Leaking stoppage cement slurry for well cementation and preparation method thereof

A technology of oil well cement and mud, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor crack resistance, low tensile strength, interlayer channeling, etc., and achieve good permeability resistance and anti-corrosion Sulfate corrosion ability, good high temperature application performance, and the effect of promoting uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

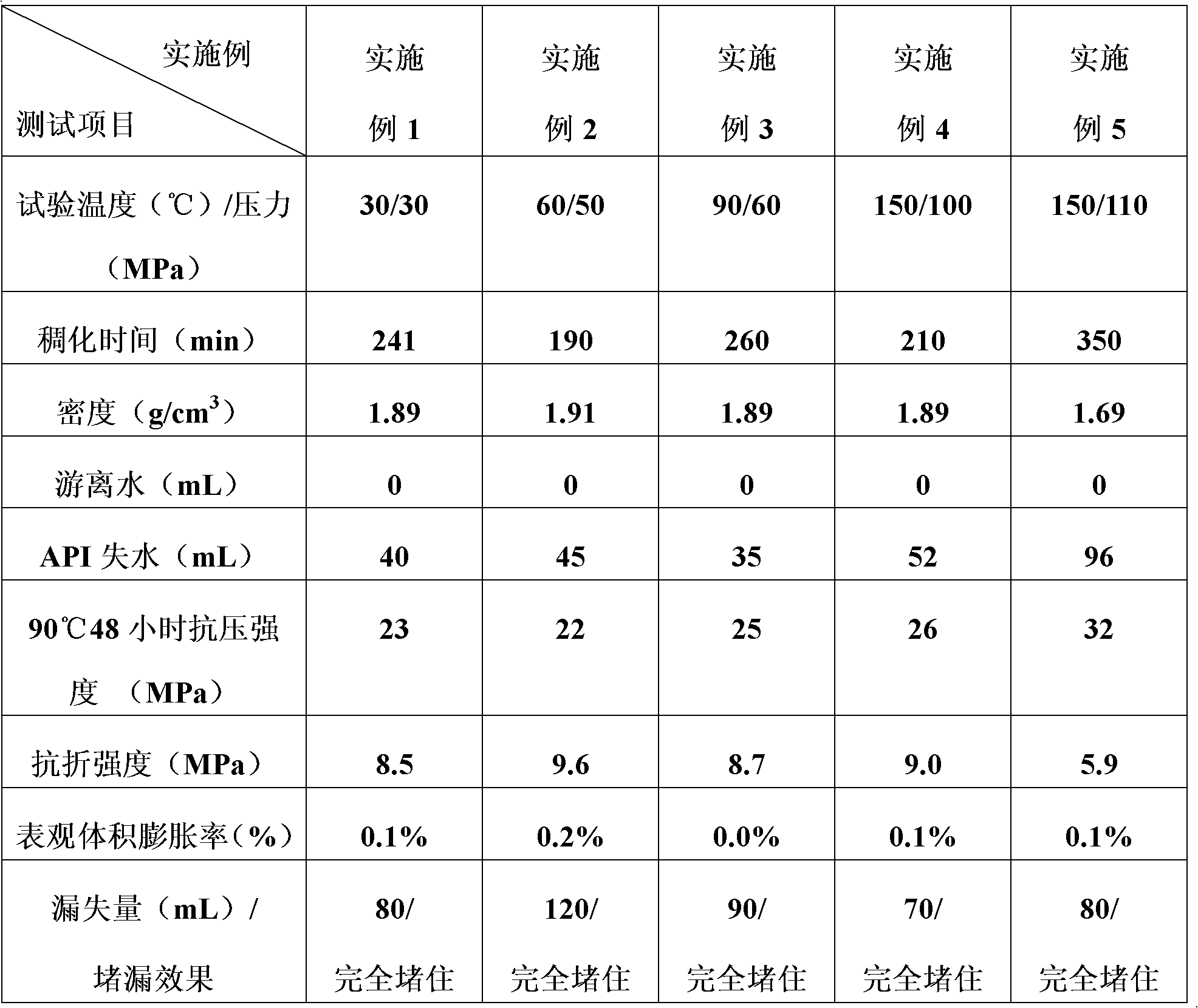

Examples

Embodiment 1

[0027] Weigh 100 parts by weight of oil well cement, 20 parts by weight of silica fume and 0.02 parts by weight of hemp fiber dry-mixed into dry powder, measure 55 parts by weight of water, weigh 6 parts by weight of sodium lauryl sulfate, 15 parts by weight of 2-acrylamide - Dissolve 2-methylpropanesulfonic acid, 2 parts by weight of citric acid, and 0.1 part by weight of simethicone in water. Then, put the aqueous solution in the mixing container, the agitator rotates at a low speed (4000±200 rpm), and add the weighed oil well cement, silica fume and hemp fiber within 15 seconds, and add all the dry powder to the water Finally, cover the lid of the agitator, and continue stirring at high speed (12000±500 rpm) for 35 seconds, and the cement slurry for well cementing and plugging is prepared.

Embodiment 2

[0029] Weigh 100 parts by weight of oil well cement, 40 parts by weight of silica fume, dry mix 0.7 parts by weight of jute fiber and 0.1 part by weight of sisal fiber into dry powder, measure 70 parts by weight of water, weigh 6 parts by weight of sodium hexametaphosphate, 10 parts by weight of sodium hexametaphosphate Parts of hydroxyethyl cellulose, 1 part by weight of citric acid, and 0.2 parts by weight of tributyl phosphate were dissolved in water. Then, put the aqueous solution in the mixing container, the agitator rotates at a low speed (4000±200 rpm), and add the weighed oil well cement, silica fume and hemp fiber within 15 seconds, and add all the dry powder to the water Finally, cover the lid of the agitator, and continue stirring at high speed (12000±500 rpm) for 35 seconds, and the cement slurry for well cementing and plugging is prepared.

Embodiment 3

[0031] Take by weighing 100 parts by weight of oil well cement, 30 parts by weight of silicon powder, 0.8 parts by weight of hemp fiber and 0.2 parts by weight of jute fiber and dry mix them into dry powder, measure 75 parts by weight of water, weigh 8 parts by weight of sodium lauryl sulfate, 6 parts by weight Parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 2 parts by weight of citric acid, and 0.5 parts by weight of tributyl phosphate are dissolved in water. Then, put the aqueous solution in the mixing container, the agitator rotates at a low speed (4000±200 rpm), and add the weighed oil well cement, silica fume and hemp fiber within 15 seconds, and add all the dry powder to the water Finally, cover the lid of the agitator, and continue stirring at high speed (12000±500 rpm) for 35 seconds, and the cement slurry for well cementing and plugging is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com