Patents

Literature

11936 results about "Precious metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A precious metal is a rare, naturally occurring metallic chemical element of high economic value. Chemically, the precious metals tend to be less reactive than most elements (see noble metal). They are usually ductile and have a high lustre. Historically, precious metals were important as currency but are now regarded mainly as investment and industrial commodities. Gold, silver, platinum, and palladium each have an ISO 4217 currency code.

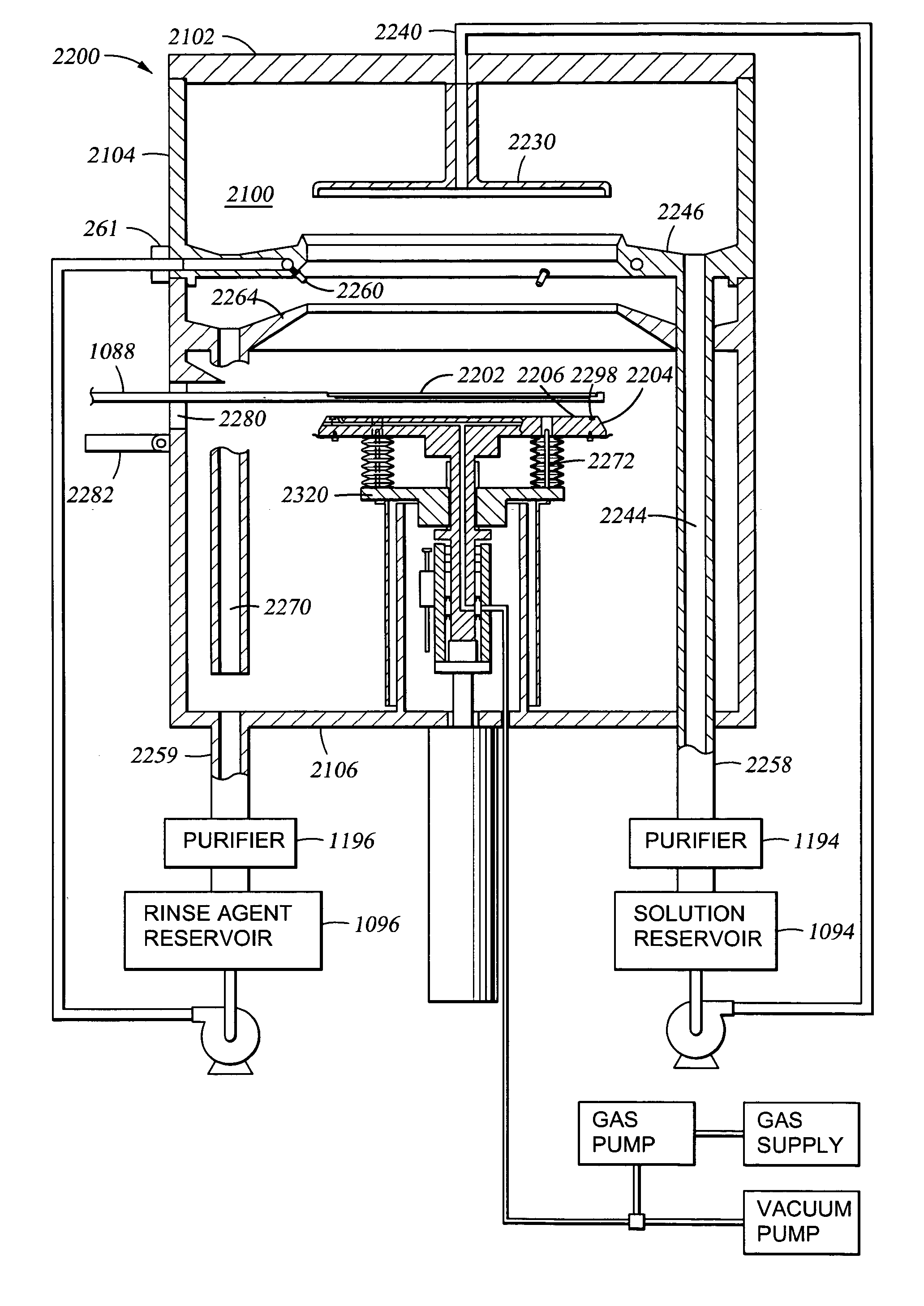

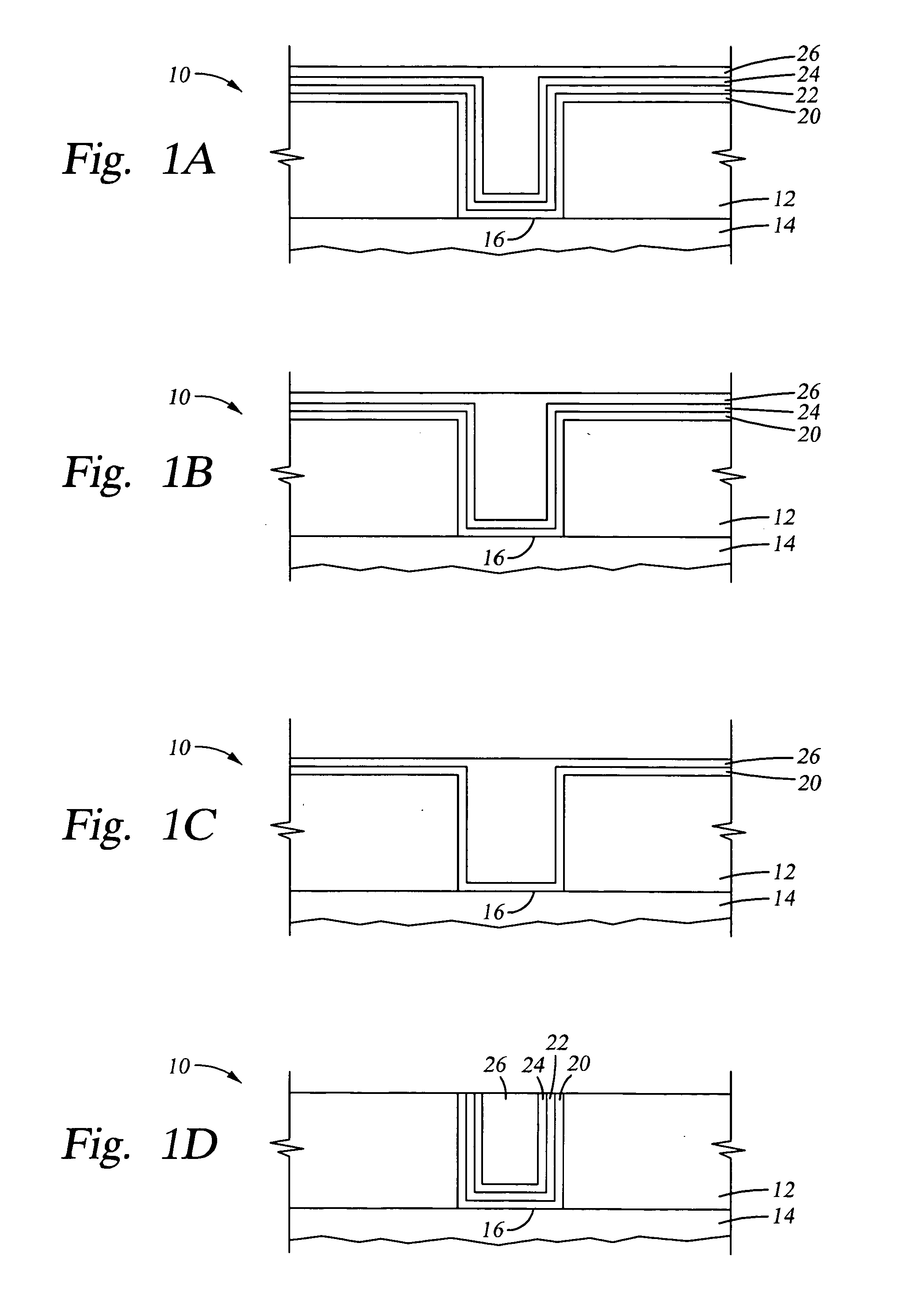

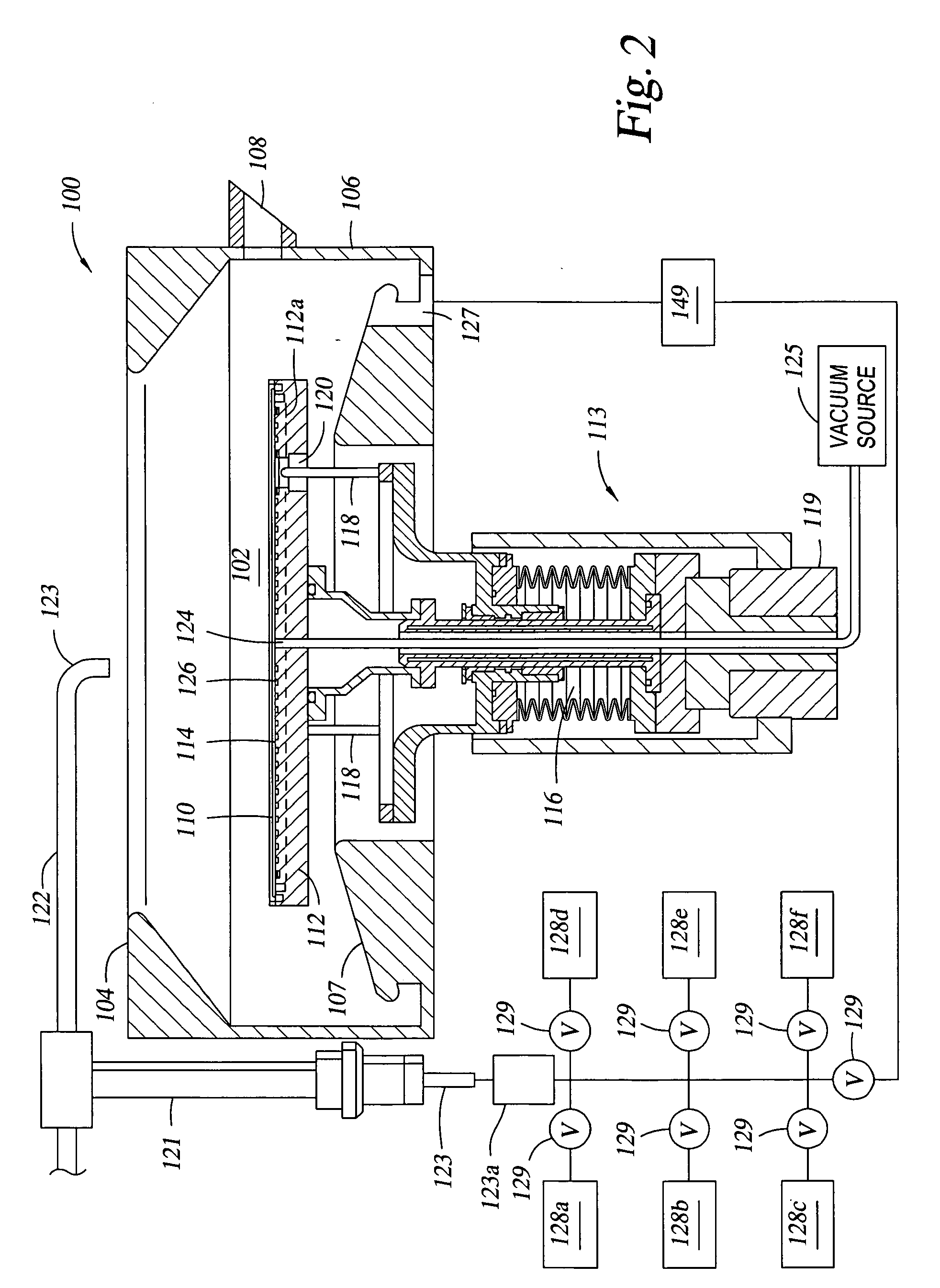

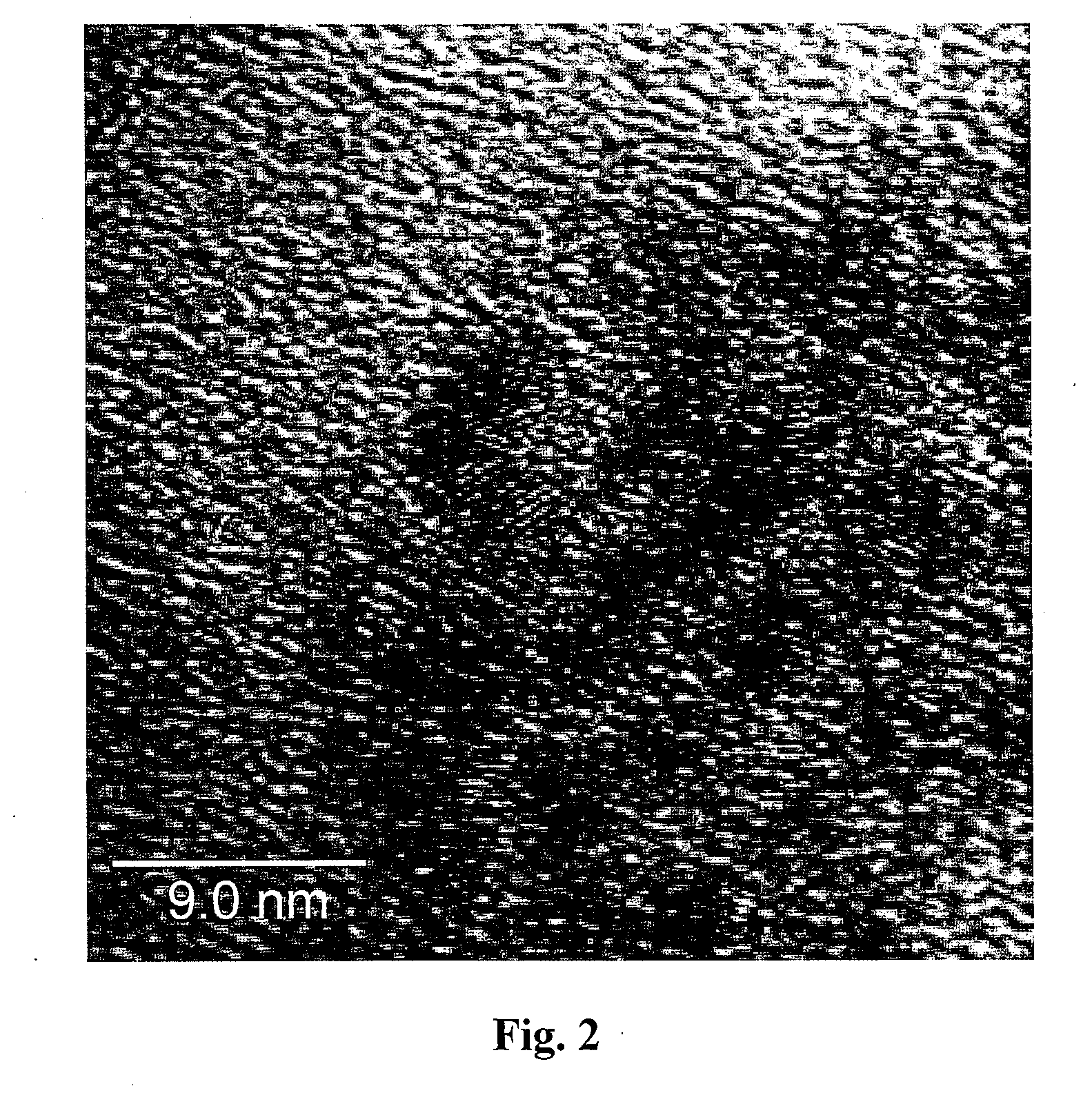

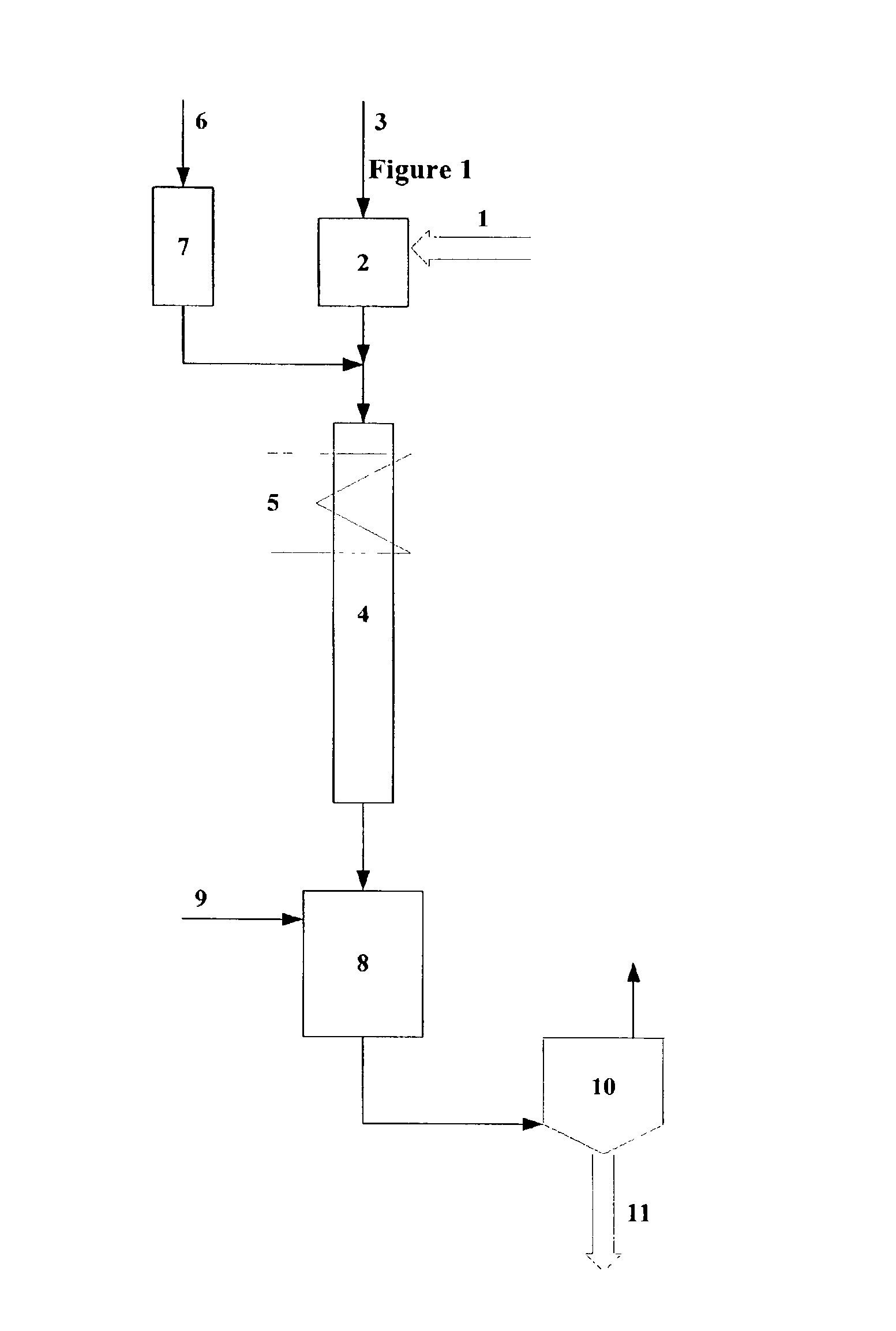

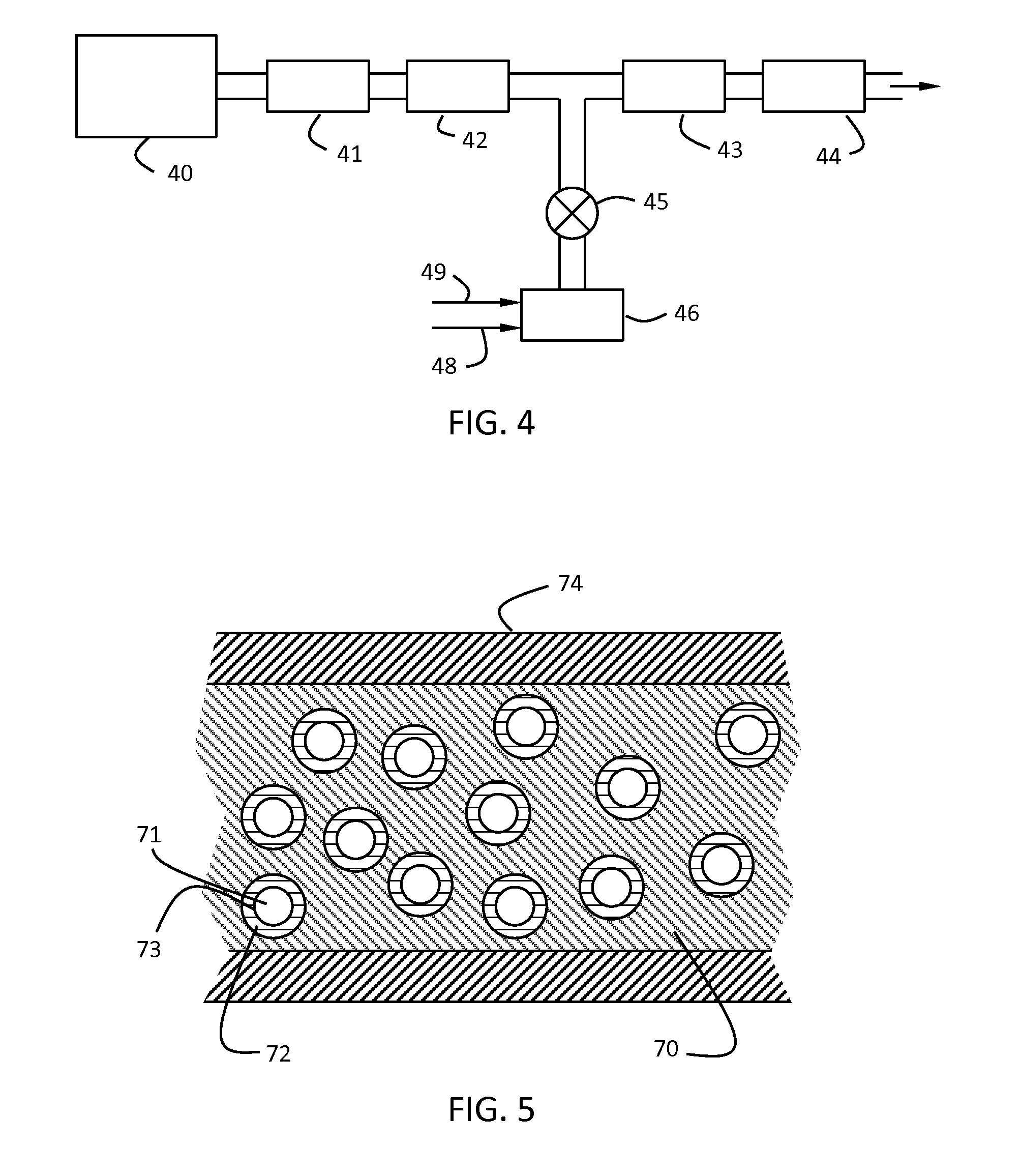

Electroless deposition apparatus

An apparatus and a method of depositing a catalytic layer comprising at least one metal selected from the group consisting of noble metals, semi-noble metals, alloys thereof, and combinations thereof in sub-micron features formed on a substrate. Examples of noble metals include palladium and platinum. Examples of semi-noble metals include cobalt, nickel, and tungsten. The catalytic layer may be deposited by electroless deposition, electroplating, or chemical vapor deposition. In one embodiment, the catalytic layer may be deposited in the feature to act as a barrier layer to a subsequently deposited conductive material. In another embodiment, the catalytic layer may be deposited over a barrier layer. In yet another embodiment, the catalytic layer may be deposited over a seed layer deposited over the barrier layer to act as a “patch” of any discontinuities in the seed layer. Once the catalytic layer has been deposited, a conductive material, such as copper, may be deposited over the catalytic layer. In one embodiment, the conductive material is deposited over the catalytic layer by electroless deposition. In another embodiment, the conductive material is deposited over the catalytic layer by electroless deposition followed by electroplating or followed by chemical vapor deposition. In still another embodiment, the conductive material is deposited over the catalytic layer by electroplating or by chemical vapor deposition.

