Patents

Literature

2856results about How to "Continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer doped zinc oxide and its prepn and application in photocatalysis to degrade organic matter and kill bacteria

InactiveCN1772375AImprove photocatalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The present invention relates to Ag and RE doped nanometer zinc oxide and its preparation process and application in photocatalysis to degrade organic matter and killing bacteria. Ag, RE metals La, Ce, Pr, Nd, Sm, etc. are doped into nanometer zinc oxide to raise its photocatalytic activity in degrading harmful chemical matter and resisting bacteria. Under lighting, the doped nanometer zinc oxide has higher photocatalytic activity and higher antibacterial capacity; and in case of no lighting, it has relatively high antibacterial effect owing to the antibacterial effect one Ag, Zn, RE and other antibacterial ions. The preparation process may be an organic matter complexing process or a sprying pyrolysis process. The doped nanometer zinc oxide may be used through mixing with other material, or used as additive added into plastic, ceramic, fiber, timber, rubber, glass, cement, metal and other material to form various kinds of photocatalytic antibacterial material and product.

Owner:NANJING UNIV

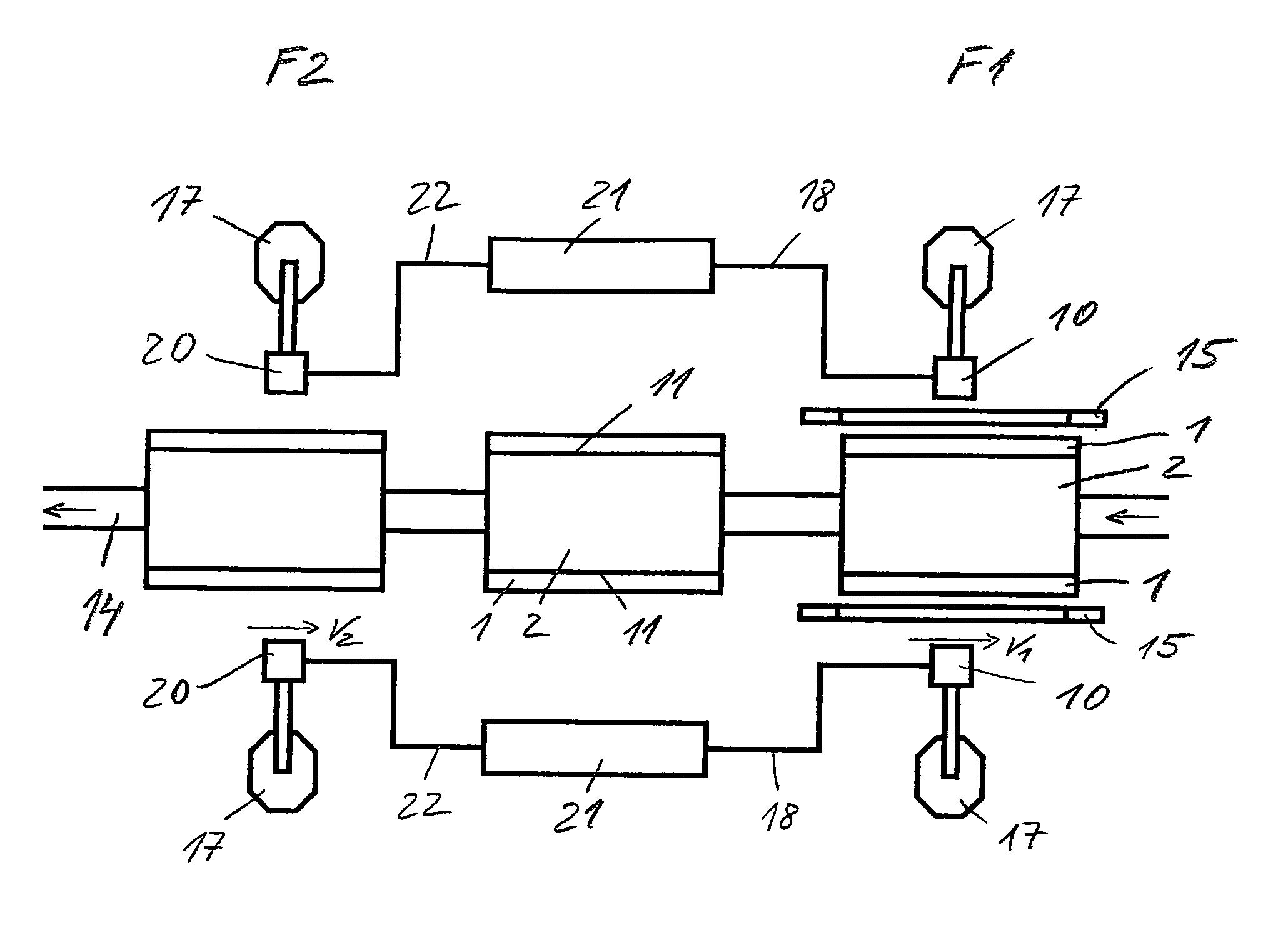

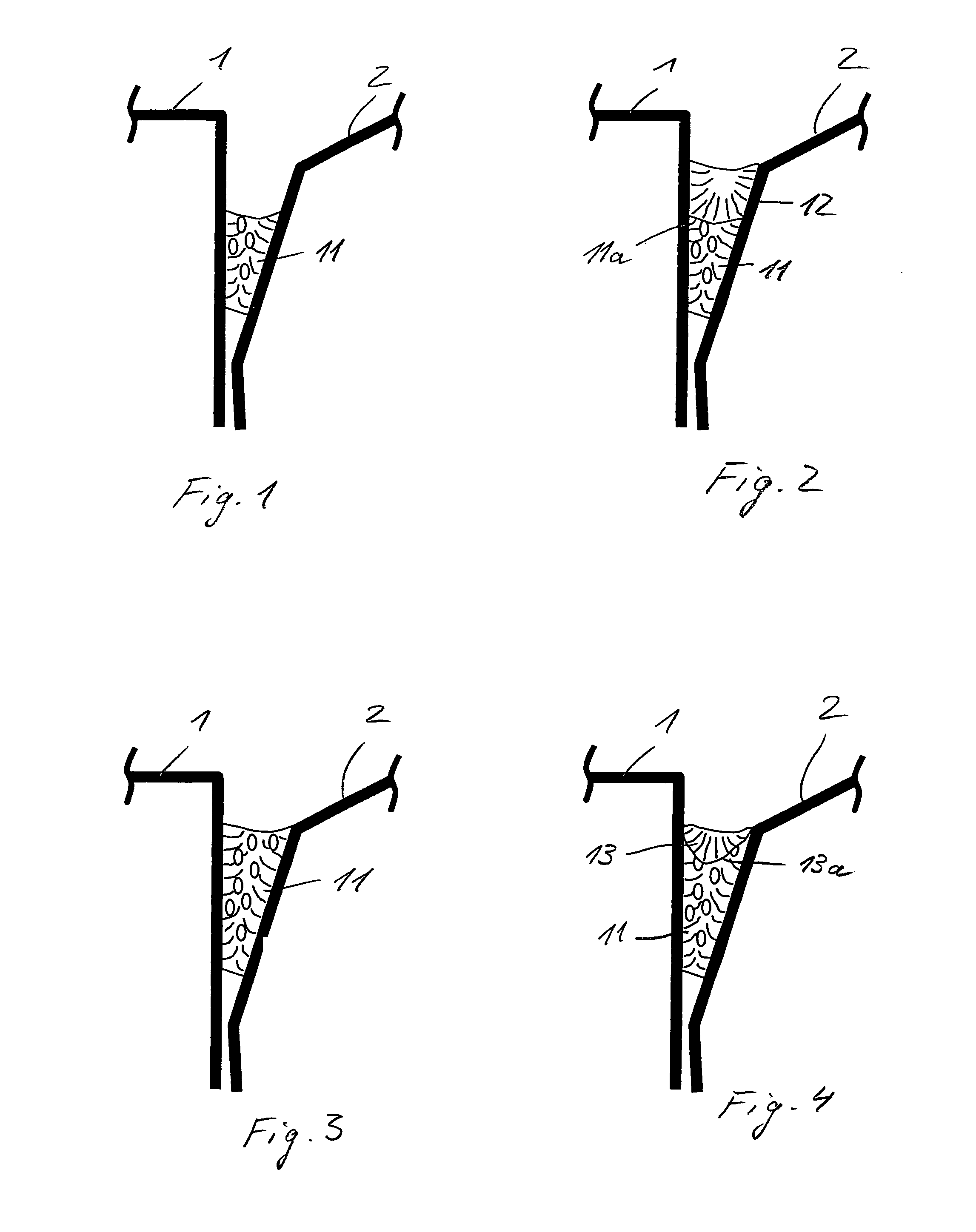

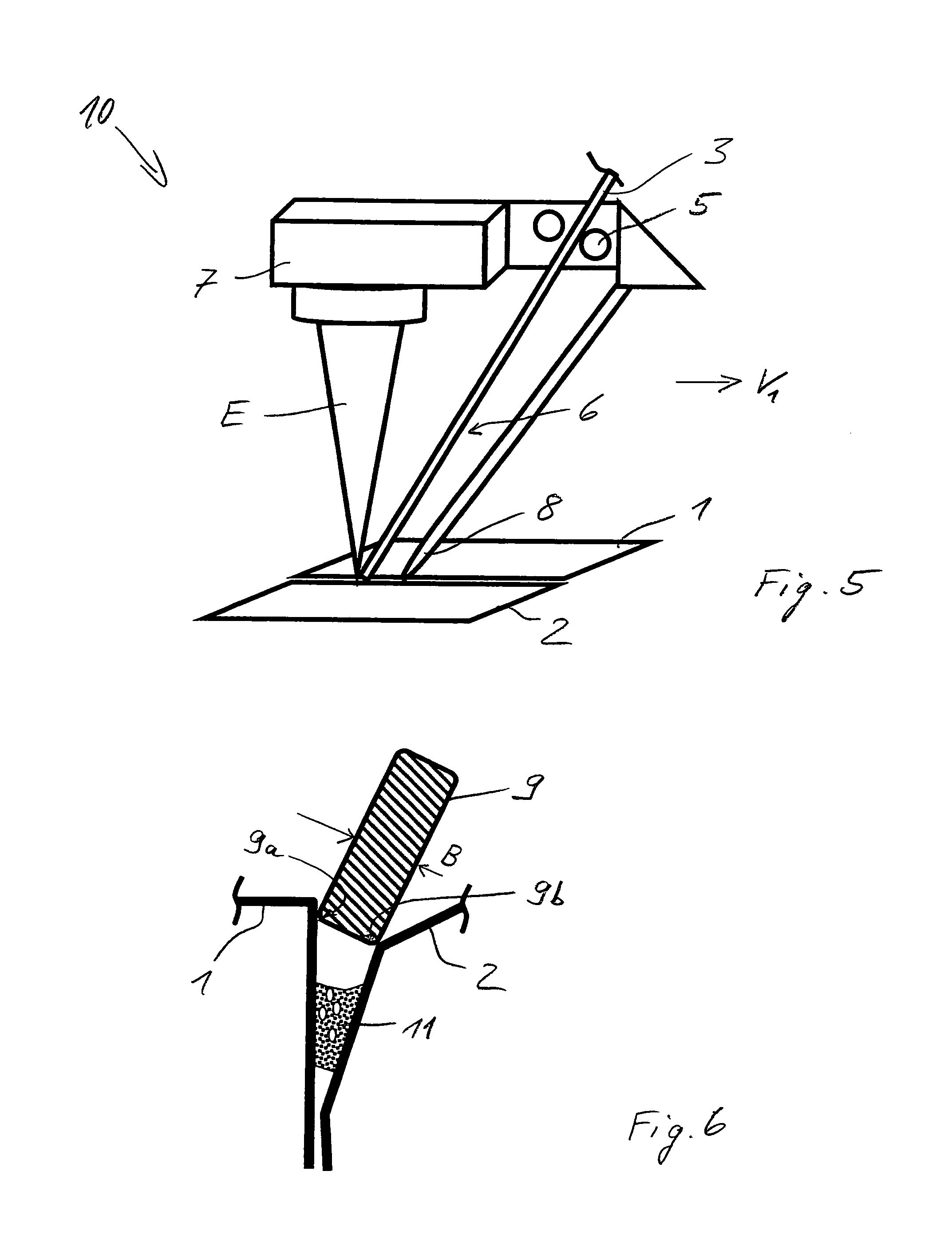

Method of soldering or welding components

ActiveUS8686314B2Increase speedIncrease production speedWelding/cutting auxillary devicesVehicle componentsEngineeringSoldering

Owner:FFT PRODIONSSYST

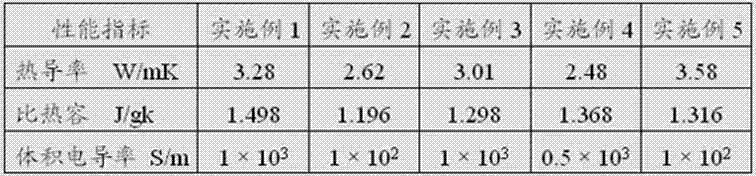

Graphene filled polymer matrix composite material and its preparation method

ActiveCN103087404AImprove conductivityImprove thermal conductivityIn situ polymerizationMechanical property

The invention discloses a graphene filled polymer matrix composite material. The composite material is prepared through using 90-99 parts by weight of a thermoplastic resin, 0.1-10 parts by weight of a graphene microchip, 0.01-1 part of a coupling agent, and 1-10 parts of a lubricant. The invention also discloses a preparation method of the graphene filled polymer matrix composite material. Compared with other carbon system filled composite materials, the graphene filled polymer matrix composite material has the advantages of easy processing, easy forming, less filler filling amount, wide raw material source, environmental protection and the like. The composite material has the characteristics of excellent electric conductivity, excellent thermal conductivity, good mechanical properties, good dimensional stability, good weather resistance and the like; and compared with present technologies for preparing a graphene / polymer composite material through in-situ polymerization or solution polymerization, the melt blending method for preparing the graphene filled polymer matrix composite material in the invention has the advantages of continuous production, suitableness for the large-scale production, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Polymer/graphene anti-static coating, preparation method and application thereof

InactiveCN104449010AEasy reunionSolving Dispersion ProblemsConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsStatic performanceCompound system

The invention discloses a polymer / graphene anti-static coating, a preparation method and application thereof. The coating comprises the following constituents by weight percent: 0.01 portions to 0.5 portions of graphene; 0 portion to 10 portions of conductive additive; 90 portions to 100 portions of polymer; and solvent; the preparation method thereof comprises the following steps: completely and uniformly mixing graphene and conductive additive in advance by various manners; preparing a graphene-conductive additive compound system; using the compound system as a base, adding in conductive additive and polymer along with the solvent, completely and uniformly mixing to obtain the coating. Additionally, an anti-static film can be prepared by using different film forming technologies. The polymer / graphene anti-static coating, the preparation method and application thereof effectively solve the problems that graphene in polymer is easy to agglomerate and difficult to be uniformly dispersed in the preparation process of anti-static coating and film; the anti-static performance and mechanical performance of the coating and the film are greatly increased; meanwhile, the preparation technology is easy to be operated; the production is continuous, and the coating and film are suitable for industrial production.

Owner:苏州格瑞丰纳米科技有限公司

Method for extracting high-content mogroside V from dried momordica grosvenori swingle

The invention discloses a method for extracting high-content mogroside V from dried momordica grosvenori swingle. The extraction technique includes the following steps: extraction, concentration, filtration, adsorption, decoloration, concentration and drying, so that the mogroside V product is obtained. The method adopts the dried momordica grosvenori swingle as material for production, the content of the obtained product is high, the taste and the color are good, the adopted equipment required by the technique is simple, continuous production can be carried out, and moreover, because the used solvents are ethanol and water, no pollution is generated.

