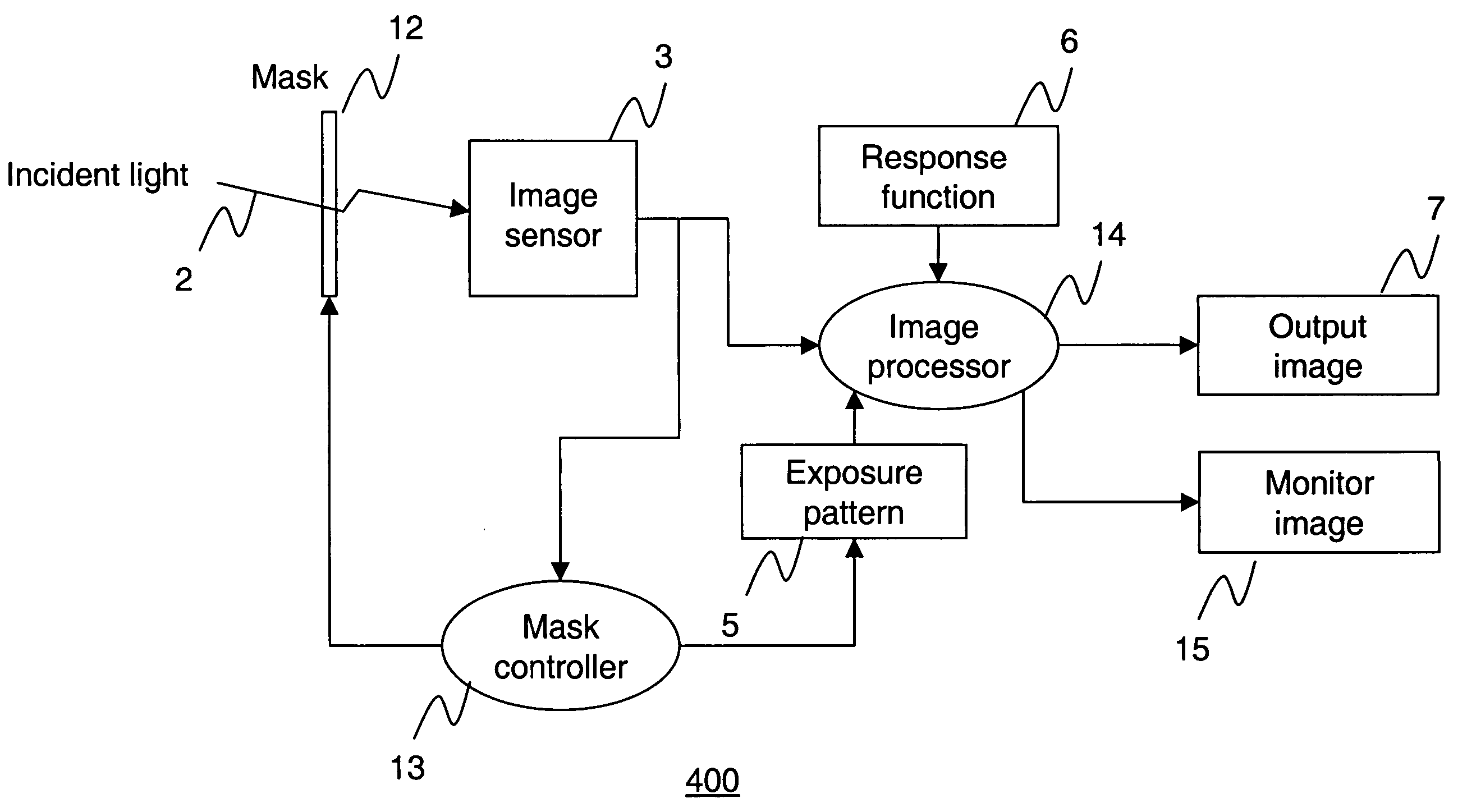

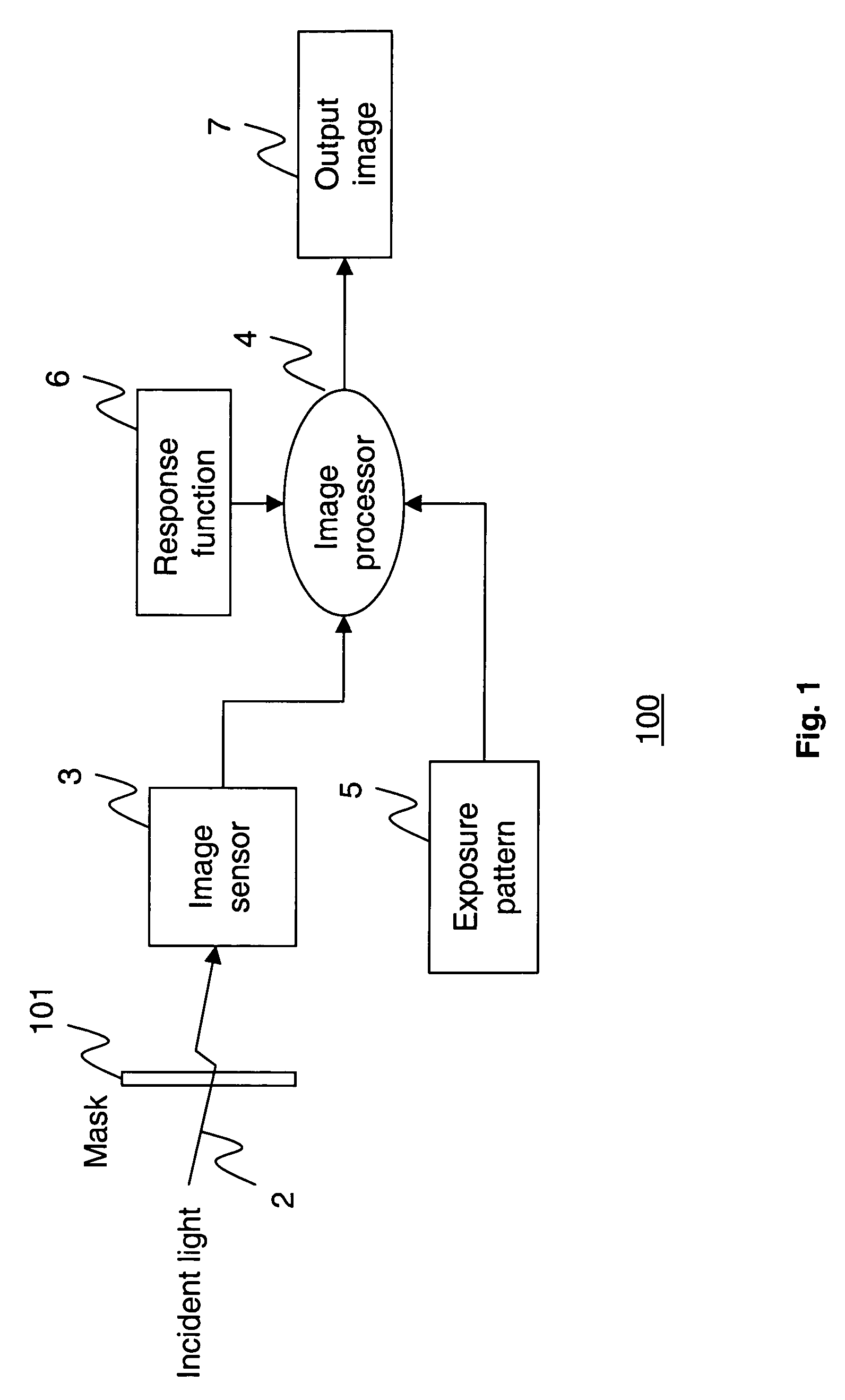

Apparatus and method for high dynamic range imaging using spatially varying exposures

InactiveUS7924321B2Minimize the numberSubstantial lossTelevision system detailsColor signal processing circuitsHigh-dynamic-range imagingUltrasound attenuation

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +1

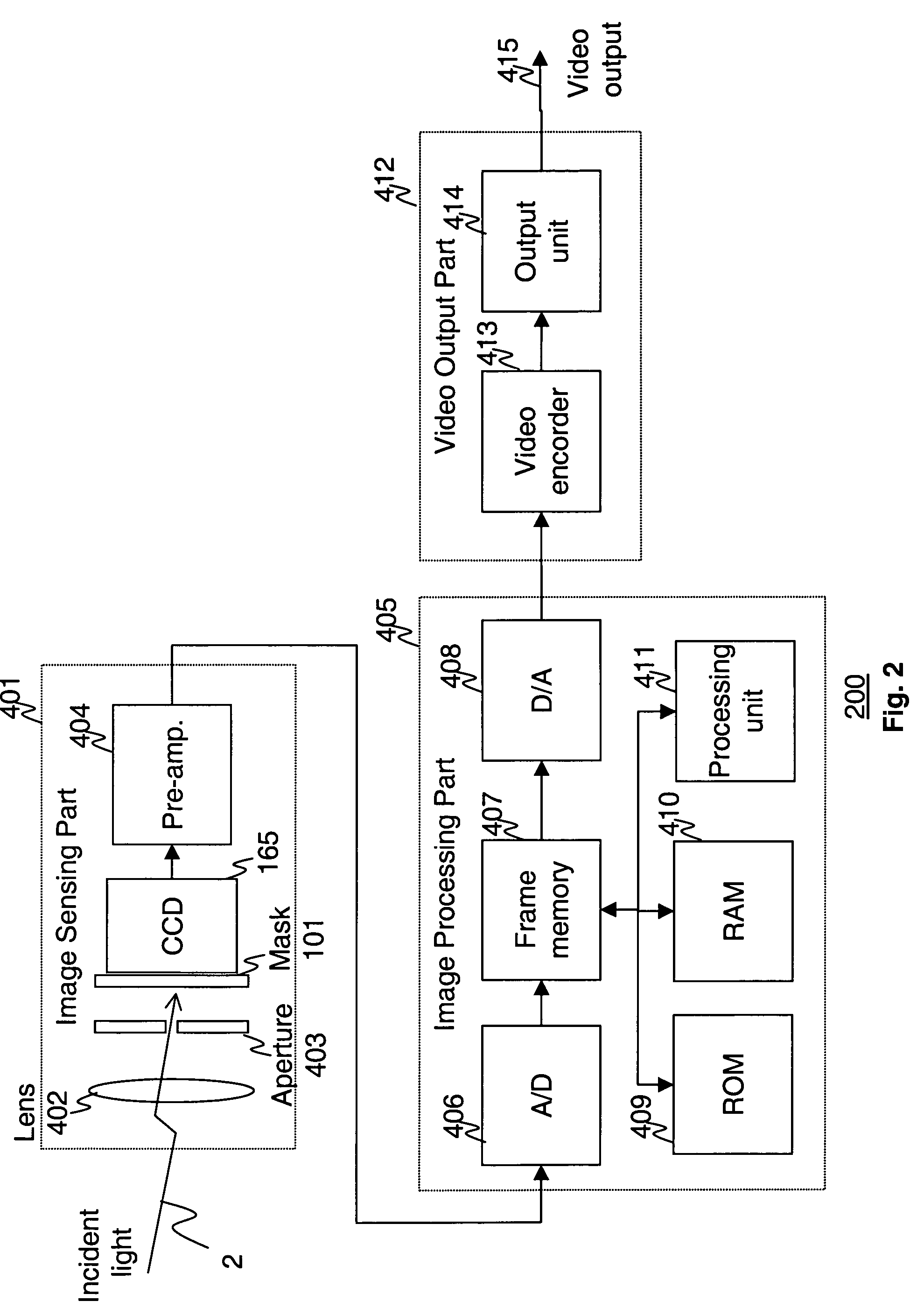

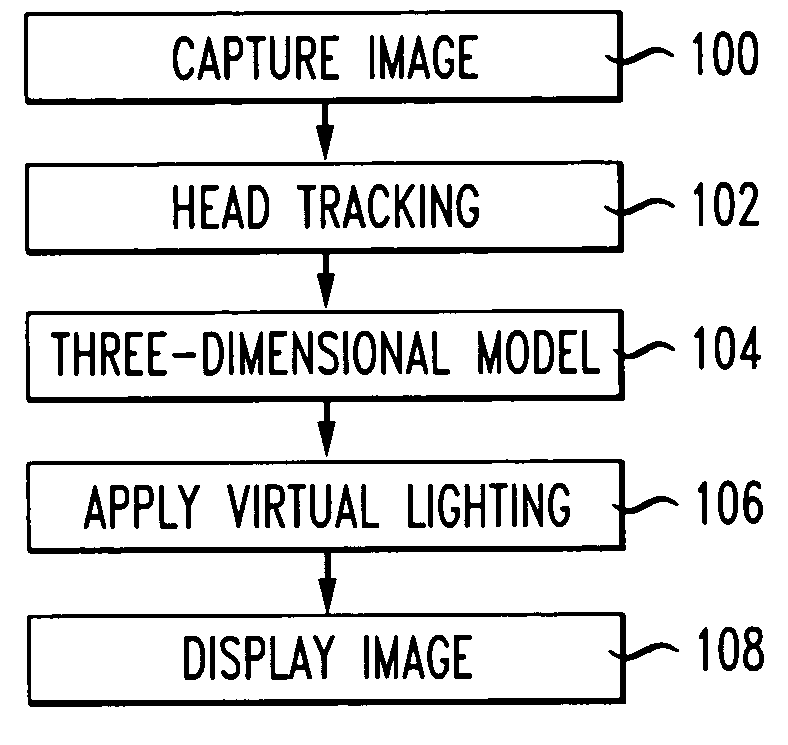

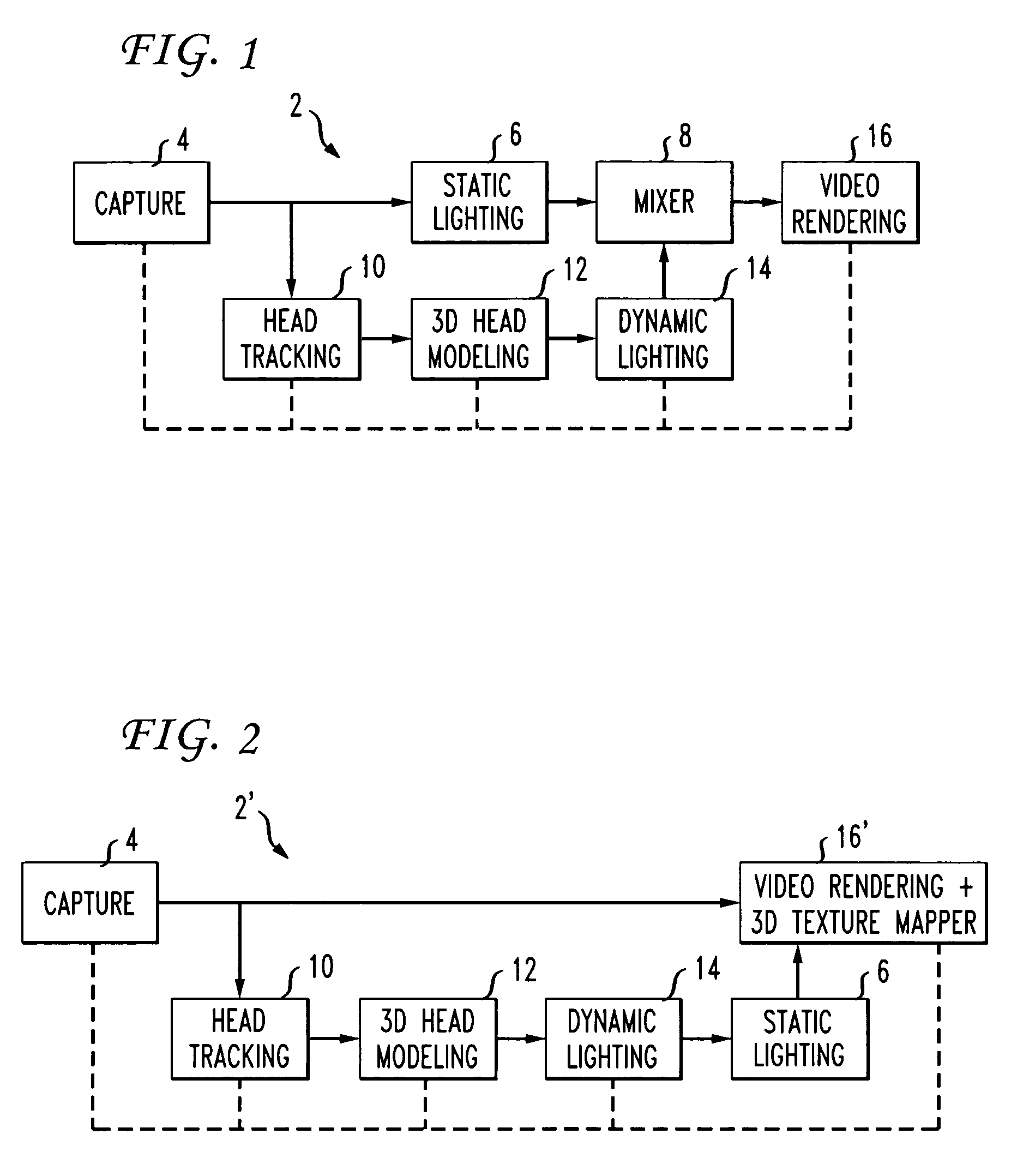

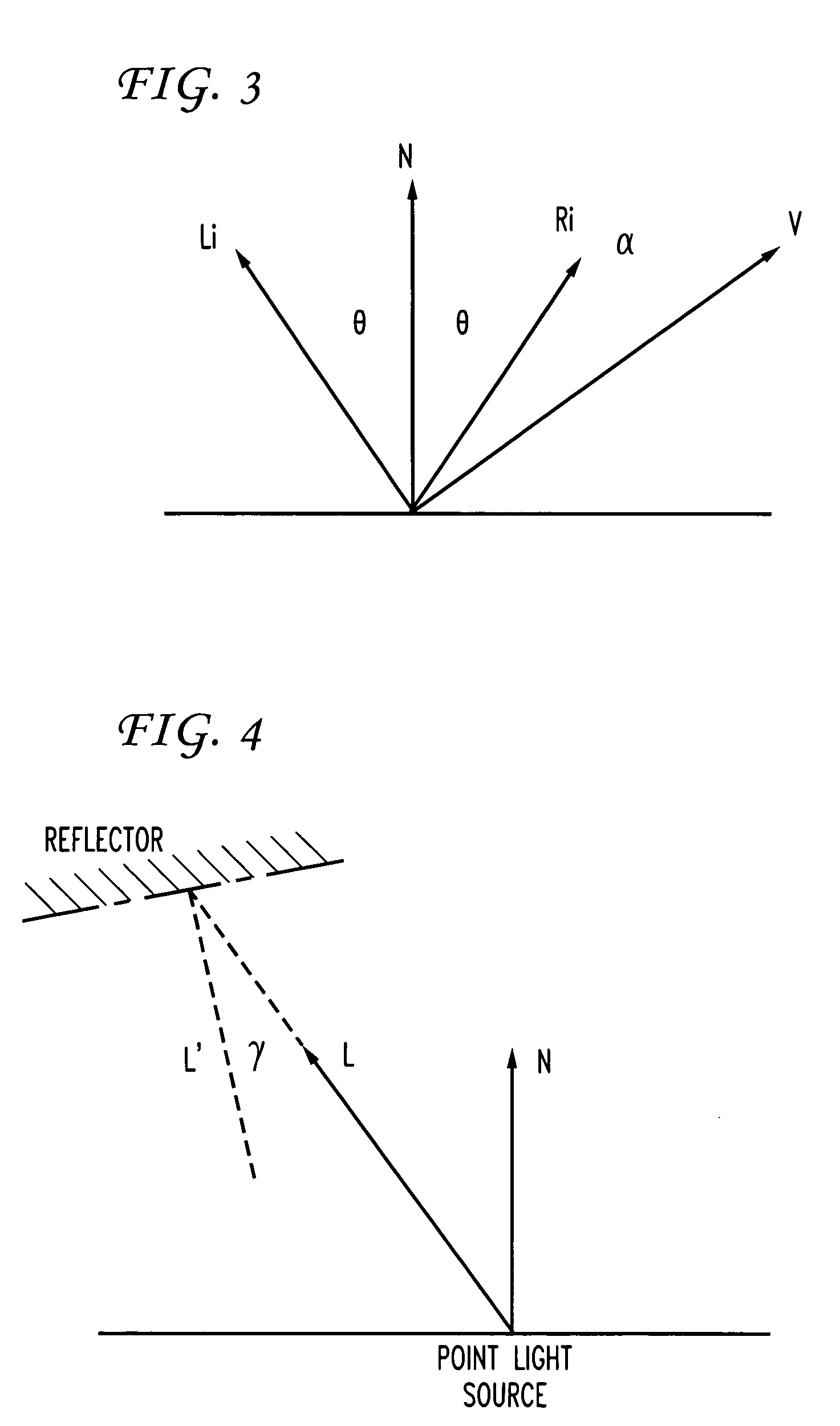

Digitally-generated lighting for video conferencing applications

ActiveUS6980697B1Improve the environmentAverage office or home environment) are poor can be greatly improvedImage enhancementDetails involving processing stepsTelecommunications networkComputer graphics (images)

A method of improving the lighting conditions of a real scene or video sequence. Digitally generated light is added to a scene for video conferencing over telecommunication networks. A virtual illumination equation takes into account light attenuation, lambertian and specular reflection. An image of an object is captured, a virtual light source illuminates the object within the image. In addition, the object can be the head of the user. The position of the head of the user is dynamically tracked so that an three-dimensional model is generated which is representative of the head of the user. Synthetic light is applied to a position on the model to form an illuminated model.

Owner:AT&T INTPROP I L P

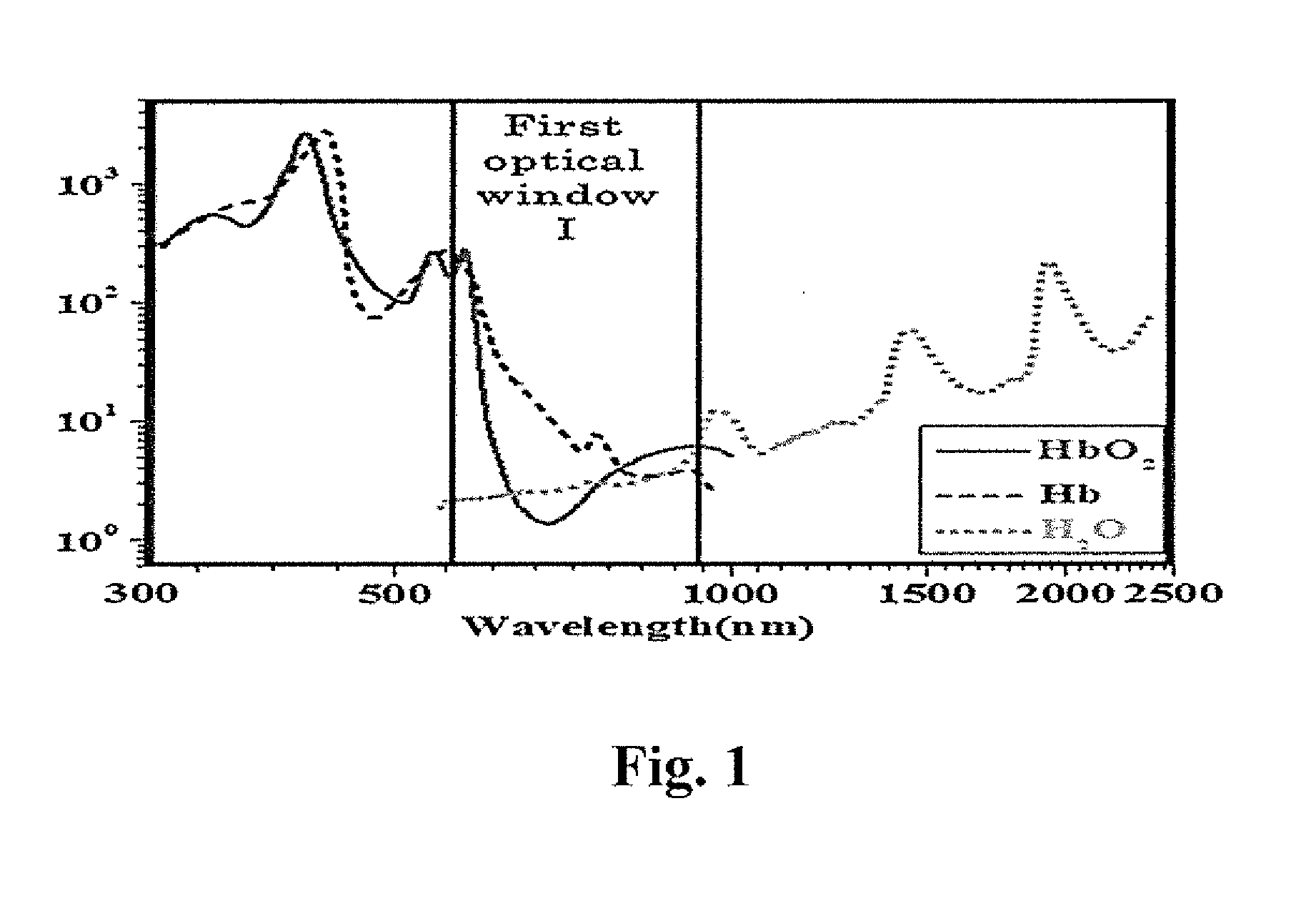

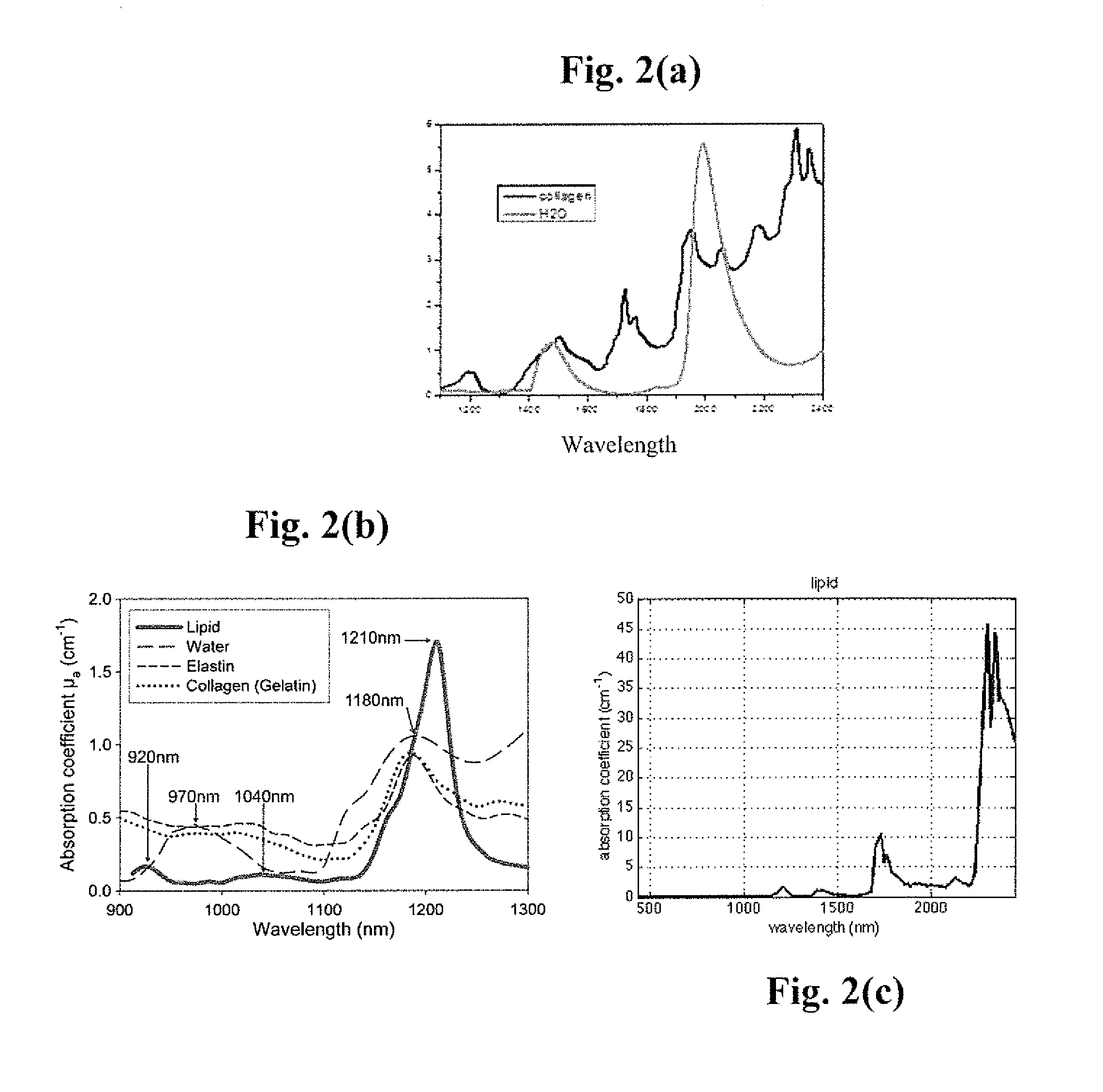

Second, third and fourth near-infrared spectral windows for deep optical imaging of tissue with less scattering

Light at wavelengths in the near-infrared (NIR) region in the second NIR spectral window from 1,100 nm to 1,350 nm and a new spectral window from 1,600 nm to 1,870 nm, known as the third NIR optical window, and fourth at 2200 cm−1 are disclosed. Optical attenuation from thin tissue slices of normal and malignant breast and prostate tissue, and pig brain were measured in the spectral range from 400 nm to 2,500 nm. Optical images of chicken tissue overlying three black wires were also obtained using the second and third spectral windows. Due to a reduction in scattering and minimal absorption, longer attenuation and clearer images can be seen in the second, third and fourth NIR windows compared to the conventional first NIR window. The second and third spectral windows will have uses in microscope imaging arteries, bones, breast, cells, cracks, teeth, and blood due to less scattering of light.