Owner:APPLIED MATERIALS INC

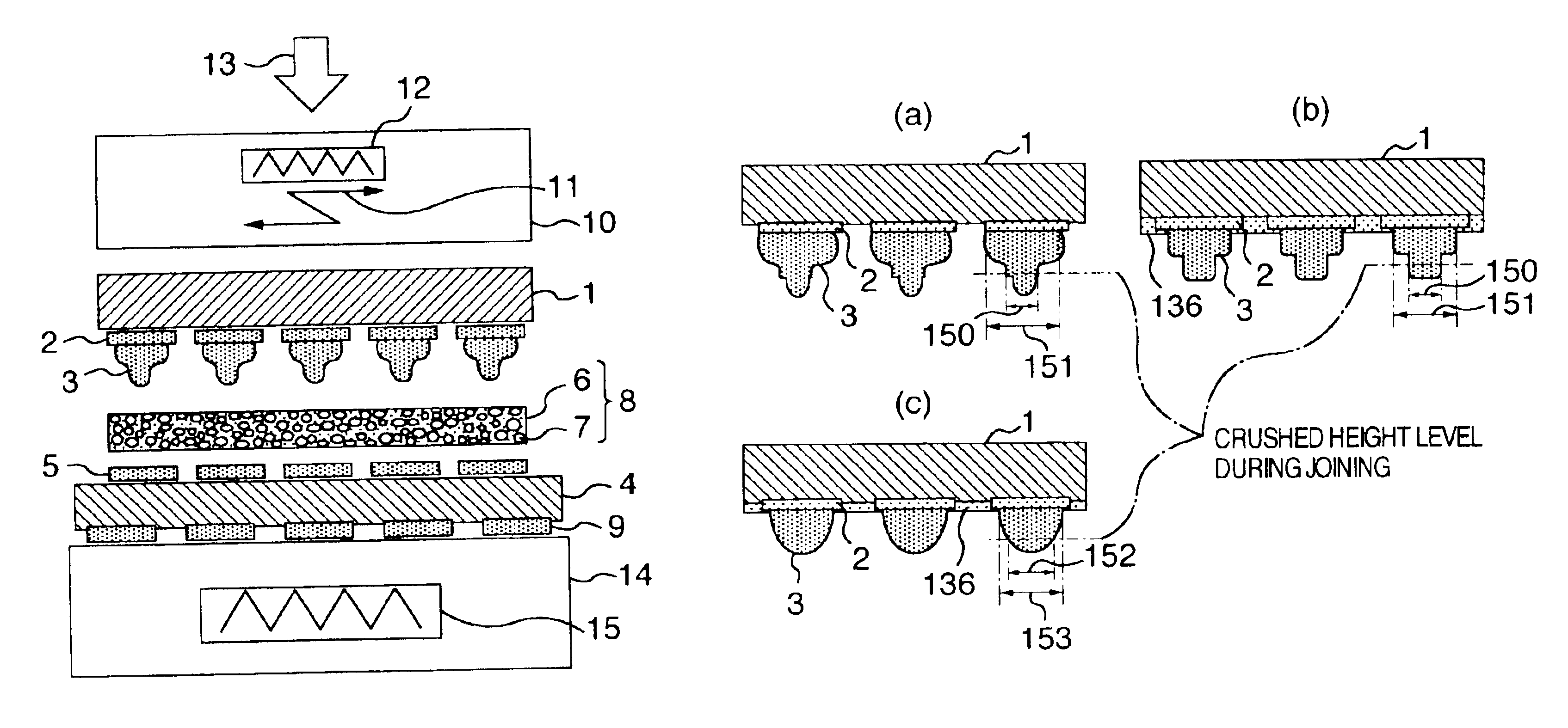

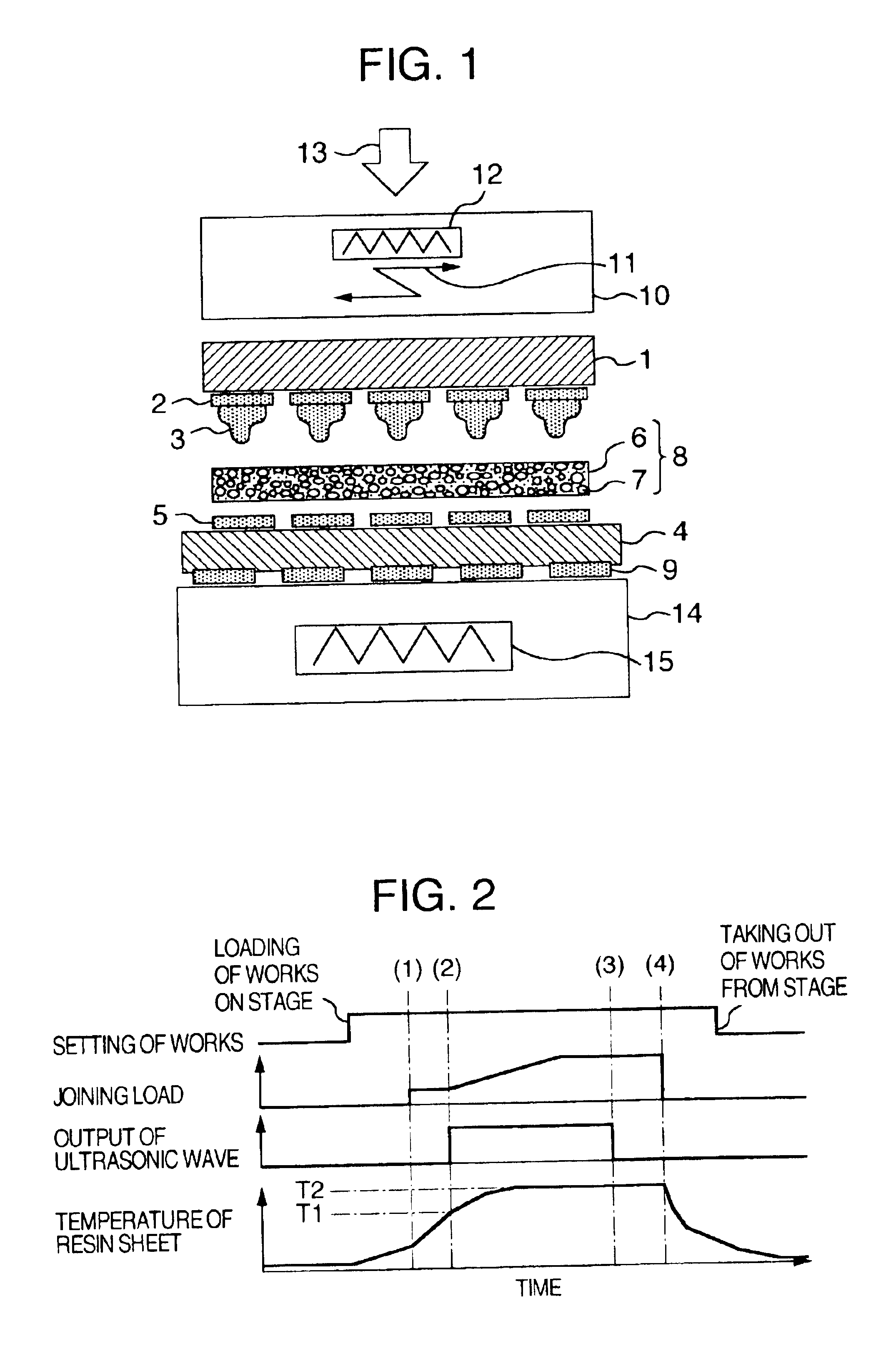

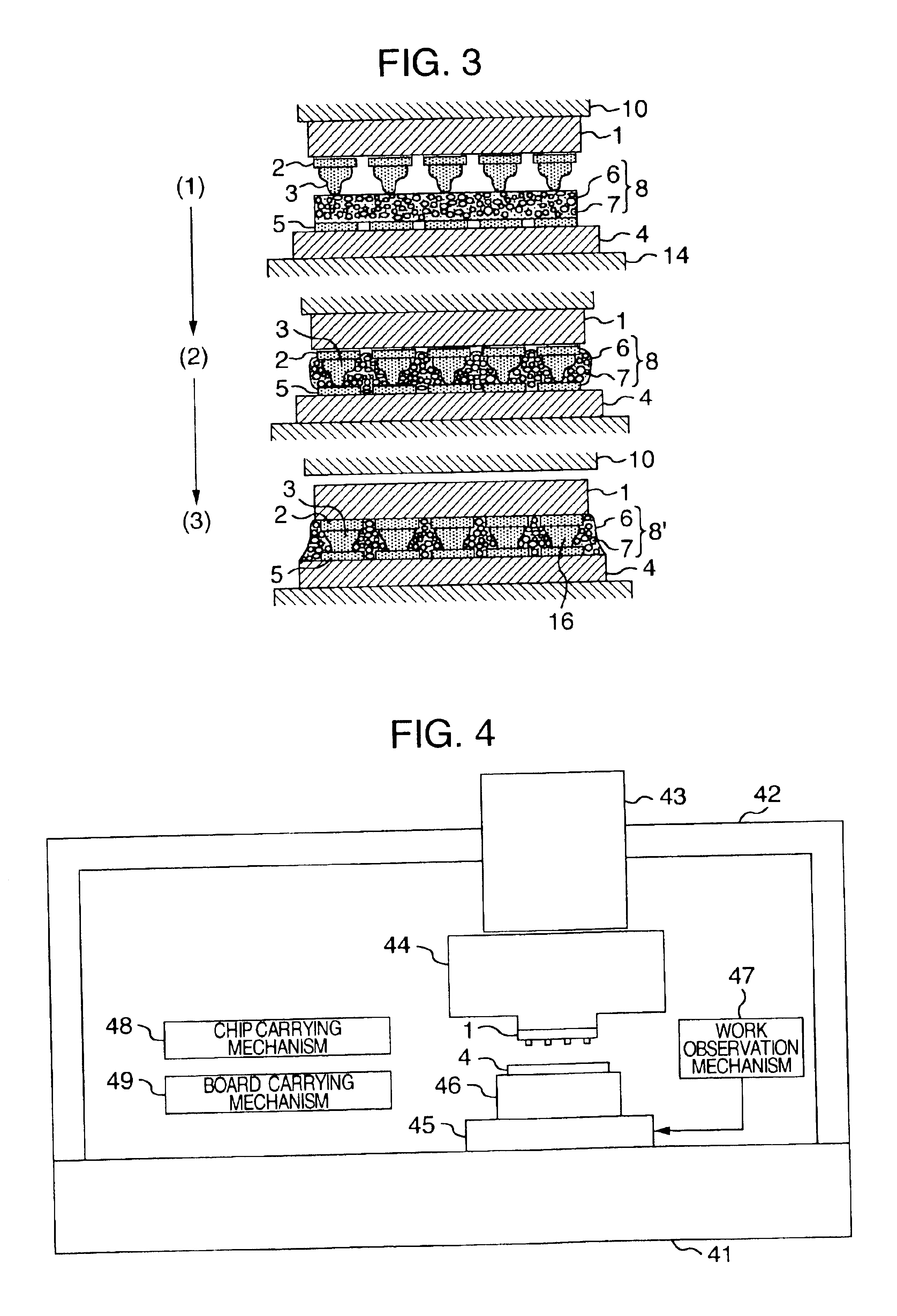

Flip chip assembly structure for semiconductor device and method of assembling therefor

InactiveUS6798072B2Improve productivityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialMetallic materials

A semiconductor device includes a semiconductor chip and a printed circuit board. Metal electrodes of the semiconductor chip and the internal connection terminals of the printed circuit board are electrically connected through the metallic joining via precious metal bumps. A melting point of a metal material constituting each of the metallic joining parts is equal to or higher than 275 degrees, and a space defined between the chip and the board is filled with resin (under fill) containing 50 vol % or more inorganic fillers.

Owner:HITACHI LTD

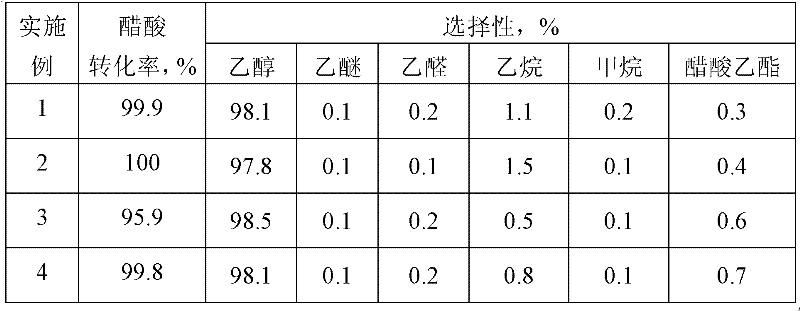

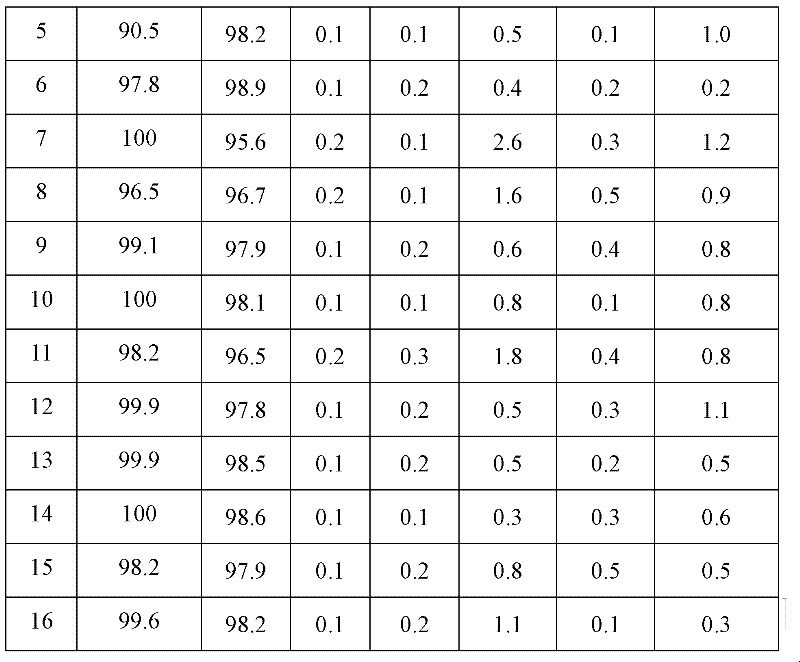

Method for preparing alcohol by acetic acid gas phase hydrogenation

ActiveCN102229520ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationHydroxy compound preparationACETIC ACID LIQUIDGas phase

The invention relates to a method for preparing alcohol by acetic acid gas phase hydrogenation. A reaction system comprises acetic acid, hydrogen and a catalyst; the reaction temperature is 120-300 DEG C; the reaction pressure is 1.0-20.0MPa; the space velocity of acetic acid liquid is 0.5-10.5h<-1>; the molar ratio of H2 to acetic acid is 1-250; the catalyst takes activated carbon as a carrier; and main active components comprise one or two of transitional metals such as W and Mo. The addition agent is one of or more of precious metals such as Pd, Re, Pt, Rh and Ru and the like; and the acetic acid and the hydrogen can be converted into alcohol with high activity and selectivity under the action of the catalyst.

Owner:JIANGSU SOPO CHEM +1

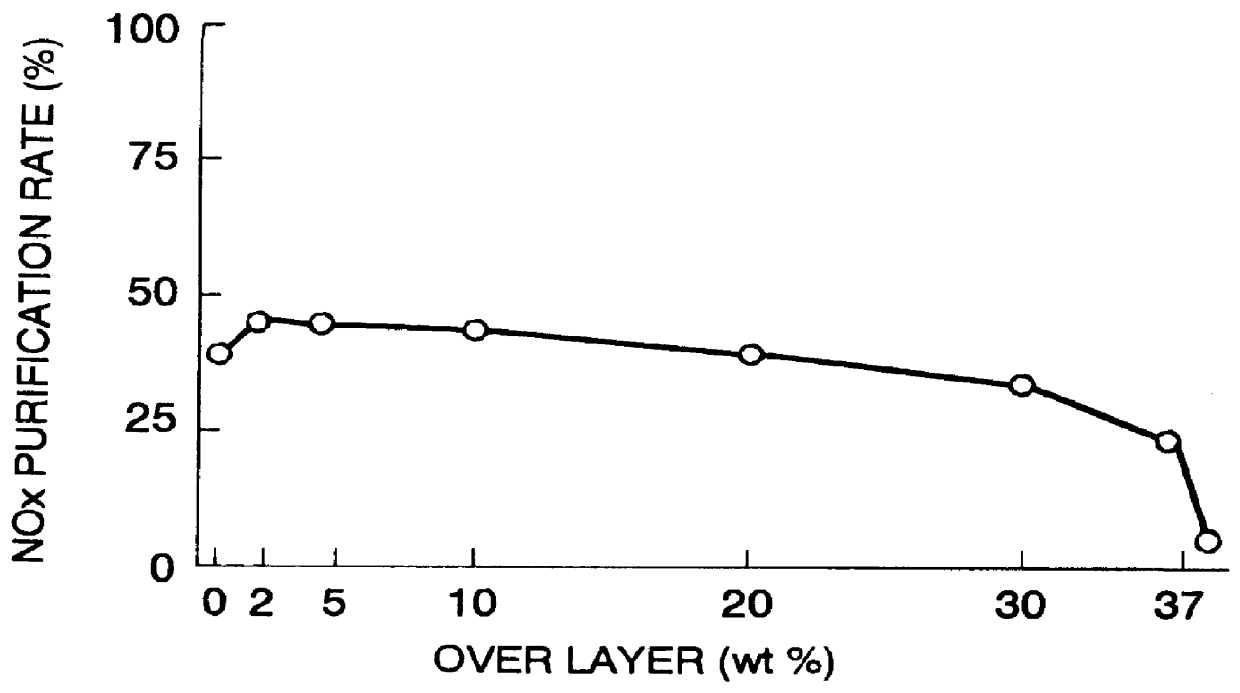

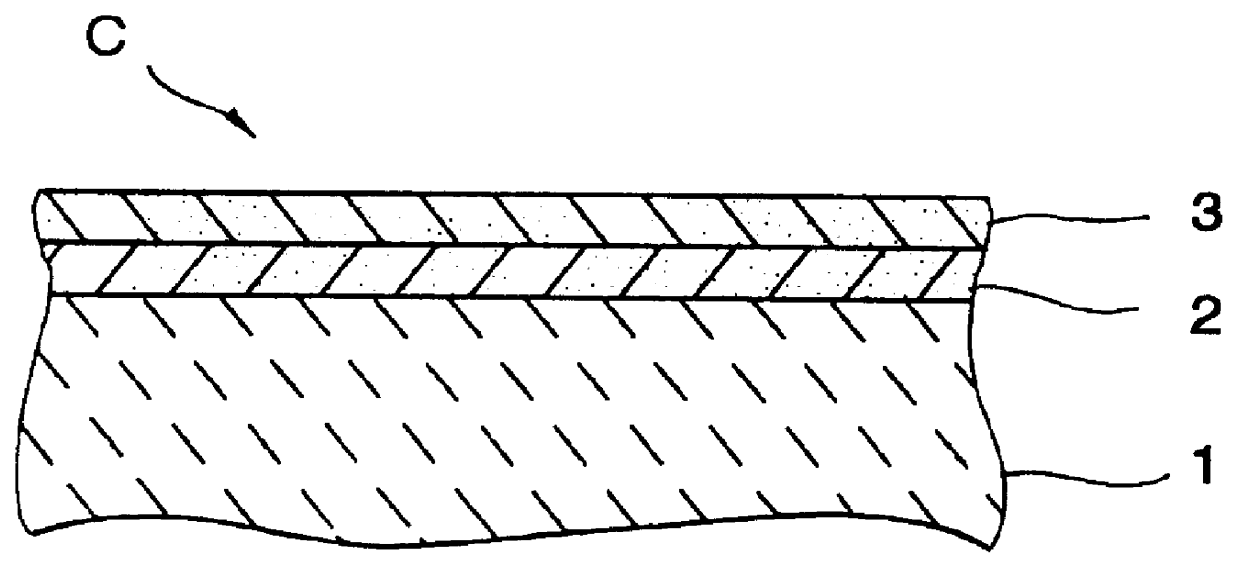

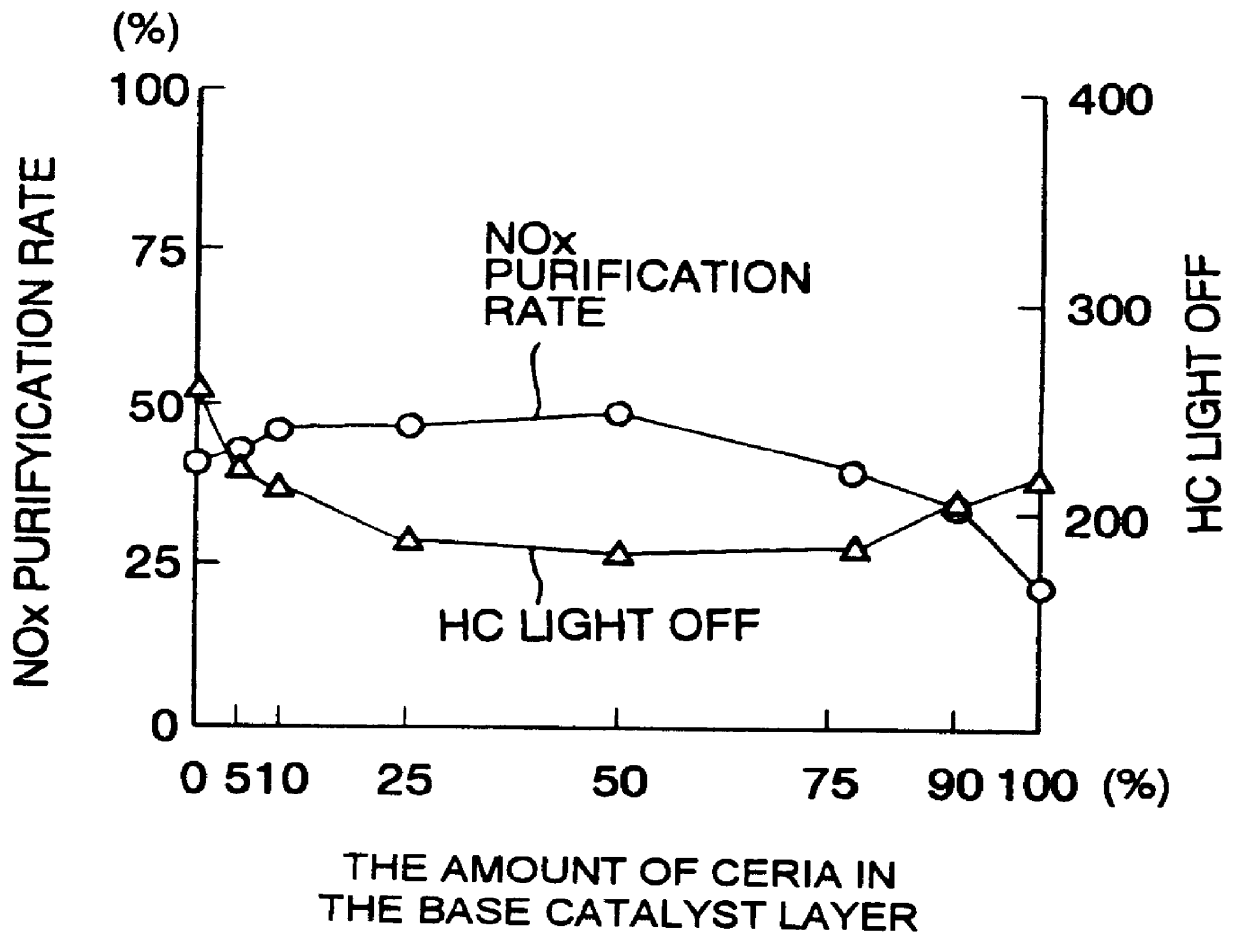

Catalyst for purifying exhaust gas

InactiveUS6066587AImprove responseImprove purification effectMolecular sieve catalystsInternal combustion piston enginesPlatinumPartial oxidation

A catalyst has a base catalyst layer containing platinum and barium as precious metal supported by alumina and an over catalyst layer containing platinum and rhodium as precious metal supported by zeolitr. The platinum and rhodium in the over catalyst layer activate NOx and HC so as to make them more reactive in terms of energy, and the barium in the base catalyst layer makes the platinum be more dispersive in the base catalyst layer. Under the existence of dispersive platinum, NOx in exhaust gas is decomposed and purified by reaction with reactive NO2 and partially oxidized HC generated in the over catalyst layer.

Owner:MAZDA MOTOR CORP

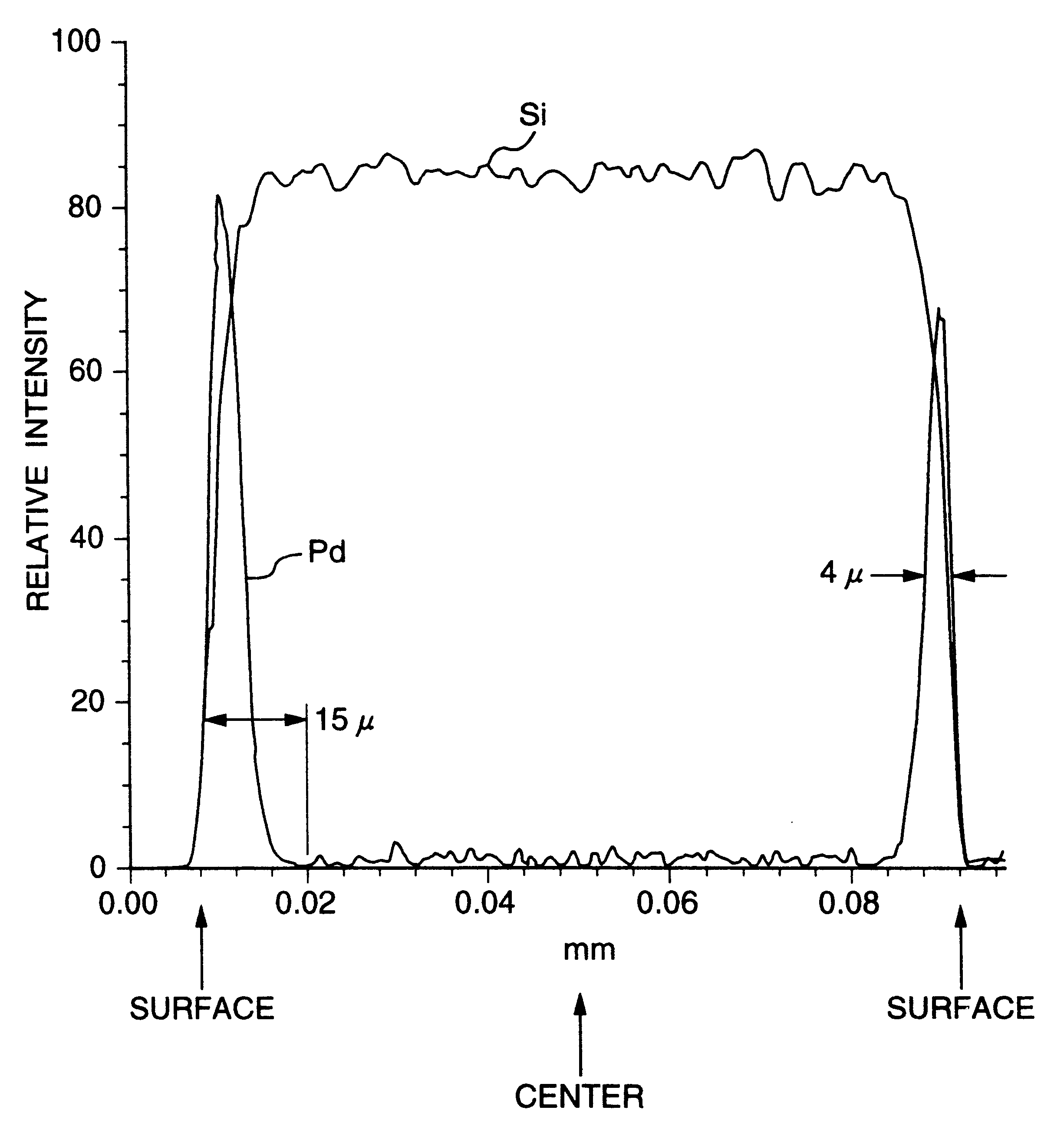

Noble metal support

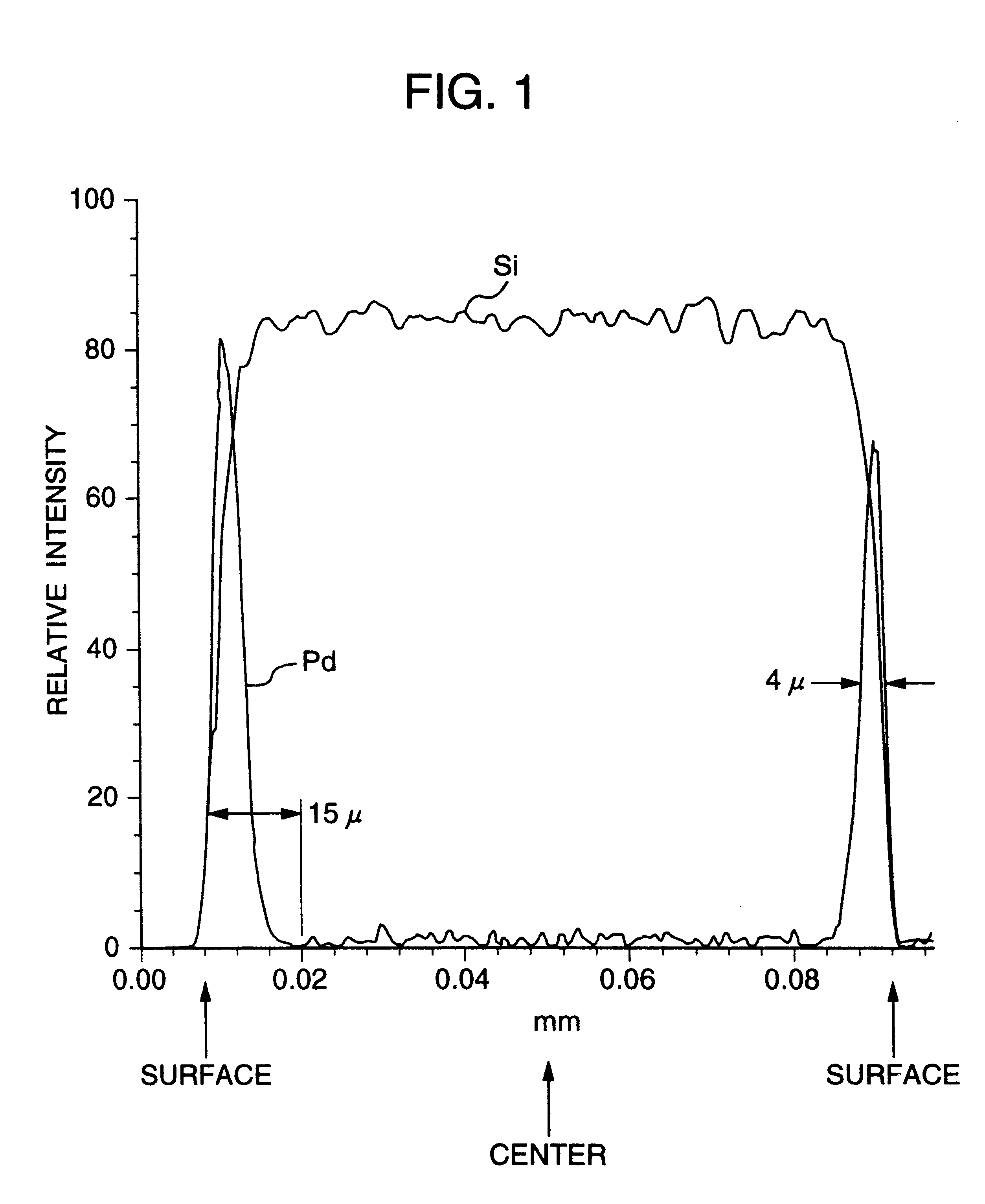

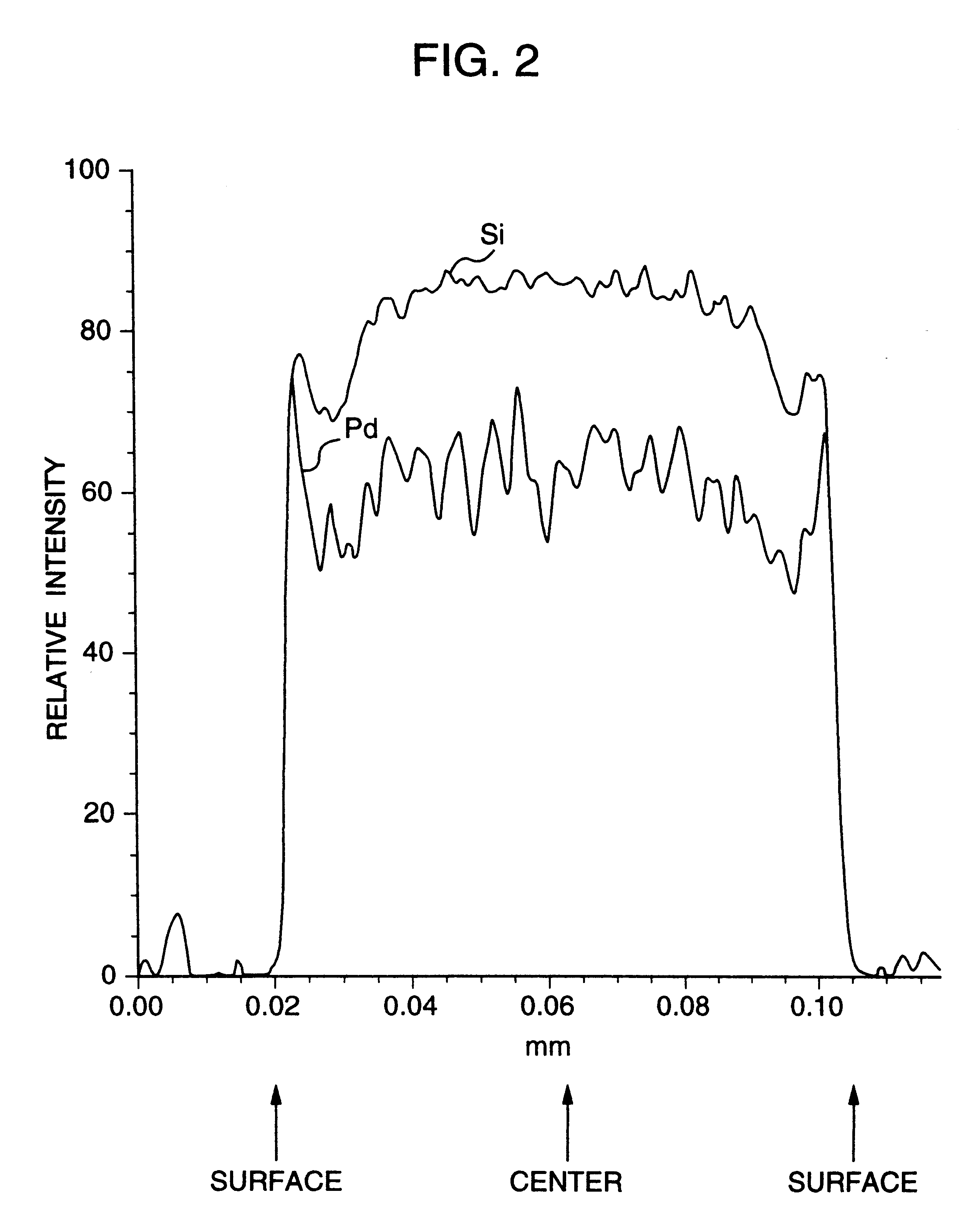

InactiveUS6228800B1Efficient use ofLong catalyst lifeOrganic compound preparationCatalyst activation/preparationPalladiumChemistry

A noble metal-supported article which comprises a carrier and a palladium-containing metal component supported on the carrier, which article has (A) a layer in which substantially no palladium is supported in the interior of the carrier and (B) a layer in which palladium is supported in the region from the outer surface to a depth of less than 100 mum of the carrier.

