Patents

Literature

340 results about "Slurry pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slurry pipeline is a specially engineered pipeline used to move ores, such as coal or iron, or mining waste, called tailings, over long distances. A mixture of the ore concentrate and water, called slurry, is pumped to its destination and the water is filtered out. Due to the abrasive properties of slurry, the pipelines can be lined with high-density polyethylene (HDPE), or manufactured completely from HDPE Pipe, although this requires a very thick pipe wall. Slurry pipelines are used as an alternative to railroad transportation when mines are located in remote, inaccessible areas.

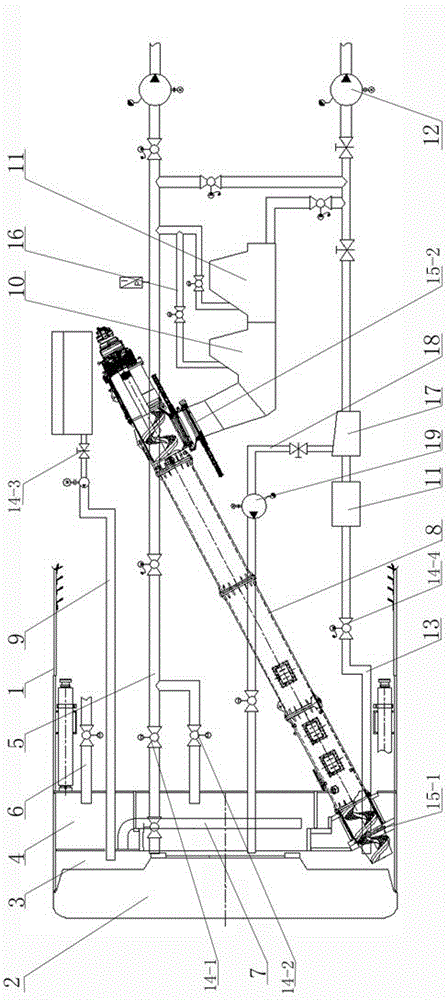

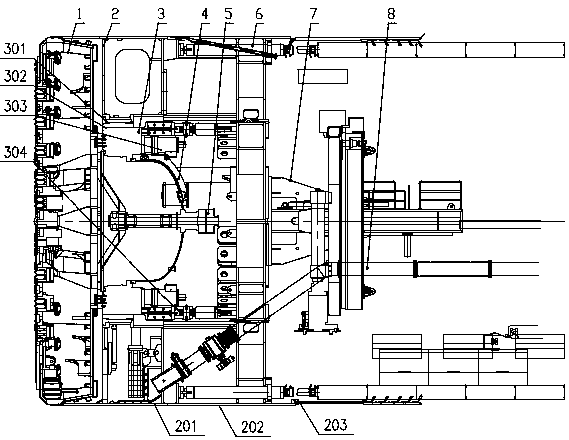

Double-mode shield tunneling machine

The invention belongs to the field of shield construction, and discloses a double-mode shield tunneling machine. The double-mode shield tunneling machine comprises a shield tunneling main engine, a cutterhead arranged on the front portion of the shield tunneling main engine, an earth bin, an air cushion bin, an earth pressure balancing system and a slurry balancing system, wherein the earth bin, the air cushion bin are sequentially formed in the rear portion of the cutterhead. When the shield tunneling machine works, the shield tunneling machine can be switched between an earth pressure balancing tunneling mode and a slurry balancing tunneling mode according to the strata of practical tunnels, so that the shield tunneling machine is adaptive to tunneling under different geological conditions, and the adaptability to complex strata and the shield construction efficiency are improved. Meanwhile, a dilution tank and a breaker are mounted on the tail of a spiral conveyer to break large rocks to the grain size which can be conveyed by a slurry pump, and the broken large rocks are then discharged through a slurry pipeline, and in this way, the situation that large rocks cannot be discharged smoothly in a slurry mode can be prevented effectively.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

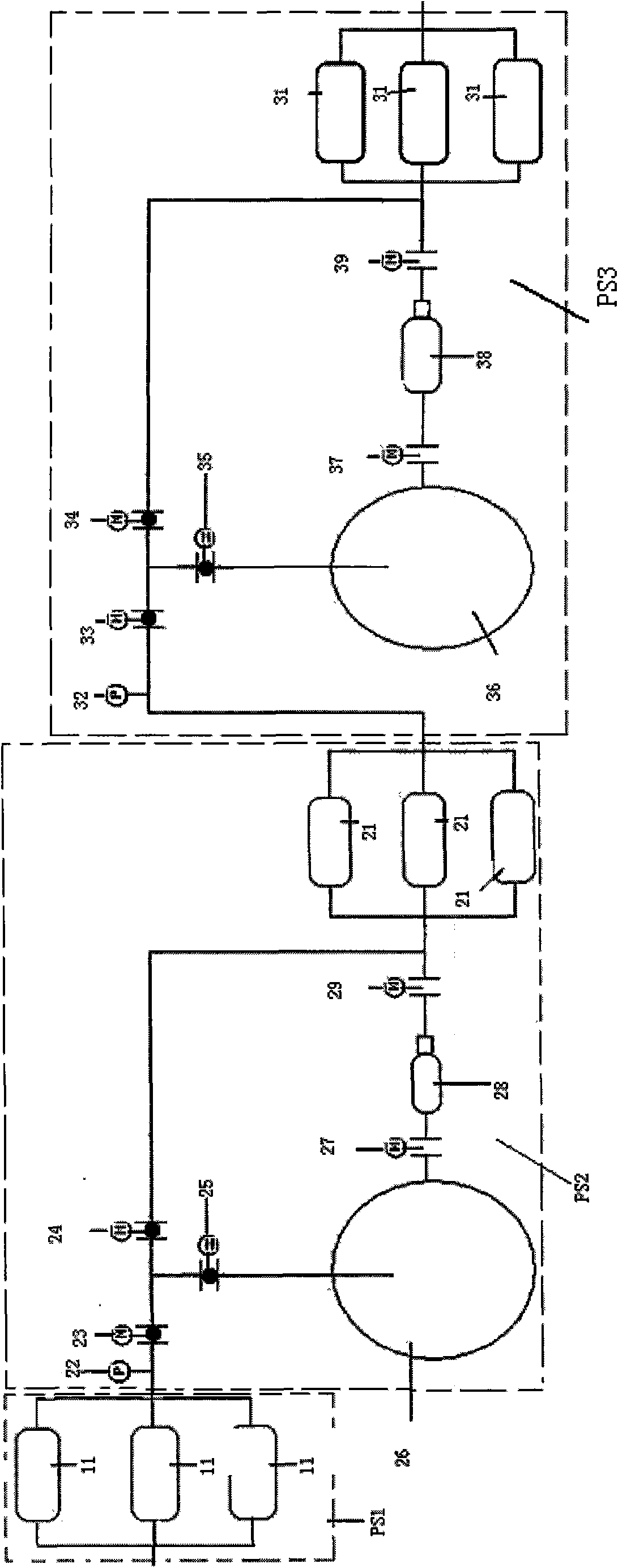

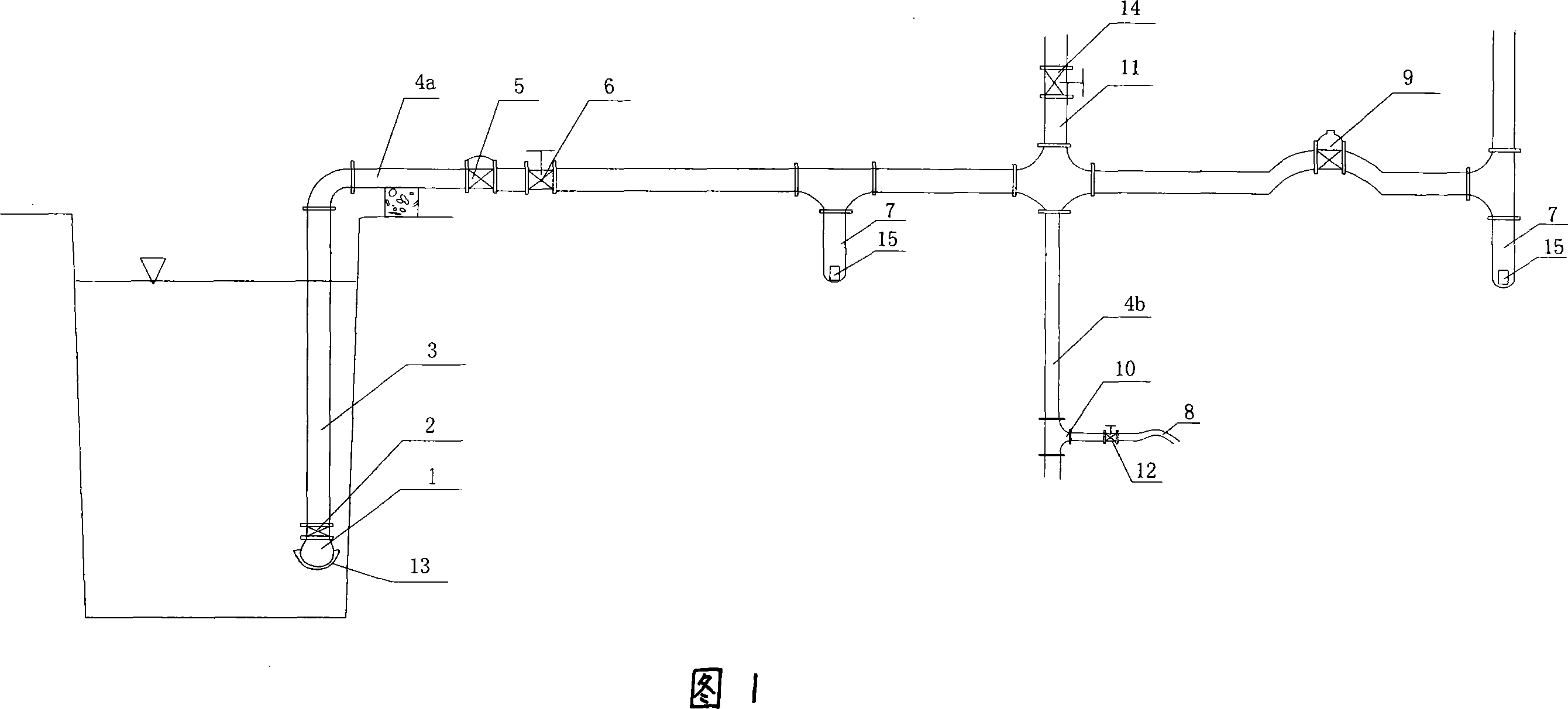

Online switching method of high-pressure long-distance slurry pipeline transmission multi-stage pump station

The invention discloses an online switching method for switching independent operation of a high-pressure long-distance slurry pipeline transmission multi-stage pump station into continuous beating operation and switching the continuous beating operation into independent operation, wherein the method ensures the inlet pressure of all secondary pump stations to be in designed range by changing the operation sequence of inlet valves of all the pump stations and reducing the pump speed of main pumps of all stages of pump stations, thus reducing shutdown times when completely changing the conveying mode, reducing operation cost, and creating conditions for restarting after an emergency shutdown and switching independent operations of all stations into complete continuous beating operations without stop.

Owner:YUNNAN DAHONGSHAN PIPELINE

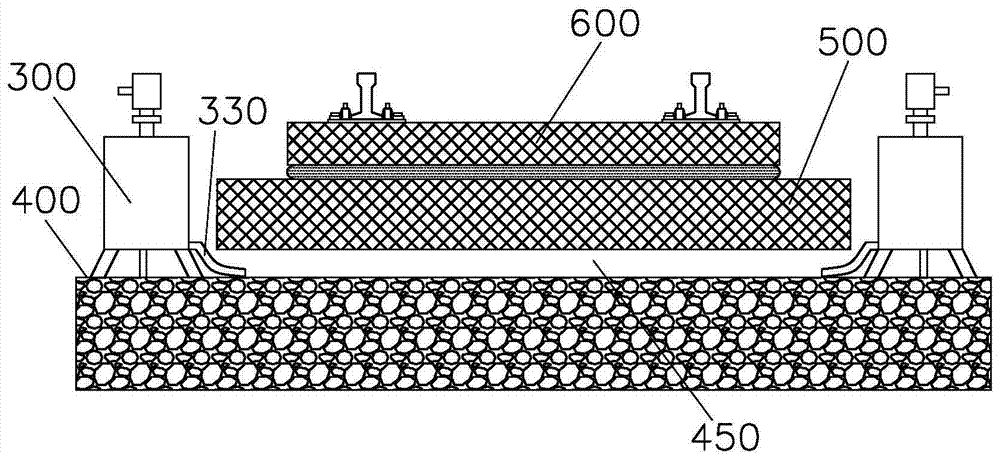

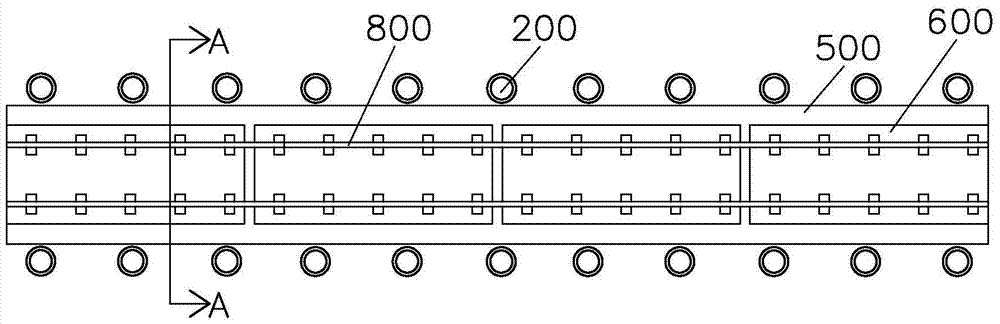

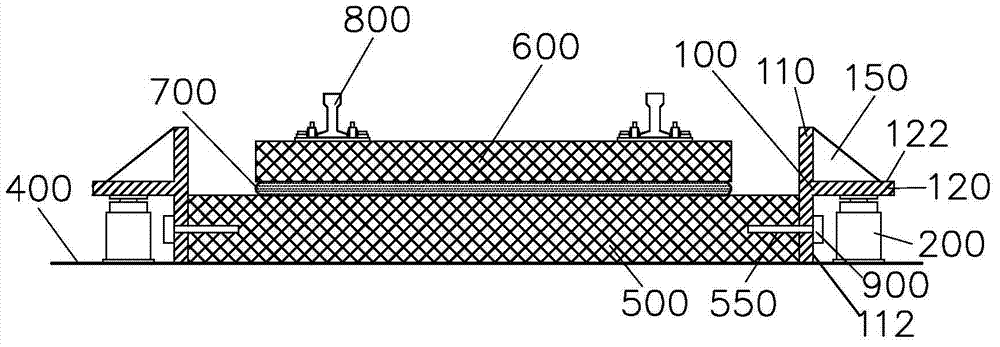

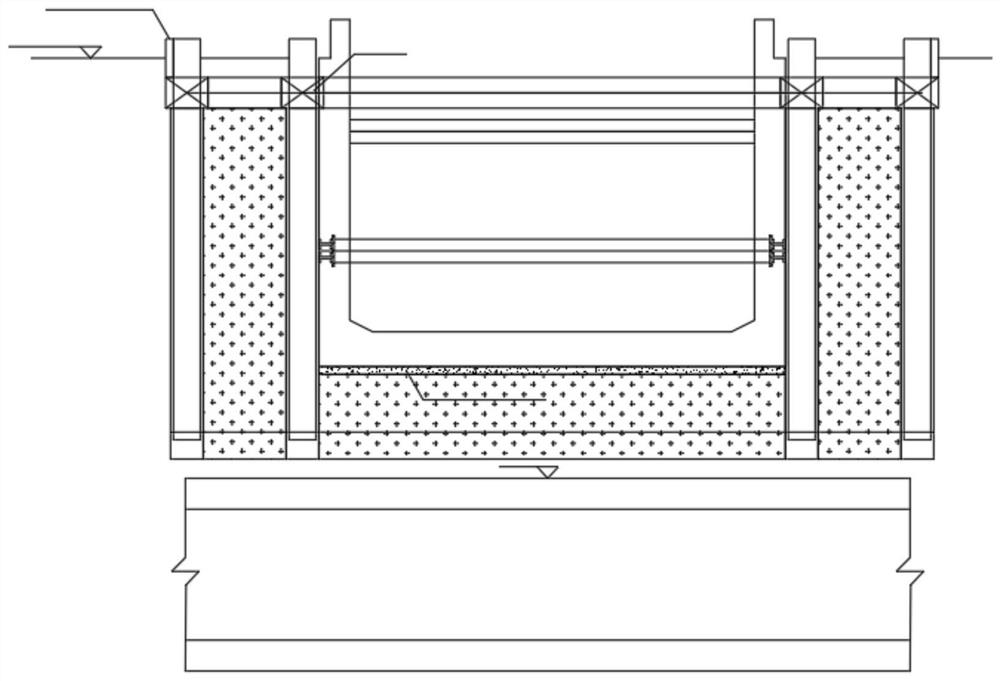

System and method for high-speed railway subgrade settlement restoration

InactiveCN103757993AGuaranteed not to breakMeet job requirementsBallastwayTrack maintainenceAutomatic controlEngineering

The invention discloses a system and method for high-speed railway subgrade settlement restoration. The system comprises at least eight lifting components, at least eight hydraulic lifting devices, a hydraulic distribution device, an automatic control system and a grouting device, wherein the at least eight lifting components are arranged at preset lifting points on a base plate, and every lifting component comprises a connecting part and a lifting part; every hydraulic lifting device is arranged between a high-speed railway subgrade and the lifting part of the lifting component; the hydraulic distribution device is connected with every hydraulic lifting device through hydraulic pipelines; the automatic control system controls the hydraulic distribution device to provide preset hydraulic pressure for every hydraulic lifting device so as to lift the base plate to a preset height of the high-speed railway subgrade; and the grouting device pours slurry in gaps formed between the base plate and the high-speed railway subgrade through slurry pipelines so as to support the base plate after the slurry is solidified. The invention further provides a method for track plate and base plate integrated lifting type high-speed railway subgrade settlement restoration.

Owner:北京中铁瑞威基础工程有限公司

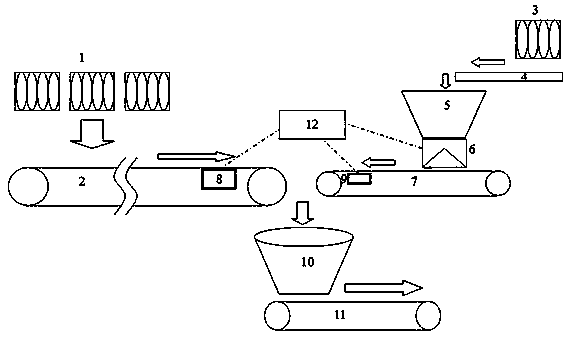

Ore blending system and method in slurry pipeline conveying system

ActiveCN103935752AImprove ore blending efficiencyReduce usageMixer accessoriesConveyor partsEngineeringSlurry pipeline

The invention provides an ore blending system and method. The ore blending system comprises a first conveying belt, a second conveying belt, a first metering device, a second metering device and a third conveying belt. The discharging end of the first conveying belt and the discharging end of the second conveying belt are located over the third conveying belt, the first metering device is arranged on the first conveying belt and used for metering ore quantity conveyed by the first conveying belt in real time, the second metering device is arragned o the second conveying belt and used for metering ore quantity conveyed by the second conveying belt in real, and the ore quantity conveyed by the first conveying belt and the ore quantity conveyed by the second conveying belt are set according to the metering values of the first metering device and the second metering device and conveyed to the third conveying belt according to the preset ore blending ratio. According to the ore blending system and method, the belt conveying system based on accurate metering is adopted, accurate matching of different regions and ore with different qualities is achieved, the ore blending cost and environmental pollution are reduced, and sustainable development of economy and environment is achieved.

