Patents

Literature

5220 results about "Screw conveyor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water.

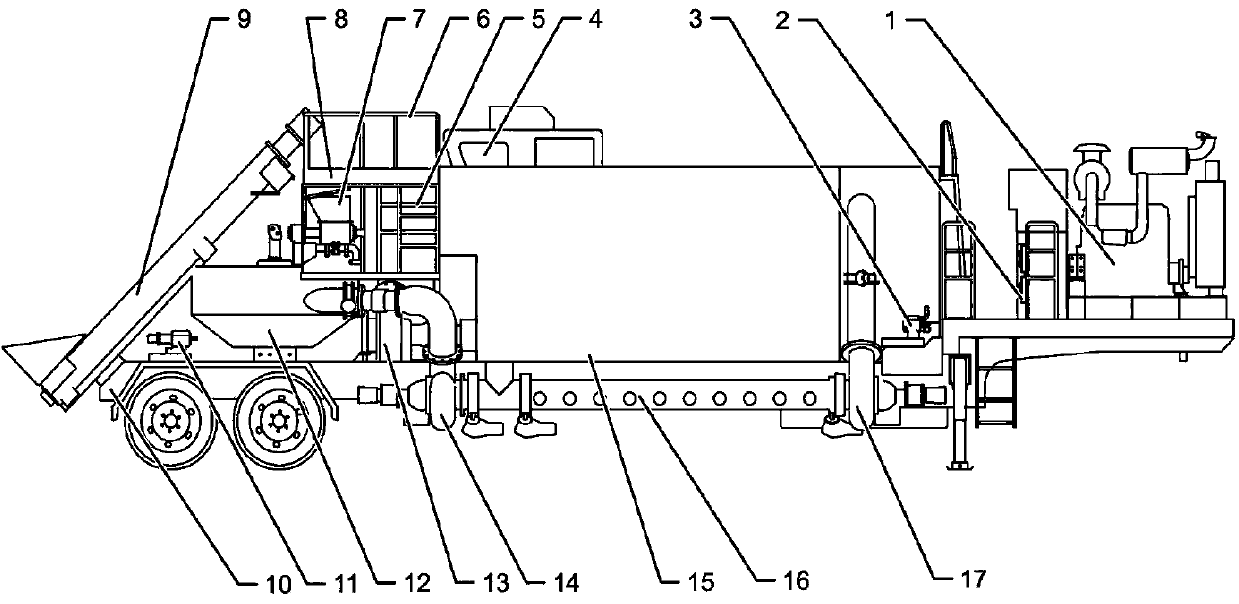

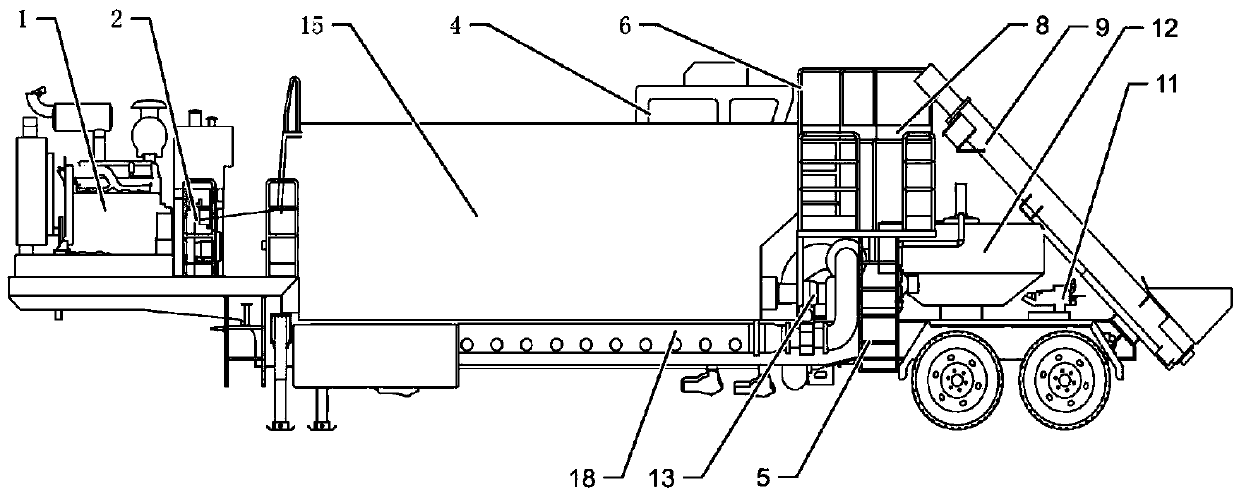

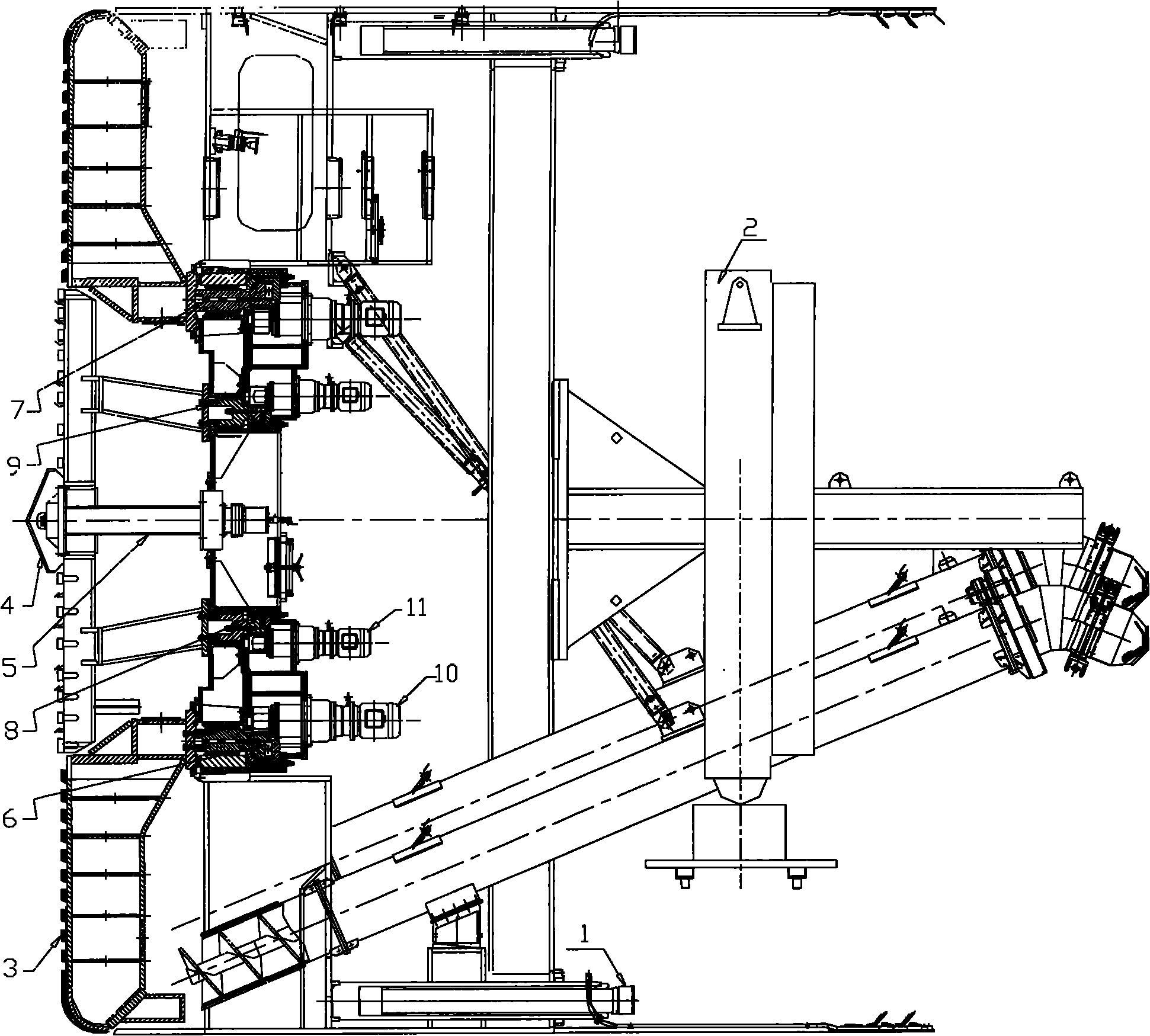

A fracturing fluid mixing sand mixing semi-trailer

ActiveCN103993869BReduce workloadLess supporting equipmentFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

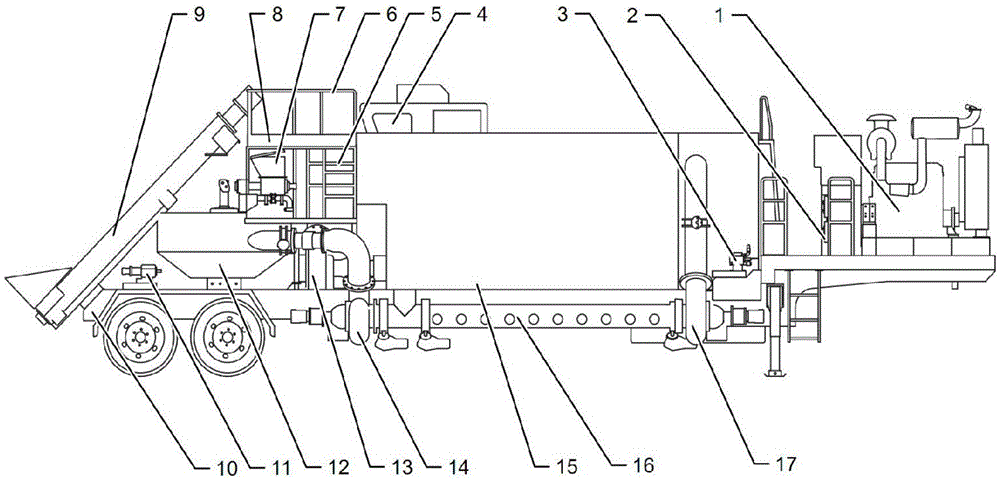

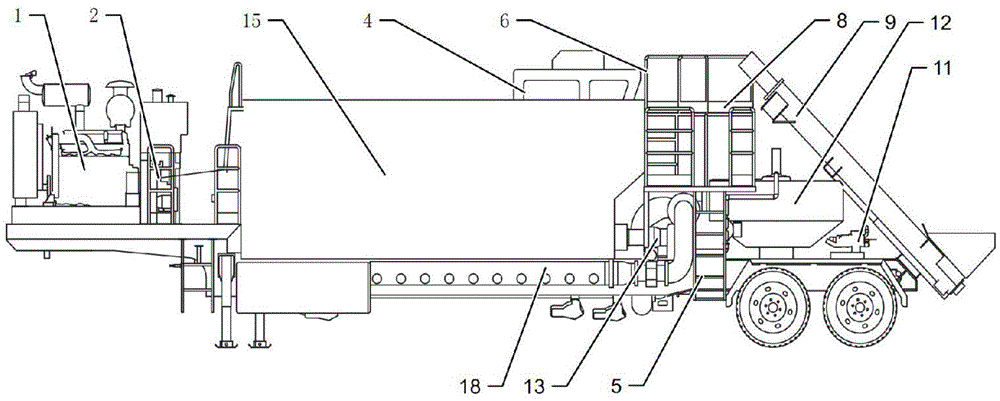

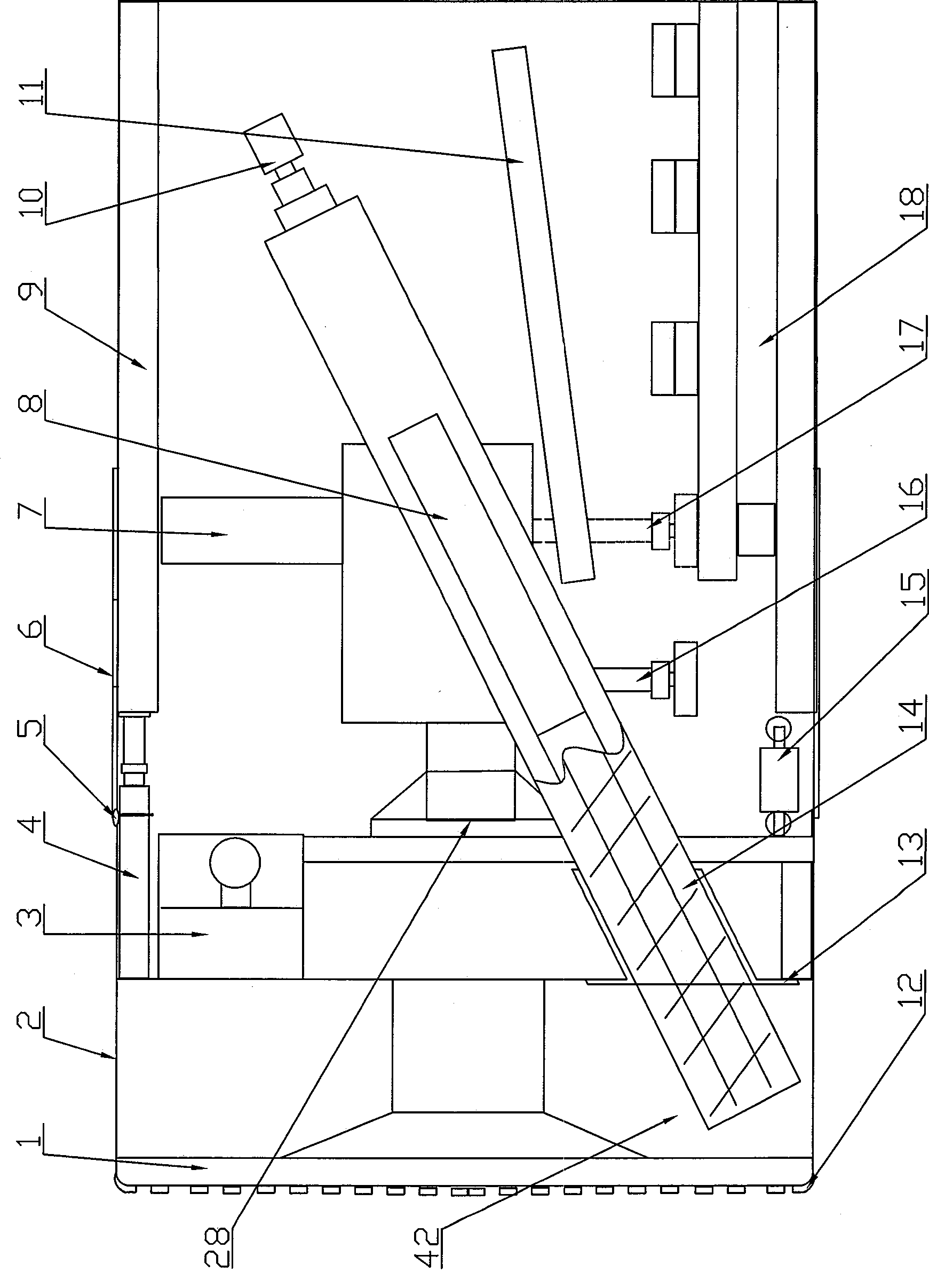

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

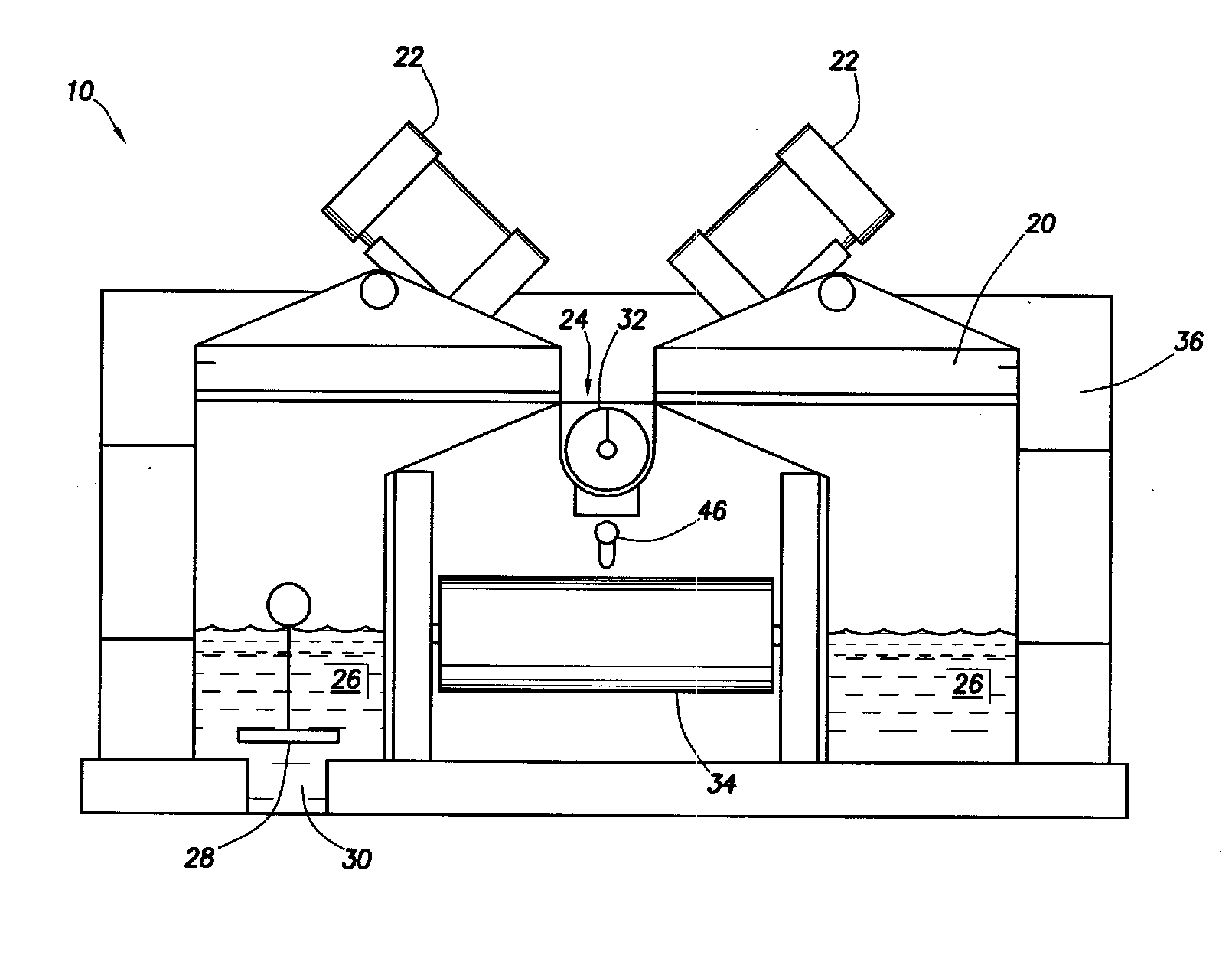

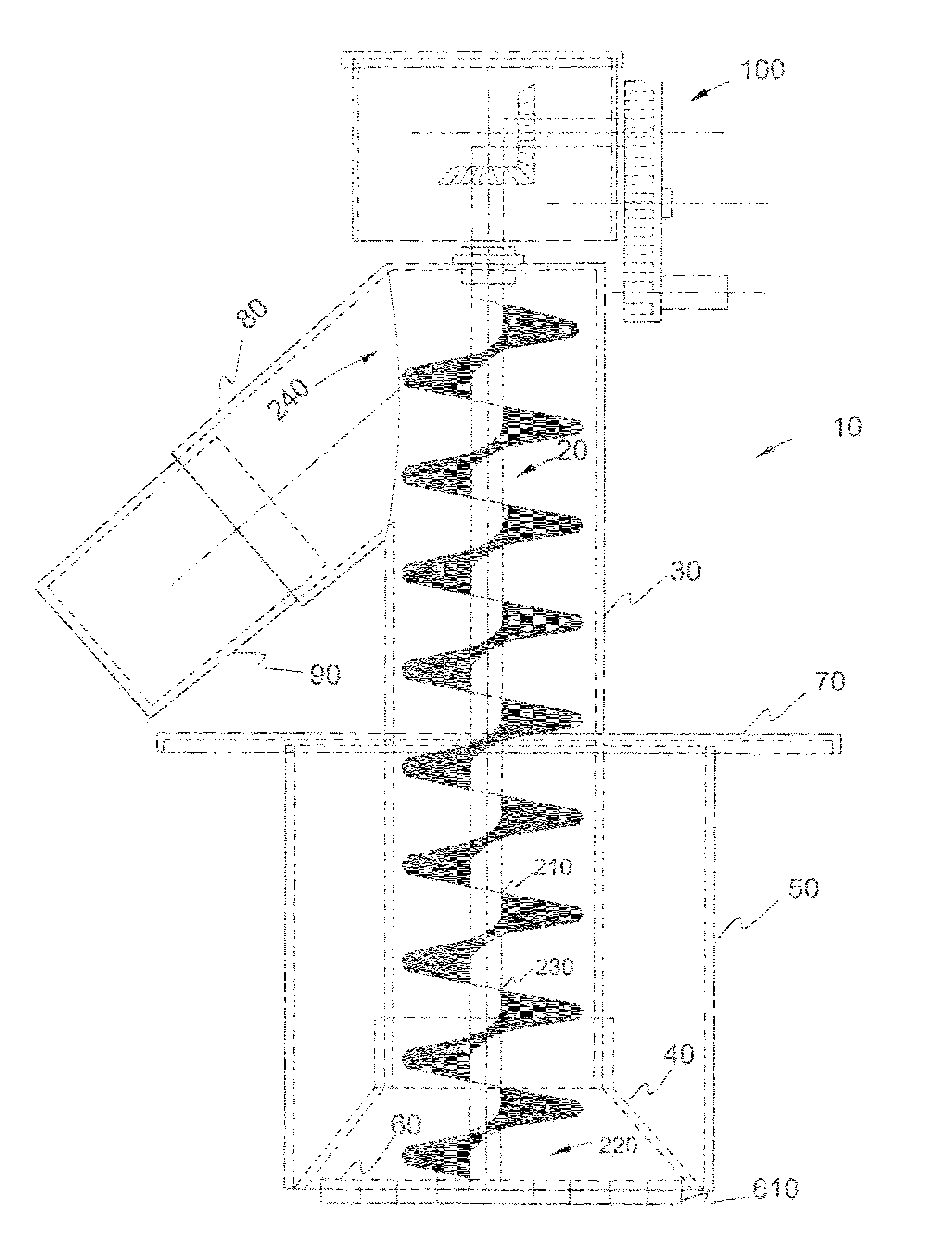

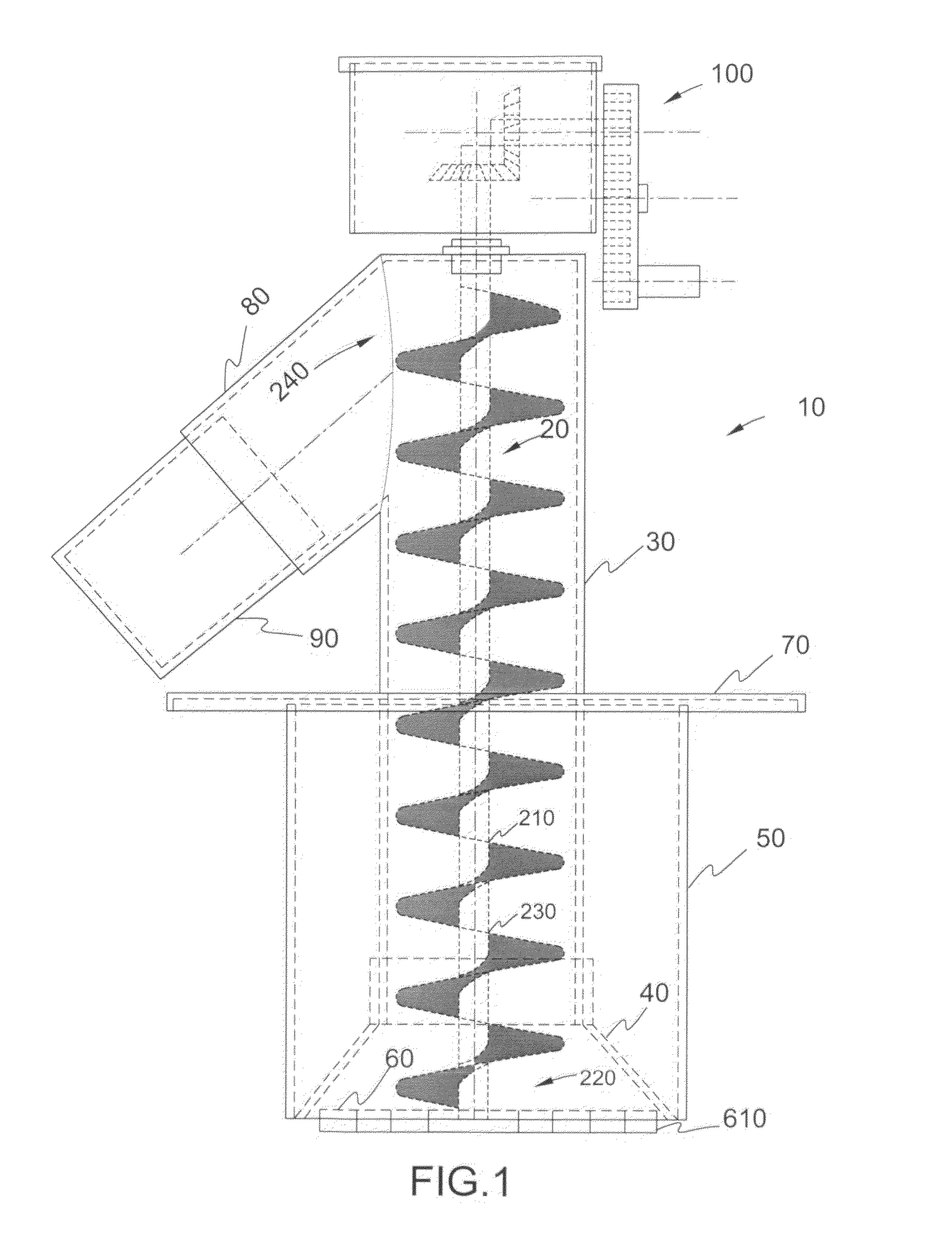

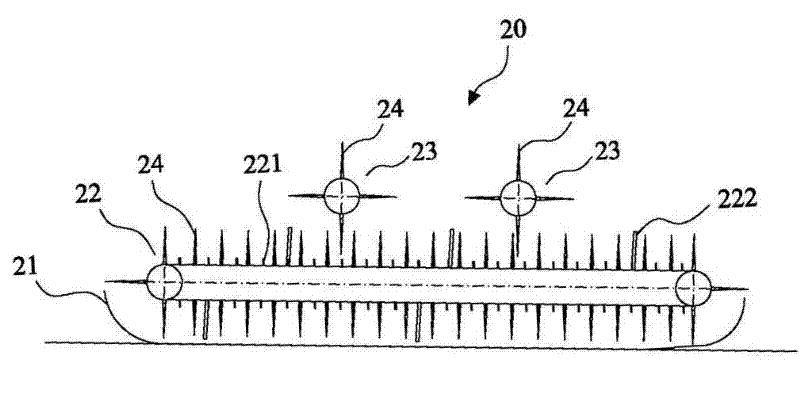

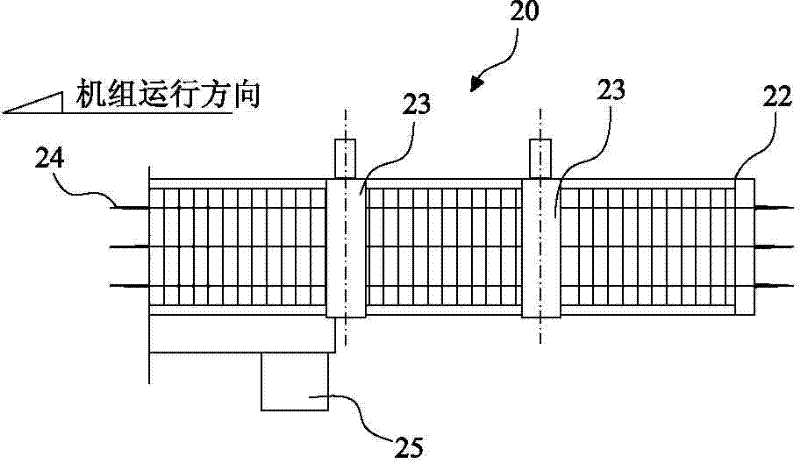

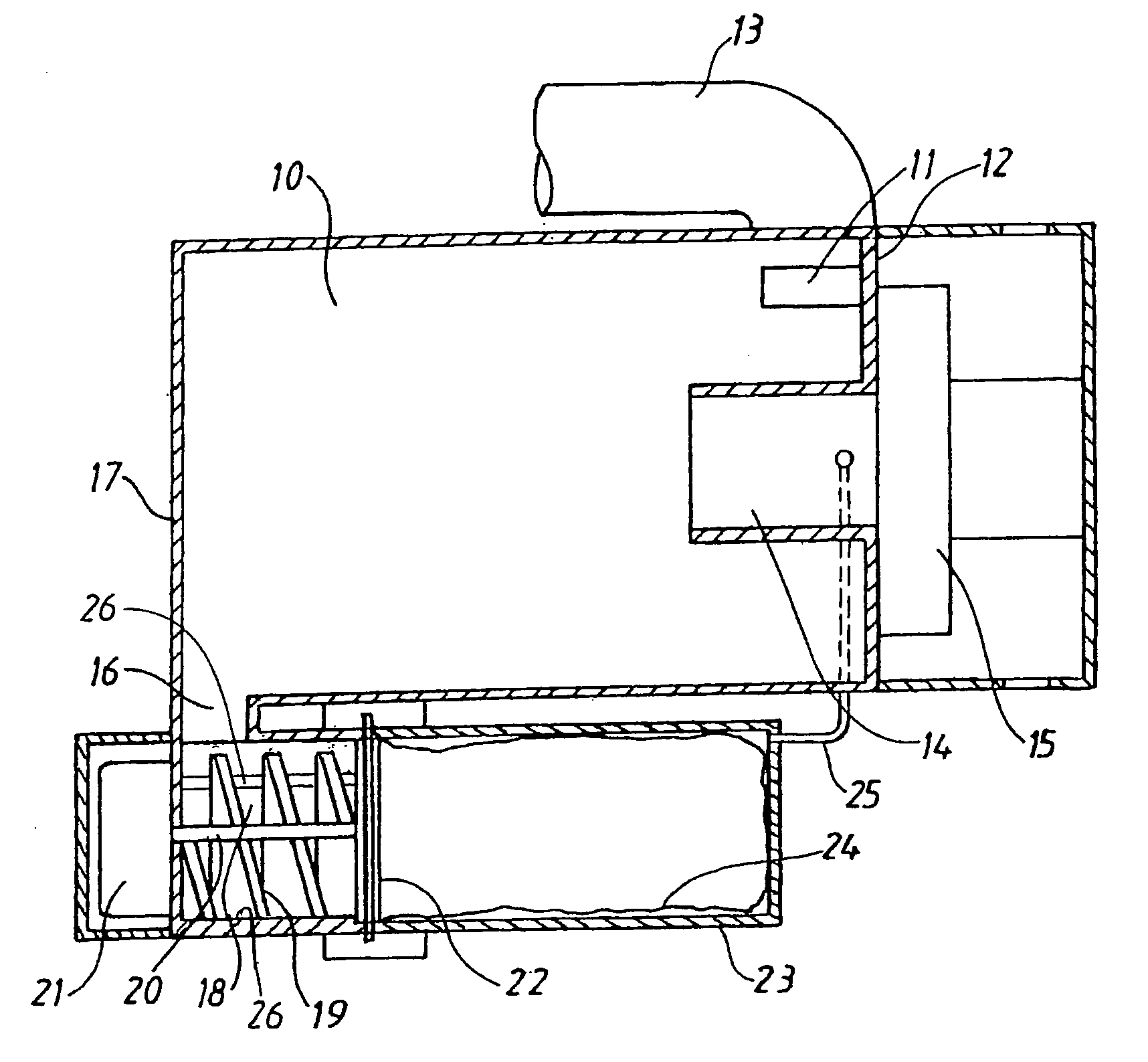

Food product surface sterilization apparatus and method

InactiveUS20040052702A1Increase temperatureReduce food product temperature changeFood preservationIndirect heat exchangersUnsafe conditionUltraviolet

An apparatus is disclosed for the micro-organism surface sterilization of foods using, a "germicidal" such as light waves (e.g., ultraviolet), and in some cases in combination with (or replaced by) one or more of sound waves and ozone. The surface sterilizer apparatus may include a plurality of germicidal (e.g., ultraviolet) emitters for surface sterilization of foods that are, e.g., rotated in a drum or rotated via a screw auger. Assemblies of emitters for the germicidal may be constructed to be watertight (i.e., withstand a high pressure, heated water spray), and movable relative to the drum or screw conveyor for easy cleaning and maintenance. The apparatus may also include a controller (e.g., programmable logic controller) for controlling the sterilization process so that the apparatus does not endanger personnel nearby, and so that the food is properly sterilized. The controller may vary the amount of germicidal used, the rate that food traverses the apparatus, the inclination of the apparatus, and terminate sterilization processing when an unsafe condition is detected. The apparatus may be used in-line with other food processing equipment for the real-time sterilization of food. The controller may also communicate with food processing components upstream of the apparatus for controlling the flow of food to the surface sterilizer

Owner:C & S EQUIP COMPANY

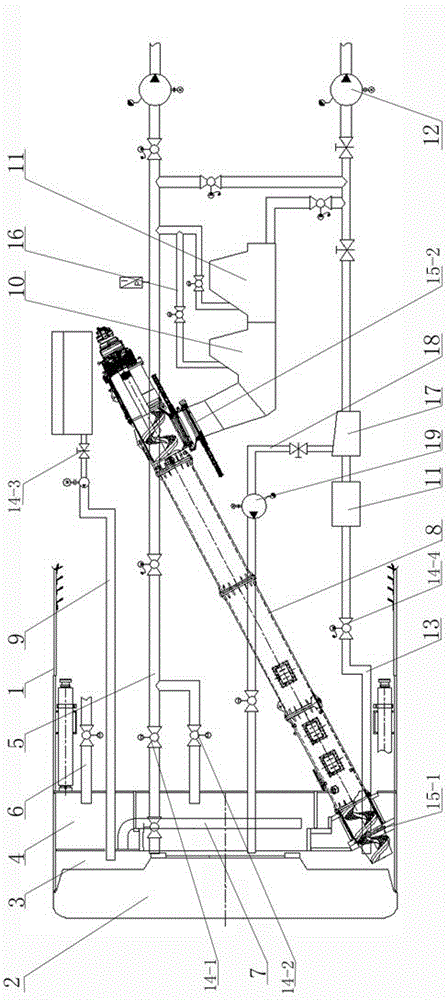

Fracturing fluid mixing and sand mixing semitrailer

ActiveCN103993869ALess supporting equipmentReduce workloadFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

