Patents

Literature

223results about How to "Improve the homogenization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for regulating lighteness of filmed display screen based on image inductor

InactiveCN101350933AGood homogenization effectImprove display qualityCathode-ray tube indicatorsTelevision systemsInductorImage sensor

The invention provides a brightness adjusting method which is based on photographing the display screen by an image sensor; the method comprising the following steps that (1) the screen of a display equipment displays all-black image under normal lighting situation and an image sensor is used for photographing the all-black image for adjusting bright spot deflection; (2) the brightness value of pixels in the all-black image which is more than 0% is adjusted lower and the position coordinates of all the bright spots and the plus adjusting value of every pixel bright spot are recorded; (3) according to the position coordinates of the bright spots and the plus adjusting values acquired from the step (2), the brightness of the display screen images which are photographed by every image sensor is automatically homogenized. The method of the invention has comparatively homogenization effect on the display screen image brightness; in particular, with the invention, the image display quality could be improved and the positioning precision of the screen positioning system with the brightness detection technique could be promoted.

Owner:GUANGDONG VTRON TECH CO LTD

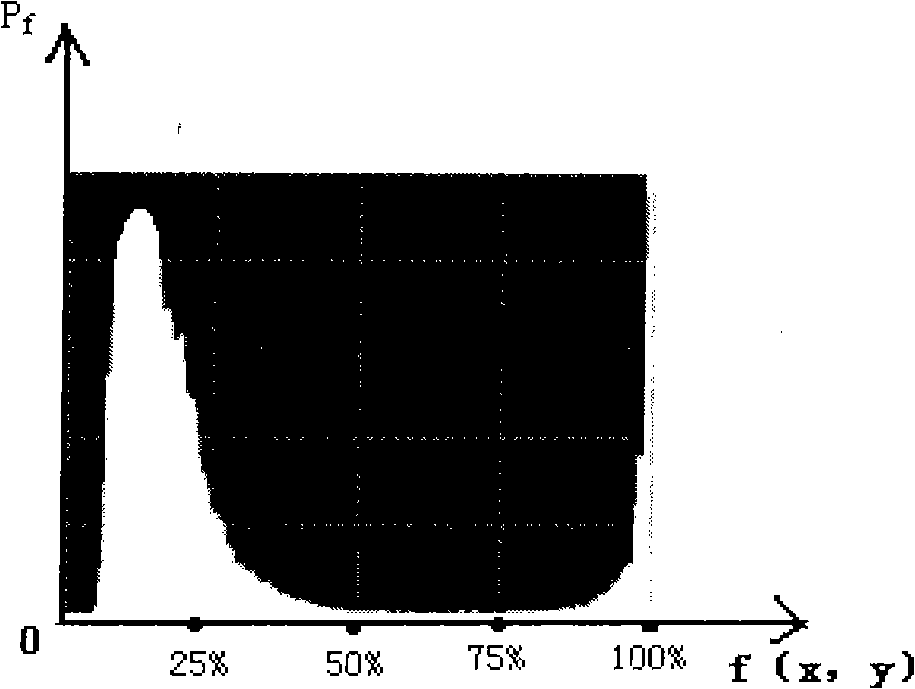

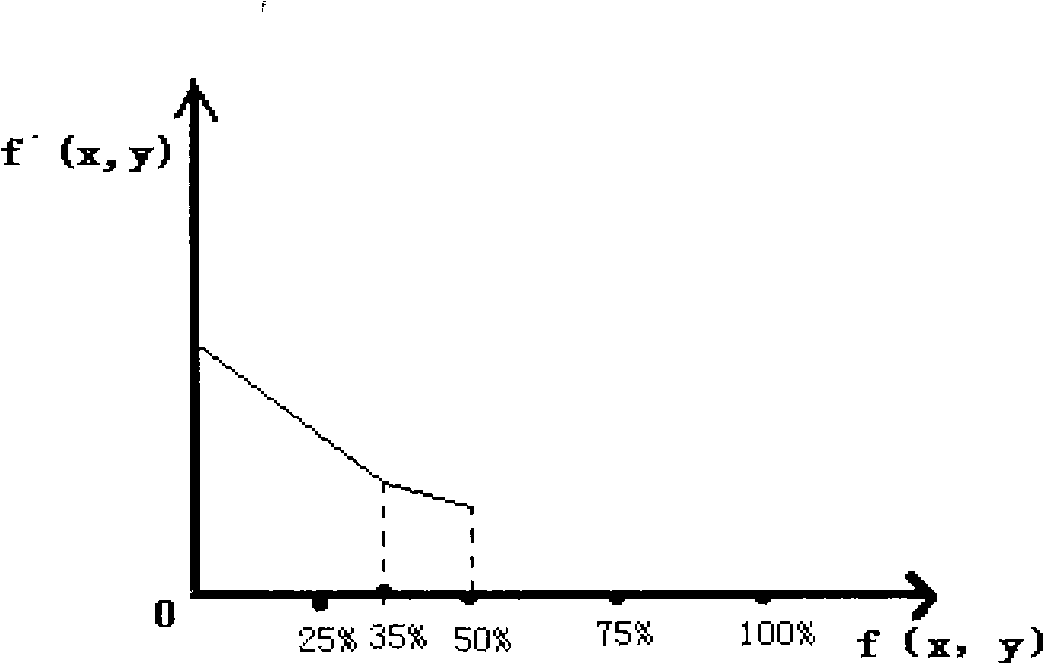

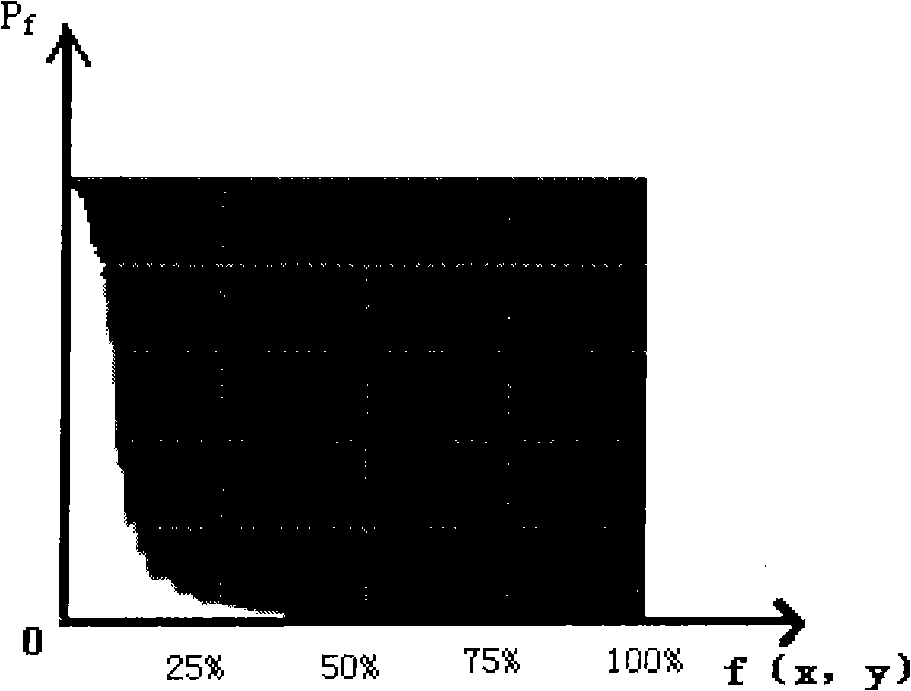

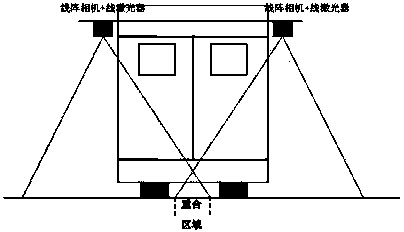

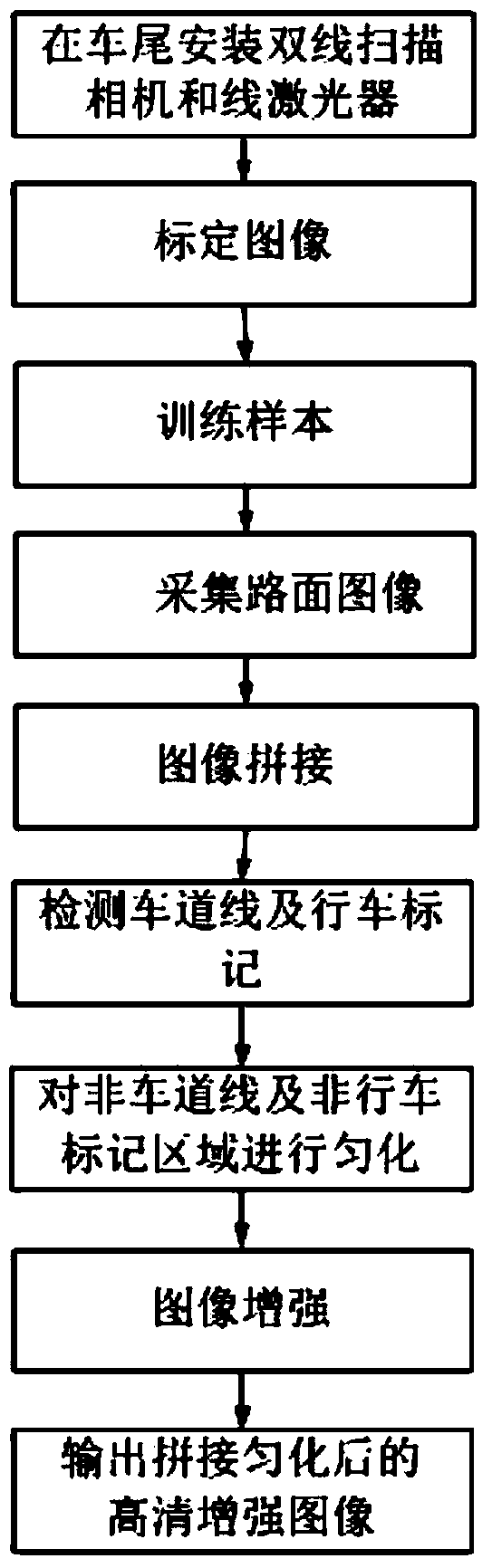

Method for splicing and homogenizing road face images collected by double-linear-array cameras under linear laser illumination condition

ActiveCN103714343AEliminate distractionsStrong real-timeCharacter and pattern recognitionRoad surfaceLaser illumination

The invention discloses a method for splicing and homogenizing road face images collected by double-linear-array cameras under the linear laser illumination condition. Two linear-scanning cameras are mounted on the top of the tail of a vehicle, a linear laser is used for illumination, a mileage sensor is used for triggering the cameras to shoot road face images, images obtained by the two cameras are spliced to form one image, lane line and running mark detection is carried out on the image, image gamma correction, namely homogenizing, is carried out on non-lane-line and non-running-mark areas in the image, and image intensification is carried out finally. The real time performance of the method can meet the requirement for real-time collection and real-time homogenizing, interference on image homogenizing of lane lines and running marks can be omitted in the homogenizing effect, and the robustness can be adaptive to images of various road faces like expressways, provincial level roads and municipal roads.

Owner:NANJING UNIV OF SCI & TECH

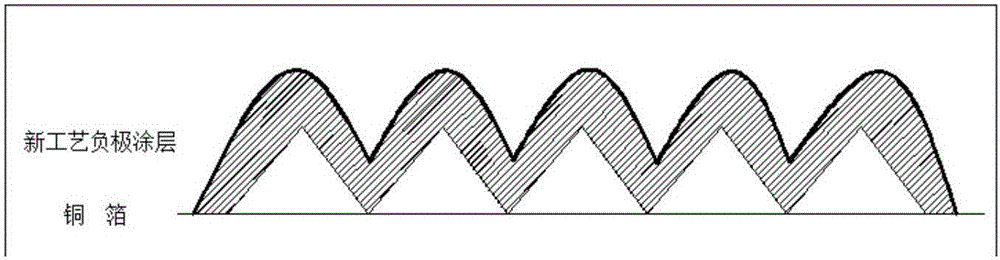

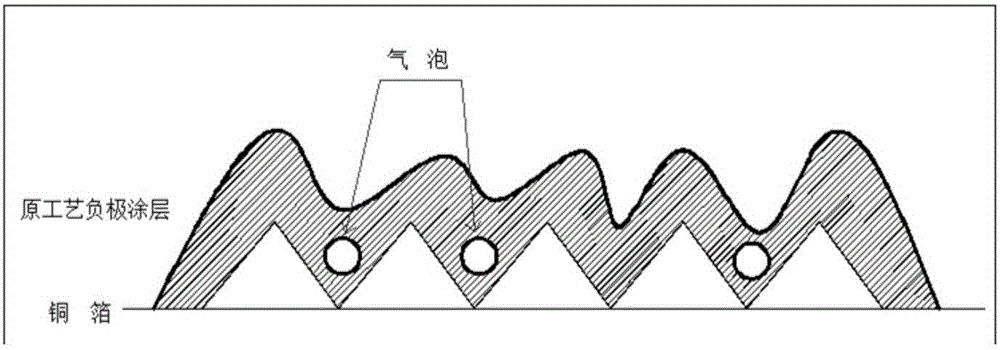

Preparation method of lithium ion power battery cathode

ActiveCN106848205AImproved mixing schemeShorten mixing timeElectrode collector coatingSodium carboxymethylcelluloseButadiene-styrene rubber

The invention relates to the field of power lithium ion batteries, in particular to a preparation method of a lithium ion power battery cathode. The preparation method comprises the following steps: first preparing sodium carboxymethylcellulose glue solution in a number 1 stirring machine, adding conducting carbon black and dry graphite powder in a number 2 stirring machine, uniformly mixing, and then adding the sodium carboxymethylcellulose glue solution in the number 1 stirring machine into the number 2 stirring machine; and adding little alcohol, vacuumizing, defoaming, adding styrene-butadiene latex, mixing, finally vacuum defoaming, and obtaining the lithium ion power battery cathode material. By improving a stirring scheme, the stirring time of the cathode slurry is shortened, the moisturizing coating performance of the cathode slurry is improved, and a bubble-free purpose is achieved.

Owner:HEFEI HENGNENG NEW ENERGY TECH

Preparation method of hybrid collector for oxide ore flotation

InactiveCN101181700AGood homogenization effectGood dispersion effectFlotationRevolutions per minuteSolvent

The invention relates to a preparation method of oxide ore flotation mixed collectors. The preparation method is characterized in that the preparation process comprises the steps that: (1) saponifier which is weighted in proportion is fully dissolved in hot water; (2) the weighted collecting flotation agent is stirred and mixed homogeneously at the speed of more than 600 revolutions per minute; (3) the prepared original mixture of the collecting flotation agent is added in the hot solvent which is dissolved with the saponifier, and the mixed solvent is stirred for 30 to 120 minutes until the solvent is homogeneous at the temperature of 50 DEG C to 90 DEG C and the speed of 10 to 200 revolutions per minute. The invention has the advantages that: agents are modified by controlling feeding order, preparation temperature, stirring speed and stirring time of agents, thus homogenization effect is good; agents do not agglomerate at comparatively low temperature, and dispersant effect is good; aging of the agents is long.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

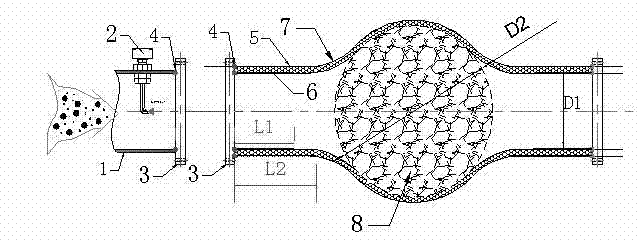

Mixed unit of foam metal ball pipe assembly

InactiveCN102345488ALow costImprovement effectExhaust apparatusDispersed particle separationComposite materialEngineering

The invention relates to a mixed unit of a foam metal ball pipe assembly. The mixed unit consists of an exhaust pipe, a nozzle, a connecting flange, a welding spot, a fastening outer sleeve, a fastening inner sleeve, a metal fiber braided pipe and a foam metal ball. The mixed unit is characterized in that: the fastening outer sleeve and the fastening inner sleeve are used for fixing the metal fiber braided pipe and welded into a whole by using the connecting flange; the inside diameter of the fastening inner sleeve is D1, the diameter of the foam metal ball is D2, and the ratio D2 / D1 of the diameter D2 of the ball to the sleeve diameter D1 is 1.5 to 2.5; the ratio L2 / L1 of the length L2 of the fastening outer sleeve to the length L1 of the fastening inner sleeve is 3 to 5 millimeters; L2 is 300 millimeters; and the mixed unit is arranged at the downstream of the nozzle for a urea reducer. The foam metal ball is wrapped by adopting the metal fiber pipe to form the mixed unit of the concentric cylindrical foam metal ball pipe assembly for the urea reducer, a catalyst is coated on the foam metal ball, and the mixed unit is applied to mixed decomposition of the urea reducer; and the mixed unit has simple structure, is efficient and durable, and is applied in an over national 4 post treatment device.

