Patents

Literature

314results about How to "Increase equipment cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming dielectric film using porogen gas

ActiveUS7955650B2Low mechanical strengthIncrease equipment costSemiconductor/solid-state device manufacturingSpecial surfacesDielectric permittivityGas formation

Owner:ASM JAPAN

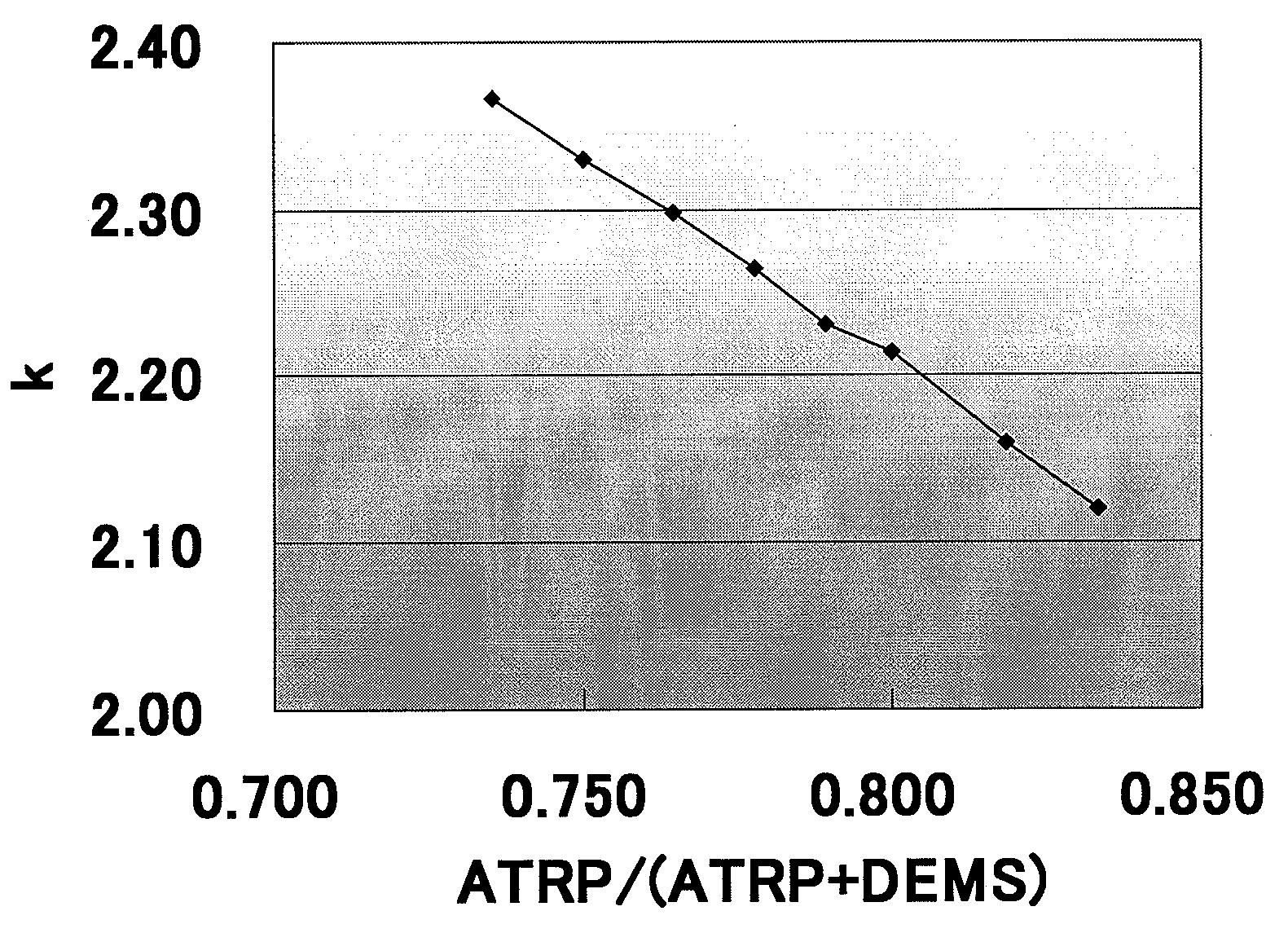

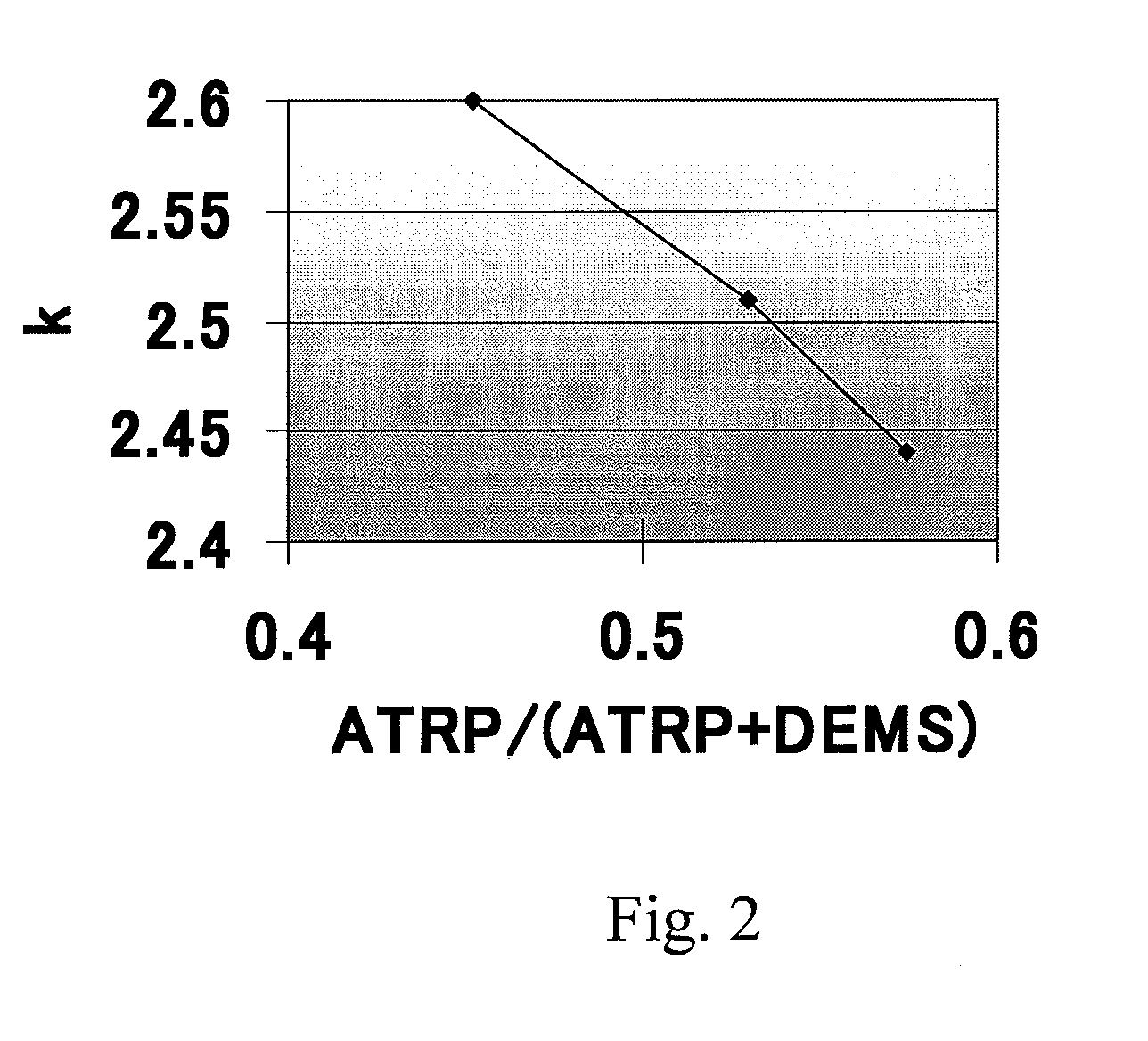

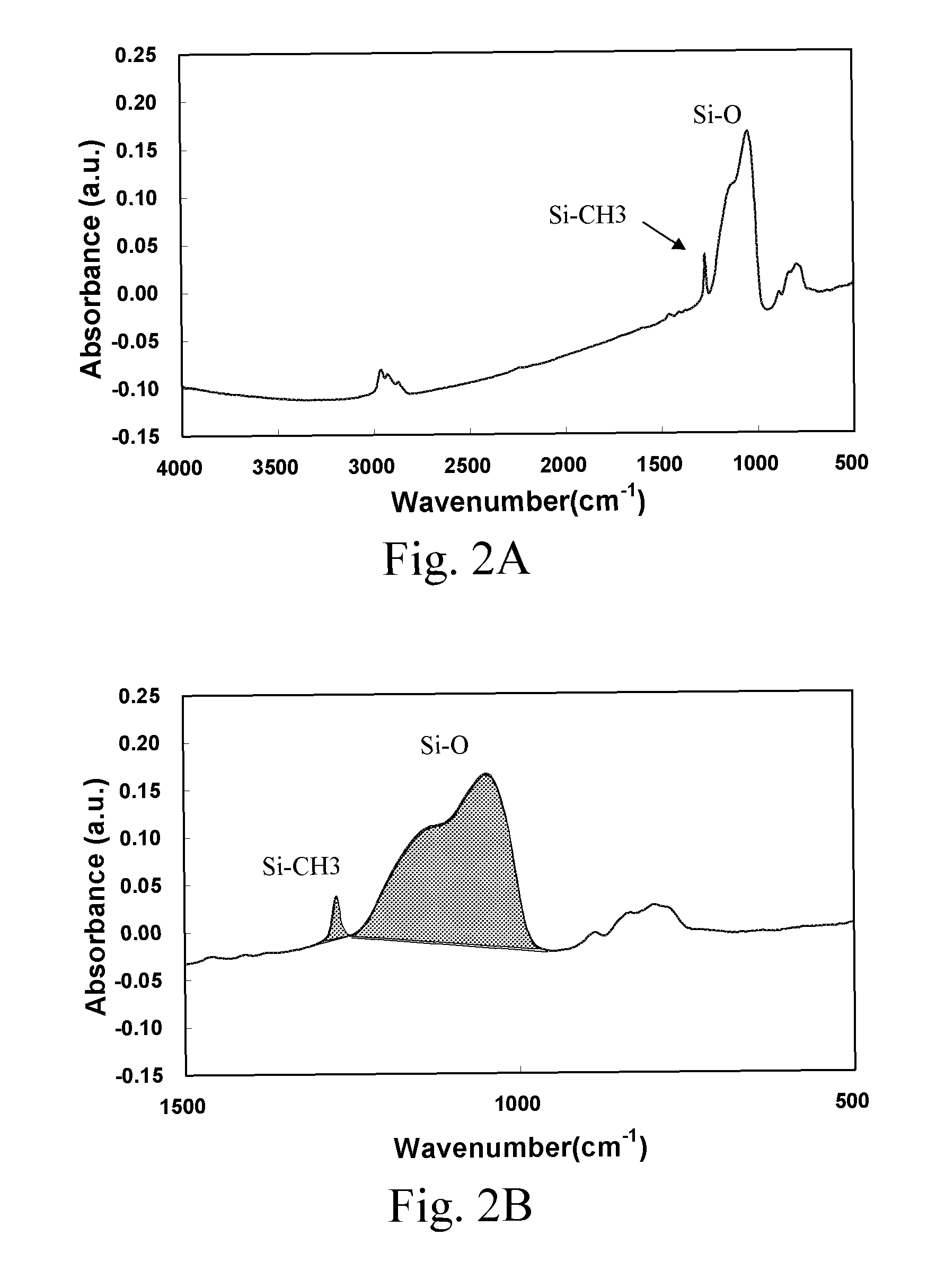

Method for forming dielectric SiOCH film having chemical stability

ActiveUS7807566B2Good chemical stabilityLow dielectric constantSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDielectricSusceptor

A method for determining conditions for forming a dielectric SiOCH film, includes: (i) forming a dielectric SiOCH film on a substrate under conditions; (ii) evaluating the conditions using a ratio of Si—CH3 bonding strength to Si—O bonding strength of the film as formed in step (i); (iii) if the ratio is 2.50 % or higher, confirming the conditions, and if the ratio is less than 2.50 %, changing the conditions by changing at least one of the susceptor temperature, the distance between upper and lower electrodes, the RF power, and the curing time; and (iv) repeating steps (i) to (iii) until the ratio is 2.50 % or higher.

Owner:ASM JAPAN

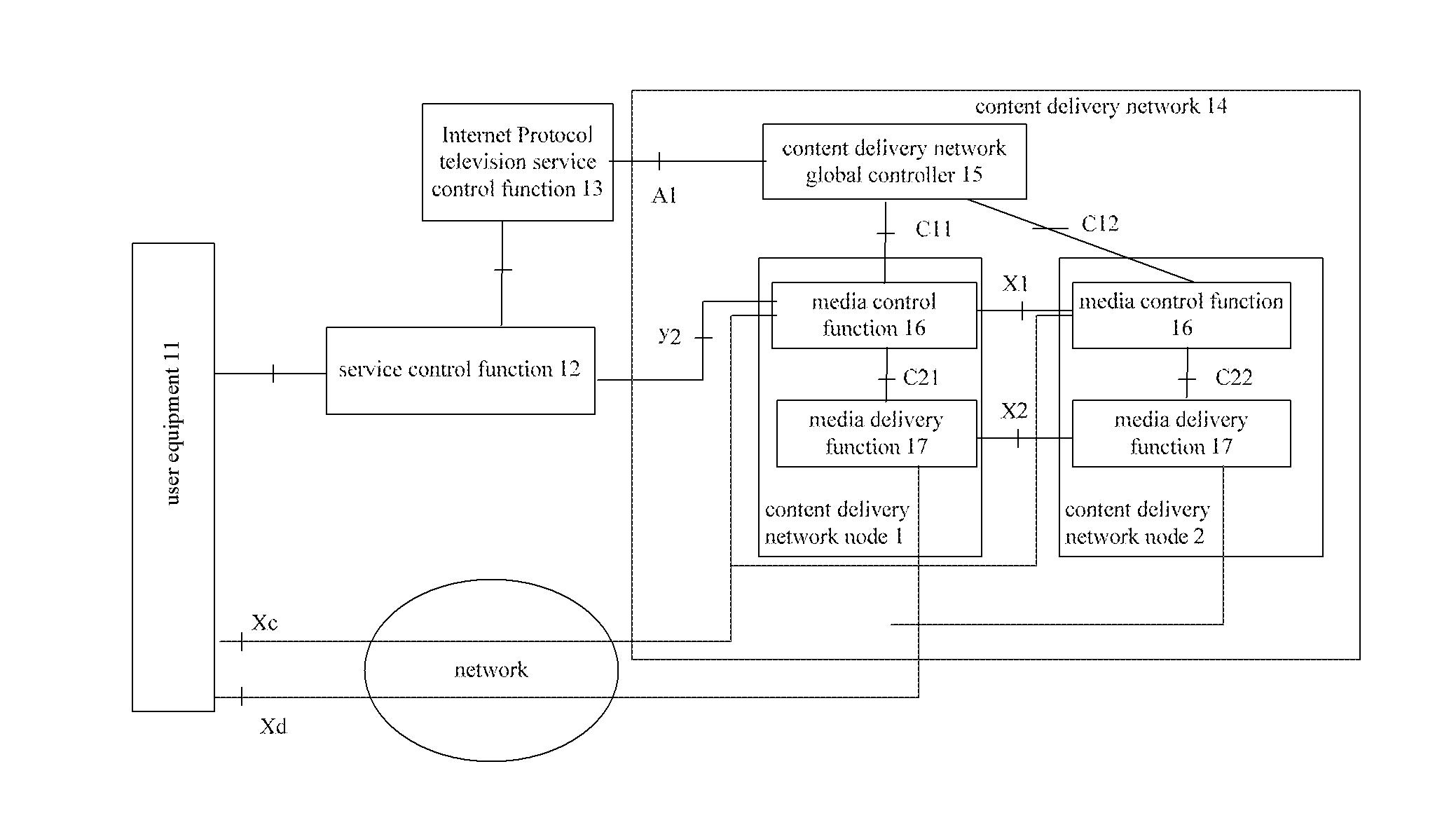

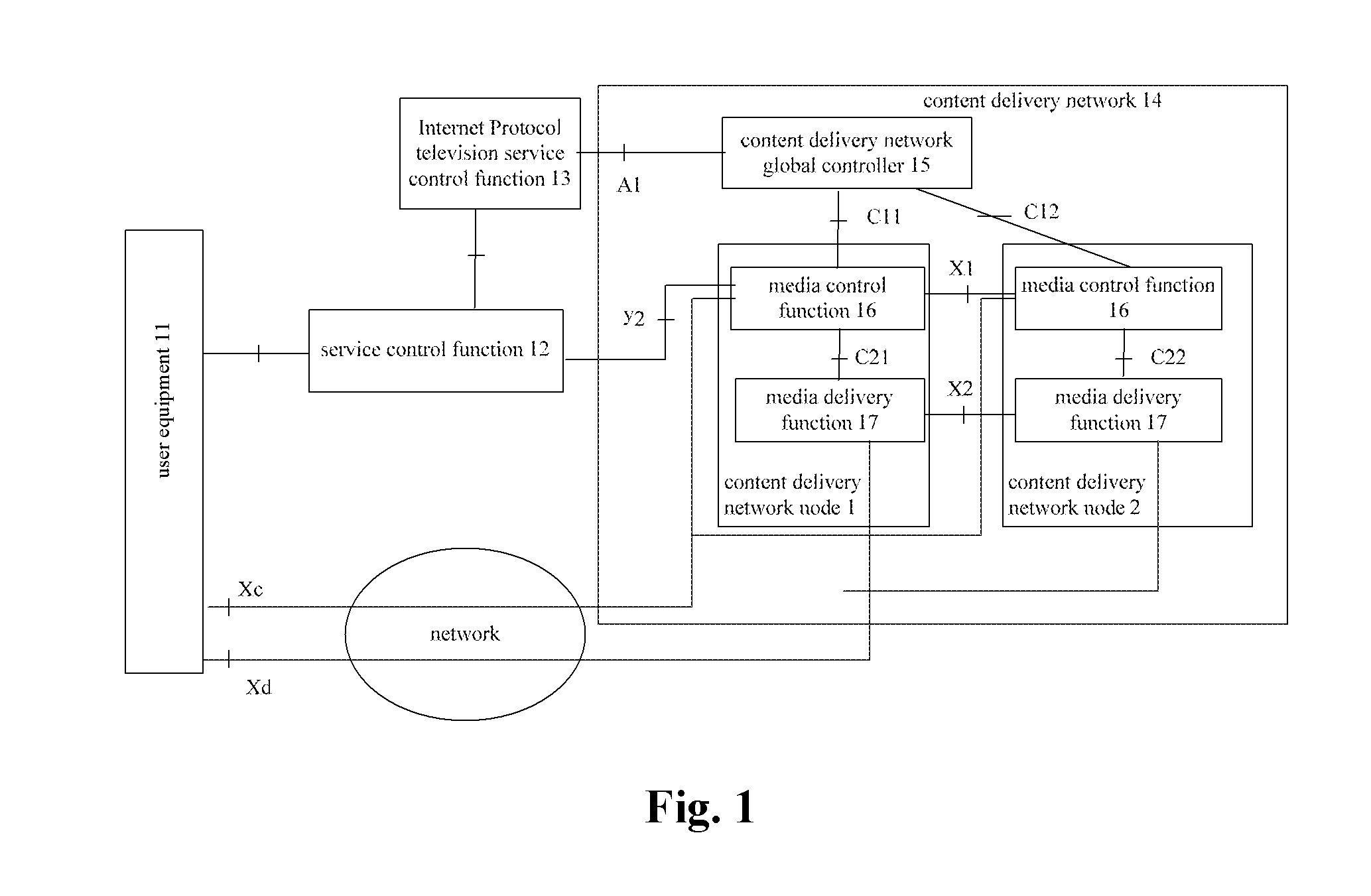

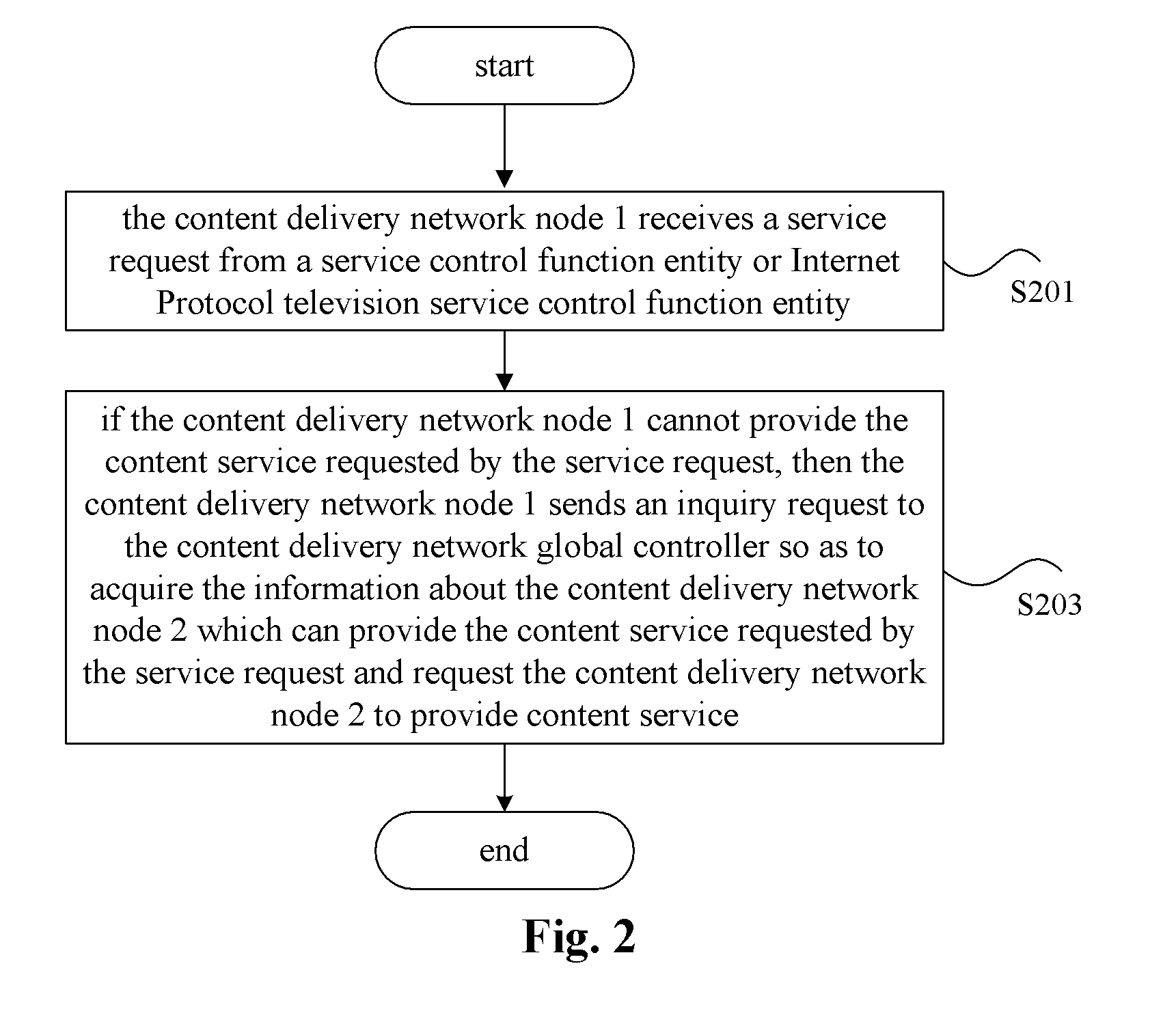

Content location method and content delivery network node

ActiveUS20120023530A1Long processing delayLow costTwo-way working systemsTransmissionContent IdentifierContent distribution

The present invention provides a content locating method and a content delivery network node. In this case, the content locating method provided by the present invention comprises: receiving by a first content delivery network CDN node a service request sent by a service control function entity or an IPTV service control function entity, wherein this service request carries a content identifier which is used to indicate requesting content corresponding to this content identifier; if the first CDN node cannot provide the content service requested by the service request, then the first CDN node sends an inquiry request to a CDN global controller so as to acquire the information about a second CDN node which can provide the content service requested by the service request and request the second CDN node to provide the content service. By way of the present invention, the pressure of the CDN global controller can be reduced and the processing delay of CDN can be shortened.

Owner:ZTE CORP

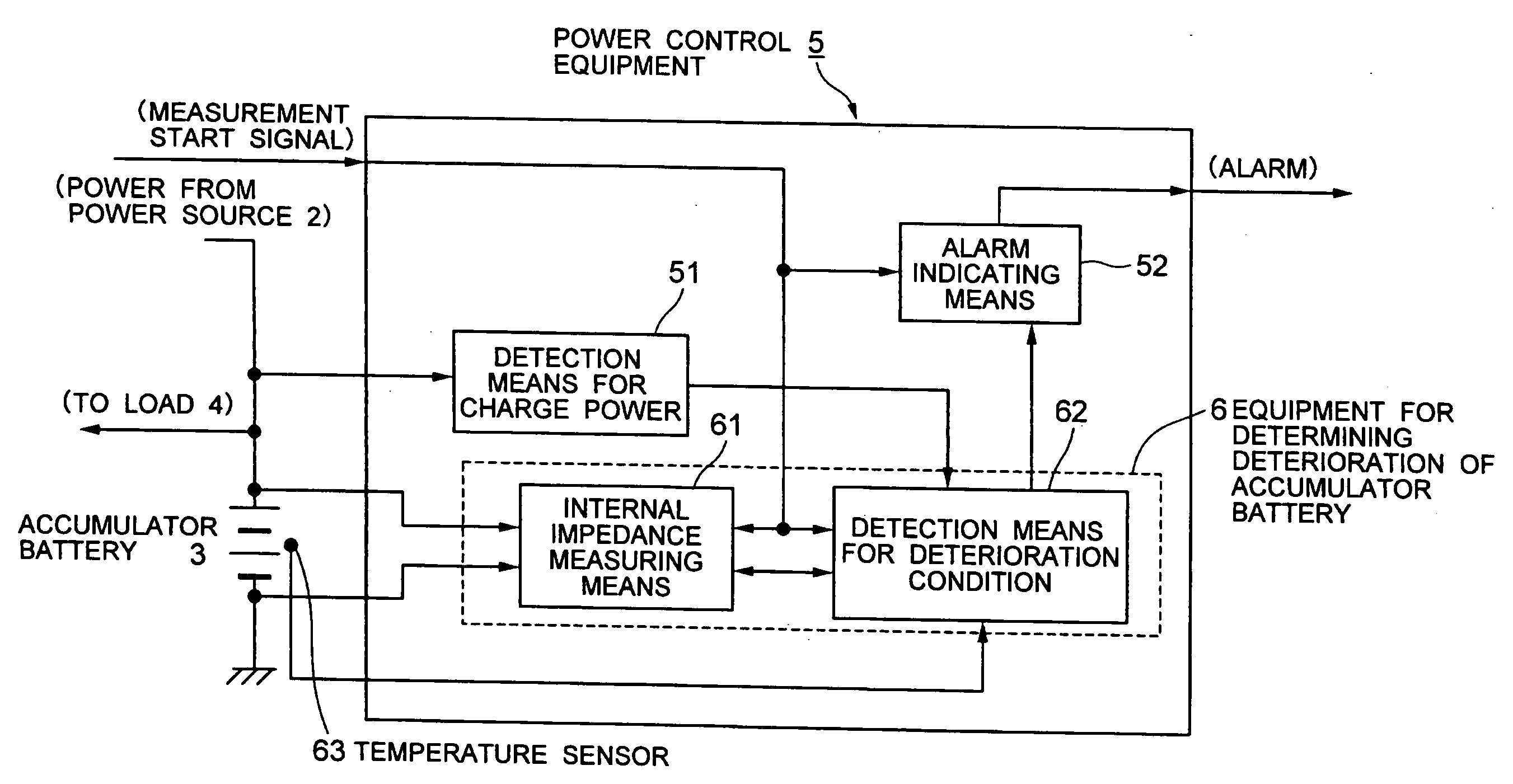

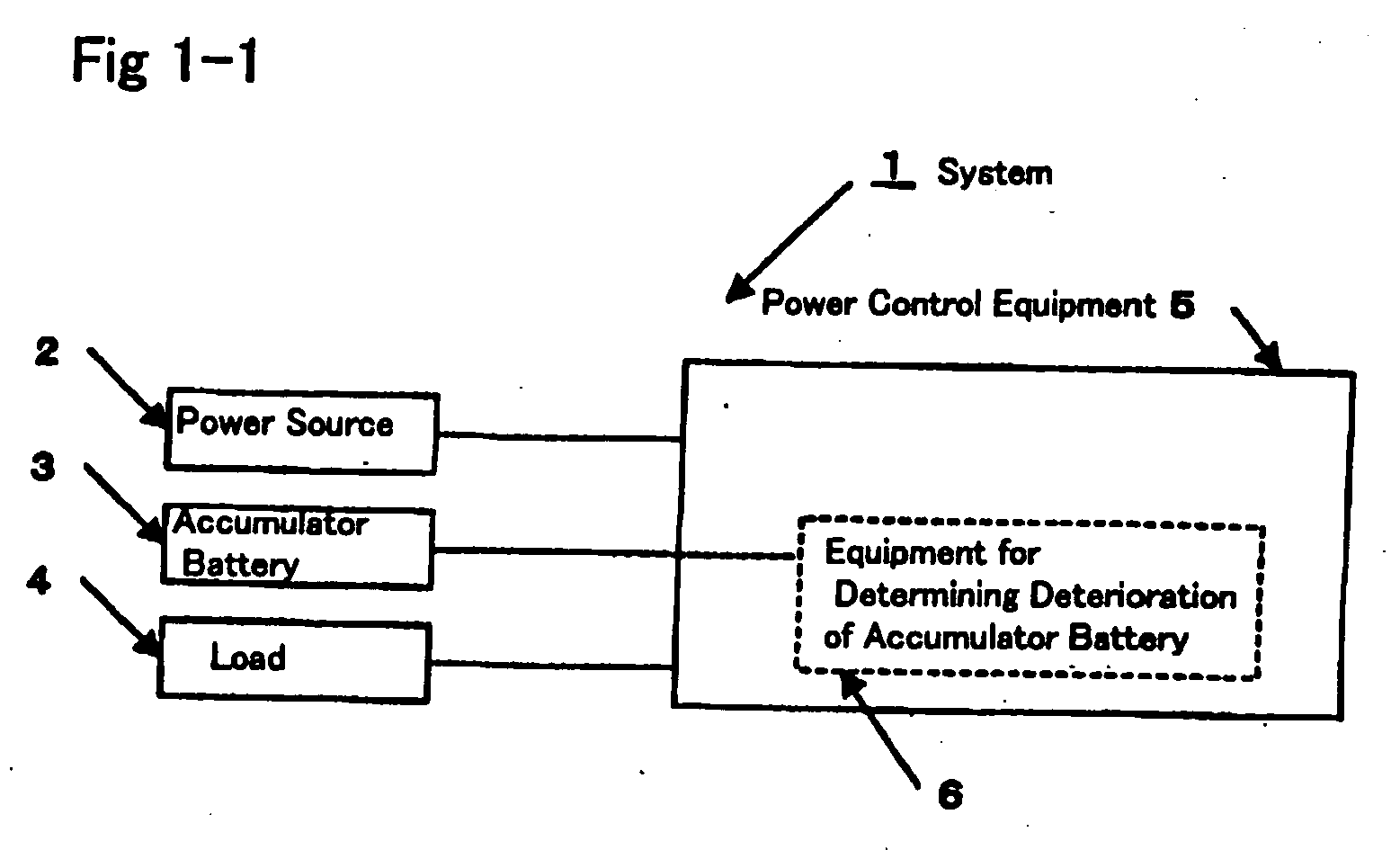

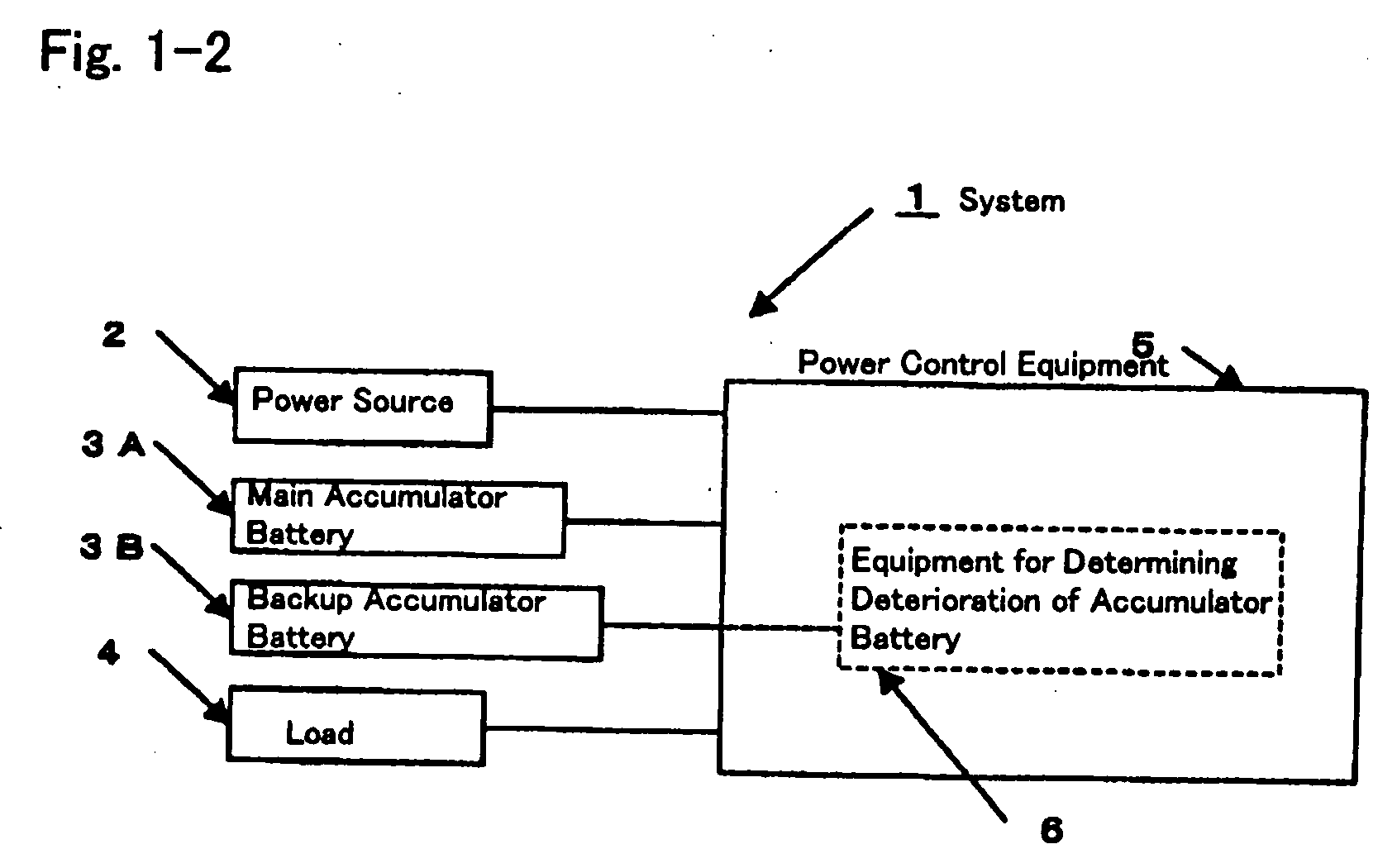

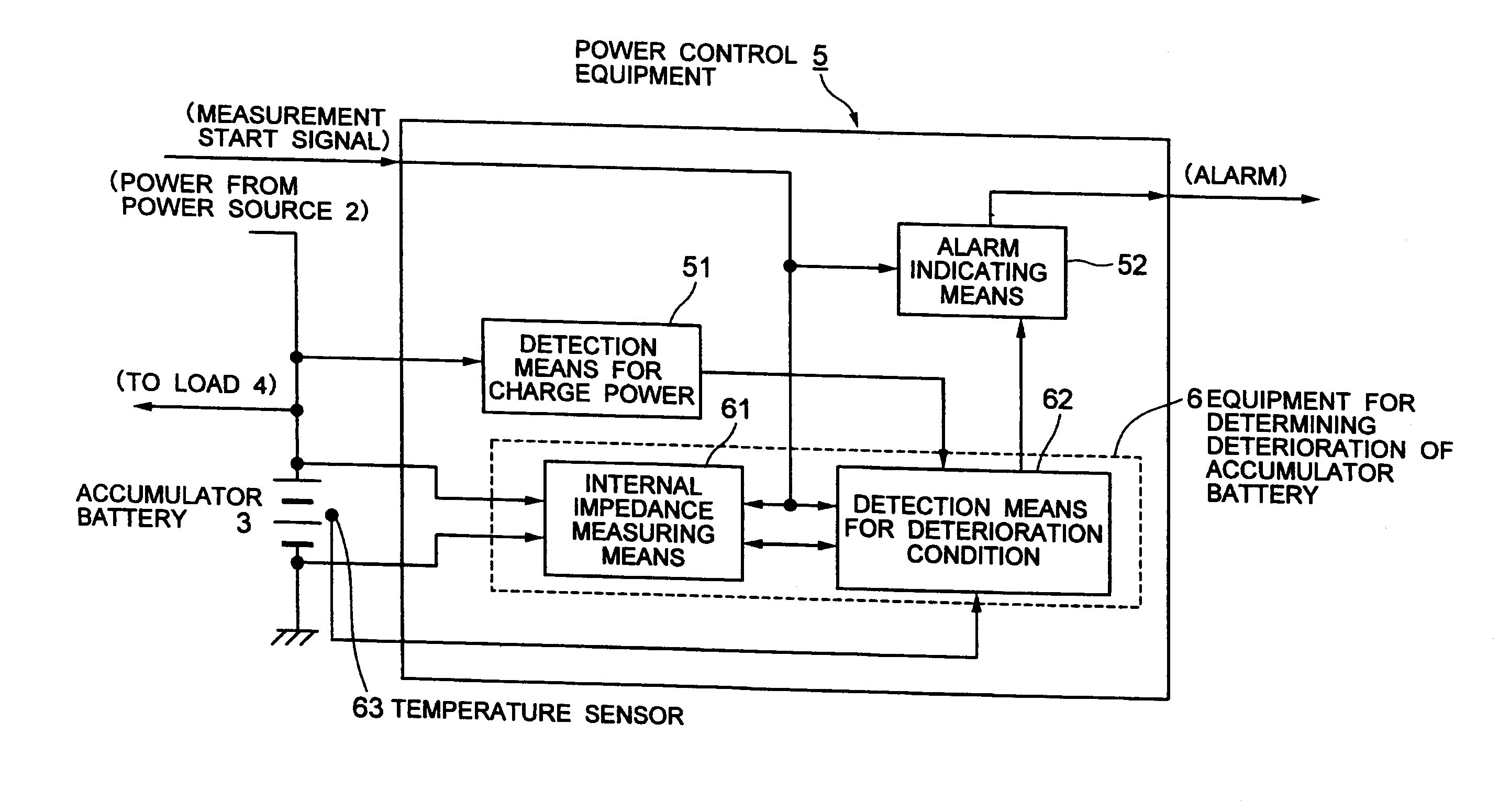

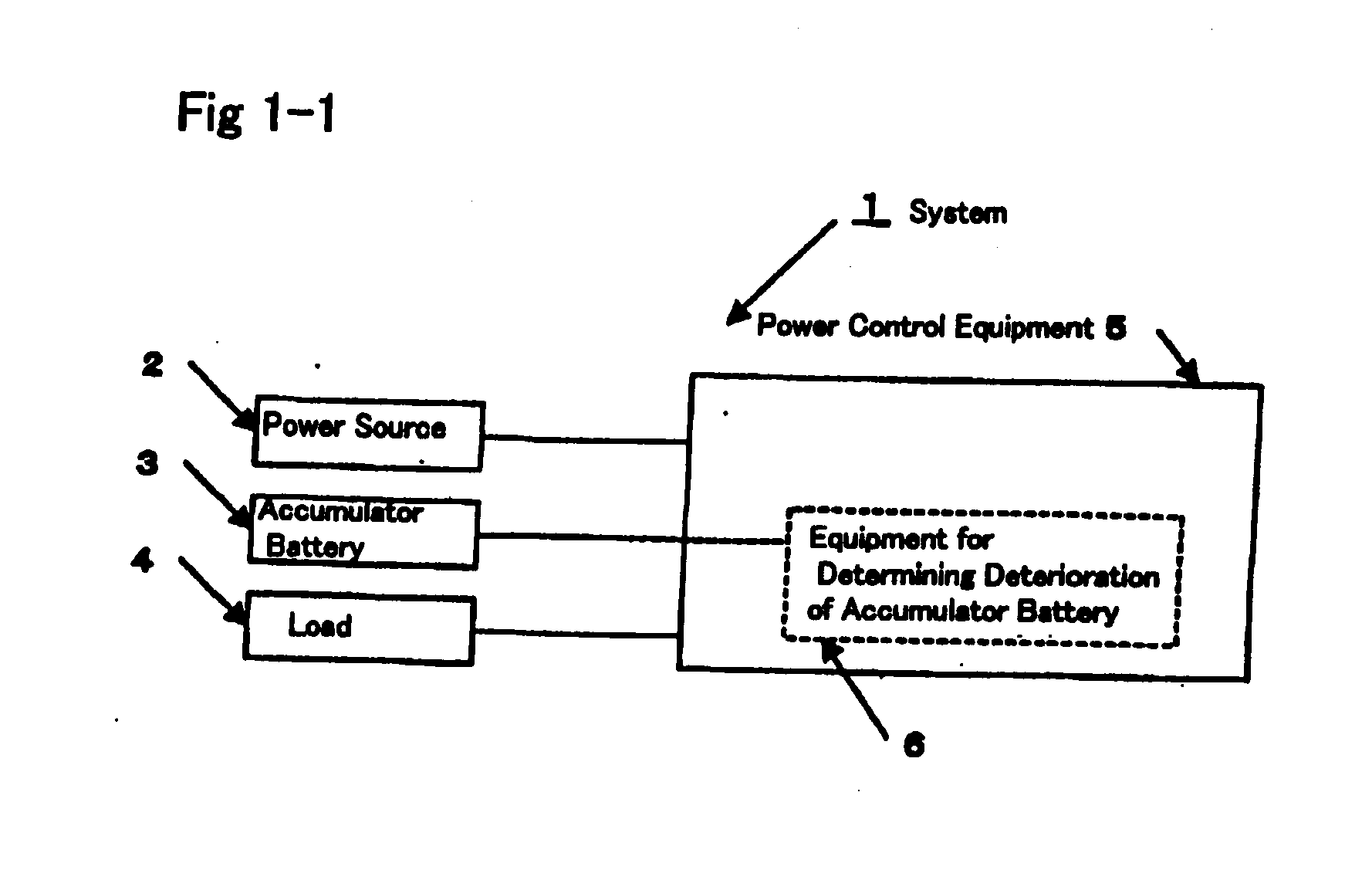

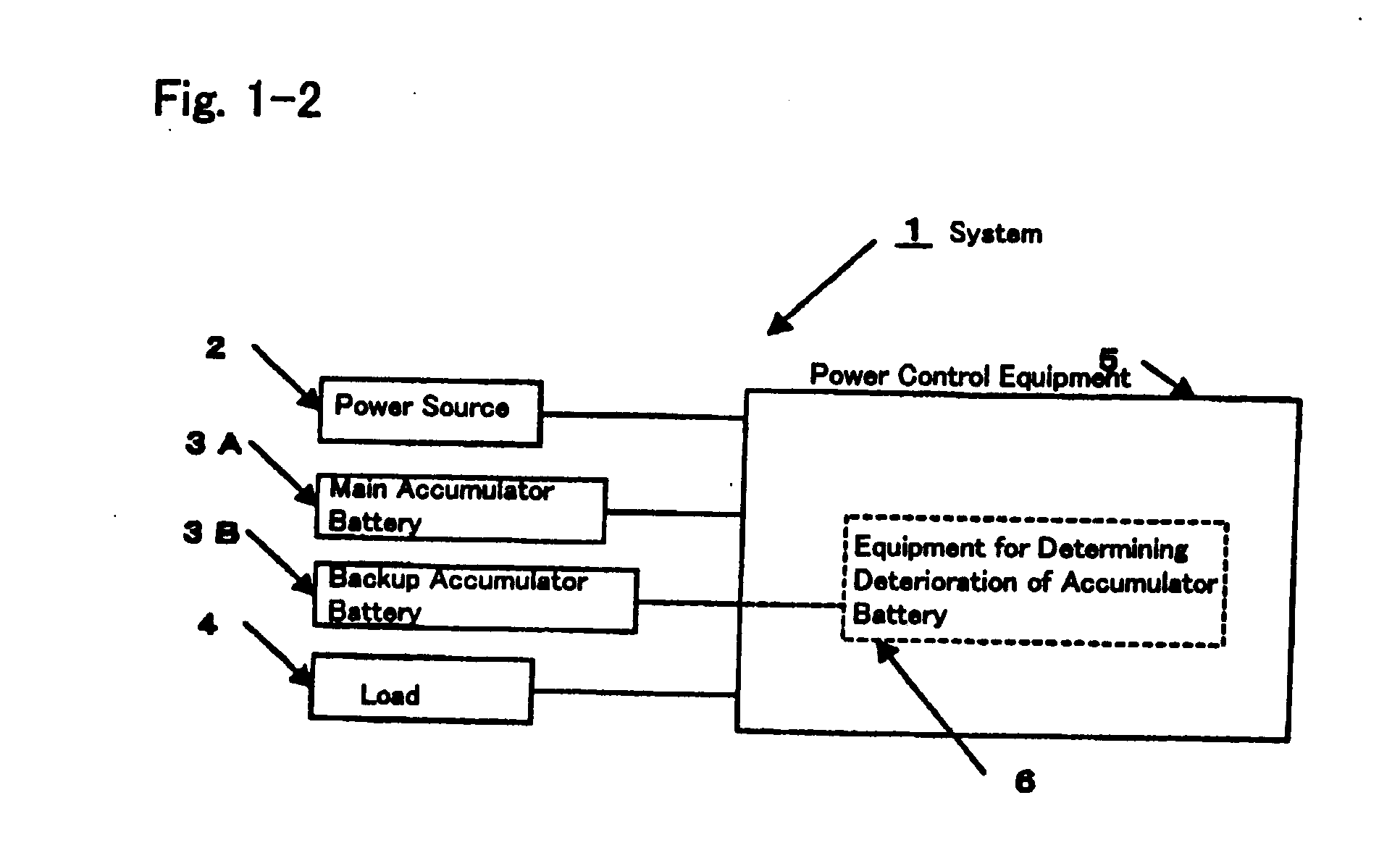

Method for determining deterioration of accumulator battery, method for measuring internal impedance of secondary battery, equipment for measuring internal impedance of secondary battery, equipment for determining deterioration of secondary battery, and power supply system