Owner:YUNNAN DAHONGSHAN PIPELINE

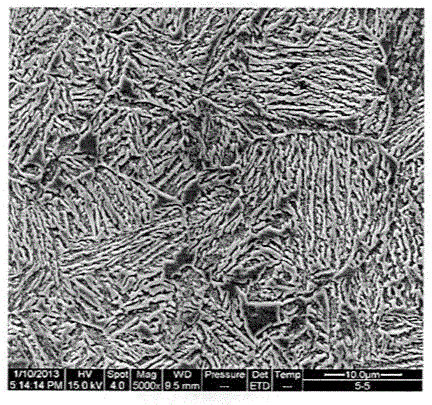

Boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and manufacturing method thereof

The invention relates to a boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and a manufacturing method thereof. The alloy comprises the following chemical components in percentage by weight: 0.3-0.6% of C, 1.6-2.6% of Si, 0.6-1.0% of Mn, 0.6-4.0% of Cr, 0.3-0.5% of Mo, 0.3-0.5% of Ni, 0.3-0.5% of Cu, 0.1-0.3% of Ti, 0.05-0.1% of B, 0.05-0.15% of Ce, 0.05-0.15% of Nb, less than 0.04% of P, less than 0.04% of S and the balance of Fe. The manufacturing method comprises the following steps: carrying out electric-furnace smelting, carrying out secondary aluminum insertion deoxidization, putting on the bottom of a casting ladle to form a casting, austenizing the casting at 850-950 DEG C, keeping the temperature for some time, putting in a salt bath at 200-260 DEG C to carry out primary isothermal quenching, keeping the temperature for 5-10 minutes, carrying out secondary isothermal quenching in a salt bath at 260-400 DEG C, keeping the temperature for 0.5-4 hours, and cooling in air to obtain the wear-resistant corrosion-resistant alloy of which the austenite-bainite base is distributed with boride. The alloy is low in preparation cost and suitable for marine silt erosion and corrosion environments, has favorable comprehensive properties of toughness, wear resistance and corrosion resistance, and can be used for dredger cutter teeth, slurry pipelines, centrifugal-pump impellers, blades and the like.

Owner:CHANGXING DETIAN ENG MACHINERY

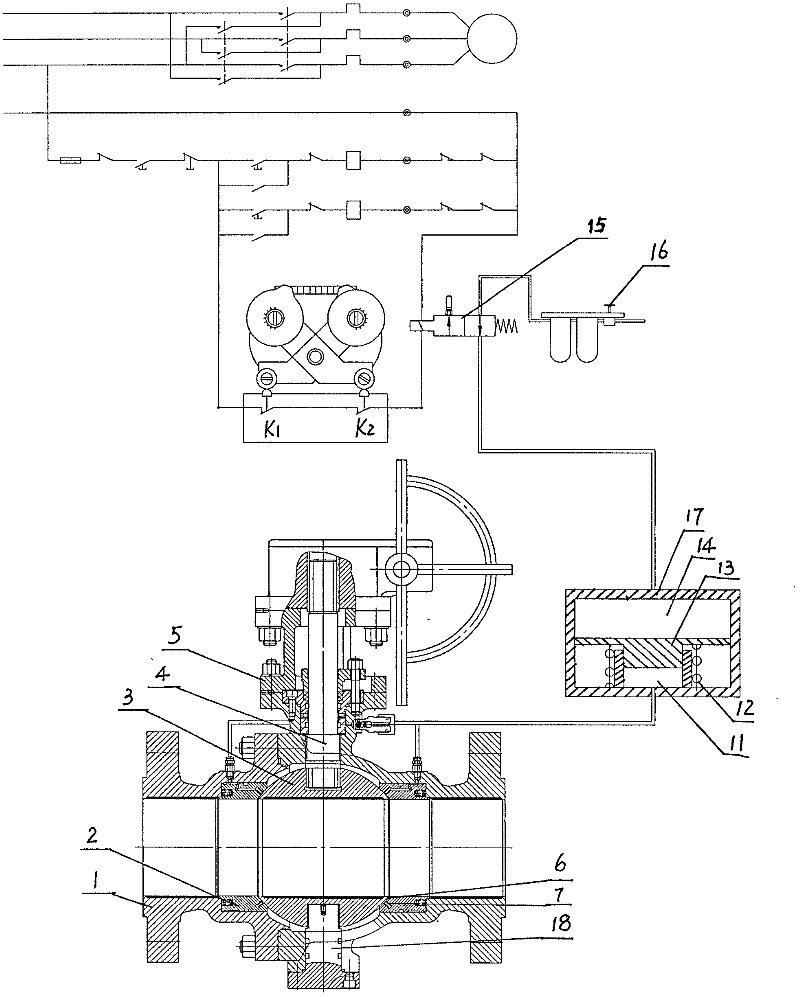

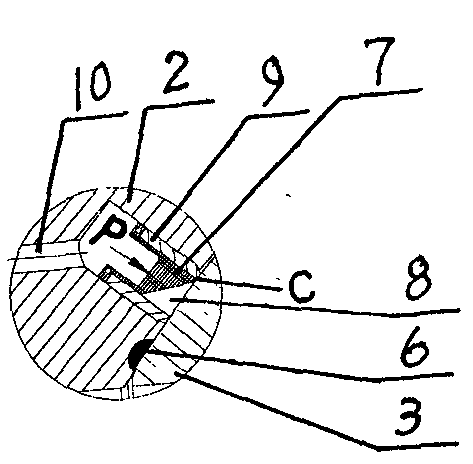

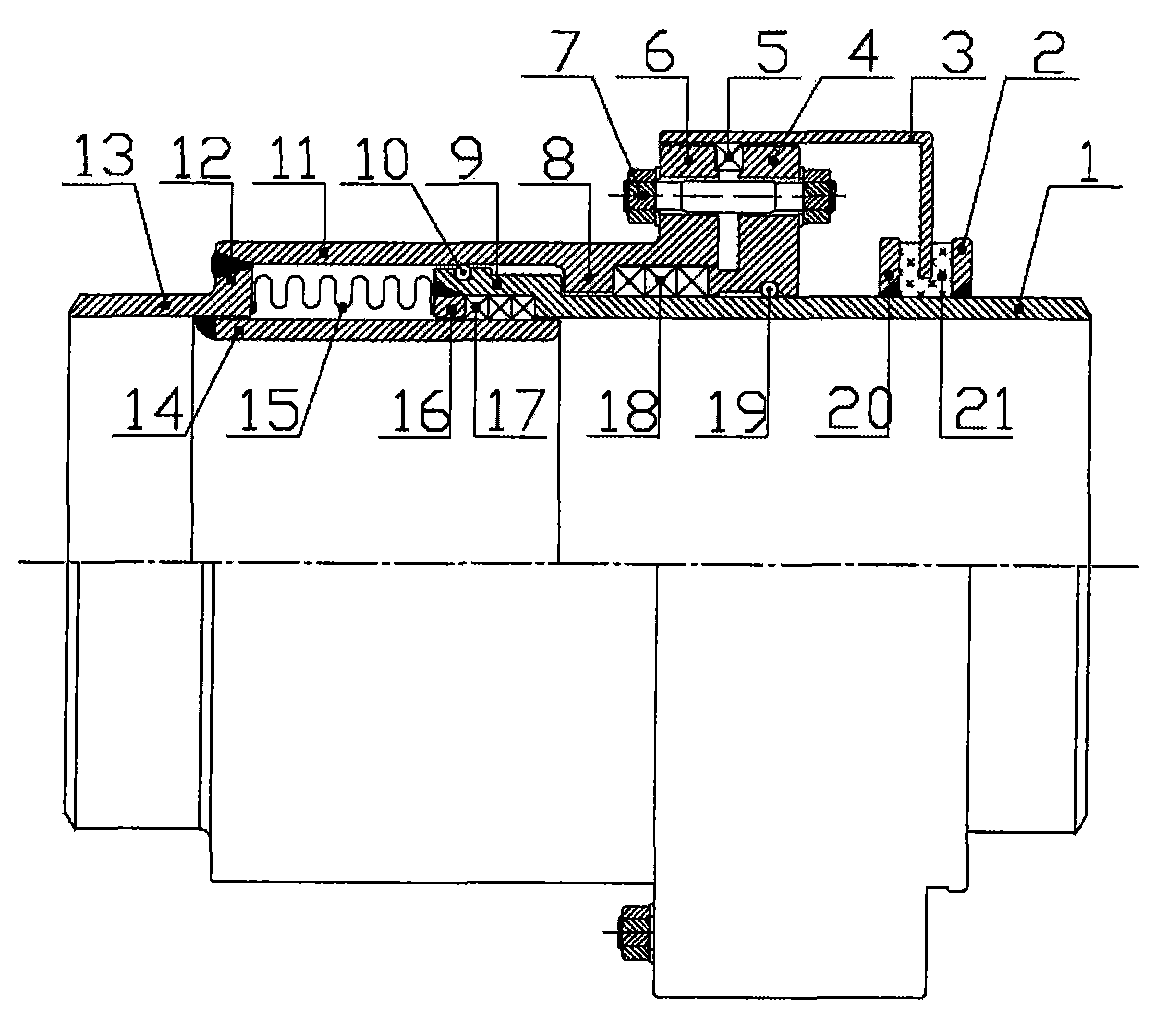

Cast stone ball valve with combined seal

The invention relates to a cast stone ball valve with combined sealing, which includes a valve body, a floating valve seat, a valve cover, a valve stem, and a ball. The sealing surface of the floating valve seat is a combined sealing surface composed of a hard sealing surface and a soft sealing surface. The soft sealing surface is a pressure-filled U-shaped ring, and its two sides are positioned in the annular groove of the floating valve seat with two side rings. The U-shaped pressure chamber communicates with the piston hydraulic chamber, and the piston air pressure chamber passes through The two-position solenoid valve and the regulating valve are connected to the air pressure source. The working coil of the two-position solenoid valve is connected to the power supply through the series branch of the valve closing position switch and the valve opening position switch. The closed and fully open positions are disconnected, and a return spring is installed between the piston and the piston cylinder on the side of the piston hydraulic chamber. The contact area between the medium and the soft sealing surface is small, which has the advantages of stable and reliable sealing performance and long service life. It is suitable for opening and closing devices of slurry and dry ash pipeline systems in power plants, mines, metallurgy, and chemical industries.

Owner:BOTELI VALVE GROUP

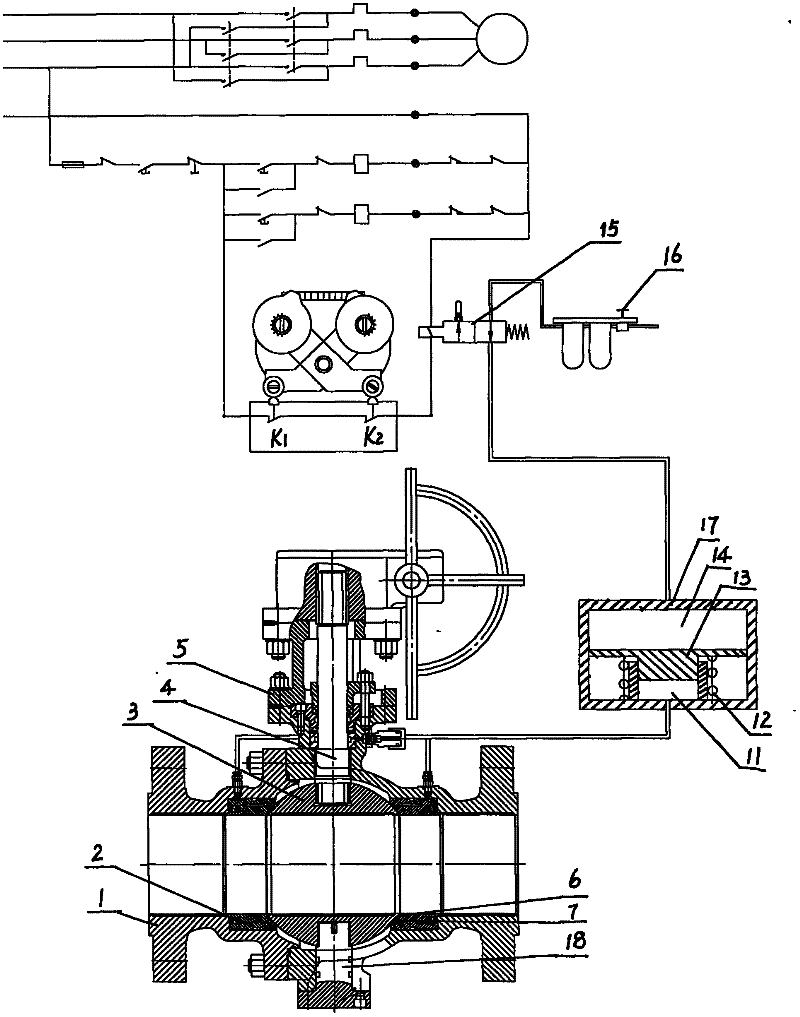

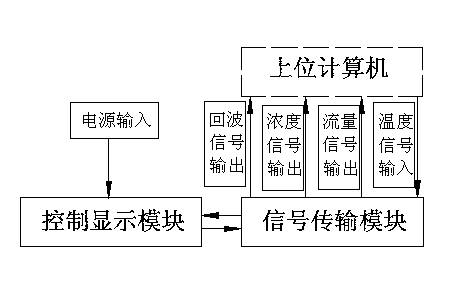

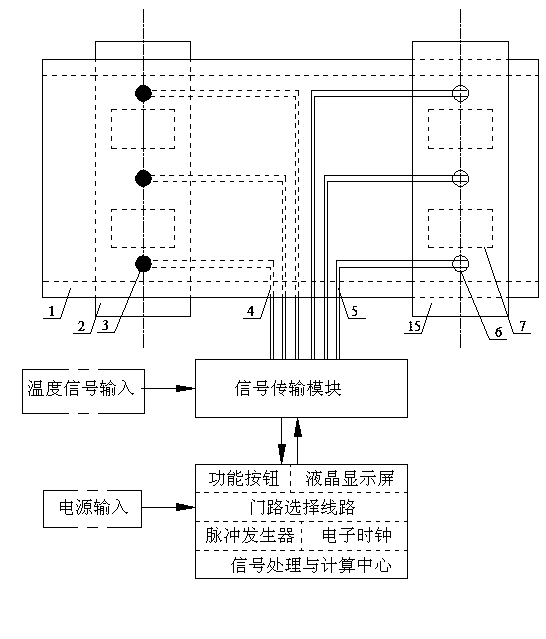

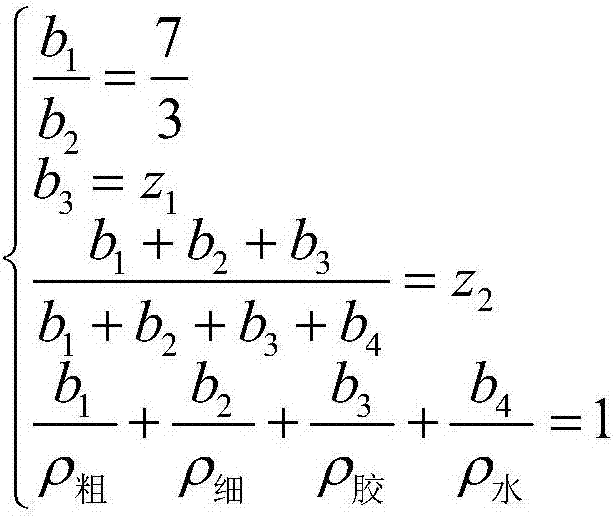

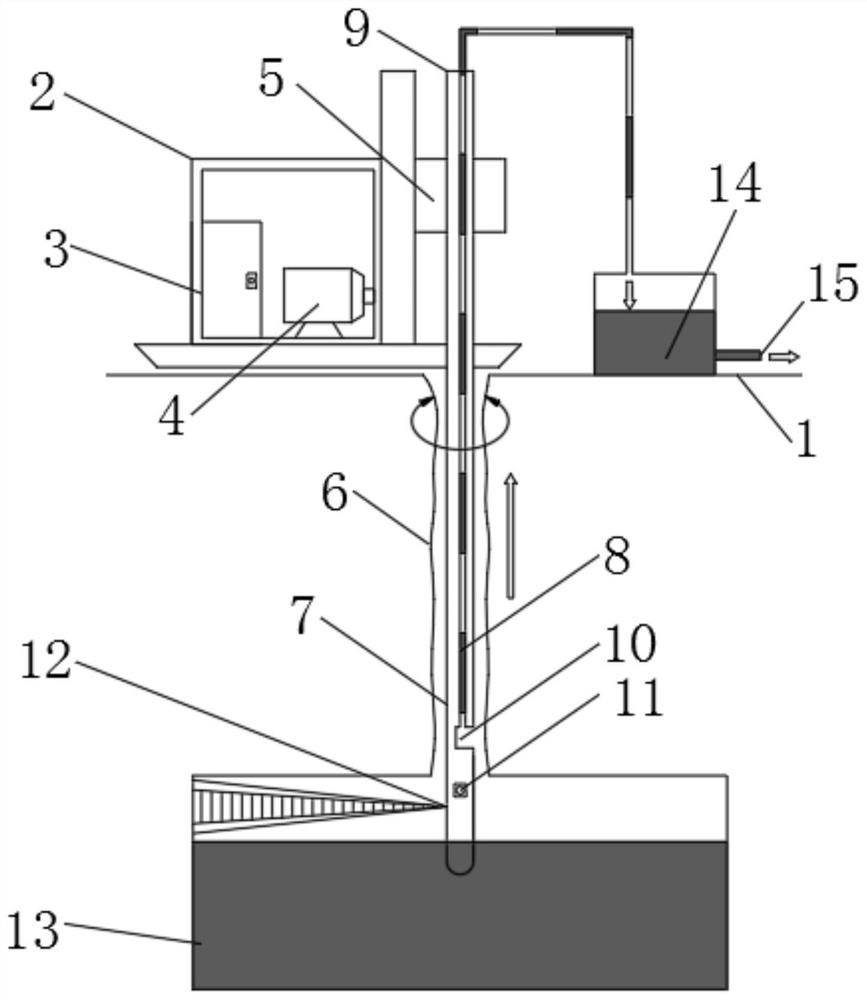

Mine filling slurry parameter detection method and monitoring device

InactiveCN103728371AGuaranteed Homologous MeasurementsSingle sourceAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerSlurry pipeline