Owner:CHINA FIRST AUTOMOBILE

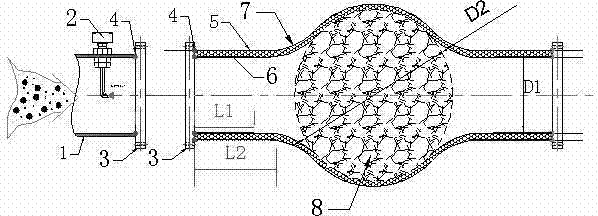

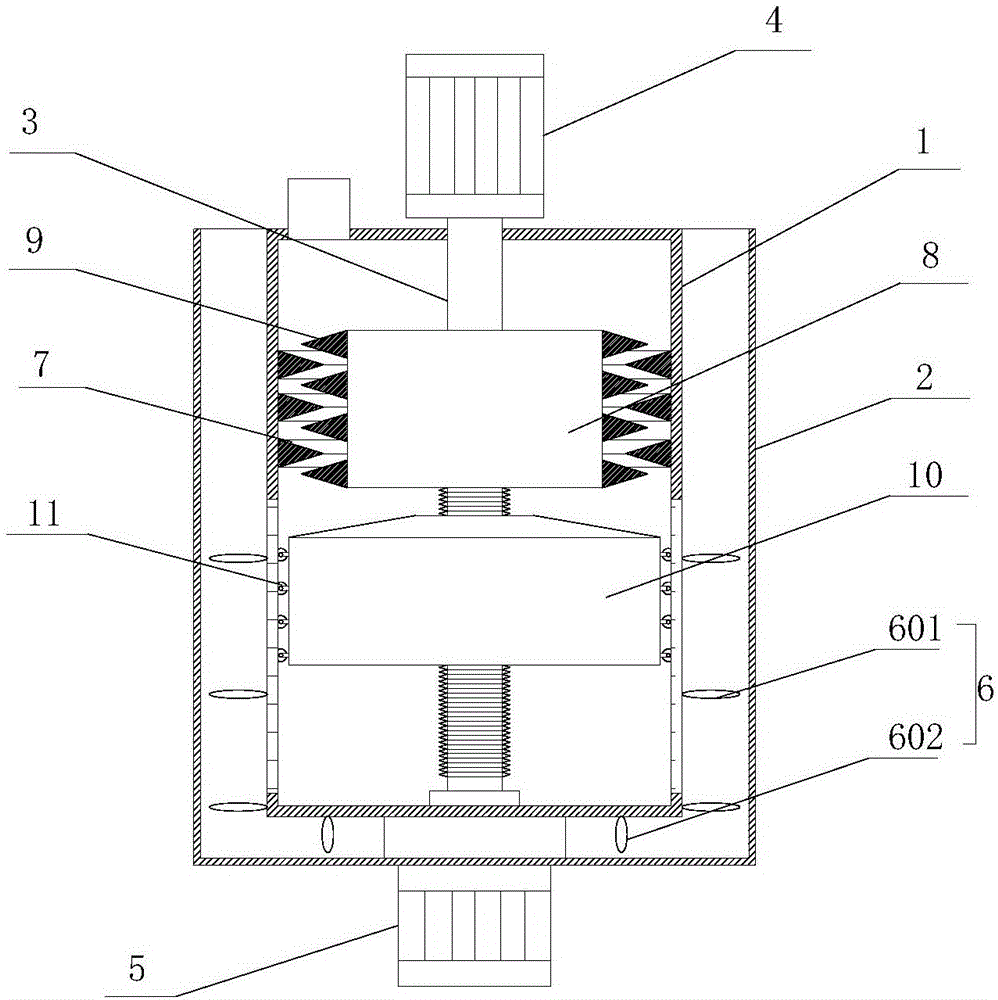

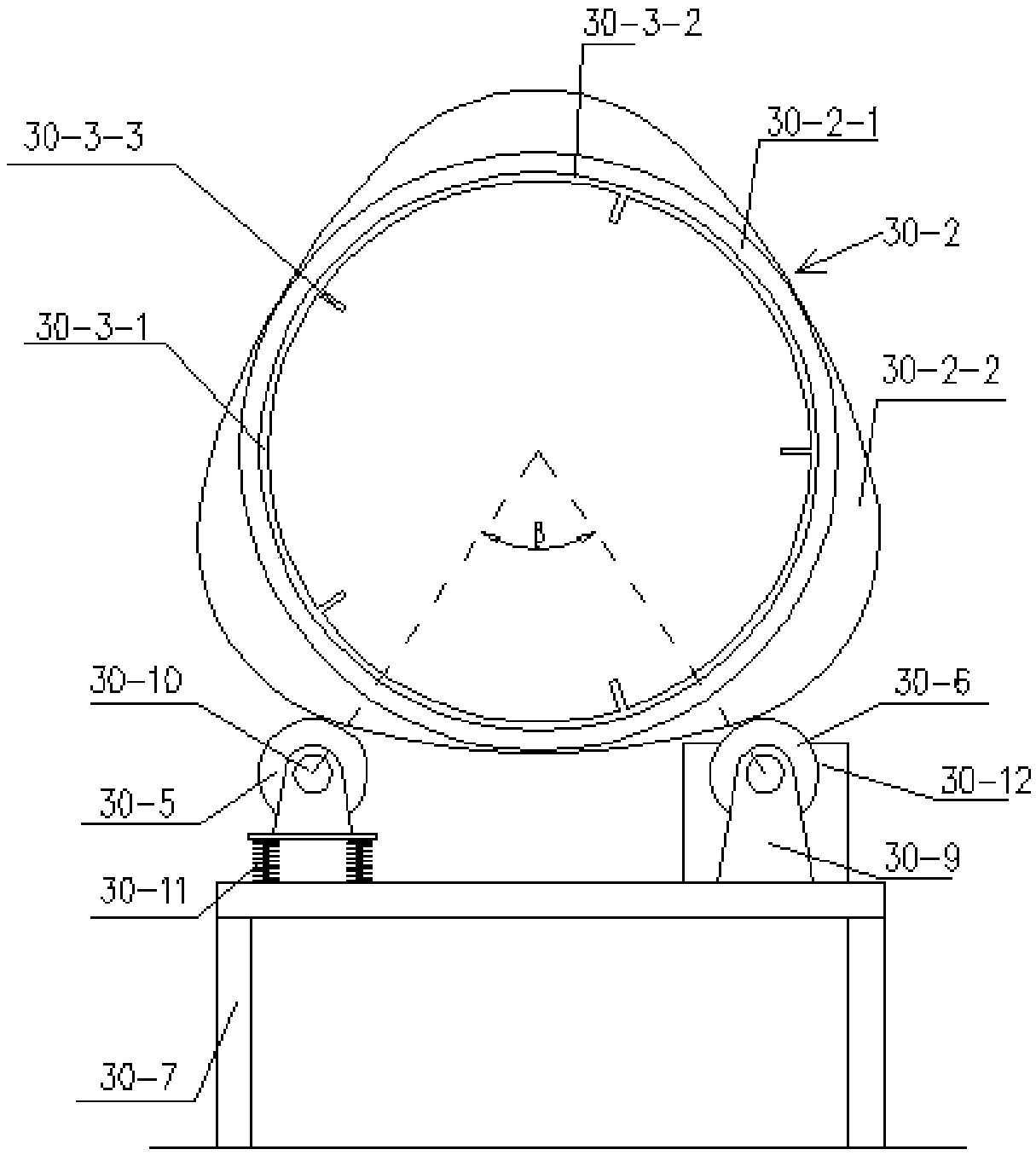

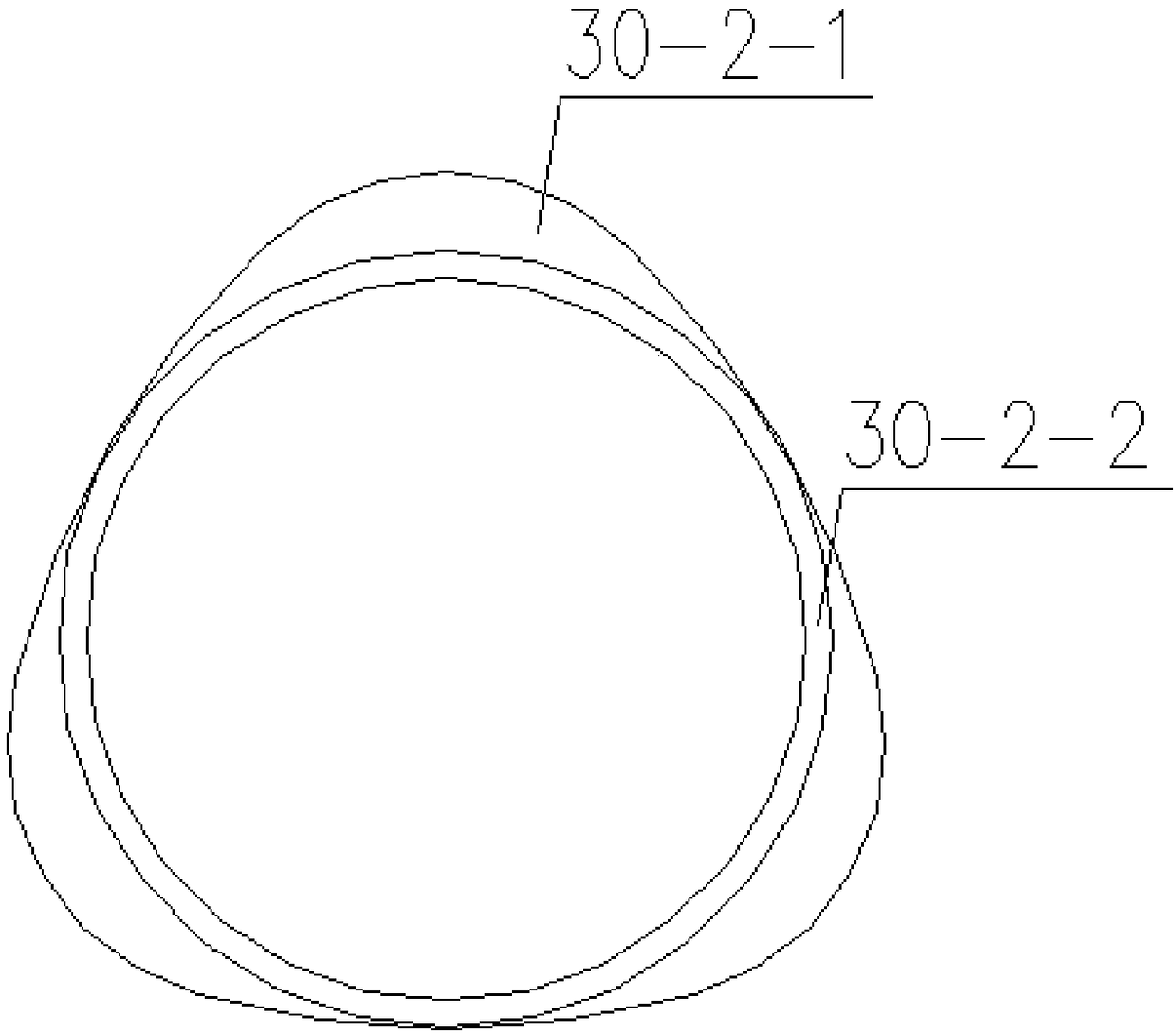

Repeated rolling type histocyte refiner

ActiveCN106281991AAchieve brokenRealize the stirring actionBioreactor/fermenter combinationsBiological substance pretreatmentsDrive shaftEngineering

The invention discloses a repeated rolling type histocyte refiner which comprises an inner barrel, an outer barrel, a stirring shaft, a first driving mechanism and a second driving mechanism. The inner barrel is located in the outer barrel, a homogenizing chamber is formed between the inner barrel and the outer barrel, and a stirring blade mounted on the inner barrel is arranged in the homogenizing chamber; a spiral fixed blade is arranged on the inner circumferential face of the inner barrel, guide grooves are formed in the positions, below the spiral fixed blade, of the inner circumferential face of the inner barrel, and through holes are formed in the bottoms of the guide grooves; the stirring shaft is located in the inner barrel and comprises an unthreaded rod part and a lead screw part, a tool apron is mounted on the unthreaded rod part, and a spiral movable blade cooperating with the spiral fixed blade to cut materials is mounted on the tool apron; the lead screw part is sleeved with a mounting base in threaded connection with the lead screw part, and rolling roll sets with the number consistent with that of the guide grooves are arranged on the peripheral face of the mounting base; the first driving mechanism and the second driving mechanism are used for driving the stirring shaft and the inner barrel to rotate forwards and reversely respectively, and the rotating directions of the driving shaft and the inner barrel are opposite. The repeated rolling type histocyte refiner has a good homogenizing effect.

Owner:ANHUI HUIEN BIOTECH

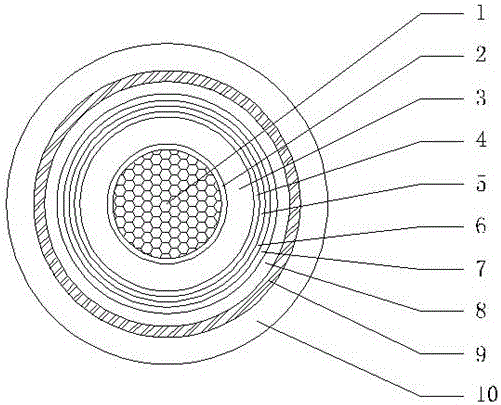

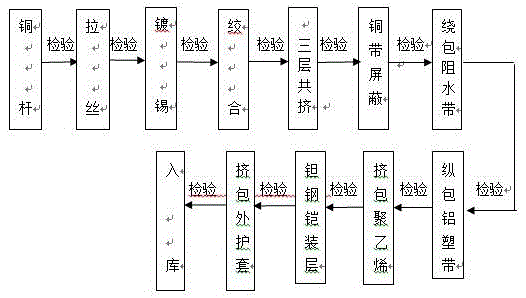

Graphene composite shielding anti-interference power cable for environment-friendly intelligent high-speed rail and fabrication method of graphene composite shielding anti-interference power cable

InactiveCN106098173AAccelerated corrosionImprove tensile propertiesPower cables with screens/conductive layersFlexible cablesCopper conductorInsulation layer

The invention discloses an environment-friendly intelligent high-speed rail graphene composite shielding anti-interference power cable and a preparation method thereof. The insulation layer and the insulation shielding layer form an insulated wire core; the outer layer of the insulating wire core is overlapped and wrapped with a metal inner shielding layer; The aluminum-plastic composite tape layer wrapped longitudinally is extruded with a polyethylene moisture barrier layer; the outer gap of the moisture barrier layer is wrapped with a double-layer tantalum steel alloy tape armor layer, and the outermost layer of the cable is extruded with an outer sheath. The invention has good insulation properties, mechanical properties, power transmission, anti-magnetic interference, lightning protection, flame retardant, halogen-free, low-smoke environmental protection, waterproof, corrosion resistance, radiation resistance and other properties; the structure is reasonable, the comprehensive performance is superior, and the product The performance index is superior to the requirements of international standards; and can produce good social and economic benefits.

Owner:WUXI CITY HENG HUI CABLE

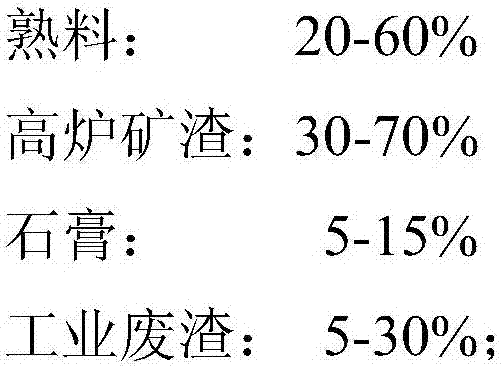

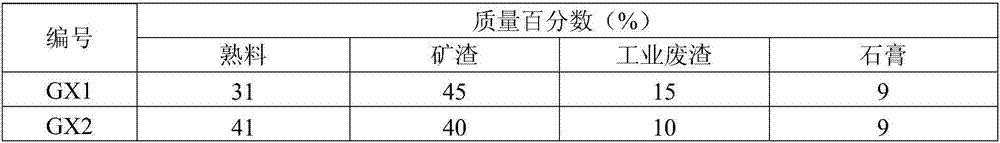

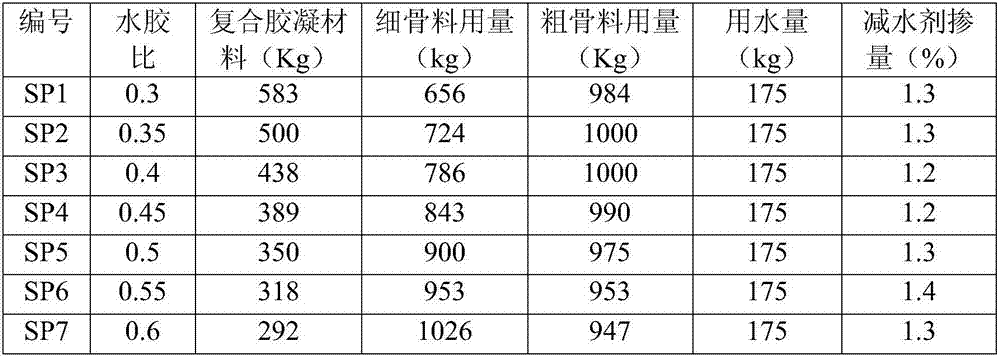

Compound gel material special for marine concrete, production method and application thereof

InactiveCN106927701AHigh initial bulk densityReasonable distributionCement productionWork performanceSlag

The invention discloses a compound gel material special for marine concrete, a production method and an application thereof. The compound gel material is prepared from 20-60% of clinker, 30-70% of granulated blast-furnace slag, 5-15% of gypsum and 5-30% of industrial residue. The method comprises the following steps: while producing, milling clinker, gypsum and industrial residue till the specific surface area is 320-380m2 / kg; milling the granulated blast-furnace slag into mineral powder with the specific surface area of not less than 420m2 / kg; uniformly mixing all the powder, thereby acquiring the compound gel material. Compared with the marine concrete prepared according to the traditional method, the high corrosion resistance marine concrete adopting the compound gel material provided by the invention has better working performance, mechanical property and chloride ion erosion resistance.

Owner:CHINA RESOURCES CEMENT TECH RES DEV

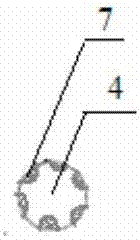

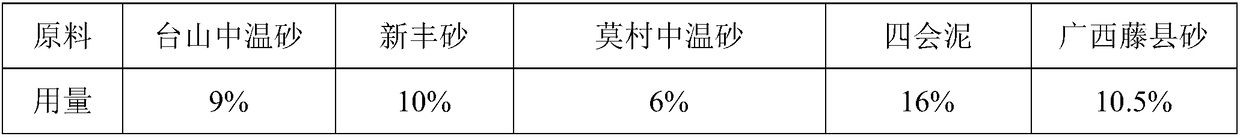

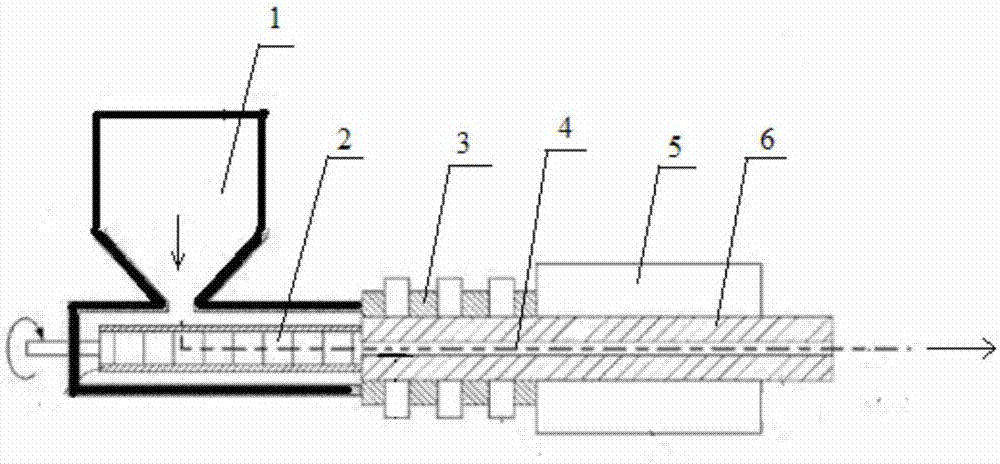

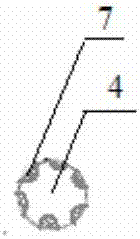

Preparation method of specially-shaped cigarettes with naturally endowed aroma

The invention discloses a preparation method of specially-shaped cigarettes with naturally endowed aroma. The preparation method comprises the following steps: respectively grinding a tobacco raw material and natural plant perfumes into powder, and uniformly mixing the powder, thus obtaining mixed powder; uniformly stirring a combustion promoter, an adhesive and a humectant, thus obtaining a mixedsolution; carrying out mixed granulation on the mixed powder and the mixed solution, and carrying out drying, thus obtaining tobacco particles; preparing the tobacco particles into tobacco particle round rods by adopting a tobacco particle round rod forming device; wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carrying out compounding withfilter sticks, thus obtaining the specially-shaped cigarettes with high homogenization, good stability and naturally endowed aroma. The cigarettes are smooth in smoking, the aroma is fresh and elegant, and good sensual experience can be endowed to a smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

