Patents

Literature

841results about How to "Has practical value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Language model generation and accumulation device, speech recognition device, language model creation method, and speech recognition method

InactiveUS20050256715A1Improve recognition accuracyHas practical valueNatural language data processingSpeech recognitionAcousticsSpeech sound

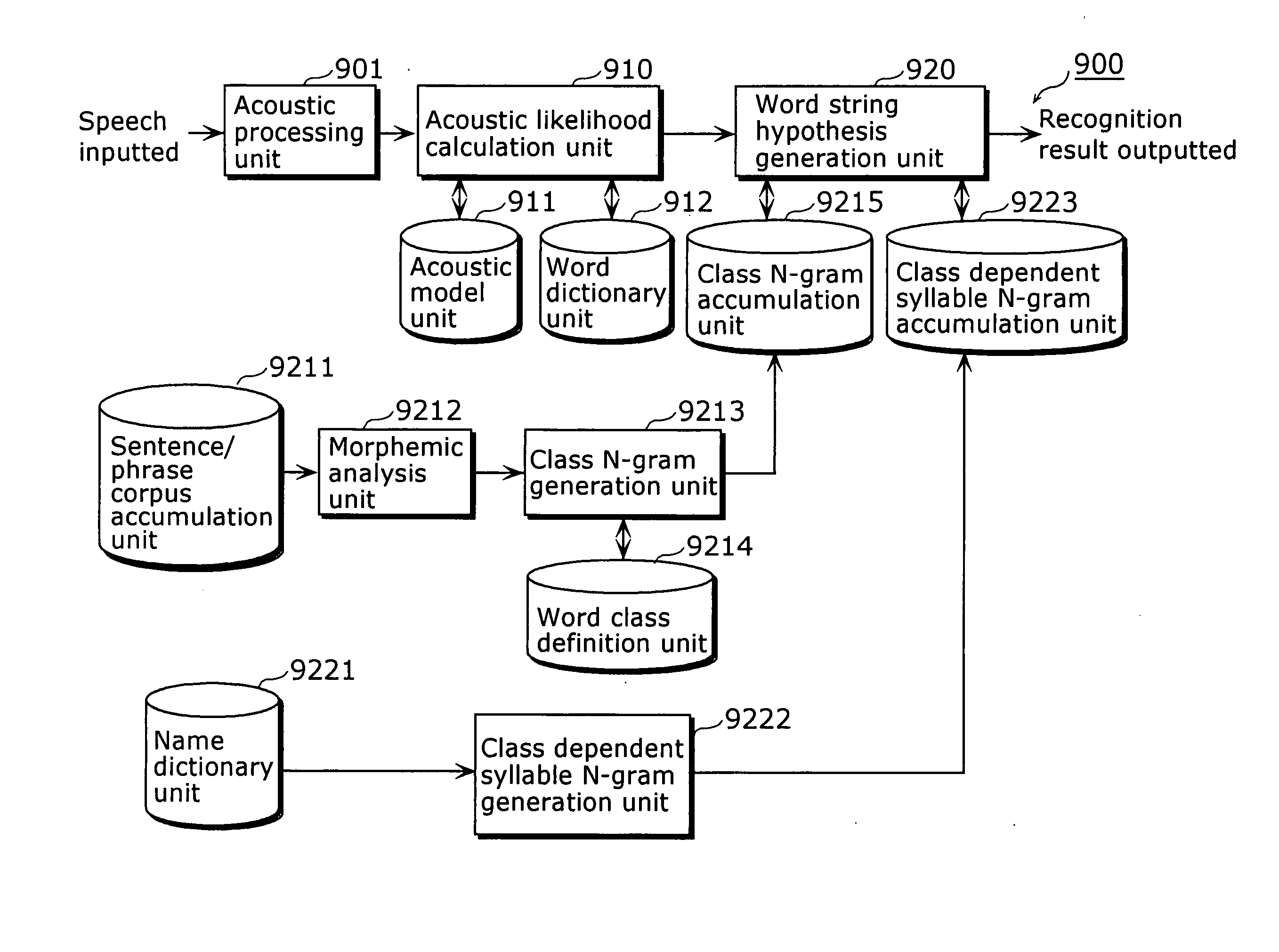

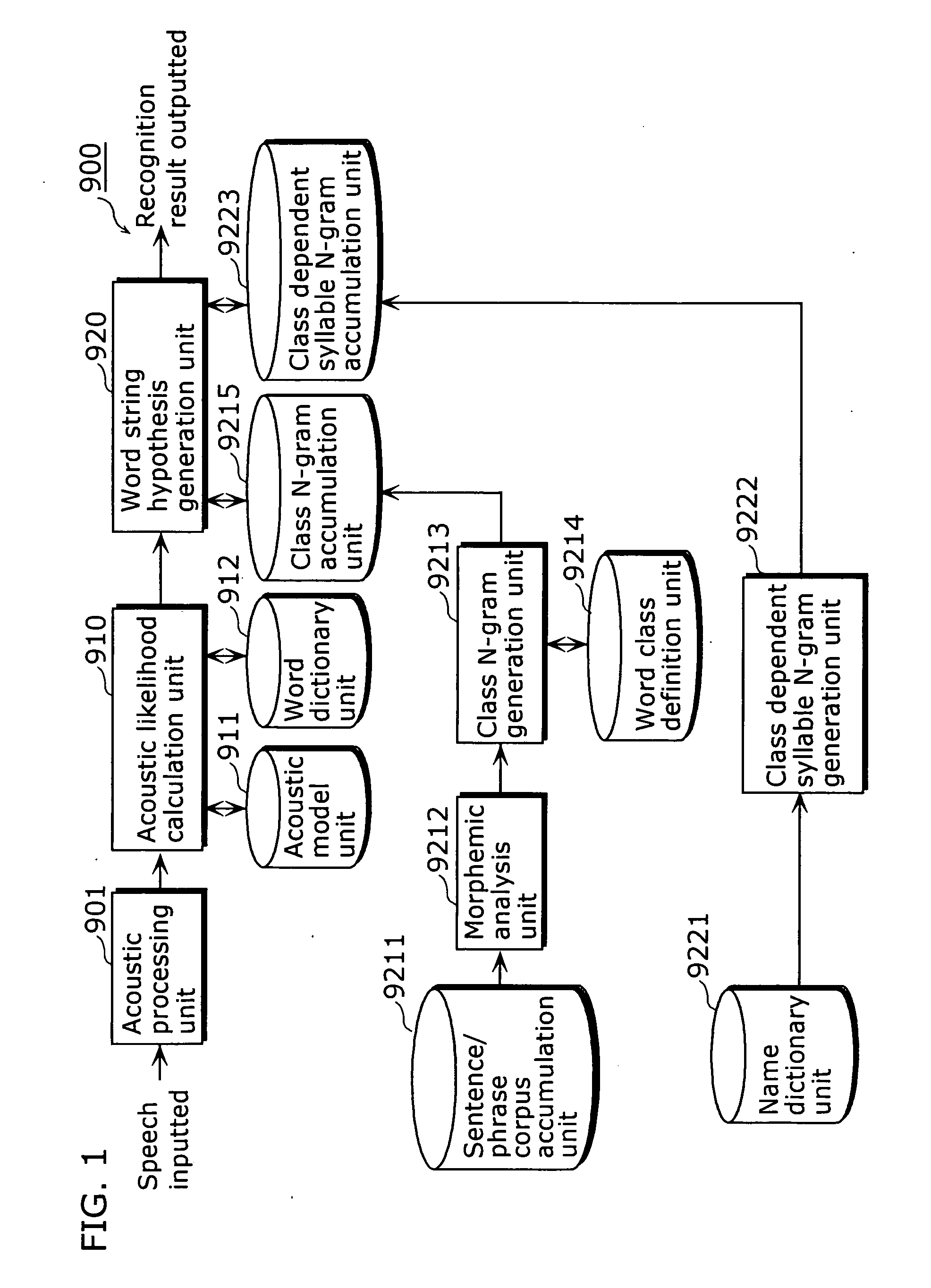

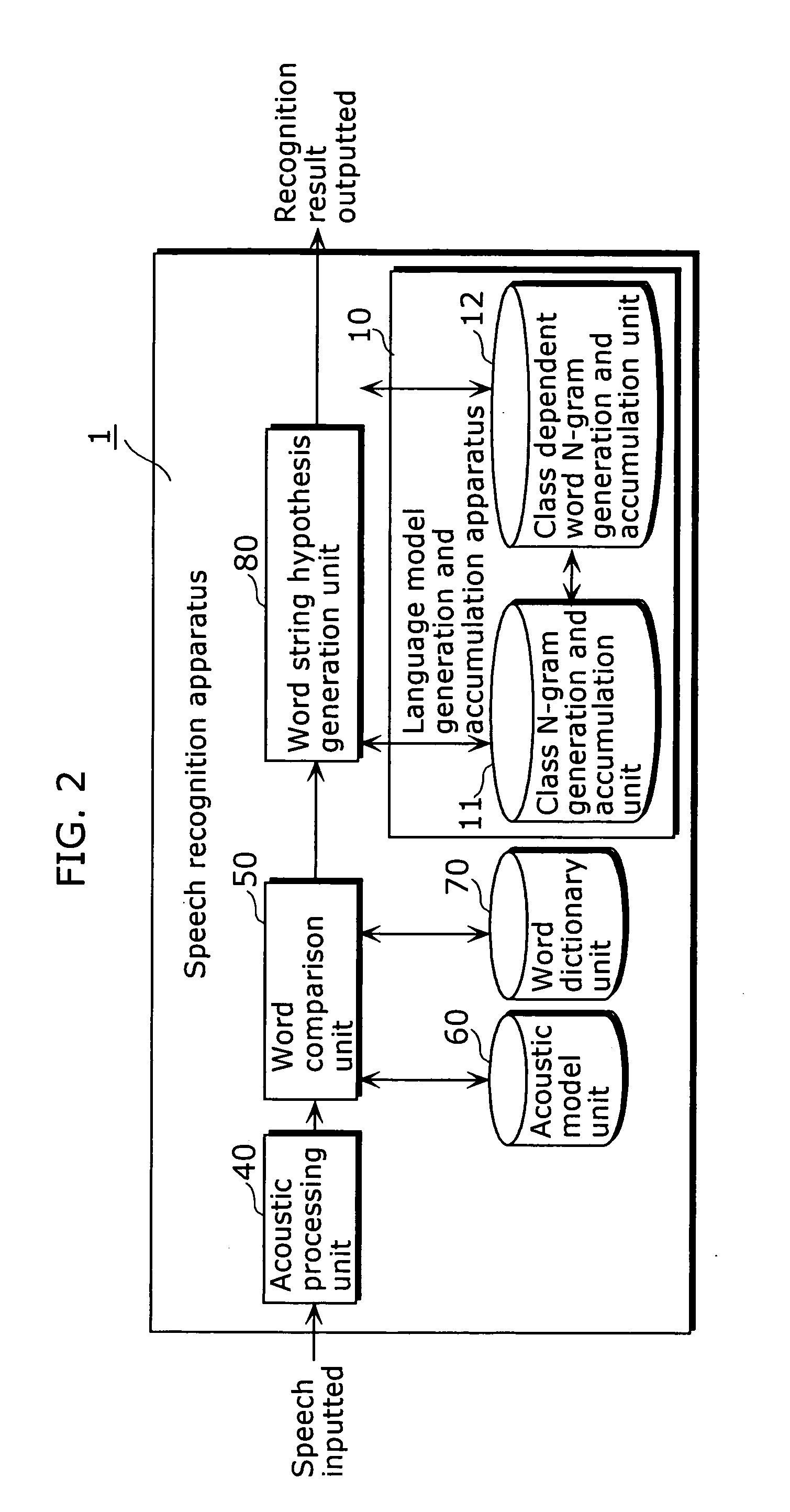

A language model generation and accumulation apparatus (10) that generates and accumulates language models for speech recognition is comprised of: a higher-level N-gram generation and accumulation unit (11) that generates and accumulates a higher-level N-gram language model obtained by modeling each of a plurality of texts as a string of words including a word string class having a specific linguistic property; and a lower class dependent word N-gram generation and accumulation unit (12) that generates and accumulates a lower-level N-gram language model obtained by modeling a sequence of words included in each word string class.

Owner:PANASONIC CORP

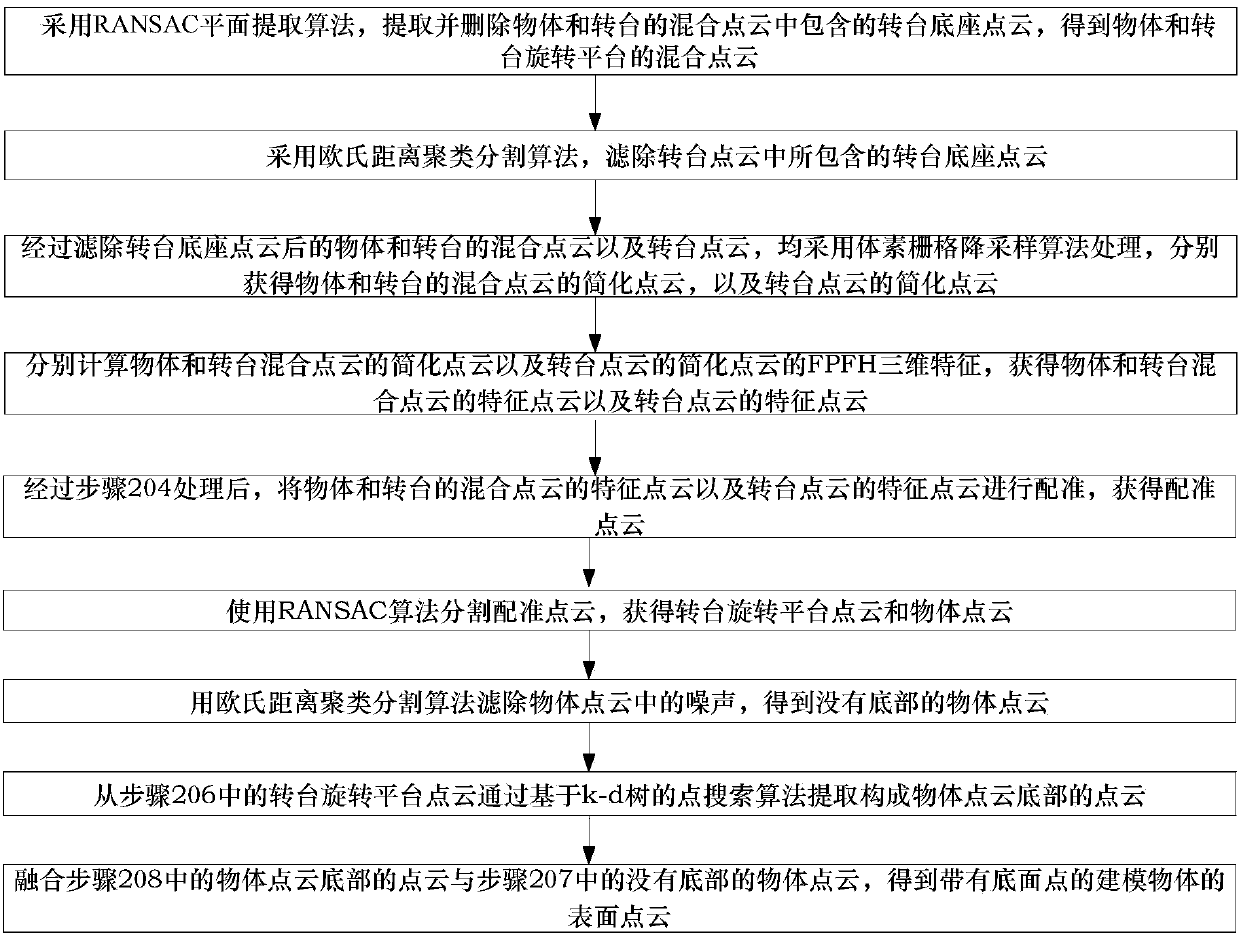

Physical three-dimensional model automatic modeling method

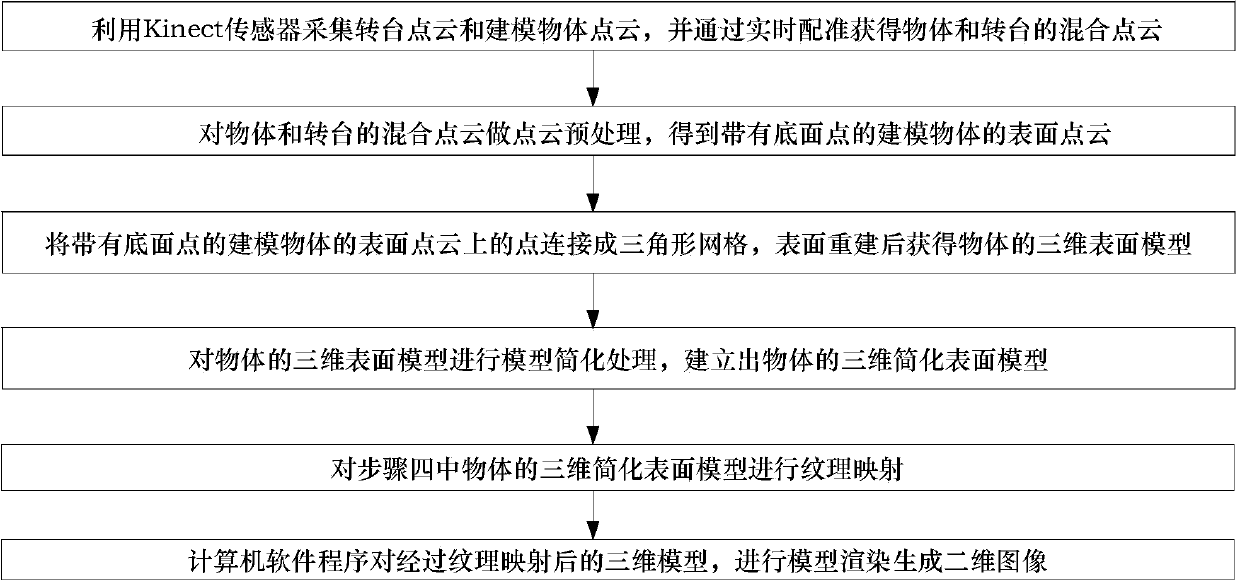

The present invention discloses a physical three-dimensional model automatic modeling method which comprises the following steps of (1) collecting a turntable point cloud and a modeling object point cloud, and carrying out real-time registration to obtain a mixed point cloud of an object and a turntable, (2) carrying out point cloud pretreatment to obtain the surface point cloud of a model object with a bottom surface point, (3) carrying out surface reconstruction to obtain the three-dimensional surface model of the object, (4) carrying out model simplification treatment on the three-dimensional surface model, and establishing the three-dimensional simplified surface model of the object, (5) carrying out texture mapping on the three-dimensional simplified surface model, and (6) carrying out model rendering on the three-dimensional model which is subjected to texture mapping to generate a two-dimensional image. The method has the advantages that the system operation is stable and reliable, the automation is realized in the operation process, a rebuilding effect is good, and the application needs of different simulation scenes can be satisfied by a built multi-granularity three-dimensional model.

Owner:BEIHANG UNIV

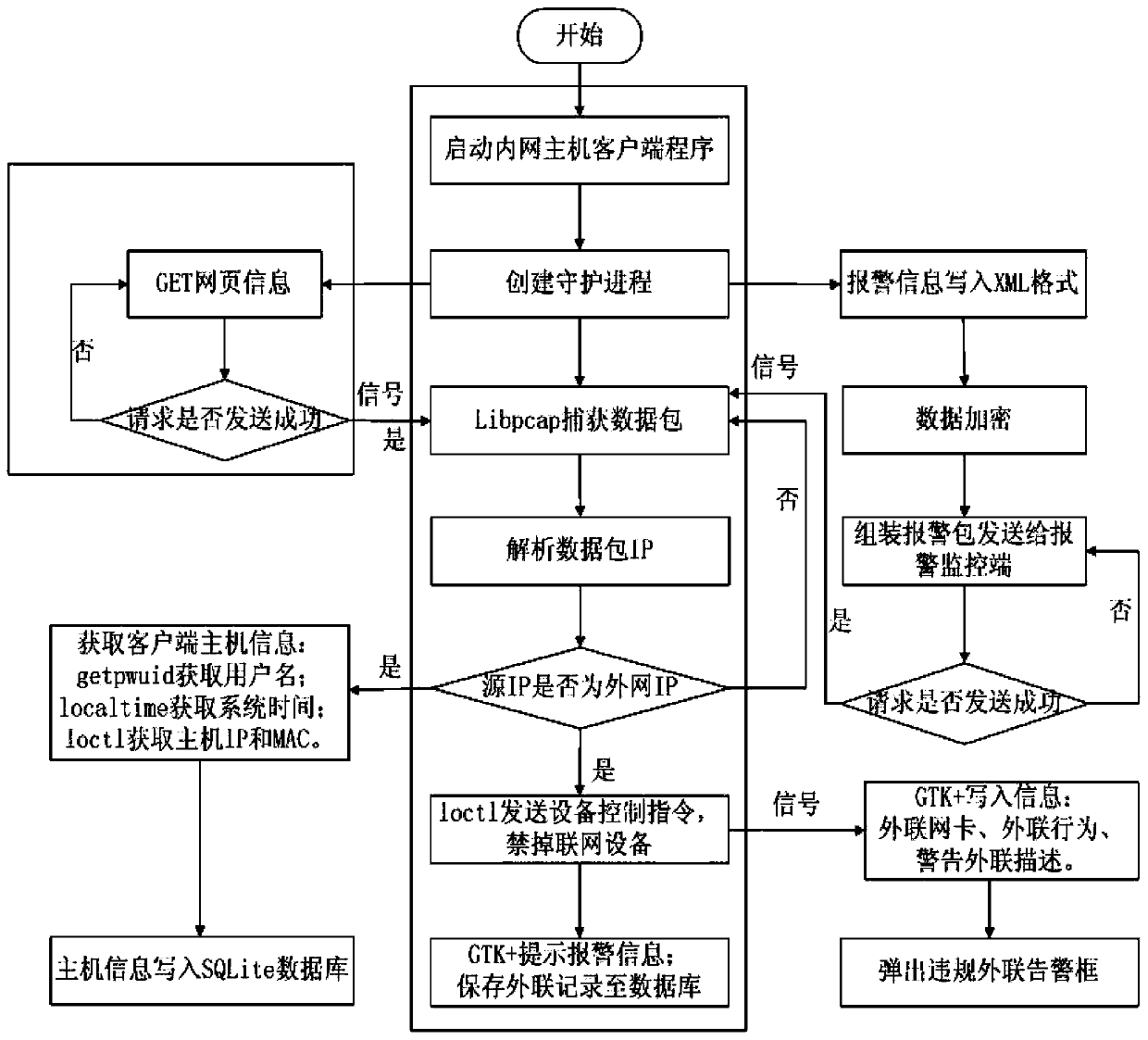

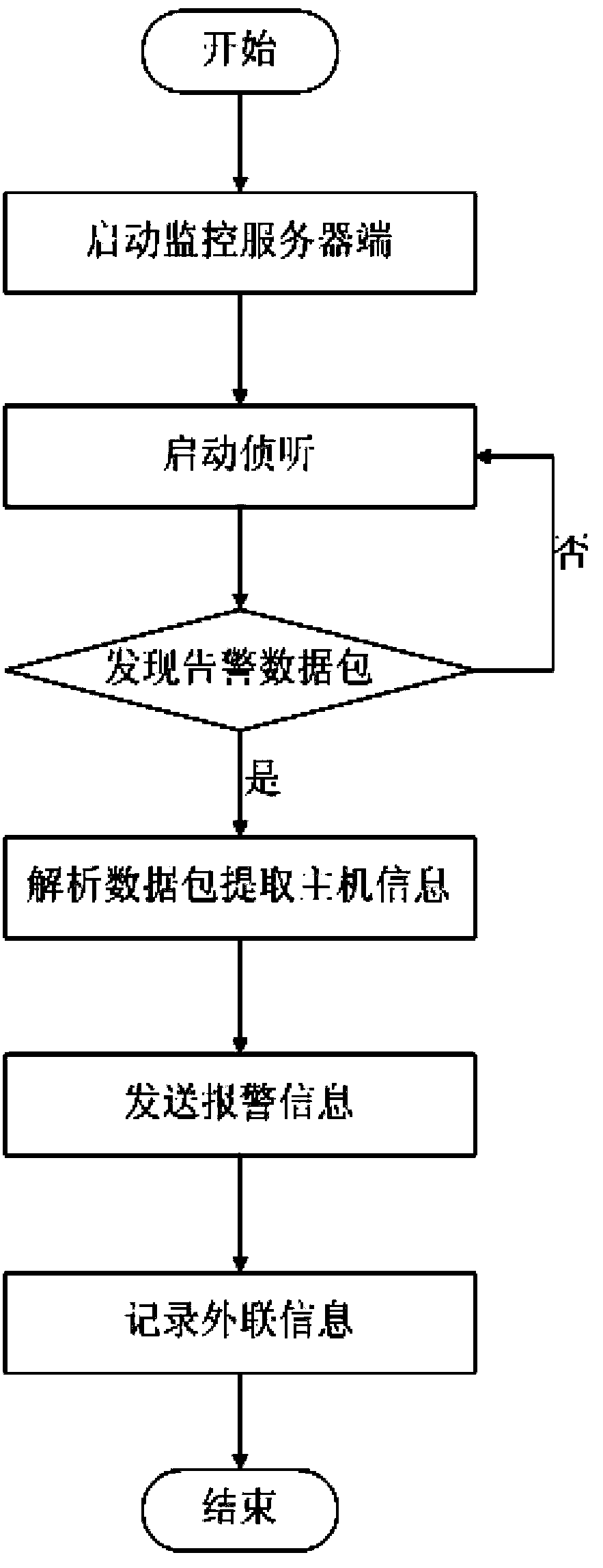

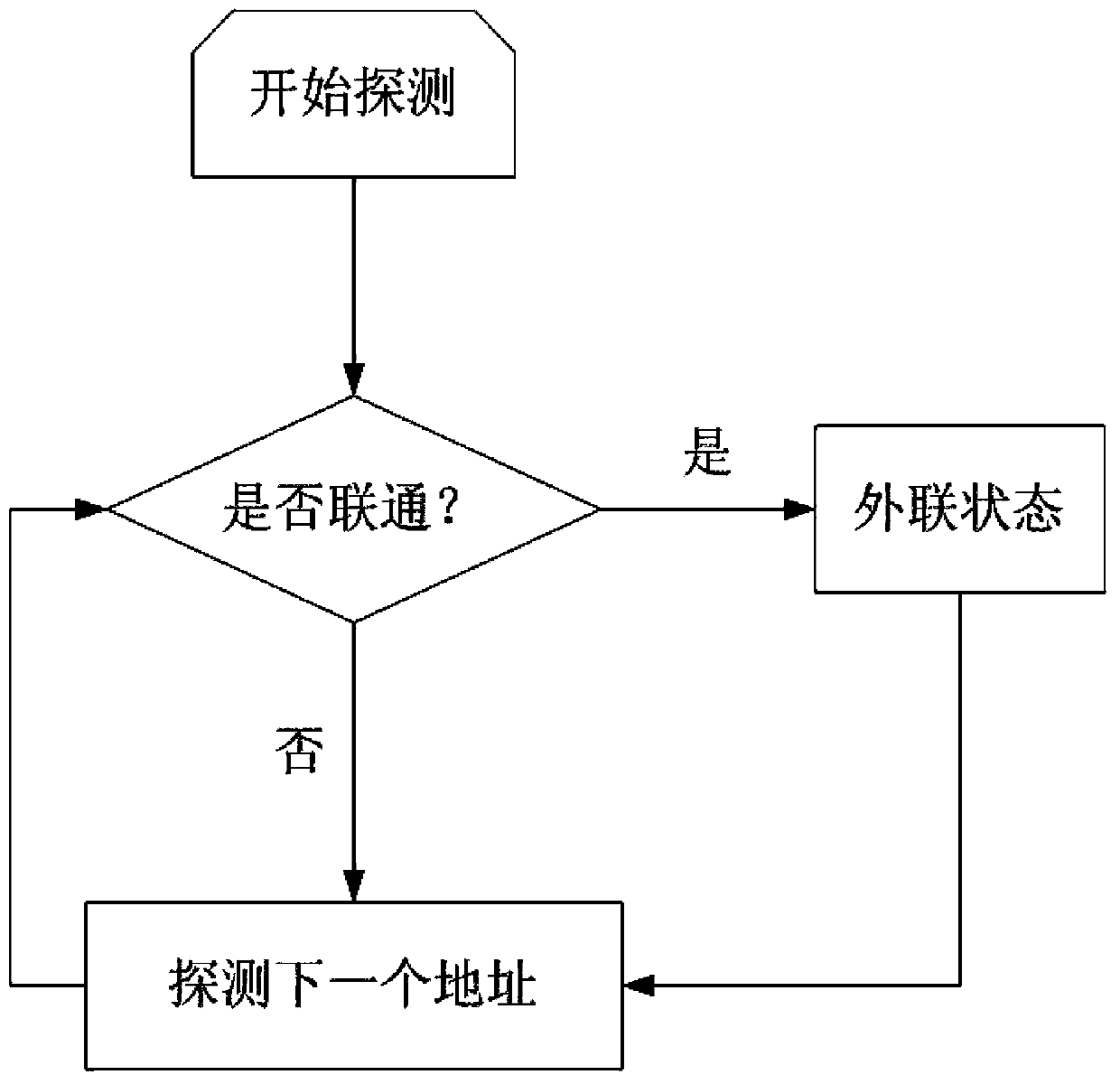

Alarm and blocking method for illegal external connections

ActiveCN103391216AEasy to deployHas practical valueData switching networksNetwork packetBlock method

The invention relates to an alarm and blocking method for illegal external connections. The alarm and blocking method comprises that 1), an intranet host client monitors networking behaviors of intranet computers in real time according to a plurality of external connection modes; 2), the intranet host client initiatively sends an encrypted alarm data packet to an external connection alarm monitoring terminal by using a Libnet function library to detect whether the intranet computers have external connection behaviors and gives an alarm for illegal external connection behaviors; 3), the intranet host client performs bottom layer packet capture on alarmed intranet hosts to obtain all data packets passing through network cards of the hosts to judge the illegal external connection behaviors; 4), blocking the network cards of the hosts having the illegal external connection behaviors through judgment. The alarm and blocking method is high in timeliness and good in monitoring performance in the aspect of illegal external connection monitoring. By means of the alarm and blocking method, the safety and the transmission efficiency of the alarm data packets in systems are improved, leaking risks caused by stealing of alarm information are effectively avoided, meanwhile, the safety of software is improved, and the software has anti-shielding and anti-unloading capacities.

