Patents

Literature

48 results about "ACETIC ACID LIQUID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetic acid is an organic solvent that is used for a variety of industrial, analytical and medical purposes. It has the structural formula "CH3COOH" and exists as a colorless liquid at room temperature. Acetic acid is a component of vinegar and is what gives vinegar its characteristic smell.

Method for preparing alcohol by acetic acid gas phase hydrogenation

ActiveCN102229520ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationHydroxy compound preparationACETIC ACID LIQUIDGas phase

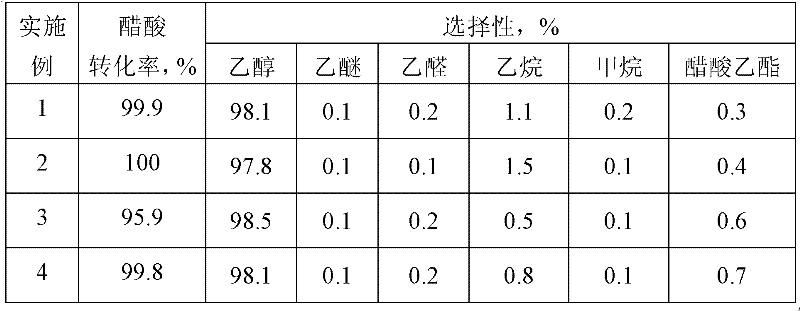

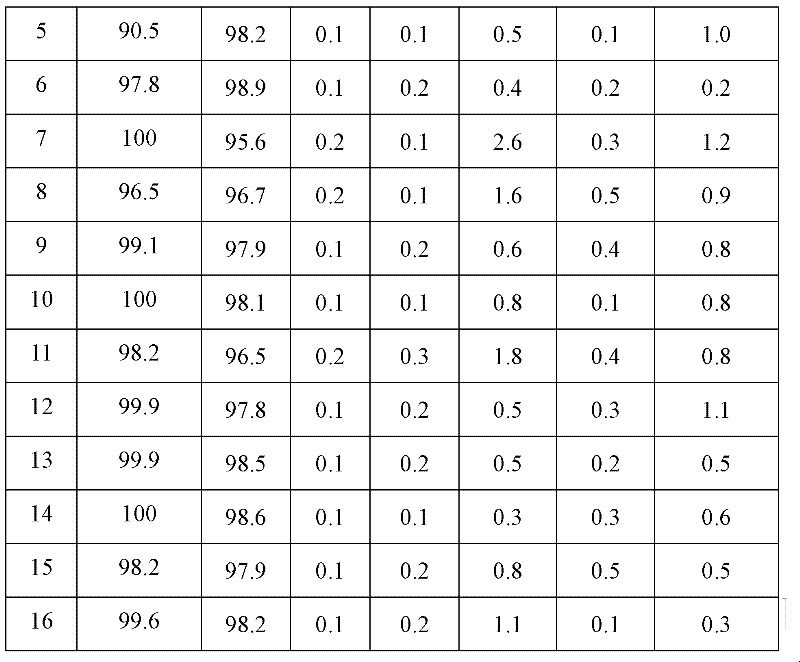

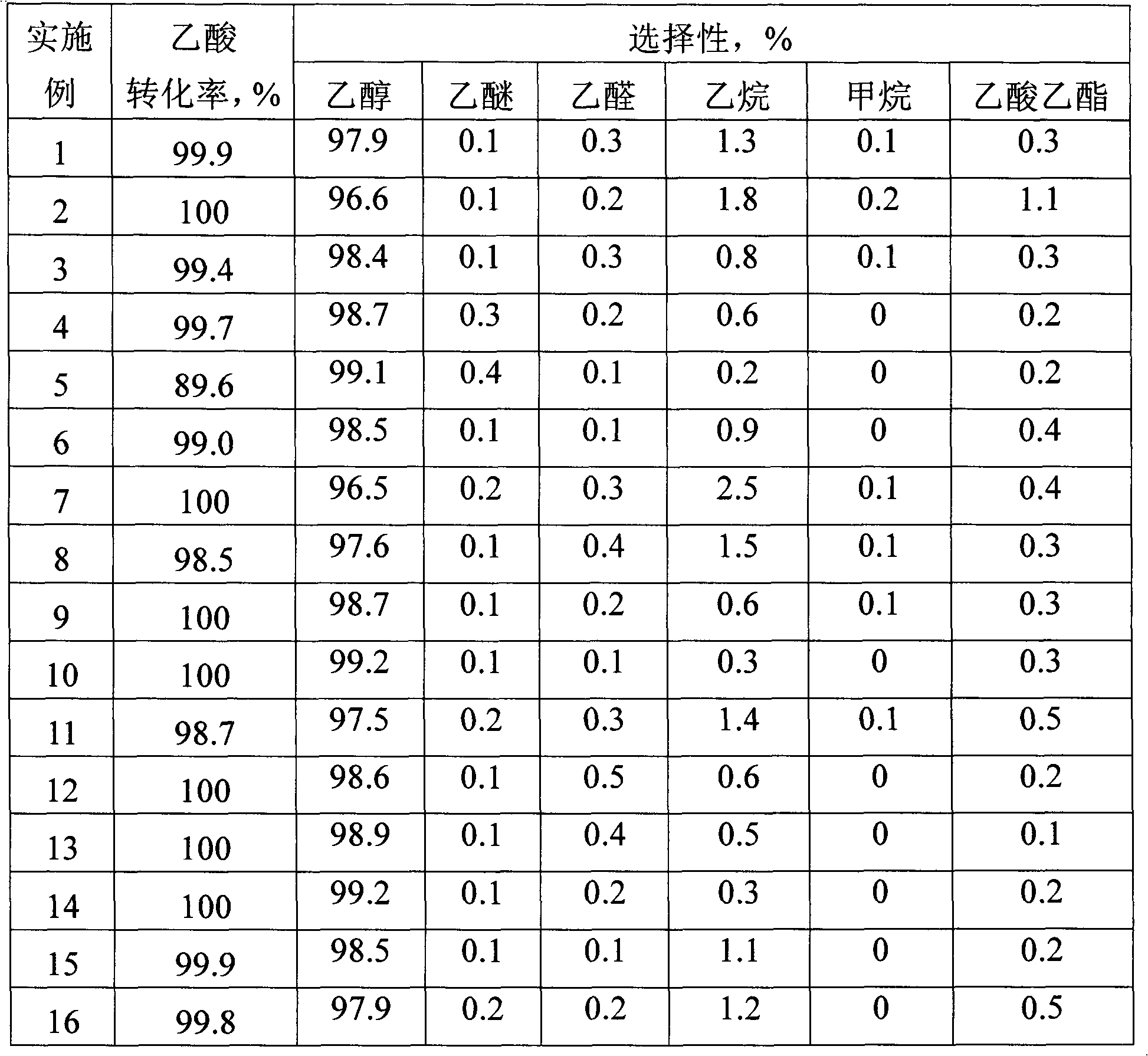

The invention relates to a method for preparing alcohol by acetic acid gas phase hydrogenation. A reaction system comprises acetic acid, hydrogen and a catalyst; the reaction temperature is 120-300 DEG C; the reaction pressure is 1.0-20.0MPa; the space velocity of acetic acid liquid is 0.5-10.5h<-1>; the molar ratio of H2 to acetic acid is 1-250; the catalyst takes activated carbon as a carrier; and main active components comprise one or two of transitional metals such as W and Mo. The addition agent is one of or more of precious metals such as Pd, Re, Pt, Rh and Ru and the like; and the acetic acid and the hydrogen can be converted into alcohol with high activity and selectivity under the action of the catalyst.

Owner:JIANGSU SOPO CHEM +1

Red rice vinegar with antihypertensive function

InactiveCN101333493AIncrease GABA contentHas the function of lowering blood pressureVinegar preparationYeastRed yeast rice

The invention relates to a red yeast vinegar having the blood pressure lowering function; and the red yeast vinegar is prepared by the following processes of: taking glutinous rice as a raw material, steaming and boiling the glutinous rice, and then adding distillers yeast made of red yeast and supplementary materials as well as functional red yeast wine lees with the weight percent of 10 percent to 20 percent of the raw material for undergoing initial fermentation and secondary fermentation, then pressing the mixture to make the red yeast yellow wine, and recovering the red yeast wine lees, and the red yeast wine is made into the red yeast vinegar having the blood pressure lowering function through the acetic acid liquid fermentation; the invention fully utilizes the supplementary material of red yeast wine lees for producing the red yeast wine, thereby increasing the added value and preparing the red yeast vinegar with high GABA content and blood pressure lowering function; and the red yeast vinegar has an unexpected effect to the treatment and prevention of hypertension, and also has the auxiliary blood pressure lowering function.

Owner:义乌市丹溪酒业有限公司

Rapid synthesis method for lauroyl-sodium methyl taurate

InactiveCN105175290AImprove conversion rateSimple processOrganic compound preparationSulfonic acids salts preparationACETIC ACID LIQUIDAlcohol ethyl