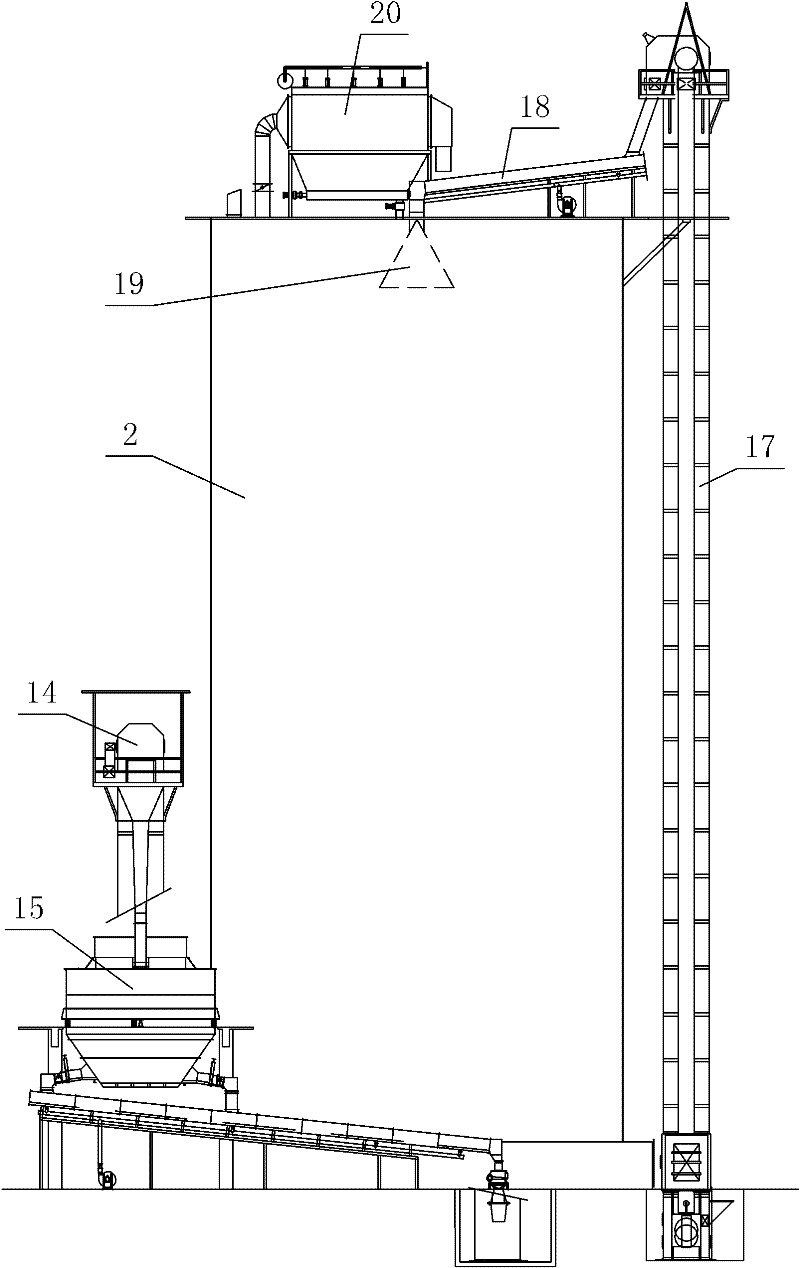

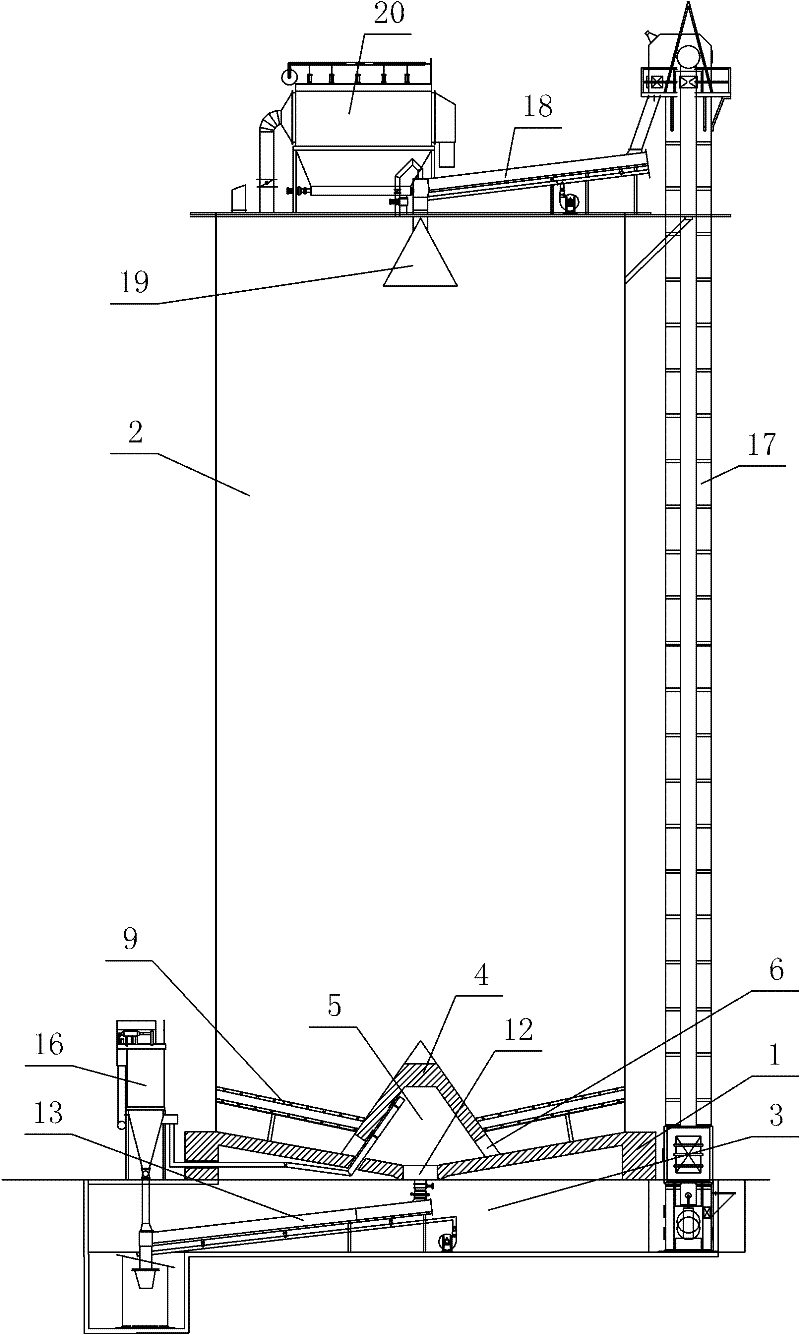

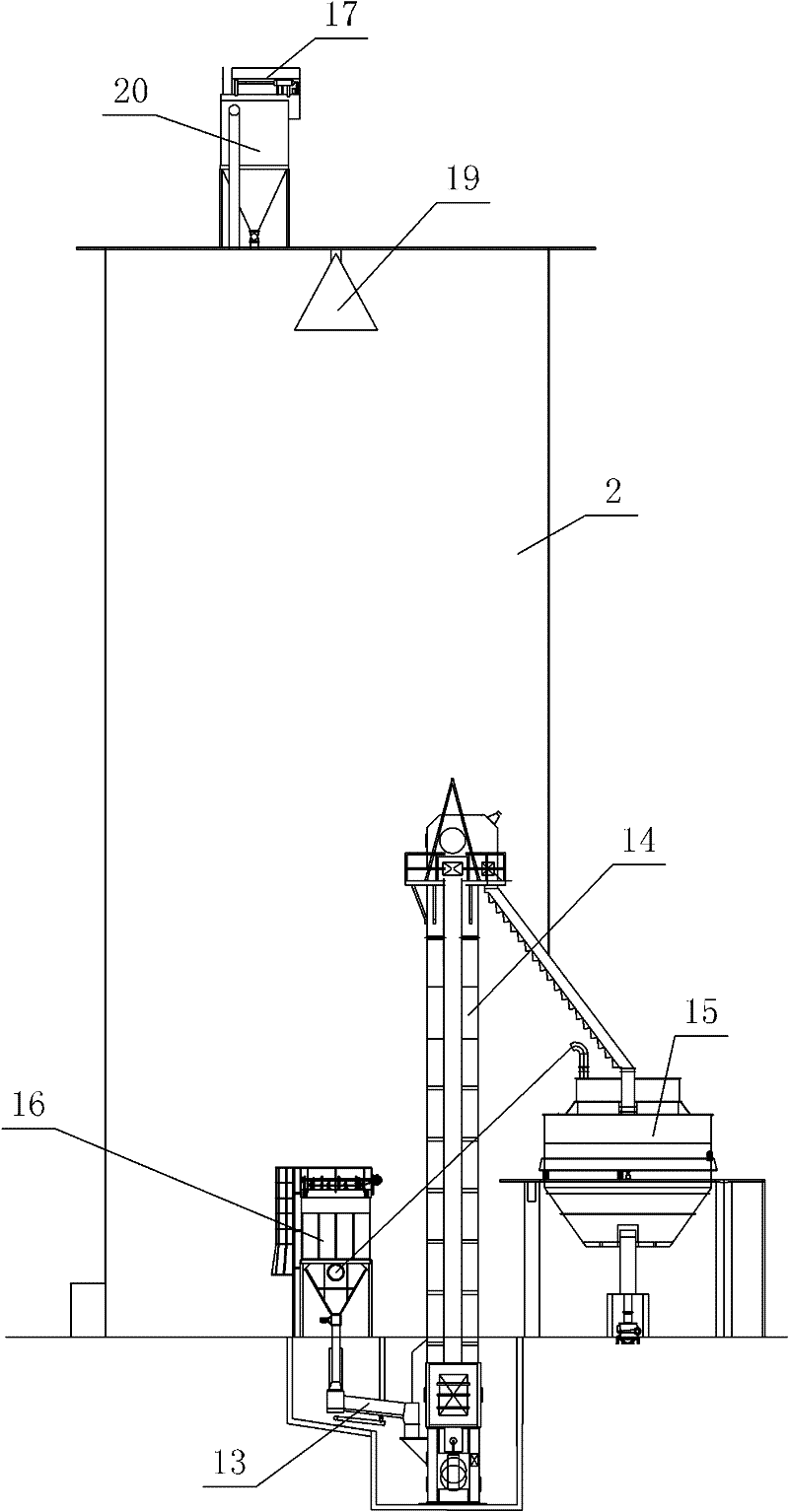

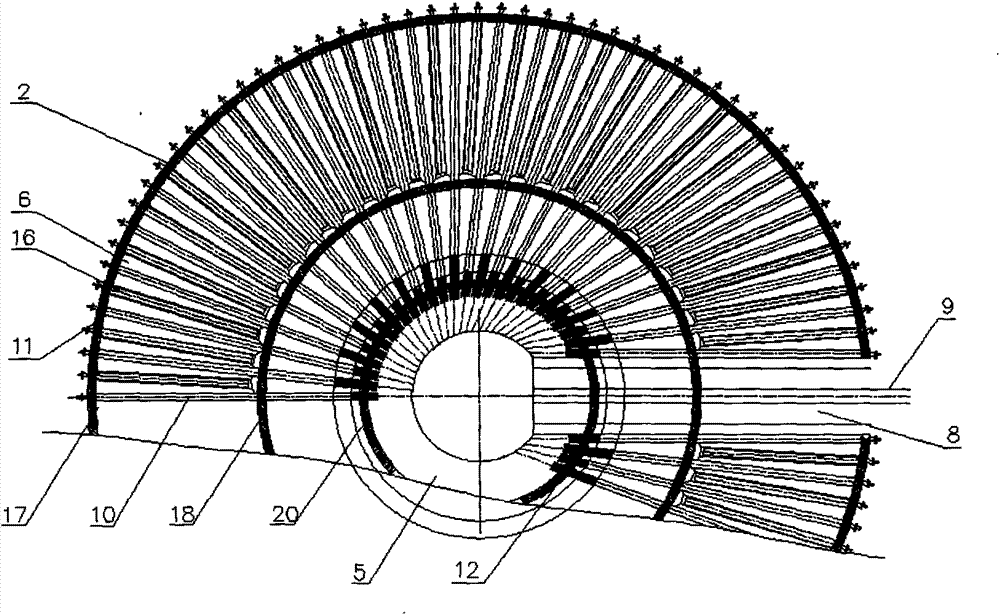

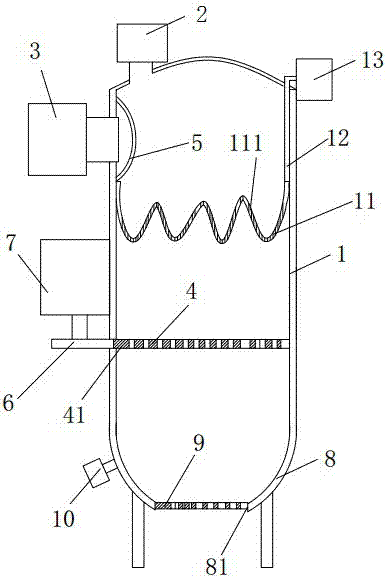

Cement raw meal homogenizing silo

InactiveCN102219408ASimple structureSafe and reliable structureClinker productionEngineeringControl valves

Owner:孙世龙

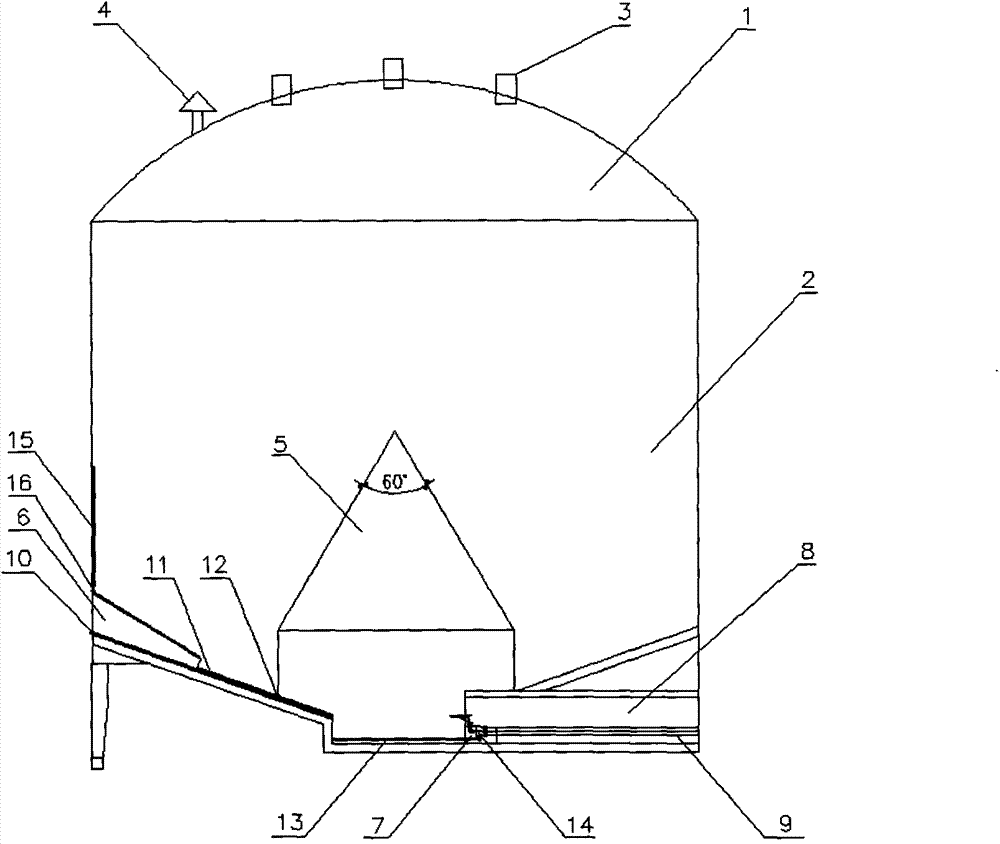

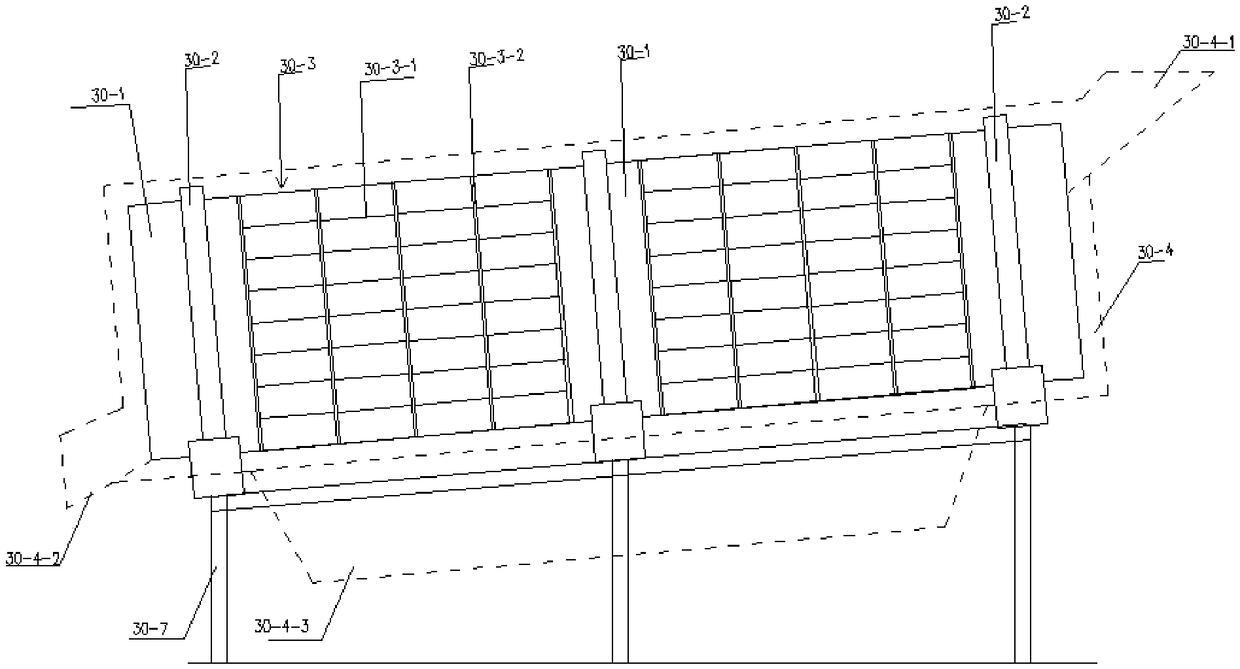

Powdery material homogenizing steel plate silo and use method thereof

InactiveCN104727588AEasy maintenanceSimple structureBulk storage containerIndustrial buildingsStructural engineeringSilo

The invention discloses a powdery material homogenizing steel plate silo which comprises a silo body and a silo top. A pressure relief cone is arranged in the center of the bottom of the silo body, an annular pressure relief cone fluidization bar is arranged in a cylindrical straight section of the pressure relief cone, fluidization bars are arranged at the bottom of the pressure relief cone, annular middle-region fluidization bars and annular edge-region fluidization bars are sequentially arranged on the periphery of the annular pressure relief cone fluidization bar, vertical fluidization bars are vertically arranged at the lower portion of the silo body along the silo body, multiple guide cones are arranged at the bottom of the silo body, the cross section of each guide cone is an isosceles triangle, one end of each guide cone is connected with the silo wall, the angle between one end of each guide cone and a horizontal bottom board is not smaller than 20 degrees, middle-region discharging pipes are arranged between the guide cones and the pressure relief cone, a V-shaped guide groove is formed between every two adjacent guide cones, edge-region discharging pipes are arranged in the guide grooves, and arch break fluidization bars are arranged at the tops of the guide cones. The powdery material homogenizing steel plate silo has the advantages of being simple in structure, convenient to use, diversified in structure and performance for a raw material homogenizing silo, good in homogenizing effect, small in gas consumption, high in delivery rate and smooth in discharging operation.