Owner:INST OF INFORMATION ENG CHINESE ACAD OF SCI

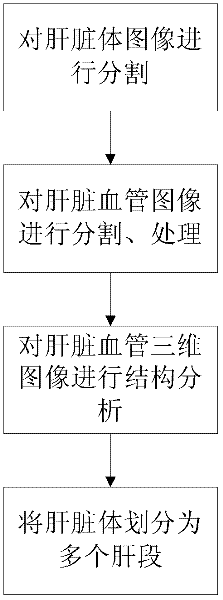

Three-dimensional structural description method of hepatic vascular system

ActiveCN102402796AAccurate divisionPrecise resectionImage enhancement3D modellingStructure analysisVoxel

The invention discloses a three-dimensional structural description method of hepatic vascular system, which belongs to the field of medical liver division. The method comprises the following steps of: firstly, dividing a hepatic image and a hepatic vascular image, structurally analyzing the hepatic vascular three-dimensional image, skeletonizing the liver and the blood vessel, and marking the skeletonized voxel points; next, storing the marked voxel points to data structure of multi-branch tree; then, distinguishing main and branch blood vessels according to master slave relation of the voxelpoints in the multi-branch tree; finally, dividing the liver body into multiple liver segments according to relation between the blood vessels in the hepatic vascular system. By the three-dimensionalstructural description method of hepatic vascular system, accurate division of liver is realized so that guidance is provided for accurate removal of liver.

Owner:SHENZHEN YORATAL DMIT

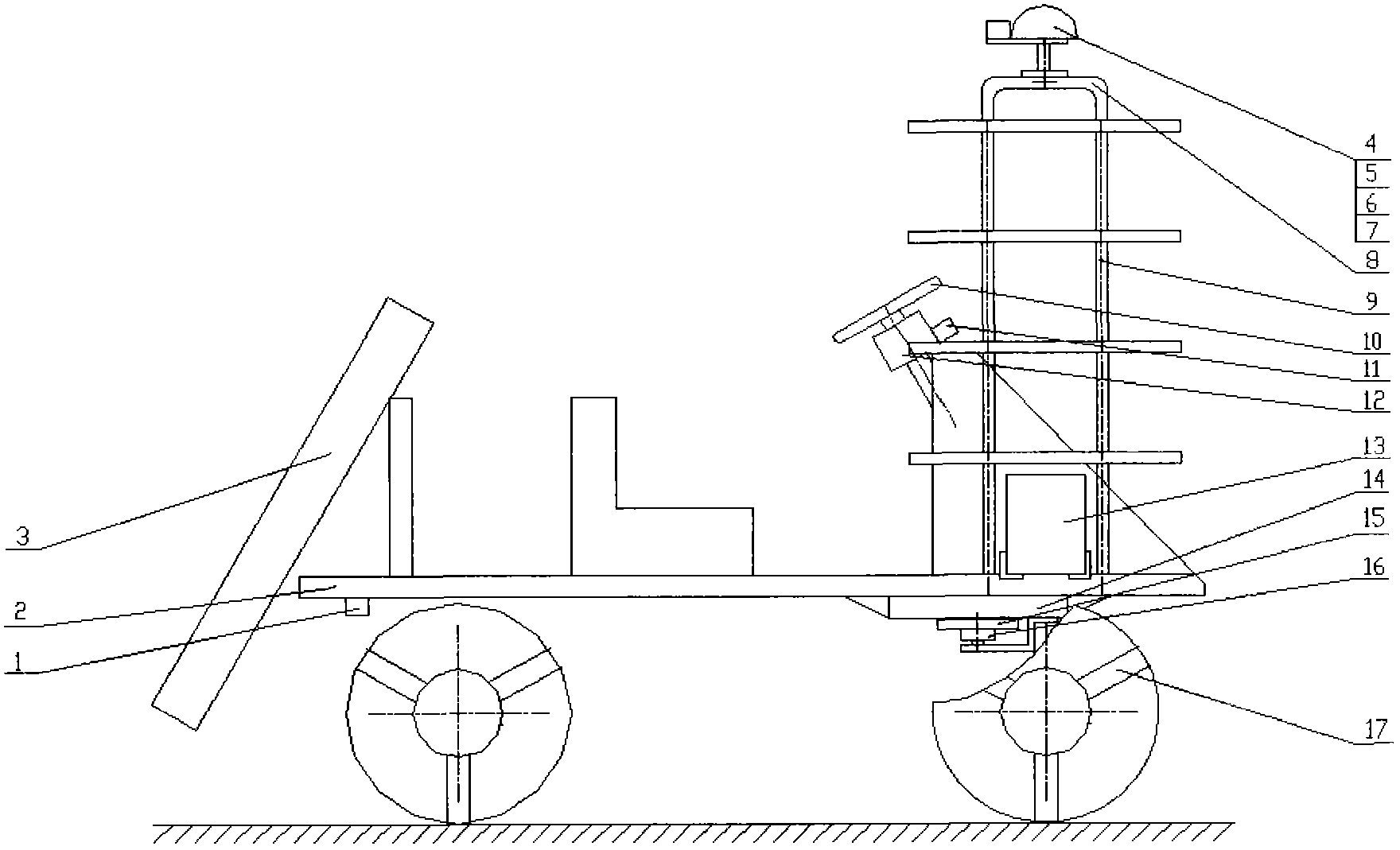

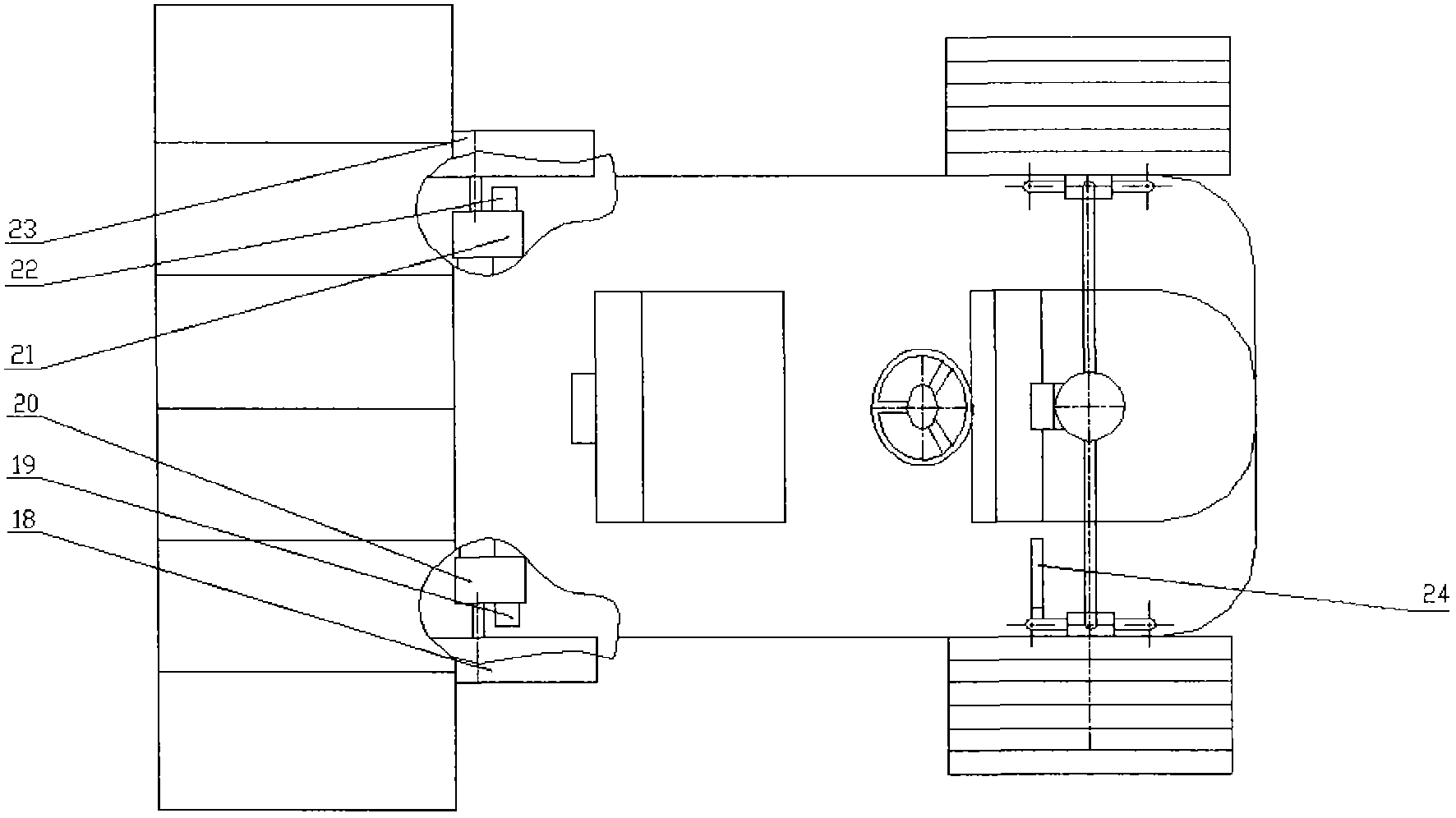

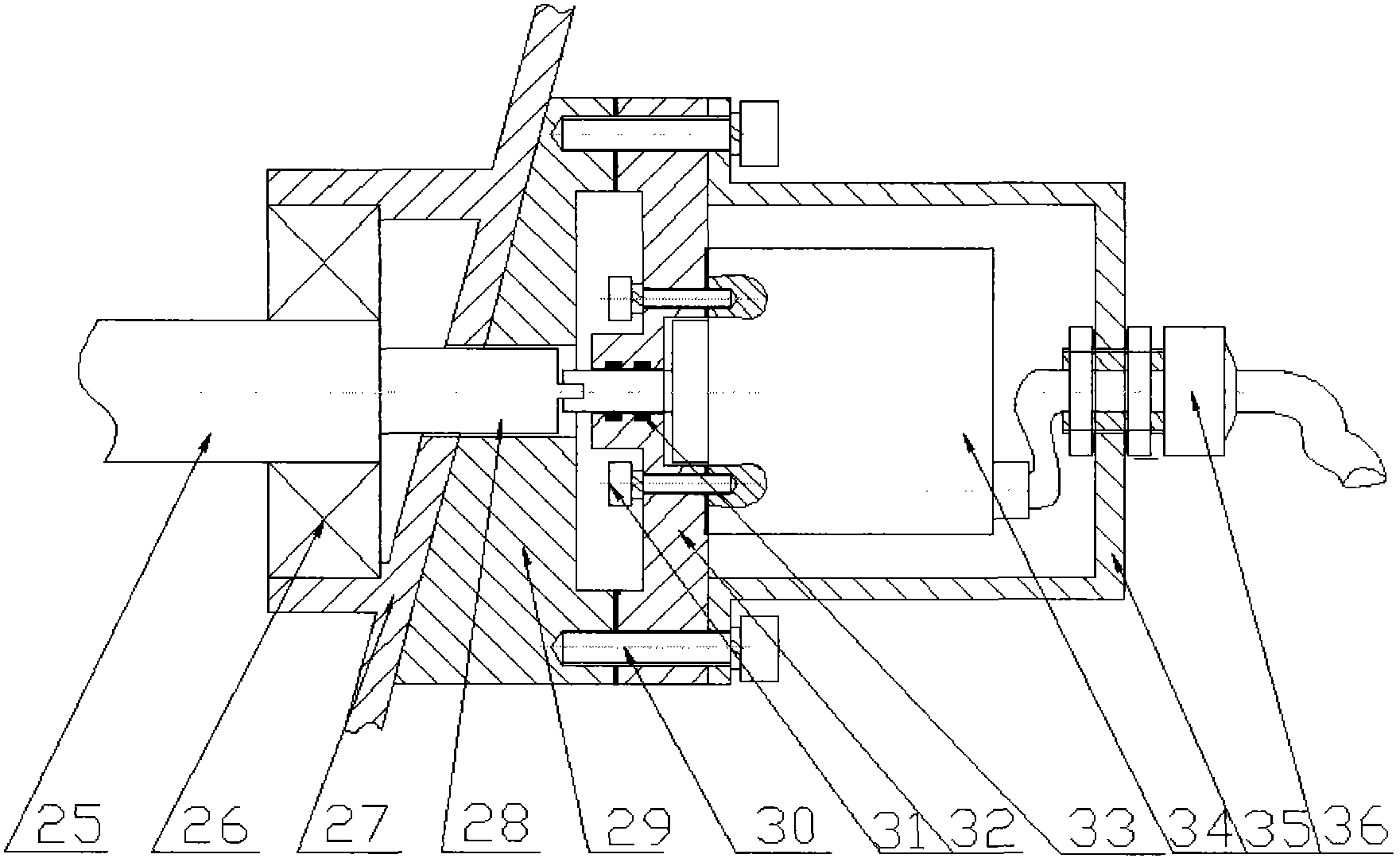

Satellite navigation automatic driving system of high-speed seedling transplanter and satellite navigation automatic driving method of high-speed seedling transplanter

InactiveCN103425134AReduce the need for skilled laborHas practical valueTransplantingAttitude controlReduction driveOdometer

A satellite navigation automatic driving system of a high-speed seedling transplanter is composed of an RTK-GPS, an attitude instrument, odometers, a rotation angle sensor, an electronic control steering wheel, a GPS data forwarding electronic control unit (ECU), an attitude instrument data forwarding electronic control unit (ECU), an odometer electronic control unit (ECU), a steering wheel electronic control unit (ECU), an embedded navigation computer EGC and the like. A traditional manual steering wheel is replaced by the electronic control steering wheel; the RTK-GPS and the attitude instrument are arranged at the center of a cross-over support on a seedling disc support; the odometers are arranged on walking reducers of left and right wheels; the rotation angle sensor is arranged at a steering mechanism of the bottom of a main reducer; each electronic control unit (ECU) is arranged near the sensor; the EGC is mounted at one side of the seedling disc support; the EGC is connected with the ECUs through a serial communication network; the EGC includes a man-machine interface as well as pre-data processing, attitude estimation and driving control modules; in seedling transplanting, a target point method is adopted to realize tracking automatic driving; and in corner turning, a method in which attitudes are adjusted around a corner turning center is adopted to realize automatic driving. With the satellite navigation automatic driving system adopted, the seedling transplanter can be driven by a computer, and therefore, onboard operation personnel can be reduced to only one seedling supplementing worker.

Owner:NINGBO YINZHOU MICROAGRI TECH

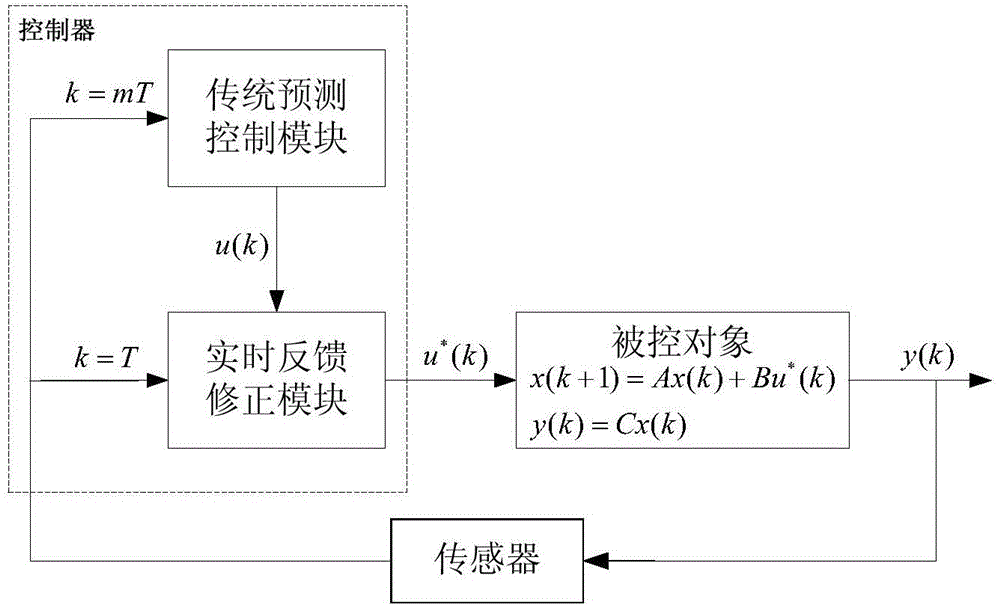

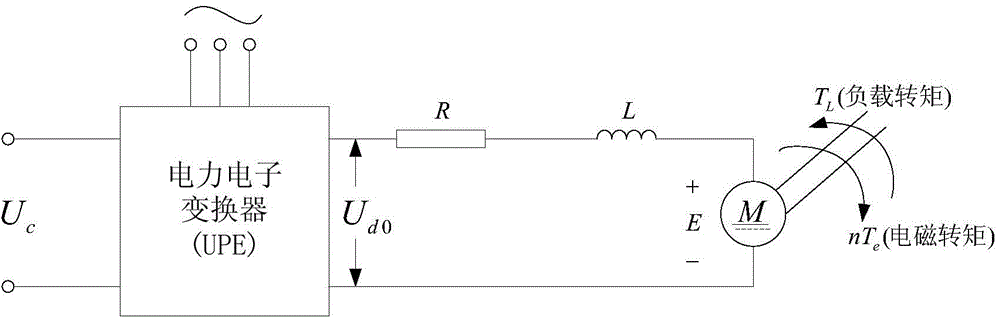

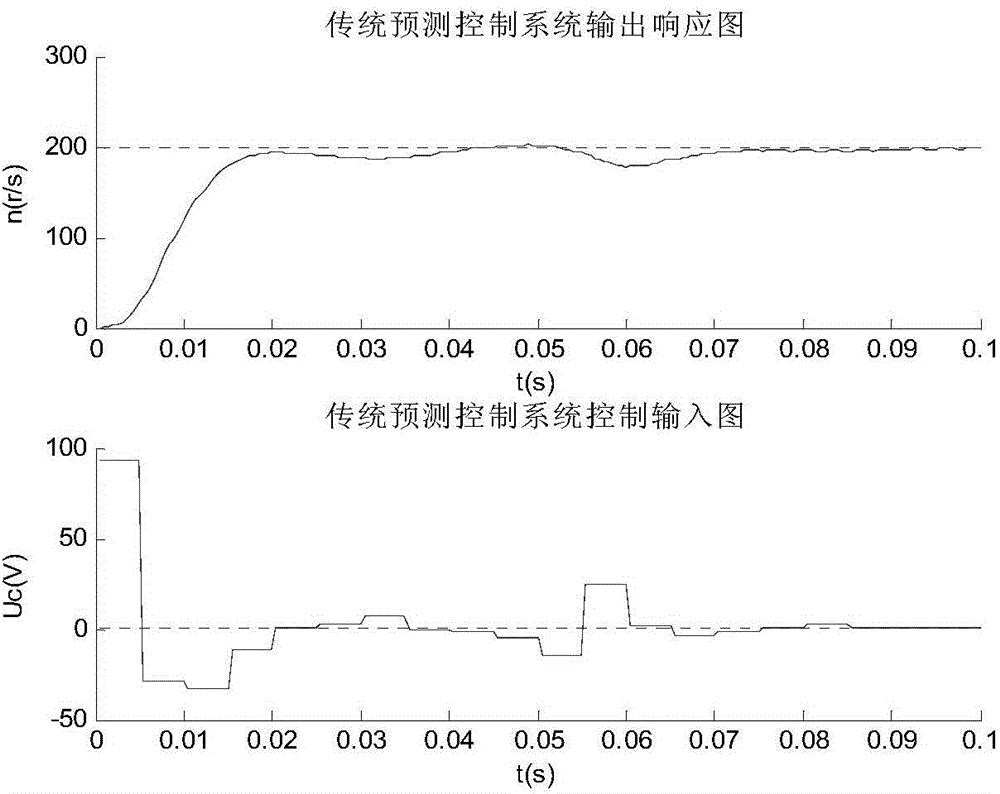

Layering predictive control system and method based on model predictive control

ActiveCN103984242ASolve problems that are not conducive to controlling fast systemsEnsure controlSimulator controlControl systemComputer module

The invention discloses a layering predictive control system and method based on model predictive control. The layering predictive control system based on model predictive control comprises an upper-layer traditional predictive control module, a sensor and a lower-layer real-time feedback correction module, wherein the input end of the upper-layer traditional predictive control module and the input end of the lower-layer real-time feedback correction module are respectively connected with the output end of the sensor, the input end of the sensor is connected with the output end of a controlled object, the upper-layer traditional predictive control module is connected with the lower-layer real-time feedback correction module, the output end of the lower-layer real-time feedback correction module is connected with the input end of the controlled object, and at every control moment, the lower-layer real-time feedback correction module can correct an optimized control quantity sent by the upper-layer traditional predictive control module and send the corrected optimized control quantity to the controlled object. The layering predictive control system and method based on model predictive control guarantee the control performance of a controller, popularize the application of a predictive controller to part of rapid systems, and have practicability and application value.