ActiveUS20060186890A1Complicated processIncrease equipment costBatteries circuit arrangementsMaterial analysis by electric/magnetic meansElectrical resistance and conductanceConversion factor

A method for determining deterioration of accumulator battery hooked up with loads in a system based on results of measuring internal resistances of an accumulator battery, the method comprising the steps of; predetermining as a specified temperature a temperature at which the deterioration of the accumulator battery is determined; calculating in advance temperature correction coefficients of the internal resistances from changes of the internal resistances depending on temperatures; predetermining resistance-voltage conversion factors to convert between the internal resistances at the specified temperature and terminal discharge voltages of the accumulator battery which are obtained at the specified temperature under a condition of flowing predetermined discharge currents from the accumulator battery; measuring the internal resistances of the accumulator battery and temperature of the accumulator battery at an internal resistance measurement; converting the measured internal resistance values into the internal resistance values at the specified temperature with use of the temperature correction coefficients of the internal resistances; converting the internal resistance values at the specified temperature into the terminal discharge voltage values of the accumulator battery at the specified temperature with use of the resistance-voltage conversion factors; and determining whether the accumulator battery is deteriorated or not by means of comparison of the terminal discharge voltage values of the accumulator battery at the specified temperature and a predetermined threshold value as a deterioration judgment standard.

Owner:FURUKAWA ELECTRIC CO LTD

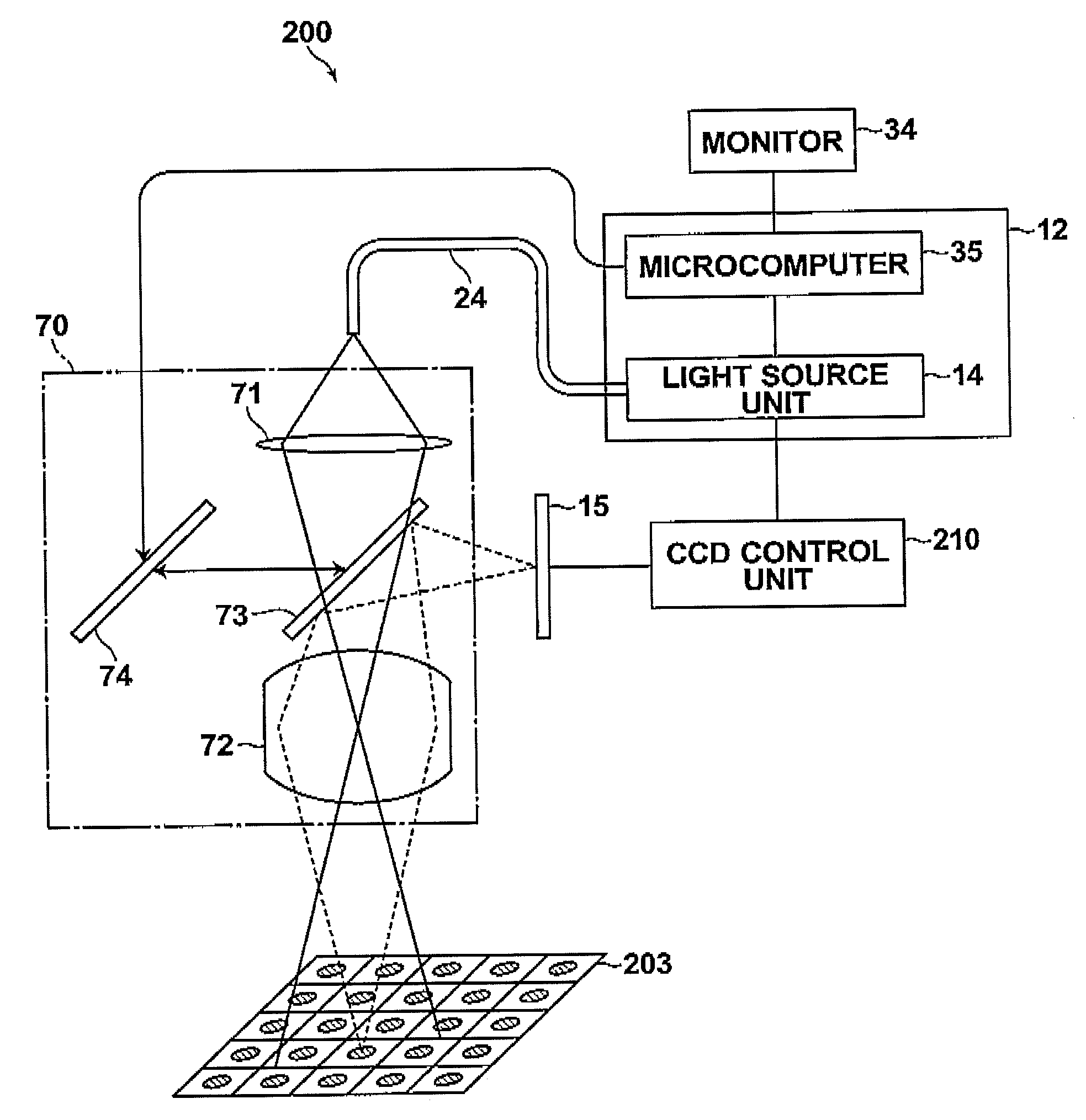

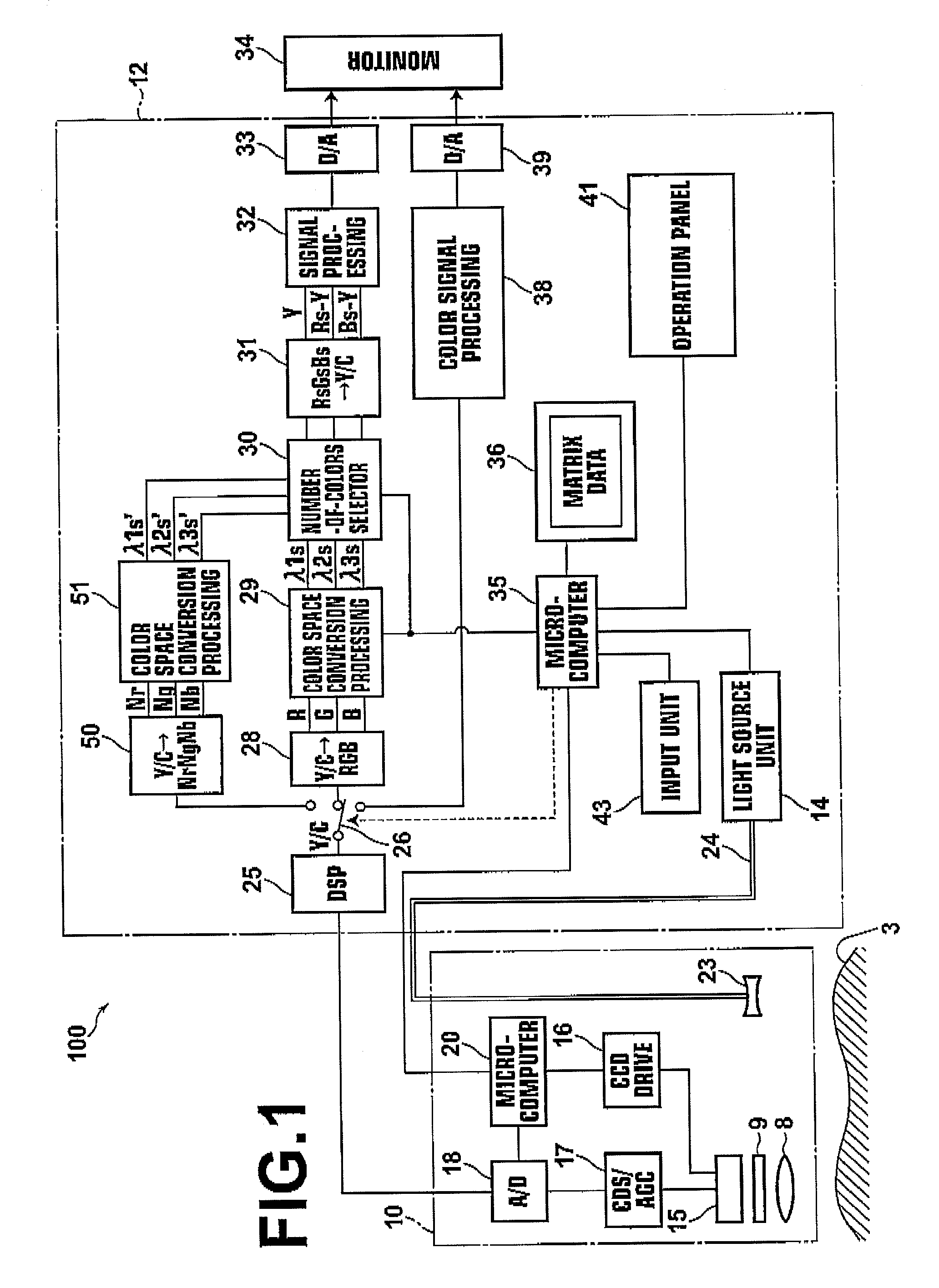

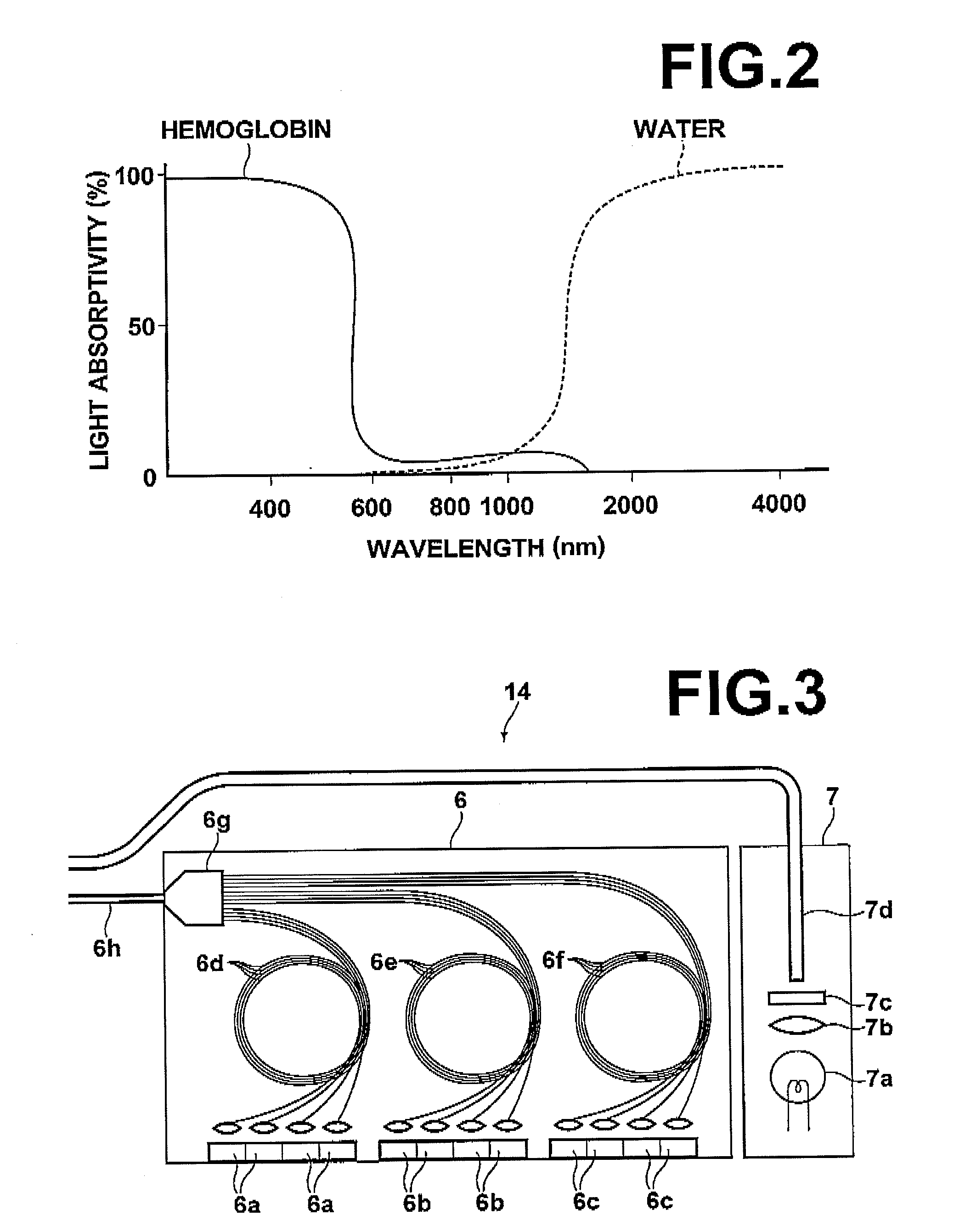

Imaging apparatus

InactiveUS20090021739A1Increasing size of apparatusIncrease in sizeTelevision system detailsSpectrum investigationLength waveImaging equipment

An imaging apparatus includes a light source unit that selectively outputs white light and light in a different wavelength band to an observation target, an imaging unit including an imaging device, and a spectral image formation circuit that generates a spectral image signal for a specified wavelength by an operation using an image signal based on an output from the imaging unit and predetermined matrix data. The imaging unit selectively obtains an image of the observation target for each of first, second and third light components in a visible light region and an image for each of at least fourth and fifth light components in a near-infrared region. Further, the imaging unit includes first spectral devices that make only the first and fourth light components enter first pixels of the imaging device and second spectral devices that make only the second and fifth light components enter second pixels thereof.

Owner:FUJIFILM CORP +1

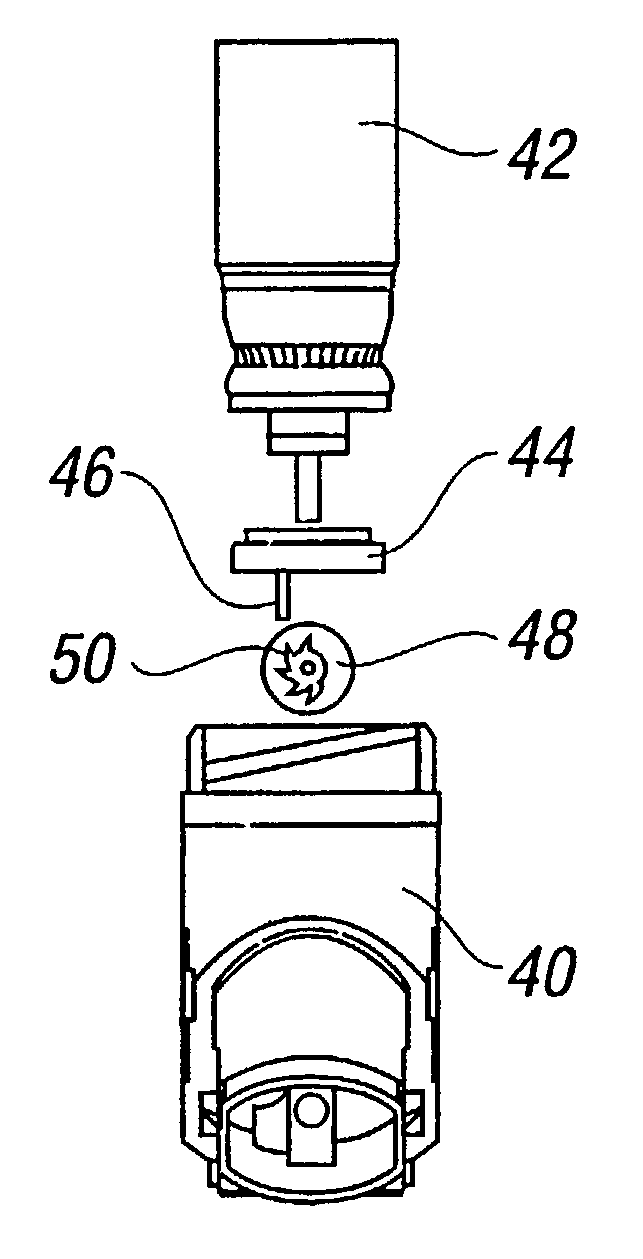

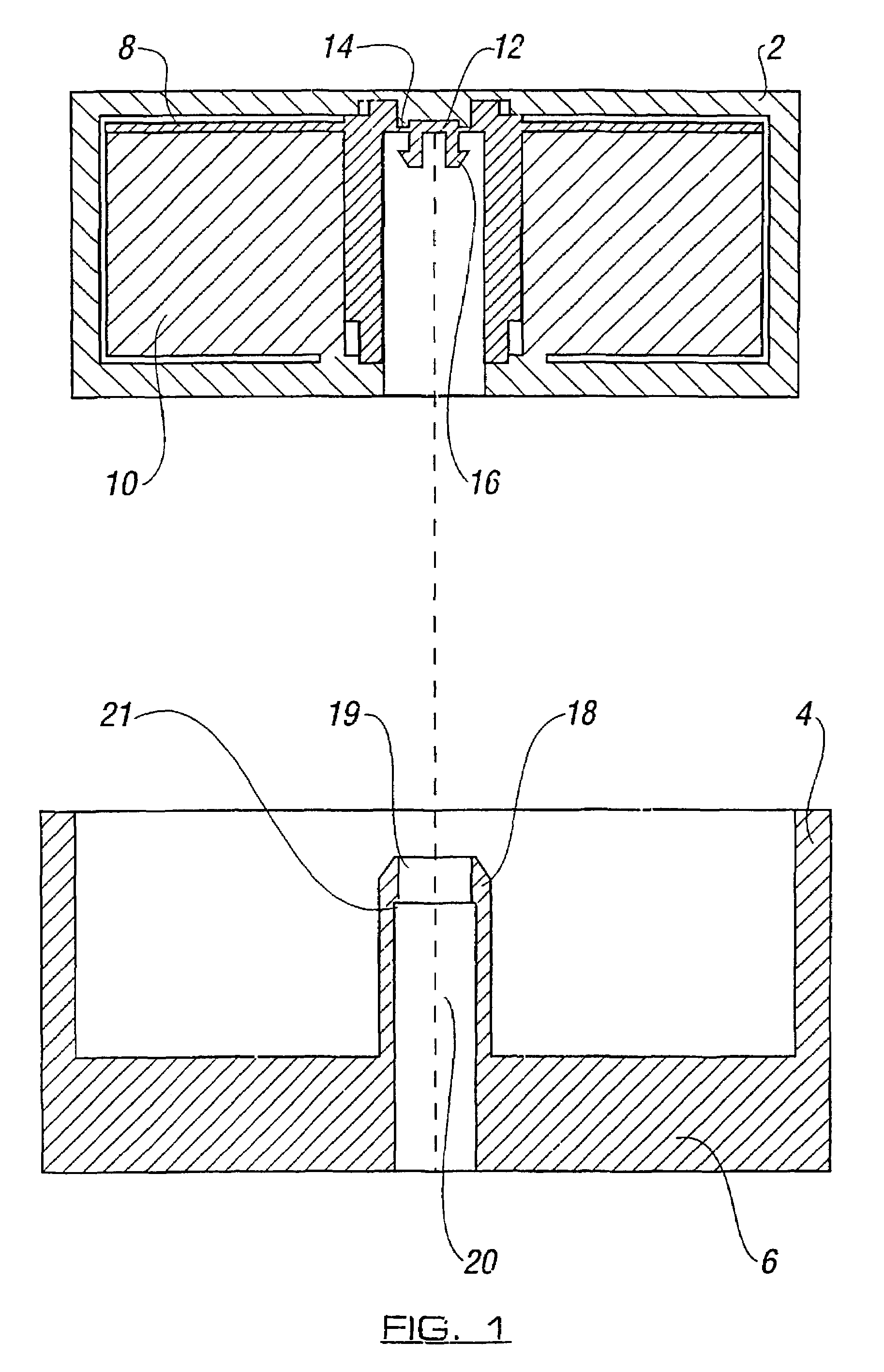

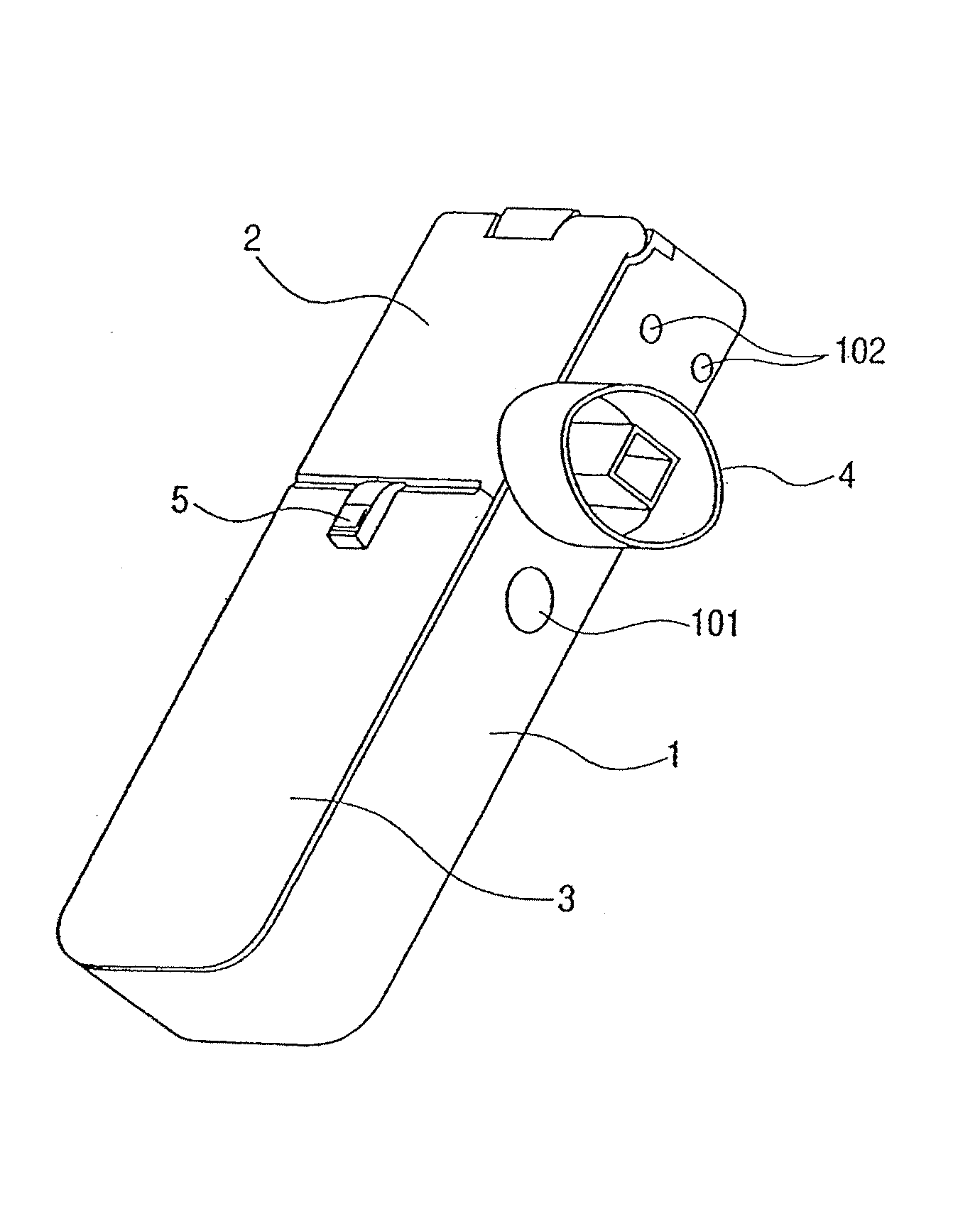

Refillable device with counting means

InactiveUS7080642B2Increase equipment costSimple mechanical structureRespiratorsMedical devicesNeedle Free InjectionMedical device

A refillable medical device comprising a base unit (4) adapted to be engaged with a refill unit (2), the device comprising means for counting the number of different refill units which are engaged with the base unit (4). The device may be in the form of a dry powder or pressurised aerosol inhaler, needleless injector, intravenous drip system etc. The device may comprise means to disable the device after a predetermined number of refill units have been used with the base.