The invention discloses a mine filling slurry parameter monitoring device, comprising an arc transmitting base and an arc receiving base, which are arranged at the outer side of a slurry pipeline, wherein an ultrasonic transmitting transducer is arranged on the transmitting base; an ultrasonic wave receiving transducer is arranged on the receiving base; the transmitting base and the receiving base are arranged along the axis of the slurry pipeline in a skewing manner; the ultrasonic transmitting transducer, the ultrasonic receiving transducer and a temperature sensor are connected with a signal processing calculation center and a control display module through a signal transmission module. By adopting the mine filling slurry parameter detection method and monitoring device disclosed by the invention, the parameters such as slurry temperature, concentration and flow at different layers and the like are detected circularly by using paired ultrasonic transmitting transducer and ultrasonic receiving transducer in different modes; a real-time monitoring signal is provided for slurry preparation and pipeline transportation; the concentration and flow velocity parameters of the slurry are measured, displayed and output in a stand-alone manner; the concentration distribution inside the pipeline and the flow velocity distribution condition are monitored; a blocking pipe accident is early warned.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

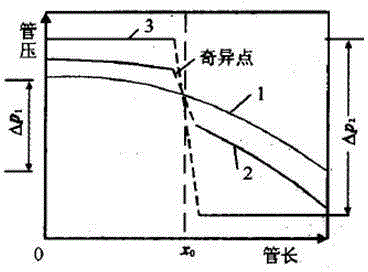

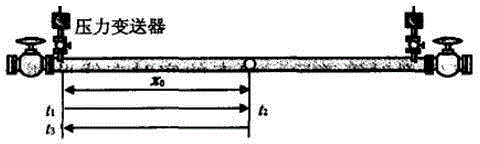

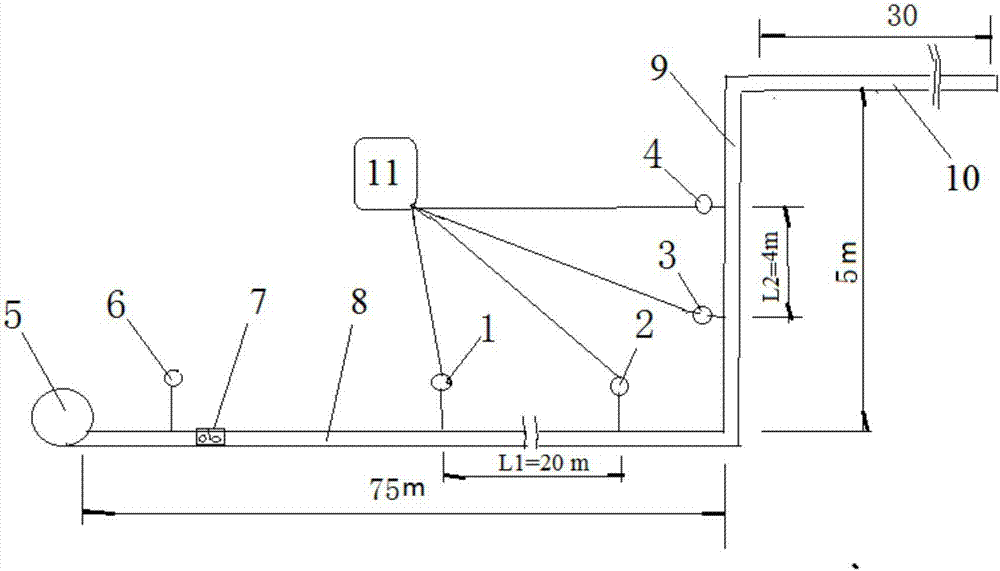

Positioning method for blocking position of ore slurry conveying pipeline

InactiveCN104989958AMonitor pressure in real timeFind blockagePipeline systemsPositive pressureEngineering

The invention provides a positioning method for blocking positions of an ore slurry conveying pipeline, and relates to a conveying control method, and especially relates to a method for determining blocked points in blocking management in an ore slurry conveying process. A positive pressure wave method is used to detect blocking of a pipeline according to violent changes of pressure differences of two ends of the pipeline before the pipeline is blocked and after the pipeline is blocked, and a principle and a method for determining ore slurry pipeline blocking positions by using positive pressure waves in a pipeline hydraulic surge process are provided for the first time. The method is advantaged by few required devices, low operation cost, and simple operation, and is better than existing pipeline blocking position determination methods.

Owner:YUNNAN DAHONGSHAN PIPELINE

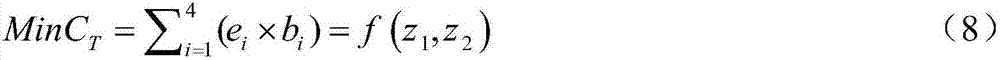

Decision method for proportional ratio of mixed aggregate filling slurry for mining

The invention discloses a decision method for a proportional ratio of mixed aggregate filling slurry for mining. The decision method comprises the following steps of testing the packing density of the mixed aggregate, drawing a relationship curve between the packing density of the mixed aggregate and the proportional ratio of coarse and fine aggregates, and obtaining the proportional ratio of coarse and fine aggregates corresponding to the maximum packing density; performing orthogonal test on the strength of a cementing filling body using different usage amounts and mass concentrations of gel materials, and orthogonal test of slump, fluidity, delaminating degree and bleeding rate of the filling slurry, establishing a function relationship between the strength of the cementing filling body, the conveying characteristic parameter of a filling slurry pipeline, and the usage amount and mass concentration of the gel material, and establishing a decision model of the proportional ratio of the mixed aggregate filling slurry by using the cost of the filling slurry material as a decision goal, using the design strength of the cementing filling body and using the critical value of conveying or pumping characteristic parameter of the filling slurry pipeline as constraint conditions; solving the decision model, so as to obtain the usage amount and mass concentration of the gel material. The decision method has the advantages that the cost of filling mining is greatly reduced, and the discharge of solid wastes is reduced.

Owner:JINCHUAN GROUP LIMITED +1

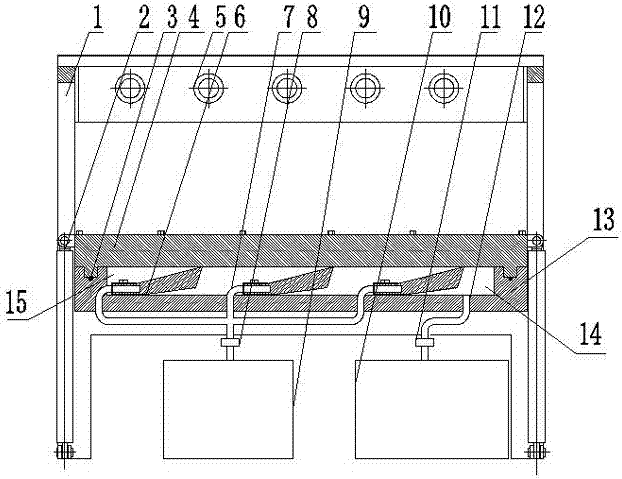

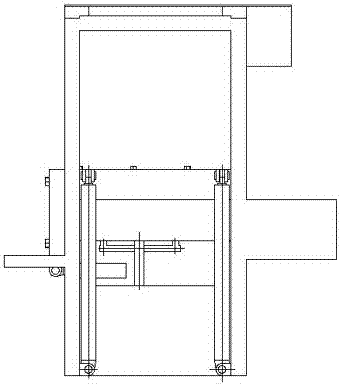

Shield tail brush sealing performance testing device and testing method thereof

PendingCN107449569AGuaranteed reliabilityMeasurement of fluid loss/gain rateHydro energy generationEngineeringHigh pressure

The invention discloses a shield tail brush sealing performance testing device and a testing method thereof. The shield tail brush sealing performance testing device comprises a framework, a pressure testing groove, a top cover and a pressure monitoring device. A plurality of tested tail brushes are installed on an in-groove bottom of the pressure testing groove. The internal of each tested tail brush is connected to an oil pipeline having an oil supply through in a sealing manner, wherein the oil pipeline is arranged in an oil supply through hole on the bottom of the pressure testing groove, and thus is communicated with an oil supply system. A rightmost cavity in an inclination direction of the tested tail brush passes through a slurry pipeline in a slurry supply hole formed on the pressure testing groove bottom in a sealing manner and is communicated with a slurry injection system. A pressure signal input terminal of the pressure monitoring device is connected to pressure testing devices which are respectively arranged in a high pressure cavity and a low pressure cavity through a cable. The shield tail brush sealing performance testing device and the testing method thereof can adopt the mode of the shield tail brush and arrange the shield tail brushes under different pressure conditions, and avoid tunnel construction risks caused by leakage due to inappropriate mode selection of the tail brush.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

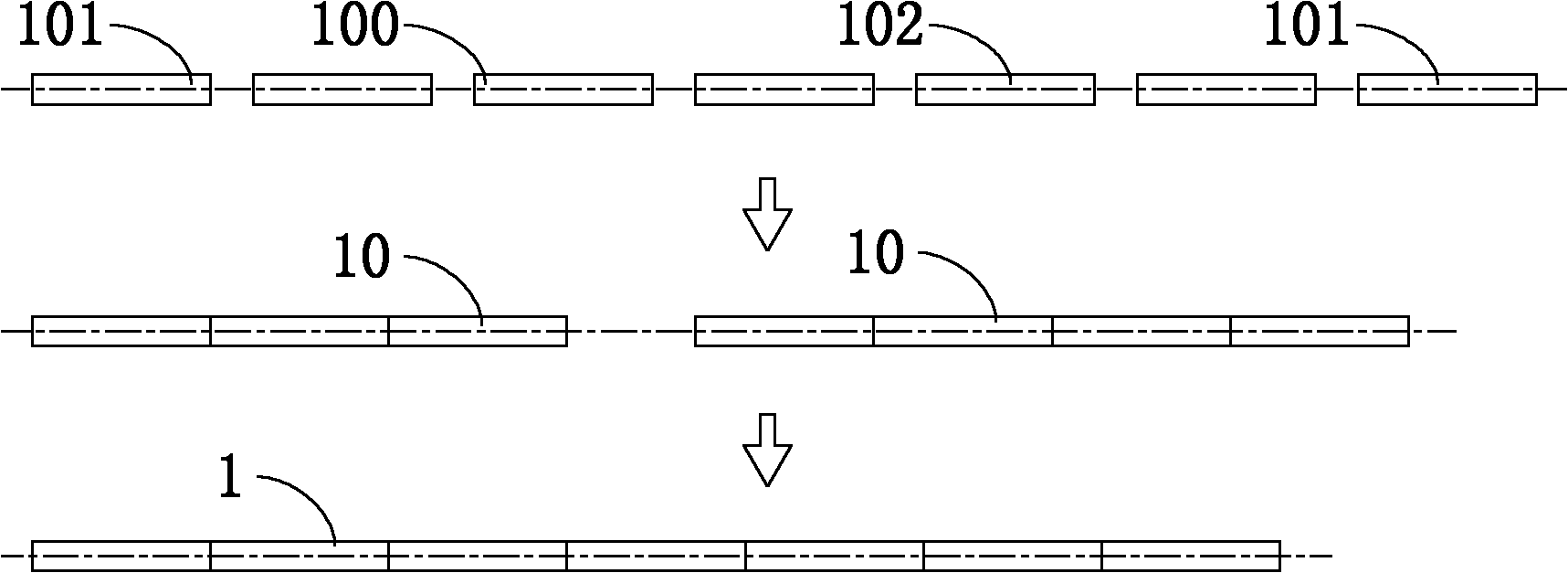

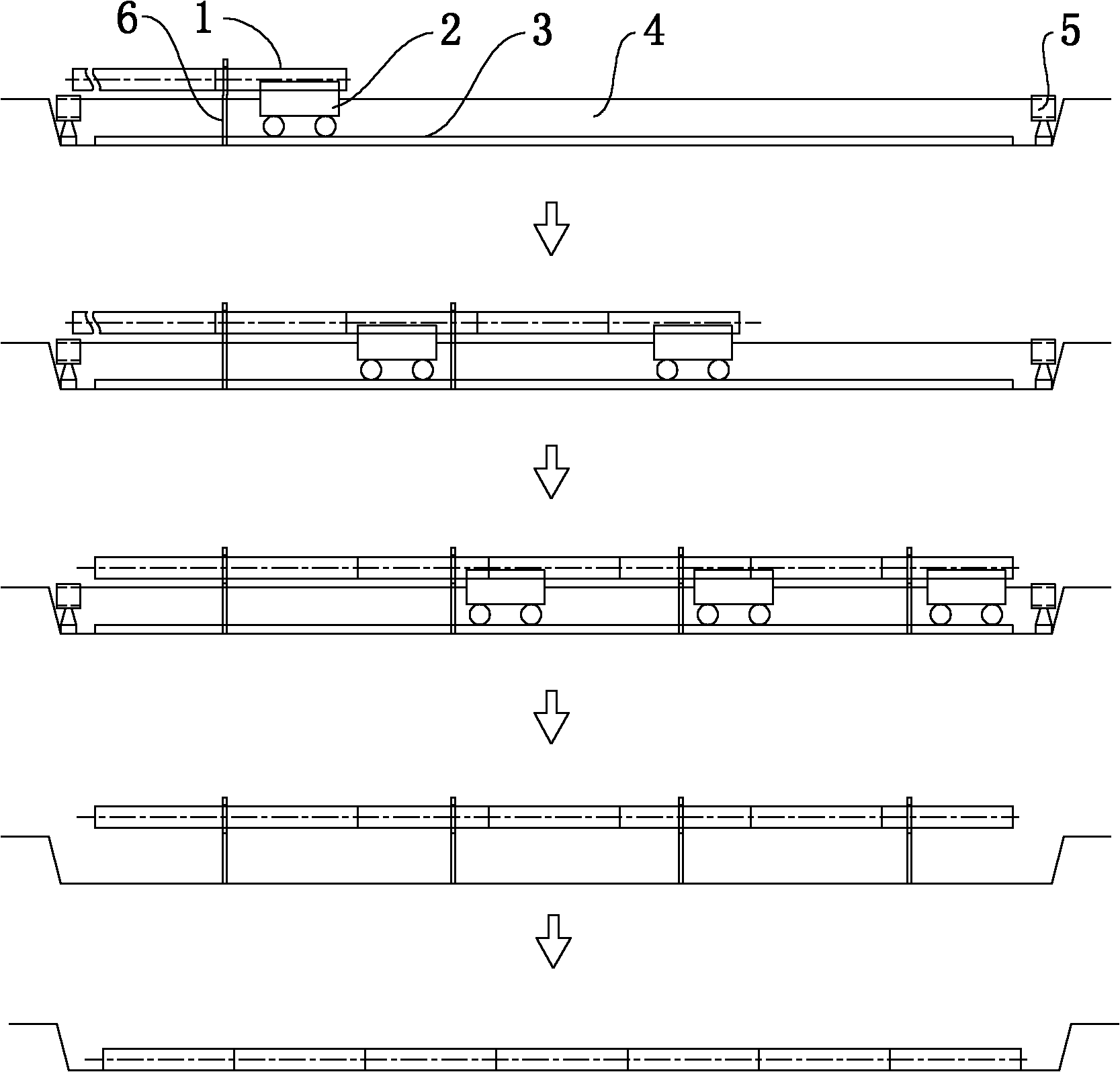

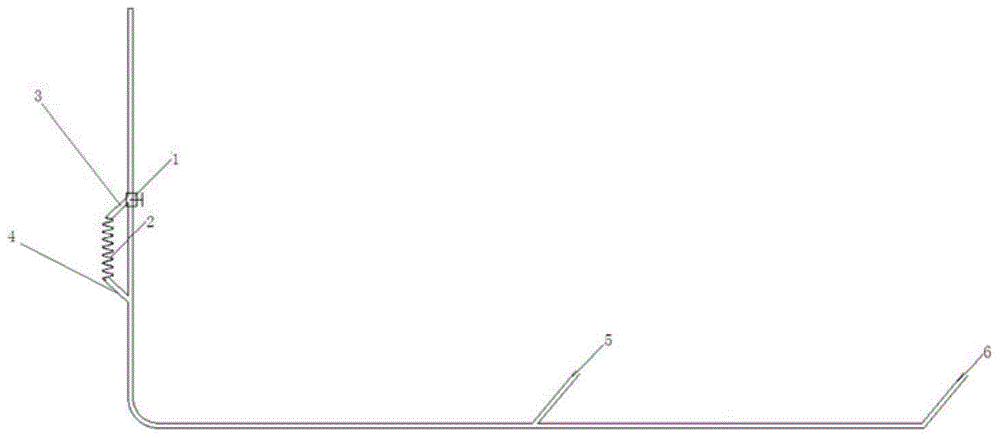

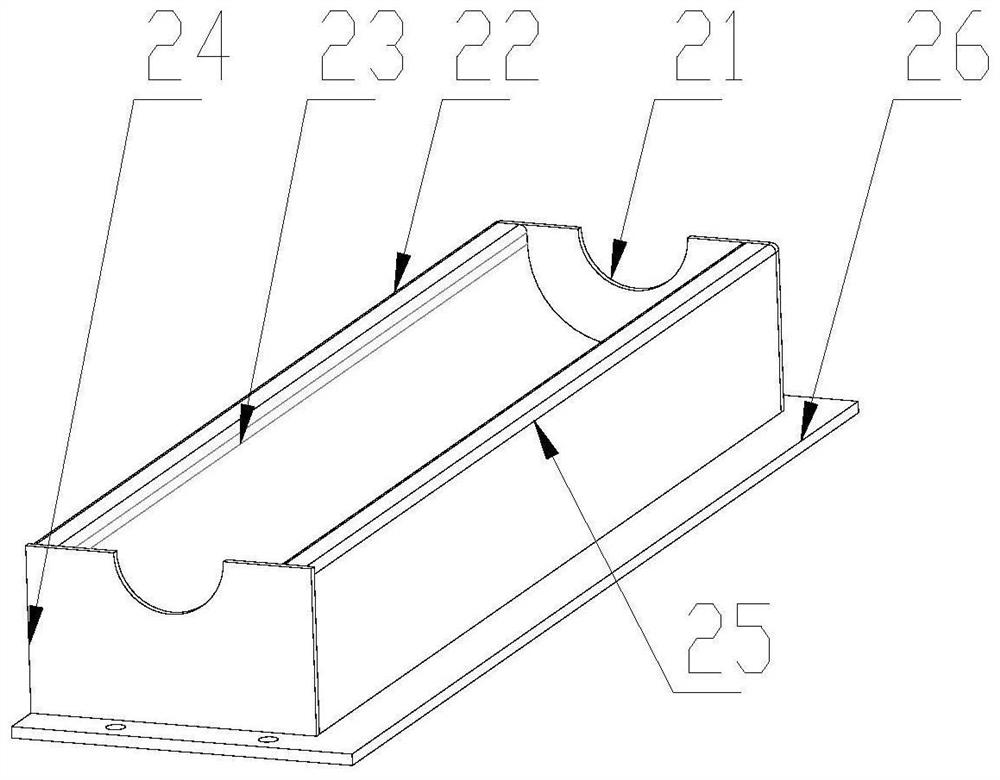

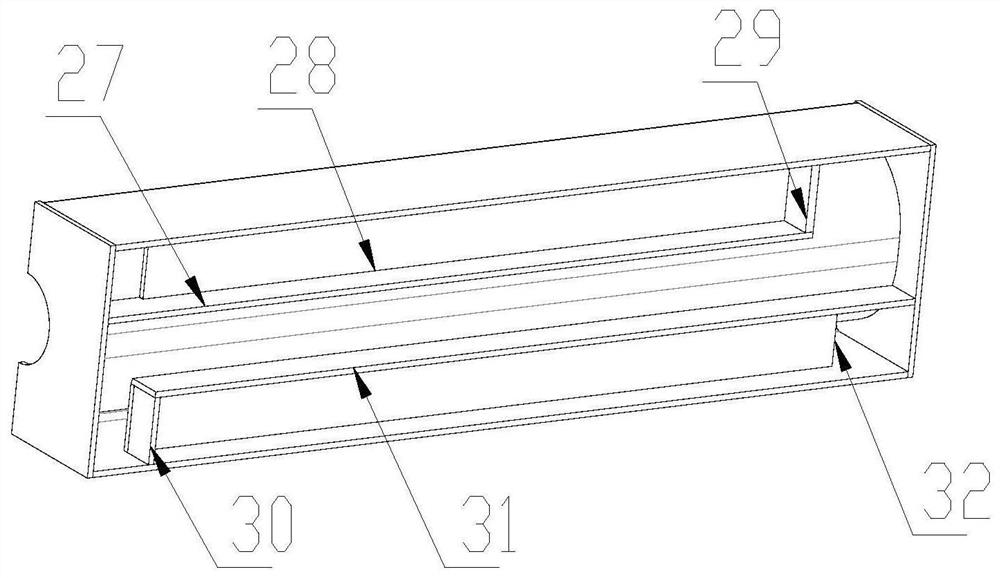

Method for laying mine slurry pipeline in long and narrow section

ActiveCN102155585ASimple processEasy to operatePipe laying and repairDemarcation pointSlurry pipeline

The invention discloses a method for laying a mine slurry pipeline in a long and narrow section, which can shorten a construction period. In the method, the length of a corresponding straight pipe section is determined by taking positions, where two bent pipes are connected in front of and behind the same straight pipe section, as demarcation points. The method comprises the following steps of: 1, grooving, laying a track in a pipe groove, arranging a trolley with a circular-arc pipe seat on the track, matching the circular arc of the circular-arc pipe seat with the outer circle of a pipeline, arranging a cushion on the circular-arc pipe seat and pairwise welding single pipes into a straight pipe section of a required length in a wide region; 2, pulling the entire straight pipe section into the pipe groove by using traction equipment and the trolley, supporting the straight pipe section with a supporting frame, removing the trolley, the traction equipment and the track and putting the straight pipe section down; and 3, connecting the straight pipe section with the bent pipe at the two ends and refilling the pipe groove. The method has a simple process, and is easy to operate; the one-step laying distance is large, the construction period is shortened, and the cost is lowered; and the method has high safety, and is particularly suitable for large-caliber long-distance mine slurry pipelines.