Owner:HILL PHARMA

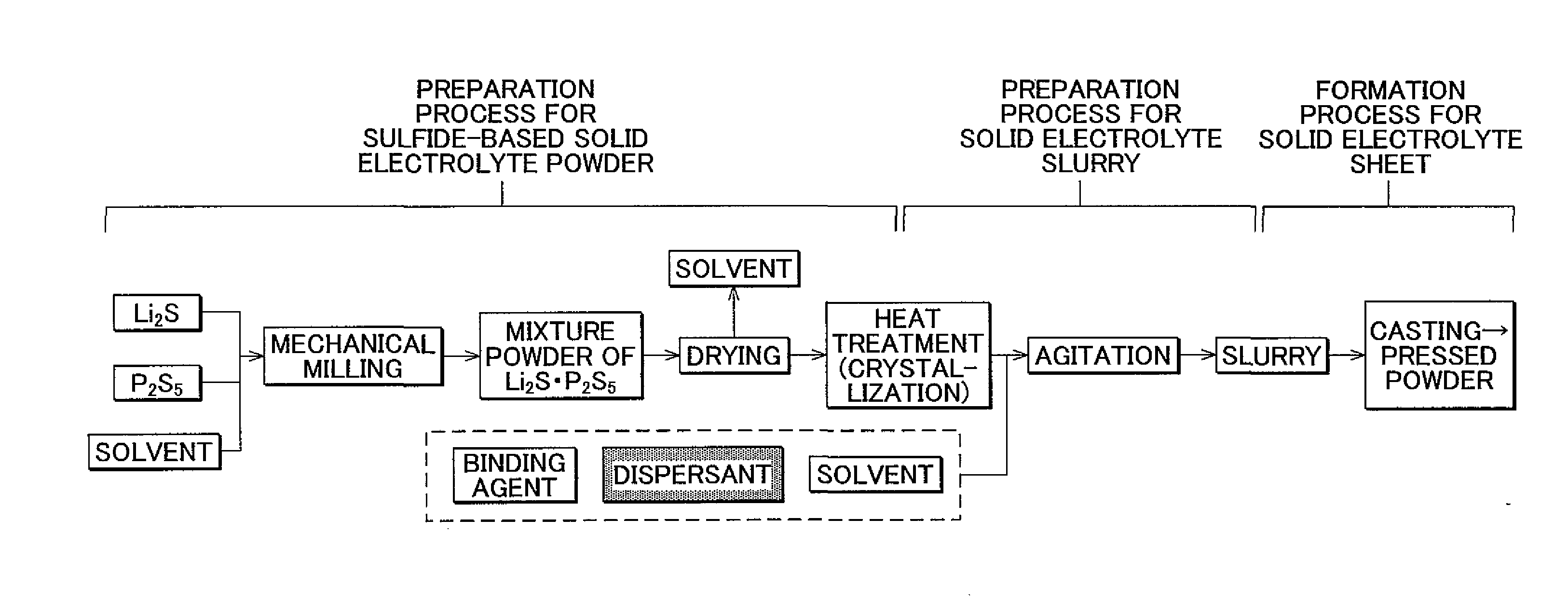

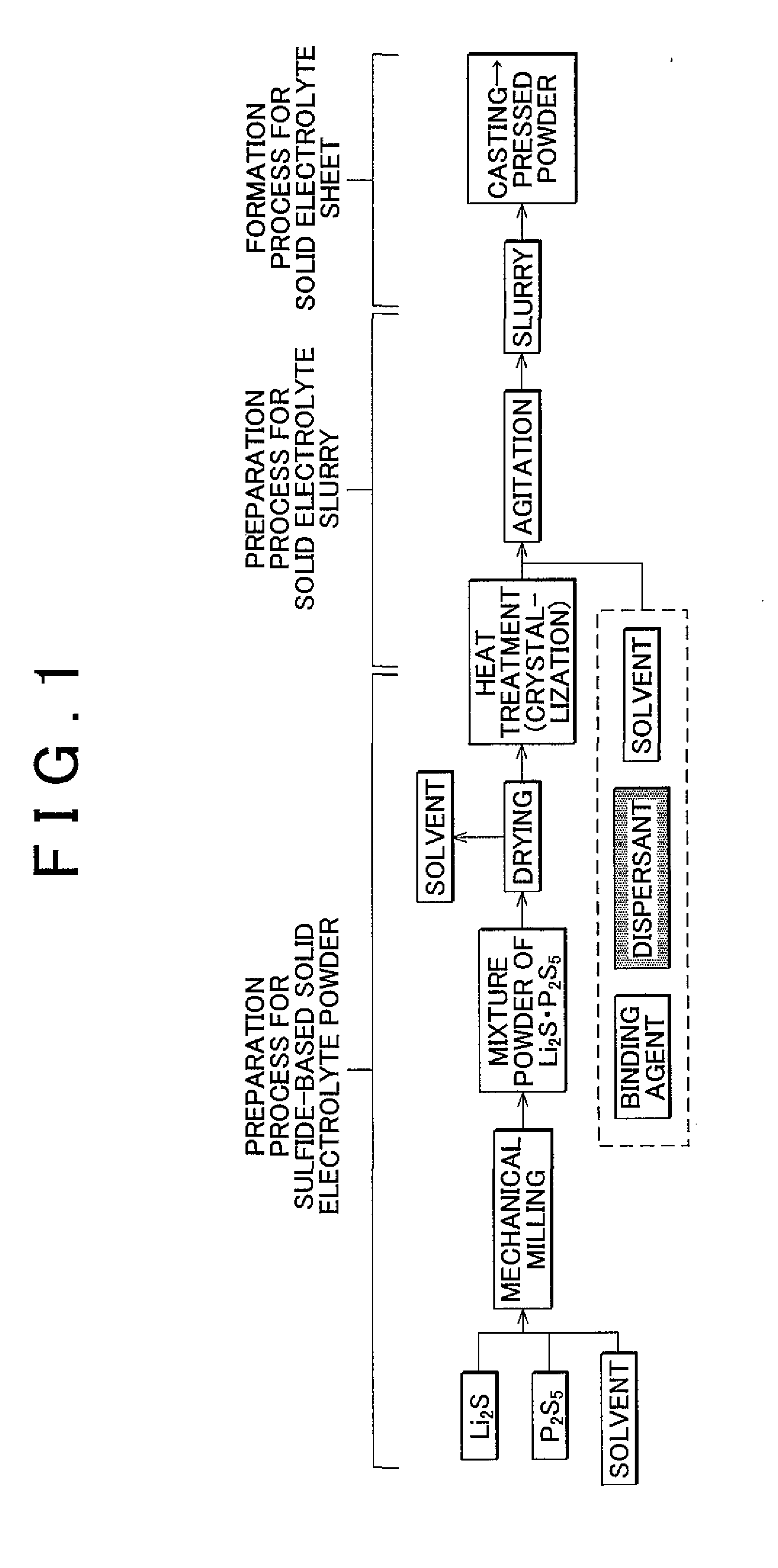

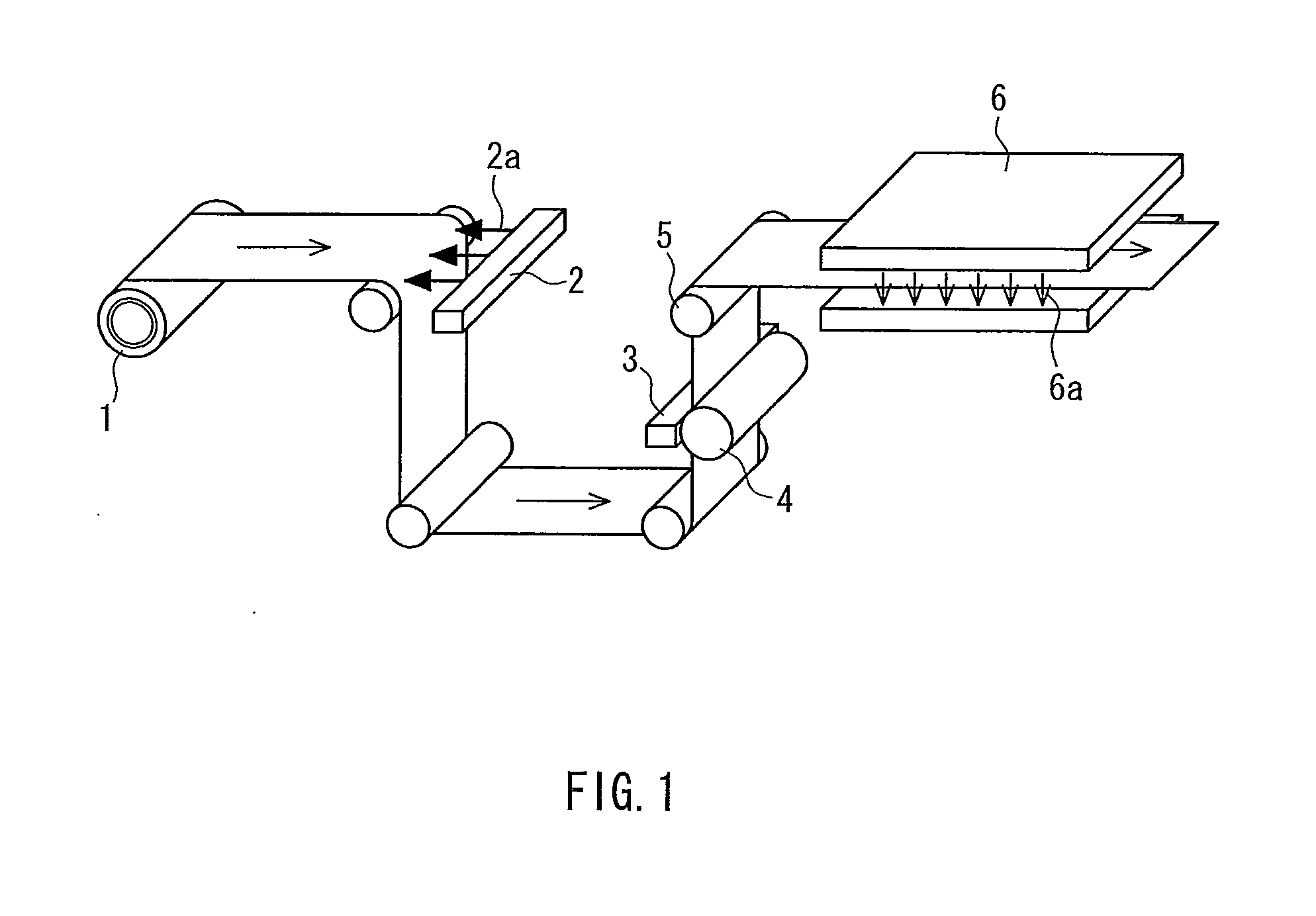

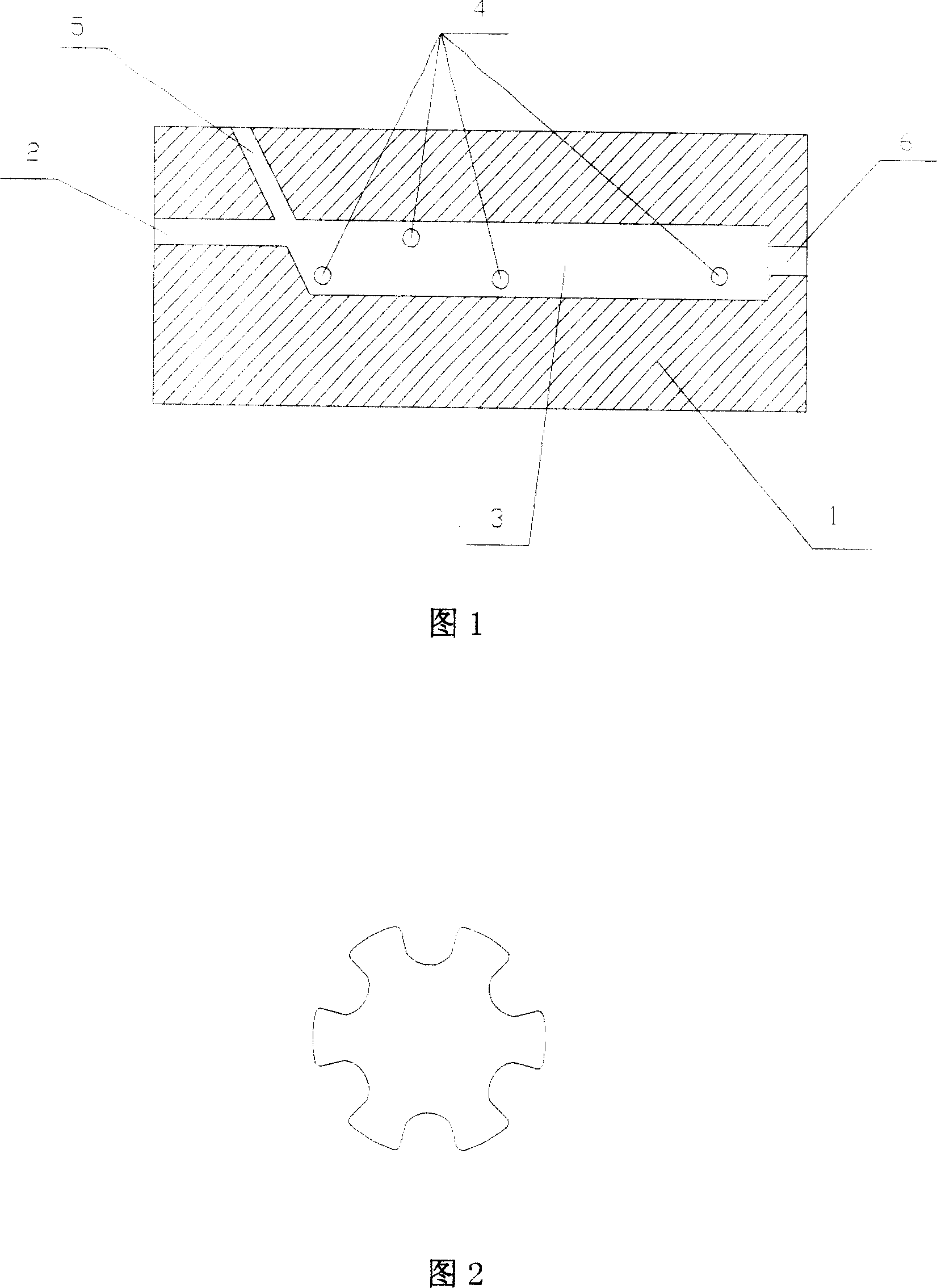

Manufacturing method for solid electrolyte sheet

InactiveUS20110049745A1Improve lithium ion conductivityUniform thicknessSecondary cellsElectrolytesSulfideSlurry

A manufacturing method for a solid electrolyte sheet includes applying slurry, which contains sulfide-based solid electrolyte powder, a sulfur-containing compound and a solvent, onto a base; and forming the slurry into a sheet.