Owner:3M INNOVATIVE PROPERTIES CO

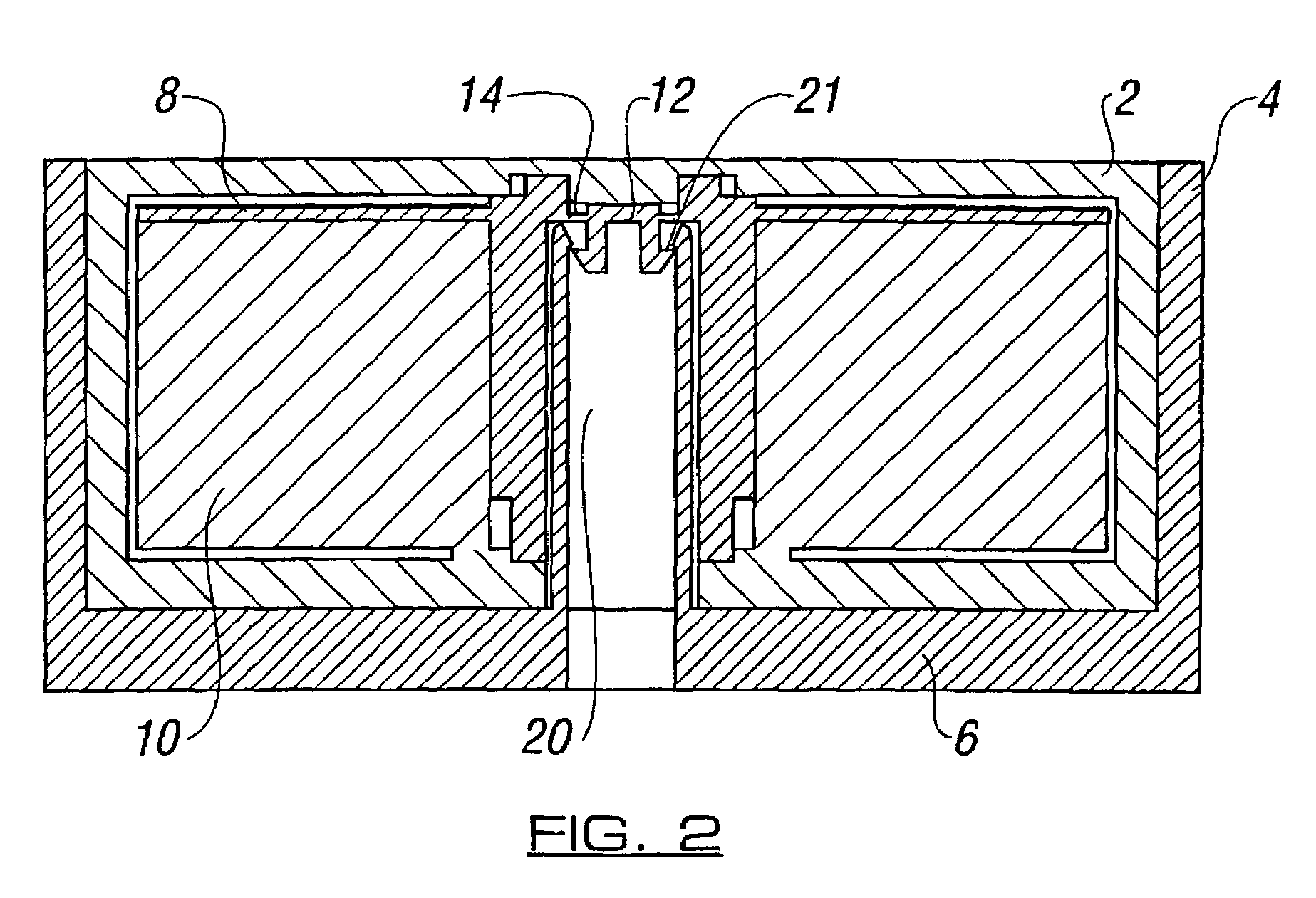

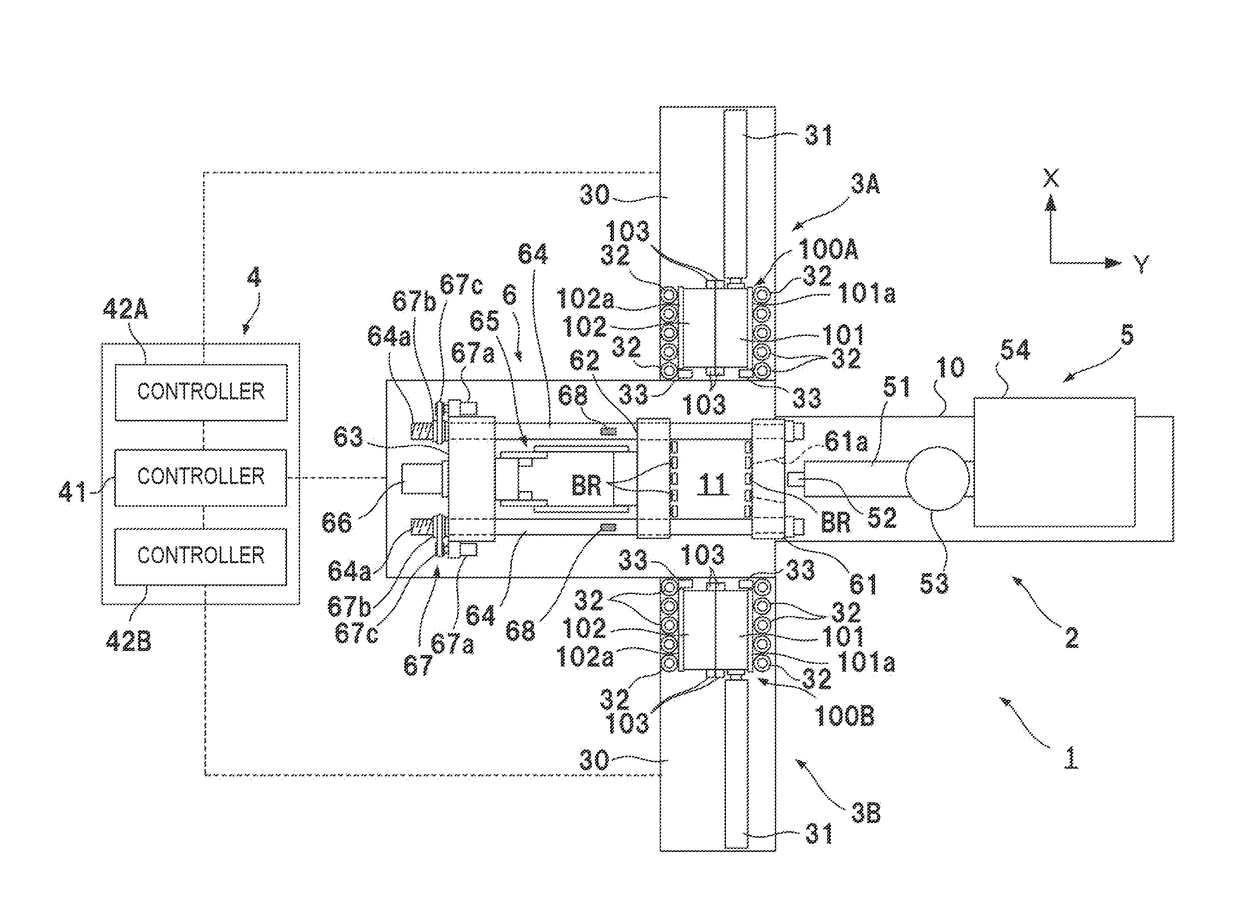

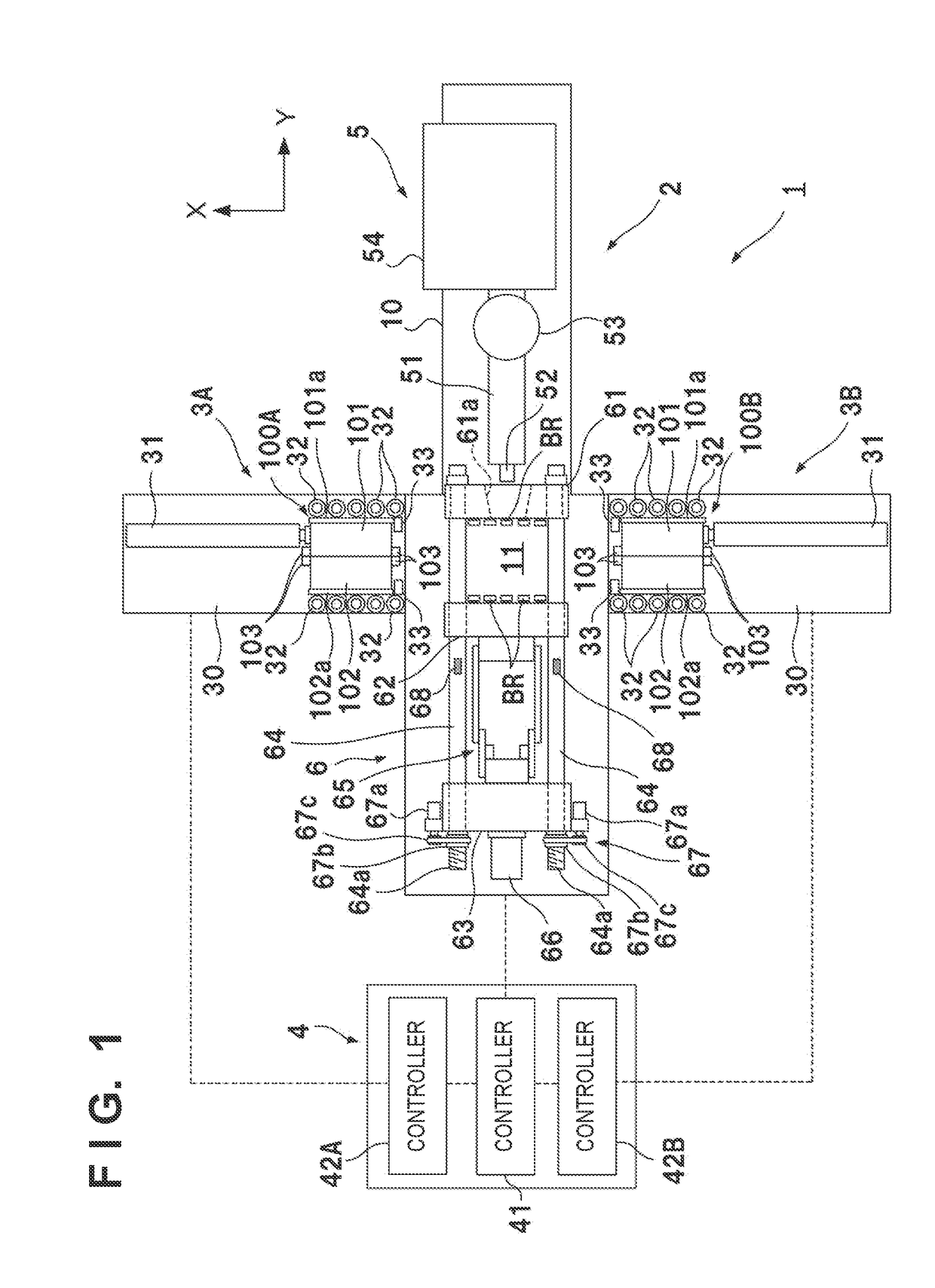

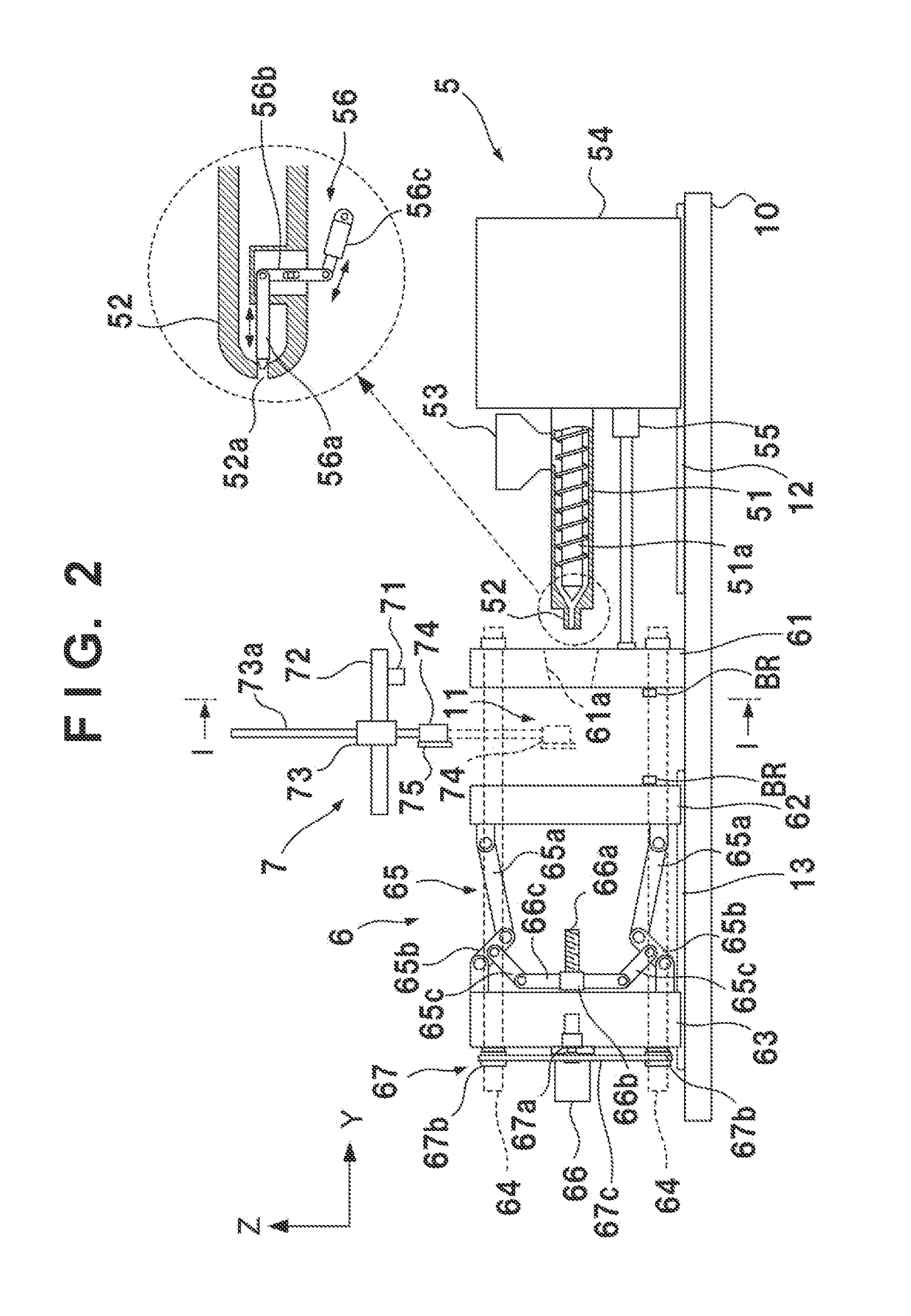

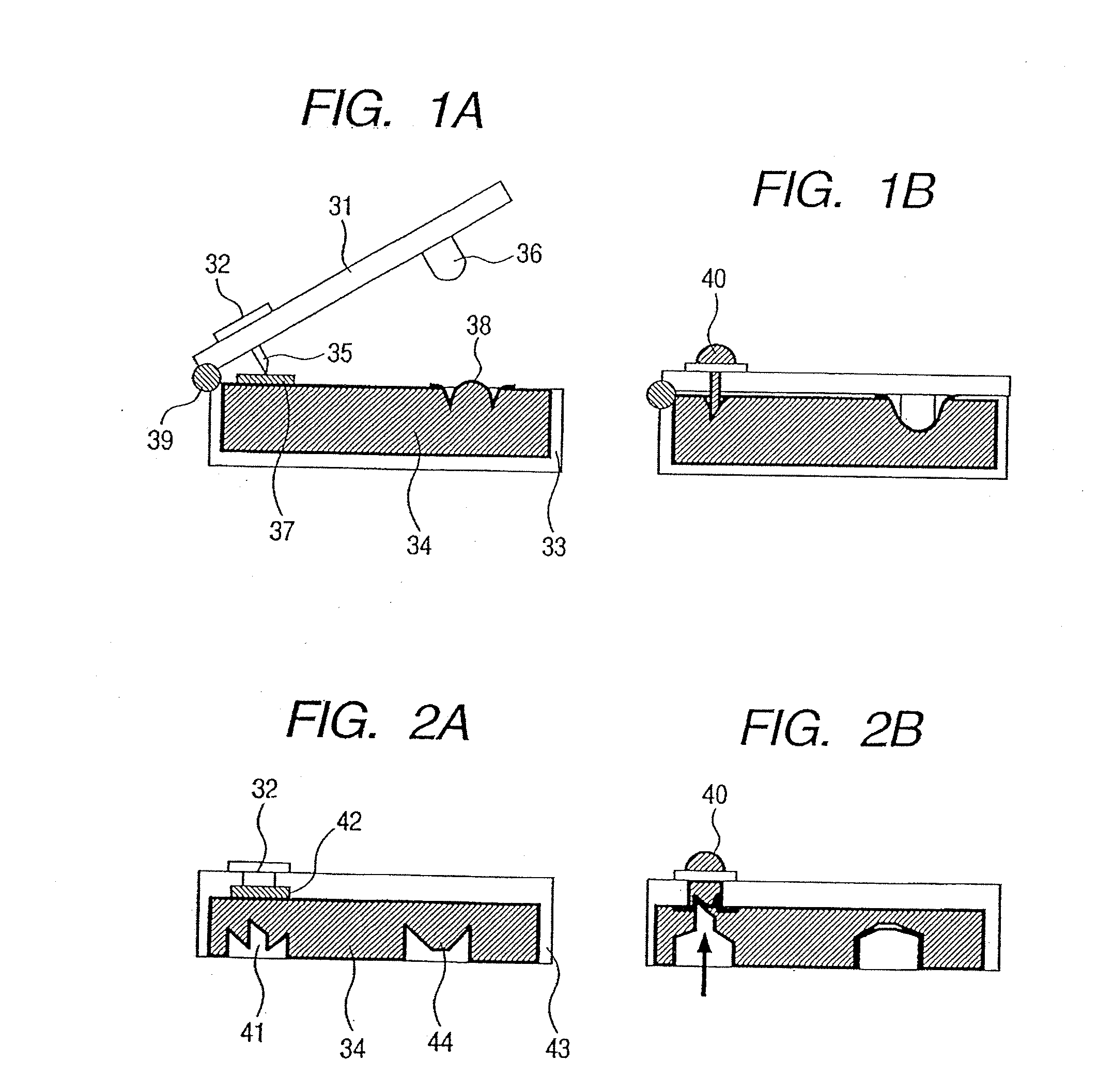

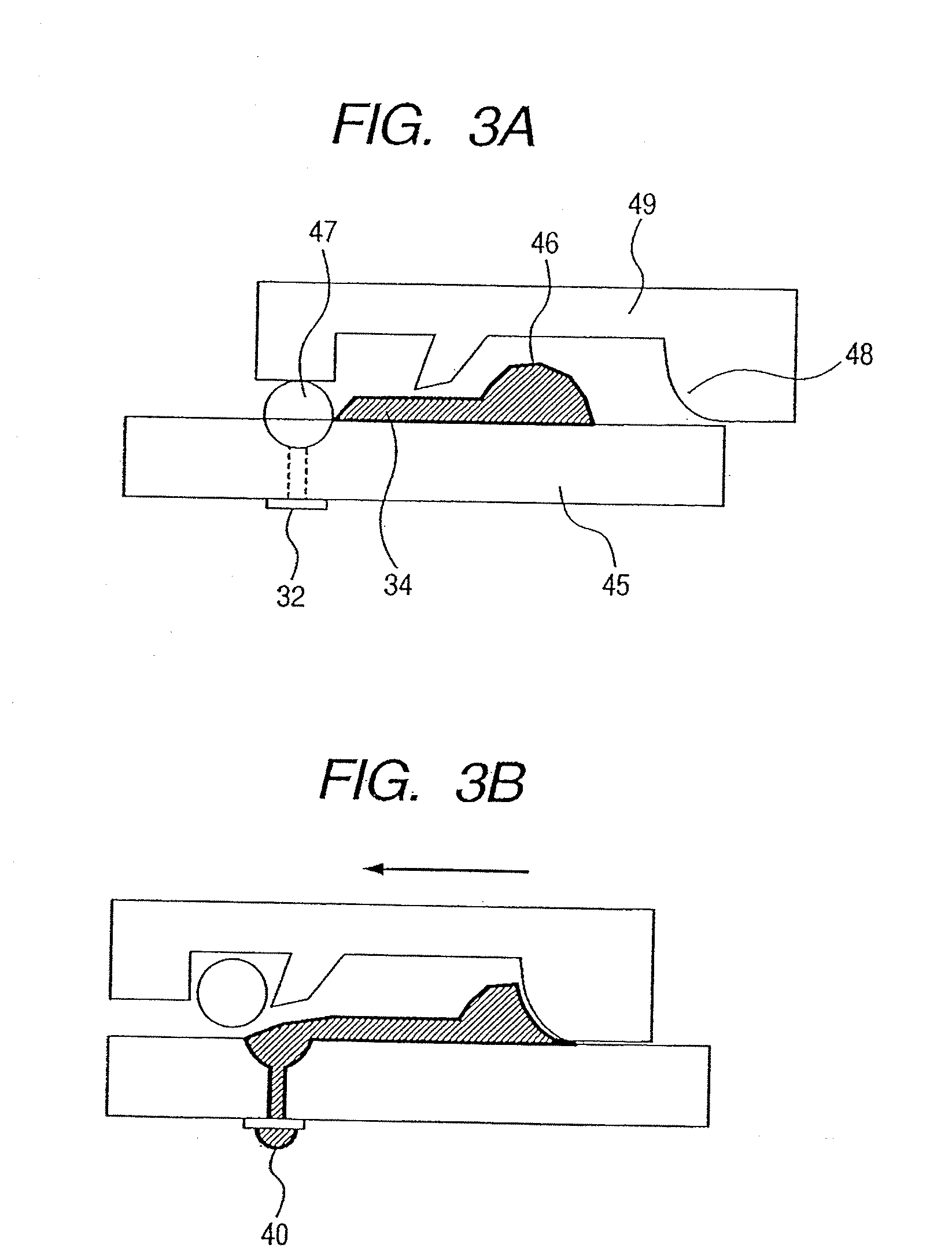

Manufacturing method and injection molding system

ActiveUS20180009146A1Improve productivityIncrease equipment costInjection molding machineMechanical engineering

A method including a first step of performing clamping of a mold, injection and dwelling in an injection molding machine, a second step of performing a conveyance and a cooling of the mold outside of the machine, and a third step of performing a conveyance of the mold into the machine, an opening of the mold and an ejection of a molded part in the machine. The second step is performed for a first mold, the third step and the next first step are performed for a second mold. The first mold is conveyed by a first conveyance apparatus which is arranged on one lateral side of the machine. The second mold is conveyed by a second conveyance apparatus which is arranged on the other lateral side and is independently driven from the first conveyance apparatus.

Owner:CANON KK

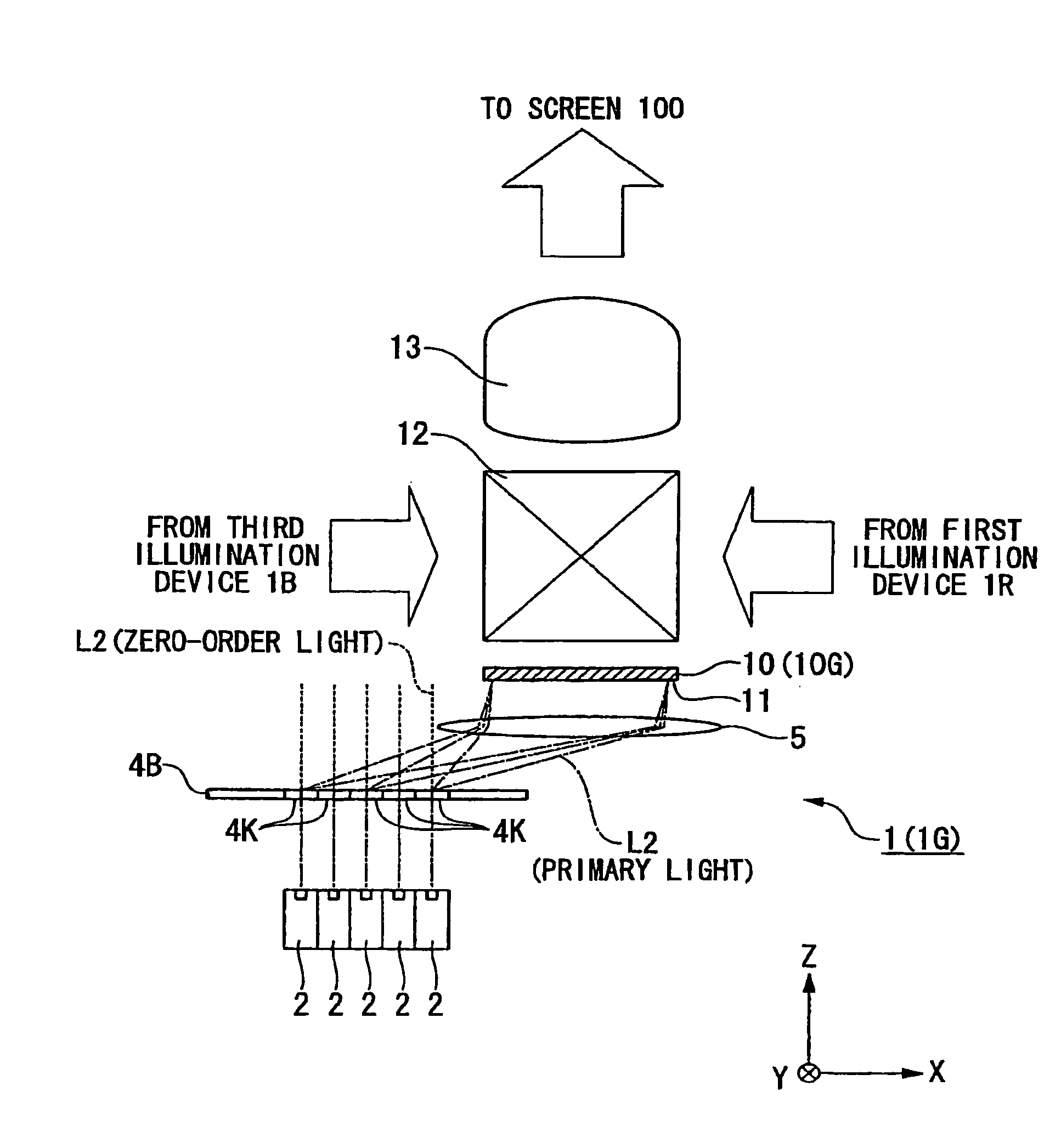

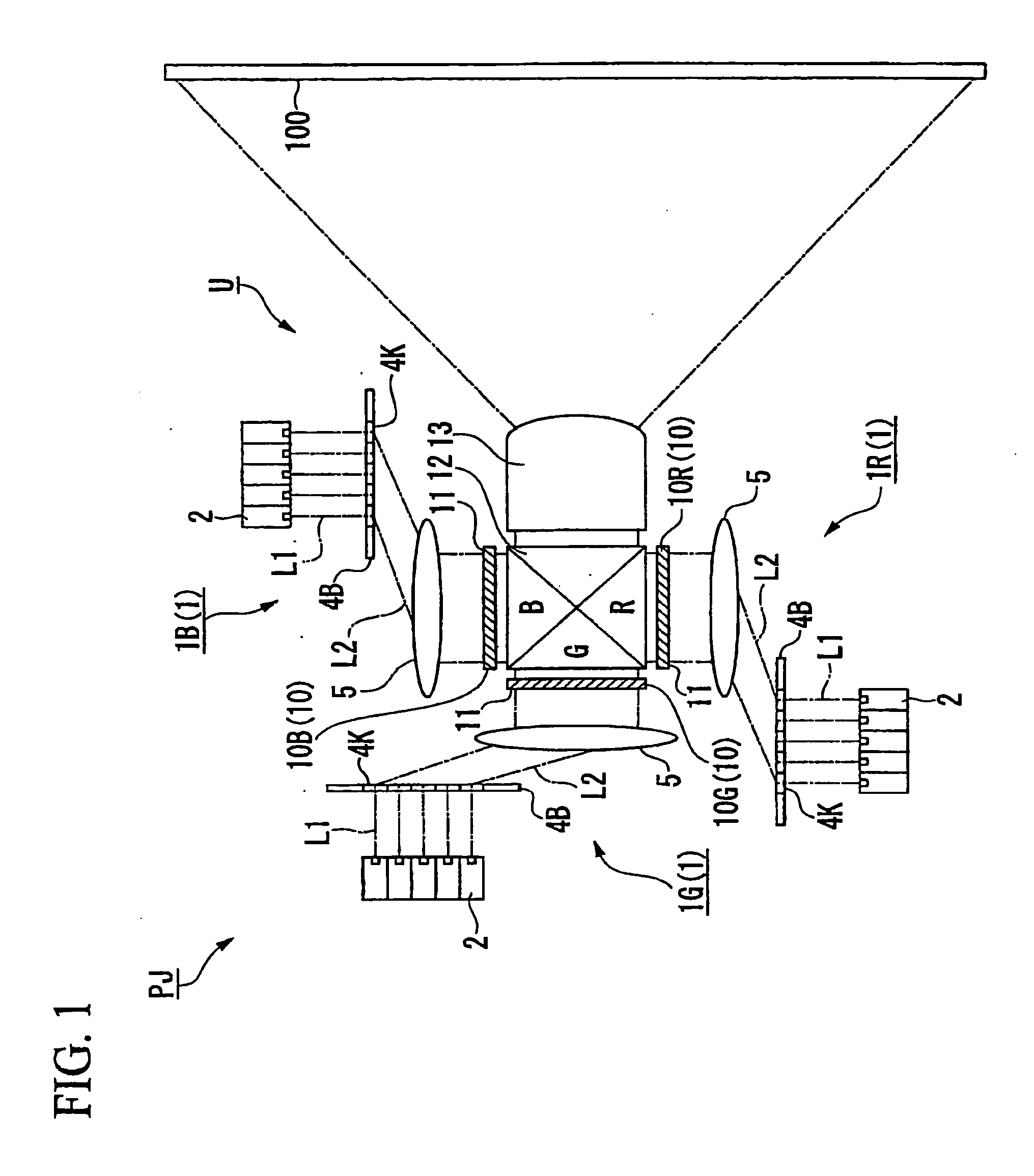

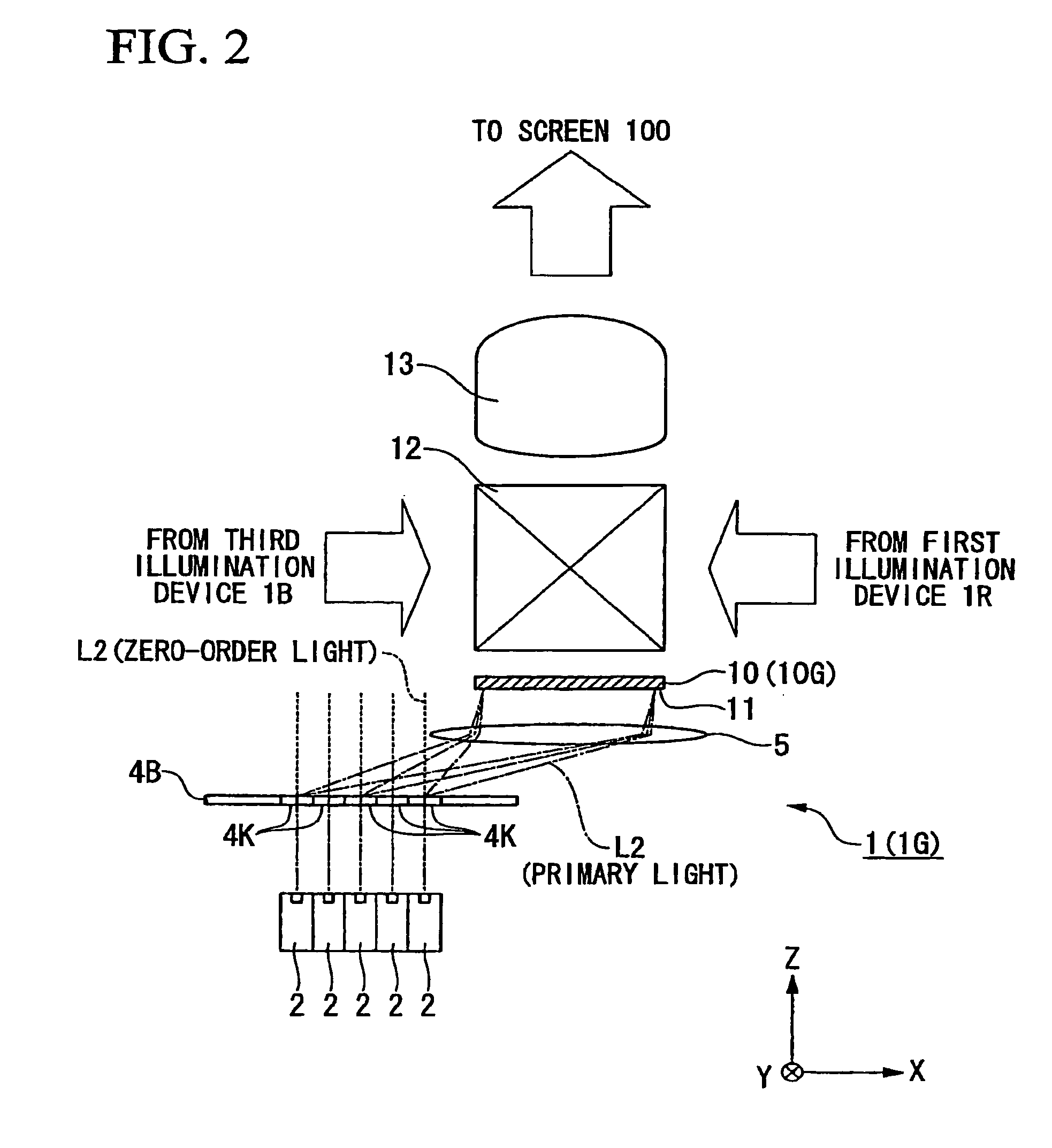

Illumination device, image display device, and projector

ActiveUS20070019909A1Increase in complexity of increaseLow costColor television detailsCoupling light guidesDisplay deviceLaser light

An image display device includes: a first face; a laser light source device emitting laser light; and a diffractive optical element on which the laser light emitted from the laser light source device is incident, generating diffracted light from the incident laser light, and illuminating the first face with the diffracted light, the first face is provided at a position on which zero-order light emitted from the diffractive optical element is not incident, and an image is displayed by light via the first face.

Owner:SEIKO EPSON CORP

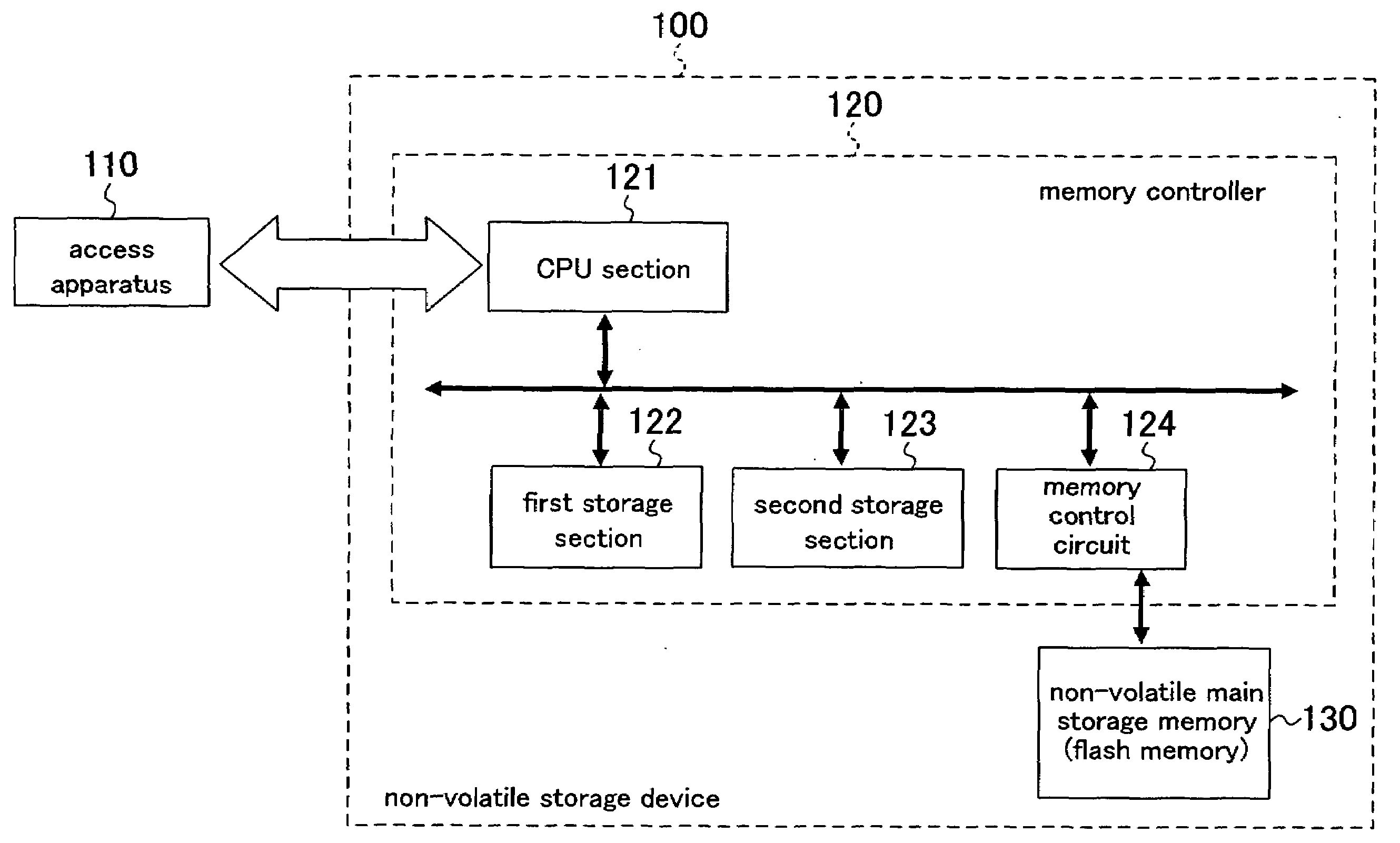

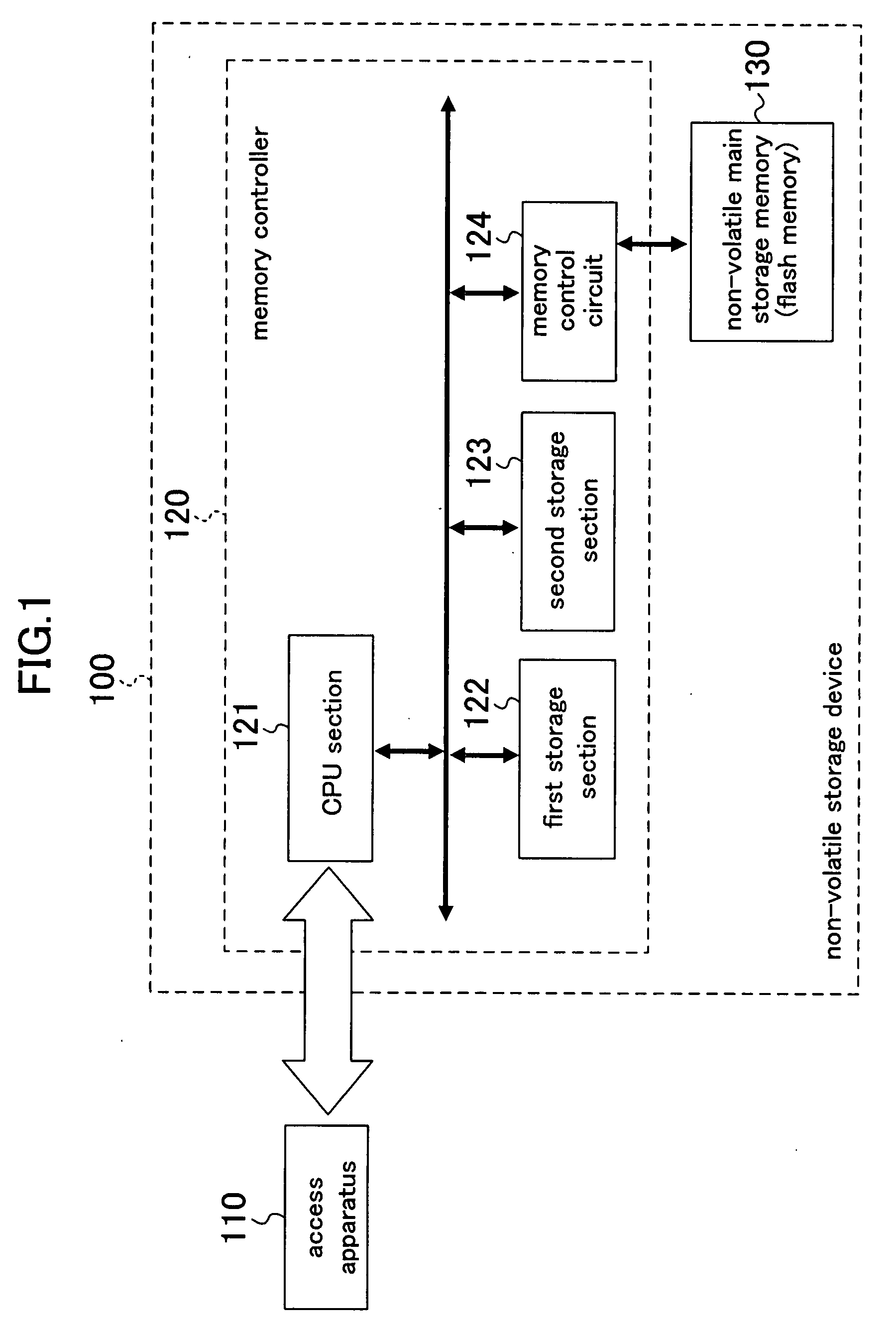

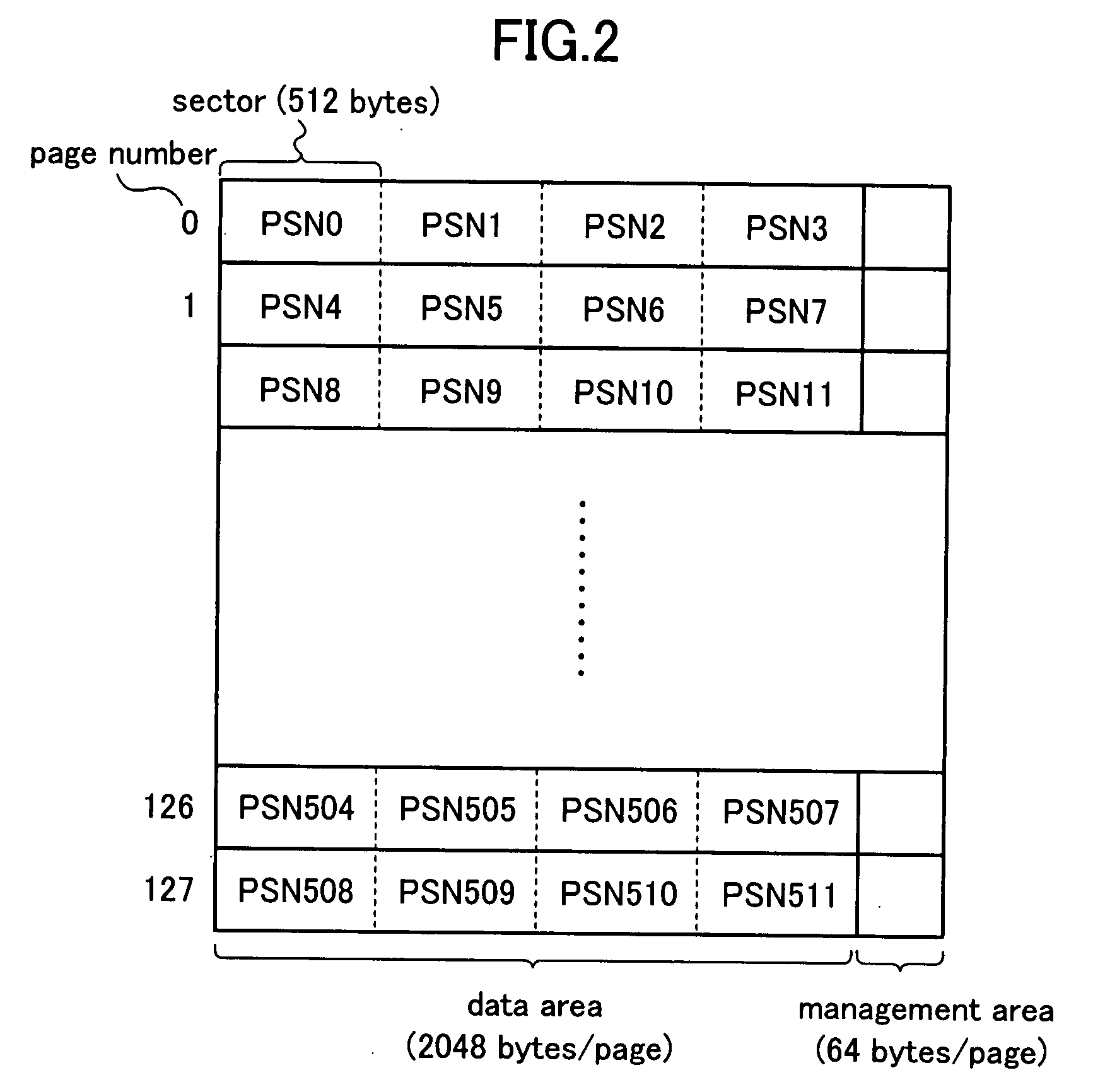

Non-volatile storage device, data storage system, and data storage method

InactiveUS20080028132A1Quickly and efficiently writtenLarge capacityMemory architecture accessing/allocationRead-only memoriesMemory controllerOperating system

A non-volatile storage device comprises a non-volatile memory into which data is written per unit area, and a memory controller for controlling writing of data into the non-volatile memory. The memory controller comprises a first storage section for holding data input from the outside of the device, a first control section for writing data which is held by the first storage section and whose amount corresponds to the unit area, into the non-volatile memory in a unit area-by-unit area basis, and writing data which is held by the first storage section and whose amount is less than the unit area, into a second storage section, and a second control section for writing data held by the second storage section into the non-volatile memory.

Owner:PANASONIC CORP

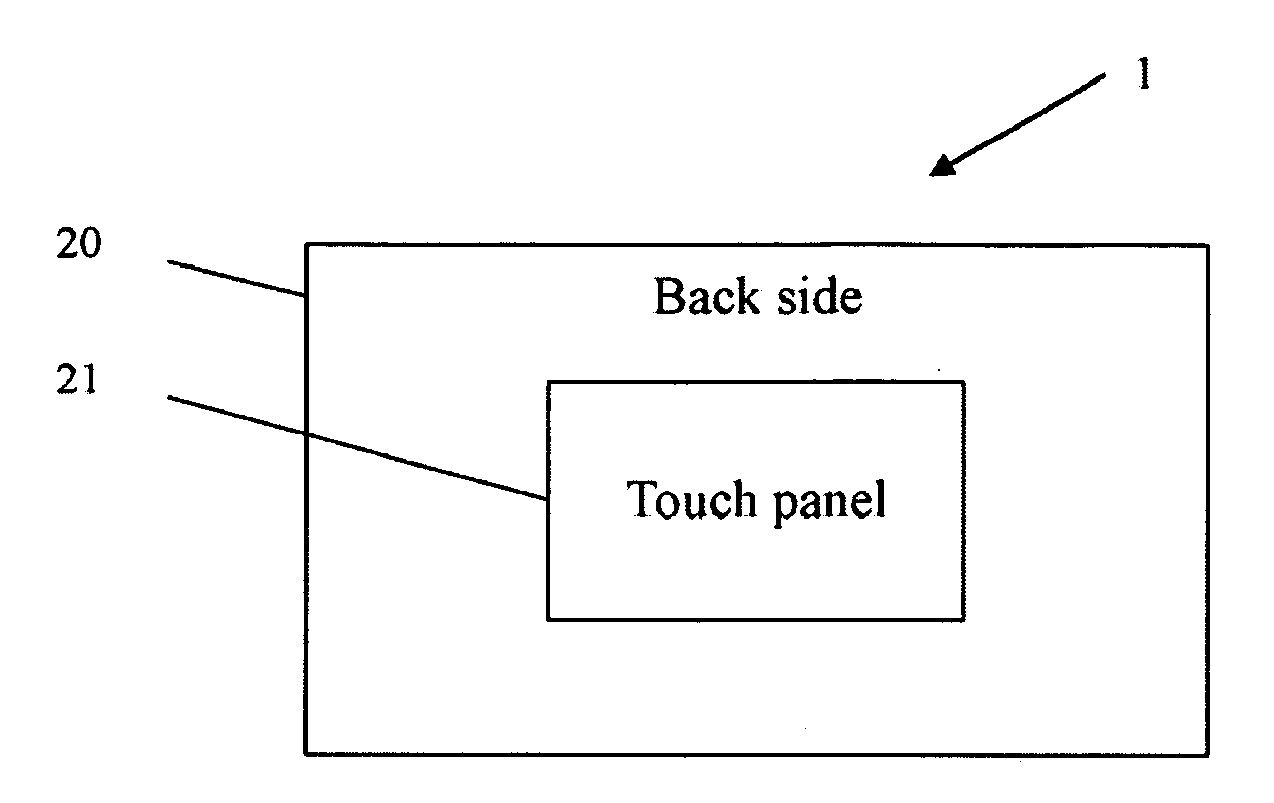

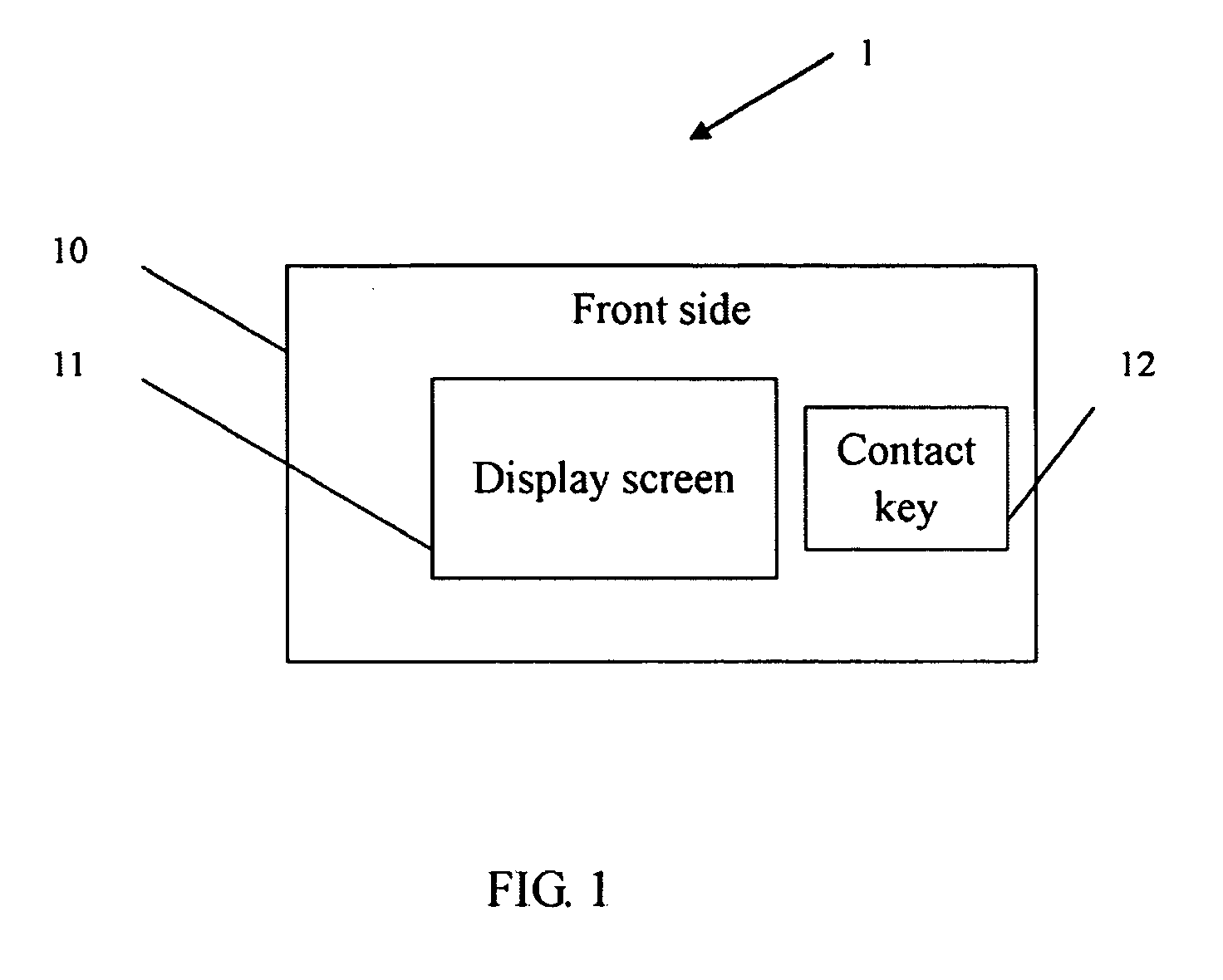

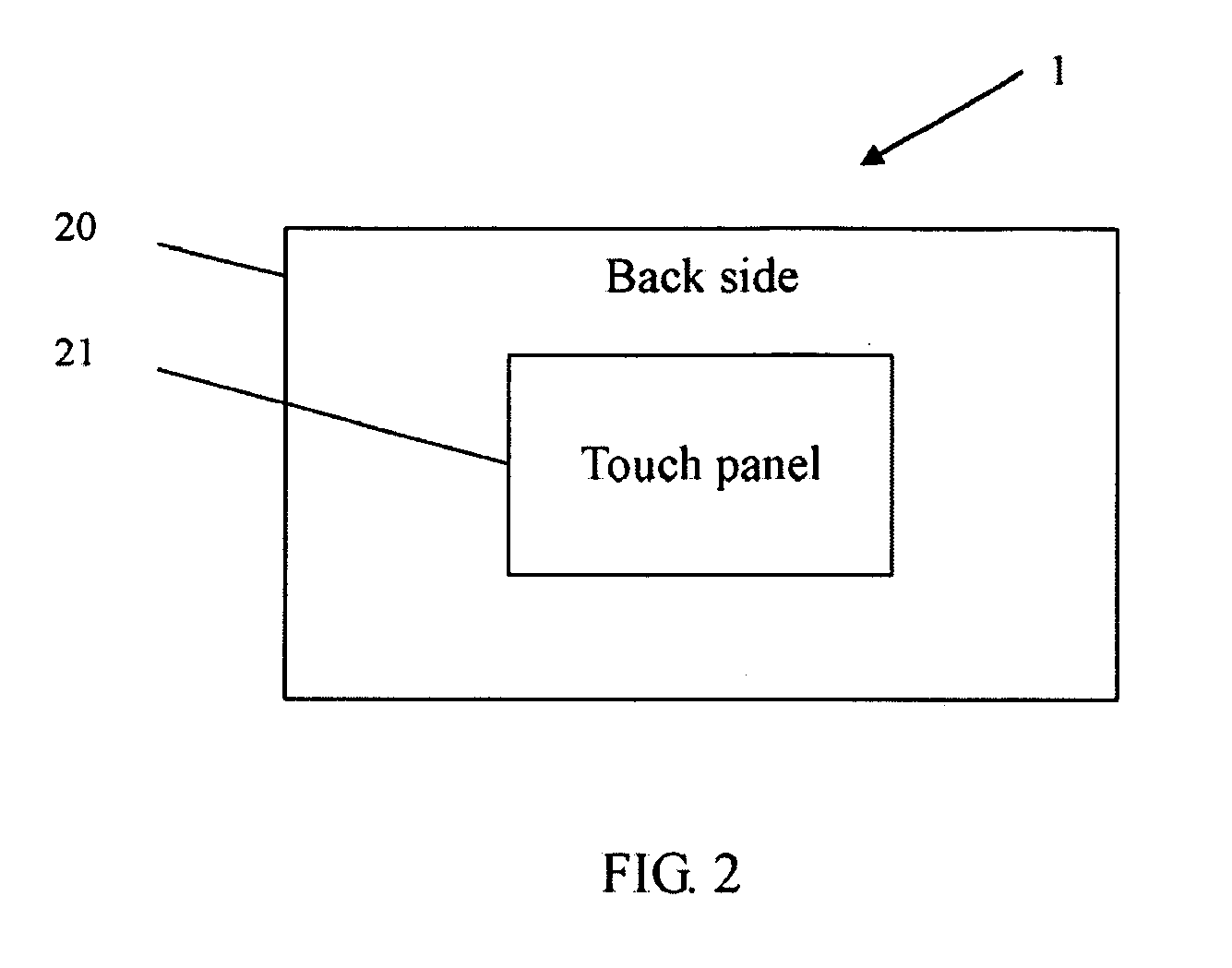

System and method for controlling an electronic device

InactiveUS20090231290A1Reduced lifespanIncrease equipment costDigital data processing detailsInput/output processes for data processingControl electronicsTouch panel