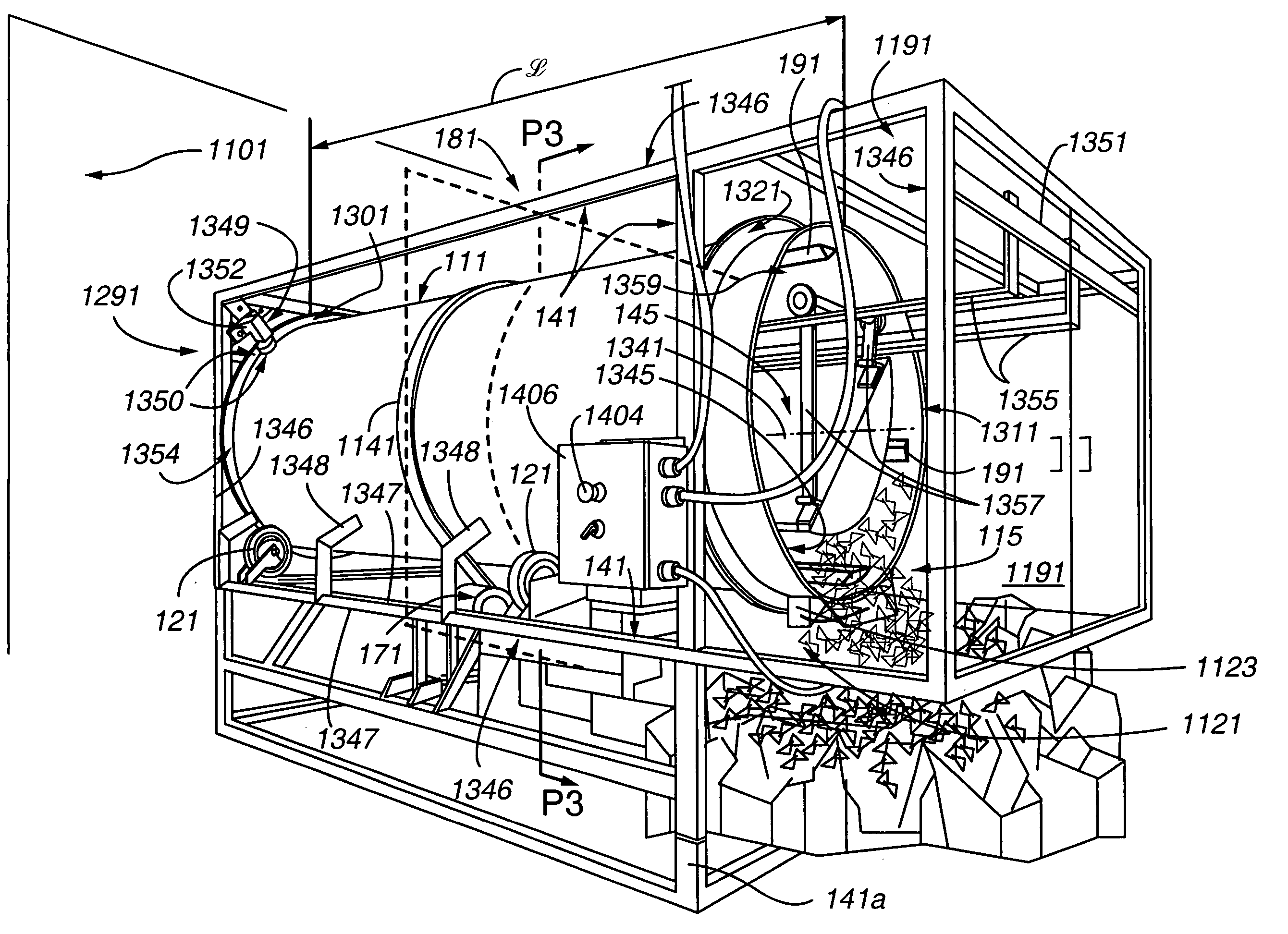

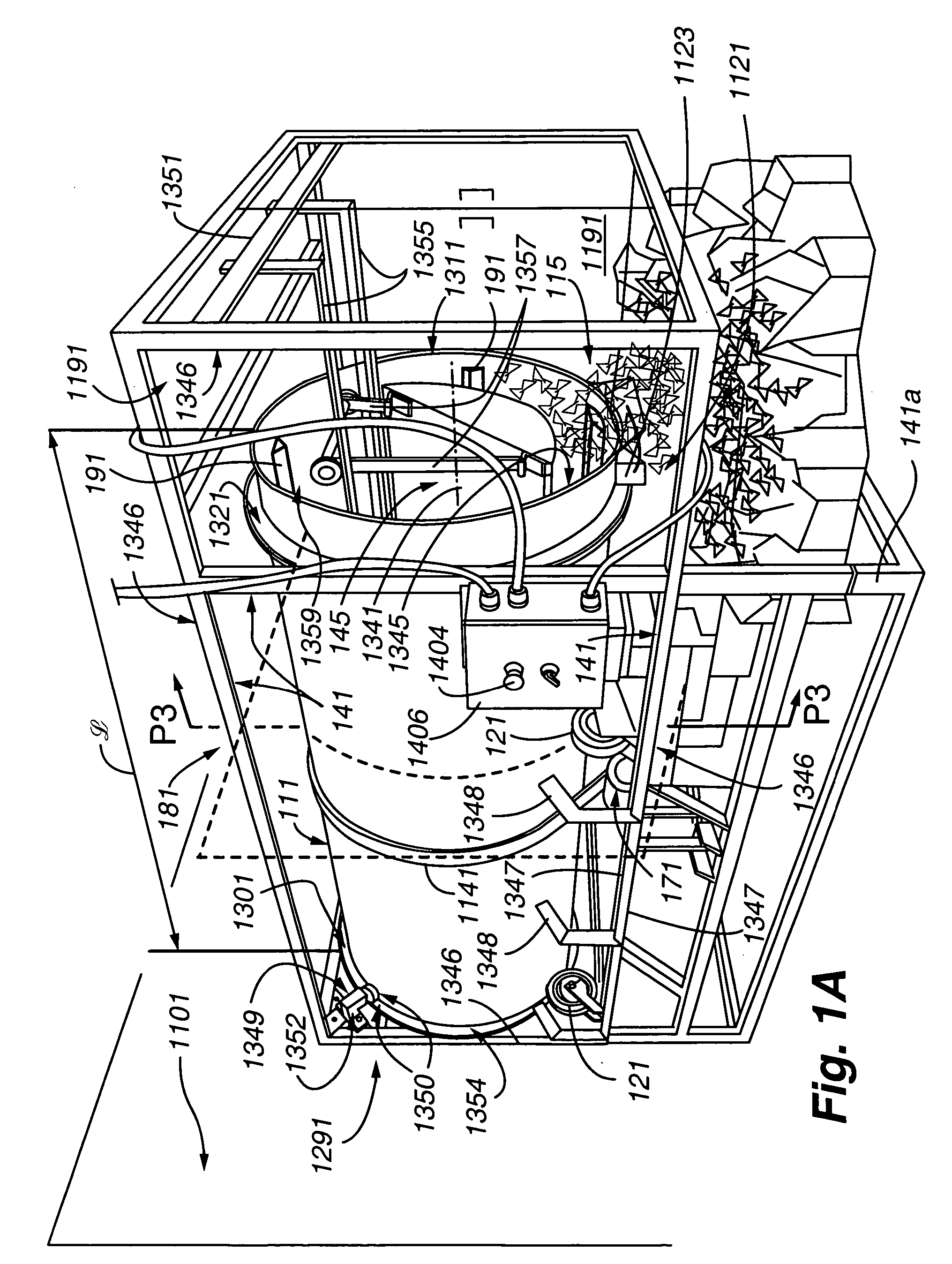

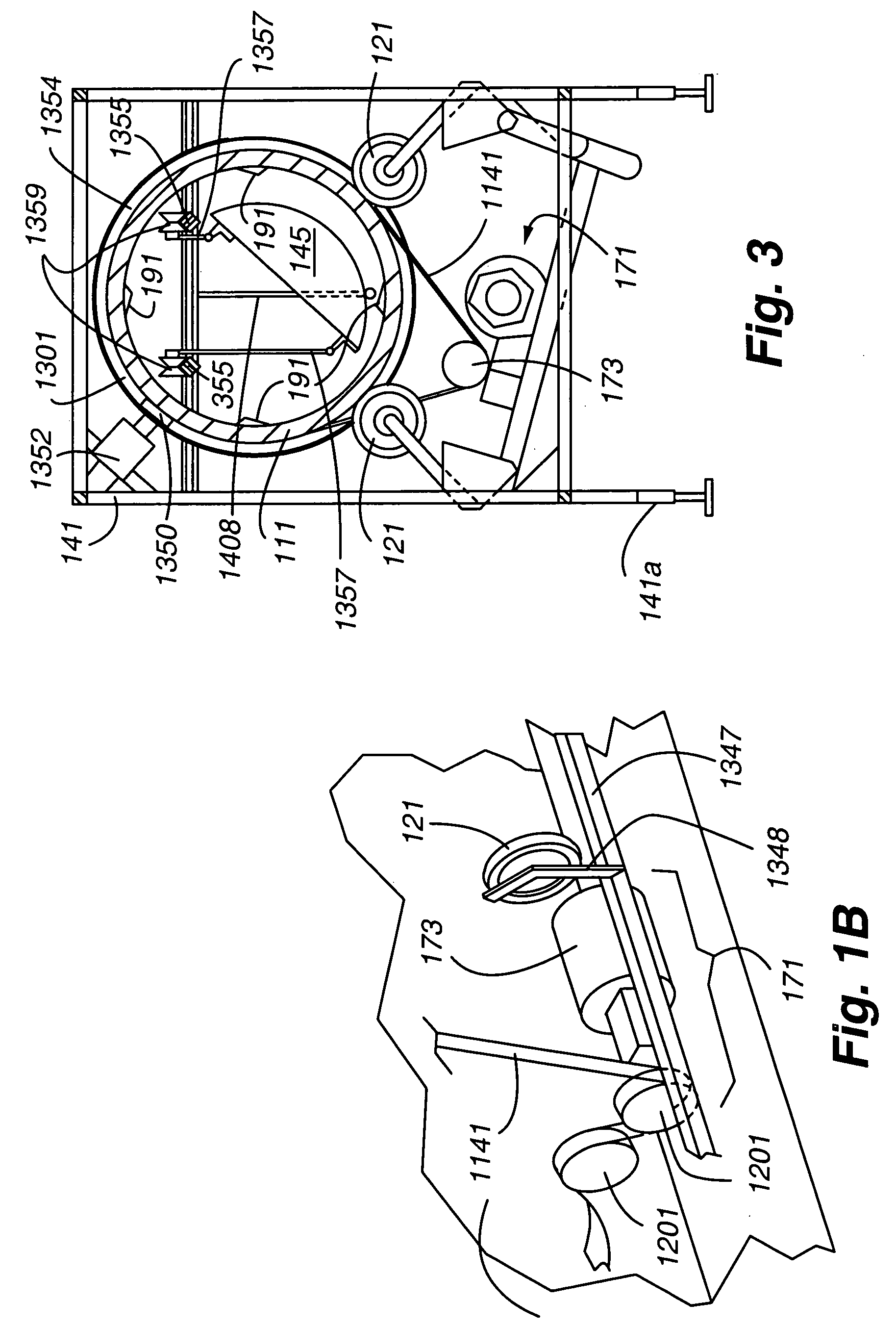

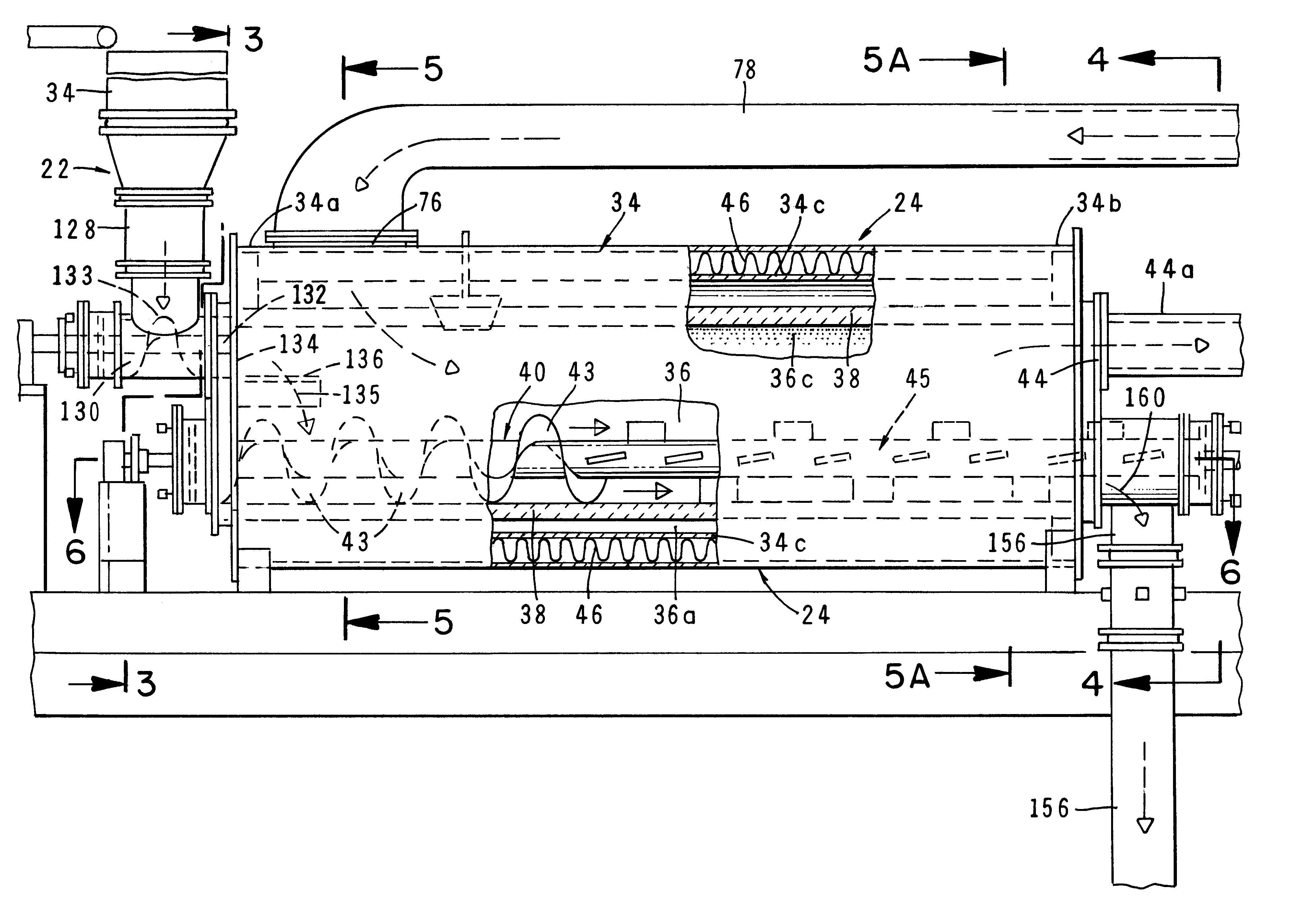

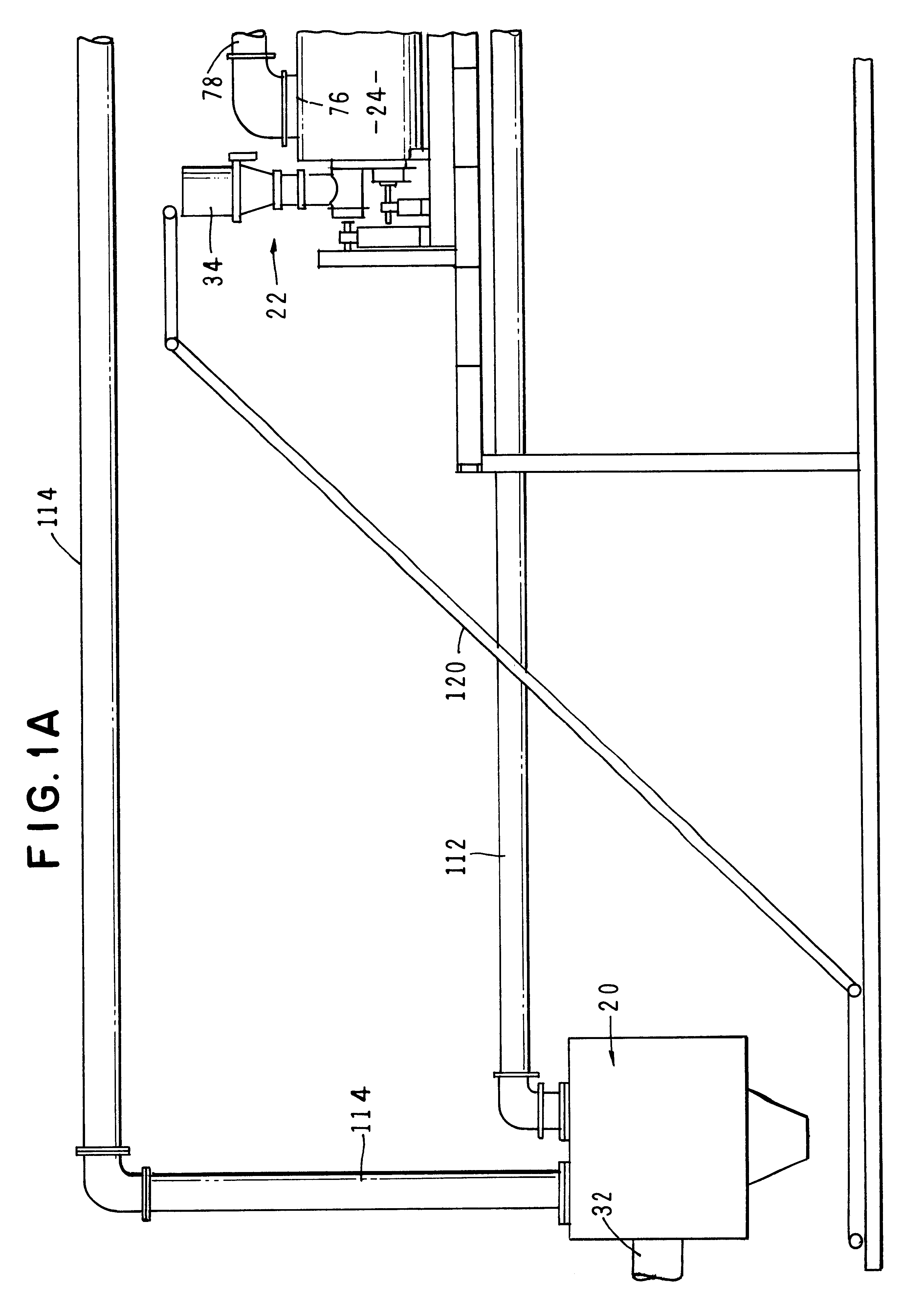

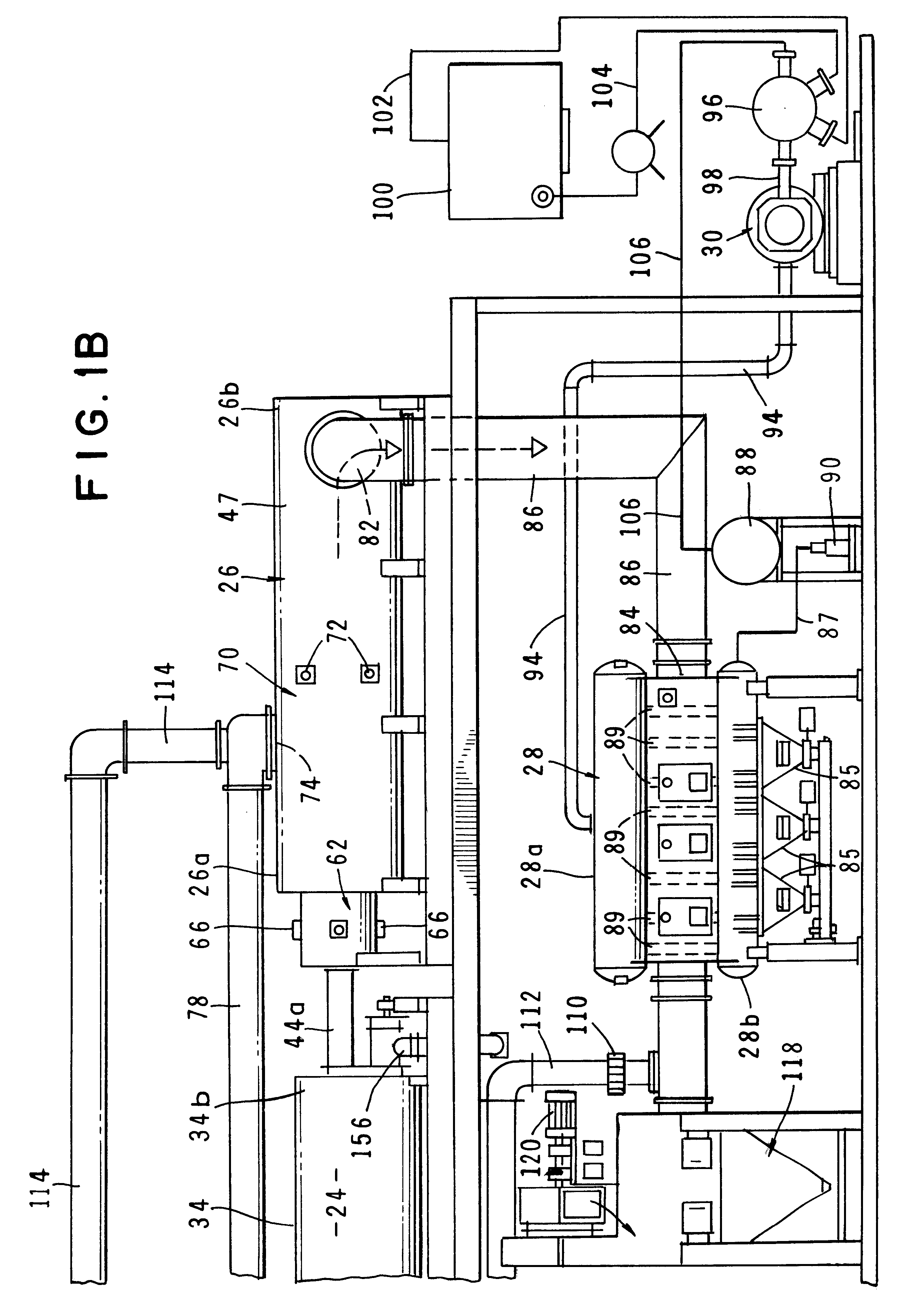

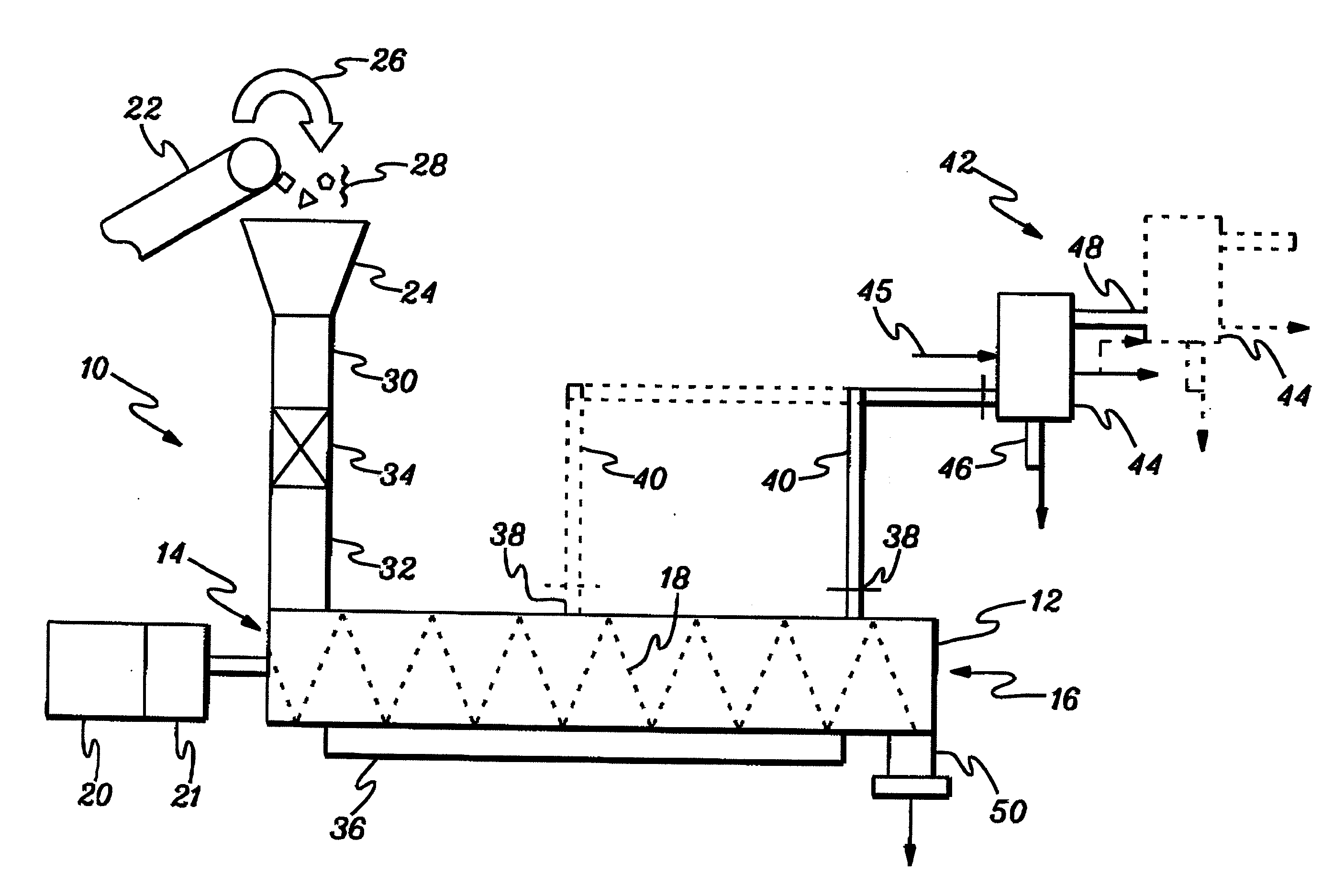

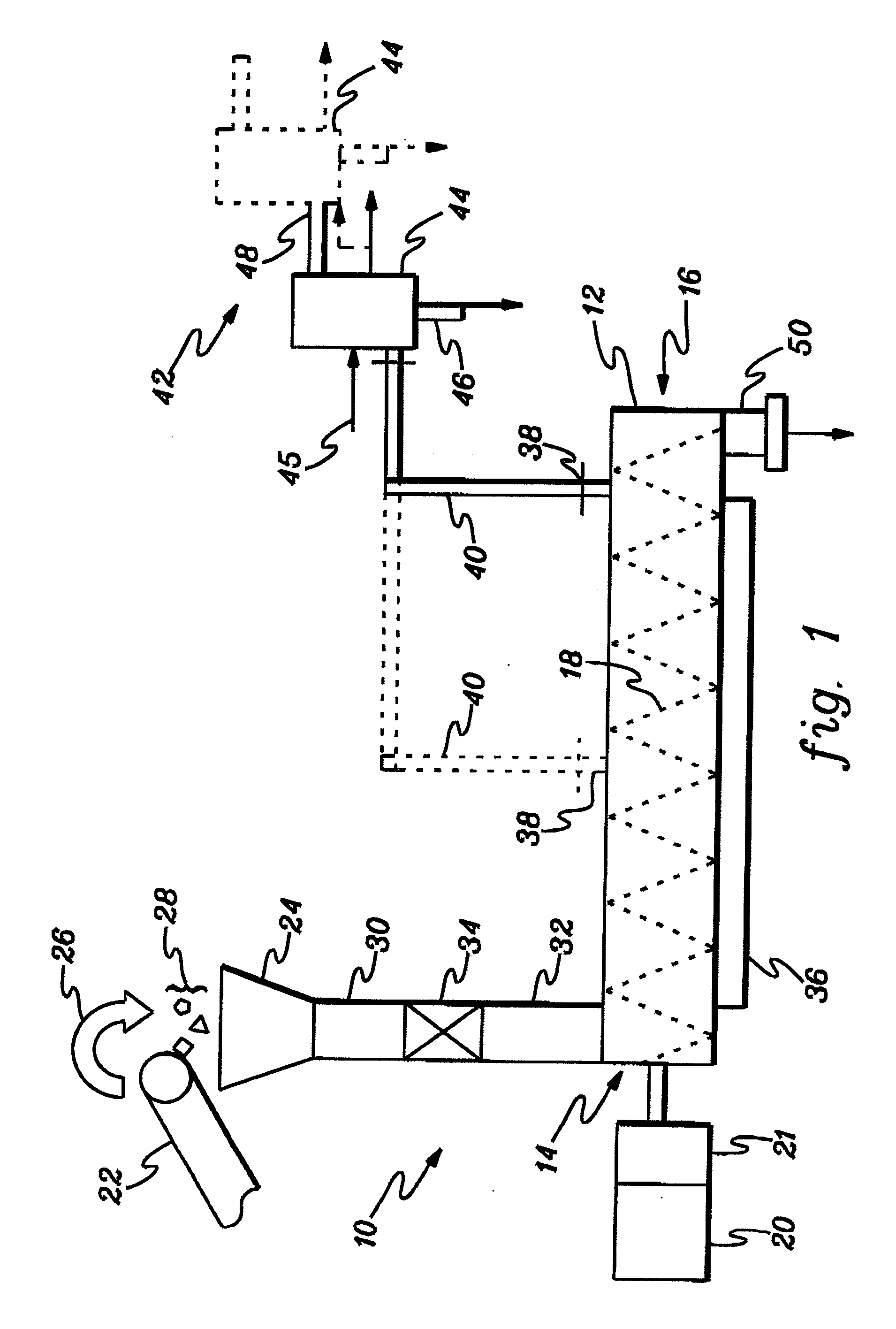

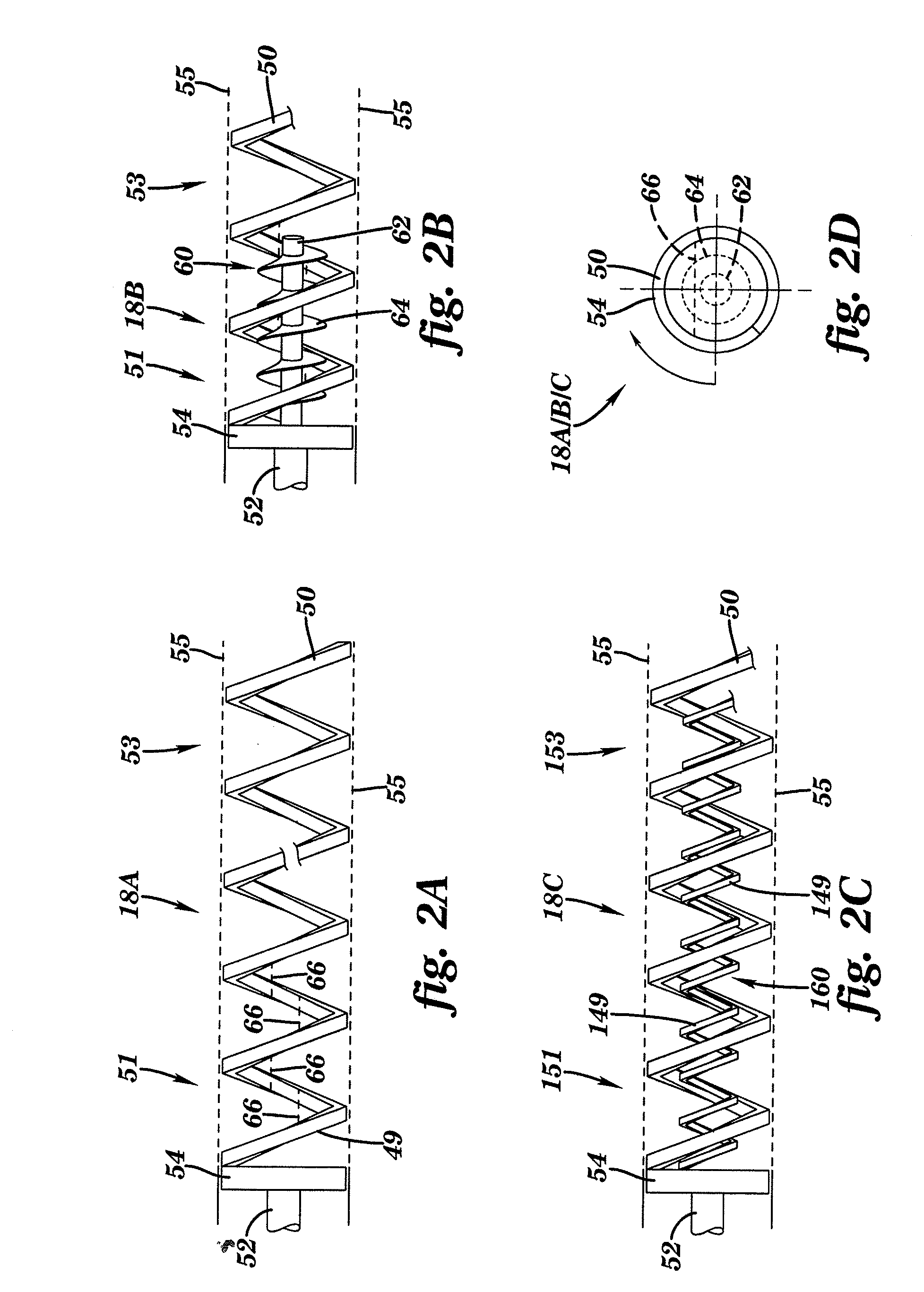

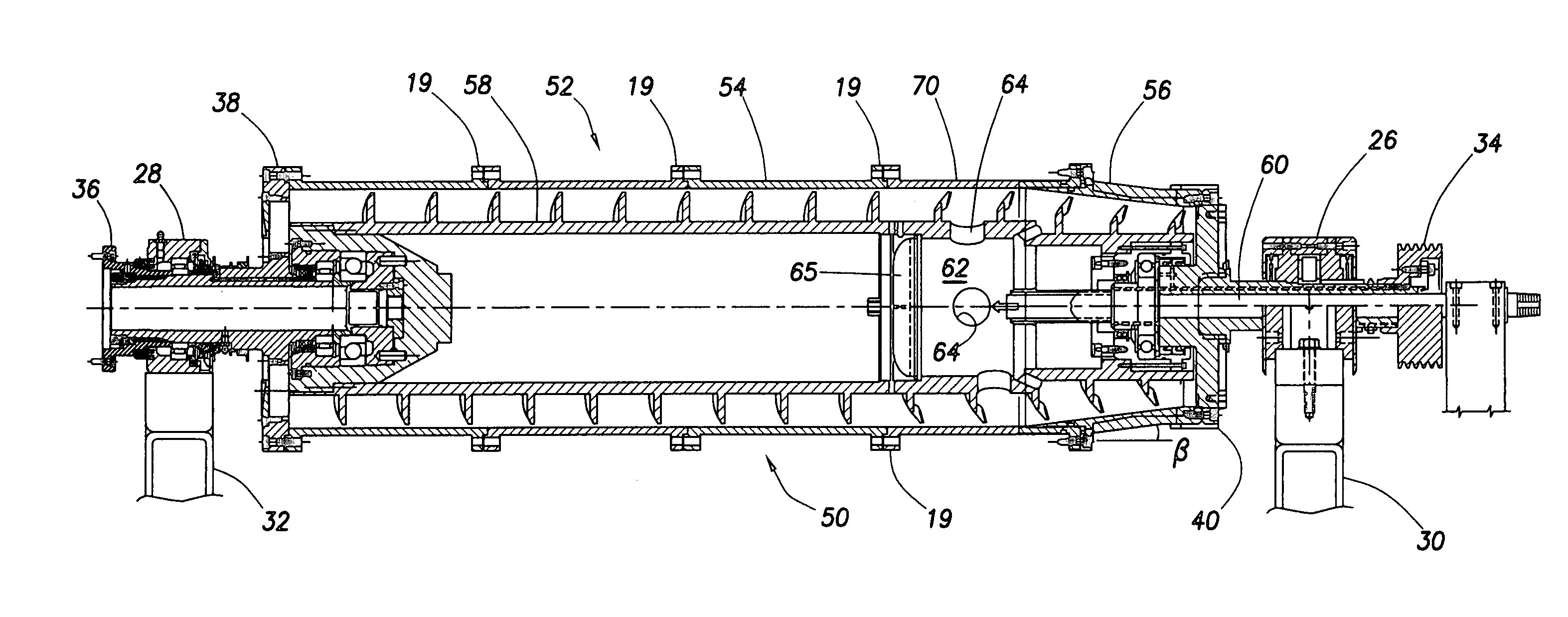

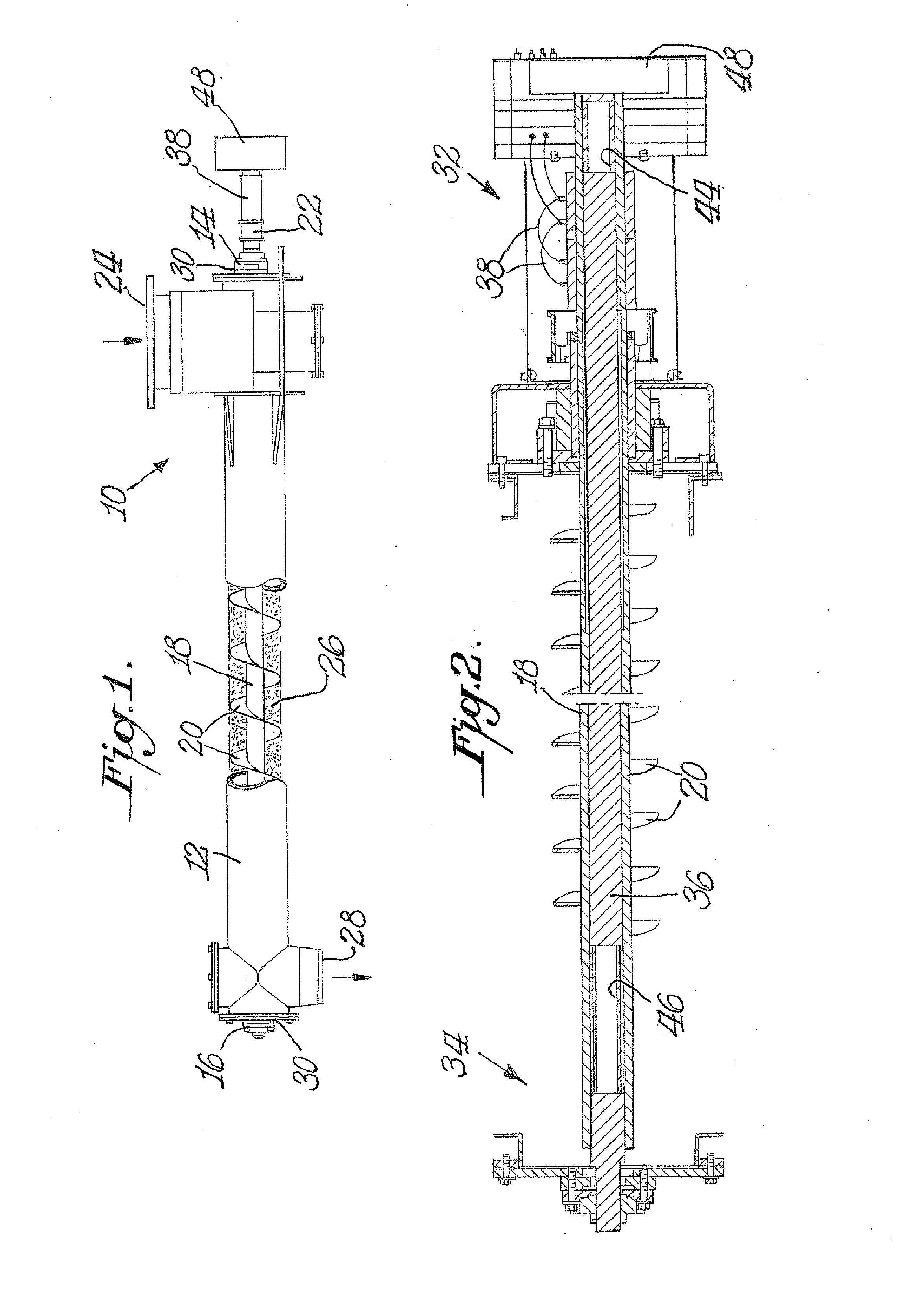

Method and apparatus for treatment of waste

InactiveUS6619214B2Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

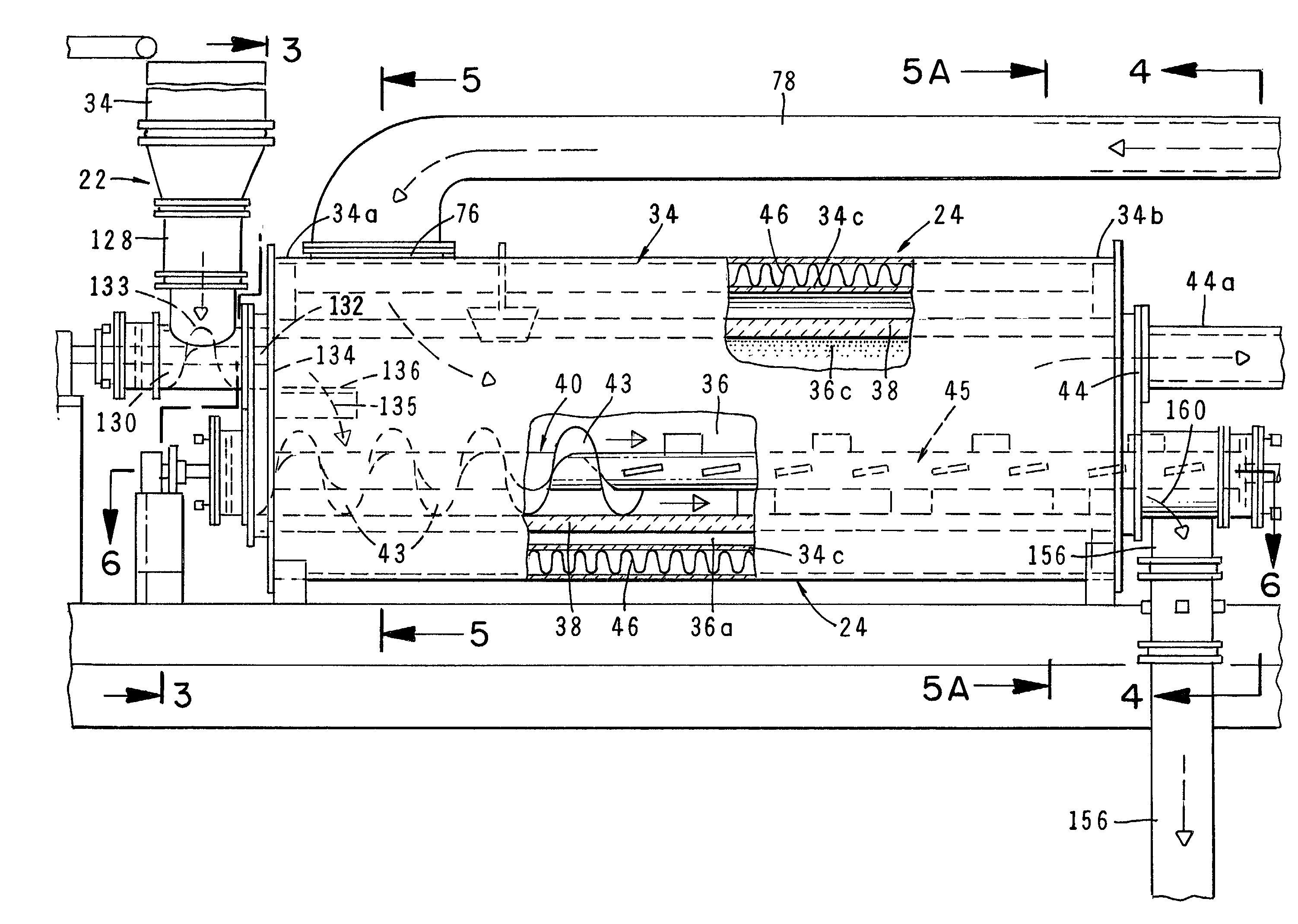

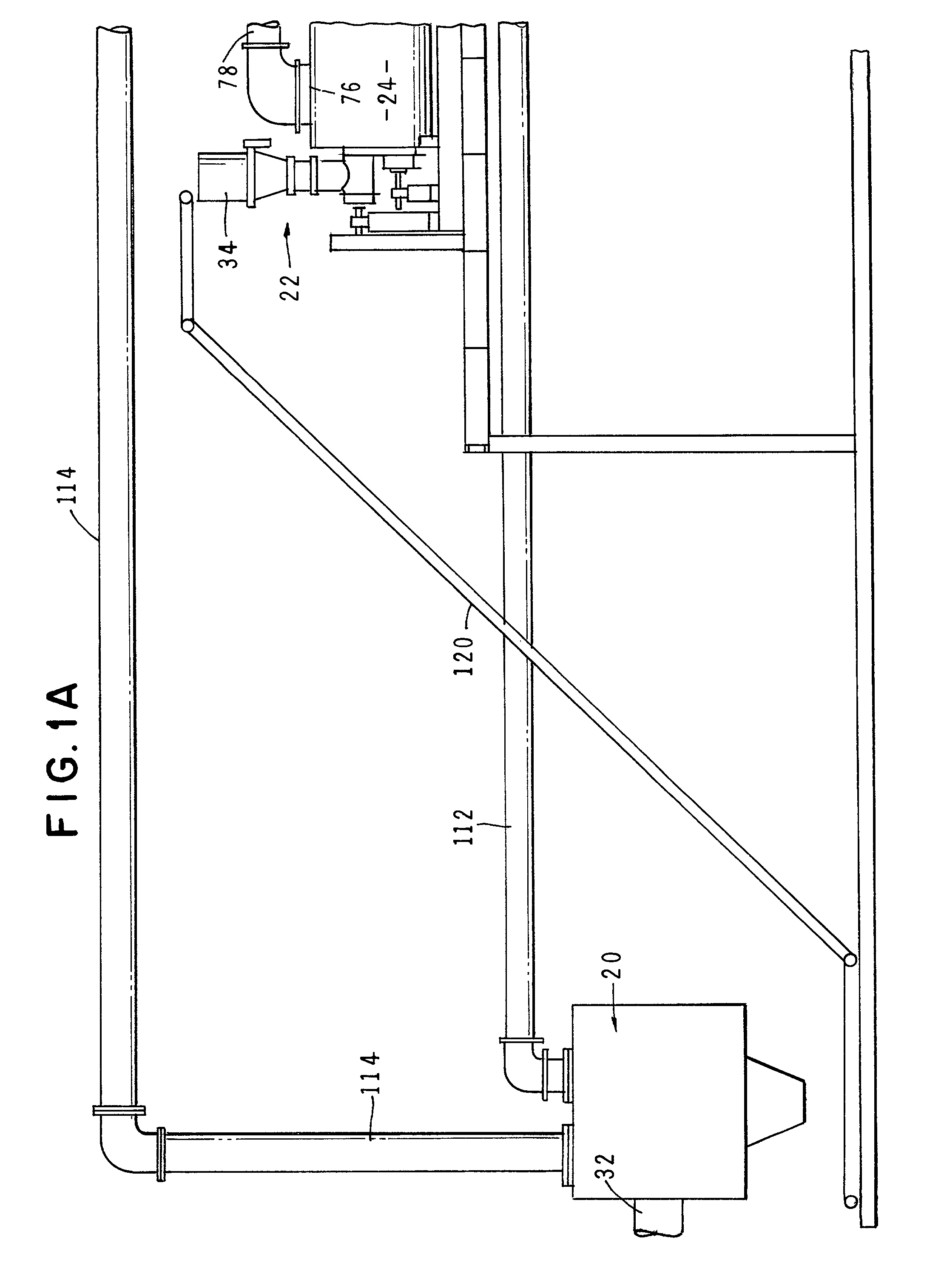

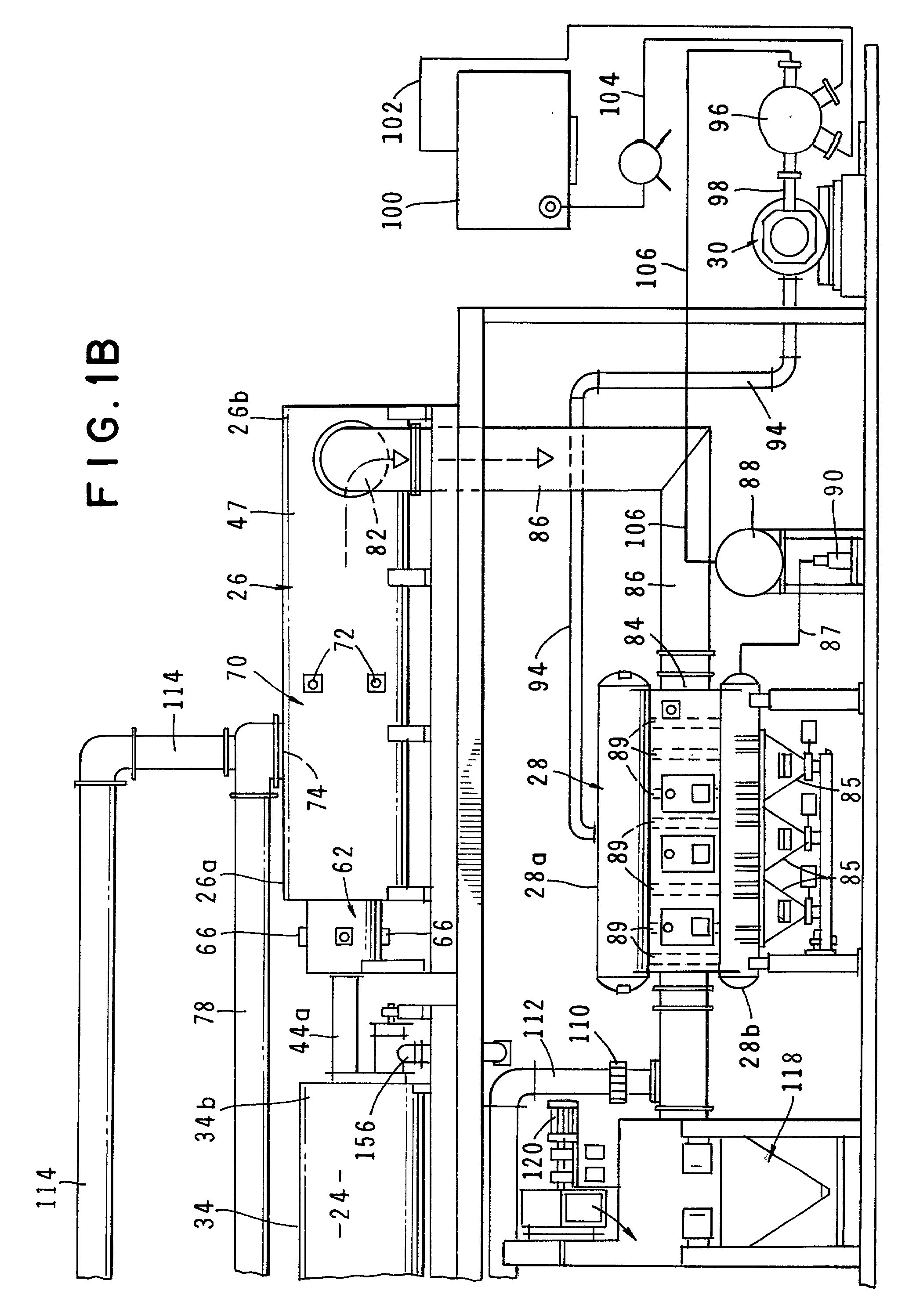

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

Method and apparatus for treatment of waste

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

Composite shield structure suitable for bad ground construction

The invention provides a compound tunnel shield suitable for construction of complex formation, relating to an architectural construction machinery. The compound tunnel shield comprises a compound cutter head suitable for construction of soft soil formation, hard rock formation, formation with uneven hardness and compound formation with both soft soil and hard rock; 3 excavation modes adopting an open mode, a local atmospheric pressure mode or an excavated surface stabilization mode of an earth pressure balance mode according to different geological characteristics of the geology, and a ground conditioning system; the cutter head is respectively provided with a soft soil layer construction tool and a hard rock layer construction tool, cutters are changed to adapt to different formations in the process of the construction thereof; addition agent is injected into the cutter head