Patents

Literature

2102 results about "Semiconductor thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin Films. A thin film, as its name implies, is a layer with a high surface-to-volume ratio. Thin films are extensively used in wafer fabrication, and can be a resistor, a conductor, an insulator, or even a semiconductor. Thin films can be deposited on a substrate by thermal growing or by vapor deposition.

Transparent oxide semiconductor thin film transistors

This invention relates to novel, transparent oxide semiconductor thin film transistors (TFT's) and a process for making them.

Owner:SAMSUNG DISPLAY CO LTD

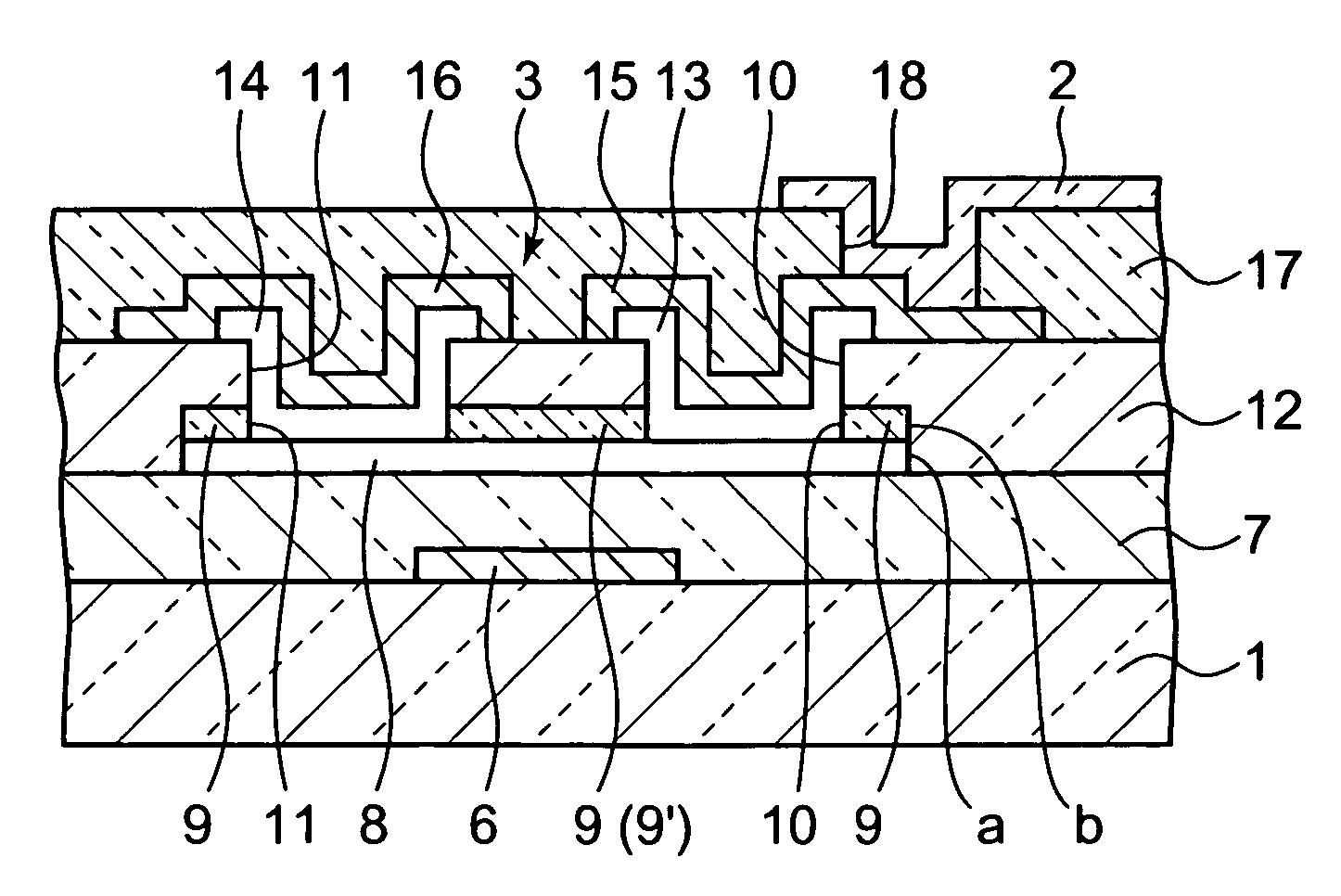

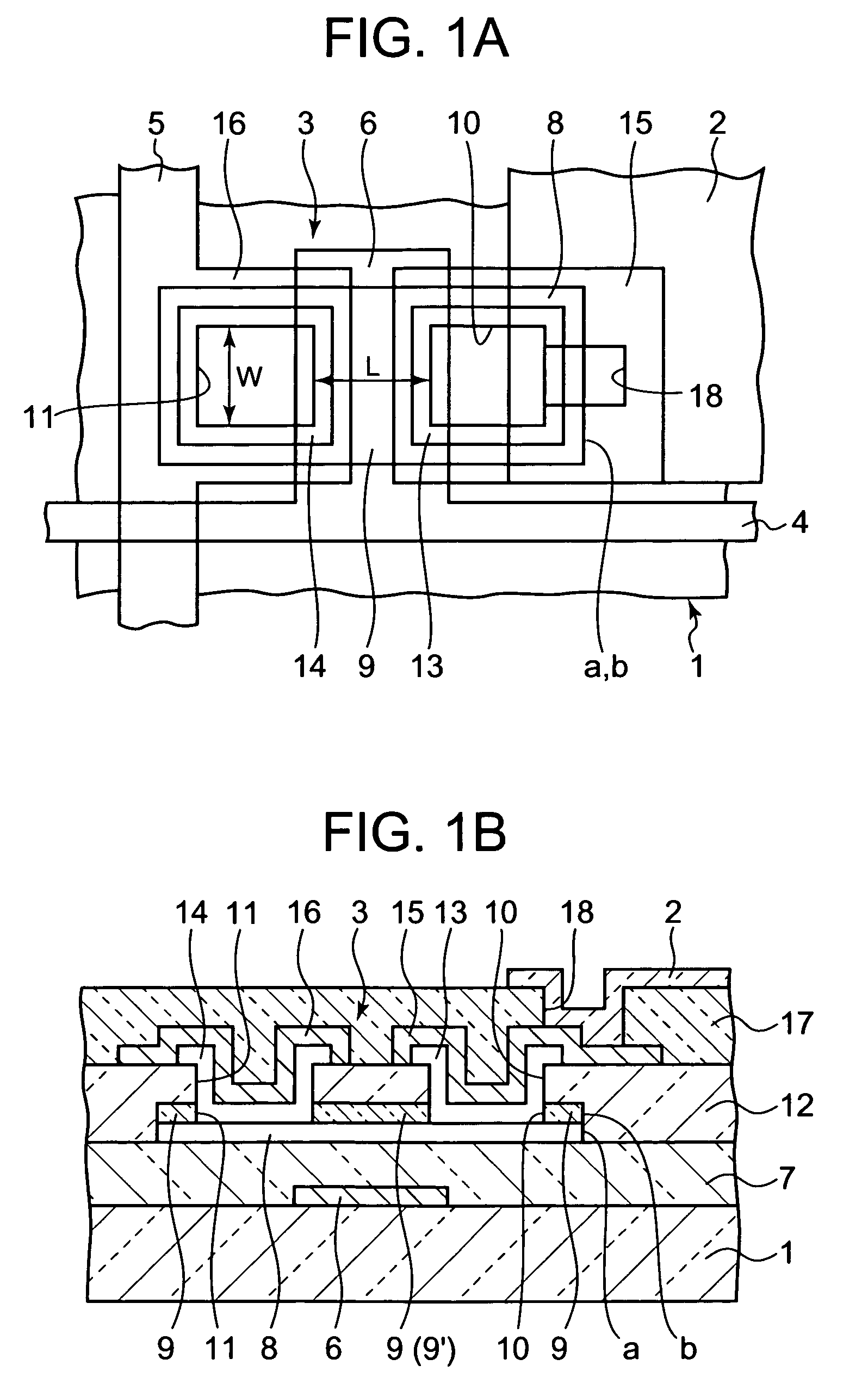

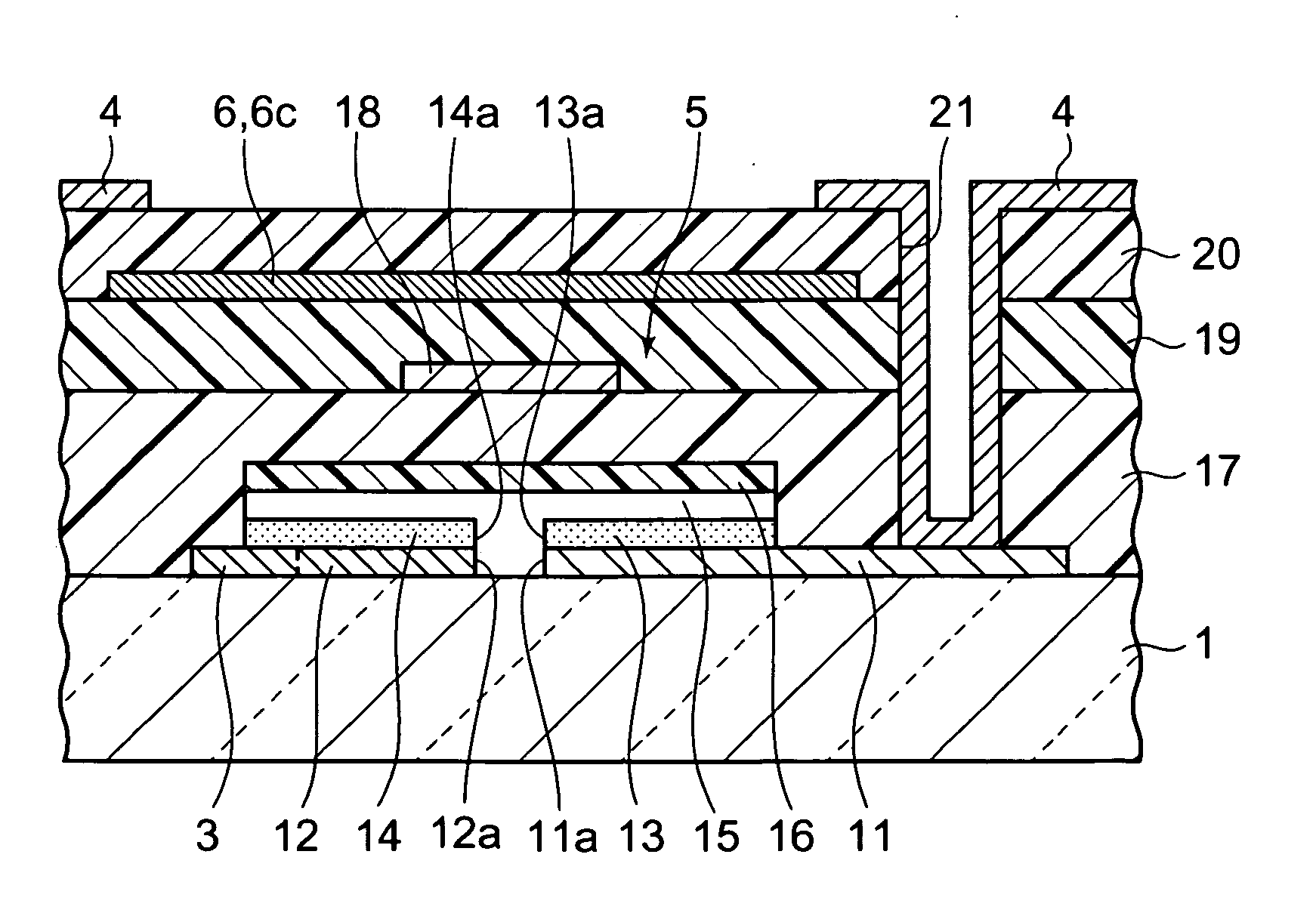

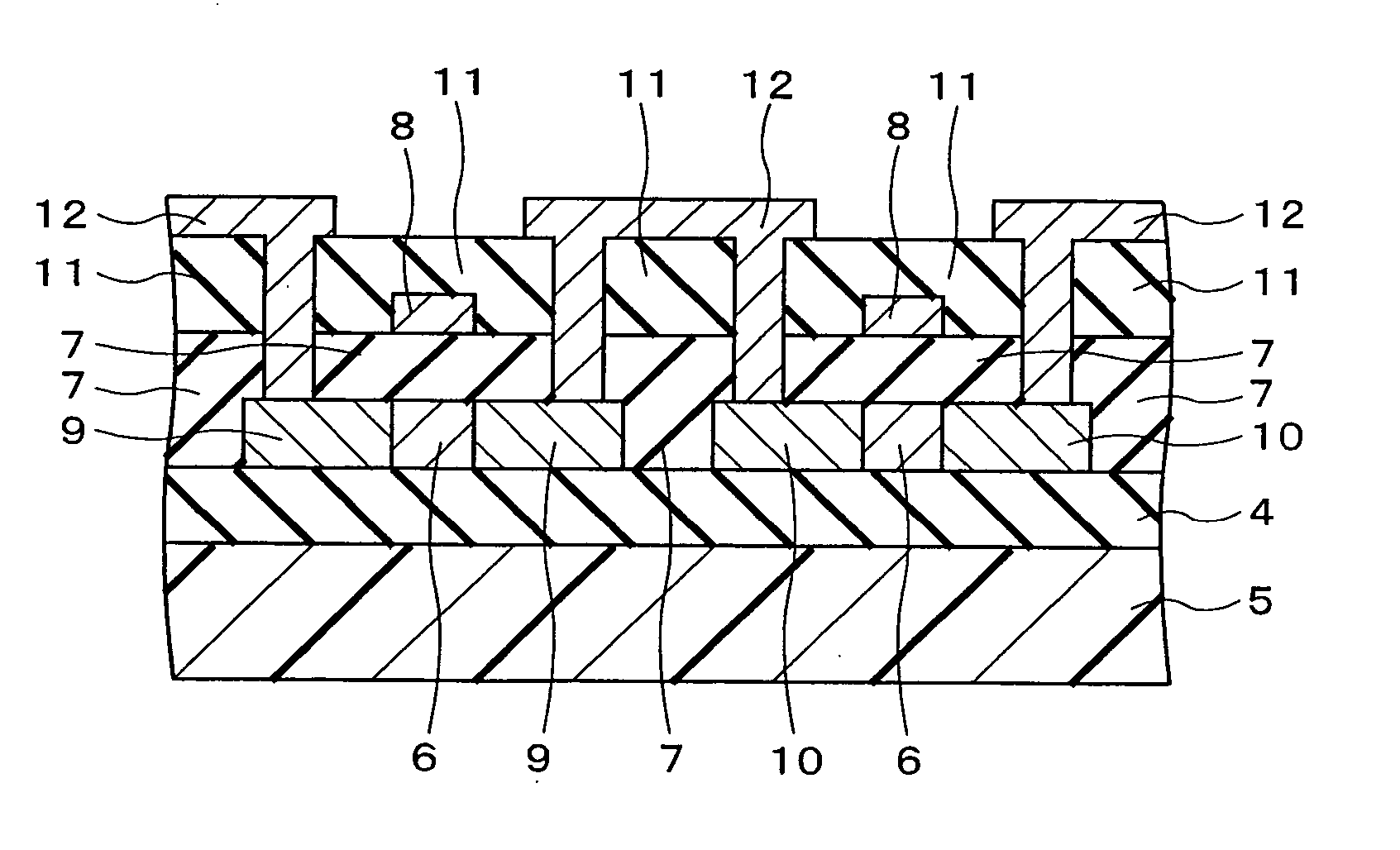

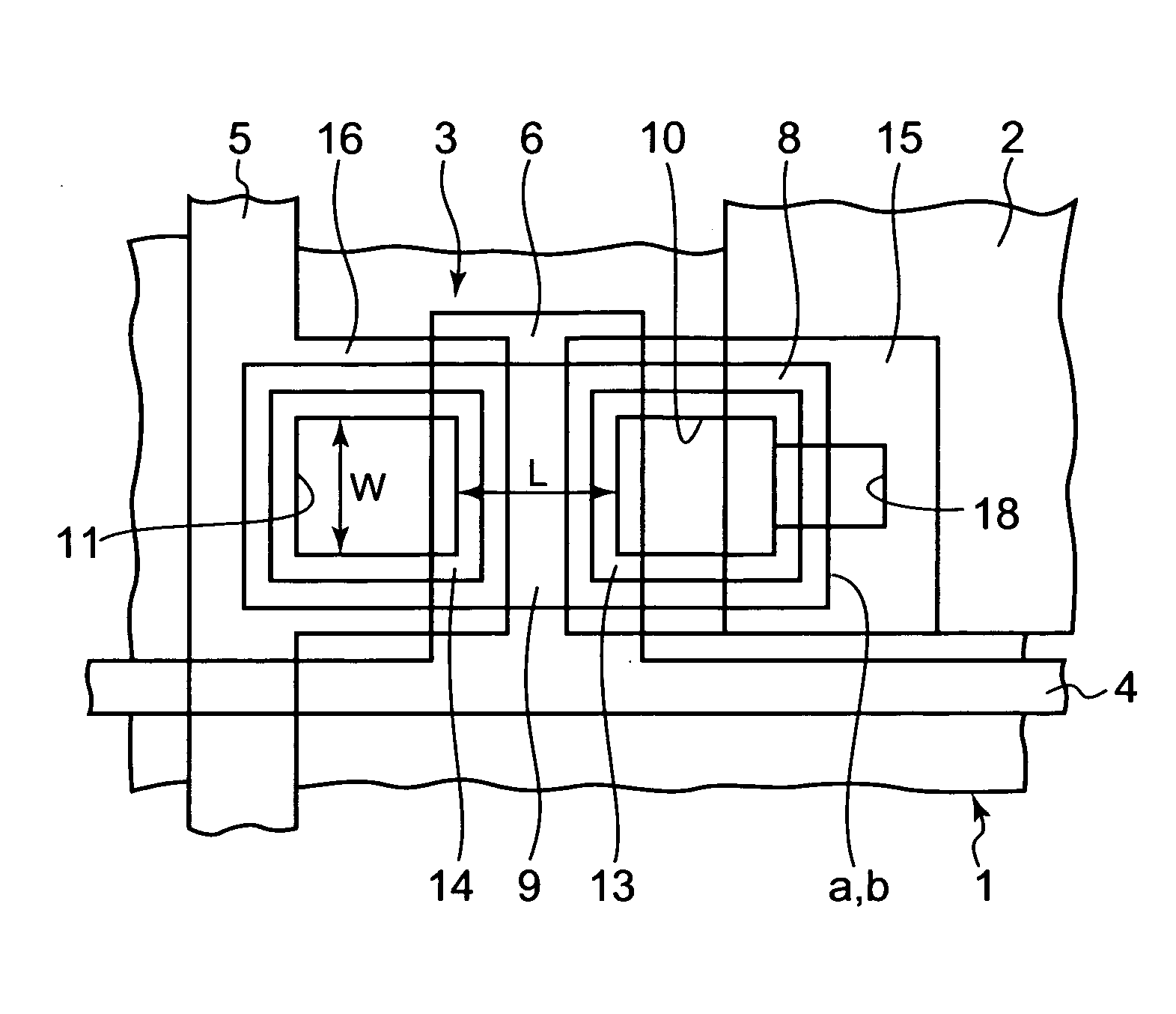

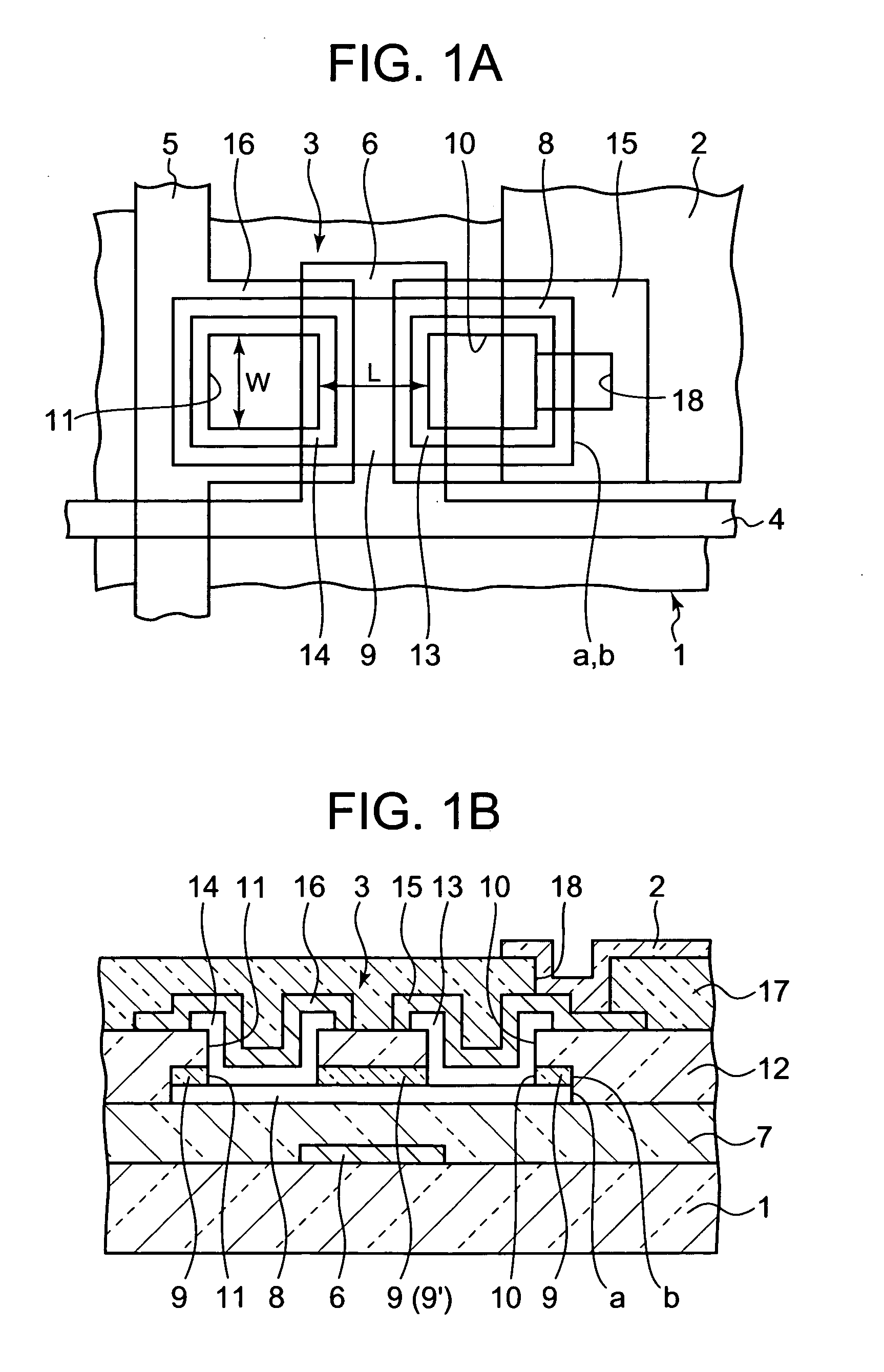

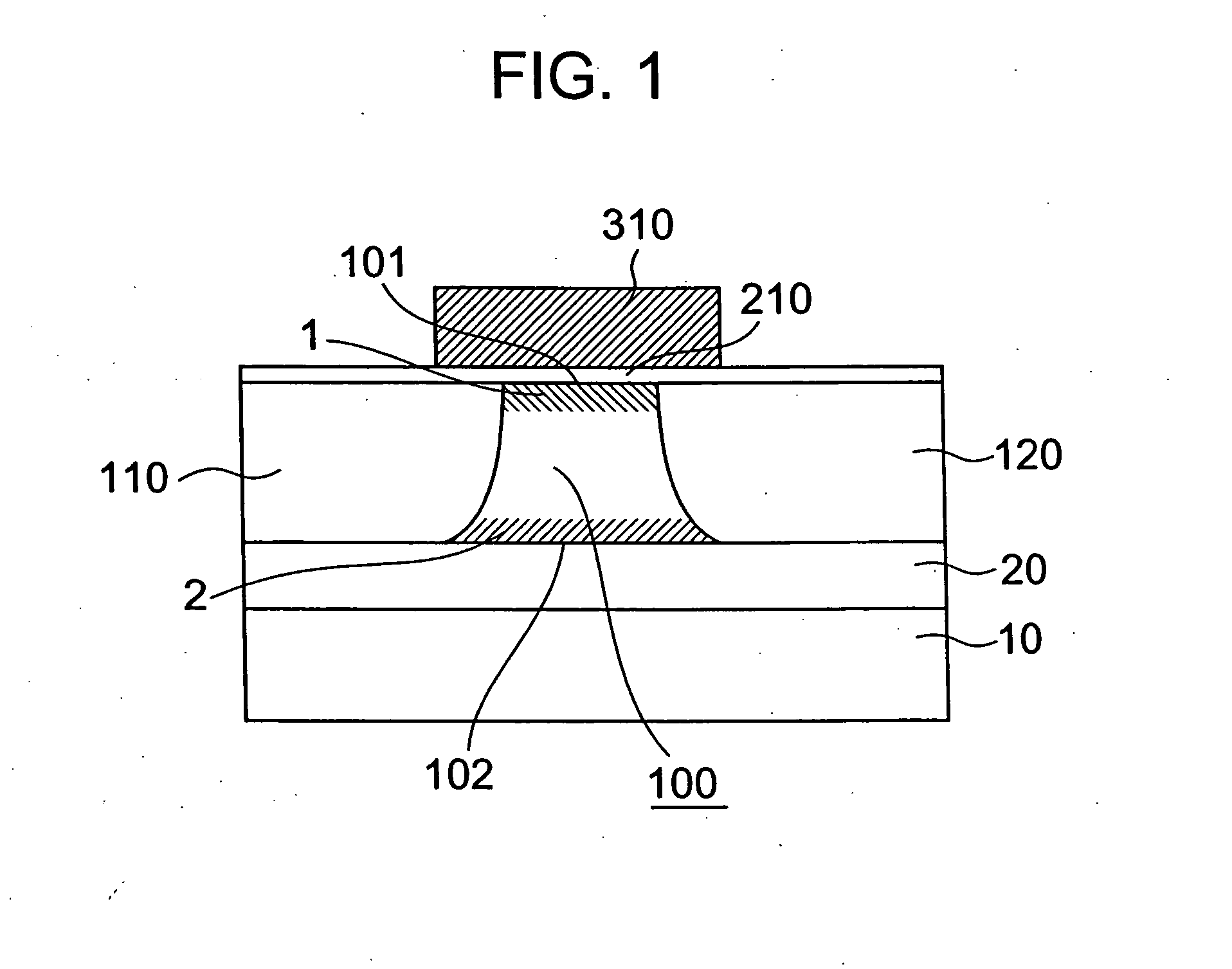

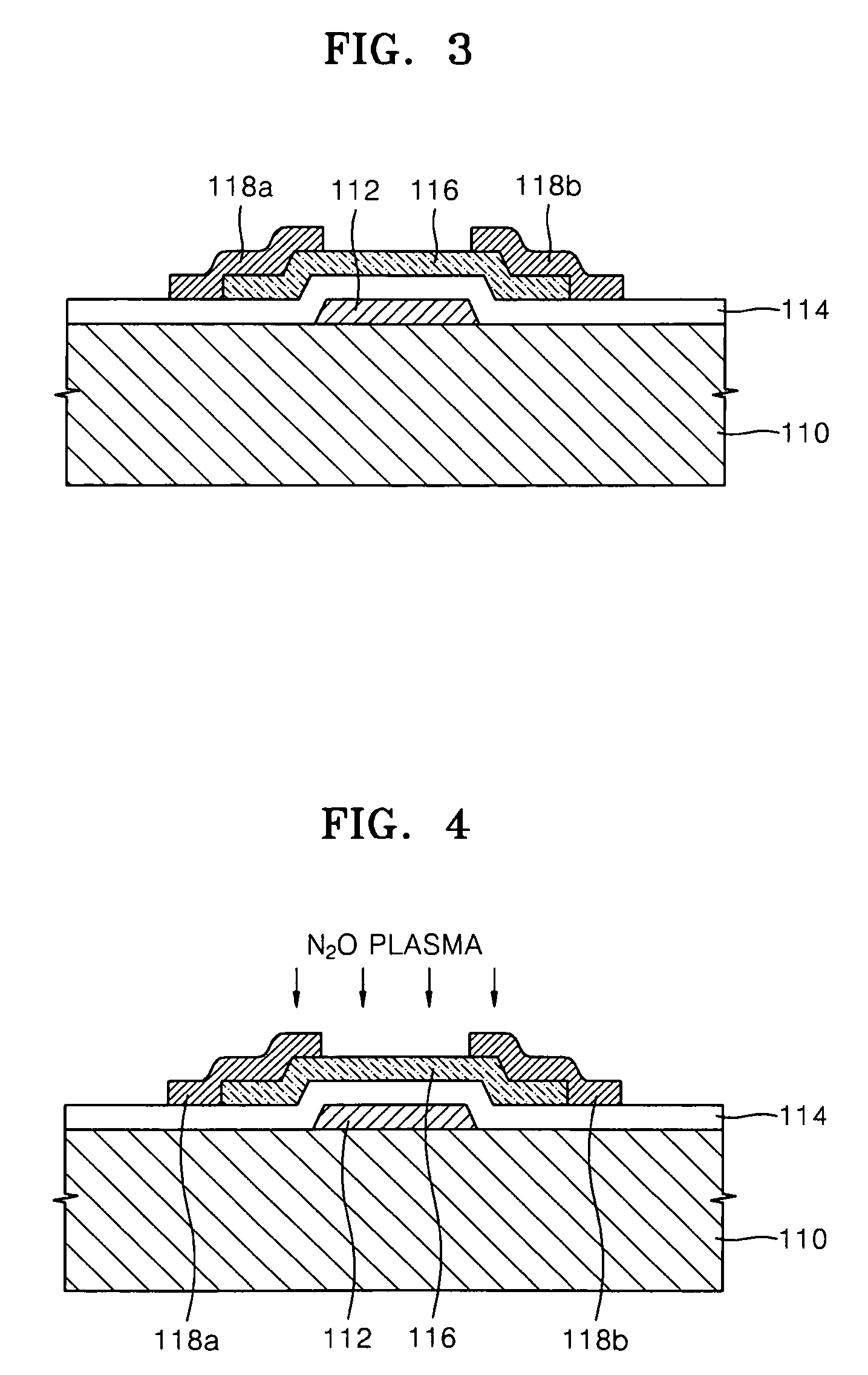

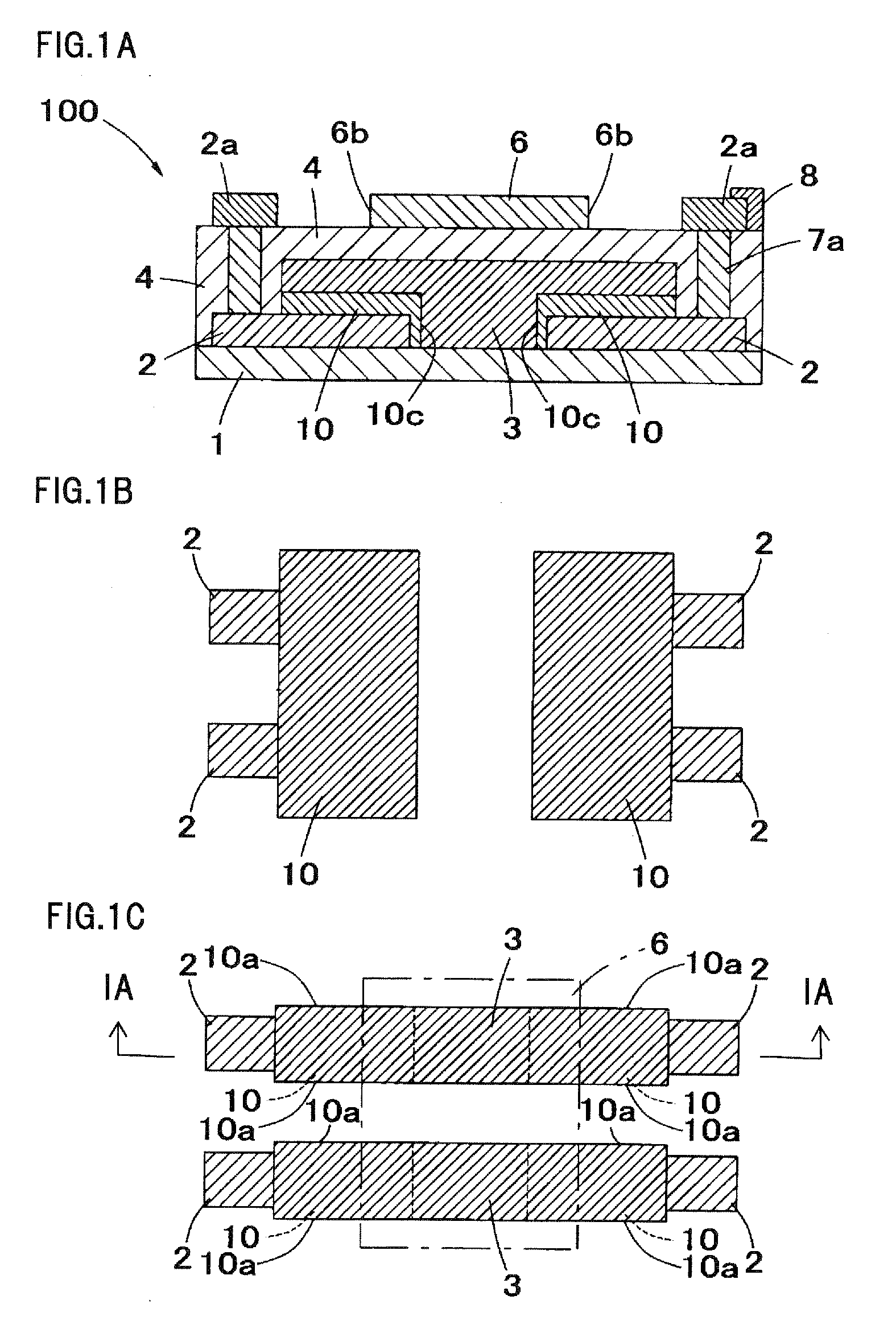

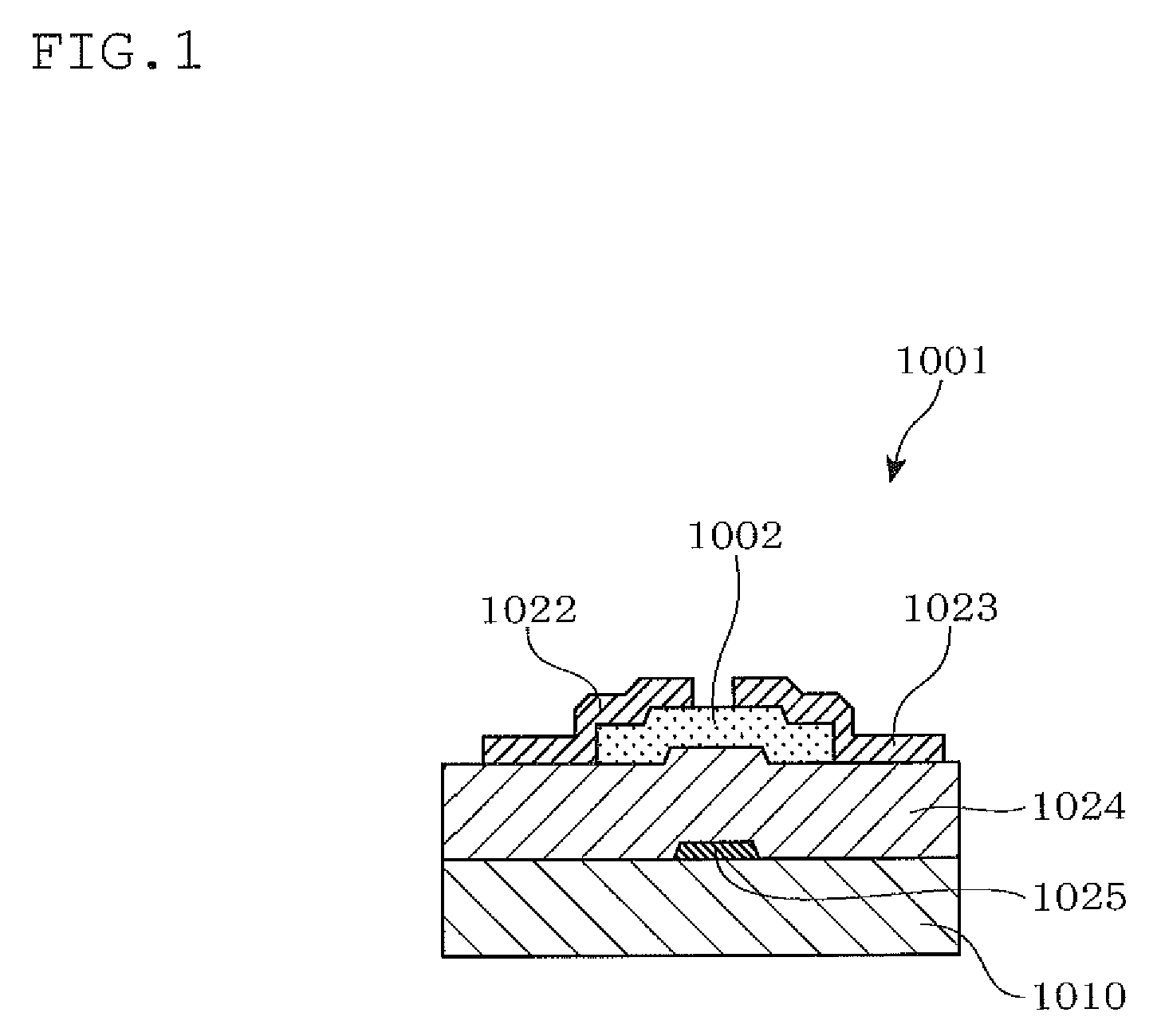

Thin film transistor having an etching protection film and manufacturing method thereof

InactiveUS7385224B2Improve machining accuracySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSemiconductor thin films

