Patents

Literature

658 results about "Amorphous semiconductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amorphous semiconductor. A solid state material that can be switched from one state to another. For example, the recording layer in phase change rewritable CDs and DVDs switches between an unstructured amorphous state that absorbs light and a structured crystalline state that allows light to pass.

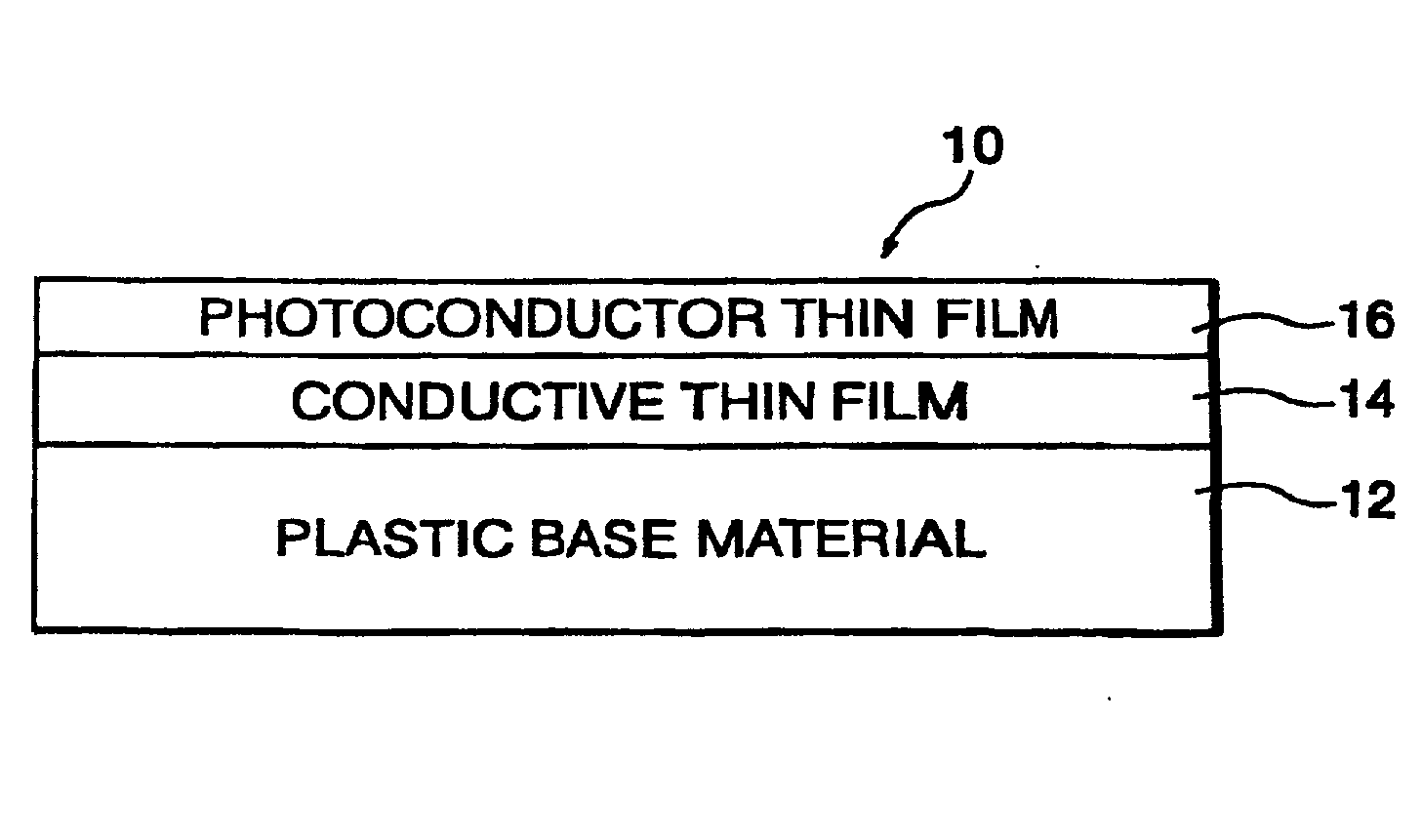

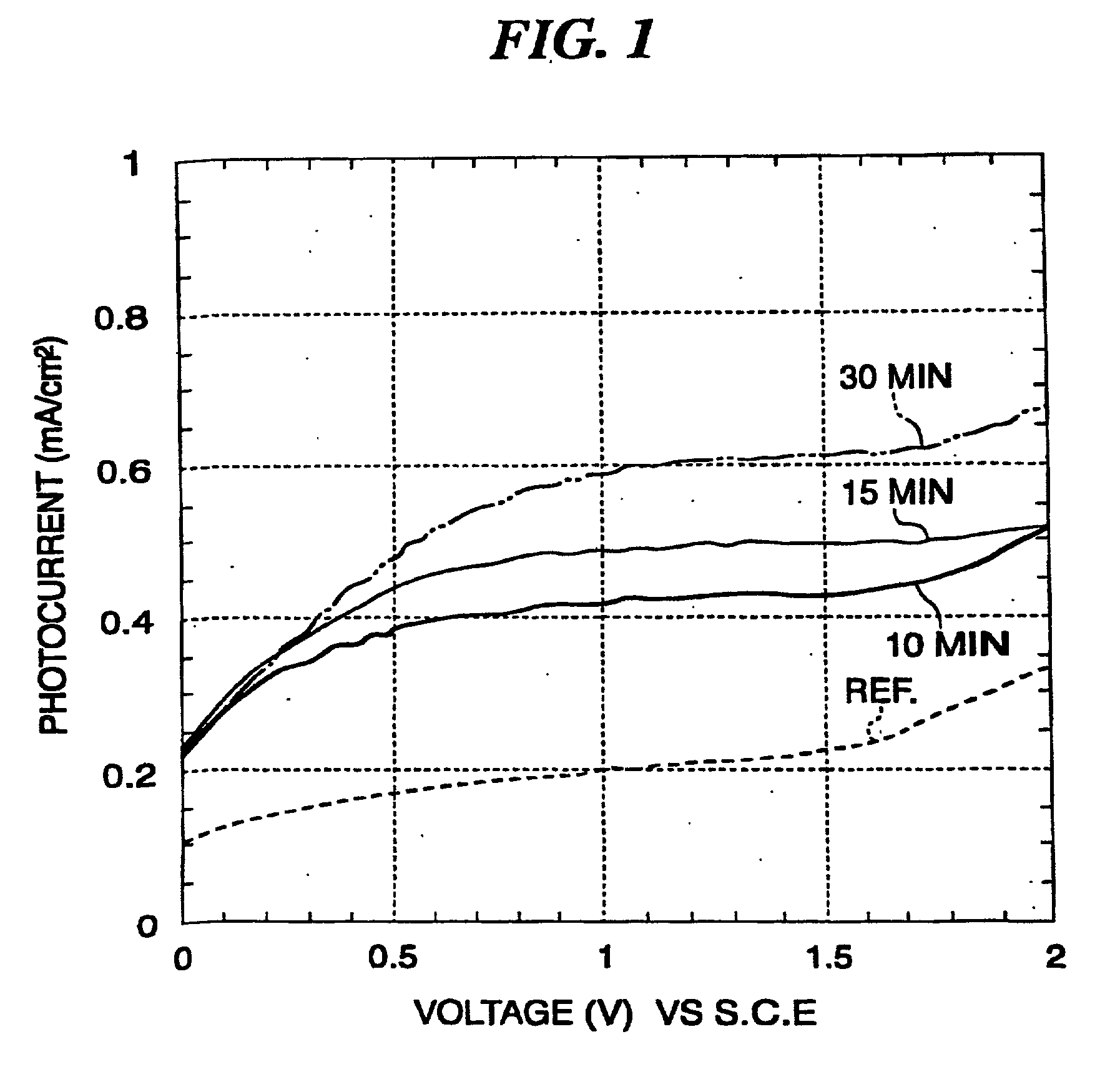

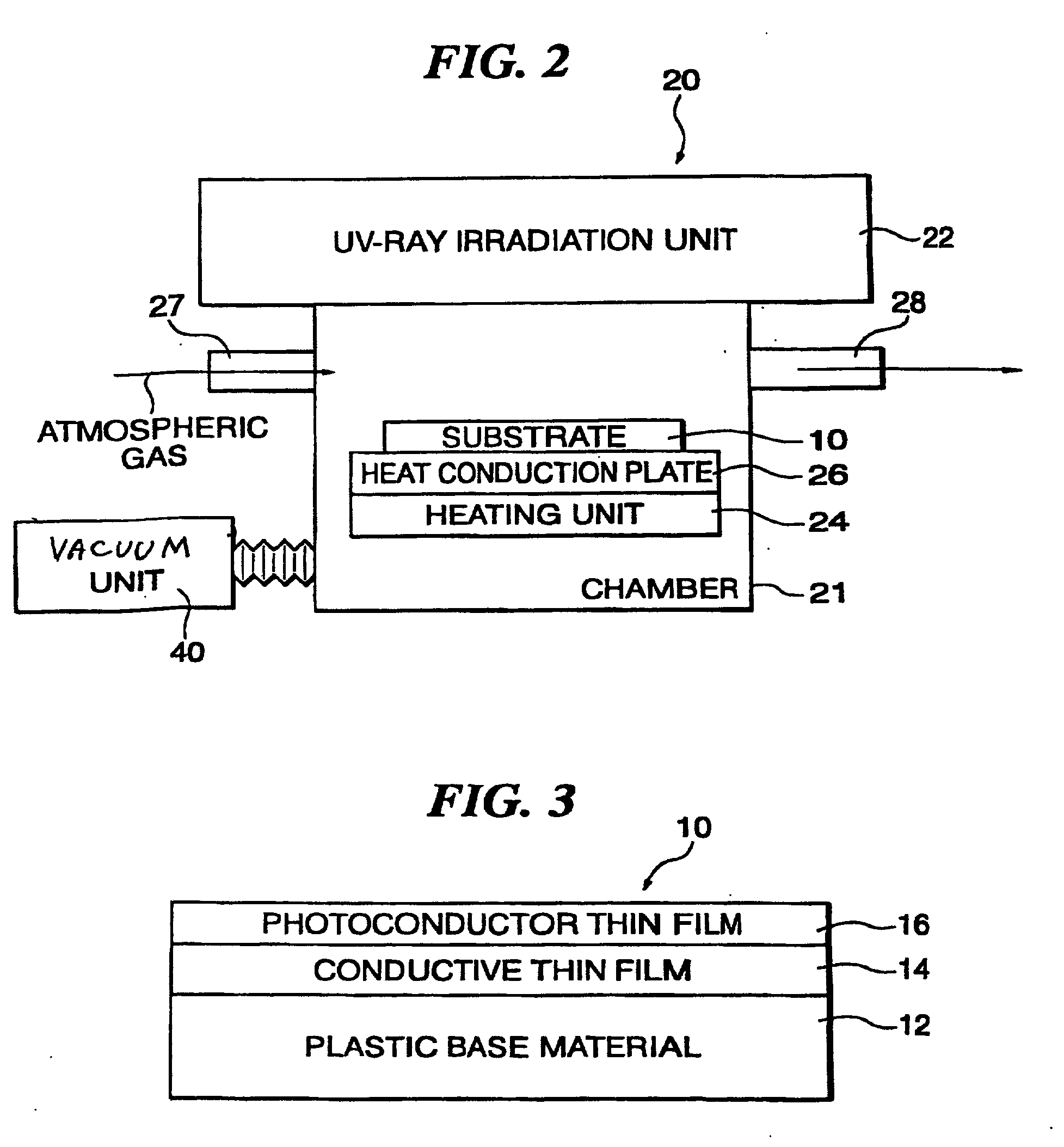

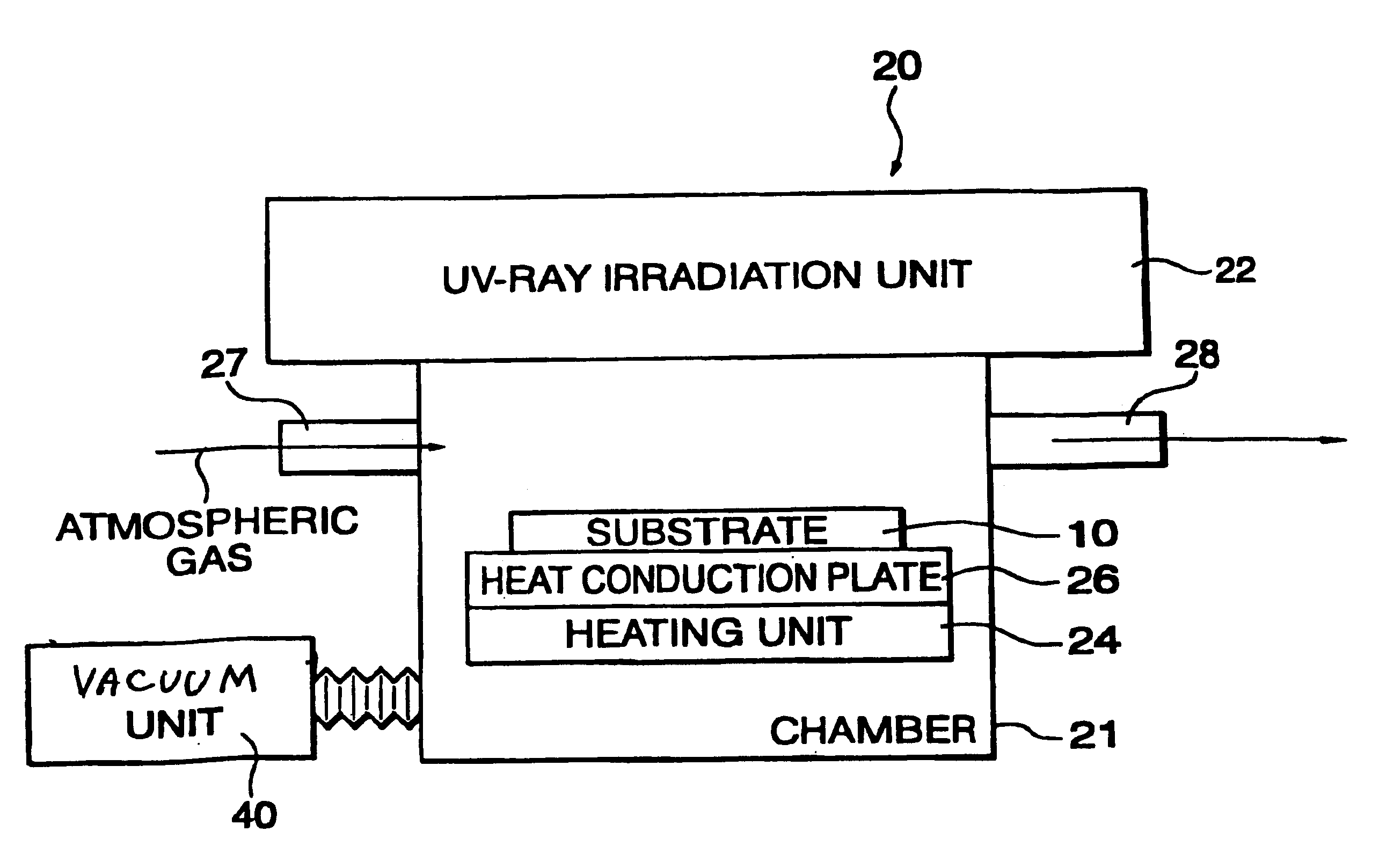

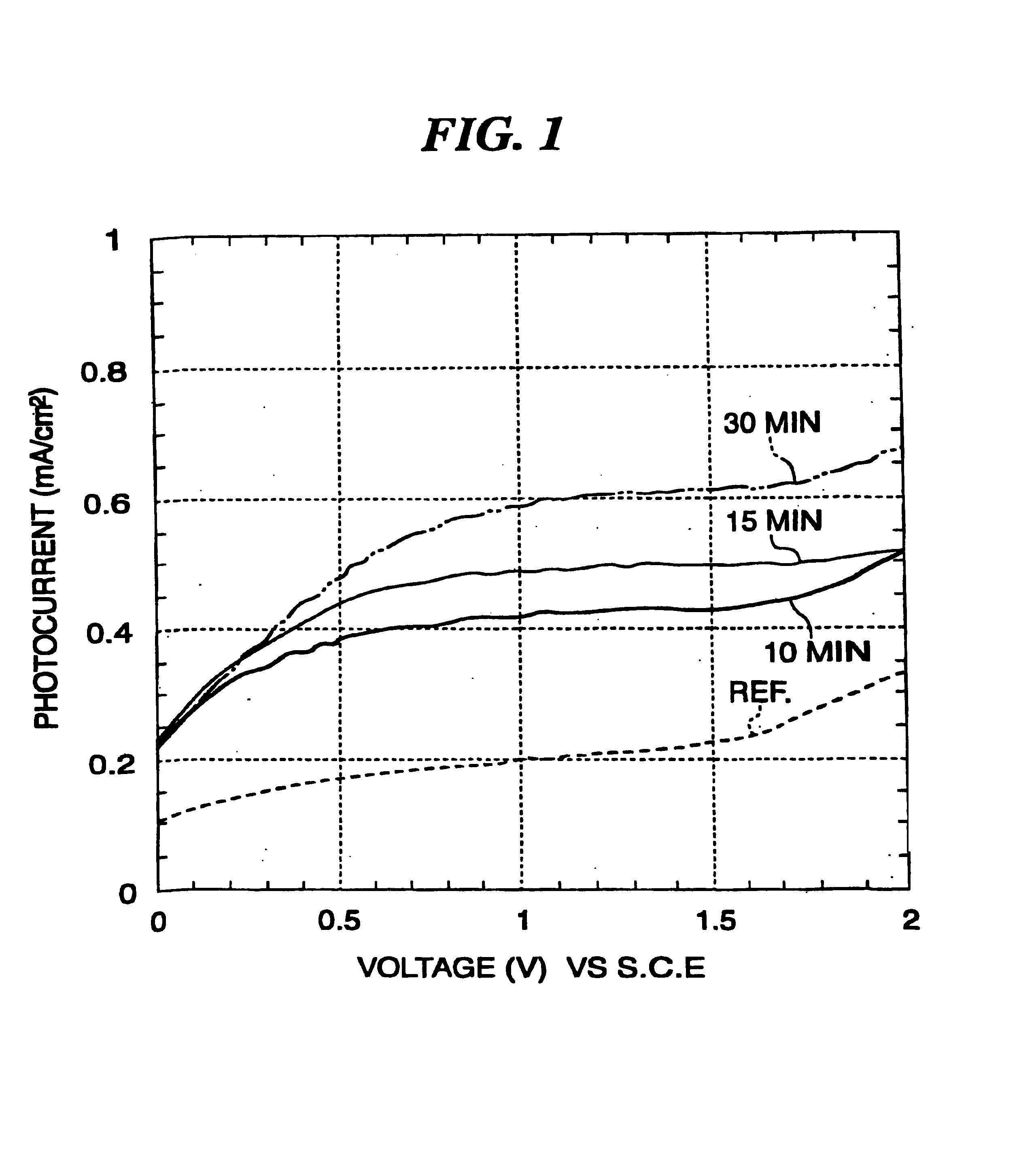

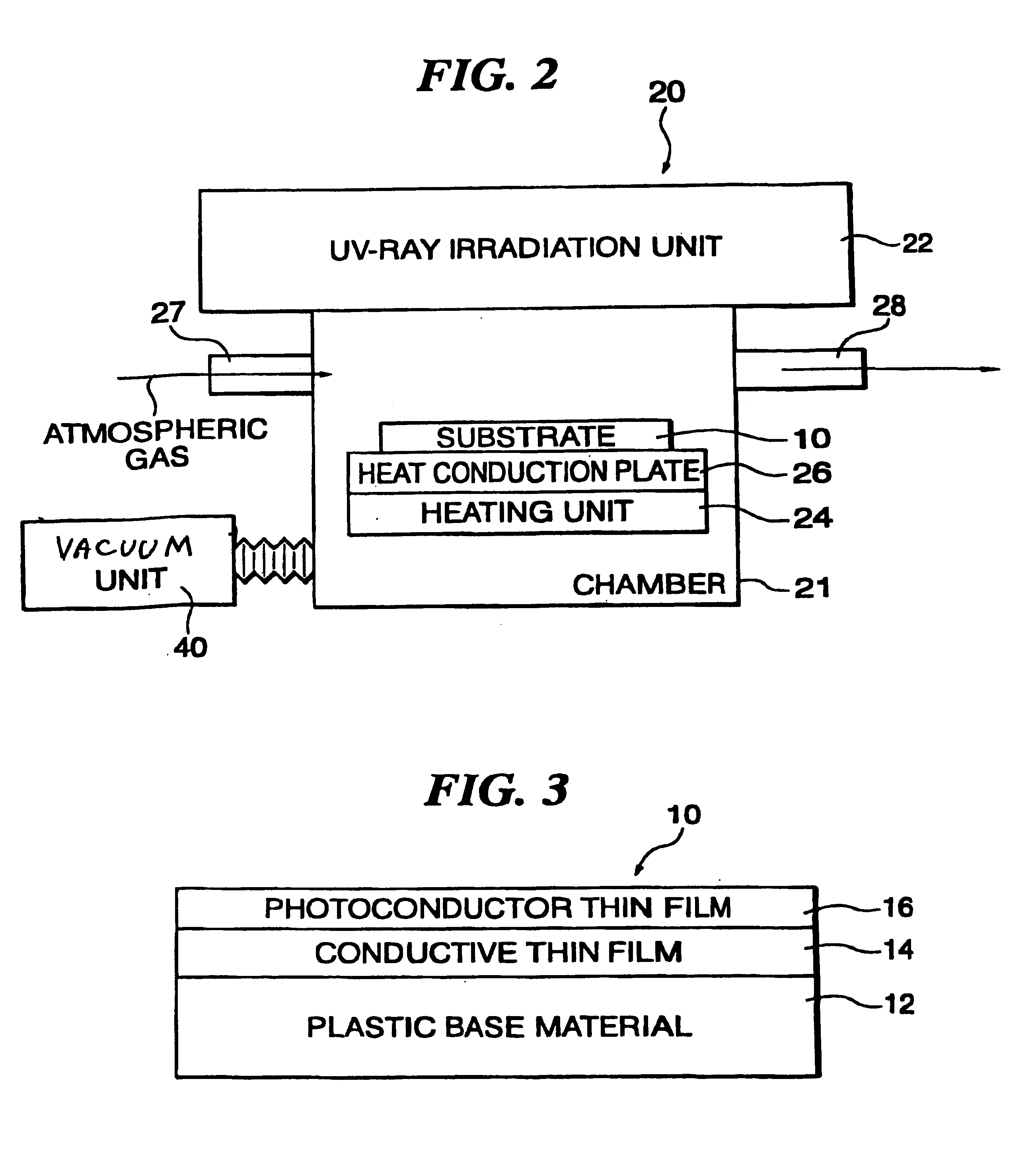

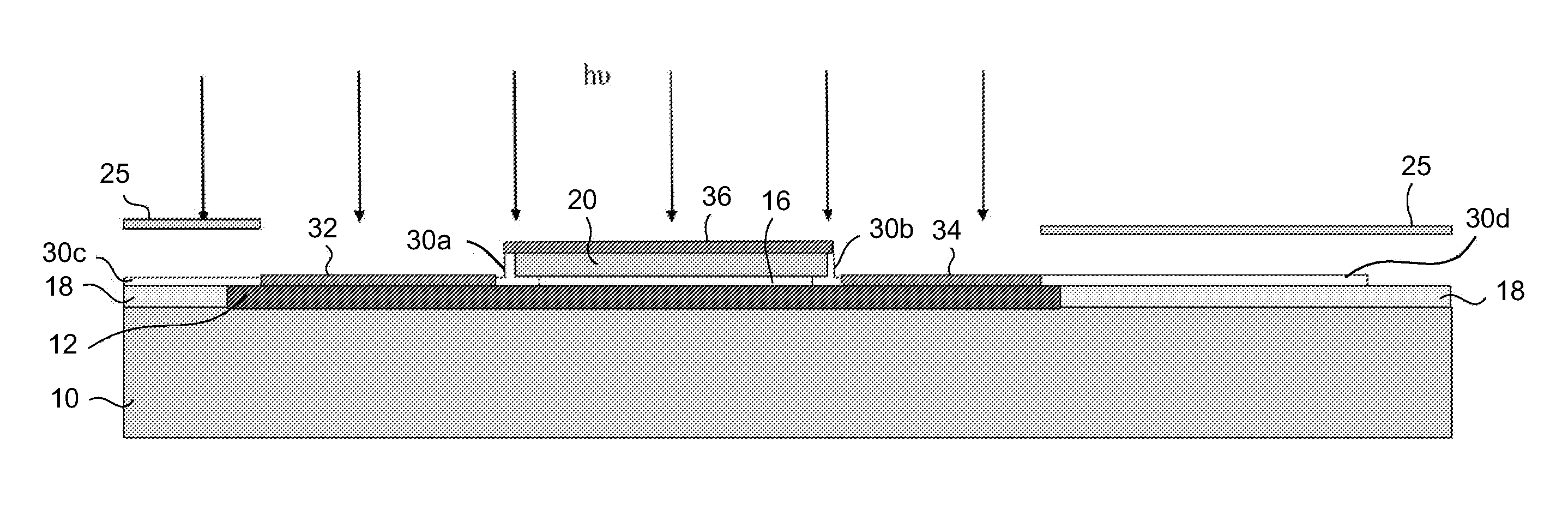

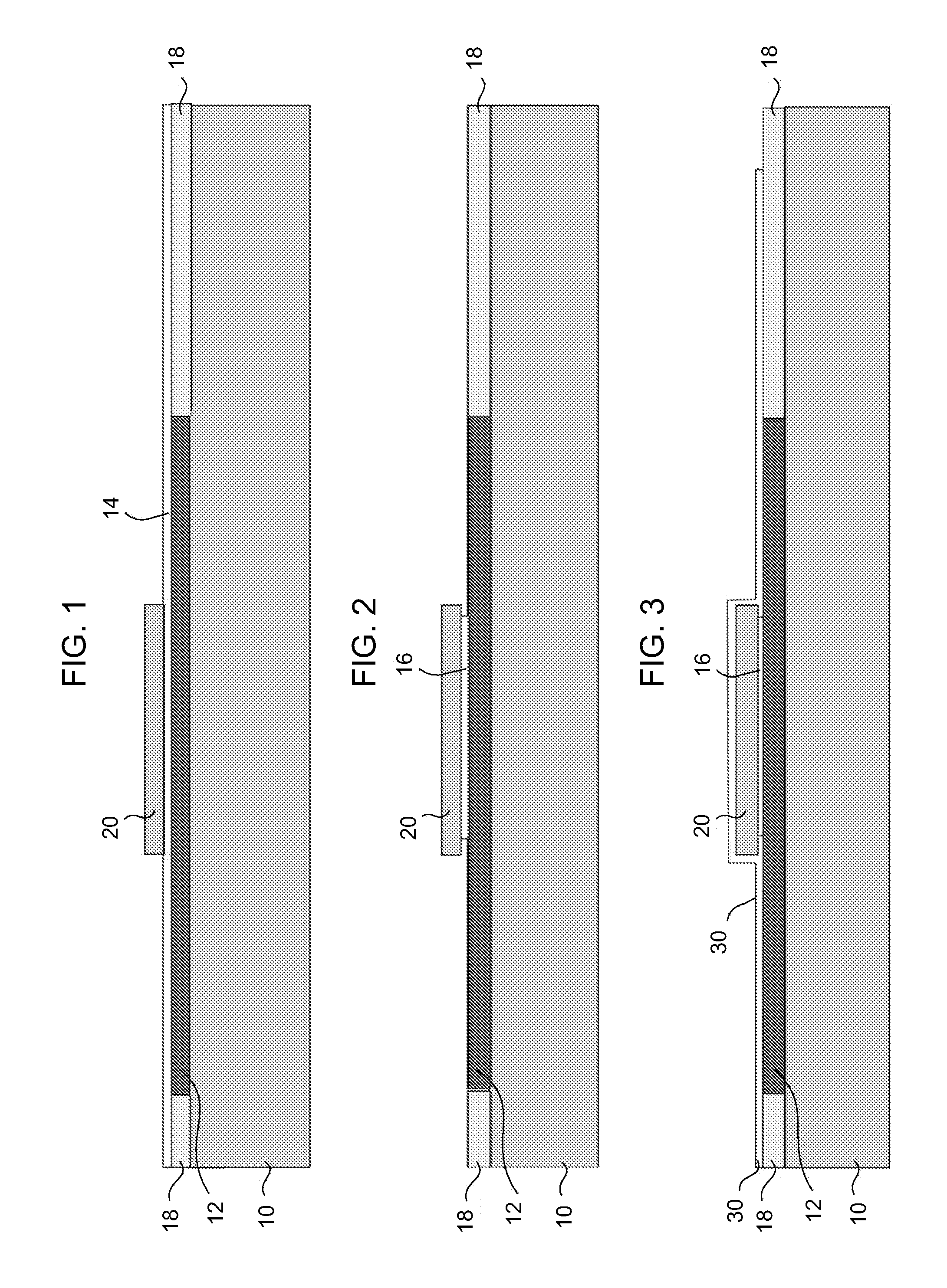

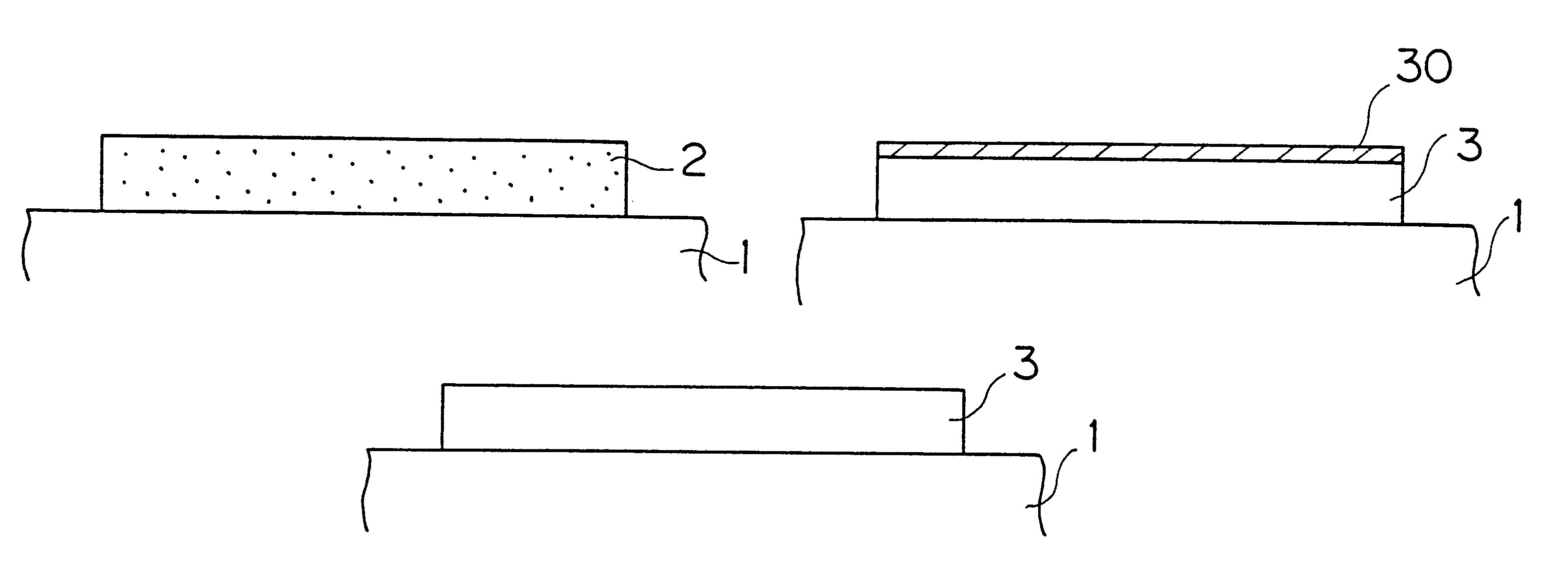

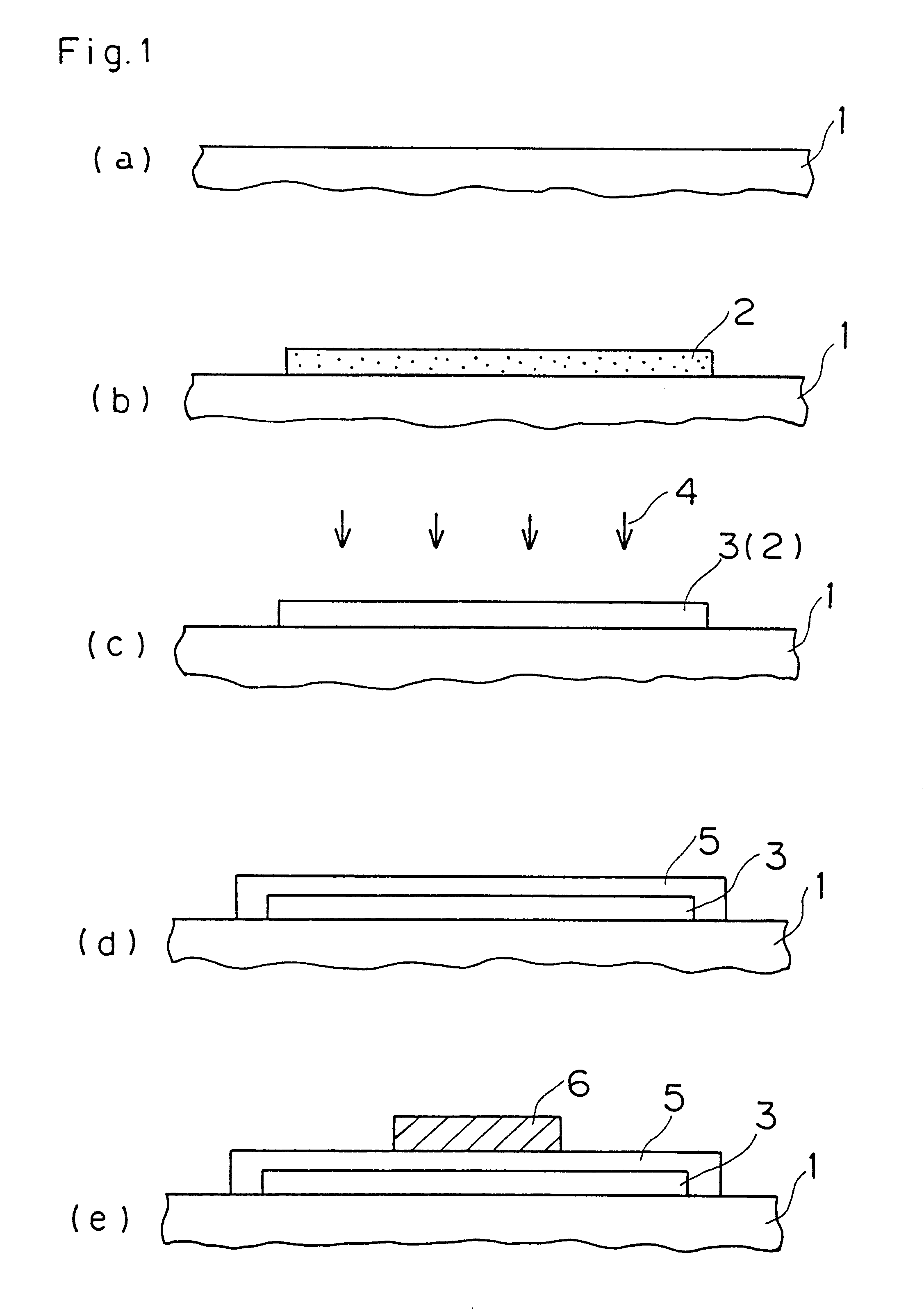

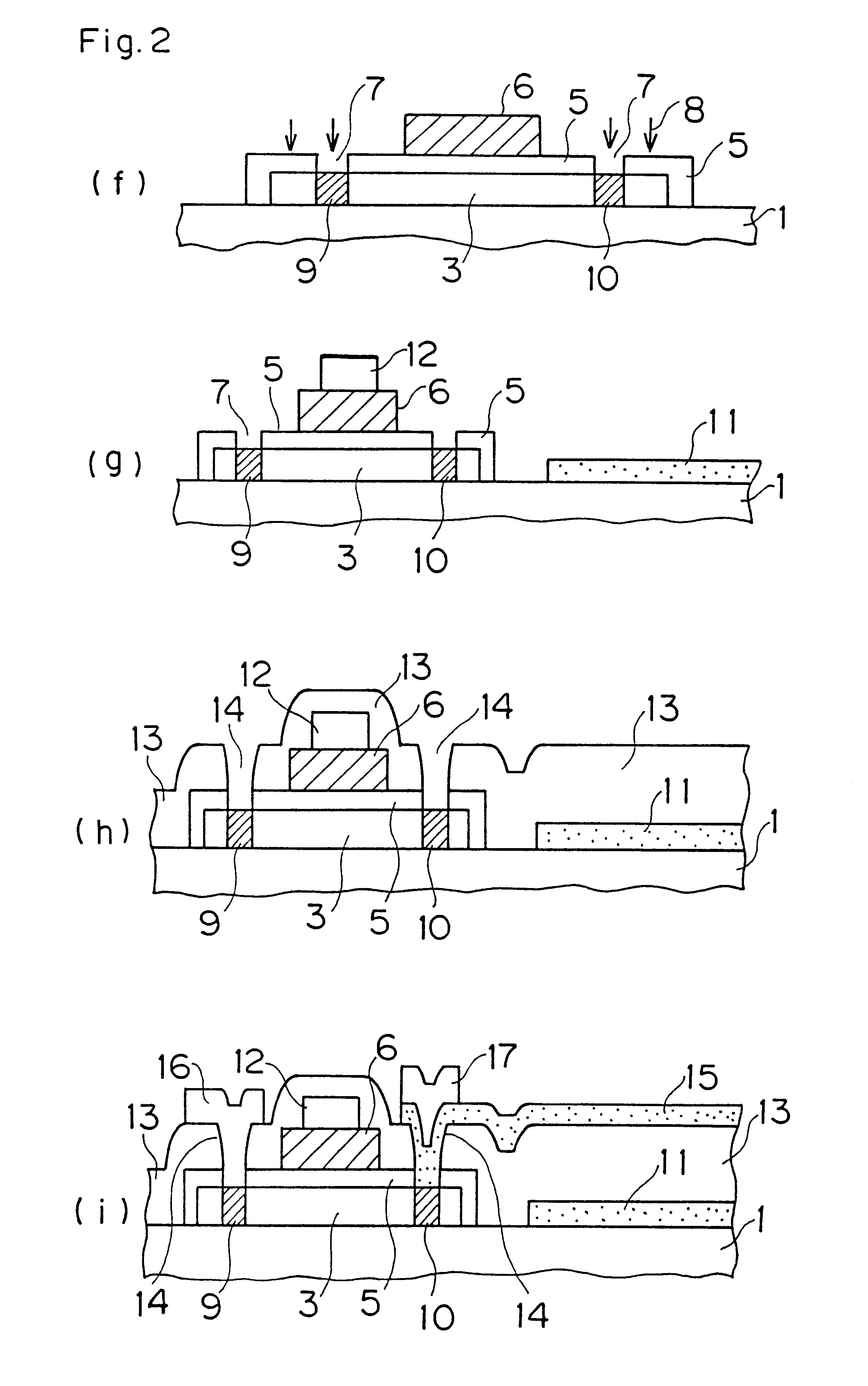

Method of forming crystalline semiconductor thin film on base substrate, lamination formed with crystalline semiconductor thin film and color filter

A method of forming a crystalline semiconductor thin film on a base material which can be prepared at a low temperature by simple step and device, the method including a processing step of applying UV-rays to an amorphous semiconductor thin film provided on a base material while keeping a temperature at not less than 25° C. and not more than 300° C. in a vacuum or a reducing gas atmosphere, as well as a substrate having the semiconductor thin film provided on the base material, a substrate for forming a color filter and a color filter using the substrate.