Owner:TOYOTA JIDOSHA KK

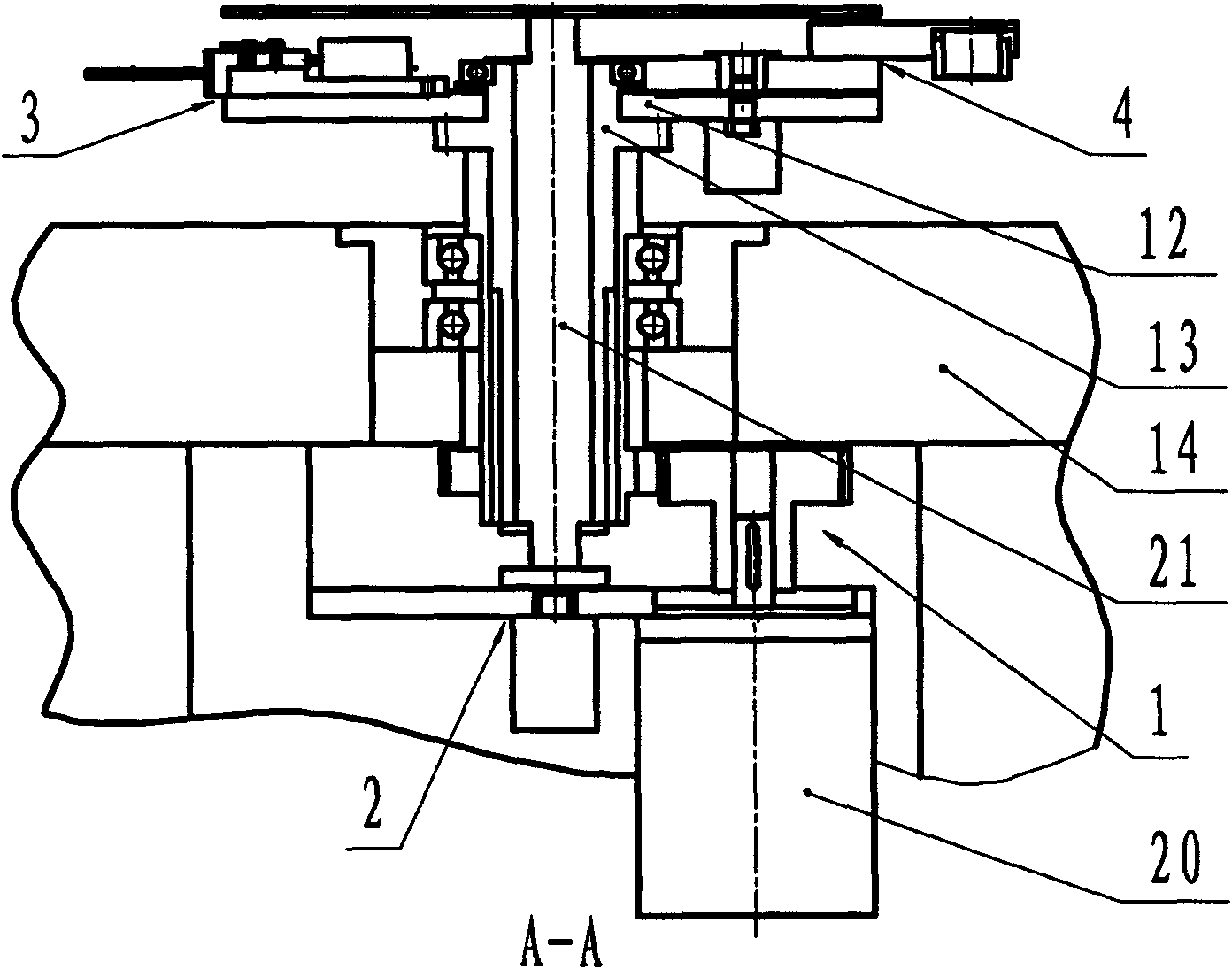

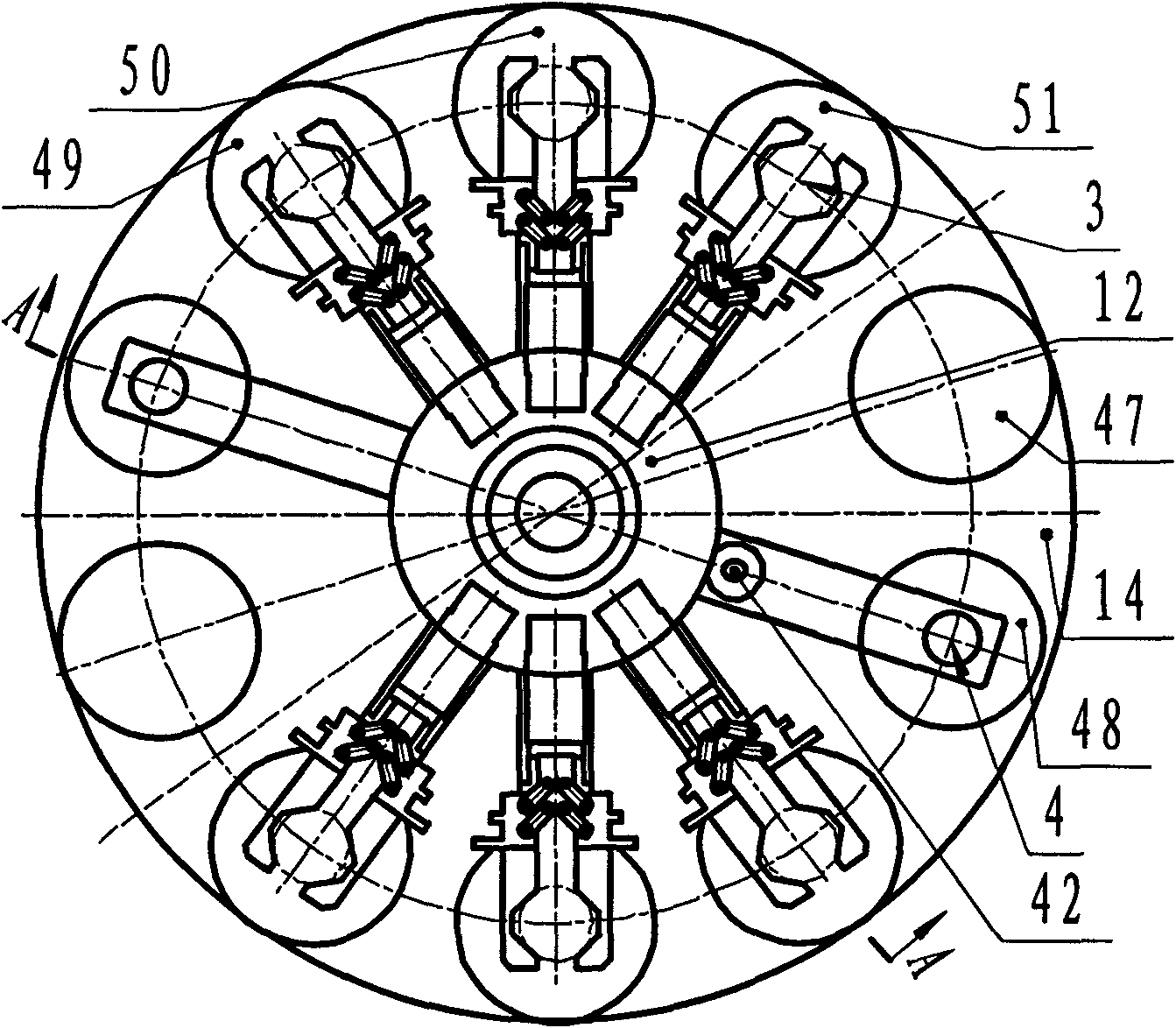

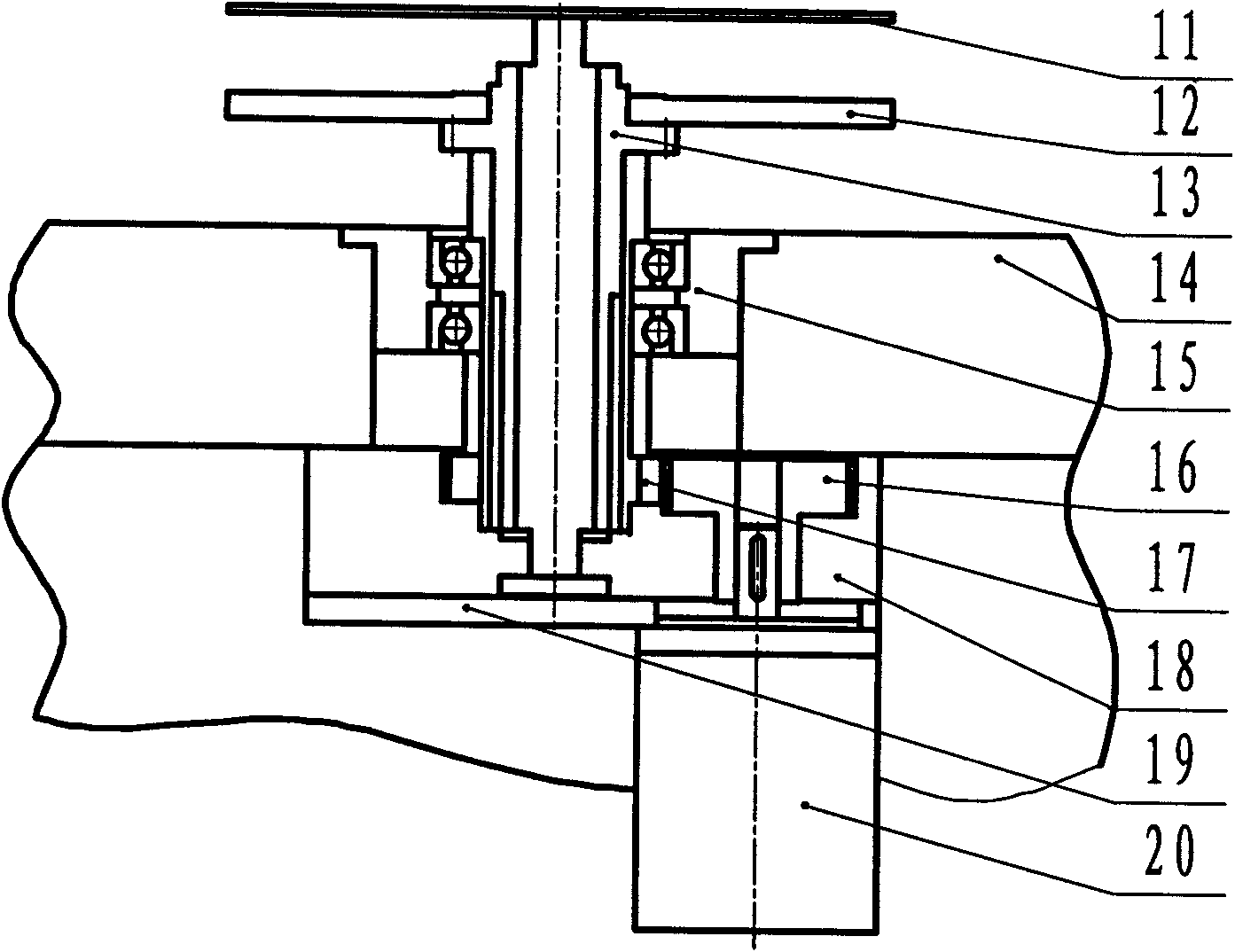

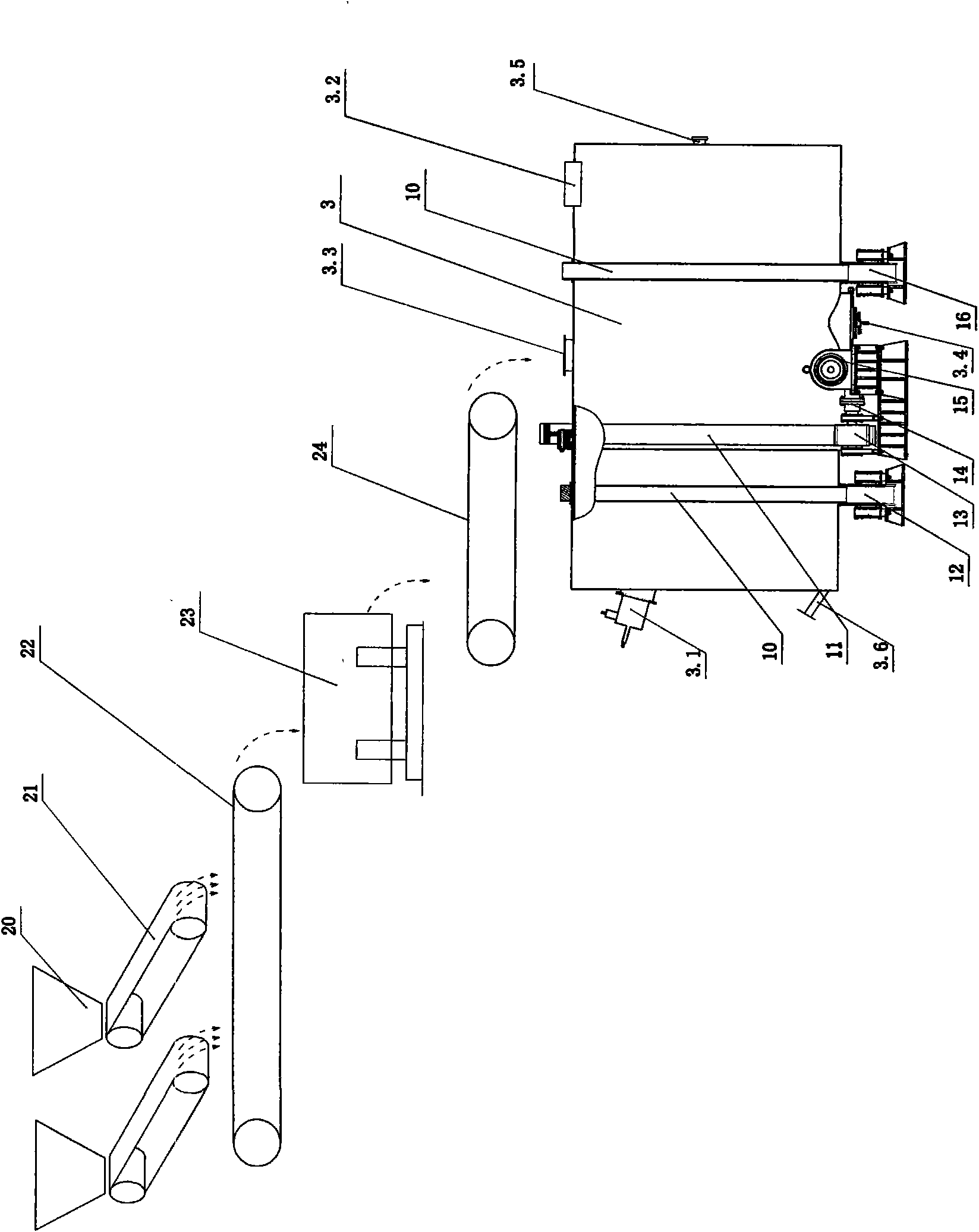

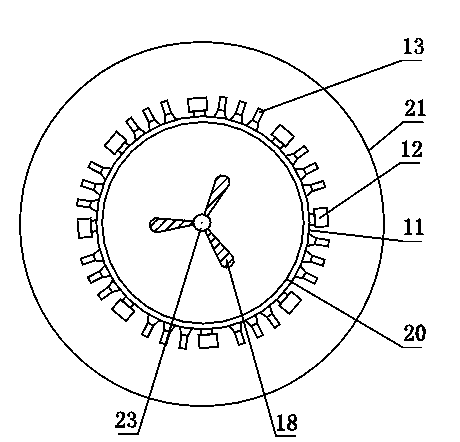

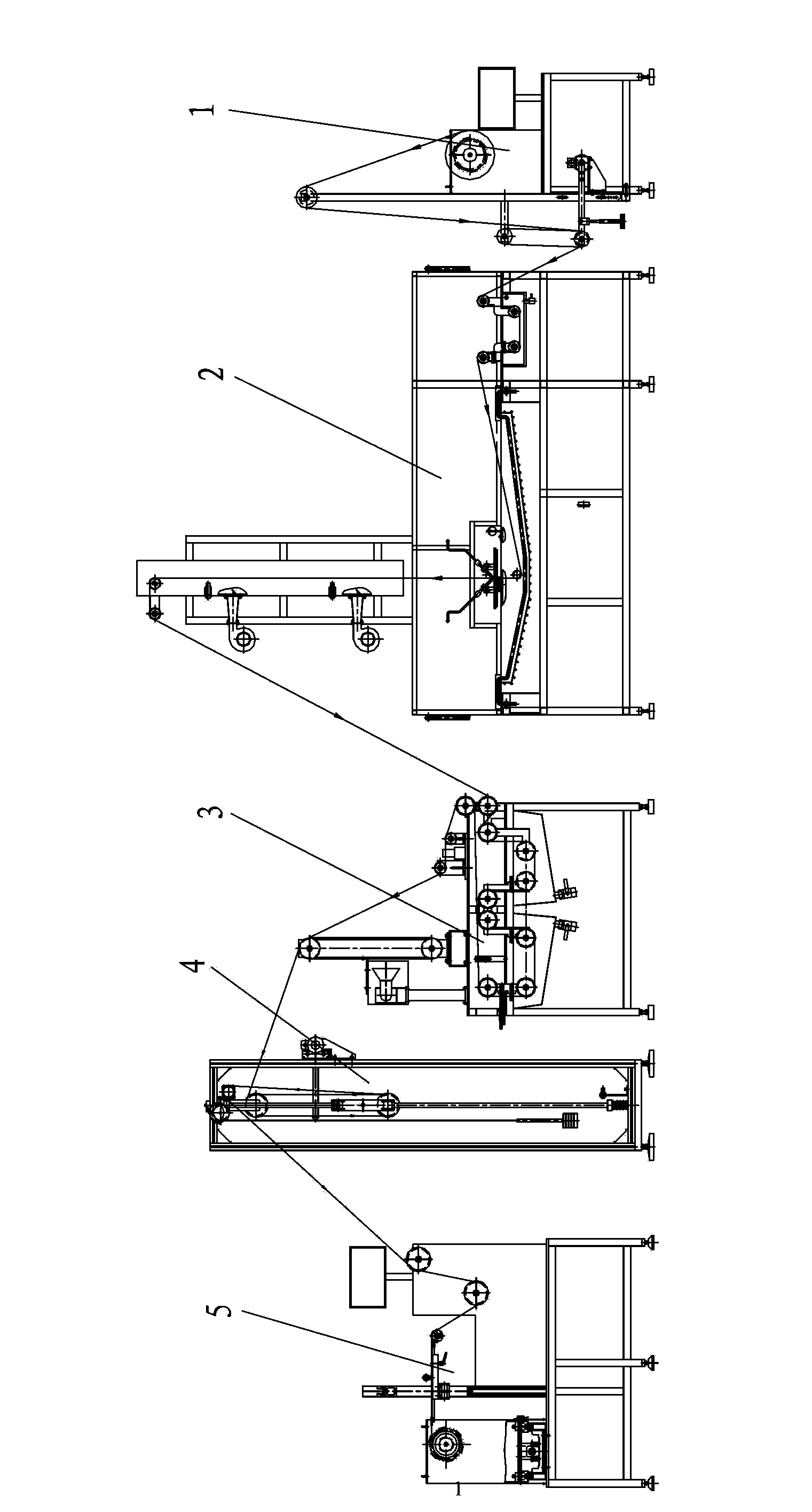

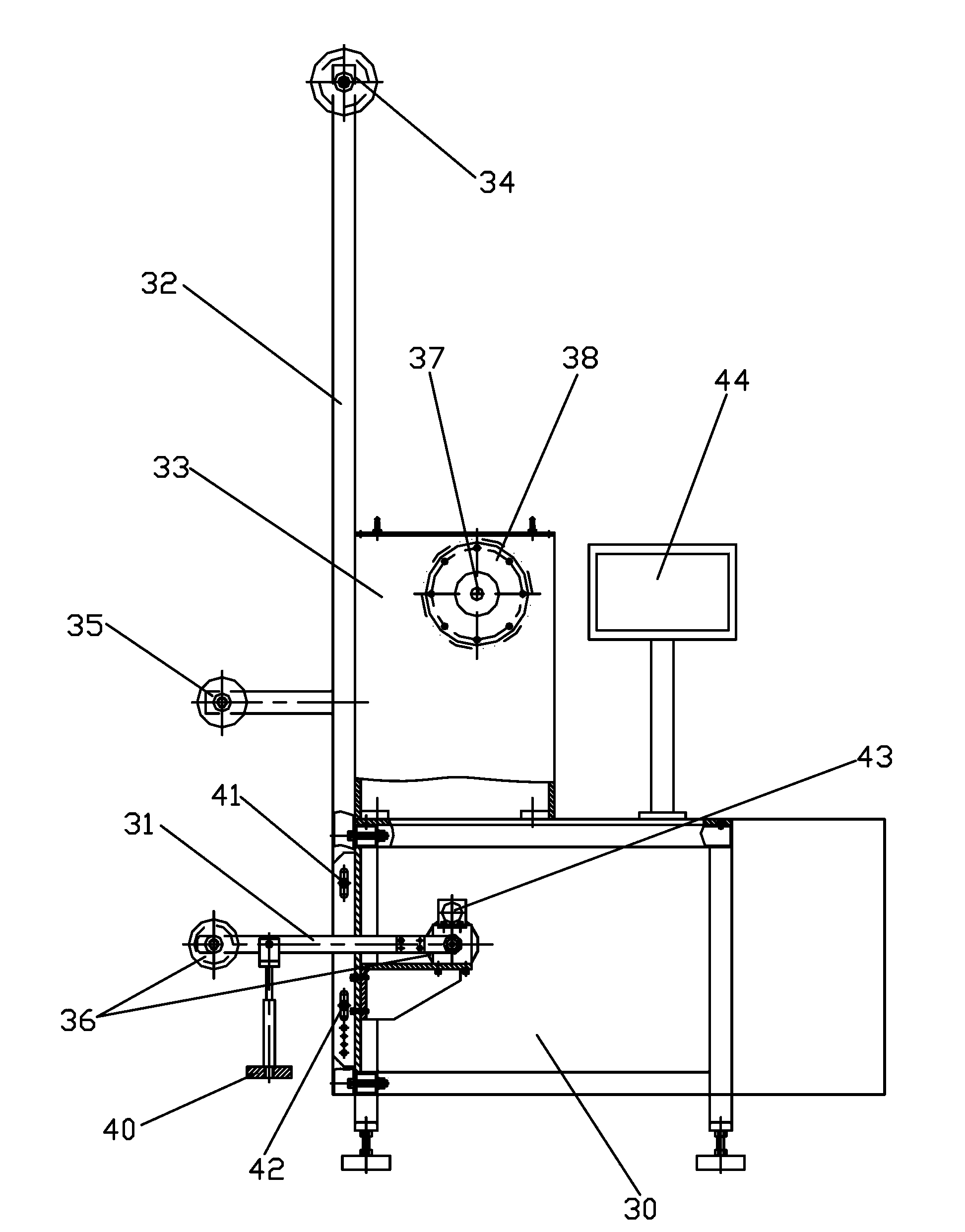

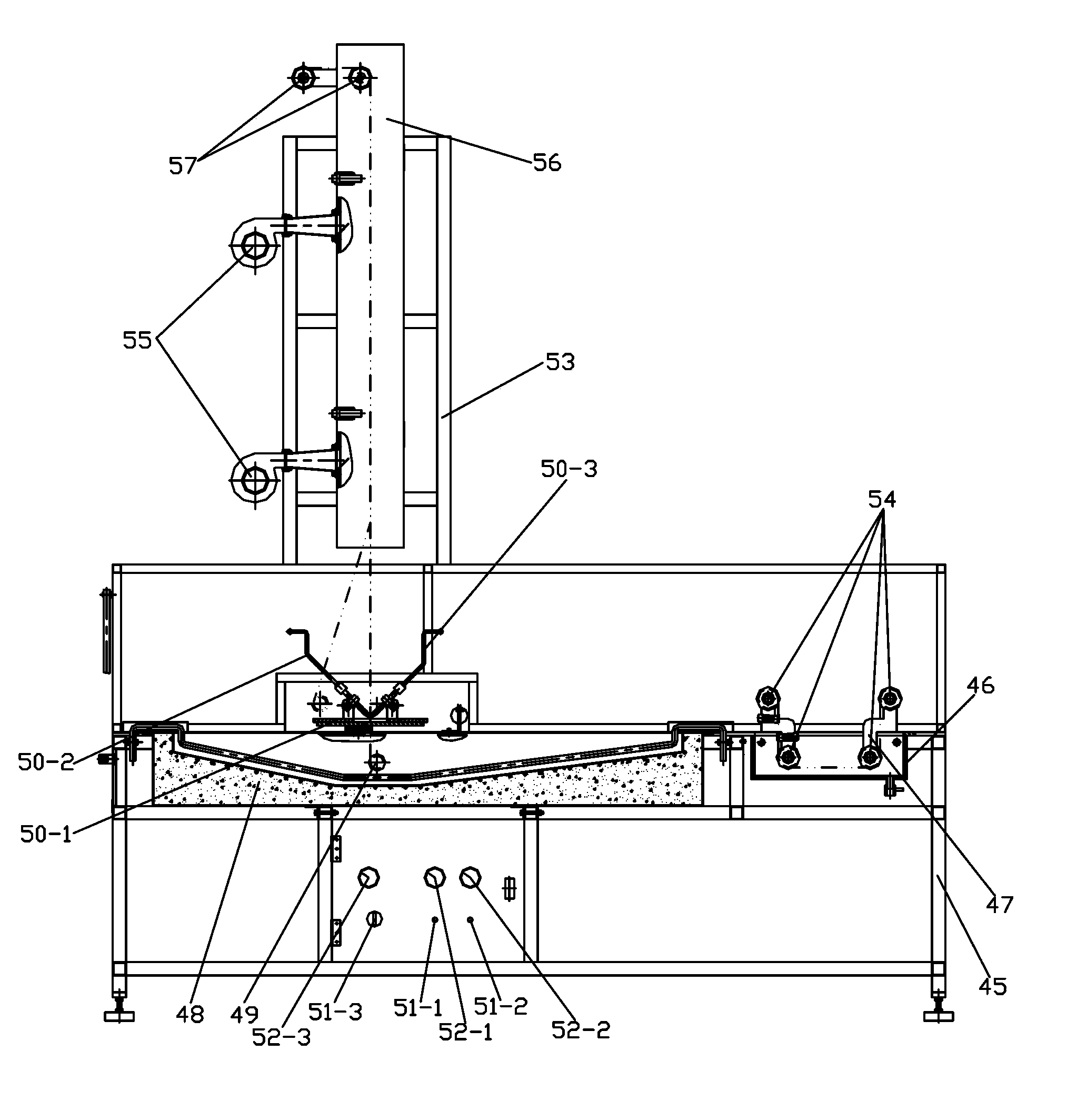

Multistation material transmission manipulator

InactiveCN101633023AImprove efficiencyQuality improvementProgramme-controlled manipulatorMetal-working feeding devicesPunchingManipulator

The invention relates to a multistation material transmission manipulator which is characterized in that the manipulator is used for a rotary sealing ring framework punching forming technique and mainly comprises a big template, a swing mechanism, a lifting mechanism, six finger mechanisms and two electromagnetic chucks, wherein the big template is round; the swing mechanism and the lifting mechanism are arranged at the center of the big template; 10 positioning slots are distributed on the periphery of the big template; the six finger mechanisms and the two electromagnetic chucks are divided into two groups, uniformly arranged on the swing mechanism in a radial shape and central symmetrical mode and are corresponding to the position of the positioning slot; and the finger mechanisms and the electromagnetic chucks are all arranged on the top of a rotary disc of the swing mechanism. The manipulator can automatically and continously finish the material transmission and carrying operation (among three working stations of stretching, reverse-drawing and punching) in the punching forming process of the rotary sealing ring framework.