Owner:ALFANO ROBERT R

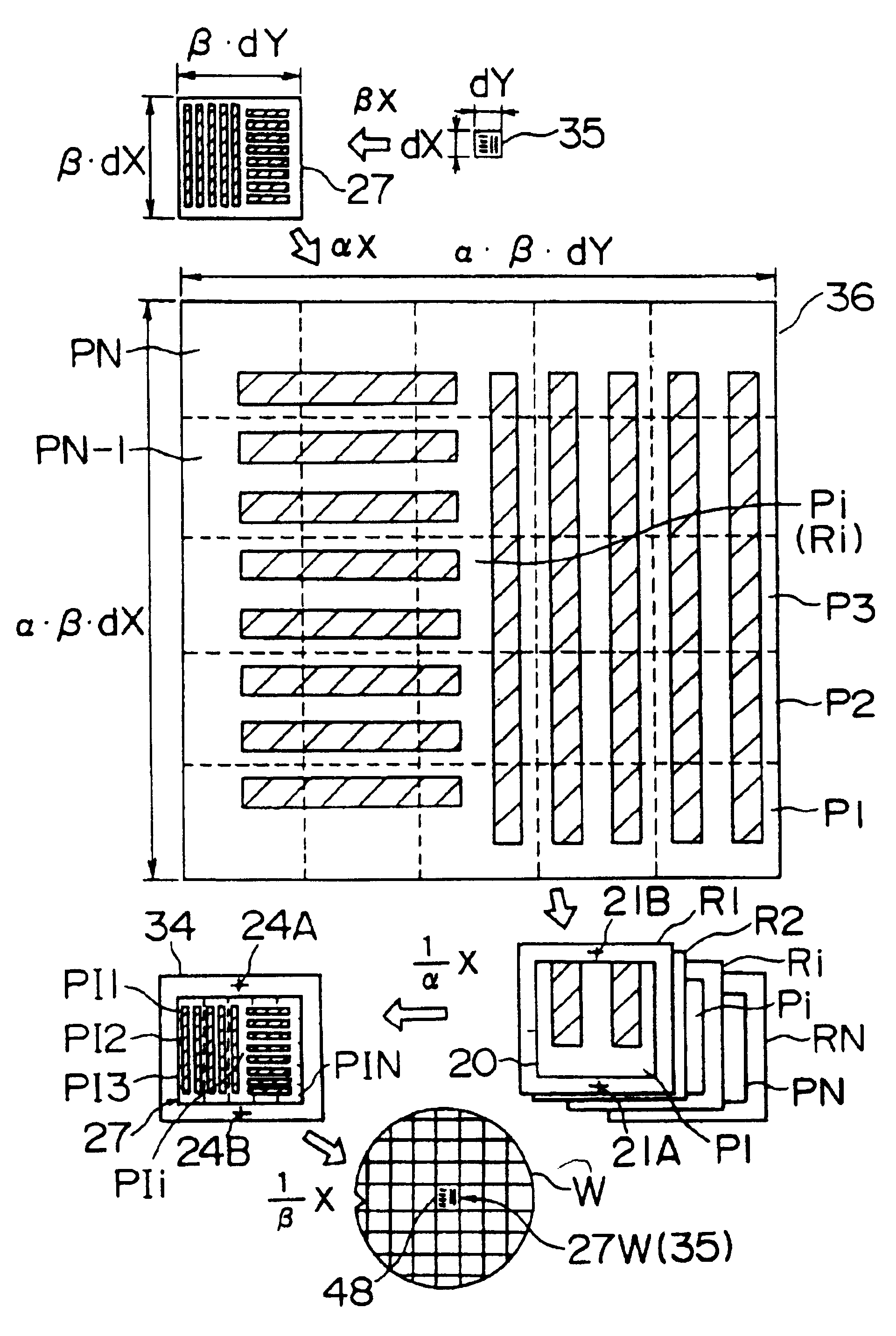

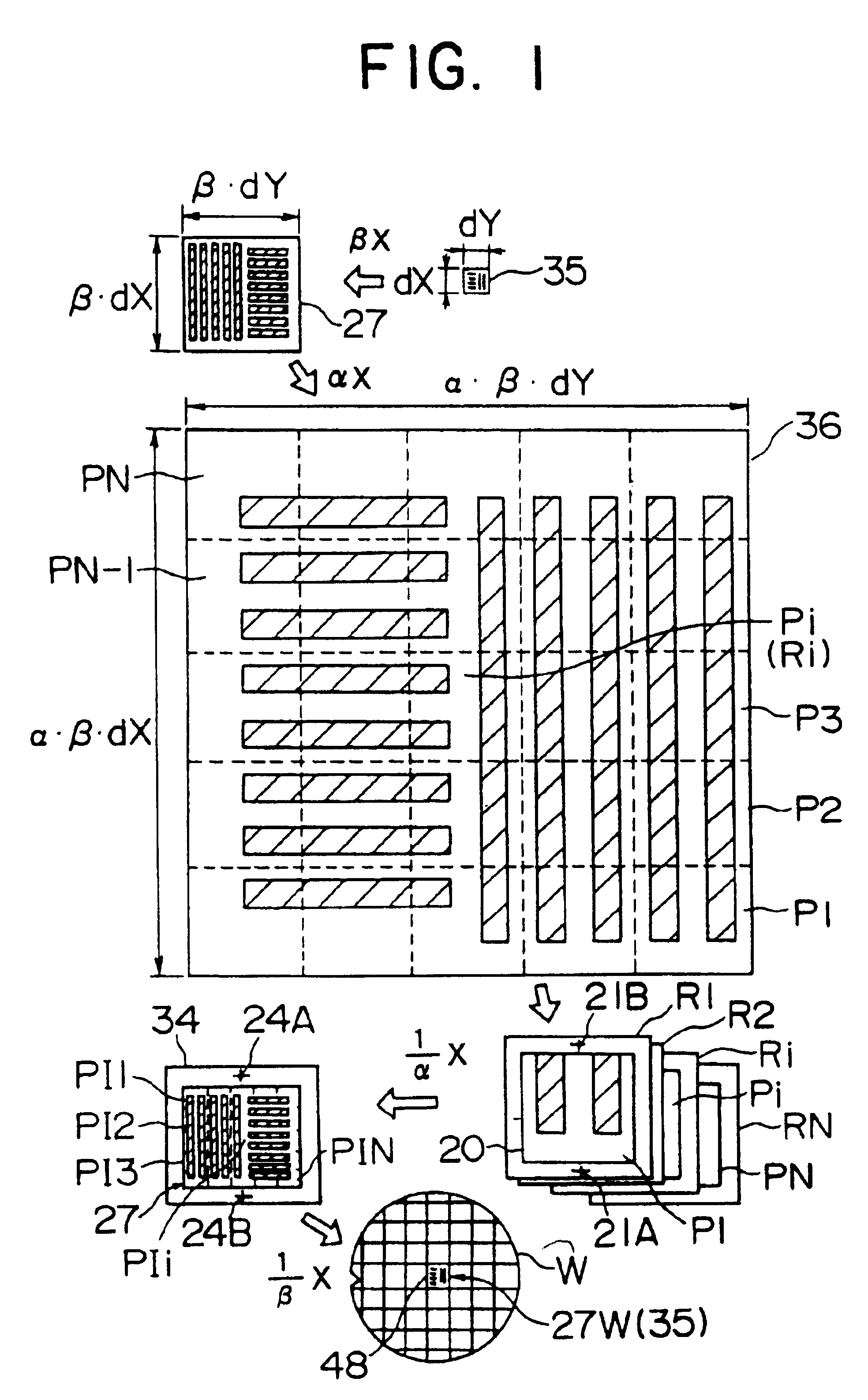

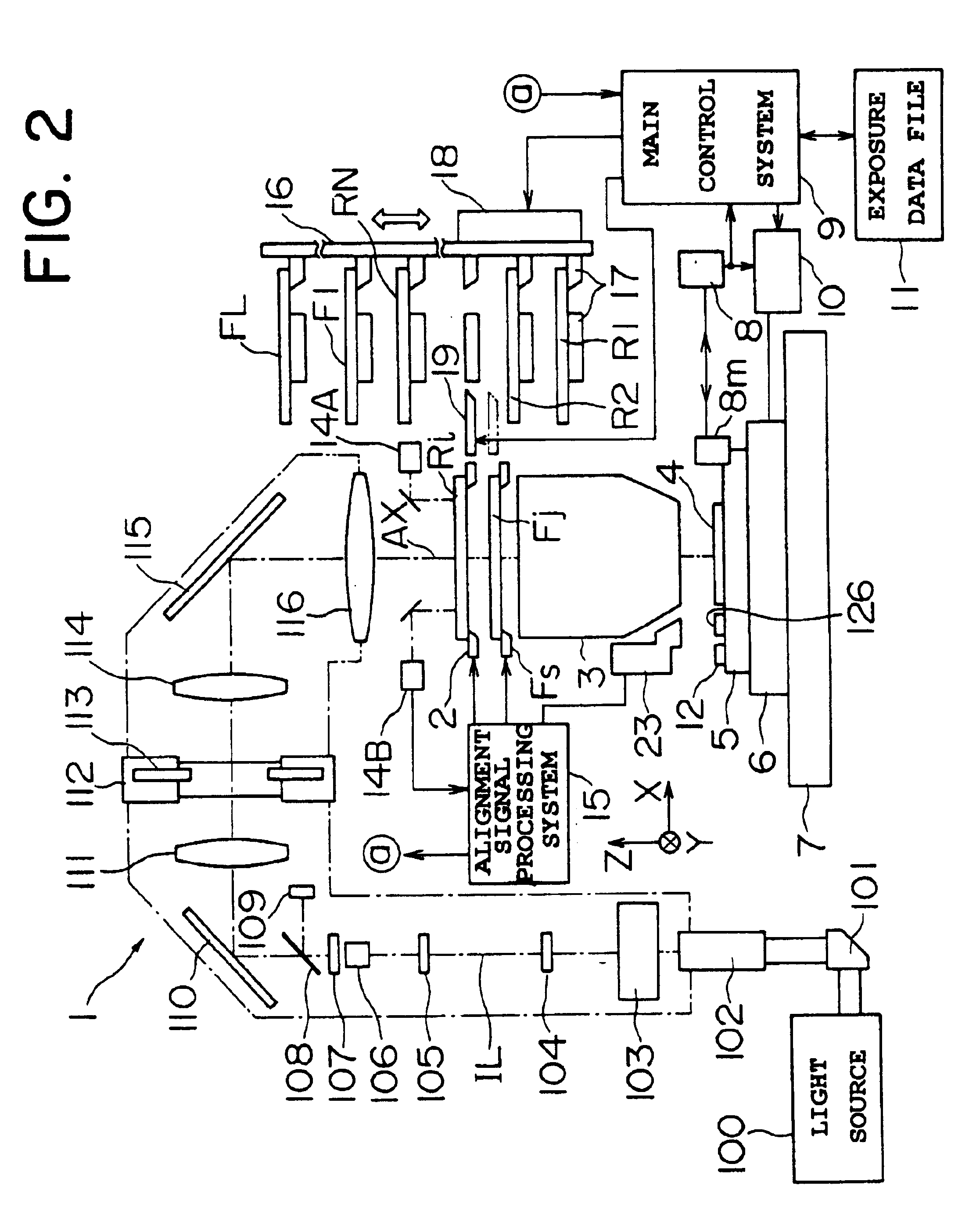

Exposure apparatus, microdevice, photomask, method of exposure, and method of production of device

InactiveUS6842225B1Reduce amount of lightImprove accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringPhotomask

A stitching type exposure apparatus for successively exposing an image of a pattern of a reticle (Ri) on different areas of a surface of a substrate (4) while overlaying parts of the same, wherein a density filter (Fj) having a light attenuating part for reducing the amount of light of overlaid parts of the image of the pattern in a sloping manner is provided in the vicinity of the reticle (Ri), the density filter (Fj) is held at a filter stage (FS) for adjusting the posture, the posture of the density filter (Fj) is detected by an illumination uniformity sensor (126) on the substrate stage (6), and the posture of the density filter (Fj) is matched with the posture of the reticle (Ri) by the filter stage (FS).