Owner:上海碧帝数据科技有限公司

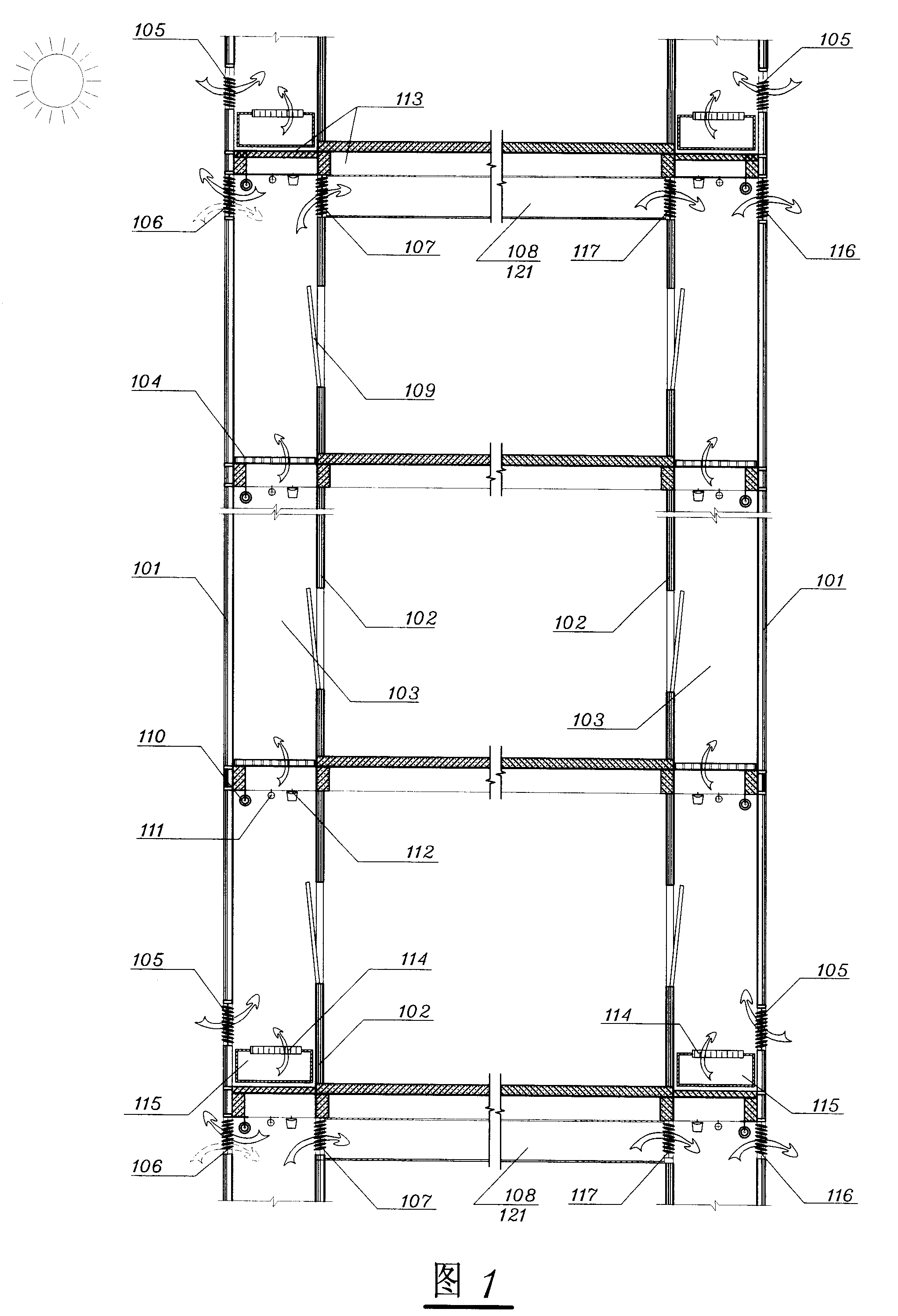

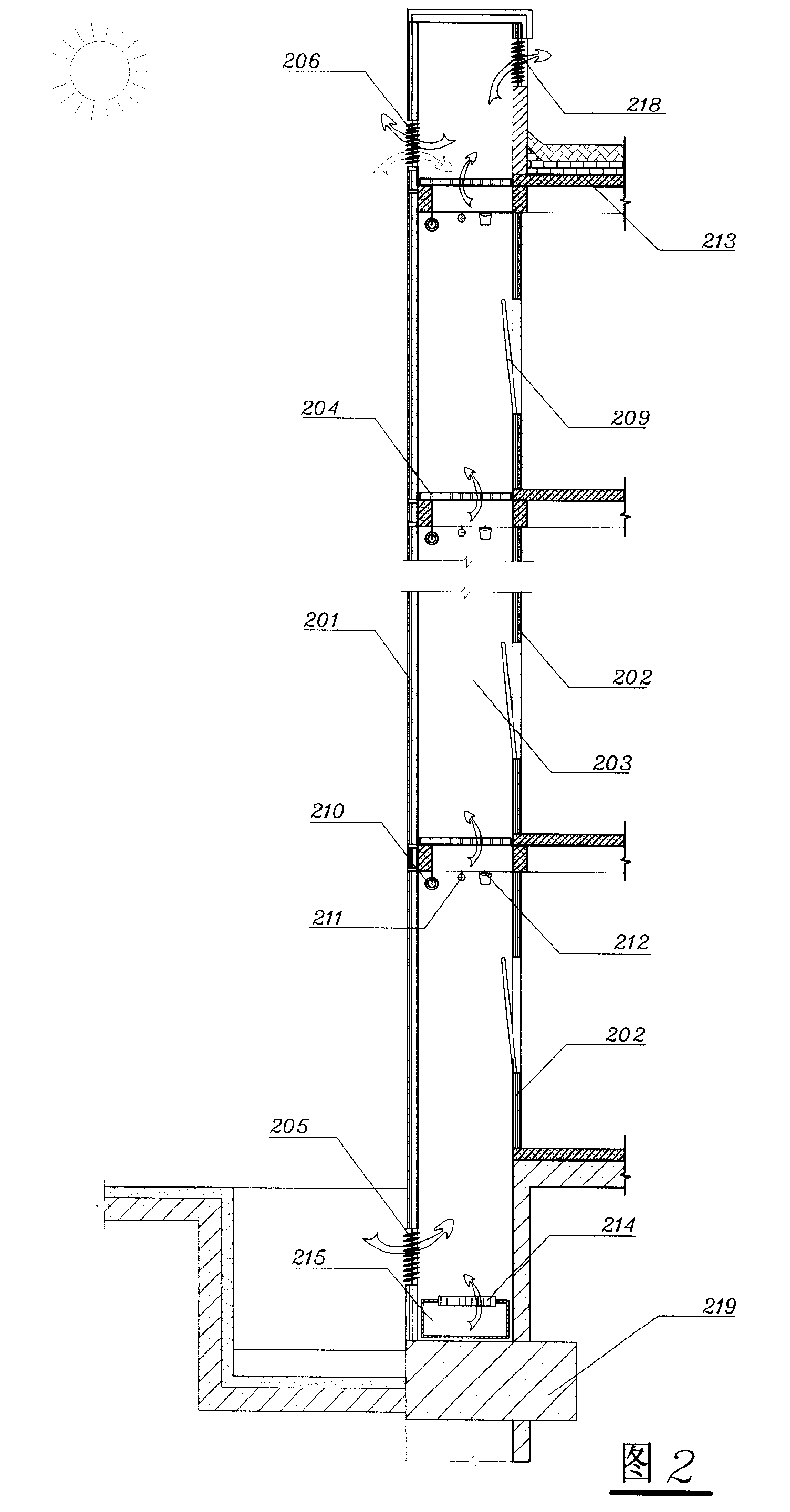

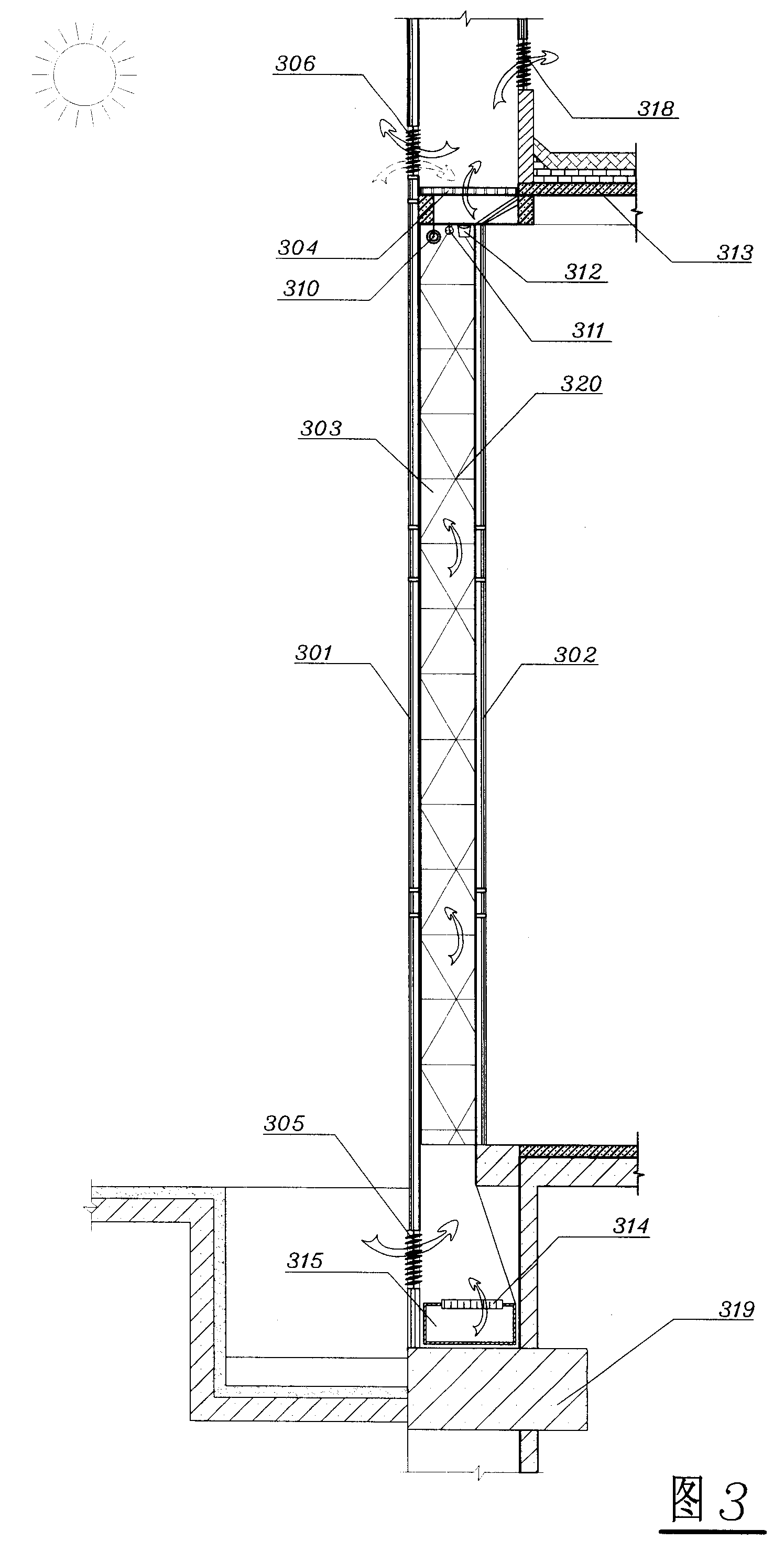

Double layer glass curtain aeration technology and method and structure

InactiveCN101187488ASolve the problem of unstable liquidityReduce the temperatureLighting and heating apparatusWallsSmoke detectorsDifferential pressure

The invention relates to a novel energy-saving glass curtain wall, wherein the shortcoming of natural wind is compensated through mechanical assisted air supply mode, and the problem of unsustainable and unstable airflow is solved. An air inlet is arranged on the windward side, an air outlet is arranged on the leeward side, the air inlet and the air outlet are connected through a ventilating duct or 'an architectural layer ventilating duct' to ensure the air flow smoothly. The distance between the air inlet and the air outlet is increased, the differential pressure of air can be realized, and the effect of 'a chimney effect' is improved. A fireproof grade of an outside curtain wall is lower than a fireproof grade of an inside curtain wall, and the fireproof capacity of a double layer curtain wall is basically same as a single layer curtain wall, the fireproof capacity can be improved through a smoke detector and a spray system. In summer, the invention adopts the mode of spray desuperheating through a fire-fighting spray system, and in daytime pollution-free power supply is supplied to an air supply system and a draught fan through solar energy. According to the improvement, the integrated effect of the double layer glass curtain wall and 'a climate adaptive capacity' is hoped to be improved, and a new idea is provided to the development of the curtain wall and the technological innovation.

Owner:周嘉陵 +2

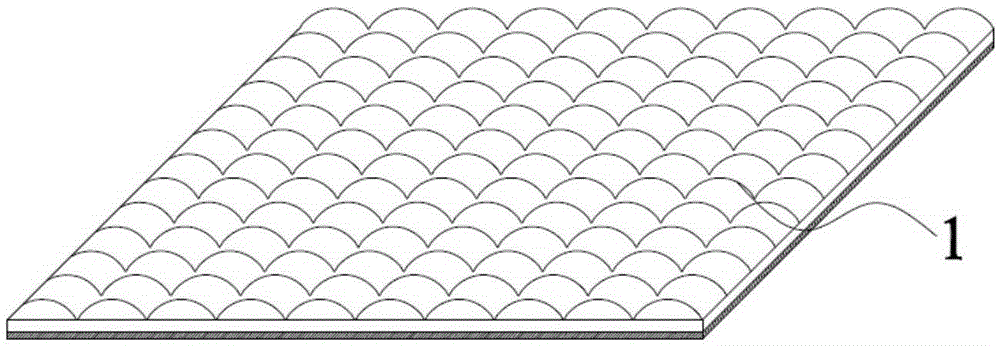

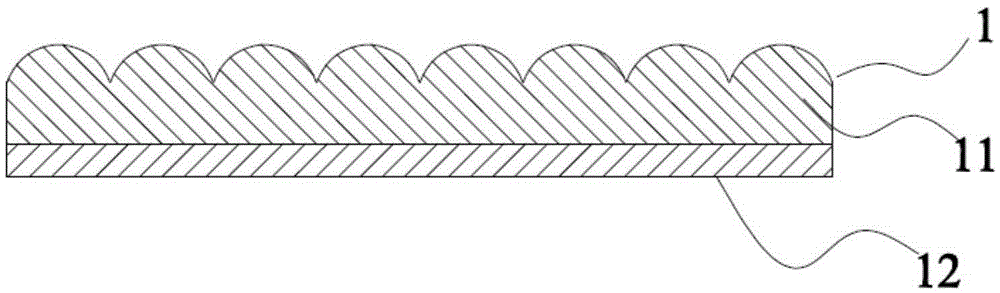

Light field imaging and printing device and thin film with three-dimensional floating images

ActiveCN105259664ARealize the imaging effectReal 3D viewing experienceOptical elementsGalvanometerLight field imaging

The invention provides a light field imaging and printing device and a micro lens thin film with three-dimensional floating images, wherein the thin film is prepared by the light field imaging and printing device. The scanning operation on a lens surface is conducted by a scanning galvanometer system, and four-dimensional light field data can be printed in combination with the variation of space three-dimensional coordinates. The light field imaging and printing device comprises a light source, a scanning galvanometer system, a lens, a diffuser, a converging lens assembly and a micro lens recording material. Light rays sequentially pass through the scanning galvanometer system, the lens, the diffuser and the converging lens assembly, and then instantaneous and dynamic focus spots are outputted. In this way, a volumetric-pixel type radiation light field is obtained. After that, the information of the instantaneous volumetric-pixel type radiation light field is recorded by the micro lens recording material. By means of the device and the thin film, more realistic three-dimensional dynamic images can be formed. Through controlling different variable values, floating images of multiple different characteristics are formed. Therefore, the multi-view imaging effect of varying images can be realized.

Owner:SVG TECH GRP CO LTD +1

Scheduling method for assisting power peak shaving by using energy storage system and system

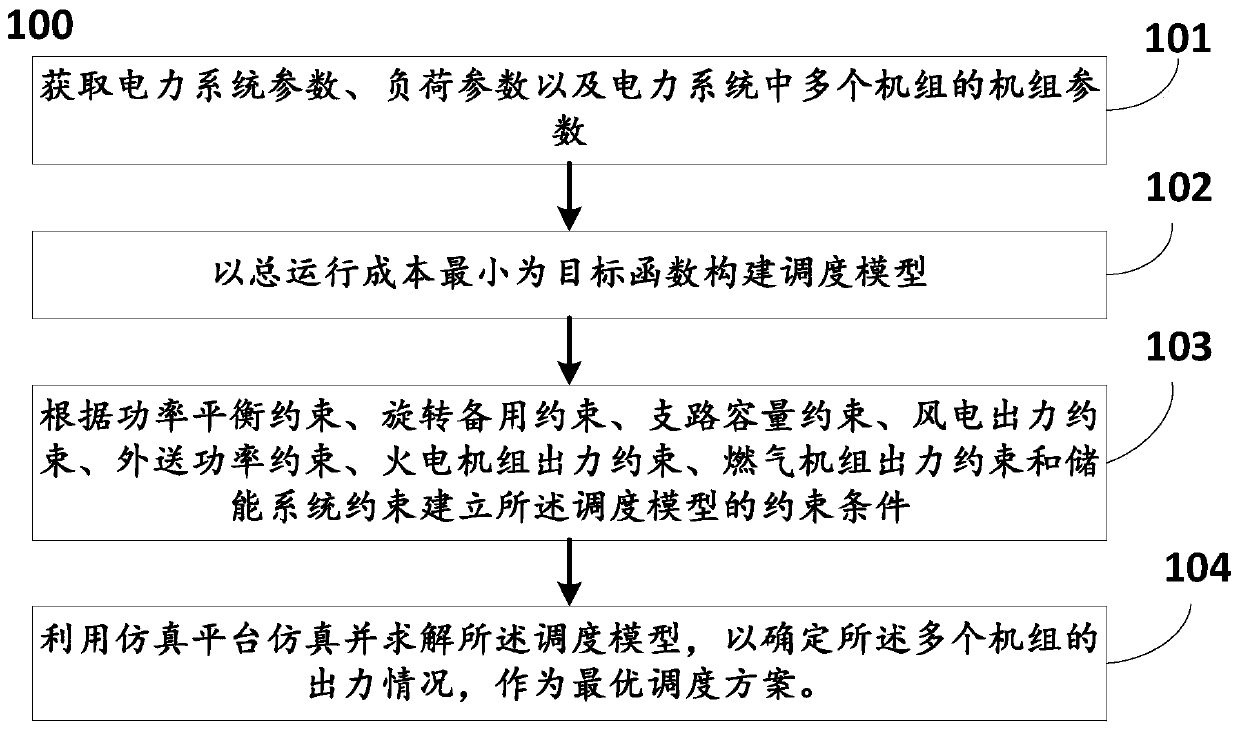

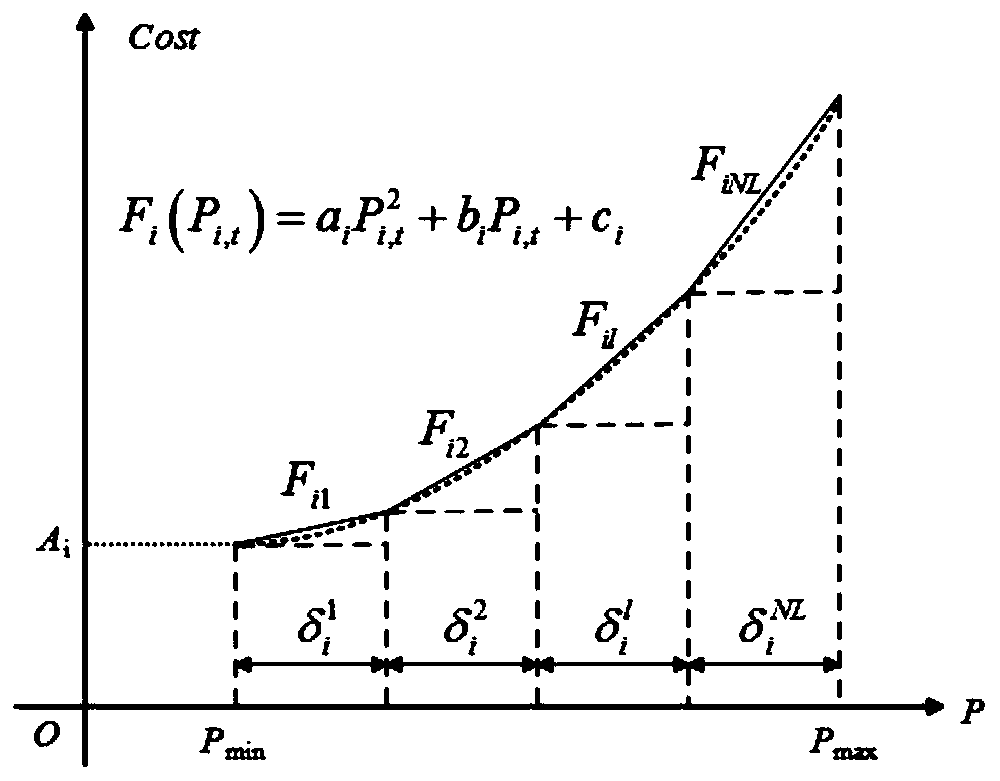

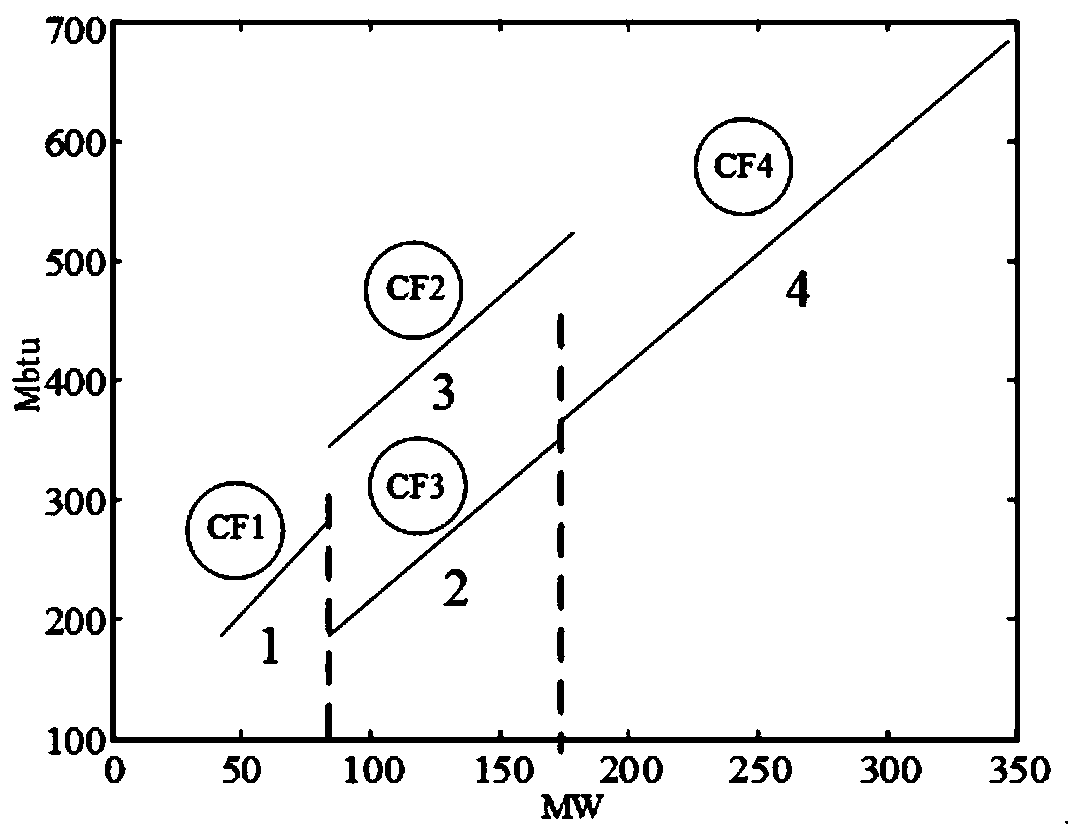

ActiveCN110429663AReflect energy storage needsImprove economySingle network parallel feeding arrangementsAc network load balancingElectric power systemDelivery cost

The invention discloses a scheduling method for assisting power peak shaving by using an energy storage system. The method comprises steps: power system parameters, load parameters and unit parametersof multiple units in the power system are obtained; a scheduling model with the minimum total operating cost as an objective function is built; constraints for the scheduling model are built; and a simulation platform is used to simulate and solve the scheduling model, and the output situation of the multiple units is determined as the optimal scheduling scheme. Based on the operation flexibilityand the rapid adjustment capability of a gas-fired genset, the scheduling model aiming at consideration of the total operating cost of the conventional thermal power unit operating cost, the gas-fired genes cost, the wind curtailment penalty cost and the delivery cost to be minimum is built, the energy storage demand for power peak shaving is more accurately embodied, and the economics of scheduling is enhanced. Based on the actual characteristics of the power grid, a scheduling model considering power delivery is built, a role of enhancing the system delivery ability when energy storage participates in power peak shaving is fully played, and the practical value is achieved.

Owner:CHINA ELECTRIC POWER RES INST +2

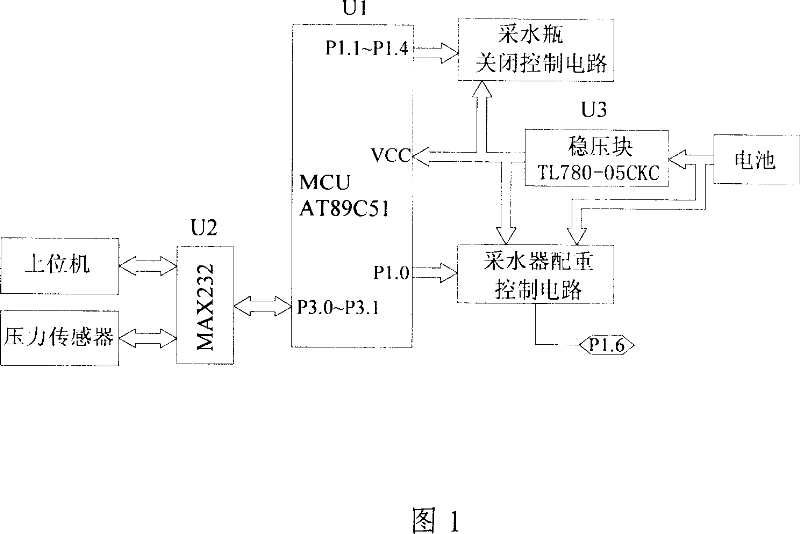

Self-recovery type water sampler control device

InactiveCN101038243ASave electricitySimple and efficient operationWithdrawing sample devicesElectrical batteryEngineering

The present invention relates to an auto-return type water sampler controlling device for a water sampler, which comprises a single chip microcomputer with its input terminal being connected to a pressure sensor through a level shifter and its output terminal being connected to a water sampler counterweight control circuit as well as a water sampling tank turnoff control circuit in a water sampler, wherein a dry battery or rechargeable battery is utilized as the working power of said control device, which is output to the single chip microcomputer, the level shifter, the water sampler counterweight control circuit and the water sampling tank turnoff control circuit, through a voltage stabilizing block. According to the present invention, a cable is not necessary during the put-in and callback of a water sampler, then some problems, such as depth illegibility, trips of castoff and plant roots in water and the destroying effect of a mechanical pump on an objective to be researched which are caused by a cable, are avoided; manpower participance during a water sampling operation course is not necessary, a depth gradient water sampling dautomatization is achieved; said device exhibits credible performances and has practical values.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