Owner:CHINA 19TH METALLURGICAL CORP

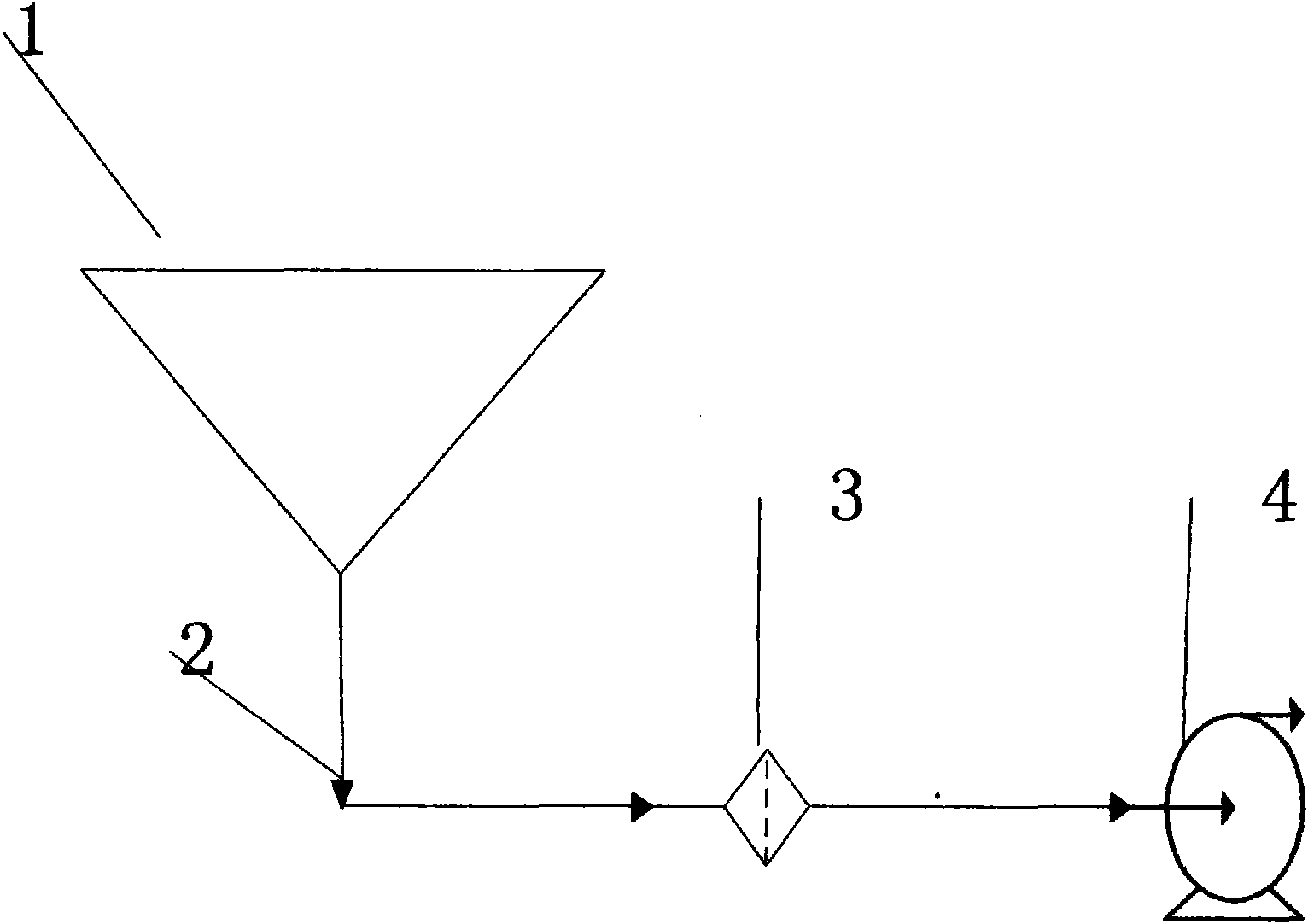

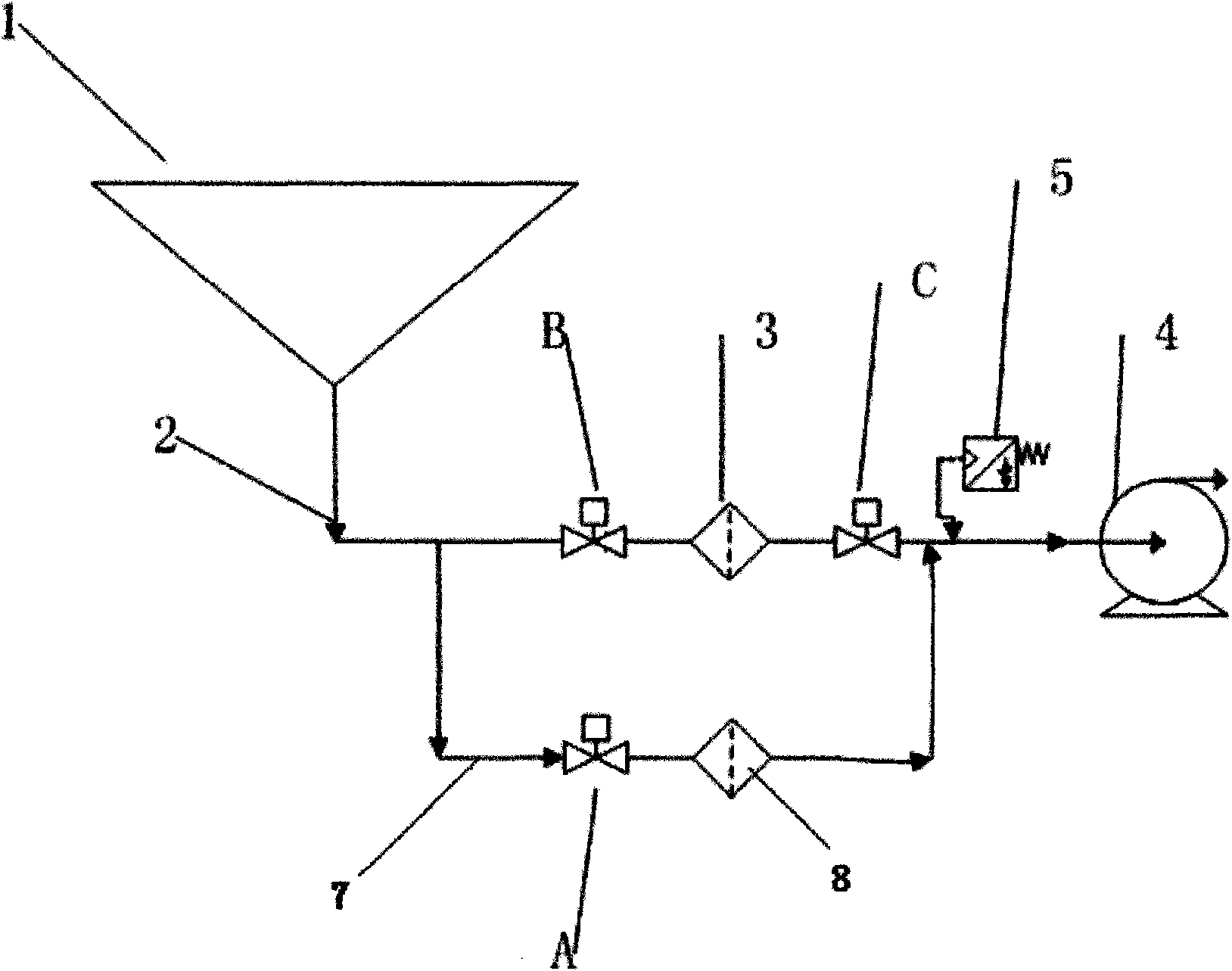

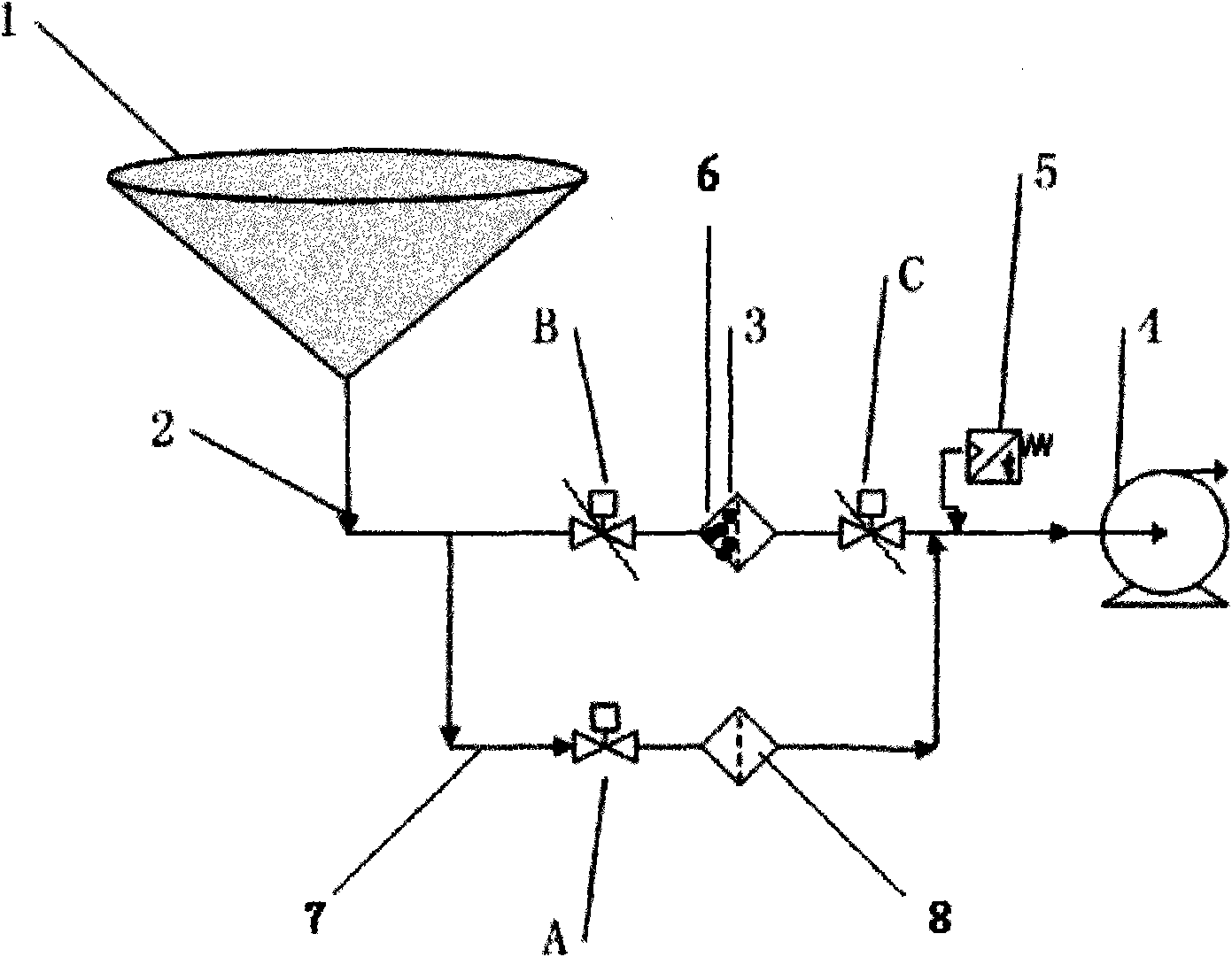

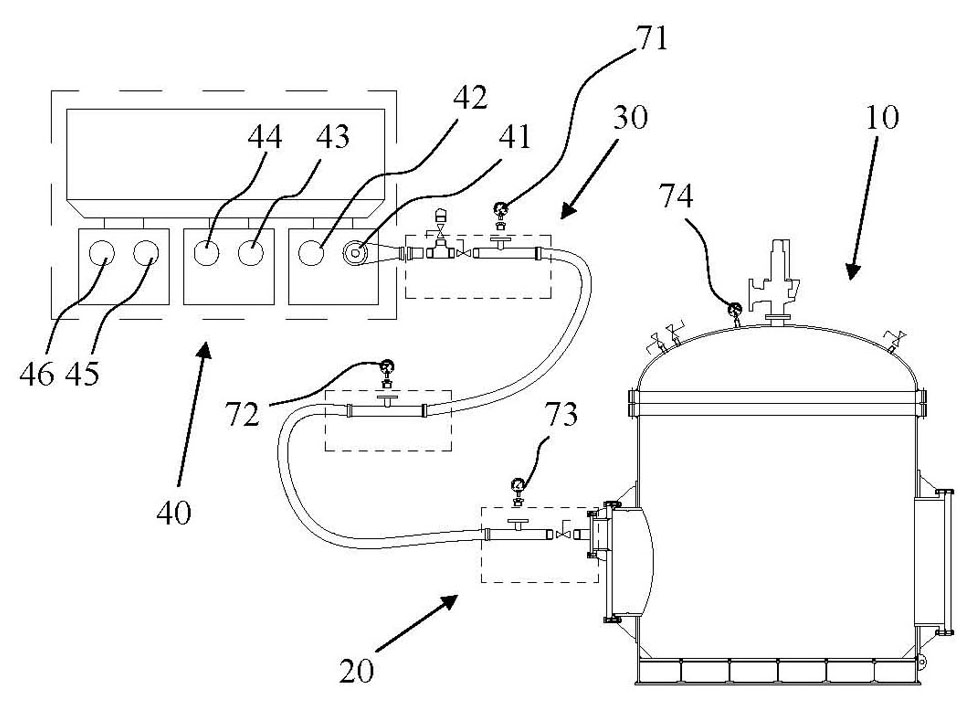

Ore slurry pipeline transport device and anti-blocking control method thereof

InactiveCN101886739ASolve the blockageOnly by solving the problem of cleaning up the original ore pipeline filter debrisPipeline systemsEngineeringSlurry pipeline

Owner:YUNNAN DAHONGSHAN PIPELINE

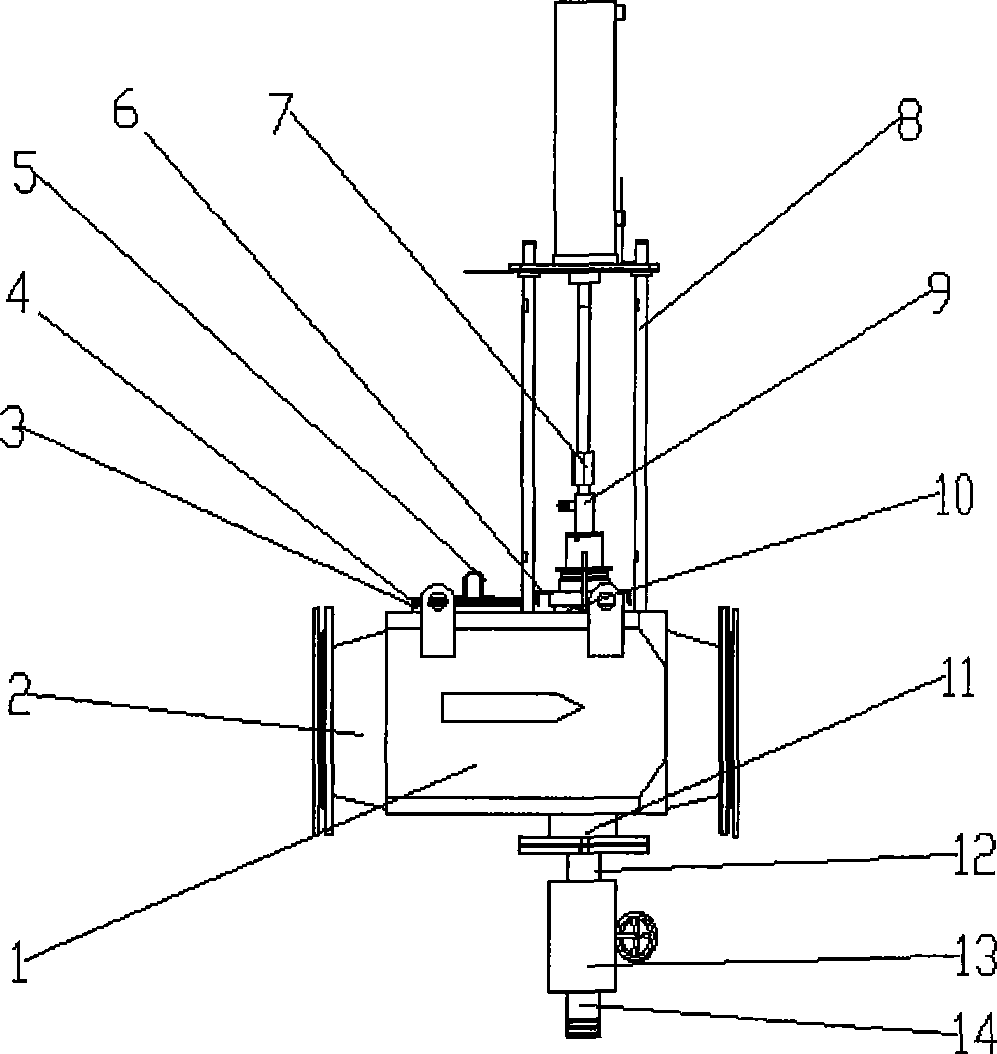

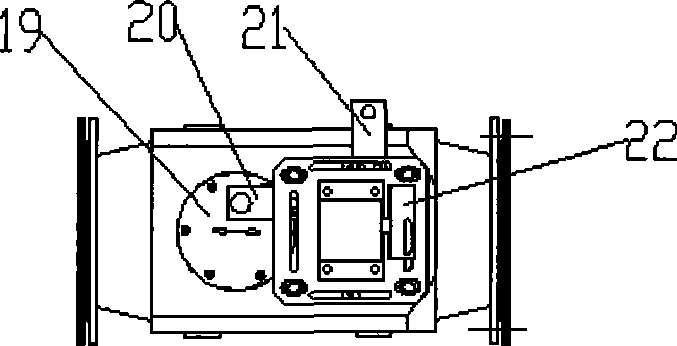

Adjustable pneumatic pulp pipe sampler

InactiveCN101419136AEasy to useImprove reliabilityWithdrawing sample devicesPipeline systemsEngineeringSlurry pipeline