surface, a soil chamber or a screw conveyer and the addition agent and muck are mixed by rotary stirring of the cutter head, the soil chamber or the screw conveyer to adapt to different formations through ground conditioning. The invention solves the problem of safe construction of the tunnel shield in soft soil, decomposed rock, formations with uneven hardness, sand layer and sand gravel formation, etc.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

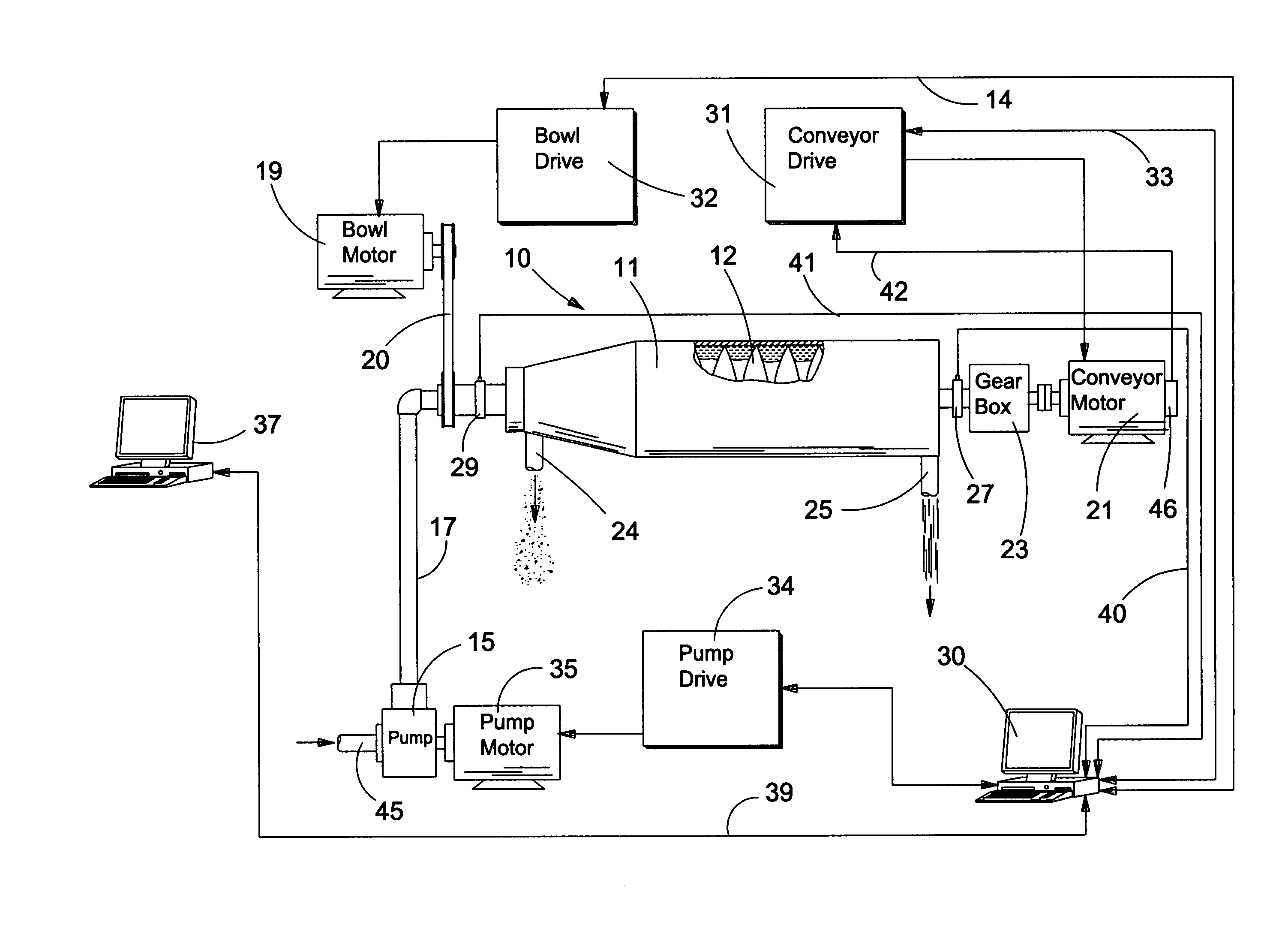

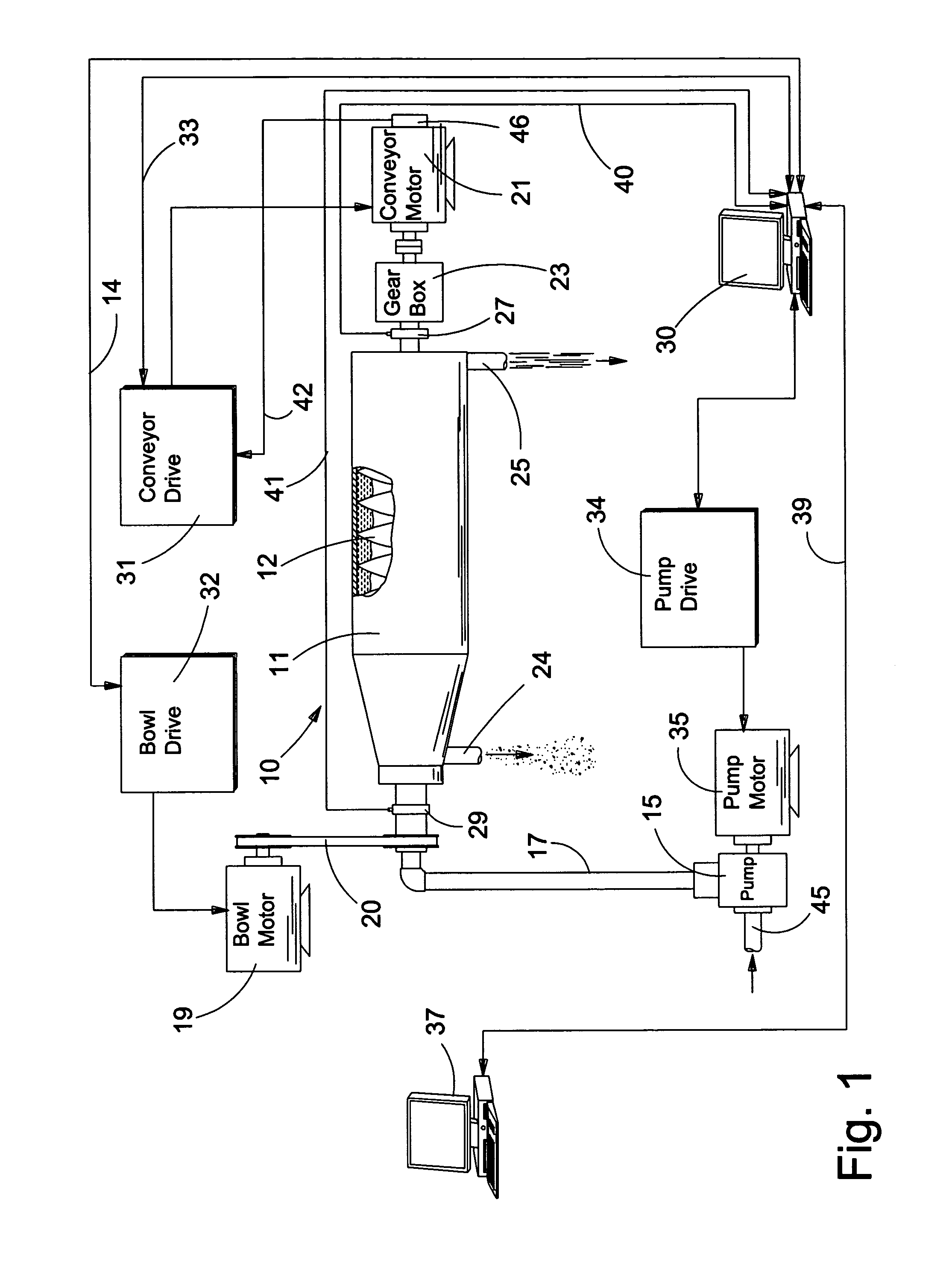

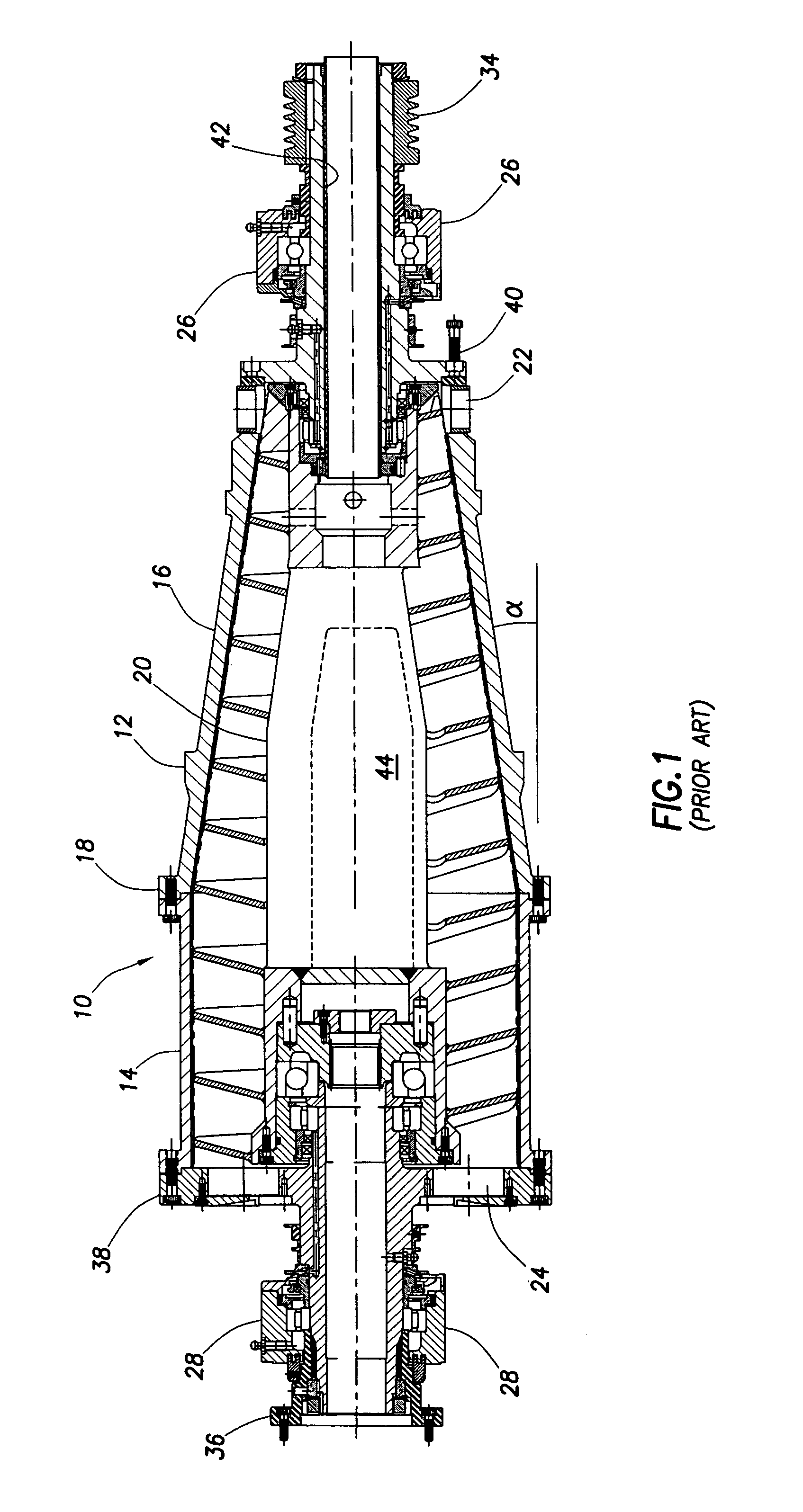

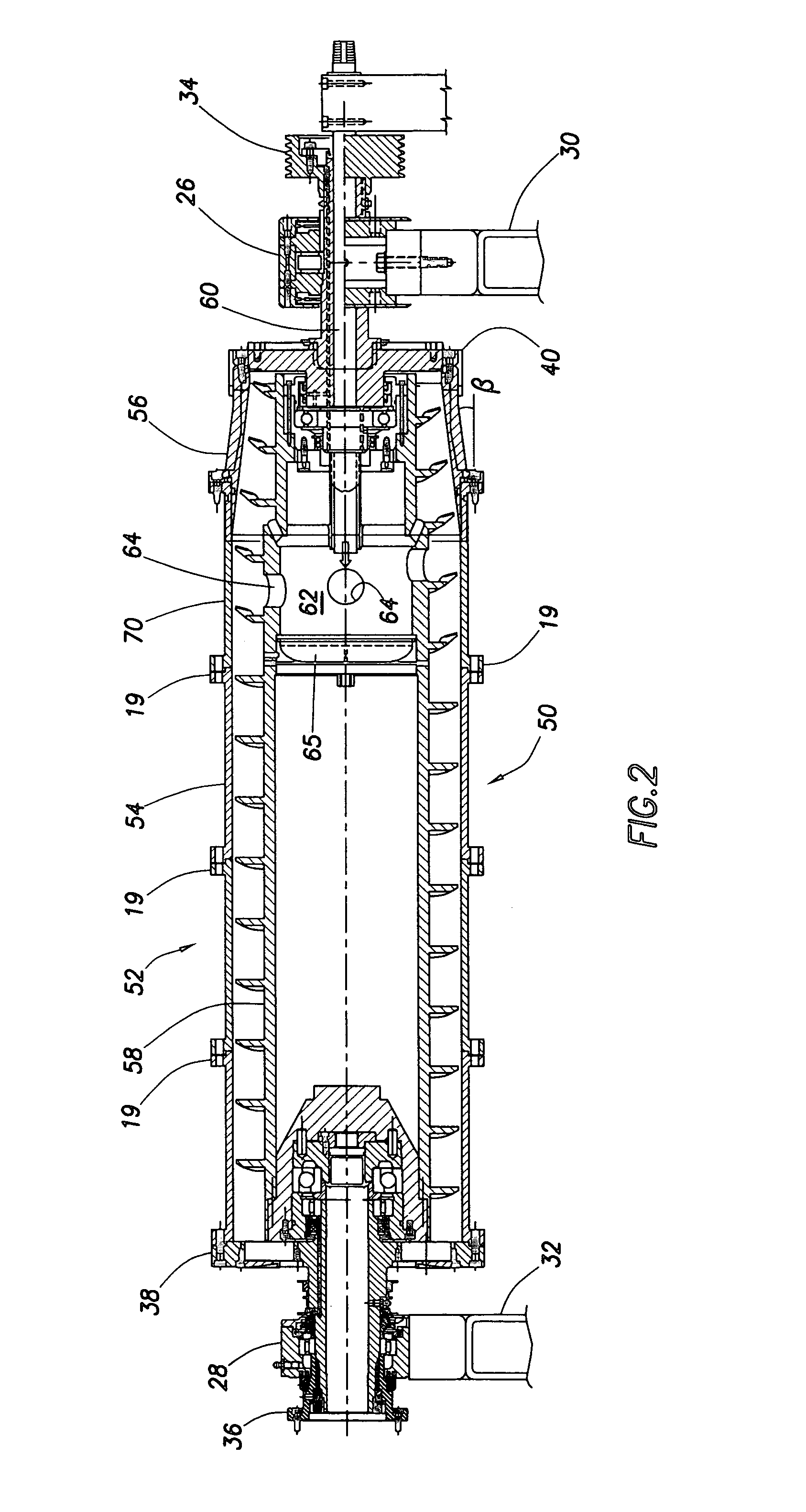

Apparatus for centrifuging a slurry

InactiveUS7387602B1Avoid the needProtection overloadSampled-variable control systemsRotary centrifugesGeneral purposeSlurry

A method and apparatus for centrifuging. The apparatus comprises a centrifuge for centrifuging a slurry, comprising a bowl driven by a bowl drive motor, a screw conveyor driven by a screw conveyor drive motor, a pump driven by a pump motor, a bowl drive unit operatively arranged to drive the bowl drive motor, a conveyor drive unit operatively arranged to drive the screw conveyor drive motor, a pump drive unit operatively arranged to drive the pump drive motor, and, a general purpose first computer specially programmed to control the bowl drive unit to drive the bowl drive motor at a first constant speed and to control the screw conveyor drive unit to drive the screw conveyor drive motor at a second constant speed and to monitor the torques of the bowl drive motor and the screw conveyor drive motor, while simultaneously controlling the pump drive unit to variably control flow of the slurry through the centrifuge so as to drive one of the bowl drive motor or the screw conveyor motor at a pre-set operating torque.