Owner:ASAHI KASEI KK

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

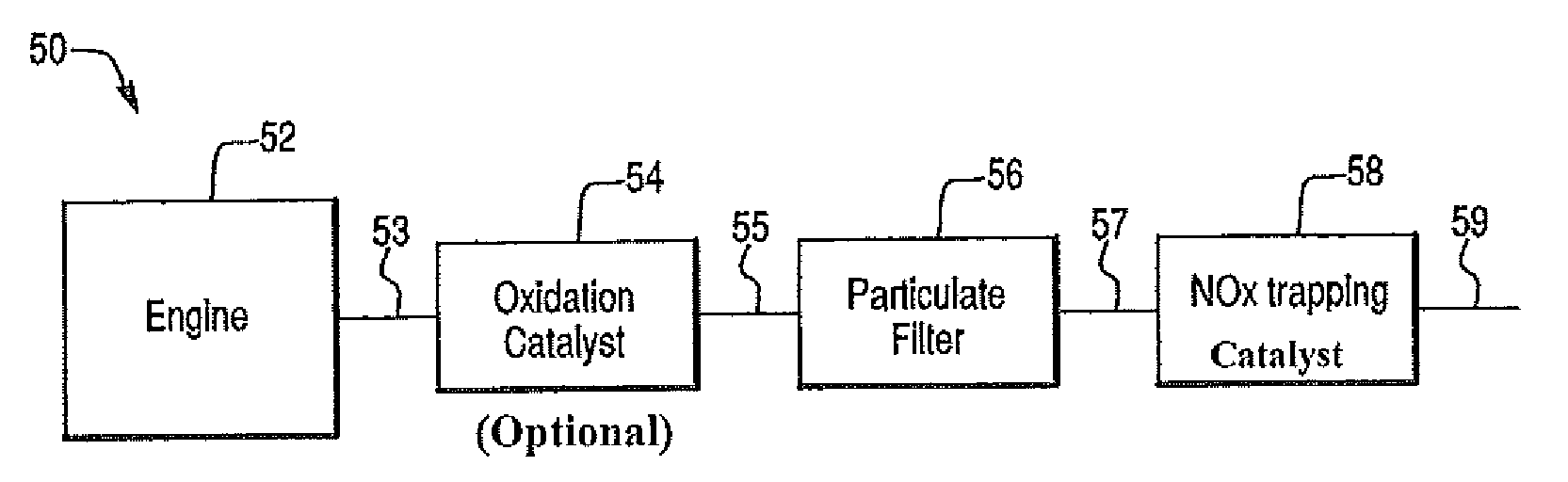

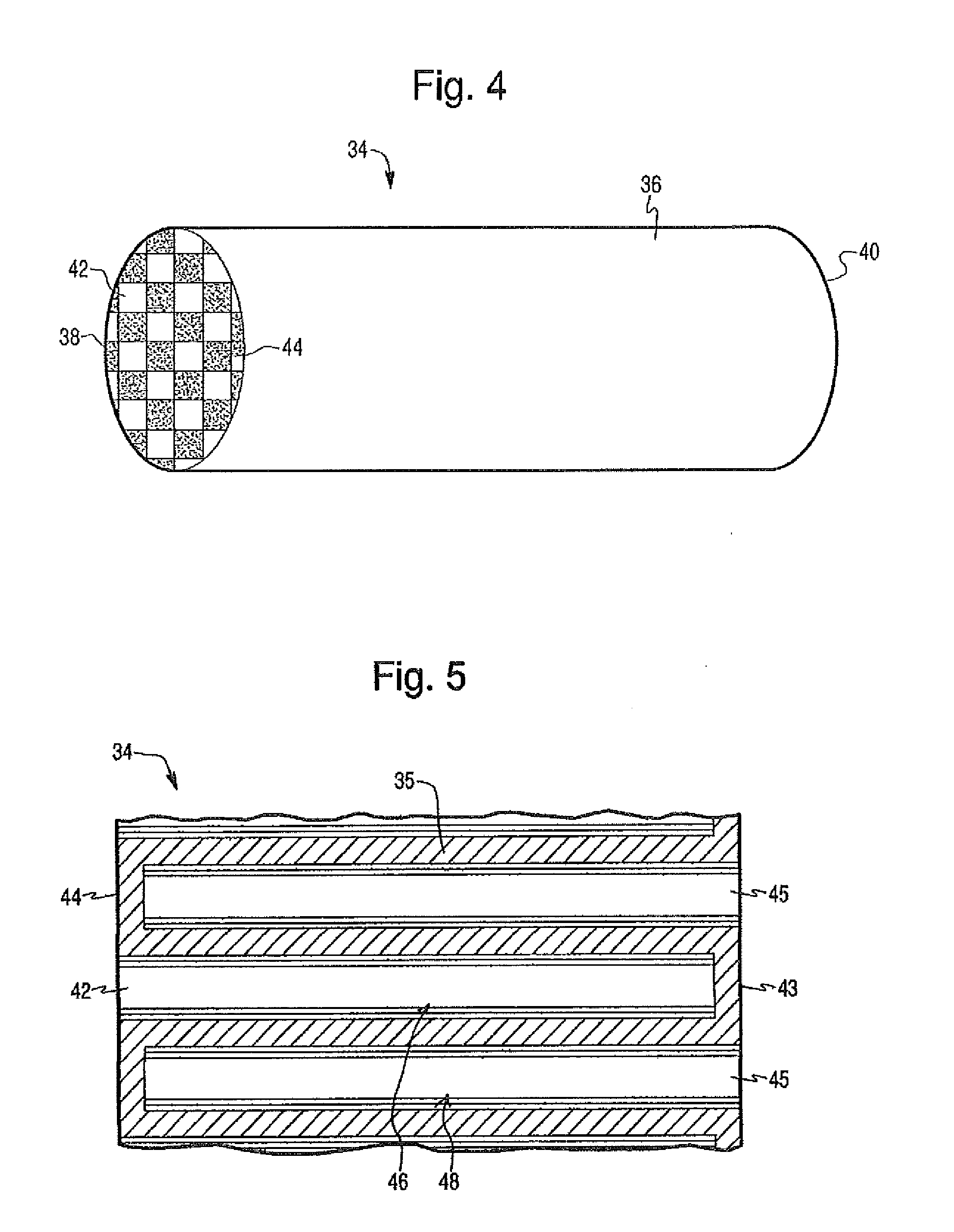

NOx Adsorber Catalyst with Superior Low Temperature Performance

The lean NOx trap catalyst composition of the present invention comprises distinct layers, or zone configuration or multi-brick arrangement. The top layer, front zone or front brick is free of any alkali or alkaline earth NOx trapping components. The under layer, rear zone or rear brick may contain any desirable NOx trapping component in contact with a precious metals group catalyst (e.g., Pt). Catalysts of this invention show wide temperature operation window with superior low temperature performance.

Owner:BASF CORP

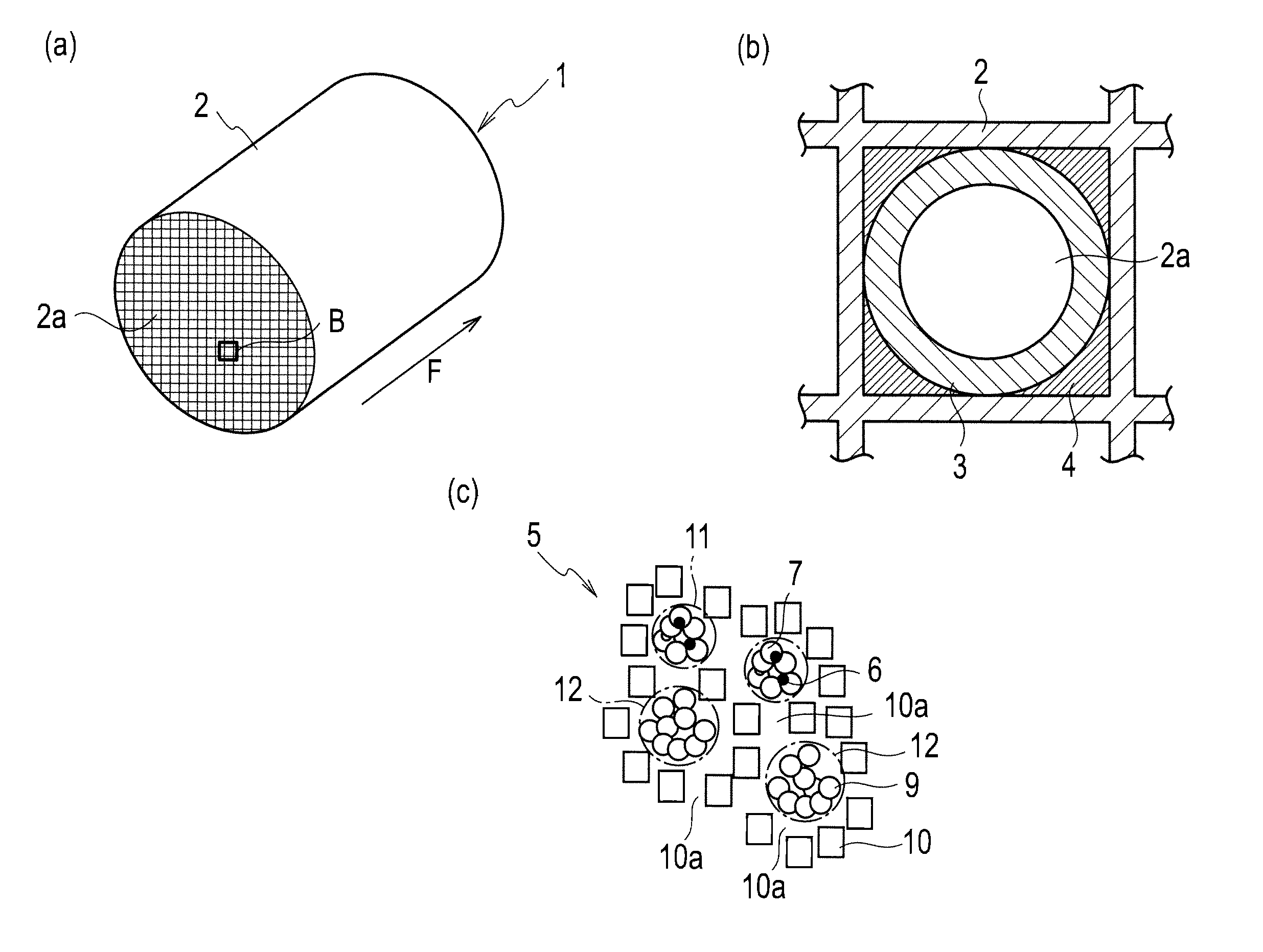

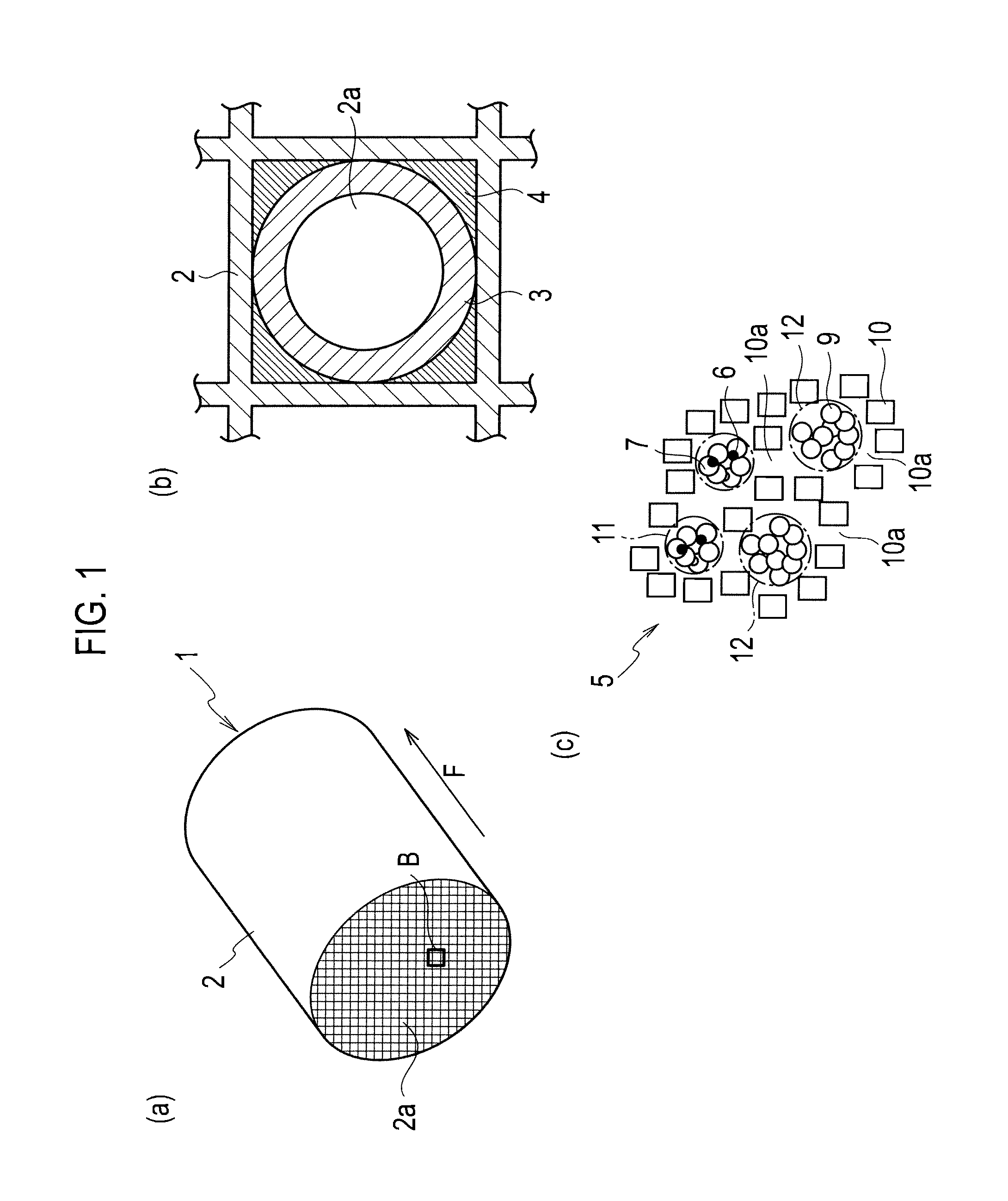

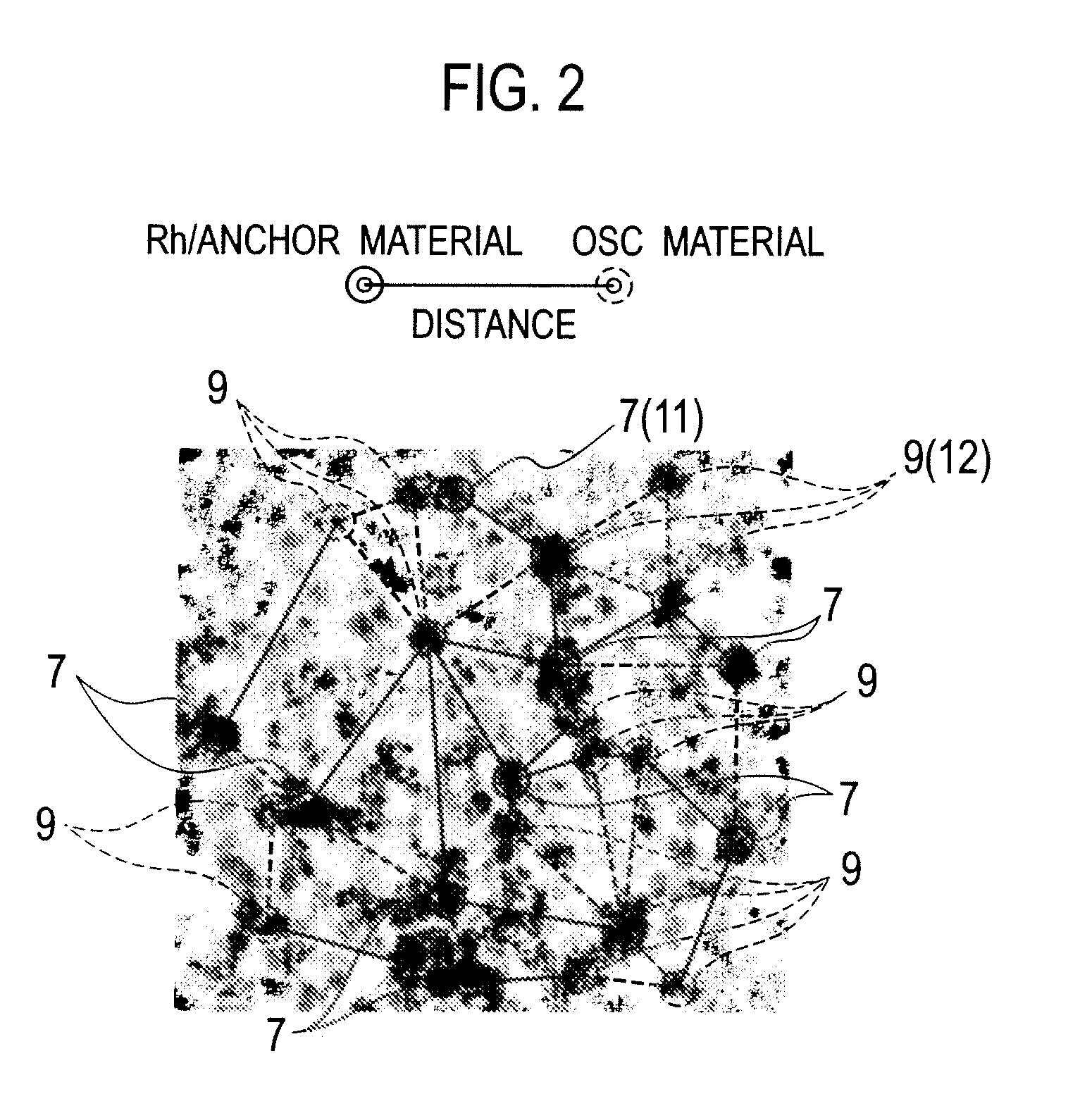

Exhaust gas purifying catalyst and method for manufacturing the same

ActiveUS8486853B2Increased durabilityImprove performanceInternal combustion piston enginesOther chemical processesExhaust fumesExhaust gas

Owner:NISSAN MOTOR CO LTD

Process for preparing noble metal nanoparticles

A process for preparing metal nanoparticles, comprising reacting suitable metal salts and anionic surfactant containing an anionic group of carboxylic group (COO-), sulfate group (SO42-) or sulfonate group (SO32-) as reducing agent in water under reflux at a temperature of 50-140° C., such that under the reducing power of said anionic surfactant itself, the metal salts can be effectively reduced into metal nanoparticles having a uniform particle size and that the reaction will be not too fast, no large microparticle will be formed, the yield will not be lowered, and the nanoparticle thus prepared can be dispersed stably in polar and non-polar solvent.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

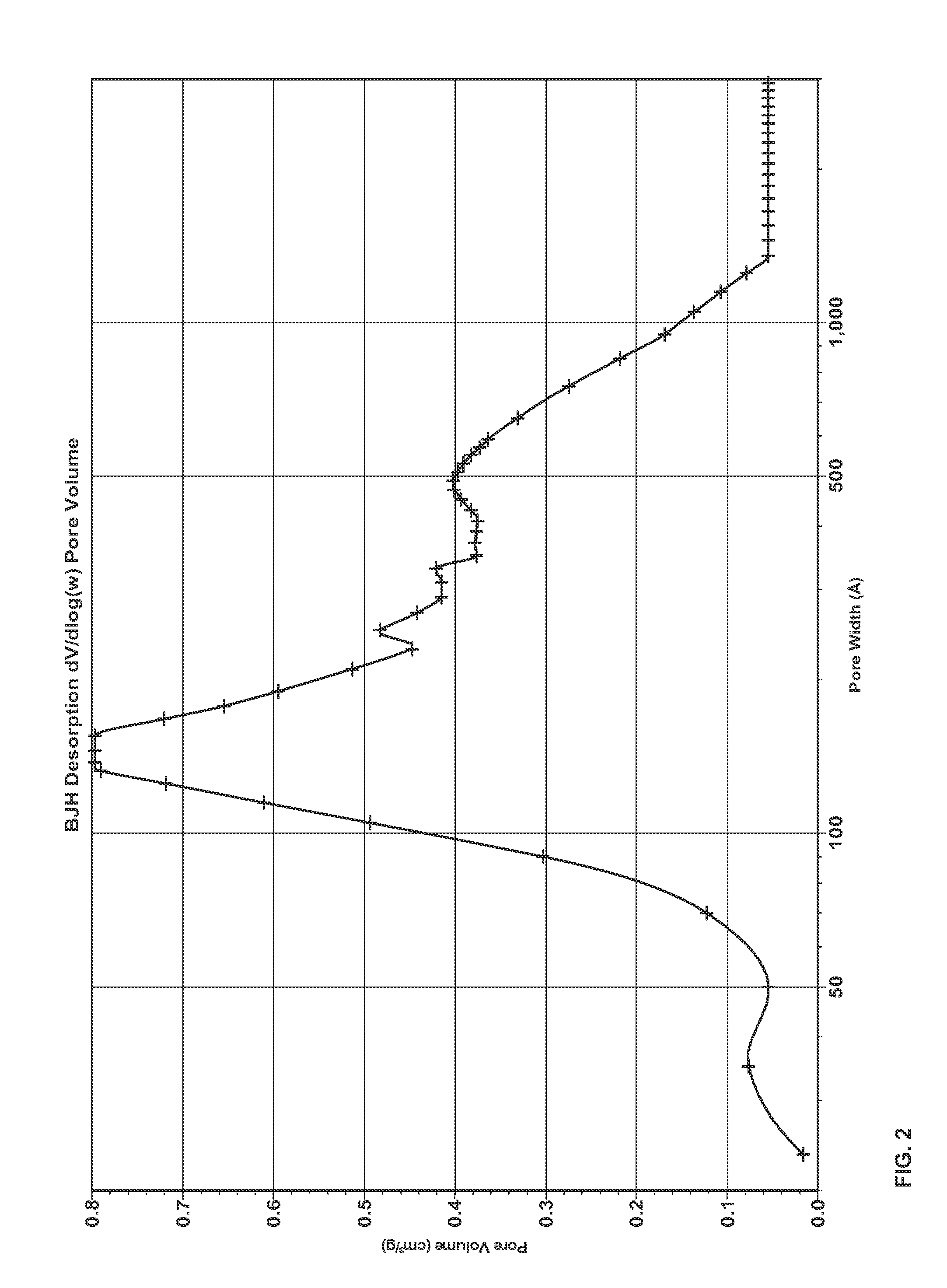

Porous inorganic composite oxide

ActiveUS20120129690A1Improve thermal stabilityHigh pore volumeHeat treatmentsInternal combustion piston enginesPtru catalystCerium

A porous inorganic composite oxide containing oxides of aluminum and of cerium and / or zirconium, and, optionally, oxides of one or more dopants selected from transition metals, rare earths, and mixtures thereof, and having a specific surface area, in m2 / g, after calcining at 1100° C. for 5 hours, of ≧0.8235[Al]+11.157 and a total pore volume, in cm3 / g, after calcining at 900° C. for 2 hours, of ≧0.0097[Al]+0.0647, wherein [Al] is the amount of oxides of aluminum, expressed as pbw Al2O3 per 100 pbw of the composite oxide; a catalyst containing one or more noble metals dispersed on the porous inorganic composite oxide; and a method for making the porous inorganic composite oxide.

