Patents

Literature

1011 results about "Microwave transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave transmission is the transmission of information by microwave radio waves. Although an experimental 40-mile (64 km) microwave telecommunication link across the English Channel was demonstrated in 1931, the development of radar in World War II provided the technology for practical exploitation of microwave communication. In the 1950s, large transcontinental microwave relay networks, consisting of chains of repeater stations linked by line-of-sight beams of microwaves were built in Europe and America to relay long distance telephone traffic and television programs between cities. Communication satellites which transferred data between ground stations by microwaves took over much long distance traffic in the 1960s. In recent years, there has been an explosive increase in use of the microwave spectrum by new telecommunication technologies such as wireless networks, and direct-broadcast satellites which broadcast television and radio directly into consumers' homes.

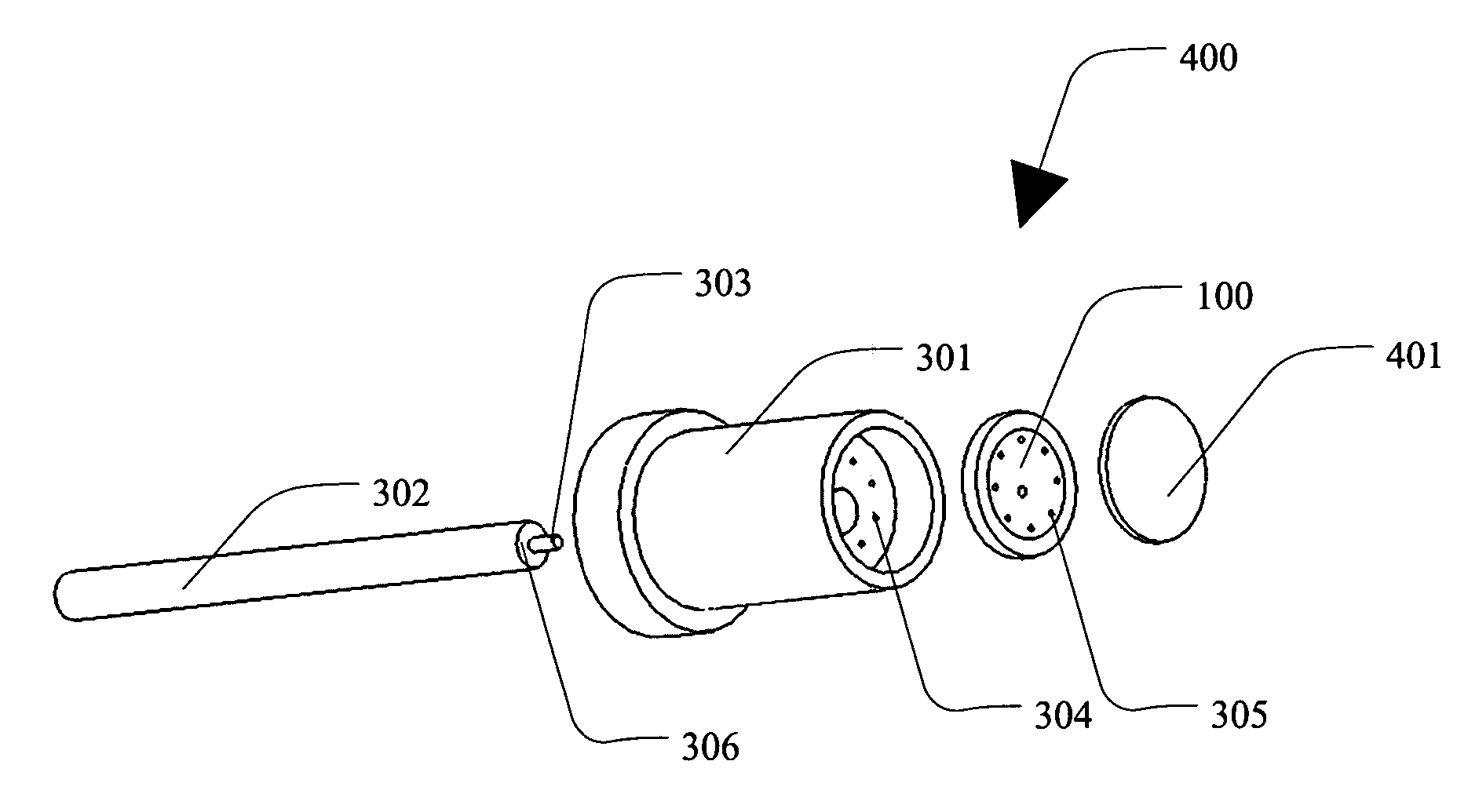

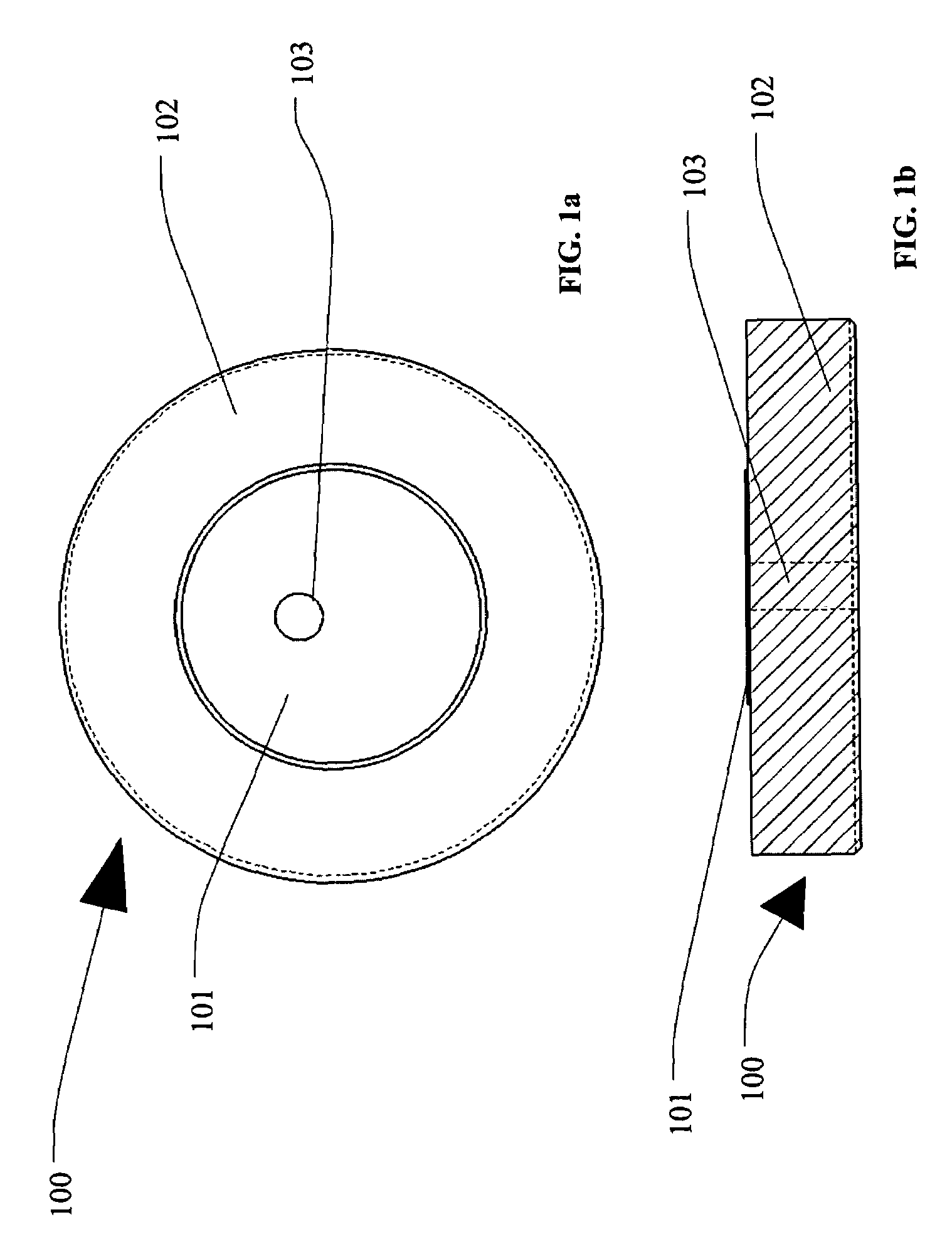

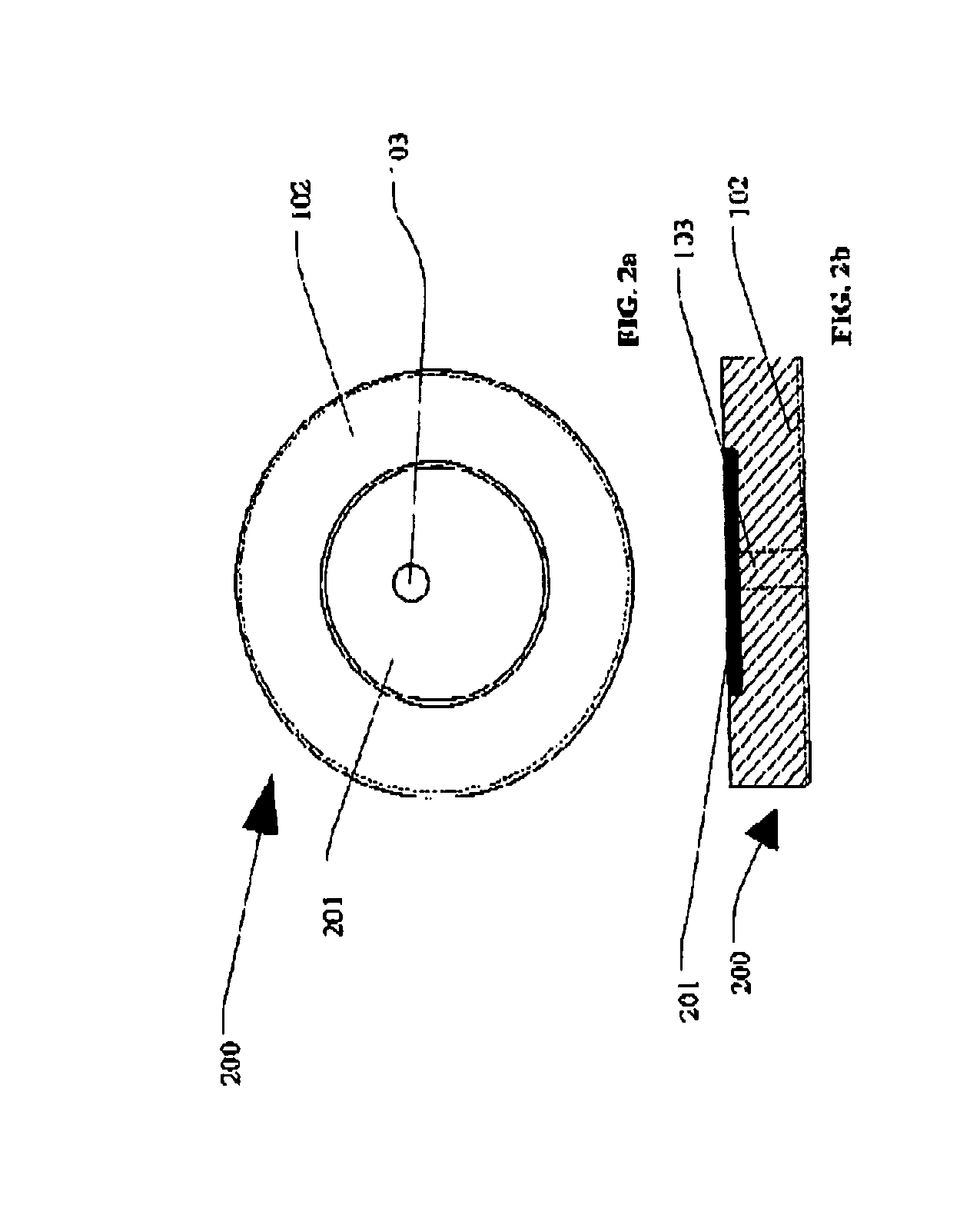

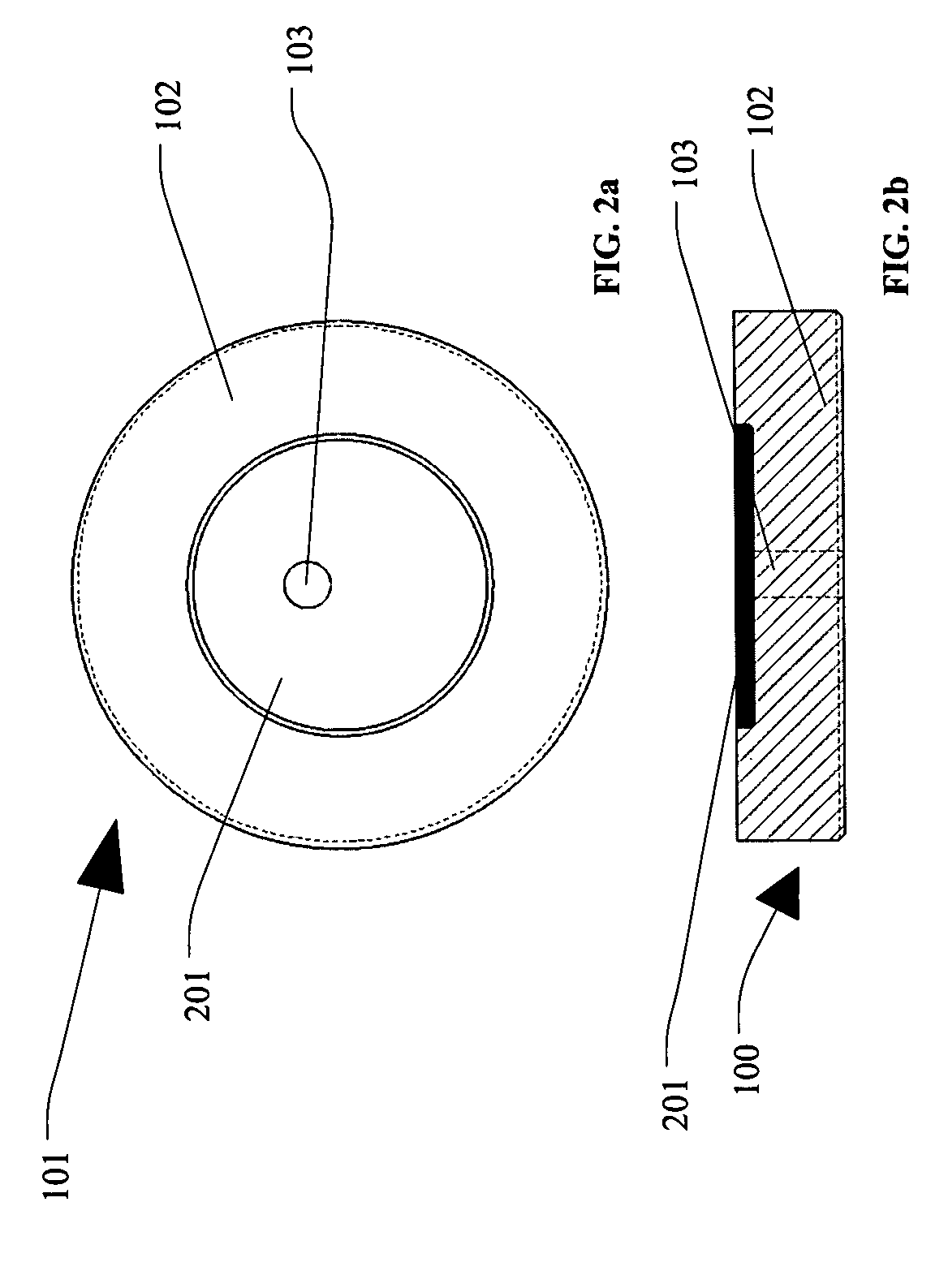

Microstrip patch antenna for high temperature environments

ActiveUS7283096B2Improve performanceImprove reliabilitySimultaneous aerial operationsAntenna adaptation in movable bodiesMicrostrip patch antennaSpray coating

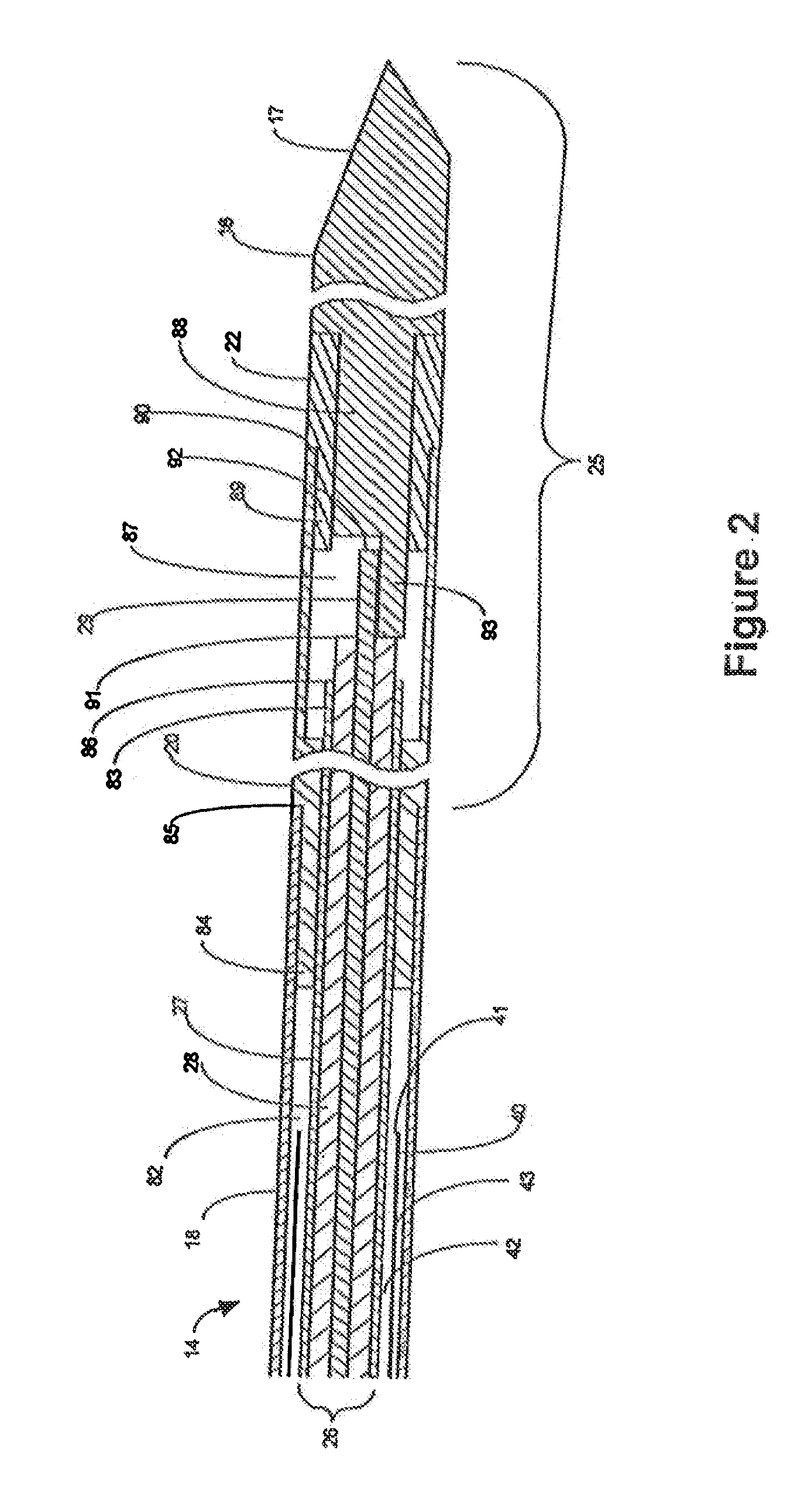

A patch antenna for operation within a high temperature environment. The patent antenna typically includes an antenna radiating element, a housing and a microwave transmission medium, such as a high temperature microwave cable. The antenna radiating element typically comprises a metallization (or solid metal) element in contact with a dielectric element. The antenna radiating element can include a dielectric window comprising a flame spray coating or a solid dielectric material placed in front of the radiating element. The antenna element is typically inserted into a housing that mechanically captures the antenna and provides a ground plane for the antenna. Orifices or passages can be added to the housing to improve high temperature performance and may direct cooling air for cooling the antenna. The high temperature microwave cable is typically inserted into the housing and attached to the antenna radiator to support the communication of electromagnetic signals between the radiator element and a receiver or transmitter device.