An electronic device includes a display screen and a contact key on a front side and a touch panel on a back side. The electronic device further includes a system configured for controlling the electronic device via contact on the touch panel and contact of the contact key, and displaying corresponding actions via a cursor on the display screen.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

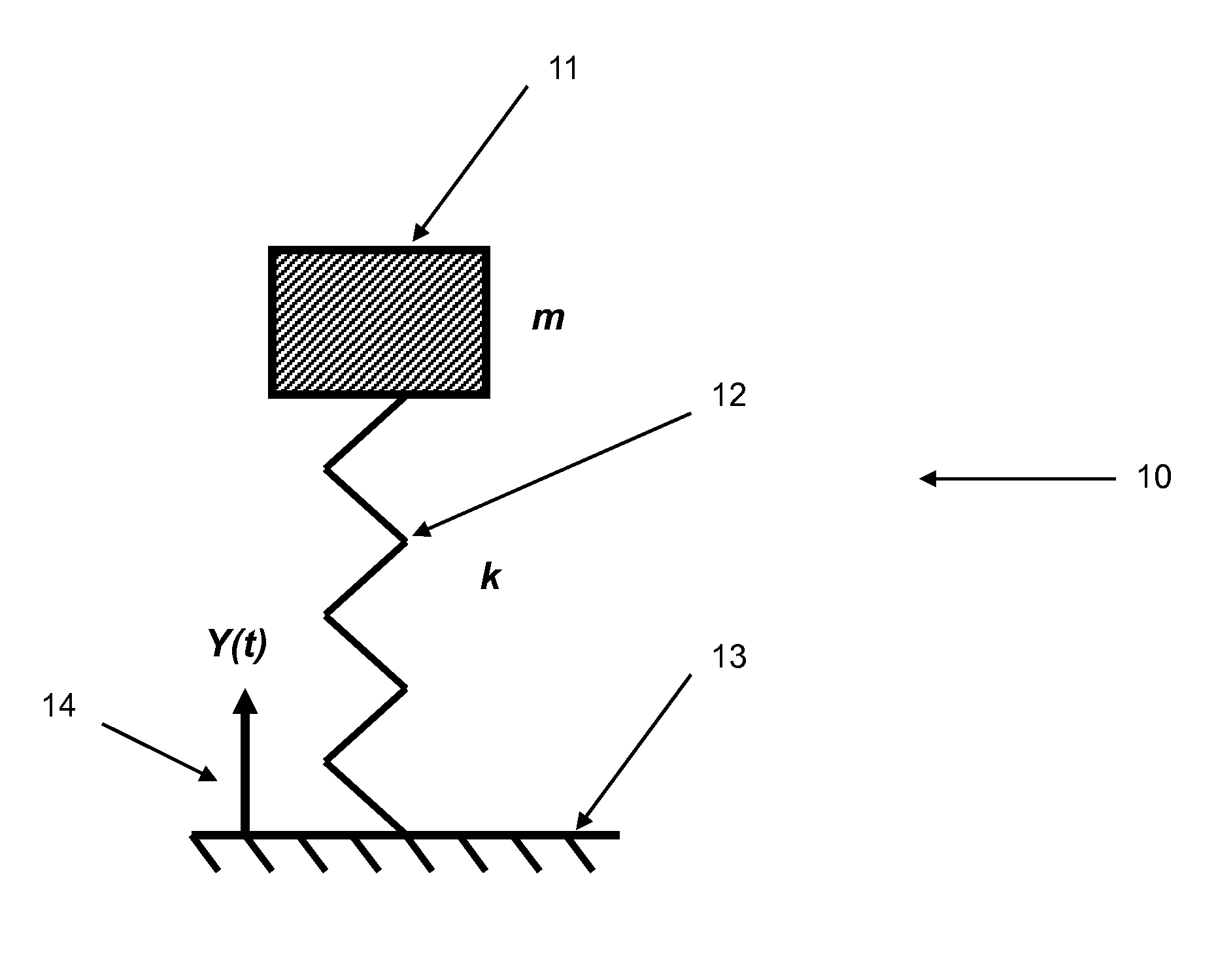

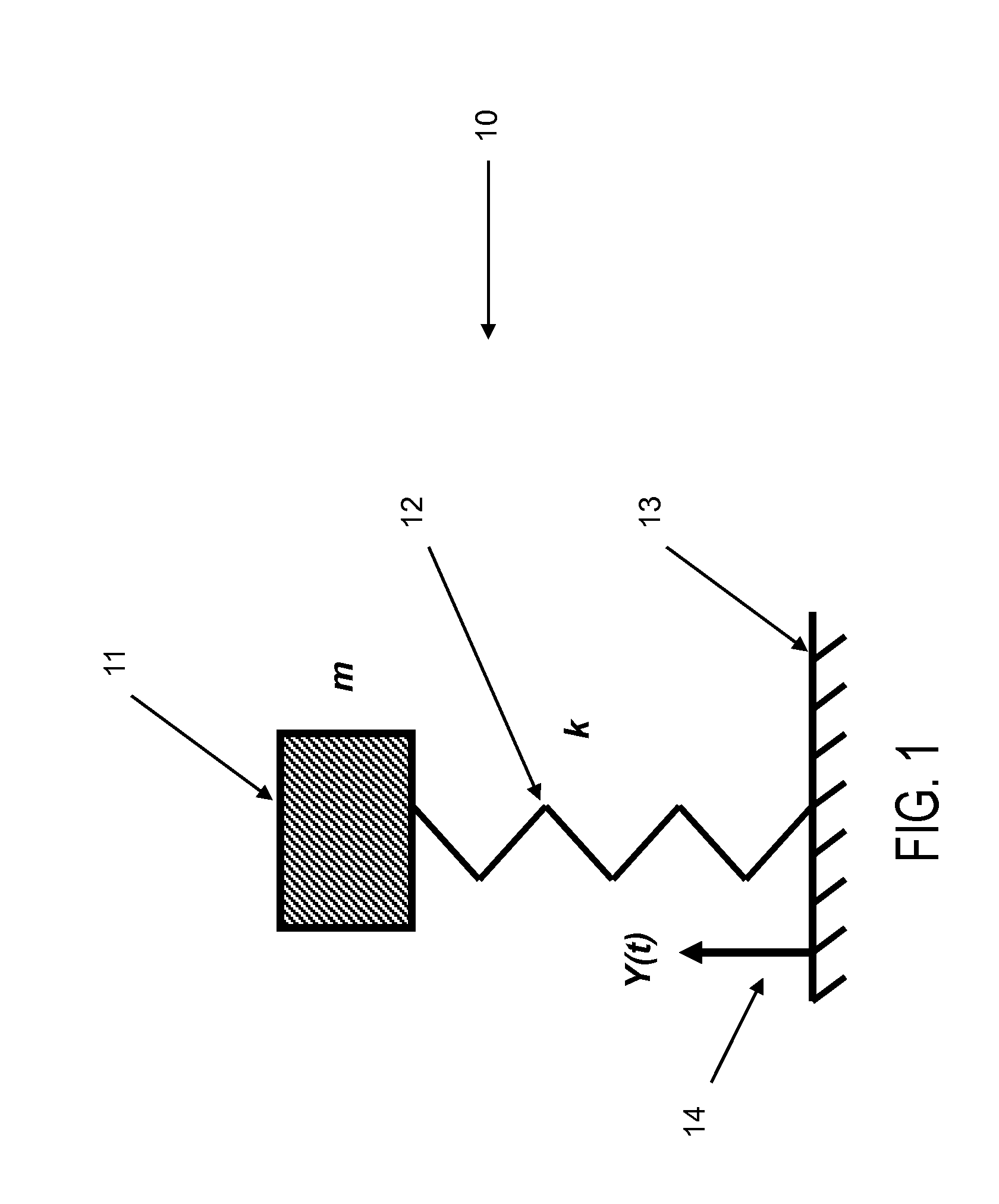

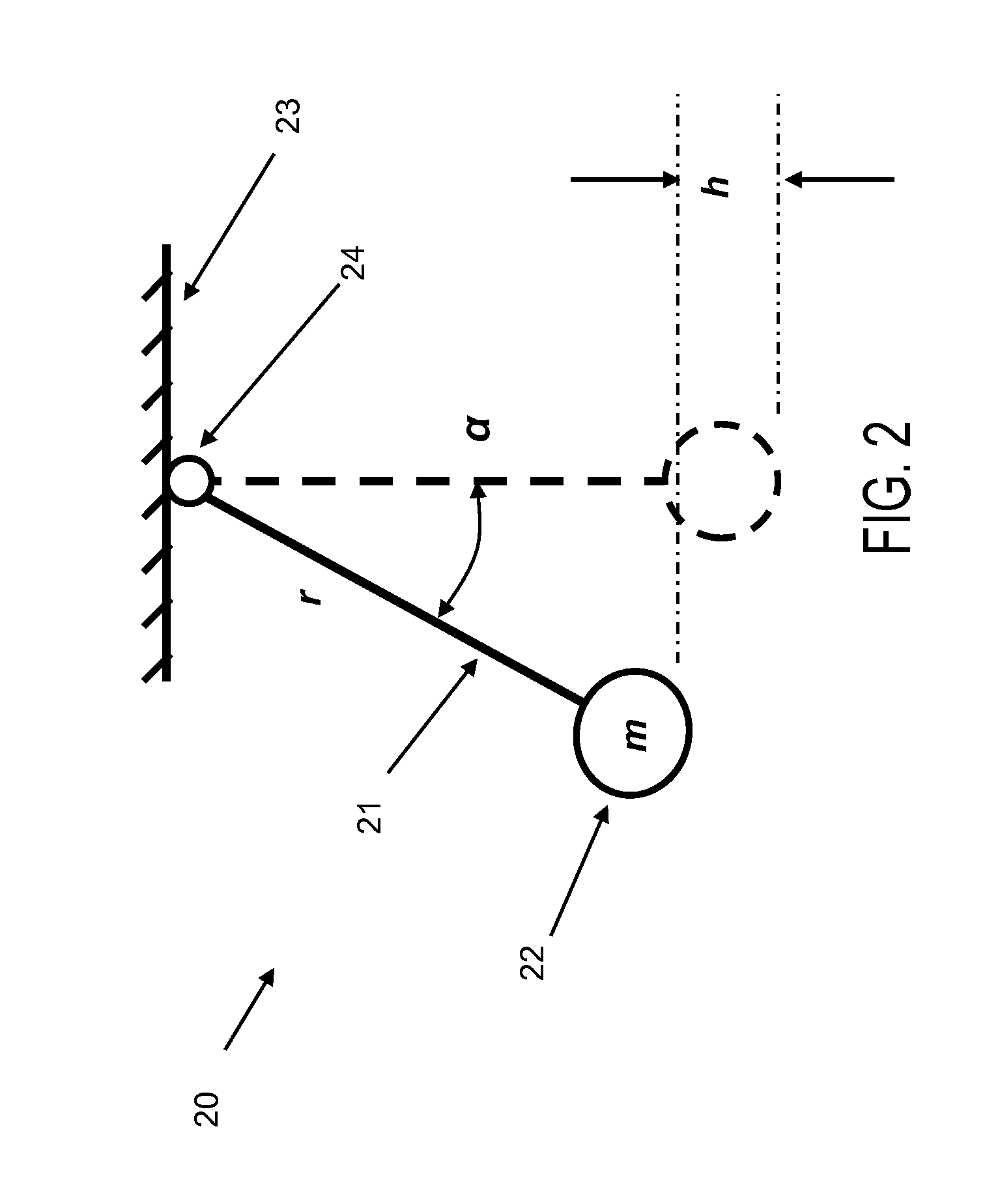

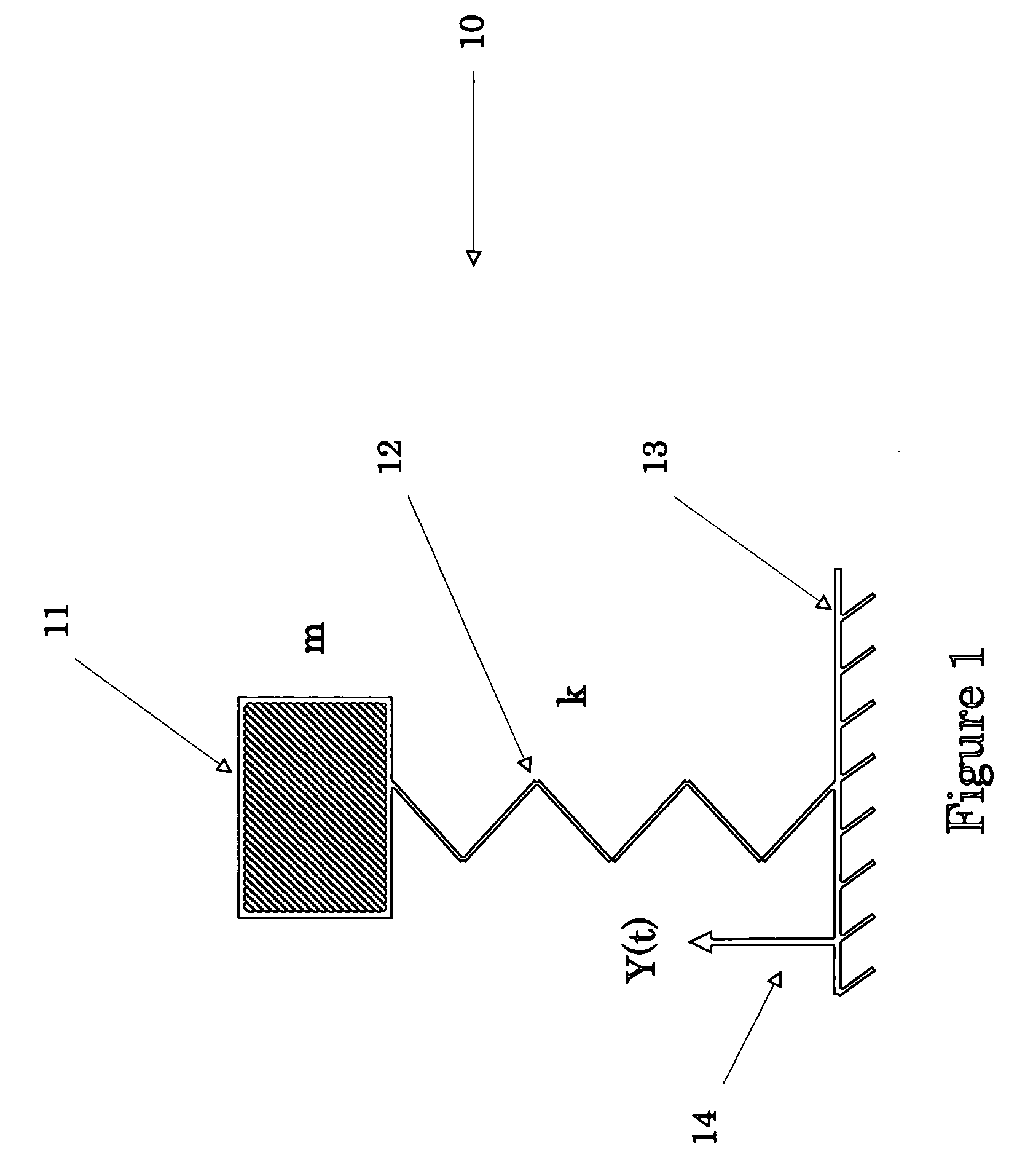

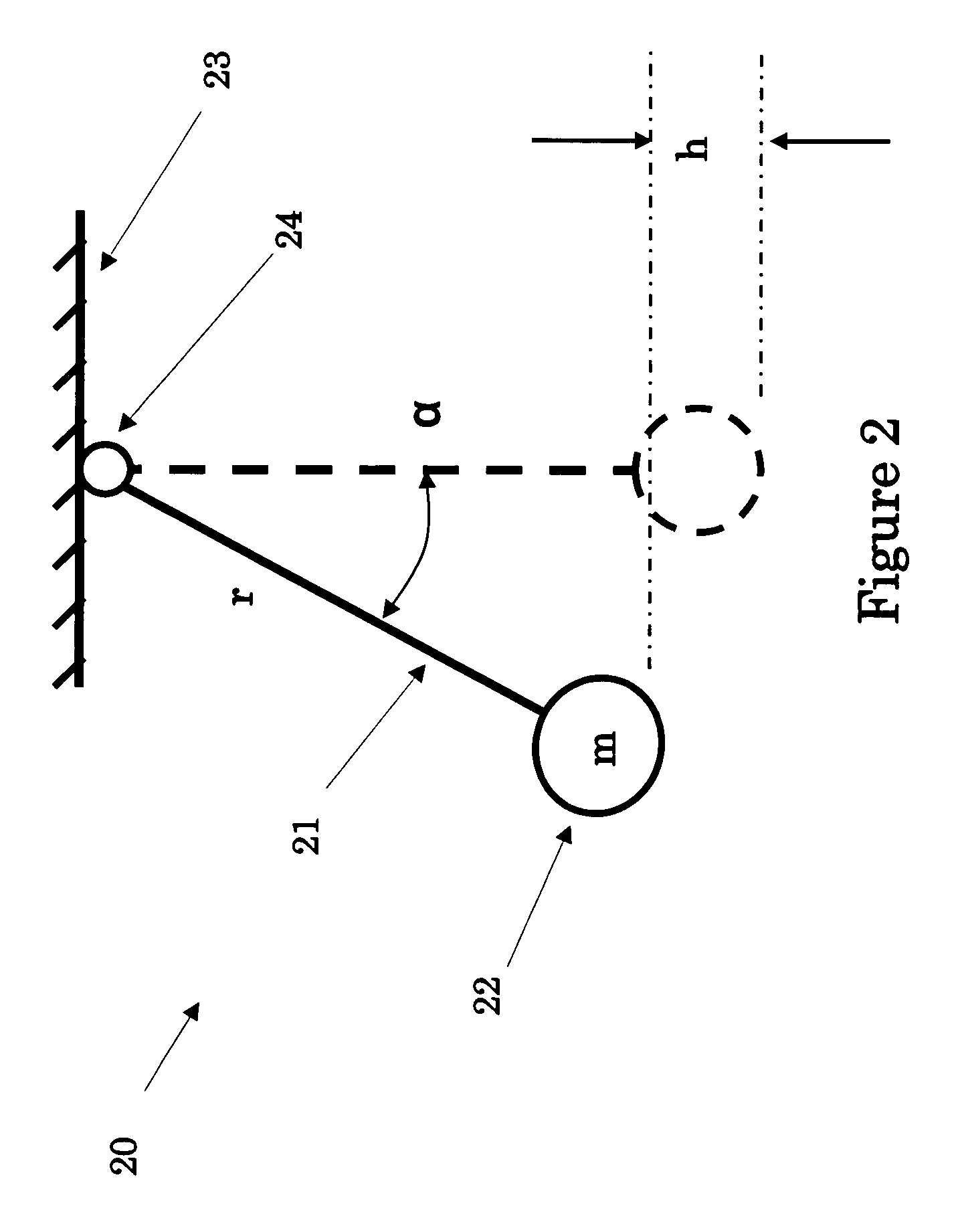

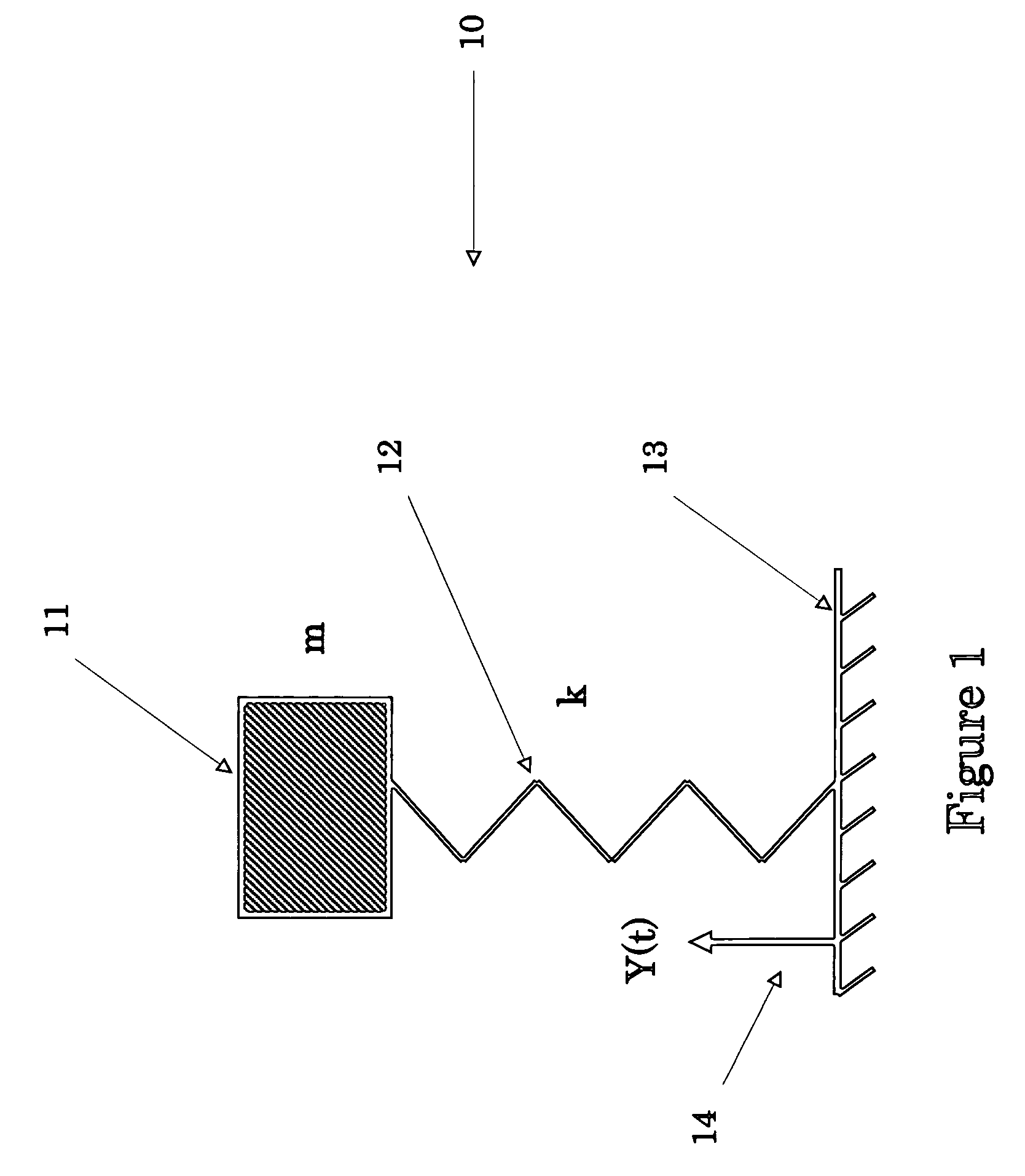

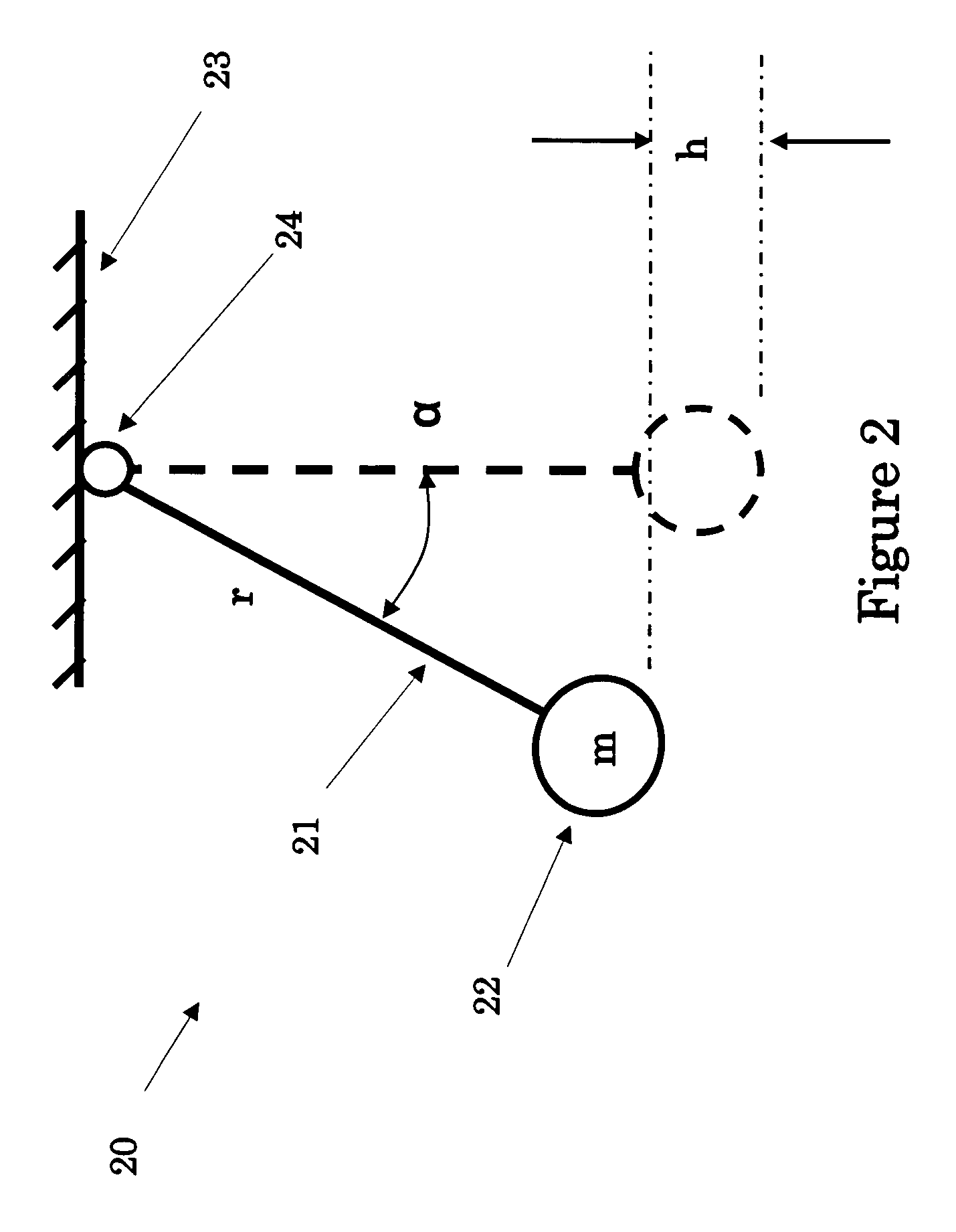

Electrical Generators For Low-Frequency and Time-Varying Rocking and Rotary Motions

ActiveUS20110193350A1Generate efficientlyHigh energyPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesElectricityEngineering

An apparatus for generating electrical energy from a first motion having a low and / or variable frequency. The apparatus including: a first device to which the first motion is transferred; and a second device to which the first motion is transferred from the first device, the second device operating at a second motion having a frequency which is higher and / or more constant that the first motion. Wherein the first device comprises one of a first rotating shaft or first translating mass; the first shaft or first mass includes a tip interacting with the second device to transfer the first motion thereto, the second device comprises a mechanism having an electrical energy generator for converting the second motion to electrical energy; and the electrical energy generator comprises a rotary or linear coil and magnet generator or a piezoelectric generator. The interaction of the tip with the shaft or mass can be contactless.

Owner:OMNITEK PARTNERS LLC

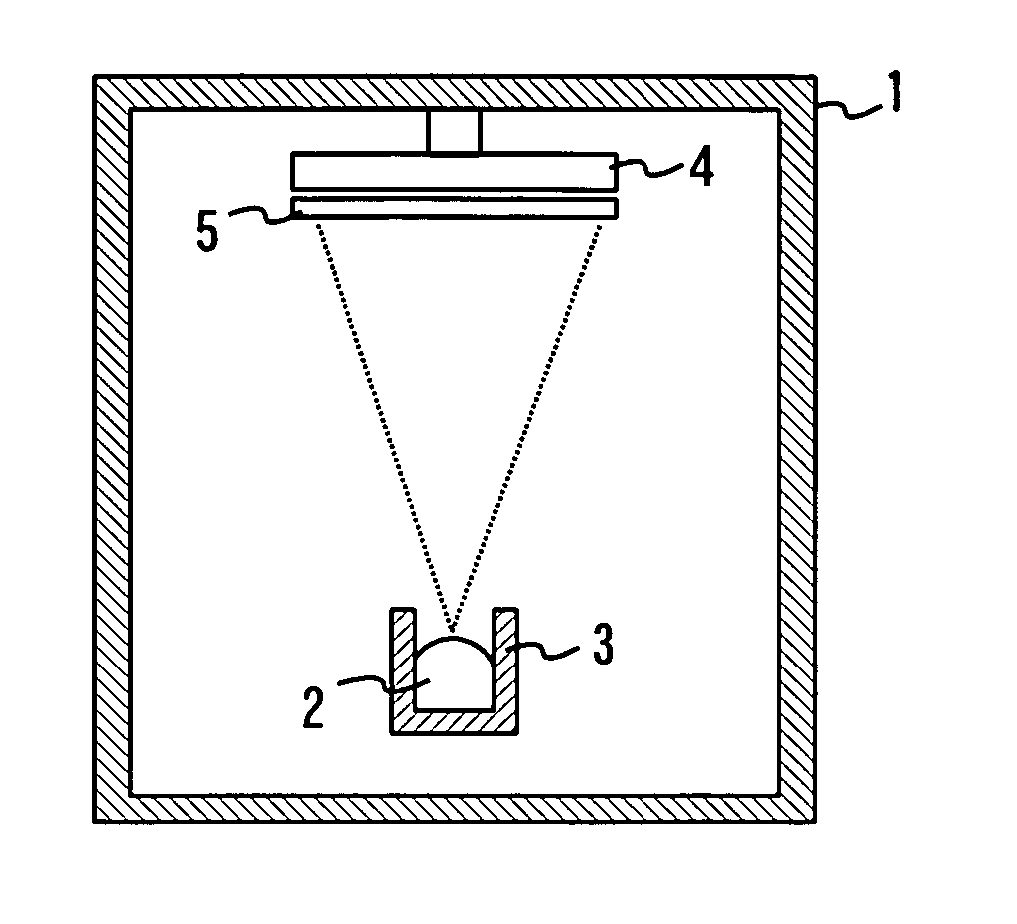

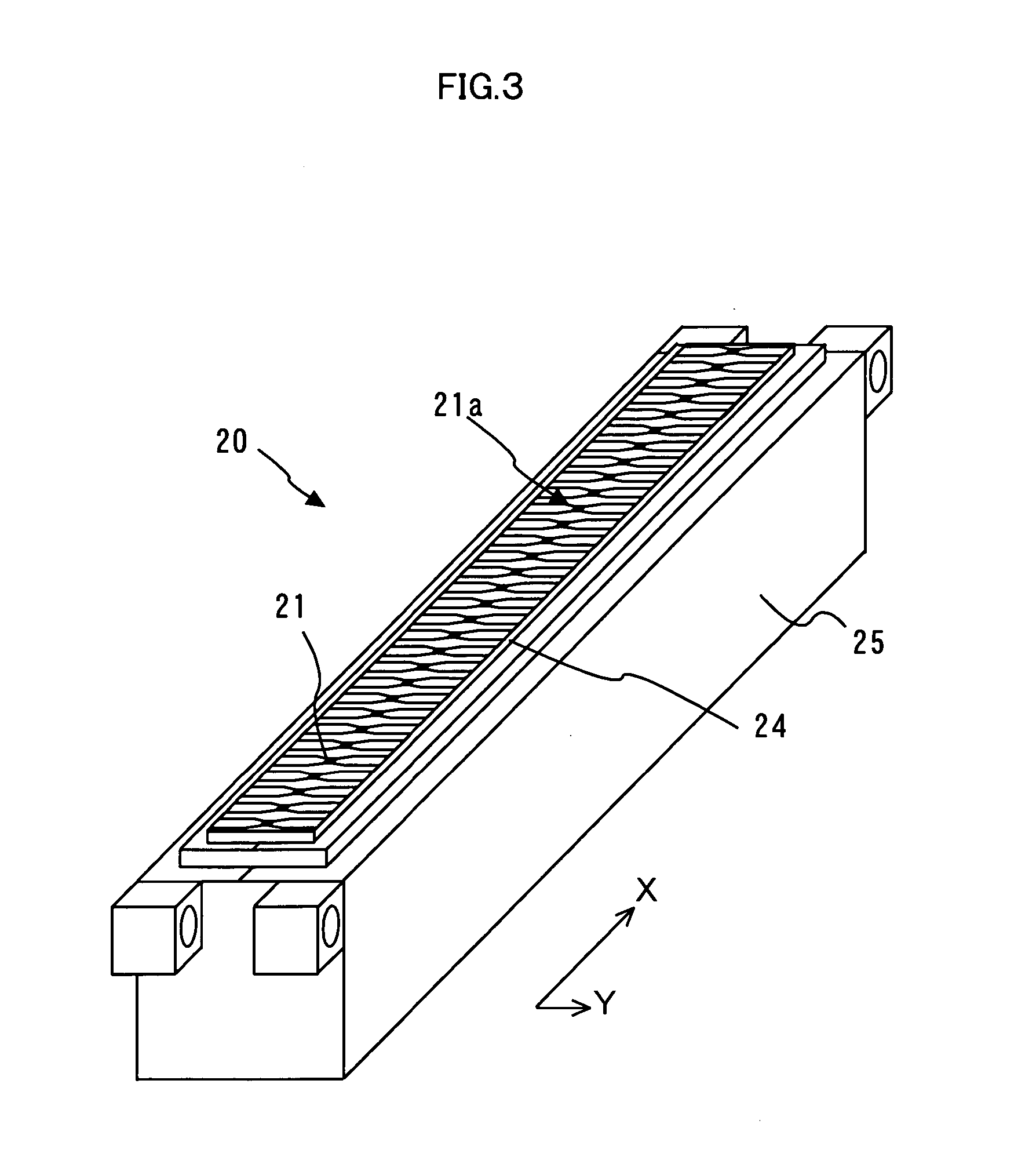

Evaporative deposition method, evaporative deposition head, method for forming pattern of deposition material, and evaporative deposition material disk

InactiveUS20050016463A1Improve material usage efficiencyEliminate the problemVacuum evaporation coatingSputtering coatingMetallurgyLaser beams

In evaporative deposition method, vaporized deposition material is supplied to a nozzle and is held by the nozzle because of temperature decrease thereof. Then, the deposition material is vaporized by heating the nozzle, thereby forming a thin film of the material on a substrate. A evaporative deposition apparatus includes a nozzle for holding deposition material. The apparatus also includes a temperature adjuster for heating and cooling the nozzle and a supplier, communicating with the nozzle, for supplying the vaporized deposition material to the nozzle. A method for forming a pattern of deposition material includes: preparing an evaporative deposition-material plate including a thin film of deposition material formed on one principal surface of a light-transmitting plate; moving the evaporative deposition-material plate within a plane parallel to a substrate; and irradiating the evaporative deposition-material plate with a laser beam incident on the other principal surface of the plate.