Owner:HEBEI UNIV OF TECH

Slurry for forming insulating layer, separator for electrochemical device, method for producing the same, and electrochemical device

InactiveUS20100221965A1Excellent heat resistanceHigh reliabilityCosmetic preparationsToilet preparationsElectrochemistryMaterials science

A slurry for forming an insulating layer of the present invention includes heat-resistant insulating fine particles, a thickening agent, and a dispersion medium. The insulating fine particles are dispersed in the dispersion medium. The slurry for forming an insulating layer has a viscosity of 5 to 500 mPa·s. The proportion of particles with a particle size of 1 μm or less in the insulating fine particles is 30 vol % or more and the proportion of particles with a particles size of 3 μm or more in the insulating fine particles is 10 vol % or less. An electrochemical device of the present invention includes a separator for an electrochemical device of the present invention that is produced using the slurry for forming an electrochemical device of the present invention.

Owner:HITACHT MAXELL LTD

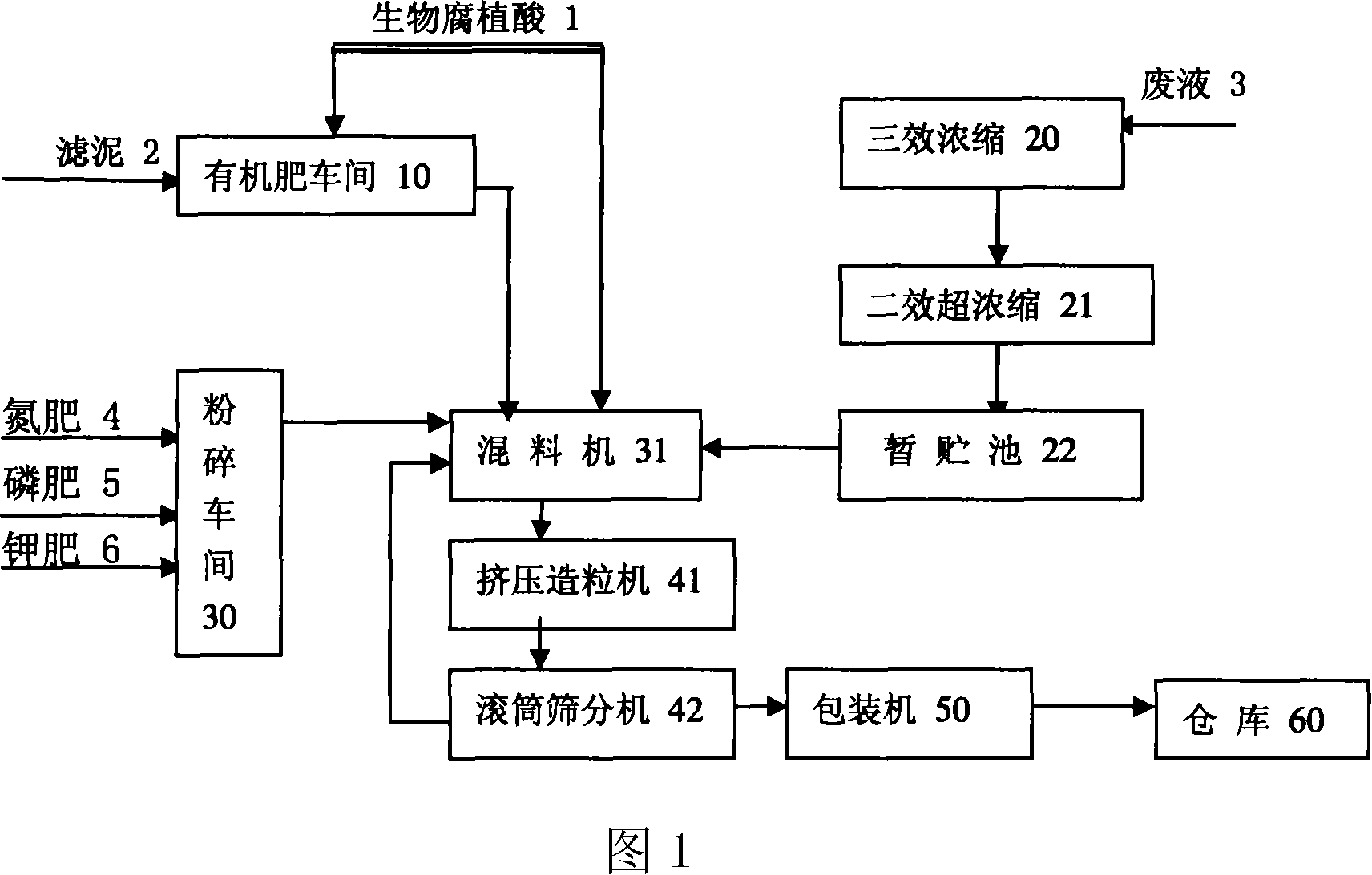

Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

InactiveCN101108779AImprove efficiencyLow efficiencyBio-organic fraction processingClimate change adaptationLiquid wasteContinuous fermentation

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Owner:越百年创新肥业(海南)有限公司

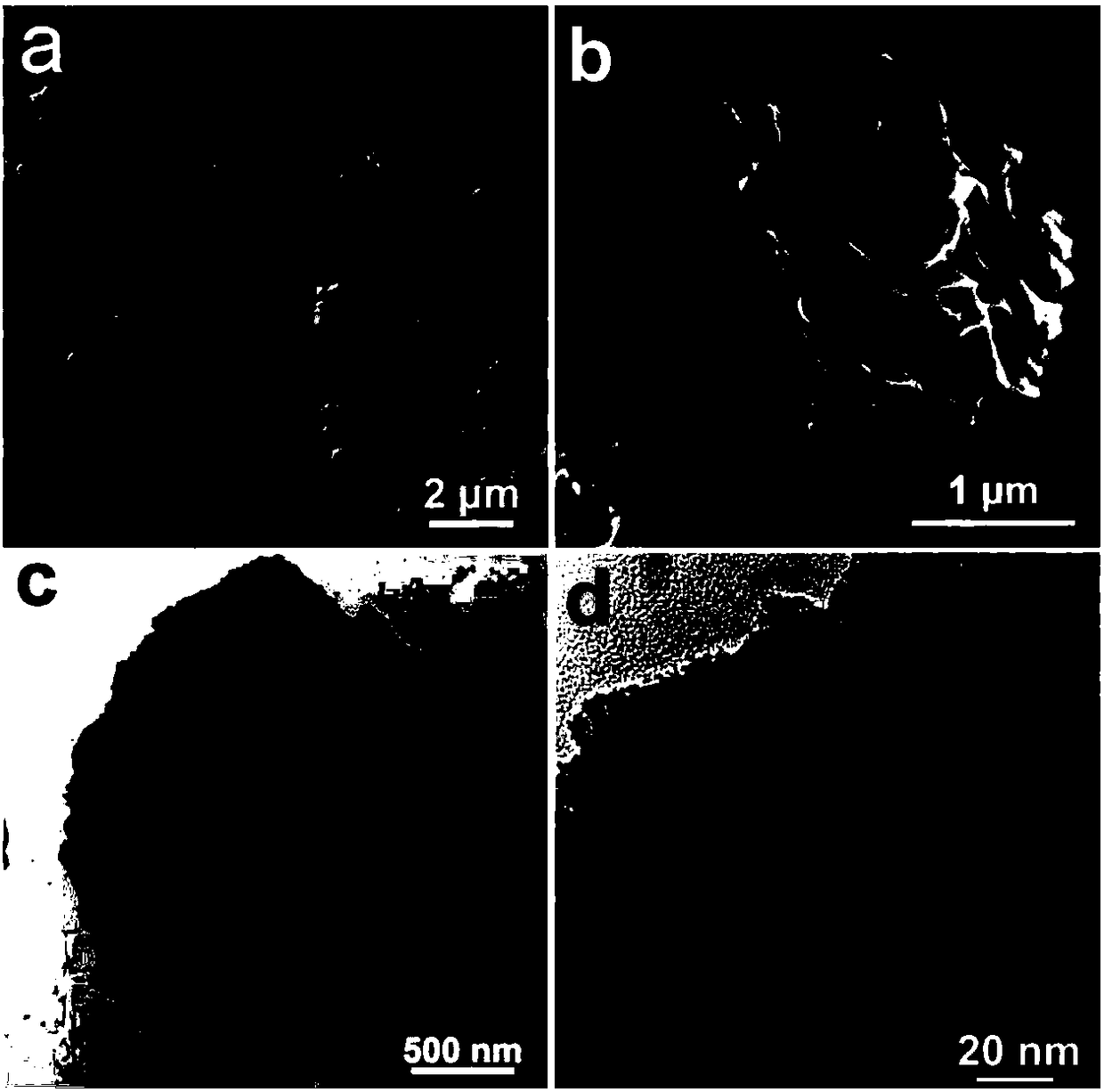

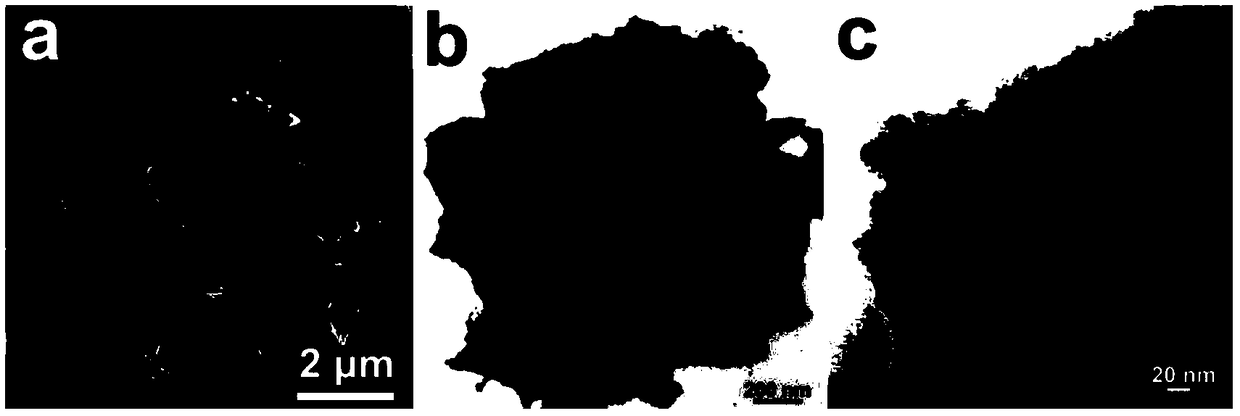

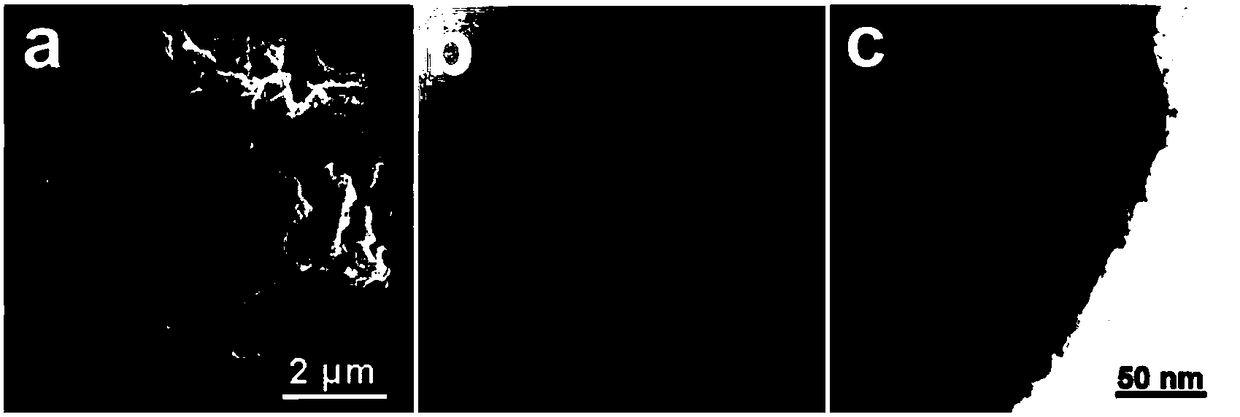

Three-dimensional compound structure based on three-dimensional MXene and general synthesis method thereof

ActiveCN108516528AReduce energy consumptionEasy to control versatilityNitrogen-metal/silicon/boron binary compoundsTitanium carbideSolventSolid phases

The invention discloses a general synthesis method of a three-dimensional compound structure based on three-dimensional MXene, and belongs to the field of nano materials. The three-dimensional compound structure is composed of a three-dimensional MXene load inorganic nano structure and is of a flower-like hierarchical porous structure. The method comprises the steps that an ultrasonic atomizer isadopted for atomizing mixed suspension liquid of three-dimensional MXene particles, metal salt and an auxiliary into aerosol micro-droplets, and under inert or reactive atmosphere, high-temperature fast drying is conducted to obtain the three-dimensional compound structure with controllable structure and size; or the three-dimensional MXene particles and metal salt or a nonmetallic compound are evenly mixed in solvent or in a solid-phase mode to obtain a mixture, and high-temperature calcination is conducted under the inert or reactive atmosphere to obtain the three-dimensional compound structure with controllable structure and size. By means of the three-dimensional compound structure based on the three-dimensional MXene, the problems of inorganic nano material particle aggregation, poorconductivity and two-dimensional MXene stacking can be solved, and thus a foundation is laid for preparation, processing and various aspects of application of a MXene-based high-performance functionalmaterial.

Owner:DALIAN UNIV OF TECH

Surface protection of neodymium iron boron permanent-magnet material

ActiveCN101029389AImprove bindingUniform surfaceMetallic material coating processesTectorial membraneBoron

A surface protection technology of neodymium-ferrous-boron permanent magnetic material is carried out by grinding for neodymium-ferrous-boron permanent magnetic material, degreasing while removing oil, removing rust while acid cleaning, activating acid liquid, putting it into black liquid or blue liquid, chemically coating and forming into blue-black or dark blue protection film. It has excellent combination and anti-corrosion performances.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