Owner:FUJIFILM BUSINESS INNOVATION CORP

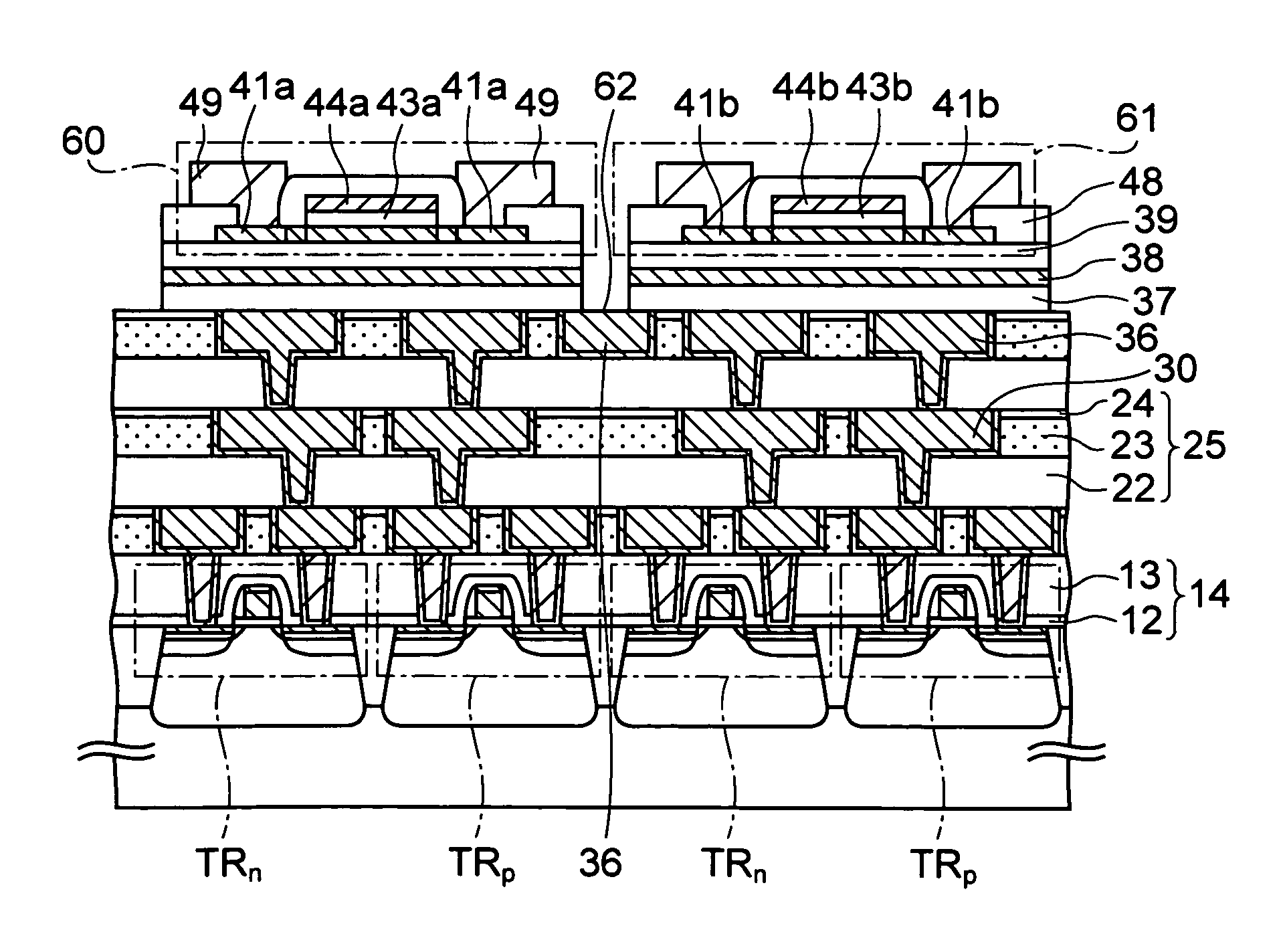

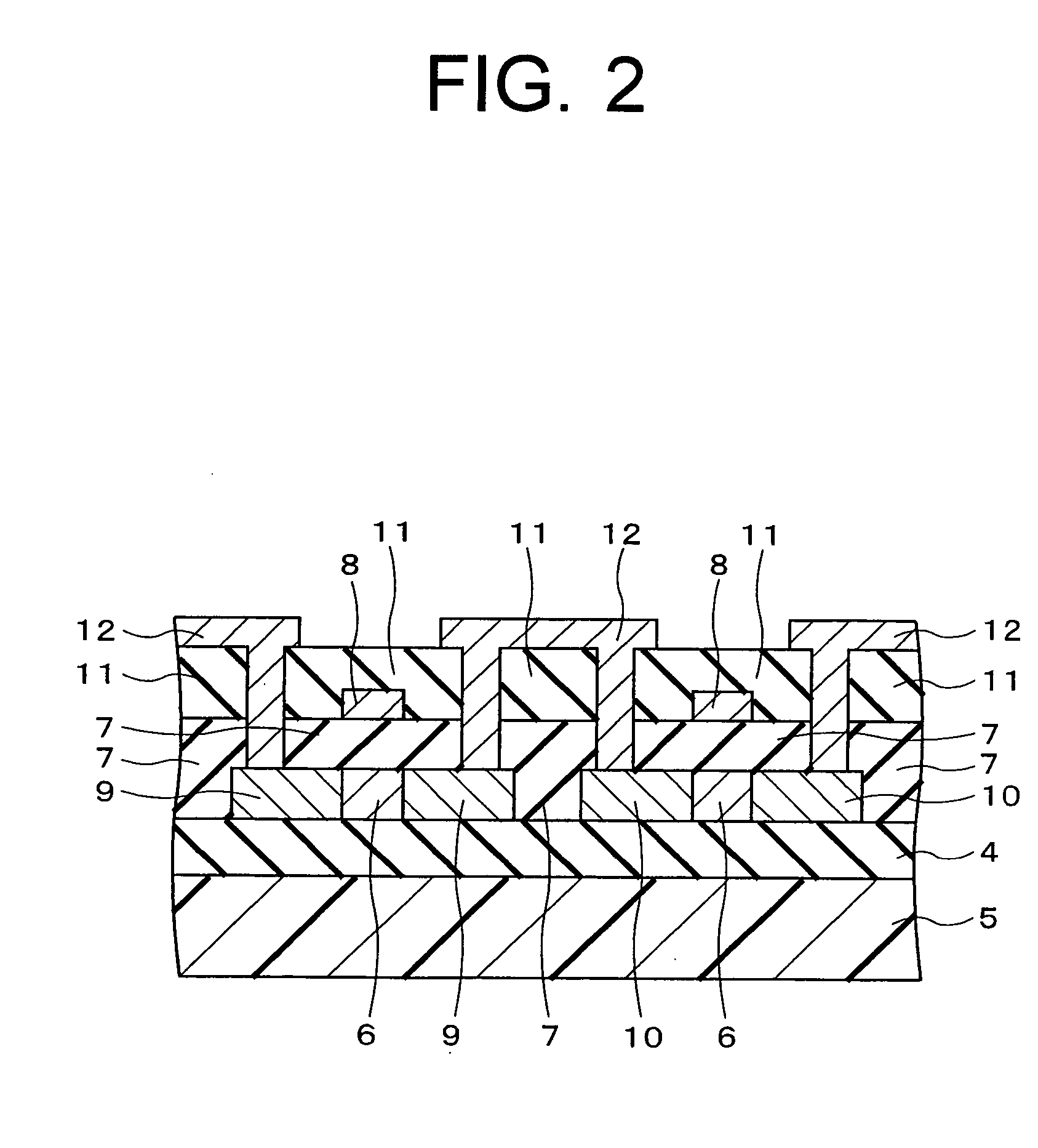

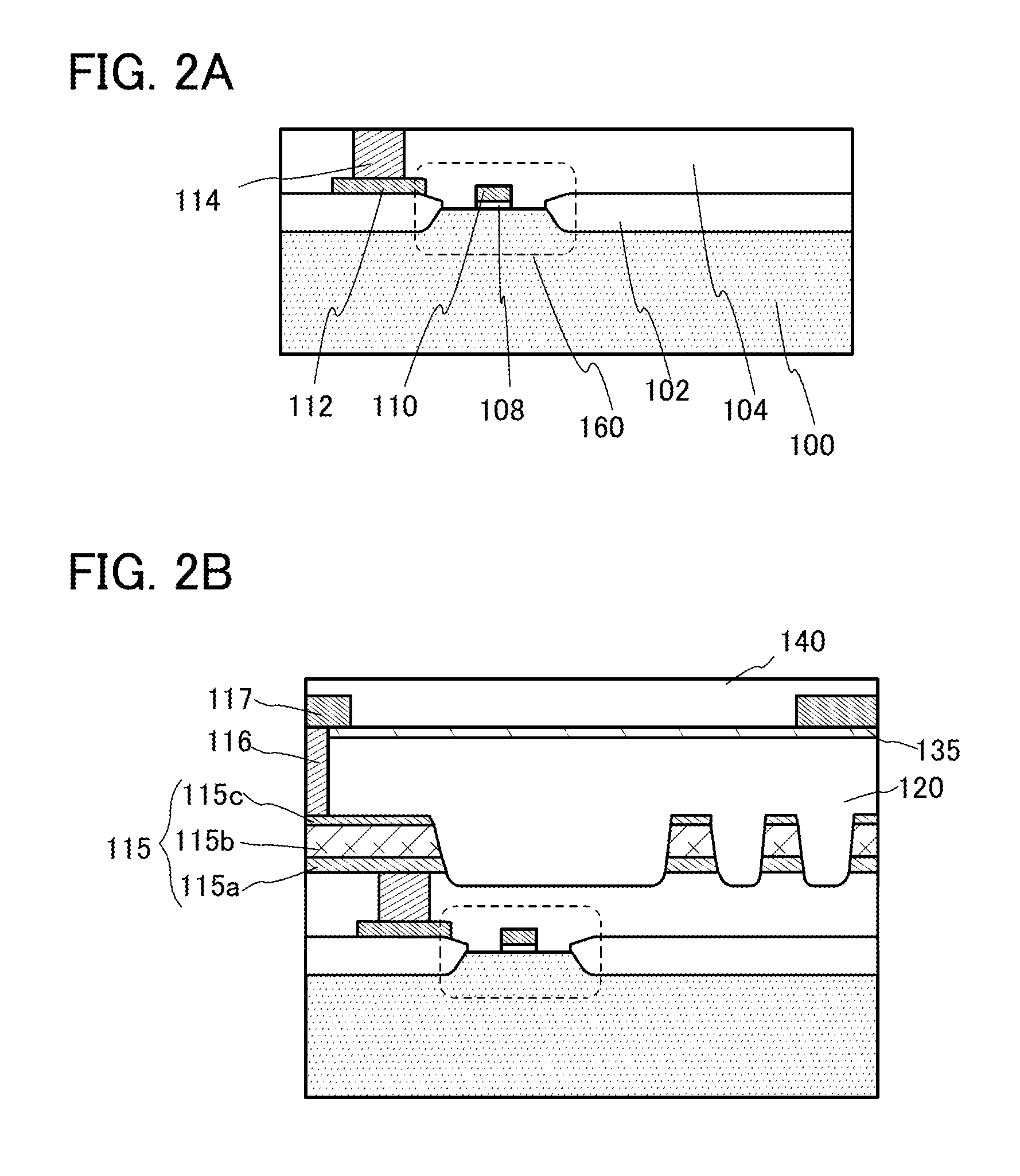

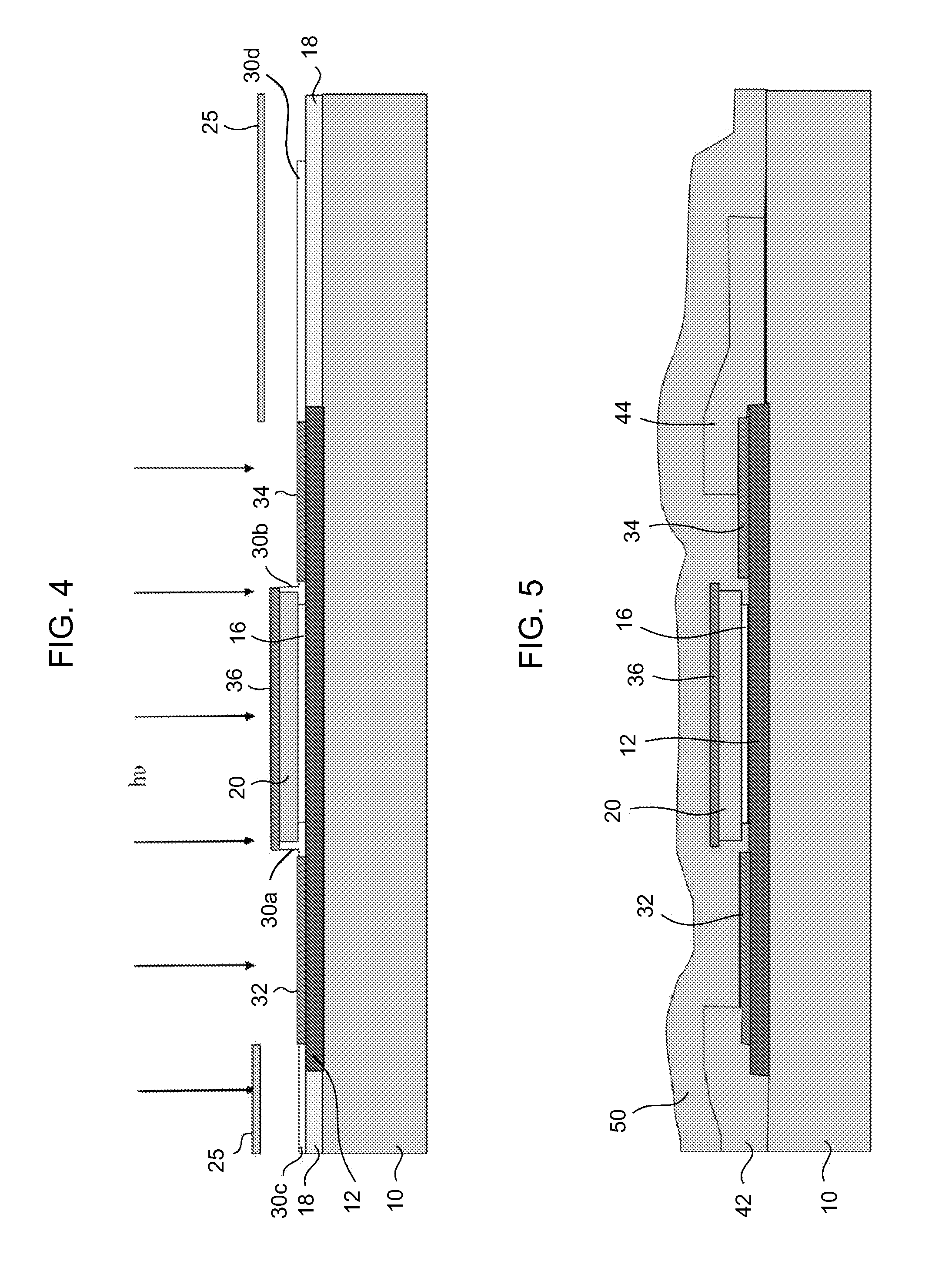

Semiconductor device

InactiveUS7795619B2Inhibit deteriorationPrevent short-circuitingSemiconductor/solid-state device detailsSolid-state devicesTransistorPhysics

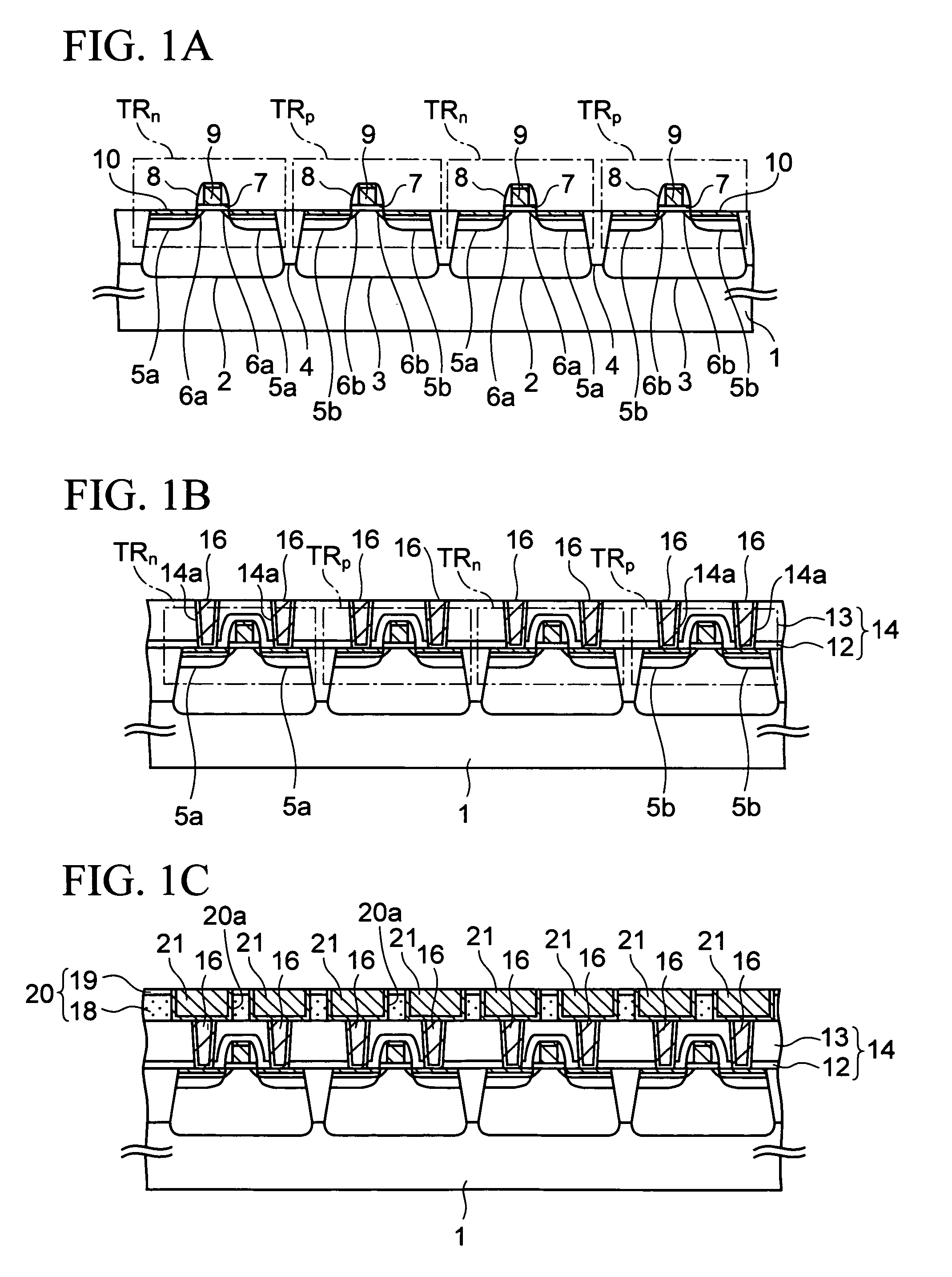

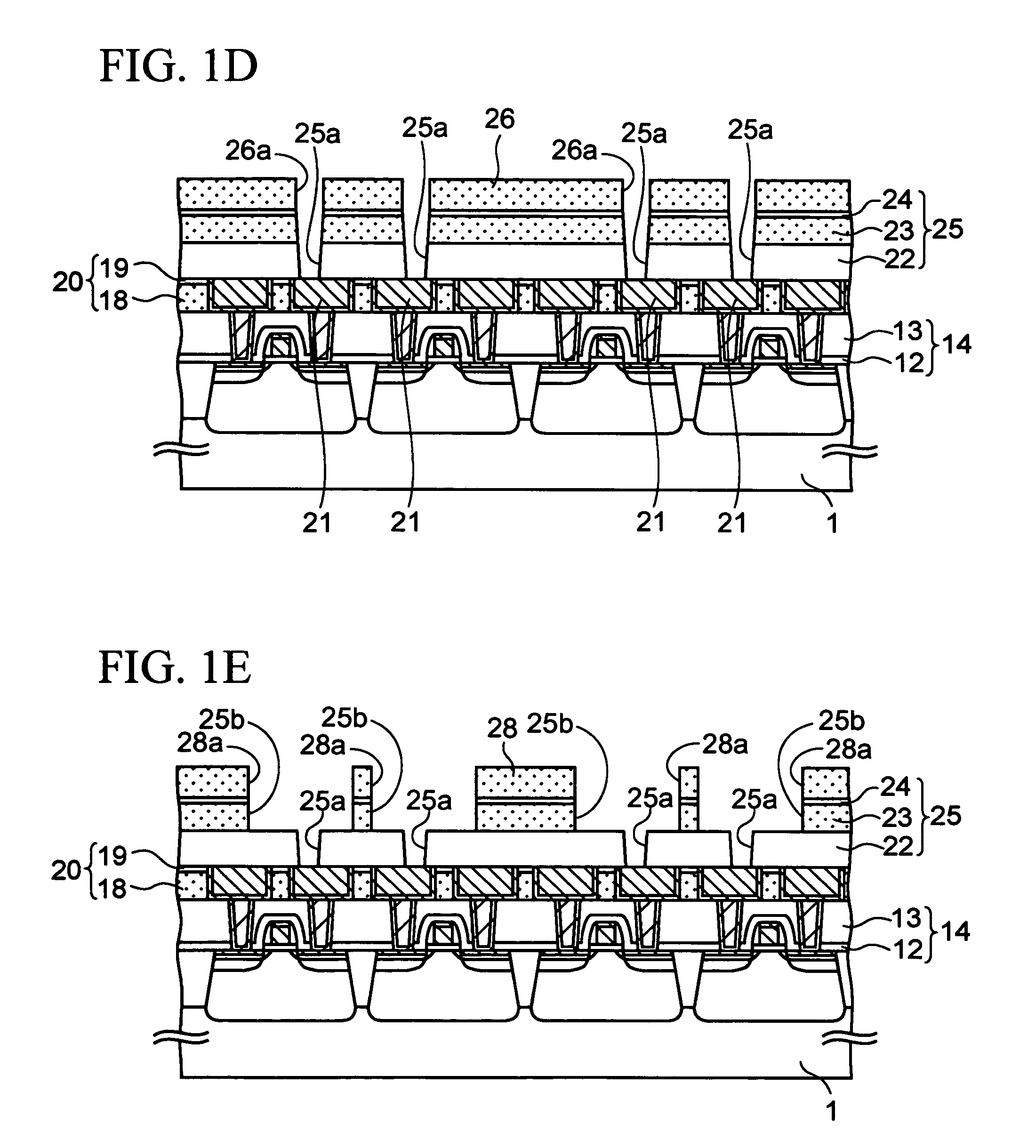

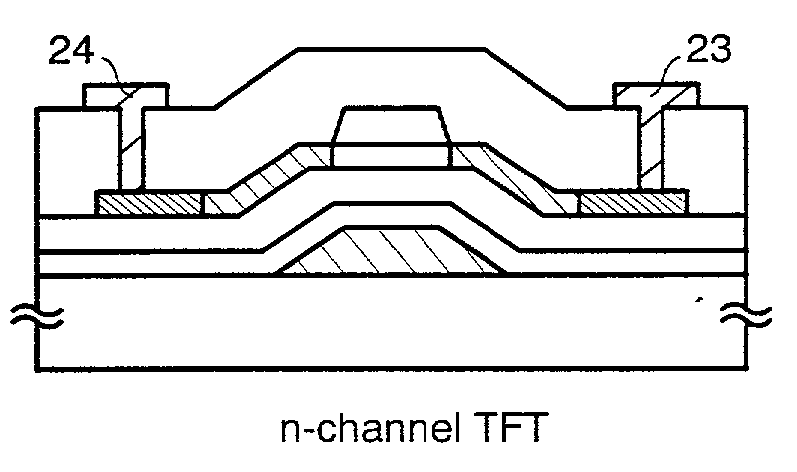

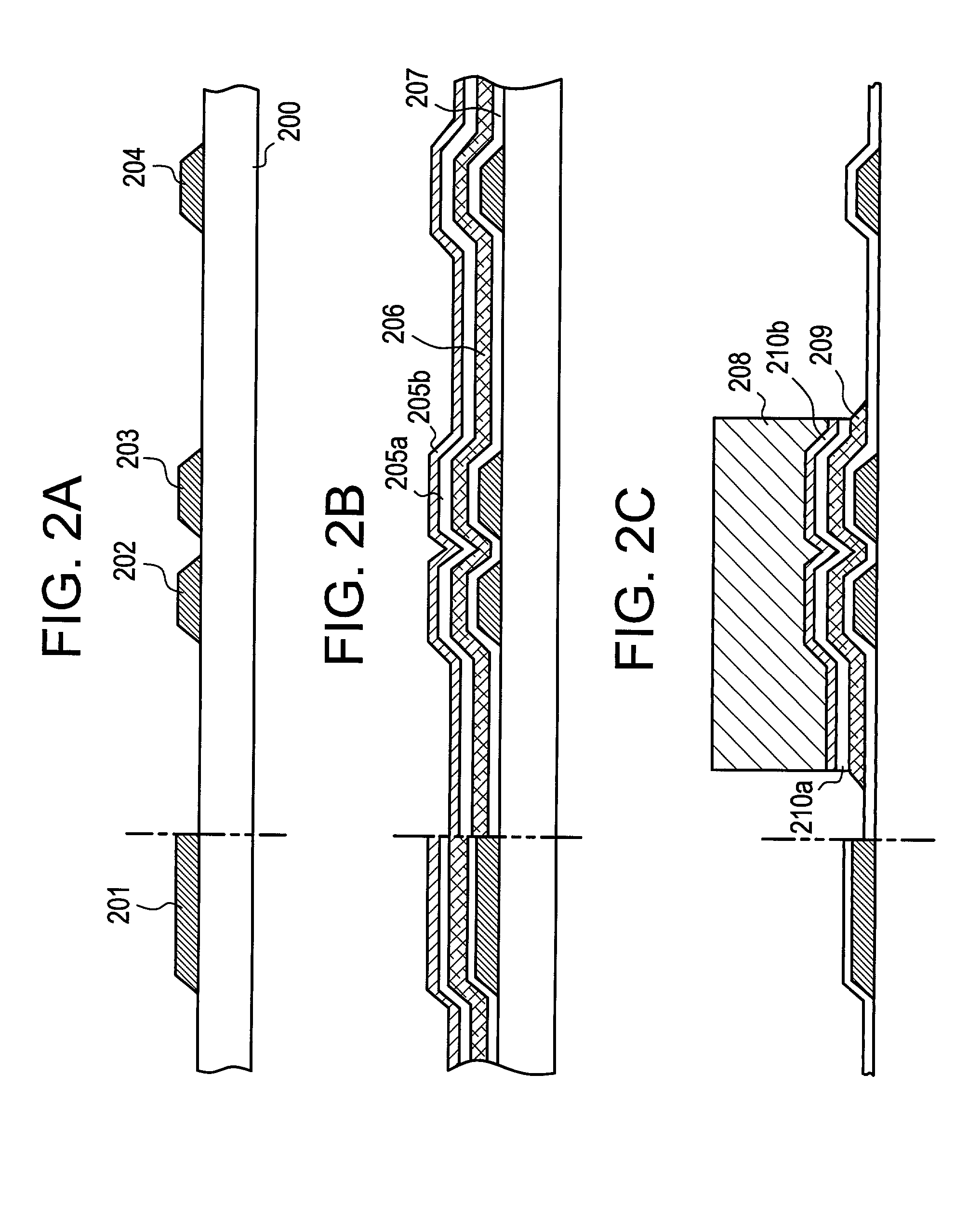

A method for manufacturing a semiconductor device, including the steps of: forming a shielding film 38 on a first insulating film 37; sequentially forming a second insulating film 39 and an amorphous semiconductor film 40 on the shielding film 38; melting the amorphous semiconductor film 40 at least in portions to be channels of thin-film transistors by irradiating an energy beam onto the amorphous semiconductor film 40, and converting the amorphous semiconductor film 40 into a polycrystalline semiconductor film 41; sequentially forming a gate insulating film 43a and a gate electrode 44a on the polycrystalline semiconductor film 41 on the channels; and forming source and drain regions 41a in the polycrystalline semiconductor film 41 on sides of the gate electrode 44a, and forming a TFT 60 by use of the source and drain regions 41a, the gate insulating film 43a, and the gate electrode 44a.

Owner:FUJITSU SEMICON LTD

Semiconductor device

InactiveUS20050236623A1Well mixedGood heat dissipationTransistorSolid-state devicesDevice materialEngineering

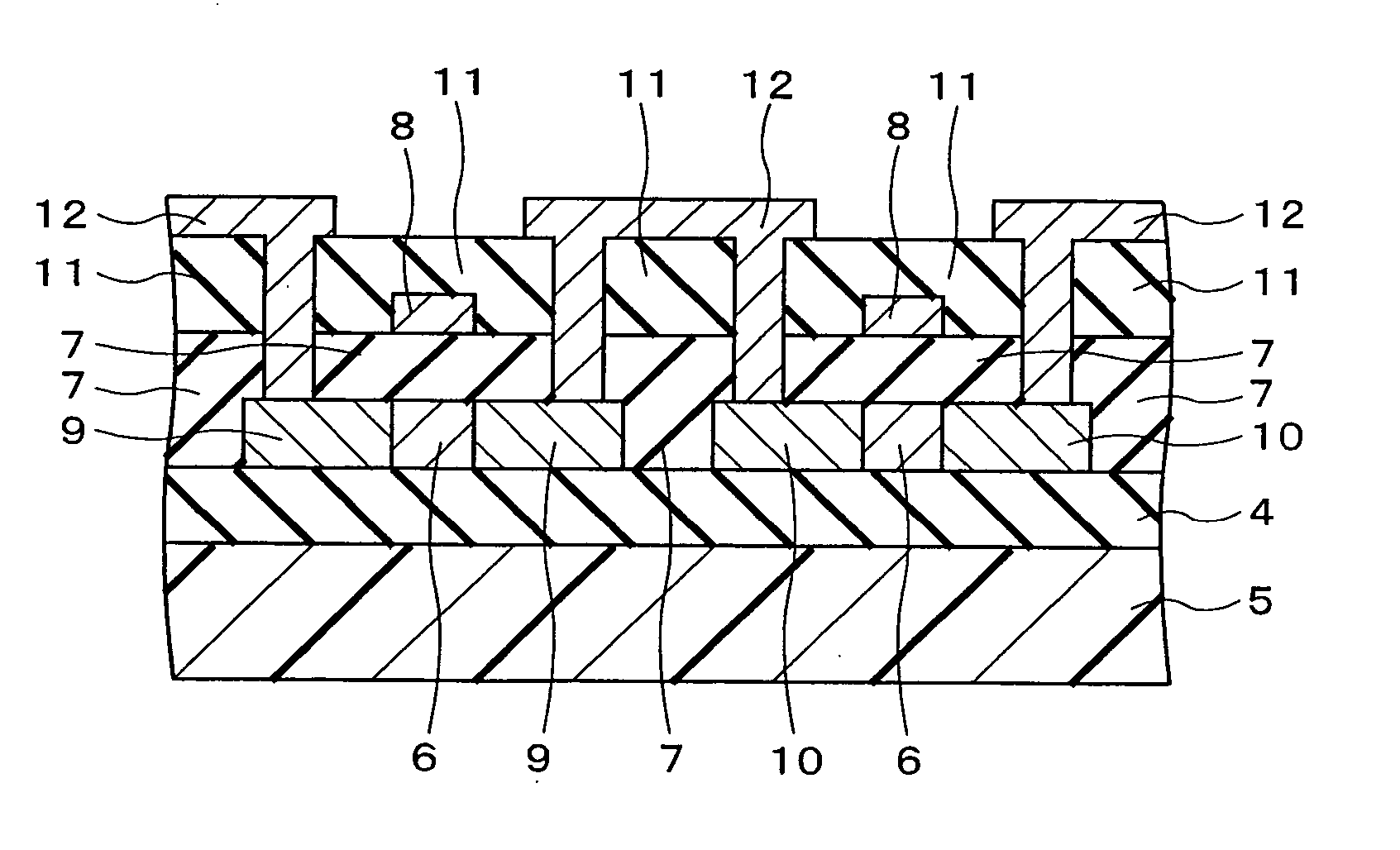

An integrated circuit is formed on a flexible substrate by using an amorphous semiconductor thin film, or a polycrystalline or a monocrystalline semiconductor thin film crystallized by laser annealing. A plurality of such flexible integrated circuit boards and mounted on a separate support substrate. This can enhance the mechanical strength of devices, such as an IC card and a liquid crystal display, and allow those devices to be manufactured at a low cost. It is also possible to provide a semiconductor device with a higher performance, on which a flexible integrated circuit board and an IC chip made from a silicon and / or glass wafer. Adhering a film substrate having a high thermal conductivity, such as a metal, to the bottom side of the flexible integrated circuit board improves the heat discharging characteristic of the integrated circuit and suppress the problem of self-heating.