Owner:PIONEER CORP

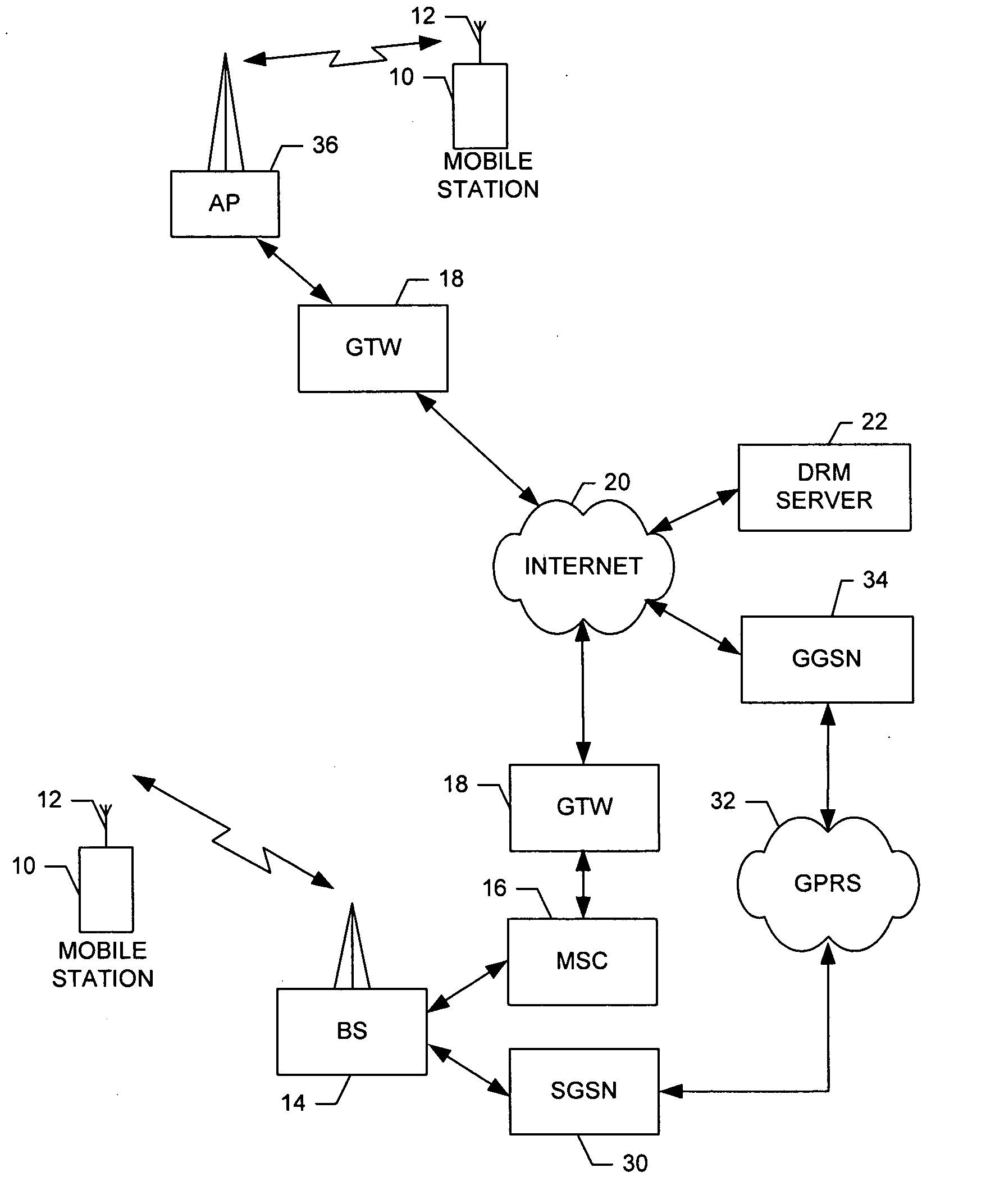

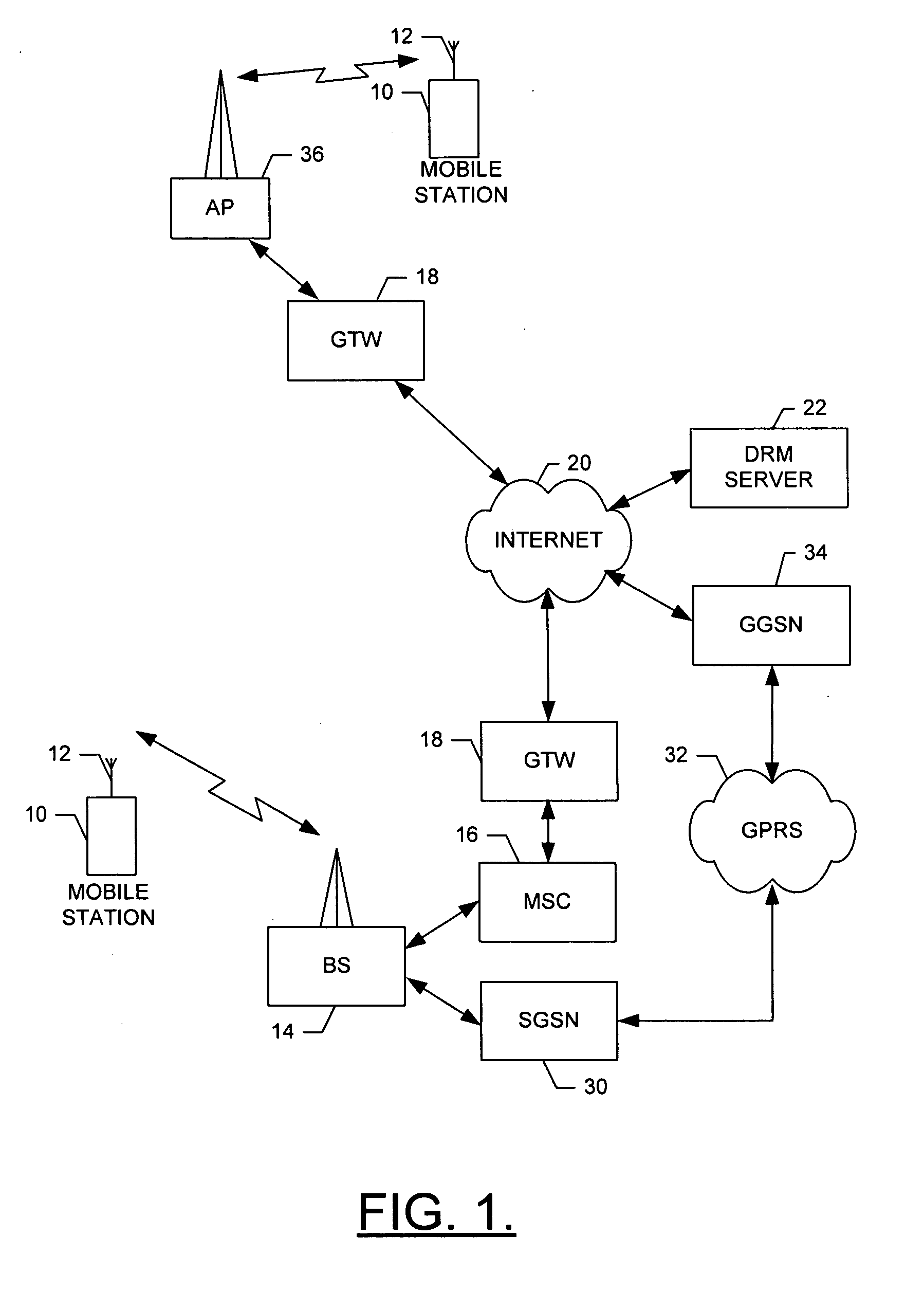

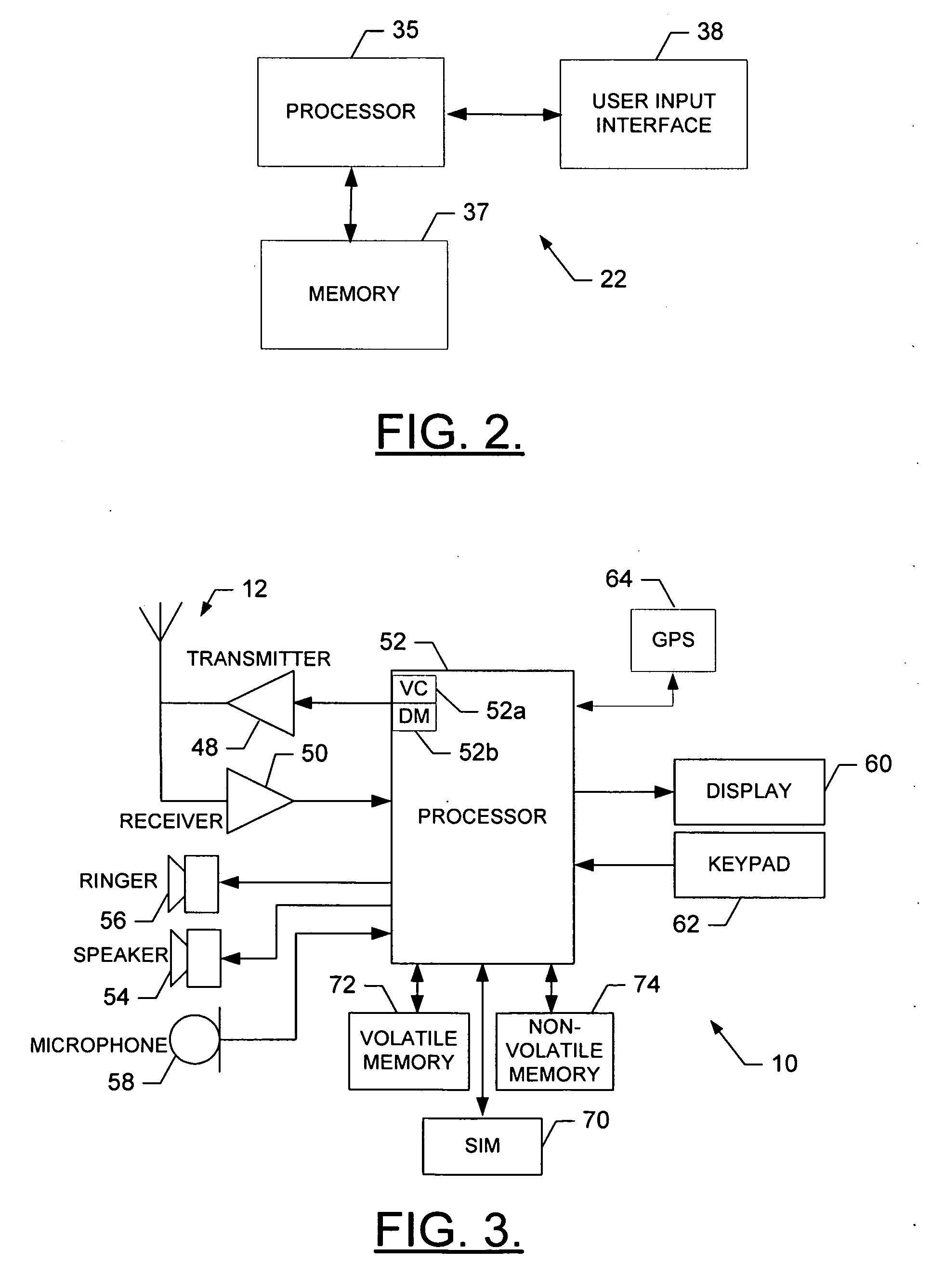

Apparatus, network entity and associated methods and computer program products for selectively enabling features subject to digital rights management

InactiveUS20080005806A1Increase equipment costDigital data processing detailsAnalogue secracy/subscription systemsRights managementDigital rights management

An apparatus, network entity, methods and computer program products are provided for selectively enabling one or more features subject to digital rights management (DRM) based upon communication between a mobile station or other end user apparatus and a network entity. By permitting selective enablement, end users need not pay for features that are not employed. However, a manufacturer can incorporate the same plurality of features into each apparatus so as to thereby effectively have a universal model of the apparatus which may be customized by the user with only selected features enabled with the others remaining disabled.

Owner:NOKIA CORP

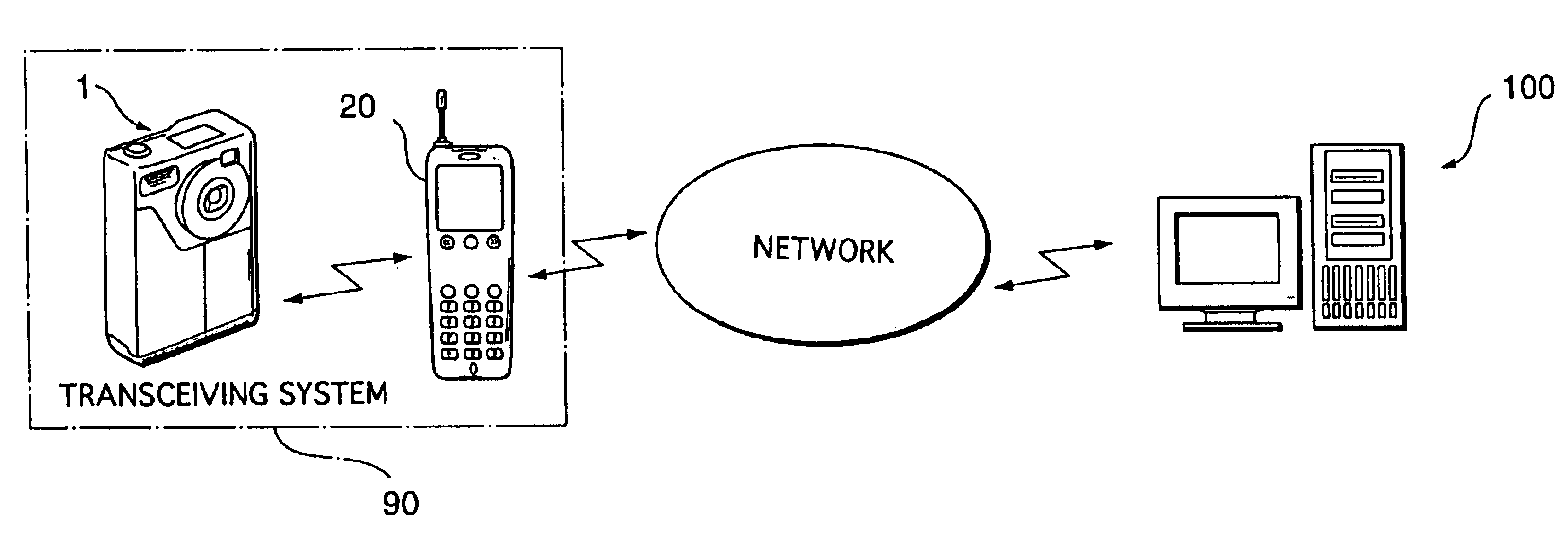

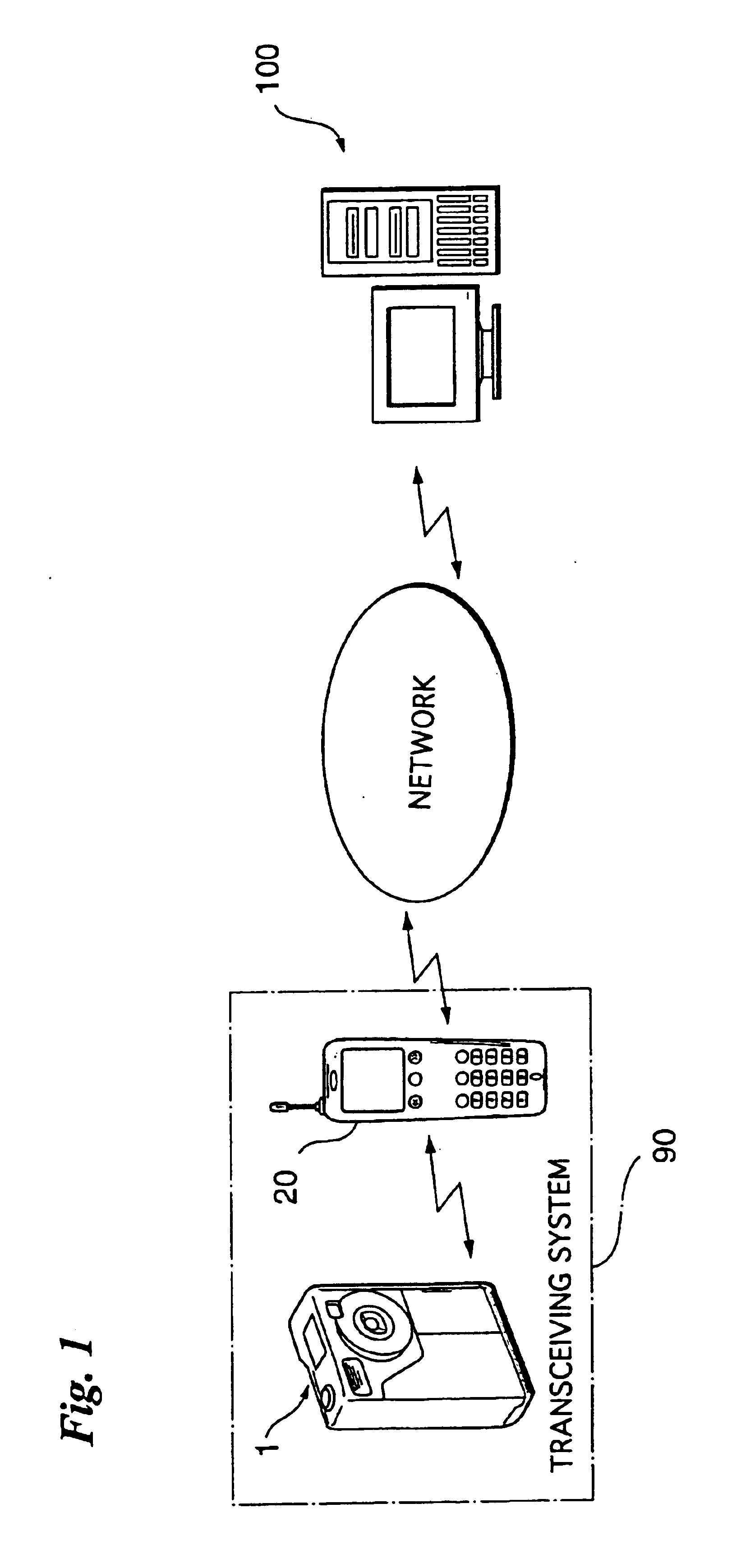

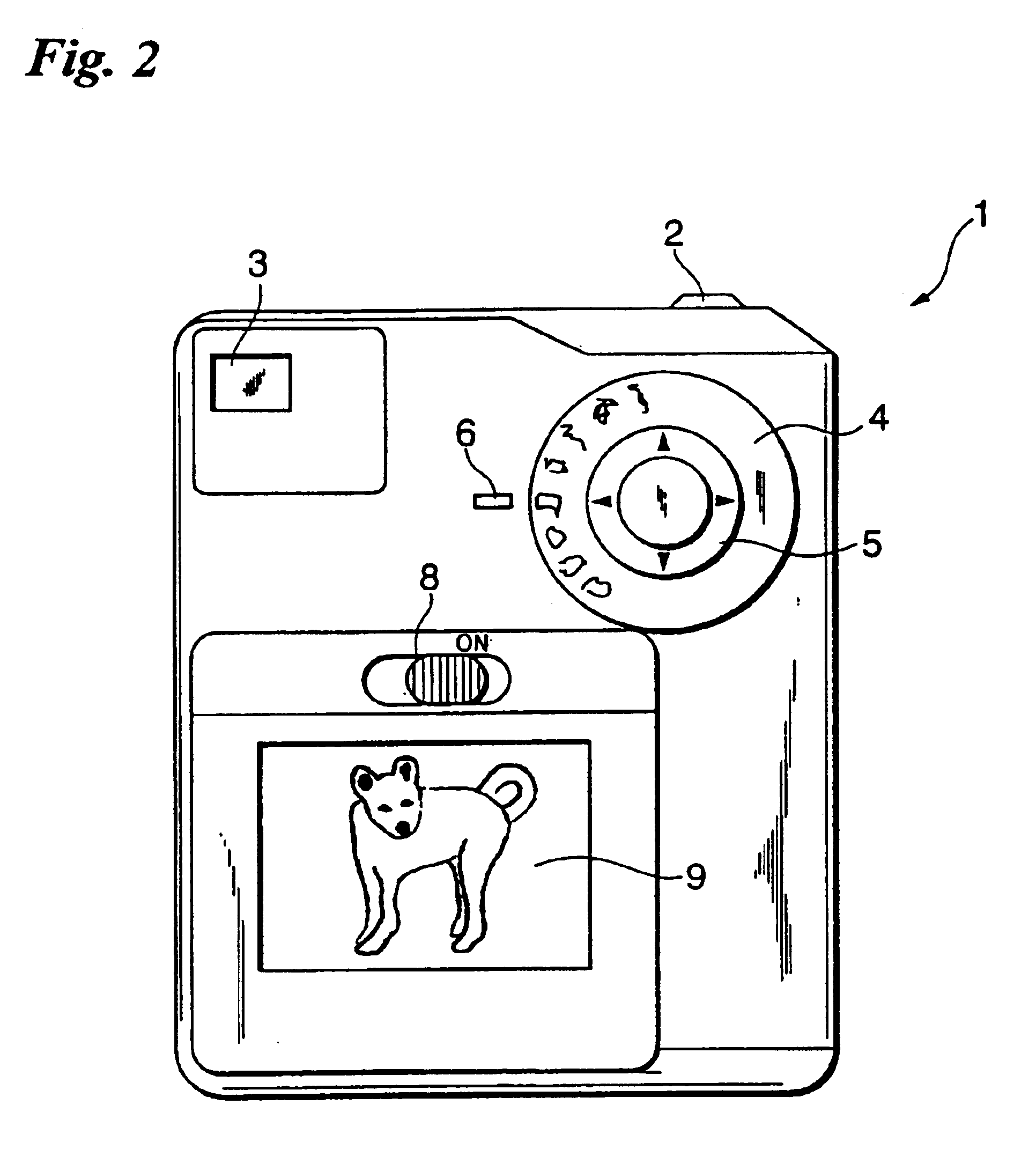

Data communication system

ActiveUS6906818B1Increase equipment costIncrease blockingTelevision system detailsDigital computer detailsComputer graphics (images)Mobile phone

A data communication system is so adapted that even if E-mail received by a mobile telephone has an image file attached thereto, the image represented by the image file can be displayed. An E-mail file is received by a mobile telephone and text represented by text data contained in the file is displayed on the display screen of the mobile telephone. When a received E-mail file has an image file attachment, the portable telephone interrogates a digital still camera as to whether the camera is capable of displaying the image contained in this image file. When the camera is capable of displaying the image, the image file is transmitted to the camera. The image represented by the image file is then displayed on the display screen of the camera.

Owner:FUJIFILM CORP

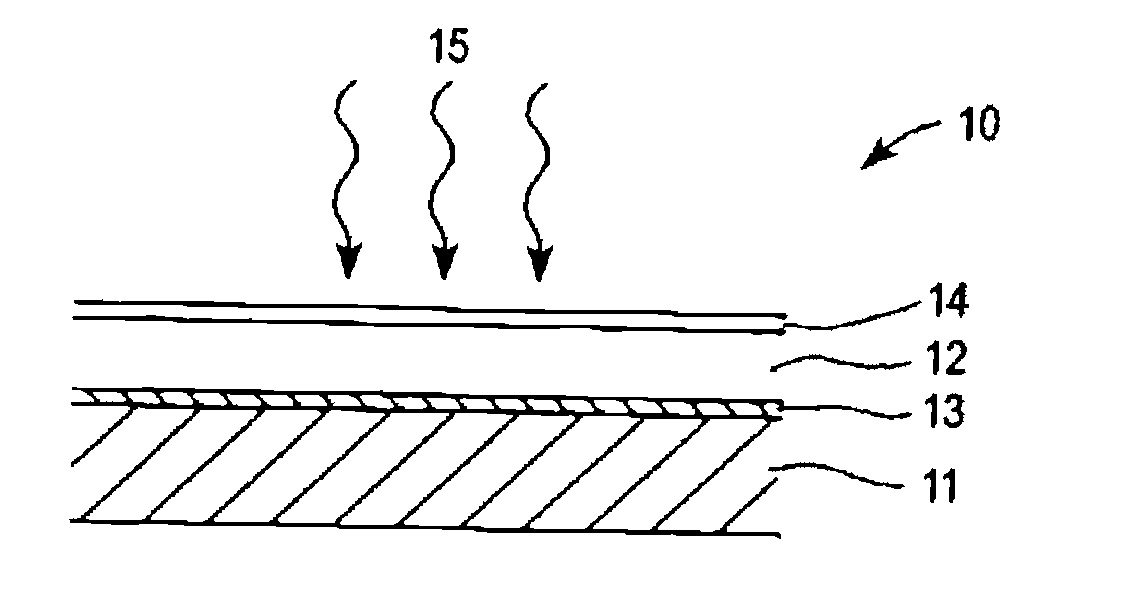

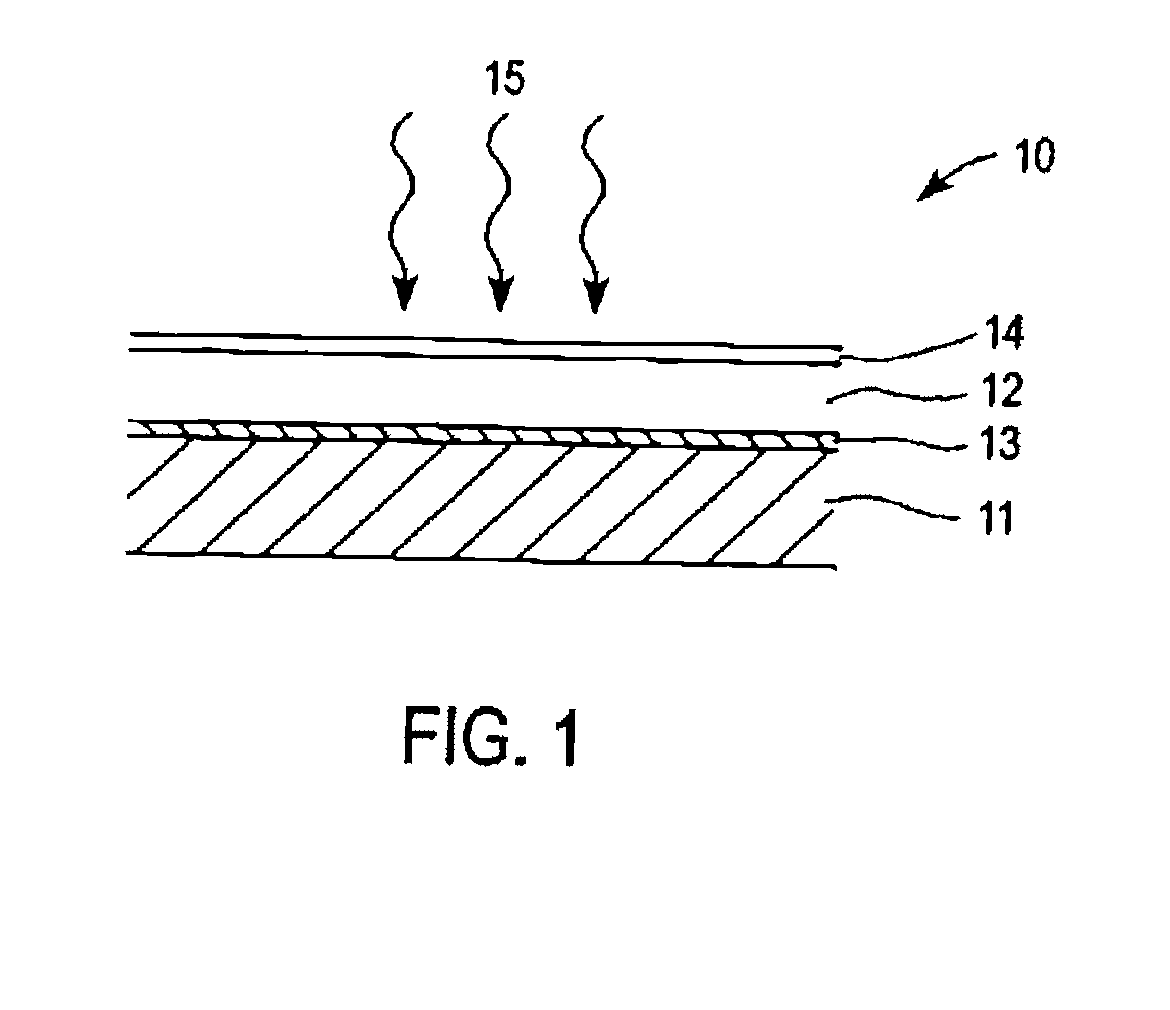

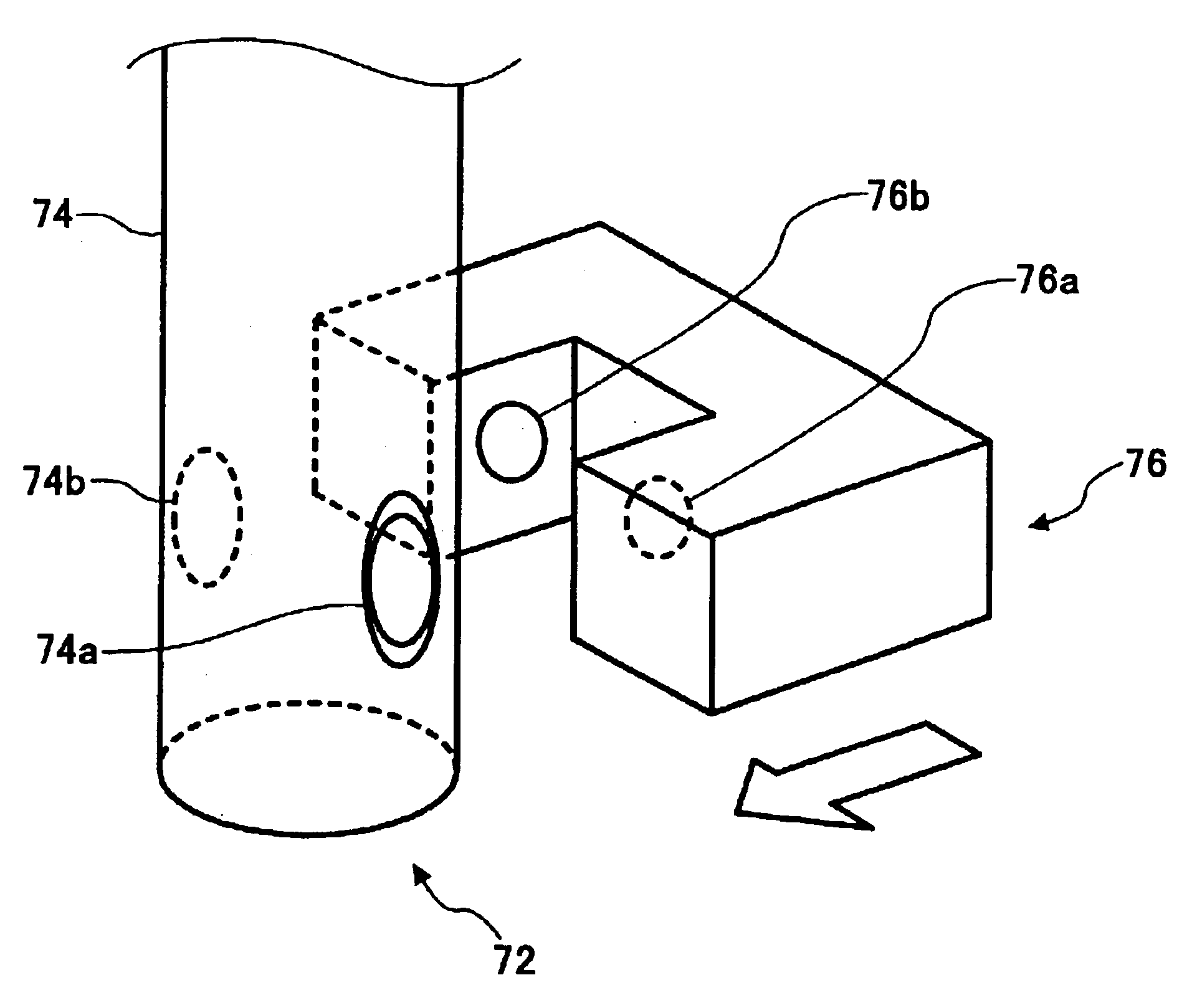

Technique for doping compound layers used in solar cell fabrication

InactiveUS20080023336A1Low material utilizationIncrease equipment costPhotovoltaic energy generationSemiconductor devicesDopantSolar cell

The present invention includes methods and apparatus therefrom for preparing thin films of doped semiconductors for radiation detector and photovoltaic applications, and particularly method and apparatus that increase dopants of alkali metals in Group IBIIIAVIA layers. In a particular aspect, the present invention includes a method of preparing a doped Group IBIIIAVIA absorber layer for a solar cell, with the absorber layer being formed by reaction, with a Group VIA material, of a metallic stack with a plurality of layers, in which each layer contains a concentration of an alkali metal selected from the group of Na, K and Li.