Owner:RHODIA OPERATIONS SAS

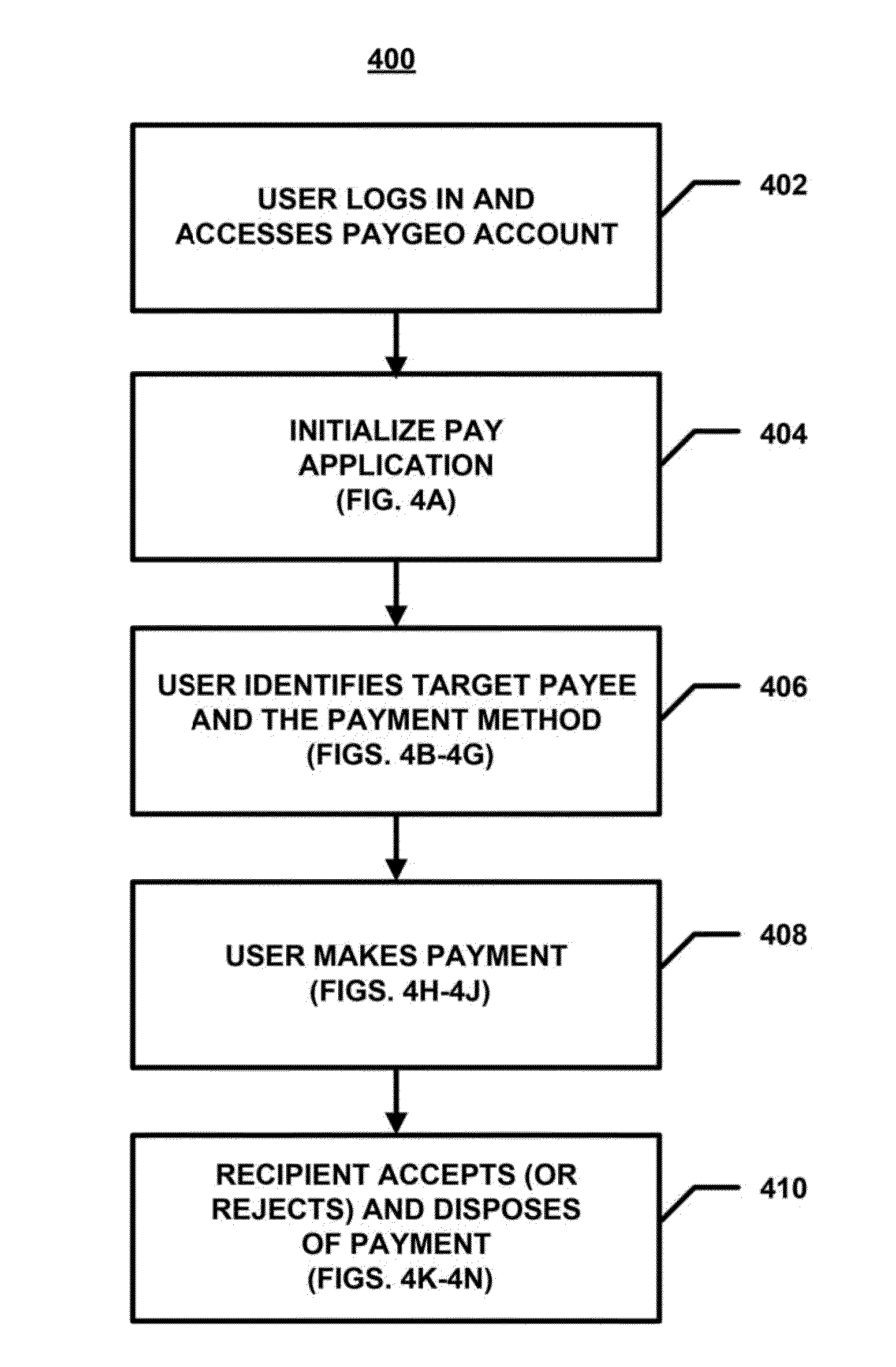

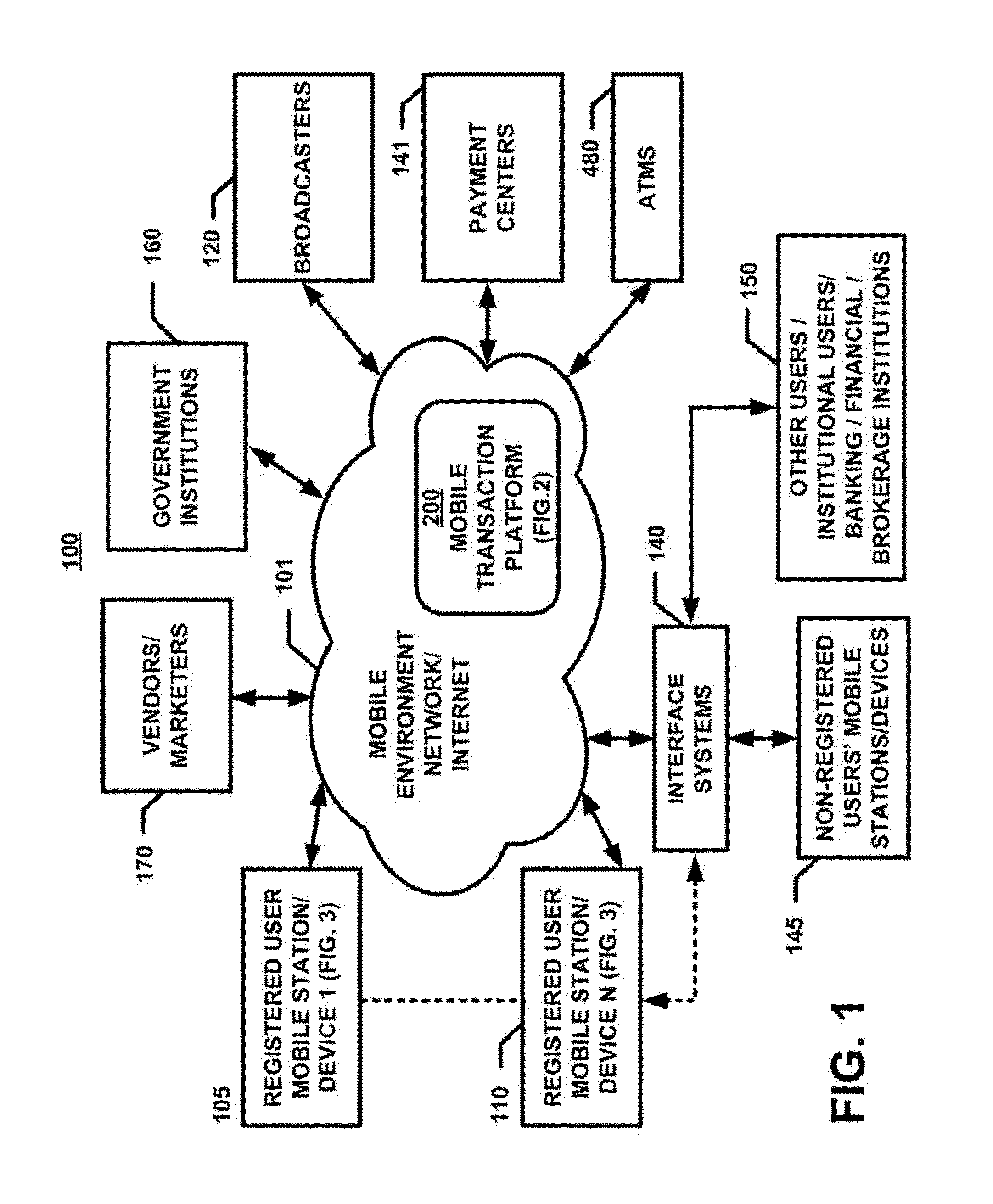

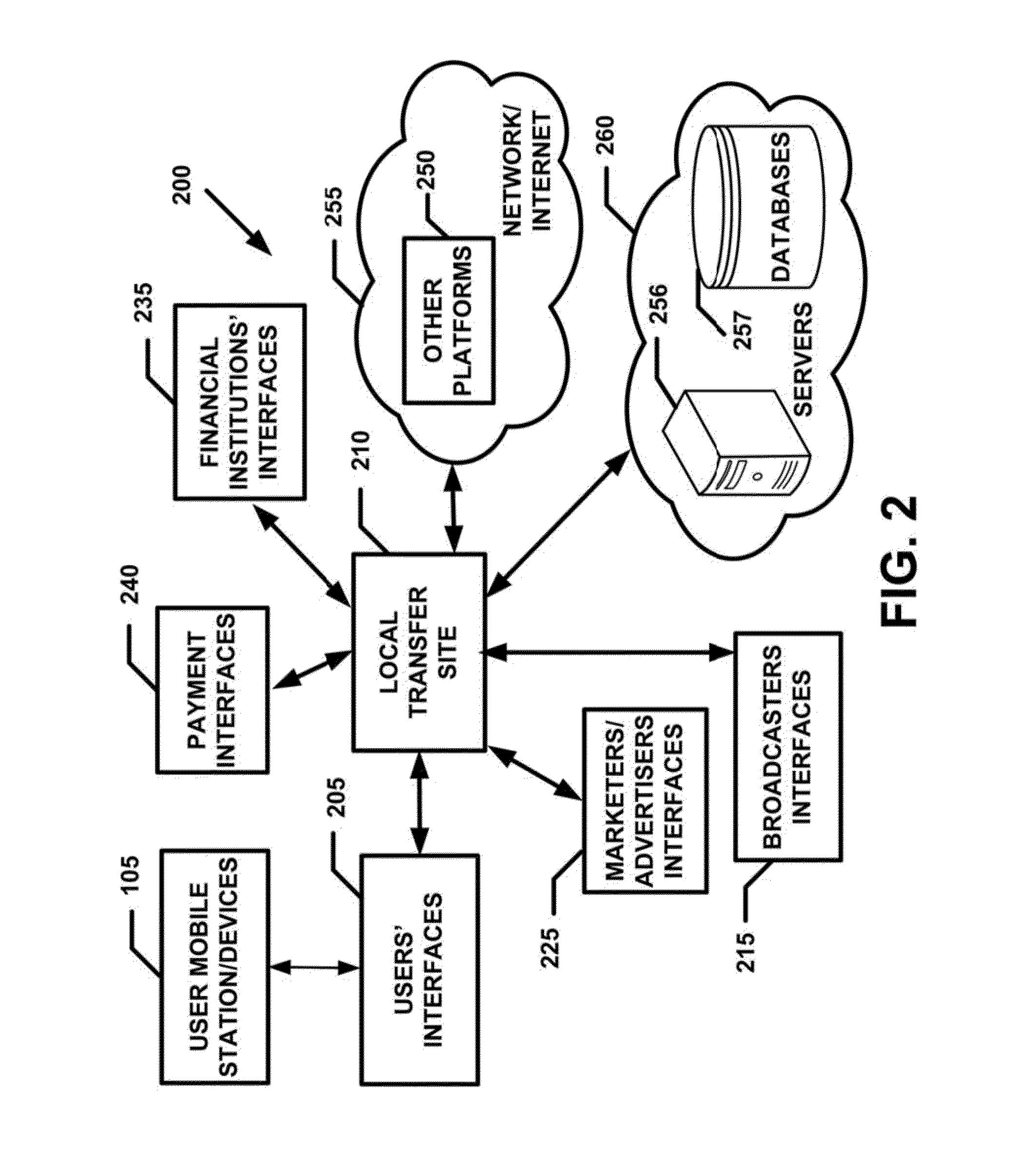

System And Associated Method And Service For Providing A Platform That Allows For The Exchange Of Cash Between Members In A Mobile Environment

ActiveUS20130024360A1Eliminate wastePrecise positioningComplete banking machinesFinanceFinancial transactionMobile context

A system and associated method and service for providing a platform that enables members to transfer, receive, or otherwise exchange cash in various international denominations and commodities, such as precious metals (e.g., gold, silver, etc.), in a mobile highly secured telecommunications environment. The system is capable of delivering cash instantly between two or more users by allowing the exchange of secure transactions between system and cash dispensing machines (ATMs). Users may pay, receive, exchange, deposit, transfer, pay bills, exchange currency, retrieve cash, deposit cash and create accounts based on the mobile phone number or a system generated code.

Owner:BALLOUT RABIH SALEM

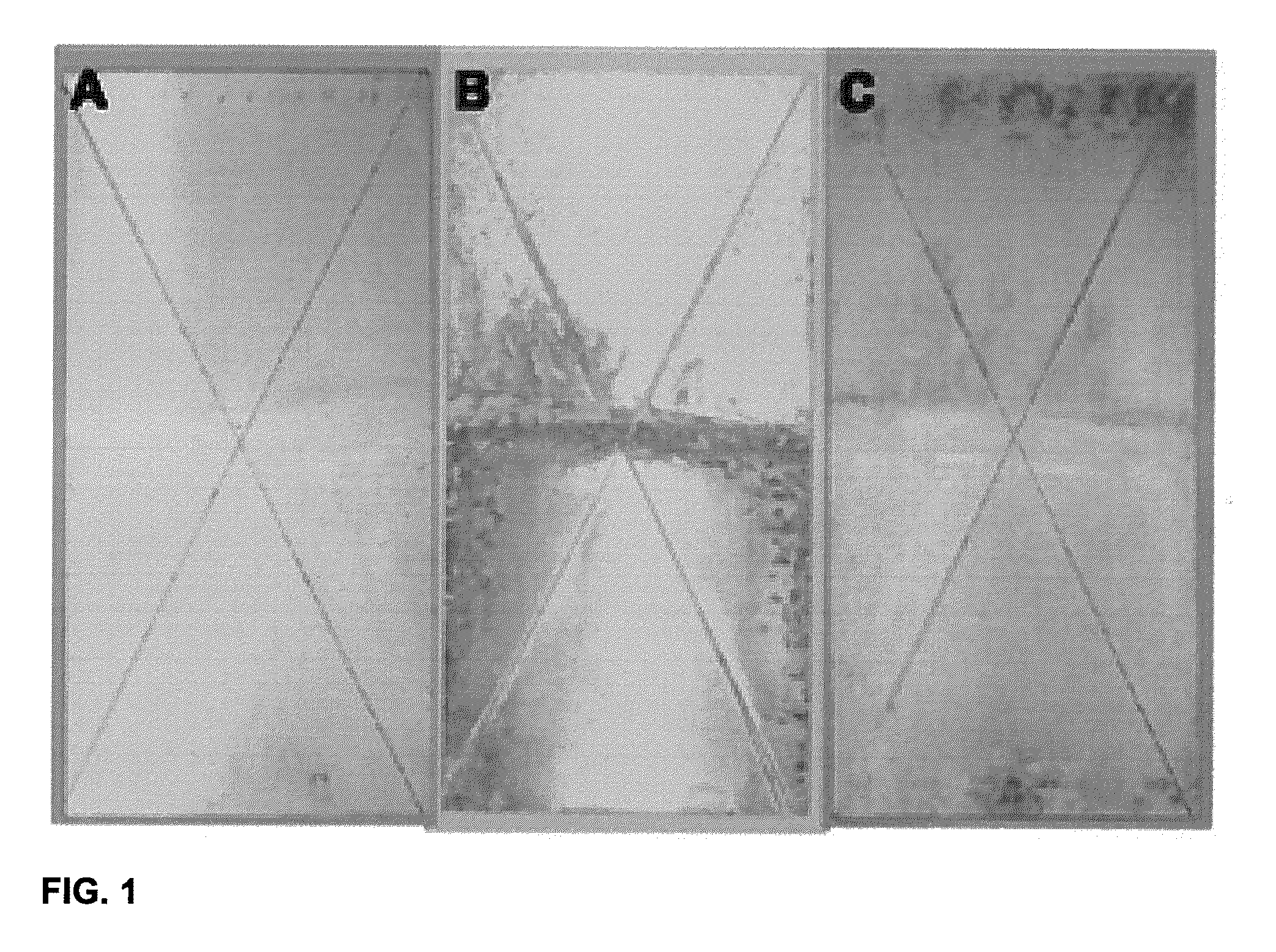

Silsesquioxane derived hard, hydrophobic and thermally stable thin films and coatings for tailorable protective and multi-structured surfaces and interfaces

ActiveUS20110062619A1Attractive balanceImprove scratch resistanceNanoinformaticsPhotomechanical apparatusDiluentRare earth

A method of forming a coating comprising the steps of dissolving an silsesquioxane (e.g., one that is primarily a cage compound with 8, 10, 12, 14 or related complete cages or with partially condensed cages containing primarily Si(O)4 units in the cage) in a solvent to form an silsesquioxane solution; introducing (e.g., dissolving) an additive in the solution (e.g., the additive being selected from a rare earth compound, an acid, an organic moiety, a precious metal or compound thereof, a transition metal compound, or any combination thereof, or any of their ionic constituents); and optionally mixing a diluent with the solution to form a coating that is applied to a substrate, wherein the resulting coating forms crosslinks between resulting pendant Si(OH)x groups and a substrate surface. The present invention also contemplates coatings and coated articles consistent with the present teachings.

Owner:LAINE RICHARD M

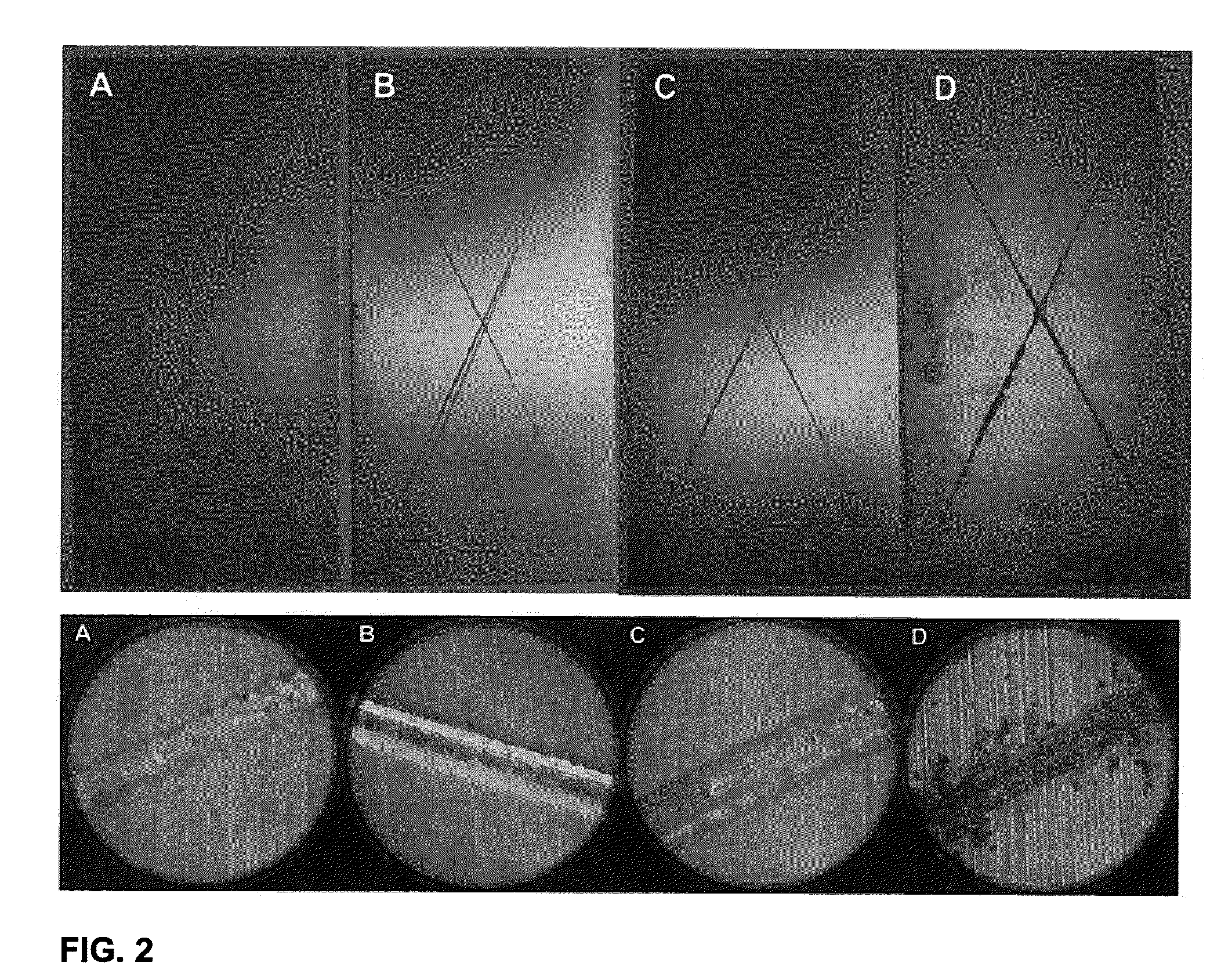

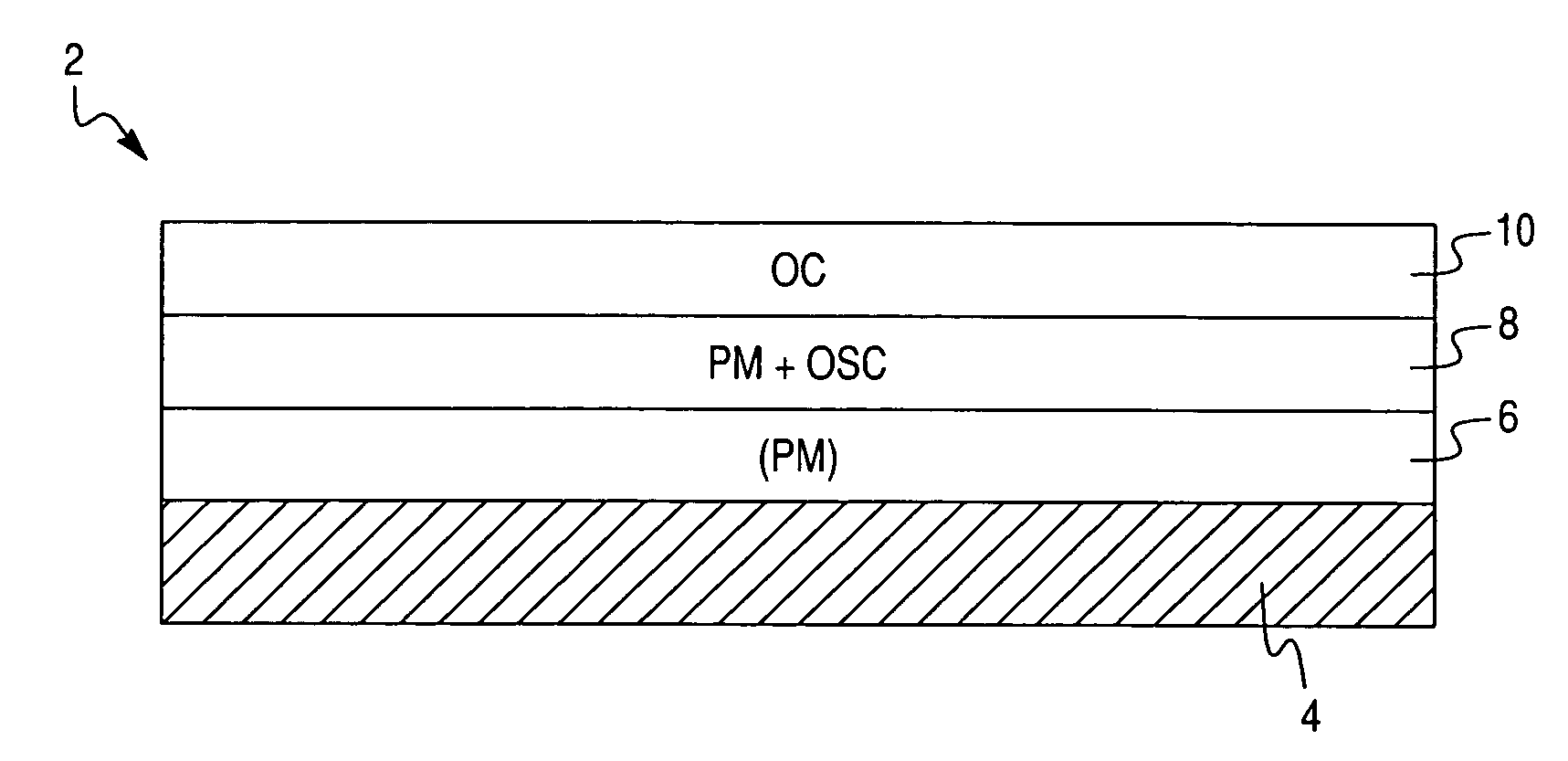

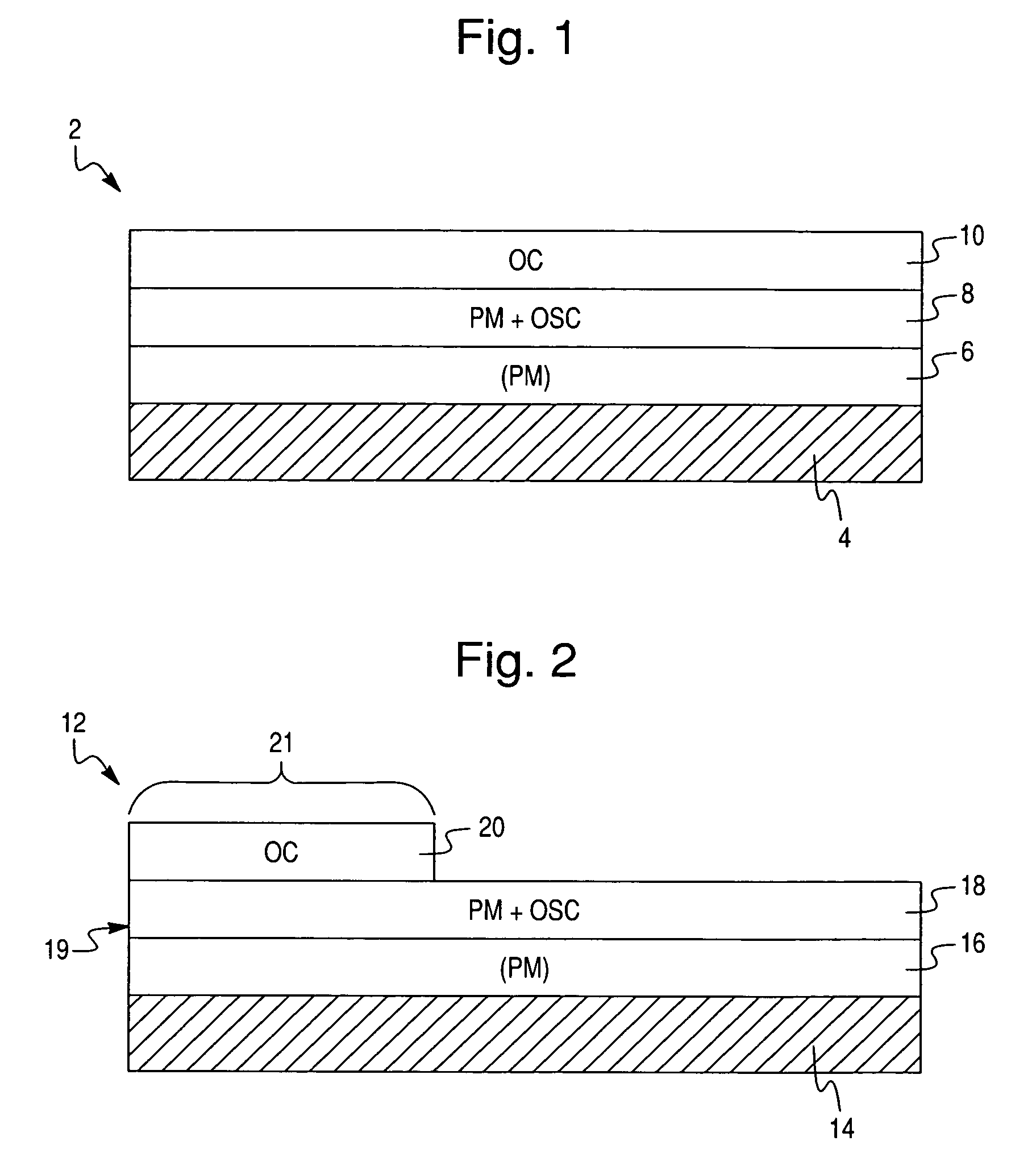

Phosgard, a new way to improve poison resistance in three-way catalyst applications

ActiveUS7749472B2Mitigates deleterious poisoning of a catalytic memberPreventing and reducing fouling and poisoningNitrogen compoundsInternal combustion piston enginesToxicantRefractory

The present invention provides for novel poisoning-resistant catalysts used for automobile exhaust gas treatment systems. To alleviate the detrimental affects of engine oil and / or fuel additive poisoning the present invention provides for an overcoat layer comprising a porous refractory oxide and one or more base metal oxides, which is coated over one or more precious metal containing washcoat layers. The overcoat of the present invention prevents phosphorous as well as other poisoning deposits, from fouling and / or negatively interacting with the underlying precious metal containing washcoats. In an alternative embodiment, the present invention provides for the coating of the upstream end of a catalytic member by the overcoat layer, thereby creating an upstream poison capture zone.