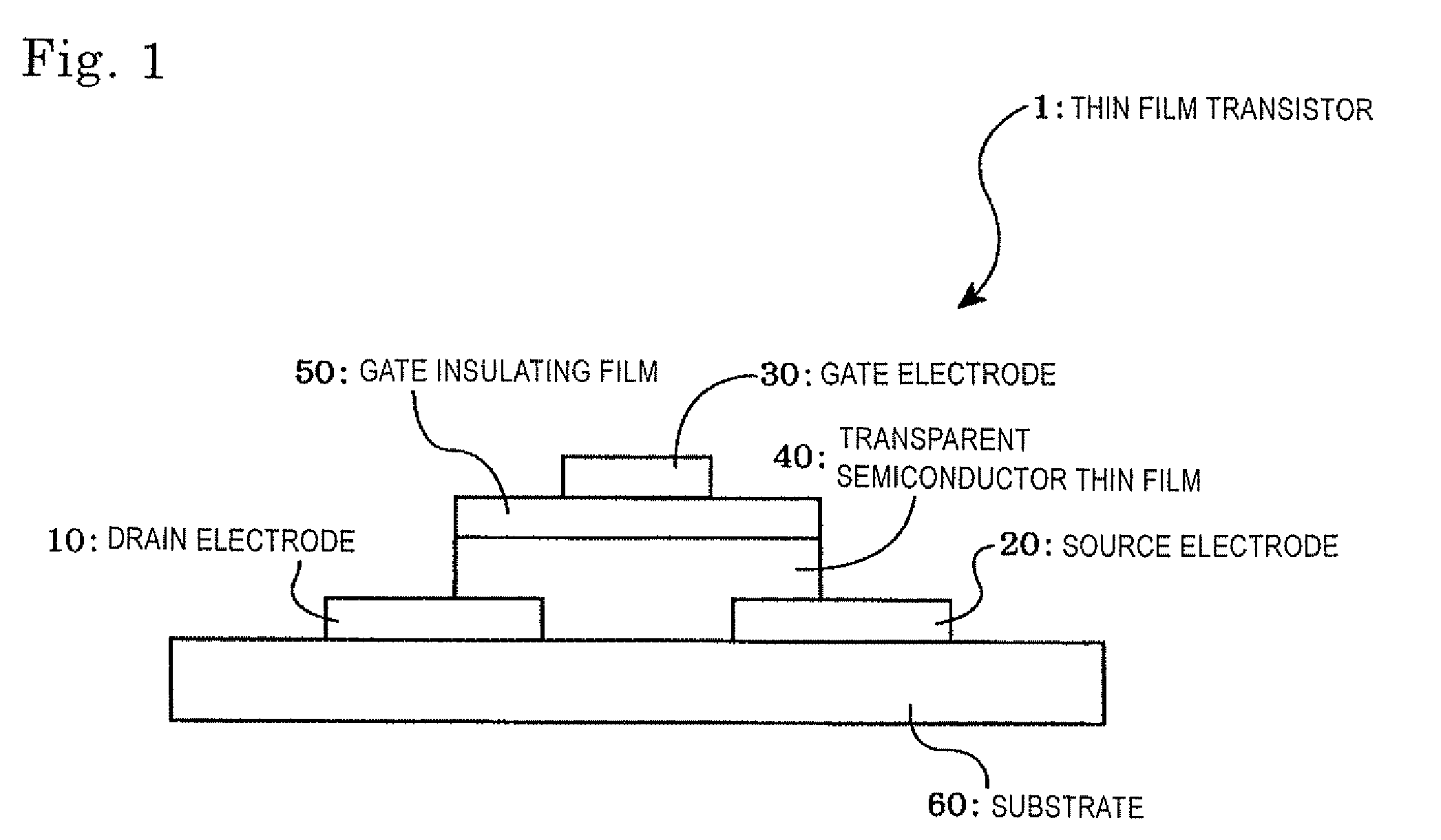

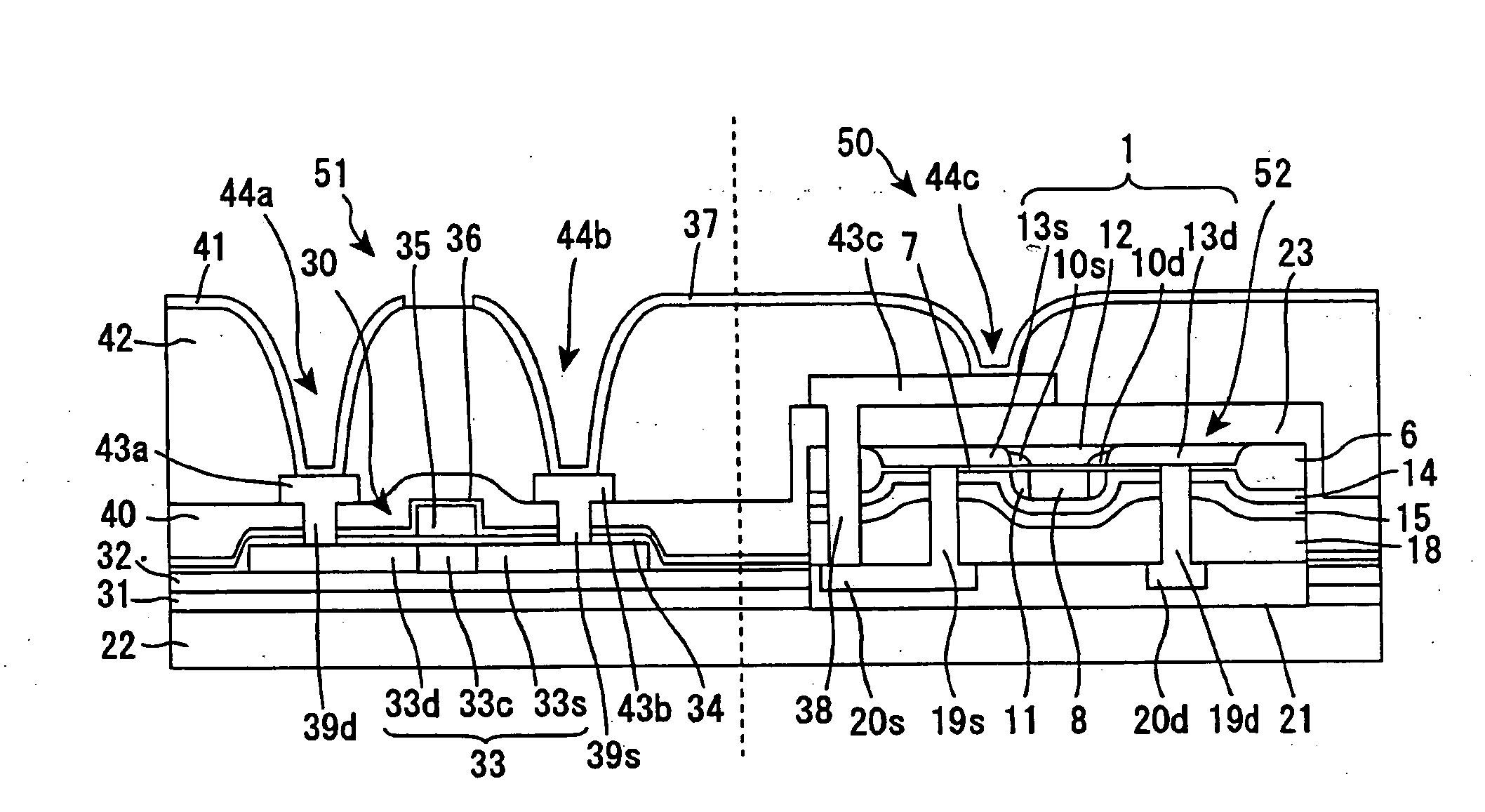

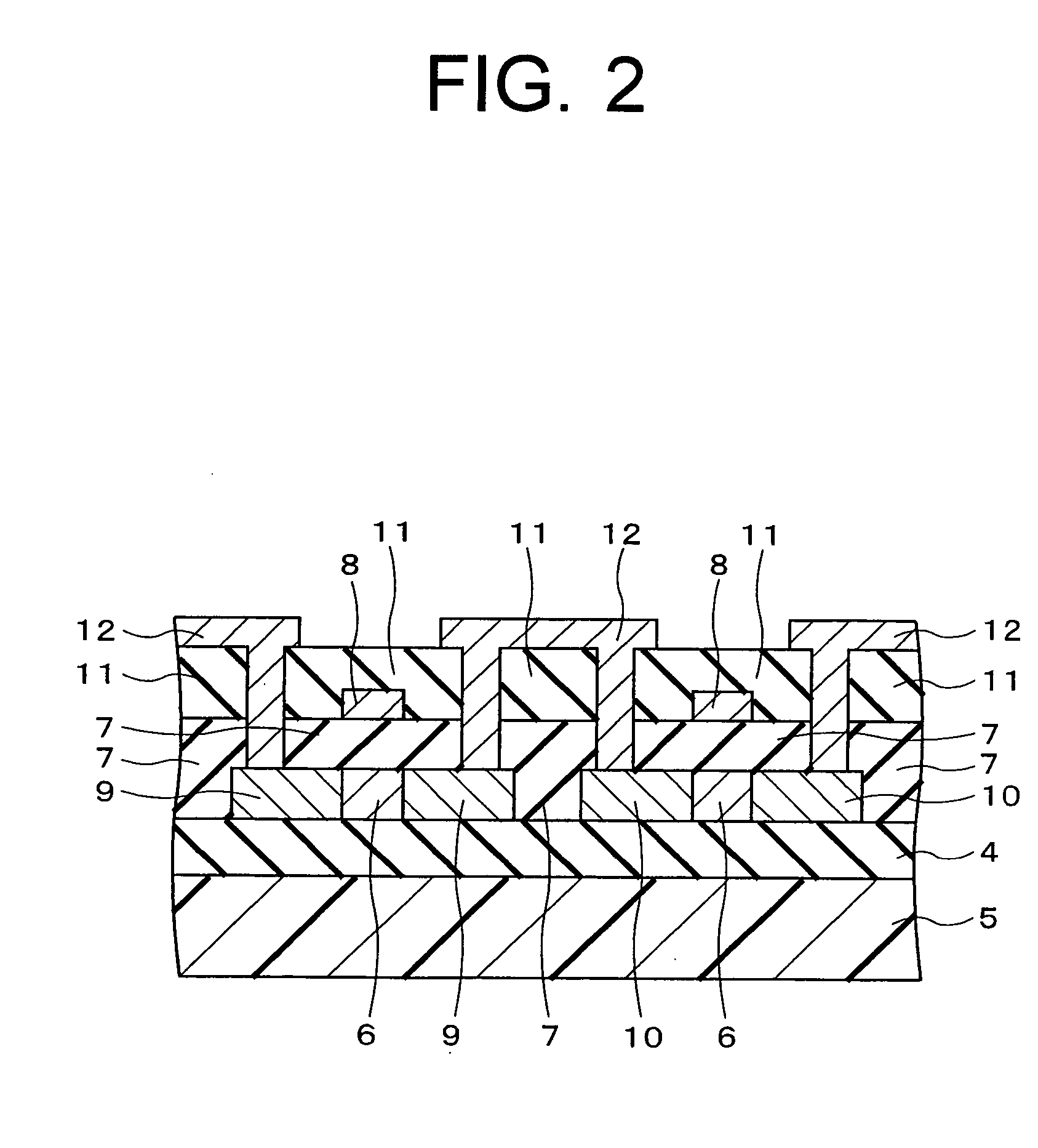

A thin film transistor of the present invention includes a semiconductor thin film (8); a gate insulating film (7) formed on one surface of the semiconductor thin film (8); a gate electrode (6) formed to be opposite to the semiconductor thin film (8) through the gate insulating film (7); a source electrode (15) and a drain electrode (16) electrically connected to the semiconductor thin film (8); a source region; a drain region; and a channel region. The thin film transistor further includes an insulating film (9) formed on a peripheral portion corresponding to at least the source region and the drain region of the semiconductor thin film (8), and having a contact hole (10, 11) through which at least a part of each of the source region and the drain region is exposed wherein the source electrode (15) and the drain electrode (16) are connected to the semiconductor thin film (8) through the contact hole (10, 11).

Owner:CASIO COMPUTER CO LTD

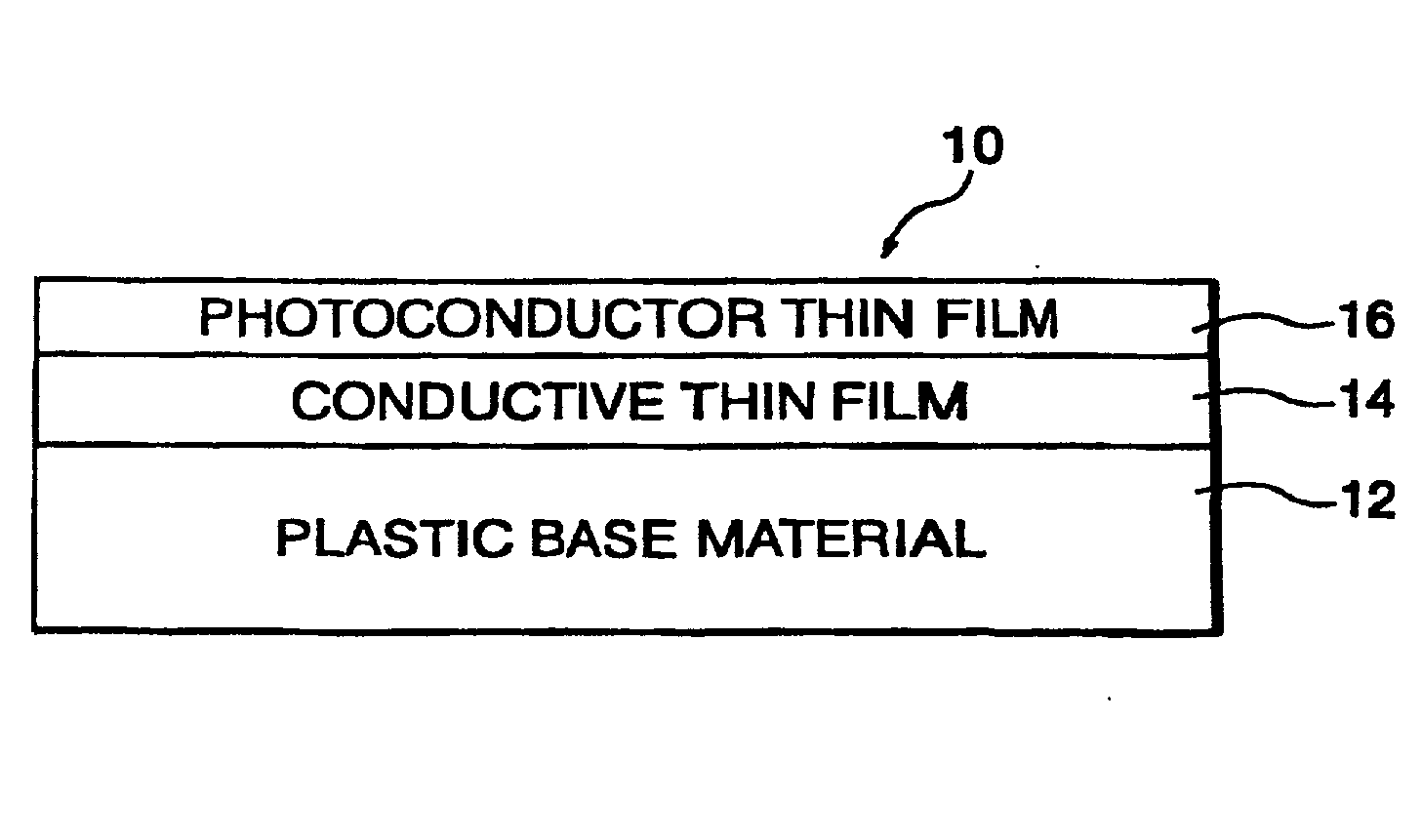

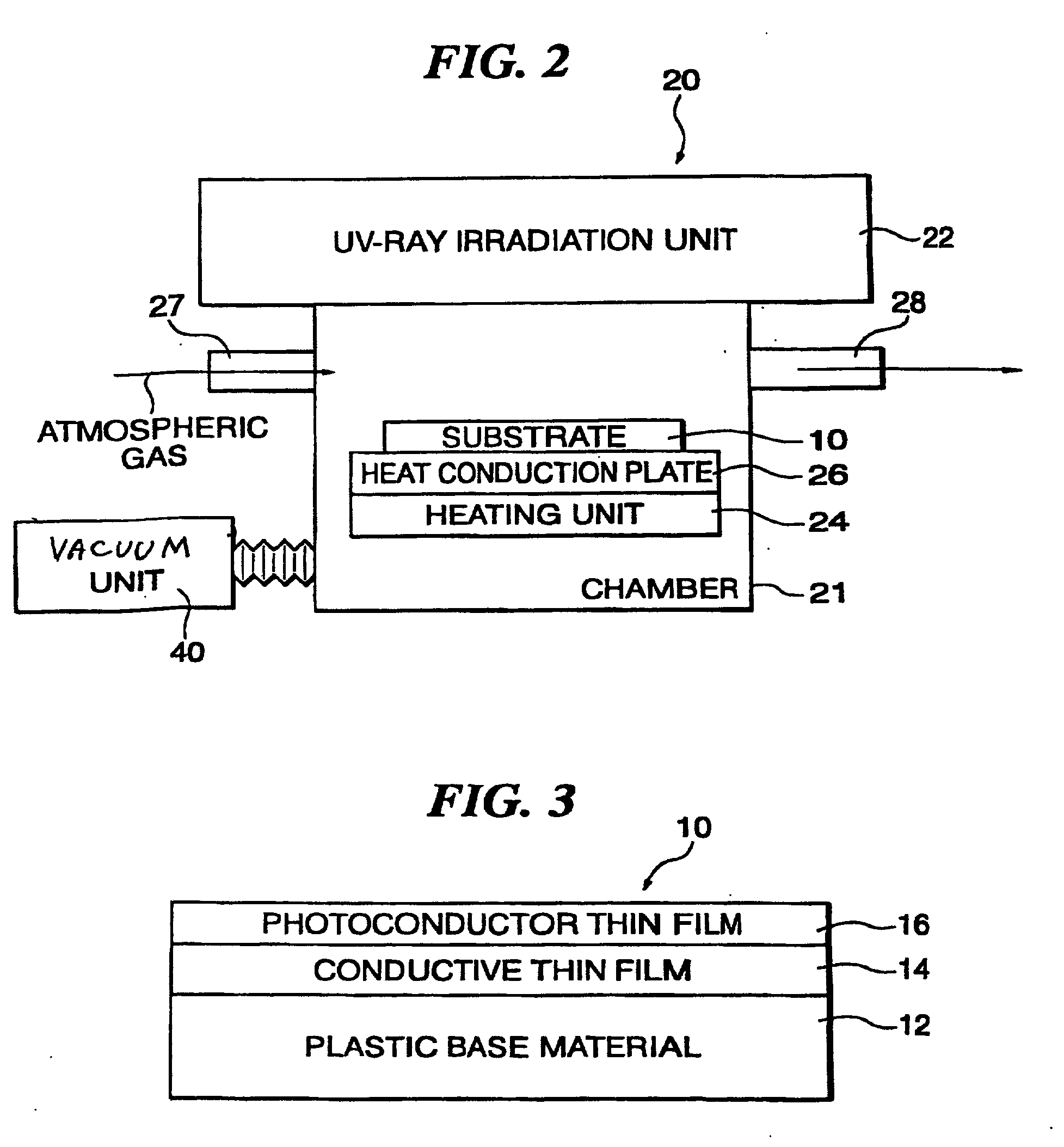

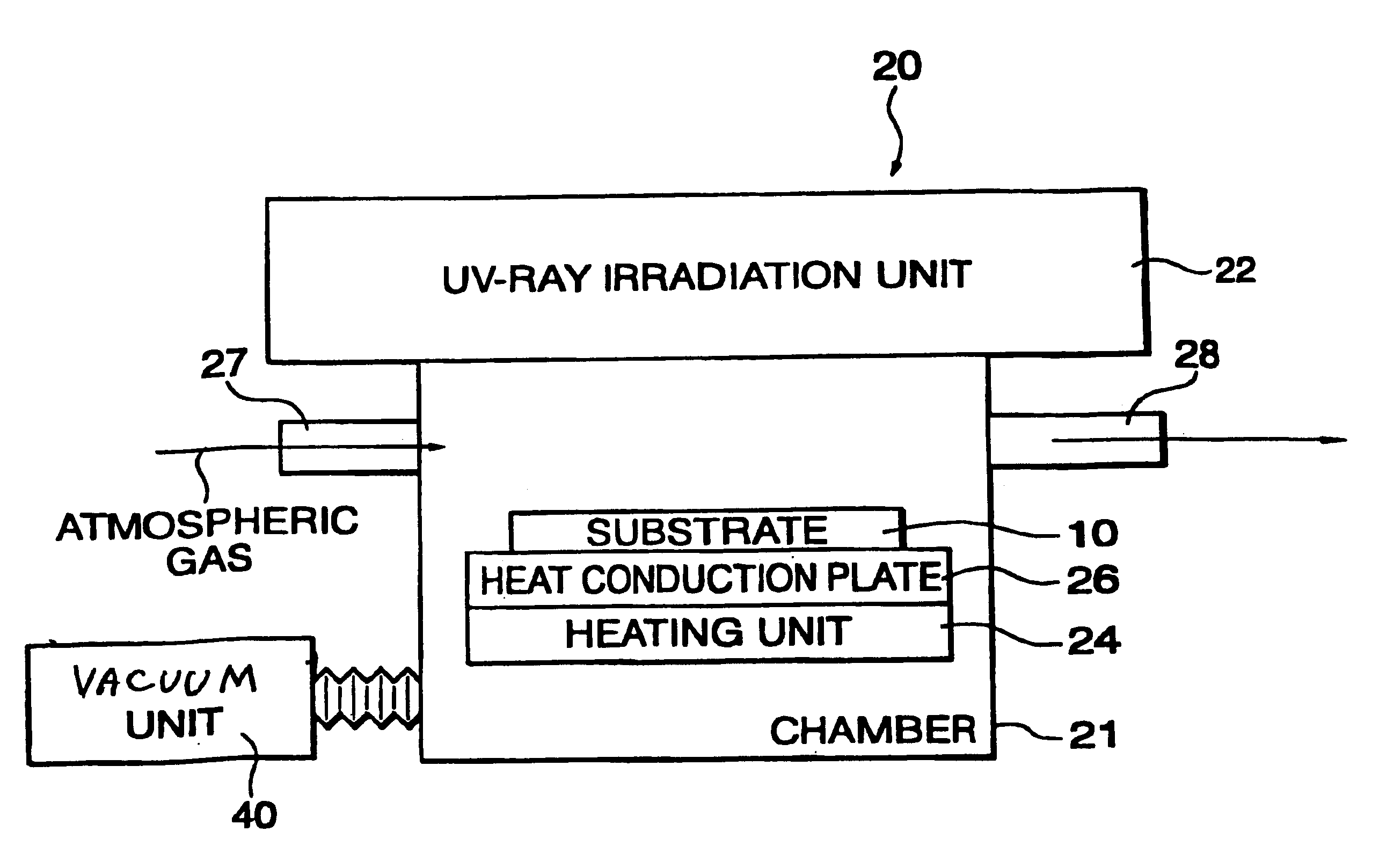

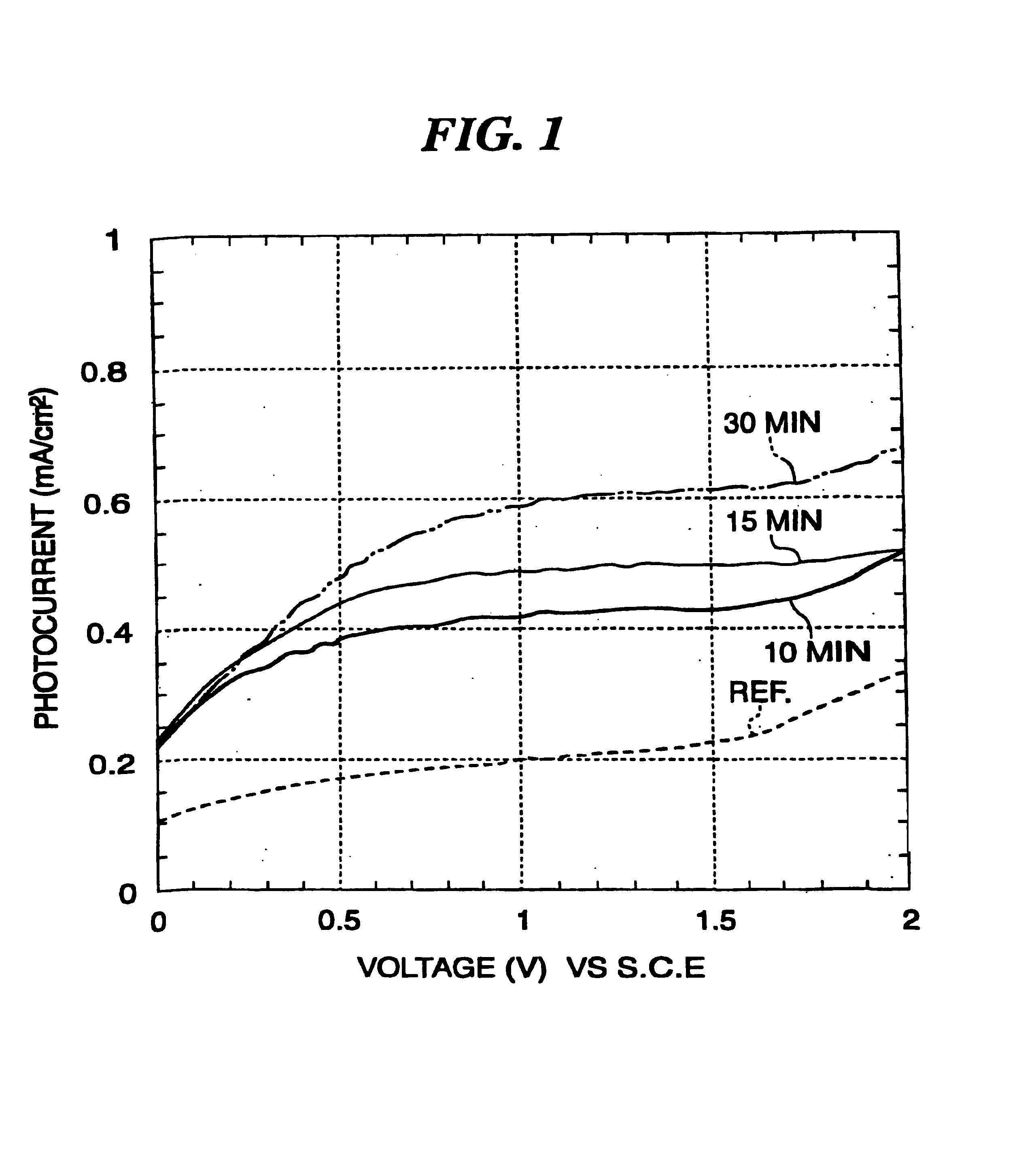

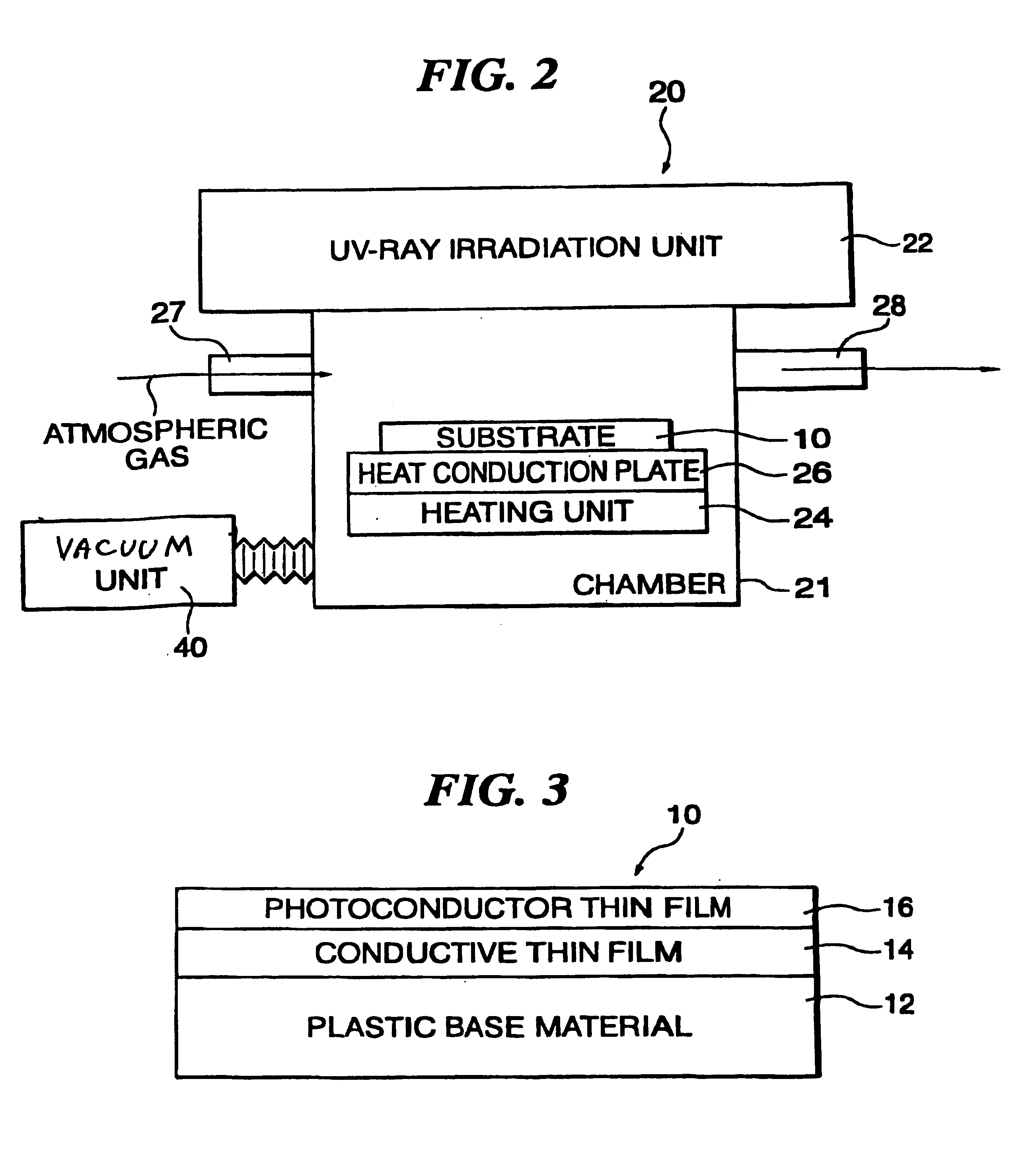

Method of forming crystalline semiconductor thin film on base substrate, lamination formed with crystalline semiconductor thin film and color filter

A method of forming a crystalline semiconductor thin film on a base material which can be prepared at a low temperature by simple step and device, the method including a processing step of applying UV-rays to an amorphous semiconductor thin film provided on a base material while keeping a temperature at not less than 25° C. and not more than 300° C. in a vacuum or a reducing gas atmosphere, as well as a substrate having the semiconductor thin film provided on the base material, a substrate for forming a color filter and a color filter using the substrate.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Thin film transistor having oxide semiconductor layer and manufacturing method thereof

ActiveUS20060284172A1Etch resistance of resist is lowPromote meltingSolid-state devicesSemiconductor/solid-state device manufacturingZincSemiconductor

A thin film transistor has a semiconductor thin film including zinc oxide, a protection film formed on entirely the upper surface of the semiconductor thin film, a gate insulating film formed on the protection film, a gate electrode formed on the gate insulating film above the semiconductor thin film, and a source electrode and drain electrode formed under the semiconductor thin film so as to be electrically connected to the semiconductor thin film.

Owner:SAMSUNG DISPLAY CO LTD

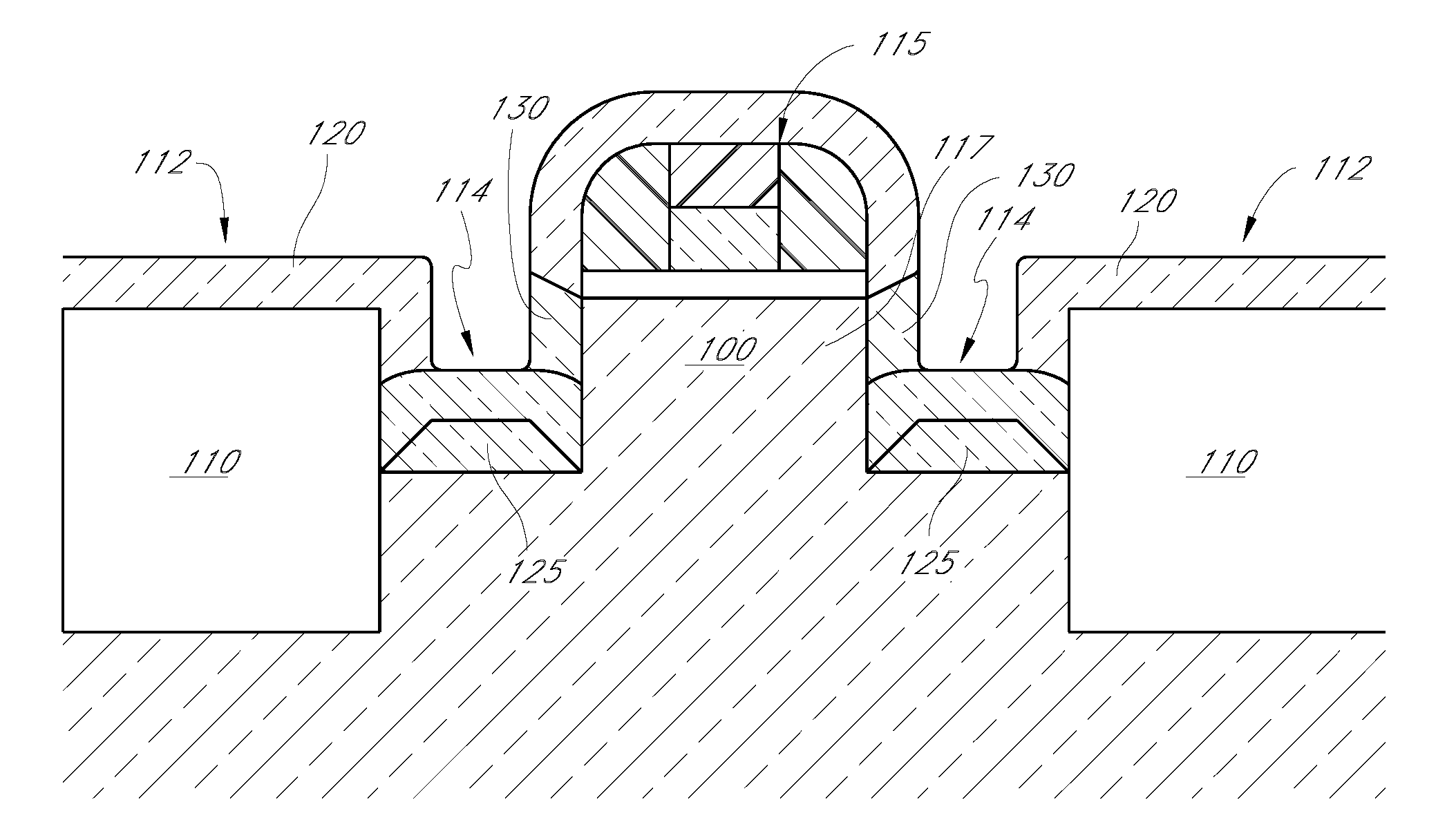

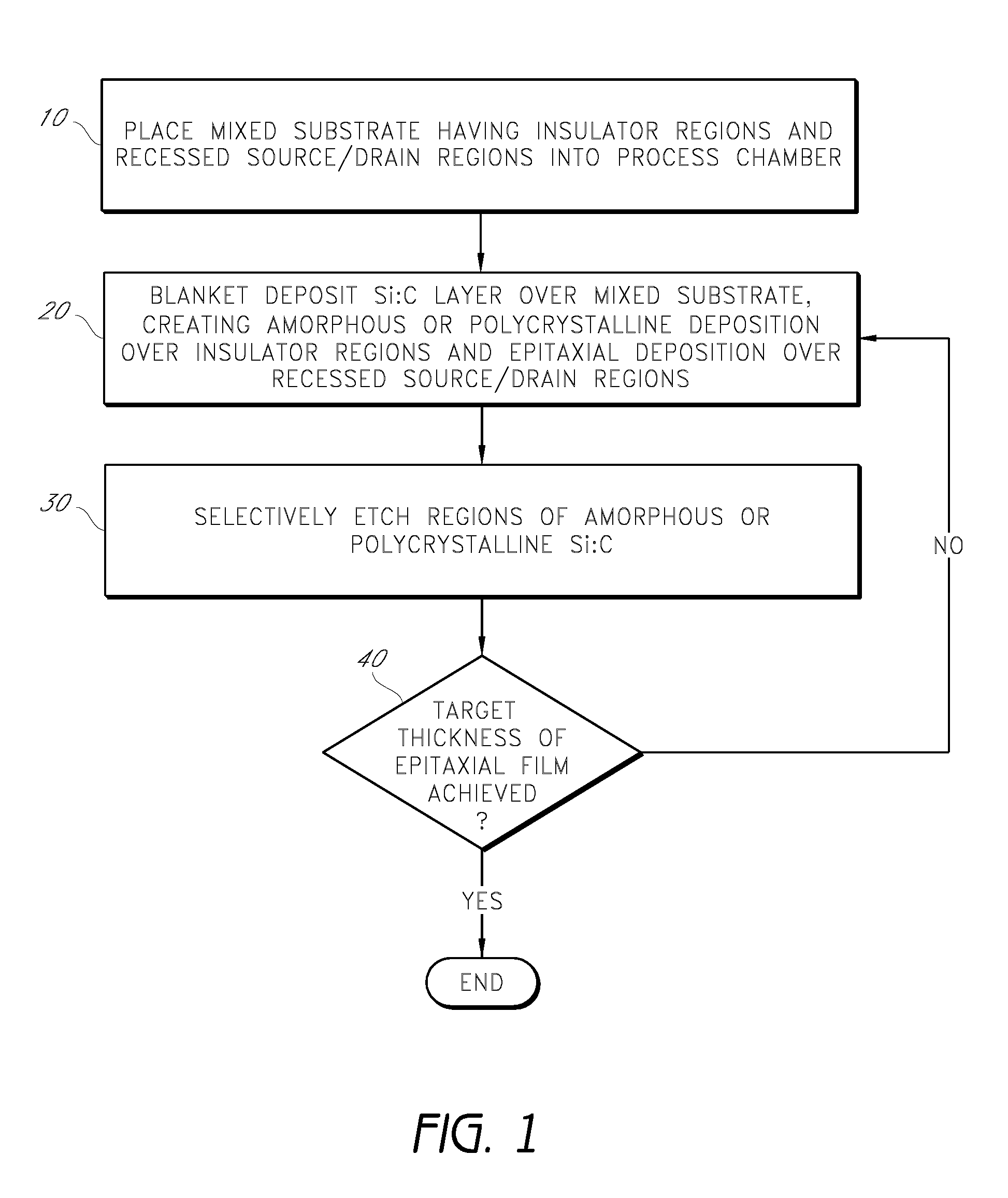

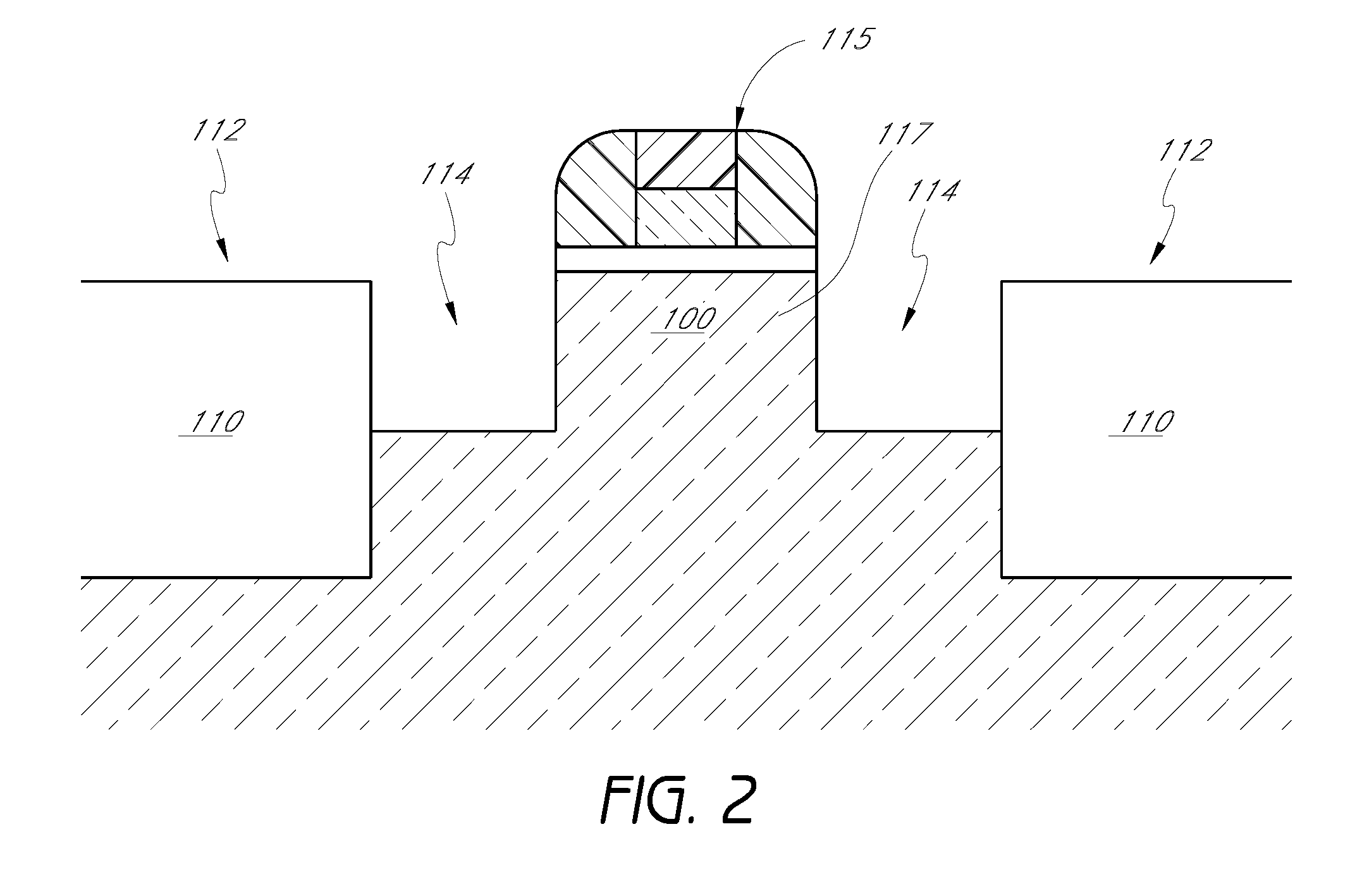

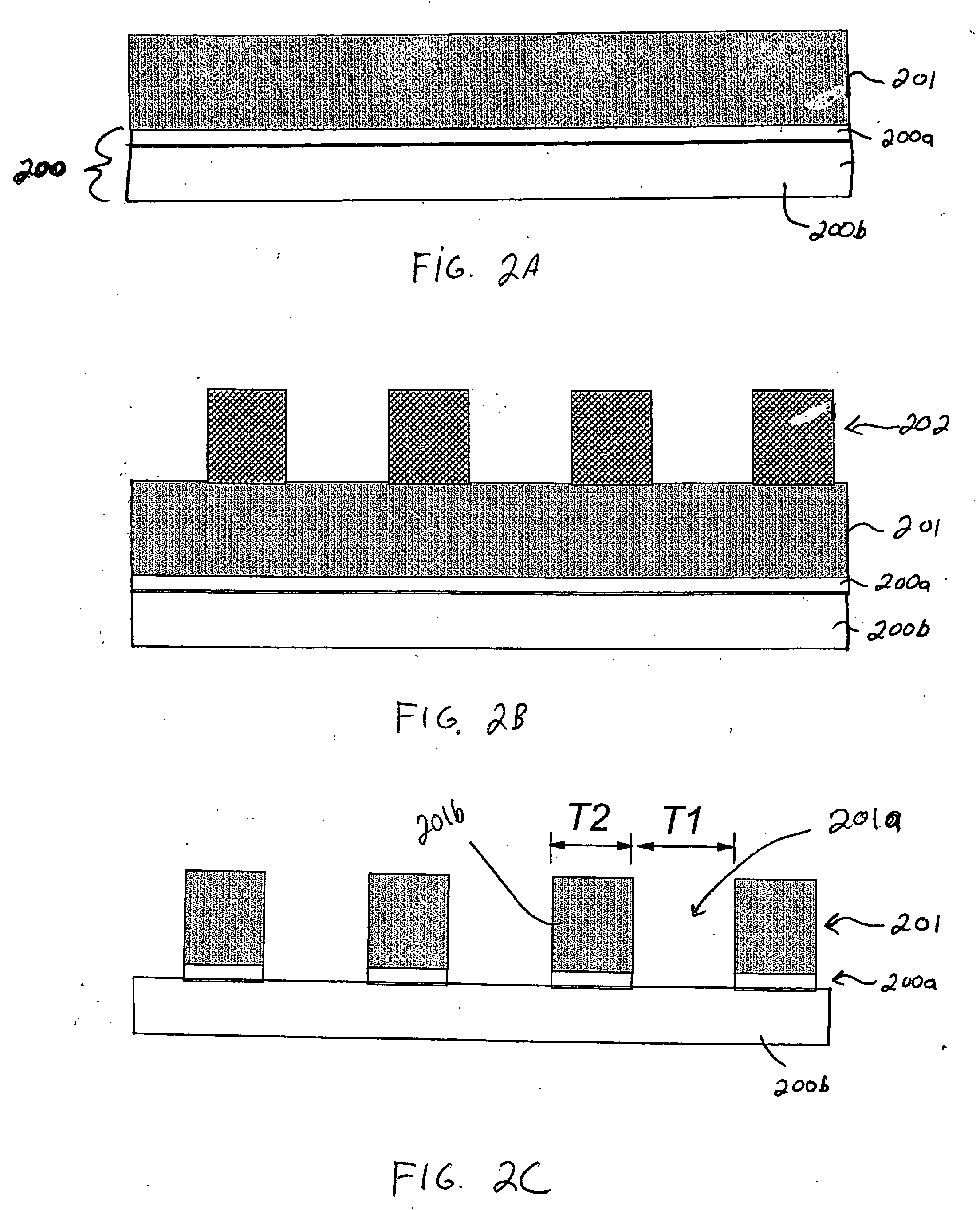

Selective epitaxial formation of semiconductor films

ActiveUS8278176B2Semiconductor/solid-state device manufacturingSemiconductor devicesCyclic processMetallurgy

Epitaxial layers are selectively formed in semiconductor windows by a cyclical process of repeated blanket deposition and selective etching. The blanket deposition phases leave non-epitaxial material over insulating regions, such as field oxide, and the selective etch phases preferentially remove non-epitaxial material while deposited epitaxial material builds up cycle-by-cycle. Quality of the epitaxial material improves relative to selective processes where no deposition occurs on insulators. Use of a germanium catalyst during the etch phases of the process aid etch rates and facilitate economical maintenance of isothermal and / or isobaric conditions throughout the cycles. Throughput and quality are improved by use of trisilane, formation of amorphous material over the insulating regions and minimizing the thickness ratio of amorphous:epitaxial material in each deposition phase.