Owner:DERRICK CORP

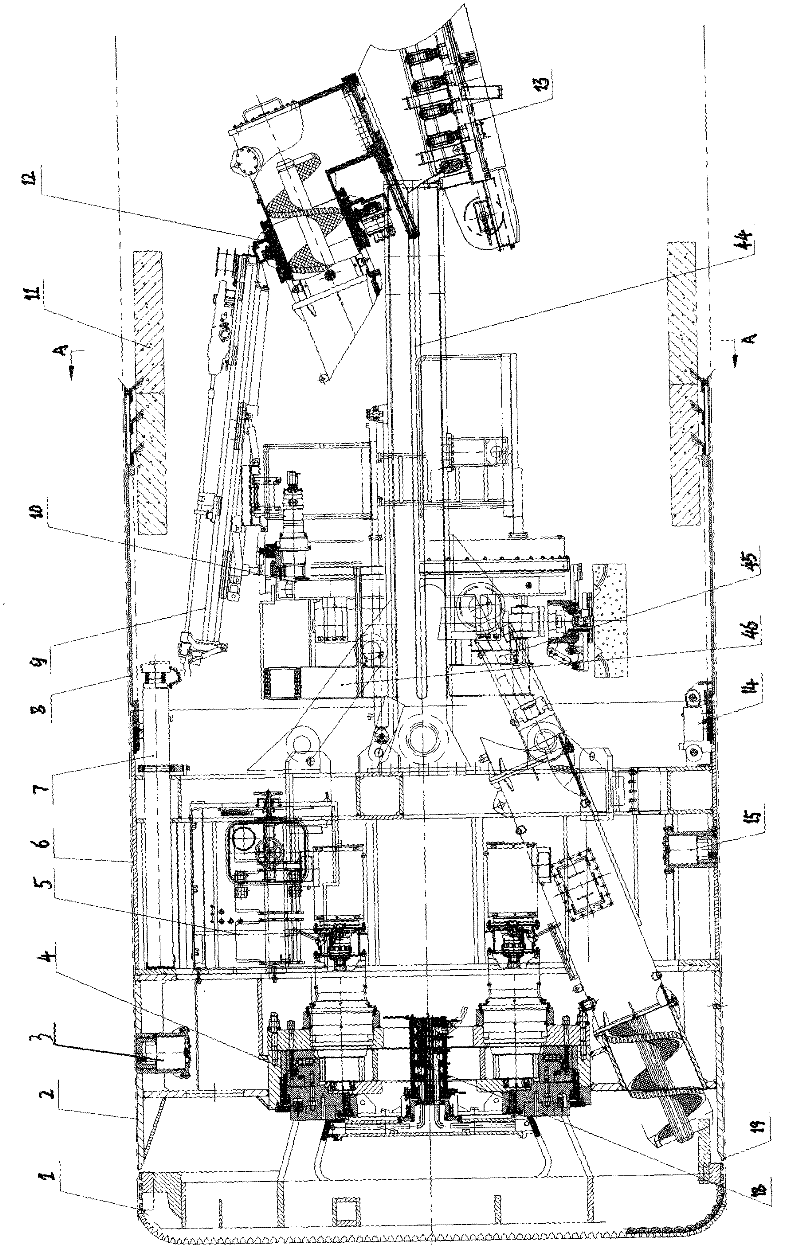

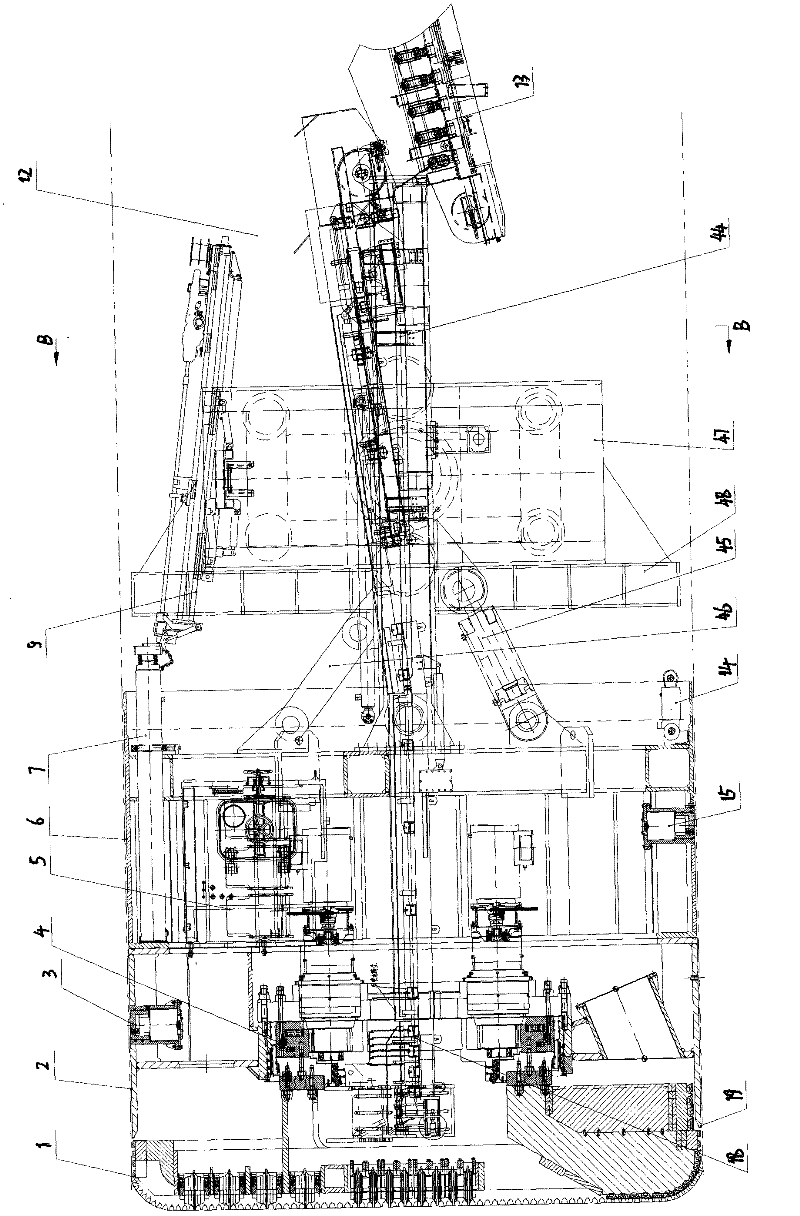

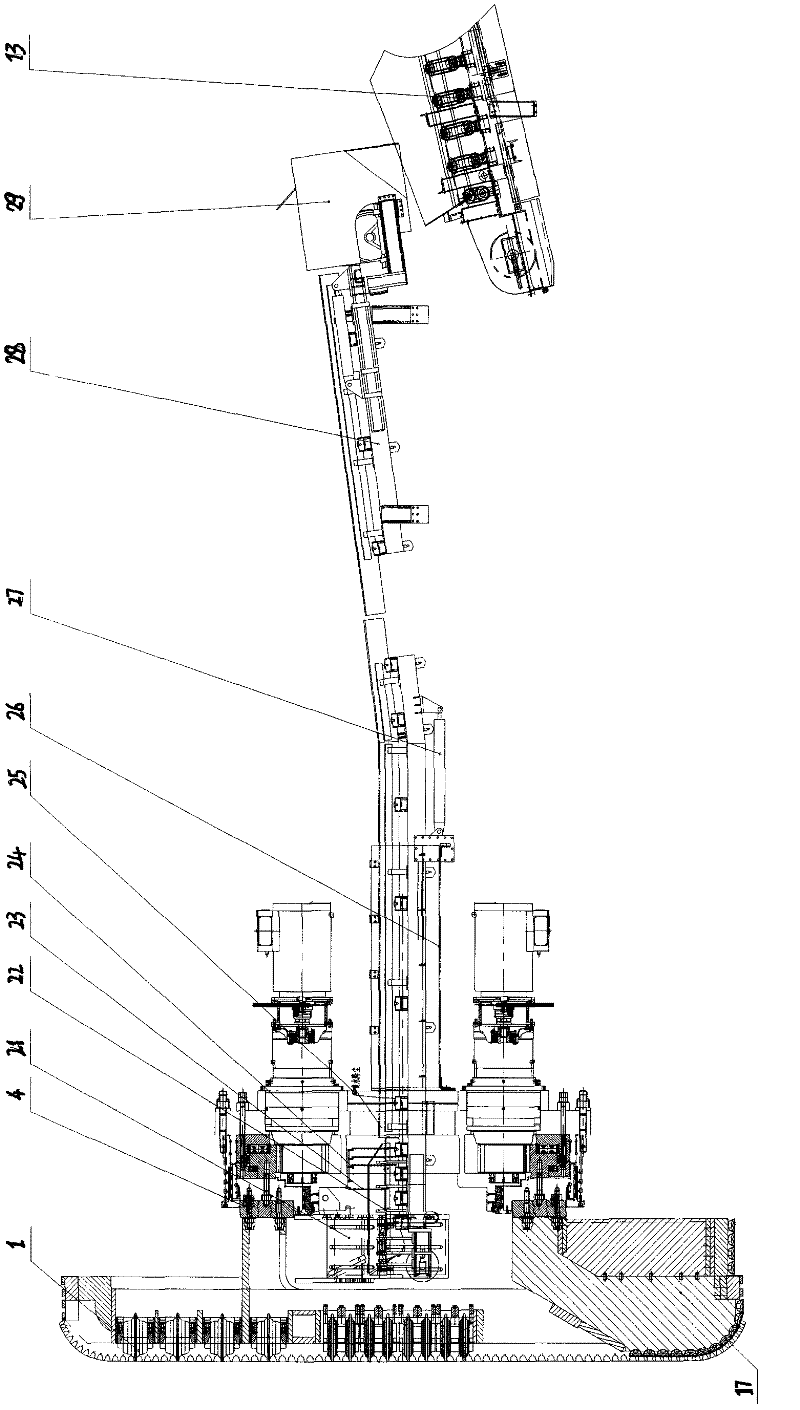

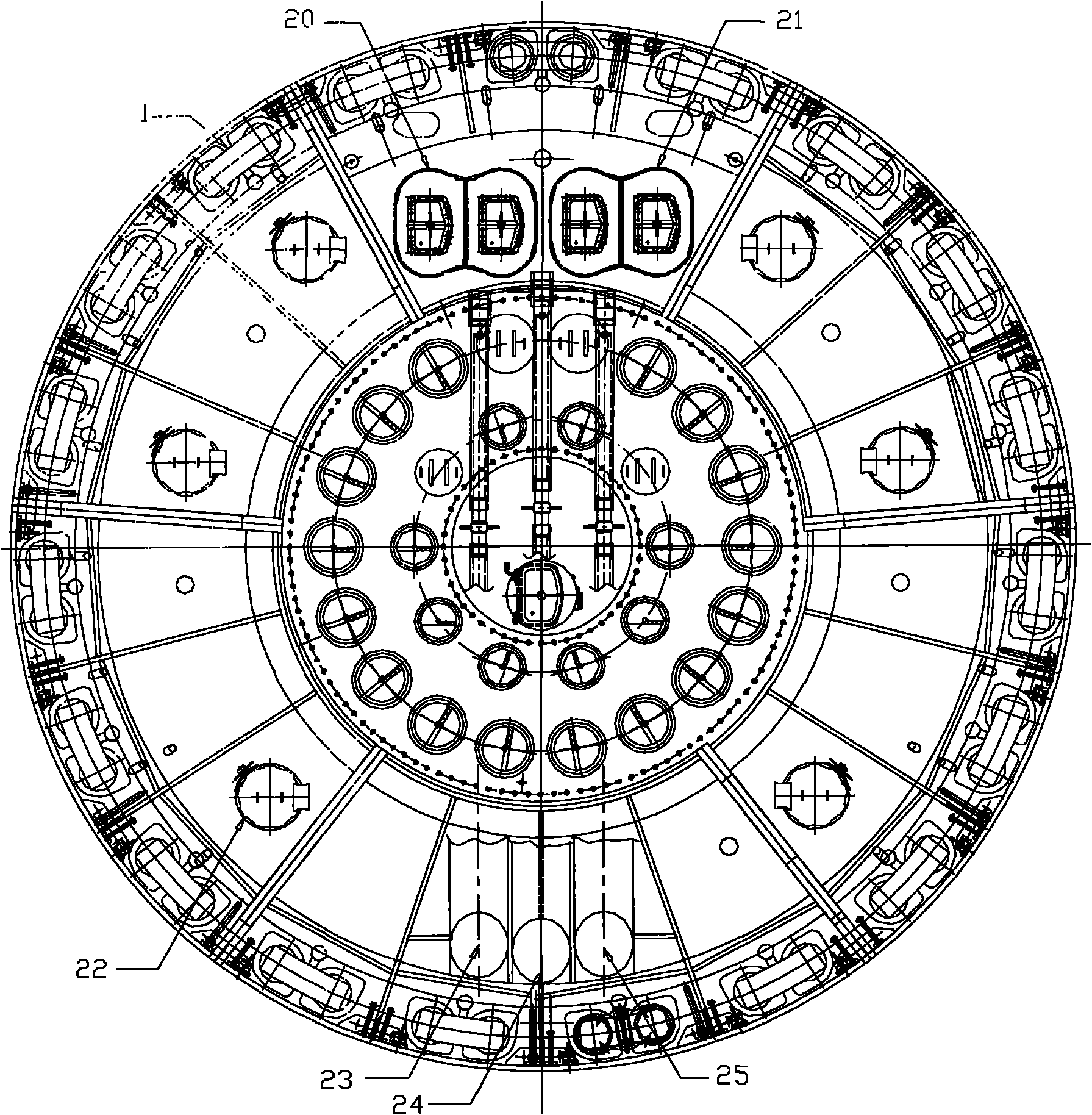

Mixed TBM (Tunnel Boring Machine) with multiple-boring mode and tunnel supporting mode

ActiveCN102383805AControl face stabilityEnsure construction safetyTunnelsSludgeTunnel boring machine

The invention discloses tunnel construction equipment, in particular a mixed TBM (Tunnel Boring Machine) with a multiple-boring mode, which is suitable for sludge, clay, sand, grit, decomposed rock, hard rock and composite transition stratum. According to the invention, three modes of an earth pressure balance mode, a shield open mode and a TBM mode are adopted for construction according to different stratum geological conditions and construction tunnel supporting requirements; a deslagging mode is that a spiral conveyer or a TBM belt conveyor is adopted for deslagging; and simultaneously, a supporting mode can adopt a finned-tube lining or flexible post-supporting mode. The mixed TBM disclosed by the invention has very strong geological adaptability, is especially suitable for soft, hard and complex stratal construction of a mains underground engineering, and simultaneously, has the advantages that the whole machine has low manufacture cost, the mode conversion is relatively simple, the interference to mating construction is small, the control is convenient, the equipment manufacture cost is low, the economic property and practicability are achieved, and the use requirements of the flexible supporting mode of the construction can be met.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

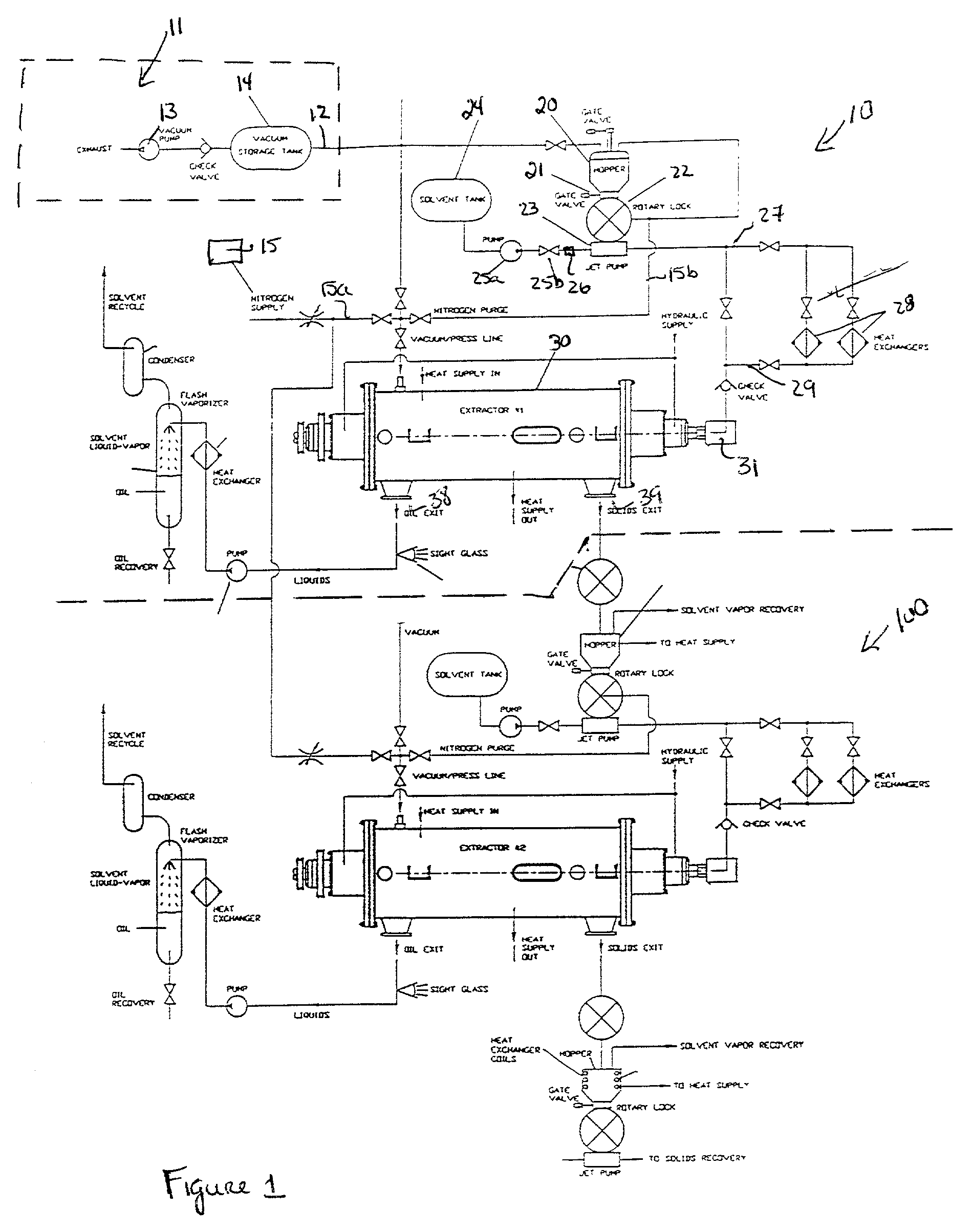

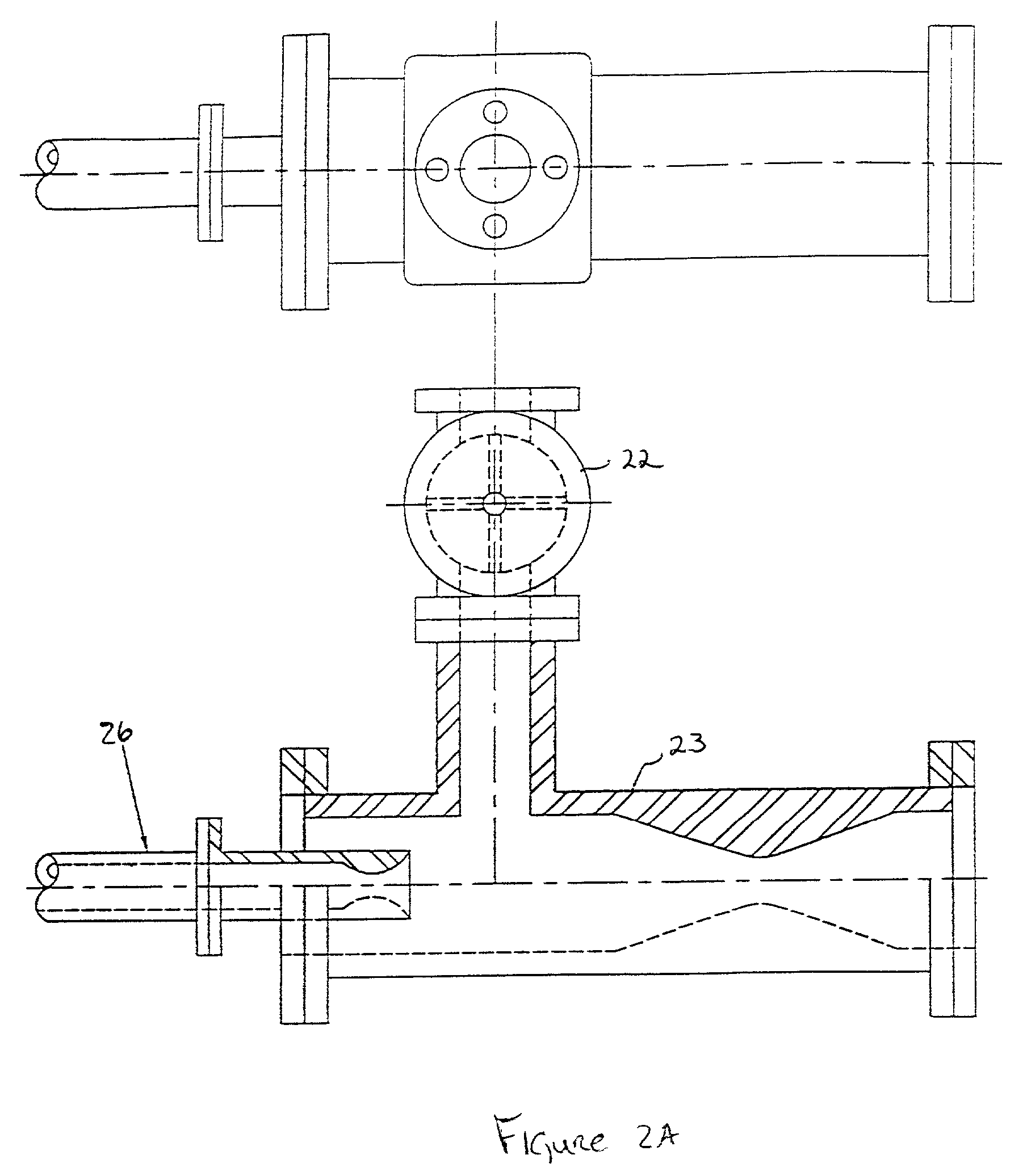

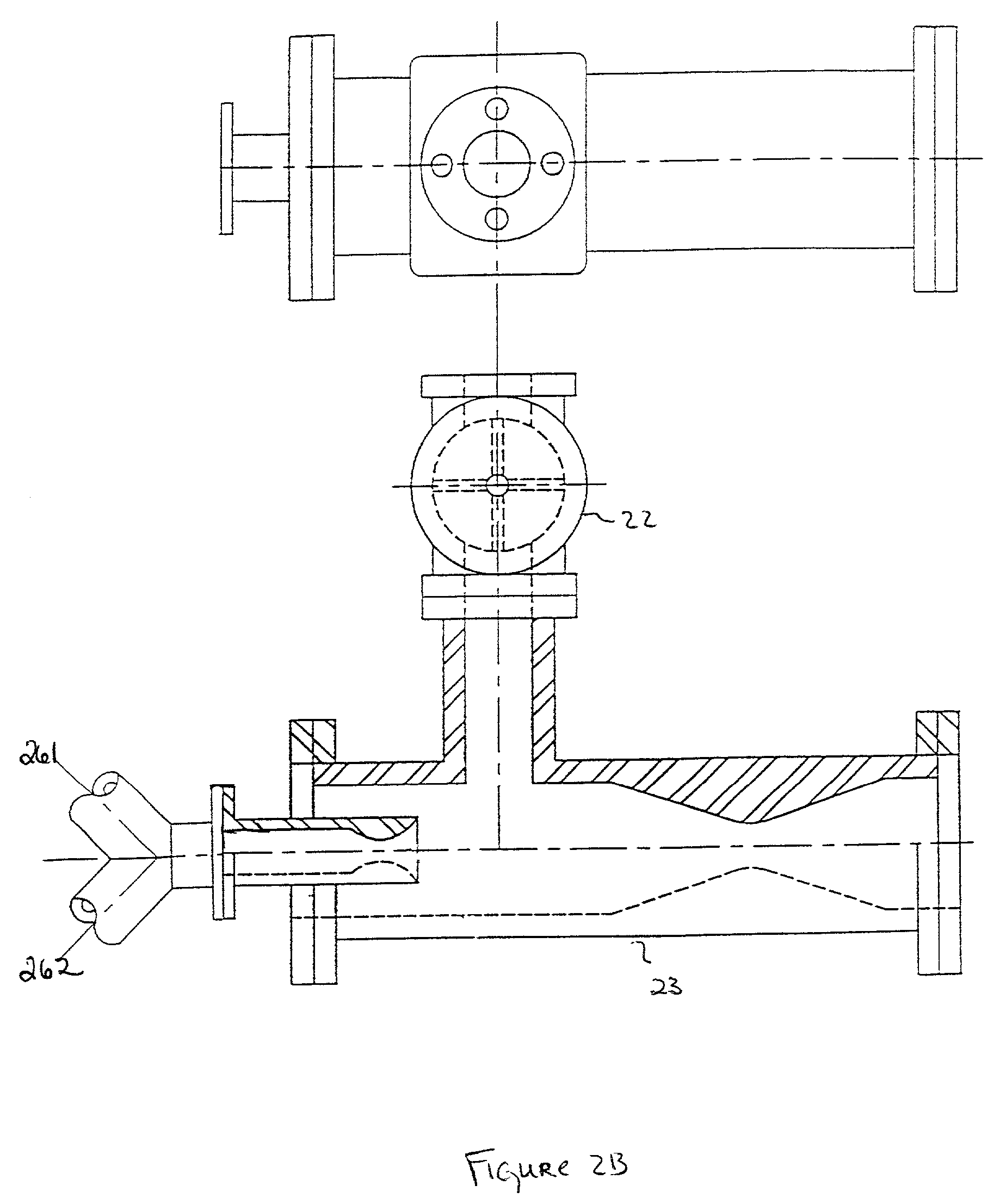

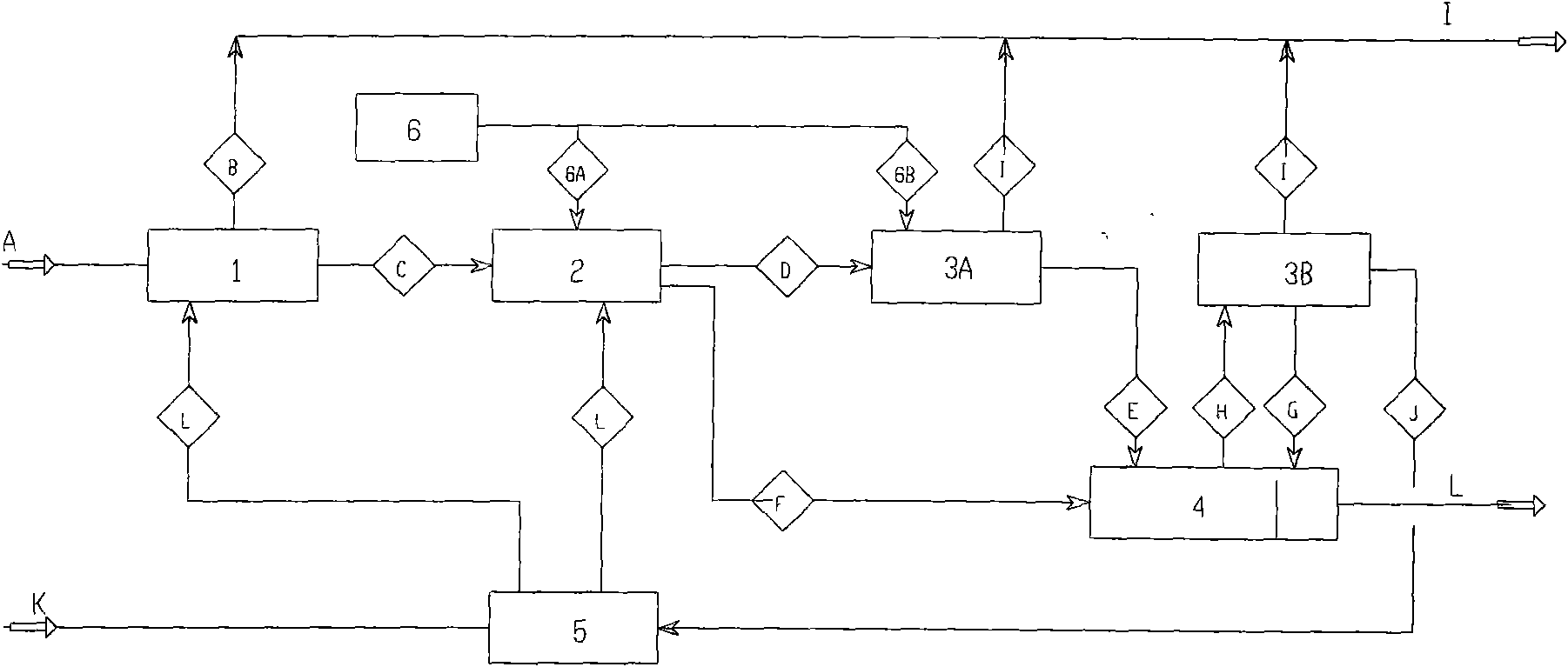

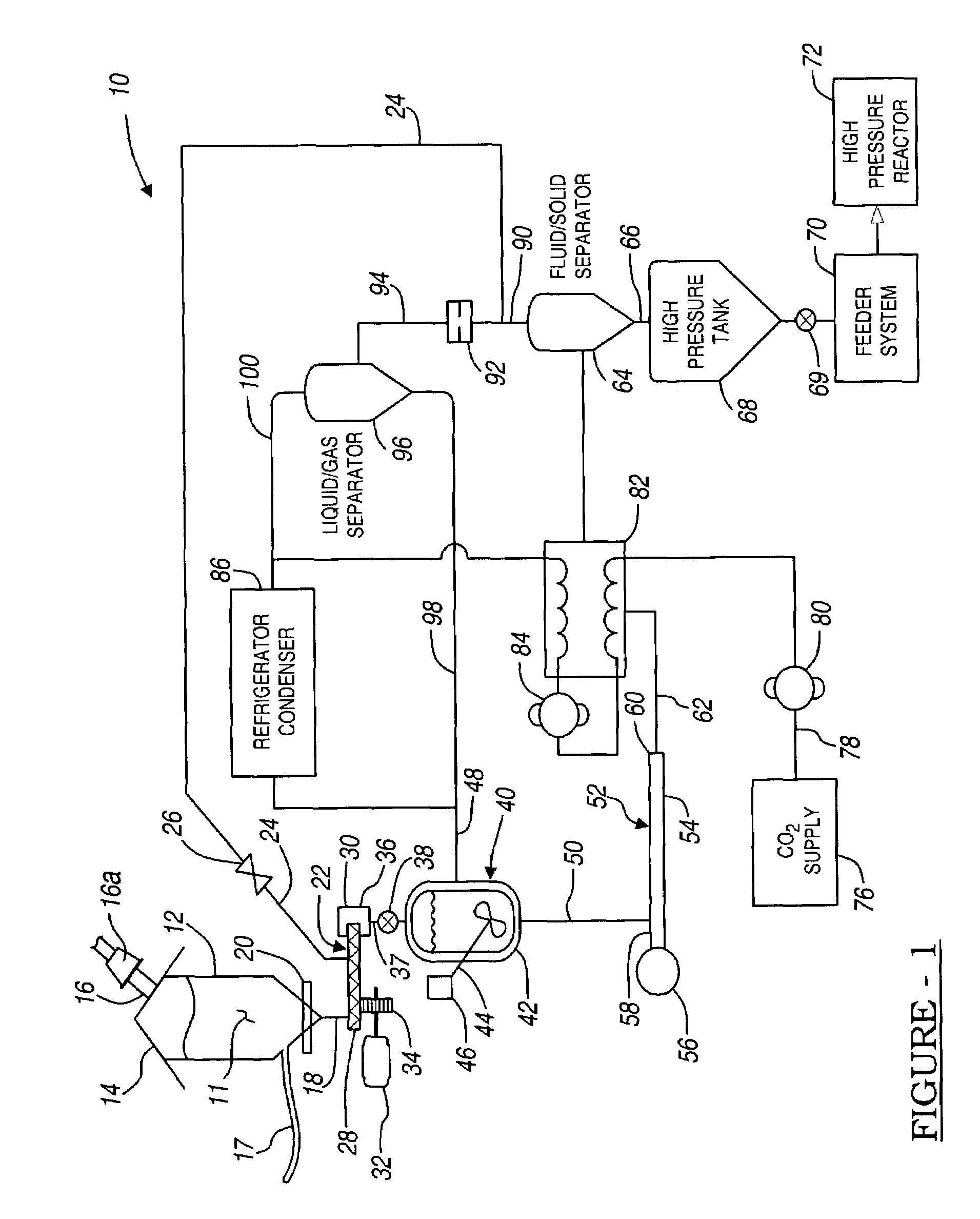

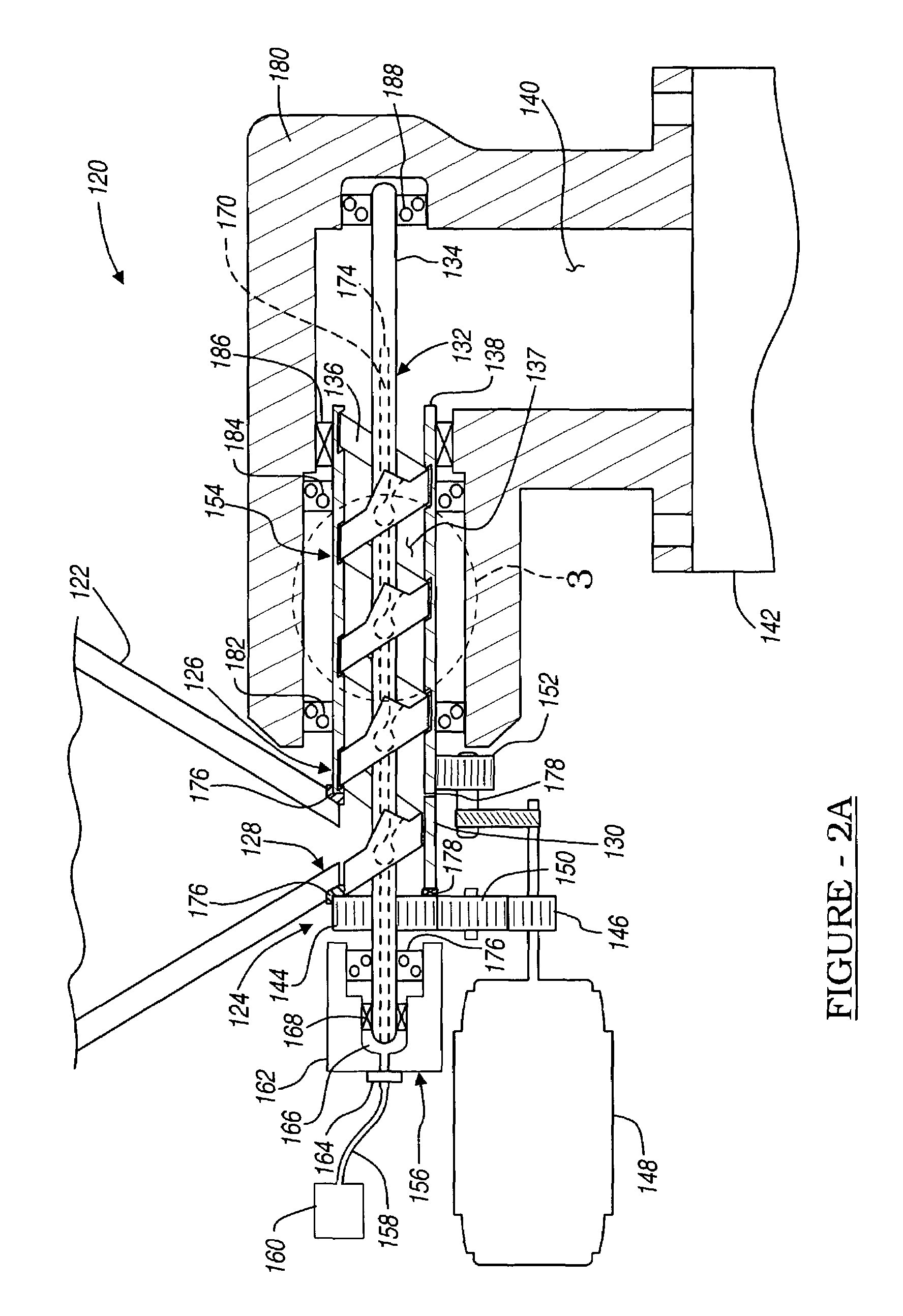

Process and system for continuously extracting oil from solid or liquid oil bearing material