Owner:SHANDONG HUAJIAN STORAGE EQUIP SCI & TECH

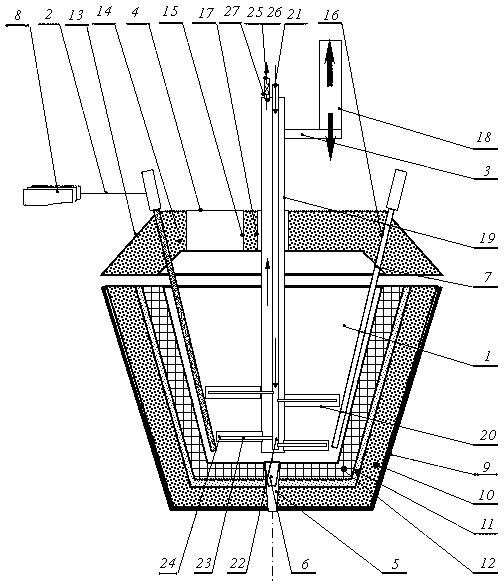

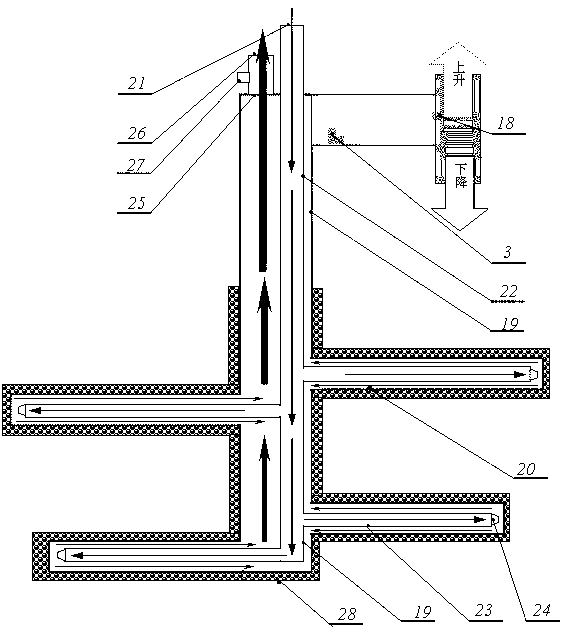

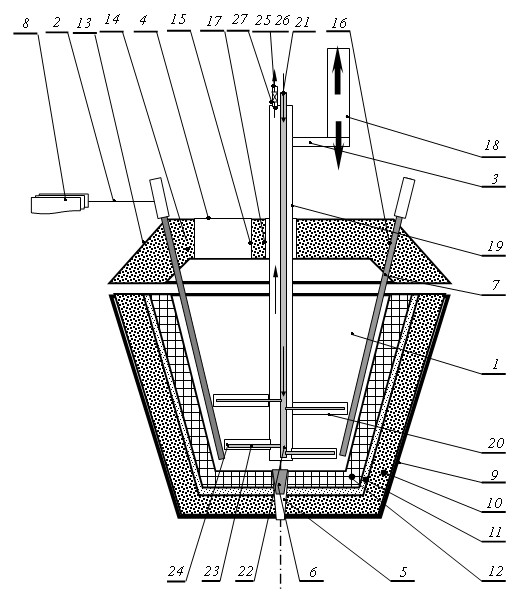

Device and method for homogenizing high-temperature melt

InactiveCN102698634AStirring power is smallIncrease the stirring areaRotary stirring mixersTransportation and packagingSlagHeating system

The invention provides a device and a method for homogenizing high-temperature melt and belongs to the technical field of melt homogenization. The device provided by the invention consists of three parts, namely a melting tank, a stirring system and a heating system. The detailed steps for homogenizing high-temperature melt carried out by the device provided by the invention are as follows: adding hot silicate slag and quenching-tempering material into the melting tank; after heating to melt the raw material, turning off the power supply; enabling the stirring part of the cooled stirring system to fall into the high-temperature melt, and finishing fall-rise-fall operating actions for stirring the melt in order, wherein the stirring process and the heating process are carried out alternatively; and under the condition that the test result of the samples shows that the composition uniformity and viscosity of the melt are suitable for the process conditions that the fiber is formed or the glass ceramics is prepared, opening a choke plug of the melting tank and making the melt flow out via the flow hole by the gravity of the melt to finish the homogenization process. The homogenizing device and the homogenizing method, provided by the invention, have the advantages of good homogenizing effect, good high-temperature strength and long service life of the stirring part.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

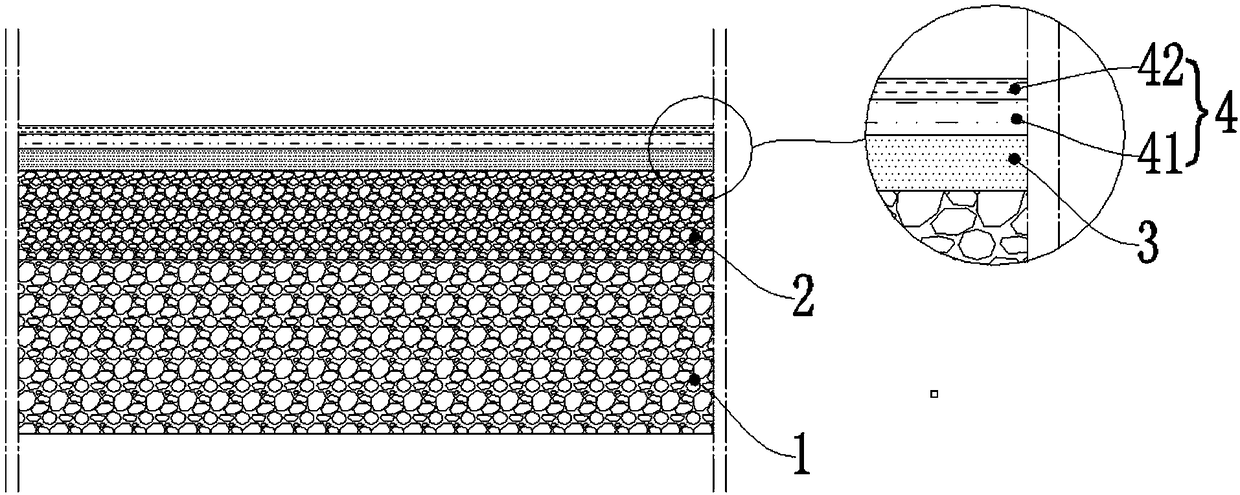

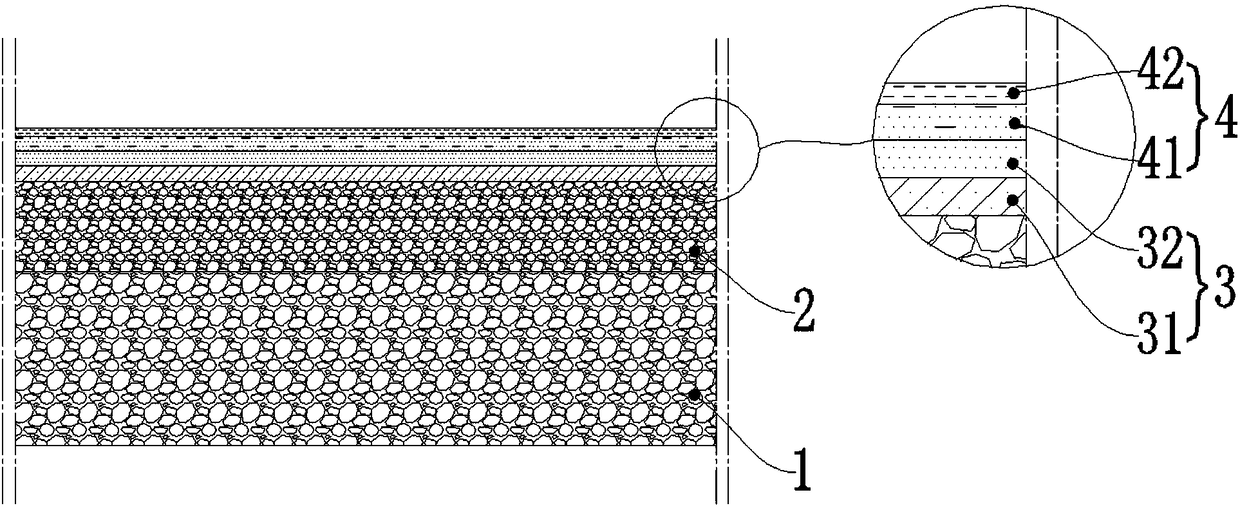

Once-firing multi-density composite foamed ceramic decorative board and preparation method thereof

The invention discloses a once-firing multi-density composite foamed ceramic decorative board. The once-firing multi-density composite foamed ceramic decorative board comprises a first foamed layer, asecond foamed layer, a sealing layer and a surface decorative layer arranged in order from bottom to top, wherein the density of the second foaming layer is less than the density of the first foaminglayer; the first foaming layer, the second foaming layer, the sealing layer and the surface decorative layer are fired once; the sealing layer is used for sealing a hole in the surface of the secondfoaming layer; the sealing layer is an engobe layer, or the sealing layer is a non-foamed ceramic slurry layer and an engobe layer, and the non-foamed ceramic slurry layer is located between the foamed layer and the engobe layer; the surface decorative layer is a glazed layer. Correspondingly, the invention also discloses a preparation method of the decorative board. The sealing layer can improvethe flatness of the product and improve the decorative effect of the product. The foamed ceramic decorative board is easy to clean. The foamed layers, the sealing layer and the surface decorative layer are fired once, and the layers are firmly bonded.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +1

Glue pot used for electronic product production and having stirring function

InactiveCN106964291AImprove the homogenization effectQuality improvementShaking/oscillating/vibrating mixersTransportation and packagingMaterial resourcesBiochemical engineering

The invention relates to a glue pot used for electronic product production, in particular to a glue pot used for electronic product production and having a stirring function. The invention solves the technical problems by providing the glue pot used for the electronic product production and having the stirring function, which can stir glue, can improve the quality of electronic products, can improve the yield of electronic products and can save manpower and material resources. In order to solve the technical problems, the invention provides such the glue pot used for the electronic product production and having the stirring function. The glue pot used for the electronic product production and having the stirring function comprises a base, wherein supporting plates are vertically connected to the left side and the right side of the top of the base through bolts; a left-and-right moving mechanism is arranged at the top of the base between the two supporting plates; a glue pot body is connected to the left-and-right moving mechanism; a cover is arranged at the top of the glue pot body; an agitating device is arranged inside the glue pot body. Through the left-and-right moving mechanism, the agitating device and a stirring device, the glue pot used for the electronic product production and having the stirring function can stir the glue in the glue pot body.

Owner:王剑

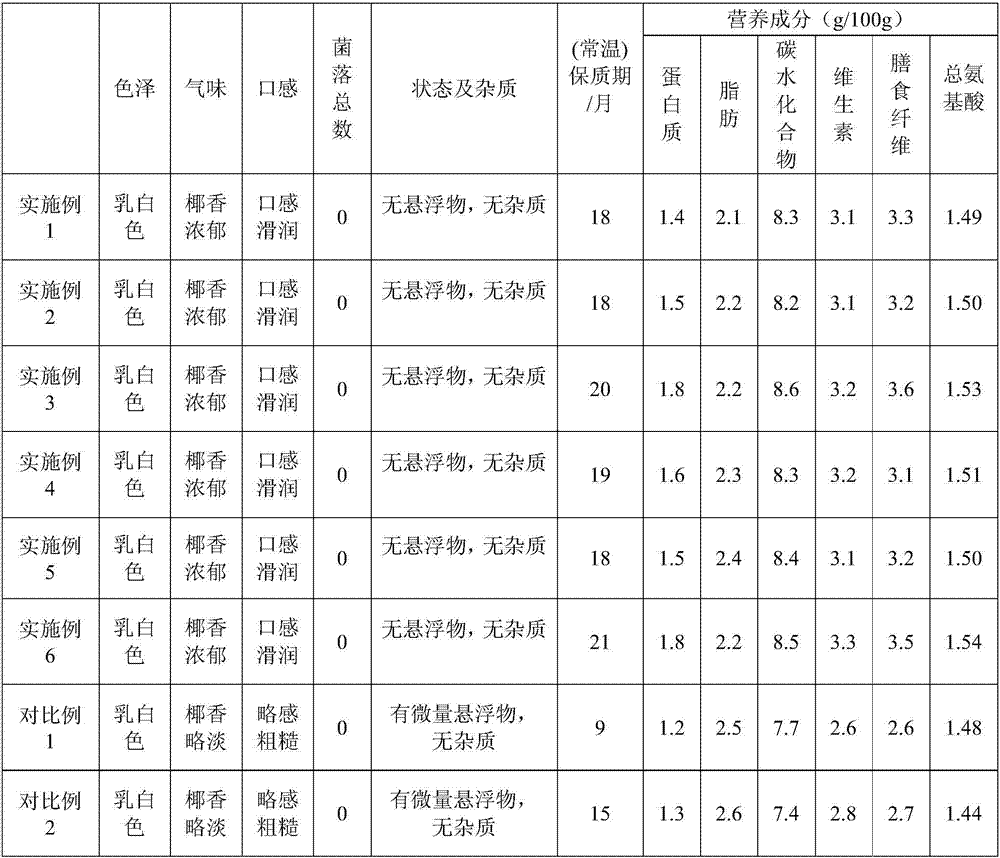

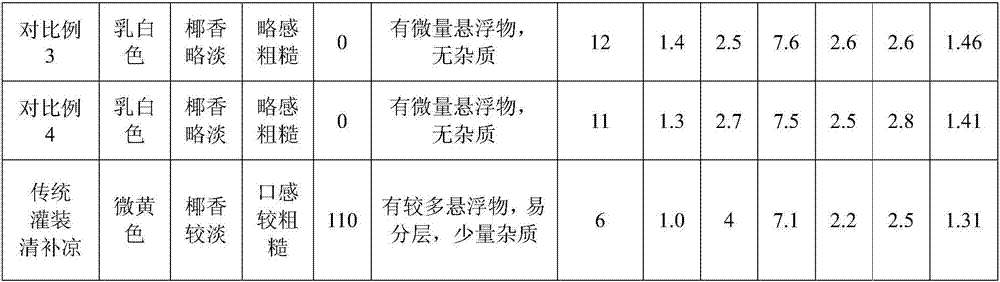

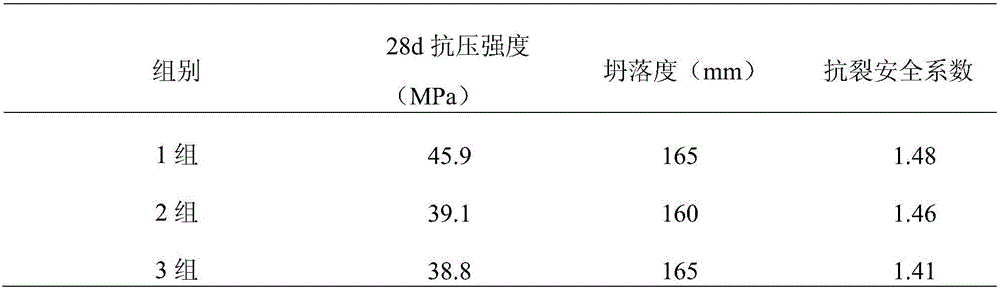

Coconut milk Qingbuliang and preparation method thereof

ActiveCN106858300AImprove stabilityGood homogenization effectFood preservationFood ingredient as emulsifierFiberSucrose

The invention discloses a coconut milk Qingbuliang and a preparation method thereof. The coconut milk Qingbuliang is prepared from the following raw materials by weight percent: 6-8% of coconut fiber fruits, 0.5-0.8% of wheat kernels, 3-5% of corn, 0.5-0.8% of sago, 0.5-1% of oat, 0.5-0.8% of ormosia, 5-10% of honey, 0.1-0.2% of an emulsion stabilizer and the balance of coconut milk, wherein the emulsion stabilizer comprises sodium caseinate, glycerin monostearate, sucrose fatty acid ester and sodium carboxymethylcellulose; and the coconut milk is prepared from coconut meat and purified water at a mass ratio of 1:(1-2). According to the invention, a gradient homogenizing method is adopted for guaranteeing a better homogenizing effect of a coconut milk mixed solution and higher stability of homogenized emulsion. The prepared coconut milk Qingbuliang has the characteristics of milk white color, thick coconut fragrance, smooth taste, flavor of fresh sold coconut milk Qingbuliang, difficulty in infecting bacteria, no suspension, no impurity, few damaged nutritional ingredients and longer shelf life.

Owner:海南岛屿食品饮料有限公司

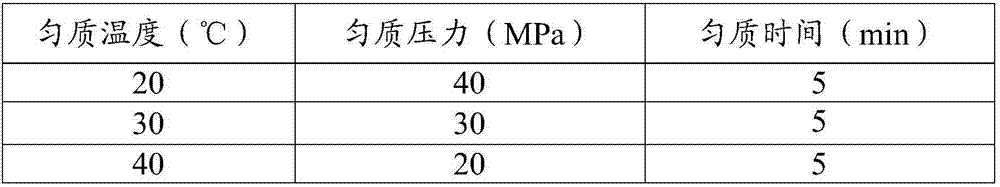

Preparation method of rubber asphalt concrete

ActiveCN105801049AHigh strengthGuaranteed StrengthSolid waste managementCrack resistancePolymer science

The invention discloses a preparation method of rubber asphalt concrete. The preparation method comprises the following steps of: (I) sufficiently stirring and uniformly mixing portland cement, mineral powder fly ash, stainless steel powder and green mud at 180-190 DEG C; adding rubber asphalt; and stirring at 180-190 DEG C to obtain a mixture; (II) mixing limestone and blast furnace slag; calcining at 500-700 DEG C for 20-30 minutes; cooling; adding limestone and blast furnace slag into the mixture, and stirring at 180-190 DEG C for 4-8 minutes; adding water and high-calcium wastewater; and continuously stirring at 180-190 DEG C for 2-4 minutes to obtain a mixture; and (III) performing layered pouring of the mixture, vibrating and curing at 15-25 DEG C for 5-10day to obtain the rubber asphalt concrete. By adopting the preparation method disclosed by the invention, the compressive strength and crack resistance of the rubber asphalt concrete can be obviously enhanced.