The invention discloses a sampling device of an adjustable pneumatic ore slurry pipeline. The sampling device comprises a box body; two ends of the box body are provided with a feed port and a discharge port respectively; a sampling tube is arranged on the box body vertical to the direction of vertical axis of the box body; the sampling tube comprises an inner sampling tube and an outer sampling tube; corresponding positions of the walls of the inner sampling tube and the outer sampling tube are provided with a sampling hole respectively; and the inner sampling tube and the outer sampling tube are sleeved together and can relatively rotate so that the sampling amount can be adjusted. The box body is square; and the feed port and the discharge port of the box body are connected with a reducing flange respectively so that ore slurry entering the box body is self-stirred and evenly mixed. A cleaning lever is inserted into the sampling pipe and is a hollow lever; the inside of the cleaning lever can be introduced with a cleaning medium; the cleaning lever is driven by a cylinder and can move up and down relative to the sampling pipe to clean the sampling pipe; and the sampling device has convenient use and high reliability.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Wear-resistant corrosion- resistant composite steel pipe and preparation method thereof

Owner:XI'AN POLYTECHNIC UNIVERSITY

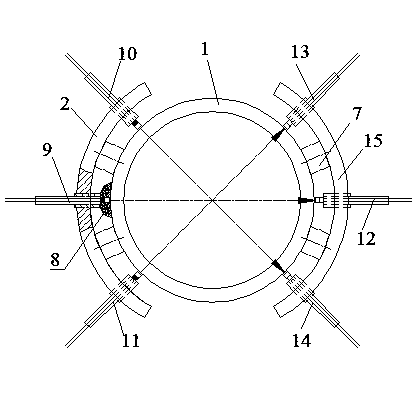

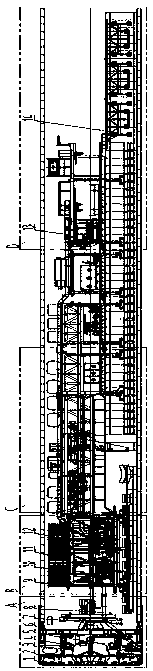

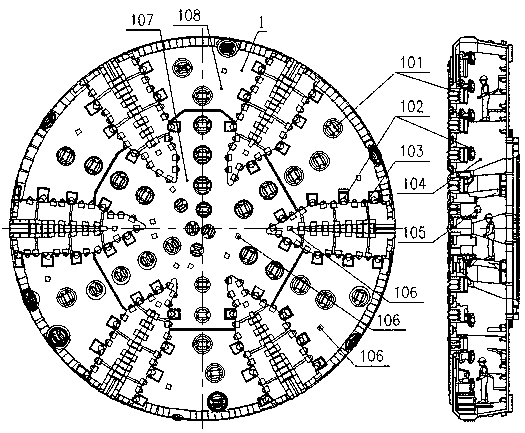

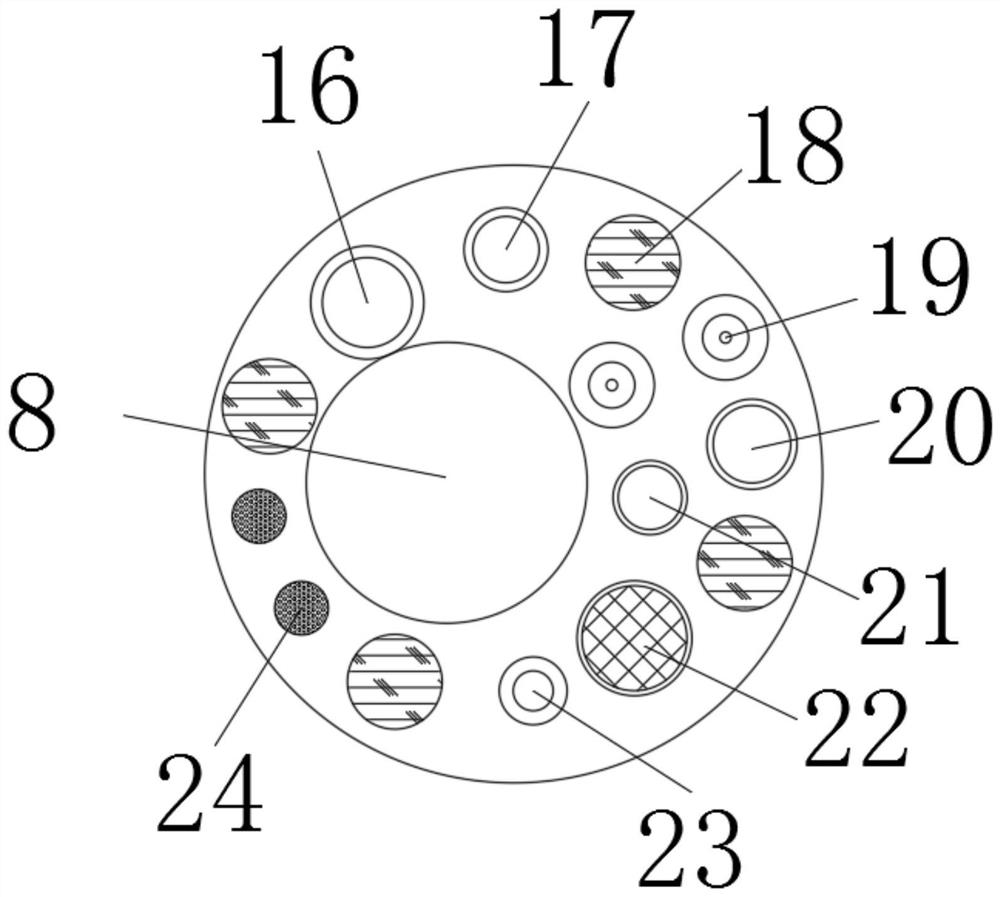

Super-large diameter slurry balance shield tunneling machine

PendingCN108590687AImprove replacement efficiencyImprove working environmentUnderground chambersTunnel liningProtection mechanismEngineering

The invention discloses a super-large diameter slurry balance shield tunneling machine. The super-large diameter slurry balance shield tunneling machine solves the problems of low tunneling efficiency, low tool replacement efficiency, serious potential safety hazard and the like of a slurry balance shield tunneling machine in the prior art. The super-large diameter slurry balance shield tunnelingmachine comprises a tunneling mechanism, a rear supporting electrical and hydraulic integration system, a fluid integration system, a slurry pipeline extension device and a dragging platform which aresequentially connected; the tunneling mechanism comprises a normal-pressure cutter head, a shield protection mechanism, a main drive system and a propulsion system, wherein the normal-pressure cutterhead is located at the front end of the shield protection mechanism, the main drive system is located inside the shield protection mechanism and is connected with the normal-pressure cutter head, theshield protection mechanism is provided with a central cabin, a pipe segment mounting machine and a mud circulation system, and the central cabin is located behind the main drive system; and the segment mounting machine is connected with the shield protection mechanism, and a slurry discharge port of the slurry circulation system is formed in the lower part of the shield protection mechanism. Thesuper-large diameter slurry balance shield tunneling machine can realize the one-time forming of a super-large diameter tunnel project, effectively improve the construction efficiency and greatly reduce the construction cost.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

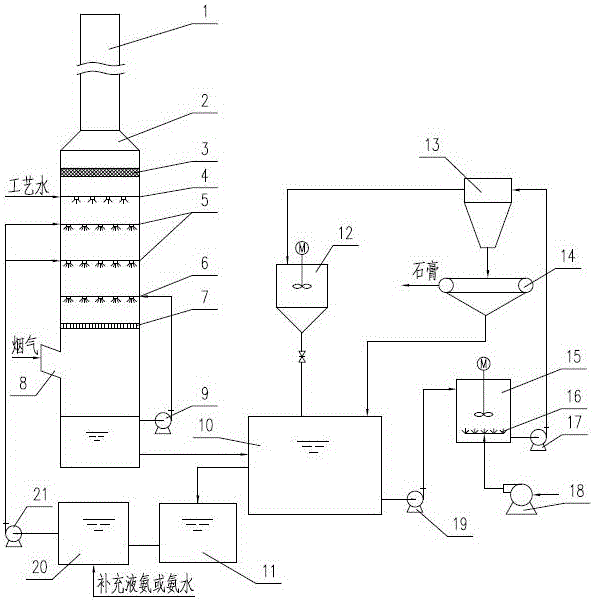

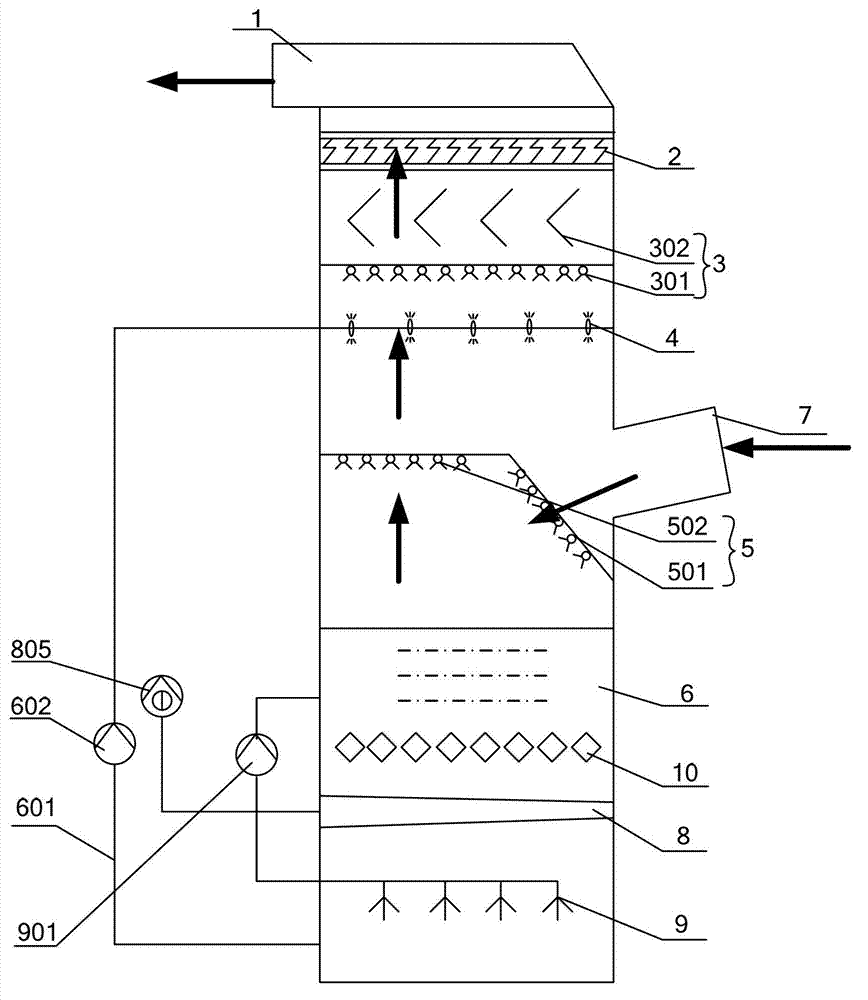

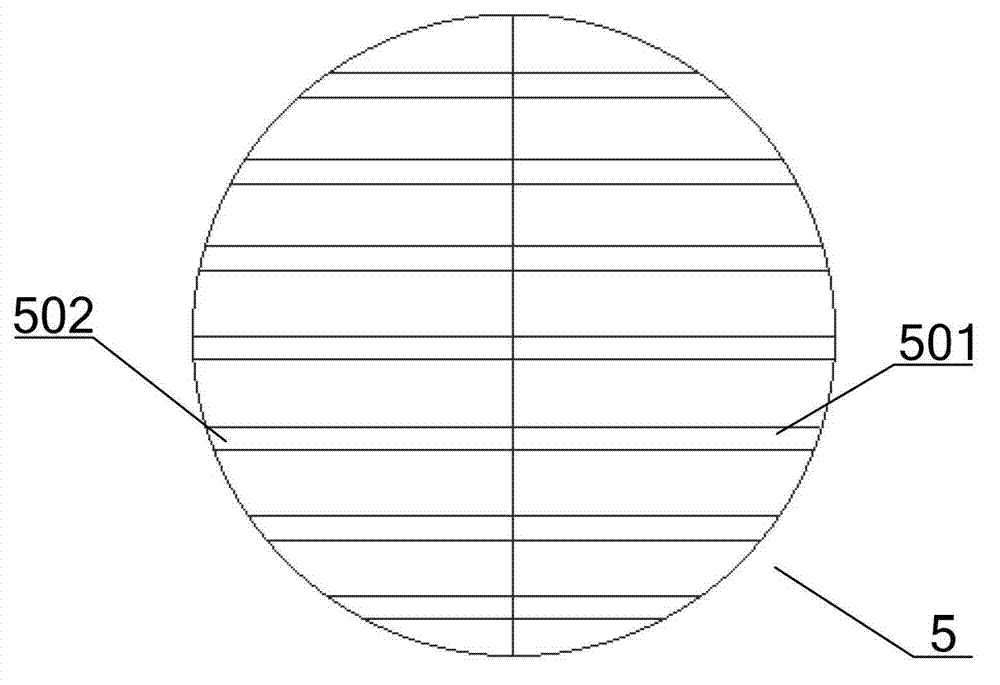

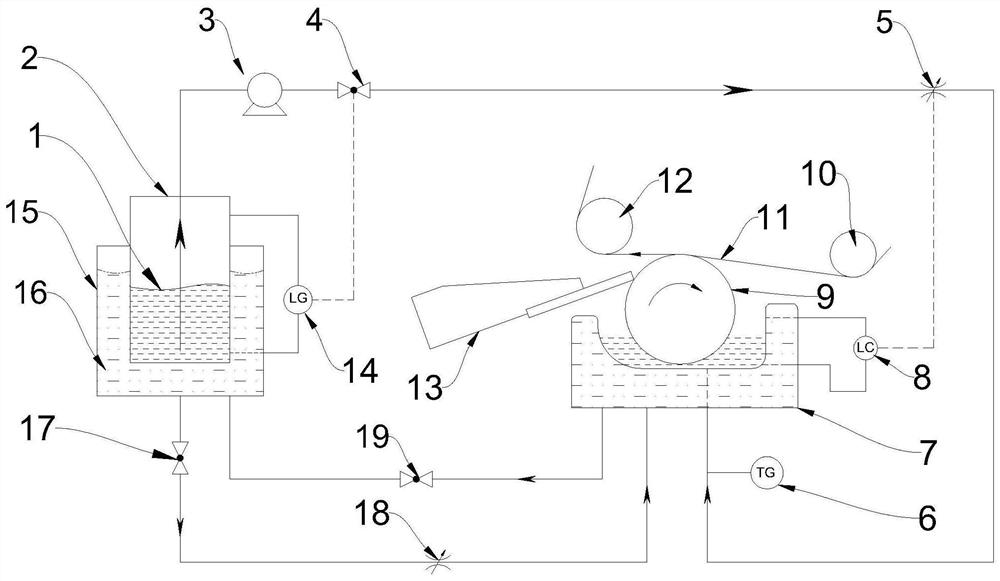

Desulphurization device and method capable of realizing cyclic utilization of ammonia water

InactiveCN106178896ALow priceImprove performanceGas treatmentDispersed particle separationFlue gasProduct gas

The invention discloses a desulphurization device and method capable of realizing cyclic utilization of ammonia water. The desulphurization device comprises a desulphurization tower with a flue gas inlet and a chimney. A defogging layer, a washing layer, an absorbing and spraying layer and a gas distributor are arranged inside the desulphurization tower in sequence from top to bottom. An ammonia gas regeneration system is arranged outside the desulphurization tower, and comprises a regeneration tank connected with the bottom of the desulphurization tower. An oxidation tank is connected with the bottom of the regeneration tank through a thick slurry pipeline. A vortex concentrator is connected with the bottom of the oxidation tank. A digestion tank is connected with the upper part of the vortex concentrator through an overflow pipe, and is led into the regeneration tank. A drying machine is connected with the bottom of the vortex concentrator. A liquid filtering hole in the bottom of the drying machine is connected with the regeneration tank. A sedimentation tank is connected onto the regeneration tank, and is connected with a recirculating tank through a pipeline. The recirculating tank is led into the absorbing and spraying layer. The desulphurization device and method can realize cyclic utilization of ammonia water as an absorbent, so that the operation cost of ammonia desulfurization is reduced greatly.