InactiveUS7008528B2Eliminating formationEasy to optimizeRefining with acid-containing liquidsLiquid hydrocarbon mixture productionSufficient timeLiquid state

A process for continuously extracting oil from a solid or liquid oil-bearing material comprises (a) removing air from the extraction system, (b) introducing an inert gas into the extraction system at a pressure sufficient to maintain a normally gaseous solvent in liquid state, (c) introducing an oil-bearing material into a silo, (d) passing the oil-bearing material from the to a jet pump mixing device, (e) introducing a liquified normally gaseous solvent into the jet pump mixing device, (f) mixing the oil-bearing material and the solvent in the jet pump mixing device for a time sufficient to permit complete wetting of oil-bearing material by the solvent to form a mixture, (g) heating the mixture to near supercritical conditions; (h) passing the mixture through an extractor having a screw conveyor adapted to rotate at a first rpm range and a centrifugal drum adapted to rotate at a second rpm range, (i) treating the mixture within the extractor in such a manner that supercritical temperature and pressure are attained, wherein treating the mixture includes a combination of increasing the rpms of the centrifugal drum, increasing the temperature inside the extractor and increasing the inert gas pressure inside the extractor, (j) extracting oil from the mixture by pressure diffusion provided by the combination of increased rpms, increased temperatures and increased inert gas pressures at supercritical conditions, (j) removing liquids extracted from the mixture through a liquids exit port, and (k) removing solids extracted from the mixture through a solids exit port.

Owner:MITCHELL ALLEN R +1

Novel process for comprehensively treating oily sludge of oil field

ActiveCN101602566AAvoid secondary pollutionHarmlessSludge treatment by de-watering/drying/thickeningSolid particleSlurry

The invention provides a novel process for comprehensively treating oily sludge of an oil field, which comprises processes for separating oil, water and sludge from the oily sludge. The process is characterized in that the processes for separating oil, water and sludge comprise a first process of fluidizing and pre-treating sludge, a second process of hardening and tempering the sludge, and a third process of mechanically separating the oily sludge; water separated through the processes can be used as process water to a circulating water recycling process; the separated cleaned oil enters an oil chamber of an oil-water separation device; and solid particles, namely the centrifuged sludge, are discharged through a screw conveyer. The process has the recovery ratio reaching 95 percent for recovering effluent oil to the utmost extent; and the treated sludge has water content less than 60 percent and oil content less than 2 percent, and can be used for underlaying a road of a well site or carrying out subsequent depth treatment. The process cyclically utilizes wastewater, prevents secondary pollution of sewage and slurry, and has large treatment capacity, wide treatment range, advanced technical proposal, high automatic degree, low operation cost, simple operation and clean production.

Owner:北京惠博普能源技术有限责任公司

Method and apparatus for continuously feeding and pressurizing a solid material into a high pressure system

A system for substantially continuously providing a solid material, for example pulverized coal, to a pressurized container. The system provides the solid material to a first container of a first pressure elevated above an initial pressure of the solid material. Generally, a screw conveyor augmented with a jet port is used to move the material where the jet port provides a gas to provide a make-up volume of the solid material. The system also provides the material to a second high pressure container after the material has been formed into a slurry. Therefore, the solid material may be substantially continuously provided in a system to a high pressure container.

Owner:THE BOEING CO +1

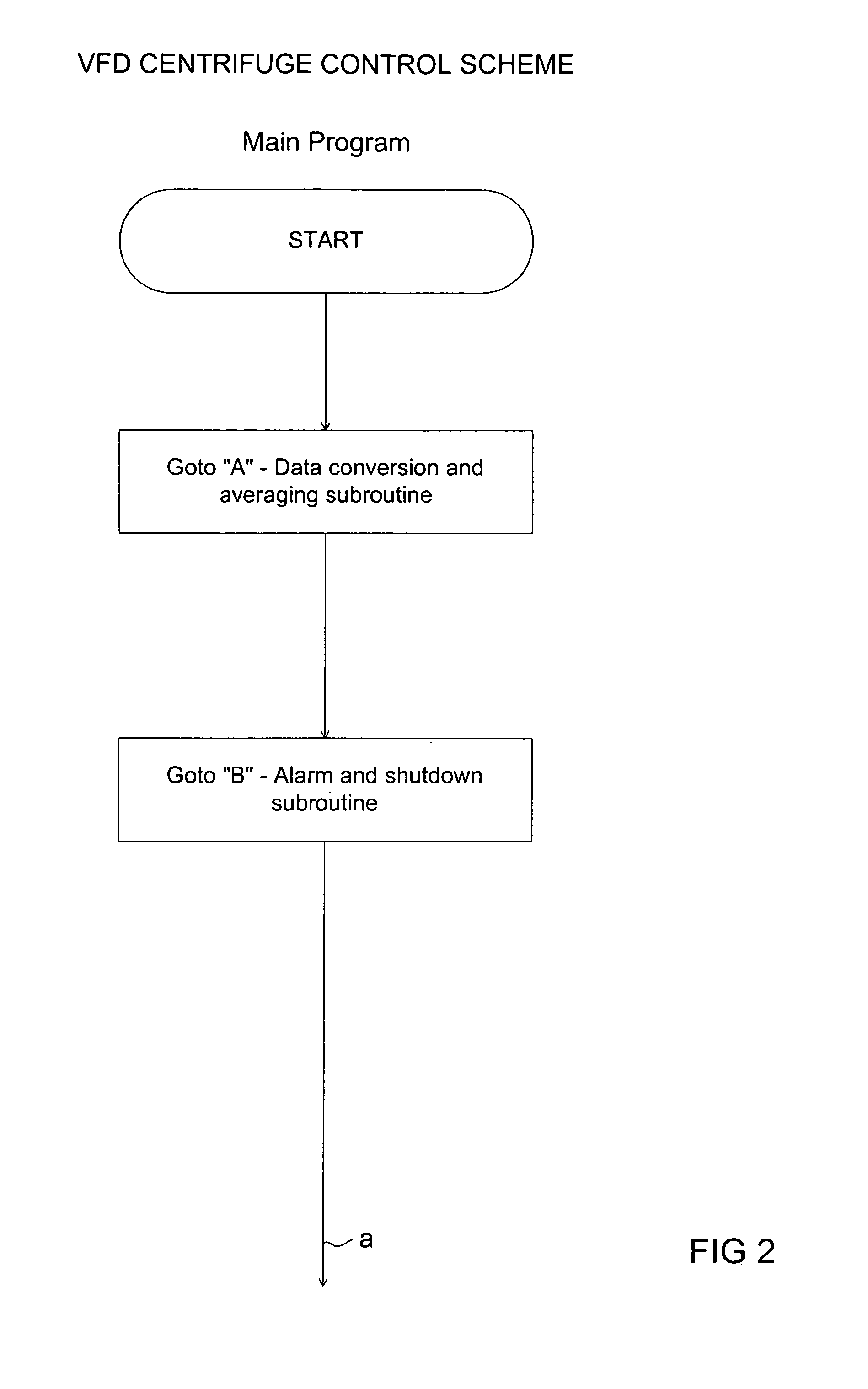

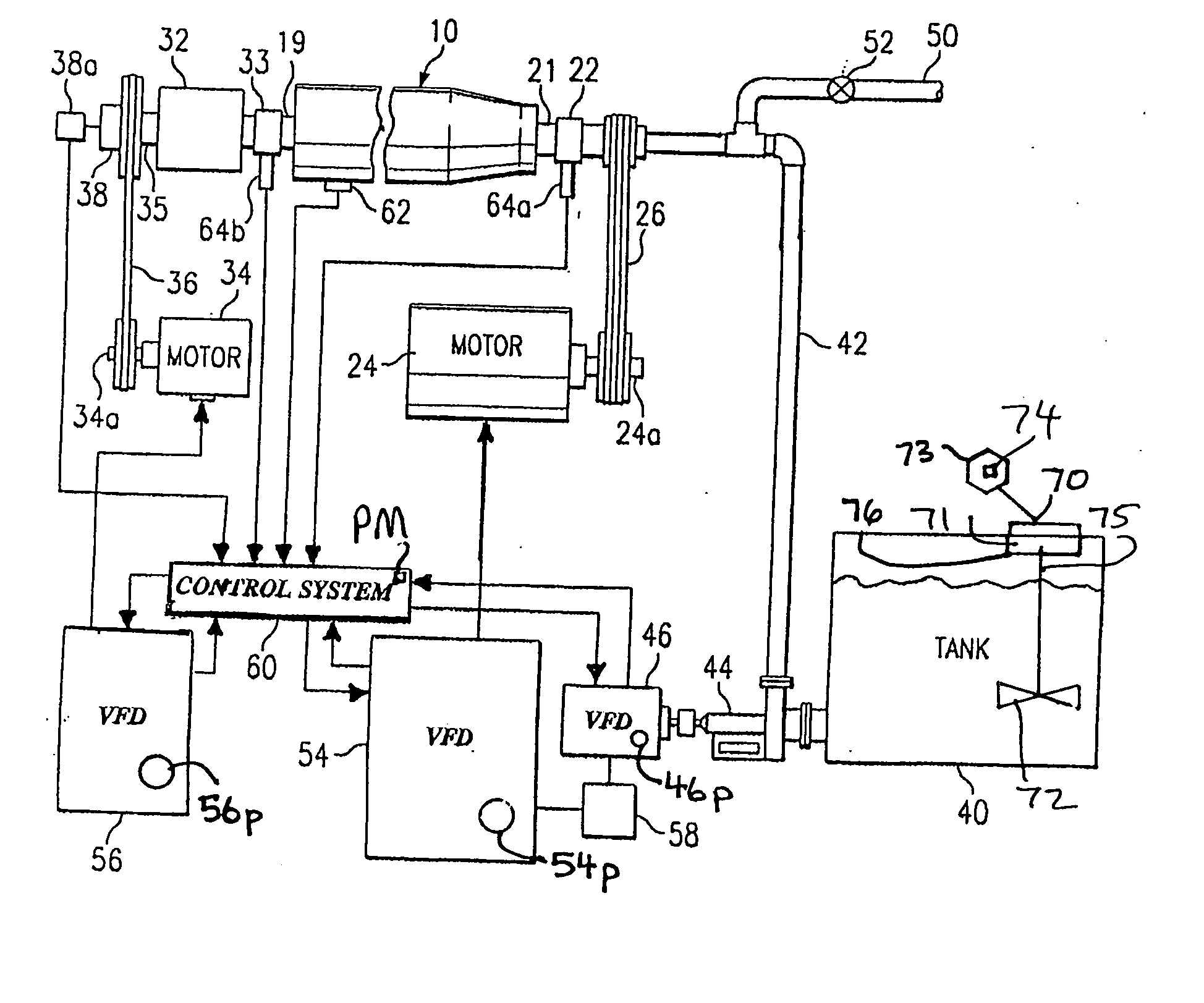

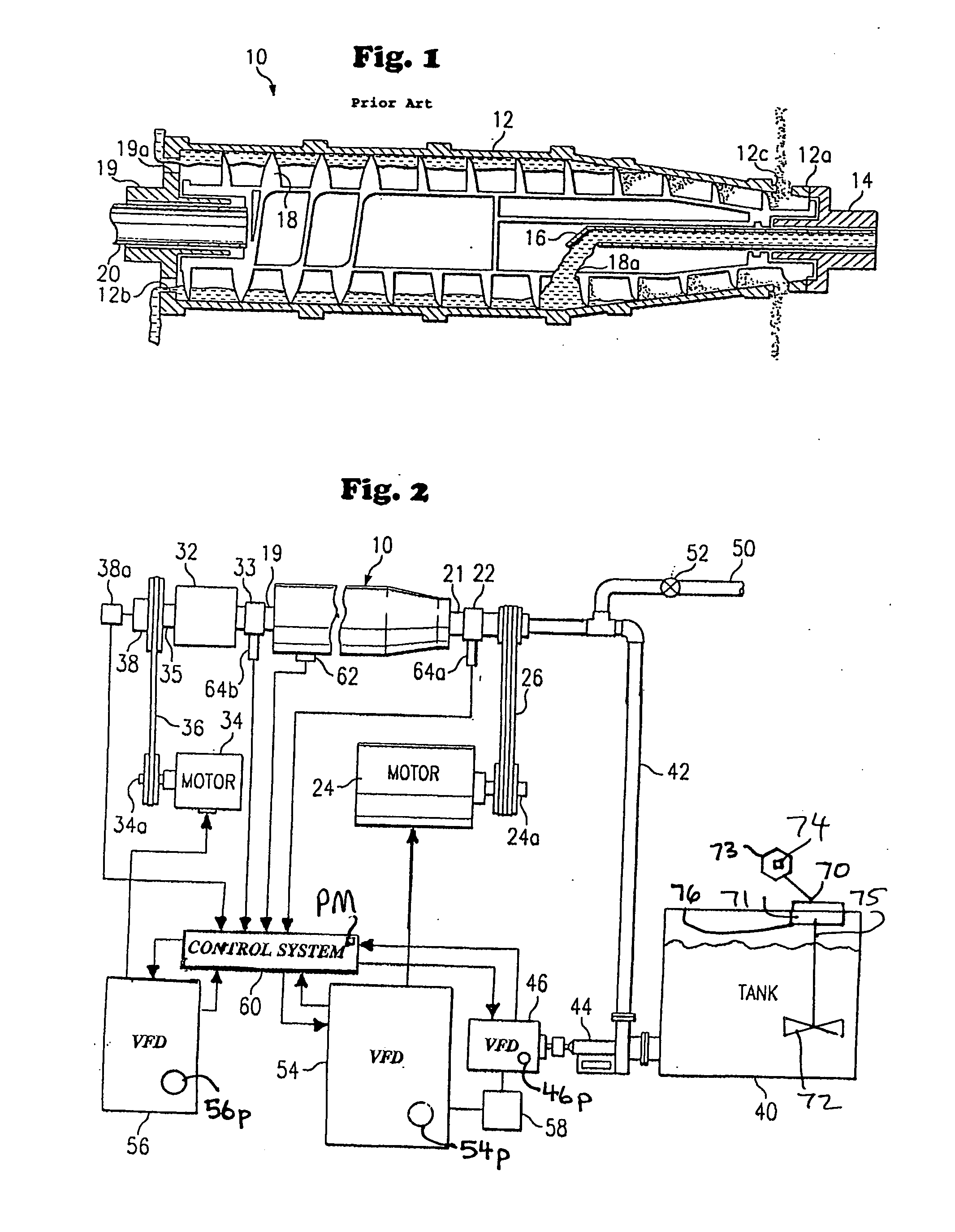

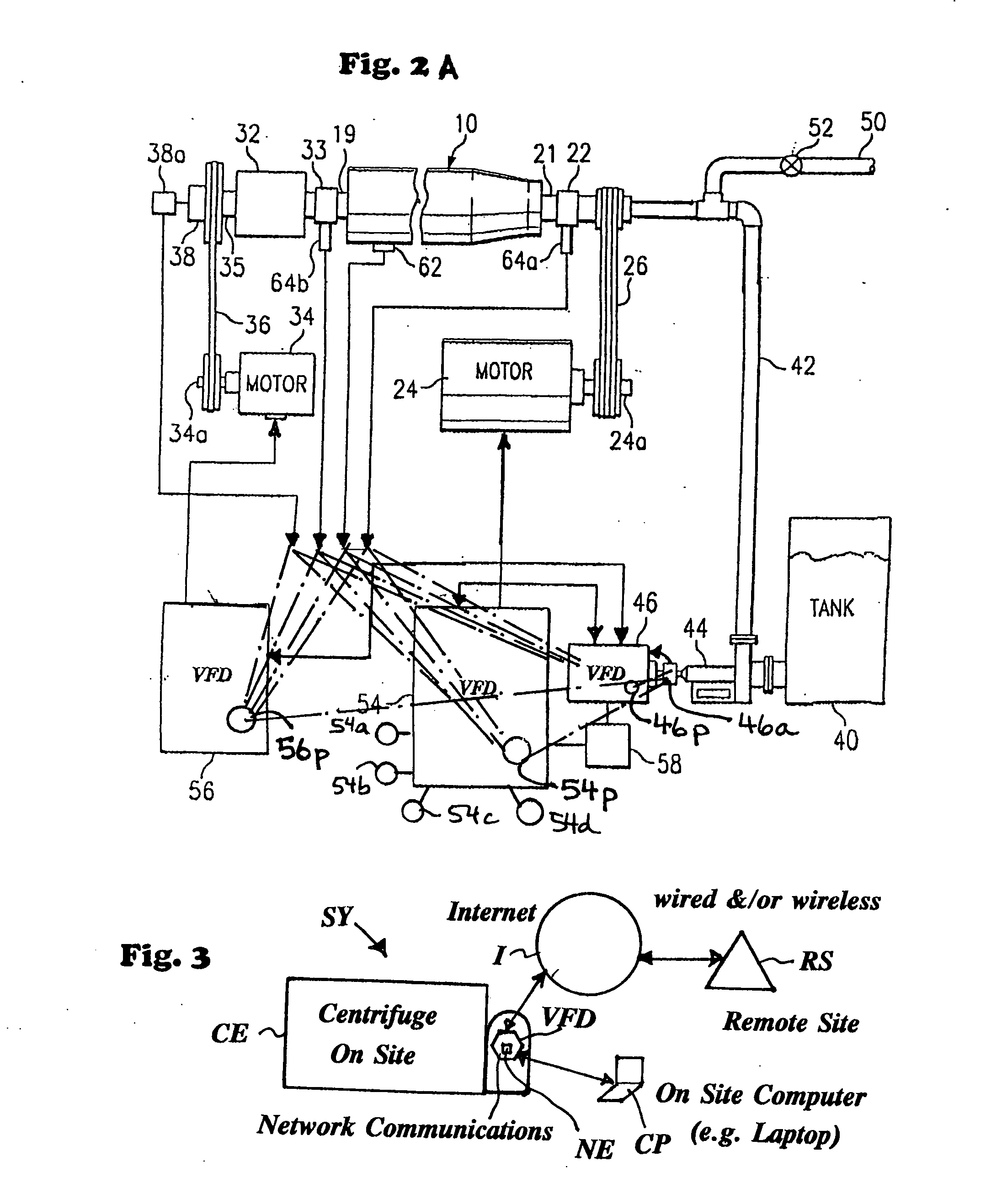

Controlled centrifuge systems

A centrifuge system for processing material, the centrifuge system including a housing, a bowl rotatably mounted within the housing, a bowl motor for rotating the bowl, a bowl motor variable frequency drive apparatus for providing power to the bowl motor, the bowl motor variable frequency drive apparatus including a bowl motor on-board controller for controlling the bowl motor variable frequency drive apparatus, a screw conveyor rotatably mounted within the housing, a screw motor for rotating the screw conveyor, a bowl motor variable frequency drive apparatus for providing power to the bowl motor, the bowl motor variable frequency drive apparatus including a bowl motor on-board controller for controlling the bowl motor variable frequency drive apparatus, and pump apparatus for pumping material to be processed into the bowl.

Owner:VARCO I P INC

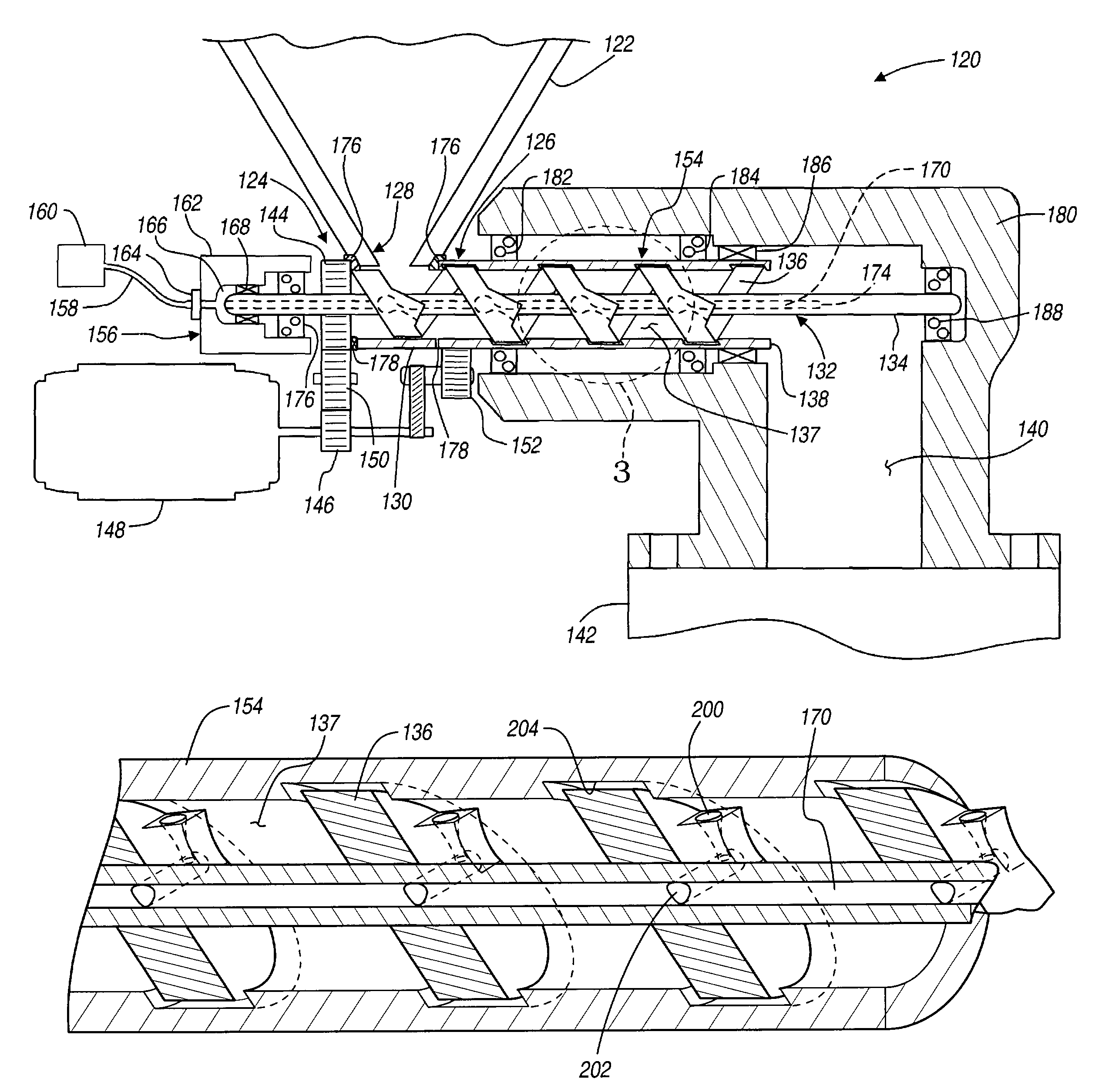

Methods and apparatus for pyrolyzing material

InactiveUS20080128259A1Direct heating destructive distillationIndirect and direct heating destructive distillationHydrogenProcess engineering

Methods and systems for substantially continuously treating comminuted material containing carbon and hydrogen, for example, used tires, are provided. The methods include the steps of introducing the tire material to an elongated chamber, transferring the tire material through the elongated chamber, heating the tire material to a temperature sufficient to pyrolyze the material to produce a gaseous stream; discharging the gaseous stream from the chamber, and cooling at least some of the gaseous stream to liquefy components of the stream. The transfer may be effected by a flexible, center-less screw conveyor to minimize material buildup in the vessel. The cooling of the gaseous stream may be practiced by reverse condensation. One or more re-usable fuel streams are provided by aspects of the invention.

Owner:KOSTEK STANISLAW

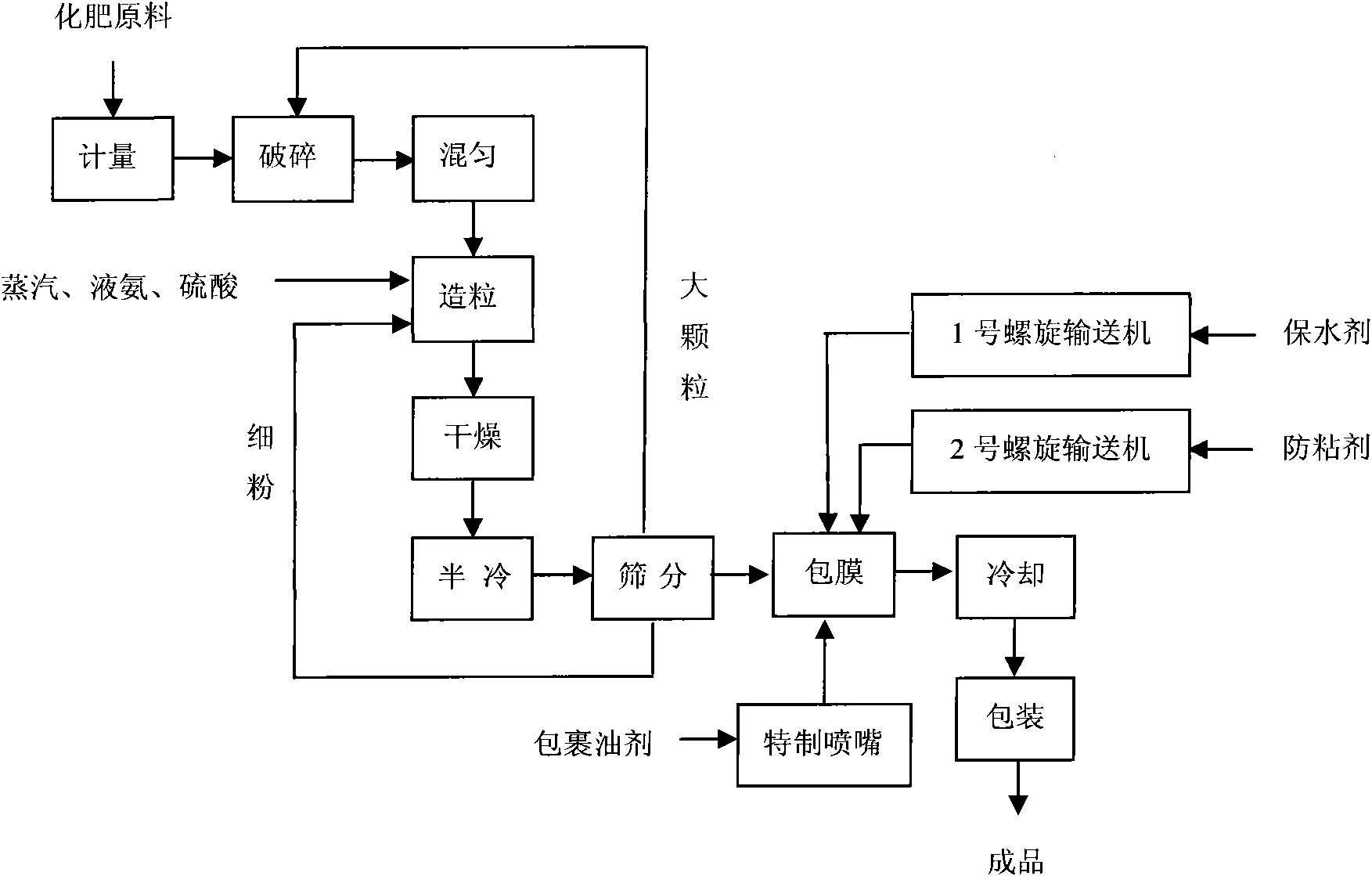

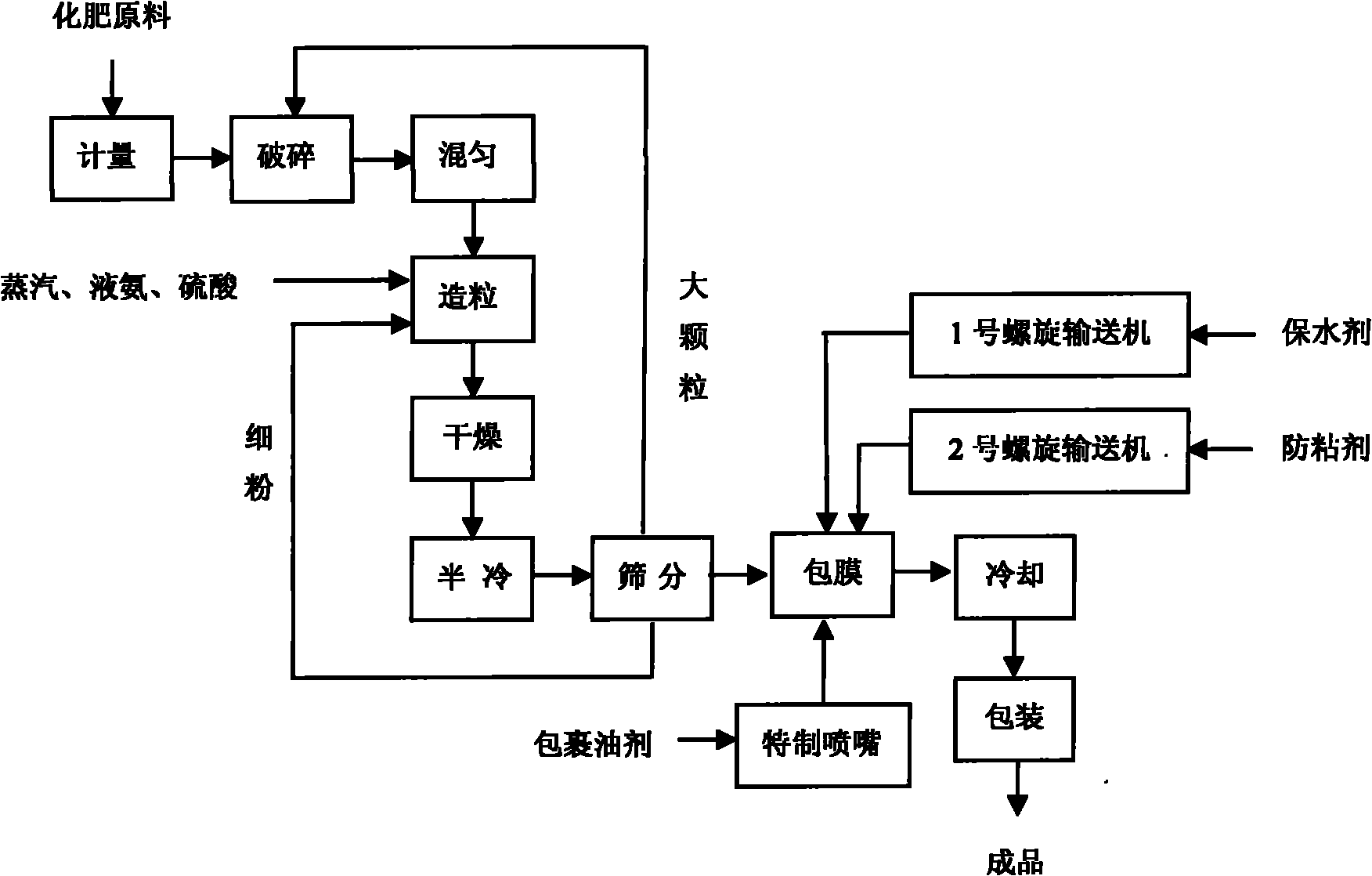

Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

ActiveCN101792354ASimple production methodHigh ball rateFertiliser formsFertilizer mixturesFilm coatingNutrient