Owner:MEGGITT SA

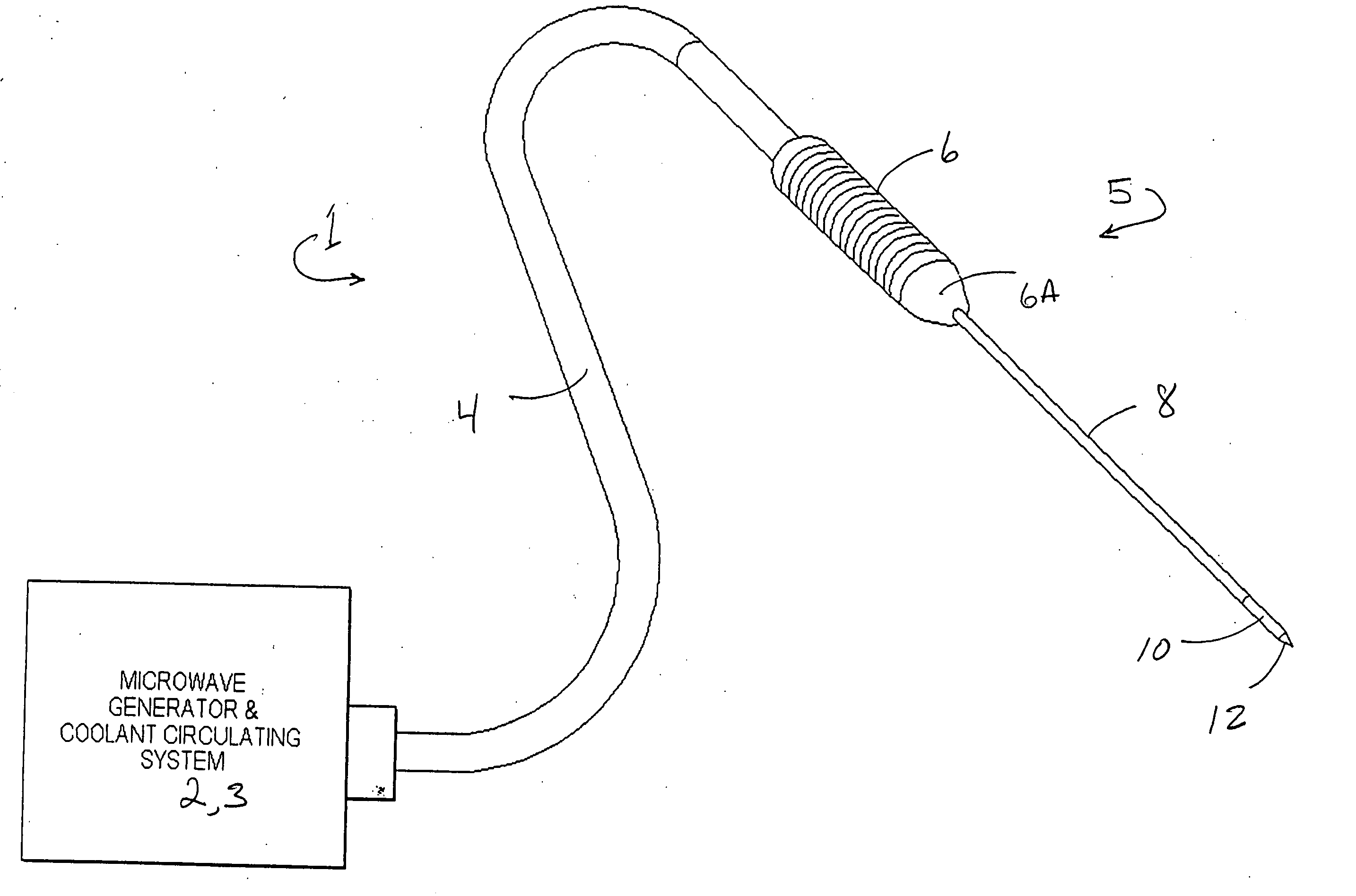

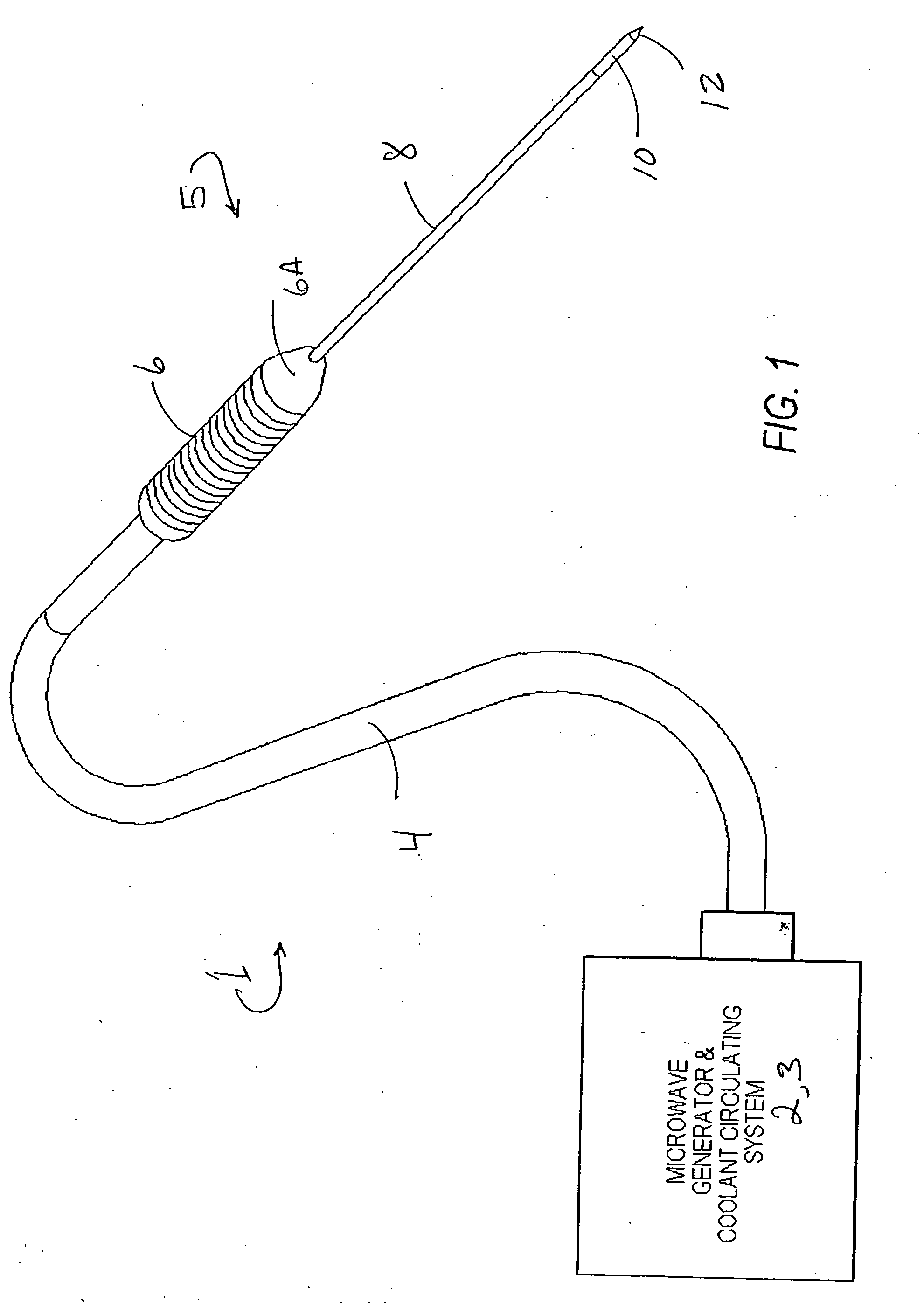

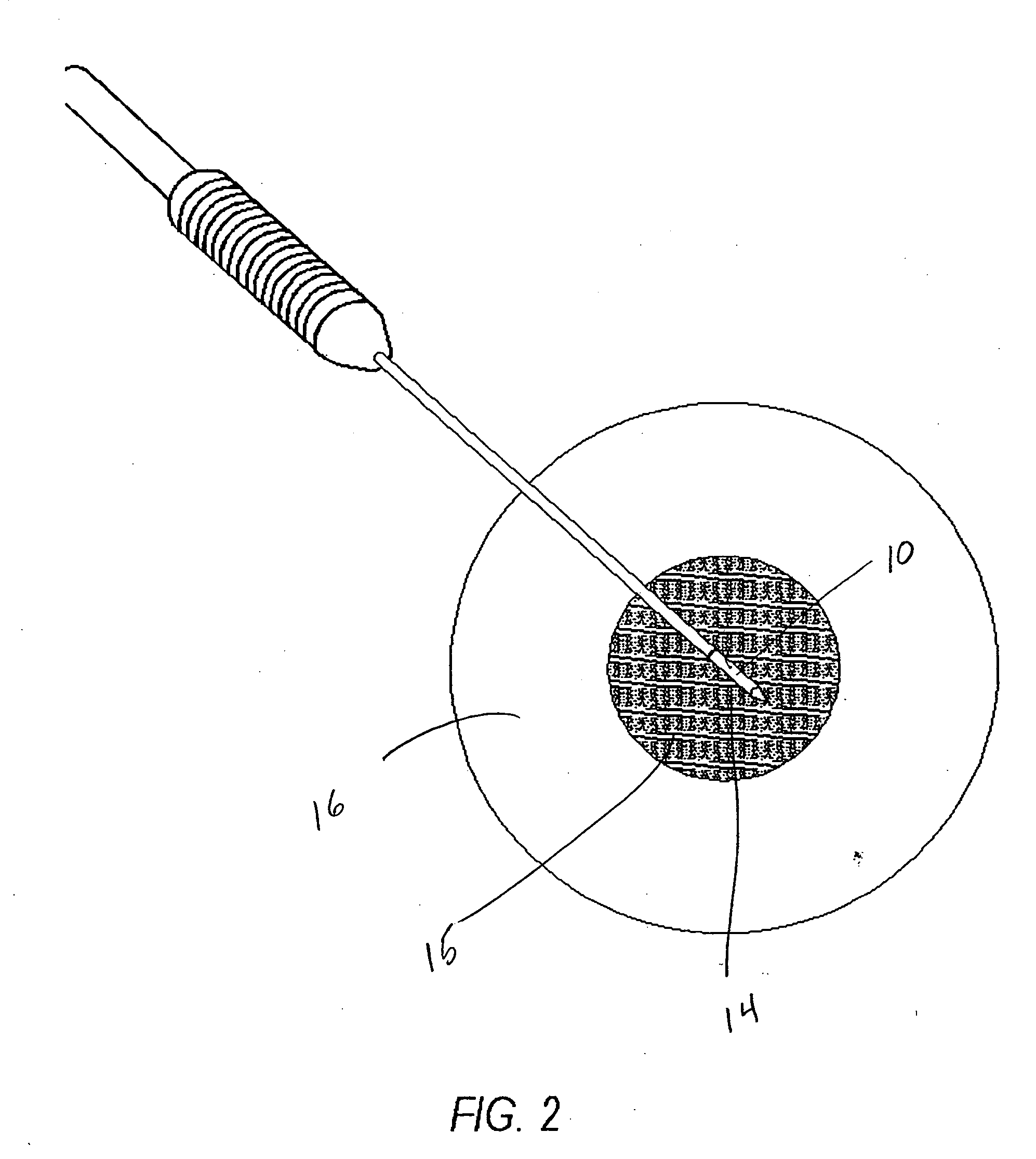

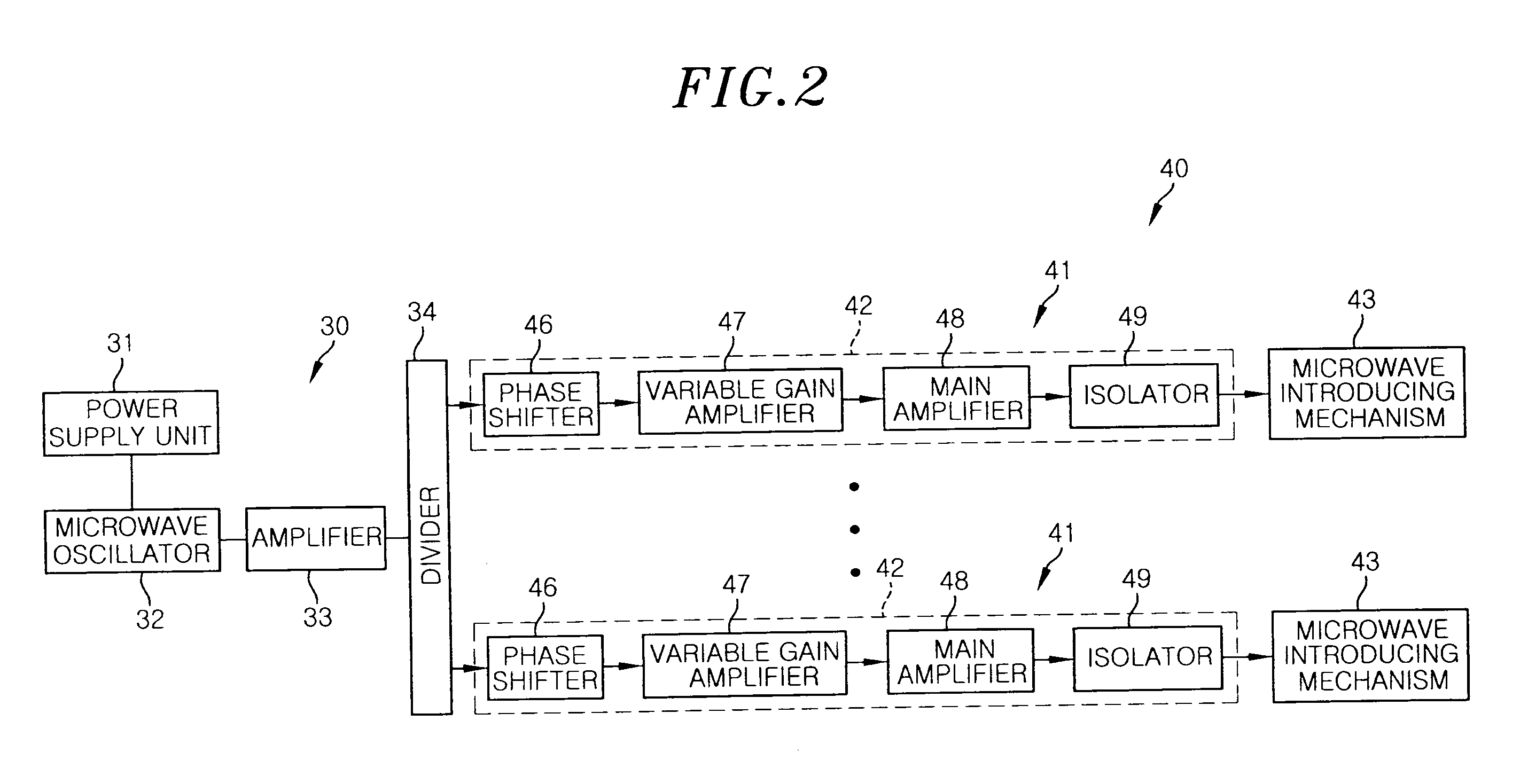

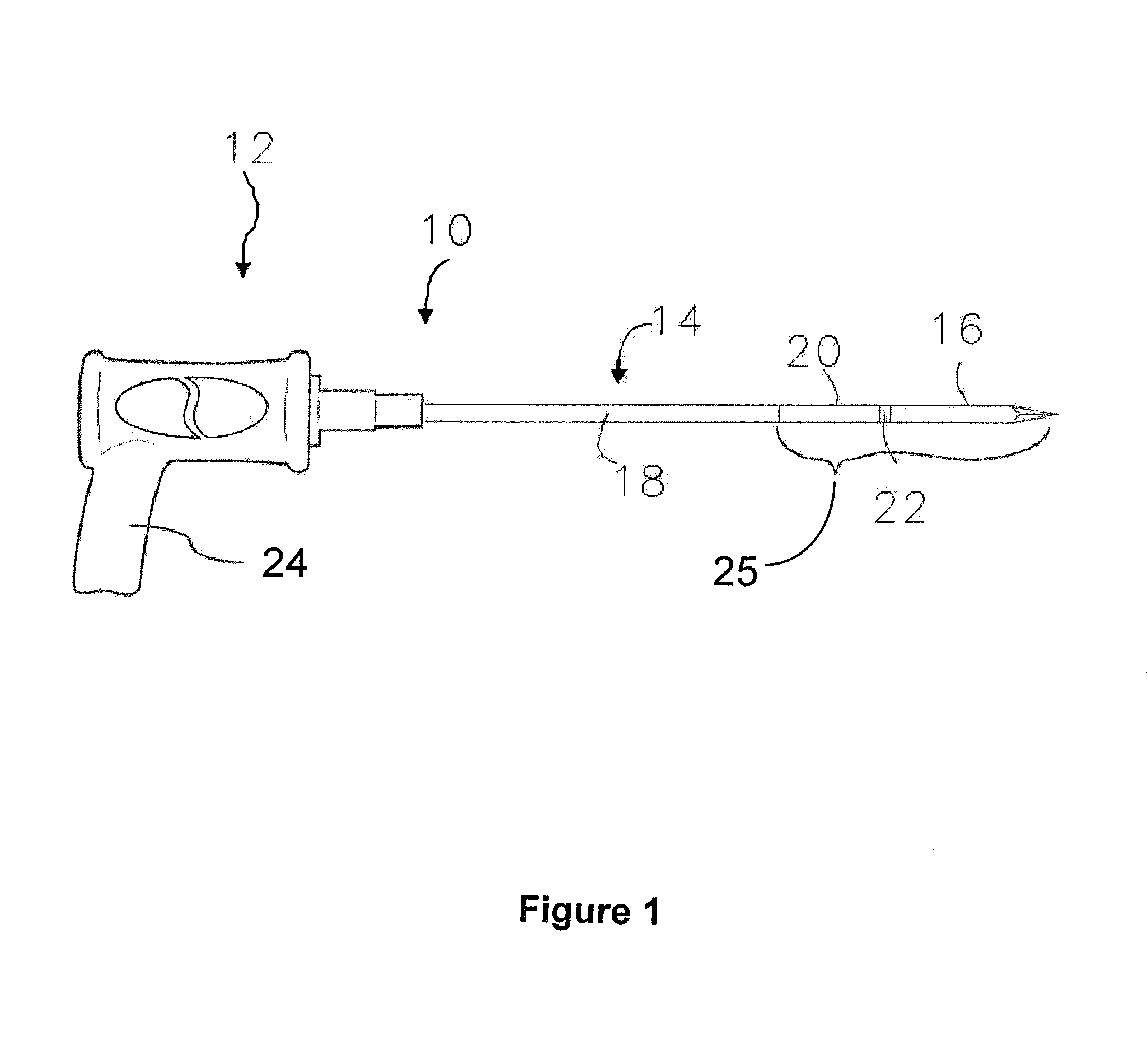

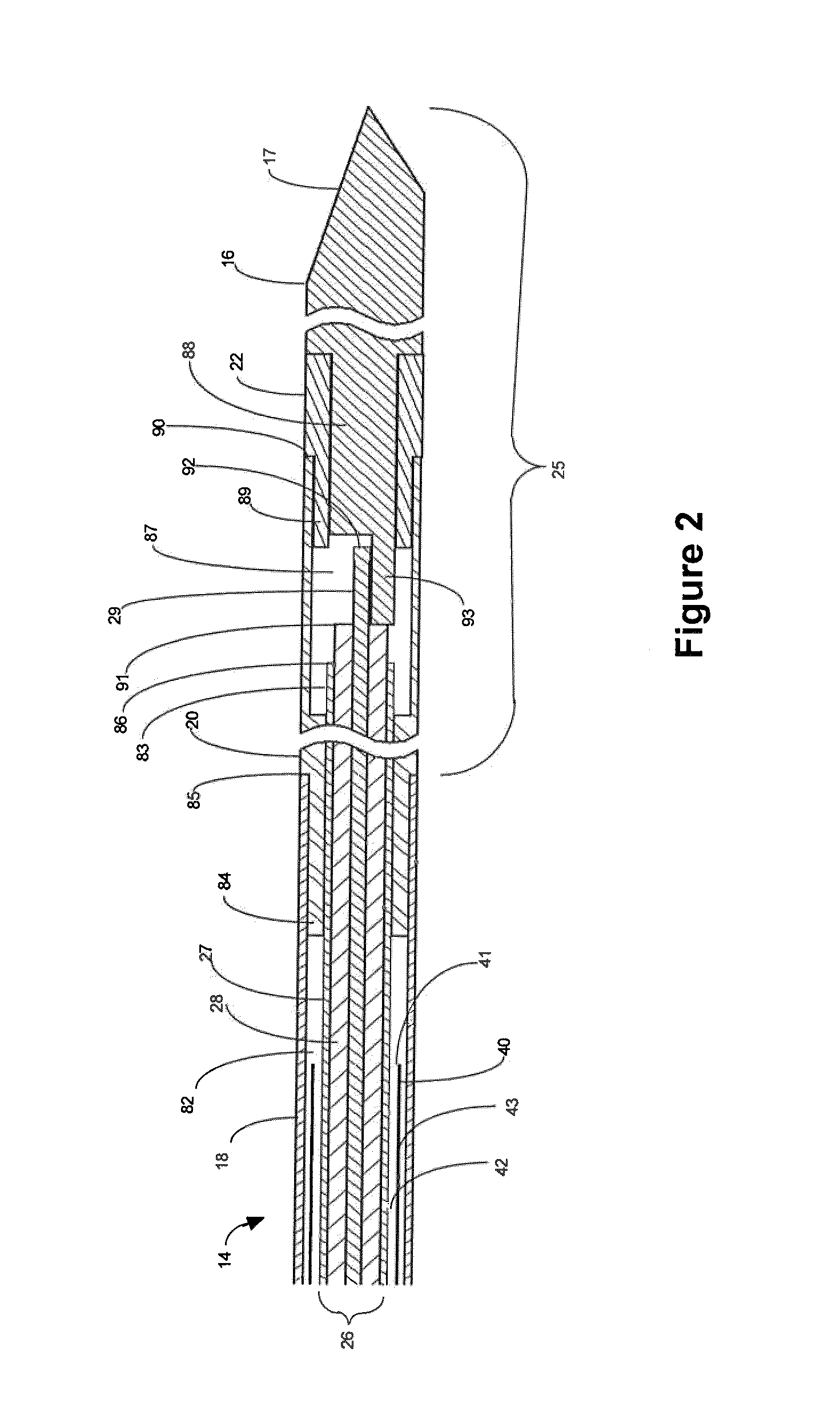

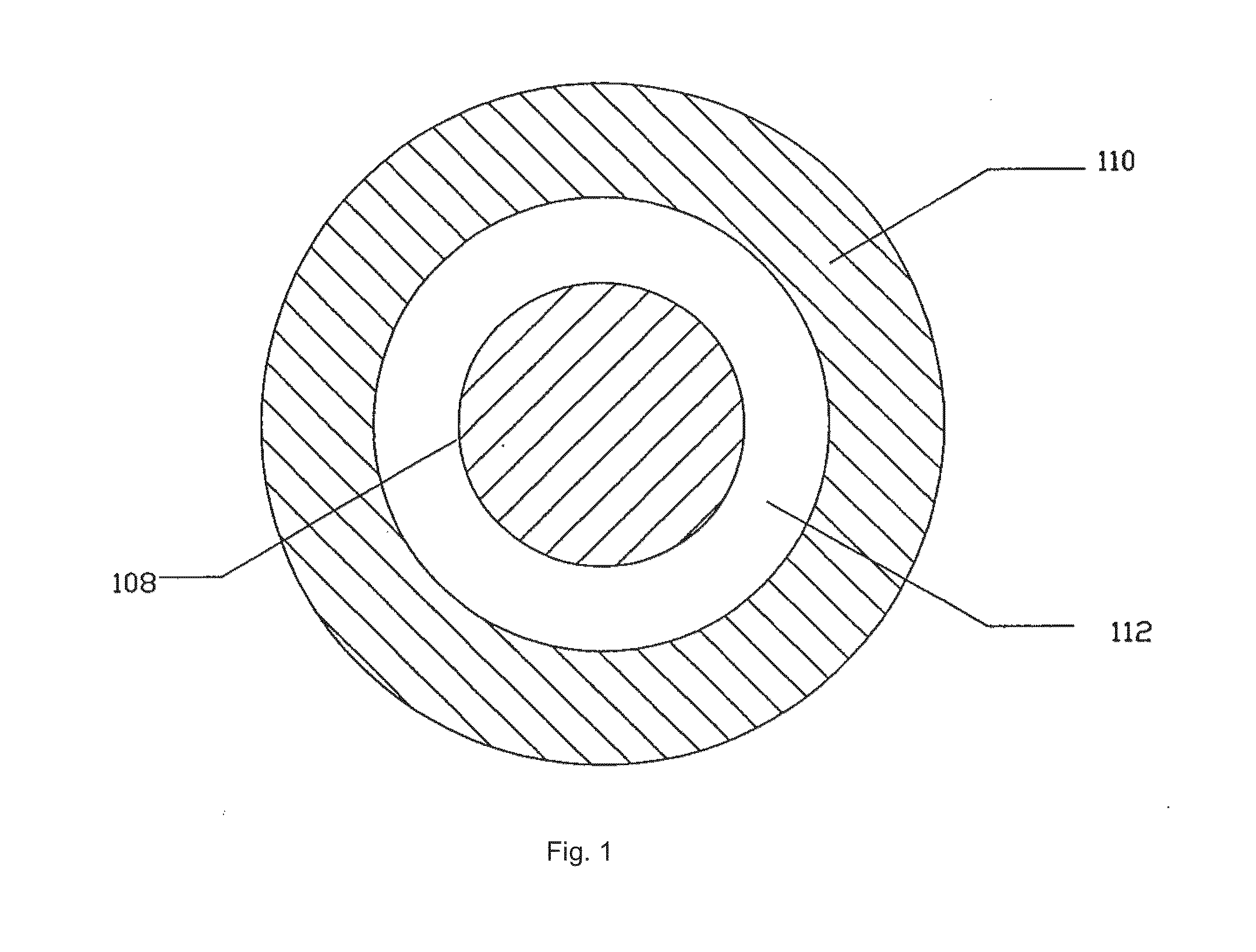

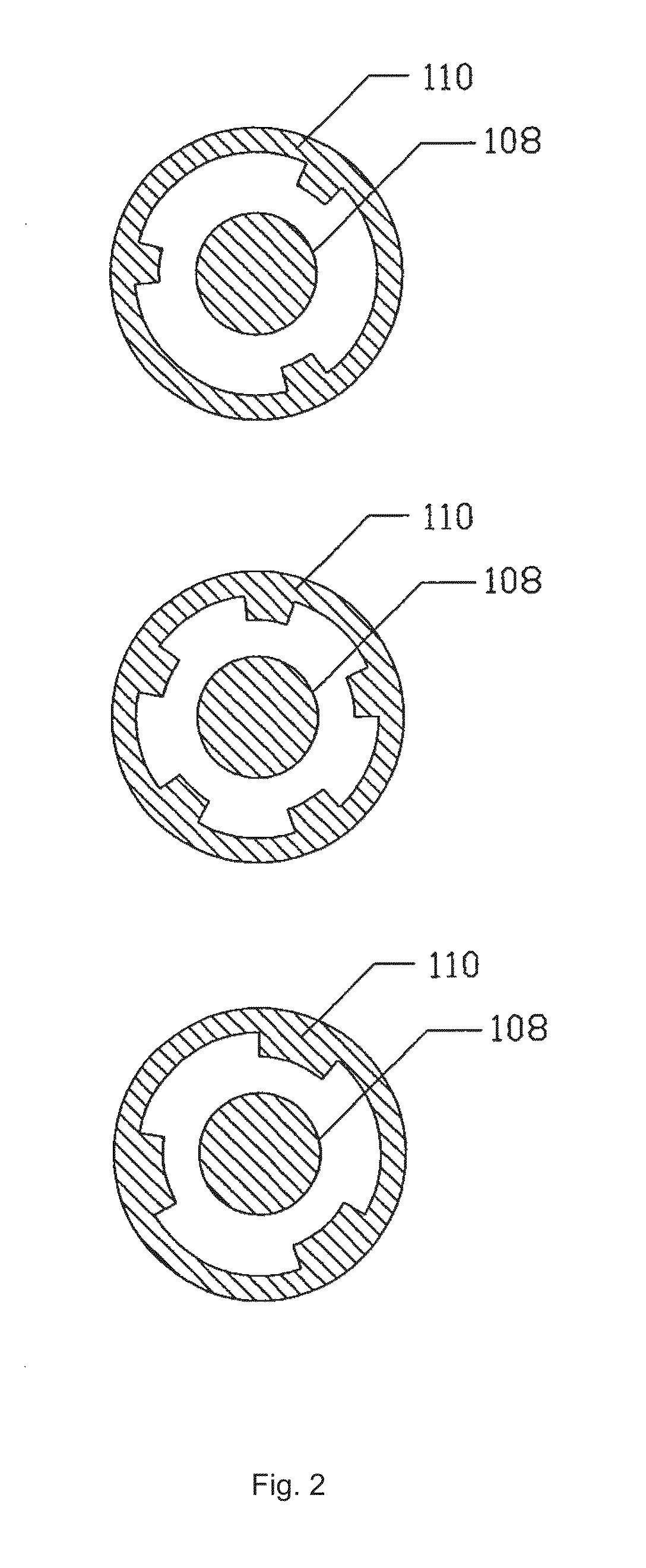

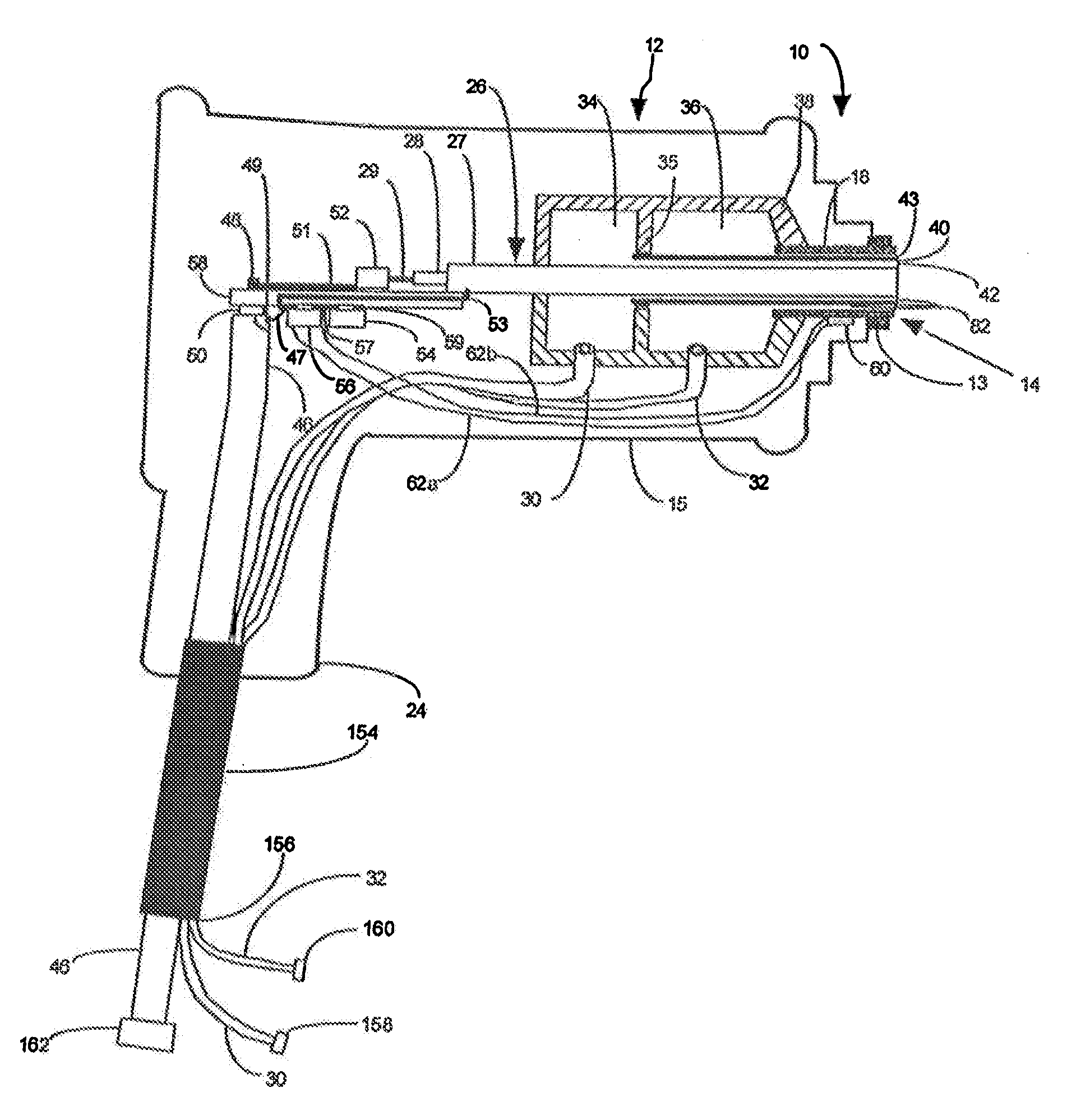

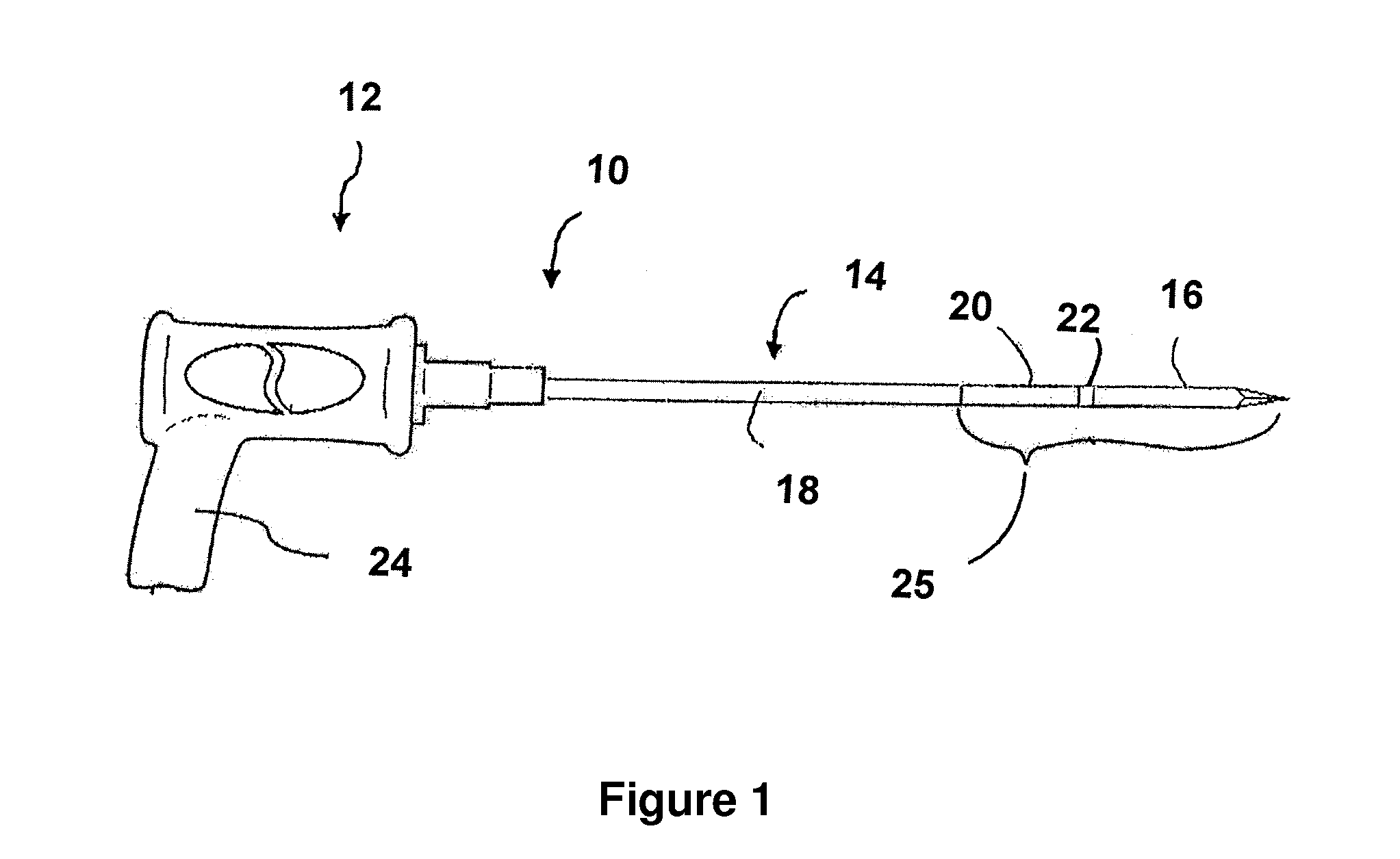

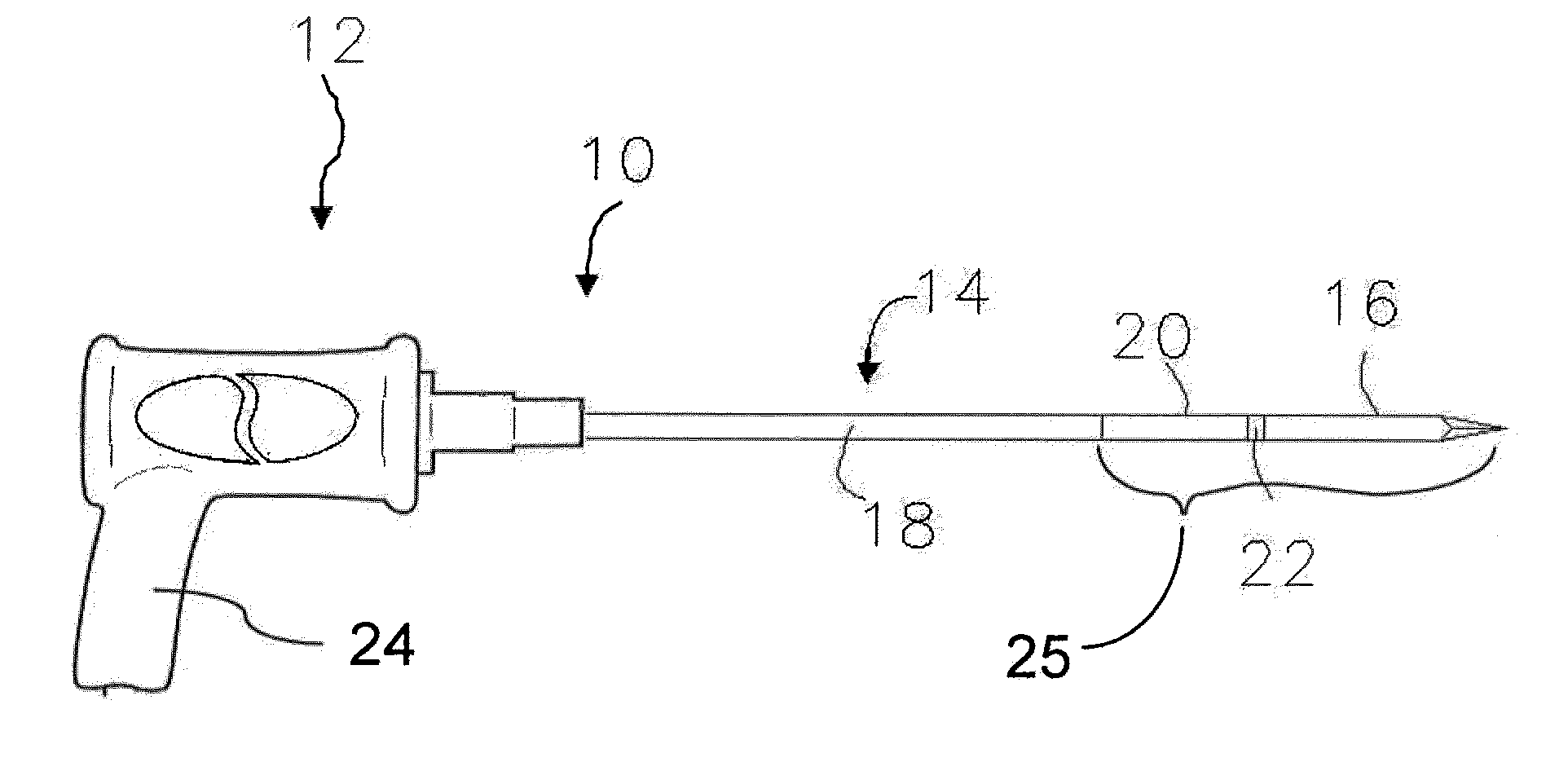

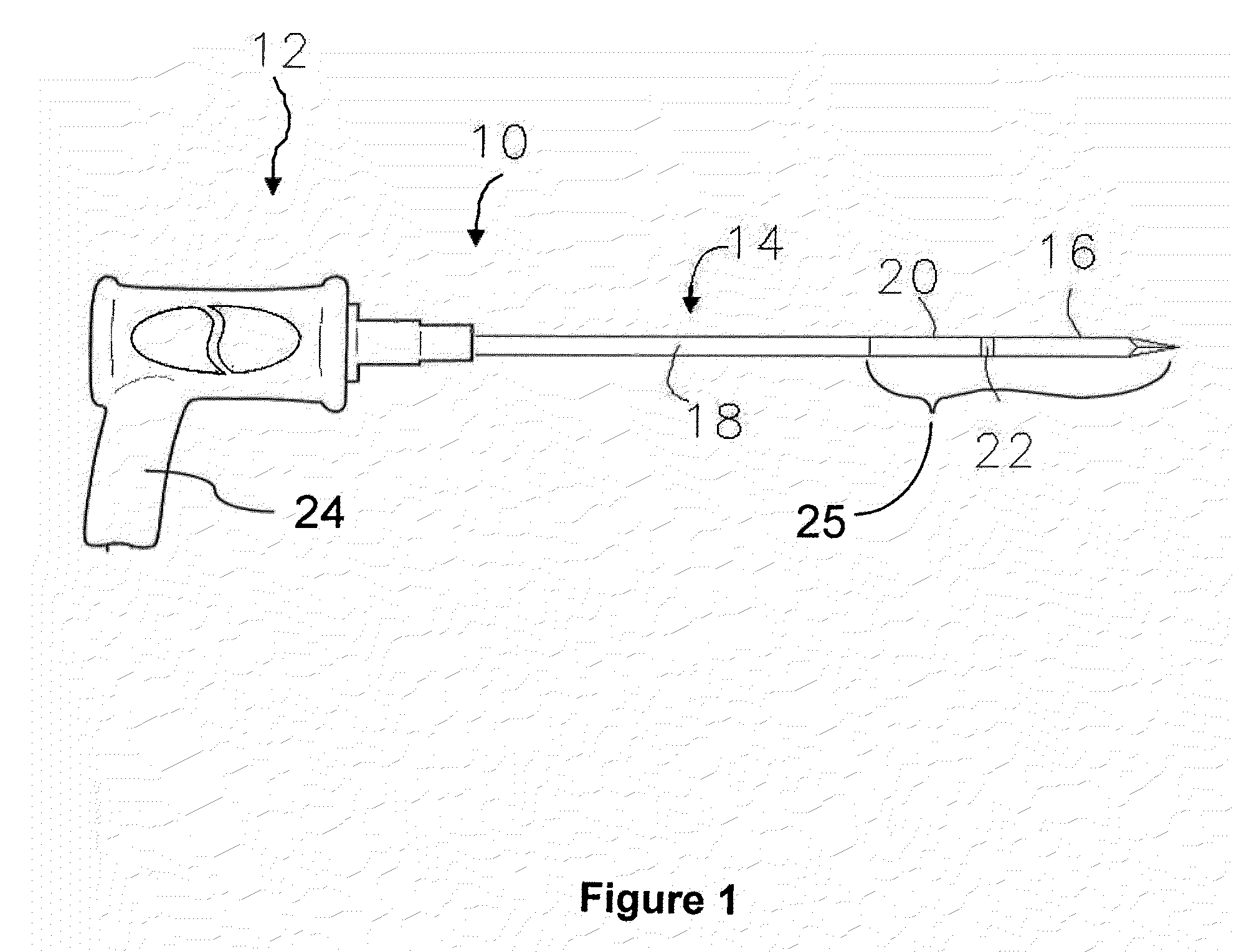

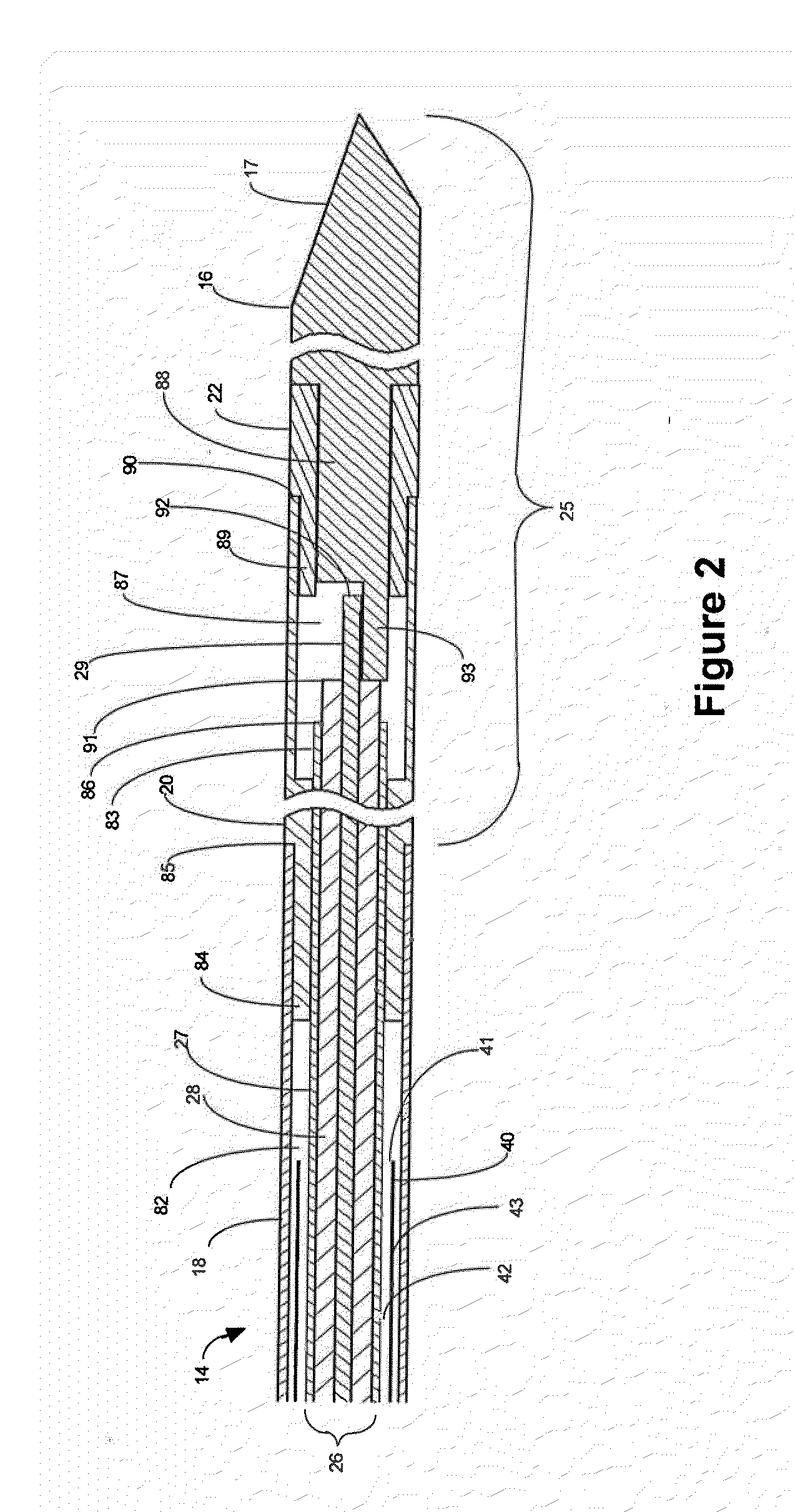

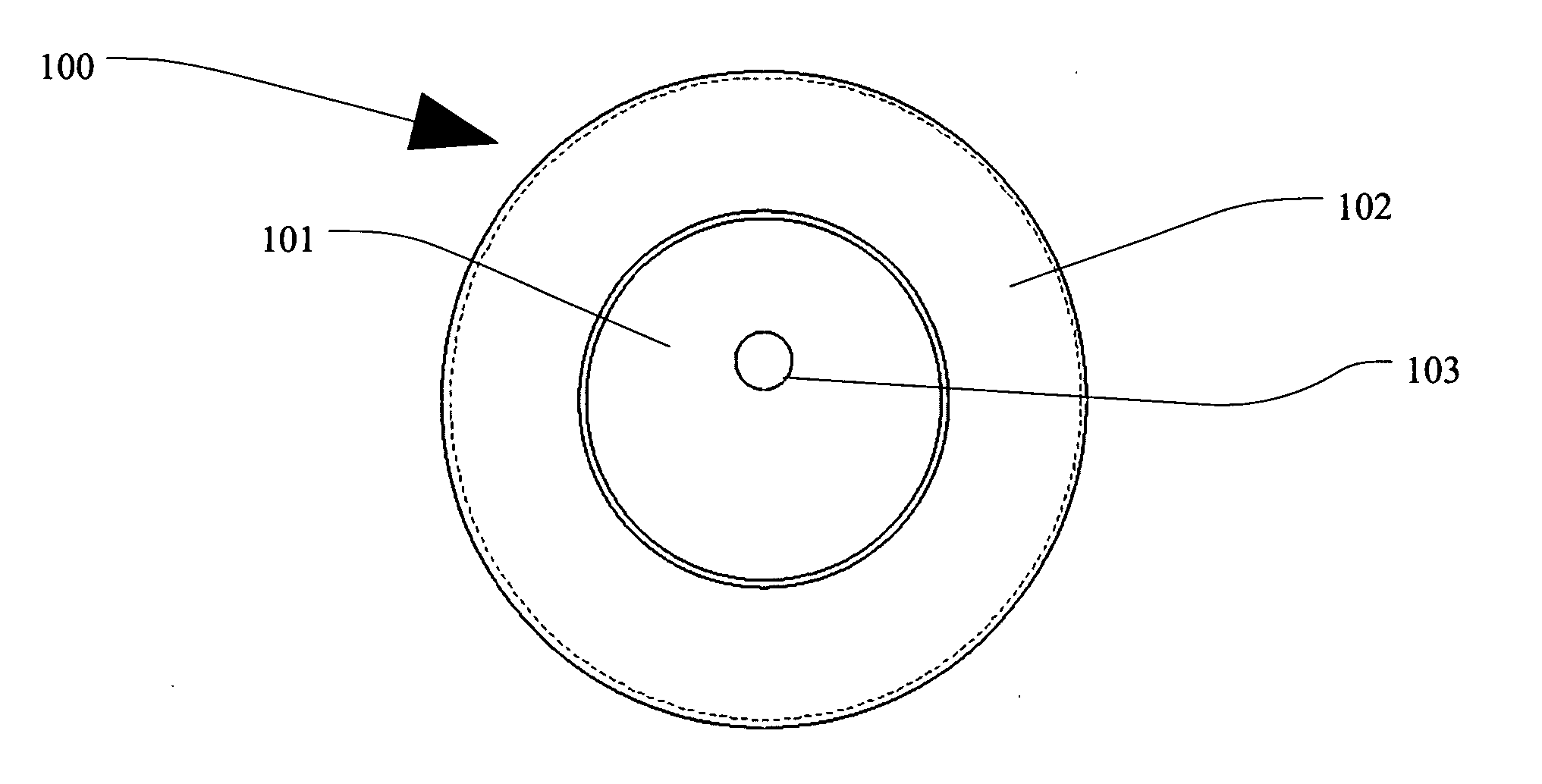

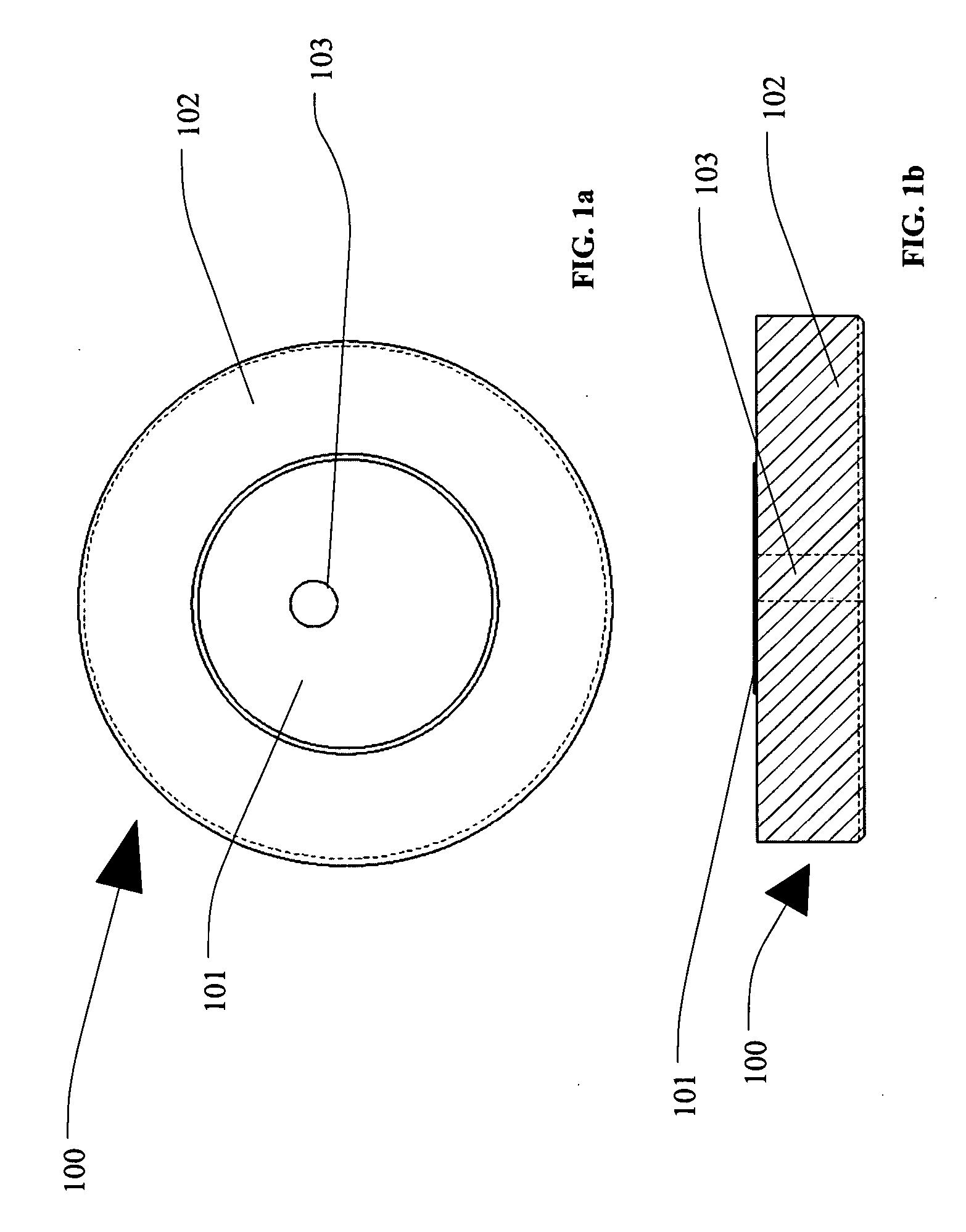

Cell necrosis apparatus with cooled microwave antenna

InactiveUS20050245920A1Minimize potential for bucklingSmall sizeElectrotherapySurgical instruments for heatingElectricityCoolant flow