Owner:BASF CORP

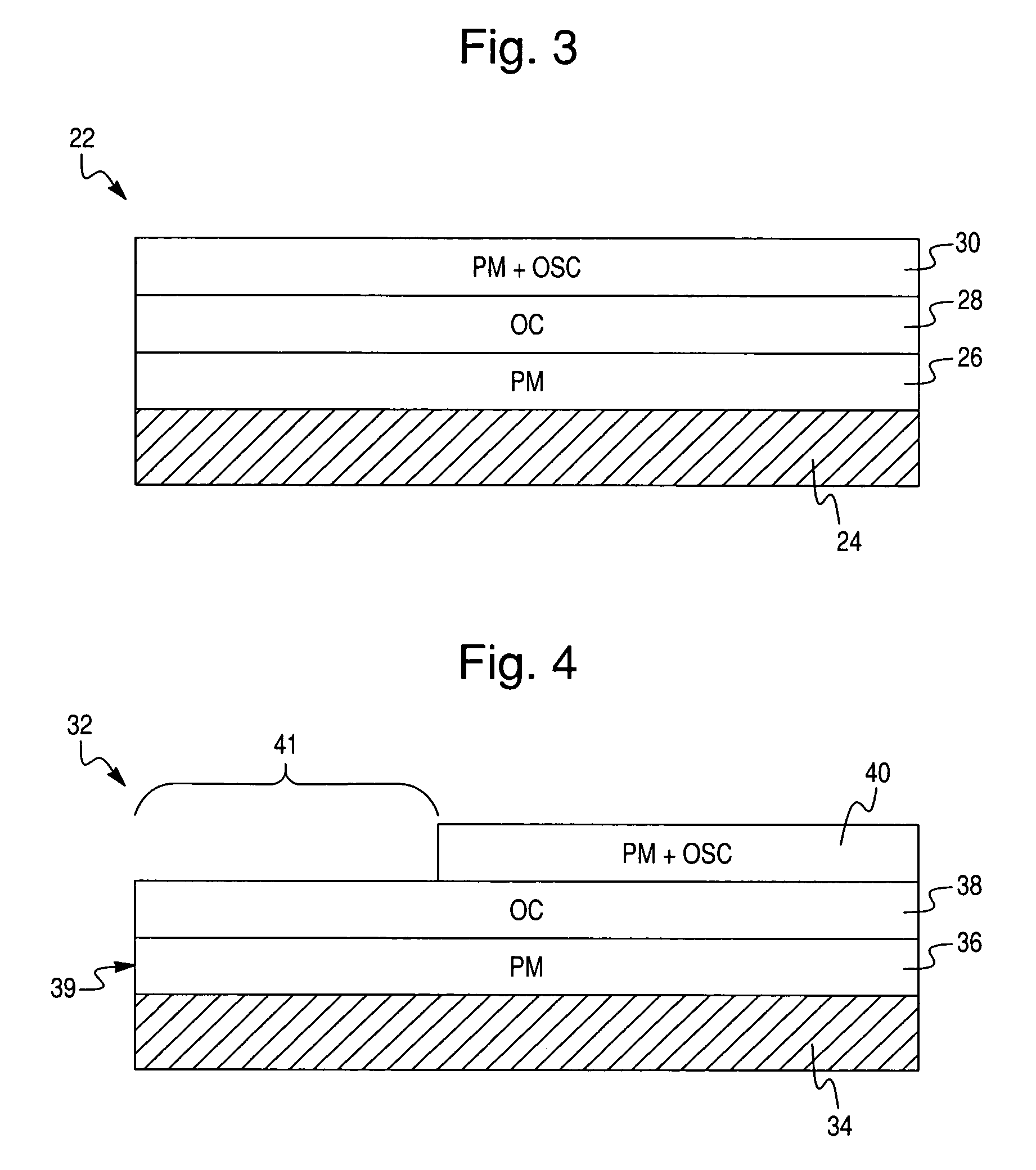

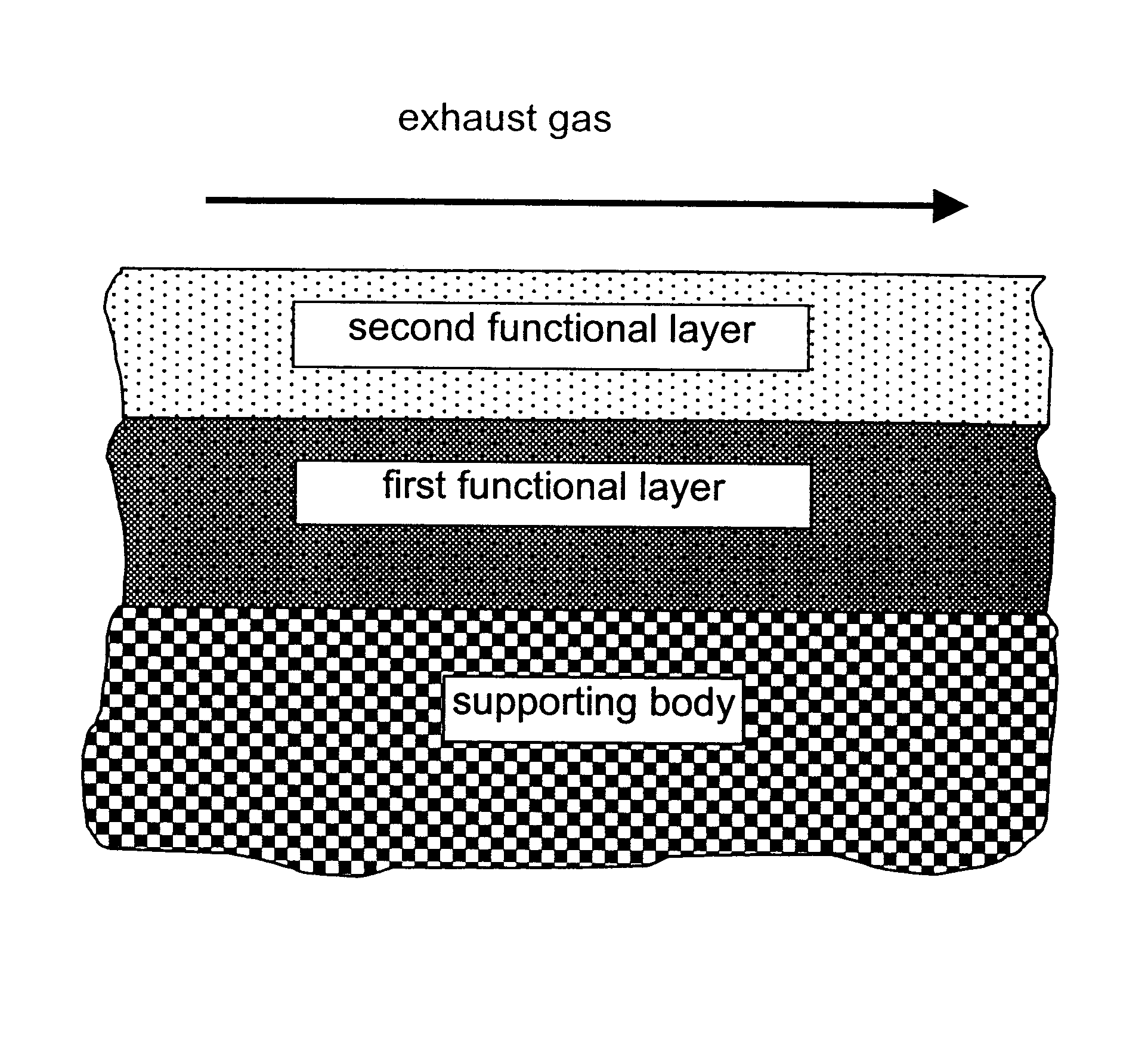

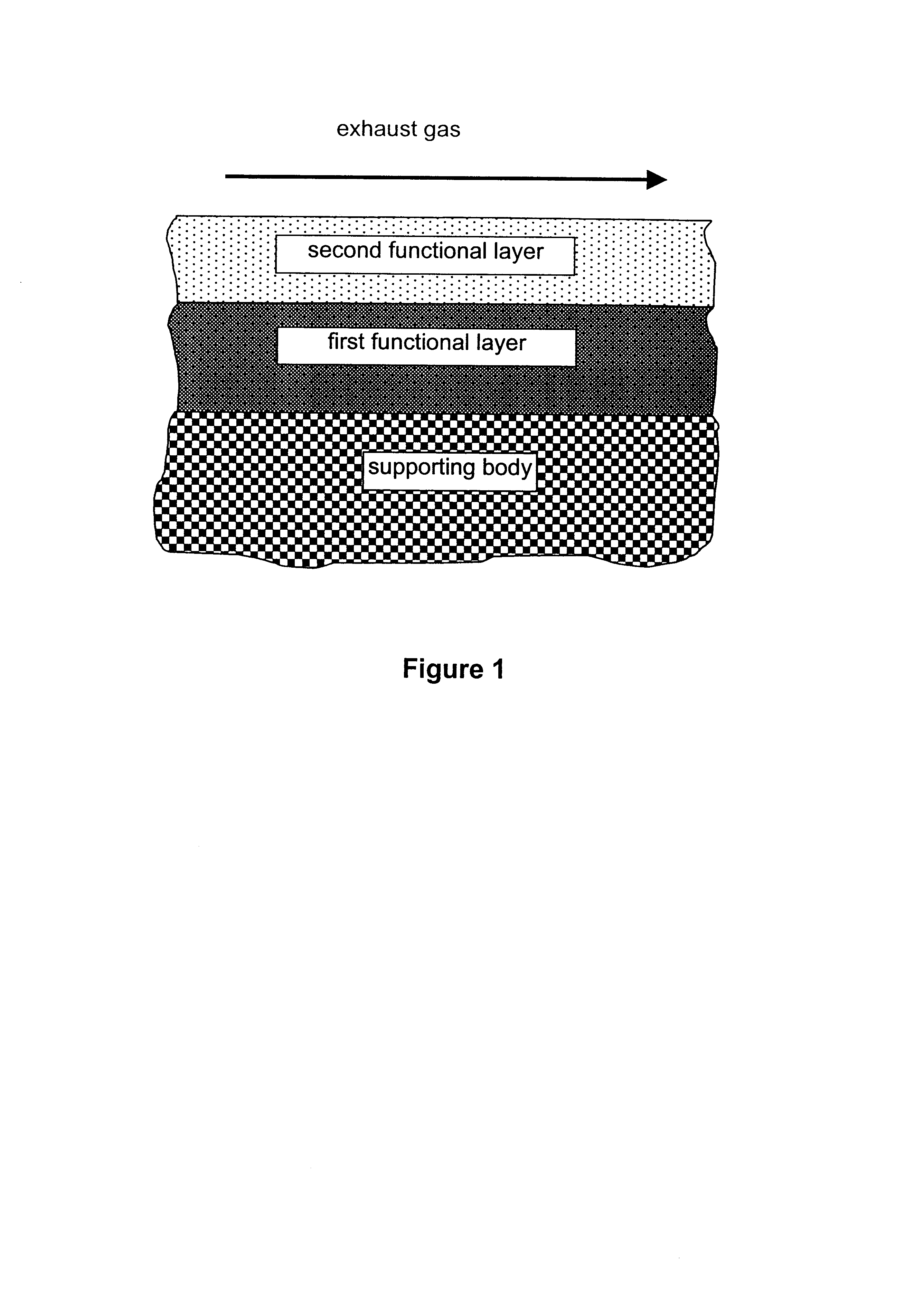

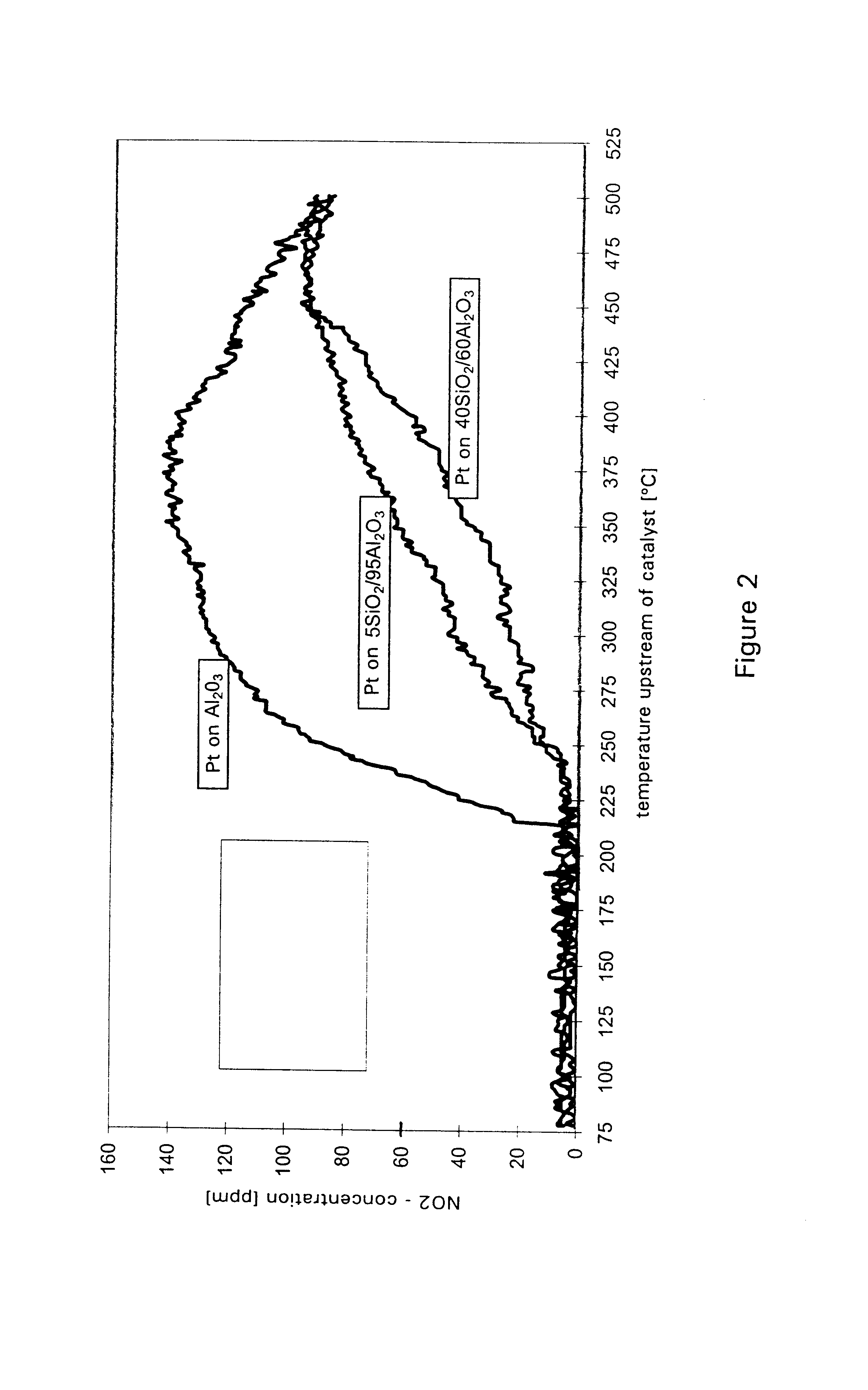

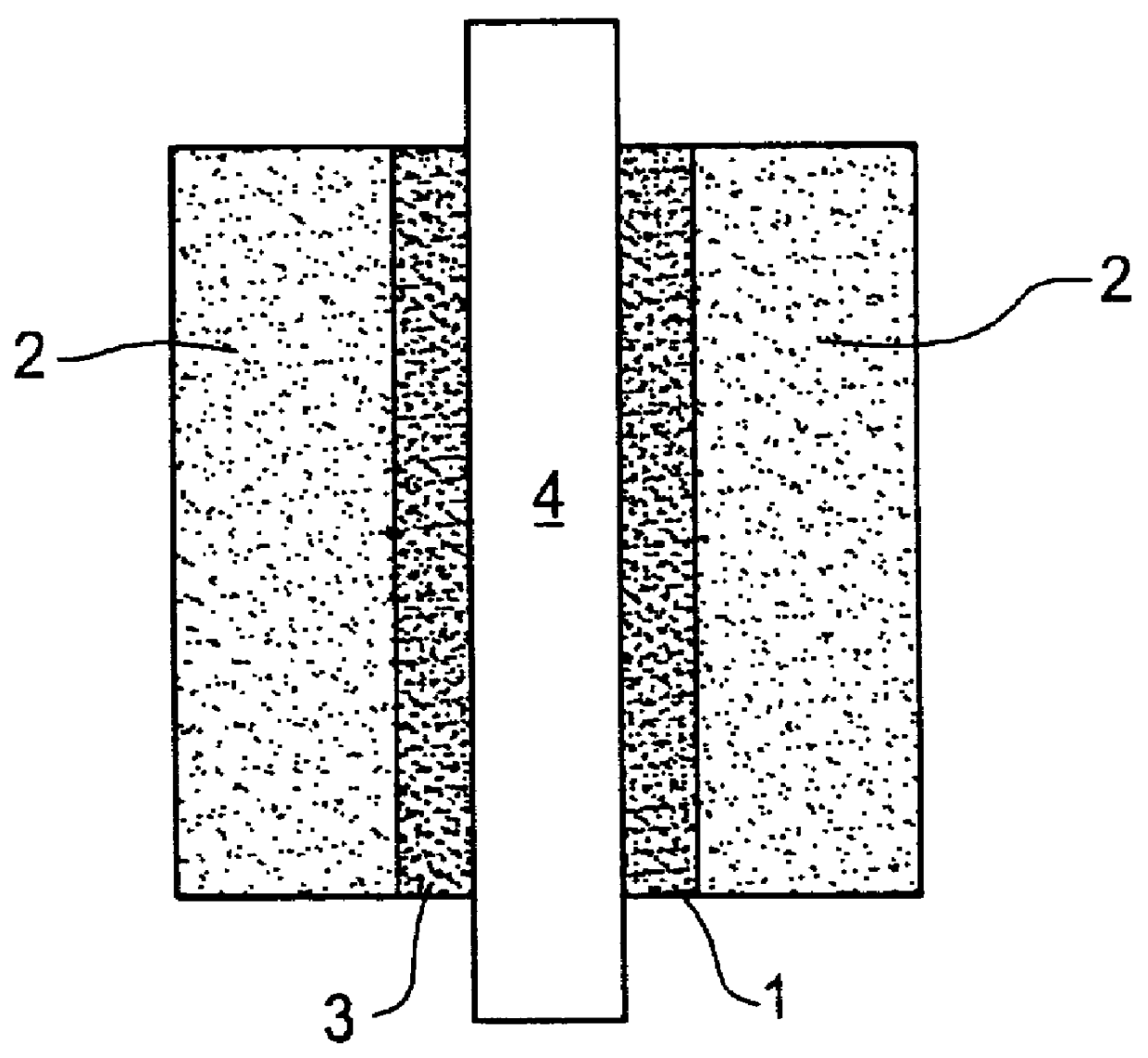

Catalyst for cleaning up the exhaust gases of a diesel engine

InactiveUS6677264B1Reduced activityReduce componentsMolecular sieve catalystsInternal combustion piston enginesCatalytic functionComponents of crude oil

A catalyst for purifying exhaust gases of a diesel engine. The catalyst contains two functional layers superimposed on an inert supporting body, whereby the first layer, which is situated directly on the supporting body, has a nitrogen oxide storage function and the second layer, which is in direct contact with the exhaust gas, has a catalytic function. The second functional layer additionally has a hydrocarbon-storage function and its catalytic function is provided by catalytically active noble metals of the platinum group which are deposited in highly dispersed form on finely divided, acidic carrier materials. Nitrogen oxides in the oxygen-rich exhaust gas of a diesel engine can be converted with optimal utilization of the reductive constituents contained in the exhaust gas. For this purpose, no reducing agents going beyond the reductive components (carbon monoxide and hydrocarbons) which are contained as a consequence of incomplete combustion need to be added to the exhaust gas. Nevertheless, rates of conversion in respect of the nitrogen oxides are obtained, averaged over practical driving cycles, which lie distinctly above the rates of conversion of conventional reduction catalysts.

Owner:UMICORE AG & CO KG +1

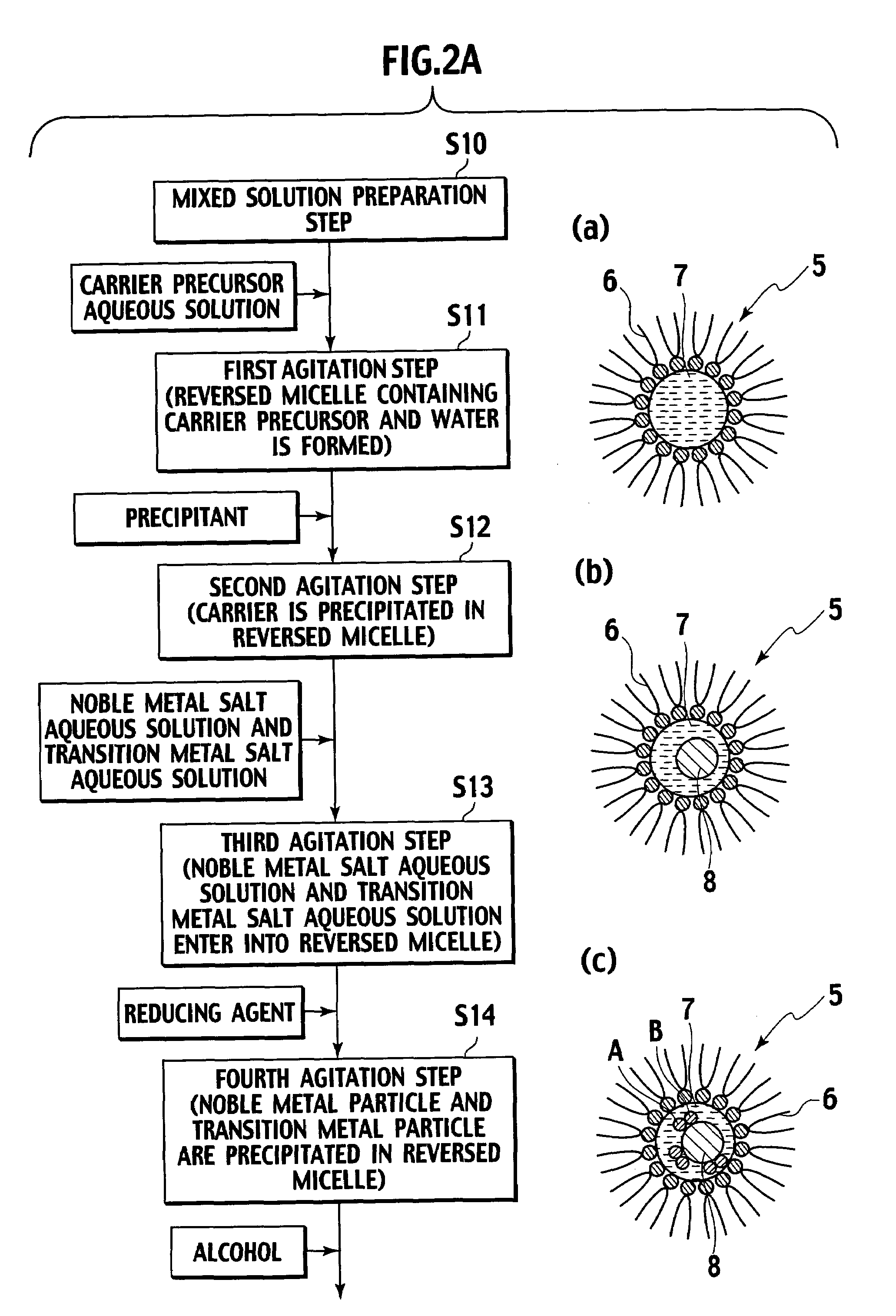

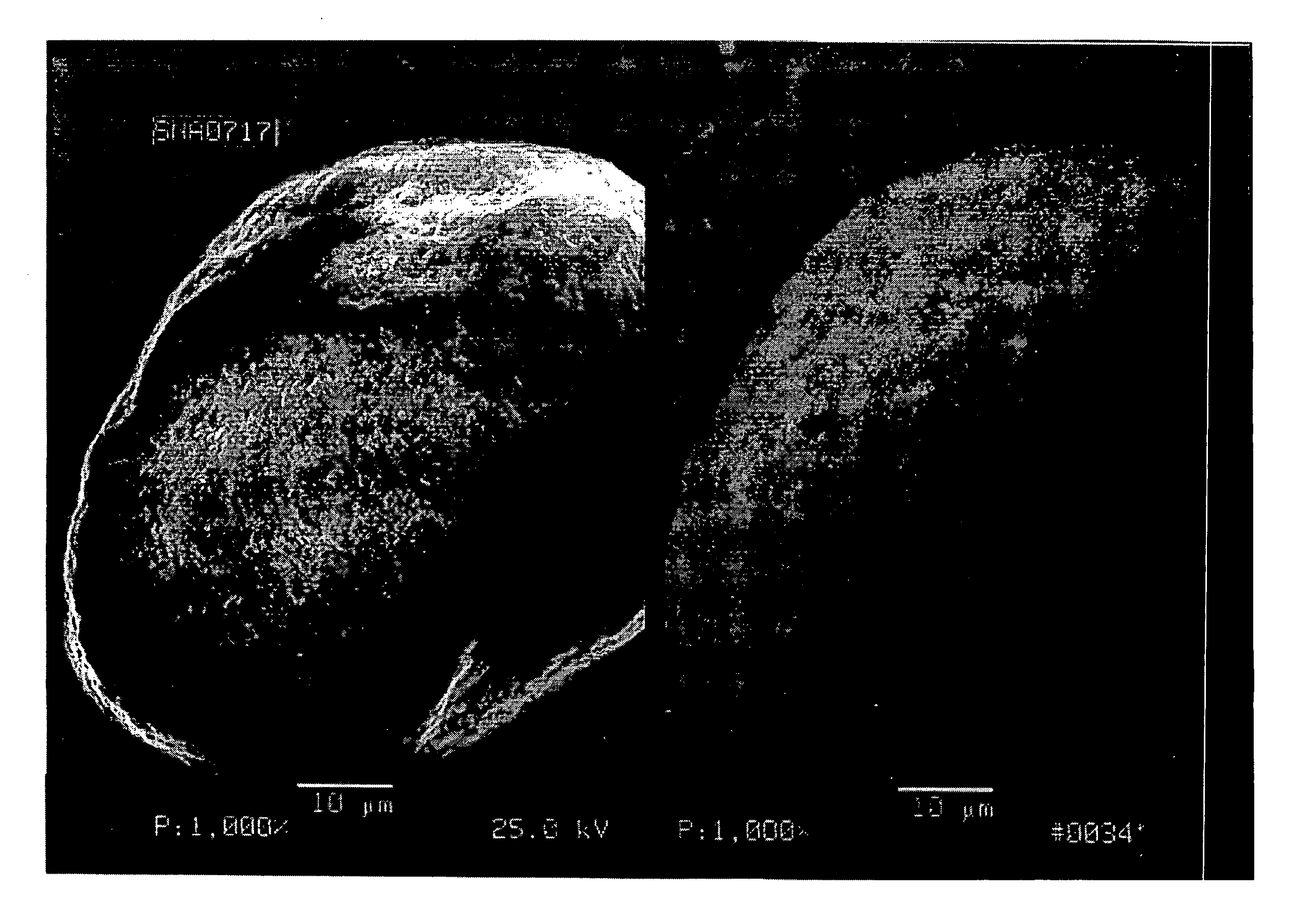

Catalyst powder, method of producing the catalyst powder, and exhaust gas purifying catalyst

ActiveUS7674744B2Reduced activityHigh activityMolecular sieve catalystsOther chemical processesHeat resistanceMicelle

A method of producing catalyst powder of the present invention has a step of precipitating a carrier in a reversed micelle, and a step of precipitating at least one of a noble metal particle and a transition metal particle in the reversed micelle in which the carrier is precipitated. By this method, it is possible to obtain catalyst powder excellent in heat resistance and high in the catalytic activity.