Owner:湖州新天字味精有限公司

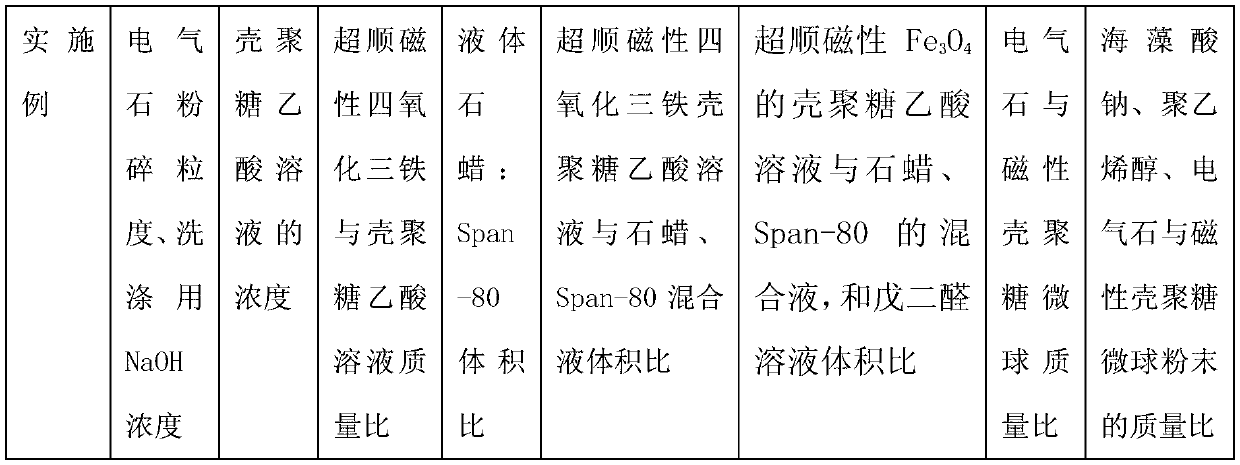

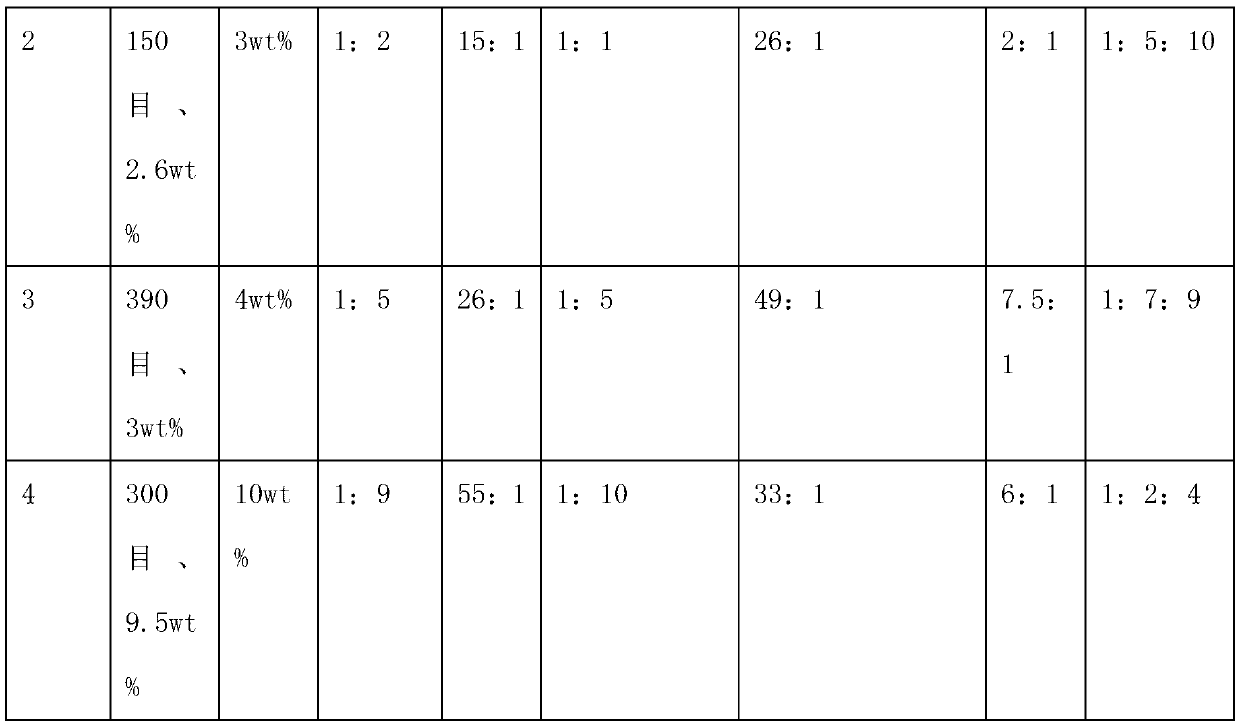

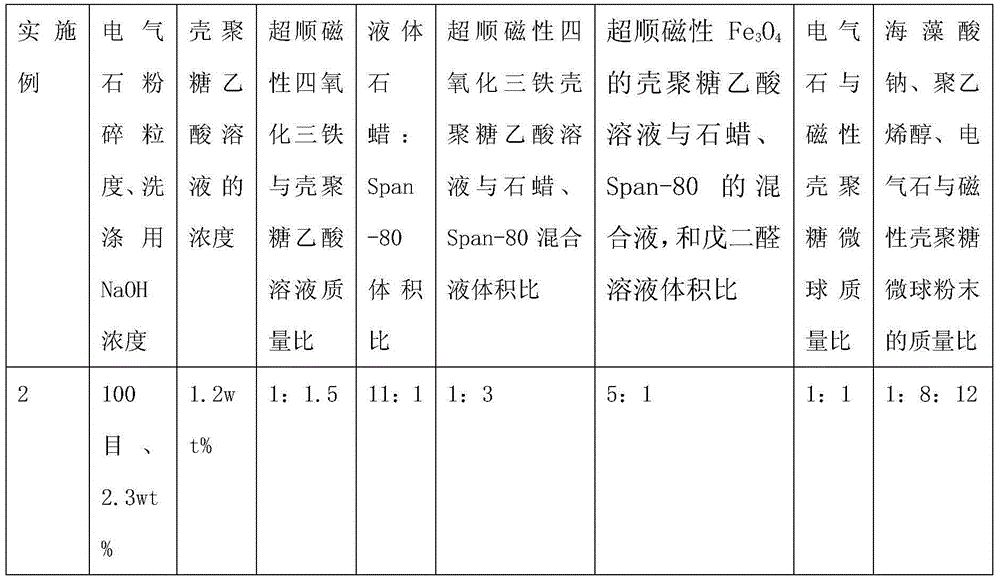

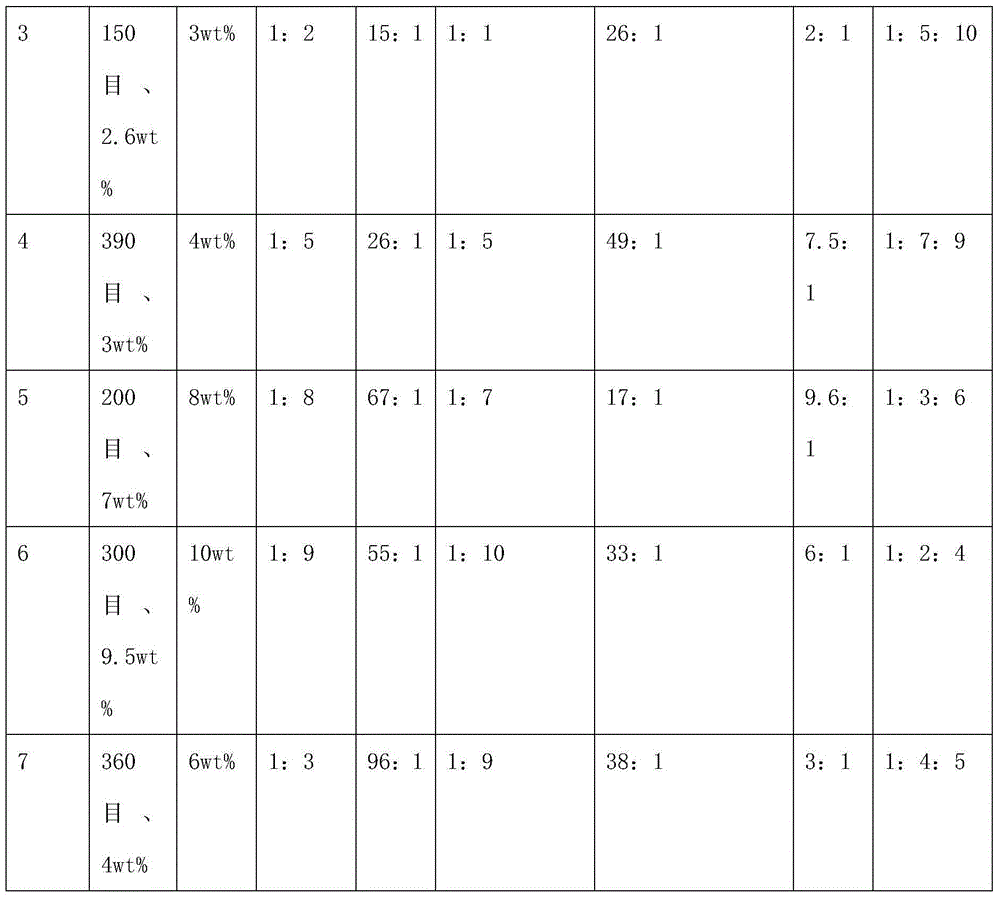

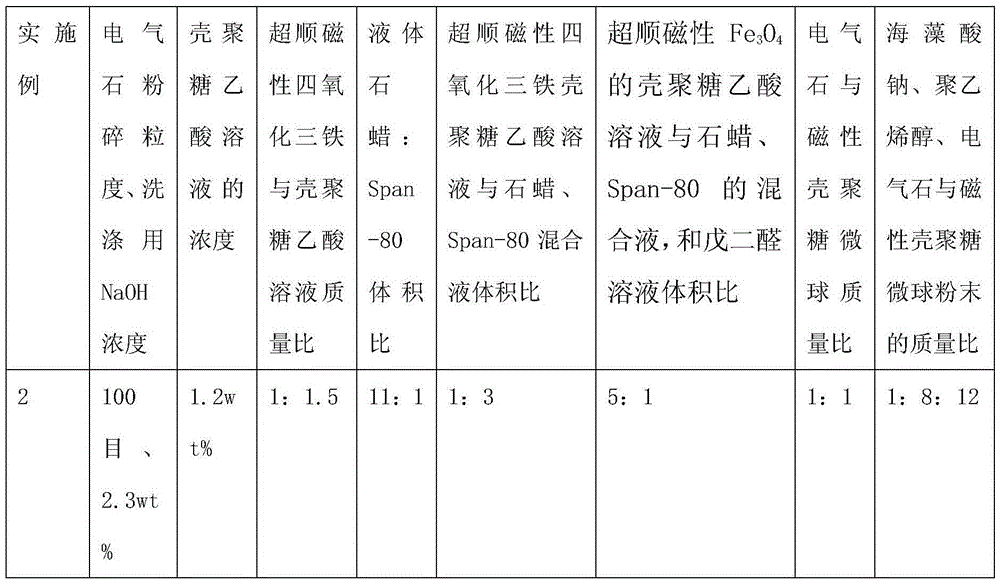

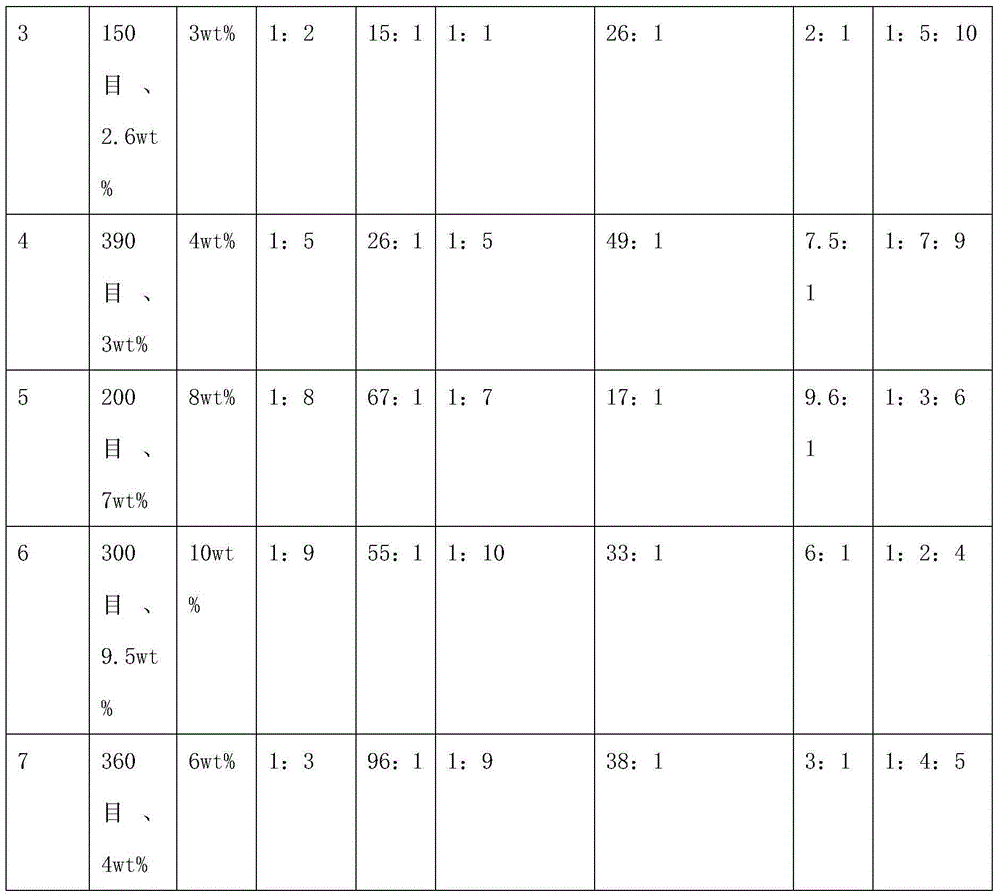

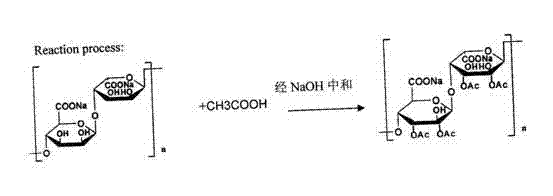

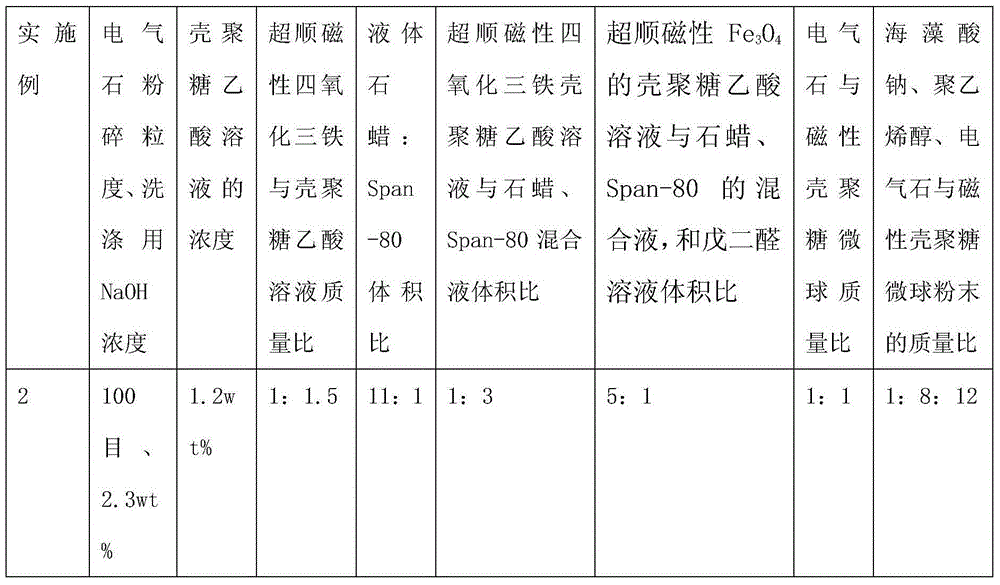

Preparation method of tourmaline/magnetic chitosan microsphere treatment agent

InactiveCN103127916ALarge adsorption capacityLow costOther chemical processesWater/sewage treatment by sorptionVolatile phenolsEmulsion

The invention provides a preparation method of a tourmaline / magnetic chitosan microsphere treatment agent which is prepared by dissolving and uniformly mixing mixed powder of tourmaline and magnetic chitosan microspheres in sodium alginate and polyvinyl alcohol, and solidifying and balling. The magnetic chitosan microsphere is prepared by using superparamagnetic ferroferric oxide, 1 to 10 weight percent of chitosan acetic acid liquid, liquid paraffin, Span-80 and glutaraldehyde as reaction materials through an emulsion crosslinking method, wherein the mass ratio of the superparamagnetic ferroferric oxide to the chitosan acetic acid liquid is 1:(1-10), the volume ratio of the liquid paraffin to the Span-80 is (10-100):1, the volume ratio of the chitosan acetic acid liquid of superparamagnetic ferroferric oxide to mixed liquid of paraffin-Span-80 is 1:(1-10), and the volume ratio of the mixed liquid of superparaferroferric oxide, paraffin and Span-80 to glutaraldehyde is (5-50):1. According to the water treating agent, the removal rate of volatile phenol in water is between 80 and 90 percent, the removal rate of chromium in water is 93 percent; and the magnetic chitosan microsphere treating agent has the advantages of large adsorption capacity, high purification efficiency, low cost, regeneration, no toxicity, no pollution to environment and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

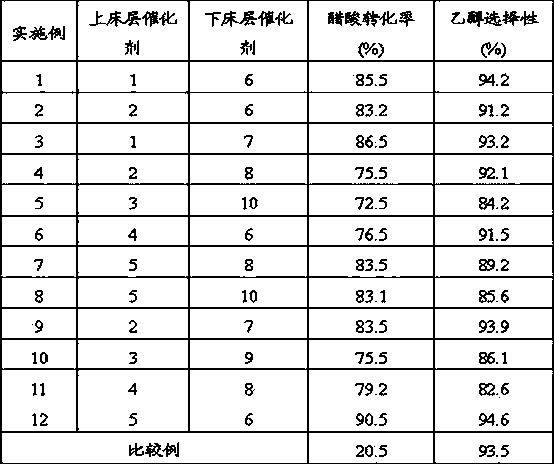

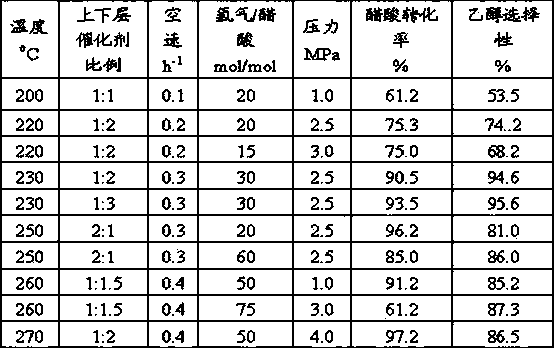

Method for preparing ethanol by acetic acid gas phase hydrogenation

ActiveCN102690170ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationHydroxy compound preparationACETIC ACID LIQUIDGas phase

The invention discloses a method for preparing ethanol by acetic acid gas phase hydrogenation. The method is characterized in that a reaction system comprises acetic acid, hydrogen and a catalyst; a reaction temperature is in a range of 120 to 300 DEG C; reaction pressure is in a range of 1.0 to 20.0MPa; an airspeed of an acetic acid liquid is in a range of 0.5 to 10.5h<-1>; a mole ratio of H2 to acetic acid is in a range of 1-250; the catalyst utilizes active carbon as a carrier and contains precious metal Pd and / or Pt as a main active ingredient; and one or more auxiliary agents are selected from Au, Ag, Fe, Re, Cu, Ru and their oxides. Through the catalyst, high activity and high selectivity transformation of an acetic acid and hydrogen into ethanol is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

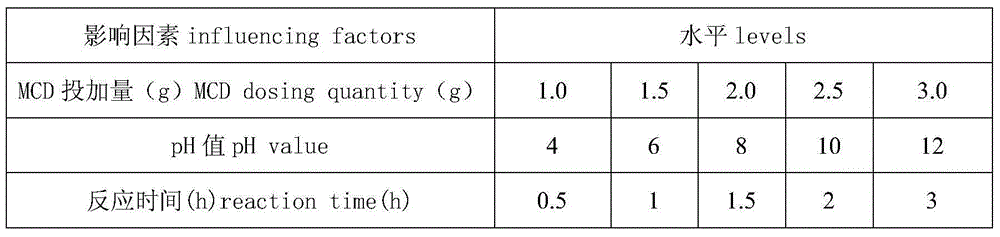

Environment-friendly magnesium-ion modified montmorillonite tap water flocculant and application thereof

InactiveCN103880136AImprove electrical performanceGood flocculation effectWater/sewage treatment by flocculation/precipitationSodium bicarbonateACETIC ACID LIQUID

The invention discloses an environment-friendly magnesium-ion modified montmorillonite tap water flocculant. The flocculant is prepared by a chitosan liquid and a magnesium-ion modified montmorillonite liquid; the chitosan liquid is an acetic acid liquid containing 0.2-2 mass percent of chitosan, and the magnesium-ion modified montmorillonite liquid is prepared by the mixing of sodium hydroxide, sodium bicarbonate, magnesium chloride, montmorillonite and water according to the mass ratio of 1:1:(1-4):(5-8):(86-92). The flocculant of the invention has large flocculation particles and fast sedimentation rate, the removal rate of raw water turbidity reaches 98.09 percent, and for the raw water with the turbidity of 70-100 NTU, the once treatment can be within 3 NTU of the national standards; and the cost is low, and the flocculant has no ingredients harmful to human bodies, and has excellent performance and stable quality.