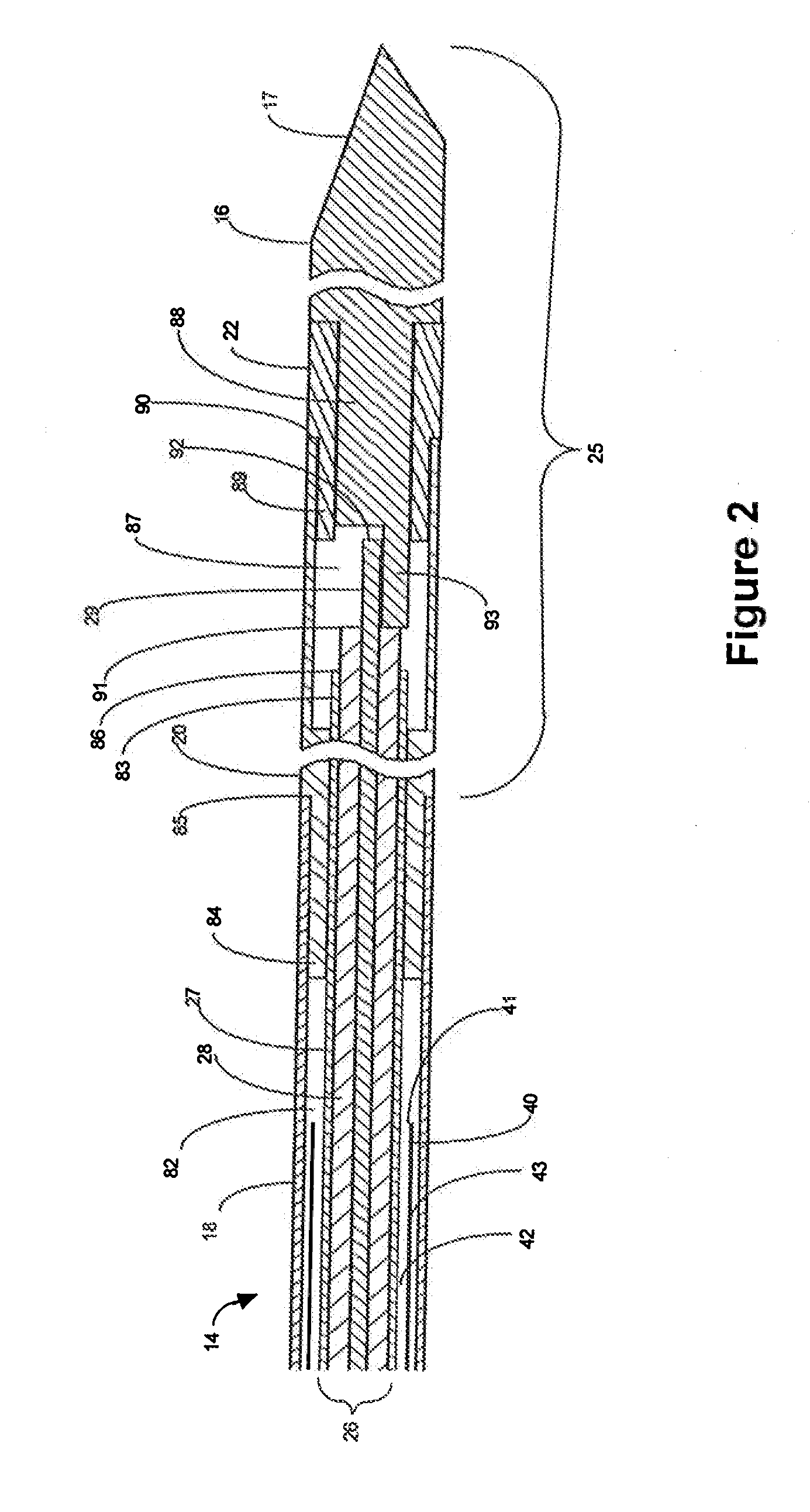

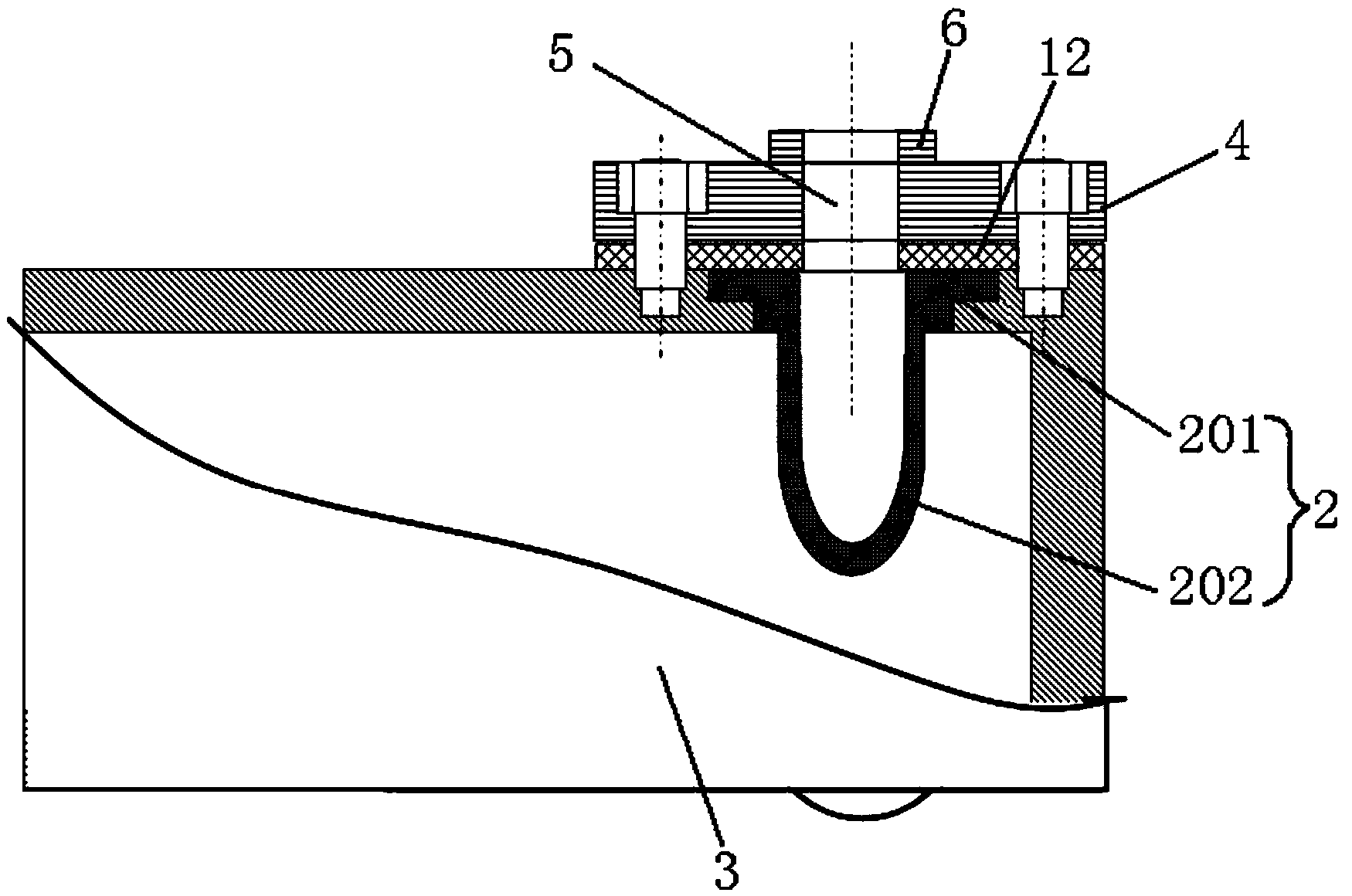

A cell necrosis apparatus for delivering thermal microwave energy to a specific site in a body, including: a. a microwave generator, b. a coolant delivery system for delivering and circulating a quantity of cooled liquid coolant via inlet and return passageways, c. a probe including a probe handle and a probe body having a proximal portion coupled to the probe handle and a distal portion, d. a microwave antenna in the distal portion of the probe body for applying thermal microwave energy to a specific site in cell necrosis treatment, and e. a microwave transmission line extending from the microwave generator to and through the probe handle and to and through the probe body to the microwave antenna and electrically coupled thereto, where the inlet and return coolant flow passageways extend from the coolant delivery system to and through the probe handle and thence extend coaxially about the microwave transmission line and along the length thereof within the probe body, and extend coaxially about the antenna and long the length thereof within the probe body, and where a first of the inlet and return coolant flow passageways is radially outward of and immediately adjacent the microwave transmission line and the antenna within the probe body and the other of the inlet flow passageways is radially outward of the first flow passageway.

Owner:TELEFLEX LIFE SCI LTD

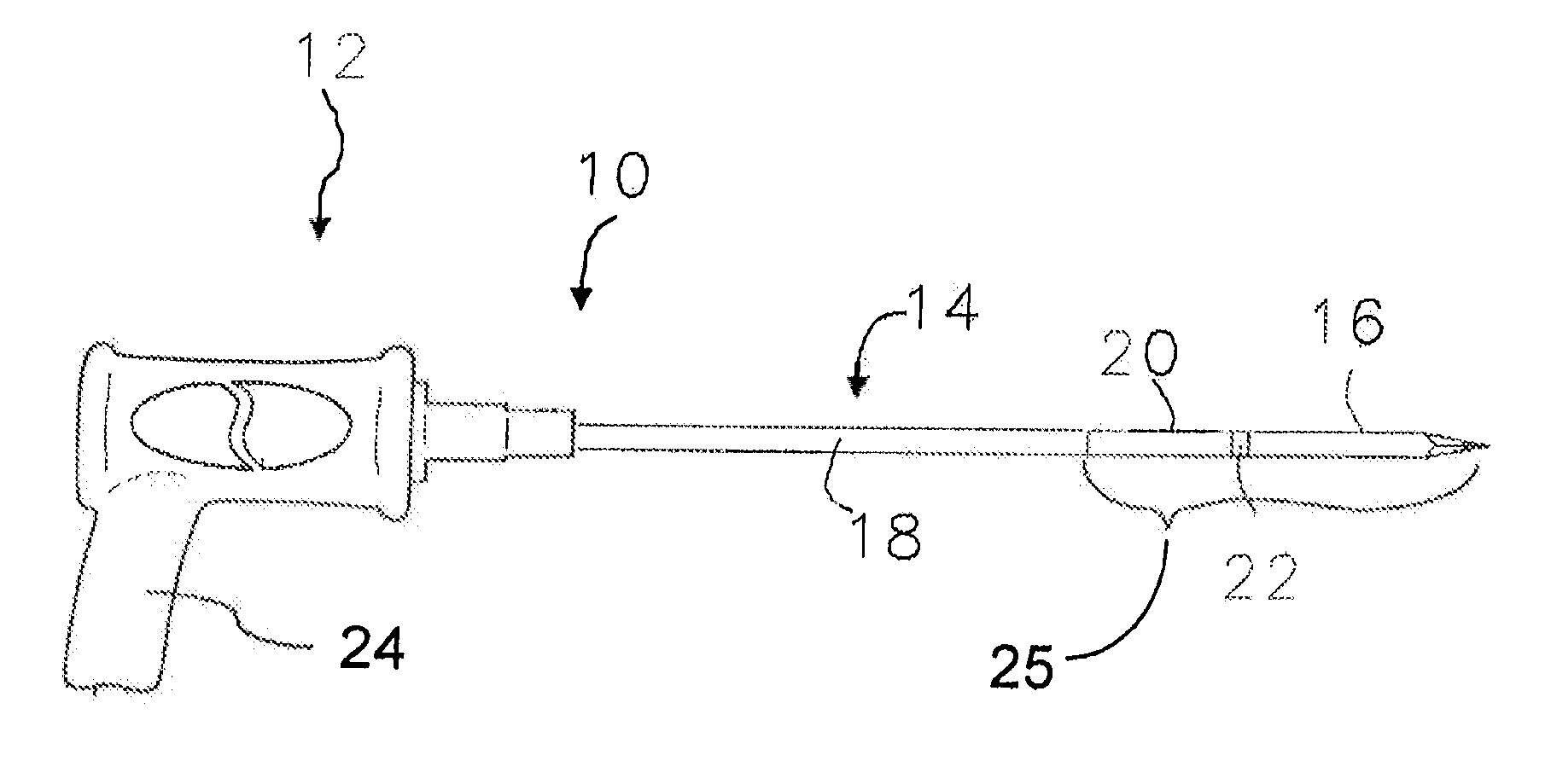

Microwave coagulation applicator and system

ActiveUS20110118723A1Reduce microwave heatingIncrease in tissue heatingSurgical needlesSurgical instruments for heatingEngineeringMicrowave coagulation

A microwave applicator for insertion into living body tissue for use in microwave coagulation and ablation treatments includes a microwave transmission line extending between an attachment end of the applicator and an antenna toward an insertion end of the applicator with an outer conductive sleeve forming an enclosed cooling fluid space around the transmission line. Circulation of cooling fluid is guided in the cooling fluid space by a guide sleeve. A fluid circulation system provides a plurality of fluid supply connectors and fluid return connectors which can be connected and used with any number of applicators between one and the number of the fluid supply connectors provided by the system. A portion of the applicator inserted into the tissue can stick to the tissue to stabilize the applicator during treatment. A warning marking on the applicator can be used during track ablation to prevent ablation of the patient skin tissue.

Owner:VARIAN MEDICAL SYSTEMS

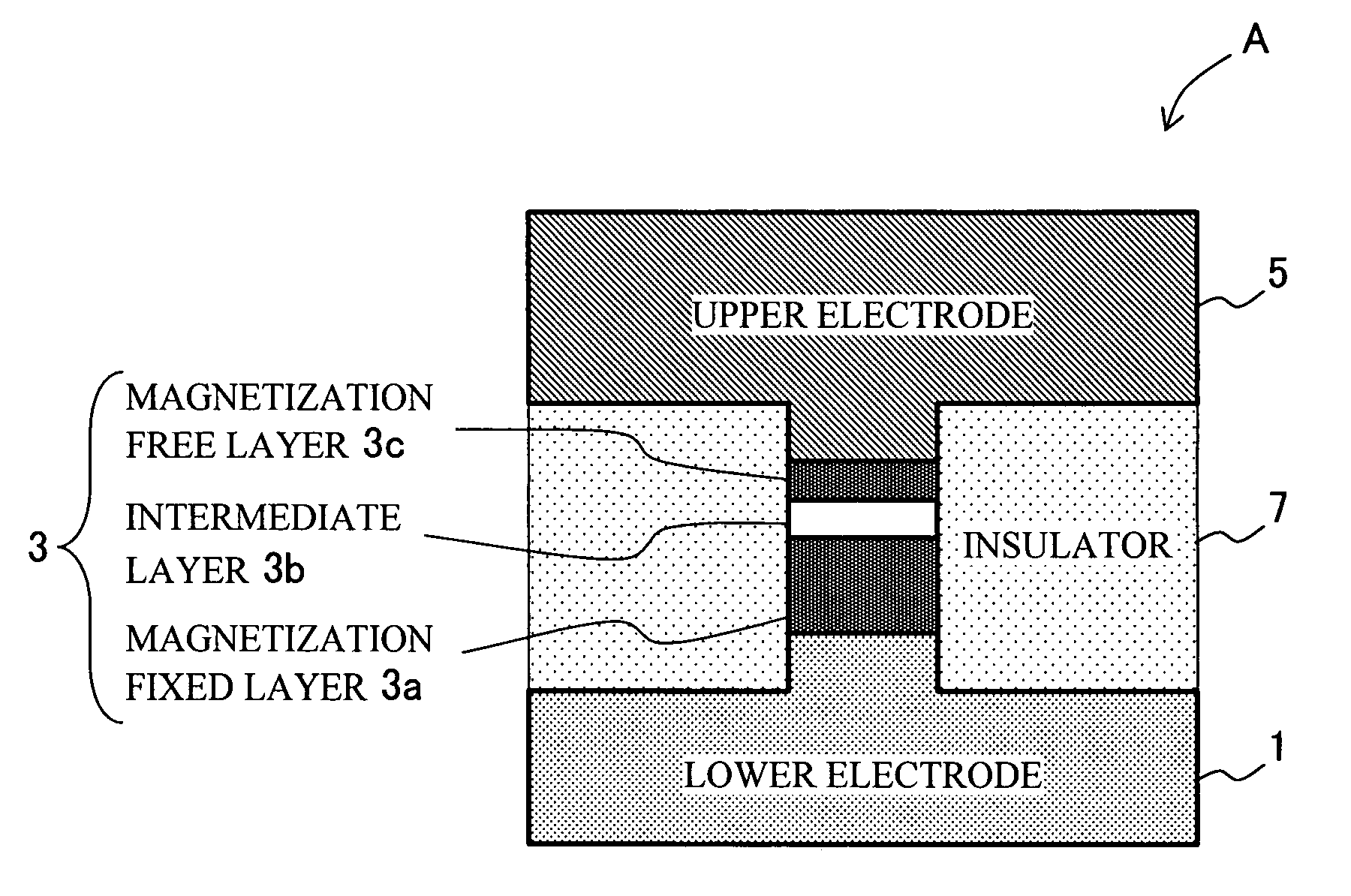

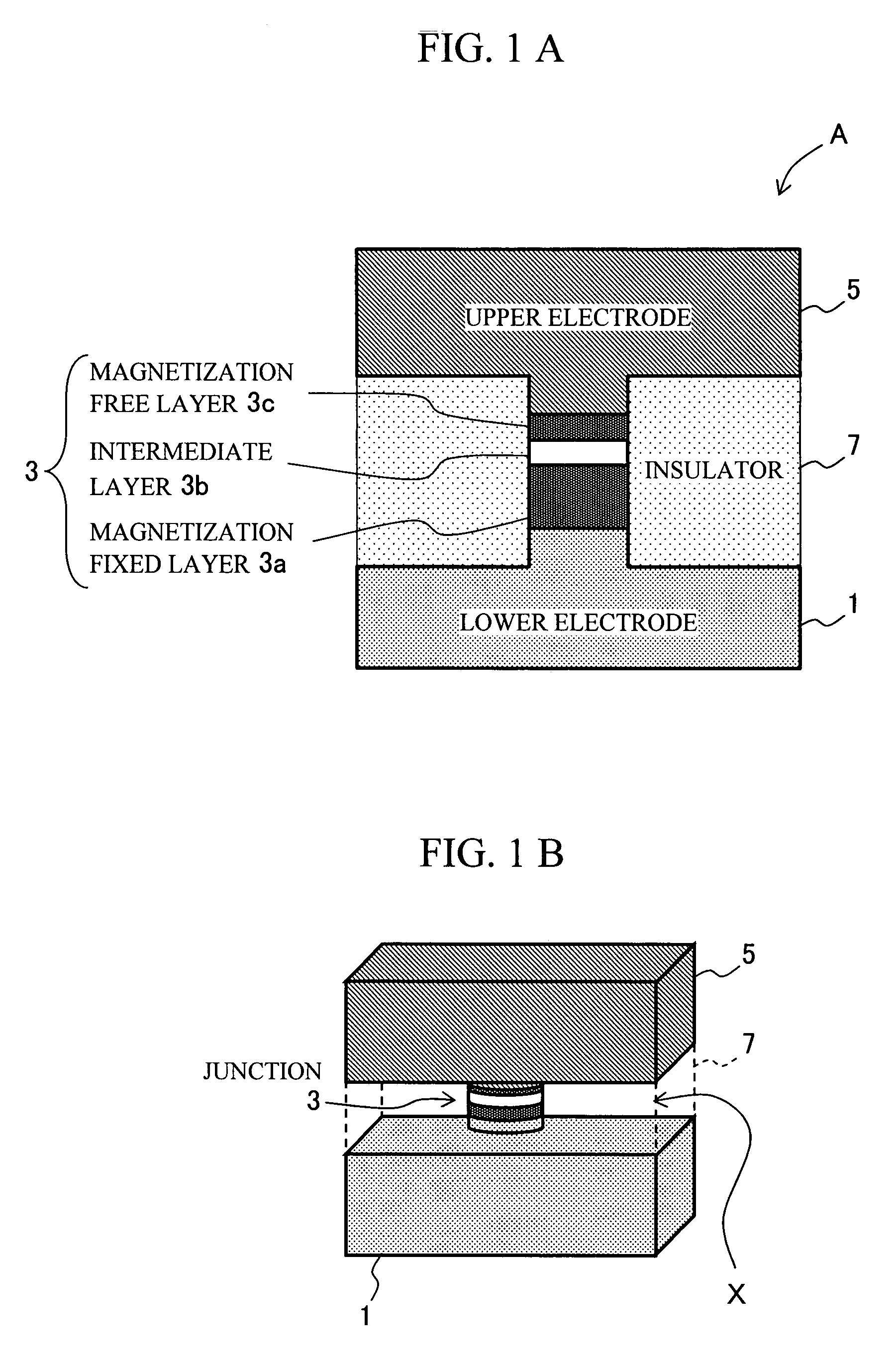

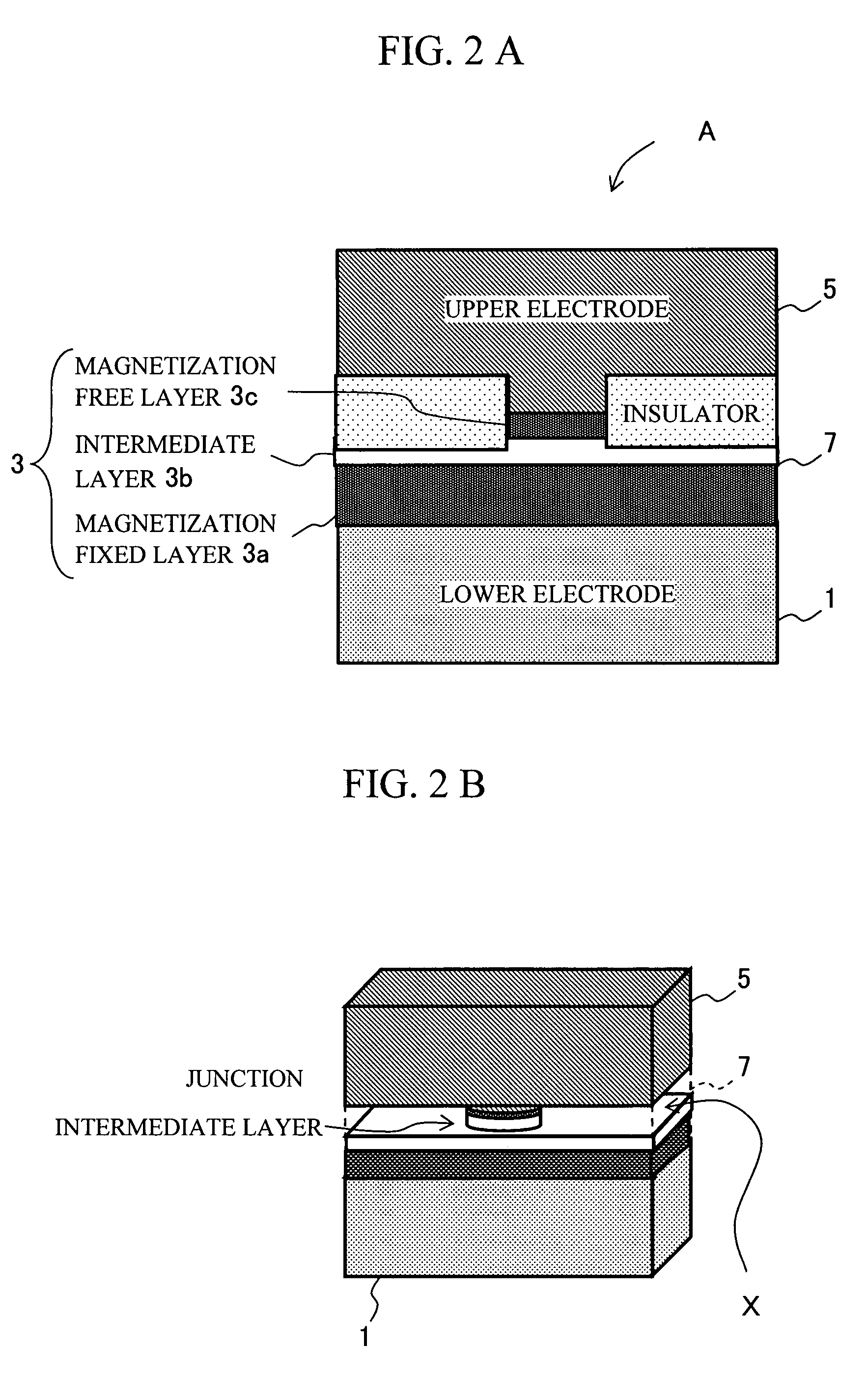

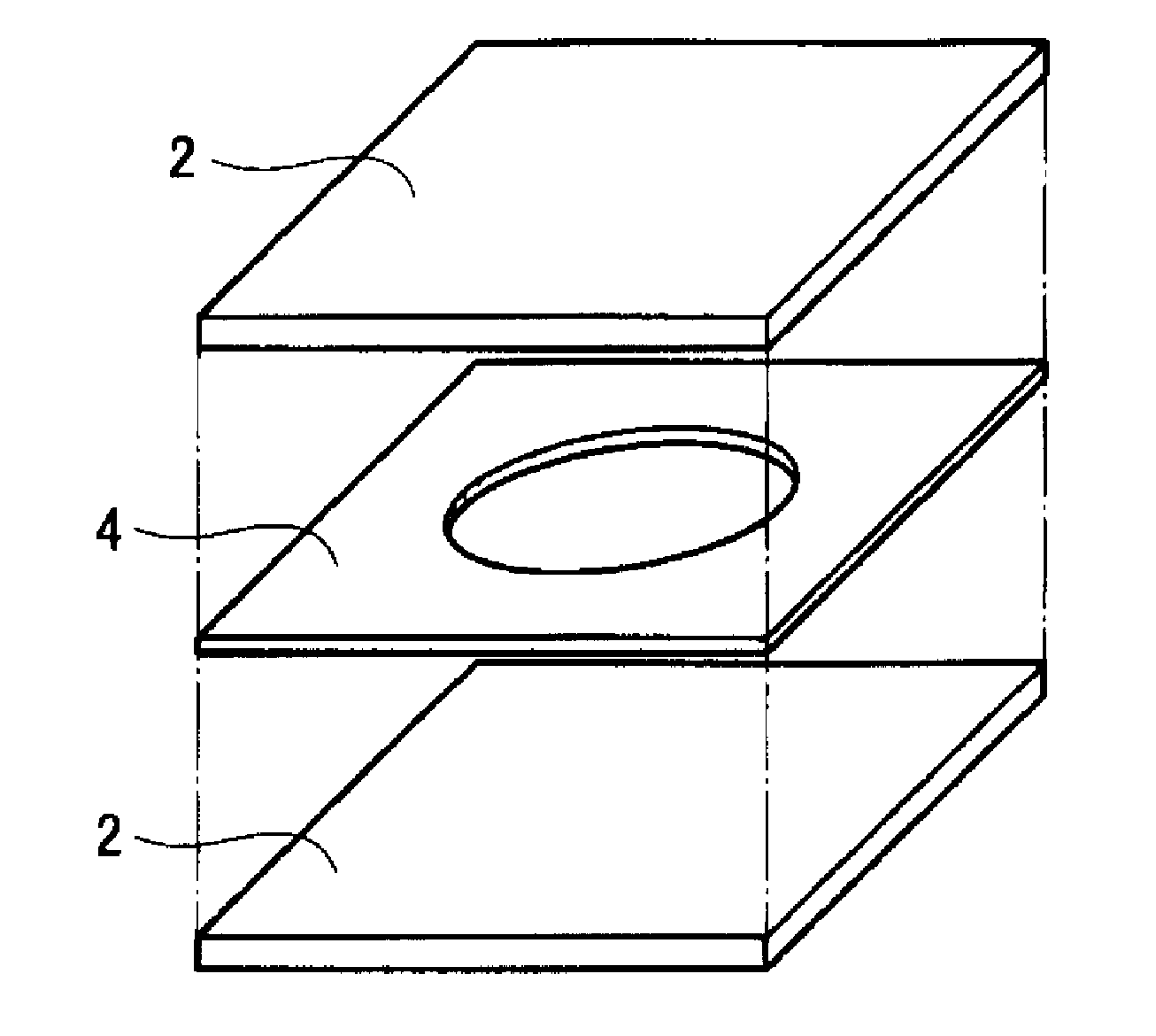

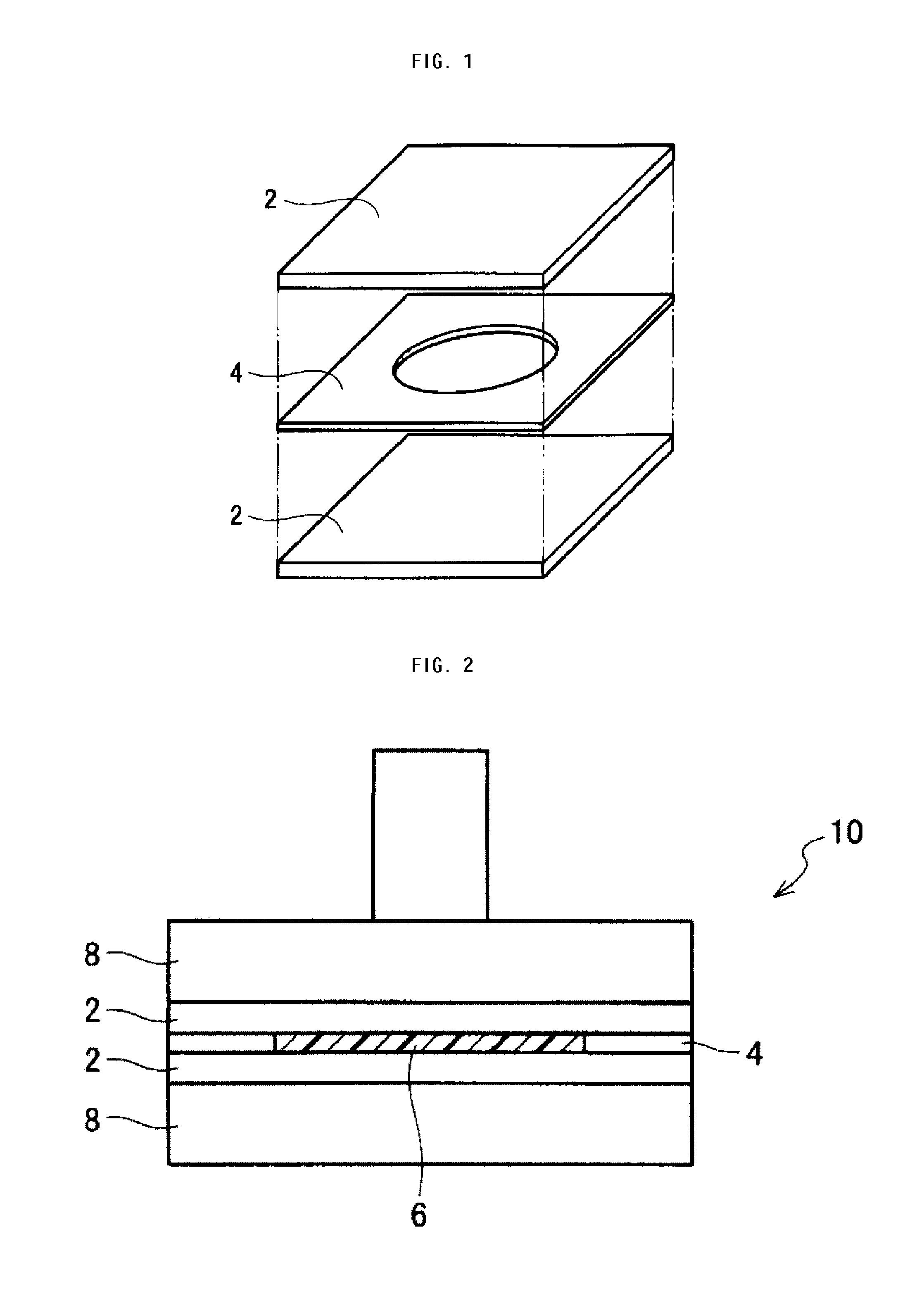

Microwave Transmission Line Integrated Microwave Generating Element and Microwave Transmission Line Integrated Microwave Detecting Element

ActiveUS20080150643A1Small sizeEliminate lossSemiconductor/solid-state device detailsMagnetic-field-controlled resistorsResonance oscillationAntiferromagnetic coupling

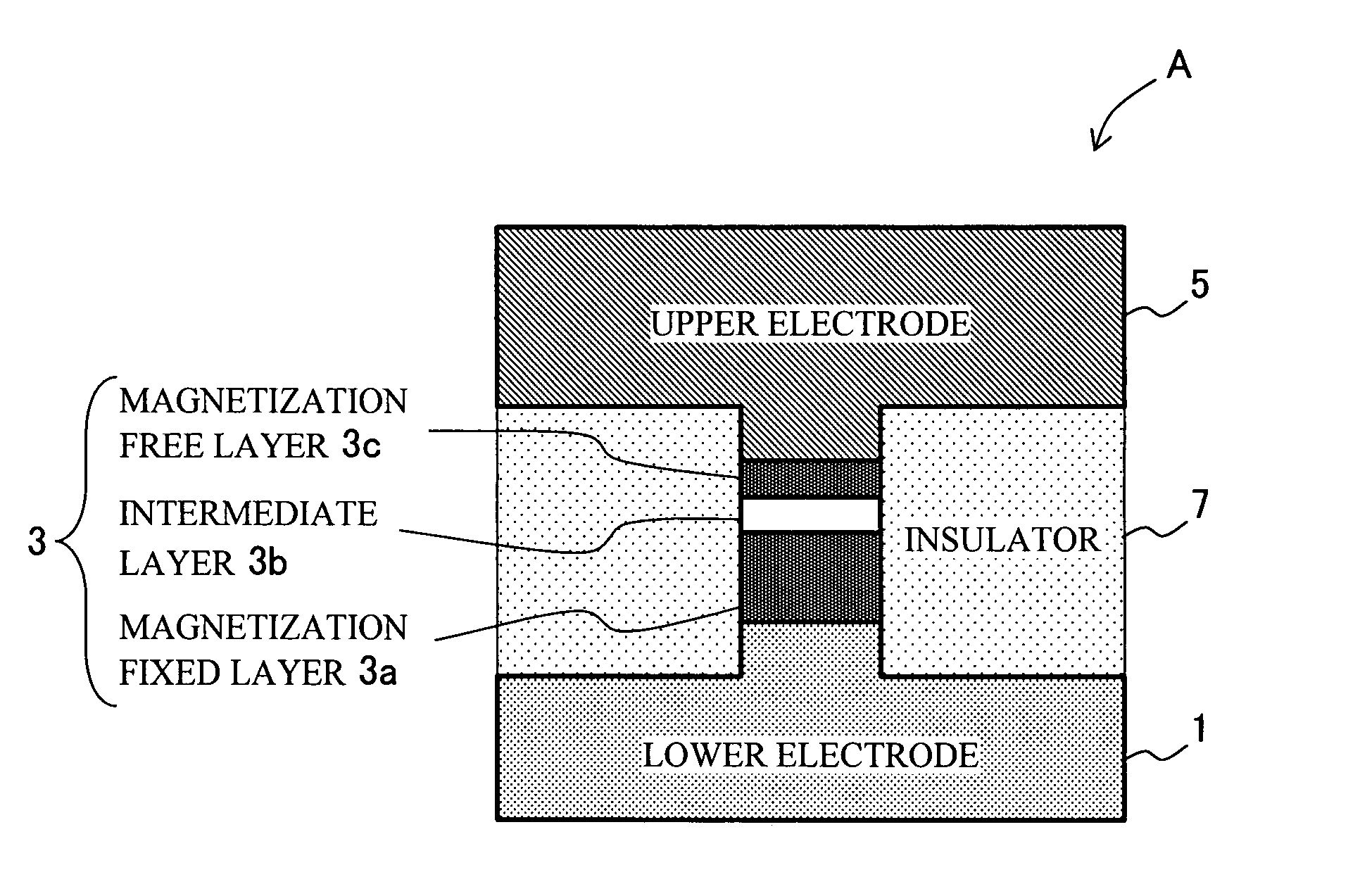

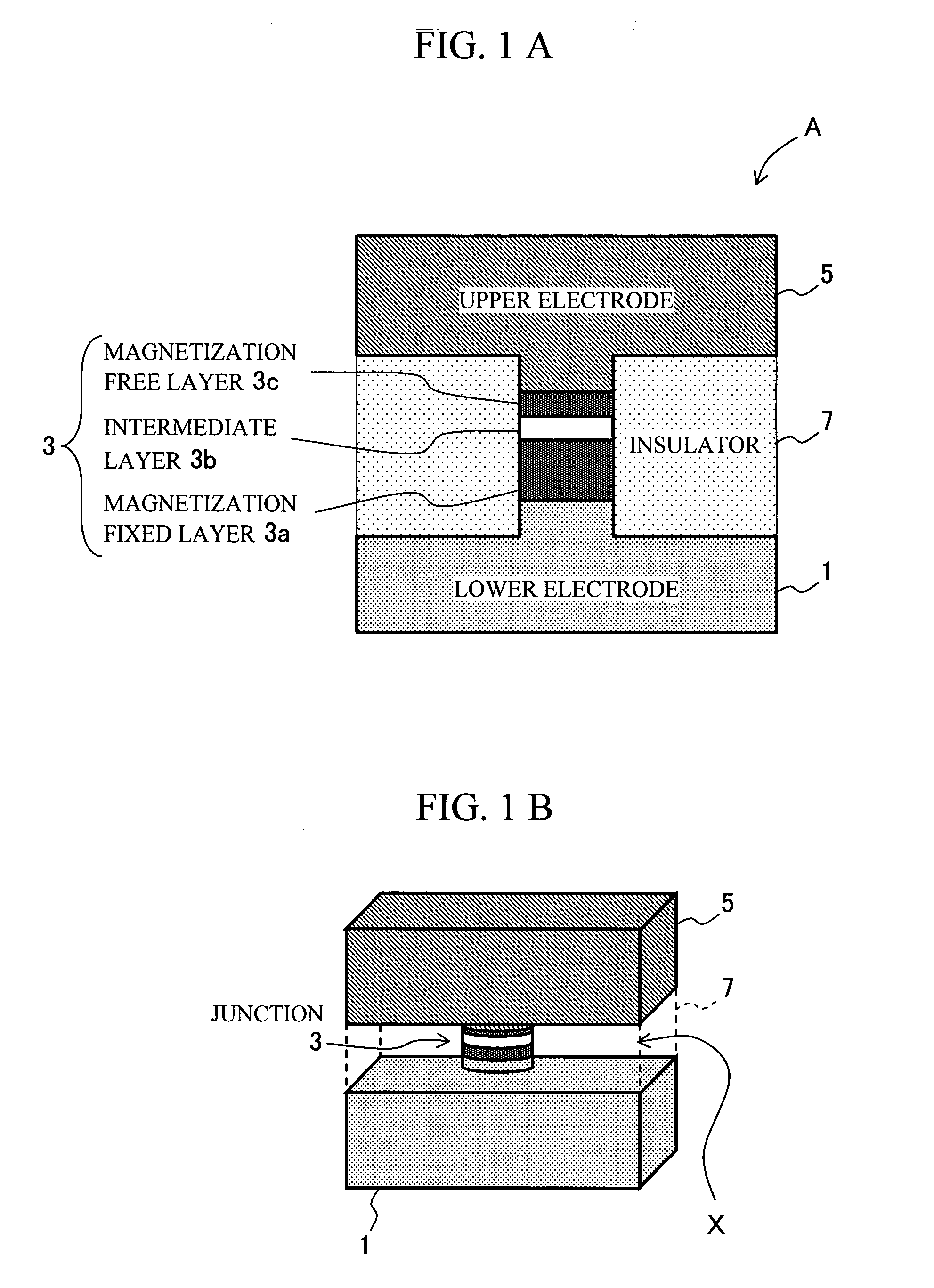

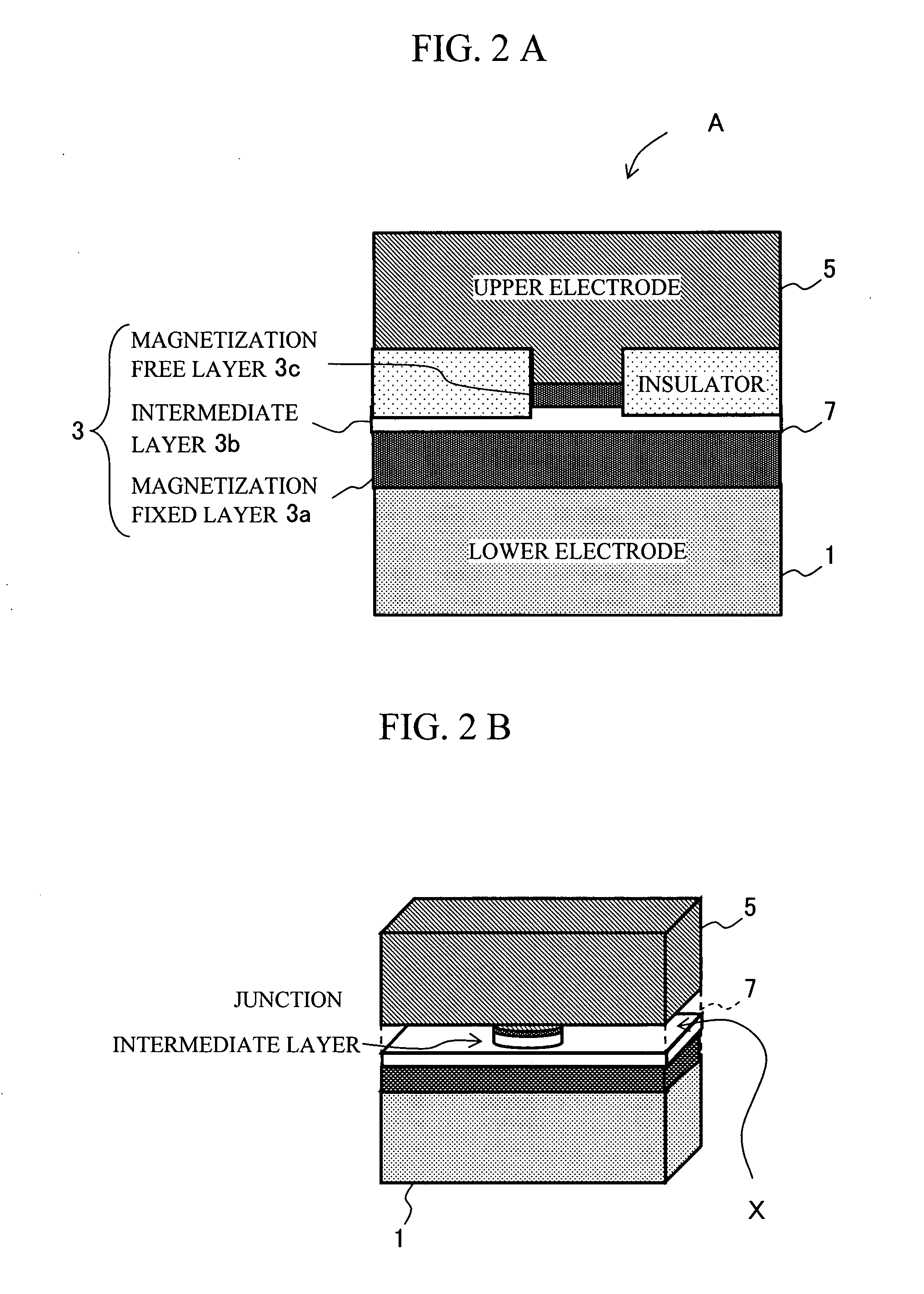

Microwave generating and detection portions of a electronic circuit is improved in efficiency and reduced in size. A microwave generating element A comprises a lower electrode 1, a layer 3 formed on the lower electrode 1 in an island shape, forming a magnetoresistance element, an insulator 7 formed on the lower electrode 1 in such a manner as to surround the layer 3 forming the magnetoresistance element, and an upper electrode 5 formed on the insulator 7 and the layer 3 forming the magnetoresistance element. The layer 3 forming the magnetoresistance element includes, in order from the side of the lower electrode 1, a magnetization fixed layer 3a, an intermediate layer 3b, and a magnetization free layer 3c. The magnetization free layer 3c, which is required to produce resonance oscillation based on a current, preferably is dimensioned to be equal to or smaller than 200 nm square in a cross-sectional area and on the order of 1 to 5 nm in film thickness, for example. The magnetization fixed layer 3a, when made of a single material, is required to have a thickness 10 times or more of the thickness of the magnetization free layer 3c. The magnetization fixed layer 3a may be comprised of a magnetic metal multilayer film that utilizes antiferromagnetic coupling.

