Gallium and indium doped single crystal silicon material for solar battery and preparation method thereof

A solar cell and monocrystalline silicon technology, which is applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of solar cells that are prone to light decay, and achieve moderate strength, less crystal defects, and low light decay Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

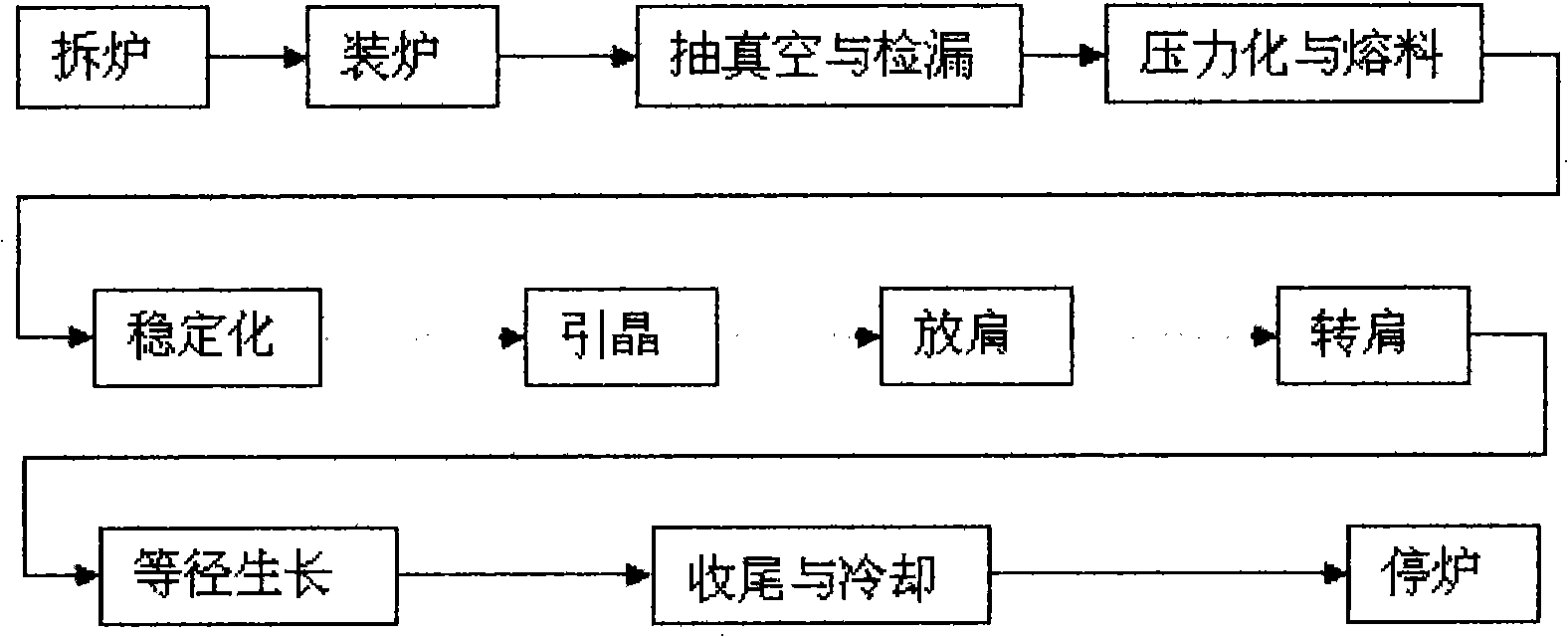

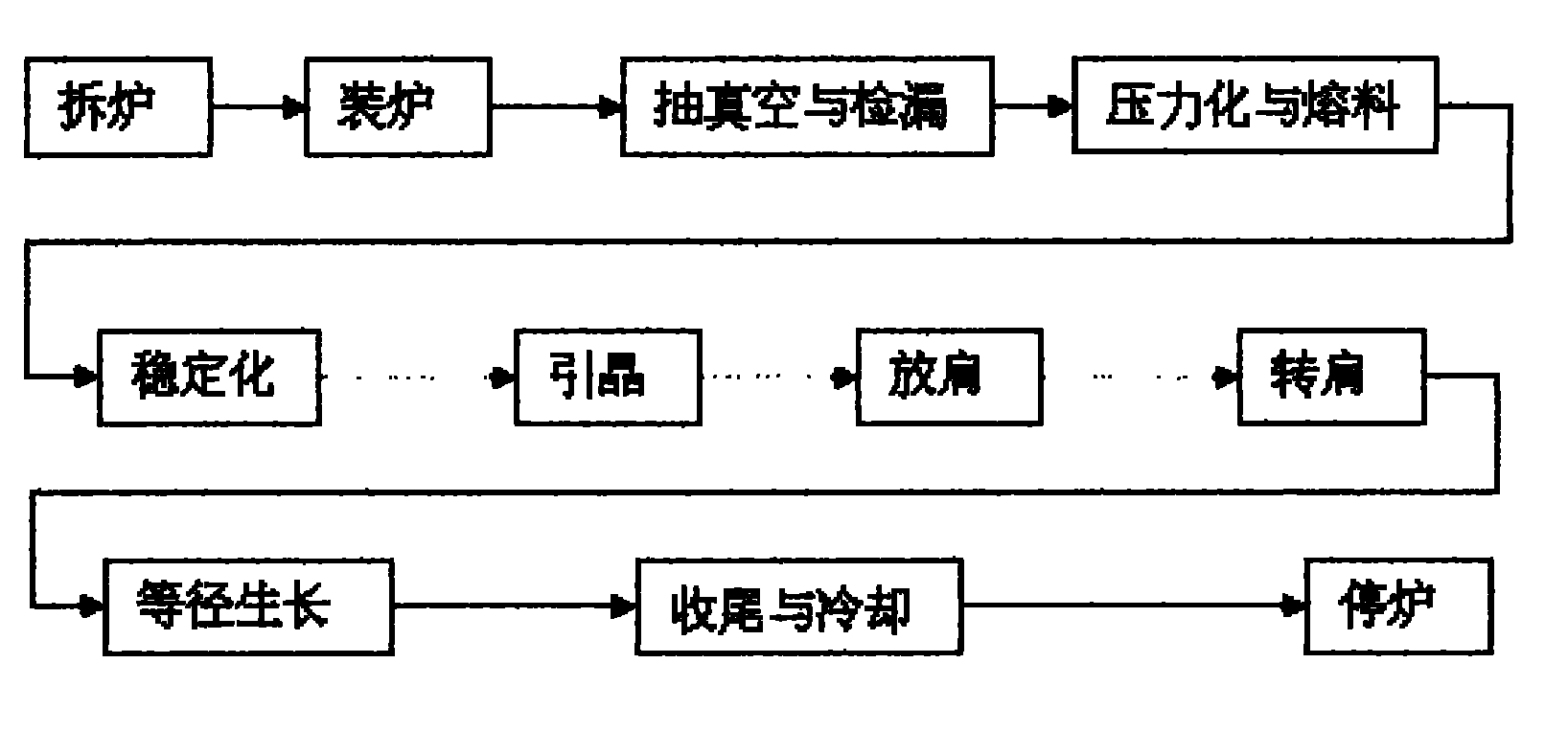

[0072] Step 1: Disassemble the furnace according to the conventional method and clean the furnace.

[0073] Step 2: Load the furnace. According to the number of atoms per cubic centimeter of single crystal silicon material, weigh 1.0 × 10 14 atoms / cm 3 Gallium, 5.0 x 10 12 atoms / cm 3 Indium, the rest is monocrystalline silicon, first spread the weighed monocrystalline silicon all over the bottom of the quartz crucible, and then put the weighed gallium and indium on the monocrystalline silicon in the quartz crucible, preferably on quartz In the central part of the crucible, more monocrystalline silicon is then placed in the quartz crucible, so that the added monocrystalline silicon completely covers the added high-purity gallium and indium, and the quartz crucible is placed in the monocrystalline furnace.