Owner:WUHAN UNIV OF TECH

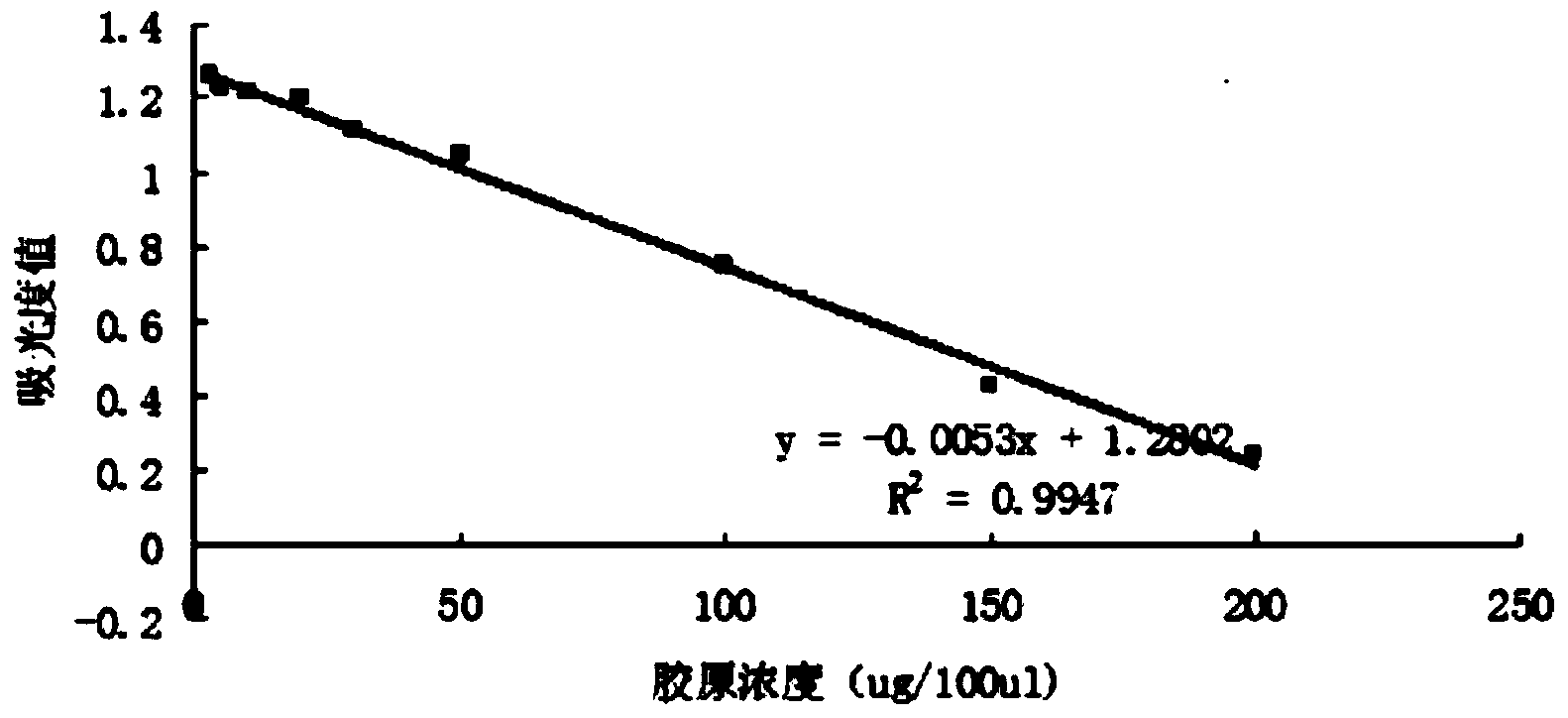

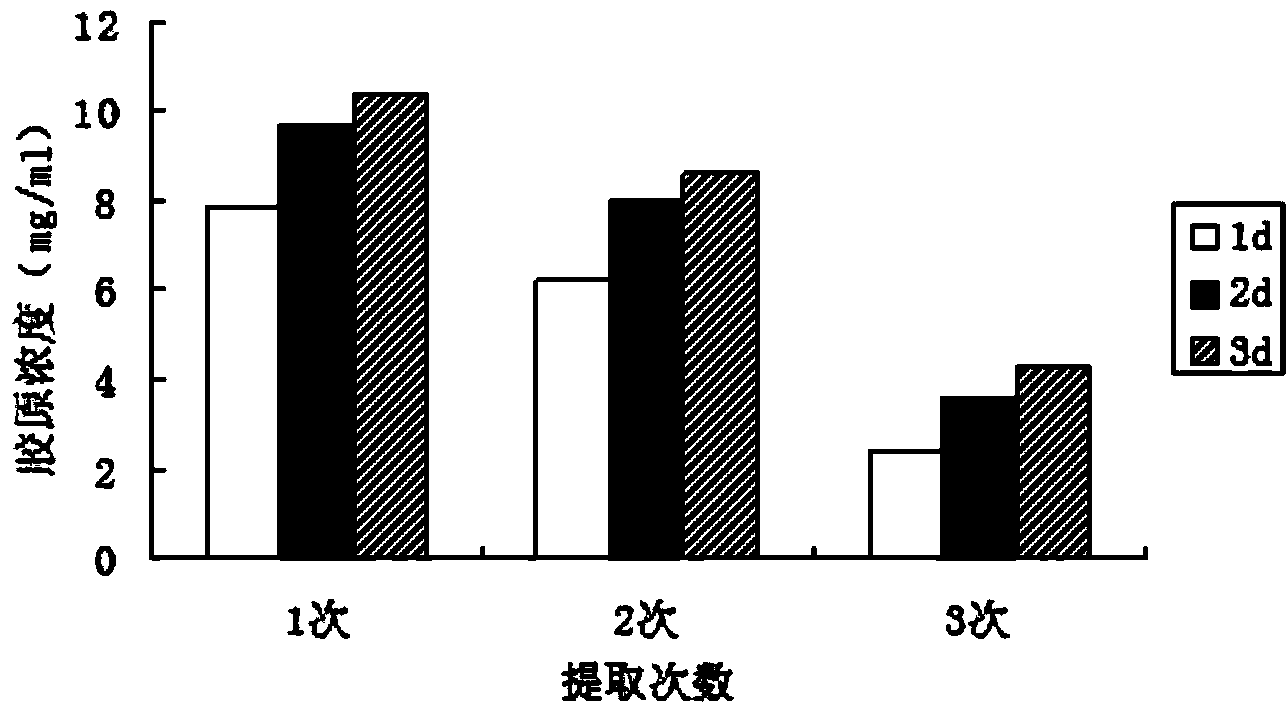

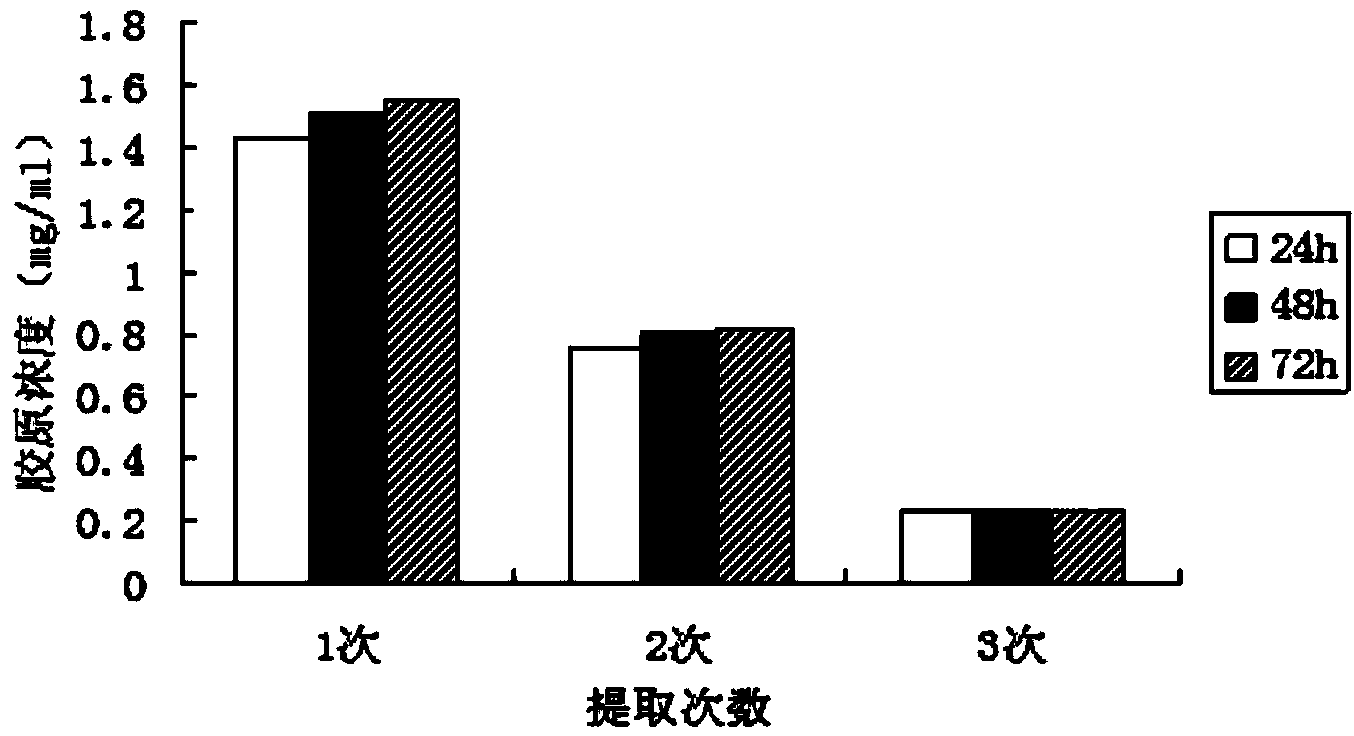

Quantitative determination method in extraction process of fish collagen and application of quantitative determination method

InactiveCN103776778AImprove stabilityThe result is accuratePreparing sample for investigationColor/spectral properties measurementsAnalysis studyACETIC ACID LIQUID

The invention belongs to the technical field of aquatic product processing and discloses a rapid quantitative determination method in an extraction process of fish collagen and an application of the quantitative determination method. The method comprises the following steps: preparing a collagen liquid by using an acetic acid liquid; after dyeing by using sirius red, centrifuging and determining the absorbance of liquid supernatant; comparing a standard curve; and quantifying the content of the collagen. According to the quantitative determination method, the specific binding of the sirius red and the collagen is utilized; after the centrifuging, the absorbance of the liquid supernatant can be determined under the condition of a special wavelength of 540nm; and the content of the collagen is determined. According to the quantitative determination method, the centrifuged liquid supernatant is determined so that a solvent is saved and the influences on specific matters formed by the collagen and the sirius red, caused by the liquid and other reagents, are avoided; the recovery rate of a sample is 95.7-104.7% and the requirements of analytical researches are met; the variable coefficient of a parallel sample is 0.35% and the stability is very good; and the quantitative determination method is applied to quantifying the collagen in an operation process and the present determination can be realized.