Owner:JAPAN SCI & TECH CORP

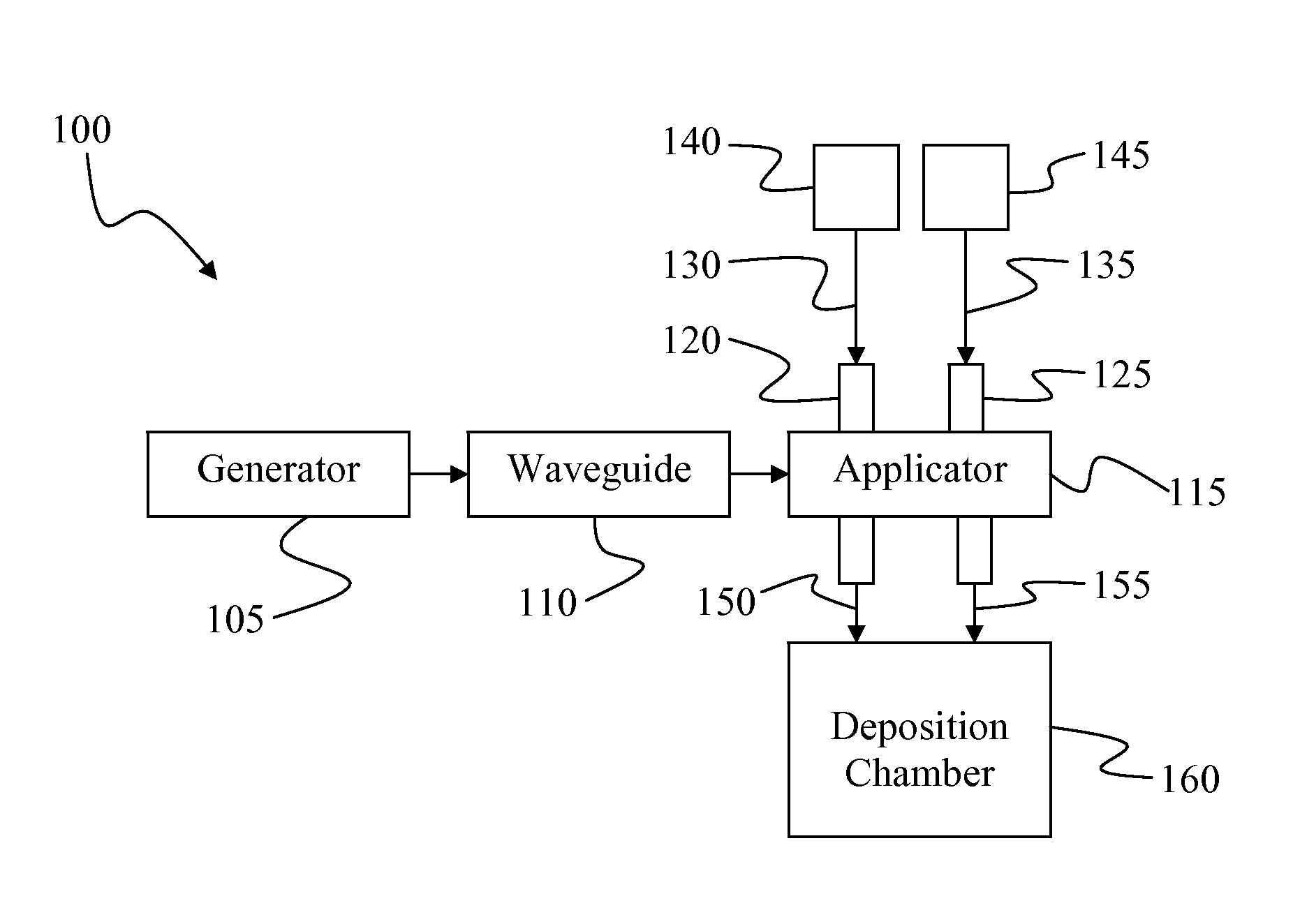

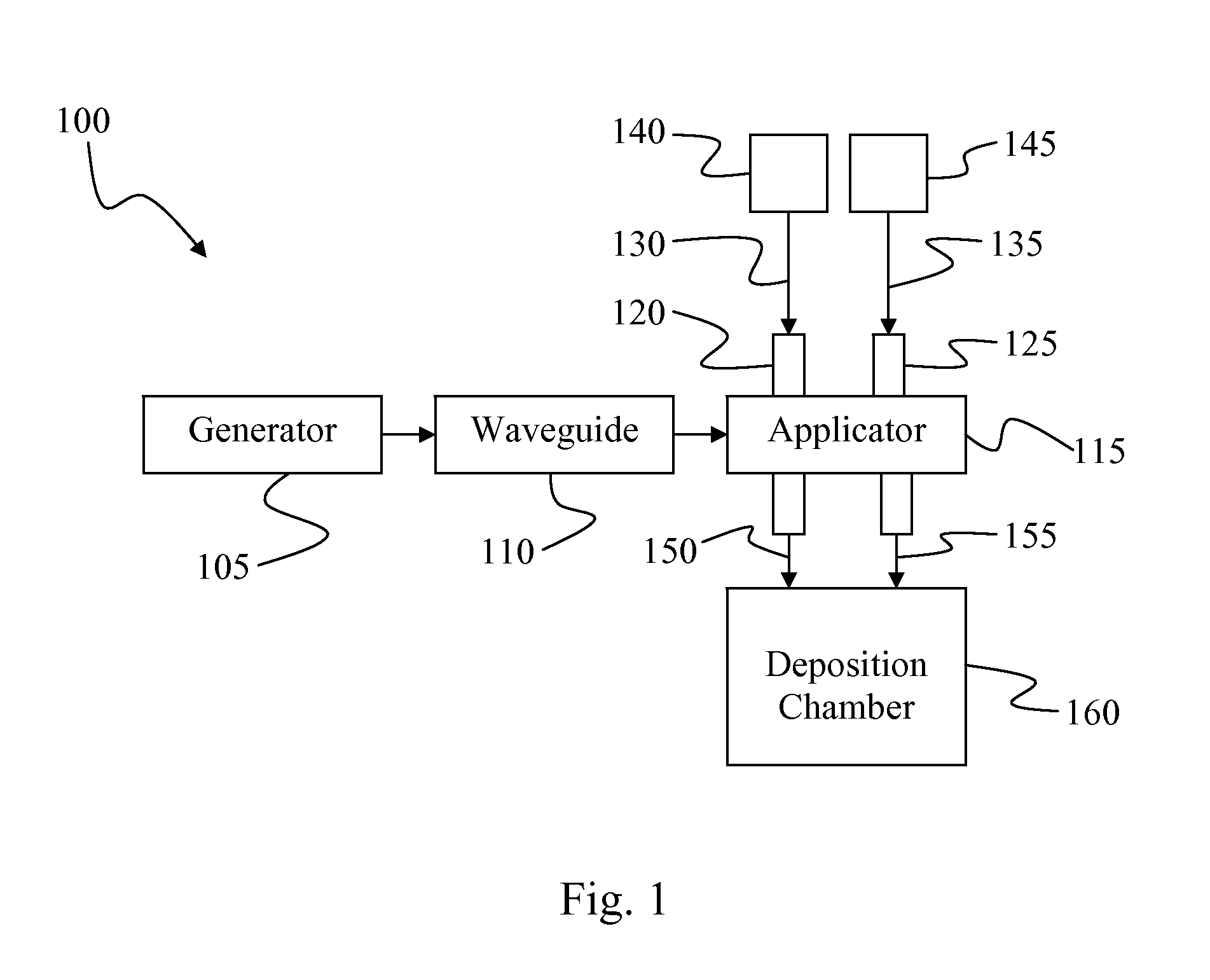

Plasma Deposition of Amorphous Semiconductors at Microwave Frequencies

InactiveUS20120040492A1Prevent and slow relaxationPrevent and slow and decayElectric discharge tubesFinal product manufacturePorosityPlasma deposition

Apparatus and method for plasma deposition of thin film photovoltaic materials at microwave frequencies. The apparatus avoids unintended deposition on windows or other microwave transmission elements that couple microwave energy to deposition species. The apparatus includes a microwave applicator with conduits passing therethrough that carry deposition species. The applicator transfers microwave energy to the deposition species to activate or energize them to a reactive state conducive to formation of a thin film material. The conduits physically isolate deposition species that would react or otherwise combine to form a thin film material at the point of microwave power transfer. The deposition species are separately energized and swept away from the point of power transfer to prevent thin film deposition. Suitable deposition species include precursors that contain silicon, germanium, fluorine, and / or hydrogen. The invention allows for the ultrafast formation of silicon-containing amorphous semiconductors that exhibit high mobility, low porosity, little or no Staebler-Wronski degradation, and low defect concentration.

Owner:OVSHINSKY TECH

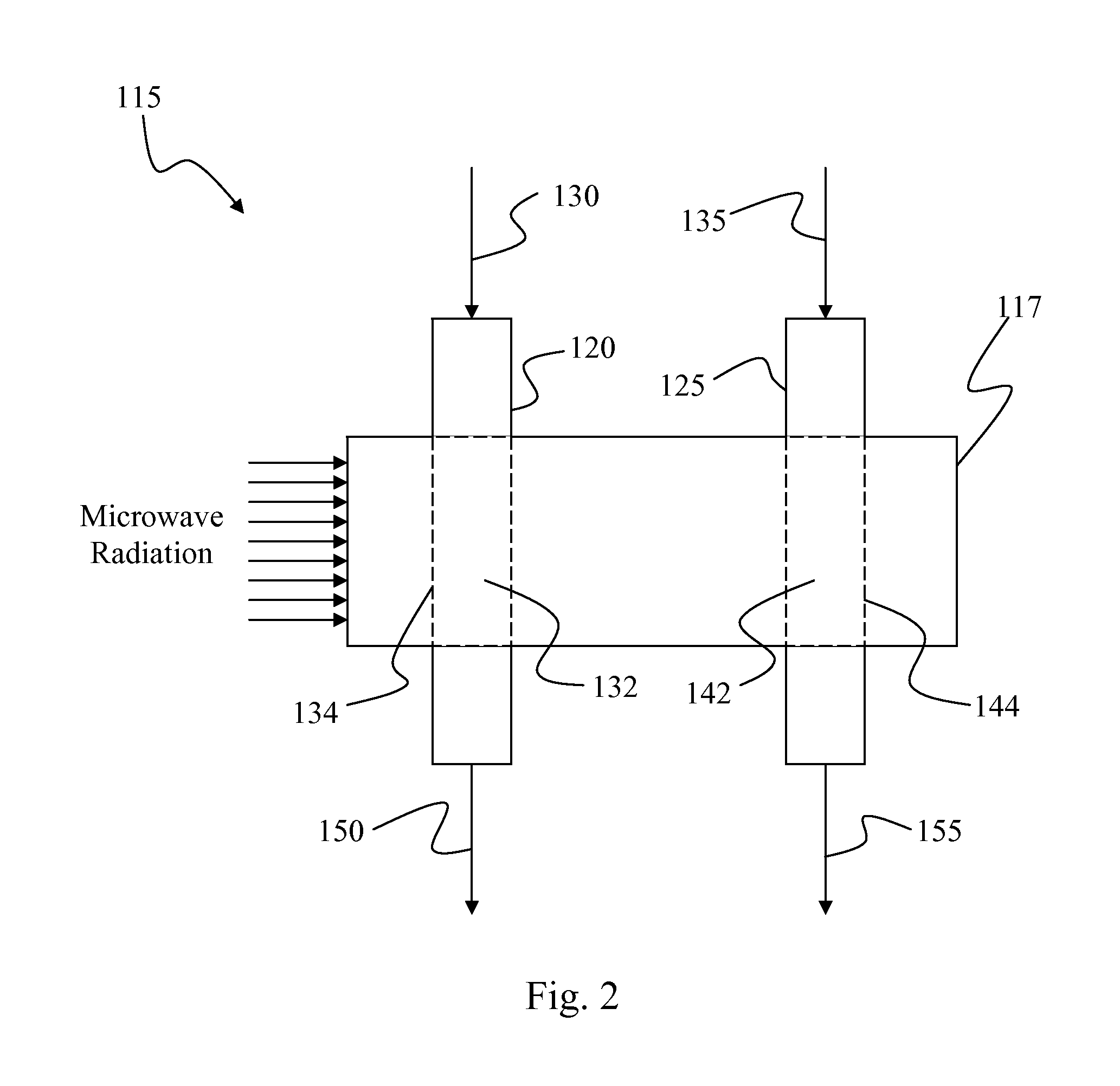

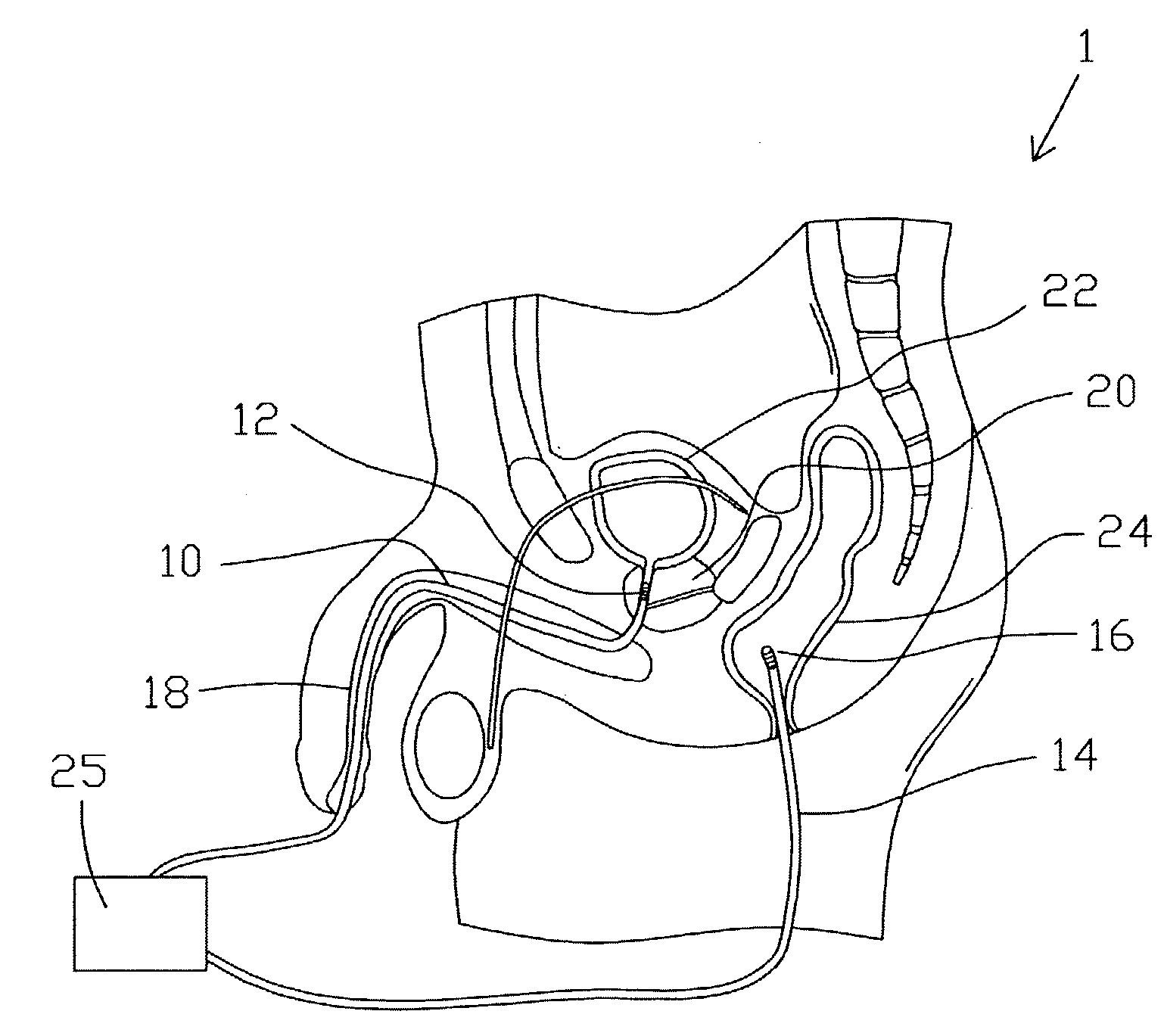

Microwave medical treatment apparatus and method

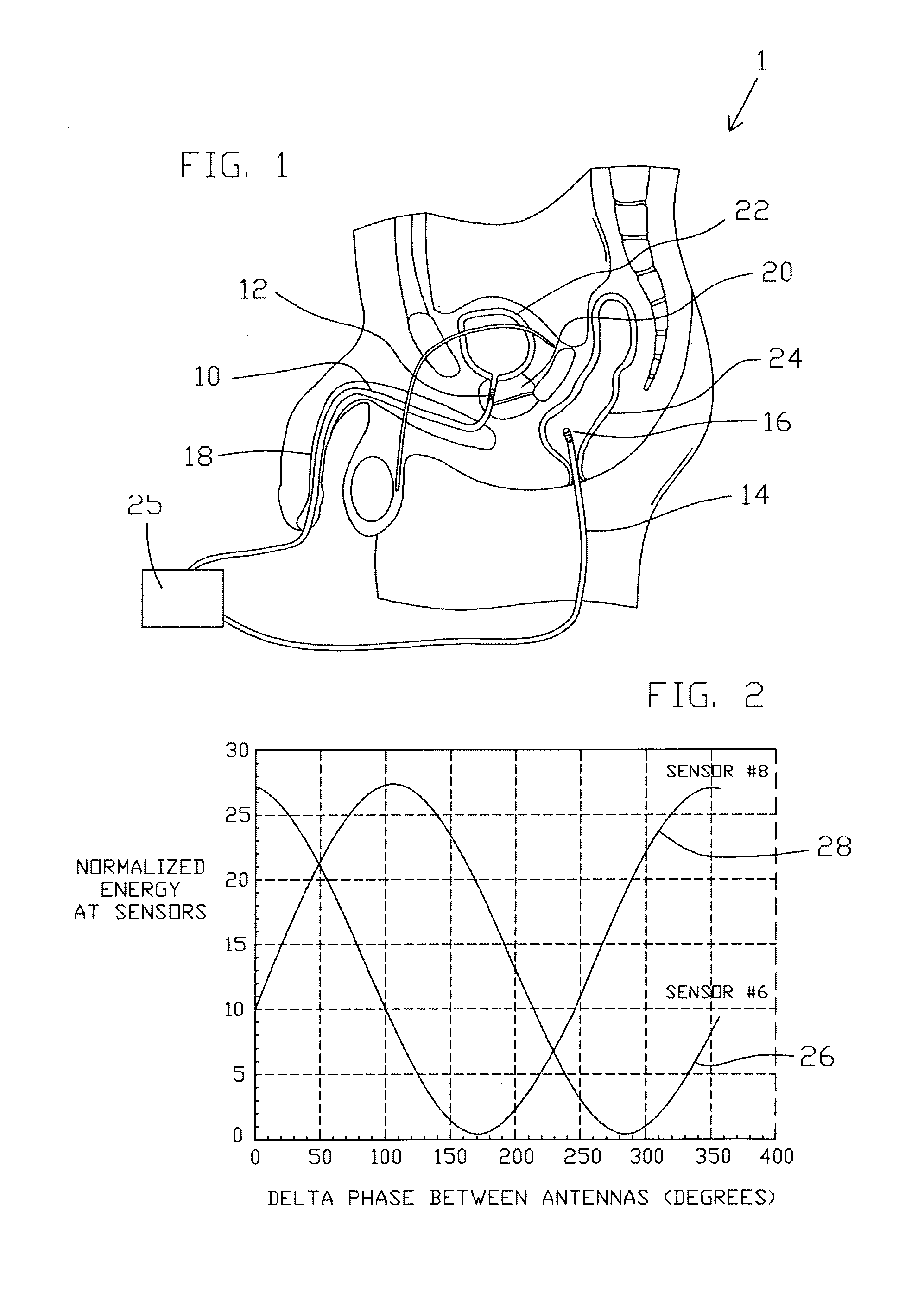

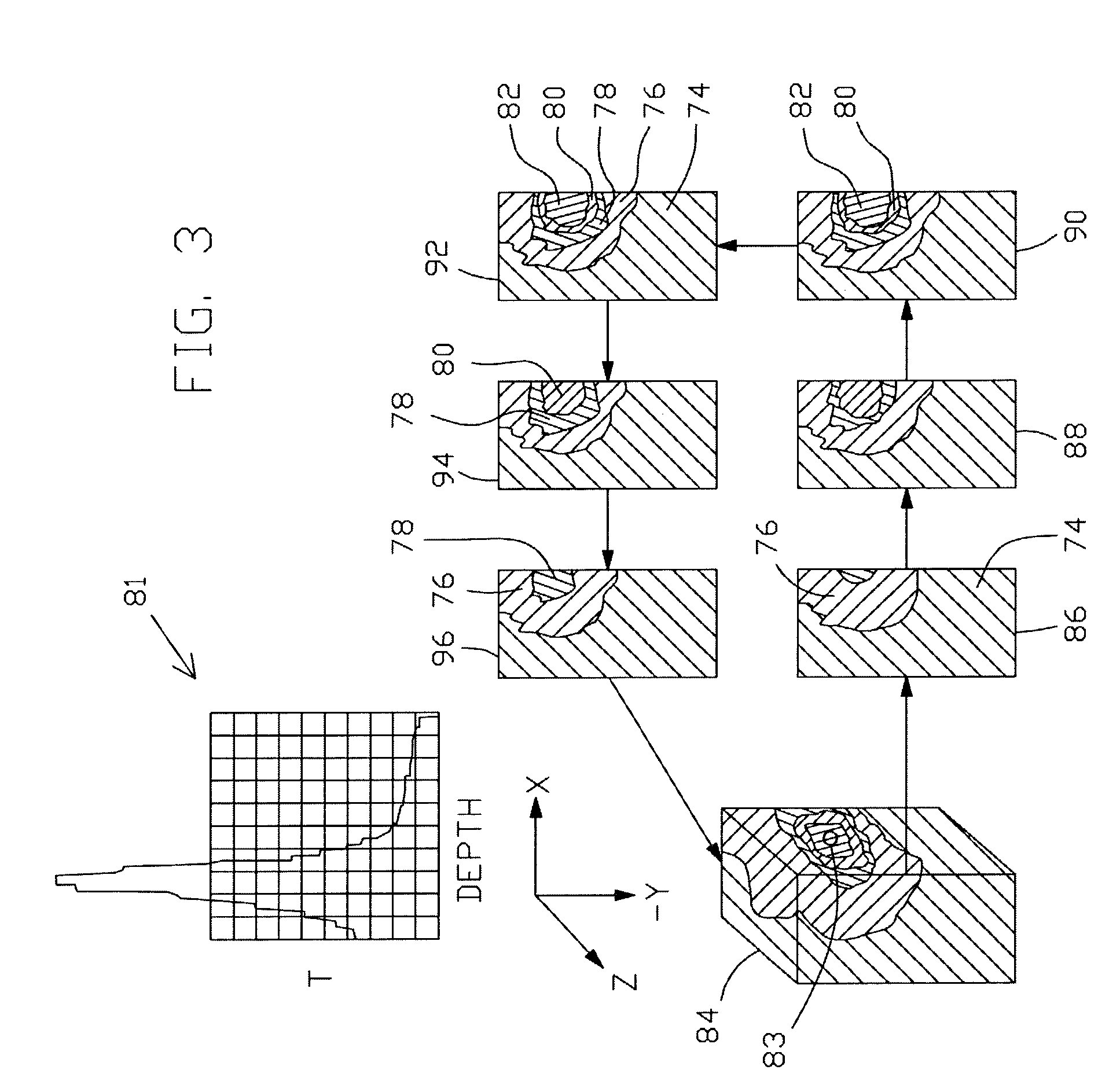

InactiveUS6944504B1Addressing slow performanceAvoid damageElectrotherapySurgical instruments using microwavesSaline injectionProstatic tissue

Methods, simulations, and apparatus are provided that may be utilized for medical treatments which are especially suitable for treatment of benign prostatic hyperplasia (BPH). In a preferred embodiment, a plurality of separate microwave antennas are utilized to heat prostatic tissue to promote necrosing of the prostatic tissue that relieves the pressure of the prostatic tissue against the urethra as the body reabsorbs the necrosed or dead tissue. By utilizing constructive and destructive interference of the microwave transmission, the energy can be deposited on the tissues to be necrosed while protecting other tissues such as the urethra. Saline injections to alter the conductivity of the tissues may also be used to further focus the energy deposits. A computer simulation is provided that can be used to predict the resulting temperature profile produced in the prostatic tissue. By changing the various control features of one or more catheters and the methods of applying microwave energy, a temperature profile can be predicted and produced that is similar to the temperature profile desired for the particular patient.

Owner:NASA

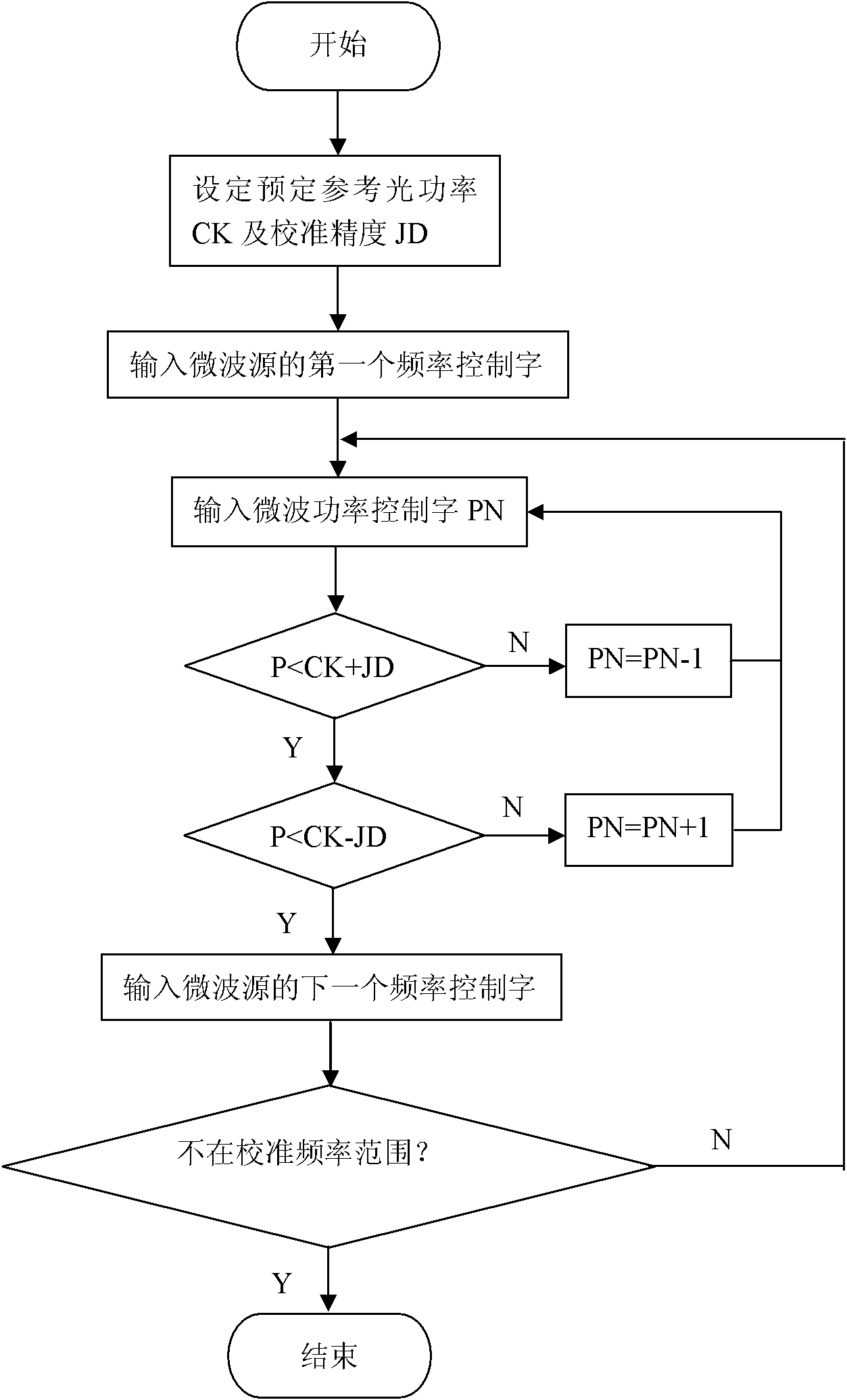

BOTDR (Brillouin Optical Time Domain Reflectometer) for calibrating optical power of reference light and calibrating method thereof

InactiveCN101839698AAccurate measurementHigh measurement accuracyThermometers using physical/chemical changesThermometer testing/calibrationTime domainOptical power

Owner:NANJING UNIV

Microwave transmission line integrated microwave generating element and microwave transmission line integrated microwave detecting element

ActiveUS7764136B2Small sizeEliminate lossDirection finders using radio wavesSemiconductor/solid-state device detailsBand shapeMagnetization

A strip line integrated microwave generating element and a microwave detecting element comprises a signal electrode and a ground electrode. The element has a magnetic tunnel junction structure which includes a magnetization fixed layer, a MgO tunnel barrier layer, and a magnetization free layer. The magnetization free layer is 200 nm square or smaller in a cross-sectional area. The magnetization fixed layer is in contact with either one of the signal electrode and the ground electrode while the magnetization free layer of the element being in contact with the other. The element is smaller than the electrodes and mounted on a part of the signal electrode or the ground electrode. A MR ratio of the element is of 100% or more. A resistance value of the element is from 50Ω to 300Ω. The resistance of the element is matched with an impedance of the microwave transmission line.