Owner:NIKON CORP

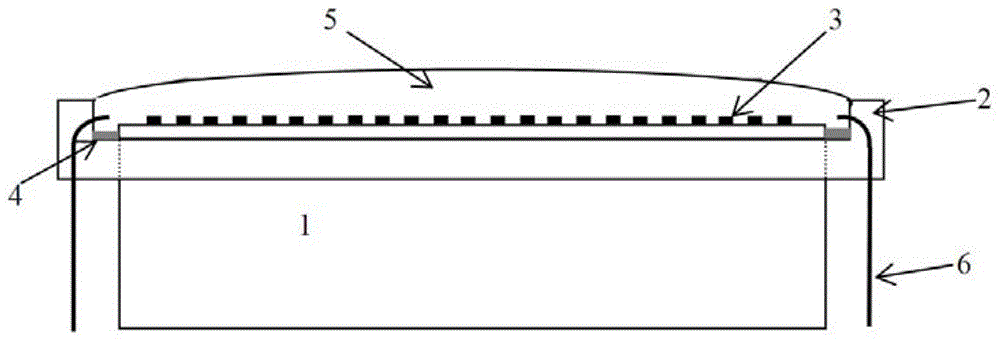

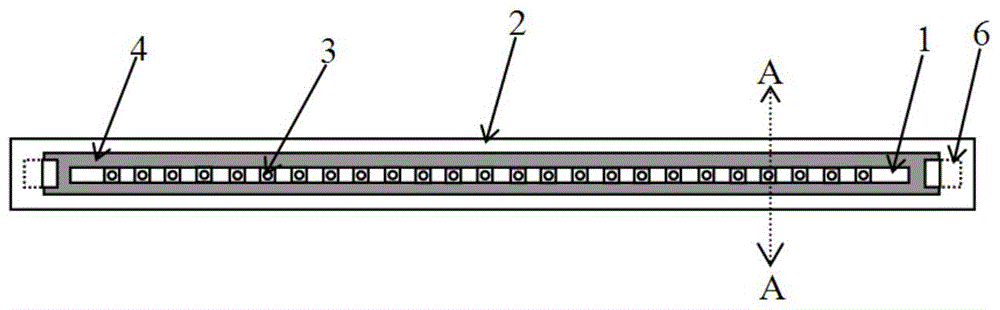

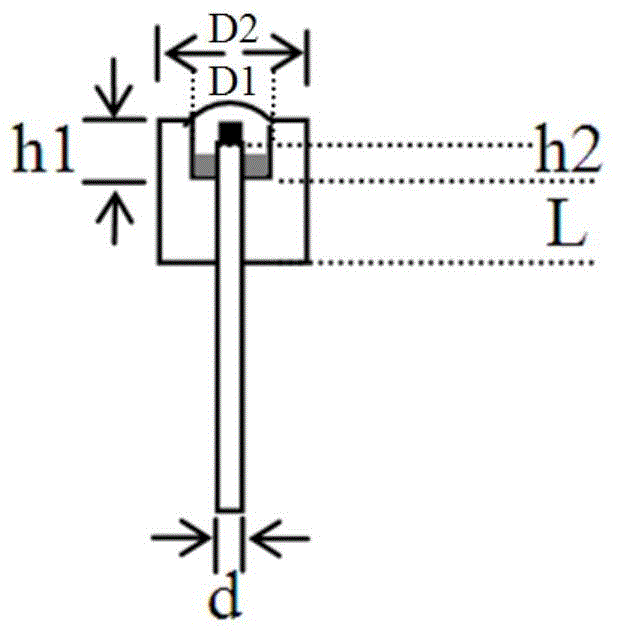

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

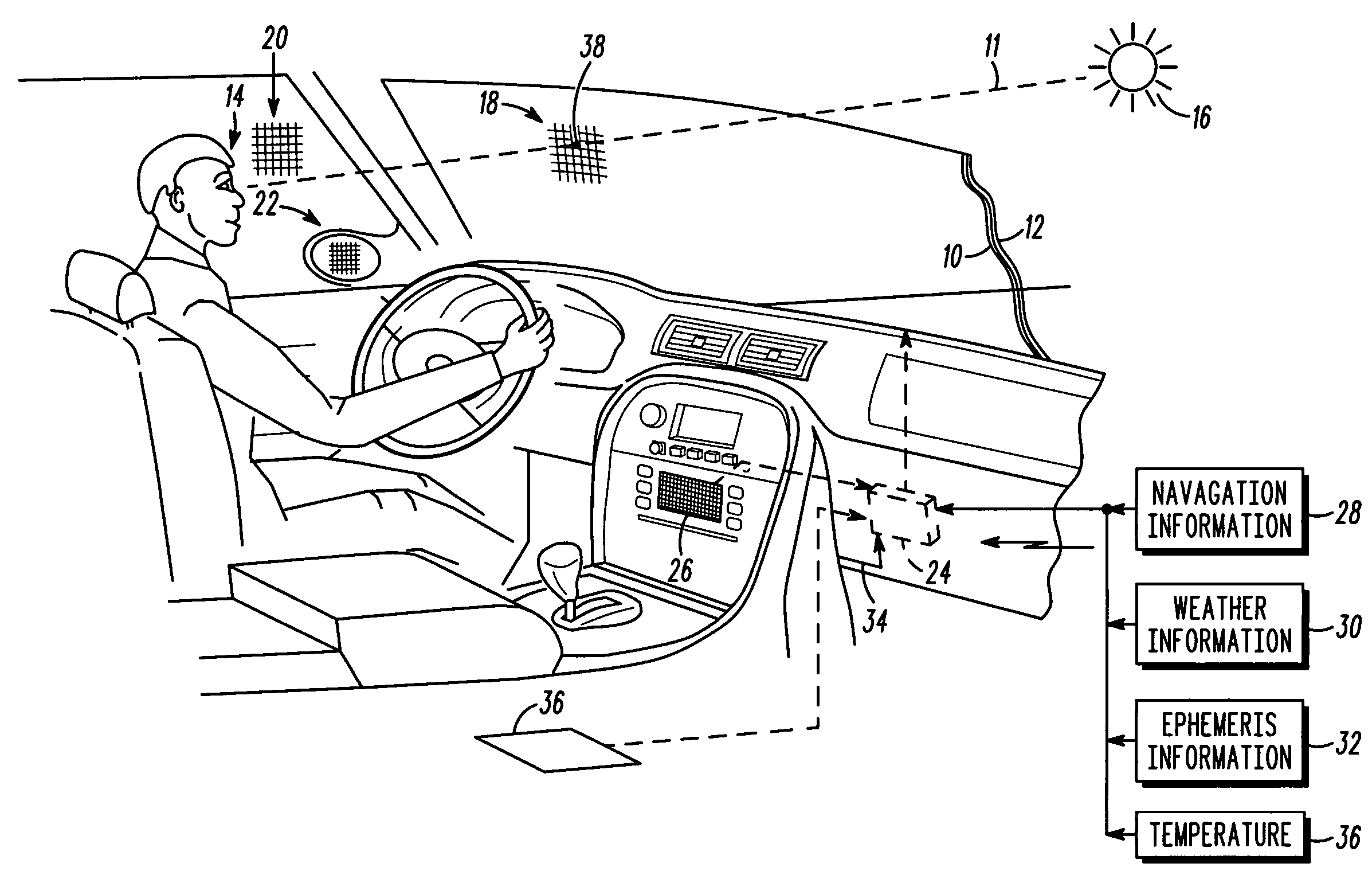

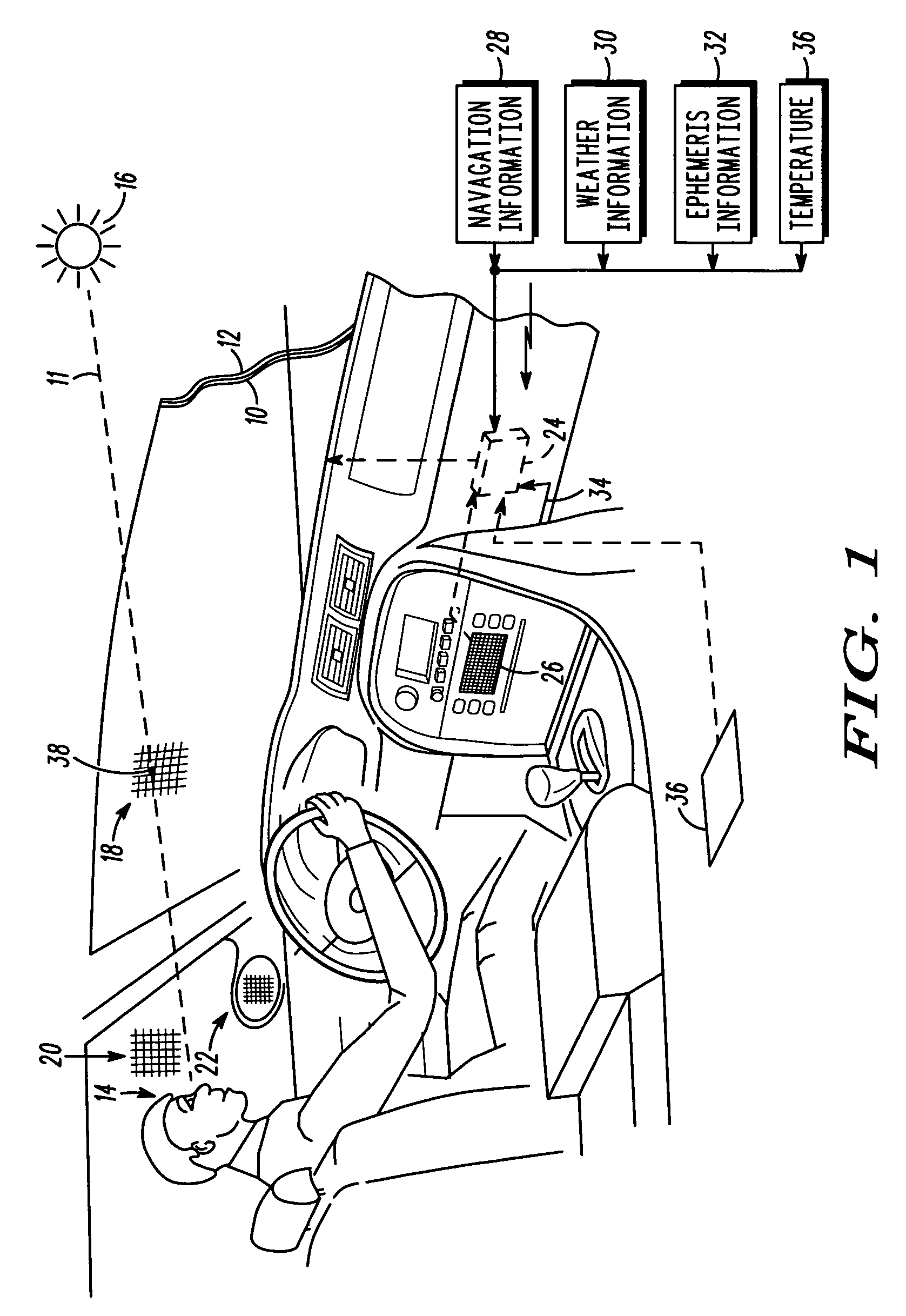

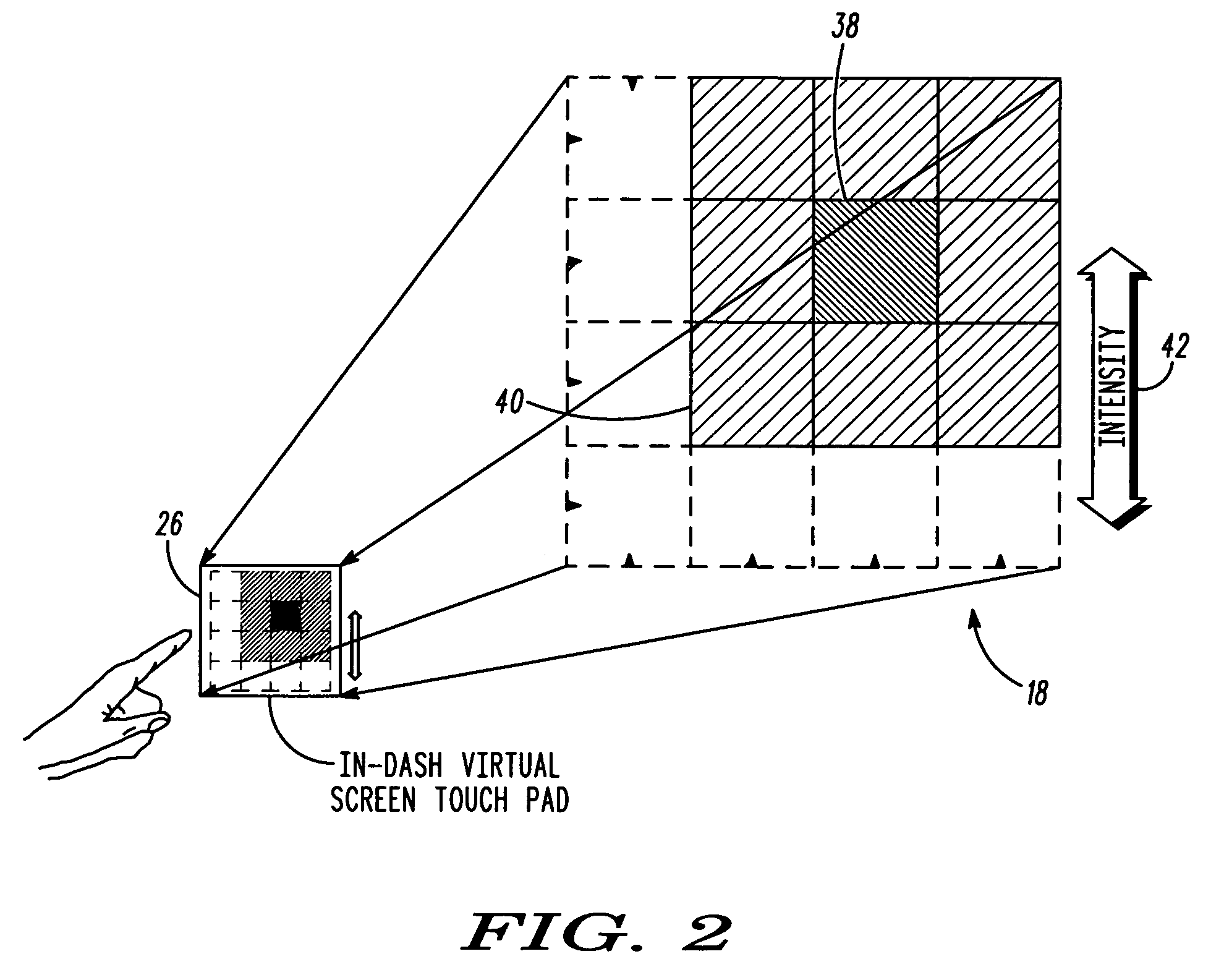

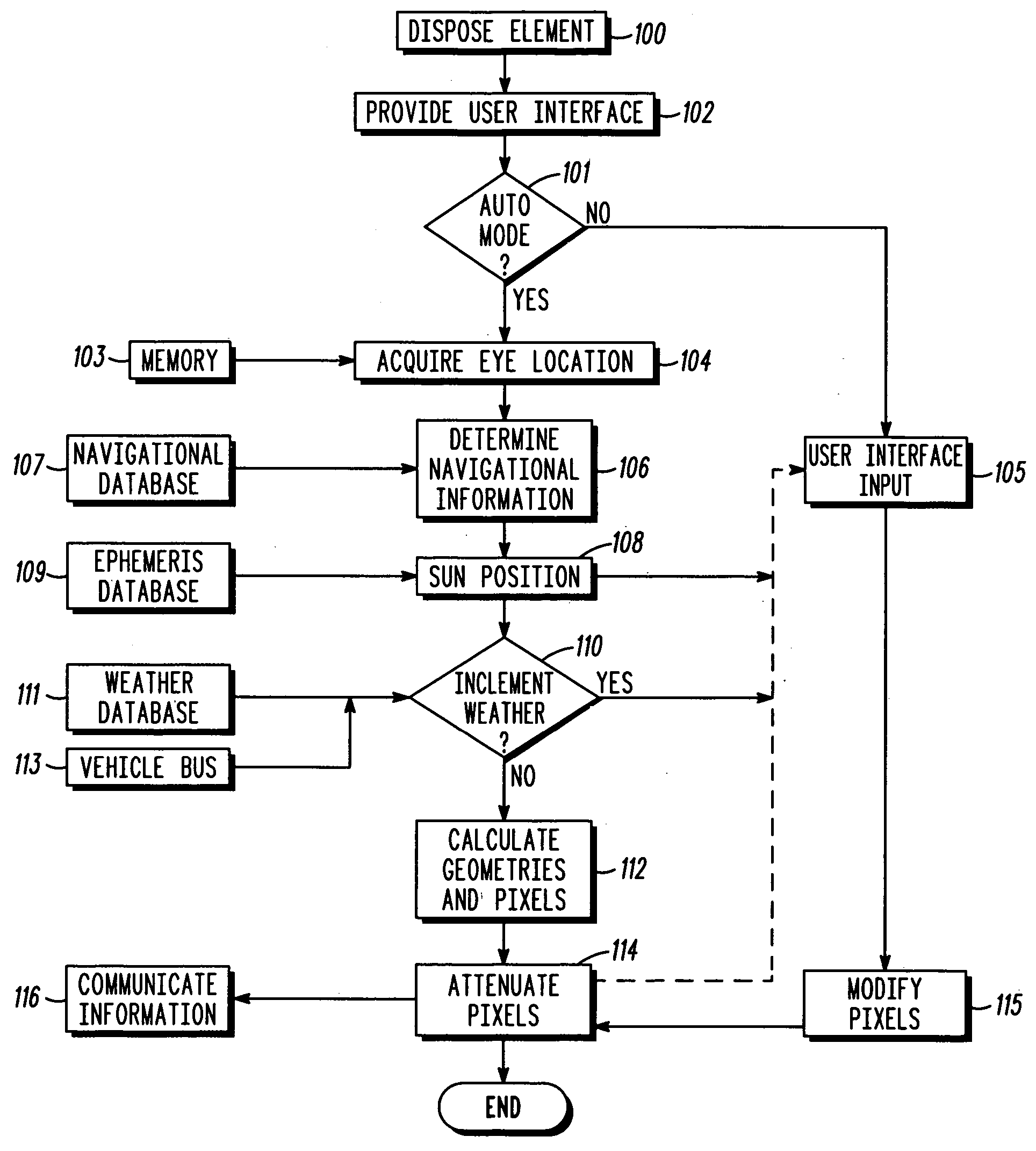

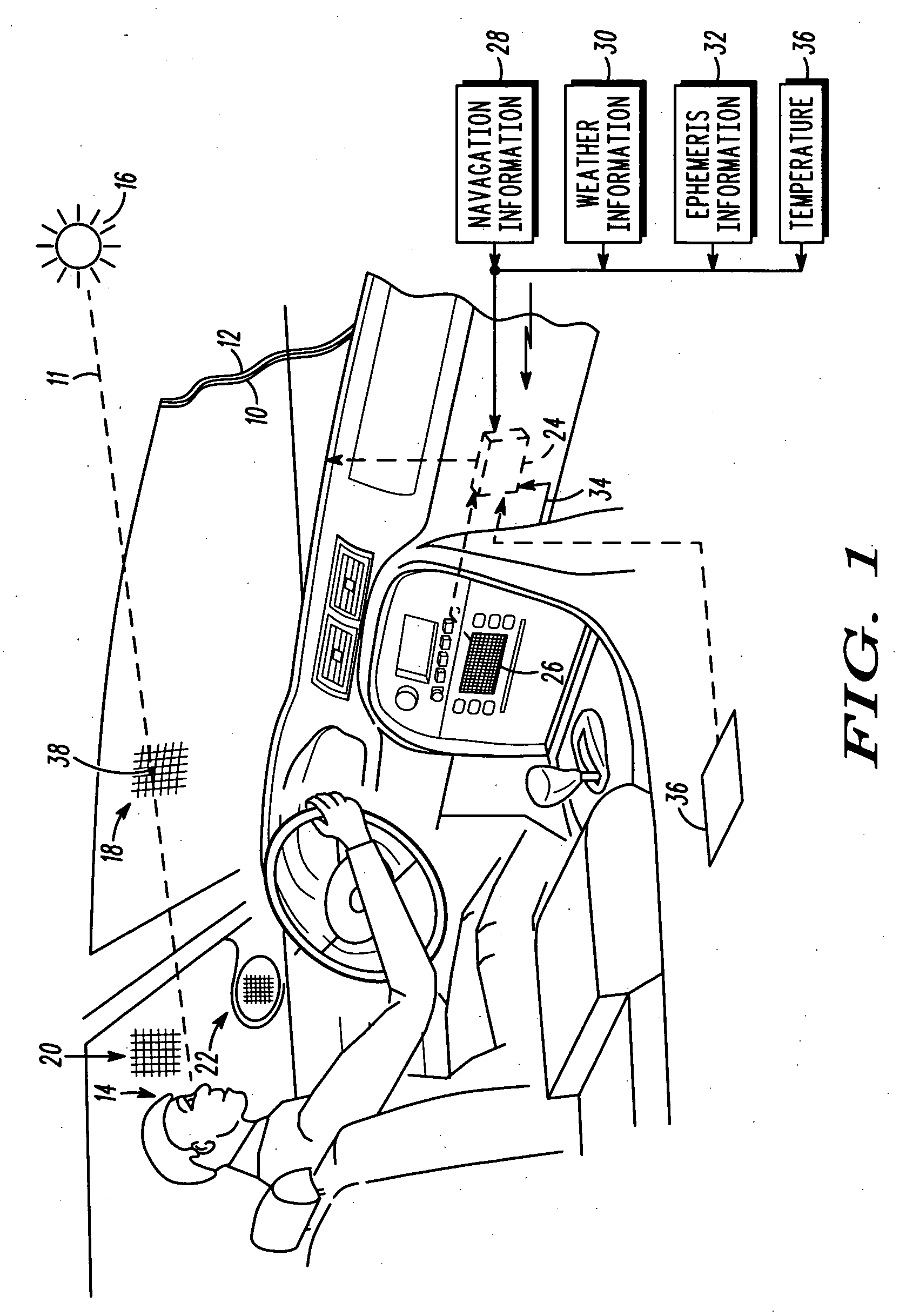

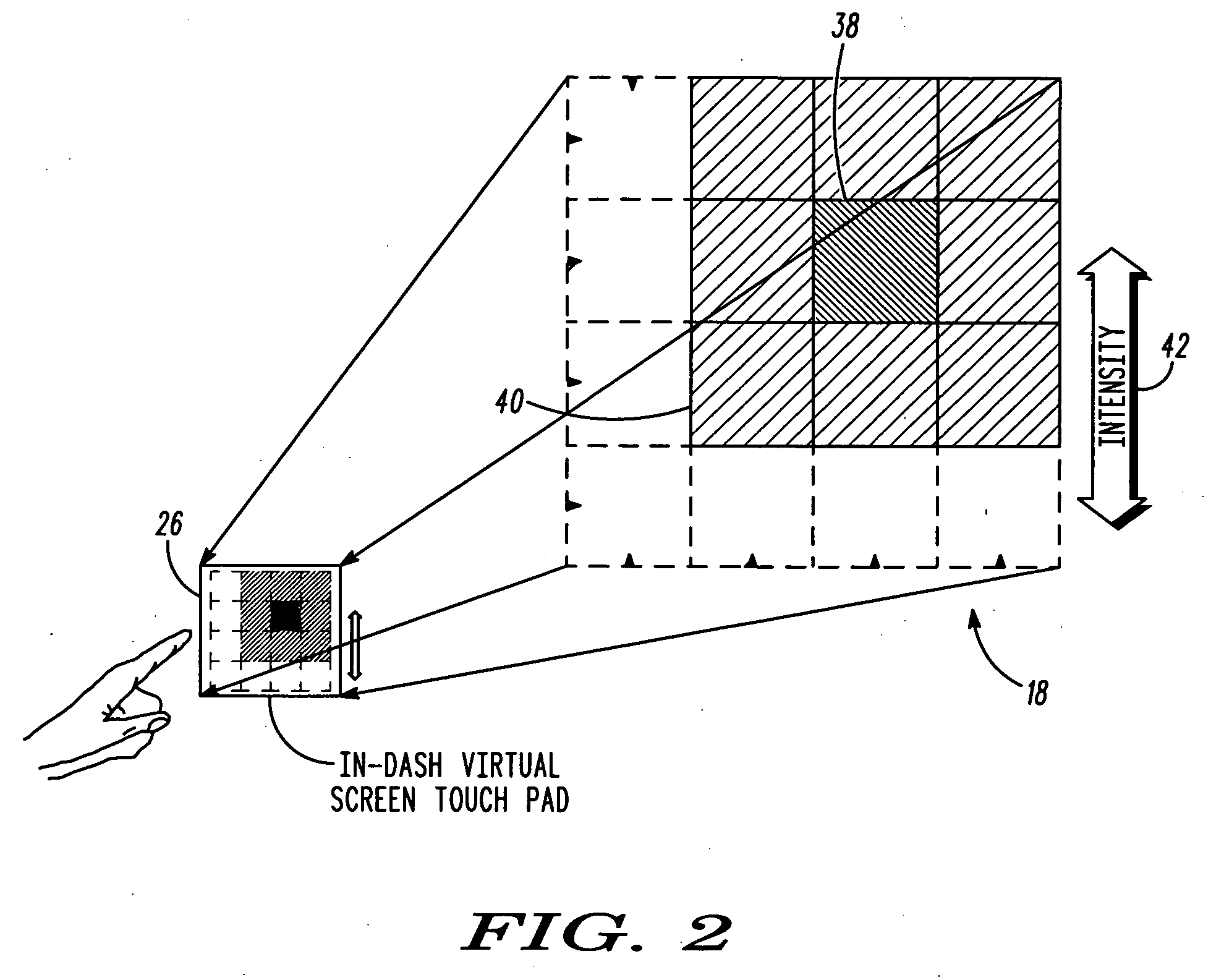

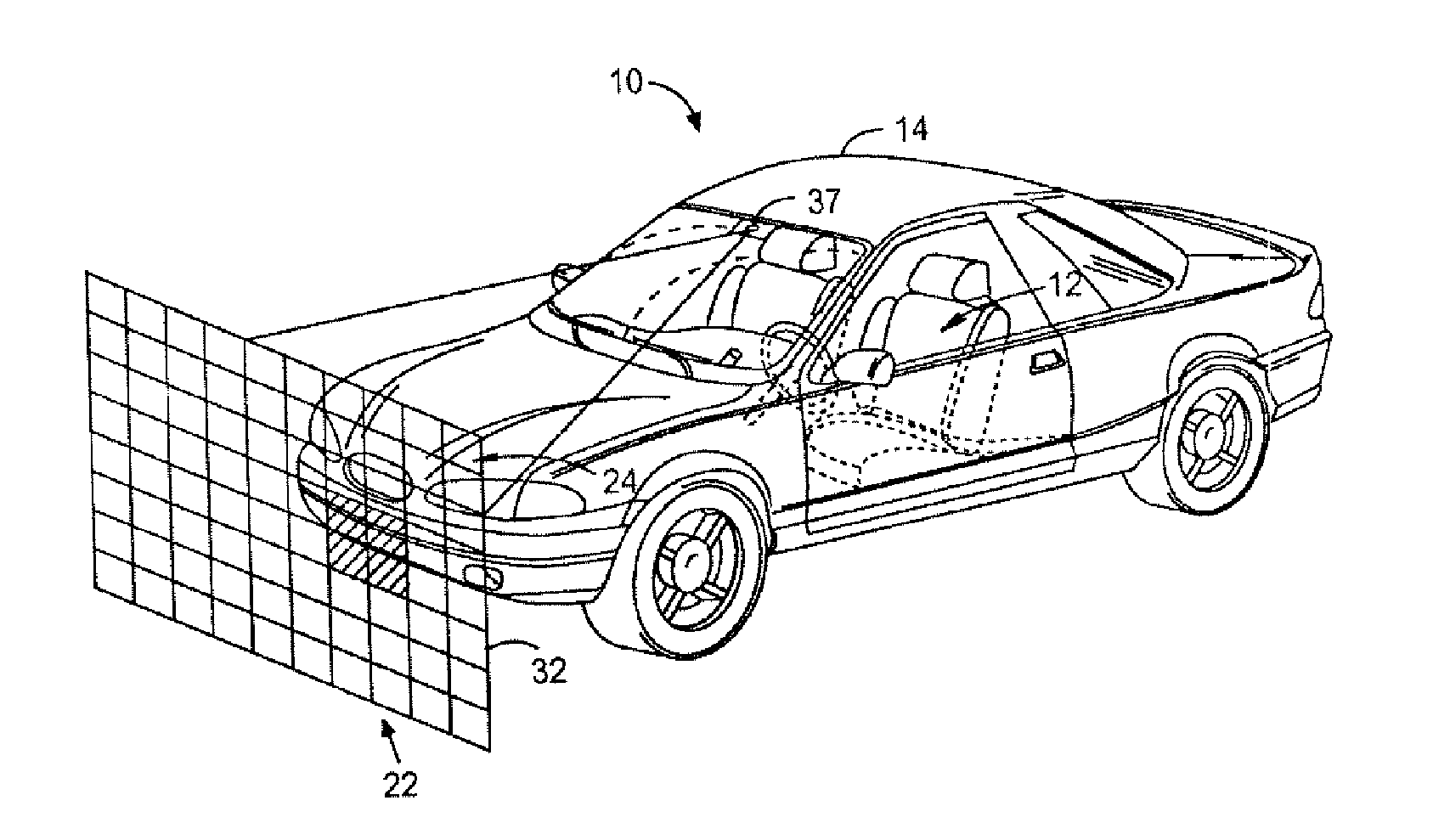

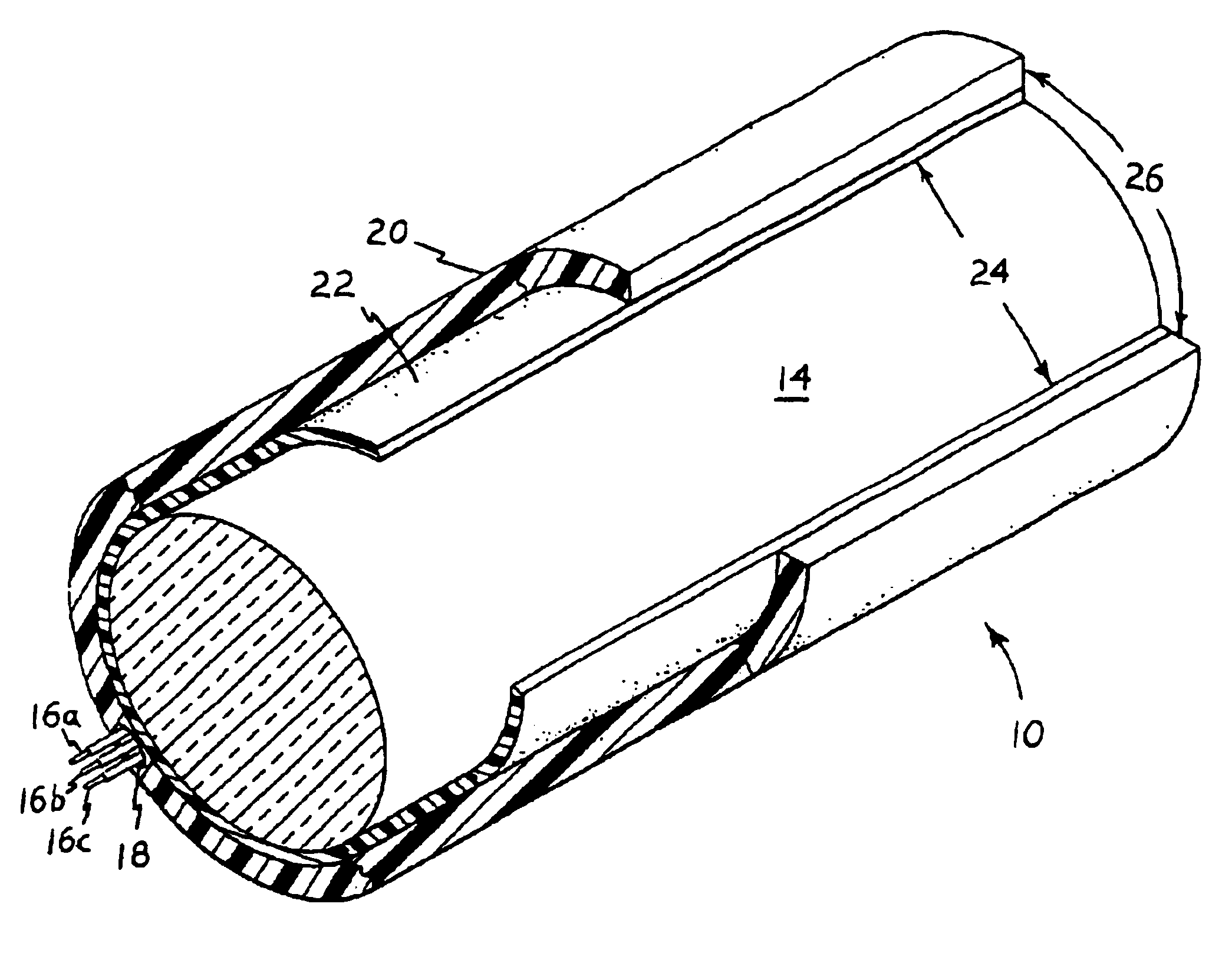

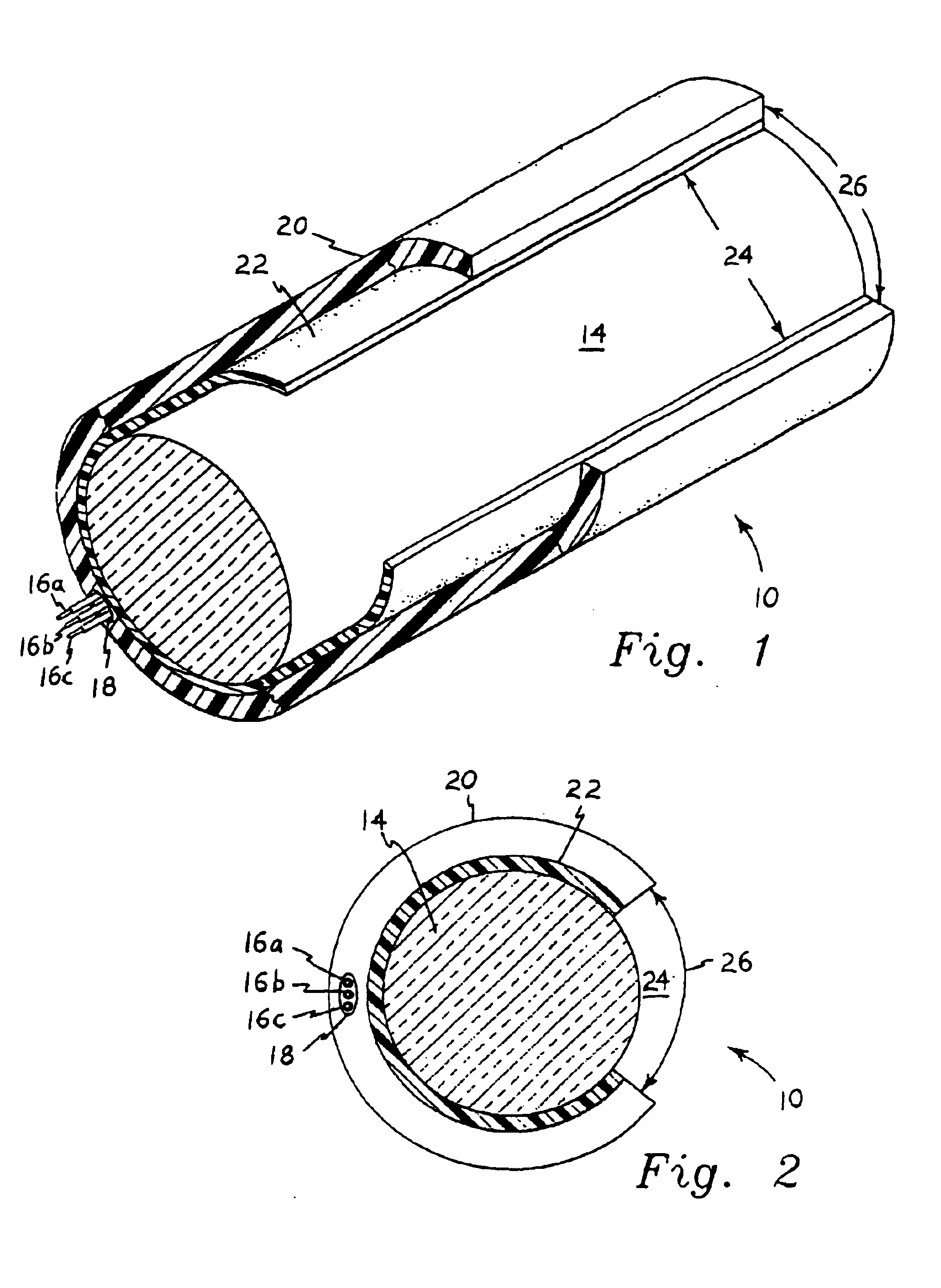

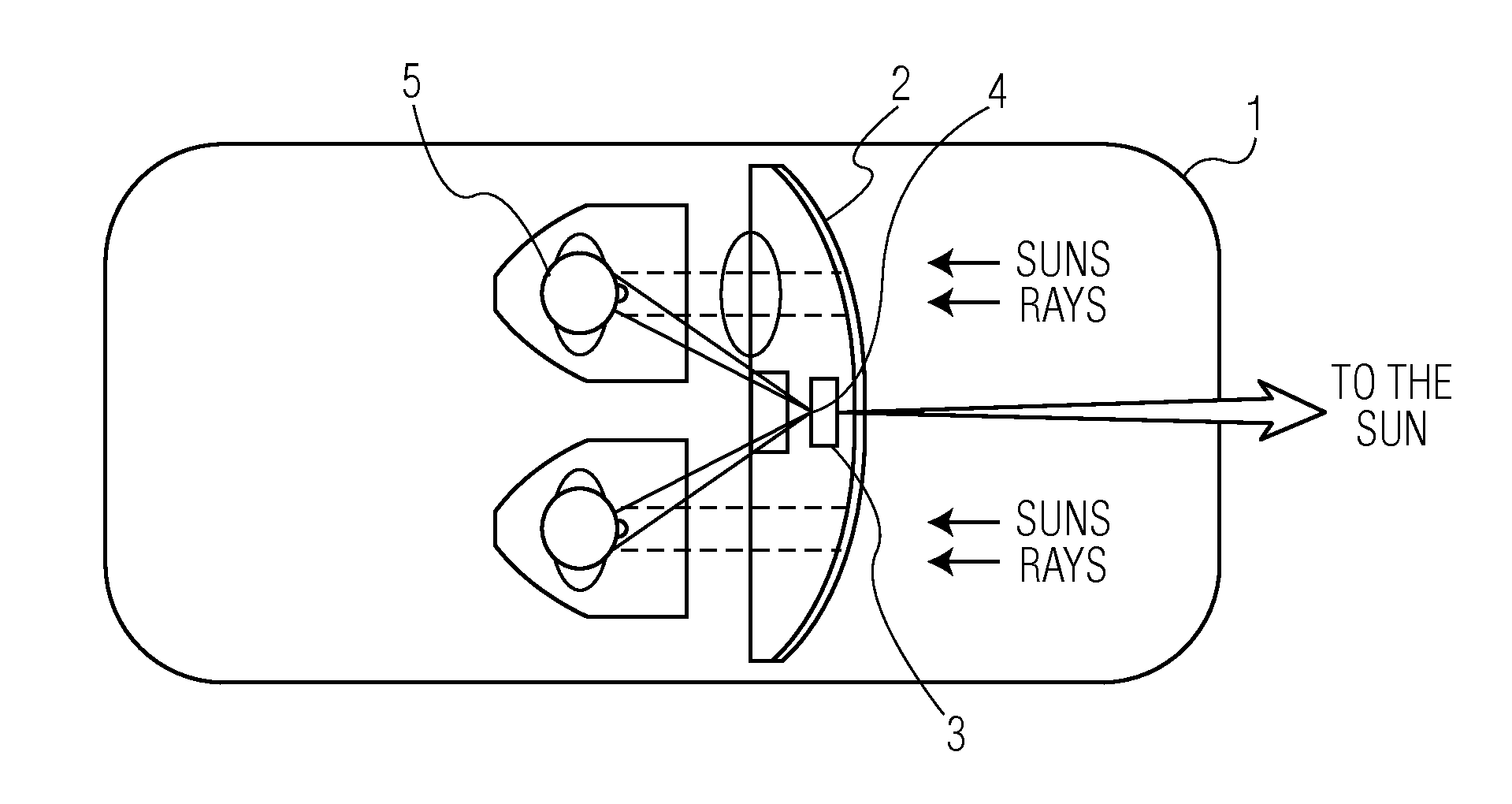

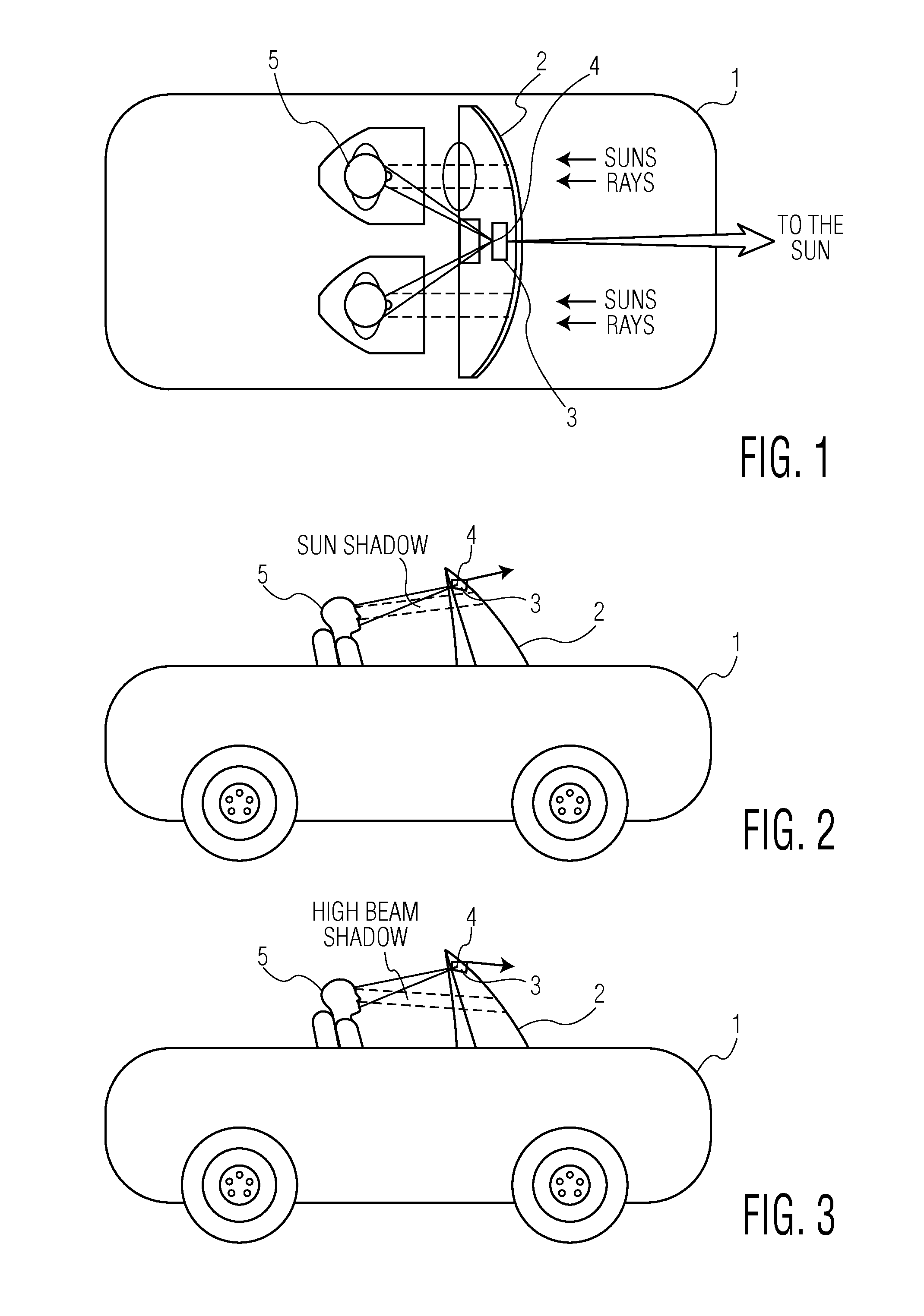

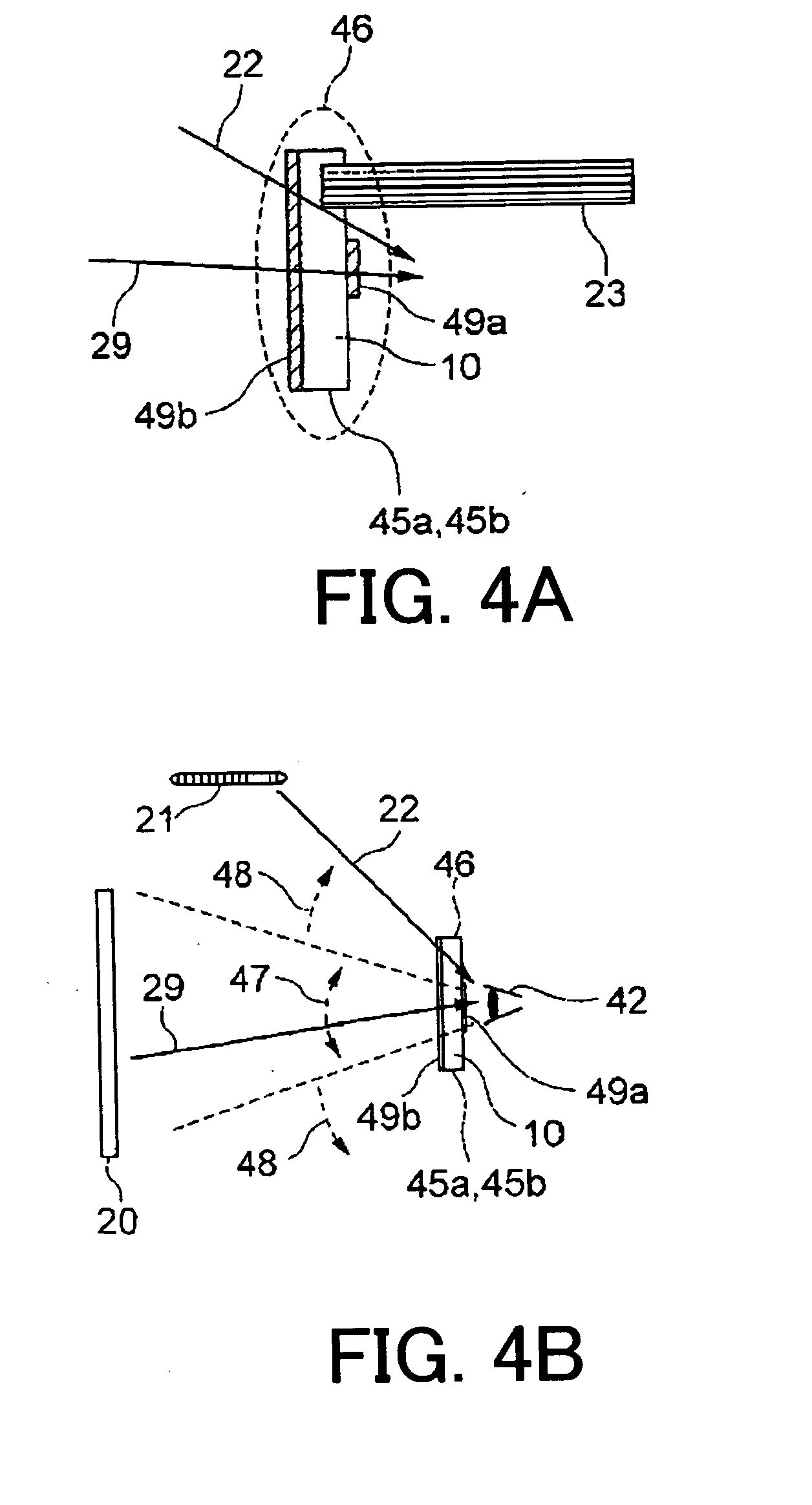

Selective light attenuation system

ActiveUS7134707B2Reduce complexityImprove reliabilityAntiglare equipmentMonocoque constructionsTransmittanceEngineering

A system for selectively attenuating light from a source of light, such as the sun, to a person's eyes in a vehicle. The system includes an electro-optical element (10) interposed between the source of light (16) and the person's eyes (14). The element (10) has pixels (18) that are operable to individually attenuate (38) light passing therethrough. A navigation system (28) determines a location and direction of travel of the vehicle. A memory (24) contains a general location for the person's eyes within the vehicle. Information (32) is made available for determining a position of the source of light. A controller (24) operates to determine those pixels of the elements that are calculated (38) to be between the person's eyes and the source of light, and to reduce the light transmittivity of those pixels (38) to attenuate the light from the source (16) to the person's eyes (14).

Owner:CONTINENTAL AUTOMOTIVE SYST INC

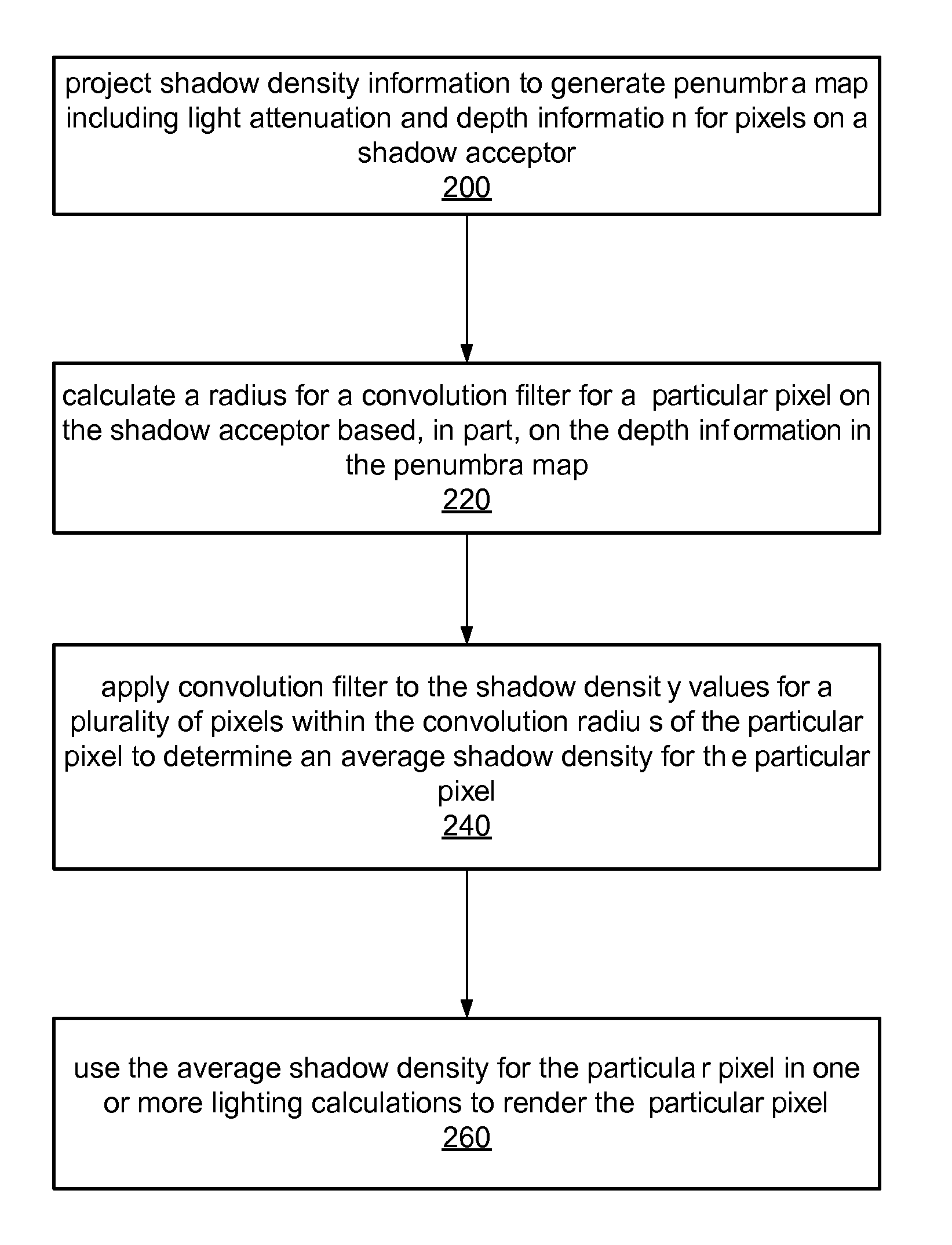

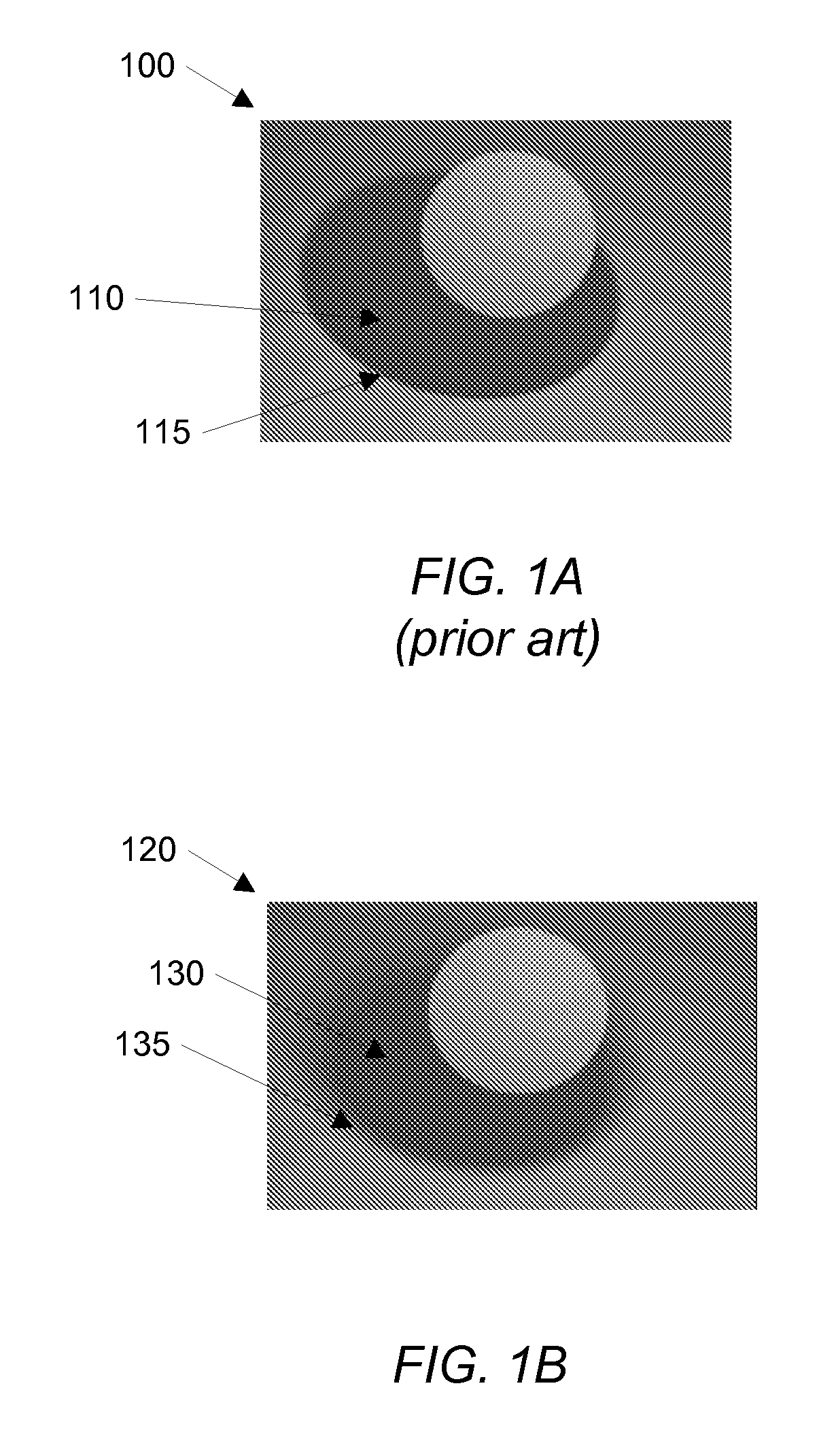

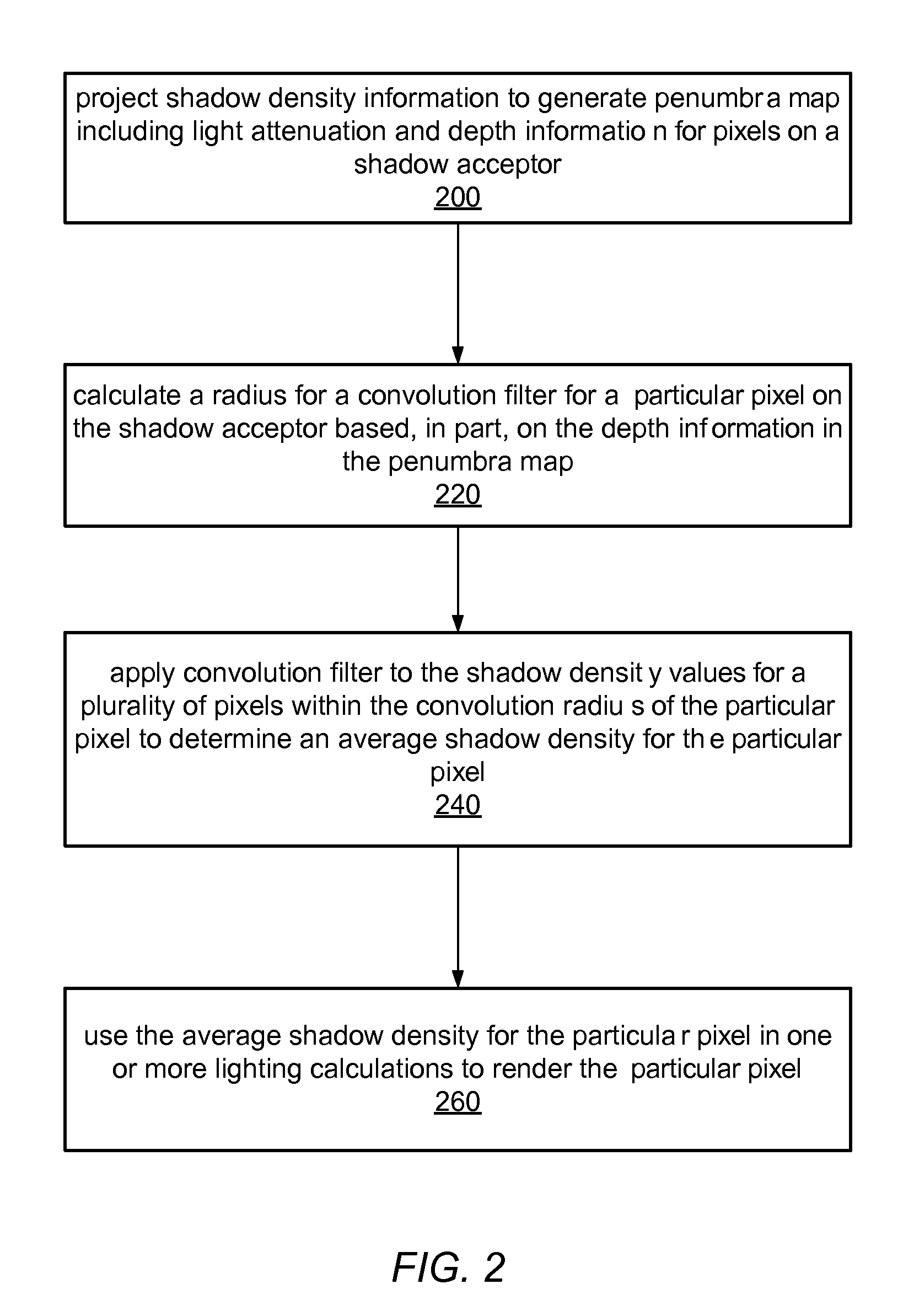

Calculating shadow from area light sources using a spatially varying blur radius

ActiveUS7817823B1Reduce the amount requiredCharacter and pattern recognition3D-image renderingComputer graphics (images)Caster

Shadows from physical lights have a penumbra region, in which the light is only partially hidden from the shadow acceptor. The intensity of light in this region may be calculated using an approximation of the amount of light visible. For example a fragment or pixel shader program execution on a GPU may generate a shadow from a light source using the light intensities for each pixel being rendered. Per-pixel shadow density information may be projected from the shadow caster onto the shadow acceptor. A penumbra map may contain both depth information and light attenuation information for the shadow acceptor. This information may be blurred using a fragment or pixel shader on a GPU to determine an average shadow density for a pixel being rendered.