Owner:ASM IP HLDG BV

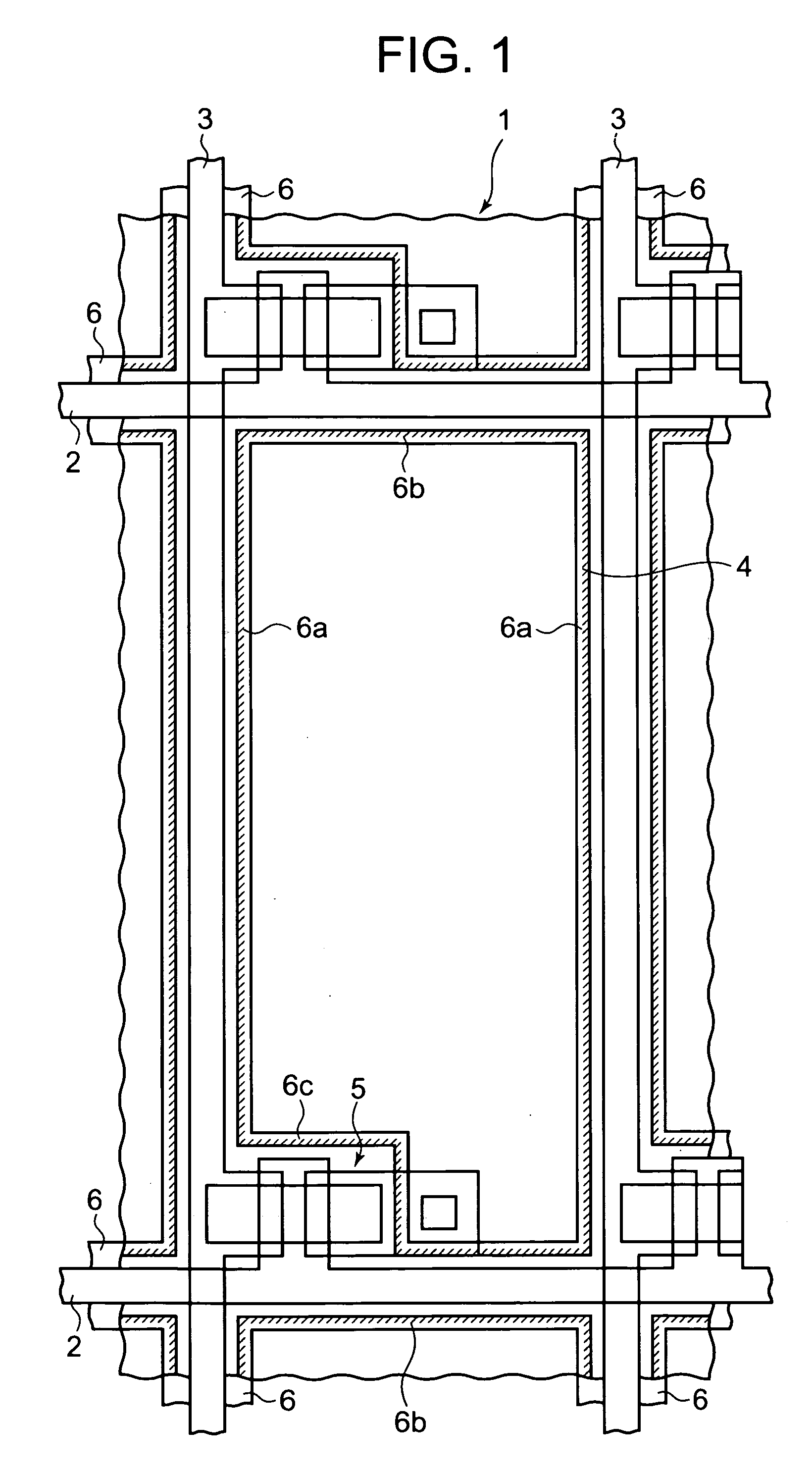

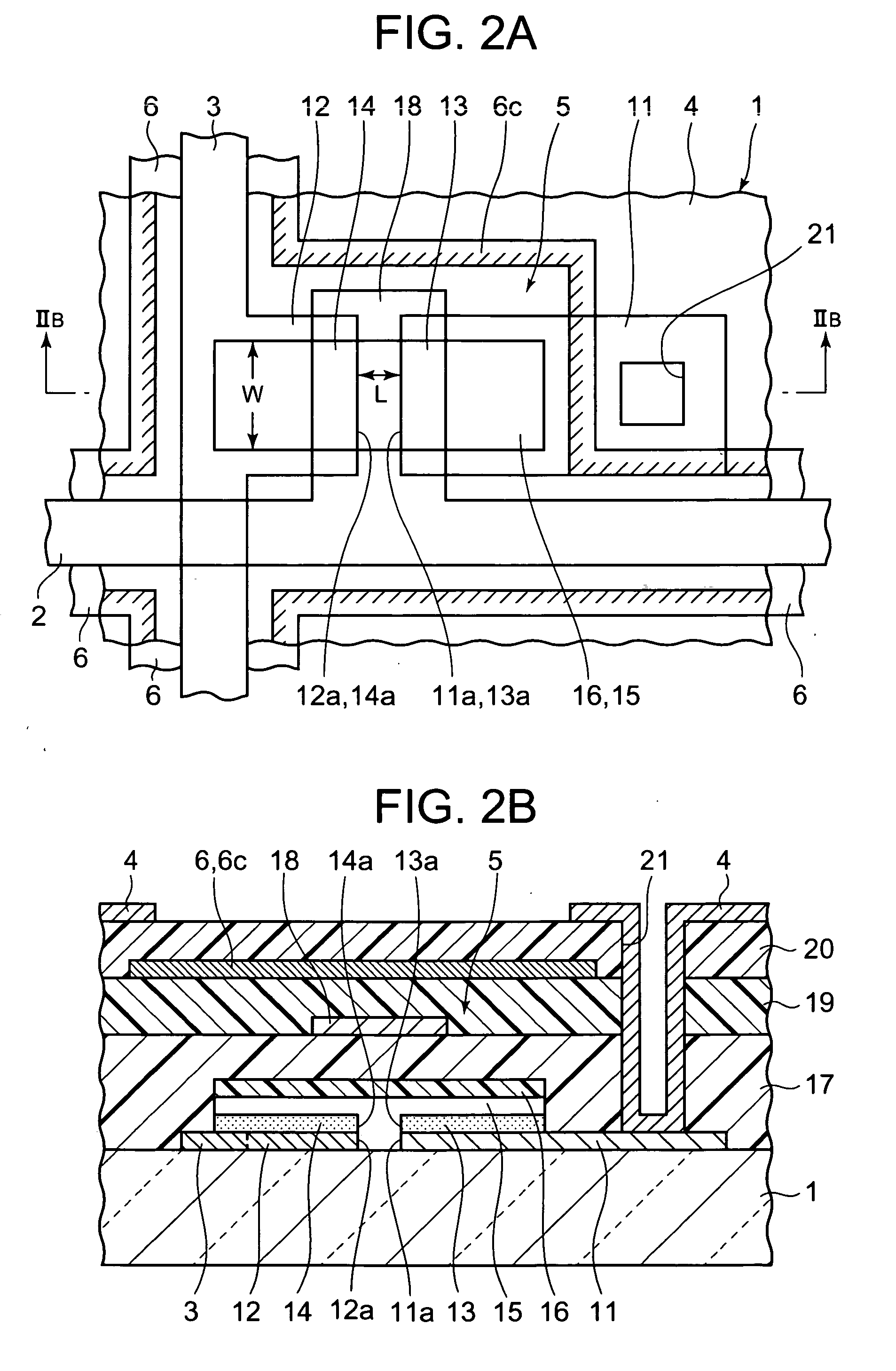

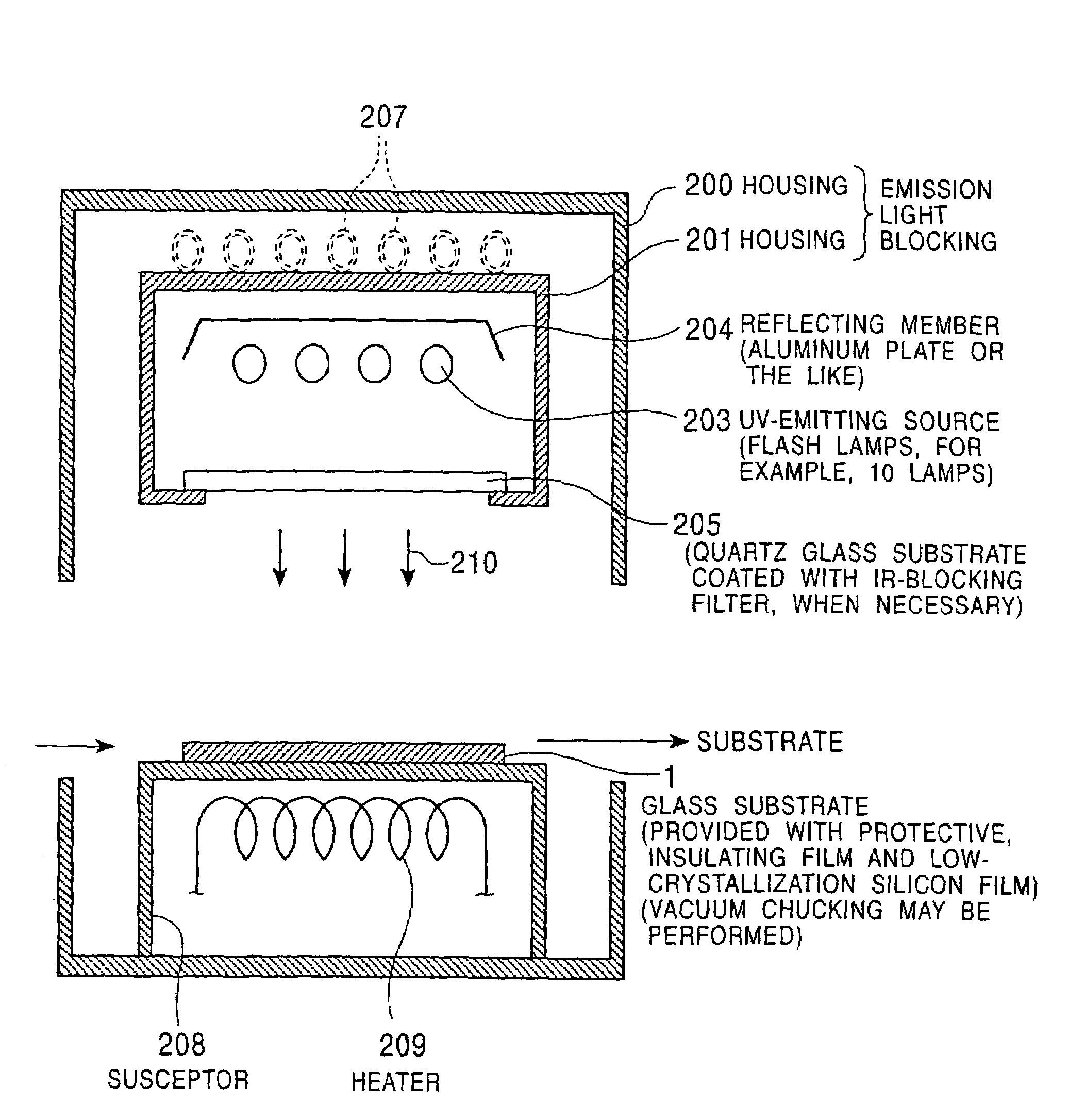

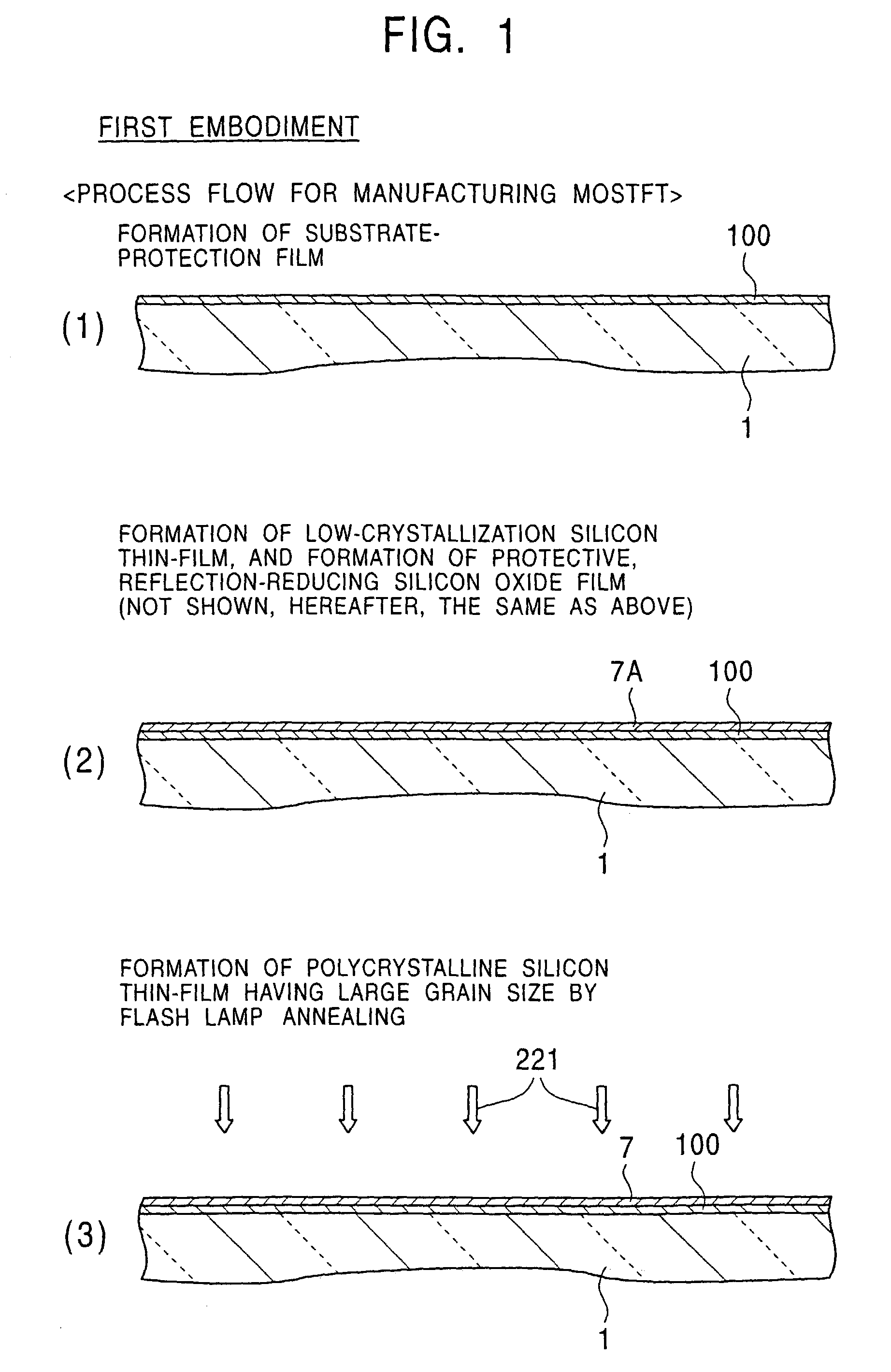

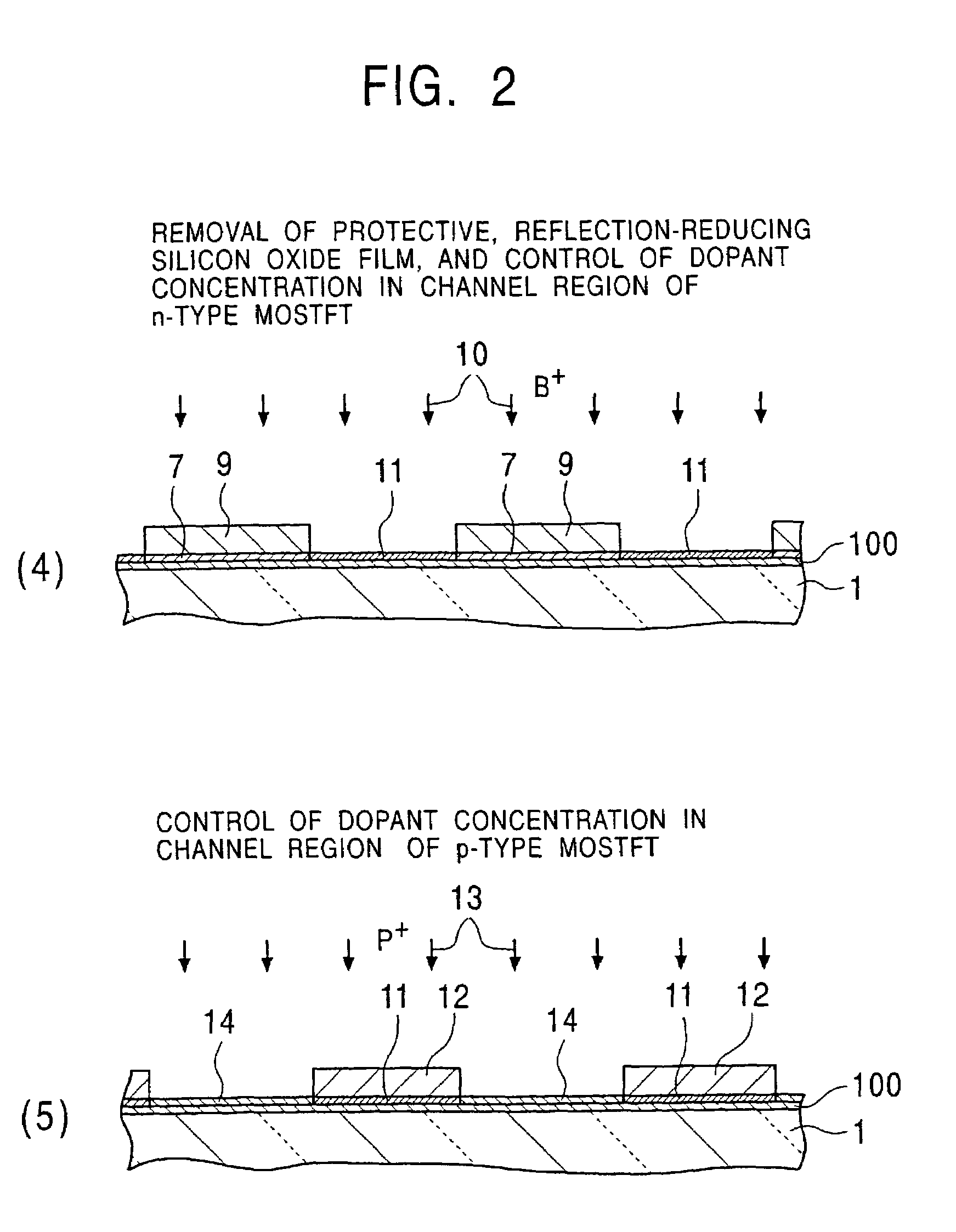

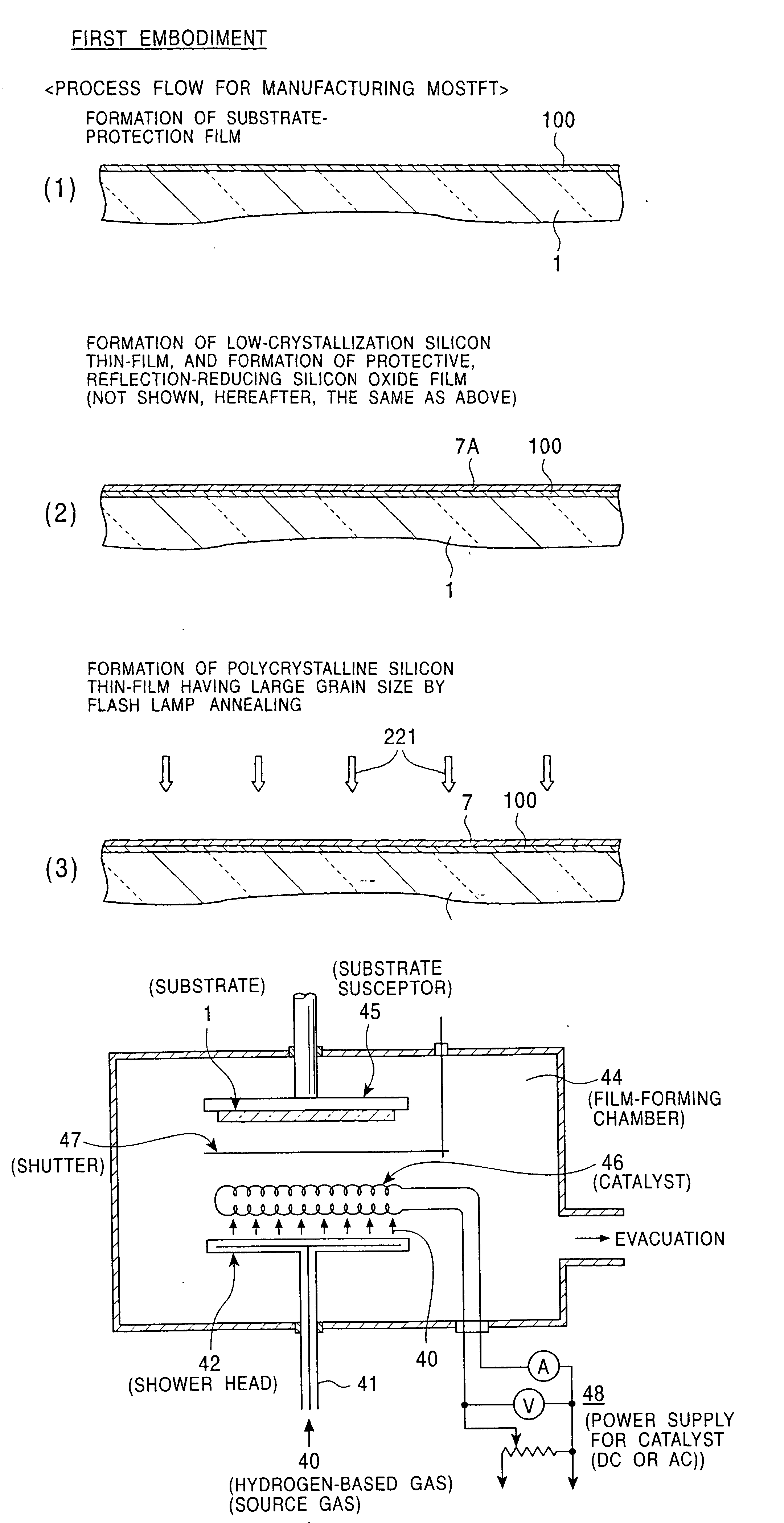

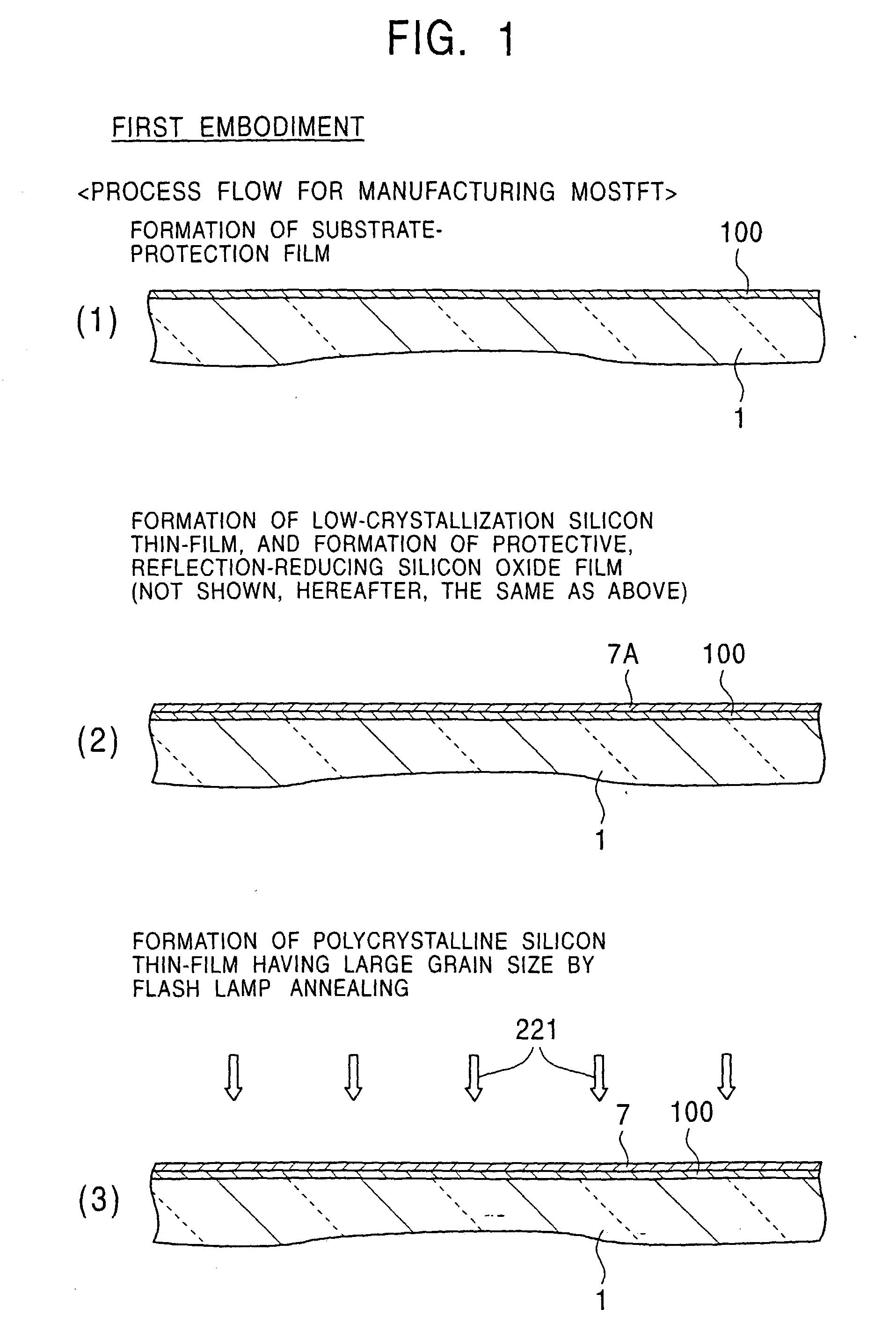

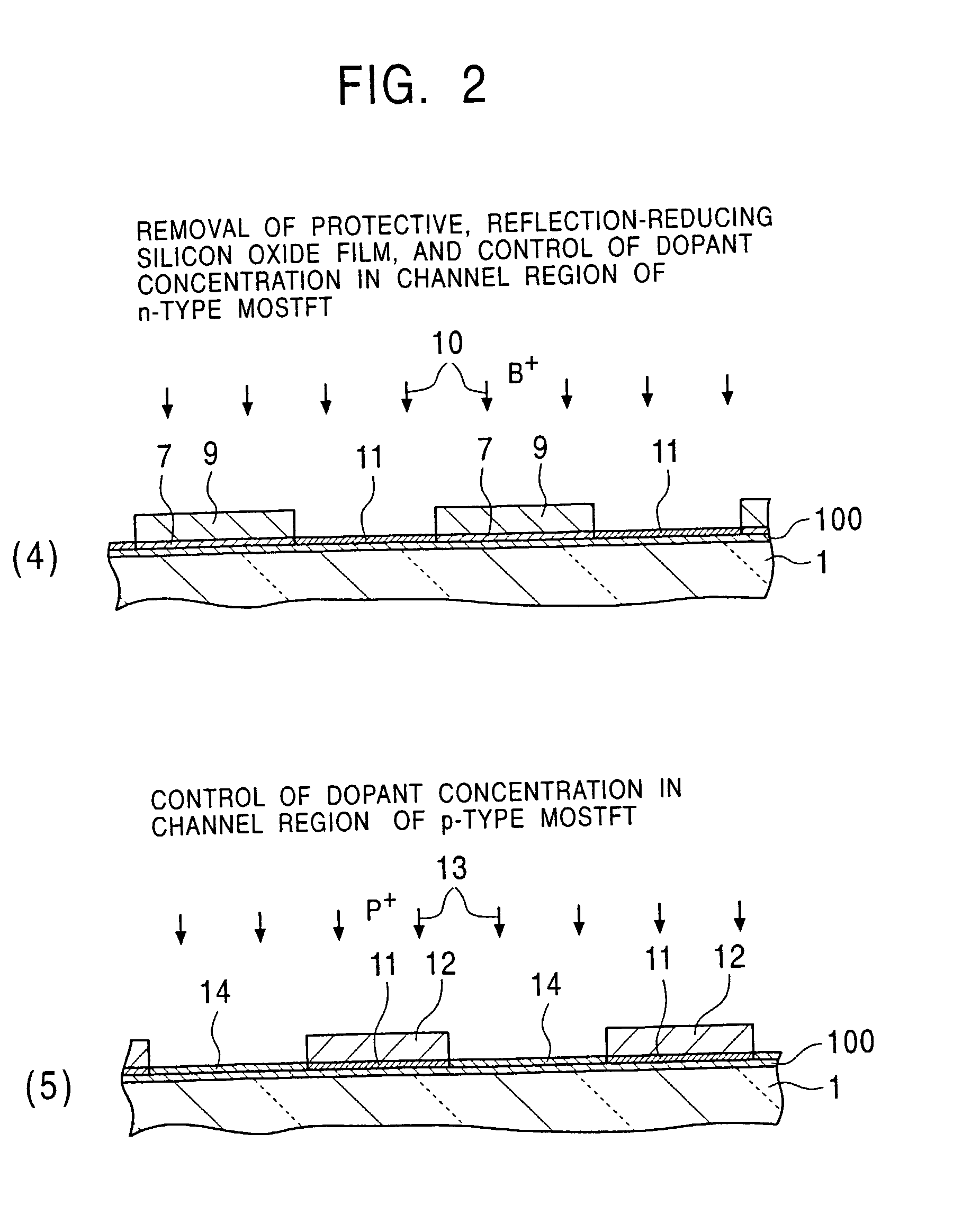

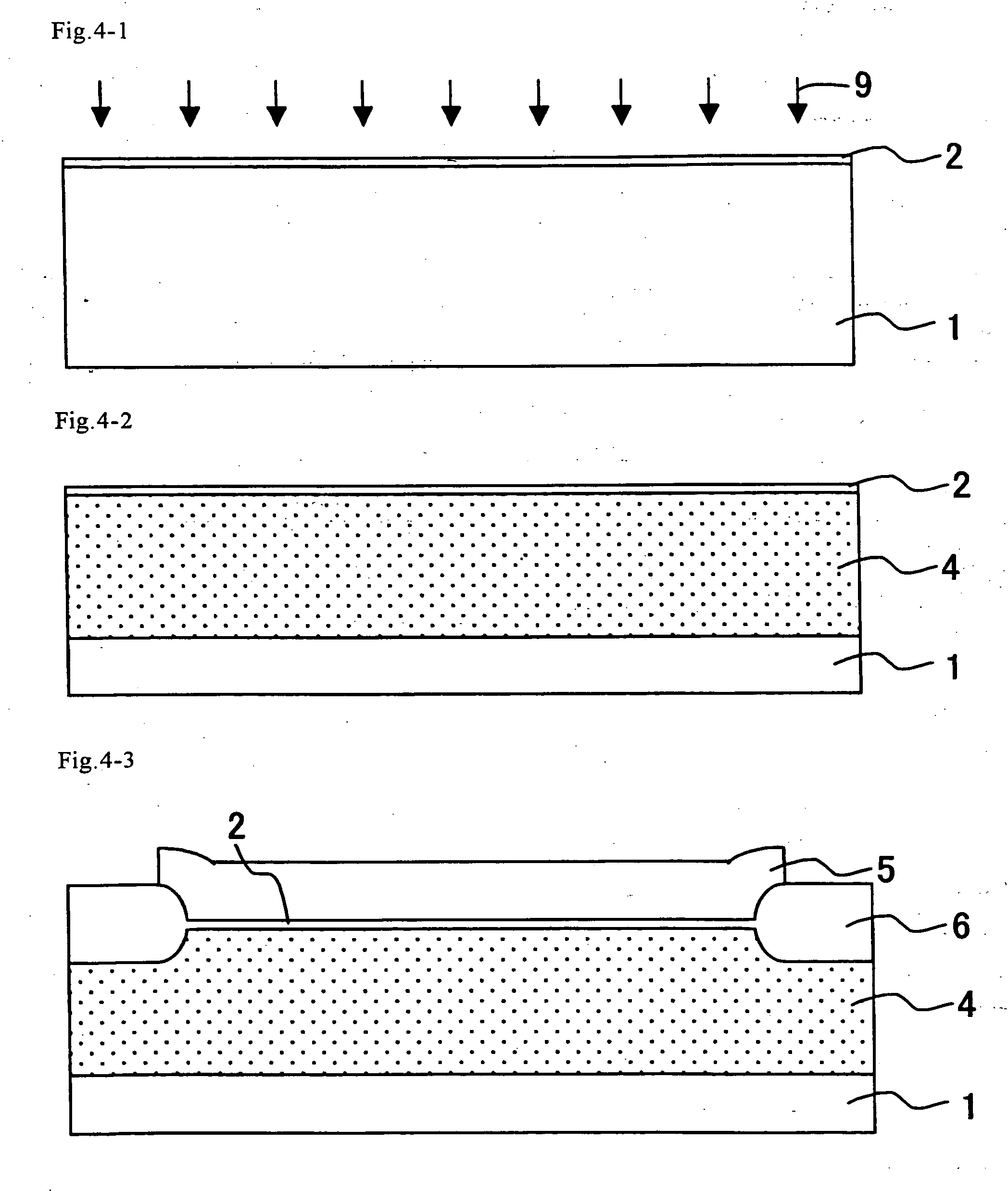

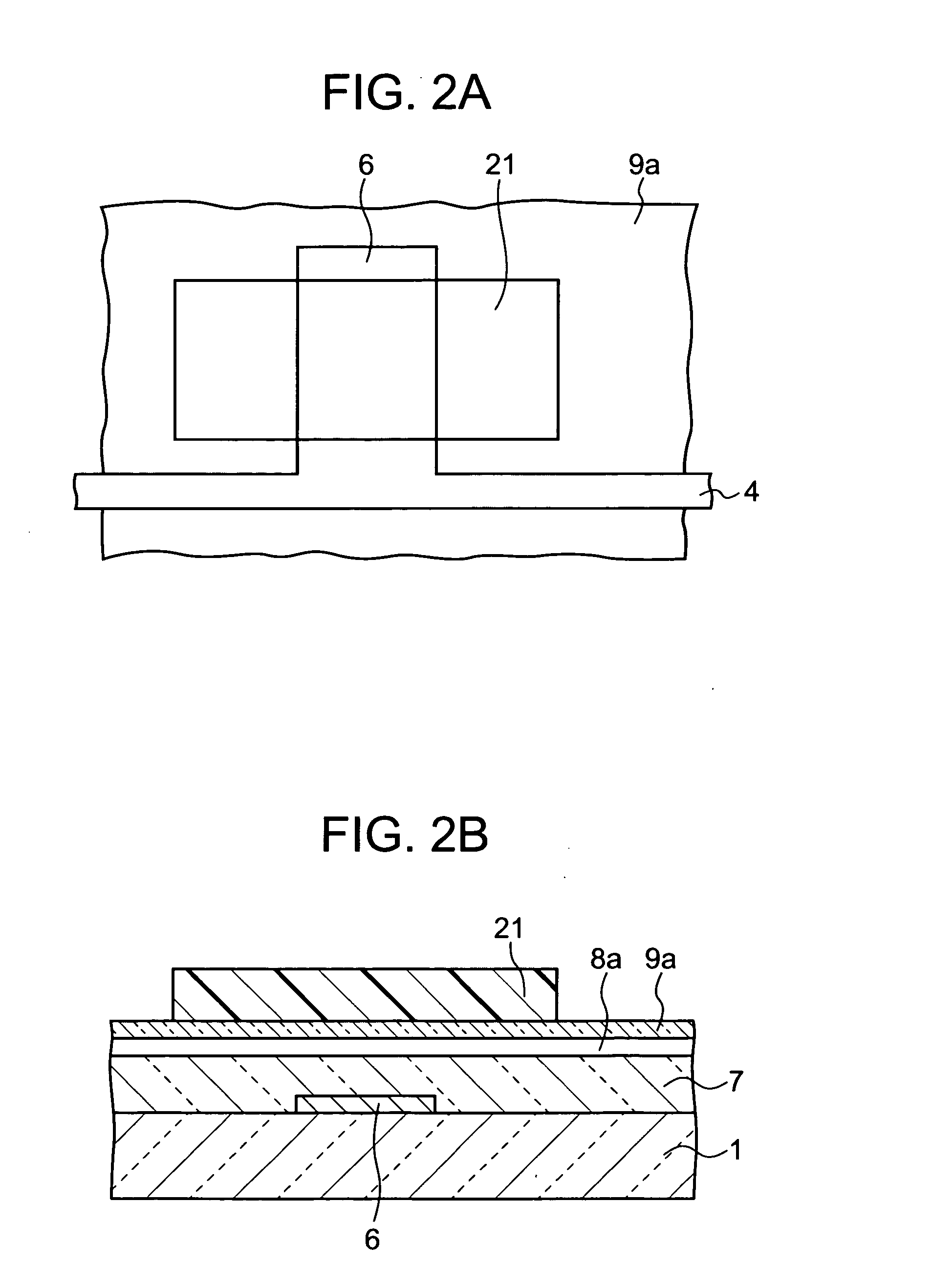

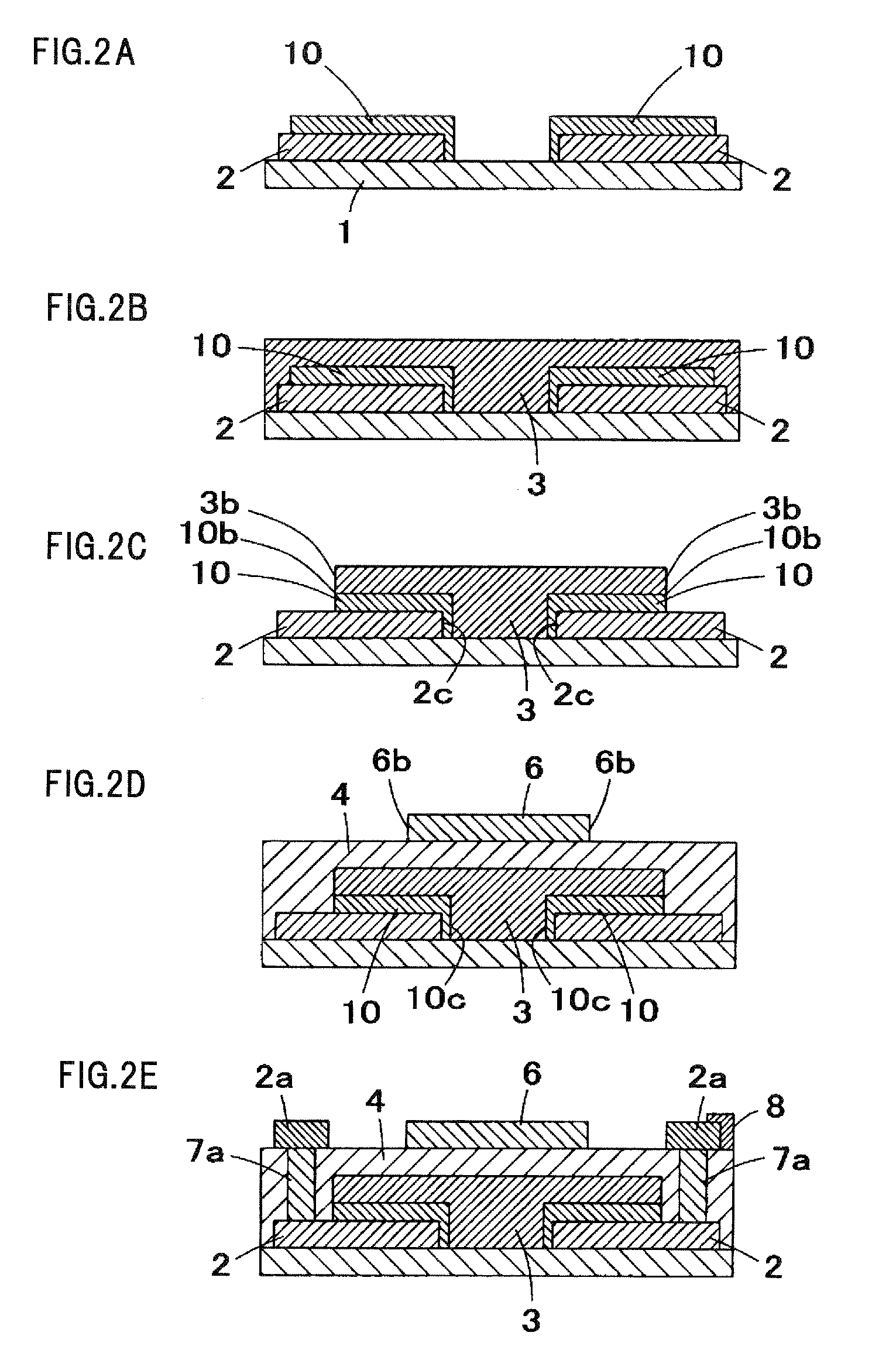

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

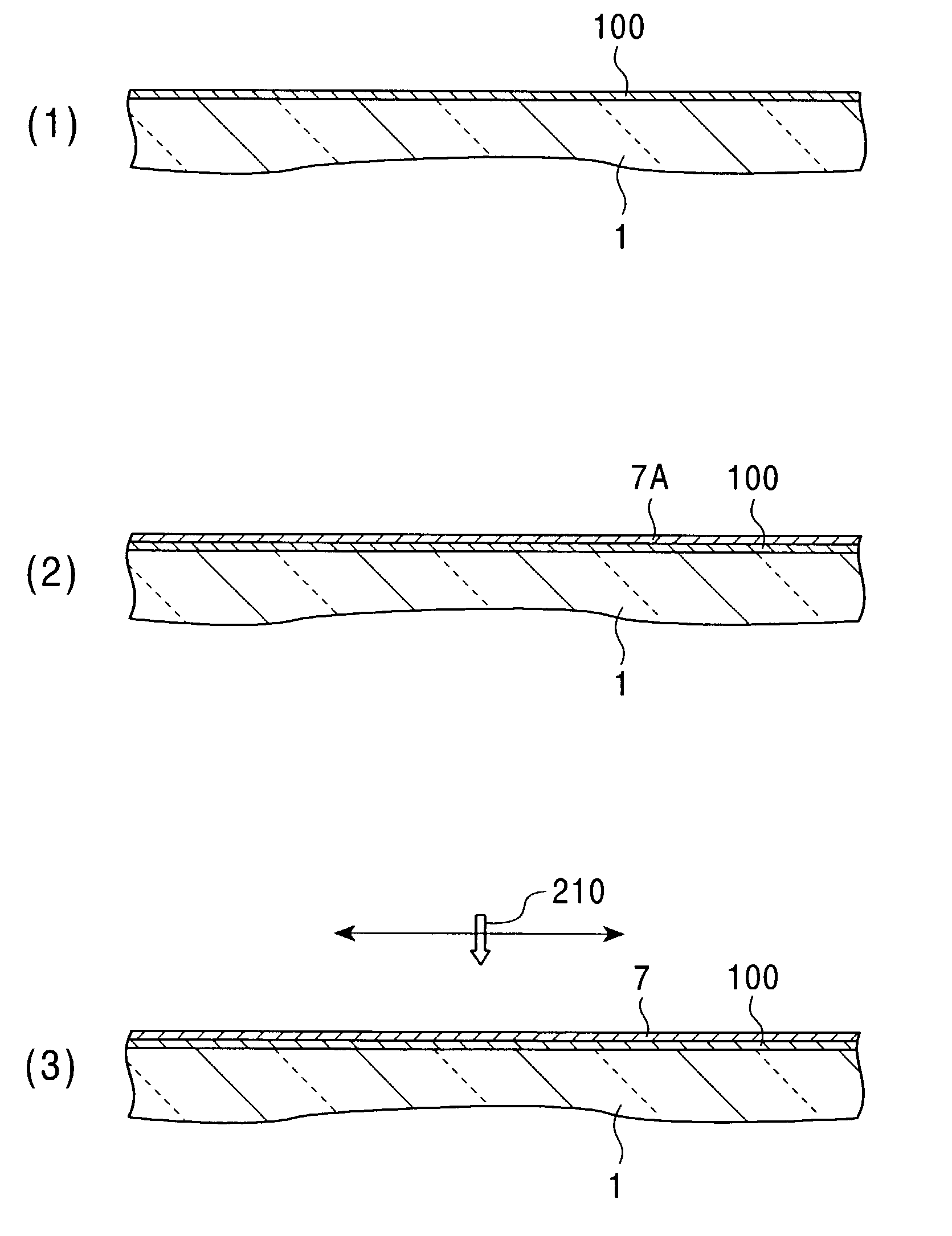

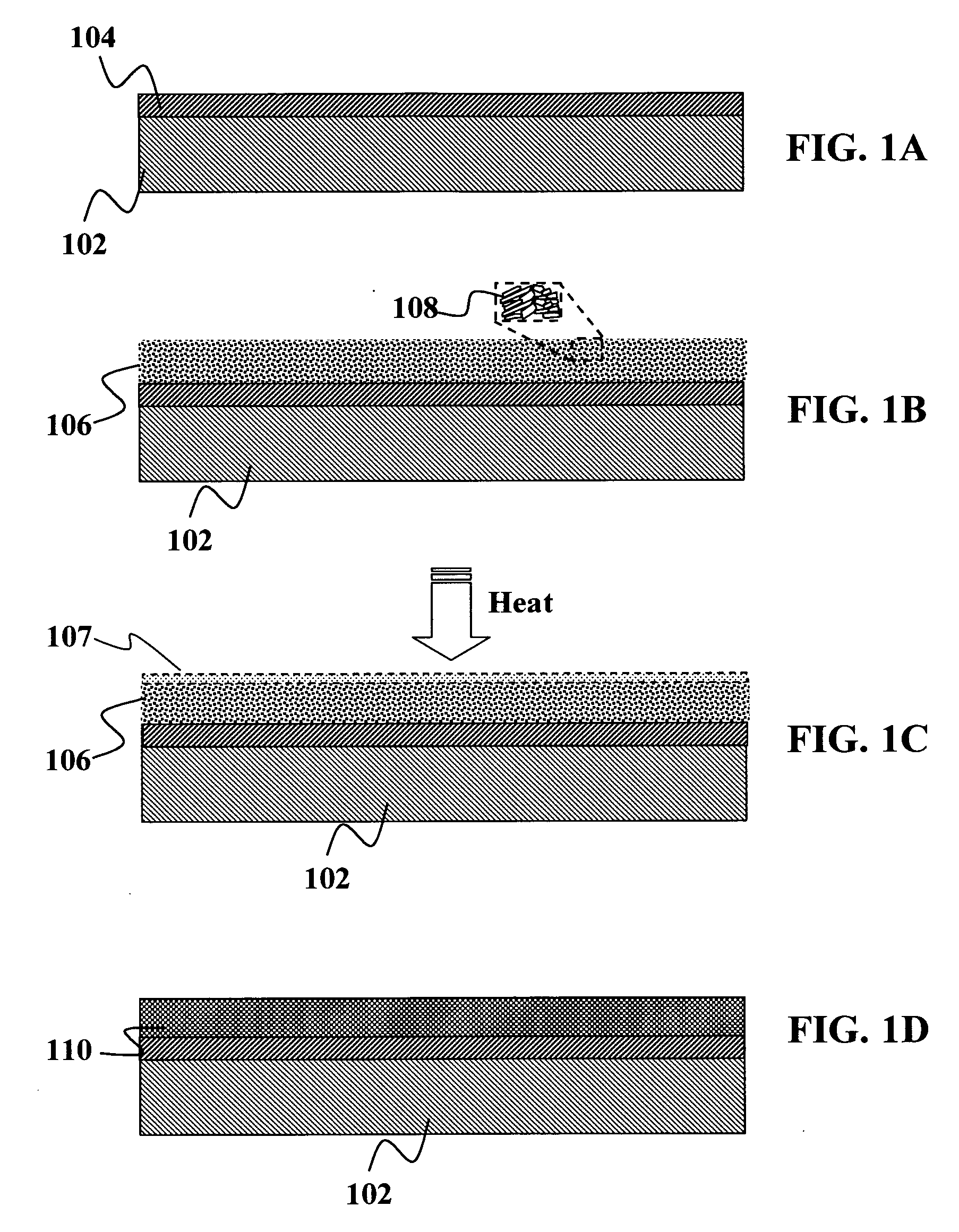

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS20030013280A1Promote crystallizationTransistorPolycrystalline material growthSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

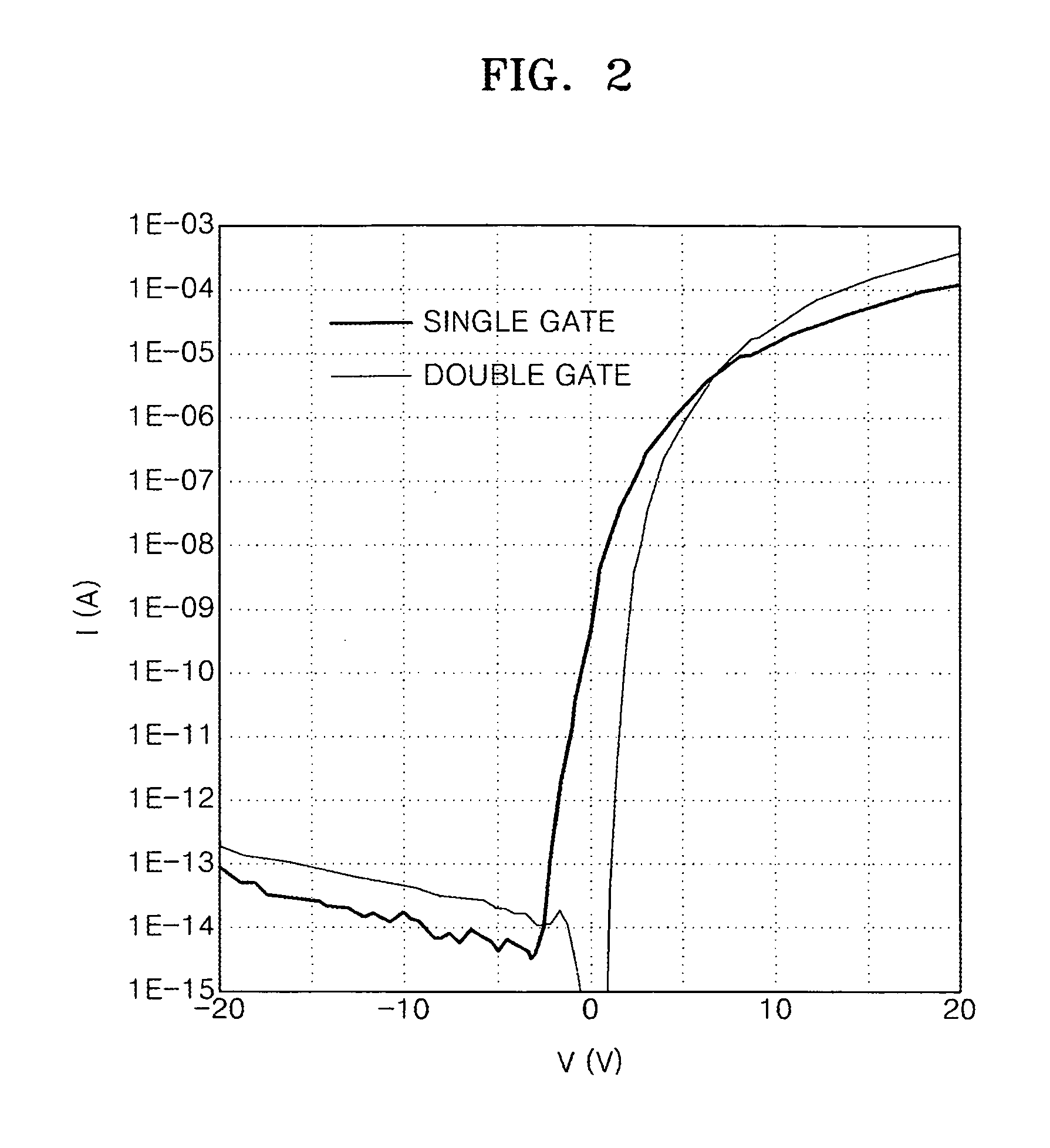

Oxide semiconductor transistor and method of manufacturing the same

ActiveUS20090206332A1TransistorSemiconductor/solid-state device manufacturingEngineeringSilicon oxide

An oxide semiconductor thin film transistor (TFT) and a method of manufacturing the oxide semiconductor TFT. The oxide semiconductor TFT includes a first gate insulating layer arranged between an oxide semiconductor channel layer and a first gate and a second gate insulating layer arranged between the channel layer and a second gate. The first and second gate insulating layers are made out of different materials and have different thicknesses. Preferably, the