Owner:JAPAN SCI & TECH CORP

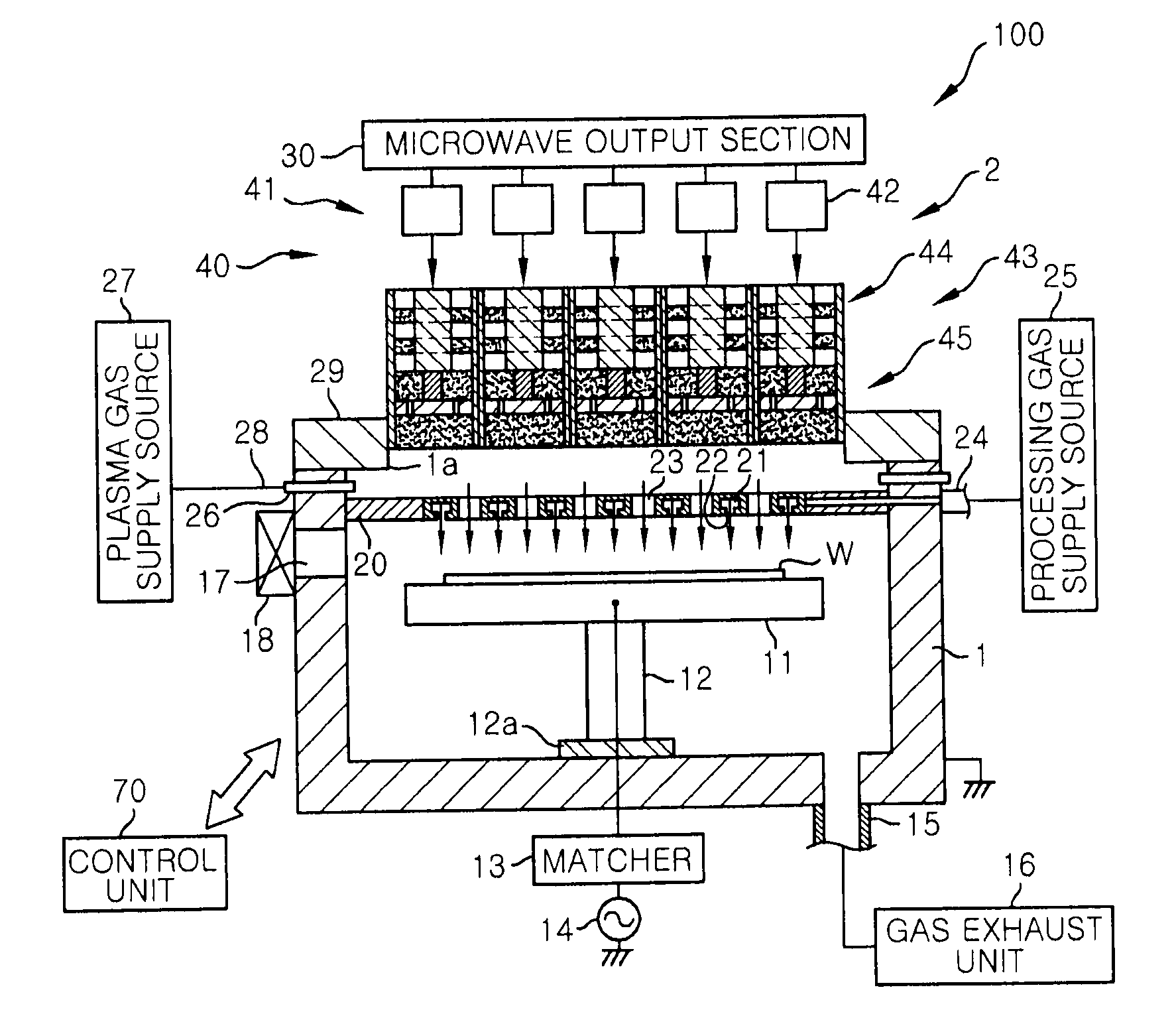

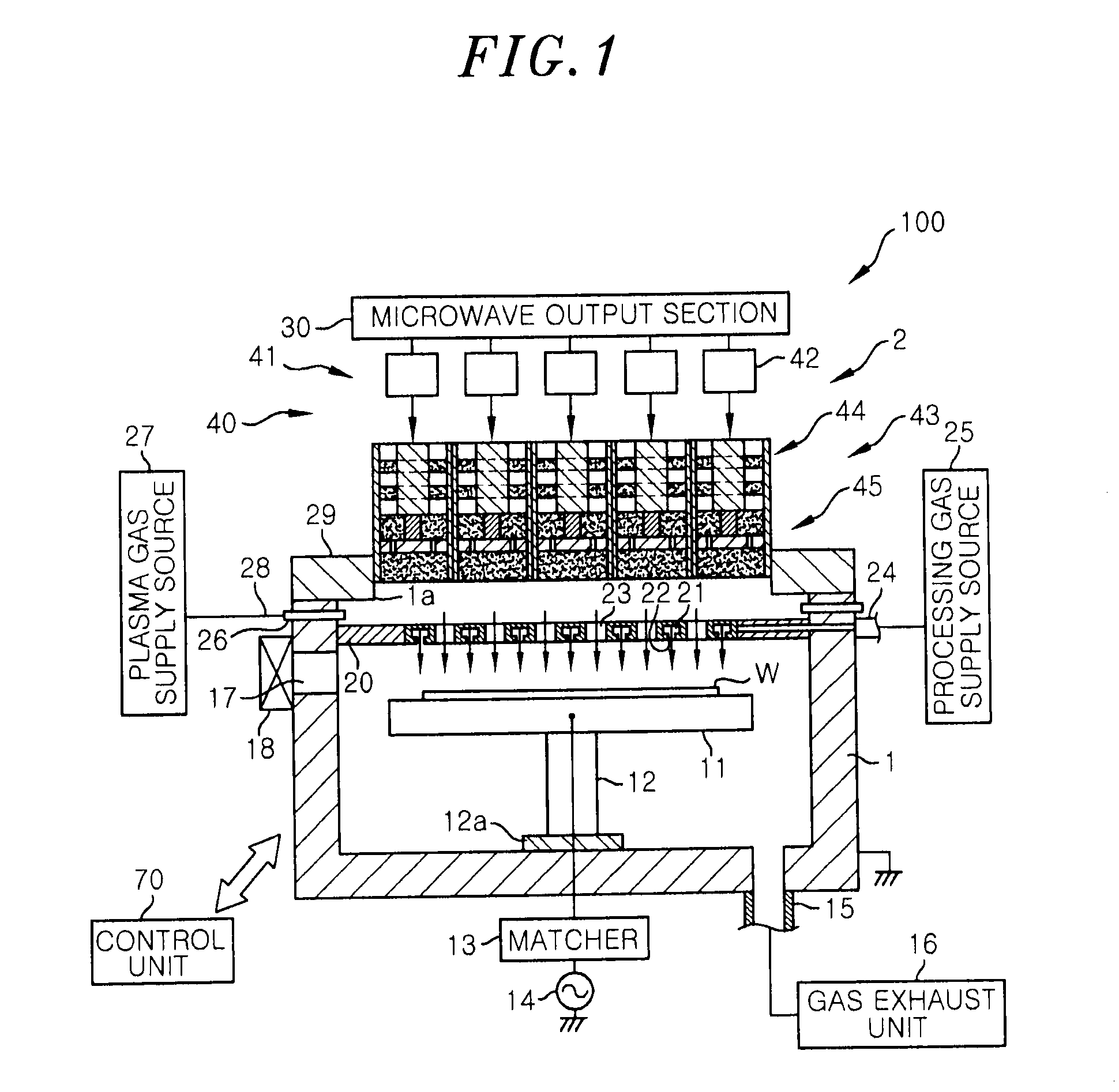

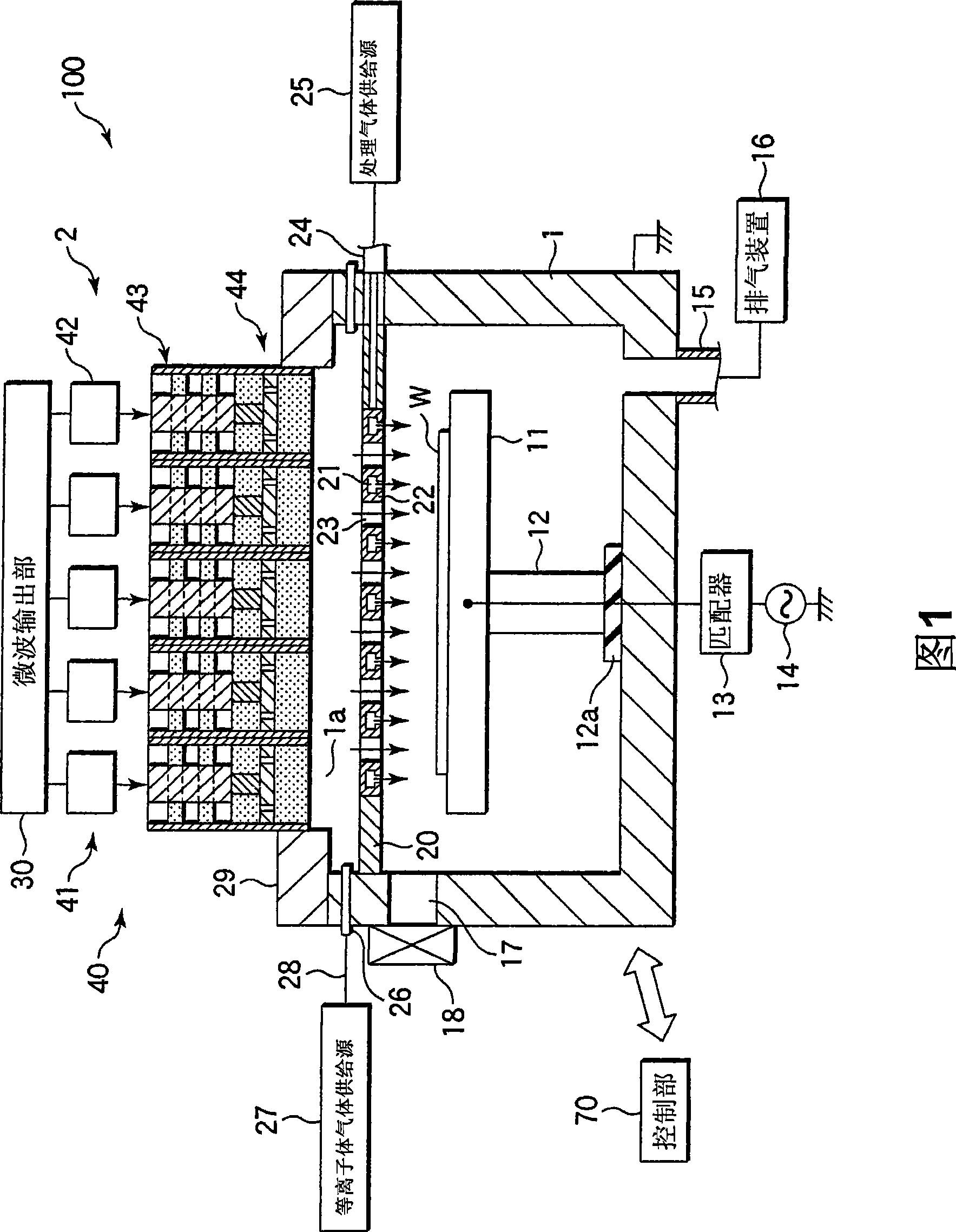

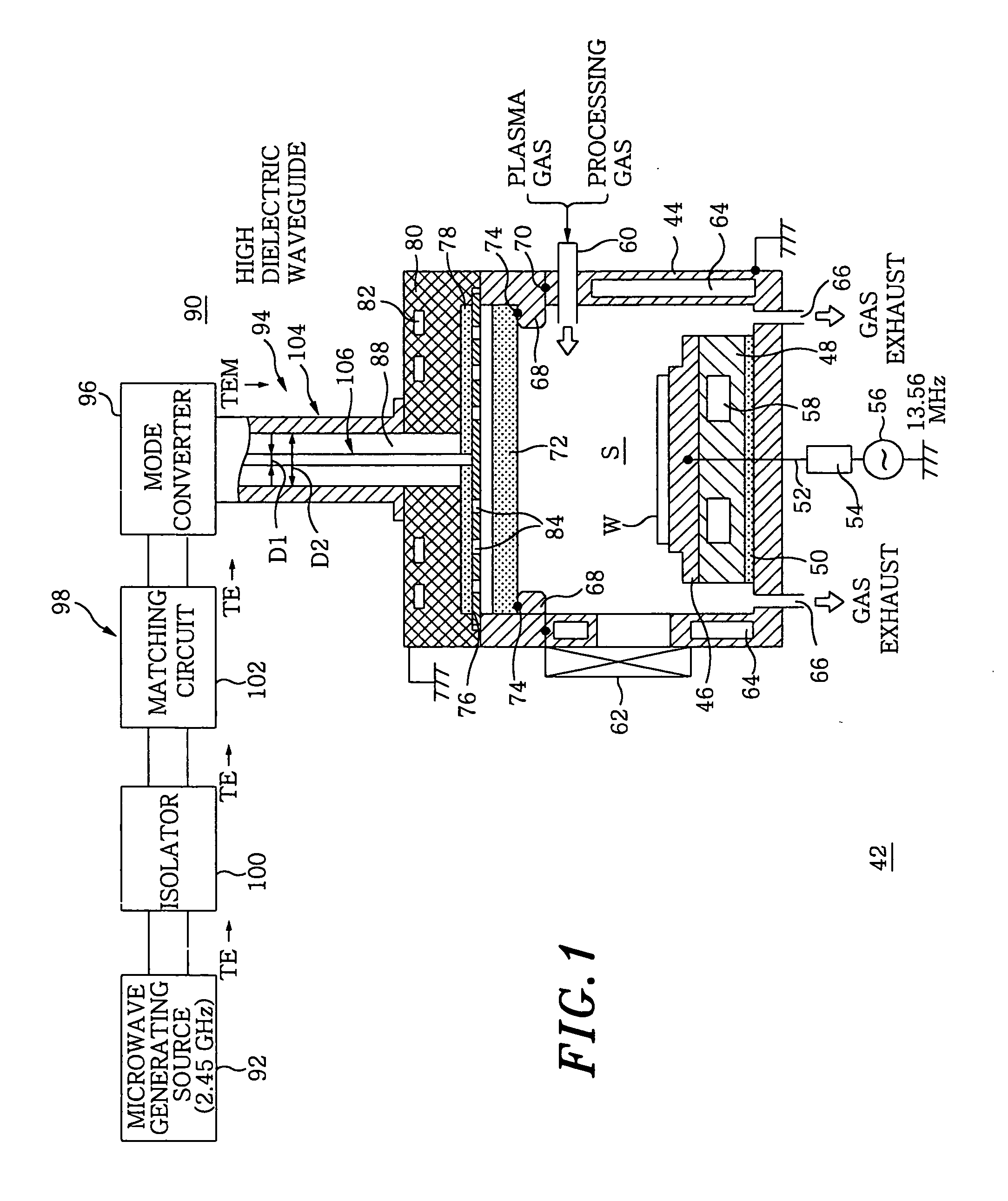

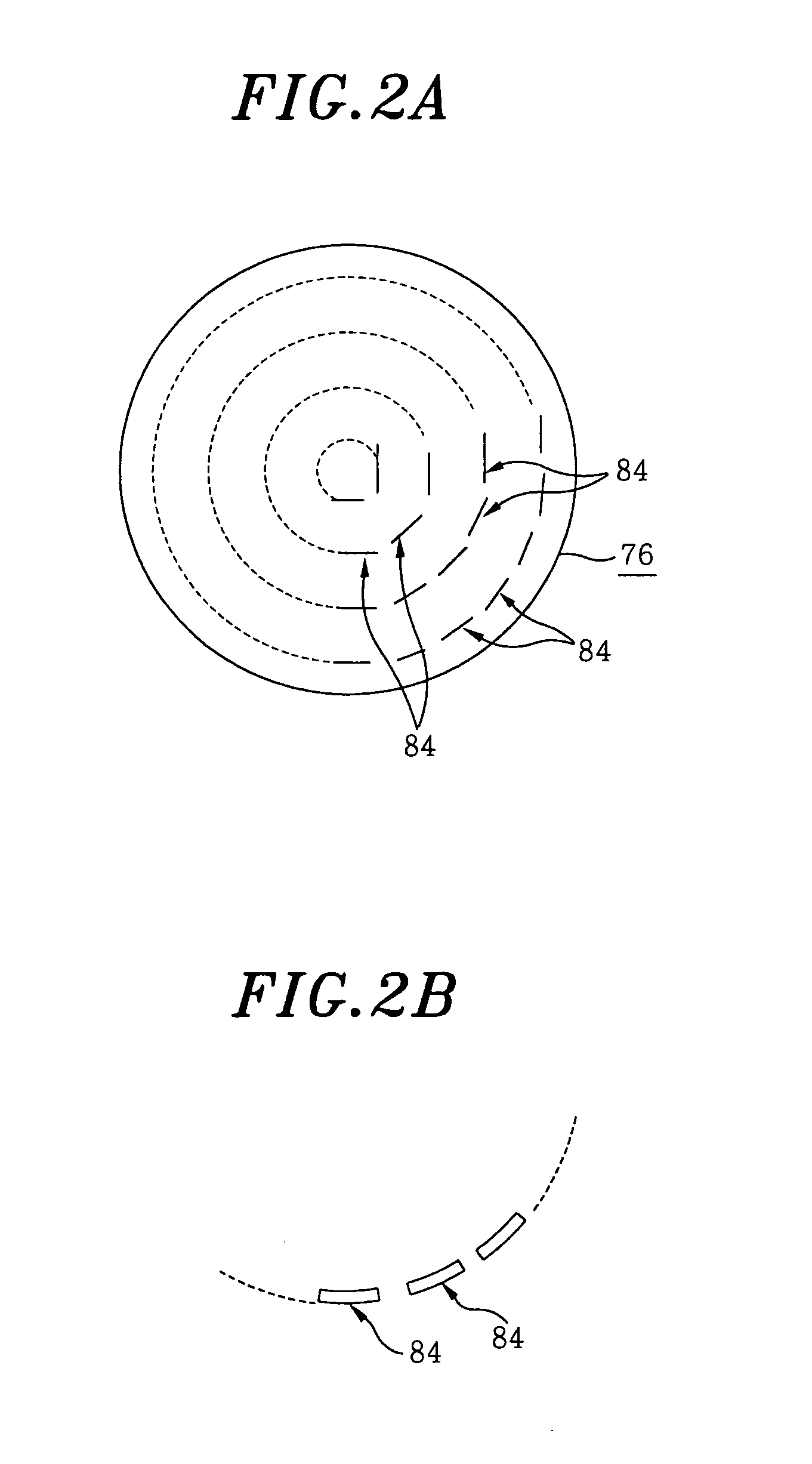

Microwave introducing mechanism, microwave plasma source and microwave plasma processing apparatus

InactiveUS20110061814A1Reduced range of movementSame distanceElectric arc lampsSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A microwave introducing mechanism 43 includes a cylindrical container 50; an inner conductor 52, coaxially provided in the container 50, a microwave transmission path being defined between the container 50 and the inner conductor 52; a tuner 44 for adjusting an impedance of the microwave transmission path 53; and an antenna section 45 including an antenna 51 for radiating to the chamber a microwave transmitted through the microwave transmission path 53. The tuner 44 includes a pair of slugs 58 made of a dielectric material and movable along the inner conductor 52; an actuator 59 for moving the slugs 58; and a controller 60. The controller 60 controls both the slugs 58 to move together in a range of a ½ wavelength of the microwave and one of the slugs 58 to move in a range of a ¼ wavelength of the microwave with regard to the other slug.

Owner:TOKYO ELECTRON LTD

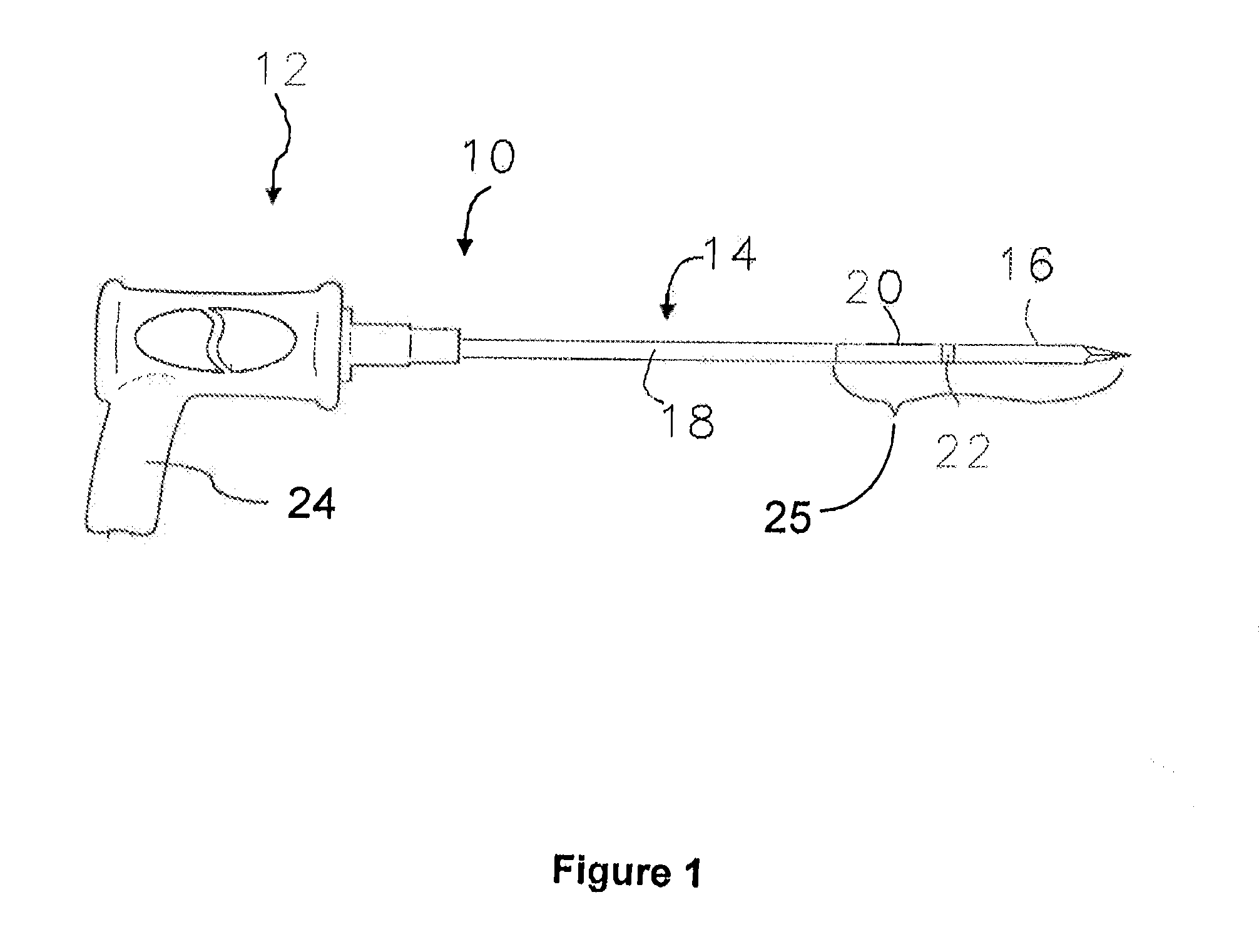

Microwave coagulation applicator and system

ActiveUS8414570B2Reduce adhesionEasy to disassembleSurgical needlesSurgical instruments for heatingMultiplexingAfter treatment

A microwave applicator for insertion into living body tissue for use in microwave coagulation and ablation treatments includes a microwave transmission line extending between an attachment end of the applicator and an antenna toward an insertion end of the applicator with an outer conductive sleeve forming an enclosed cooling fluid space around the transmission line. Circulation of cooling fluid is guided in the cooling fluid space by a guide sleeve. A temperature sensor senses the approximate temperature of cooling fluid to indicate cooling fluid is circulating. A multiplexing and power splitting circuit provides outputs tuned for one or for more than one applicator to be attached and detects the number of applicators and correct connection. A cadence sound generator can be used in conjunction with depth markings on the applicator to provide substantially constant withdrawal of the applicator from the treated tissue after treatment to provide track ablation.

Owner:VARIAN MEDICAL SYSTEMS

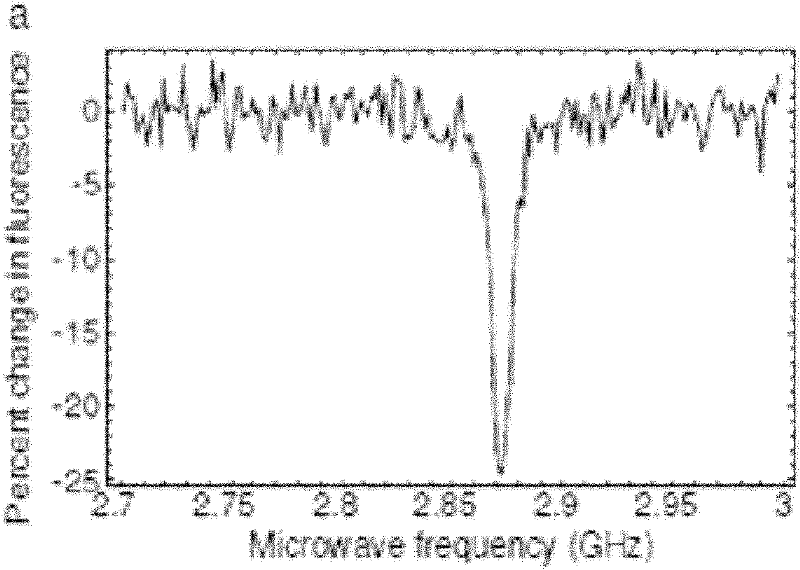

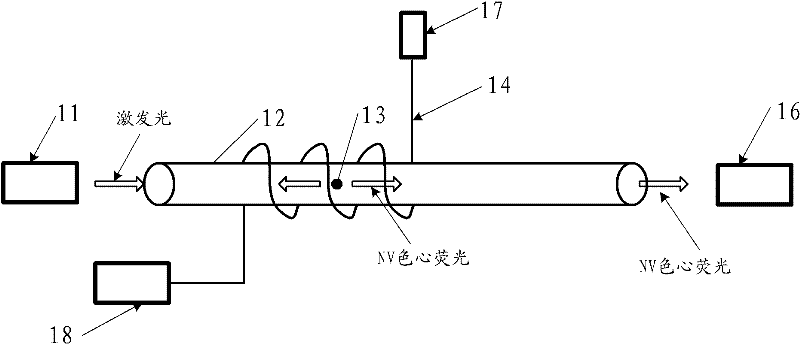

Magnetic-field measurement device and manufacturing method thereof as well as magnetic-field measurement method

InactiveCN102193074ALow costShorten the timeMagnetic field measurement using magneto-optic devicesMeasurement deviceSingle crystal

The embodiment of the invention discloses a magnetic-field measurement device and a manufacturing method thereof as well as a magnetic-field measurement method. The magnetic-field measurement device comprises a combined optical fiber, monocrystal diamond particles, a microwave transmission line, a microwave generator, a laser device and a spectrometer, wherein the combined optical fiber is prepared by connecting two optical fibers; the monocrystal diamond particles are packaged between the end faces of the two optical fibers and provided with single NV colour centers; the microwave transmission line is arranged at the external wall of the combined optical fiber; the microwave generator is connected with the microwave transmission line; the laser device is connected with one end of the combined optical fiber; and the spectrometer is connected with the other end of the combined optical fiber; and exciting lights are input from one end of the combined optical fiber, and fluorescent lights of single NV colour centers are received from the other end of the combined optical fiber. In the invention, through carrying out measurement on magnetic fields by using the single NV colour centerspackaged in the optical fiber, the application of a confocal microscope system is avoided, the cost for finding the single NV colour centers is reduced, and the time and manpower are saved; and meanwhile, the magnetic-field measurement can be conveniently performed by using the single NV colour centers in any magnetic-field environment without being limited by the confocal microscope system.

Owner:UNIV OF SCI & TECH OF CHINA

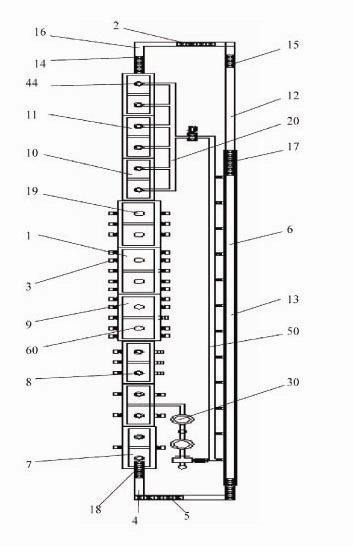

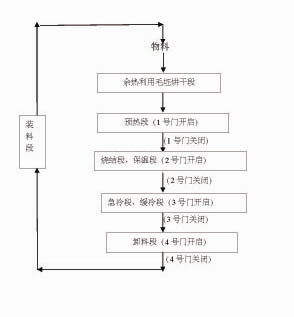

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

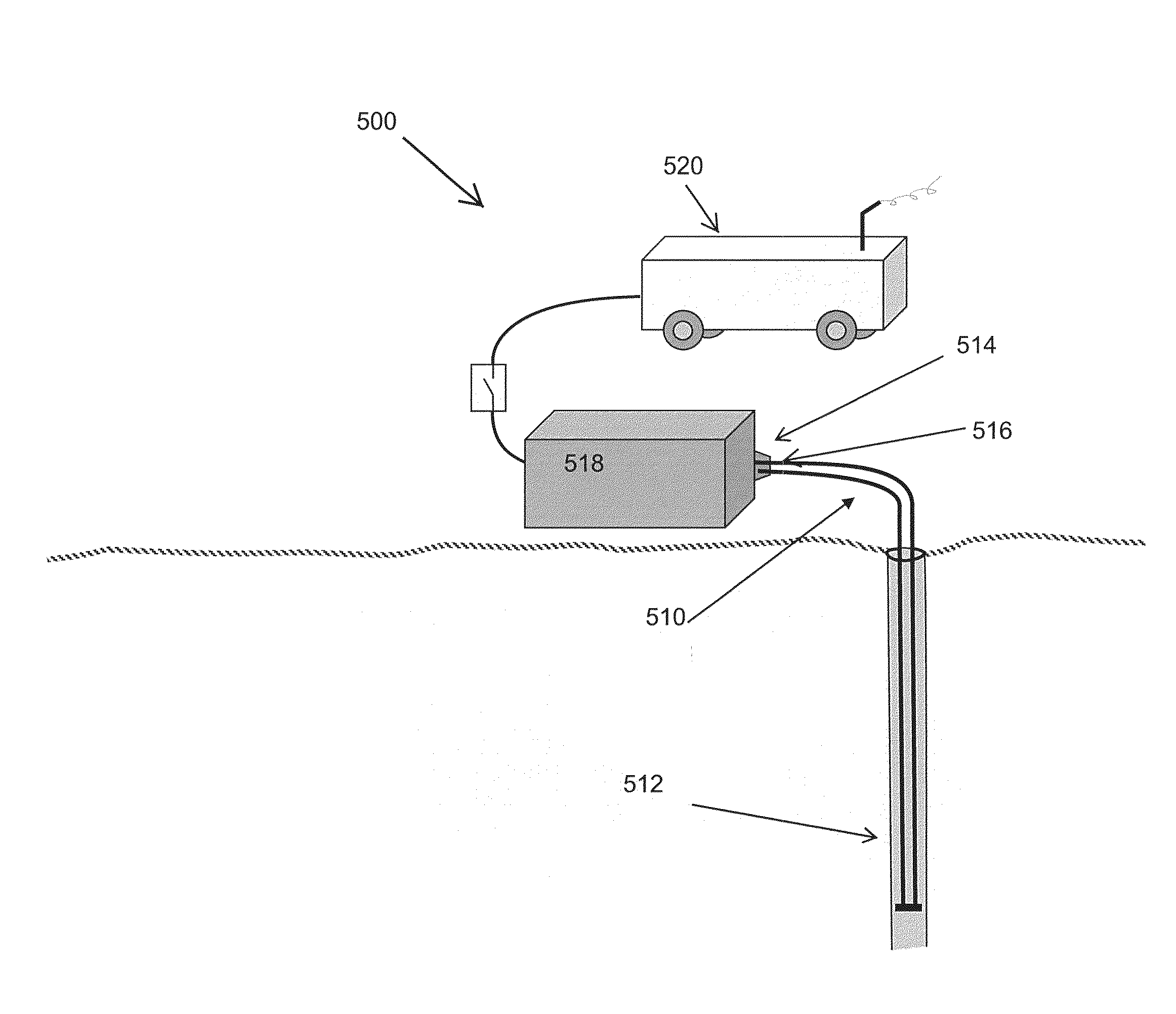

Apparatuses and methods for supplying electrical power to an electrocrushing drill

InactiveUS20140008968A1Reduce lossesGood power deliveryDrilling rodsPower distribution line transmissionAbove groundPulse power systems

Methods and apparatuses for directly charging capacitors in a down-hole pulsed power system used for electrocrushing drilling. An above ground power supply is directly connected to the capacitors. The power supply can be a switching power supply, a DC supply, or an AC supply. Capacitor voltage is monitored and controlled. The system reduces noise caused by coupling control signal cables and the power cable, and does not have the ground swing control problems of other charging schemes. The power may alternatively be provided by microwave transmission.

Owner:SDG LLC

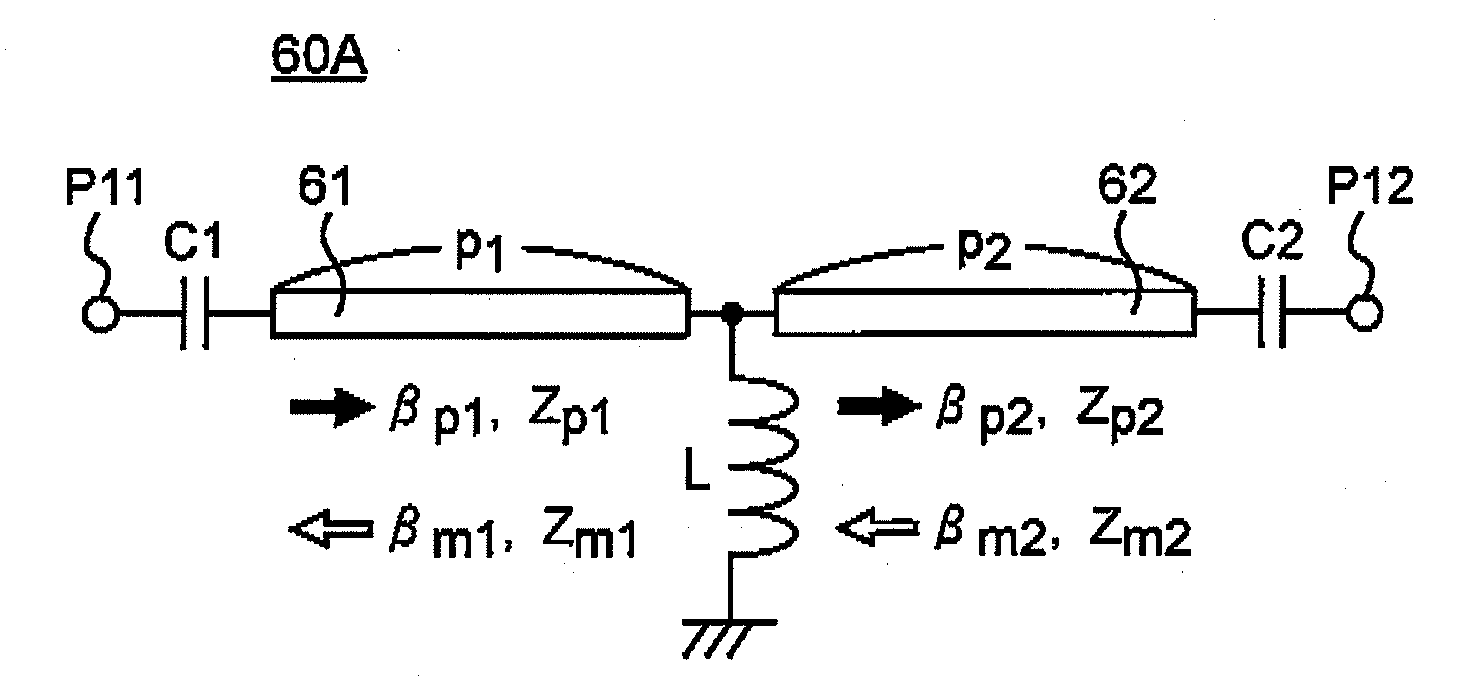

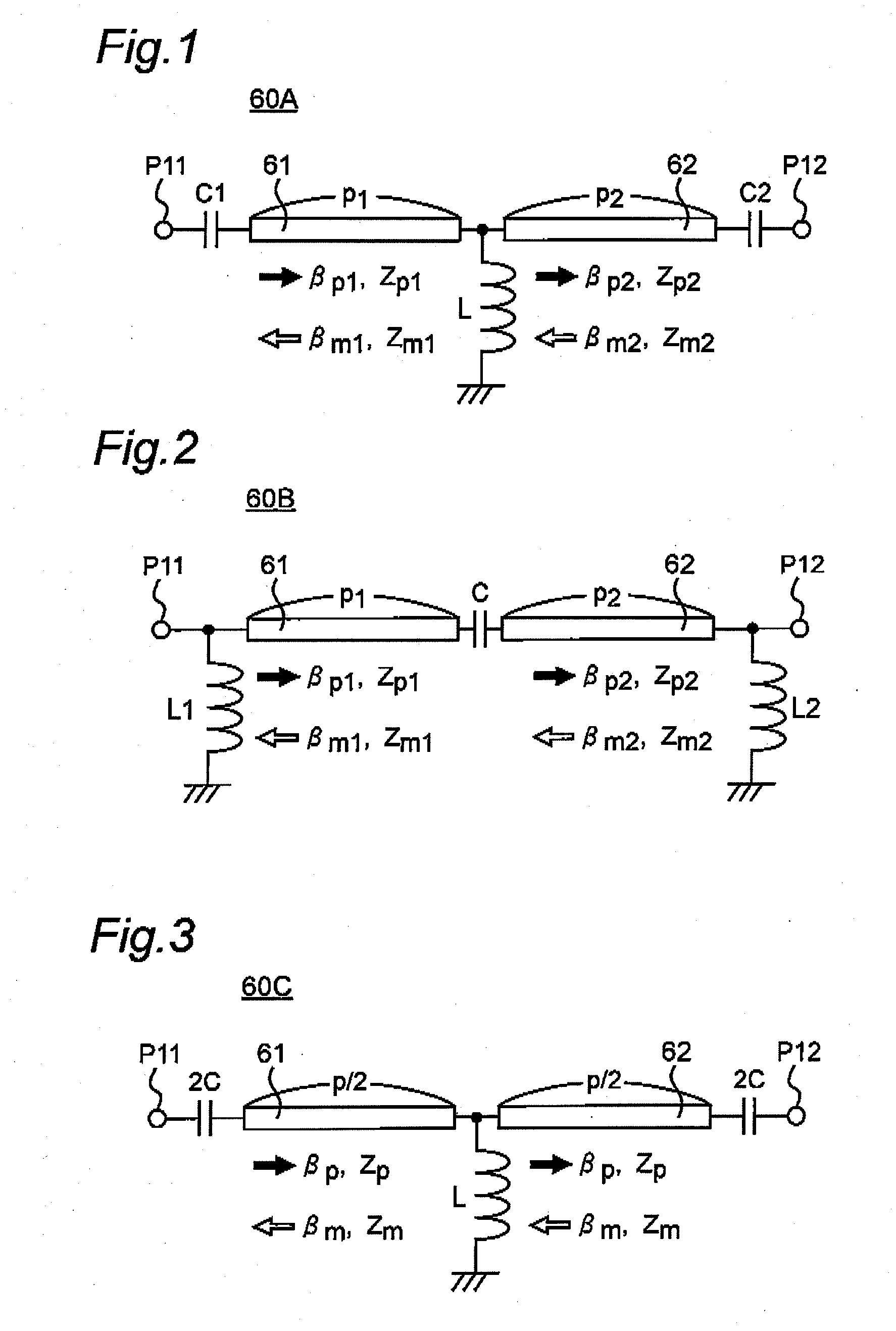

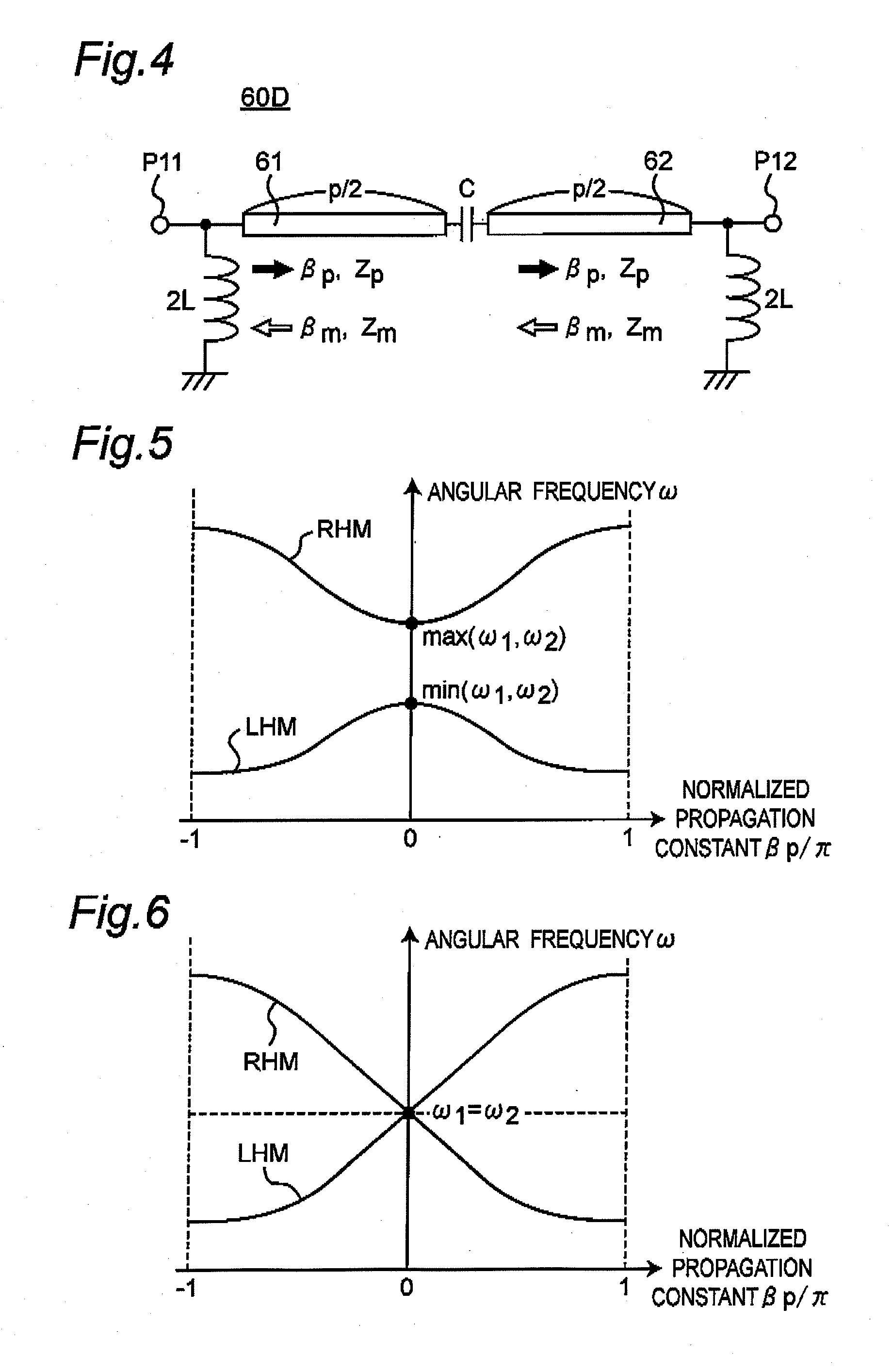

Transmission line microwave apparatus including at least one non-reciprocal transmission line part between two parts

ActiveUS20100060388A1Small sizeGood effectRadiating elements structural formsWaveguidesCapacitanceDispersion curve

A transmission line microwave apparatus includes at least one nonreciprocal transmission line part, which includes a series branch circuit equivalently including a capacitive element and a shunt branch circuit equivalently including an inductive element. The nonreciprocal transmission line part has gyrotropic characteristic by being magnetized in a magnetization direction different from the propagation direction of a microwave, and has an asymmetric structure to a plane formed by the propagation direction and the magnetization direction. The nonreciprocal transmission line part has a propagation constant and an operating frequency set in a dispersion curve that represents a relation between the propagation constant and the operating frequency so that the propagation constant in the forward direction and the propagation constant in the backward direction have nonreciprocal phase characteristics different from each other. A microwave transmission line is constituted by cascade-connecting at least one non-reciprocal transmission line part between first and second ports.