Owner:SOLOPOWER

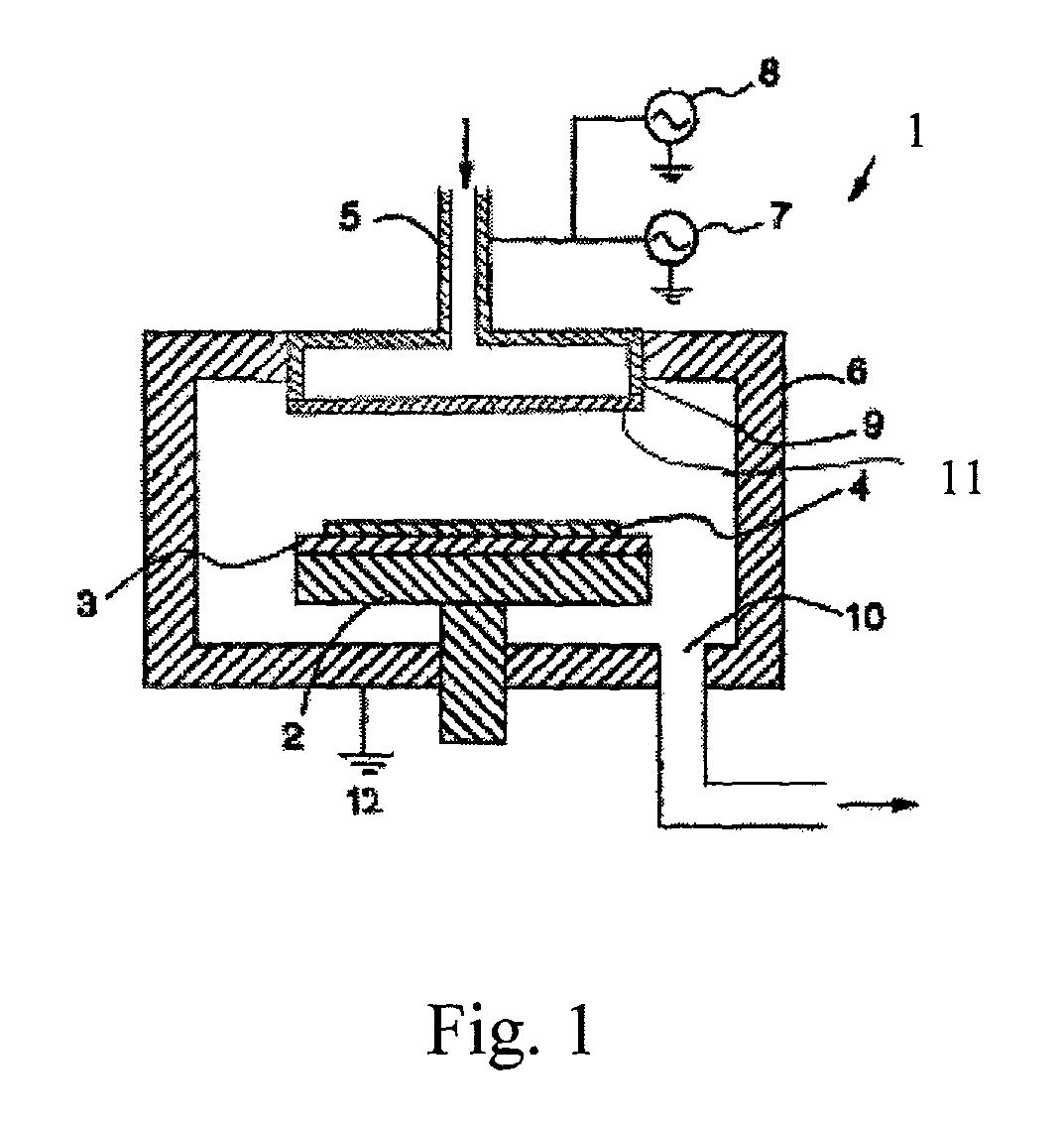

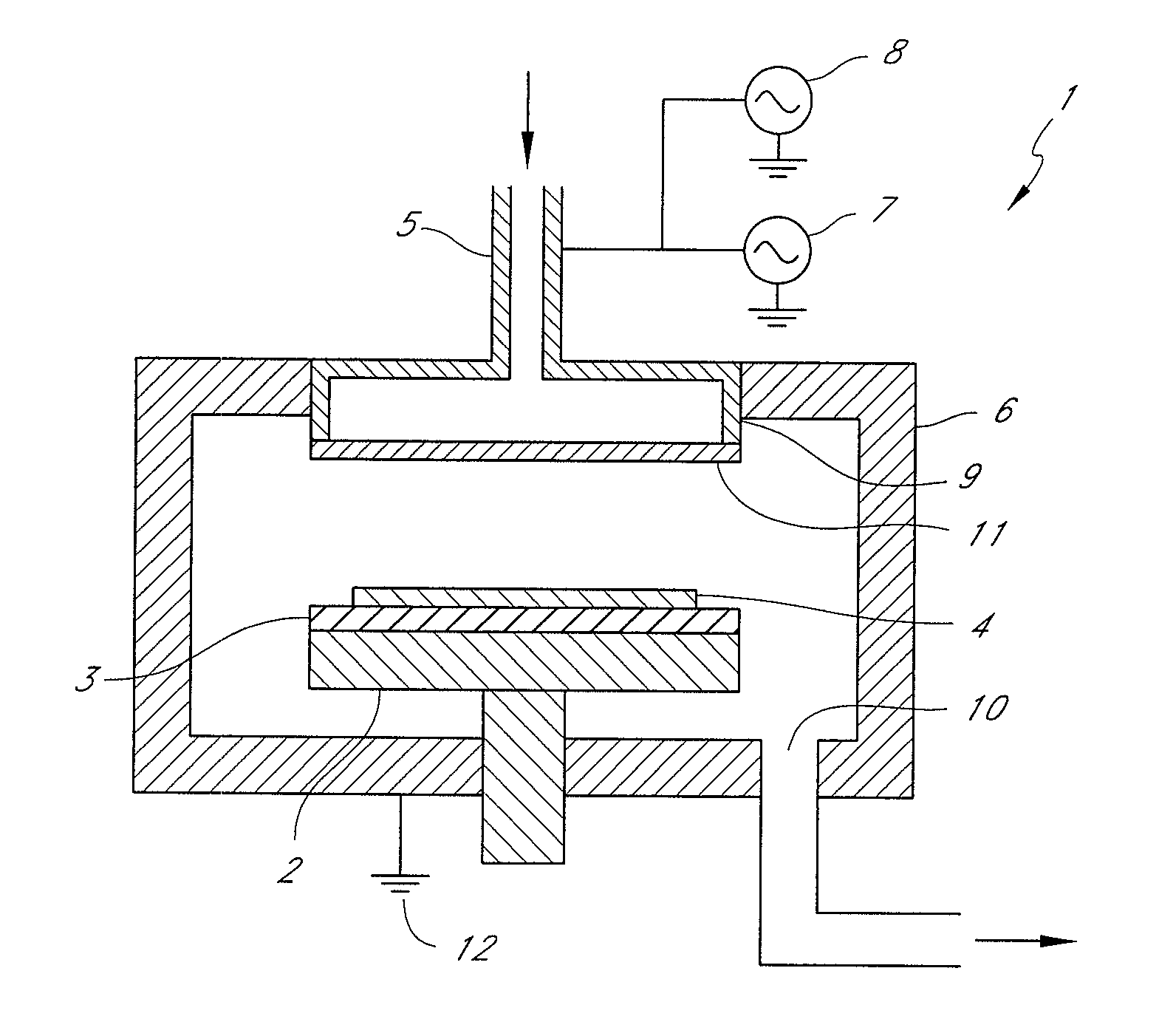

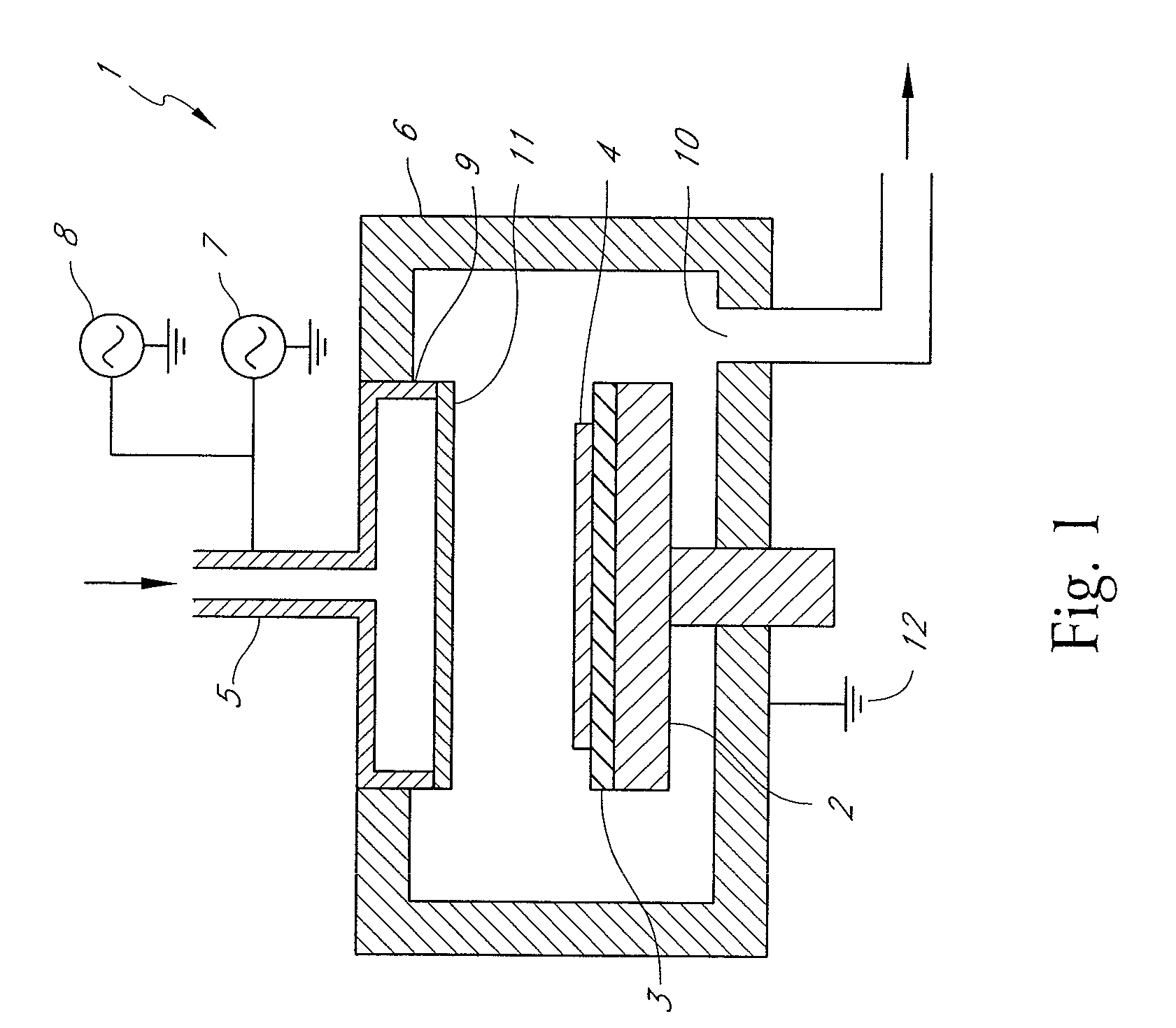

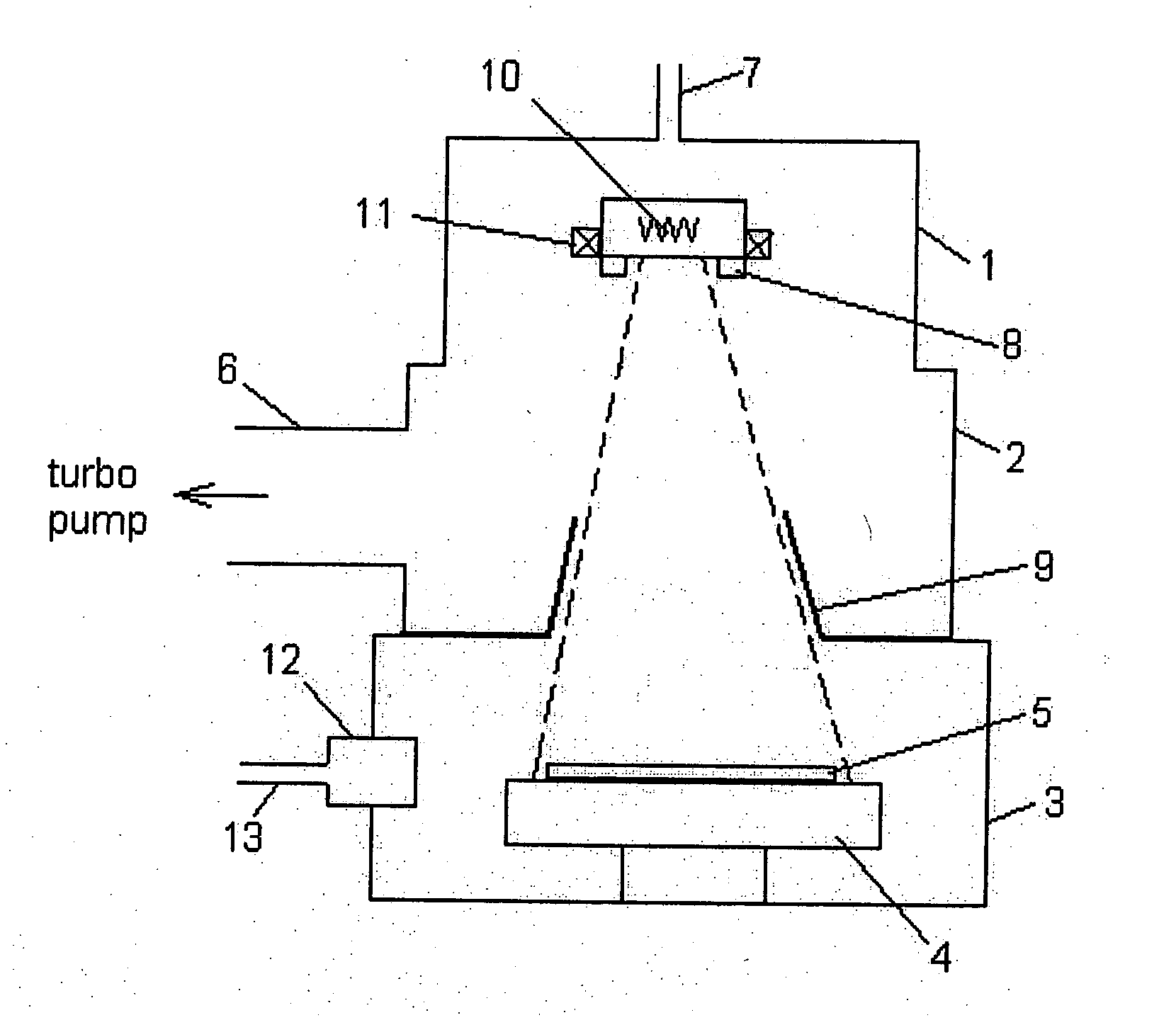

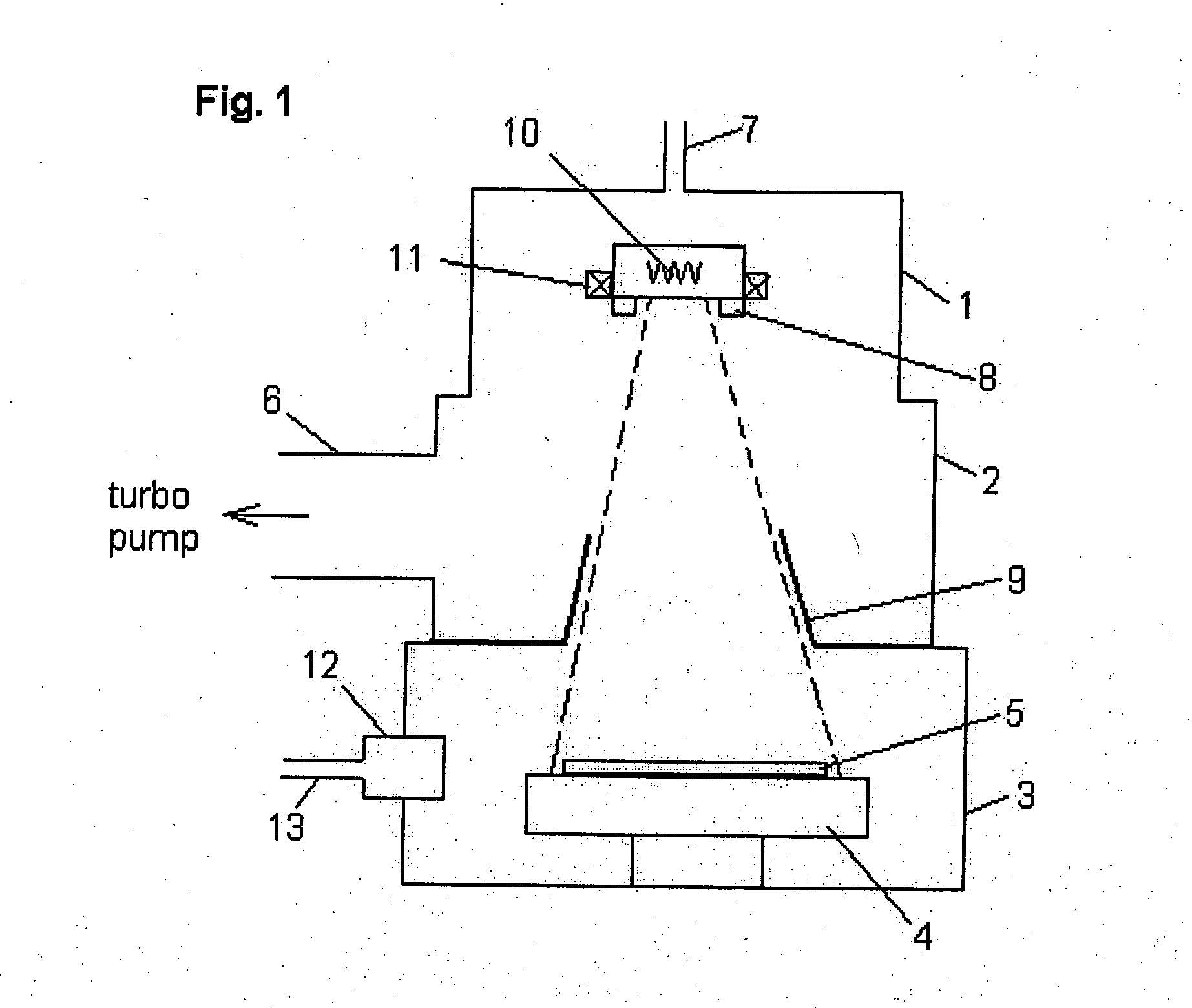

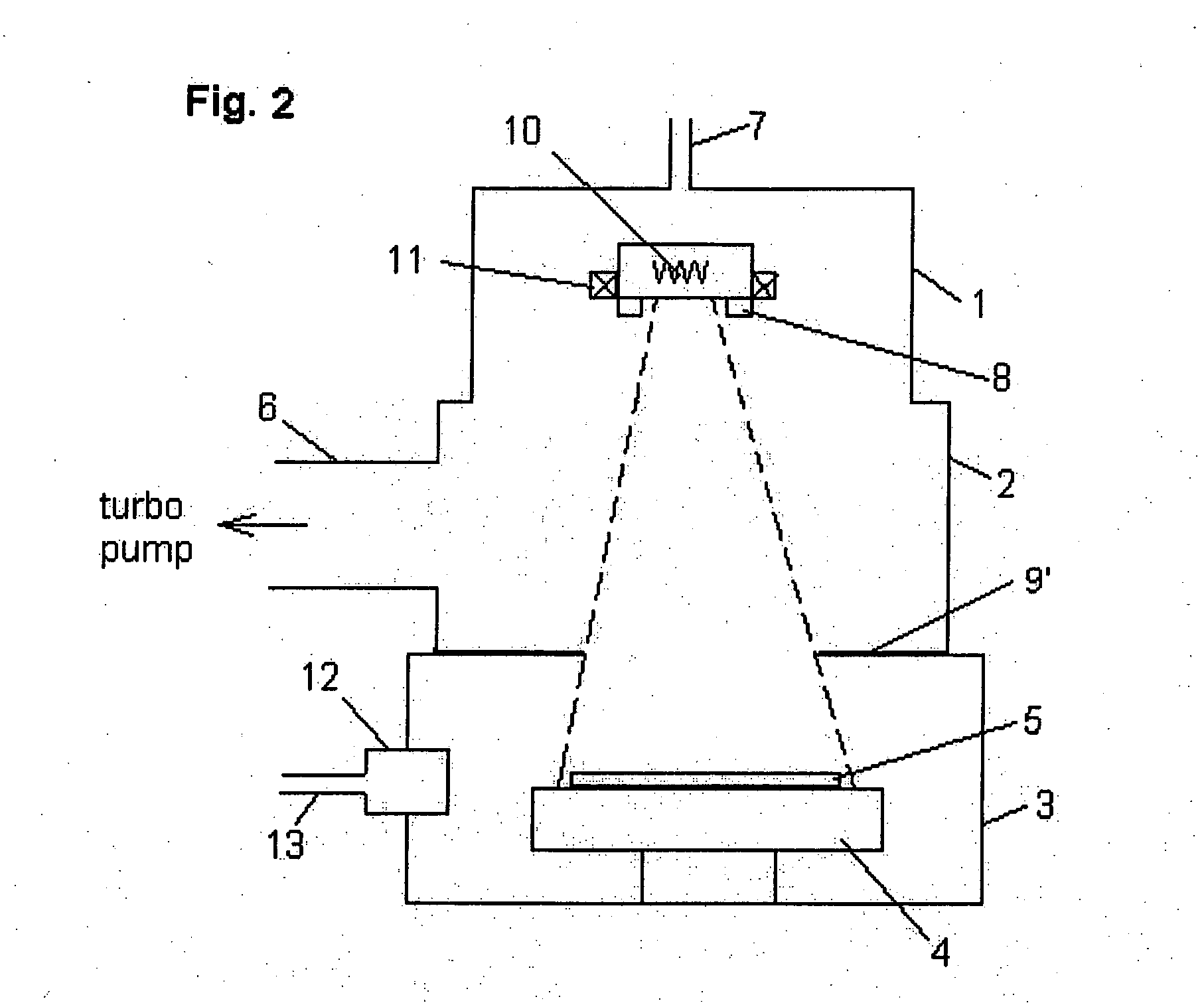

Method and apparatus for forming silicon-containing insulation film having low dielectric constant

ActiveUS20050034667A1Low dielectric constantHigh mechanical strengthElectric discharge tubesPretreated surfacesPhysical chemistryDielectric permittivity

A silicon-containing insulation film is formed on a substrate by plasma reaction using a reaction gas including (i) a source gas comprising a silicon-containing hydrocarbon compound containing multiple cross-linkable groups, (ii) a cross-linking gas, and (iii) an inert gas, into a reaction chamber where a substrate is placed. The insulation film is then exposed to electron beam radiation, thereby increasing mechanical strength of the film without substantial alternation of its dielectric constant.

Owner:ASM JAPAN

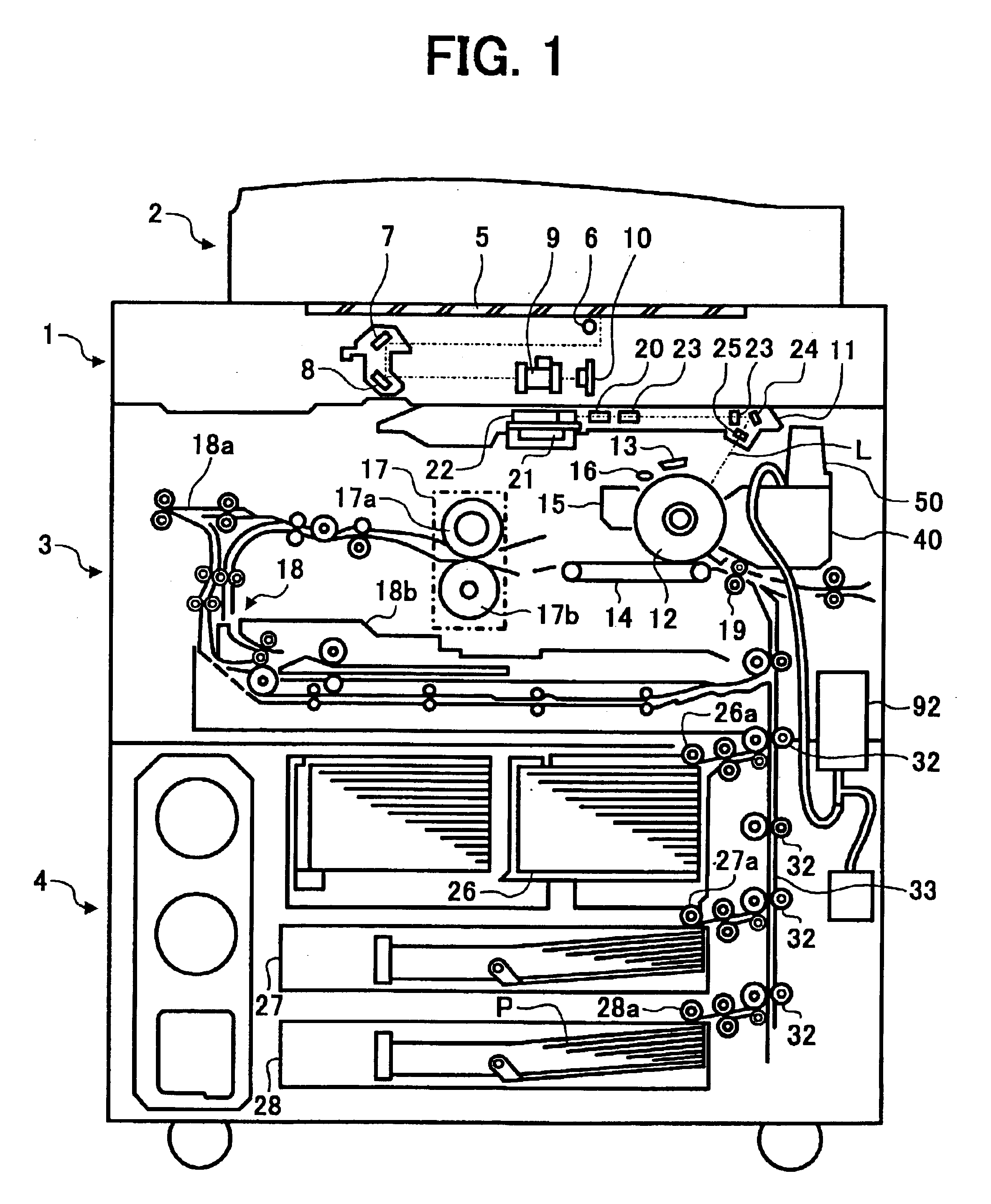

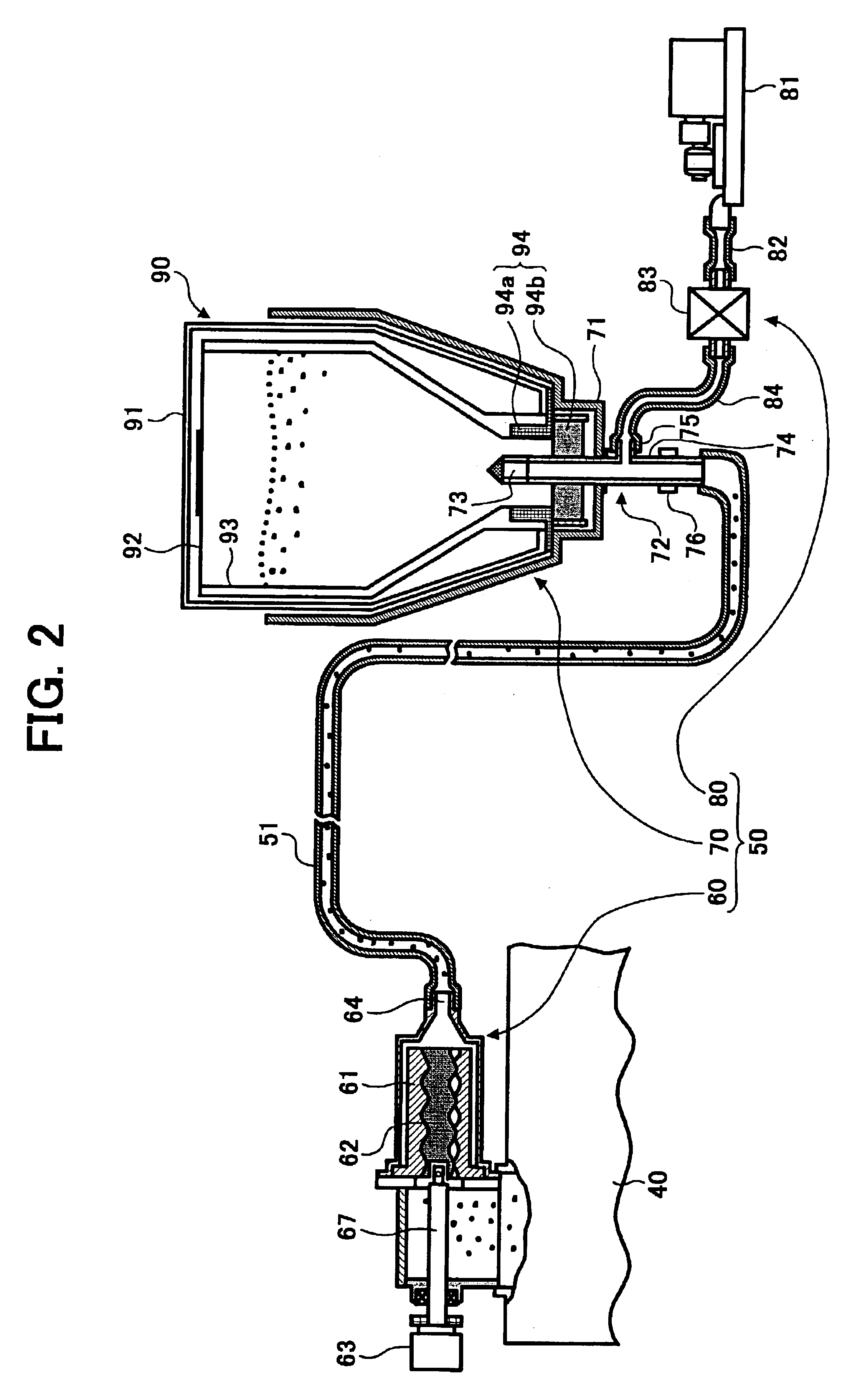

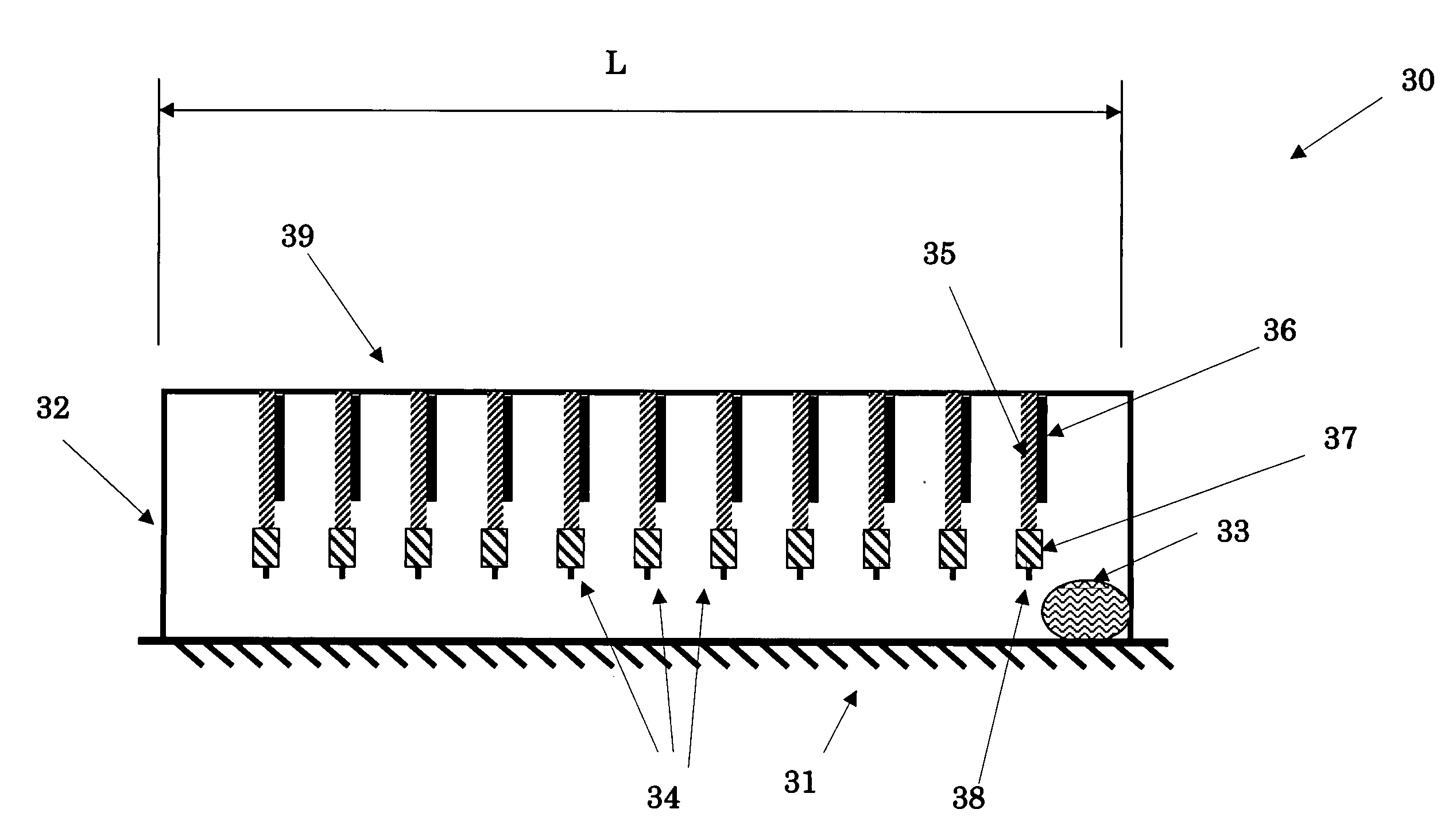

Toner conveying device and image forming apparatus including the toner conveying device

InactiveUS6917779B2Increase equipment costThe location is limitedElectrographic process apparatusEngineeringElectrical and Electronics engineering

A toner conveying device includes a toner container that contains toner, a toner discharge urging device that urges the discharge of the toner from the toner container, a toner conveying mechanism that conveys the toner discharged from the toner container through a toner conveying path member, and a flow amount detecting device that detects the flow amount of the toner conveyed in the toner conveying path member.

Owner:RICOH KK

Electrical generators for low-frequency and time-varying rocking and rotary motion

ActiveUS20090315431A1Easy to operateMinimal servicePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringLow frequency

Owner:OMNITEK PARTNERS LLC

Method for determining deterioration of accumulator battery, method for measuring internal impedance of secondary battery, equipment for measuring internal impedance of secondary battery, equipment for determining deterioration of secondary battery, and power supply system

ActiveUS20070252601A1Complicated processIncrease equipment costMaterial analysis by electric/magnetic meansElectrical testingElectrical resistance and conductanceConversion factor

Owner:FURUKAWA ELECTRIC CO LTD

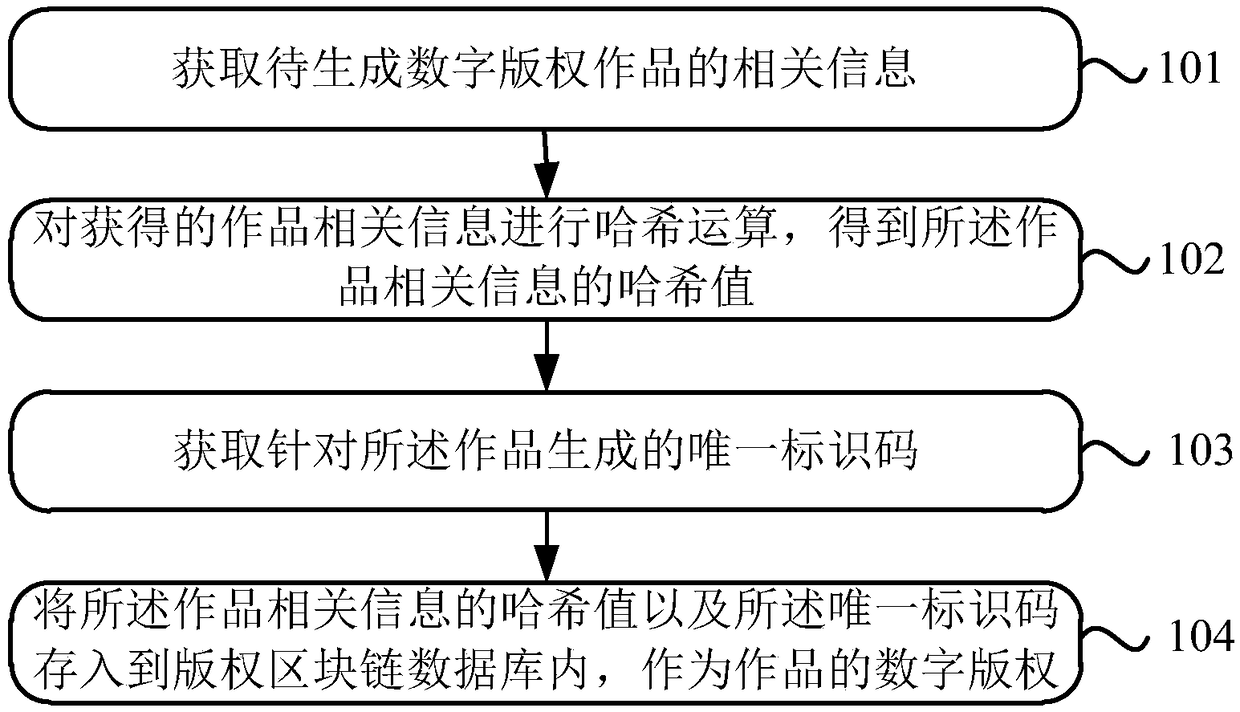

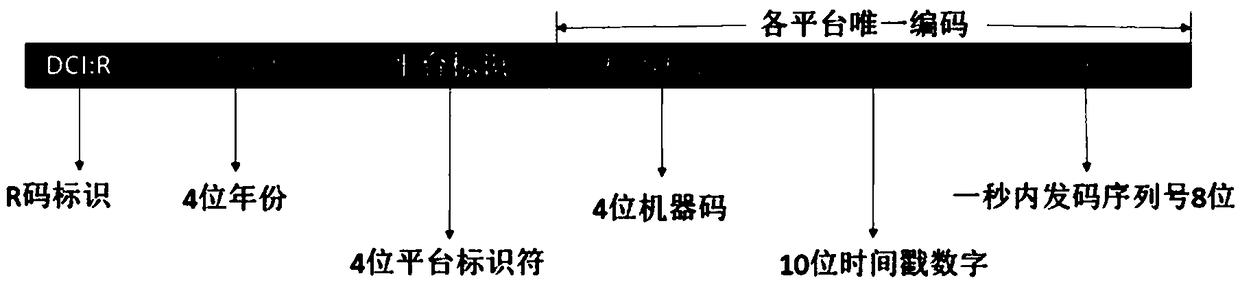

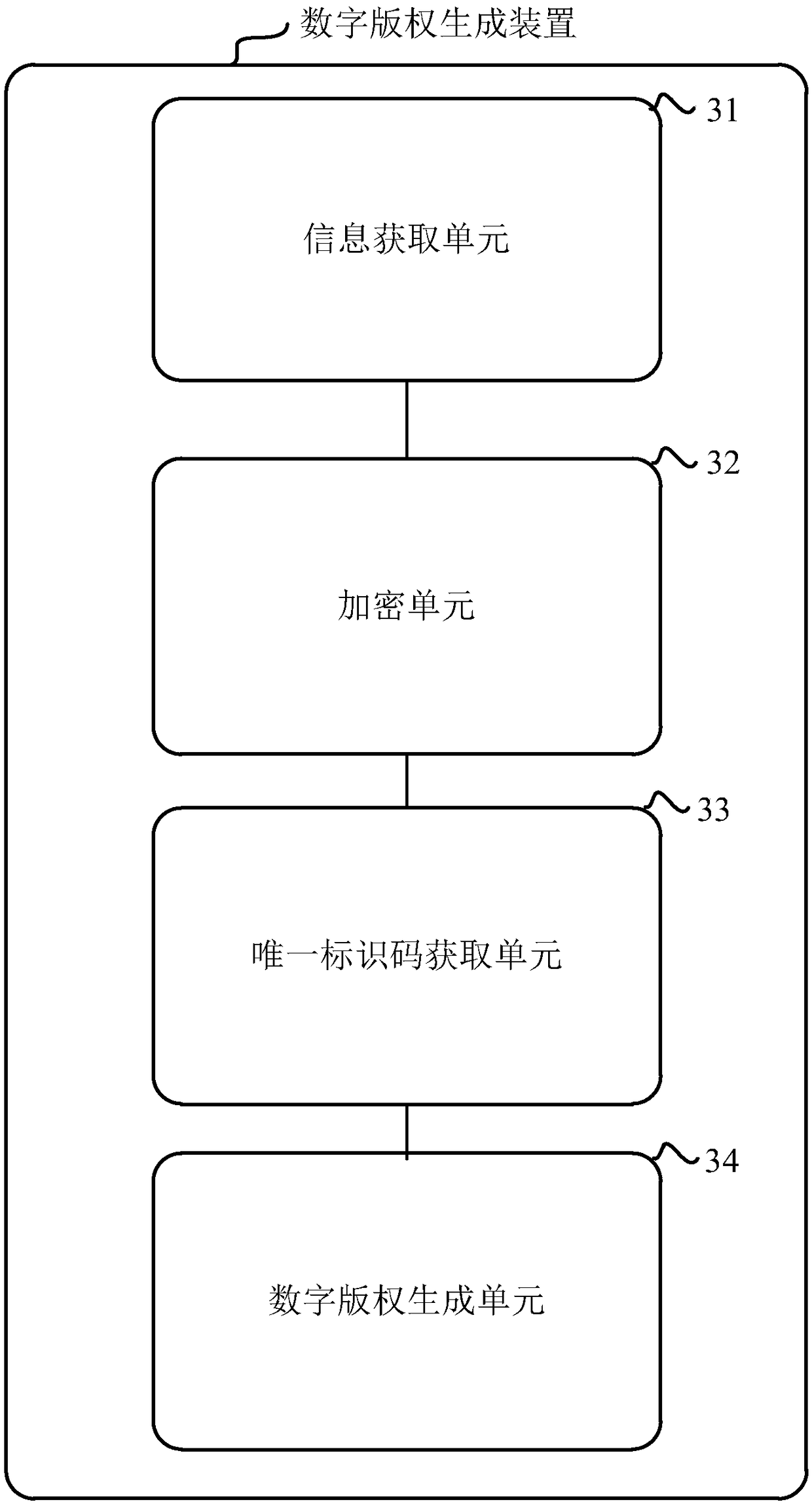

A method and apparatus for generating digital rights

InactiveCN109409030AAffect performanceIncrease equipment costProgram/content distribution protectionPlaintextRelevant information

A method for generating digital rights The invention is used for solving the problem that in the prior art, the plaintext information of a work is uploaded to a block chain for preservation so as to realize copyright storage of the work, thereby causing high construction cost of a digital copyright storage system on the one hand, and unfriendly uploading of the plaintext information on the other hand to paid works on the other hand. The method comprises the following steps: obtaining relevant information of the work, wherein, the work-related information includes author information and work information; performing hashing operation on the work-related information to obtain a hash value of the work-related information; acquiring a unique identification code generated for the work; the hashvalue of the work-related information and the unique identification code are uploaded to the digital rights server, so that the digital rights server stores the hash value in the copyright block chaindatabase as the digital rights of the work. The present application also discloses a digital copyright generating apparatus.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

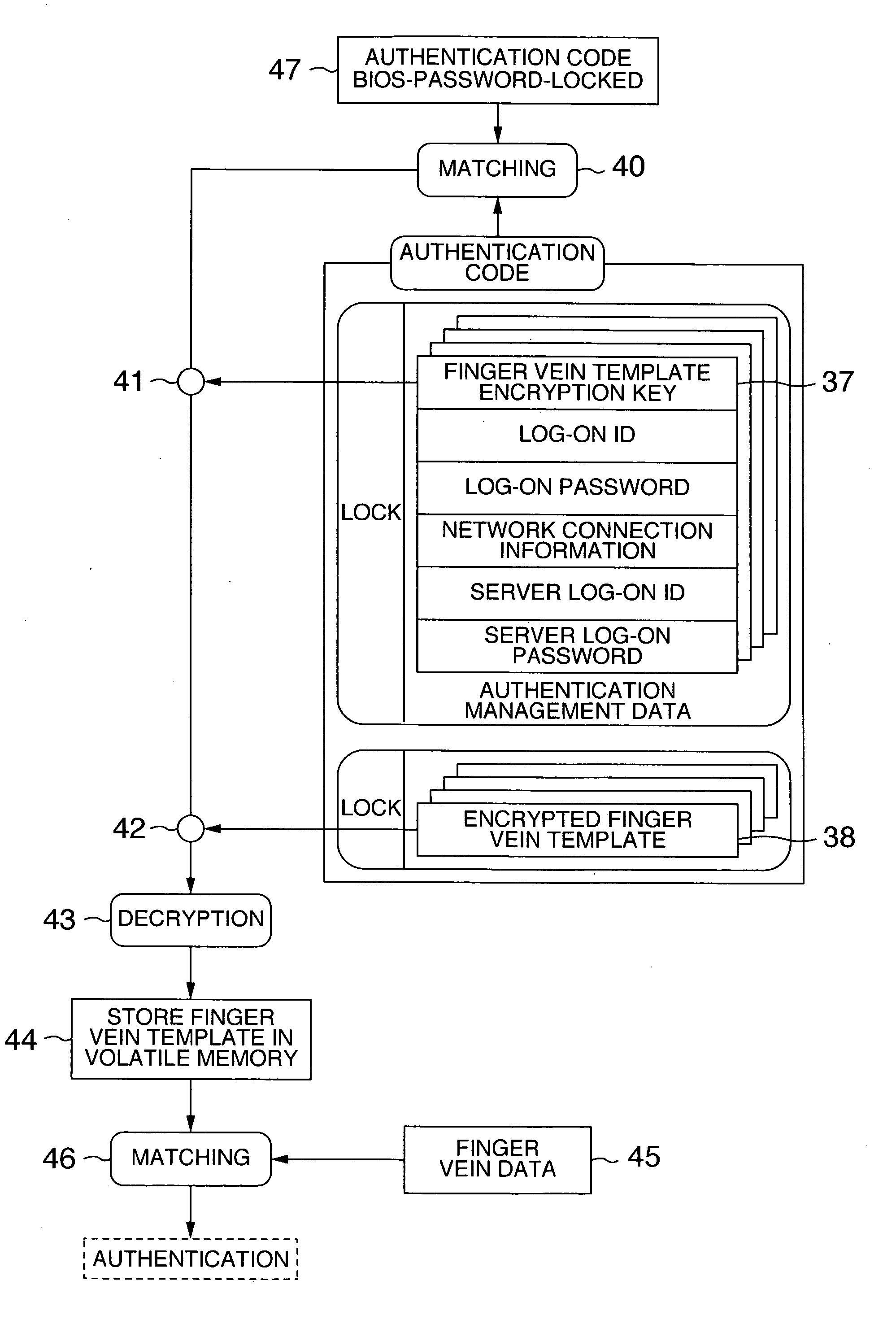

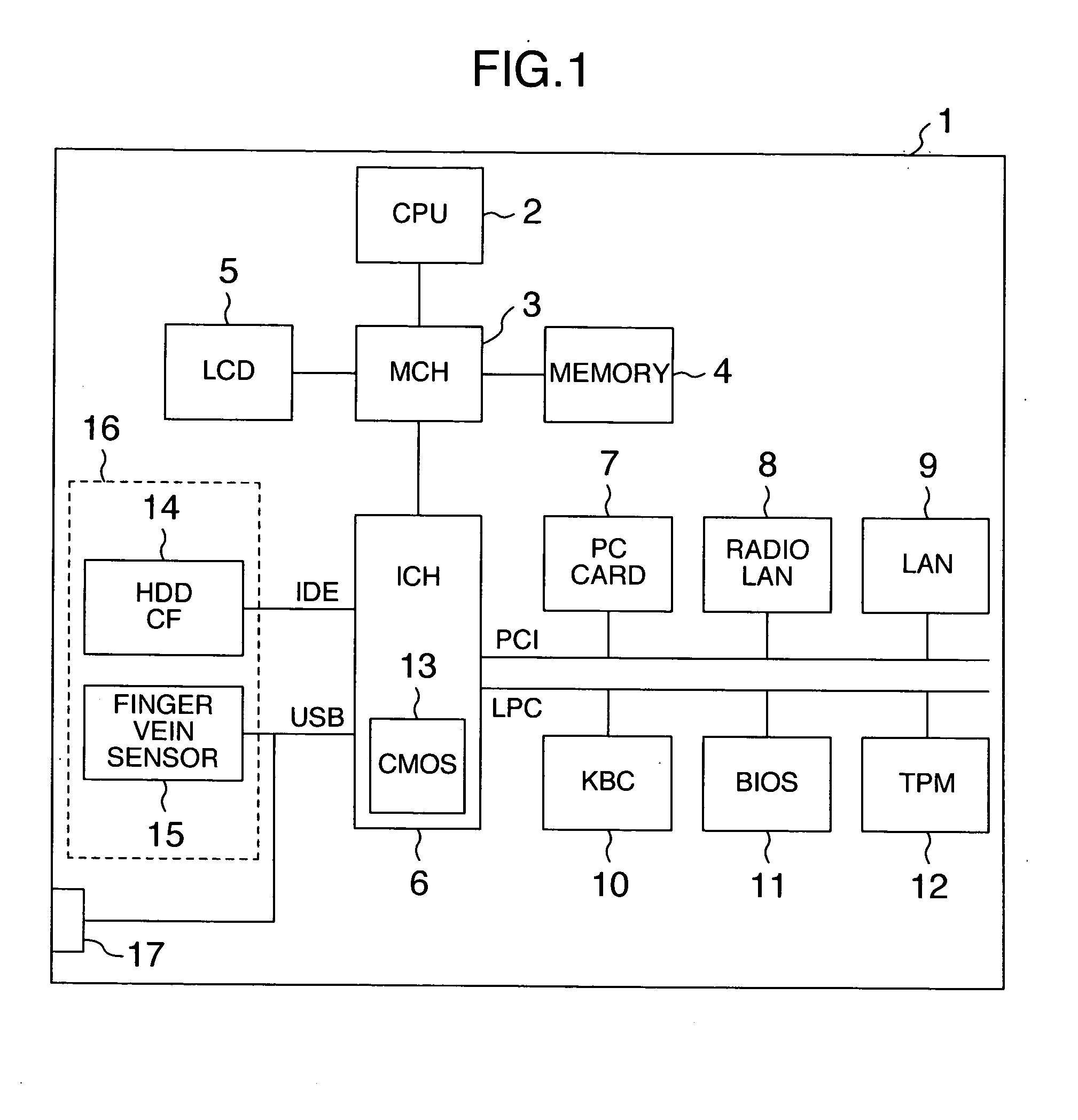

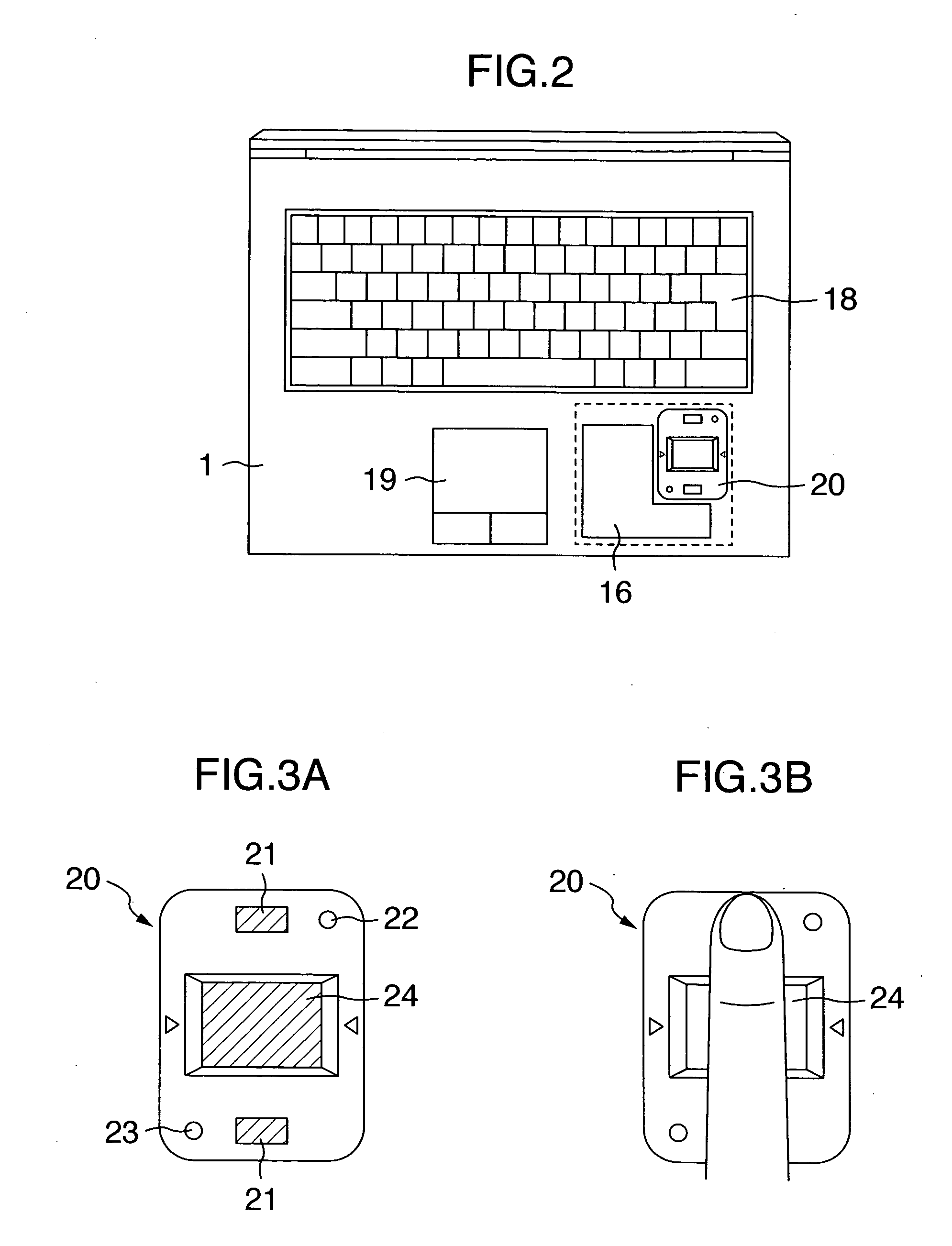

Information processing device and authentication method

InactiveUS20070177769A1Reduced portabilityImprove securityDigital data protectionDigital data authenticationComputer hardwareInformation processing

The present invention provides an information processing device includes: a biometrics device, an interface control unit for controlling the biometrics device, a first storage unit for concealing a user identifier and user authentication information, a second storage unit for storing a program executed by the information processing device, and a processor for releasing the concealment of the first storage unit based on the program stored in the second storage unit and acquiring biometrics information inputted from the biometrics device, so as to compare it with the user authentication information. Thus, it is possible to prevent lowering of user-friendliness and increase of the cost when using an external authentication device in a laptop type personal computer and to provide an authentication control configuration and an authentication procedure optimal for an information processing device such as a laptop type personal computer.