Owner:NISSAN MOTOR CO LTD

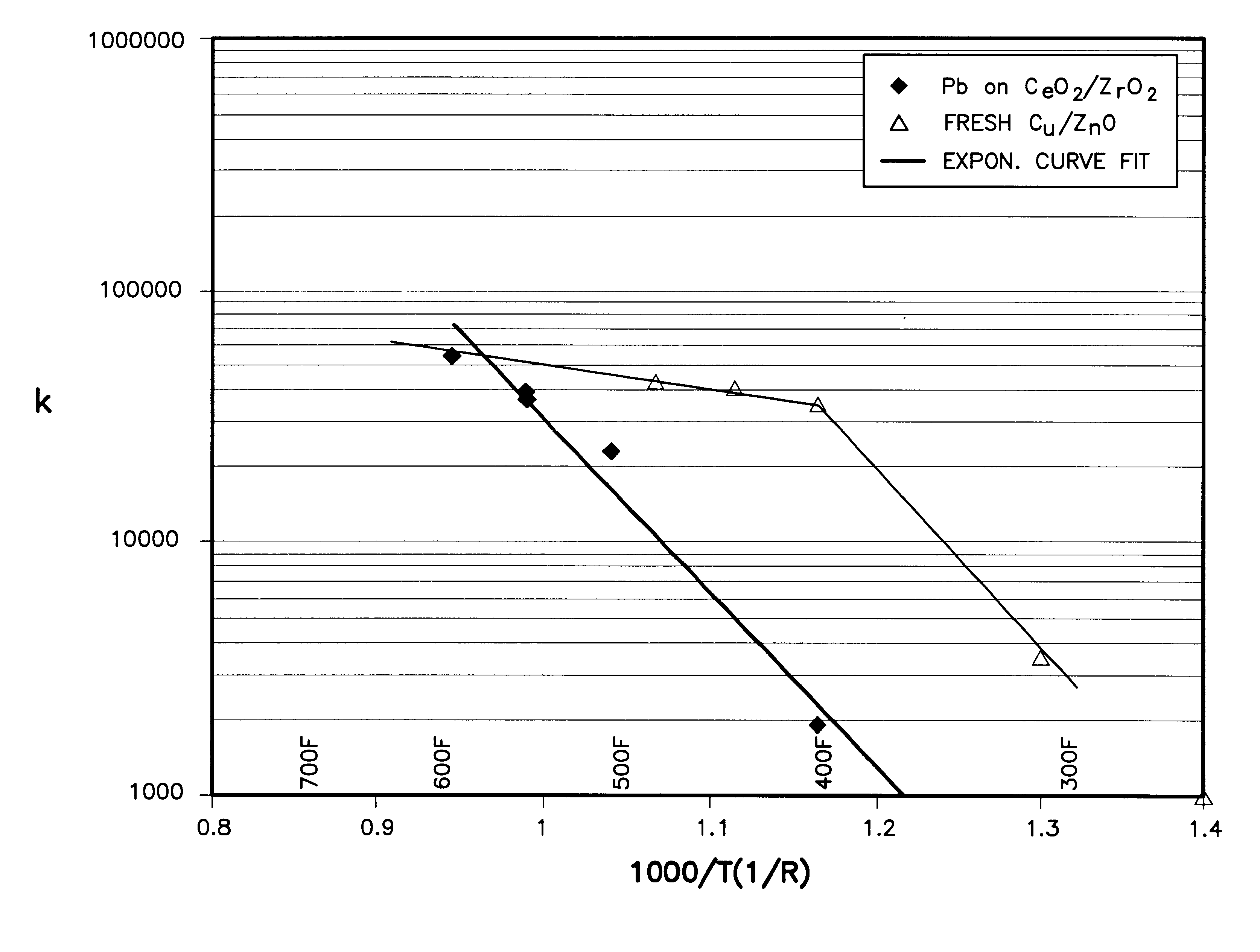

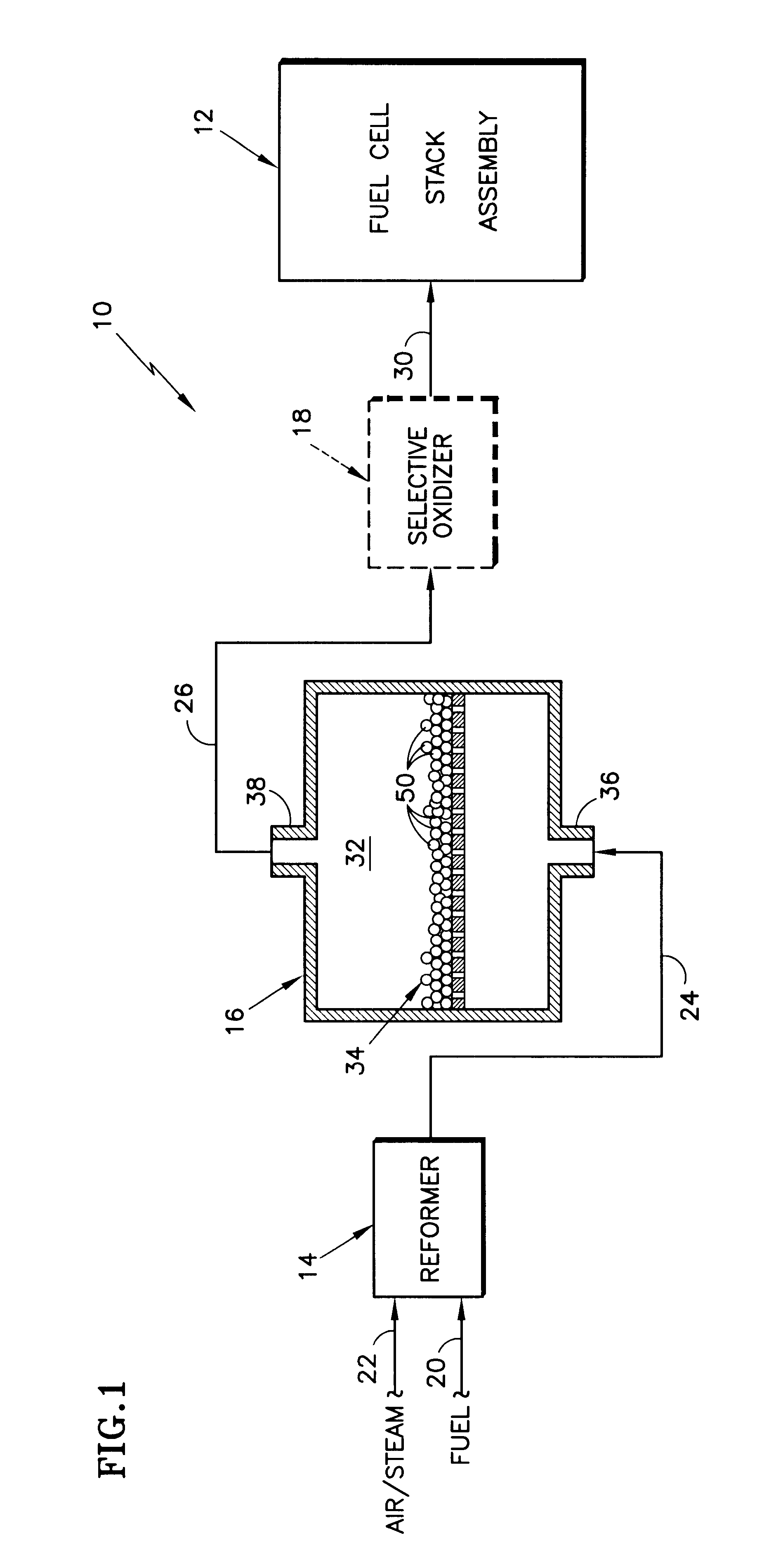

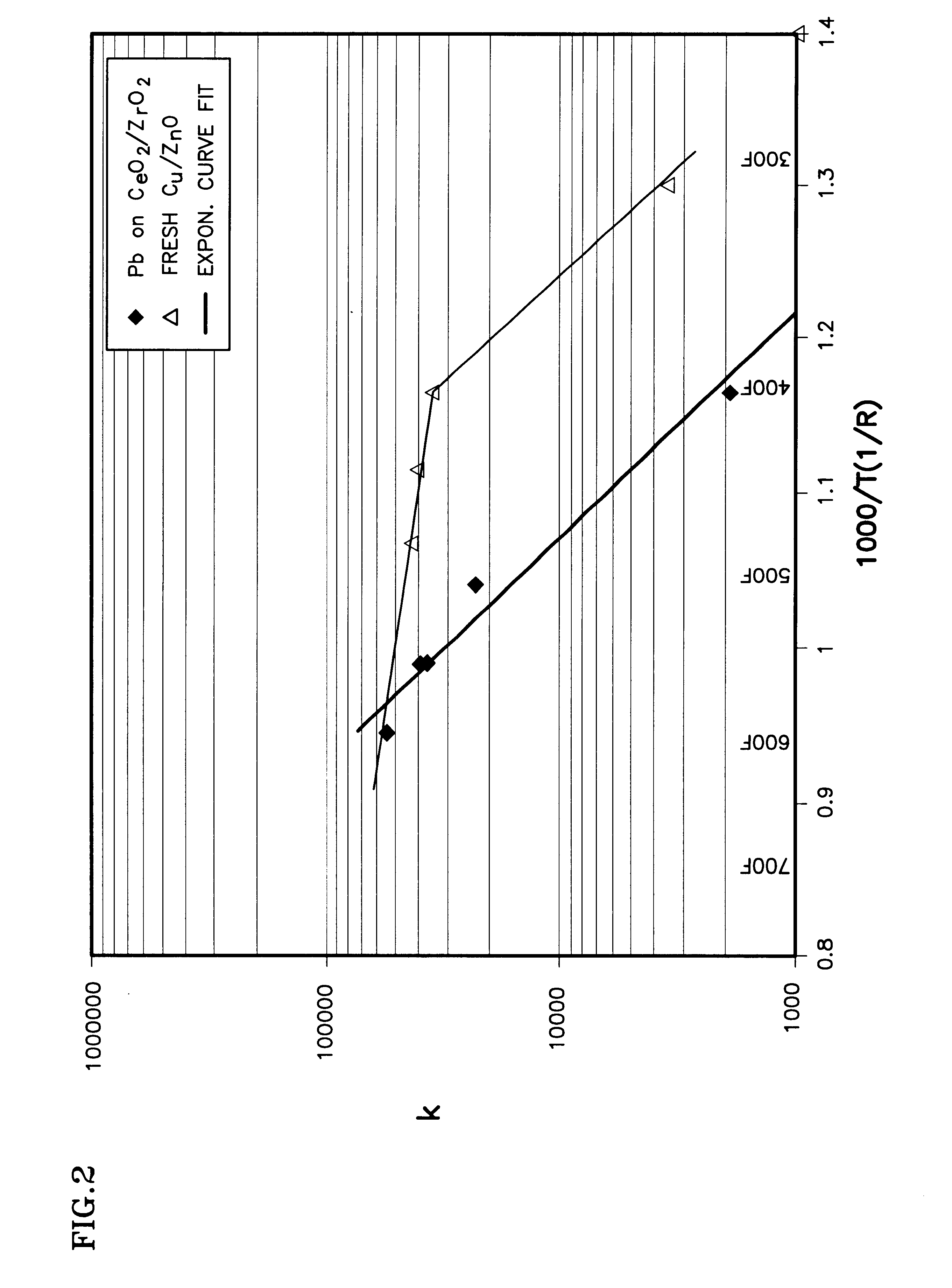

Shift converter having an improved catalyst composition, and method for its use

InactiveUS6455182B1Reduce amountImproved catalyst compositionHydrogenCatalyst carriersFuel cellsCerium

A shift converter (16) in a fuel processing subsystem (14, 16, 18) for a fuel cell (12) uses an improved catalyst composition (50) to reduce the amount of carbon monoxide in a process gas for the fuel cell (12). The catalyst composition (50) is a noble metal catalyst having a promoted support of mixed metal oxide, including at least both ceria and zirconia. Cerium is present in the range of 30 to 50 mole %, and zirconium is present in the range of 70 to 50 mole %. Additional metal oxides may also be present. Use of the catalyst composition (50) obviates the requirement for prior reducing of catalysts, and minimizes the need to protect the catalyst from oxygen during operation and / or shutdown.

Owner:HYAXIOM INC

Molecular sieve-containing catalyst for cracking hydrocarbons and a method for preparing the same

ActiveUS20040266608A1Reduced activityEasy to crackCatalytic crackingMolecular sieve catalystsReduction ActivityMolecular sieve

A molecular sieve-containing catalyst for cracking hydrocarbons, comprising molecular sieve, refractory inorganic oxide, clay and a metal component, wherein the amount of said molecular sieve is from 1 to 90% by weight, the refractory inorganic oxide is from 2 to 80% by weight, the clay is from 2 to 80% by weight, and the metal component is from 0.1 to 30% by weight, calculated as the oxide of said metal having its maximum valence state, based on the total amount of the catalyst, wherein said metal component exists essentially in a reduction state and is one or more metals selected from the group consisting of metals of Group III A(other than aluminum), and metals of Group IVA, VA, IB, IIB, VB, VIB and VIIB, and non-noble metals of Group VIII of the periodic table. The catalyst has higher cracking activity and higher sulfur reduction activity.