Owner:JIANGSU SUNPOWER TECH

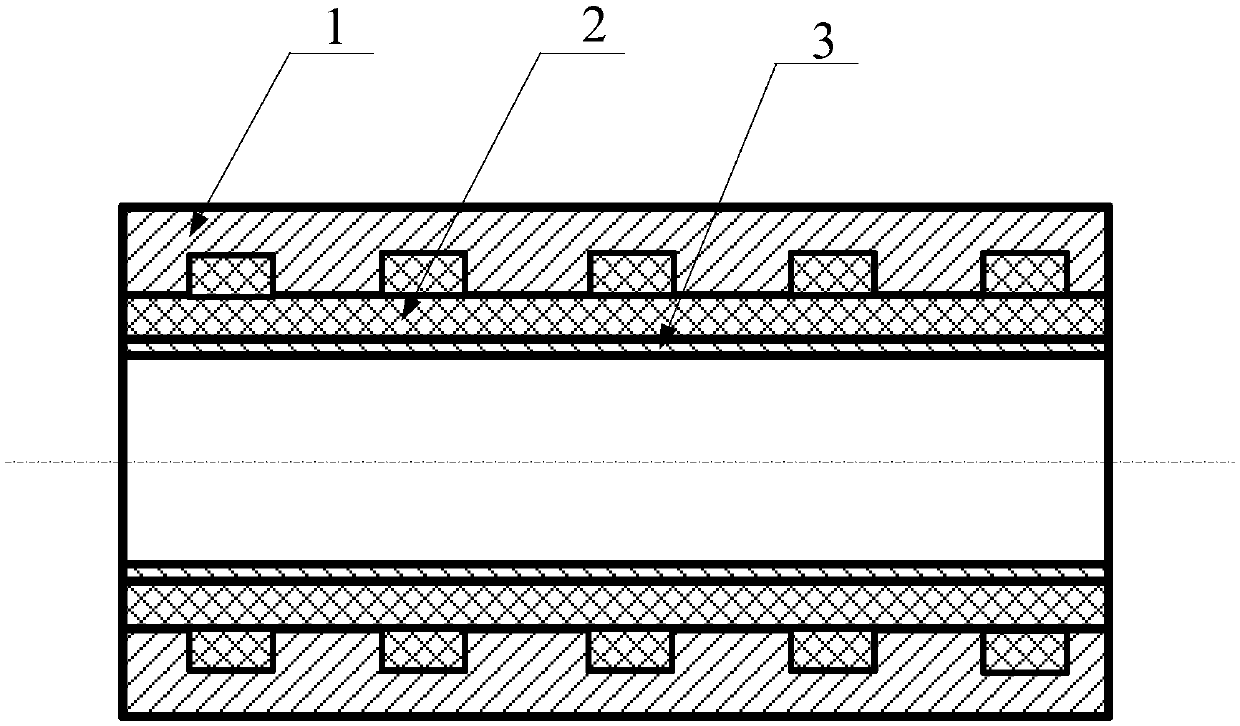

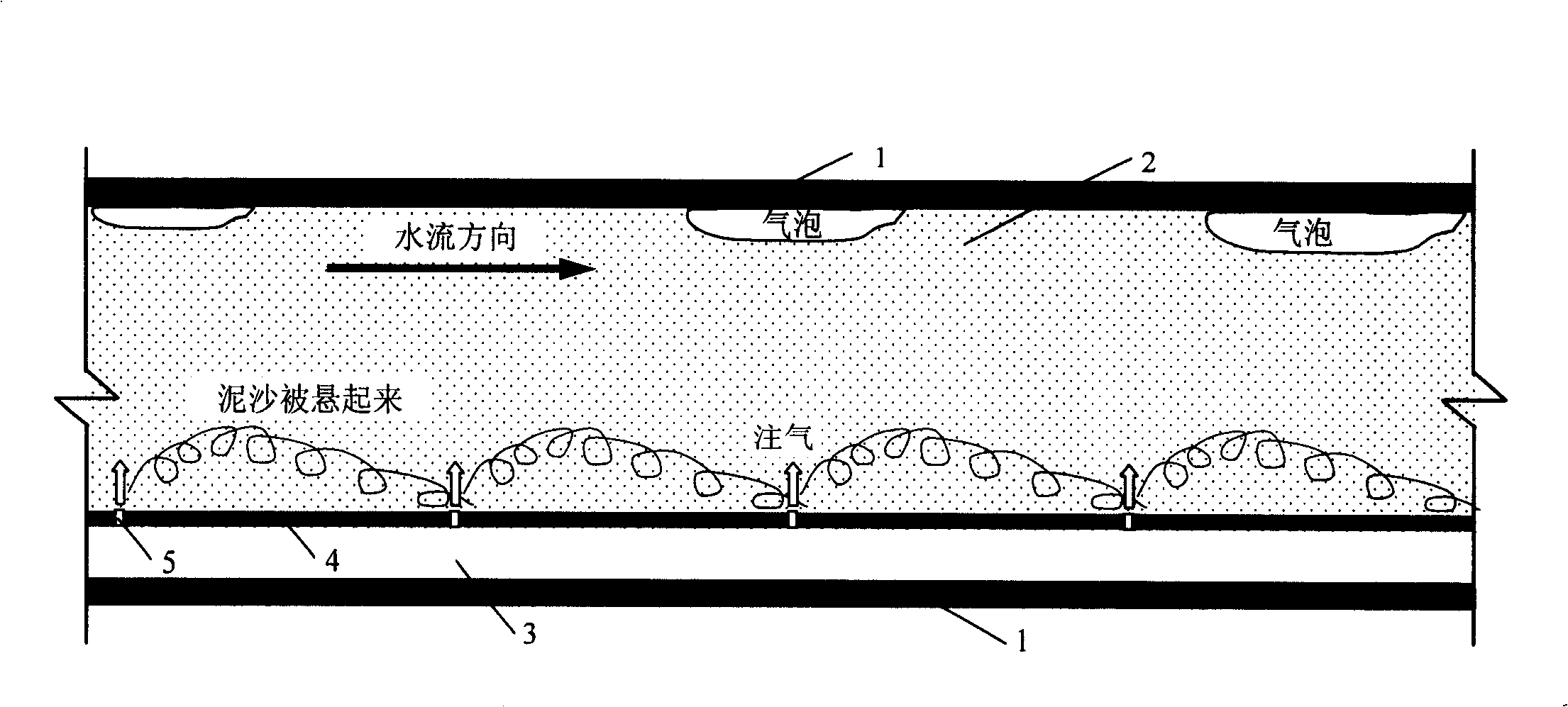

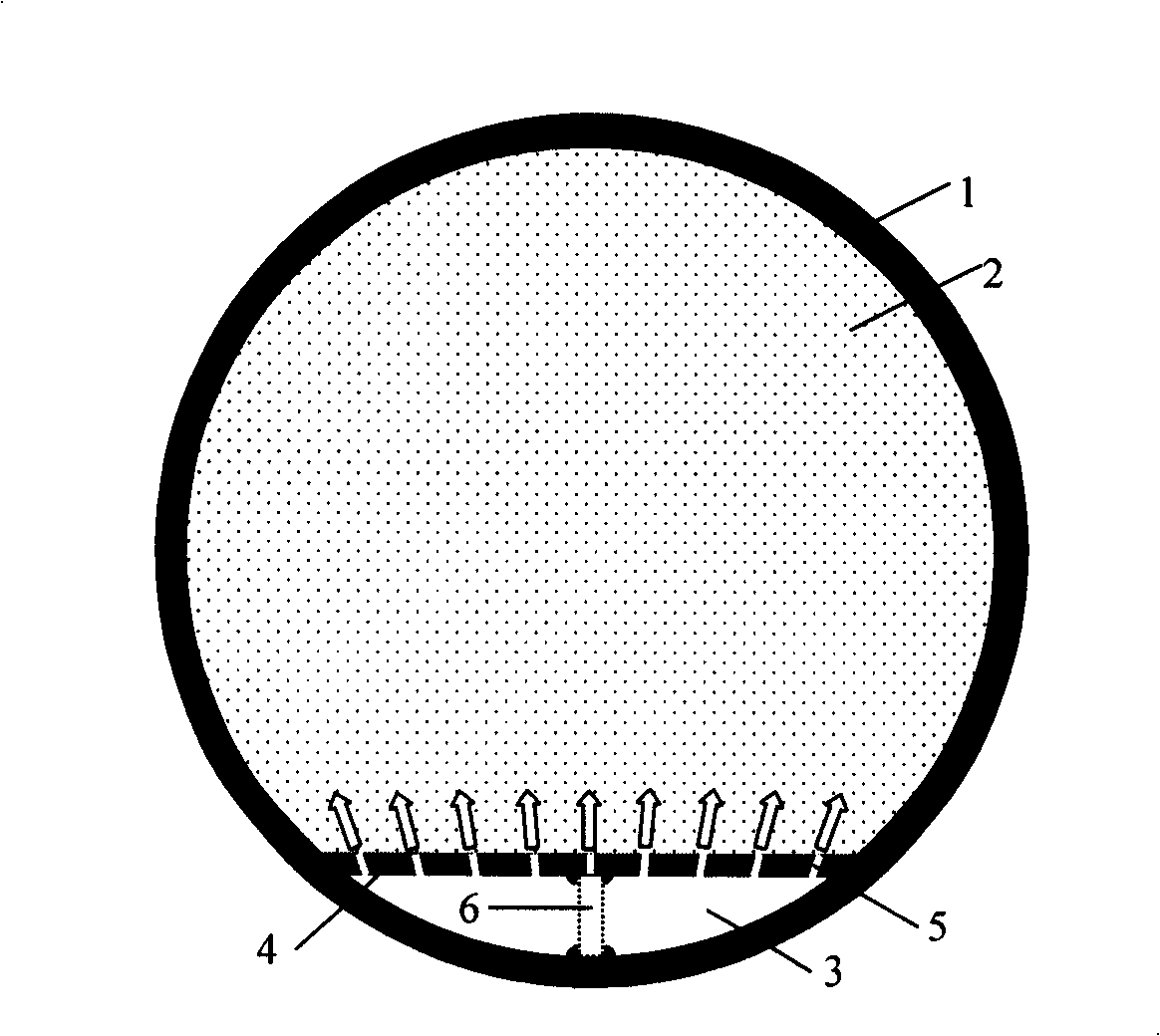

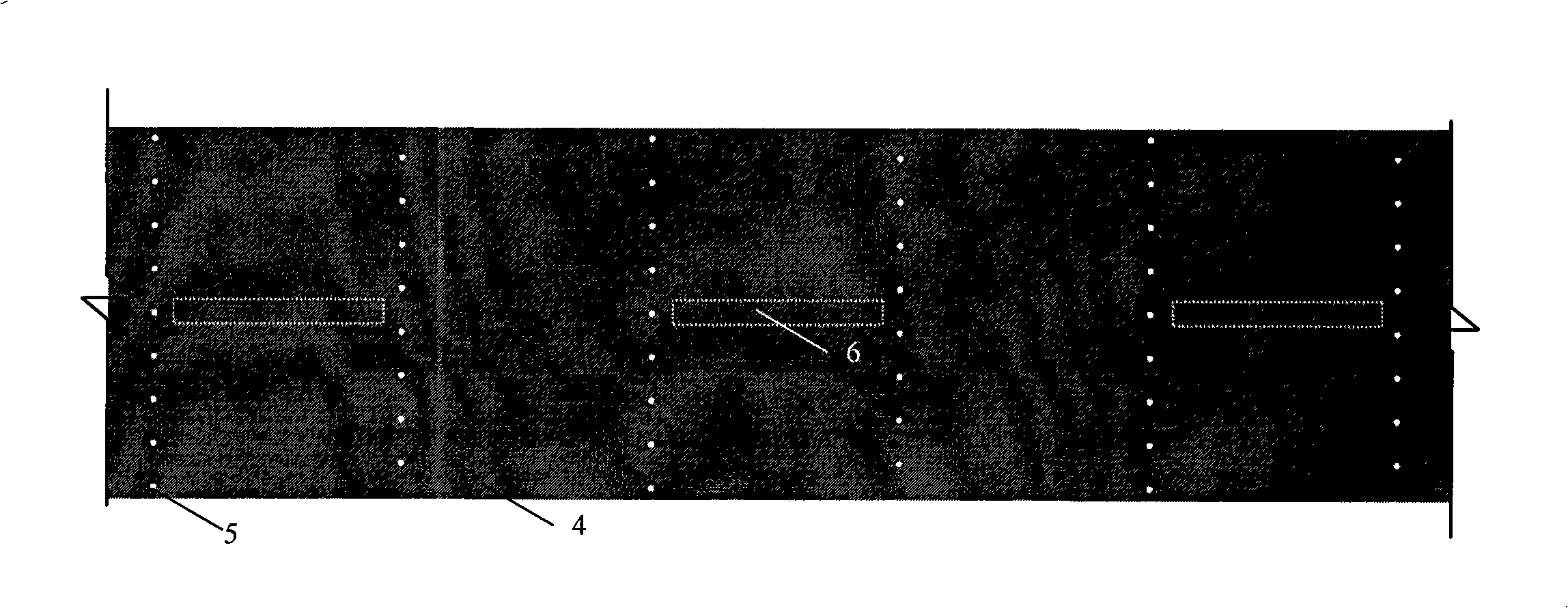

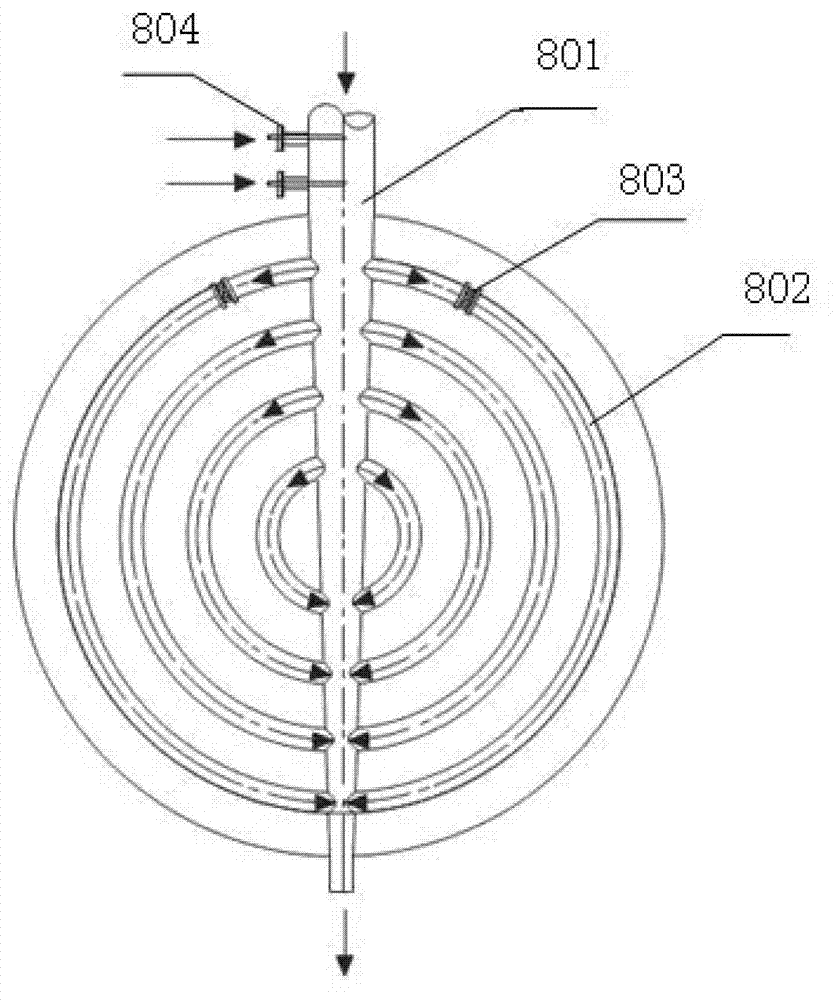

Gas injection type slurry pipe-line transportation method and device

InactiveCN101270848AReduce resistanceReduced sand carrying capacityPipeline systemsProduct gasSlurry pipeline

A gas injection type of slurry pipeline transportation method relates to a novel method which injects the gas into the sediment fluid to reduce the transportation resistance of the slurry and the sedimentation of the sediment and improve the transportation efficiency of the slurry. The transportation method comprises that the transportation pipelines which contain the gas injection channels are prepared; the gas injection type of transportation pipelines are connected according to the traditional pipeline connection method; a gas supply device is connected with the gas injection channels; during the transportation process of the slurry, the gas is injected into the sediment fluid continuously; the gas supply pressure is adjusted until the best sediment transportation efficiency is attained; after the transportation of the sediment, the gas continues to be injected into the transportation pipeline until the cleaning of the pipeline is completed. The invention has simple implementation technology and low sediment transportation cost. The invention can not only reduce the sedimentation of coarse sediment in the transportation pipeline, improve the transportation efficiency of the sediment and produce great transportation effect under the working conditions of wide sediment gradation and coarse grain size, but also improve the transportation distance and slurry concentration, reduce the post-processing dehydration working load of the dredging and reclamation and decrease the environmental pollution.