Owner:NEC CORP

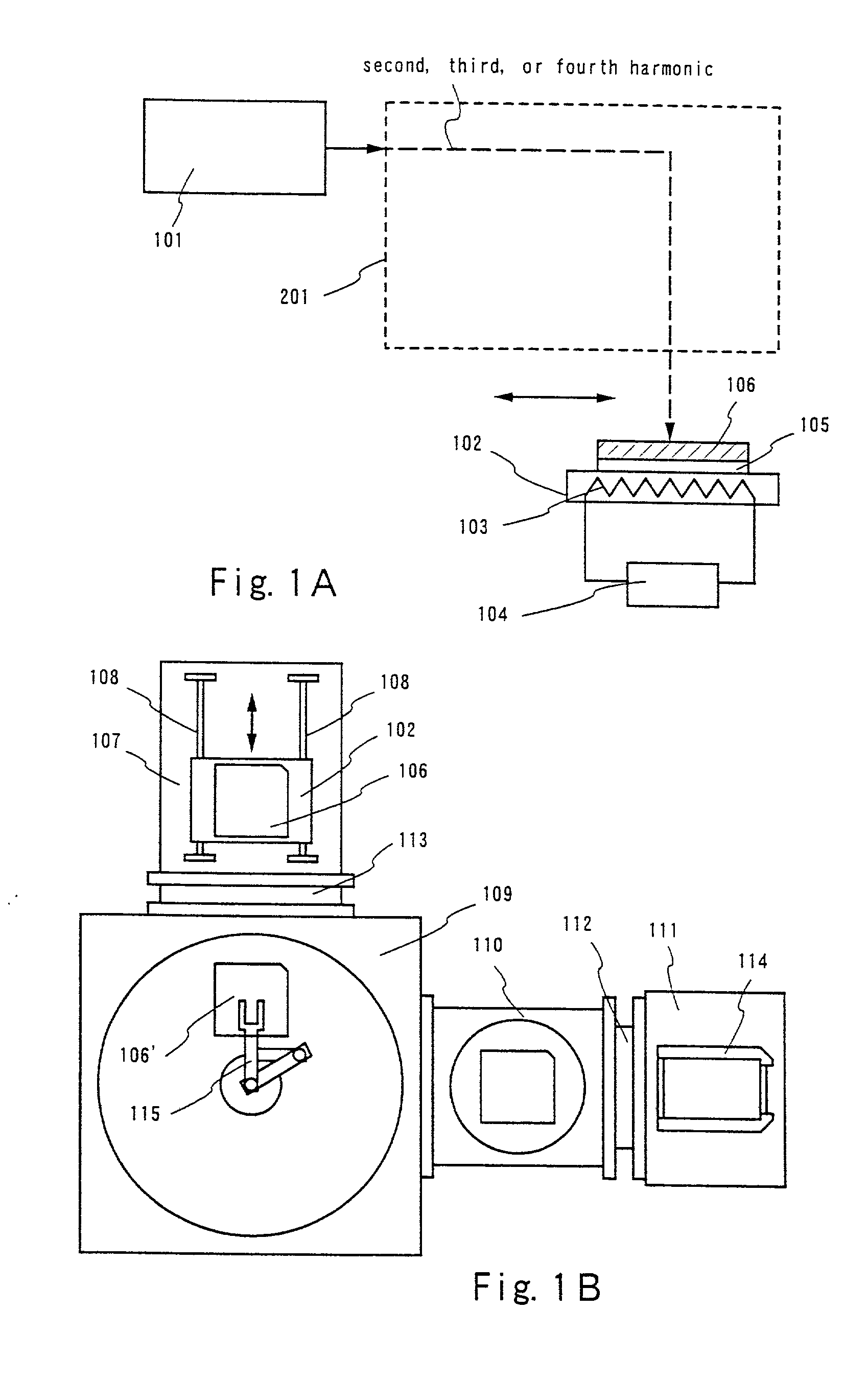

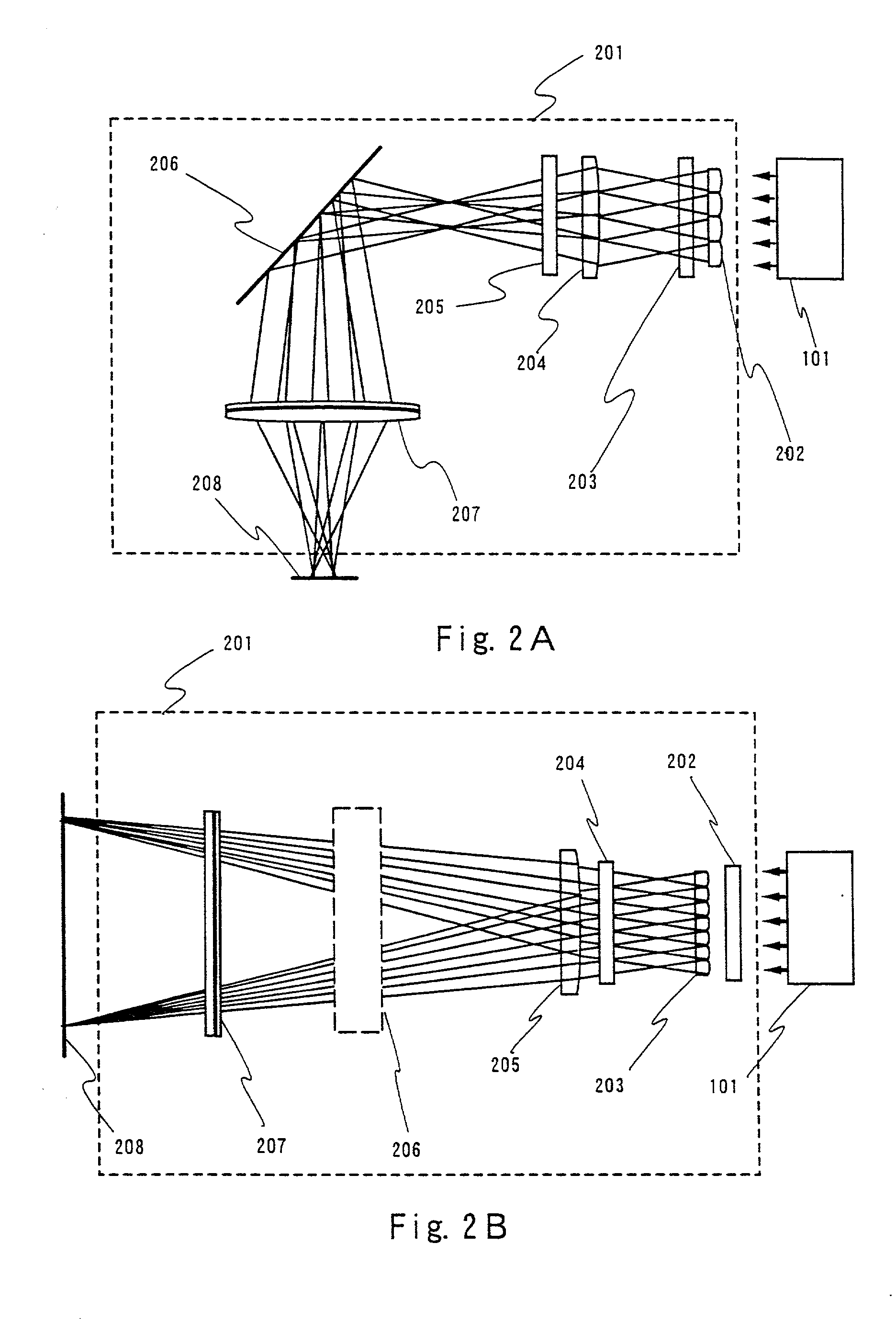

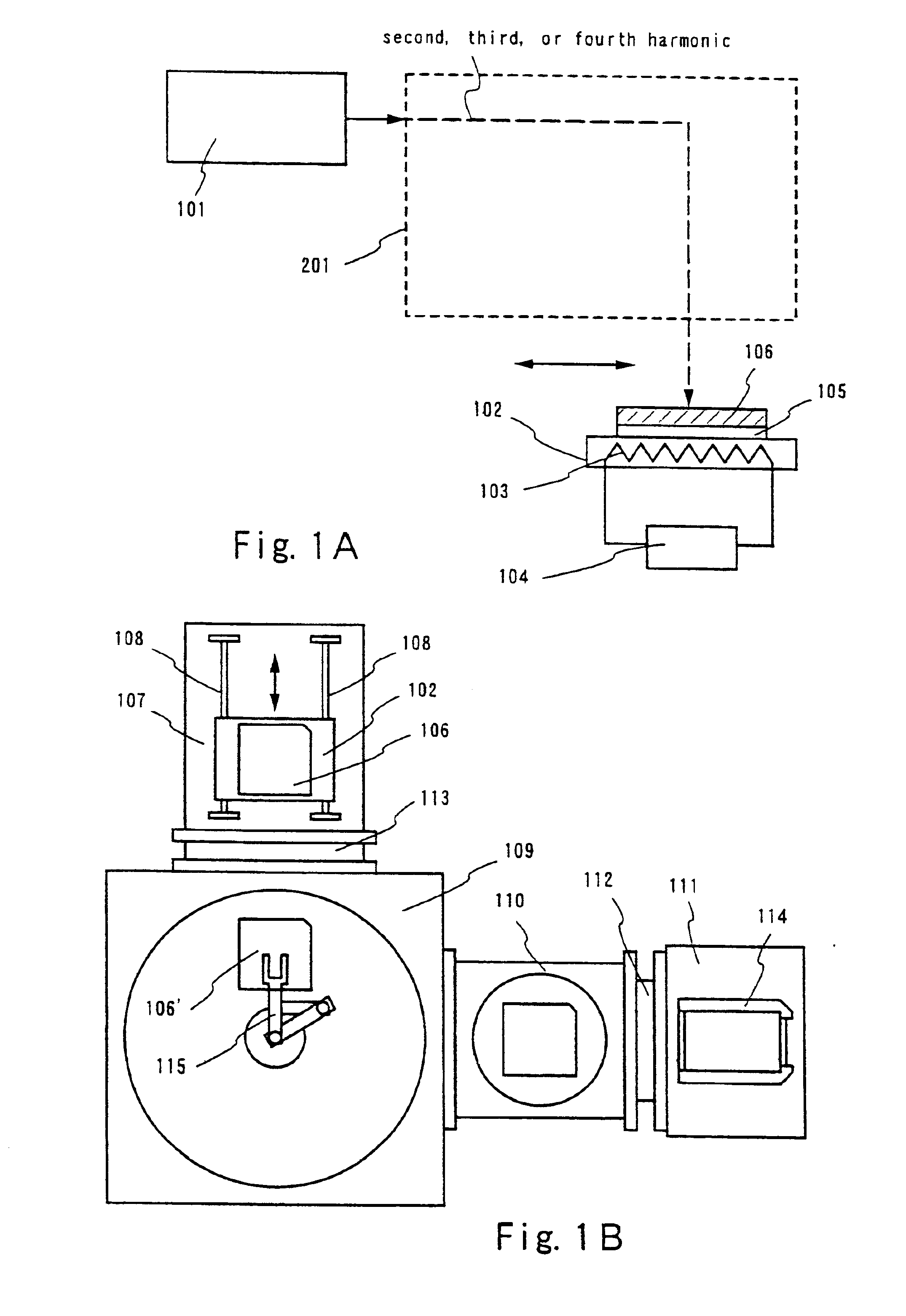

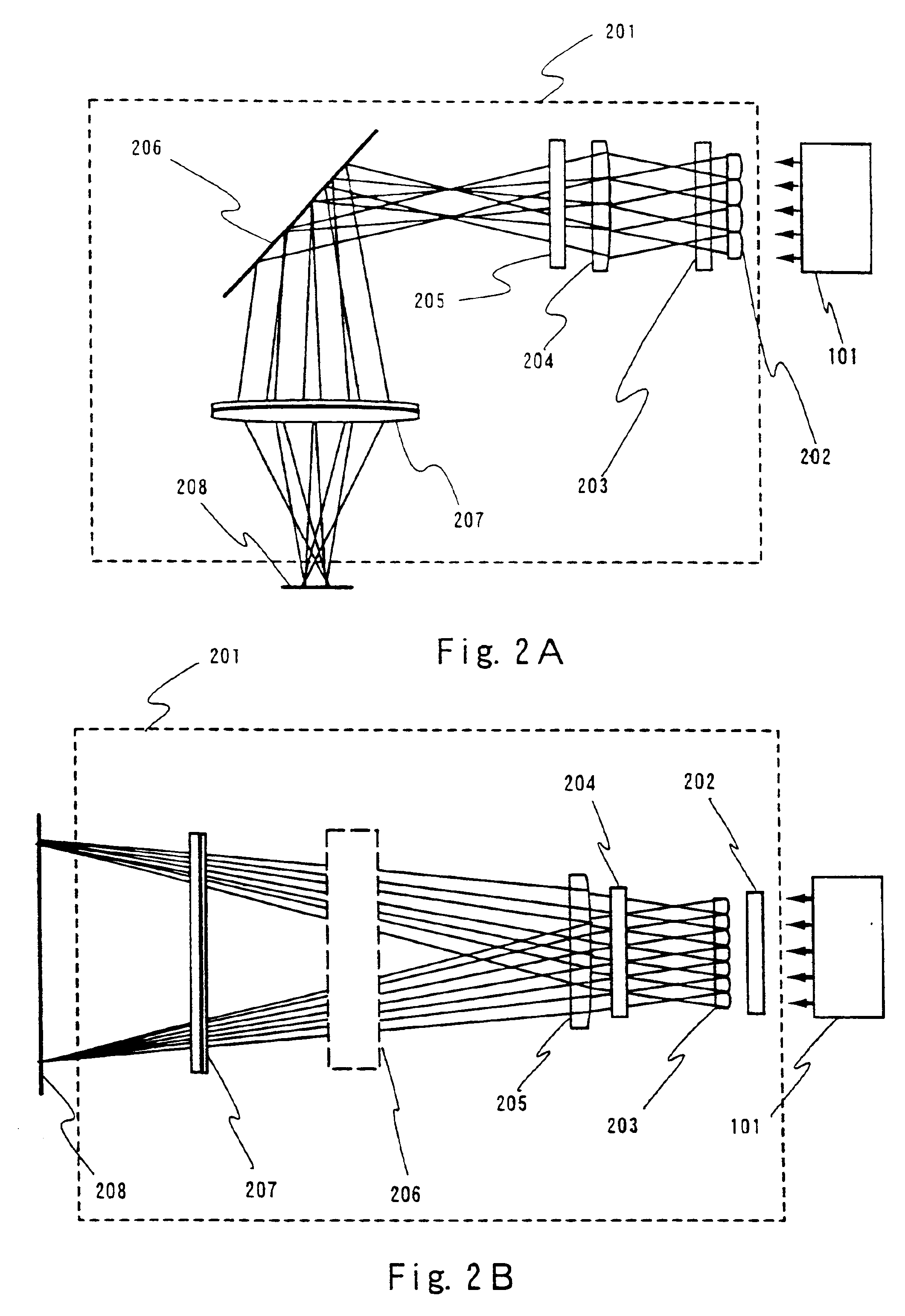

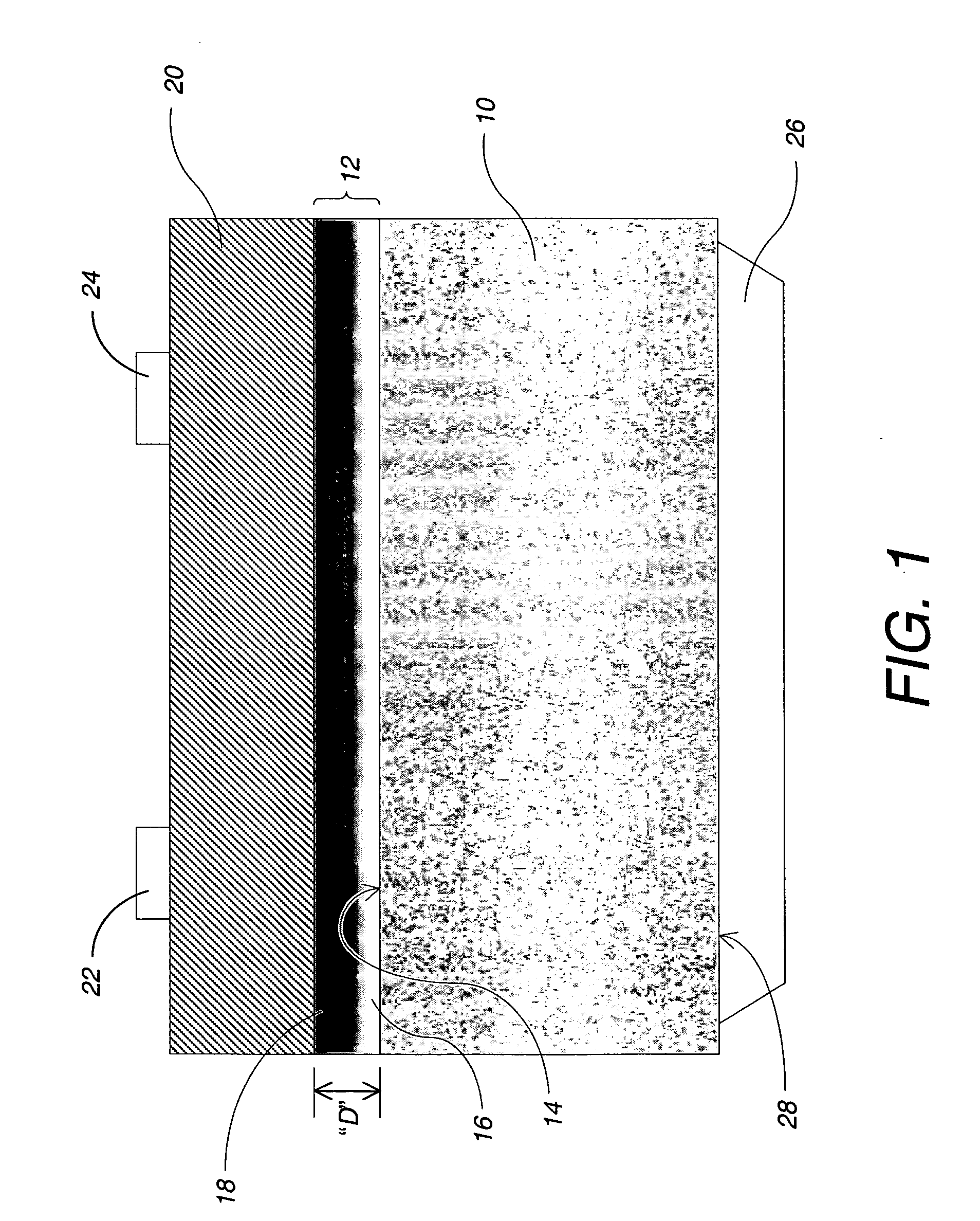

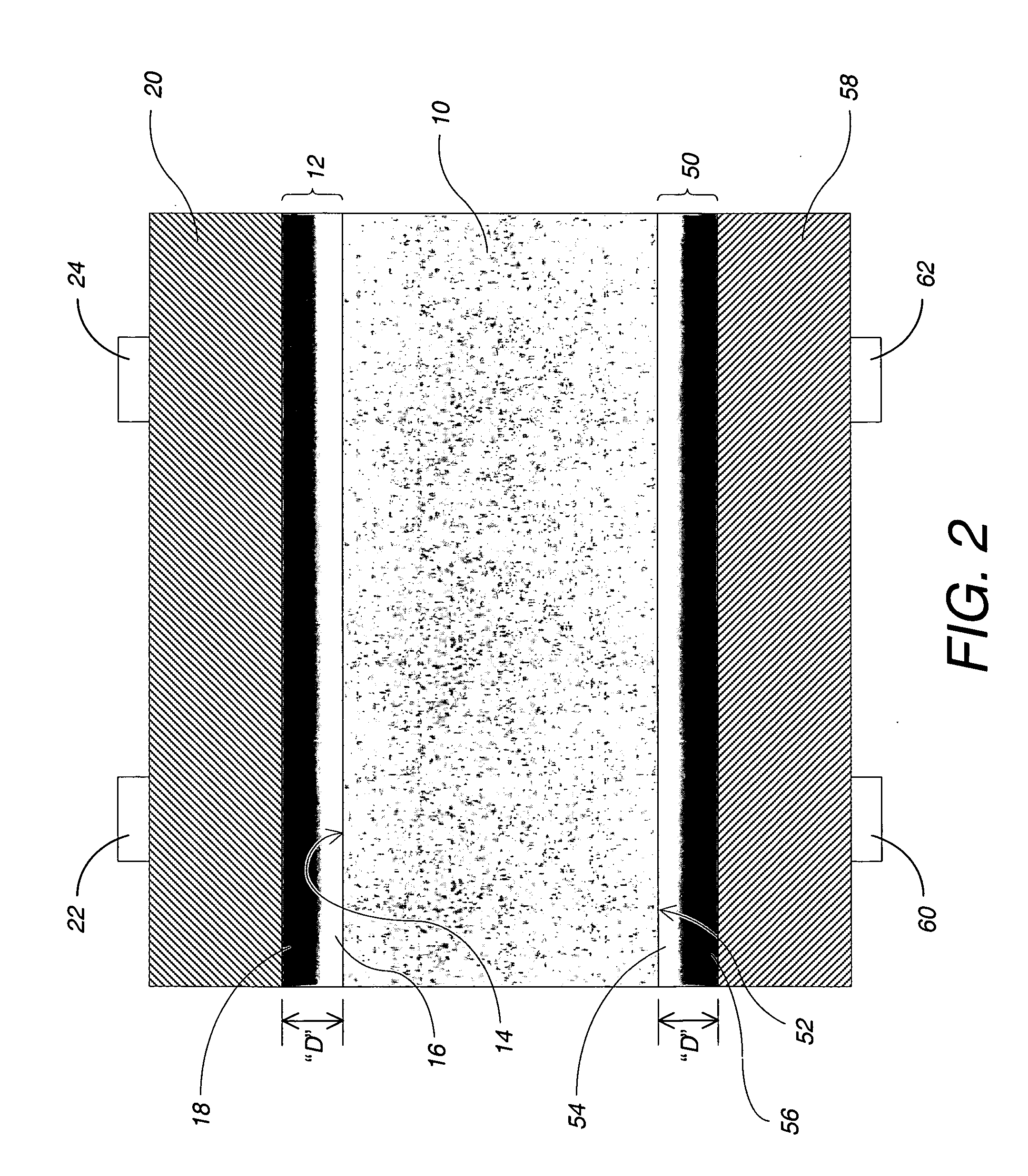

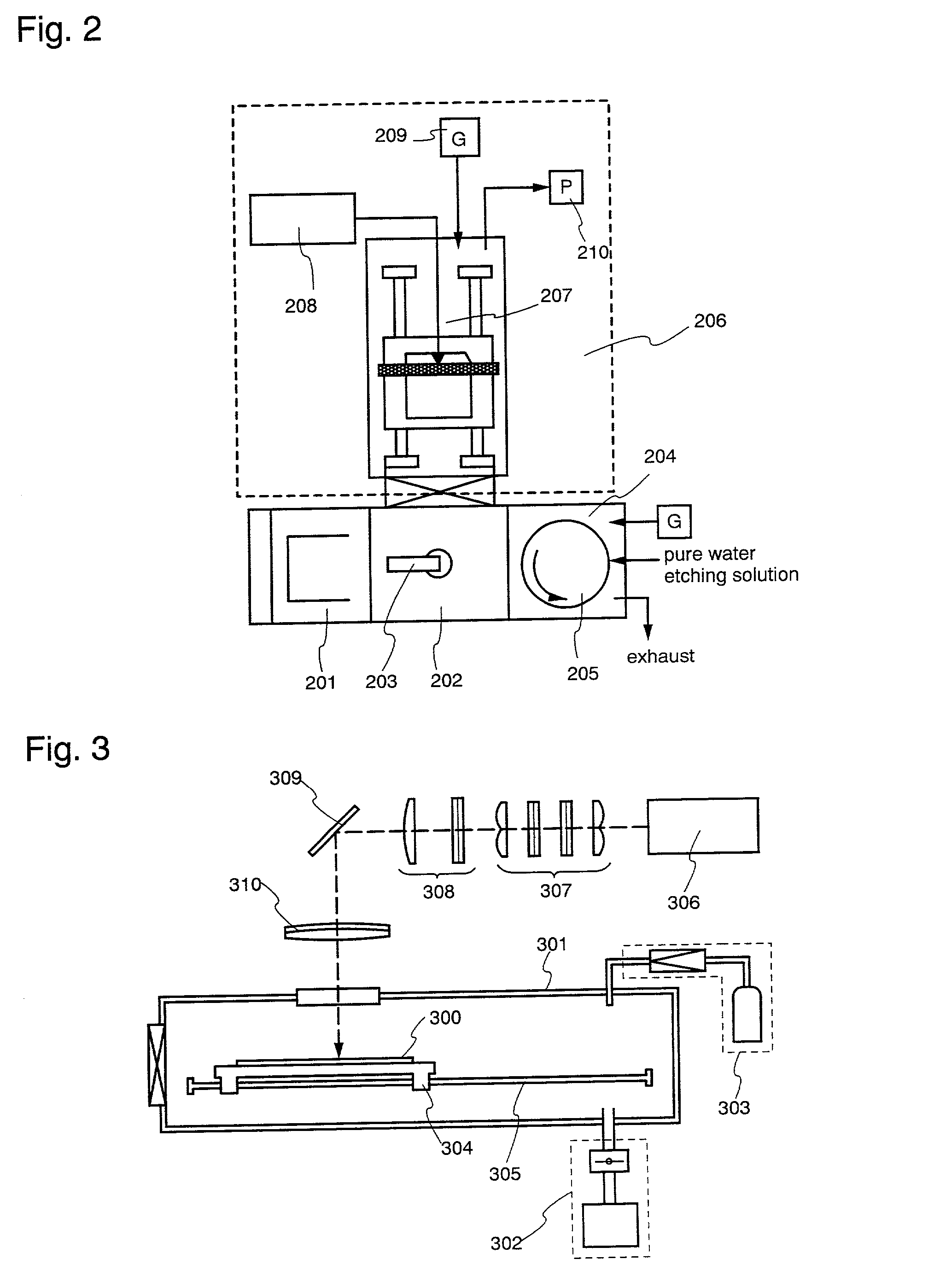

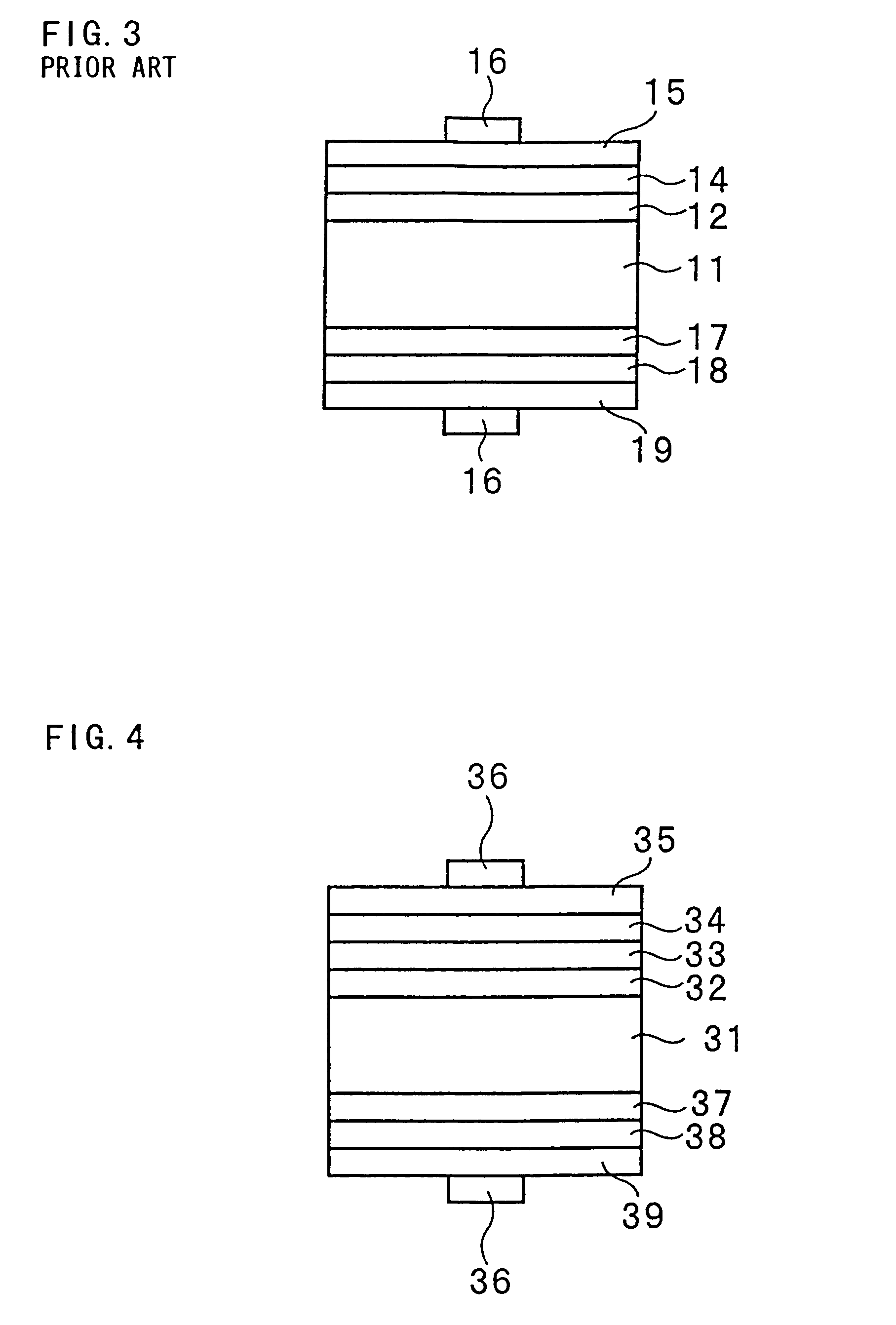

Laser apparatus, laser annealing method, and manufacturing method of a semiconductor device

InactiveUS20020048864A1Solution value is not highIncrease valueSemiconductor/solid-state device testing/measurementSolid-state devicesLaser lightSolid-state laser

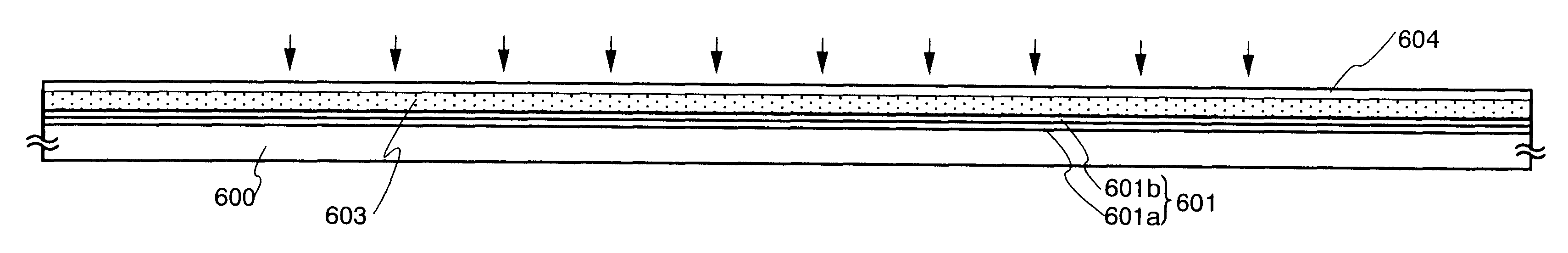

To provide a laser apparatus and a laser annealing method with which a crystalline semiconductor film with a larger crystal grain size is obtained and which are low in their running cost. A solid state laser easy to maintenance and high in durability is used as a laser, and laser light emitted therefrom is linearized to increase the throughput and to reduce the production cost as a whole. Further, both the front side and the back side of an amorphous semiconductor film is irradiated with such laser light to obtain the crystalline semiconductor film with a larger crystal grain size.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device

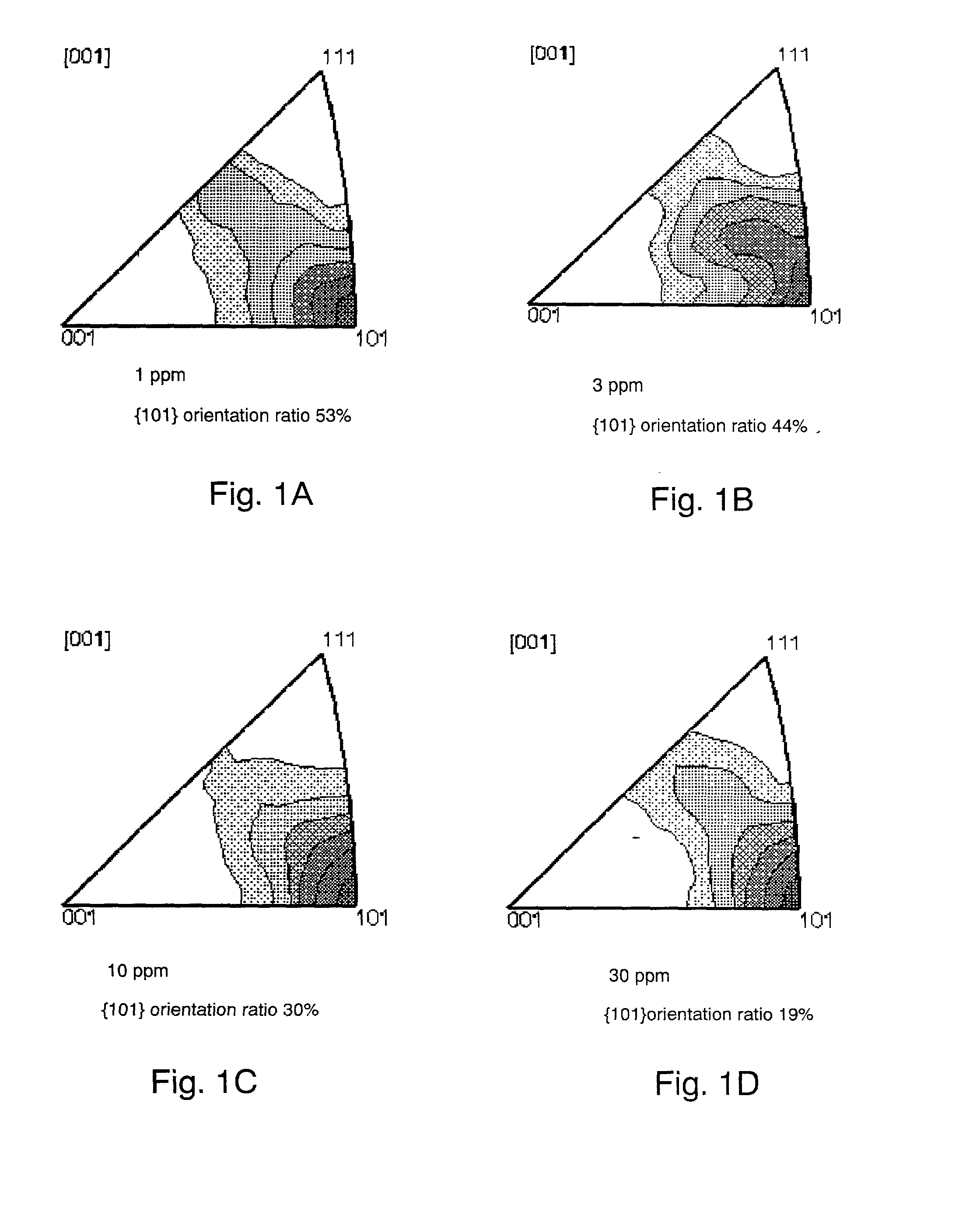

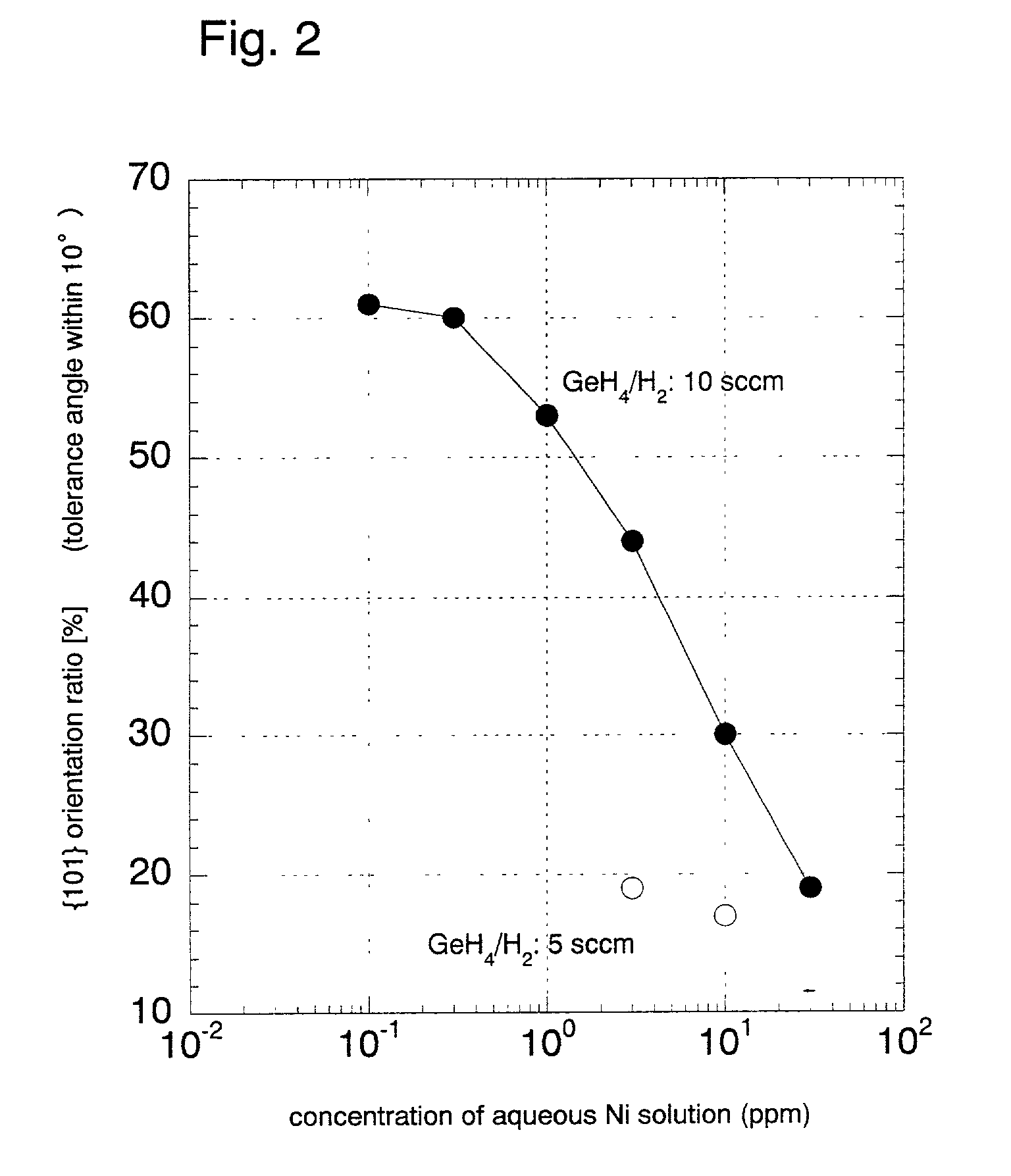

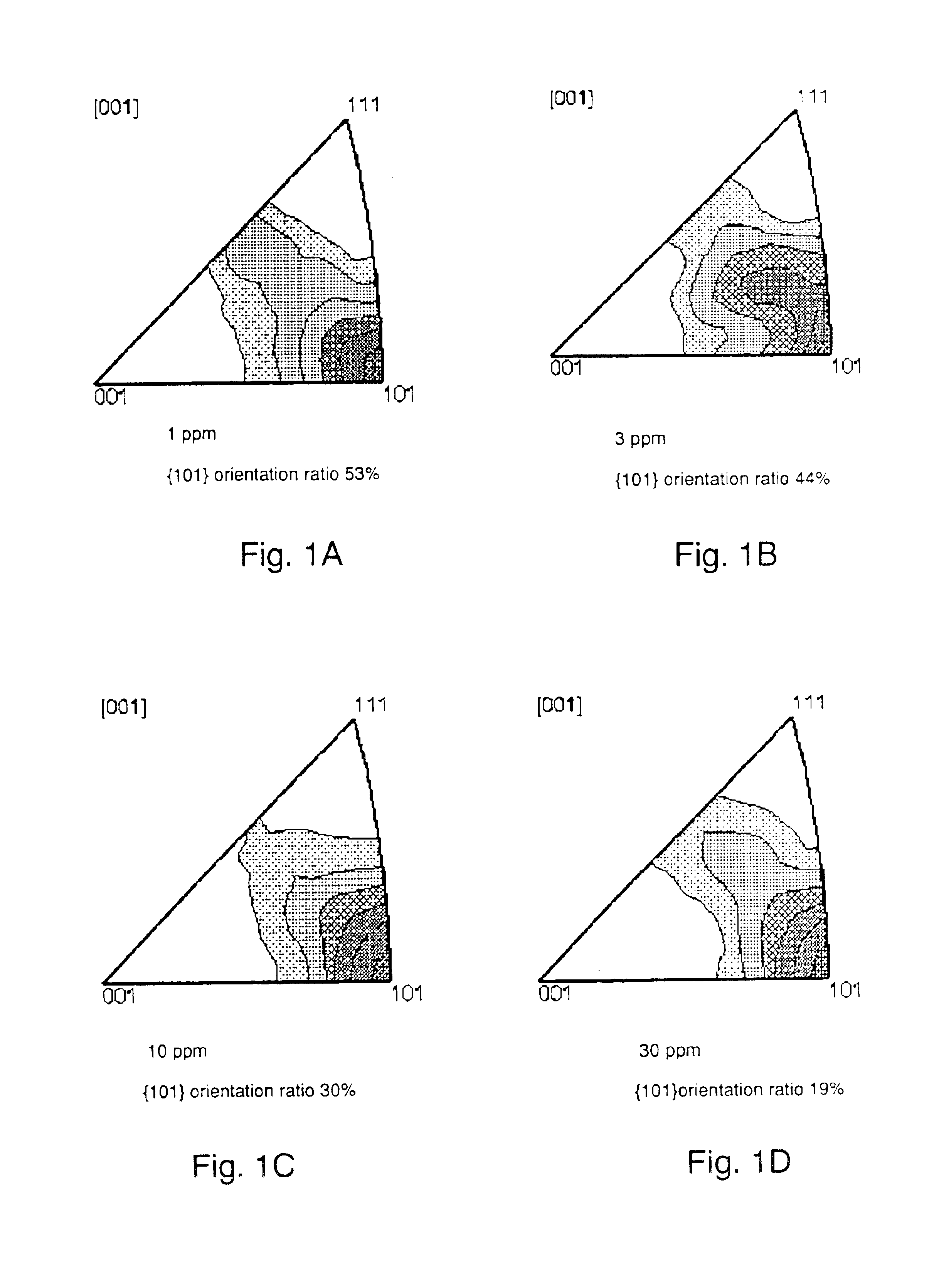

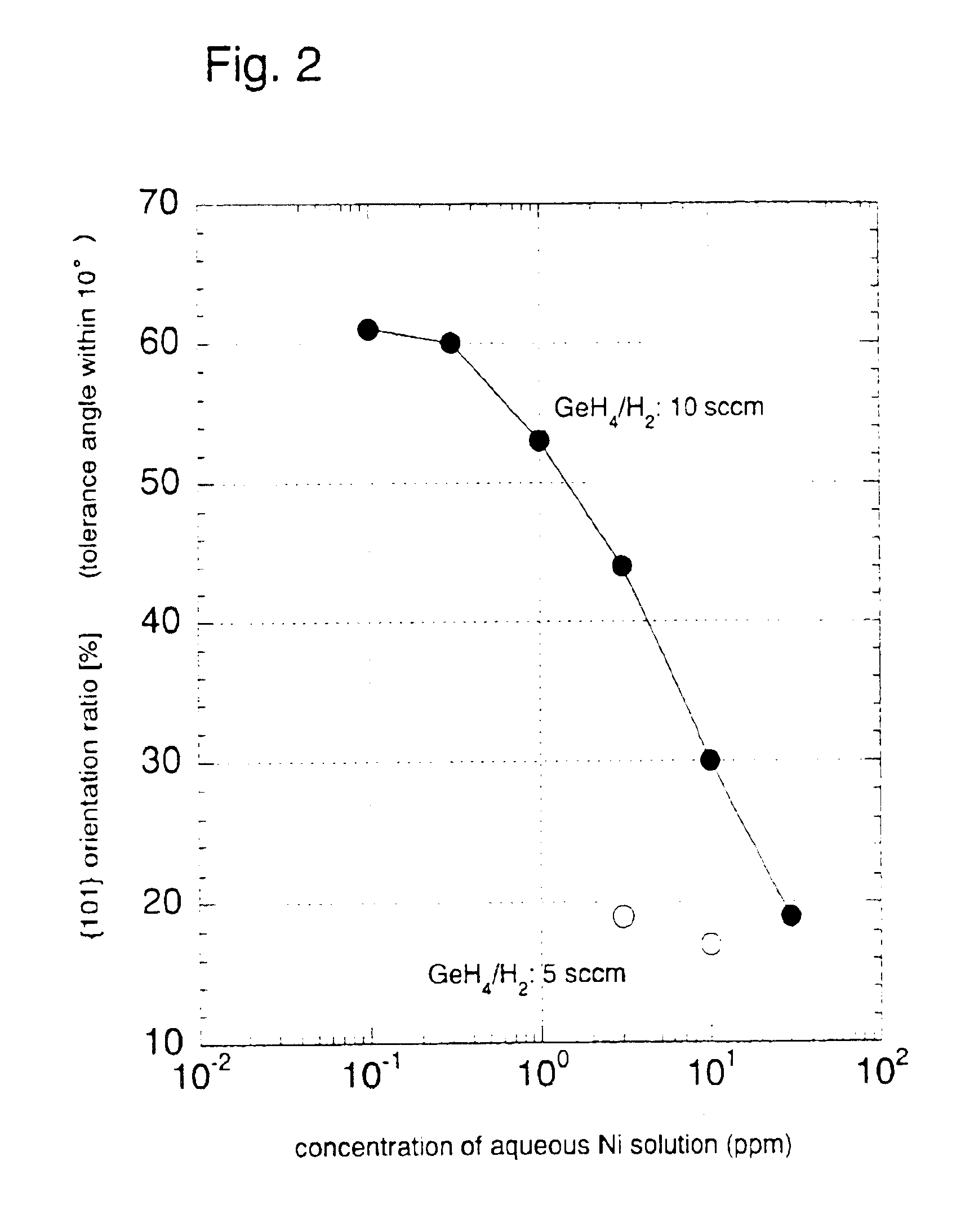

Crystal orientation planes exist randomly in a crystalline silicon film manufactured by a conventional method, and the orientation ratio is low with respect to a specific crystal orientation. A semiconductor film having a high orientation ratio for the {101} lattice plane is obtained if crystallization of an amorphous semiconductor film, which has silicon as its main constituent and contains from 0.1 to 10 atom % germanium, is performed after introduction of a metal element. A TFT is manufactured utilizing the semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

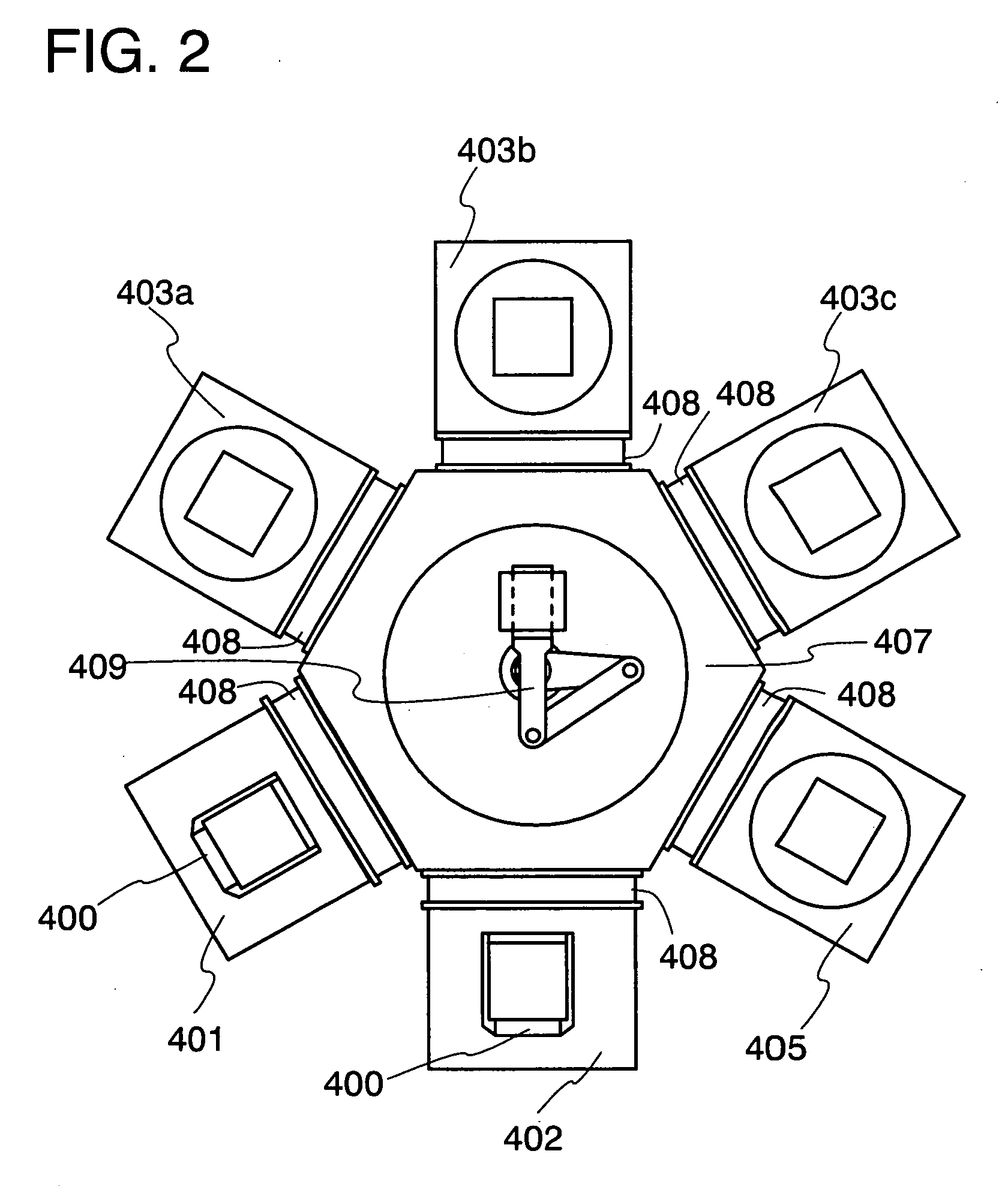

Method of manufacturing a semiconductor device having a crystallized amorphous silicon film