Owner:CCCC THIRD HIGHWAY ENG

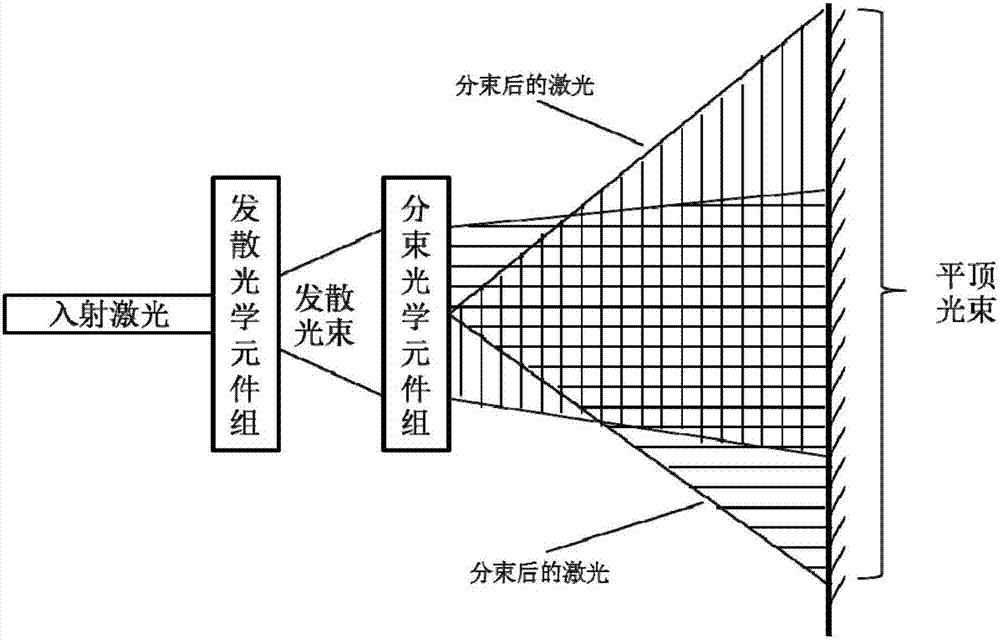

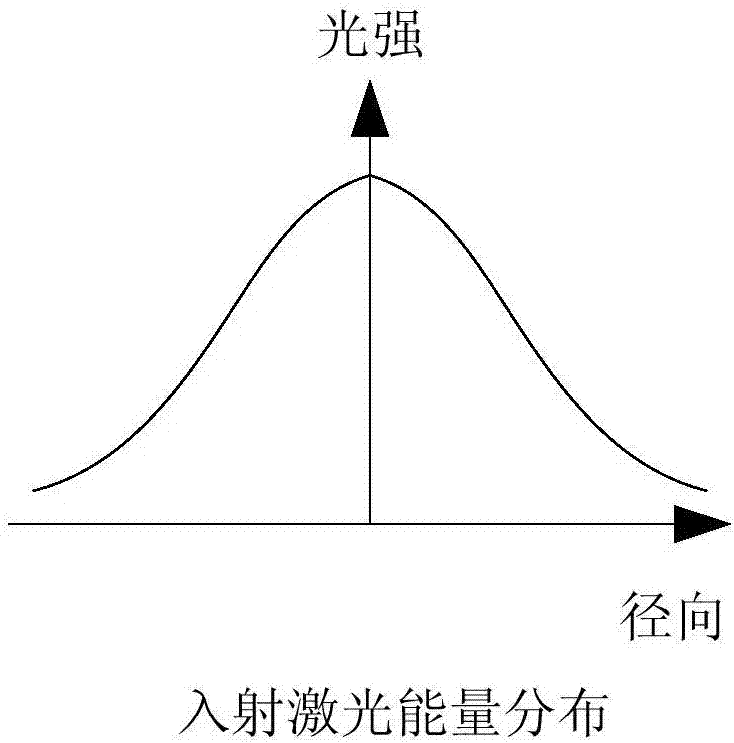

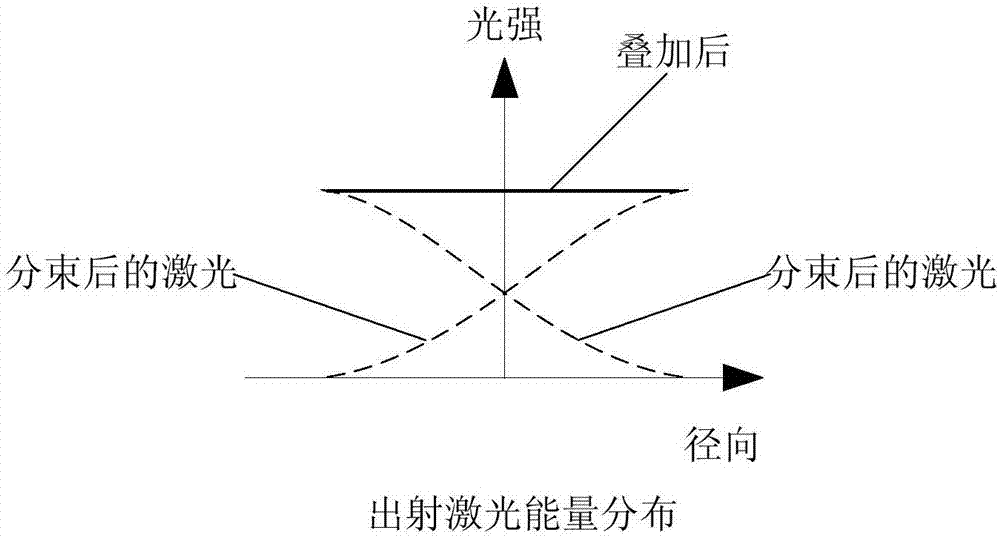

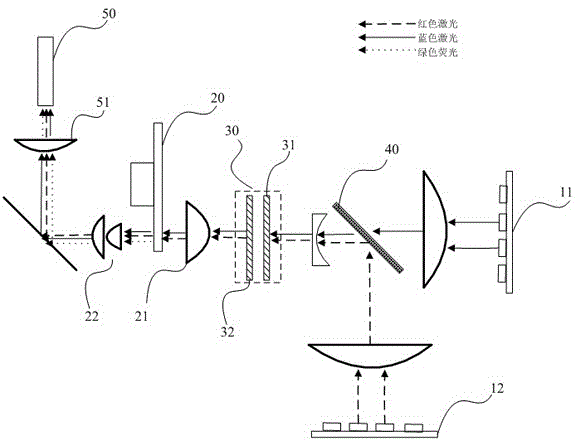

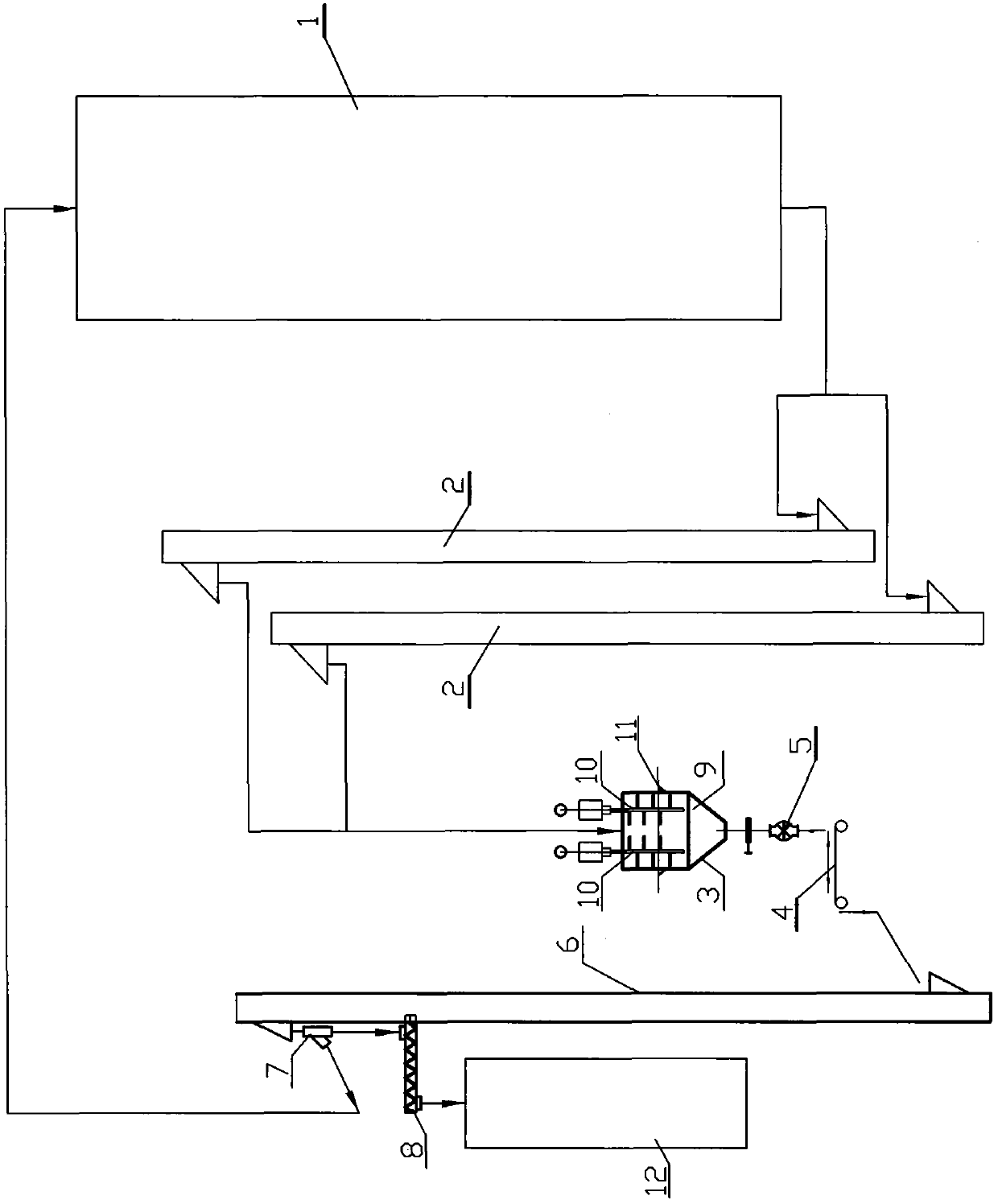

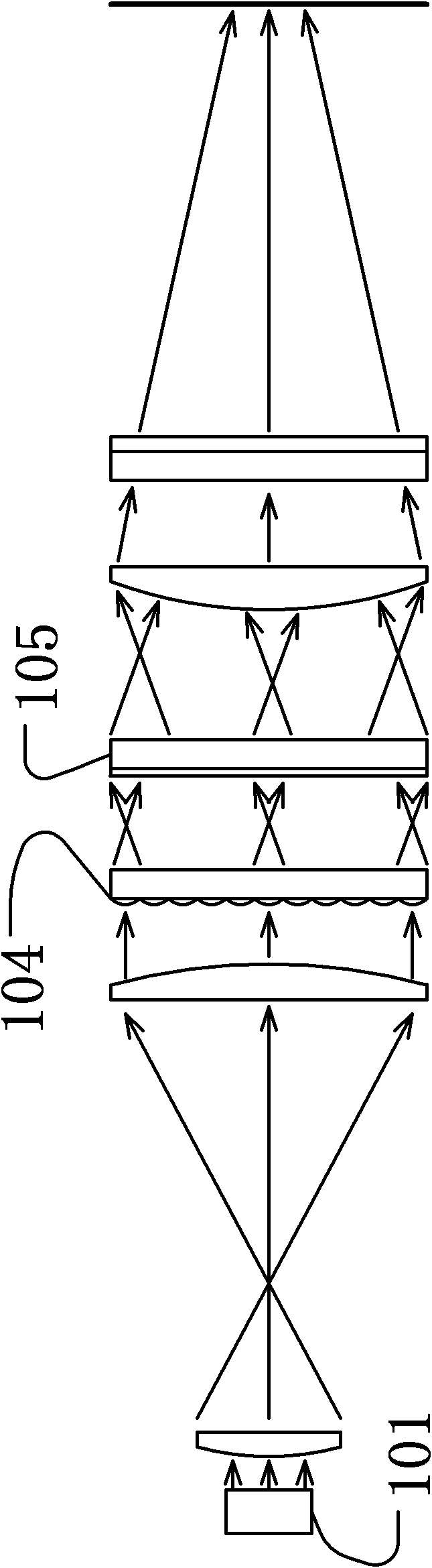

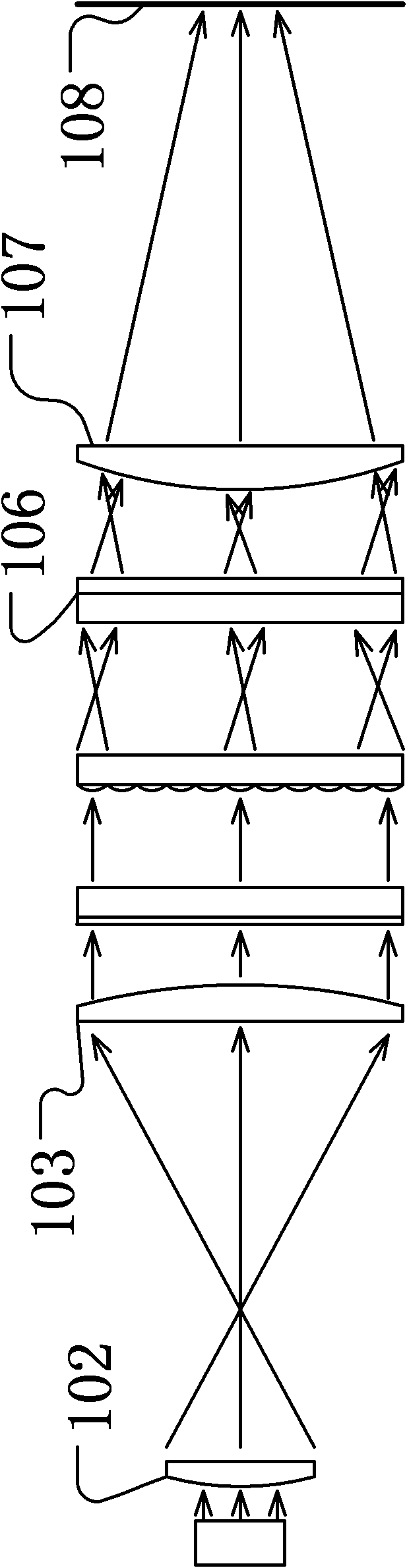

Laser beam homogenizing device and method

The invention provides a laser beam homogenizing device and method, and is used for homogenizing laser of which power distribution is Gaussian distribution. The laser beam homogenizing device comprises a divergent optical element group which is used for converting incident laser into divergent light; and a beam splitting optical element group which is used for performing beam splitting on the divergent light and superposing the laser after beam splitting to form flat-topped beams. With application of the laser beam homogenizing device and method, the laser of which power distribution is Gaussian distribution is shaped into the flat-topped light so that the cost is low without selectivity for the wavelength and the rectangular spot size is flexible and adjustable, and the homogenizing effect is great within a large scope of the depth of field.

Owner:LAZON MEDICAL LASER CO LTD

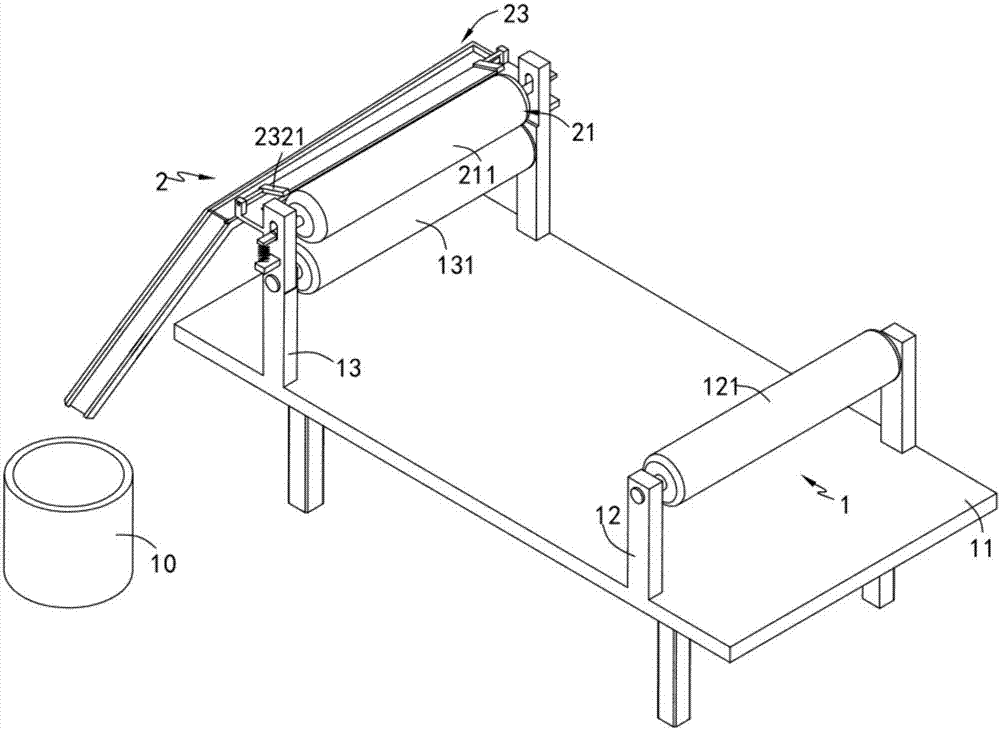

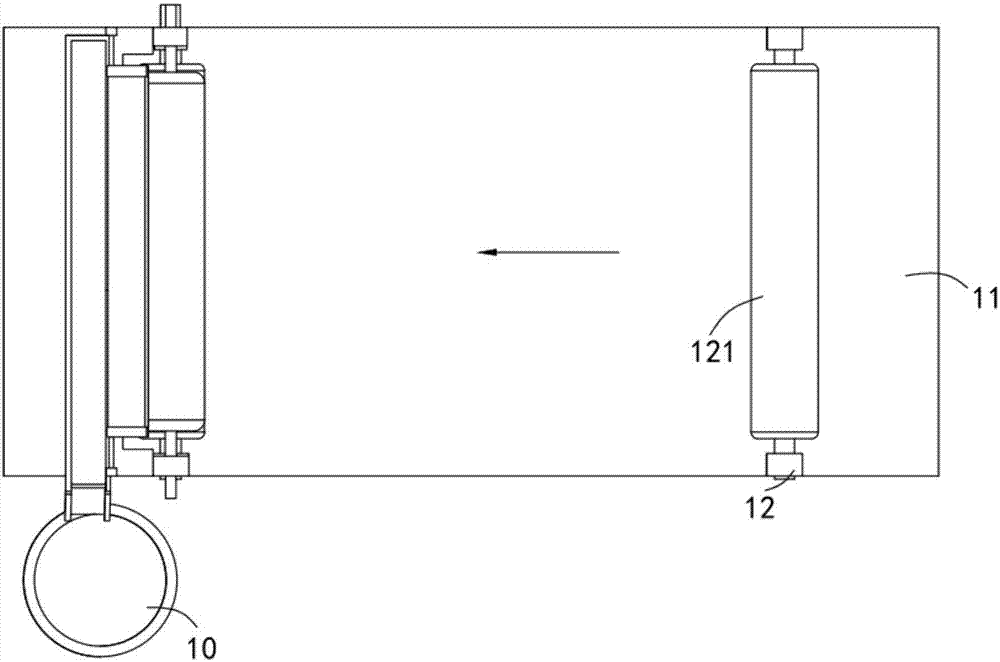

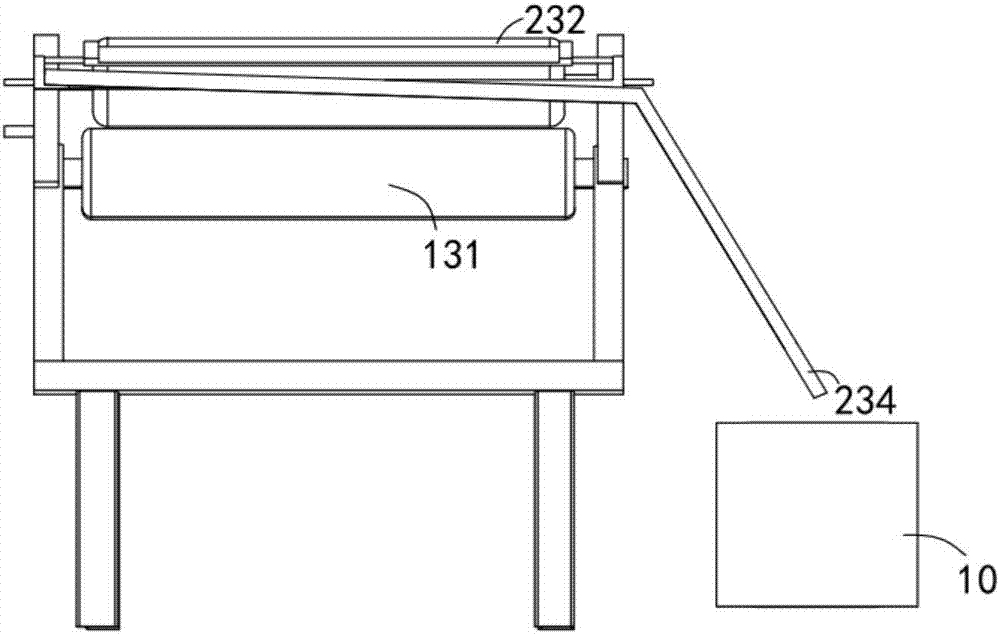

Textile fabric automatic homogenizing equipment

InactiveCN107151881AUniform sizeImprove the homogenization effectTextile treatment machine arrangementsFiberPulp and paper industry

The invention relates to an automatic homogenization equipment for textile fabrics, which comprises a transmission mechanism, which is used for conveying textile fabrics; A homogenizing device for smoothing and uniformity and a scraping device for scraping off the residual slurry on the surface of the homogenizing device arranged on one side of the homogenizing device; Furthermore, the problem of non-uniform thickness of the slurry sprayed on the surface of the cloth during the sizing process is overcome.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

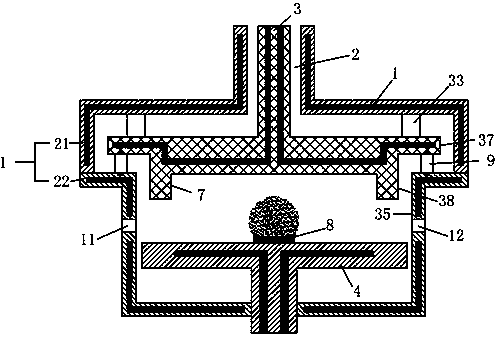

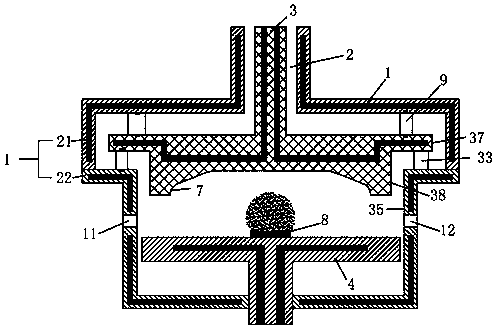

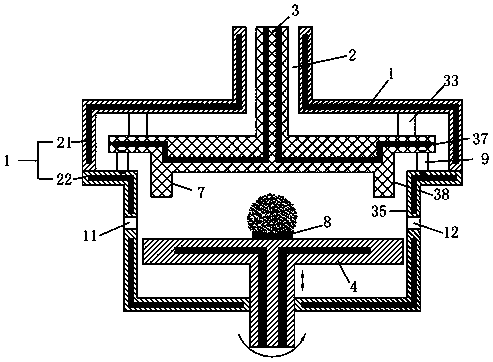

MPCVD (microwave plasma chemical vapor deposition) device

ActiveCN110565160ASolving Plasma Etching ProblemsSolve etching problemsPolycrystalline material growthFrom chemically reactive gasesPhysicsMicrowave plasma chemical vapor deposition

The invention discloses an MPCVD (microwave plasma chemical vapor deposition) device. The MPCVD device comprises an upper cavity, a lower cavity, a center shaft, a sample table, sealed insulating parts, insulated supporting parts, a gas inlet and a gas outlet, wherein the center shaft is arranged above a reaction cavity and forms a coaxial waveguide allowing microwave feed-in with the reaction cavity; the sample table arranged below the reaction cavity is used for substrate placement, and the center shaft facing one side of the sample table is provided with a sunken structure surface; the sealed insulating parts and the insulated supporting parts are arranged in the coaxial waveguide, meanwhile, the lower end surface of the center shaft is lower than the lower end surfaces of the sealed insulating parts and the lower end surfaces of the insulated supporting parts, and the sealed insulating parts and the insulated supporting parts are away from plasma, thereby avoiding being etched by the plasma; and the gas inlet and the gas outlet adopt a horizontal gas inlet and outlet mode, and high-quality and high-uniformity epitaxial growth on the substrate is facilitated. The problem about high-power microwave feed-in in the reaction cavity is solved, stable and reliable vacuum sealing is realized, and uniformity of reaction gas is guaranteed.