Owner:SOUTH CHINA UNIV OF TECH

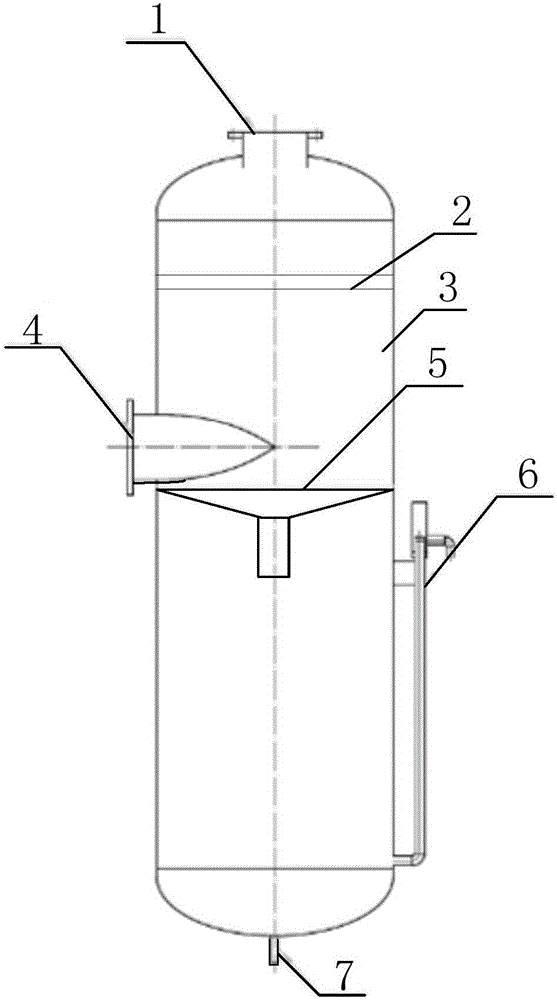

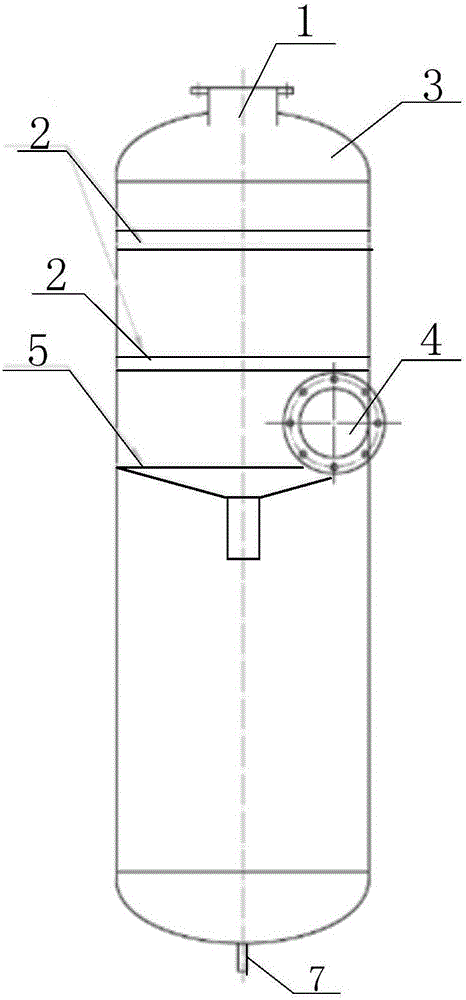

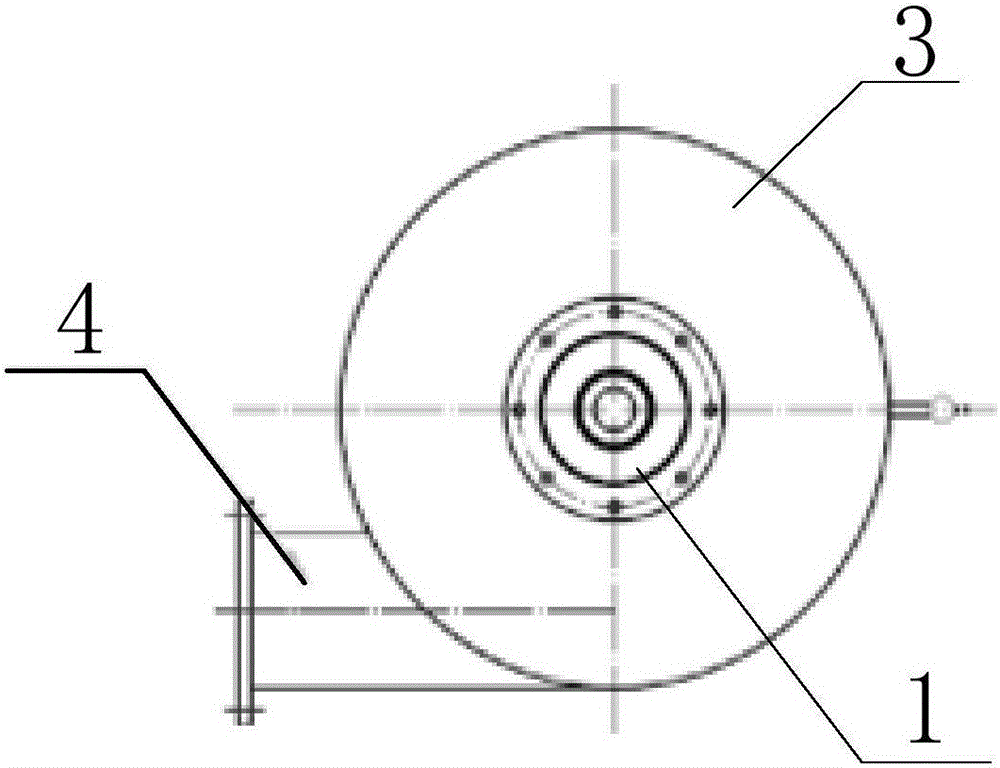

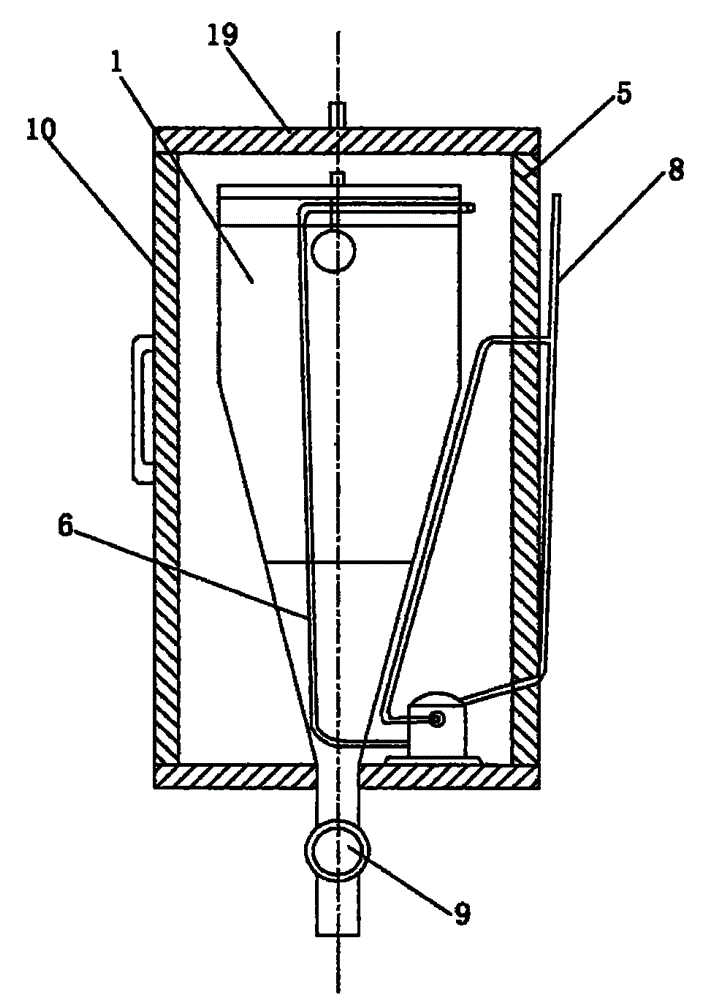

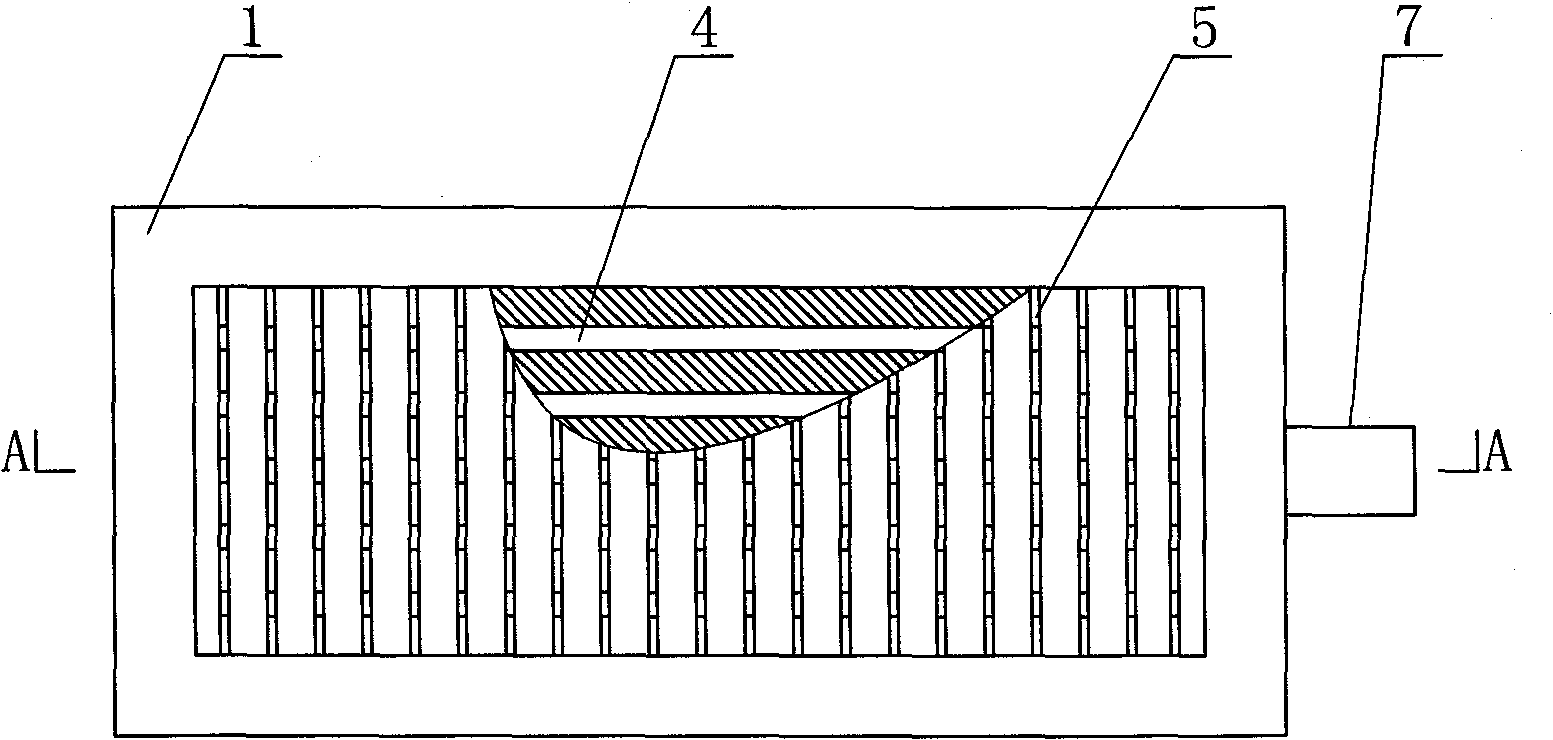

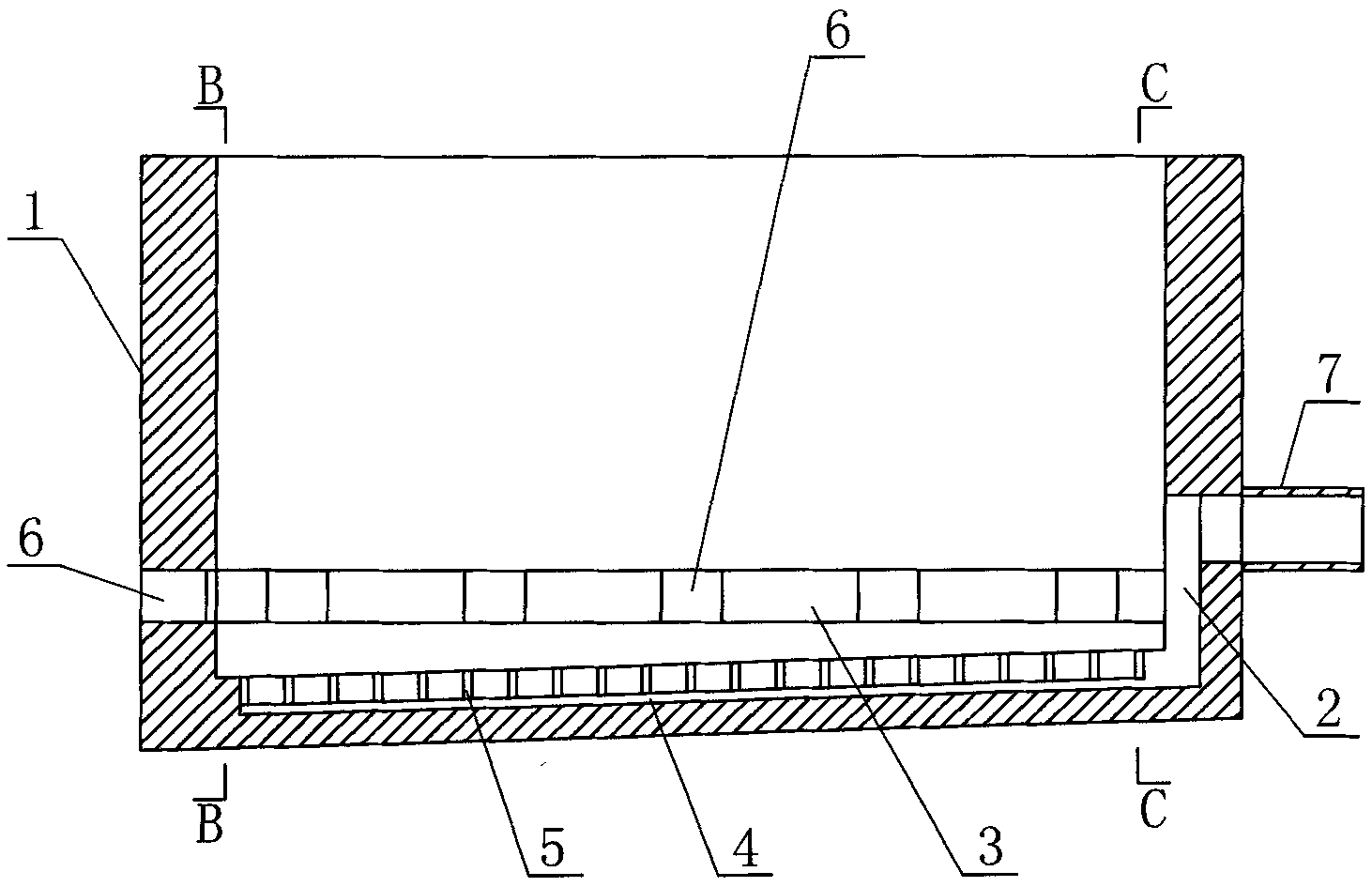

Collision type separator and biomass comprehensive utilization system

ActiveCN105854423AAchieve separationSolve the purificationDispersed particle separationBiofuelsEnergy technologyACETIC ACID LIQUID

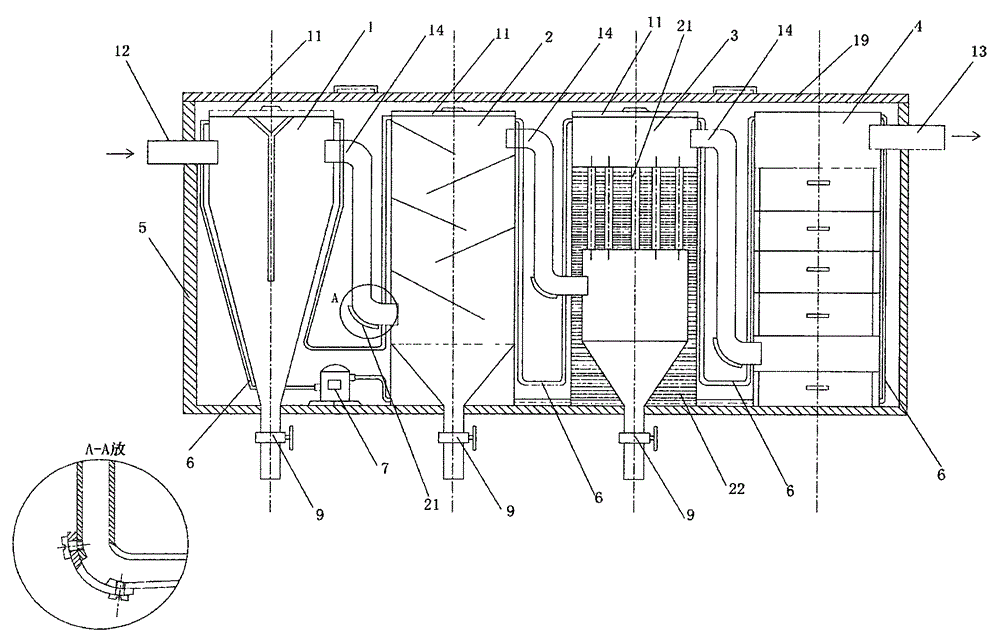

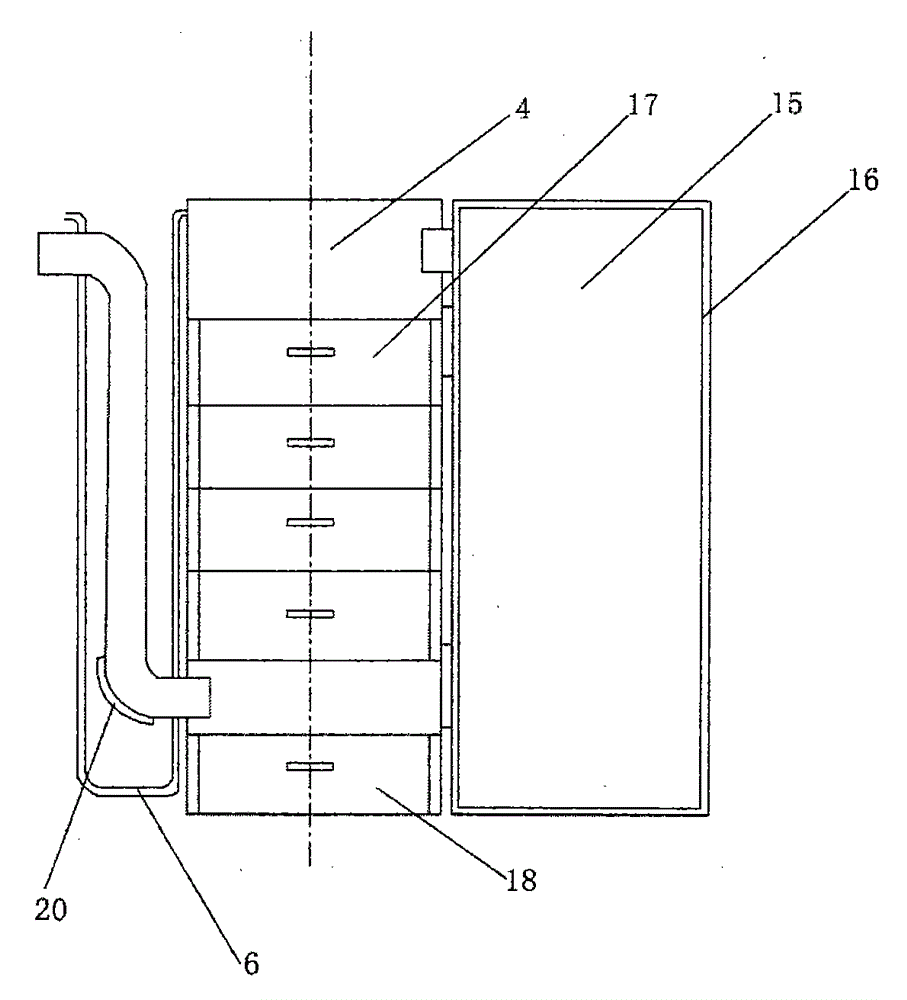

The invention relates to the technical field of biological energy, in particular to a collision type separator and a biomass comprehensive utilization system. The collision type separator is formed by combining an exhaust pipe, a separator body, turbine blades, a gas inlet pipe, a separation device and a blowdown device. The biomass comprehensive utilization system is formed by combing a carbonization furnace, a first separation unit, the collision type separator, a second separation unit, a third separation unit, a draught fan, a fourth separation unit and a gas storage cabinet. Through the collision type separator, the decoking effect is improved, meanwhile, separation of tar and acetic acid liquid can be realized, and the industrial cost is reduced. The decoking effect of the biomass comprehensive utilization system is good, no wastewater is generated in the production process, equipment has no blockage risk, and continuous and automatic production can be realized.

Owner:HEBEI TIANSHAN BIOTECH CO LTD

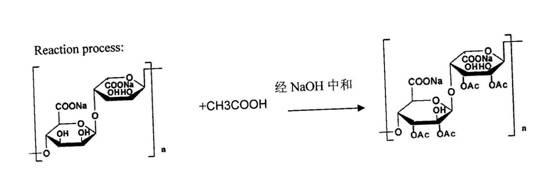

Drug for treating and preventing fracture

ActiveCN102349929AGood effectThe effect is quick and obviousOrganic active ingredientsSkeletal disorderAcetic anhydridePolymer science

The invention discloses a drug for treating and preventing fracture, which is prepared by the ingredients of kelp, marine alga plant rich in algin and acetic acid or acetic anhydride. The preparation method of the drug is as follows: a, getting kelp and marine alga plant rich in algin, drying and grinding to powder, soaking the powder in acetic acid, wherein, the amount of the acetic acid added is in a standard that the acetic acid immerses the marine alga powder to carry out reaction for 2-3 weeks at normal temperature, pouring out the acetic acid liquid after the reaction is finished, drying under normal temperature, after drying, neutralizing through sodium hydroxide or other alkaline substance, after neutralizing, drying under normal temperature, and getting the substance used for preparing the drug for promoting fracture healing; and b, getting the kelp and the marine alga plant rich in the algin, drying and grinding to powder, soaking the powder in the acetic anhydride, the amount of the acetic anhydride added is in a standard that the acetic anhydride immerses the marine alga powder, then adding sulfuric acid for catalytic reaction, wherein the amount of the sulfuric acid added is 0.3% of the amount of the acetic anhydride, pouring out the acetic acid liquid after the reaction is over, drying under normal temperature, after drying, neutralizing through sodium hydroxide or other alkaline substance, after neutralizing, drying under normal temperature, and finally getting the substance used for preparing the drug for promoting fracture healing.

Owner:郭宏昌

Corn stalk carbonization production organic fertilizer

InactiveCN108440132AIncrease profitFunctionalBio-organic fraction processingExcrement fertilisersACETIC ACID LIQUIDAdhesive

The invention discloses a corn straw carbonization production organic fertilizer, which comprises the following raw materials in parts by weight: wherein, the main raw materials are corn straw charcoal, mixed sheep manure, a fermentation agent, an adhesive and a forming auxiliary agent; the ingredients are wood acetic acid liquid; According to the invention, the corn straw and the sheep manure aremixed, the utilization rate of the fertilizer is improved through the characteristics of adsorption and slow release, the utilization rate of the fertilizer is improved, and the soil improvement function and the fertilizer efficiency are balanced; The method comprehensively utilizes the recovery of nitrogen and phosphorus elements in the corn straw carbon and the sewage and does not discharge waste water, waste liquid and waste residues in the production, and all indexes meet the industry standard of the organic fertilizer; Compared with the prior art, the invention is characterized by reducing planting component, improving the economic benefit, and giving consideration to both soil improvement function and fertilizer synergistic effect.