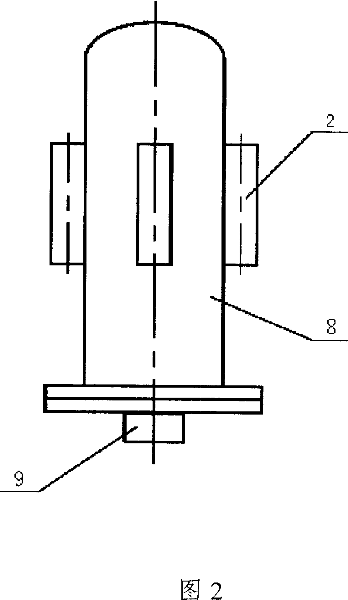

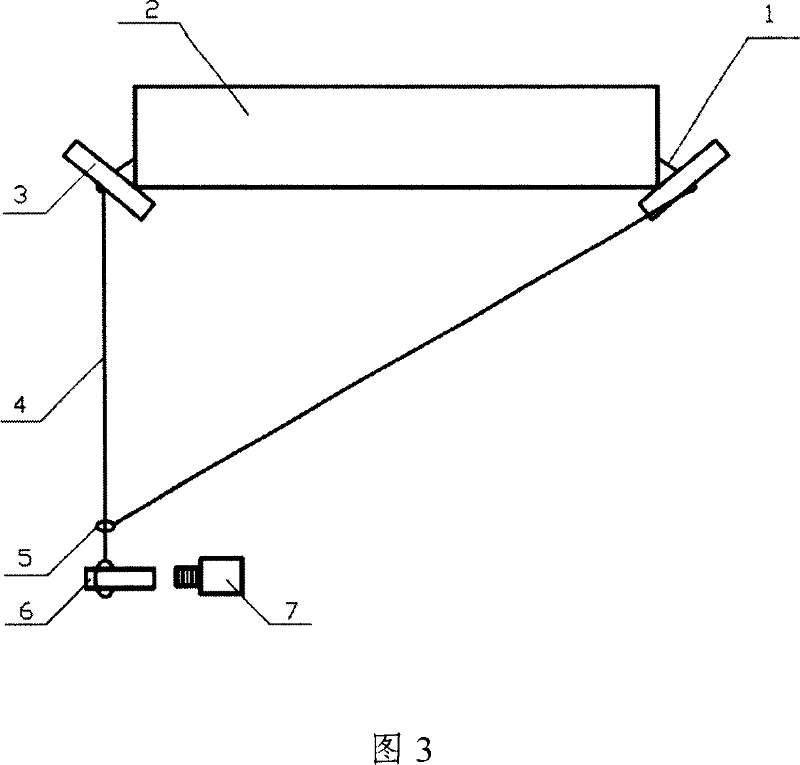

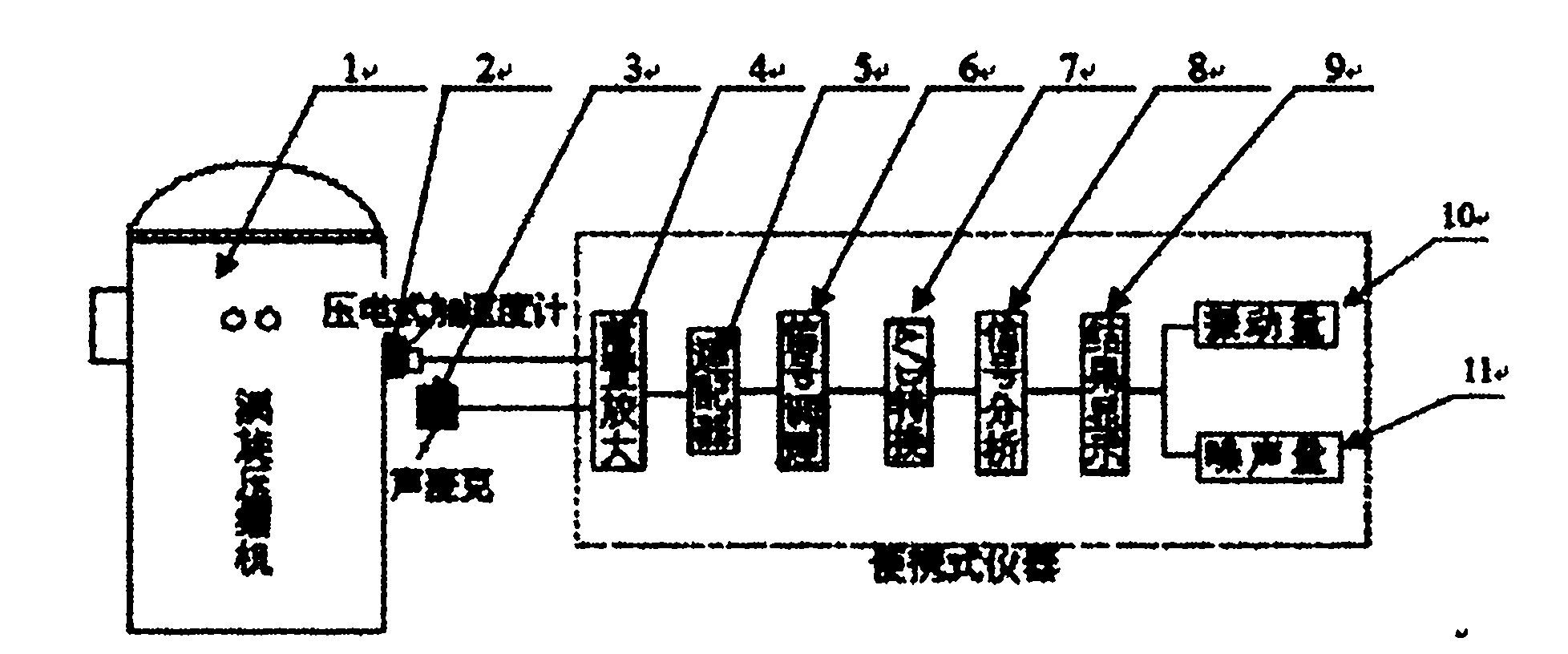

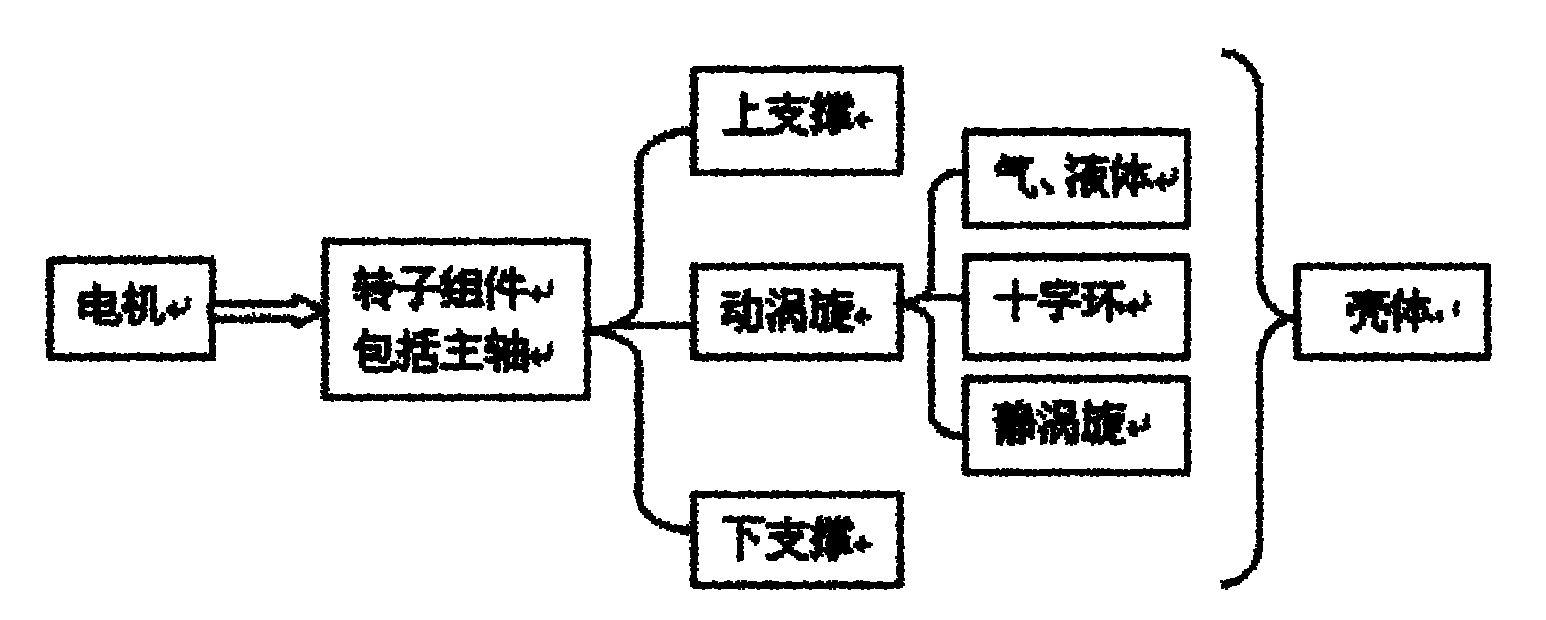

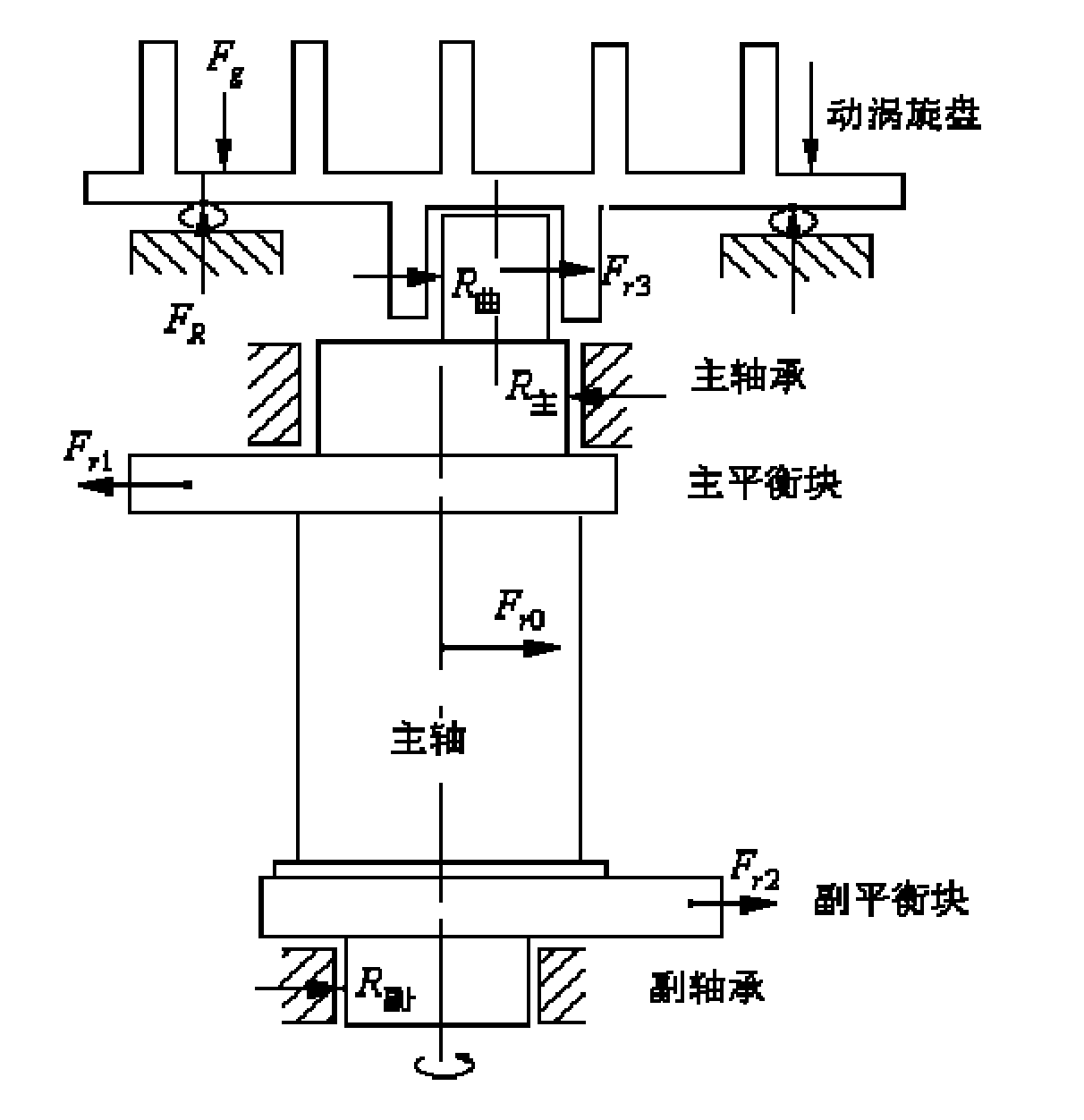

Vibration and noise online monitoring and fault diagnosis system of scroll compressor

InactiveCN102072144AFunctionalHas practical valuePump testingPositive-displacement liquid enginesAccelerometerSignal conditioning

The invention comprises a vibration and noise online monitoring device and a fault diagnosis system of a scroll compressor. The vibration and noise online monitoring device of the scroll compressor is composed of a scroll compressor, a piezoelectric-type accelerometer, a sound microphone, a preamplifier, an adapter, a signal conditioning module, an A / D (analog / digital) conversion module, a signal analysis module and a result displaying module, wherein the piezoelectric-type accelerometer is fixed on a shell of the scroll compressor; the sound microphone is arranged near the scroll compressor; the piezoelectric-type accelerometer and the sound microphone respectively collect the vibration amount and the noise amount of the scroll compressor; an analog signal is amplified and converted into a digital signal by the preamplifier, the adapter, the signal conditioning module and the A / D conversion module, and then the digital signal is sent to a computer and is analyzed by a computer software; and the analysis result is displayed. The fault diagnosis system of the scroll compressor is characterized in that the signal analysis module analyzes the vibration amount and the noise amount, and the operation stability and the faults of the scroll compressor device are judged through the result displaying module.

Owner:DALIAN UNIV

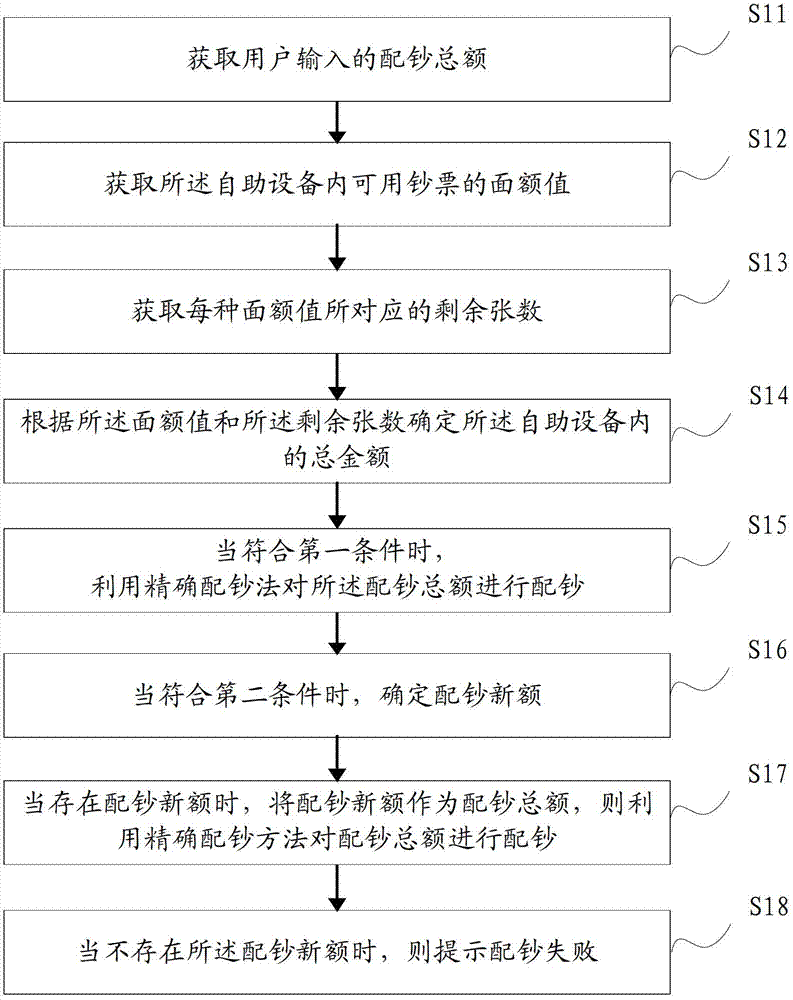

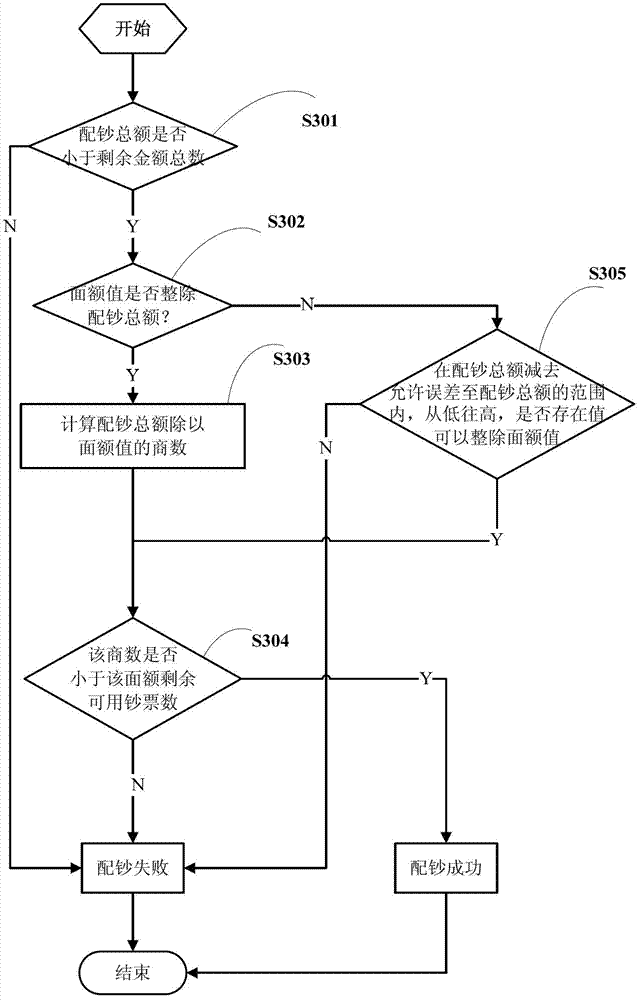

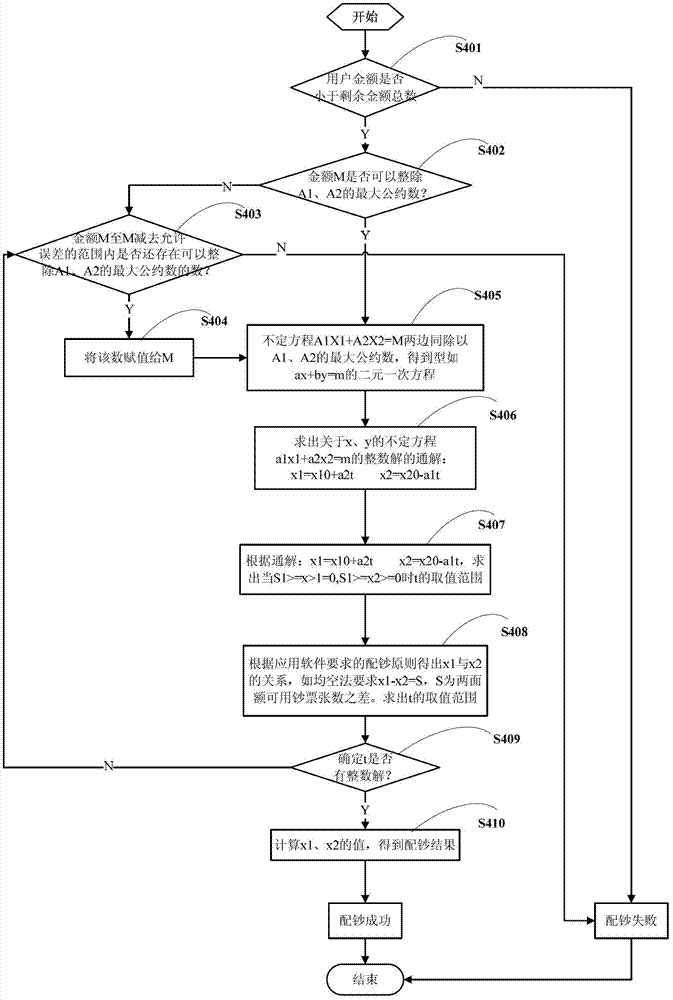

Cash dispensing method of financial self-service equipment

ActiveCN102903177AMeet needsEasy to use and flexibleApparatus with change-givingCoin/currency accepting devicesEngineeringSelf-service

Owner:GRG BAKING EQUIP CO LTD

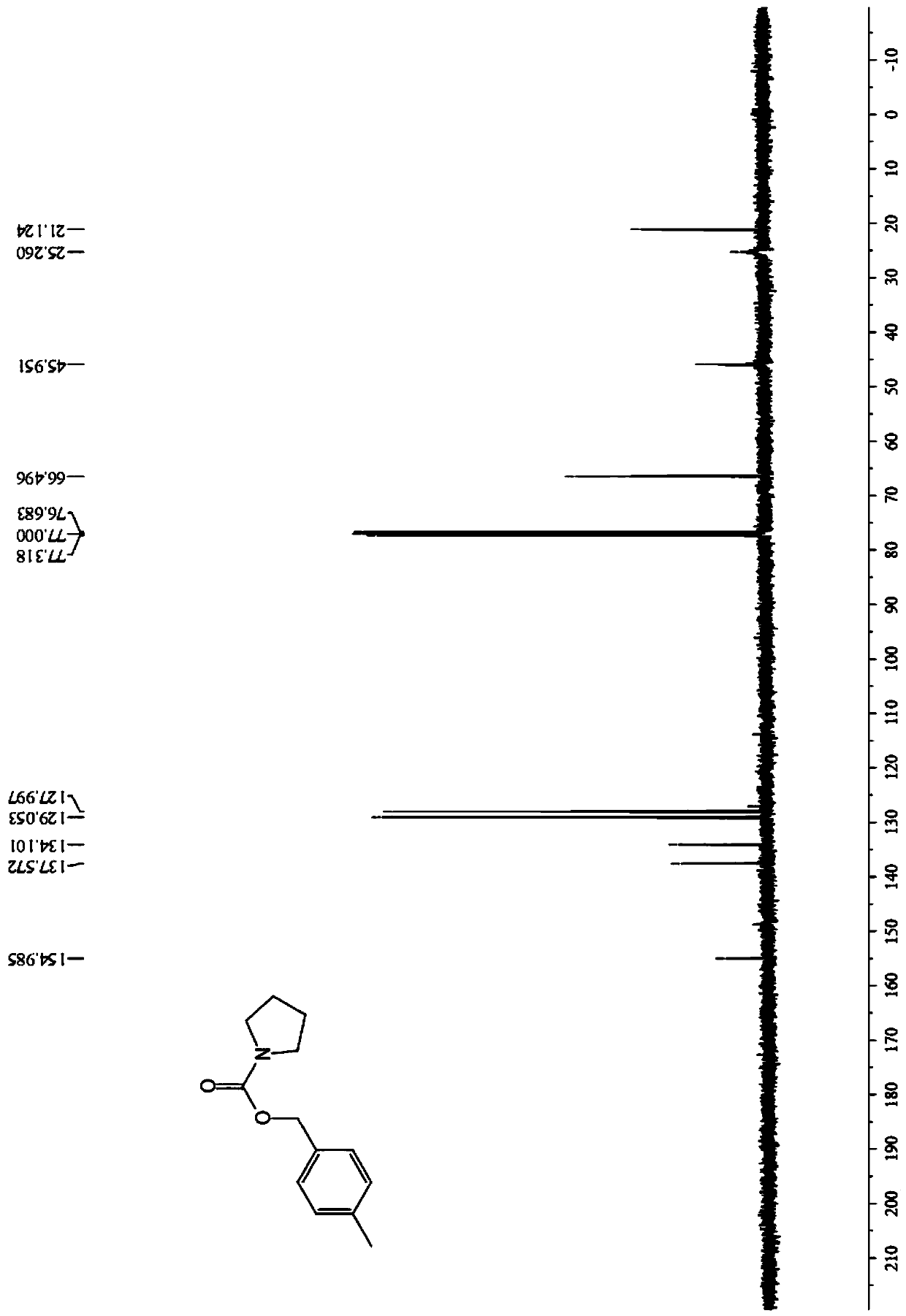

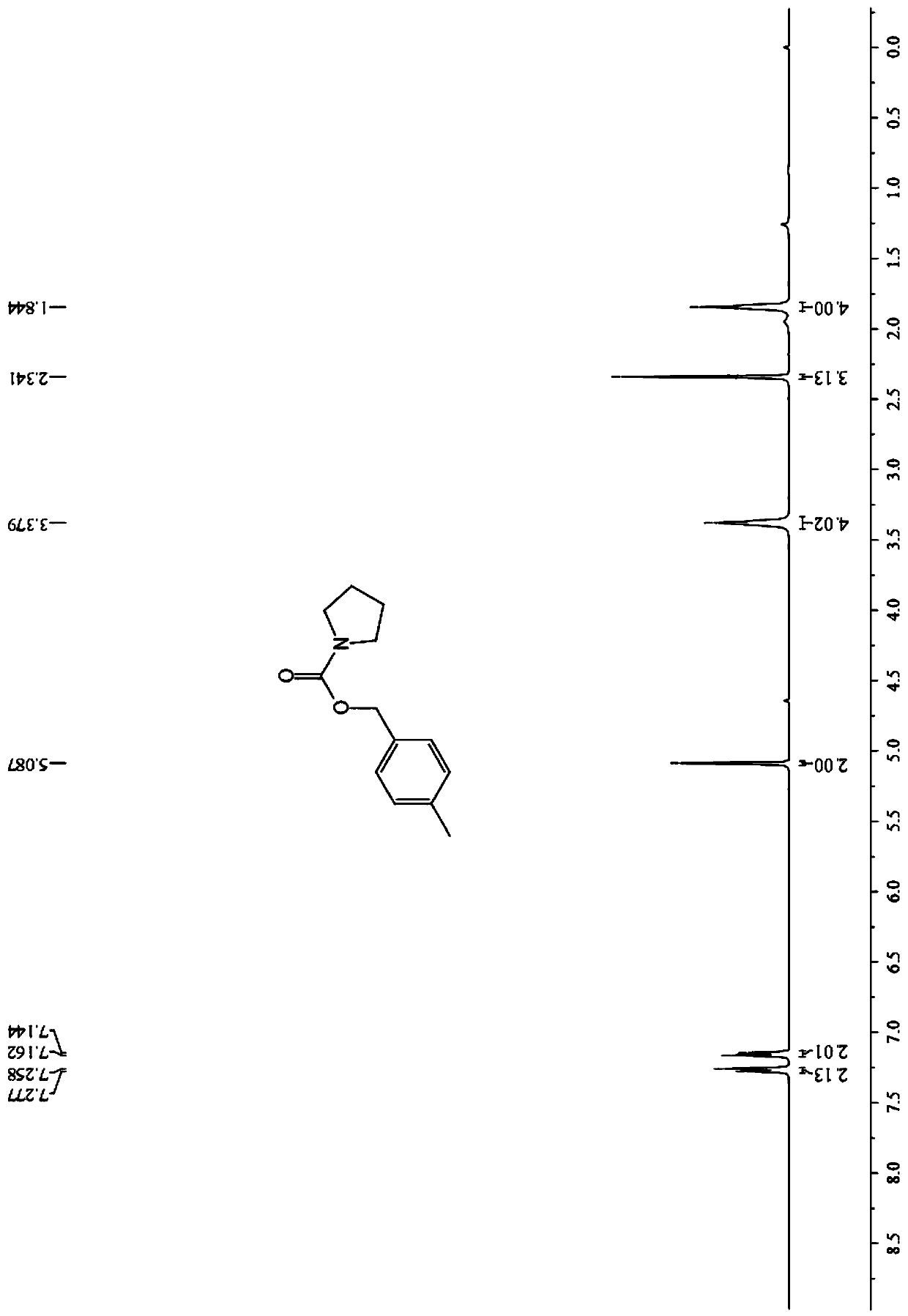

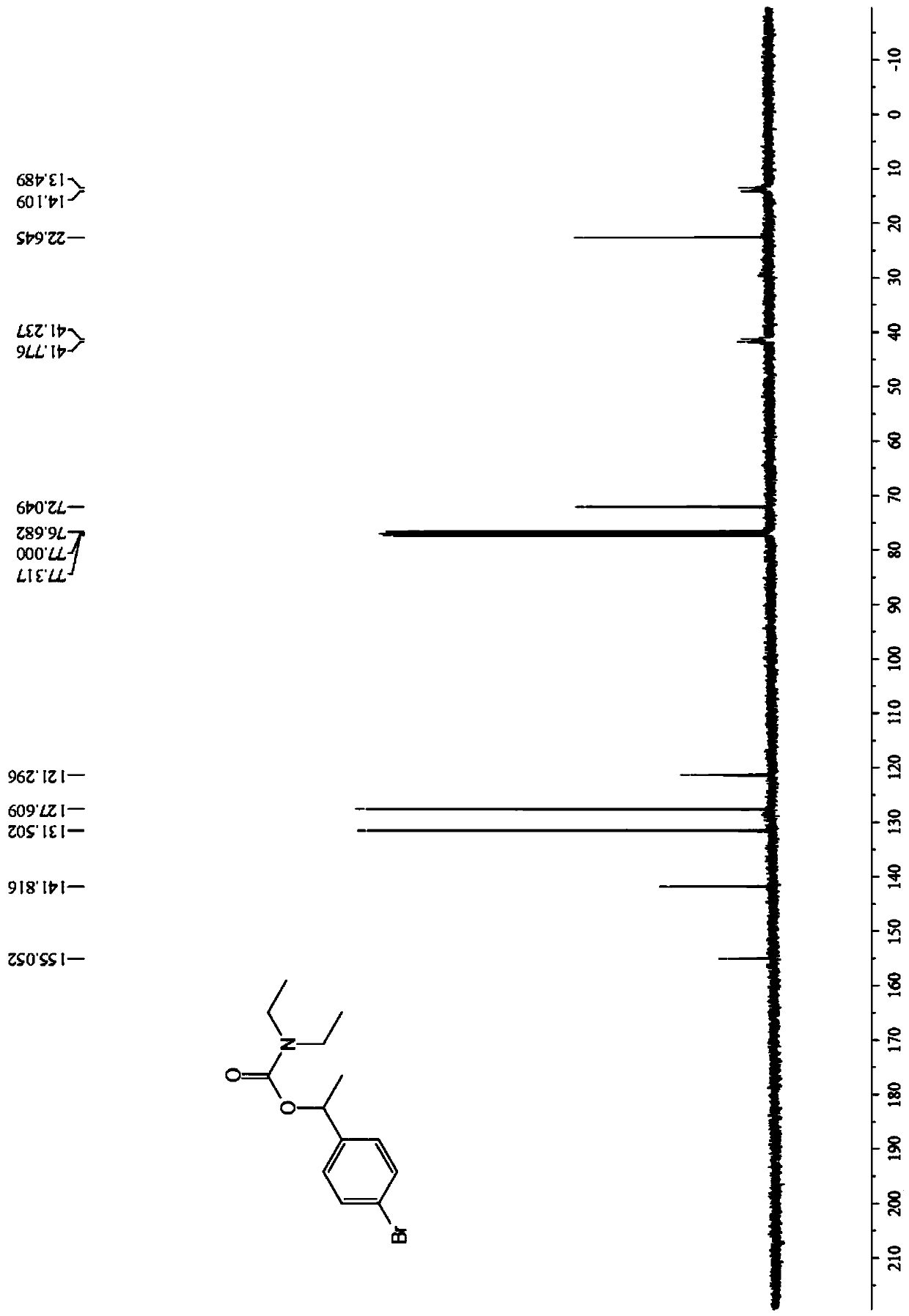

Method for synthetizing carbamate

ActiveCN104355955ARaw materials are easy to getLow priceCarbamic acid derivatives preparationOrganic compound preparationCarbamateNatural product

The invention relates to a method for synthetizing carbamate. The method comprises the following steps: adding sulfonyl hydrazones, amine and solvents in a high-pressure kettle, adding alkali as an accelerant, introducing carbon dioxide, performing a stirring reaction for 6-72 hours at the temperature of 40-150 DEG C, cooling the high-pressure kettle to the room temperature after the reaction is completed, slowly releasing carbon dioxide which is not reacted to constant pressure, filtering a reaction liquid, decompressing and stewing the solvents to obtain crude products, and obtaining a series of carbamate chemical compounds through refining in a column chromatography. The method for synthetizing carbamate is safe and simple to operate, the prices of raw materials are low, the raw materials are easy to obtain, the adaptability for functional groups is high, the adaptability for substrates is wide, the method is environmental-friendly, industrial production is facilitated, and the method is widely applied to the synthesis of agricultural chemicals, medicines and natural products.