second gate insulating layer is silicon oxide and is thinner than the first gate insulating layer which is preferably silicon nitride. Oxide semiconductor refers to an oxide material such as Zinc Oxide, Tin Oxide, Ga—In—Zn Oxide, In—Zn Oxide, In—Sn Oxide, and one of Zinc Oxide, Tin Oxide, Ga—In—Zn Oxide, In—Zn Oxide and In—Sn Oxide.

Owner:SAMSUNG ELECTRONICS CO LTD

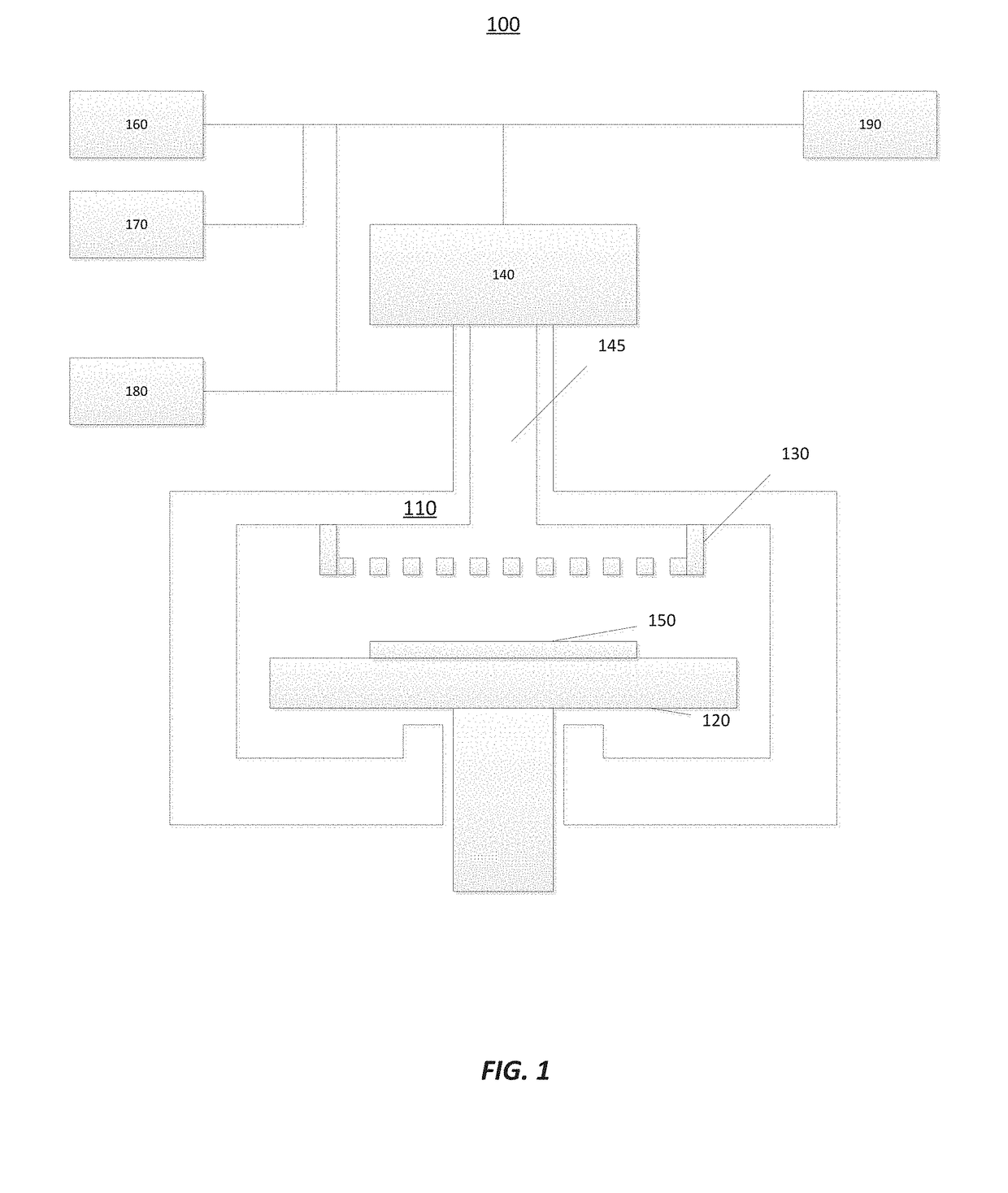

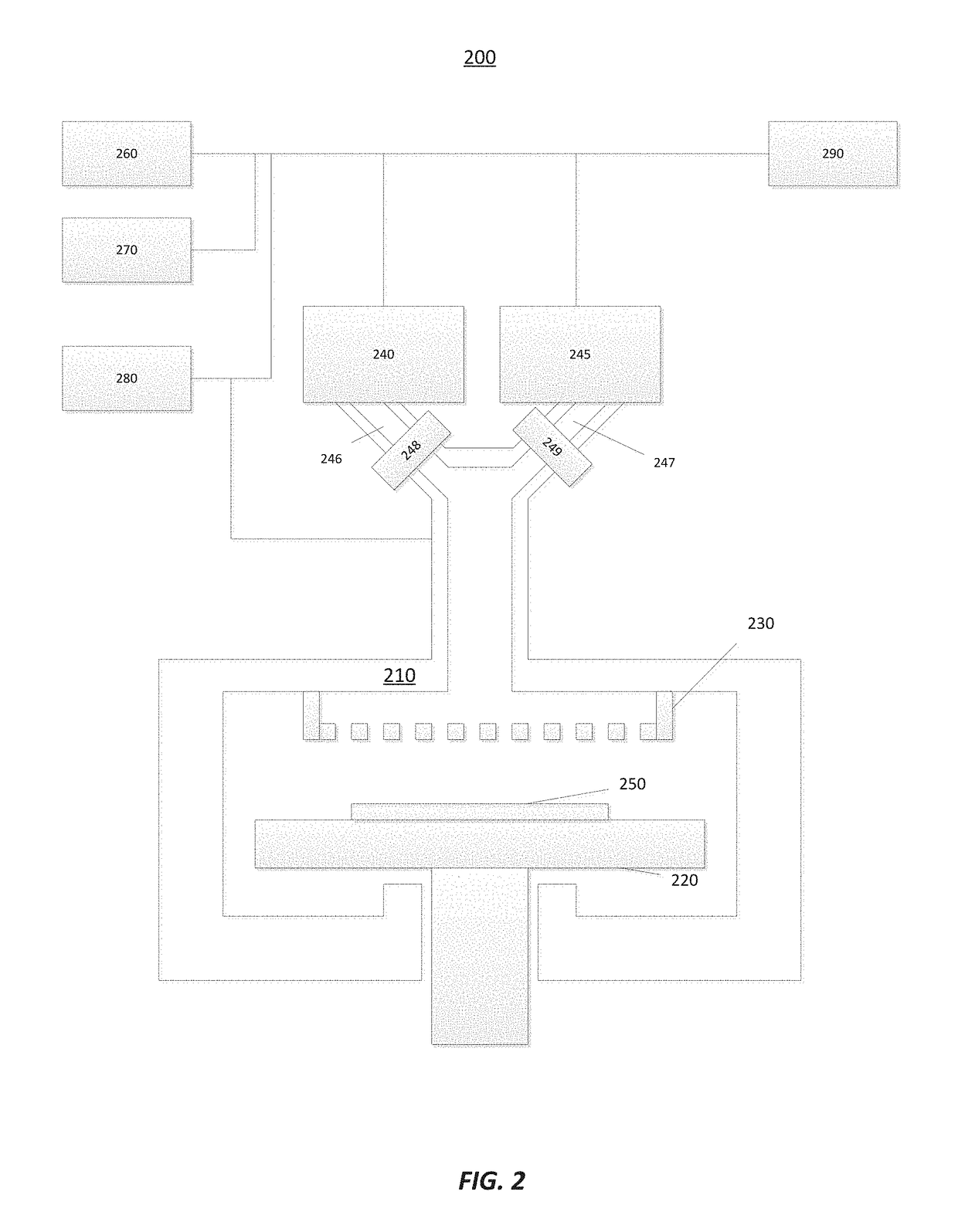

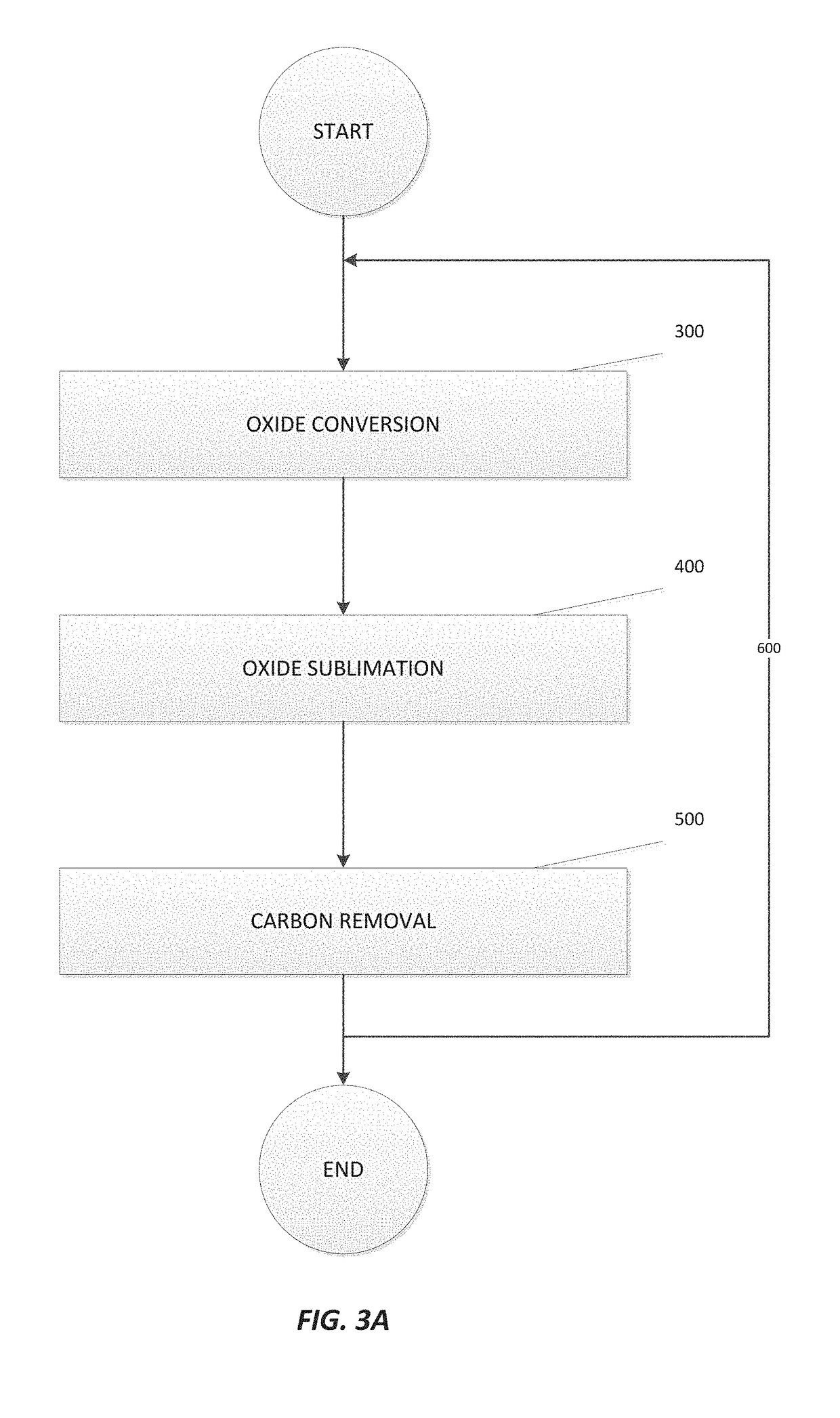

Apparatus and method for removal of oxide and carbon from semiconductor films in a single processing chamber

InactiveUS20190019670A1Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaSingle process

A system and method for removing both carbon-based contaminants and oxygen-based contaminants from a semiconductor substrate within a single process chamber is disclosed. The invention may comprise utilization of remote plasma units and multiple gas sources to perform the process within the single process chamber.

Owner:ASM IP HLDG BV

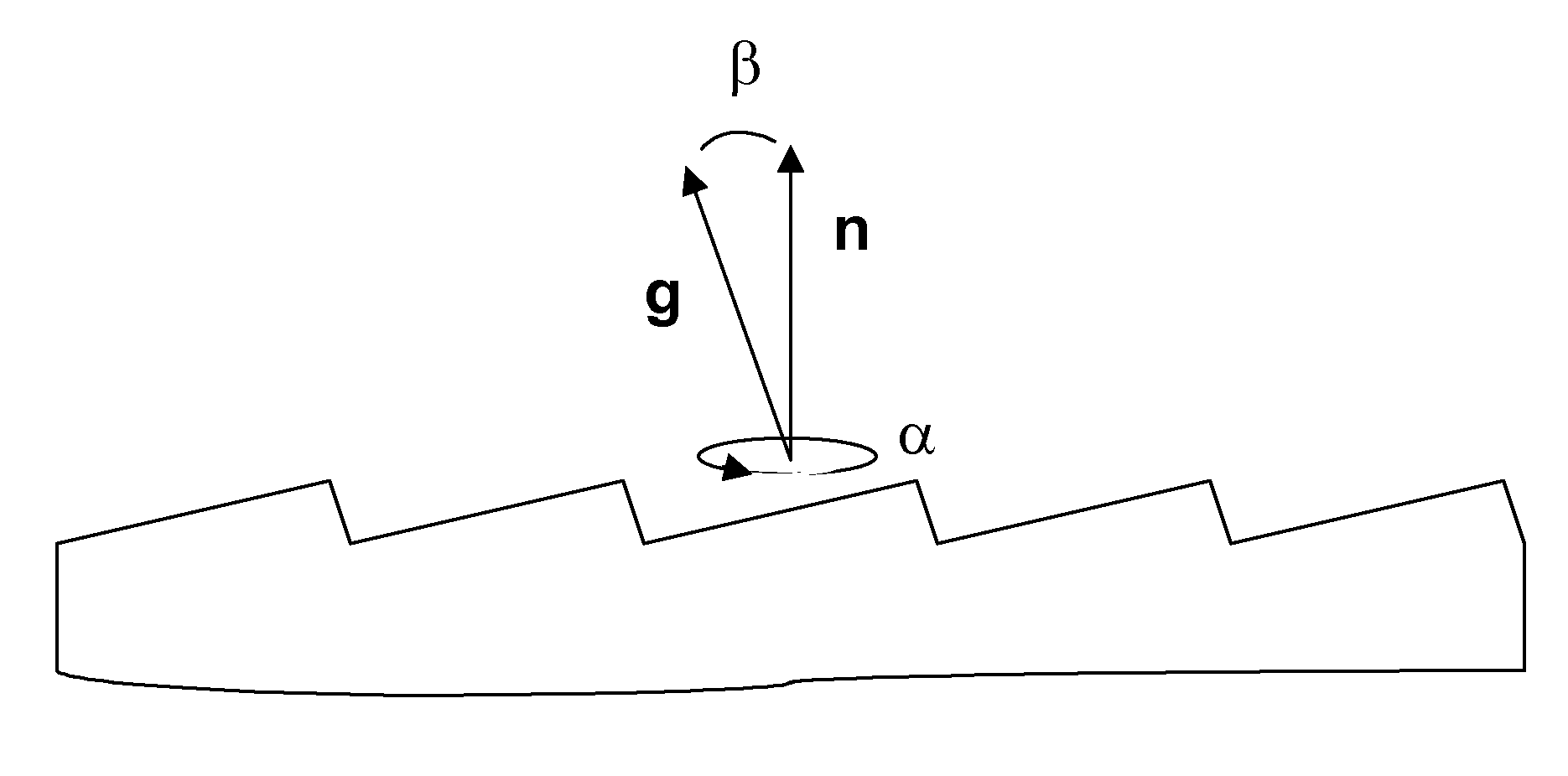

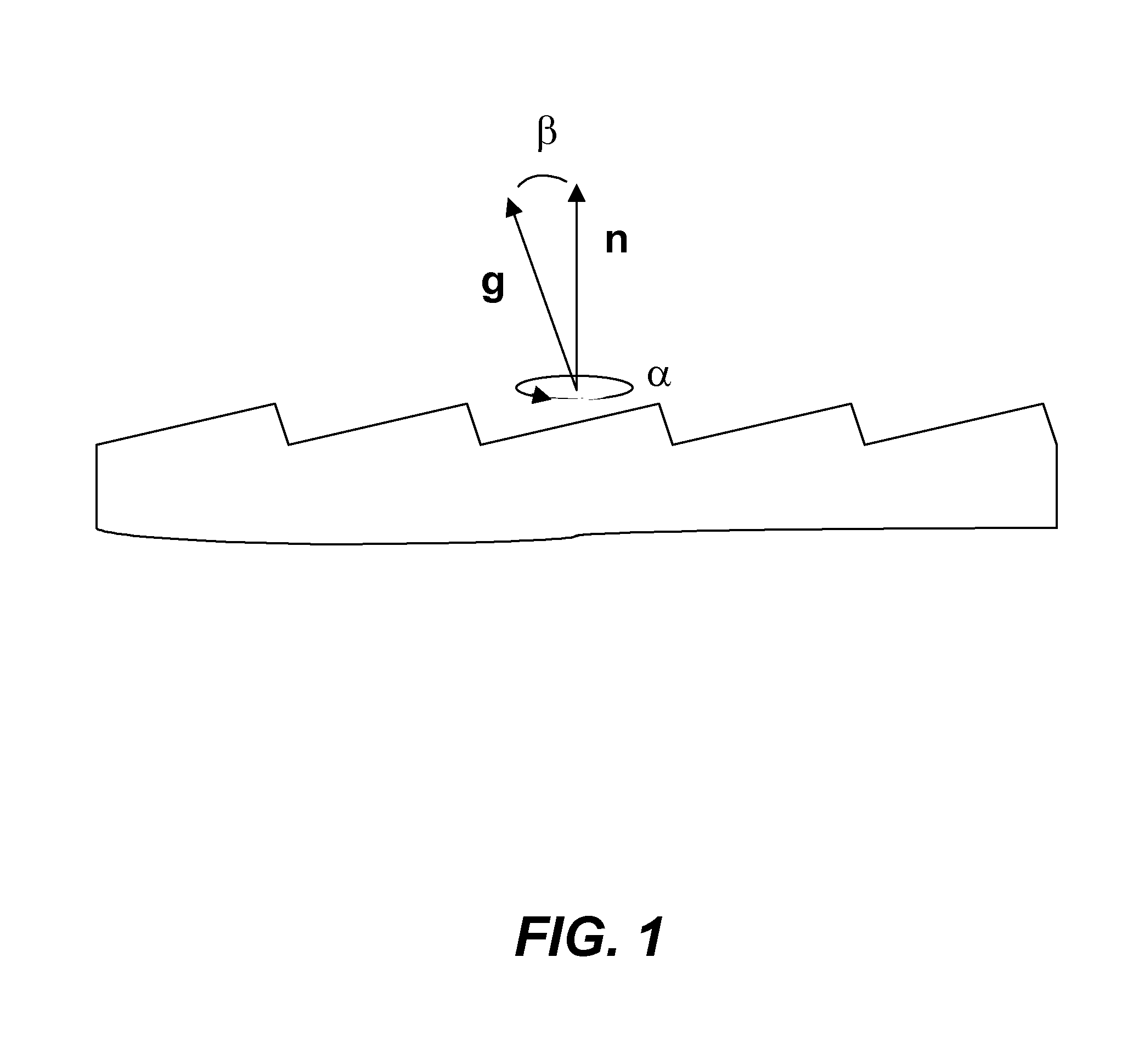

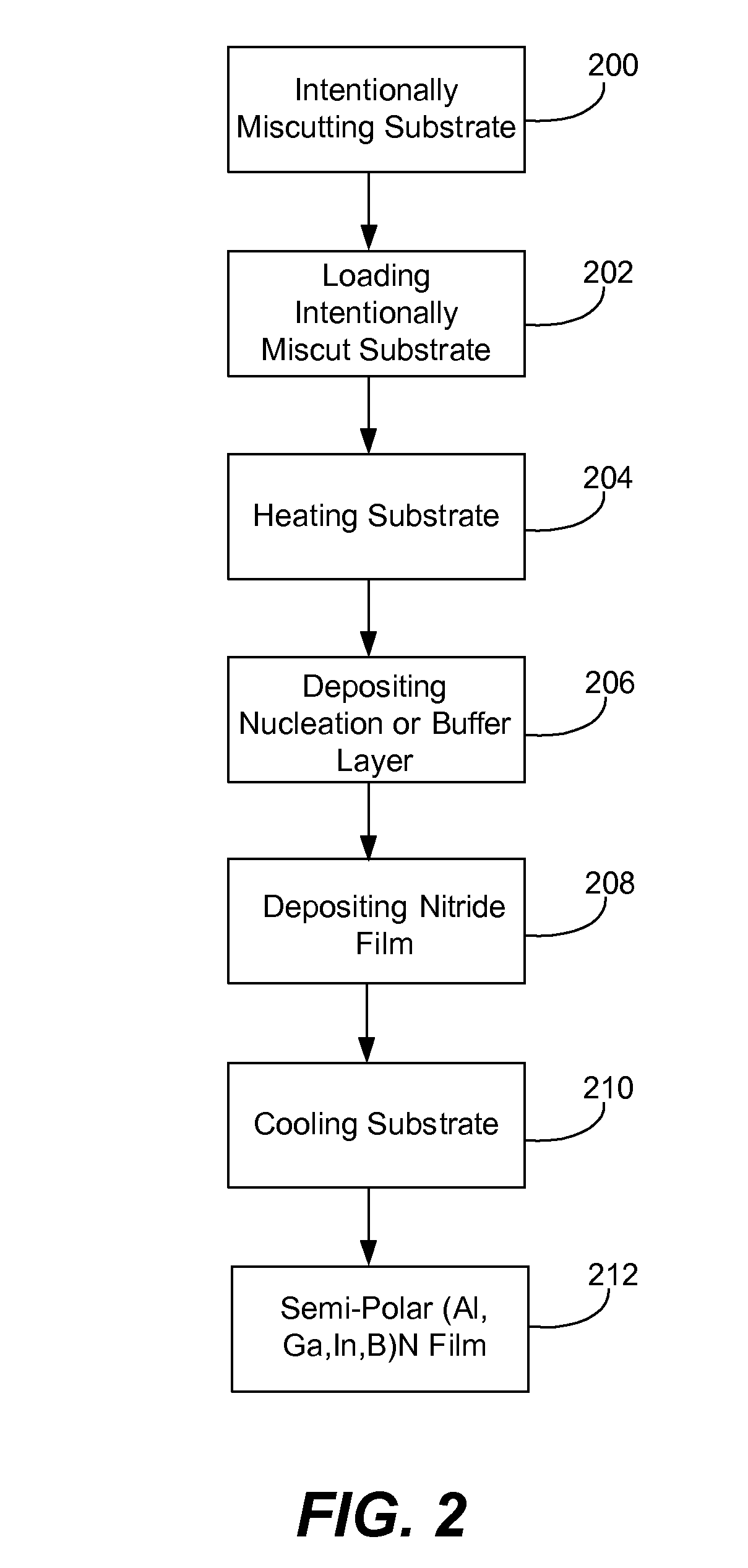

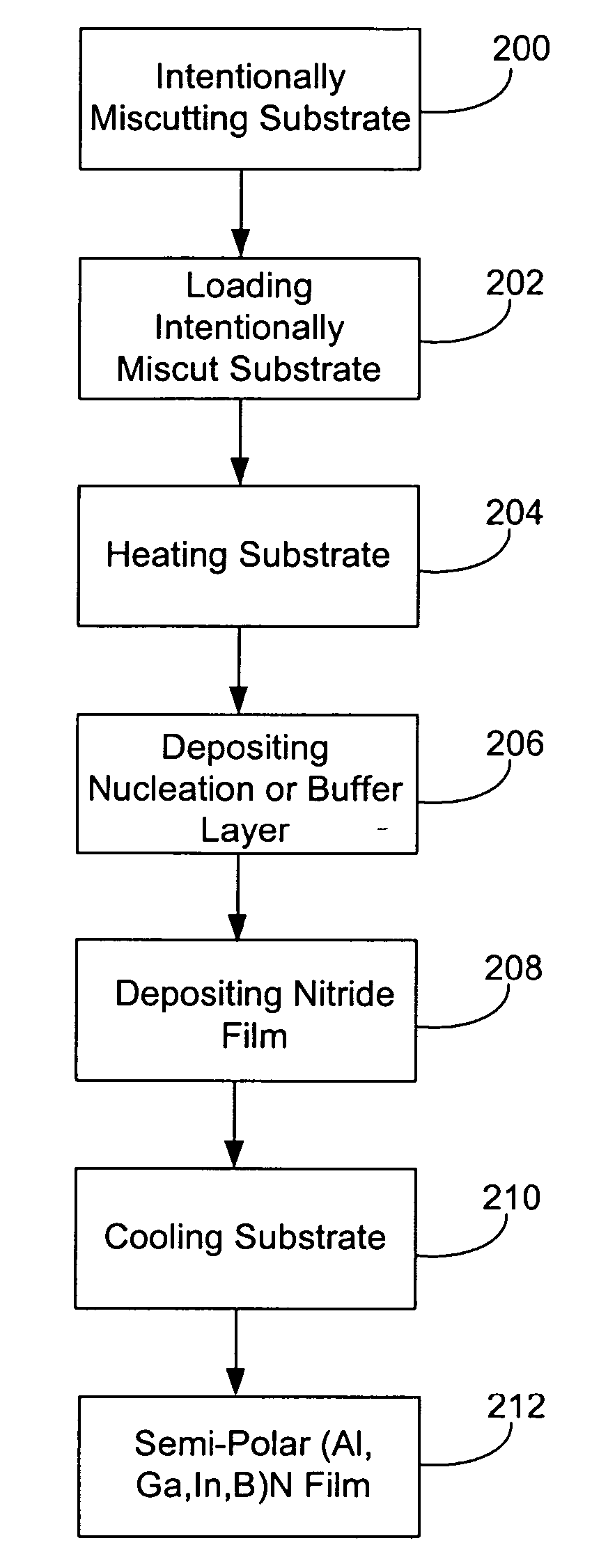

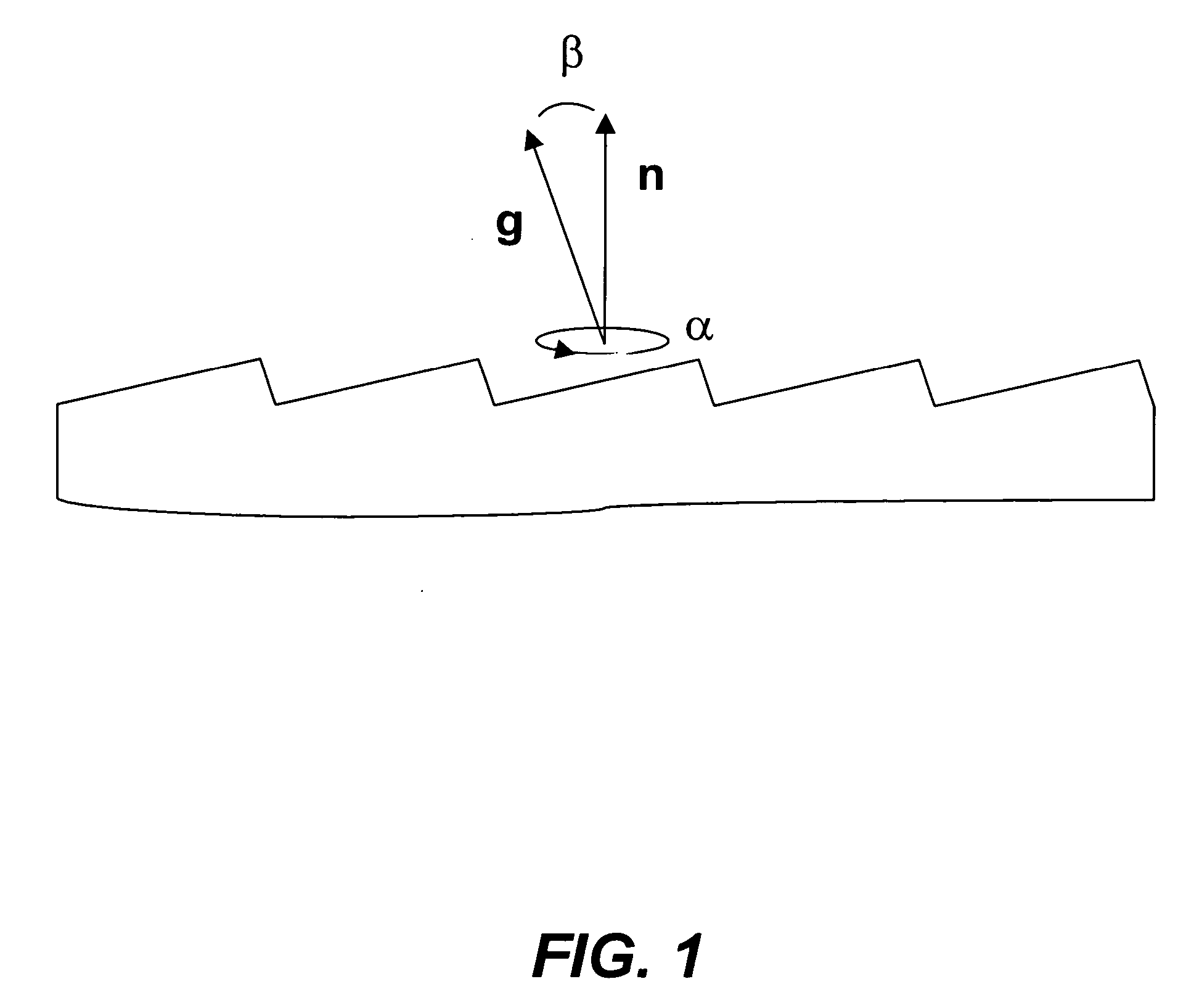

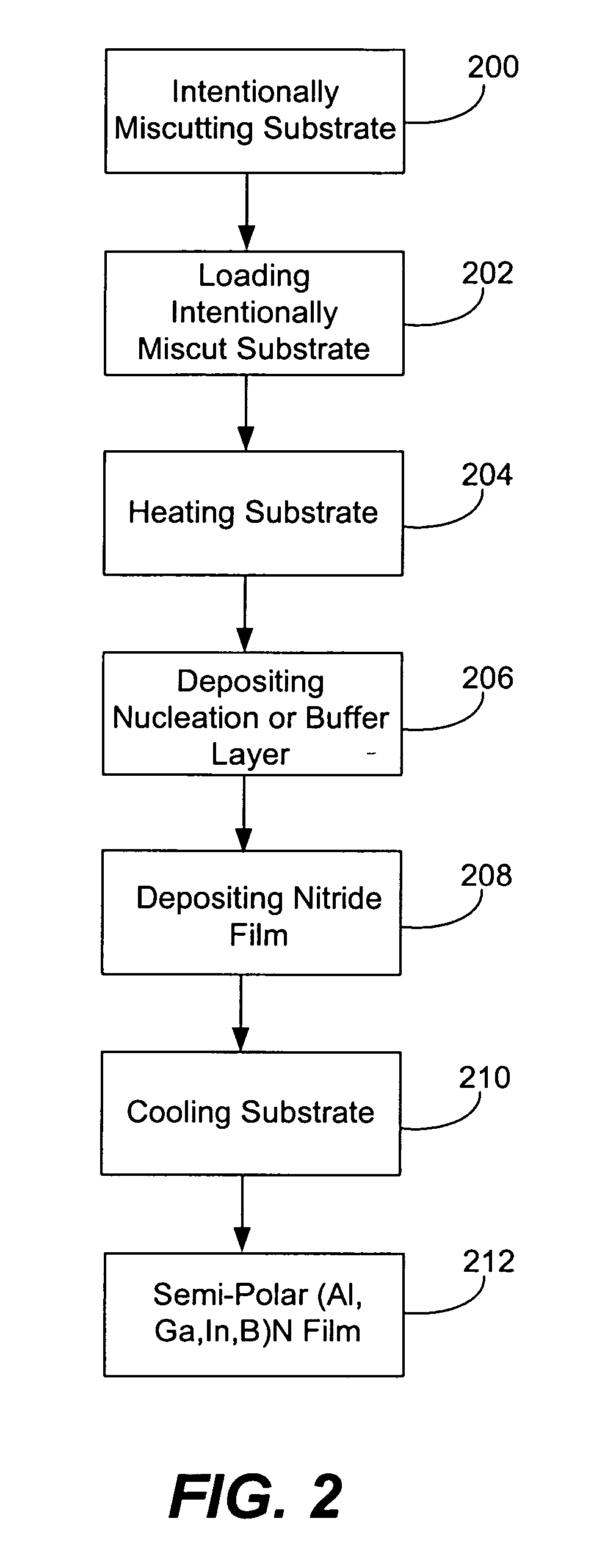

Method for improved growth of semipolar (Al,In,Ga,B)N

ActiveUS7691658B2Reduce symmetryImprove propertiesPolycrystalline material growthSolid-state devicesHydrogenNitrogen