Owner:农安县学海生物秸秆加工有限公司

Ethanol production method

ActiveCN103896734AOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystACETIC ACID LIQUID

The invention relates to an ethanol production method. The problems of strict catalytic reaction conditions and low once-through conversion rate of acetic acid hydrogenation catalysts in the prior art in the ethanol production process are solved in the invention. The method comprises the following steps: allowing raw materials comprising acetic acid and hydrogen to contact and react with a composite bed catalyst composed of a Pd-based catalyst and a Cu-based catalyst at a reaction temperature of 180-270DEG C under a reaction pressure of 0.5-5.0MPa under an acetic acid liquid volume air speed of 0.1-0.5h<-1> to generate ethanol and water, wherein a molar ratio of hydrogen to acetic acid is 1:0.1-0.01; and separating to obtain ethanol. The above technical scheme well solves the problems, and the method can be used in the industrial production of ethanol through acetic acid hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Montmorillonite modified melamine/chitosan painting mist coagulant

InactiveCN104229967AImprove processing efficiencyWide variety of sourcesWater/sewage treatment by flocculation/precipitationACETIC ACID LIQUIDMontmorillonite

The invention relates to a montmorillonite modified melamine / chitosan painting mist coagulant. The montmorillonite modified melamine / chitosan painting mist coagulant is characterized by being composed of an individually-stored montmorillonite modified melamine liquid and an acetic acid liquid of chitosan, wherein during use, a volume ratio of the montmorillonite modified melamine liquid to the acetic acid liquid of the chitosan is 1 to (0.2-1.0). A preparation method of the montmorillonite modified melamine liquid comprises the following steps: mixing a crosslinked polymer, which is generated by carrying out condensation reaction on melamine, urea and formaldehyde, with the montmorillonite liquid in a mass ratio of (1-5) to 1, regulating a pH value of the mixed liquid to 1.8-2.2 at a temperature of 40-50 DEG C, and ageing the mixed liquid. The painting mist coagulant has painting mist treatment efficiency over 95%; the raw materials are wide in source and low in price, small in dosage for treating paint-containing wastewater and obvious in cost performance advantage; and the preparation process is simple, convenient in treating spraying paint wastewater and simple in process.

Owner:WUHAN UNIV OF TECH

Preparation method of drinking water treatment agent

InactiveCN103127917ALarge adsorption capacityImprove purification efficiencyOther chemical processesAlkali metal oxides/hydroxidesVolatile phenolsPolyvinyl alcohol

The invention provides a drinking water treatment agent which is prepared by dissolving and uniformly mixing mixed powder of tourmaline and magnetic chitosan microspheres in sodium alginate and polyvinyl alcohol, and solidifying and balling. The magnetic chitosan microsphere is prepared by using superparamagnetic ferroferric oxide, 1-10wt% chitosan acetic acid liquid, liquid paraffin, Span-80 and glutaraldehyde as reaction materials through an emulsion crosslinking method, wherein the mass ratio of the superparamagnetic ferroferric oxide to the chitosan acetic acid liquid is 1:(1-10), the volume ratio of the liquid paraffin to the Span-80 is (10-100):1, the volume ratio of the chitosan acetic acid liquid of superparamagnetic ferroferric oxide to mixed liquid of paraffin-Span-80 is 1:(1-10), and the volume ratio of the mixed liquid of superparaferroferric oxide, paraffin and Span-80 to glutaraldehyde is (5-50):1. According to the water treatment agent, the removal rate of volatile phenol in water is between 80 and 90 percent, and the removal rate of chromium in water is 93 percent; and the magnetic chitosan microsphere treating agent has the advantages of large adsorption capacity, high purification efficiency, low cost, regeneration, no toxicity, no pollution to environment and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

Method for preparing ethyl alcohol by acetic acid hydrogenation

ActiveCN105503521ALow selectivityGuaranteed efficient selectivityOrganic compound preparationHydroxy compound preparationAlcoholACETIC ACID LIQUID

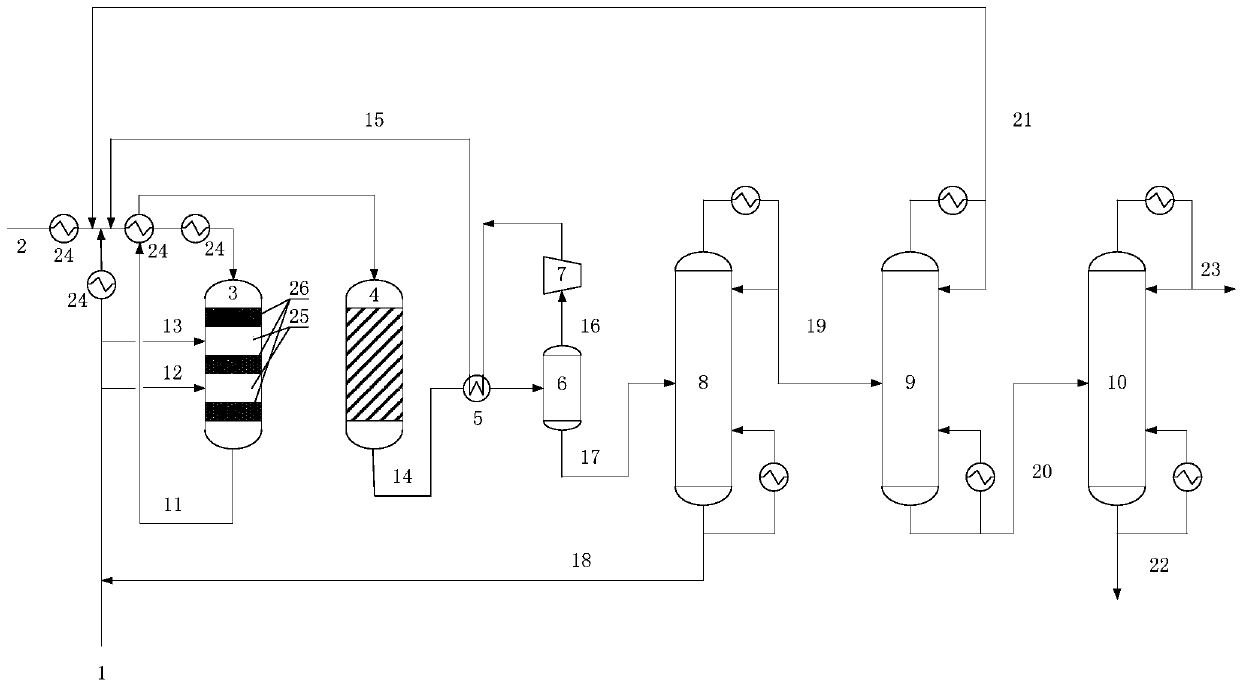

The invention relates to a method for preparing ethyl alcohol by acetic acid hydrogenation and mainly solves the problem that ethyl alcohol selectivity in the prior art is low. By using the method for preparing the ethyl alcohol by acetic acid hydrogenation, two flows or multiple flows of acetic acid material enter various hydrogenation reaction stages, acetic acid liquid feeding or acetic acid partial liquid feeding is among the reaction stages, the temperature rise of an acid hydrogenation reactor catalyst bed is effectively controlled, direct heat exchange cooling and material supplementing are enabled, hydrogen acid ratio of an acetic acid hydrogenation reaction system is greatly reduced with each reaction area high in hydrogen acid ratio, and a technical scheme ensuring high ethyl alcohol selectivity well solves the above problems and is applicable to the preparation of ethyl alcohol by acetic acid hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

Condensation type purifying series apparatus for combustible gas from biomass pyrolysis

InactiveCN105273770AQuality improvementEasy to separateGas purification by non-gaseous materials condensationGas dust removalRefrigeration compressorACETIC ACID LIQUID

Owner:叶安生

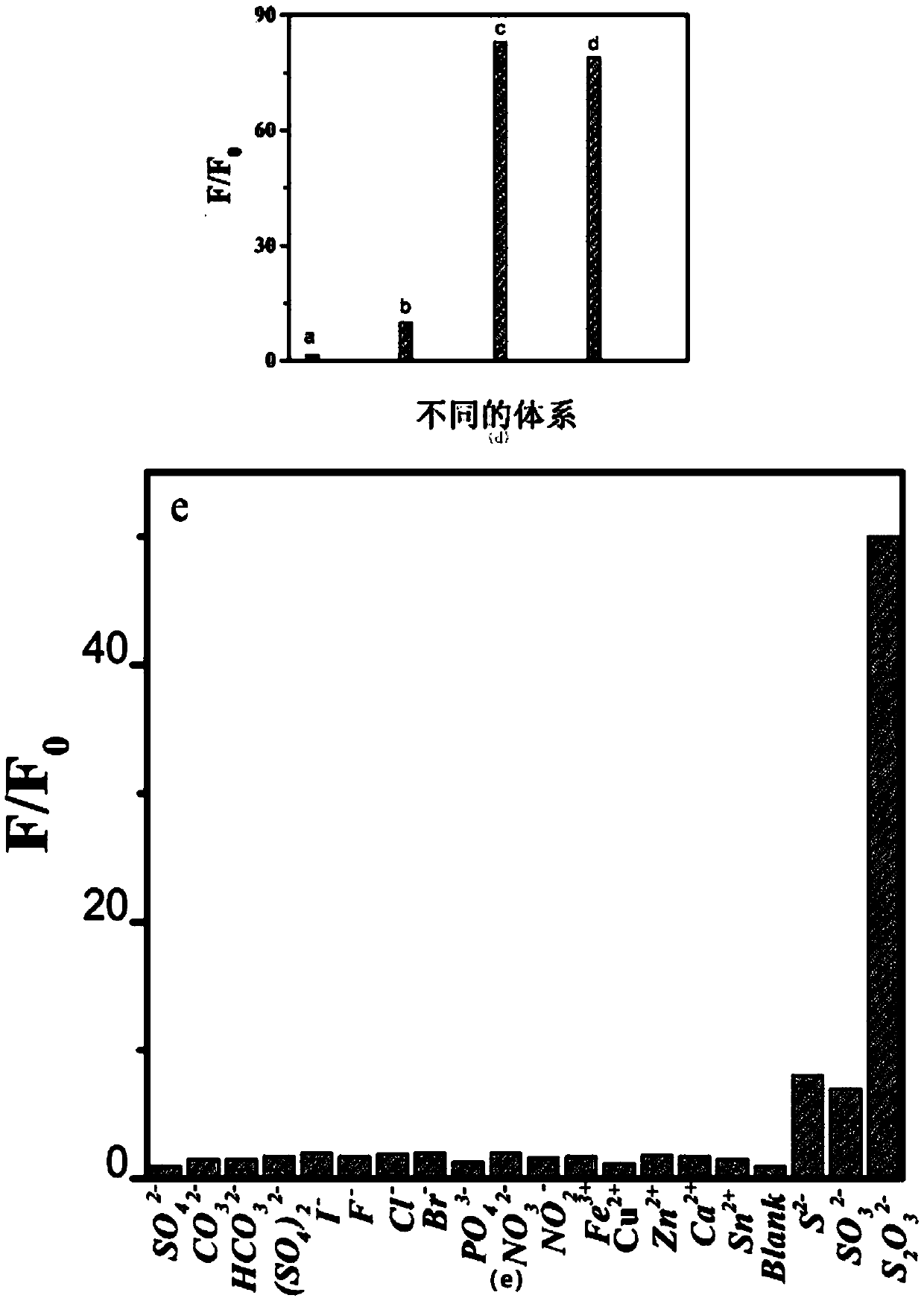

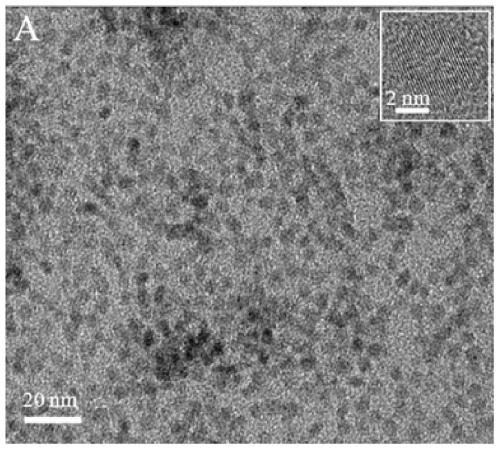

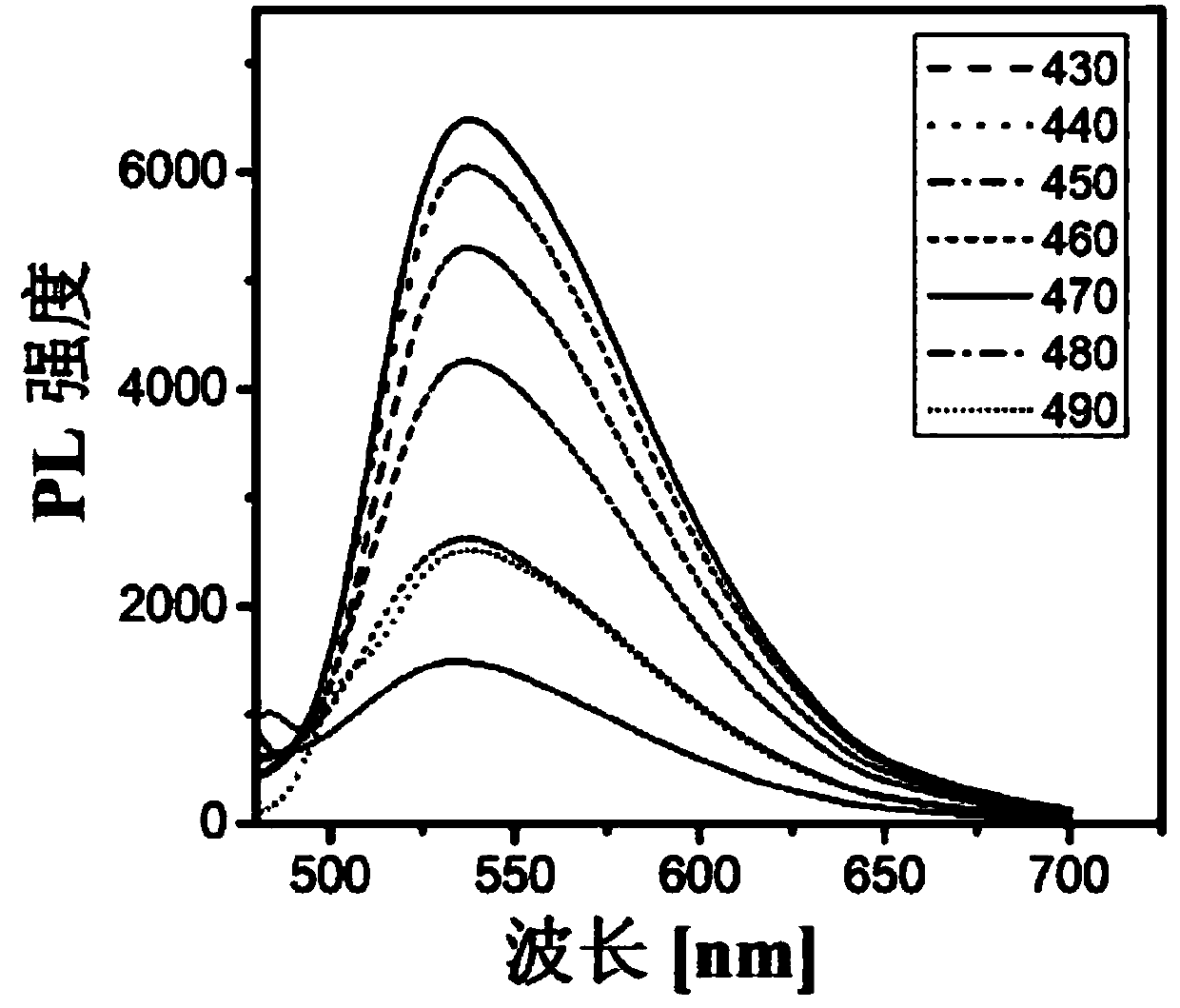

Yellow fluorescent graphene quantum dot, method for preparing same and application of yellow fluorescent graphene quantum dot

ActiveCN109735332AUniform particle sizeParticle size non-toxicGrapheneNanoopticsACETIC ACID LIQUIDSolvent

The invention discloses a yellow fluorescent graphene quantum dot, a method for preparing the same and application of the yellow fluorescent graphene quantum dot. The method includes steps of S1, mixing Julolidine solid, absolute ethyl alcohol liquid and acetic acid liquid with one another according to a feed ratio of 0.1 g:30 mL:2 mL and then carrying out ultrasonic treatment under the room-temperature condition for 10 minutes; S2, placing reaction liquid in high-pressure reaction kettles after the ultrasonic treatment is carried out on the reaction liquid, and preparing graphene quantum dotsby the aid of solvothermal processes; S3, purifying reaction liquid by the aid of dialysis processes and concentrating, freezing and drying dialysate to obtain the yellow fluorescent graphene quantumdot. The yellow fluorescent graphene quantum dot, the method and the application have the advantages that the method includes simple technologies and is low in cost, the yellow fluorescent graphene quantum dot prepared by the aid of the method has uniform particle sizes, is nontoxic, can be used as a fluorescent probe to be directly applied to detecting thiosulfuric acid radicals and hydrogen peroxide in water samples and serum from human bodies and can be conveniently and quickly operated, and accurate detection results can be obtained.