The invention discloses a color drought-resistance water-retention sustained-release compound fertilizer and a method for producing the same, wherein the method comprises the followings steps of: measuring, crushing and uniformly mixing fertilizer raw materials, granulating by adopting an ammonia-acid method rotary drum granulating process, performing one-stage drying, semi-cooling and screening of grains, and sending the mixture to a coating machine; adopting a continuous melting rotary drum film-coating method coating process to perform compressed air atomization and uniform coating of color coating oil sprayed by a special nozzle; and adding a water-retaining agent and an anti-adhesive agent by a screw conveyor, and performing full stirring, cooling and packaging to obtain the finishedproducts. The color drought-resistance water-retention sustained-release compound fertilizer has the effects of drought resistance, water retention, nutrient preservation, soil condition improvement and environmental protection, and the appearance of the fertilizer has color marks; and when the fertilizer is applied to crops, the fertilizer has the advantages of increasing yield and incoming, along with simple production method, convenient operation, low cost and high benefits.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

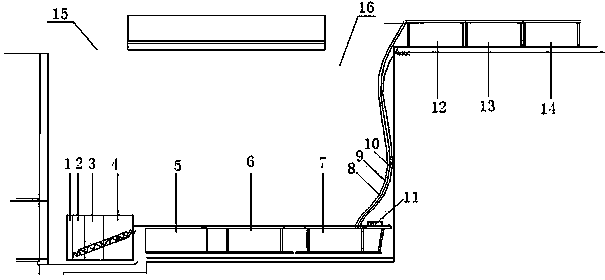

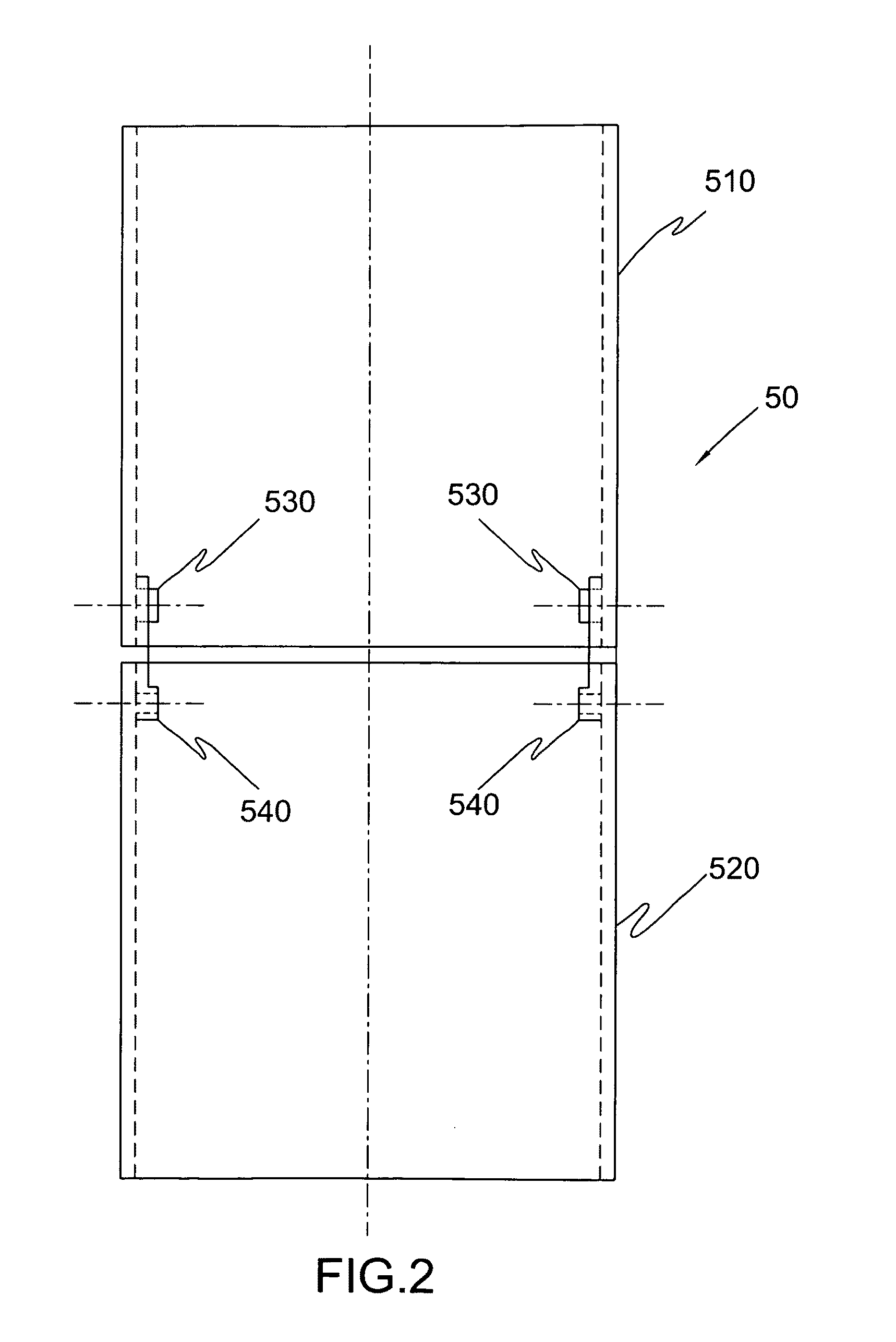

Shield tunneling machine split starting construction method

InactiveCN103711499AImprove construction efficiencyLow construction costTunnelsArchitectural engineeringShield tunneling

The invention discloses a shield tunneling machine split starting construction method and belongs to the technical field of building construction. The method comprises the following steps: (1) cleaning an underground site, (2) starting base seat underground assembling and laying rails, (3) moving a first trolley and a second trolley underground and moving the first trolley and the second trolley backward, (4) moving a duct piece cart underground, (5) moving a connecting bridge and a spiral conveyor underground in a hoisting mode, and moving the connecting bridge and the spiral conveyor backward, (6) moving a starting table underground, smear ing lubricating grease, moving a cutter disk and a shield body underground and locating and assembling the cutter disk and the shield body, (7) assembling, (8) starting trying tunneling, (9) restoring to normal shield tunneling. The method has the advantages of effectively solving the problem that a shield tunneling machine cannot be operated and run normally for being restricted by the actual environment of a shield tunneling staring operation shaft on a construction site, greatly improving construction efficiency, saving construction cost, and reducing construction difficulty.

Owner:CHINA RAILWAY 13TH BUREAU GRP 6TH ENG COMPANY

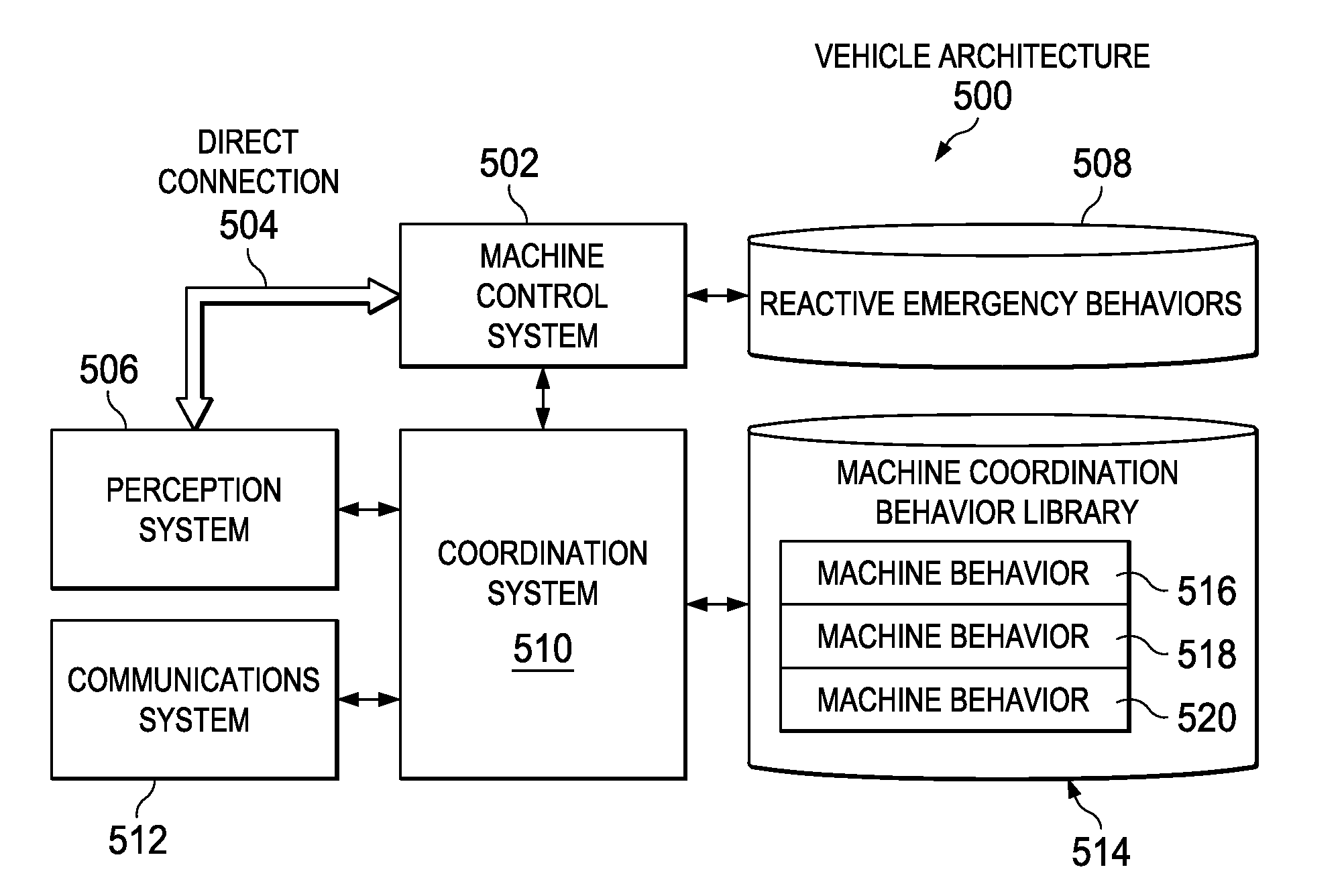

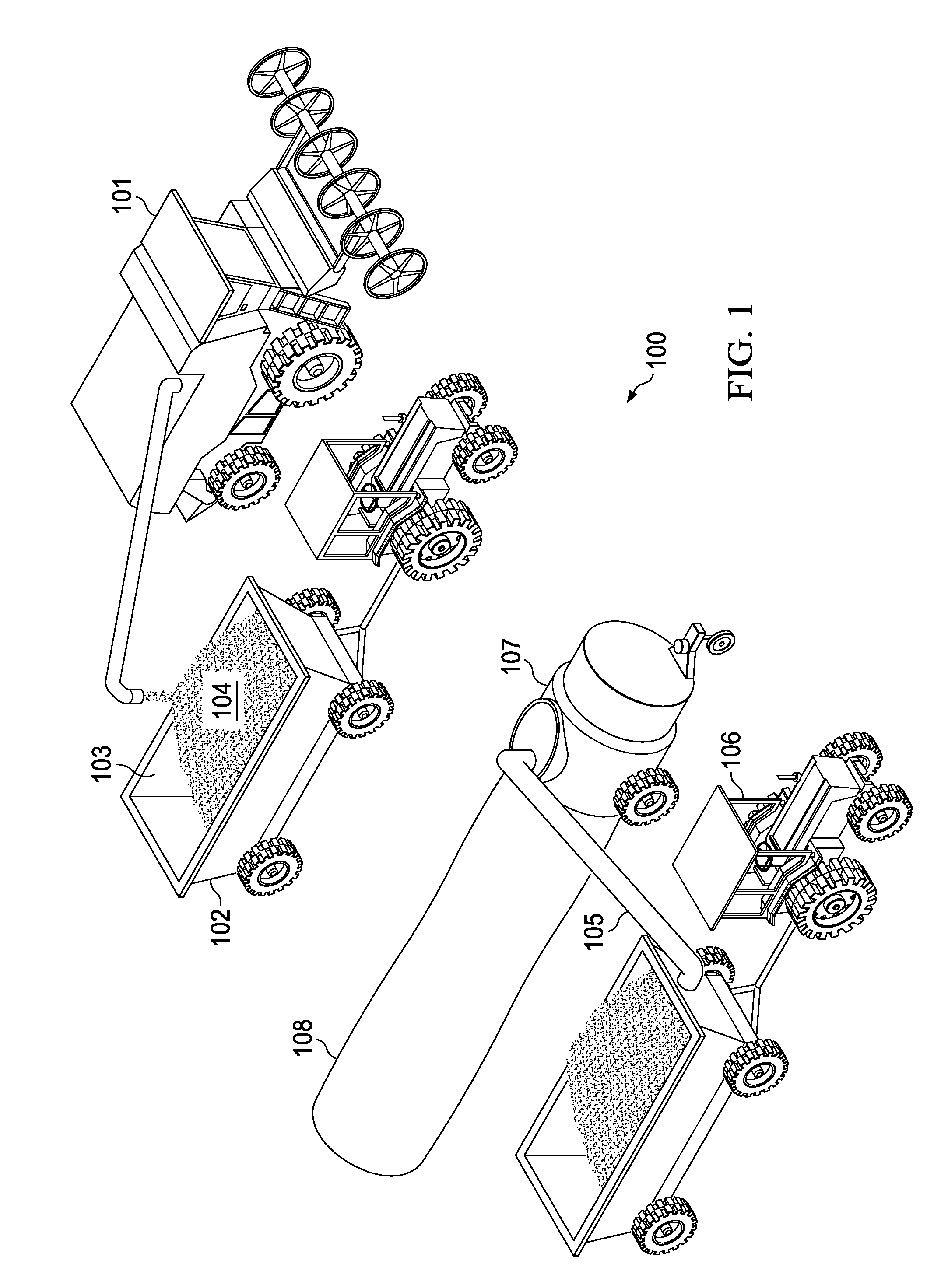

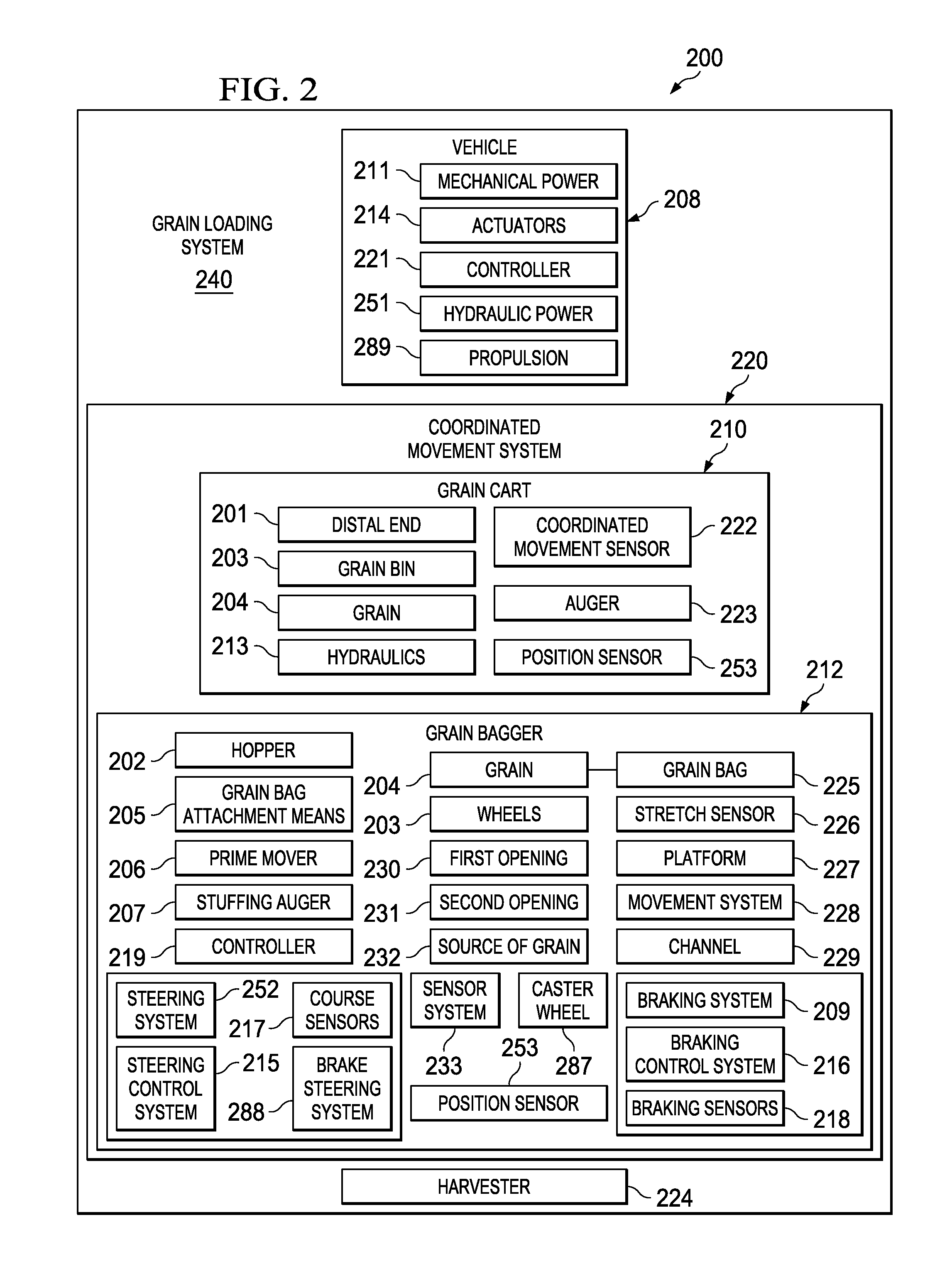

Intelligent grain bag loader

A system for controlling the loading of grain in a grain bag is described. The system includes a grain cart, a tractor attached to the grain cart, and a grain bagger with an attached grain bag. The grain bagger further comprises a steering and steering control systems and a braking and braking control system. A hopper connected to the grain bagger receives grain from an auger connected with the hopper and auger and defines a loading position in which a distal end of the auger is positioned relative to the hopper such that grain transfers from the auger into the hopper. A controller provides velocity and steering commands to the tractor and a coordinated movement system connected to the controller receives position information as to the auger and hopper and provides course adjusting information so as to maintain the auger and hopper in the loading position.

Owner:DEERE & CO

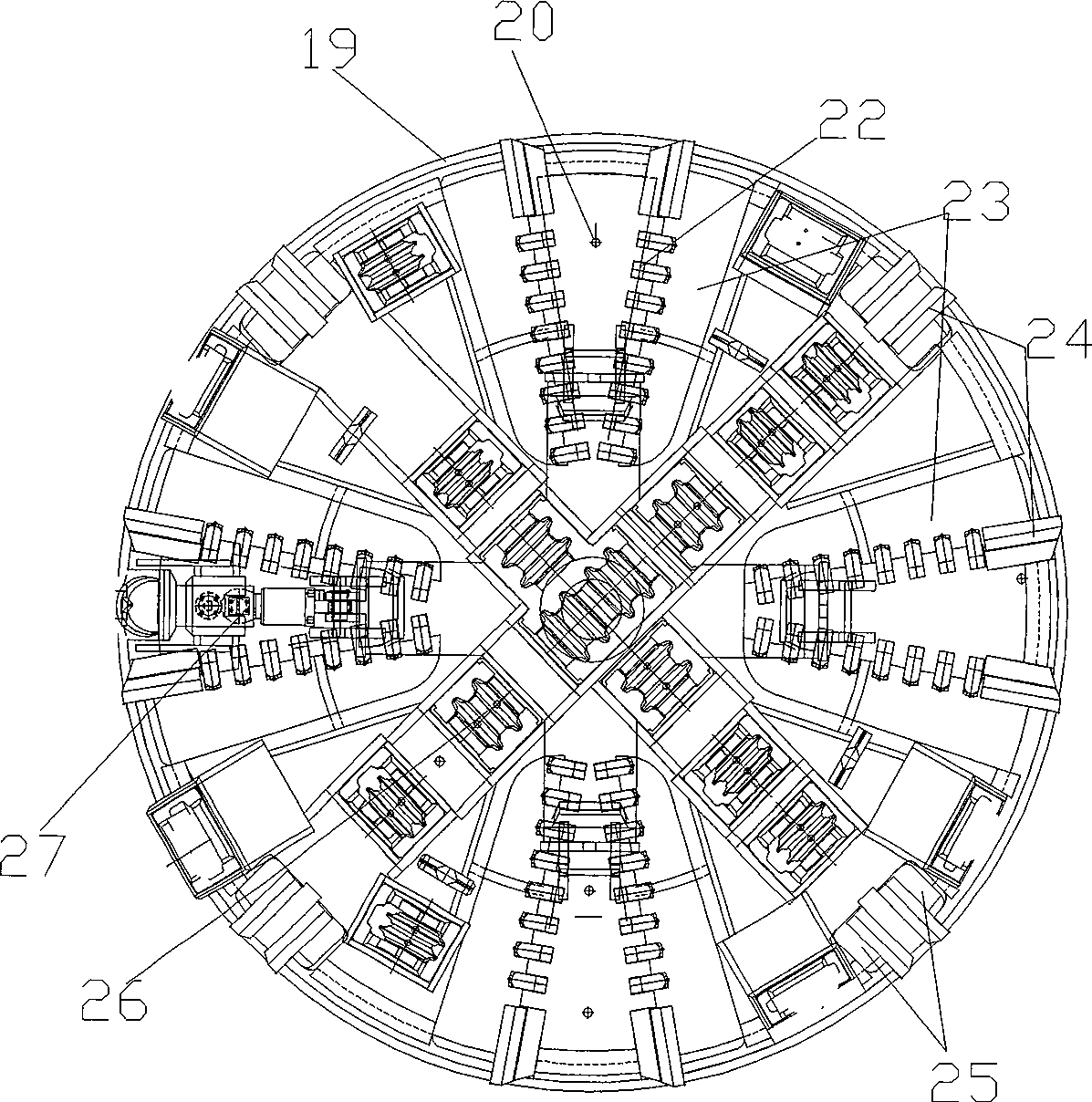

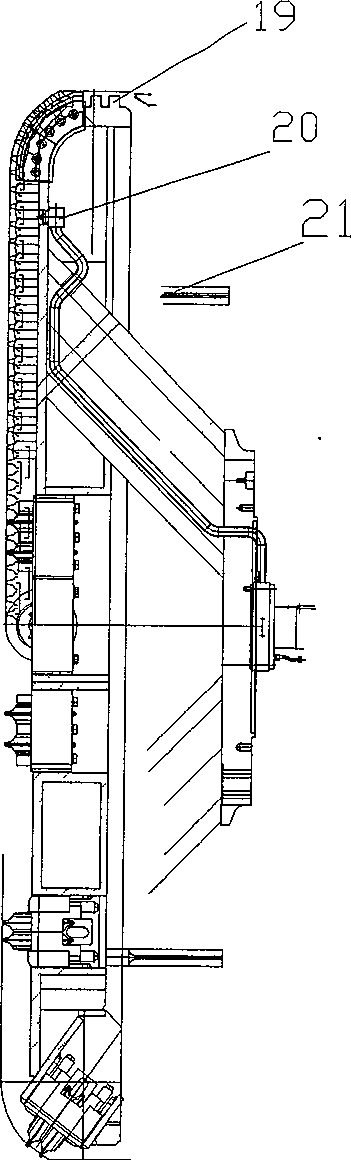

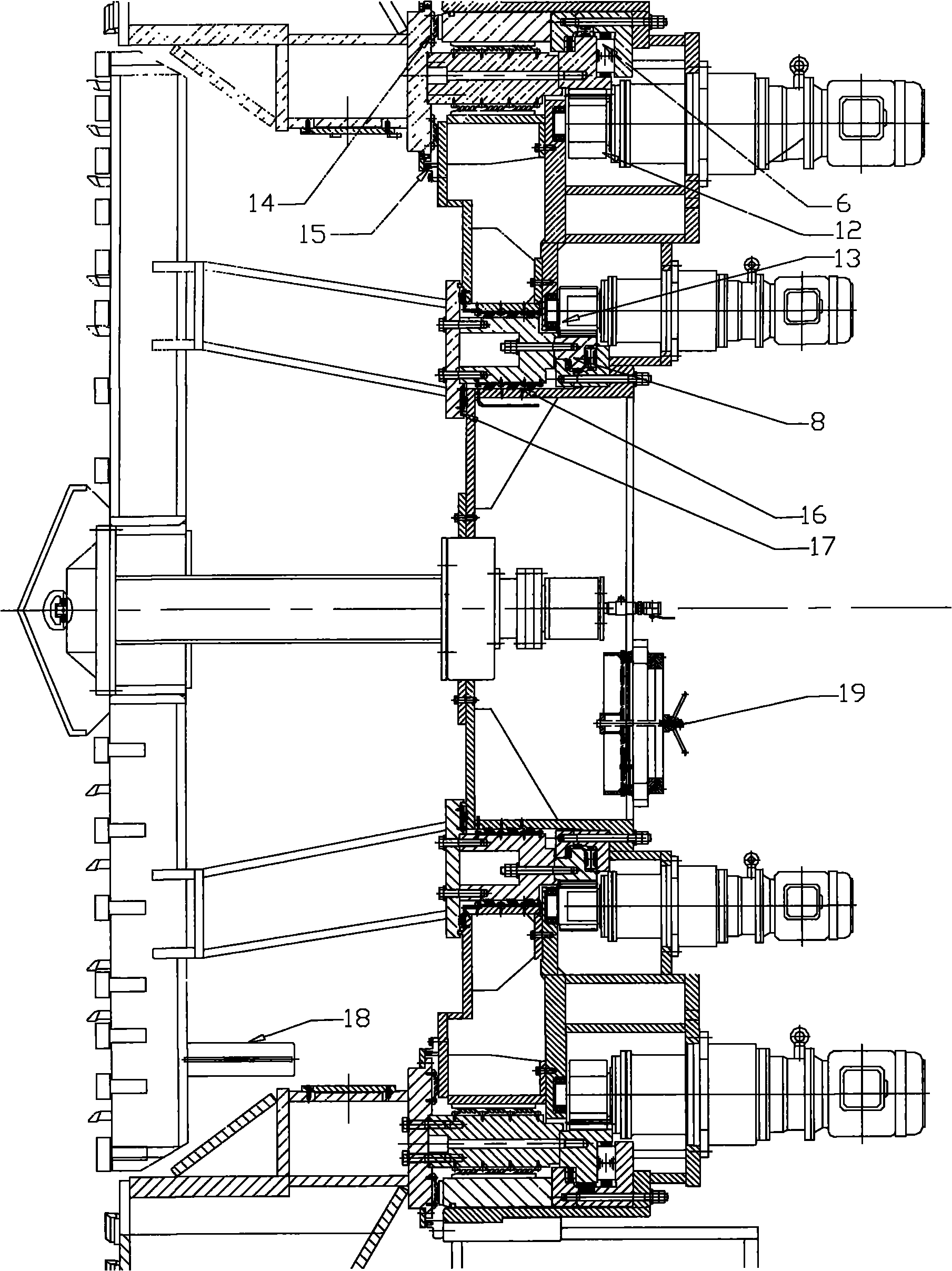

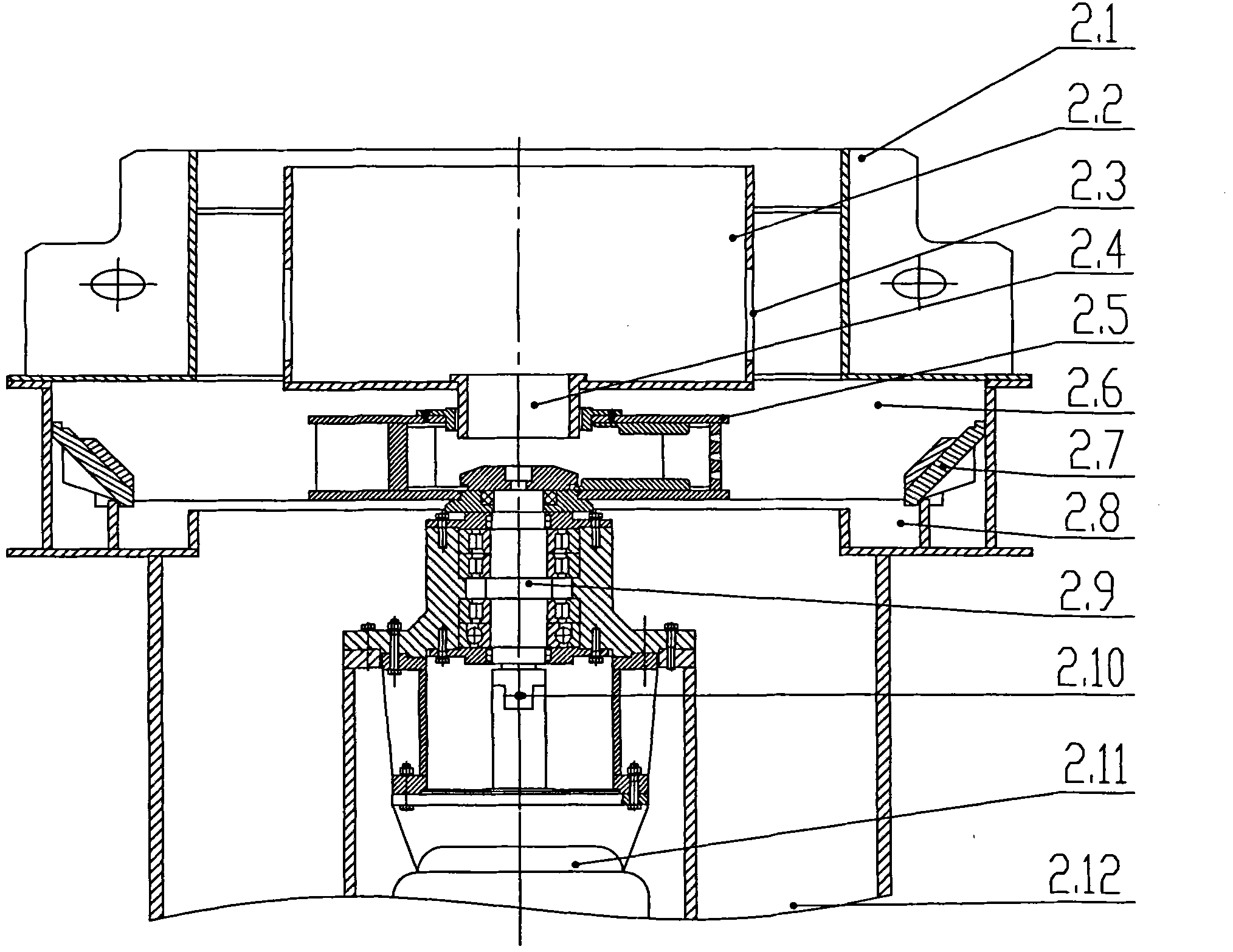

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

Integrated Shale Shaker and Dryer

InactiveUS20050183994A1Increase flow rateEasy to wearSievingGas current separationPropellerEngineering

An integrated, transportable cuttings treatment system includes a multi-part shale shaker, preferably formed of six screens vibrated by at least one electric vibrator, and preferably four such vibrators. Solids are screen from drilling mud flowing onto the screens, and directed into a trough wherein is located a screw conveyor or augur. A pressure differential is developed across the screens to increase the flow rate of drilling mud through the screens.