A method for improved growth of a semipolar (Al,In,Ga,B)N semiconductor thin film using an intentionally miscut substrate. Specifically, the method comprises intentionally miscutting a substrate, loading a substrate into a reactor, heating the substrate under a flow of nitrogen and / or hydrogen and / or ammonia, depositing an InxGa1−xN nucleation layer on the heated substrate, depositing a semipolar nitride semiconductor thin film on the InxGa1−xN nucleation layer, and cooling the substrate under a nitrogen overpressure.

Owner:JAPAN SCI & TECH CORP

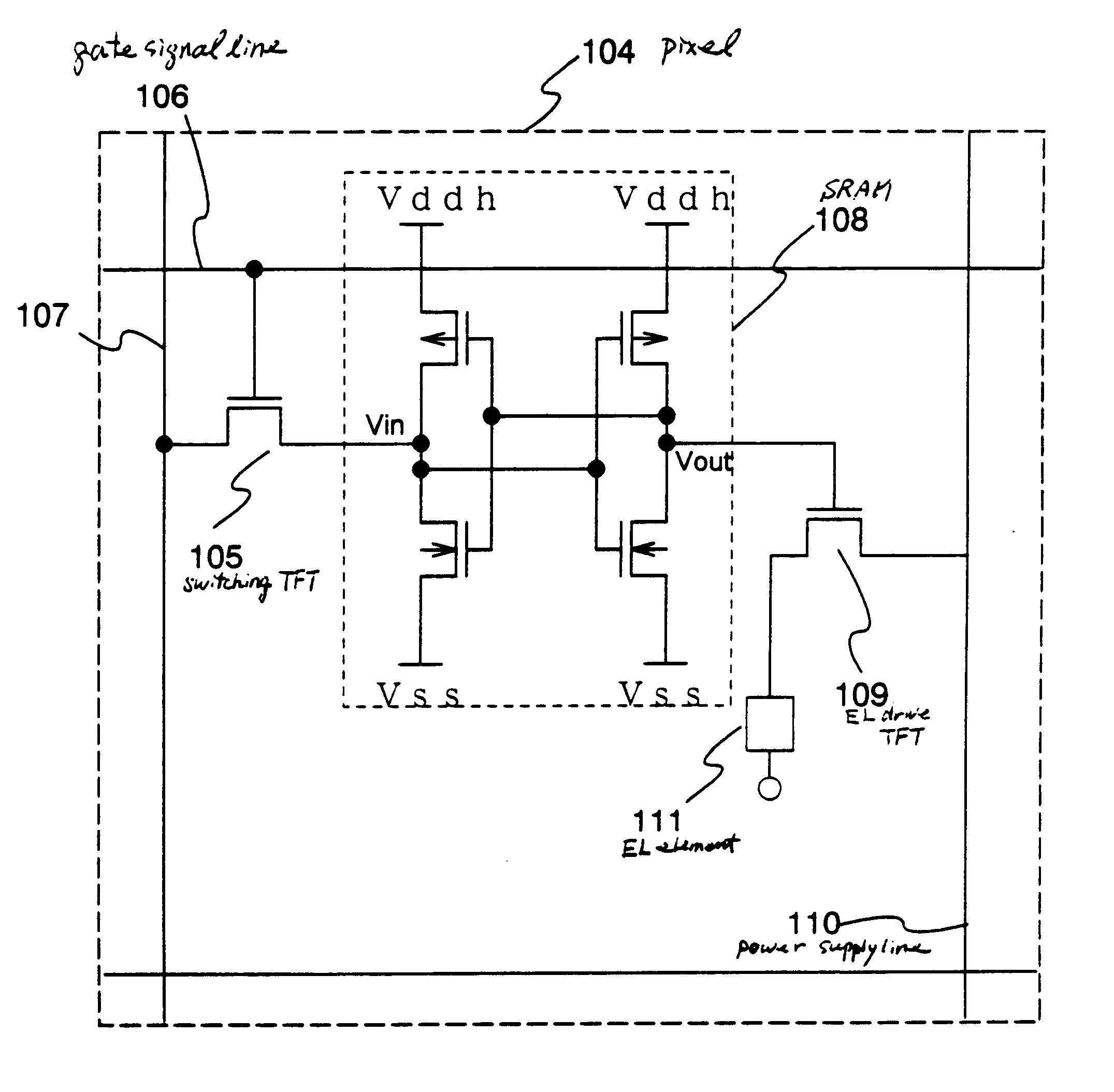

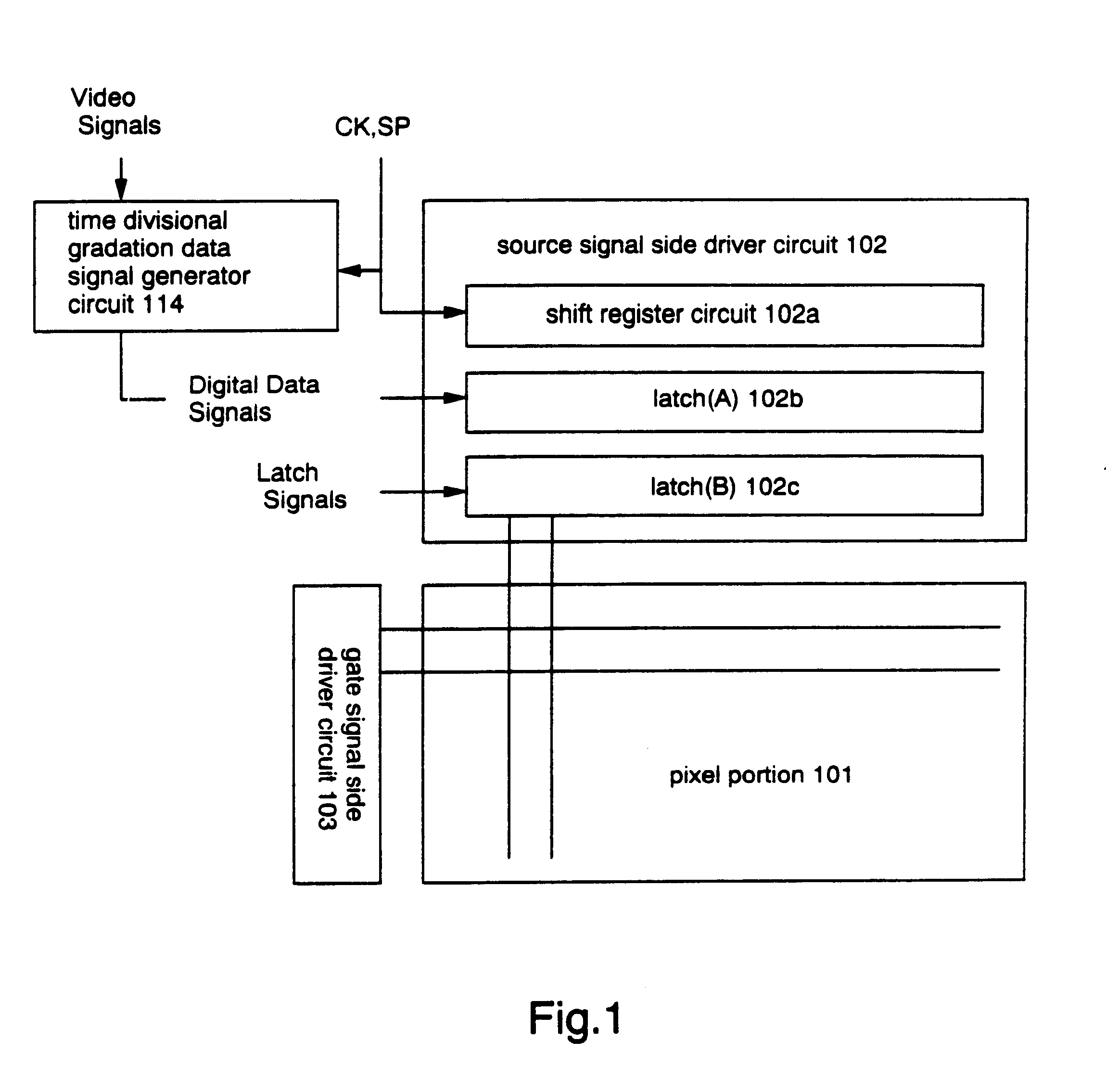

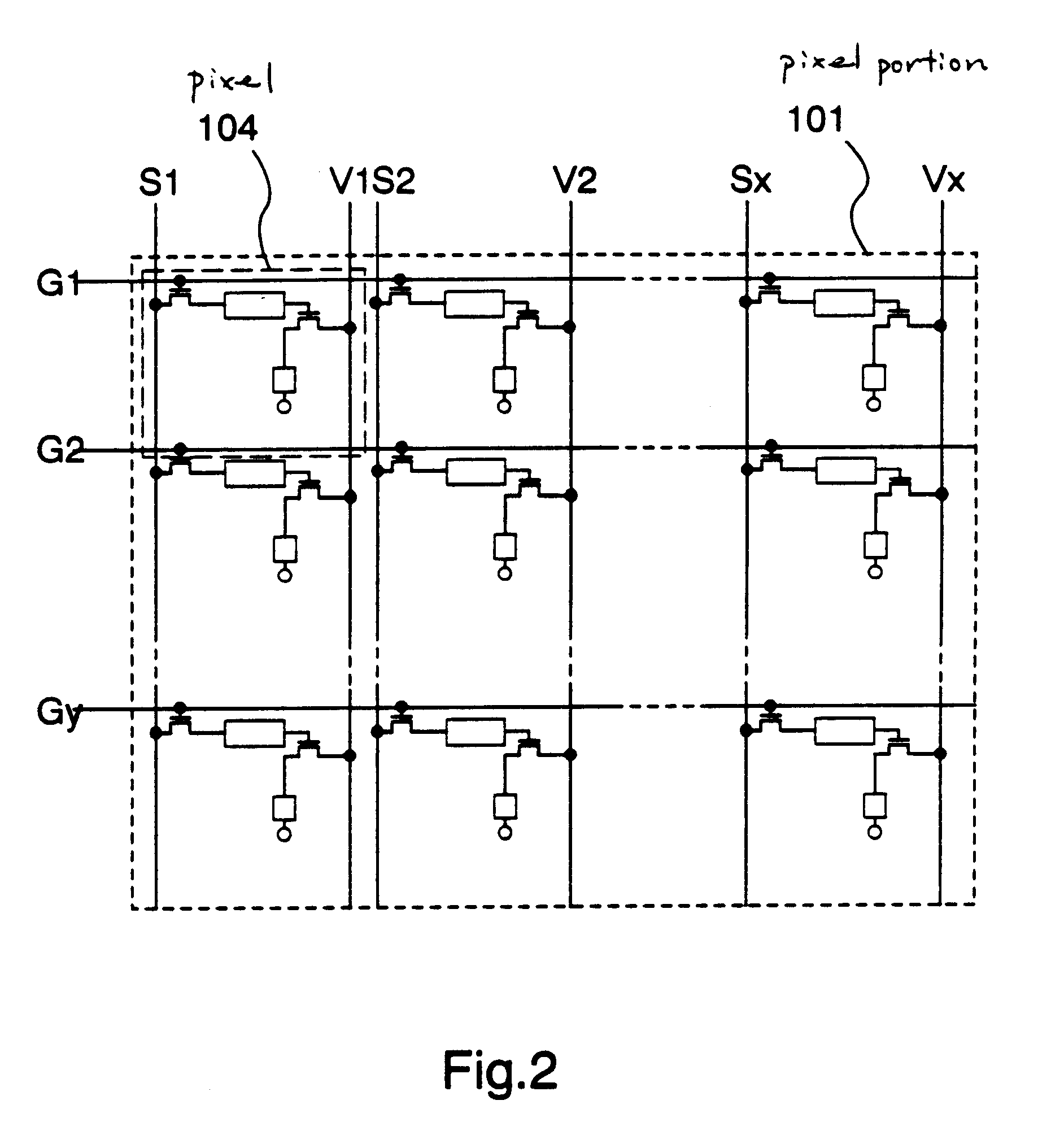

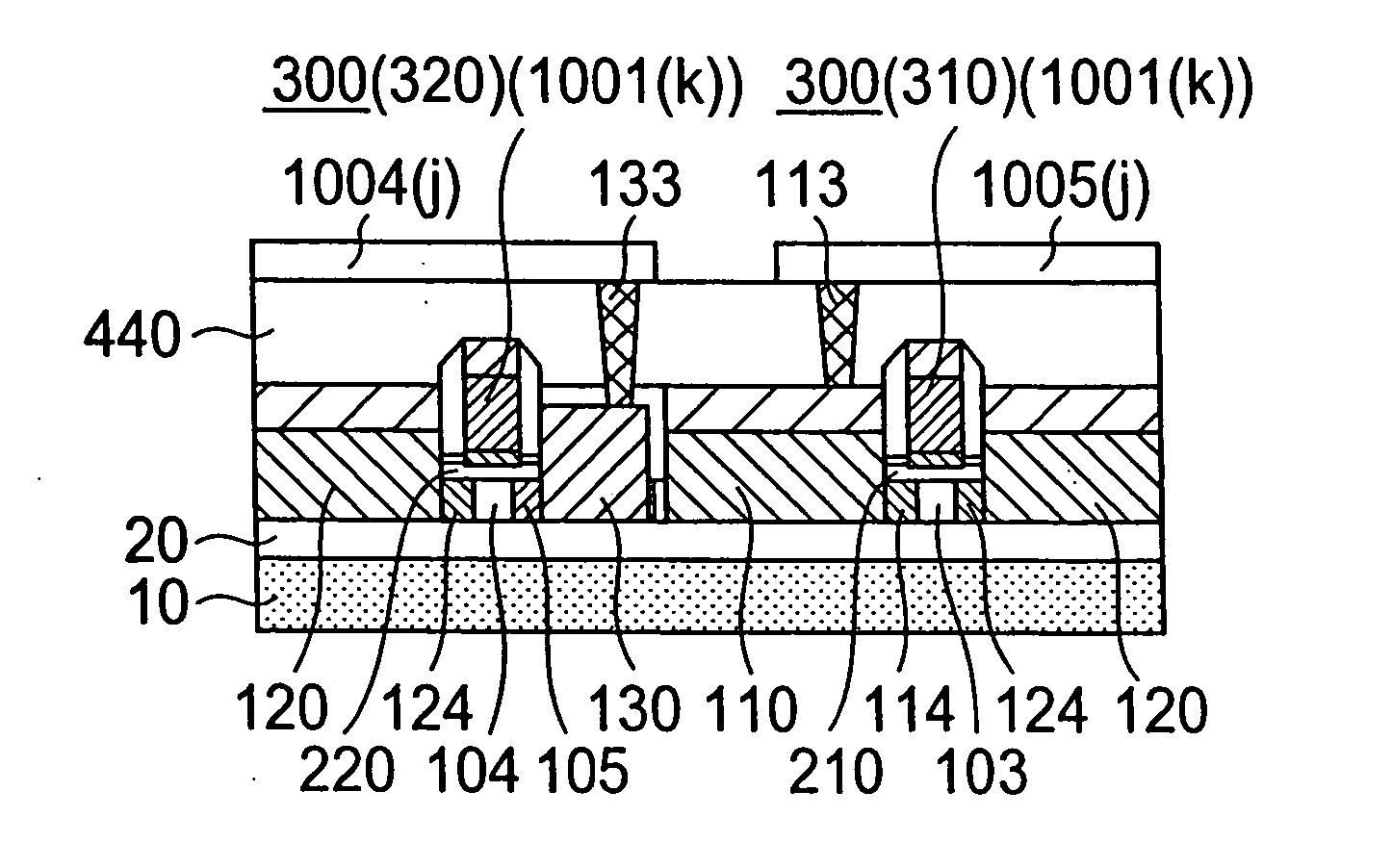

EL display using a semiconductor thin film transistor

There is provided an electric device which can prevent a deterioration in a frequency characteristic due to a large electric power external switch connected to an opposite electrode and can prevent a decrease in the number of gradations. The electric device includes a plurality of source signal lines, a plurality of gate signal lines, a plurality of power source supply lines, a plurality of power source control lines, and a plurality of pixels. Each of the plurality of pixels includes a switching TFT, an EL driving TFT, a power source controlling TFT, and an EL element, and the power source controlling TFT controls a potential difference between a cathode and an anode of the EL element.

Owner:SEMICON ENERGY LAB CO LTD

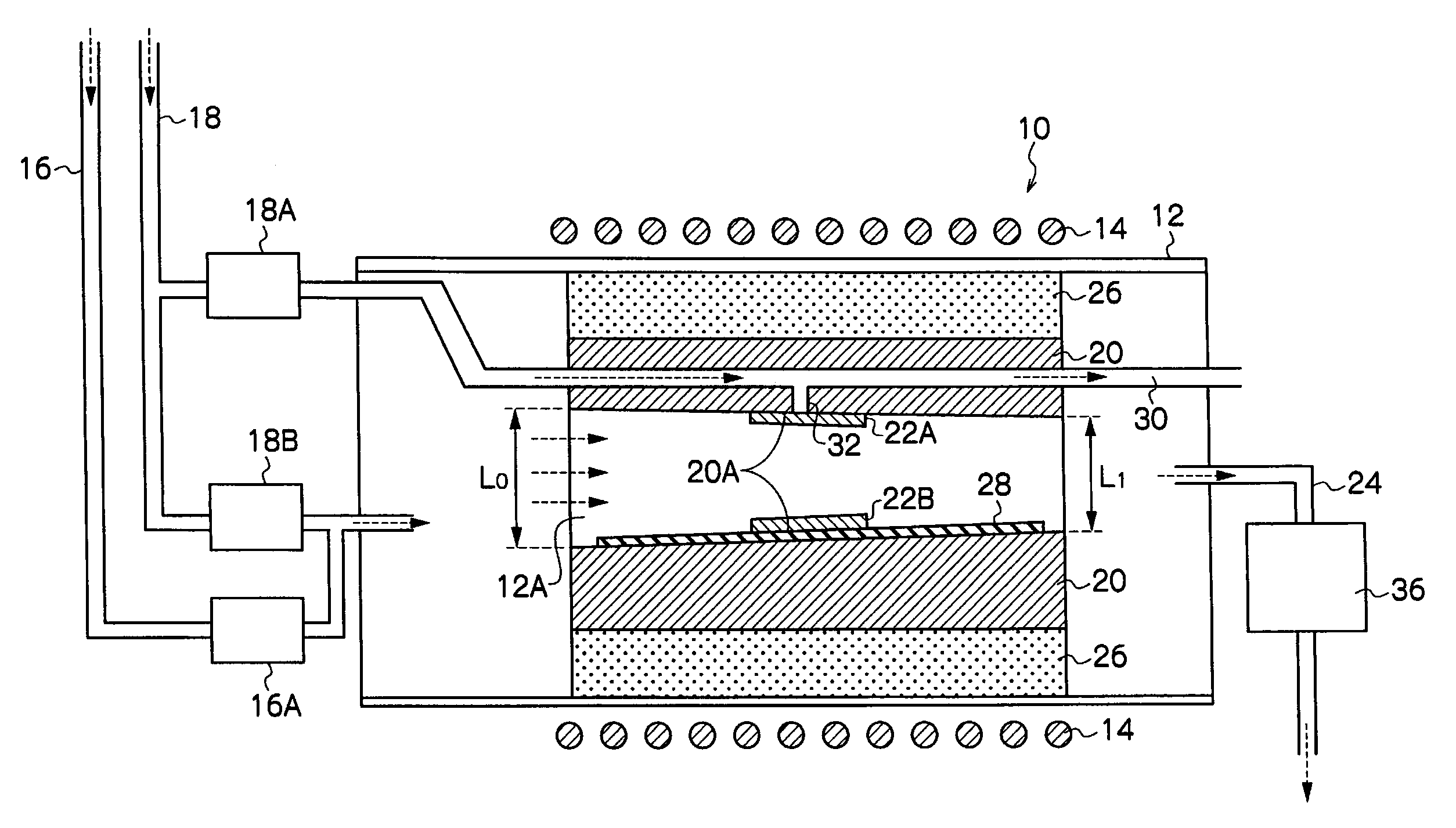

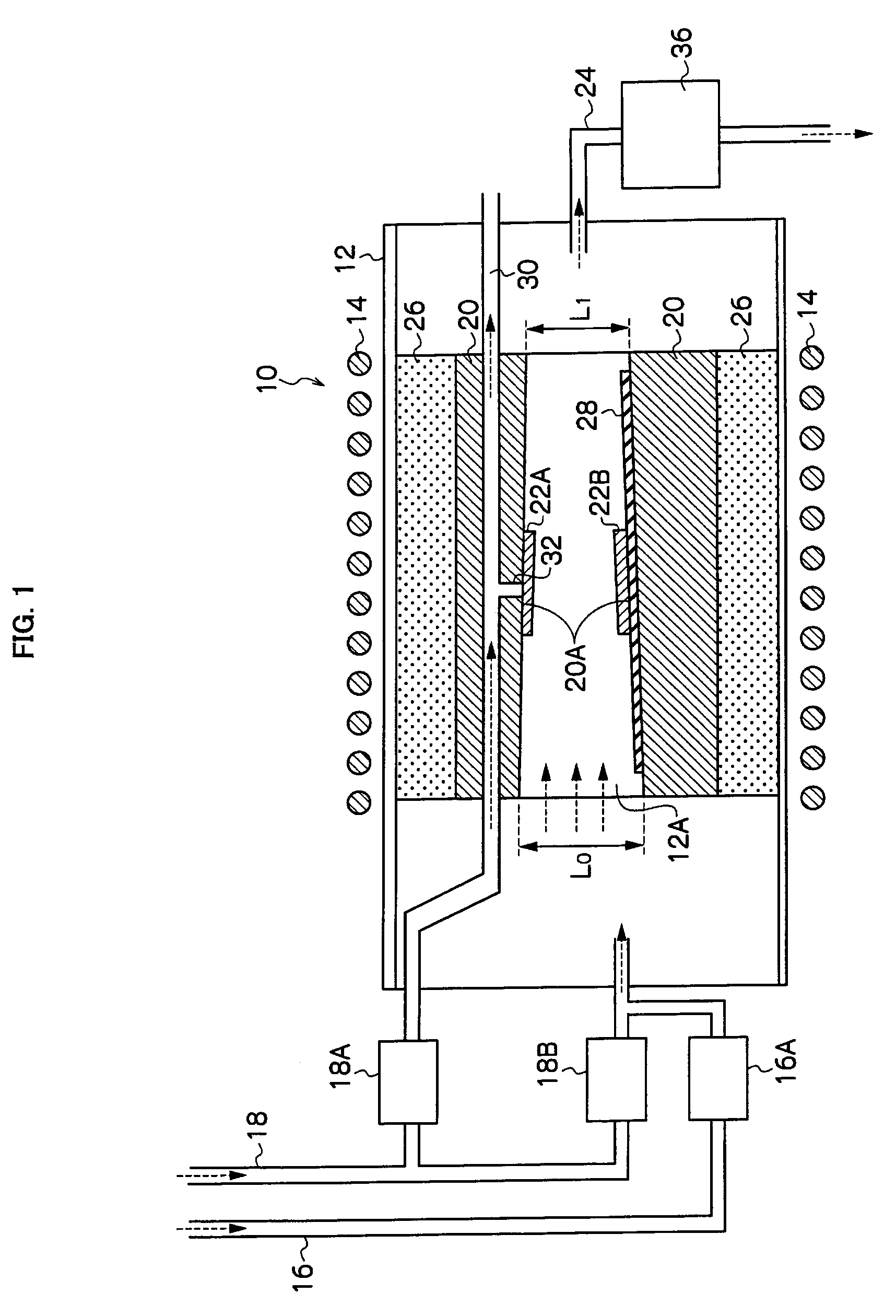

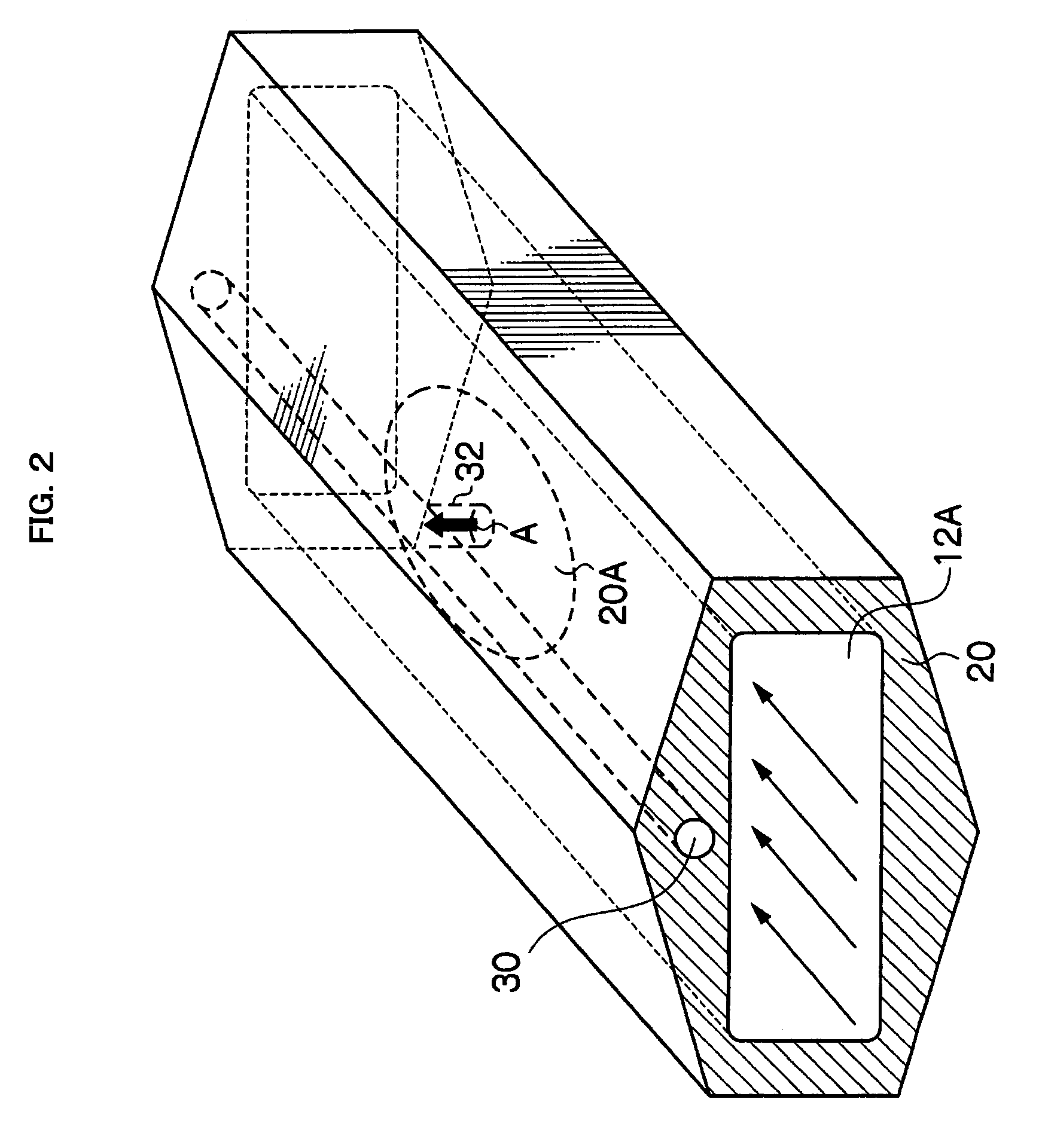

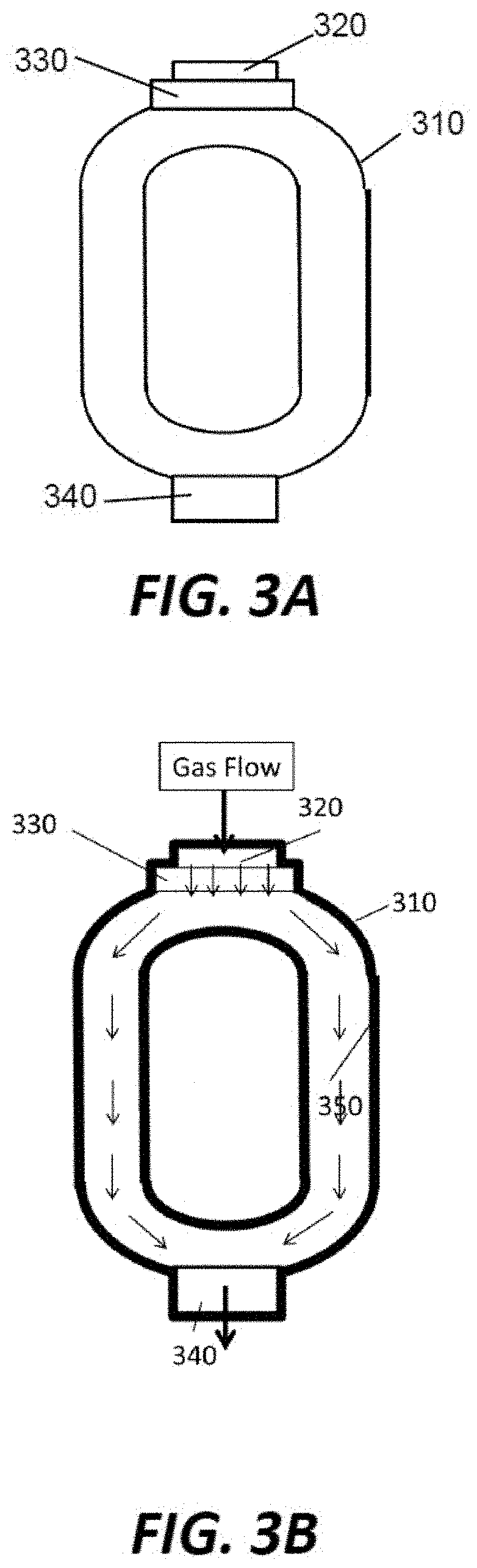

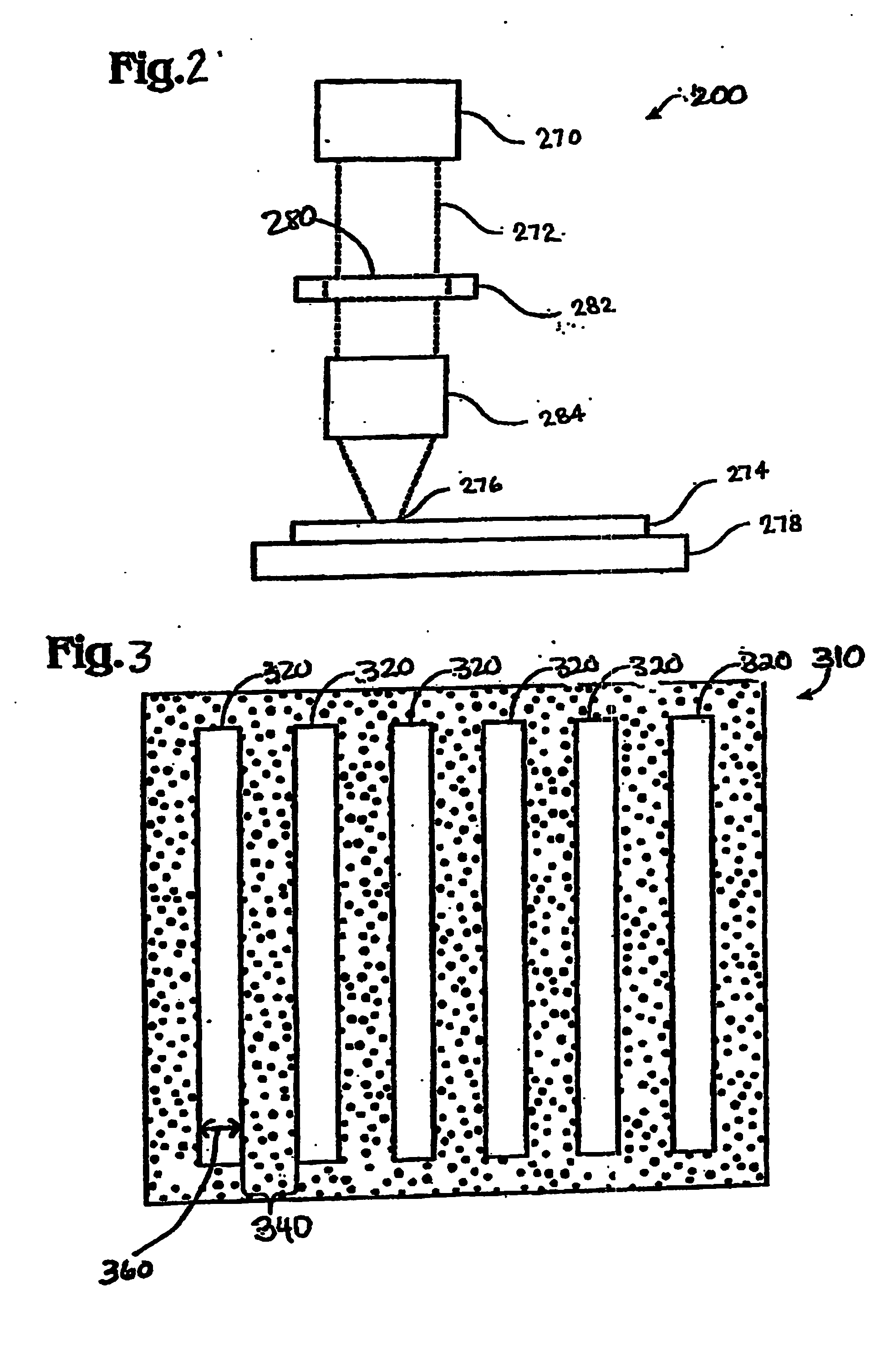

Apparatus for manufacturing semiconductor thin film

InactiveUS20090229519A1Improve in-plane evennessPolycrystalline material growthSemiconductor/solid-state device manufacturingIn planeSusceptor

The present invention provides an apparatus for manufacturing a semiconductor thin film that is capable of manufacturing an even thin film with substantially no adhesion of impurities, and is capable of improving in-plane evenness of a grown thin film. The invention is an apparatus for manufacturing a semiconductor thin film includes a reaction tube 12, a susceptor 20 disposed in the reaction tube 12, and a negative pressure generator, the negative pressure generator applying a negative pressure to a substrate 22A placed on the susceptor 20 to hold the substrate, and the substrate 22A is placed so that an angle of a normal line to a crystal growth face of the substrate 22A to a vertical downward direction is less than 180°.