Owner:SHANGHAI INST OF TECH

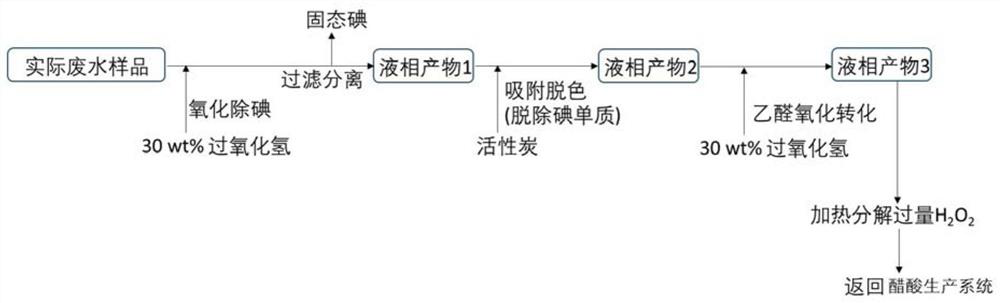

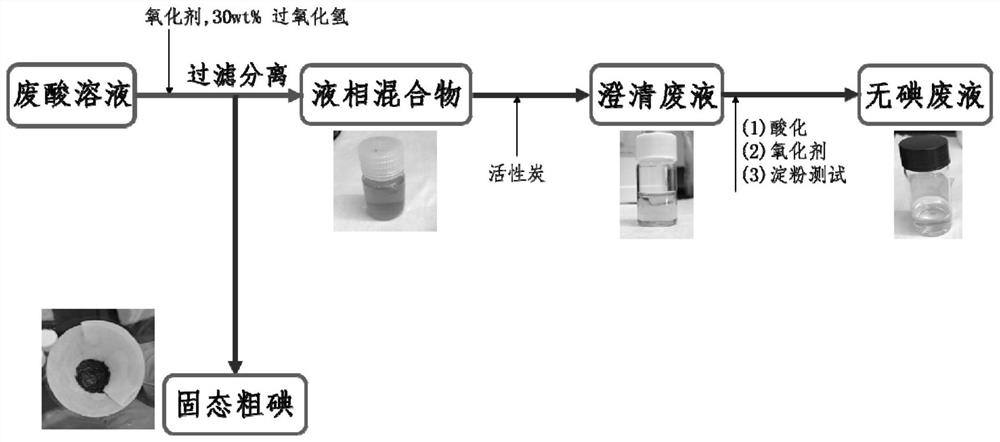

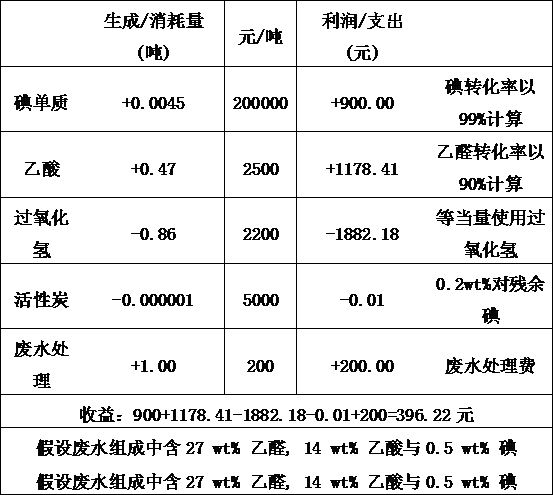

Acetic acid production wastewater treatment process

ActiveCN112919678AHigh yieldLow in acetaldehydeOrganic compound preparationIodineActivated carbonFluid phase

The invention discloses an acetic acid production wastewater treatment process which comprises the following steps: adding a hydrogen peroxide aqueous solution into acetic acid production wastewater, and reacting hydrogen peroxide with iodide ions in the wastewater to generate elemental iodine; filtering out the solid iodine elementary substance generated by the reaction from the wastewater, wherein the residual liquid is a liquid-phase product 1; adding activated carbon powder into the treated liquid phase product 1; filtering the treated liquid phase product 1, and separating out activated carbon in the liquid phase product 1 so that residual liquid is a liquid phase product 2; and adding an aqueous hydrogen peroxide solution into the treated liquid-phase product 2, reacting hydrogen peroxide with acetaldehyde in the liquid-phase product 2 to generate acetic acid, converting the liquid into a liquid-phase product 3, and conveying the liquid-phase product 3 to an acetic acid production system to separate acetic acid. According to the acetic acid production wastewater treatment process, iodine in the wastewater can be converted into iodine simple substances to be recycled, acetaldehyde in the wastewater is converted into acetic acid, the yield of acetic acid is increased, and environmental pollution is avoided.

Owner:JIANGSU JITRI-TOPSOE JOINT RES & DEV CENT CO LTD +2

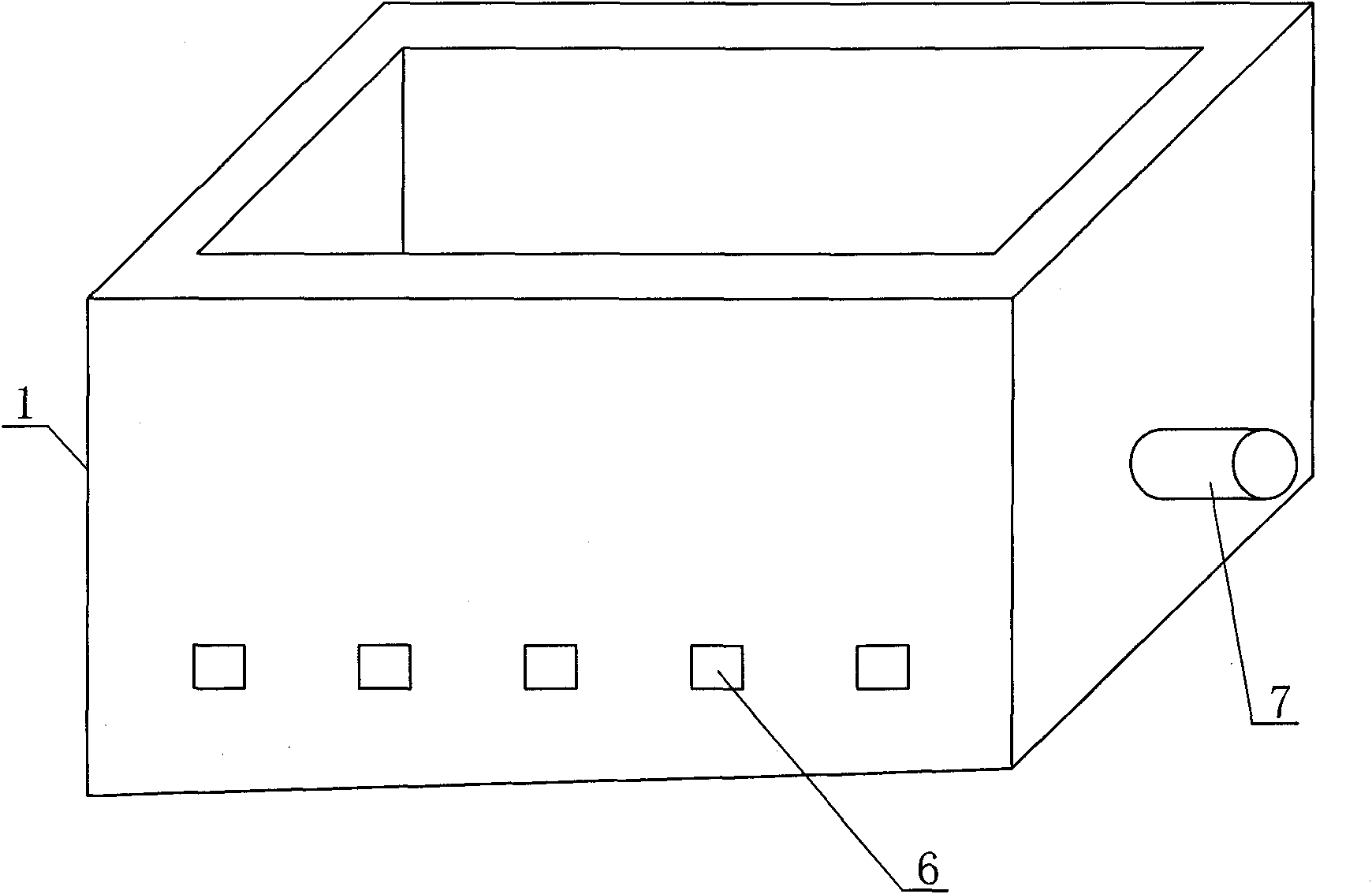

Biomass pyrolysis method

InactiveCN102220149AEasy to moveNo emissionsBiofuelsSpecial form destructive distillationCycloneACETIC ACID LIQUID

The invention discloses a biomass pyrolysis method, which comprises the following steps: putting biomass in a rectangular container with an opening, wherein the bottom plane of the container is inclined, the short wall of the container is provided with a flue along the bottom part, the other three walls of the container are respectively provided with an air flue along the bottom part, the flue is communicated with a plurality of ventilation channels in the bottom part of the container, the bottom surface of the container is provided with a plurality of air sucking channels which are communicated with the ventilation channels, and the walls and the bottom of the container are provided with ventilation holes; adopting medium and low heat, after 1-2h, using carbon powder with the water content being 30% to cover the surface of the biomass to seal and break off oxide, and carrying out pyrolysis for 6-8h; and carrying out cooling separation, cyclone separator, temperature pyrolysis, gas cooling baffling, catalysis, cleaning, dehydration, and multiple-layer filtering to crude gas to obtain pyrolytic combustible gas, liquid tar, acetic acid liquid and unshaped carbon. By the method, no polluted air and polluted water are emitted. The method has the characteristics of high gasification efficiency, accurate composition extraction composition and environment protection as well as energy conservation.

Owner:WANGJIANG GUIHE BIOMASS ENERGY EQUIP MFG

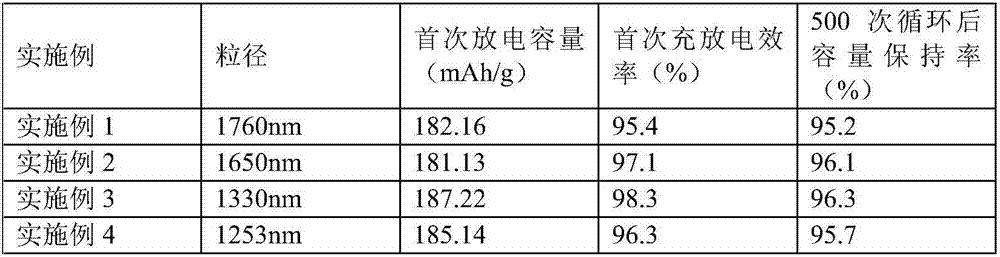

Method for preparing low-particle size ternary cathode material

InactiveCN107134571AHigh activityImprove efficiencyCell electrodesAluminium chlorideLithium chloride

The invention discloses a method for preparing a low-particle size ternary cathode material. The method comprises the following steps: by taking lithium chloride, nickel chloride, cobalt chloride and aluminum chloride as raw materials, and polyvinylpyrrolidone as a dispersing agent, dissolving in absolute ethyl alcohol, performing sealed heating reaction so as to obtain a coated gel liquid, performing reduced pressure distillation and laminated backflow reaction so as to obtain an acetic acid liquid, further adding distilled water, distilling acetic acid so as to obtain a mixed solution, performing aeration reaction so as to obtain metal precipitate, washing with acetone, and sintering with a protection gas, thereby obtaining the ternary cathode material. By adopting a mode that the particle size of the metal oxide is reduced, the performance efficiency of the ternary cathode material prepared by using the method is effectively improved, and meanwhile the ternary cathode material is good in circulation property, high in capacity and good in activity.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Method for preparing instant noodle kelp seasoning packet

ActiveCN104323195AReduce toughnessRetain nutrientsFood ingredientsFood preparationBiotechnologyMonosodium glutamate

The invention provides a method for preparing an instant noodle kelp seasoning packet, and belongs to the technical field of food processing. The method comprises the following steps: removing and screening silt and dry salt; soaking through calcium chloride, soaking through an acetic acid liquid, and soaking through a salt liquid; slitting, curing, seasoning, packaging, sterilizing and the like. The seasoning comprises the following materials in percentage by weight: 1%-6% of salt, 0.1%-2% of D-sodium isoascorbate, 1%-5% of citric acid, 4%-10% of pepper oil (red oil), 1%-4% of monosodium glutamate, 0.1%-1% of flavor nucleotides disodium, 1%-6% of ginger and 1%-5% of broken red pepper. The method provided by the invention reduces the toughness and fishy smell of kelp, reserves the freshness and inherent nutrient components of the kelp and solves the problem that shredded kelp has heavier taste if being independently eaten, increases the nutrient components of the instant noodle, improves the poor image of the instant noodle and solves the problem of contradiction between instant kelp food production and a consumer eating habit as the seasoning packet of an instant noodle.

Owner:红河宏斌食品有限公司

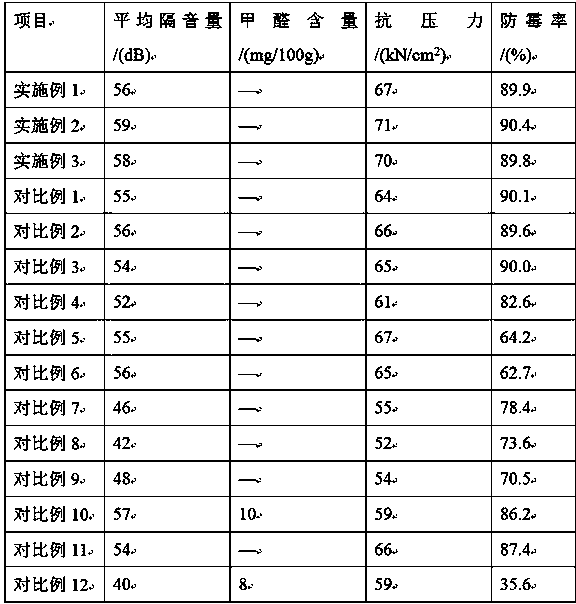

Natural mildew-proof sound-insulation density board

InactiveCN110480789AHigh strengthAvoid uneven structureWood treatment detailsFlat articlesFiberACETIC ACID LIQUID

The invention mainly relates to the technical field of artificial board machining, and discloses a preparation method of a natural mildew-proof sound-insulation density board. The preparation method comprises the steps of wood crushing, drying, raw material mixing, glue applying and hot pressing. The preparation method of the natural mildew-proof sound-insulation density board has a natural mildew-proof function, the mildew-proof rate reaches 90.4%, and sound insulation can be effectively performed; the wood is cut into long sections, the sections are soaked in an acetic acid liquid, the length of wood fibers can be prolonged, the problems that the strength of a density board is low due to short fibers and the structure of the density board is uneven due to long fibers can be avoided, andthe strength and practicability of the density board are improved; and the wood sections are subjected to freezing and drying after being soaked, so that the porosity of the sections is increased, breaking of the fibers is reduced during longitudinal rolling, and the strength of the density board is improved.