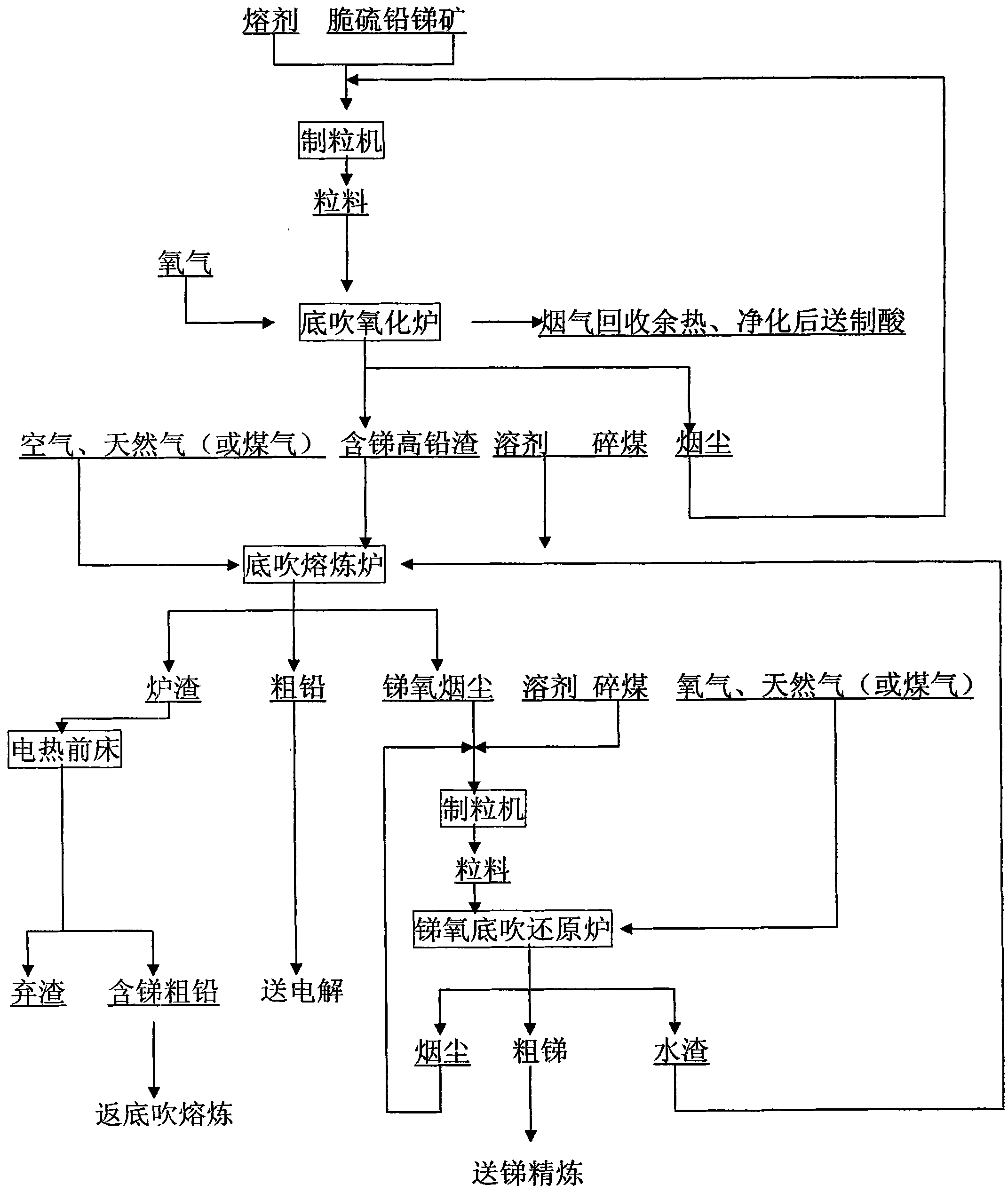

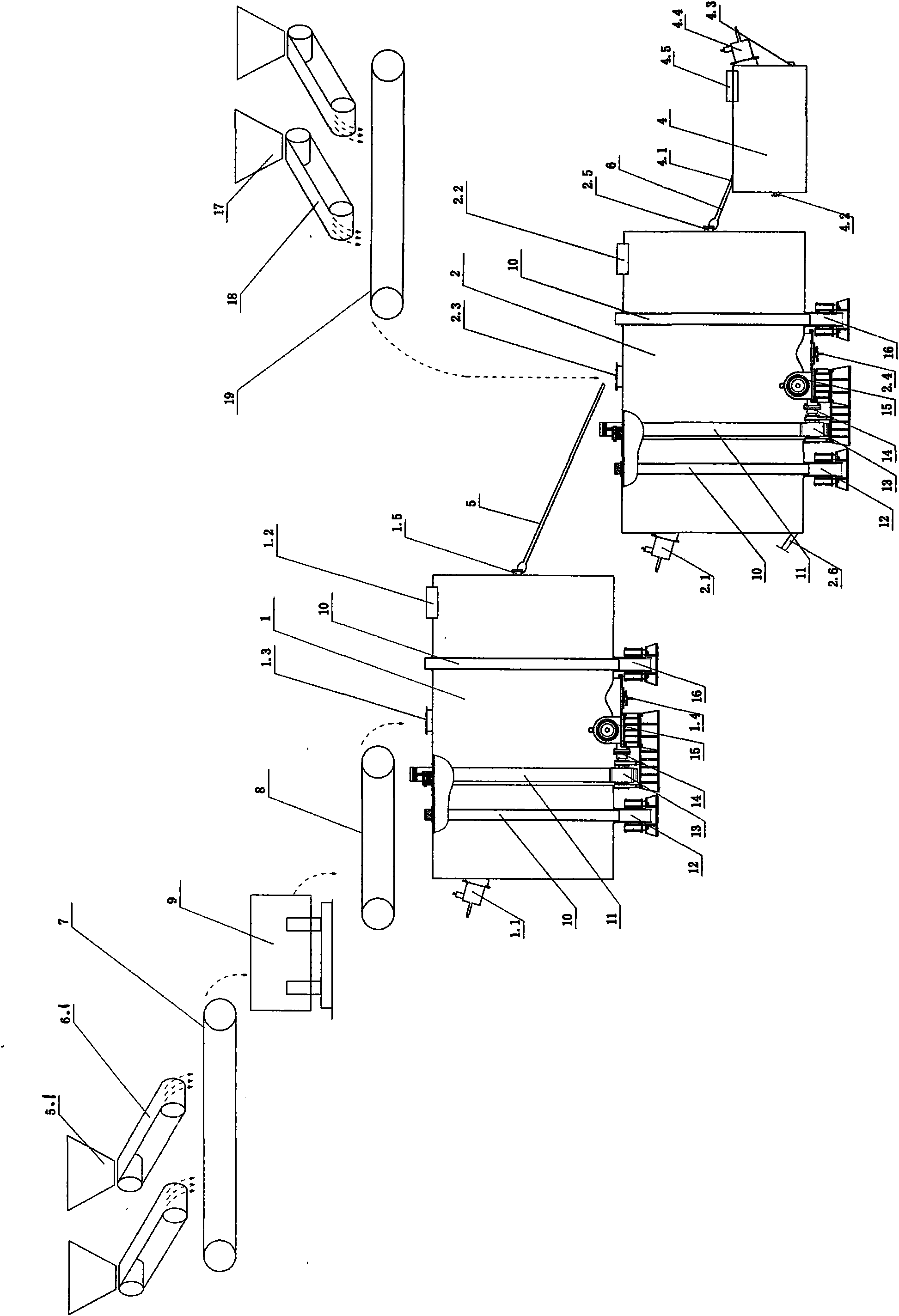

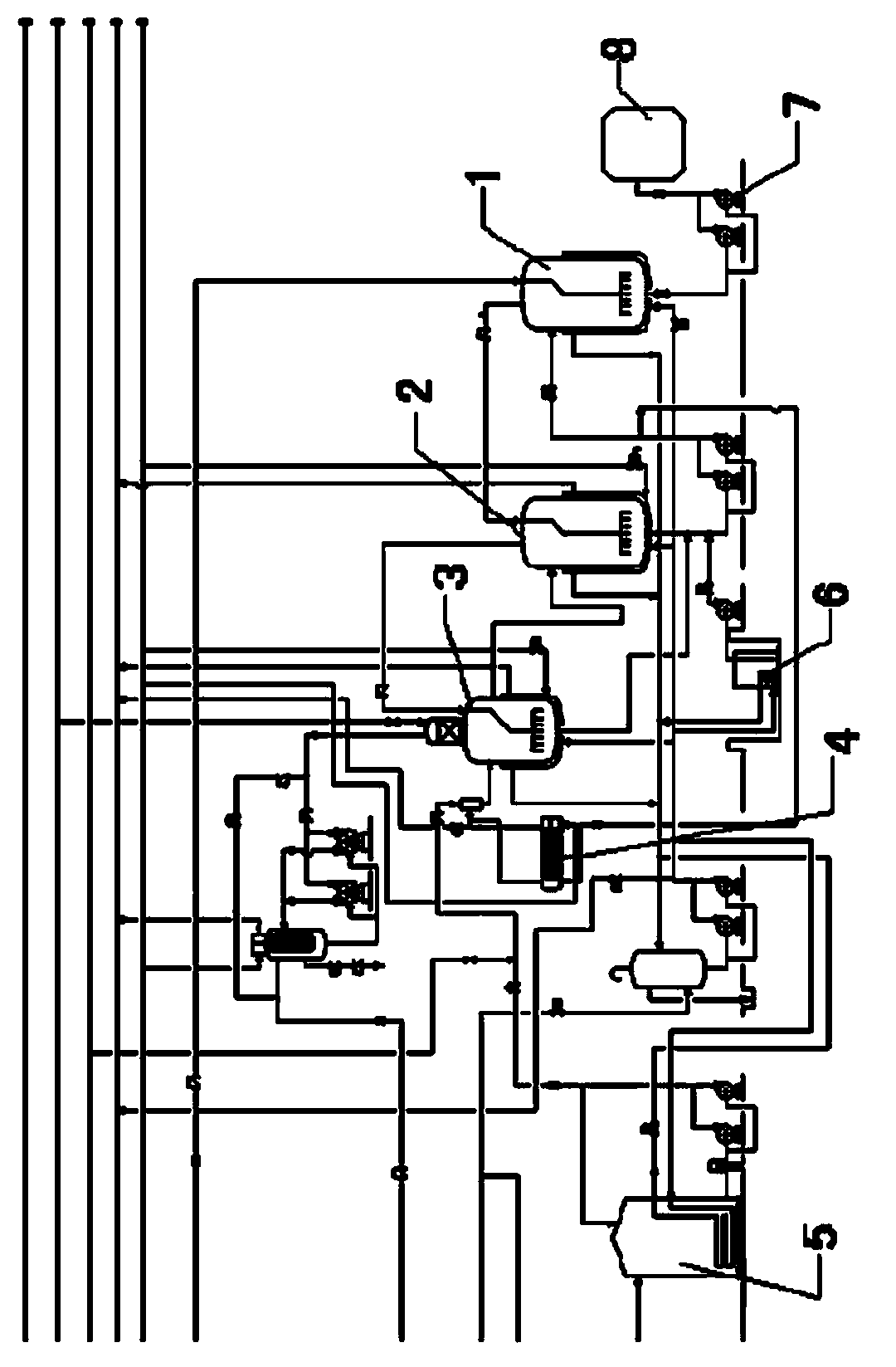

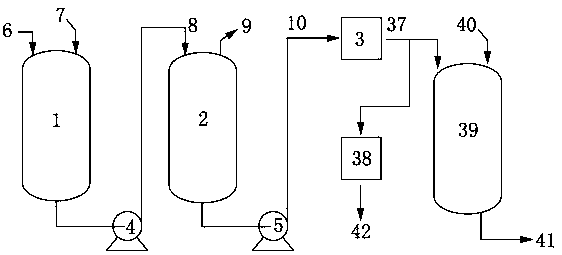

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

Method for shaping continuous fiber reinforced thermoplastic resin and shaping equipment thereof

ActiveCN101152767AAvoid mutual interferenceContinuous and stable productionFiber bundleFree rotation

The present invention discloses a molding method and molding equipment for a continuous fiber reinforced thermoplastic resin. The molding equipment of the present invention comprises a melting soakage mould. The melting soakage mould comprises a soakage mould outer body and a thermoplasticity resin fused mass crack flow passage, a soakage independent flow passage, a continuous fiber inlet passage and a soakage outlet which are arranged in the soakage mould outer body. The thermoplasticity resin fused mass crack flow passage is arranged on upstream end and forms an angle with the continuous fiber inlet passage. The thermoplasticity resin fused mass crack flow passage and the continuous fiber inlet passage are both communicated with the soakage independent flow passage. The soakage outlet is arranged on downstream end and is communicated with the end of the soakage independent flow passage. The soakage independent flow passage is also provided with at least one tension roller group which is capable to rotate freely. Using the molding equipment of the present invention for manufacturing continuous fiber reinforced thermoplastic resin avoids the interference and impairment between fiber bundles, guarantees the stable and continuous production and improves the dipping effect, so fiber reinforced thermoplastic resin with excellent performance can be obtained.

Owner:KINGFA SCI & TECH CO LTD +1

High-strength high-toughness low-odor polypropylene composition and preparation method and usage thereof

ActiveCN102757597AMeet the requirements of interior comfortIncrease productivityGlass fiberPolymer science

Owner:滁州格美特科技有限公司

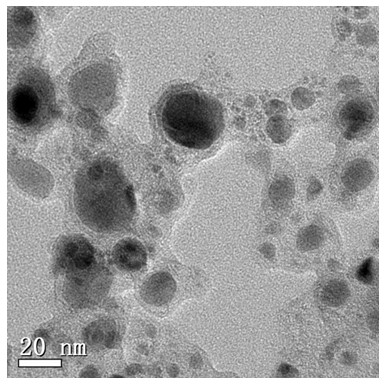

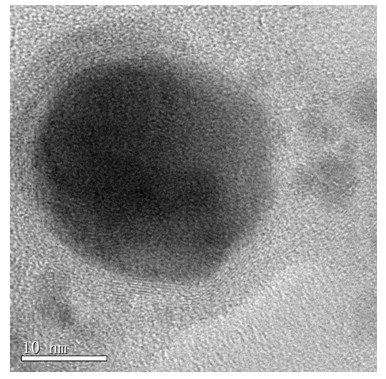

Method for preparing carbon-coated core-shell nanoparticles continuously

The invention relates to a method for preparing carbon-coated core-shell nanoparticles continuously, in particular to a method for preparing carbon-coated metallic oxides, carbon-coated metals, carbon-coated metallic carbides and carbon-coated metal alloy nanoparticles continuously. The method comprises the following steps of: in the process of flame combustion, forming a reducing atmosphere of different degrees in a reactor by controlling the fuel oxygen ratio; atomizing organic solvent solution of a metal salt, adding the atomized solution into the reactor to perform incomplete combustion at the temperature of between 1,000 and 1,800 DEG C; and performing thermal decomposition, nucleating, growing and in-situ carbon coating on a precursor at the high temperature a reducing atmosphere ofdifferent degrees to form the carbon-coated core-shell nanoparticles finally. In the obtained core-shell material, the nanoparticles are coated by carbon effectively and have the good heat stability and acid-base stability. Nanometer core-shell structures of the carbon-coated nanoparticles prepared by the method have the advantages of simple equipment process, no need of substrates, large-scale continuous production and easy industrial implementation.

Owner:EAST CHINA UNIV OF SCI & TECH

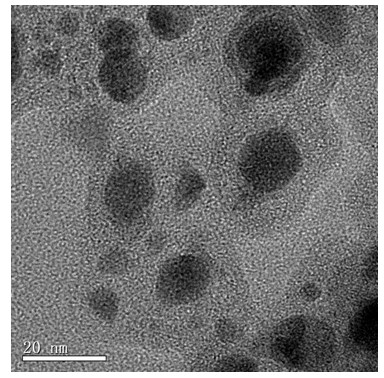

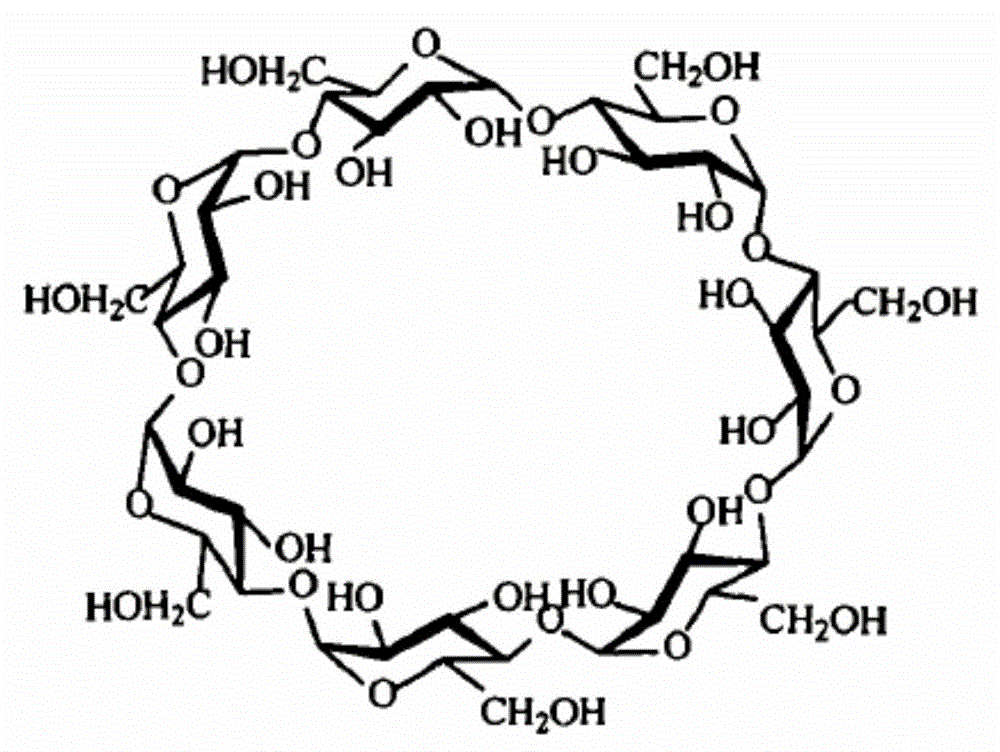

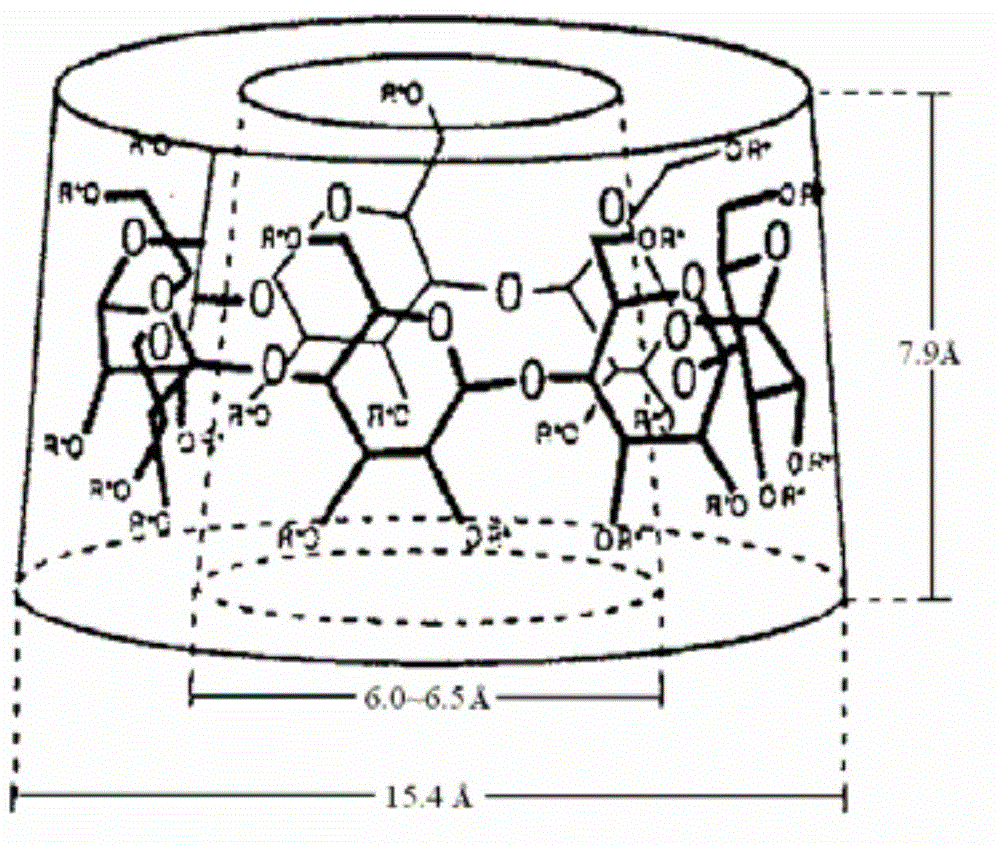

Preparation method of polymer porous membrane for removing water pollutants

ActiveCN104548949AHigh porosityLarge surface area of membrane poresSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkCyclodextrin

The invention relates to the technical field of separation membranes and discloses a preparation method of a polymer porous membrane for removing water pollutants. The preparation method comprises the following steps of blending cyclodextrin and a membrane preparation material, and adding a cross-linking agent into the mixture to fix the cyclodextrin to the membrane material so that repeated use is avoided, cyclodextrin is lost from the polymer porous membrane, a selective separation function of the polymer porous membrane is lost and polymer porous membrane hydrophility is changed. The polymer porous membrane has a substantial capability of adsorption and removal of organic pollutants such as phenols and aromatic amines (aromatic substances) in water, has good heavy metal ion removal effects, has high separation efficiency and low pressure drop, is convenient for regeneration, can be massively produced and used easily, and can be widely used in an ecological protection water purification treatment system and a water treatment system.

Owner:CHINA PETROLEUM & CHEM CORP +1

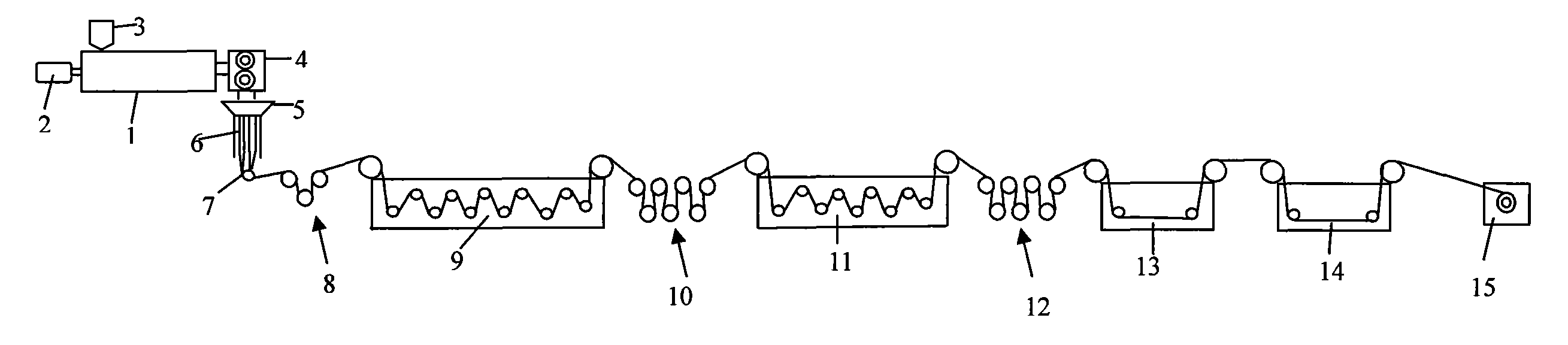

Continuous production technology of three kettle type sodium hydrosulfide

InactiveCN103466559AContinuous productionRealize continuous productionSulfur compoundsContinuous productionSulfur hydride

The invention relates to a continuous production technology of three kettle type sodium hydrosulfide. The continuous production technology comprises the following processing steps: (1) firstly, hydrogen sulfide enters into the bottom of a first reaction kettle and is reacted with a mixed liquid pumped by a second reaction kettle, the unreacted gas at the top of the first reaction kettle enters into the bottom of the second reaction kettle and is reacted with a material from a third reaction kettle, and the reaction temperature is adjusted by cooling water in a jacket; (2) gases which are incompletely reacted at the top of the second reaction kettle and cooled through a gas cooler enter into the bottom of the third reaction kettle and are fully reacted with 48% sodium hydroxide liquor from an alkali liquor tank, and the reaction material on the upper part of the third reaction kettle enters into the second reaction kettle to react due to gravitational flow; (3) the material which is fully reacted at the bottom of the first reaction kettle is pumped into a sodium hydrosulfide product tank through a pump to store and sell. The technology provided by the invention has the beneficial effect that sodium hydrosulfide production units are arranged linearly, so that continuous production of NaHS liquor is realized.