InactiveUS6506636B2Interface is preventedTransistorSolid-state devicesCrystal structureAmorphous silicon

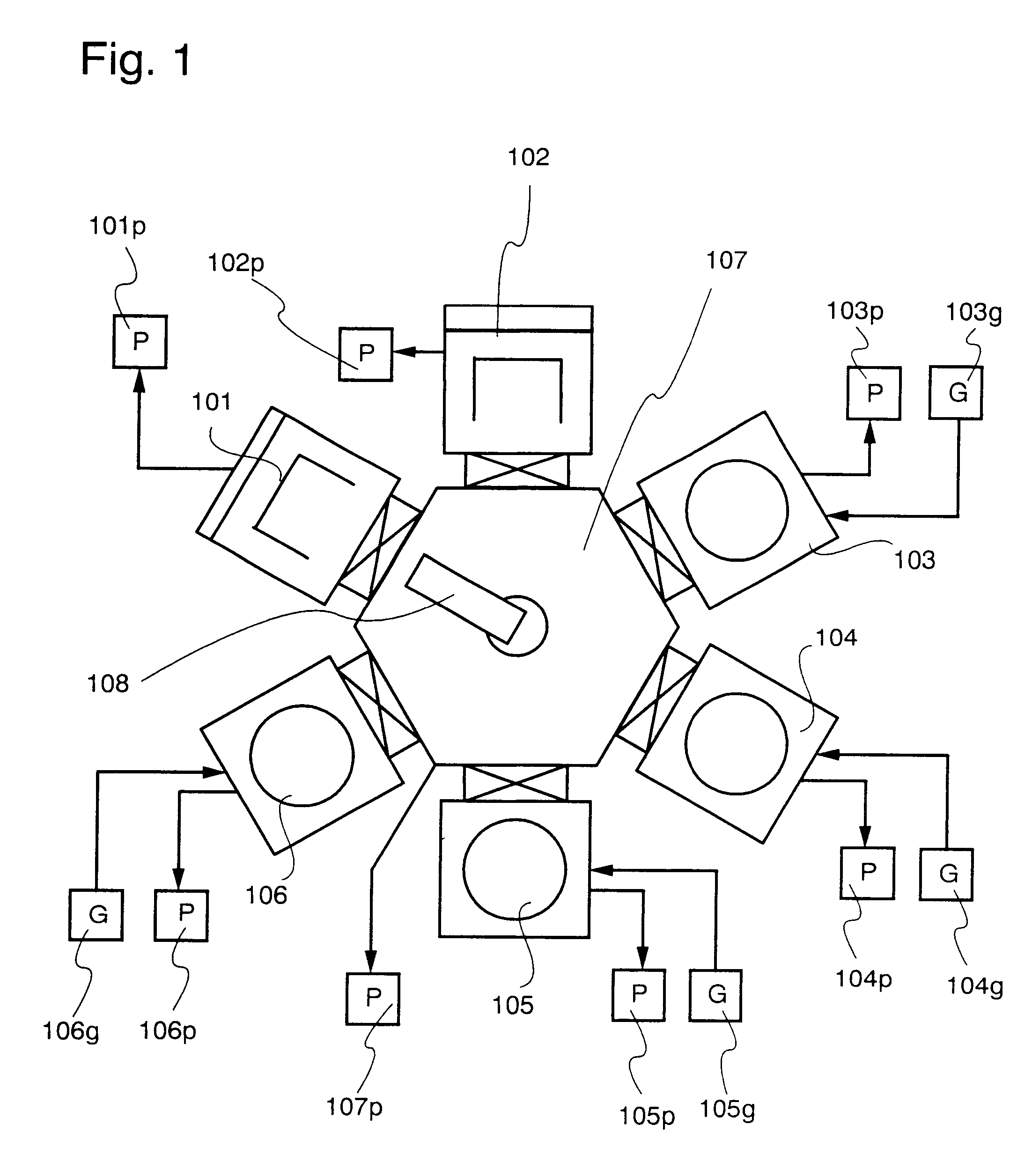

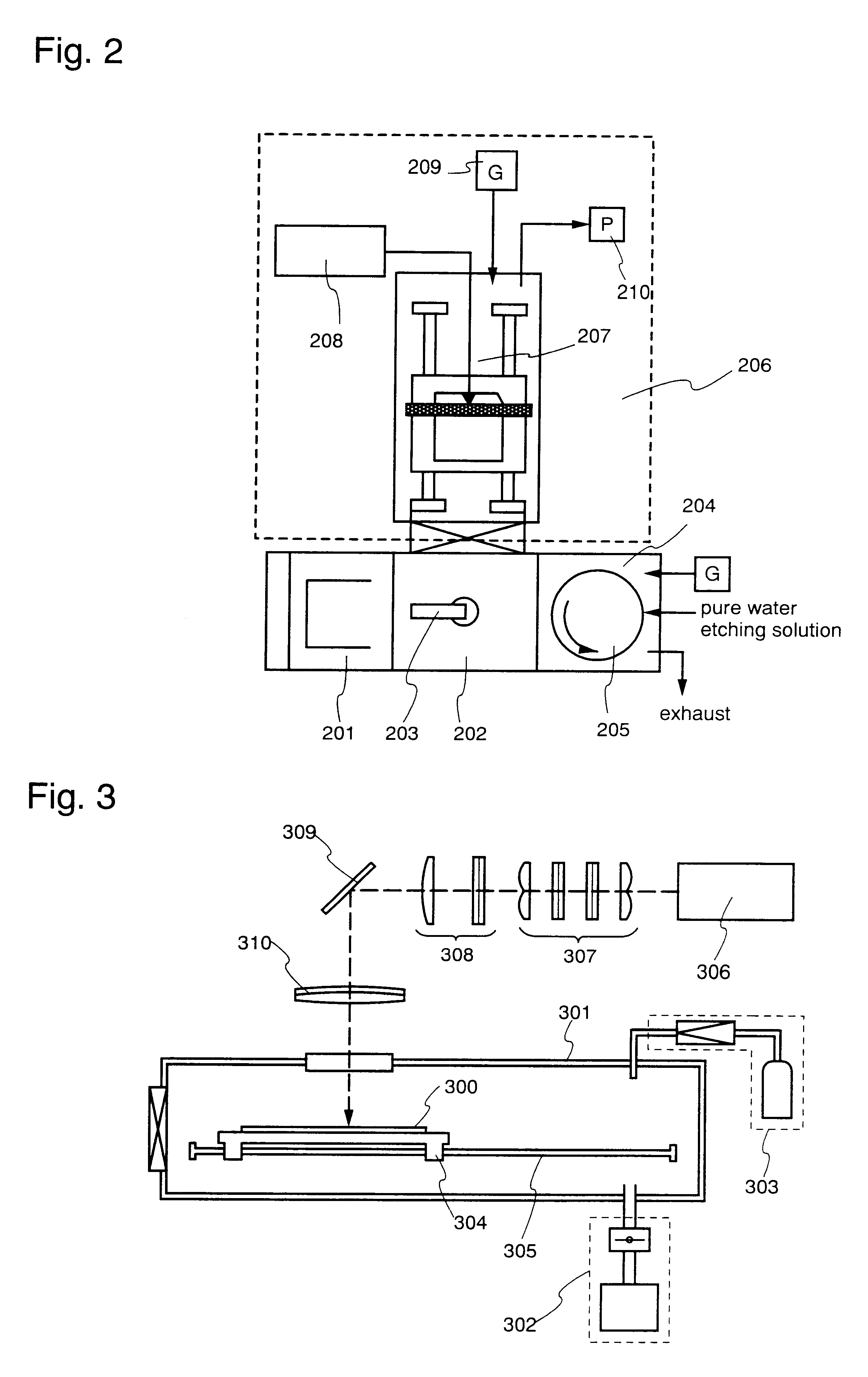

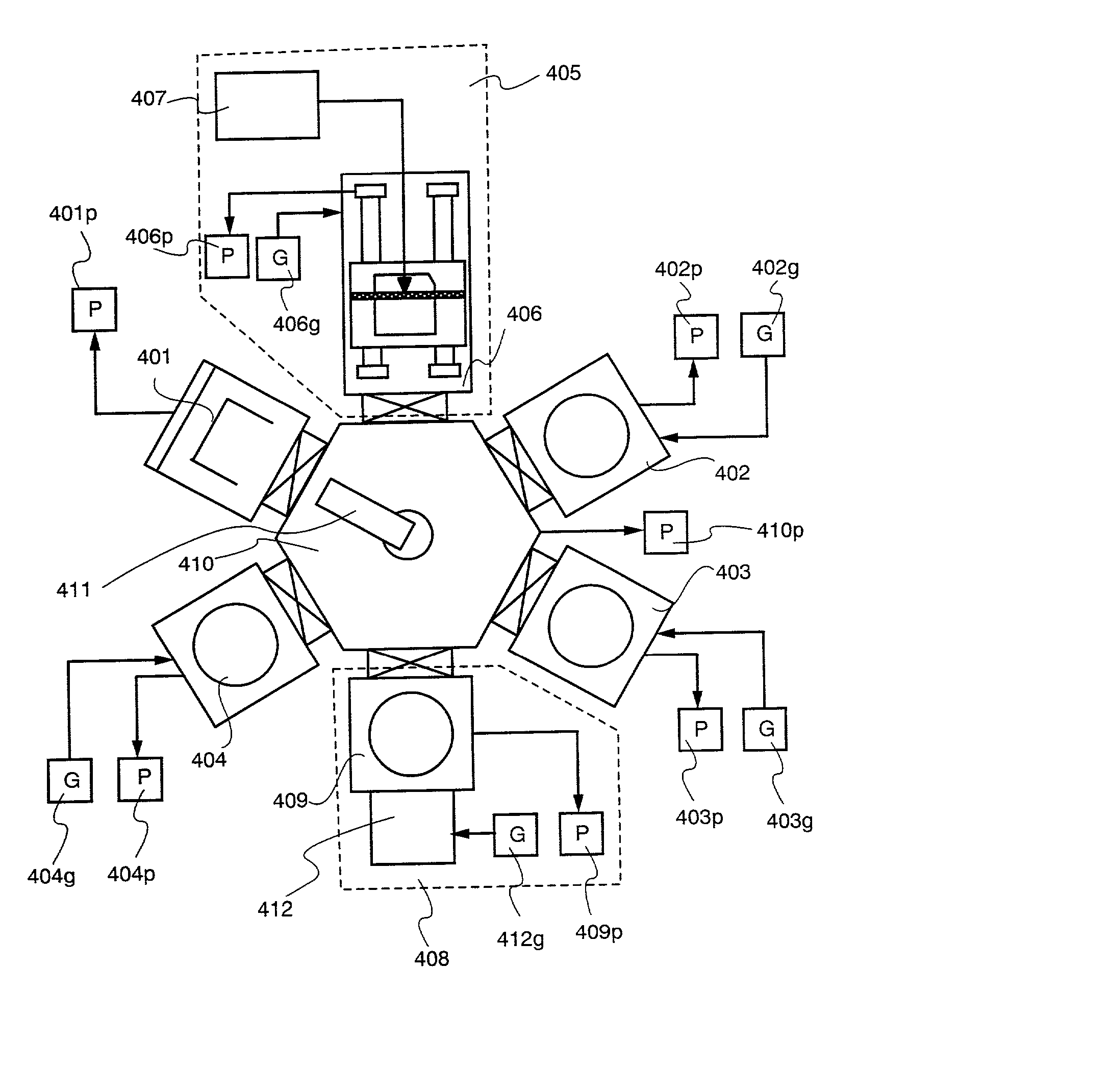

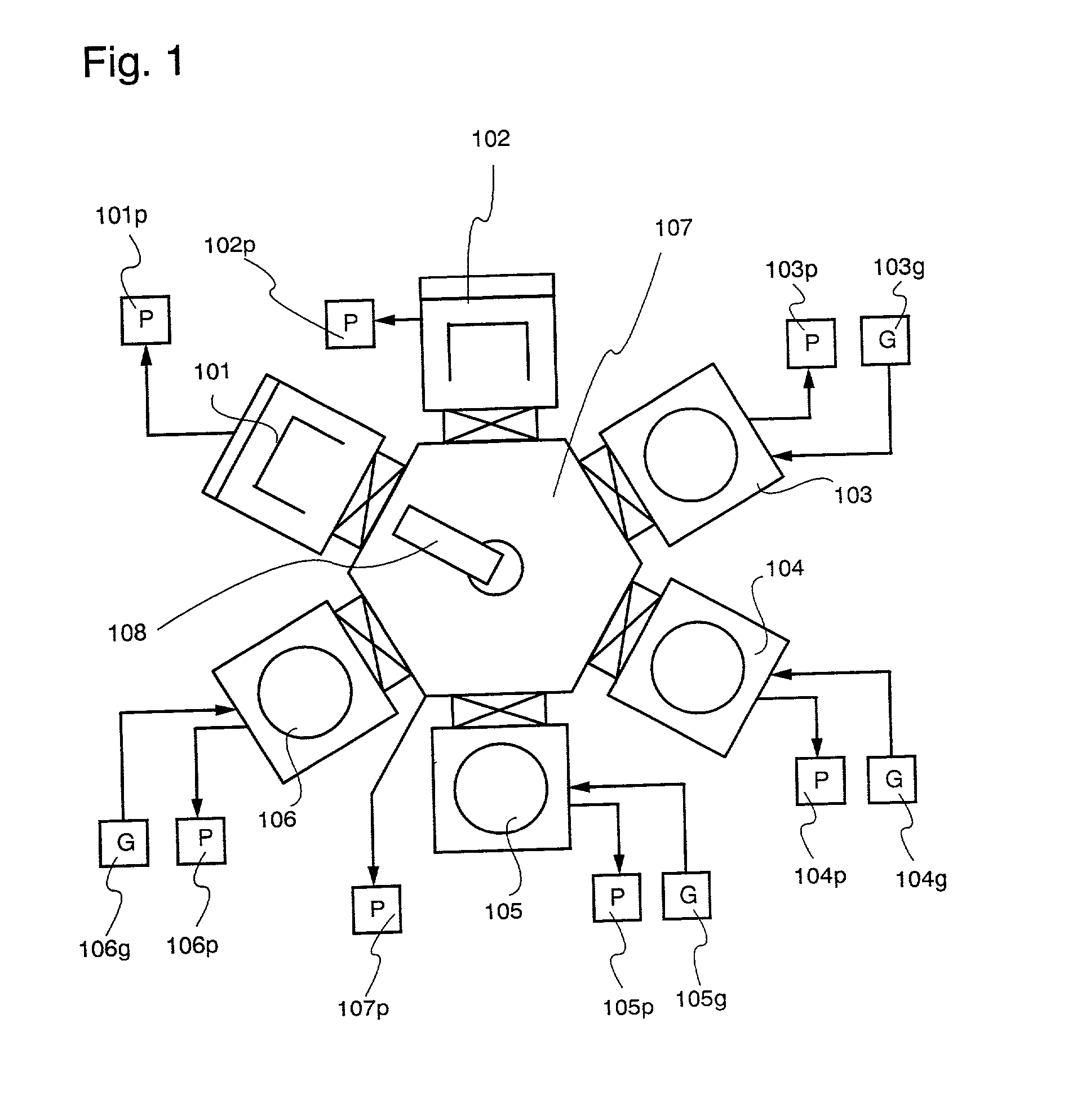

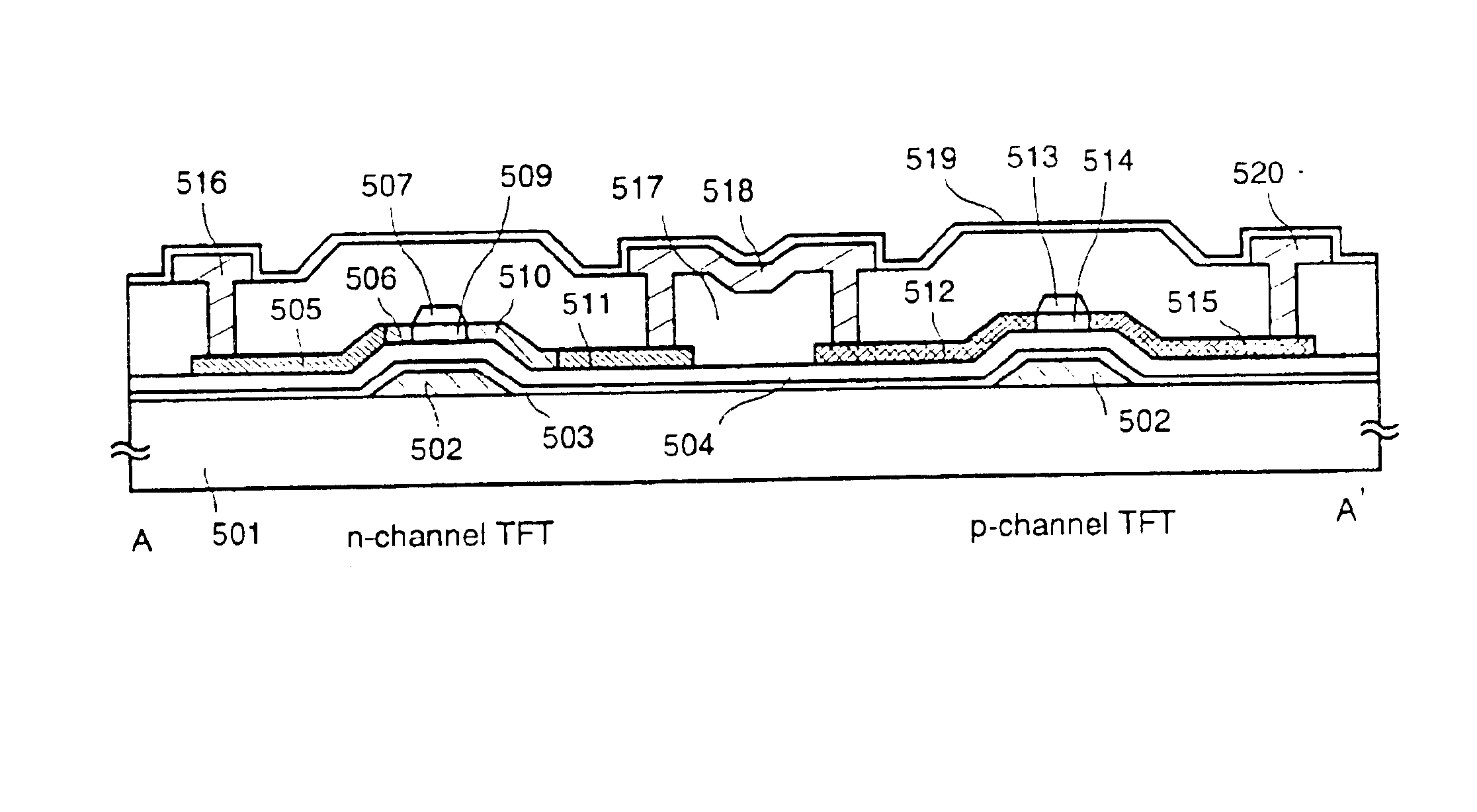

Contamination of an interface of respective films constituting a TFT due to an contaminant impurity in a clean room atmosphere becomes a great factor to lower the reliability of the TFT. Besides, when an impurity is added to a crystalline semiconductor film, its crystal structure is broken. By using an apparatus for manufacturing a semiconductor device including a plurality of treatment chambers, a treatment can be made without being exposed to a clean room atmosphere in an interval between respective treatment steps, and it becomes possible to keep the interface of the respective films constituting the TFT clean. Besides, by carrying out crystallization after an impurity is added to an amorphous semiconductor film, the breakdown of the crystal structure of the crystalline semiconductor film is prevented.

Owner:SEMICON ENERGY LAB CO LTD

Laser apparatus, laser annealing method, and manufacturing method of a semiconductor device

InactiveUS6974731B2Large grainLow running costSolid-state devicesSemiconductor/solid-state device manufacturingLaser lightSolid-state laser

To provide a laser apparatus and a laser annealing method with which a crystalline semiconductor film with a larger crystal grain size is obtained and which are low in their running cost. A solid state laser easy to maintenance and high in durability is used as a laser, and laser light emitted therefrom is linearized to increase the throughput and to reduce the production cost as a whole. Further, both the front side and the back side of an amorphous semiconductor film is irradiated with such laser light to obtain the crystalline semiconductor film with a larger crystal grain size.

Owner:SEMICON ENERGY LAB CO LTD

Method of forming crystalline semiconductor thin film on base substrate, lamination formed with crystalline semiconductor thin film and color filter

A method of forming a crystalline semiconductor thin film on a base material which can be prepared at a low temperature by simple step and device, the method including a processing step of applying UV-rays to an amorphous semiconductor thin film provided on a base material while keeping a temperature at not less than 25° C. and not more than 300° C. in a vacuum or a reducing gas atmosphere, as well as a substrate having the semiconductor thin film provided on the base material, a substrate for forming a color filter and a color filter using the substrate.

Owner:FUJIFILM BUSINESS INNOVATION CORP

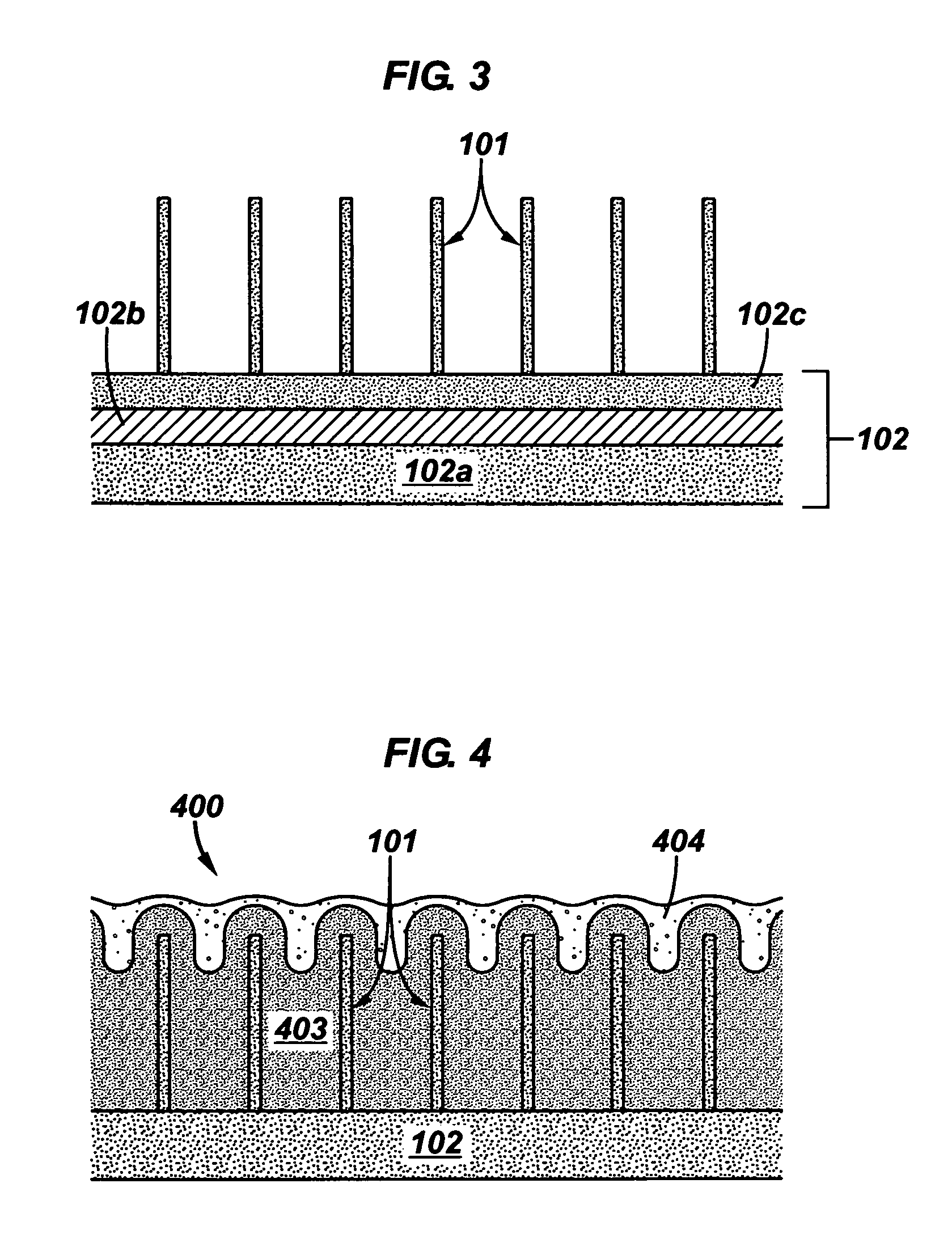

Graded hybrid amorphous silicon nanowire solar cells

InactiveUS20080135089A1Raise VocIncrease IscPV power plantsSemiconductor/solid-state device manufacturingAmorphous siliconSilicon nanowires

In some embodiments, the present invention is directed to compositionally-graded hybrid nanostructure-based photovoltaic devices comprising elongated semiconductor nanostructures and an amorphous semiconductor single layer with continuous gradation of doping concentration across its thickness from substantially intrinsic to substantially conductive. In other embodiments, the present invention is directed to methods of making such photovoltaic devices, as well as to applications which utilize such devices (e.g., solar cell modules).

Owner:GENERAL ELECTRIC CO

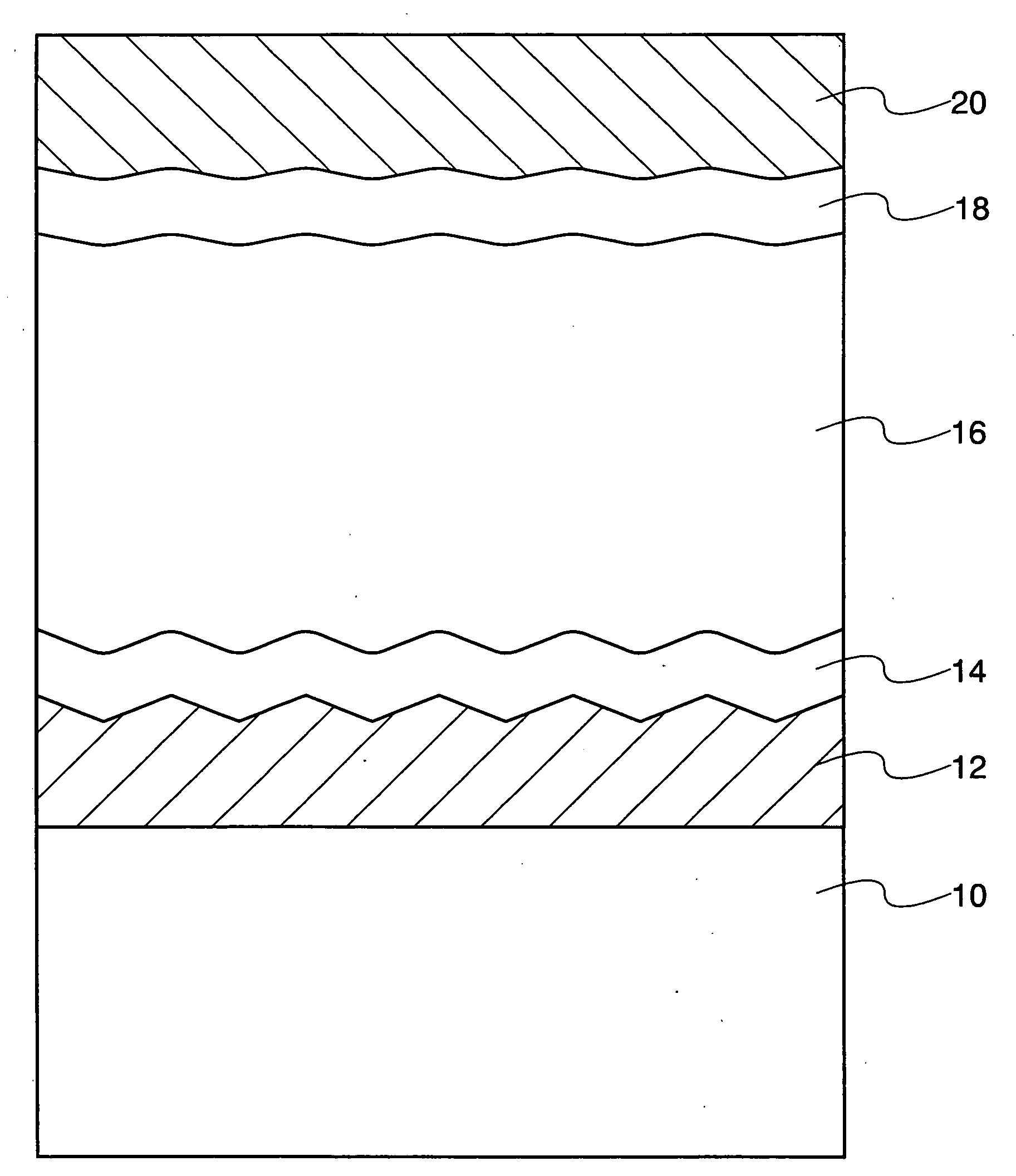

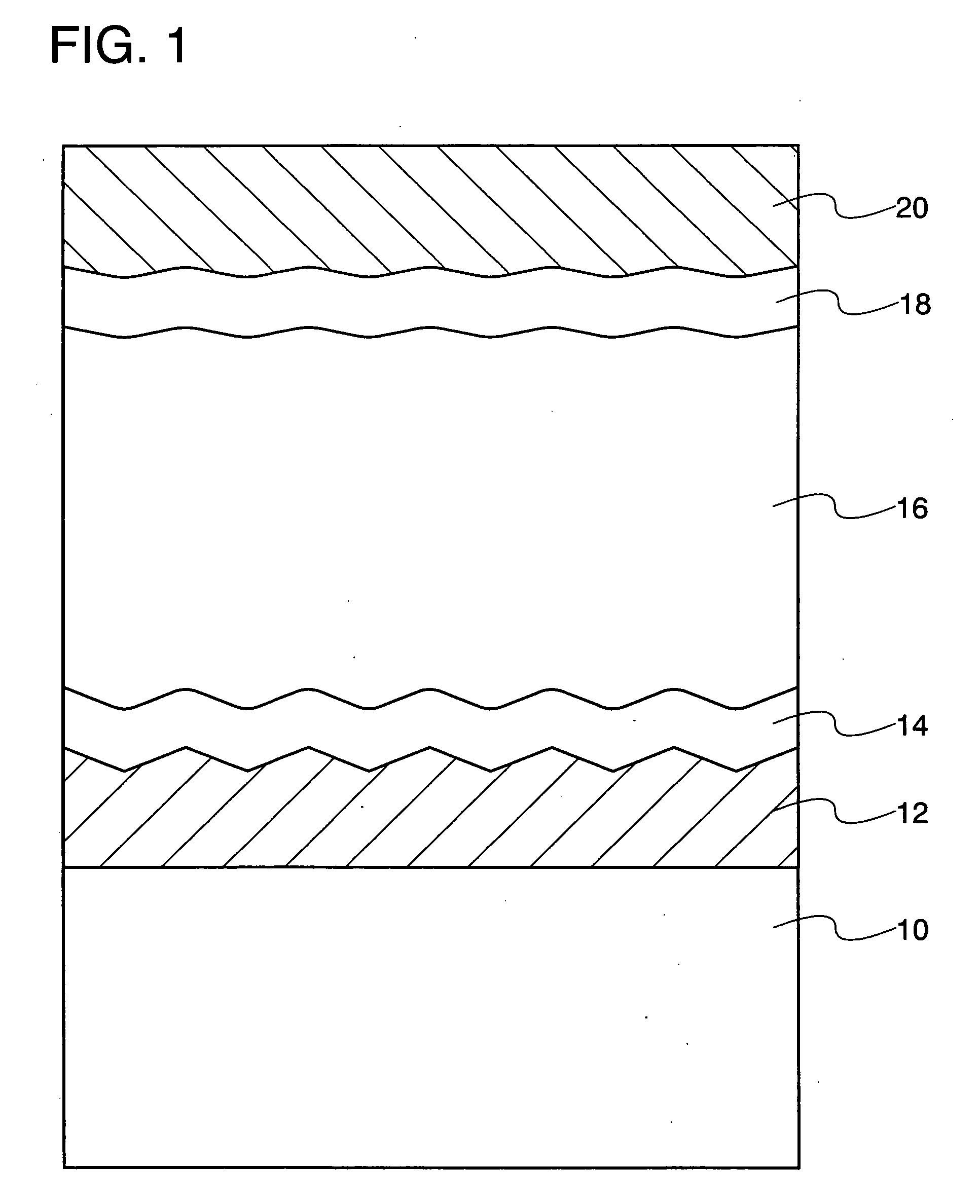

Compositionally-graded photovoltaic device and fabrication method, and related articles

InactiveUS20070023081A1Final product manufacturePV power plantsSemiconductor structureOptoelectronics

A semiconductor structure is described, including a semiconductor substrate of one conductivity type; and an amorphous semiconductor layer disposed on at least one of its surfaces. The amorphous semiconductor layer is compositionally graded through its depth, from substantially intrinsic at the interface with the substrate, to substantially conductive at the opposite side. Photovoltaic devices which include such a structure are also disclosed, as are solar modules made from one or more of the devices. Related methods are also described.

Owner:GENERAL ELECTRIC CO

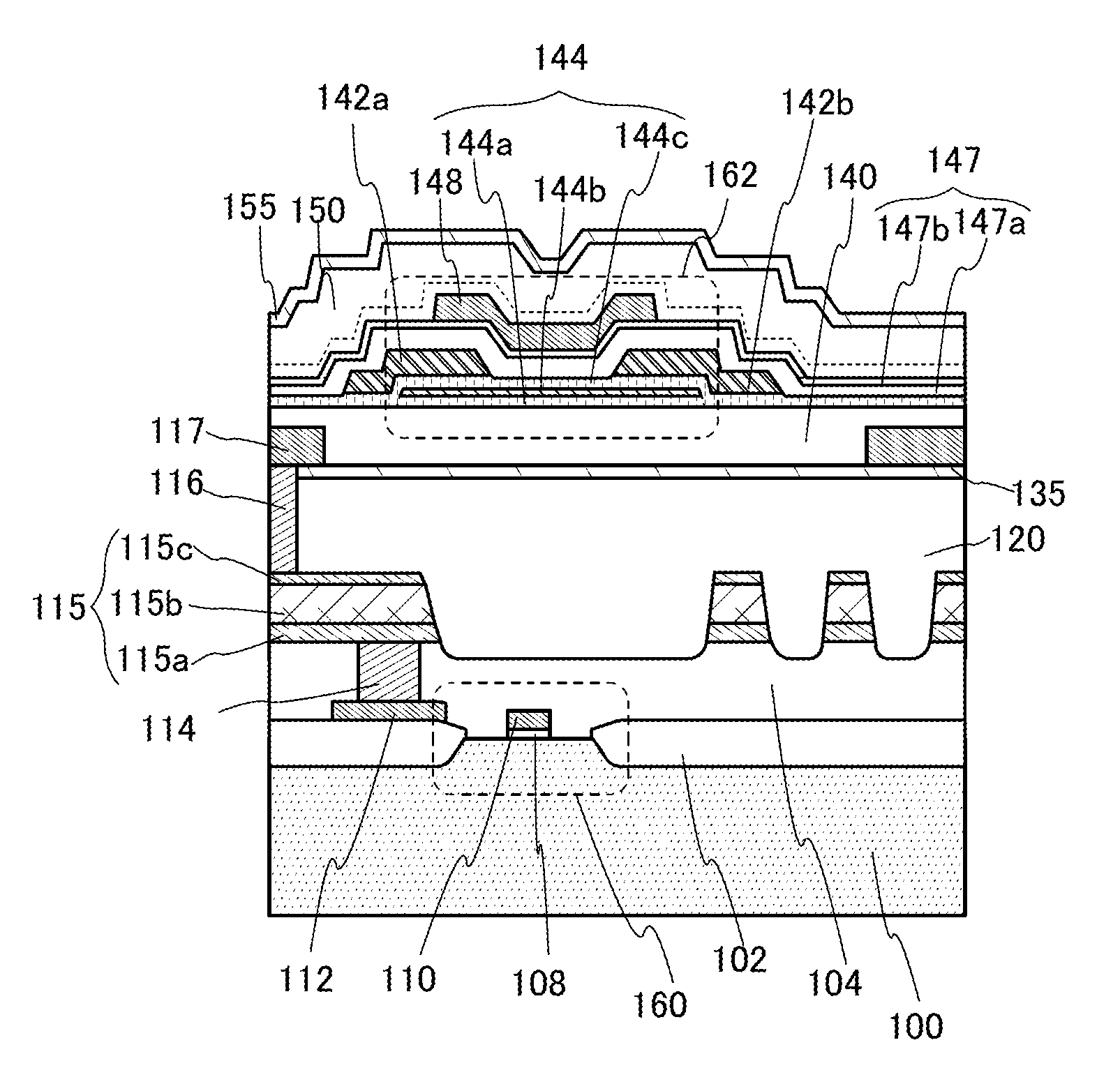

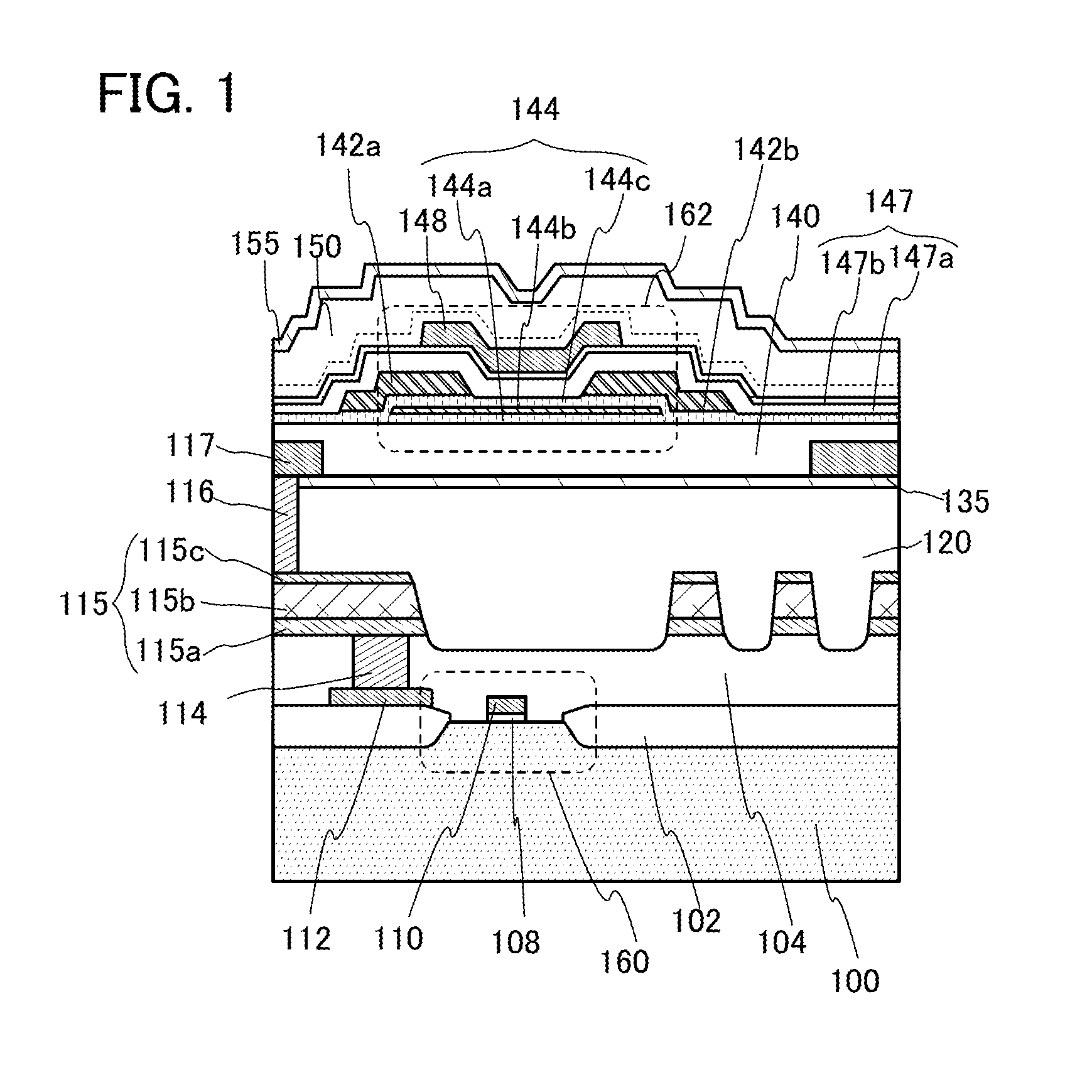

Semiconductor device and manufacturing method thereof

InactiveUS20050167573A1Low costLower the volumeSolid-state devicesSemiconductor/solid-state device manufacturingAudio power amplifierCrystal structure

The object of the present invention is to miniaturize the area occupied by the element and to integrate a plenty of elements in a limited area so that the sensor element can have higher output and smaller size. In the present invention, higher output and miniaturization are achieved by uniting a sensor element using an amorphous semiconductor film (typically an amorphous silicon film) and an output amplifier circuit including a TFT with a semiconductor film having a crystal structure (typically a poly-crystalline silicon film) used as an active layer over a plastic film substrate that can resist the temperature in the process for mounting such as a solder reflow process. According to the present invention, the sensor element that can resist the bending stress can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