Owner:ADOBE INC

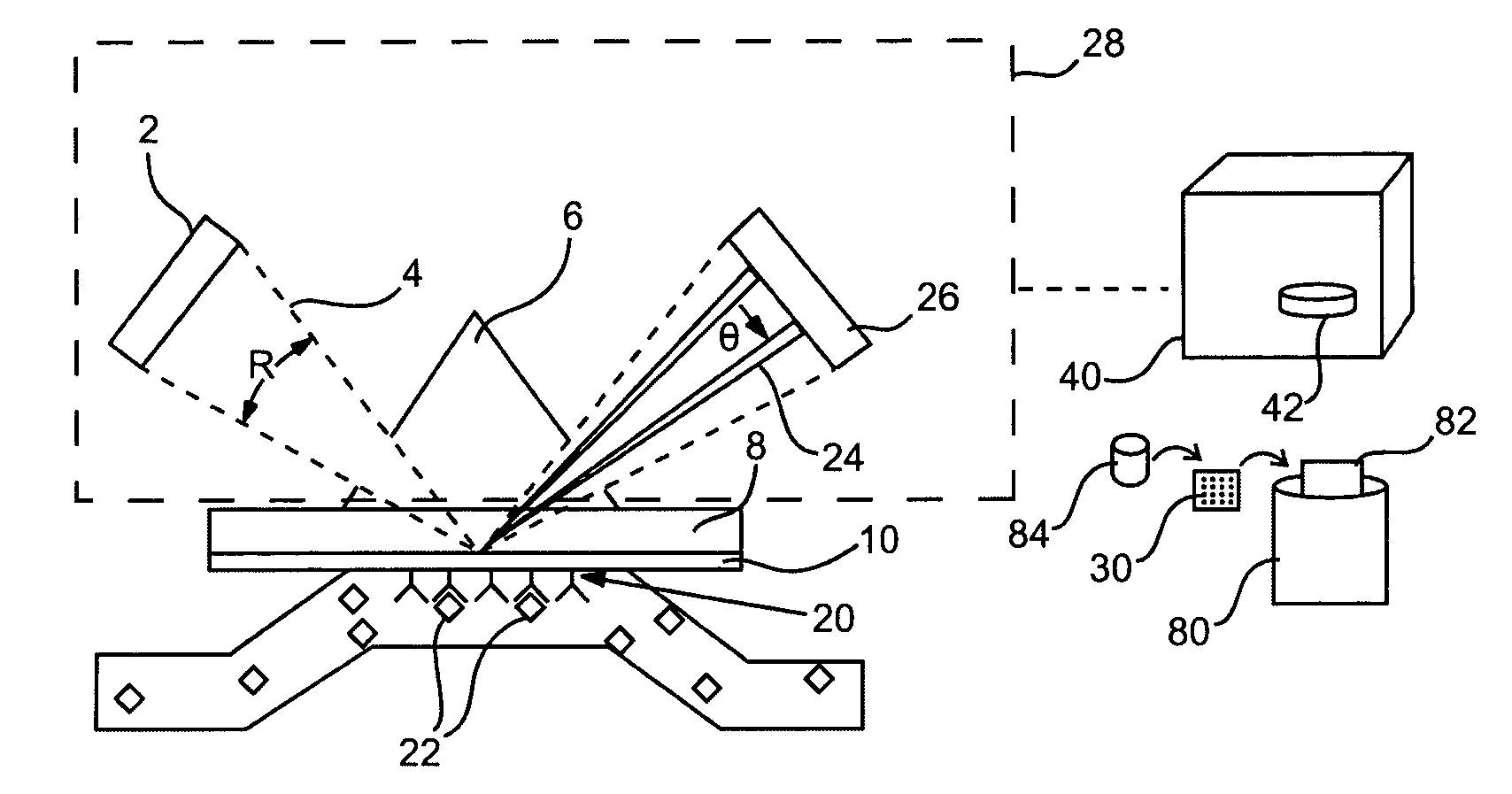

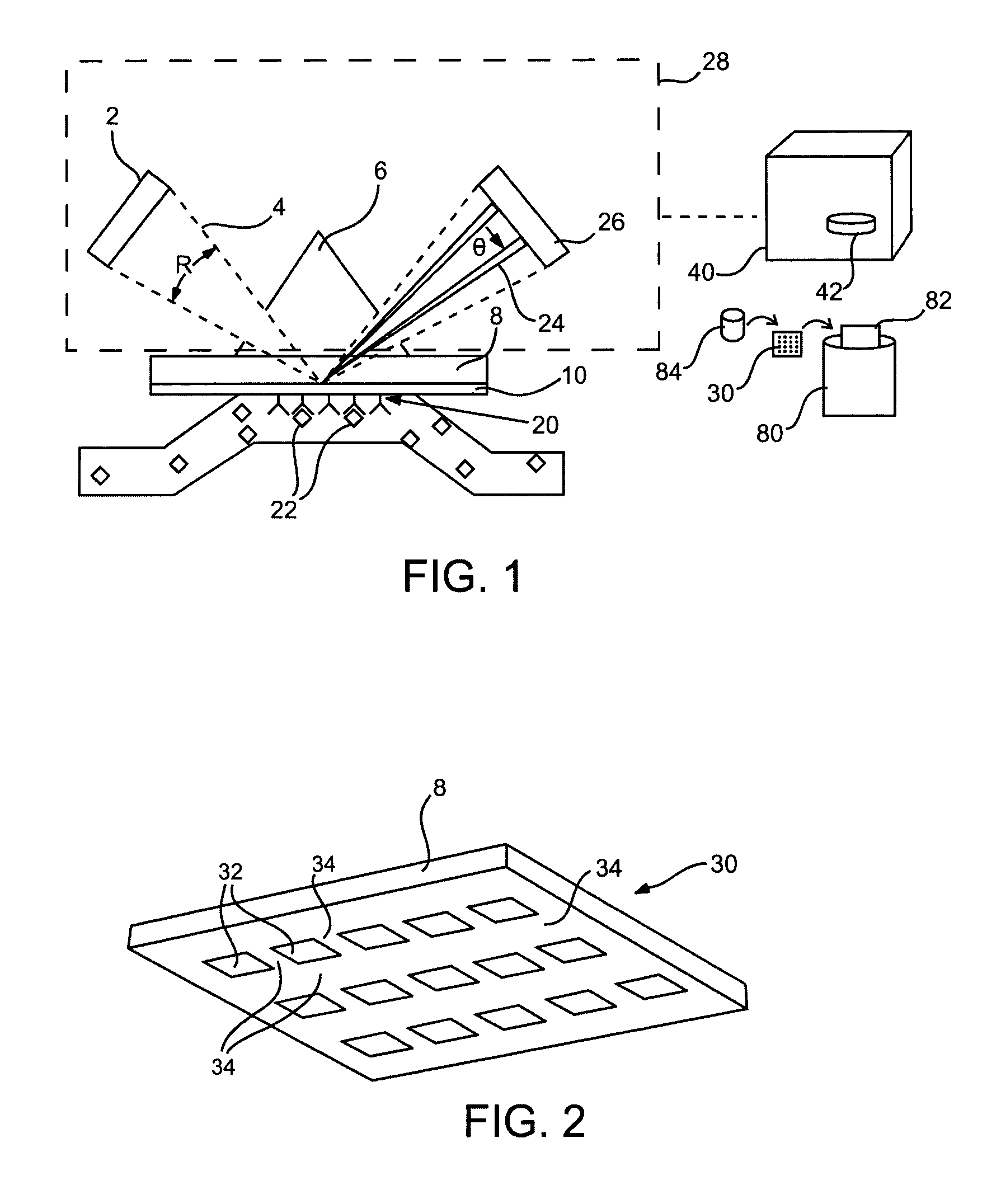

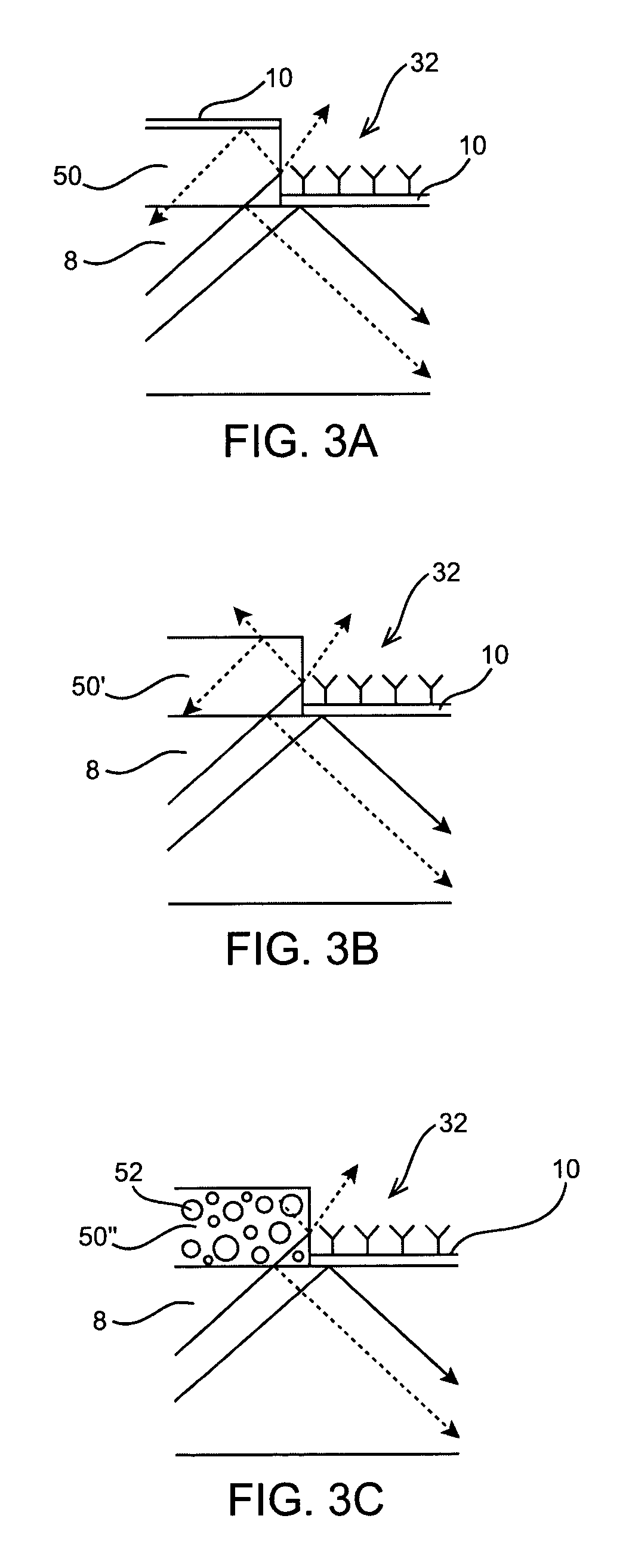

Arrays for multiplexed surface plasmon resonance detection of biological molecules

ActiveUS7223609B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBiopolymerSurface plasmonic resonance

Arrays are provided for multiplexed evanescent scanning by allowing for high-contrast Surface Plasmon Resonance images thereof. The arrays target features are typically biopolymeric in nature, though they may be any sort of chemical or ligand. The type of scanning is such that there is no need for probe labeling. As no labeling is required, a broader range of applications than otherwise possible is facilitated. In the subject arrays, target features are set upon a noble metal film deposited on a substrate. Interfeature areas are adapted to trap, divert and / or bleed-away light so that light directed through the substrate will not be reflected by those areas and interfere with evanescent scanning of the reflective areas upon which intended target features are provided. Geometric and materials-based light attenuating features are contemplated. Arrays as described, hardware and software as required for reading such arrays, and associated methodology are covered.

Owner:BRUKER DALTONIK GMBH & CO KG

Selective light attenuation system

ActiveUS20060175859A1Reduce complexityImprove reliabilityAntiglare equipmentMonocoque constructionsEngineeringNavigation system

A system for selectively attenuating light from a source of light, such as the sun, to a person's eyes in a vehicle. The system includes an electro-optical element (10) interposed between the source of light (16) and the person's eyes (14). The element (10) has pixels (18) that are operable to individually attenuate (38) light passing therethrough. A navigation system (28) determines a location and direction of travel of the vehicle. A memory (24) contains a general location for the person's eyes within the vehicle. Information (32) is made available for determining a position of the source of light. A controller (24) operates to determine those pixels of the elements that are calculated (38) to be between the person's eyes and the source of light, and to reduce the light transmittivity of those pixels (38) to attenuate the light from the source (16) to the person's eyes (14).

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Tissue oximetry apparatus and method

ActiveUS8055321B2High precisionExclude influenceDiagnostic signal processingOptical sensorsOptical propertyMedicine

An apparatus and method for determining tissue oxygenation such as arterial and venous oxygenation and cerebral oxygenation. In one embodiment, the optical properties of tissue are determined using measured light attenuations at a set of wavelengths. By choosing distinct wavelengths and using light attenuation information, the influence of variables such as light scattering, absorption and other optical tissue properties can be minimized.

Owner:BERNREUTER PETER

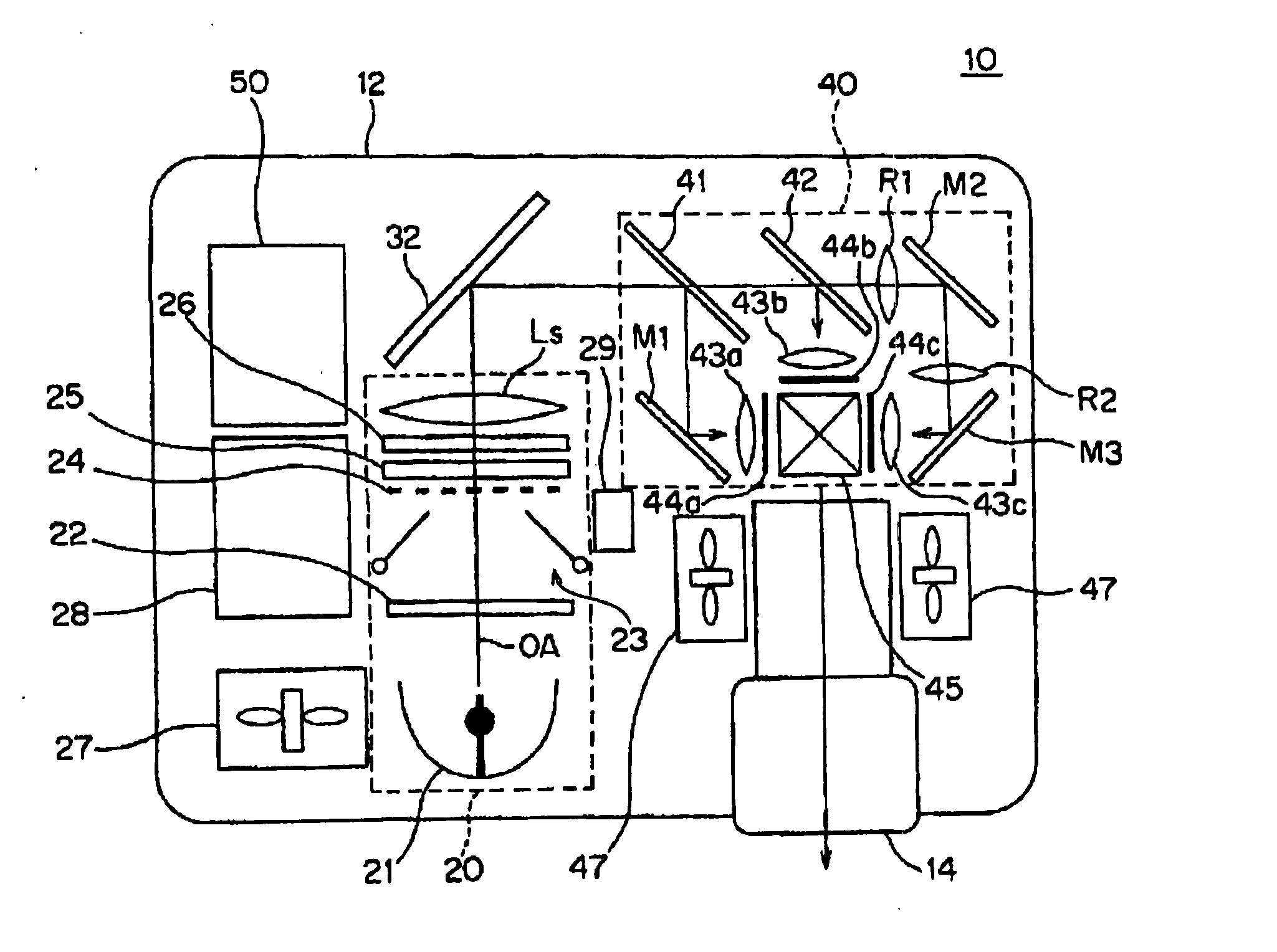

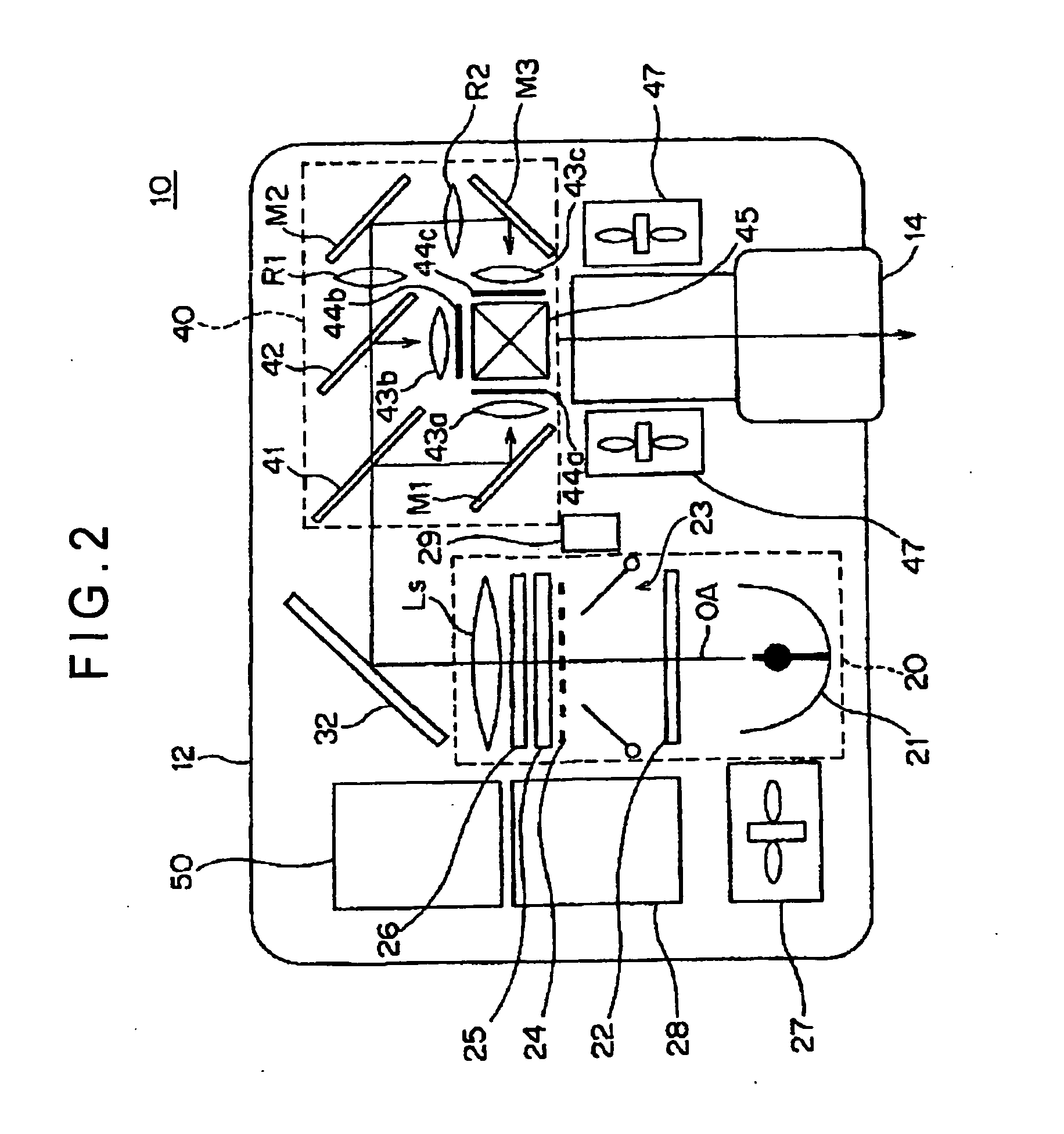

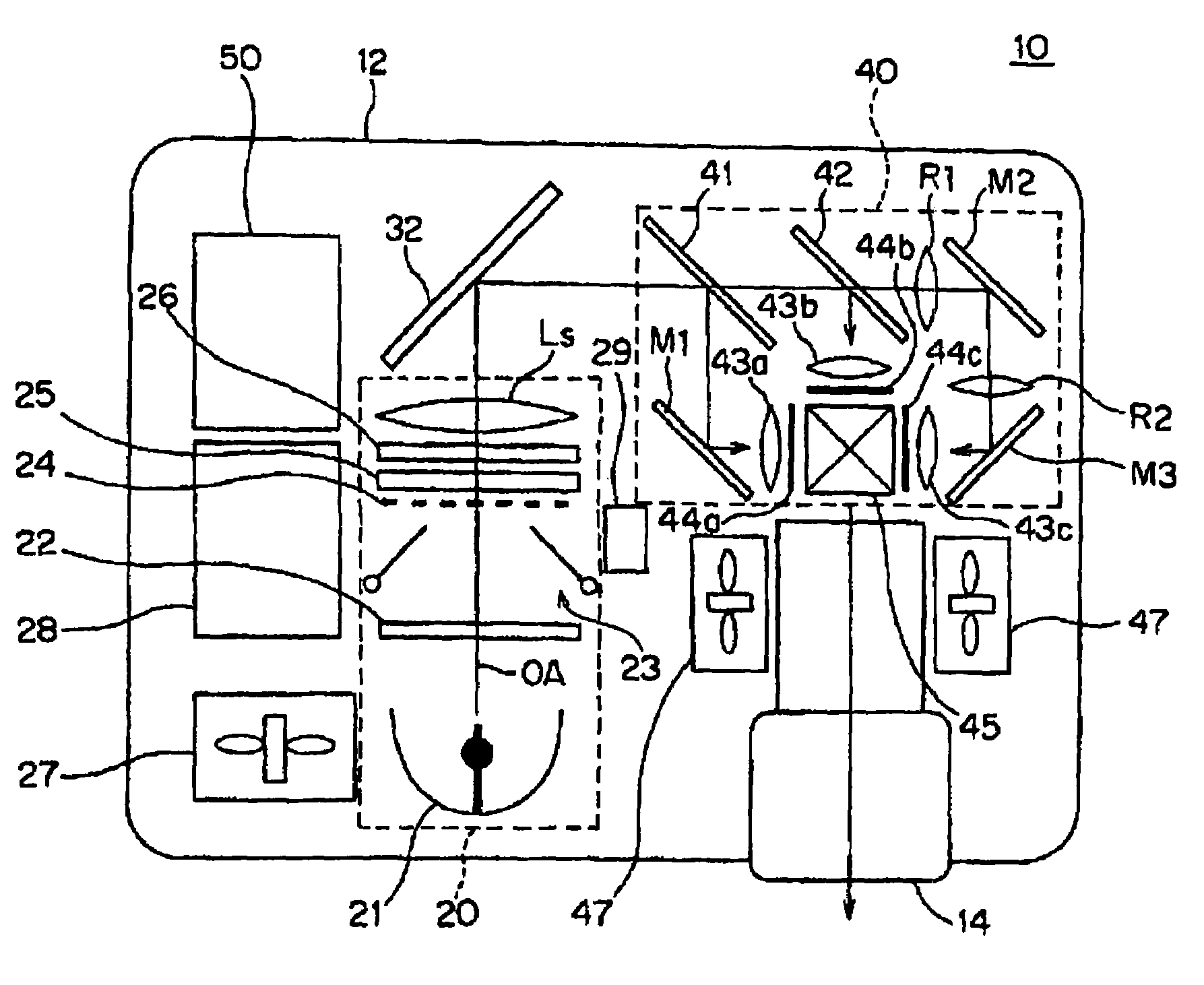

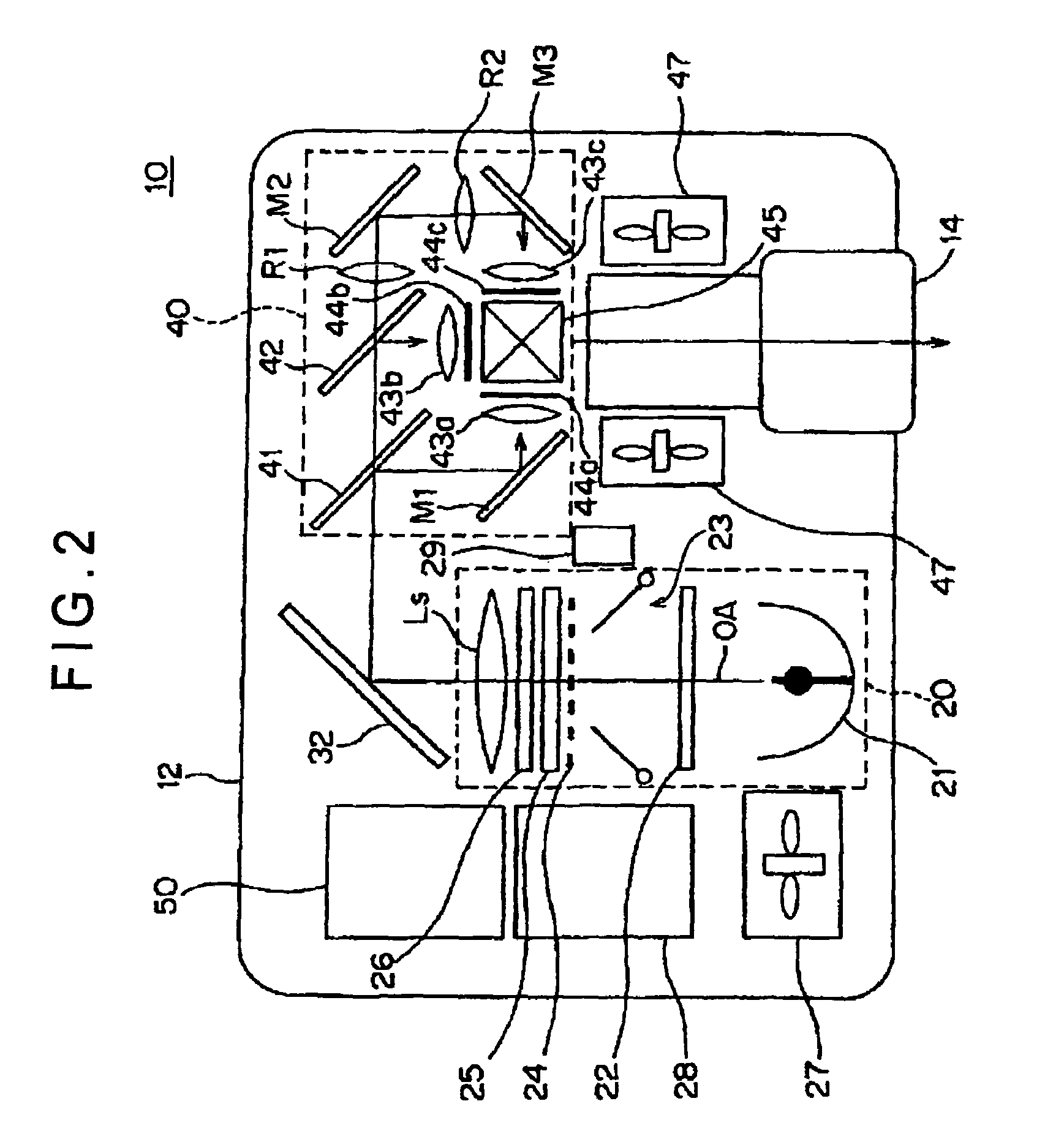

Illuminator and projector

ActiveUS20050068505A1Regulation stabilityIncrease contrastTelevision system detailsNon-electric lightingLens hoodPeak value

When a video signal is inputted to a projector (10) through a video input terminal, a luminance peak value of an image of the video signal is detected by an image-analyzing circuit (61) to be outputted to a CPU (71). A gain-adjusting circuit (63) adjusts a luminance signal in the video signal based on a command from the CPU (71). The CPU (71) determines a gain adjustment amount based on the luminance peak value of the image obtained by the image-analyzing circuit (61) and outputs the result to the gain-adjusting circuit (63). For instance, when the luminance peak value (lp) of the image is 50% of the upper limit (Imax) thereof, a gain-adjusting amount AG is doubled In this case, an illuminating light volume of a light valve (44a) has to be reduced to 50%, which is achieved by light-attenuation by a light-source lamp (21) and an open / close light shield (23).

Owner:SEIKO EPSON CORP

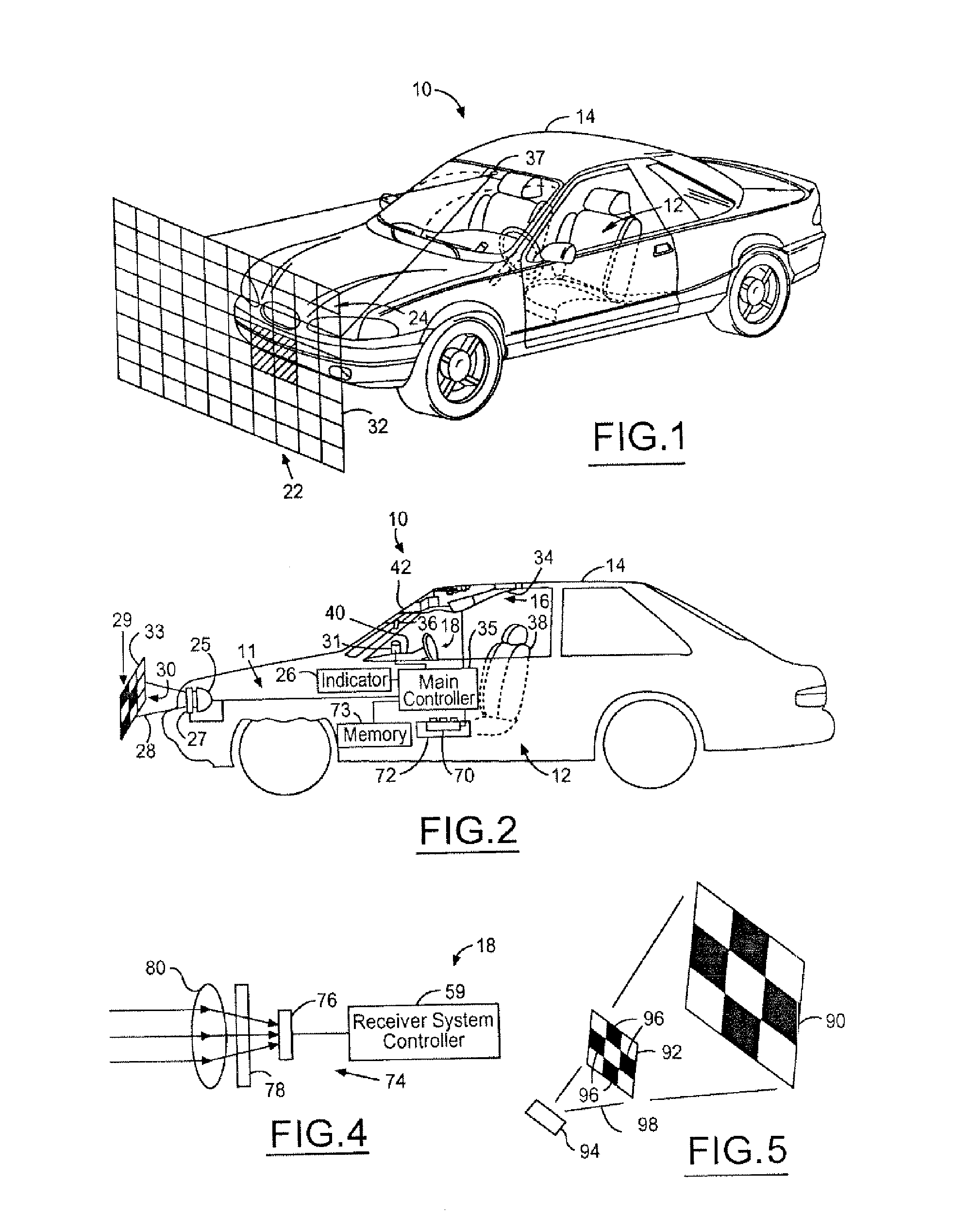

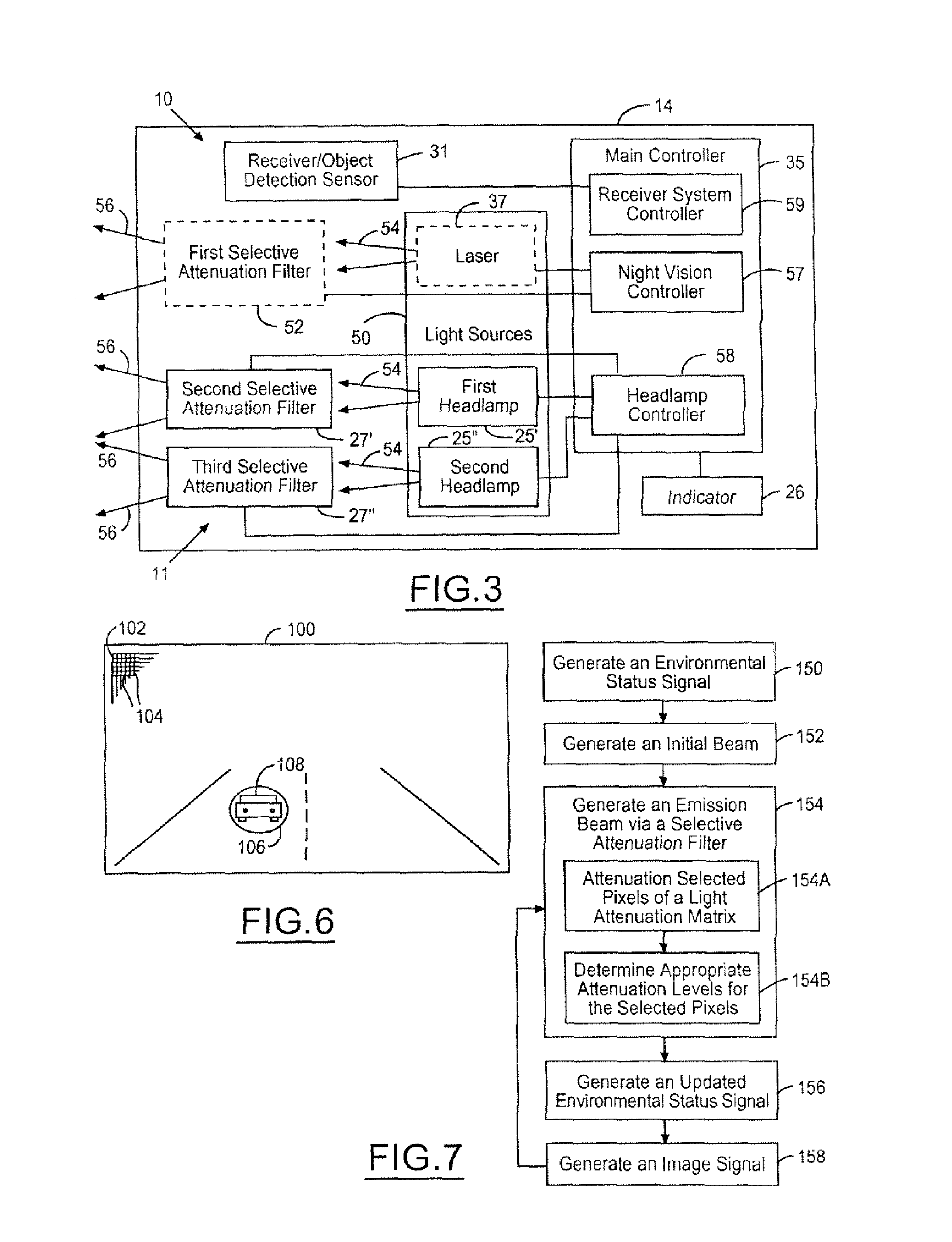

Anti-blinding system for a vehicle

InactiveUS20060146552A1Reduce complexityLow costNon-electric lightingVehicle headlampsUltrasound attenuationObject detection

An active light source operating system (10,11) for a vehicle (14) includes a light source (50) that generates an initial illumination beam (54). A selective attenuation filter (27,52) forms an emitted illumination beam (56), with an associated light attenuation matrix (32,33), in response to the initial illumination beam (54). A sensor (31) detects an object and generates an object detection signal. A controller (35) is coupled to the selective attenuation filter (27,52) and said sensor (31). The controller (35) attenuates a pixel (104) in the light attenuation matrix (32,33) in response to the object detection signal.