Owner:TONGJI UNIV

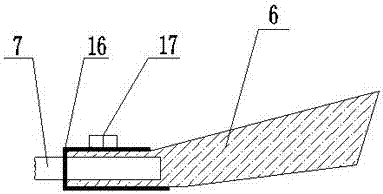

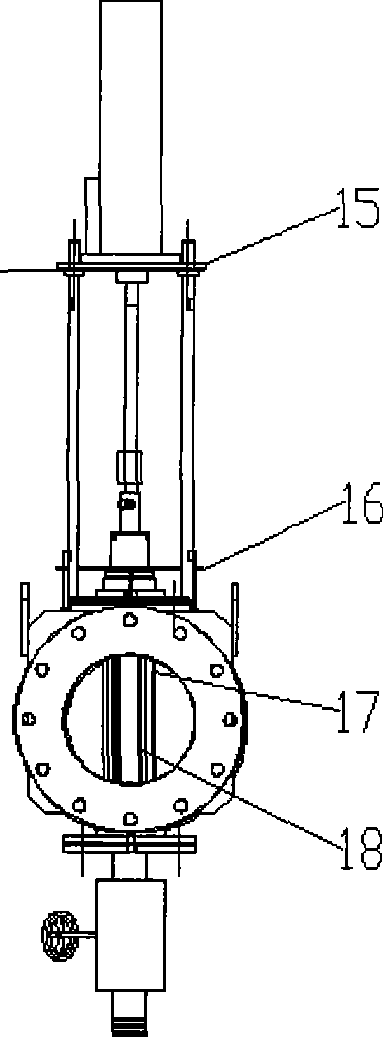

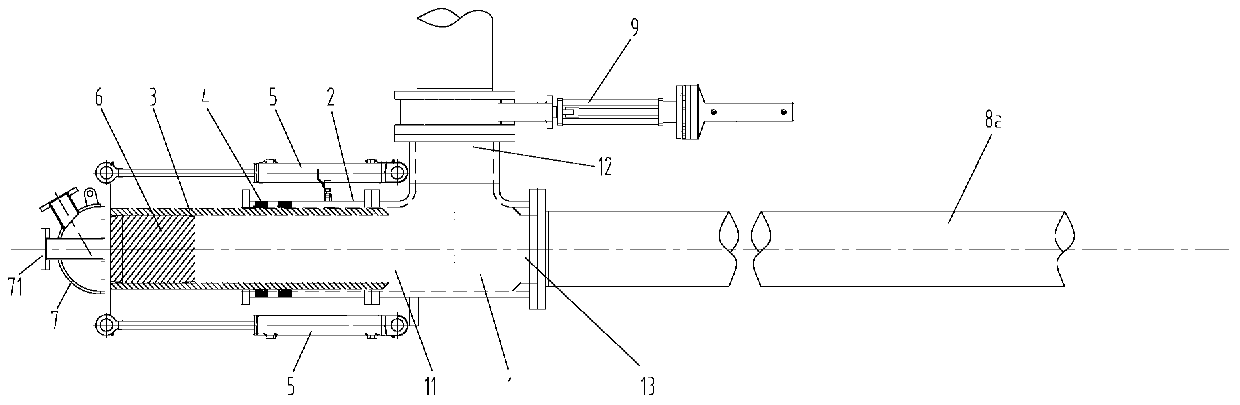

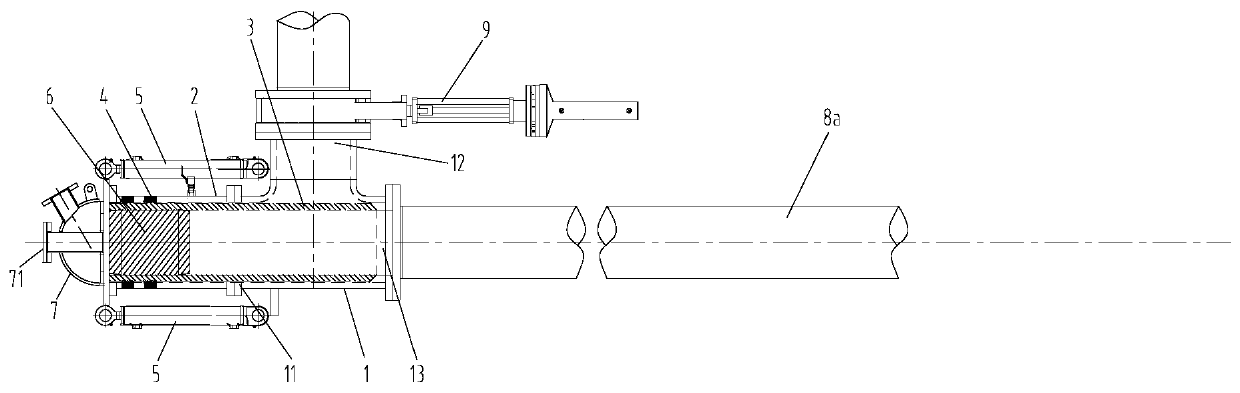

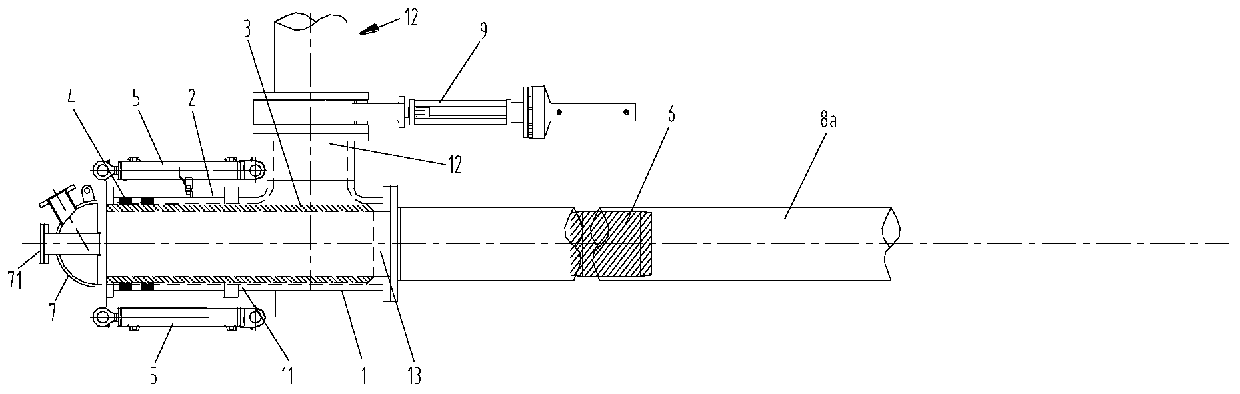

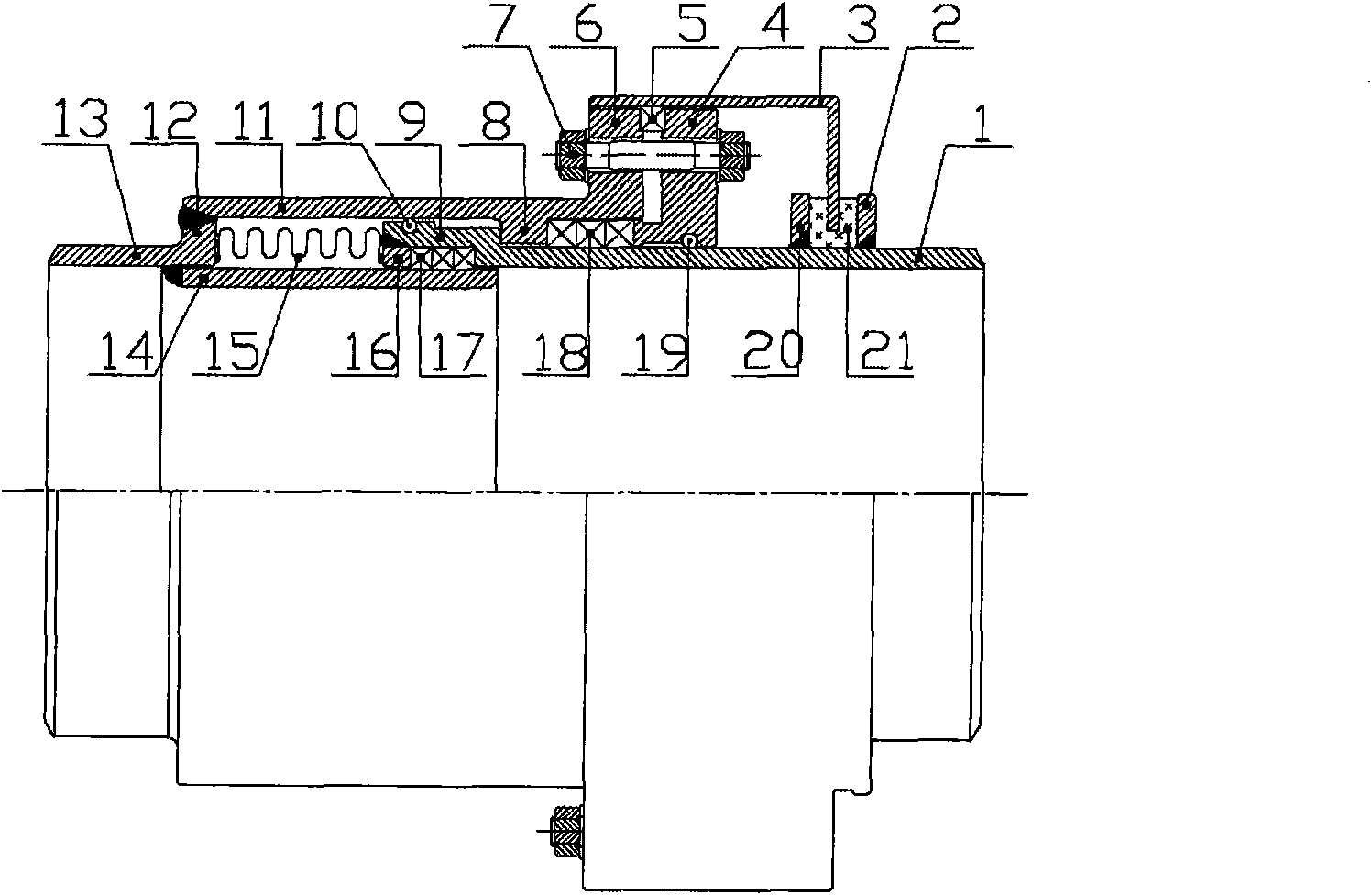

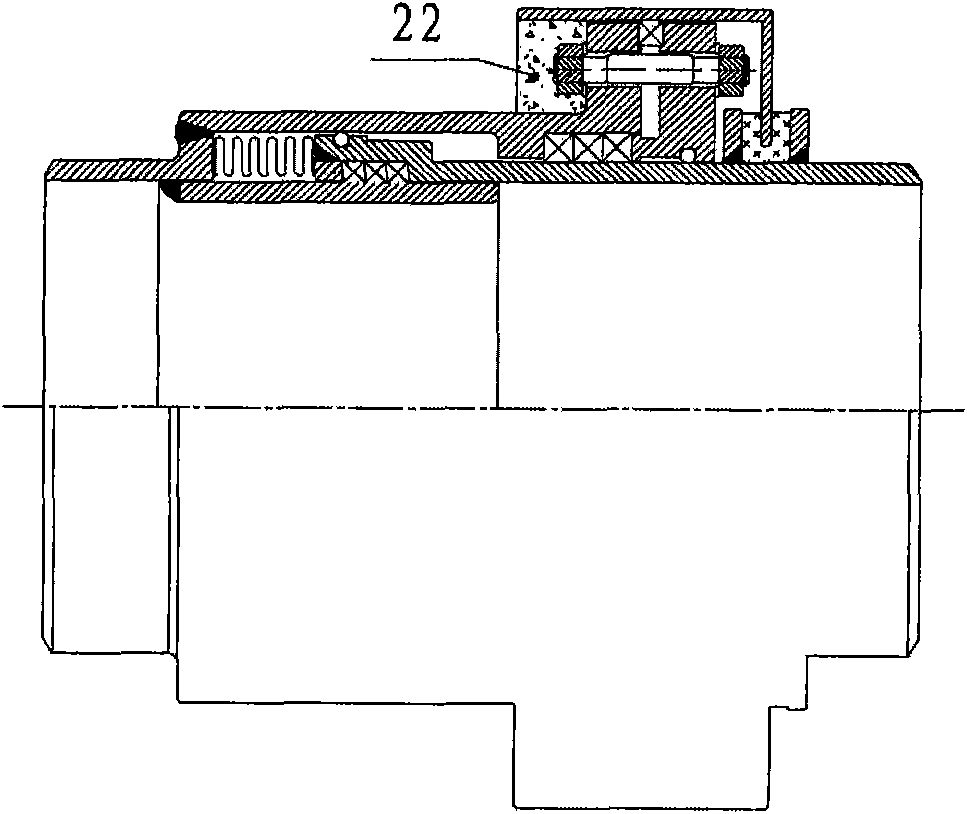

Shield machine pipe extension device and connecting method for slurry pipeline in tunnel

ActiveCN110145324AGuaranteed not to leakPrevent leakageTunnelsArchitectural engineeringSlurry pipeline

The invention discloses a shield machine pipe extension device and a connection method for a slurry pipeline in a tunnel. The device comprises a three-way pipe with a first port, an outer sleeve pipewith one end connected with the first port, a telescopic pipe with one end telescopically inserted and stretches into the three-way pipe from the other end of the outer sleeve pipe, a sealing elementarranged between the telescopic pipe and the outer sleeve pipe, a driving device for driving the telescopic pipe to move and a blocking ball capable of entering or disengaging from the telescopic pipeunder the effect of pressure. The three-way pipe is further provided with a second port which is connected with the slurry pipeline of a shield machine in a blocking manner, and a third port which isconnected with the slurry pipeline in the tunnel in a disengaging manner. According to the shield machine pipe extension device and the connection method for the slurry pipeline in the tunnel, slurrydoes not need to be transported backwards, the mechanism is simple, the economy is good, and operation and maintenance are convenient.

Owner:TIANHE MECHANICAL EQUIP MFG

Compound compensator for high pressure pipeline

InactiveCN101832443AStress reliefLow running costPipeline expansion-compensationAxial displacementEngineering

The invention discloses a compound compensator for a high pressure pipeline, belonging to the technical field of the compensating equipment of the heat distribution pipeline. The compound compensator comprises an inner pipe, an anticorrosive pipe, a gland cover flange, a wear sleeve flange, a wear sleeve, a reduction adapter, a guide pipe, a corrugated pipe, a pressure head and the like, wherein the wear sleeve is ringed on one end of the inner pipe, the outer ring of the outer end of one side of the wear sleeve is provided with the wear sleeve flange, the end on other side of the wear sleeve is welded and fixed with a reduction adapter supporting platform integrated with the reduction adapter; the reduction adapter and the inner pipe are separately sleeved on the two ends of the guide pipe, one end of the guide pipe is fixedly connected with the reduction adapter, the corrugated pipe is arranged between the guide pipe and the wear sleeve, and the two ends are butted with the pressure head and the reduction adapter and are connected and fixed through welding. By adopting the structure, when the inner pipe is extruded and pushed by the axial heat expansive force, the axial displacement can be absorbed through the flexible deformation of the corrugated pipe; the coaxial, synchronous and integral movement of the anticorrosive pipe and the like along with the inner pipe can be performed along the axial direction, thus the compound compensator can be used as the buried pipeline or the overhead pipeline; in addition, the compound compensator has multifunctional characteristics of being used as the gas or liquid pipeline and also as the slurry pipeline.

Owner:陈墅庚

Production method of snowflake art paper

ActiveCN102660886ASoft colorEasy to processNatural cellulose pulp/paperWater-repelling agents additionOperabilitySlurry pipeline

The invention relates to a production method of snowflake art paper. The production method comprises the following steps of: preparing a basic size and a titanium dioxide size, and dyeing the prepared basic size in the drifting process, wherein the adding position of dyeing dye is located in a slurry pipeline in front of a paper machine slushing pump; pumping the titanium dioxide size into a drifting pipeline along the flowing direction of dyeing paper pulp size in a size flowing pipeline in front of a size flowing box, and evenly mixing with the dyed paper pulp size; carrying out papermaking on the prepared paper pulp size, spraying to a net from the size flowing box, dehydrating via the net part to form a wet paper sheet with white snowflakes, drying and carrying out surface sizing on the squeezed paper sheet through a drying cylinder, and drying to form the snowflake art paper with snowflake-like mottled-texture paper surface. According to the invention, the process and production are simple, the production technology is reliable, the operability is strong, and the paper surface is soft in color and is rich in color and texture characteristics and has the snowing effect. The production method can be used for packaging of special products, covers of books, clothing tags, high-grade office paper and the like.

Owner:SHANDONG KAILI SPECIAL PAPER

Removal tower and method for collaboratively desulfurizing and removing PM2.5 (Particulate Matter 2.5) in smoke

ActiveCN103041690AImprove purification efficiencyAchieve desulfurizationCombination devicesParticulatesInlet channel

The invention discloses a removal tower and a removal method for collaboratively desulfurizing and removing PM2.5 (Particulate Matter 2.5) in smoke. The removal tower is internally provided with a smoke outlet channel, a defogging device, a phase change condensing area, a slurry spraying layer, a first smoke humidifying device and a slurry tank which are arranged from top to bottom in sequence; the slurry tank is communicated to the slurry spraying layer through a slurry pipeline and a circulating pump; a smoke inlet channel is arranged between the slurry spraying layer and a first smoke humidifying device; an oxide-isolation device, an oxide air distributing device and a stirrer are arranged in the slurry tank from top to bottom in sequence; and the phase change condensing area comprises a second smoke humidifying device and a plurality of bent baffle plates. The removal tower is provided with a structure for desulfurizing and also has a structure for removing the PM2.5, and the two structures are distributed in the same removal tower; and the steam phase technology is carried out, so that the purposes of desulfurizing and removing the PM2.5 can be realized at the same time, and the purifying efficiency of the smoke can be improved; and furthermore, the whole removal tower is simple in structure, the floor space is saved, and the operation cost is reduced.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

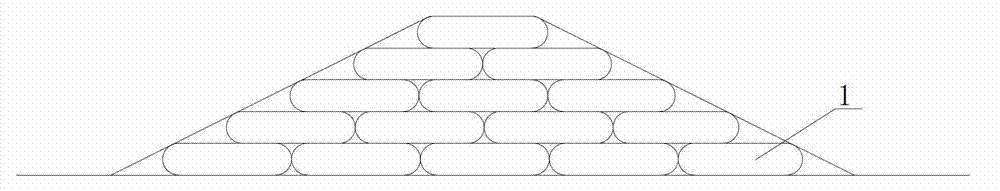

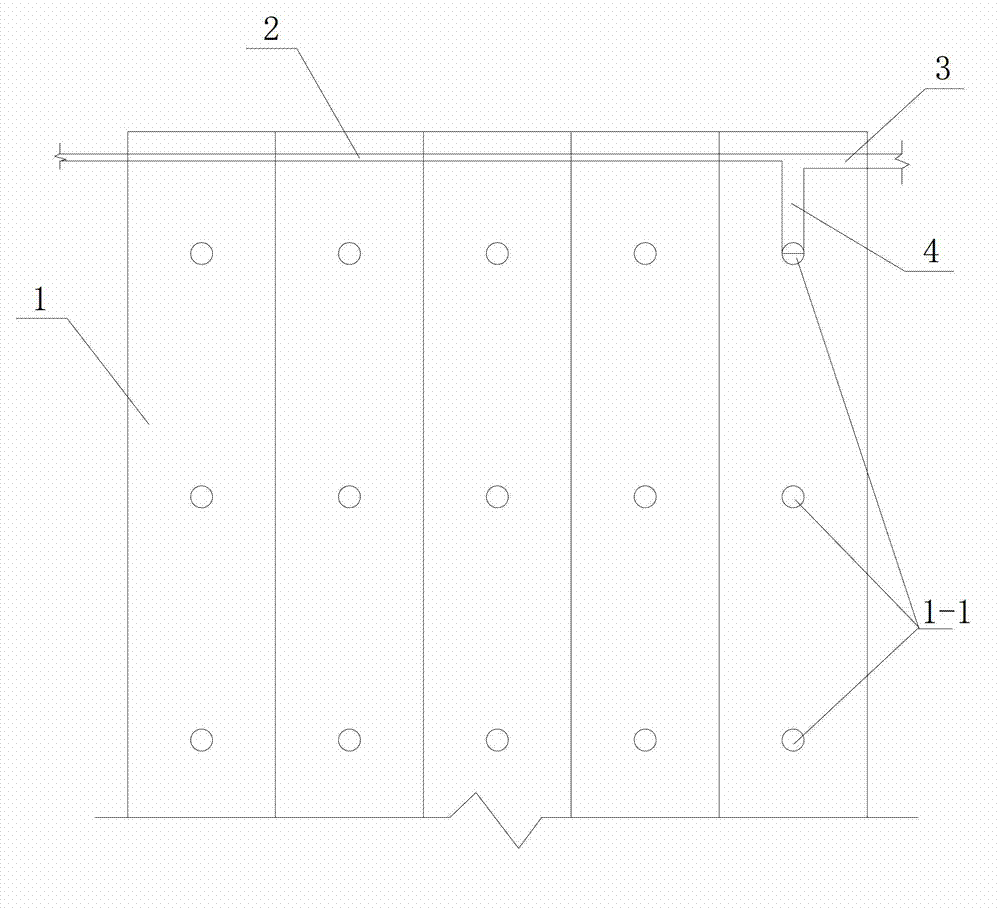

Diking method through filling sludge and curing agent into mold bags

The invention relates to a diking method through filling sludge and a curing agent into mold bags. The method includes the following steps: step one, laying a layer of permeable filling mold bags provided with filling openings on a target mud flat surface; step two, pumping curing agent grout and sludge simultaneously into the filling mold bags from the filling openings through a curing agent pipeline and a slurry pipeline until the mold bags are full; step three, leaving the filling mold bags to stand until the sludge in the bags is solidified; step four, laying a next layer of filling mold bags on the layer, and repeating the step two and the step three; and step five, laying each following layer of mold bags sequentially according to step four and enabling the sludge in the bags to be solidified until a designed height is reached. According to the method, a technical scheme of separate slurry production and mixing filling is adopted, processes of mixing and stirring the sludge and the curing agent in advance are omitted skillfully, the curing agent grout can be prepared at an emptying point directly, materials and stirring equipment are not needed to be delivered to a construction site, and construction efficiency improvement and cost reduction are facilitated.