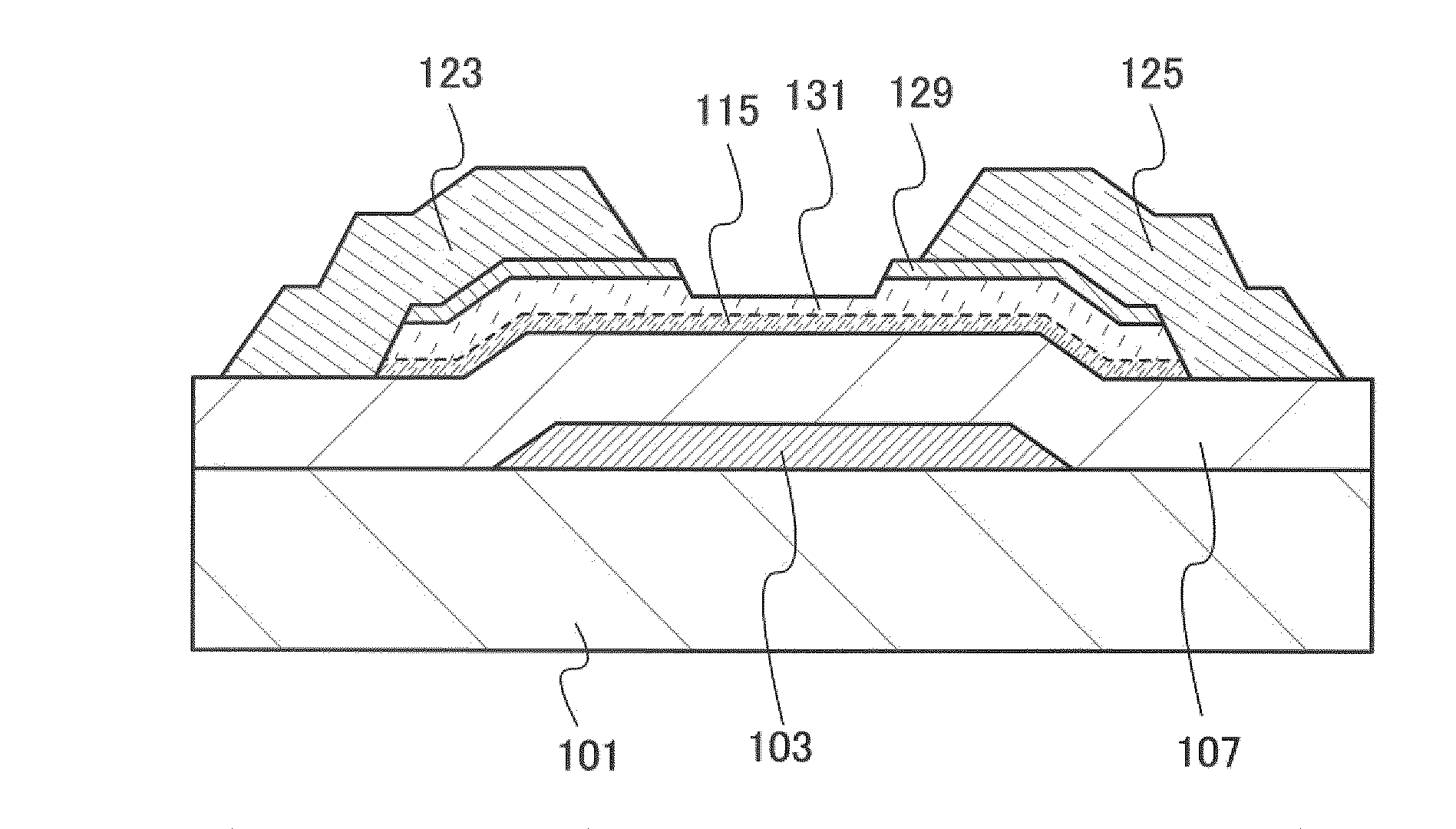

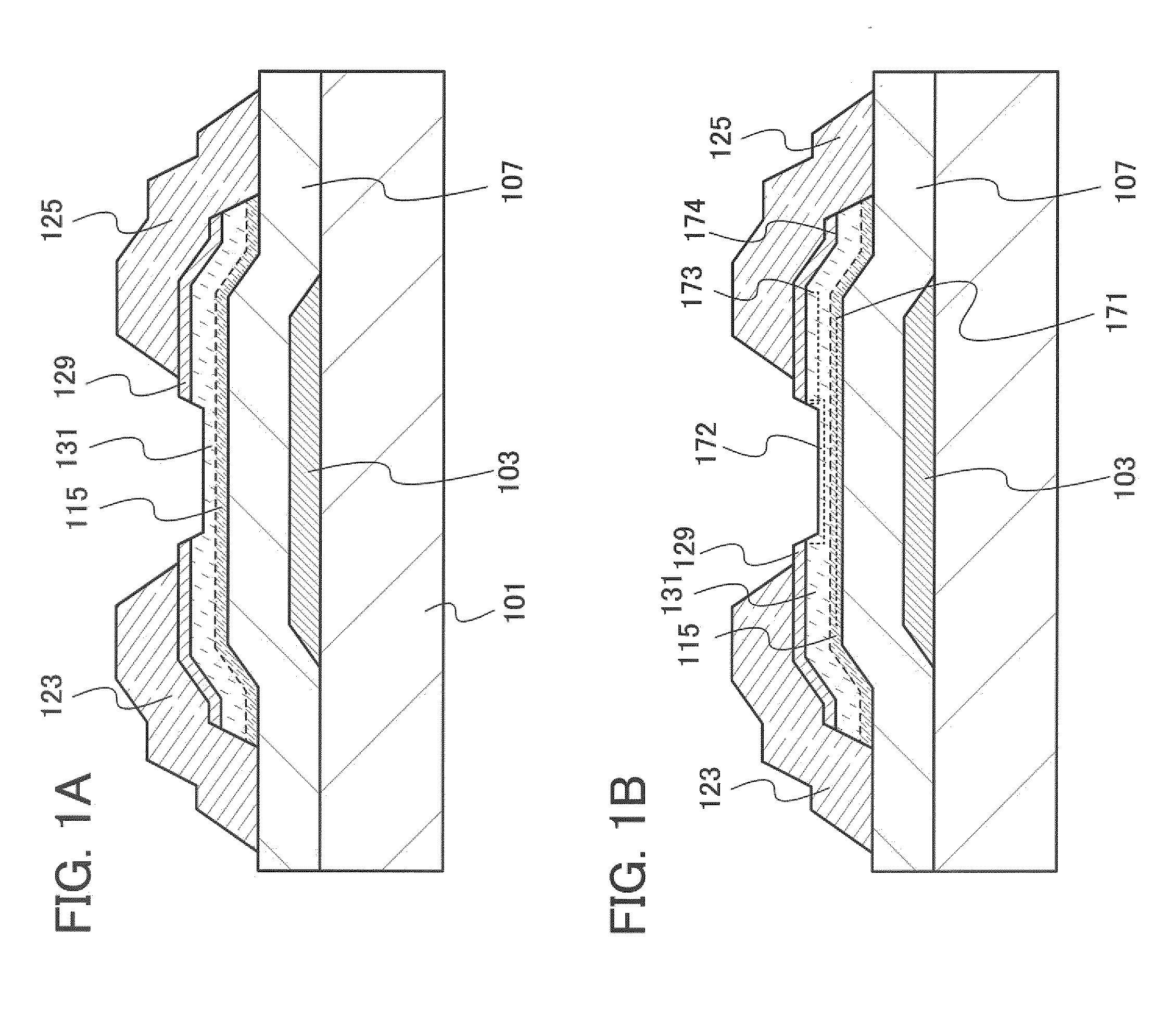

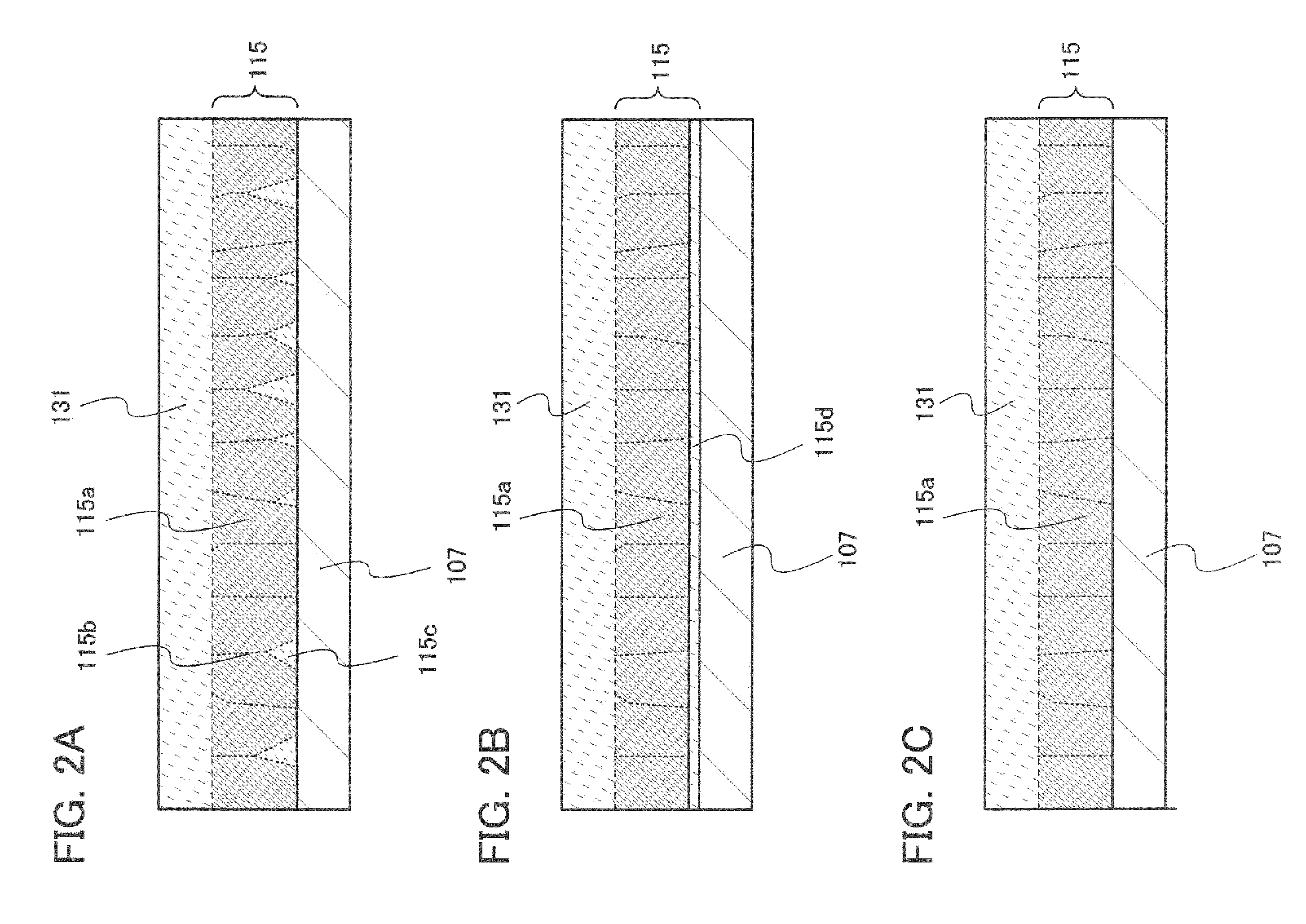

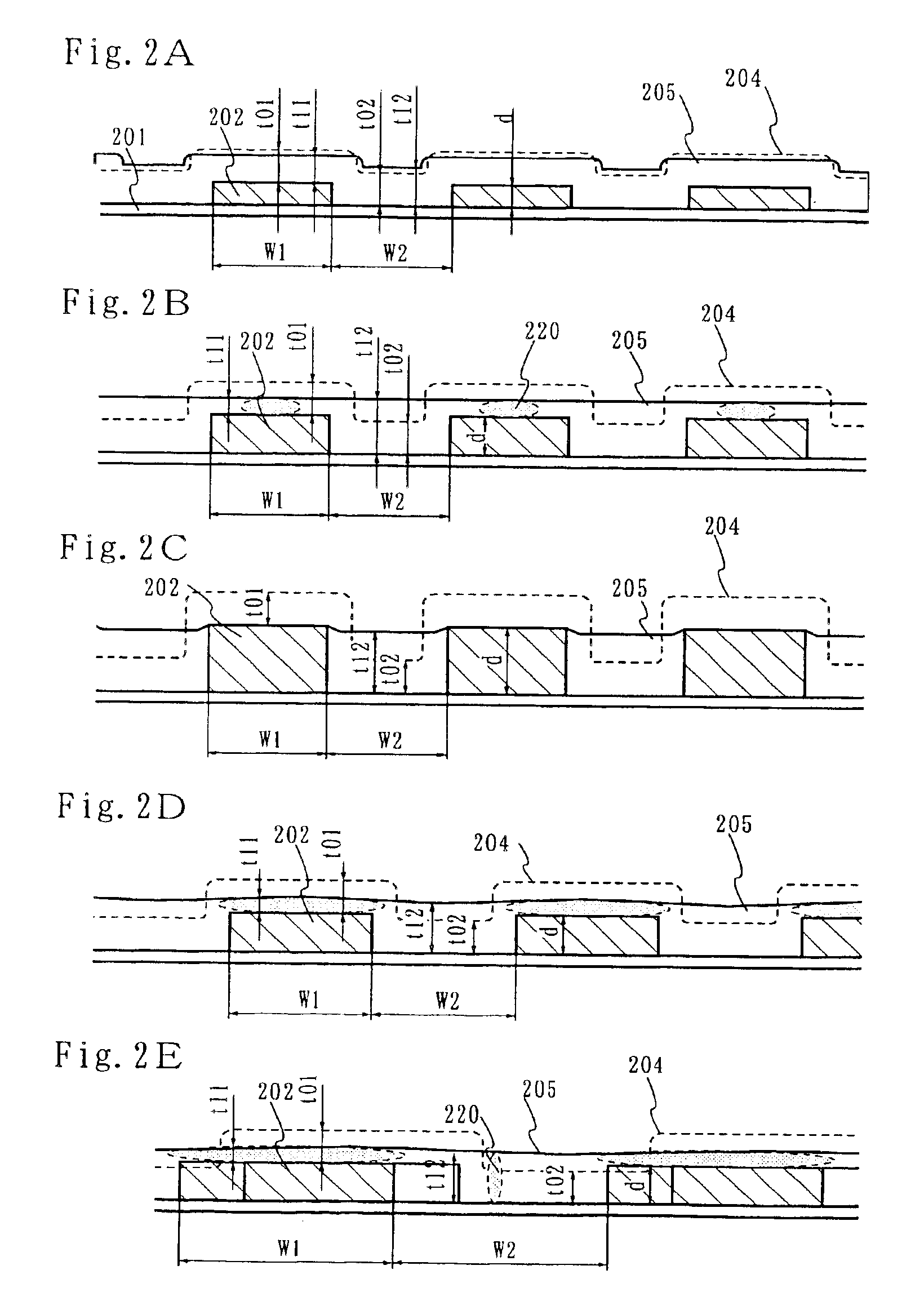

Thin film transistor

InactiveUS20090321737A1Increase the on-currentOff-current can be reducedSolid-state devicesSemiconductor devicesNitrogenSemiconductor

A thin film transistor includes, as a buffer layer, a semiconductor layer which contains nitrogen and includes crystal regions in an amorphous structure between a gate insulating layer and source and drain regions, at least on the source and drain regions side. As compared to a thin film transistor in which an amorphous semiconductor is included in a channel formation region, on-current of a thin film transistor can be increased. In addition, as compared to a thin film transistor in which a microcrystalline semiconductor is included in a channel formation region, off-current of a thin film transistor can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

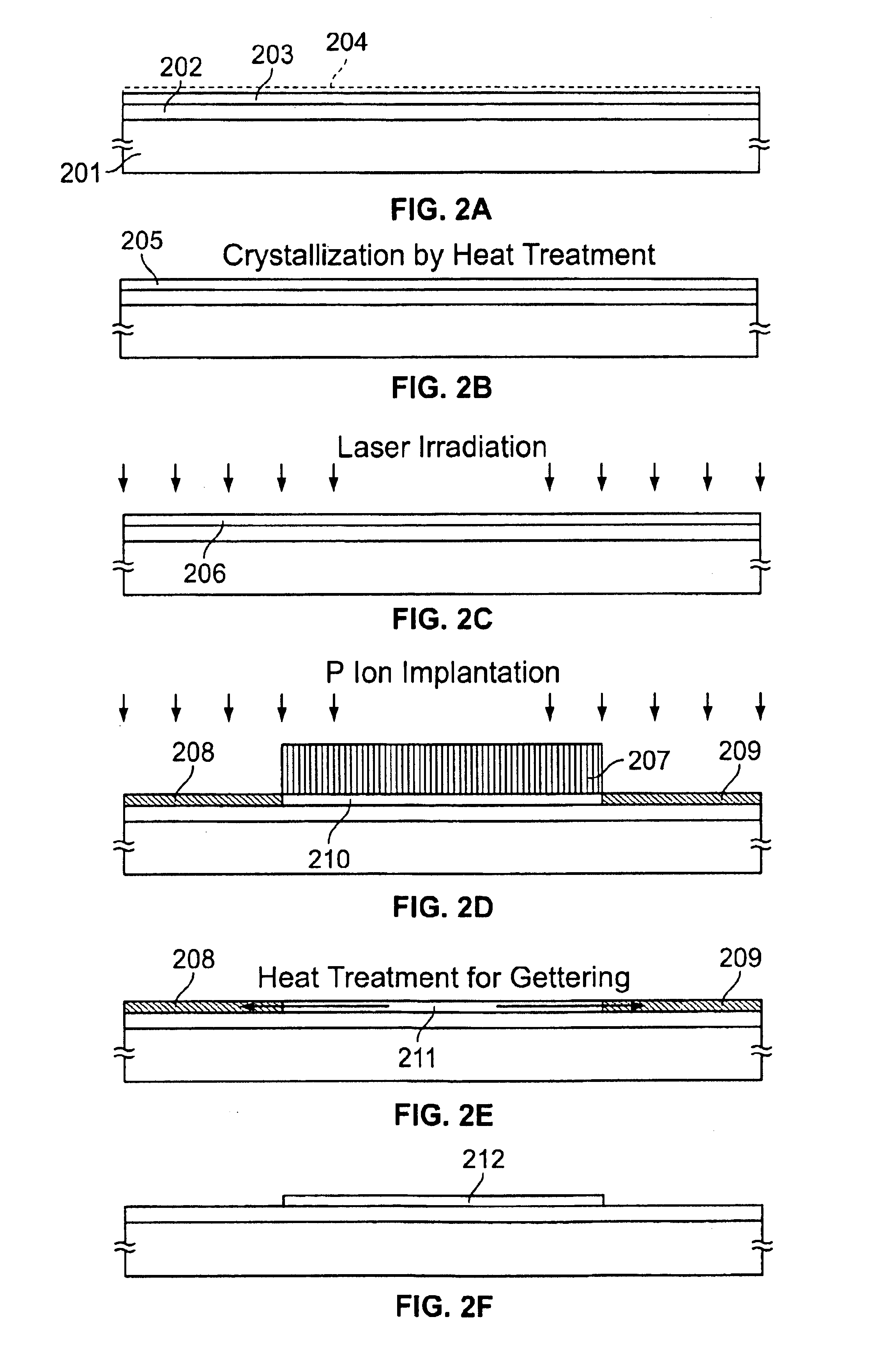

Method of manufacturing a semiconductor device

InactiveUS20020013022A1Interface is preventedTransistorSolid-state devicesCrystal structureEngineering

Contamination of an interface of respective films constituting a TFT due to an contaminant impurity in a clean room atmosphere becomes a great factor to lower the reliability of the TFT. Besides, when an impurity is added to a crystalline semiconductor film, its crystal structure is broken. By using an apparatus for manufacturing a semiconductor device including a plurality of treatment chambers, a treatment can be made without being exposed to a clean room atmosphere in an interval between respective treatment steps, and it becomes possible to keep the interface of the respective films constituting the TFT clean. Besides, by carrying out crystallization after an impurity is added to an amorphous semiconductor film, the breakdown of the crystal structure of the crystalline semiconductor film is prevented.

Owner:SEMICON ENERGY LAB CO LTD

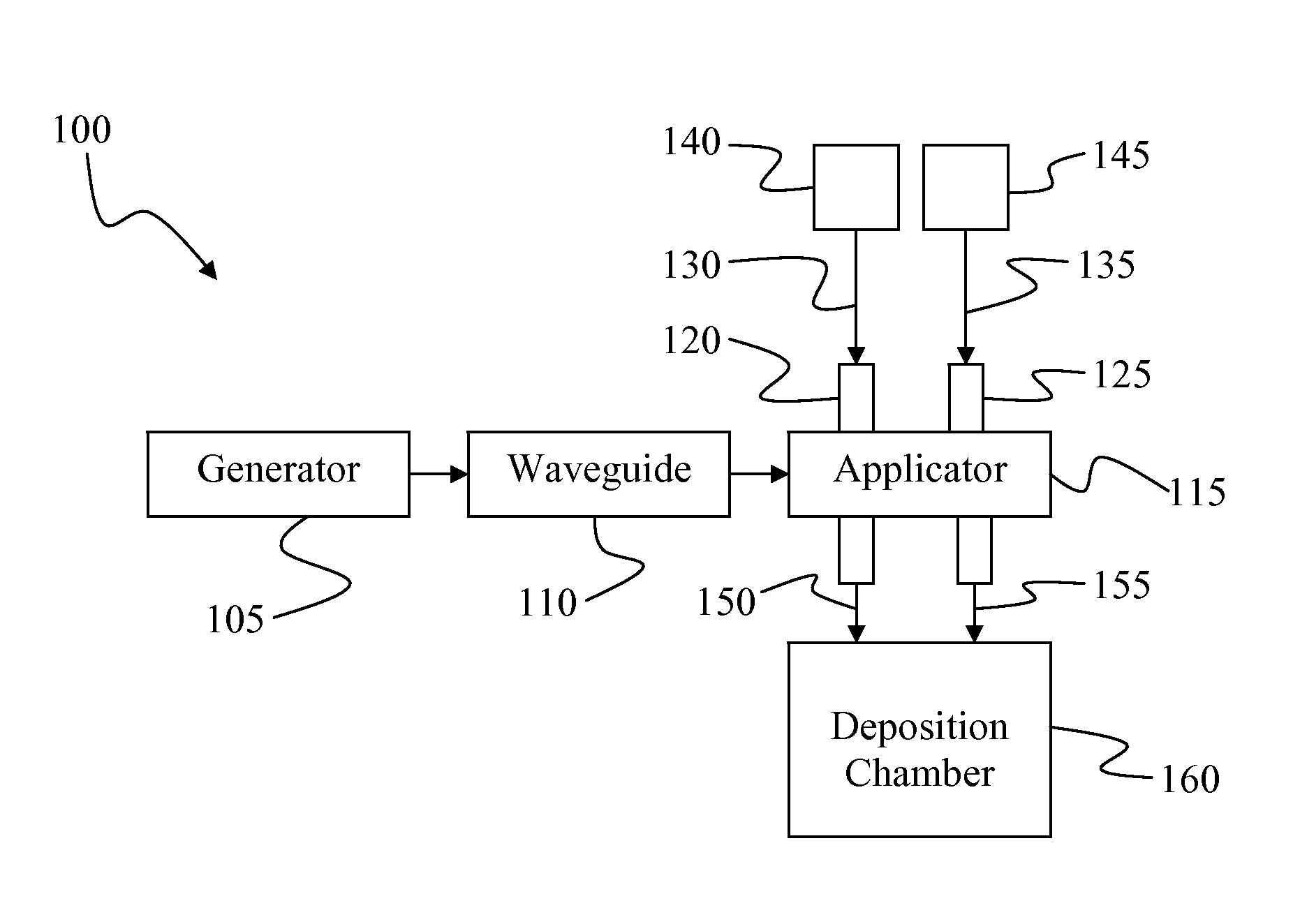

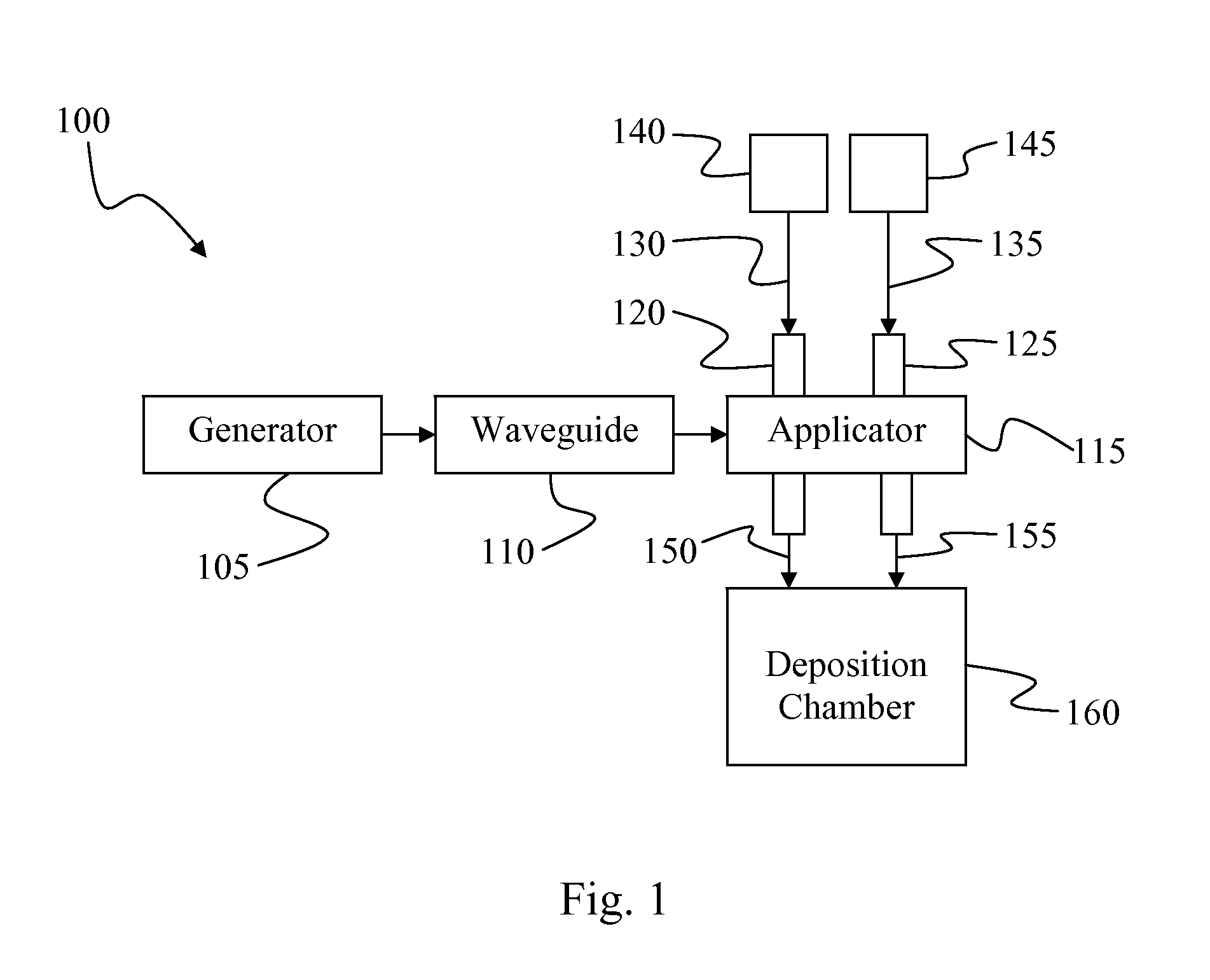

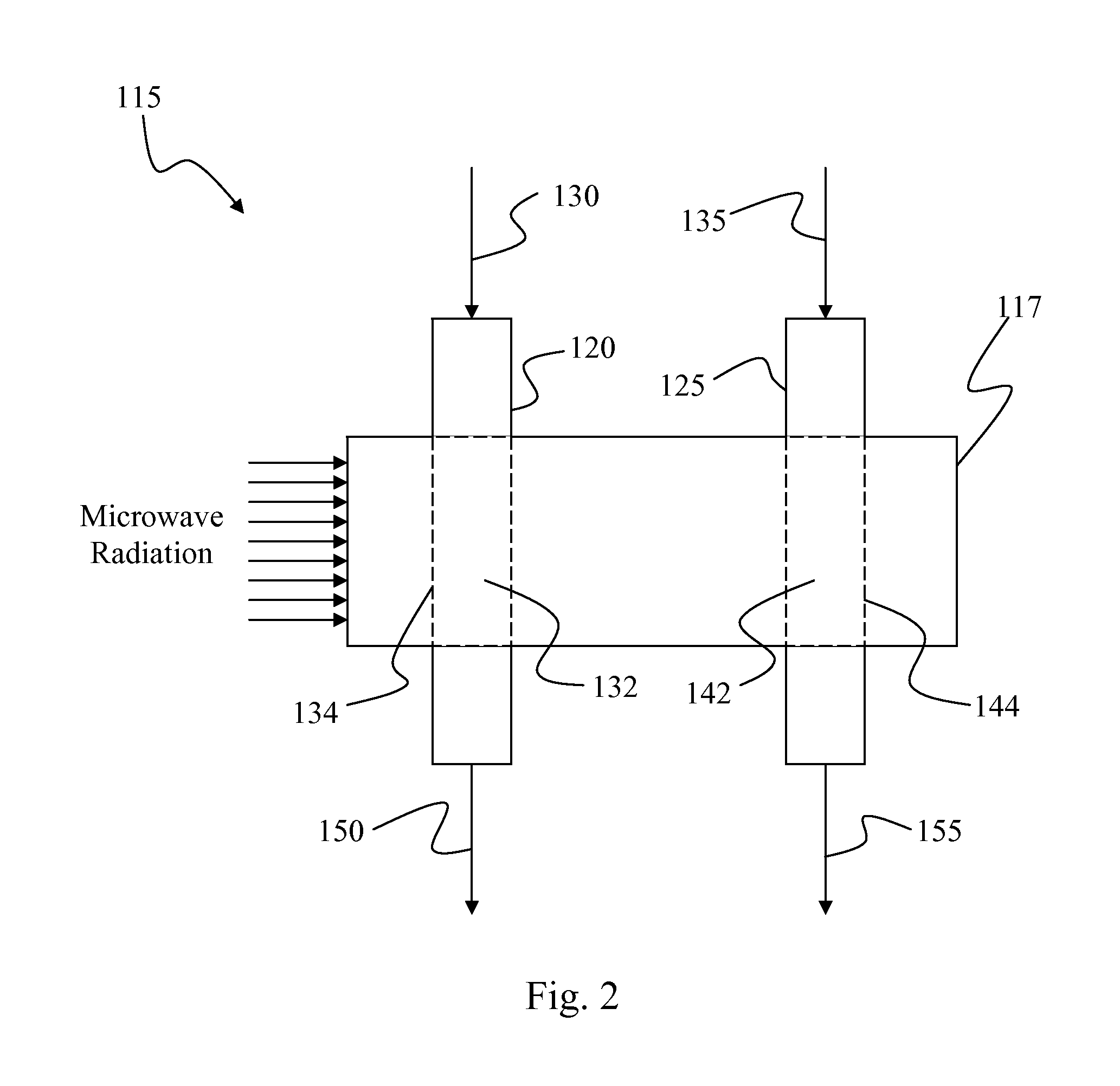

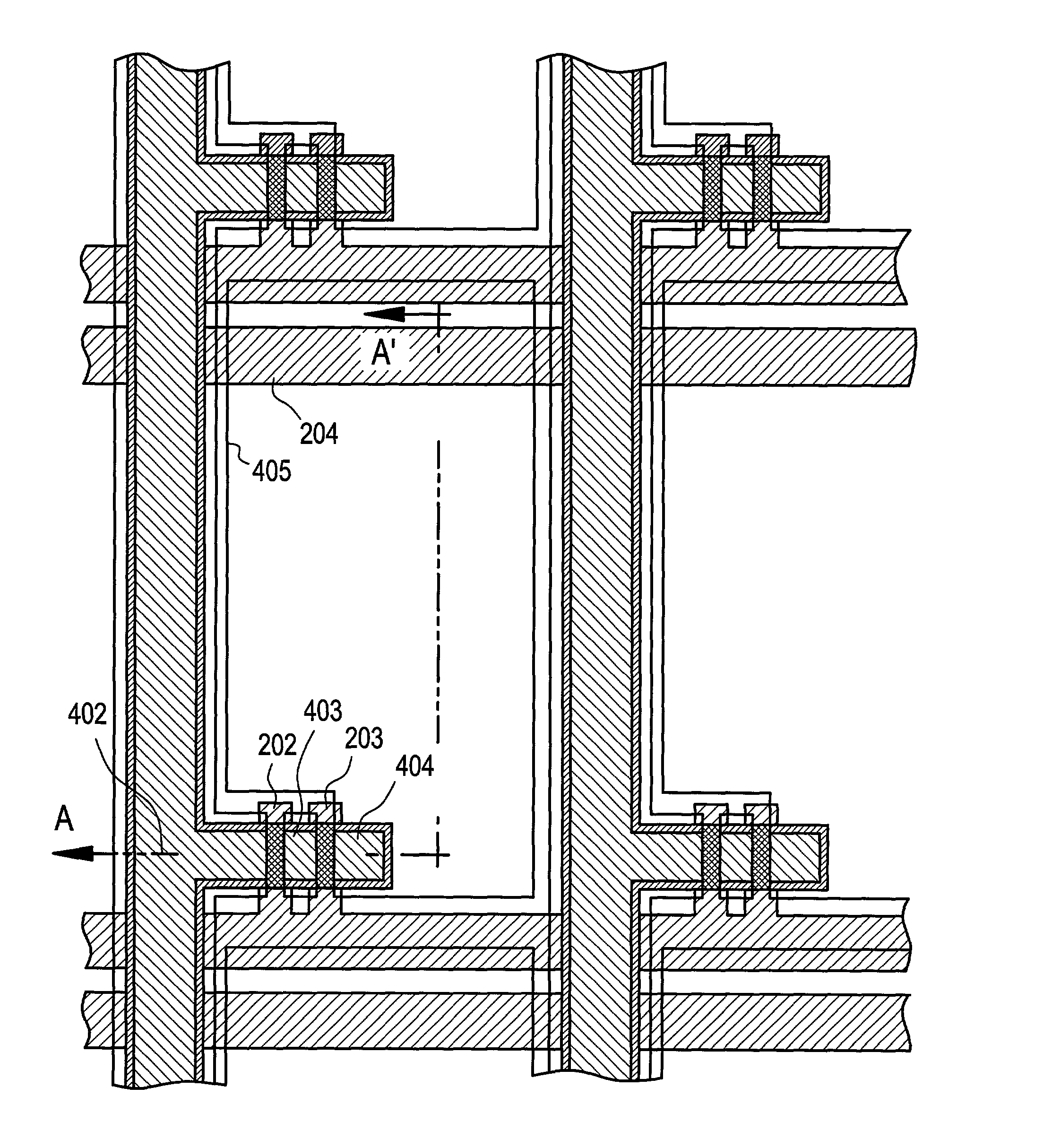

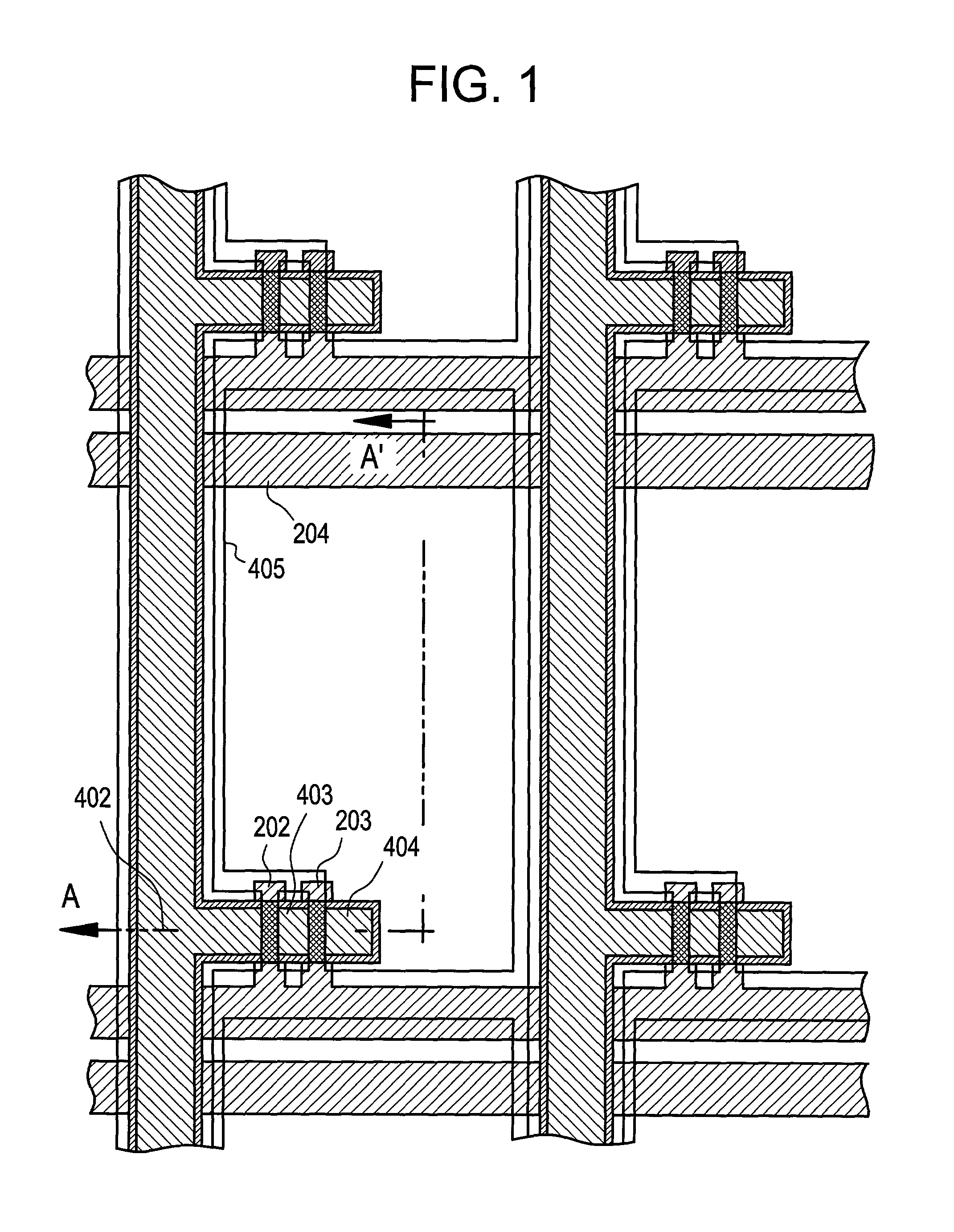

Plasma Deposition of Amorphous Semiconductors at Microwave Frequencies

InactiveUS20120040492A1Prevent and slow relaxationPrevent and slow and decayElectric discharge tubesFinal product manufacturePorosityPlasma deposition

Apparatus and method for plasma deposition of thin film photovoltaic materials at microwave frequencies. The apparatus avoids unintended deposition on windows or other microwave transmission elements that couple microwave energy to deposition species. The apparatus includes a microwave applicator with conduits passing therethrough that carry deposition species. The applicator transfers microwave energy to the deposition species to activate or energize them to a reactive state conducive to formation of a thin film material. The conduits physically isolate deposition species that would react or otherwise combine to form a thin film material at the point of microwave power transfer. The deposition species are separately energized and swept away from the point of power transfer to prevent thin film deposition. Suitable deposition species include precursors that contain silicon, germanium, fluorine, and / or hydrogen. The invention allows for the ultrafast formation of silicon-containing amorphous semiconductors that exhibit high mobility, low porosity, little or no Staebler-Wronski degradation, and low defect concentration.