Owner:SOUTH CHINA UNIV OF TECH

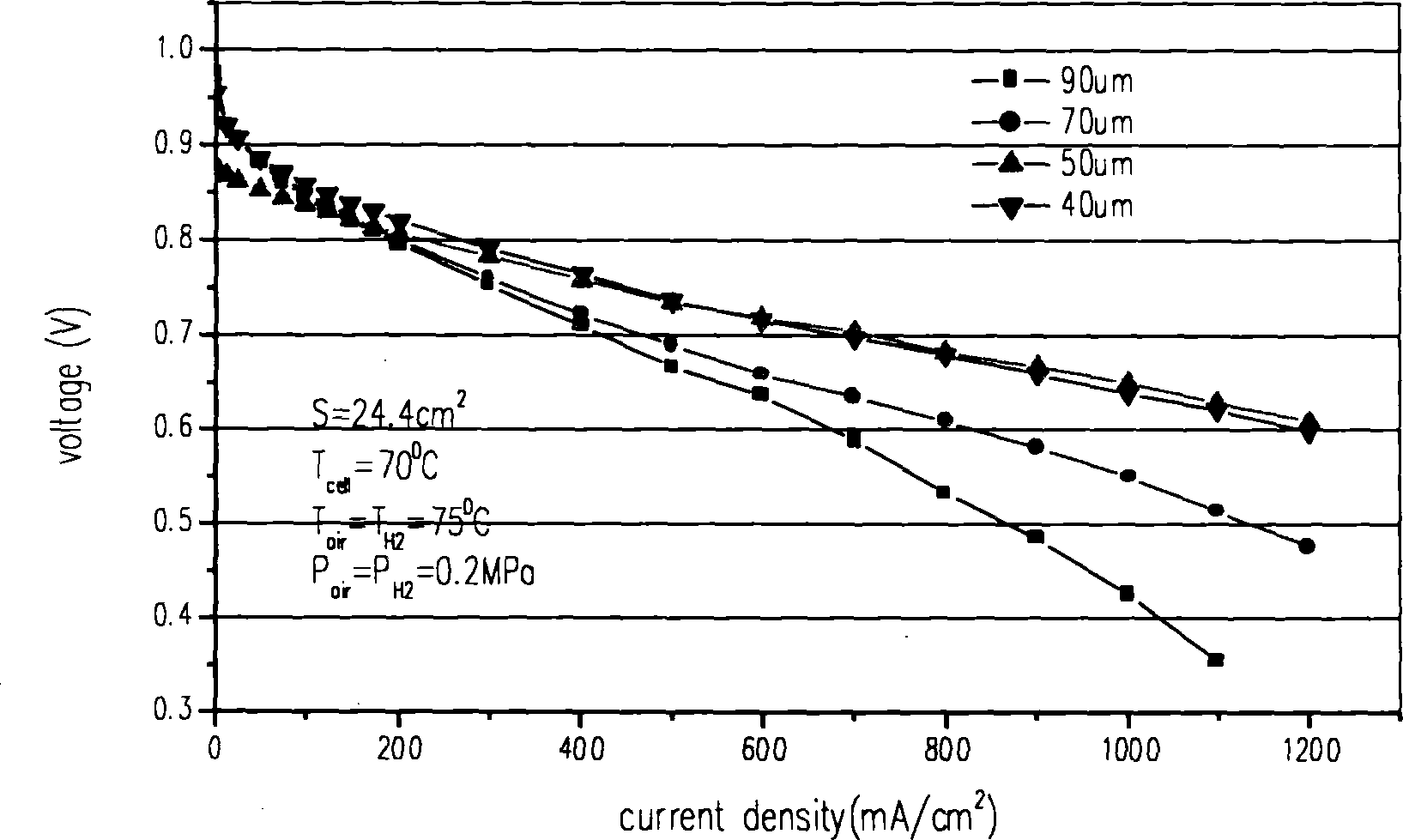

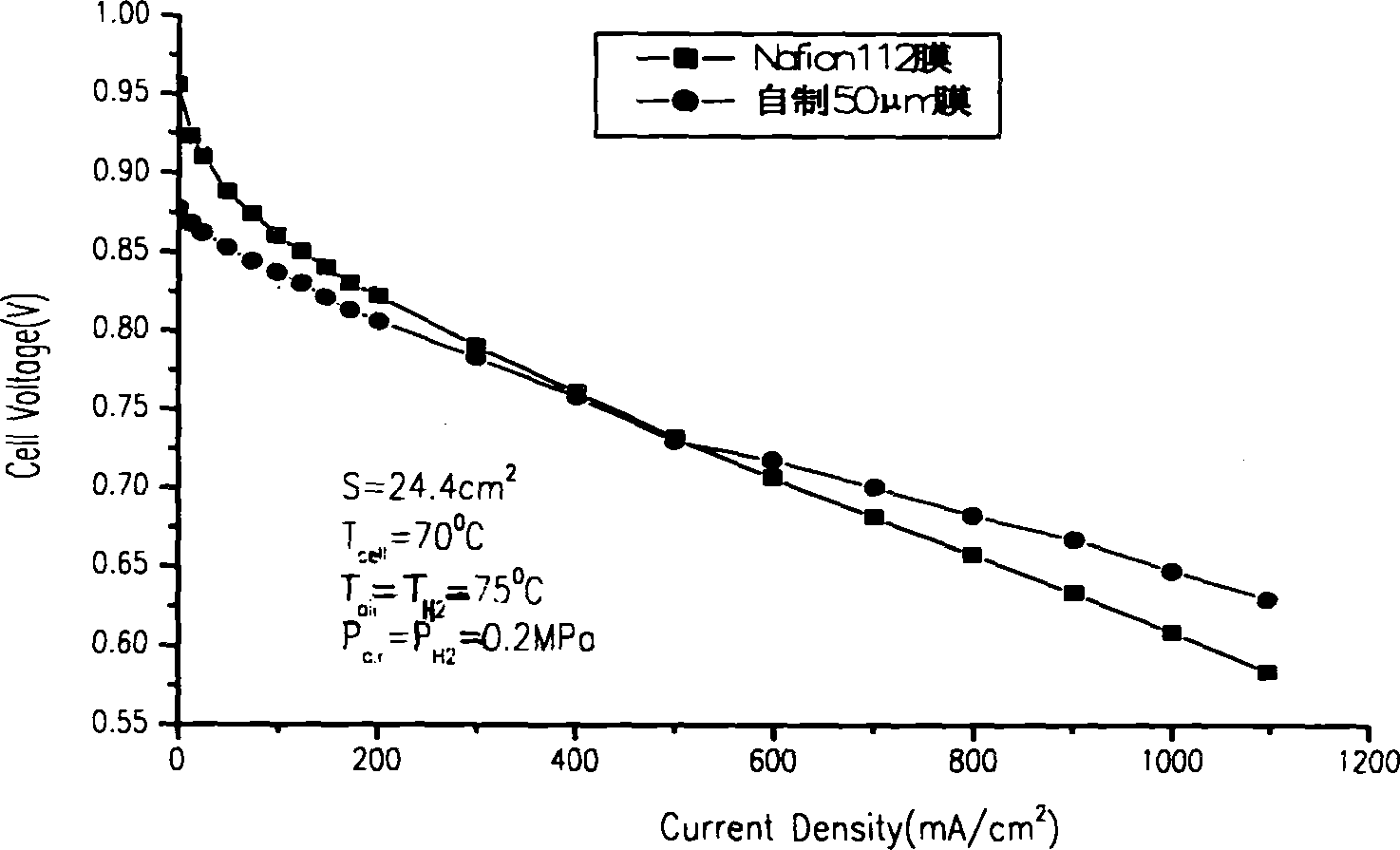

Process for preparing perfluorinated sulfonic resin solution by using waste ion exchange membrane in chlor-alkali industry

The invention discloses a method for preparing perfluoro sulfonic resin with abandoned ion exchange membrane in alkali-chloride industry, comprising following steps: swelling said abandoned ion with lower alcohol, emulsifying it with emulsion machine to resin particle, adding alcohol / water solvent and resin particle into autoclave, dissolving resin particle under high temperature and pressure and protection of nitrogen; getting solid mixture of perfluoro sulfonic resin and solution, separating with solid-liquid separation method and getting perfluoro sulfonic resin solution and solid perfluoro sulfonic resin. The resin solution is characterized by transparent, low content of foreign matter, high purity, similar property to that of Nafion EW 1100 solution, usage in field of mending ionic membrane pinhole and other mechanical damage, preparation of fuel battery proton exchange membrane and stereoscopic electrode and chemical catalysis.

Owner:SUNRISE POWER CO LTD

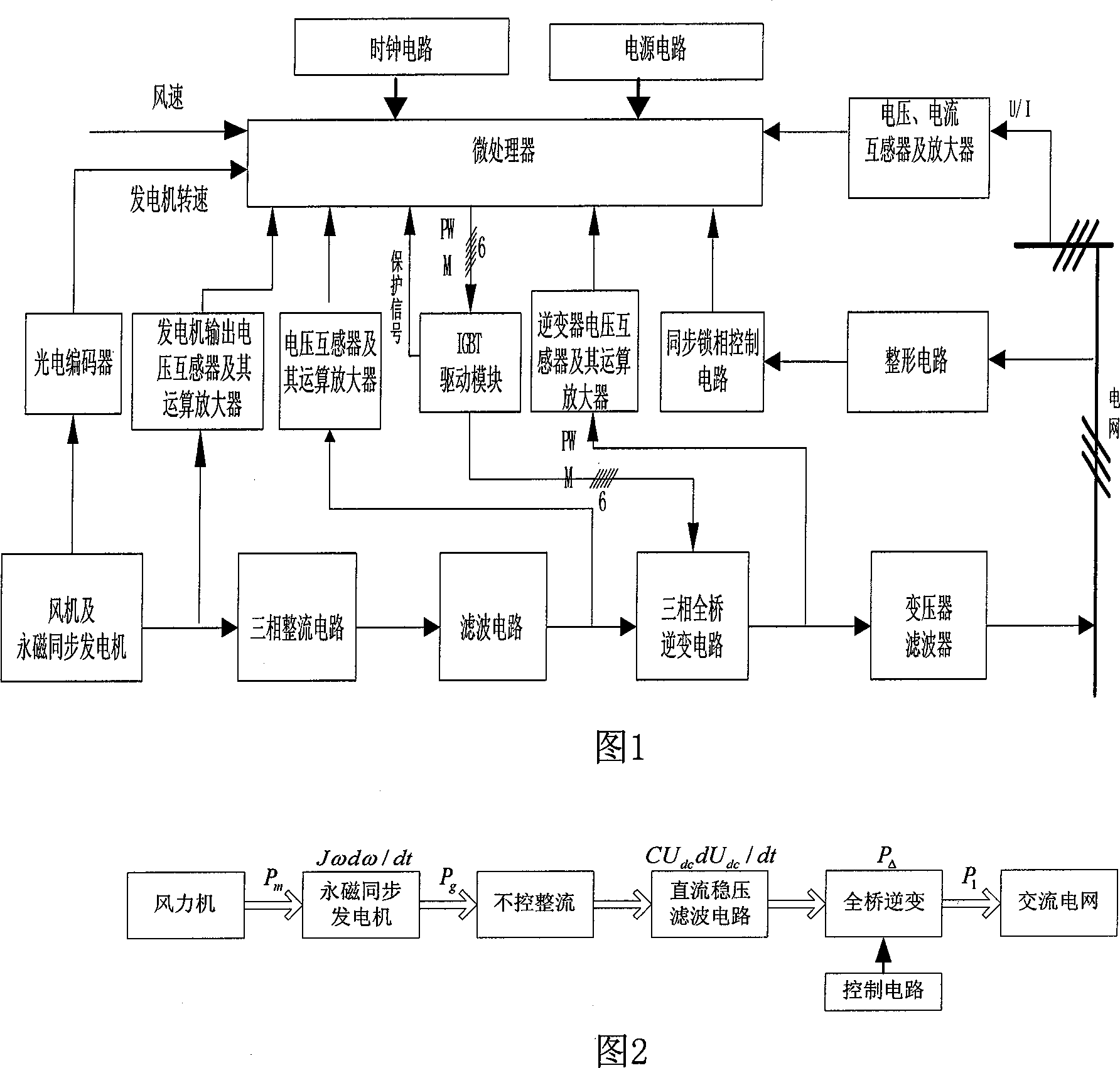

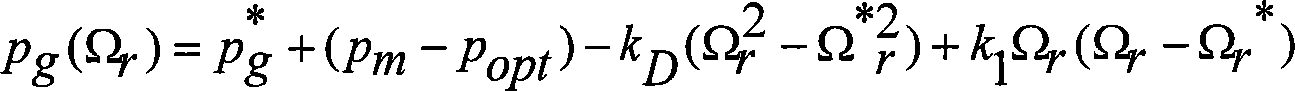

Merged network and power adjustment system for direct drive permanent magnetic synchronization generator and its method

InactiveCN101106279AAchieving maximum wind energy trackingReduce harmonic contentSingle network parallel feeding arrangementsMachines/enginesMeasuring instrumentPermanent magnet synchronous generator

The invention discloses a direct-drive permanent magnet synchronization wind turbine generator grid combination and a power-conditioning approach. The approach comprises the following steps: (1) a wind speed measuring instrument measures the wind speed and transmits the wind speed signal to a microprocessor. The microprocessor realizes maximum wind energy capture to the control of a three-phase full bridge inverter output power and a power grid voltage phase power angle Delta; wherein, the power angle Delta is of the included angle of an output voltage ul of the inverter and a net measure voltage us; (2) the permanent magnet synchronization wind turbine generator is driven by the wind turbine to generate electricity, and the current is converted through a three-phase rectifier circuit and then enters into a three-phase full bridge inverter as a DC bus through a filter circuit; (3) the DC bus voltage is combined with a step-up transformer in grid through a filter reactor under the control of the microprocessor. The invention has the advantages of the better realization of the wind energy track, high stability, miniaturization, convenient maintenance and easy to improve the performance etc. control effects, thus the whole system is simpler in control and lower in cost.

Owner:SOUTH CHINA UNIV OF TECH

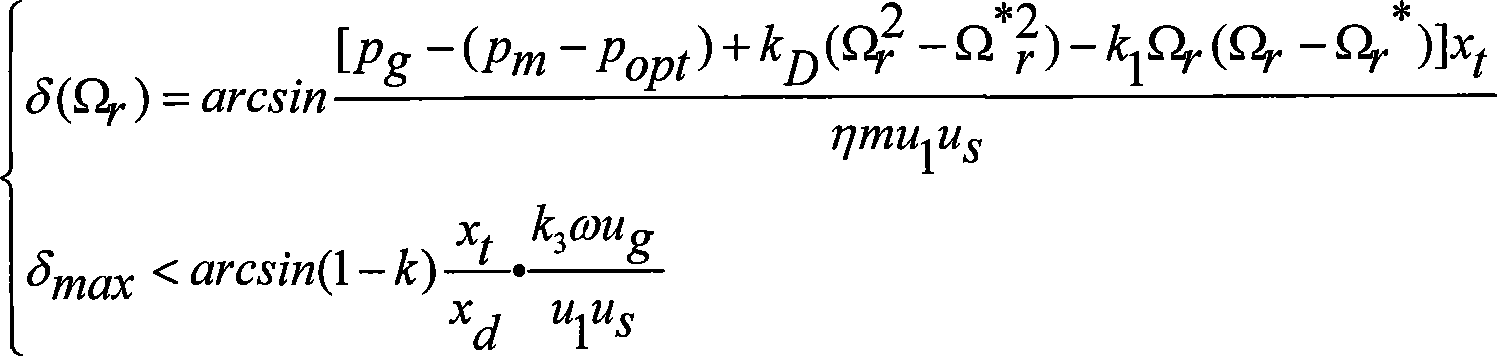

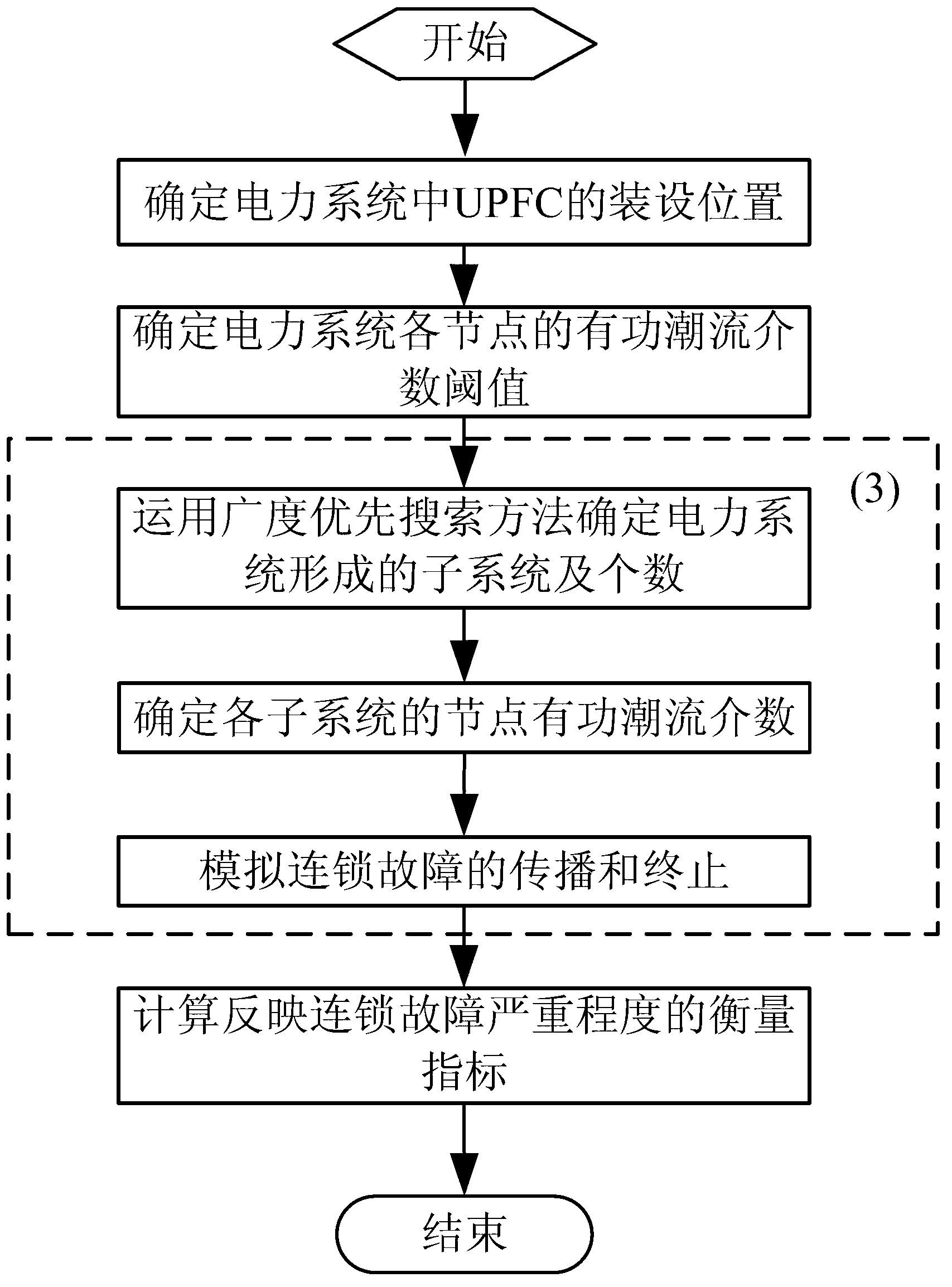

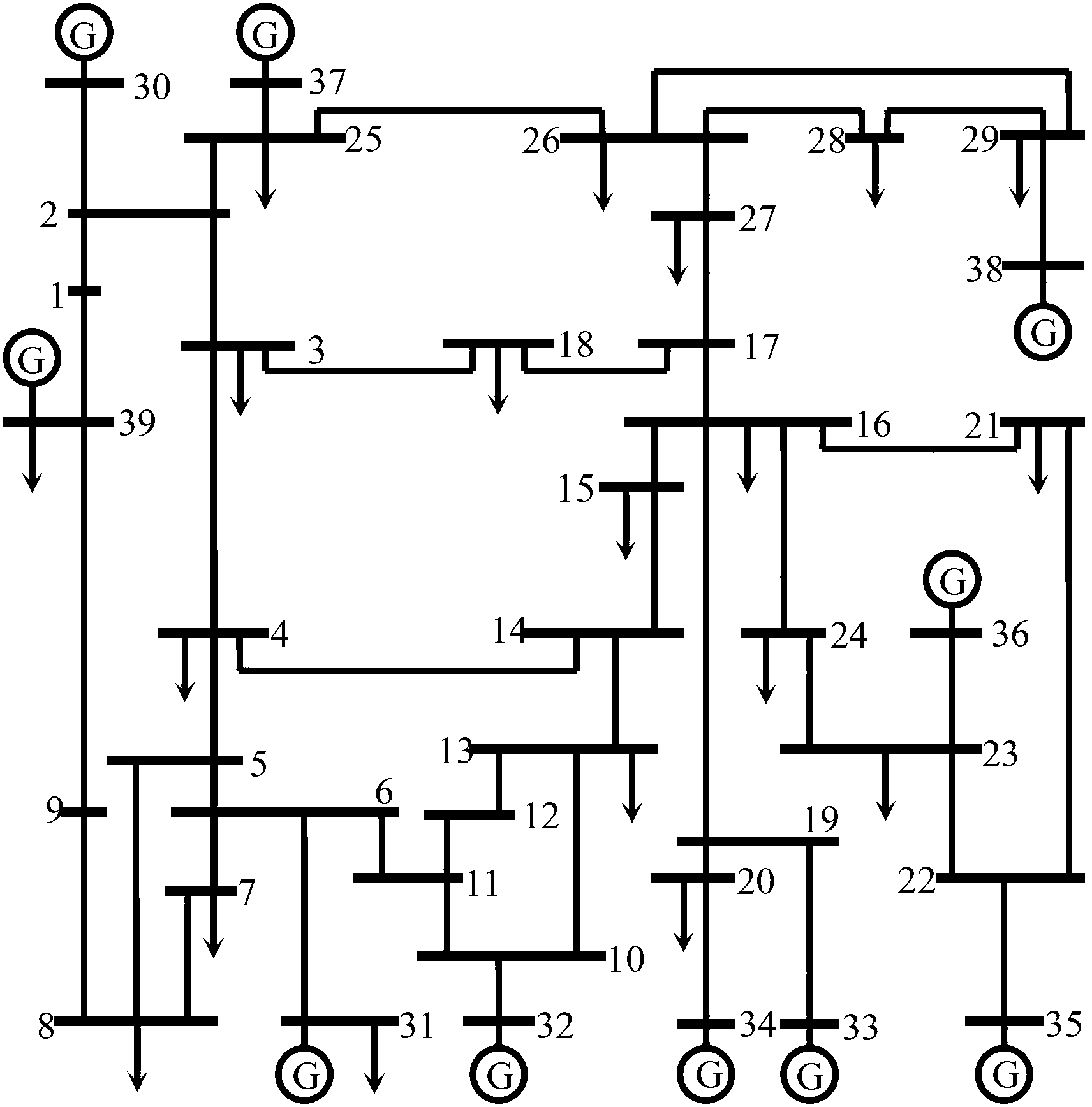

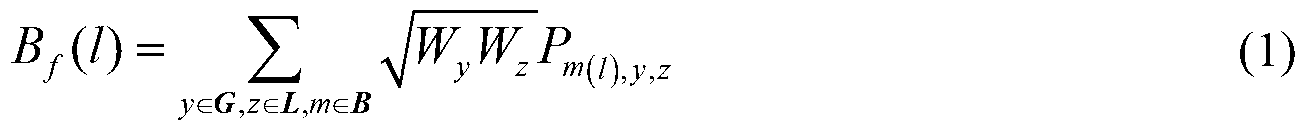

Power system cascading failure simulation method based on unified power flow controller

ActiveCN103311926AIn line with actual operating conditionsPracticalSpecial data processing applicationsAc network circuit arrangementsCascading failureSimulation

The invention provides a power system cascading failure simulation method based on a unified power flow controller and belongs to the technical field of power system security and reliability protection. A computer is used for determining the installation position of the unified power flow controller in a power system firstly, determining an active power flow betweenness threshold value of each node of the power system, performing power system cascading failure simulation based on the unified power flow controller and finally calculating measurement index for reflecting severity of cascading failure through procedures. The power system cascading failure simulation method gives consideration to power flow directivity and the operation mode of the system, optimizes the installation position for installing the unified power flow controller, effectively performs line parameter regulation while meeting safe operation constraints of the power system, and can reflect the propagation process of the cascading failure of the power system actually. The power system cascading failure simulation method based on the unified power flow controller can be widely applied to the cascading failure simulation of the power system, is particularly suitable for the cascading failure simulation of a large-scale complicated power system, and provides a scientific basis for preventing occurrence of the cascading failure of the power system.