Owner:HITACHI LTD

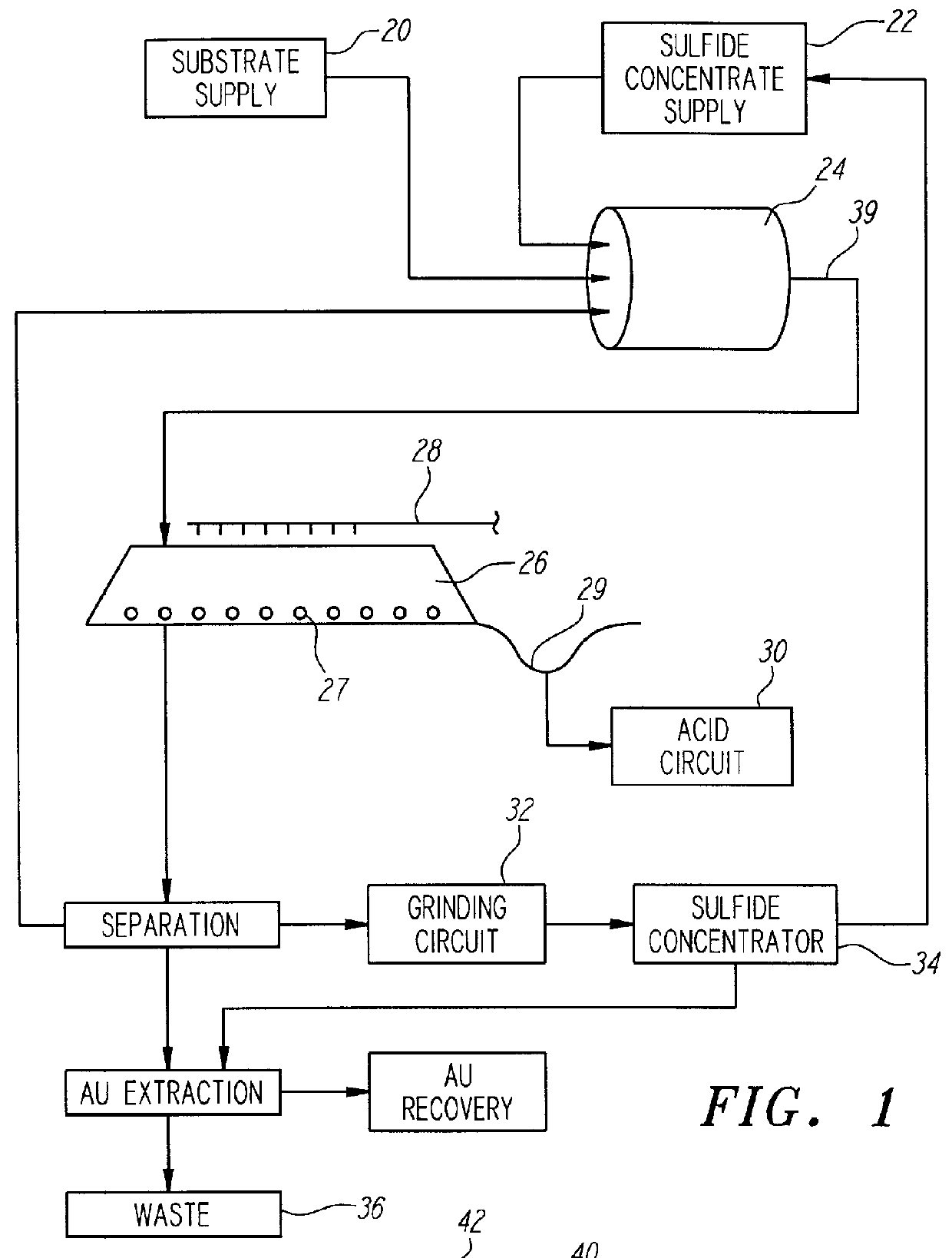

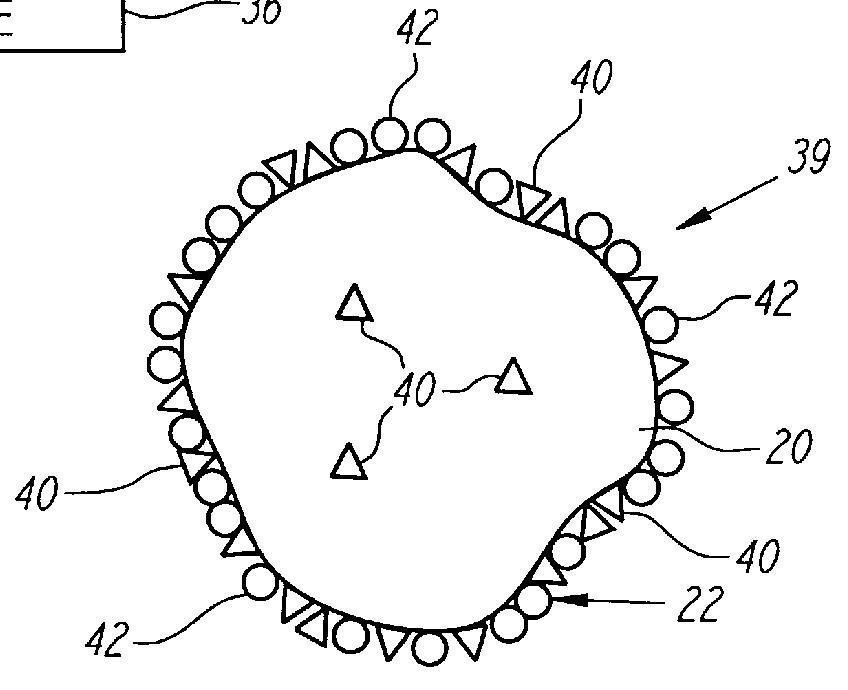

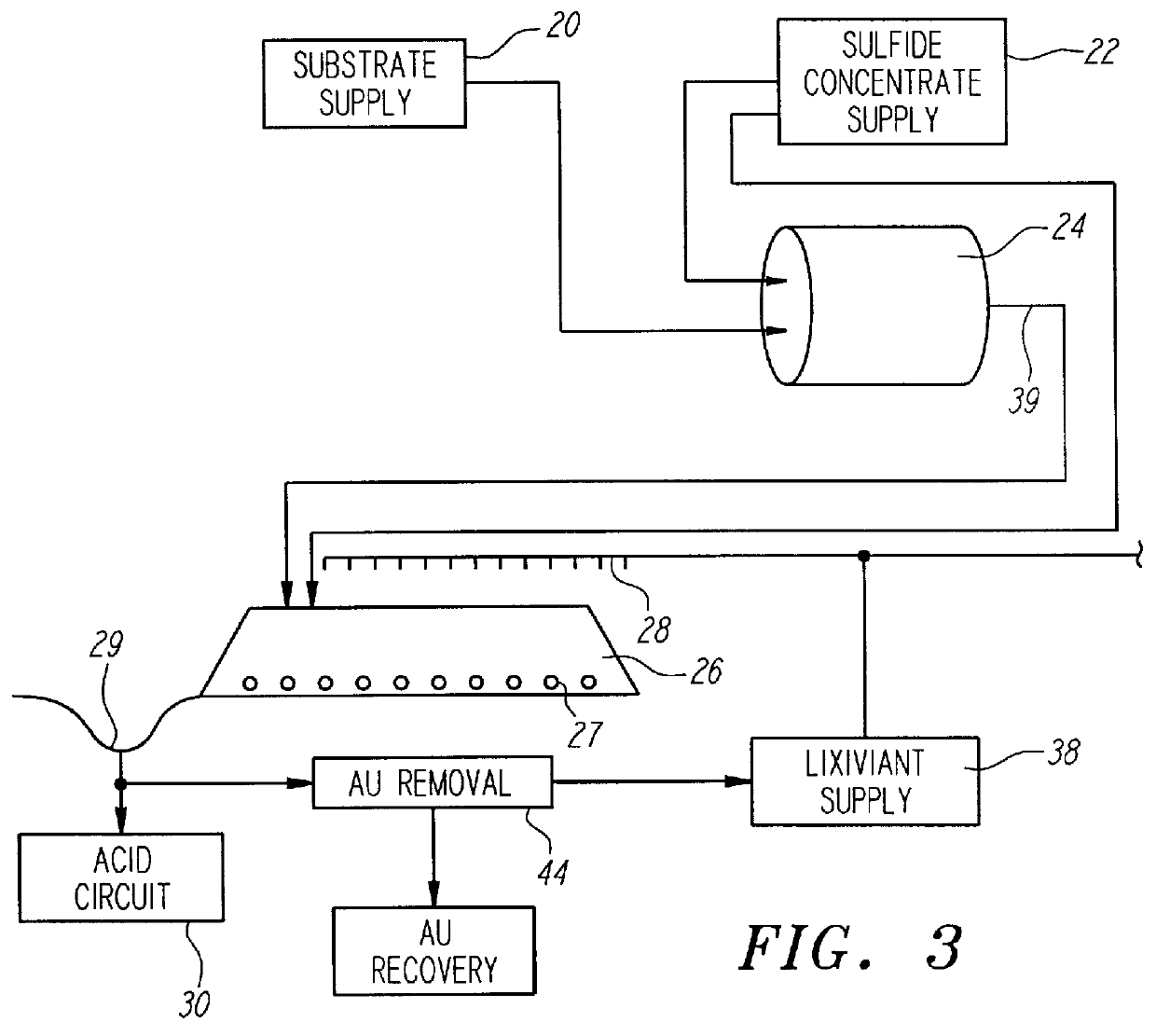

Nonstirred bioreactor for processing refractory sulfide concentrates and method for operating same

InactiveUS6083730AReduced pHIncrease equipment costSolvent extractionContaminated soil reclamationSulfide mineralsMetallic sulfide

A method of biooxidizing sulfide minerals in a nonstirred bioreactor is provided. According to the disclosed method, a concentrate of sulfide minerals is coated onto a substrate, such as coarse ore particles, lava rock, gravel or rock containing mineral carbonate as a source of CO2 for the biooxidizing bacteria. After the sulfide minerals are coated onto the substrate, a heap is formed with the coated substrates or the coated substrates are placed within a tank. The sulfide minerals are then biooxidized to liberate the metal value of interest. Depending on the particular ore deposit being mined, the sulfide mineral concentrates used in the process may comprise sulfide concentrates from precious metal bearing refractory sulfide ores or they may comprise sulfide concentrates from metal sulfide type ores, such as chalcopyrite, millerite or sphalorite. The distinction being that in the former, the metal of interest is a precious metal occluded within the sulfide minerals, whereas in the latter, the metal to be recovered is copper, nickel or zinc and is present as a metal sulfide in the sulfide concentrate.

Owner:GEOSYNFUELS LLC (US)

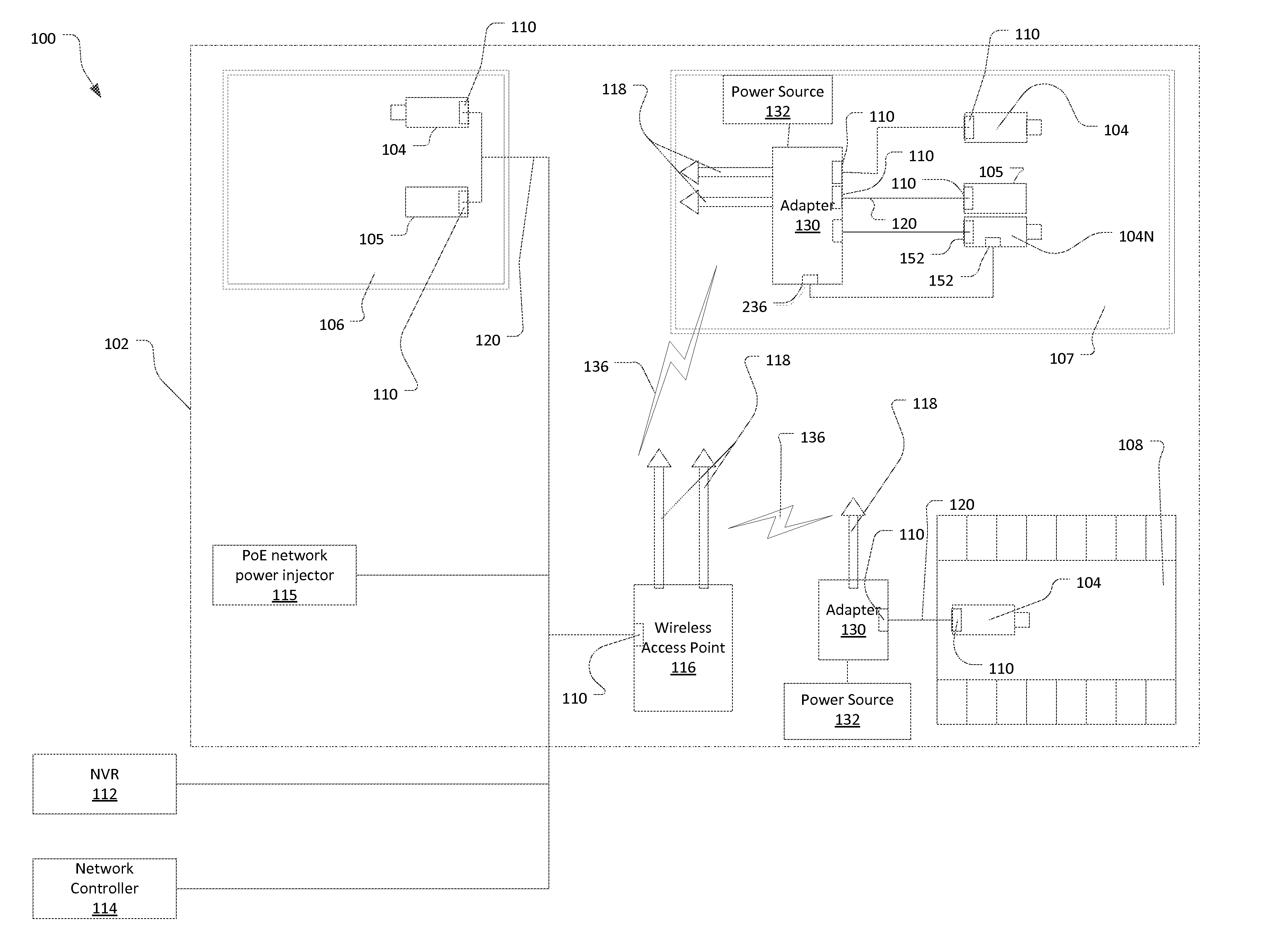

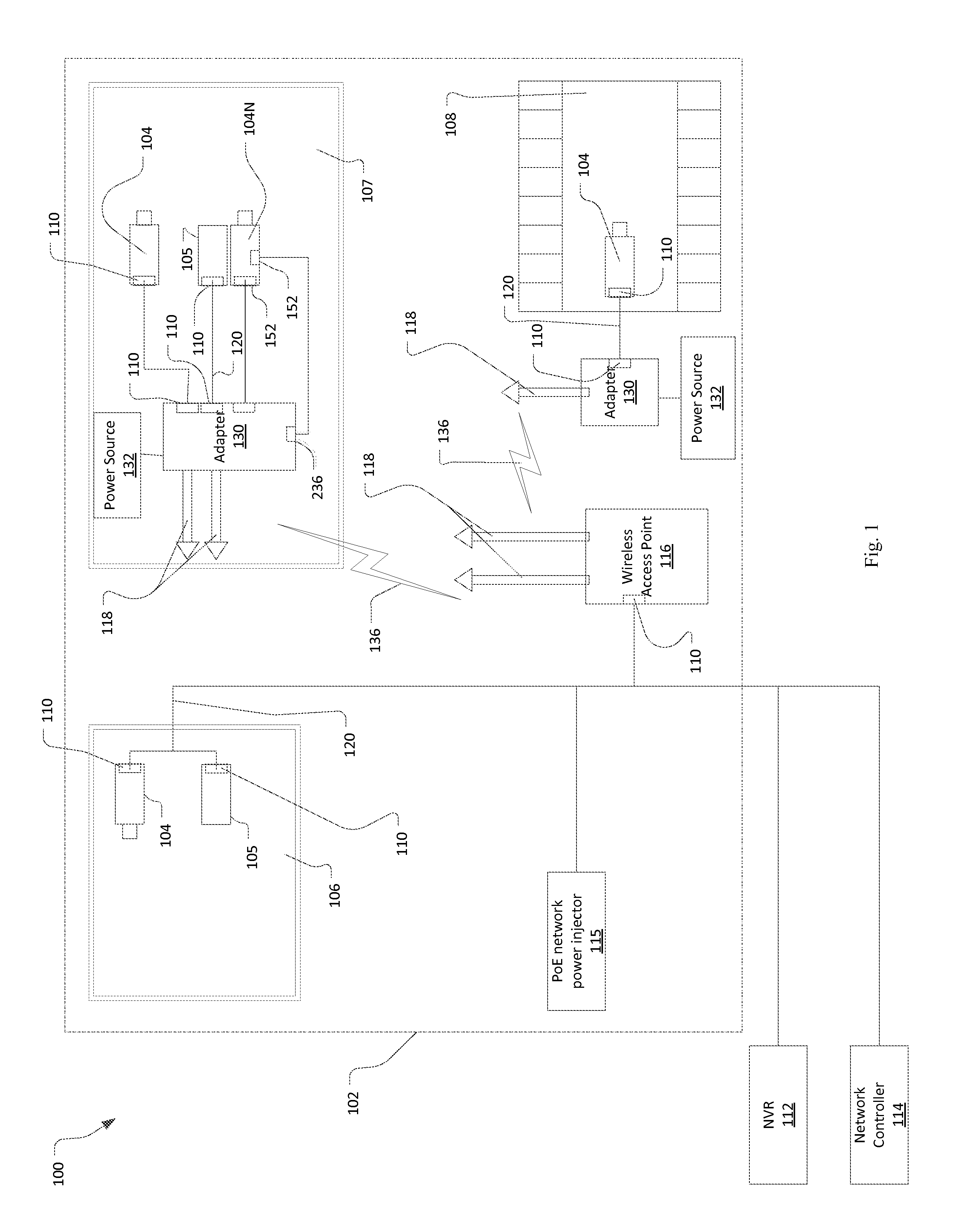

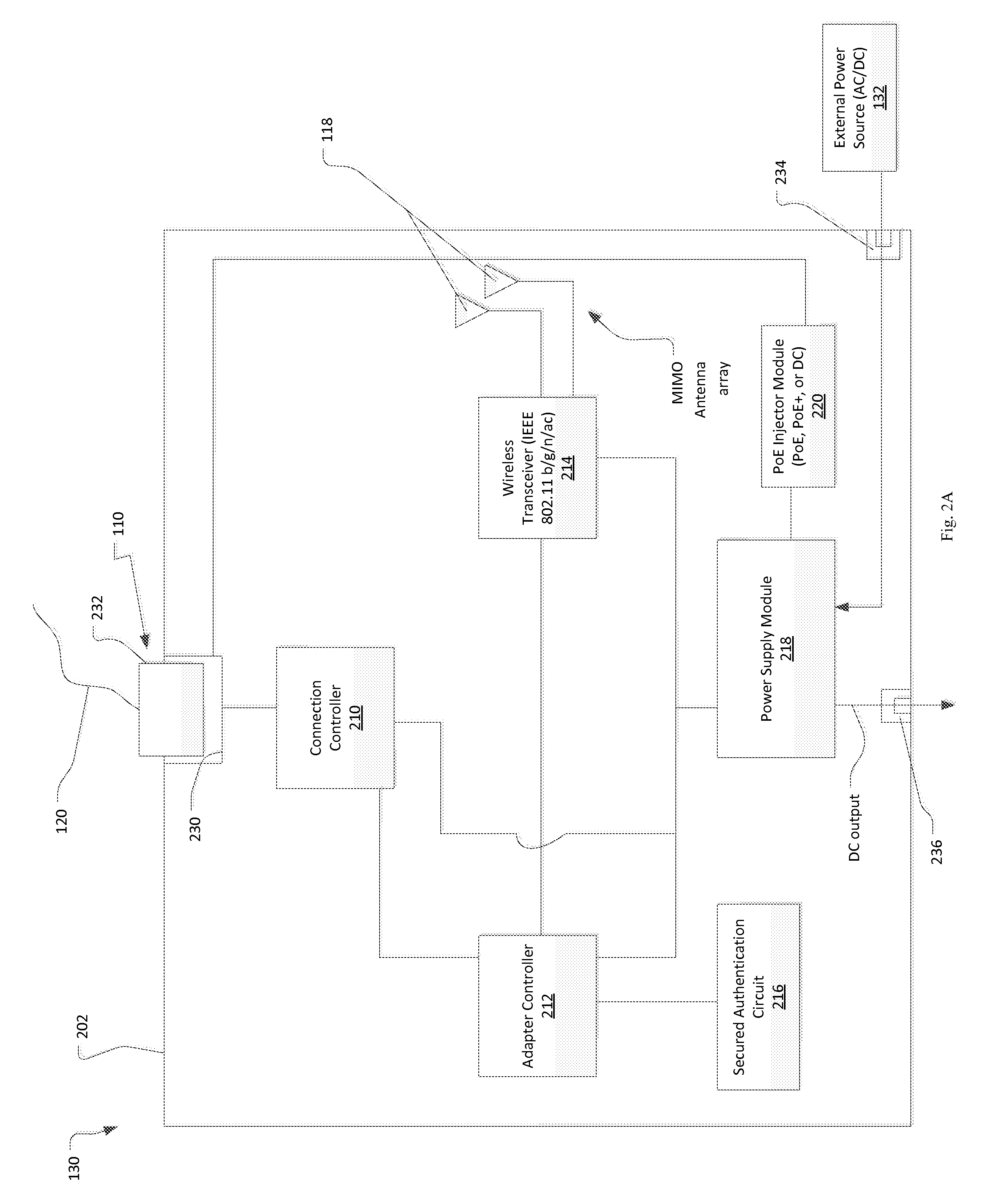

Security System and Method using Wireless Adapters and PoE Cameras

InactiveUS20130342688A1Increased installation costIncrease manufacturing costColor television detailsData switching current supplyData connectionComputer module

A wireless adapter and method for providing a wireless connection to at least one wired security device includes at least one combined data / power physical port to which the wired security device connects. A power supply module receives power from an external power source and a power injector provides power to the combined data / power physical port to thereby power the wired security device. In this way, the wireless adapter supplies both power and data connection at the same physical port / jack of the wired security devices, such as IP security cameras, via an interface cable from the wireless adapter. This configuration has advantages in lowering the manufacturing costs of the cameras and reducing installation costs. Furthermore, the same standard camera can be used for both standard wired connections and wireless connections.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Electrical generators for low-frequency and time-varying rocking and rotary motion

ActiveUS7821183B2Generate efficientlyHigh and relatively constant input motion frequencyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringElectric generator

Owner:OMNITEK PARTNERS LLC

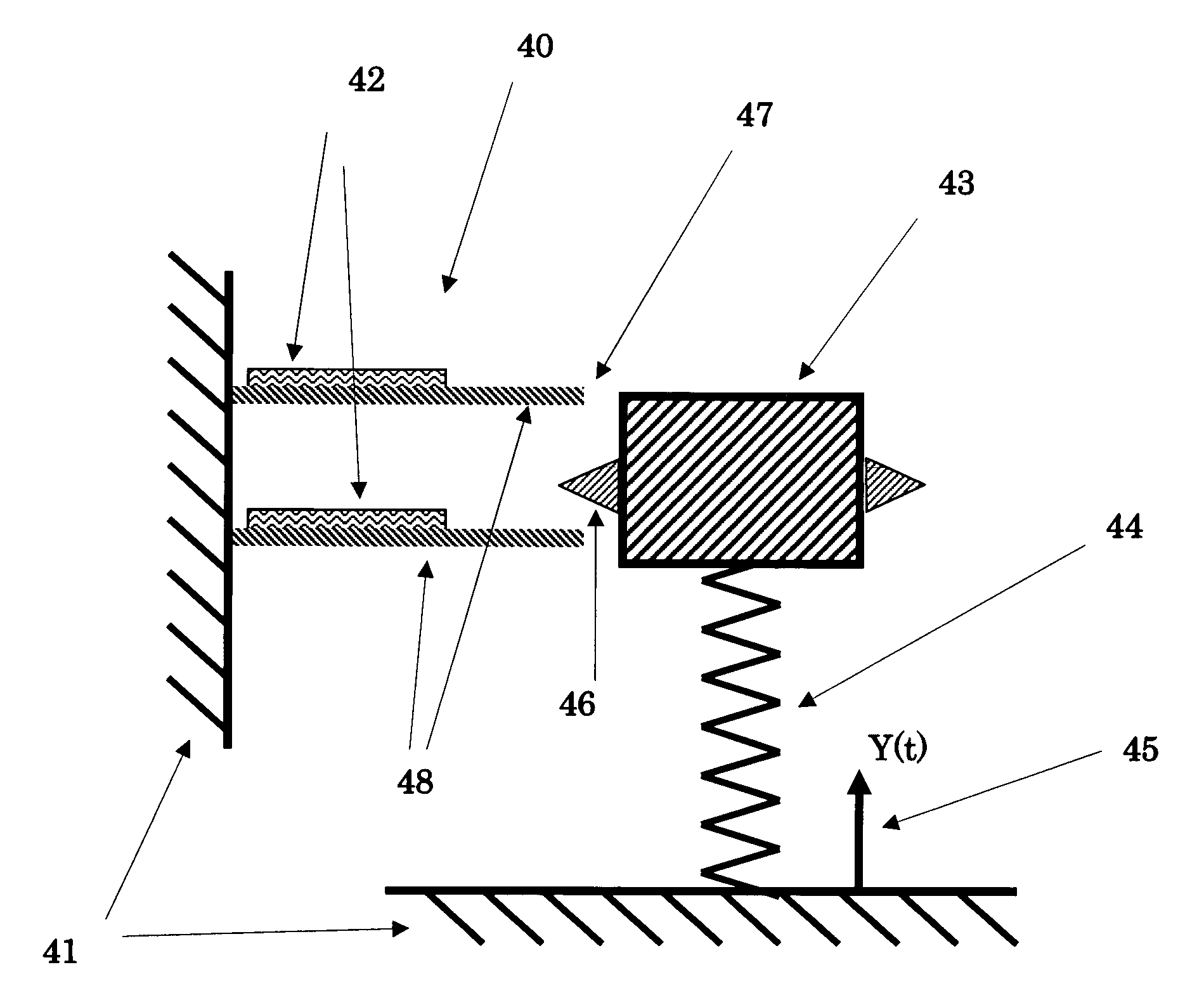

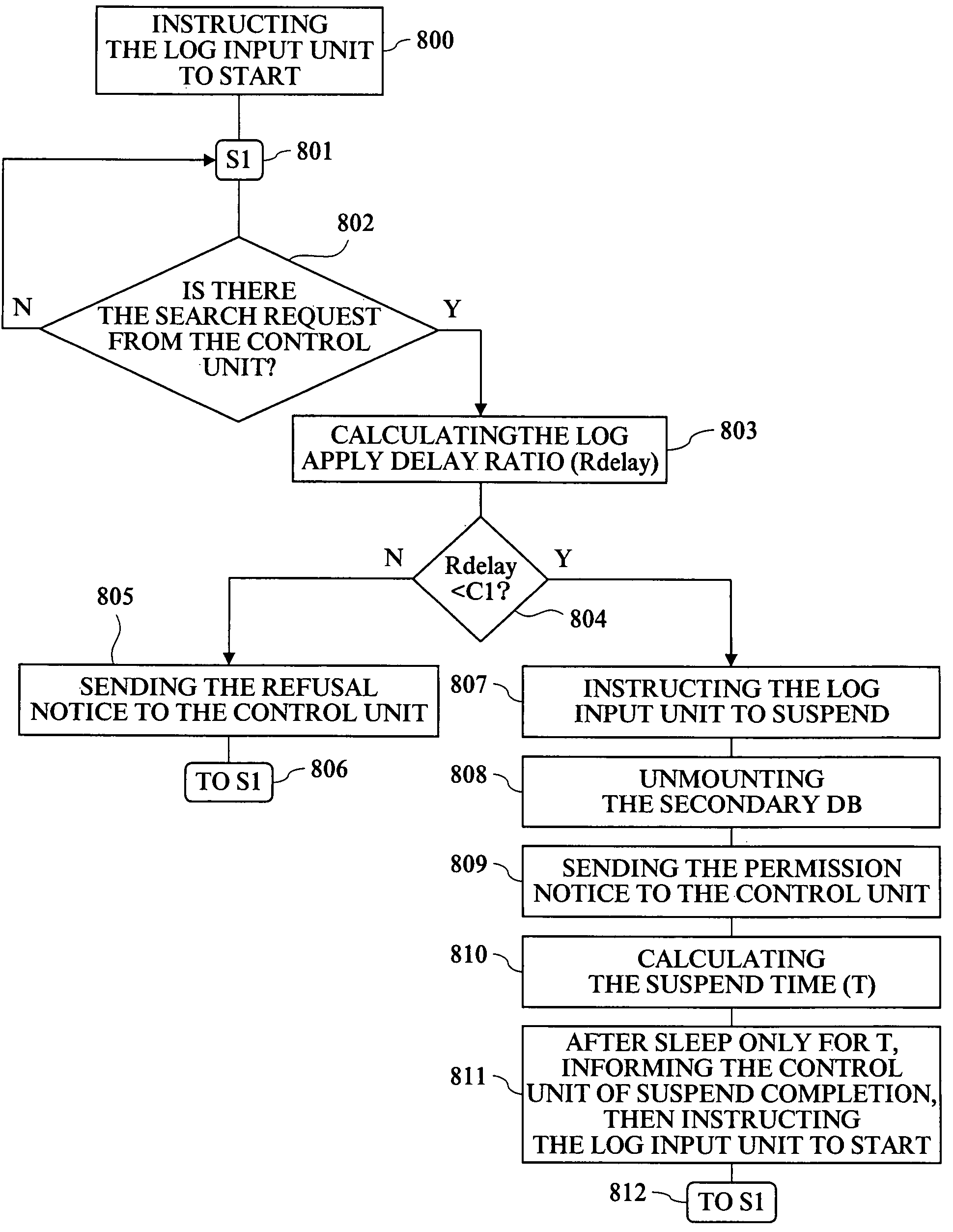

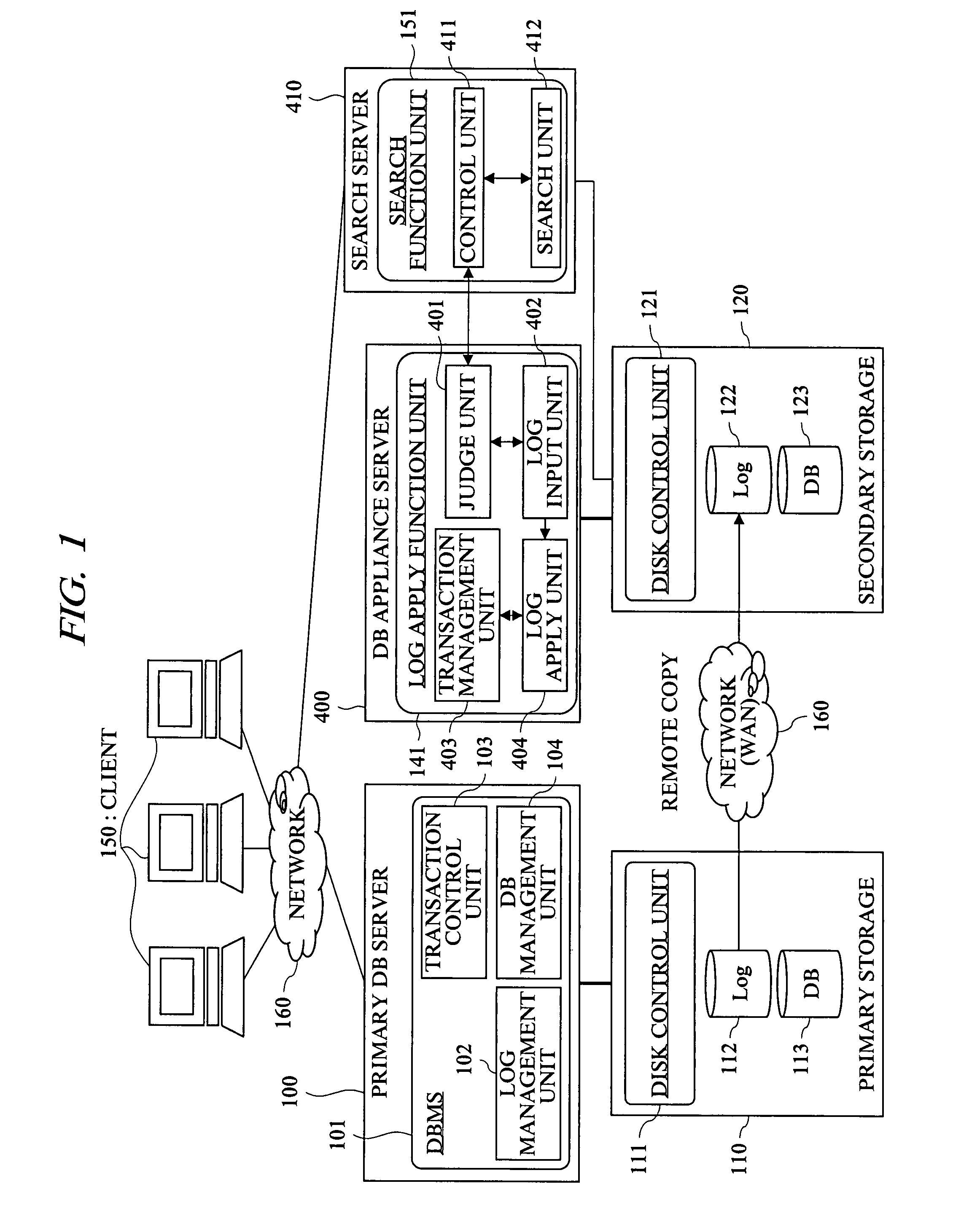

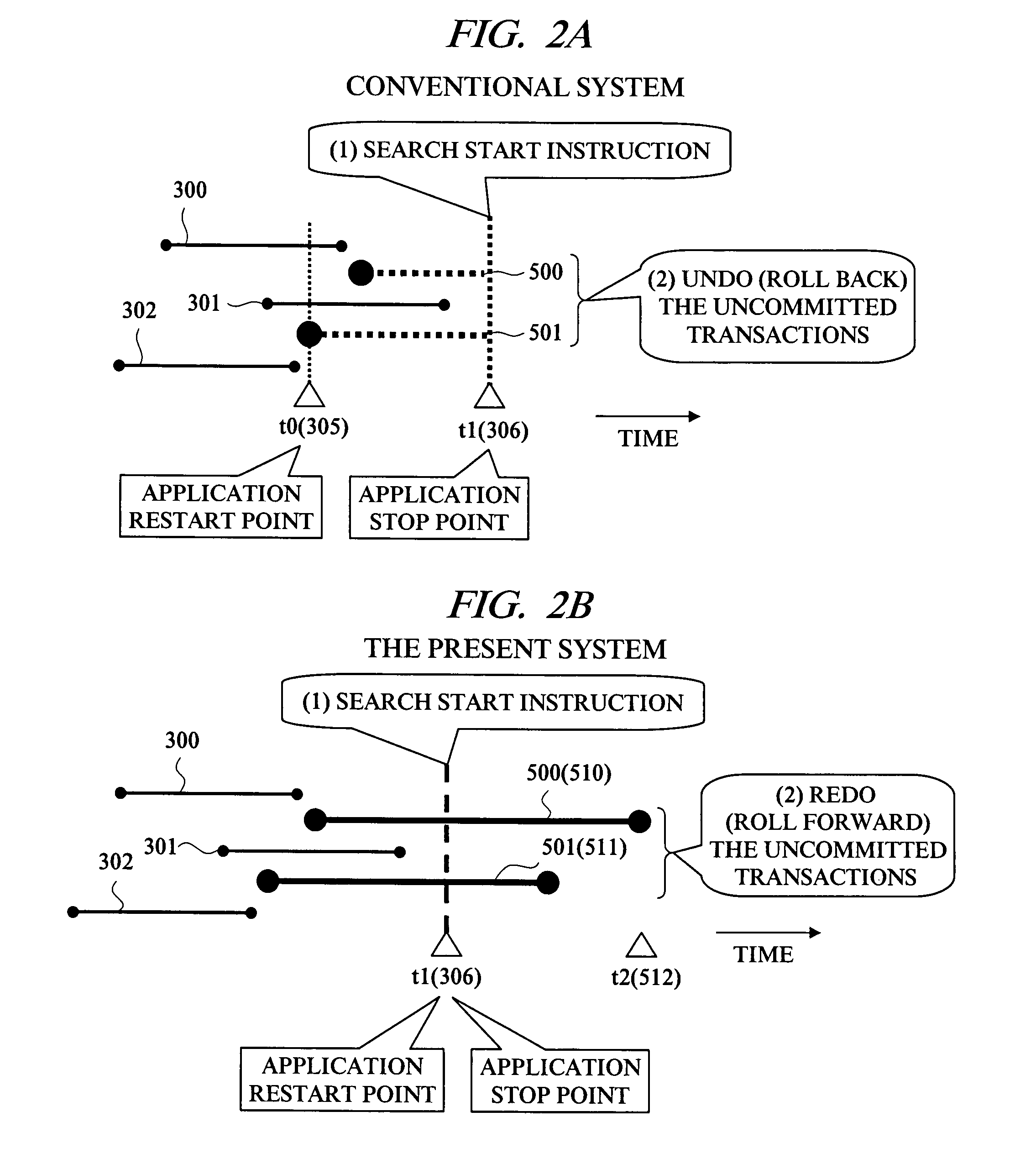

System and method of disaster recovery

InactiveUS7860824B2Fast processingIncrease equipment costDigital data information retrievalDigital data processing detailsViewpointsApplication software

In a DR system, from the viewpoint of device cost, when search is not carried out, a physical application where log recovery is available by inexpensive DB appliance server is adopted. Further, a local mirror operation at a secondary site is not carried out. Furthermore, from the viewpoint of operation, by a log apply function unit, the tendencies of a log application and operations are monitored, and a search process is accepted according to the progress conditions of the log application. When the log application does not catch up sufficiently, the search is not accepted. Moreover, when a consistency guarantee of a secondary DB is made, not transactions in process at the moment of search instruction are undone (rolled back), but only transactions in process at the moment of a search instruction are redone (rolled forward).