Owner:SHANDONG KENLI PETROCHEM GRP

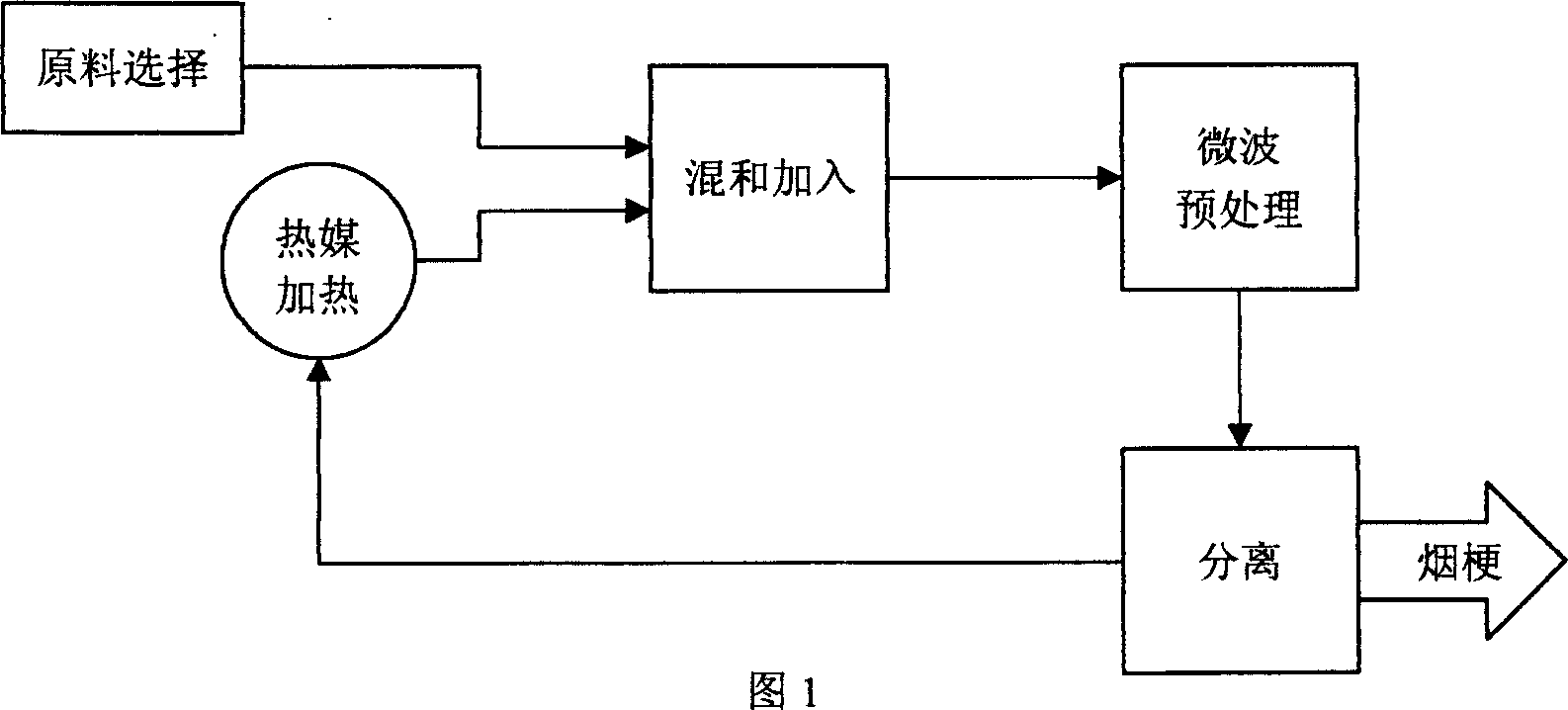

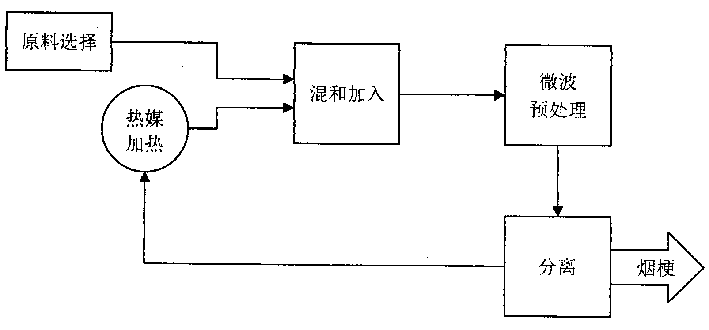

Technique for pretreating cabo

InactiveCN1518906AReduce energy consumptionGood smokeTobacco preparationPretreatment methodMicrowave

A technology for pre-processing the stems of tobacco leaves includes heating the low-loss granular solid microwave medium as thermal medium to 100-200 deg.c, mixing said stems with said thermal medium, heating in microwaven over for puffing the stems, and separating the tobacco stems from thermal medium. The pre-processed stems feature high loseness and elasticity, and good smell.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

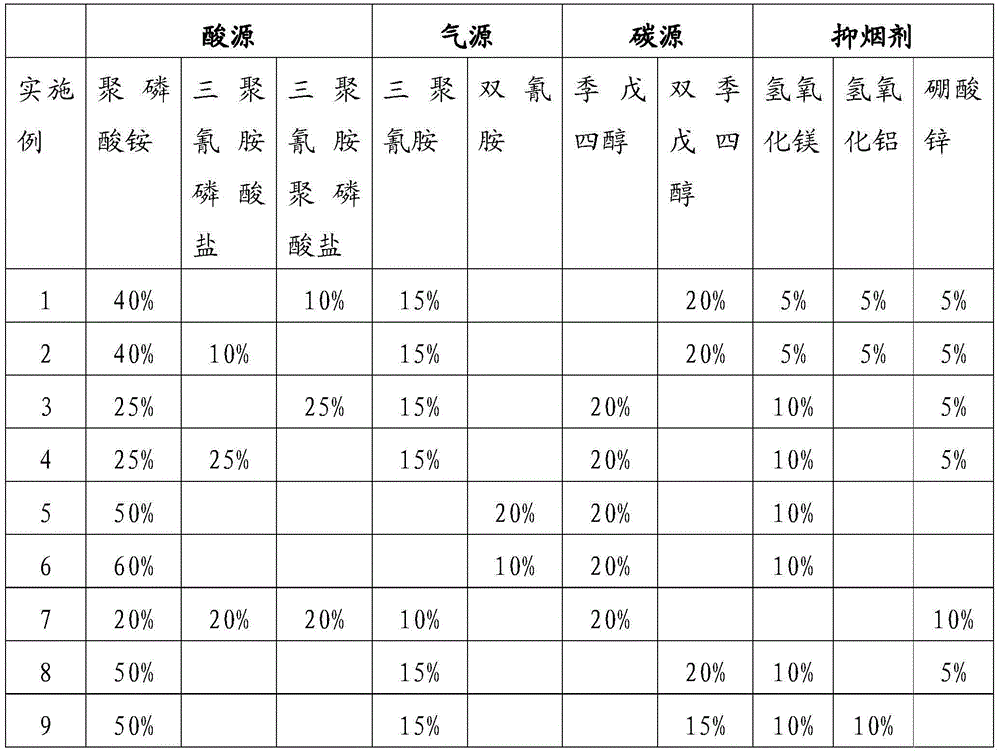

Composite intumescent flame retardant and preparation method thereof

InactiveCN104532588AReduce generationImprove flame retardant performanceFibre typesMelamine phosphateAluminium hydroxide

The invention discloses a composite intumescent flame retardant which is composed of the following components in percentage by weight: 50-65% of acid source, 10-20% of gas source, 15-20% of carbon source and 10-20% of smoke inhibitor. The acid source is composed of at least one of ammonium polyphosphate, melamine phosphate and melamine polyphosphate, wherein the ammonium polyphosphate is crystal II ammonium polyphosphate with the average degree of polymerization of greater than 1000; the gas source is composed of at least one of melamine and dicyandiamide; the carbon source is composed of at least one of pentaerythritol and bis pentaerythritol; and the smoke inhibitor is composed of at least one of magnesium hydroxide, aluminum hydroxide and zinc borate. The invention also discloses a preparation method of the composite intumescent flame retardant.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

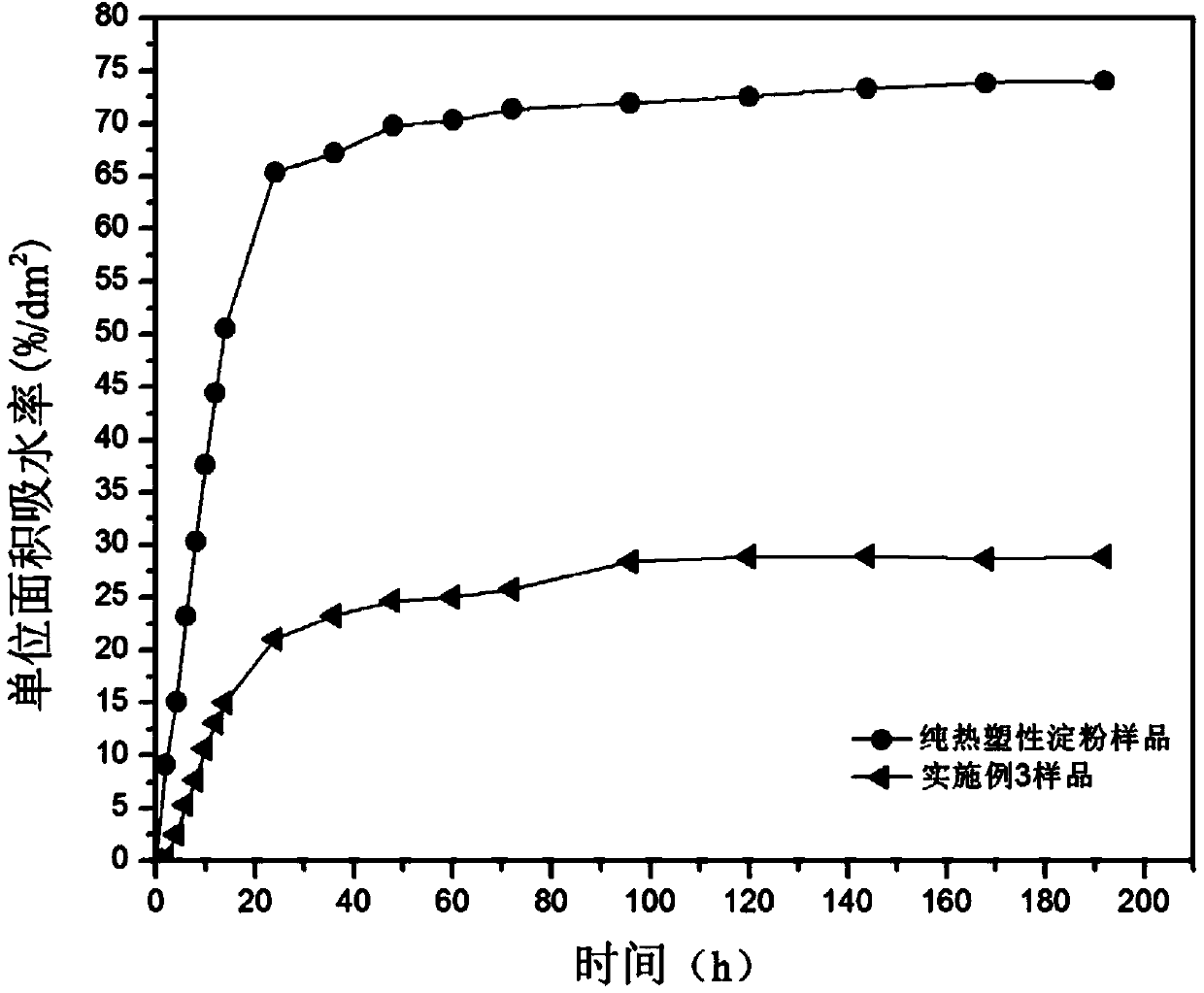

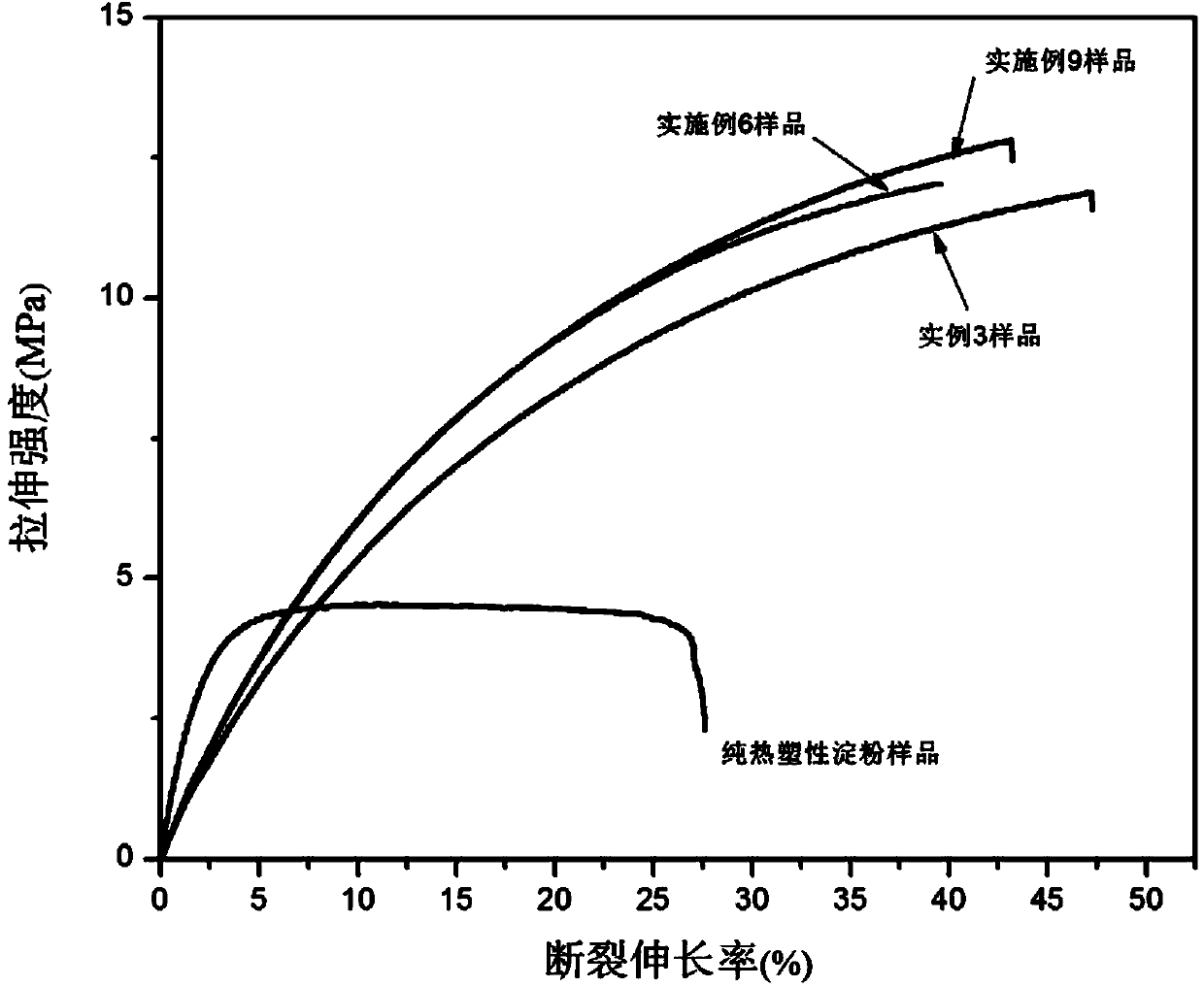

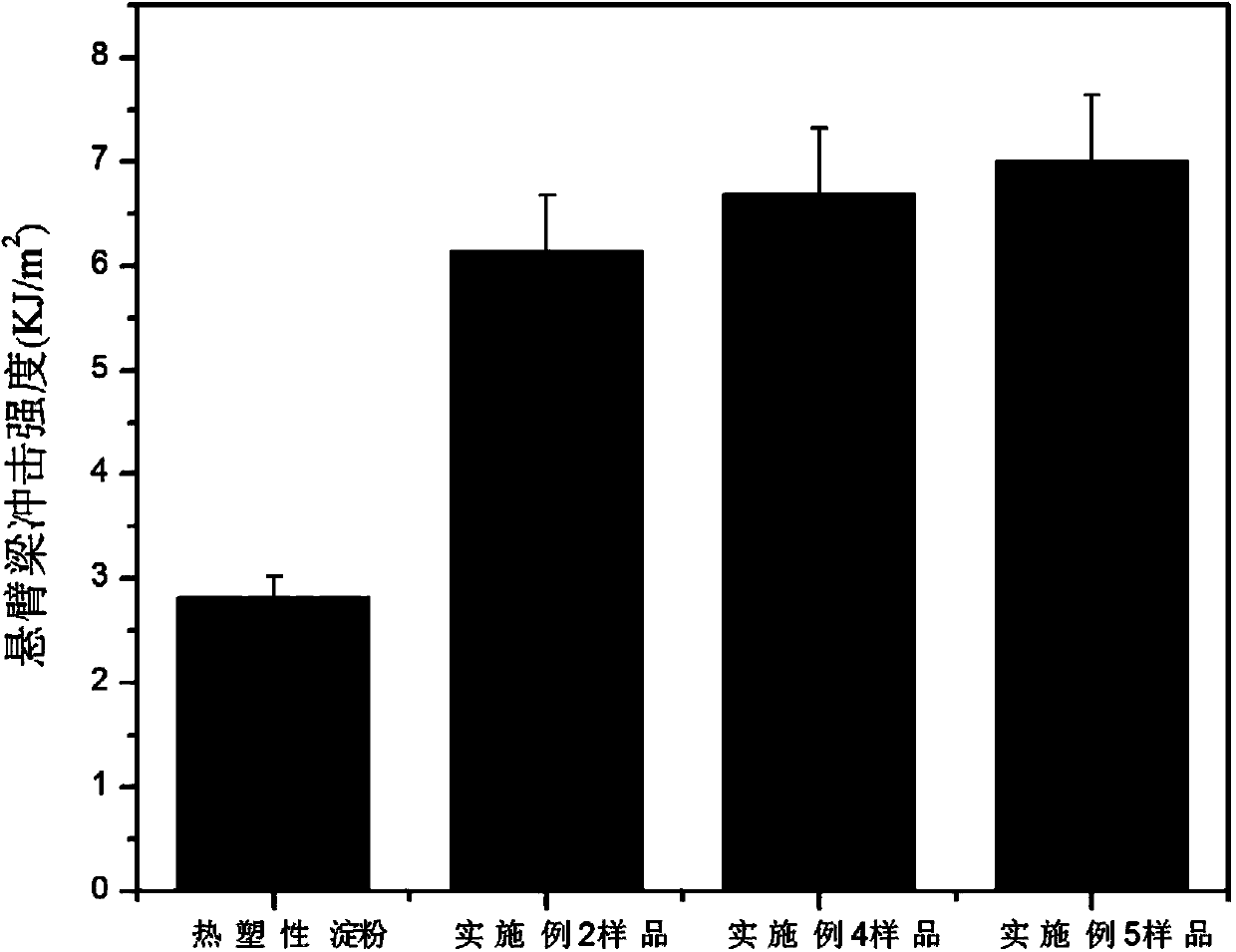

Continuously-produced full-degradable starch-based plastic alloy and preparation method thereof

The invention discloses a continuously-produced full-degradable starch-based plastic alloy and a preparation method thereof. The starch-based plastic alloy contains the following components in parts by weight: 40-90 parts of starch, 5-60 parts of poly(butylene succinate), 5-60 parts of polylactic acid, 10-40 parts of plasticizer, 0.1-10 parts of compatibilizer and 1-10 parts of processing acid. The preparation method comprises the steps of mixing starch, plasticizer and part of processing aid, and extruding to obtain thermoplastic starch particles; then, mixing the thermoplastic starch particles with poly(butylene succinate), polylactic acid, compatibilizer and the residual processing aid, and extruding to obtain the starch-based plastic alloy. The starch-based plastic alloy disclosed by the invention is favorable in hydrophobicity and strength, good in component compatibility, favorable in thermoplastic processability, capable of realizing continuous production and processing as well as simple and feasible in technical process.