Owner:JAPAN SCI & TECH CORP

Microwave coagulation applicator and system with fluid injection

ActiveUS20110118724A1Higher microwave loss factorWeaken energySurgical needlesSurgical instruments for heatingFluid injectionCorneal ablation

A microwave applicator for insertion into living body tissue for use in microwave coagulation and ablation treatments includes a microwave transmission line extending between an attachment end of the applicator and an antenna toward an insertion end of the applicator with an outer conductive sleeve forming an enclosed fluid space around the transmission line. A fluid circulation system circulates fluid in the fluid space. A portion of or all of the circulating fluid can be injected into tissue that surrounds the applicator body from approximately the proximal end of a desired heating zone produced by microwave energy radiated from the antenna along the applicator body toward the proximal end of the applicator to hydrate and wet the tissue outside the proximal end of the desired heating zone to reduce the drying of this tissue and limit extension of the heating and ablation zone proximally along the applicator body.

Owner:VARIAN MEDICAL SYSTEMS

Microwave generating device and microwave high-temperature air pressure device with microwave generating device

ActiveCN104236302AGuaranteed gas pressureGuaranteed internal temperatureMuffle furnacesRetort furnacesSource functionEngineering

The invention discloses a microwave generating device and a microwave high-temperature air pressure device with the microwave generating device. The microwave generating device comprises a microwave source, a wave transmission pressure-resistant element and a pressure-resistant waveguide, wherein the microwave source is used for giving out microwaves, the wave transmission pressure-resistant element is used for bearing the pressure and transmitting the microwaves, the pressure-resistant waveguide is used for bearing the pressure, transmitting electromagnetic waves and feeding back energy, an energy feedback antenna of the microwave source is arranged in the wave transmission pressure-resistant element, the energy feedback antenna and the wave transmission pressure-resistant element are simultaneously connected into the waveguide, the inner wall surface of the pressure-resistant waveguide defines and forms a microwave resonant cavity so that the microwaves generated by the microwave source can enter the pressure-resistant waveguide through the wave transmission pressure-resistant element, and the resonance is formed in the pressure-resistant waveguide and is transmitted to a target cavity. Through a combined structure of the wave transmission pressure-resistant element and the pressure-resistant waveguide, the pressure resistance in the microwave transmission position is realized, the air pressure outward leakage condition can be effectively prevented, the air pressure and the inside temperature of the target cavity are ensured, and the microwave source function failure caused when airflow enters the microwave source through the pressure-resistant waveguide can be effectively prevented.

Owner:湖南华冶微波科技有限公司

Microwave coagulation applicator and system

ActiveUS20110118720A1Reduce microwave heatingIncrease in tissue heatingSurgical needlesSurgical instruments for heatingMultiplexingAfter treatment

A microwave applicator for insertion into living body tissue for use in microwave coagulation and ablation treatments includes a microwave transmission line extending between an attachment end of the applicator and an antenna toward an insertion end of the applicator with an outer conductive sleeve forming an enclosed cooling fluid space around the transmission line. Circulation of cooling fluid is guided in the cooling fluid space by a guide sleeve. A temperature sensor senses the approximate temperature of cooling fluid to indicate cooling fluid is circulating. A multiplexing and power splitting circuit provides outputs tuned for one or for more than one applicator to be attached and detects the number of applicators and correct connection. A cadence sound generator can be used in conjunction with depth markings on the applicator to provide substantially constant withdrawal of the applicator from the treated tissue after treatment to provide track ablation.

Owner:VARIAN MEDICAL SYSTEMS

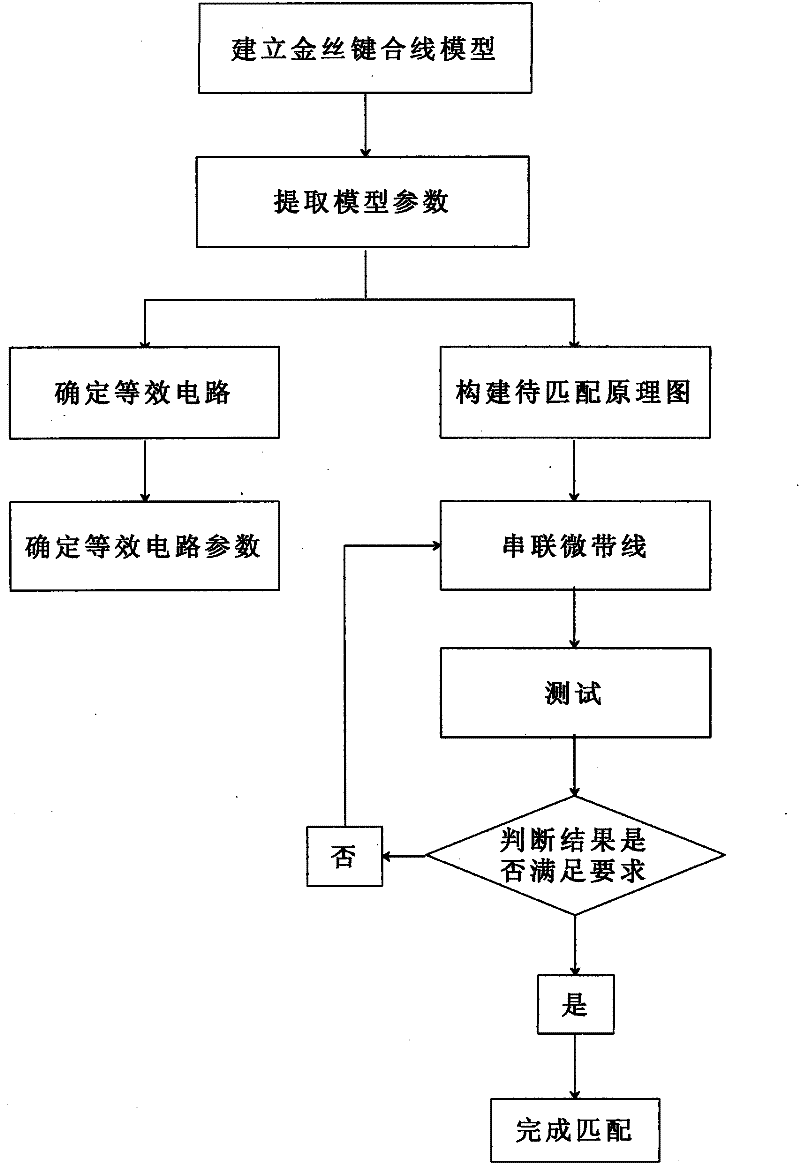

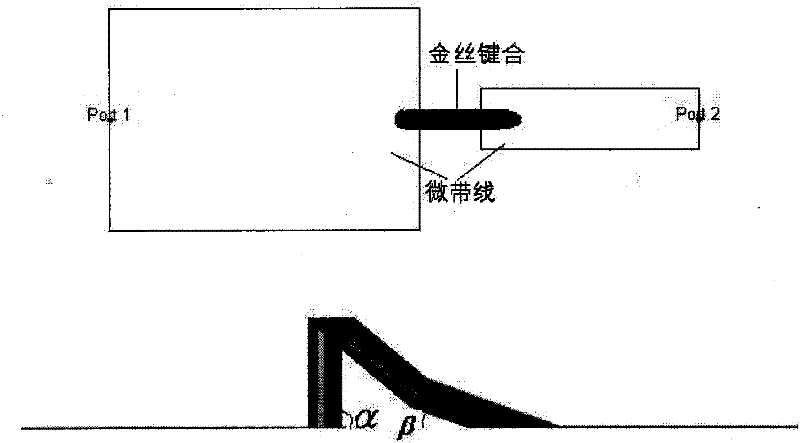

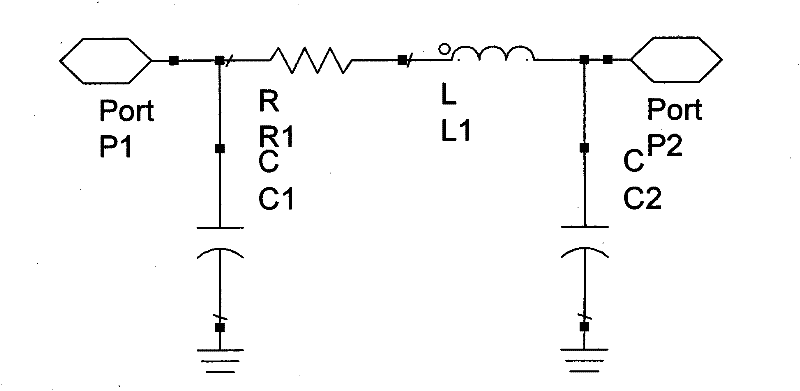

Impedance matching method for gold bonding wire

InactiveCN102393863AOvercoming the lack of cumbersome designThe design idea is simpleSpecial data processing applicationsSmith chartCompensation effect

The invention discloses an impedance matching method for a gold bonding wire. The method comprises the following steps: establishing a gold bonding wire model; extracting model parameters in a circuit application frequency band; causing the gold bonding wire model to be equivalent to a TT-shaped low-pass filter network; fitting equivalent network parameters by using the extracted model parameters; and introducing the extracted model parameters into a to-be-matched schematic diagram and adding a Smith chart matching control. In the Smith chart, 2-4 sections of micro-strip wires are serially connected so as to establish a matching network; a load impedance is converted into an actual impedance by first to second sections; the actual impedance is converted into a source impedance by a third section which is a Lambda / 4 converting wire, thereby achieving impedance matching; and a fourth section is a gradual changing wire used for transition. The impedance matching method has the advantagesof simple design concept, easiness in application, capability of saving a circuit board space, small frequency limitation, wide frequency band width and excellent compensation effect. The impedance matching method is used for interconnecting monolithic microwave integrated circuits, coplanar waveguides, microwave transmission lines or RF (Radio Frequency) grounding sides.

Owner:XIDIAN UNIV

Microstrip patch antenna for high temperature environments

ActiveUS20070024505A1Improve performanceImprove reliabilitySimultaneous aerial operationsAntenna adaptation in movable bodiesMicrostrip patch antennaSpray coating

A patch antenna for operation within a high temperature environment. The patent antenna typically includes an antenna radiating element, a housing and a microwave transmission medium, such as a high temperature microwave cable. The antenna radiating element typically comprises a metallization (or solid metal) element in contact with a dielectric element. The antenna radiating element can include a dielectric window comprising a flame spray coating or a solid dielectric material placed in front of the radiating element. The antenna element is typically inserted into a housing that mechanically captures the antenna and provides a ground plane for the antenna. Orifices or passages can be added to the housing to improve high temperature performance and may direct cooling air for cooling the antenna. The high temperature microwave cable is typically inserted into the housing and attached to the antenna radiator to support the communication of electromagnetic signals between the radiator element and a receiver or transmitter device.

Owner:MEGGITT SA

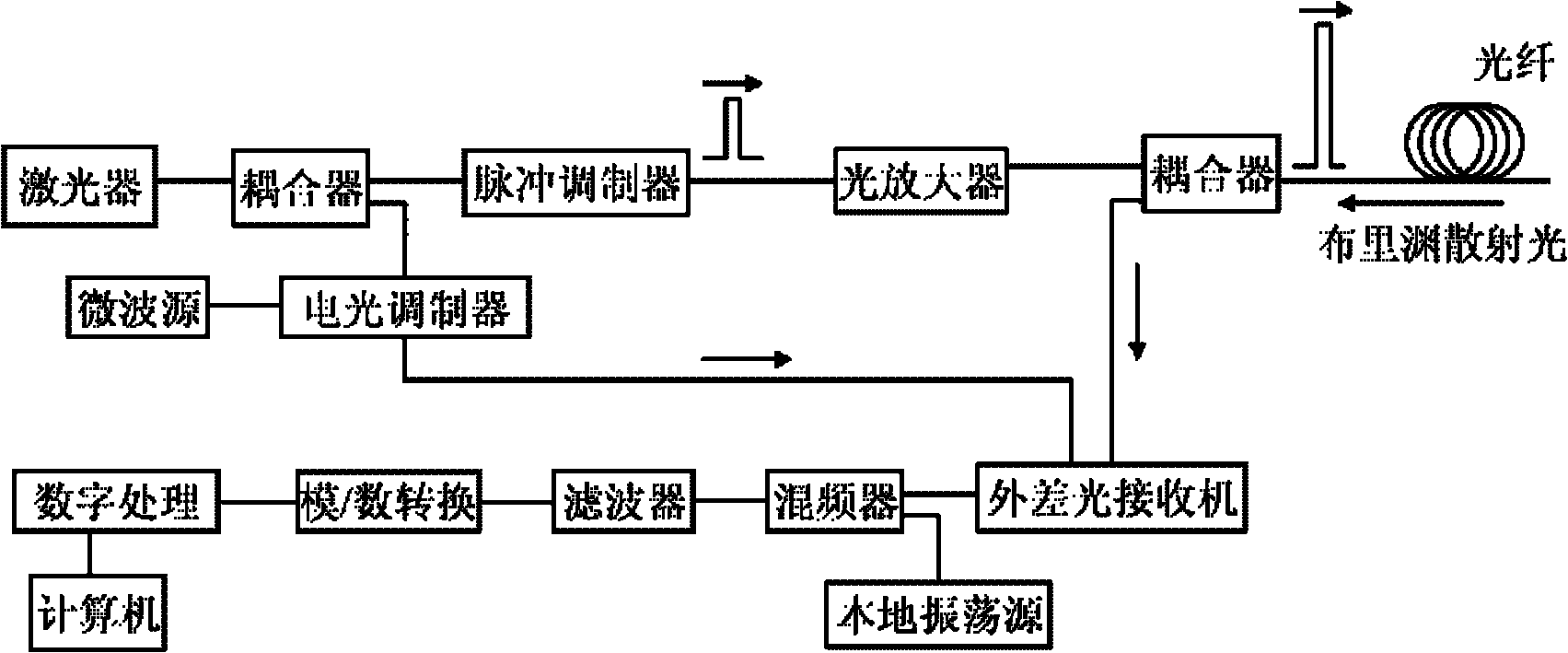

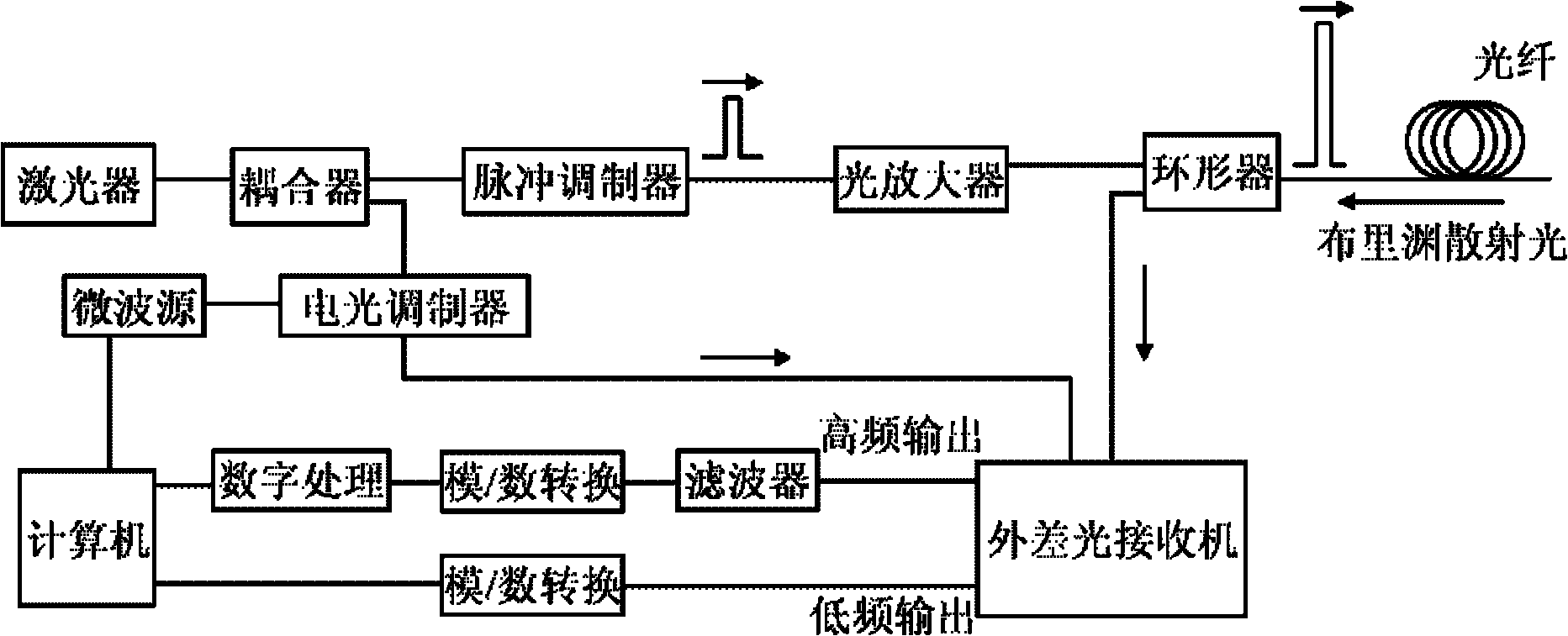

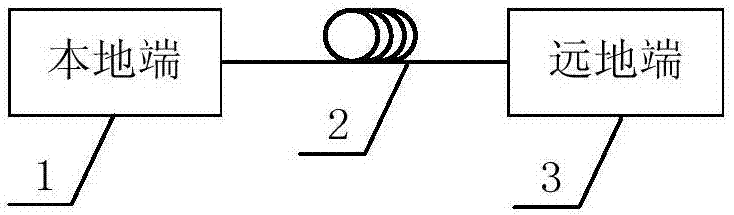

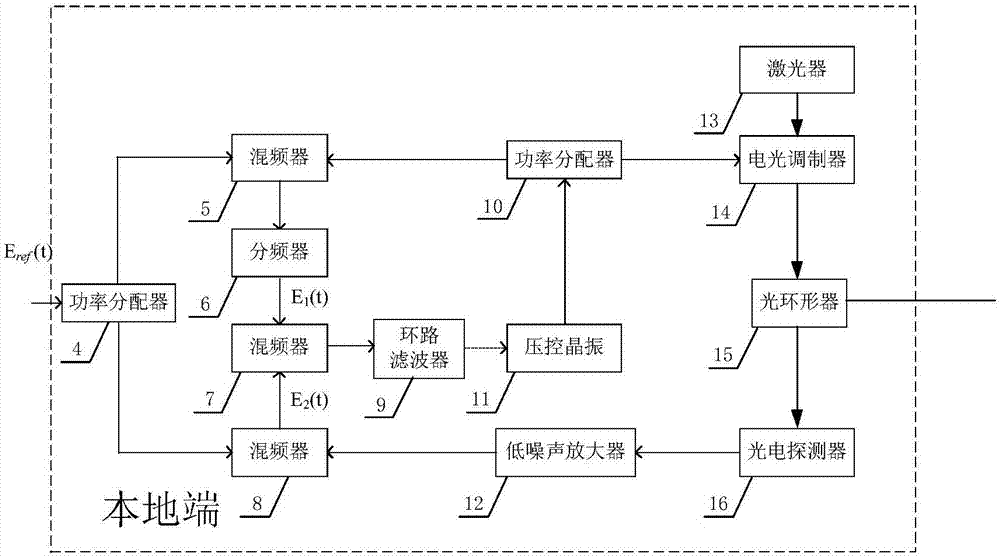

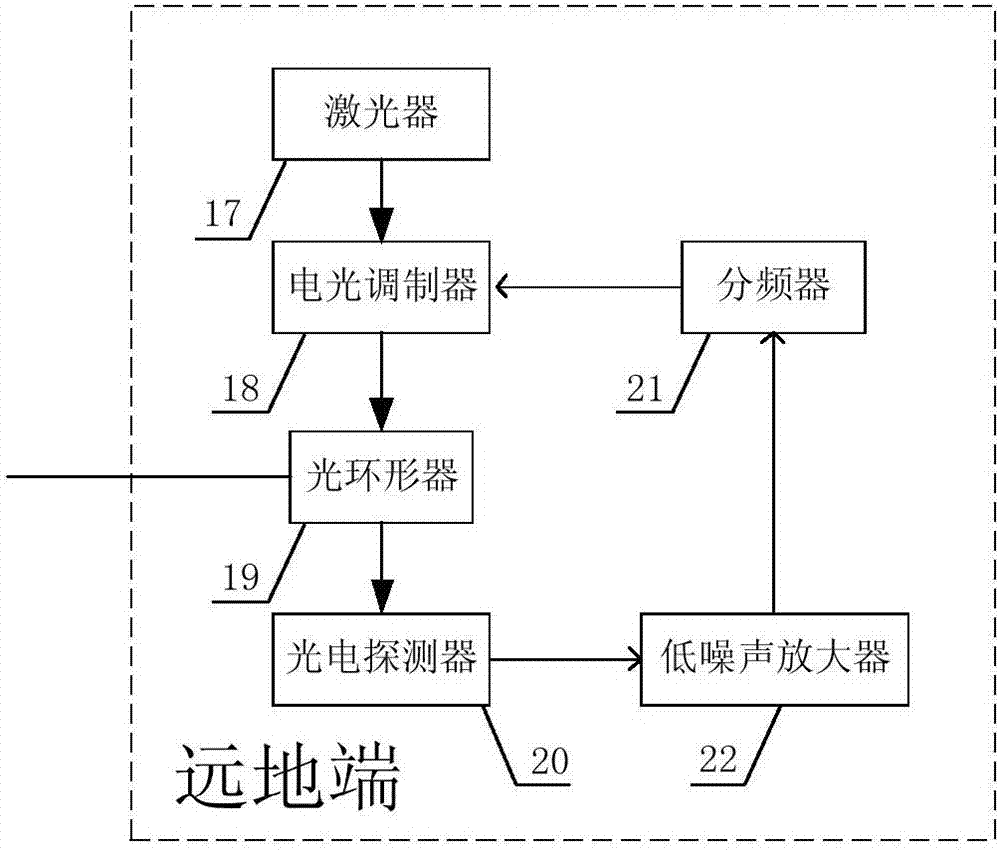

Frequency conversion compensating microwave frequency transmission system and method

ActiveCN108011667APrevent phase interferenceImprove stabilitySynchronisation by photonic/optical meansDistortion/dispersion eliminationPhase noiseMicrowave emission

The invention discloses a frequency conversion compensating microwave frequency transmission system and method. A phase pre-compensated microwave transmission signal is loaded into a laser signal, thelaser signal is transmitted to a remote end through utilization of an optical fiber, and the remote end restores the laser signal into a frequency signal synchronous with a microwave reference frequency signal of a local end through detection. According to a specific process, after a local signal is transmitted to the remote end, frequency conversion is carried out on a detection signal of the remote end, the detection signal is returned to the local end, a return signal comprises phase noise imported into an optical fiber link; the return signal and the local transmission signal are respectively mixed with the local reference signal, comparison is carried out to acquire pre-compensation quantity and a crystal oscillator generating the transmission signal is controlled according to the compensation quantity, so phase compensation of high precision frequency transmission is finished. Compared with existing frequency transmission, the method mainly has the advantages that frequencies ofthe signals transmitted by the local end and returned by the remote end are different, the phase interference of strong signals of stations at the two ends for detected and received weak signals is avoided, and the frequency transmission stability is further improved.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

