Mixed unit of foam metal ball pipe assembly

A technology of foam metal and mixing unit, which is applied in the directions of engine components, mechanical equipment, dispersion particle separation, etc., can solve the problems of different shapes and structures, no application of foam metal, etc., and achieves the effect of low cost and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

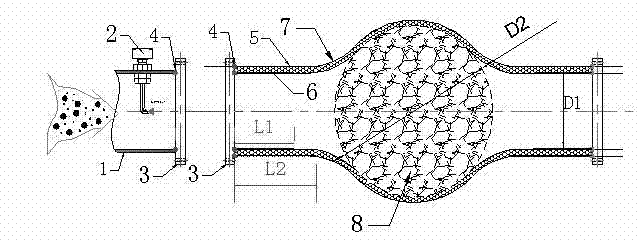

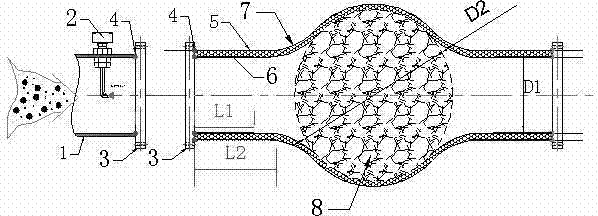

[0031]Select a commercially available metal foam sphere with a mesh number of 5ppi and nickel foam as a material, and process it into a sphere with a diameter of 180 mm; use a stainless steel metal fiber braided tube with a length of 600 mm and a thickness of 2 to 3 mm, with an inner diameter of 185 mm, and nickel foam Put it in the middle of the metal fiber braided pipe, use a fastening inner sleeve with a length of 100mm and an outer diameter of 90mm, use a fastened outer sleeve with a length of 105mm and an inner diameter of 120mm, close the mouth, combine the inlet and outlet of the mixing unit, and use a flange with an inner diameter of 90mm , complete welding at the inlet and outlet respectively, and prepare the main body of the mixing unit; it is arranged downstream of the nozzle of the urea reducing agent.

[0032] First, put the whole unit into a high-temperature furnace, raise the temperature of the furnace to 450-550°C and keep it warm for 40-60 minutes to complete t...

Embodiment 2

[0034] The mixer prepared in Example 1 is weighed W1, purged with clean air of 0.2Mpa for 5 minutes, weighed W2, and the weight loss of W1-W2 is less than 1.5%; then, put the mixer of the present invention back into the high-temperature furnace, Keep warm at 600°C for 40min, immediately put it into 1000mL of commercially available 32.5%wt urea reducing agent at room temperature, take it out after 5min, wash with tap water once, dry in a drying oven at 90°C for 40min, weigh W3, W2-W3 weight loss Less than 2.5%.

[0035] Installed in the exhaust pipe on the 9L diesel engine bench, the mixer is installed behind the urea reducing agent nozzle, about 5mm away from the outlet point of the nozzle, connected by flange, and the distance between the end of the mixer and the nozzle is about 302mm; start the engine, Tested under different working conditions, comparing the NOX removal rate before and after the installation of the mixer, the NOX removal rate is improved by 3~5%, and the bac...

Embodiment 3

[0037] Select a commercially available metal foam sphere with a mesh number of 5ppi, made of aluminum foam, and process it into a sphere with a diameter of 180mm; use a stainless steel metal fiber braided tube with a length of 600mm and a thickness of 3mm, and the inner diameter of the tube is 185mm, and put the nickel foam into the In the middle of the metal fiber braided pipe, use a fastening inner sleeve with a length of 100mm and an outer diameter of 90mm, and a fastened outer sleeve with a length of 105mm and an inner diameter of 120mm. Welding is completed at the inlet and outlet to prepare the main body of the mixing unit; it is arranged downstream of the nozzle of the urea reducing agent.

[0038] Put the whole spherical unit of Example 2 into a high-temperature furnace, raise the temperature with the furnace to 450-550°C and keep it warm for 40-60 minutes to complete the degreasing operation;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com