Owner:CHONGQING UNIV

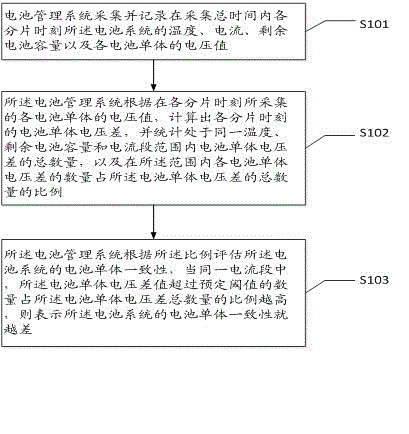

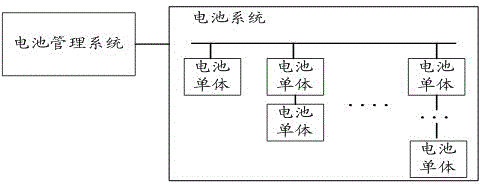

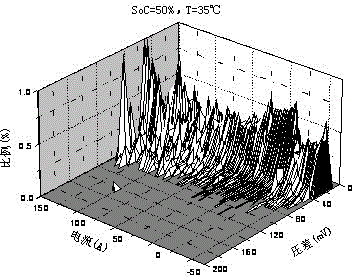

Method and system for evaluating battery monomer consistency

The embodiment of the invention discloses a method for evaluating the battery monomer consistency. The method comprises the following steps: acquiring and recording the temperature, the current, and the remaining battery capacity of the battery system at each shard moment in the total time and the voltage value of each monomer through a battery management system; calculating the monomer voltage difference according to the voltage value of each monomer and counting the total quantity of the monomer voltage differences within the range of the same temperature, remaining battery capacity and current section and the proportion of the quantity of each monomer voltage difference in the total quantity; evaluating the monomer consistency according to the proportion, wherein when the proportion of the quantity of each monomer voltage difference exceeding a predefined threshold value in the same current section in the total quantity is higher, the monomer consistency is shown to be worse. The embodiment of the invention further discloses a system for evaluating the battery monomer consistency. The embodiment of the invention solves the problem in the prior art that the battery monomer consistency under the static condition before and after the assembly of the battery system only can be evaluated, and the battery monomer consistency in a use state after assembly cannot be evaluated.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

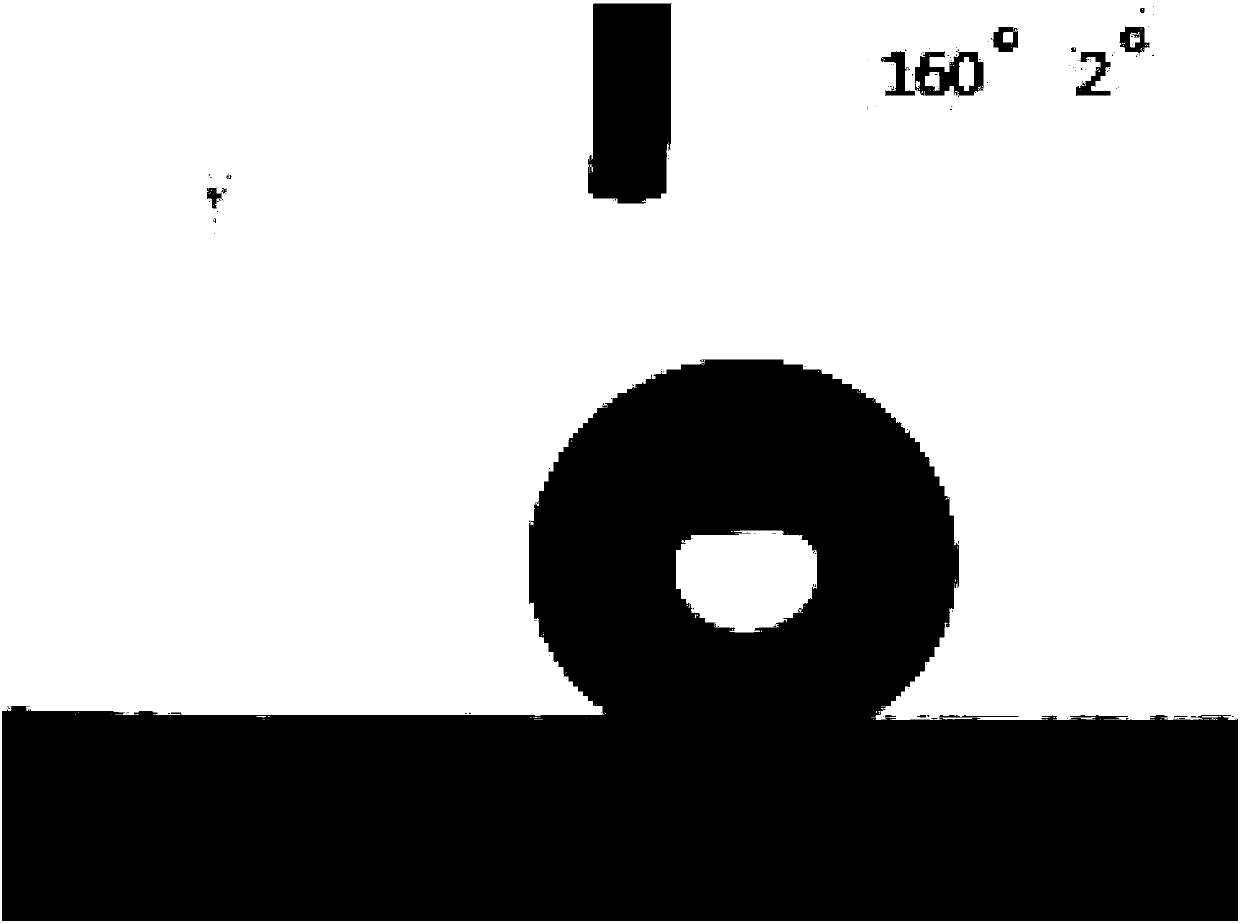

Film with self-cleaning property and preparation method thereof

InactiveCN107626211ASimple processSimple ingredientsSemi-permeable membranesGeneral water supply conservationSurface energySolvent

The invention discloses a film with a self-cleaning property and a preparation method thereof. The method comprises the following steps: selecting a high-molecular polymer as a substrate; using a solvent compatible with high-molecular polymer for dissolving the high-molecular polymer; taking a nanometer filler as a hydrophobic group introducing source; forming a dispersing solution with the solvent by adopting an ultrasonic auxiliary physical blending method; adding cosolvent and additive; and lastly, adopting a low surface energy reagent for modifying and forming a super-hydrophobic surface.According to the invention, the preparation method is simple in process and low in cost; the operation process is controllable; the preparation method is simple and convenient; the maximal contact angle between the film with the self-cleaning property and water reaches up to 160 degrees and the minimal rolling angle is at 2 degrees; the film has a self-cleaning function, is high in water flux, hasexcellent mechanical properties and durability and can be applied to the dehumidification or seawater desalination.

Owner:SOUTH CHINA UNIV OF TECH +1

Thinned high-barrier liquid packaging film and manufacturing method thereof

InactiveCN101274690AImprove rigidityIncreasing the thicknessFlexible coversWrappersHigh densityMedium density

The invention relates to a thin-reducing and high impermeable liquid packaging membrane and a manufacturing method thereof. The product comprises a polyvinyl basilar membrane, a high impermeable polyvinyl alcohol layer, a composite adhesive layer and a protective polythene membrane layer, wherein, the polyvinyl basilar membrane comprises an outer layer, a middle layer and an inner layer and the outer layer and the middle layer comprise at least one of the two materials which are medium-density polythene or high-density polythene. The manufacturing method of the product comprises the steps of the preparation of the polyvinyl basilar membrane, the preparation of polyvinyl alcohol coating liquid and the preparation of the protective polythene membrane layer, coating and compounding, wherein, the polyvinyl alcohol coating liquid is diluted and the diluted polyvinyl alcohol coating liquid is coated on the outer layer of the polyvinyl basilar membrane to form the high impermeable polyvinyl alcohol layer and then the protective polythene member layer and the polyvinyl alcohol coating layer are compounded, cured and cut. The product of the invention has low thickness, good rigidness, high impermeable property, environmental protection, convenient use, low cost and simple technique.

Owner:马龙升

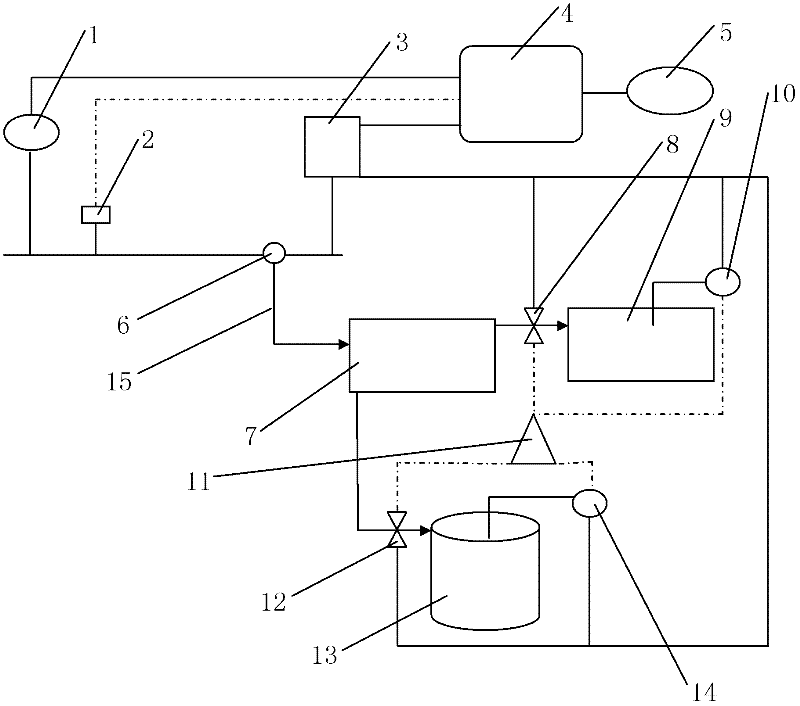

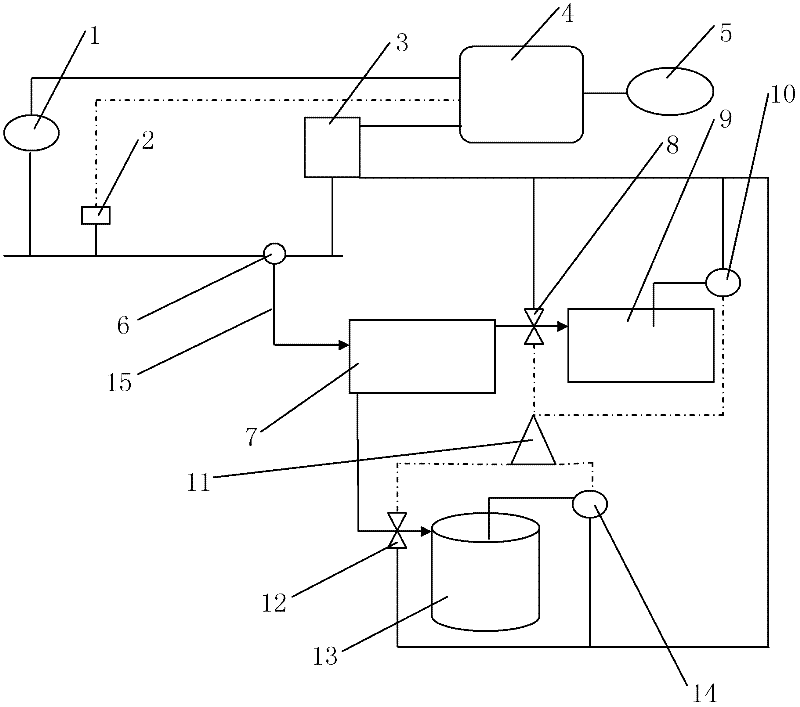

Hazardous chemical leakage monitoring and emergency treatment system for sensitive water body bridge section

ActiveCN102354180AProactivePositiveProgramme total factory controlCollection systemSurveillance camera

The invention relates to a hazardous chemical leakage monitoring and emergency treatment system for a sensitive water body bridge section. The system mainly comprises a hazardous chemical leakage emergency monitoring system, a bridge surface runoff collection system, a hazardous chemical emergency storage system and a bridge surface runoff treatment system. When a traffic accident does not happenon the bridge section, bridge surface runoff initial rainwater enters a collection pipeline system, and directly flows into the bridge surface runoff treatment system for purification treatment afterpassing through a runoff electric butterfly valve switch of an emergency regulating pondage, and 30 minutes later, the bridge surface runoff is directly discharged through an overflow port of the emergency regulating pondage. When the traffic accident happens on the bridge section, firstly, the traffic accident is discovered through a bridgehead monitoring camera and an alarm telephone, and whether hazardous material leakage exists is determined; secondly, an emergency control system is started by a monitoring center, and the emergency electric butterfly valve switch in the runoff regulating pondage is turned on; and finally, the leaked hazardous material and a diluent thereof enter the regulating pondage through a collection pipeline and then directly flow into an emergency storage pool.

Owner:CHINA ACAD OF TRANSPORTATION SCI

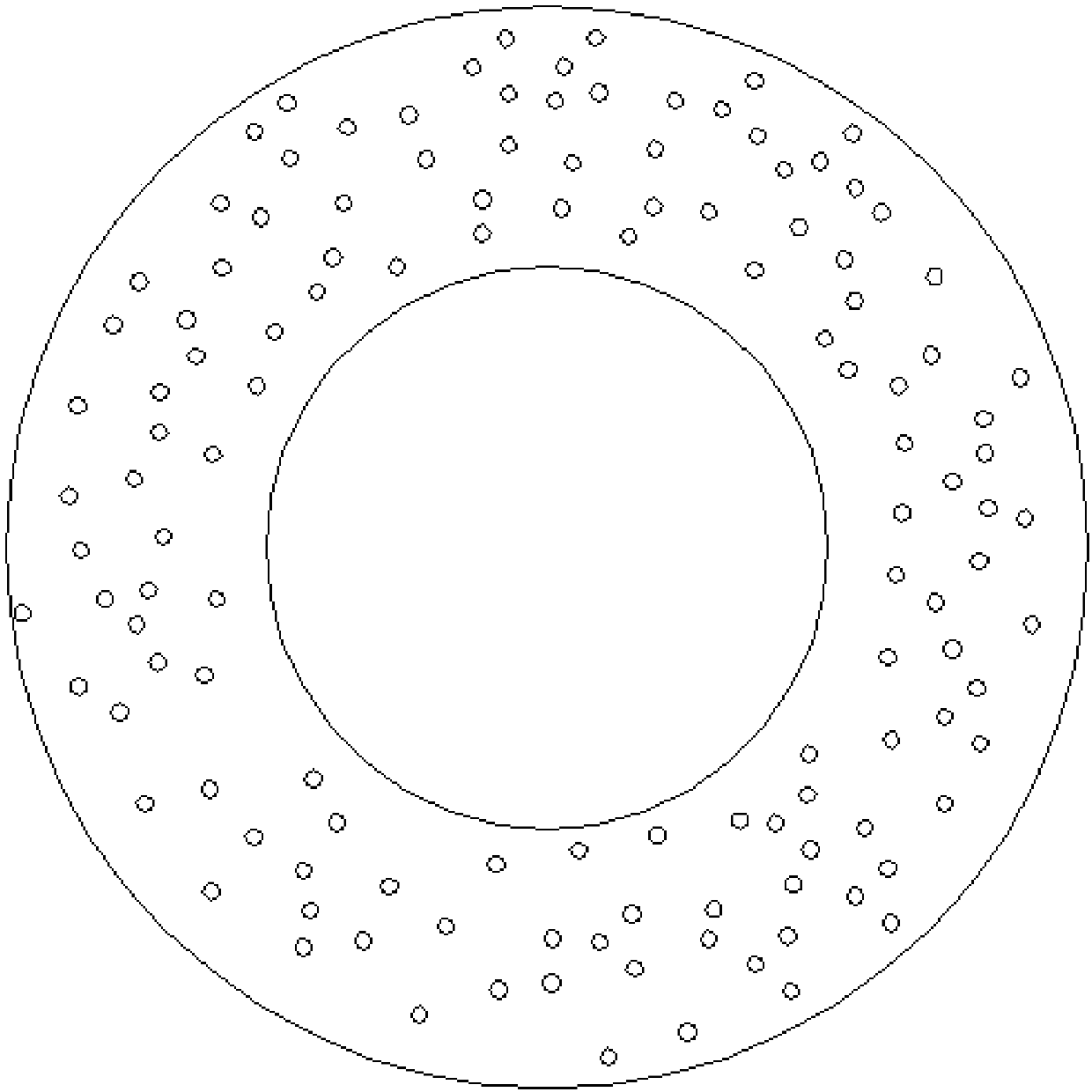

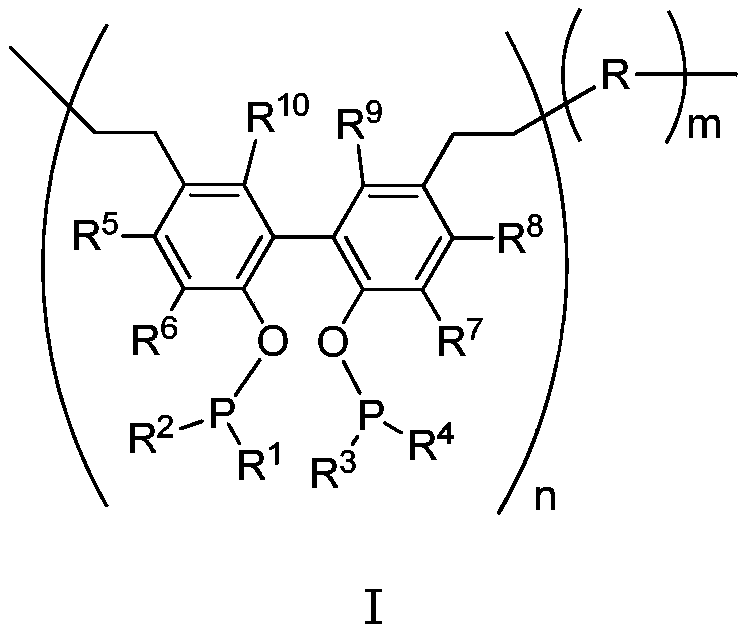

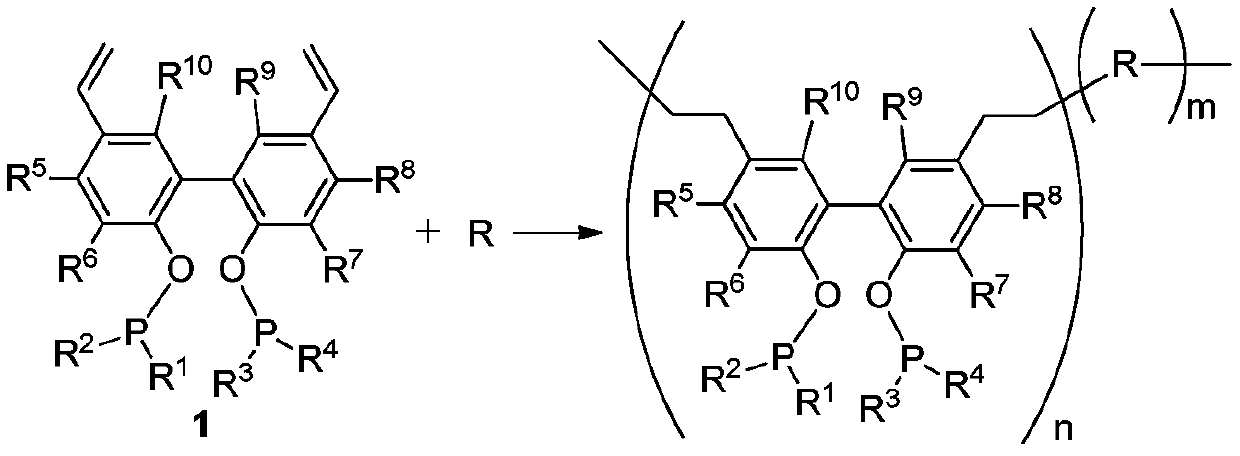

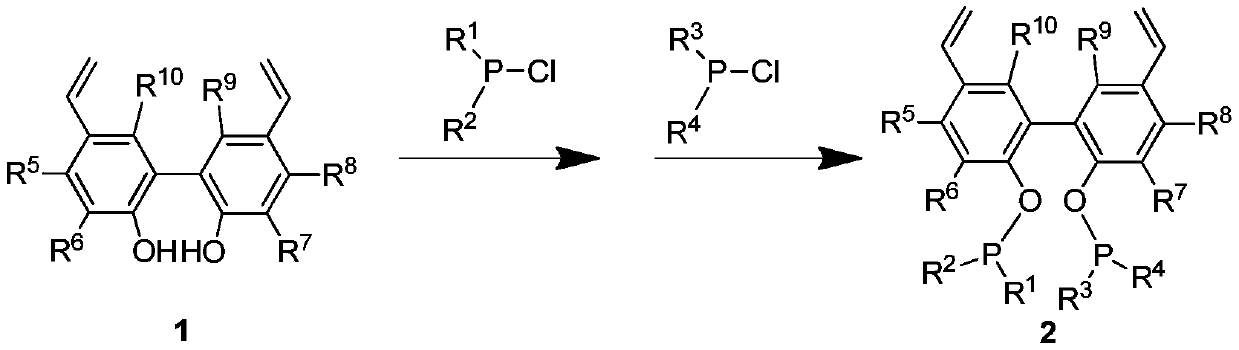

Porous organic polymer containing bidentate phosphoramidite ligands, as well as preparation method and application thereof

ActiveCN109942750AHigh mole percentageIncrease catalytic rateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionIsomerizationOrganic polymer

The invention discloses a porous organic polymer containing bidentate phosphoramidite ligands, as well as a preparation method and application thereof. The polymer has a general formula as shown in the specification, and is prepared from compounds through polymerization. After being formed from the porous organic polymer containing bidentate phosphoramidite ligands and transition metal salt, a catalyst can be used in hydroformylation of terminal olefin and isomerization-hydroformylation reaction of nonterminal olefin, has high catalyzing speed and good selectivity and cyclicity, and has practical values.

Owner:QINGDAO UNIV OF SCI & TECH

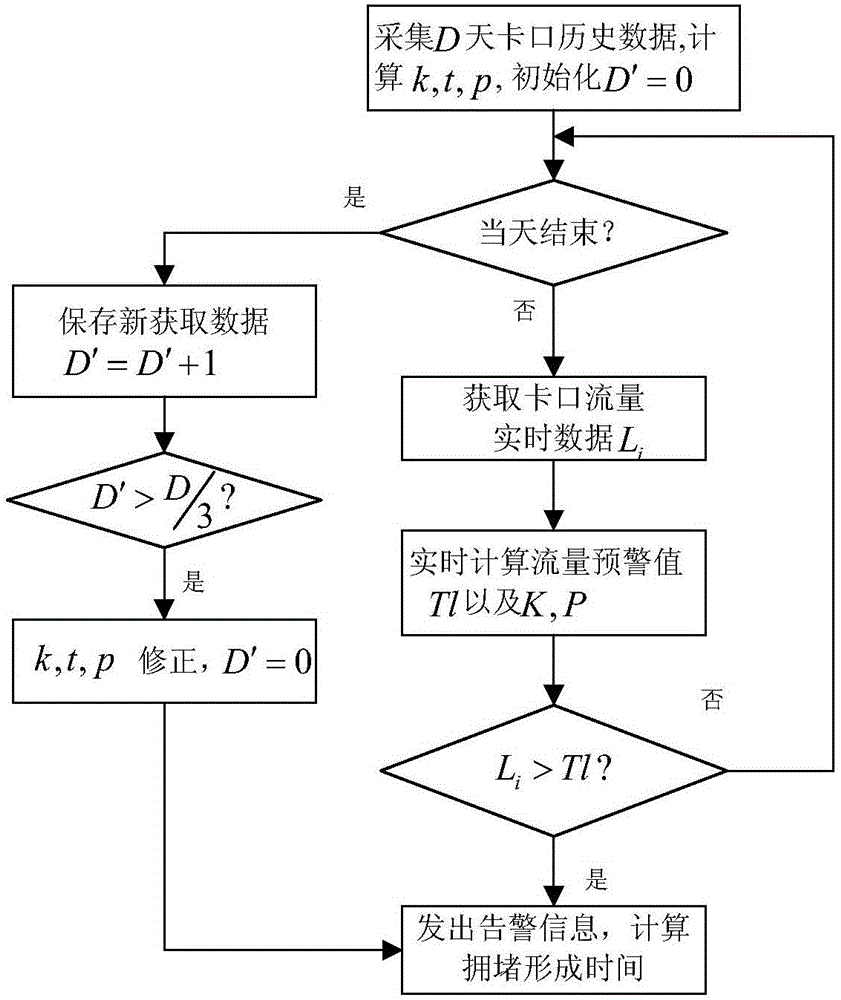

Road congestion early warning and congestion forming time prediction method

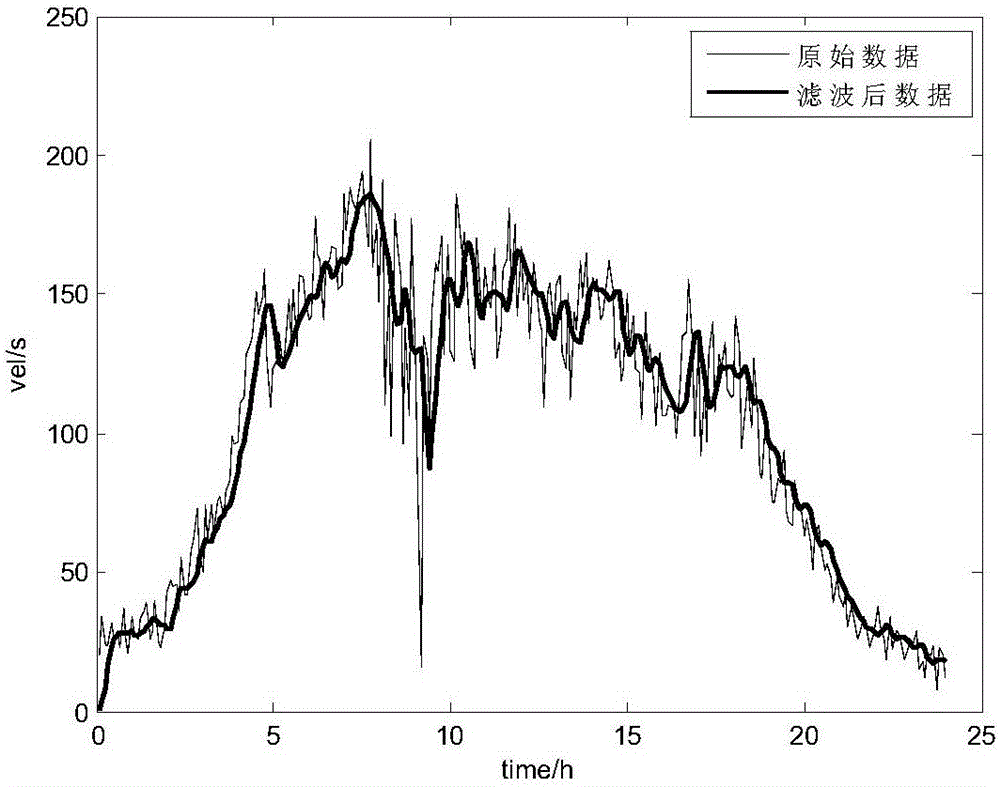

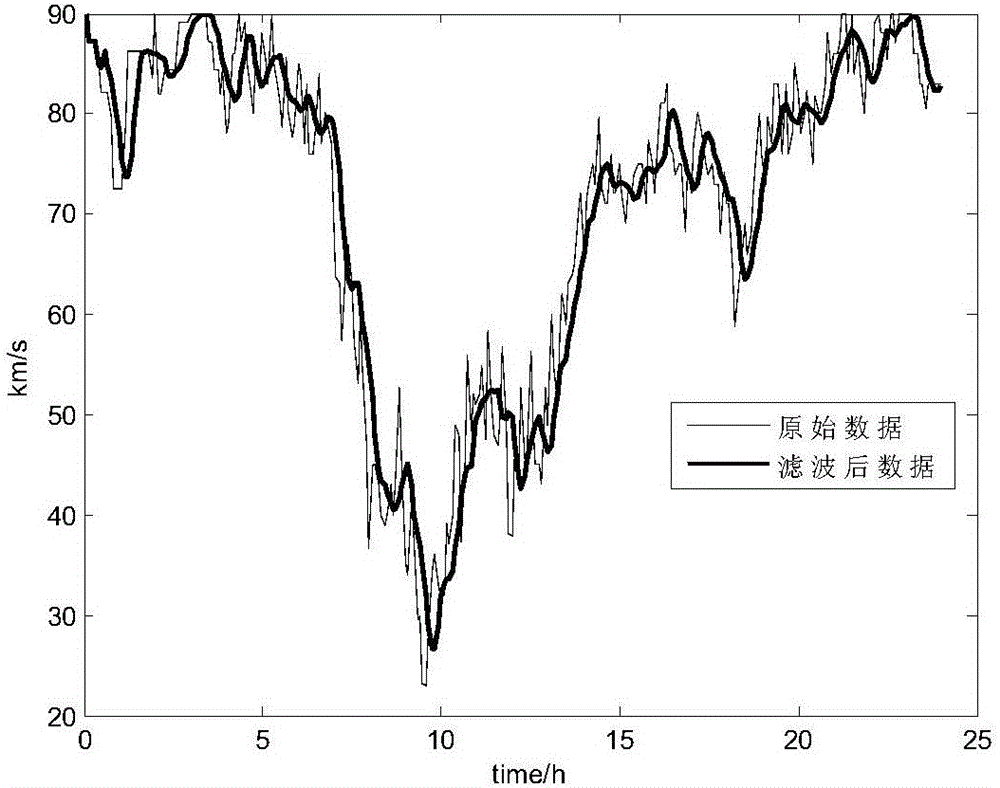

ActiveCN106816008ADynamic calculation of congestion warning valueHigh reference valueDetection of traffic movementReal-time computingTraffic volume

The invention discloses a road congestion early warning and congestion forming time prediction method. The road congestion early warning and congestion forming time prediction method comprises steps that step1, road flow and speed historical data in D days is acquired, and Gaussian filtering processing is carried out; step2, a flow increasing slope reference value k of a road segment about to be congested, a congestion forming time reference value t, and a ratio p of a flow continuously exceeding the reference value are calculated; step3, a flow early warning threshold value is calculated in a real-time manner, and according to a road segment historical flow increasing slope k and i-1 moment real-time flow increasing slope Ki-1, a real-time flow early warning threshold value Tli is calculated, and when a current flow exceeds the Tli, flow alarms are given, and real-time congestion forming time is calculated; step 4, according to the road segment historical flow increasing slope k and the current real-time flow increasing slope Ki, the ratio p of the road segment historical flow continuously exceeding the reference value, and the ratio Pi of the real-time flow continuously exceeding the Tli, and a road segment historical congestion forming time reference value, real-time congestion forming time T is calculated. The traffic congestion forming time is predicted effectively, and the road congestion early warning is realized effectively.