Owner:含山县金中环装饰材料有限公司

Method for preparing vapor-phase coated modified lithium nickelate, cobaltate and manganate positive electrode materials

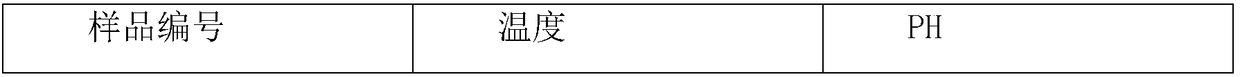

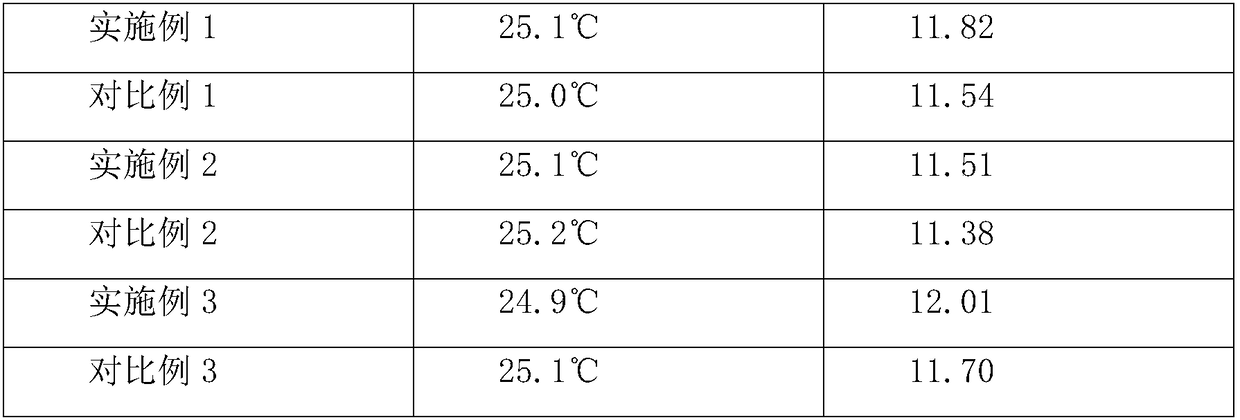

The invention discloses a method for preparing vapor-phase coated modified lithium nickelate, cobaltate and manganate positive electrode materials. The method includes steps of S1, heating anhydrous acetic acid liquid until the anhydrous acetic acid liquid is boiling at the temperature of 120 DEG C, delivering acetic acid steam to gas inlets of pulse type gas flow mixing machines via pipelines andkeeping gas inlet pressures higher than or equal to 0.8 Mpa; S2, feeding conventional lithium nickelate, cobaltate and manganate positive electrode materials into bins of pneumatic mixing machines and allowing the conventional lithium nickelate, cobaltate and manganate positive electrode materials to move at the high speeds under the effects of acetic acid vapor so as to obtain coated lithium nickelate, cobaltate and manganate materials; S3, heating the coated lithium nickelate, cobaltate and manganate materials obtained at the step S2 until the temperatures of the lithium nickelate, cobaltate and manganate materials reach 650-800 DEG C and preserving heat for 8-12 h; S4, naturally cooling sintered products obtained at the step S3 until the temperatures of the sintered products reach theroom temperature and smashing and sieving the sintered products to obtain the vapor-phase coated modified lithium nickelate, cobaltate and manganate positive electrode materials which are target products. The method has the advantages that the PH (potential of hydrogen) values of lithium nickelate, cobaltate and manganate surfaces can be lowered to a great extent by the aid of material surface alkaline and acidic vapor neutralization principles, accordingly, the cycle performance and the processing properties of the lithium nickelate, cobaltate and manganate materials can be improved, and theinput cost of high-nickel ternary materials used by battery enterprises can be reduced to a great extent.

Owner:WUXI JEWEL POWER & MATERIALS

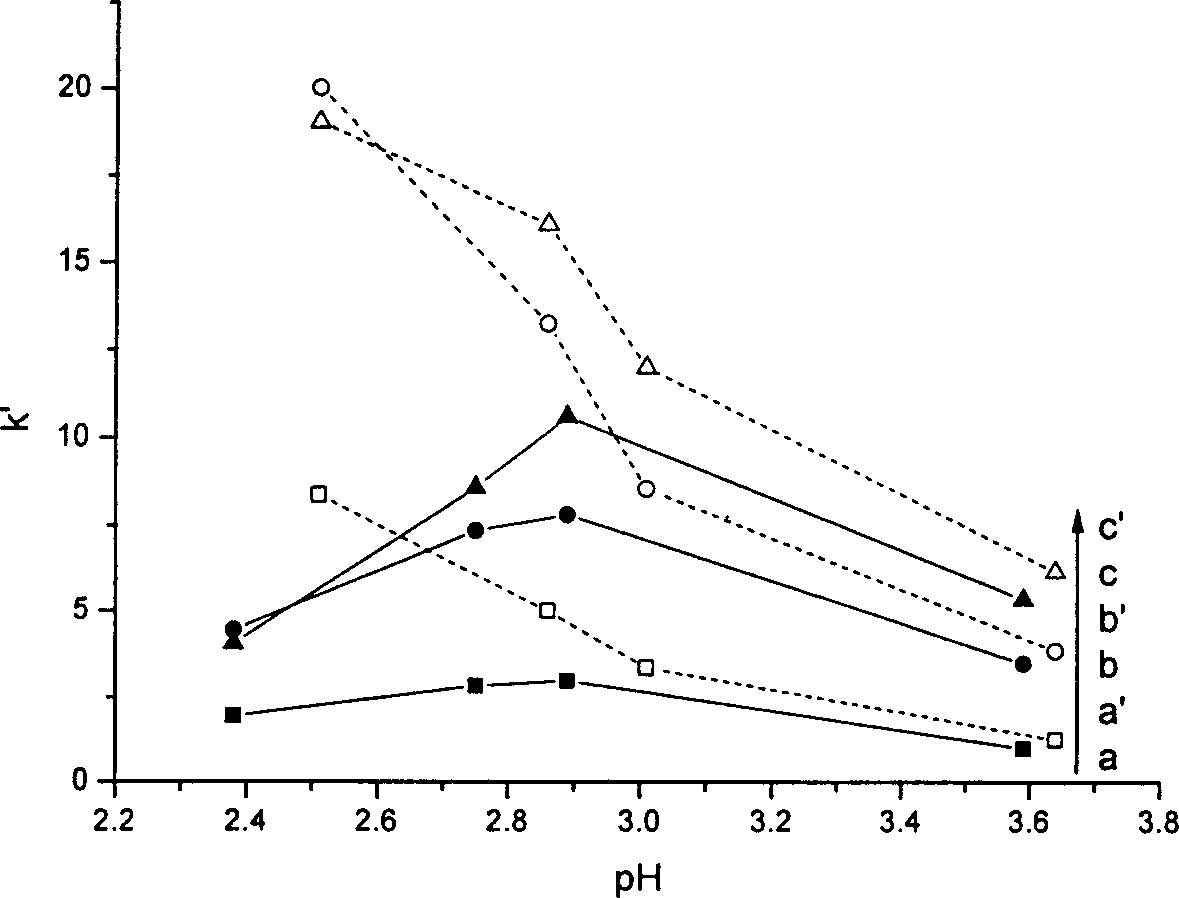

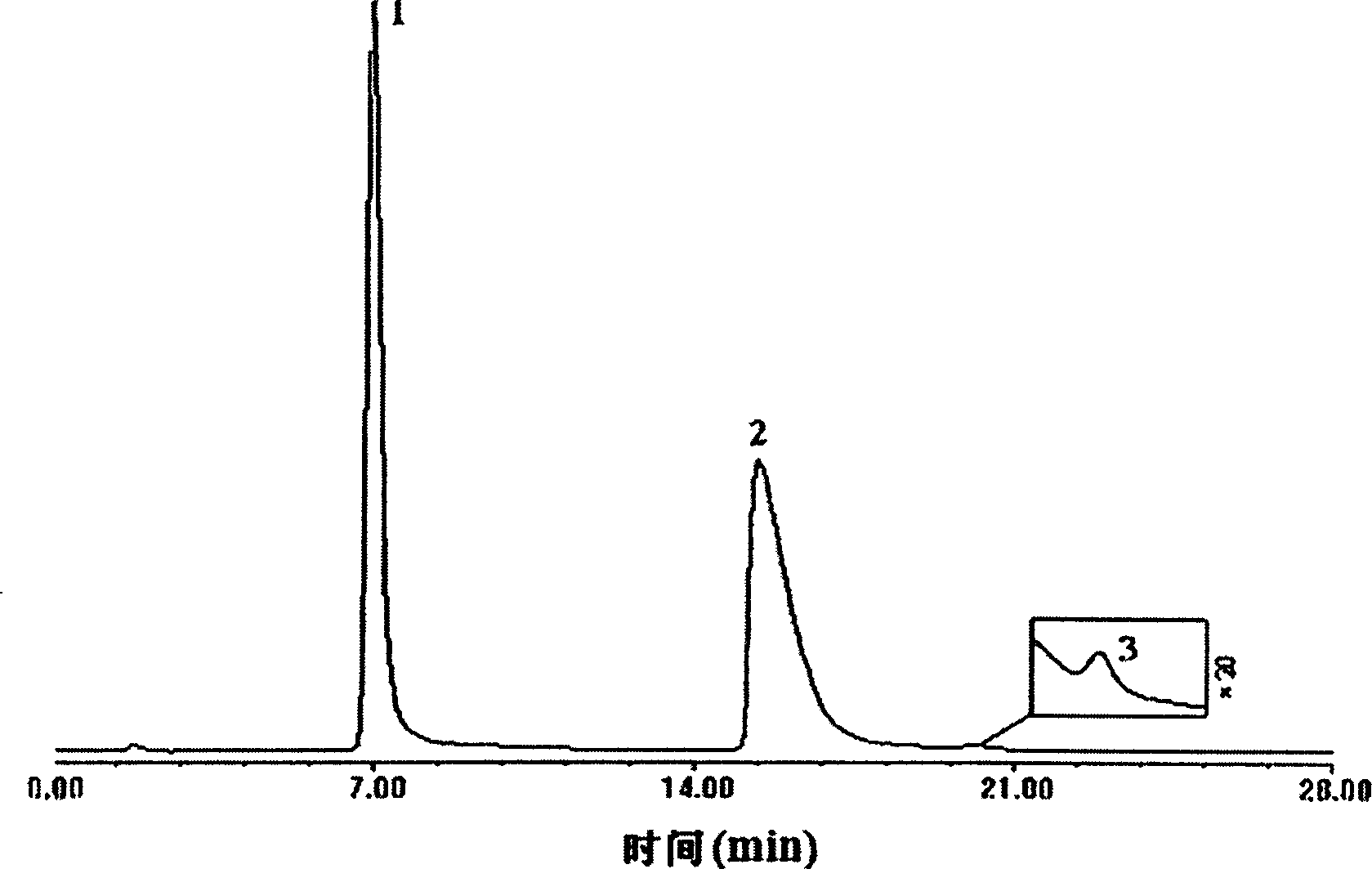

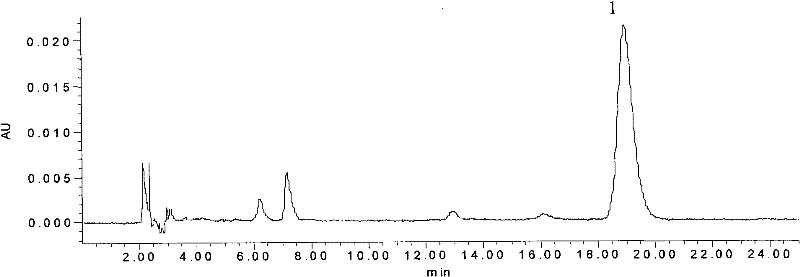

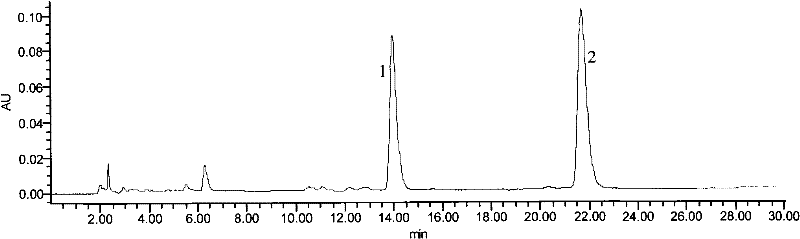

Liquid phase chromatographic analysis method for 3-nitro or 4-nitrophthalic acid and impurities thereof

InactiveCN1632567AEasy to operateThe result is accurateComponent separationACETIC ACID LIQUIDRetention time

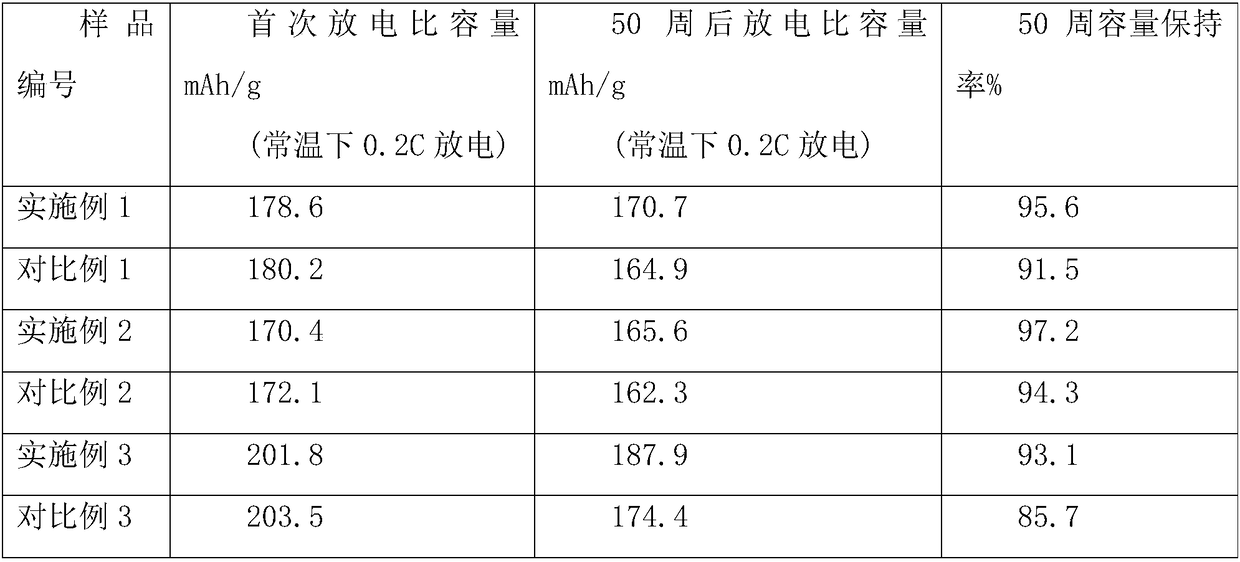

It is a high effective liquid chromatogram analysis method of a mixture composed of three-nitryl phthalandione, four-nitryl phthalandione and phthalandione. Its conditions are the following: chromatogram of Kromasil C#-[18]ú¼5ªmú¼150í4.6mm(I.D.); flow phase of carbinol to acetic acid liquid (0.1mol / Lú¼pH2.89) with volume proportion as 10í 90; flow speed of 1.0mL / min; column temperature as thirty degrees; sample-in volume: 10ªL; test wavelength: 254nm; accuracy: 0.2aufs.

