Graphene composite material and preparation method thereof

A technology of composite materials and graphene, which is applied in the field of composite materials, can solve the problems of graphene composite materials with unobvious mechanical properties, uniform dispersion of graphene, easy agglomeration, etc., and achieve the effect of excellent interface compatibility and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention discloses a preparation method of a graphene composite material, comprising:

[0026] Step a) reacting graphene and organosilane in a mixed solution of organic solvent and water to obtain organosilane-modified graphene;

[0027] Step b) mixing the organosilane-modified graphene with a polymer to obtain a graphene composite material.

[0028] According to the present invention, the organic solvent in the step a) is preferably methanol, ethanol, acetone, butanone, chloroform, dichloroethane, carbon tetrachloride, cyclohexane, benzene, toluene, xylene, tetrahydrofuran, dimethyl sulfoxide, N,N-dimethylformamide, N,N-dimethylacetamide or N-methylpyrrolidone. The reaction temperature in step a) is preferably 25-150°C, more preferably 30-130°C, most preferably 50-100°C. The reaction time of step a) is preferably 1-24 hours, more preferably 2-20 hours, most preferably 5-15 hours. Said addition of water and organosilane preferably includes ultrasonic dispersion....

Embodiment 1

[0042] Add 0.5g of graphene powder into 100ml of N,N-dimethylformamide, ultrasonically disperse at a frequency of 20 Hz for 2 hours, then add 0.5g of γ-aminopropyltrimethoxysilane and 0.5g of distilled water at 25°C Stir mechanically and react for 24 hours. After the reaction, use suction filtration to obtain a black powdery solid product, namely organosilane-modified graphene;

[0043] Add 0.3 g of the above organosilane-modified graphene into 80 ml of N, N-dimethylformamide, then add 10 g of polyurethane, ultrasonically disperse at a frequency of 20 Hz for 2 hours, and then mechanically stir for 24 hours to remove N, N-dimethylformamide. Methylformamide, to obtain graphene composites.

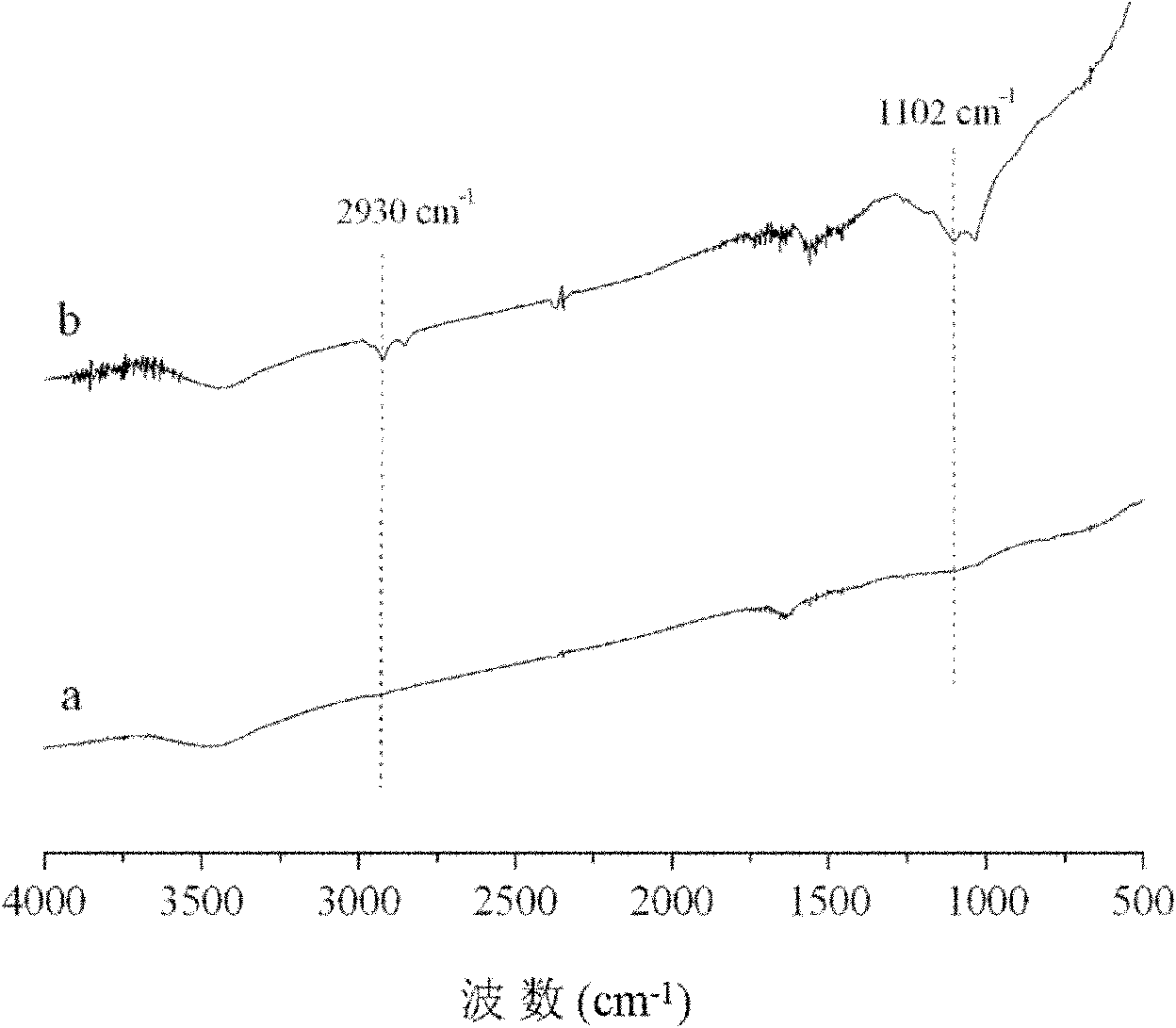

[0044] The infrared spectrogram of the graphene composite material prepared in this embodiment is as follows figure 1 shown, from figure 1 It can be seen that the graphene composite material prepared in this example has Si-O bonds, indicating that organosilanes with specific functional grou...

Embodiment 2

[0046] Add 0.5g of graphene powder into 100ml of N,N-dimethylformamide, ultrasonically disperse at a frequency of 100 Hz for 5 minutes, add 10.0g of γ-aminopropyltriethoxysilane and 10.0g of distilled water, at 150°C Stir mechanically, react for 2 hours, and use suction filtration after the reaction to obtain a black powdery solid product, that is, organosilane-modified graphene;

[0047] Add 0.3 g of the above organosilane-modified graphene to 80 ml of N,N-dimethylformamide, add 10 g of polyurethane, disperse ultrasonically at a frequency of 100 Hz for 5 minutes, then mechanically stir for 2 hours to remove N,N-dimethylformamide base formamide to obtain organosilane-modified graphene-polyurethane composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com