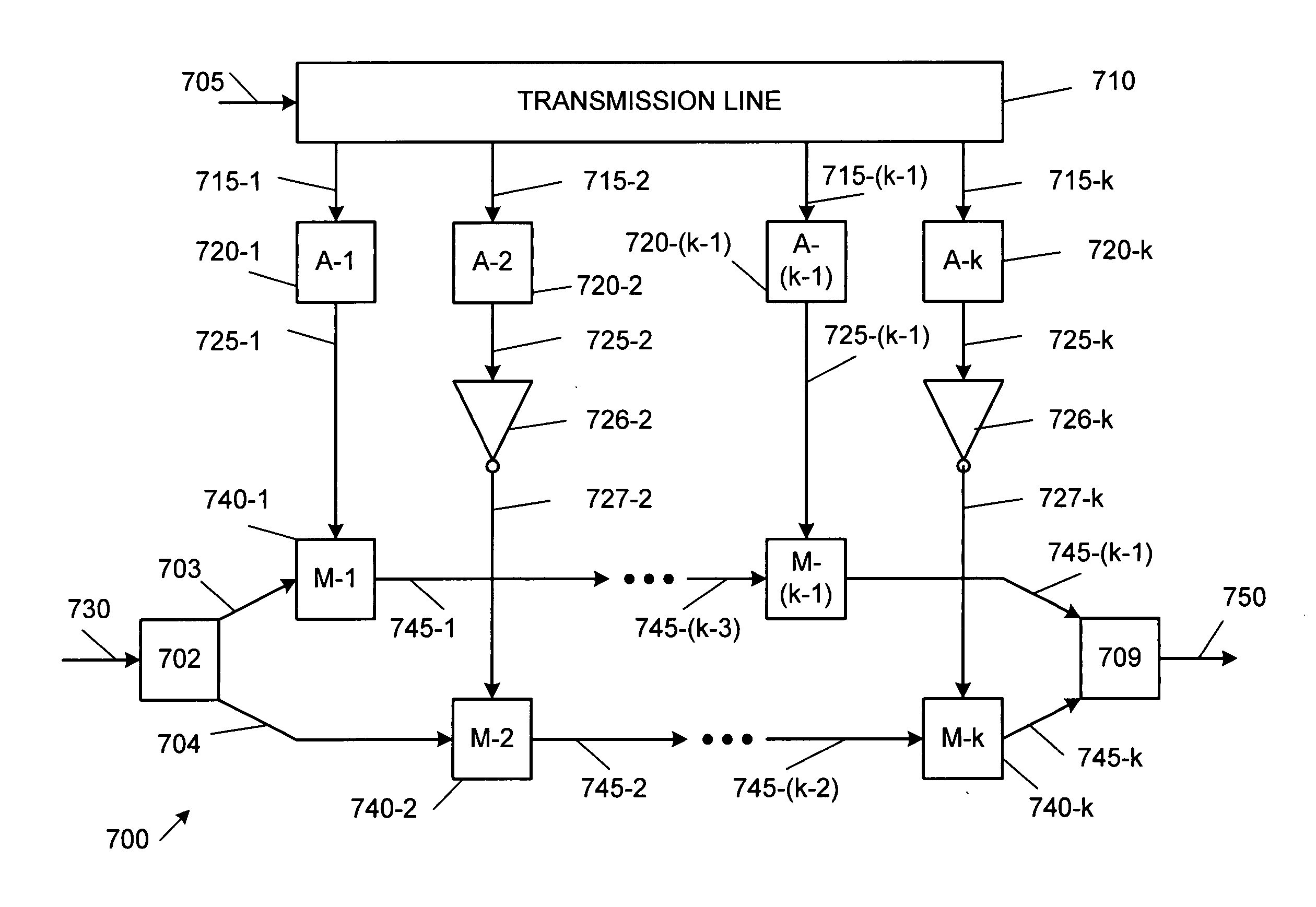

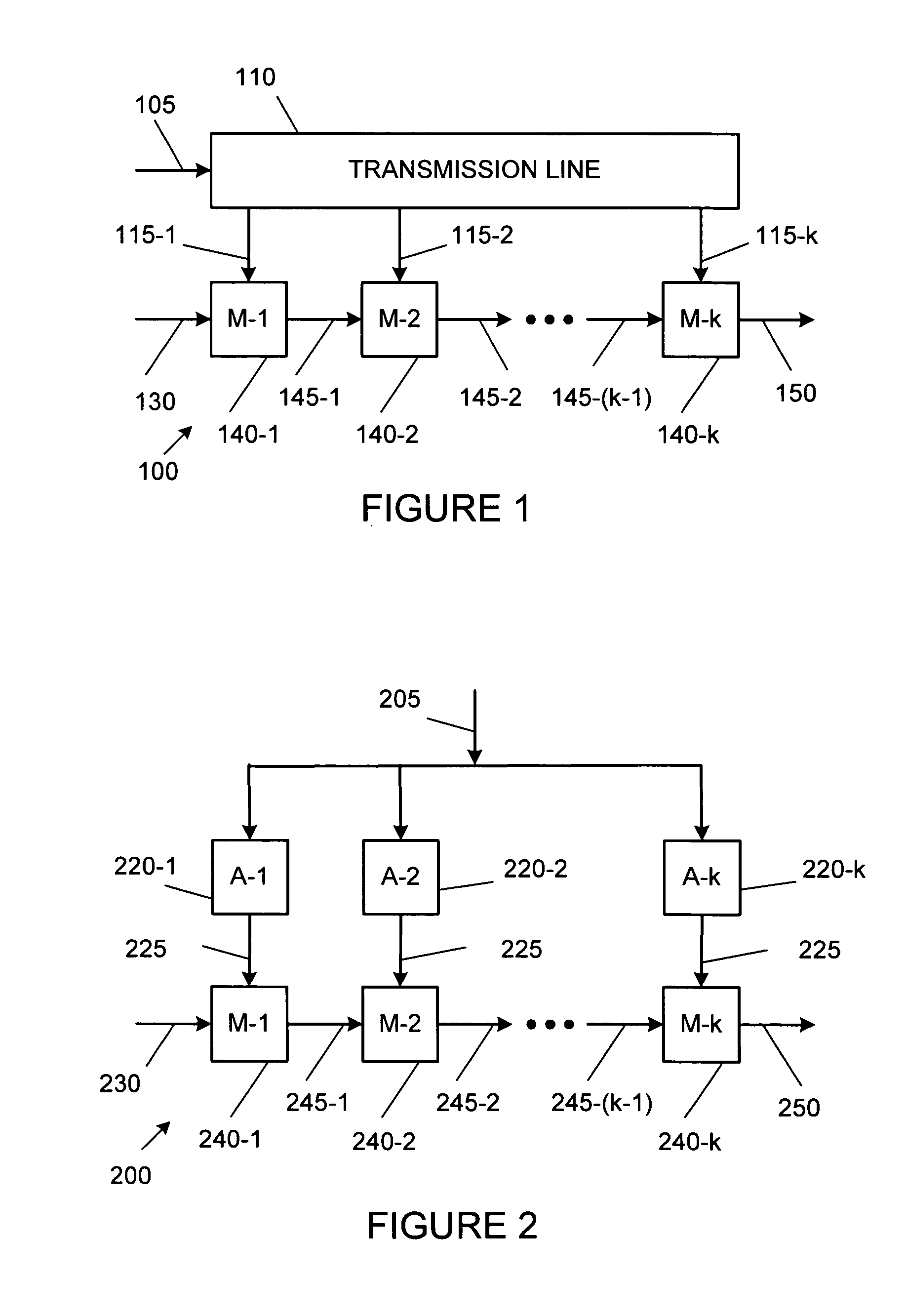

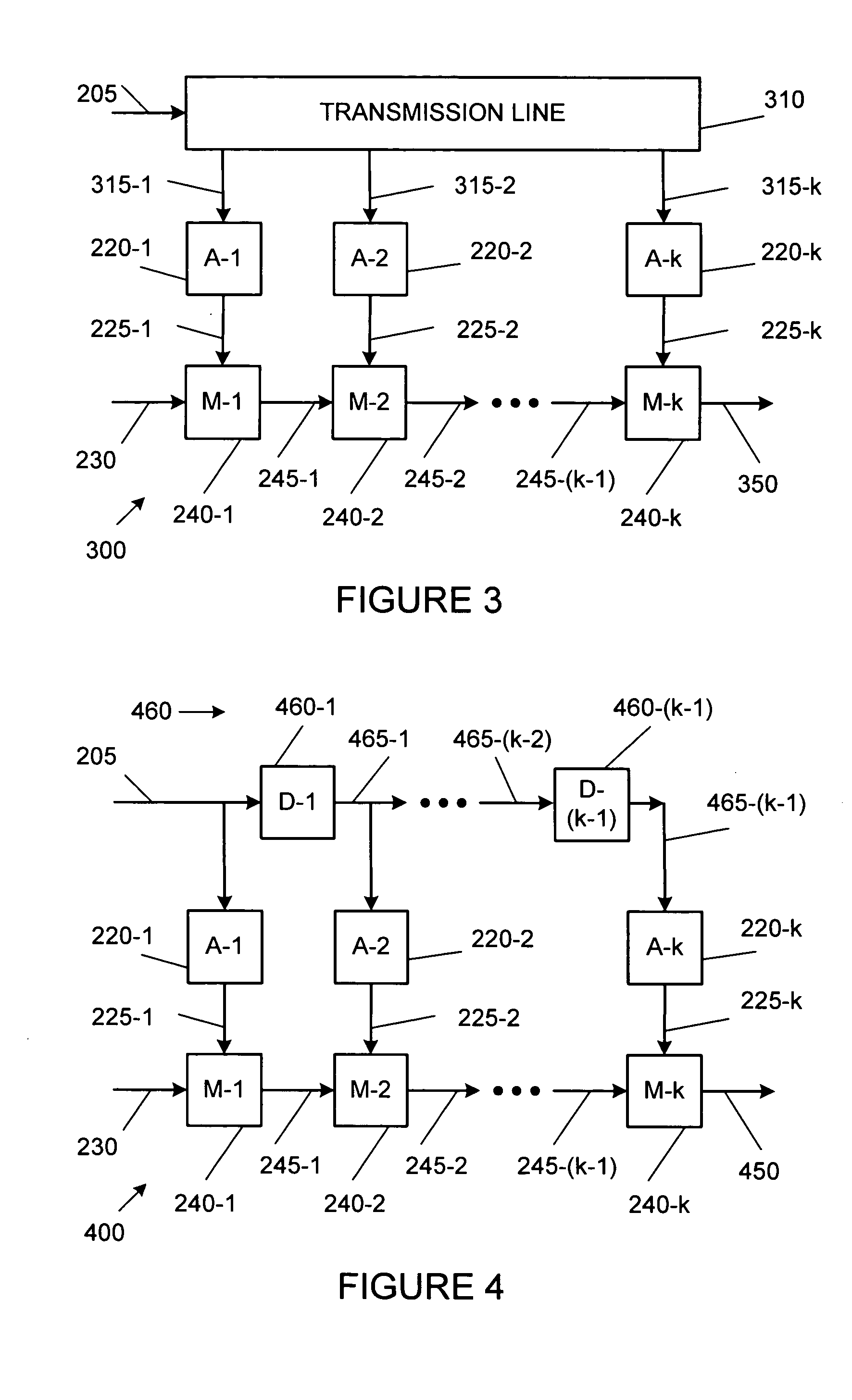

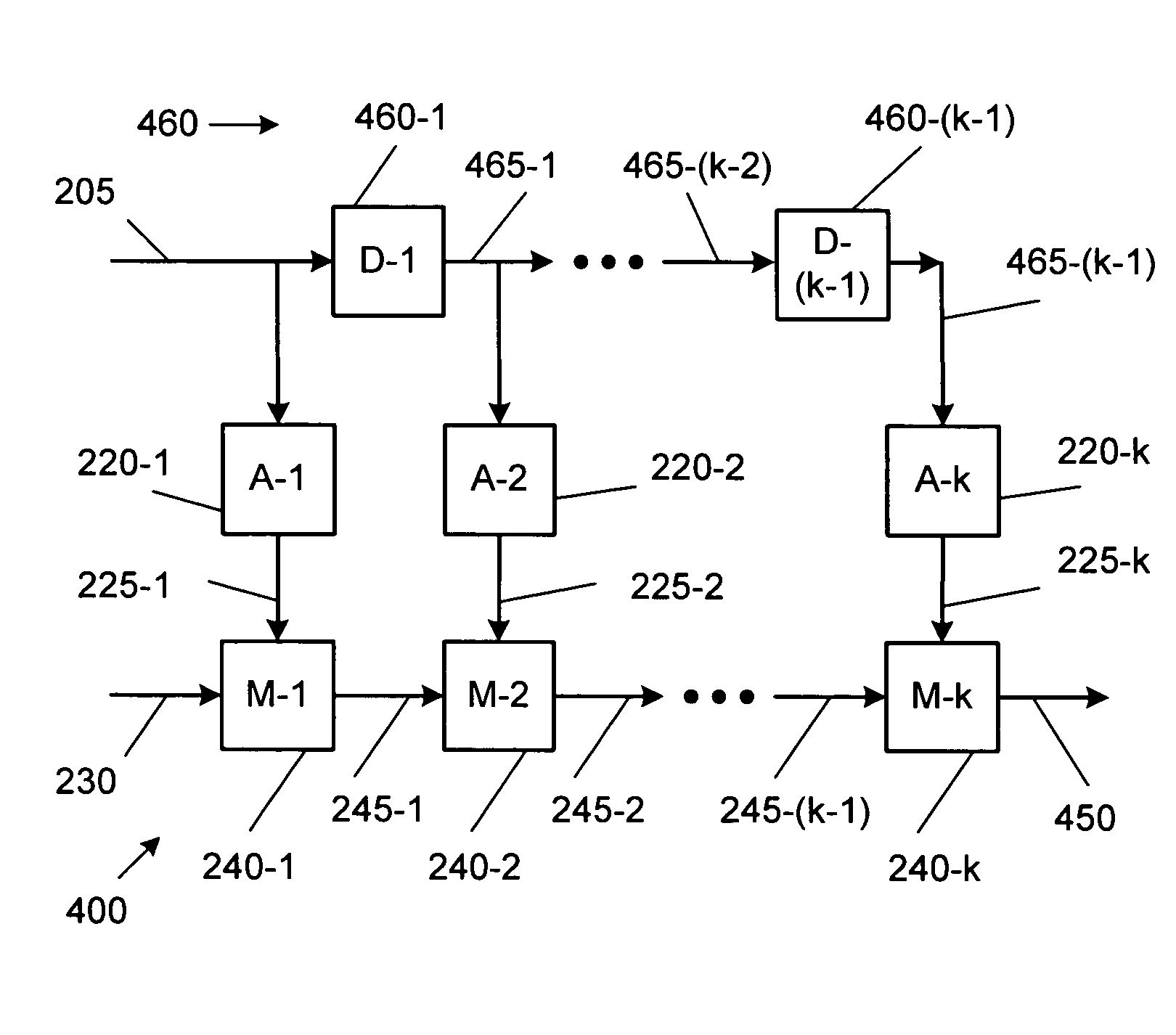

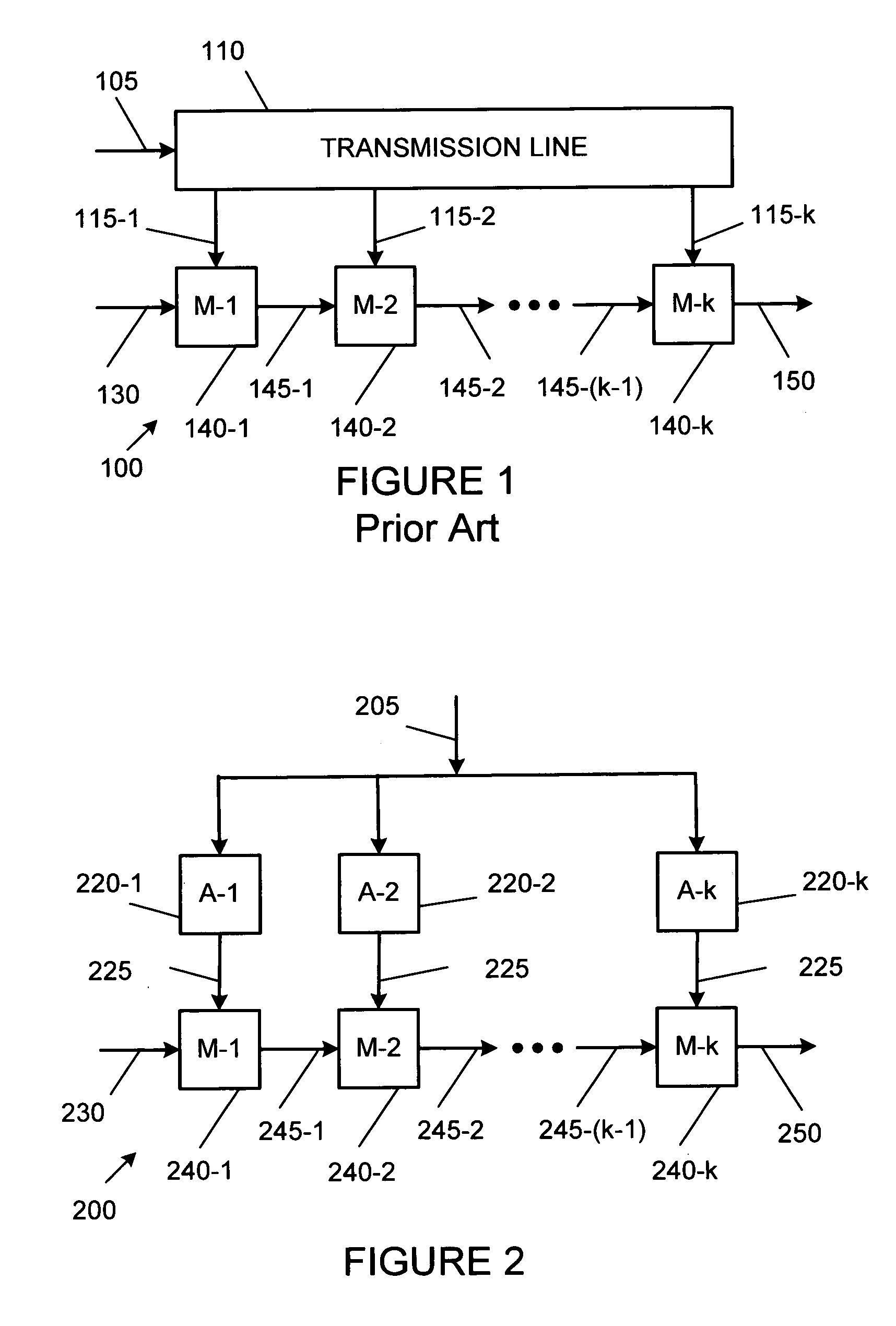

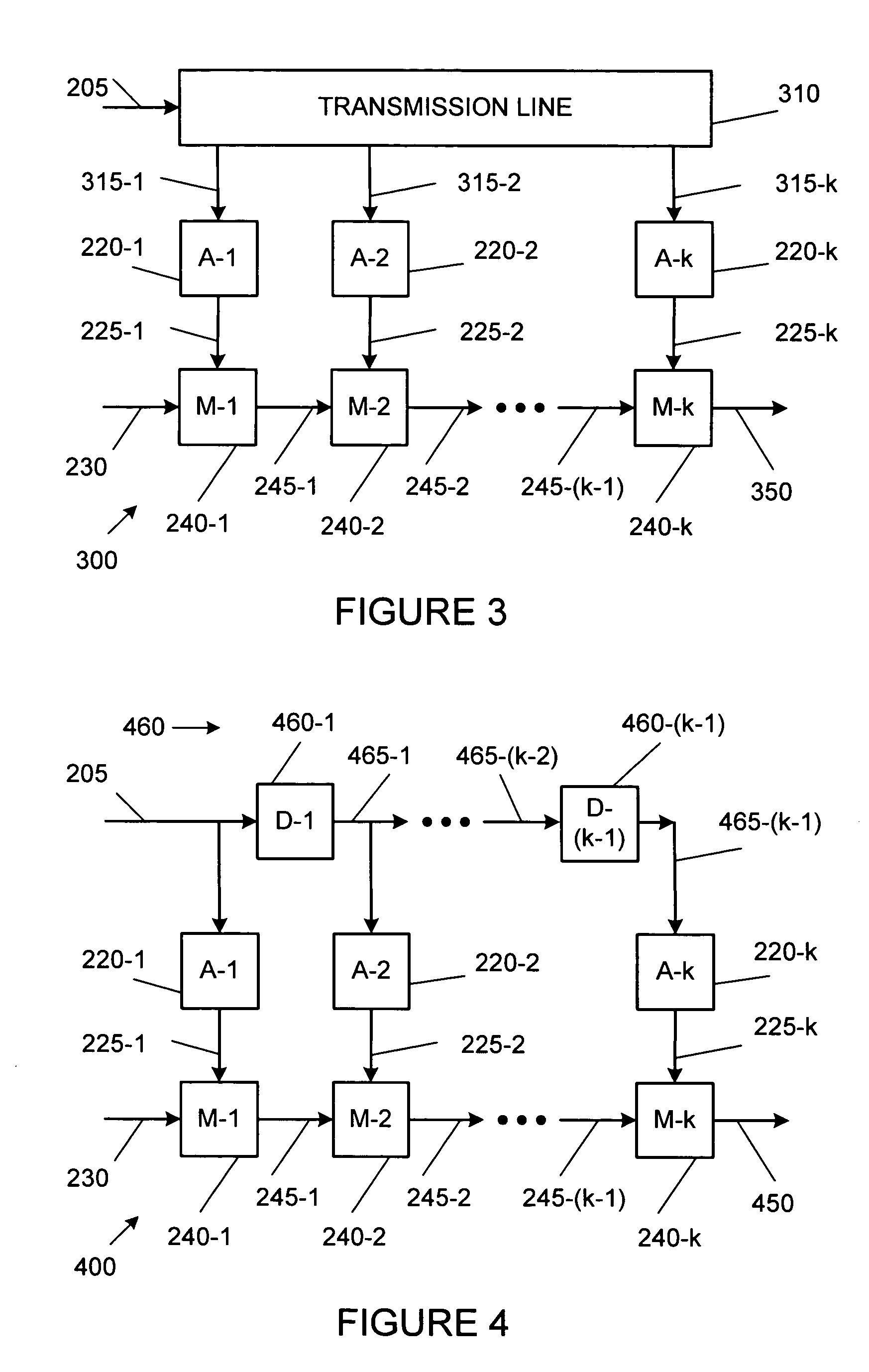

Distributed amplifier optical modulators

ActiveUS20050036791A1High modulation speedReduce capacitanceElectromagnetic transmittersSemiconductor lasersCapacitanceAudio power amplifier

High speed optical modulators can be made of k modulators connected in series disposed on one of a variety of semiconductor substrates. An electrical signal propagating in a microwave transmission line is tapped off of the transmission line at regular intervals and is amplified by k distributed amplifiers. Each of the outputs of the k distributed amplifiers is connected to a respective one of the k modulators. Distributed amplifier modulators can have much higher modulating speeds than a comparable lumped element modulator, due to the lower capacitance of each of the k modulators. Distributed amplifier modulators can have much higher modulating speeds than a comparable traveling wave modulator, due to the impedance matching provided by the distributed amplifiers.

Owner:CISCO TECH INC

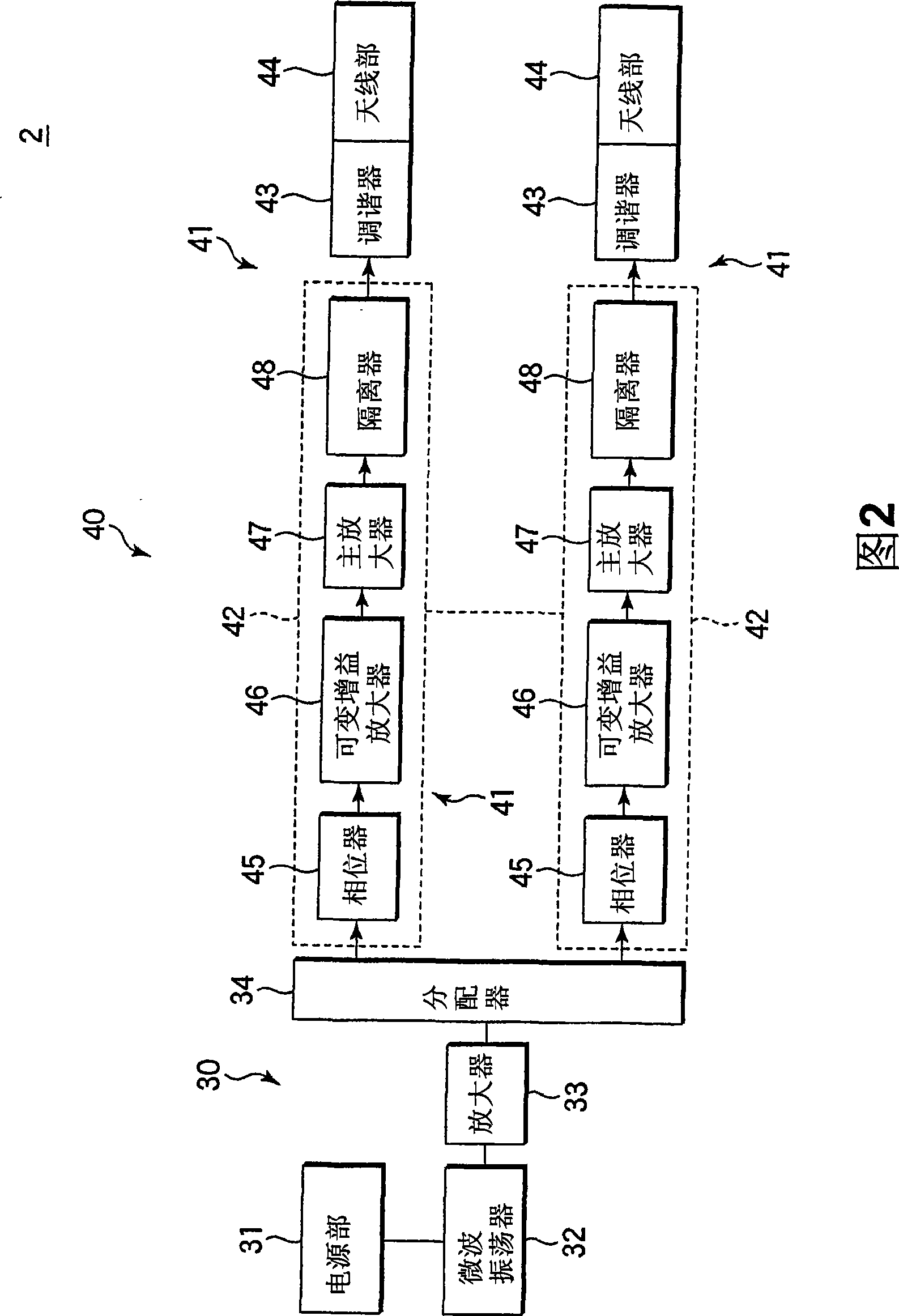

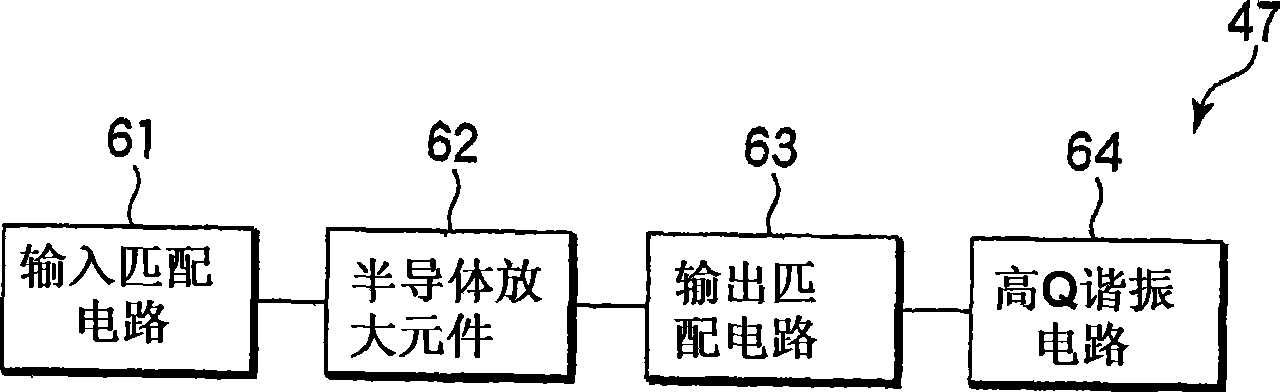

Microwave plasma source and plasma processing apparatus

ActiveCN101385129AMiniaturizationEliminate the effects of reflectionsElectric discharge tubesSemiconductor/solid-state device manufacturingAudio power amplifierMicrowave transmission

Owner:TOKYO ELECTRON LTD

Distributed amplifier optical modulators

High speed optical modulators can be made of k modulators connected in series disposed on one of a variety of semiconductor substrates. An electrical signal propagating in a microwave transmission line is tapped off of the transmission line at regular intervals and is amplified by k distributed amplifiers. Each of the outputs of the k distributed amplifiers is connected to a respective one of the k modulators. Distributed amplifier modulators can have much higher modulating speeds than a comparable lumped element modulator, due to the lower capacitance of each of the k modulators. Distributed amplifier modulators can have much higher modulating speeds than a comparable traveling wave modulator, due to the impedance matching provided by the distributed amplifiers.

Owner:CISCO TECH INC

Piezoelectric polymer material and method for producing same

ActiveUS20120132846A1High constantExcellent transparency and dimensional stabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionCrystallinityMicrowave transmission

The invention provides a piezoelectric polymer material comprising a helical chiral polymer having a weight average molecular weight of from 50,000 to 1,000,000 and optical activity, the piezoelectric polymer material having: crystallinity as obtained by a DSC method of from 20% to 80%; a transmission haze with respect to visible light of 50% or less; and a product of the crystallinity and a standardized molecular orientation MORc, which is measured with a microwave transmission-type molecular orientation meter at a reference thickness of 50 μm, of from 40 to 700.

Owner:MITSUI CHEM INC +1

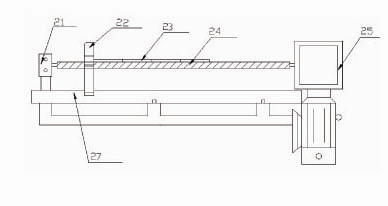

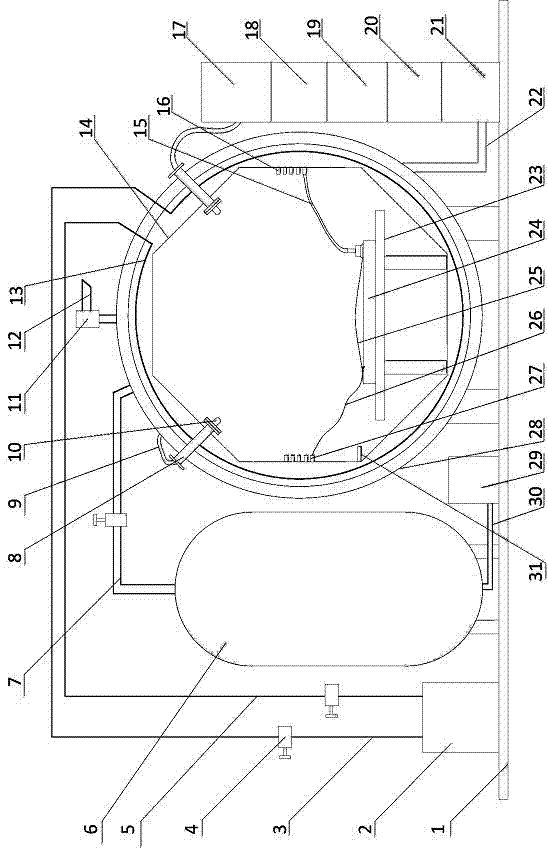

Method and device for forming high-performance composite material structural member through microwave-pressure tank

ActiveCN103587128AShorten the timeMicrowave heating and curing time is shortResonant cavityEngineering

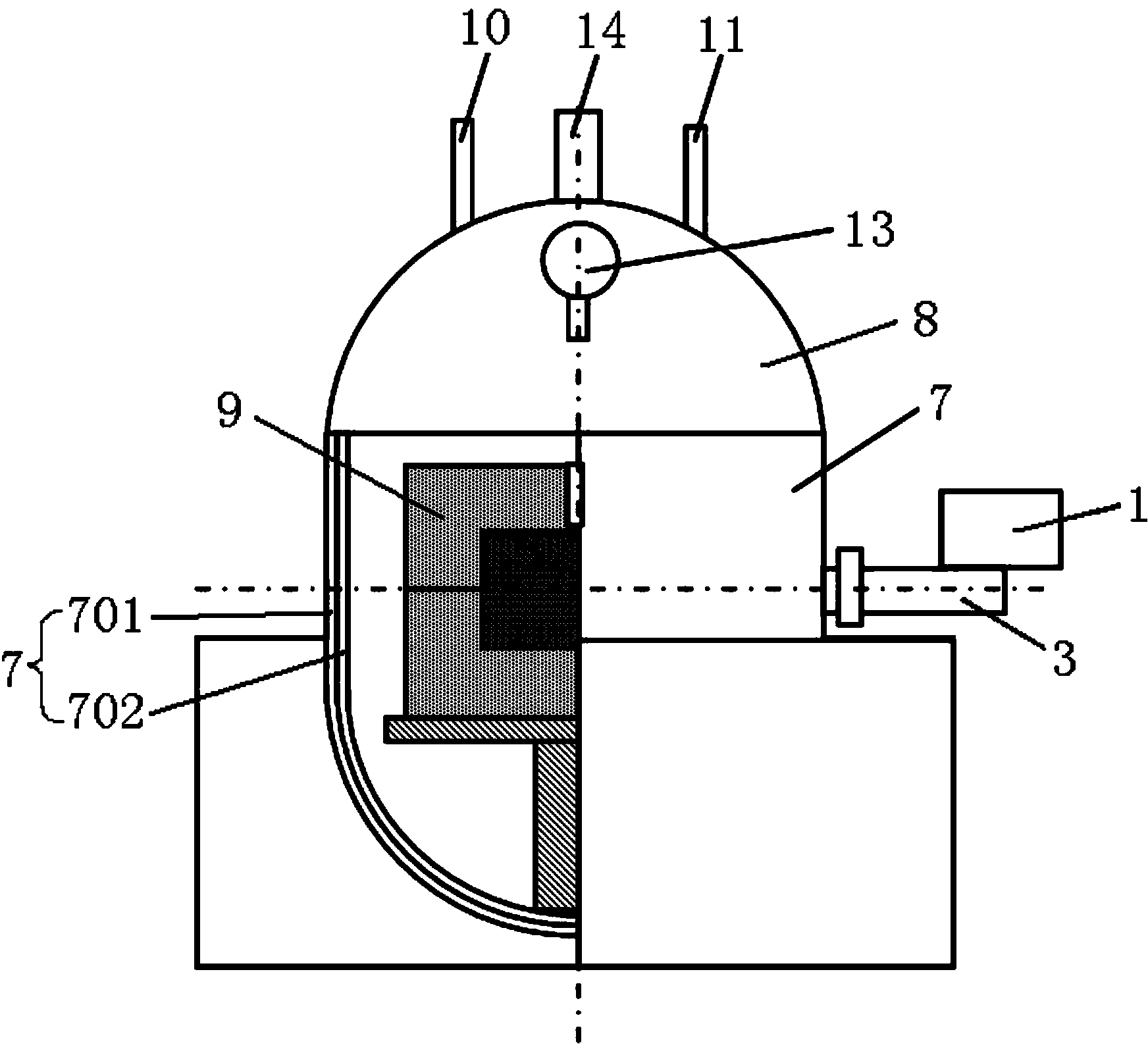

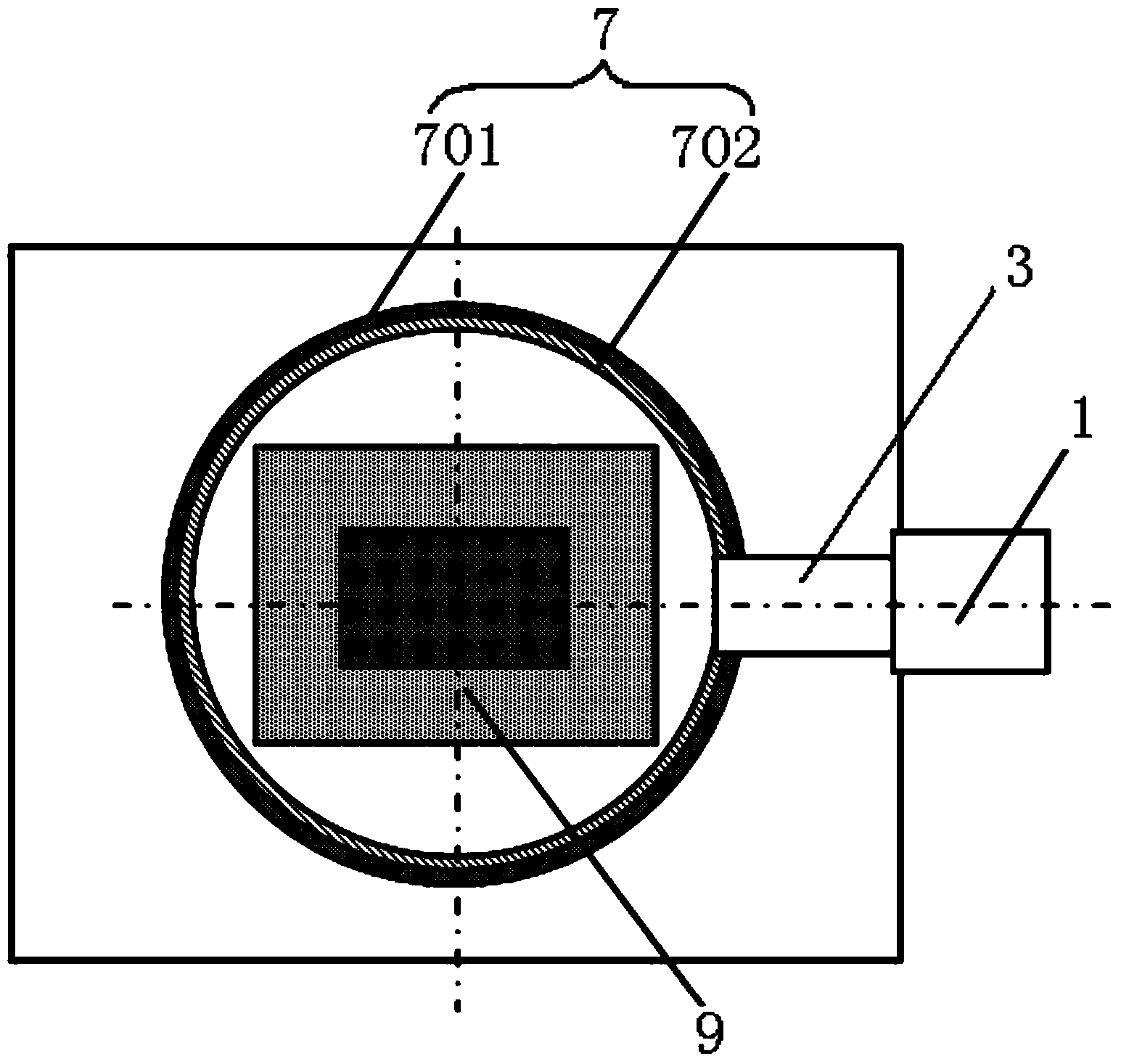

The invention discloses a method and a device for forming a high-performance composite material structural member through a microwave-pressure tank. The device mainly comprises a cooling system (2), a gas storage tank (6), microwave transmission lines (9), microwave radiation antennas (10), a pressure safety valve (11), a polygonal multi-mode resonant cavity (14), a microwave generation and measurement module (17), a temperature measurement and control module (18), a vacuumizing and control module (19), a pressure measurement and control module (20), a power supply module (21), a material platform (23), a forming mold (24), a temperature sensor (26) and a tank body (28). The equipment is microwave forming equipment for the high-performance composite material structural member; a non-solidified composite material structural member is put into the equipment, and the high-performance composite material structural member can be quickly formed by technologies of vacuum bag vacuumizing, gas pressurization and microwave heating; the quality and the performance of the composite material structural member can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

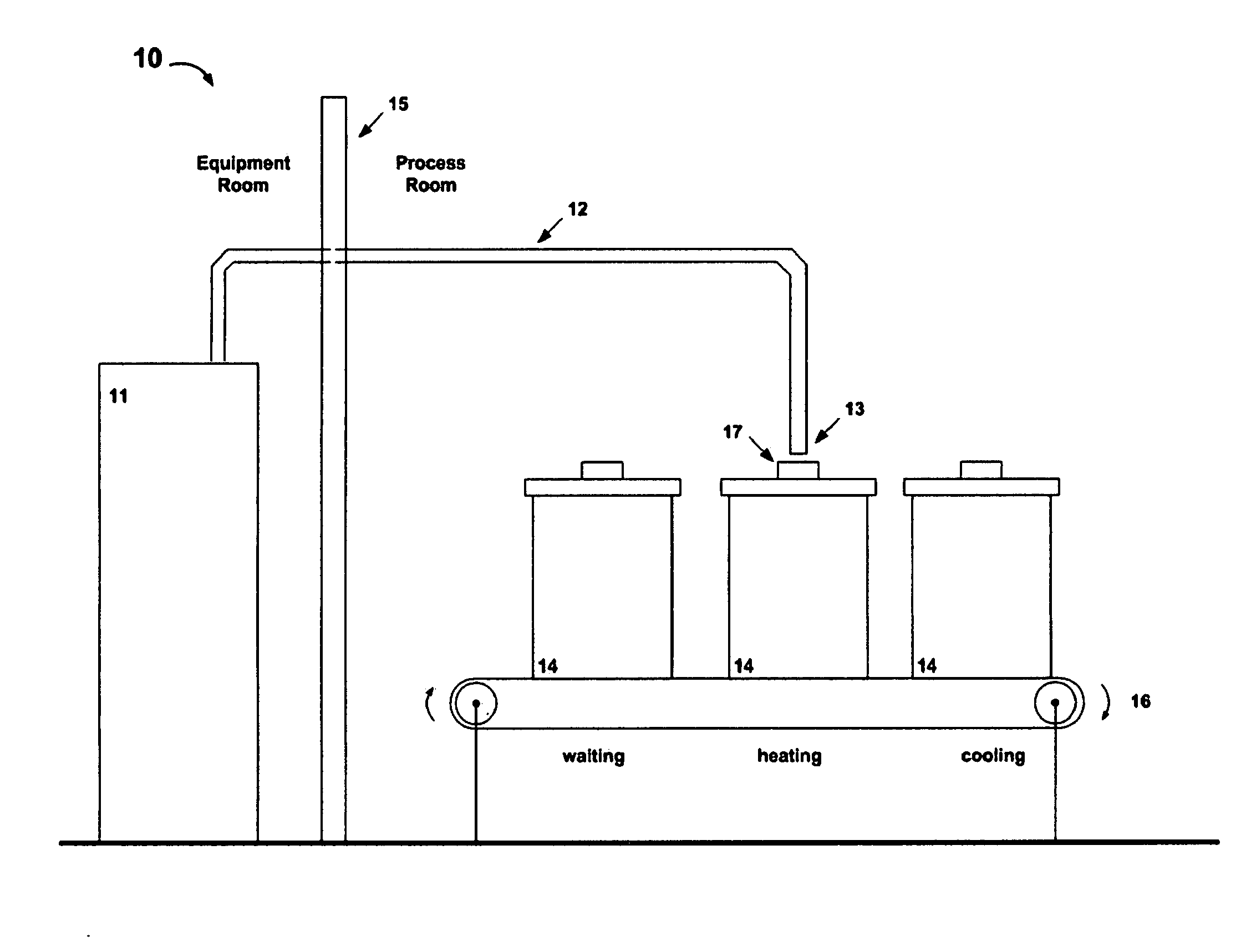

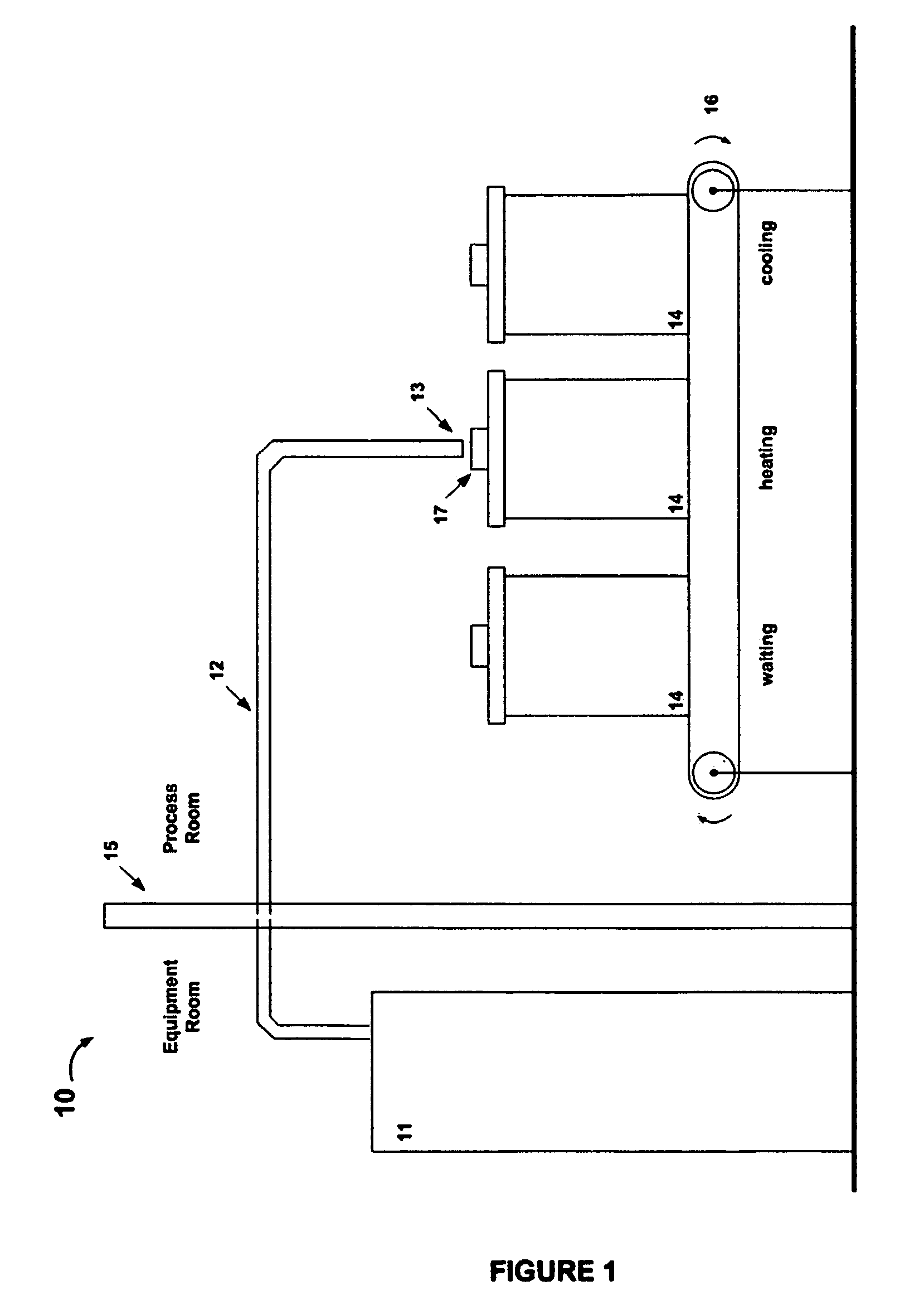

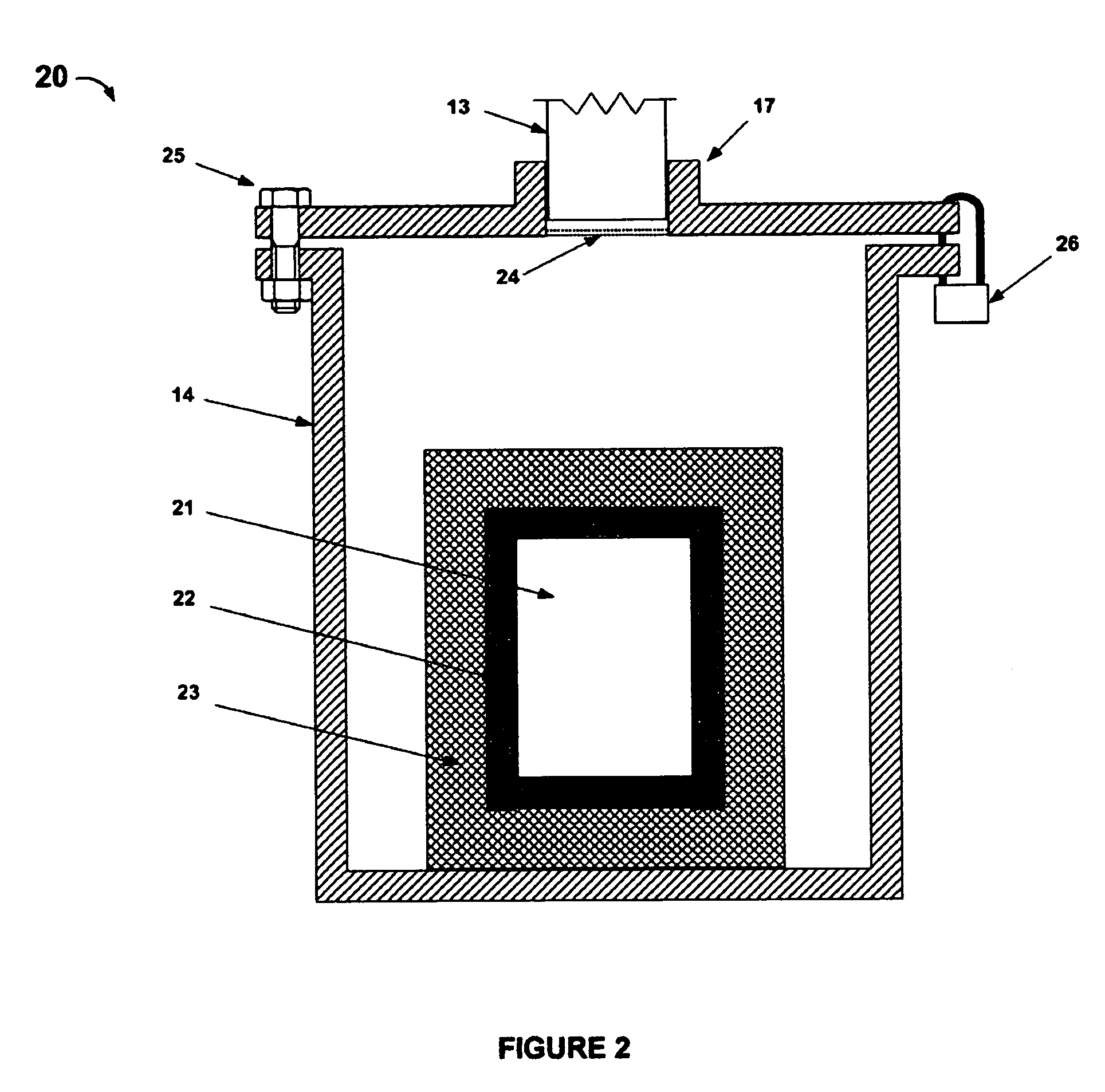

Modular microwave processing system

A modular microwave processing system includes a microwave source, a transmission line, and a detachable processing cavity or chamber. The chamber is adapted to maintain a controlled atmosphere surrounding a workpiece, and further contains an interface to engage the microwave transmission line so that power for heating the workpiece is introduced through the interface. The system is particularly suited for remote operation and for processing hazardous or accountable materials. It may also be adapted for operation in a hot cell or other controlled area while locating the microwave power source outside of the controlled area for ease of maintenance.