Owner:TOYOTA JIDOSHA KK

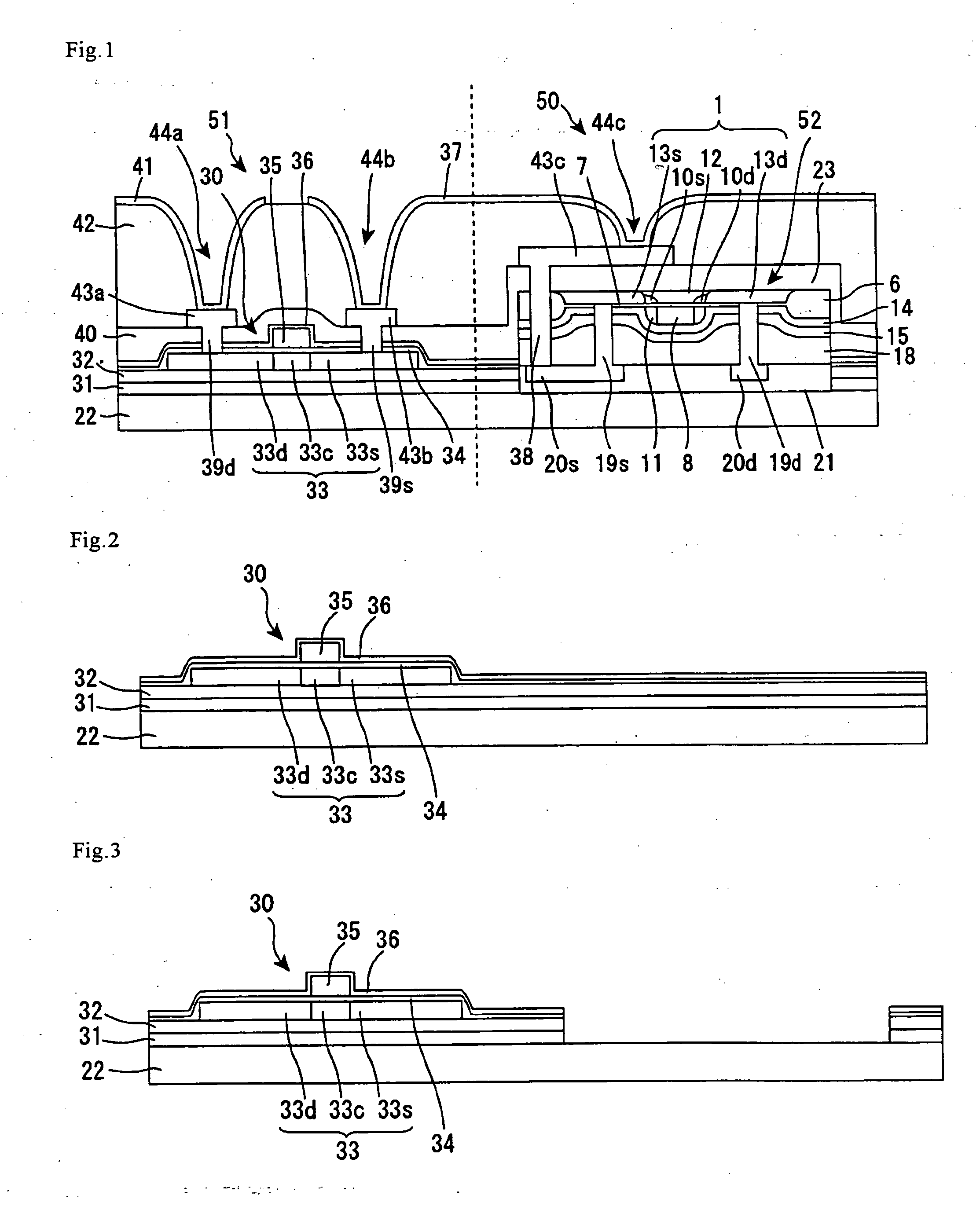

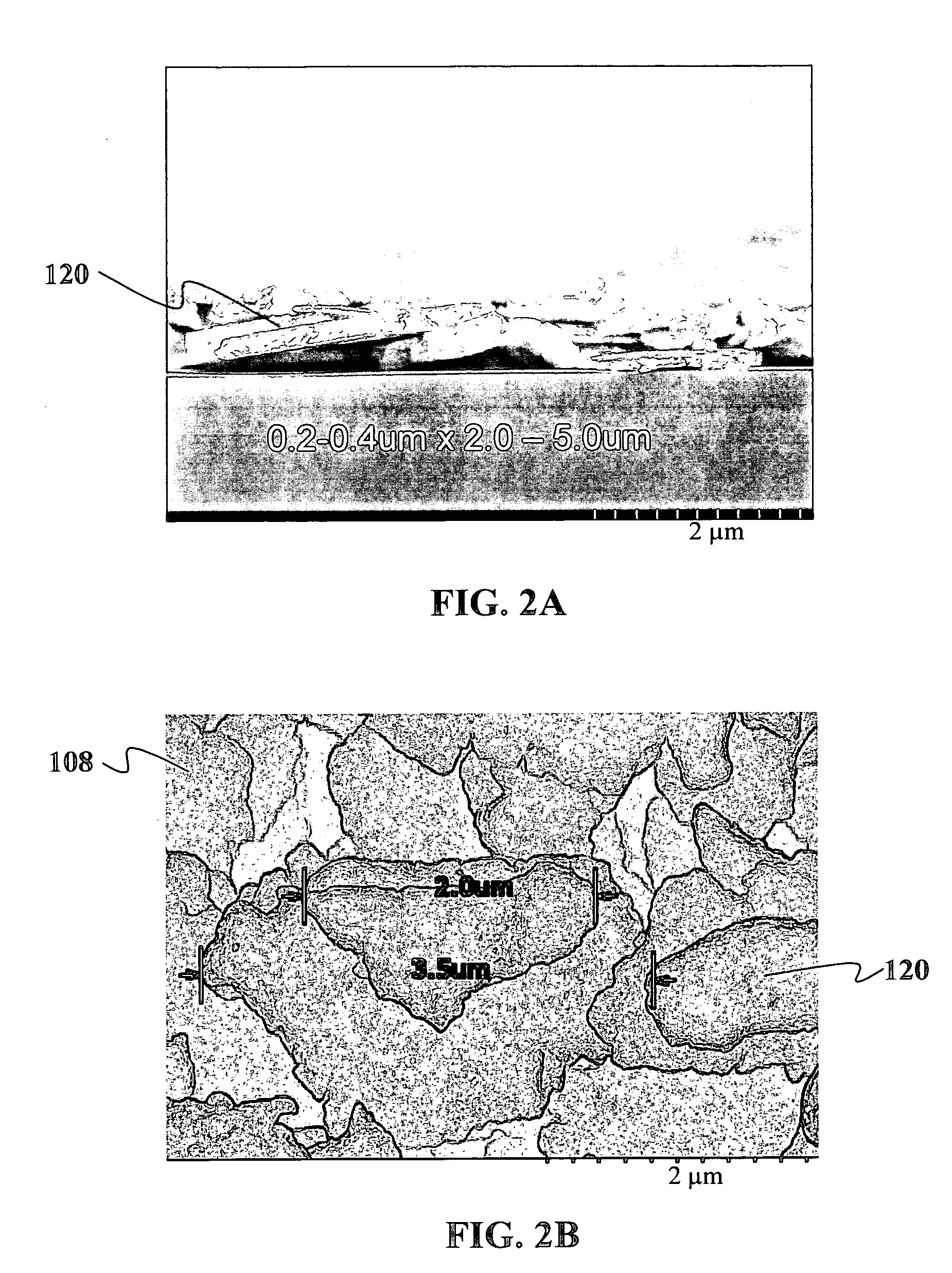

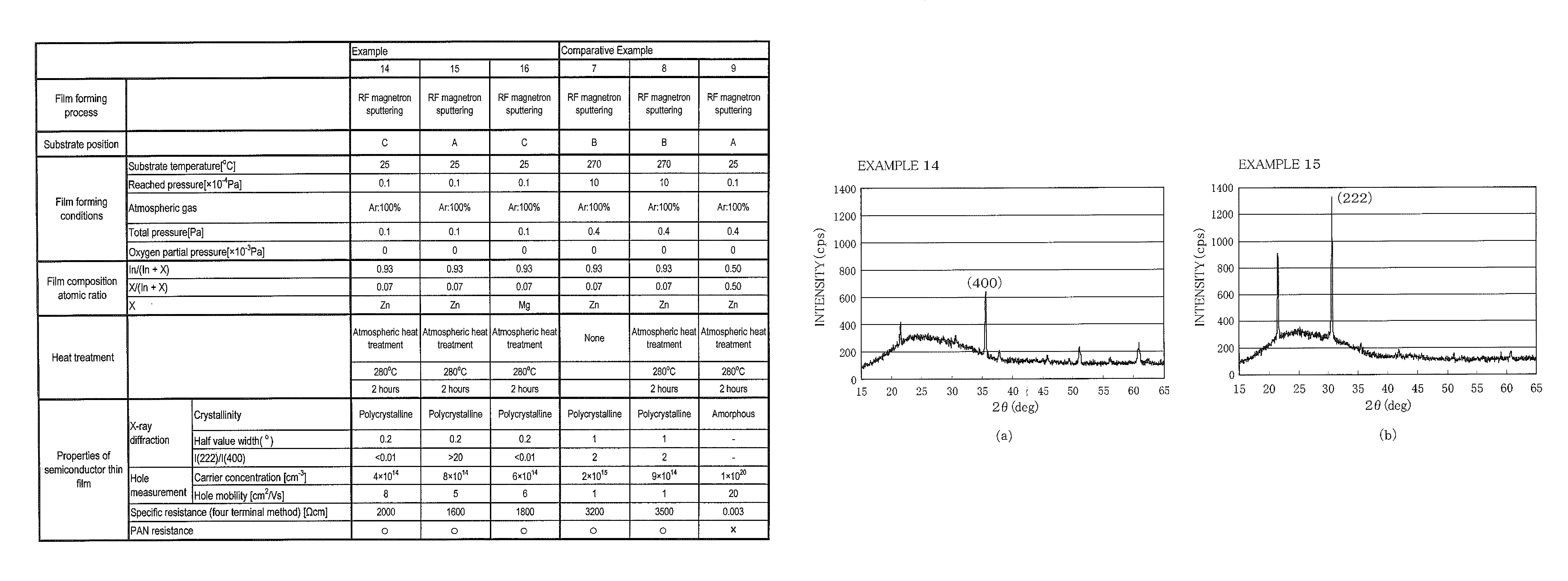

Semiconductor thin film, method for manufacturing the same, thin film transistor, and active-matrix-driven display panel

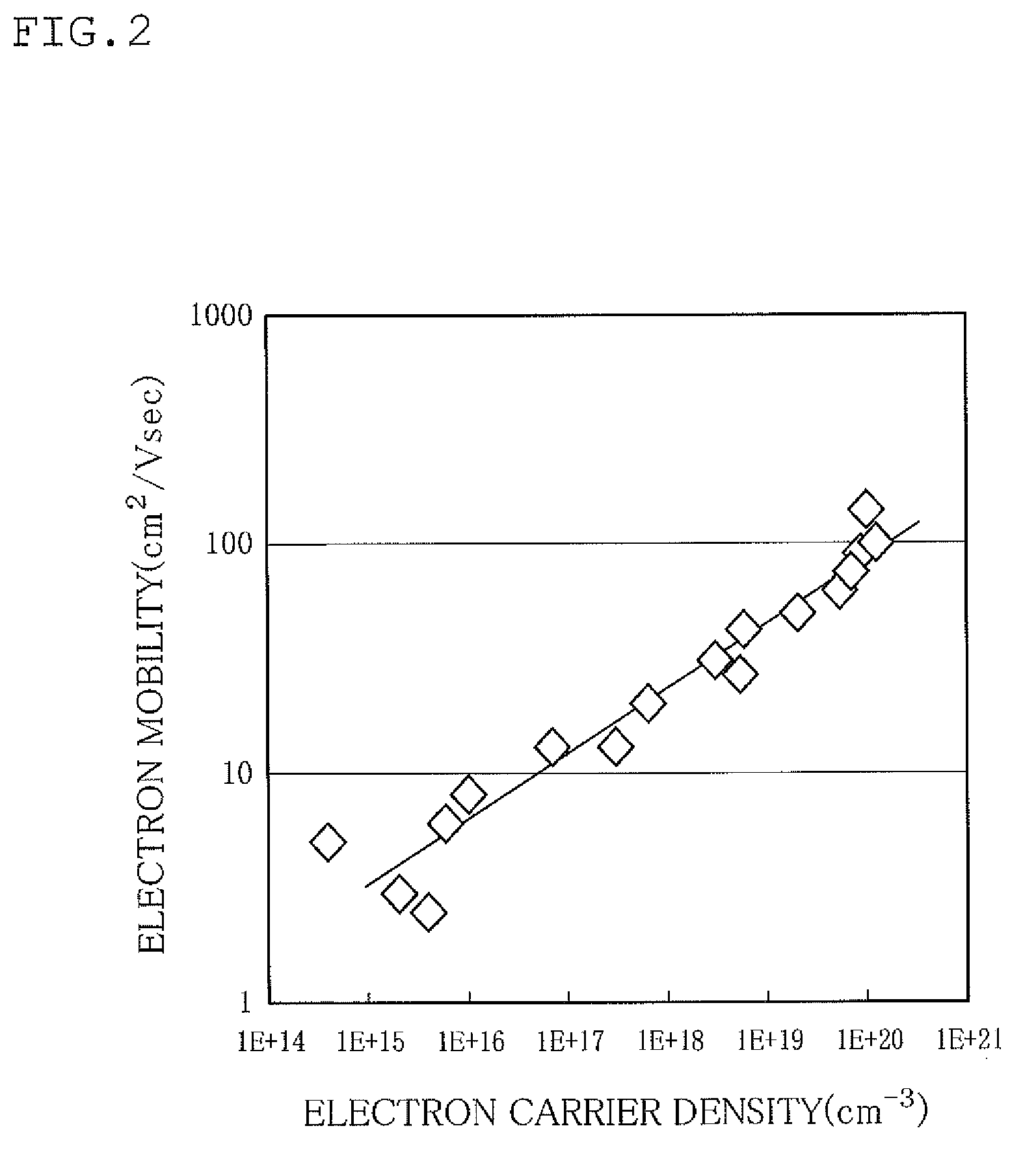

ActiveUS7998372B2Hardly erroneously operatesSmall currentNanotechConductive materialIndiumActive matrix

Disclosed is a semiconductor thin film which can be formed at a relatively low temperature even on a flexible resin substrate. Since the semiconductor thin film is stable to visible light and has high device characteristics such as transistor characteristics, in the case where the semiconductor thin film is used as a switching device for driving a display, even when overlapped with a pixel part, the luminance of a display panel does not deteriorate. Specifically, a transparent semiconductor thin film 40 is produced by forming an amorphous film containing zinc oxide and indium oxide and then oxidizing the film so that the resulting film has a carrier density of 10+17 cm−3 or less, a Hall mobility of 2 cm2 / V·sec or higher, and an energy band gap of 2.4 EV or more.

Owner:IDEMITSU KOSAN CO LTD

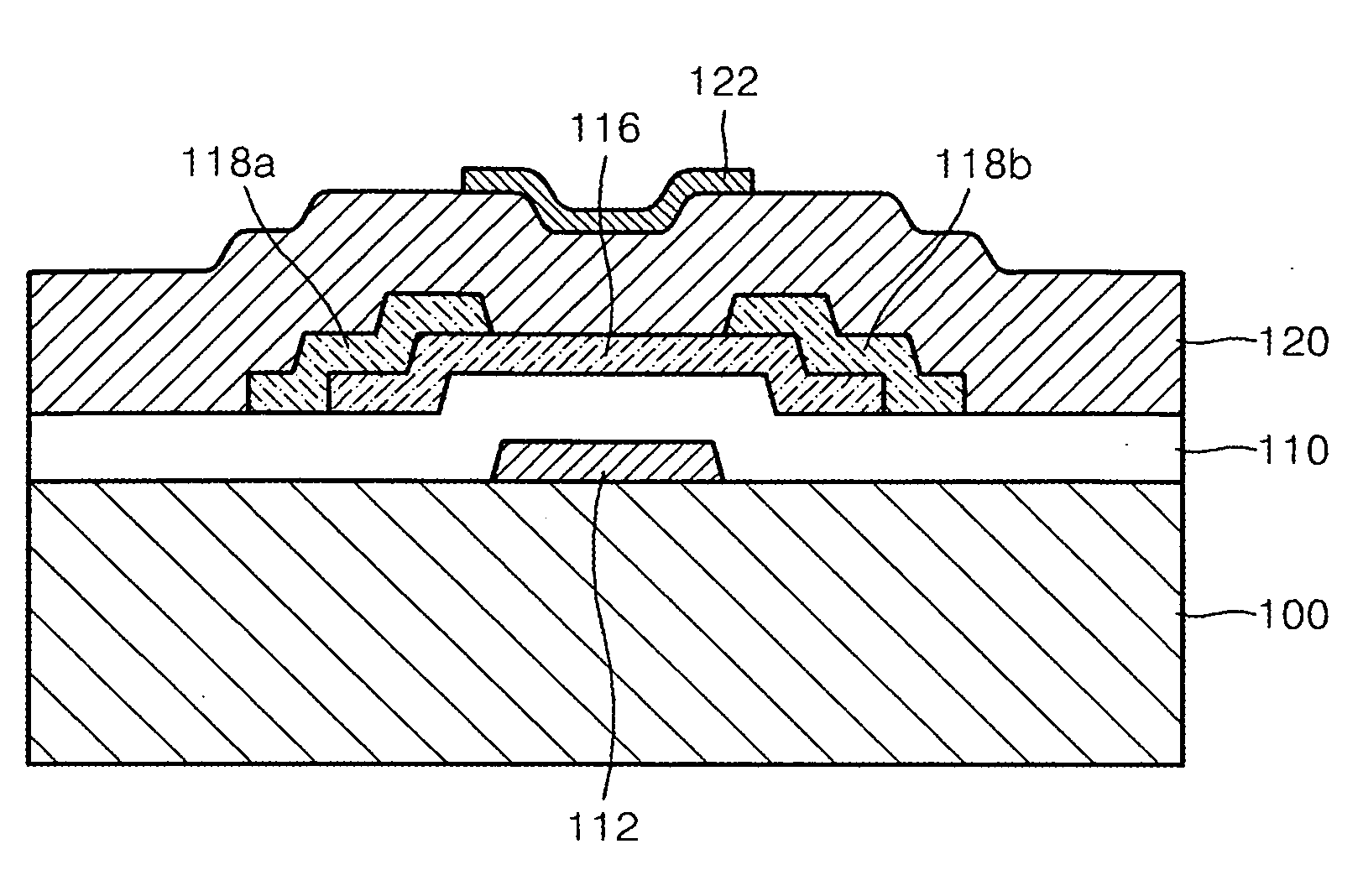

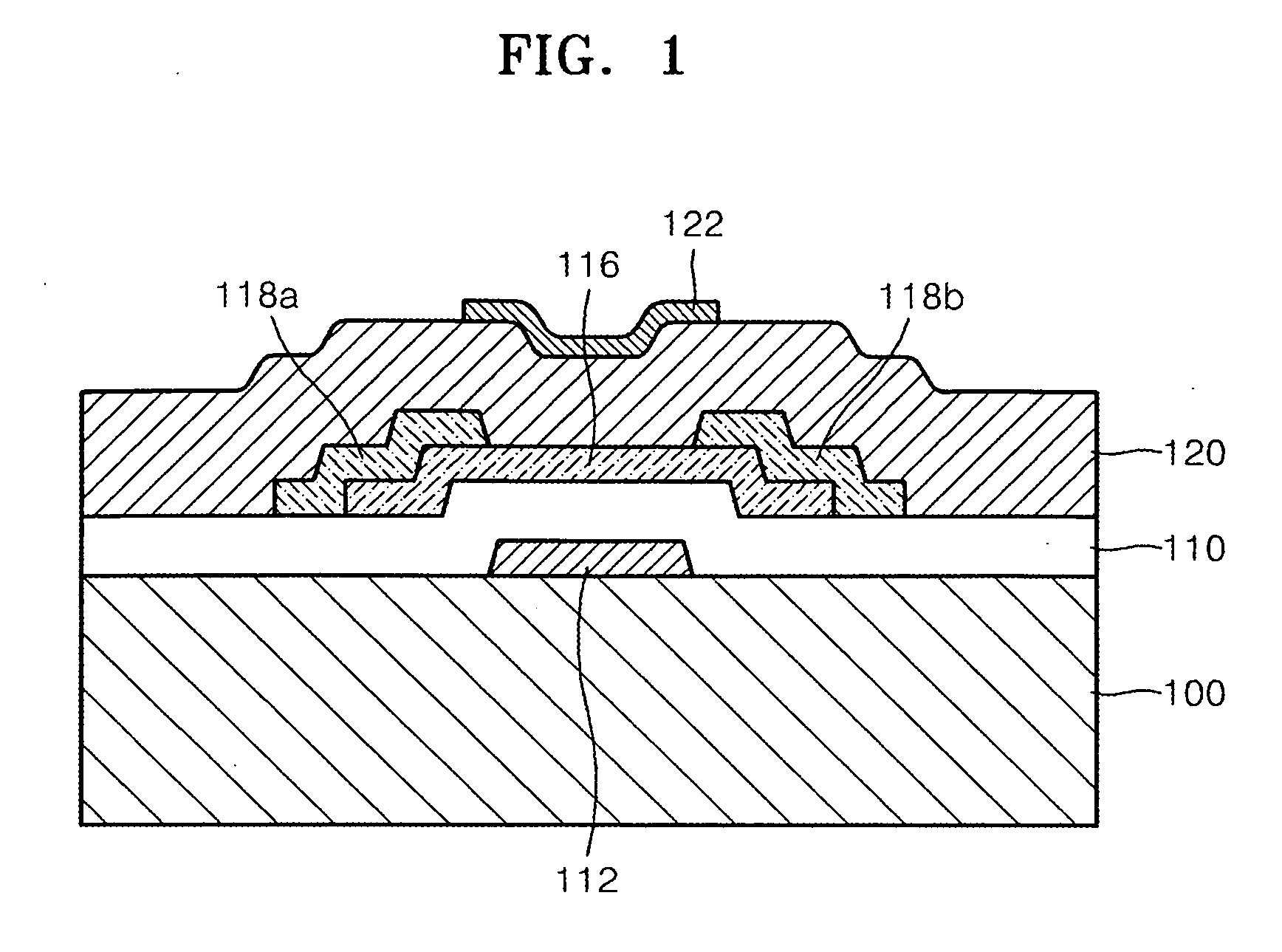

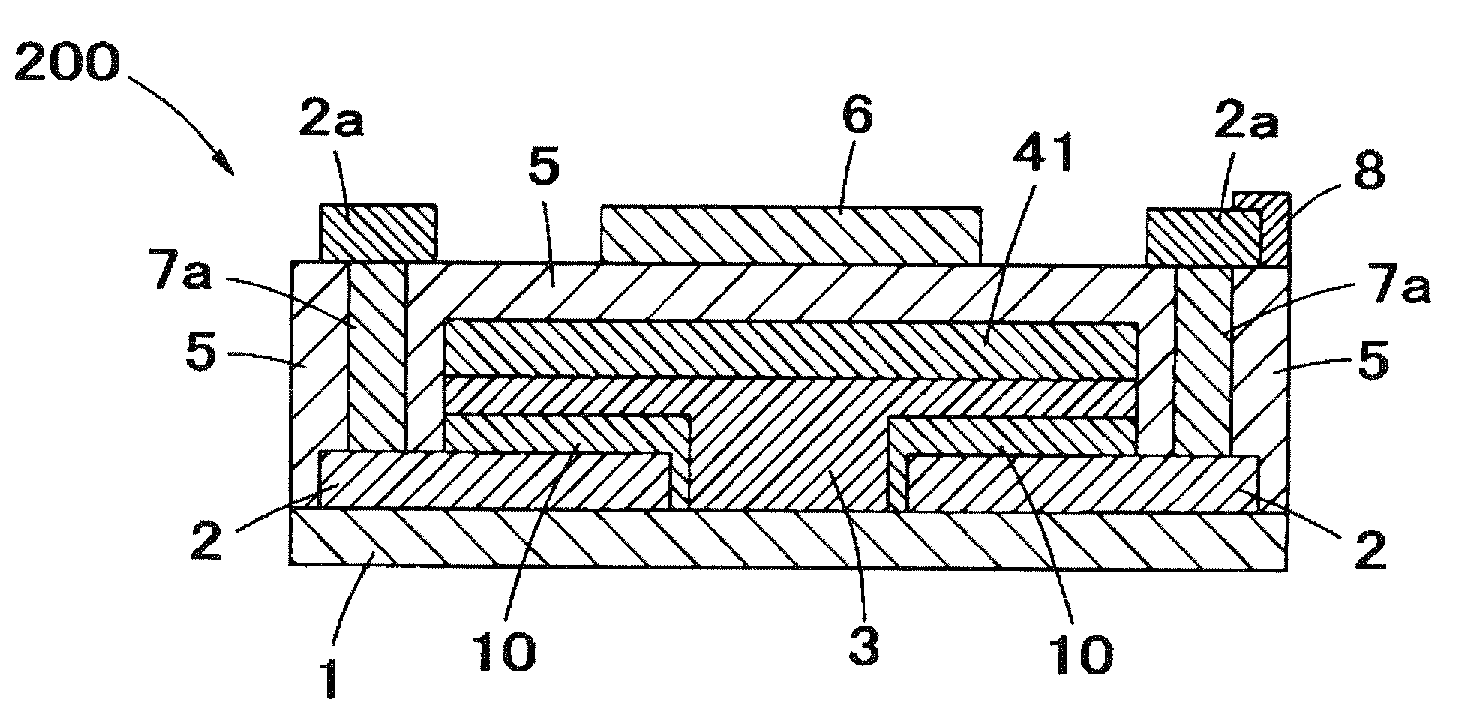

Semiconductor device, production method thereof, and display device

InactiveUS20090242893A1Reduce parasitic capacitanceReduce power consumptionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention provides a semiconductor device which can be produced by simple and cheap processes and effectively achieve improved performances and a reduced electric power consumption. Further, the present invention provides a production method thereof and a display device including the semiconductor device or a semiconductor device produced by the production method. The present invention is a semiconductor device including a pixel part and an integrated circuit part on a substrate, the pixel part including a switching element having a gate electrode formed on a semiconductor thin film, the integrated circuit part including a semiconductor layer on a gate electrode, wherein a passivation film is formed on the gate electrode in the pixel part.

Owner:SHARP KK

High temperature coatings for a preclean and etch apparatus and related methods

PendingUS20200131634A1Well formedElectric discharge tubesSemiconductor/solid-state device manufacturingWaferingSemiconductor

A coating and a method to form the coating is proposed for a semiconductor film pre-clean and etch apparatus. The coating may be employed in environments where it is difficult to use a traditional coating or coating method. The coatings provide advantages including: an ability to effectively deliver hydrogen radicals and fluorine radicals to a wafer surface in one apparatus or individually in two apparatuses; a coverage of high aspect ratio features on critical components; an operability in high temperatures exceeding 150° C.; and a protection of a part with high aspect ratio features underneath the coating, thereby preventing metal and particles on a processed wafer.

Owner:ASM IP HLDG BV

Semiconductor device

InactiveUS20050236623A1Well mixedGood heat dissipationTransistorSolid-state devicesDevice materialEngineering

An integrated circuit is formed on a flexible substrate by using an amorphous semiconductor thin film, or a polycrystalline or a monocrystalline semiconductor thin film crystallized by laser annealing. A plurality of such flexible integrated circuit boards and mounted on a separate support substrate. This can enhance the mechanical strength of devices, such as an IC card and a liquid crystal display, and allow those devices to be manufactured at a low cost. It is also possible to provide a semiconductor device with a higher performance, on which a flexible integrated circuit board and an IC chip made from a silicon and / or glass wafer. Adhering a film substrate having a high thermal conductivity, such as a metal, to the bottom side of the flexible integrated circuit board improves the heat discharging characteristic of the integrated circuit and suppress the problem of self-heating.

Owner:NEC CORP

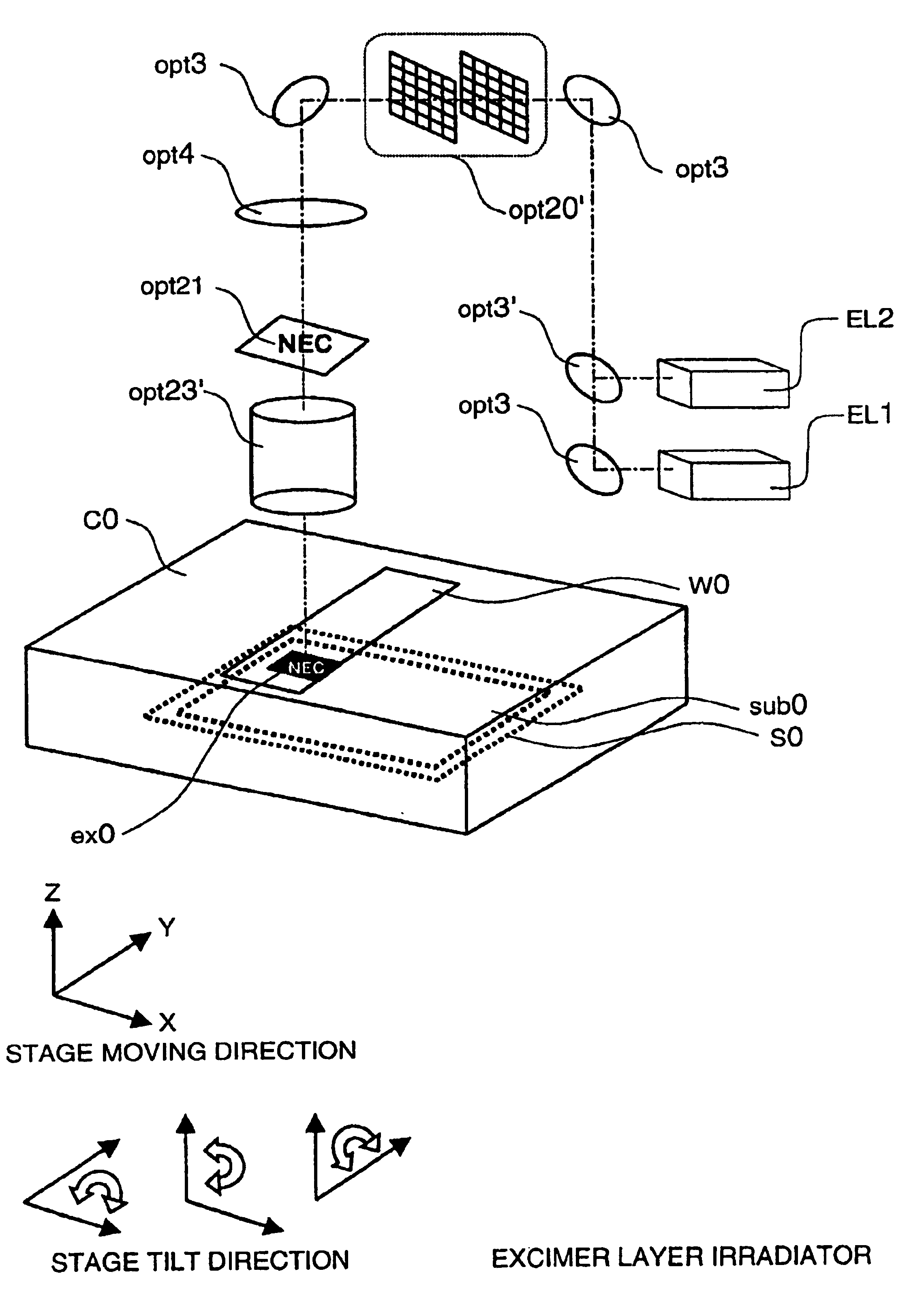

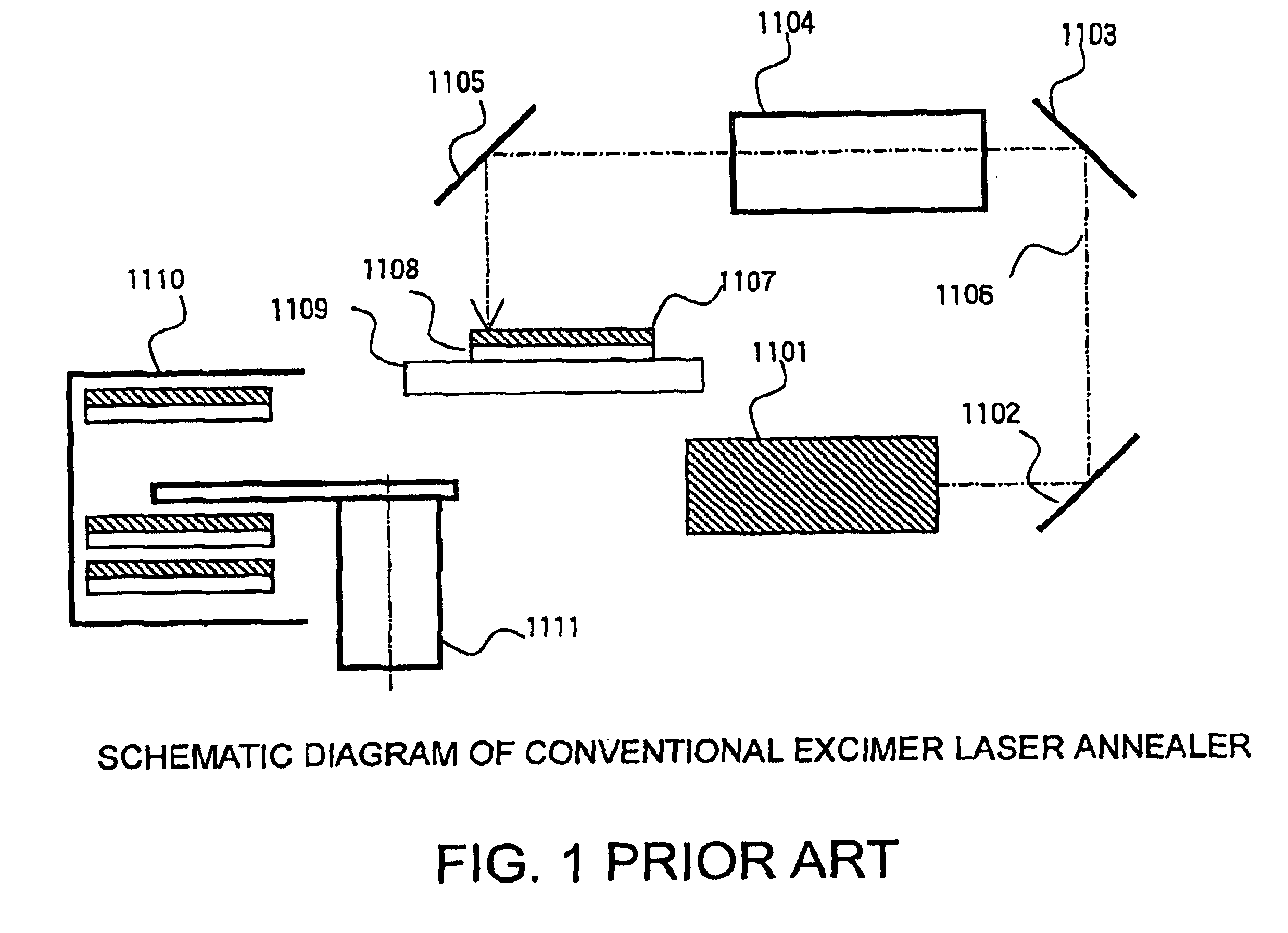

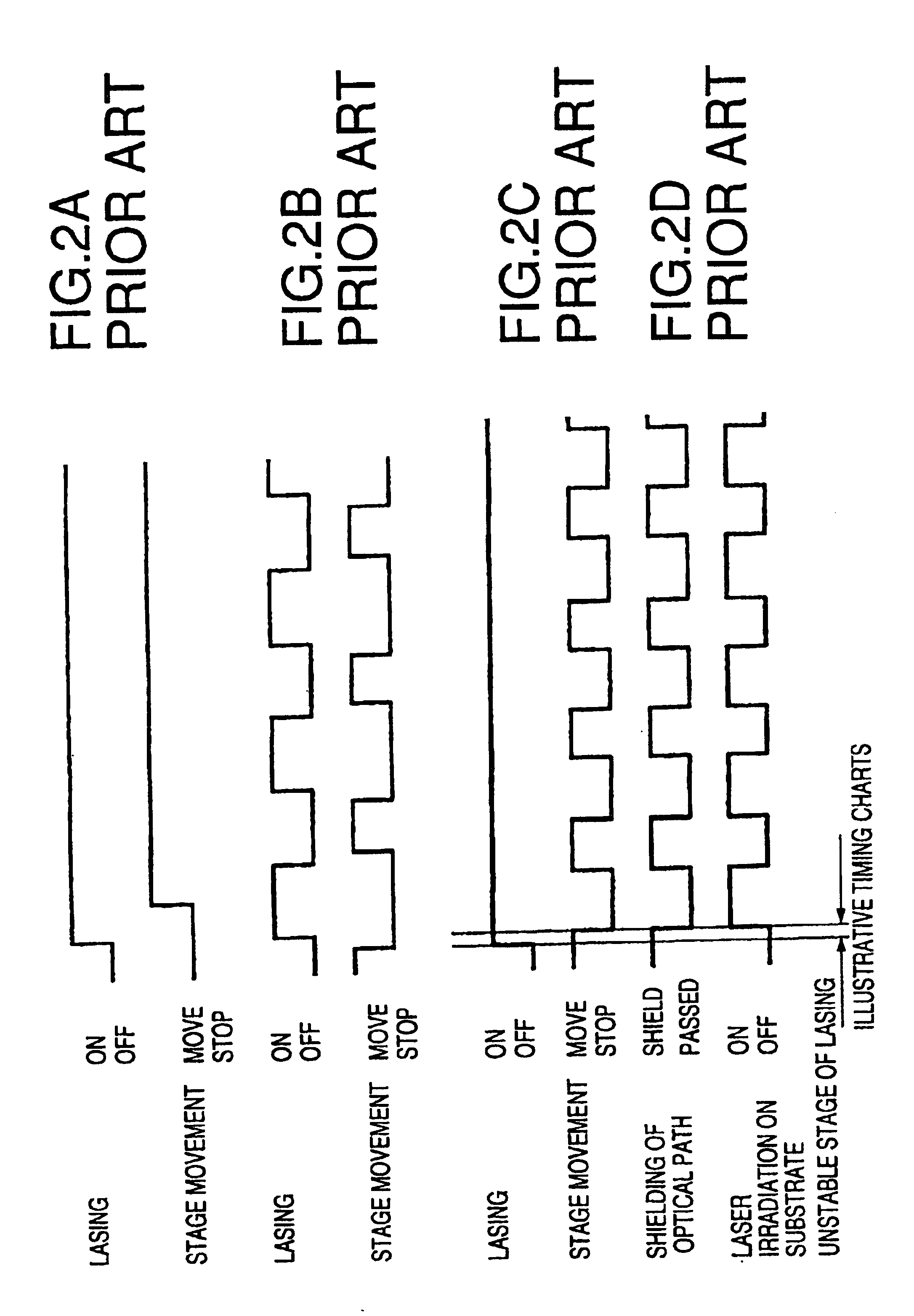

Method for forming thin semiconductor film, method for fabricating semiconductor device, system for executing these methods and electrooptic device

InactiveUS20030148565A1Promote crystallizationEasily realizedTransistorSolid-state devicesMolten stateUltraviolet

The present invention provides a method capable of easily forming a polycrystalline or monocrystalline semiconductor thin film of polycrystalline silicon with a high degree of crystallization and high quality at low cost, and an apparatus for carrying out the method. In a method of forming a polycrystalline (or monocrystalline) semiconductor thin film, a method of manufacturing a semiconductor device and an apparatus for carrying out these methods, in order to form a large-grain polycrystalline (or monocrystalline) semiconductor thin film (7) such as a polycrystalline silicon film with a high degree of crystallization on a substrate (1) or manufacturing a semiconductor device having the polycrystalline (or monocrystalline) semiconductor thin film (7), a low-crystalline semiconductor thin film (7A) is formed on the substrate (1), and then heated in a molten, semi-molten or non-molten state by laser annealing with ultraviolet rays (UV) or / and deep ultraviolet rays (DUV) and cooled to promote crystallization of the low-crystalline semiconductor thin film (7A), obtaining the polycrystalline (or monocrystalline) semiconductor thin film (7).

