Graphene-supported copper-nickel composite nanometer photocatalyst, and preparation method and application thereof

A nano-photocatalyst and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of Ni-based bimetal composite nanoparticle synthesis Reporting and other issues, to achieve the effect of easy operation, good development prospects and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

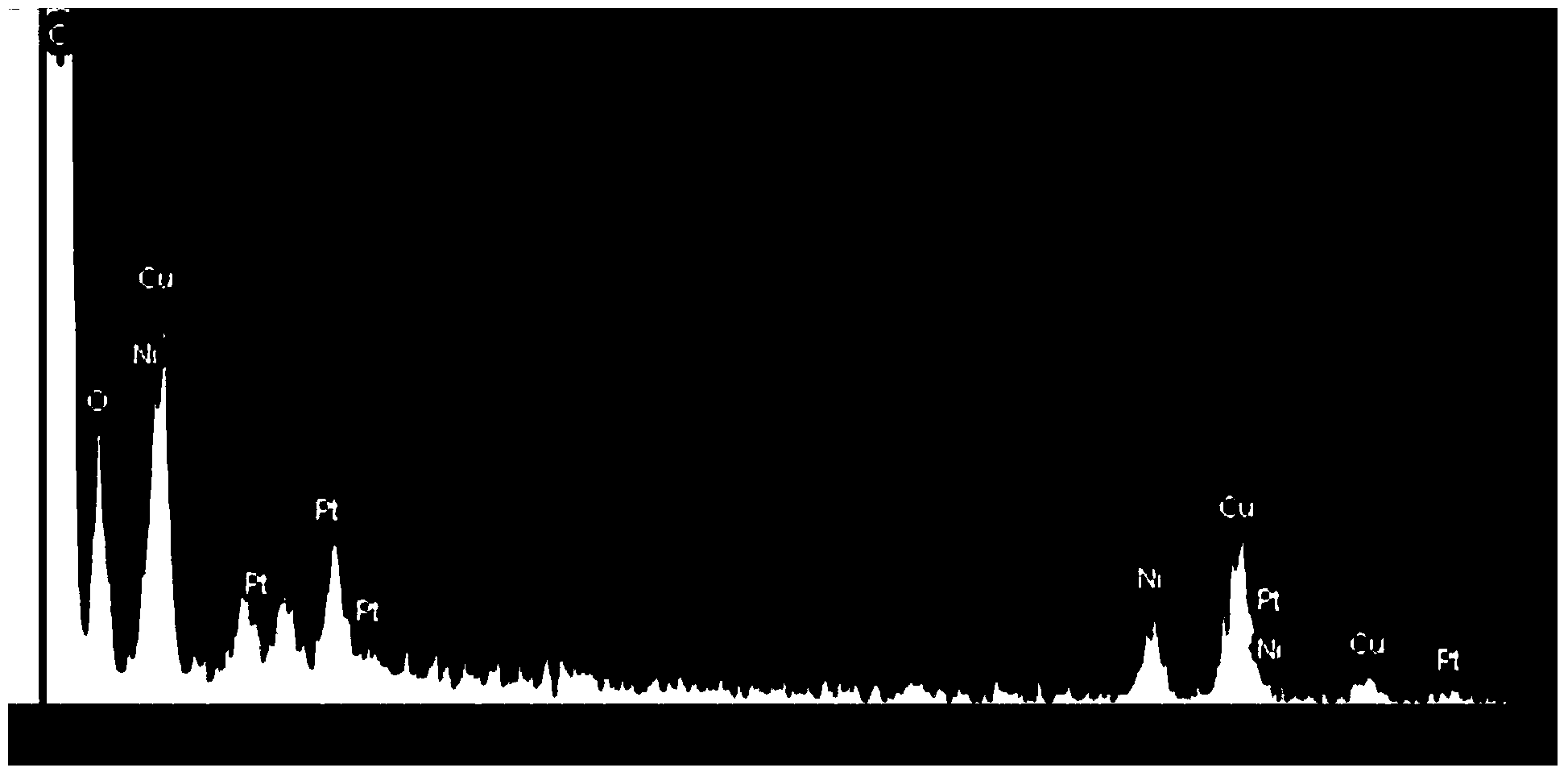

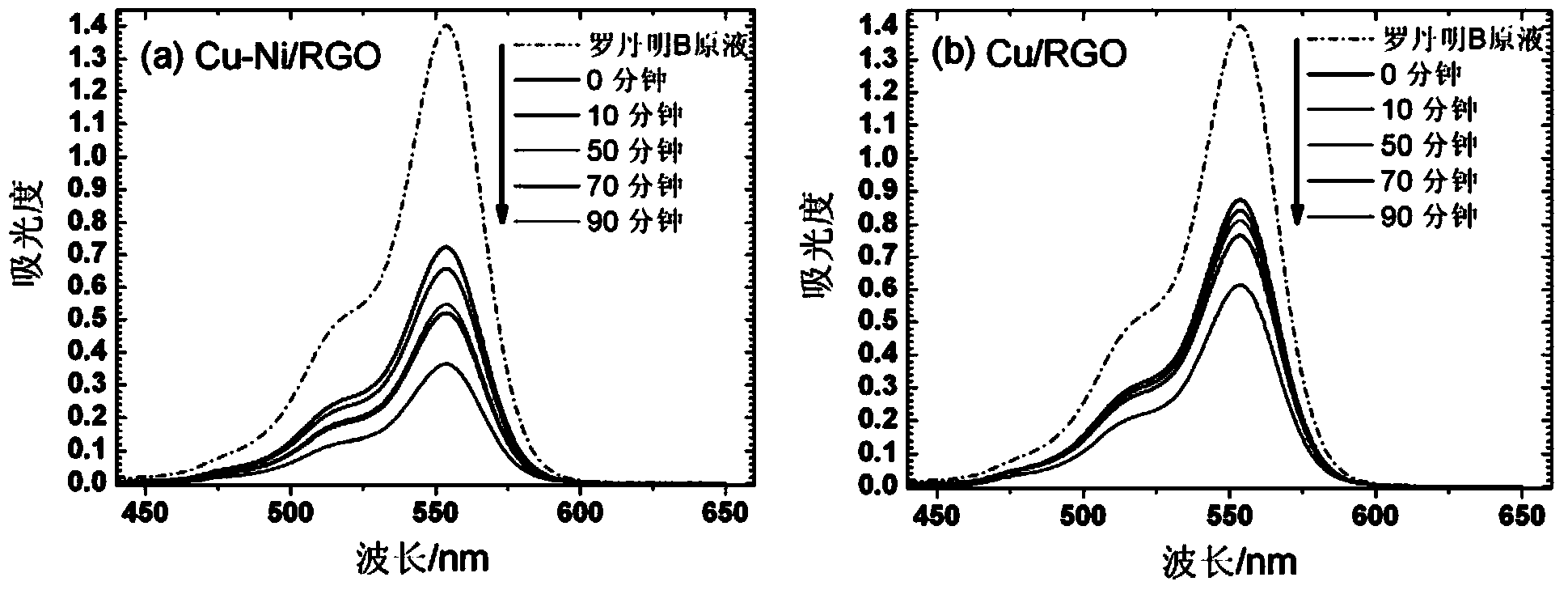

[0023] Take 100mg of solid graphite oxide and add it to 25ml of ethanolamine, magnetically stir and ultrasonically disperse at room temperature for 30min each; then add 100ml of deionized water, continue magnetically stirring for 24h, and wash the solution centrifugally to remove excess ethanolamine; each measure 50ml of Cu( NO 3 ) 2 (6mmol / L) and Ni(NO 3 ) 2 (6mmol / L) ethylene glycol solution was added to the above-mentioned graphene oxide, and then NaOH with a concentration of 0.1 g / L was added to adjust the pH value to 4, magnetically stirred for 30min under the temperature of a water bath at 80°C, and magnetically stirred to the solution at the same time Nitrogen was introduced into the solution to remove the dissolved oxygen in the solution; the mixed solution was quickly transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, and the reaction kettle was reacted at a constant temperature of 80°C for 0.5h; naturally cooled to room temperat...

Embodiment 2

[0025] Take 100mg of solid graphite oxide and add it to 25ml of polyvinyl alcohol, magnetically stir and ultrasonically disperse at room temperature for 60 minutes each; then add 100ml of deionized water, continue to magnetically stir for 24 hours, and wash the solution