Owner:OVSHINSKY TECH

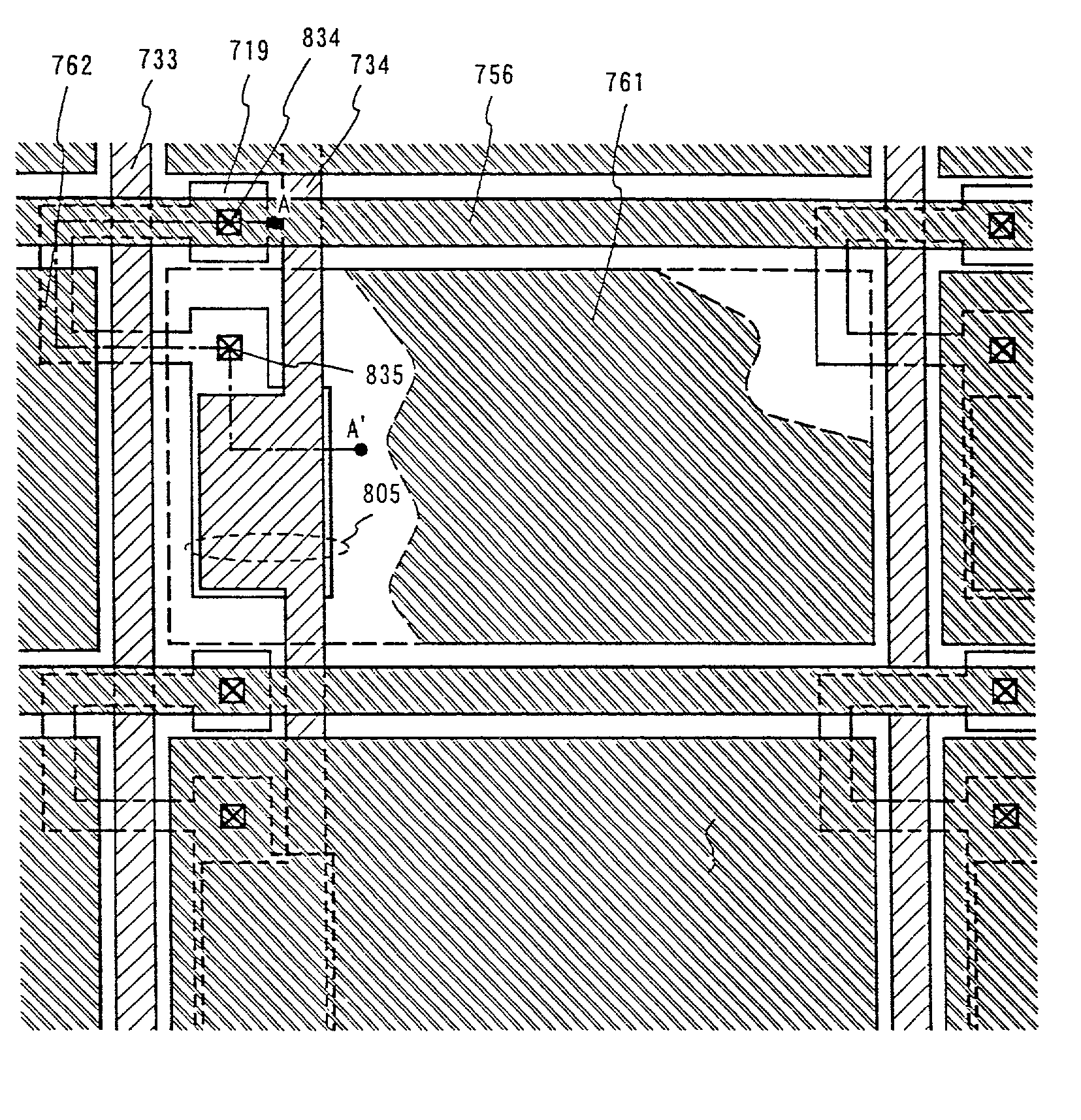

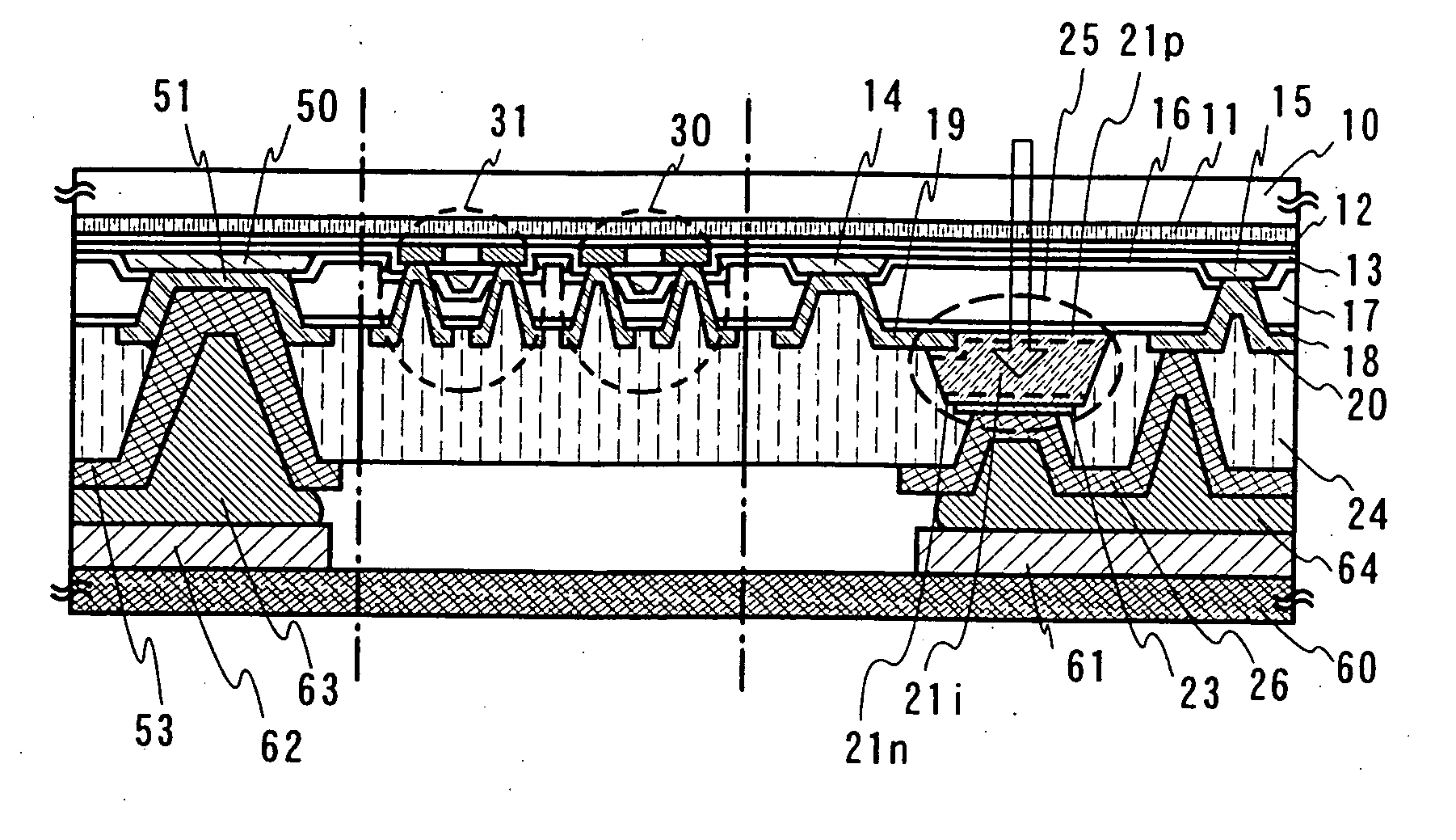

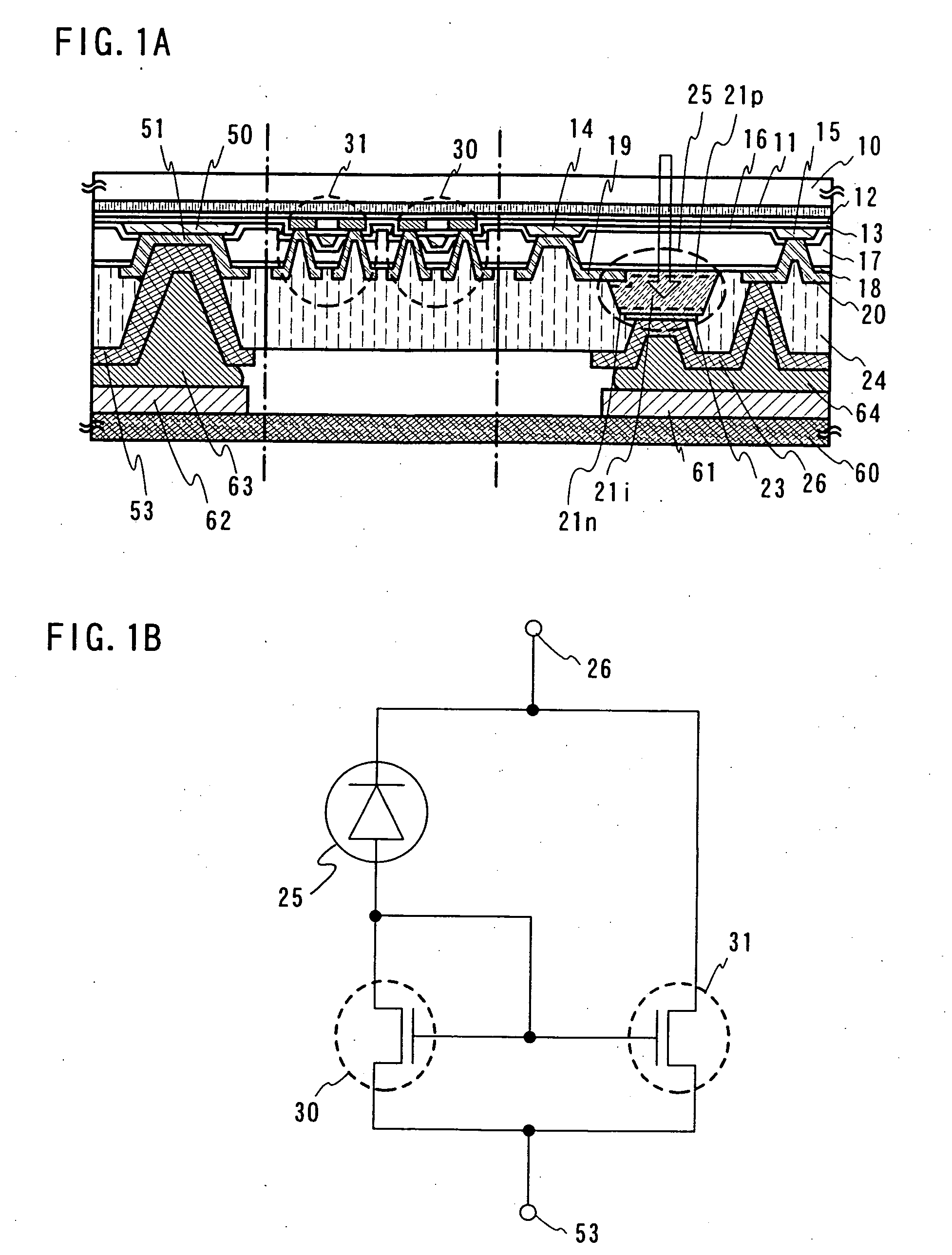

Semiconductor device and manufacturing method thereof

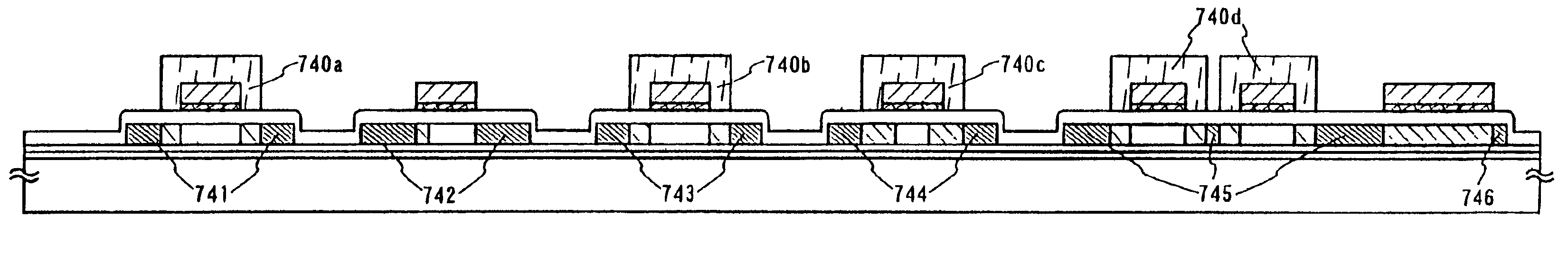

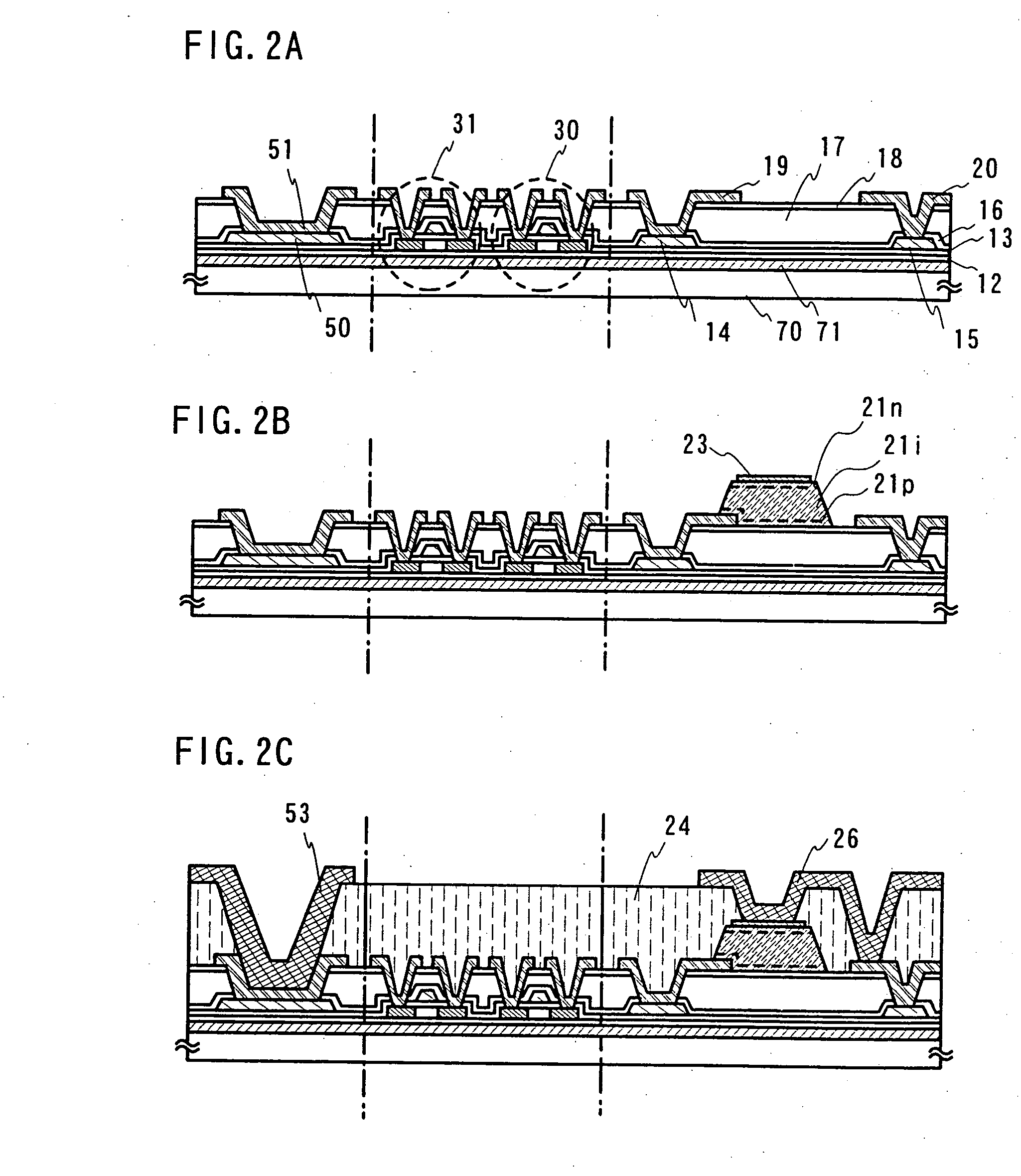

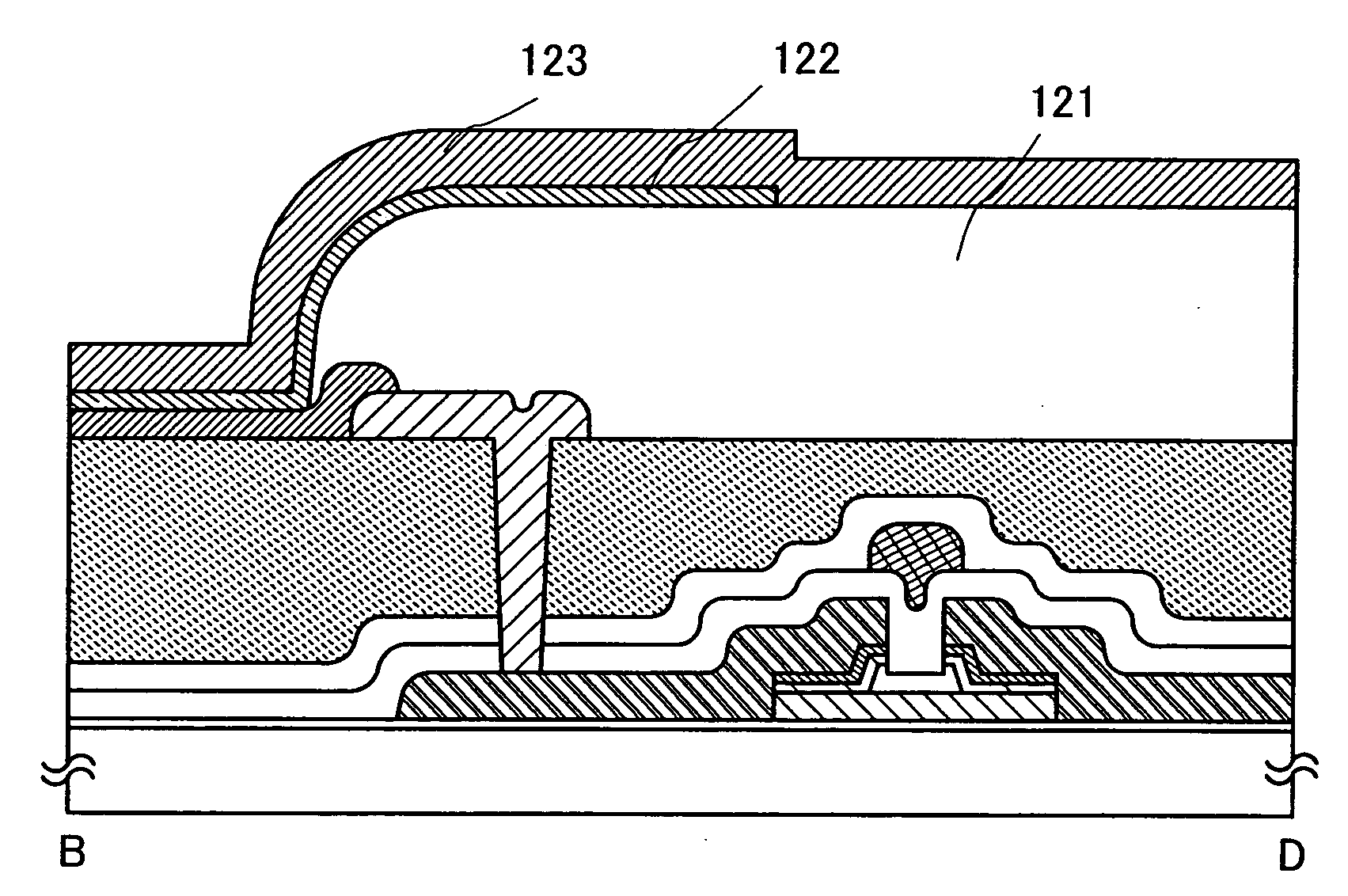

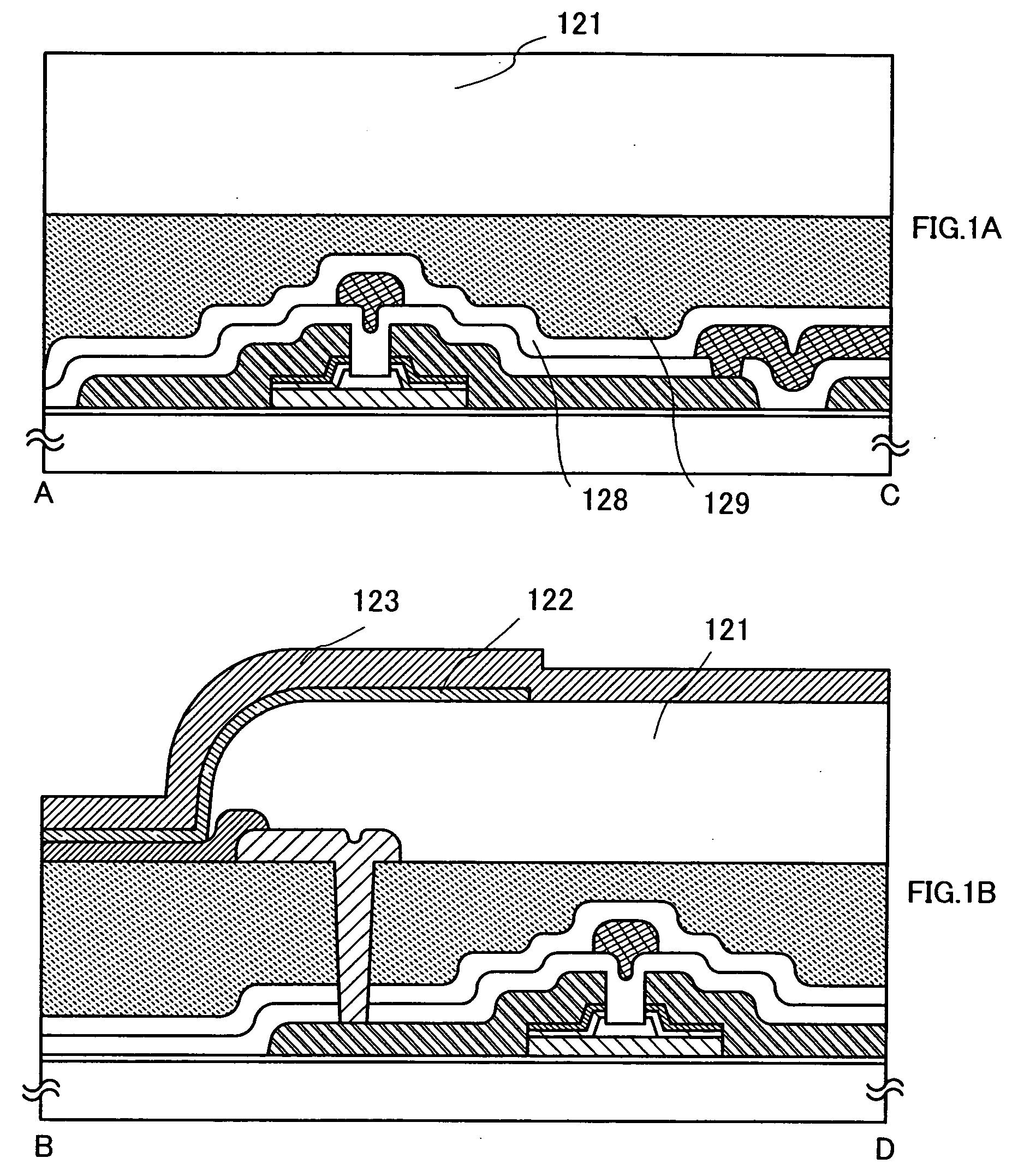

InactiveUS20020171085A1TransistorSolid-state devicesActive-matrix liquid-crystal displayProduction rate

The present invention has an object to provide an active-matrix liquid crystal display device that realizes the improvement in productivity as well as in yield. In the present invention, a laminate film comprising the conductive film comprising metallic material and the second amorphous semiconductor film containing an impurity element of one conductivity type and the amorphous semiconductor film is selectively etched with the same etching gas to form a side edge of the first amorphous semiconductor film 1001 into a taper shape. Thereby, a coverage problem of a pixel electrode 1003 can be solved and an inverse stagger type TFT can be completed with three photomask. Selected figure is FIG. 15.

Owner:SEMICON ENERGY LAB CO LTD +1

Semiconductor device

Crystal orientation planes exist randomly in a crystalline silicon film manufactured by a conventional method, and the orientation ratio is low with respect to a specific crystal orientation. A semiconductor film having a high orientation ratio for the {101} lattice plane is obtained if crystallization of an amorphous semiconductor film, which has silicon as its main constituent and contains from 0.1 to 10 atom % germanium, is performed after introduction of a metal element. A TFT is manufactured utilizing the semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

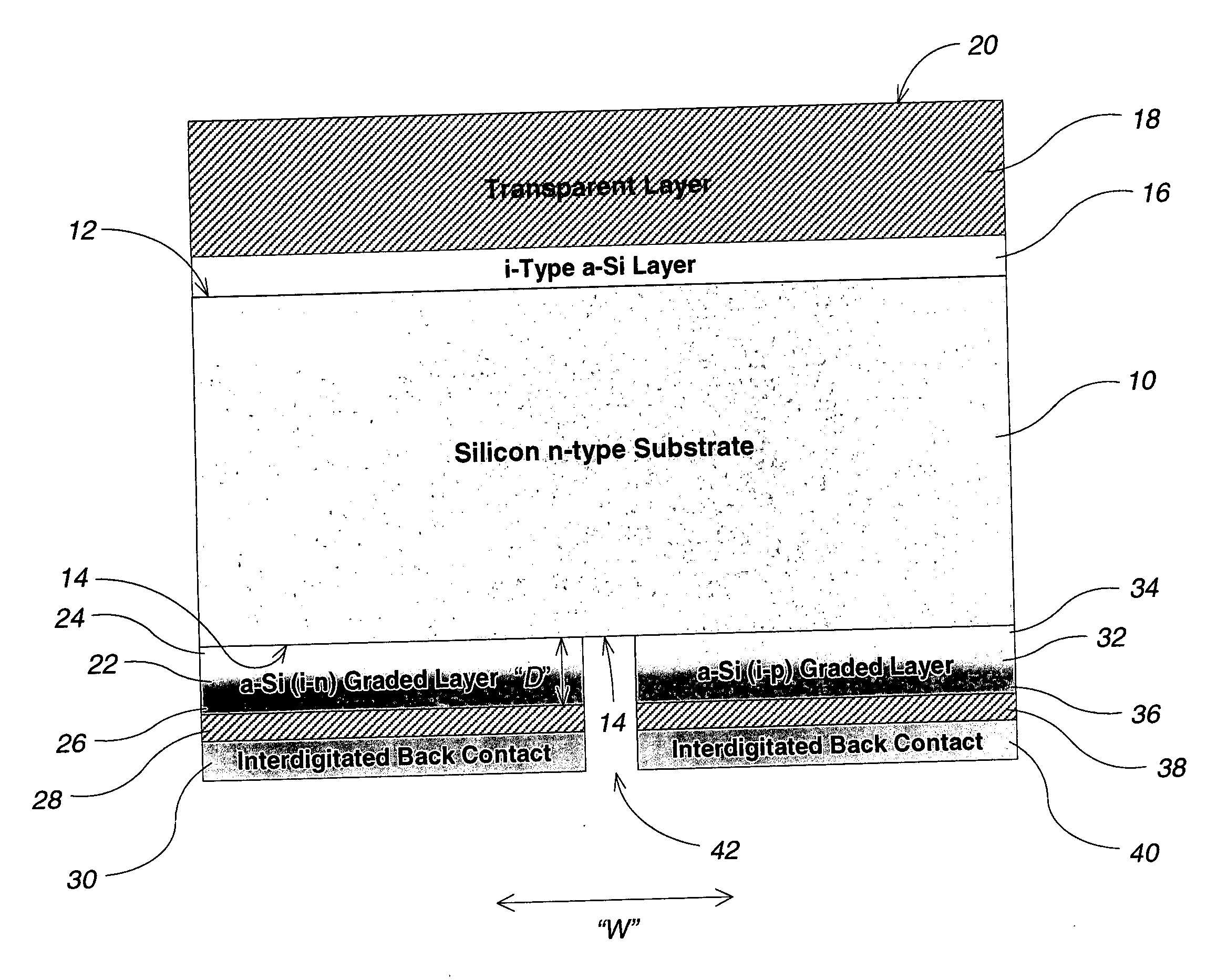

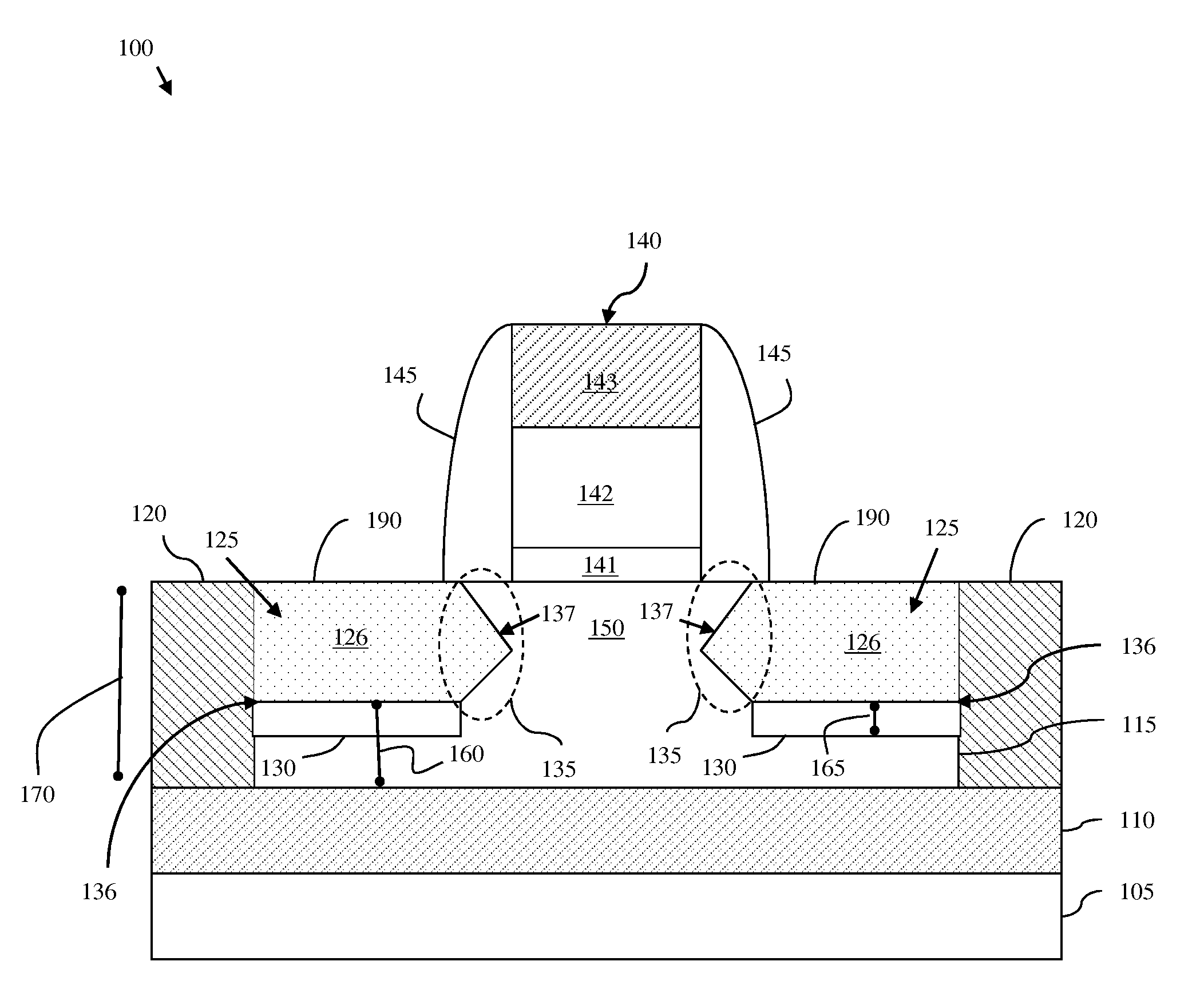

Semiconductor Device with Heterojunctions and an Inter-Finger Structure

InactiveUS20080061293A1Improve insulation performanceSimple structureFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionDevice material

A semiconductor device including, on at least one surface of a crystalline semiconductor substrate, at least one first amorphous semiconductor region doped with a first type of conductivity. The semiconductor substrate includes, on the same at least one surface, at least one second amorphous semiconductor region doped with a second type of conductivity, opposite the first type of conductivity. The first amorphous semiconductor region, insulated for the second amorphous semiconductor region by at least ore dielectric region in the contact with the semiconductor substrate, and the second amorphous semiconductor region form an interdigitated structure.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

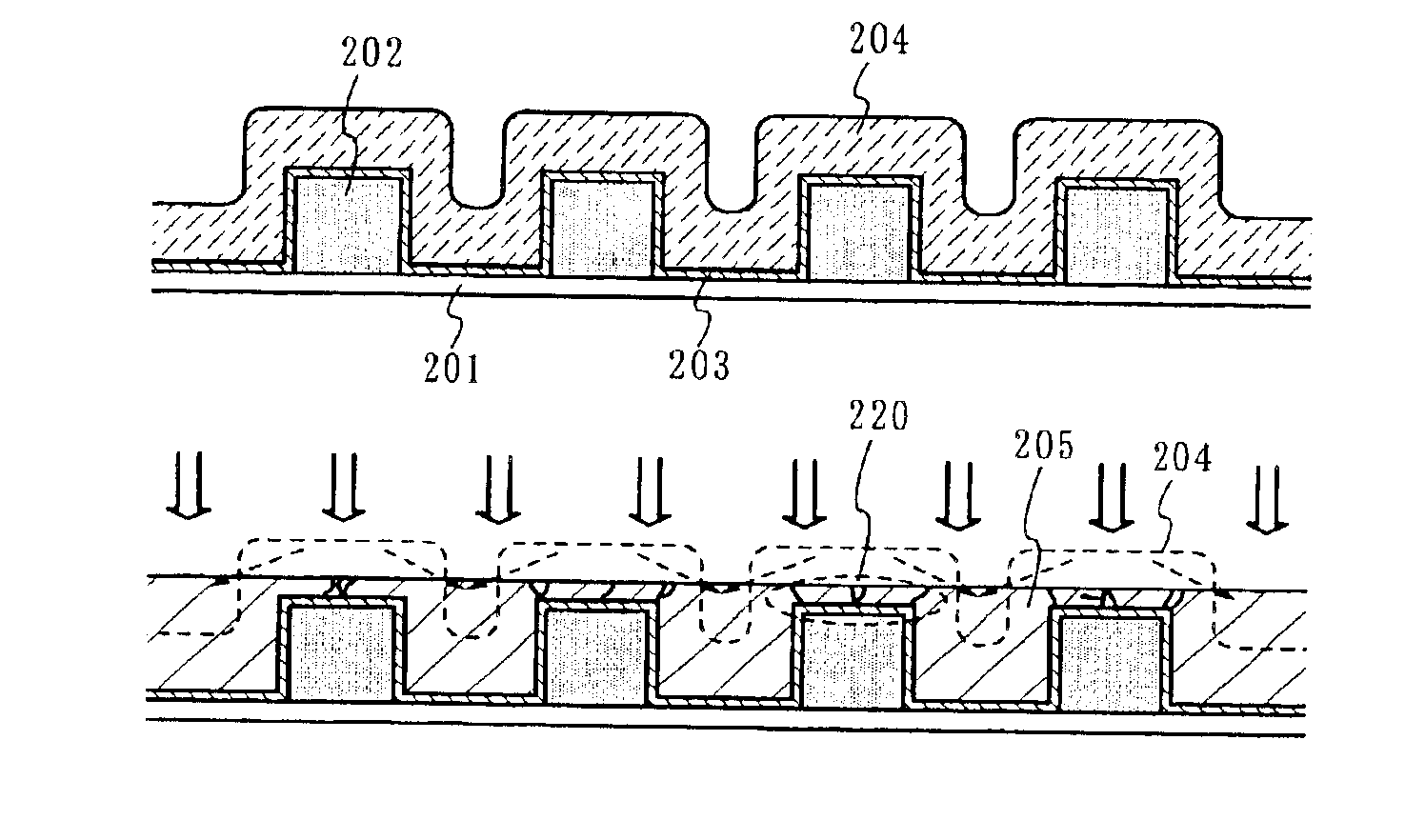

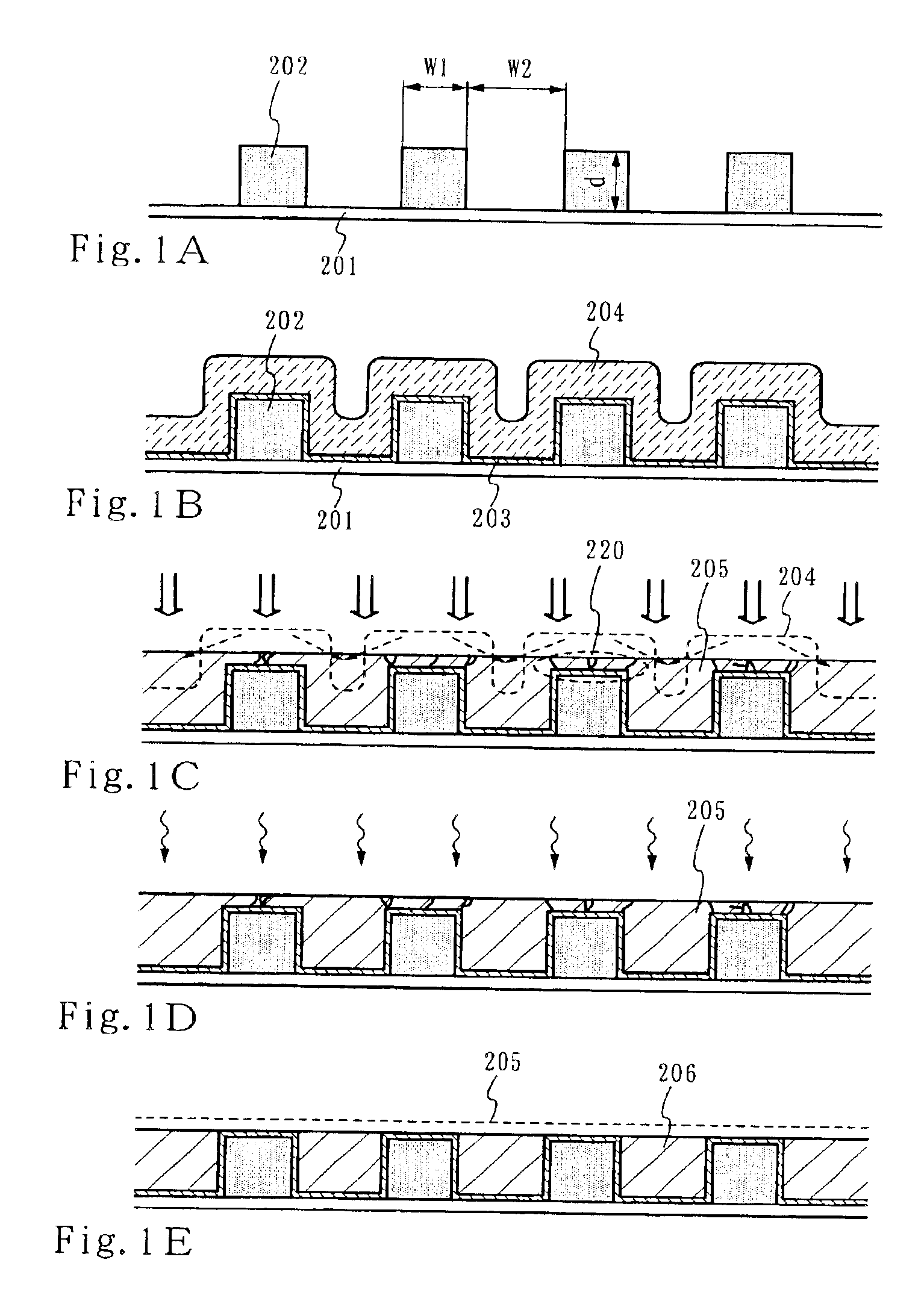

Method for manufacturing display device

InactiveUS20060046336A1Improve mobilityLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention provides a method for manufacturing a display device having a TFT that can be operated at high speed while using a small number of photomasks and improving the utilization efficiency of materials, where the threshold value is difficult to be varied. In the invention, a catalytic element is applied to an amorphous semiconductor film and the amorphous semiconductor film is heated to form a crystalline semiconductor film. After removing the catalytic element from the crystalline semiconductor film, a top-gate type thin film transistor with a planar structure is manufactured. Moreover, by using the droplet discharging method where an element of a display device is formed selectively, the process can be simplified, and loss of materials can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