Owner:SONY CORP

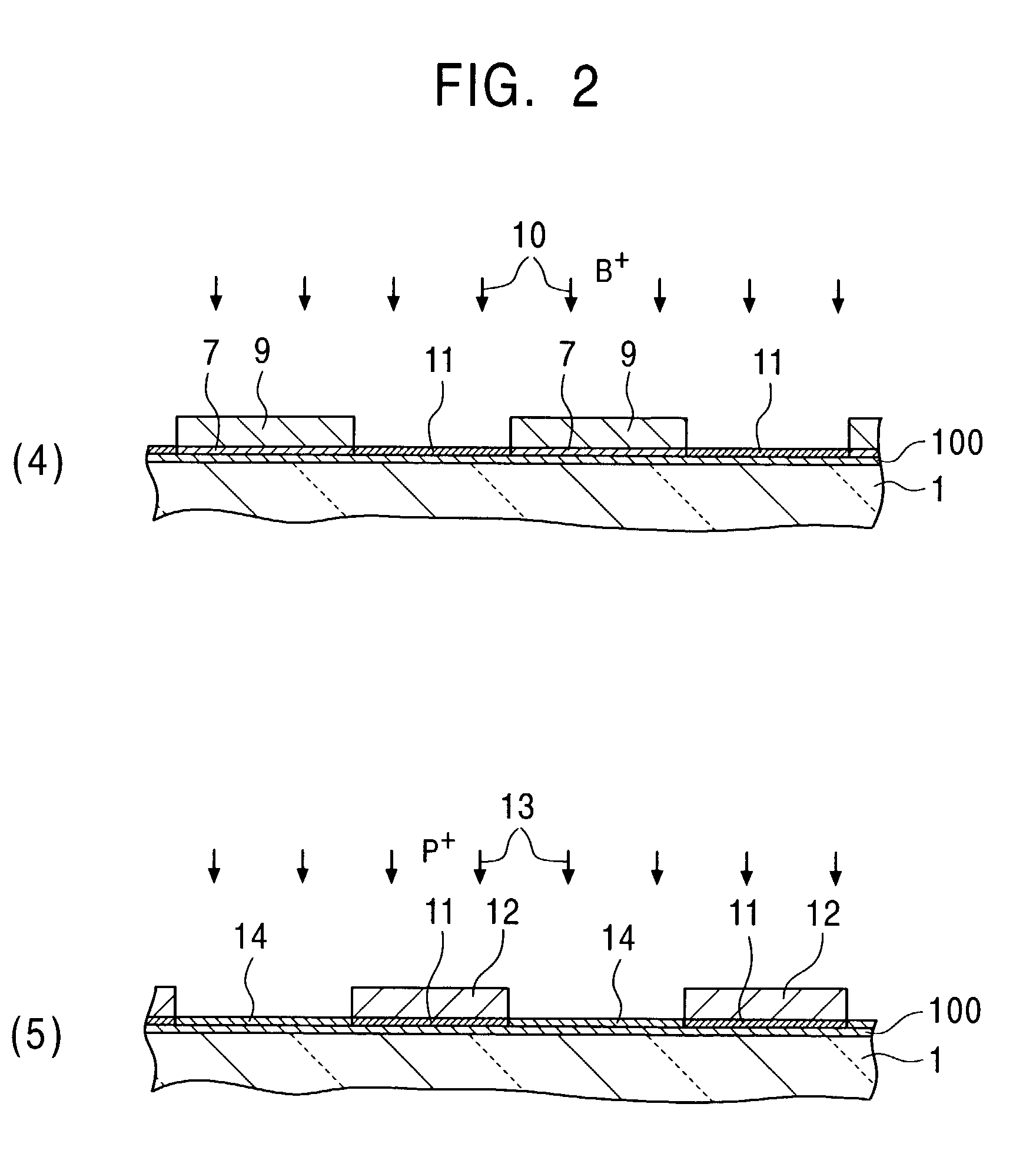

Thin film transistor having an etching protection film and manufacturing method thereof

InactiveUS20060043447A1Improve machining accuracySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSemiconductor thin films

A thin film transistor of the present invention includes a semiconductor thin film (8); a gate insulating film (7) formed on one surface of the semiconductor thin film (8); a gate electrode (6) formed to be opposite to the semiconductor thin film (8) through the gate insulating film (7); a source electrode (15) and a drain electrode (16) electrically connected to the semiconductor thin film (8); a source region; a drain region; and a channel region. The thin film transistor further includes an insulating film (9) formed on a peripheral portion corresponding to at least the source region and the drain region of the semiconductor thin film (8), and having a contact hole (10, 11) through which at least a part of each of the source region and the drain region is exposed wherein the source electrode (15) and the drain electrode (16) are connected to the semiconductor thin film (8) through the contact hole (10, 11).

Owner:CASIO COMPUTER CO LTD

Thin film memory, array, and operation method and manufacture method therefor

A memory cell which is formed on a fully depleted SOI or other semiconductor thin film and which operates at low voltage without needing a conventional large capacitor is provided as well as a memory cell array. The semiconductor thin film is sandwiched between first and second semiconductor regions which face each other across the semiconductor thin film and which have a first conductivity type. A third semiconductor region having the opposite conductivity type is provided in an extended portion of the semiconductor thin film. From the third semiconductor region, carriers of the opposite conductivity type are supplied to and accumulated in the semiconductor thin film portion to change the gate threshold voltage of a first conductivity type channel that is induced by a first conductive gate voltage in the semiconductor thin film between the first and second semiconductor regions through an insulating film.

Owner:HAYASHI YUTAKA +1

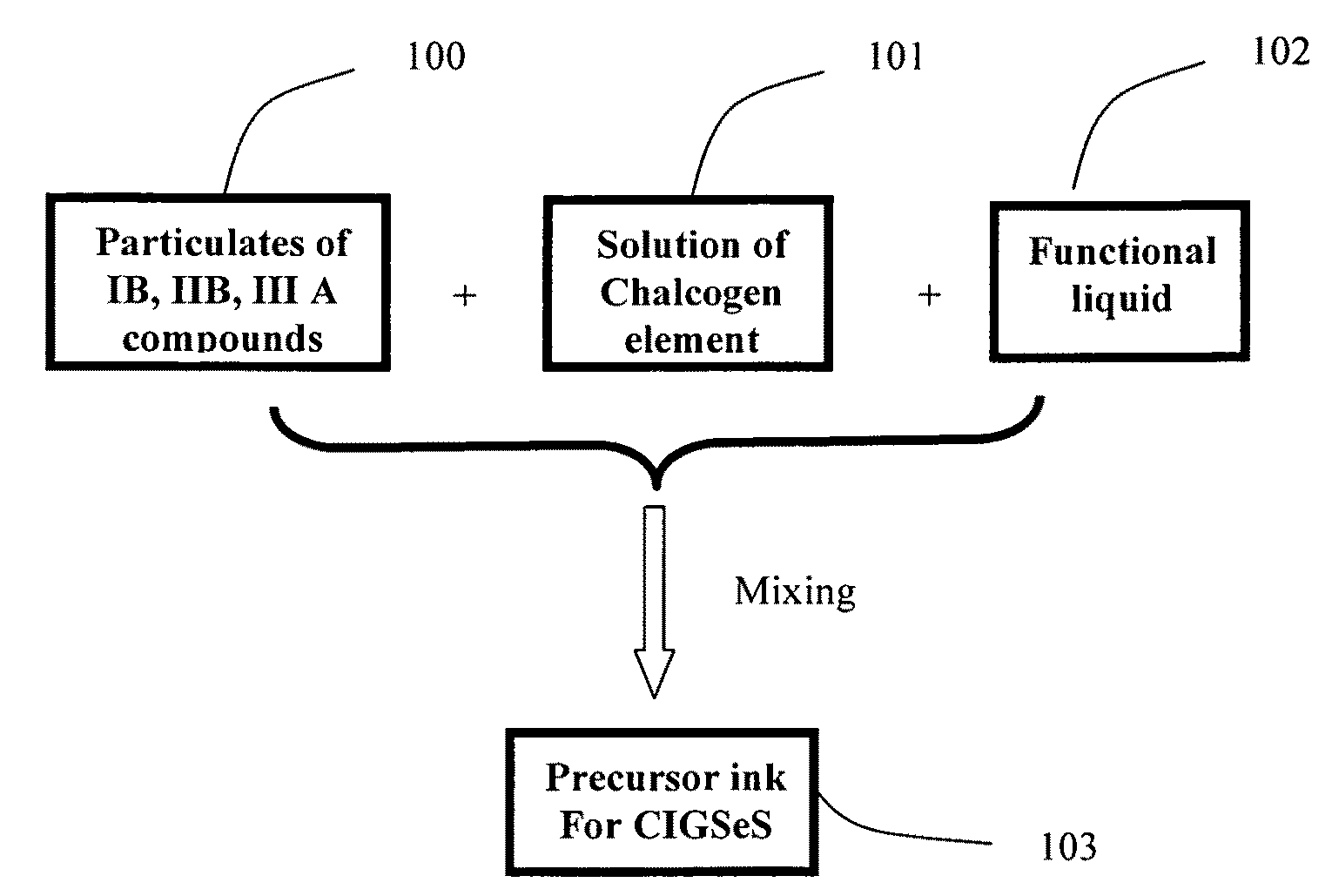

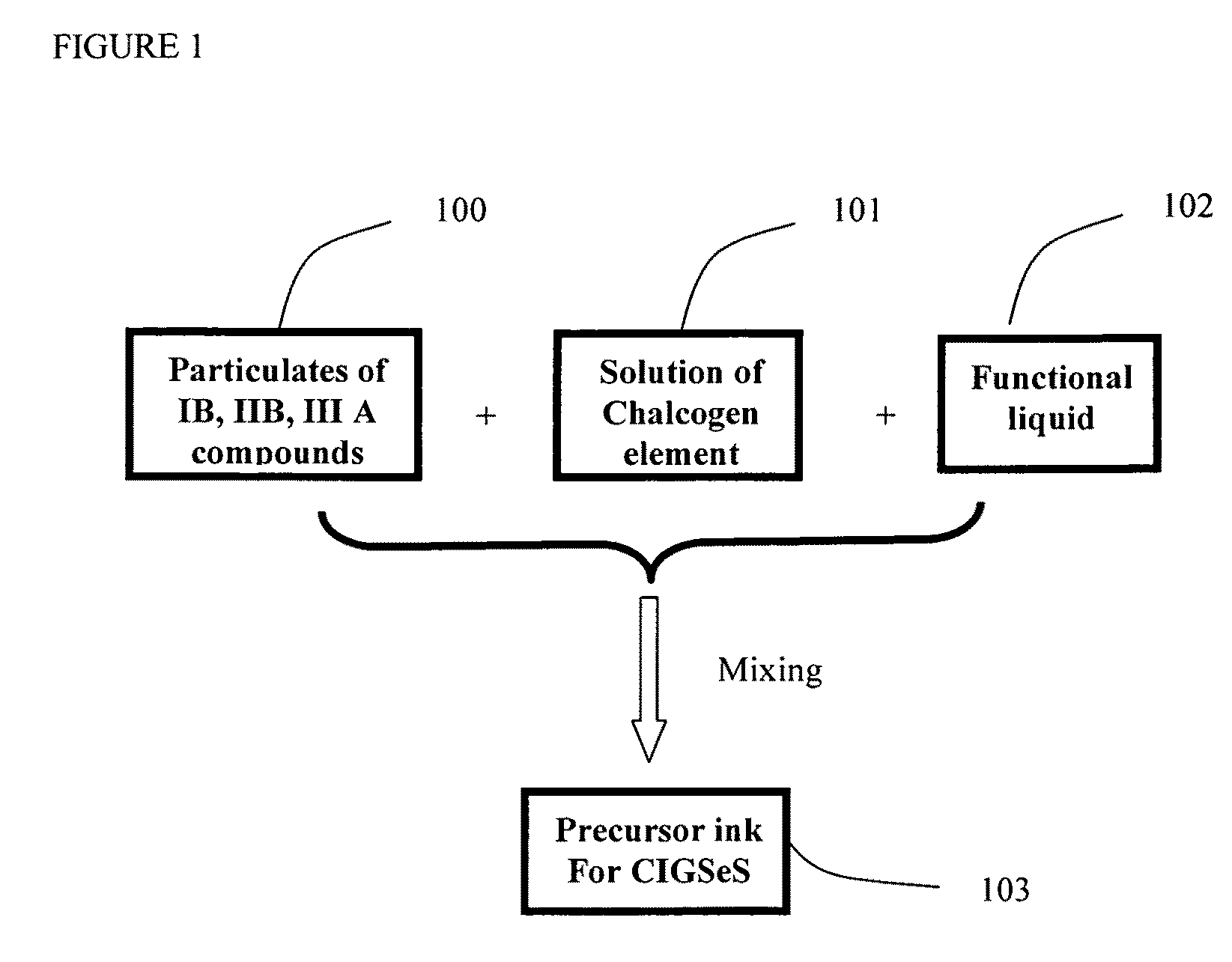

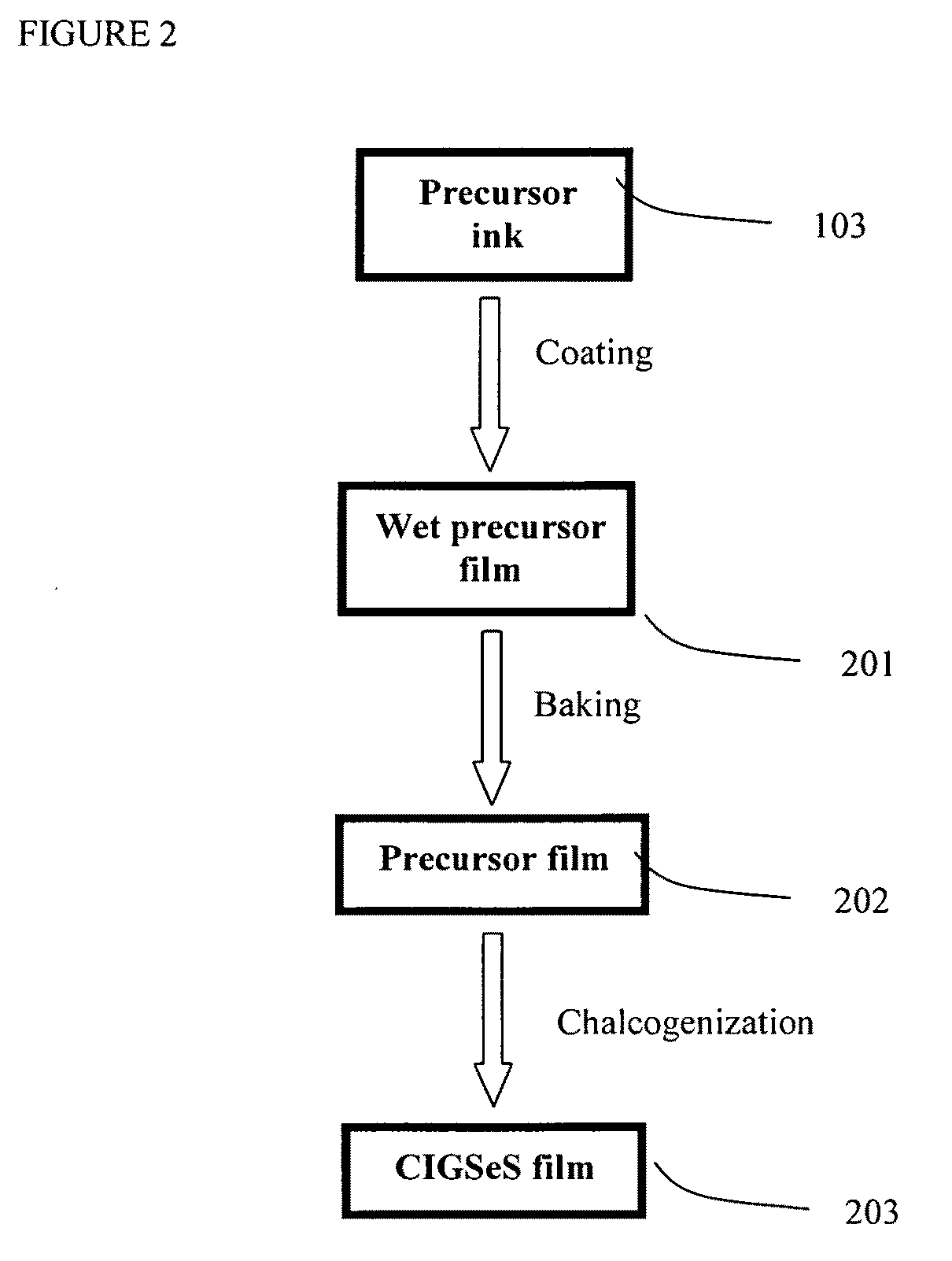

Precursor ink for producing IB-IIIA-VIA semiconductors

InactiveUS20090260670A1Overcome disadvantagesFinal product manufacturePV power plantsIndiumSemiconductor thin films

Copper indium diselenide, copper indium gallium diselenide, and other IB-IIIA-VIA compounds are produced by the liquid deposition on a substrate of a precursor-containing ink, followed by heating to produce the desired material. The precursor containing ink is a mixture of three parts. The first part is plurality of particulates of metal compounds of IB, IIIA. The second part is chalcogen source of selenium, sulfur, or organic chalcogen compounds dissolved in a liquid organic solvent. The third part solution function as viscosity adjustment, as introduction of dopant of sodium ion and / or as ink stabilizer. The precursor ink can be coated on substrate at room temperature and it can be transferred into copper indium (gallium) chalcogenide semiconductor thin film upon baking and a chalcogenization process. The resulting thin film semiconducting material can be incorporated into photovoltaic and other electronic devices.

Owner:LI XIAO CHANG CHARLES

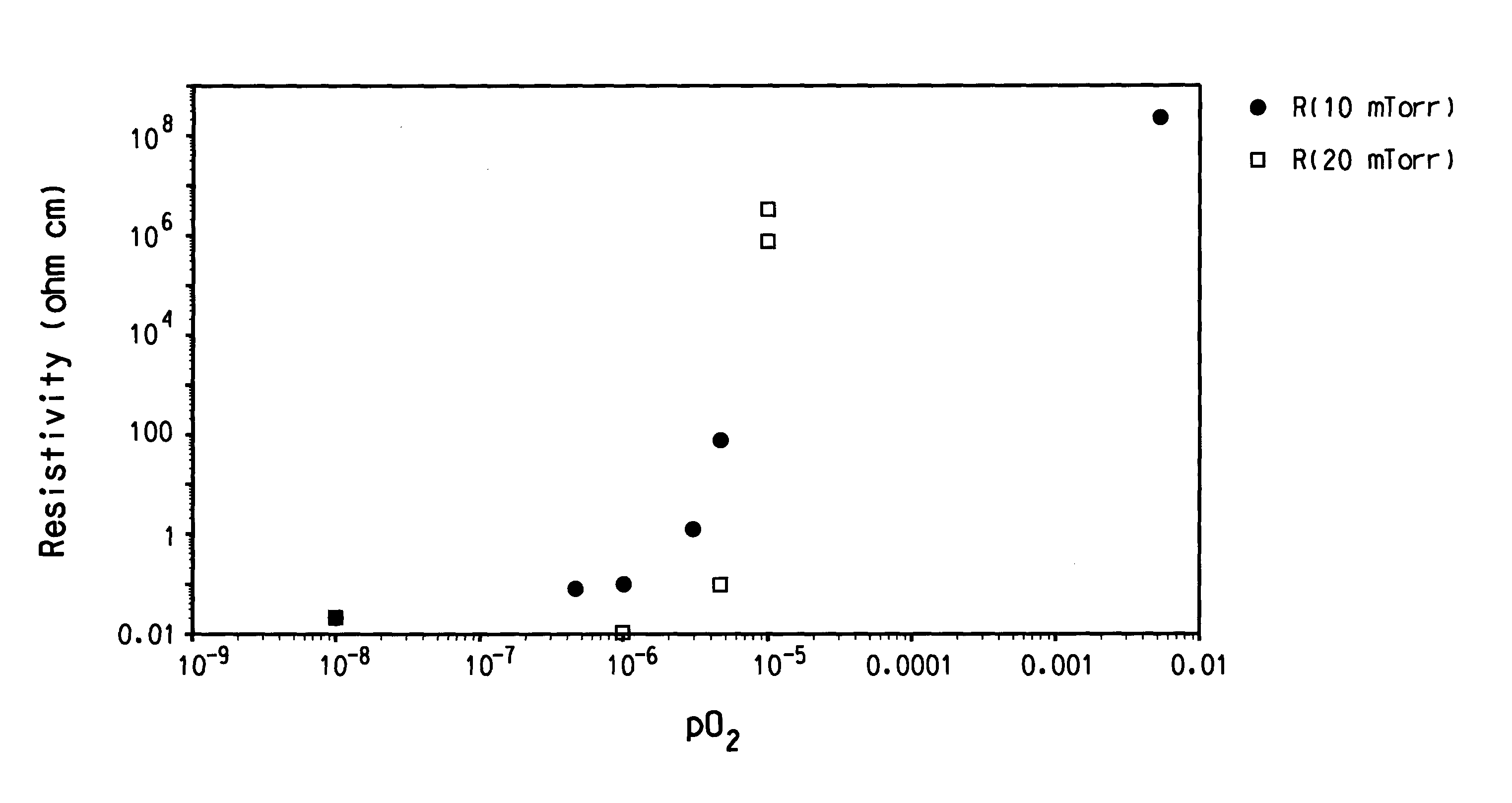

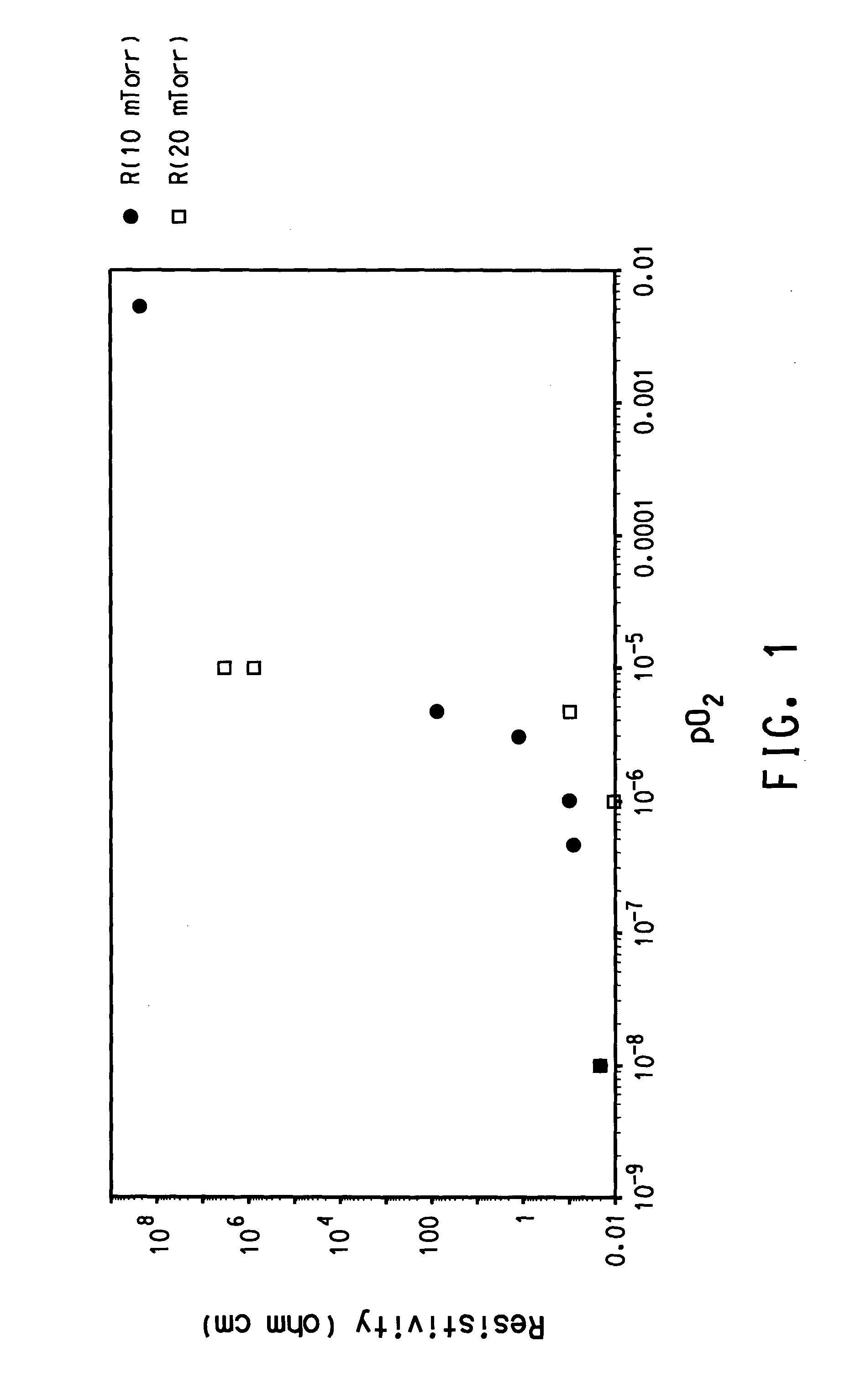

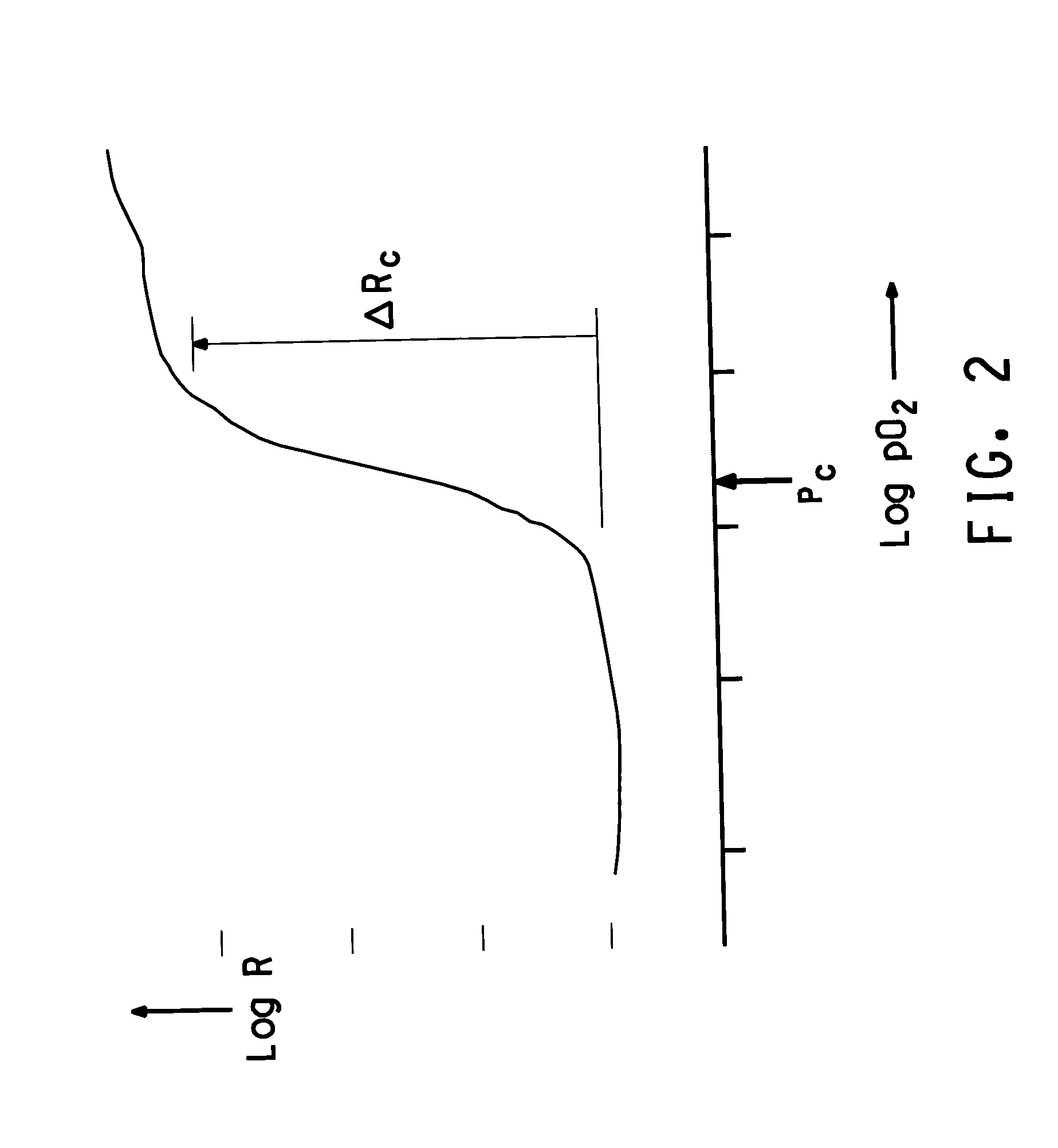

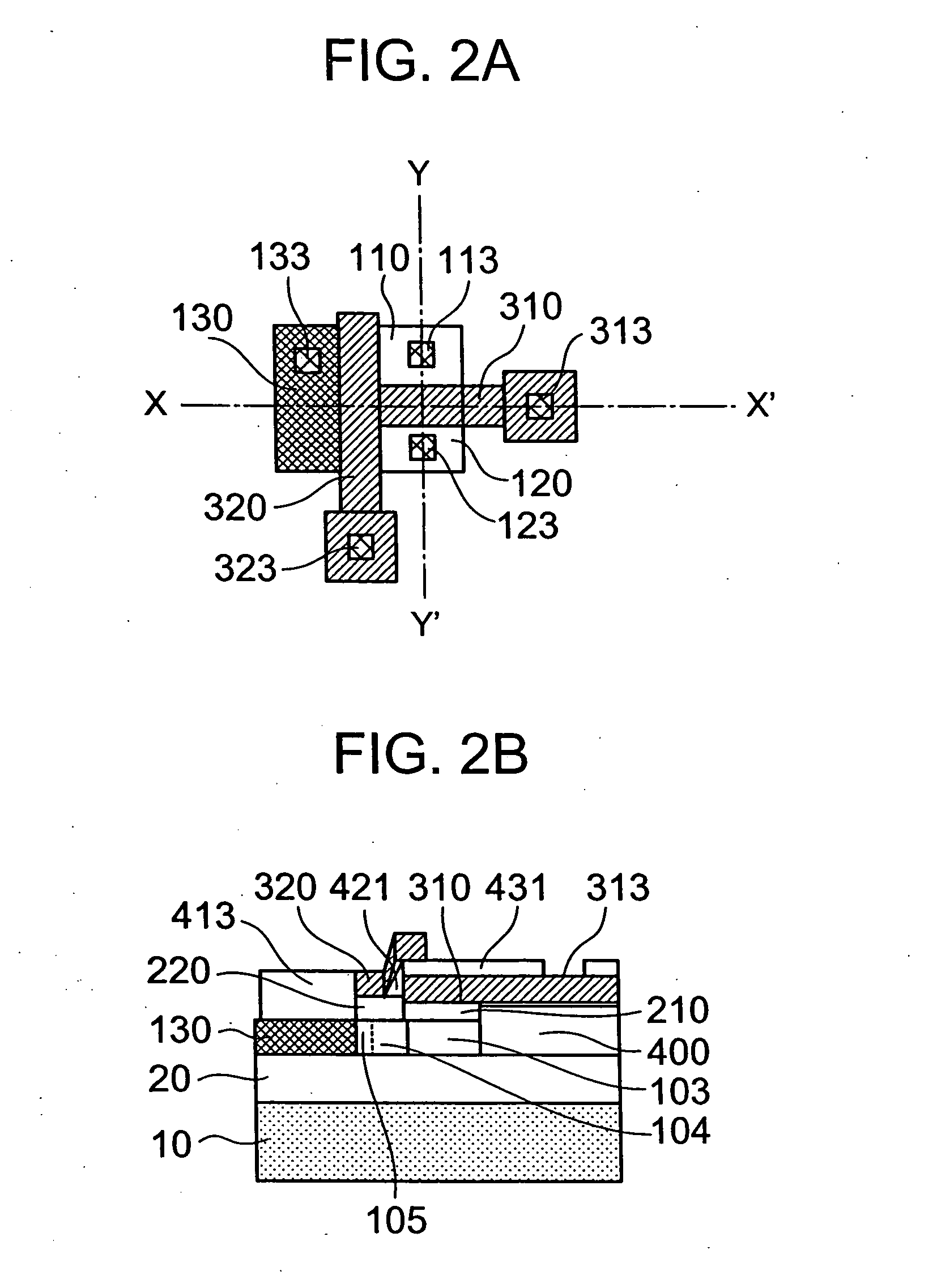

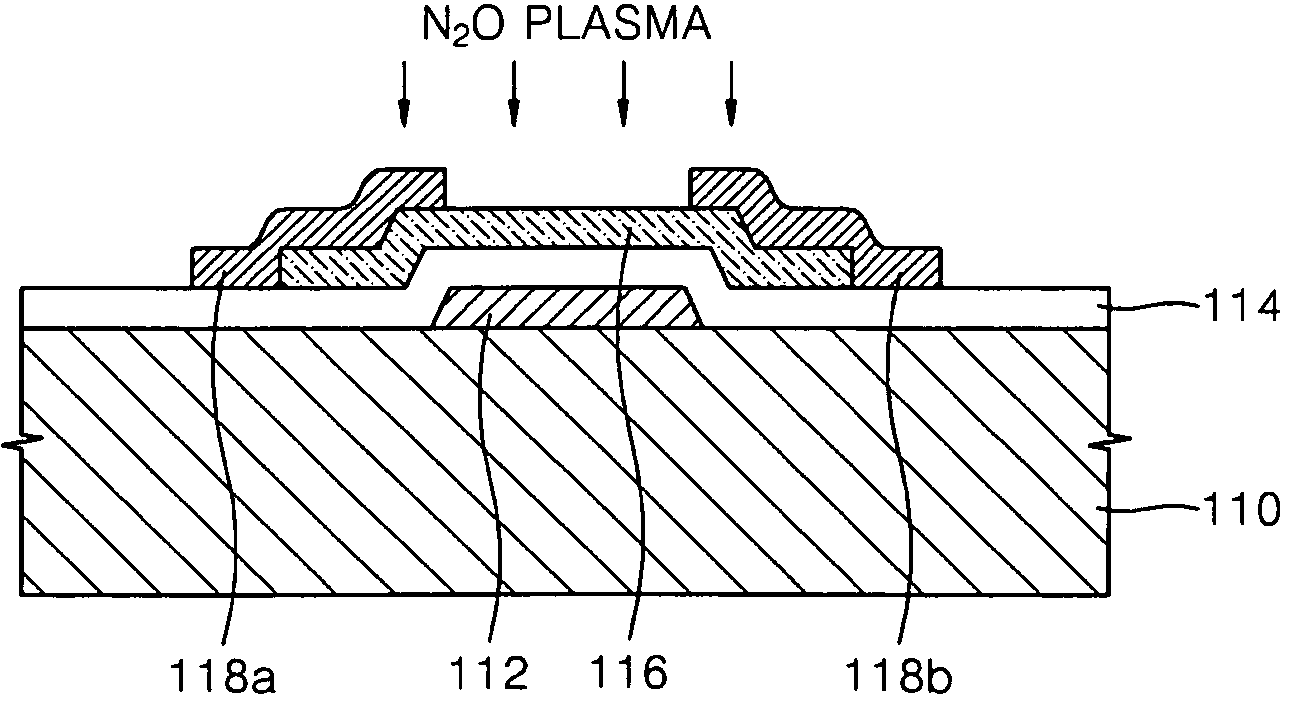

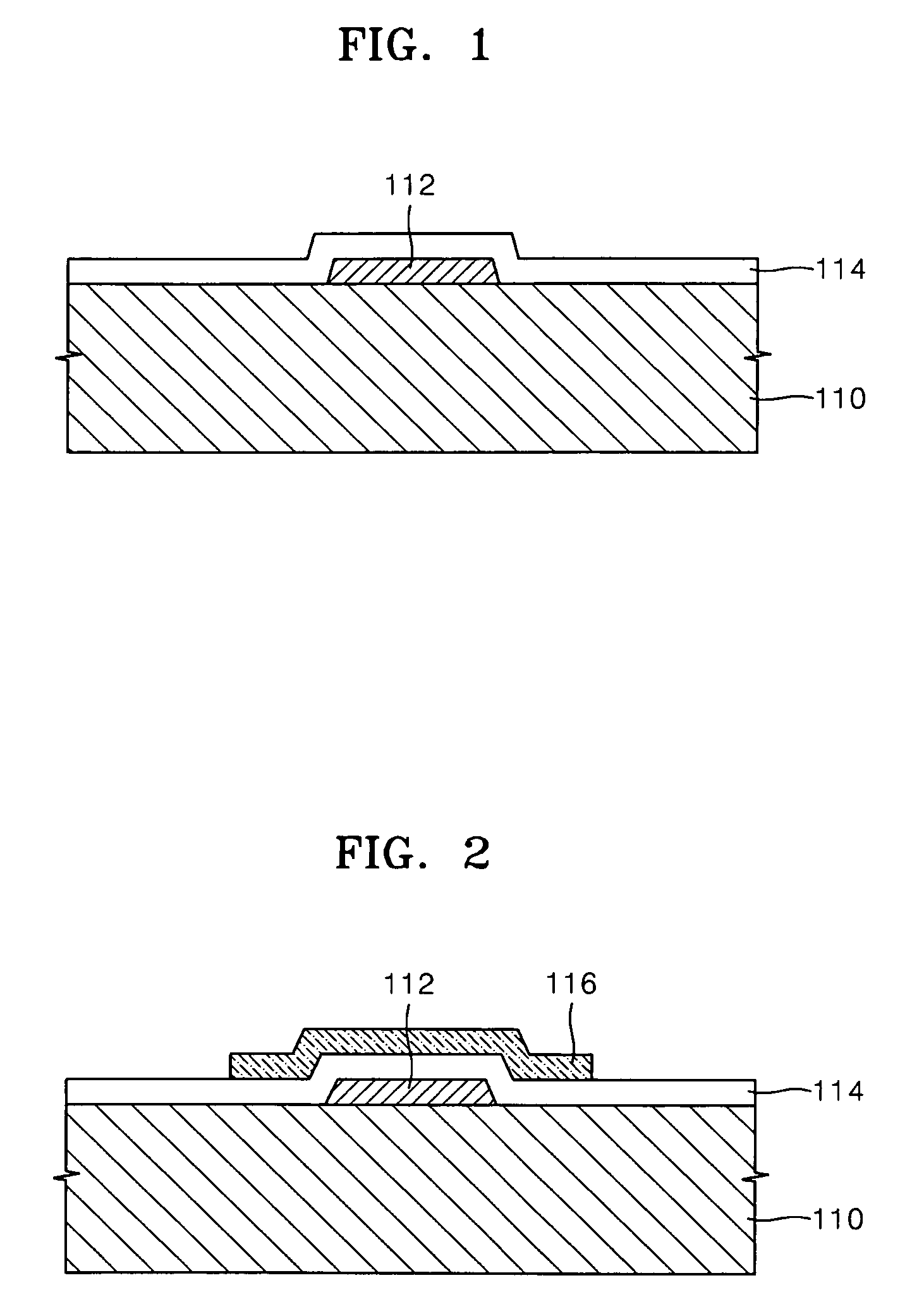

Methods of manufacturing an oxide semiconductor thin film transistor

ActiveUS7767505B2Semiconductor/solid-state device manufacturingSemiconductor devicesEngineeringOxygen

Methods of manufacturing an oxide semiconductor thin film transistor are provided. The methods include forming a gate on a substrate, and a gate insulating layer on the substrate to cover the gate. A channel layer, which is formed of an oxide semiconductor, may be formed on the gate insulating layer. Source and drain electrodes may be formed on opposing sides of the channel layer. The method includes forming supplying oxygen to the channel layer, forming a passivation layer to cover the source and drain electrodes and the channel layer, and performing an annealing process after forming the passivation layer.

Owner:SAMSUNG ELECTRONICS CO LTD

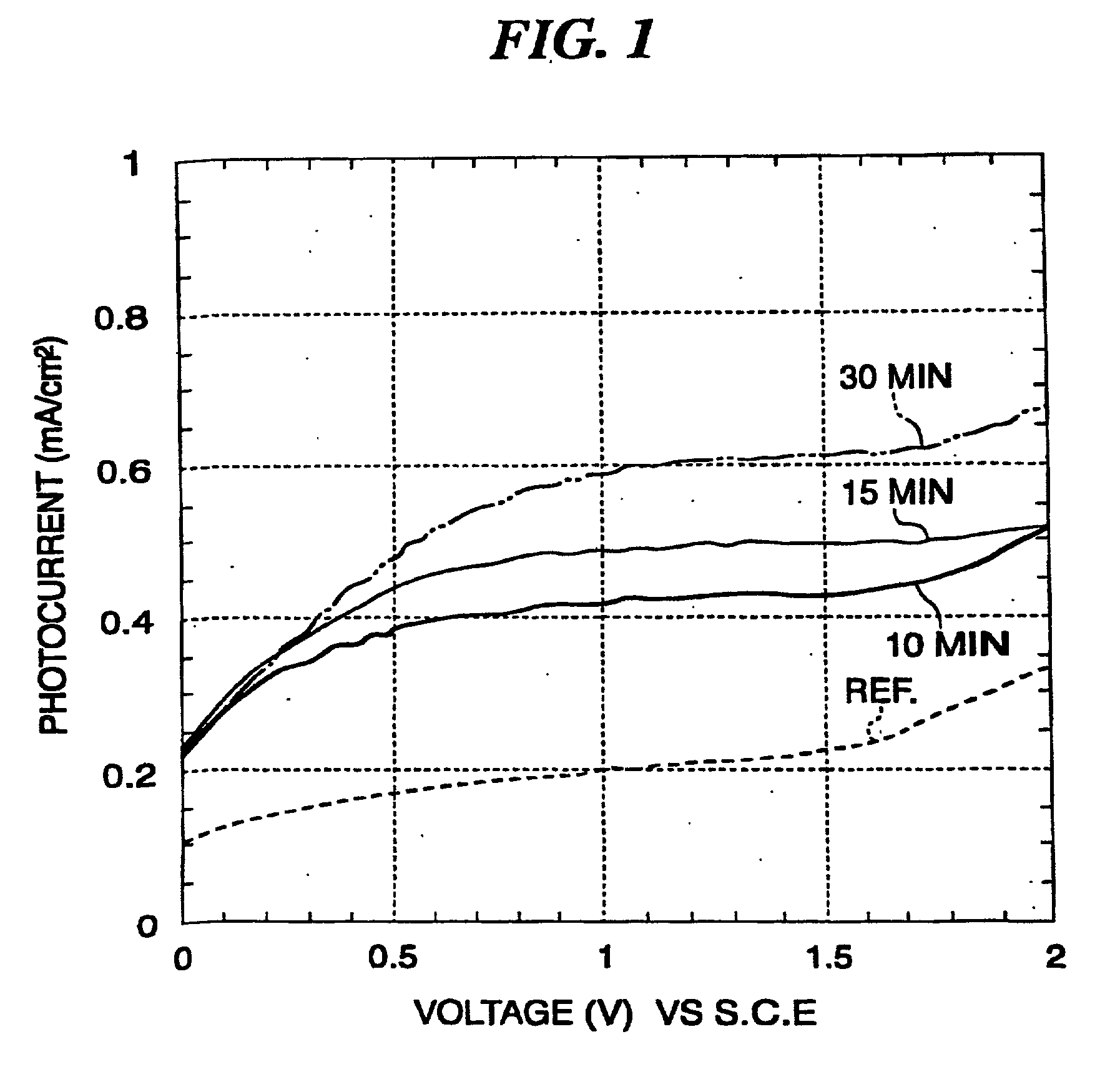

System for the formation of a silicon thin film and a semiconductor-insulating film interface

InactiveUS6861614B1Reduced trap state densityGood reproducibilityTransistorLaser detailsSilicon thin filmState density

In a semiconductor thin film forming system for modifying a predetermined region of a semiconductor thin film by exposing the semiconductor thin film to a projected light patterned through a pattern formed on a photo mask, the system includes a mechanism (opt20′) for uniformizing the light for exposure in a predetermined area on the photo mask. This system can provide a crystallized silicon film having a trap state density less than 1012 cm−2 and can provide a silicon-insulating film interface exhibiting a low interface state density.