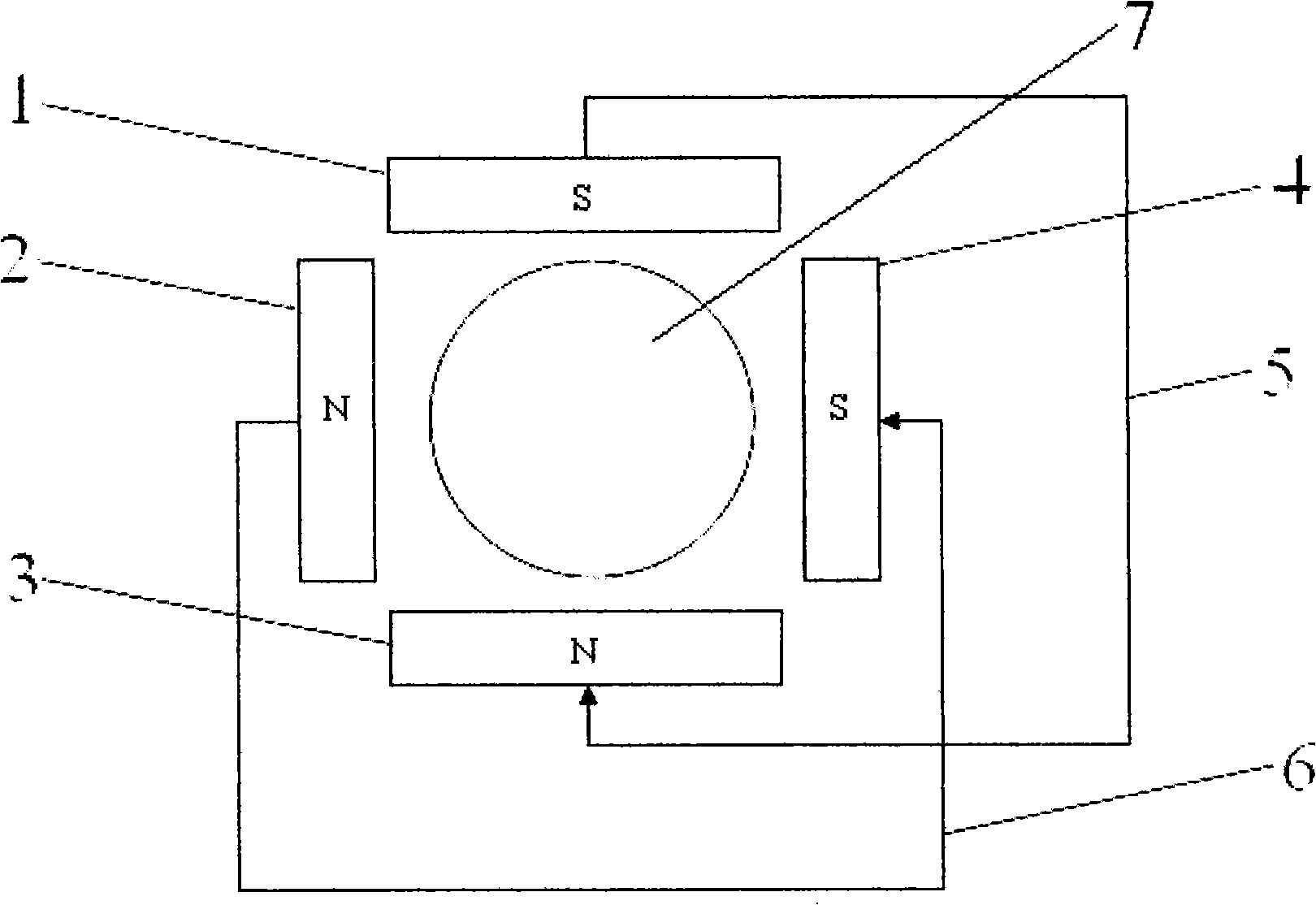

[0074] And, the magnetic field is arranged outside the single crystal furnace, and the specific implementation is carried out according to the following steps: outside t...

Embodiment 2

[0085] Step 1: Disassemble the furnace according to the conventional method and clean the furnace.

[0086] Step 2: Load the furnace. According to the number of atoms per cubic centimeter of single crystal silicon material, weigh 1.0 × 10 18 atoms / cm 3 Gallium, 5.0 x 10 16 atoms / cm 3 Indium, the rest is monocrystalline silicon, first spread the weighed monocrystalline silicon all over the bottom of the quartz crucible, and then put the weighed gallium and indium on the monocrystalline silicon in the quartz crucible, preferably on quartz In the central part of the crucible, more monocrystalline silicon is then placed in the quartz crucible, so that the added monocrystalline silicon completely covers the added high-purity gallium and indium, and the quartz crucible is placed in the monocrystalline furnace.

[0087] And, the magnetic field is arranged outside the single crystal furnace, and the specific implementation is carried out according to the following steps: outside t...

Embodiment 3

[0098] Step 1: Disassemble the furnace according to the conventional method and clean the furnace.

[0099] Step 2: Load the furnace. According to the number of atoms per cubic centimeter of single crystal silicon material, weigh 3.03×10 15 atoms / cm 3 Gallium, 8.3 x 10 12 atoms / cm 3 The indium and the rest are single crystal silicon, and the silicon crystal with high concentration of gallium-doped or gallium-doped indium is obtained by drawing through the cz furnace; then, the silicon crystal is broken, mixed with the single crystal silicon and added to the quartz crucible, and the quartz crucible is placed in the single crystal crucible. inside the furnace.

[0100] And, the magnetic field is arranged outside the single crystal furnace, and the specific implementation is carried out according to the following steps: outside the conventional single crystal furnace, two sets of perpendicular permanent magnets fixed with yoke plates are arranged along the two radial directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com