Owner:FORD GLOBAL TECH LLC

Illuminator and projector

ActiveUS7055966B2Improve image contrastLittle changeTelevision system detailsNon-electric lightingPeak valueComputer science

When a video signal is inputted to a projector (10) through a video input terminal, a luminance peak value of an image of the video signal is detected by an image-analyzing circuit (61) to be outputted to a CPU (71). A gain-adjusting circuit (63) adjusts a luminance signal in the video signal based on a command from the CPU (71). The CPU (71) determines a gain adjustment amount based on the luminance peak value of the image obtained by the image-analyzing circuit (61) and outputs the result to the gain-adjusting circuit (63). For instance, when the luminance peak value (Ip) of the image is 50% of the upper limit (Imax) thereof, a gain-adjusting amount AG is doubled. In this case, an illuminating light volume of a light valve (44a) has to be reduced to 50%, which is achieved by light-attenuation by a light-source lamp (21) and an open / close light shield (23).

Owner:SEIKO EPSON CORP

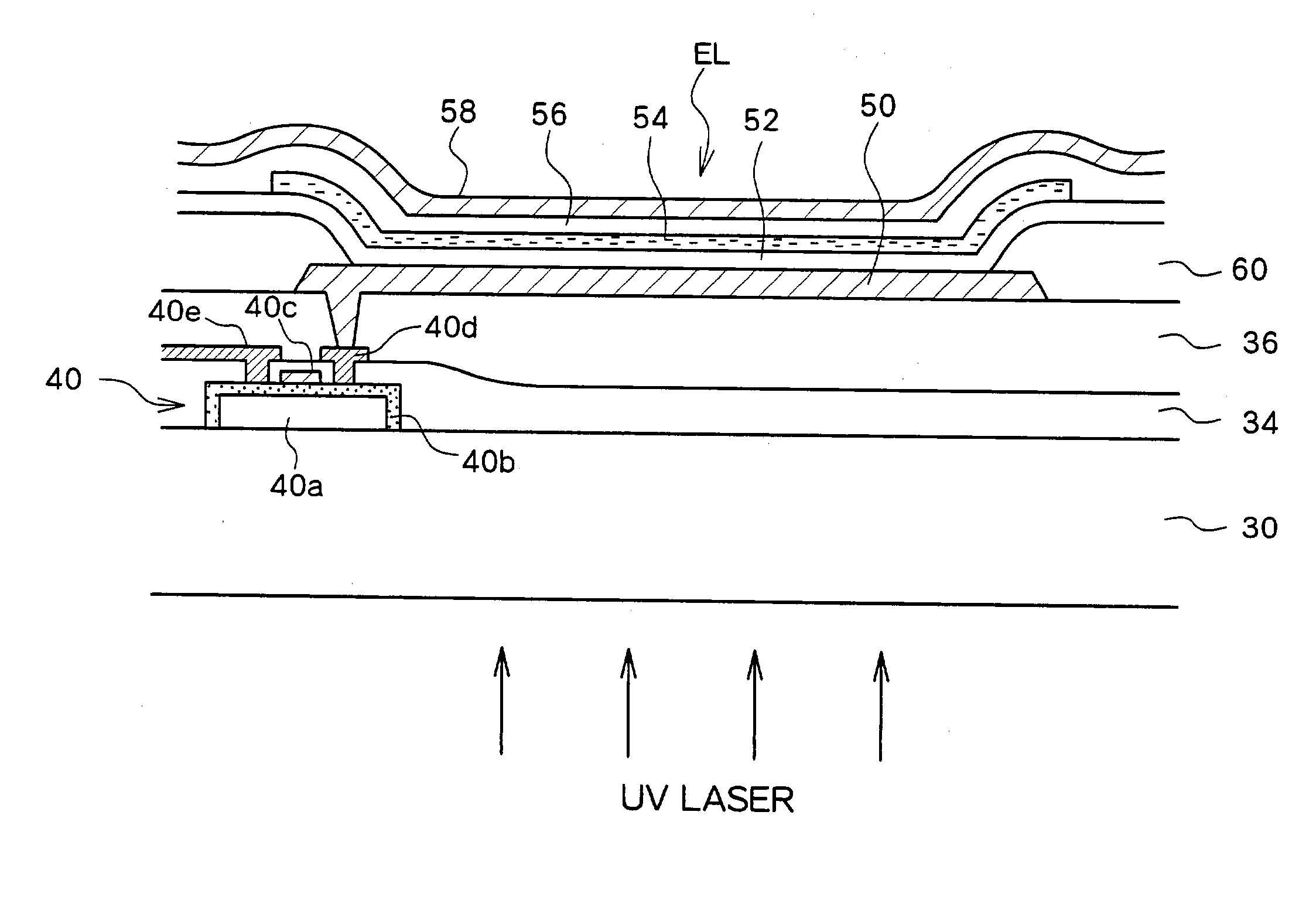

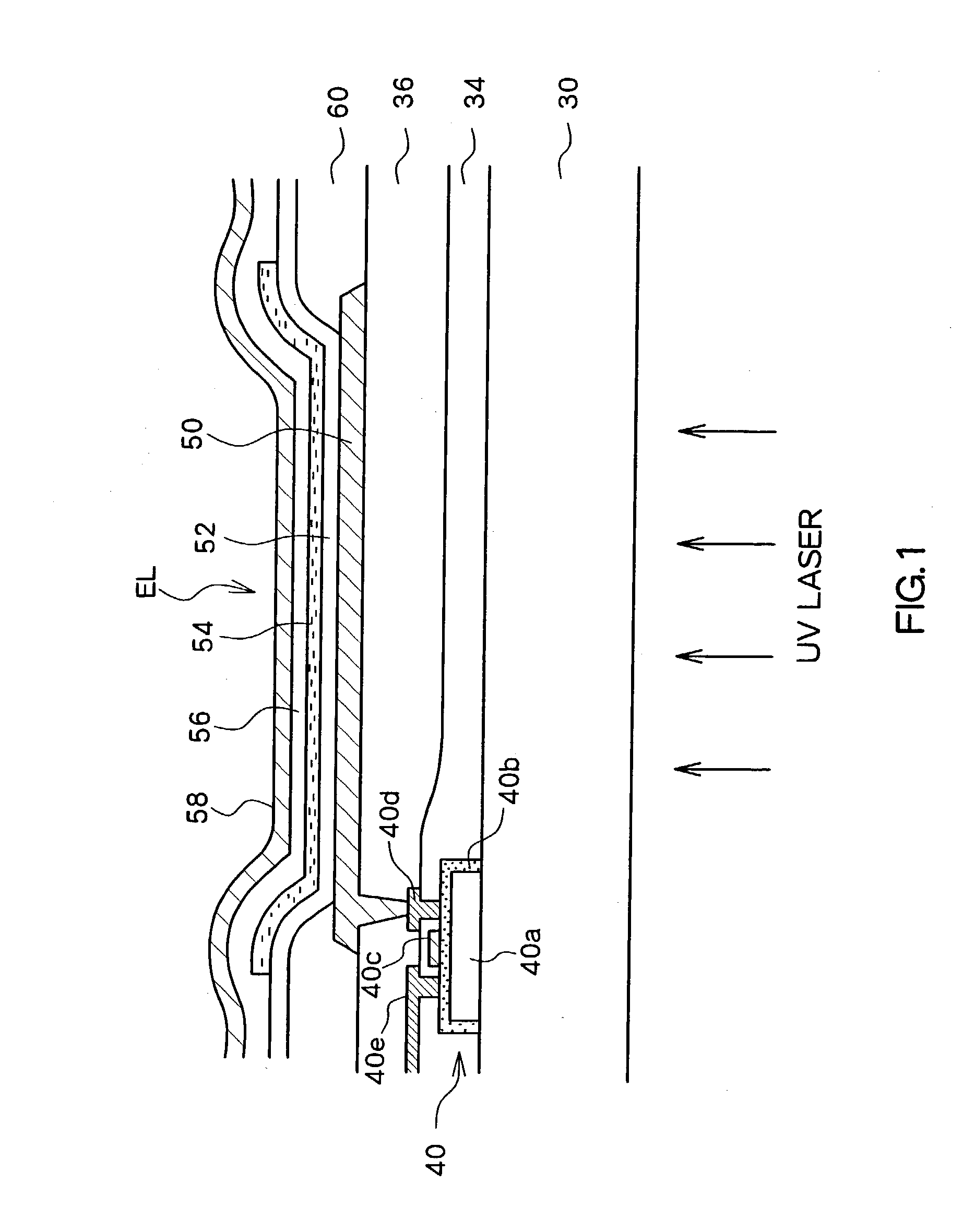

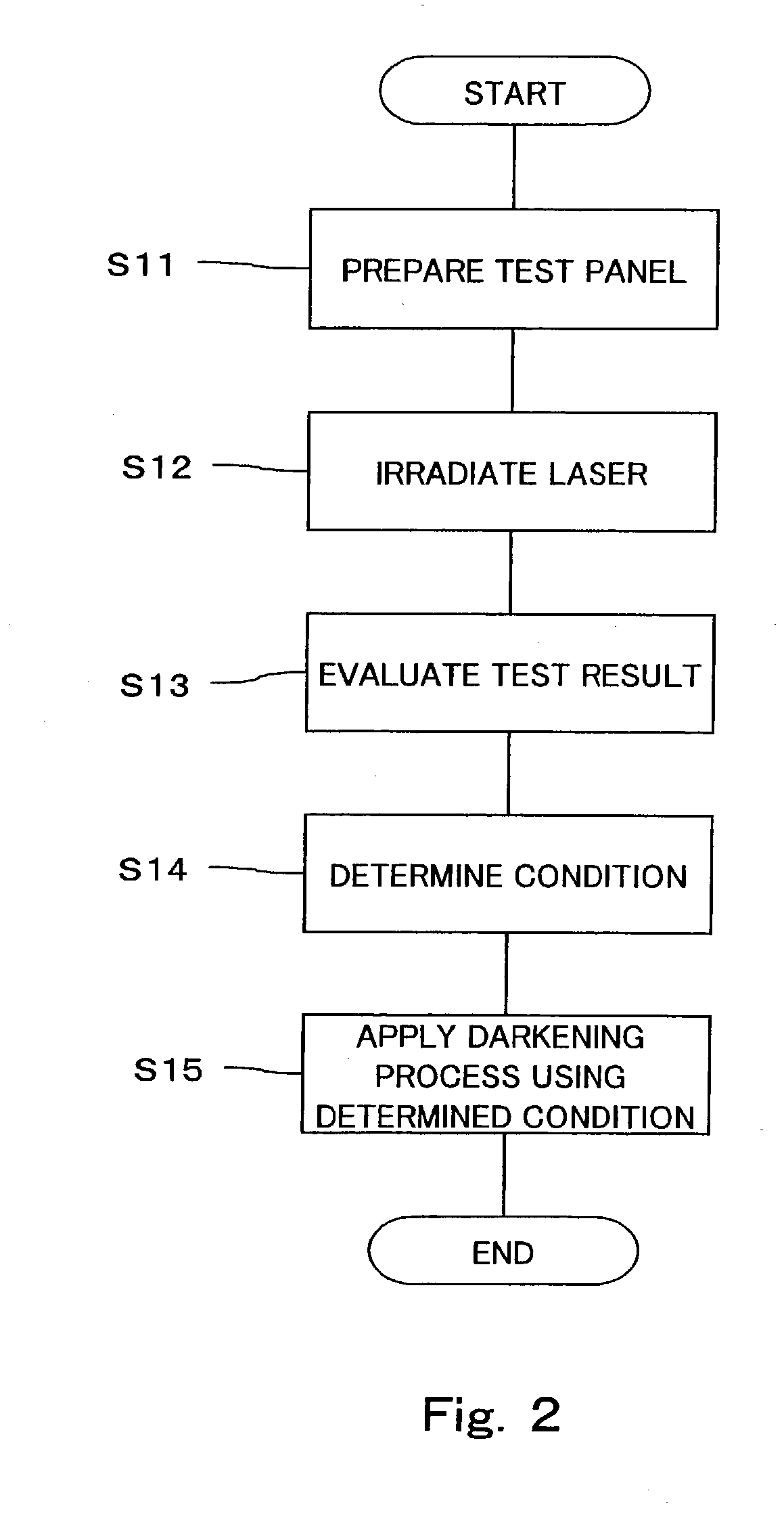

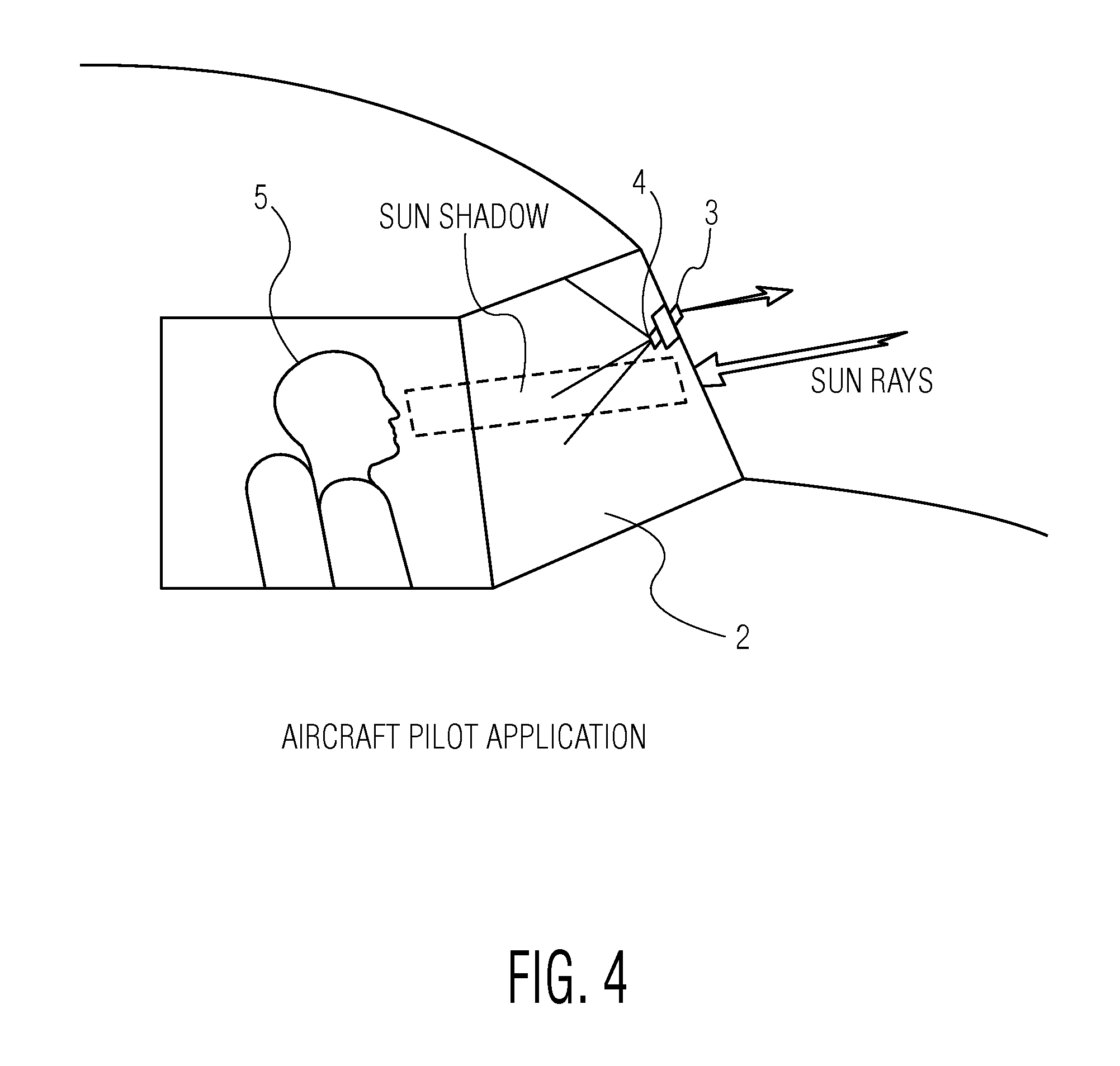

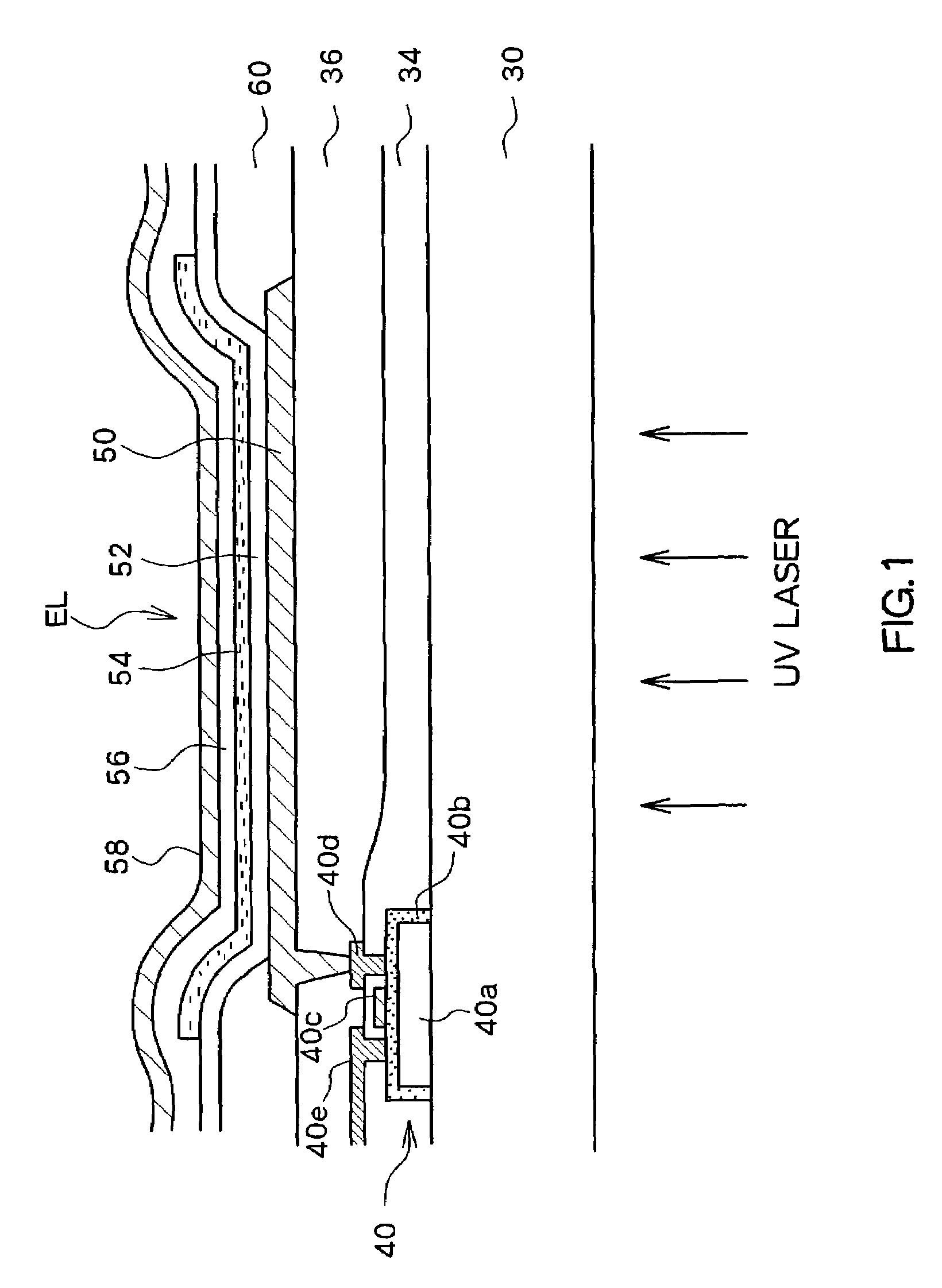

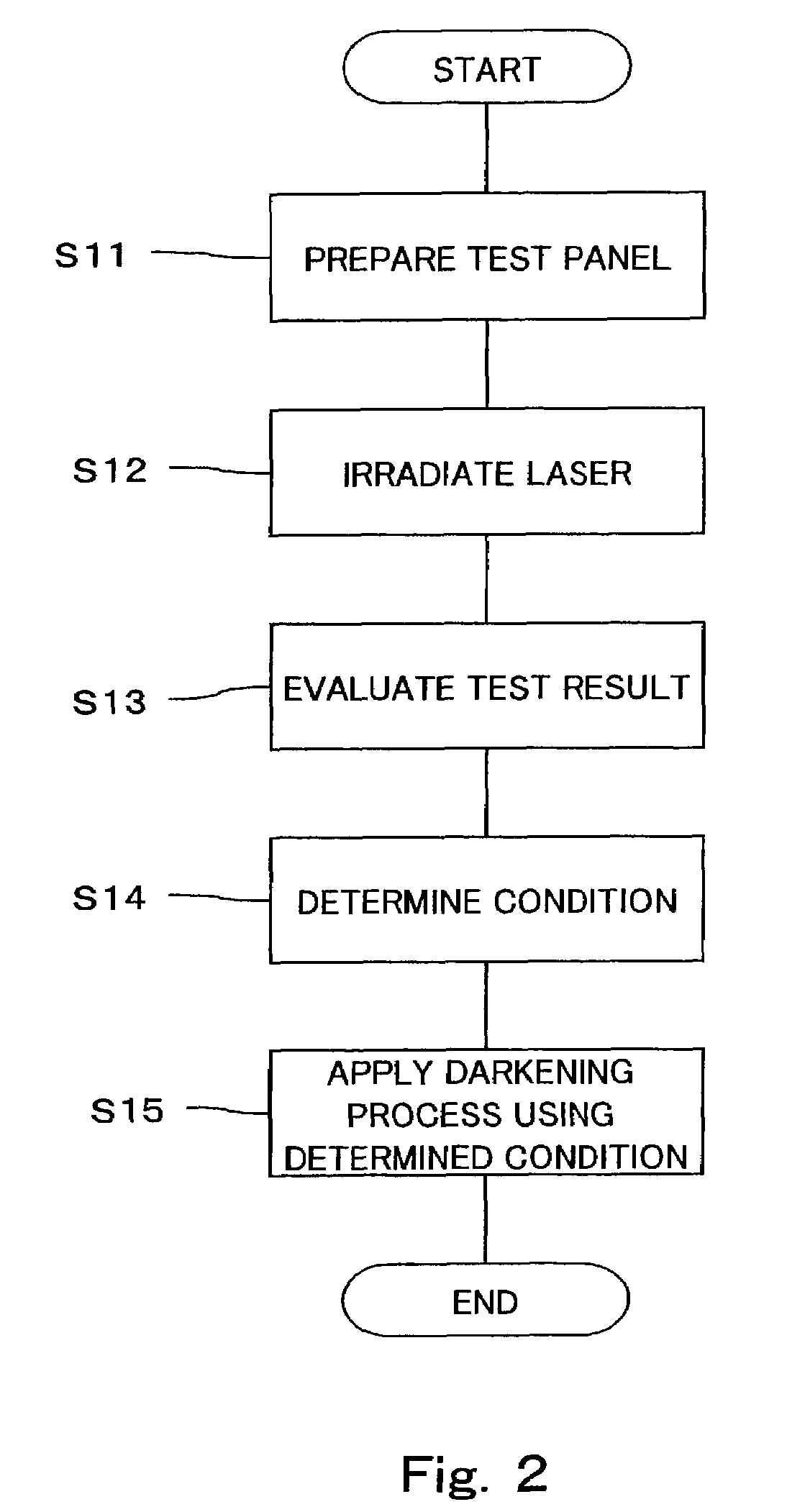

Light attenuation in defective pixel in organic EL panel

ActiveUS20030222861A1Increase in the resistance of the organic layersElectroluminescent light sourcesSolid-state devicesOrganic layerLaser light

An organic EL element of one pixel is selectively irradiated with laser light. With the laser irradiation, the functionality of the organic layer of the organic EL element is selectively degraded and the light emission capability is removed without damaging the cathode.

Owner:SANYO ELECTRIC CO LTD

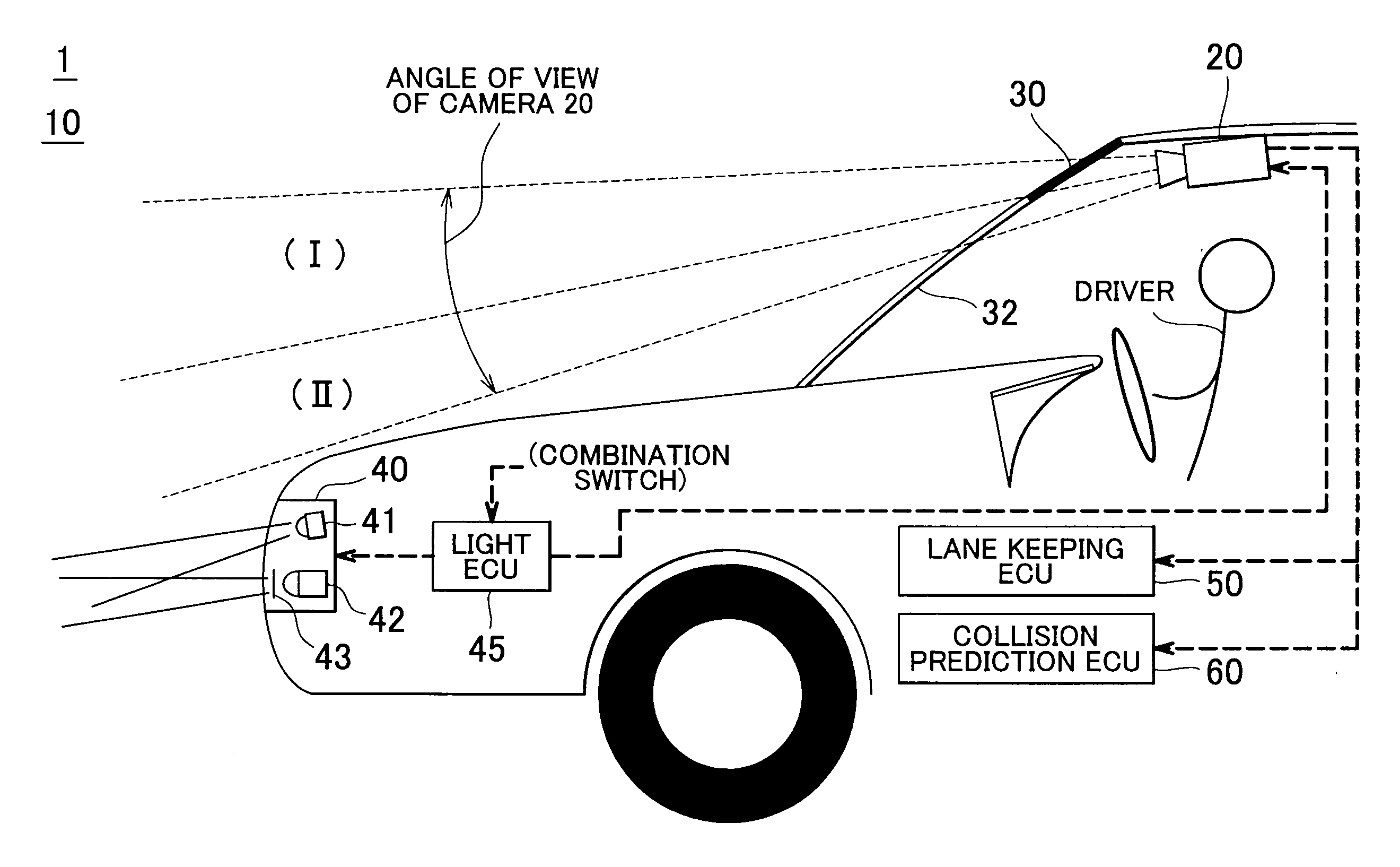

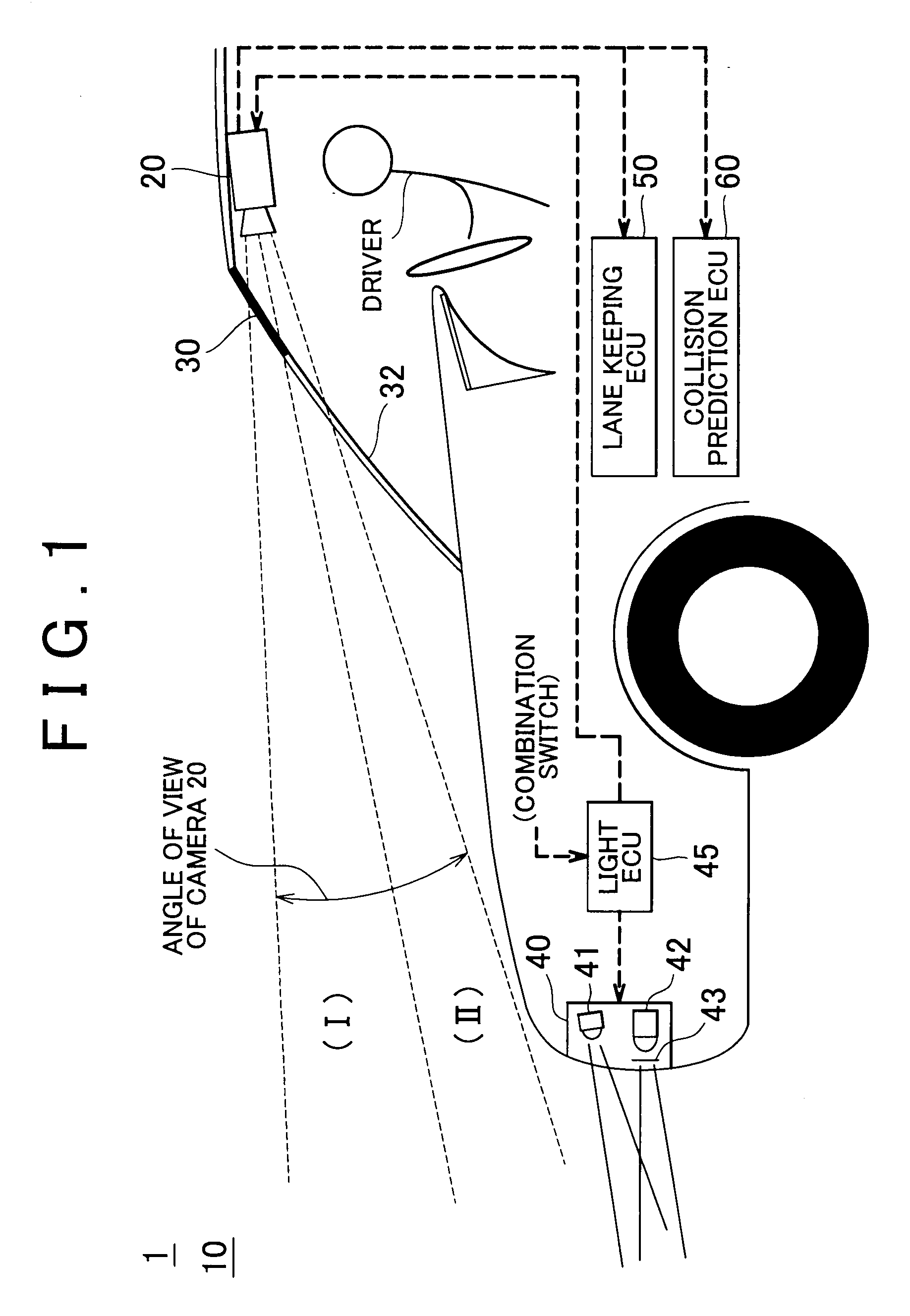

Vehicle imaging system and vehicle control apparatus

A vehicle imaging system includes an imaging device that images at least a part of an area around a vehicle; and a visible light attenuation device that attenuates part of visible light that enters the imaging device. The imaging device includes an imaging element that converts both of the infrared light and an infrared ray to electric signals. The imaging device outputs both of image data produced based on the electric signal to which the visible light, which has entered the imaging device without passing through the visible light attenuation device, has been converted, and image data produced based on the electric signal to which the infrared ray, which has passed through the visible light attenuation device, has been converted.