Owner:NEC CORP +1

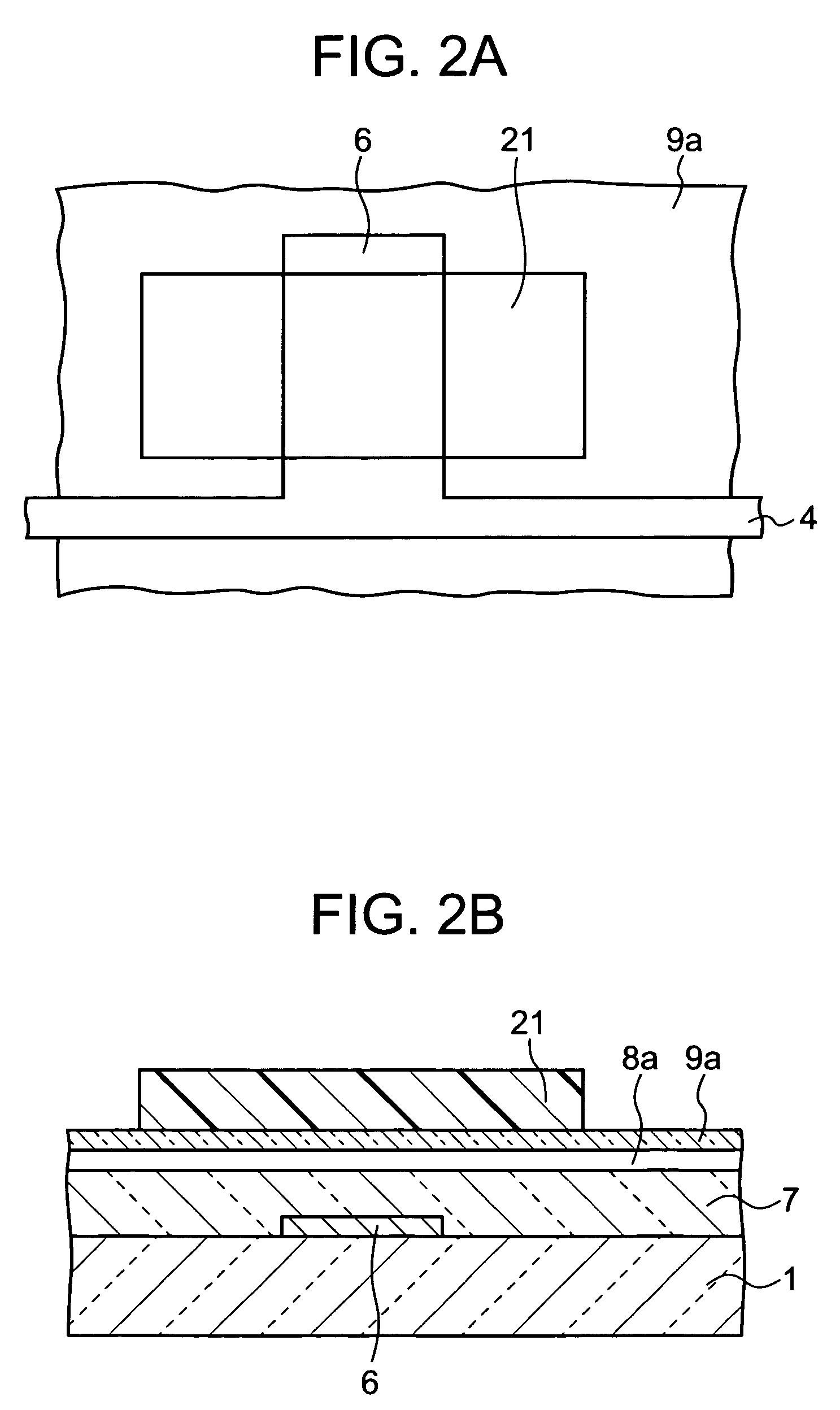

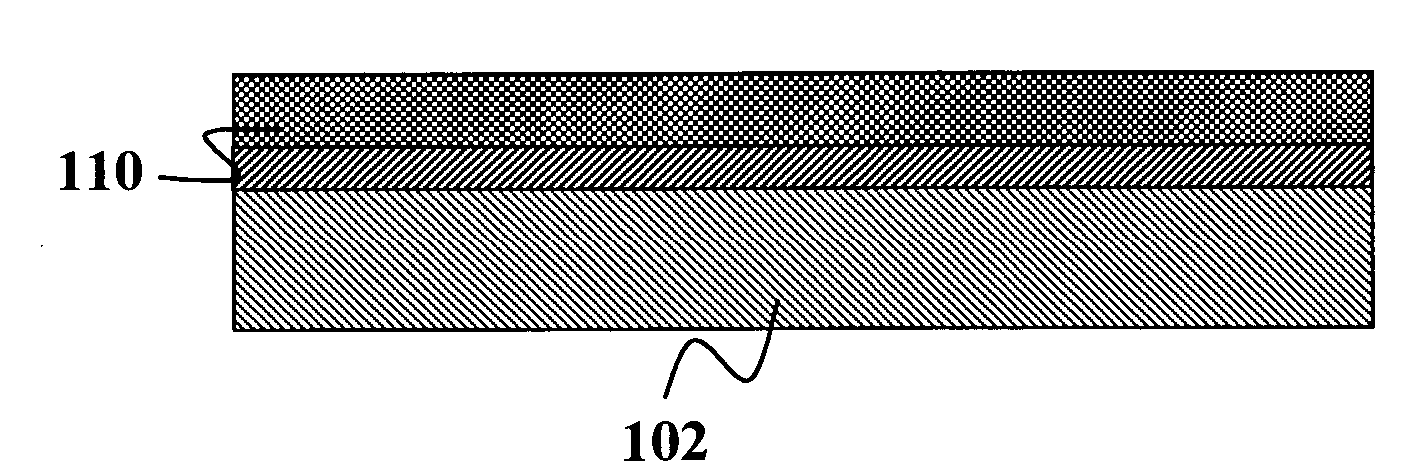

Manufacturing method of thin film transistor including low resistance conductive thin films

InactiveUS20090269881A1Decrease distance DHighly integratedSemiconductor/solid-state device manufacturingSemiconductor devicesChannel widthSemiconductor

A manufacturing method of a thin film transistor includes forming a pair of source / drain electrodes on a substrate, such that the source / drain electrodes define a gap therebetween; forming low resistance conductive thin films, which define a gap therebetween, on the source / drain electrodes; and forming an oxide semiconductor thin film layer on upper surface of the low resistance conductive thin films and in the gap defined between the low resistance conductive thin films so that the oxide semiconductor thin film layer functions as a channel. The low resistance conductive thin films and the oxide semiconductor thin film layer are etched so that side surfaces of the resistance conductive thin films and corresponding side surfaces of the oxide semiconductor thin film layer coincide with each other in a channel width direction of the channel. A gate electrode is mounted over the oxide semiconductor thin film layer.

Owner:KOICHI IND PROMOTION CENT +1

Method for improved growth of semipolar (Al,In,Ga,B)N

ActiveUS20070218703A1Reduce symmetryImprove electricityPolycrystalline material growthSolid-state devicesHydrogenNitrogen

A method for improved growth of a semipolar (Al,In,Ga,B)N semiconductor thin film using an intentionally miscut substrate. Specifically, the method comprises intentionally miscutting a substrate, loading a substrate into a reactor, heating the substrate under a flow of nitrogen and / or hydrogen and / or ammonia, depositing an InxGa1-xN nucleation layer on the heated substrate, depositing a semipolar nitride semiconductor thin film on the InxGa1-xN nucleation layer, and cooling the substrate under a nitrogen overpressure.

Owner:JAPAN SCI & TECH CORP

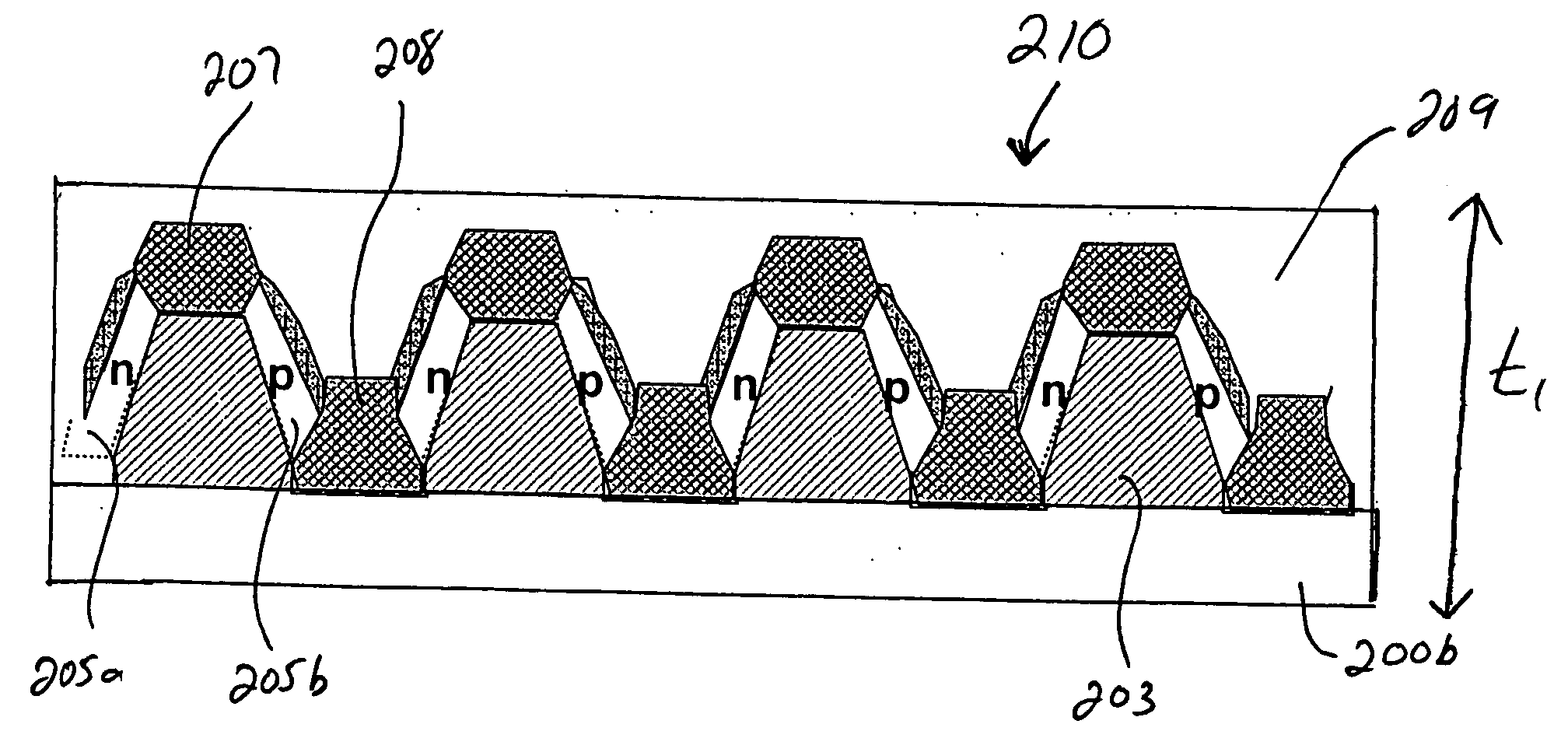

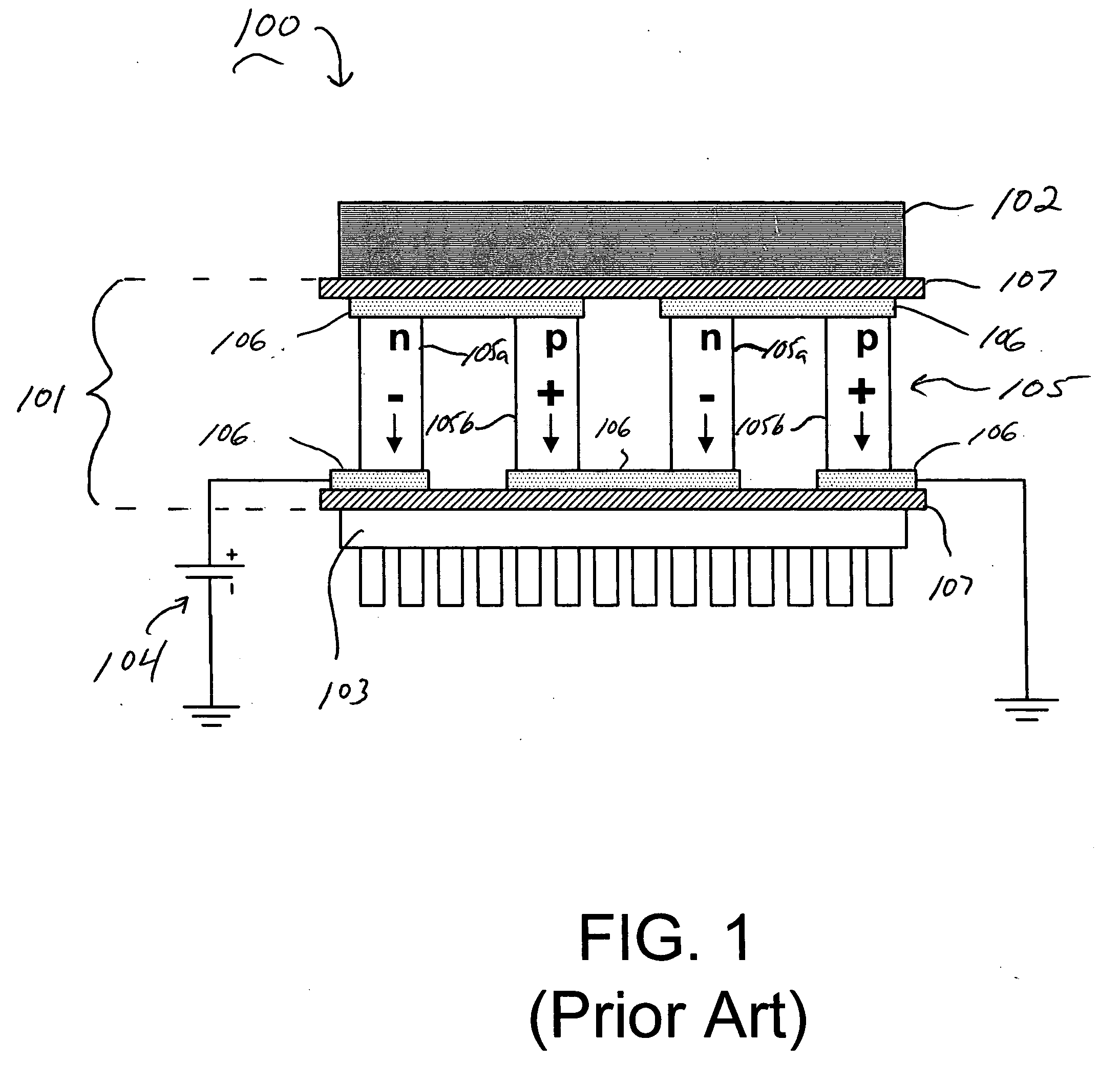

Integrated thermoelectric cooling devices and methods for fabricating same

ActiveUS20060102223A1Reduced dimensionIncrease heatThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric coolingHigh density

Semiconductor integrated thermoelectric devices are provided, which are formed having high-density arrays of thermoelectric (TE) elements using semiconductor thin-film and VLSI (very large scale integration) fabrication processes. Thermoelectric devices can be either separately formed and bonded to semiconductor chips, or integrally formed within the non-active surface of semiconductor chips, for example.

Owner:GLOBALFOUNDRIES US INC

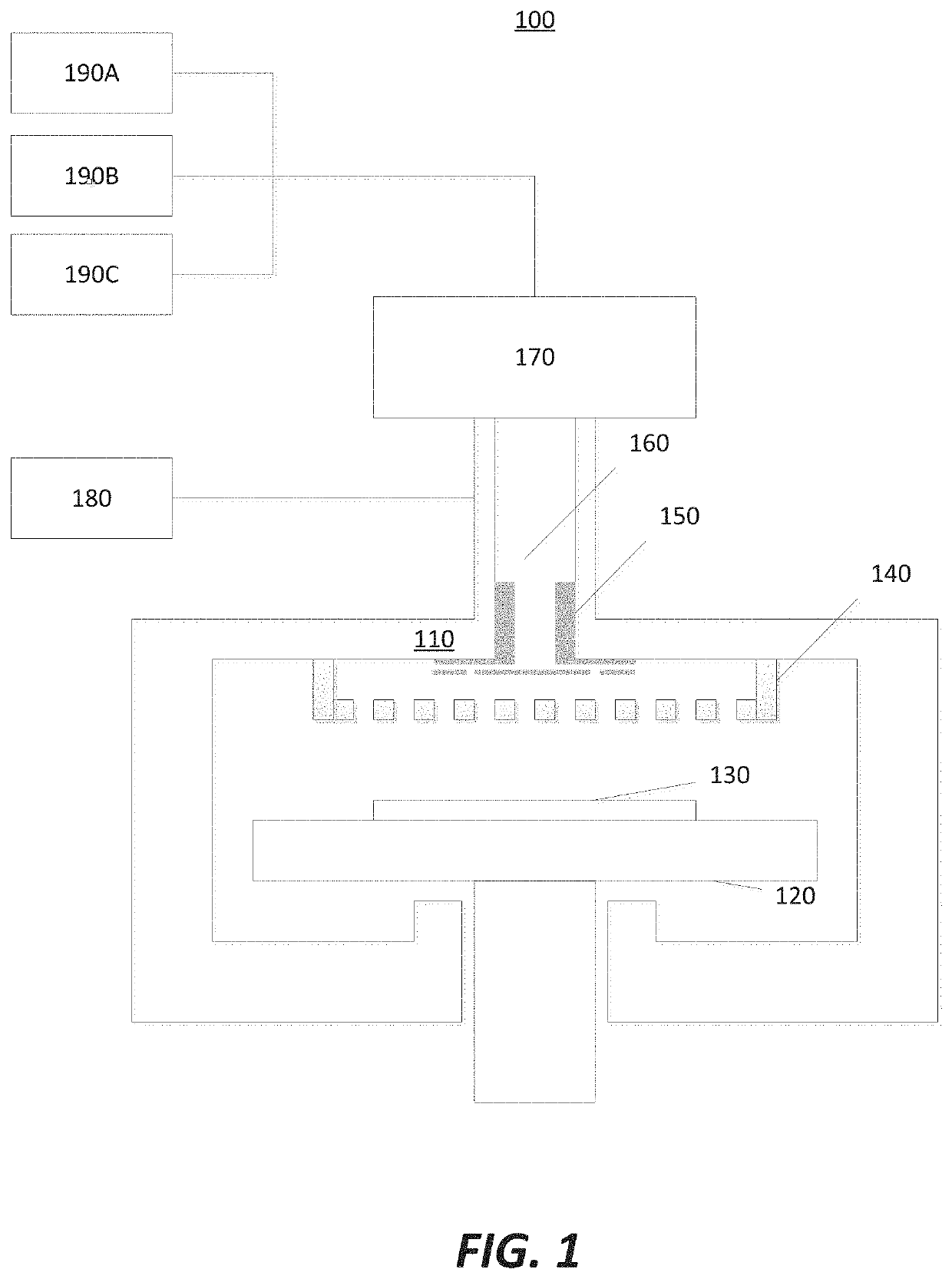

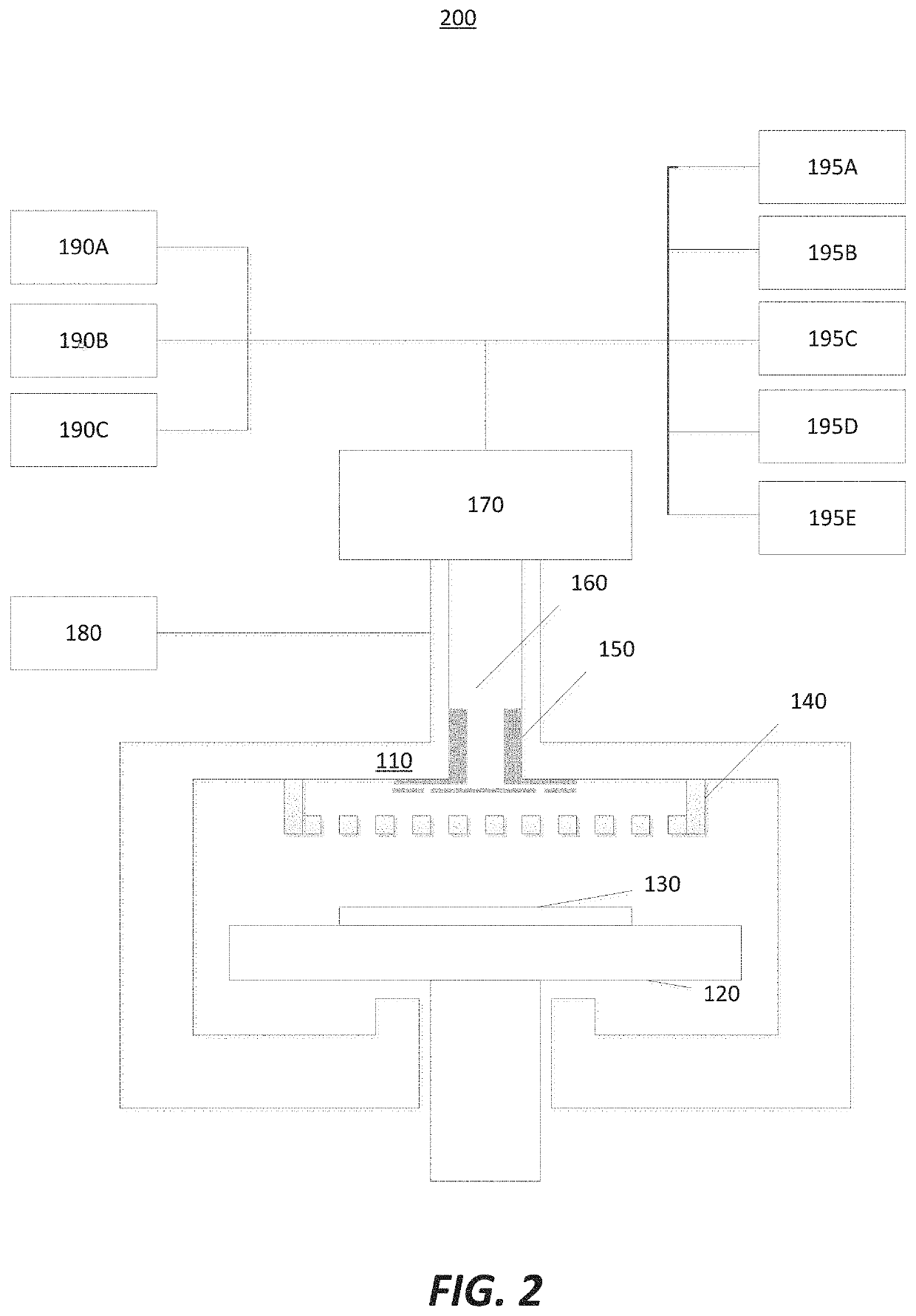

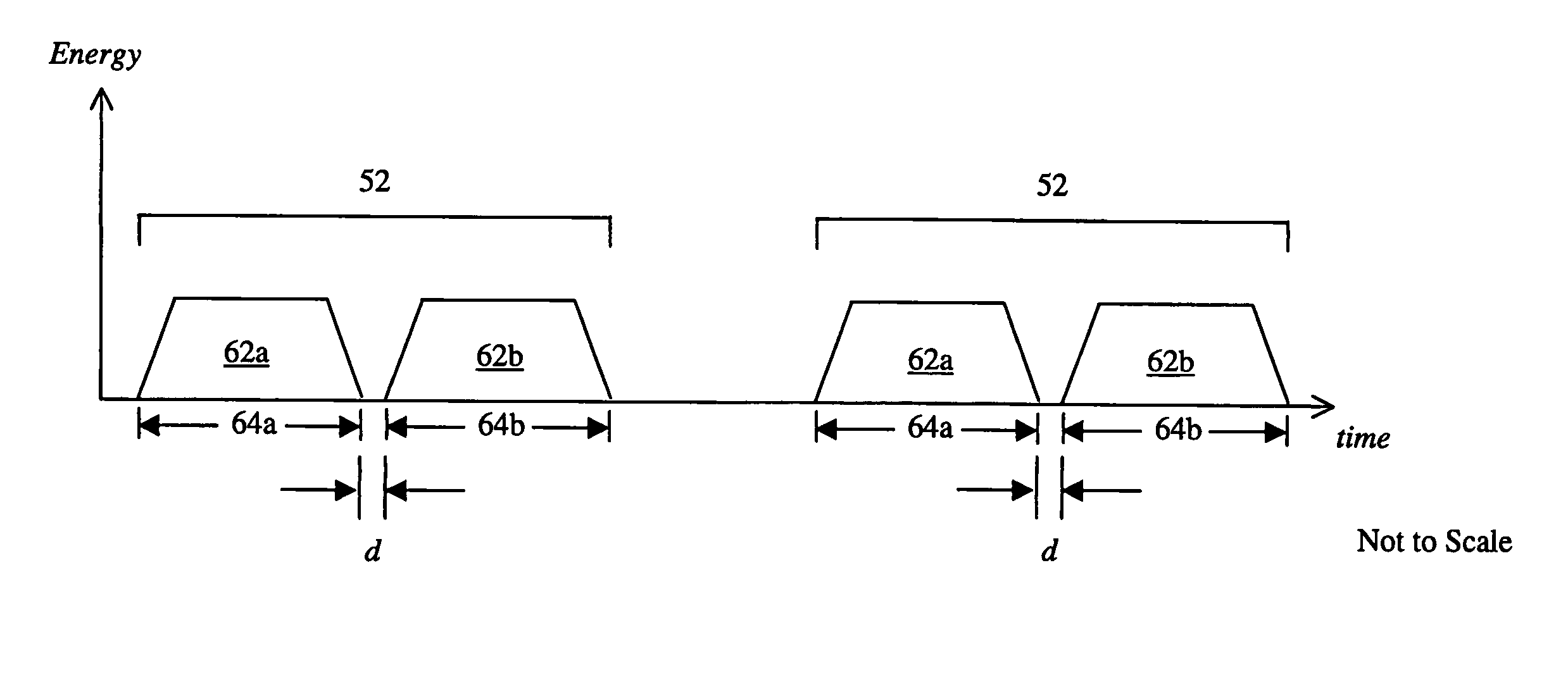

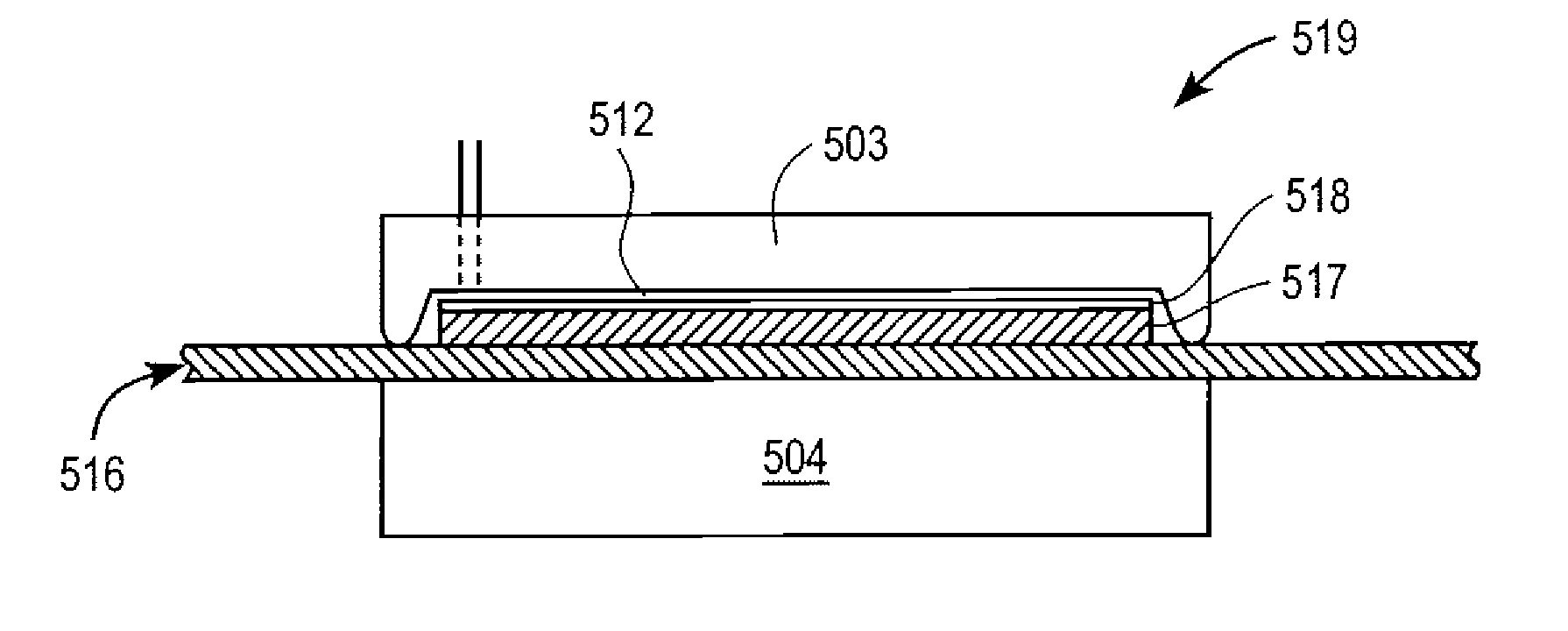

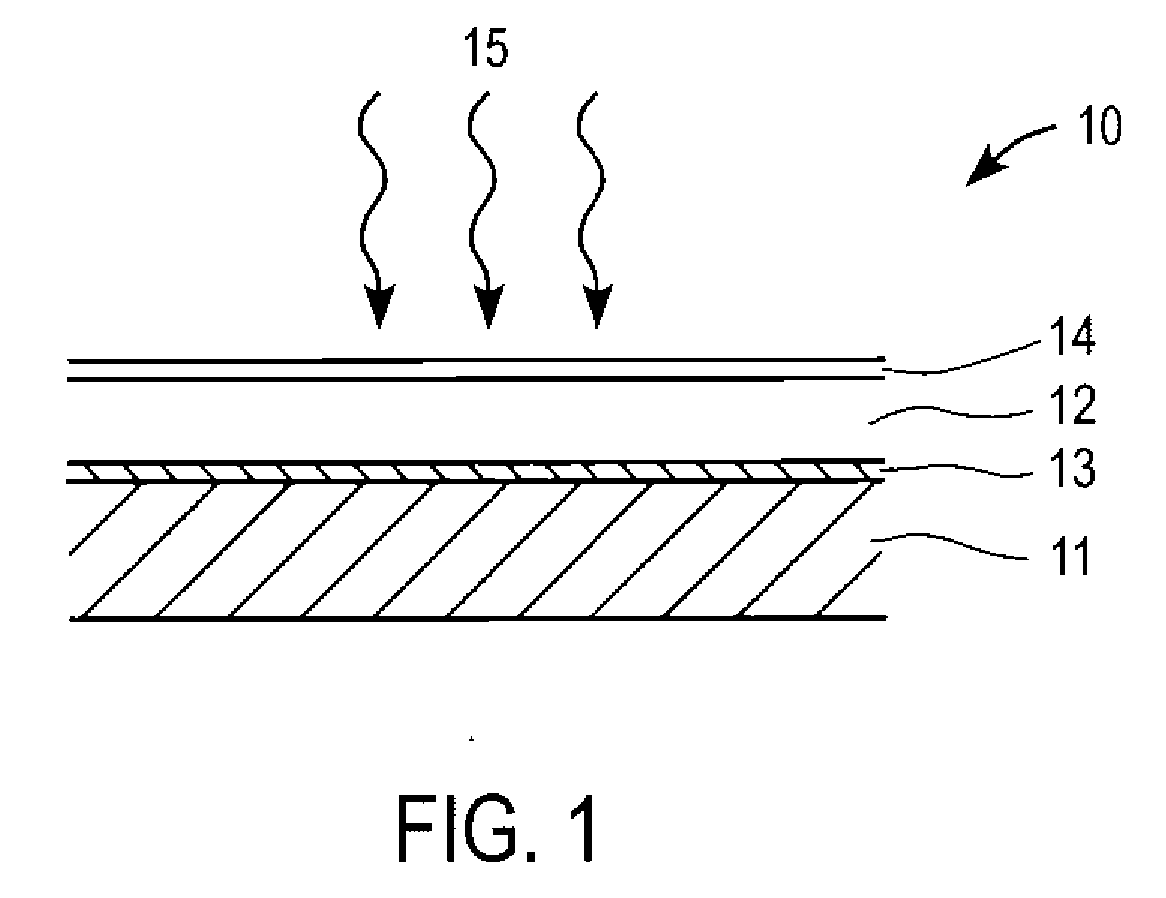

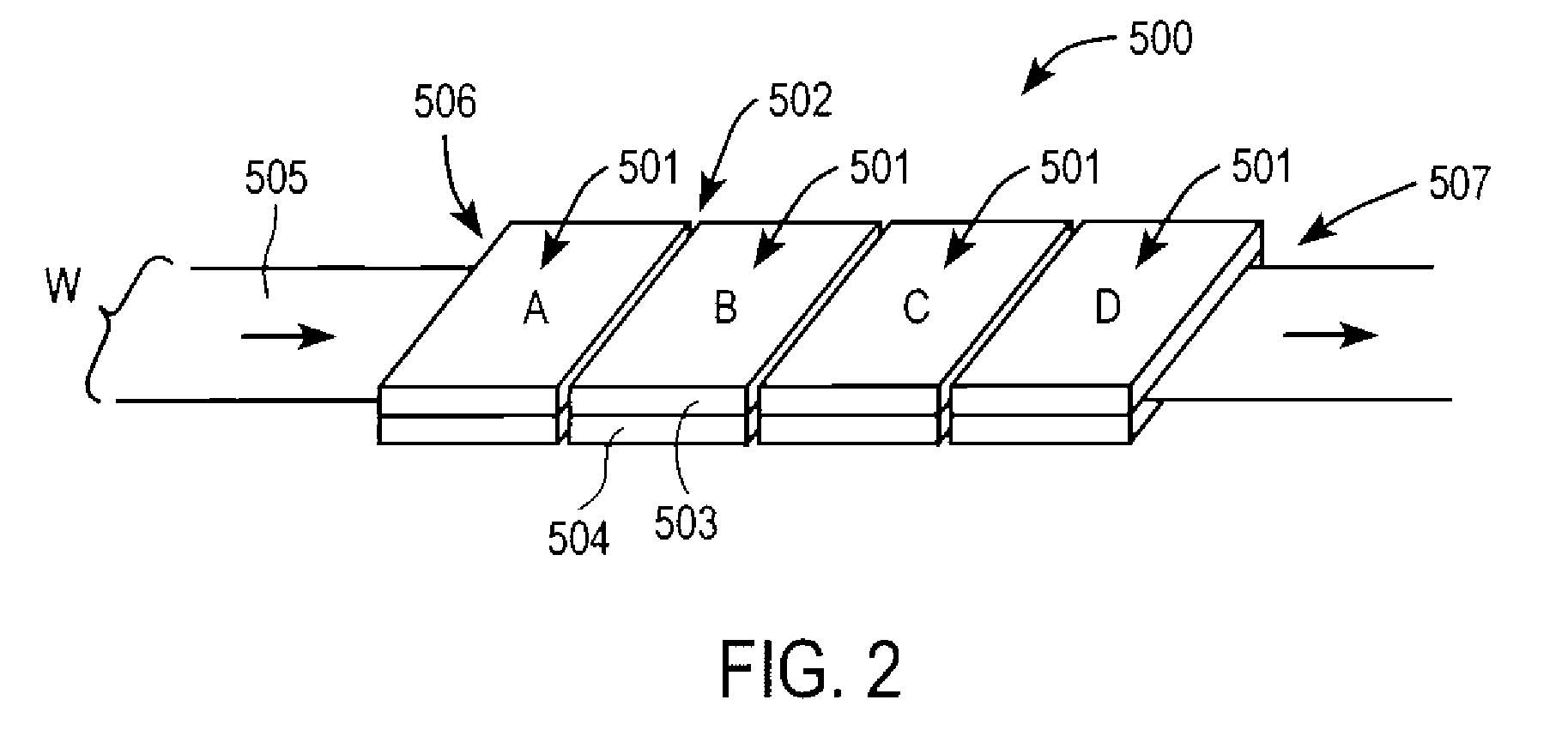

Systems and methods for processing thin films

InactiveUS20050059265A1Utilizing energyReduce manufacturing costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingIntegratorIrradiation

The present disclosure is directed to methods and systems for processing a thin film samples. In an exemplary method, semiconductor thin films are loaded onto two different loading fixtures, laser beam pulses generated by a laser source system are split into first laser beam pulses and second laser beam pulses, the thin film loaded on one loading fixture is irradiated with the first laser beam pulses to induce crystallization while the thin film loaded on the other loading fixture is irradiated with the second laser beam pulses. In a preferred embodiment, at least a portion of the thin film that is loaded on the first loading fixture is irradiated while at least a portion of the thin film that is loaded on the second loading fixture is also being irradiated. In an exemplary embodiment, the laser source system includes first and second laser sources and an integrator that combines the laser beam pulses generated by the first and second laser sources to form combined laser beam pulses. In certain exemplary embodiments, the methods and system further utilize additional loading fixtures for processing additional thin film samples. In such methods and systems, the irradiation of thin film samples loaded on some of the loading fixtures can be performed while thin film samples are being loaded onto the remaining loading fixtures. In certain exemplary methods and systems, the crystallization processing of the semiconductor thin film samples can consist of a sequential lateral solidification (SLS) process.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Method of forming crystalline semiconductor thin film on base substrate, lamination formed with crystalline semiconductor thin film and color filter

A method of forming a crystalline semiconductor thin film on a base material which can be prepared at a low temperature by simple step and device, the method including a processing step of applying UV-rays to an amorphous semiconductor thin film provided on a base material while keeping a temperature at not less than 25° C. and not more than 300° C. in a vacuum or a reducing gas atmosphere, as well as a substrate having the semiconductor thin film provided on the base material, a substrate for forming a color filter and a color filter using the substrate.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Photovoltaic devices printed from nanostructured particles

InactiveUS20070163638A1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingParticle methodSolar cell

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, a solar cell is provided that comprises of a substrate, a back electrode formed over the substrate, a p-type semiconductor thin film formed over the back electrode, an n-type semiconductor thin film formed so as to constitute a pn junction with the p-type semiconductor thin film, and a transparent electrode formed over the n-type semiconductor thin film. The p-type semiconductor thin film results by processing a dense film formed from a plurality of microflakes having a material composition containing at least one element from Groups IB, IIIA, and / or VIA, wherein the dense film has a void volume of about 26% or less. The dense film may be a substantially void free film.

Owner:AERIS CAPITAL SUSTAINABLE IP

Semiconductor device, polycrystalline semiconductor thin film, process for producing polycrystalline semiconductor thin film, field effect transistor, and process for producing field effect transistor

ActiveUS8158974B2Easy to produceEasily enlargedSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialHeat resistance

An object of the present invention is to provide a novel semiconductor device which is excellent in stability, uniformity, reproducibility, heat resistance, durability and the like, and can exert excellent transistor properties. The semiconductor device is a thin-film transistor, and this thin-film transistor uses, as an active layer, a polycrystalline oxide semiconductor thin film containing In and two or more metals other than In and having an electron carrier concentration of less than 1×1018 / cm3.

Owner:IDEMITSU KOSAN CO LTD

Method and apparatus for converting precursor layers into photovoltaic absorbers

InactiveUS20070111367A1Low material utilizationIncrease equipment costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlSemiconductor

The present invention relates to method and apparatus for preparing thin films of semiconductor films for radiation detector and photovoltaic applications. In one aspect, the present invention includes a series of chambers between the inlet and the outlet, with each chamber having a gap that allows a substrate to pass therethrough and which is temperature controlled, thereby allowing each chamber to maintain a different temperature, and the substrate to be annealed based upon a predetermined temperature profile by efficiently moving through the series of chambers. In another aspect, each of the chambers opens and closes, and creates a seal when in the closed position during which time annealing takes place within the gap of the chamber. In a further aspect, the present invention provides a method of forming a Group IBIIIAVIA compound layer on a surface of a flexible roll.

Owner:SOLOPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com