Cement raw meal conveying system

A conveying system, a technology for raw cement meal, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems such as the inability to know the amount of raw meal in time, the damage of the dust lifting pump motor, and the small storage capacity of the homogenization storehouse. Achieve simple and easy equipment maintenance and troubleshooting, prevent full warehouses and blockage of conveying pipelines, and reduce equipment power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

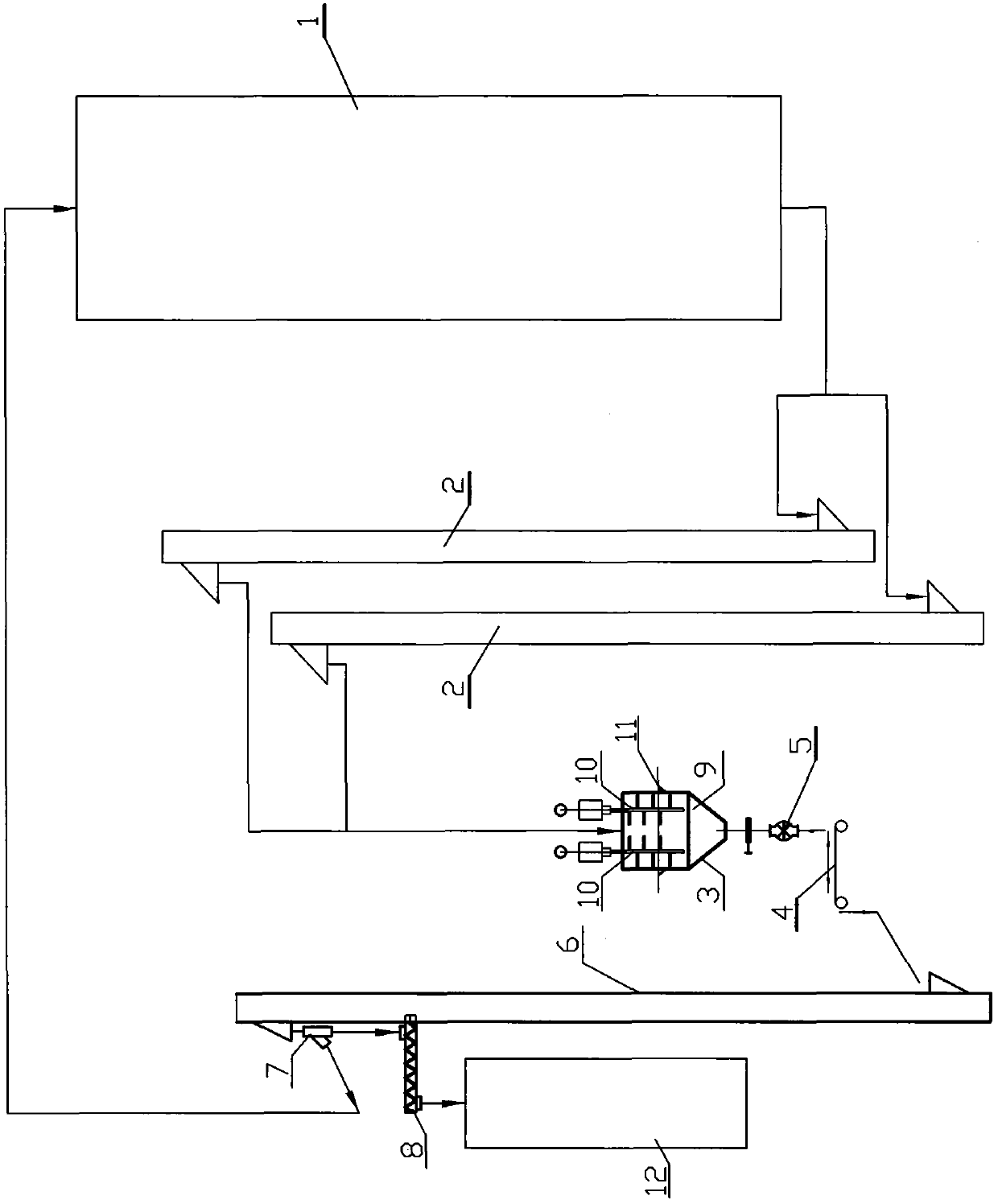

[0009] Embodiment 1: as figure 1 As shown, the cement raw meal conveying system includes a homogenization storehouse 1, two bucket elevators 2, a raw meal homogenization metering bin 3, a speed-adjustable quantitative feeder 4, an impeller feeder 5, and a steel wire rope hoist machine 6, electric positive three-way slide 7 and screw conveyor 8, wherein the outlet of the homogenization storehouse 1 is connected to the inlet of two bucket elevators 2, and double buckets are used to lift the raw material, which increases the homogenization capacity The outlets of the two bucket elevators 2 are connected to the inlet of the raw meal homogenization metering bin 3, and the outlet of the raw meal homogenization metering bin 3 is connected to the inlet of the speed-regulating quantitative feeder 4 The raw meal homogenization metering bin 3 comprises a metering bin main body 9, two adjustable-speed shock-absorbing screw mixers 10 and a load sensor 11, and two adjustable-speed shock-abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com