Owner:CHINA PETROCHEMICAL CORP +1

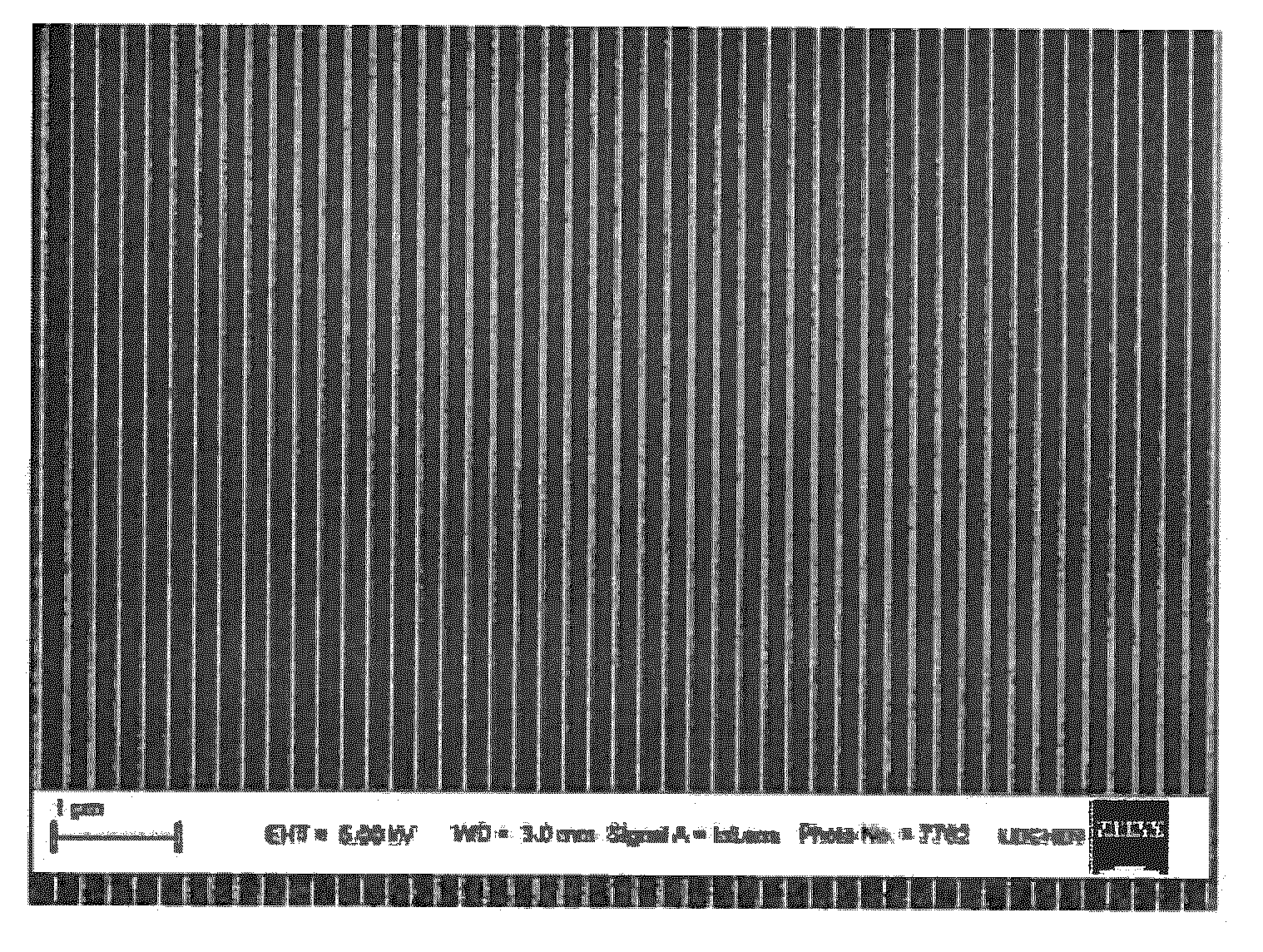

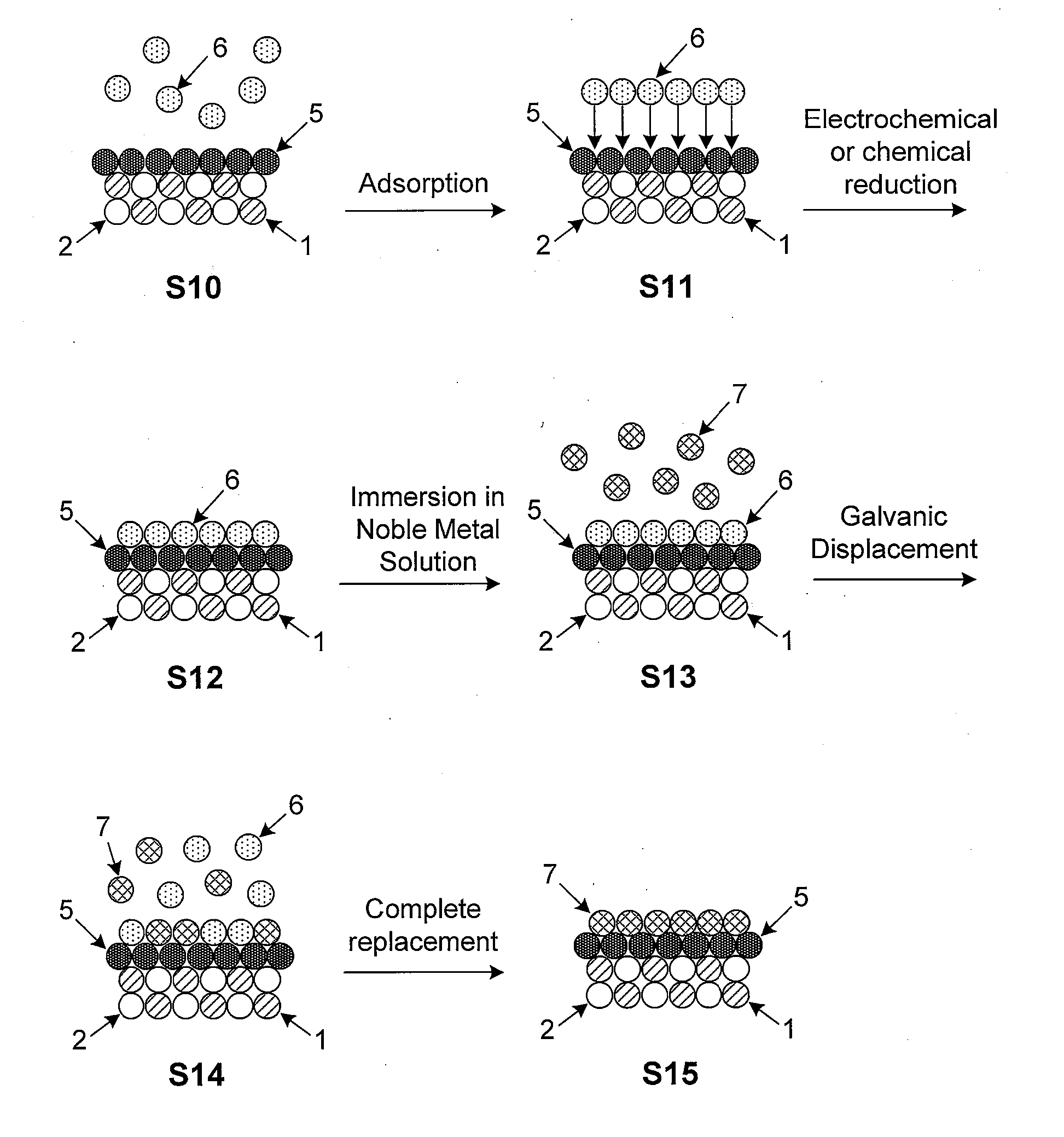

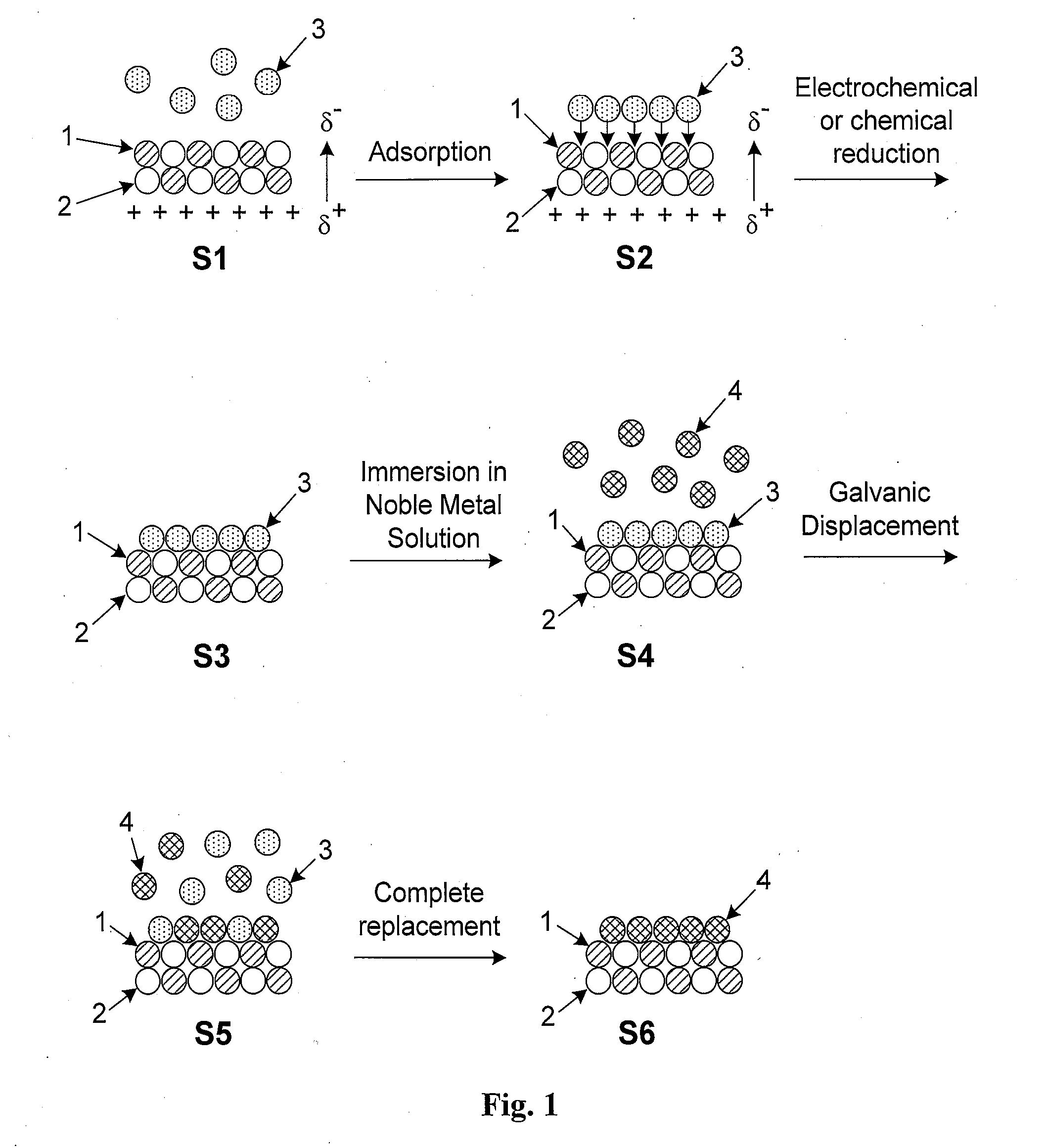

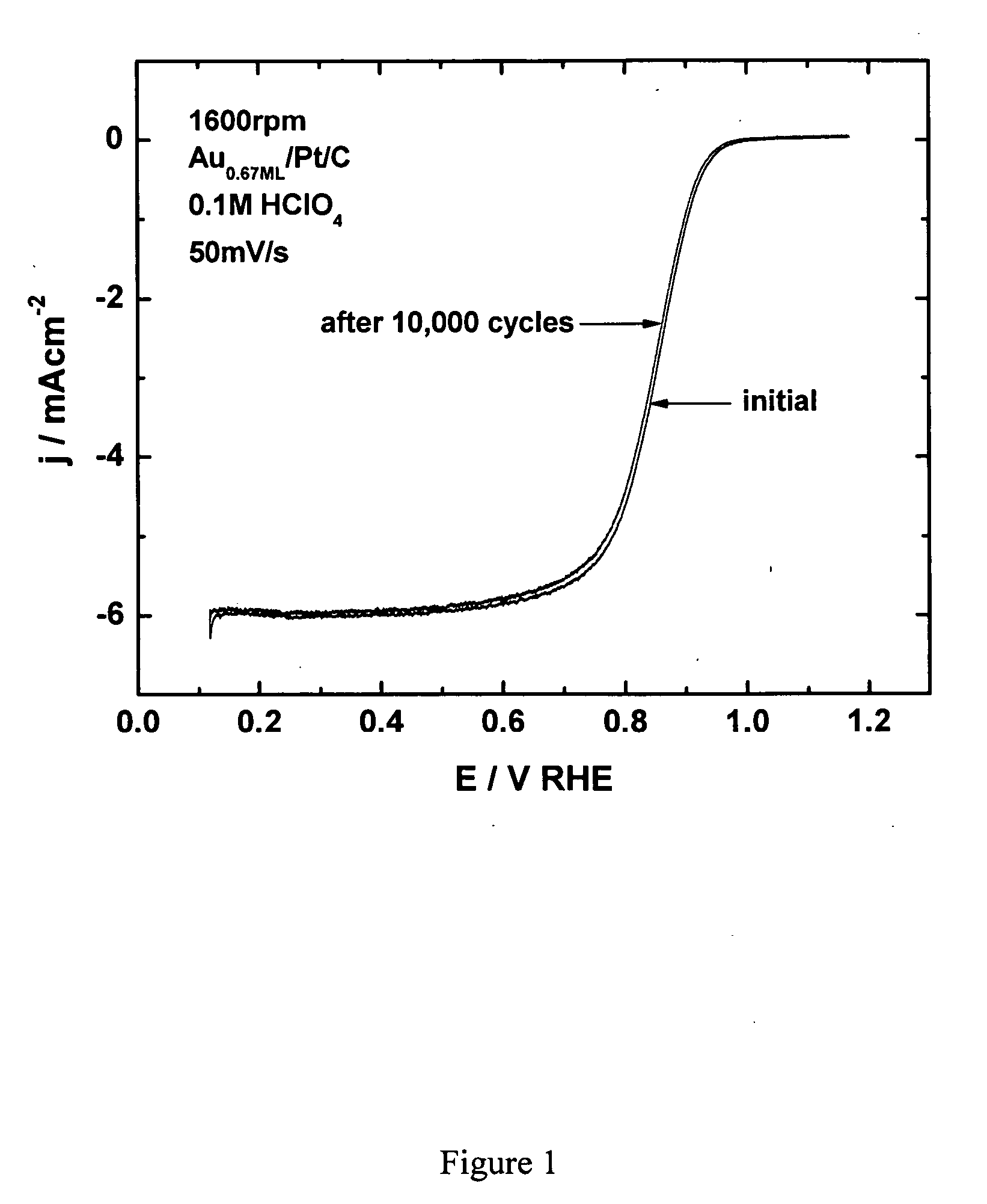

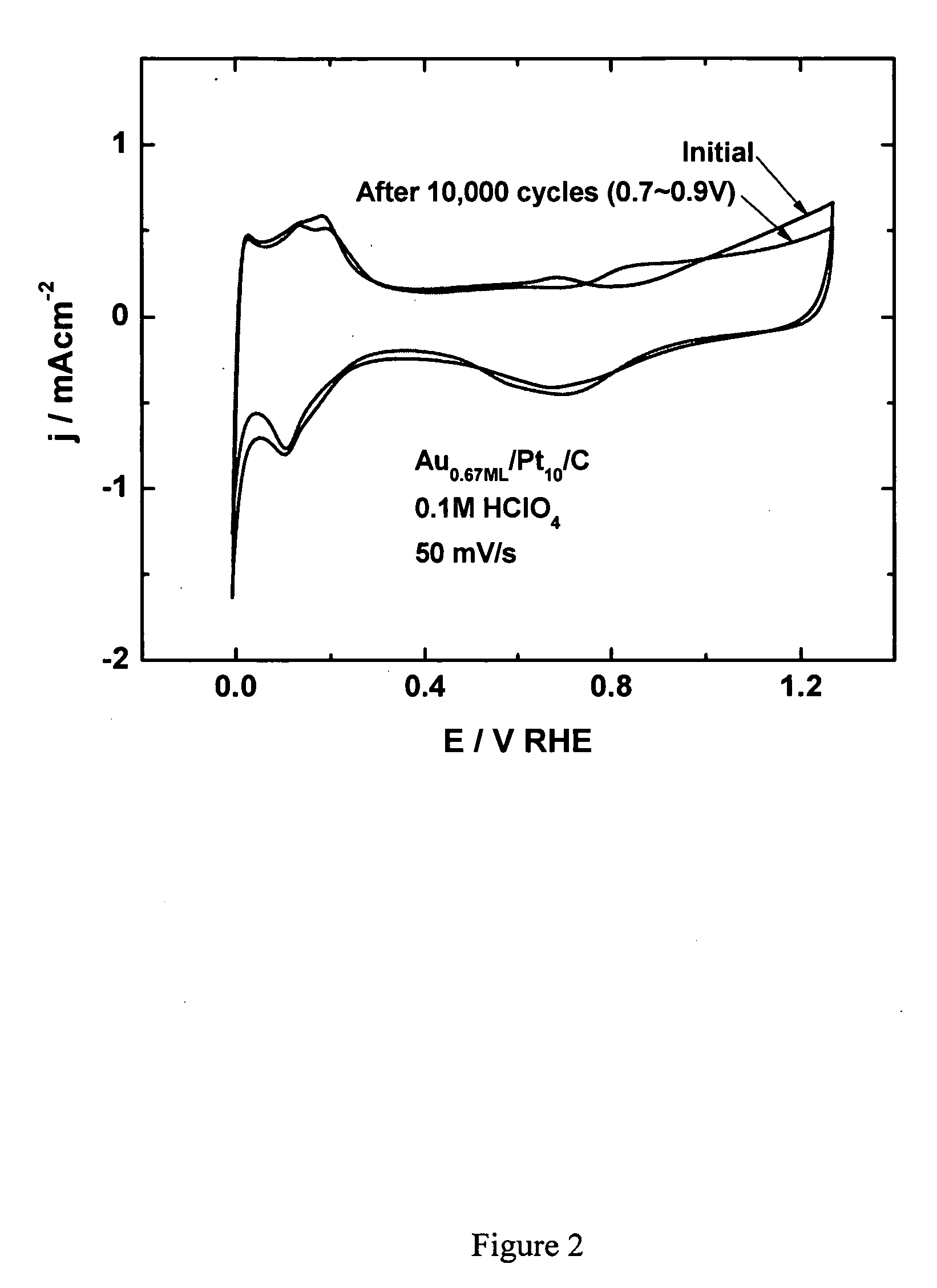

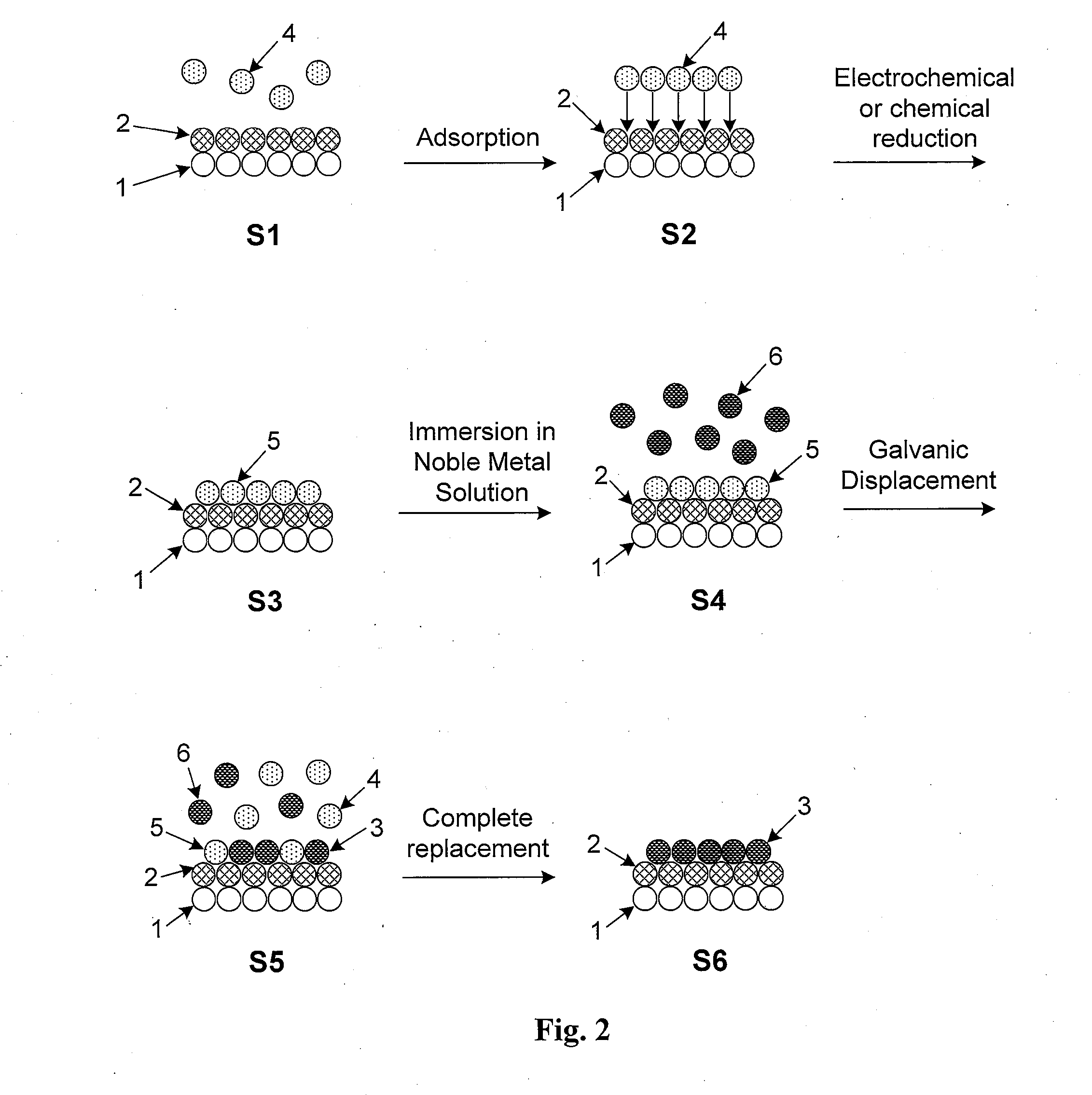

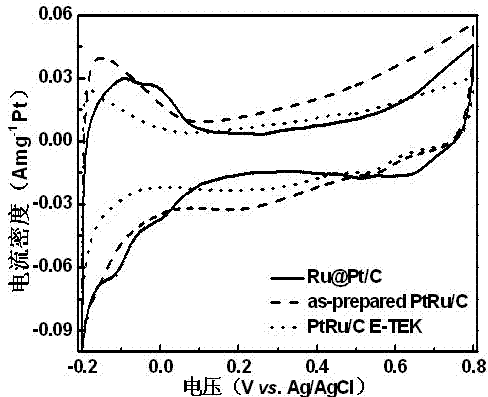

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

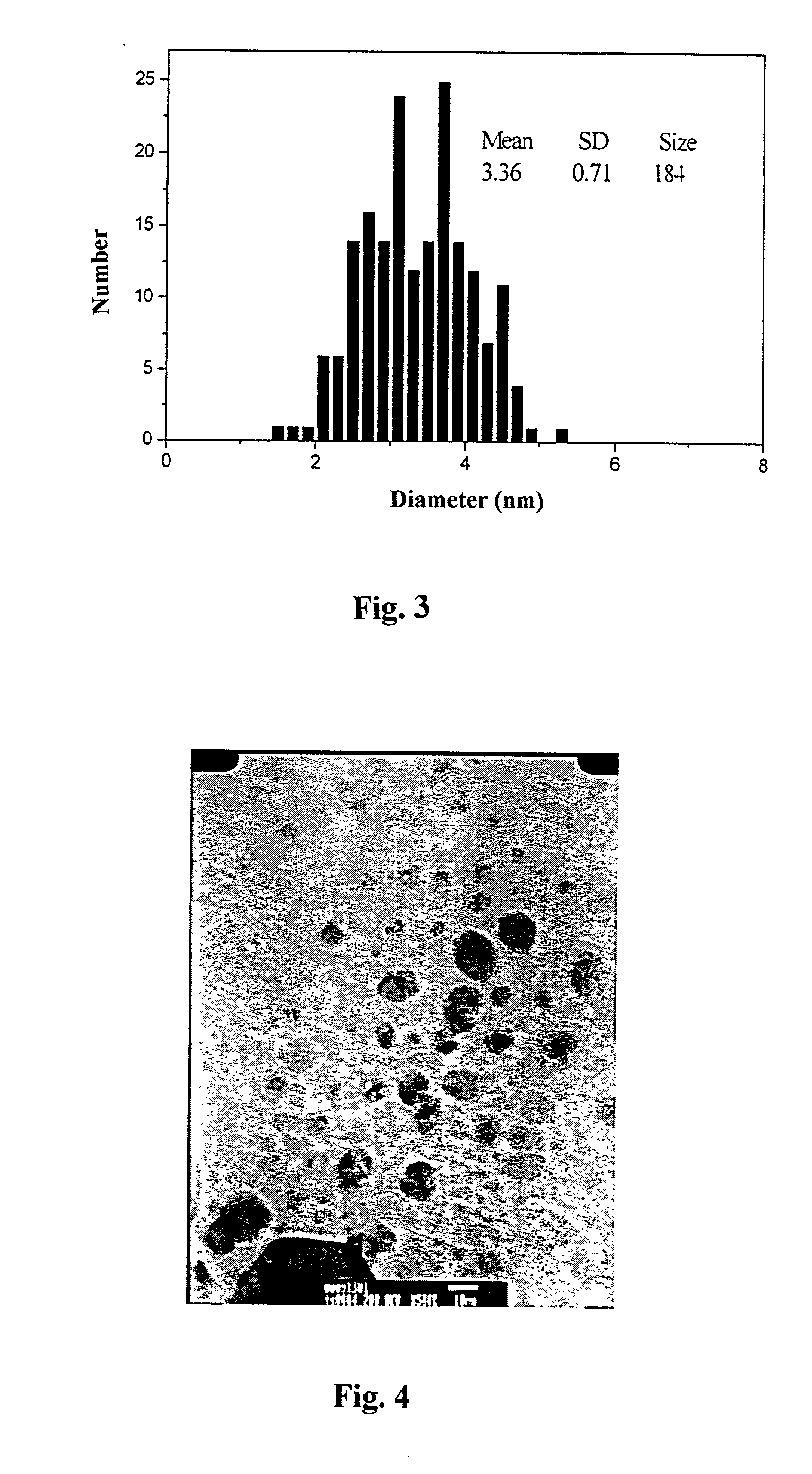

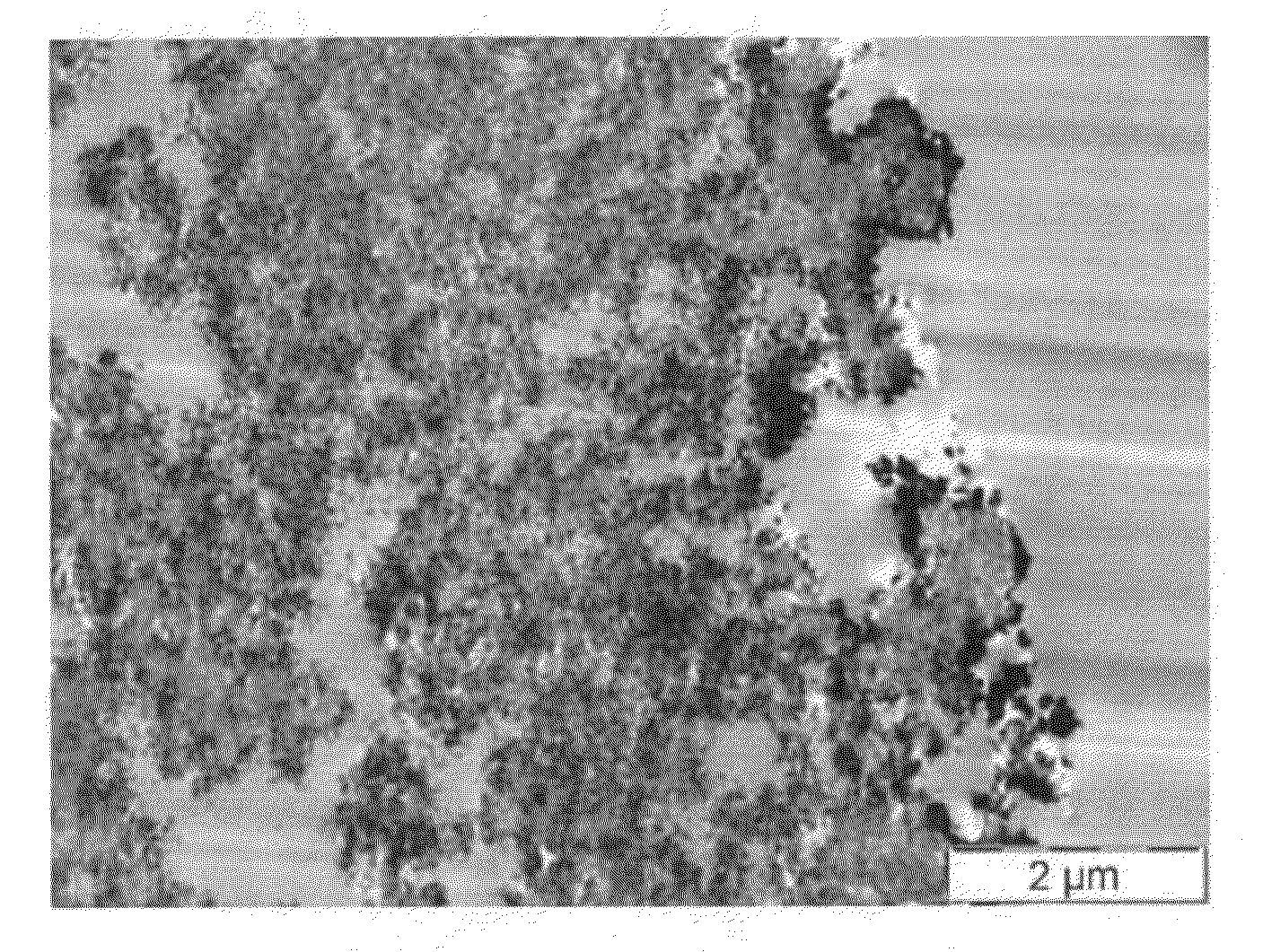

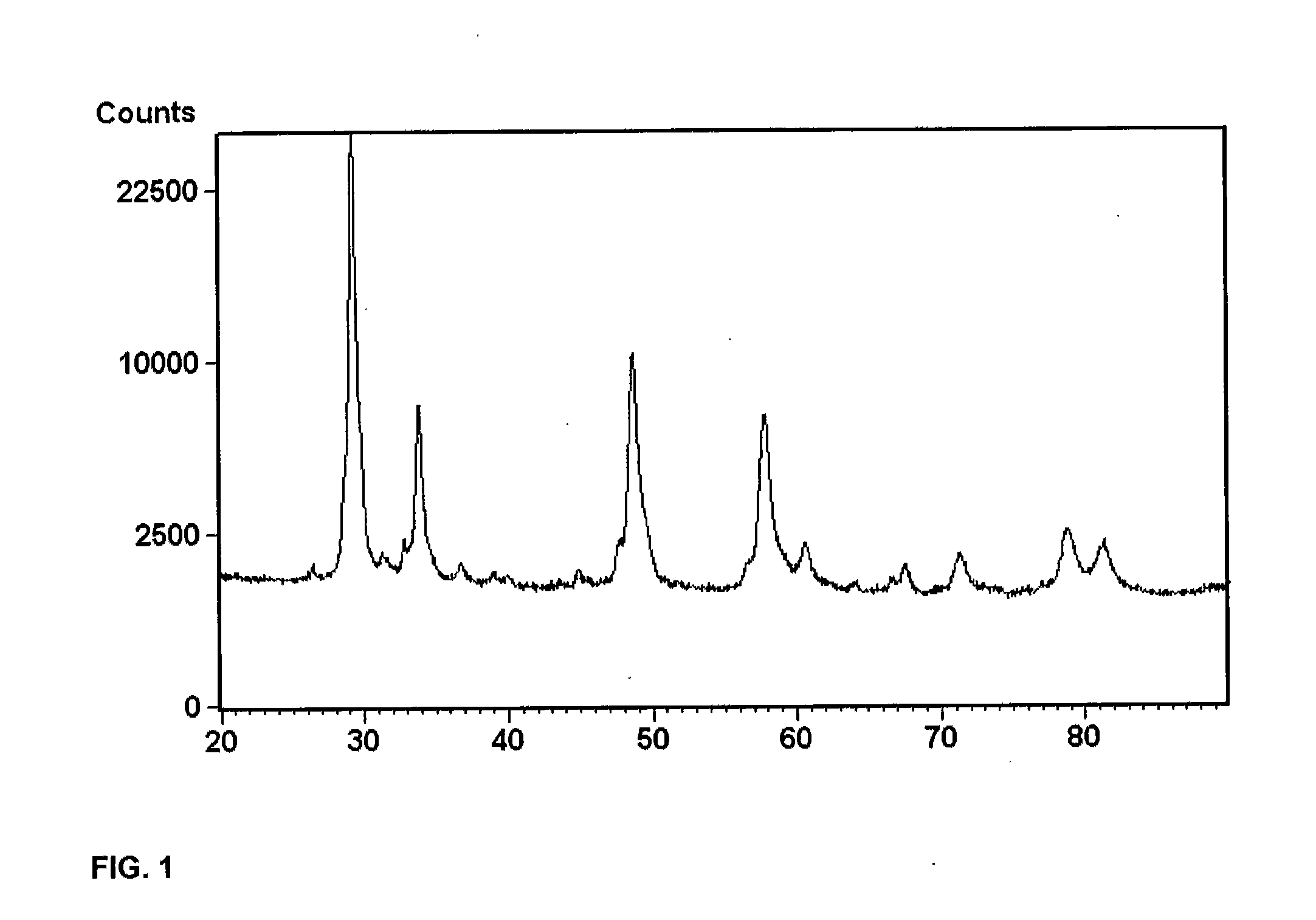

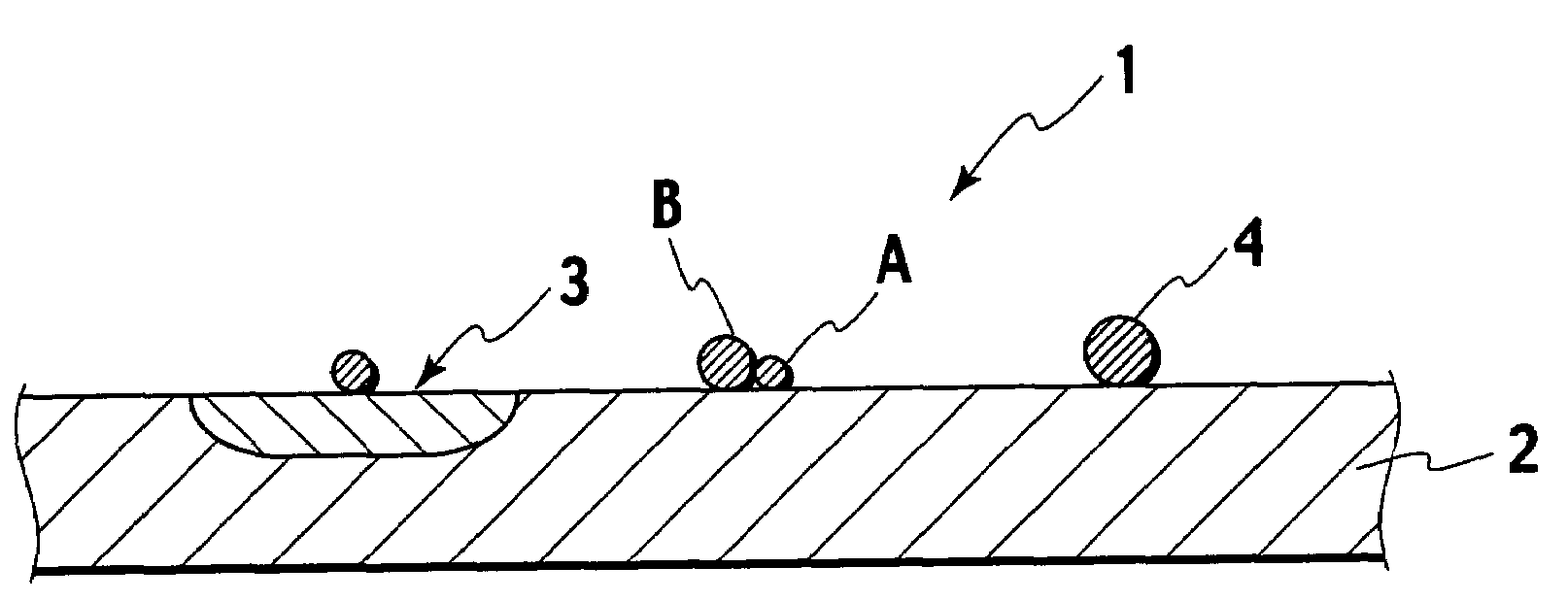

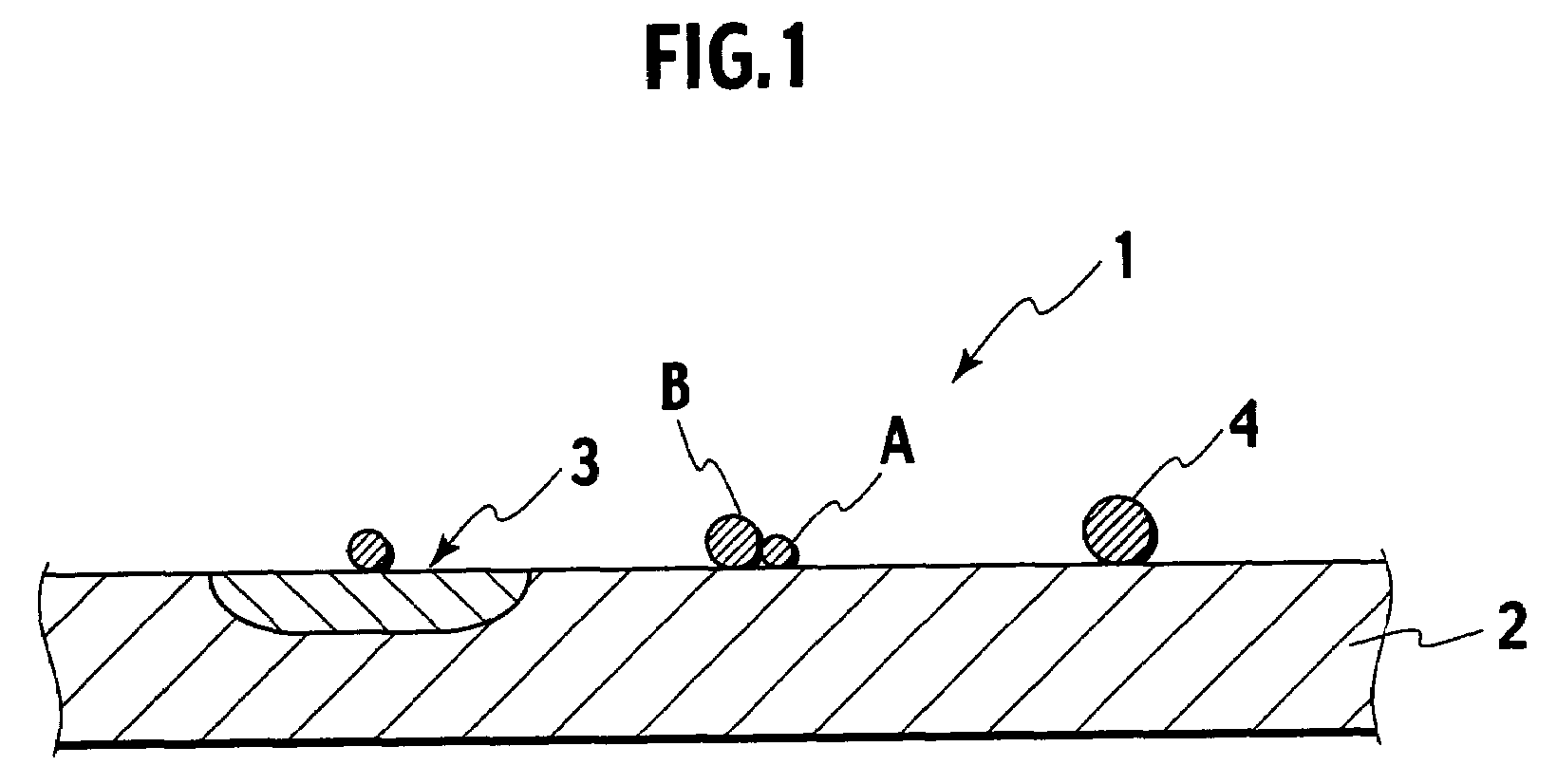

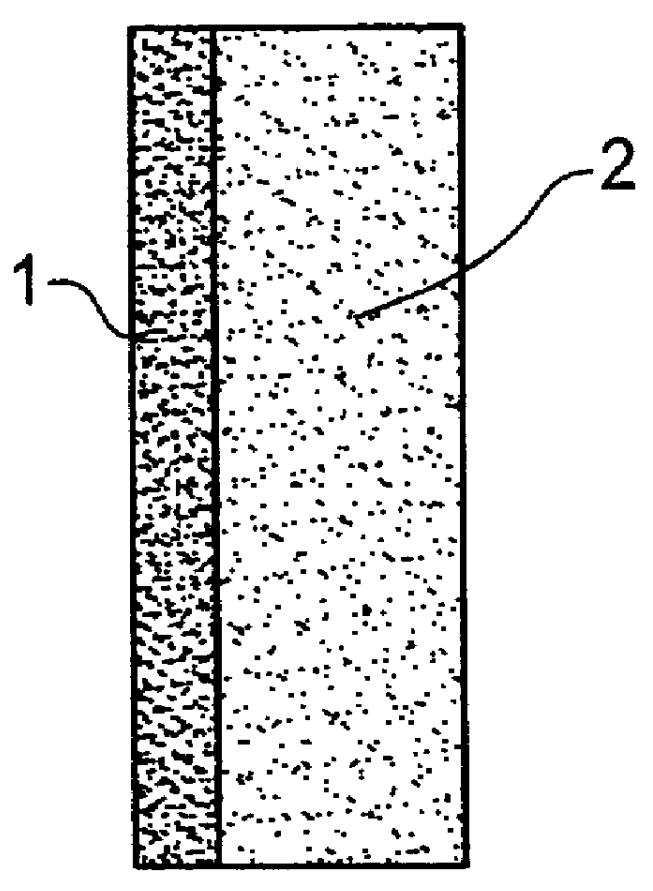

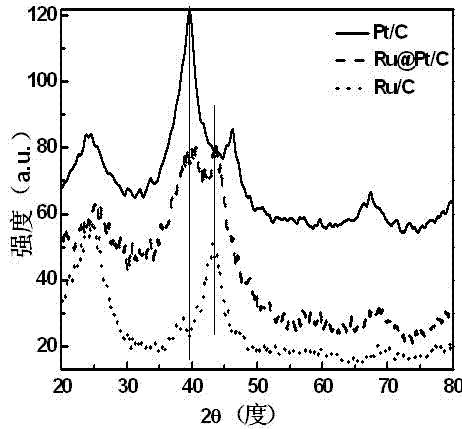

Noble metal-containing supported catalyst and a process for its preparation

The invention provides a noble metal-containing supported catalyst which contains one of the noble metals from the group Au, Ag, Pt, Pd, Rh, Ru, Ir, Os or alloys of one or more of these noble metals in the form of noble metal particles on a powdered support material. The particles deposited on the support material have a degree of crystallinity, determined by X-ray diffraction, of more than 2 and an average particle size between 2 and 10 nm. The high crystallinity and the small particle size of the noble metal particles lead to high catalytic activity for the catalyst. It is particularly suitable for use in fuel cells and for the treatment of exhaust gases from internal combustion engines.

Owner:UMICORE AG & CO KG

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

InactiveUS20080312480A1Hydrocarbon from carbon oxidesFatty acid chemical modificationAlkaneVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises molybdenum, a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of even-numbered hydrocarbons to odd-numbered hydrocarbons of at least 2:1.

Owner:EI DU PONT DE NEMOURS & CO

Electrocatalysts having gold monolayers on platinum nanoparticle cores, and uses thereof

InactiveUS20070026292A1Maintain efficiencyReduce loadMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumFuel cells

The invention relates to gold-coated particles useful as fuel cell electrocatalysts. The particles are composed of an electrocatalytically active core at least partially encapsulated by an outer shell of gold or gold alloy. The invention more particularly relates to such particles having a noble metal-containing core, and more particularly, a platinum or platinum alloy core. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

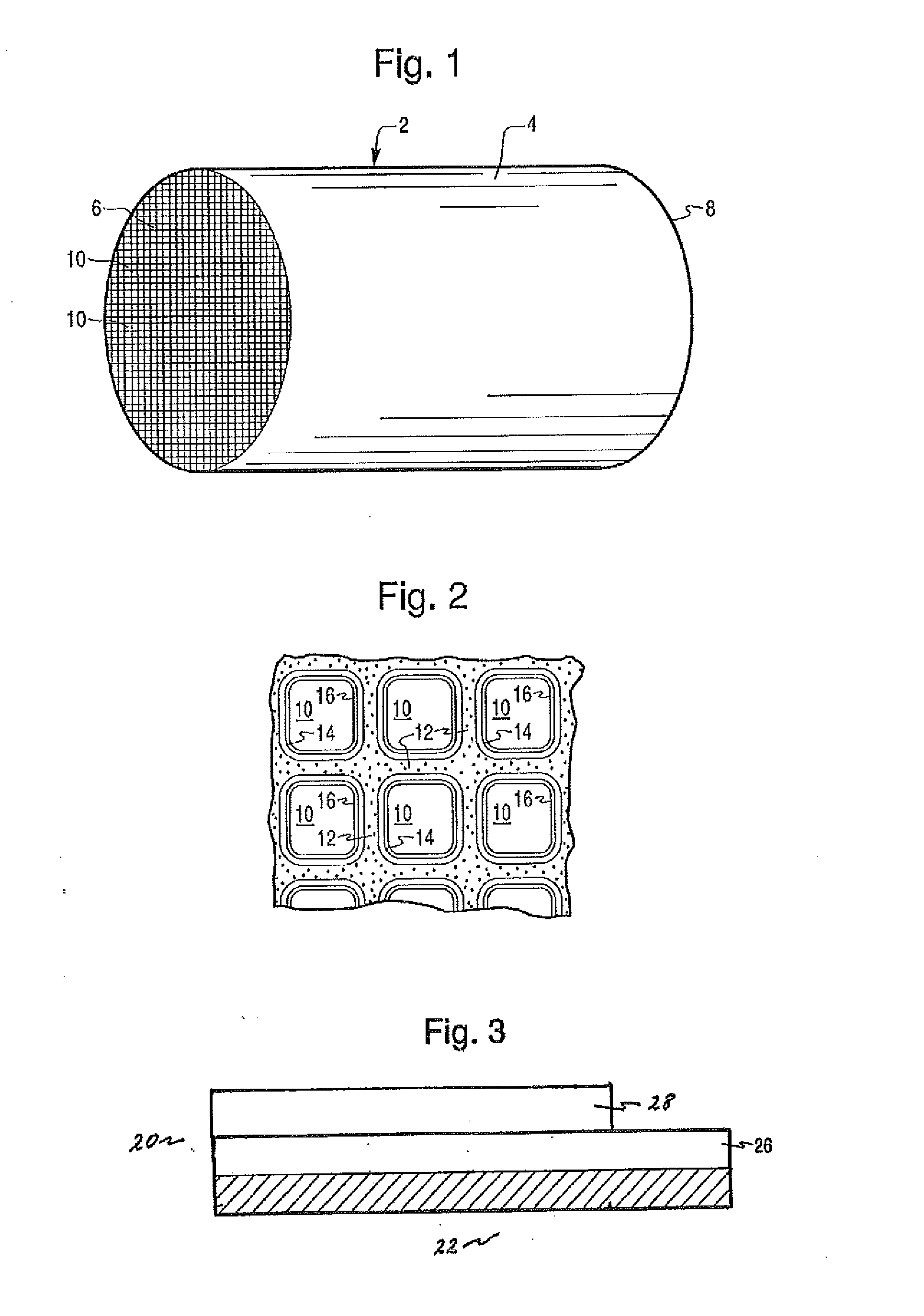

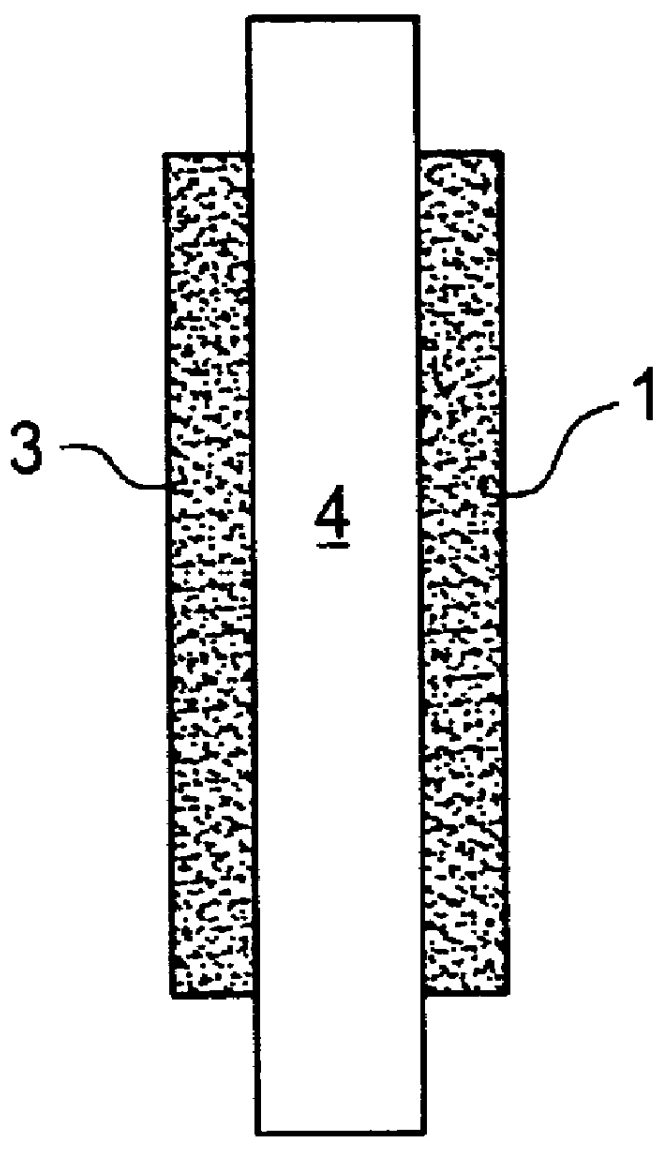

Catalyst layer for polymer electrolyte fuel cells

A catalyst layer on a substrate material which contains a proton-conducting polymer (ionomer), electrically conductive carbon particles and fine particles of at least one precious metal. The catalyst layer is obtainable by coating the substrate material with an ink which contains a dispersion of the carbon particles and at least one organic precious metal complex compound in a solution of the ionomer, and drying the coating below a temperature at which the ionomer or the substrate material is thermally damaged, the precious metals in the complex compounds being present with an oxidation number of 0 and the complex compounds being thermally decomposed during drying to form the fine precious metal particles.