Owner:TOYOTA JIDOSHA KK

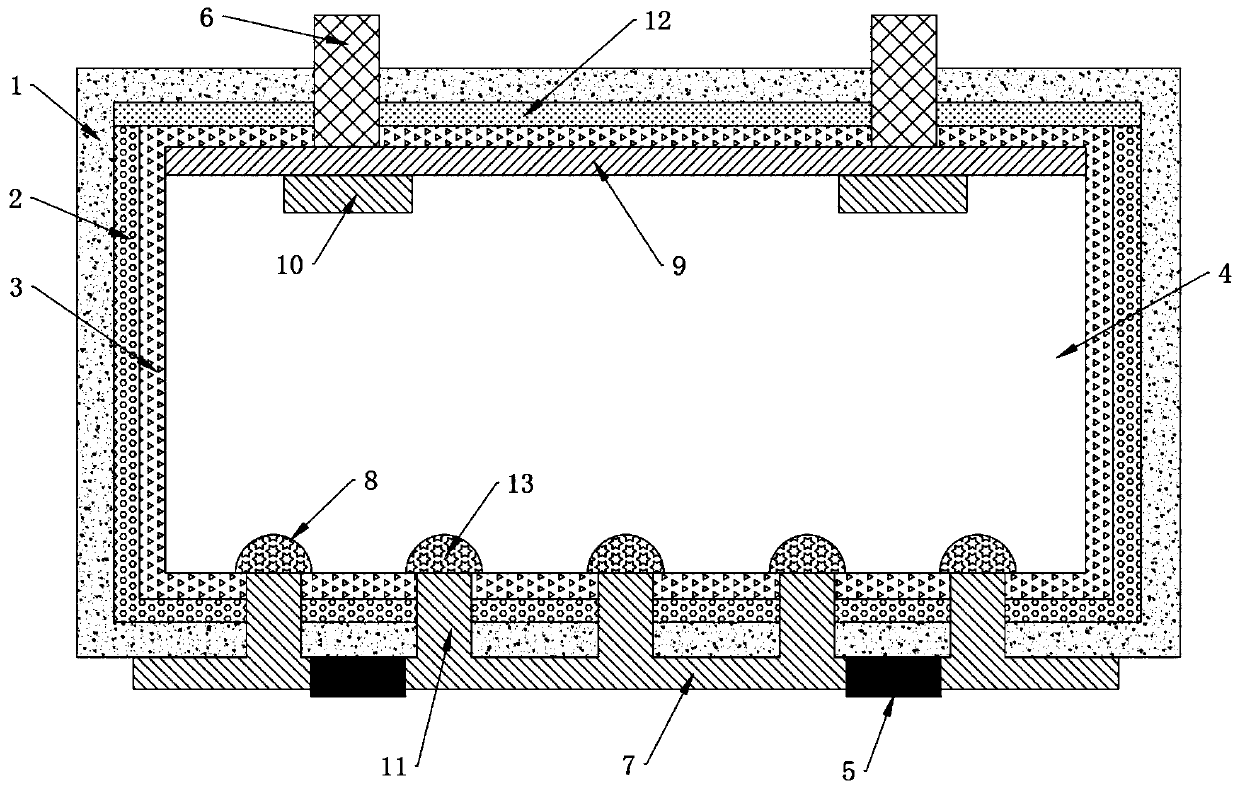

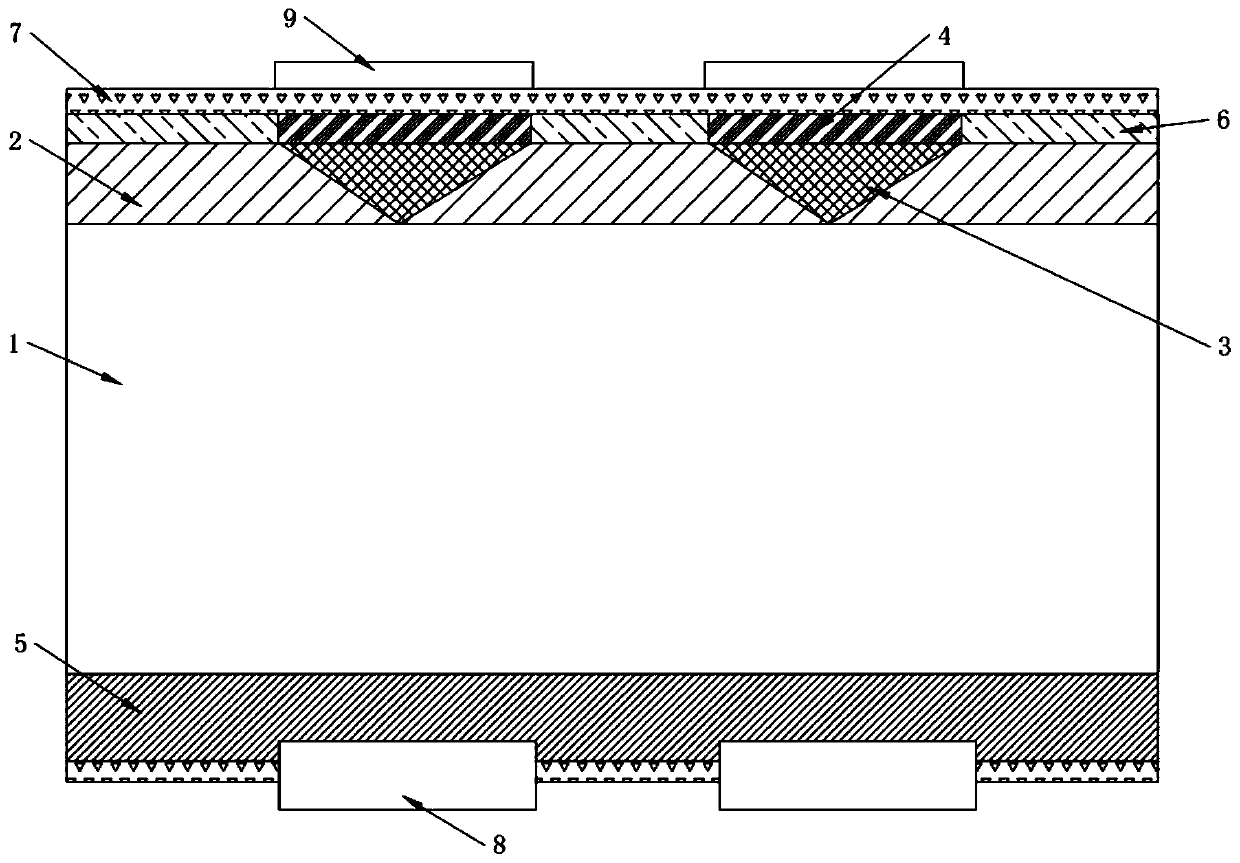

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

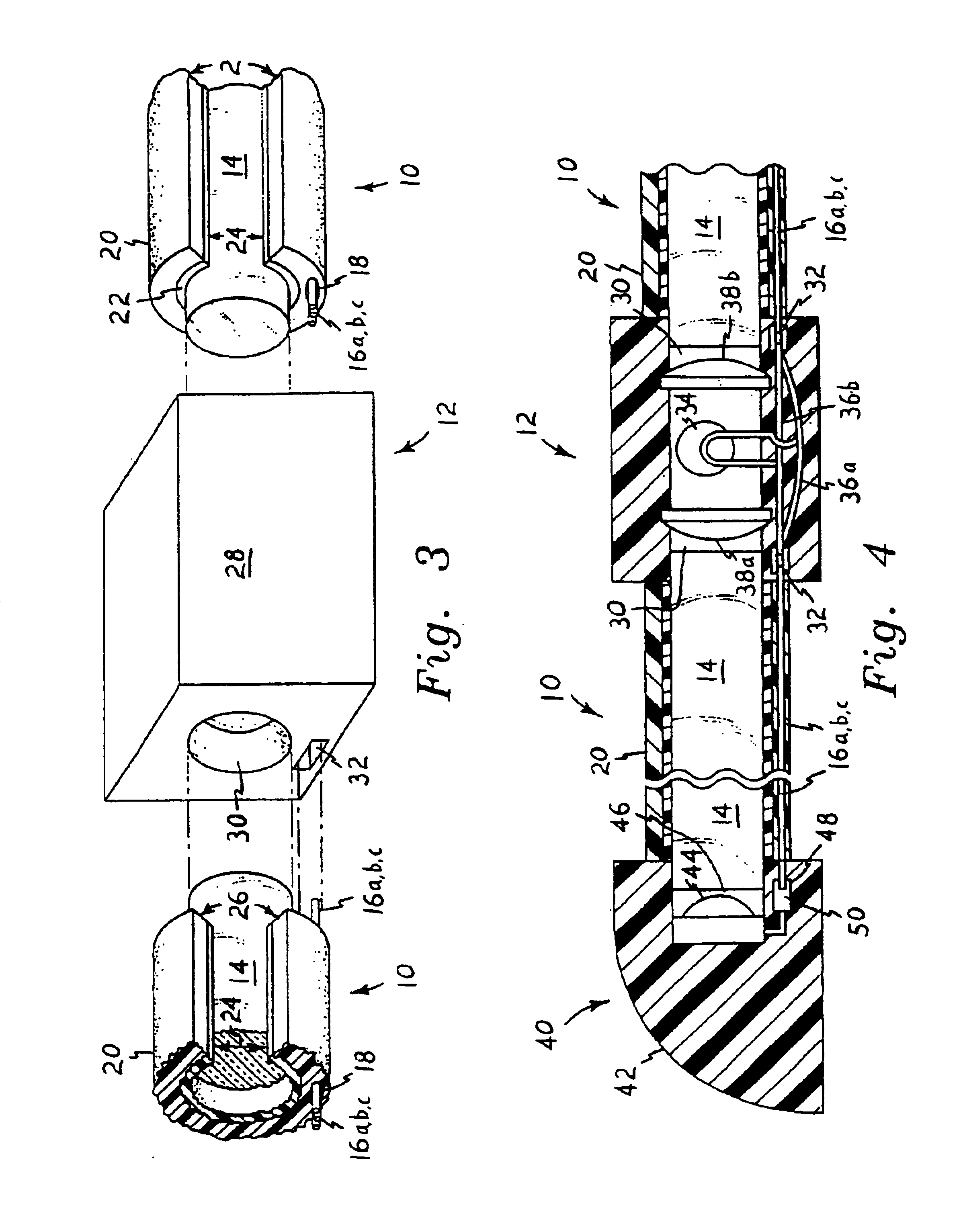

Compound optical and electrical conductors, and connectors therefor

A compound optical and electrical conductor includes a fiberoptic light transmitting element (multiple fibers or single solid rod) with at least one solar cell with LED therewith. The electrical conductor or conductors may be imbedded or otherwise secured within the optically conducting element or its surrounding jacket or sheath, or may be contained in a separate elongate retainer which may be provided to hold the optically conducting element in place as desired. The conductors may include a jacket or retainer which is optically open along one side thereof, allowing the optical conductor to emit light laterally therefrom subtending an angle defined by the optical gap in the jacket or retainer. One or more compound connectors may be provided, for linking two or more such compound conductors together as desired. The connectors provide for both the concentric alignment of the optical conductors, and also the electrical connection of the electrical conductors of the compound devices. The connectors preferably each include one or more lighting elements (halogen, high output LED, etc.) to compensate for light attenuation along the lengths of the attached optical conductors. The electrically conducting elements of the compound conductors provide electrical power to the lighting elements enclosed within the connectors, to provide an increase in light power at points along the length of an assembly. Different colors of lights may be provided, with the electrical conductors providing for the selective illumination of each as desired.

Owner:PLASTICS INVENTIONS & PATENTS INC

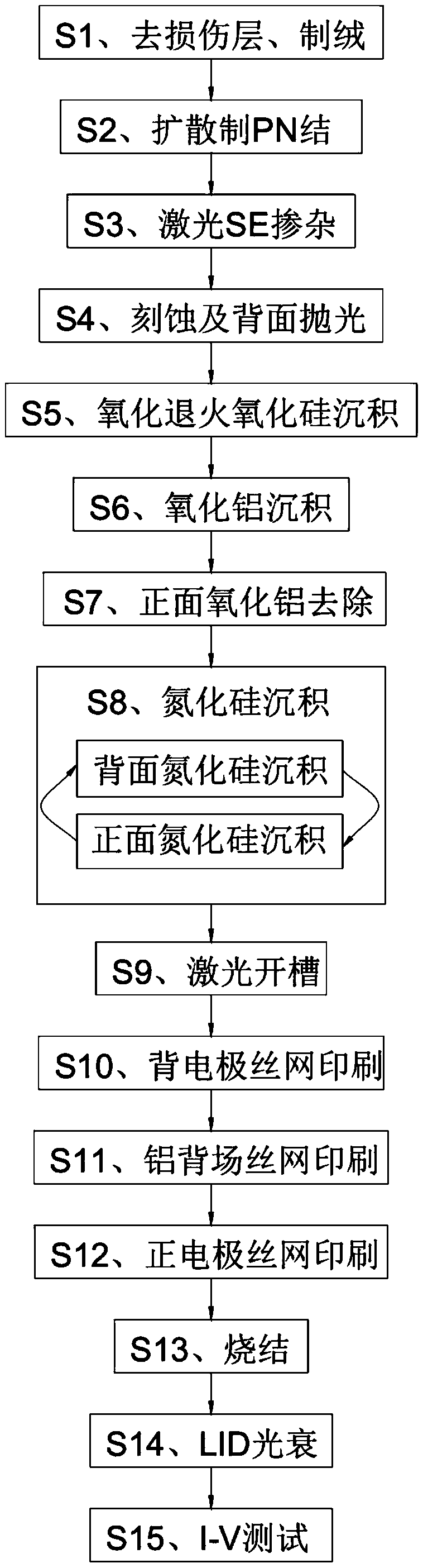

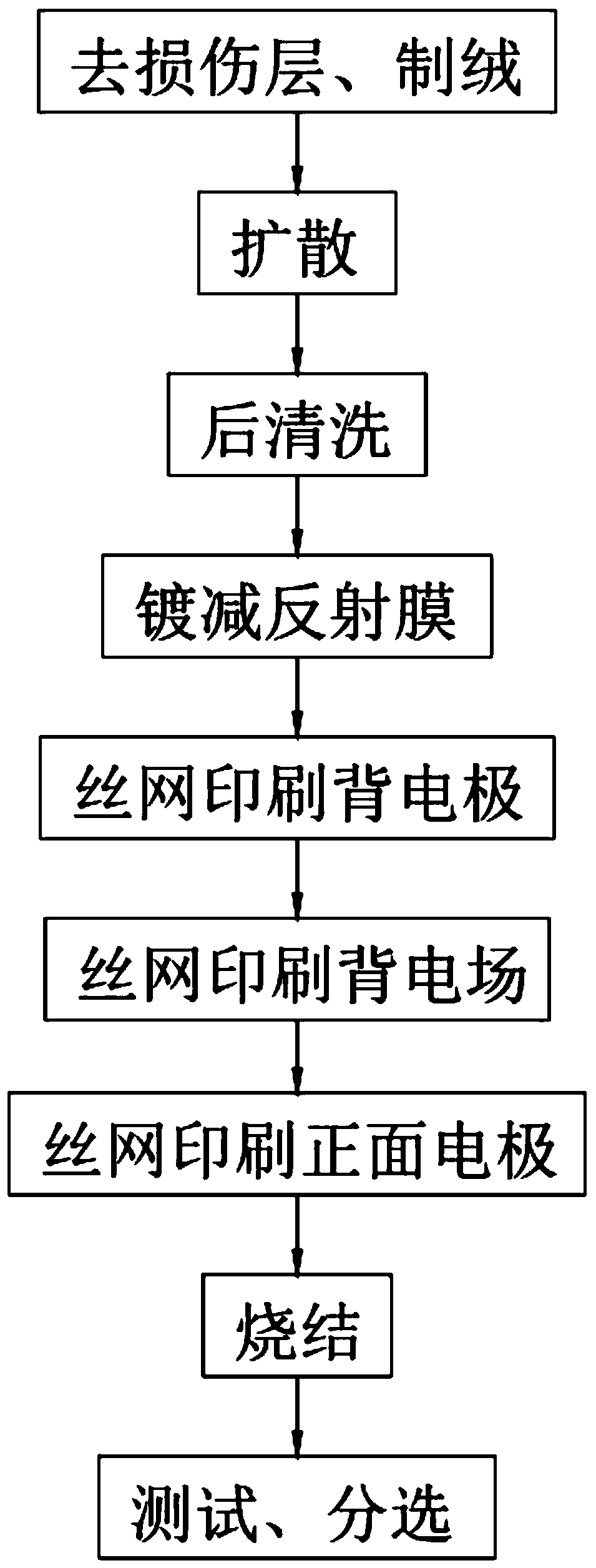

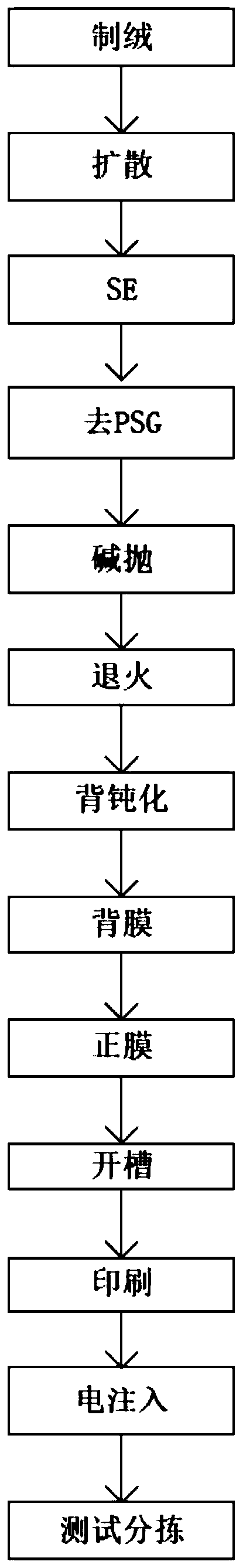

Alkali-polishing efficient PERC battery and preparation process thereof

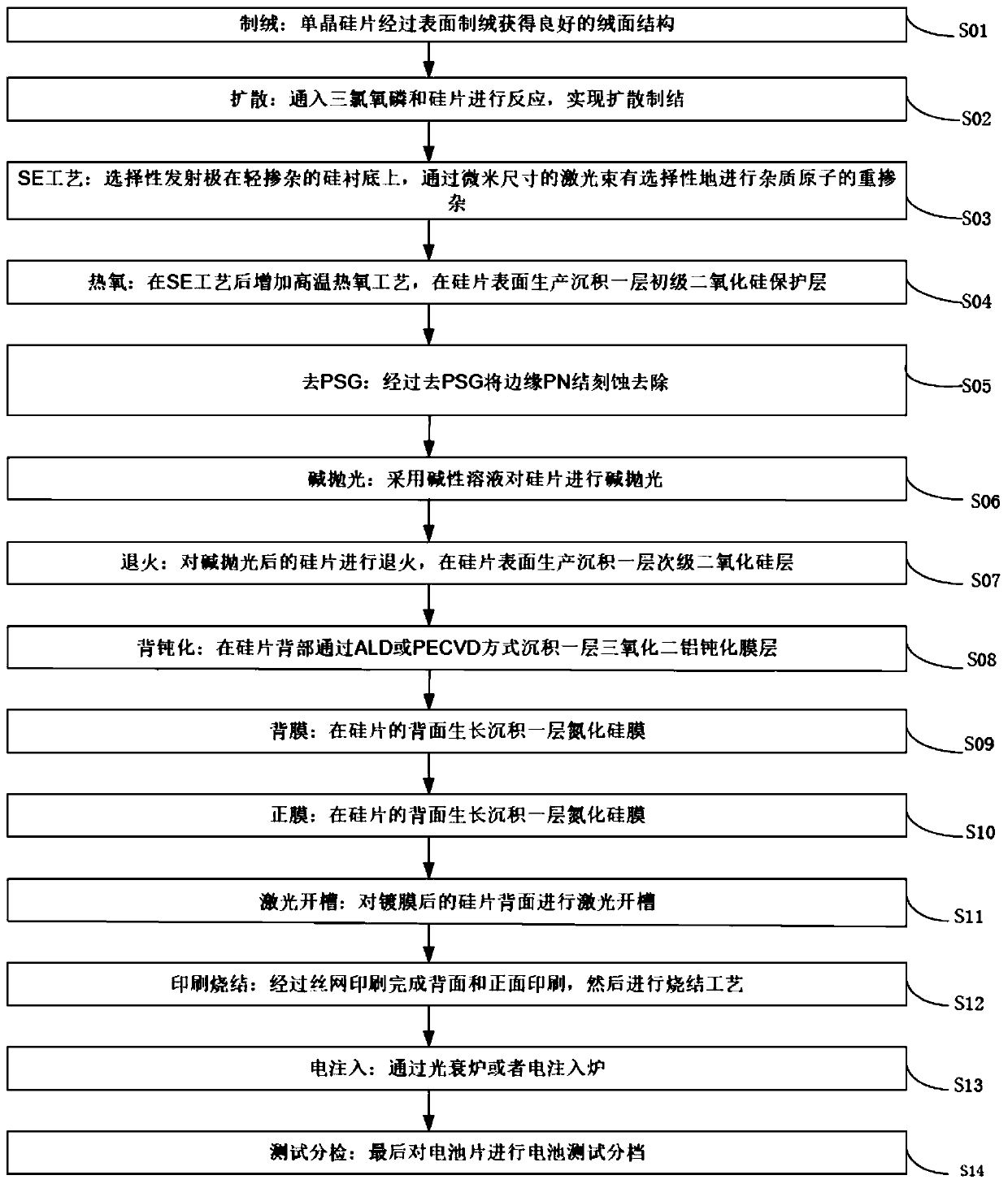

ActiveCN109888061AReduce usageEnvironmental protectionFinal product manufacturePhotovoltaic energy generationScreen printingSilicon dioxide

The invention discloses a preparation process of an alkali-polishing efficient PERC battery. The preparation process comprises the following steps: step S01, texturing; step S02, diffusing; step S03,SE process; step S04, thermal oxidation; step S05, removing PSG; step S06, alkali-polishing; step S07, annealing; step S08, back passivating; step S09, back film; step S10, front film; step S11, laserslotting; and step S12, printing and sintering: accomplishing the back printing and the back printing through silk-screen printing, and then performing sintering process; step S13, electric injection: electric injection: through a light attenuation furnace or an electric injection furnace; and step S14, testing and sorting: performing battery testing and sorting on the cell. The invention furtherdiscloses an alkali-polishing efficient PERC battery. By adding the high-temperature thermal oxidation process flow after the SE, a layer of silicon dioxide protection layer is grown at the front SEregion at high temperature, a pyramid textured surface of the SE region is effectively protected, and the process flow can guarantee that the stable and continuous production of the SE alkali-polishedPERC battery.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

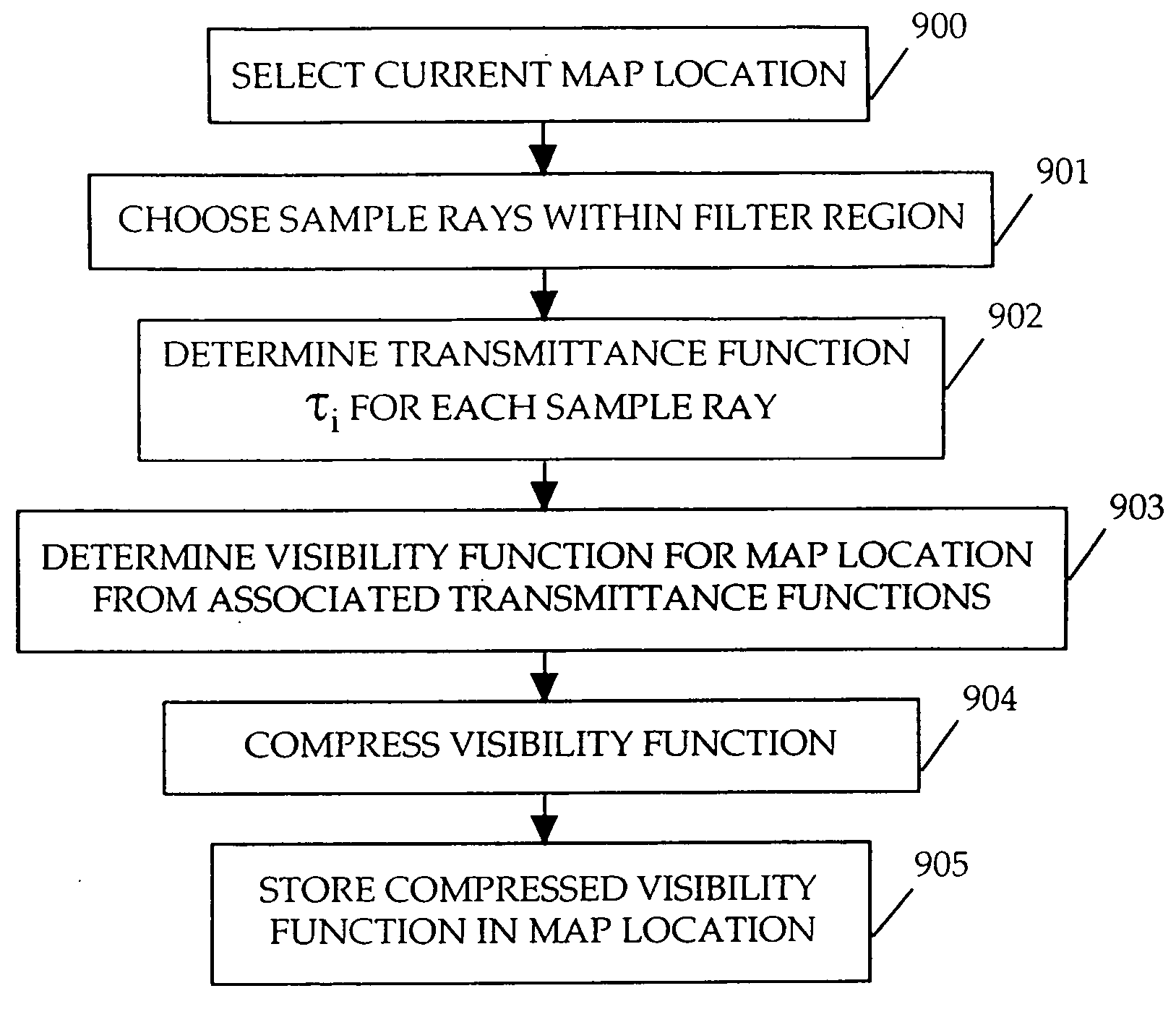

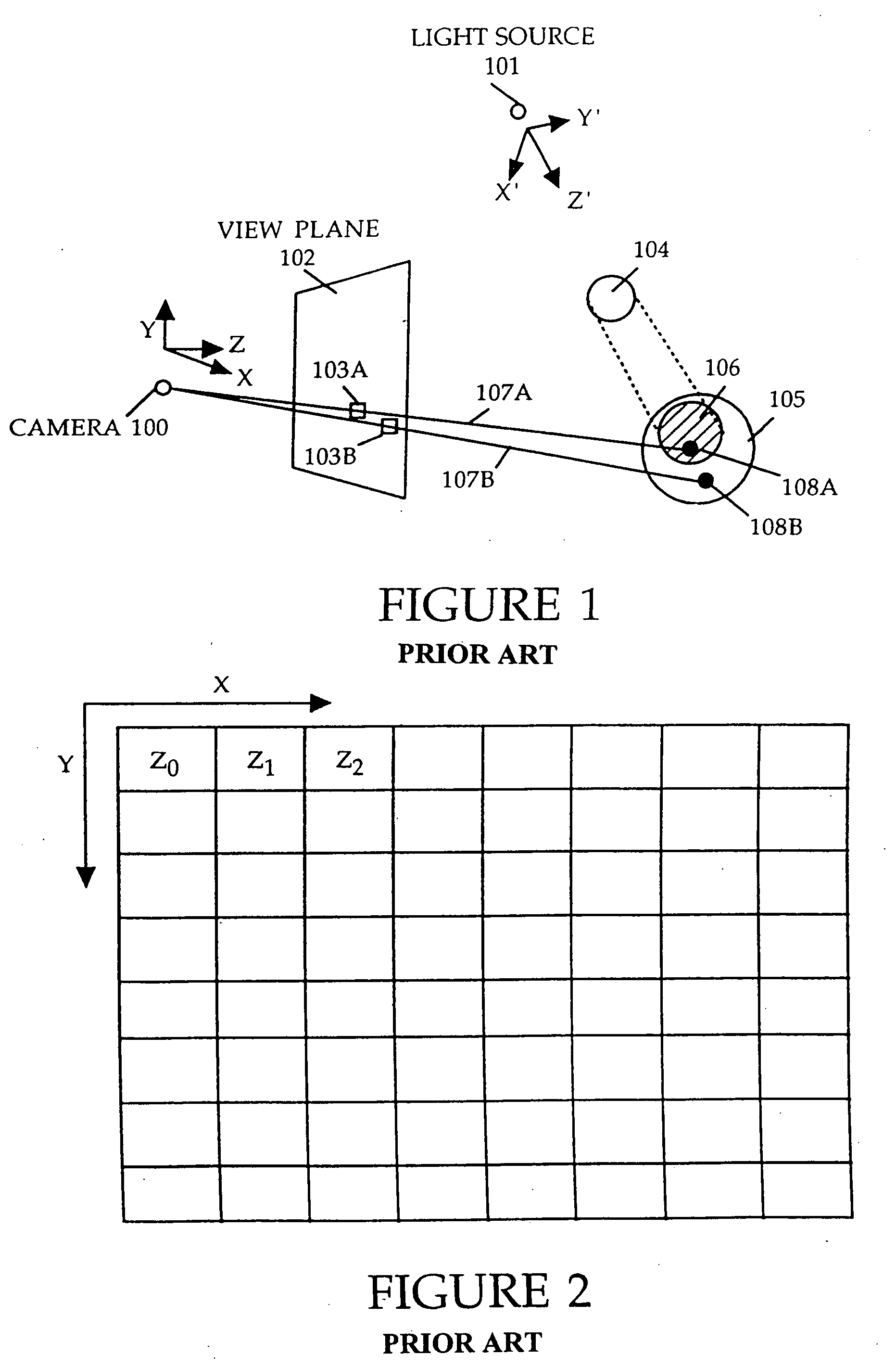

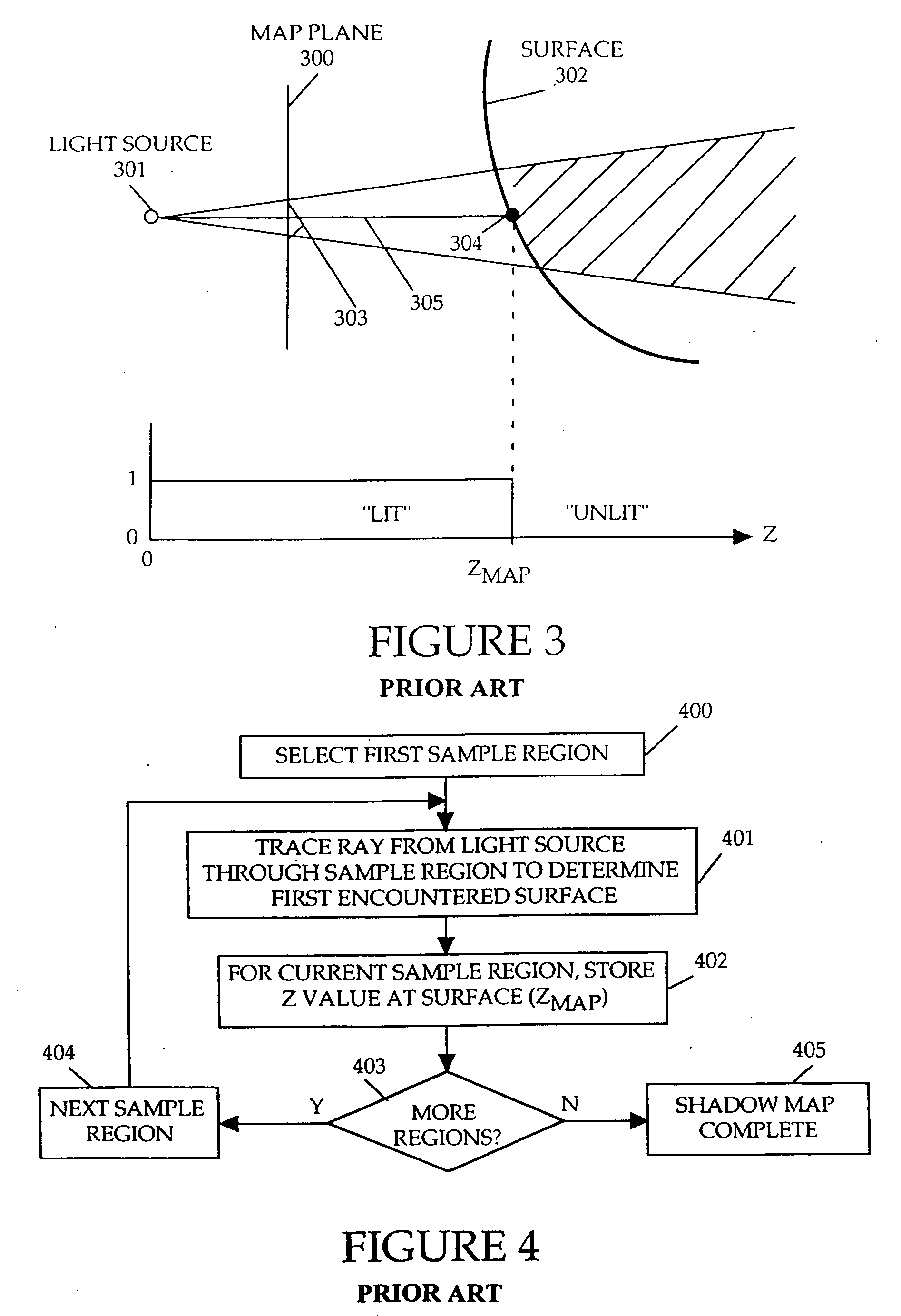

Method and apparatus for rendering shadows

InactiveUS20060119600A1Efficiently determinedAccurate modelingCathode-ray tube indicators3D-image renderingComputer graphics (images)Transmittance

A method and apparatus for rendering shadows. A pre-rendering process implements a two dimensional array or map of depth-based functions, such as a visibility function in z. During rendering of an object scene, these functions are accessed via lookup operations to efficiently determine the function value for a sample point at a given depth. The use of visibility functions allows for partial light attenuation effects. Each visibility function is computed by filtering multiple transmittance functions obtained by casting sample rays from a light source onto an object scene. The visibility function is implemented as a sequence of vertices. Colored shadows are modeled by vertices comprising a depth value and separate visibility function values for red, green, and blue light at a given depth value. Compression is achieved by minimizing the number of vertices needed to represent a visibility function within a desired error tolerance.