Owner:NANJING UNIV

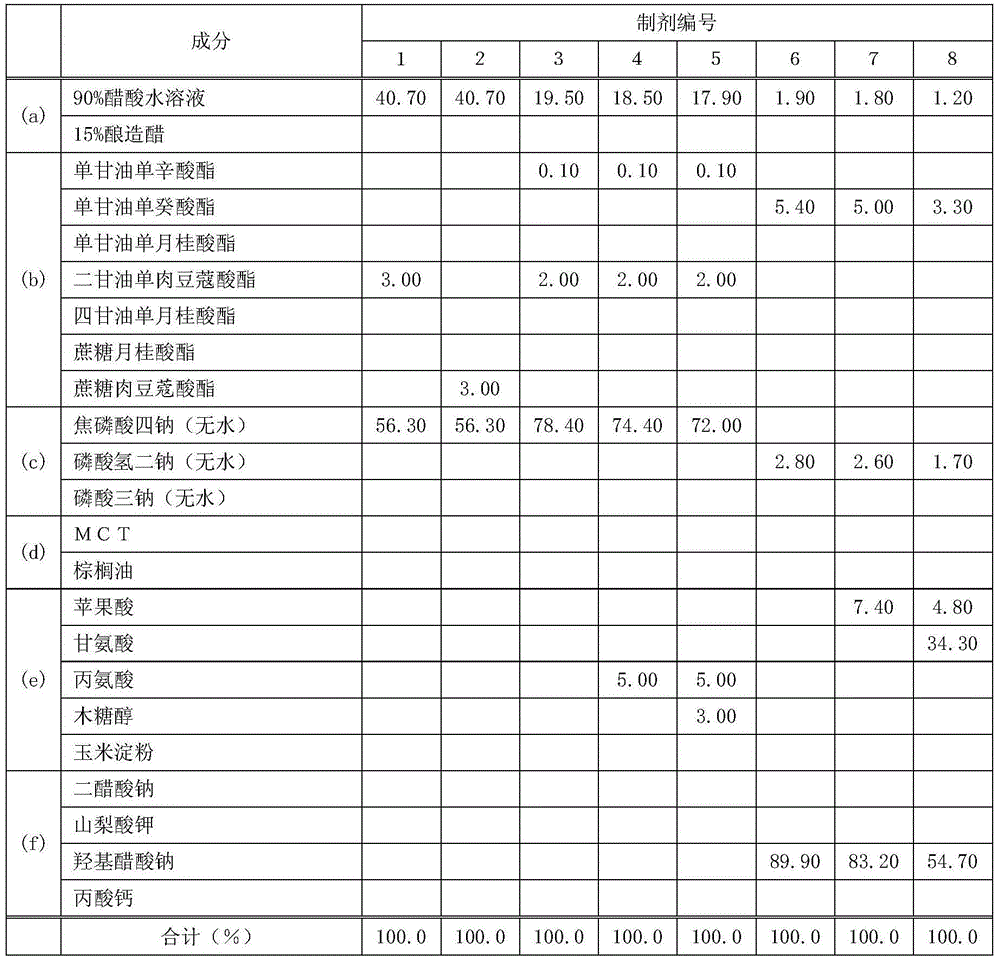

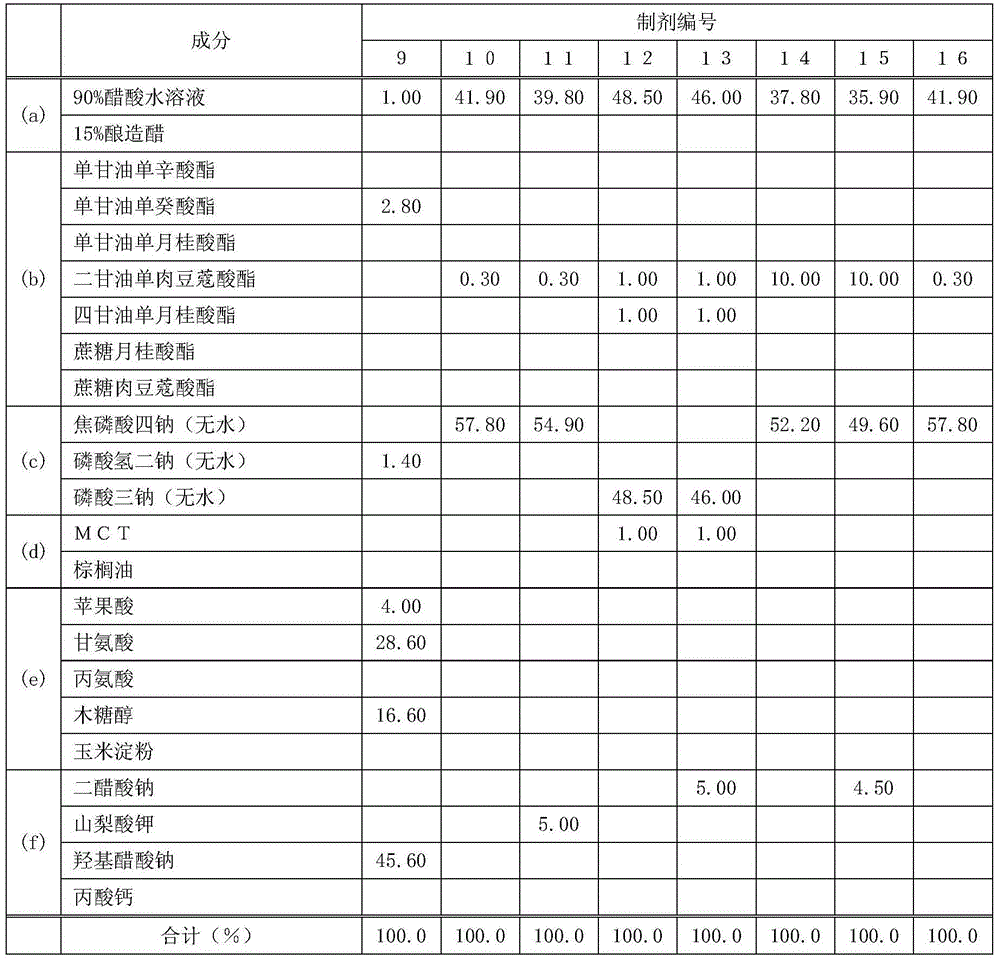

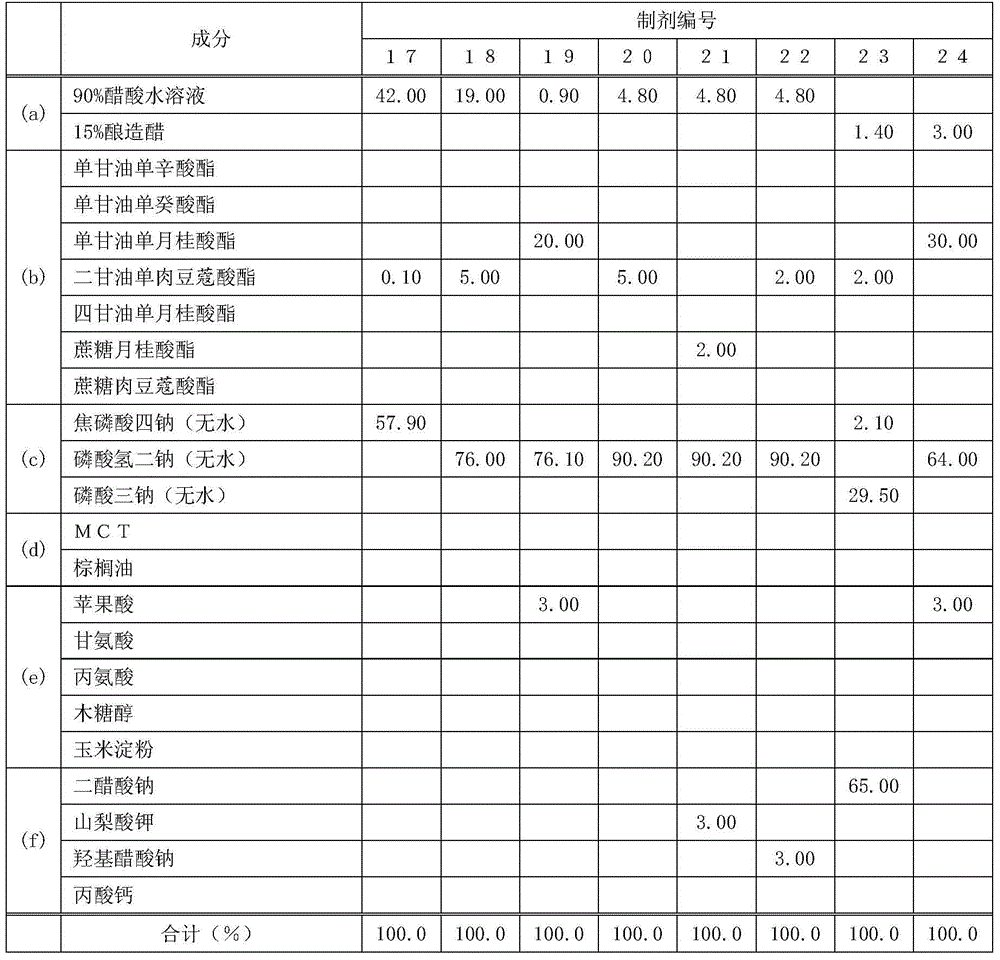

Flavor-quality modifier for food, manufacturing method thereof and food processed by same

ActiveCN104366655AReduce flavorReduced flavor qualityFood preservationFood ingredient as taste affecting agentInorganic phosphateFlavor

The invention relates to a flavor-quality modifier for food, a manufacturing method thereof and the food processed by same, and the task is to provide the food flavor-quality modifier which is capable of safely storing the flavor quality of the food as long as possible. The flavor-quality modifier for food is a powder or a paste obtained by using an inorganic phosphate powder to adsorb an acetic acid liquid containing dissolved glycerin fatty acid ester or cane sugar fatty acid ester, or is a substance containing the powder or the paste, and thus the above task is solved.

Owner:小川博卫 +1

Magnetic chitosan microsphere treatment agent and preparation method thereof

InactiveCN103127914BLarge adsorption capacityImprove purification efficiencyOther chemical processesAlkali metal oxides/hydroxidesVolatile phenolsParaffin wax

The invention provides a magnetic chitosan microsphere treatment agent, which is prepared by dissolving and uniformly mixing mixed powder of tourmaline and magnetic chitosan microspheres in sodium alginate and polyvinyl alcohol, and solidifying and balling. The magnetic chitosan microsphere is prepared by using superparamagnetic ferroferric oxide, 1 to 10 weight percent of chitosan acetic acid liquid, liquid paraffin, Span-80 and glutaraldehyde as reaction materials through an emulsion crosslinking method, wherein the mass ratio of the superparamagnetic ferroferric oxide to the chitosan acetic acid liquid is 1:(1-10), the volume ratio of the liquid paraffin to the Span-80 is (10-100):1, the volume ratio of the chitosan acetic acid liquid of superparamagnetic ferroferric oxide to mixed liquid of paraffin-Span-80 is 1:(1-10), and the volume ratio of the mixed liquid of superparaferroferric oxide, paraffin and Span-80 to glutaraldehyde is (5-50):1. According to the water treatment agent, the removal rate of volatile phenol in water is between 80 and 90 percent, and the removal rate of chromium in water is 93 percent; and the magnetic chitosan microsphere treatment agent has the advantages of large adsorption capacity, high purification efficiency, low cost, regeneration, no toxicity, no pollution to environment and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

Preparation method of drinking water treatment agent

InactiveCN103127917BLarge adsorption capacityImprove purification efficiencyOther chemical processesAlkali metal oxides/hydroxidesVolatile phenolsParaffin wax

The invention provides a drinking water treatment agent which is prepared by dissolving and uniformly mixing mixed powder of tourmaline and magnetic chitosan microspheres in sodium alginate and polyvinyl alcohol, and solidifying and balling. The magnetic chitosan microsphere is prepared by using superparamagnetic ferroferric oxide, 1-10wt% chitosan acetic acid liquid, liquid paraffin, Span-80 and glutaraldehyde as reaction materials through an emulsion crosslinking method, wherein the mass ratio of the superparamagnetic ferroferric oxide to the chitosan acetic acid liquid is 1:(1-10), the volume ratio of the liquid paraffin to the Span-80 is (10-100):1, the volume ratio of the chitosan acetic acid liquid of superparamagnetic ferroferric oxide to mixed liquid of paraffin-Span-80 is 1:(1-10), and the volume ratio of the mixed liquid of superparaferroferric oxide, paraffin and Span-80 to glutaraldehyde is (5-50):1. According to the water treatment agent, the removal rate of volatile phenol in water is between 80 and 90 percent, and the removal rate of chromium in water is 93 percent; and the magnetic chitosan microsphere treating agent has the advantages of large adsorption capacity, high purification efficiency, low cost, regeneration, no toxicity, no pollution to environment and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

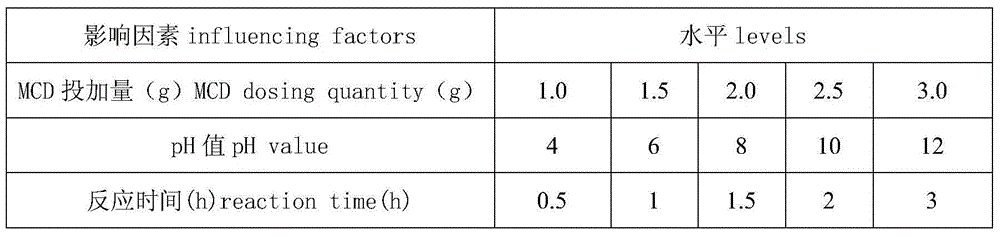

Selfheal quality control method

ActiveCN101744877BThe method is simple and effectiveAvoid medicineComponent separationMedicinal herbsACETIC ACID LIQUID

The invention discloses a selfheal quality control method which is a high performance liquid chromatography and a thin layer chromatography the marker components of which contain compound salviaflaside. The high performance liquid chromatography comprises the following steps: preparation of comparison products: carbinol is used to dissolve the salviaflaside compound so as to prepare the comparison product solution of the salviaflaside compound; preparation of test product solution : selfheal medicinal material powder is taken to be precisely weighed, added with carbinol, and filtered by a microfiltration membrane to be used as the test product solution; and injection to a liquid chromatograph, determination and mobile phase: elution by acetonitrile acetic acid liquid. The thin layer chromatography comprises the following steps: rosmarinic acid of the comparison product solution and salviaflaside solution and the test product solution are respectively absorbed to be sampled on the samethin board, chloroform:carbinol:formic acid or chloroform: water are taken as developers, developing, taking and drying are carried out, vanillin concentrated sulphuric acid is used for developing, and heating is carried out until spots are clear. The method is simple and effective, and thereby preventing illegal producers from using roots, stems, leaves and other non-medical parts to substitute the cluster parts of the selfheal to be used for the medical purpose.

Owner:GUANGZHOU XINGQUN PHARMA

Environment-friendly magnesium ion modified montmorillonite tap water flocculant and its application

InactiveCN103880136BImprove electrical performanceGood flocculation effectWater/sewage treatment by flocculation/precipitationSodium bicarbonateACETIC ACID LIQUID

The invention discloses an environment-friendly magnesium-ion modified montmorillonite tap water flocculant. The flocculant is prepared by a chitosan liquid and a magnesium-ion modified montmorillonite liquid; the chitosan liquid is an acetic acid liquid containing 0.2-2 mass percent of chitosan, and the magnesium-ion modified montmorillonite liquid is prepared by the mixing of sodium hydroxide, sodium bicarbonate, magnesium chloride, montmorillonite and water according to the mass ratio of 1:1:(1-4):(5-8):(86-92). The flocculant of the invention has large flocculation particles and fast sedimentation rate, the removal rate of raw water turbidity reaches 98.09 percent, and for the raw water with the turbidity of 70-100 NTU, the once treatment can be within 3 NTU of the national standards; and the cost is low, and the flocculant has no ingredients harmful to human bodies, and has excellent performance and stable quality.

Owner:WUHAN UNIV OF TECH

Drug for treating and preventing fracture

ActiveCN102349929BLow cost of osteoporosisShorten the timeOrganic active ingredientsSkeletal disorderSubstance usePolymer science

The invention discloses a drug for treating and preventing fracture, which is prepared by the ingredients of kelp, marine alga plant rich in algin and acetic acid or acetic anhydride. The preparation method of the drug is as follows: a, getting kelp and marine alga plant rich in algin, drying and grinding to powder, soaking the powder in acetic acid, wherein, the amount of the acetic acid added is in a standard that the acetic acid immerses the marine alga powder to carry out reaction for 2-3 weeks at normal temperature, pouring out the acetic acid liquid after the reaction is finished, drying under normal temperature, after drying, neutralizing through sodium hydroxide or other alkaline substance, after neutralizing, drying under normal temperature, and getting the substance used for preparing the drug for promoting fracture healing; and b, getting the kelp and the marine alga plant rich in the algin, drying and grinding to powder, soaking the powder in the acetic anhydride, the amount of the acetic anhydride added is in a standard that the acetic anhydride immerses the marine alga powder, then adding sulfuric acid for catalytic reaction, wherein the amount of the sulfuric acid added is 0.3% of the amount of the acetic anhydride, pouring out the acetic acid liquid after the reaction is over, drying under normal temperature, after drying, neutralizing through sodium hydroxide or other alkaline substance, after neutralizing, drying under normal temperature, and finally getting the substance used for preparing the drug for promoting fracture healing.

Owner:郭宏昌

Preparation method of tourmaline/magnetic chitosan microsphere treatment agent

InactiveCN103127916BLarge adsorption capacityImprove purification efficiencyOther chemical processesWater/sewage treatment by sorptionParaffin waxVolatile phenols

The invention provides a preparation method of a tourmaline / magnetic chitosan microsphere treatment agent which is prepared by dissolving and uniformly mixing mixed powder of tourmaline and magnetic chitosan microspheres in sodium alginate and polyvinyl alcohol, and solidifying and balling. The magnetic chitosan microsphere is prepared by using superparamagnetic ferroferric oxide, 1 to 10 weight percent of chitosan acetic acid liquid, liquid paraffin, Span-80 and glutaraldehyde as reaction materials through an emulsion crosslinking method, wherein the mass ratio of the superparamagnetic ferroferric oxide to the chitosan acetic acid liquid is 1:(1-10), the volume ratio of the liquid paraffin to the Span-80 is (10-100):1, the volume ratio of the chitosan acetic acid liquid of superparamagnetic ferroferric oxide to mixed liquid of paraffin-Span-80 is 1:(1-10), and the volume ratio of the mixed liquid of superparaferroferric oxide, paraffin and Span-80 to glutaraldehyde is (5-50):1. According to the water treating agent, the removal rate of volatile phenol in water is between 80 and 90 percent, the removal rate of chromium in water is 93 percent; and the magnetic chitosan microsphere treating agent has the advantages of large adsorption capacity, high purification efficiency, low cost, regeneration, no toxicity, no pollution to environment and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com