Owner:GIVENS KENNETH R

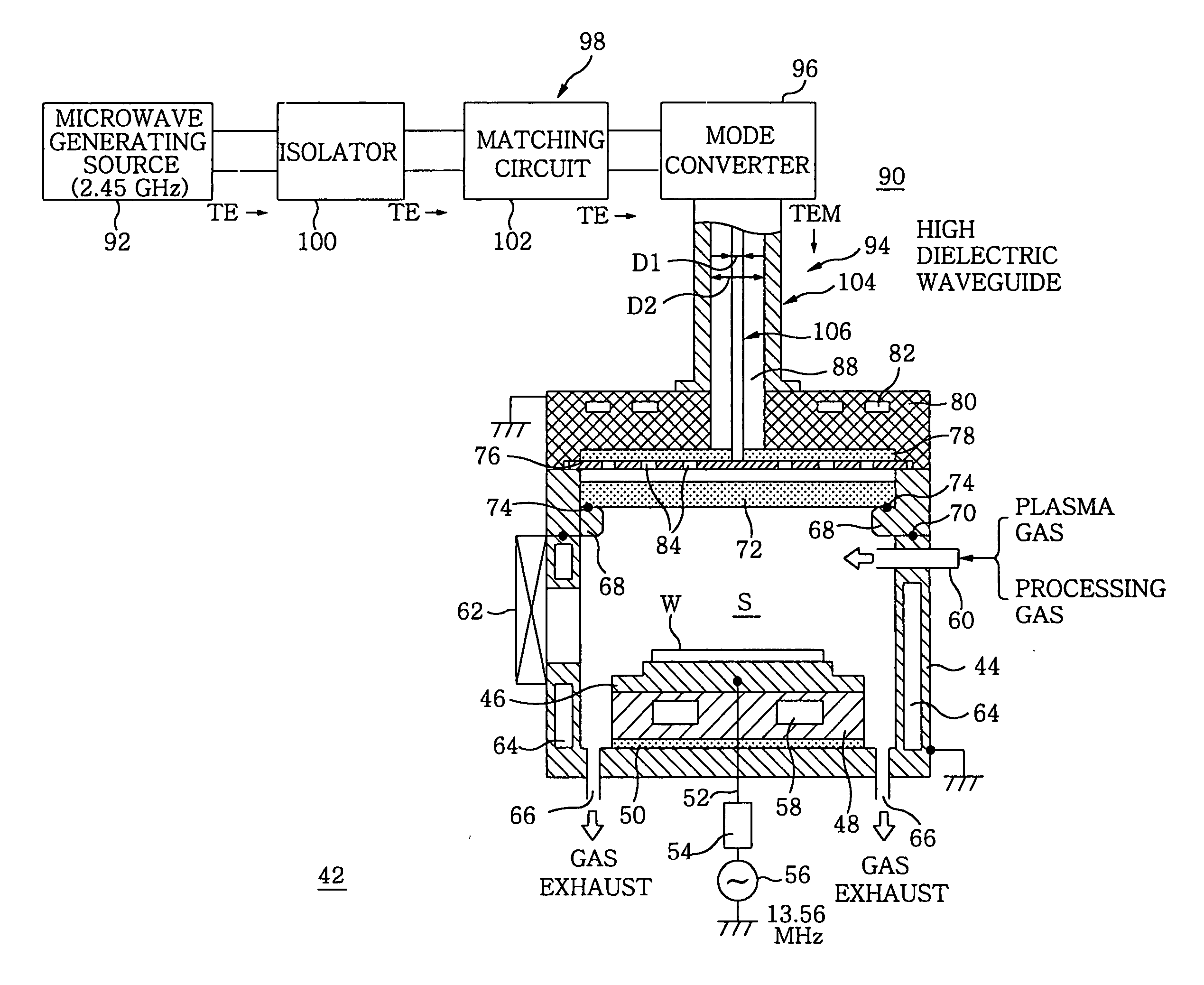

Plasma processing equipment

InactiveUS20050082004A1Eliminating mode conversion lossLow costElectric discharge tubesSemiconductor/solid-state device manufacturingHeat resistanceEngineering

Plasma processing equipment capable of increasing the heat resistance of a wave guide by using a high dielectric material, comprising a processing container 44 formed to allow vacuuming, a loading table 46 installed in the processing container for placing a processed body W thereon, a microwave transmission plate 72 installed in an opening part at the ceiling of the processing container, a flat antenna member 76 for feeding microwave into the processing container through the microwave transmission plate, a shield cover body 80 earthed so as to cover the upper part of the flat antenna member, and a waveguide 90 for feeding the microwave from a microwave generating source to the flat antenna member, characterized in that the waveguide is formed of a high dielectric waveguide 94 using the high dielectric material, whereby the heat resistance of the waveguide can be increased.

Owner:TOKYO ELECTRON LTD

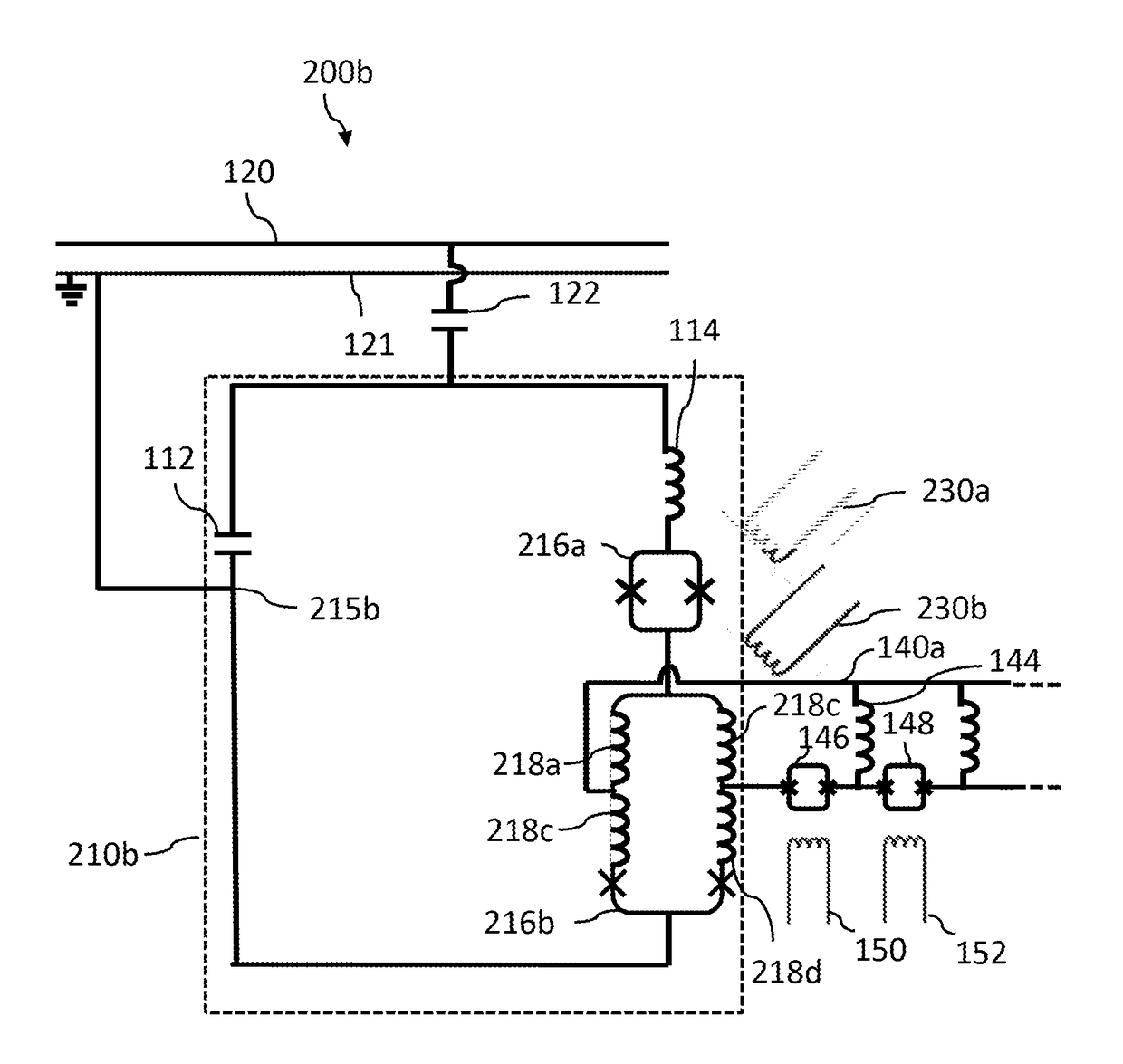

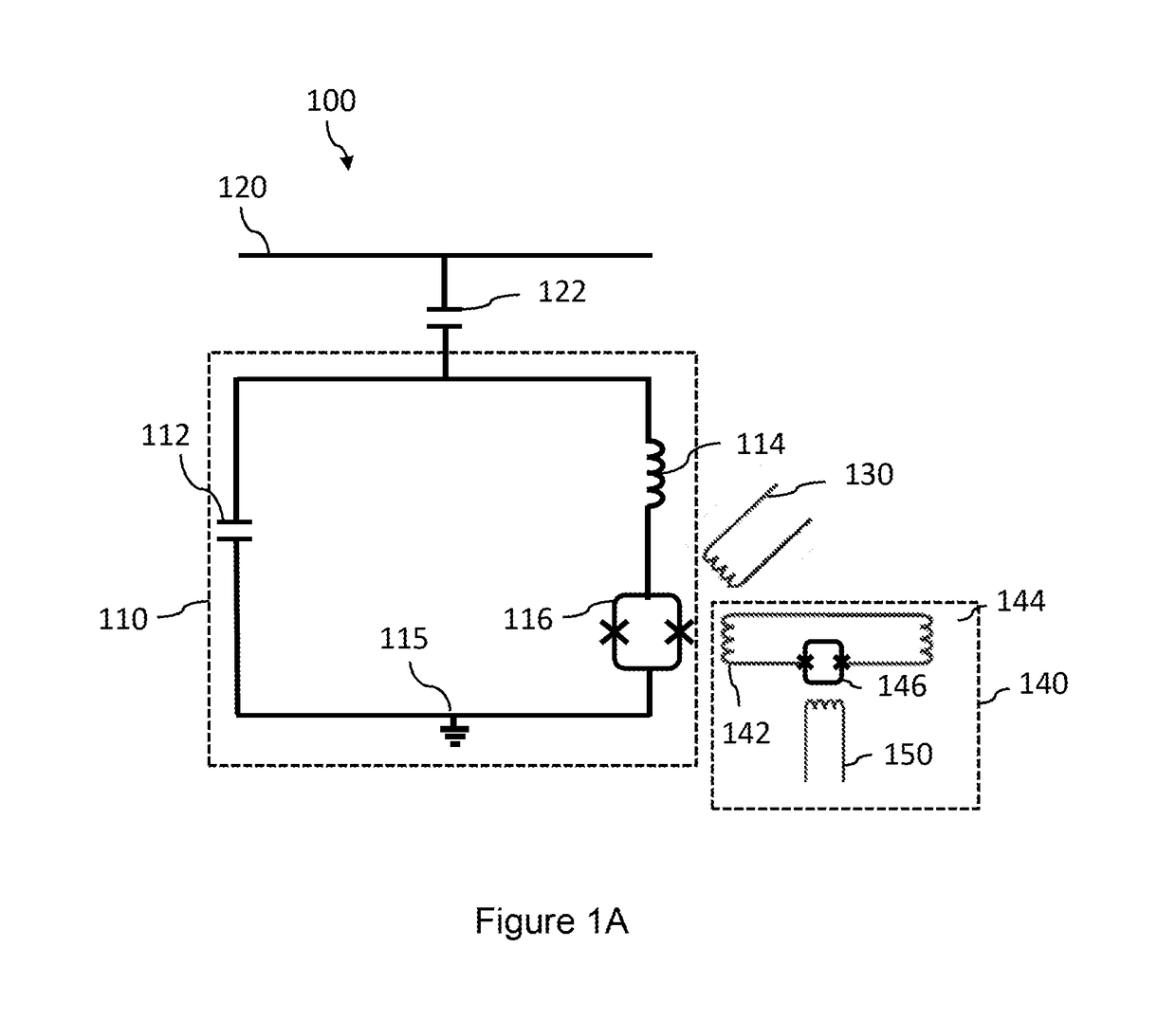

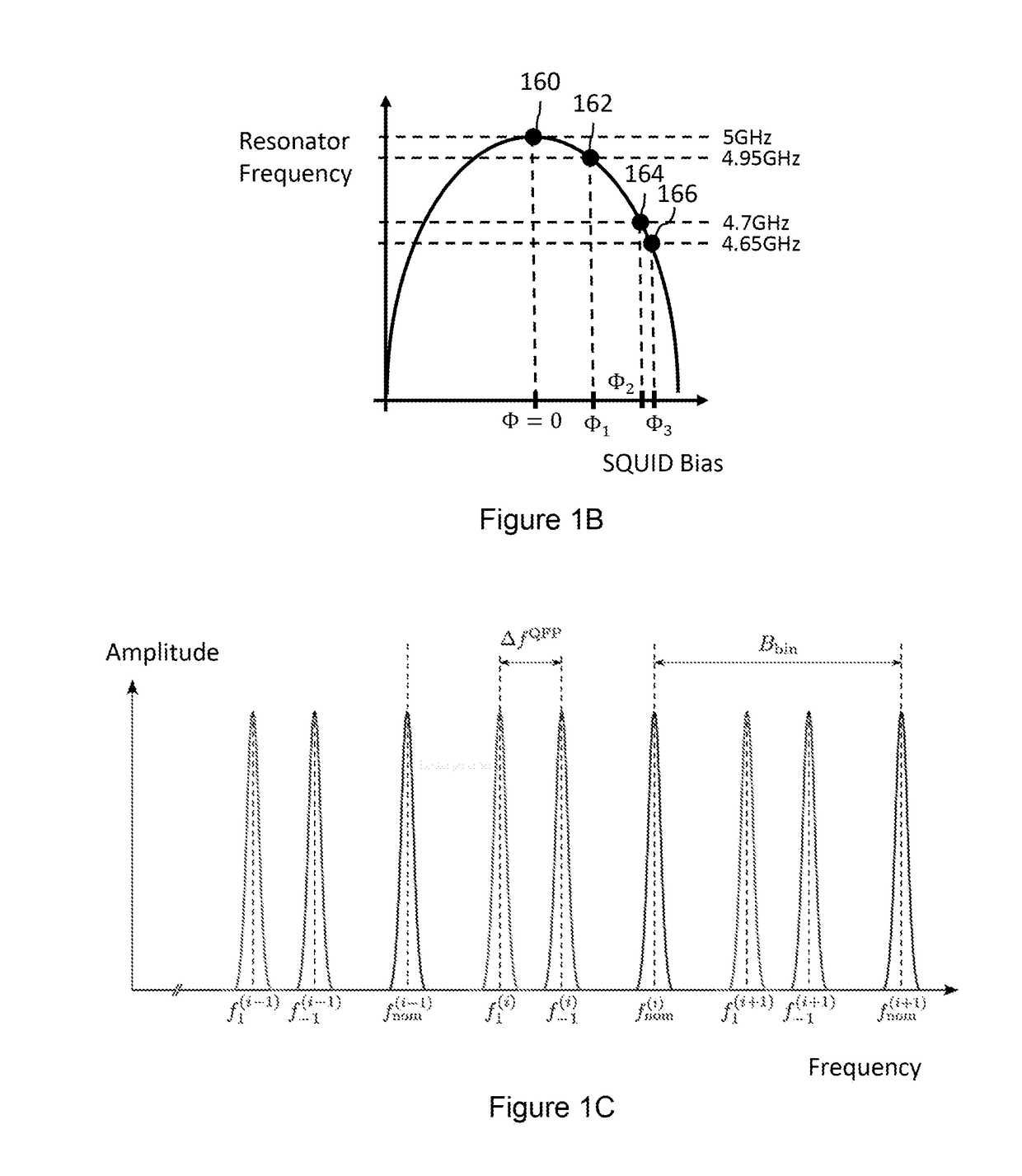

Frequency multiplexed resonator input and/or output for a superconducting device

ActiveUS20180145631A1Increase powerIncrease hardware costQuantum computersMultiple-port networksCapacitanceShift register

A superconducting input and / or output system employs at least one microwave superconducting resonator. The microwave superconducting resonator(s) may be communicatively coupled to a microwave transmission line. Each microwave superconducting resonator may include a first and a second DC SQUID, in series with one another and with an inductance (e.g., inductor), and a capacitance in parallel with the first and second DC SQUIDs and inductance. Respective inductive interfaces are operable to apply flux bias to control the DC SQUIDs. The second DC SQUID may be coupled to a Quantum Flux Parametron (QFP), for example as a final element in a shift register. A superconducting parallel plate capacitor structure and method of fabricating such are also taught.

Owner:D WAVE SYSTEMS INC

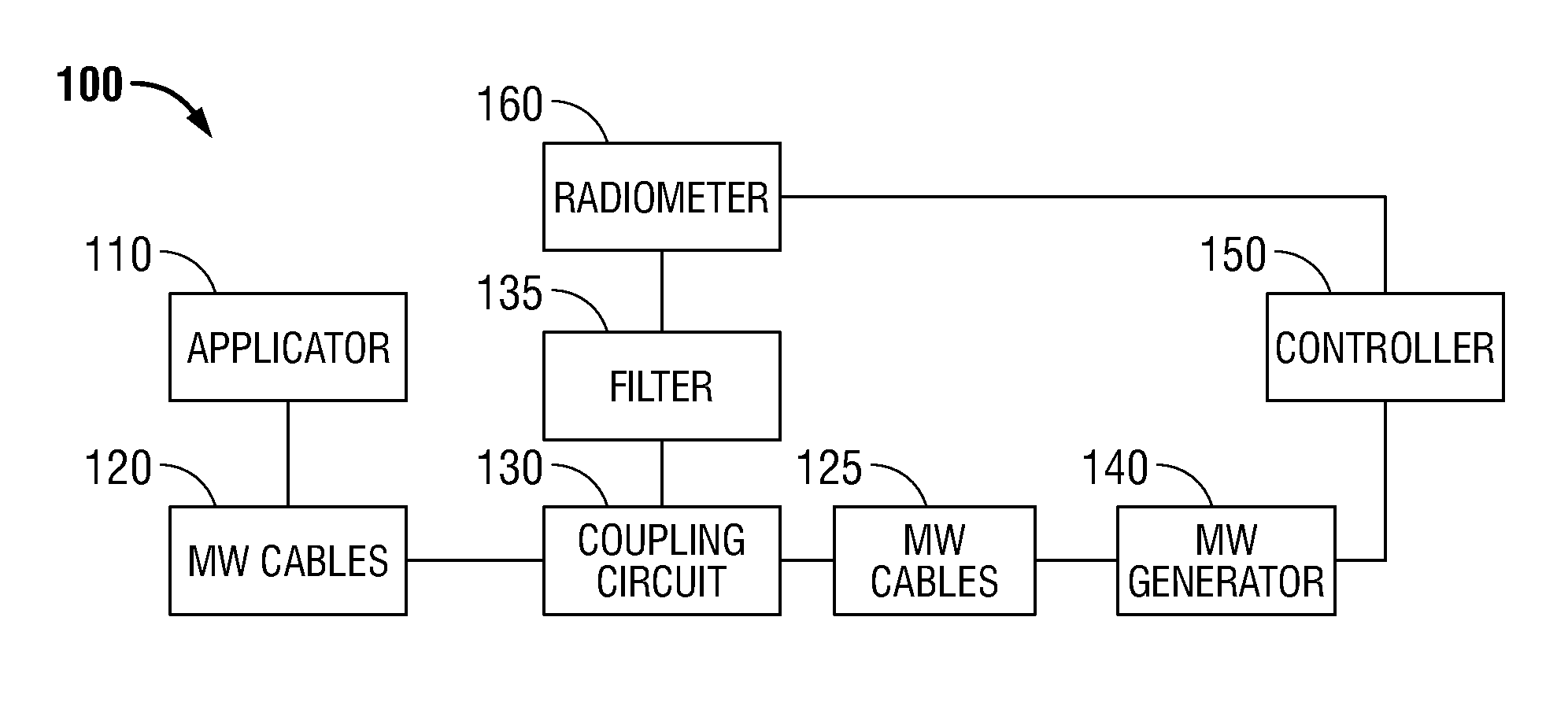

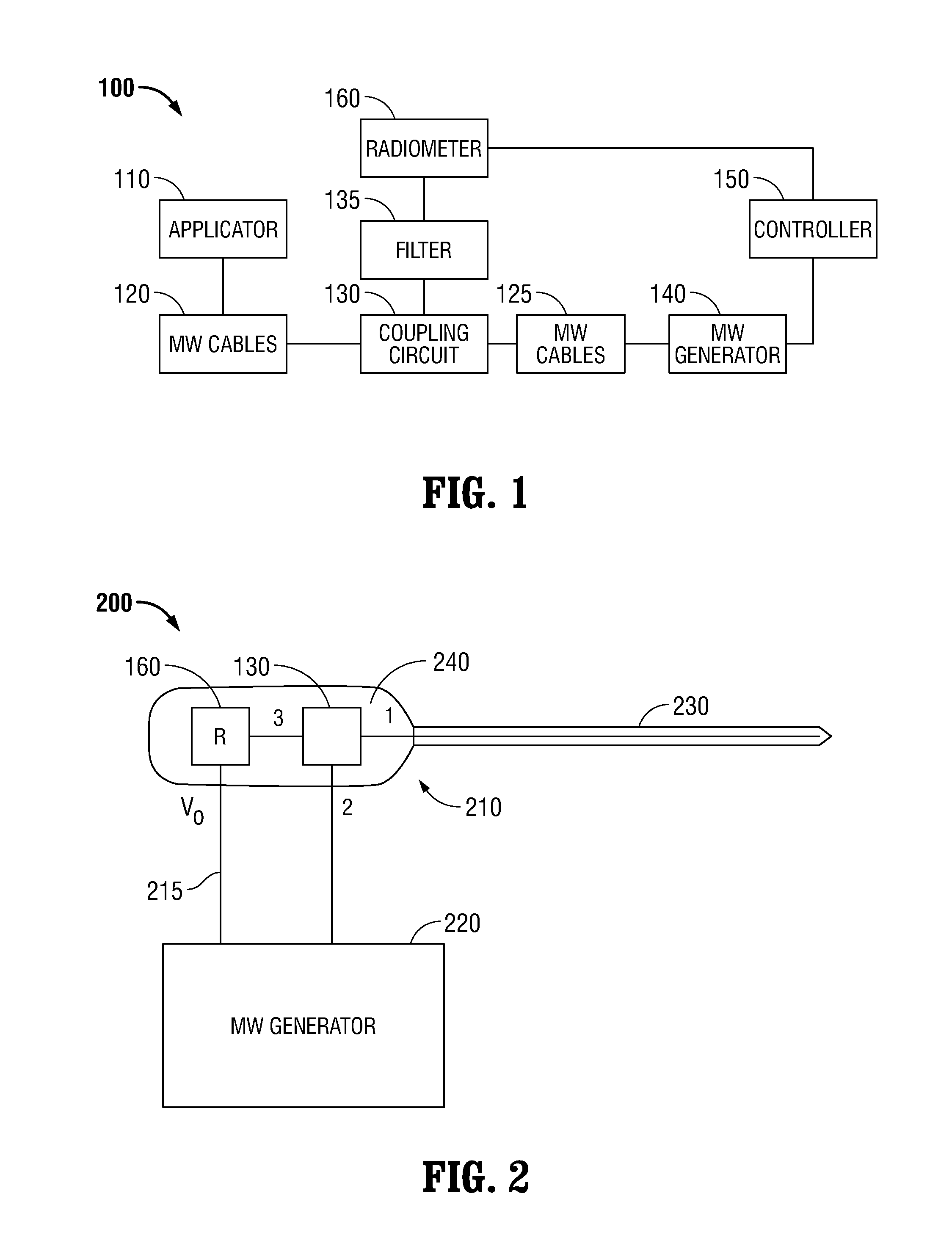

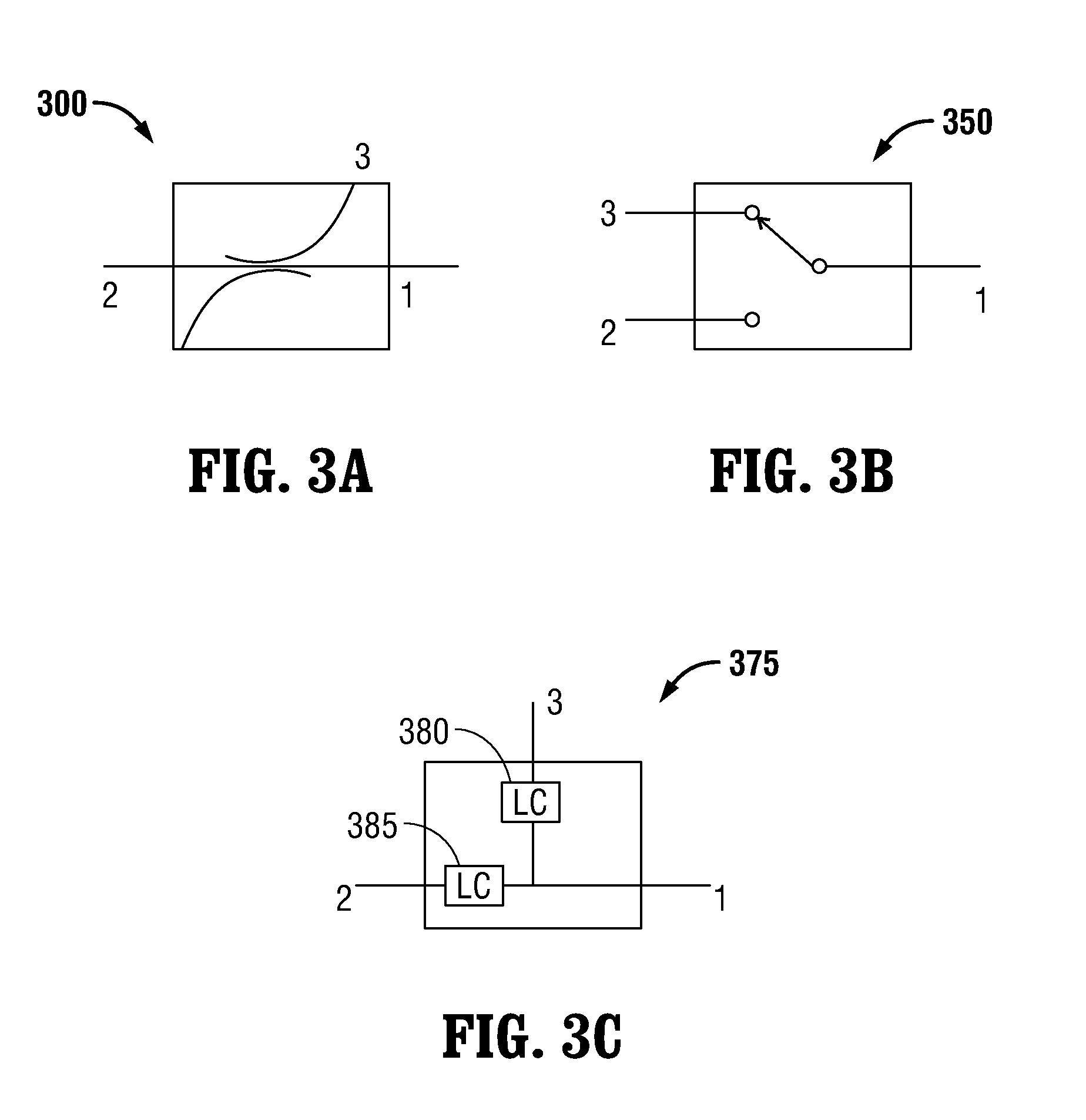

Microwave thermometry for microwave ablation systems

ActiveUS20130345692A1Reducing duty cycleThermometers using electric/magnetic elementsCoupling device detailsRadiometerEngineering

Owner:TYCO HEALTHCARE GRP LP

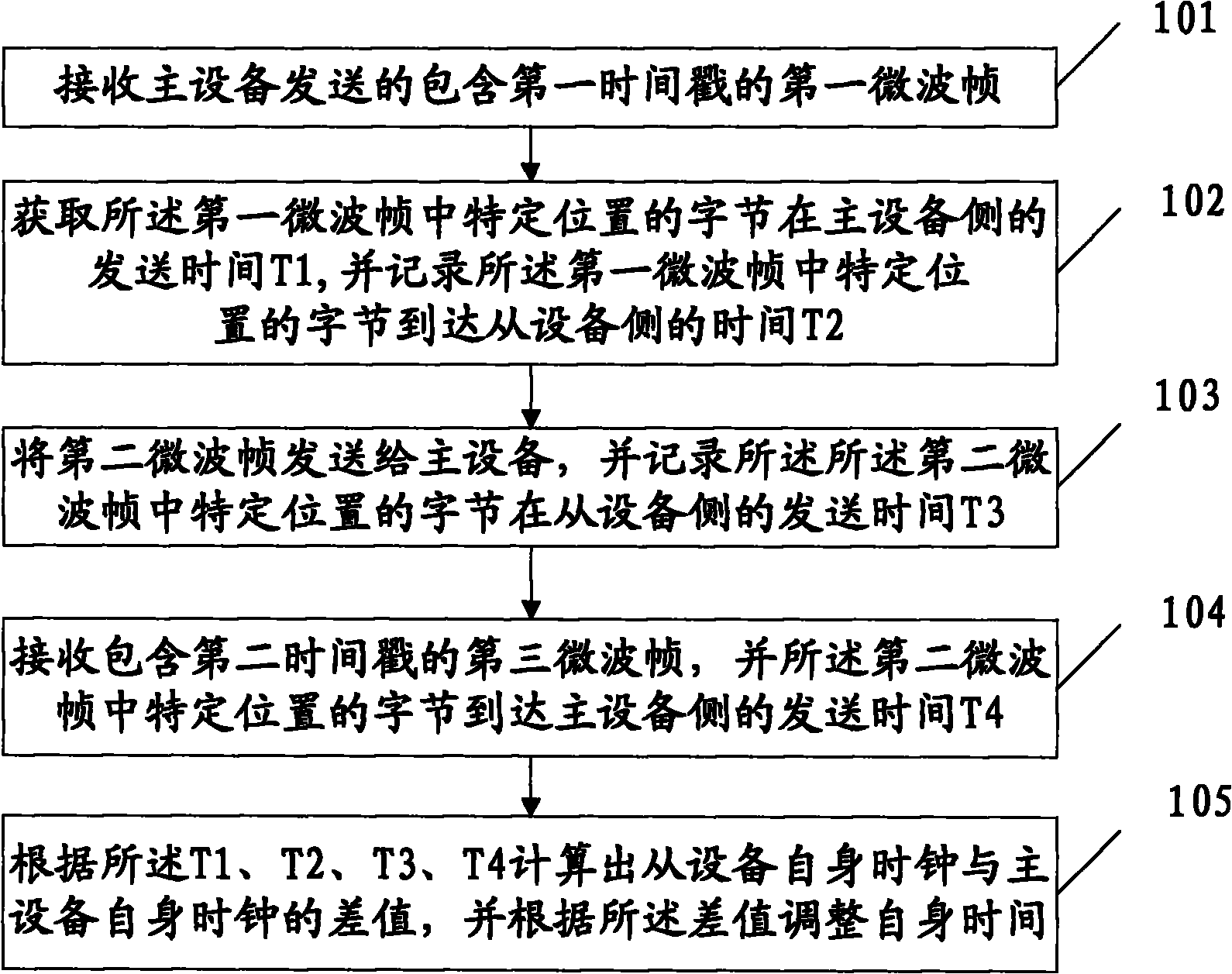

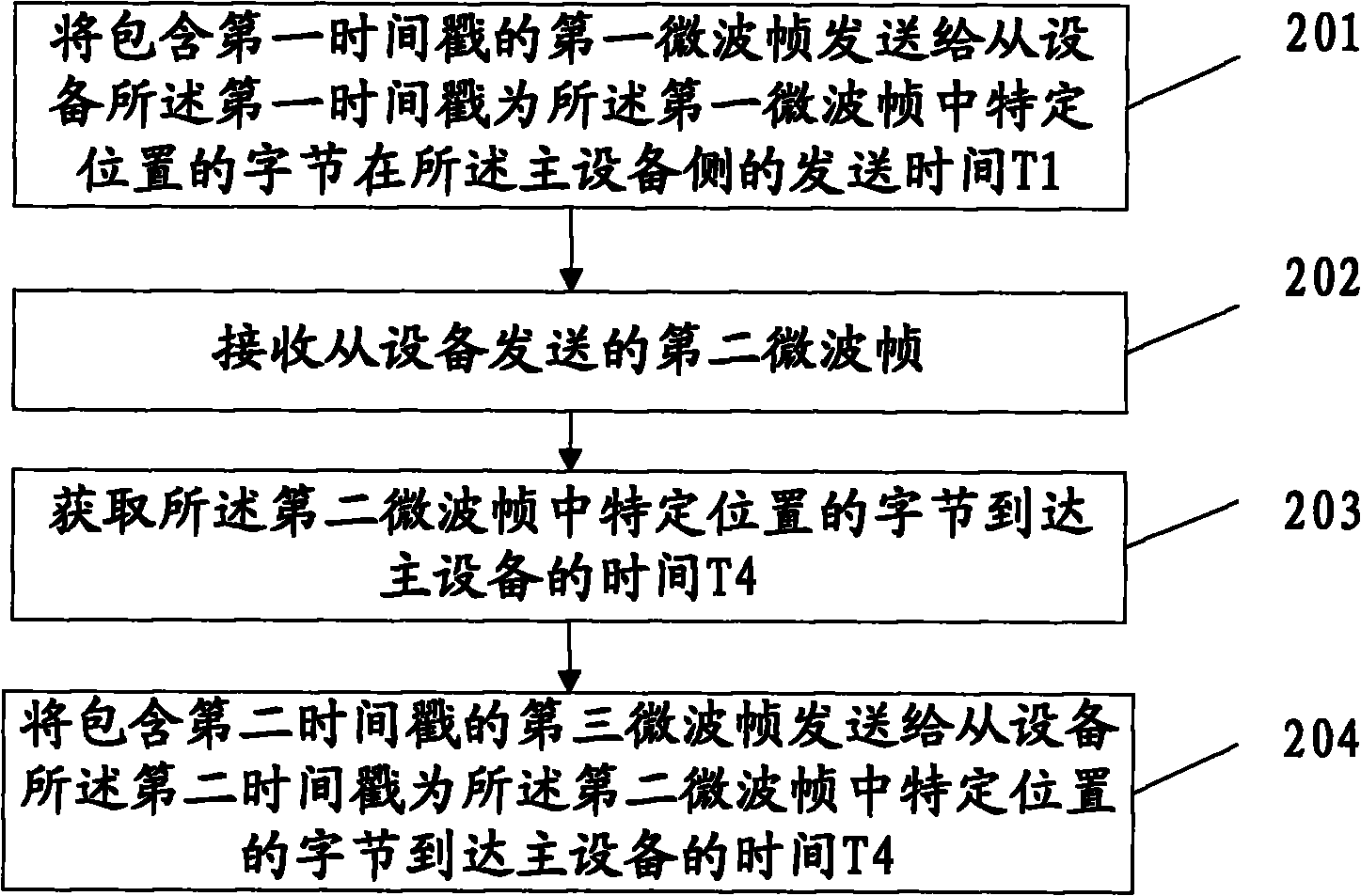

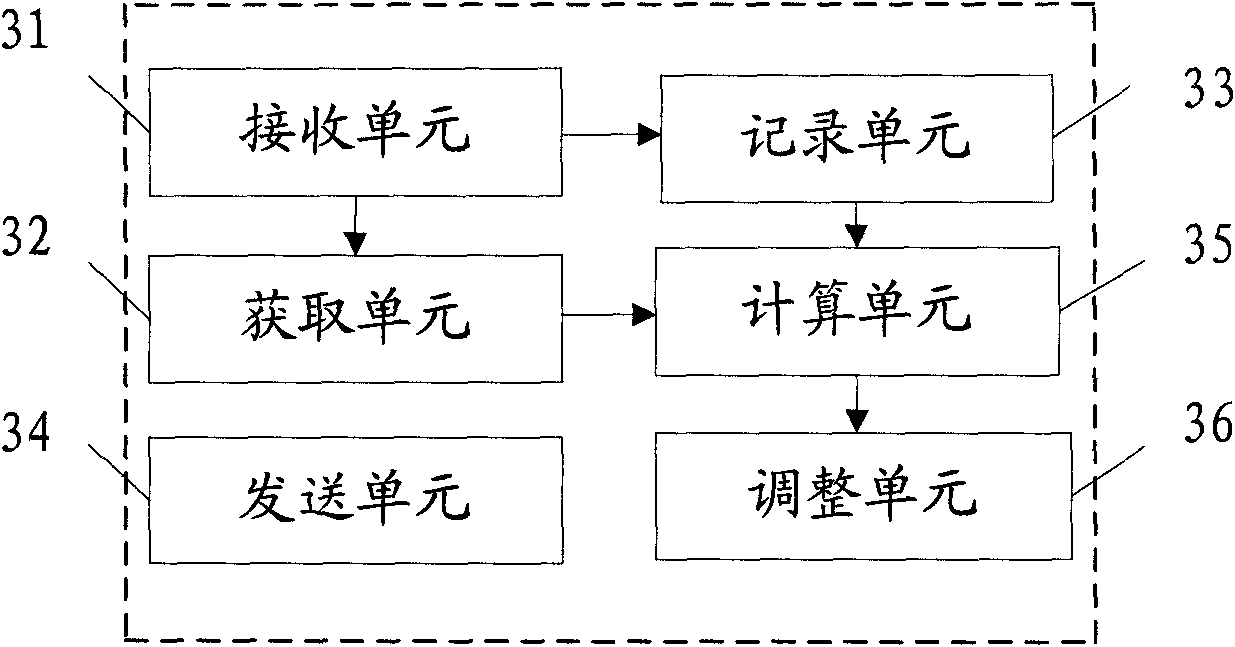

Method, device and system for realizing time synchronization

InactiveCN101958745ATime synchronizationSynchronisation arrangementNetwork topologiesNetwork controlByte

The invention discloses a method, a device and a system for realizing time synchronization and relates to the field of communication for realizing high-precision time synchronization between a wireless base station and a network controller. The invention comprises the following steps of: receiving a first microwave frame including the sending time T1 of bytes in specific positions in the first microwave frame at a master unit side and acquiring the sending time T1; recording a time T2 on arriving at a slave unit by the bytes in the specific positions in the first microwave frame; sending a second microwave frame to the master unit and recording the sending time T3 of bytes in specific positions in the second microwave frame at the slave unit side; receiving a third microwave frame including a second time stamp which is used as a time T4 on arriving at the master unit by the bytes in the specific positions in the second microwave and acquiring the time T4; and calculating the time difference between a slave unit self clock and a master unit self clock according to T1, T2, T3 and T4, and adjusting self time according to the time difference. The embodiment of the invention is mainly applied to the process of microwave transmission.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com