Owner:ENJOYOR COMPANY LIMITED

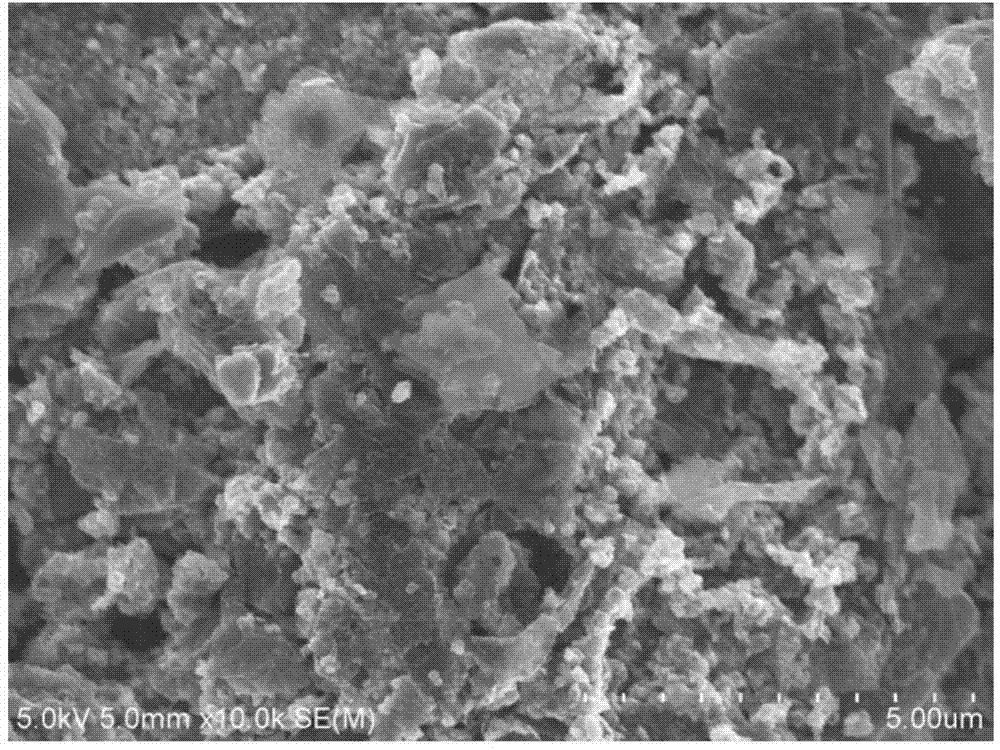

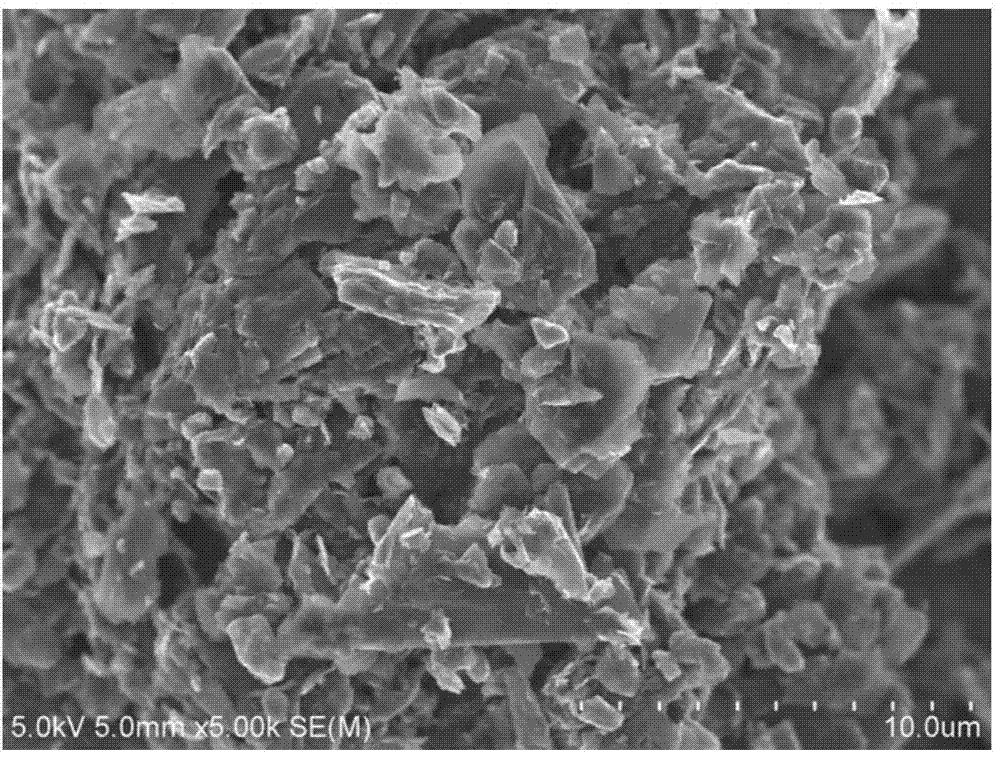

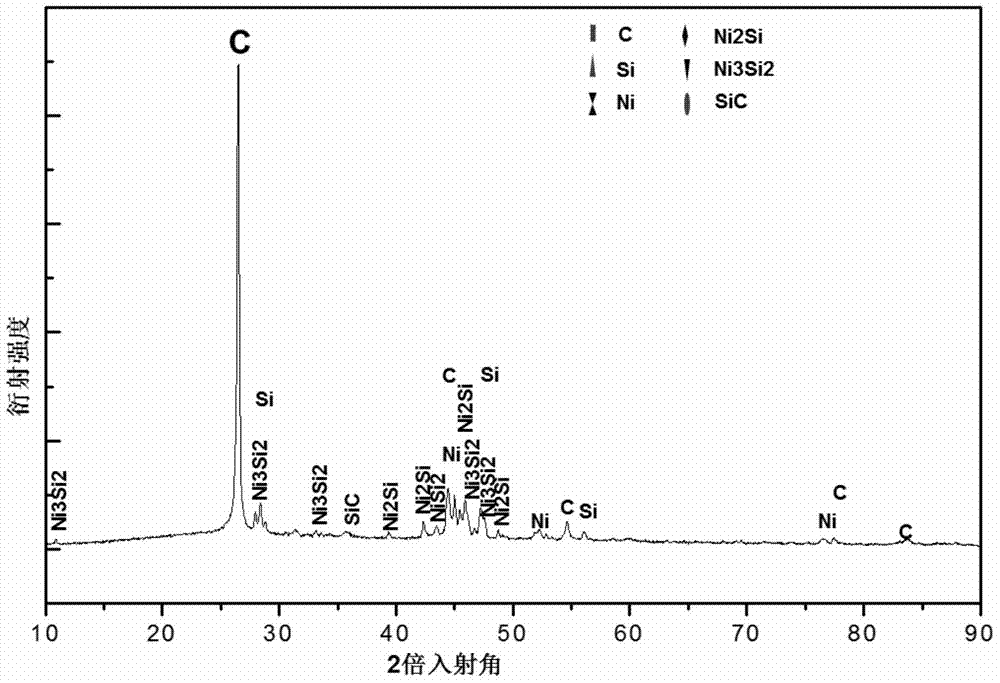

Lithium ion battery silicon metal composite negative electrode material and preparation method thereof

InactiveCN104852019AImprove conductivityImproved magnification performanceCell electrodesGraphiteLithium-ion battery

The invention discloses a lithium ion battery silicon metal composite negative electrode material and preparation method thereof. The composite negative electrode material is prepared by mutually filling silicon-containing material SiOx and metal oxide-containing material, then coating with amorphous carbon and dispersing in graphite material, wherein x is greater than or equal to 0 and less than or equal to 2, and y is greater than or equal to 0 and less than 4. The stoichiometric equation of the composite negative electrode material is SiMzOw-aC. The preparation method is as follows: (1) weighting a certain amount of a silicon-based SiOx material, a metal oxide-containing material MOy, organic carbon and a graphite precursor raw material for screw extrusion for 0.5-24 h to fully mix the precursor material; and (2) calcining the mixed precursor raw material in a protective atmosphere at 600-1400 DEG C for 0.5-12 h, and performing post-processing to obtain the silicon metal composite negative electrode material. The silicon metal composite negative electrode material has good electrochemical stability. The preparation method is simple, the used equipment is general industrialization equipment, and mass production is easy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

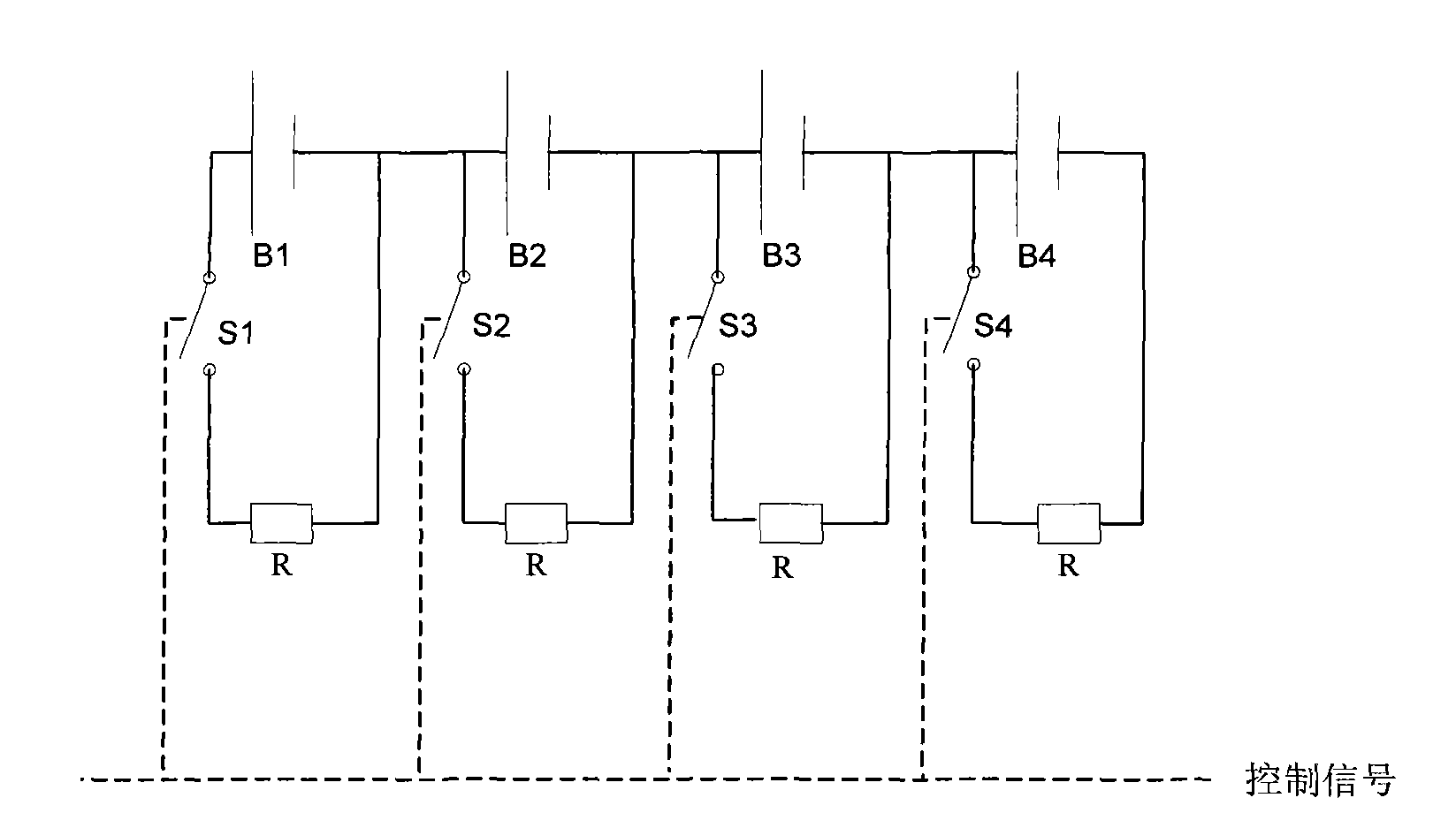

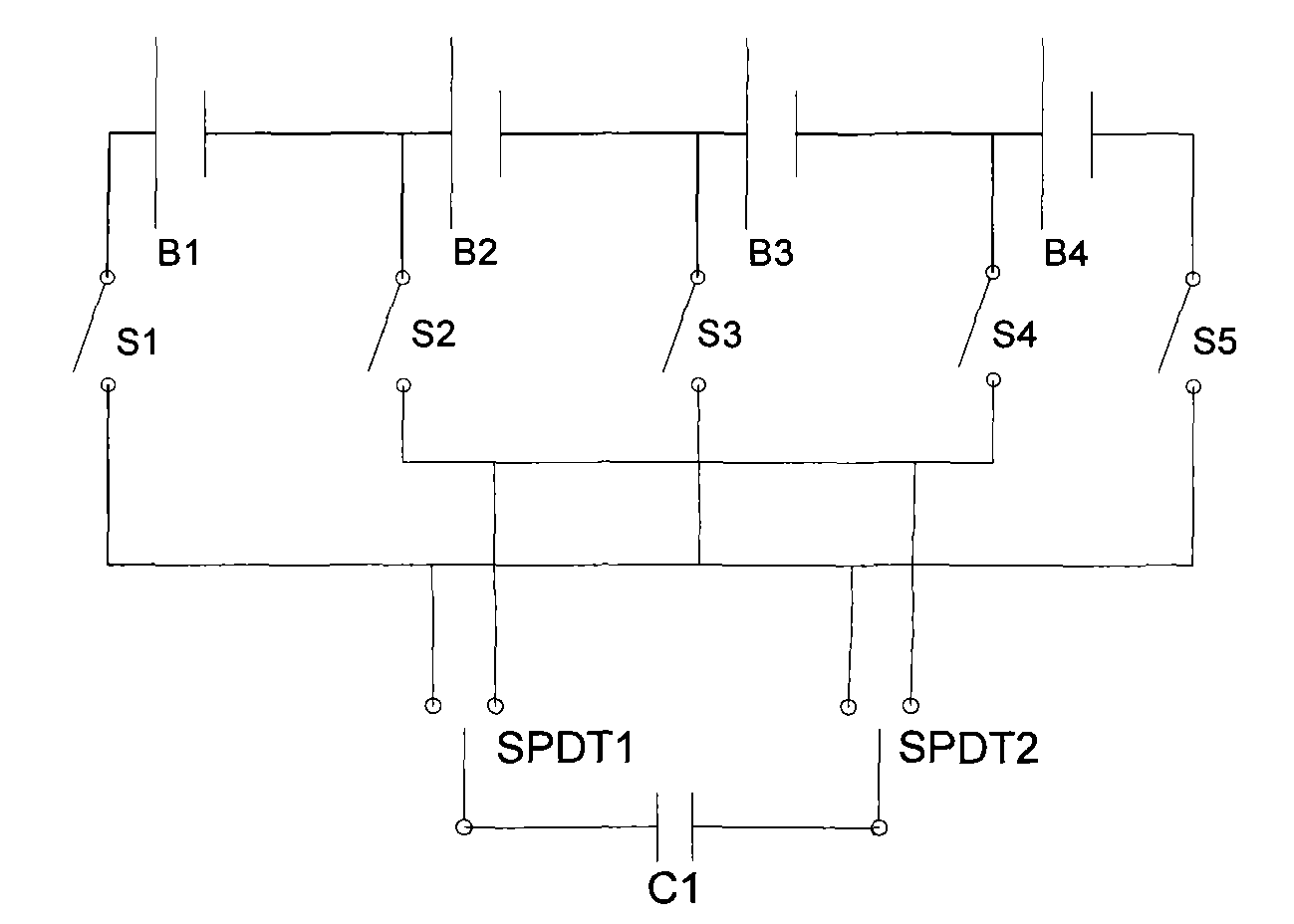

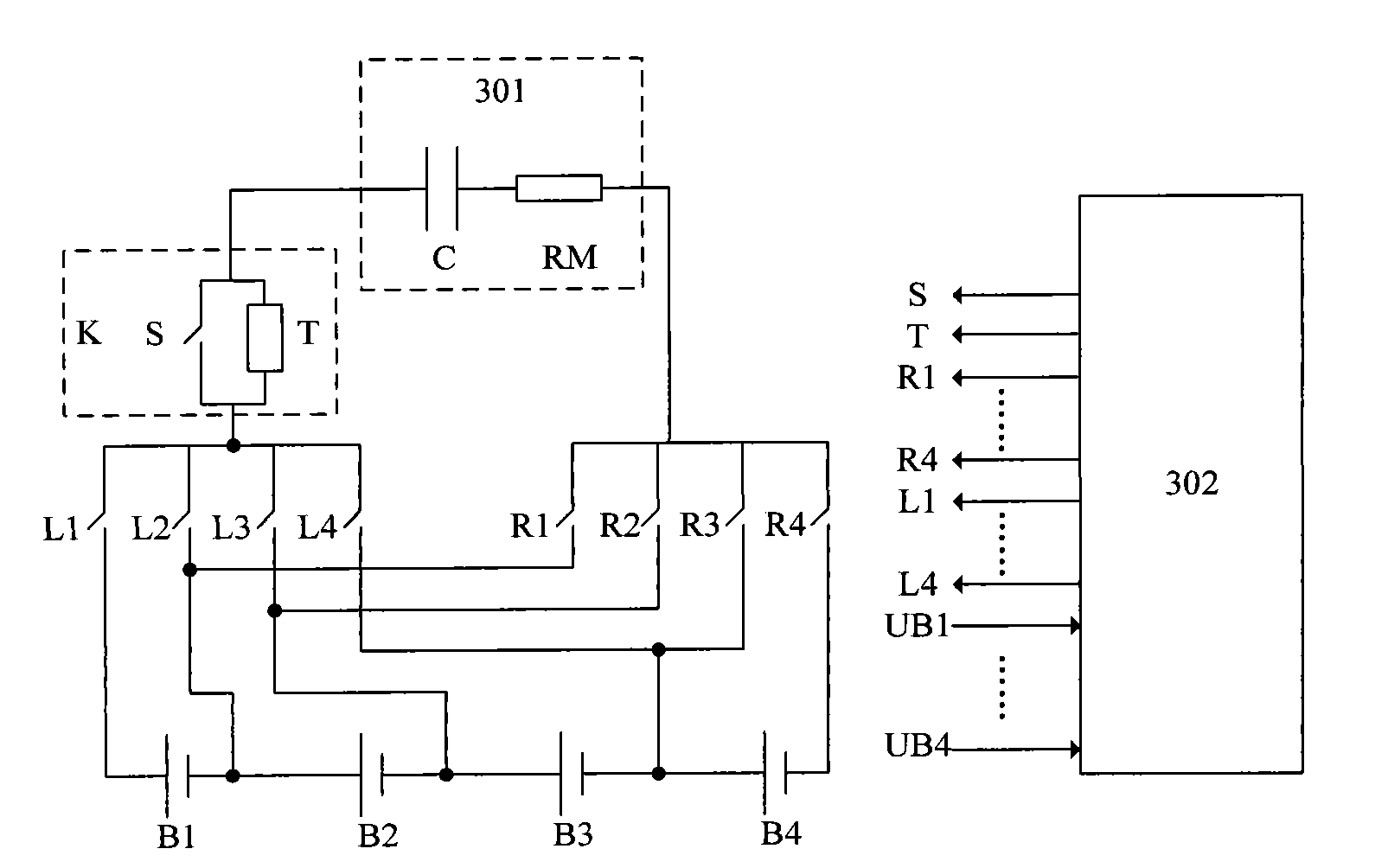

Accumulator battery voltage balancer

InactiveCN102025177AAvoid arcingAvoid the Effects of Equalizing ChargeBatteries circuit arrangementsElectric powerEnergy transferControl system

The invention discloses an accumulator battery voltage balancer which comprises an accumulator battery, an energy transfer carrier (301), a balance control system (302) and switches of two stages, wherein the energy transfer carrier (301) is a medium which can be charged and discharged; and switches of two stages comprise a primary switch and a secondary switch. Aiming at solving the problem of switch selection in the energy transfer type balance method, a balanced charge circuit comprising switches of two stages and one energy transfer carrier as well as a perfect control strategy are designed, thereby preventing the switches from arcing in the switching process and preventing the balance effect from being influenced by pressure drop of switching tubes.

Owner:CHINA AGRI UNIV

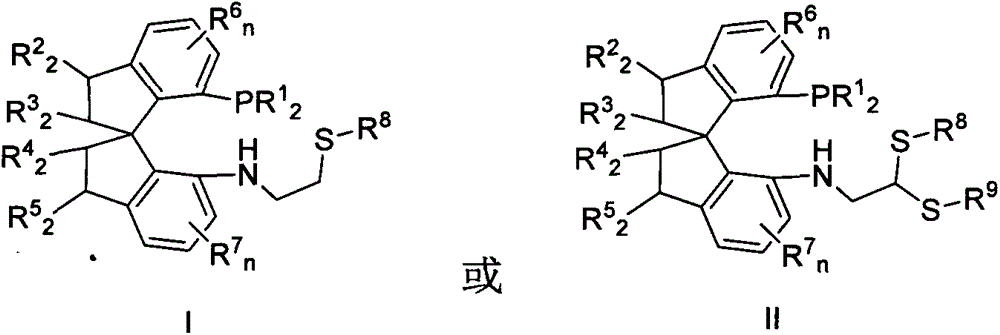

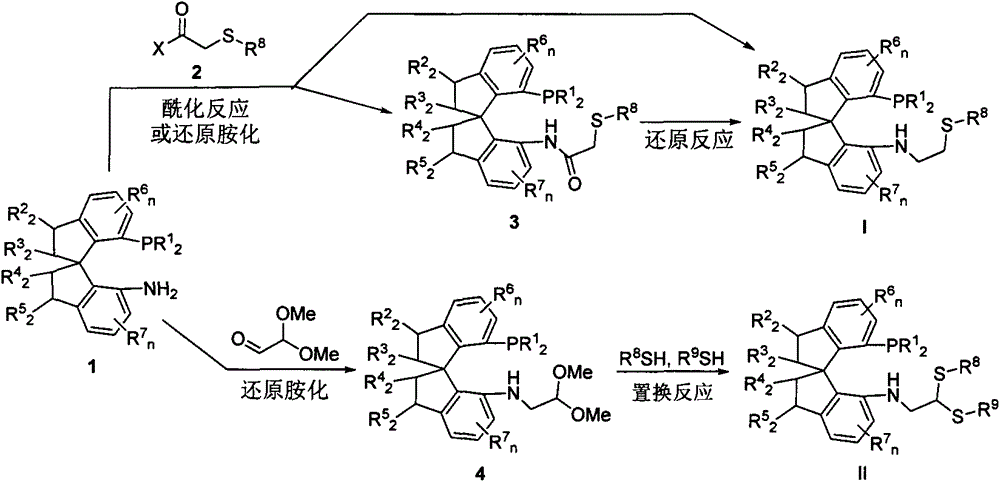

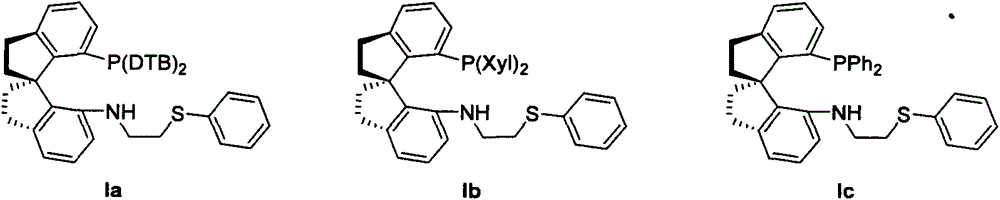

Chiral spiro phosphine-nitrogen-sulfur tridentate ligand and preparation method and application thereof

ActiveCN104892672AHigh catalytic activityHigh enantioselectivityCarbamic acid derivatives preparationIndium organic compoundsIridiumSulfur

The invention relates to a chiral spiro phosphine-nitrogen-sulfur tridentate ligand and a preparation method and application thereof. The chiral spiro phosphine-nitrogen-sulfur tridentate ligand is a compound with a formula I or formula II, or a racemate or optical isomer thereof, or a catalytically-acceptable salt thereof, and has the main structure characteristic of having a chiral spiro indan skeleton and a sulfoether group. The chiral spiro phosphine-nitrogen-sulfur tridentate ligand can be synthesized from chiral starting materials of 7-diaryl / alkyl phosphino-7'-amino-1,1'-spiro indan compound with a spiro skeleton. The chiral spiro phosphine-nitrogen-sulfur tridentate ligand and transition metal salt form a complex, which can be used in catalysis of an asymmetric catalytic hydrogenation reaction of a carbonyl compound. Especially, the iridium complex shows high catalytic activity (catalyst amount of 0.0002% mol) and enantioselectivity (up to 99.9%ee) in asymmetric hydrogenation reaction of beta-alkyl-beta-keto ester, and has practical value.

Owner:ZHEJIANG RAYBOW PHARM CO LTD

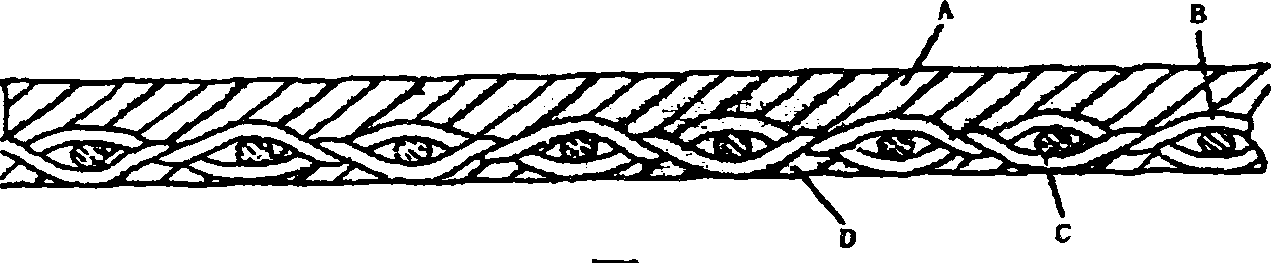

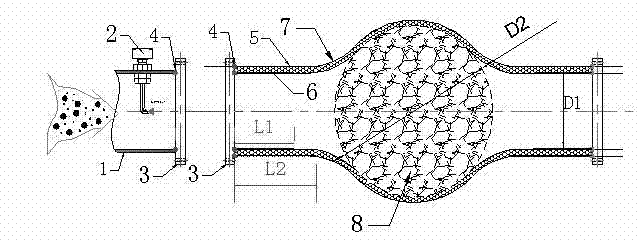

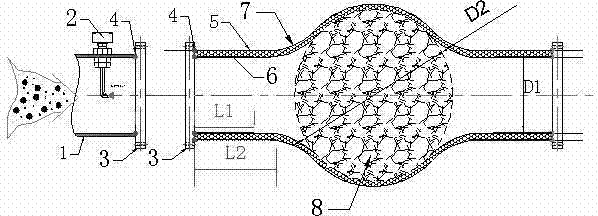

Mixed unit of foam metal ball pipe assembly

InactiveCN102345488ALow costImprovement effectExhaust apparatusDispersed particle separationComposite materialEngineering

The invention relates to a mixed unit of a foam metal ball pipe assembly. The mixed unit consists of an exhaust pipe, a nozzle, a connecting flange, a welding spot, a fastening outer sleeve, a fastening inner sleeve, a metal fiber braided pipe and a foam metal ball. The mixed unit is characterized in that: the fastening outer sleeve and the fastening inner sleeve are used for fixing the metal fiber braided pipe and welded into a whole by using the connecting flange; the inside diameter of the fastening inner sleeve is D1, the diameter of the foam metal ball is D2, and the ratio D2 / D1 of the diameter D2 of the ball to the sleeve diameter D1 is 1.5 to 2.5; the ratio L2 / L1 of the length L2 of the fastening outer sleeve to the length L1 of the fastening inner sleeve is 3 to 5 millimeters; L2 is 300 millimeters; and the mixed unit is arranged at the downstream of the nozzle for a urea reducer. The foam metal ball is wrapped by adopting the metal fiber pipe to form the mixed unit of the concentric cylindrical foam metal ball pipe assembly for the urea reducer, a catalyst is coated on the foam metal ball, and the mixed unit is applied to mixed decomposition of the urea reducer; and the mixed unit has simple structure, is efficient and durable, and is applied in an over national 4 post treatment device.