Owner:广东众元半导体科技有限公司

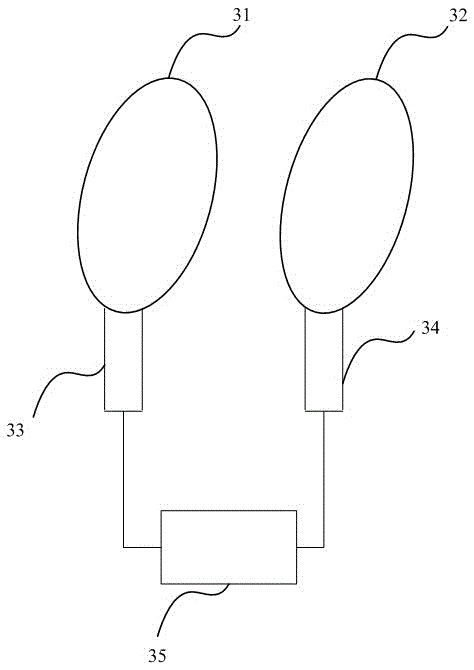

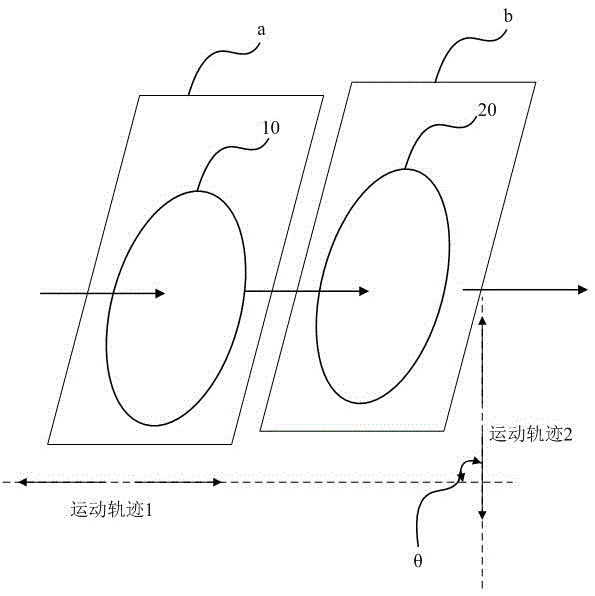

Laser light source and laser projection equipment

ActiveCN105629647AIncrease the number ofImprove display qualityProjectorsOptical elementsLight beamLaser light

The invention discloses a laser light source, which comprises one or more groups of lasers, wherein each laser emits a laser light of at least one color; a spot dispersing device is arranged in a transmission light path of the laser light of at least one color; the spot dispersing device comprises a first diffusion component and a second diffusion component, which are sequentially arranged; one of the two diffusion components is driven to rotate and the other one is driven to swing or translate, so that, when laser beams sequentially pass through the two diffusion components, the ranges of spatial positions with phase changes are increased; the probability of relatively low correlation between the changed phases is increased; the quantity of random phase patterns can be greatly increased; the spot dispersing effect is weakened by human eye integration action; and the target of relatively well dispersing the spots is achieved. The invention further discloses laser projection equipment employing the laser light source disclosed by the invention.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

Cement powder strength homogenizing device with higher uniformity

InactiveCN106976160AImprove uniformityImprove the homogenization effectSievingGas current separationEngineeringMotor drive

The invention discloses a cement powder pneumatic homogenization device with higher uniformity, which includes a homogenization tank, a feeding device, a homogenization fan and a homogenization mesh screen, wherein: the feeding device is arranged on the top of the homogenization tank, and The homogenizing fan is installed on the side of the homogenizing tank, and the homogenizing screen is located near the bottom of the homogenizing tank; in addition, the homogenizing fan is equipped with a spherical filter towards the center of the homogenizing tank; the outer surface of the homogenizing screen passes through The transmission gear and the screen motor drive it to rotate, and a gear structure is provided at the joint between the homogenization screen and the transmission gear; and the bottom of the homogenization tank is provided with a hemispherical outlet. The pneumatic homogenization device of the present invention is provided with a homogenizing mesh screen near the bottom of the homogenizing tank, and the homogenizing mesh screen uses a transmission gear and a motor to drive the rotation, which can be controlled independently and has a good homogenization effect. The obtained cement The uniformity of the powder is good, and the effect of later use is better.

Owner:NANTONG HONGYA MACHINERY MFG

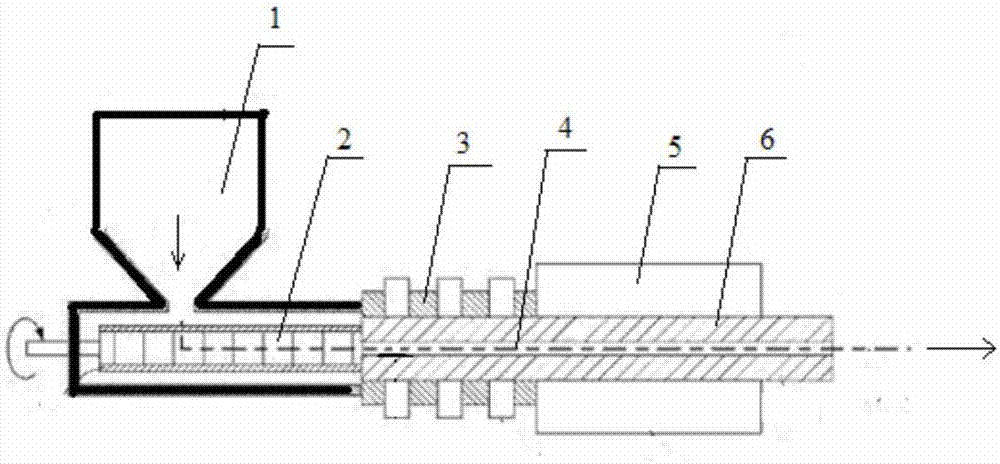

Preparation method of homogenized specially-shaped cigarettes

The invention discloses a preparation method of homogenized specially-shaped cigarettes. The preparation method comprises the following steps: grinding a tobacco raw material, carrying out mixed granulation on the grinded tobacco raw material and a solution containing a combustion promoter, an adhesive, a humectant and tobacco essence, and carrying out drying, thus obtaining reconstituted tobaccoparticles; adding an adhesive on the surfaces of the reconstituted tobacco particles, and preparing tobacco particle round rods by adopting a tobacco particle round rod forming device; and wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carrying out compounding with filter sticks, thus obtaining the highly homogenized specially-shaped cigarettes. The specially-shaped cigarettes are good in quality controllability, the homogeneity and stability of the quality of the cigarettes can be guaranteed to the maxim, the phenomena of tobacco shredfalling at the cut openings and empty heads existing in the conventional cigarettes are avoided, the smoking is smooth, and the satisfaction is strong. The cross sections of the cigarettes have special patterns, the appearance is novel, and good sensual experience can be endowed to a consumer.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Method for preparing brick material of wall body with sludge compound mineralized refuse

ActiveCN108947483ARealize resource utilizationTurn waste into treasureSievingSludge treatment by de-watering/drying/thickeningBrickSludge

The invention discloses a method for preparing a brick material of a wall body with sludge compound mineralized refuse. The method comprises the following steps: homogenizing mineralized refuse powderand dried sludge powder in a horizontal homogenizer; adding a doping material, and mixing to obtain a mixed material; stirring the mixed material for three times, aging twice and extruding once to obtain a raw brick; and finally drying the raw brick in a drying kiln, and sintering and molding in a roasting kiln to obtain the brick material of a wall body. The brick material of a wall body sintered by the dried sludge powder, the mineralized refuse powder and the doping material has performance in conformity with national standard, the comprehensive resource utilization performance of sludge and mineralized waste can be improved, and the sludge homogenizing problem can be solved. The preparation method is simple in process and is favorable to popularization.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Controlling method of center segregation of continuous casting

The invention belongs to the technical field of steel-making continuous casting, and discloses a controlling method of center segregation of a continuous casting. The method comprises the steps of high superheat controlling: the superheat of molten steel in a pouring box is controlled at 30 DEG C or above; strong secondary cooling controlling: in secondary cooling, secondary cold water amount is increased by 20-50%; downward screwing controlling: at the solidifying final stage of the production process of the continuous casting, the downward screwing depth is controlled at 4.2-7.2 mm; the components of the molten liquid is controlled at, by mass, 0.09-0.12% C, 1.85-2.20% Mn and 0.1-0.2% Ti. The controlling method of the center segregation of the continuous casting is used for high-strengthsteel and pipe line steel, through specific component element controlling and superheat, downward screwing amount and secondary cooling strength controlling, the segregation is compressed at a central line region, and component homogenizing performance is improved.

Owner:SHOUGANG CORPORATION +1

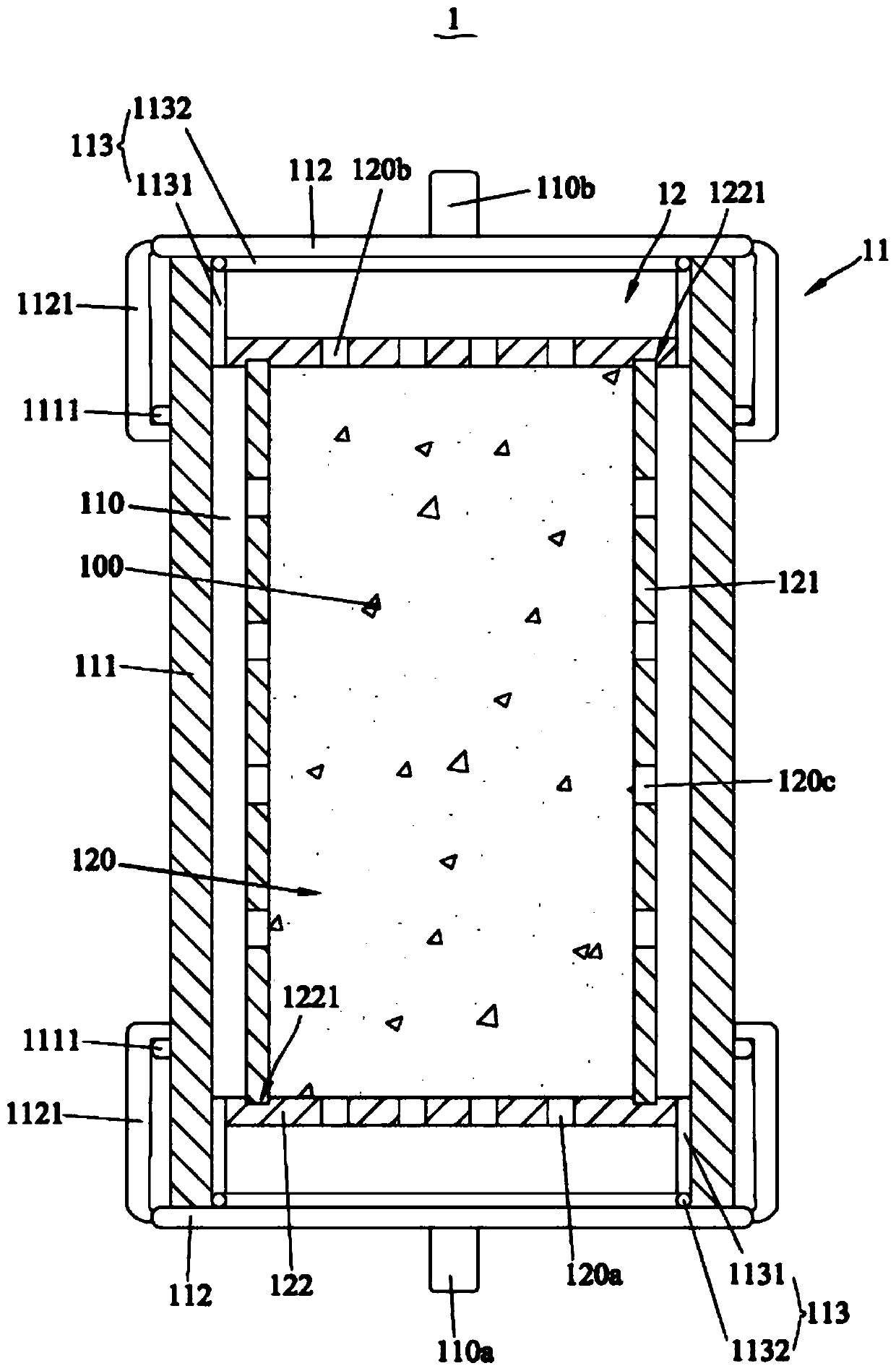

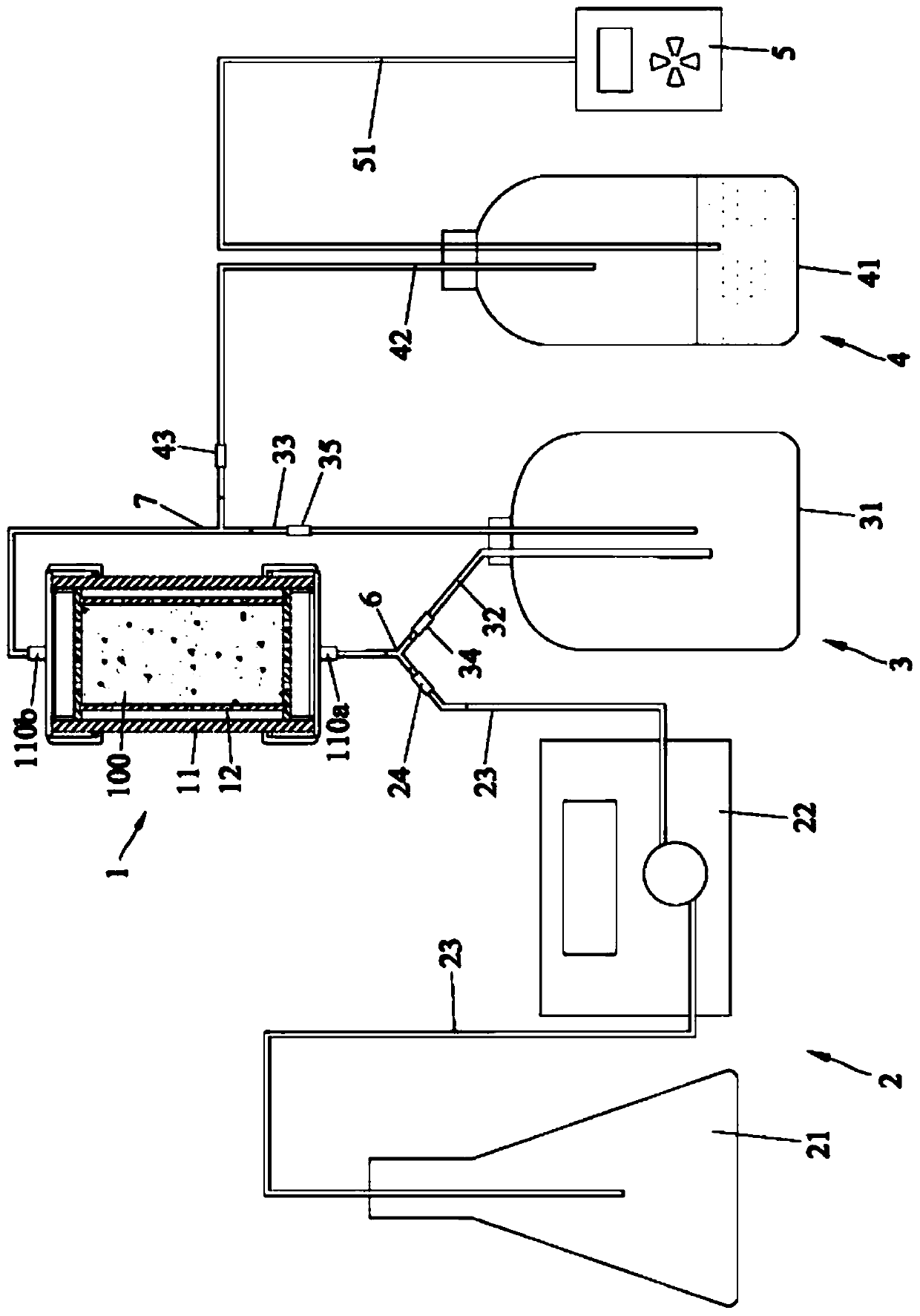

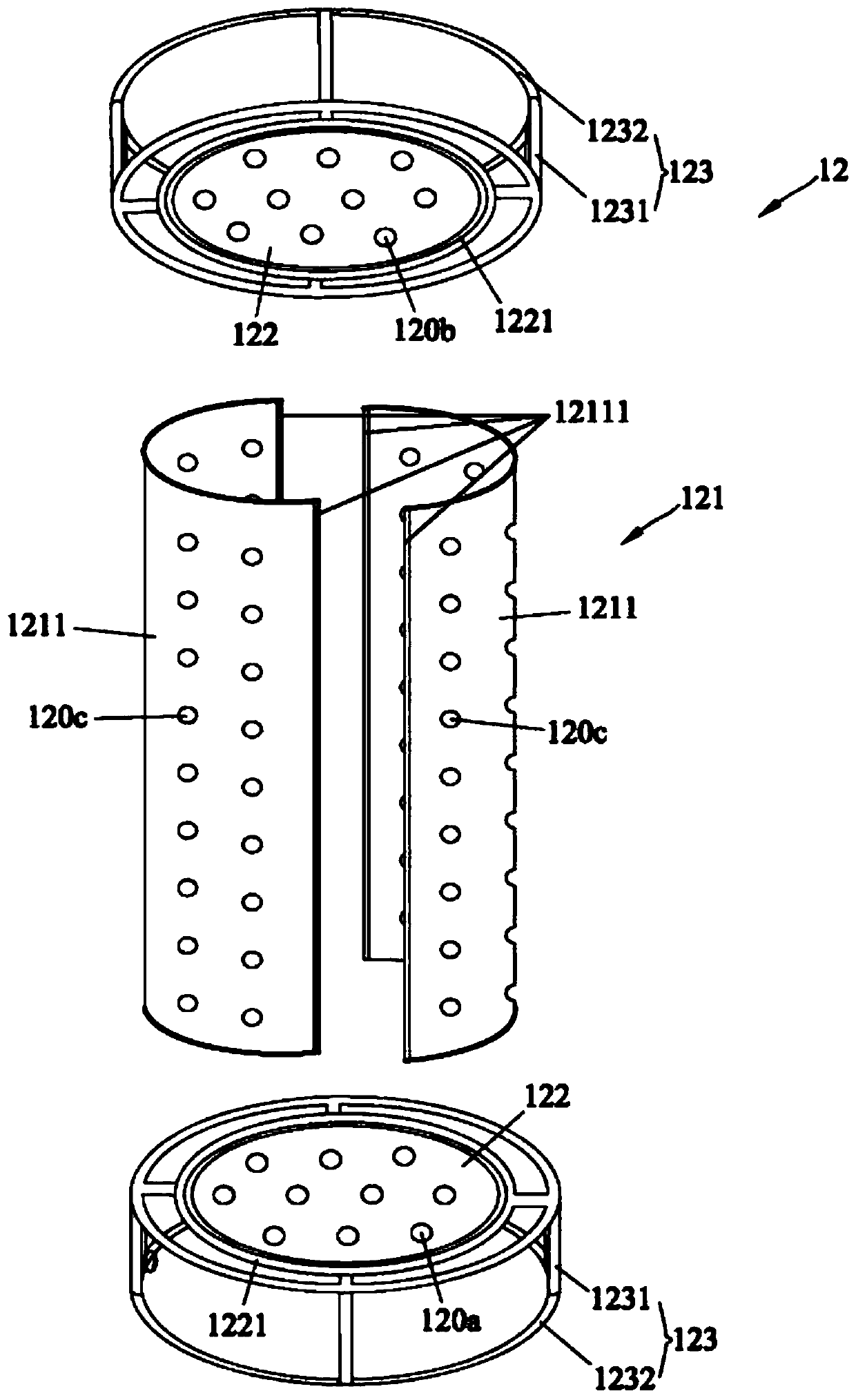

Microorganism reinforcing reaction Device, system and method

InactiveCN111334419AUniform gelationImprove the homogenization effectBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryBiology

The invention discloses a microorganism reinforcing reaction device, system and method. According to the microorganism reinforcing reaction device disclosed by the invention, the two axial ends of aninner cylinder arranged in a chamber of an outer cylinder are propped against the end wall of the outer cylinder through a supporting frame, so that the inner cylinder is positioned; and first throughholes, second through holes and third through holes, which communicate with an accommodating chamber, are formed in two end walls and the periphery wall of the inner cylinder in the axial direction,so that channels allowing substances to pass in and out of the accommodating chamber are formed in the periphery of the inner cylinder. In the sample preparing process, after reaction liquid of the predetermined capacity is injected into the chamber through a first channel or a second channel, under the action of pressure, the reaction liquid enters into a rock sample in the accommodating chamberin a multi-oriented manner through the first through holes, the second through holes and the third through holes, and is uniformly, relatively quickly and gradually diffused to the inner part of the whole rock sample for reaction, so that the rock sample can be uniformly gelled, and the homogenizing effect is improved.