Owner:PIXAR ANIMATION

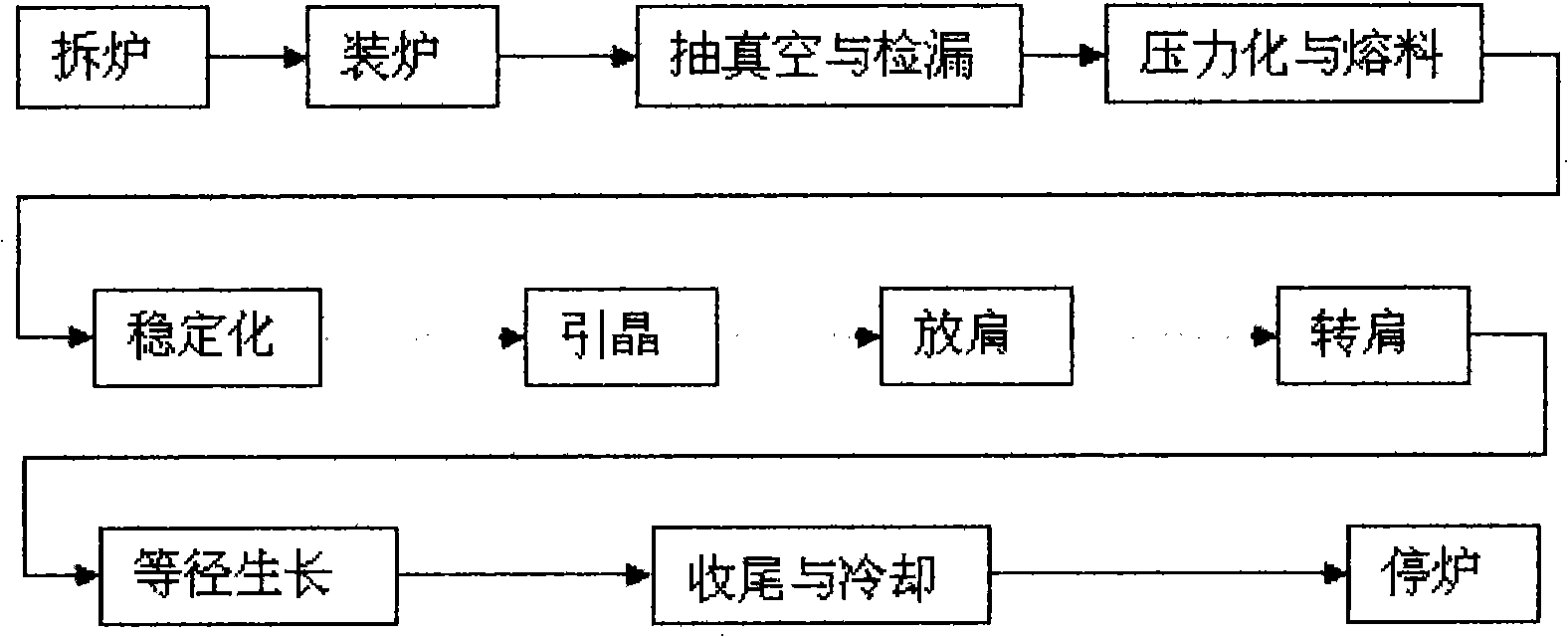

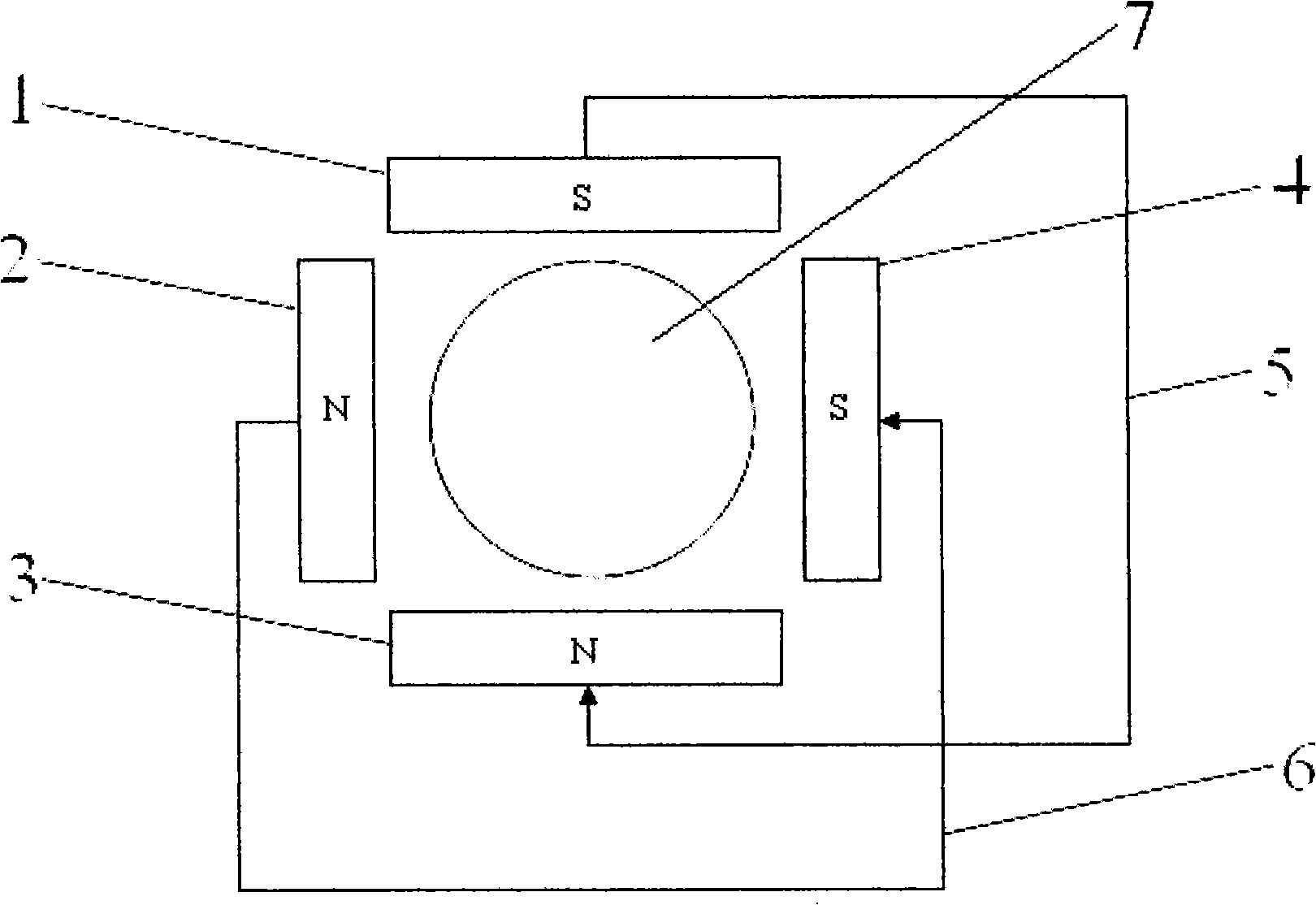

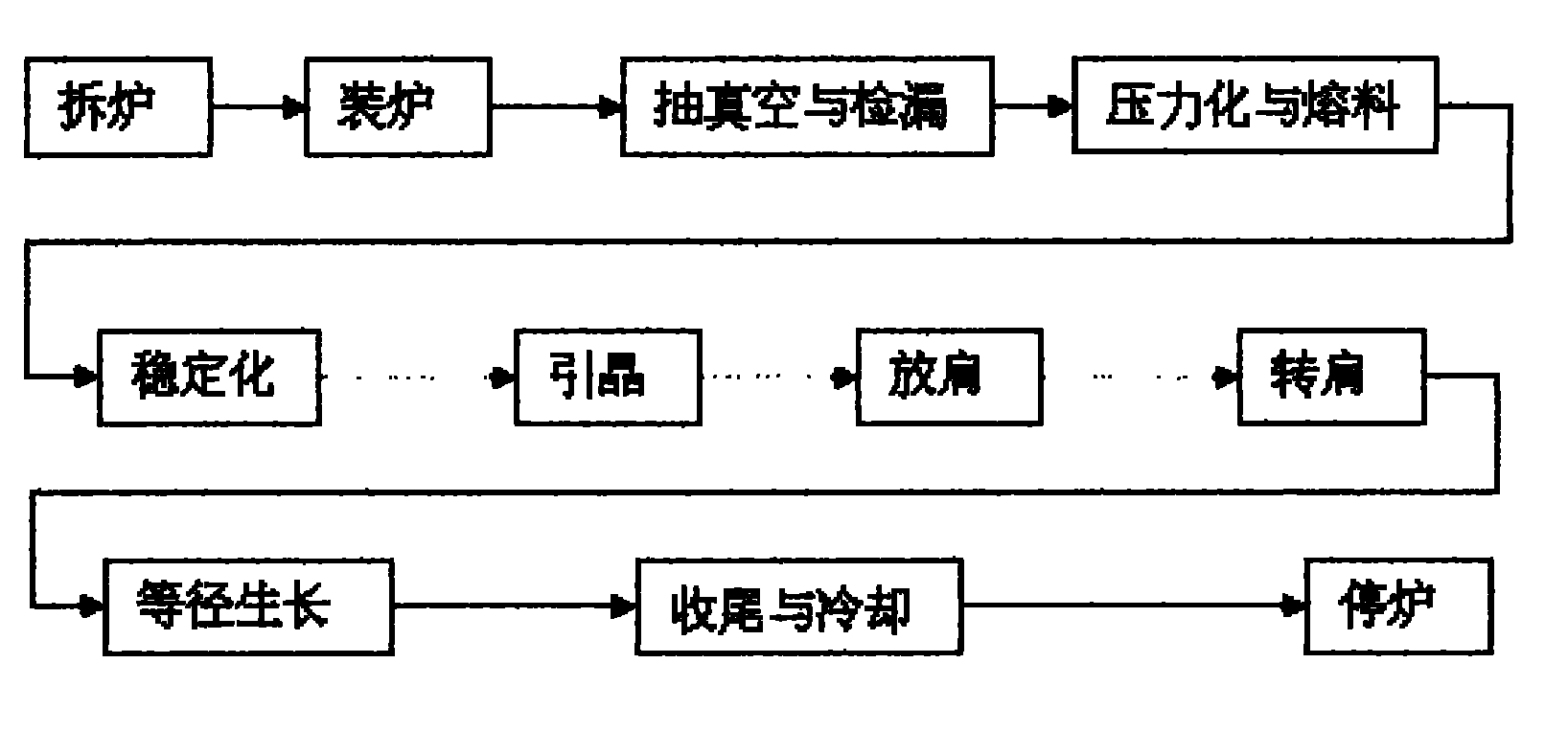

Gallium and indium doped single crystal silicon material for solar battery and preparation method thereof

ActiveCN101805925AReduce precipitationReduce crystal defectsPolycrystalline material growthBy pulling from meltIndiumHearth

The invention discloses a gallium and indium doped single crystal silicon material for a solar battery, which consists of the following components according to atom number per cubic centimeter of the single crystal silicon material: 1.0X10<14> to 1.0X10<18> gallium, 5.0X10<12> to 5.0x10<16> indium and the balance of single crystal silicon. The invention also discloses a method for preparing the gallium and indium doped single crystal silicon material for the solar battery, which is implemented by the following steps of: dismantling a furnace by using a regular method, cleaning a hearth and assembling the furnace; vacuumizing the inside of a single crystal furnace and detecting the leakage of the single crystal furnace by using a regular method; pressuring materials and smelting the materials; stabilizing the melt; seeding crystals; performing shouldering; performing shoulder rotation; performing isodiametric growth; performing ending and cooling the obtained product; and stopping the furnace. The gallium and indium doped single crystal silicon material for the solar battery has the advantages of high conversion efficiency, low light attenuation, low oxide content in the single crystal silicon and uniform radial distribution in a single crystal silicon rod; and the preparation method of the invention effectively controls the thermal conversion of silicon melt and grows the high-quality gallium and indium doped single crystal silicon material for the solar battery.

Owner:LONGI GREEN ENERGY TECH CO LTD

Window Having A Selective Light Modulation System

An electrochromic vehicular window system having a multiplicity of individually electrically switchable electrochromic elements, a vehicle operator face (eye) sensor to determine the position of the face of the operator in the vehicle, a sensor of the source external light entering the vehicle and impinging on the operators eyes and a system processor utilizing data from the sensors to determine and control which portions of the electrochromergic window to activate (or deactivate) so as to automatically reduce or eliminate glare on the eyes of the operator while still allowing essentially normal light transmission through other sections of the window. The system can also include a control switch for manual operation and or limiting the degree of light attenuation.

Owner:DEWELL DOUGLAS A

Light attenuation in defective pixel in organic EL panel

InactiveUS7234984B2Increase in the resistance of the organic layersDischarge tube luminescnet screensStatic indicating devicesOrganic layerLaser light

An organic EL element of one pixel is selectively irradiated with laser light. With the laser irradiation, the functionality of the organic layer of the organic EL element is selectively degraded and the light emission capability is removed without damaging the cathode.

Owner:SANYO ELECTRIC CO LTD

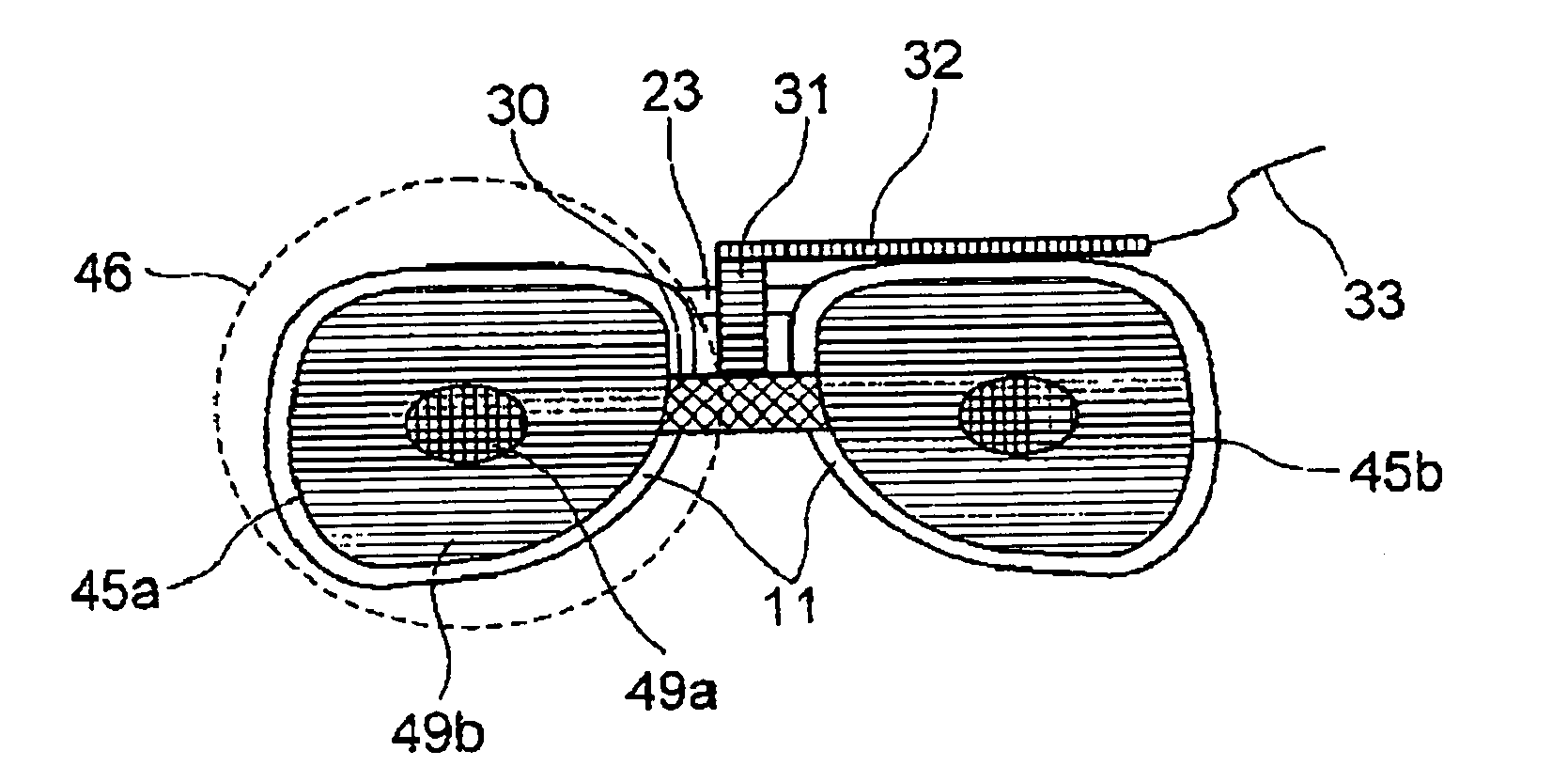

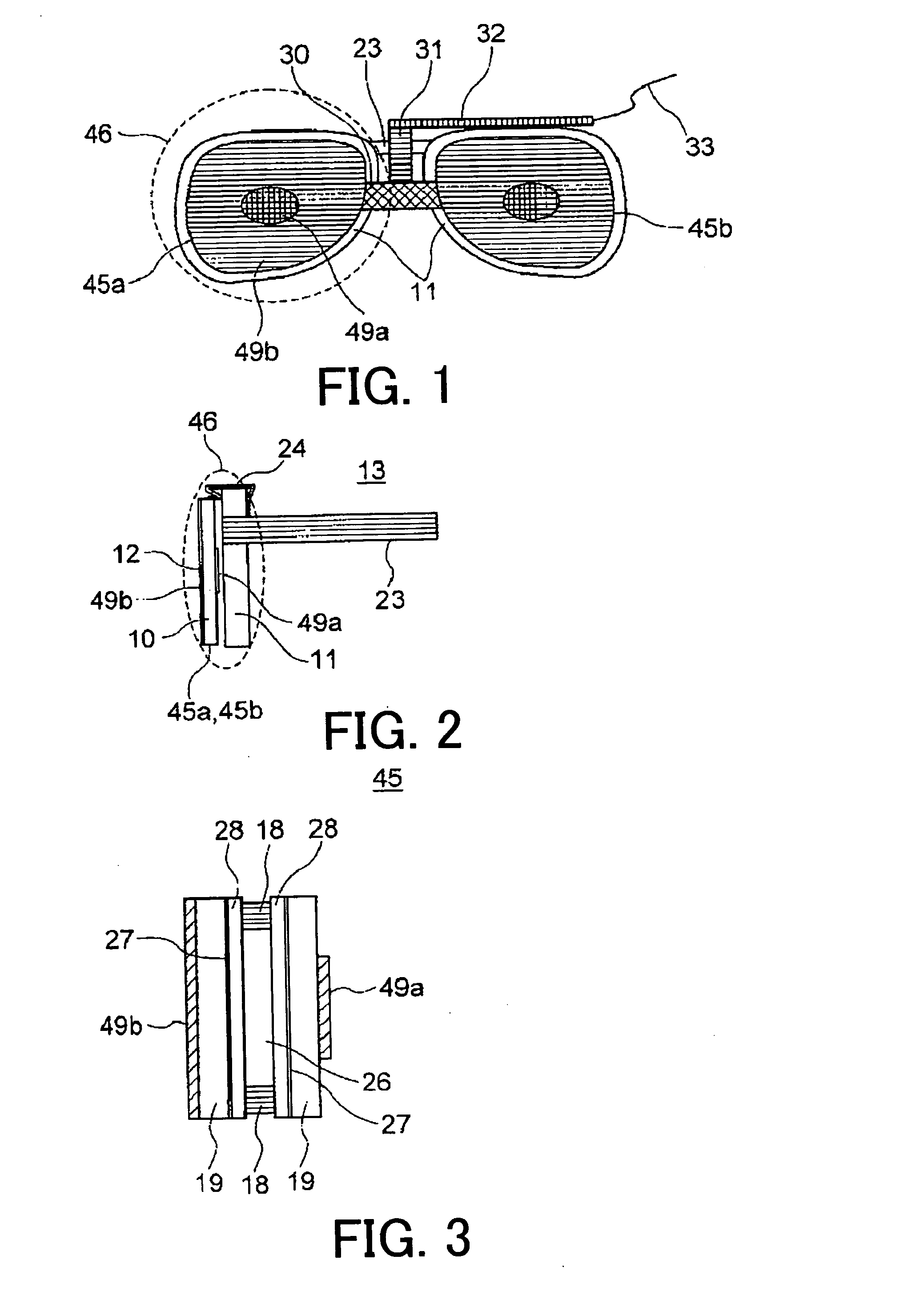

Liquid crystal shutter glasses

ActiveUS20100201897A1Reduce flickerPrevent peekingPolarising elementsSteroscopic systemsLiquid crystalLight attenuation

A liquid crystal shutter glasses comprises a liquid crystal shutter placed within the view angle of the observer of a display apparatus wherein the liquid crystal shutter has an effective shutter region in which the transmission or shielding of incident light is controllable and a light attenuation region positioned outside the effective shutter region for attenuating incident light.

Owner:NEC CORP

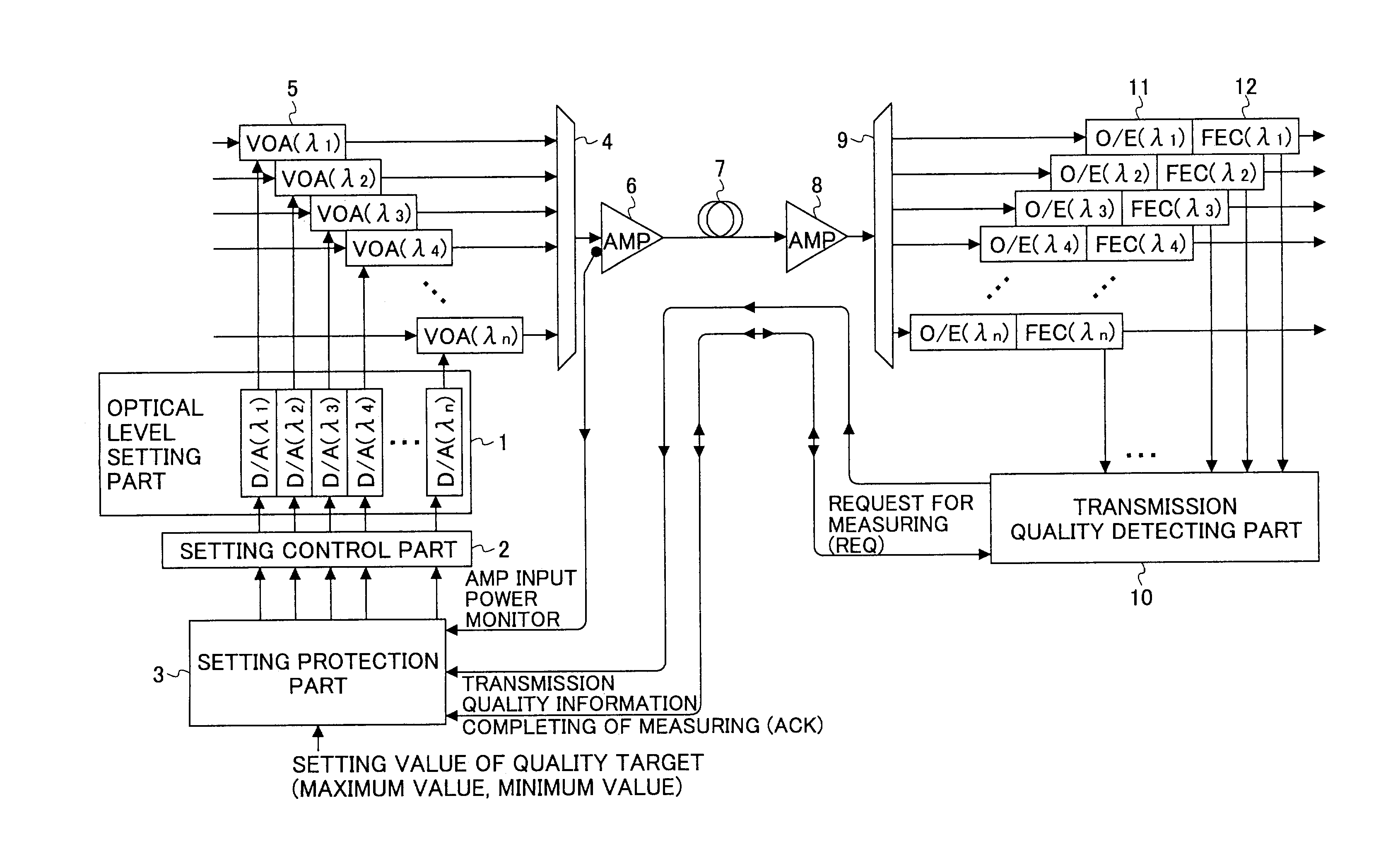

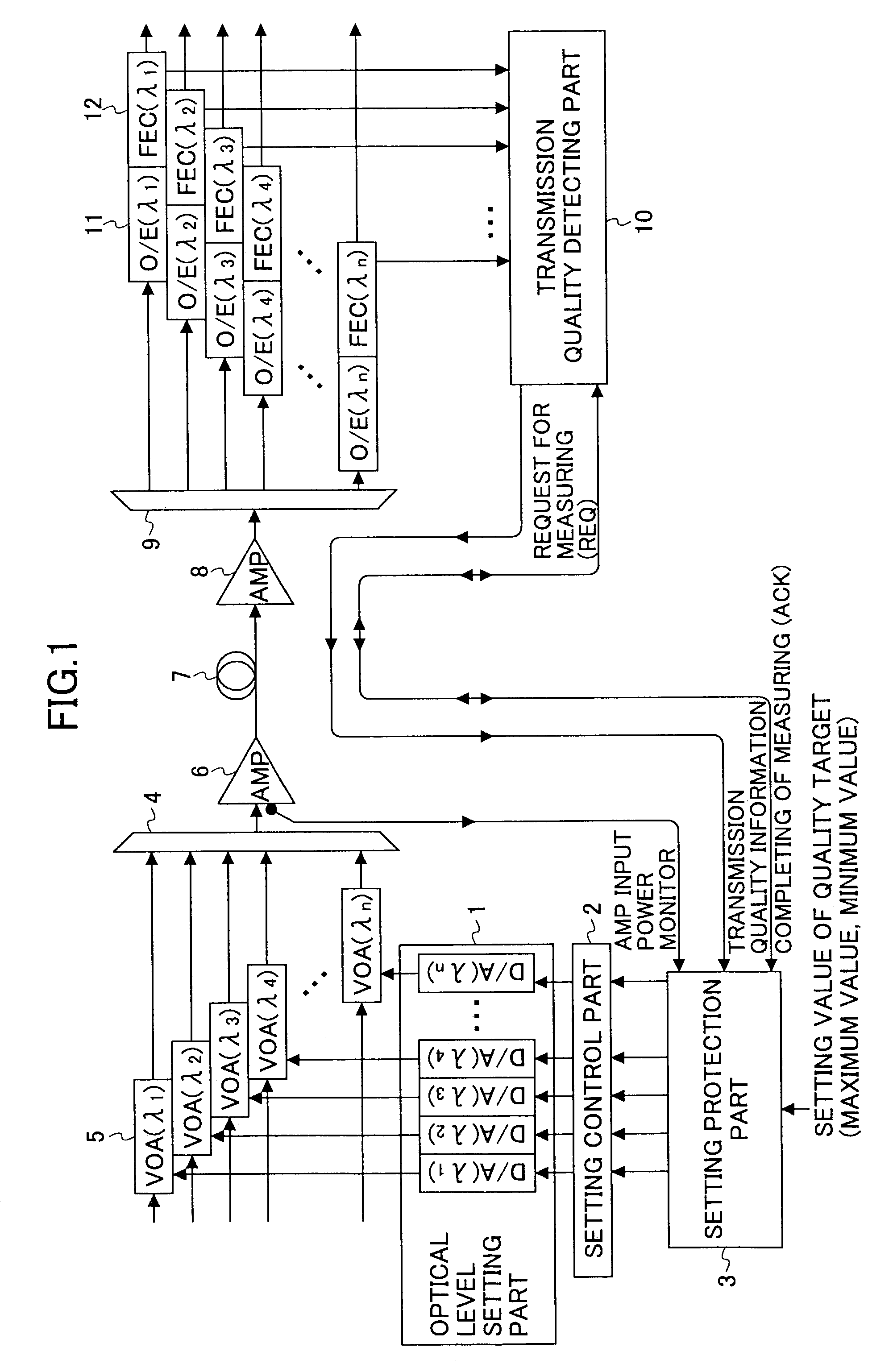

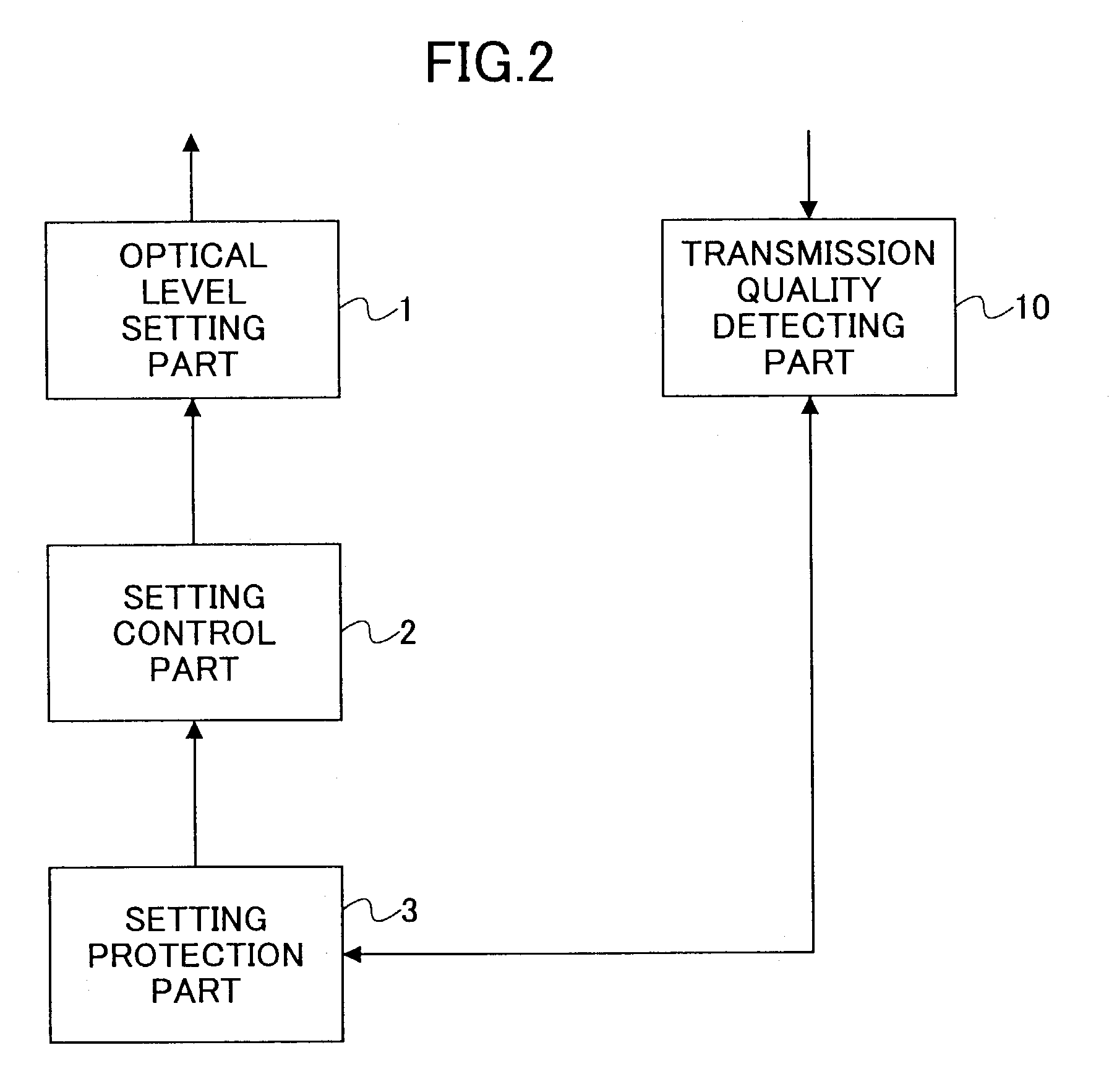

Optical multiplex communication system, optical transmission apparatus, and control method of optical multiplex communication

InactiveUS7092638B2Eliminate the problemStable communicationWavelength-division multiplex systemsTransmission monitoringUltrasound attenuationEngineering

An optical multiplex communication system includes a transmission part and a receiving part, wherein the transmission part includes a transmission quality detecting part which measures and transmits a transmission quality information for the channels based on a request from the transmission part; the receiving part includes a variable optical attenuation part controls the optical signal level for the channels, an optical level setting part controls the variable optical attenuation part based on a setting value, a setting control part adding the setting value to the optical level setting part based on a request for setting.