Owner:CHINA FIRST AUTOMOBILE

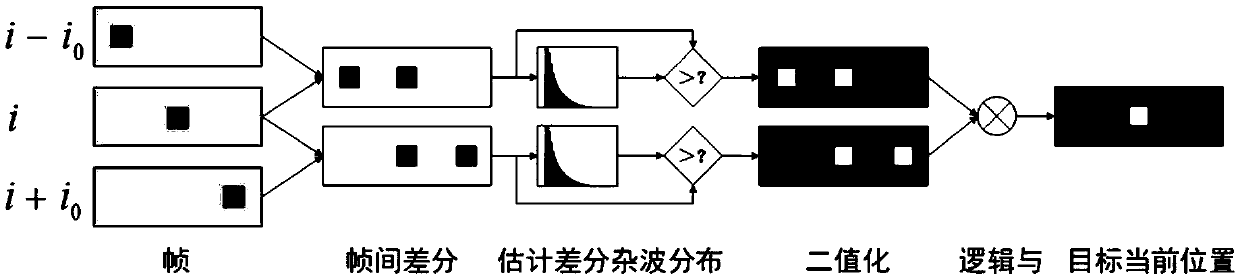

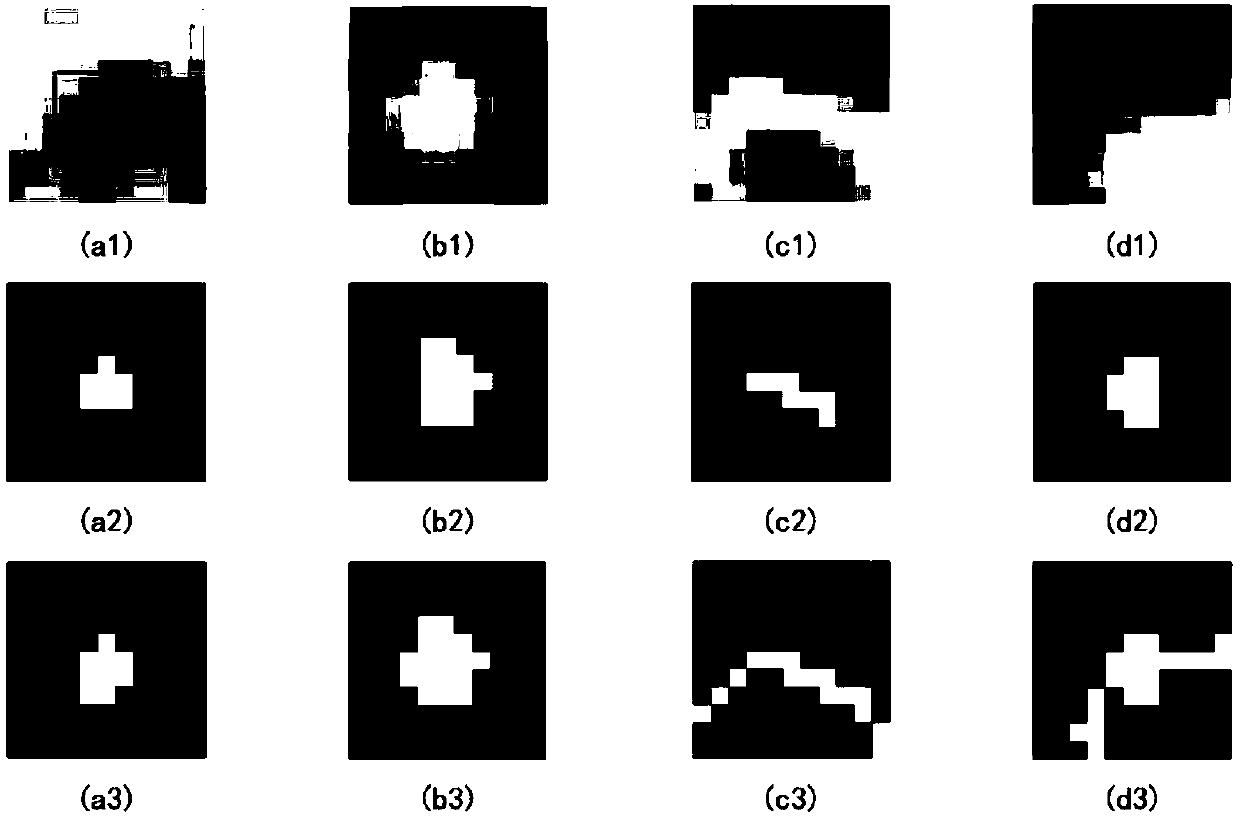

Detection and tracking method of moving object in satellite video

ActiveCN108734103AHigh precisionHas practical valueImage enhancementImage analysisKaiman filterVideo processing

The invention belongs to the technical field of the image and video processing, specifically a detection and tracking method of a moving object in a satellite video. The method comprises the followingsteps: detecting a moving target-vehicle in the city in the satellite video by adopting the detection technology based on movement and local clutter modelling; identifying the detected moving objectby adopting the identification technology based on region growing and multi-thread; and further tracking the ground moving object by adopting the target tracking technology based on a Kalman filter and associating multiple detected vehicle targets with multiple trajectories being tracked. The method disclosed by the invention is strong in practicability, and can be used for traffic monitoring, city monitoring, military monitoring and like fields, and is extensive in application prospect.

Owner:FUDAN UNIV

Method for preparing high-performance wave-absorbing composite powder

The invention belongs to the technical field of microwave absorbing material, and more particularly relates to a preparation method of high-performance wave-absorbing composite powder, comprising thesteps of: respectively adding distilled water into soluble metal nitrate, ferric nitrate and citric acid for dissolving, and then mixing the water solutions to prepare a precursor; dripping ammonia water solution to adjust the pH value of the mixed solution to be neutral; putting the solution into water bath with the temperature of 70-90 DEG C to be stirred, adding inorganic porous medium and modifying agent in the stirring process, stirring until the liquid is sticky colloid; drying the prepared colloidal sol for 7.5-8.5h at the temperature of 115-125 DEG C, and obtaining dried gel; putting the gel into a muffle furnace for calcining, heating up to 850 DEG C, preserving the temperature for 1-2h, naturally and slowly cooling, and obtaining ferrite composite powder; and finally, mixing thecomposite power and carbonyl iron powder, and then obtaining the needed product. The stoichiometric proportion among the nitrate, the ferric nitrate and the citric acid is 1: 12: 19 or 1: 2: 4, the ratio between the theoretical value of the ferrite and the mass of the modifying agent is 1: 0.1-1:0.05, the ratio between the theoretical value of the ferrite and the mass of the porous medium is 1: 0.2-1: 5, and the mass ratio between ferrite-porous medium composite power and the carbonyl iron powder is 1: 0.2-1: 5. Compared with the traditional product, the wave-absorbing powder improves the wave-absorbing performance, and has good covering effect and a certain function of heat insulation. Therefore, the method can be used for preparing building wave-absorbing paint.

Owner:TONGJI UNIV

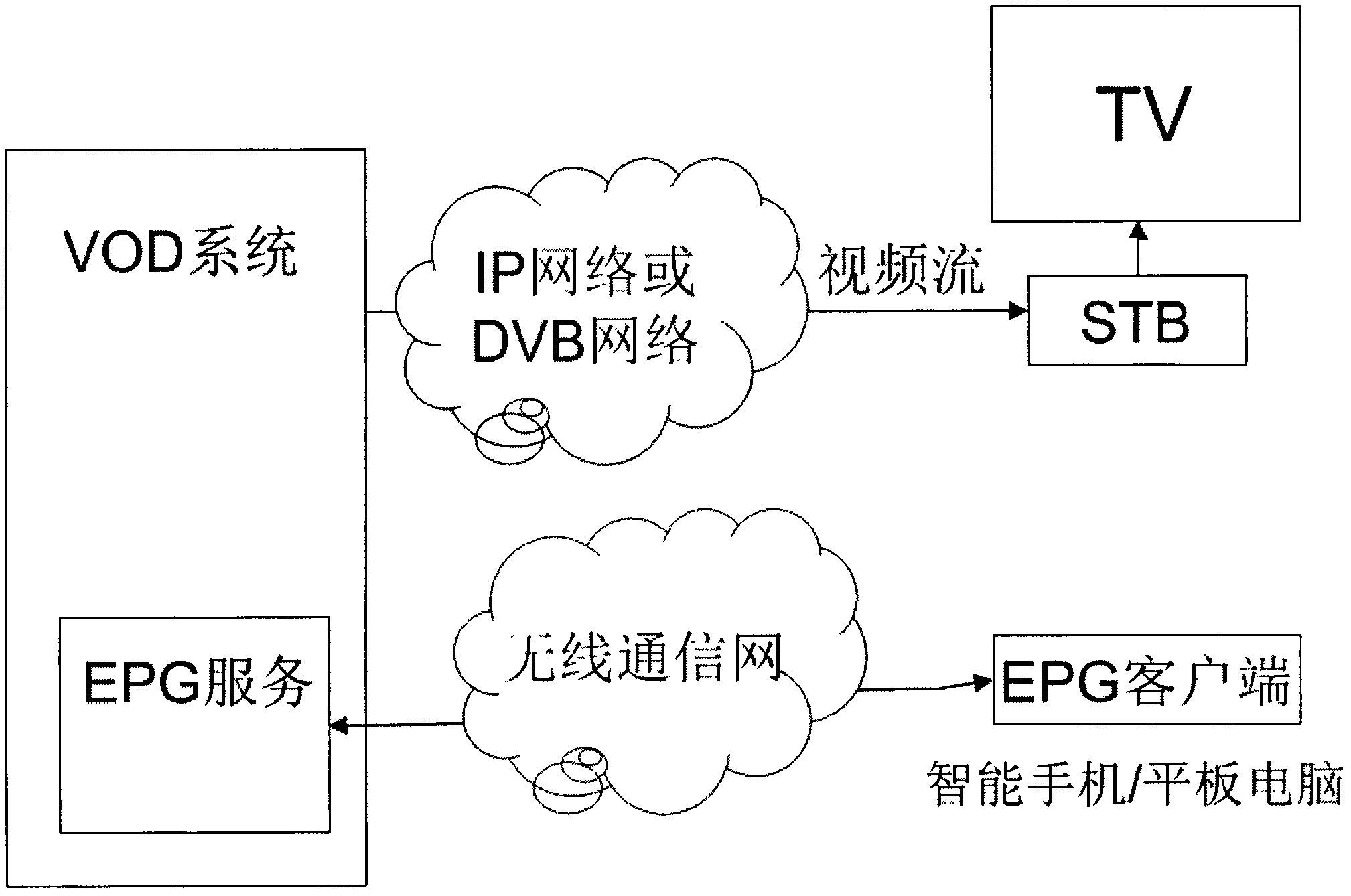

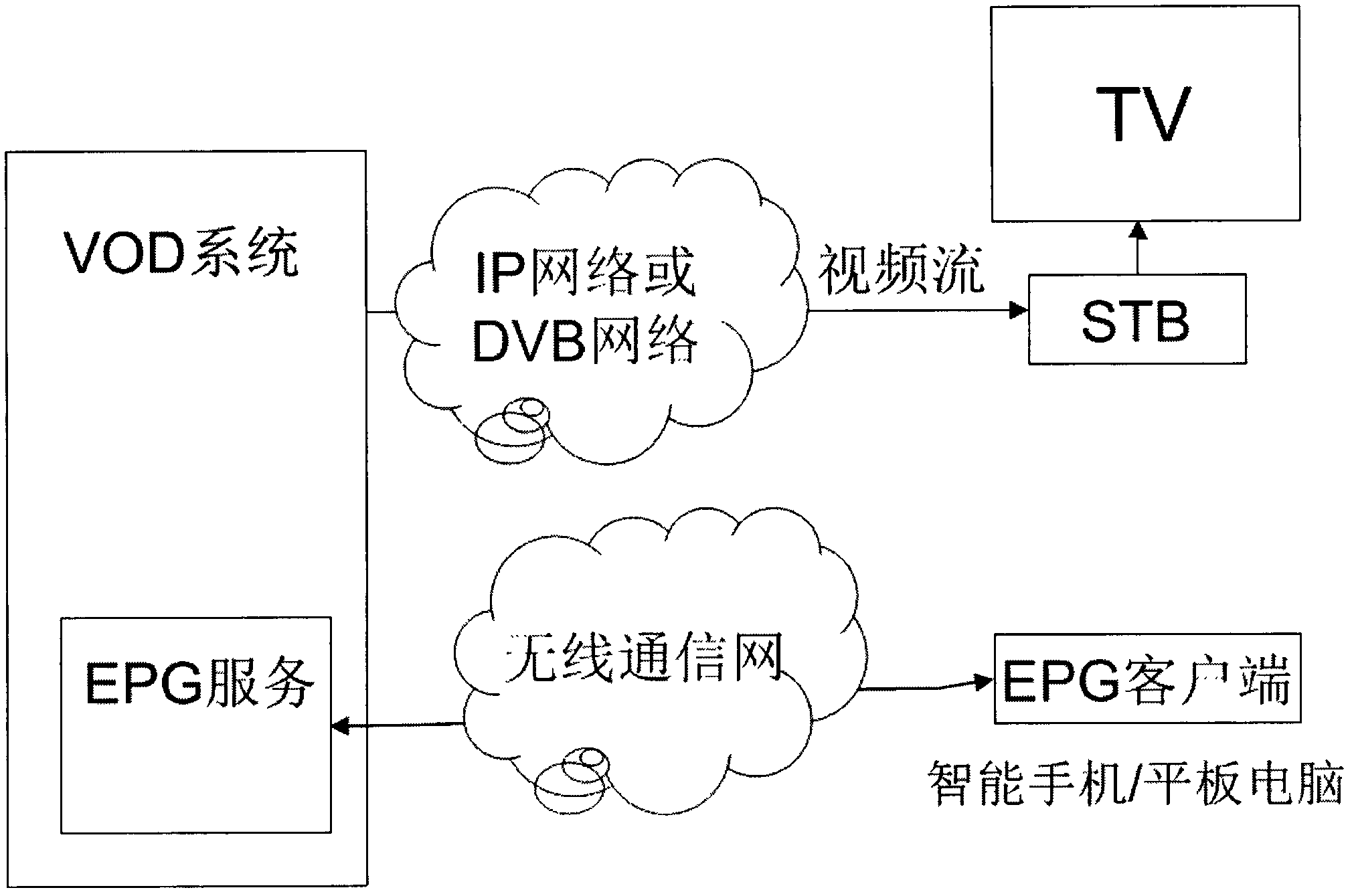

Video-on-demand method

InactiveCN102630047AGood experiencePowerful human-computer interfaceSelective content distributionData connectionTerrestrial television

The invention provides a video-on-demand method. The video-on-demand method sequentially comprises the following steps: a wireless handheld terminal such as a smart phone or a panel personal computer and the like is used by a television user for establishing bidirectional communication data connection through wireless communication network and a video-on-demand (VOD) system, and on-demand request information is transmitted to the VOD system through the data connection; the VOD system transmits requested television programs and VOD authorized instructions to a terminal set top box or a terminal television all-in-one machine by using IP (Internet Protocol) network or DVB (Digital Video Broadcasting) network; and the terminal set top box or the terminal television all-in-one machine plays television programs on a television according to the VOD authorized instructions. The video-on-demand method has the advantages of providing a more powerful human-computer interaction function for video-on-demand business and solving the unidirectional problem of digital video broadcasting network, thereby the video-on-demand business can be supplied without needing bidirectional network transformation and replacing the set top box.

Owner:SUZHOU DAOWEI INFORMATION TECH

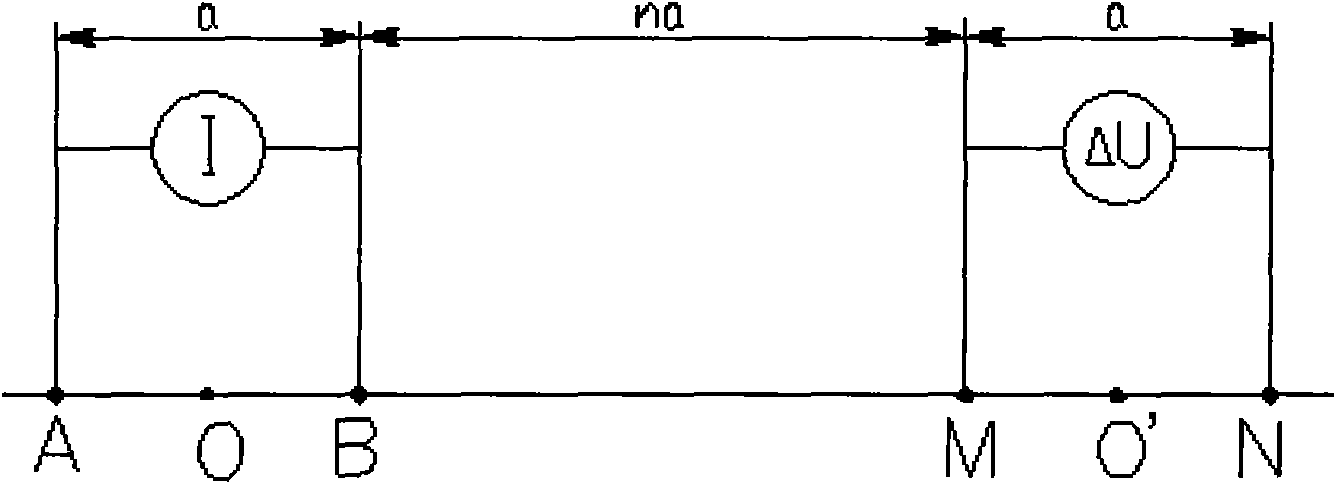

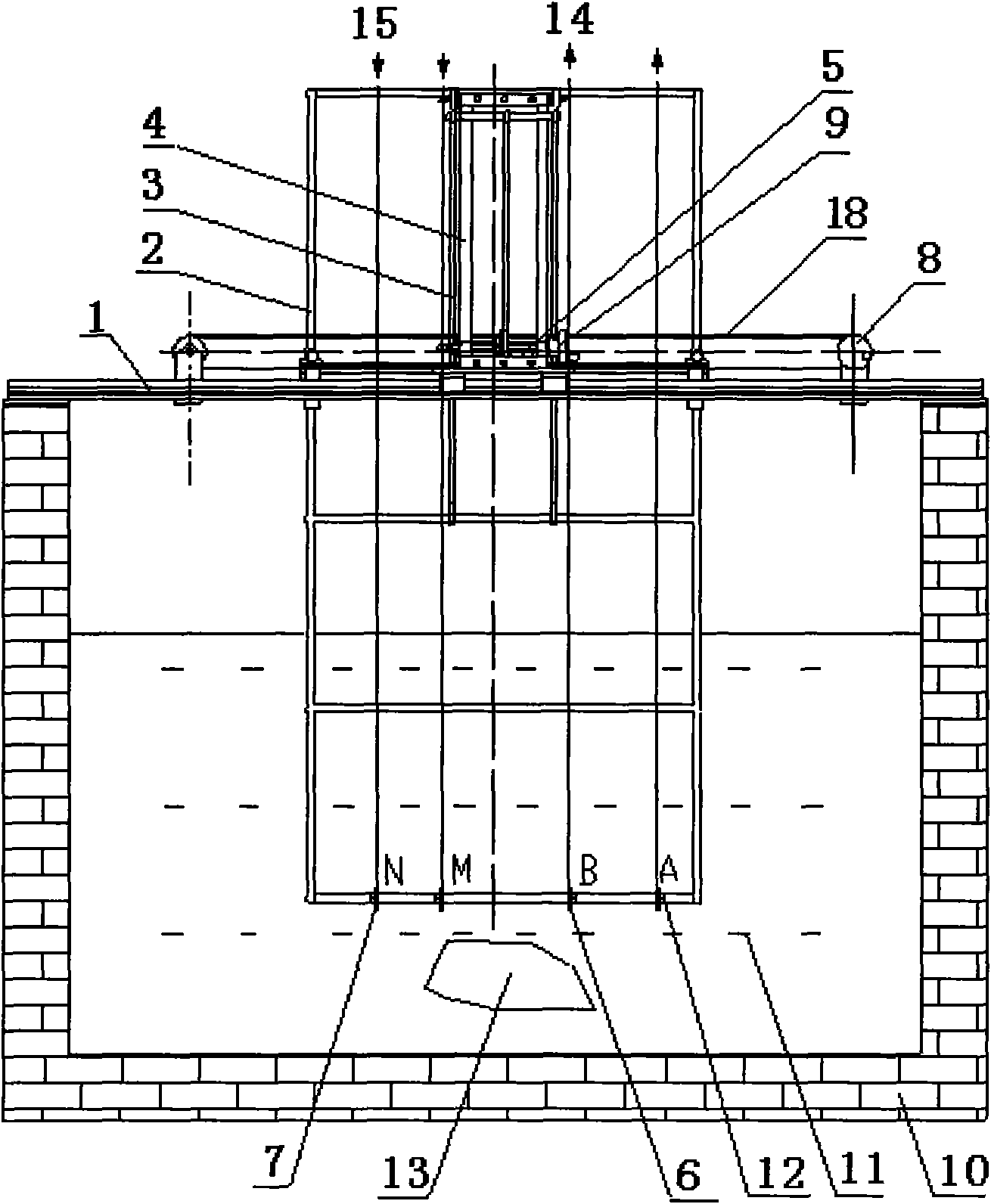

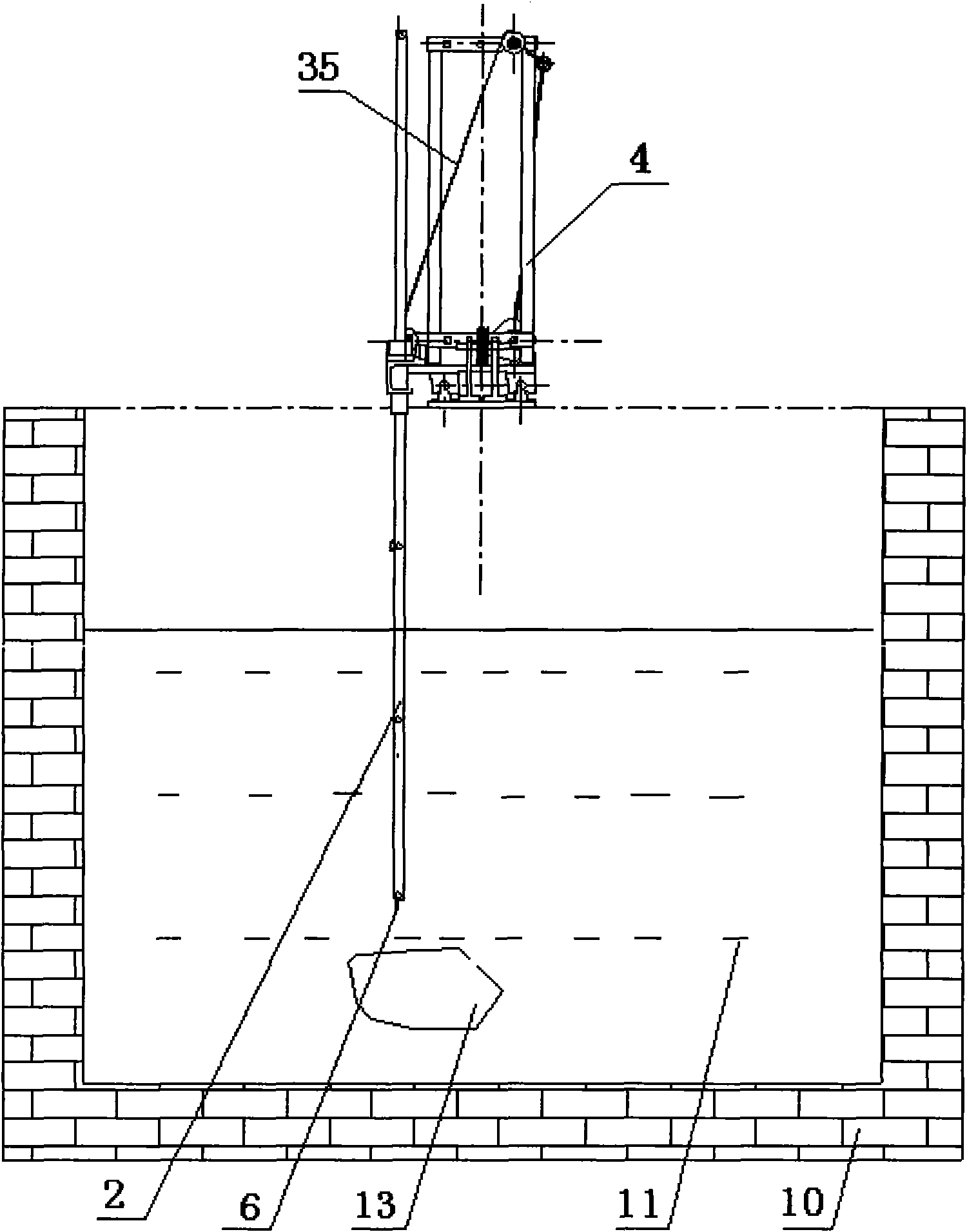

Double-frequency induced polarization method water tank physical simulation experiment device

InactiveCN101881837AGuidance is sensitive and more reliableHigh precisionElectric/magnetic detectionAcoustic wave reradiationElectricityEngineering

The invention relates to a double-frequency induced polarization method water tank physical simulation experiment device which comprises a guide rail platform, a pulley block, a vertical bracket, a leveling instrument, an emission electrode, a receiving electrode, a movable hand wheel, a lifting hand wheel and a water tank, wherein the guide rail platform is a guide rail pair formed by two long guide rails, a bottom plate and a sliding block; the guide rail platform is provided with the leveling instrument, the movable hand wheel, a synchronous belt wheel and a synchronous belt; the two ends of the guide rails are fixed on the water tank; the vertical bracket is provided with a guide sleeve; two vertical rods of an experiment frame pass through a central hole of the guide sleeve; the vertical bracket is provided with the pulley block, flat belts, the lifting hand wheel, a balance weight shaft and a roll spring steel belt; one end of the two flat belts is fixed on a cross rod in the middle of the experiment frame; an electrode is installed in a hole at the lower transverse side of the experiment frame; the movable hand wheel is rotated to drive the experiment frame to horizontally move; and the lifting hand wheel is rotated to drive the experiment frame to be vertically lifted. The double-frequency induced polarization method water tank physical simulation experiment device can simulate marine environment in the water tank, and can measure the activation rate, the electrical resistivity profile and electric depth of ore by adopting a double-frequency induced polarization method.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com