Owner:EAST CHINA UNIV OF SCI & TECH

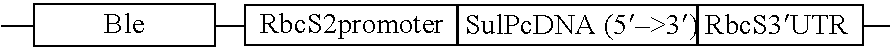

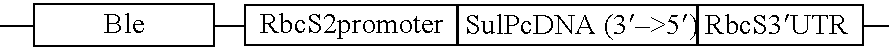

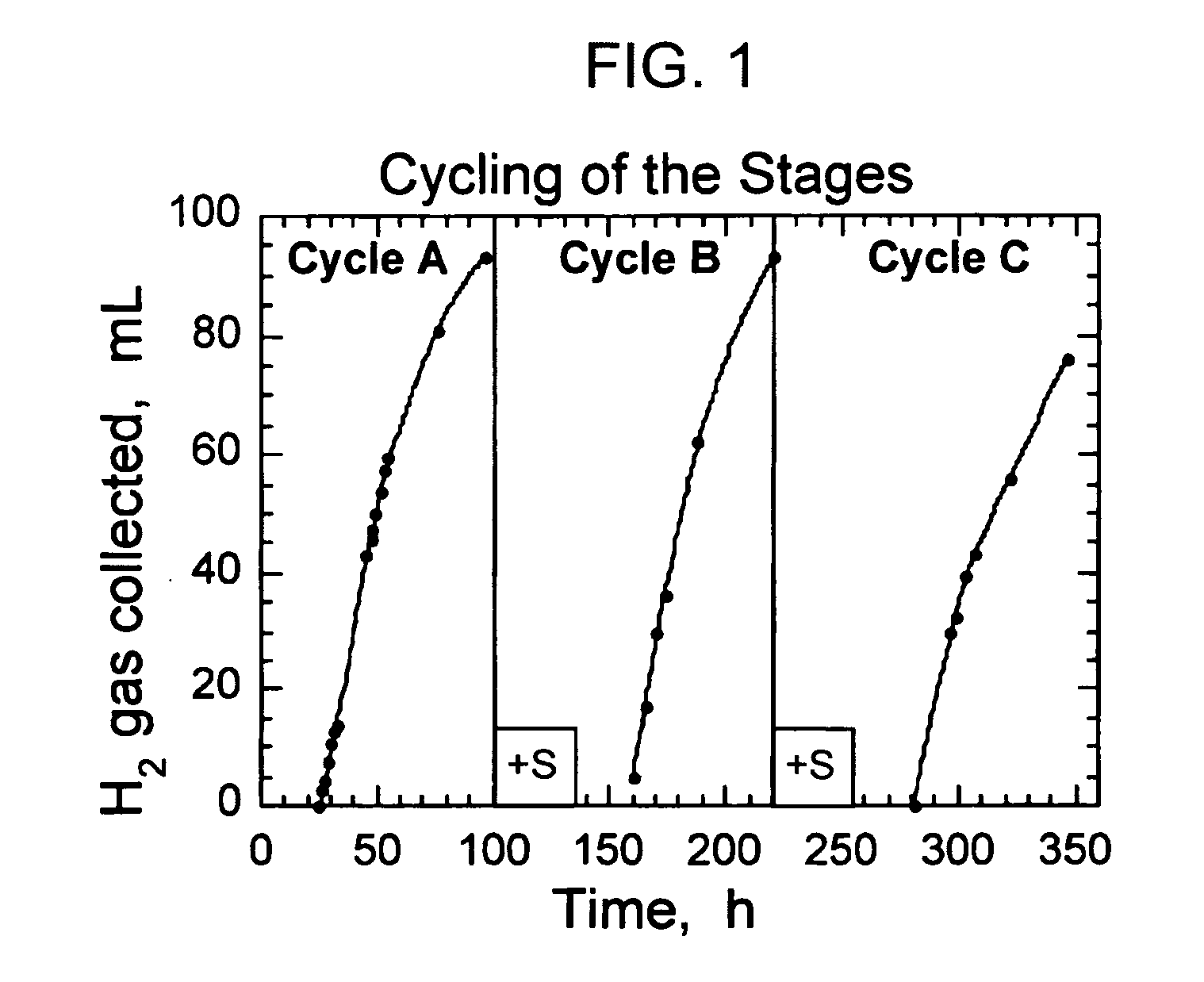

Modulation of sulfate permease for photosynthetic hydrogen production

InactiveUS20050014239A1Closely alignedContinuous productionSugar derivativesBacteriaAlgaenanWild type

Sustained hydrogen production is obtained by the culturing of a genetically-modified algae, where the ability of the chloroplasts to intake sulfate is reduced or eliminated compared to wild-type algae. The alga is cultured in a sealed environment in a liquid or solid medium that contains sulfur, and hydrogen is generated continuously. Alternatively, the algae may be cultured in the presence of bacteria that also produce hydrogen gas. The hydrogen produced can be collected and used as a clean energy source.

Owner:RGT UNIV OF CALIFORNIA

Method of continuously preparing 1,2-dihydroxypropane by glycerin catalytic hydrogenation

The invention discloses a making method of 1, 2-propanediol under mild condition, which is characterized by the following: adopting copper, zinc and manganese and or aluminium catalyst; aerating glycerin and hydrogen continuously from the top of reactor; hydrogenating glycerin at 200-250 deg.c under 2.5-5Mpa; outputting and collecting reacting product from the bottom of reactor continuously; separating gas; returning to recycle; setting the weight rate of metal element of catalyst at 16-48:24-48:0.15-4:0-8.

Owner:NANJING TECH UNIV

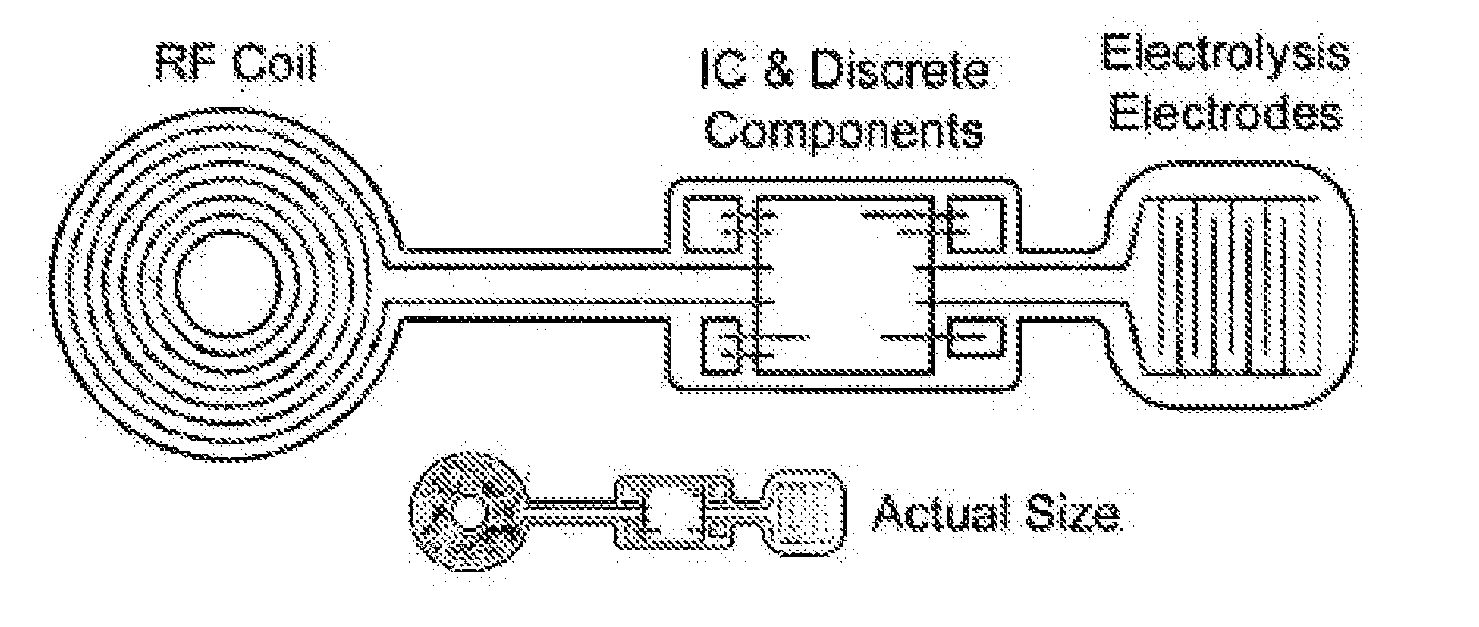

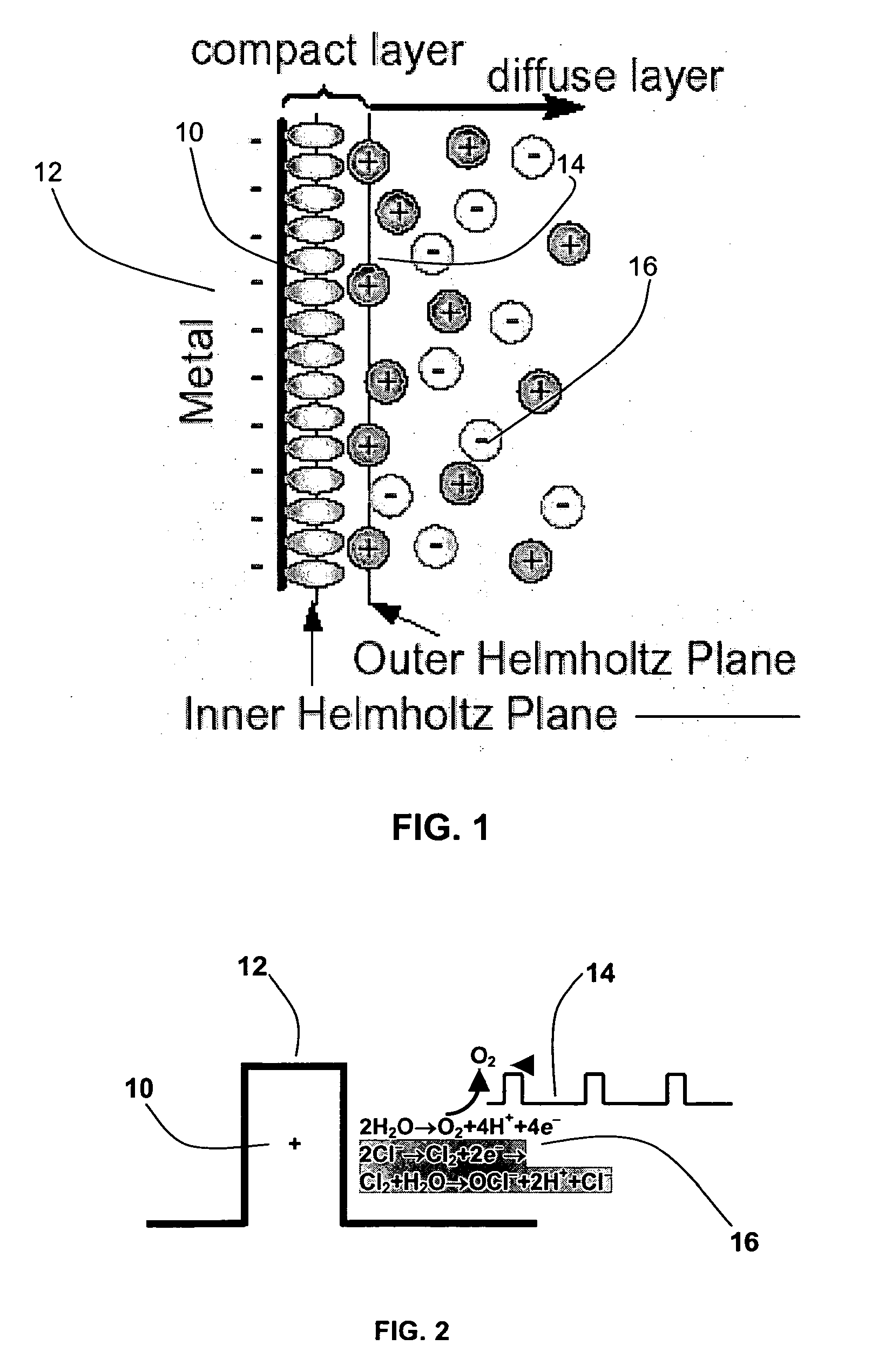

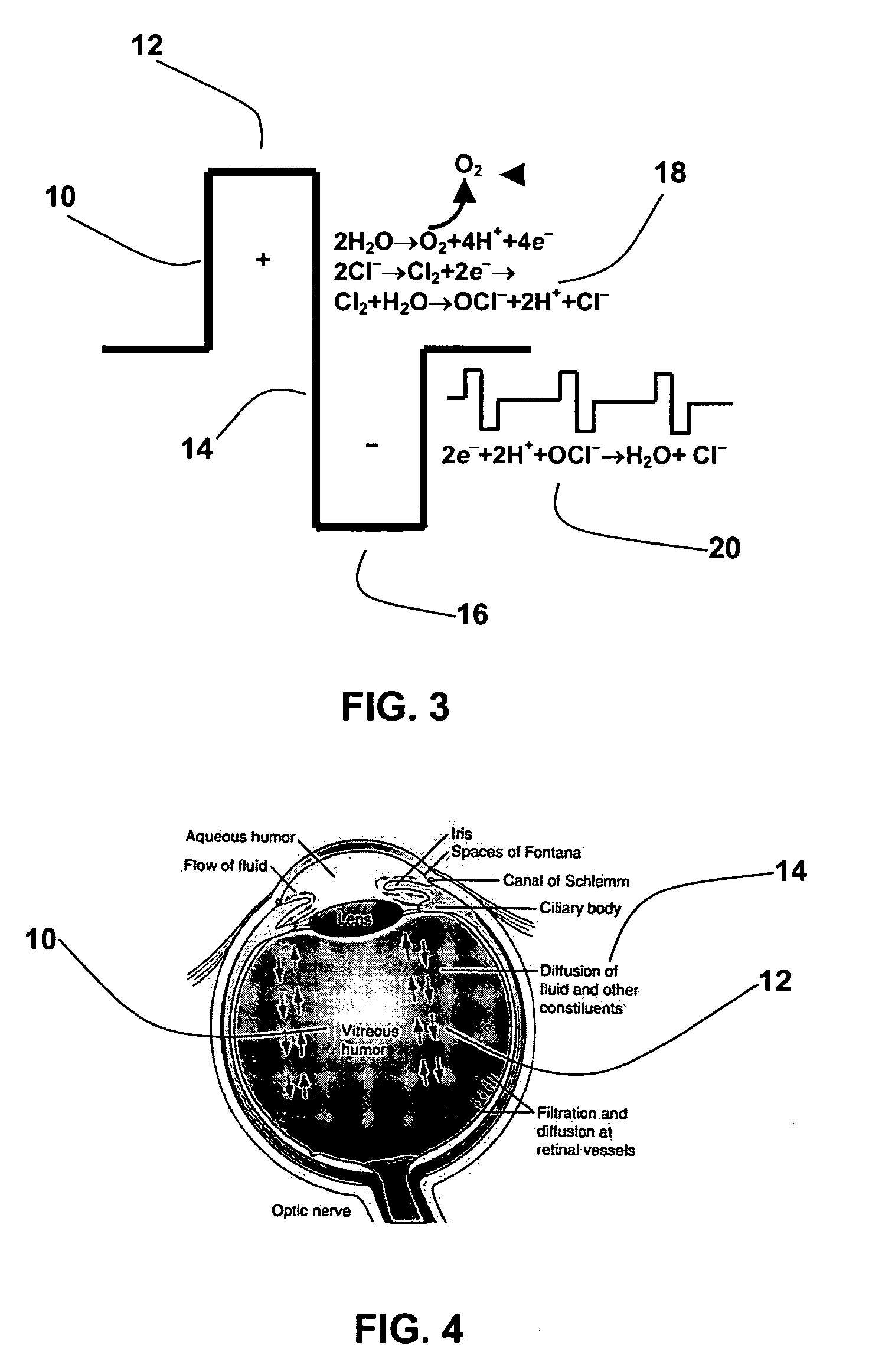

Method and apparatus for treating ischemic diseases

ActiveUS20100168646A1Formation of free chlorine is avoidedInhibition formationSenses disorderElectrotherapyDiabetic retinopathyRetinal Vascular Disorder

The present invention relates to the treatment of ischemic diseases, and more particularly, to treatment of diabetic retinopathy and ischemia of the retinal and choroidal tissues. The treatment, which will work in vitrectomized eyes as well as non-vitrectomized eyes, is based on selective and fractional electrolysis of the vitreous humor to produce oxygen and optionally active chlorine while simultaneously controlling pH. Oxygen or active chlorine can suppress or reverse the onset of diabetic retinopathy, other retinovascular diseases, and choroidal neovascularization.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

Method for producing 1,1,1,3,3-pentafluoropropane

InactiveUS6316681B1High yieldContinuous productionPhysical/chemical process catalystsPreparation by halogen halide additionHydrogen fluorideGas phase

The present invention relates to a method for producing 1,1,1,3,3-pentafluoropropane. This method includes a first step of fluorinating 1-chloro-3,3,3-trifluoropropene in a liquid phase by hydrogen fluoride in the presence of an antimony compound as a catalyst, or a second step of fluorinating 1-chloro-3,3,3-trifluoropropene in a gas phase by hydrogen fluoride in the presence of a fluorination catalyst. If the first step is taken, 1,1,1,3,3-pentafluoropropane can be produced with a high yield. If the second step is taken, 1,1,1,3,3-pentafluoropropane can continuously be easily produced. Therefore, the second step is useful for an industrial scale production thereof. According to the invention, 1-chloro-3,3,3-trifluoropropene may be produced by a method including a step of reacting 1,1,1,3,3-pentachloropropane with hydrogen fluoride in a gas phase in the presence of a fluorination catalyst. This method is useful, because yield of 1-chloro-3,3,3-trifluoropropene is high.