Owner:UMICORE AG & CO KG +1

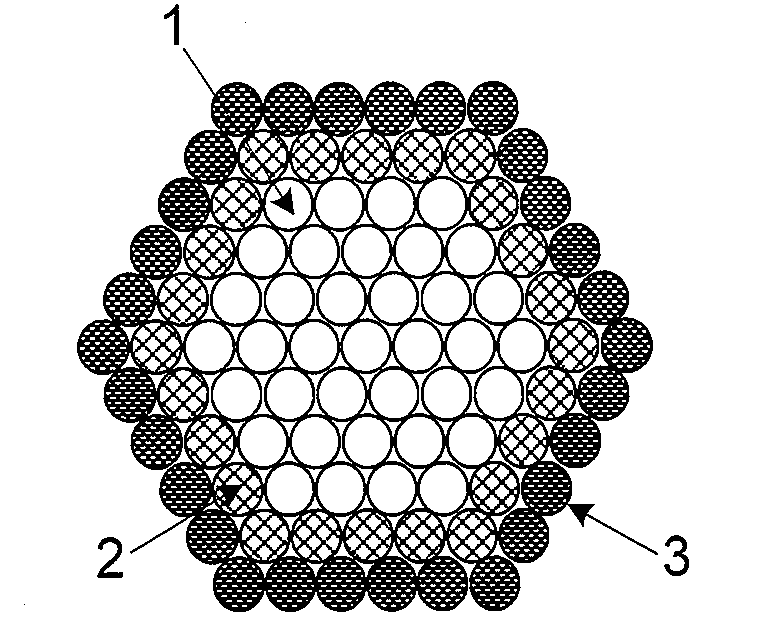

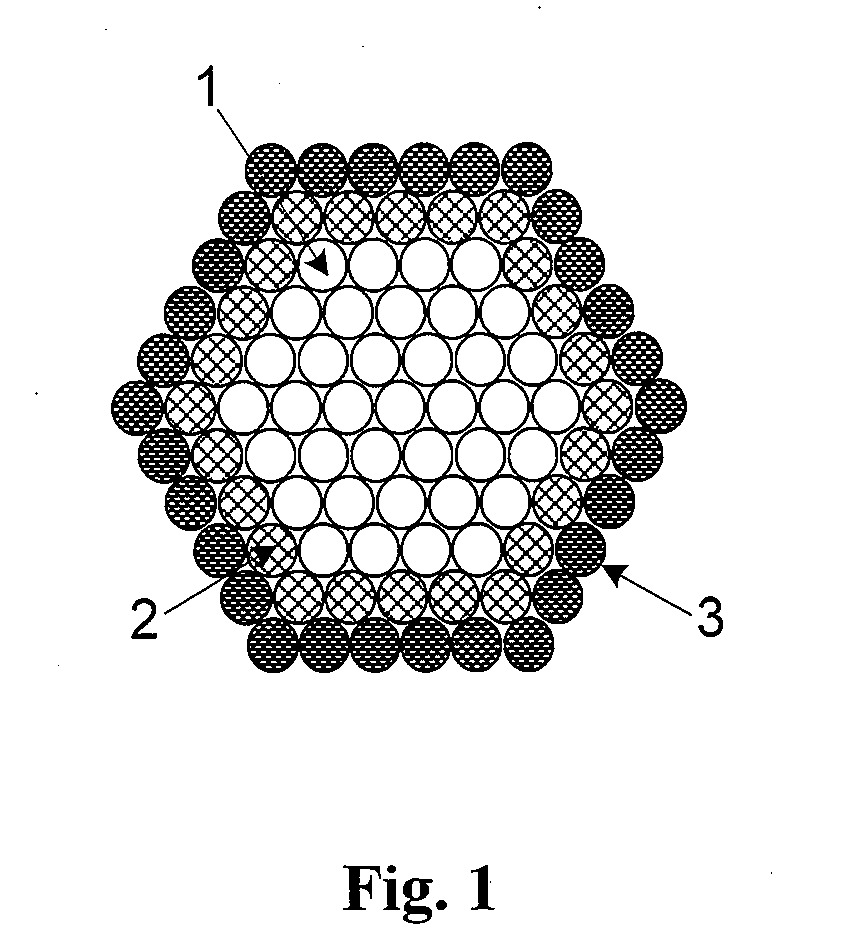

Core / shell-type catalyst particles comprising metal or ceramic core materials and methods for their preparation

ActiveUS20100092841A1High specific activityLow precious metal contentMaterial nanotechnologyCell electrodesFuel cellsAlloy

The invention is directed to core / shell type catalyst particles comprising a Mcore / Mshell structure with Mcore=inner particle core and Mshell=outer particle shell, wherein the medium diameter of the catalyst particle (dcore+shell) is in the range of 20 to 100 nm, 5 preferably in the range of 20 to 50 nm. The thickness of the outer shell (tshell) is about 5 to 20% of the diamet the inner particle core of said catalyst particle, preferably comprising at least 3 atomic layers. The inner particle core (Mcore) of the particles comprises metal or ceramic materials, whereas the material of the outer shell (Mshell) comprises precious metals and / or alloys thereof. The core / shell type catalyst particles are preferably supported on suitable support materials such as carbon black and can be used as electrocatalysts for fuel cells and for other catalytic applications.

Owner:UMICORE AG & CO KG

High surface area, small crystallite size catalyst for Fischer-Tropsch synthesis

ActiveUS7452844B2Promote growthEvenly distributedCatalyst protectionMolecular sieve catalystsCobaltHigh surface area

Owner:CLARIANT INT LTD

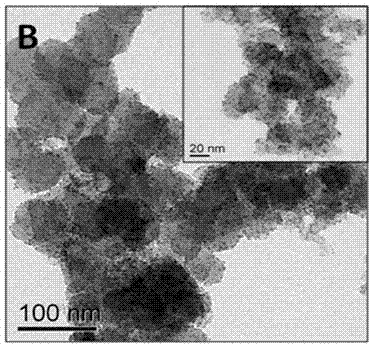

Nuclear shell nanometer catalyst packaged with noble metal nanometer grains and method thereof

InactiveCN101623634AShape controllableControllable shapeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystHeterojunction

The invention relates to a nuclear shell nanometer catalyst packaged with noble metal nanometer grains and a method thereof, which relate to a nanometer catalyzing material. The invention provides a nuclear shell nanometer catalyst packaged with noble metal nanometer grains, which has a size of the noble metal grains less than 10nm, and higher contact level among noble metal grains and stability of the catalyst, can be reused and is adaptive to different using conditions by multi-level derivation, and also provides a preparation method thereof. The catalyst has a formula of NMP@X, NMP is nanometer grains such as Pd, AgPd or Au, and the like, and X is spherical SiO2, hollow SnO2 ball or hollow C ball. The method comprises the following steps: synthesizing noble metal nanometer grains and adorning the surface to obtain noble metal-iron oxide nanometer heterojunction; coating a silicon dioxide to obtain noble metal iron heterojunction oxide @ silicon dioxide nuclear shell nanometer material, growing porous pores on the surface, removing the silicon dioxide, and removing iron oxide on the noble metal nanometer grains so that the noble metal nanometer grains are located in a nanometer capsule of the hollow porous pores to obtain the product.

Owner:XIAMEN UNIV

Formaldehyde gas oxidation catalyst under room temperature

ActiveCN1714930ARaw materials are readily availableSimple conditions of useDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationSilicon dioxide

The present invention provides a kind of formaldehyde gas oxidizing catalyst for room temperature use. Metal oxide is first obtained with soluble metal nitrate, carbonate or other inorganic salt and through oxidation and precipitation; and then loaded with small amount of metal to form the catalyst with room temperature formaldehyde oxidizing activity. The catalyst has metal oxide as main body and supported noble metal as active component, and features that the metal oxide may be oxide of Al, Ni, Mn, Si or Fe, and the noble may be Pt, Ru, Au, Rh or Pd. The catalyst of the present invention has high catalytic activity, and long sustaining time. The catalyst has formaldehyde converting rate up to 100 %, and results in low power consumption.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

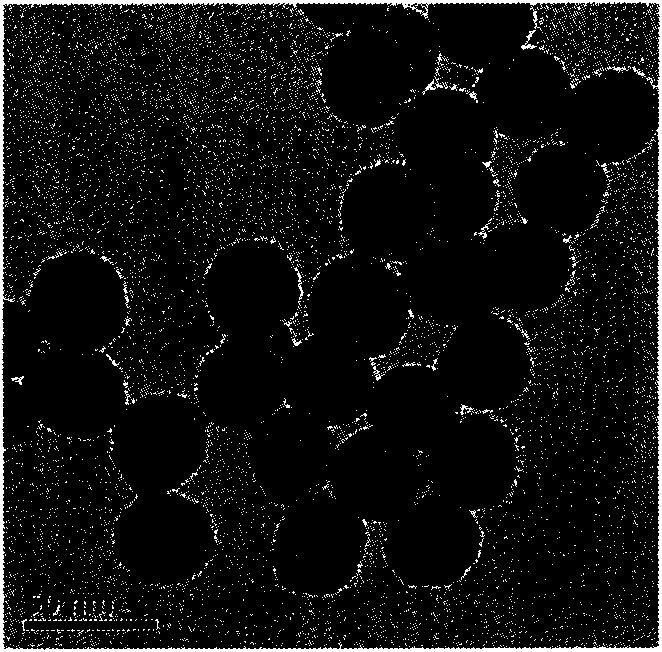

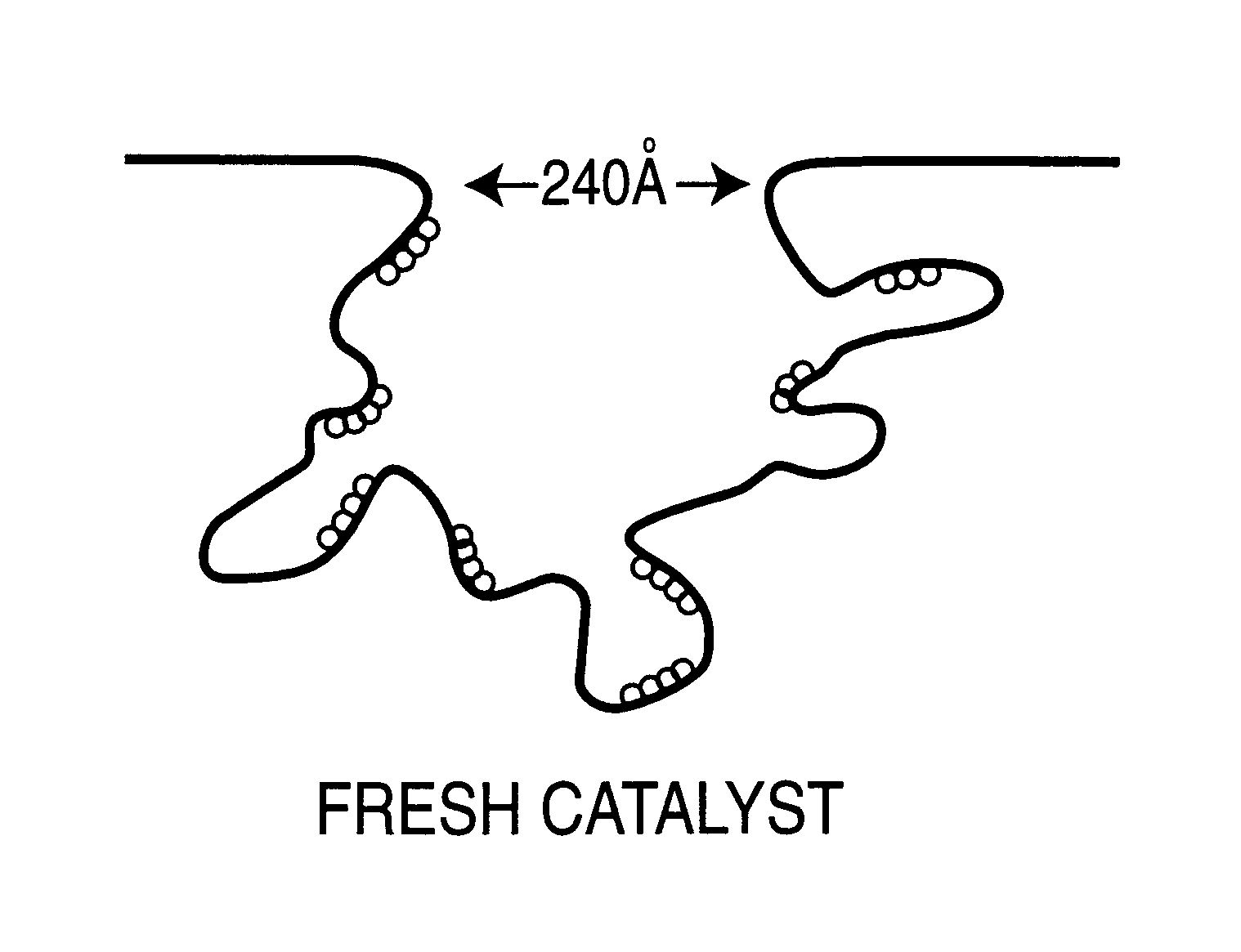

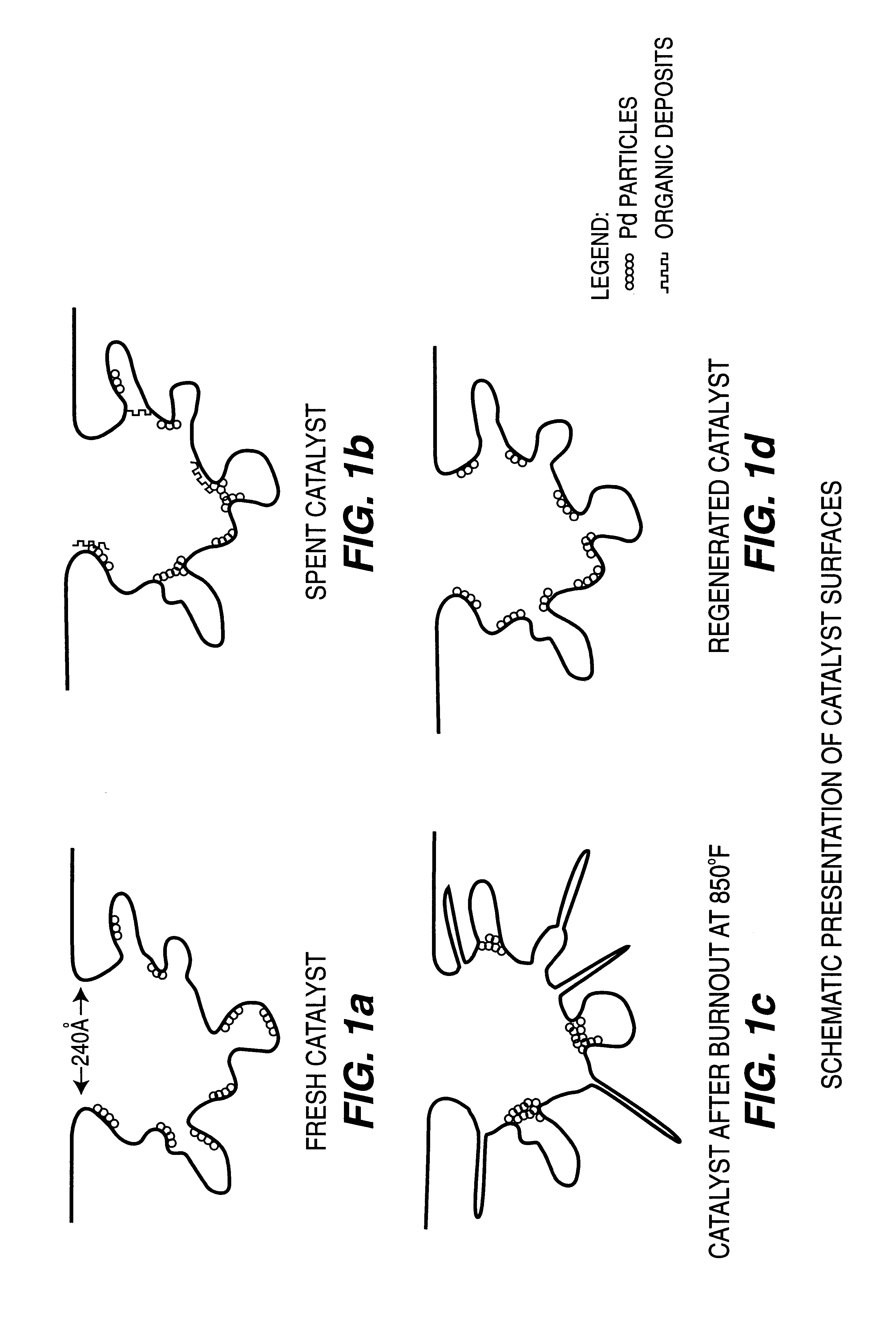

Regeneration of used supported noble metal catalysts

InactiveUS6740615B2Efficient removalImproves expositionHydrogen peroxideOther chemical processesPalladium catalystMetal particle

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

Platinum-Coated Non-Noble Metal-Noble Metal Core-Shell Electrocatalysts

InactiveUS20100197490A1Minimal loadingEfficiently formedMaterial nanotechnologyCell electrodesAlloyPt element

Core-shell particles encapsulated by a thin film of a catalytically active metal are described. The particles are preferably nanoparticles comprising a non-noble core with a noble metal shell which preferably do not include Pt. The non-noble metal-noble metal core-shell nanoparticles are encapsulated by a catalytically active metal which is preferably Pt. The core-shell nanoparticles are preferably formed by prolonged elevated-temperature annealing of nanoparticle alloys in an inert environment. This causes the noble metal component to surface segregate and form an atomically thin shell. The Pt overlayer is formed by a process involving the underpotential deposition of a monolayer of a non-noble metal followed by immersion in a solution comprising a Pt salt. A thin Pt layer forms via the galvanic displacement of non-noble surface atoms by more noble Pt atoms in the salt. The overall process is a robust and cost-efficient method for forming Pt-coated non-noble metal-noble metal core-shell nanoparticles.

Owner:BROOKHAVEN SCI ASSOCS

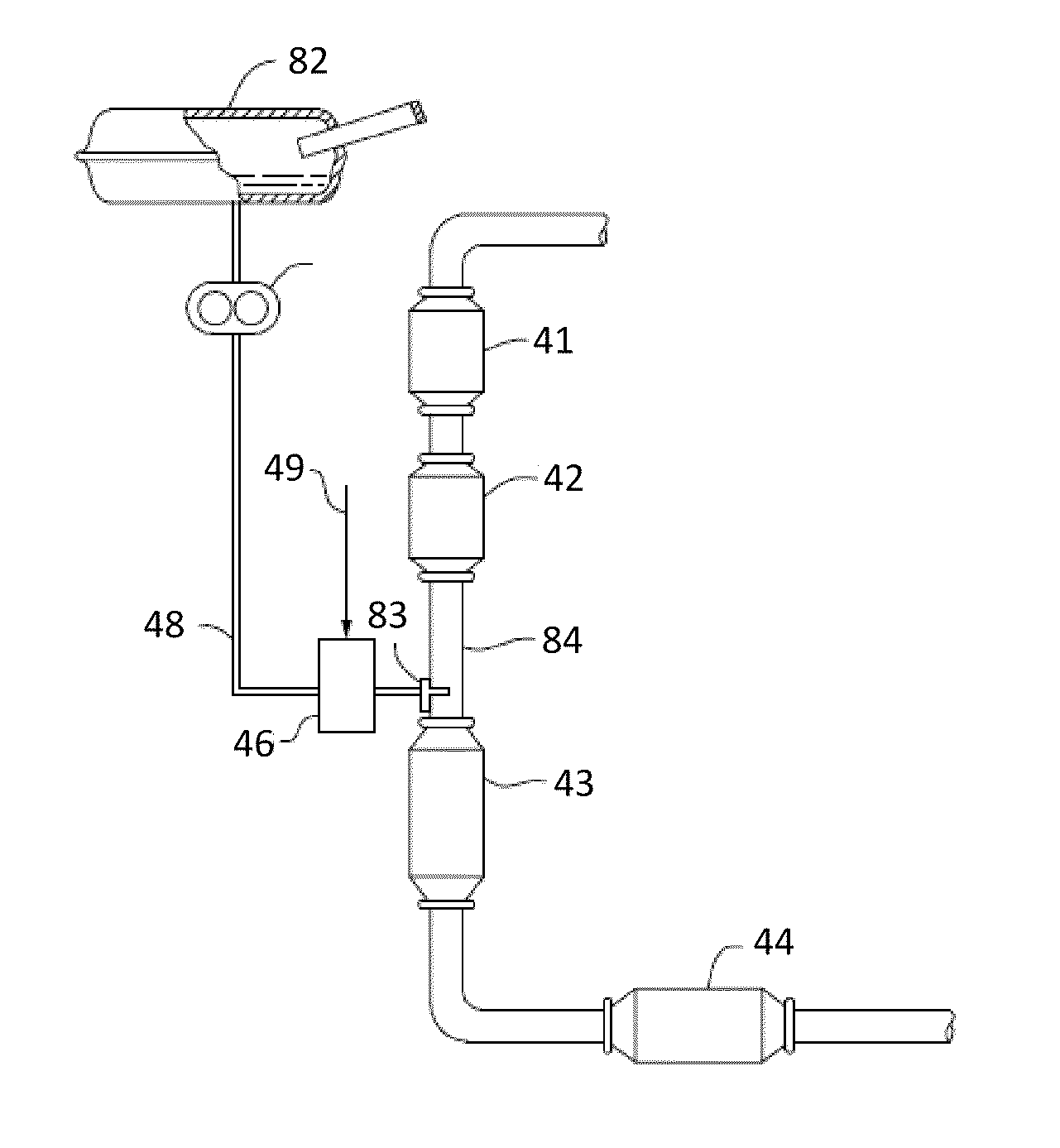

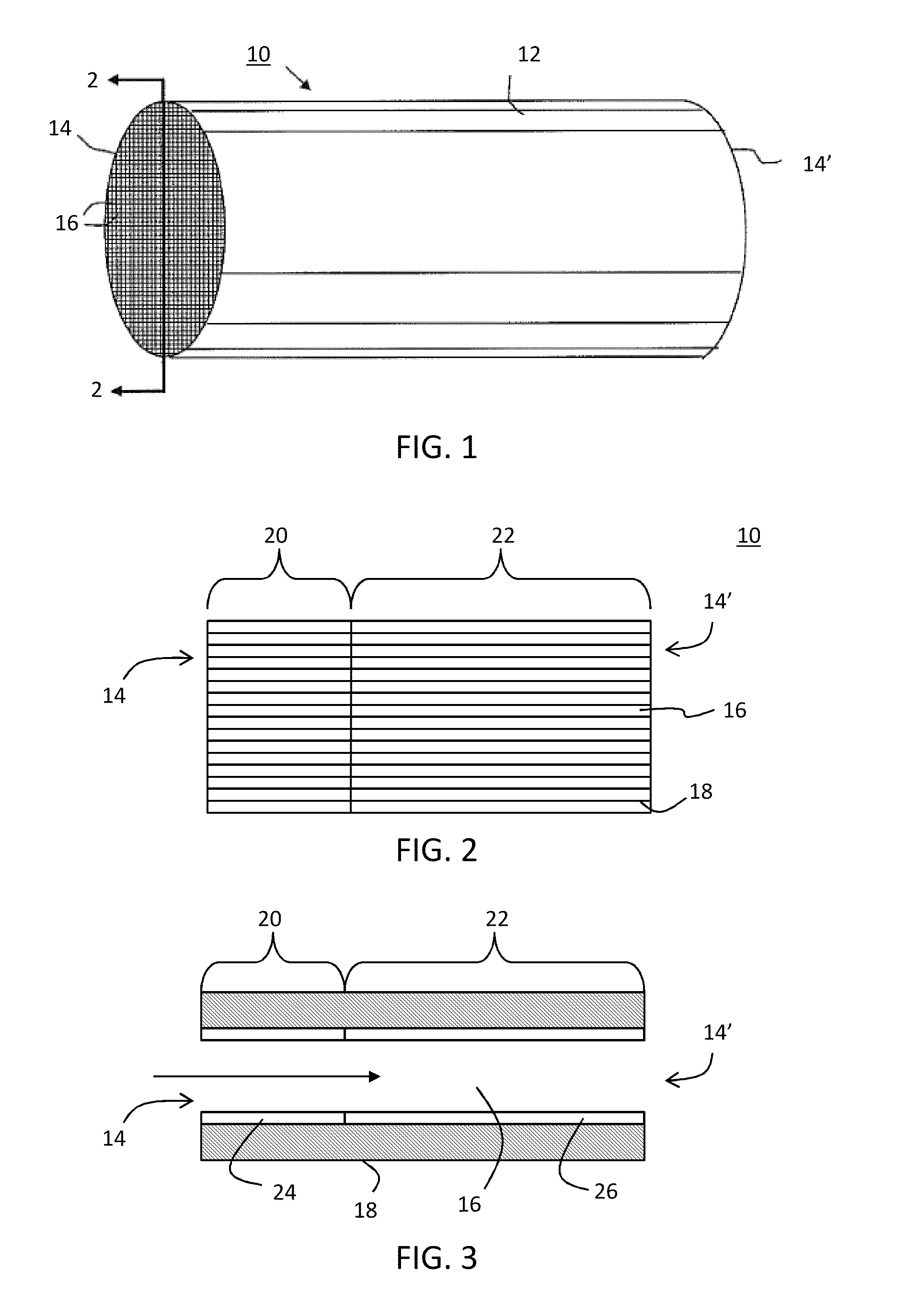

Emission Treatment Catalysts, Systems and Methods

ActiveUS20090288402A1Easy to controlNitrogen compoundsInternal combustion piston enginesNitrogen oxideTreatment system

Zoned diesel oxidation catalysts containing a higher precious metal loading in the inlet zone that the outlet zone and an equal or shorter length inlet zone are described. Emission treatment systems and methods of remediating nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons using zoned diesel oxidation catalysts are also described.

Owner:BASF CORP

Preparation method of catalyst with core-shell structure for low-temperature fuel cell

InactiveCN102500365AHigh catalytic activitySolve the costCell electrodesCatalyst activation/preparationIridiumPtru catalyst

The invention discloses a preparation method of a catalyst with a core-shell structure for a low-temperature fuel cell, belonging to the technical field of fuel cells. In the catalyst with the core-shell structure prepared with the preparation method, platinum is taken as a shell, a metal alloy consisting of more than one of metals including ruthenium, platinum, iron, cobalt, nickel, copper, tin, iridium, gold and silver is taken as an inner core, and the shell and the inner core are loaded on a carbon carrier. The preparation method comprises the following preparation steps of: reducing a metal chloride or a metal nitrate with a reducing agent, and forming a core on the carbon carrier with a large specific surface area; stabilizing the core; and precipitating Pt on a core layer with a impregnation reduction method, a high-pressure organic sol method, a microwave method or an electrodeposition process to form the catalyst with the core-shell structure. Due to the adoption of the preparation method, the utilization ratio of noble metal platinum is increased, the cost of an electro-catalyst is reduced effectively, and the methanol oxidizing capability and oxygen reducing activity of the obtained catalyst are increased by 10.8 times and 8.7 times in maximum respectively in comparison to the mass ratio and activity of a commercial JM4100Pt / C catalyst.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com