Owner:SUN YAT SEN UNIV

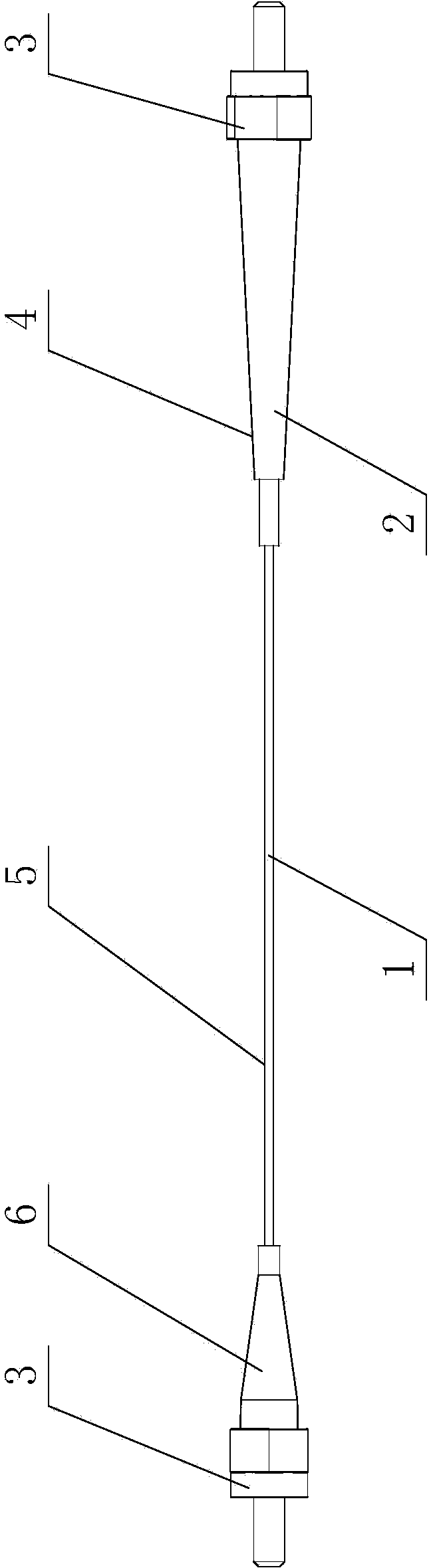

Light spot homogenizing device and manufacturing method thereof

ActiveCN103439772AGood homogenization effectEasy to makeLaser detailsCoupling light guidesSemiconductorCoating

The invention discloses a light spot homogenizing device. The light spot homogenizing device comprises an optical fiber, wherein the optical fiber comprises an input end socket, an output end socket and a homogenized optical fiber formed by heat treatment; an optical fiber protecting sleeve is sleeved outside the optical fiber; the output end socket of the optical fiber is provided with an optical fiber tail sleeve; an optical fiber heat shrinkable tube is arranged on the homogenized optical fiber of the optical fiber. The invention further discloses a manufacturing method of the light spot homogenizing device. The manufacturing method comprises the steps of stripping a coating layer on the optical fiber; carrying out heat treatment on the optical fiber part without the coating layer, wherein the temperature is 1300-1500 DEG C; after enabling the optical fiber without the coating layer to reach a fused state, cooling the optical fiber; covering the optical fiber protecting sleeve on the whole optical fiber and covering the optical fiber tail sleeve on the output end socket of the optical fiber; fixing the optical fiber of the heat treatment part by using the optical fiber heat shrinkable tube. The light spot homogenizing device is good in homogenizing effect and the manufacturing method is simple and convenient; the problem that output light spots of a semiconductor laser device are not uniform is solved effectively.