Owner:CENT GLASS CO LTD

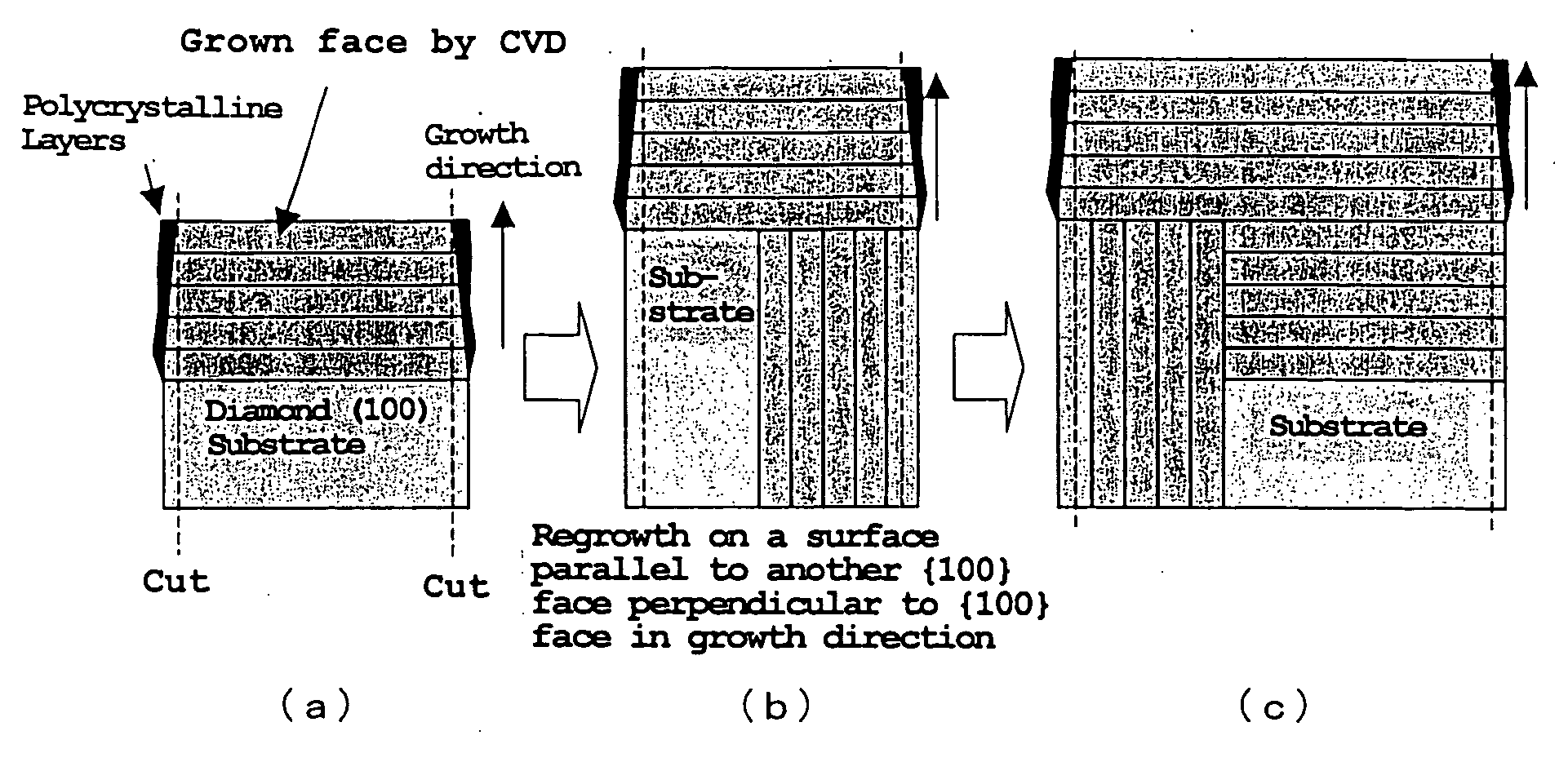

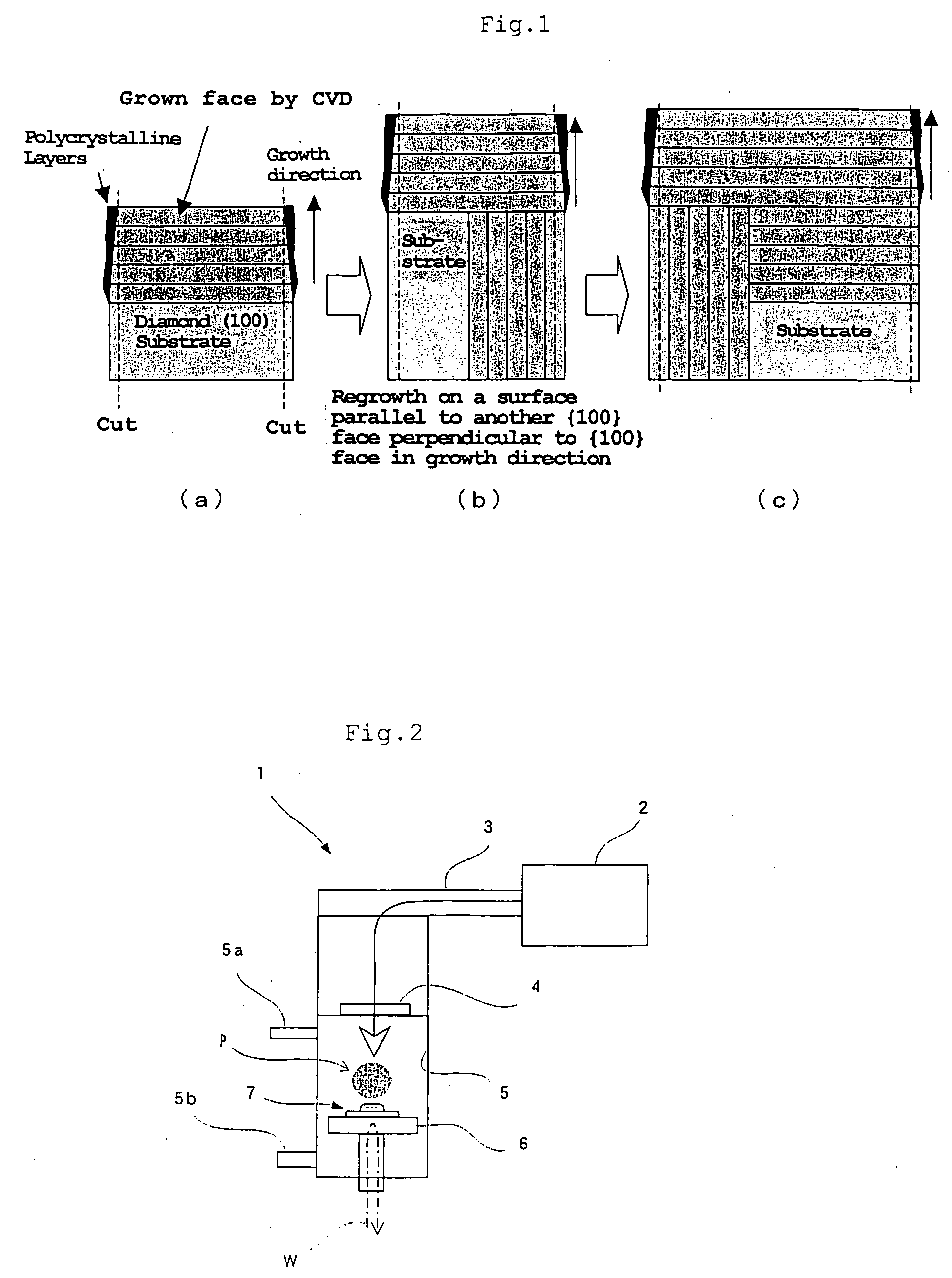

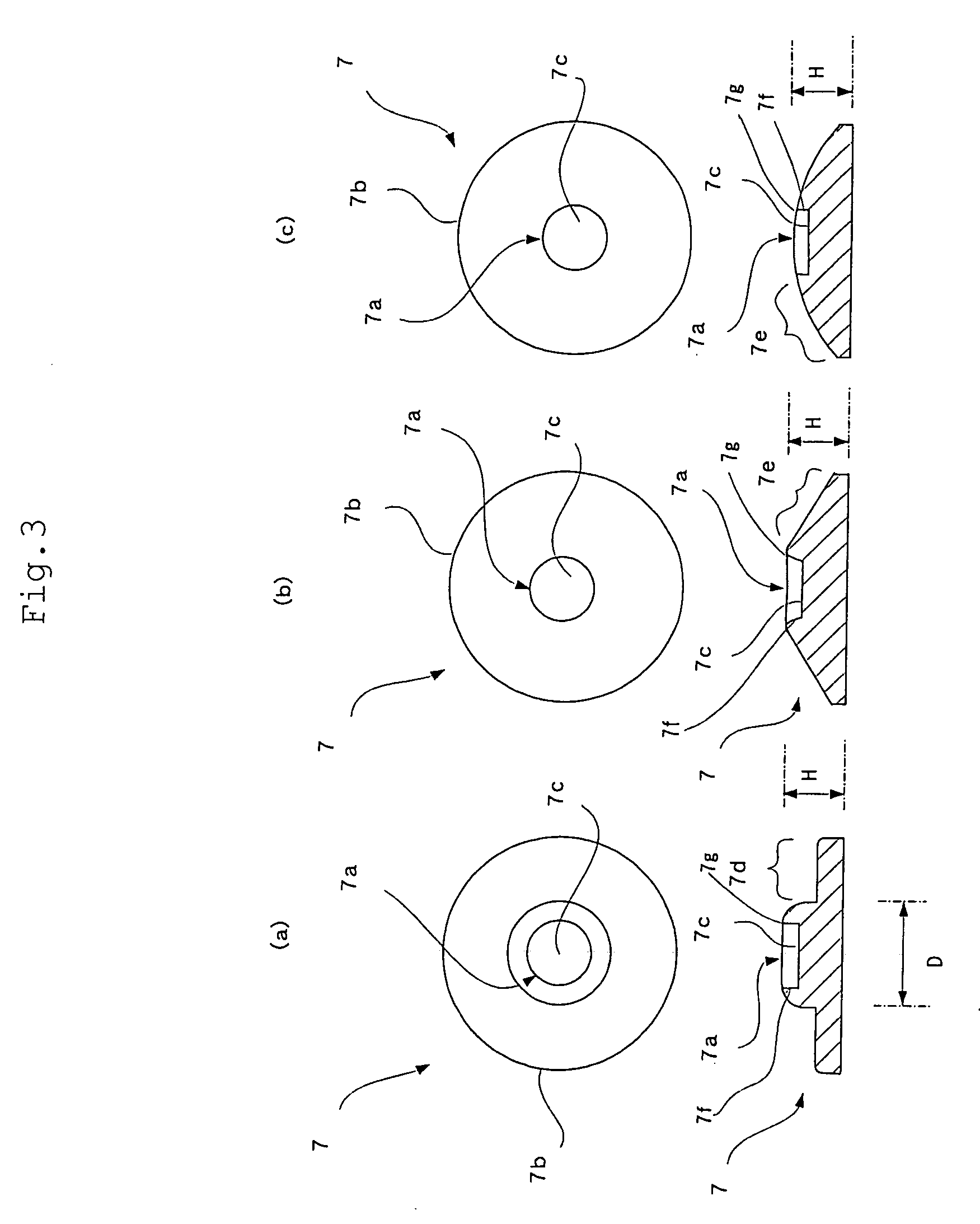

Method of producing single crystal

ActiveUS20060266279A1Low costProduce significantPolycrystalline material growthFrom normal temperature solutionsGas phaseSingle crystal

The present invention provides a method for producing a single crystals by preferential epitaxial growth of {100} face, the method comprising the steps of (1) growing the crystal on a single crystal {100} substrate; (2) forming on the side of the grown crystal a surface parallel to a {100} face different from the {100} face in the growth direction, and (3) growing the crystal on the formed {100} surface; and the steps (2) and (3) being performed once or more than once. The present invention further provides a method for producing a single-crystal diamond wherein used is a metallic holder for the single-crystal diamond having a crystal holding portion which is raised above an outer peripheral portion of the holder, is apart from the outer peripheral portion of the holder, and has a recessed shape. According to the present invention, a method for producing a single crystal by epitaxial growth, in particular a method for producing a single-crystal diamond using gaseous phase synthetic methods enable the production of a large single-crystal diamond in a comparatively short time at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

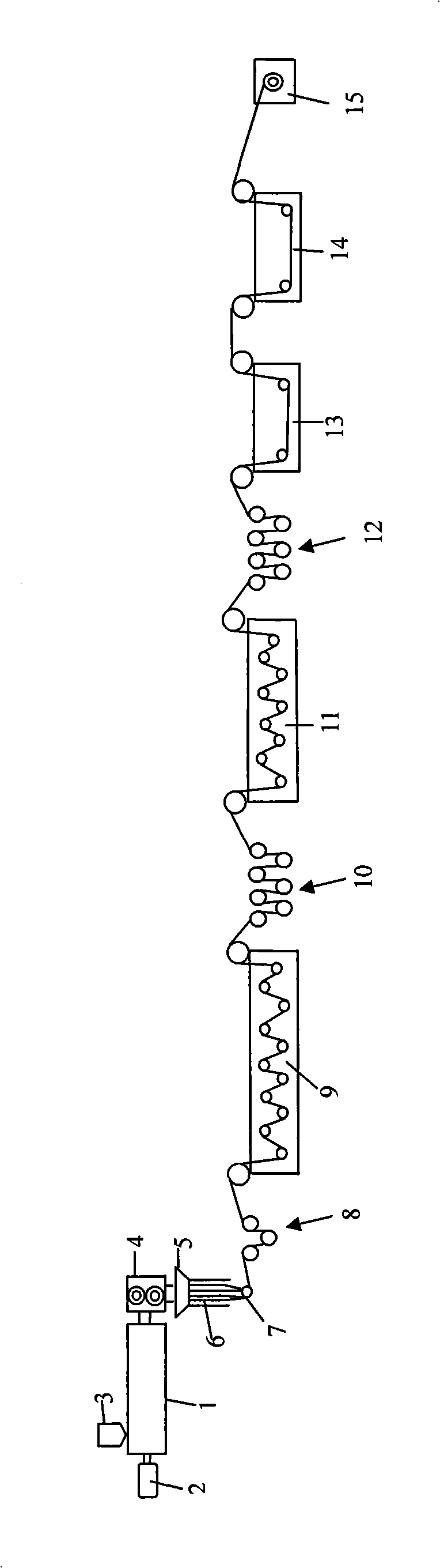

Method and equipment for preparing ultrahigh molecular weight polyethylene fibers

InactiveCN101935894AContinuous productionShort processArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

The invention discloses a method and equipment for preparing ultrahigh molecular weight polyethylene fibers. The method comprises the following steps of: blending and melting ultrahigh molecular weight polyethylene and a modifier to prepare a granular or powdery modified ultrahigh molecular weight polyethylene raw material; melting and extruding the raw material by using an extruder to form melt of which a flow rate is 0.01 to 0.2 grams per 10 minutes, feeding the melt to a spinning mould by using a melt pump to form melt strips, and cooling and pre-stretching the melt strips to obtain primary yarns; and stretching the primary yarns in a plurality of stages to obtain the ultrahigh molecular weight polyethylene fibers. The equipment comprises the extruder, the melt pump, the spinning mould, a cooling channel, a three-roller tractor, a primary hot-stretching box, a first seven-roller tractor, a secondary hot-stretching box, a second seven-roller tractor, a rinsing trough, a drying box and a winder which are arranged sequentially. The method and the equipment have the characteristics of continuous production capability, relatively shorter process flow, relatively fewer equipment components, no need of solvent, low production cost and the like.

Owner:王庆昭

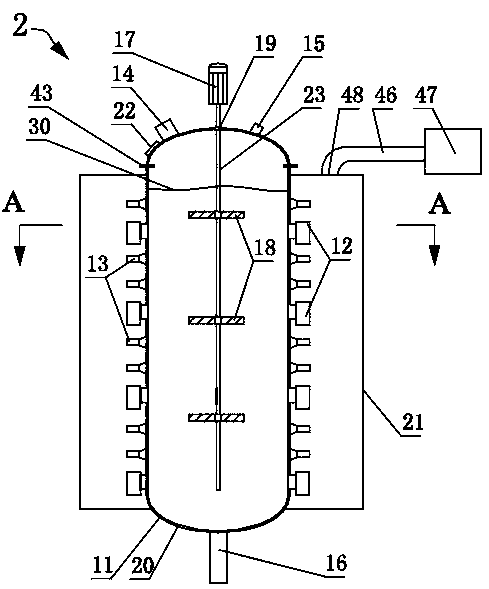

Industrial microwave ultrasonic reaction kettle

InactiveCN103418323ASave operating timeImprove work efficiencyChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesMicrowaveEngineering

Disclosed is an industrial microwave ultrasonic reactor. The inner wall of the reactor is provided with a liner; a microwave generation device is composed of microwave units distributed over the outer sidewall of the reactor in a spaced manner, or of a microwave pipe provided outside the reactor and microwave units distributed over the microwave pipe in a spaced manner. One end of the microwave pipe is in communication with the bottom of the reactor via a connecting pipe I and the other end is in communication with the top of the reactor via a return pipe. A shield is provided outside the microwave generation device to space the microwave units apart from the outer space, with a heat removal device being provided outside the shield. The microwave generation device is composed of ultrasonic pulse units provided along the outer sidewall of the reactor in a spaced manner; there are 10 - 30 sets of ultrasonic pulse units provided from top to bottom, each set having 10 - 50 members and being distributed along the circumferential direction of the reactor, and a stirring shaft of a stirring device is fixed below a stirring motor and extends into the reactor. The present reactor can shorten the time for chemical leaching, improve the purity of a product extracted and increase operation efficiency.

Owner:SONGXIAN EXPLOITER MOLYBDENUM

Method for preparing silver metallized organic fiber and textile

This is a argent metallization producing method of organic fibre and fabric, which belongs to vacuum membrane plating and electroplating technologic field and mainly solves the problems of quality and producing batches of silver-gilt organic and fabric. Through physical vapour phase deposition technology, it firstly arranges smoothly and rolls up tidily the organic fibre bundle and fabric; lay them in the vacuum room, plate silver by magnetic controlling and sputtering, and monolayer or multilayer continuously plate membrane; then plate mulriple argent membrane according to different using demands. The binding force of the metallic argentic ion and organ fibre of the present invention is strong, it has no pollution, low costs and can be continuously produced. The products are applied in such industry as electronics, war industry communication, medical treatment, special type of spinning and so on. For instance, electric shielded products, military used shielded tent, special type of spinning antibacterial materials and civil health care spinning products.

Owner:夏芝林

Method for continuously recycling solvent-flux for industrially compounding PPTA

The invention relates to a method for recycling a solvent-flux for industrially compounding PPTA, comprising the following steps: (1) a mother solution which comprises NMP solvent, salt, water and trace oligomer and is obtained after synthetic PPTA resin is washed by water is extracted and separated to respectively obtain an extract phase NMP-extractant system and a raffinate phase salt-water-extractant system; (2) water obtained after an raffinate phase is stripped and separated is used for washing the resin, and the obtained extractant is recycled; (3) water obtained after an extract phase is rectified and delaminated is used for washing the resin, the obtained extractant is recycled, and coarse NMP obtained through separation is recycled after being purified. By extraction for desalination, the method solves the problem that NMP is thermally cracked under the condition of salt existence because the salty mother solution is directly distilled, largely enhances the solvent recovery rate (reaching above 97 percent), has low energy consumption, and recycles the flux simultaneously, such as calcium chloride. The method can realize closed, continuous and clean production and is beneficial to protecting the environment.

Owner:中国平煤神马控股集团有限公司

High speed automatic tin-plating machine

InactiveCN103834891ACompact structureNovel and reasonable designHot-dipping/immersion processesControl systemTin plating

The invention discloses a high speed automatic tin-plating machine which comprises an unreeling mechanism, a tin-plating mechanism, a driving and cleaning mechanism, a storage mechanism, a reeling mechanism and a control system sequentially arranged, wherein the unreeling mechanism comprises an unreeling frame, a paying off swing rod, an unreeling transitional wheel, an unreeling belt wheel, a tension adjusting wheel and an unreeling motor; the tin-plating mechanism comprises a tin-plating frame, an acidifying box, an acidifying transitional wheel frame, a solder machine, a pinch roller, a wind knife assembly and an air flue frame; the driving and cleaning mechanism comprises a cleaning frame, a cleaning agent groove, a cleaning transitional wheel bracket, a thickness measuring assembly and a traction assembly; the storage mechanism comprises a storage frame, a fixed wire storage wheel set, a mobile wire storage wheel set and a tension detection mechanism; the reeling mechanism comprises a reeling frame, a reeling guide rail bracket, a vertical wiring device and a horizontal wiring device. The high speed automatic tin-plating machine disclosed by the invention is novel and reasonable in design, ensures the quality and efficient production of tin-plating welding strips, is high in working reliability, better realizes continuous, efficient, high-quality and low-cost tin plating, and is convenient to popularize and use.

Owner:THE NORTHWEST MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com