Owner:HUTCHISON HAYES INT

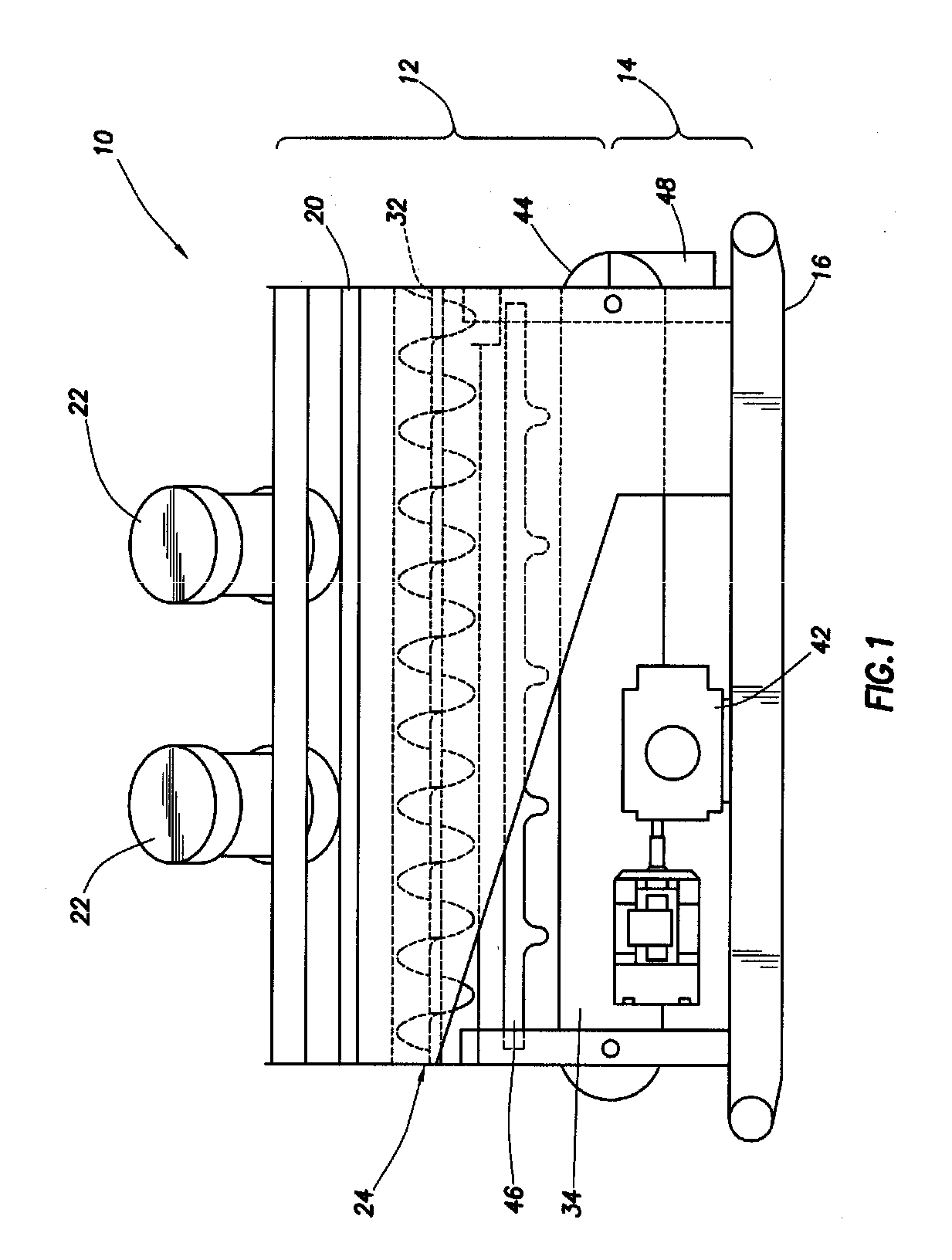

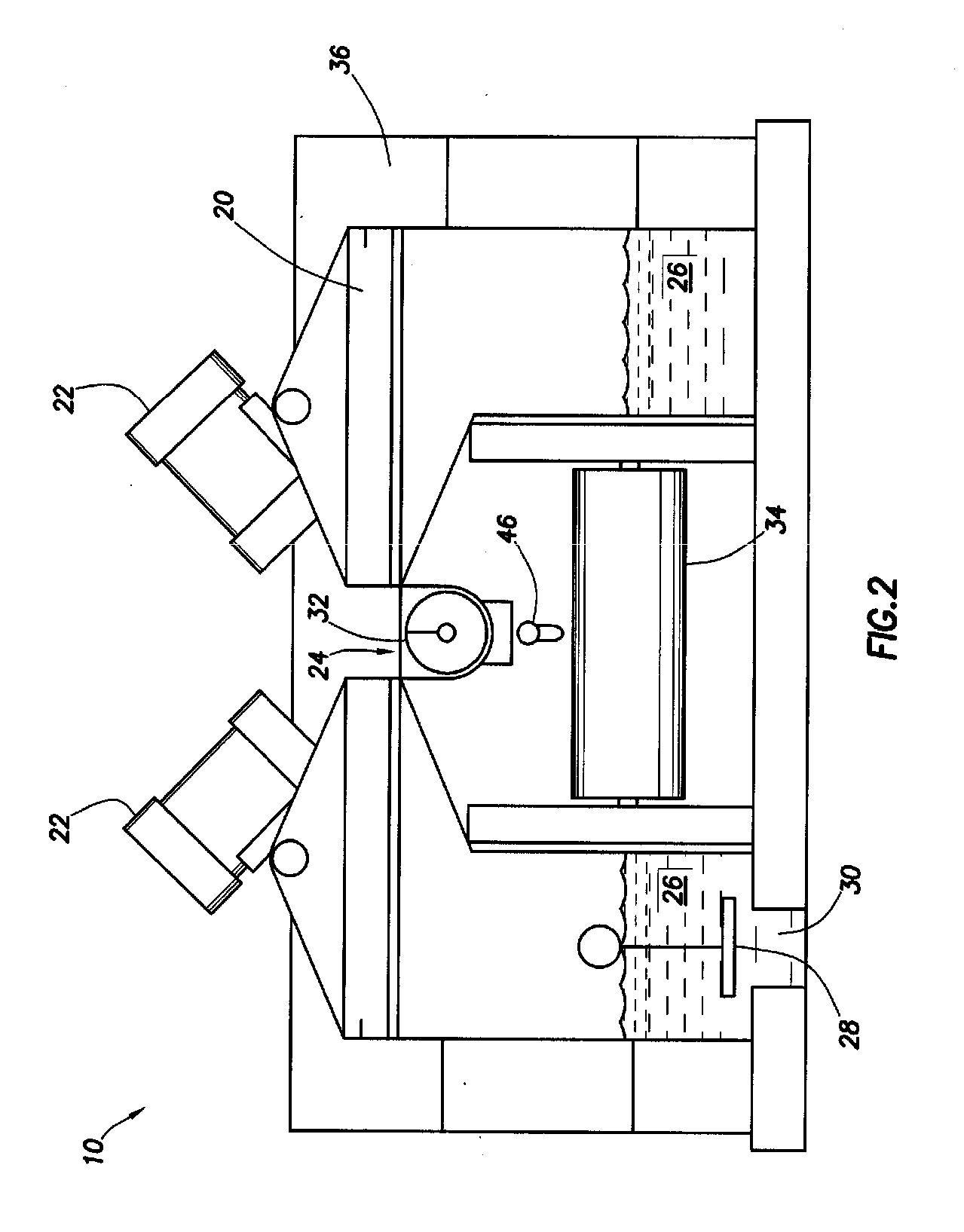

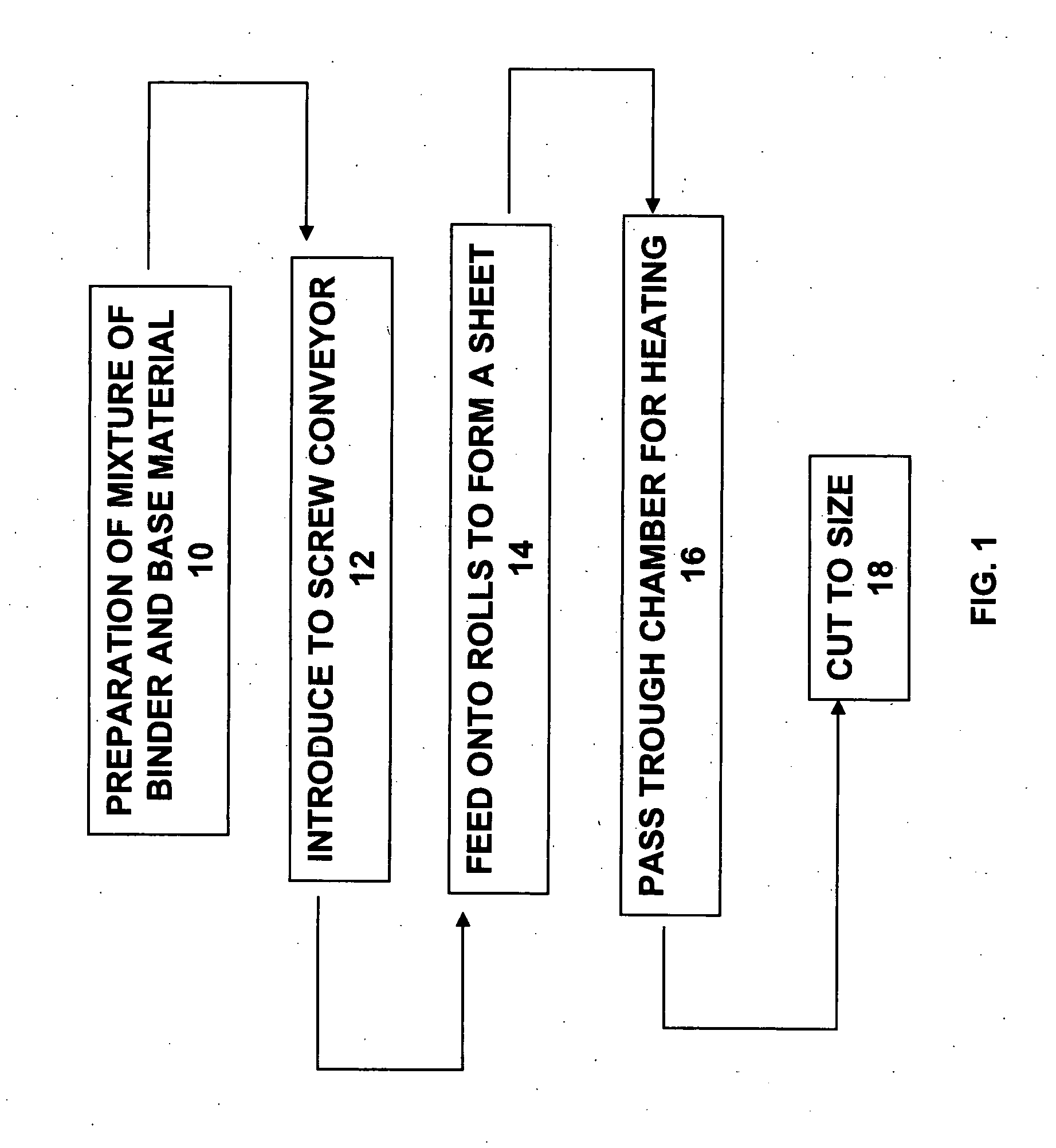

Apparatus and process for forming pet treats

An animal chew is provided formed by rolling a mixture of binder and base material into a sheet. Base material, such as an edible material, including but not limited to starch, protein matter, vegetable or plant matter, is mixed with a binder. The mixture is then supplied to a screw conveyor followed by introduction onto rollers to form a sheet. The sheet may then be cut into a desired shape. The overall process may be made continuous, and the manufacturing conditions may be selectively controlled at each step, with respect to variable such as temperature and moisture levels, to substantially maintain the overall nutritional value of the formed edible compositions.

Owner:T F H PUBLICATIONS

Method of retrofitting a decanting centrifuge

A method of retrofitting a centrifuge is provided. The method includes disassembling a known centrifuge and replacing a bowl section of the centrifuge outer body with a longer bowl section. The method further comprises replacing the conical beach section with a shorter beach section, i.e. a beach section having a greater slope. The screw conveyor is replaced with another screw conveyor having outlet nozzles adapted to impart rotational movement to the inlet feed. The retrofitted centrifuge provides enhanced performance through an additional length of cylindrical section, thereby making the clarification length longer, and improving the effectiveness of the centrifuge in removing solids from the inlet feed. The retrofitted centrifuge preferably remains mounted to the same pedestal as the centrifuge prior to retrofit.

Owner:HUTCHISON HAYES PROCESS MANAGEMENT

Earth working digging tool and system for digging holes in ground

InactiveUS20110232551A1Prevent avalancheEfficient and effectivePlantingFurrow making/coveringEngineeringScrew conveyor

This invention was intended to develop an earth working equipment and system for digging holes in ground particularly in agricultural soils for needs including but not limited to transplanting of seedlings of flowers, vegetables, fruits, bushes, and shrubs; and for making holes for other purposes where hollow-cylindrical shapes are desired. One very important feature of the equipment is the provision of a removable or embeddable cylindrical retaining wall around the hole being dug thus preventing hole-deforming avalanches of soils, common in trowel assisted hole digging that results in V-shaped rather than cylindrical shaped holes. This provision and other features of the equipment ensure formation of consistent hollow-cylindrical holes effectively, efficiently and economically. The equipment consists of a tilling tool to loosen the soil, a screw conveyor to dig into and transport the soil away, and a cylindrical retaining wall to maintain cylindrical shape of the hole by preventing soil avalanches.

Owner:HAQUE EKRAMUL

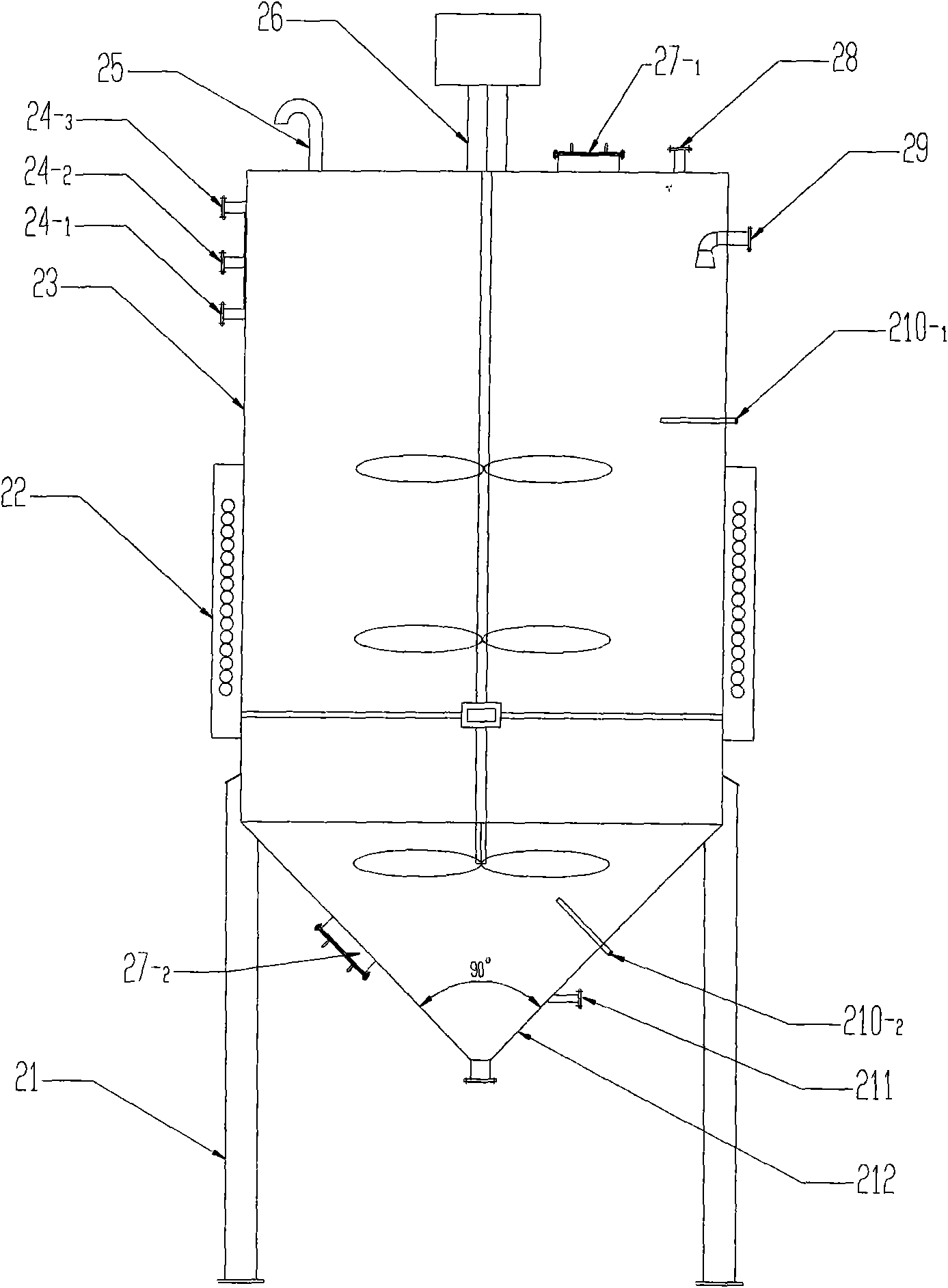

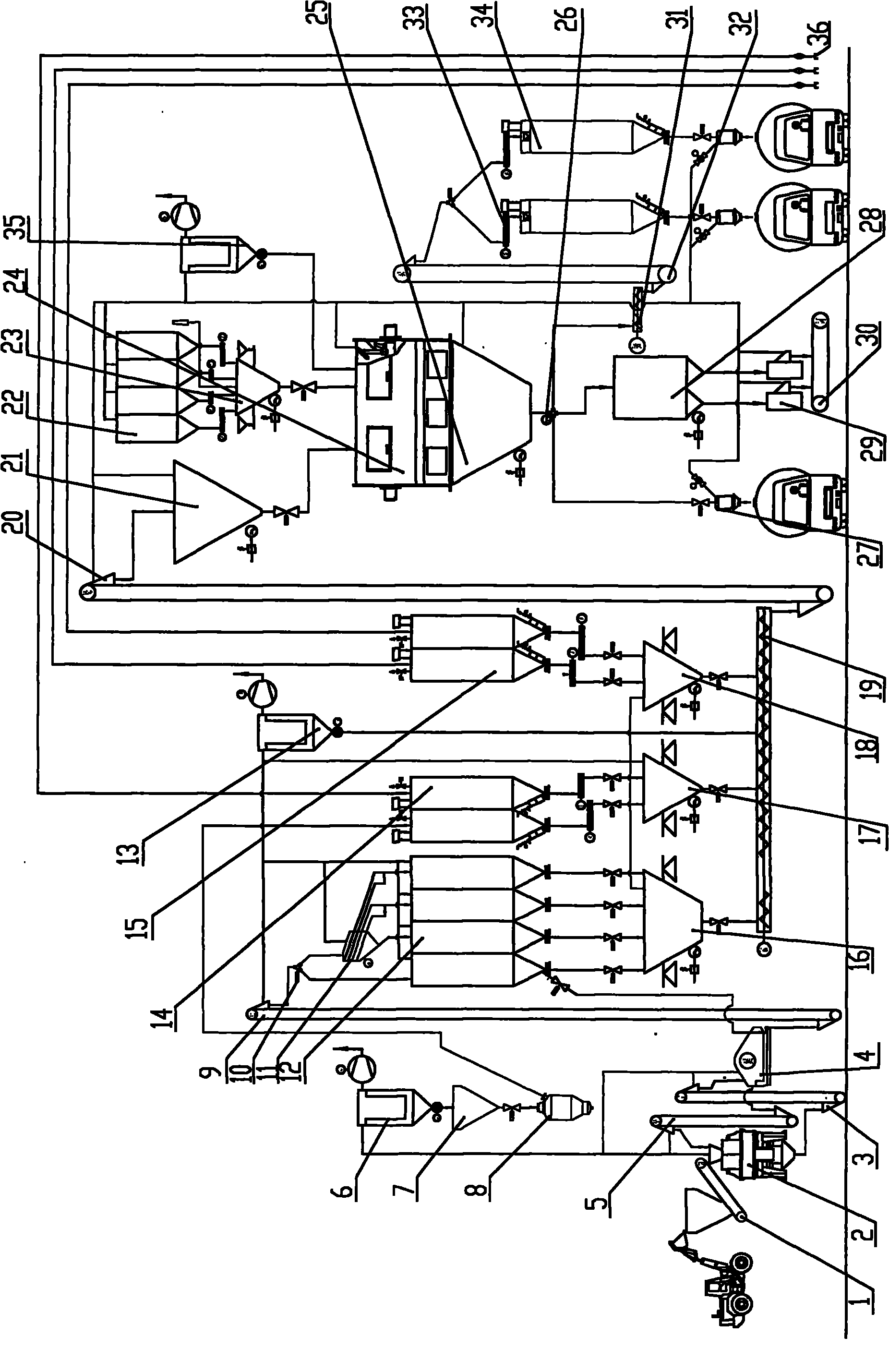

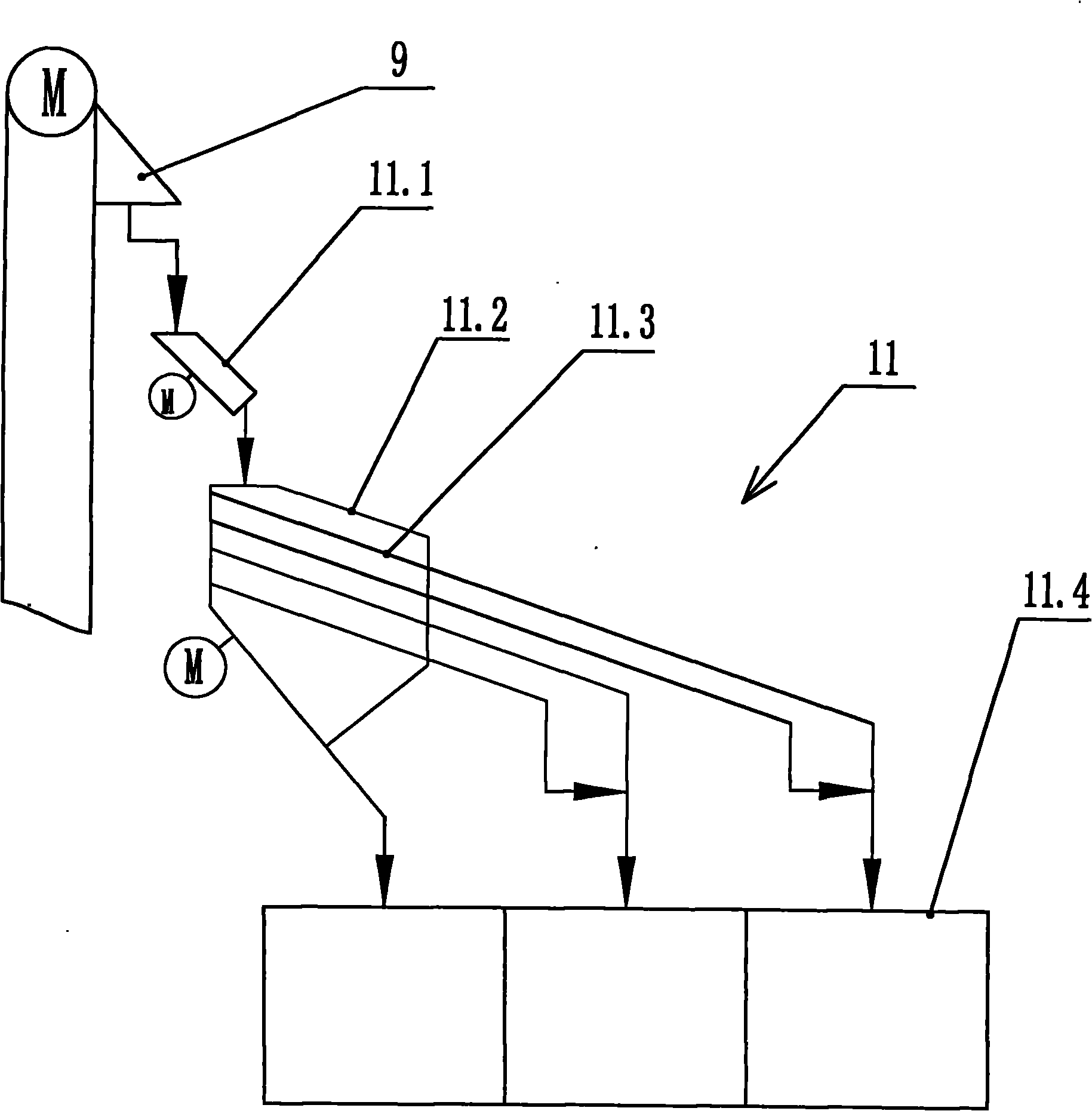

Drying-free dry-mixed mortar complete equipment

The invention relates to drying-free dry-mixed mortar complete equipment, comprising a charging belt conveyor (1), a crusher sand making machine (2), a discharging bucket elevator (3), a circulating vibration screen (4), a screening bucket elevator (9), a vibrating screen classifier (11), a classified sand warehouse (12), a return bucket elevator (5), a stone powder dust collector (6), a stone powder temporary storage bin (12), a stone powder delivery tank (8), a stone powder additive bin (14), a cement bin (15), a sand dispensing and metering device (16), an additive dispensing and metering device (17), a cement dispensing and metering device (18), a metering material spiral conveyer (19), a metering material bucket elevator (20), a metering material intermediate transition bin (21), an additive storage silo (22), an accurate dispensing and metering device (23), a mixer (24), a finished product material transition bin (25), a bulk head (27), a wrapping finished product bin (28), a sack filler (29), a package belt conveyer (30), a finished product material storage spiral conveyer (31), a finished product material storage bucket elevator (32), a dissociation-proof transport unloading device (33) and a finished product material bulk storage silo (34). The invention can omit drying and realizes drying-free effect.

Owner:WUXI JIANGJIA CONSTR MACHINERY

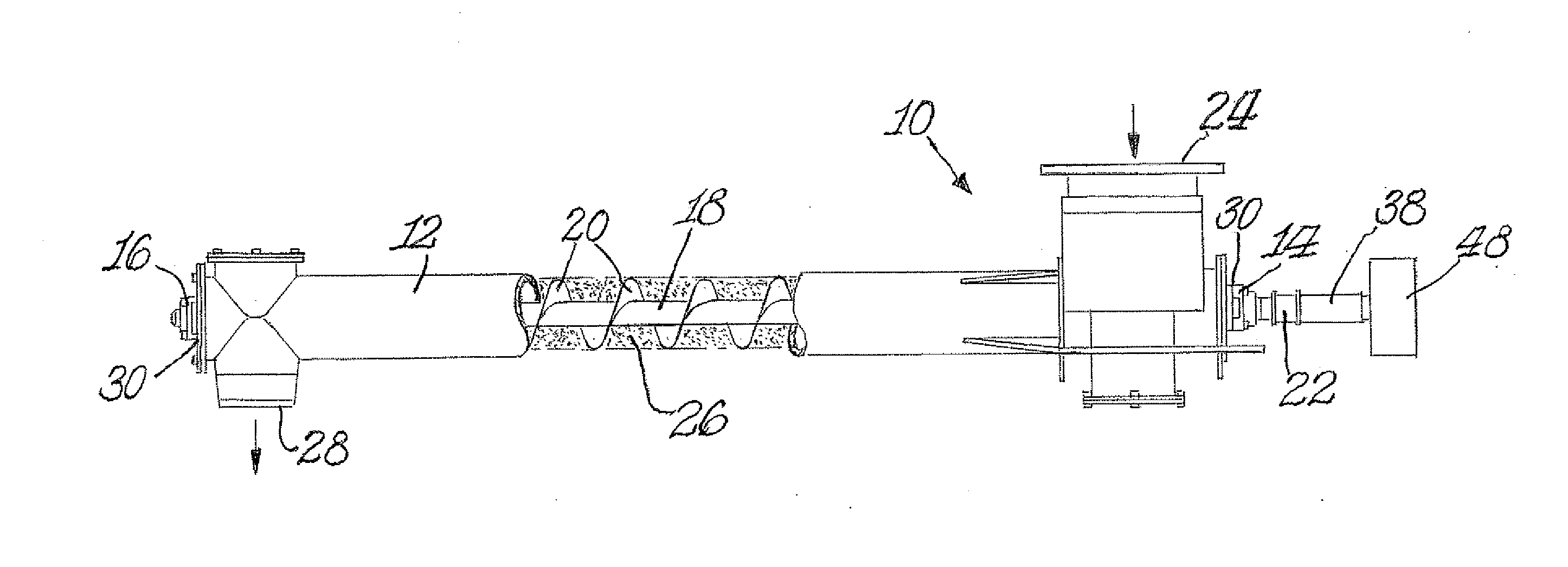

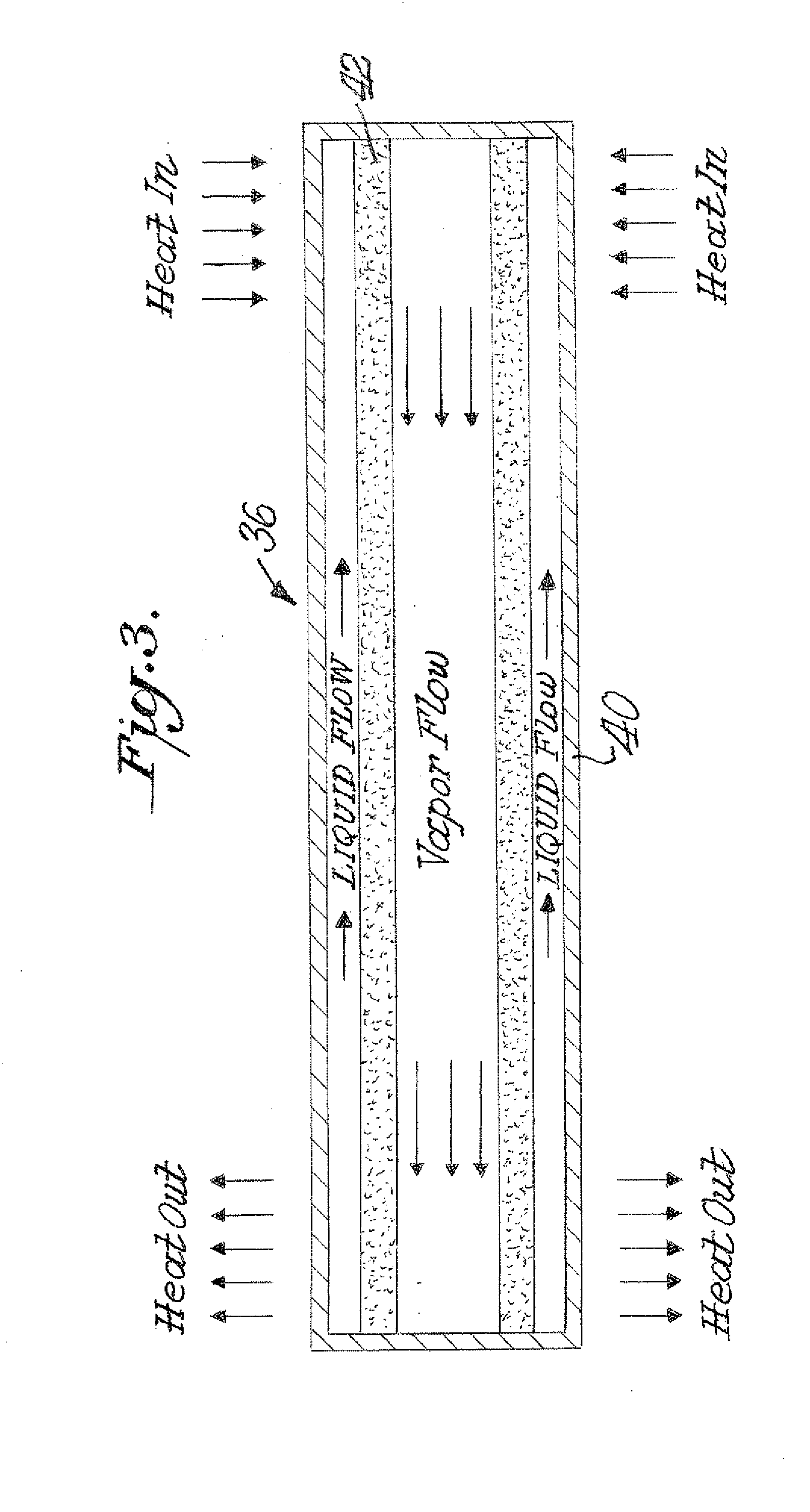

Heated/cool screw conveyor

InactiveUS20080121497A1Uniform temperatureThermally efficientCharge manipulationPackagingEngineeringScrew thread

A screw conveyor includes a hollow rotatable shaft having an externally mounted flight extending along a portion of its length. Thermal applicating structure is provided at one end of the shaft for heating or cooling the screw conveyor. A thermosyphon is mounted within the shaft. The thermosyphon includes a hollow tube mounted against and in direct surface to surface contact with the shaft to rotate co-jointly with the shaft.

Owner:ESTERSON CHRISTOPHER +1

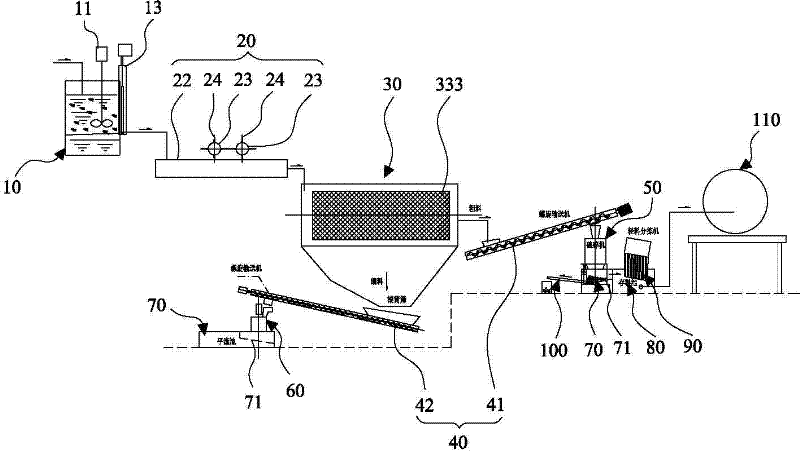

Restaurant-kitchen garbage sorting system

InactiveCN102327890AImprove processing efficiencyAccurate classificationSievingScreeningPlastic packagingProcess engineering

The invention discloses a restaurant-kitchen garbage sorting system. The system orderly comprises a scrubbing oil groove for separating grease from residues, a bag breaking conveyor for tearing a plastic package and a drum screening machine for screening the residues into coarse material and fine material, and a coarse material outlet and a fine material outlet are arranged on the drum screening machine, a coarse material spiral conveyor and a fine material spiral conveyor are respectively arranged corresponding to the coarse material outlet and the fine material outlet, a crusher is arranged at an outlet of the coarse material spiral conveyor, a pulping machine is arranged at an outlet of the fine material spiral conveyor, and a horizontal flow pool for dividing the pulp from the crusher and the pulping machine into light material and heavy material. Therefore, the restaurant-kitchen garbage sorting system can effectively treat the bagged garage without manual operation, and improve the garage processing efficiency; and the garage can be classified so as to be convenient for recycle.