Owner:WUXI LUMISOURCE TECH

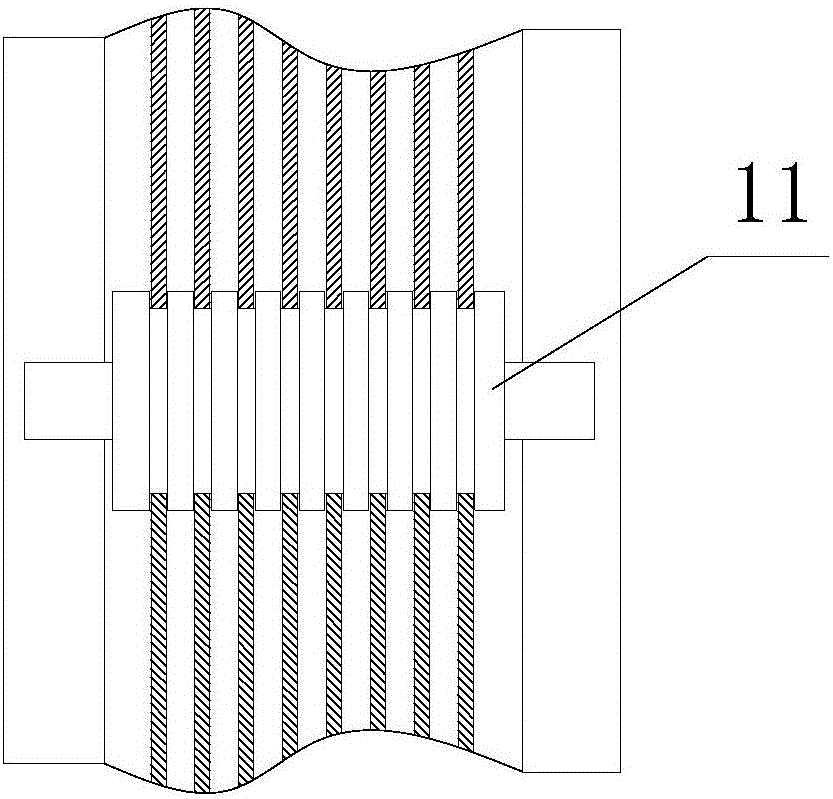

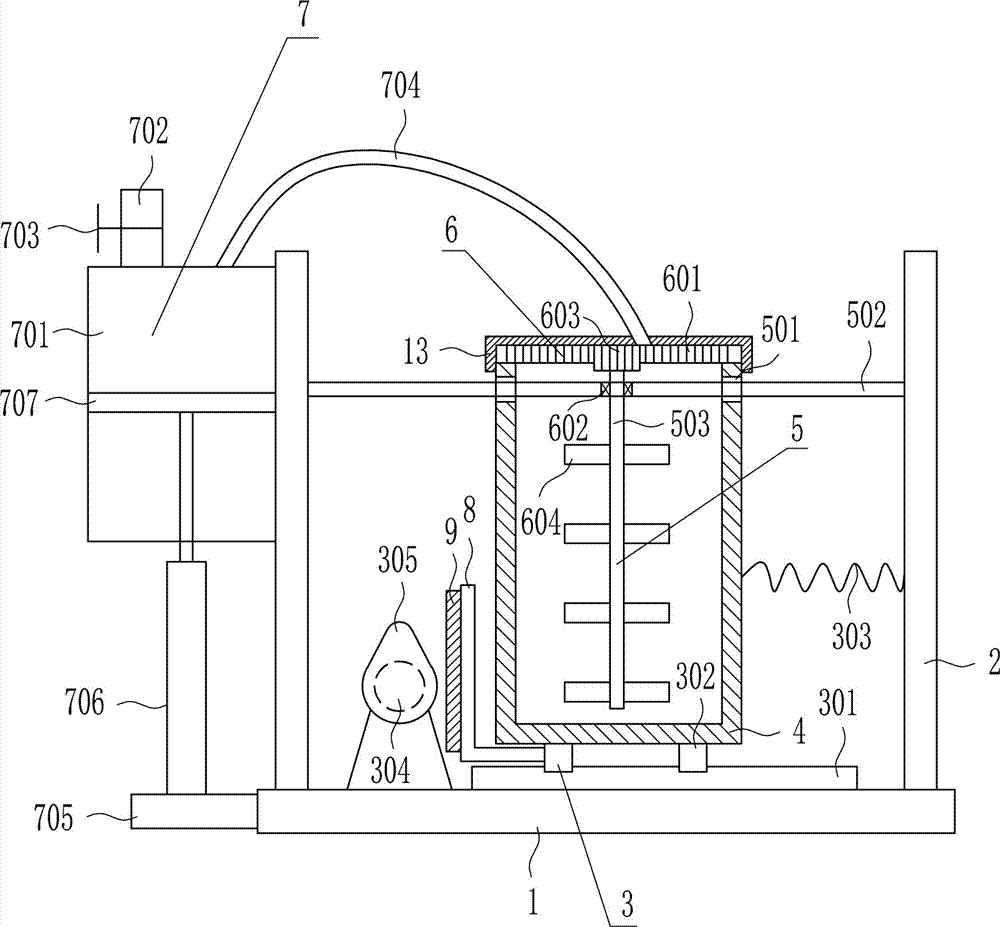

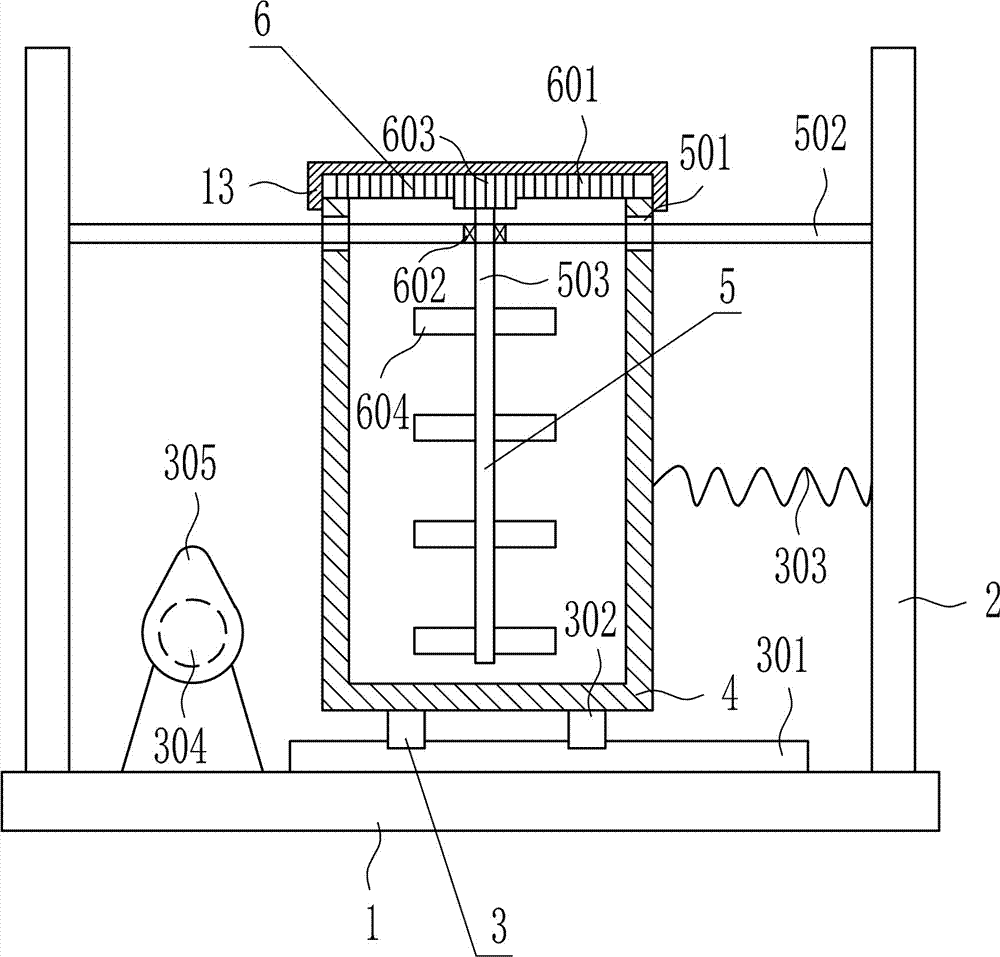

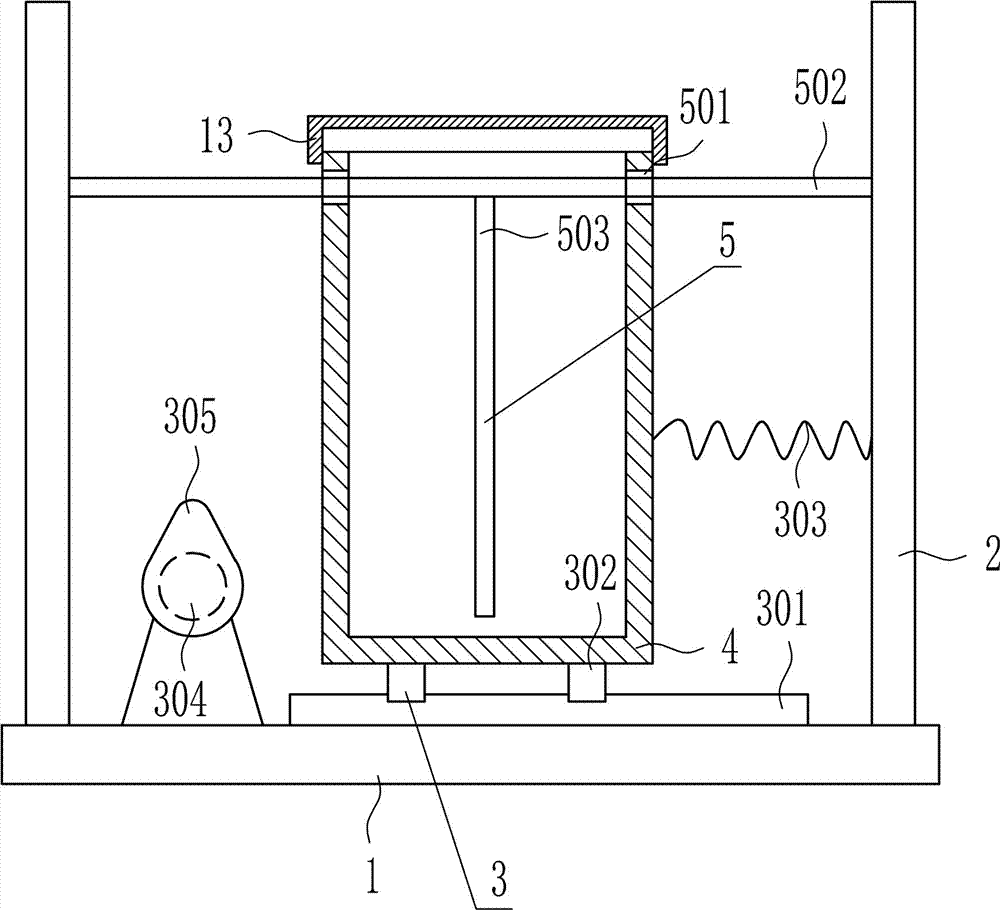

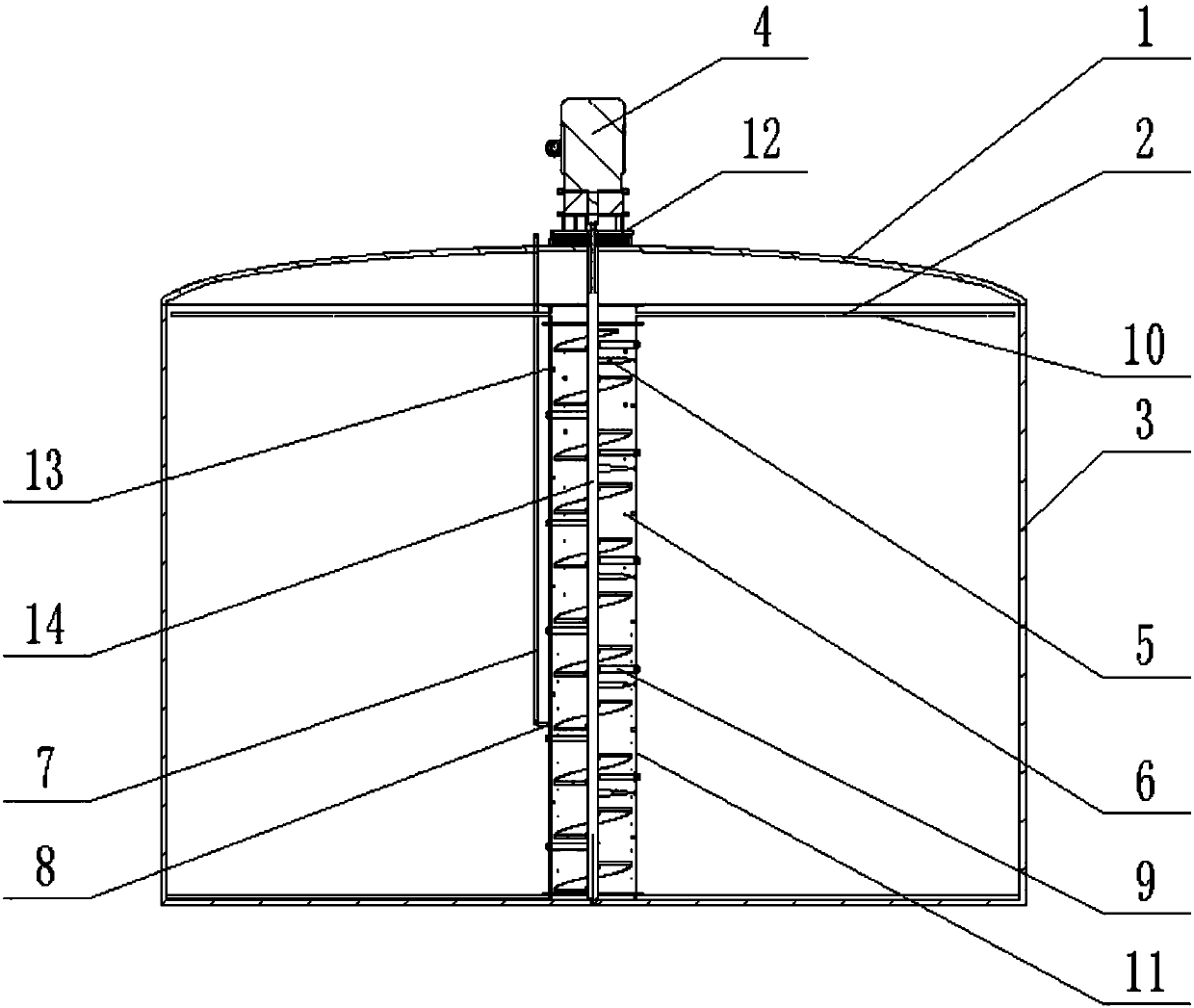

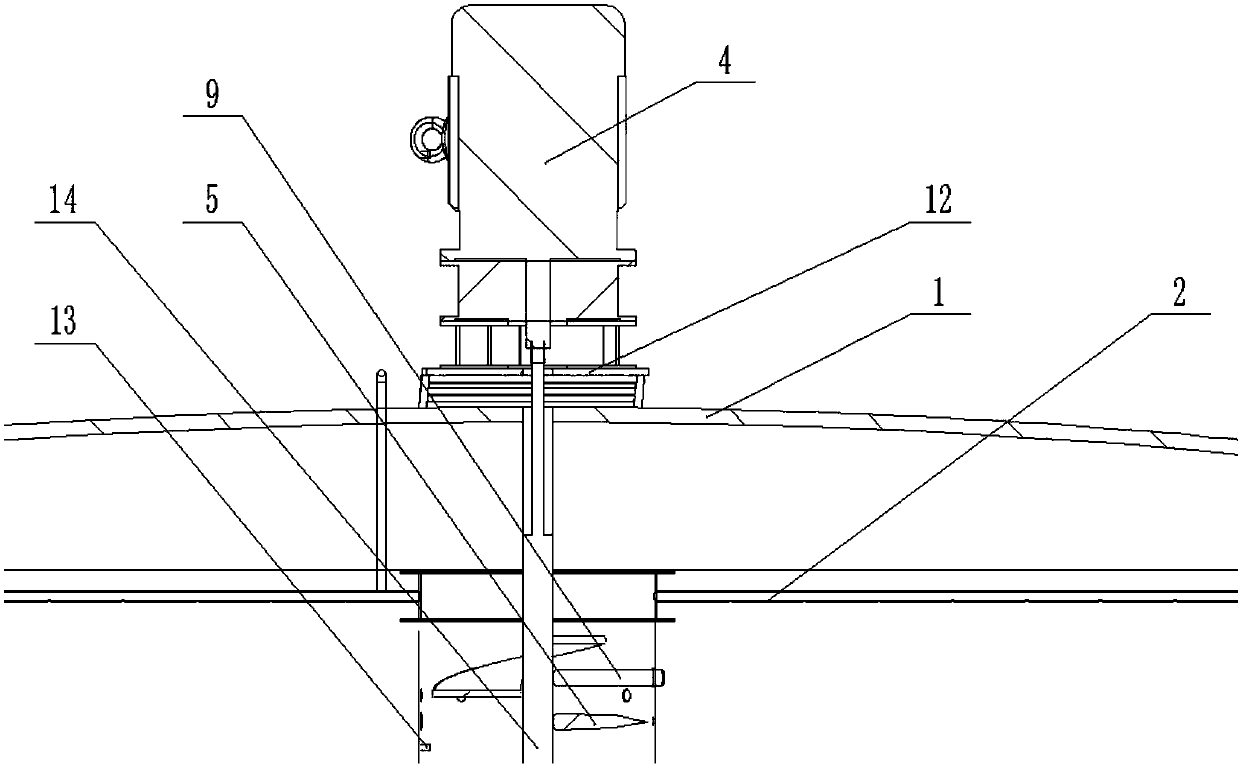

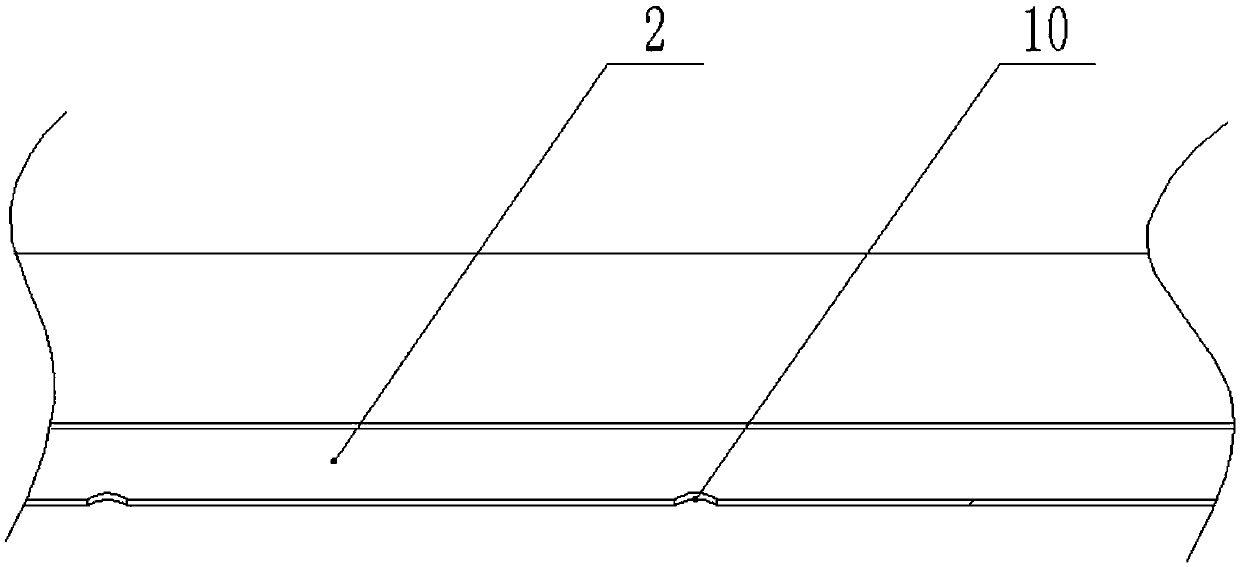

Mechanical ultrasonic composite homogenization system in storage tank

PendingCN107930475AImprove the homogenization effectEvenly distributedShaking/oscillating/vibrating mixersTransportation and packagingChemical industryUltrasonic sensor

The invention relates to a mixer and in particular to a mechanical ultrasonic composite homogenization system in a storage tank. The system comprises an upper tank cover, a tank, a mechanical rotationstirring motor, a motor fixing rack, a liquid taking tube, a liquid mixing cylinder, packing auger spiral blades, ultrasonic transducers and temperature sensors, wherein a plurality of ultrasonic transducers are alternately staggered on the inner wall of the liquid mixing cylinder and are alternately arranged with the packing auger spiral blades; liquid inlet holes and a liquid taking hole are formed in the outer wall of the liquid mixing cylinder; liquid discharge tubes are arranged at the top end of the liquid mixing cylinder; liquid discharge holes are formed in the lower surfaces of the liquid discharge tubes; the motor fixing rack is used for fixing the mechanical rotation stirring motor in the center of the upper tank cover and is connected with the central shaft of the liquid mixing cylinder; when the motor is powered on, the packing auger spiral blades are rotated around the central shaft, then vortex liquid flows are formed, and the vortex liquid flows are ejected out from the liquid discharge holes in the top ends under the action of the ultrasonic transducers. The system is applicable to homogenization of petroleum and non-homogeneous liquids of the chemical industry, and by adopting the system, the problems that conventional homogenization mixing equipment is poor in homogenization mixing effect, high in energy consumption, low in efficiency, and the like.

Owner:HARBIN HITTOP TECH CO LTD

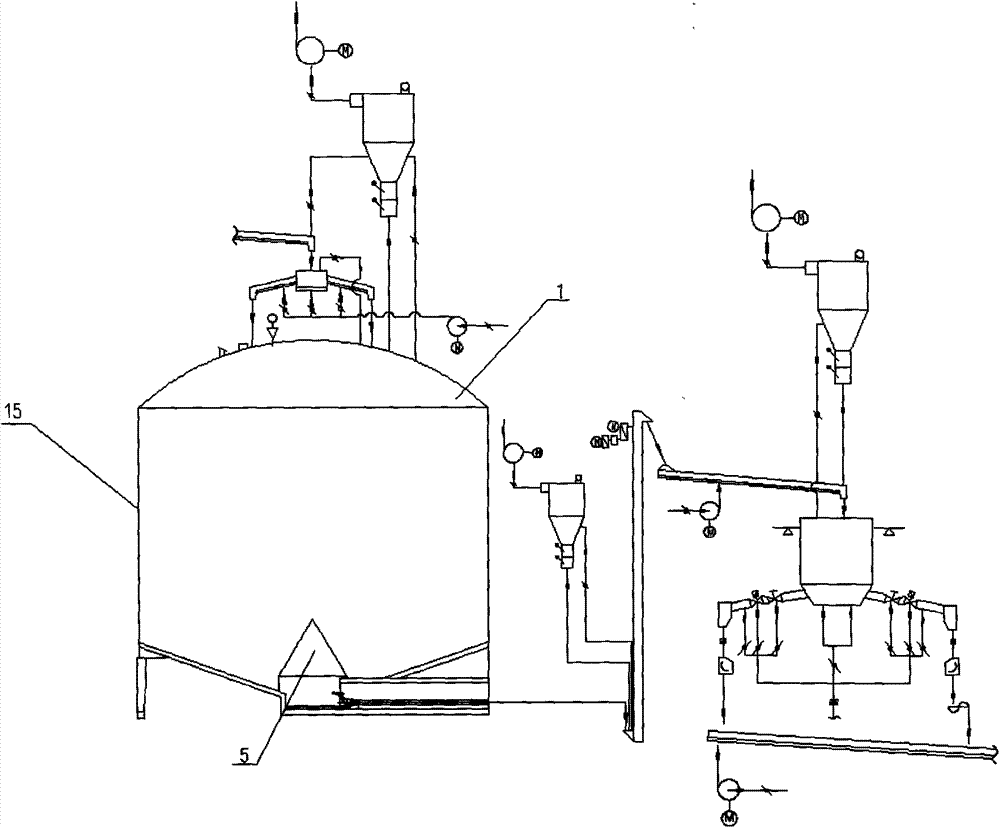

Cement raw meal conveying system

InactiveCN103387121AImprove homogenizationHigh strengthMechanical conveyorsImpellerAdditive ingredient

The invention discloses a cement raw meal conveying system, which comprises a homogenization silo, two hopper type lifting machines, a raw meal homogenization measuring cabin, a speed regulating and quantitative feeding machine, an impeller feeding machine, a steel wire twisted lifting machine, an electric equal tee valve and a spiral conveyor. The system has the advantages that by adopting a double-hopper lifting machine to lift raw meal, the capability of homogenization is improved, a spiral stirring device and a load sensor are additionally mounted on a raw meal cabin, the phenomena of a full cabin and the blockage of conveying pipelines are eliminated, the homogenization function on the raw meal is improved again, and the homogenization degree of the raw meal is improved; after the system is used, the problem of fluctuation in raw meal ingredients is thoroughly solved, and the quality of ripe meal is greatly promoted; and the overall raw meal conveying system forms a self-circulation system, once material blockage or a fault occurs in a preheater, raw meal in the conveying device can be timely circulated back to the raw meal homogenization silo, and as long as the position of the homogenization silo premits, the raw meal preparation system is not required to be shut down for long due to the fault of the preheater.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

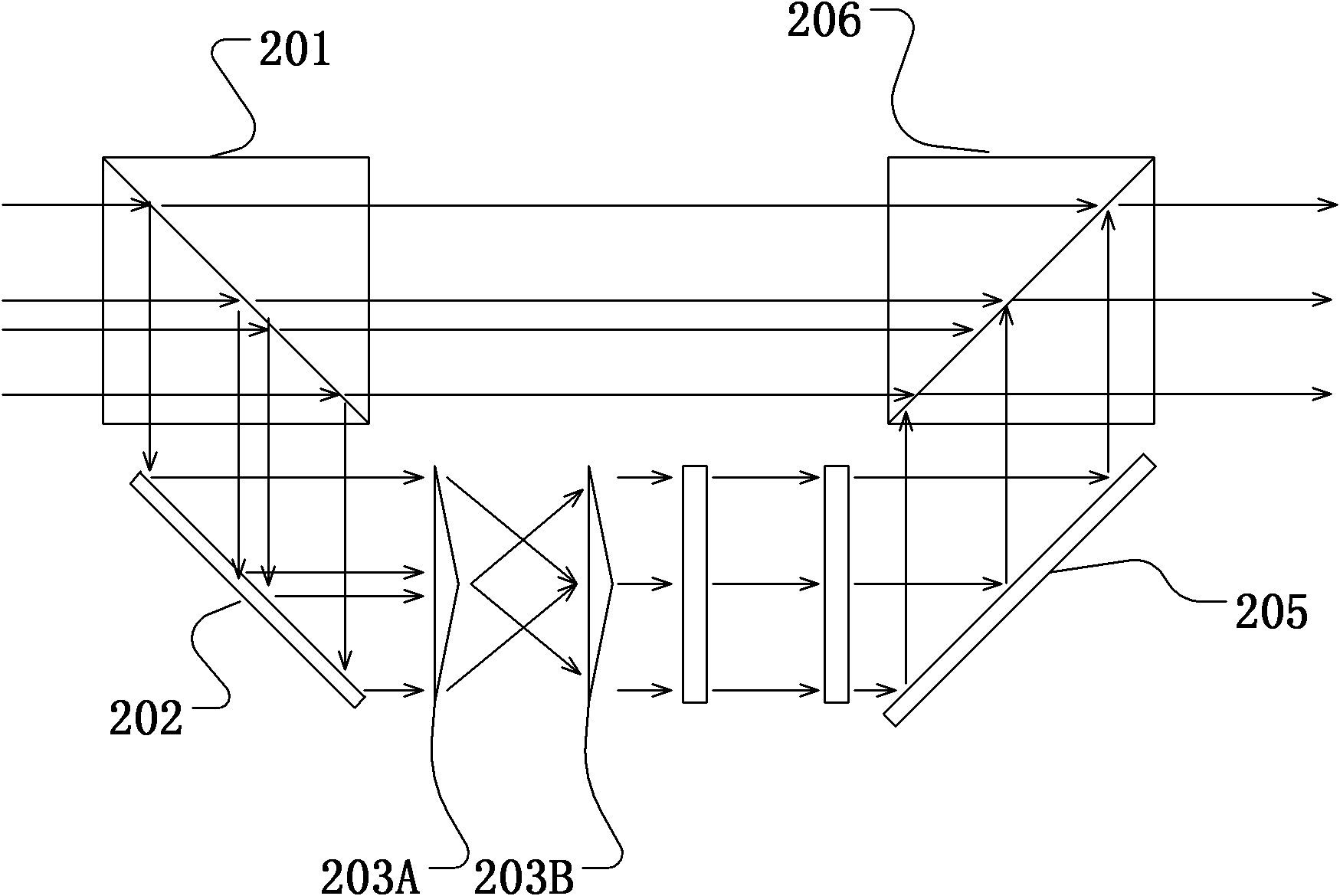

Improved development process for light beam homogenization device

InactiveCN102053372AImprove the homogenization effectReduce difficultyOptical elementsLight beamOptoelectronics

The invention relates to an improved development process for a light beam homogenization device. The device can be applied to laser annealing or other fields having demand on homogenizing light beams. The improved development process provided by the invention is characterized in that the pre-homogenization process is introduced, a random phase plate, a lens array and an integral rod are organically combined, multistage homogenization is carried out on the light beams and the coherence influence is eliminated, thus the effect of homogenizing light beams is greatly increased, the demand on processing lens array is reduced, and the cost is lowered.

Owner:TSINGHUA UNIV

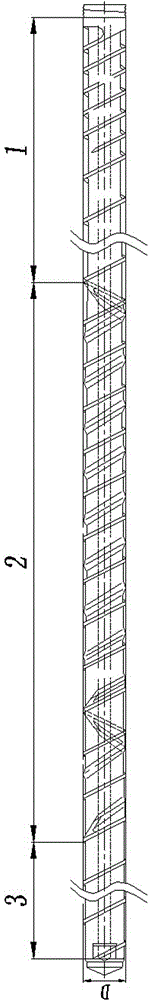

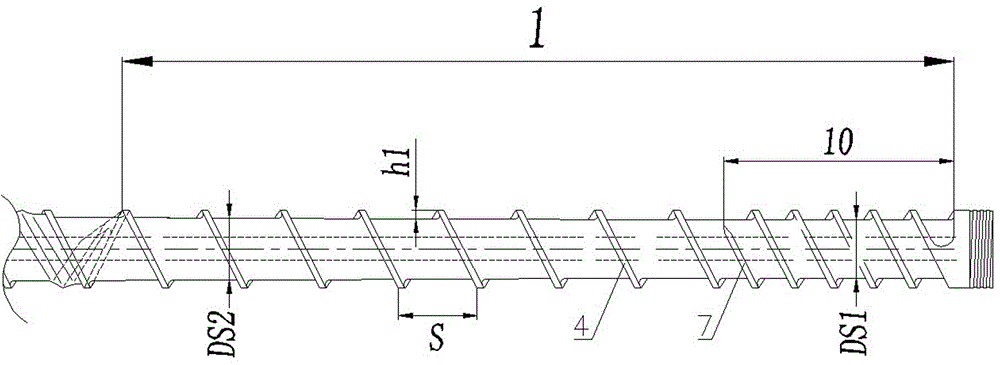

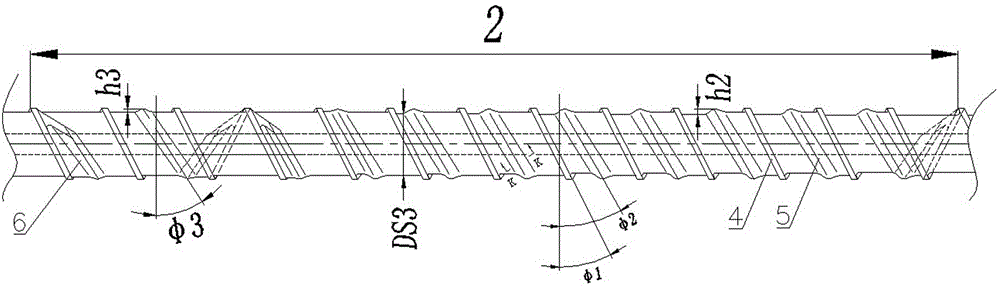

Special two-section BM type screw rod for wire and cable extruder

The invention provides a special two-section BM type screw rod for a wire and cable extruder. The homogenization effect is ideal, the probability of material self-heating is low, the consumed motor power is low, and the material conveying capacity is high. The special two-section BM type screw rod comprises a feeding section, a melting section and a homogenizing section, wherein a main thread is formed in the screw rod in the whole course; a first auxiliary thread and a second auxiliary thread which are connected end to end are formed in the melting section in the whole course; the groove depth h1 of the main thread is larger than the groove depth h2 of the first auxiliary thread and the groove depth h3 of the second auxiliary thread; the spiral angle Phi 1 of the main thread is smaller than the spiral angle Phi 2 of the first auxiliary thread; the spiral angle Phi 2 of the first auxiliary thread is smaller than the spiral angle Phi 3 of the second auxiliary thread; a double thread is arranged on the front section of the feeding section; the upper surfaces of the first auxiliary thread and the second auxiliary thread are arc-shaped; and the length-diameter ratio of the screw rod is 30:1, and the compression ratio i of the screw rod is equal to 1.3-1.8.

Owner:安徽普瑞斯电工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com