Technique for pretreating cabo

A tobacco stem pretreatment and pretreatment technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of high cost of high-power microwave equipment, uneven microwave field, difficult engineering realization, etc., and achieves easy mass production, microwave Low energy density, simple composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

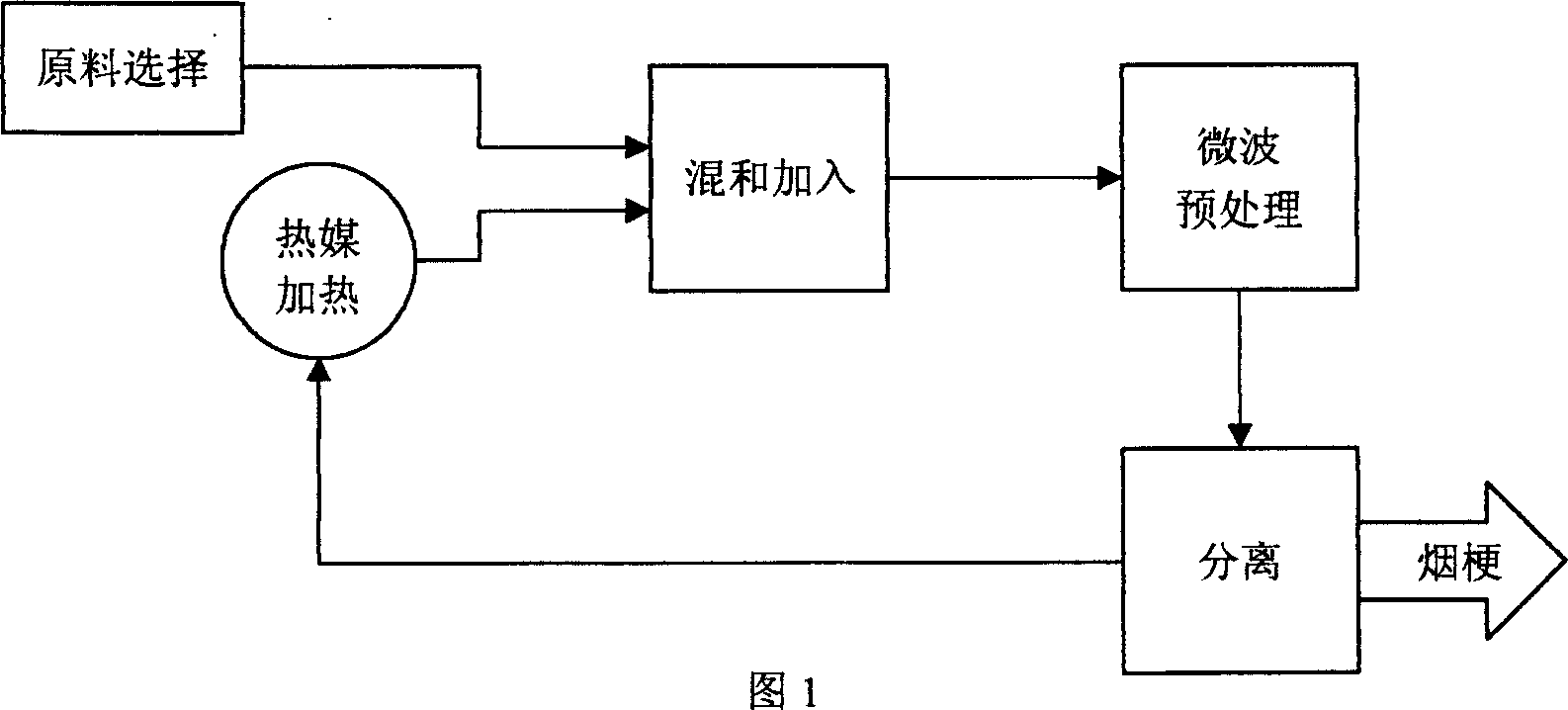

Embodiment 1

[0024] Embodiment 1: Before starting production, the tobacco stems that meet the requirements of "raw material selection" (moisture balance, controlled at 8-14%, and no metal impurities) are prepared, and a heating furnace is used to evenly "heat the heat medium" to 100 ~200°C. The tobacco stems are mixed with heat medium and added to the equipment with microwave field. The tobacco stem processing device adopts a 10-160KW multi-mode cavity tunnel type microwave device (composed of a microwave source part, a microwave transmission part, a microwave cavity part, an air suction system, and a drag part). After 10-220 seconds of mixing and microwave action in the microwave device, the volume increases by 0.5-4 times, and the mixture is output from the outlet of the microwave device. And sent to the separator to separate the tobacco stems from the heat medium. After separation, the pretreated tobacco stems can be obtained with the advantages of low density, good elasticity, less wo...

Embodiment 2

[0025] Embodiment 2: Prepare the tobacco stems that meet the requirements of "raw material selection" (moisture balance, controlled at 8-14%, free of metal impurities) before starting production, and use the tobacco stem preheating device to heat it up to 90°C ±5. Use a heating furnace to evenly "heat the heat medium" to 100-200°C. The tobacco stems are mixed with heat medium and added to the equipment with microwave field. The tobacco stem processing device can use a 10-160KW multi-mode cavity rotary microwave device (consisting of a microwave source part, a microwave transmission part, a microwave cavity part, a microwave rotary cavity part, a suction air system, and a drag part). After 10-220 seconds of mixing and microwave action in the microwave device, the volume increases by 0.5-4 times, and the mixture is output from the outlet of the microwave device. And sent to the separator to separate the tobacco stems from the heat medium. After separation, the pretreated tobac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com