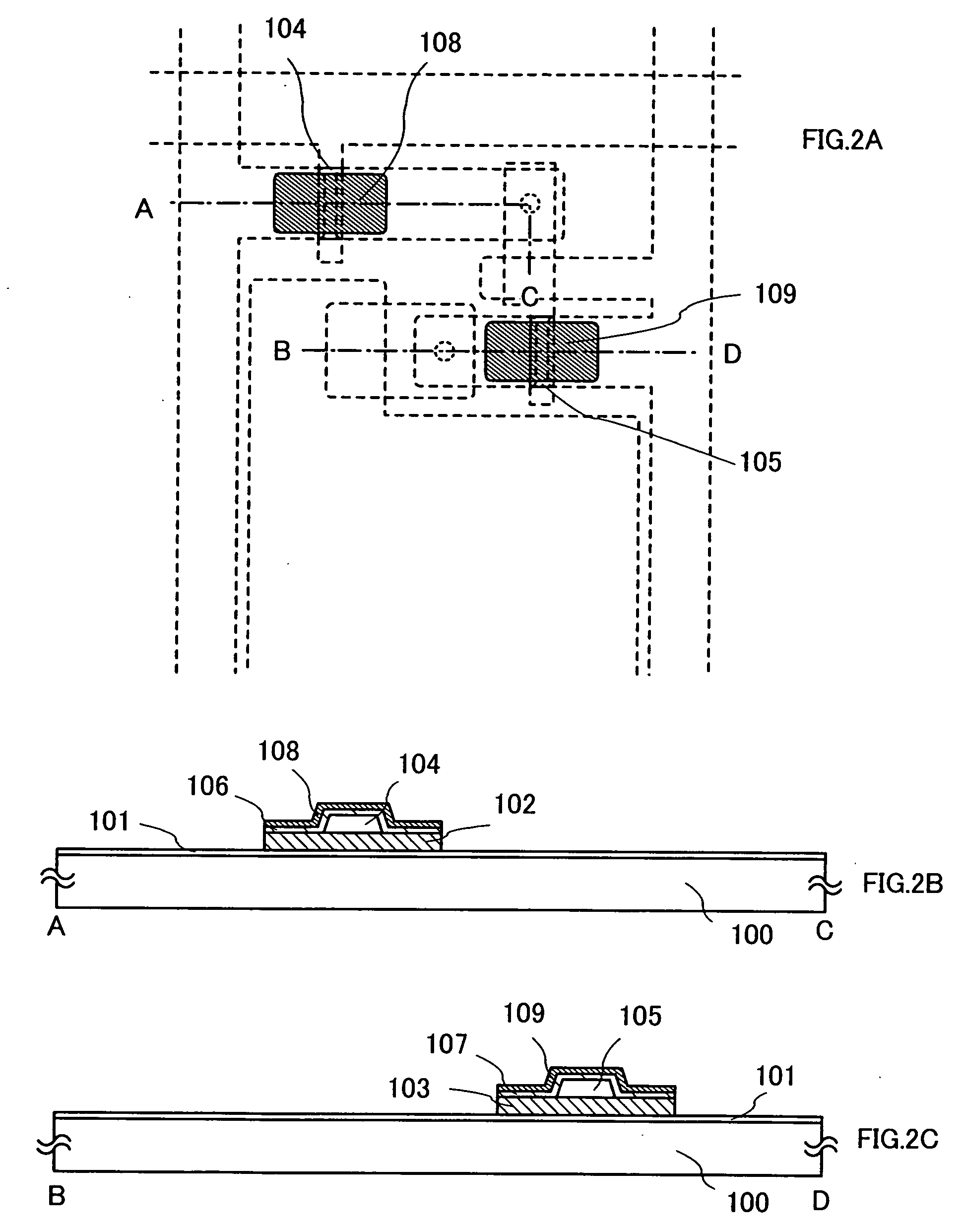

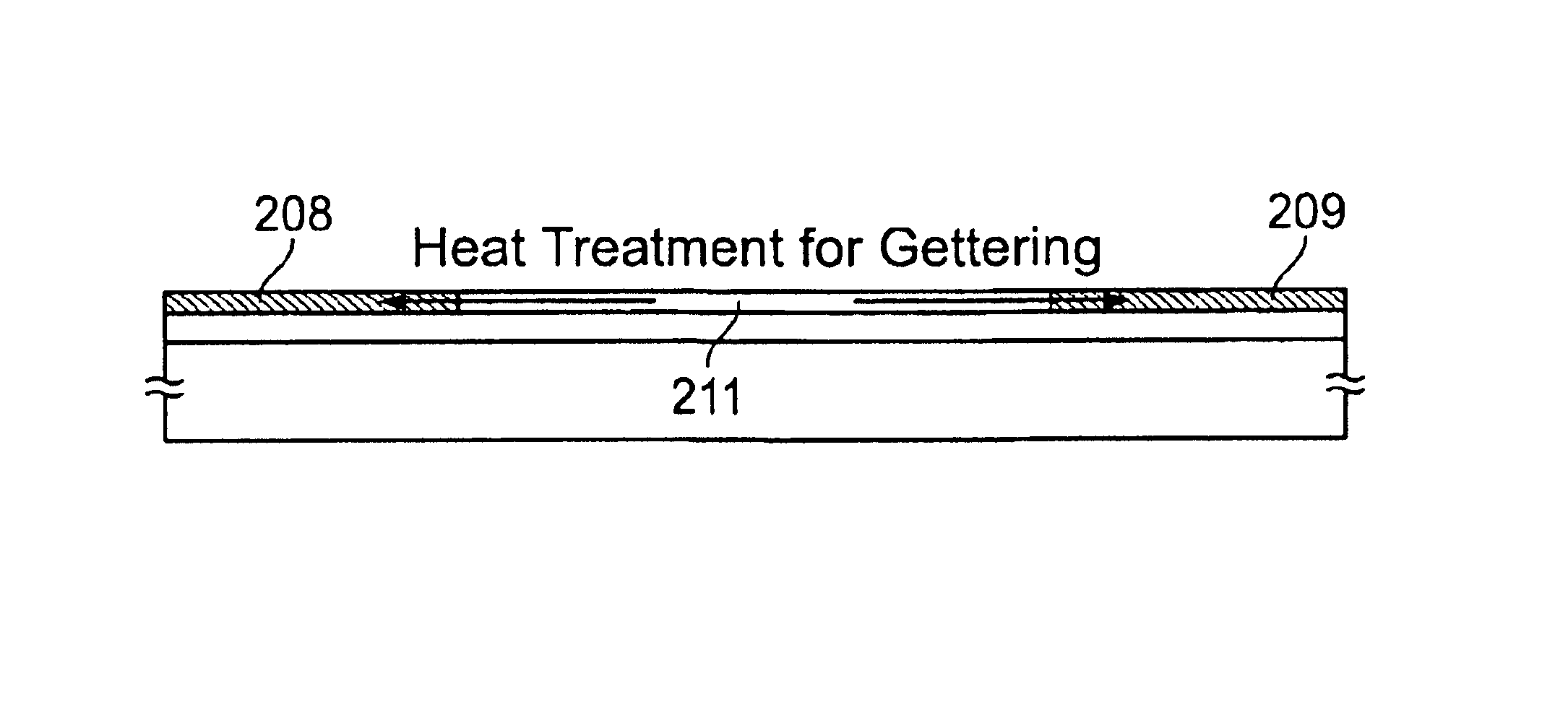

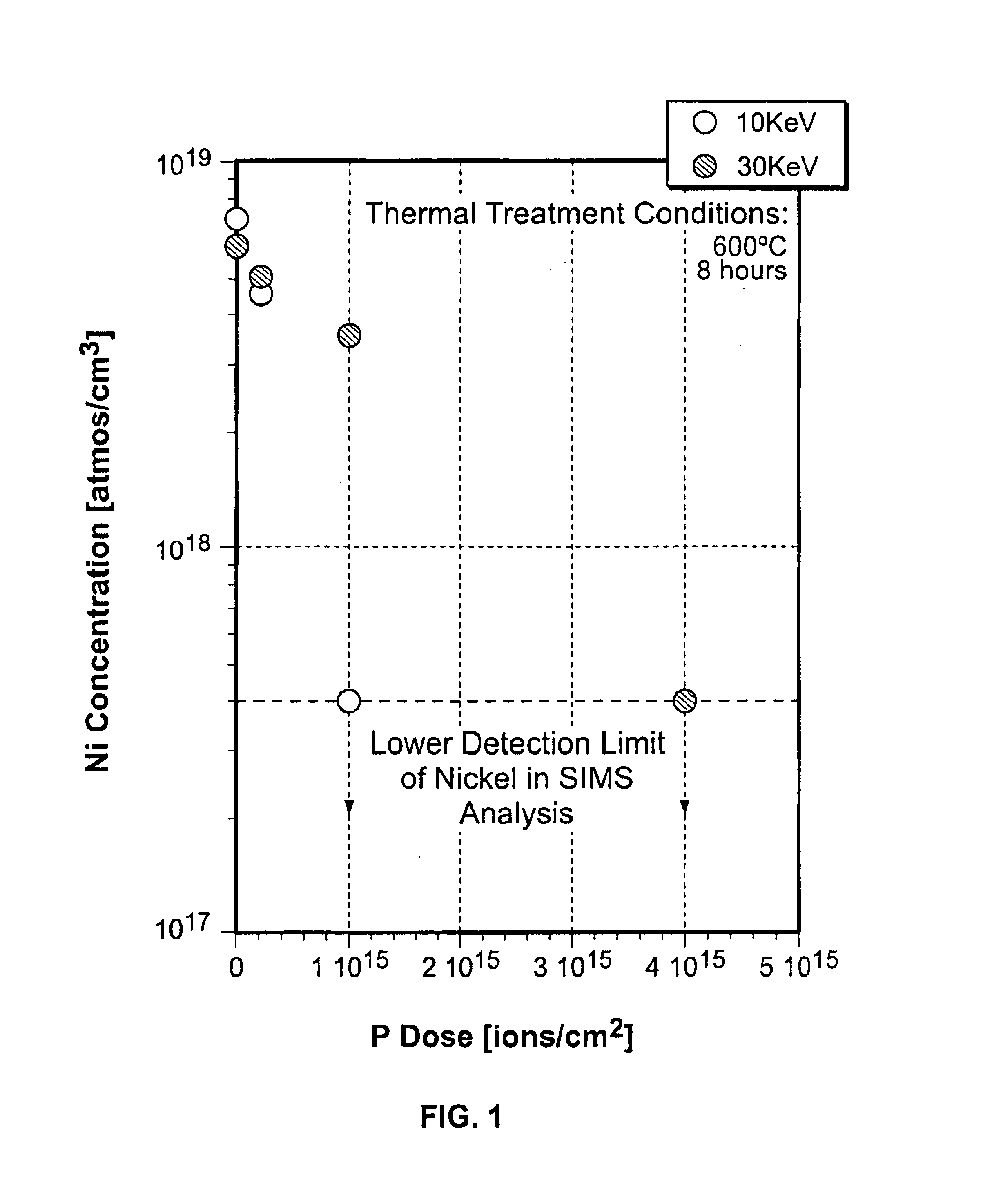

Method of manufacturing a semiconductor device

InactiveUS6893503B1Eliminate the problemTransistorPolycrystalline material growthSilicon membraneCrystalline silicon

A method of producing a semiconductor device which removes catalyst elements from a silicon-containing semiconductor film while maintaining the advantage of low temperature process is provided. The method comprises the steps of: forming an amorphous semiconductor film containing silicon on a glass substrate to crystallize it by using a catalyst element; selectively introducing into the amorphous semiconductor film an impurity belonging to Group 15 to form gettering regions and regions to be gettered; and causing the catalyst element in the silicon film to move to the gettering regions by heat treatment. Through the gettering process, the crystalline silicon film can be obtained in which the concentration of nickel contained therein is sufficiently reduced.

Owner:SEMICON ENERGY LAB CO LTD

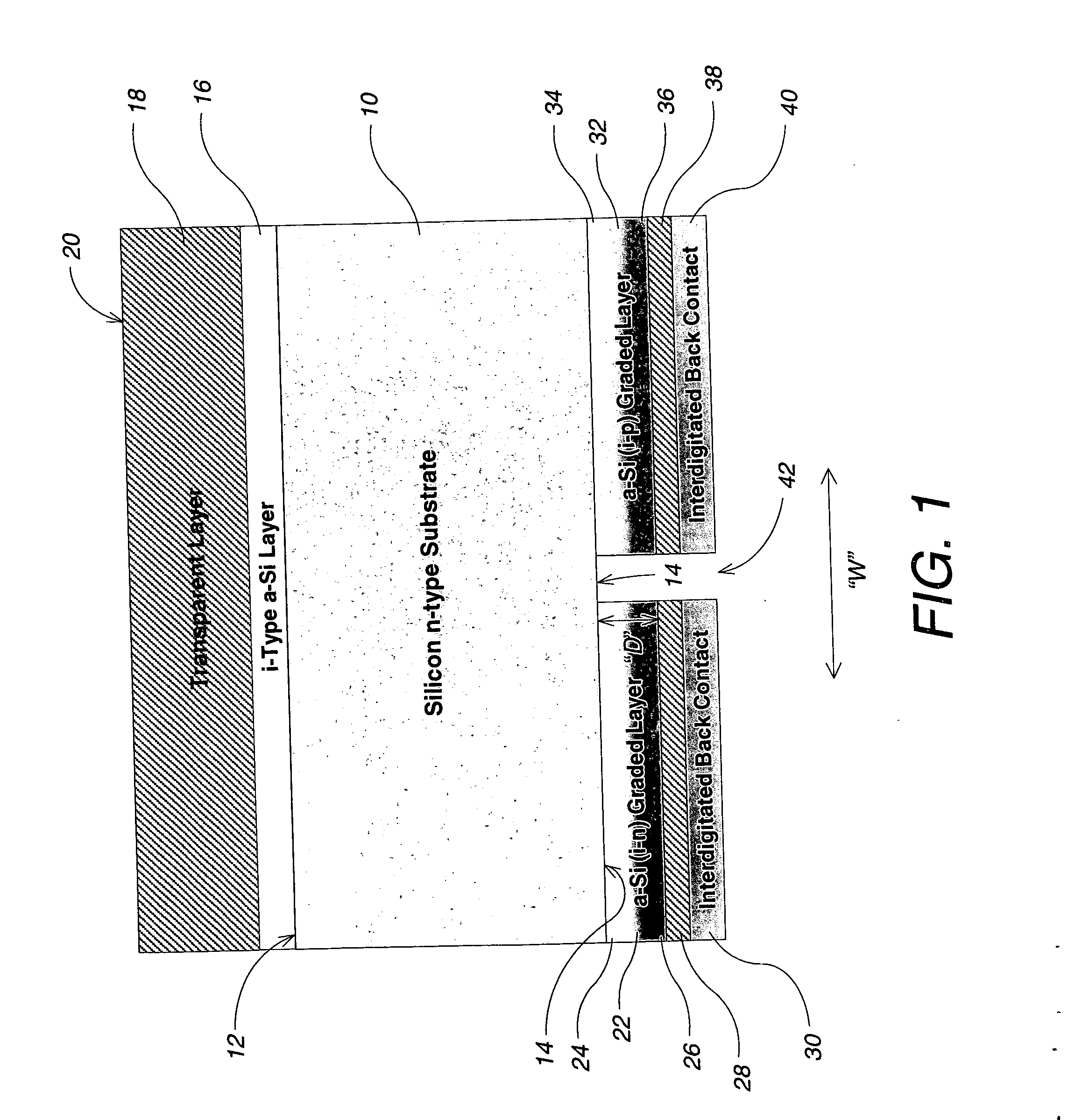

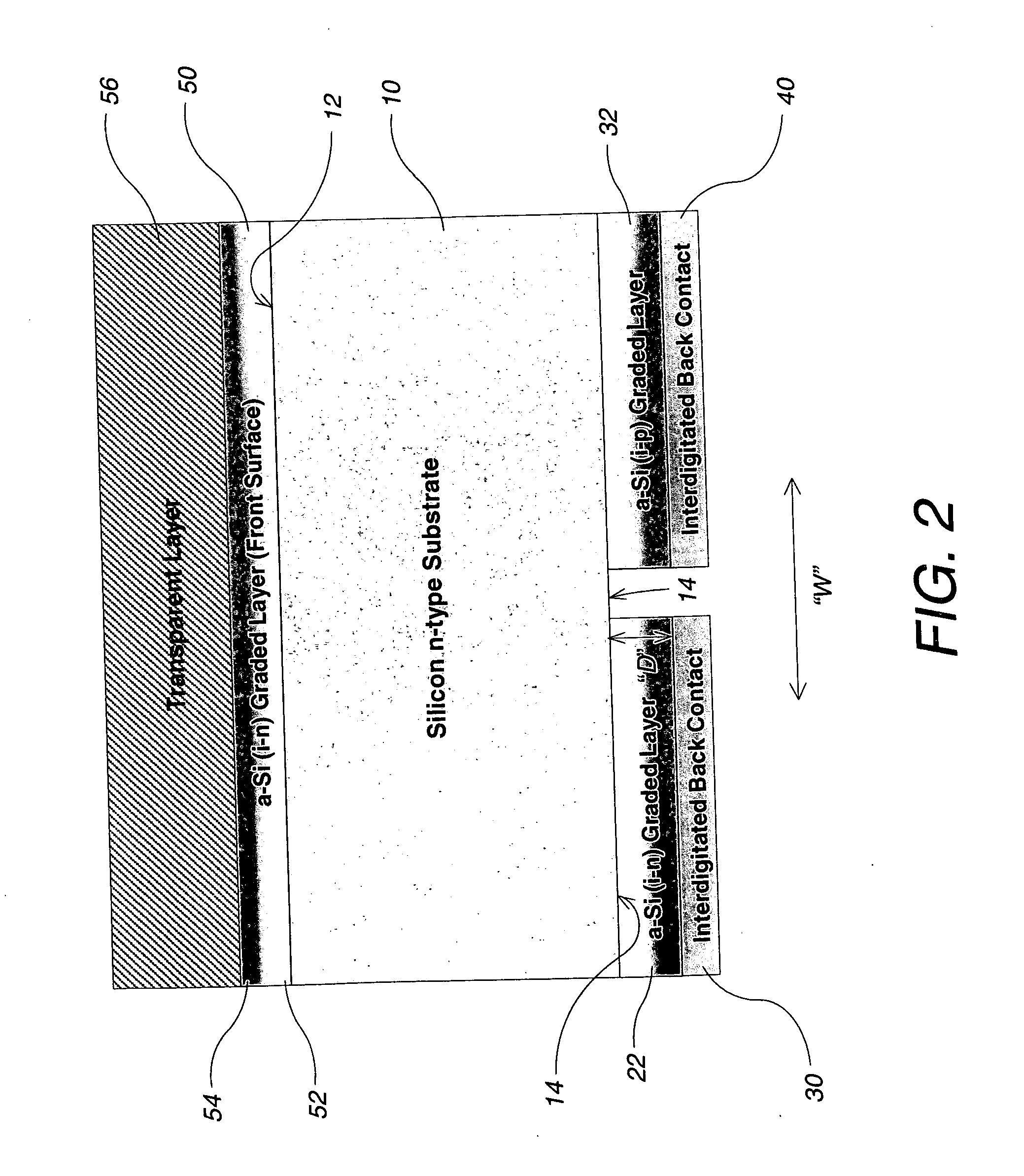

Photovoltaic device which includes all-back-contact configuration; and related processes

InactiveUS20080000522A1PV power plantsPhotovoltaic energy generationSemiconductor structureComputer module

A semiconductor structure is described, which includes a semiconductor substrate of one conductivity type, having a front surface and a back surface. A first amorphous semiconductor layer is applied on the front surface; and second and third amorphous semiconductor layers are disposed on portions of the back surface of the substrate. The second and third layers are each compositionally graded through their depth, from substantially intrinsic at the interface with the substrate, to substantially conductive at their opposite surfaces. In some instances, the first semiconductor layer is also compositionally graded, while in other instances, it is intrinsic in character. The semiconductor structures can function as solar cells; and modules which include a number of such cells represent another embodiment of the invention. Methods for making a photovoltaic device are also described.

Owner:GENERAL ELECTRIC CO

Semiconductor device and method for fabricating the same

ActiveUS20140042436A1High carrier mobilityEliminate the effects ofSolid-state devicesSemiconductor/solid-state device manufacturingIndiumZinc

To provide a highly reliable semiconductor device exhibiting stable electrical characteristics. To fabricate a highly reliable semiconductor device. Included are an oxide semiconductor stack in which a first to a third oxide semiconductor layers are stacked, a source and a drain electrode layers contacting the oxide semiconductor stack, a gate electrode layer overlapping with the oxide semiconductor layer with a gate insulating layer provided therebetween, and a first and a second oxide insulating layers between which the oxide semiconductor stack is sandwiched. The first to the third oxide semiconductor layers each contain indium, gallium, and zinc. The proportion of indium in the second oxide semiconductor layer is higher than that in each of the first and the third oxide semiconductor layers. The first and the third oxide semiconductor layers are each an amorphous semiconductor film. The second oxide semiconductor layer is a crystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

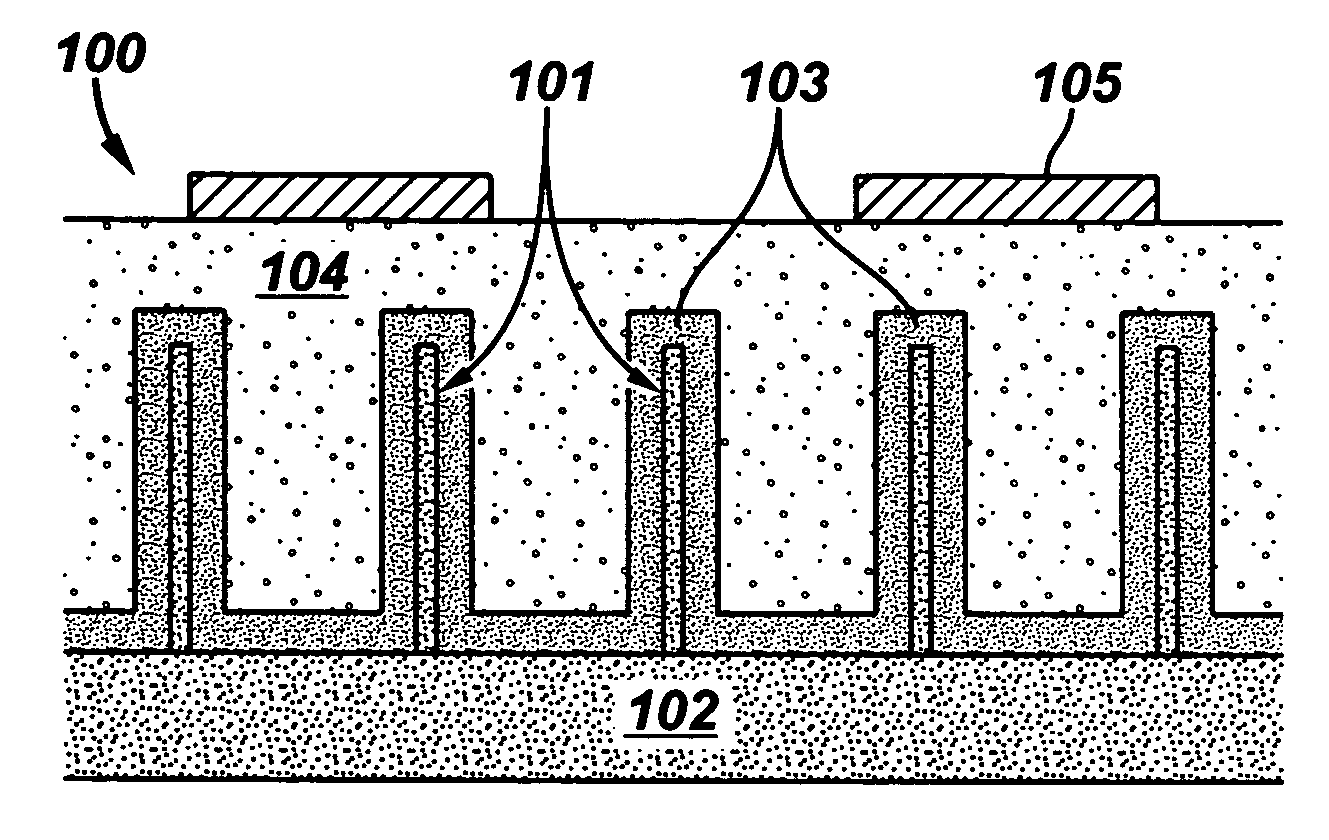

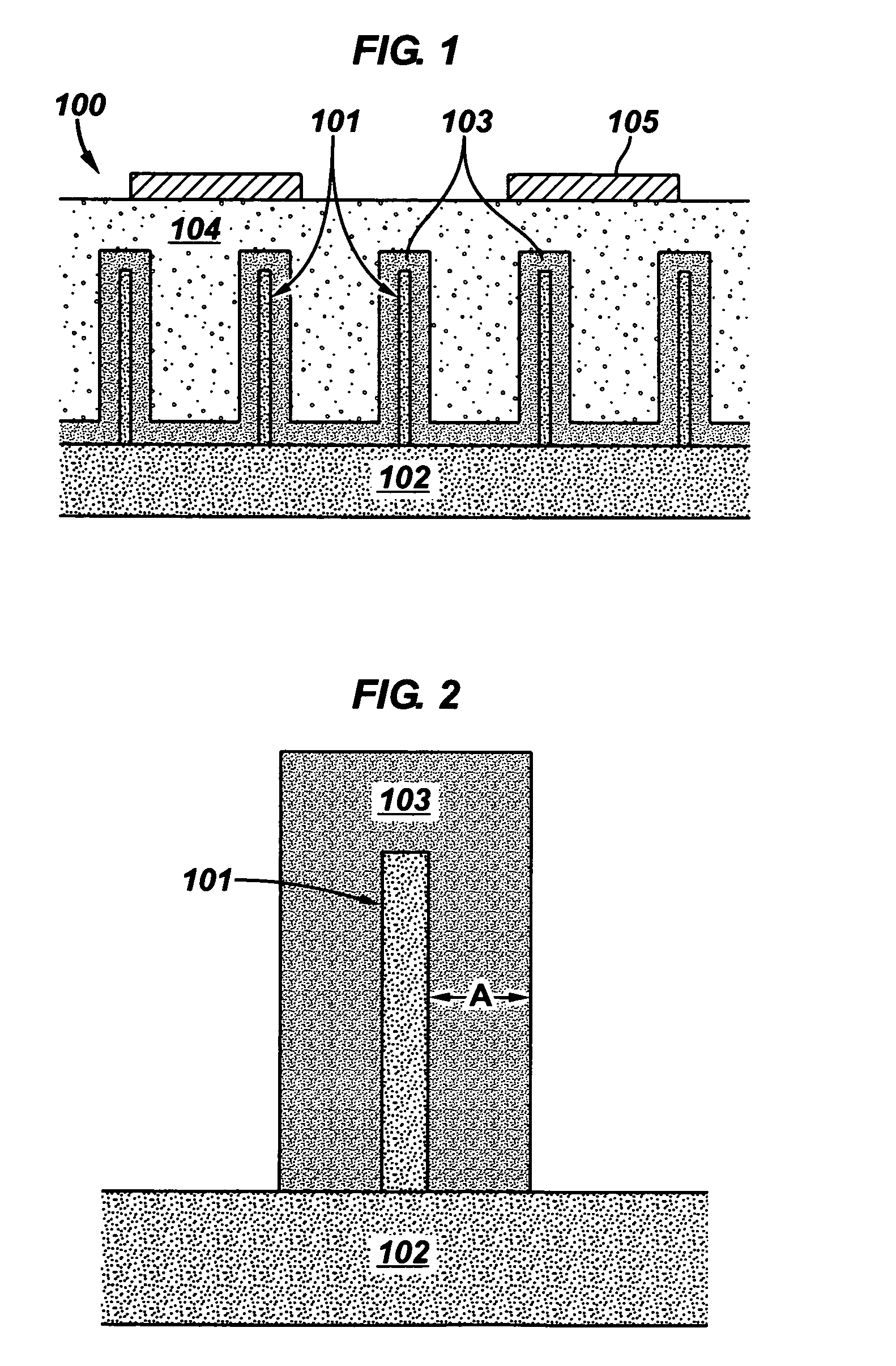

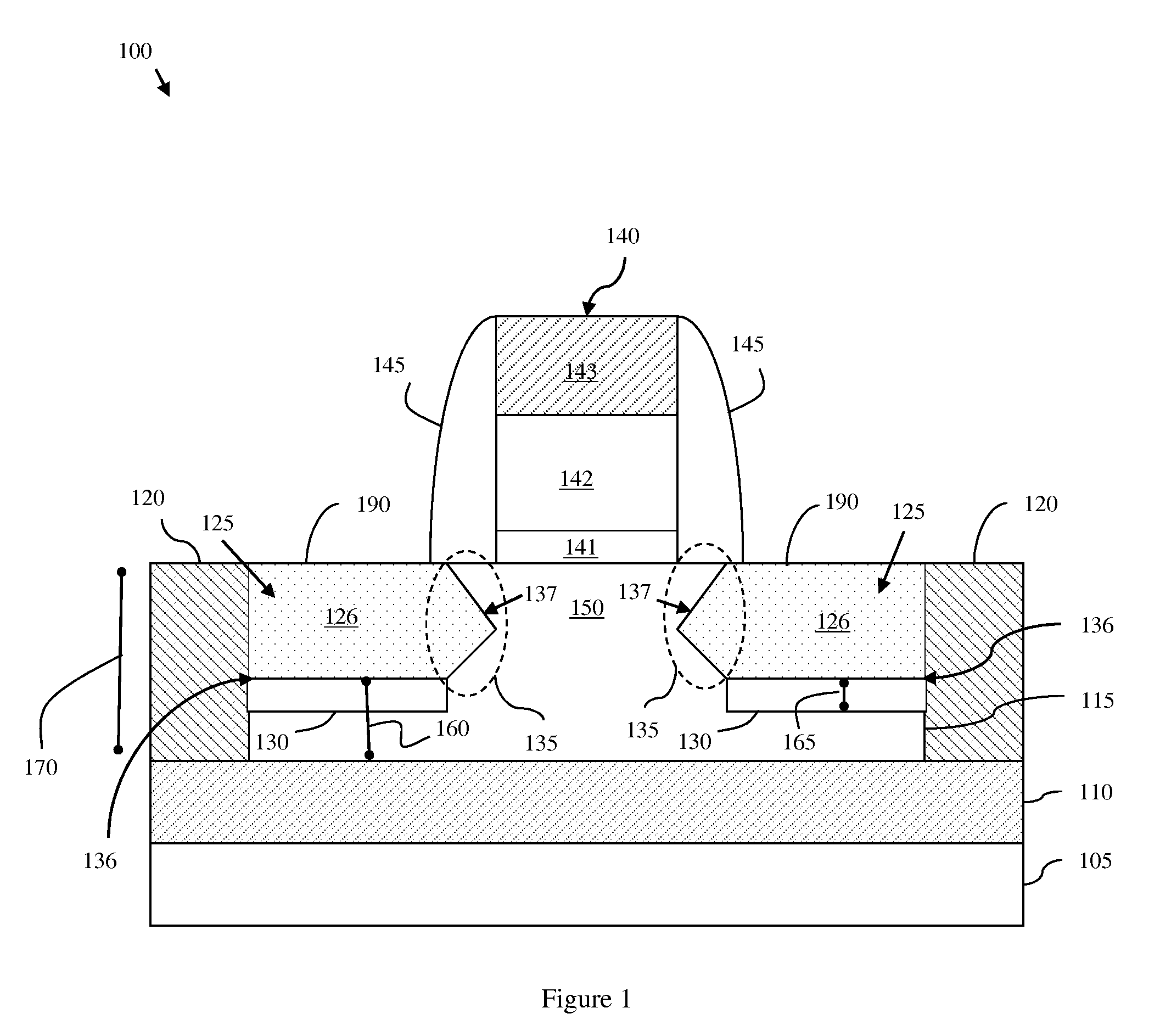

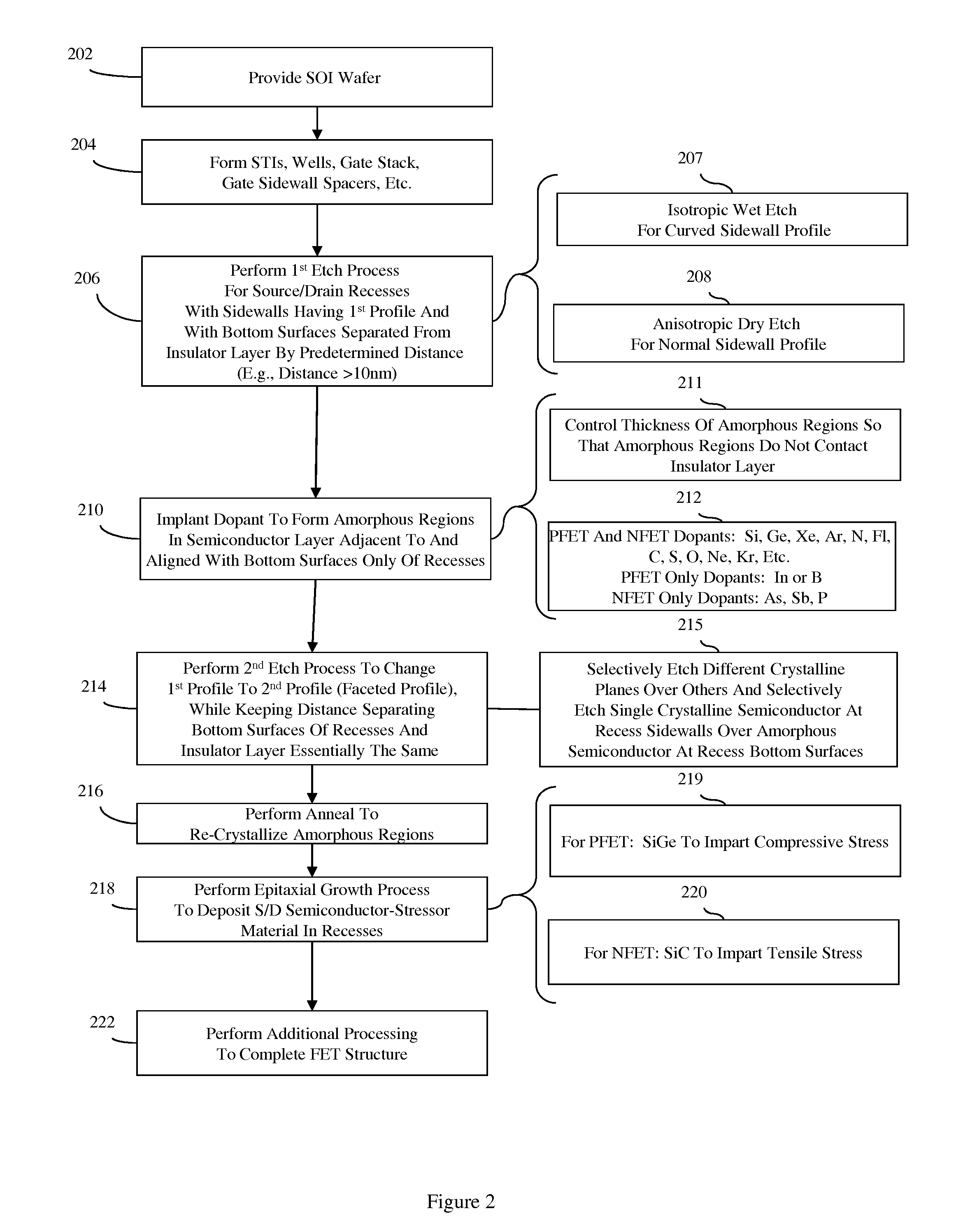

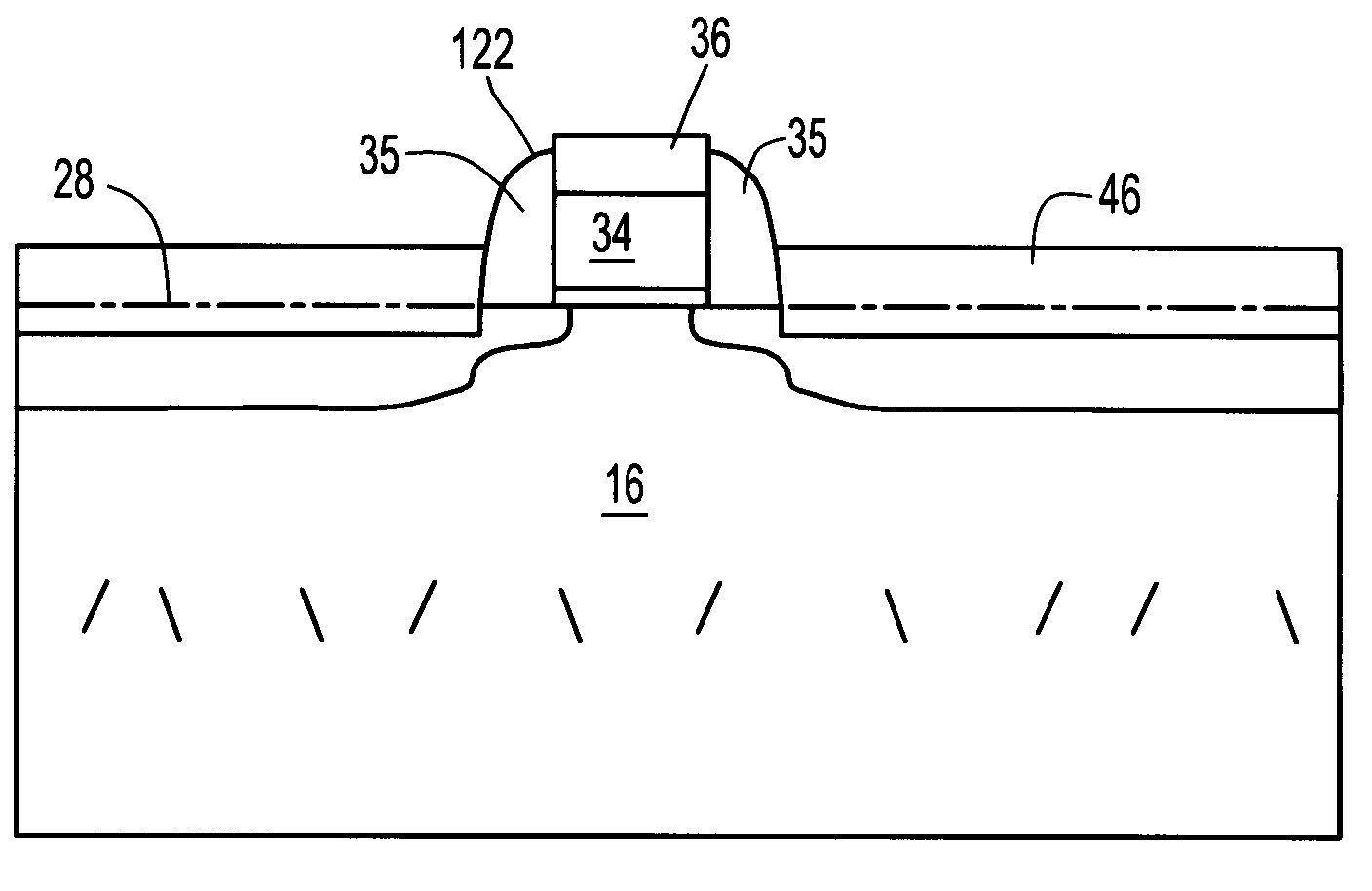

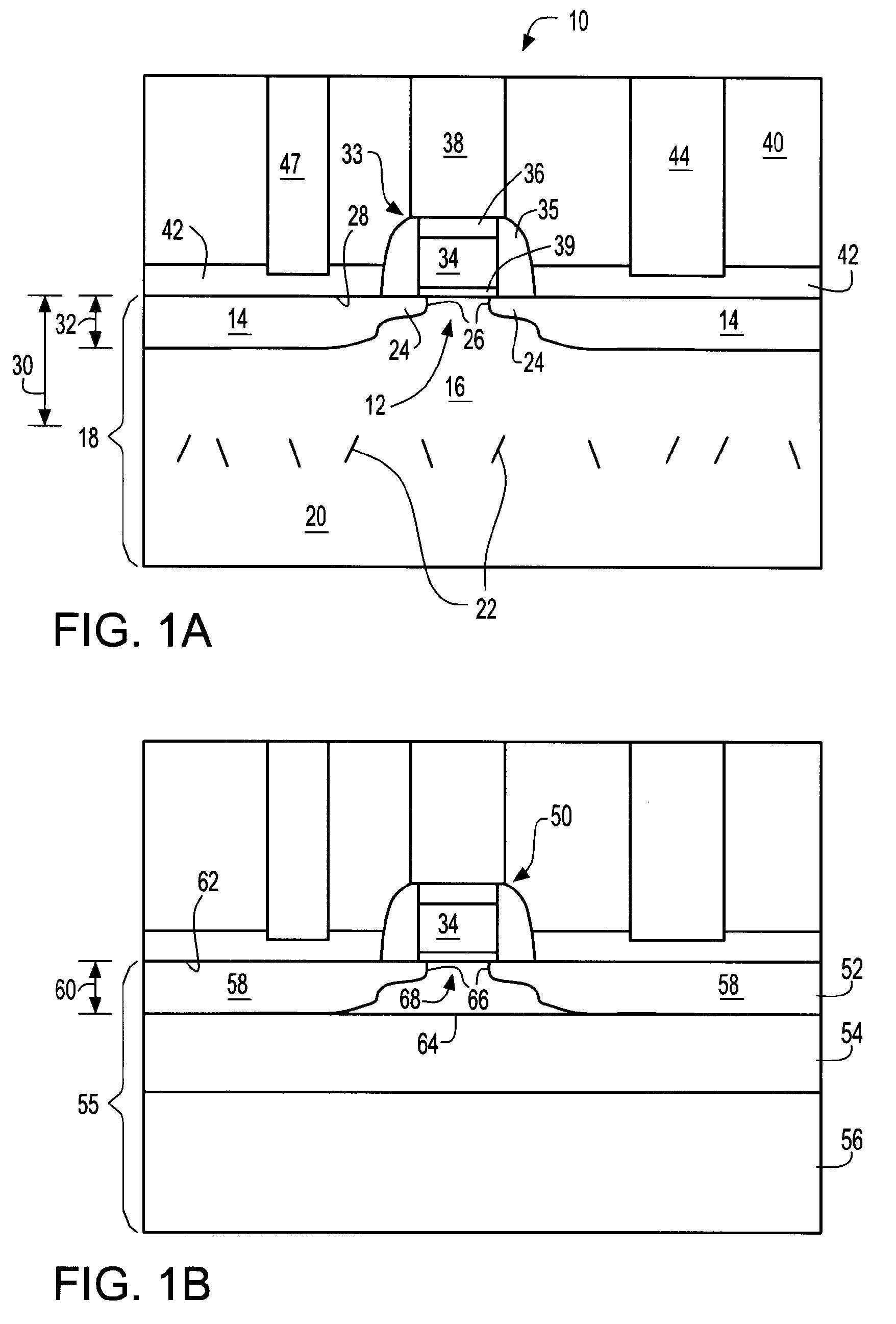

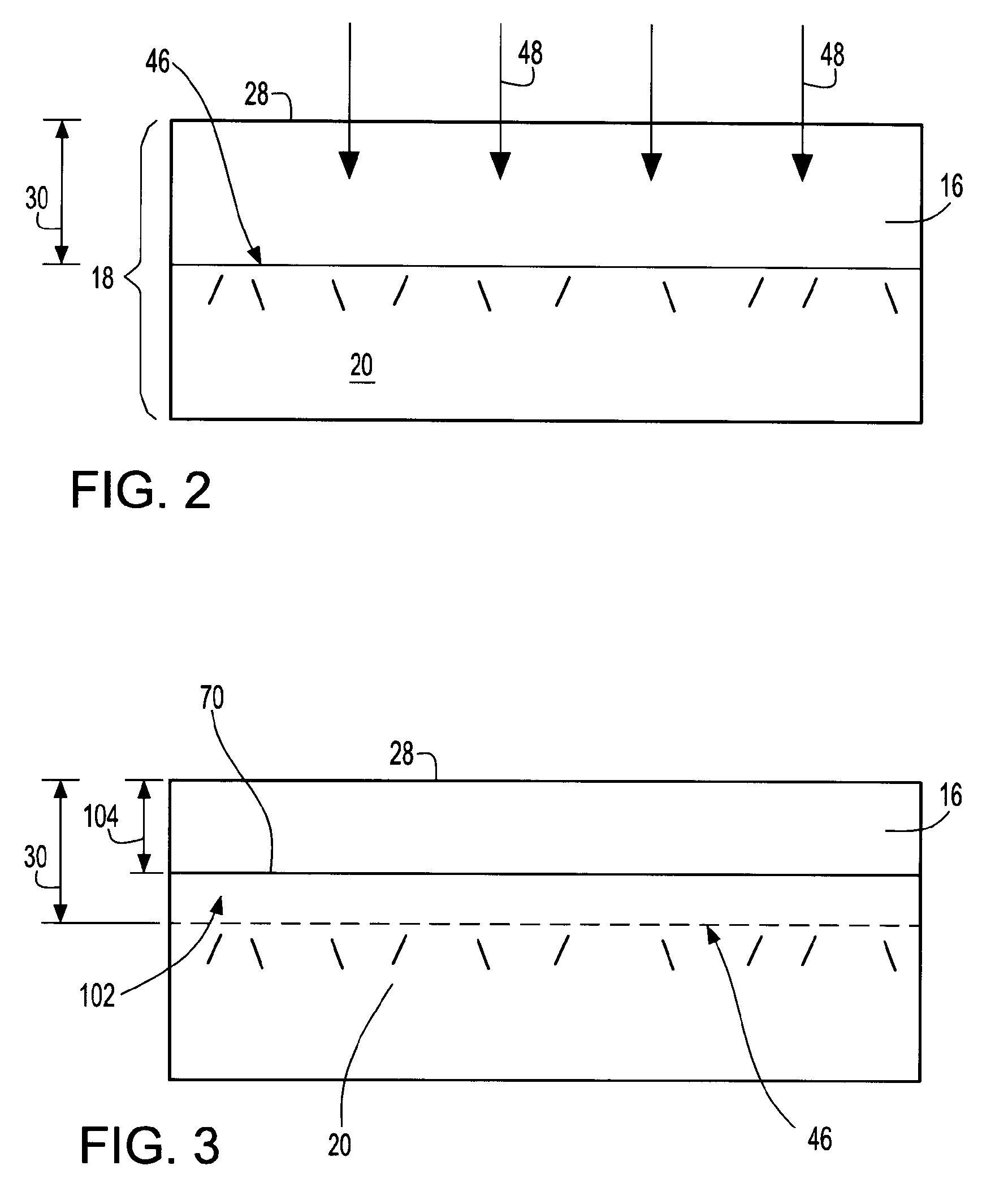

Method of forming a planar field effect transistor with embedded and faceted source/drain stressors on a silicon-on-insulator (SOI) wafer, a planar field effect transistor structure and a design structure for the planar field effect transistor

ActiveUS20100295127A1Add depthTransistorSolid-state devicesOrganic field-effect transistorSingle crystal

Disclosed are embodiments of a method of forming, on an SOI wafer, a planar FET with embedded and faceted source / drain stressors. The method incorporates a directional ion implant process to create amorphous regions at the bottom surfaces of source / drain recesses in a single crystalline semiconductor layer of an SOI wafer. Then, an etch process selective to different crystalline planes over others and further selective to single crystalline semiconductor material over amorphous semiconductor material can be performed in order to selectively adjust the shape (i.e., the profile) of the recess sidewalls without increasing the depth of the recesses. Subsequently, an anneal process can be performed to re-crystallize the amorphous regions and an epitaxial deposition process can be used to fill the recesses with source / drain stressor material. Also disclosed are embodiments of a planar FET structure and a design structure for the planar FET.