Owner:DONGGUAN CAMDA GENERATOR WORK

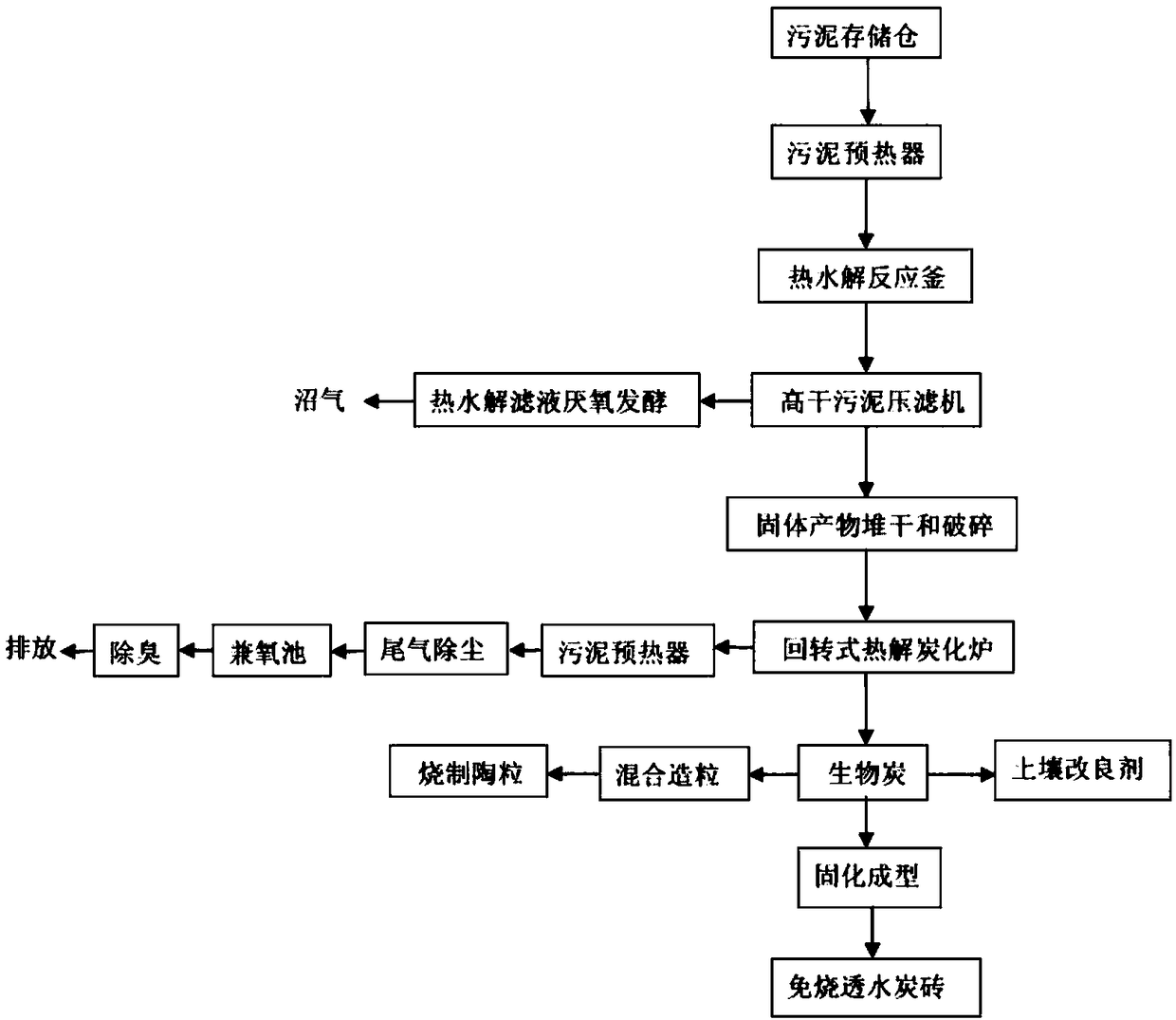

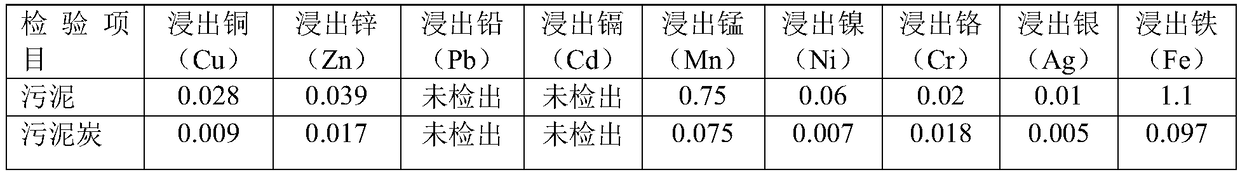

Resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization

InactiveCN108423959AImproved Anaerobic Digestion PerformanceImprove dehydration effectWater treatment parameter controlSpecific water treatment objectivesSludgeHigh energy

The invention discloses a resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization. The method includes the steps of: (1) transporting dehydrated sludge to a sludge preheater; (2) sending the preheated sludge into a sludge thermal hydrolysis reaction kettle; (3) subjecting the thermal hydrolysis product to solid-liquid separation to obtain thermal hydrolysis filtrate and a solid product; (4) carrying out natural heap drying, crushing, activation and granulation on the solid product successively, then conveying the product to a rotary controllable pyrolysis carbonization furnace by a spiral conveyer, and conducting high-temperature rapid pyrolysis to obtain biochar, tar and high-temperature waste gas, introducing the high-temperature waste gas into the sludge preheater, and subjecting the biochar to resource comprehensive utilization; and (5) subjecting the thermal hydrolysis filtrate to anaerobic fermentation, and using the generated biogas as the fuelof the pyrolysis carbonization furnace. The method provided by the invention overcomes the problems of high energy consumption of the sludge carbonization process and nonstandard resource utilizationmethod of sludge biochar in sewage treatment plants at present, and realizes reduction, stabilization, harmless and resource comprehensive utilization of sludge in sewage treatment plants.

Owner:浙江合泽环境科技有限公司

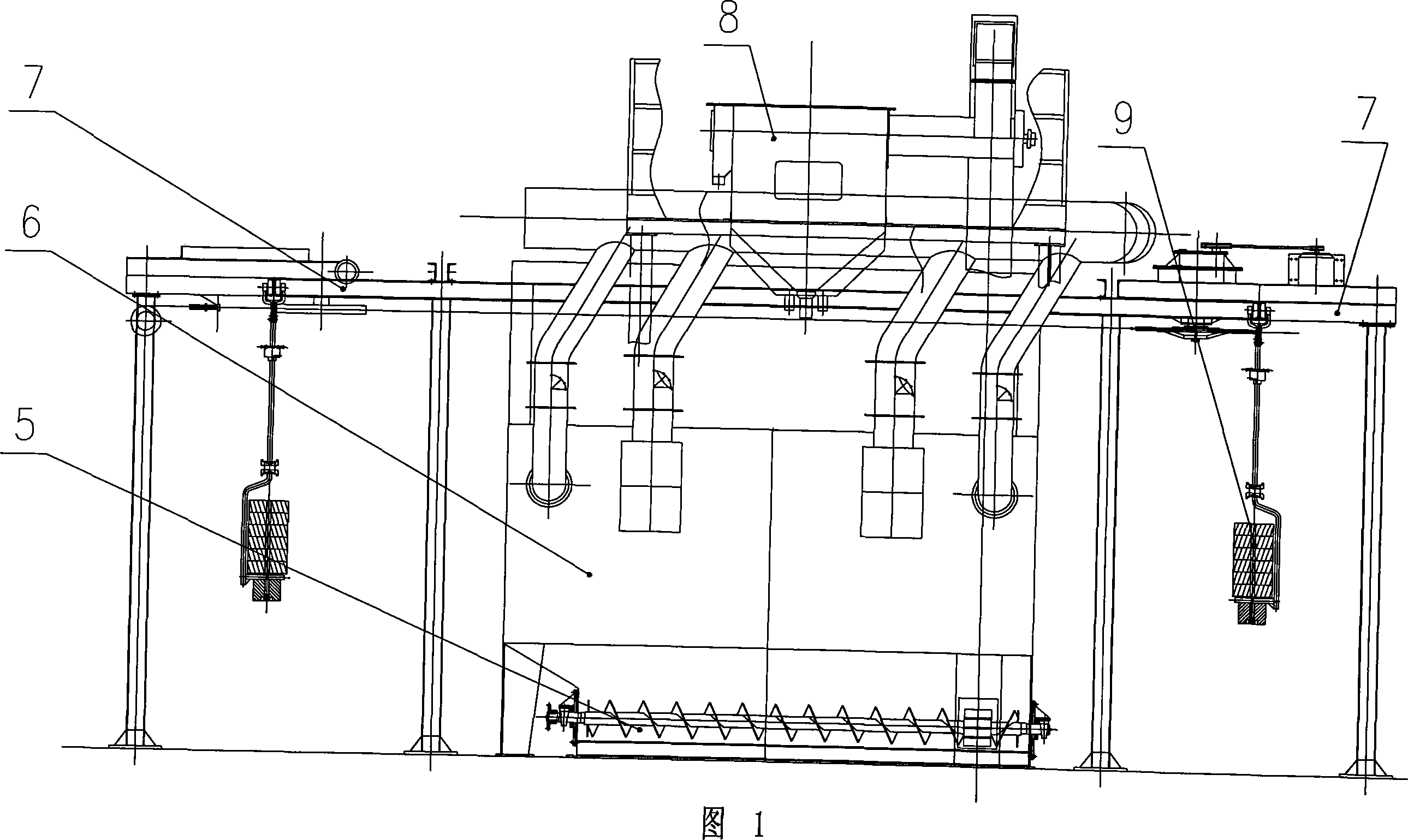

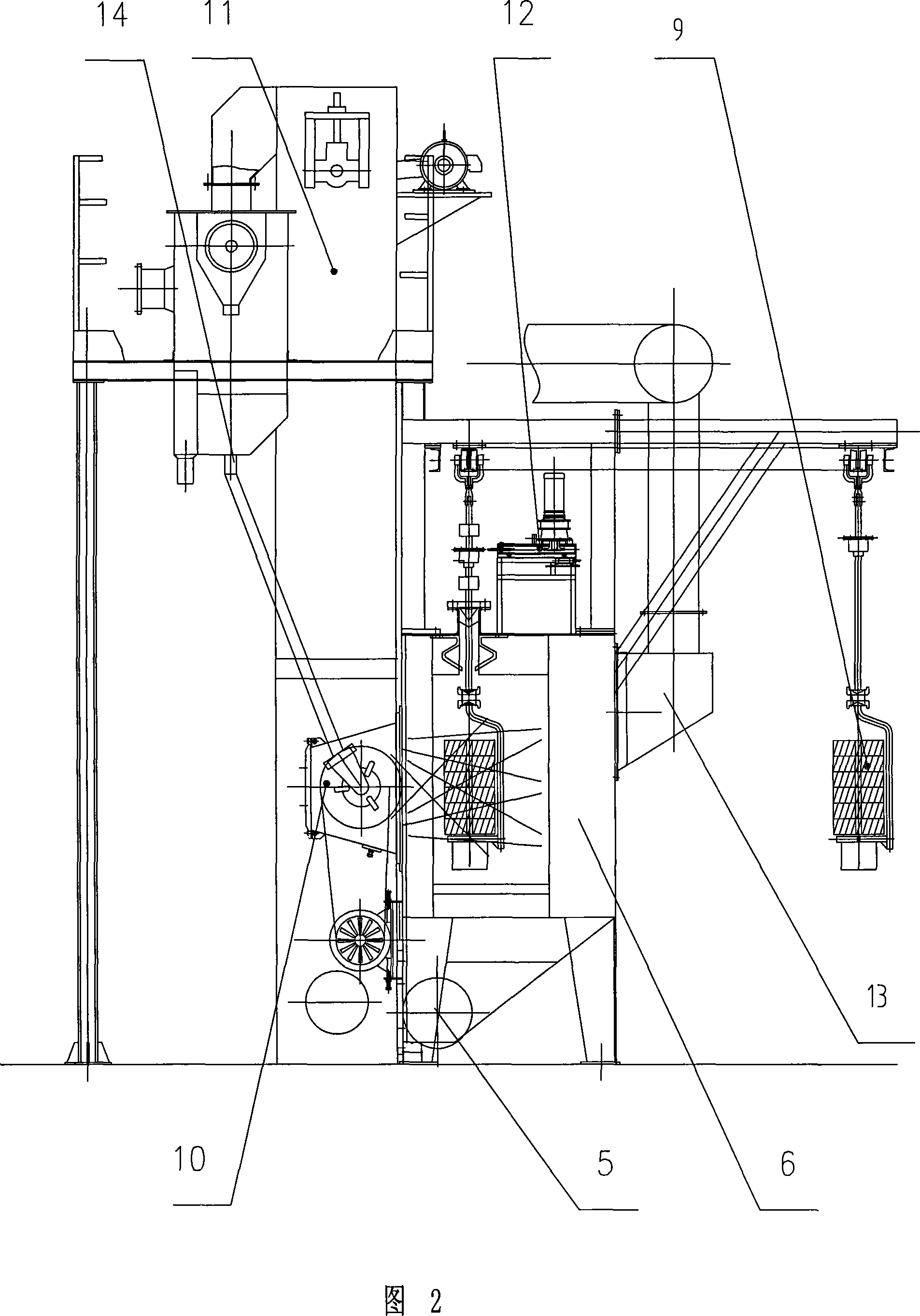

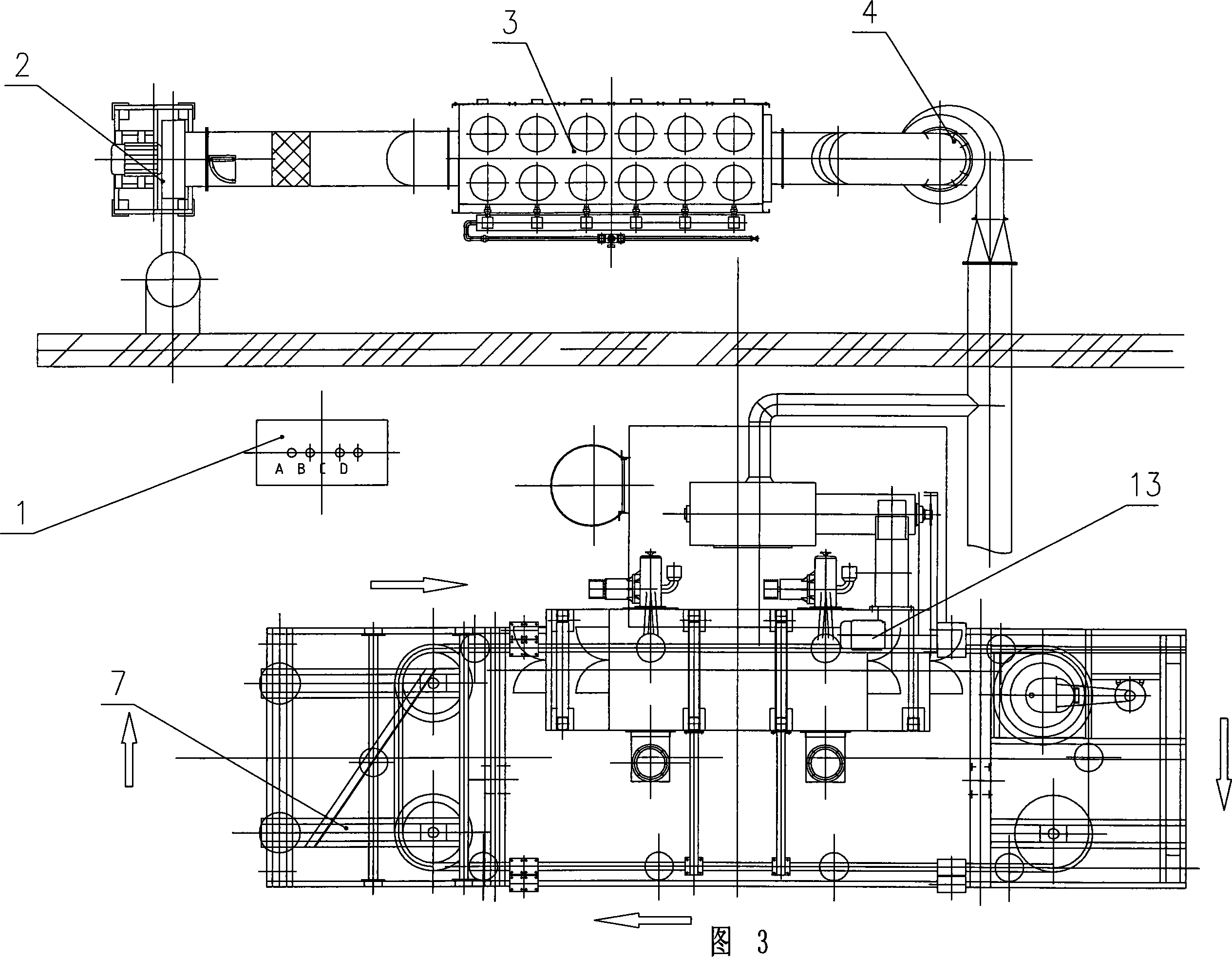

Automobile gear ruggedization shot-blasting machine

InactiveCN101157203AReduce energy consumptionImprove work efficiencyImpeller wheelsBlast gunsGear wheelEngineering

The invention belongs to equipment for cleaning the surface of a machine element by utilizing a shot blasting method, in particular to an automotive gear enhanced shot blasting machine. According to the technical proposal provided by the invention, the shot blasting machine is arranged on a shot blasting cleaning chamber. The invention is characterized in that a suspend conveyer installed on a supporting bracket is arranged at the upper part of the shot blasting cleaning chamber, the suspend conveyer is in a sealed state and circled around the shot blasting cleaning chamber, and one section passes through the shot blasting cleaning chamber, a plurality of rotating racks which can rotate under the driving of the suspend conveyer are suspended on the suspend conveyer, a curtain separator is arranged above / on the shot blasting cleaning chamber, a chamber hoisting gear is arranged on the flank of the shot blasting cleaning chamber, and a worm conveyer is arranged at the bottom of the shot blasting cleaning chamber. The input end of the curtain separator is connected with the output end of the chamber hoisting gear, and the output end of the worm conveyer is connected with the input end of the chamber hoisting gear. The invention can improve the effect of the shot blasting cleaning and the quality of the product.

Owner:无锡国达机械设备有限公司

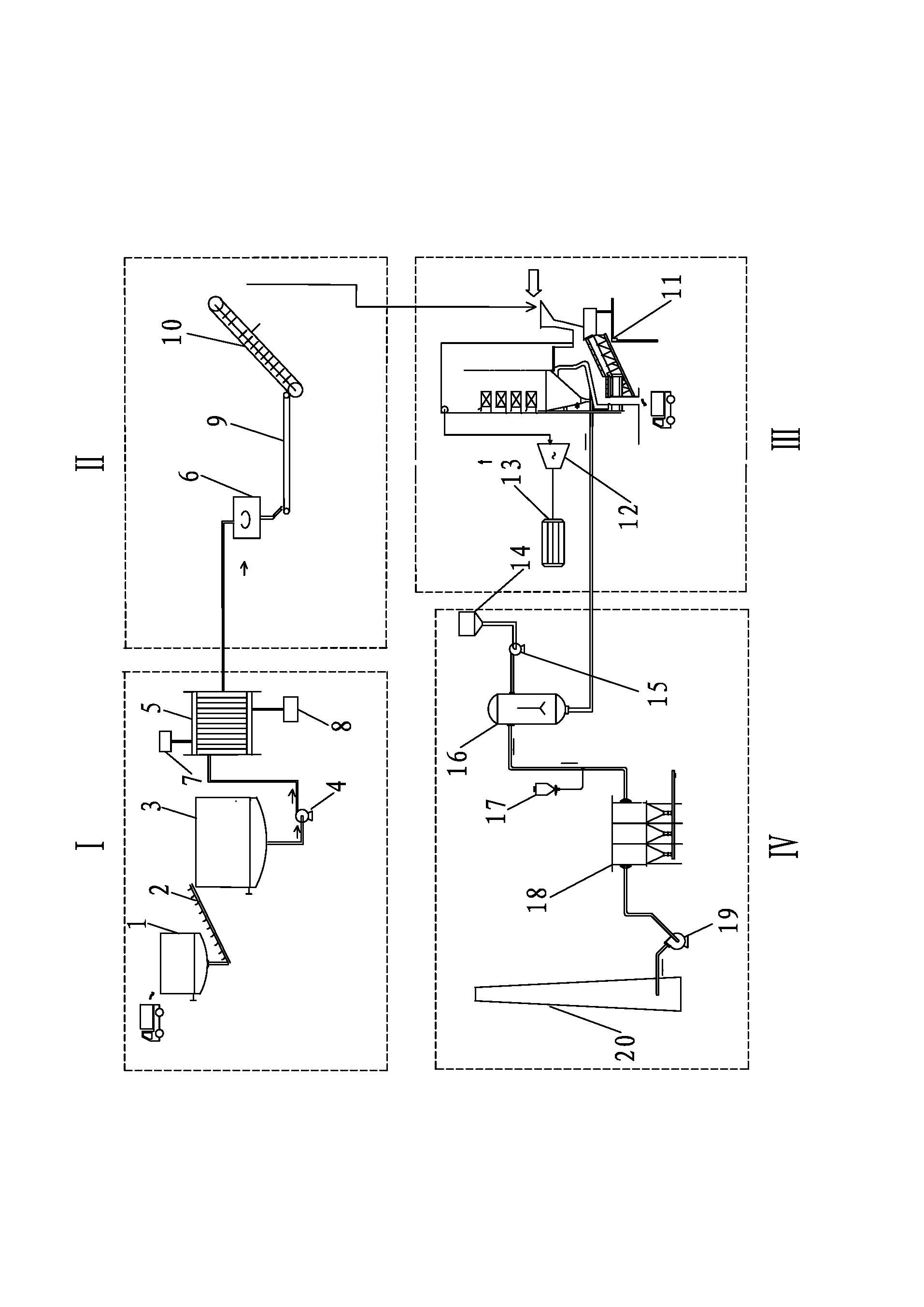

Sludge drying and incinerating system on basis of incineration of waste grate furnace and treatment method thereof

InactiveCN102322642AMeet environmental protection requirementsHigh degree of reductionSludge treatment by de-watering/drying/thickeningMachines/enginesScrew conveyorSewage treatment

The invention relates to a sludge drying and incinerating system on the basis of incineration of a waste grate furnace and a treatment method thereof. In the system, after entering a factory, sludge with the moisture content of 80 percent is unloaded into a front material storage bin; the sludge is quantitatively fed into a conditioning tank by a sludge screw conveyer at the bottom of the front material storage bin under a uniform speed; when the sludge enters the conditioning tank, dilution water and the sludge are added into the conditioning tank according to a weight ratio of the dilution water to the sludge of 1:1; when the sludge reaches a high limit liquid level, the sludge is stopped being added; the mixture is stirred uniformly to complete conditioning the sludge; the conditioned sludge with the moisture content of 90 percent is fed into a two-diaphragm vacuum air compressor through a sludge screw pump to be subjected to pressure filtration dehydration and steam heating drying, wherein a dehydrated and dried sludge cake has the moisture content of below 30 percent; after waste heat gas generated in the drying process of the sludge is vacuumized and condensed, wastewater is generated, enters a sewage treatment system to be treated and is discharged after reaching the standard; the waste gas is collected and enters a waste pond of a waste grate furnace incineration system; after the dried sludge is crushed by a crusher, the dried sludge and municipal domestic waste are fed into the grate incineration furnace to be incinerated according to a certain ratio; and the waste gas, fly ash, slags and the like which are generated in the incinerating process can be treated by the existing treatment system of a waste incineration power plant.

Owner:NEWSKY CHINA ENVIRONMENT & TECH +2

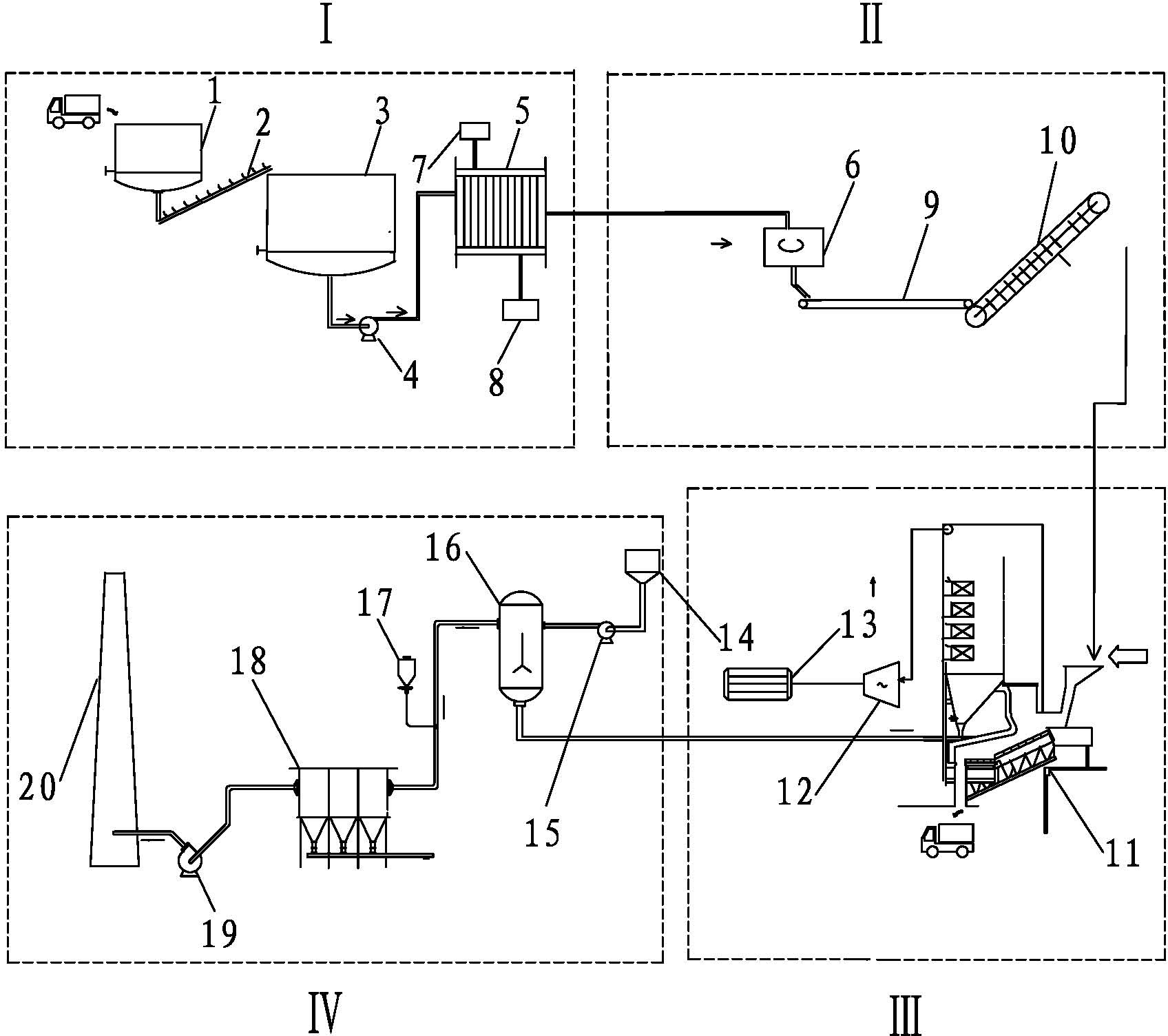

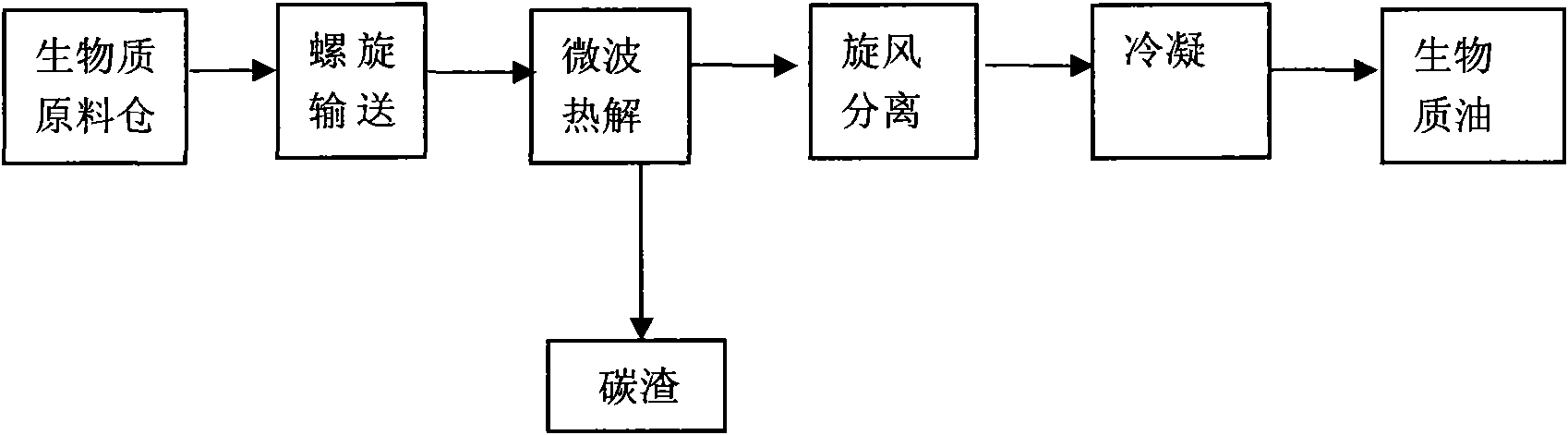

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

Double-mode shield tunneling machine

The invention belongs to the field of shield construction, and discloses a double-mode shield tunneling machine. The double-mode shield tunneling machine comprises a shield tunneling main engine, a cutterhead arranged on the front portion of the shield tunneling main engine, an earth bin, an air cushion bin, an earth pressure balancing system and a slurry balancing system, wherein the earth bin, the air cushion bin are sequentially formed in the rear portion of the cutterhead. When the shield tunneling machine works, the shield tunneling machine can be switched between an earth pressure balancing tunneling mode and a slurry balancing tunneling mode according to the strata of practical tunnels, so that the shield tunneling machine is adaptive to tunneling under different geological conditions, and the adaptability to complex strata and the shield construction efficiency are improved. Meanwhile, a dilution tank and a breaker are mounted on the tail of a spiral conveyer to break large rocks to the grain size which can be conveyed by a slurry pump, and the broken large rocks are then discharged through a slurry pipeline, and in this way, the situation that large rocks cannot be discharged smoothly in a slurry mode can be prevented effectively.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

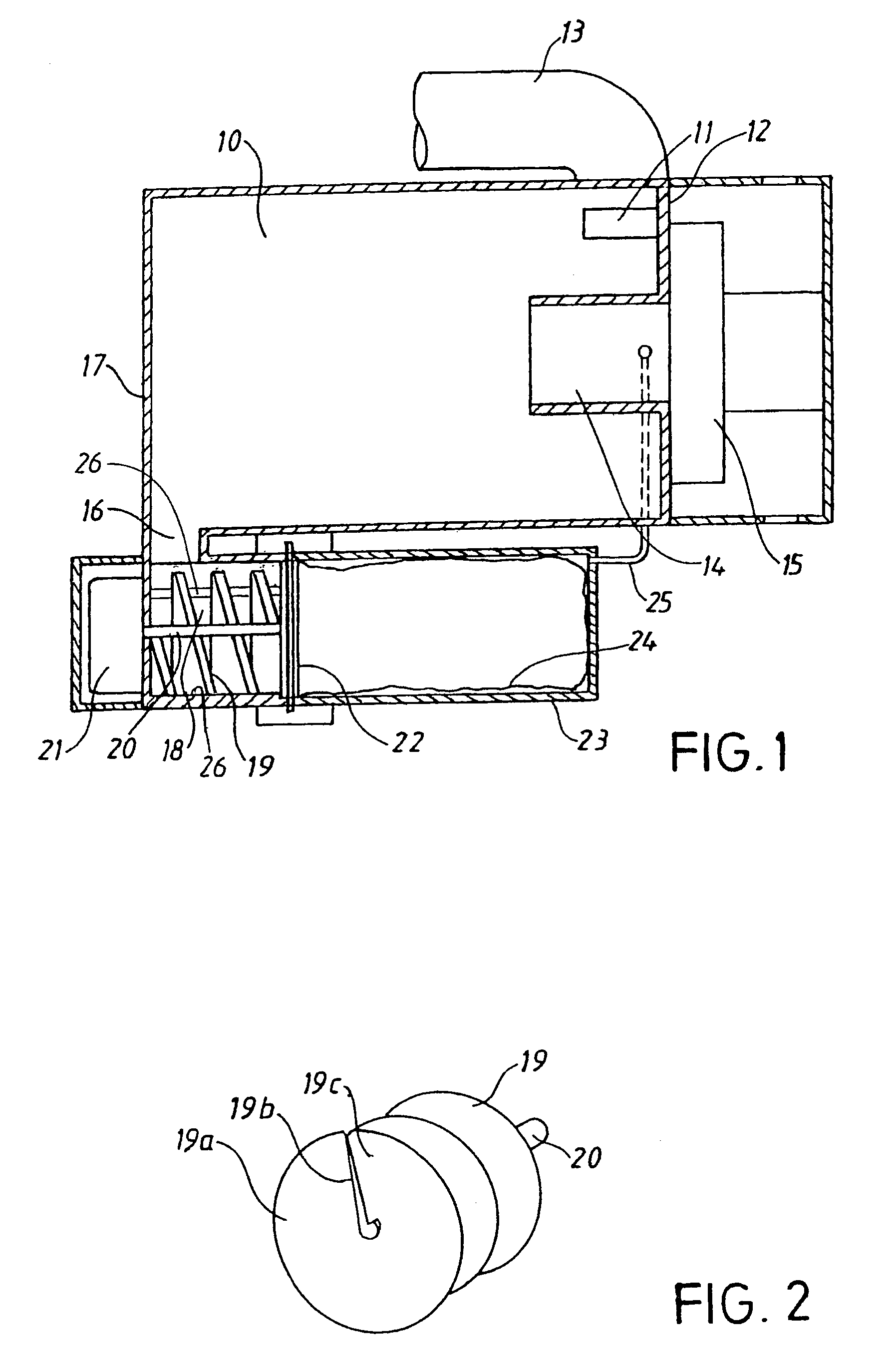

Vacuum cleaner device with a screw conveyor

InactiveUS7171725B2Simple processCleaning filter meansSuction filtersScrew conveyorParticle separators

A device for a vacuum cleaner comprising a particle separator, which is provided with an inlet (11) for dust laden air, an outlet (16) for the separated particles, and an outlet (14) for cleaned air that is connected to a vacuum source (14). The particle outlet (16) is connected to a screw conveyor (18, 19), which is provided with an outlet part ending in a mainly closed collecting chamber (23) for the separated particles.

Owner:AB ELECTROLUX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com