Owner:南京水科院瑞迪科技集团有限公司

Biogas slurry, water and fertilizer integrated safe application method for protected cucumbers

The invention discloses a method for safely applying biogas slurry, water and fertilizer integration of facility cucumbers. The steps include covering the top film of facility greenhouses and flooding the high-temperature stewed sheds with biogas slurry; adding fertilizer when preparing the ground before planting cucumbers; watering cucumber seedlings once after planting Slow seedling water: After the cucumber seedlings grow to 12 leaves, start to water the biogas slurry and water until 7 days before harvesting and pulling the seedlings. Water the biogas slurry first and then water each time. The application rate is 4 tons of biogas slurry per mu, 6 tons Water, water with high calcium and high potassium dissolved in fertilization. In the invention, the biogas slurry is filtered and directly used for irrigation of cucumber greenhouses, so that the biogas slurry can be irrigated first and then clear water or water and fertilizer can be irrigated, which saves manpower. It also saves the step of flushing the biogas slurry pipeline with water, avoids the phenomenon of microorganism breeding and blocking the pipe network, and further strengthens the anti-blocking safety performance of the entire system. The yield of the facility cucumber of the invention is higher than that of conventional planting, the environmental benefit is good, and the cost is low. The goal of maximizing biogas slurry utilization on the premise of safe utilization is realized.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

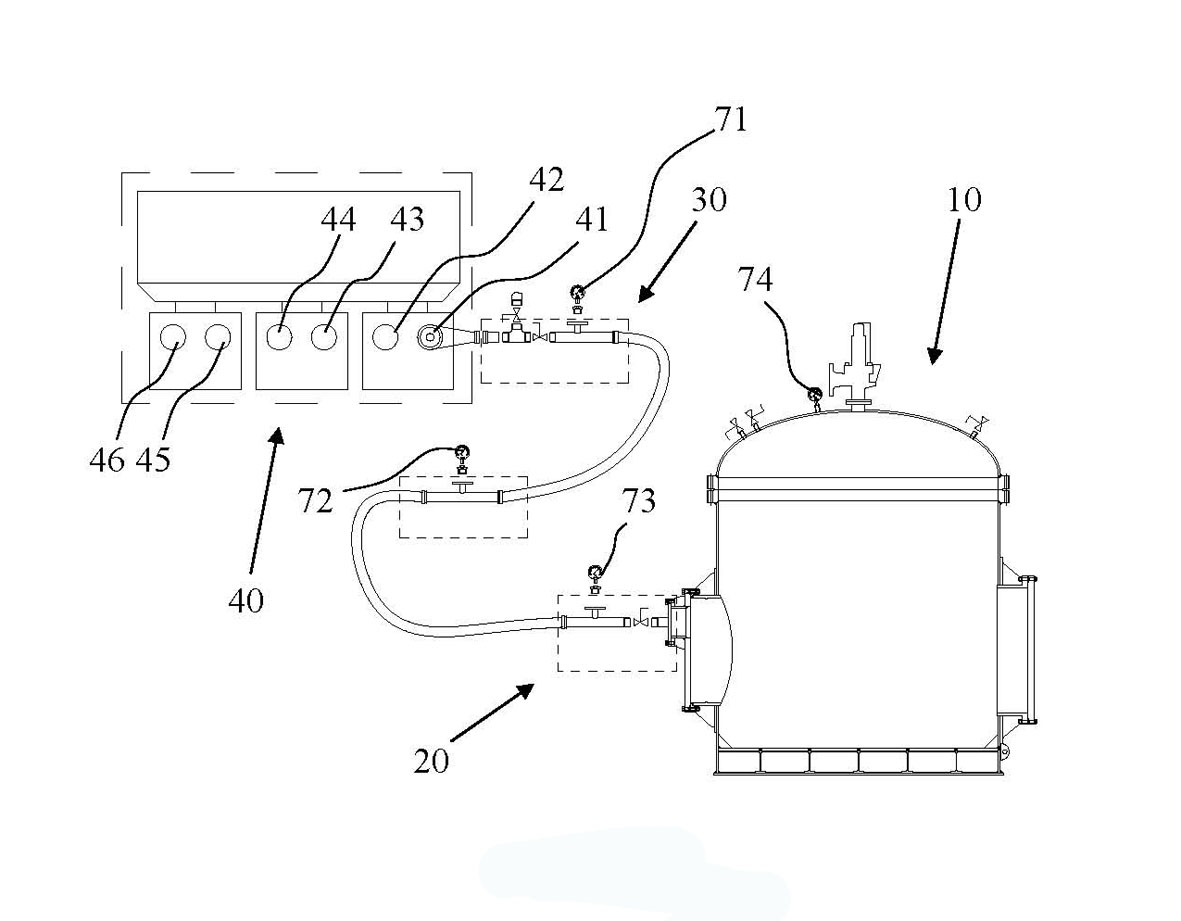

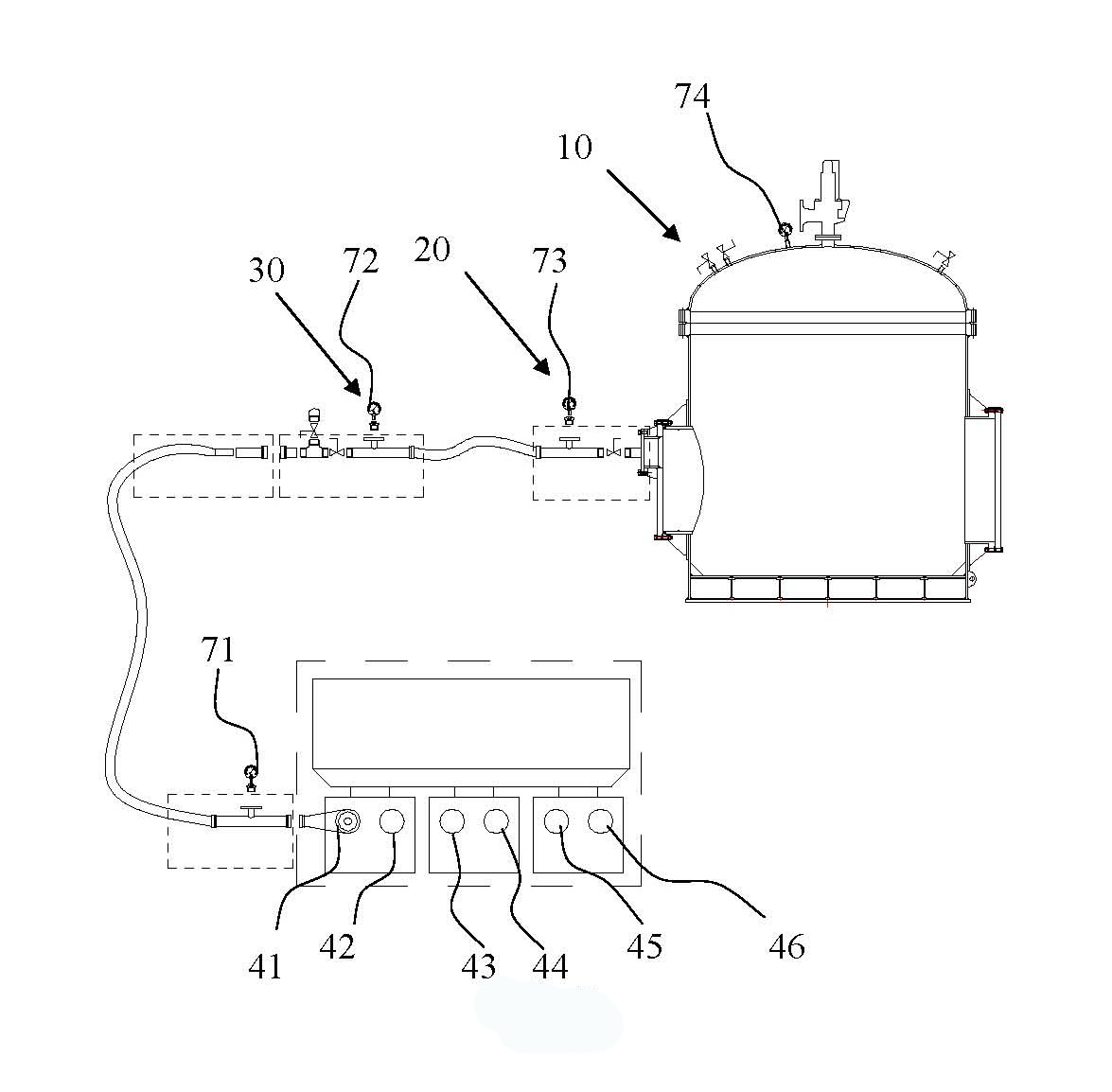

Method for calibrating synchronous grouting quantity and grouting pressure of shield

ActiveCN101982747AContainer/cavity capacity measurementPressure difference measurement between multiple valvesReciprocating motionEngineering

The invention provides a method for calibrating synchronous grouting quantity and grouting pressure of a shield with super-large diameter. The method comprises the following steps: performing a slurry pumping test by combining the conventional synchronous grouting equipment of a shield machine and simulation strata pressure condition provided by a home-made slurry barrel for test; calculating and concluding loss of slurry pipeline pressure according to the slurry pump outlet pressure and the test device pipeline outlet pressure, and calibrating the actual grouting pressure of the shield with super-large diameter; and calculating and concluding the correction coefficient of single stroke grouting quantity of a piston of the grouting pump according to weight changes of a closed vessel before and after grouting the number of reciprocating motion times of the piston of the grouting pump so as to calibrate the grouting quantity of synchronous grouting of the shield with super-large diameter. Calibration of the grouting quantity of the synchronous grouting of the shield and the grouting pressure provides accordance for control of the shield machine by a 'double control' principle in synchronous grouting, so the method can effectively reduce the deformation of the rear and the late ground sedimentation, and shorten the stabilizing time of later sedimentation.

Owner:SHANGHAI TUNNEL ENG CO LTD

Device for increasing resistance and regulating pressure in filling slurry pipeline transportation

InactiveCN104948224AFluid stabilityThere will be no problems such as subsidenceJoints with fluid cut-off meansMaterial fill-upSlurry pipelineLocal pressure

The invention relates to a device for increasing the transportation resistance of slurry in a filling pipeline in a small time line high pressure head mine filling system, and discloses a device for increasing the resistance and regulating the pressure in filling slurry pipeline transportation. The problem that the local pressure in filling slurry pipeline transportation is too large is solved in a mode of increasing the resistance loss of the slurry in the pipeline. The input end and the output end of the device for increasing the resistance and regulating the pressure are both connected to the pipeline for transporting the filling slurry, and the horizontal height of the input end of the device for increasing the resistance and regulating the pressure is larger than that of the output end of the device for increasing the resistance and regulating the pressure. The device is simple in technological process and convenient to install, and the flow state of mortar in the pipeline is stable.

Owner:UNIV OF SCI & TECH BEIJING

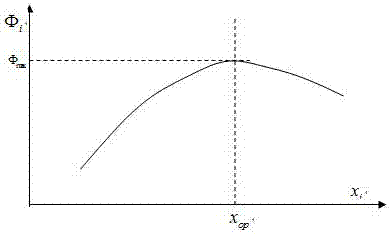

Dynamical correcting method for paste slurry pipeline on-way conveying resistance

ActiveCN106969263ALow running costExtend your lifePipeline systemsInformaticsSlurry pipelineMechanical engineering

The invention discloses a dynamical correcting method for paste slurry pipeline on-way conveying resistance. The method comprises the steps that on-way resistance is theoretically calculated, and a theoretical calculation value is obtained; then, a representative horizontal conveying pipe section and a representative vertical conveying pipe section are selected on site, conveying resistance of the two conveying pipe sections is measured and calculated, and on-way resistance of the horizontal conveying pipe section and on-way resistance of the vertical conveying pipe section are calculated according to the conveying resistance correspondingly; the theoretical calculation value of the on-way resistance is compared with the measured value, and a conveying dynamic correcting coefficient is obtained; the on-way resistance theoretical calculation value is dynamically corrected through the dynamic correcting coefficient, and practical conveying resistance of a whole system is obtained. Calculation is carried out according to the parameter obtained through real-time monitoring, the on-way resistance theoretical value is corrected at any time, and therefore the real-time on-way resistance value is obtained. According to differences of real-time on-way resistance, a controller is used for automatically controlling the conveying pressure of a conveying pump to be appropriate, and therefore it is ensured that energy is saved to the largest degree and the service life of the conveying pump and the service life of an auxiliary motor are prolonged.

Owner:SHANDONG UNIV OF SCI & TECH

Fuel cell membrane electrode coating and feeding device and method

PendingCN111672715ASolve the problem that the temperature is affected by the environmentEven heat dissipationLiquid surface applicatorsCell electrodesFuel cellsEngineering

The invention relates to a fuel cell membrane electrode coating and feeding device which comprises a slurry tank, a slurry groove and a low temperature constant temperature groove; a refrigerant is filled in the low temperature constant temperature groove; the slurry tank is arranged in the low temperature constant temperature groove and is filled with slurry; a slurry taking pipe is inserted in the bottom of the slurry in the slurry tank; a slurry pump is connected with the other end of the slurry taking pipe; the output end of the slurry pump is connected with the slurry groove through a pipeline; a slurry pipeline switching valve, a slurry flow regulating valve and a slurry temperature measuring meter are sequentially arranged on a pipeline between the slurry pump and the slurry groove;the lower part of a coating roller is immersed in the slurry of a slurry pond and takes the slurry up through rotation; a plurality of holes are distributed in the outer surface of the coating roller; and the slurry filled in the holes of the coating roller is transferred onto a release back film above the coating roller. The fuel cell membrane electrode coating and feeding device can solve the problems that during the process about indirect coating preparation of CCM through a membrane electrode, the temperature of feed solution in a coating trough is affected by the environment, as a result, the temperature of the slurry is raised due to heating, and the slurry is reduced in viscosity, likely to generate bubbles and is not uniform in coating.

Owner:上海亿氢科技有限公司

Biogas slurry pipeline fertilizing device

InactiveCN101238770AAvoid cloggingTimely air intakeLiquid fertiliser distributionWatering devicesExhaust valveControl valves

The invention relates to a biogas liquid pipeline fertilization device, which includes waste water disposal pump placed at the bottom part of the biogas liquid storage pool, the inverted valve which is placed above the immersed type waste water disposal pump, the liquid inlet tube which is connected to the inverted valve, the main tube which is connected to the liquid inlet tube, the fast pressure-relief valve and gate valve which are installed on the main tube, many branch tubes which are connected to the main tube, the water outlet pile which is connected to the main tube or the branch tube, the control valve which is fixed on the said water outlet pile, the soft tube which is connected to the water outlet pile, the deposit collecting tubes which are installed at the bottom part and the right angle corner of the main tube and branch tubes, the outlet valve which are installed on the said main tube and the branch tubes. The biogas liquid pipeline fertilization device can fertilize the field, which is good for environmental protection, and has the advantages of low cost and long lifespan.

Owner:熊棣文

Construction device for short-distance overpass building

PendingCN112575813AReasonable designImprove connection stabilityArtificial islandsFoundation testingAir compressorElectric control

The invention discloses a construction device for a short-distance overpass building. The construction device comprises a foundation plane, an electric control equipment box, an air compressor, a cement pump, a fixed column, a formed hole, a perforated pipe, a mud discharge pipe, a pressure gauge, a mud discharge port, a pressure detection head, a cement slurry discharge port, a filling reinforcing cavity, a slurry box, a slurry outlet, a main air pipeline, a suck-back water pipeline, bolt connecting holes, a mud discharge valve, a pressure sensor circuit pipe, a hole-cutting water pipeline, ahigh-pressure slurry pipeline, a standby pipeline and a suck-back air pipeline. The construction device has the beneficial effects that the pile body quality is good, cement slurry is directly adopted for spraying, the pile body quality is good after spraying is completed, the influence on the surrounding environment is small, ultra-deep construction is guaranteed, the MJS construction method regulates and controls the in-ground pressure through the in-ground pressure monitoring and forced slurry discharging means, disturbance of construction to the surrounding environment can be greatly reduced, and the ultra-deep construction effect is ensured.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

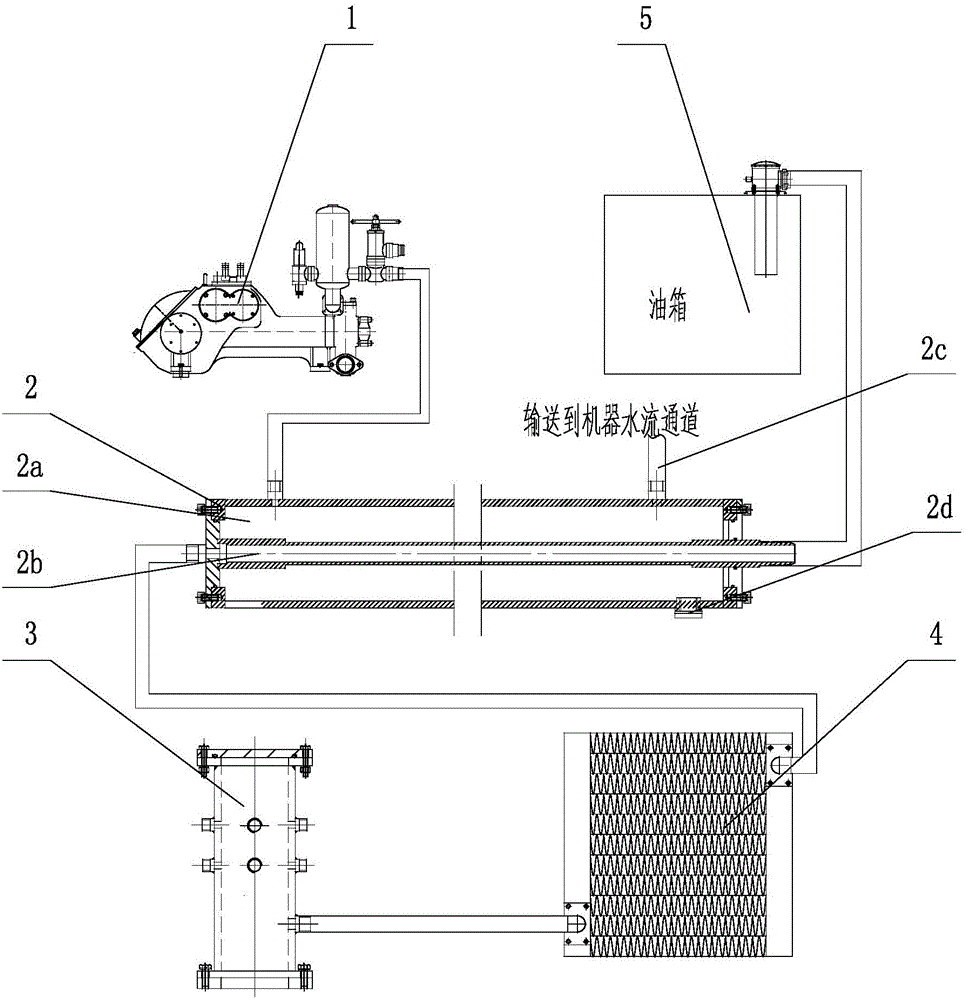

Hydraulic oil circulation cooling system of drilling machine

ActiveCN105840596AImprove cooling efficiencyLow costFluid-pressure actuator componentsWater flowFan blade

The invention relates to a hydraulic oil circulation cooling system of a drilling machine. The hydraulic oil circulation cooling system of the drilling machine is characterized by comprising an oil returning pipe device; the oil returning pipe device comprises a square pipe and a seamless steel pipe arranged on the inner side of the square pipe; an inner hole of the seamless steel pipe is a hydraulic oil channel; a slurry channel is formed between the seamless steel pipe and the square pipe; one end of the square pipe is connected with a slurry pump through a slurry pipeline; an outlet in the other end of the square pipe is connected with a water flow channel; one end of the hydraulic oil channel is connected with an oil tank through an oil pipe; the other end of the hydraulic oil channel is connected with an oil outlet of an oil radiator device through an oil pipe; and an oil inlet of the oil radiator device is connected with an oil storage tank. A drainage plug is arranged on the lower portion of the square pipe. The oil radiator device is a wind radiator and comprises a gear motor, blowing fan blades and a radiator. Water supplied by the slurry pump is effectively utilized to flow into the oil returning pipe, high-temperature oil inside the oil returning pipe is cooled along with water flow, and on the premise of not increasing the cost, the oil cooling efficiency is greatly improved.

Owner:无锡市钻通工程机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com