centrifugally to remove excess polyvinyl alcohol; Take 50mlCu(NO 3 ) 2 (12mmol / L) and Ni(NO 3 ) 2 (12mmol / L) ethylene glycol solution was added to the above-mentioned graphene oxide, and then NaOH with a concentration of 1.2g / L was added to adjust the pH value to 13, and magnetic stirring was carried out for 80min under the temperature condition of 120°C water bath, and the magnetic stirring was added to the solution at the same time Nitrogen was introduced into the solution to remove dissolved oxygen in the solution; the mixed solution was quickly transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, and the reaction kettle was reacted at a constant temperature of 80°C for 1...

Embodiment 3

[0027] Take 100mg of solid graphite oxide and add it to 25ml of ethylenediamine, magnetically stir and ultrasonically disperse at room temperature for 30min each; then add 100ml of deionized water, continue magnetically stirring for 24h, and centrifuge the solution to remove excess ethylenediamine; Take 50mlCu(NO 3 ) 2 (8mmol / L) and Ni(NO 3 ) 2 (8mmol / L) ethylene glycol solution was added to the above-mentioned graphene oxide, and then NaOH with a concentration of 0.8g / L was added to adjust the pH to 13, magnetically stirred for 120min under the temperature of a water bath at 100°C, and magnetically stirred to the solution at the same time Nitrogen was introduced into the solution to remove dissolved oxygen in the solution; the mixed solution was quickly transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, and the reaction kettle was reacted at a constant temperature of 120°C for 0.5h; naturally cooled to room temperature, the obtained prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com