Owner:HITACHI LTD

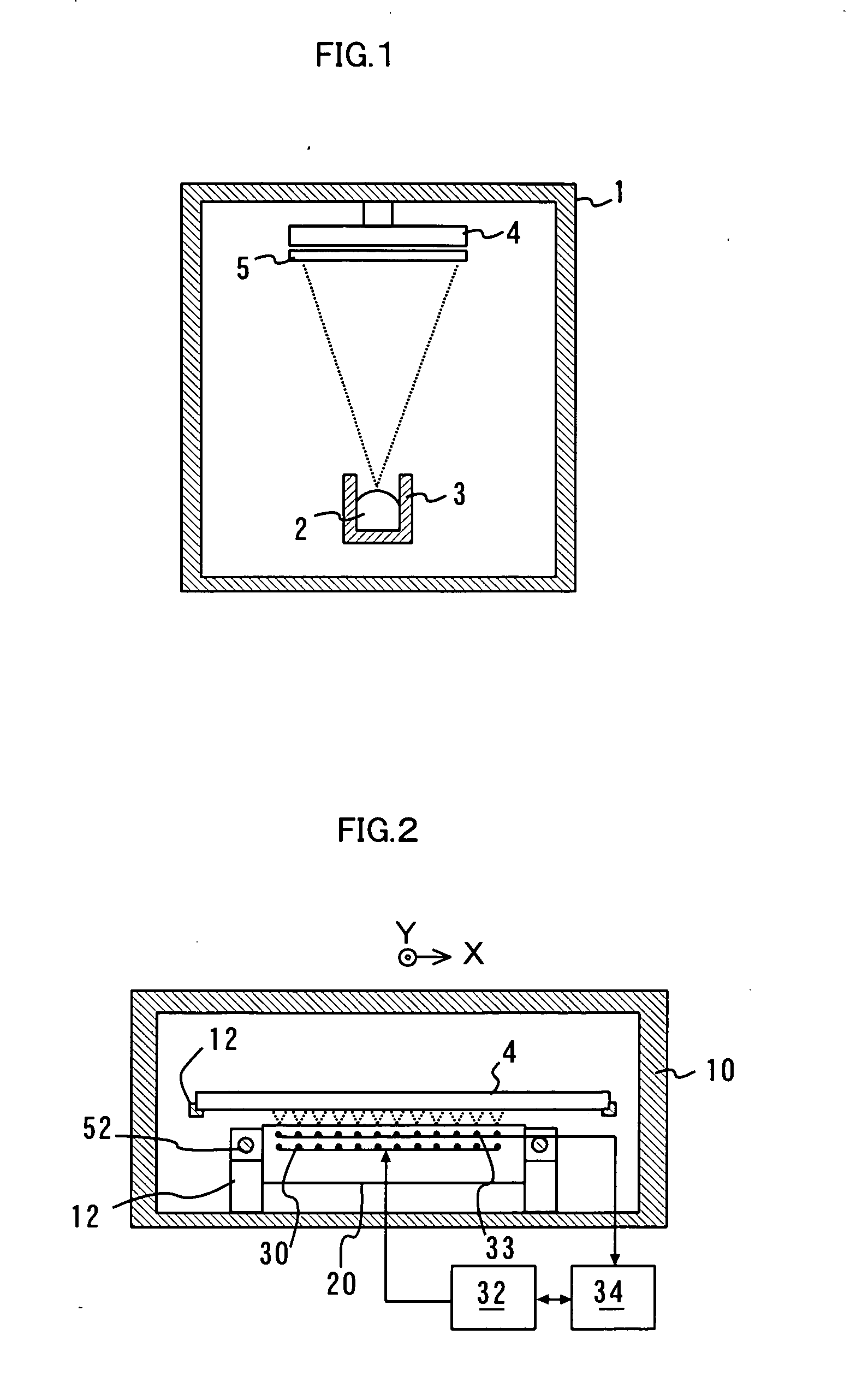

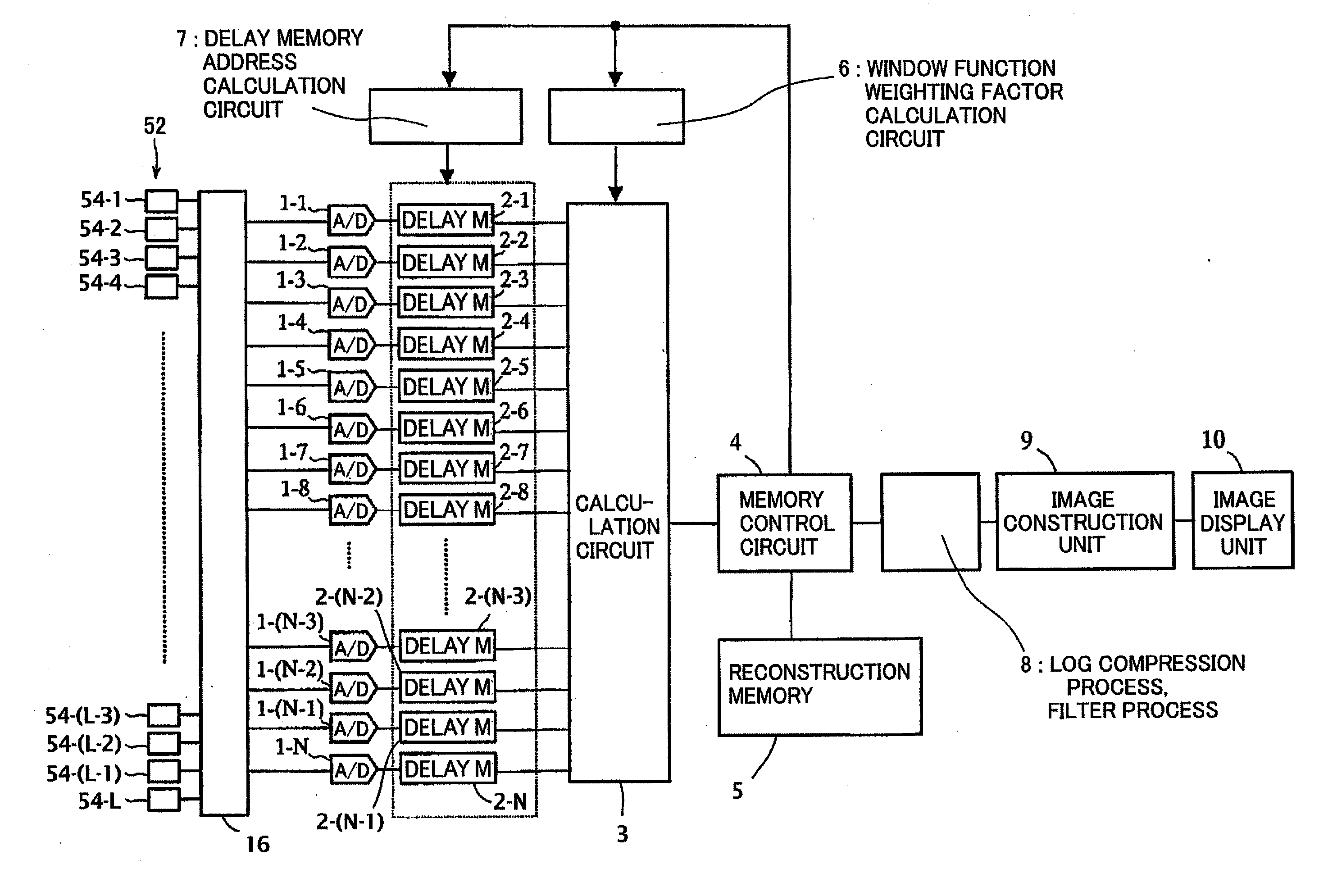

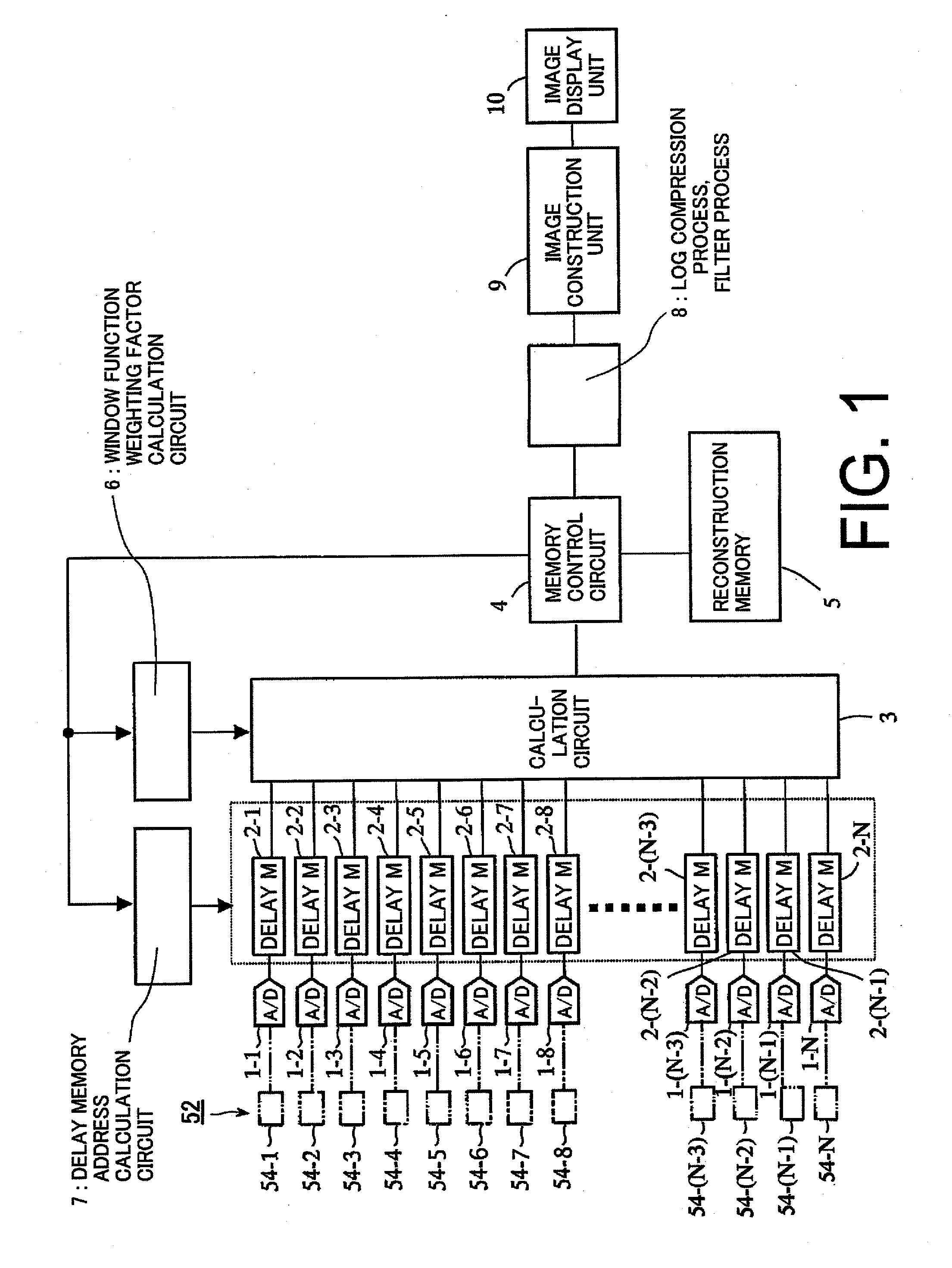

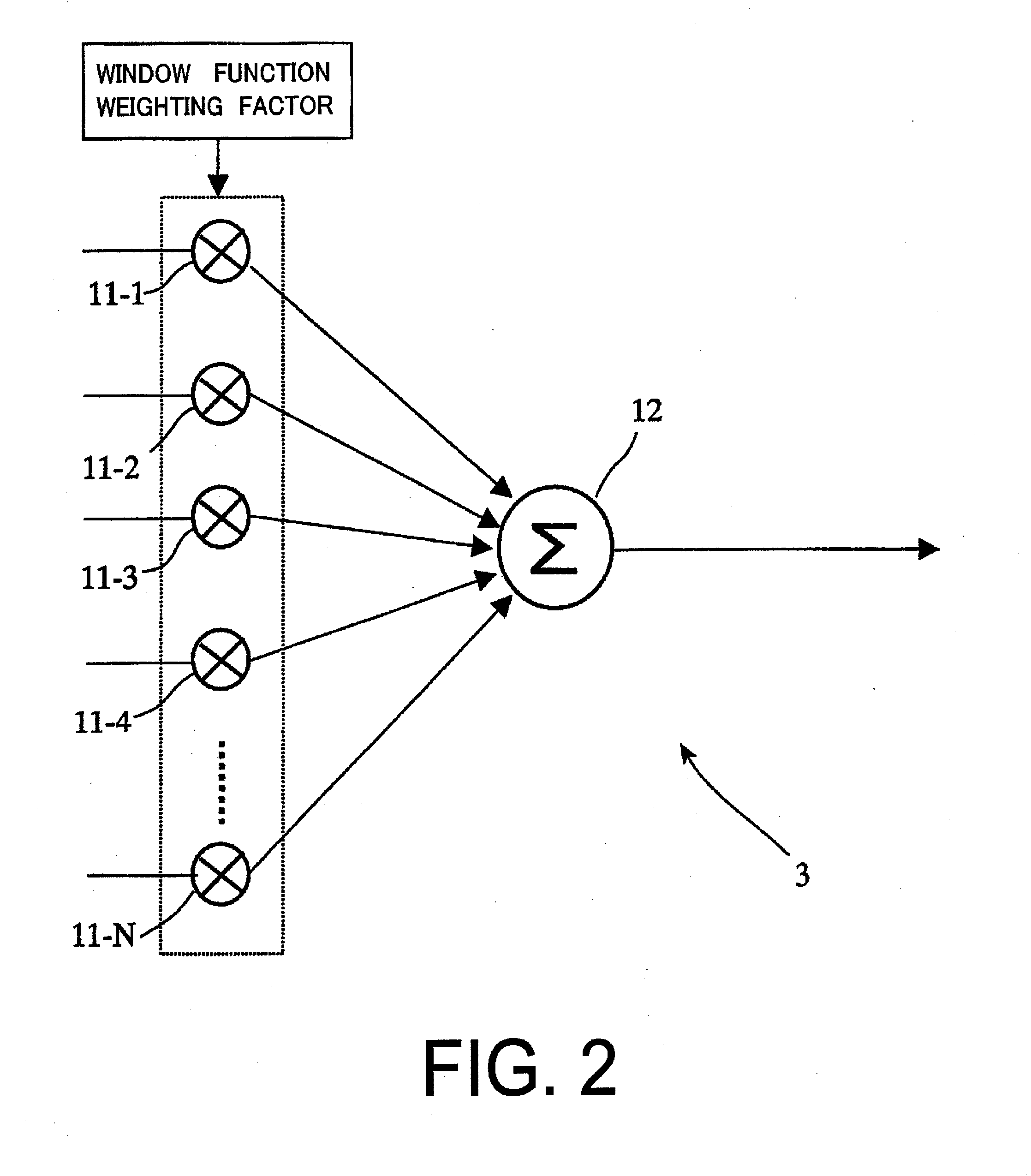

Received data processing apparatus of photoacoustic tomography

ActiveUS20110128816A1Increase in sizeIncrease equipment costUltrasonic/sonic/infrasonic diagnosticsDiagnostics using tomographyDelay and sumAcoustic wave

There is provided a received data processing apparatus of photoacoustic tomography including a minimum constitution unit data composition unit that sequentially reads receiving digital signals from first storage units and composes minimum constitution unit data of the acoustic wave of the minimum constitution units by performing a delay-and-sum process; a second storage unit that stores the minimum constitution unit data of the entire region of the specimen; an image construction unit that constructs an image of the specimen based on the minimum constitution unit data stored in the second storage unit; and a control unit that sequentially stores the minimum constitution unit data calculated by the minimum constitution unit data composition unit in the second storage unit and reads the stored minimum constitution unit data of the entire region of the specimen to transmit the minimum constitution unit data to the image construction unit.

Owner:CANON KK

No-mold fusion stacking manufacture method of parts or mold

InactiveCN101362272AReduce or eliminate dropReduce or eliminate droolingWelding/cutting auxillary devicesArc welding apparatusNumerical controlMelting tank

The invention relates to a method for die-free fused deposition modeling of a part or a die, which belongs to the method of die-free modeling, and solves the problems of falling, flowing and collapsing of fusing material in the process of support-free and die-free fused deposition modeling of the existing method. The method comprises the following steps: (1) hierarchy slicing processing is performed to the three-dimensional CAD model of the part or the die; (2) a computer generates numerical control codes required by the shaping of each hierarchy according to the hierarchy slicing data and the characteristics of the slicing size and shape of each hierarchy; and (3) numerically controlled gas-shielded welding arc or laser bean is adopted to fuse and shape the fusing material on the base plate in sequence according to the numerical control codes of each hierarchy, until the requirements on the size and the surface of the part or the die are met; simultaneously, electromagnetic field acting on the fusing material in the melting bath is generated through an electromagnetic device. By adopting the method, the part or the die made of metal, intermetallic compound, metal ceramics, ceramics and functionally gradient material can be quickly obtained with low cost and high quality.

Owner:HUAZHONG UNIV OF SCI & TECH

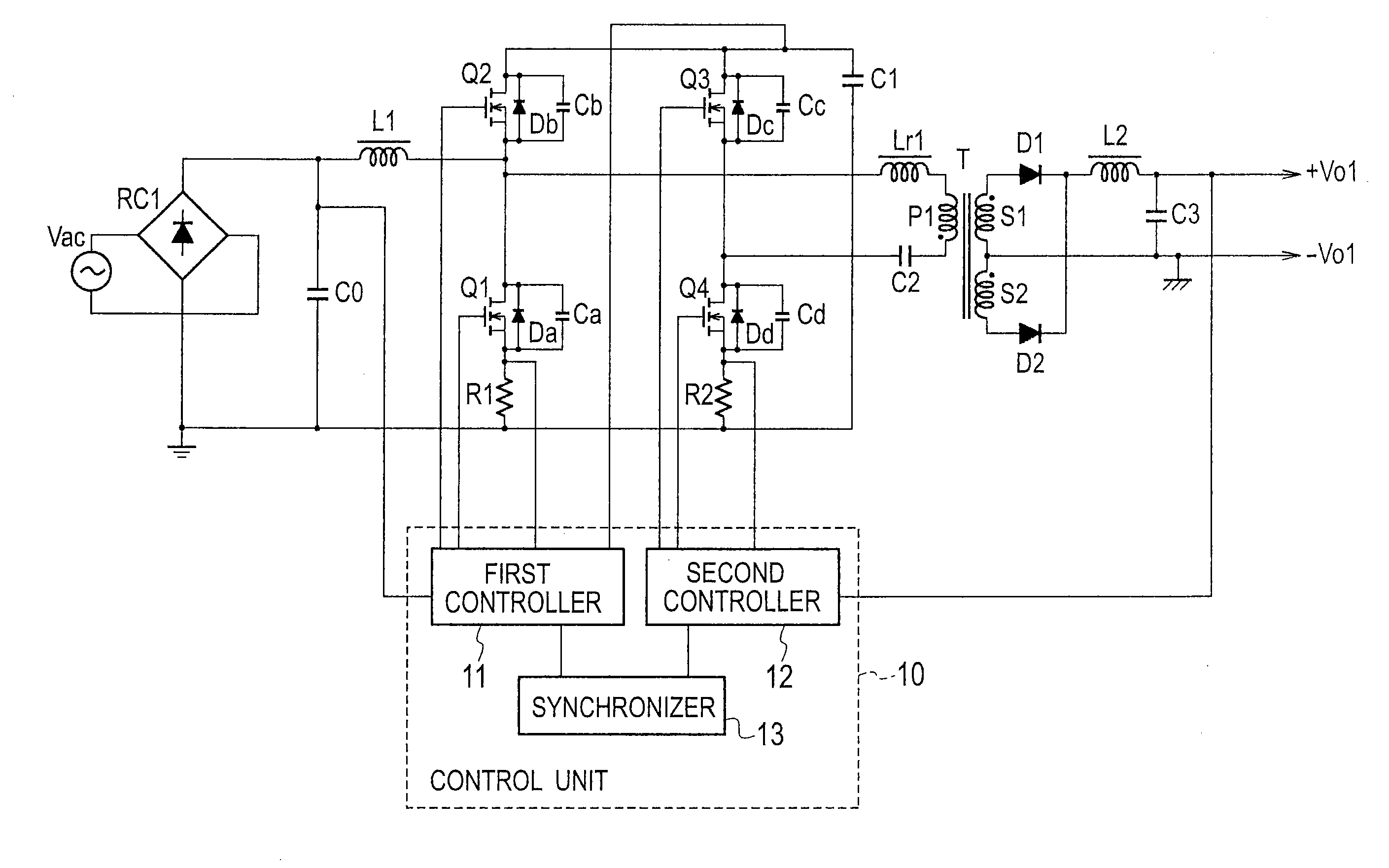

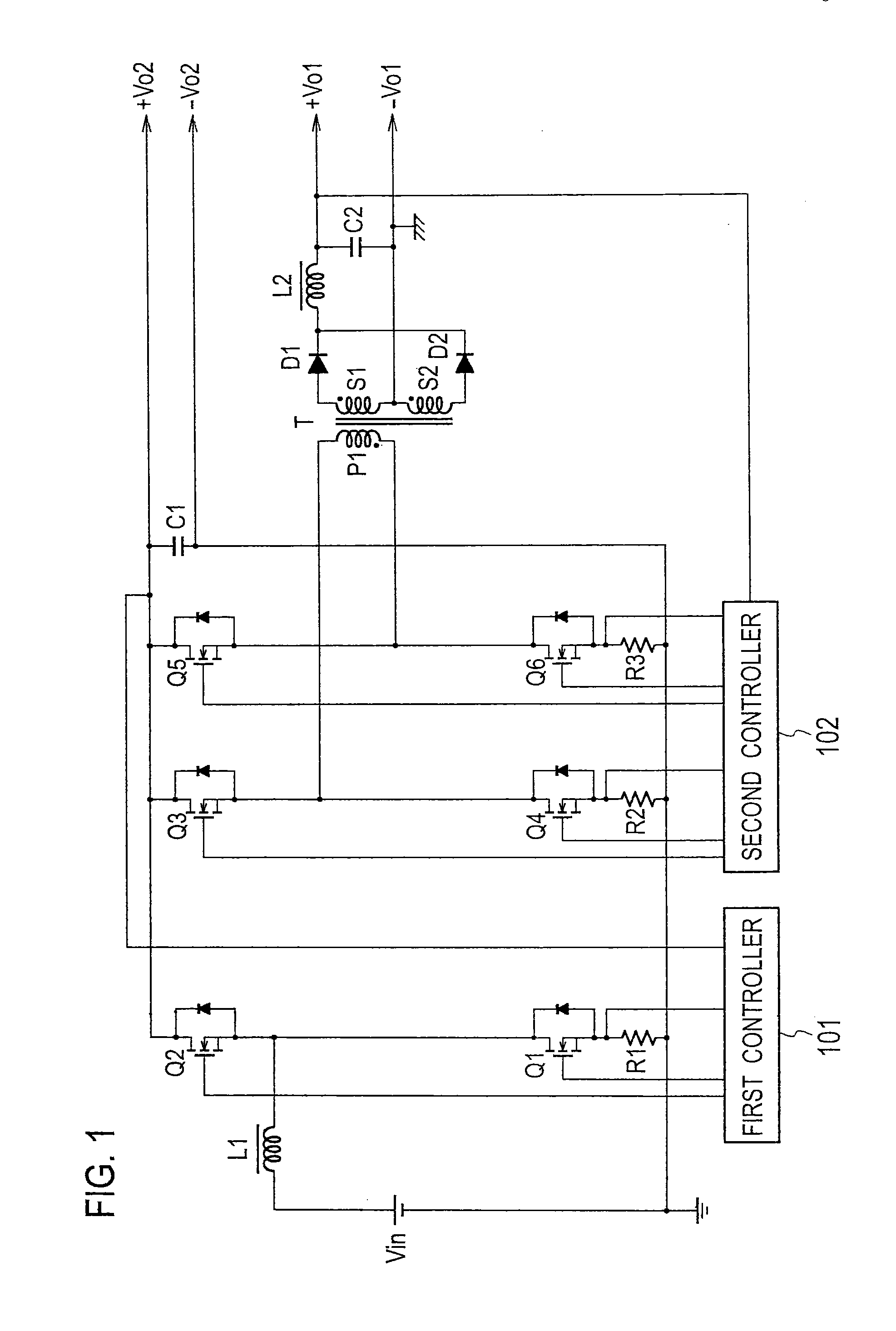

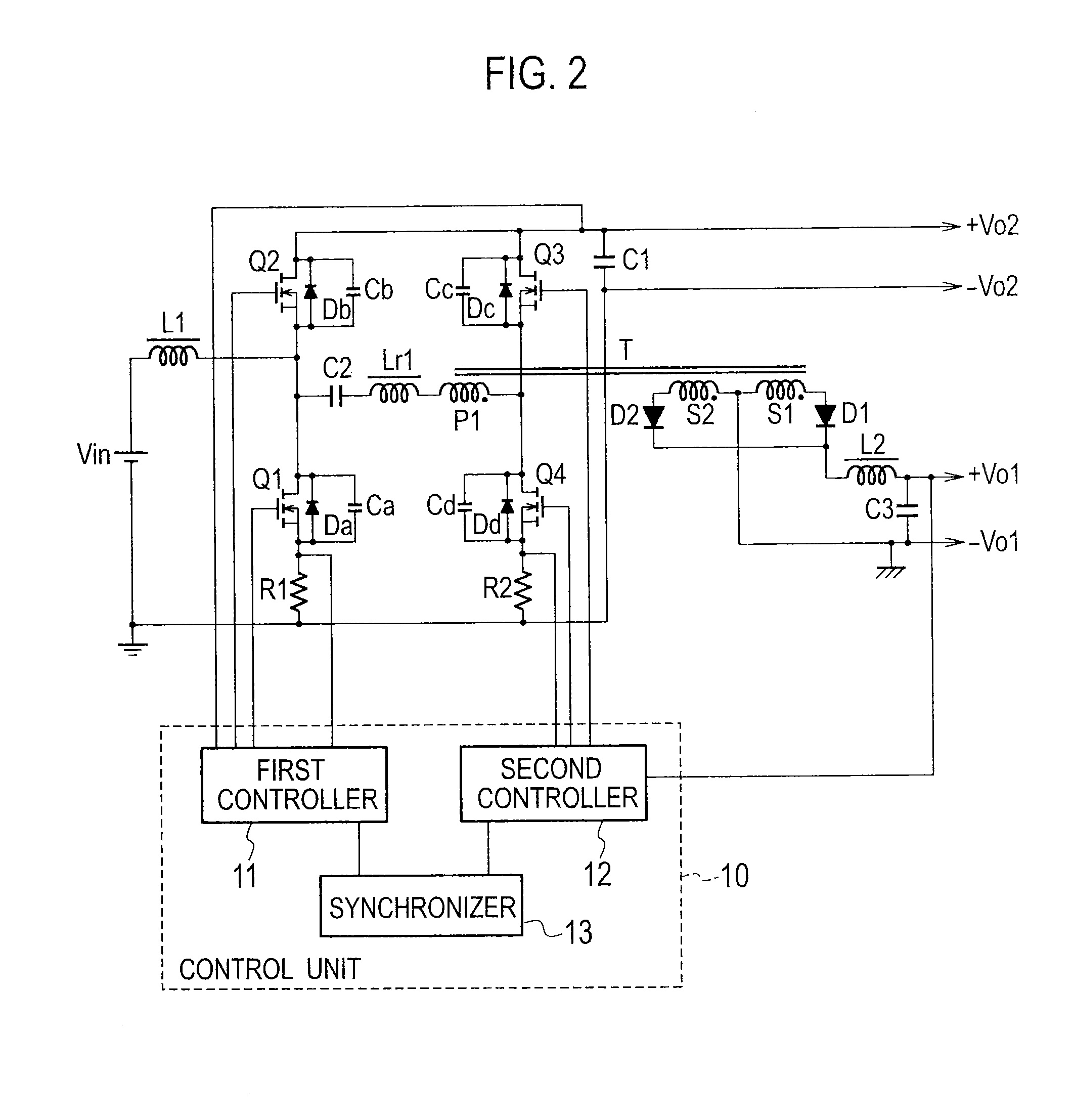

Switching power source apparatus

ActiveUS20120307529A1Complicate apparatusIncrease equipment costDc-dc conversionElectric variable regulationConductor CoilSwitching power

A switching power source apparatus includes a first arm including first and second switching elements, a second arm including third and fourth switching elements, a series circuit connected between a connection point of the first and second switching elements and a connection point of the third and fourth switching elements and including a capacitor and a primary winding, a rectifying-smoothing circuit that rectifies and smoothes a voltage of a secondary winding and provides an output voltage, a reactor connected to a connection point of the first and second switching elements and a DC input end, and a controller that turns on / off the first and second switching elements alternately and the third and fourth switching elements alternately and synchronizes the first and third switching elements with each other and the second and fourth switching elements with each other.

Owner:SANKEN ELECTRIC CO LTD

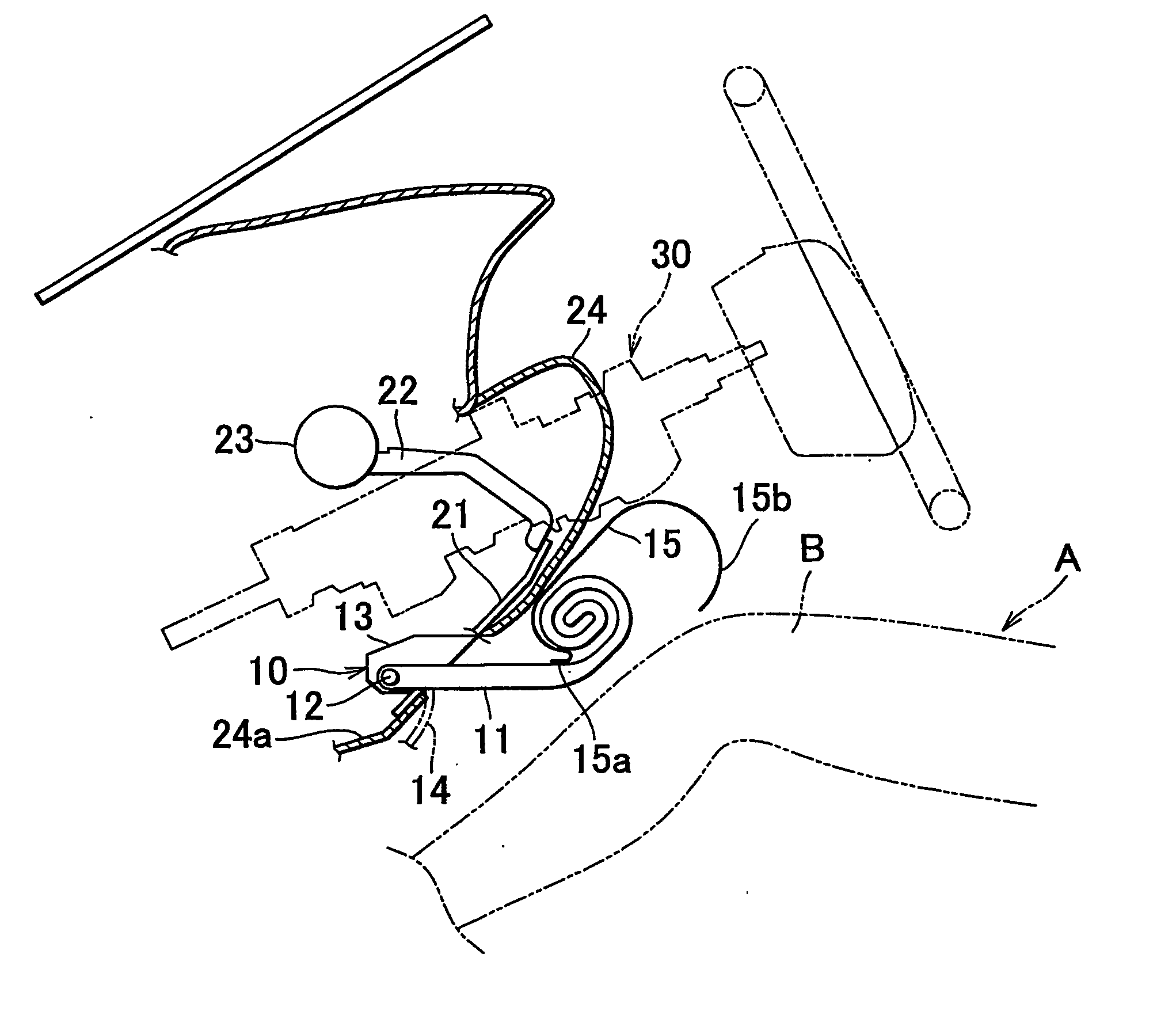

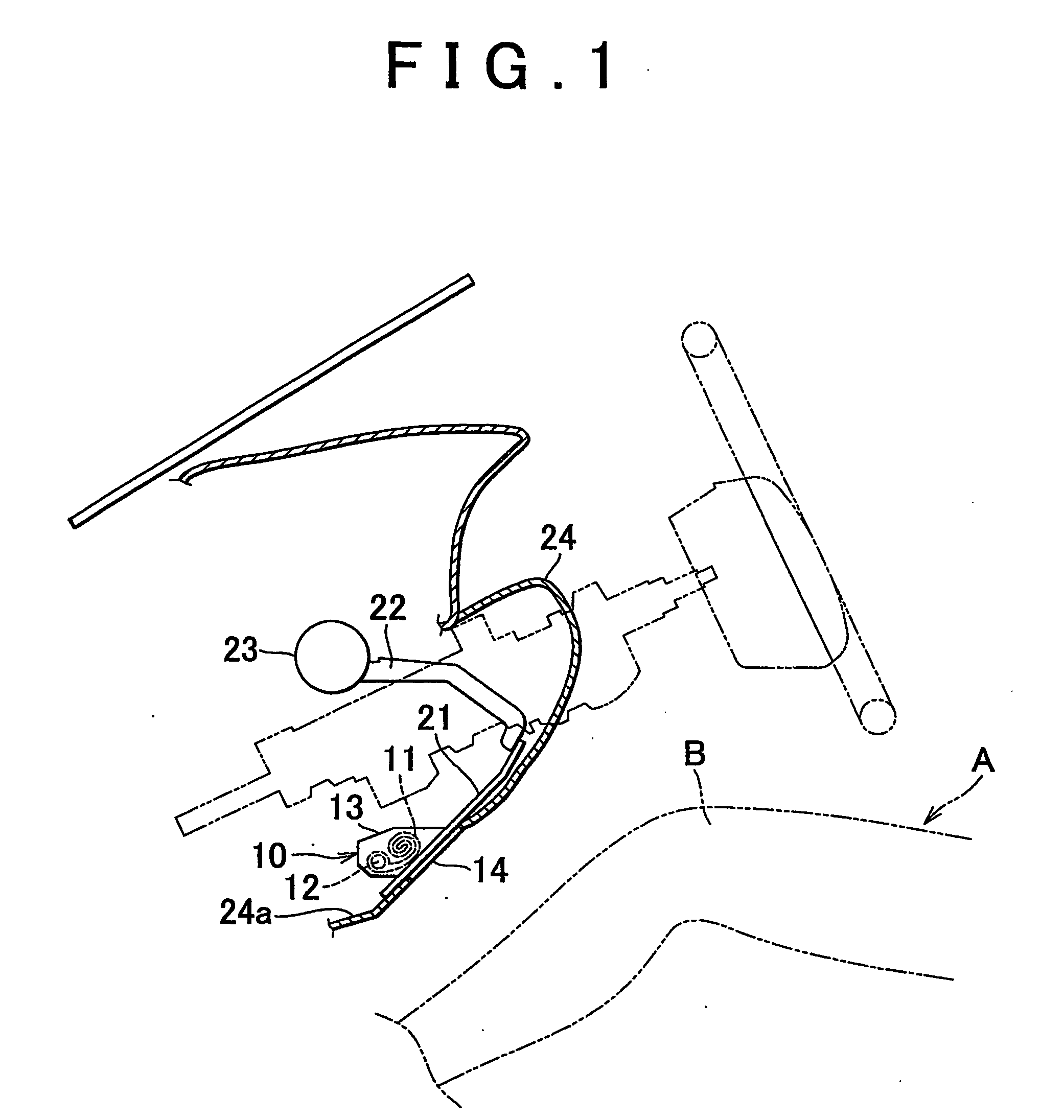

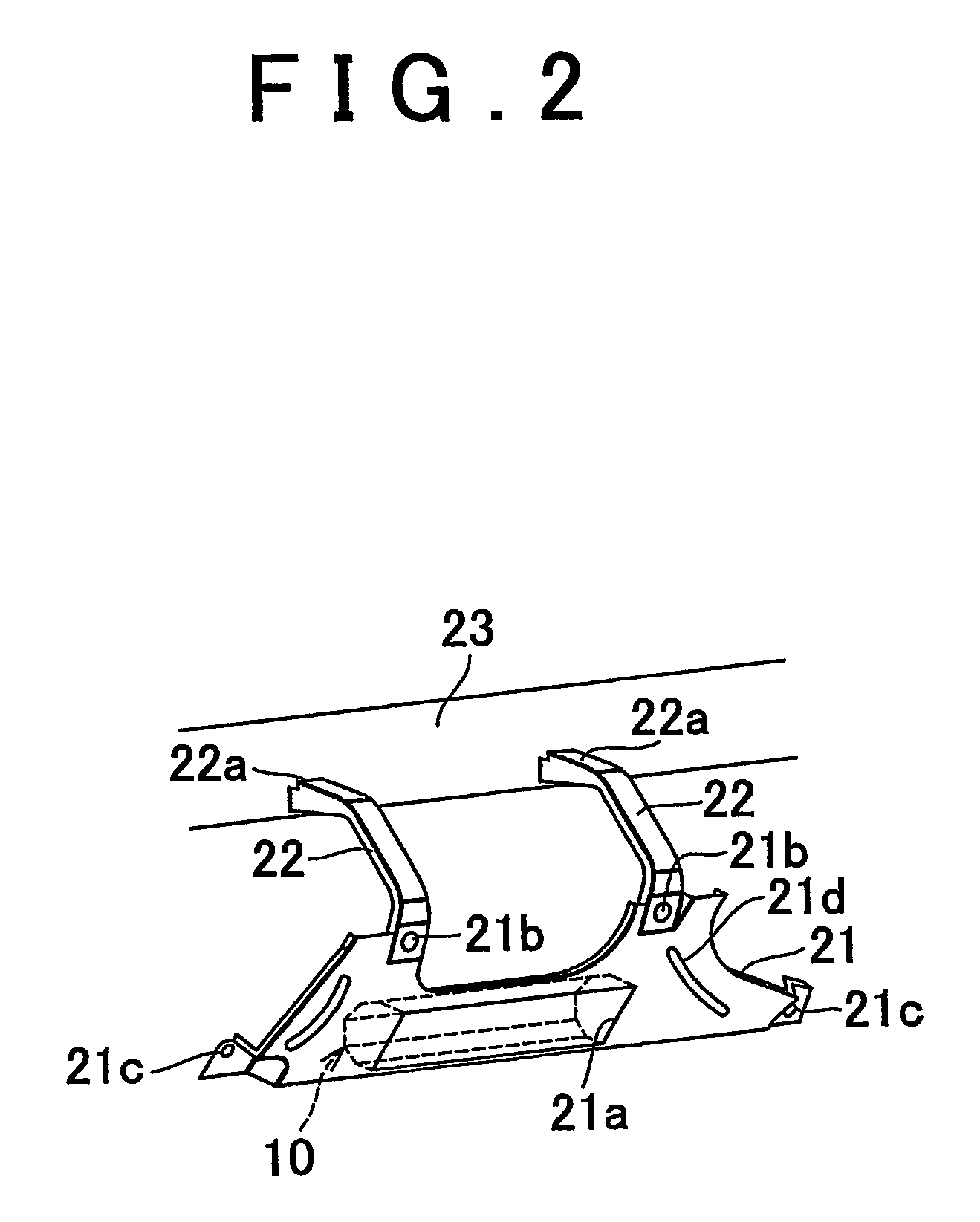

Knee protection apparatus for vehicle occupant

InactiveUS20060071459A1Reduce chanceIncrease equipment costPedestrian/occupant safety arrangementEngineeringAirbag

Owner:TOYOTA JIDOSHA KK

Liquid medication cartridge and inhaler using the cartridge

InactiveUS20070240706A1Weight increaseComplicated constructionRespiratorsMedical devicesEngineeringMechanical engineering

A liquid medication cartridge includes an accommodating portion for accommodating a liquid medication; a liquid discharge portion having a discharge port for discharging the liquid medication by using an ink jet technique, a communicating member for establishing communication between the accommodating portion and the liquid discharge portion and a filling member for filling the liquid discharge portion with the liquid medication.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com