Owner:GLOBALFOUNDRIES US INC

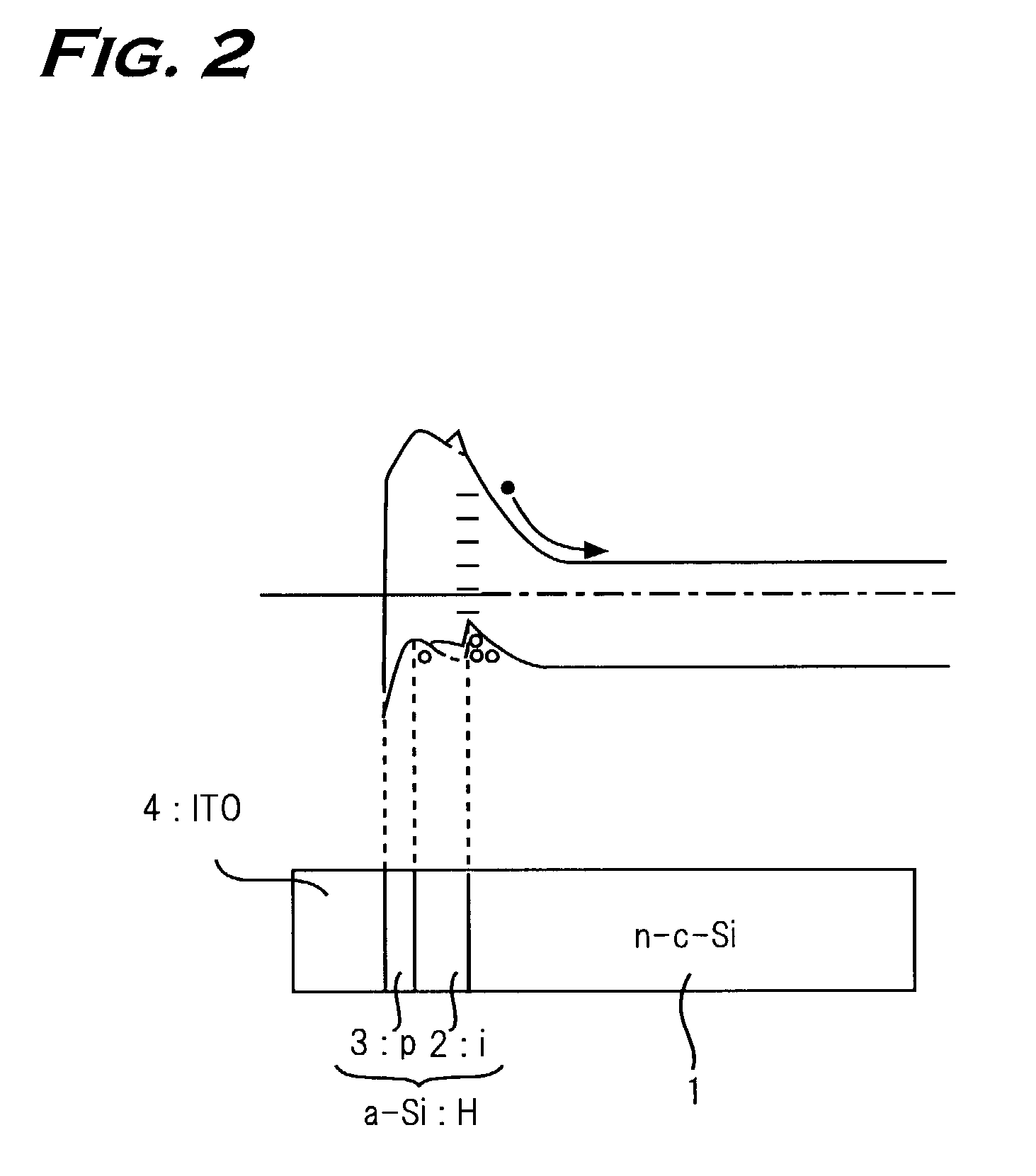

Photovoltaic device with intrinsic amorphous film at junction, having varied optical band gap through thickness thereof

InactiveUS7030413B2Reduce current consumptionQuality improvementFinal product manufacturePV power plantsCrystalline semiconductorCrystallization

In a photovoltaic device comprising a thin intrinsic amorphous semiconductor film inserted in a junction portion of a crystalline semiconductor substrate and an amorphous semiconductor film which have conductive types reverse to each other, an optical band gap of the intrinsic amorphous semiconductor film is expanded on a side in contact with the amorphous semiconductor film.

Owner:SANYO ELECTRIC CO LTD

MOS transistor with self-aligned source and drain, and method for making the same

InactiveUS7619248B1Low costReliable and commercially acceptable electrical characteristicSemiconductor devicesSemiconductor materialsEngineering

A MOS transistor with self-aligned source / drain terminals, and methods for its manufacture. The transistor generally includes an electrically functional substrate, a dielectric film on portions of the substrate, a gate on the dielectric film, and polycrystalline source and drain terminals self-aligned with the gate. The method generally includes forming an amorphous semiconductor material on a gate and on exposed portions of an electrically functional substrate, irradiating an upper surface of the amorphous semiconductor material to form self-aligned polycrystalline semiconducting source / drain terminal layers, and (optionally) selectively removing the non-irradiated amorphous semiconductor material portions. The present invention advantageously provides MOS thin film transistors having reliable electrical characteristics quickly, efficiently, and / or at a low cost by eliminating one or more conventional photolithographic steps.

Owner:ENSURGE MICROPOWER ASA

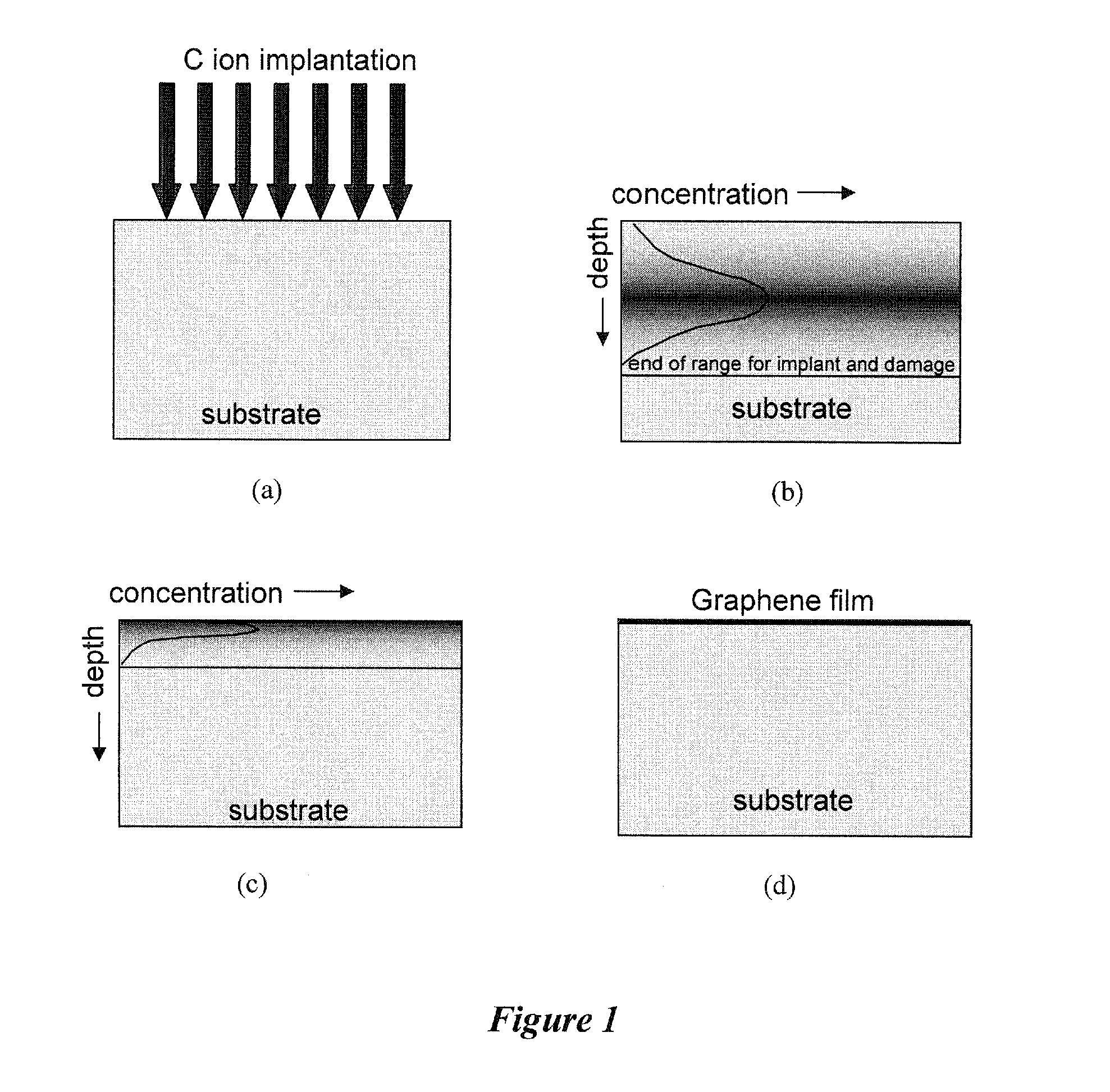

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

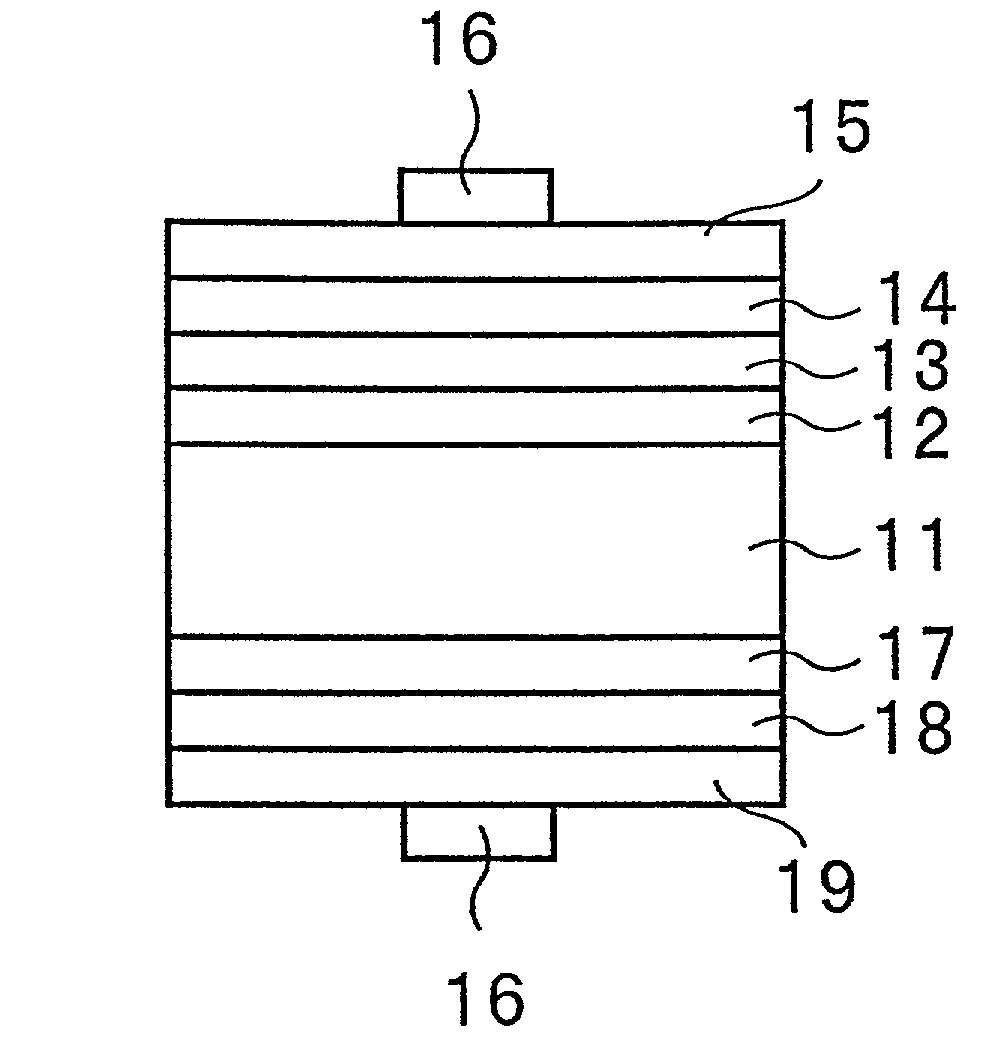

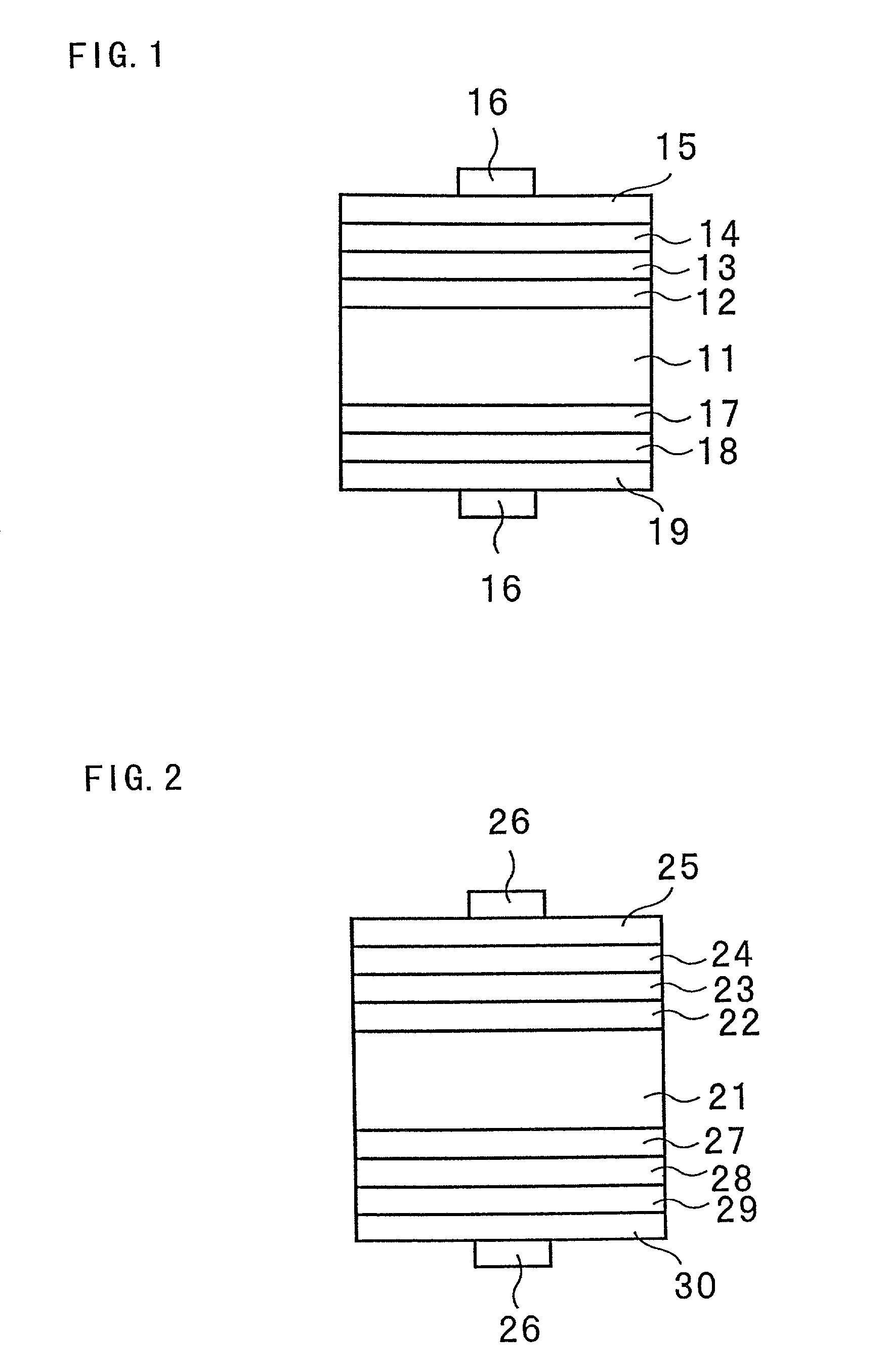

Photovoltaic device and manufacturing method thereof

InactiveUS20030168578A1Electron flowIncrease the open circuit voltageFinal product manufactureMaterial analysis by optical meansHydrogenThin layer

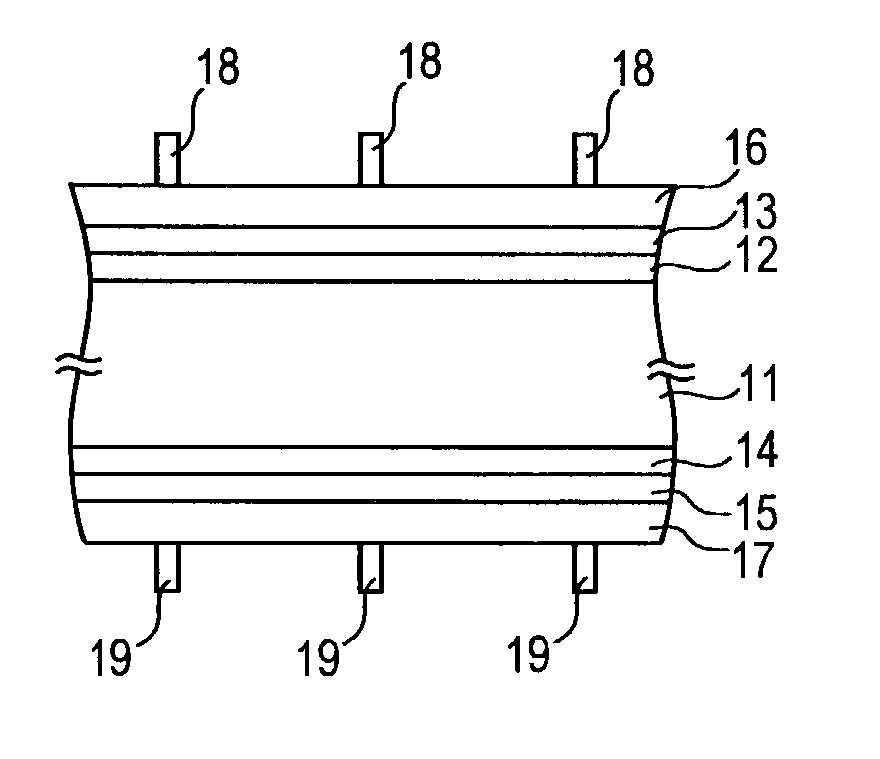

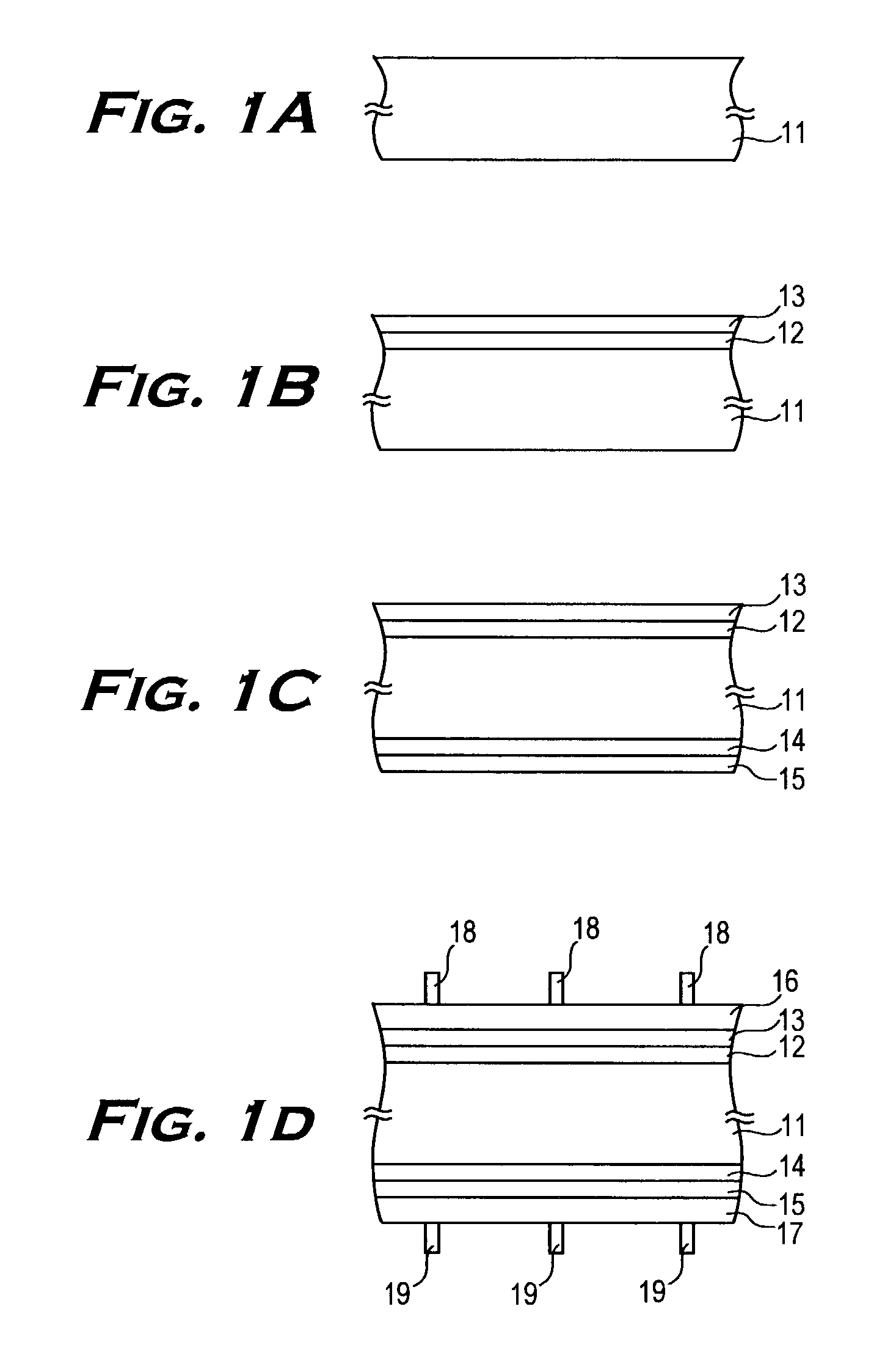

The present invention was made to improve interface characteristics between a crystalline semiconductor and an amorphous semiconductor thin film so that junction characteristics can be upgraded. A manufacturing method of a photovoltaic device comprising an i-type amorphous silicon thin film (12) and a p-type amorphous silicon thin layer (13) laminated in this order on a front surface of an n-type single crystalline silicon substrate (11), and an i-type amorphous silicon layer (14) and an n-type amorphous silicon layer (15) laminated in this order on a rear surface of the single crystalline silicon substrate, wherein an i-type amorphous silicon layer (12) is formed after the front surface of the single crystalline silicon substrate (11) is exposed to a plasma discharge using mixed gas of hydrogen gas and a gas containing boron so that atoms of boron may be interposed on an interface between the single crystalline silicon substrate (11) and the i-type amorphous silicon layer (12).

Owner:SANYO ELECTRIC CO LTD

Method for manufacturing photoelectric conversion device

InactiveUS20090047752A1Quality improvementReduce deterioration rateFinal product manufactureSolid-state devicesProduction rateMicrowave

It is an object to form a high-quality crystalline semiconductor layer directly over a large-sized substrate with high productivity without reducing the deposition rate and to provide a photoelectric conversion device in which the crystalline semiconductor layer is used as a photoelectric conversion layer. A photoelectric conversion layer formed of a semi-amorphous semiconductor is formed over a substrate as follows: a reaction gas is introduced into a treatment chamber where the substrate is placed; and a microwave is introduced into the treatment chamber through a slit provided for a waveguide that is disposed in approximately parallel to and opposed to the substrate, thereby generating plasma. By forming a photoelectric conversion layer using such a semi-amorphous semiconductor, a rate of deterioration in characteristics by light deterioration is decreased from one-fifth to one-tenth, and thus a photoelectric conversion device that has almost no problems for practical use can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device manufacturing with amorphous film cyrstallization using wet oxygen

A method of fabricating a semiconductor device includes the steps of forming an amorphous semiconductor film on a substrate, oxidizing the surface of the amorphous semiconductor film in an atmosphere containing water vapor and oxygen, and removing the oxide film which is formed on the surface of the semiconductor film.

Owner:SANYO ELECTRIC CO LTD

Method of fabricating a field effect transistor having improved junctions

InactiveUS7247547B2TransistorSemiconductor/solid-state device manufacturingDopantElectrical conductor

A method of forming a field effect transistor is provided which includes forming an amorphized semiconductor region having a first depth from a single-crystal semiconductor region and subsequently forming a first gate conductor above a channel portion of the amorphized semiconductor region. A first dopant including at least one of an n-type dopant and a p-type dopant is then implanted to a second depth into portions of the amorphized semiconductor region not masked by the first gate conductor to form source / drain portions adjacent to the channel portion. The substrate is then heated to recrystallize the channel portion and the source / drain portions of the amorphized semiconductor region. After the heating step, at least a part of the recrystallized semiconductor region is locally heated to activate a dopant in at least one of the channel portion and the source / drain portion.

Owner:GOOGLE LLC

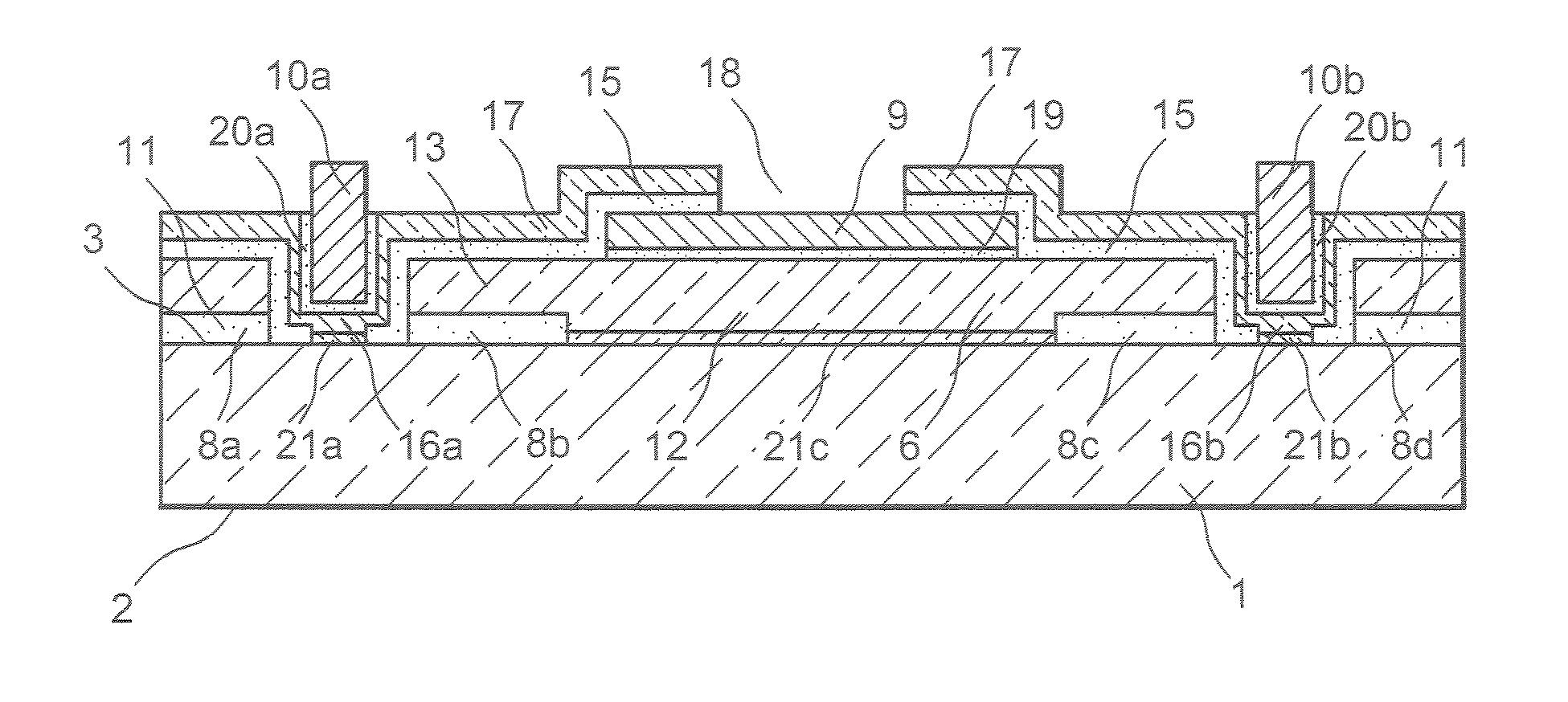

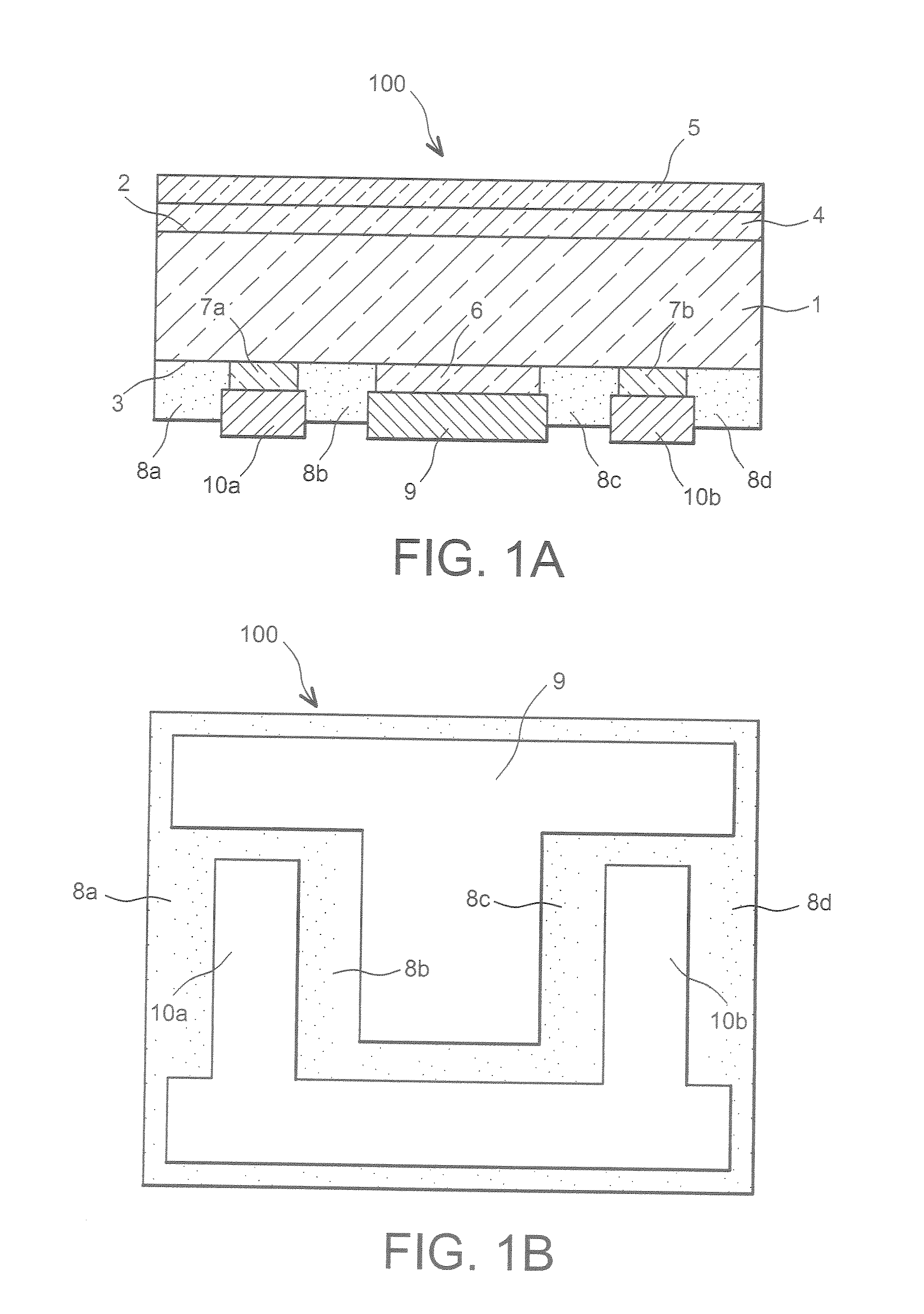

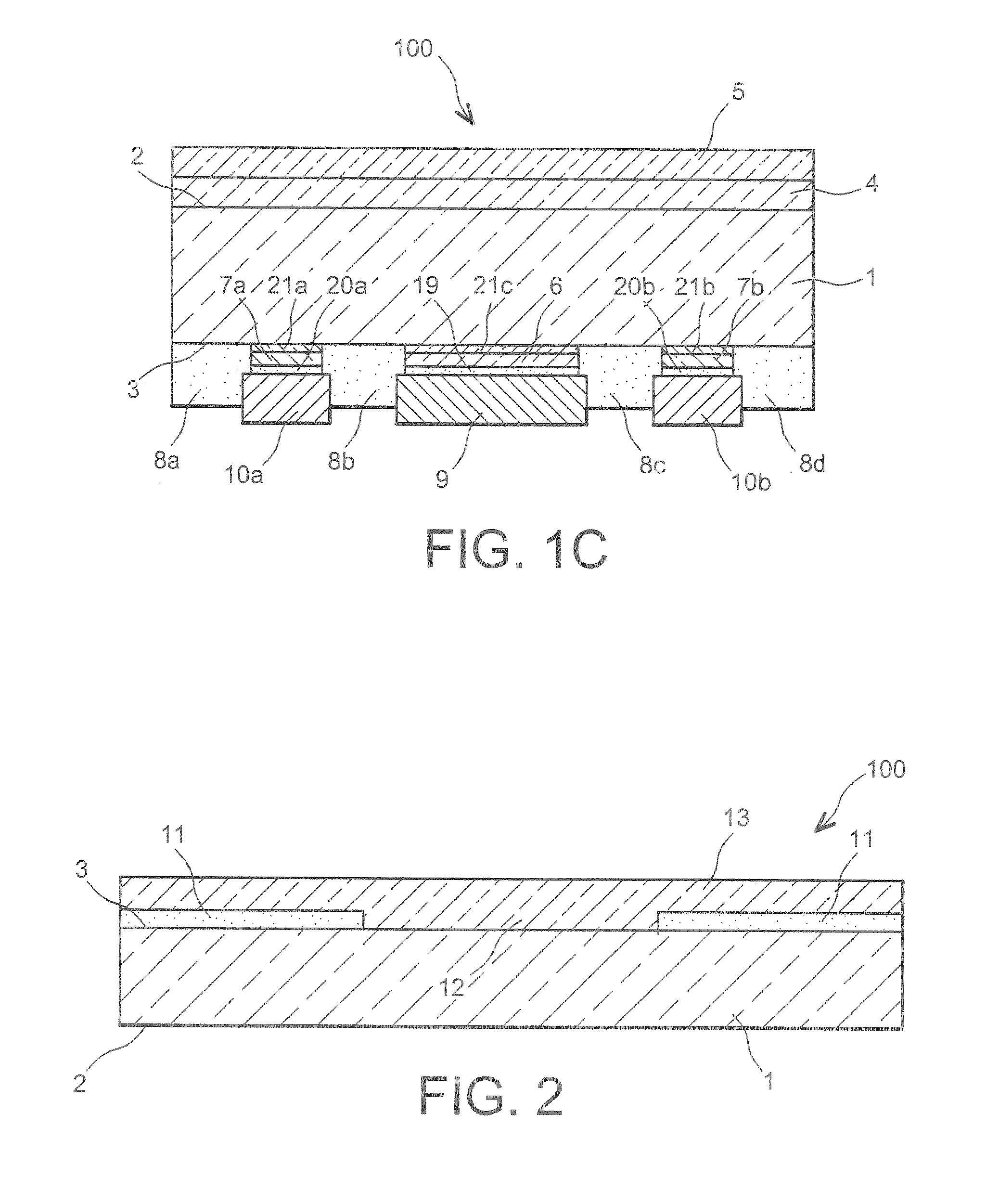

Semiconductor device and method of manufacturing the same

InactiveUS7148092B2Increase speedLess fluctuationTransistorSolid-state devicesEngineeringCrystalline semiconductor

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com