Owner:FUJITSU LTD

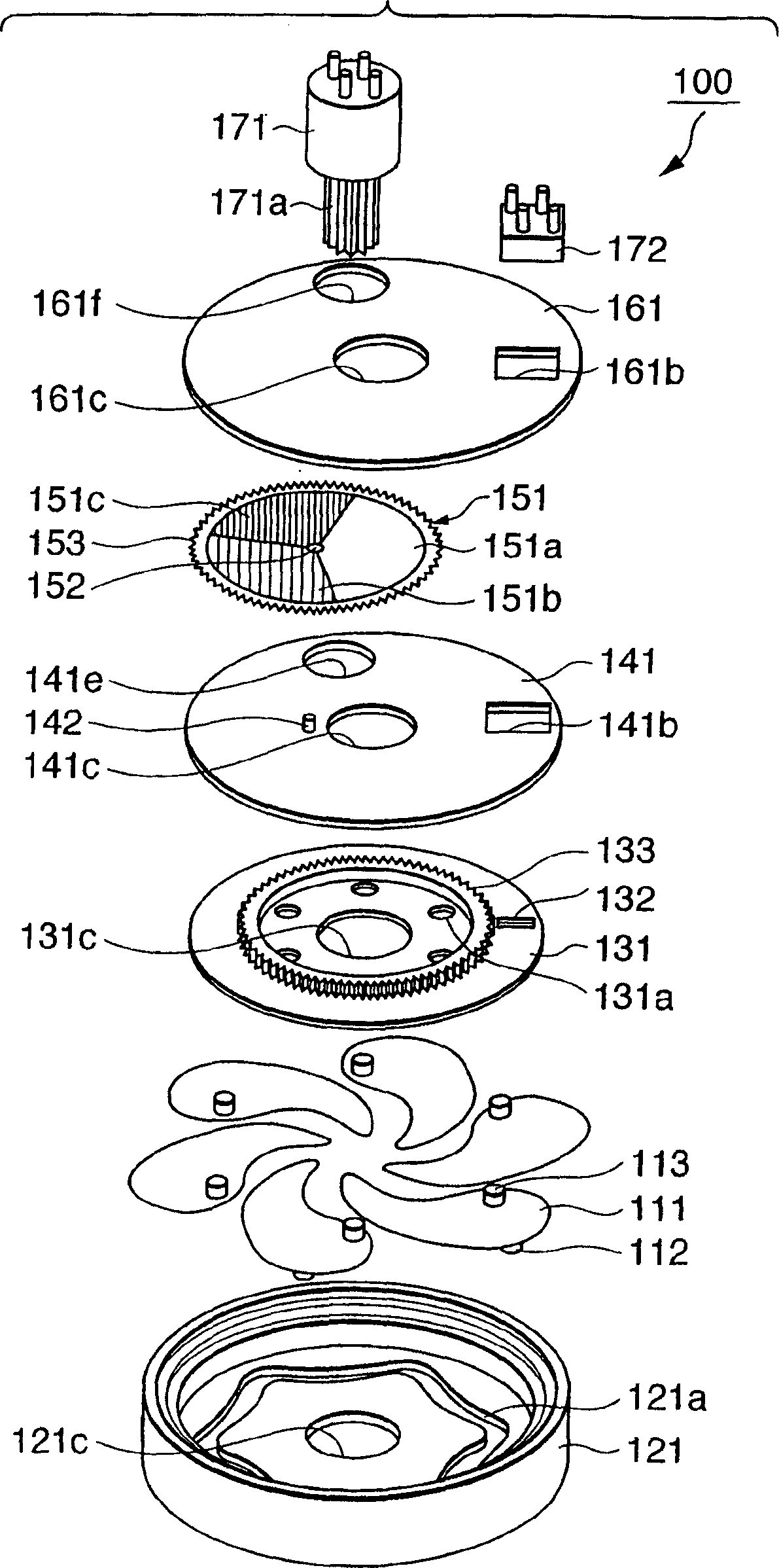

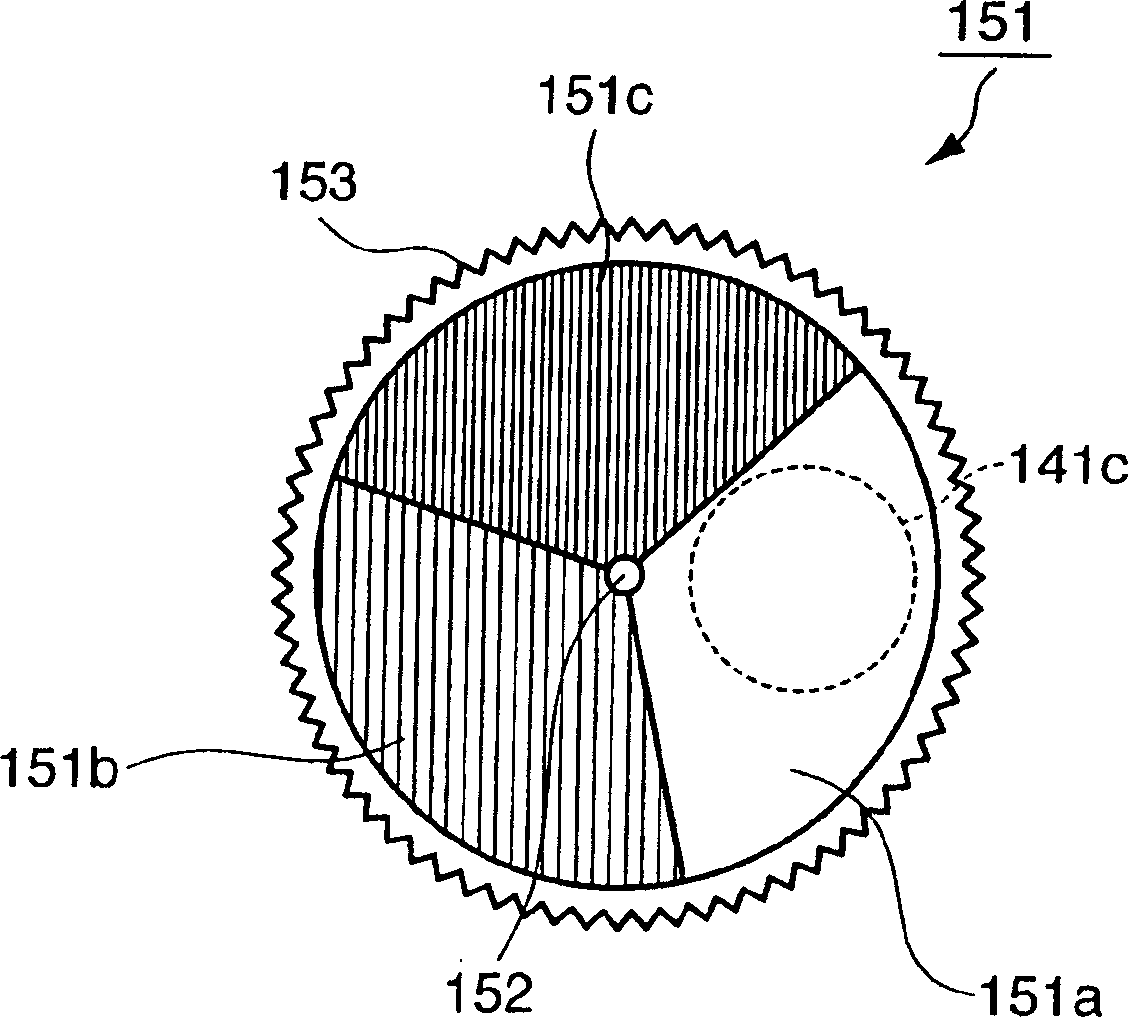

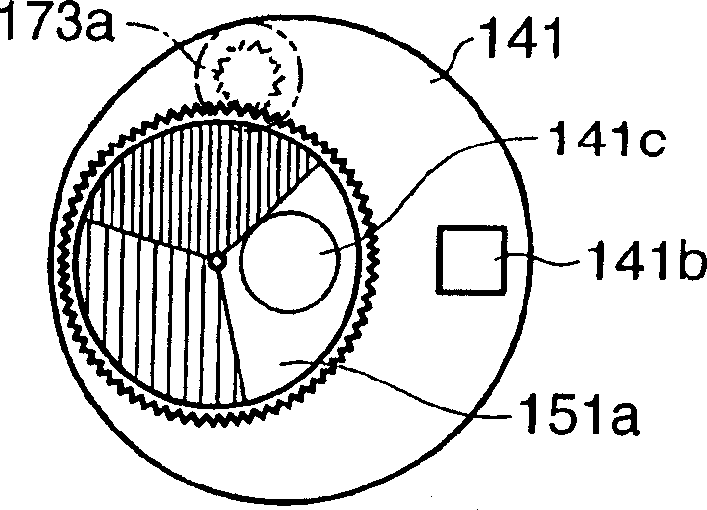

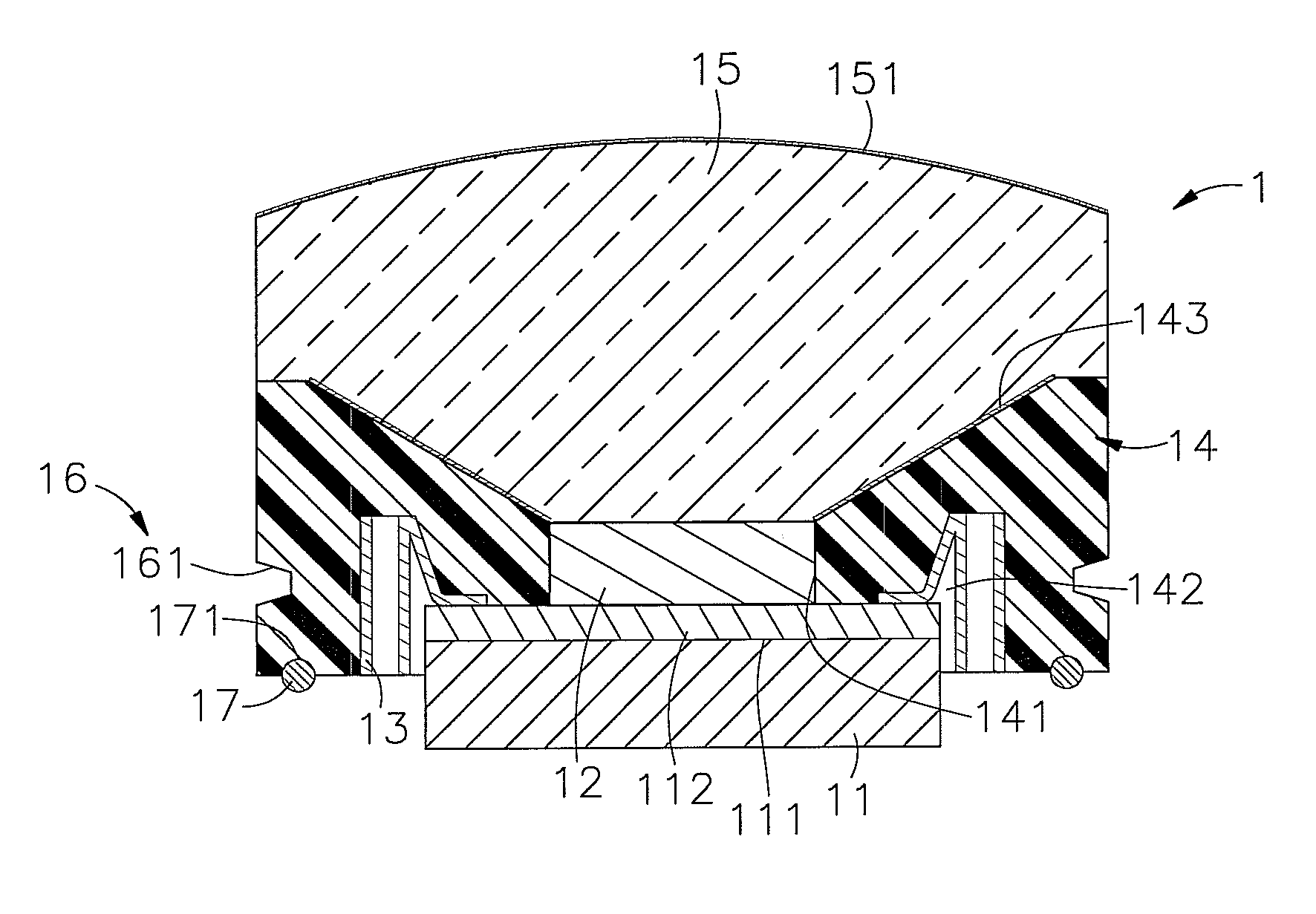

Light amount control apparatus photographing apparatus, and filter

InactiveCN1542533ALarge degree of freedom in adjusting the amount of lightHigh quality imageTelevision system detailsOptical filtersTransmittanceActuator

It is an object of this invention to independently control the F-number and the number of light attenuation steps of a multi-density ND filter by using a light amount control apparatus using an iris stop and the ND filter. The iris stop mechanism made up of a plurality of aperture blades and the ND filter having a multi-density pattern are stacked in a single unit. This simultaneously realizes continuous control of the F-number, multi-step control of the light attenuation ratio of the ND filter, a substantially circular stop aperture, and a uniform transmittance distribution in the stop aperture. In the first embodiment, the driving region of an actuator is divided into an ND control region and aperture control region. This makes it possible to independently control the F-number and the number of ND steps by the single actuator.

Owner:CANON KK

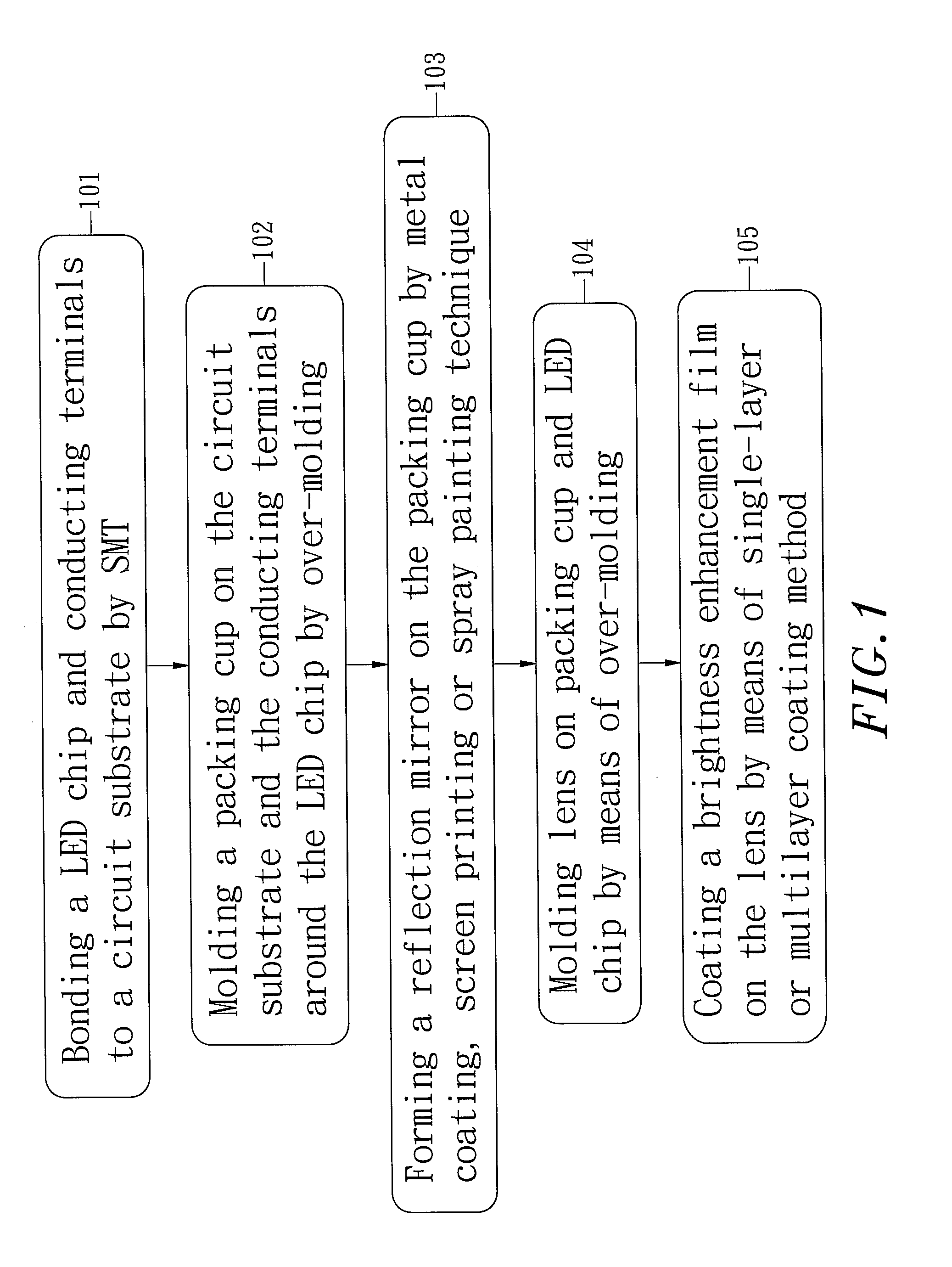

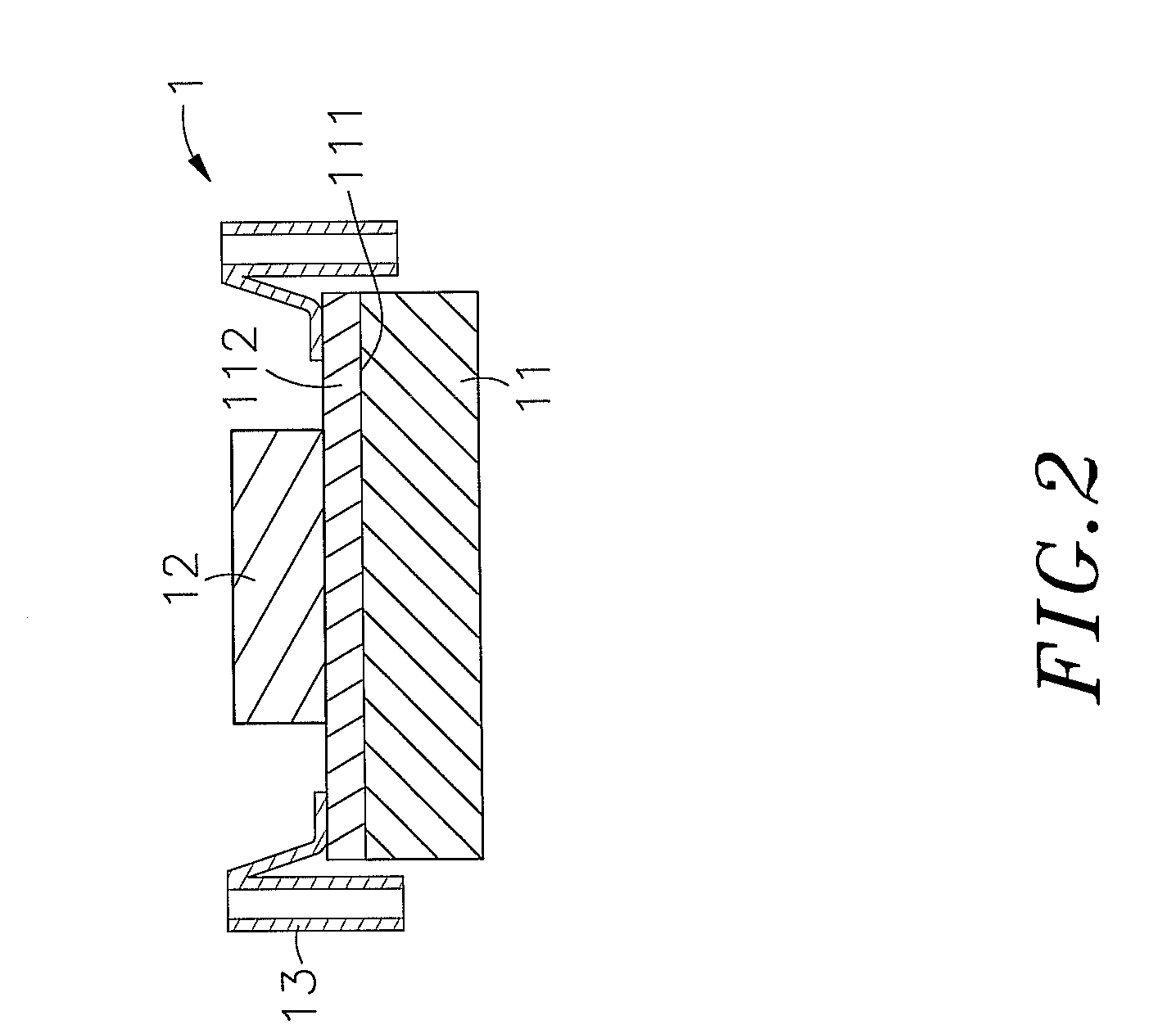

LED module fabrication method

InactiveUS20100311193A1Eliminates deflection and total reflection and light attenuationAssures uniform distributionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBrightness perception

A method of fabricating a LED module by: bonding one or multiple LED chips and multiple conducting terminals to a circuit substrate, and then molding a packing cup on the circuit substrate over by over molding for enabling the LED chip(s) and the conducting terminals to be exposed to the outside of the packing cup, and then molding a lens on the packing cup and the LED chip(s) by over-molding. By means of directly molding the lens on the packing cup and the LED chip(s), no any gap is left in the lens, avoiding deflection, total reflection or light attenuation and enhancing luminous brightness and assuring uniform distribution of output light.

Owner:KWO GER METAL TECH

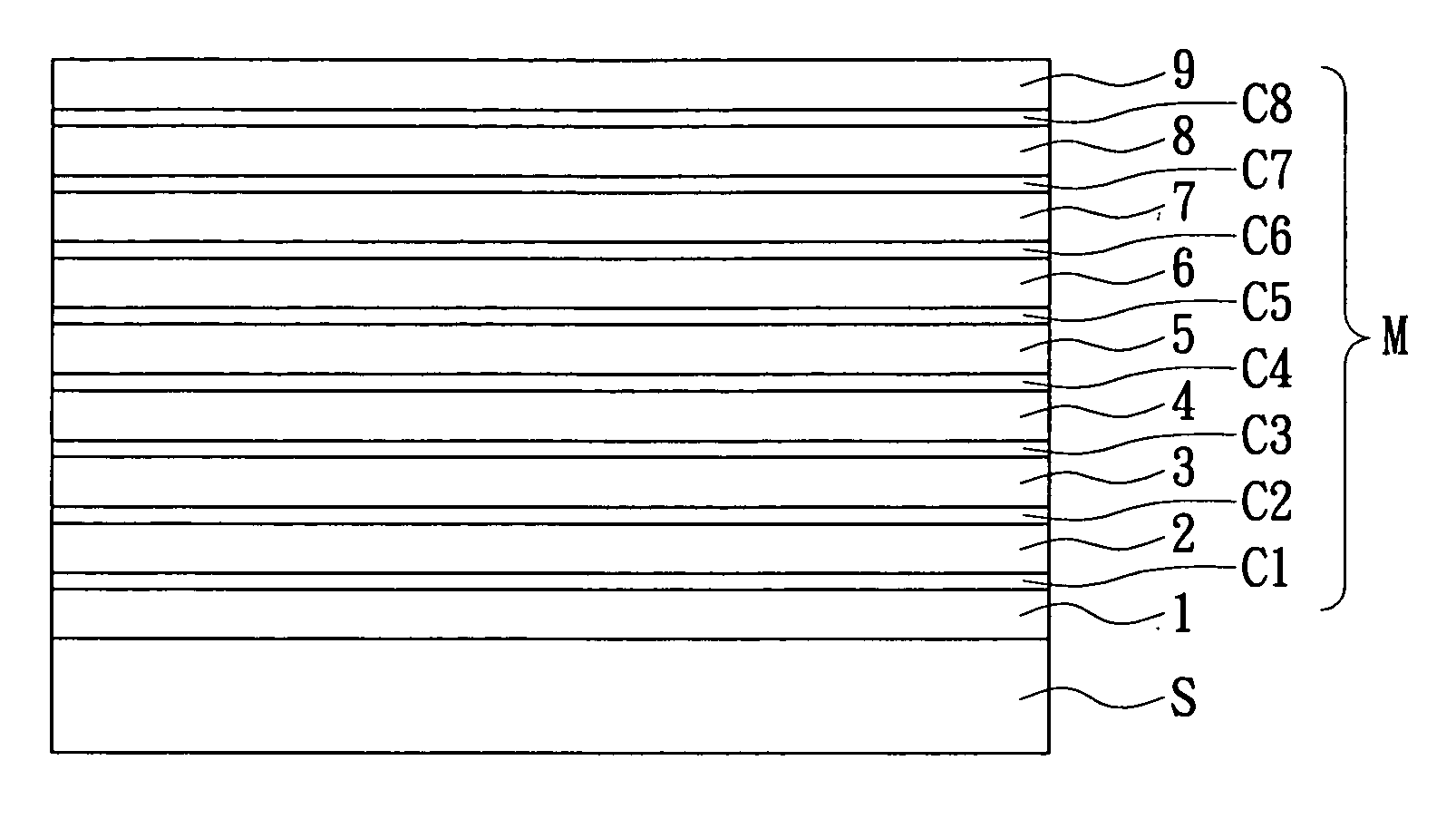

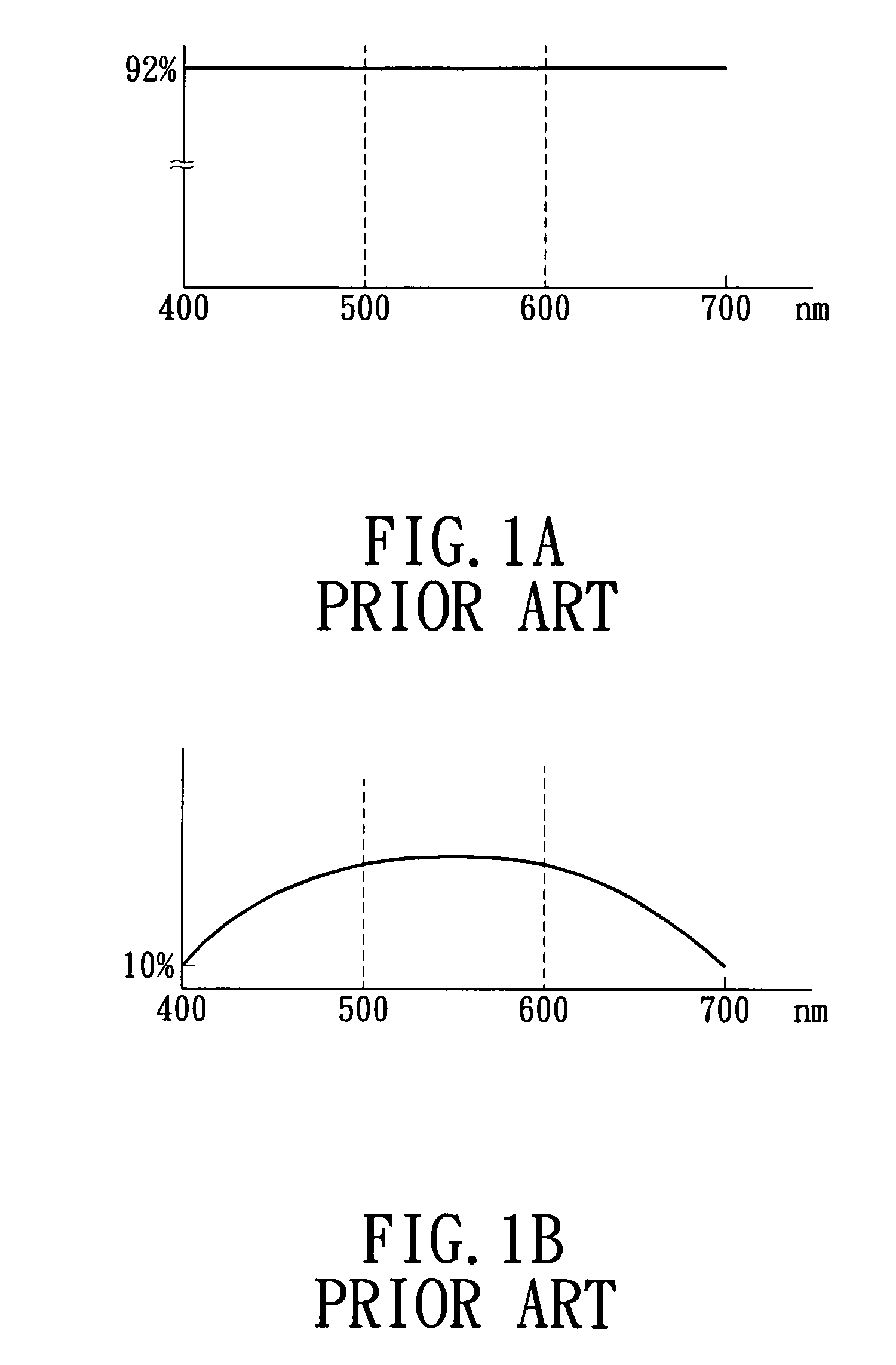

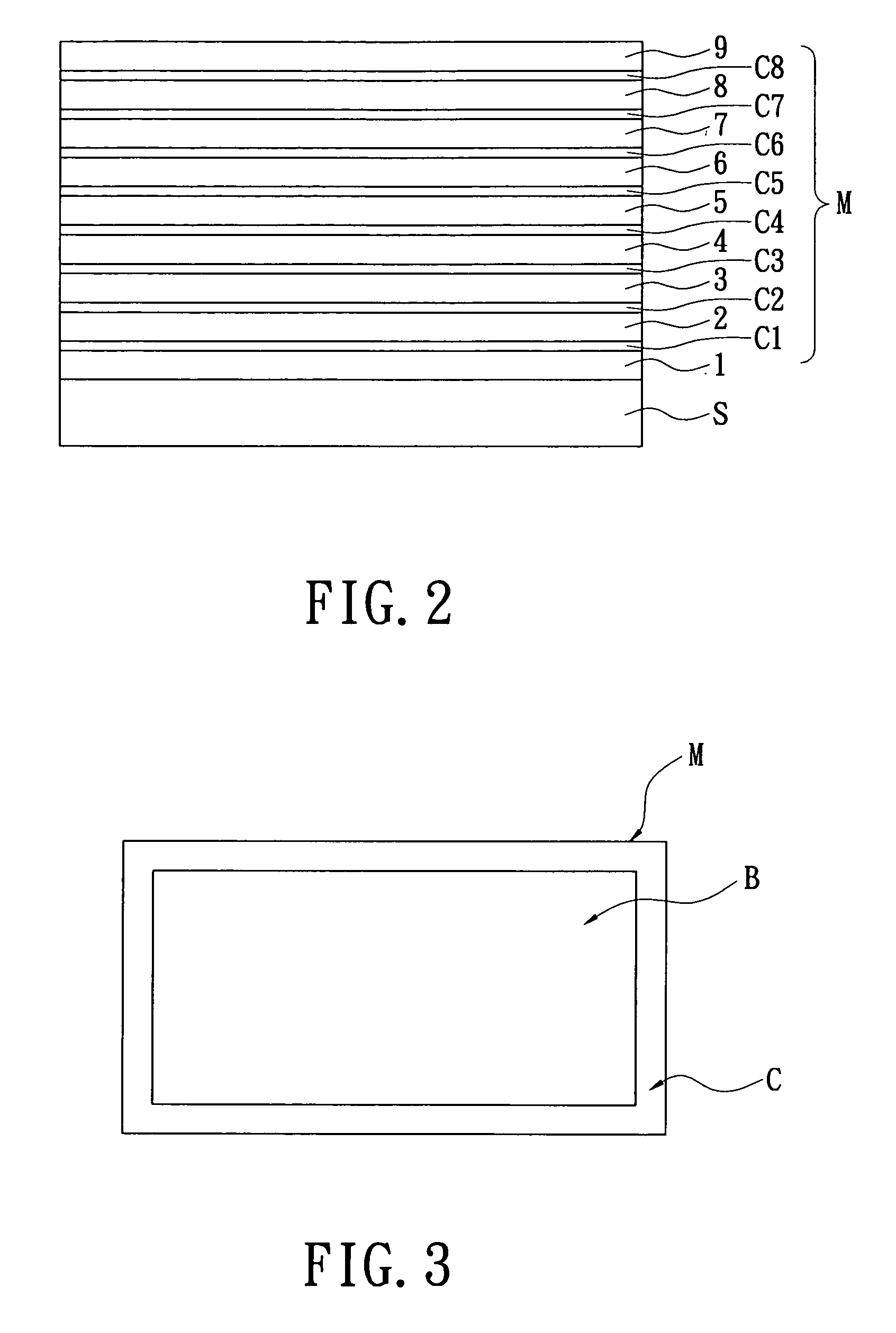

Extreme low resistivity light attenuation anti-reflection coating structure in order to increase transmittance of blue light and method for manufacturing the same

InactiveUS20090297877A1High light transmittanceLow resistivityRecord information storageMagnetic recordingMetal coatingTransmittance

An extreme low resistivity light attenuation anti-reflection coating structure in order to increase transmittance of blue light, includes a substrate and a coating module. The coating module is formed on a front surface of the substrate and composed of a plurality of silicon carbide compound coating layers, a plurality of Al-based oxide coating layers and a plurality of metal coating layers that are alternately stacked onto each other.

Owner:INNOVATION & INFINITY GLOBAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com