Liquid phase chromatographic analysis method for 3-nitro or 4-nitrophthalic acid and impurities thereof

A technology of nitrophthalic acid and high-performance liquid chromatography, which is applied in the direction of analyzing materials, separating materials, measuring devices, etc., to achieve the effect of accurate results and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

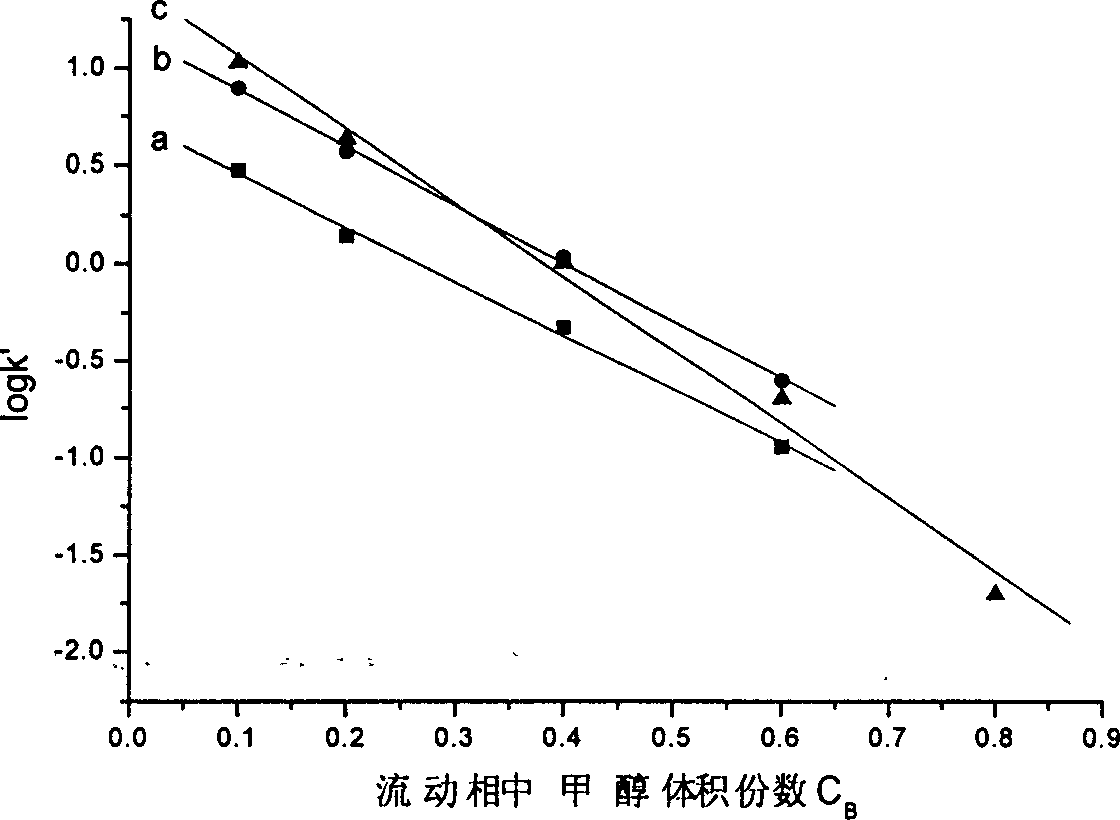

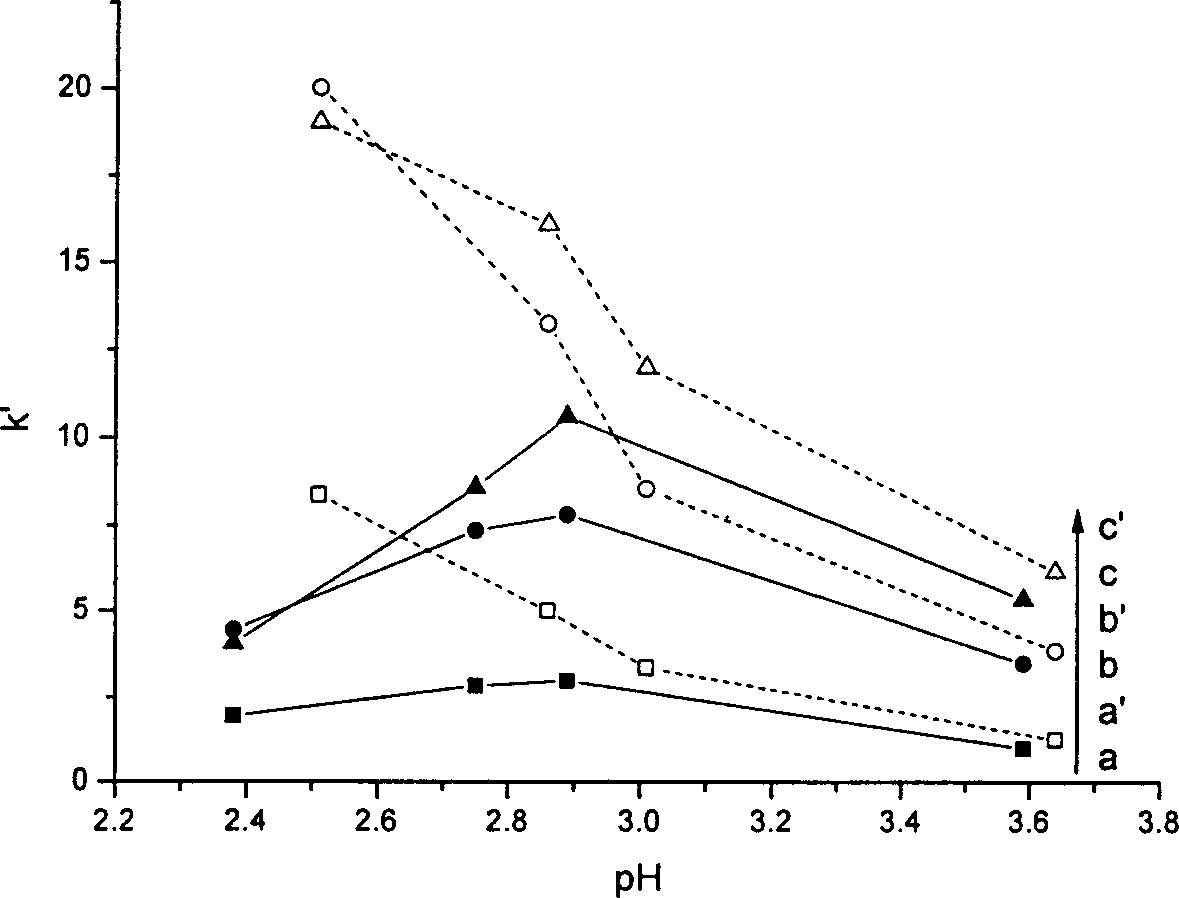

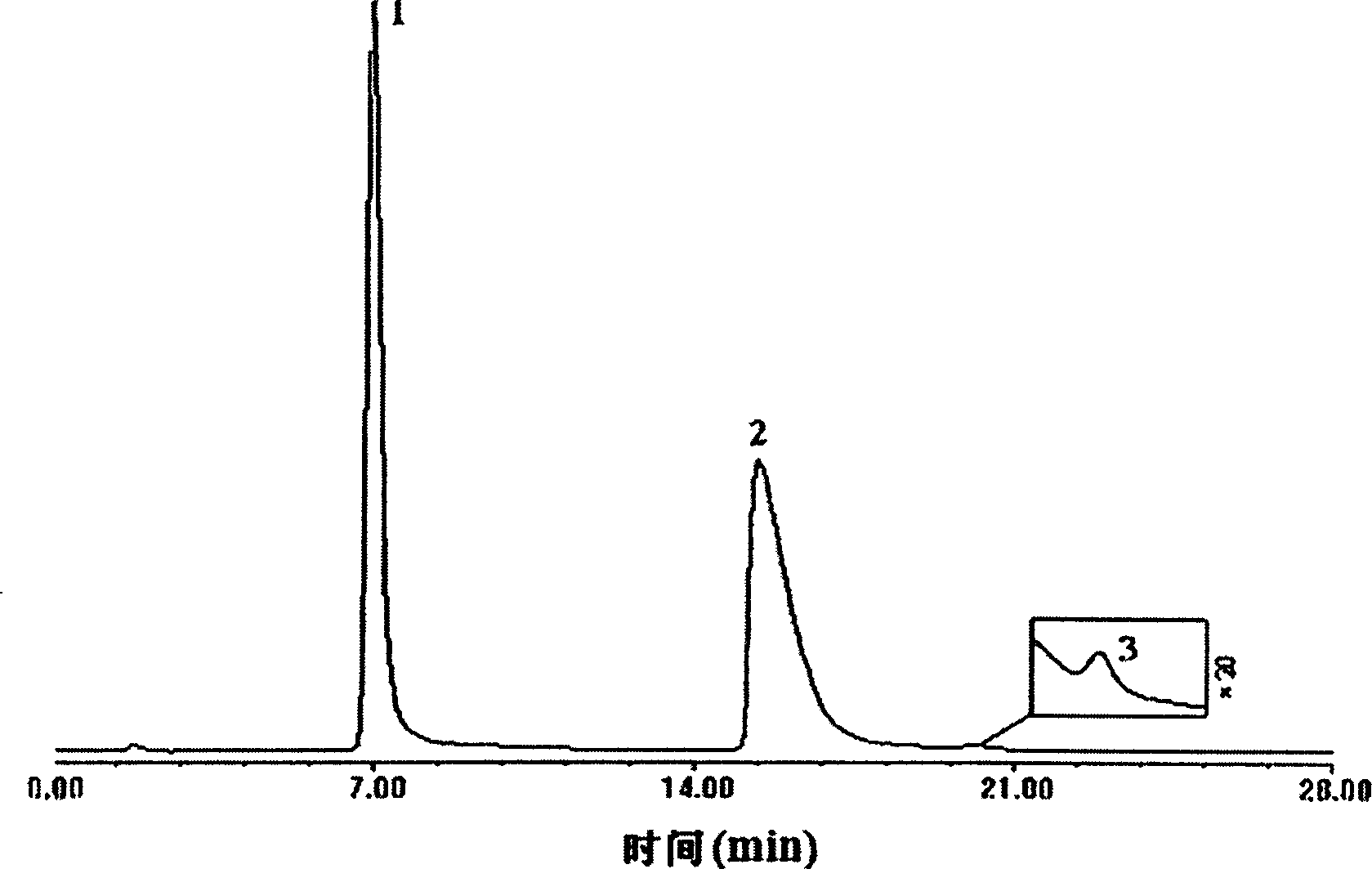

Method used

Image

Examples

Embodiment Construction

[0023] 1.1 Instrument

[0024] Varian 5060 type high performance liquid chromatograph (U.S. Varian company), is equipped with Rheodyne7725i six-port sampling valve (U.S. Rheodyne company); Waters 486 type ultraviolet-visible spectrophotometric detector (U.S. Waters company); JS-3050 chromatographic workstation ( Dalian Jiangshen Separation Science and Technology Company); the chromatographic recorder is a Type 3066 pen recorder (Sichuan Instrument No. 4 Factory); the PHS-3D type pH meter (Shanghai Sanxin Instrument Factory) for solution pH measurement is equipped with a pH composite electrode ( Shanghai Precision Scientific Instrument Co., Ltd).

[0025] 1.2 Drugs and reagents

[0026] Phthalic acid, 3-nitrophthalic acid, 4-nitrophthalic acid reference substance (99.0%); methanol (chromatographically pure); glacial acetic acid (analytical pure); perchloric acid (excellent pure) ; The mobile phase water used in the experiment was commercially available Wahaha purified water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com